Patents

Literature

1634results about How to "Improve compaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

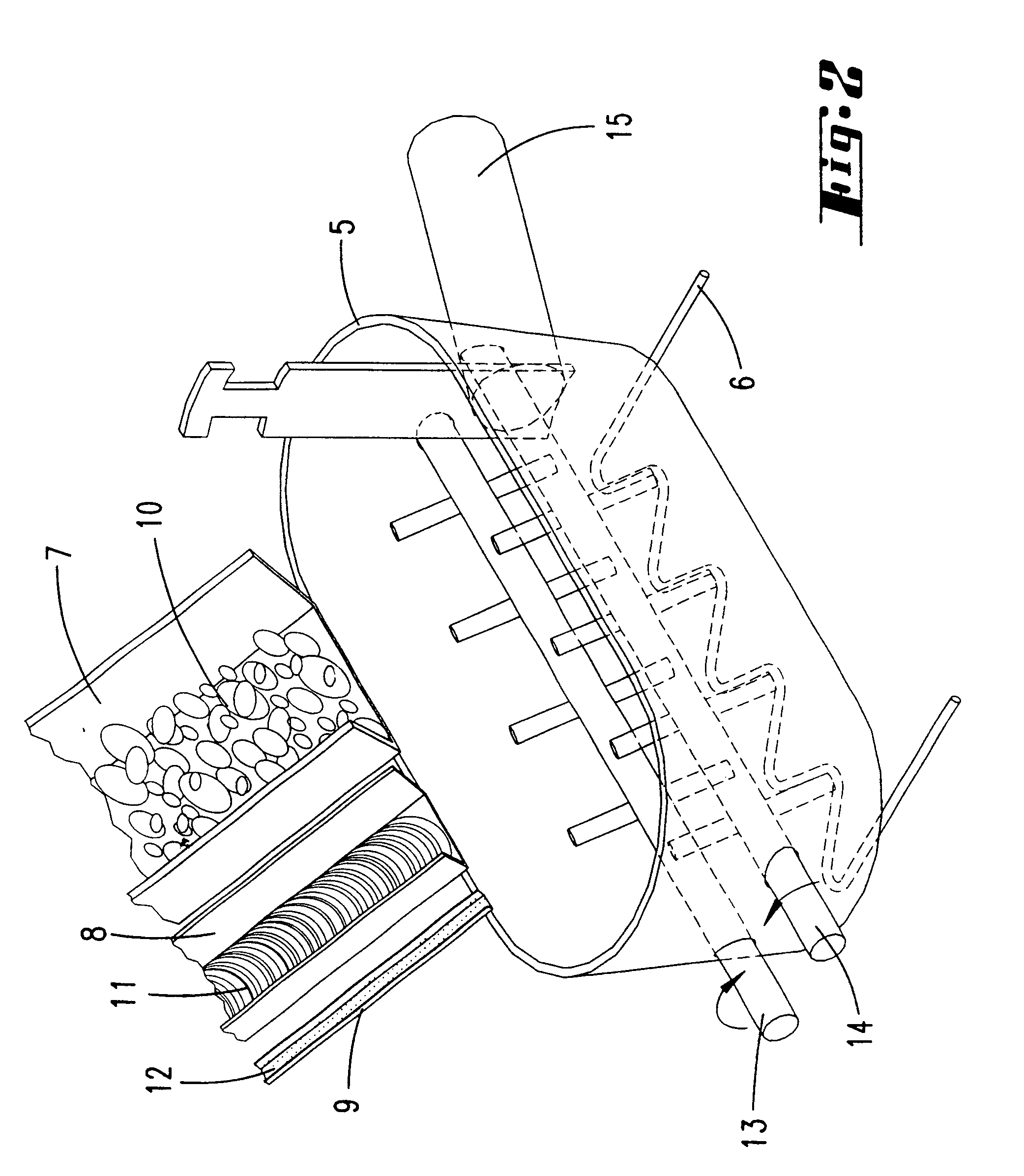

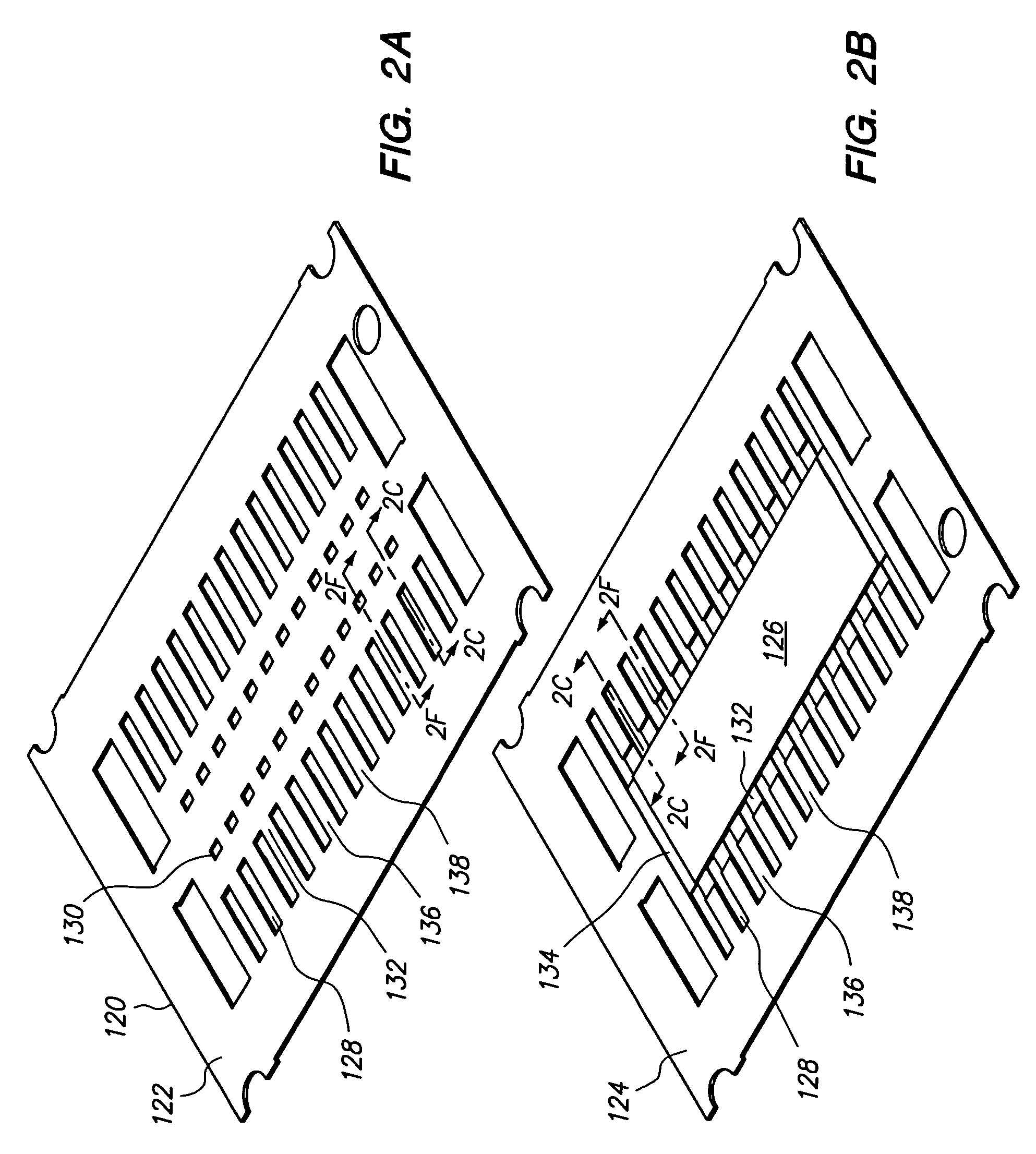

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

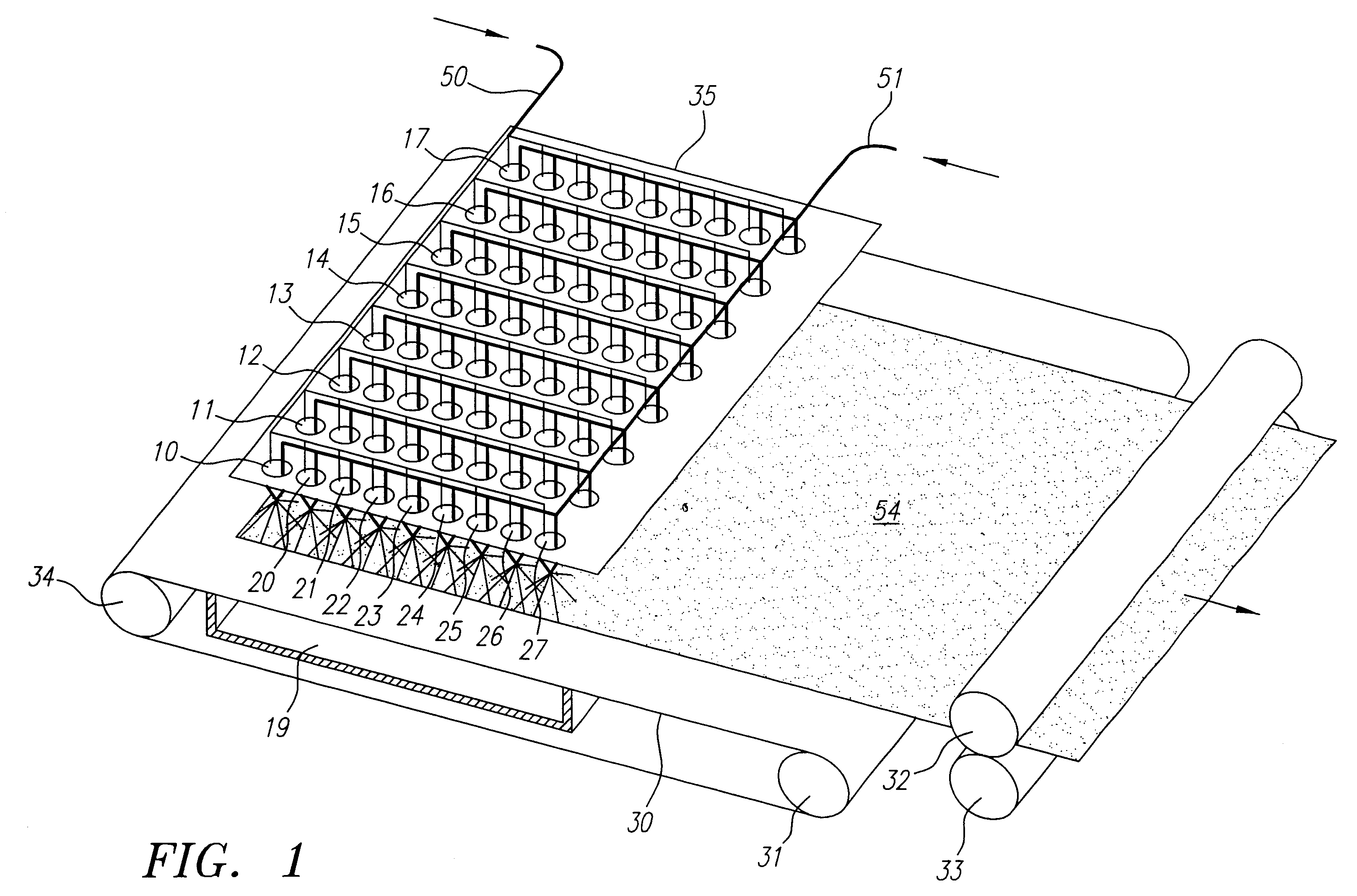

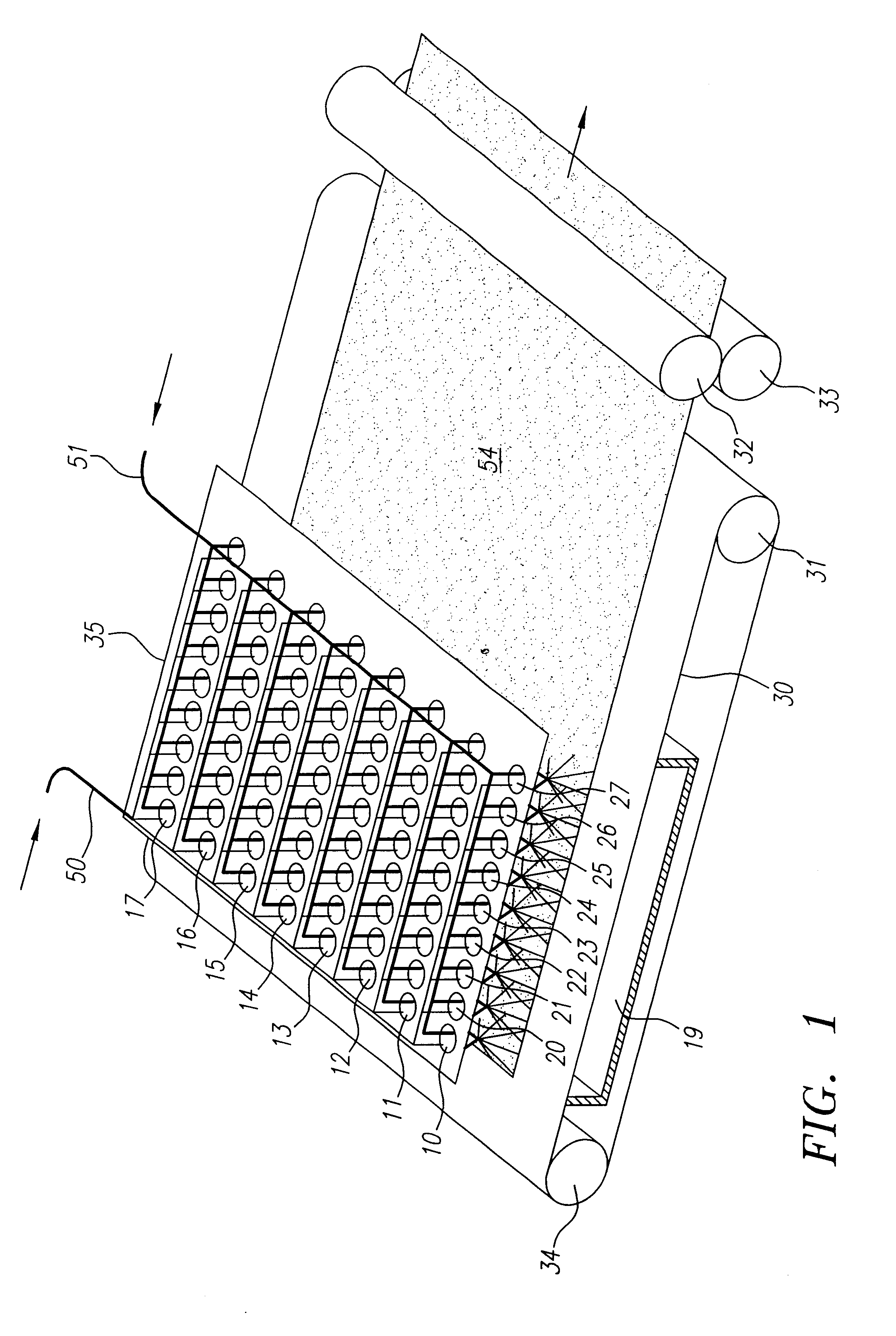

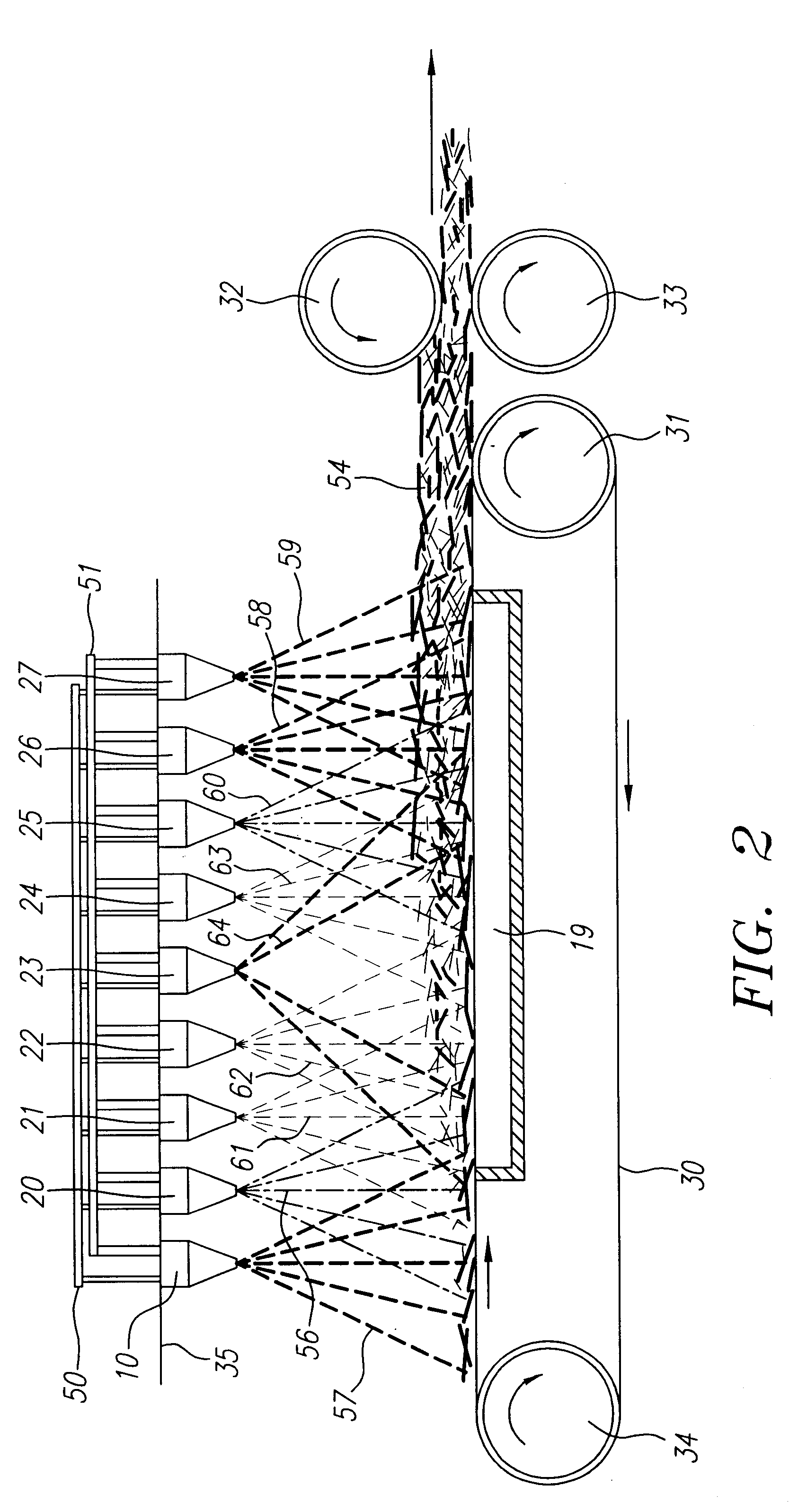

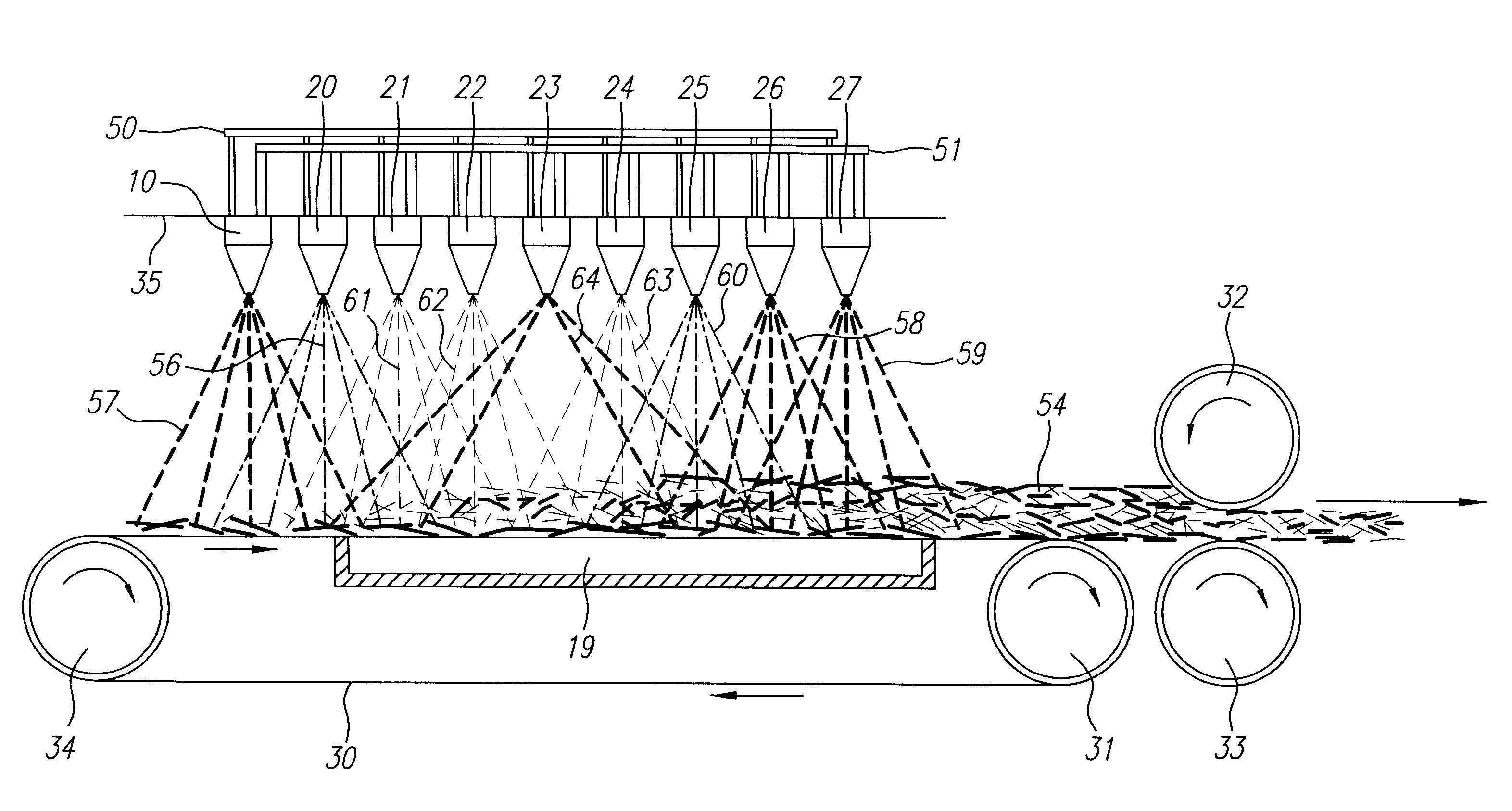

