Patents

Literature

615 results about "Bunker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bunker is a defensive military fortification designed to protect people and valued materials from falling bombs or other attacks. Bunkers are mostly underground, in contrast to blockhouses which are mostly above ground. They were used extensively in World War I, World War II, and the Cold War for weapons facilities, command and control centers, and storage facilities. Bunkers can also be used as protection from tornadoes.

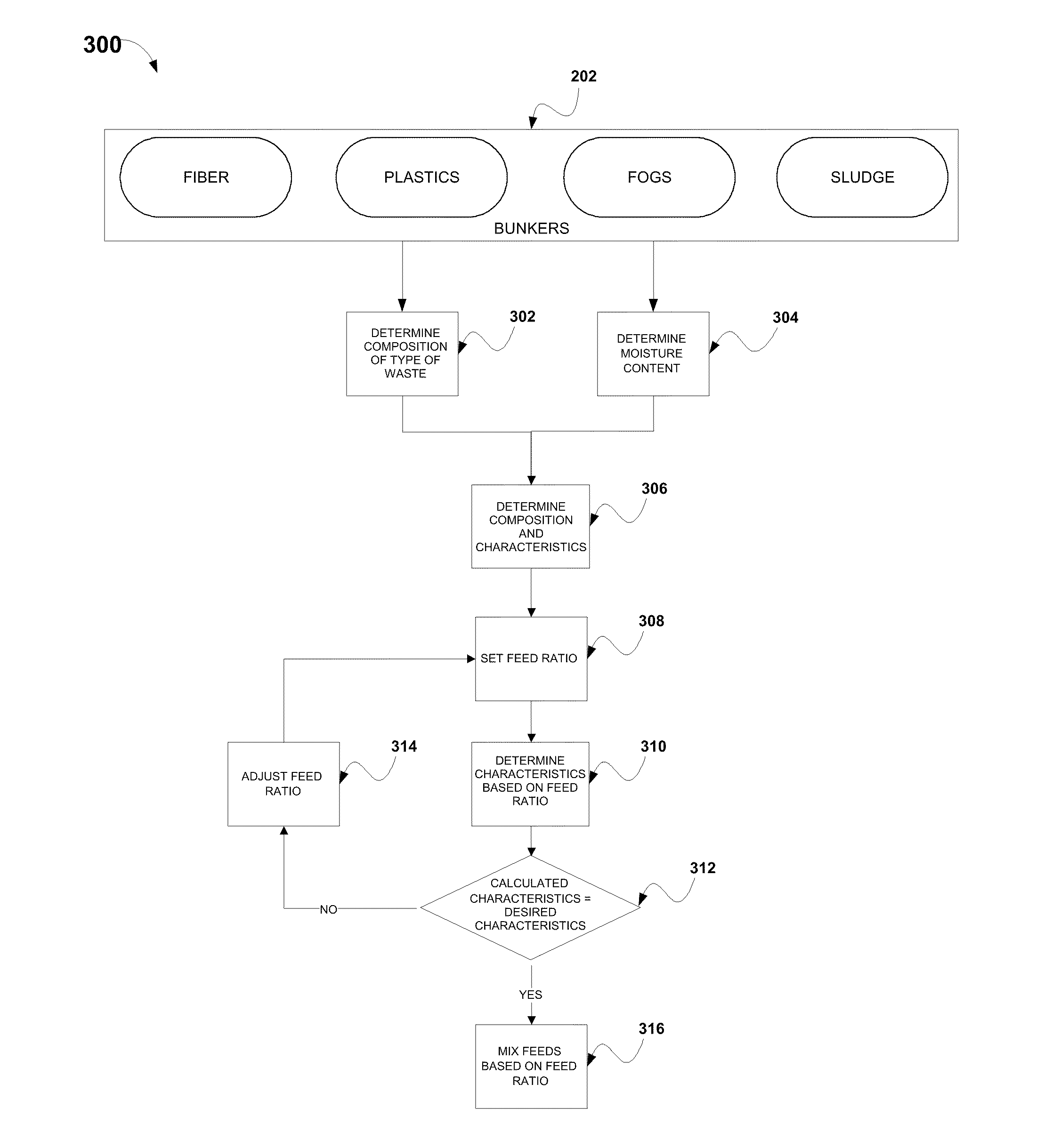

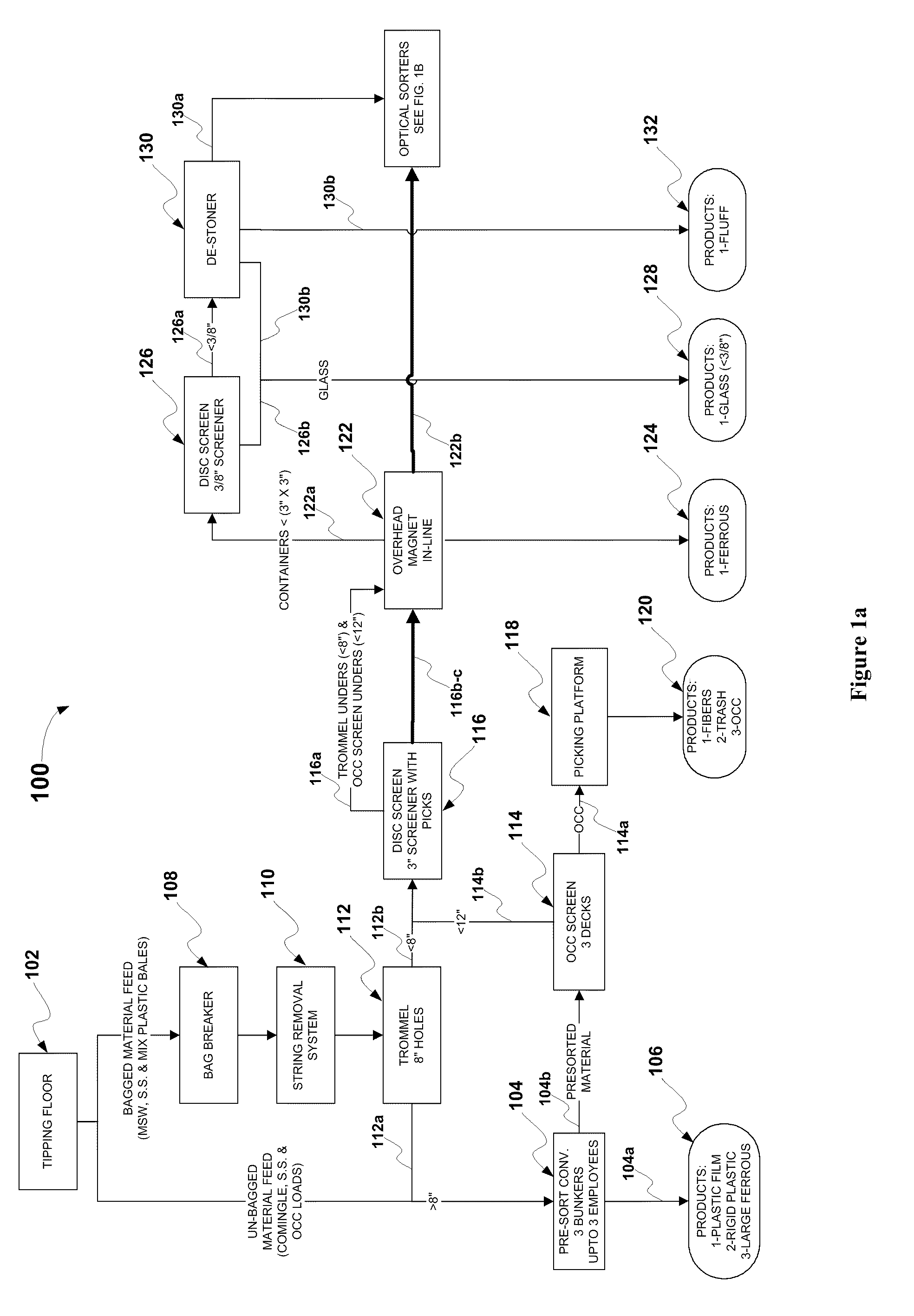

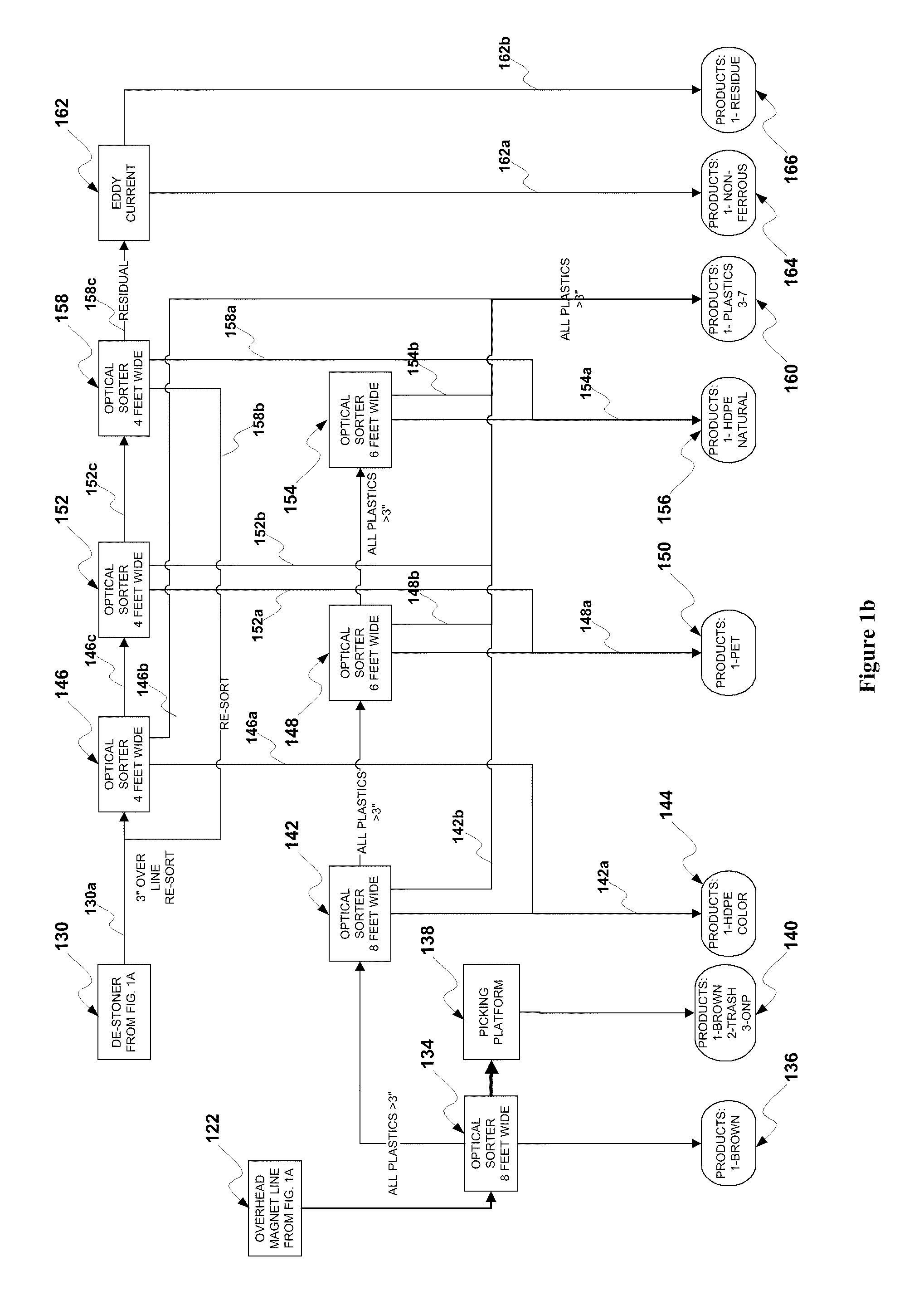

System and Method for Integrated Waste Storage

The present invention provides integrated bunker storage systems for waste streams based on the composition and characteristics of waste streams. In particular, the present invention provides a process for generating individual waste streams based on a set of material characteristics. According to the system and method of the present invention, individual waste streams from wastes stored in bunkers are mixed in a given feed ratio to generate a feed stock that will produce a desired output from a chemical conversion process, e.g., gasification. Optionally, composition data regarding the feed stock can be certified to a third party.

Owner:REPOWER IP LLC

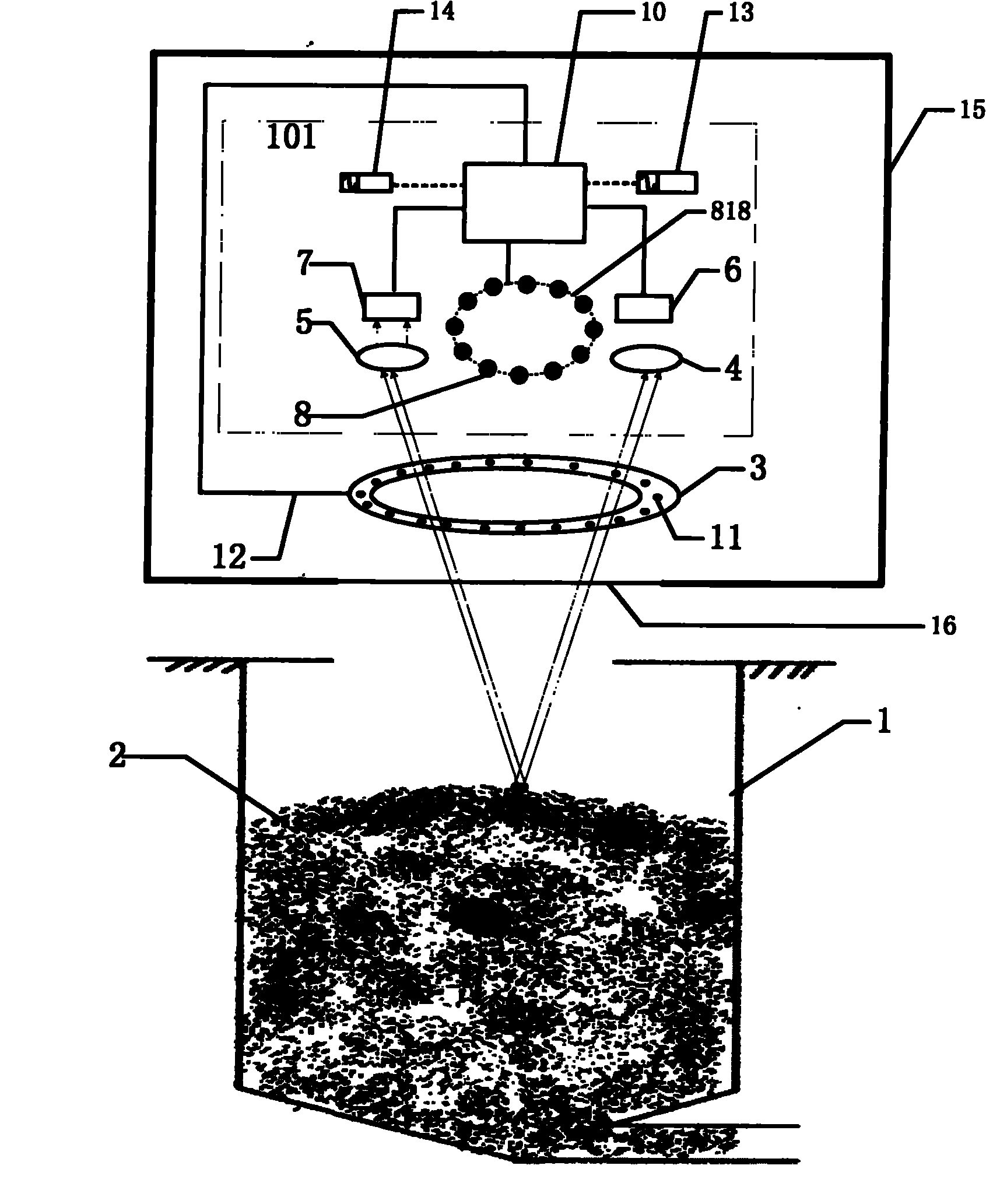

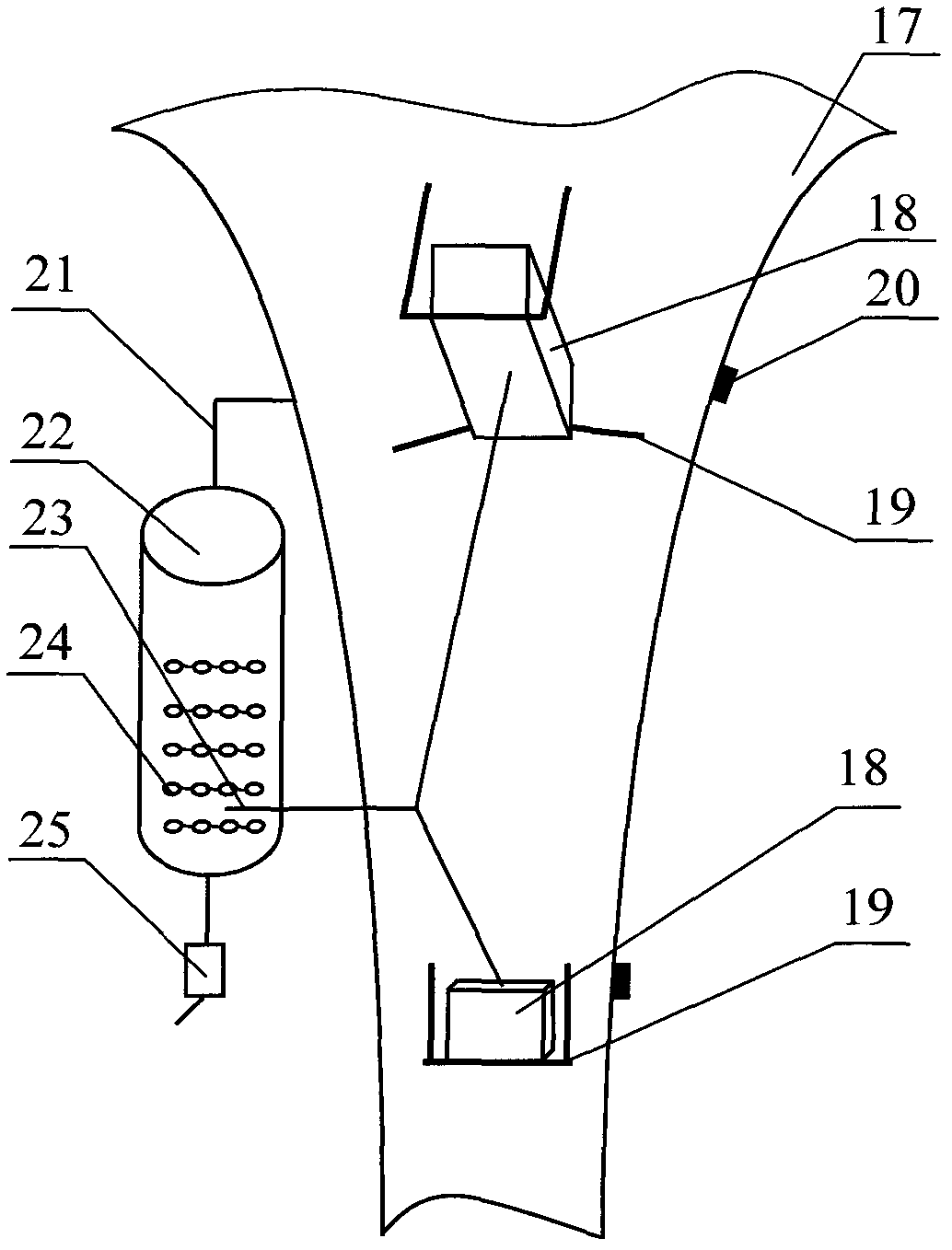

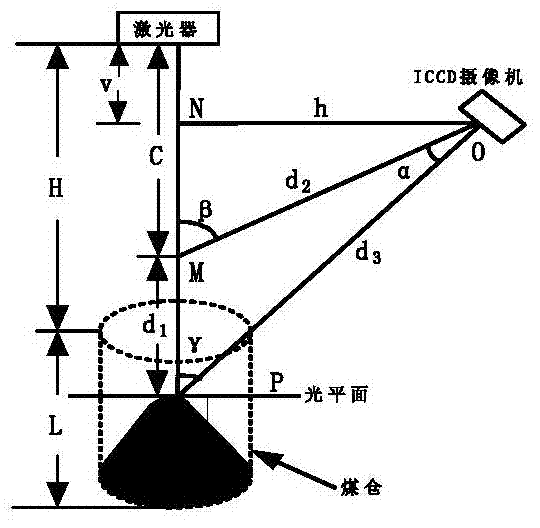

Method for measuring coal bunker material level based on laser and binocular vision and device thereof

InactiveCN101949721AHigh precisionImprove robustnessImage enhancementImage analysisCamera lensLight spot

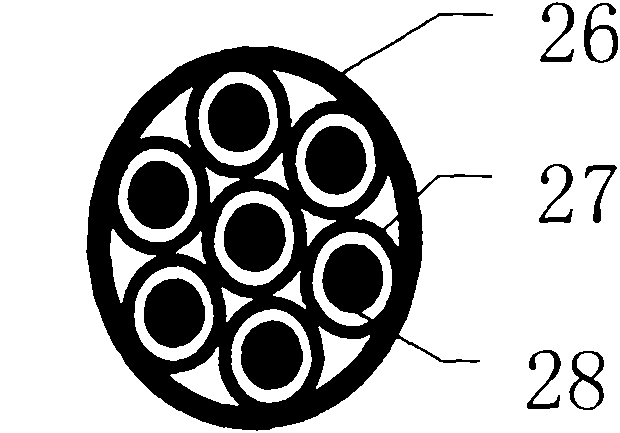

The invention relates to a method for measuring coal bunker material level based on laser and binocular vision and a device thereof, belonging to the field of machine vision. The device comprises two CCD cameras with the same parameters, two lenses with consistent parameters, one or a plurality of lasers, a light source, a processing element and an explosion-proof case provided with a window. A rotating mechanism is also included when one laser is used. The method includes that the laser emits variable size laser beams, so as to form a light spot on coal surface, image parallax of the light spot between the two cameras is utilized to measure material level, and an image pair is acquired by the two cameras; corrosion expansion pre-treatment is carried out on the obtained images by utilizing an improved algorithm; for the two images after being pretreated, a new rapid stereoscopic vision algorithm is utilized to calculate a depth map; depth is obtained according to the depth map, and finally high efficiency, real time and accurate coal bunker material level measurement is realized. The device has two measuring modes, namely real-time detection mode and sensor detection mode.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

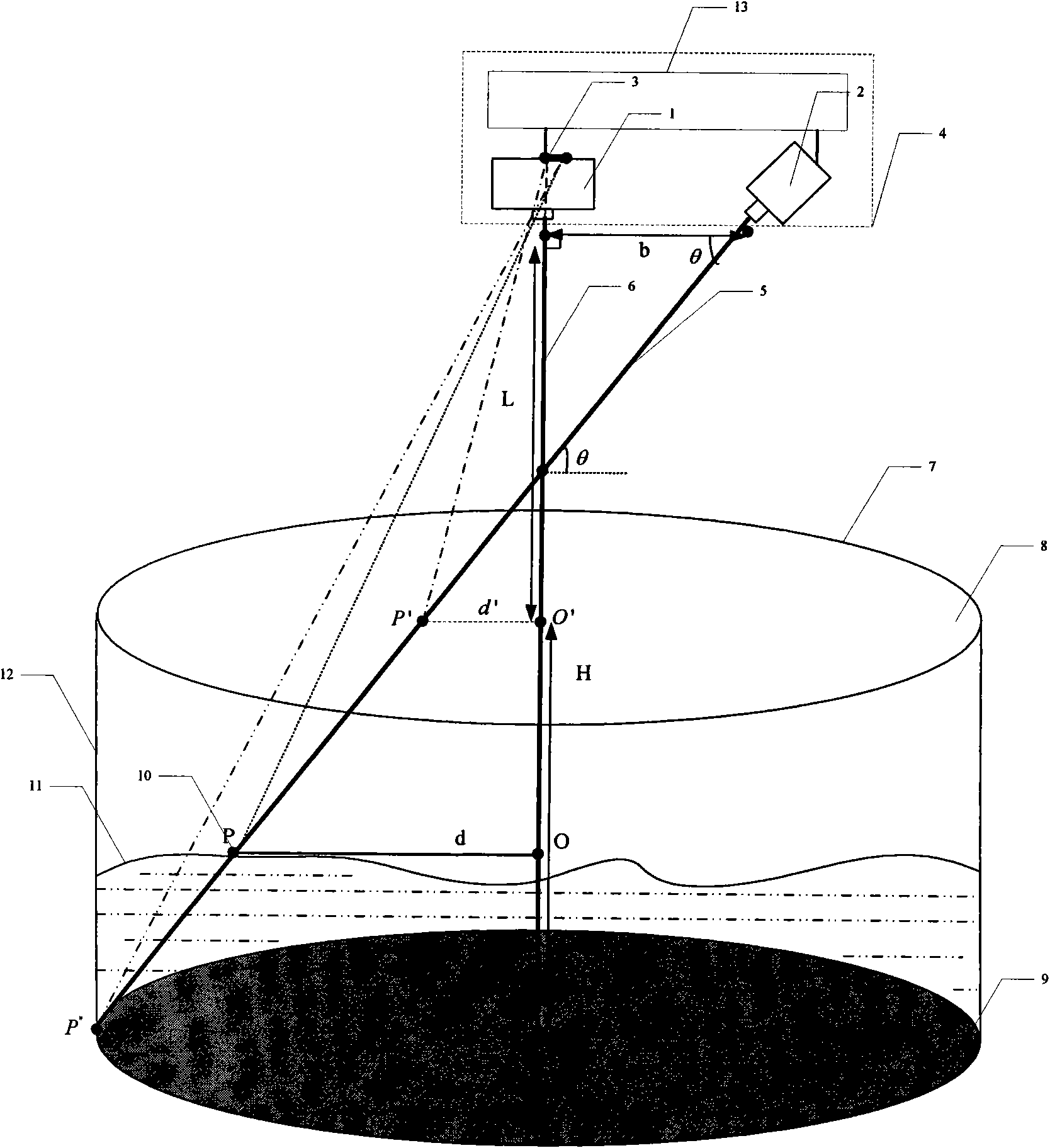

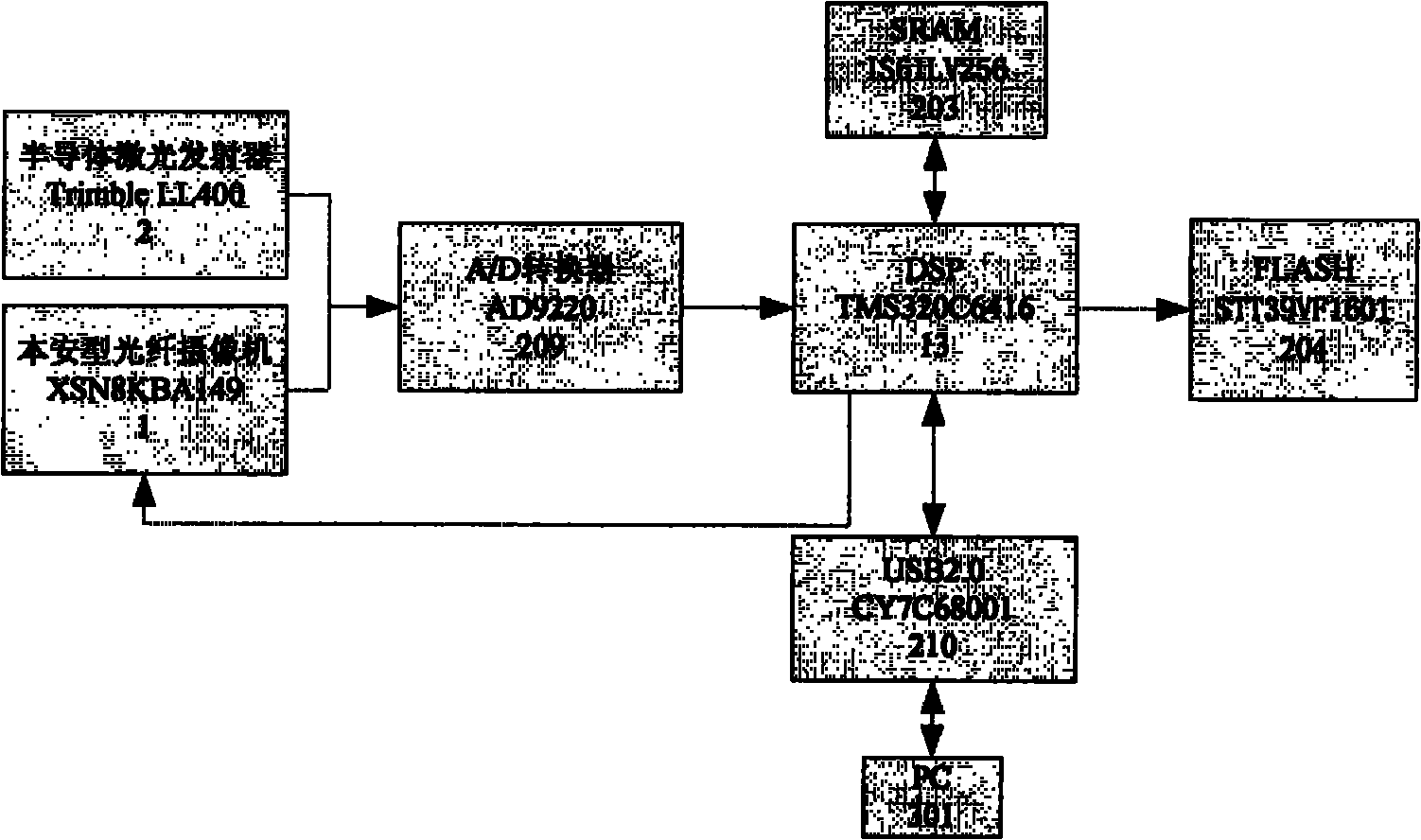

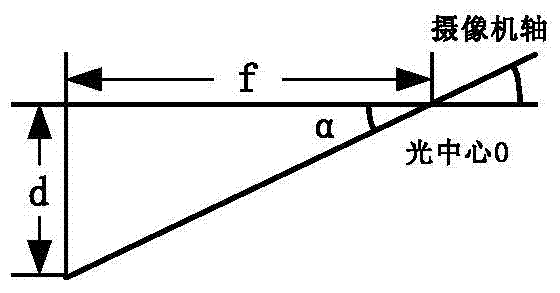

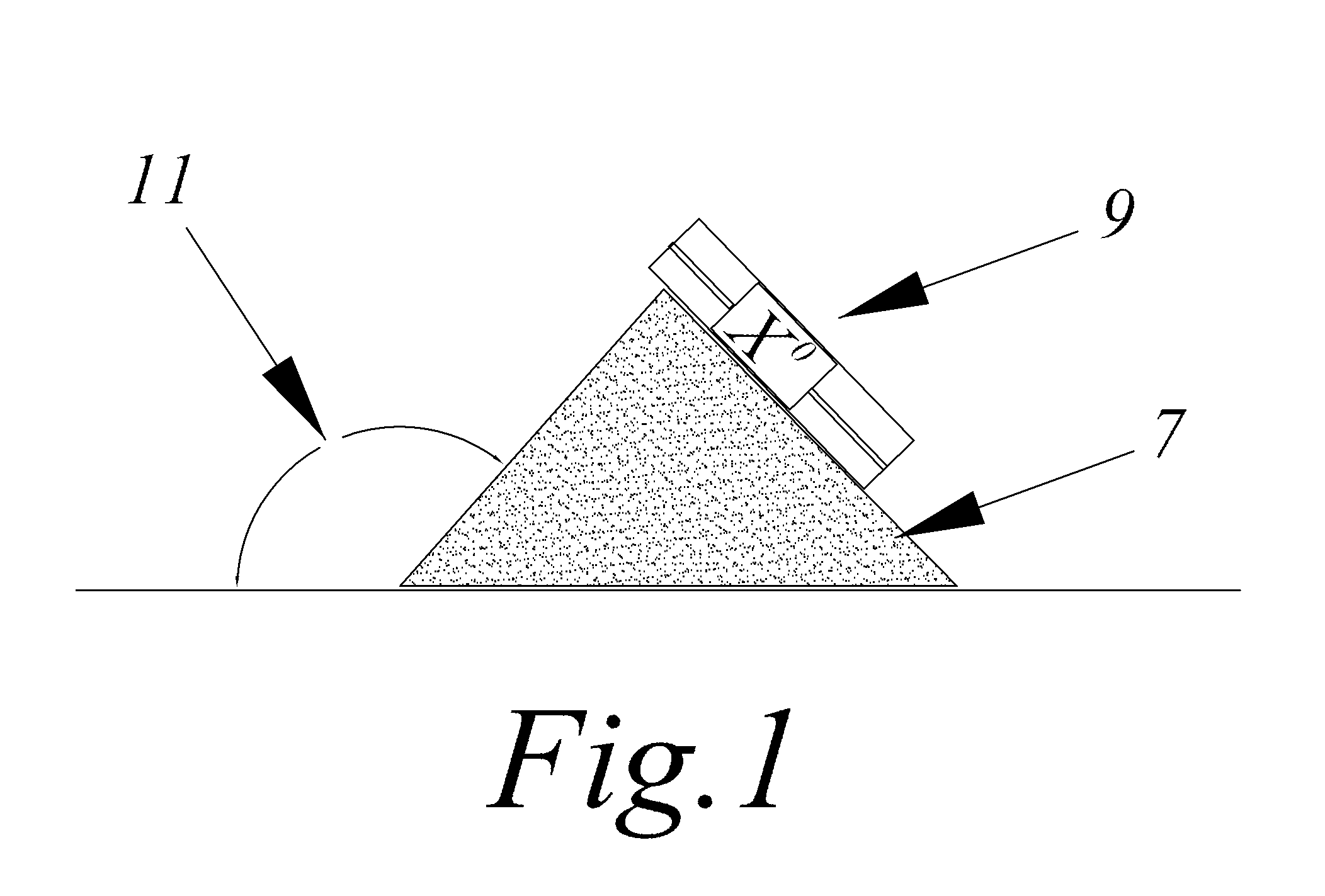

Non-contact photoelectric measurement method and device for bunker coal position

InactiveCN102023045ANo accumulationAccurate measurement dataMachines/enginesLevel indicatorsLaser transmitterMeasurement device

