Patents

Literature

1486results about "For bulk goods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

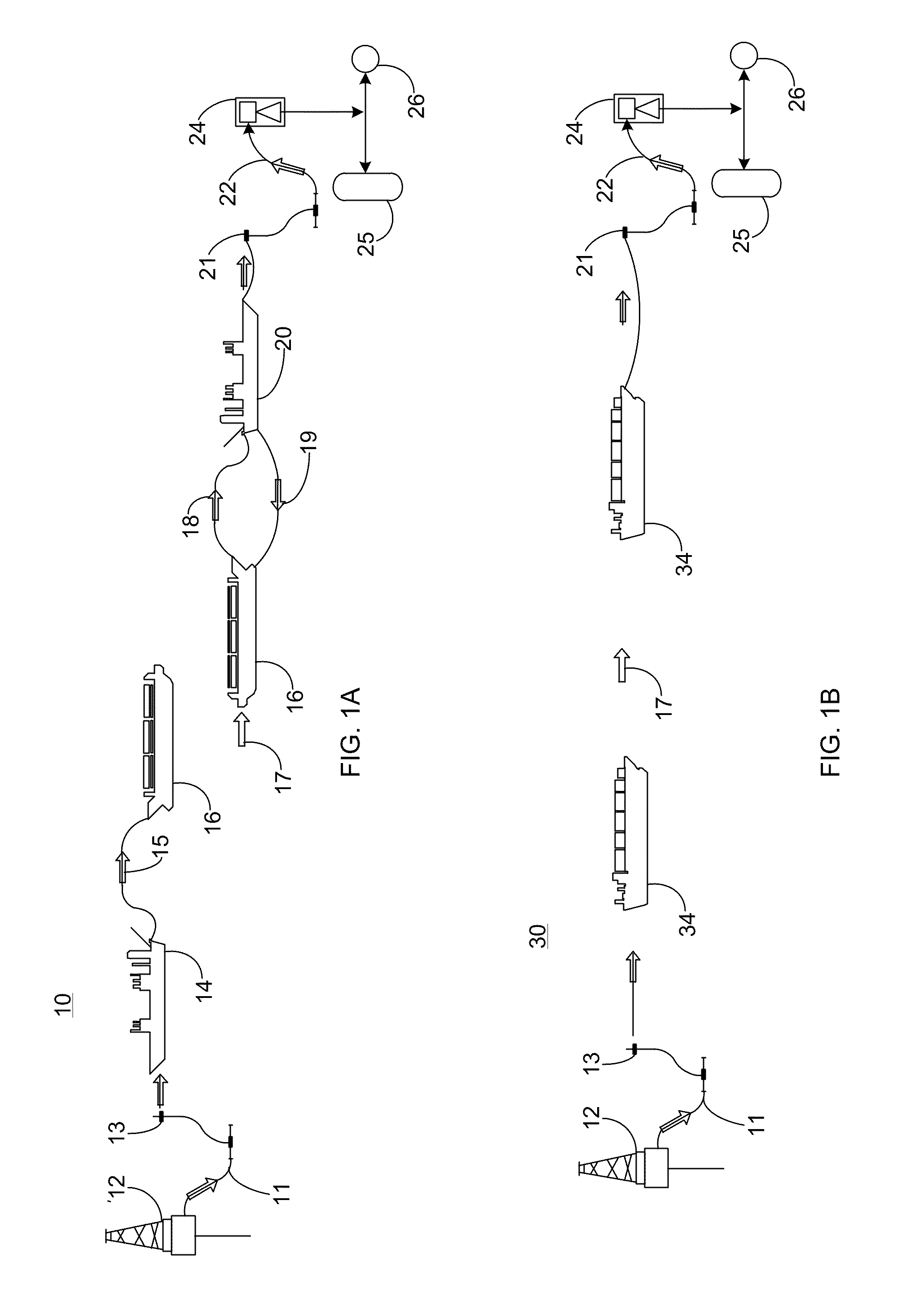

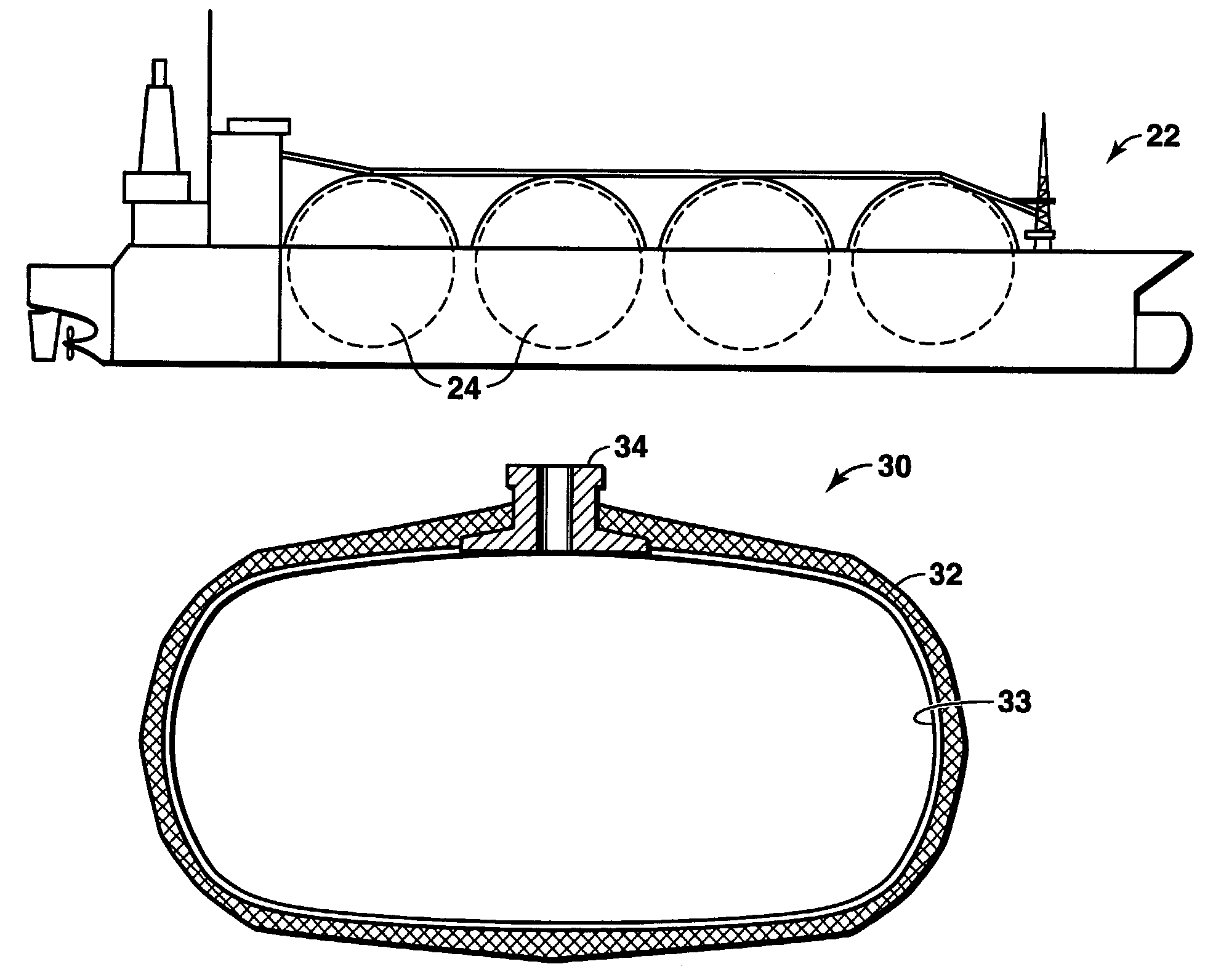

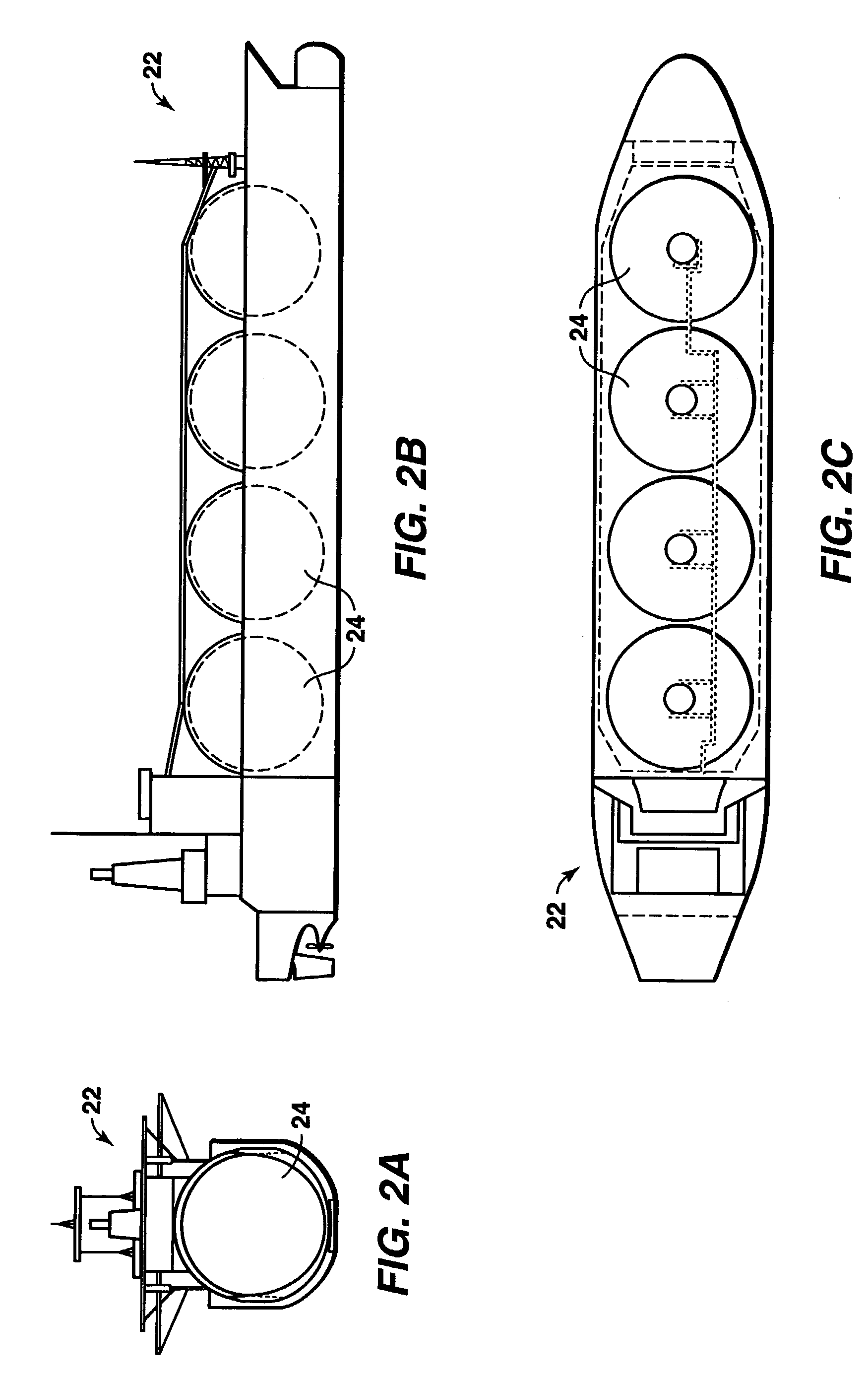

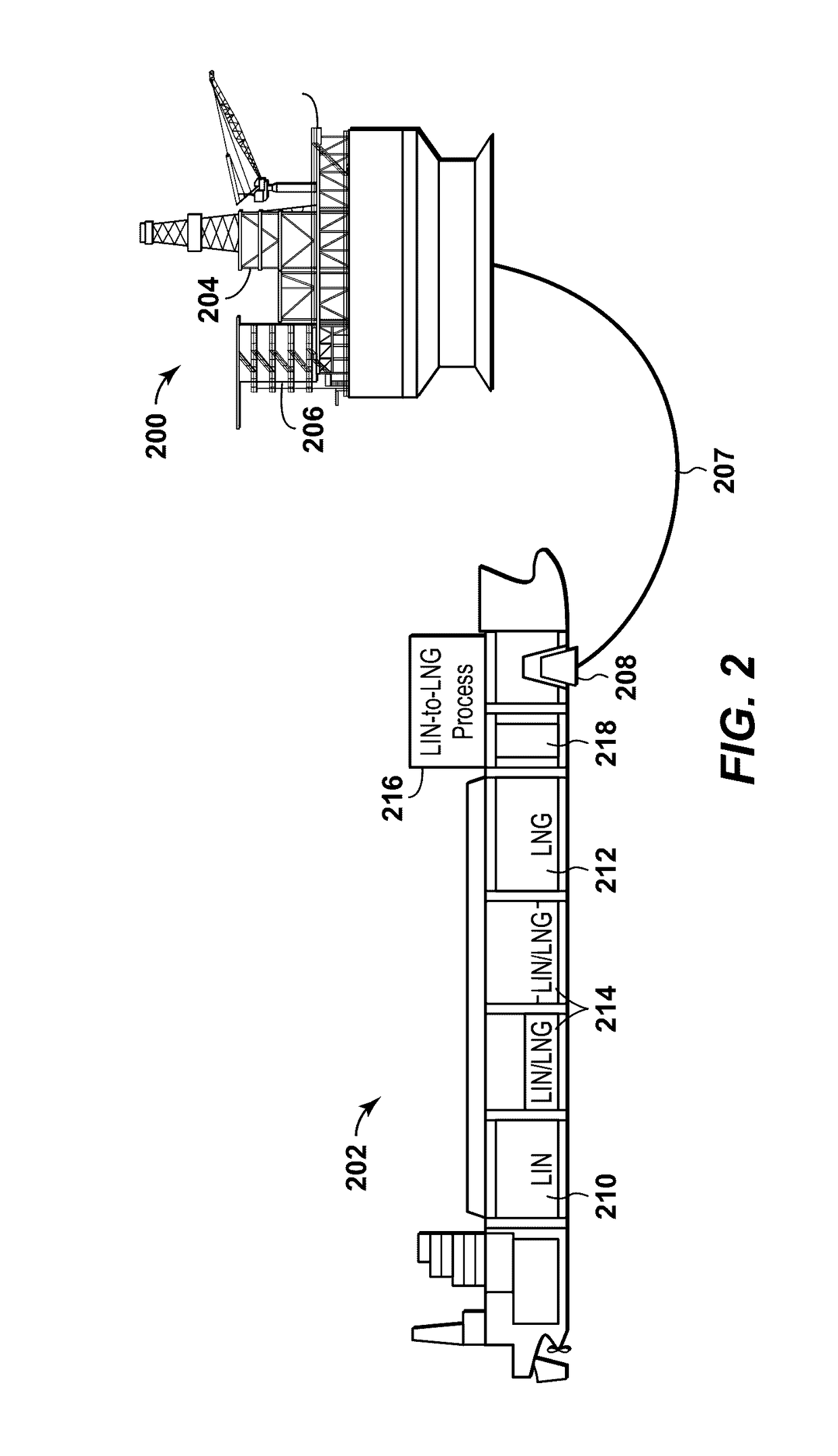

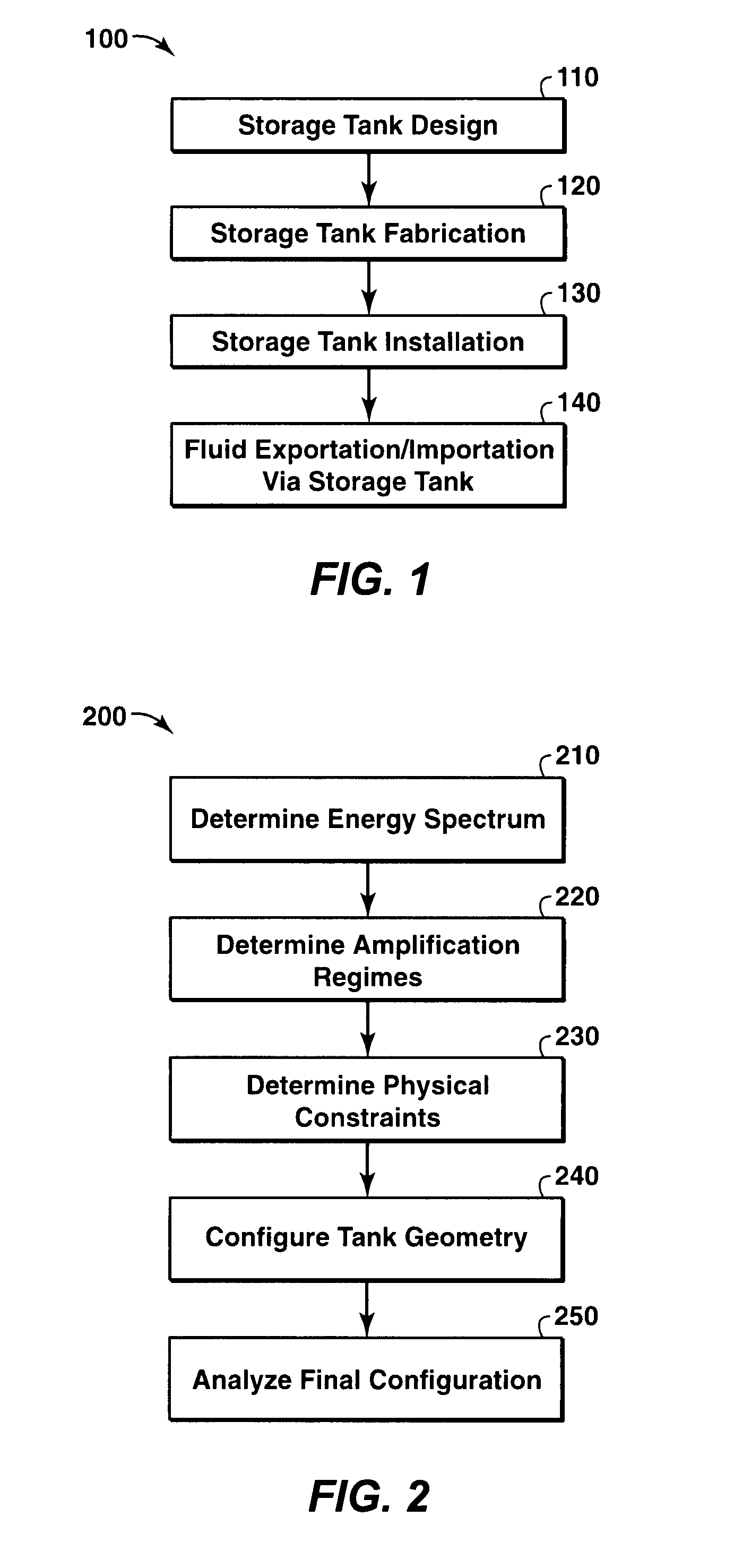

System and process for transporting LNG by non-self-propelled marine LNG carrier

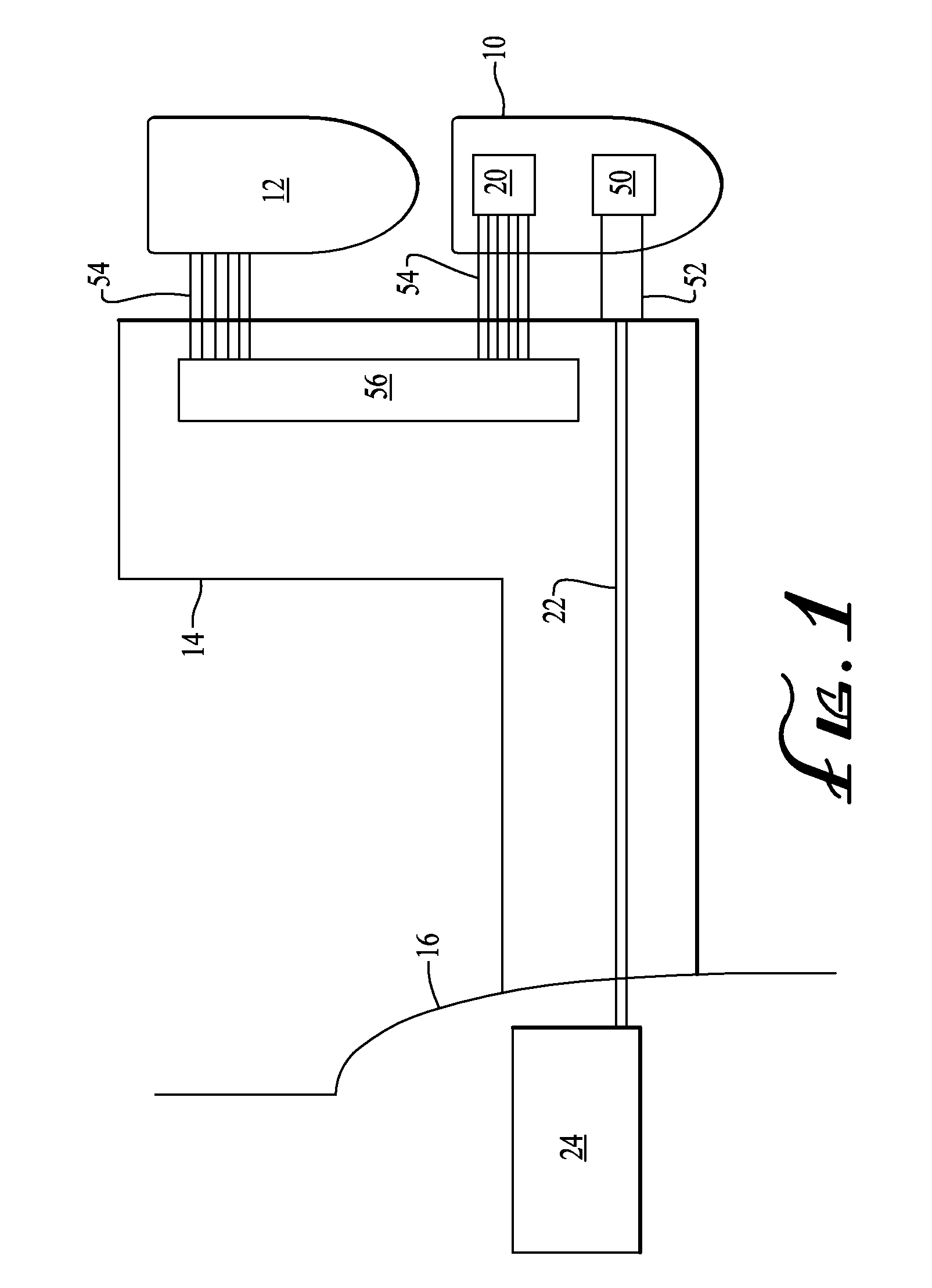

Marine LNG carrier and method of operating the marine LNG carrier. The LNG carrier carries LNG in at least one tank. Gas composed of evaporated LNG within the at least one tank is removed. The gas is fed to at least one gas consuming prime mover of the LNG carrier. Power is provided with the at least one gas consuming prime mover. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:ARGENT MARINE MANAGEMENT