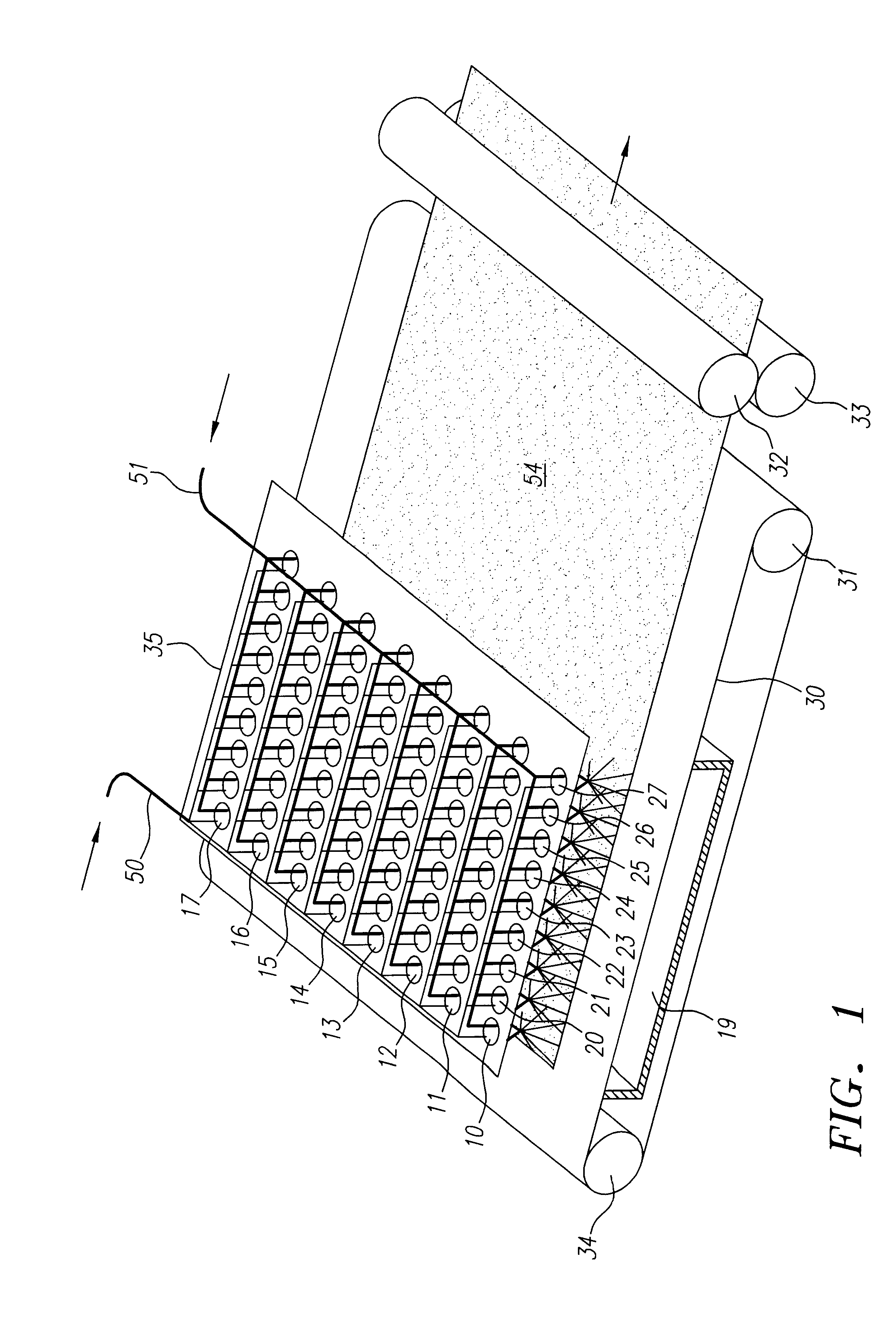

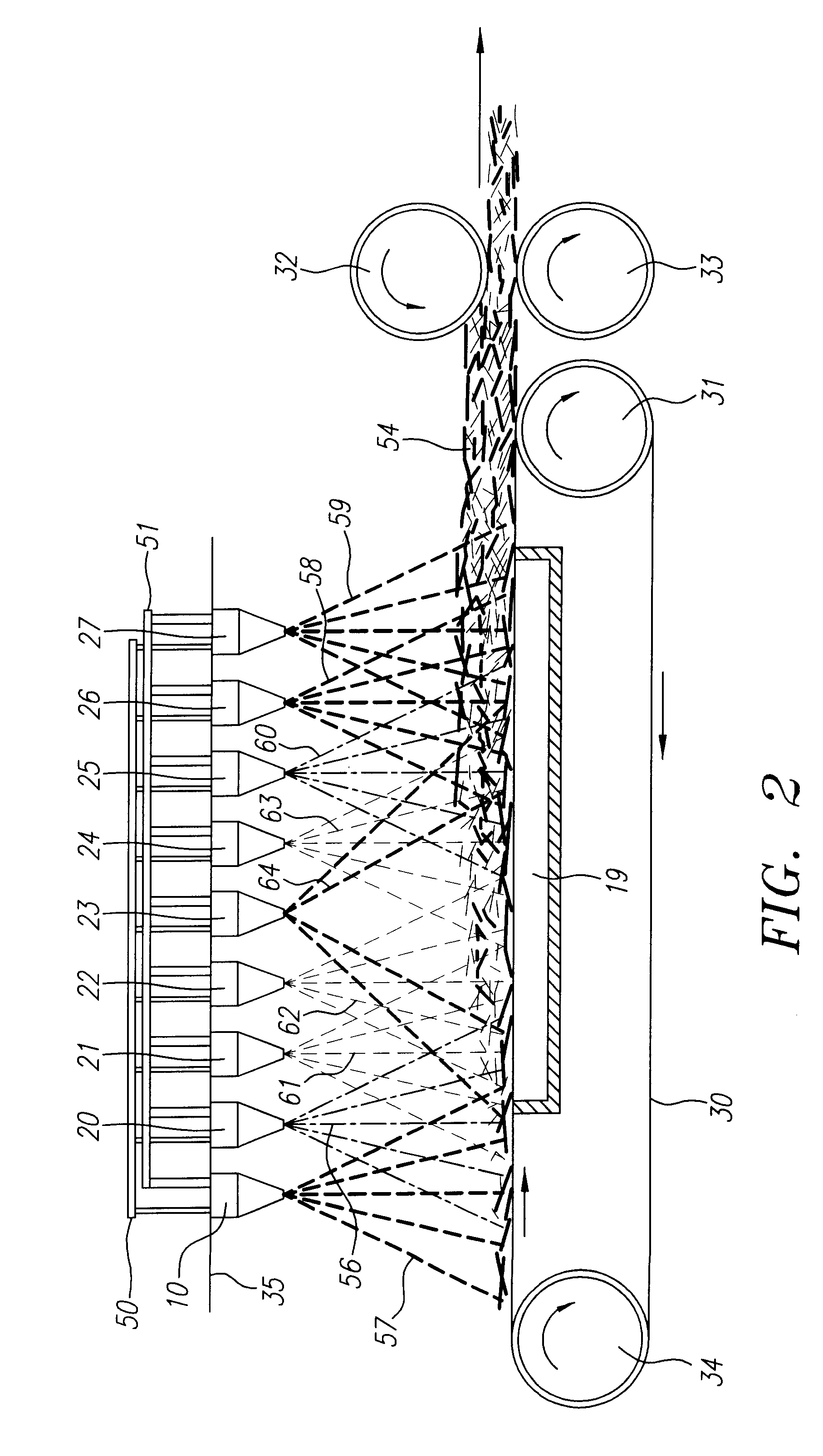

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6183670B1Increase collisionImprove compactionFilament/thread formingAuxillary shaping apparatusMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

Bitumen or asphalt for producing a road topping, road topping and method for the production of bitumen or asphalt

InactiveUS6588974B2Good effectReduction in strengthIn situ pavingsPaving detailsParaffin waxParaffin oils

The invention relates to bitumen or asphalt for producing a road topping, whereby said bitumen or asphalt contains a proportion of paraffin obtained by Fischer-Tropsch synthesis (FT paraffin). The invention also relates to a road topping with said bitumen and to a method for producing a corresponding road topping or roadway / covering using said bitumen.