The invention provides a non-contact photoelectric measurement method and device, which obtains the depth value of materials in a bunker on the basis of the number of pixels between a laser facula imaging spot and an image center spot in an image, belonging to the technical field of material position measurement. The invention is especially suitable for measuring the depth of the bunker coal position. In the device of the invention, a digital camera and a laser emitter are fixed on the top of the principal axis of a barrel-shaped bunker, so that the light path of the camera is vertical to the surface of material. The laser emitter is arranged on the position at the angle theta with the horizontal direction so as to ensure that the imaging zone of the laser facula can be projected on the material surface within the field range of the camera. The camera focuses by N-gear segment so as to satisfy the situation that clear images can be shot on all different coal positions of the bunker. DSP (Digital Signal Processor) serves as the inner core of a processor. The number of pixels between the laser facula imaging spot and the image center spot is calculated, and a depth table which is calibrated in advance and corresponds to different pixel number mean values is inquired to finish depth detection. The measurement device is composed of the digital camera, the laser emitter, the image processor and a real-time display module.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

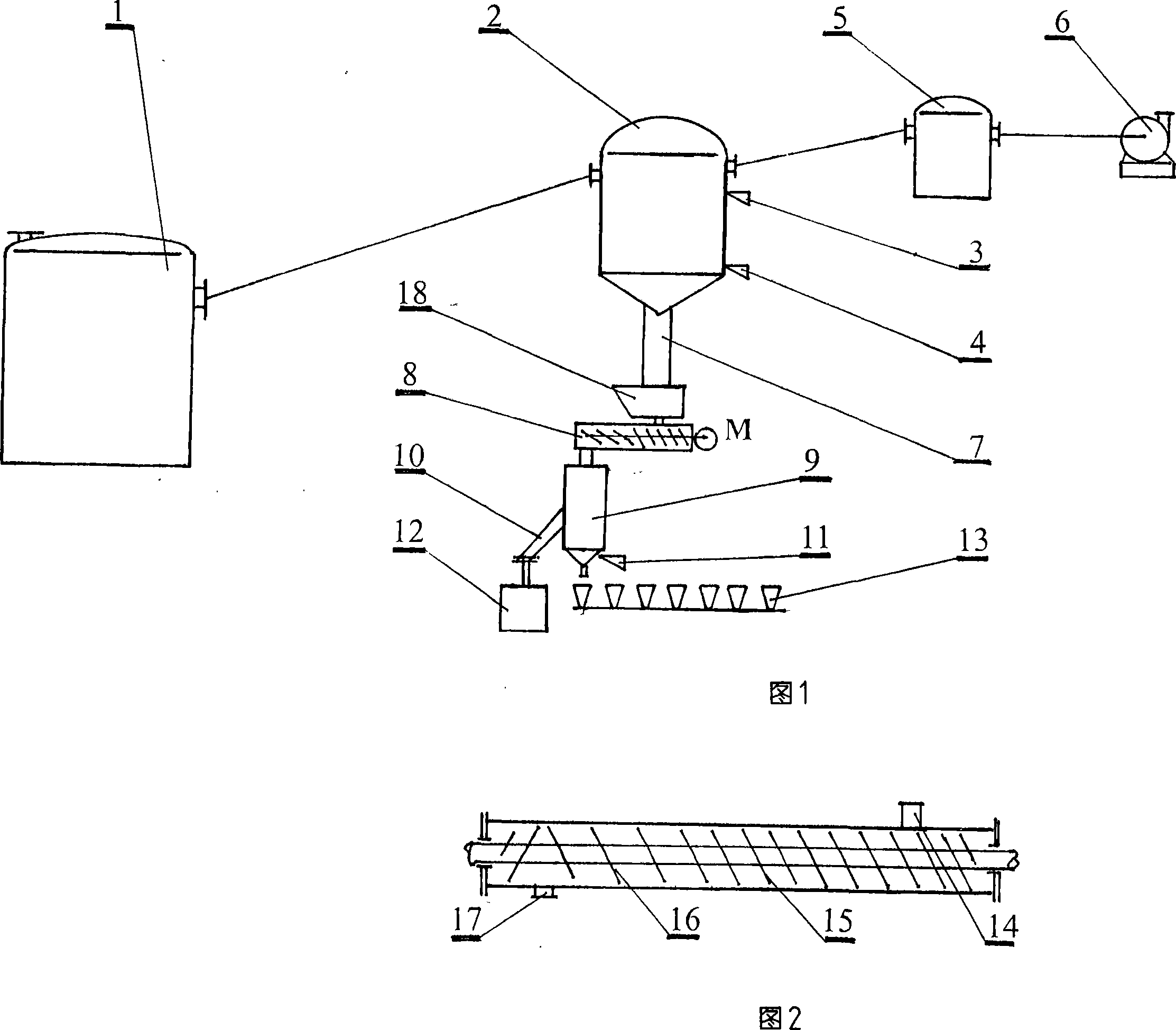

Automatic accurate weighing device for powdery material

InactiveCN101105409ANo leakageNo pollution in the processWeighing apparatus with automatic feed/dischargeMotor speedGrating

The invention discloses a powdery material accurate weighing device, which comprises a raw material tank and a weighing cup. The invention is characterized in that the feeding process is operated under vacuum, a high-level switch and a low-level switch are disposed above a vacuum intake tank, an auger conveying mechanism is disposed below the vacuum intake tank, the spiral pitch has two classes, the motor speed has two classes, a optical fiber grating pressure sensor is disposed below a weighing bunker, an automatic reverse turning bed is disposed in the weighing bunker, the signal from a material level switch and the optical fiber grating pressure sensor is transmitted to PLC, and the PLC outputs control signal to a motor of a vacuum pump, vacuum air passages and material control valves. The invention remarkably improves the weighing accuracy from above plus or minus 10 g error of the existing automatic weighing to within plus or minus 1 g error, even lower. It has the advantages of whole sealing operation under vacuum condition, no dust pollution, improved operating environment, accurate weighing, and good consistency. The invention is helpful for further improving the production quality of friction wafer product; and has high spreading and application values, and good market prospect.

Owner:李红

Domestic refuse incinerator

InactiveCN1375656AAids in mashingReduce heat burn rateTravelling grateIncinerator apparatusAir volumeLitter

Owner:屠柏锐 +2

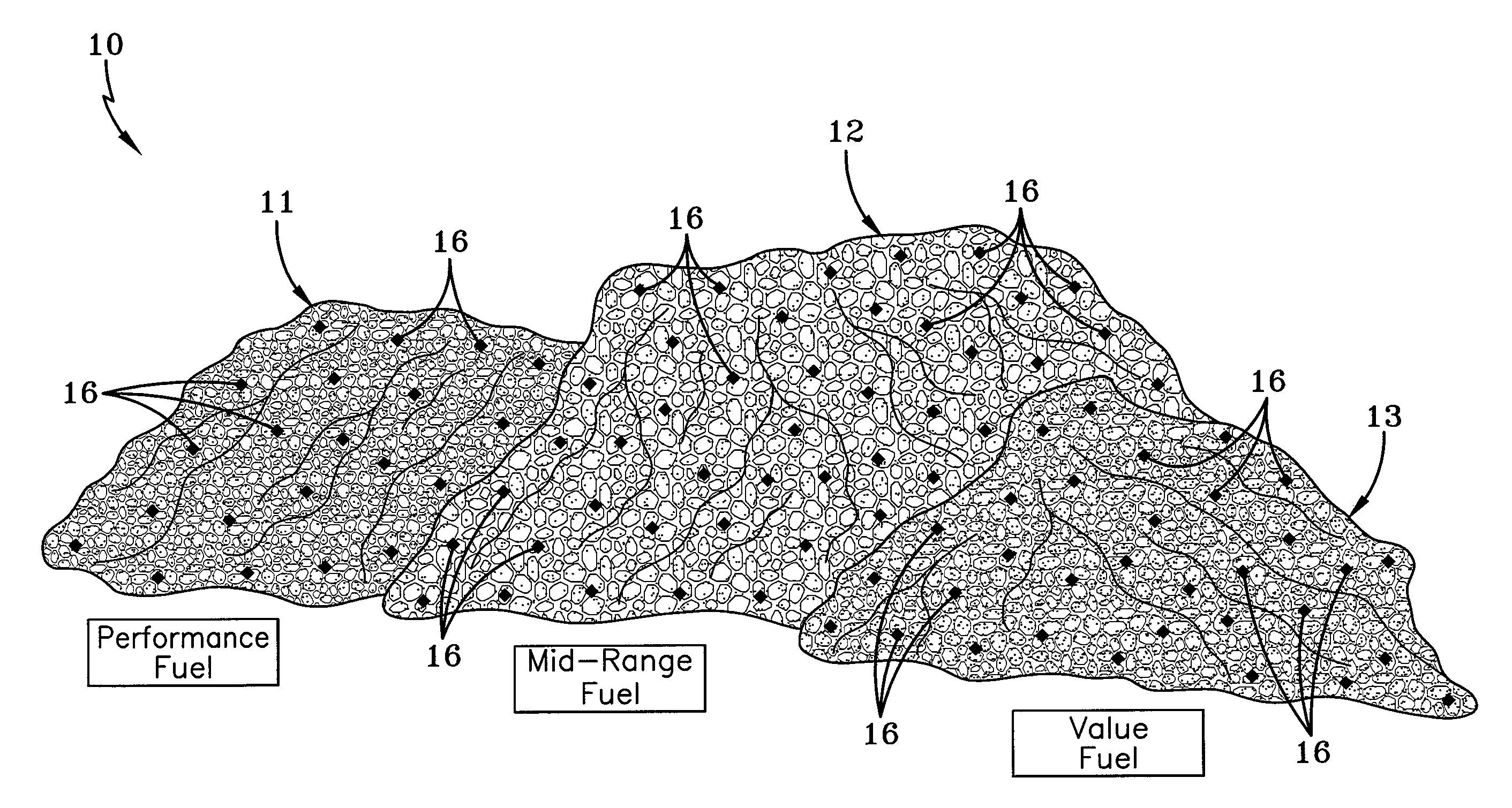

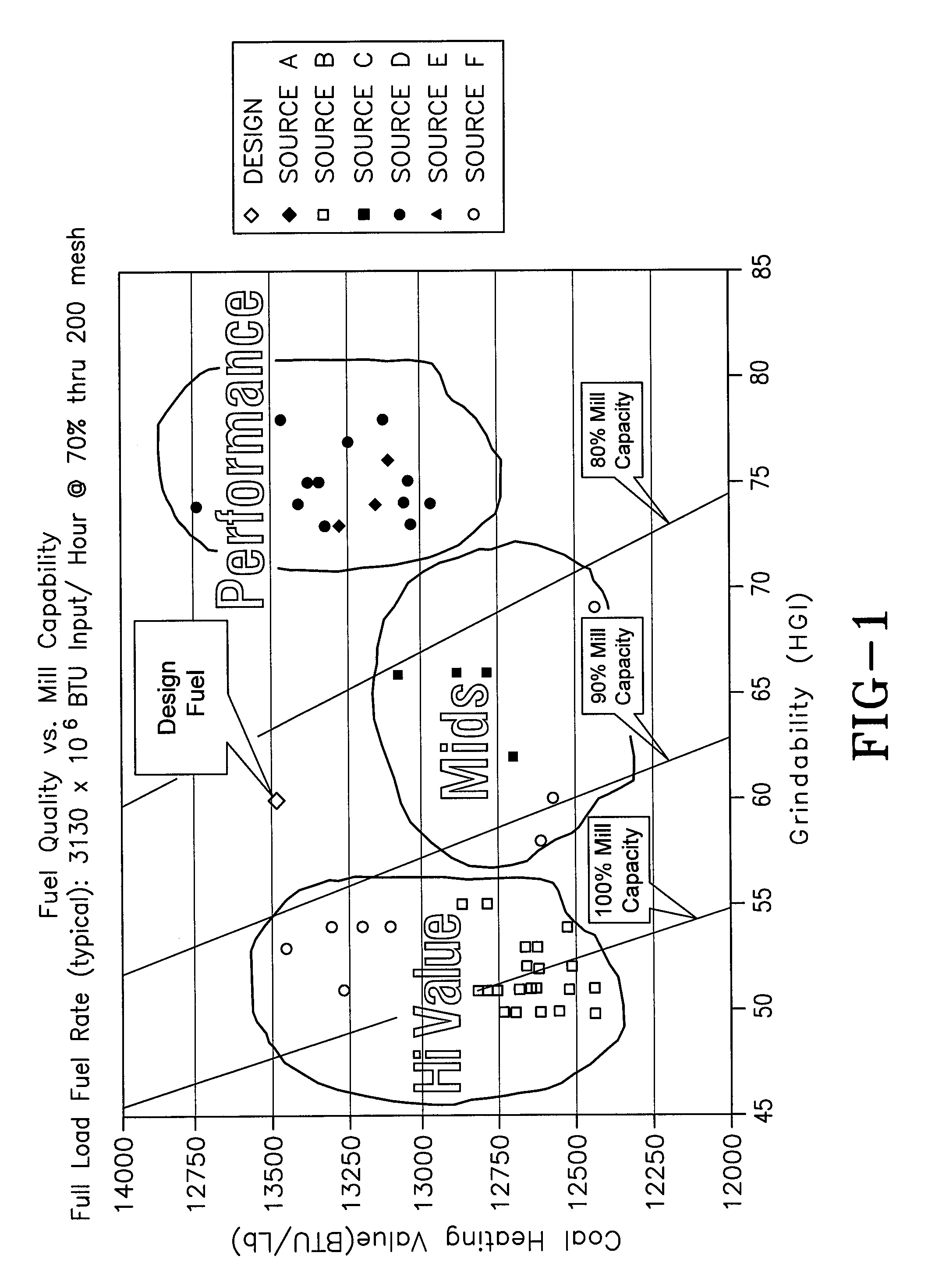

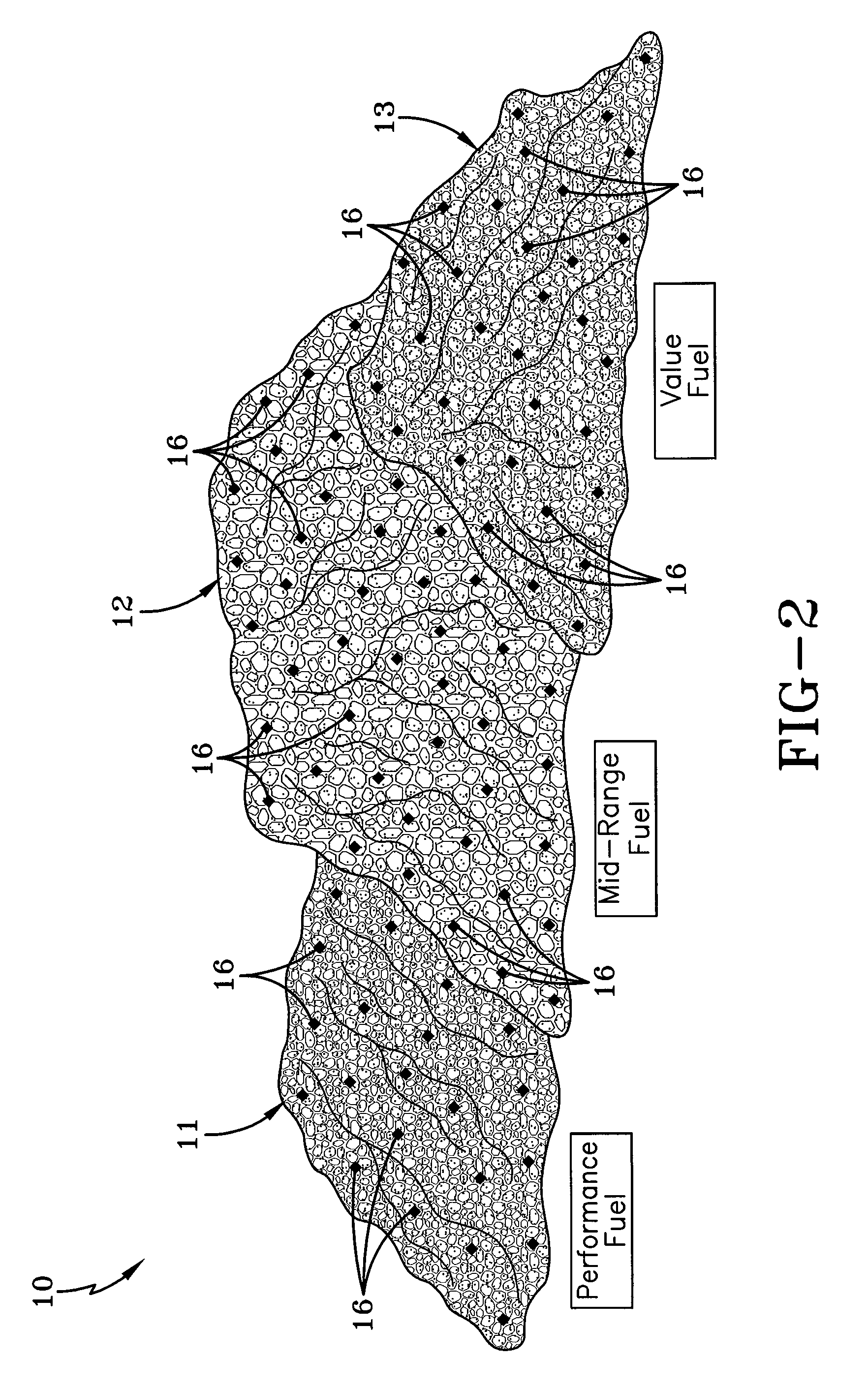

Tracking and properties control system for bulk materials

The invention provides a system of devices and a set of methods for accurately characterizing, tracking and controlling bulk material flows. Measurements of input material properties, dynamical measurements involving identifiable tags, and fast, discrete simulations are combined to predict and control the composition of bulk material exiting a container, such as a silo, bunker or hopper. In one embodiment, a system is provided for a coal-fired power plant where the properties of coal are assessed, then the coal is marked and tracked to provide the plant's operators improved control over the coal mixture and target bulk properties as it makes its way from a coal receiving station to delivery for combustion in a furnace.

Owner:ENG CONSULTANTS GROUP

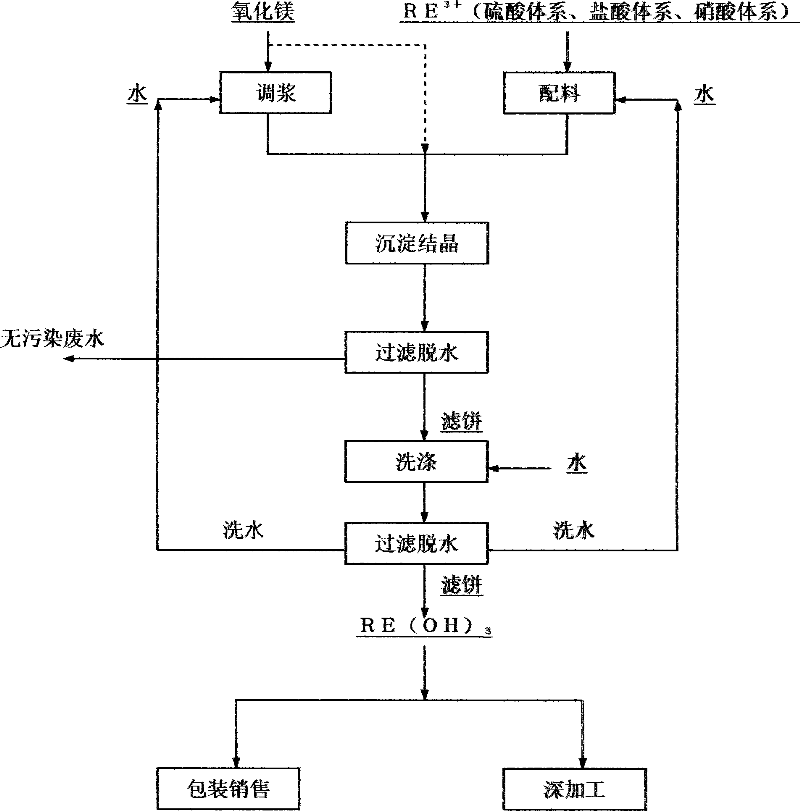

Production process of magnesia used for rear earth solution precipitator

ActiveCN101037219ASolve processing problemsPromote cleaner productionRare earth metal compoundsSurge tankWash water

The present invention belongs to the rare earth preparation field, wherein magnesia serving as precipitator is used for the precipitation process of rare earth solution. The surge tank is filled with water and heated, and magnesia is added into the water to be confected; an amount of water and rare earth feed liquid are confected and injected into dosage bunker to be heated; the confected rare earth feed liquid and magnesia feed liquid are injected into precipitation tank in term of equal equivalent to execute precipitation reaction; the slime after precipitation reaction is pumped into a filter kettle to execute filter dehydration to obtain filter cake which is confected by water and is scrubbed, and then solid rare earth hydrate is obtained after filter dehydration, wherein the wash water can be recovered and reused. The present invention is capable of overcome the disadvantage of the prior art, reducing the cost greatly, overcoming the problem of wastewater treatment, enlarging the application field of precipitator, promoting the clean production of rare earth industry.

Owner:BAOTOU HUAMEI RE PRODS

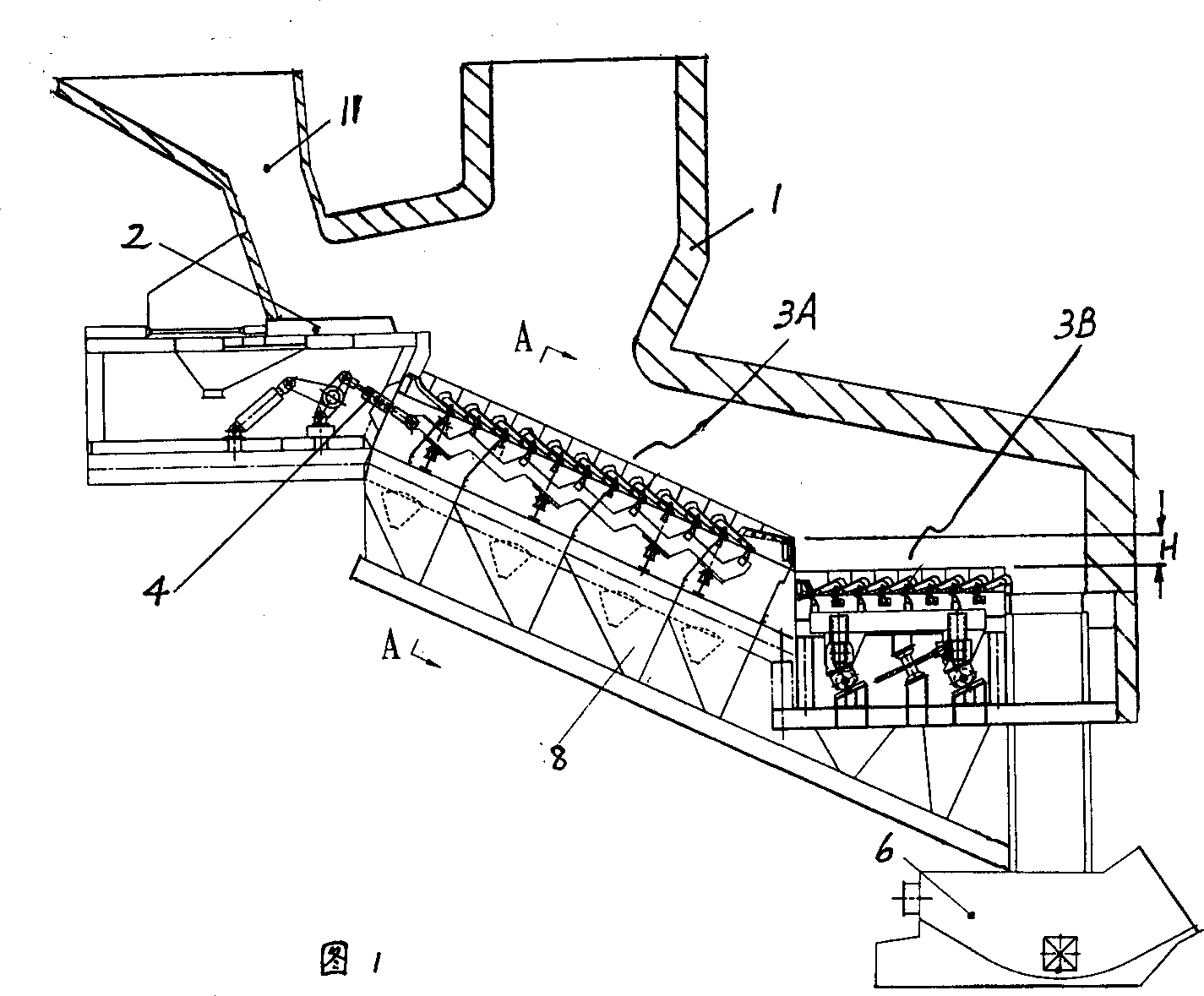

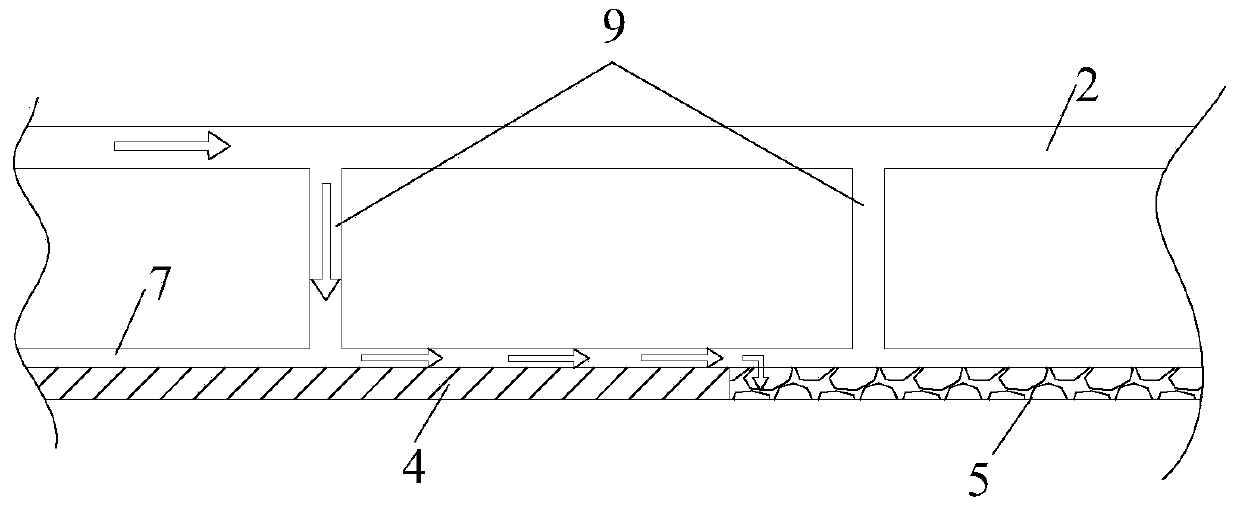

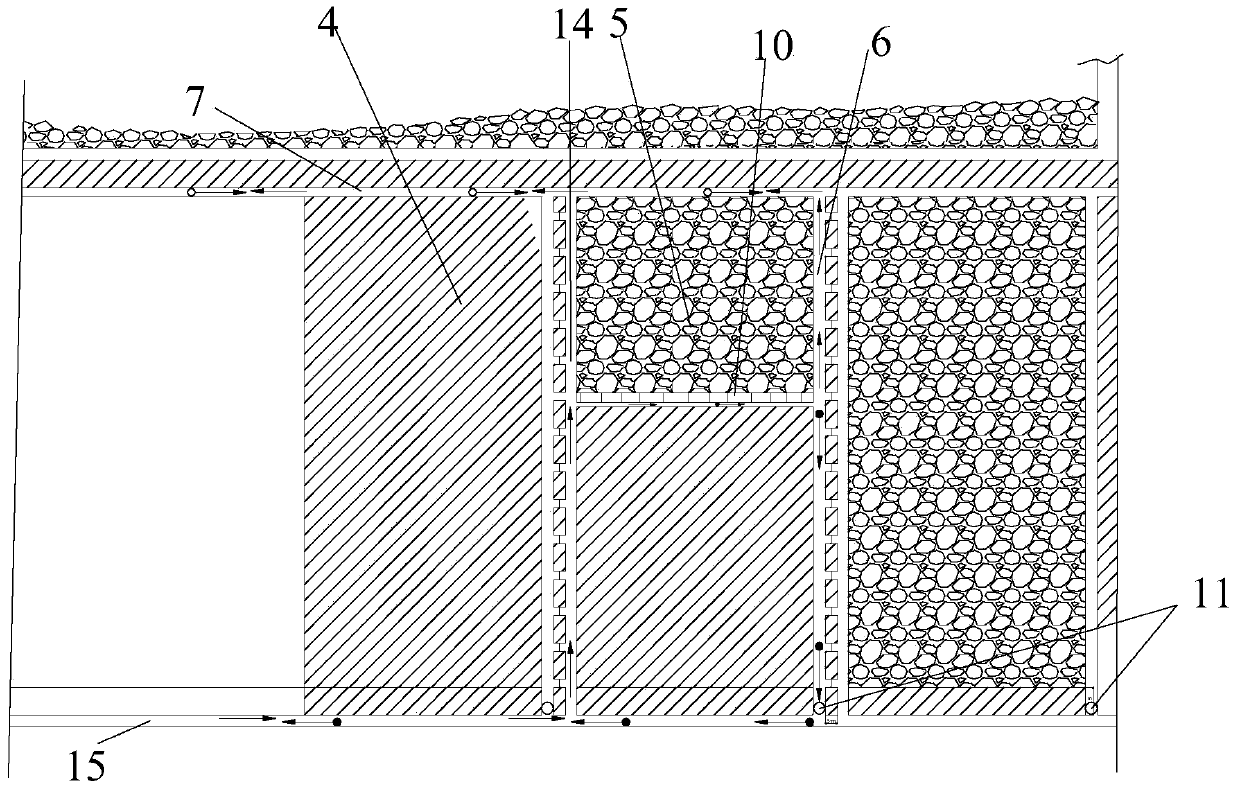

Gangue-filling coal mining method for sharp inclined coal seam under flexible shield support