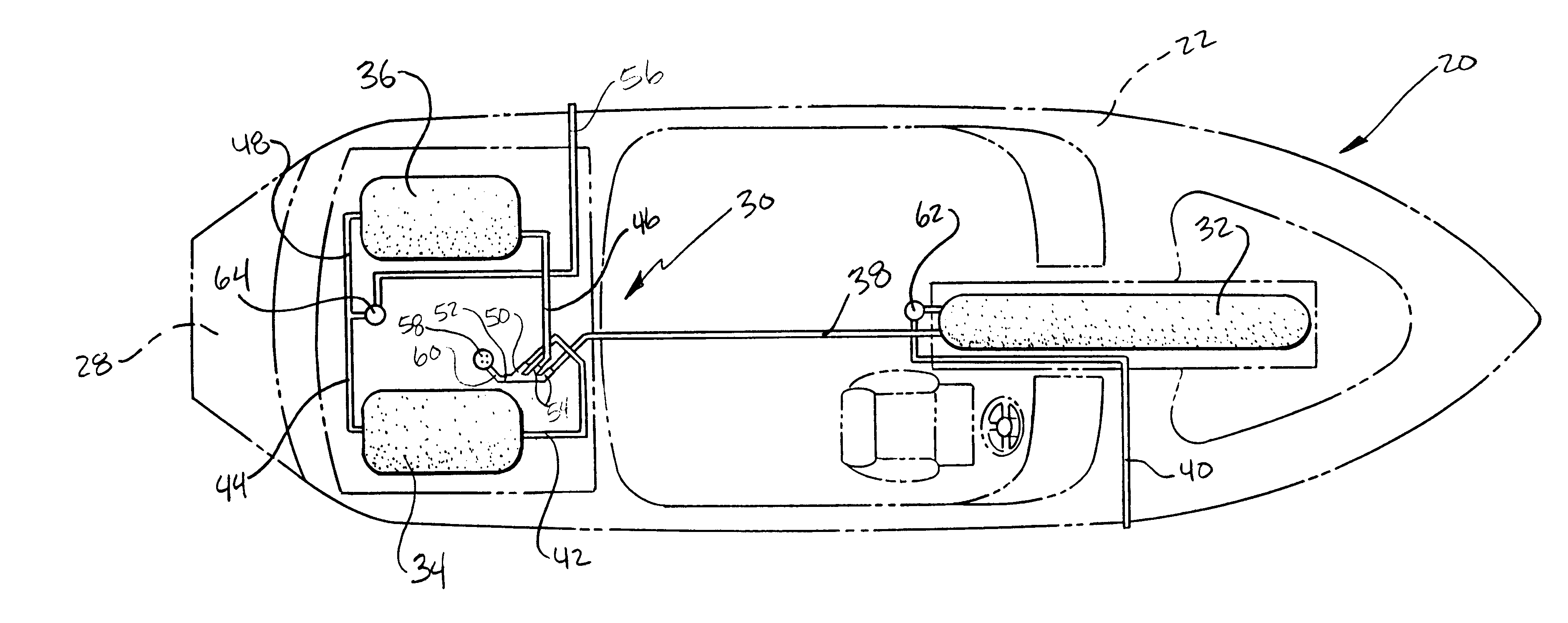

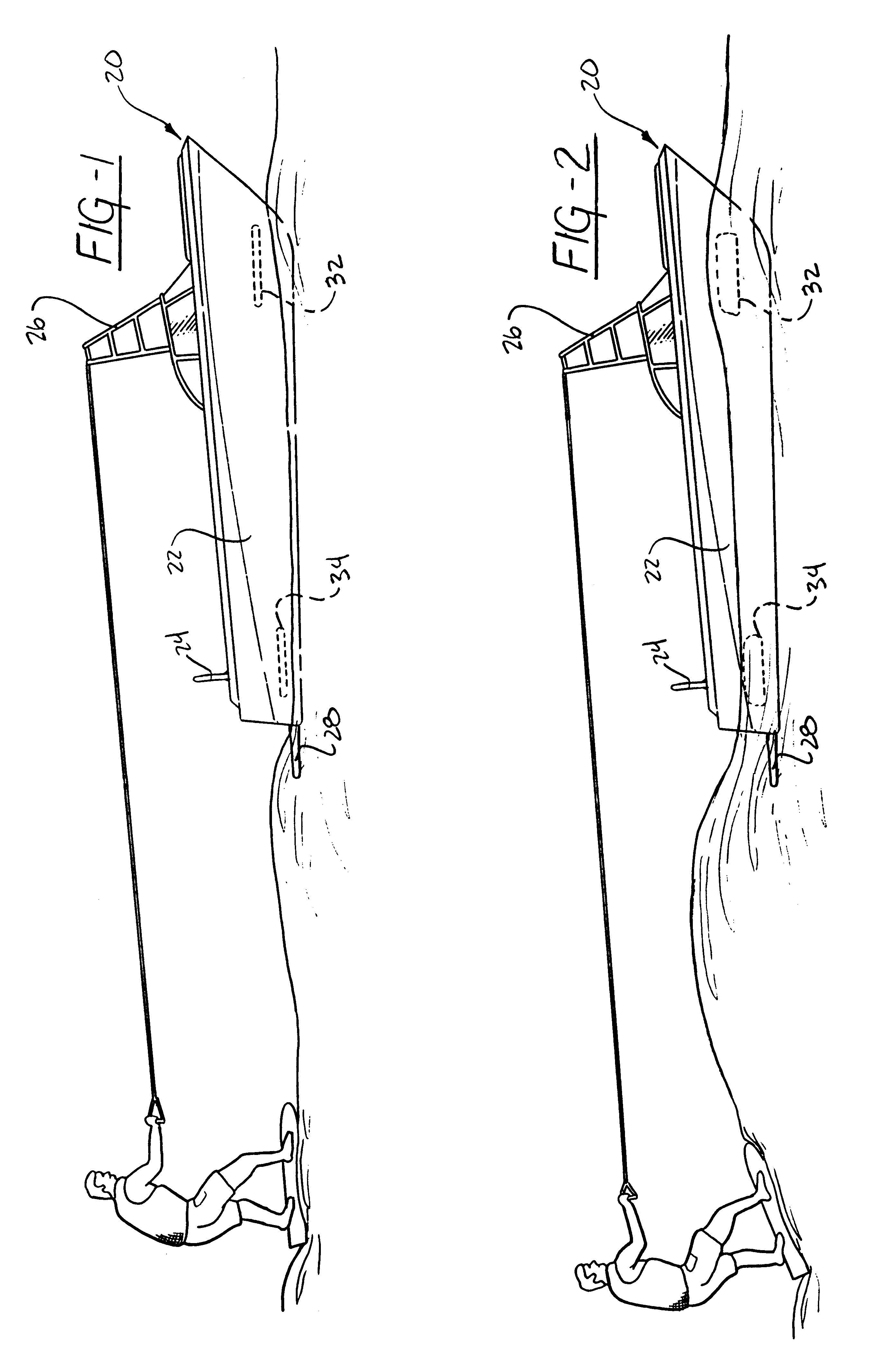

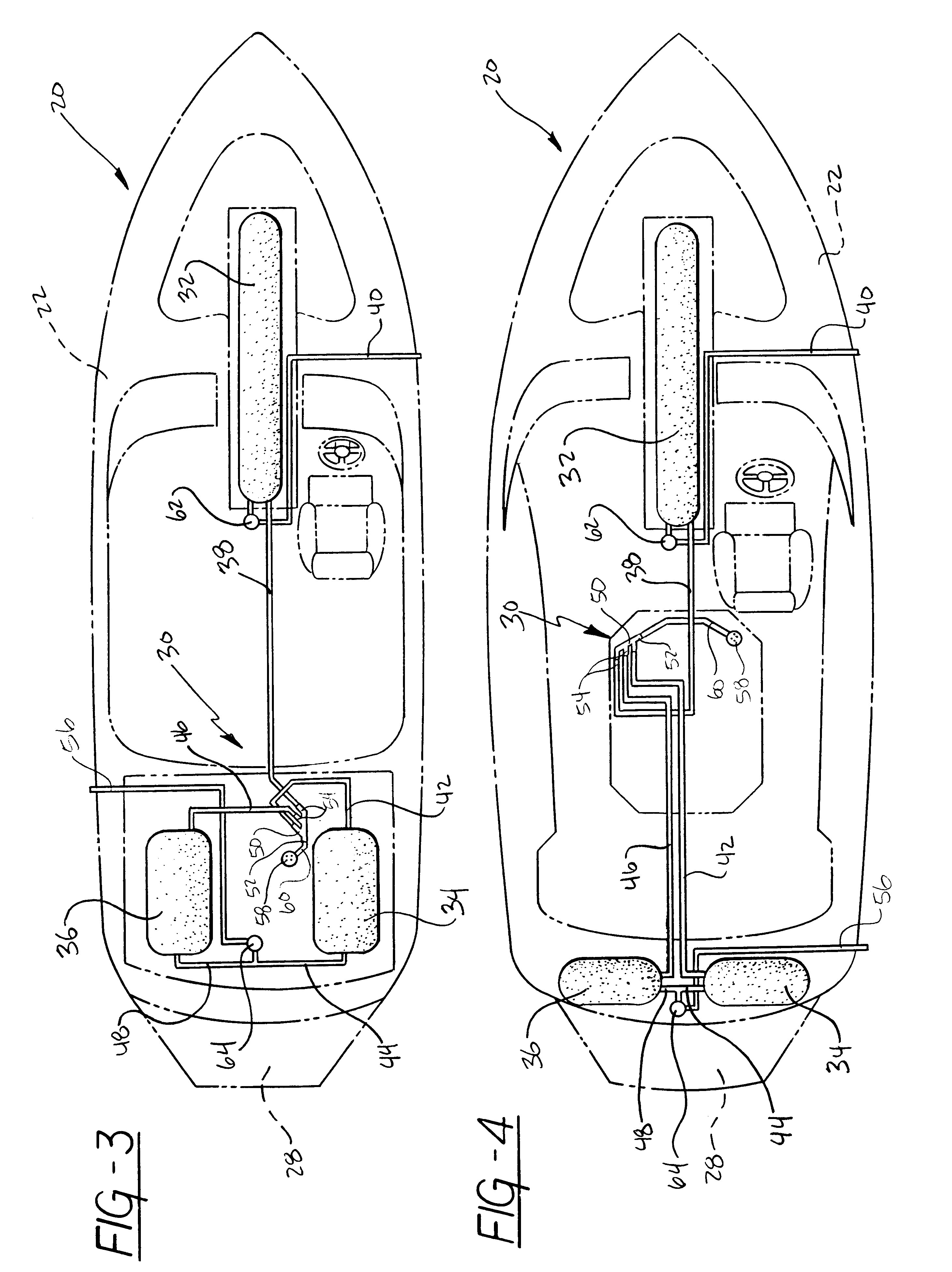

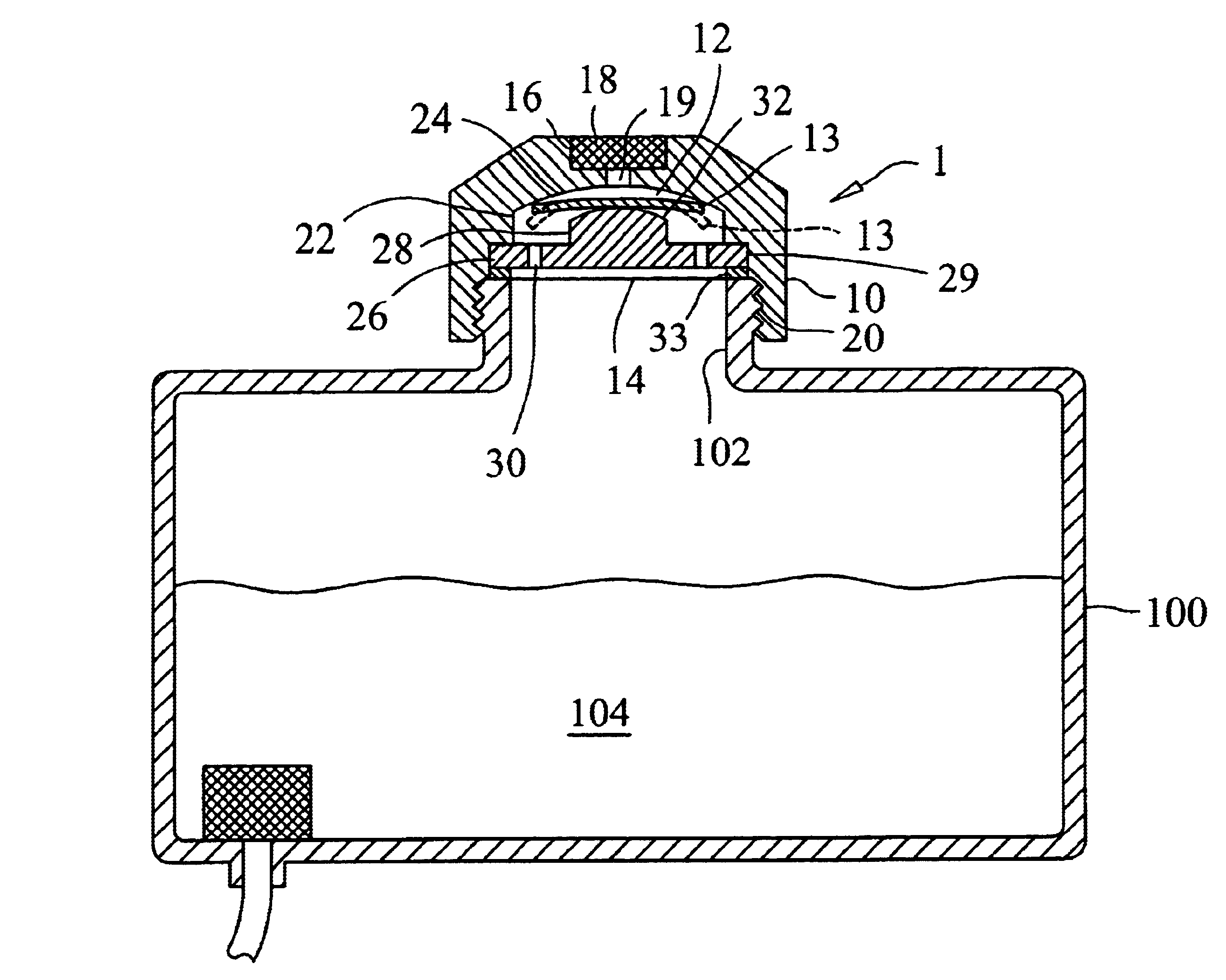

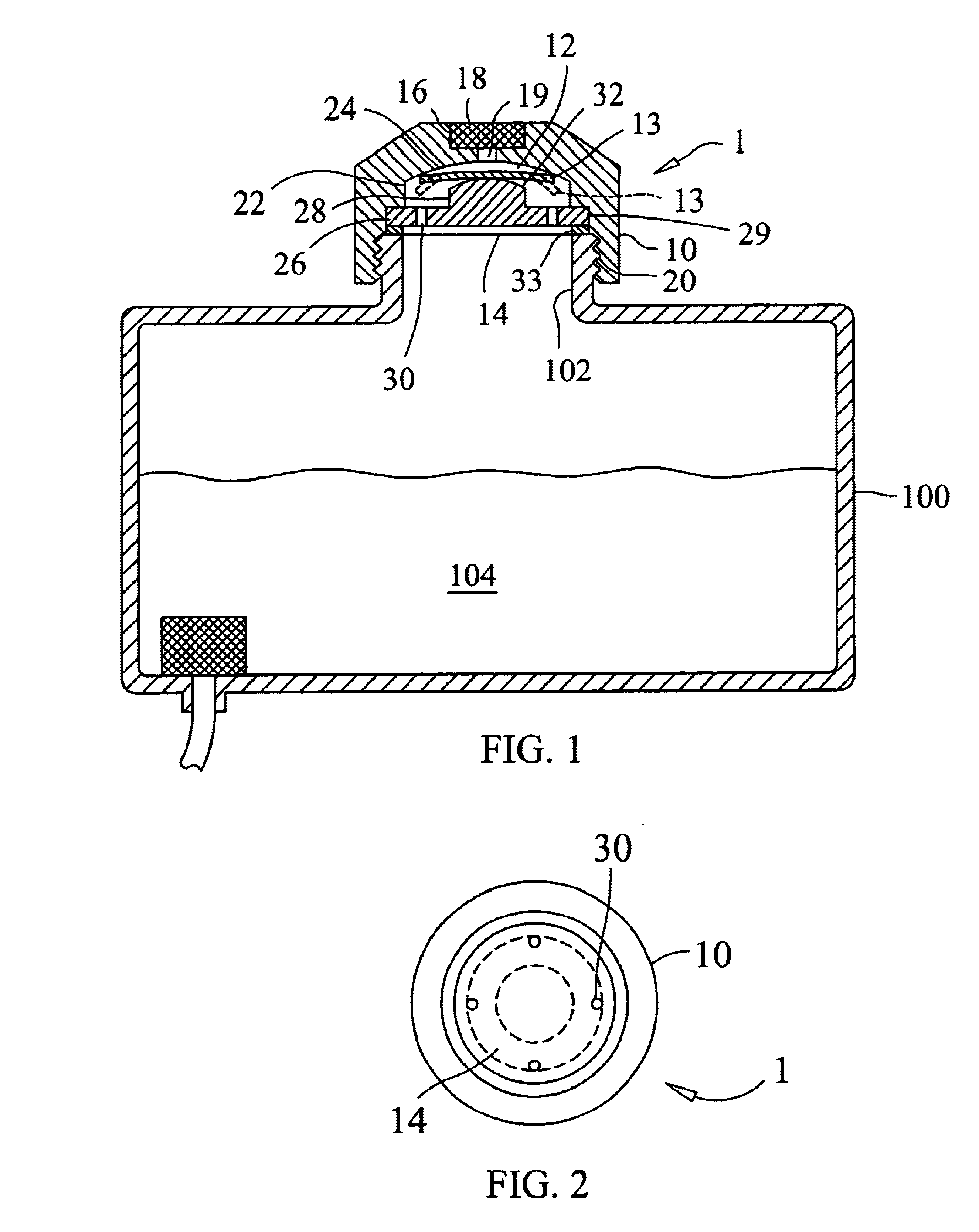

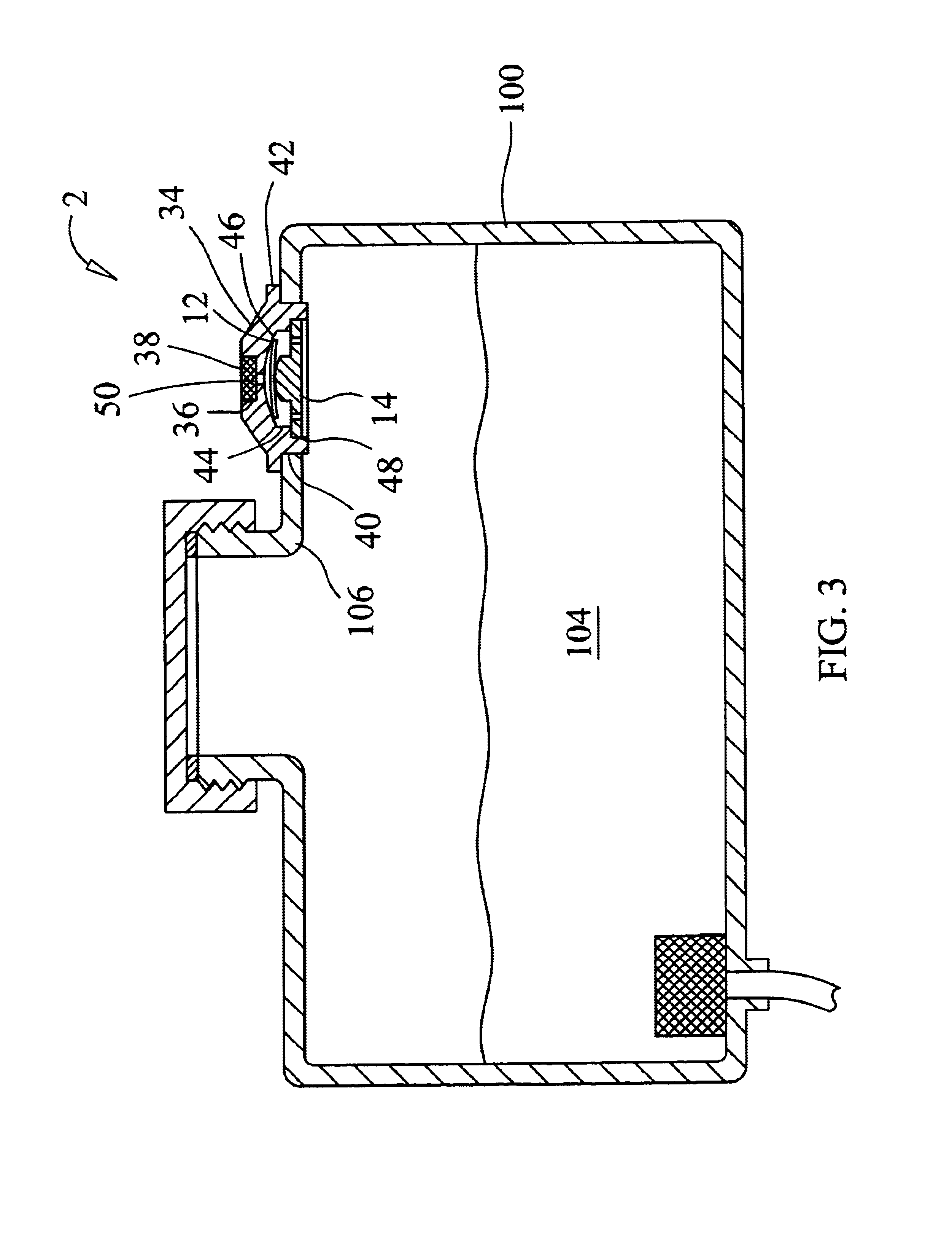

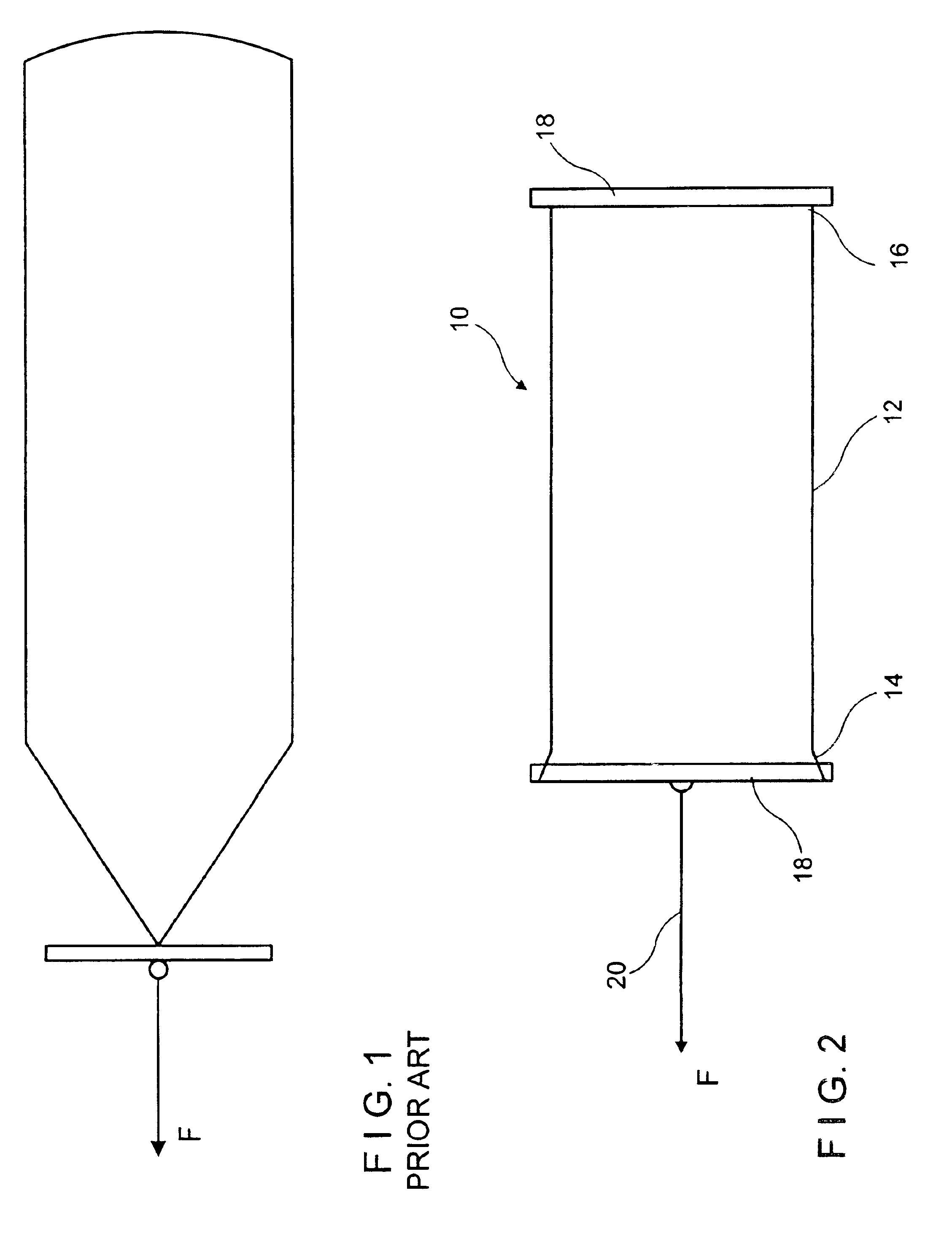

Wake enhancement assembly

InactiveUS6427616B1Inexpensively retrofittedLarge weighting factorWave generating vesselsWater sport boardsBiomedical engineeringVALVE PORT

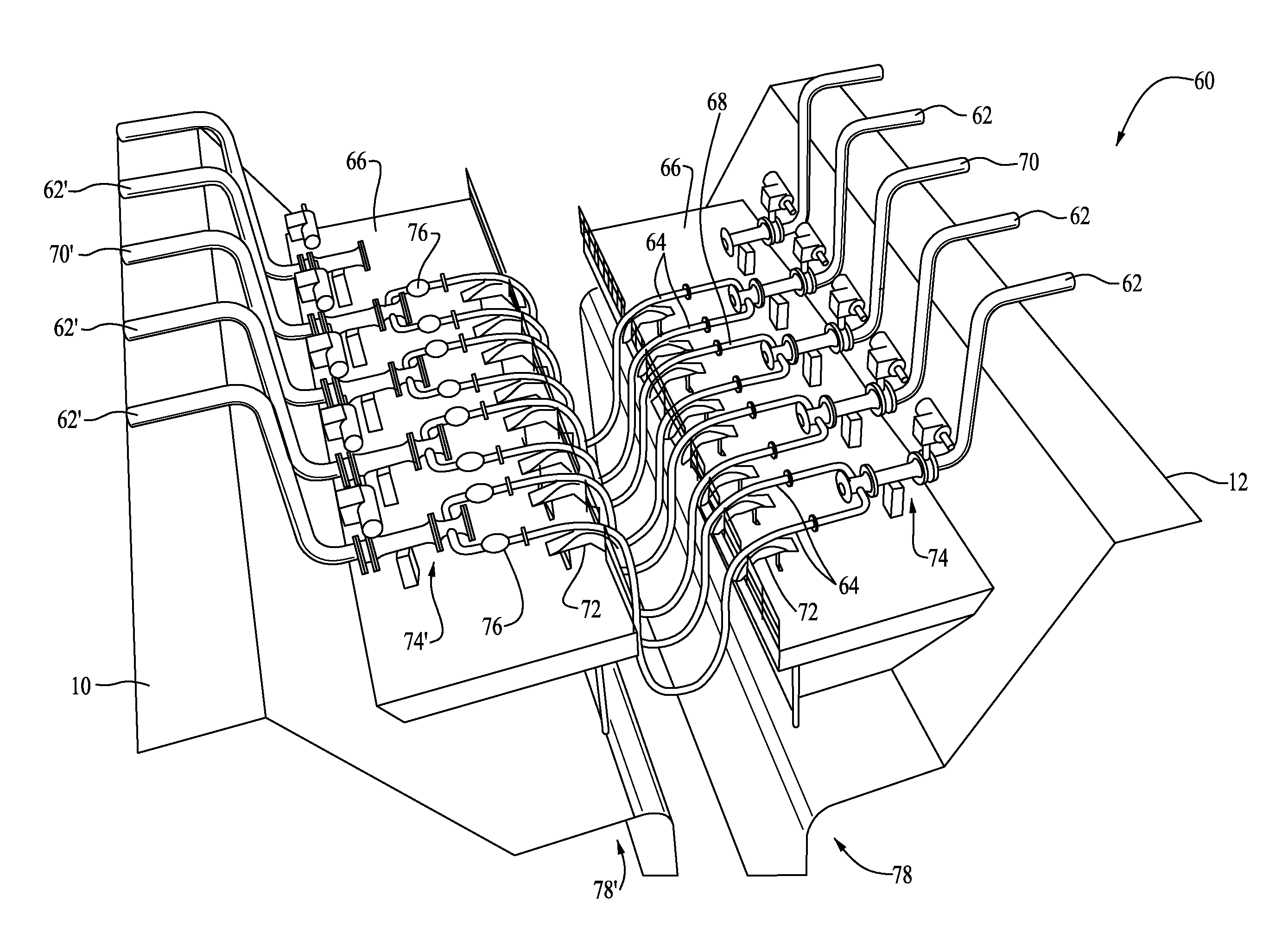

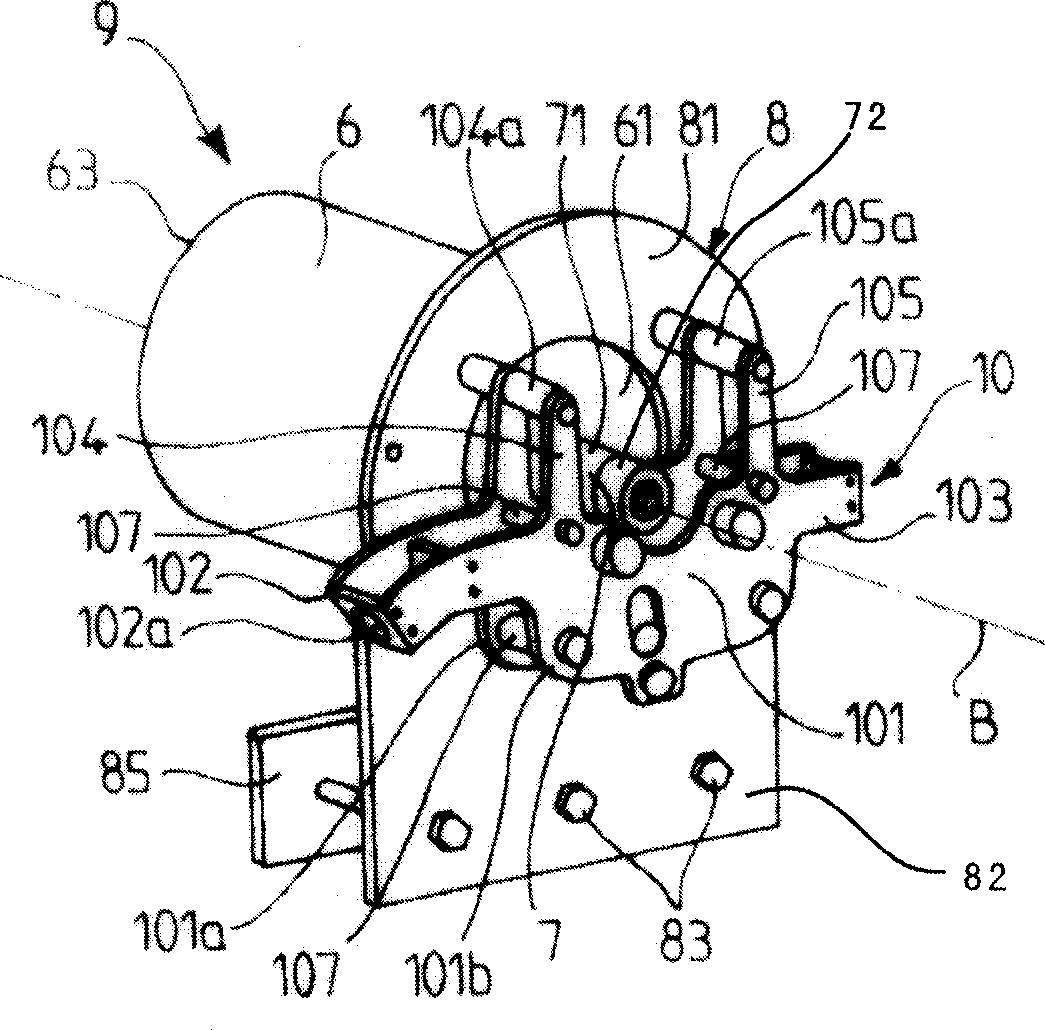

The subject invention is a wake enhancement assembly to vary a configuration of a wake produced by the hull of a boat. The assembly preferably includes three or four fluid chambers adapted to be disposed within the hull of the boat. The fluid chambers can be filled to provide added weight in selected areas of the hull. The added weight alters how the hull rides within a body of water and as such will alter the wake of the boat. A plurality of hoses are mounted to and in fluid communication with the fluid chambers for selectively filling and draining the fluid chambers. The assembly is characterized by a manifold having an inlet and a plurality of outlets. Each of the outlets has a valve disposed in fluid communication therewith. The filling hoses are connected to the outlets such that the valves of the manifold control a flow of fluid to and from the fluid chambers independently of each other. The valves and manifold electronically and remotely control the selective filling and draining of the fluid chambers.

Owner:HAGEN TONI LYNN

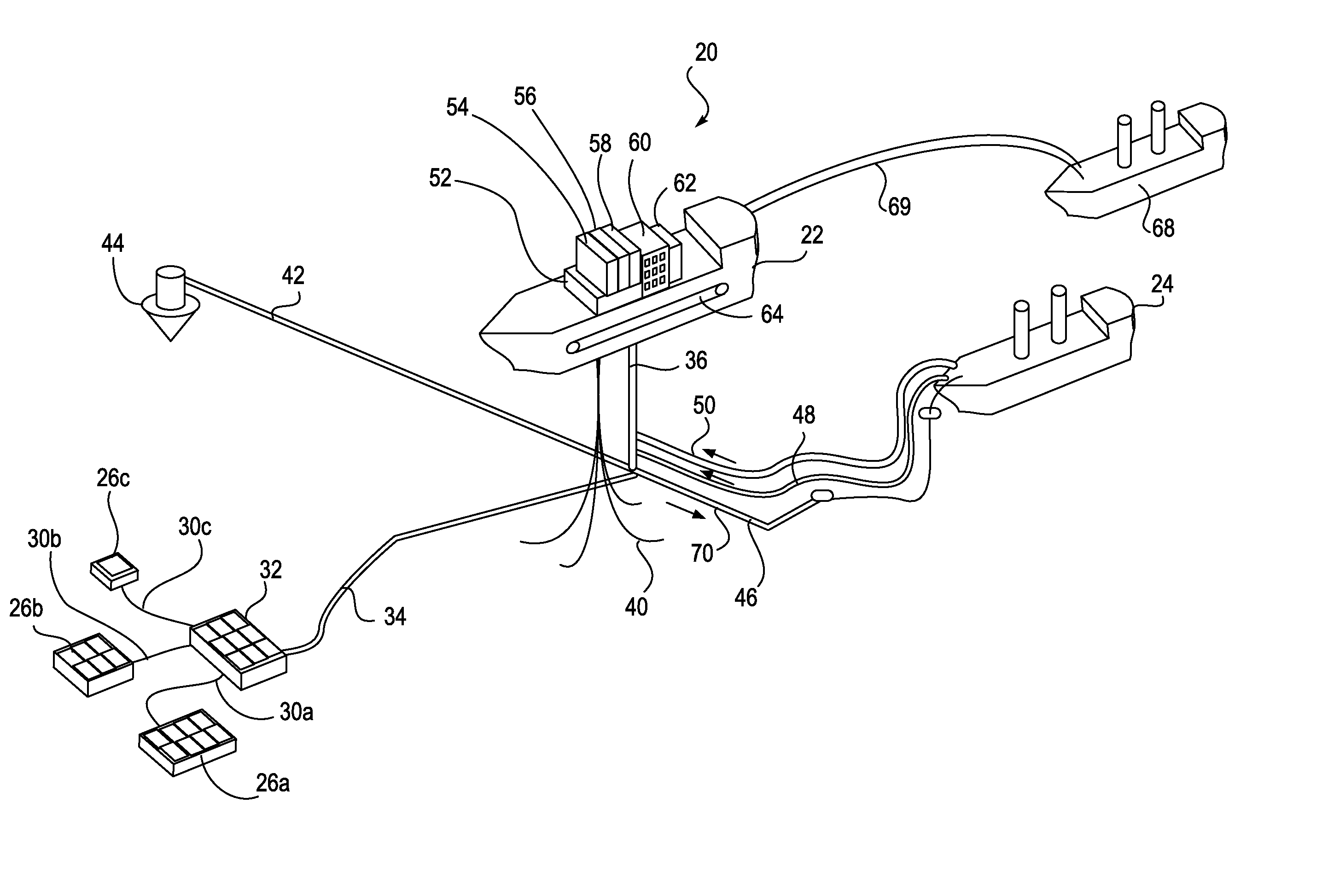

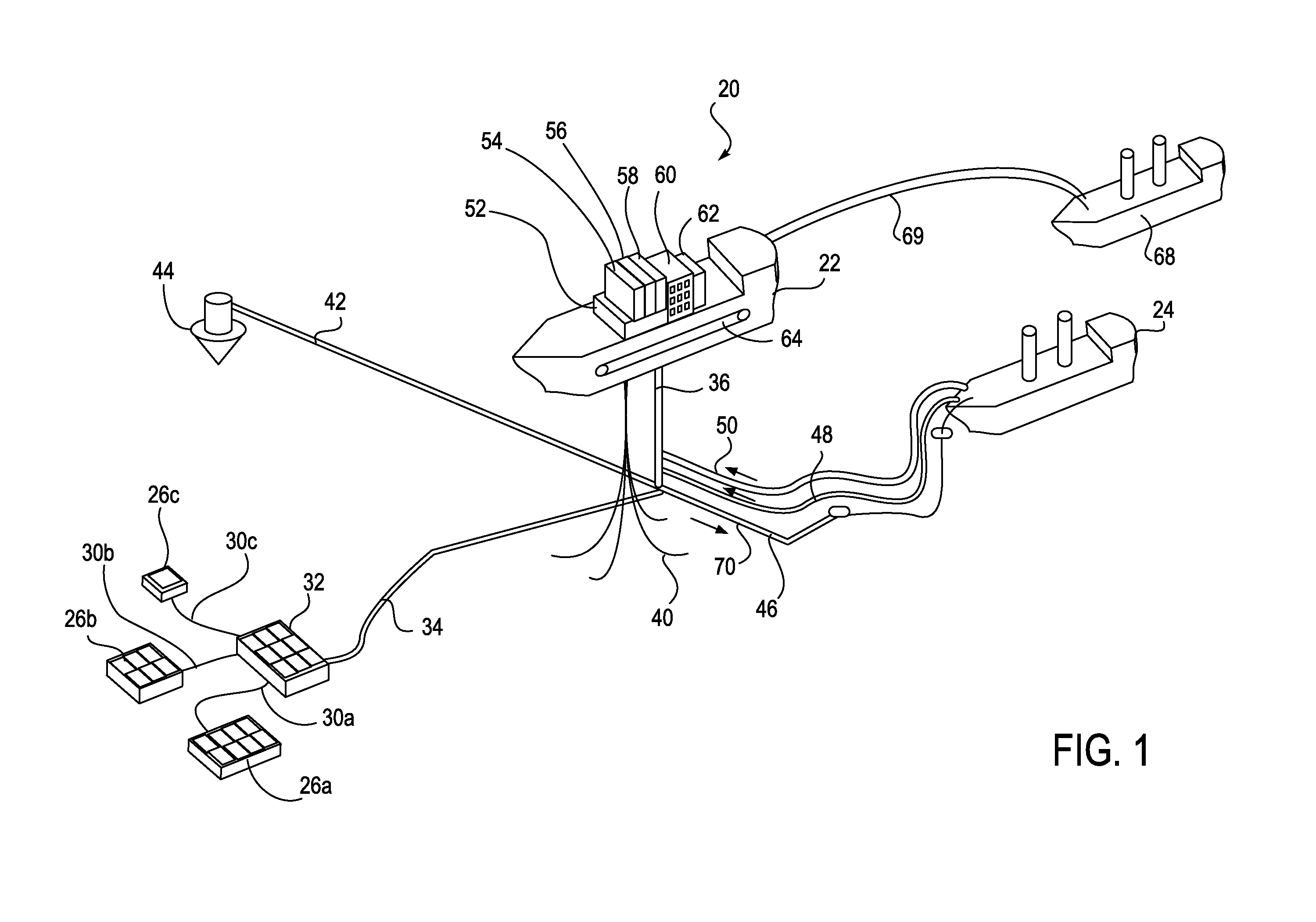

Liquefied natural gas floating storage regasification unit

InactiveUS20060156744A1Reduce the amount requiredProvide protectionGas handling applicationsGas handling/storage effectsMooring systemMarine engineering

An offshore liquefied natural gas floating storage regasification unit that may receive, store, and process liquefied natural gas from carriers. A floating storage regasification unit may include transfer equipment to offload liquefied natural gas from a carrier, a first mooring system to provide for mooring of a floating storage regasification unit at a location in a body of water, a second mooring system to provide for mooring a carrier to the floating storage regasification unit, and combinations thereof. A portion of the floating storage regasification unit may be composed of a double-hull containment structure.

Owner:SHELL OIL CO

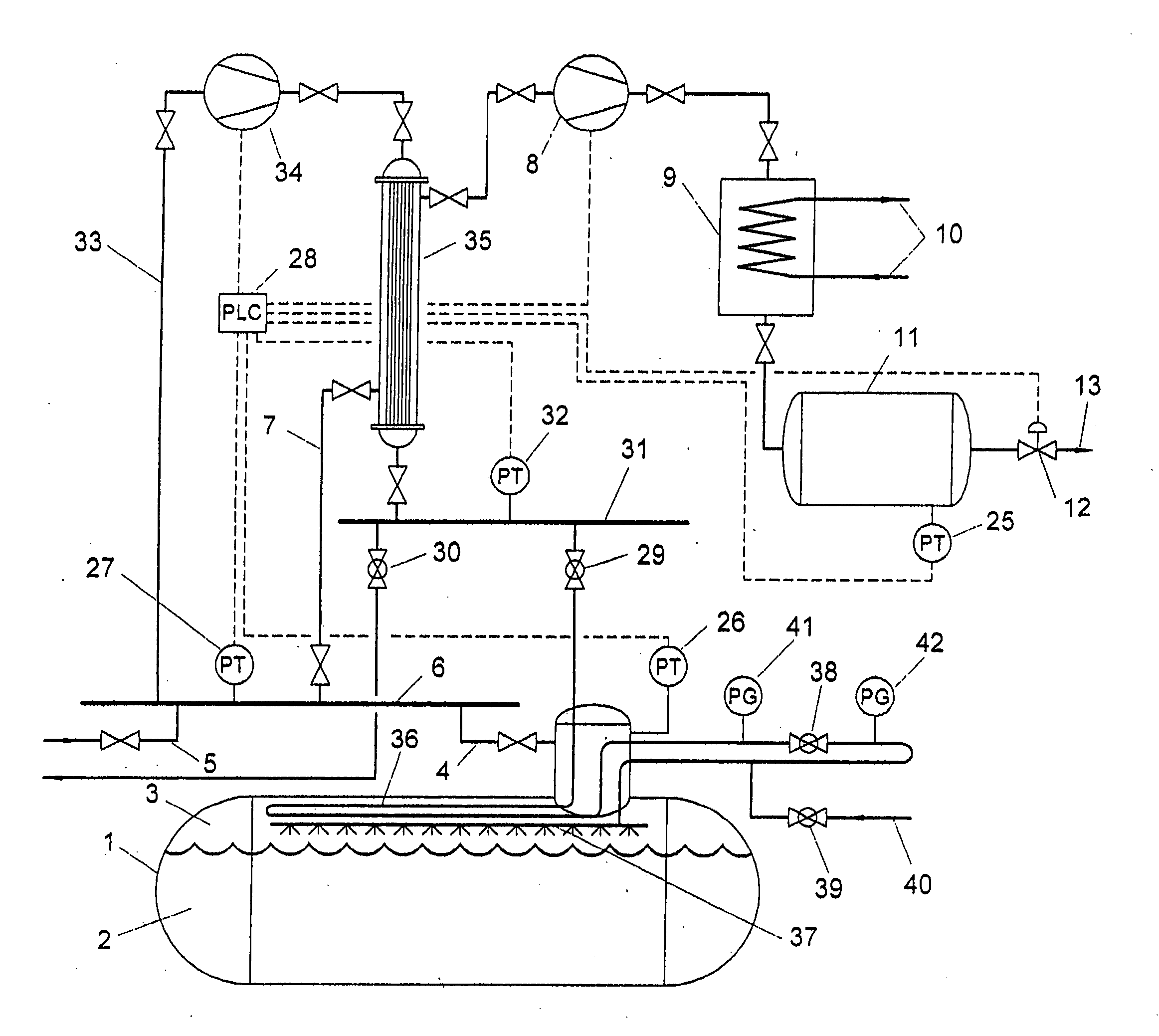

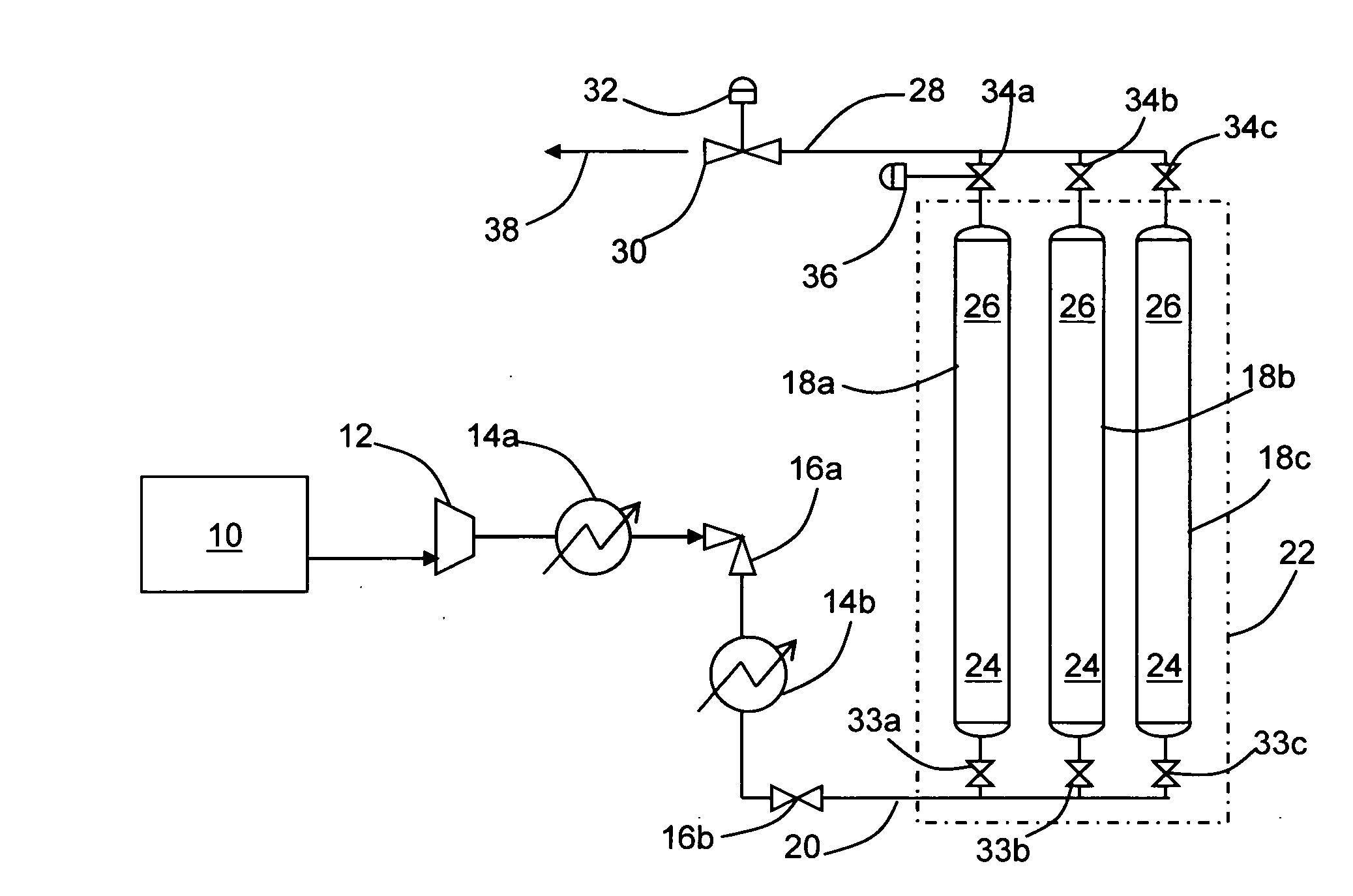

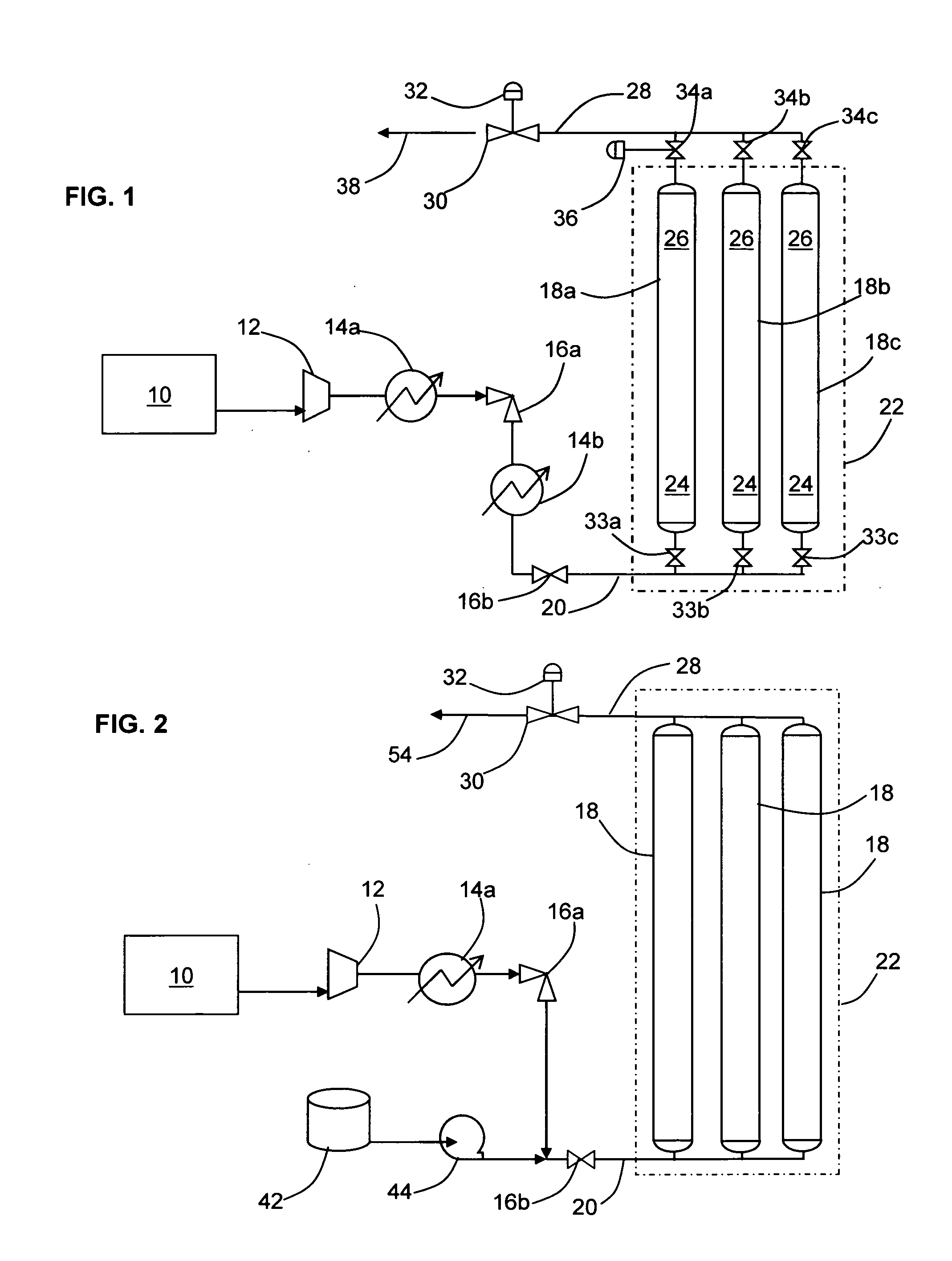

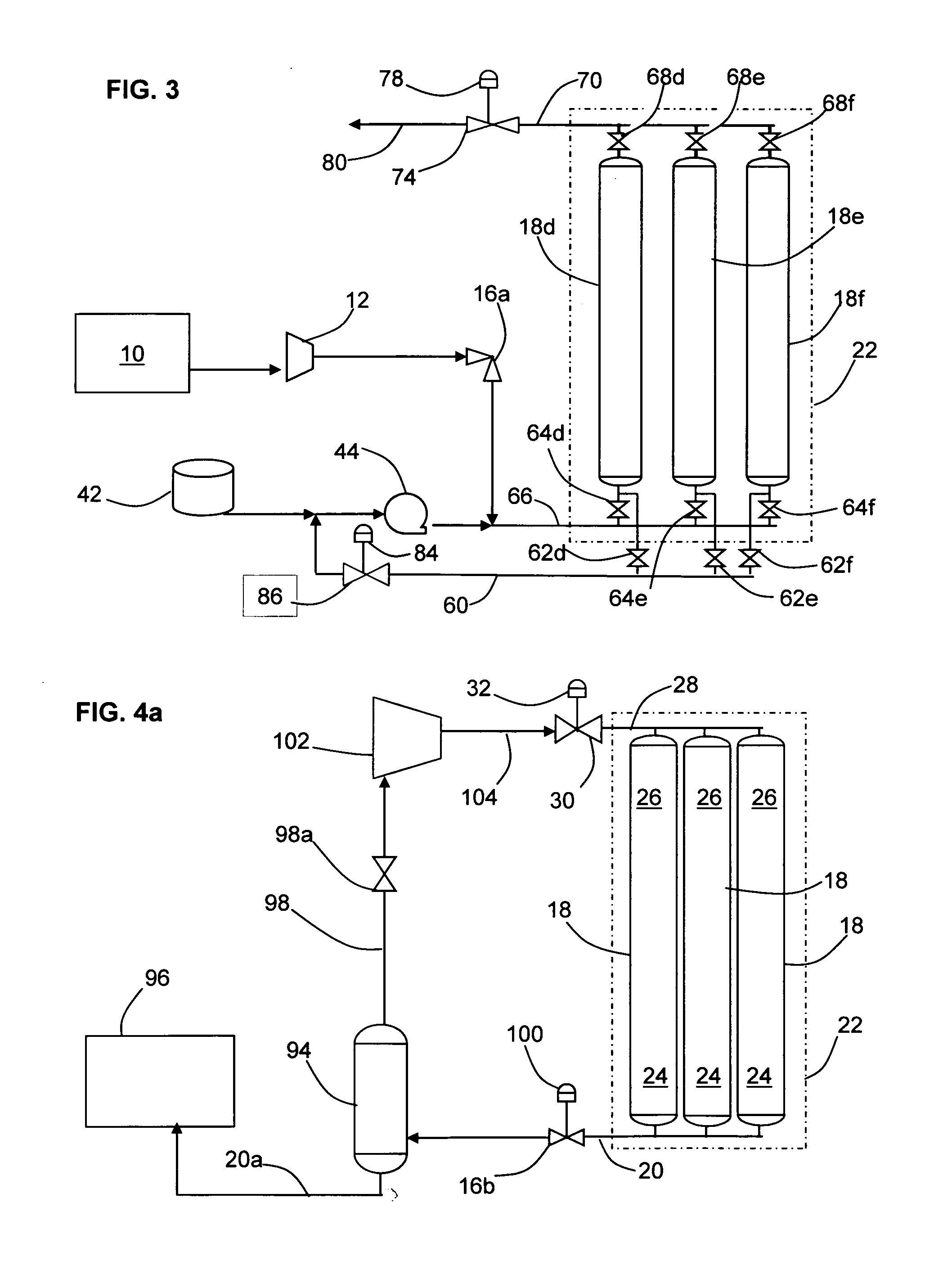

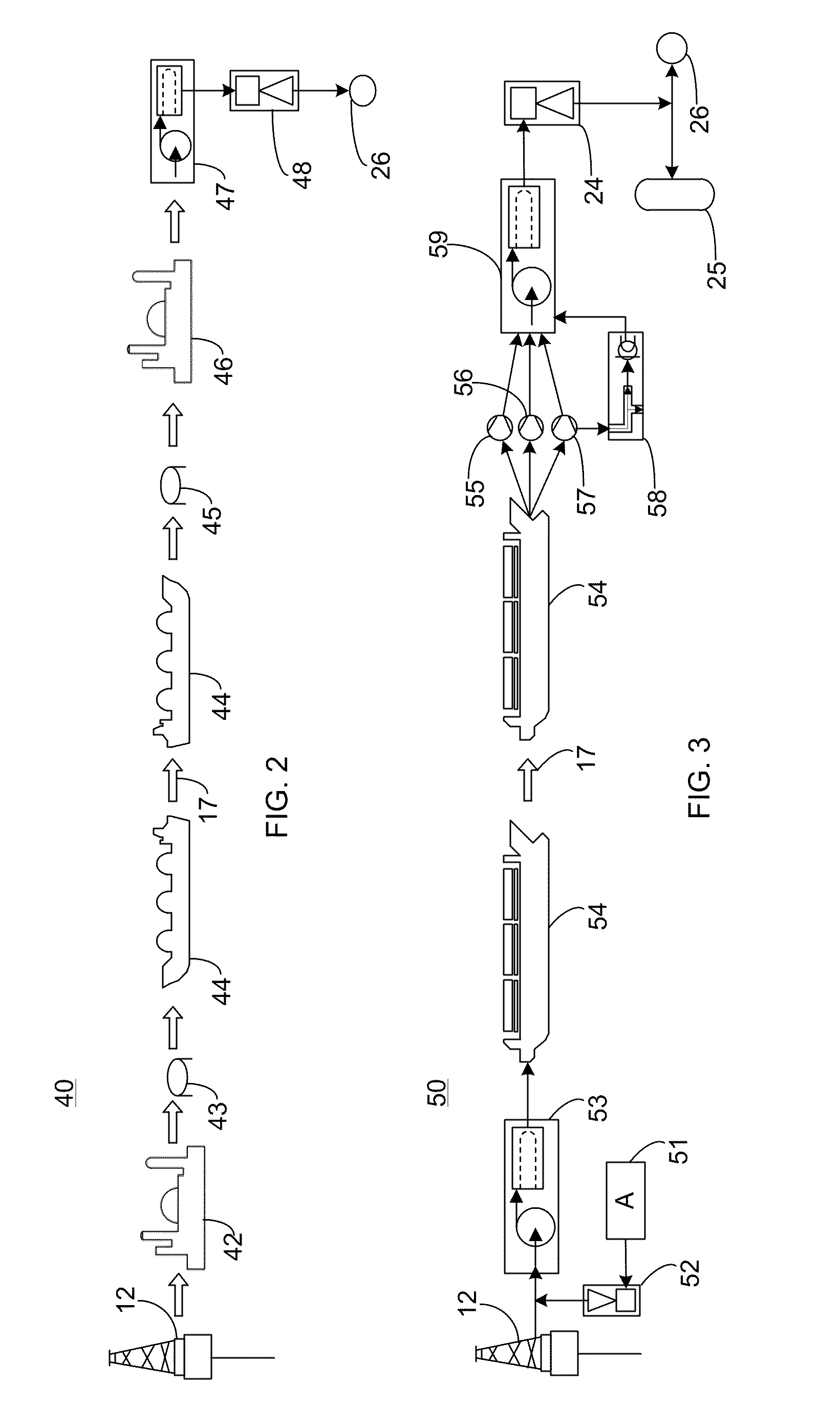

Apparatus and method for flowing compressed fluids into and out of containment

ActiveUS20080209916A1Adjustable temperatureGas handling applicationsGas handling/storage effectsChemical compositionCompressed fluid

Methods for loading a compressed fluid, such as natural gas, into and discharging the compressed fluid out of containment are provided. The compressed fluid is injected into a bottom portion of a container system for storage and / or transport until a target pressure is reached after which gas is withdrawn from an upper portion of the container system at a rate to maintain the target pressure while the compressed fluid is injected in the bottom portion. The compressed fluid is cooled through an expansion valve and by refrigerated chillers or by injecting a cold liquid of the same chemical composition as the compressed fluid, such as liquid natural gas, into the compressed fluid prior to injection into the container system. Withdrawal or discharge from the container system to a receiving facility begins with blow down from the bottom portion of the container system without a displacement fluid and continues until pressure falls below an acceptable differential pressure. The discharge stream is passed through a separator and a light gas from the separator is pressurized and injected into an upper portion of the container system to drive the compressed fluid out the bottom. The light gas is pressurized using either a compressor or a heated tank system, where two vessels operate in parallel, trapping and heating the light gas and then discharging to the container system from one while filling the other and alternating the operation between the two.