Owner:SCHUMANN SASOL SOUTH AFRICA

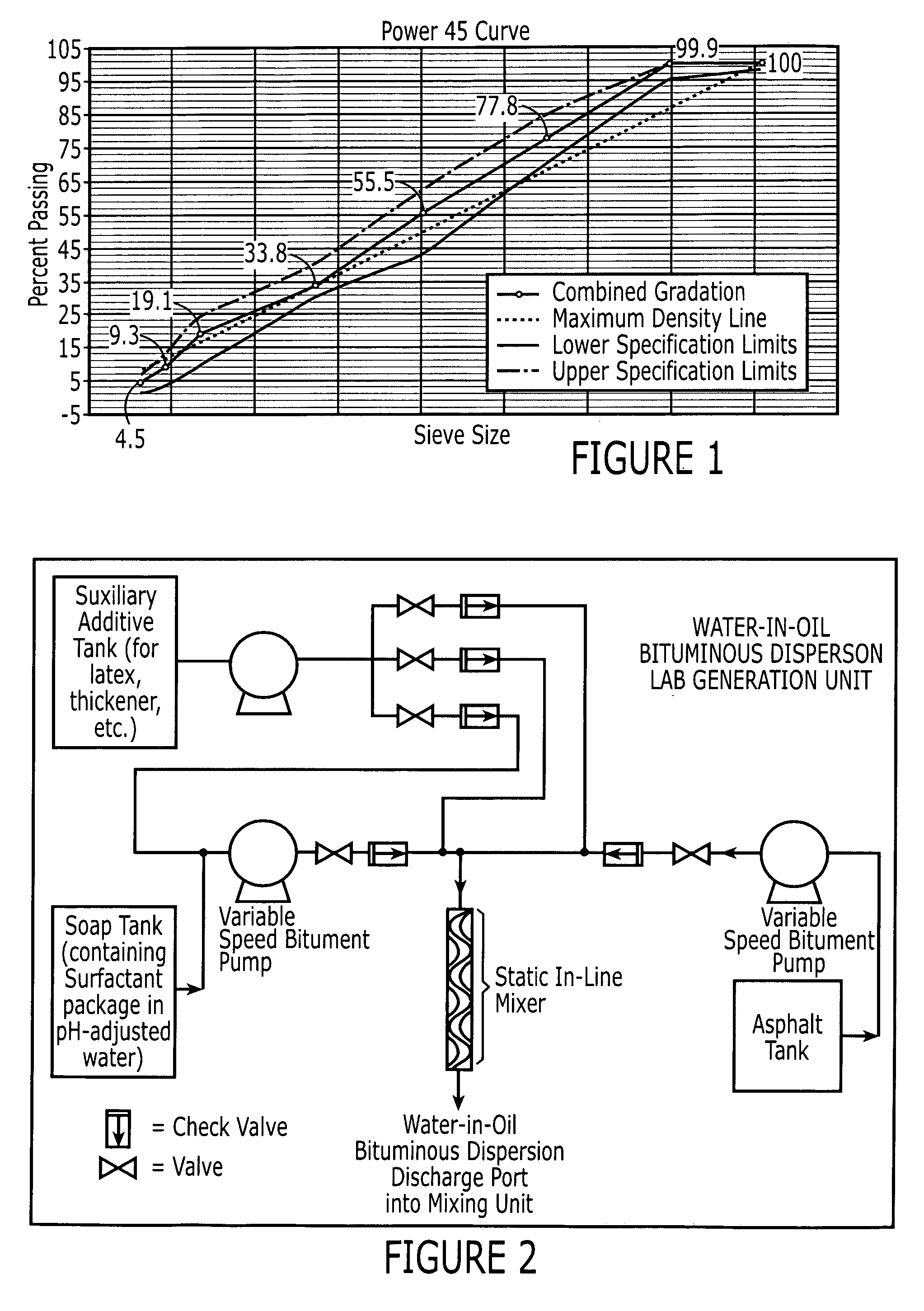

Water-in-oil bituminous dispersions and methods for producing paving compositions from the same

ActiveUS20070082983A1Low viscosityAccelerated strength developmentProductsIn situ pavingsSolvent freeSURFACTANT BLEND

There is provided a method for making bituminous compositions comprising water-in-oil bituminous dispersion and aggregate by the steps of: preparing a solvent-free, water-in-oil bituminous dispersion comprising: (1) bitumen, in an amount from about 75.0% to about 95.0% by total weight of the bitumen dispersion; (2) a surfactant in an amount from about 0.05% to about 2.0% by total weight of the bitumen dispersion; and (3) water in an amount to complete the water-in-oil bituminous dispersion, and producing the bituminous composition having a temperature from about 50° C. to about 120° C. by mixing: (1) the water-in-oil bituminous dispersion of step (A), having a temperature from about 75° C. to about 95° C., in an amount from about 2.0% to about 10.0% by total weight of the bituminous composition, and (2) aggregate, having a temperature from about 60° C. to about 140° C., in an amount from about 90.0% to about 98.0% by total weight of the bituminous composition.

Owner:INGEVITY SOUTH CAROLINA

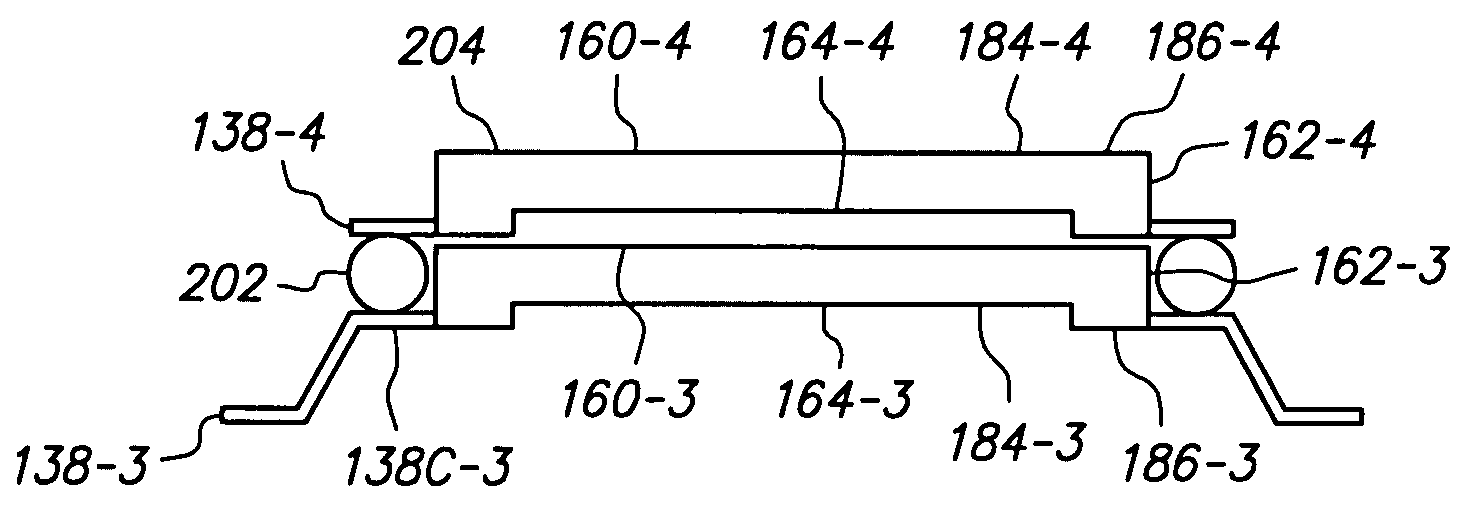

Three-dimensional stacked semiconductor package device with bent and flat leads and method of making same

InactiveUS7190060B1Easy to manufactureReduce spacingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A three-dimensional stacked semiconductor package device includes first and second semiconductor package devices and a conductive bond. The first device includes a first insulative housing, a first semiconductor chip and a first lead that is bent outside the first insulative housing. The second device includes a second insulative housing, a second semiconductor chip and a second lead that is flat outside the second insulative housing. The conductive bond contacts and electrically connects the leads.