ActiveCN103742148AReduce labor intensityEasy to operateUnderground miningSurface miningEngineeringWorking space

The invention provides a gangue-filling coal mining method for a sharp inclined coal seam under flexible shield support. The method comprises the steps of distributing working faces corresponding zones in a downhill mining mode, dropping coal by adopting an air pick, supporting the working face by using the corresponding flexible shield support to form a working space, and filling gangues above the flexible shield support through the corresponding floor tunnel along with the gradual mining operation to a coal body which is positioned below the working face, so as to enable the corresponding flexible shield support to be sunk under the dead weight and the weight of the covered gangues and form a mode of mining while filling, wherein trenches are distributed in the working faces corresponding to the zones, workers work in the trenches, produced coal is pushed to inclined coal dropping roadways corresponding to the zones by a scraper bucket and drops into a coal bunker at the underside, and then the coal is transported to a mining area through a haulage roadway after being loaded in a mine car. The flexible shield support does not need to be removed and lengthened for multiple times during mining, the filling procedure is simplified, the filling cost is reduced and the labor intensity of workers is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

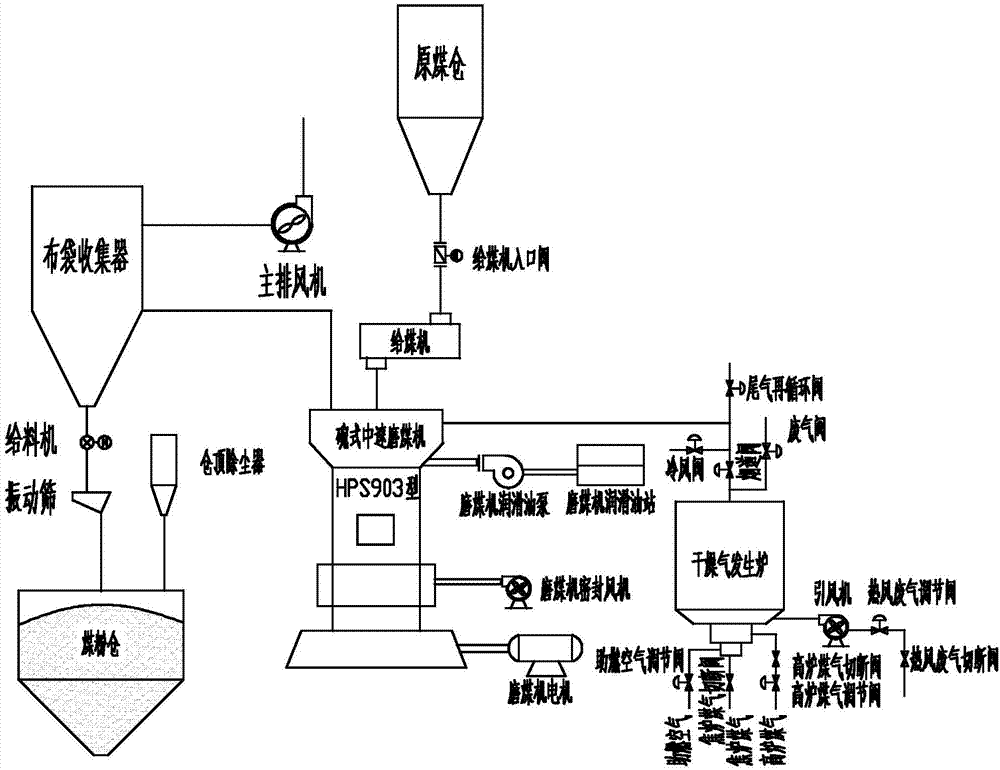

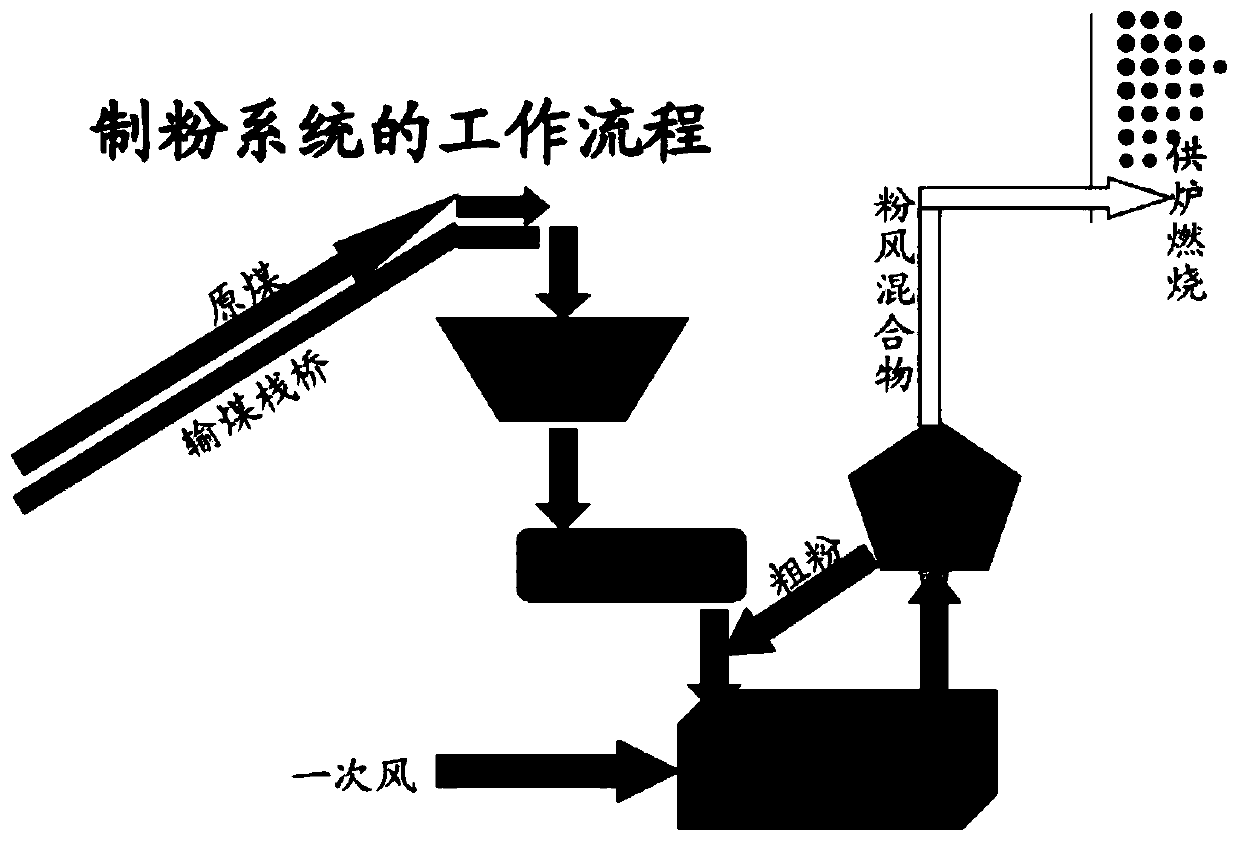

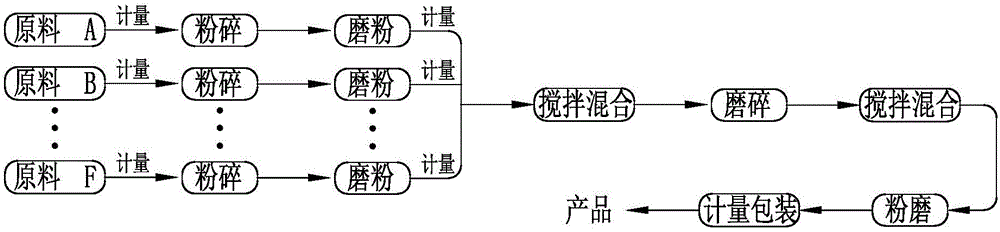

Full automatic control method and system for blast furnace pulverizing systems

ActiveCN103495488AReduce labor intensityReduce mental tensionBlast furnace componentsBlast furnace detailsAutomatic controlBunker

The invention discloses a full automatic control method and system for blast furnace pulverizing systems. Each blast furnace is provided with at least two pulverizing systems. All the pulverizing systems share the same pulverized coal bunker. The method comprises the following steps: preparing and starting, wherein starting judgments and starting control are included; operation adjustments; halt control. The method can realize uniform operation through program control, adjusts the number of started pulverizing systems according to actual conditions, and realizes full automatic control operation of the blast furnace pulverizing systems. The method greatly reduces labor intensity and thought tension degree of workers and improves working efficiency so as to eradicate manual operation errors and solve the problems that the equipment operation rate is high, running fluctuation is large, and index stability is poor when a manual operation system is used. Moreover, the method enables one person to monitor a plurality of pulverizing systems, improves the running efficiency of the systems, reduces operation cost, enables the systems to have more time to be maintained and repaired, and enables the whole pulverizing system to be in a virtuous circle.

Owner:JIANGSU JINHENG INFORMATION TECH CO LTD

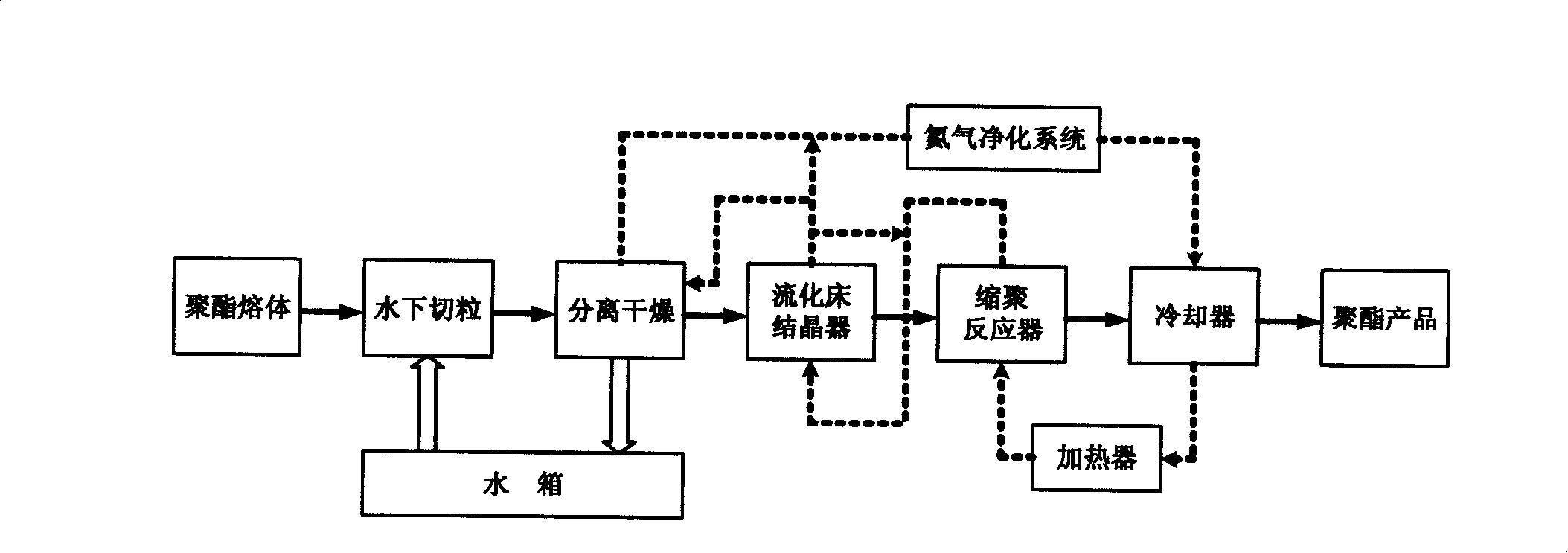

Polyethylene terephthalate solid-state polycondensation technique

The invention relates to a technique for further generating high viscosity polyester through solid phase polycondensation by using a PET polymer obtained through melt polycondensation. Firstly, medium viscosity polyester is used for granulation in warm water at 80 to 97 DEG C, the formed polyester granules and water are delivered to solid-liquid separation and drying equipment to ensure the granules to be separated from the water, the separated water flows into a water tank and is then delivered to a granule cutting room for periodic operation, the granules enter into crystallization equipment to be crystallized in inert gas atmosphere, the crystallized granules enter into a solid phase polycondensation reactor for reaction, the inherent viscosity is further improved, and the granules after the reaction enter into a cooler to be cooled down. The process of the technique is short, the chip bunker of a PET melt polymerization device, the raw material bin of a solid phase polycondensation device, and a delivery device can be saved, and crystallization is only required to be performed once during the solid phase polycondensation step; the energy saving effect is very remarkable, in each kilogram of polyester pellets, the energy can be saved by 69.1 kcal, the heating energy can be saved by 75.23 kcal, therefore, the economic efficiency is very remarkable.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

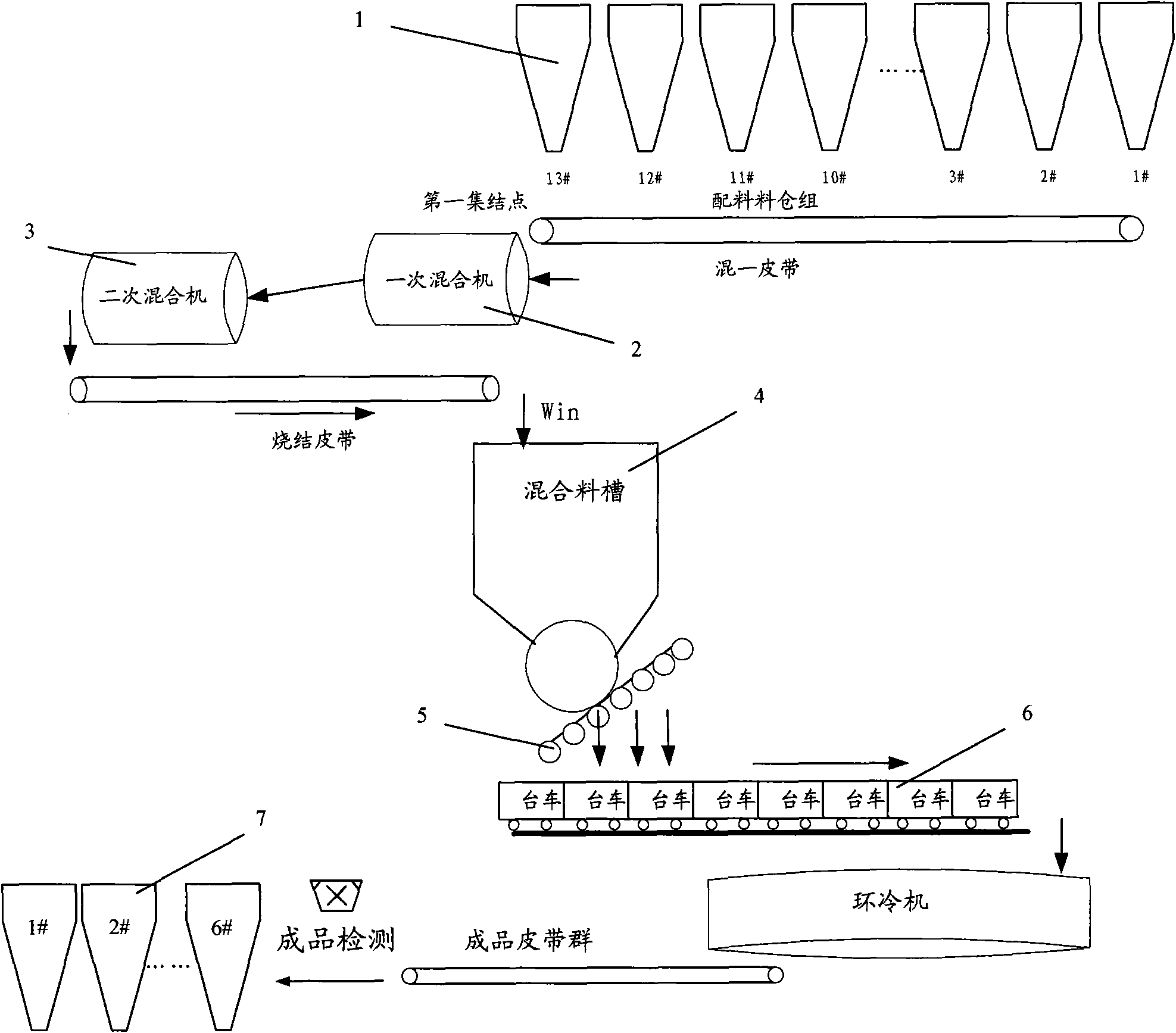

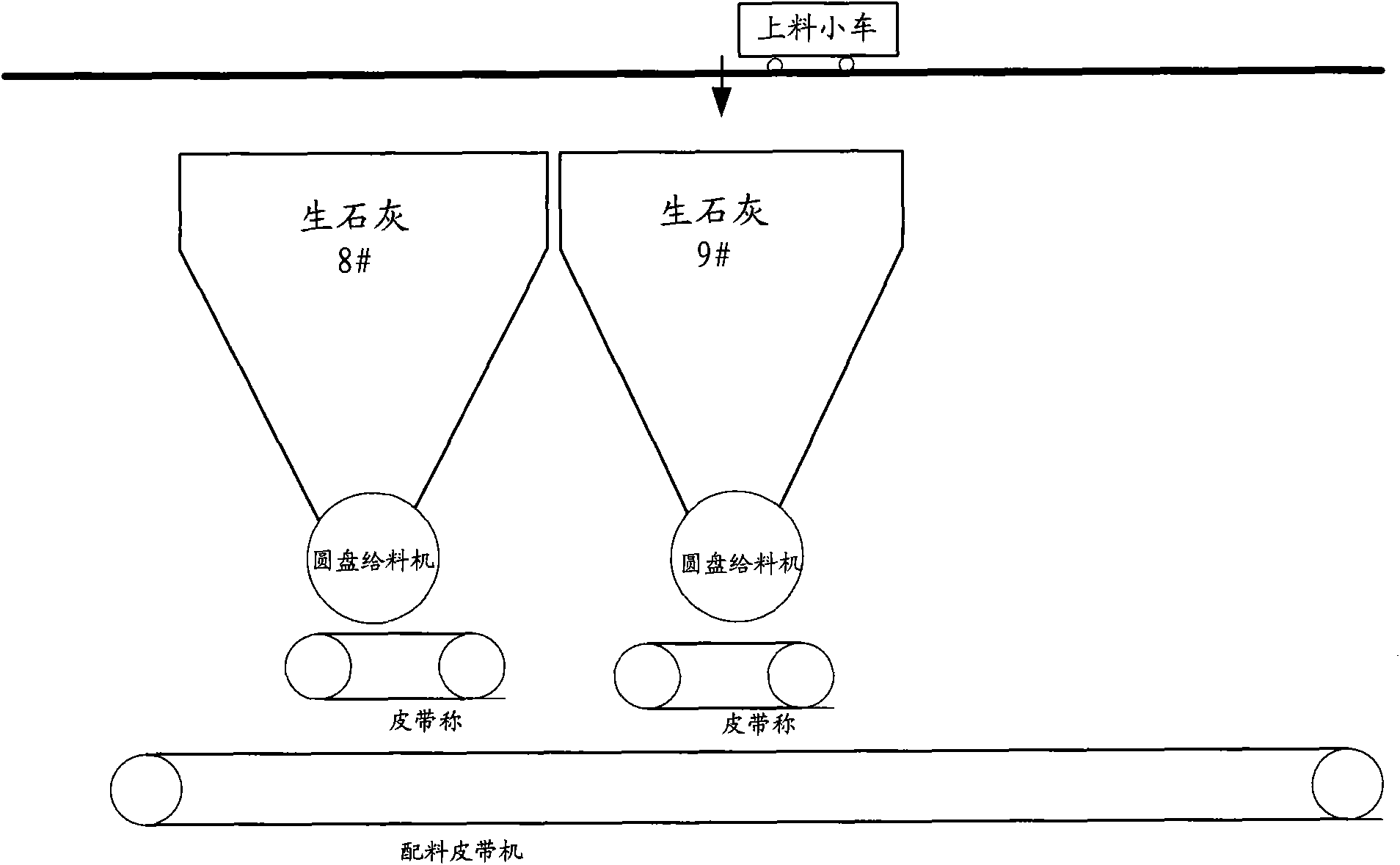

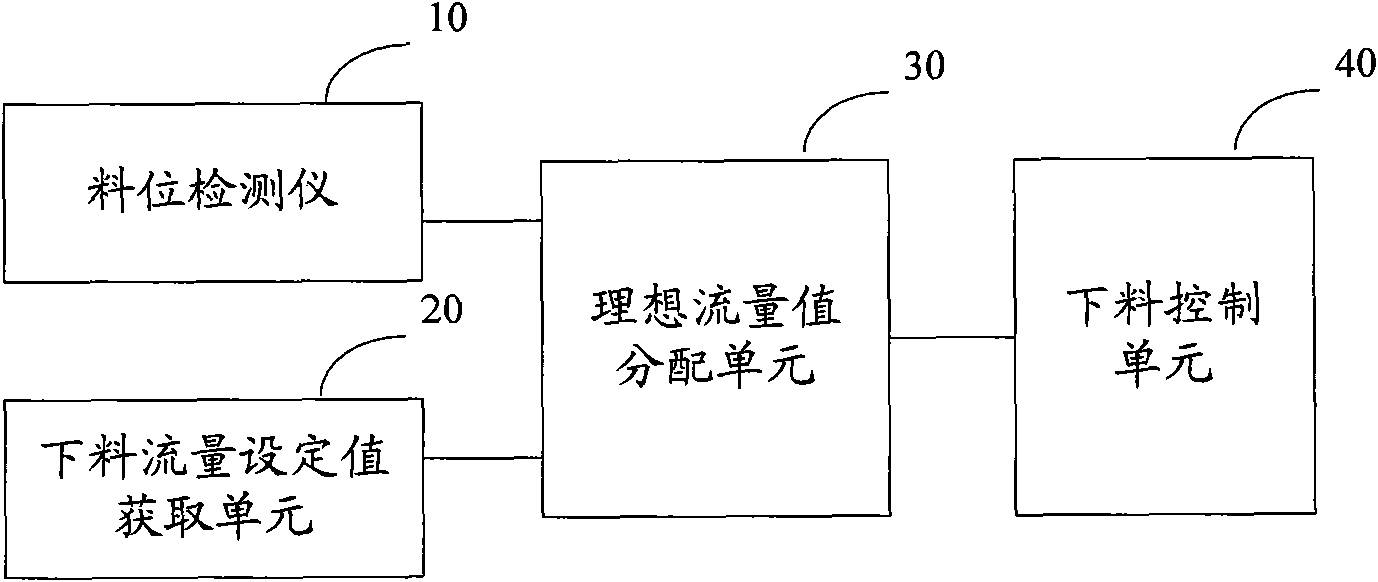

Device and method for controlling discharge of sintering bunker group

ActiveCN101929799ALarge feeding flowLess material flowMixer accessoriesFurnace typesBunkerControl cell

The invention provides a device for controlling the discharge of sinter bunker group. The device comprises: a level detector for obtaining current level values of bunkers by means of detection; a discharge flow setting value acquisition unit for acquiring discharge flow setting values to which the bunkers are corresponding; an ideal flow value allocation unit for allocating, according to the current level values and the discharge flow setting values of the bunkers as well as a preset allocation rule, ideal discharge flow values to the bunkers to which raw materials of the same type are corresponding respectively; and a discharge control unit for controlling the discharge of bunkers according to the ideal discharge flow values of the bunkers. The invention further provides a method for controlling the discharge of sintering bunker group. By adopting the device and the method, coordinated discharge between the bunkers, to which raw materials are corresponding, in a sintering system discharge group can be achieved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

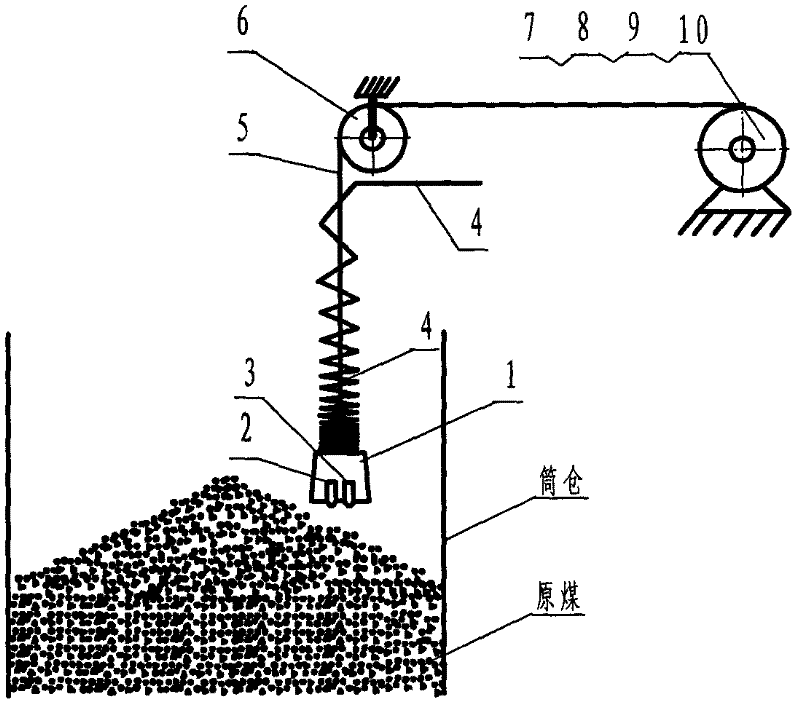

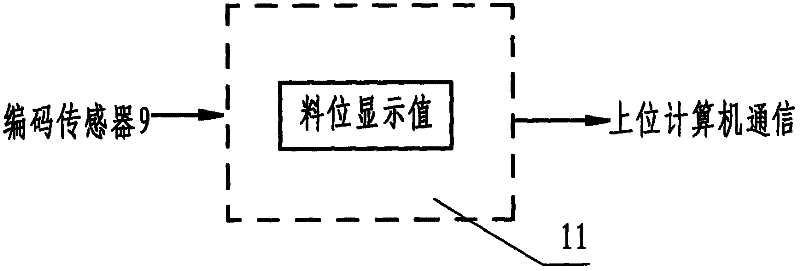

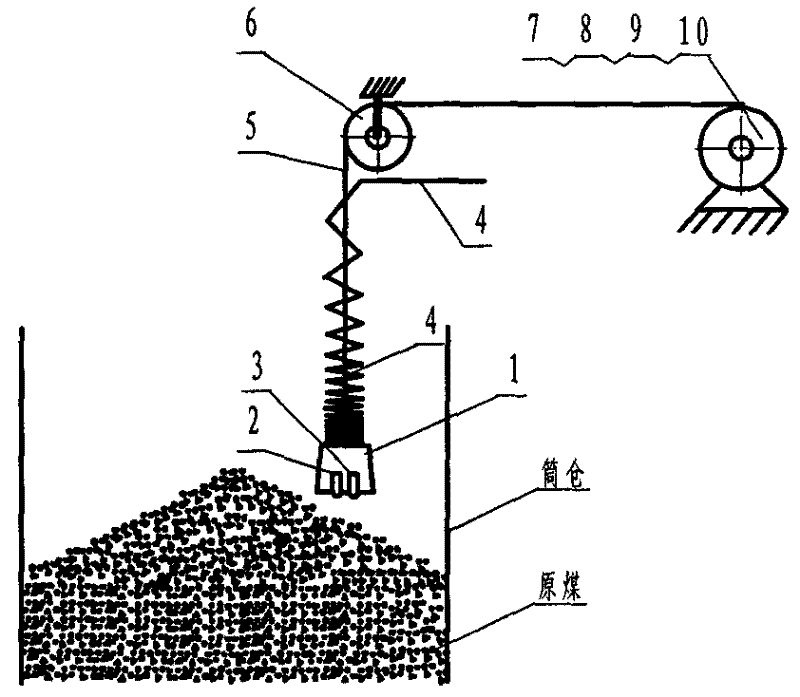

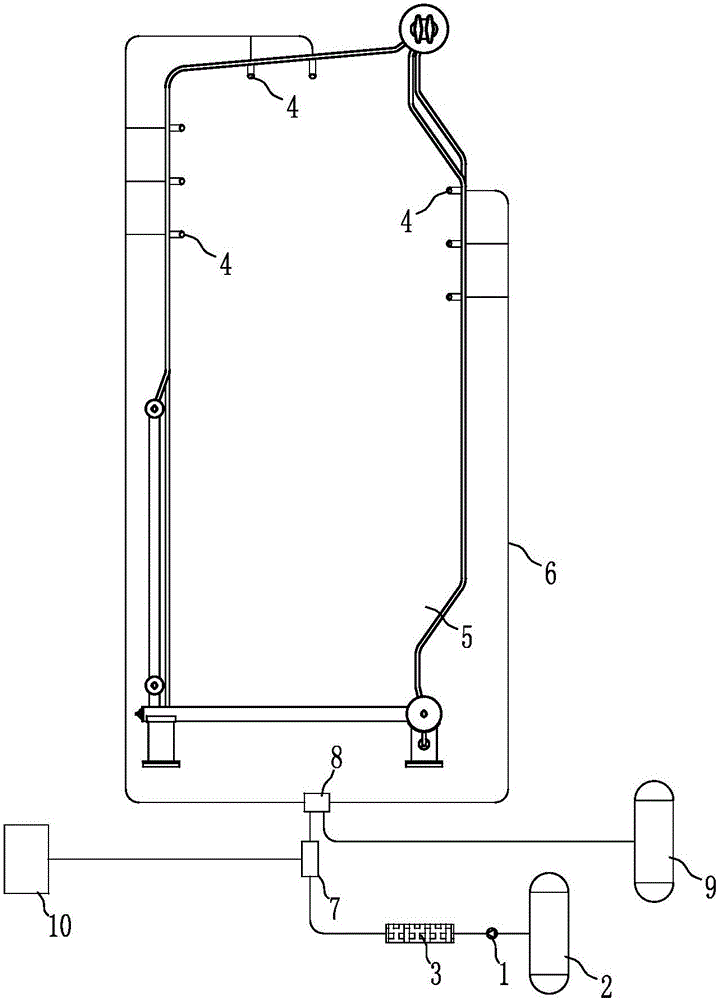

Tracking type coal bunker material level measurement device

ActiveCN102313585ARealize real-time continuous dynamic measurementRealize continuous dynamic measurementMachines/enginesLevel indicatorsInfraredMeasurement device

The invention relates to a tracking type coal bunker material level measurement device and belongs to the technical field of automatic detection and measurement. The tracking type coal bunker material level measurement device is characterized in that the continuous coal bunker material level automatic measurement device consists of a probe 1, a transmission system and a measurement system; the probe 1 is a metal cone hollow body; the whole metal cone hollow body is filled with epoxy resin; an upper limit sensor 2 and a lower limit sensor 3 are mounted inside the metal cone hollow body; the upper limit sensor 2 and the lower limit sensor 3 are reflection infrared photoelectric proximity switches integrating transmitters with receivers; when a material level in a coal bunker is changed, switching value signals output by the upper limit sensor 2 and the lower limit sensor 3 are transmitted to a material level intelligent meter 11 through an electric cable 4; the transmission system consists of a steel wire rope 5, a pulley 6, a motor 7, a speed reducer 8 and a steel wire rope roller 9; and the measurement system consists of a coding sensor 10 and the material level intelligent meter 11. The tracking type coal bunker material level measurement device has the advantages of high measurement precision, long service life and continuous dynamic tracking measurement and is mainly used for measuring the material level of the coal bunker of a coal mine, a coal washery and a power station.