Owner:WHITE CHARLES N +1

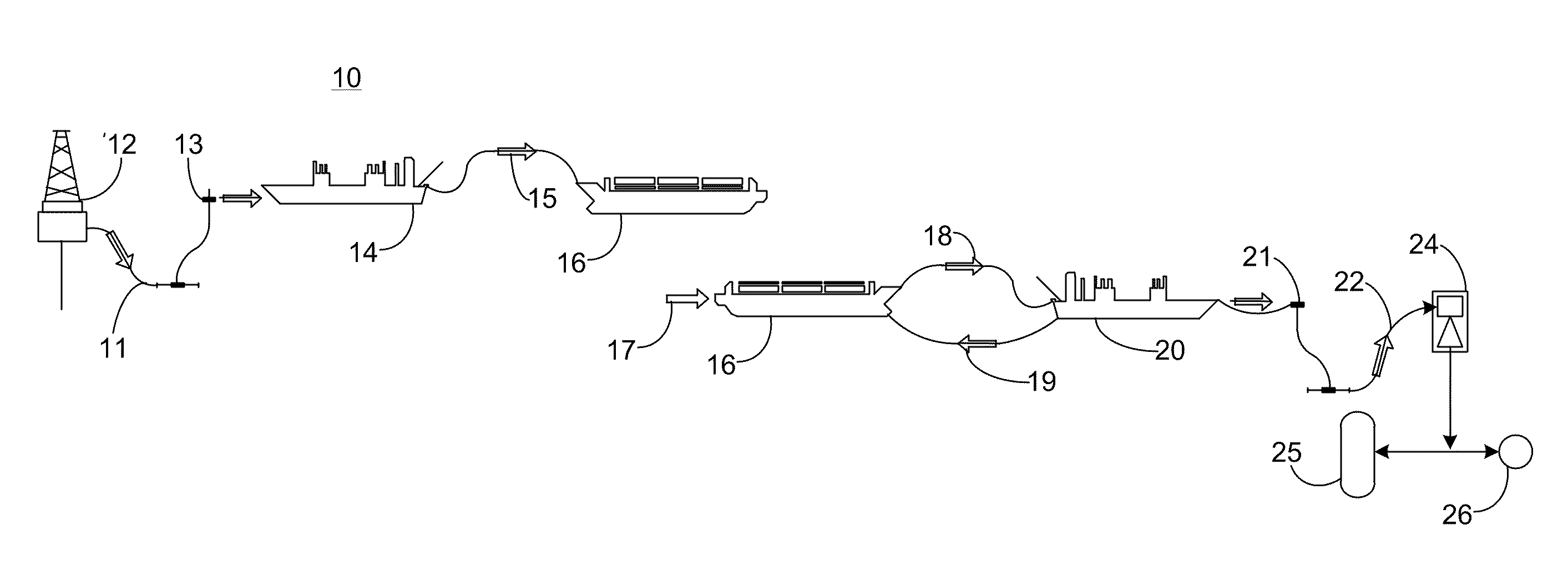

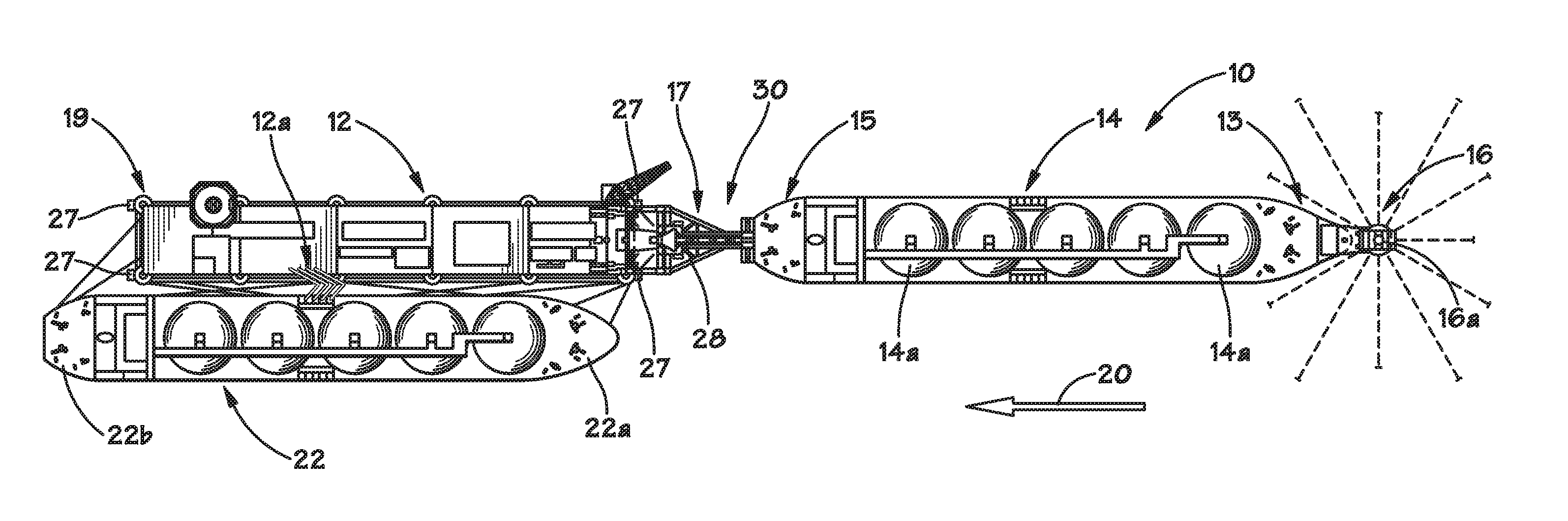

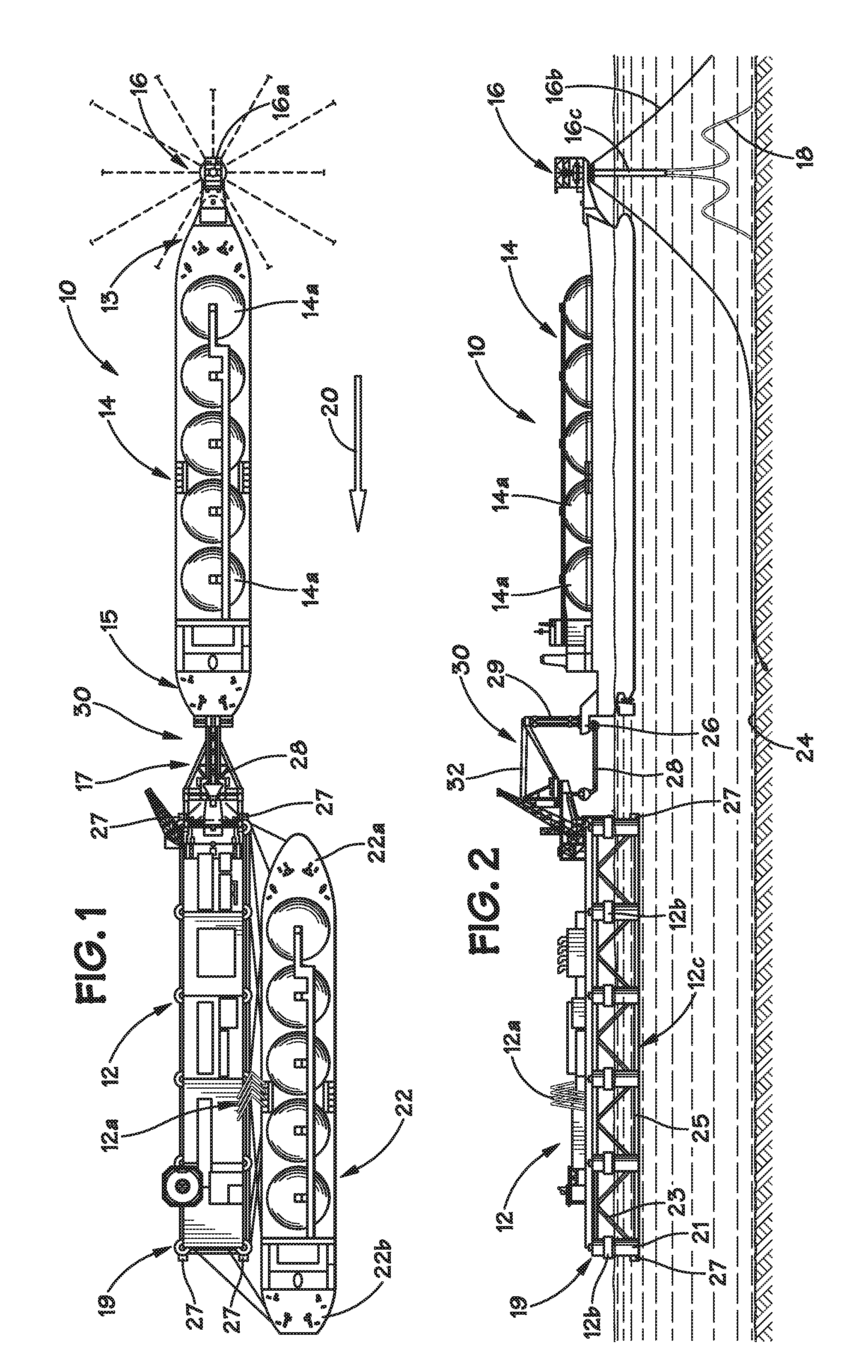

Comprehensive system for the storage and transportation of natural gas in a light hydrocarbon liquid medium

ActiveUS20100000252A1Rapid economic developmentRaise the ratioSolidificationLiquefactionProcess systemsLiquid medium

This invention provides a means of loading, processing and conditioning raw production gas, production of CGL, storage, transport, and delivery of pipeline quality natural gas or fractionated products to market. The CGL transport vessel utilizes a pipe based containment system to hold more densely packed constituents of natural gas held within a light hydrocarbon solvent than it is possible to attain for natural gas alone under such conditions. The containment system is supported by process systems for loading and transporting the natural gas as a liquid and unloading the CGL from the containment system and then offloading it in the gaseous state. The system can also be utilized for the selective storage and transport of NGLs to provide a total service package for the movement of natural gas and associated gas production. The mode of storage is suited for both marine and land transportation and configured in modular form to suit a particular application and / or scale of operation.

Owner:SEAONE HLDG

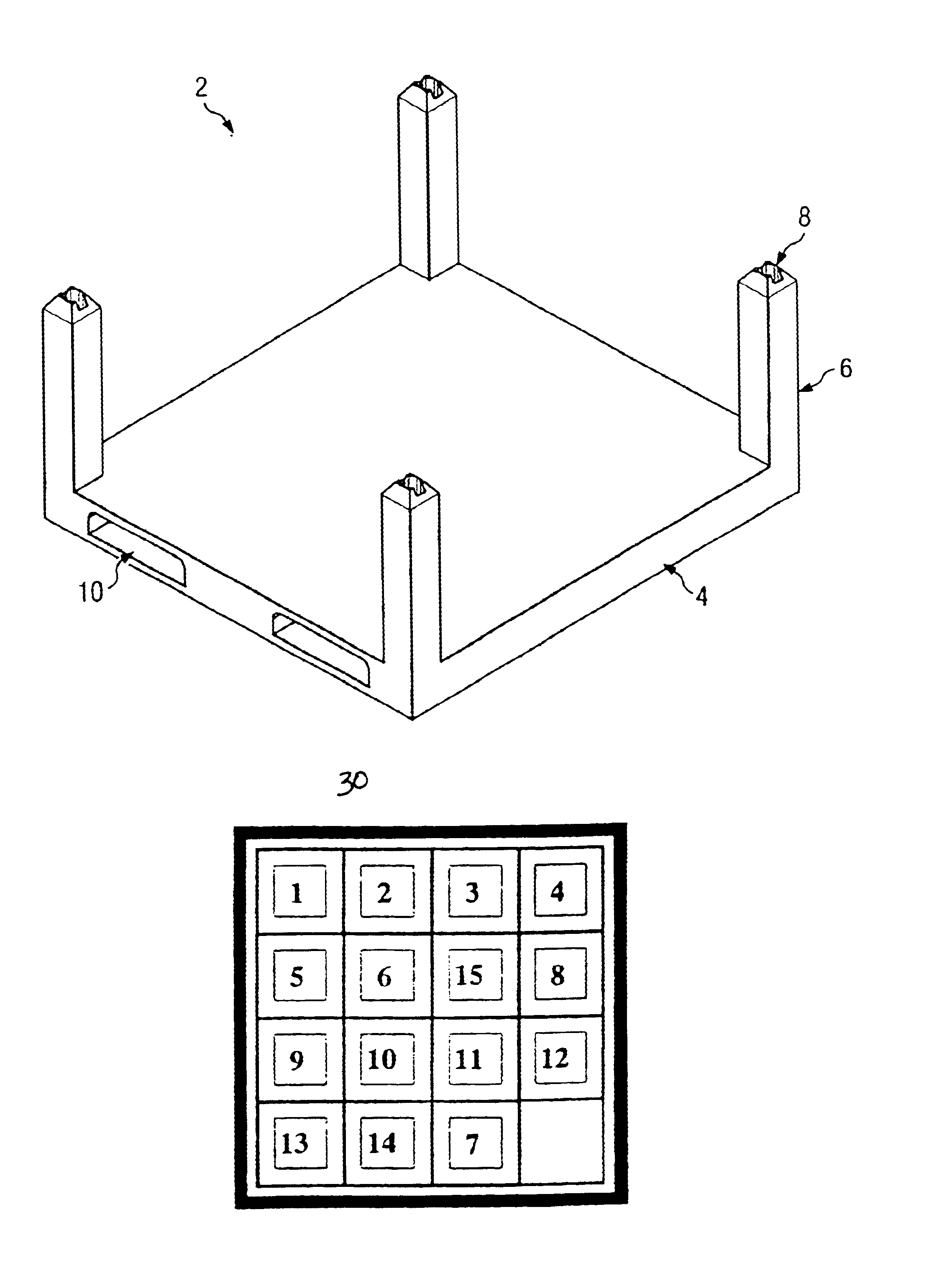

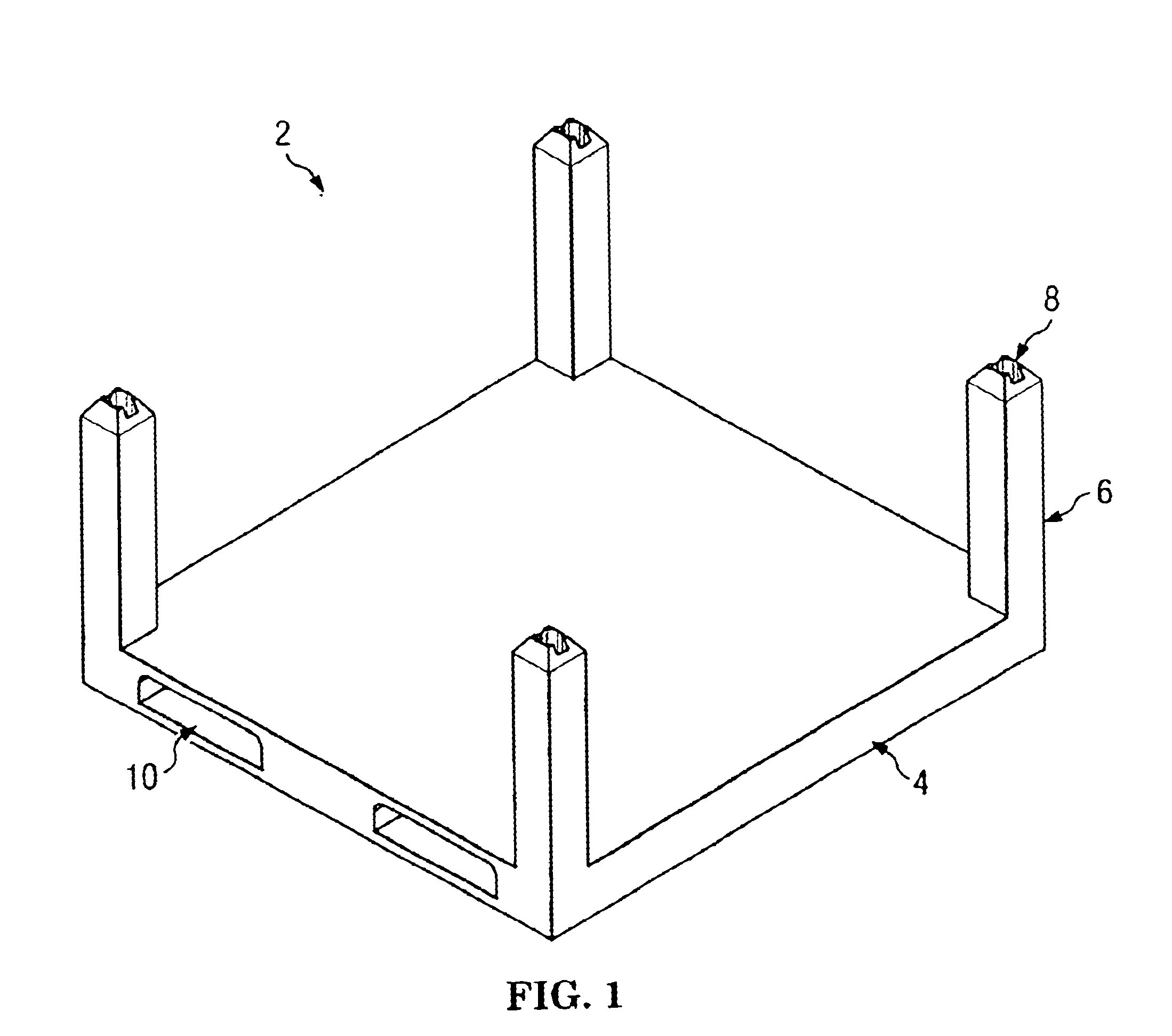

Stowage and retrieval system

InactiveUS6842665B2High bulk densityHigh densityDigital data processing detailsLarge containersContainerizationEngineering

A storage and retrieval system is provided that automates the process of handling a mixed inventory of palletized and containerized items. The invention is particularly useful in handling cargo and weapons within a ship's hold or magazine. When used on a ship, the invention provides for the stowing and unstowing of loads quickly and efficiently, to automatically secure such payloads for sea and to achieve high stowage density, while retaining the capability to select and retrieve any ordered payload, move it to and load it on elevator trays under computer control.

Owner:KARLEN JAMES P

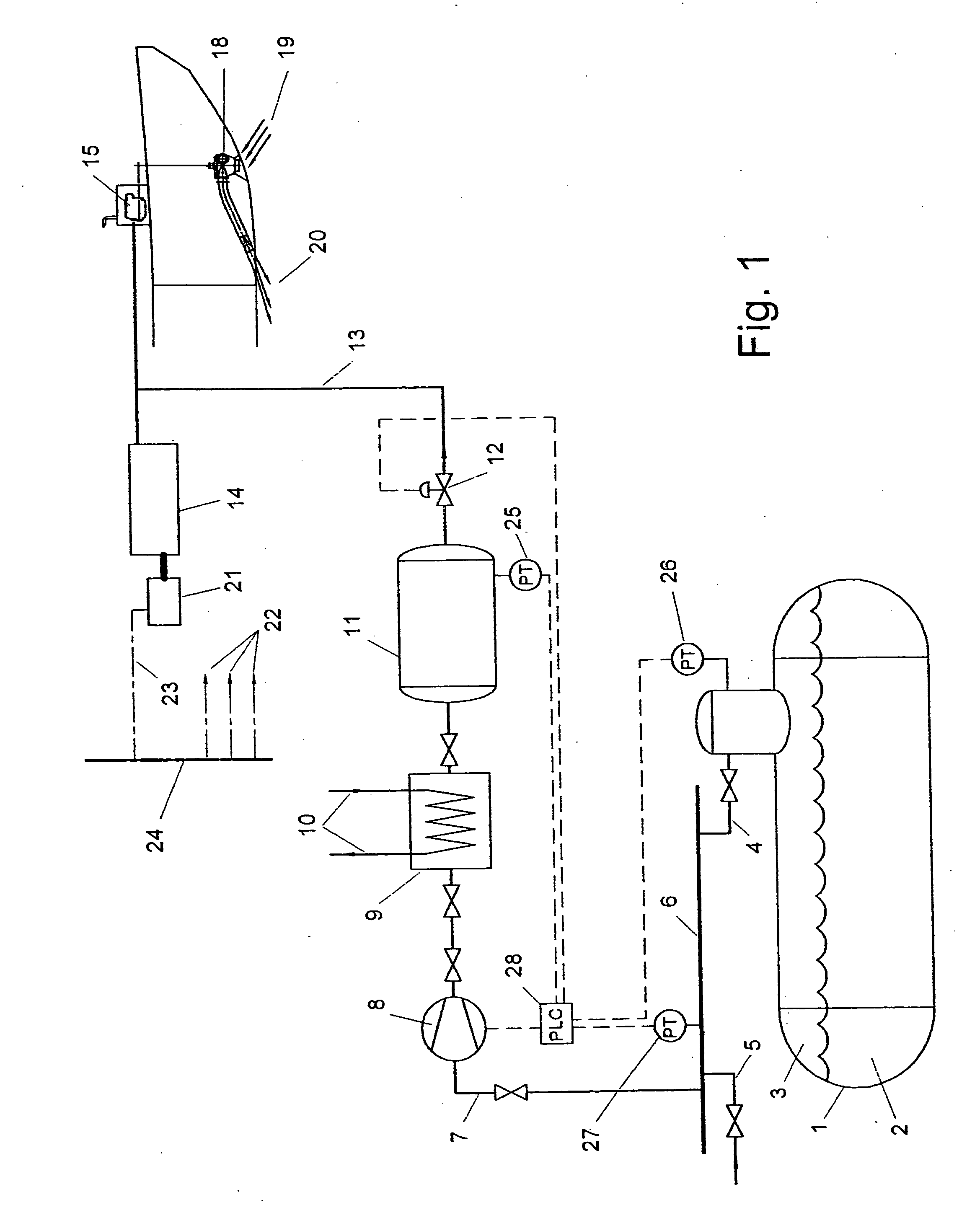

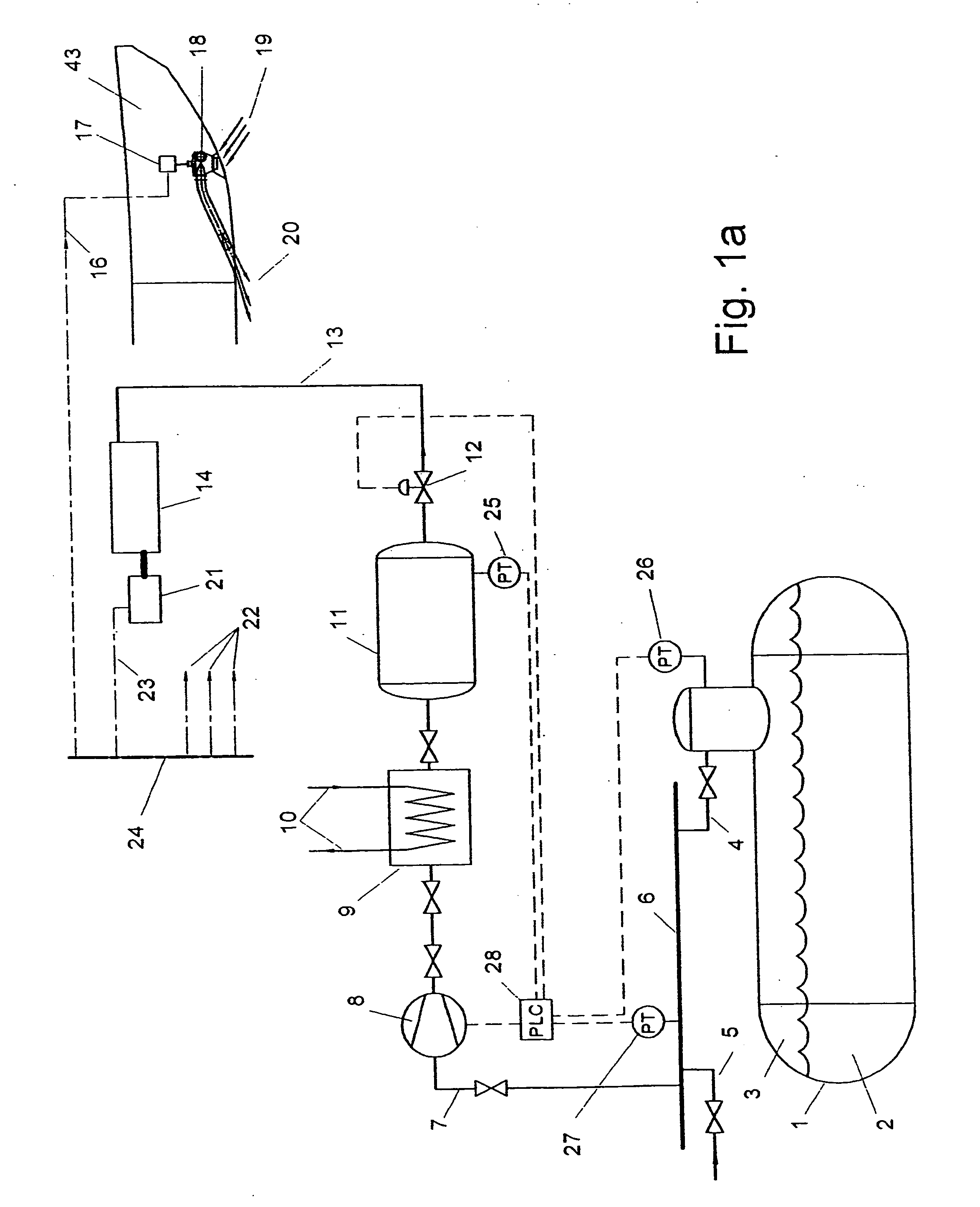

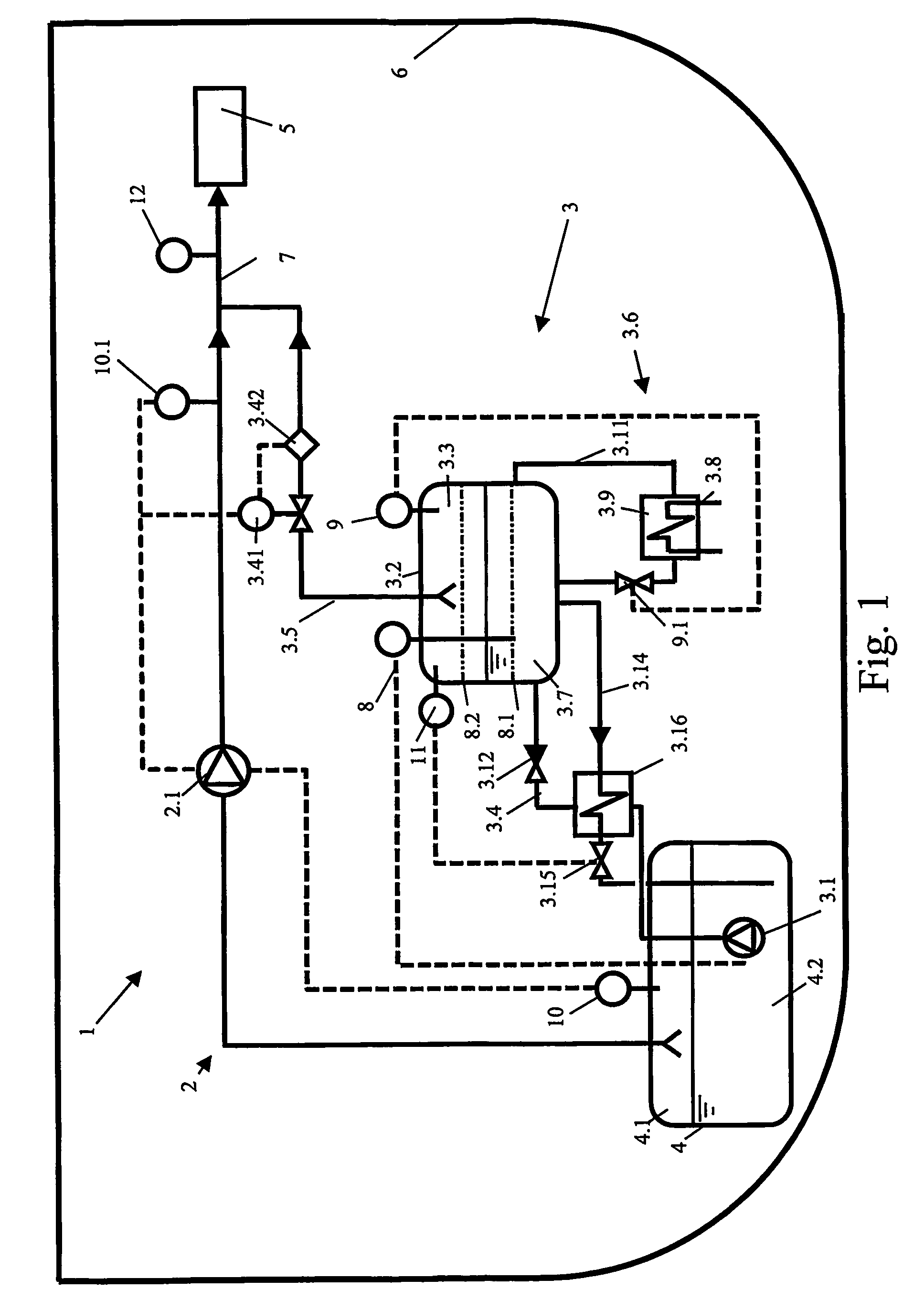

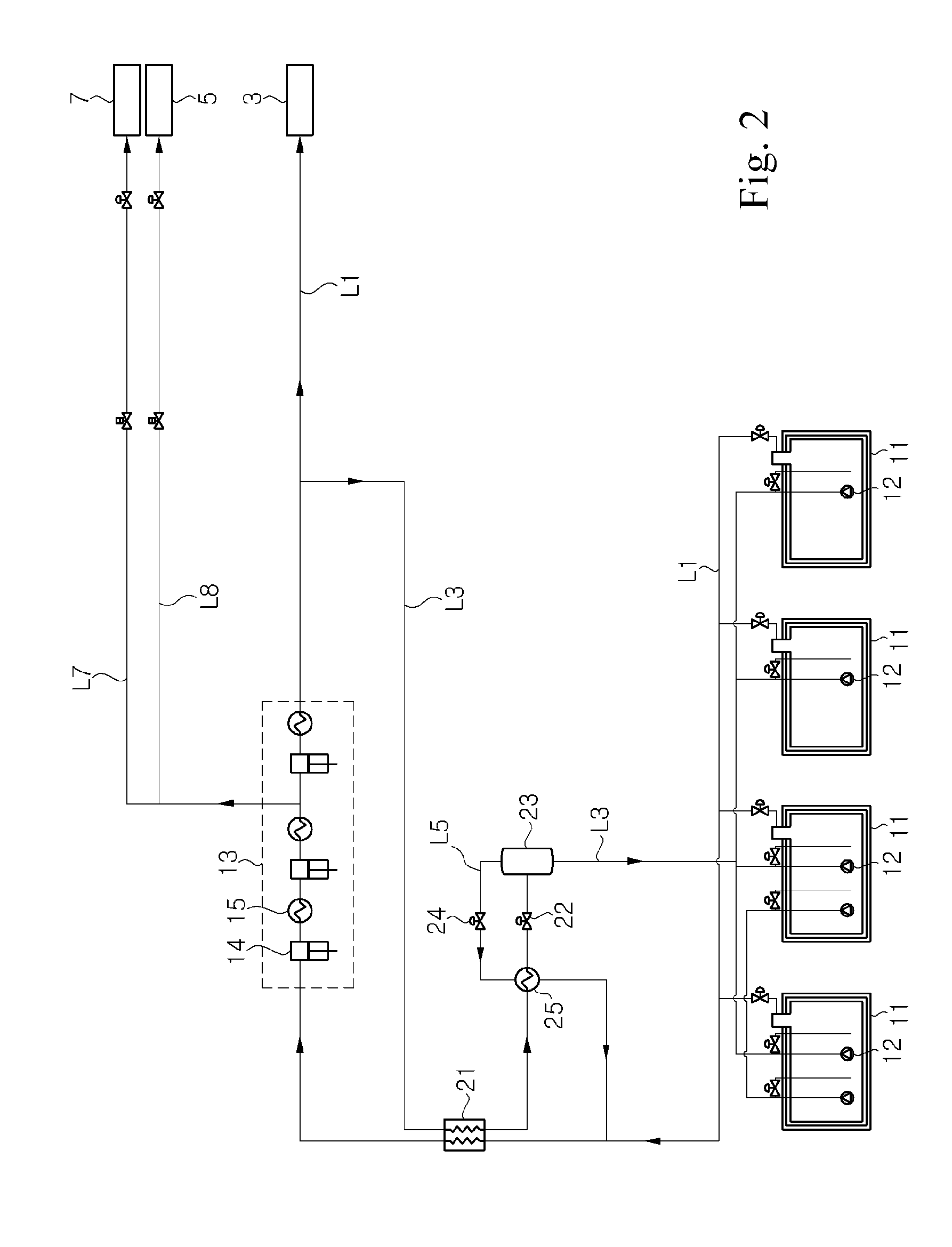

Gas supply arrangement of a marine vessel and method of providing gas in a gas supply arrangement of a marine vessel

InactiveUS7497180B2Easy to maintain temperatureReduce the impactAuxillariesContainer filling methodsEngineeringControl valves

A gas supply arrangement of a marine vessel being adapted to carry liquefied gas in its cargo tank having an ullage space section and a liquid phase section, which arrangement utilizes the gas as fuel to provide power for the vessel, the arrangement comprising a first gas supply line provided for processing the natural boil-off gas formed in the cargo tank, a second gas supply line which connects the cargo tank and the gas main supply line and which is provided with at least a pump for raising the pressure of the liquid gas and for pumping it forward. The second gas supply line is provided with a gas reservoir having an ullage space section and liquid phase section, and that the arrangement is provided with a first duct section of the second gas supply line connecting the liquid phase section of the cargo tank and the liquid phase section of the gas reservoir, and being provided with the pump, and that the arrangement is additionally provided with a return line connecting the liquid phase section of the reservoir and the cargo tank being provided with a control valve for controllable returning liquid gas back into the cargo tank.

Owner:WARTSILA FINLAND OY

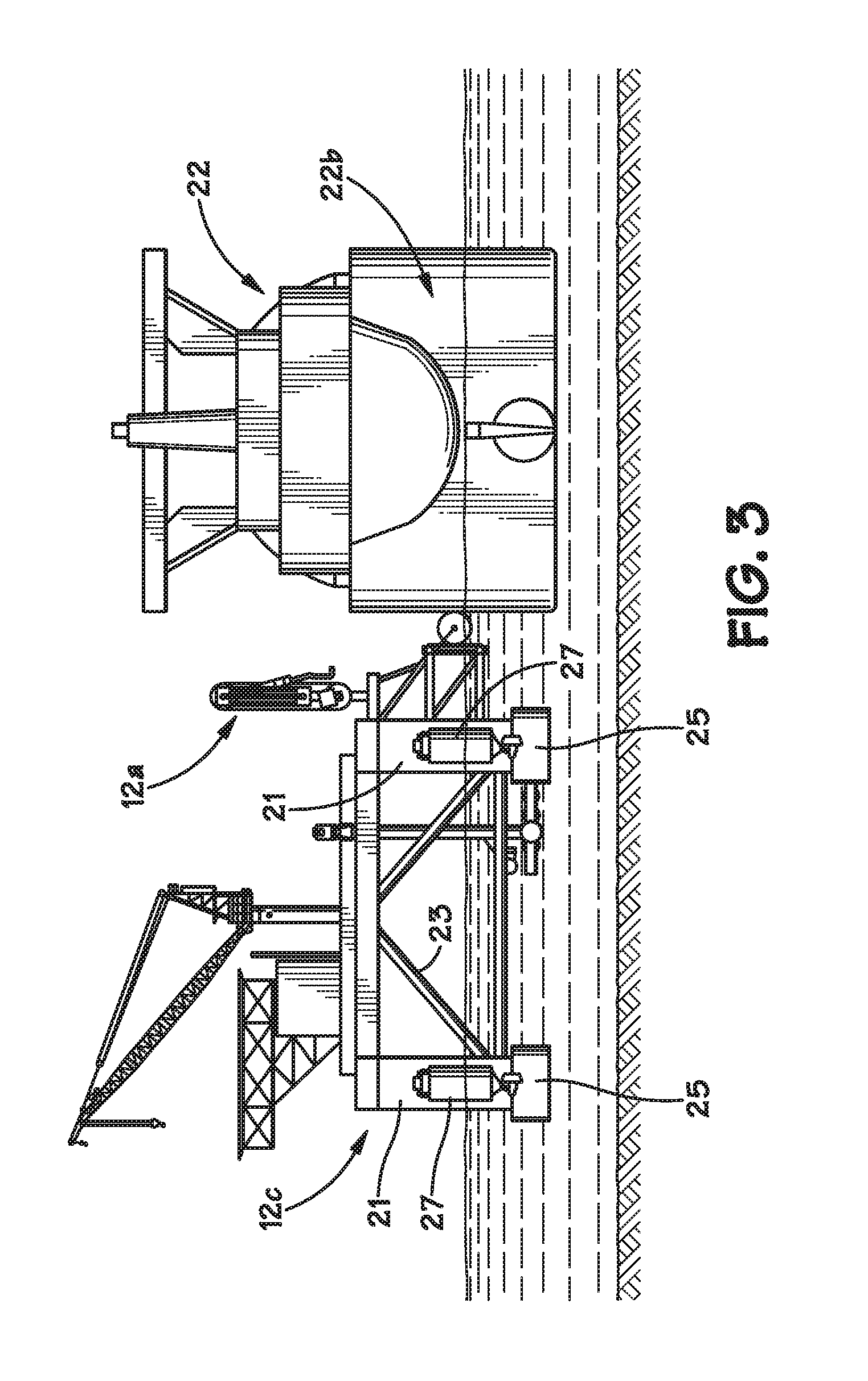

Dockside Ship-To-Ship Transfer of LNG

InactiveUS20100263389A1Gas handling applicationsGas handling/storage effectsMarine engineeringEngineering

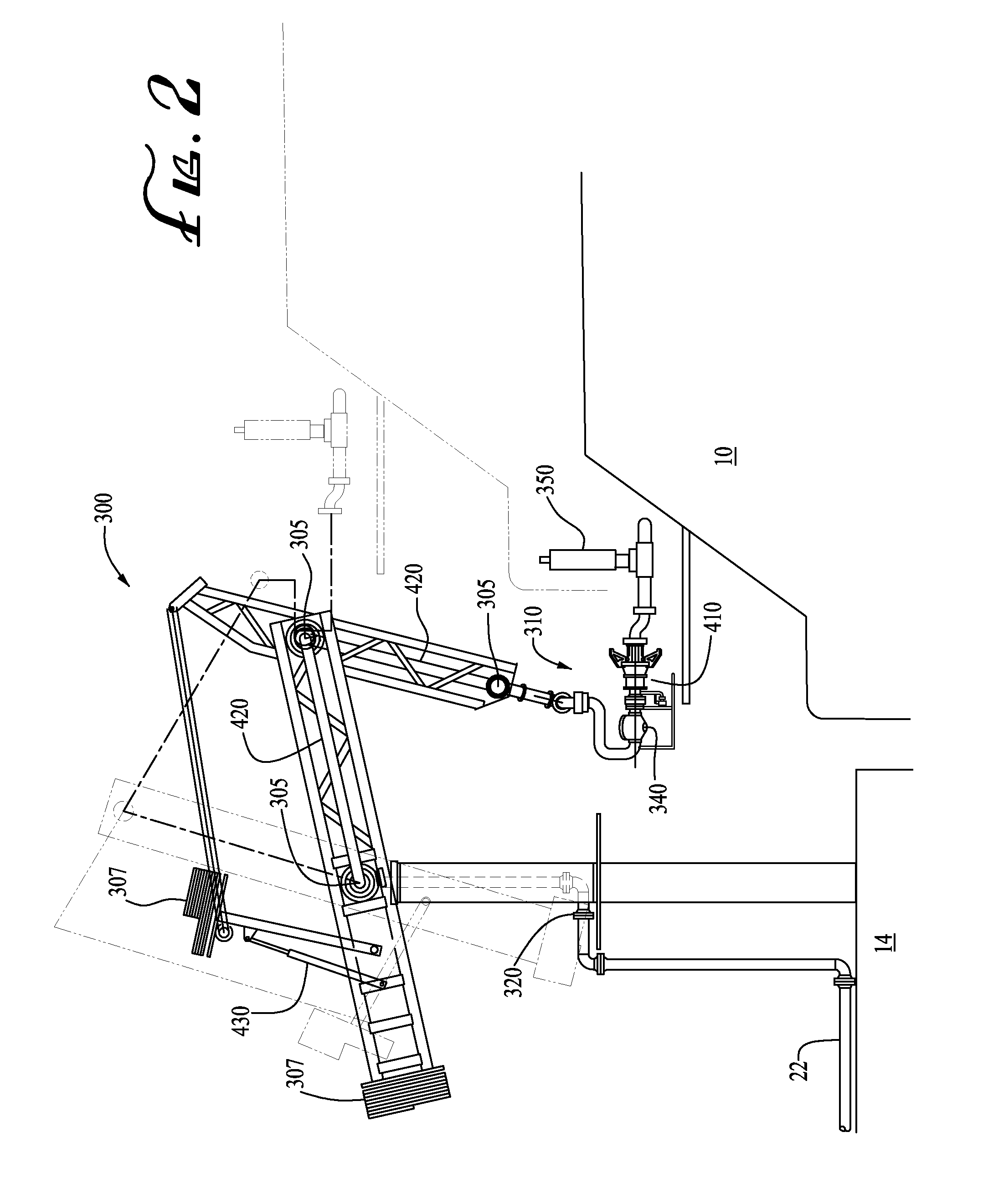

Systems and methods for dockside regasification of liquefied natural gas (LNG) are described herein. The methods include providing LNG from a LNG carrier to a regasification vessel. The LNG may be regasified on the regasification vessel. The regasified natural gas may be discharged with a high pressure arm to a dock and delivered onshore. The regasification vessel may be moored to the dock. The LNG carrier may be moored to the regasification vessel or the dock.