Owner:BRIDGE SEMICON

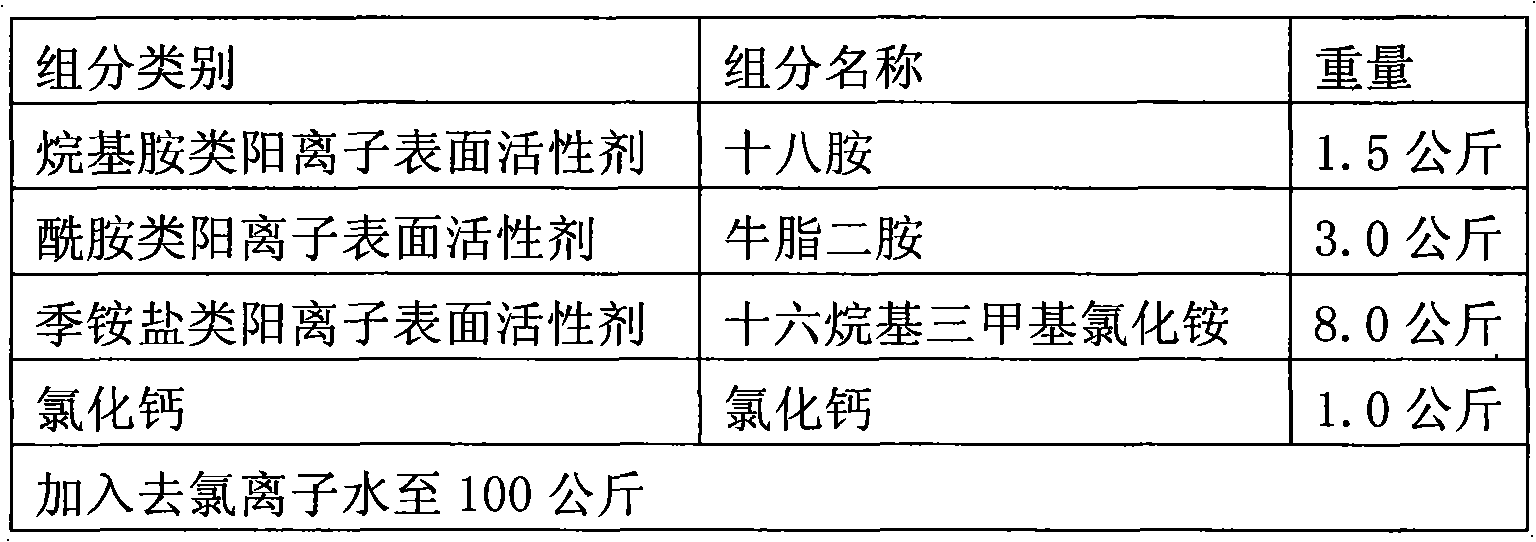

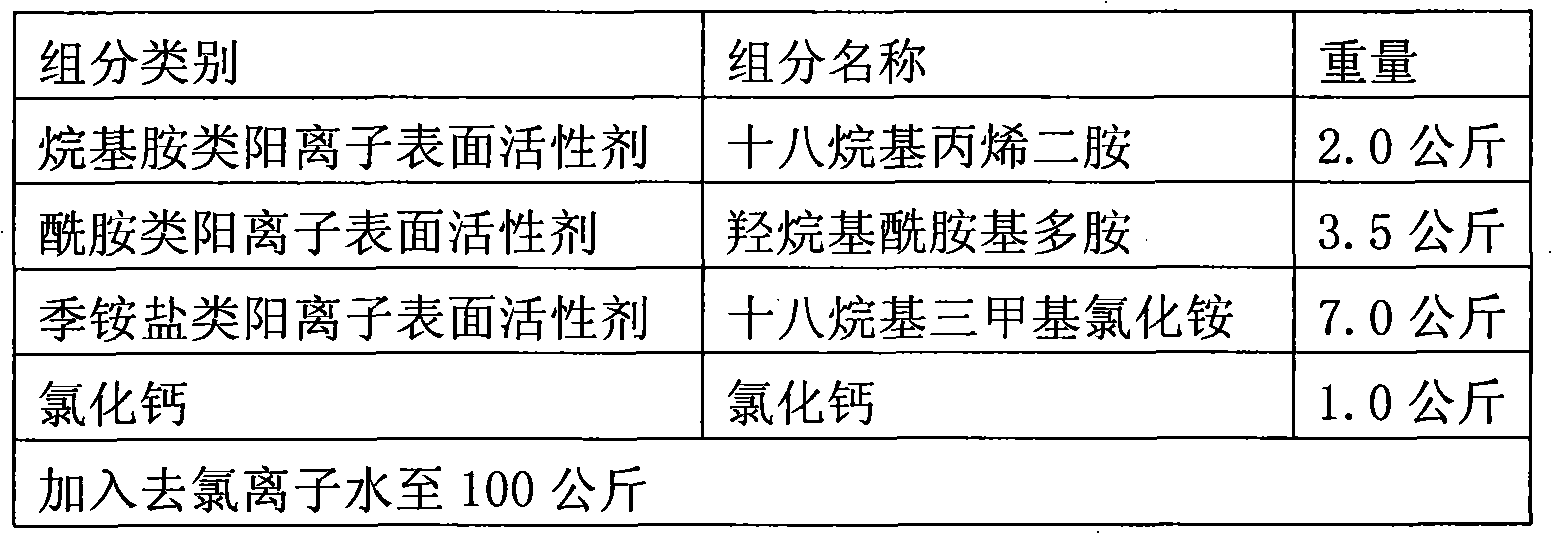

Asphalt warm-mix agent and asphalt mixture mixed by same as well as preparation methods thereof

ActiveCN101899218AWith viscosity reductionWith foamClimate change adaptationBuilding insulationsChlorideRoad surface

The invention relates to an asphalt warm-mix agent, comprising the following components in percentage by weight: 1.0-2.0% of alkylamine type cationic surfactant, 3.0-5.0% of amide type cationic surfactant, 5.0-10.0% of ammonium salt type cationic surfactant, 1.01.5% of calcium chloride, and water with residual percentage. The invention also relates to an asphalt mixture with the pavement applicability basically same as the traditional hot-mix asphalt mixture and the mixing and construction temperature lower than 20-50 DEG C; the purposes of energy saving, emission reduction, longer construction season, asphalt aging reduction and easier compaction are realized by reducing the mixing temperature; the indexes of the compaction degree, the water stability, the high-temperature performance, the low-temperature performance and the like of the pavement after paving the asphalt are not lower than those of hot-mix asphalt mixture at the same stage; and the service life of the asphalt pavement is efficiently guaranteed.

Owner:天津市市政工程研究院 +1

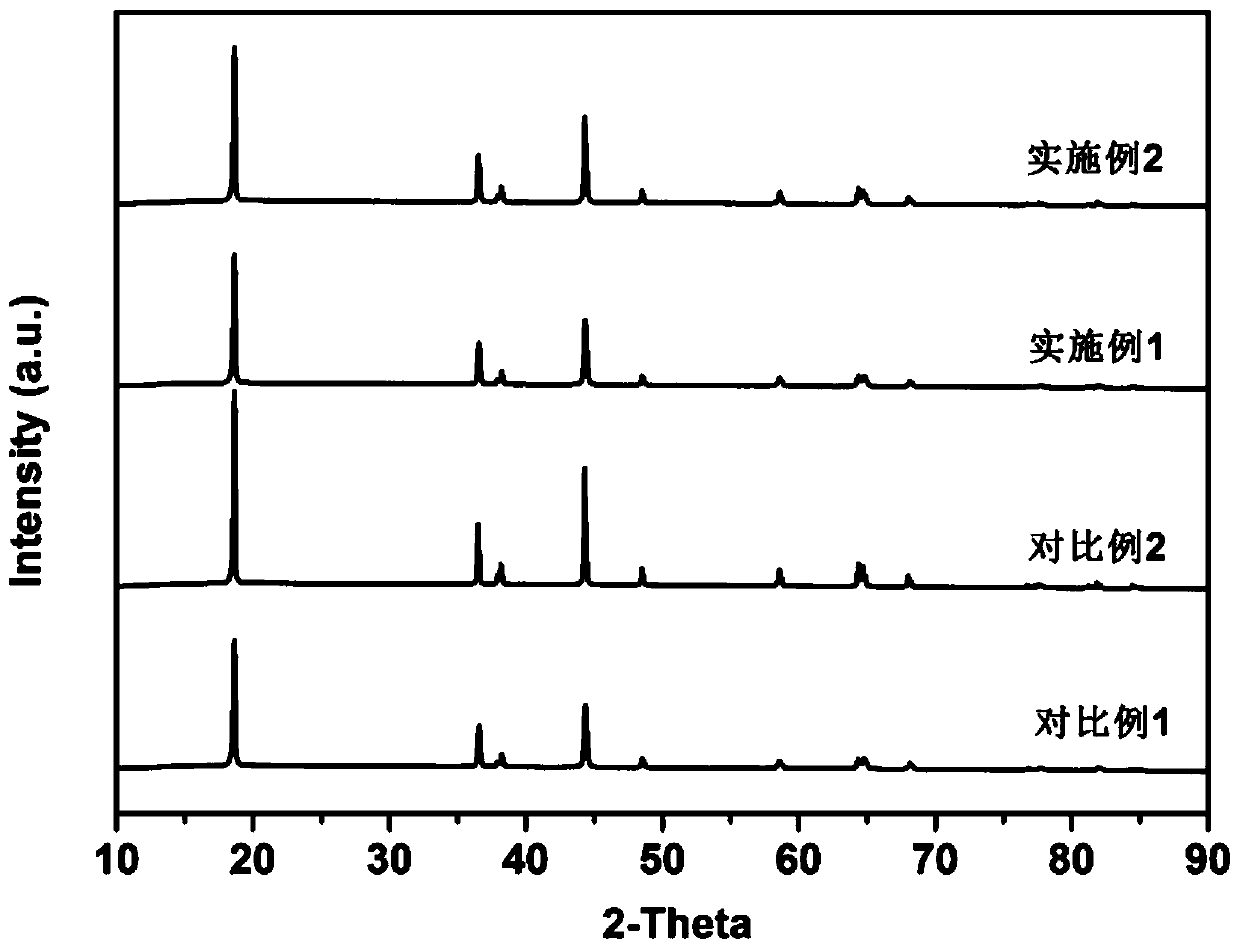

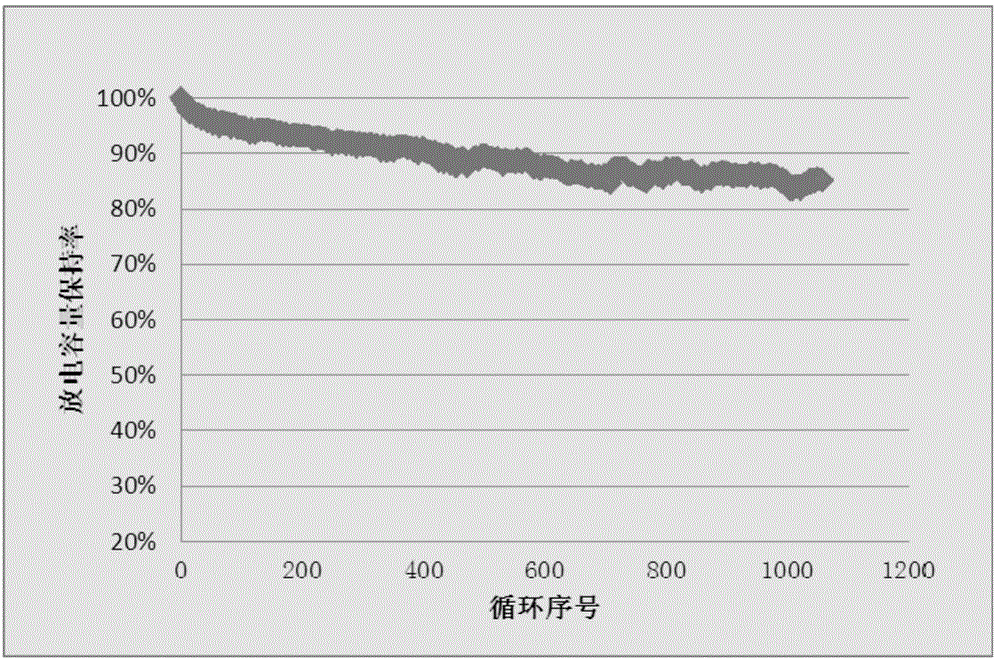

Graded high-nickel ternary anode material, and preparation method and application thereof