Owner:TAIYUAN UNIV OF TECH

Silo wall rapping air hammer

The invention discloses a bunker wall vibration air hammer, which solves the problem of lower hopper-plugging dredging efficiency at present and is characterized by comprising an electromagnetic reversing valve, an air cylinder, a hammer head, a quick exhaust valve and the like, wherein the electromagnetic reversing valve is connected with an air outlet pipeline of an air storage tank through an air inlet pipeline, connected to one end of the air cylinder through a front air pipe and connected to the other end of the air cylinder through a rear air pipe and the quick exhaust valve; an adjustment valve is arranged between the rear air pipe and the quick exhaust valve; the air cylinder is fixed on a base; and a piston rod of the air cylinder is connected with the hammer head. The bunker wall vibration air hammer has a simple structure and low manufacturing cost; the whole device is arranged outside the wall of a hopper, so openings are not required to be formed on the hopper, the dredging capability is higher and the bunker wall vibration air hammer is quick and convenient to install and maintain; due to an electric control system, regular and continuous vibration can be realized and the vibration frequency can be set randomly; furthermore, the vibration strength is higher, can be adjusted and much higher than manual strength; the vibration is uniform and an effect is outstanding, so the working efficiency can be improved by multiple times; and the bunker wall vibration air hammer is particularly applicable to dredging of raw coal bunkers of thermal power plants.

Owner:ANHUI KANGDI ELECTRIC POWER SCI & TECH

Clay vibrating bunker

InactiveCN101148215AGuarantee unimpededPrevent bridgingLarge containersLoading/unloadingBunkerEngineering

The clay vibrating bin includes one upper cone, one lower cone, one vibrating unit set in between the upper cone and the lower cone. The upper cone has one air gun with nozzle in the inner wall, and the lower cone has one hand valve and one electric valve in the lower part. The clay vibrating bin has fluent and homogeneous material feeding and easy cleaning.

Owner:JIANGSU WANLI MACHINERY

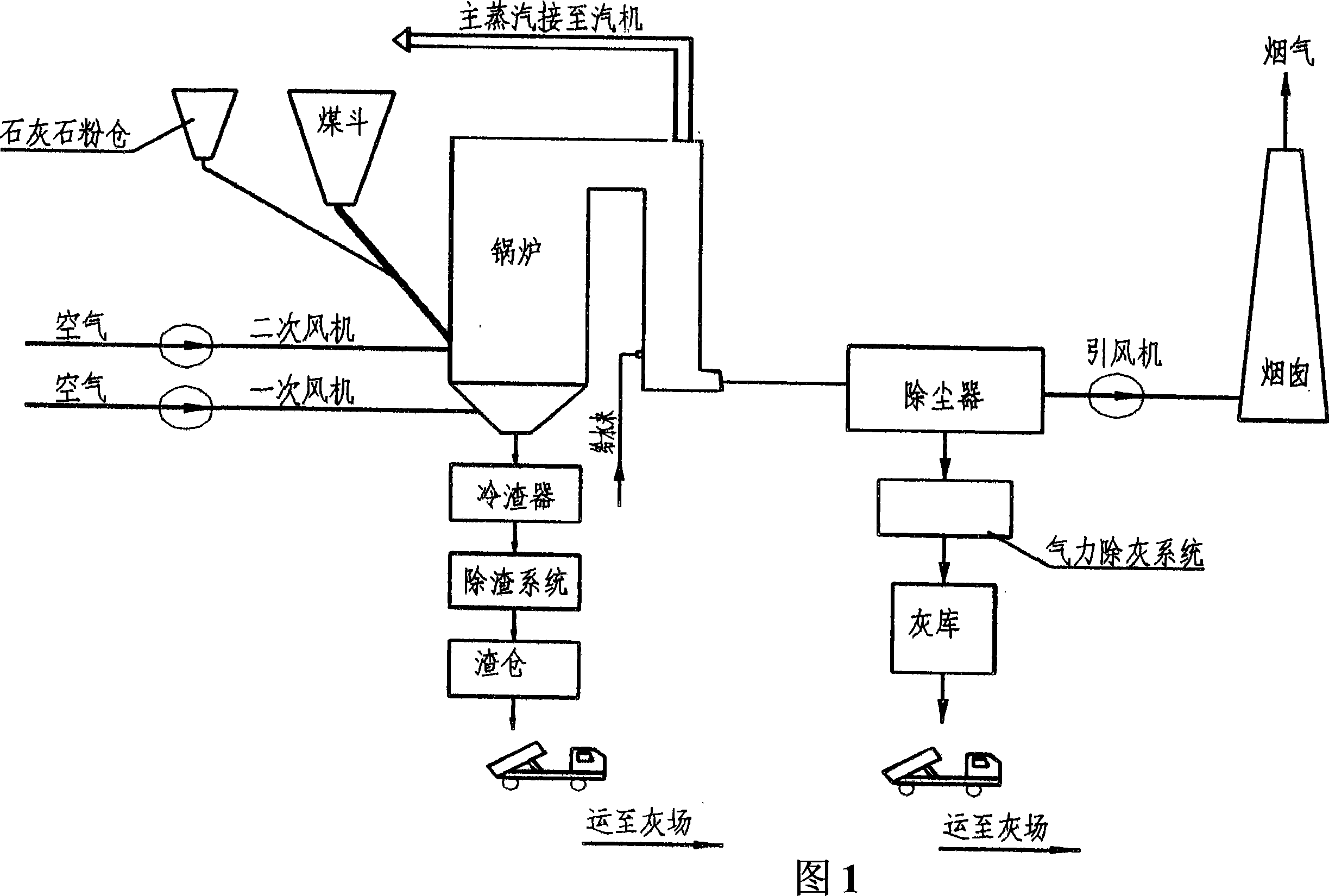

300MW circulating fluidized bed boiler island

InactiveCN101162087ASuppress generationReduce exhaust heat lossFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention discloses a 300MW circulating fluidized bed boiler island device; the boiler of the invention adopts the circulating fluidized bed profile, limestone powders are added in the boiler and combusted at the temperature of 840 DEG C to 950 DEG C; the boiler comprises a separator, a material return system, a first-level raw coal crushing system, a second-level raw coal crushing system, a first-level coal feeder, a second-level coal feeder, an air-water combined fluidized type cold slag apparatus, a mechanical dry type slag removing system, a deoxidizing chamber and a coal bunker, wherein an outlet of the second-level coal feeder is provided with a helical type dispenser; the deoxidizing chamber and the coal bunker adopt the combination single frame arrangement, the deoxidizing chamber is provided with a built-in deaerator; the invention has the advantages of high efficiency, environmental protection, cleanliness, smooth slag removal, safety, reliability and high efficiency and energy save of the equipment; moreover, the coal feeding system is not blocked, all environmental protection emitting values of the boiler operation reach or exceed the National Environmental Protection Emission Standard, the main workshop arrangement of the invention is optimized, compact and reasonable, which meets the requirements of the production operation and the maintenance and the whole project is low in investment.

Owner:ENERGY CHINA YNPD

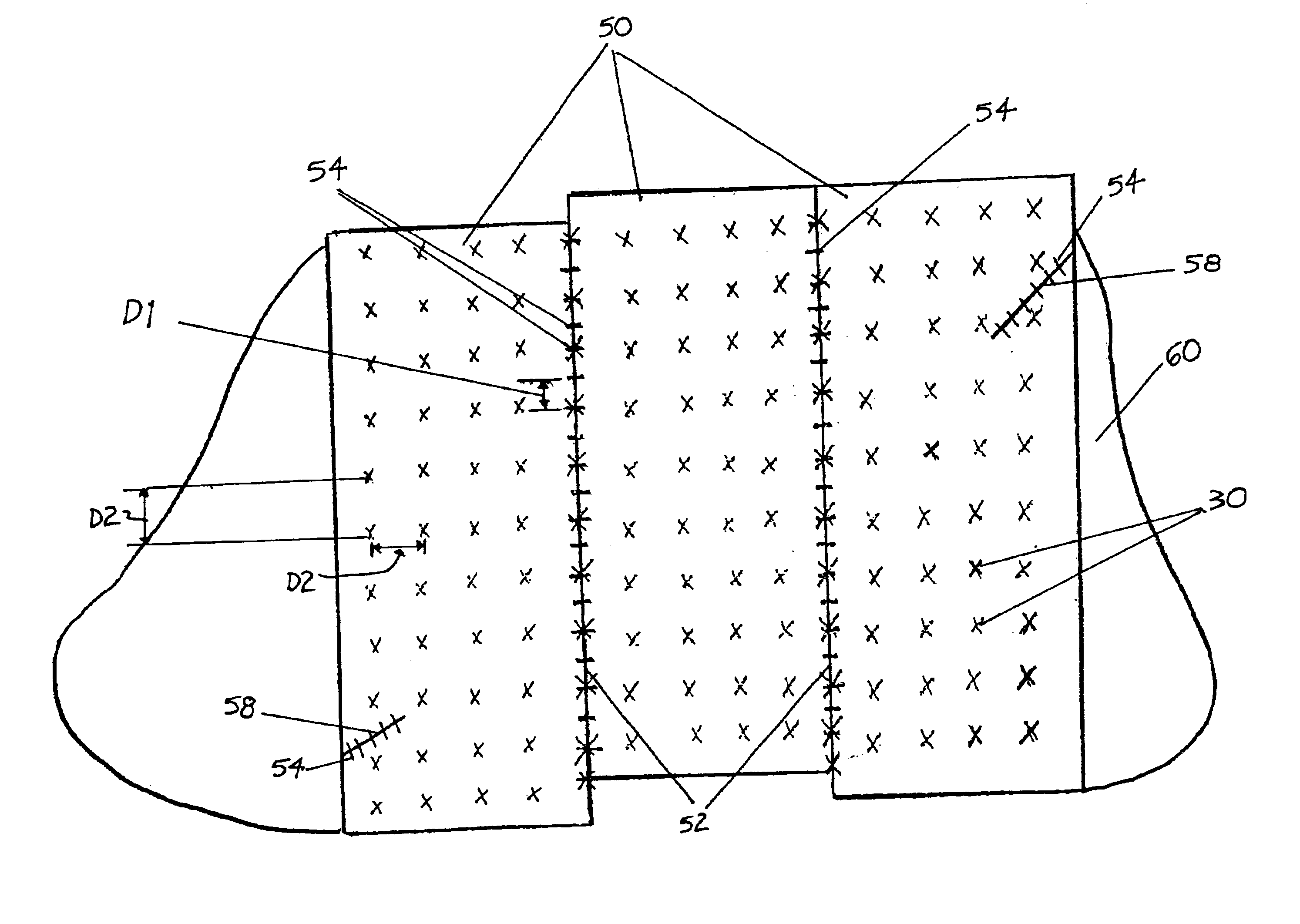

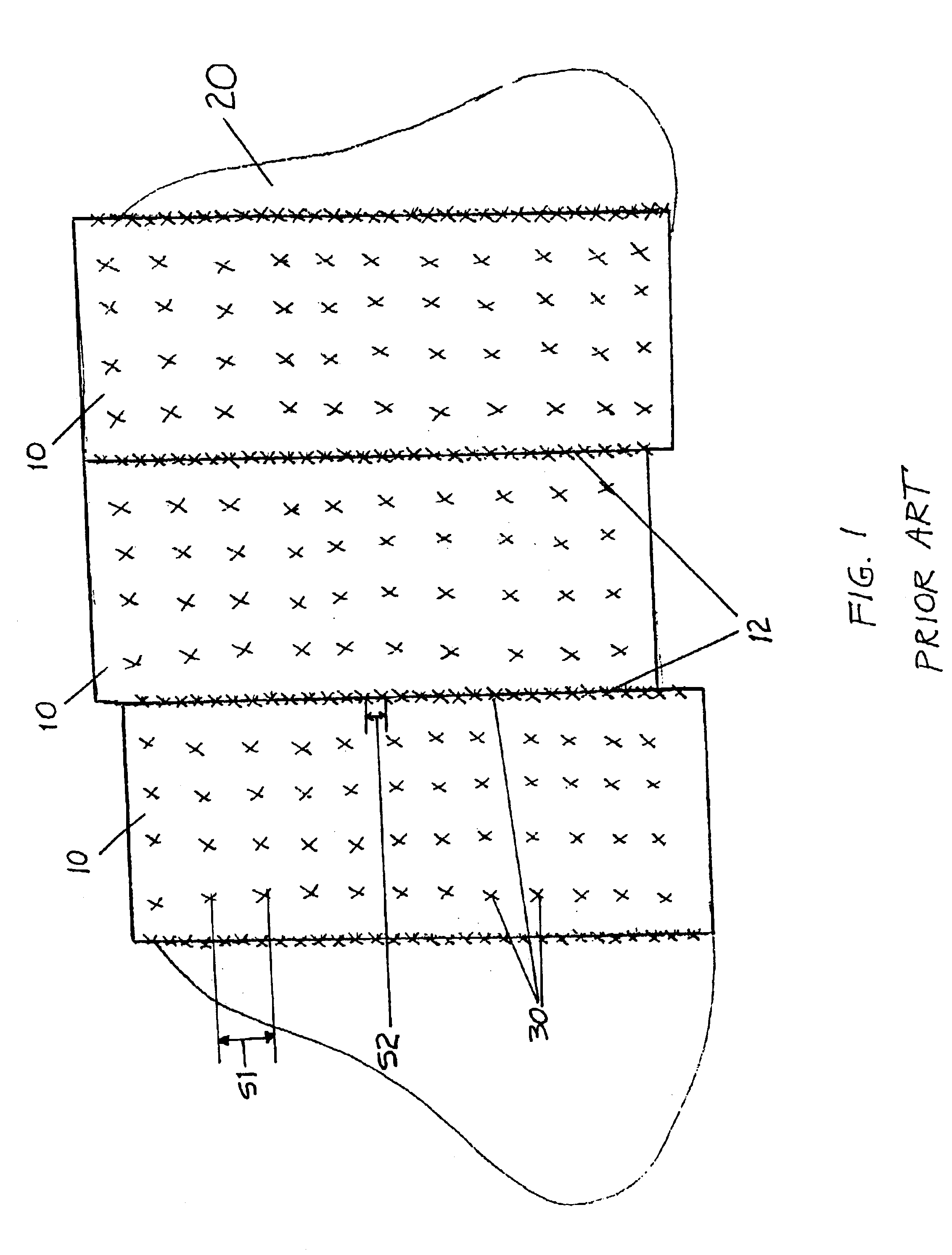

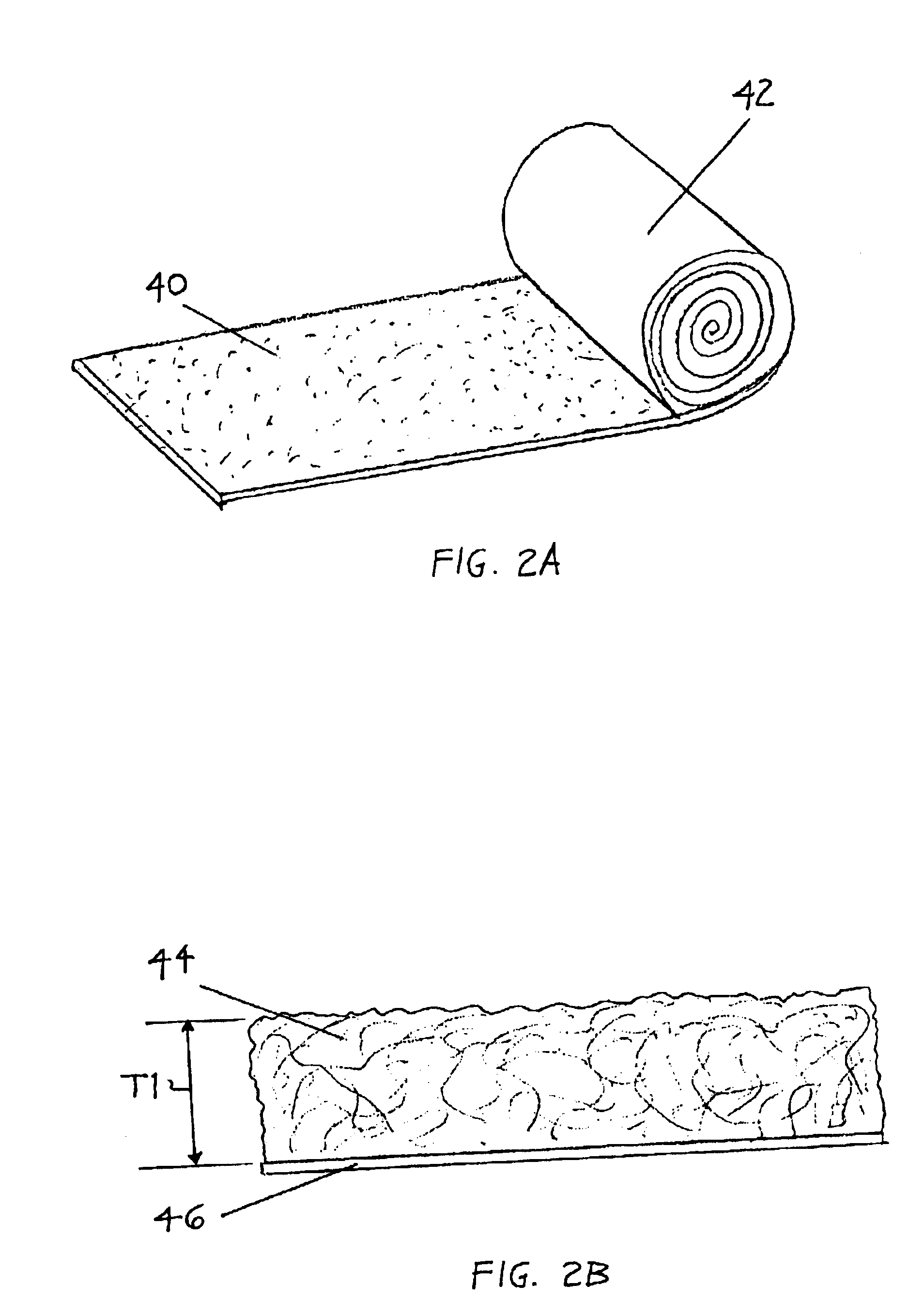

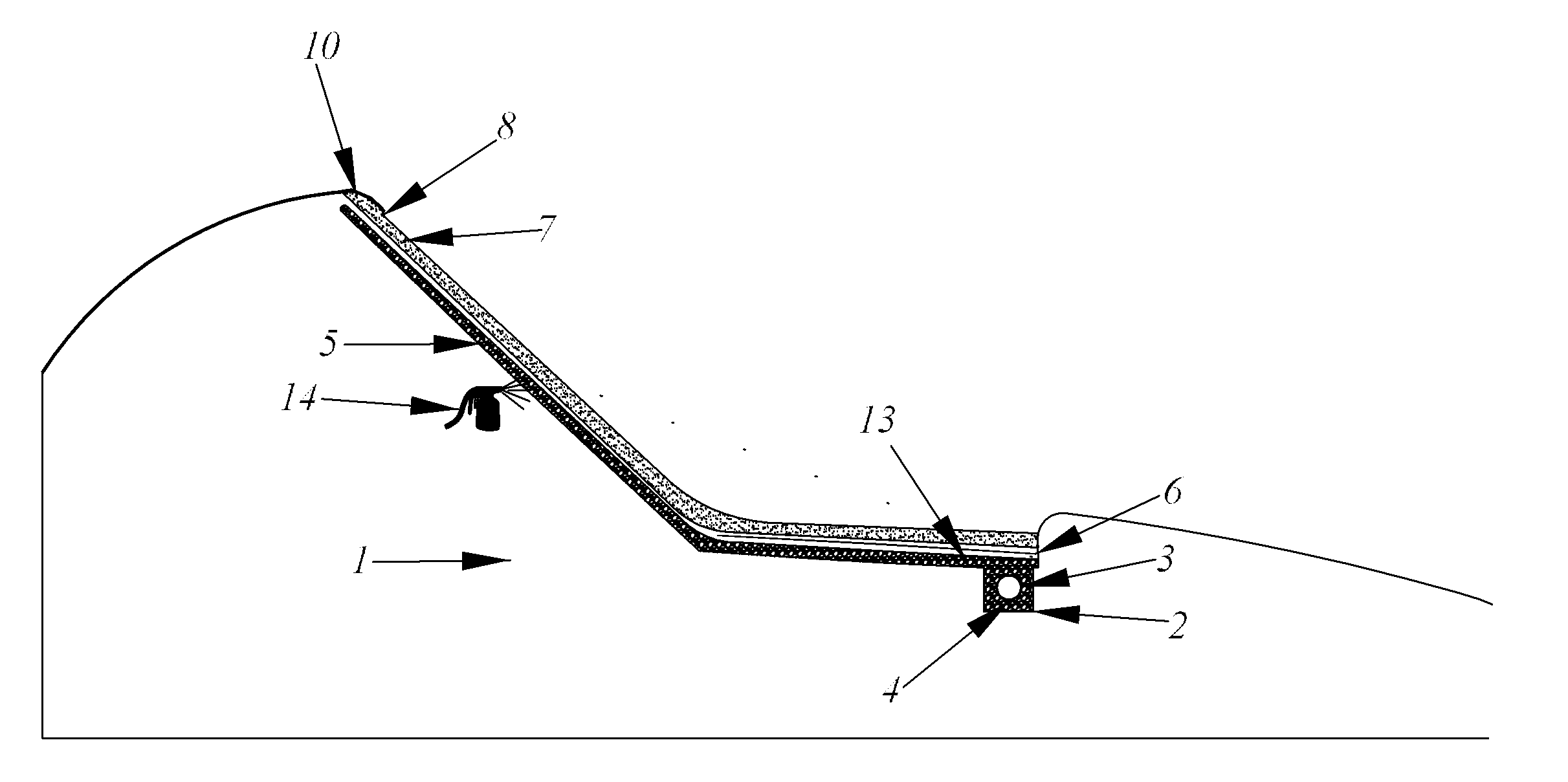

Method and material for preventing erosion and maintaining playability of golf course sand bunkers

InactiveUS6863477B2Avoid erosionMaintaining playabilityRoads maintainenceSoil conditioning compositionsGolf course turfHand held

A method and material for preventing erosion and maintaining playability of golf course sand bunkers. A geotextile liner is formed of two water-permeable layers. A first non-woven layer of randomly-aligned, synthetic fibers is configured and adapted to maintain sand in place within a sand bunker. A second backing layer formed of spunbond synthetic fiber is impervious to sand and configured and adapted to prevent downward migration of sand through the liner, while also preventing the upward migration of weeds, rocks and other contaminants that hinder the playability of the sand bunker. The backing layer also permits seams between adjacent sections of the liner to be joined by staples that penetrate the second layer but do not penetrate the native soil. Sections of the liner are laid within an unfilled sand bunker, and cut to fit the contours of the bunker as necessary. The liner is anchored to the bunker base using a plurality of sod staples, and seams between adjacent sections of the liner are joined using staples that are not sod staples and are configured and adapted to penetrate the backing layer of the liner but not penetrate soil. The staples used to join the seams between adjacent sections of the liner may be installed using a hand-held, pneumatic stapler.