Owner:EXCELERATE ENERGY LTD PARNERSHIP

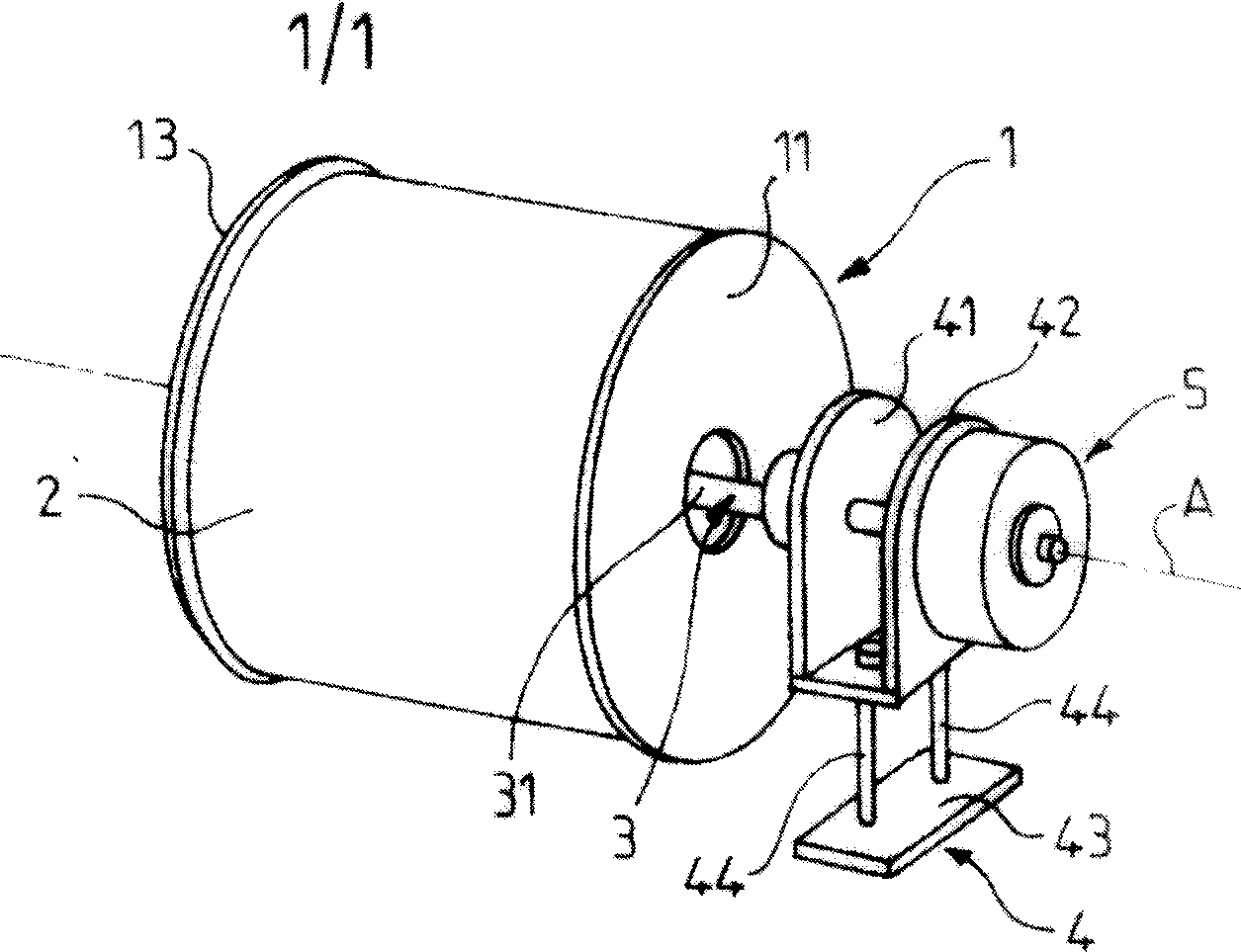

Modular system for storing gas cylinders

InactiveUS6994104B2High procedureIncrease profitabilitySolidificationLiquefactionSystems designGas cylinder

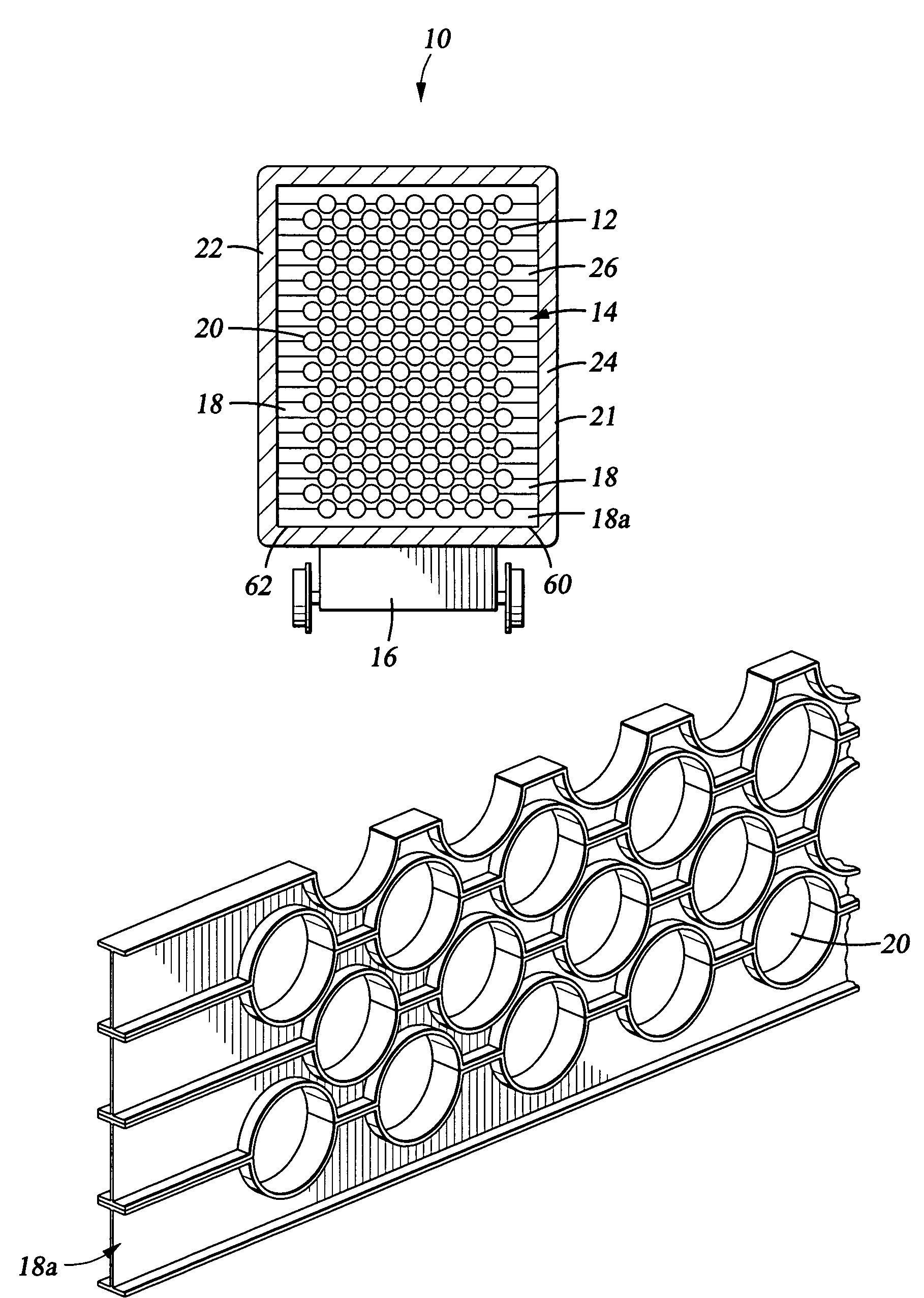

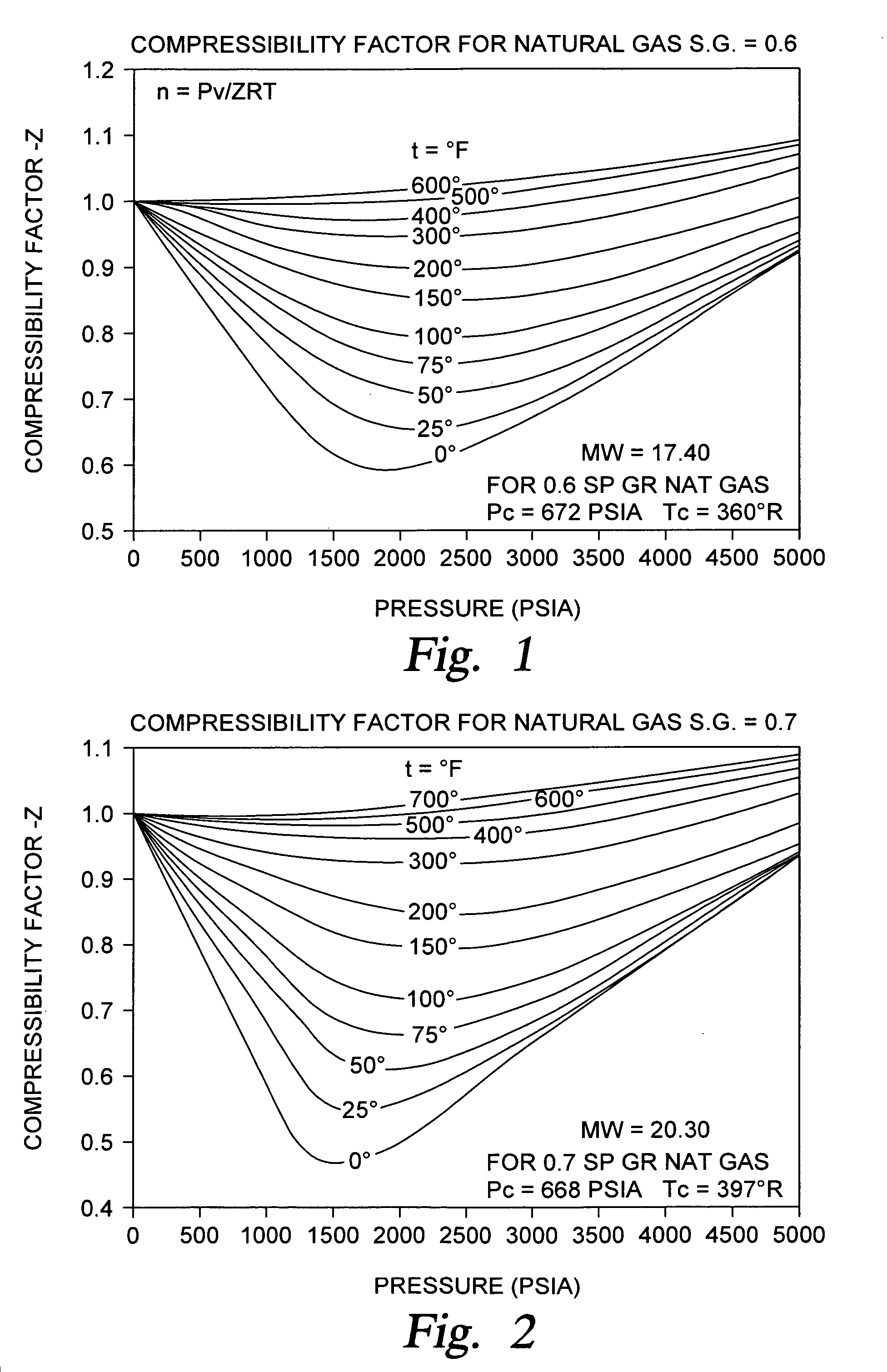

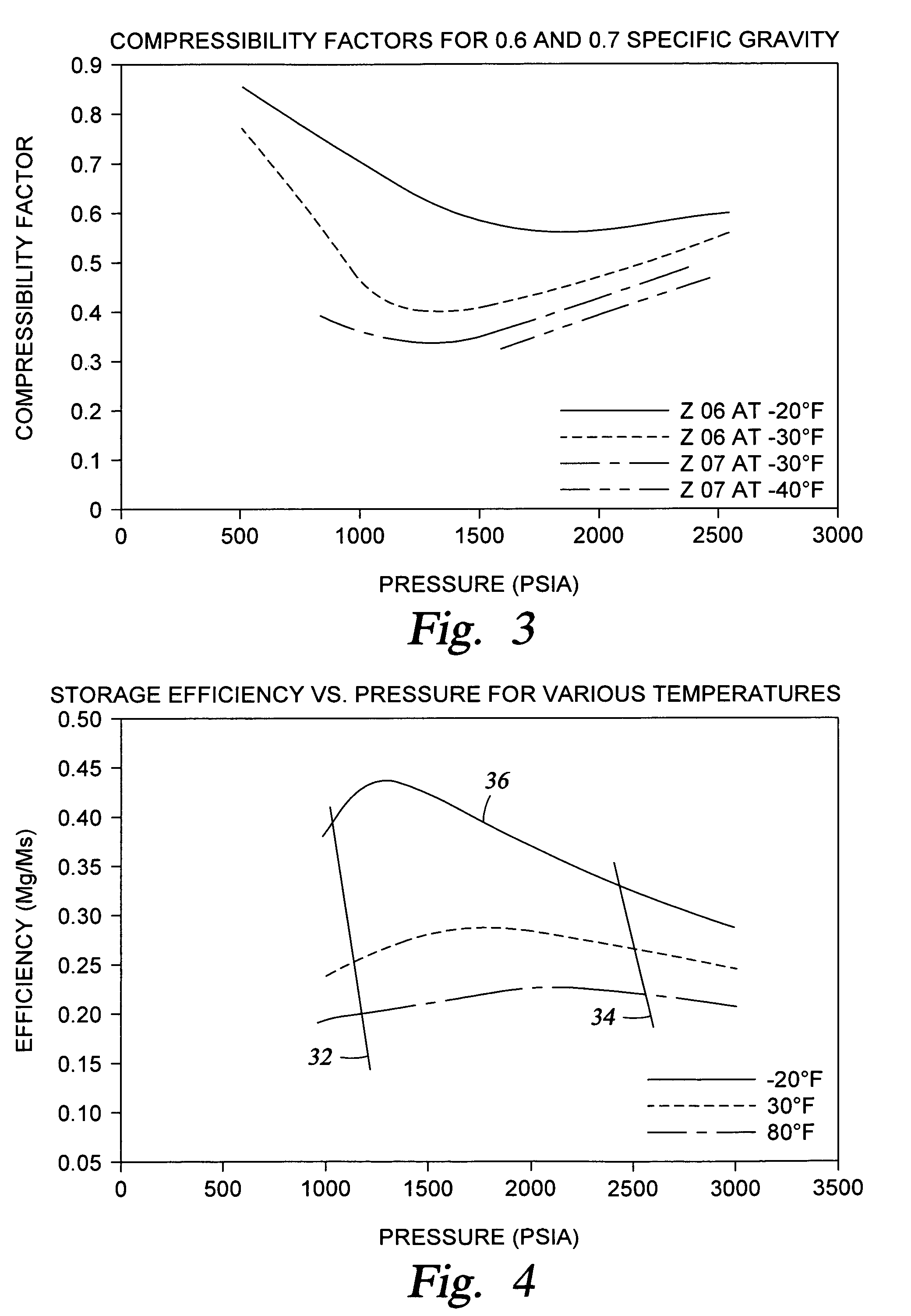

The methods and apparatus for transporting compressed gas includes a gas storage system having a plurality of pipes connected by a manifold whereby the gas storage system is designed to operate in the range of the optimum compressibility factor for a given composition of gas. The pipe for the gas storage system is preferably large diameter pipe made of a high strength material whereby a low temperature is selected which can be withstood by the material of the pipe. Knowing the compressibility factor of the gas, the temperature, and the diameter of the pipe, the wall thickness of the pipe is calculated for the pressure range of the gas at the selected temperature. The gas storage system may either be modular or be part of the structure of a vehicle for transporting the gas. The gas storage system further includes enclosing the pipes in an enclosure having a nitrogen atmosphere. A displacement fluid may be used to offload the gas from the gas storage system. A vehicle with the gas storage system designed for a particular composition gas produced at a given location is used to transport gas from that producing location to a receiving station miles from the producing location.

Owner:ENERSEA TRANSPORT

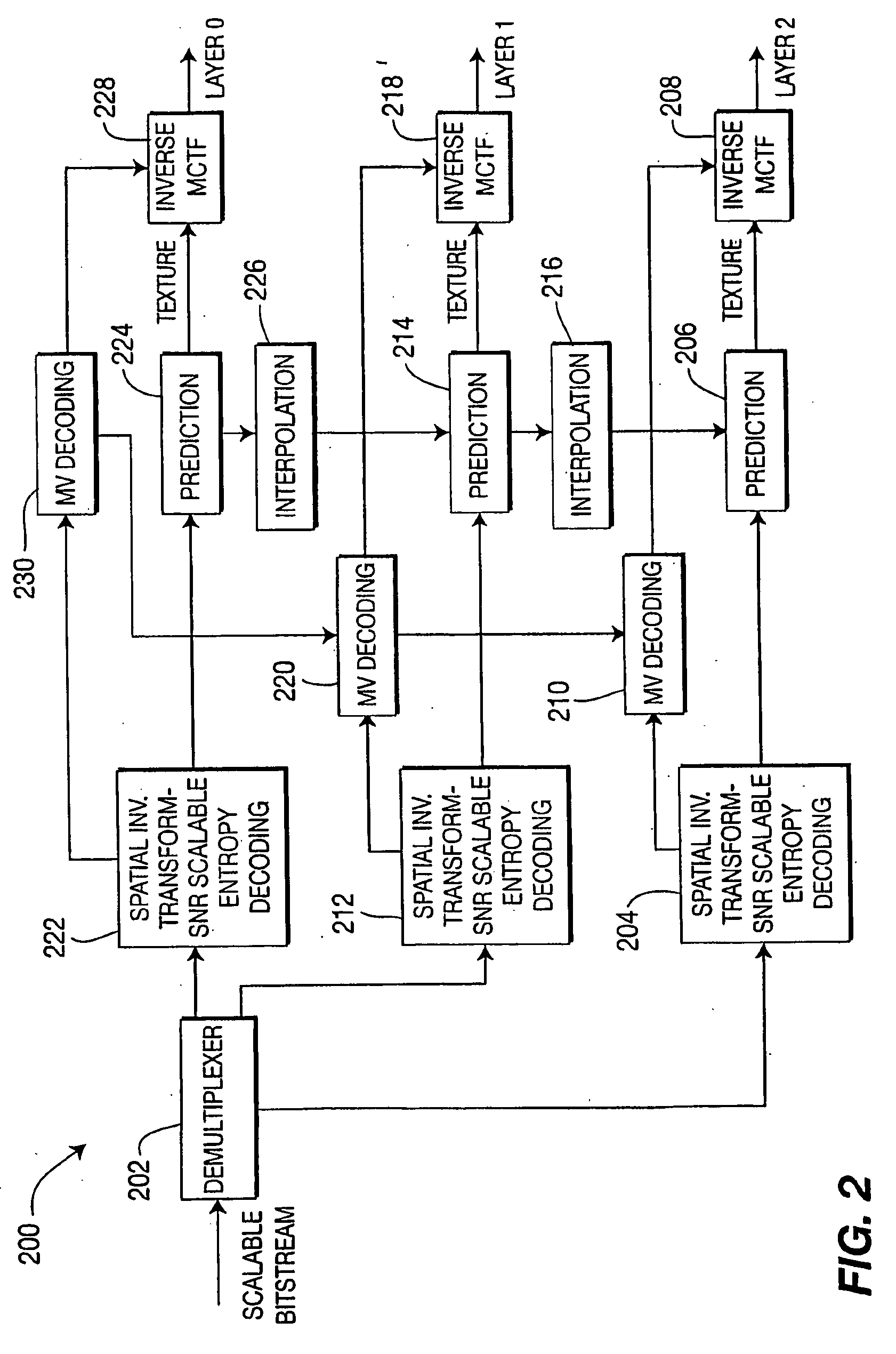

Method and Apparatus for Macroblock Adaptive Inter-Layer Intra Texture Prediction

ActiveUS20090074061A1Container filling methodsPicture reproducers using cathode ray tubesComputer architectureInter layer

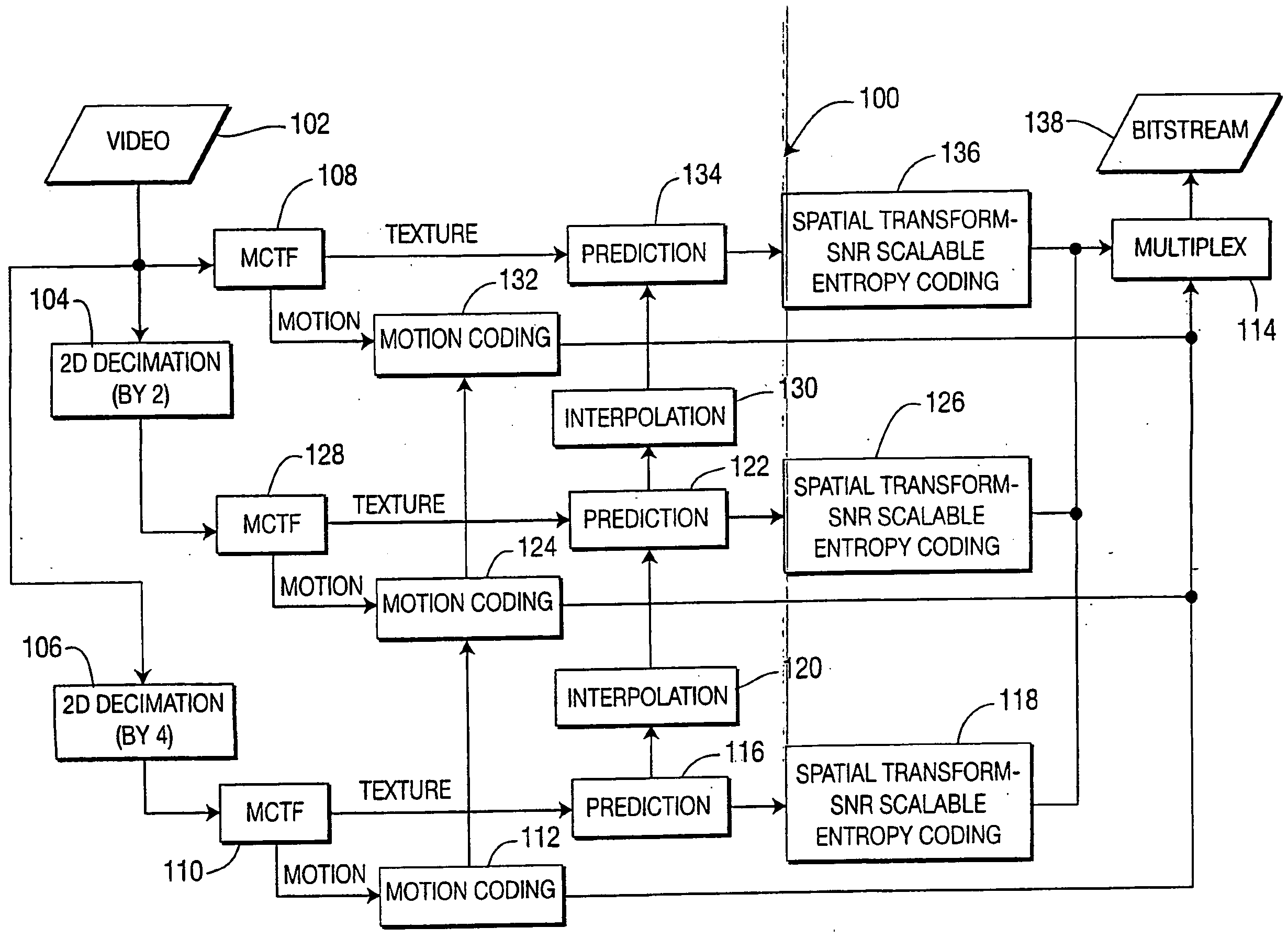

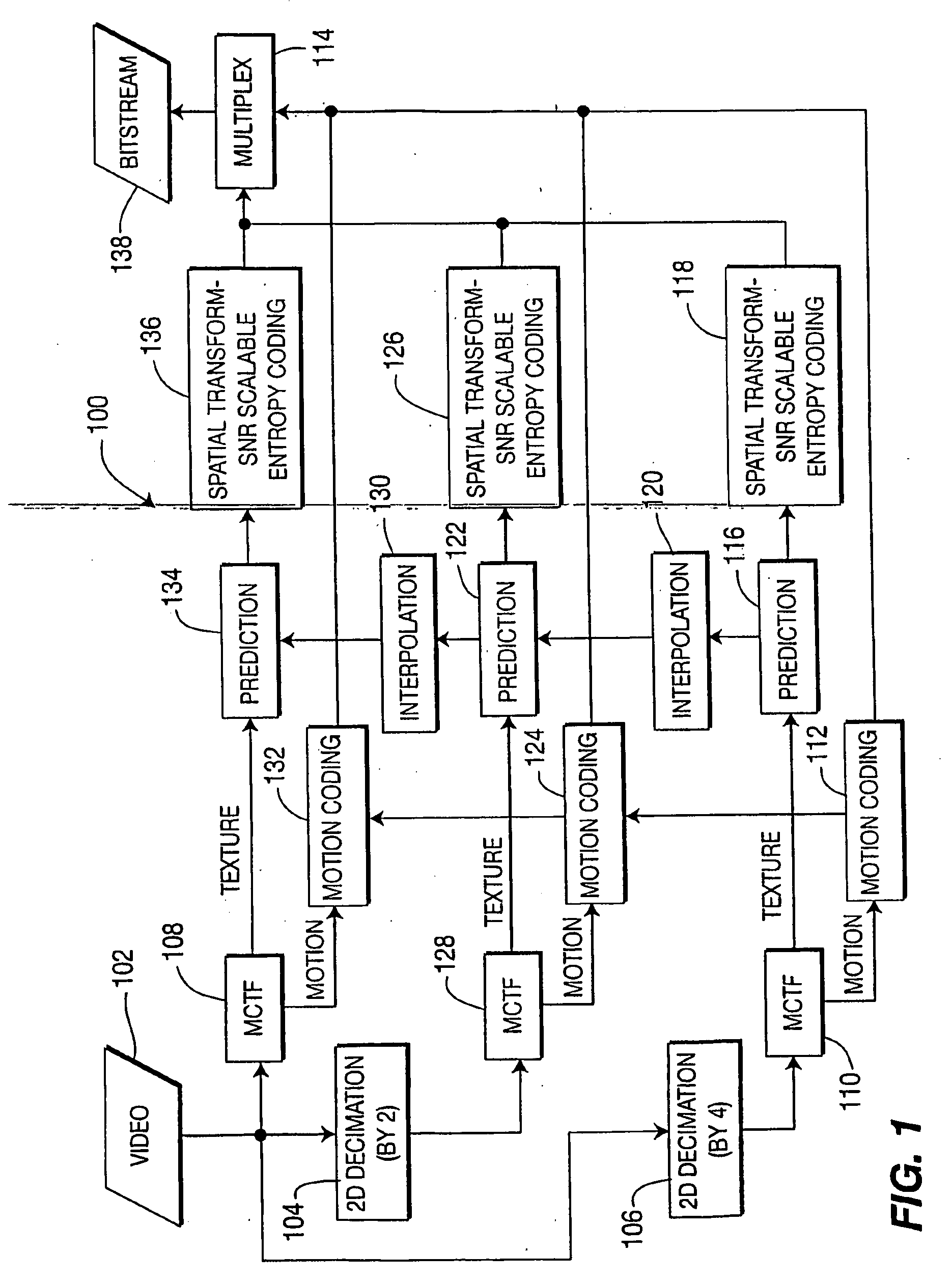

There are provided scalable video encoders and decoders and corresponding methods for scalable video encoding and decoding. A scalable video encoder includes an encoder for selectively using spatial intra prediction to code, on a macroblock adaptive basis, an enhancement layer residue generated between an enhancement layer macroblock and a corresponding upsampled base layer macroblock.

Owner:INTERDIGITAL MADISON PATENT HLDG

Fuel tank venting system

Owner:COUNTRY INDS TECH

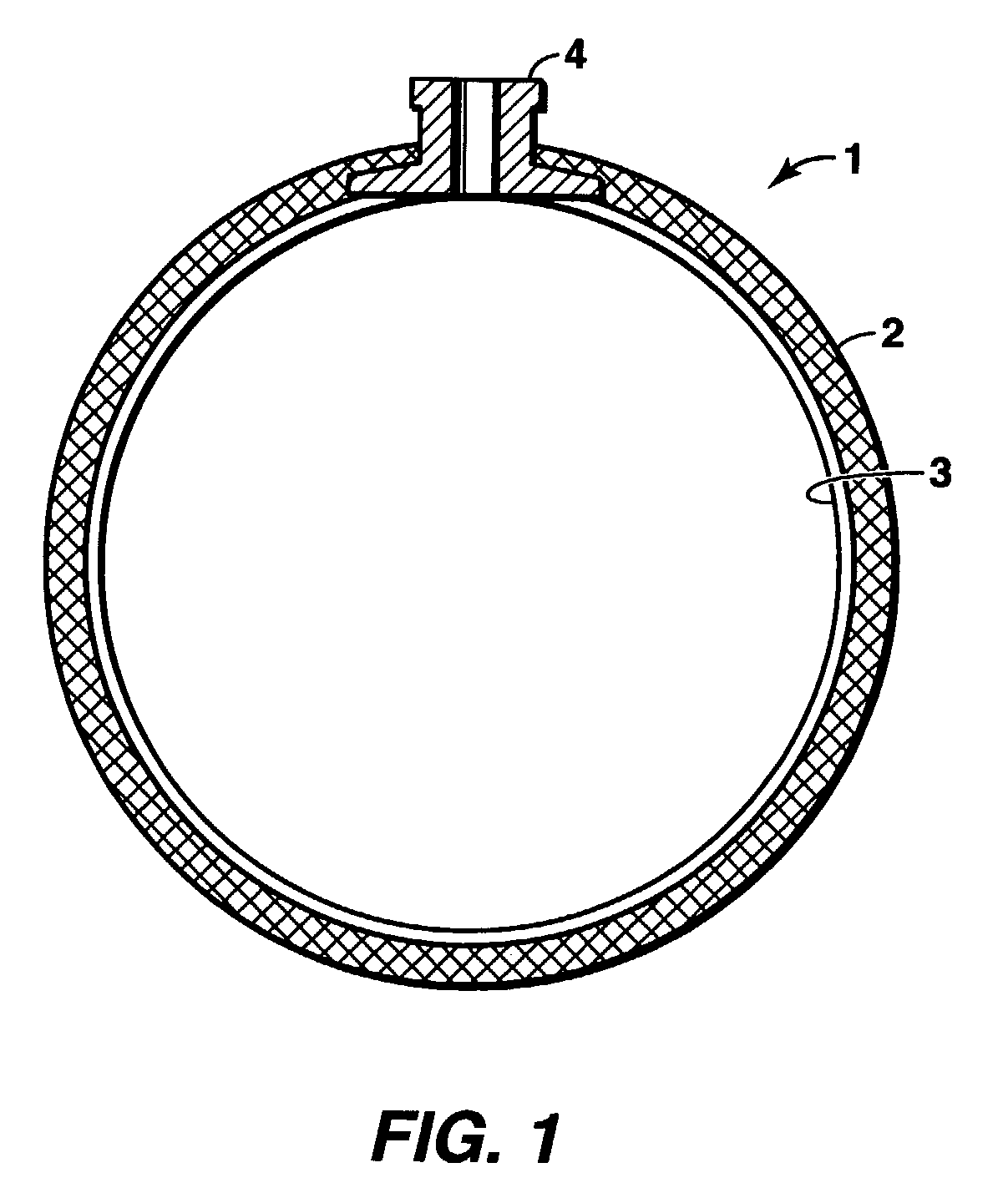

Containers and methods for containing pressurized fluids using reinforced fibers and methods for making such containers

InactiveUS7147124B2Improve creep performanceImprove compactionVessel mounting detailsVessel manufacturingFiberPolymer science

Containers suitable for storing pressurized fluids at cryogenic temperatures of −62° C. (−80° F.) and colder are provided and comprise a self-supporting liner and load-bearing composite overwrap, whereby means are provided for substantially preventing failure of the container during temperature changes.