InactiveCN109888235AImprove compactionImprove cycle stabilityCell electrodesSecondary cellsSingle crystalMixed materials

The invention discloses a graded high-nickel ternary anode material, and a preparation method and an application thereof. The graded high-nickel ternary anode material is prepared by the following method: 1) mixing a high-nickel polycrystalline precursor with anhydrous LiOH and a doping additive, performing sintering, mixing the obtained product with a coating additive, and performing sintering toobtain a high-nickel polycrystalline material; 2) mixing a ternary monocrystalline silicon precursor with a lithium source and the doping additive, performing sintering, mixing the obtained product with the coating additive, and performing sintering to obtain a ternary monocrystalline silicon material; and 3) mixing the high-nickel polycrystalline material with the ternary monocrystalline siliconmaterial, or mixing the mixed material with the coating additive, and then performing sintering. The invention further discloses an application of the graded high-nickel ternary anode material in lithium batteries. The graded material prepared by the method provided by the invention has higher compaction and cycle stability than the single polycrystalline material, has higher capacity than the single monocrystalline silicon, and the gas production and service life problems of the battery can be effectively improved after the grading modification.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

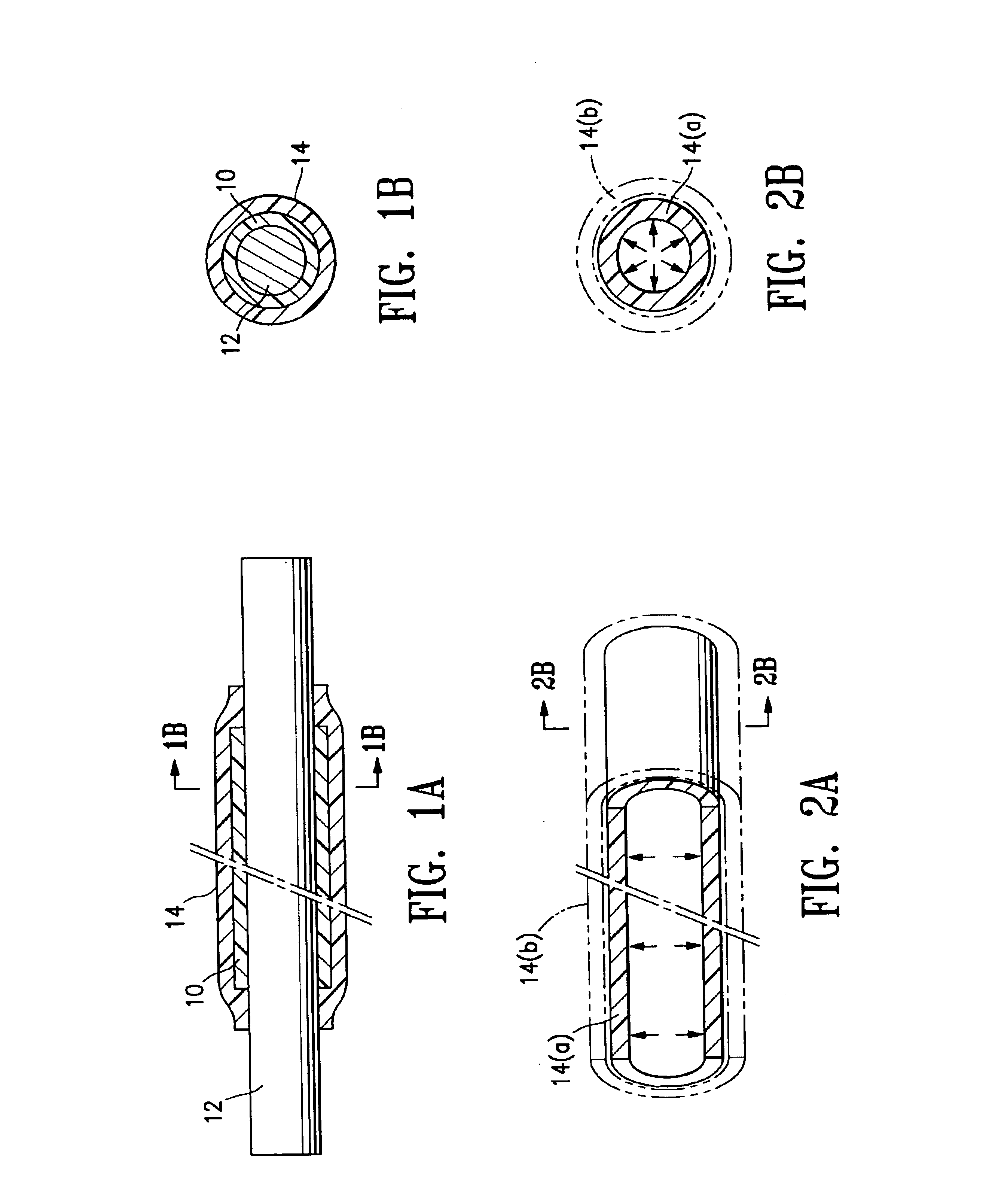

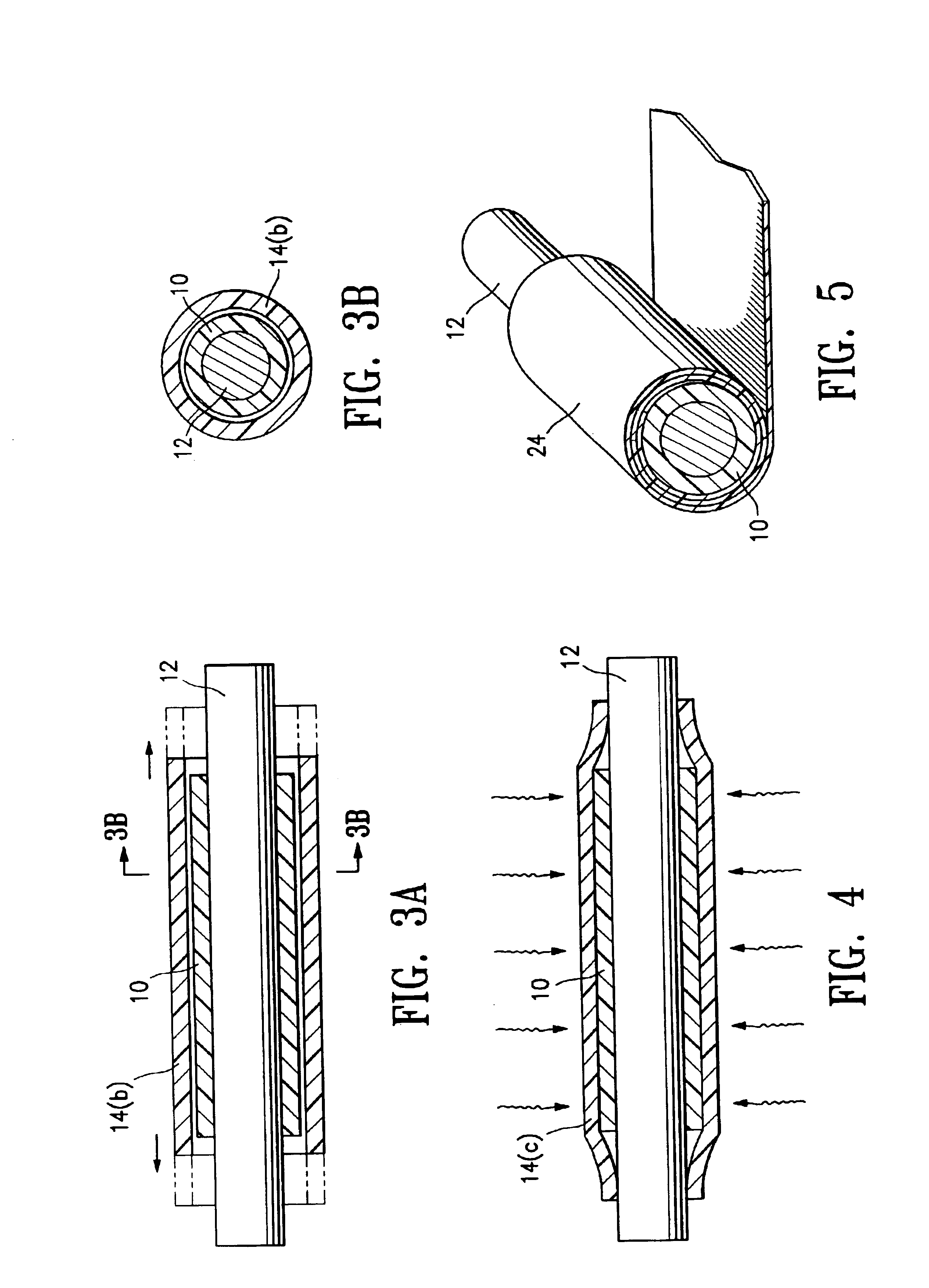

Method of making an expandable medical device formed of a compacted porous polymeric material

InactiveUS6863757B1Easy to manufactureBroaden applicationLaminationLamination apparatusCatheterMedical device

A method of making a catheter balloon or other expandable tubular medical device or component thereof formed of a compacted porous polymeric material, in which a tube of porous polymeric material is axially compacted, preferably without increasing the outer diameter of the tube, by positioning heat shrink material on the porous polymeric tube and heating the heat shrink material to decrease the length and diameter of the heat shrink material.