Owner:CONTINENTAL COMML PRODS

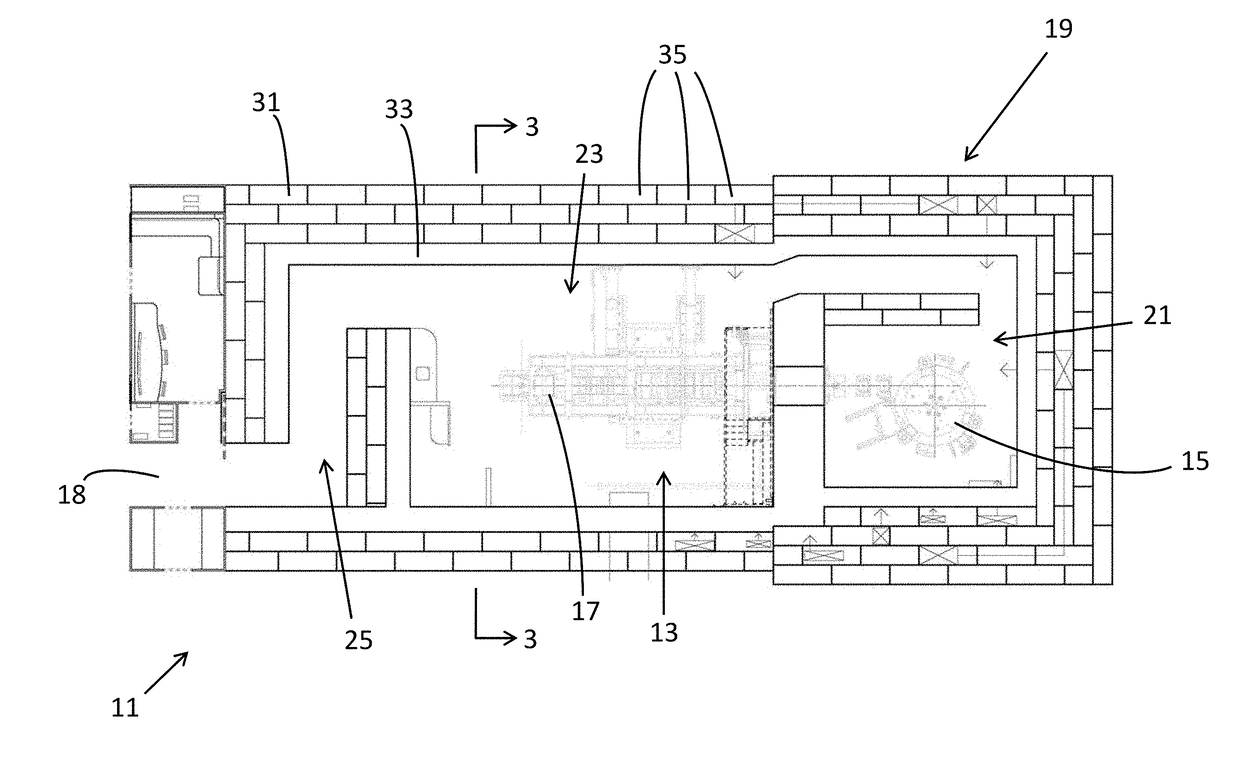

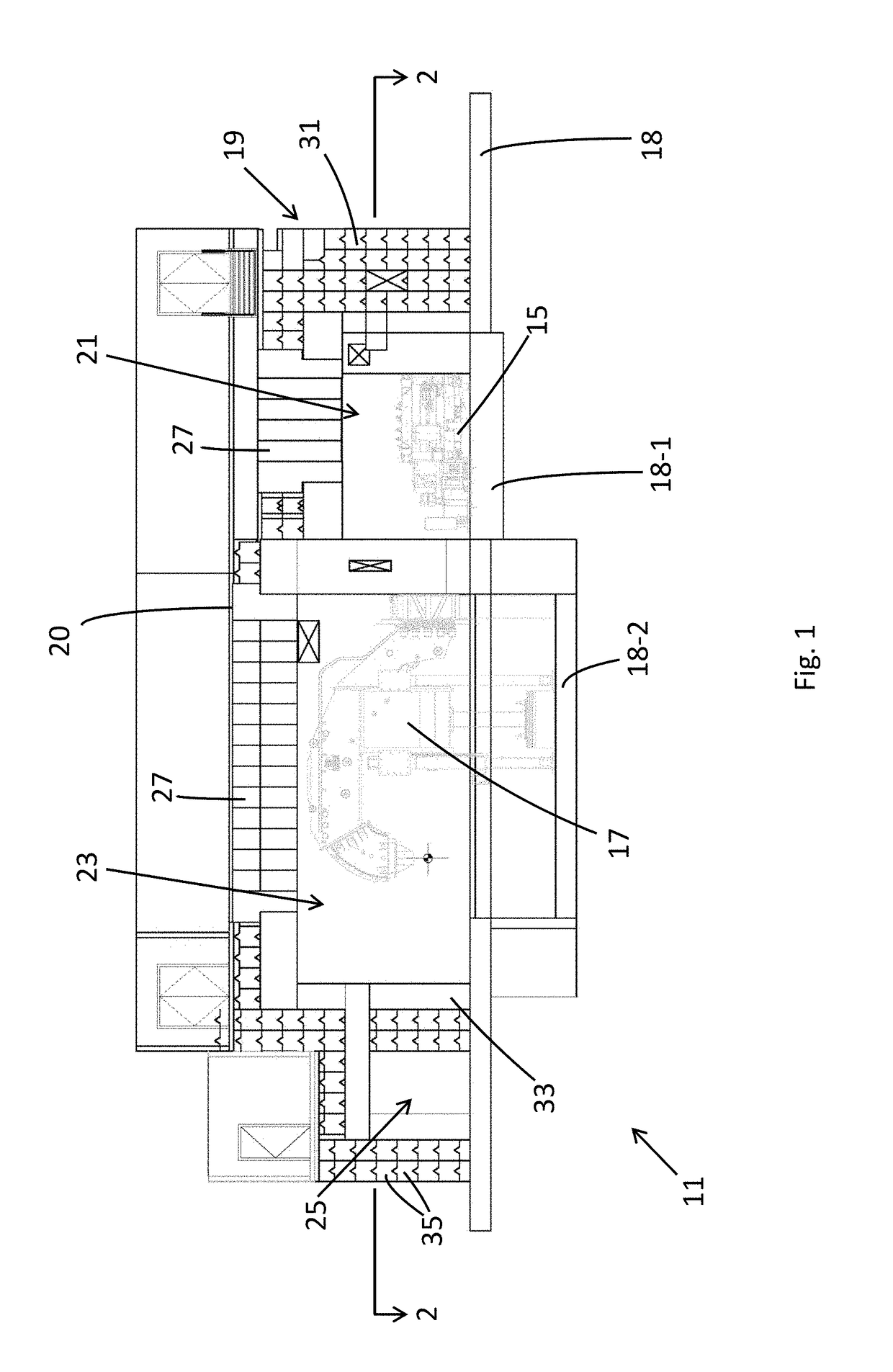

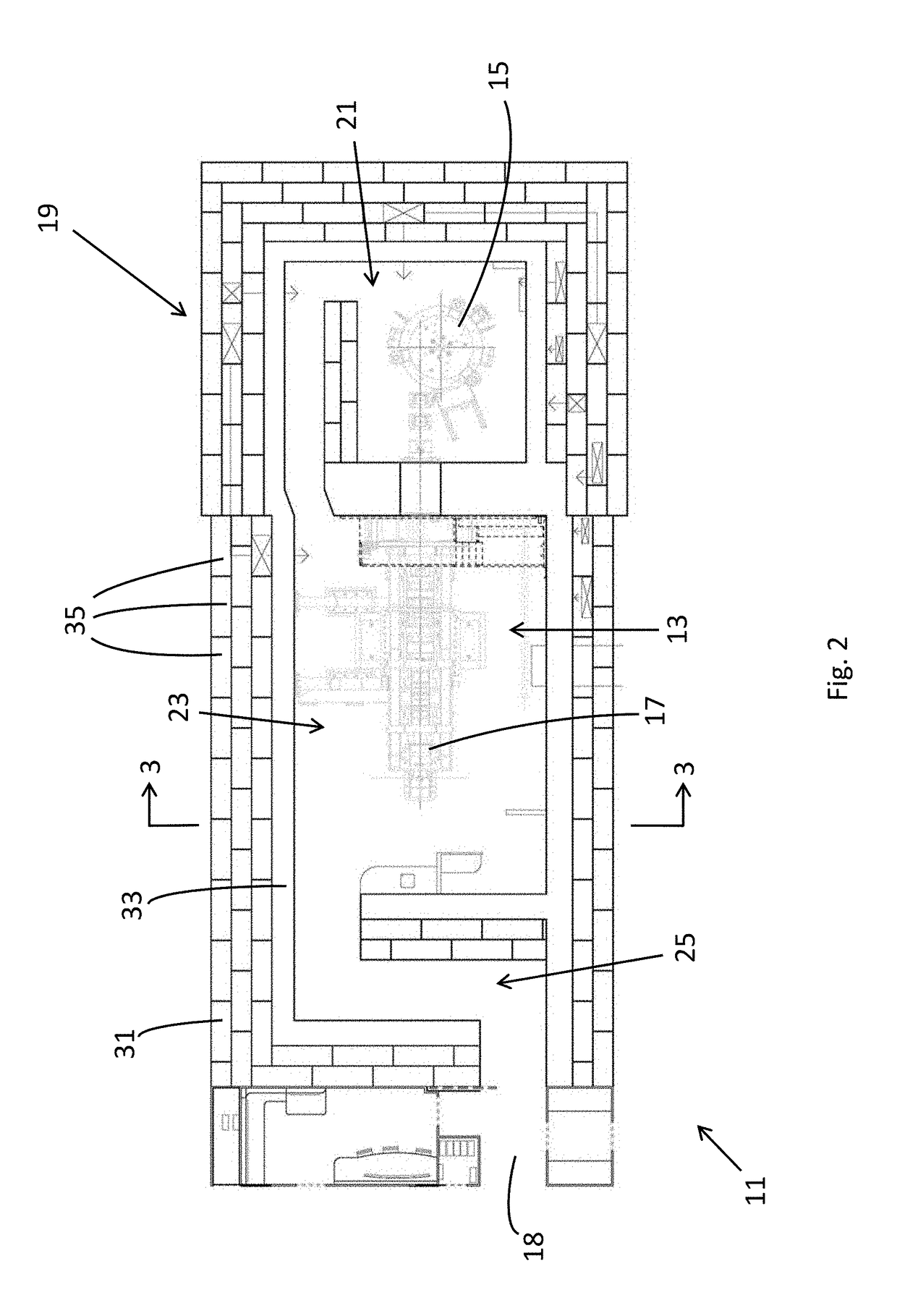

Bunker system for radiation therapy equipment

A bunker system for shielding radiation emitted from a radiation treatment device includes a multi-core wall structure that completely surrounds the radiation treatment device. The wall structure includes a cast-in-place concrete inner core of limited thickness in order to minimize curing time requirements. The inner core is immediately surrounded by an outer core constructed from a plurality of preformed modular blocks. Each modular block is constructed of a radiation shielding material, such as concrete. As part of the assembly process, the preformed modular blocks are designed to be stacked top-to-bottom and side-by-side in an interlocking fashion to form a continuous wall structure, with blocks additionally arranged in a front-to-back relationship to achieve the required outer core thickness. The dual-core construction of the wall structure enables the bunker system to be quickly and efficiently assembled with enhanced quality control and potential reusability.

Owner:NEW ENGLAND LEAD BURNING CO INC

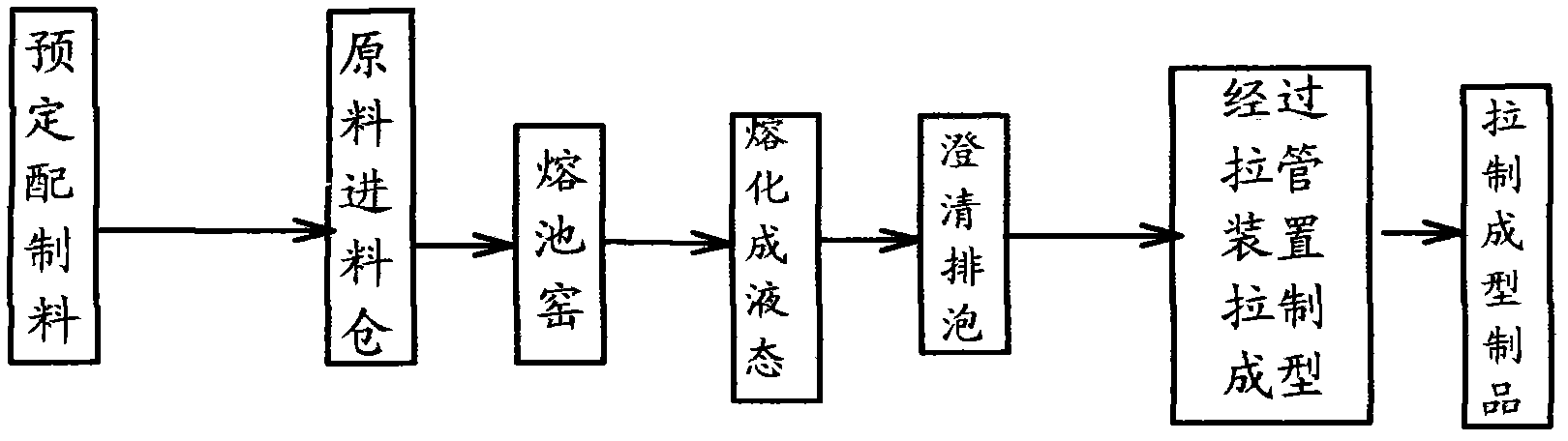

Process for preparing high-strength, energy-saving, environmentally-friendly and low-viscosity glass

The invention relates to a process for preparing high-strength, energy-saving, environmentally-friendly and low-viscosity glass. The glass comprises the following components in percent by weight: 0-1% of boron oxide, 0.01-14% of sodium oxide, 0.01-5% of ferric oxide, 0% of fluorine oxide, 8.1-20.2% of magnesium oxide, 8-30% of aluminium oxide, 1.9-4.1 times weight of calcium oxide of silicon oxide, and 1.2-1.6 times weight of magnesium oxide of calcium oxide. The process comprises the following steps of: (1) preparing raw materials required for the glass according to the requirements; (2) metering the prepared components and putting in a large material tube or a bunker which loads burdening; (3) putting the mixed material into a bath, melting at melting temperatures corresponding to each glass formula, and forming a molten glass with a predetermined viscosity, then homogenizing, clearing, exhausting bubbles, and forming a flowing melt; and (4) moulding by selecting or adopting a pull tube moulding process, a blowing moulding process or a compression moulding process, annealing and cooling, thus the high-strength, energy-saving, environmentally-friendly and low-viscosity glass is obtained, and a water absorption of the glass being within 0-0.3% range and a fracture resistance strength of the glass being 70-180MPa.

Owner:SHENZHEN QIANHAIFA NEW MATERIAL TECH CO LTD

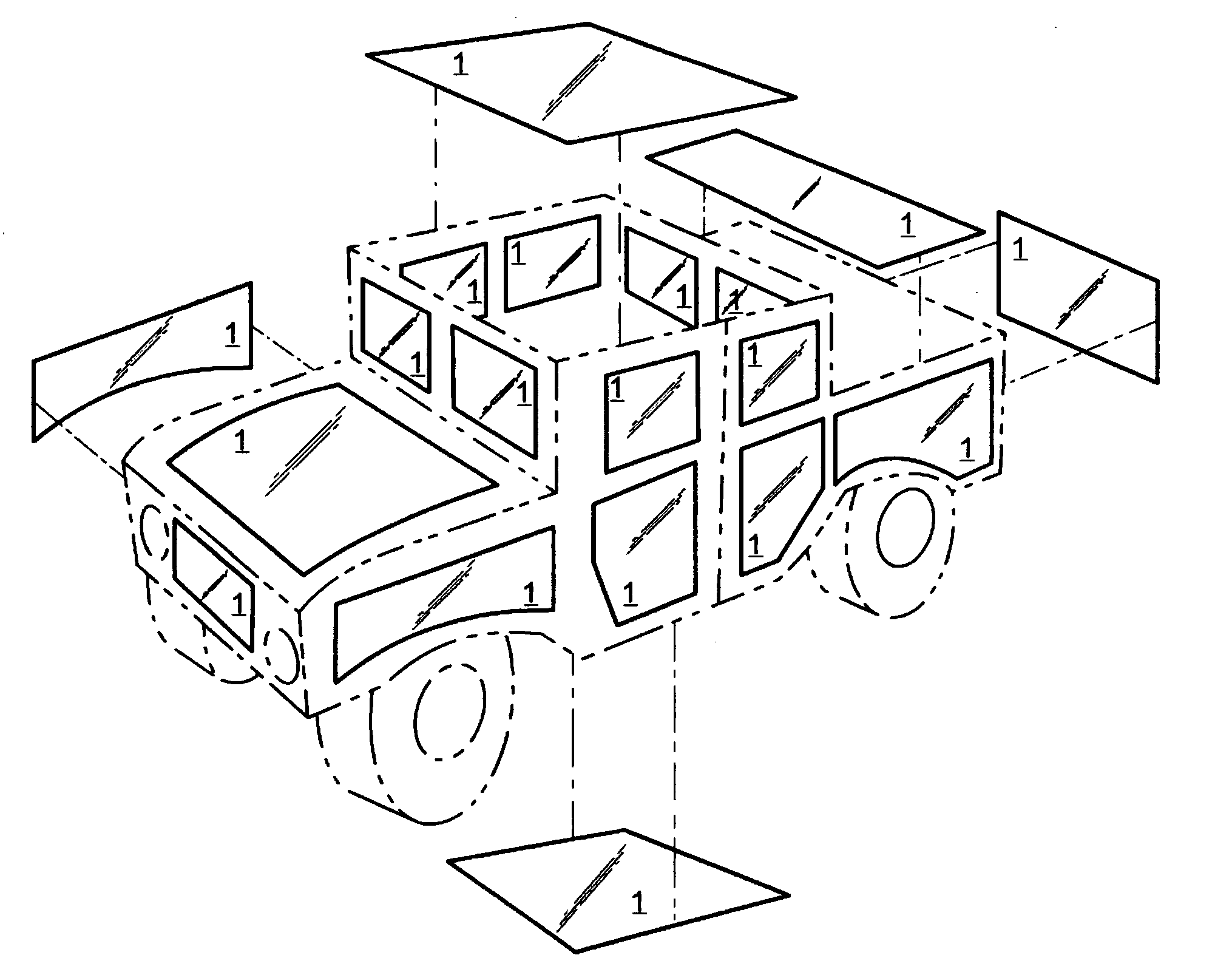

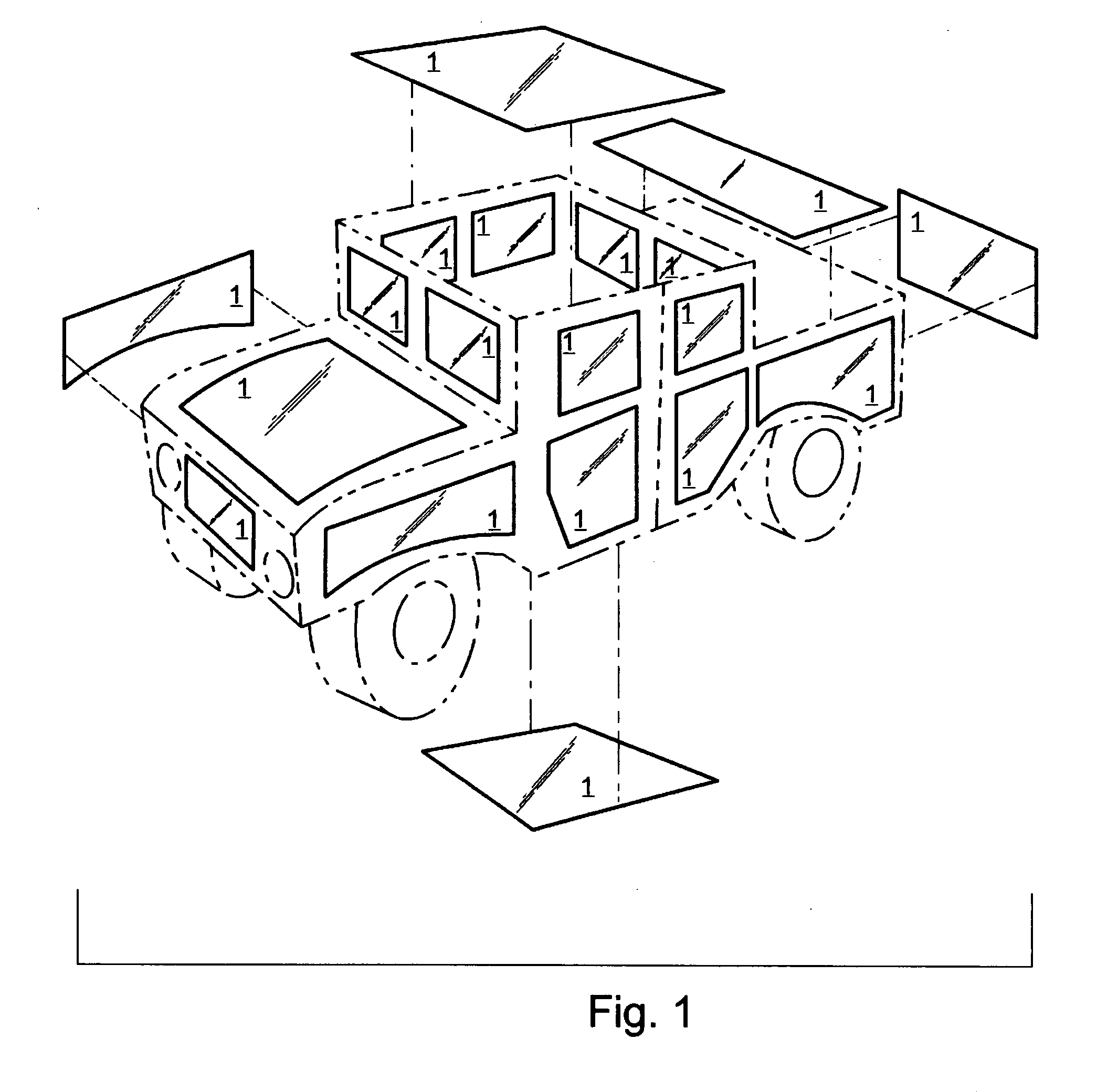

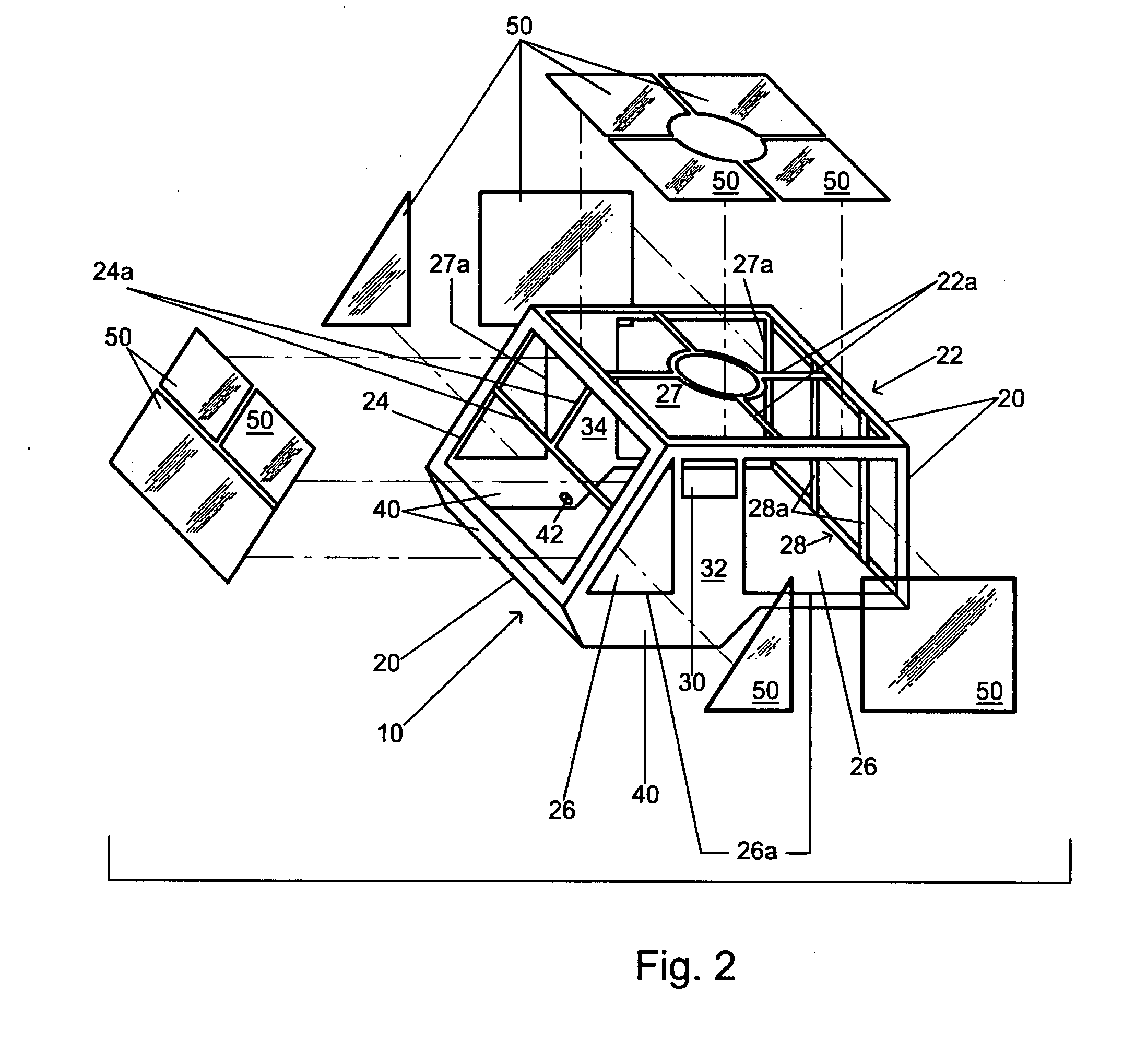

Articles, manufactures, and assemblies utilizing configured and sized plates comprised of penetration-proof laminated constructs formed of asymmetric composite materials

InactiveUS20100024633A1Improve penetration resistanceArmoured vehiclesArmour platesBunkerTelevision screen

The present invention is directed to structures, constructions and assemblies able and functional to protect living subjects from a range and variety of moving objects differing in size, volume, and overall shape; from projectiles traveling at many different rates of speed, and from the effects of exploding and / or advancing solid fragments moving at high velocity. More specifically, the present invention relates to protecting living human and animal subjects through the use of three-dimensional designed structures and assemblies which employ configured and dimensioned penetration-resistant plates prepared from laminated constructs comprising multiple individual layers composed of asymmetric composite materials. These penetration-resistant plates will protect living subjects from high velocity projectiles and fragments in both civilian and combat situations.More specifically, the invention relates to protecting subjects through the use of penetration-resistant prepared plates for use in a wide range and variety of erections, constructions and assemblies. As typical examples, the penetration-resistant plates can be used to great advantage as in the making of shatter-proof windows, doors, curtain wails, face masks, vests, flooring, helmets, tires, computer screens, television screens, housing, aircraft shelters / bunkers, boats, security vehicles, buildings, automotive, sport arenas, guard shields.

Owner:AMERICAN DEFENSE SYSTEMS

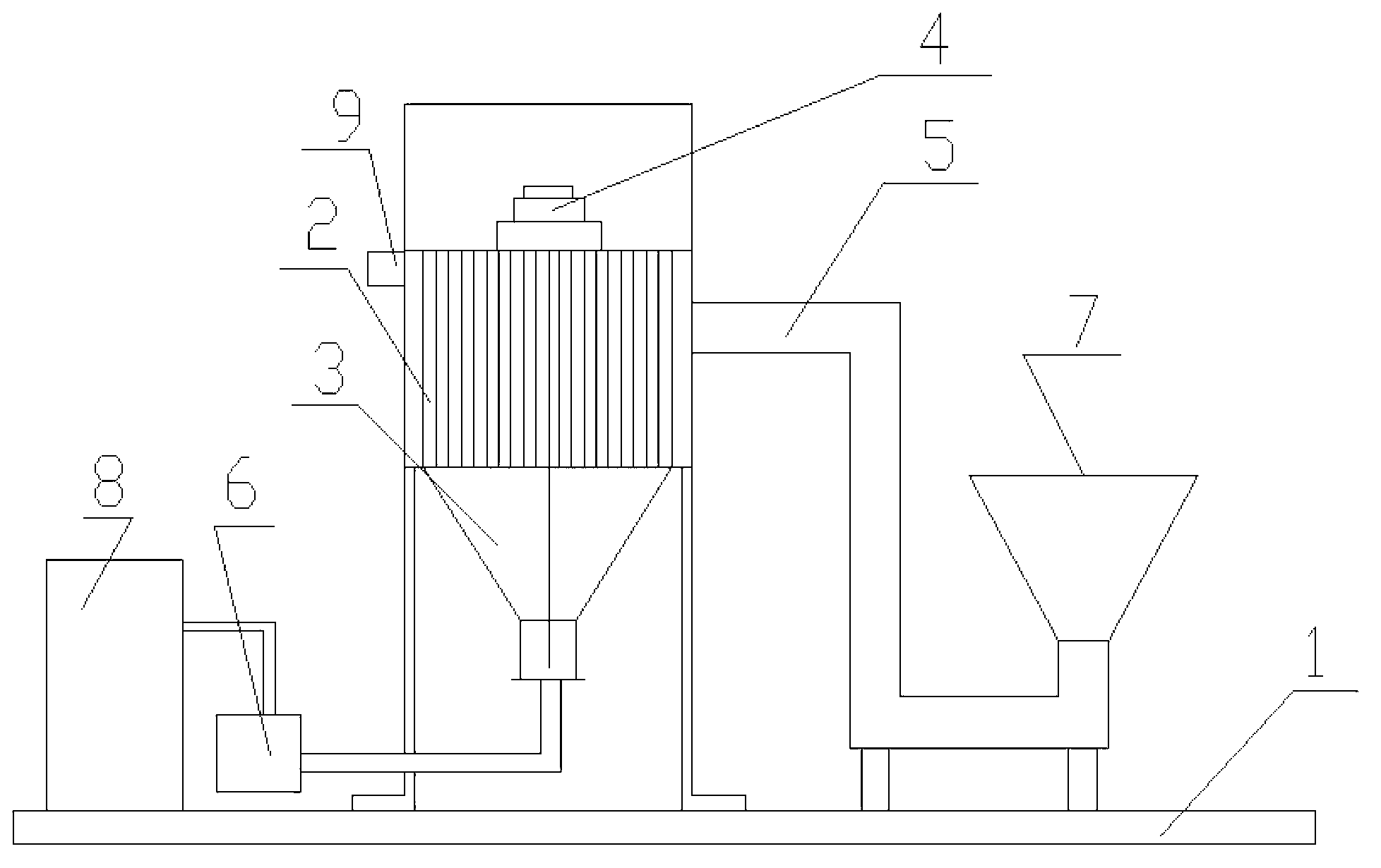

Discharging and dedusting device on bunker

InactiveCN103230714AImprove work efficiencyImprove filtration efficiencyDispersed particle filtrationBaghouseWorking environment

The invention discloses a discharging and dedusting device on bunker, which comprises a movable unloading trailer and a supporting platform, and the supporting platform is arranged with a cloth bag deduster, a flue-dust retainer, a sound wave ash removing device, a dedusting pipeline and a centrifugal blower fan; the flue-dust retainer is arranged below the cloth bag deduster, and the sound wave ash removing device is arranged above the cloth bag deduster, and the centrifugal blower fan and the flue-dust retainer are communicated, and one end of the dedusting pipeline is provided with an ash suction port which is communicated with an ash outlet of the movable unloading trailer, and the other end of the dedusting pipeline is communicated with the upper part of the cloth bag deduster. When discharging, primary air containing dust enters into a deduster casing from an air inlet of the cloth bag deduster, and an outer filter cloth filters the dust in the primary air containing dust, and the dust adheres to the cloth bag; when the set value is reached, the sound wave ash removing device starts for vibrating and beating the dust which is adhered to the cloth bag, and dust drops into the flue-dust retainer, and is sent to an electric ash discharging and storing apparatus by the centrifugal blower fan for carrying away. The equipment has the advantages of high work efficiency, good filtering efficiency, improved work environment, thereby realizing energy saving and emission reduction without secondary pollution.