Owner:EXXONMOBIL UPSTREAM RES CO

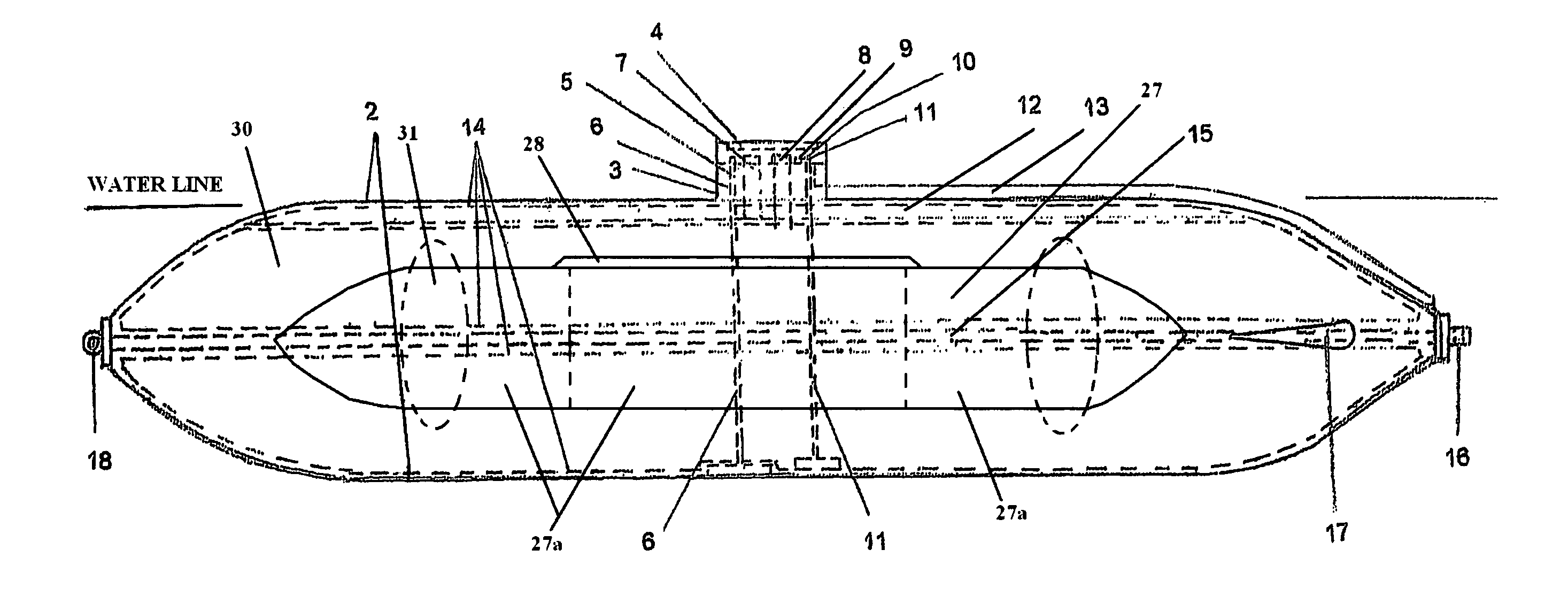

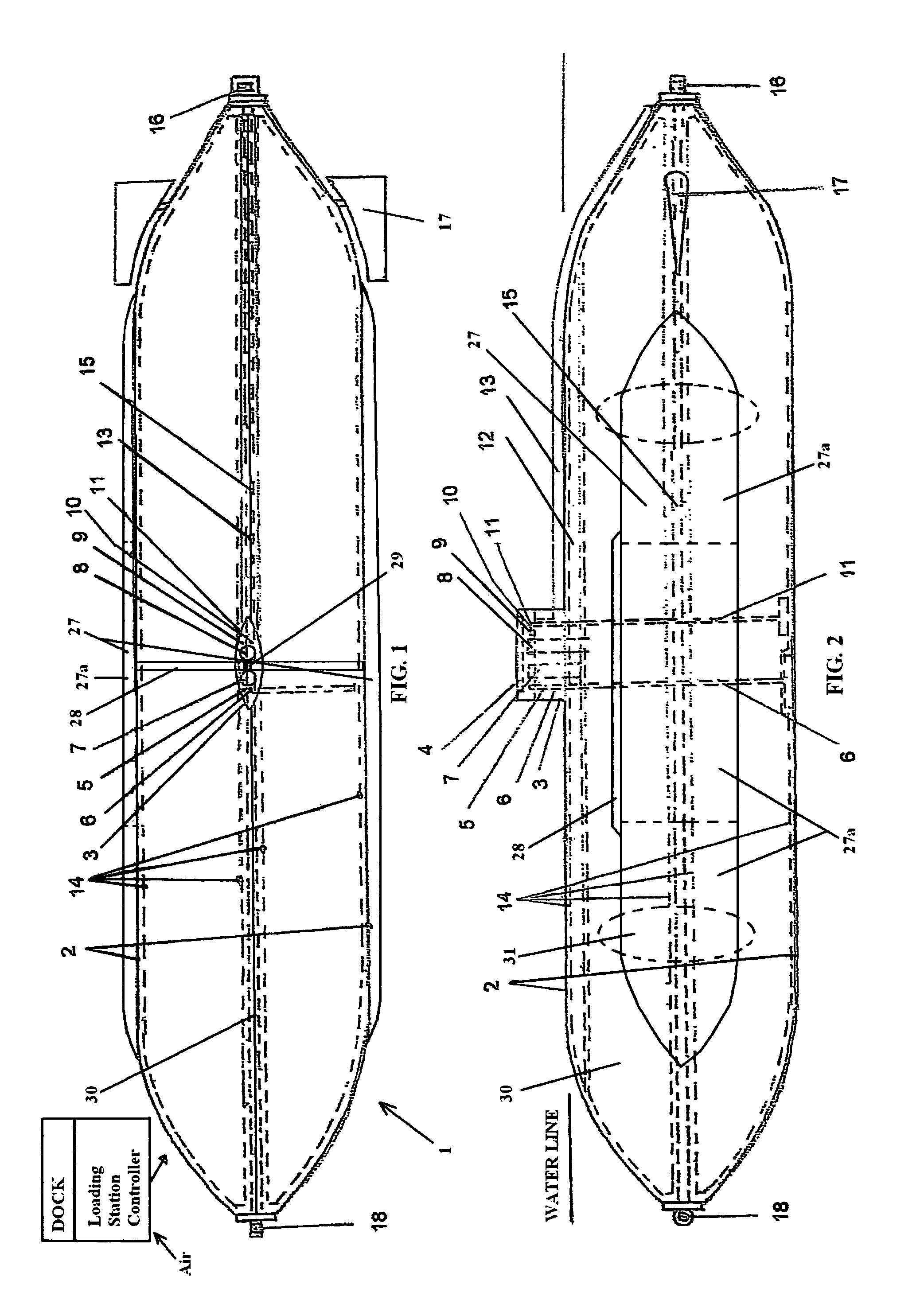

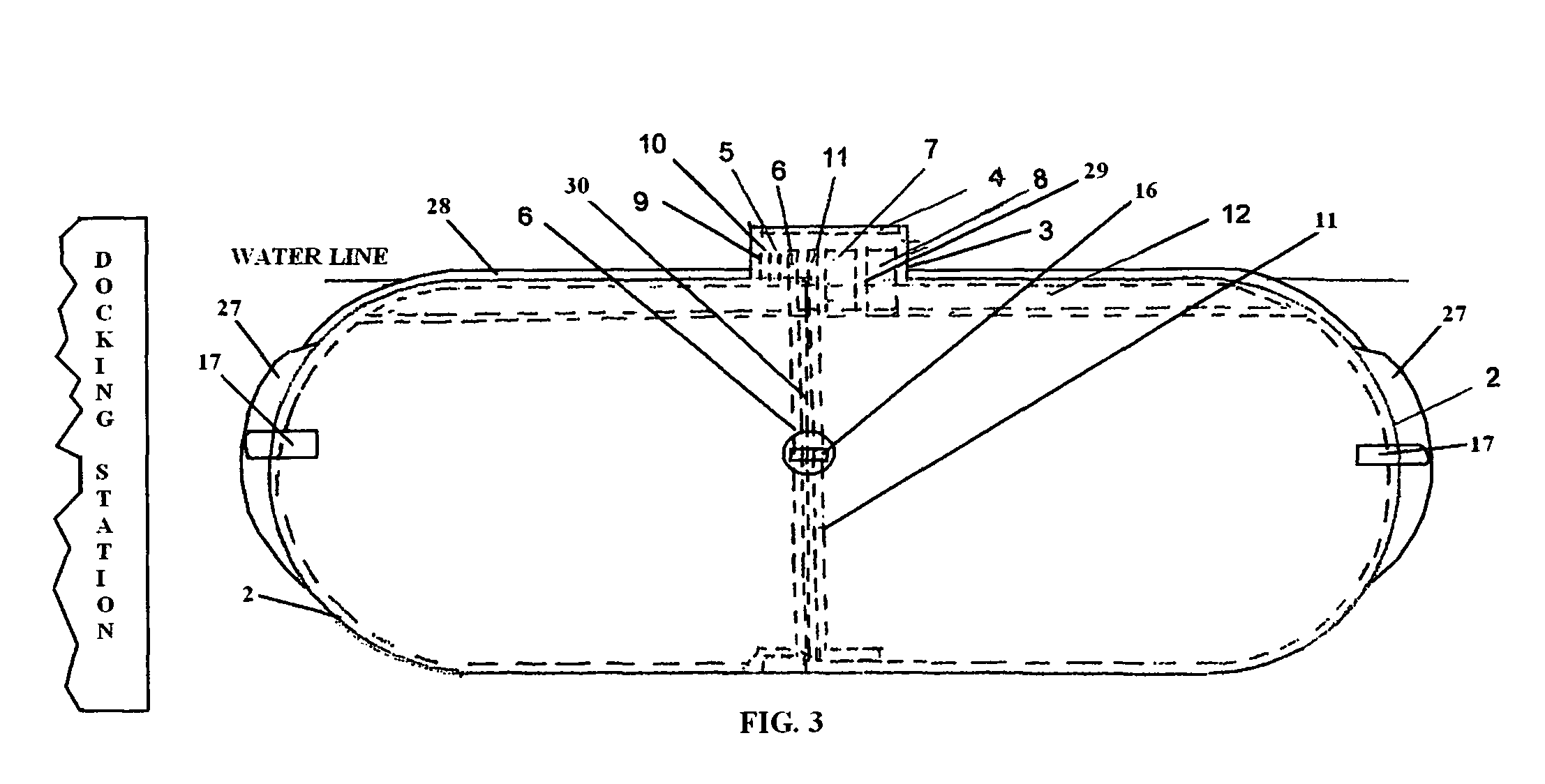

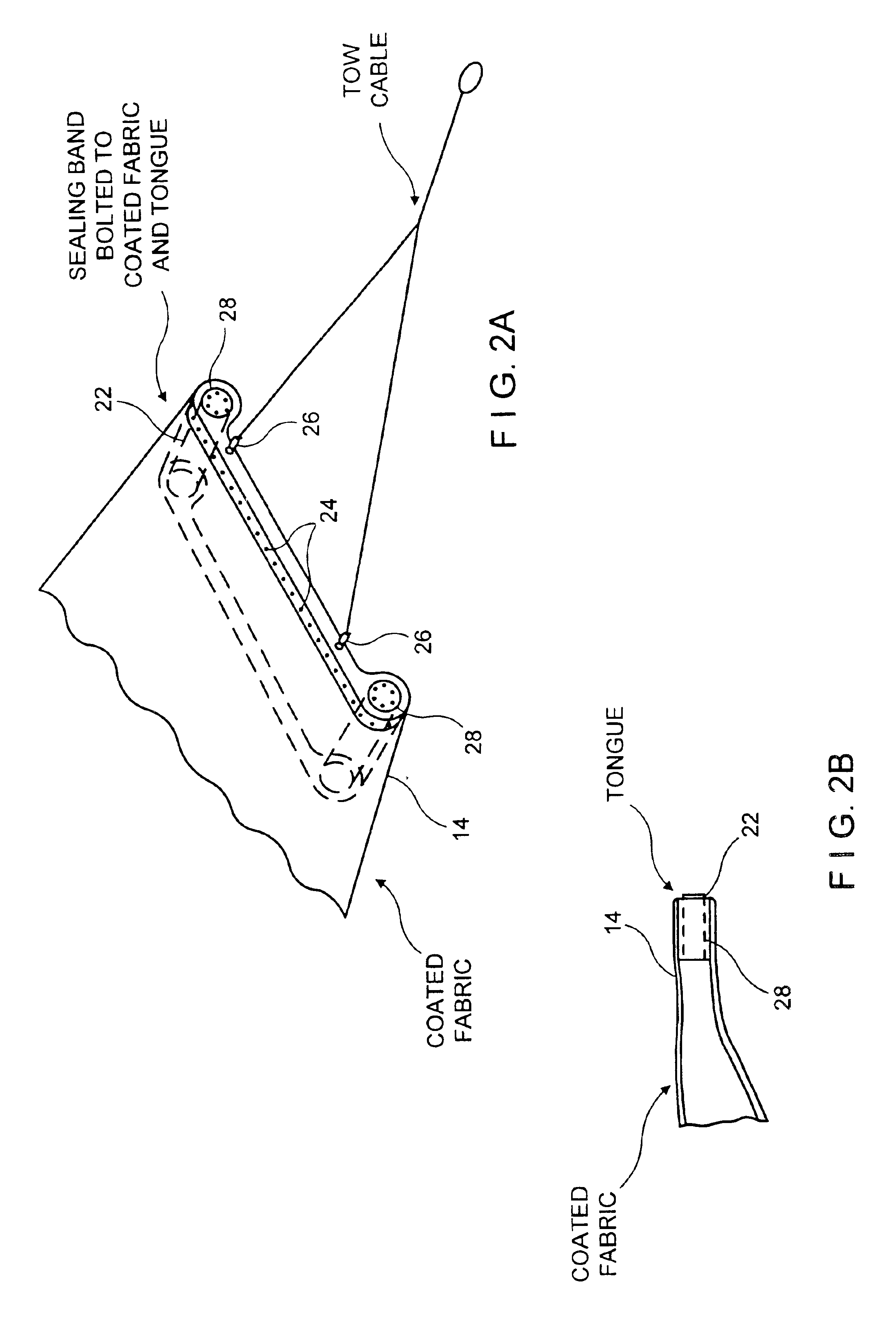

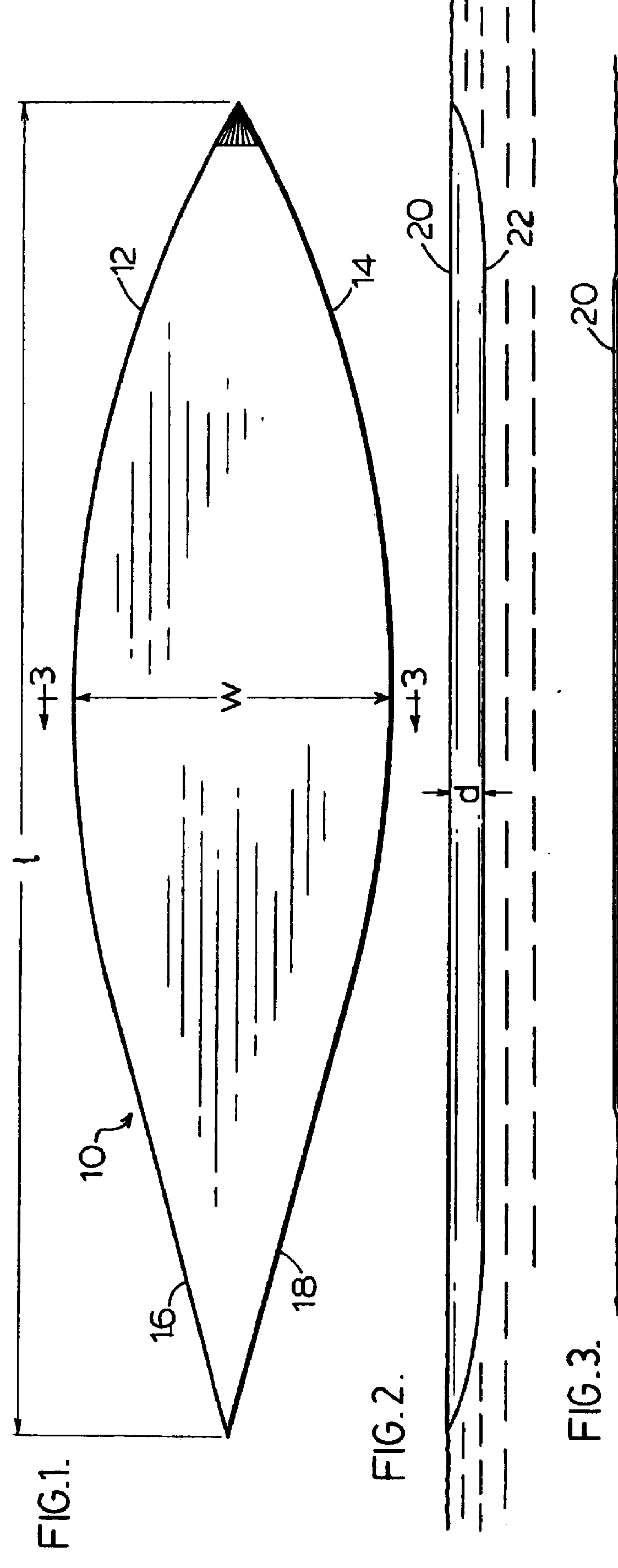

Water level and/or sub surface water transporter/storage systems for liquids and solids simultaneously or in single cargo

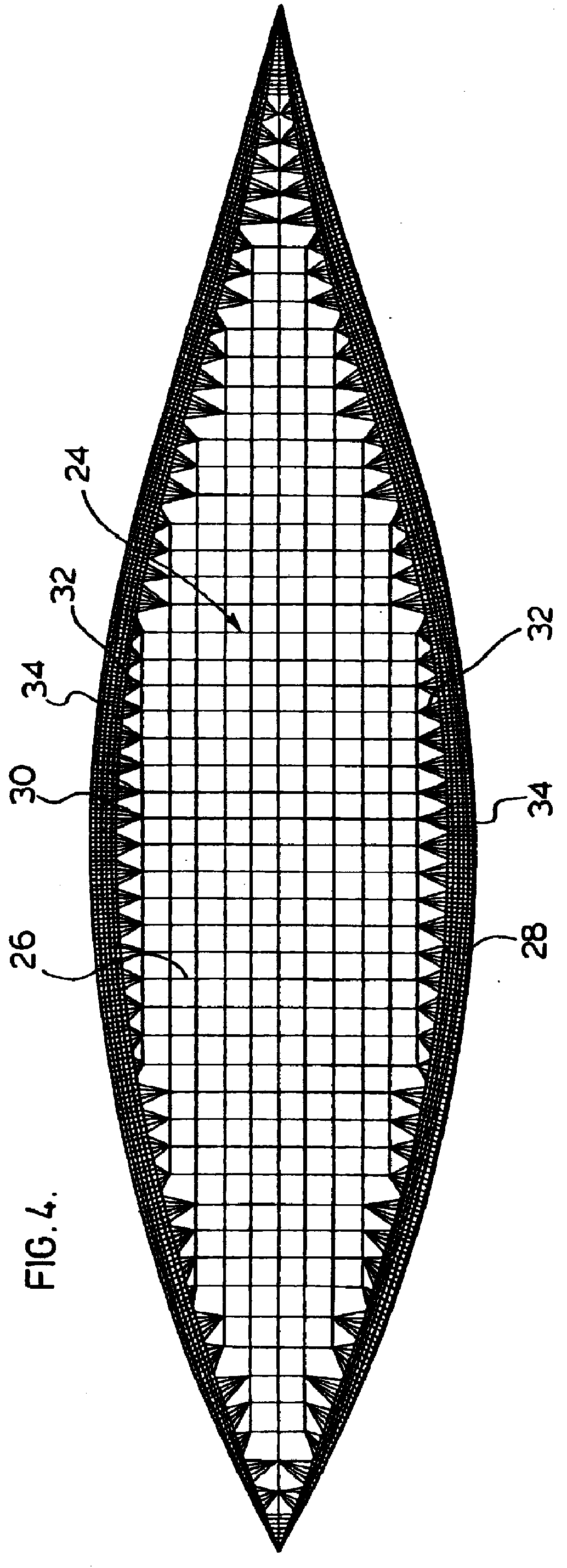

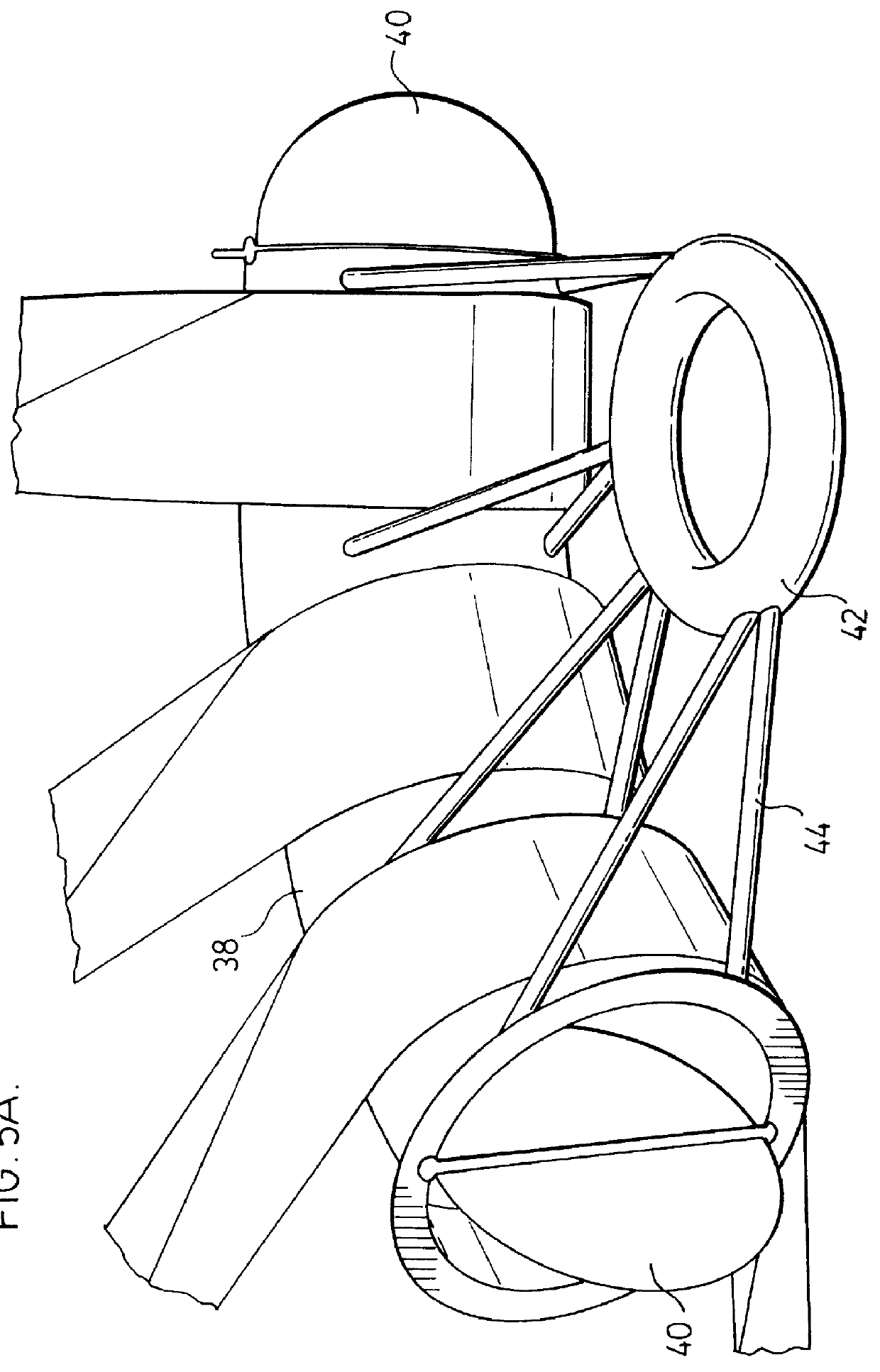

InactiveUS7841289B1Prevent longitudinal deformationAvoid distortionLarge containersFor bulk goodsSurface waterWater level

A lightweight towed submersible water transporter and storage system for liquids and solids, which employs a streamlined towable hull with exterior ballast / buoyancy cells and optional air and liquid storage bladders used not only to adjust buoyancy, but to allow the simultaneous transport and storage of different solids and liquids.

Owner:SCHANZ II

Floating LNG regasification facility with LNG storage vessel

InactiveUS20080295526A1Well formedContainer filling methodsGas handling applicationsMarine engineeringSubmarine pipeline

An LNG terminal is disclosed which includes an offshore mooring turret, an LNG storage vessel operatively coupled to the mooring turret, the LNG storage vessel including at least one LNG storage tank for the storage of liquid natural gas and a regasification vessel operatively coupled to the LNG storage vessel. A method of operating an offshore LNG terminal is also disclosed which includes obtaining liquefied natural gas from at least one LNG storage tank on an LNG storage vessel that is operatively coupled to a mooring turret, regasifying the liquefied natural gas from the LNG storage vessel using a regasification vessel operatively coupled to the LNG storage vessel, and supplying the regasified gas to at least one subsea pipeline via the mooring turret.

Owner:SOFEC

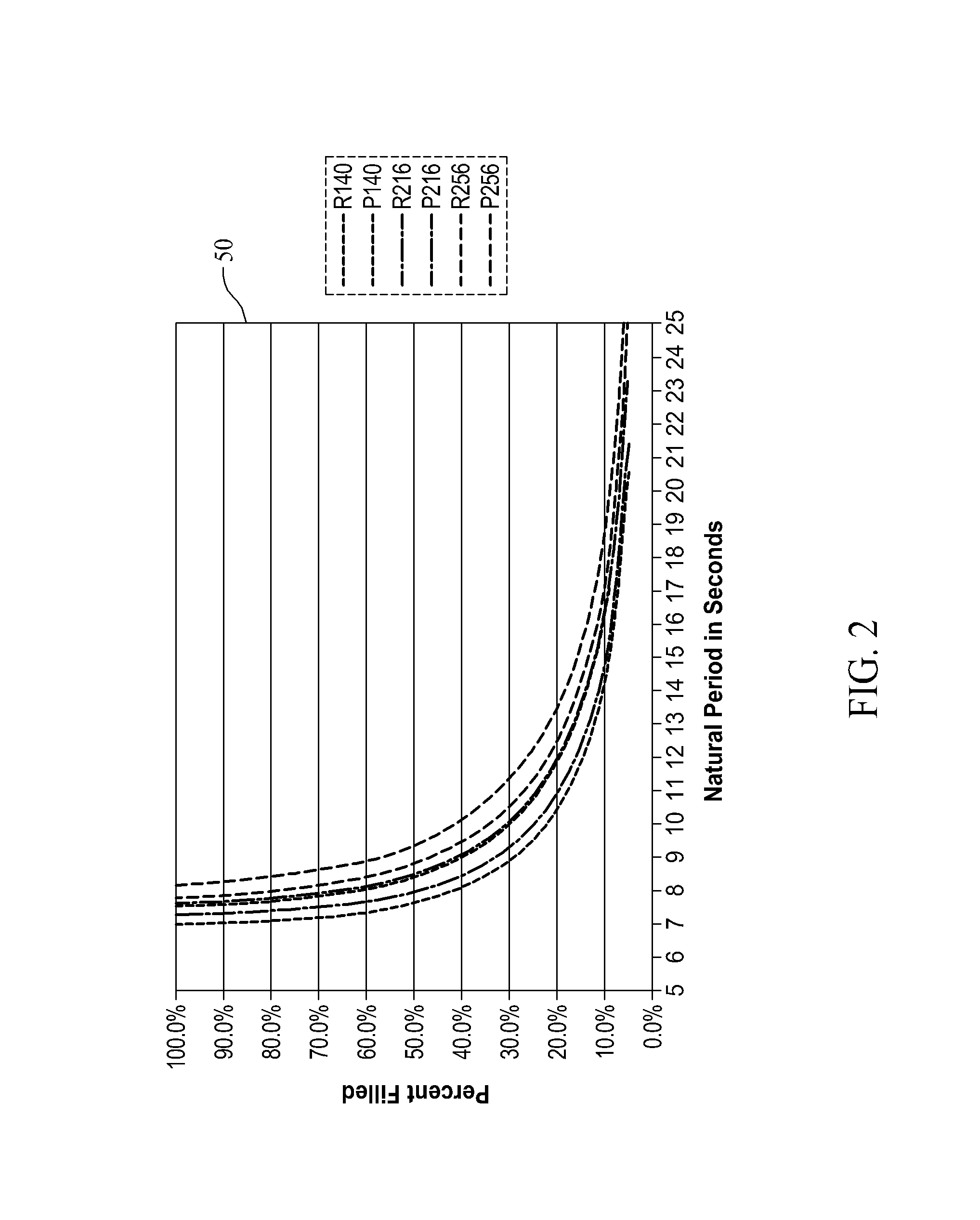

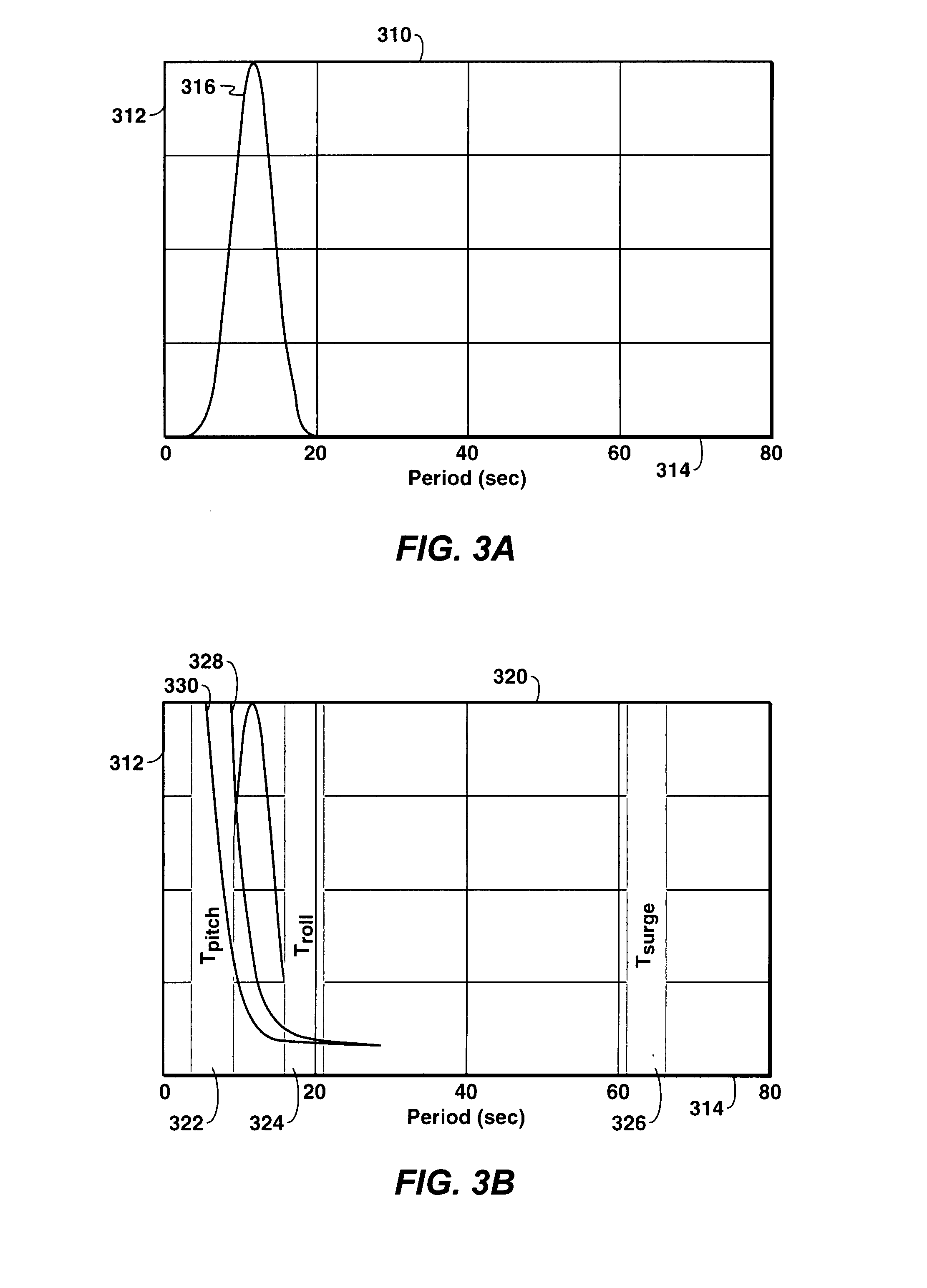

Methods and systems for providing sloshing alerts and advisories

A method is described for providing an alert when the motion of a ship indicates a potential of sloshing damage from liquid cargo being transported by the ship. The method includes calculating, with a processing device, a natural period for the tanks holding the liquid cargo based on the configuration and fill levels of the tanks, receiving, at the processing device, data describing the actual or predicted motion of the ship with respect to three orthogonal axes, determining, with the processing device, a proximity of the natural period of the tanks to a period defined by the actual or predicted motion of the ship, and providing an alert to a user if the proximity in periods is within a threshold value.

Owner:THE BOEING CO

Glassfiber-reinforced polyurethane-polyisocyanurate foam

ActiveCN1834130ASatisfactory thermal insulation propertiesSurprising mechanical propertiesPressure vesselsFor bulk goodsGlass fiberPolymer science

Polyurethane polyisocyanurate foam reinforced by glass fibers, obtained by: reacting an isocyanate component and a polyol component comprising first, second and third polyols, in the presence of a catalyst, a physical and / or chemical blowing agent, an emulsifier and optionally a flame retarding agent to obtain a composition; impregnating, the composition in a glass fiber stacking; and expanding and solidifying the composition to form a reinforced foam block containing the glass fiber stacking. Said reinforced foam block has an average density of 115-135 kg / m3>, and an isocyanate index of 100-180.

Owner:GAZTRANSPORT & TECHNIGAZ

Lng storage tank and constructing method thereof

InactiveCN1898124AMaintain liquid-tight propertiesAvoid breakingContainer filling methodsRailway vehiclesEngineeringStructural engineering

Disclosed is a liquid container adapted to store liquefied natural gas (LNG). The LNG storage container include a sealing wall directly contacting liquid contained in the tank and a structural wall, which is an exterior wall or inner structure integrated with the exterior wall. The container further includes a plurality of connectors mechanically connecting the sealing wall and the structural wall and an intermediate wall structure positioned between the structural wall and the interior wall. The intermediate wall structure is configured to move relative to at least one of the interior wall and the structural wall.

Owner:KC LNG TECH CO LTD ENTIRE RIGHT

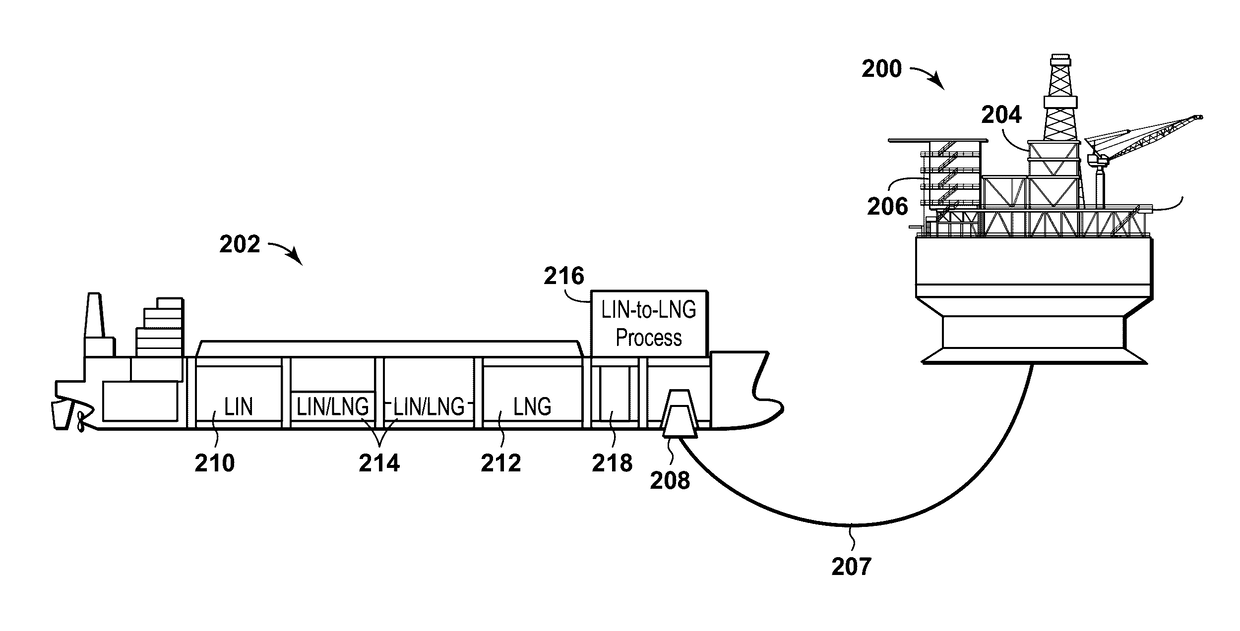

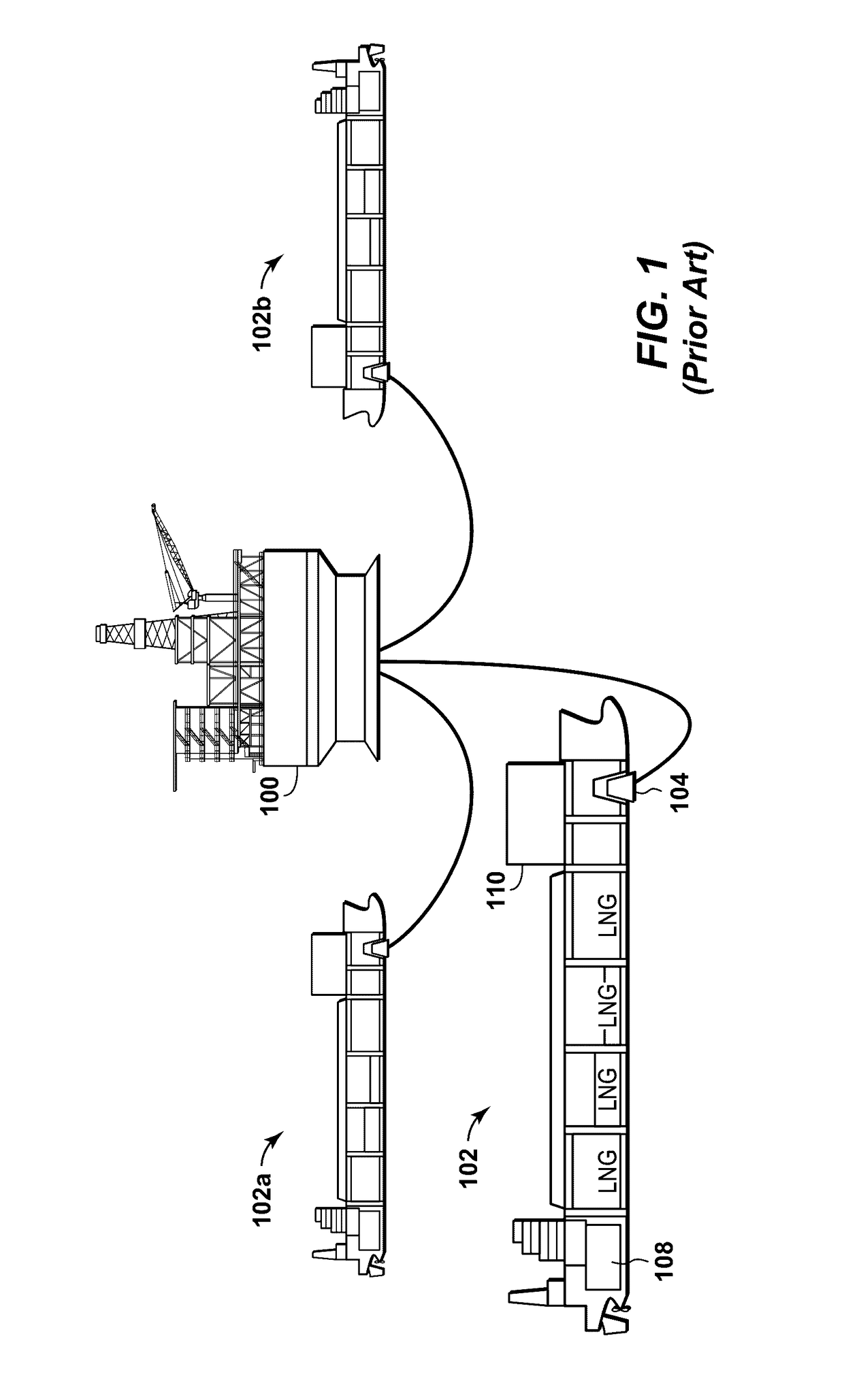

Method of Natural Gas Liquefaction on LNG Carriers Storing Liquid Nitrogen

A method for producing liquefied natural gas (LNG). A natural gas stream is transported to a liquefaction vessel. The natural gas stream is liquefied on the liquefaction vessel using at least one heat exchanger that exchanges heat between the natural gas stream and a liquid nitrogen stream to at least partially vaporize the liquefied nitrogen stream, thereby forming a warmed nitrogen gas stream and an at least partially condensed natural gas stream comprising LNG. The liquefaction vessel includes at least one tank that only stores liquid nitrogen and at least one tank that only stores LNG.

Owner:EXXONMOBIL UPSTREAM RES CO

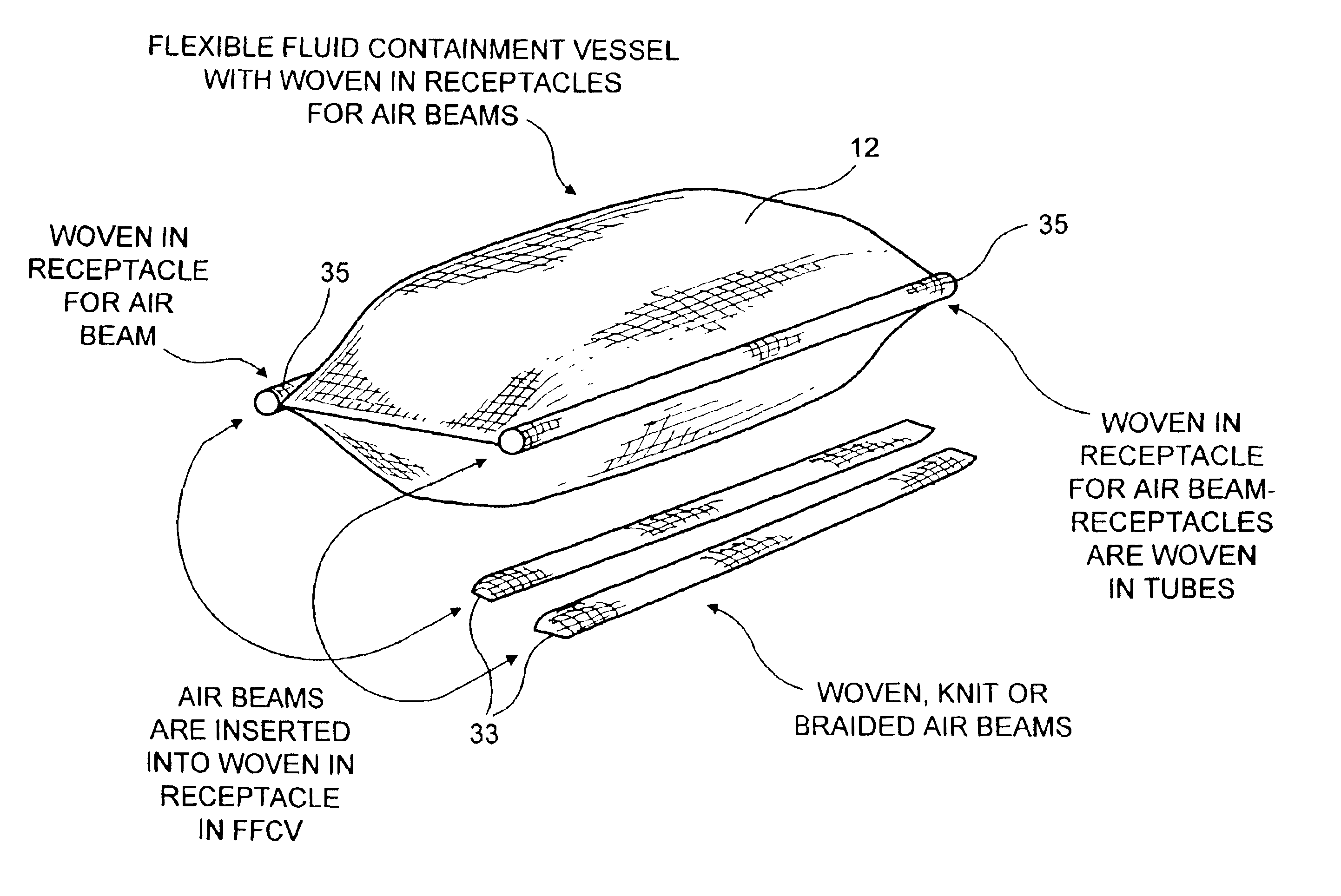

Flexible fluid containment vessel

InactiveUS6860218B2Light weightEffective distributionLarge containersTextiles and paperEngineeringFresh water

A seamless, woven, flexible fluid containment vessel or vessels for transporting and containing a large volume of fluid, particularly fresh water, having beam stabilizers, beam separators, reinforcing, and the method of making the same.