Owner:安徽华龙环保技术工程有限公司

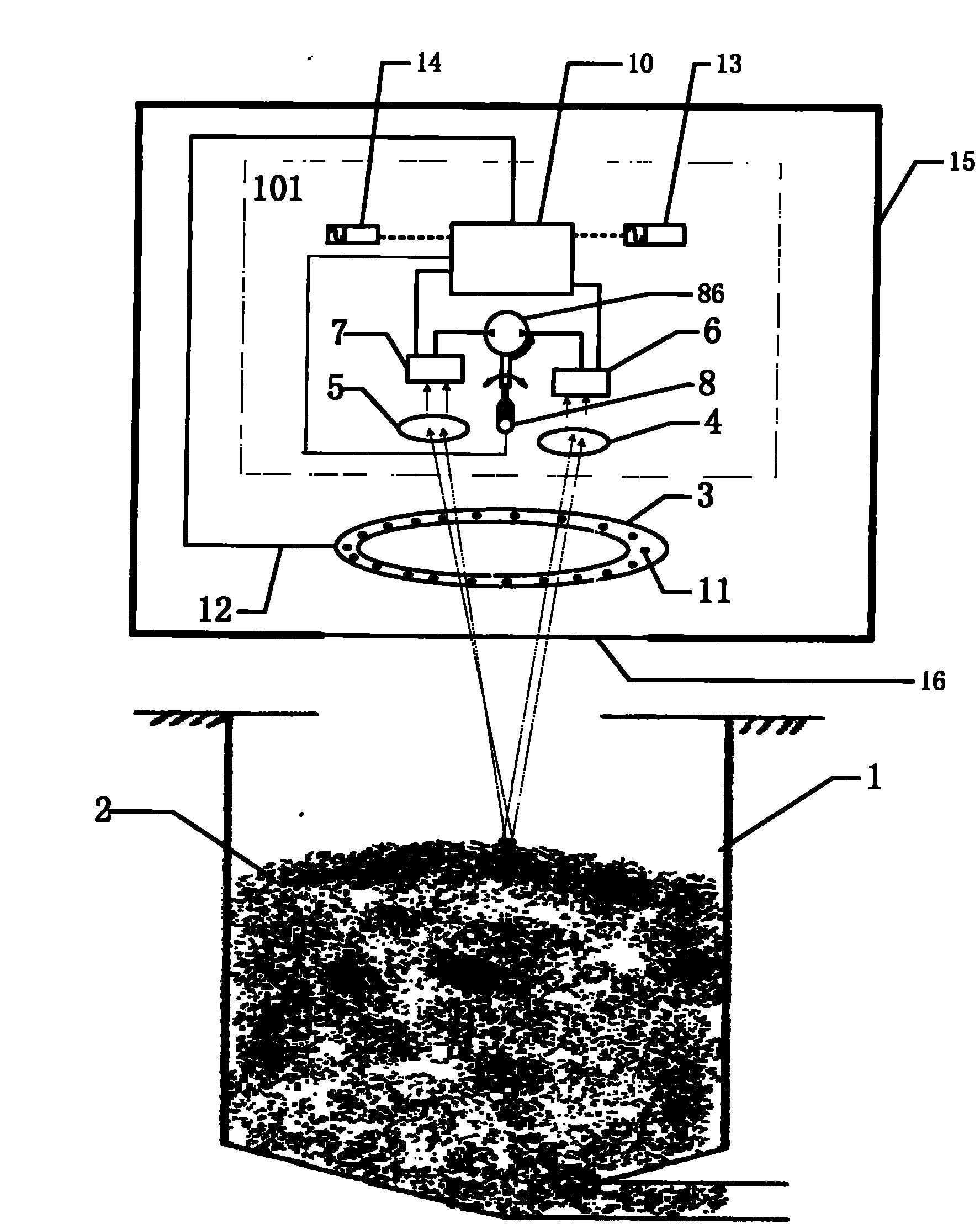

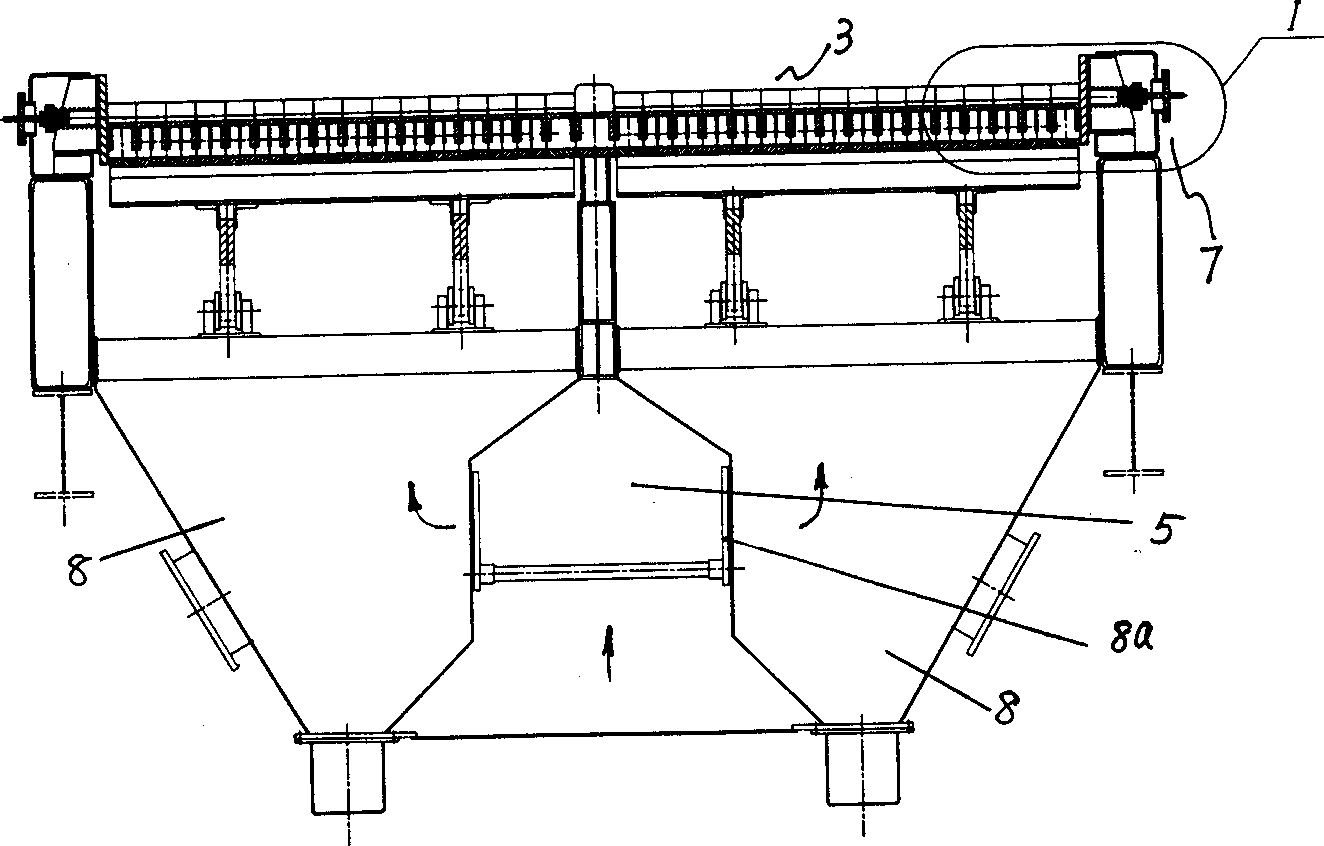

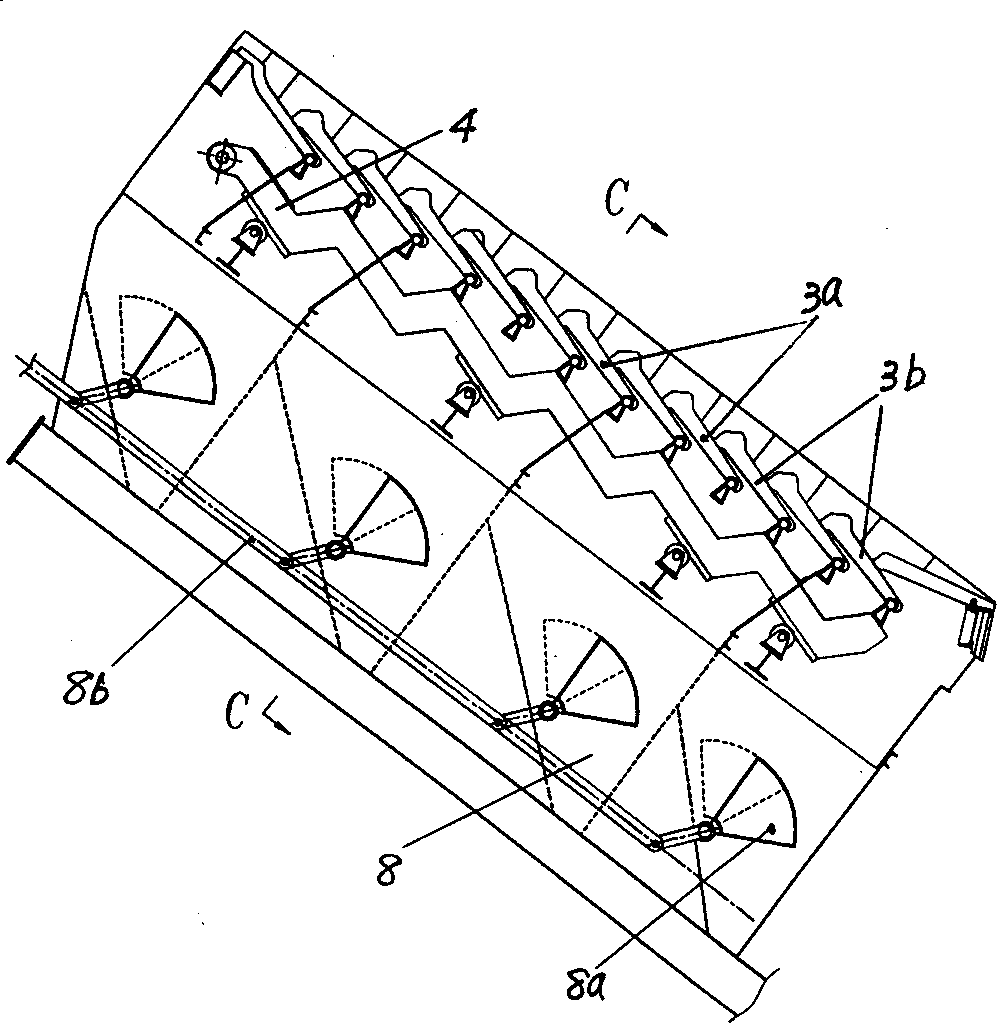

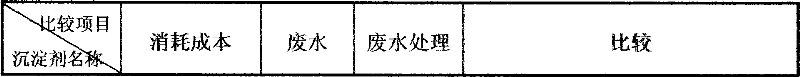

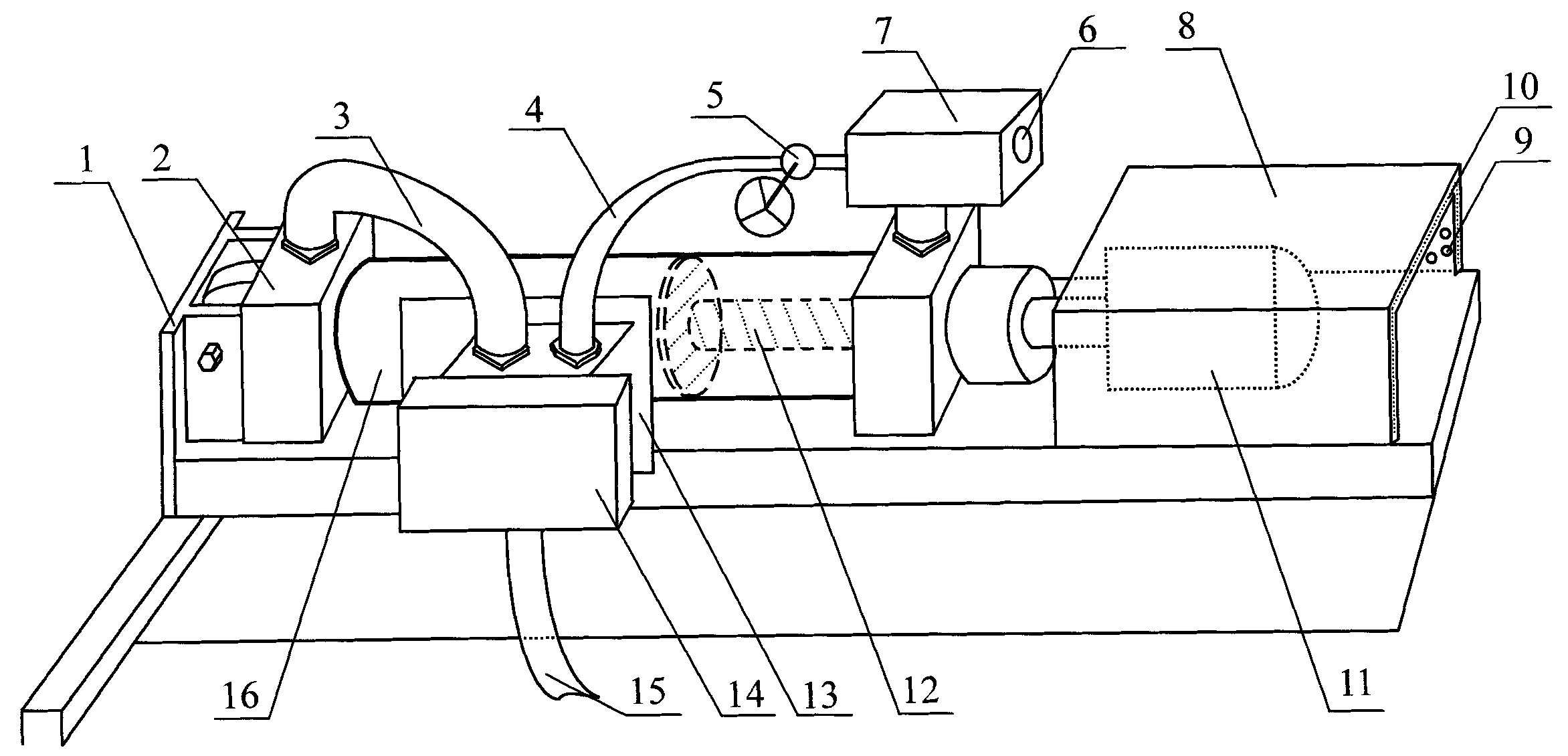

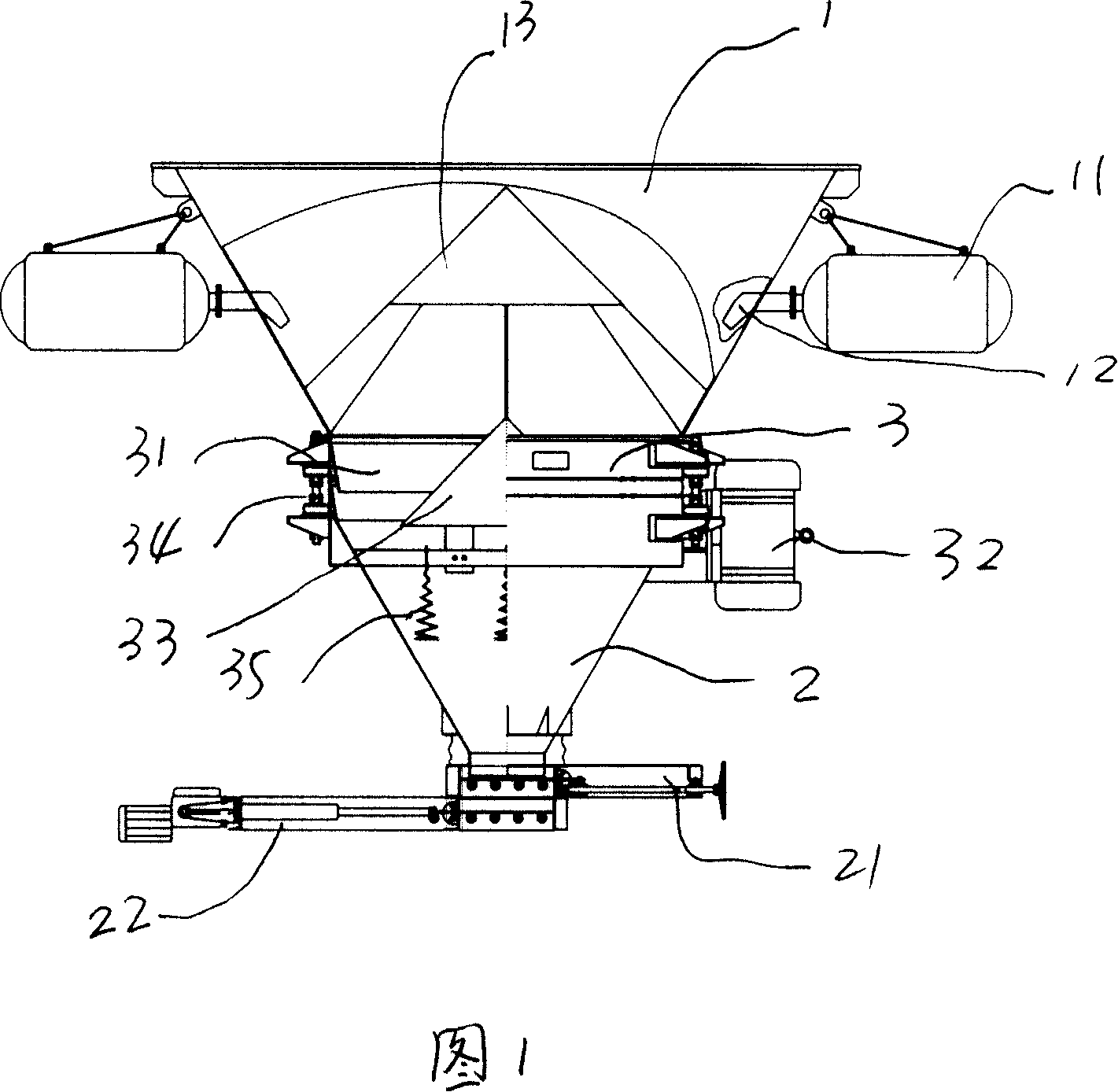

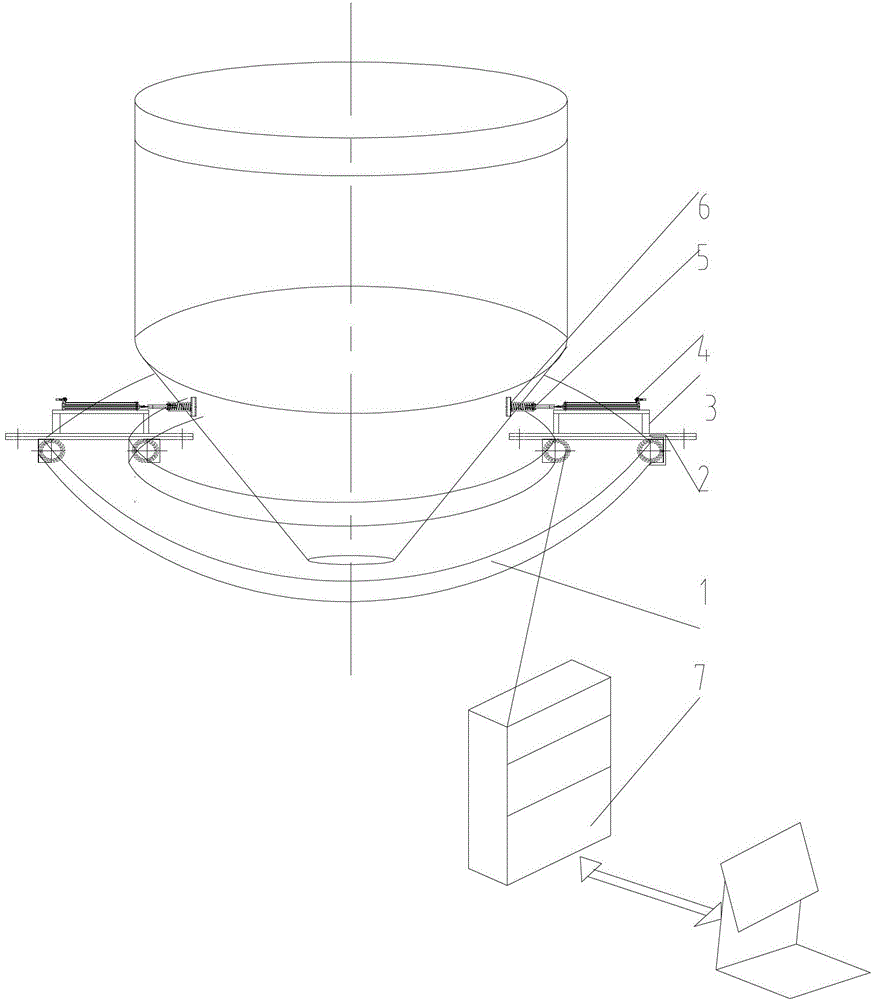

Mobile vibrating and activating device of large bunker

The invention relates to an external mobile vibrating and activating device of a large bunker for stocked materials which are susceptible to a processing unit, sticky and thereby unsmooth in feeding. The mobile vibrating and activating device comprises a roundabout circular bunker rail 1, vibrating and activating device fixing carts 2, vibrating and activating device frames 3, air cylinders 4, buffer springs 5, arc-shaped vibrating and beating plates 6 and an electrical control system 7. The mobile vibrating and activating device is characterized in that various parts of the vibrating and activating device are mounted on the vibrating and activating device fixing carts 2 and move along the roundabout circular rail 1, and the materials are activated by beating the wall of the bunker with the arc-shaped vibrating and beating plates 6 and consequently can be fed smoothly. The mobile vibrating and activating device has the advantages of simple design, low cost and maintenance workload; the materials sticky to the wall can be fed smoothly, continuously, stably and uniformly, and no activating blind areas exist.

Owner:NINGXIA JIAXIANG AUTOMATIC CONTROL TECH

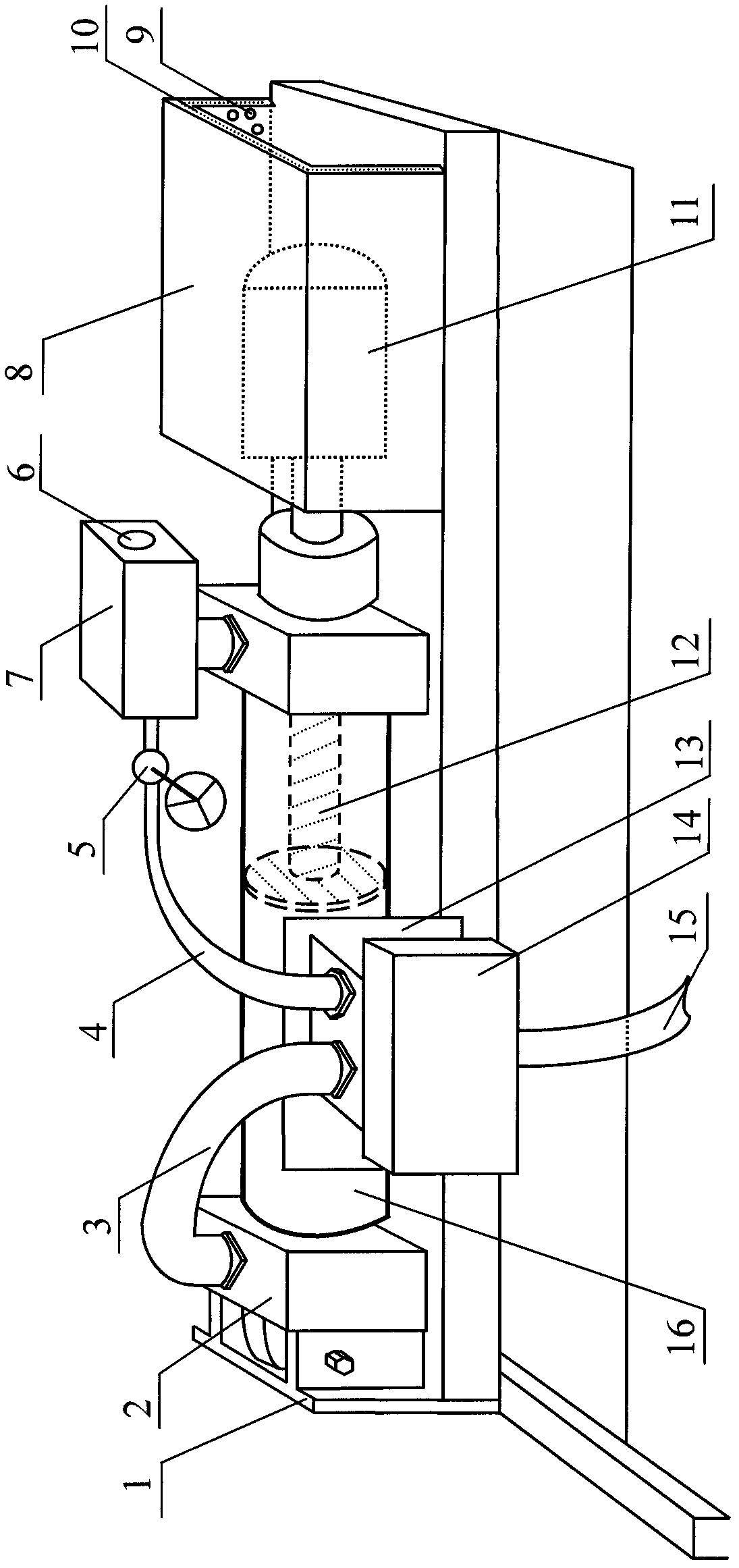

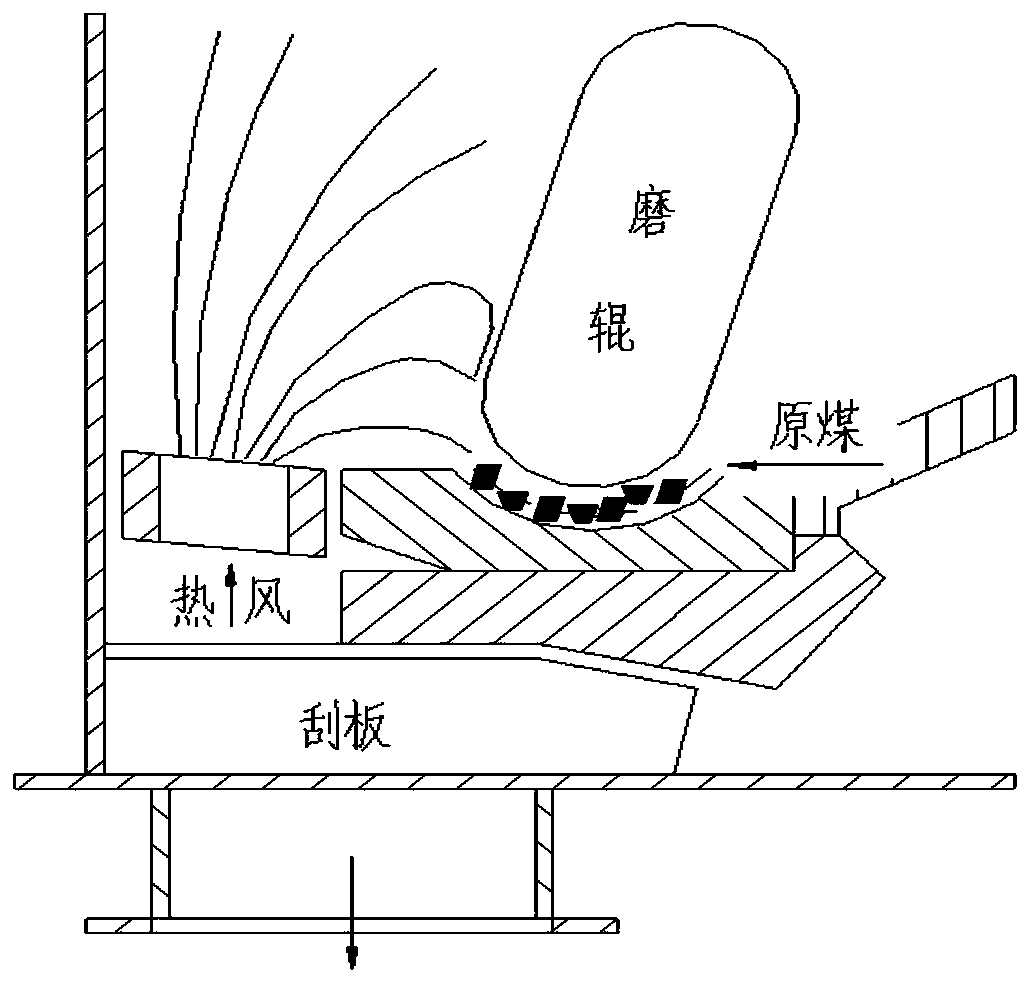

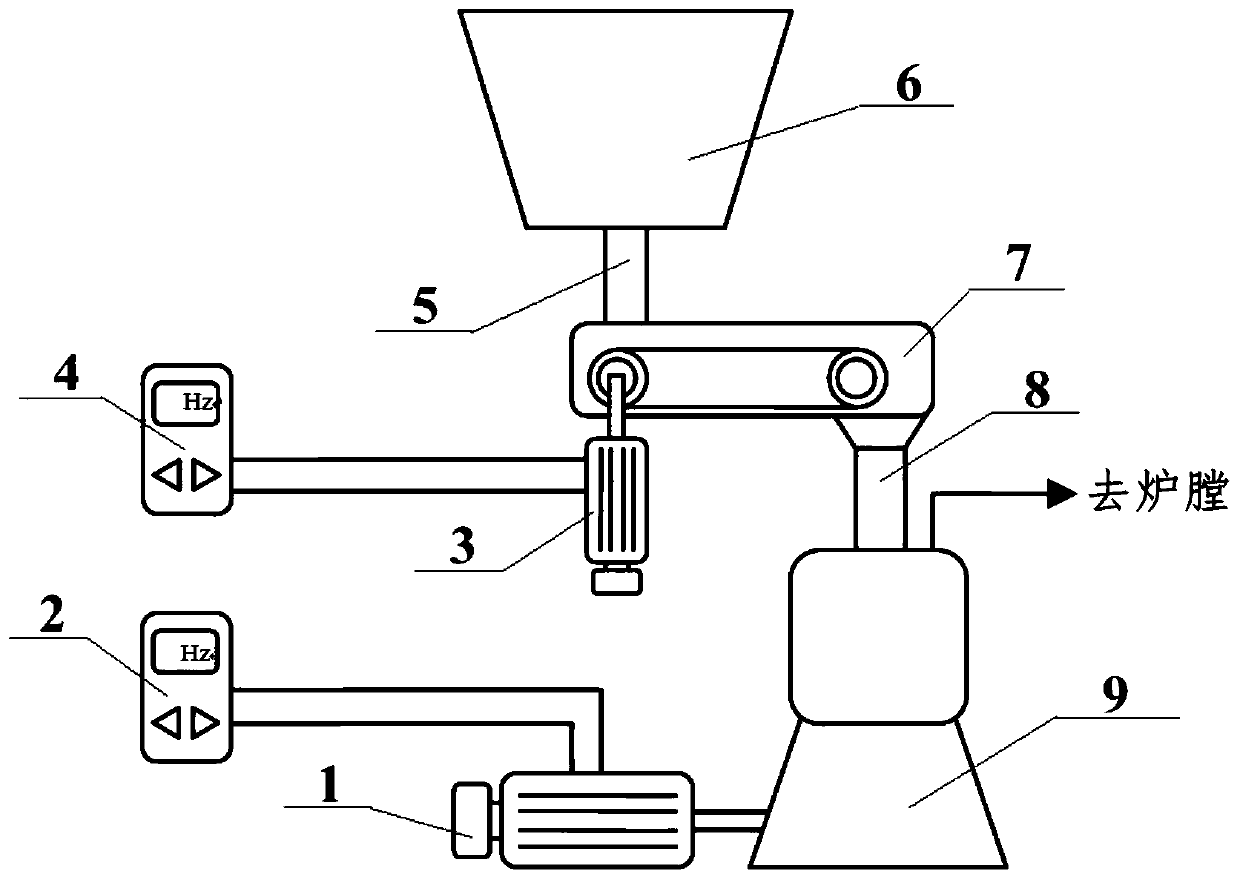

Full-variable-frequency pulverizing system without minimum coal quantity limitation and debugging method

PendingCN111515009ASafe and stable operationRealize continuous adjustmentGrain treatmentsFrequency changerElectric machine

The invention discloses a full-variable-frequency pulverizing system without minimum coal quantity limitation and a debugging method. A raw coal bunker communicates with a belt coal feeder through a coal discharging pipe, and the belt coal feeder communicates with a grinding disc of a roller type coal mill through a coal falling pipe; the grinding disc of the roller type coal mill is driven to rotate by a coal mill motor through a speed reducer, and the rotating speed of the coal mill motor is adjusted through a coal mill frequency converter; the rotating speed of the grinding disc is furtheradjusted, and the grinding force is adjusted; and the belt coal feeder is driven by a coal feeder motor, and the coal feeder motor is controlled by a coal feeder frequency converter 4 to realize speedregulation. The rotating speeds of the grinding disc of the coal mill and a belt of the coal feeder are cooperatively adjusted, so that deep matching of the coal feeding quantity and the grinding force is realized, then the minimum coal quantity limitation set by an existing belt coal feeder is completely cancelled, the force of the pulverizing system can be adjusted from zero, therefore, in thevariable load process of a boiler, the total coal quantity can not have jump-changes when the coal mill is increased or decreased, and thus the stable combustion and stable steam temperature and steampressure in the boiler are ensured.

Owner:XIAN THERMAL POWER RES INST CO LTD

High-efficient aiding burn environmental protection coal saving agent

The invention is a high-performance combustion-supporting environmental-protection coal-saving agent, including the following components in weight percent: MgCl2 5-12%, sodium phosphate 6-15%, potassium permanganate 0.8-1.2%, iron hydroxide 0.1-0.3%, and magnesium hydroxide0.1%, and its formula is reasonable and its synthetic cost is low. As used in a boiler, it can make bunker coal fully burned, increasing combustion heat by 15-25%, reducing the quantity of CO, CO2 and smoke dust discharged into the atmosphere and reducing the pollution of harmful substances to the atmosphere environment.

Owner:高保安

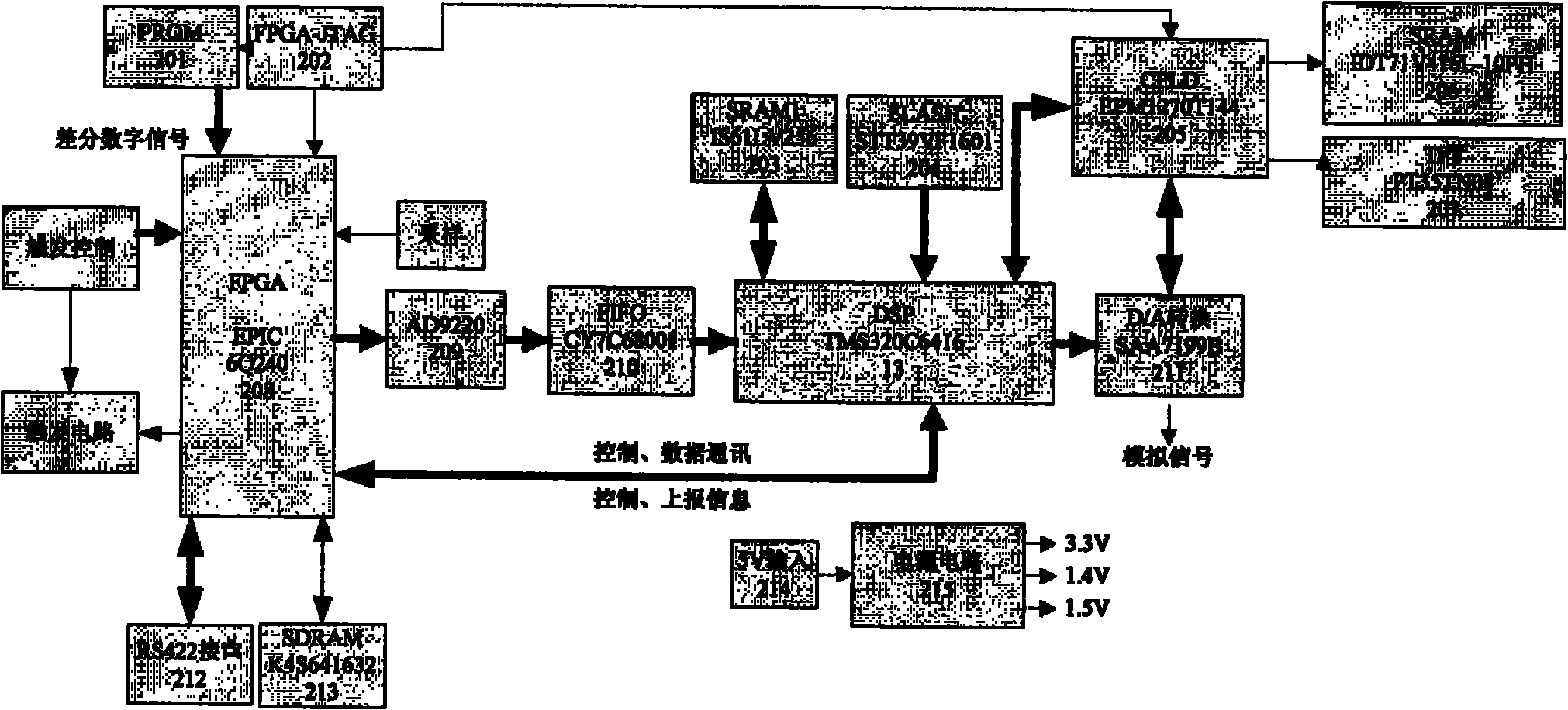

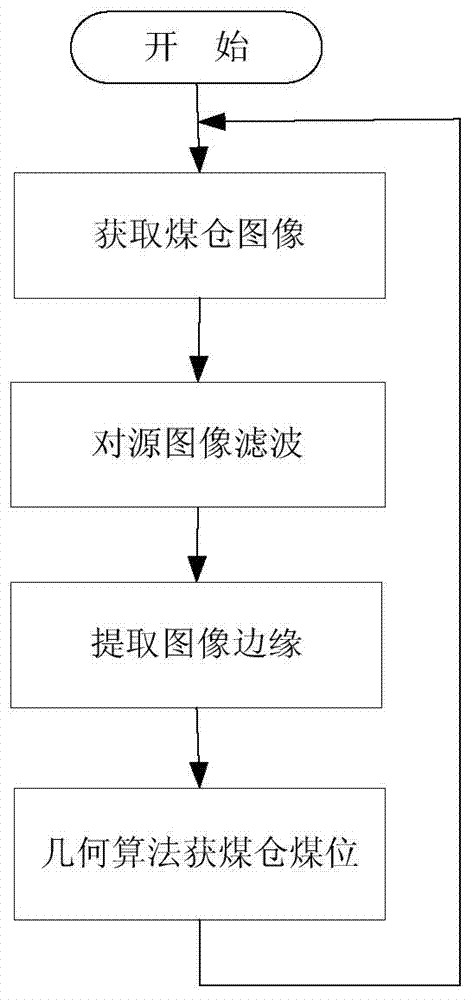

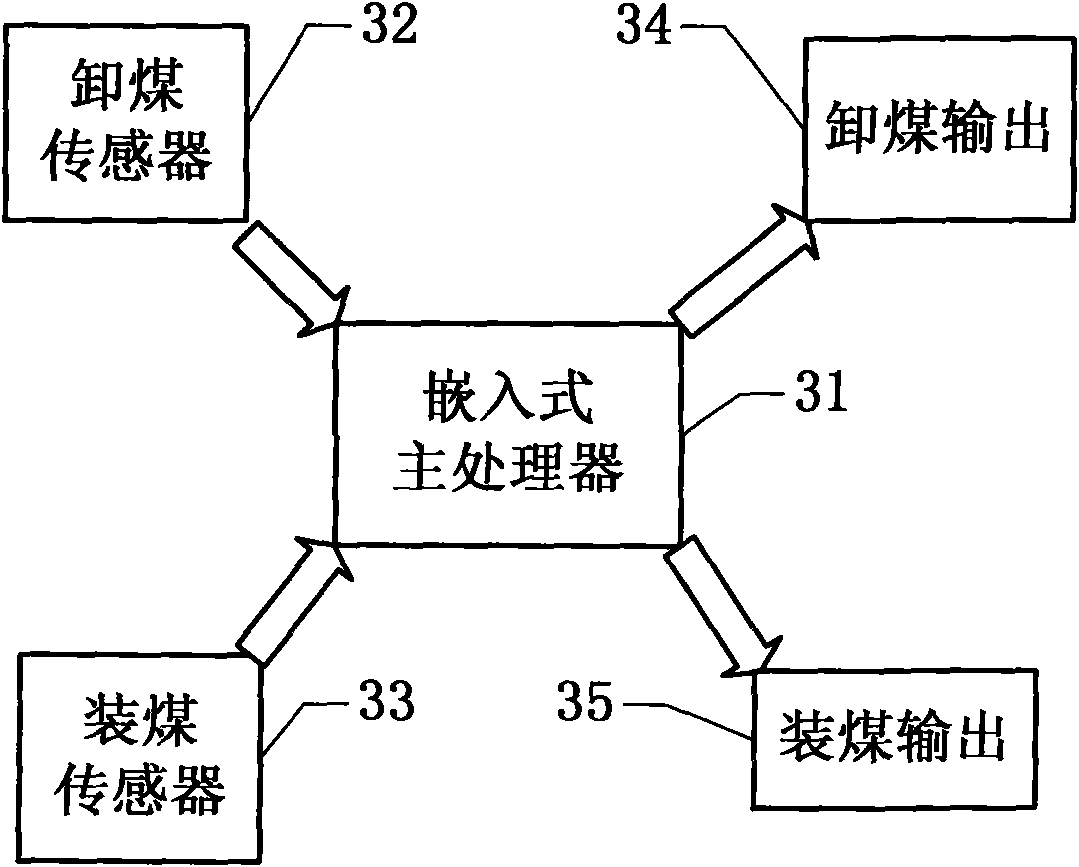

Underground coal bunker coal level detecting method based on image processing technology

ActiveCN103679790AValid reservationEasy to keepCharacter and pattern recognitionMachines/enginesDecompositionEdge extraction

The invention discloses an underground coal bunker coal level detecting method based on the image processing technology. The method comprises the steps that firstly, an enhancement type camera ICCD is utilized for collecting images of a coal bunker according to the range gating laser active imaging technology; collected analog signals are converted into digital signals through a video decoder SAA7113H, wherein the digital signals can be processed through a DM642 chip; the DM642 chip is used for reading image data from a memorizer and filtering the image data; the edge extraction is carried out on the filtered images by combining the advantages of the BEMD decomposition, mutual information entropy and image overlapping; the coal level height information is extracted according to the coal level detecting and recognizing algorithm that the geometrical information of the scenery based on the pre-determined geometrical information in the lighting. The method is high in distance measuring precision, good in anti-interference performance and high in real-time performance, solves the key problem of coal mine safety production monitoring and communicating and plays a positive, real and long-term significant role on coal mine safety production and economical benefit increasing.

Owner:ANHUI UNIV OF SCI & TECH

Coal burning boiler polymer dry-process denitrifying agent, preparation method thereof and denitrifying process

InactiveCN105771645AImprove combustion efficiencyImprove denitrification efficiencyGas treatmentDispersed particle separationChemical reactionSodium Bentonite

The invention discloses a coal burning boiler polymer dry-process denitrifying agent, a preparation method thereof and a denitrifying process. The coal burning boiler polymer dry-process denitrifying agent comprises, by weight, 30-40 parts of urea, 20-30 parts of silicon dioxide powder, 20-30 parts of sodium carbonate, 20-30 parts of bentonite, 10-15 parts of anhydrous sodium sulphate and 20-30 parts of shale powder. The denitrifying agent can effectively lower activation energy of oxidation reaction of bunker coal, oxynitride in smoke during the burning process is eliminated, emitted hazardous substances such as oxynitride is turned into harmless ash and nitrogen through chemical reaction, and the smoke is enabled to meet the emission standard.

Owner:CHANGYI DAWEI ENVIRONMENTAL PROTECTION TECH CO LTD

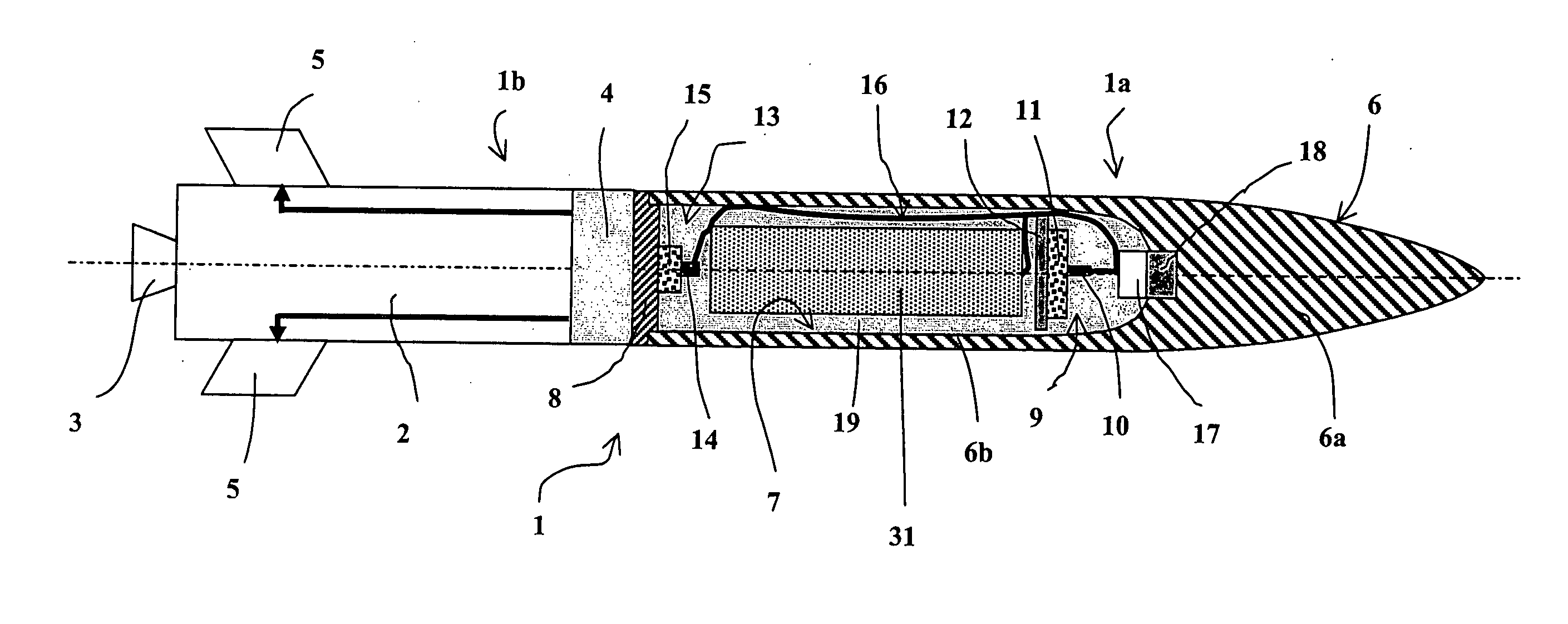

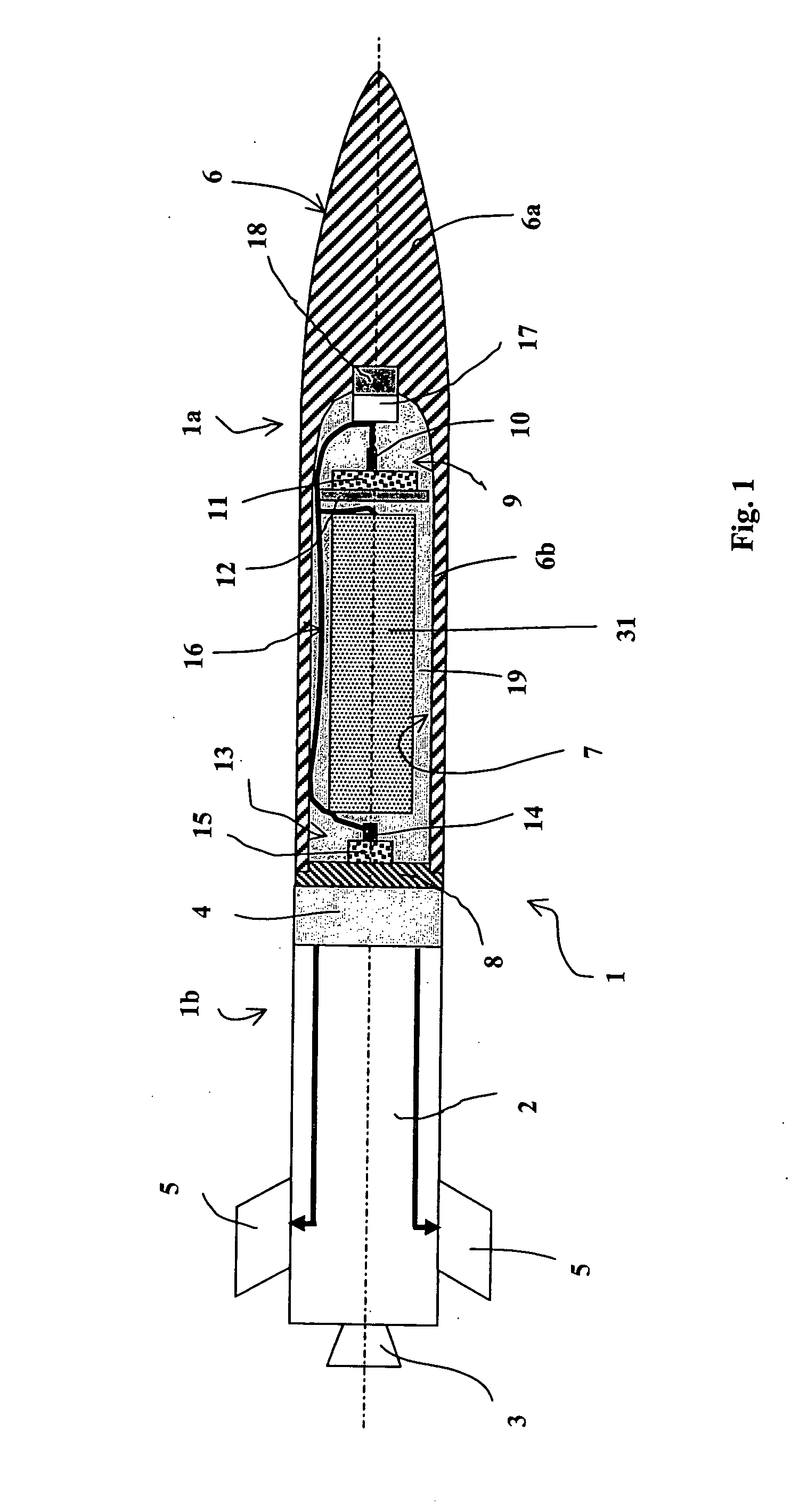

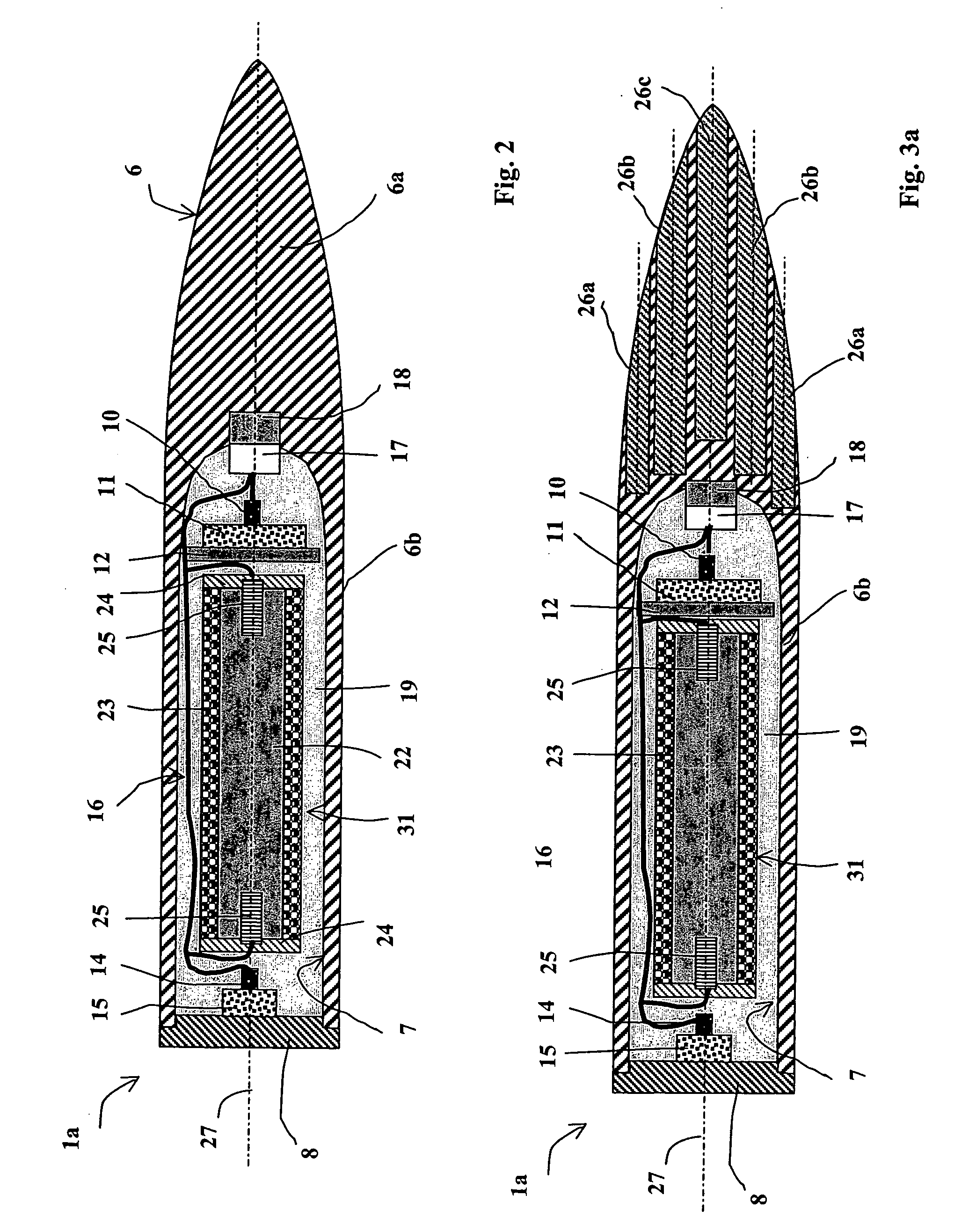

Anti-bunker ammunition

InactiveUS20060016360A1Limited effectivenessAmmunition projectilesProjectilesBunkerElectrical and Electronics engineering

The invention relates to an anti-bunker ammunition comprising a penetration body delimiting an internal cavity closed by a base characterized in that the cavity encloses at least one sub-munition, a device to eject said sub-munition as well as a device to eject the base, the sub-munition and the ejection devices being insulated from the walls of the internal cavity by shock-absorbing means.

Owner:GIAT INDS SA

Methods and Materials for Golf Course Sand Bunker Construction

ActiveUS20110200401A1Improve stabilityReduce the possibilitySoil drainageBall sportsGolf course turfBunker

A method for building and renovating golf course sand bunkers to improve infiltration of water through a drainage system reduces the chance of contamination of the sand and to reduce erosion and maintenance and provide consistent playable sand for golf. The bunker is built to slopes based on the sand selected for use. A drainage system and a layer of fine pea gravel is installed over the entire floor of the bunker. A pre-polymer is sprayed onto the layer of pea gravel to secure it in place. The polymer sprayed bunker is permitted to cure for approximately 24 hours. A sufficient amount of bunker sand is added and compacted so the entire bunker is covered. Washed sod is placed around the bunker to stabilize the edge of the bunker.

Owner:LEMONS JERRY

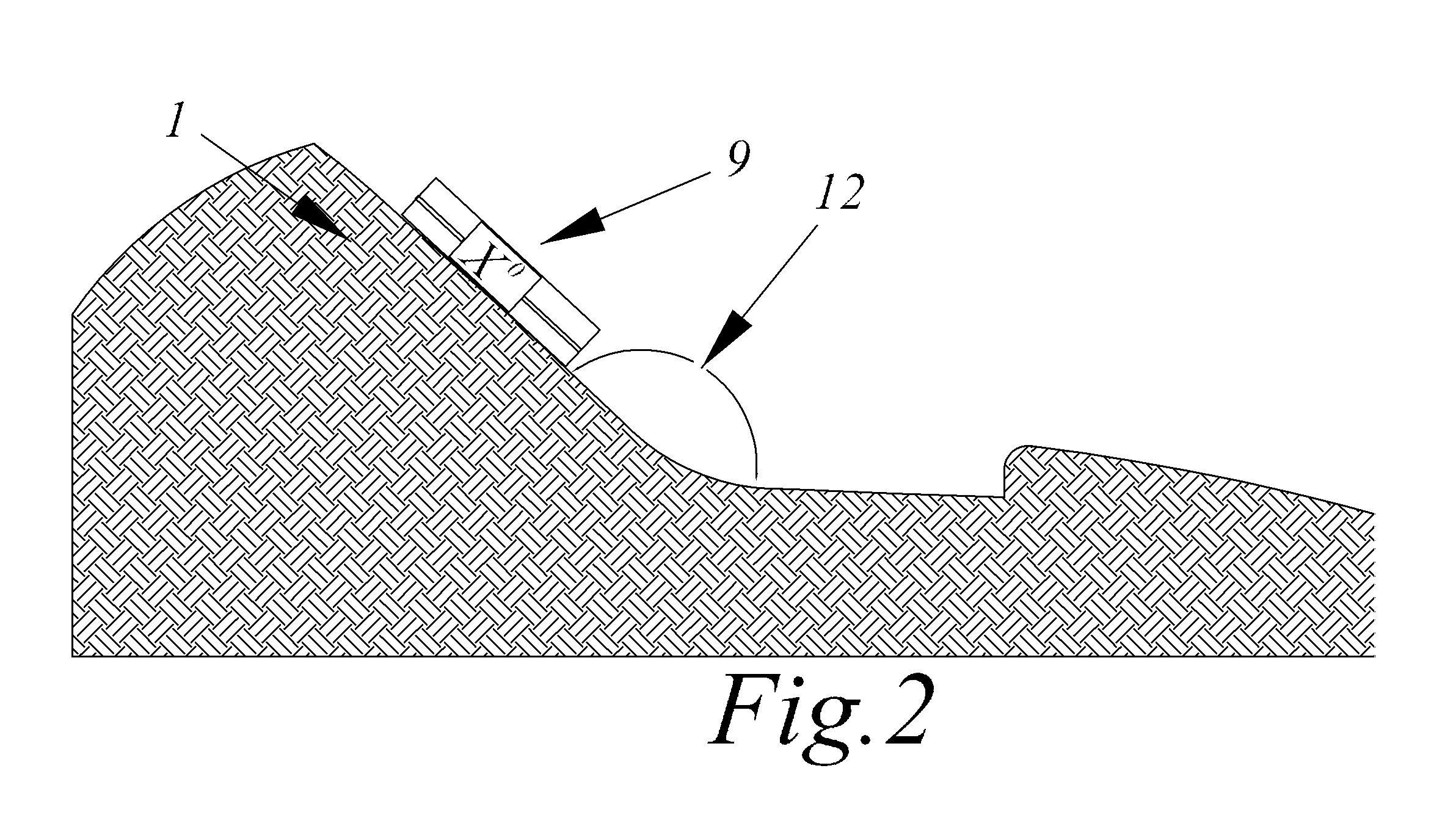

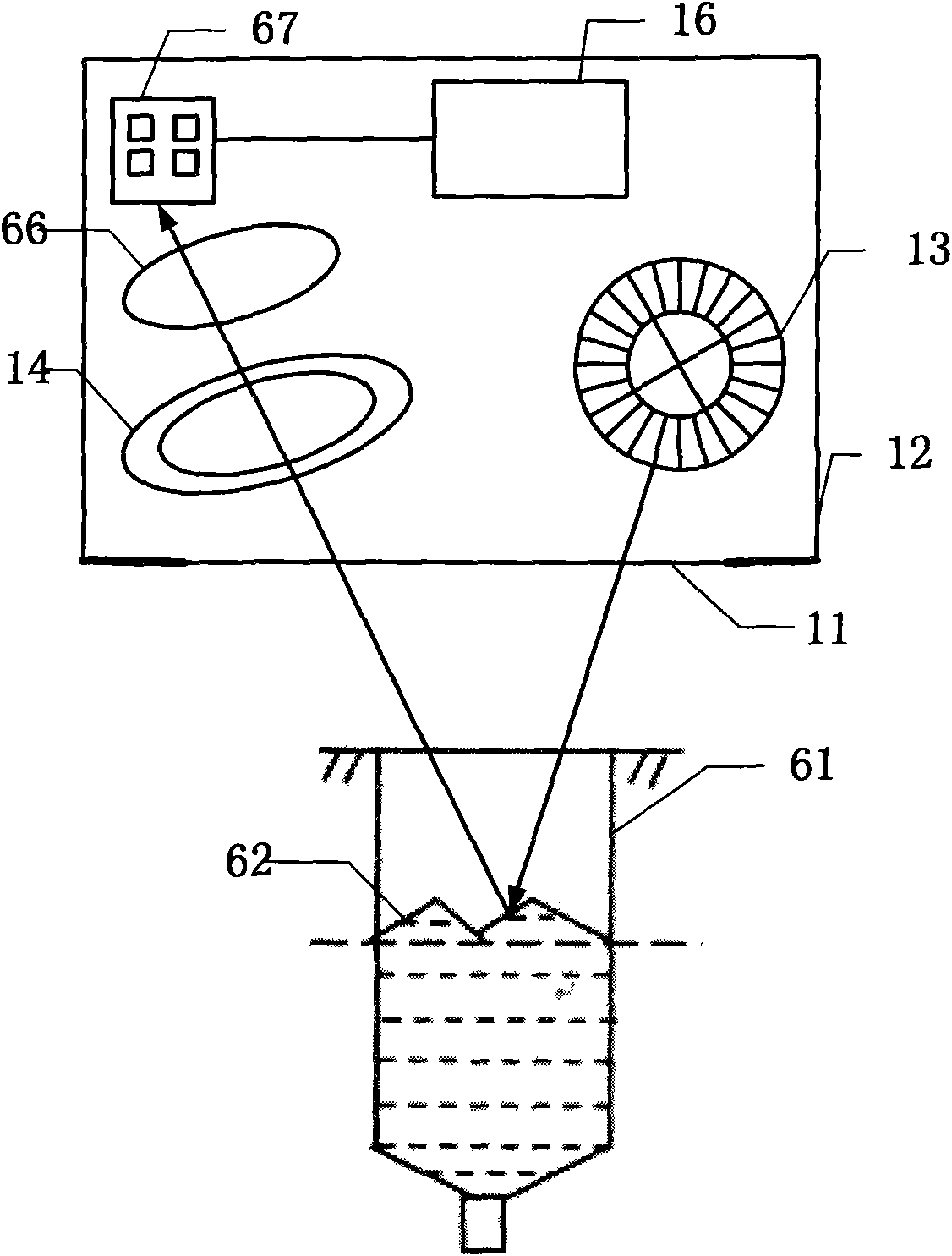

Coal bunker material level measuring method and system based on stereo vision

InactiveCN101943595AHigh precisionImprove robustnessMachines/enginesLevel indicatorsLuminous intensityBunker