Owner:ALBANY INT CORP

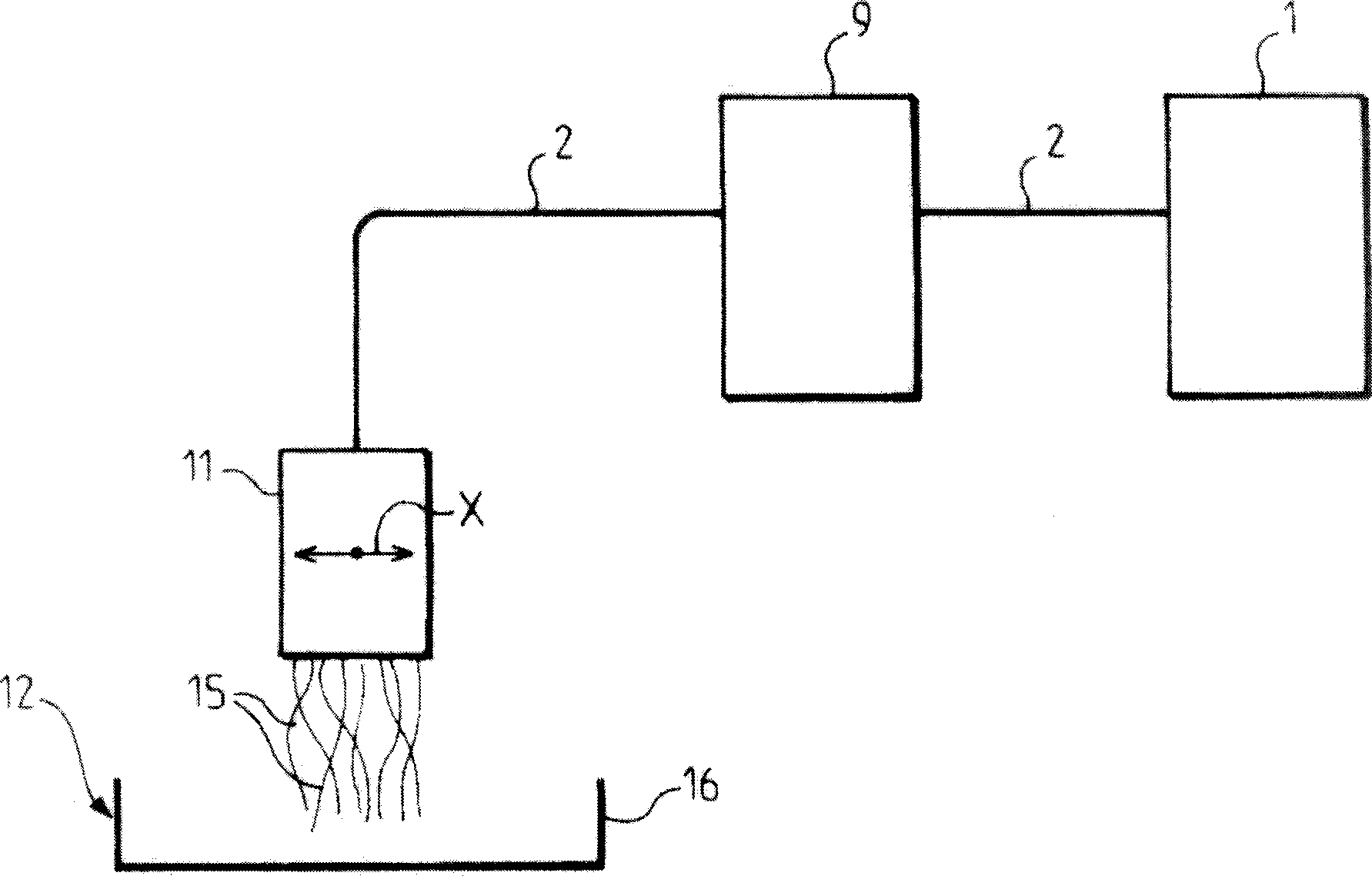

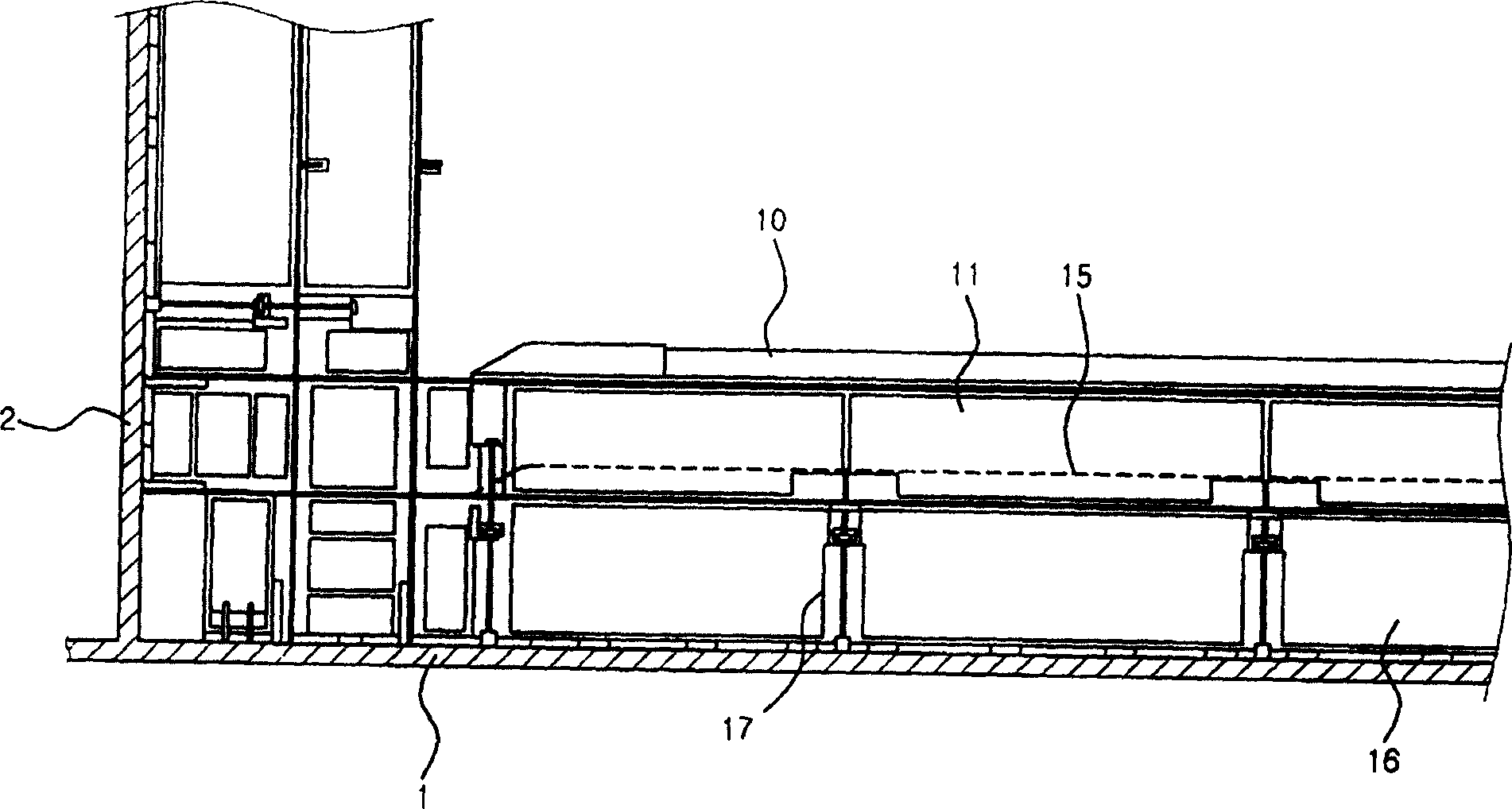

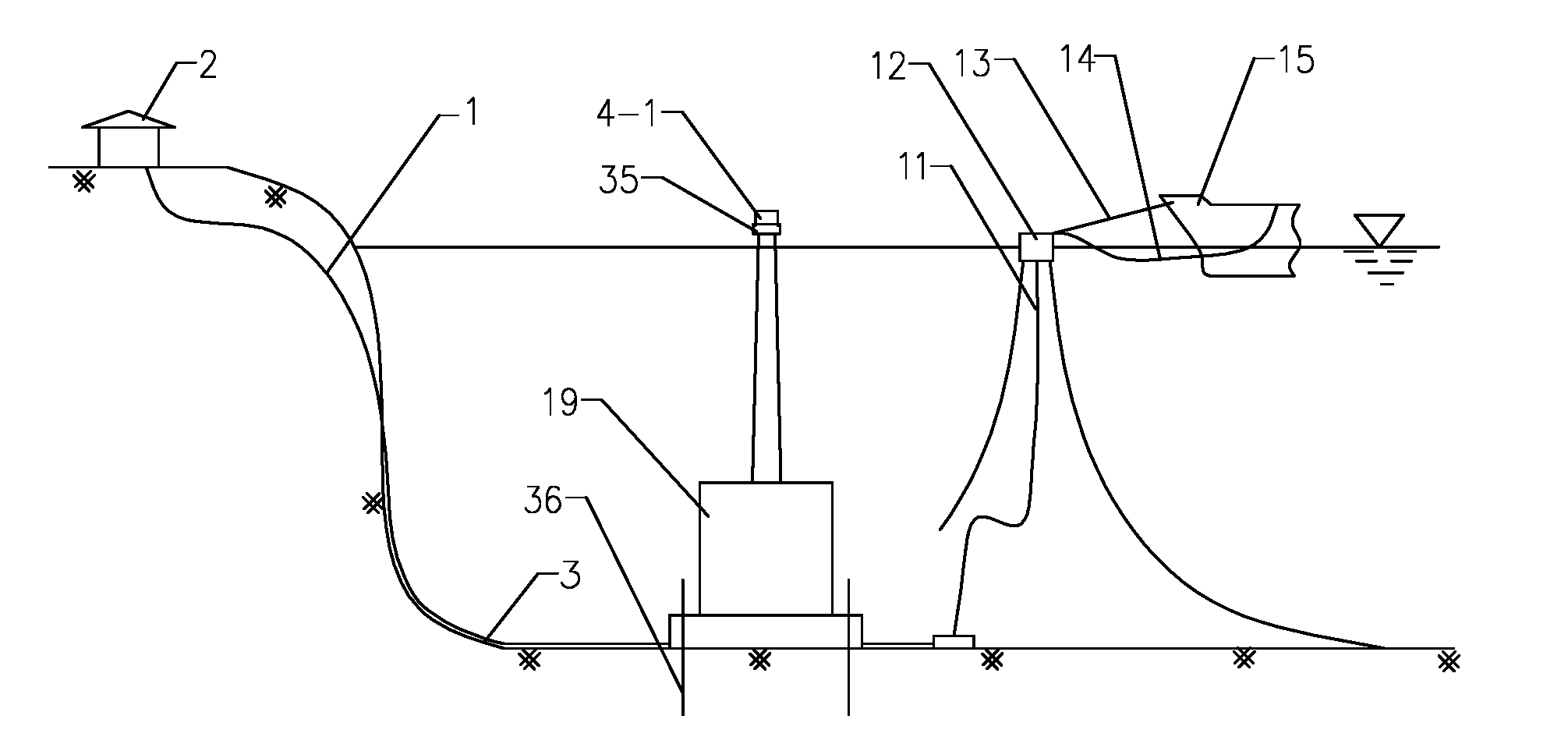

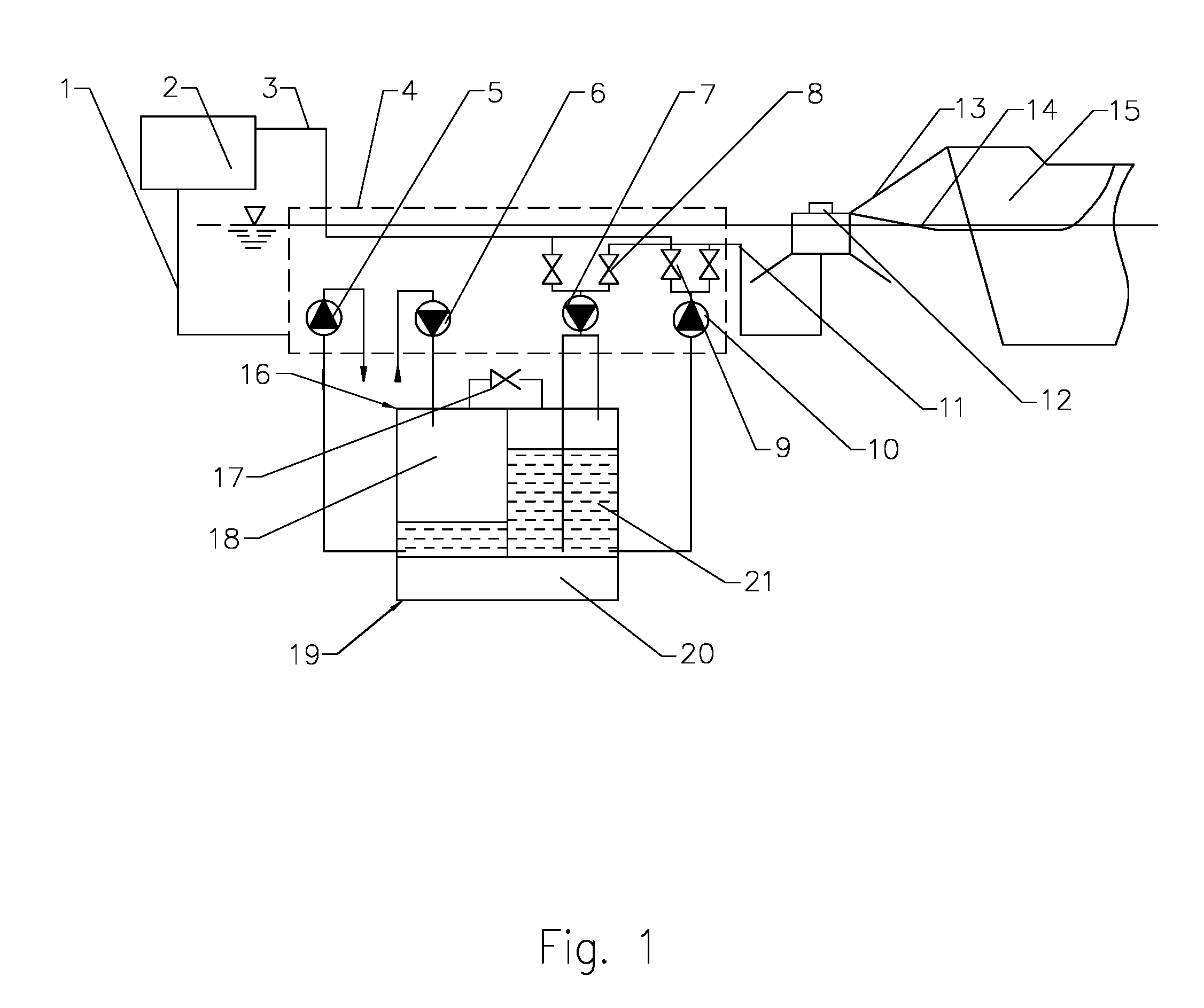

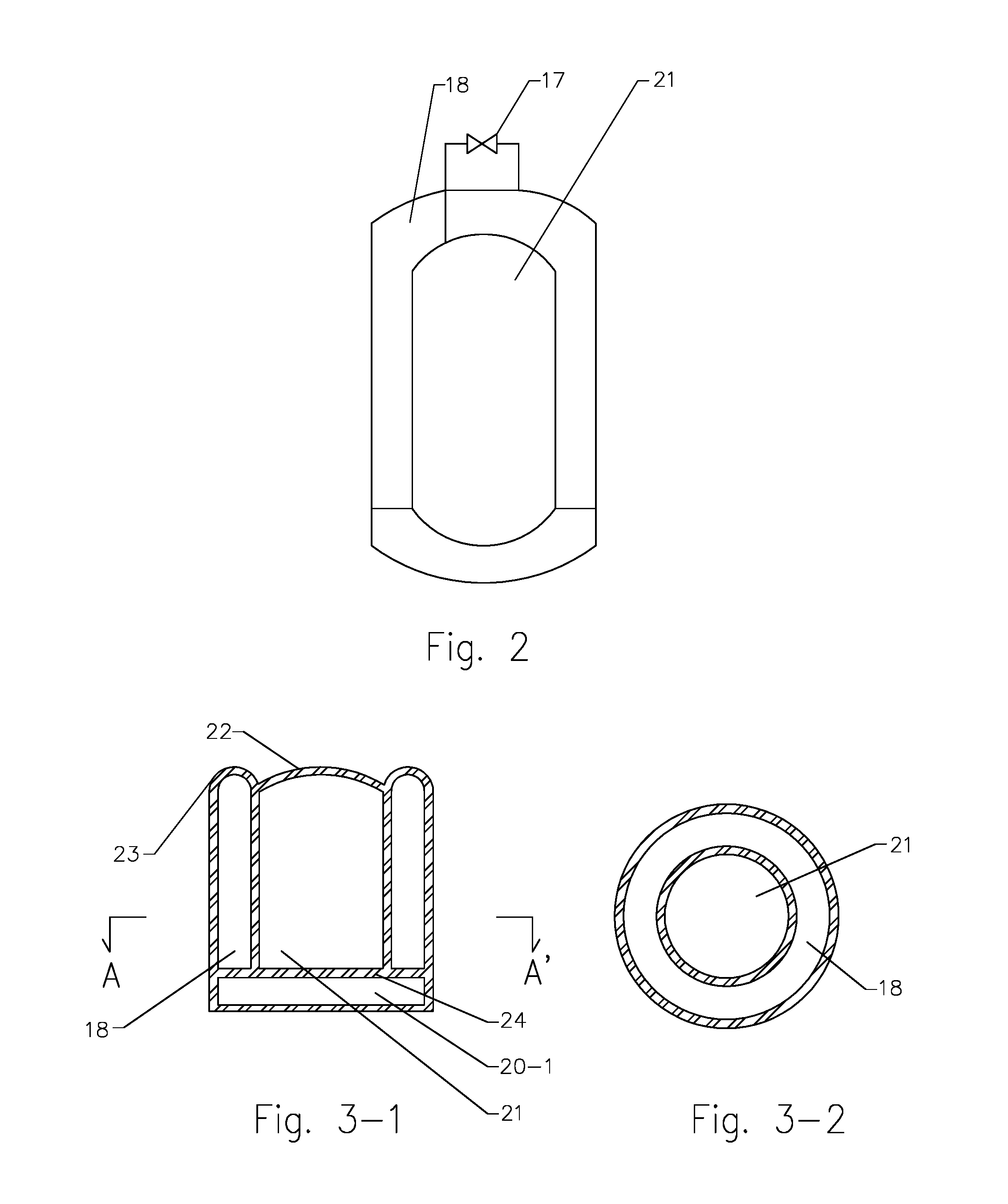

Liquid Storage, Loading and Offloading System

InactiveUS20110013989A1Increase dampingImprove hydrodynamic performanceArtificial islandsCargo handling apparatusEngineeringBallast

A liquid storage, loading and offloading system includes a storage tank having a water ballast compartment for storing water and a liquid storage compartment for storing liquid. The water ballast compartment and the liquid storage compartment are coupled to each other to form a closed interconnected system with pressurized inert gas above water and liquid. The storage tank is configured symmetrically and the center of gravity and buoyancy of it move along a vertical Z axis. Besides, a pump module may also be included and have a pair of loading pumps and a pair of offloading pumps. The pair of loading pumps operates substantially at equal mass flow rate to displace water with liquid. The pair of offloading pumps also operates substantially at equal mass flow rate to displace liquid with water. Therefore an equal mass flow rate displacement system is formed to keep a constant draft.

Owner:WU ZHIRONG

Flexible barge

InactiveUS6047655AReadily accommodates wave motionHigh strengthCargo handling apparatusLarge containersSurface oceanEngineering

Owner:ALTA PLAN CONSULTANTS

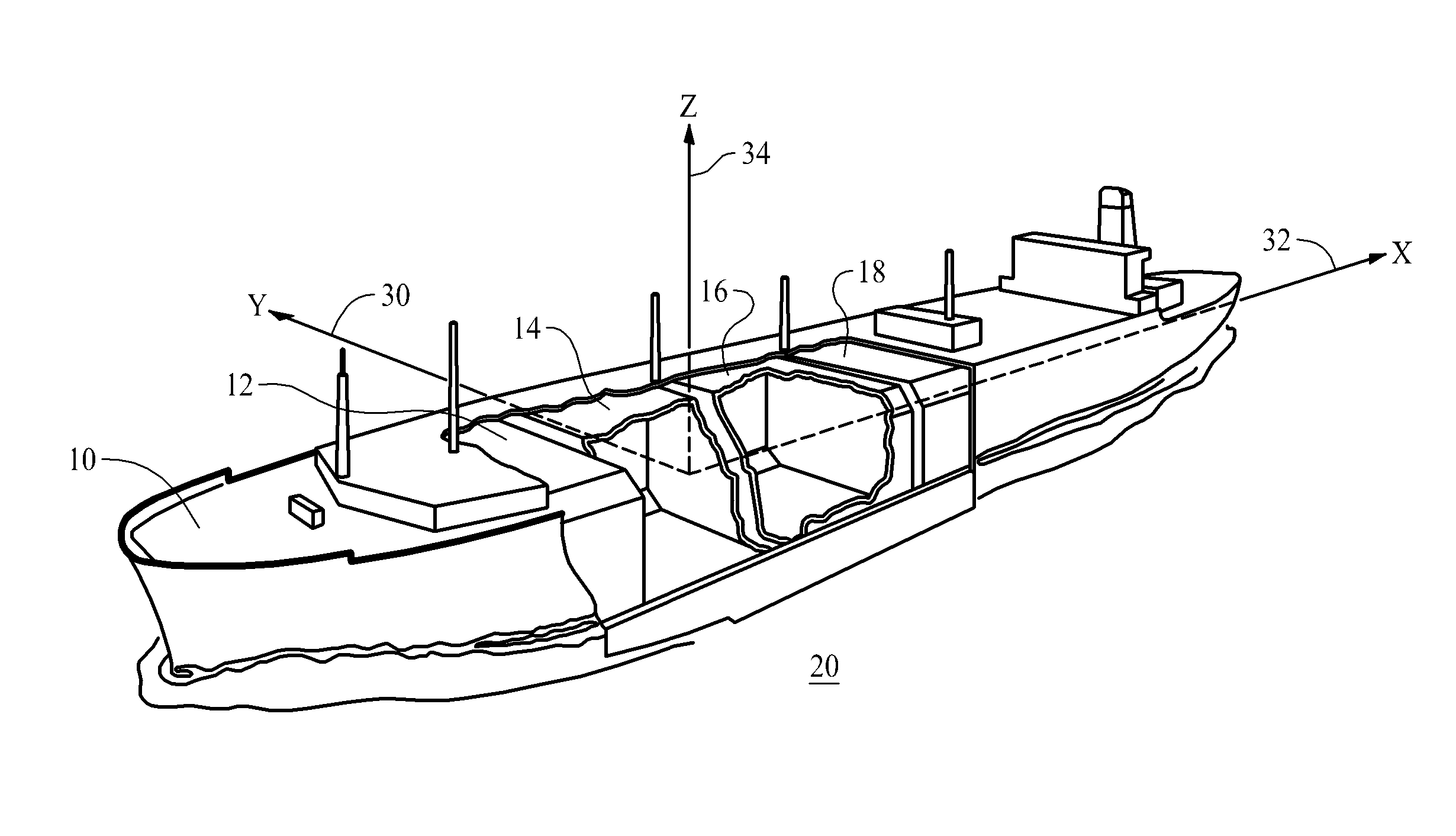

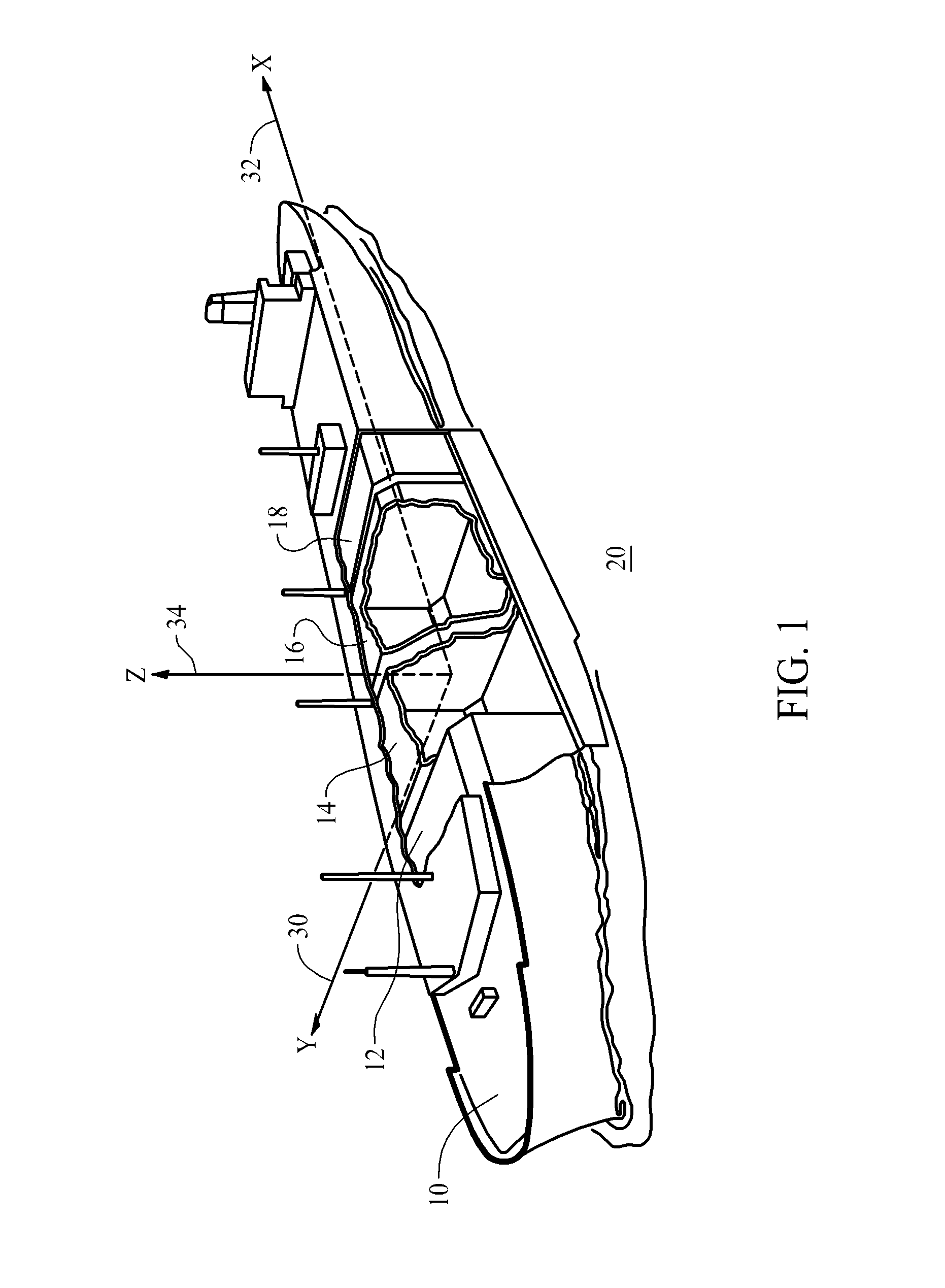

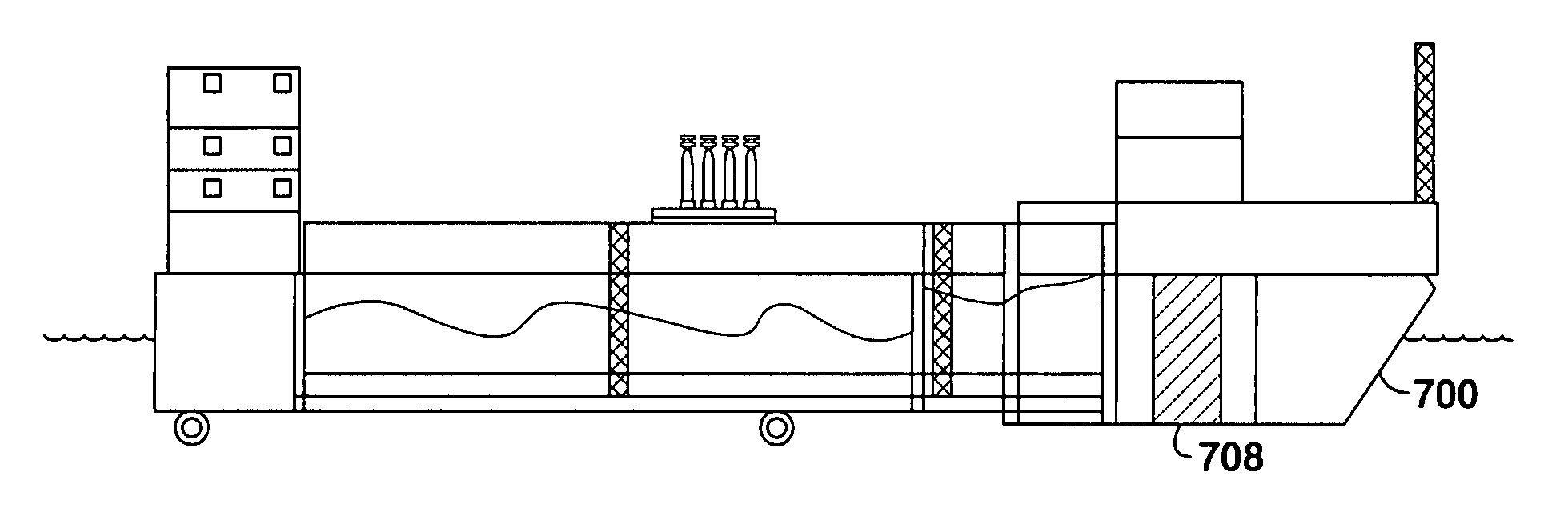

Long tank FSRU/FLSV/LNGC

A method and apparatus for storing liquid within a storage tank such that a natural resonance of fluid motion of the stored fluid falls between natural resonance periods of a floating vessel that includes the storage tank. As a result, resonant energy of the floating vessel imparted to fluid stored in the storage tank may be controlled and sloshing loads may be reduced, thereby avoiding damage to the floating vessel.

Owner:EXXONMOBIL UPSTREAM RES CO

Sealed, thermally insulated tank incorporated into the load-bearing structure of a ship

Owner:GAZTRANSPORT & TECHNIGAZ

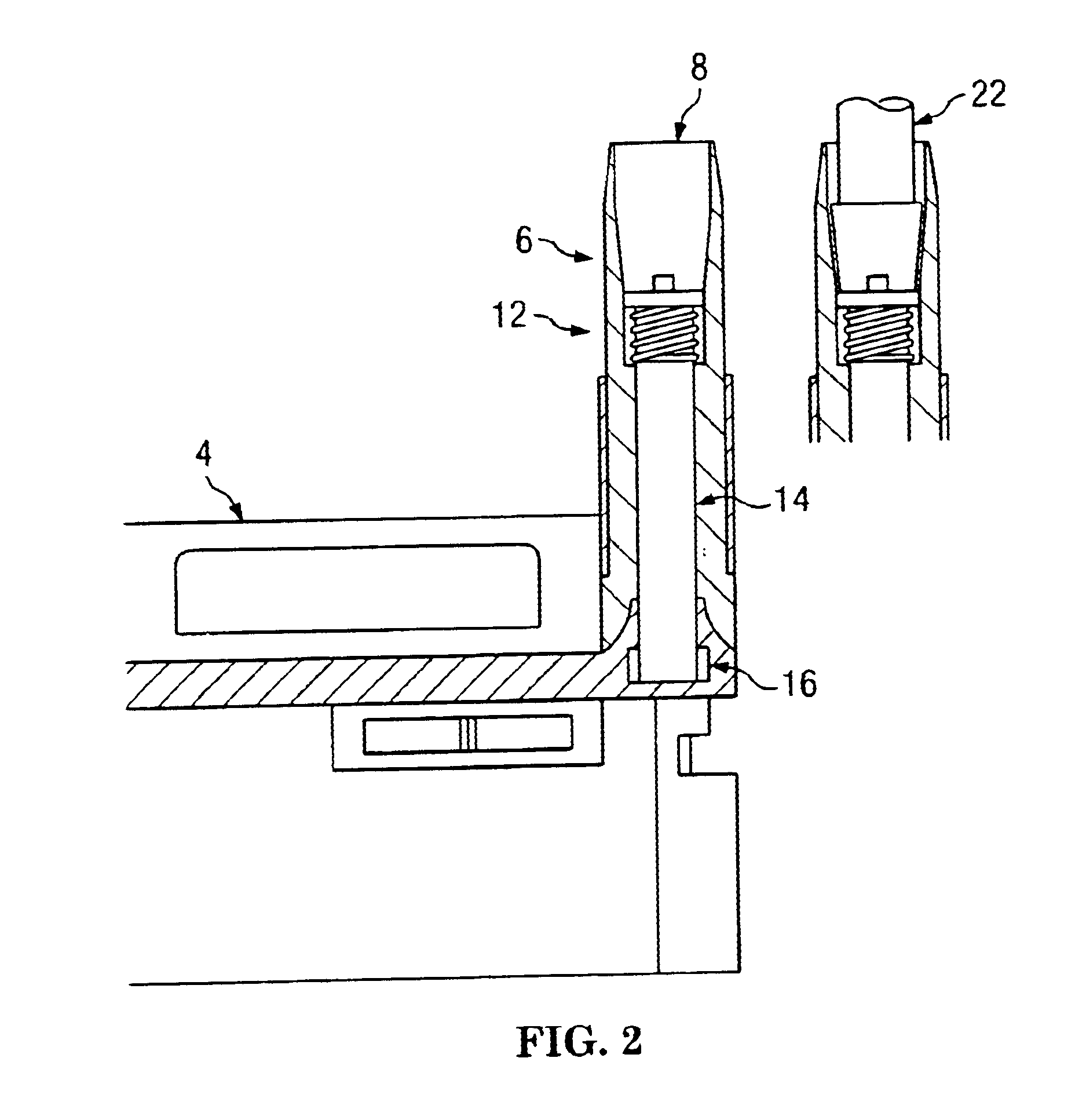

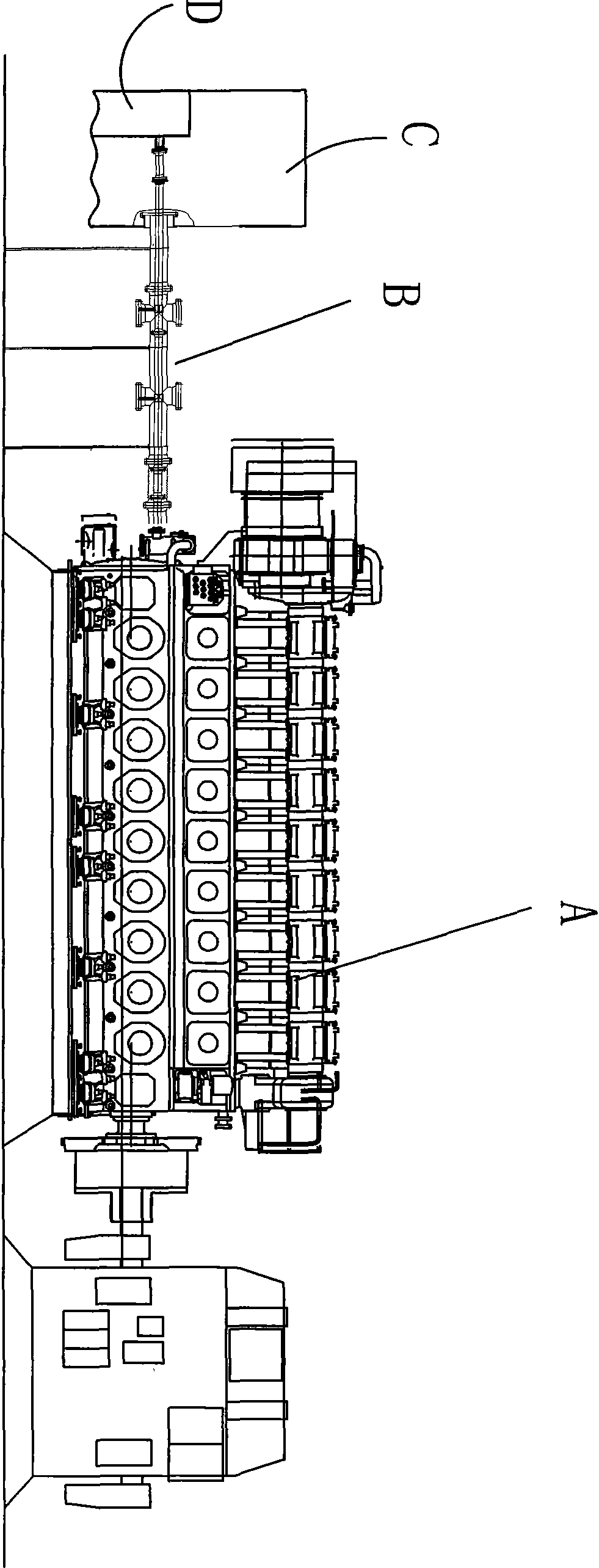

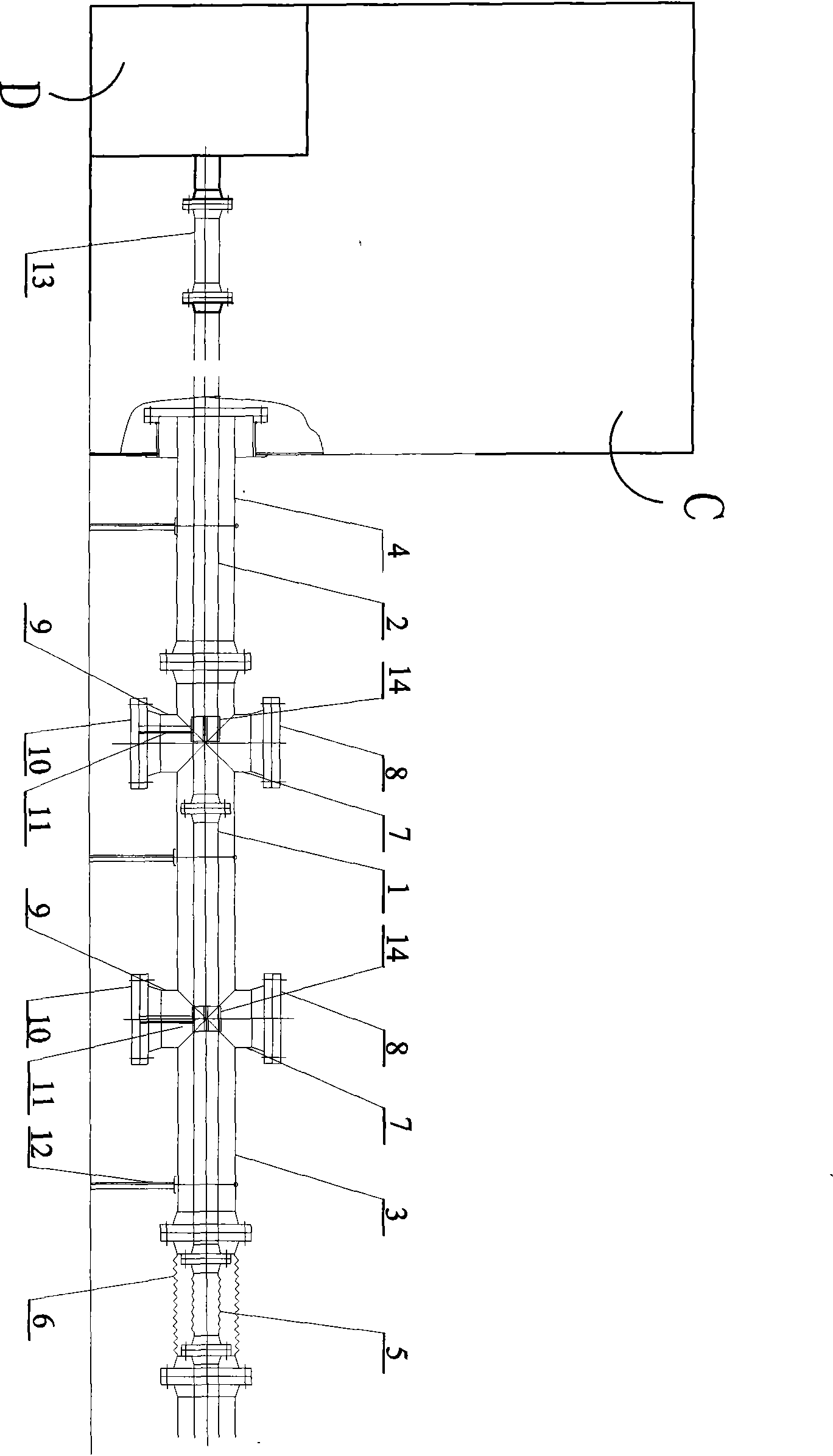

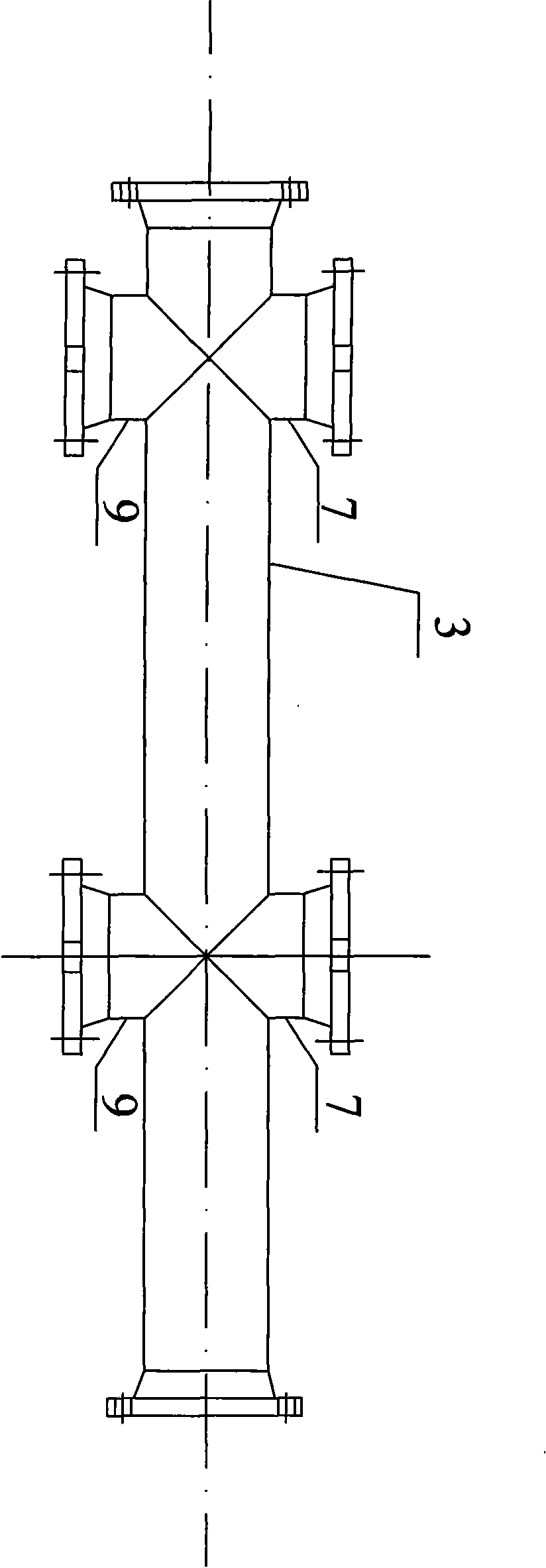

Double-wall pipeline for the connection of fuel-gas valve set and engine on LNG ship and installation method of double-wall pipeline