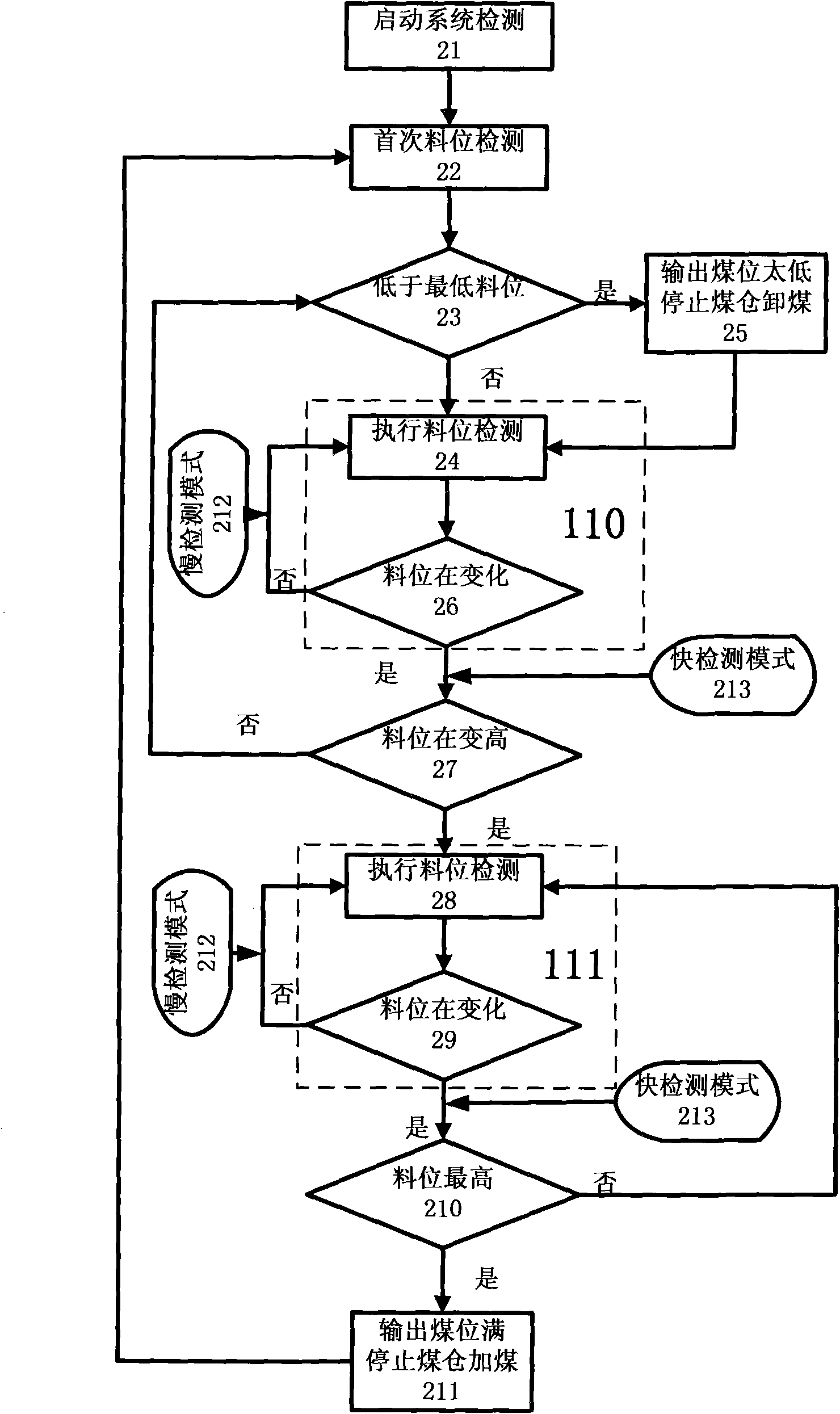

The invention relates to a coal bunker material level measuring method and system based on stereo vision, and the system mainly comprises an optical subsystem, an embedded processing subsystem and a flameproof shell with a window. Light emitted from a light source module is projected on a coal surface in a coal bunker, and based on the phase delay integral principle of reflected light and emitted light, a vision sensor collects the light reflected from the coal surface and converts the light to depth images and light intensity images. A processor analyzes image data and realizes the measurement of the material level so as to stop filling and unloading coal timely. A light source drive controller adjusts the number of lighted LEDs automatically according to the intensity of returned light which is measured by an annular photometer and enables the luminous intensity to be within an appropriate range. In the measurement, the processor is used for changing the parameters of the vision sensor according to the material level and the condition of material level changing, thus realizing intelligent switching between a slow detection mode and a fast detection mode. The slow detection mode realizes high-accuracy detection; and the fast detection mode realizes fast detection.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Golf Course Bunker

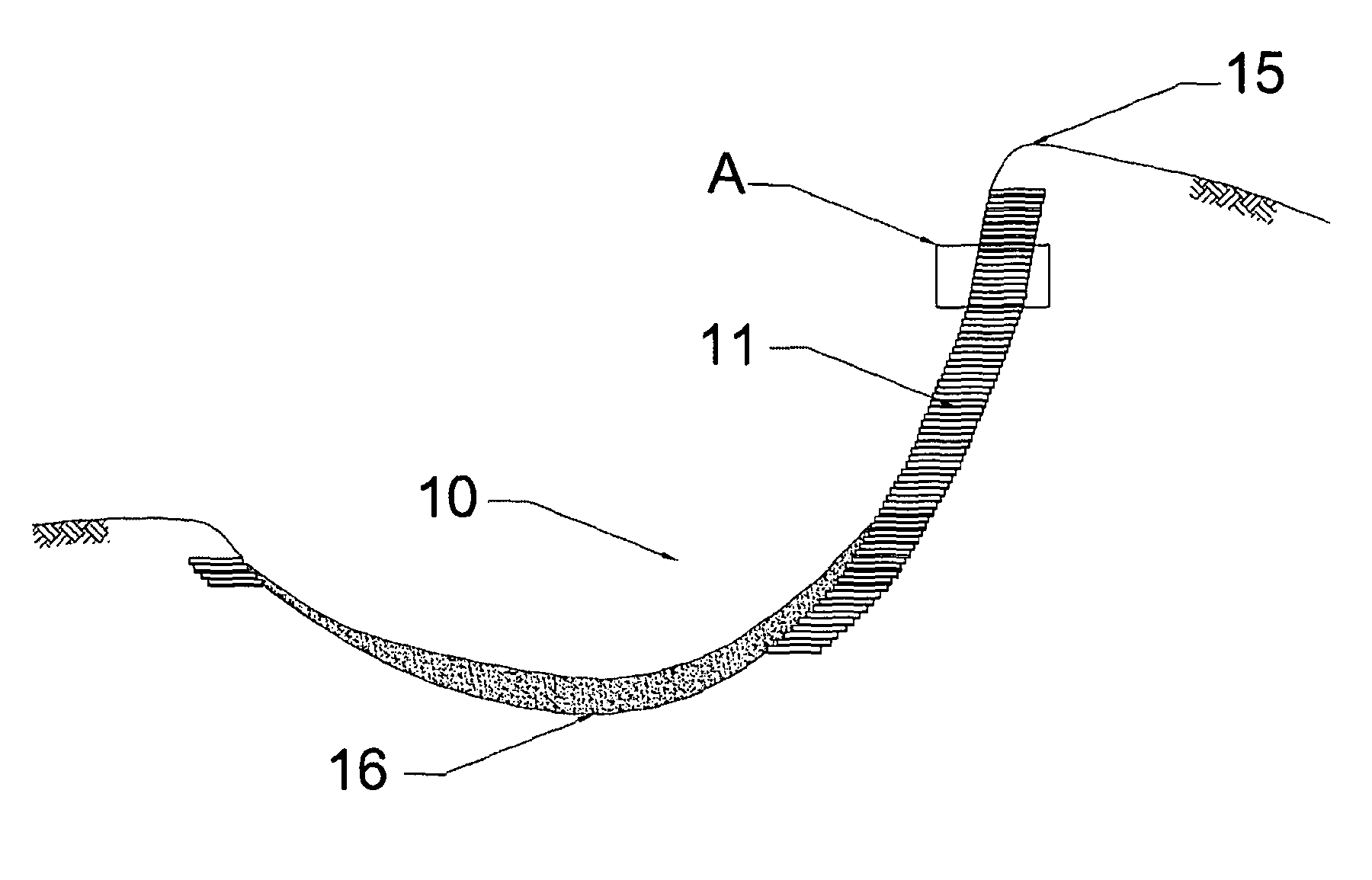

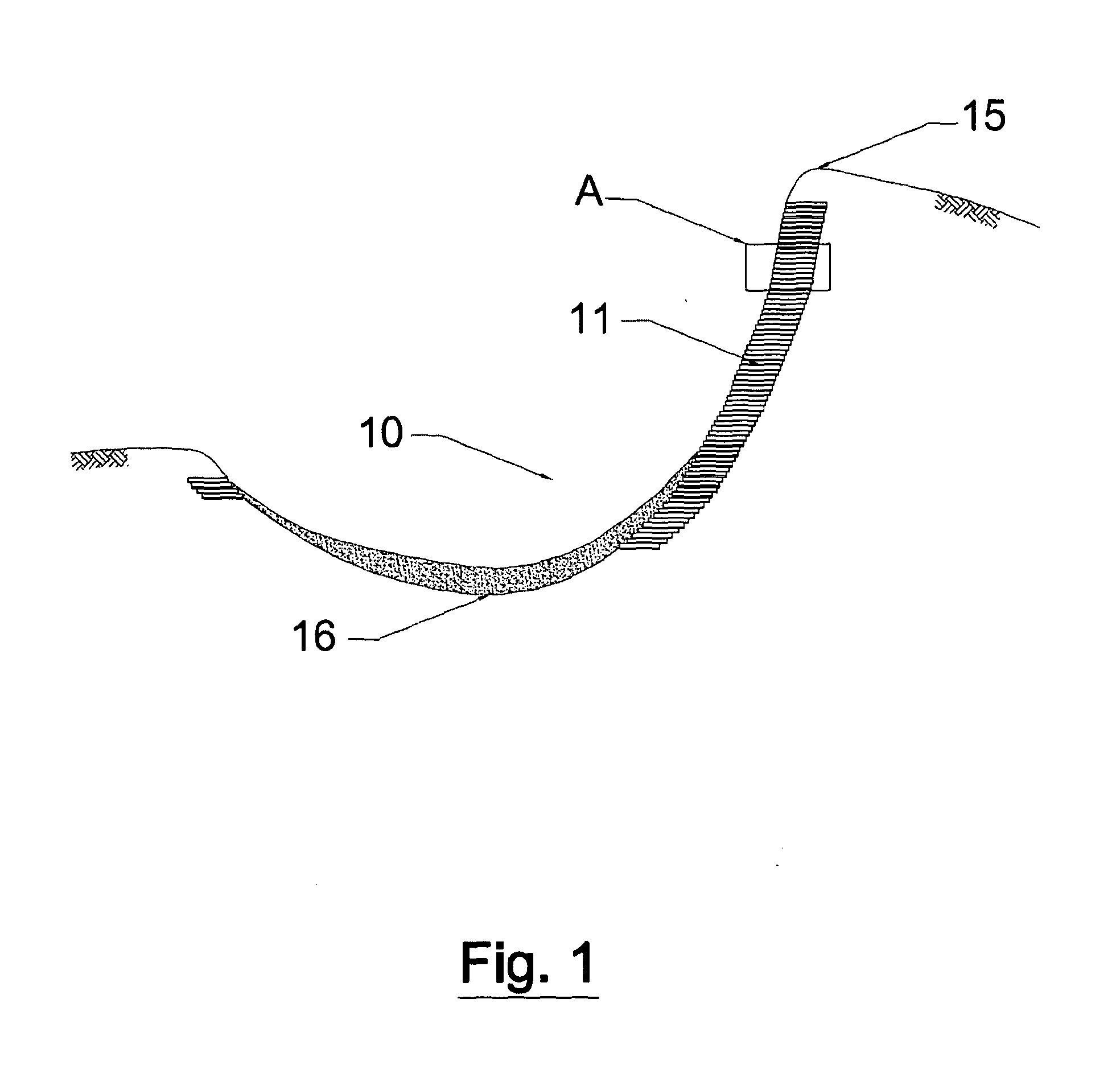

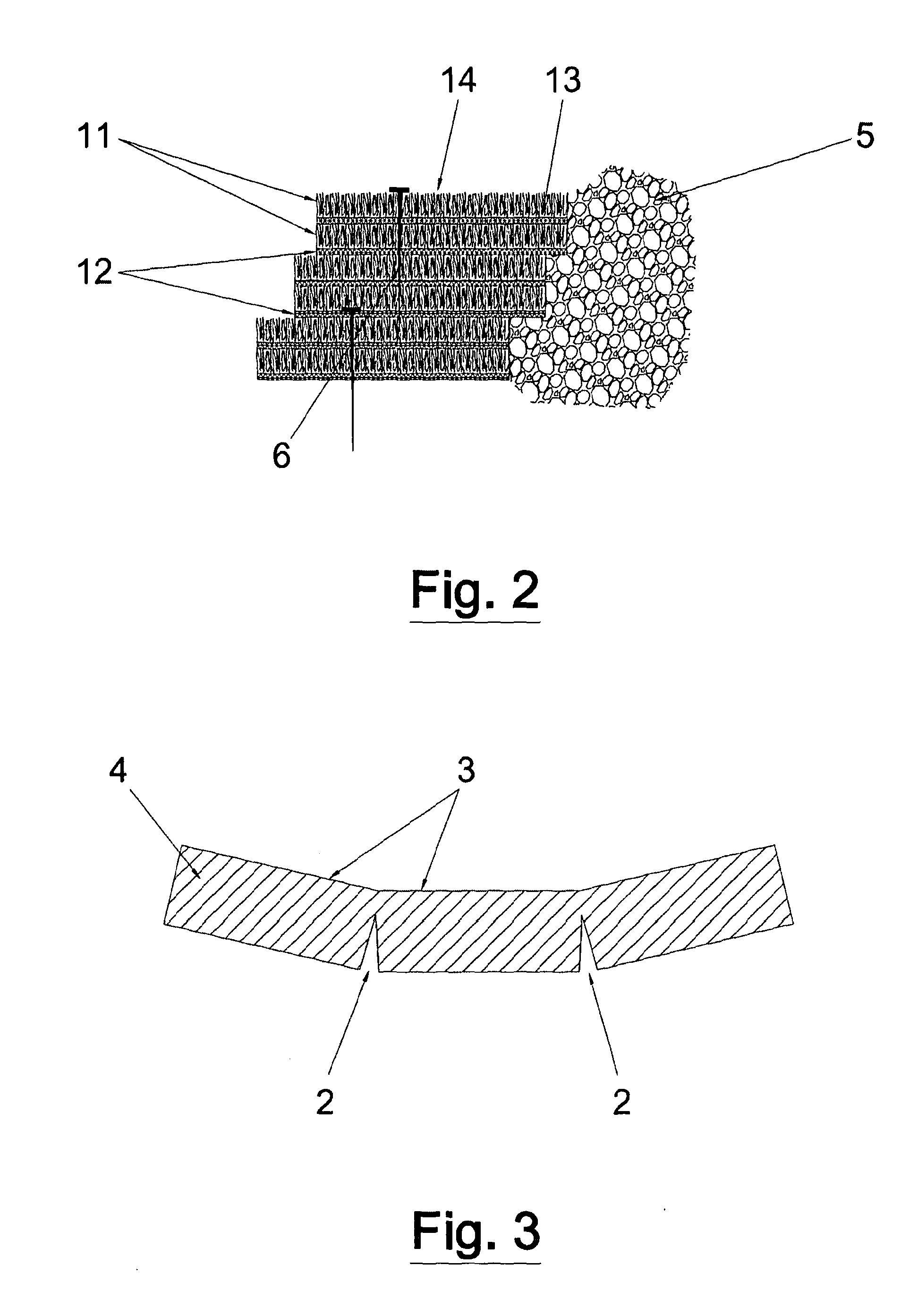

A golf course bunker (10) comprising a plurality of substantially horizontal and staggered layers (11)of artificial grass turf is disclosed. The layers (11) may each be pre-impregnated with sand. The layers of artificial grass define an exterior surface of the bunker and the interior (5) of the bunker may be formed of different material. A method of construction is also disclosed which may include steps of excavating a bunker and laying artificial grass in horizontal layers (11) to face the exterior surface of the excavation.

Owner:ALLEN RICHARD ALEC +1

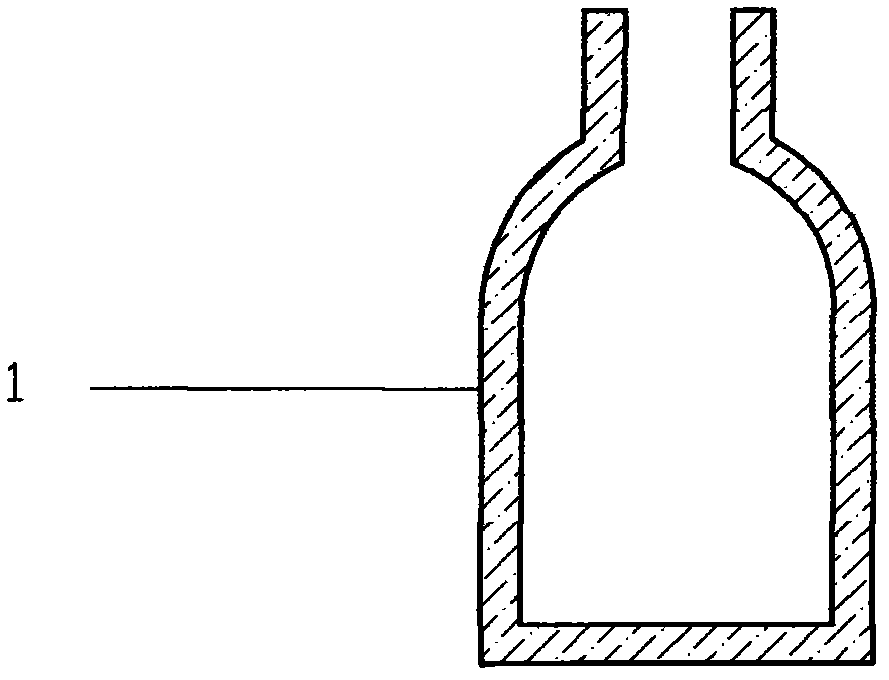

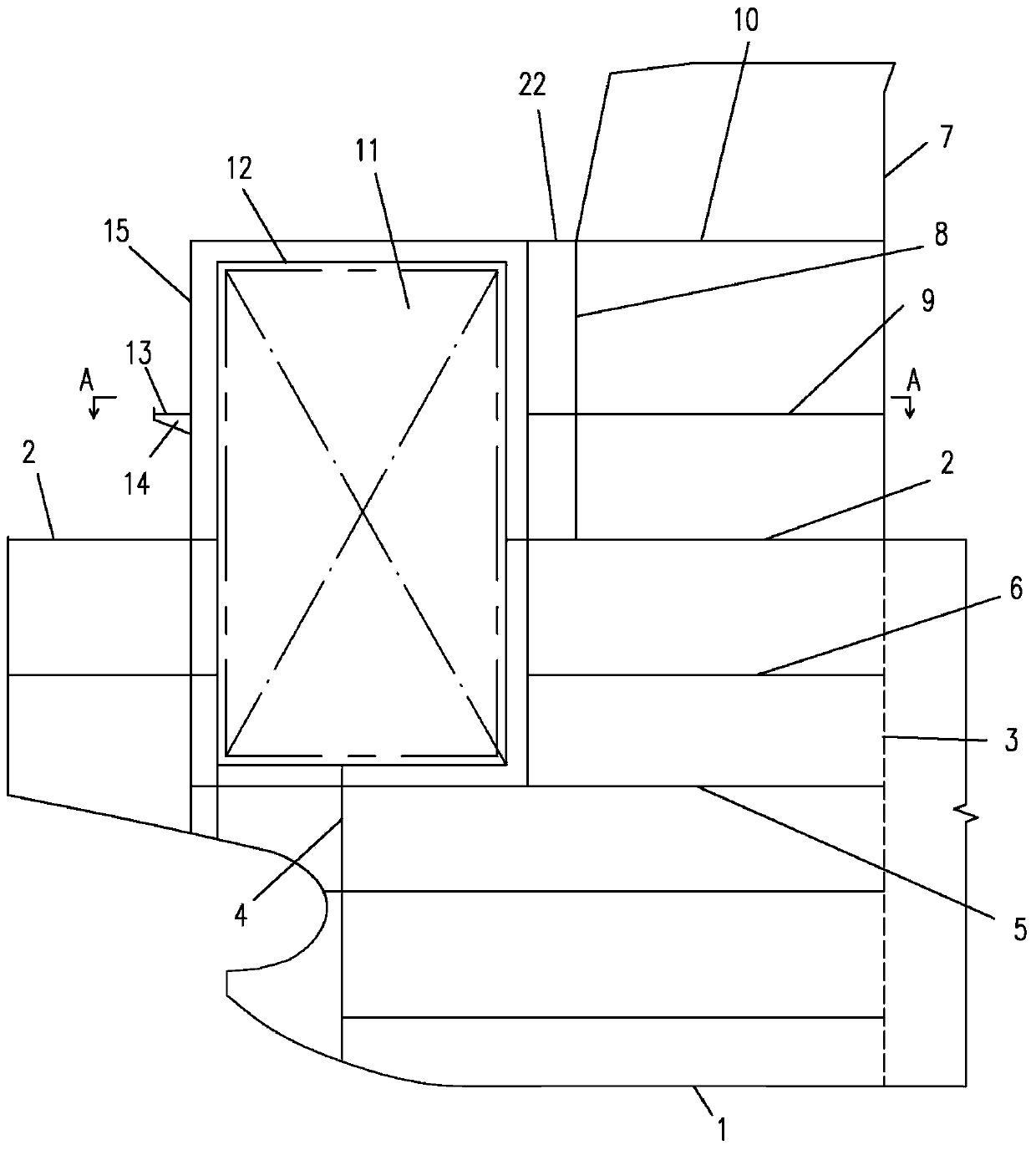

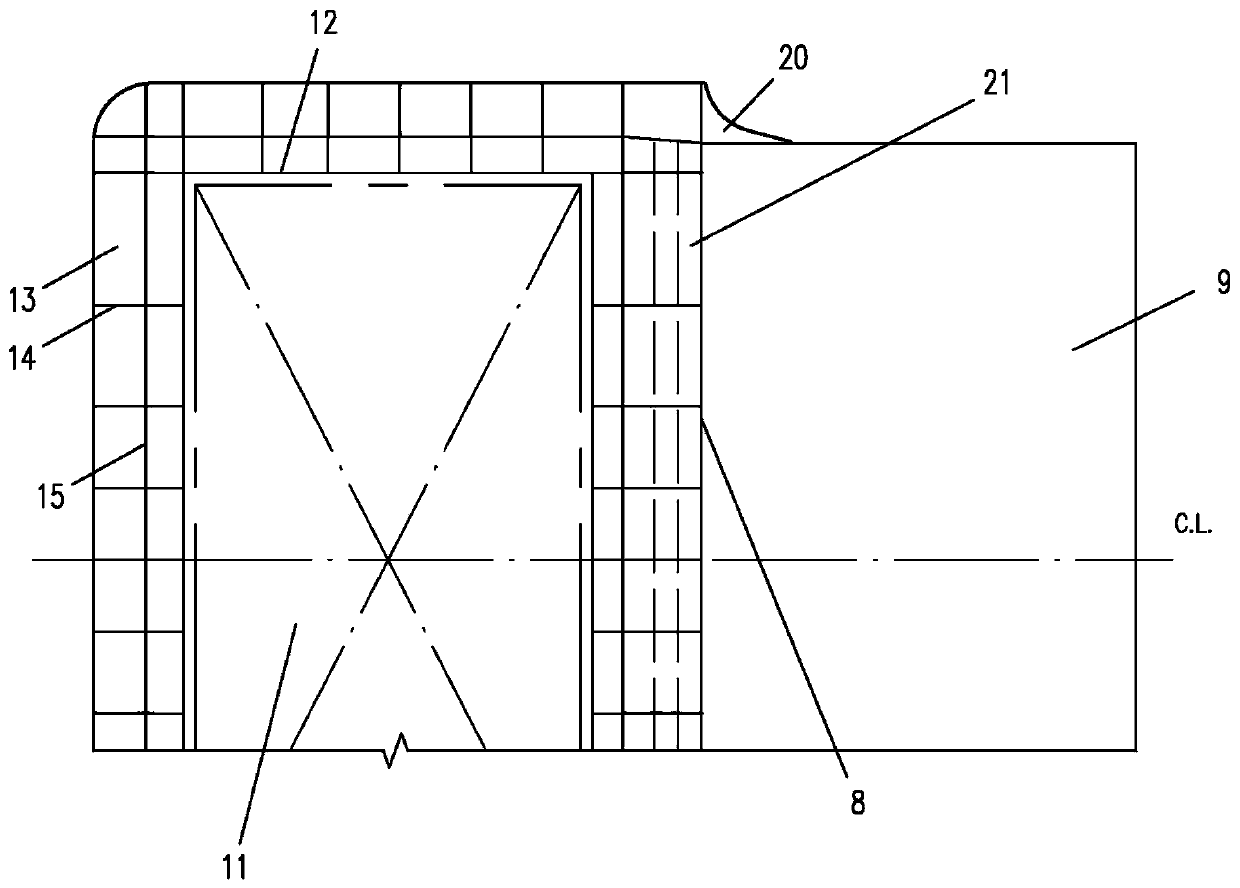

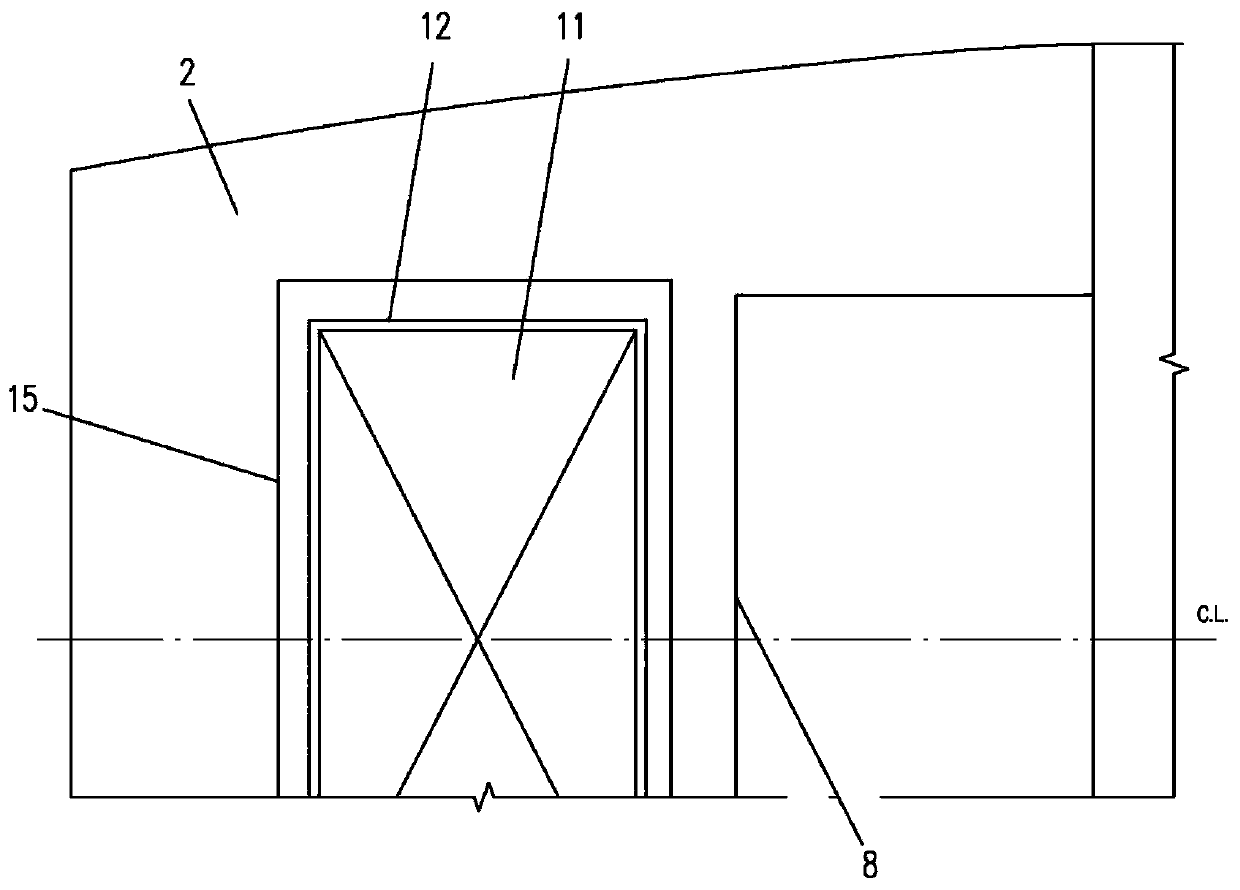

Bulk cargo ship liquefied natural gas bunker arrangement structure

ActiveCN110789663ASolve the problem of insufficient support strengthAddress structural strengthHull interior subdivisionFor bulk goodsBulk cargoBunker

The invention discloses a bulk cargo ship liquefied natural gas bunker arrangement structure which comprises a liquefied natural gas bunker. The liquefied natural gas bunker includes an outer shell and an inner shell, the liquefied natural gas bunker is arranged behind a superstructure, the liquefied natural gas bunker is embedded on an upper deck, the top of the liquefied natural gas bunker is flush with a middle deck of the superstructure, and the bottom of the liquefied natural gas bunker is flush with a platform of an engine room; the outer shell of the liquefied natural gas bunker is fixedly provided with an overhanging T-beam; and a web of the overhanging T-beam is fixedly connected to the outer shell, and the web of the overhanging T-beam is flush with a lower deck of the superstructure. The bulk cargo ship liquefied natural gas bunker arrangement structure effectively solves the problem about structural strength of the fuel bunker and can be used on the lower platform of the engine room, the utilization ratio in the height direction is higher, and layout of the entire engine room is more optimized.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com