ActiveCN101525048ASimple structureEasy to manufactureInternal combustion piston enginesFuel supply apparatusDouble-walled pipeDouble wall

The invention relates to a double-wall pipeline for the connection of a fuel-gas valve set and an engine on an LNG ship, which comprises an internal pipe and an external pipe, wherein the internal pipe and the external pipe are coaxially sleeved and supported by a plurality of detachable clips, one end of the external pipe is fixed on the side wall of a fuel-gas valve set chamber provided with the fuel-gas valve set, one end of the internal pipe is communicated with the fuel-gas valve set by a transitional connection pipe, the other end of the internal pipe is communicated with the air inlet of a double fuel-gas engine by an internal corrugated pipe, the aperture of the internal pipe is the same as that of the air inlet of the engine, and a circular chamber is arranged between the internal pipe and the external pipe and communicated with the fuel-gas valve chamber to together realize air change. The double-wall pipe of the invention has simple and practical structure, uses common material of easy production and low cost, and can be rapidly and conveniently assembled and disassemble by using common tools when being applied on the LNG ship.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

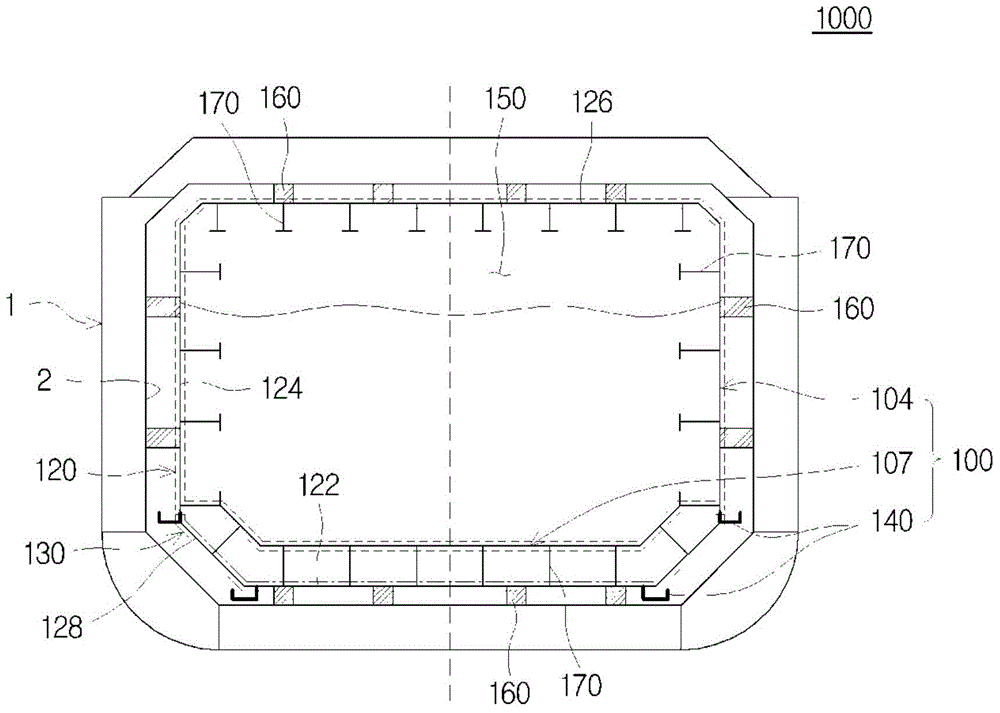

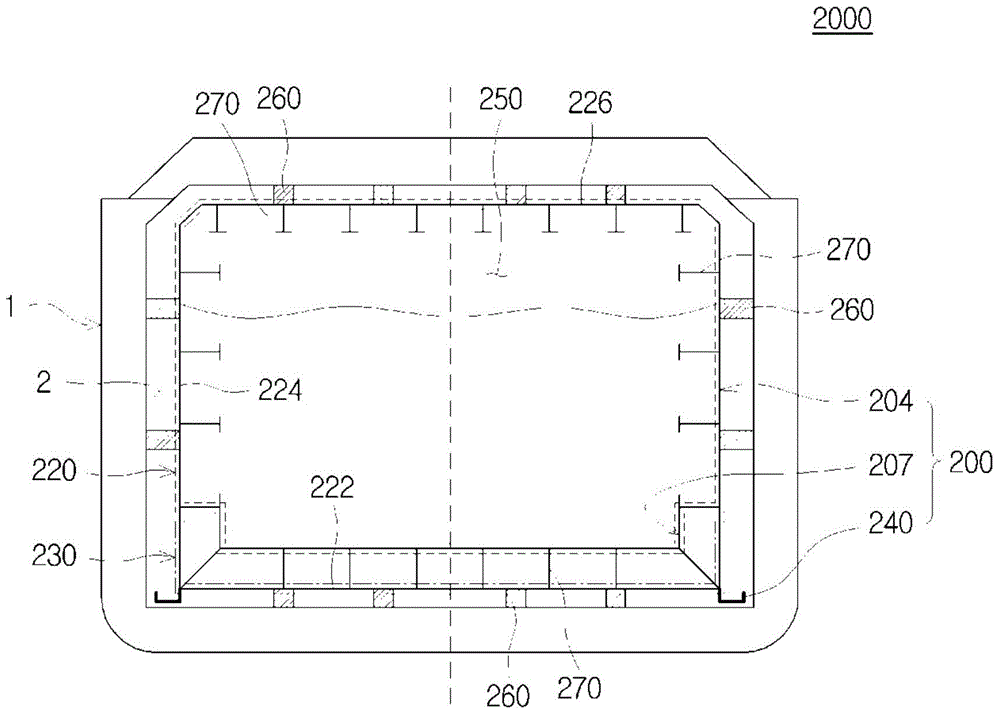

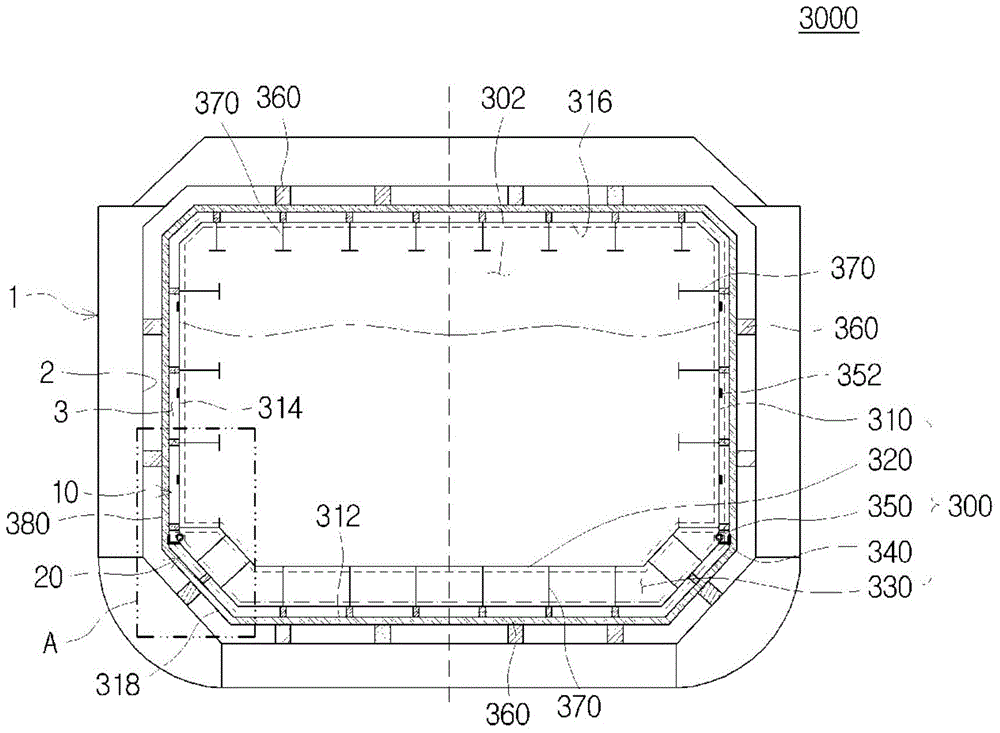

Storage tank for liquefied materials and ship comprising same

ActiveCN103562061APrevent leakageVessel geometry/arrangement/sizeVessel wallsMarine engineeringStorage tank

Disclosed are a storage tank for liquefied materials, and a ship comprising same. The storage tank for liquefied materials according to one embodiment of the present invention comprises: a main body which is installed within a hull of the ship such that a space is formed between said main body and said hull, and which has an interior with an accommodating space for accommodating a liquefied material therein; and a reinforcement plate which is installed in a lower portion of the interior of said main body such that the reinforcement plate is spaced apart from the bottom surface of said main body, so as to form the bottom of said accommodating space.

Owner:SAMSUNG HEAVY IND CO LTD

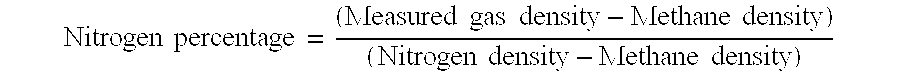

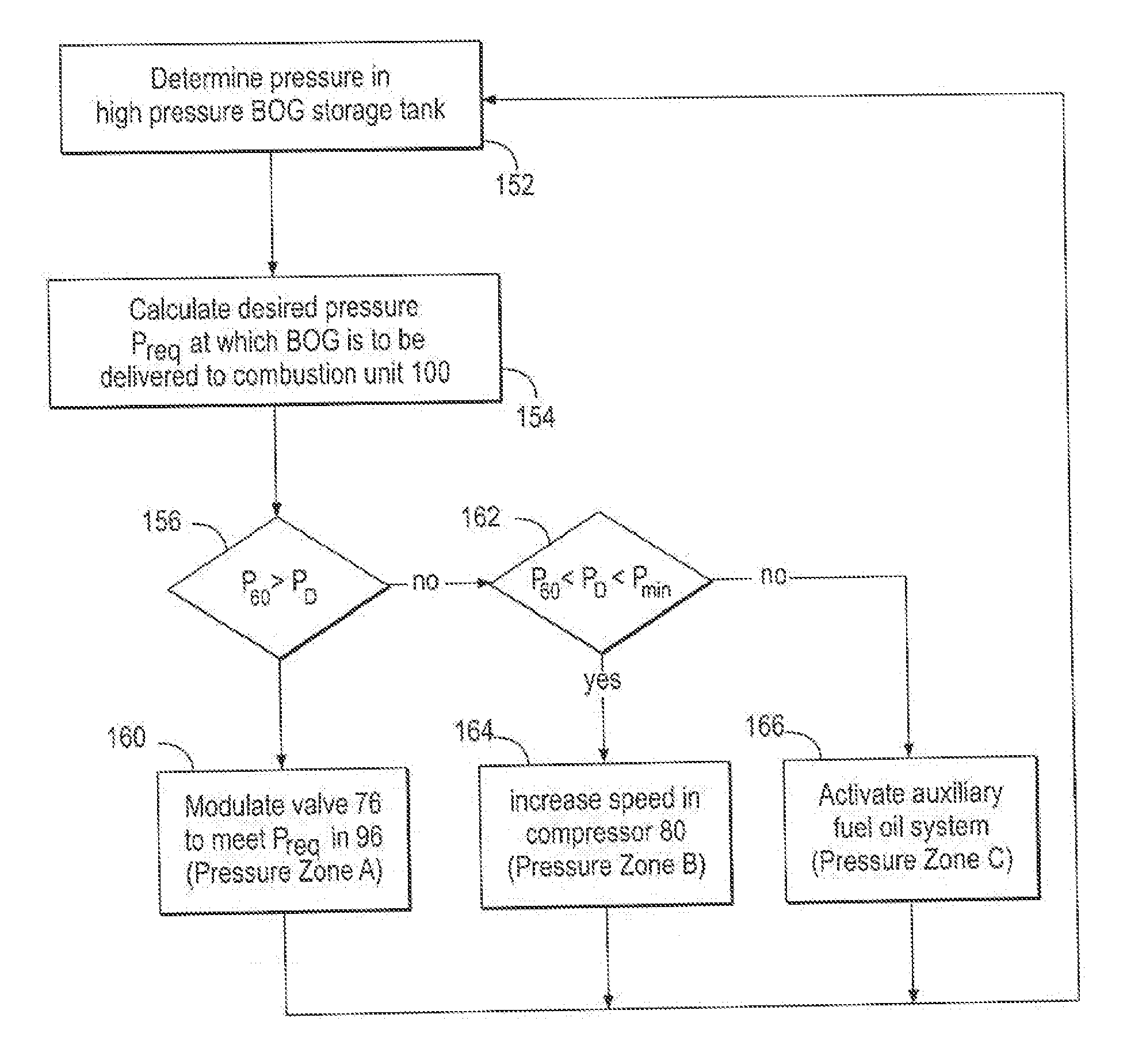

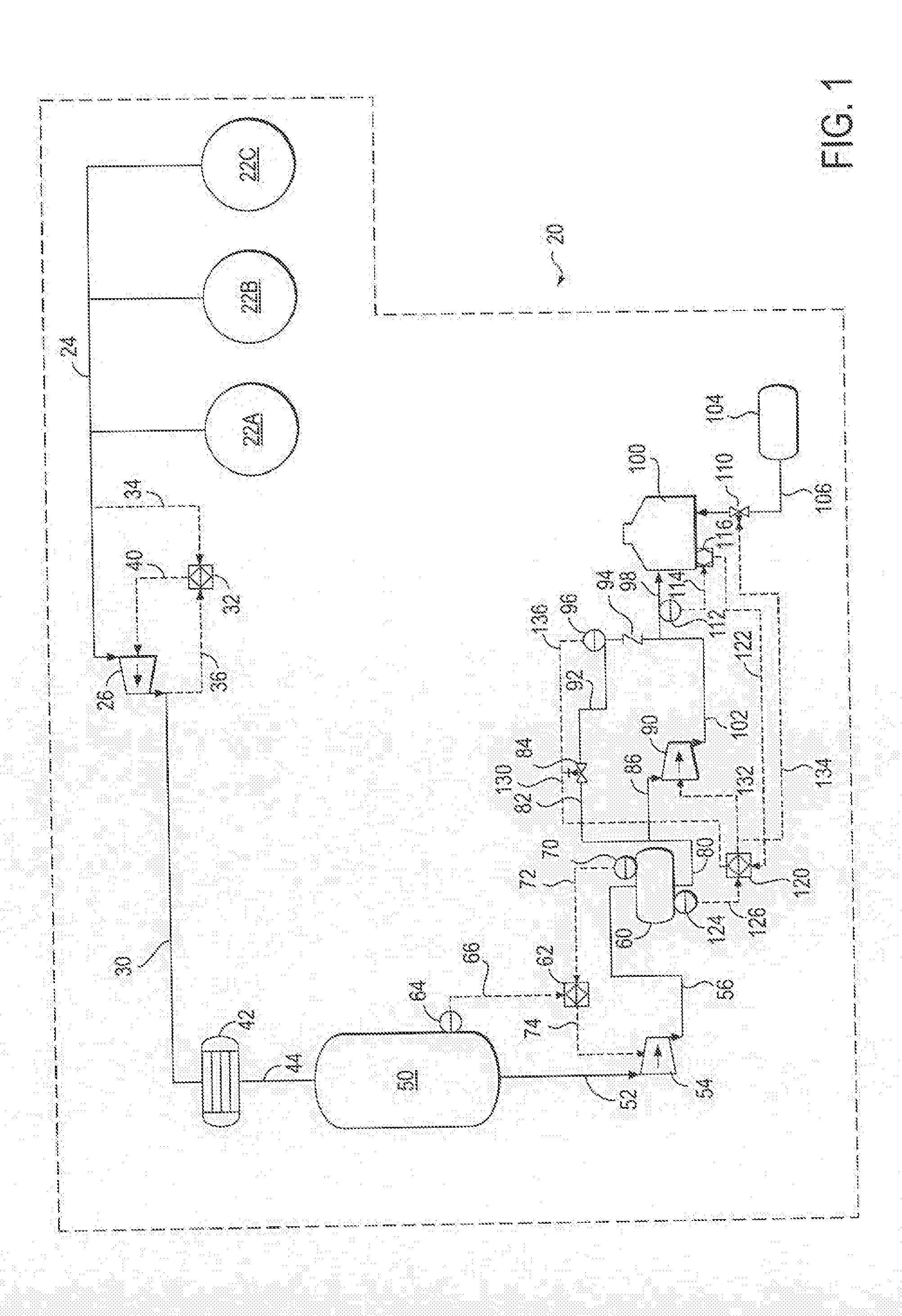

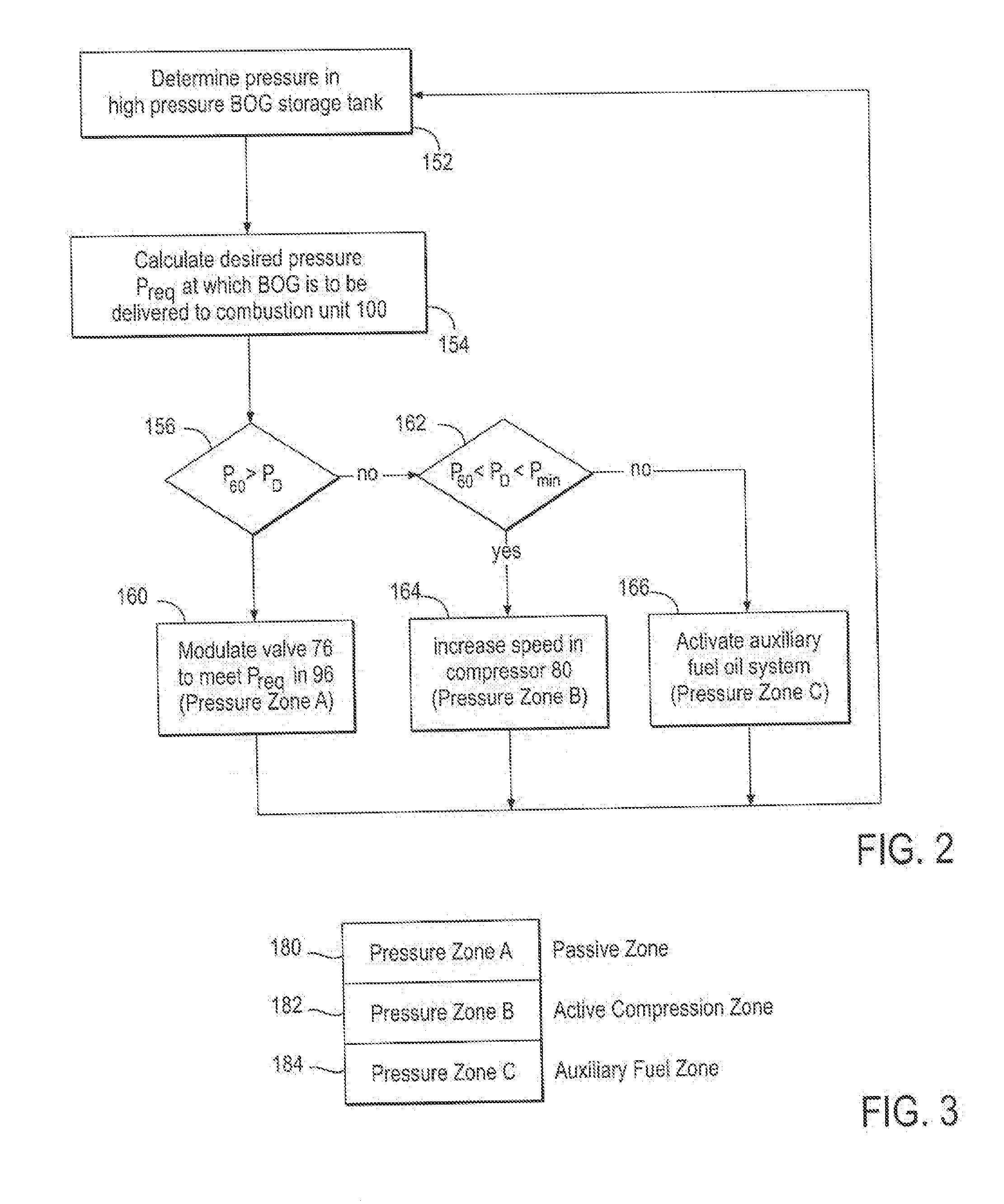

LNG transport vessel and method for storing and managing excess boil off gas thereon

InactiveUS20110302923A1Sufficient pressureReciprocating combination enginesFuel supply regulationCombustionHigh pressure

A liquefied natural gas (LNG) transport vessel for transporting liquefied natural gas (LNG) is disclosed which is capable of storing excess boil off gas BOG until needed for combustion in one or more combustion apparatus on the vessel. A method for managing the delivery of the BOG to the combustion apparatus is also described. The LNG vessel includes at least one insulated LNG storage tank which stores LNG. A first stage LNG receiver receives and stores BOG from the at least one LNG storage tank. A second stage or high pressure BOG storage tank receives compressed BOG from the receiver and stores the BOG as needed for combustion by one or more combustion apparatus of the vessel. A pressure regulator allows BOG gas to be delivered to the combustion apparatus if there is sufficient pressure in the high pressure storage tank to passively deliver the BOG at a predetermined delivery pressure. If the pressure in the high pressure BOG storage tank is insufficient to passively delivery the BOG to combustion apparatus, then a combustion apparatus compressor may be used to actively increase the pressure in BOG such that the BOG is delivered at the necessary delivery pressure. If there is still insufficient BOG in the high pressure BOG storage tank, then it may be necessary to supply supplemental auxiliary fuel to meet the needs of the combustion apparatus.

Owner:CHEVROU USA INC

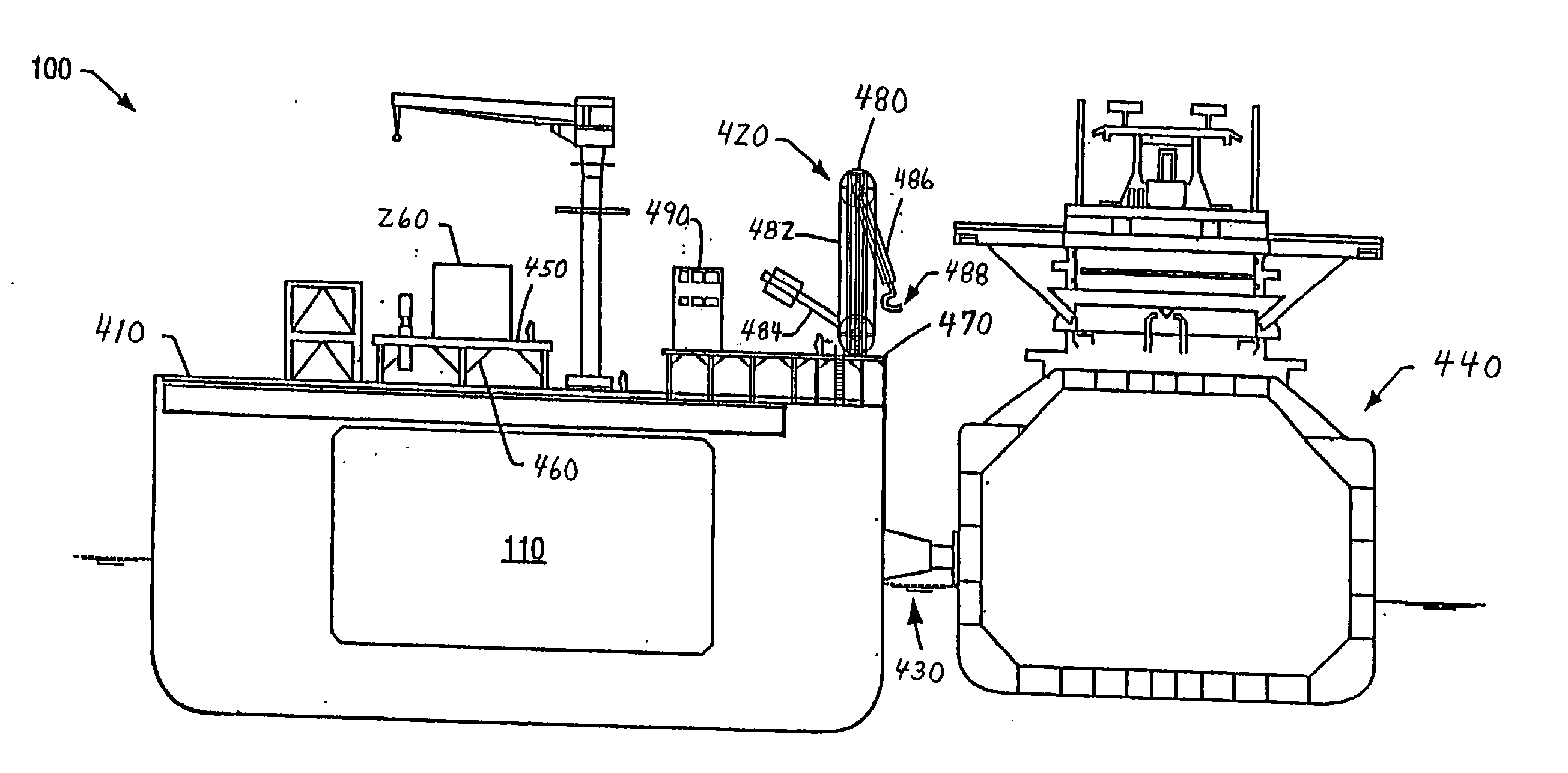

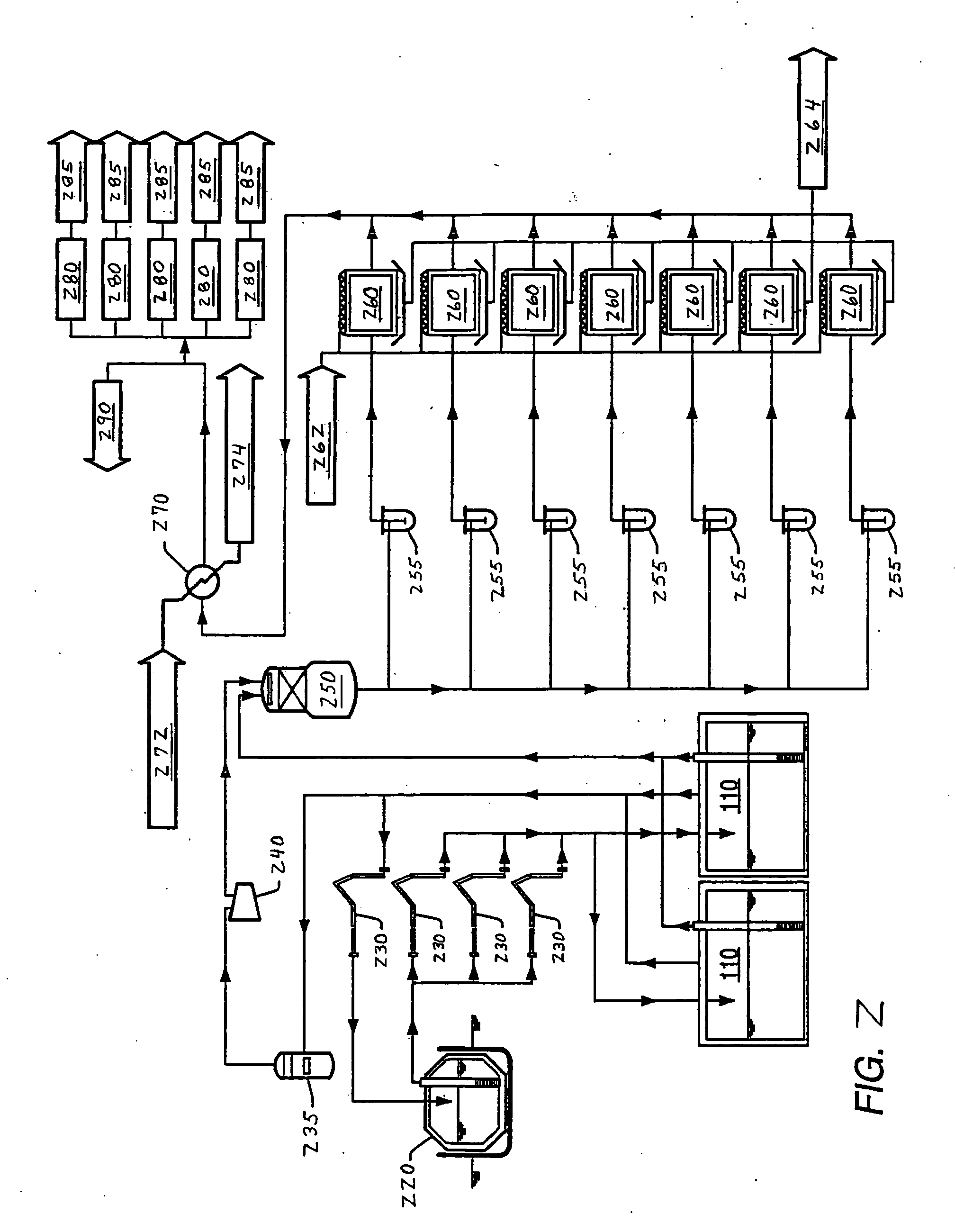

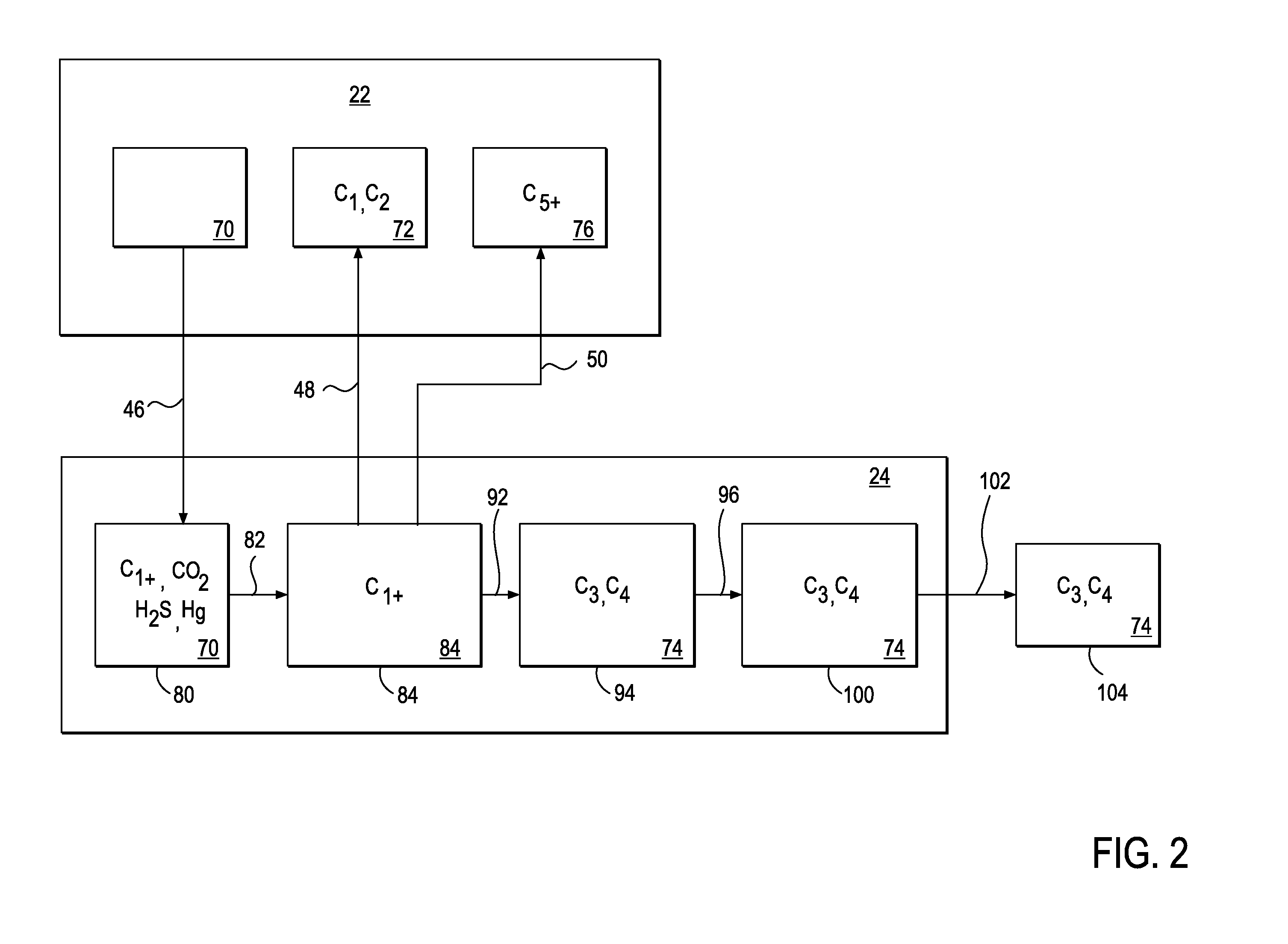

METHOD, SYSTEM, AND PRODUCTION AND STORAGE FACILITY FOR OFFSHORE LPG and LNG PROCESSING OF ASSOCIATED GASES

A method, system and production and storage facility is disclosed for offshore LPG and LNG processing of associated gases. The system includes a first production facility and a second production and storage facility. The first facility receives and processes produced fluids to produce crude oil, water and rich associated gases. The second facility includes a gas treatment unit for processing the rich associated gases to remove contaminants and produce a treated gas stream of hydrocarbons. The second facility also has at least one LPG and / or LNG production unit for producing one of LPG and / or LNG from the treated gas stream. At least one storage tank on the second facility stores at least one of the LPG and / or LNG. The second production facility may be a retrofit LNG or LPG carrier. The treatment unit, LPG and / or LNG production and needed offloading facilities and equipment can be added to the LNG / LPG carrier. Existing storage tanks can be modified as needed or else new storage tanks can also be added.

Owner:CHEVROU USA INC

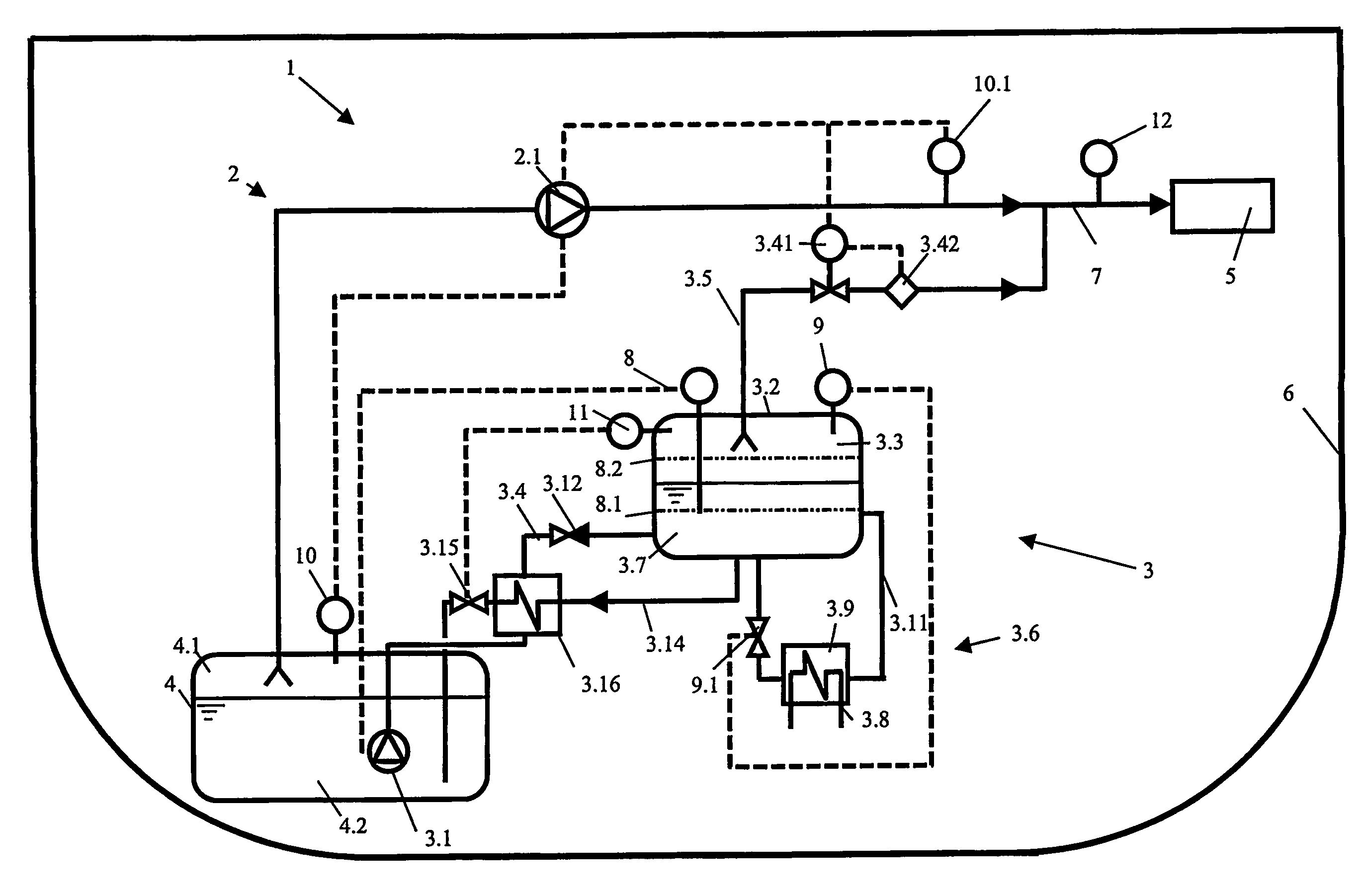

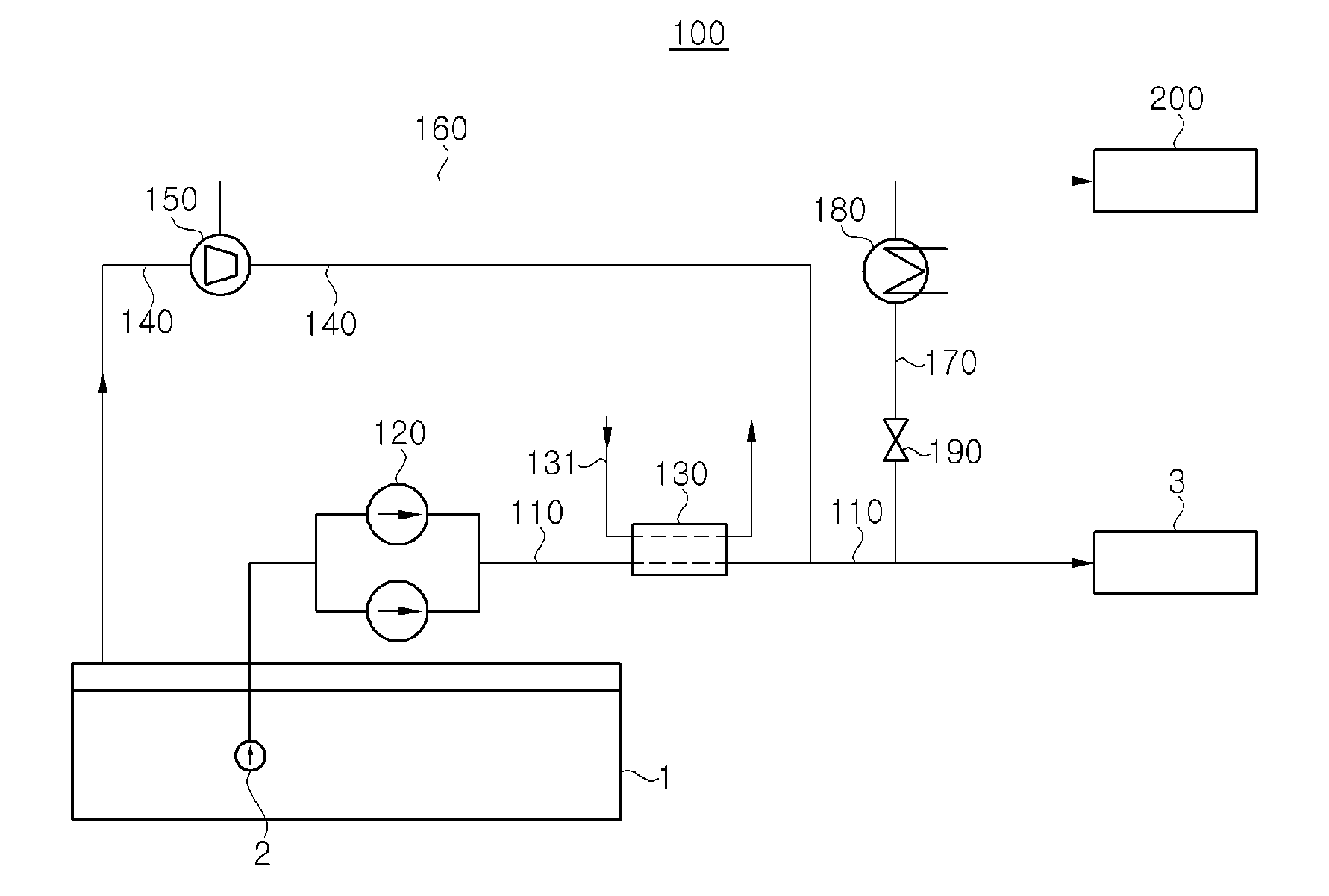

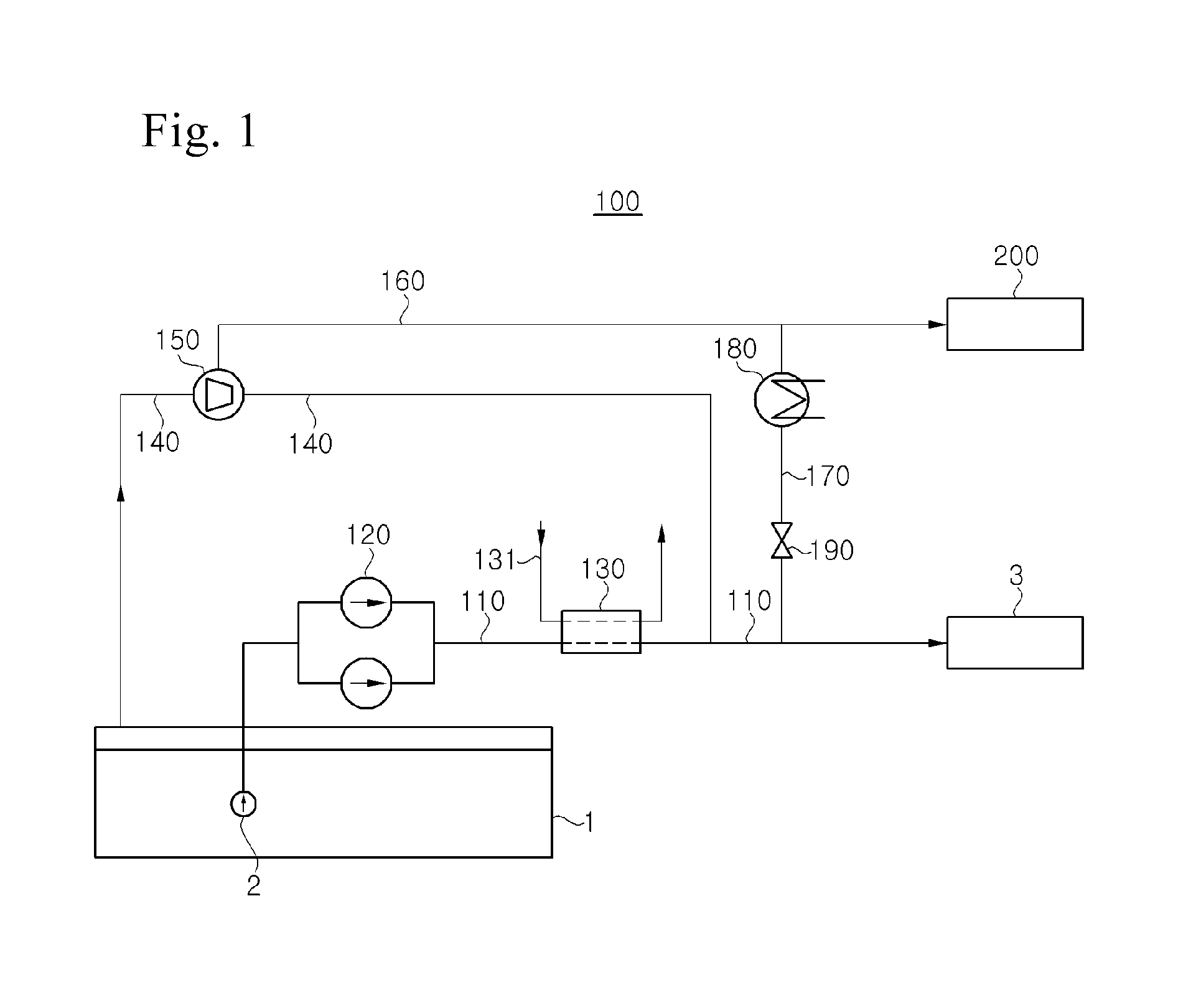

Liquefied gas processing system for ship

InactiveUS20150316208A1Easy to useReduce energy consumptionSolidificationLiquefactionProcess engineeringLiquid gas

Disclosed is a liquefied gas processing system for a ship that includes a storage tank that stores liquefied natural gas, and an engine that uses the liquefied natural gas stored in the storage tank as fuel. The liquefied gas processing system of the present invention comprises: a storage tank that stores liquefied gas; an engine that uses the liquefied gas stored in the storage tank as fuel; and a fuel supply line that can vaporize the liquefied gas and supply the generated gas to the engine as fuel. The engine receives a supply of the fuel gas that is pressurized at a low pressure.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

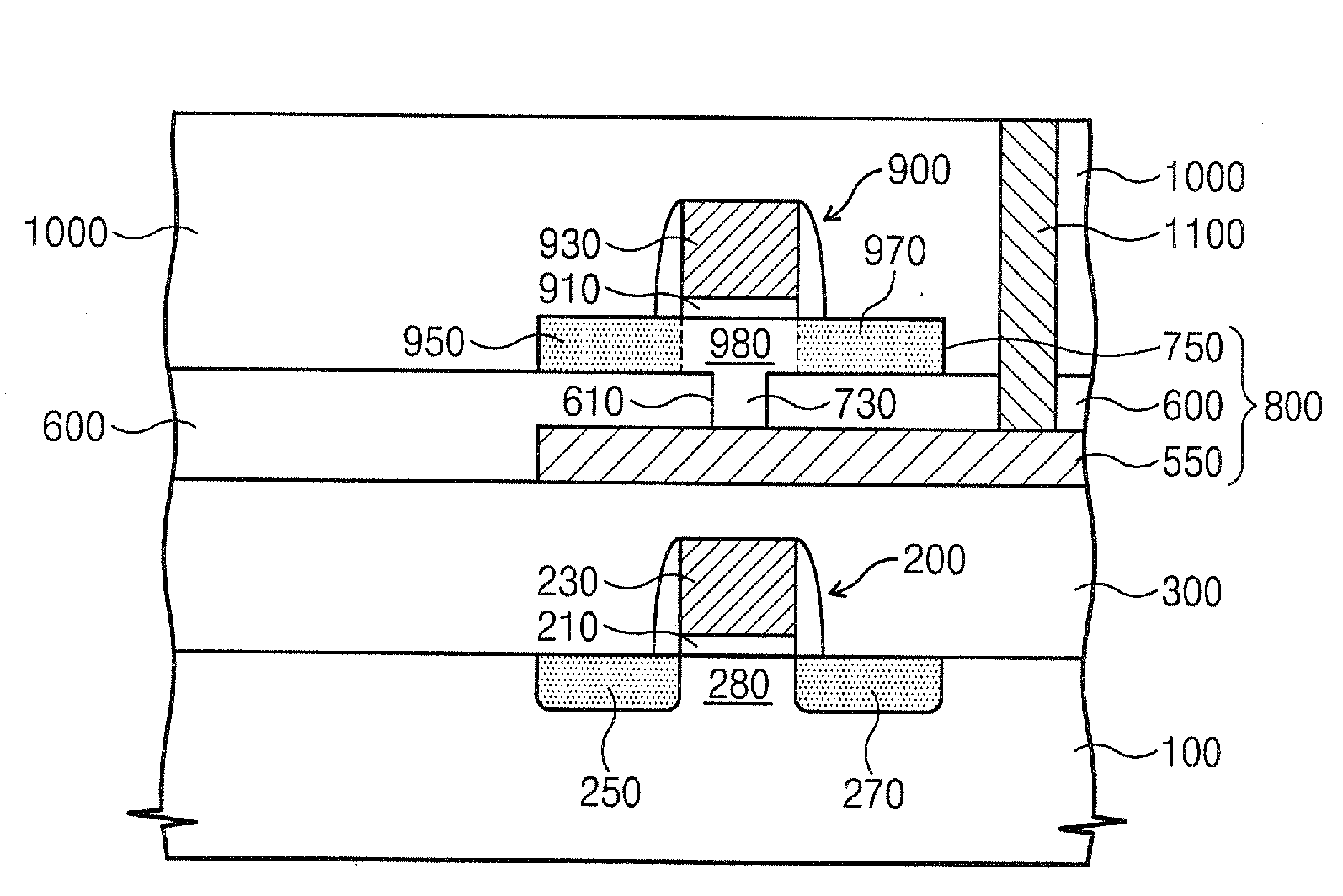

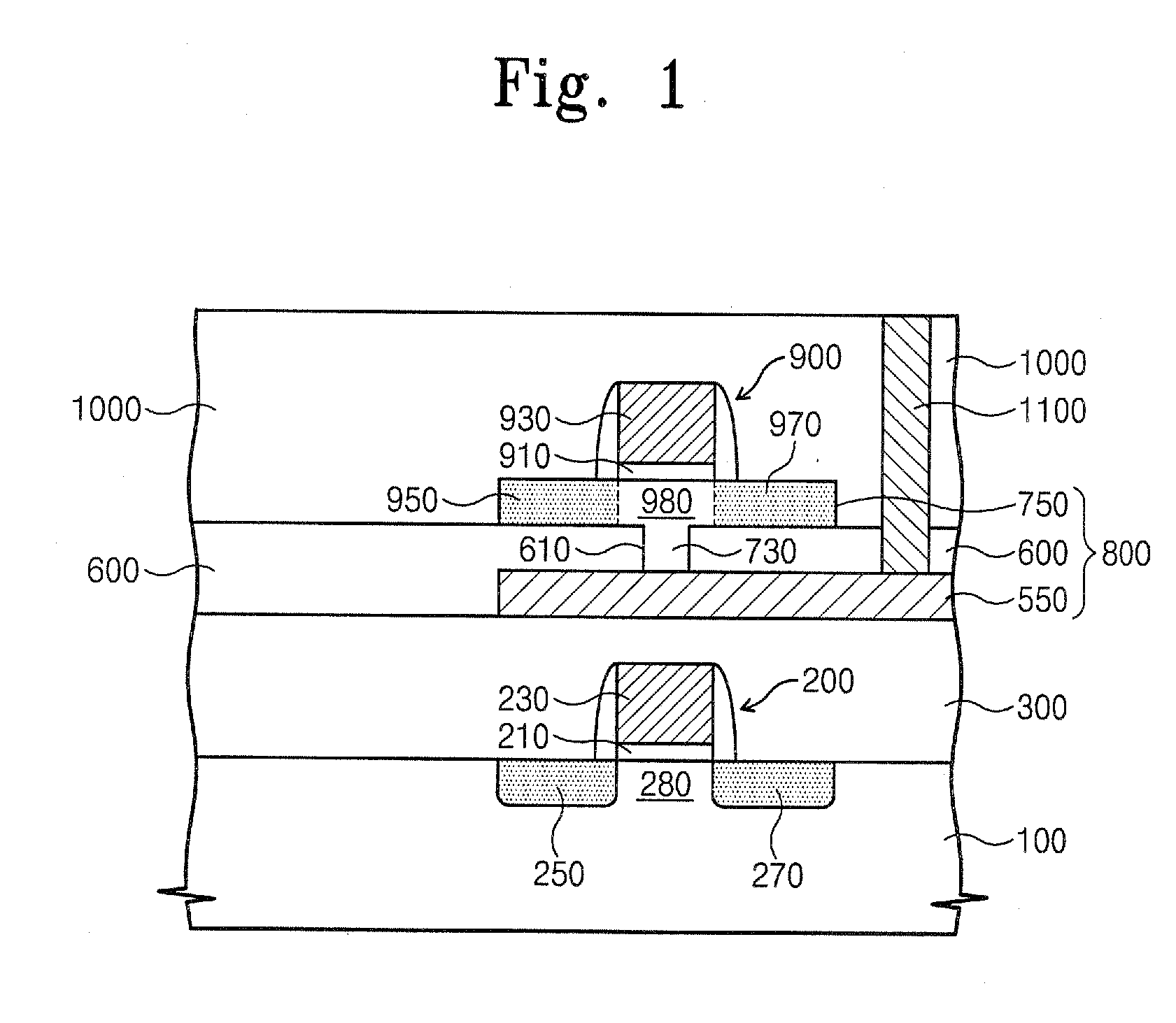

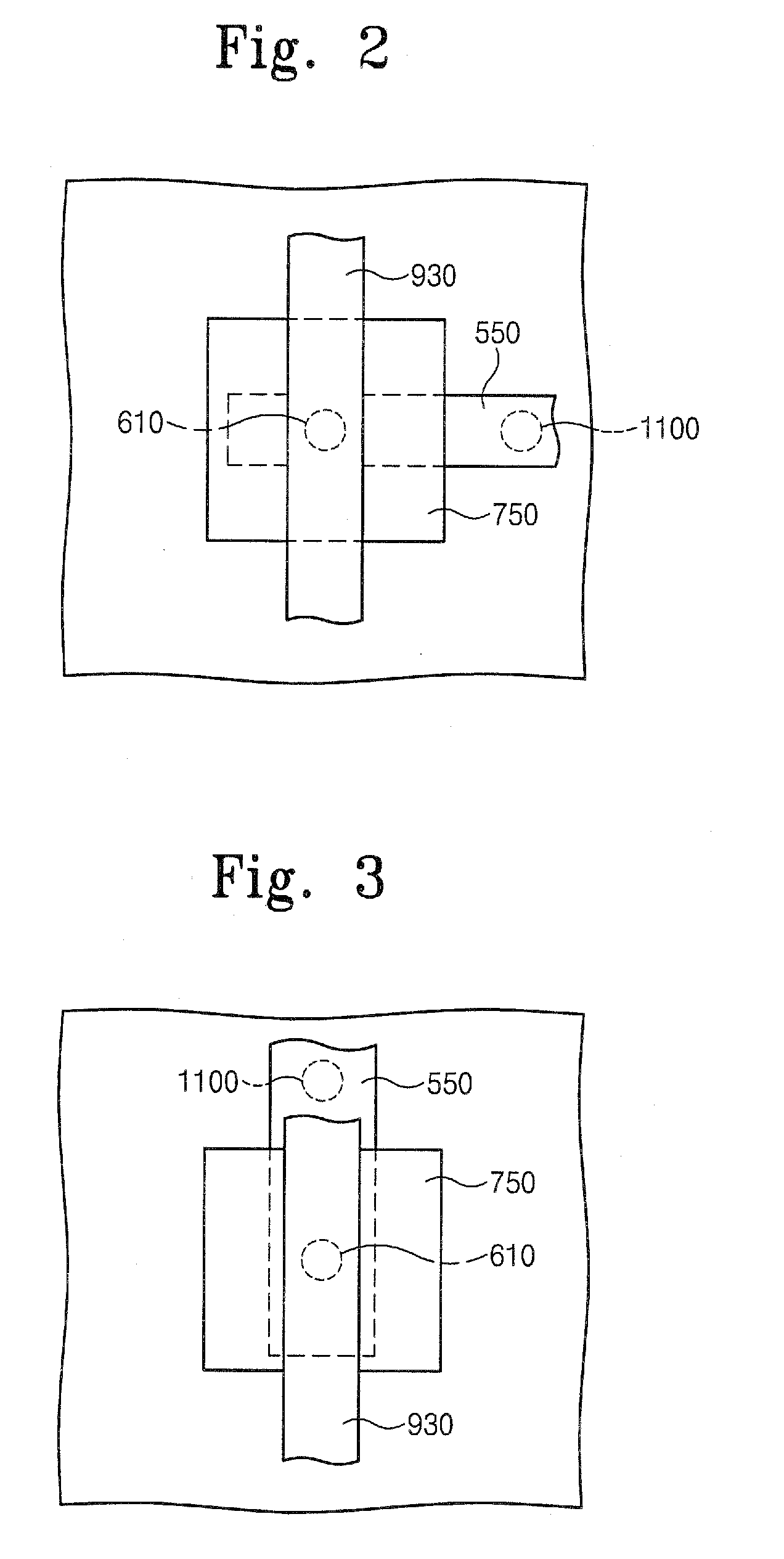

Semiconductor device and method for forming the same

InactiveUS20070181880A1Suppression of floating body effectEliminate the effects ofTransistorAuxillariesInsulation layerDevice material

A semiconductor device includes a conductive layer formed on a semiconductor substrate. An insulation layer is formed on the conductive layer and includes an opening defined therein that exposes the conductive layer. A semiconductor pattern is formed on the insulation layer and is electrically connected to the conductive layer through the opening. A transistor is formed on the semiconductor pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

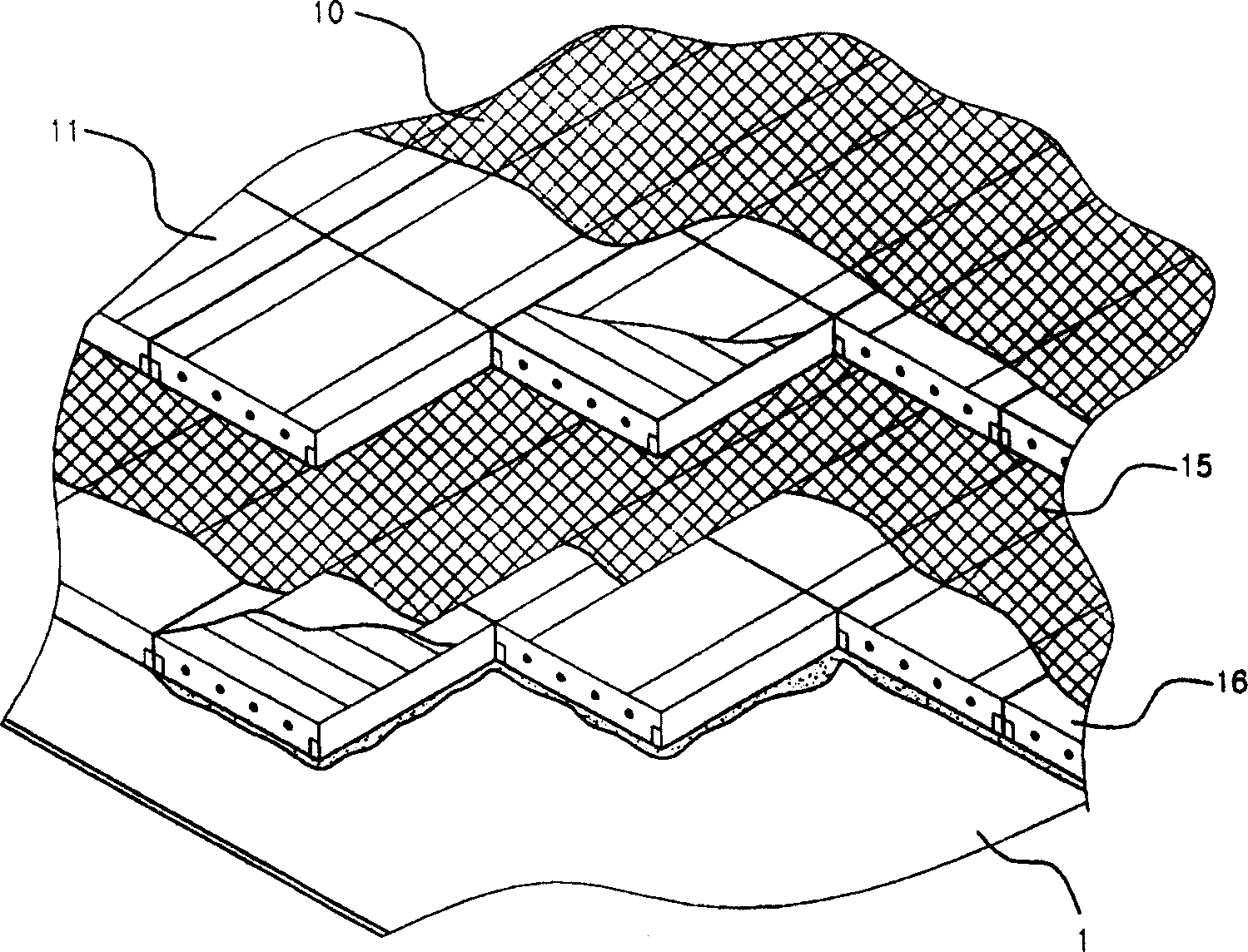

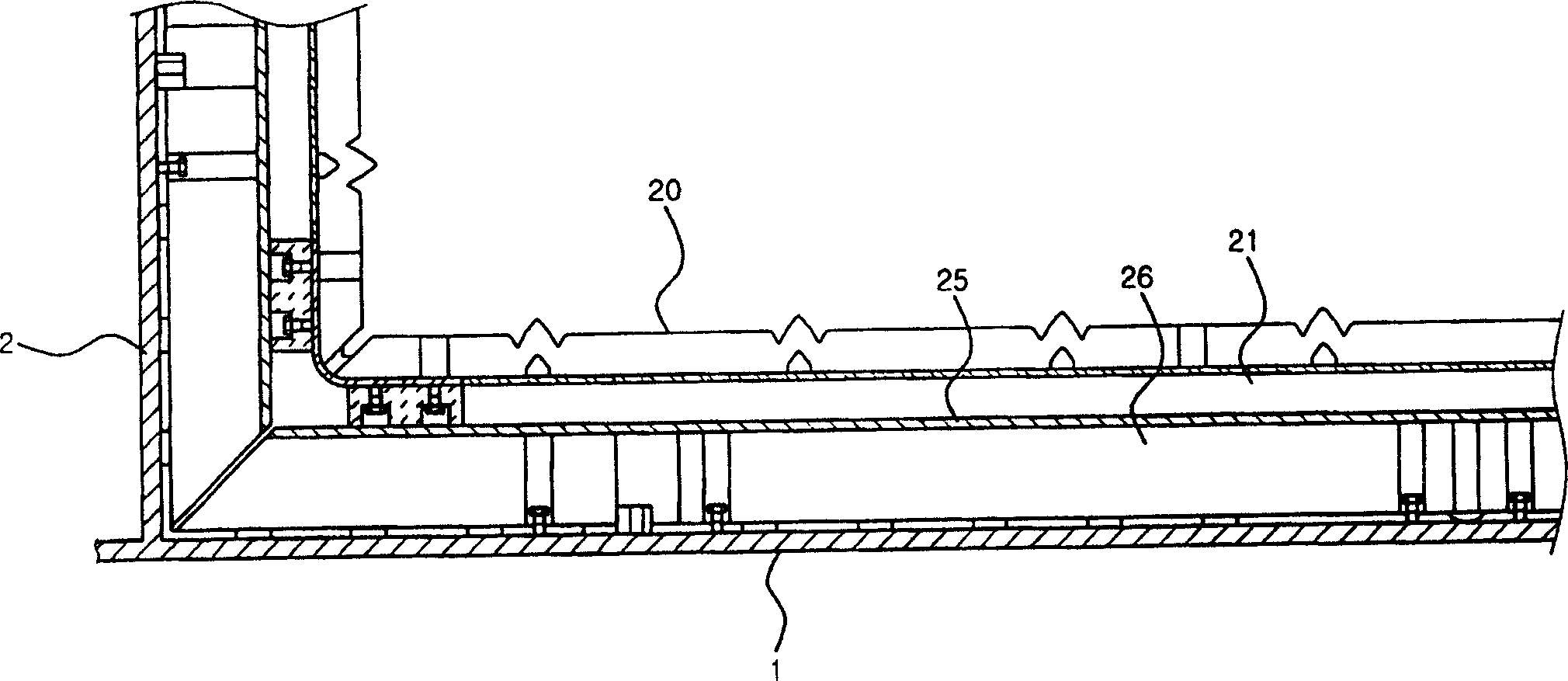

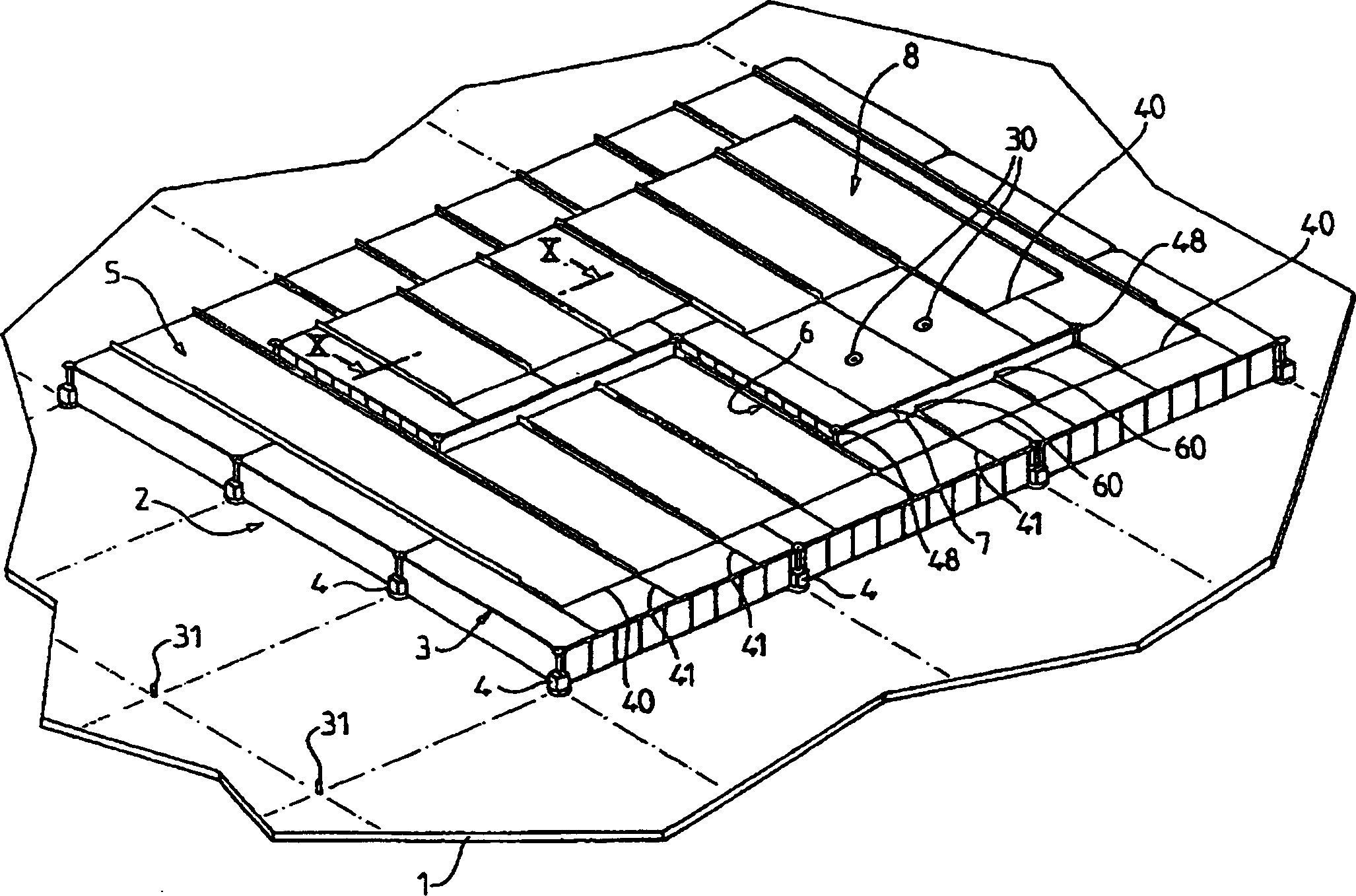

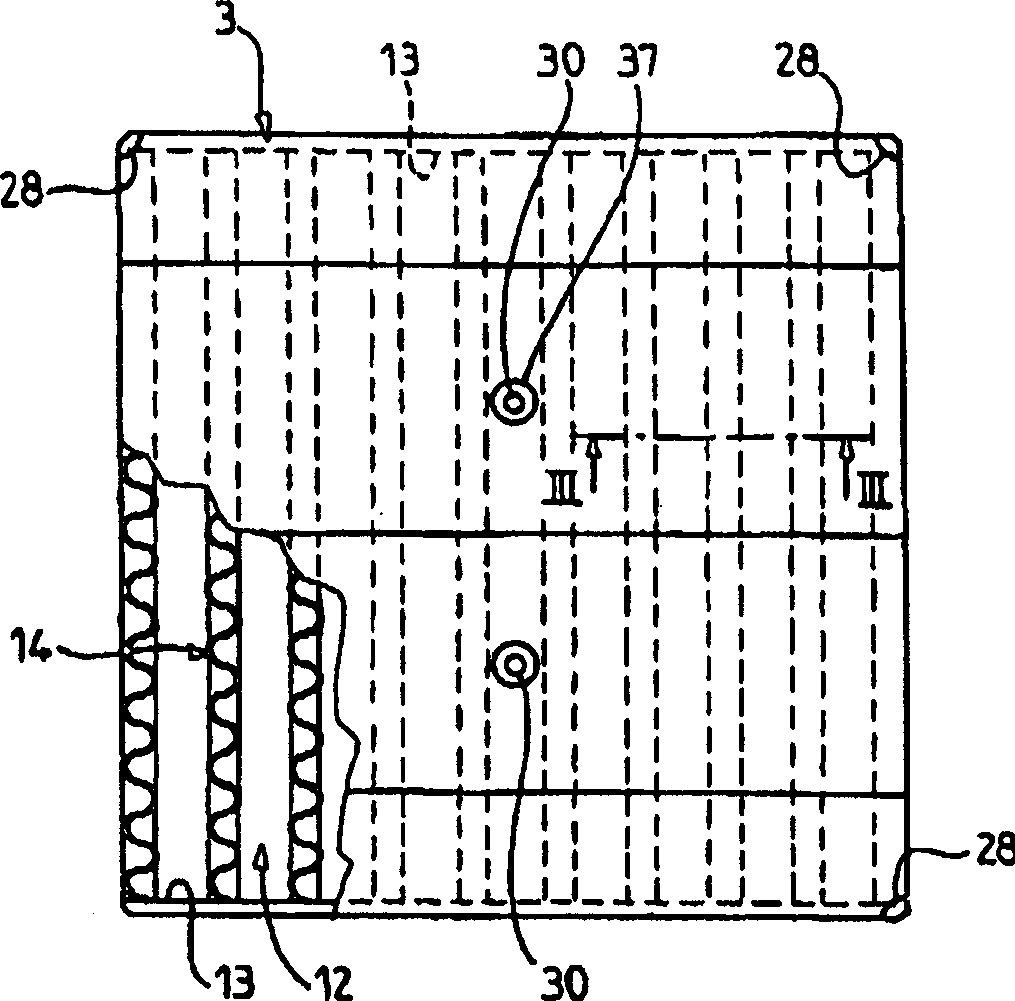

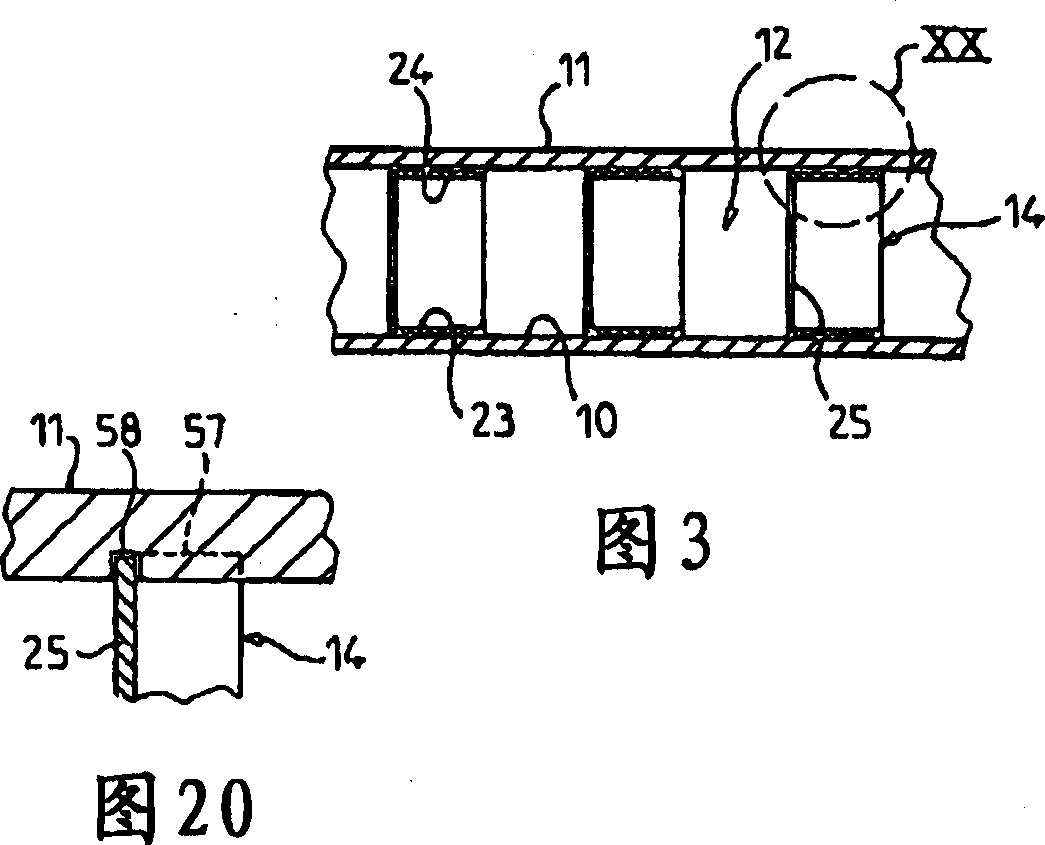

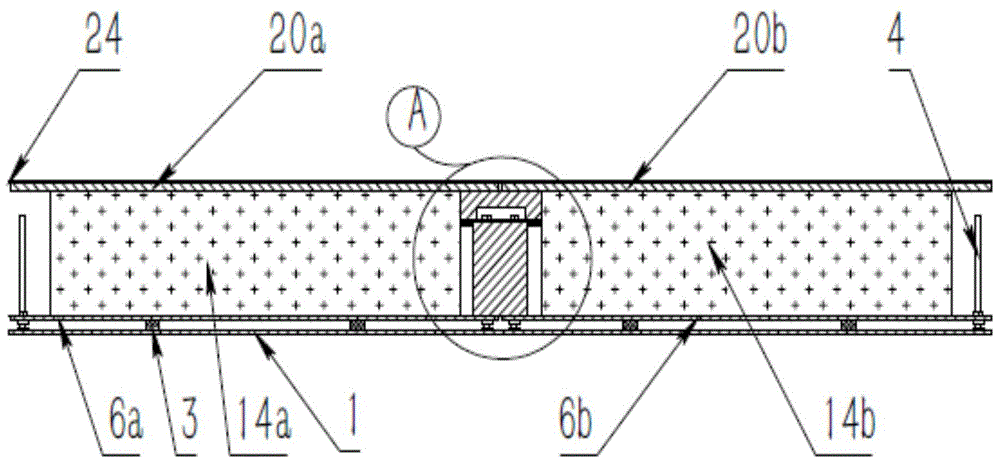

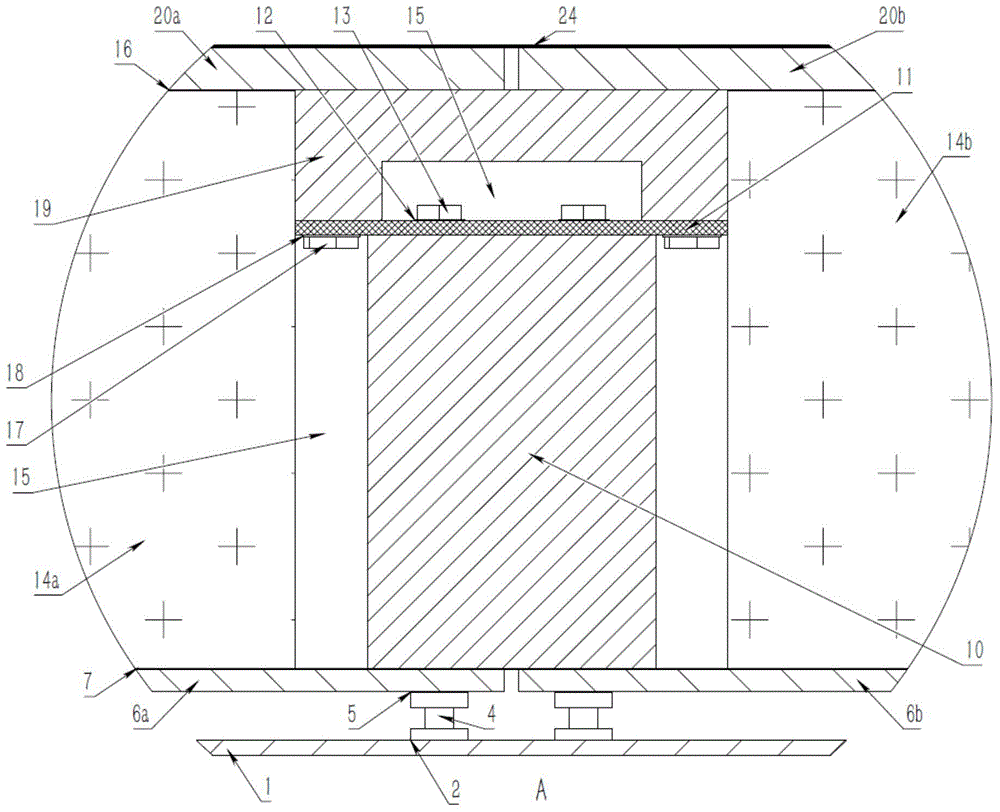

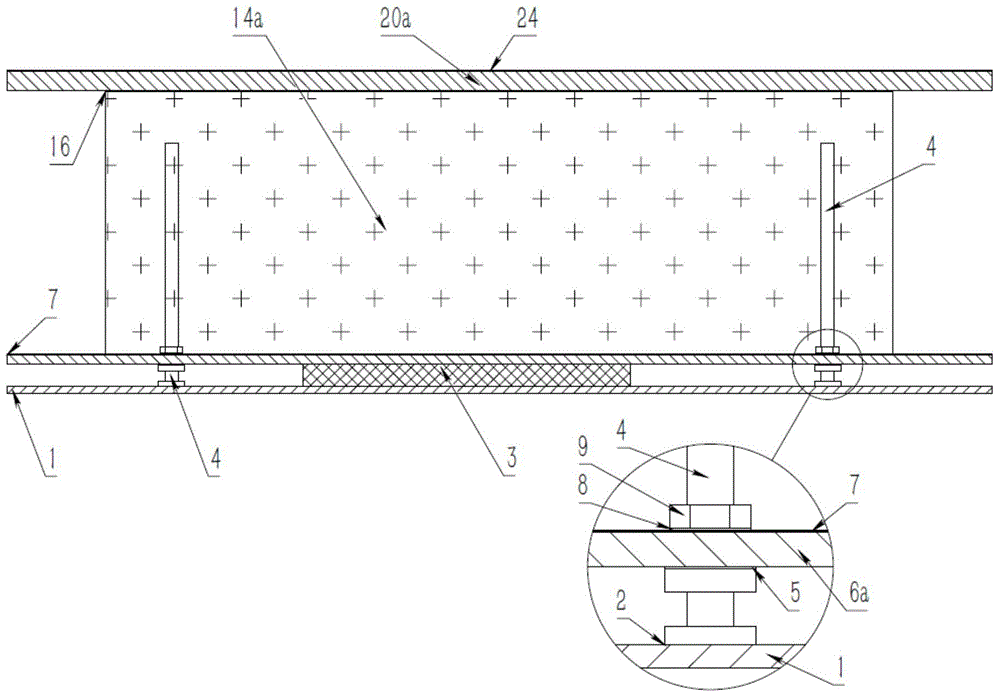

Liquefied natural gas carrier B type independent liquid cargo tank thermal insulation system and construction method thereof

ActiveCN104443284ASolve Design StructureSolve the design processFor bulk goodsThermal insulationEngineering

The invention relates to a liquefied natural gas carrier B type independent liquid cargo tank thermal insulation system with a sealing secondary screen wall. The liquefied natural gas carrier B type independent liquid cargo tank thermal insulation system comprises a thermal insulation layer, wherein the thermal insulation layer comprises a splash-proof screen, a secondary screen wall layer, a thermal insulation plate, an upper plate piece and a protection layer, the secondary screen wall layer is continuously bonded on the upper surface of the splash-proof screen, the thermal insulation plate is arranged between the splash-proof screen and the upper plate piece in a clamped mode, and the protection cover covers the outer surface of the upper plate piece. The thermal insulation layer of the thermal insulation system is continuously installed on and fixed to the periphery of a liquid cargo tank main screen wall, so that a thermal insulation enclosure layer for an LNG liquid cargo tank is formed. By means of the structure of the thermal insulation system, it is ensured that a communication interval passageway is formed between the main screen wall and the splash-proof wall, and when leakage happens to the main screen wall, liquefied natural gas which leaks can flow into a collection container through an interval space. The thermal insulation system further comprises a fixing mechanism of the thermal insulation layer, wherein the fixing mechanism can stably support the whole thermal insulation layer and fix the whole thermal insulation layer to the main screen wall.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com