Owner:ABBOTT CARDIOVASCULAR

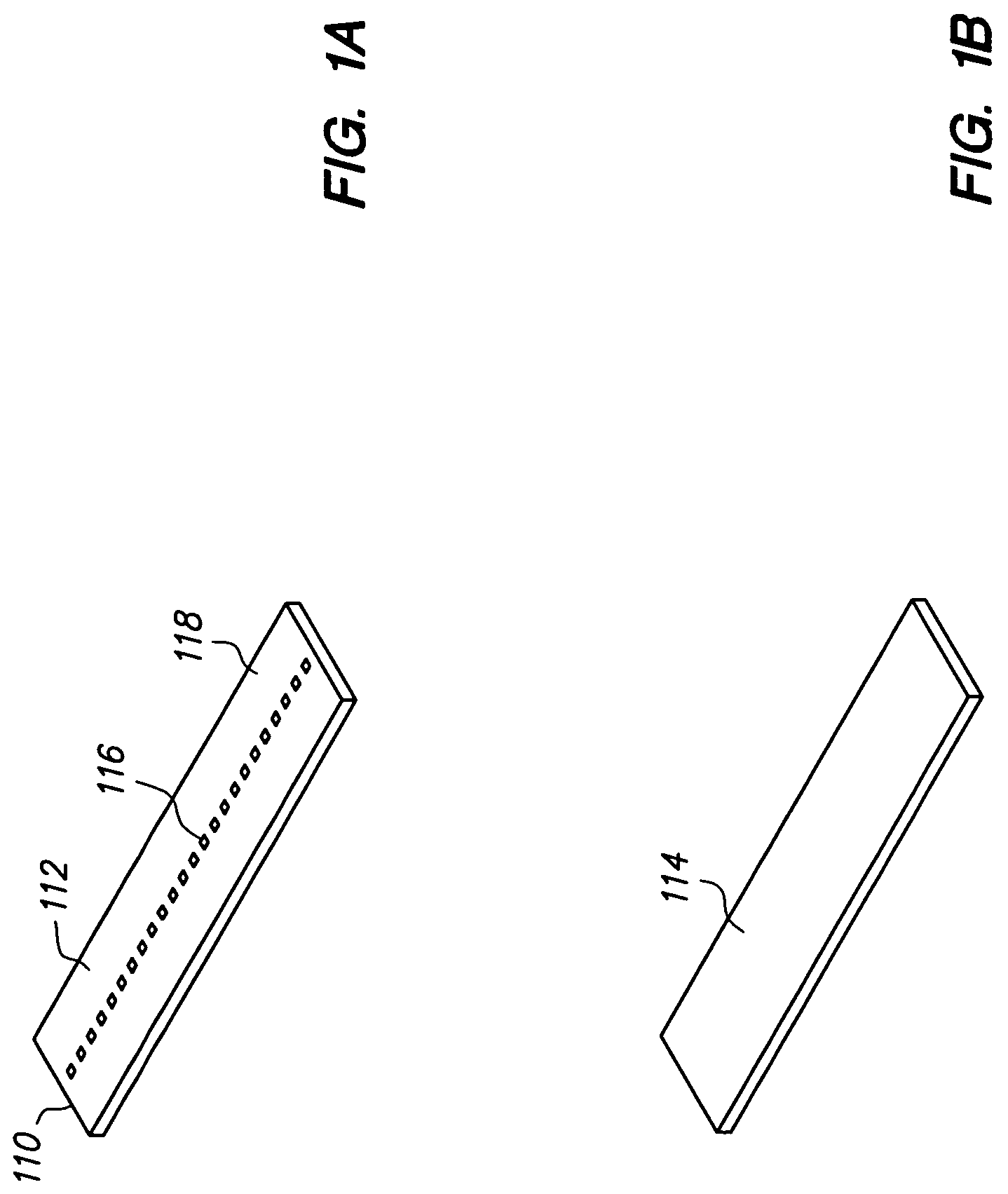

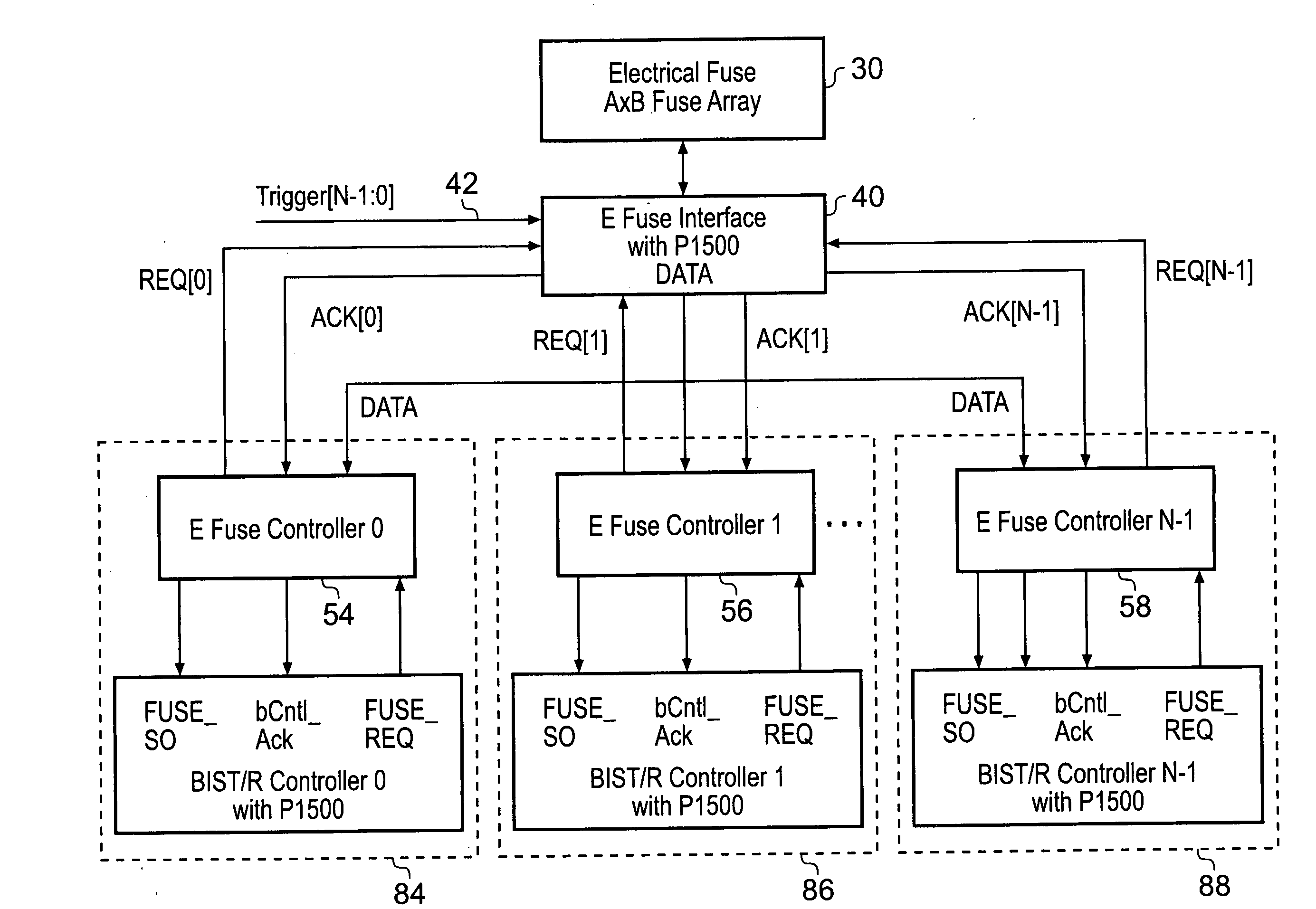

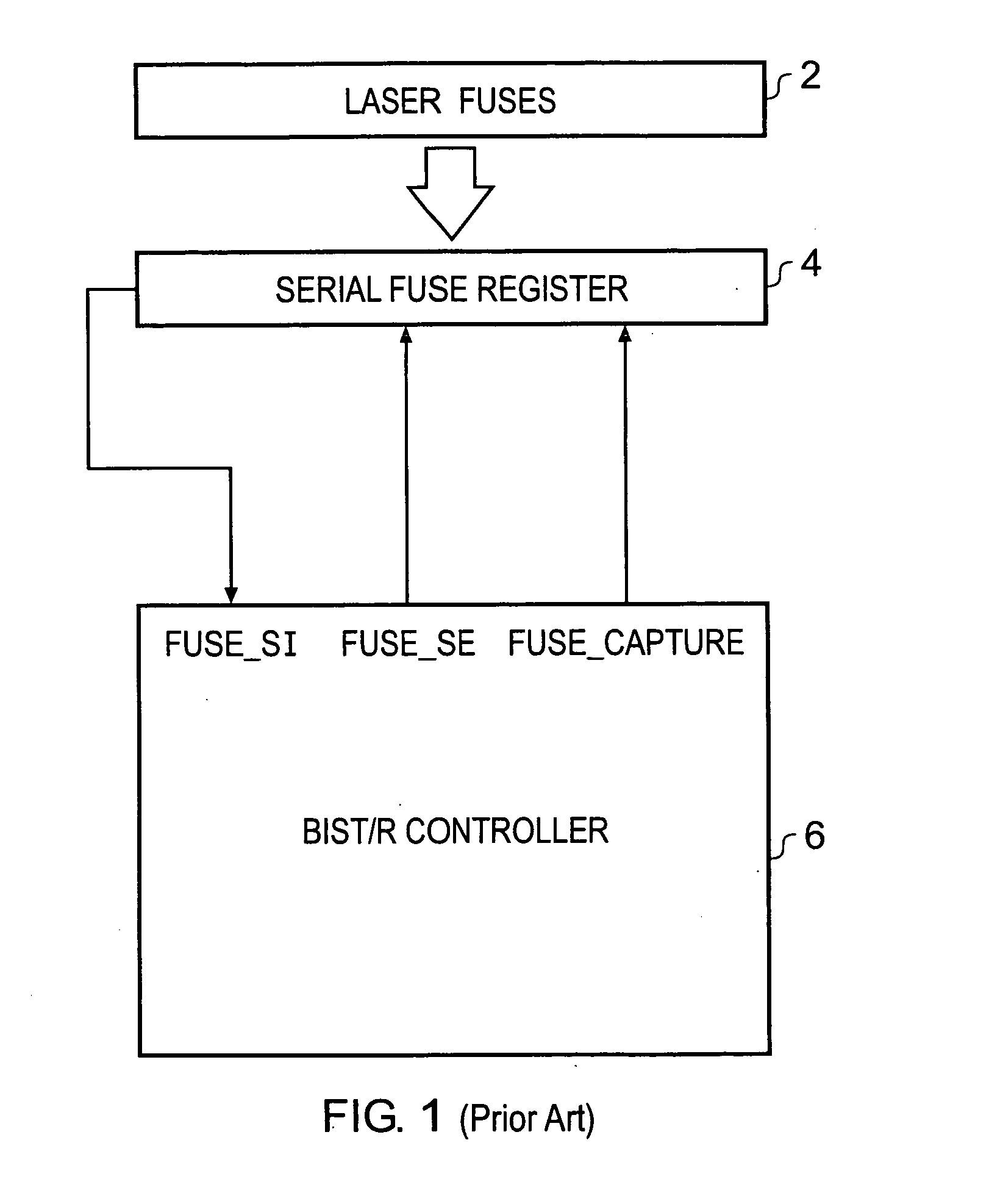

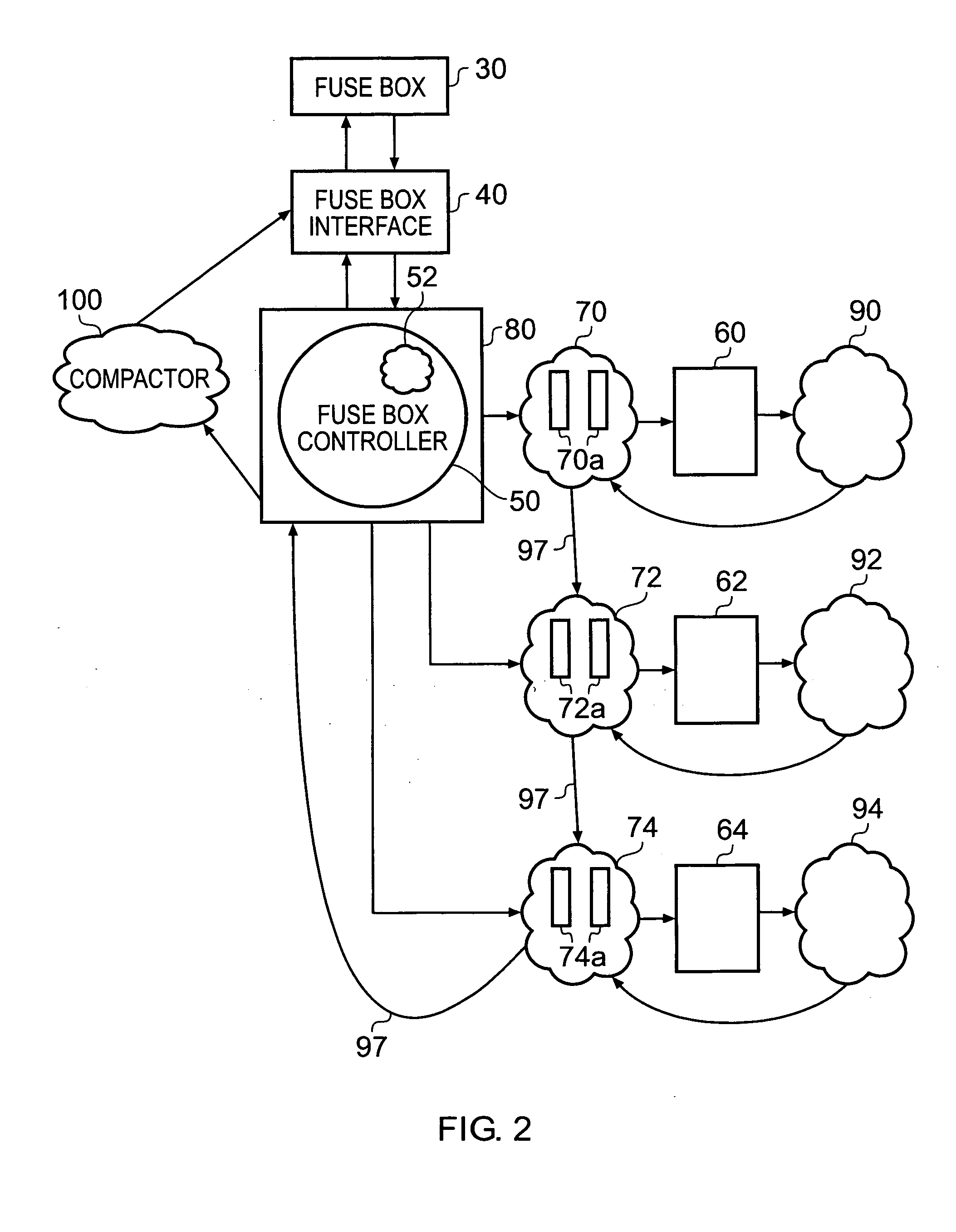

Electronic fuses

ActiveUS20090190422A1Few transmissionOptimize dataElectronic circuit testingRead-only memoriesData storingIntegrated circuit

The application discloses an integrated circuit comprising: circuitry; a fusebox for storing an array of data identifying faulty elements within said circuitry; at least one fusebox controller for repairing said faulty elements in said circuitry in response to data received from said fusebox; a data communication path linking said fusebox controller with said fusebox; wherein said data stored in said fusebox is compacted data and said at least one fusebox controller comprises a data expander for expanding said compacted data received from said fusebox via said data communication path prior to repairing any faulty elements in said circuitry.

Owner:ARM LTD

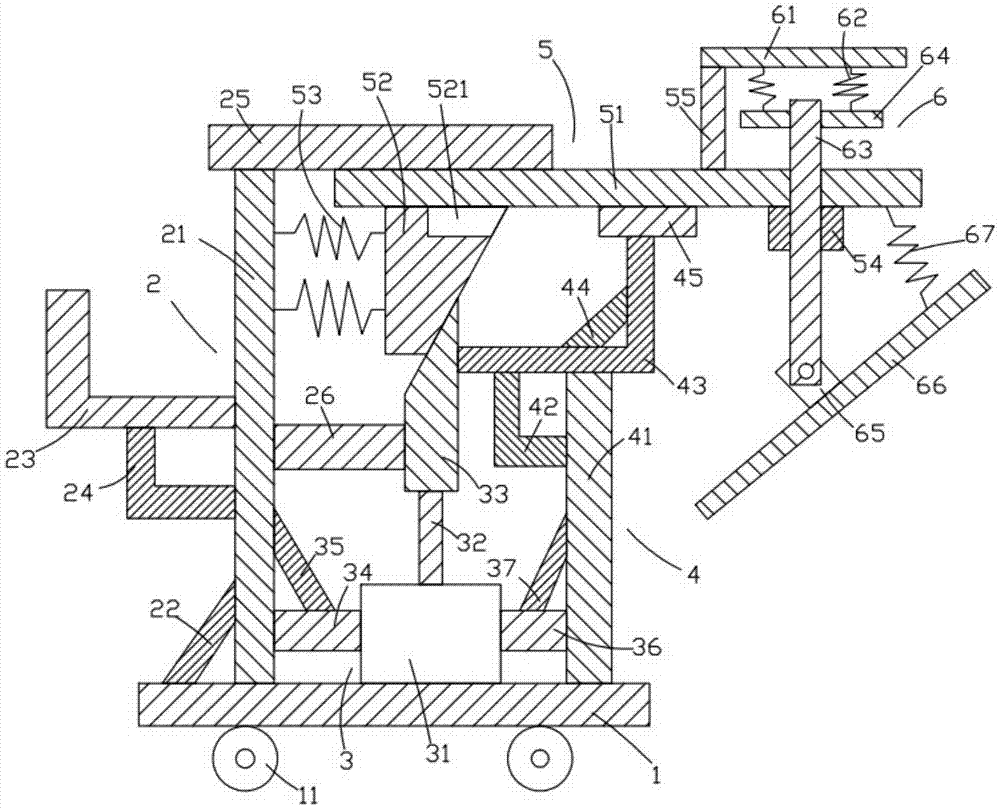

Multifunctional tamping machine

The invention discloses a multifunctional tamping machine which comprises a bottom plate, a first bracket device, a cylinder device, a second bracket device, a mobile device and a compaction device, wherein a rolling wheel is arranged on the bottom plate; the first bracket device is composed of a first supporting rod, a first slanting rod, a holding frame, a first bracket, a first positioning rod and a first transverse rod; the cylinder device is composed of a cylinder, a push rod, a push block, a second transverse rod, a second slanting rod, a third transverse rod and a third slanting rod; the second bracket device is composed of a second supporting rod, a second bracket, a third bracket, a fourth slanting rod and a first sliding block; the mobile device is composed of a mobile rod, a fixed block, a first spring, a buffer ring and a first vertical rod; and the compaction device is composed of a horizontal plate, a second spring, a fourth transverse rod, a second vertical rod, a rotational block, a compaction plate and a third spring. The multifunctional tamping machine can rapidly and effectively compact the inclined surface, is remarkable in compaction effect and good in effect, can completely meet the needs for existing small-sized compaction and ensures the construction efficiency to be greatly improved.

Owner:中建路桥集团第六工程有限公司

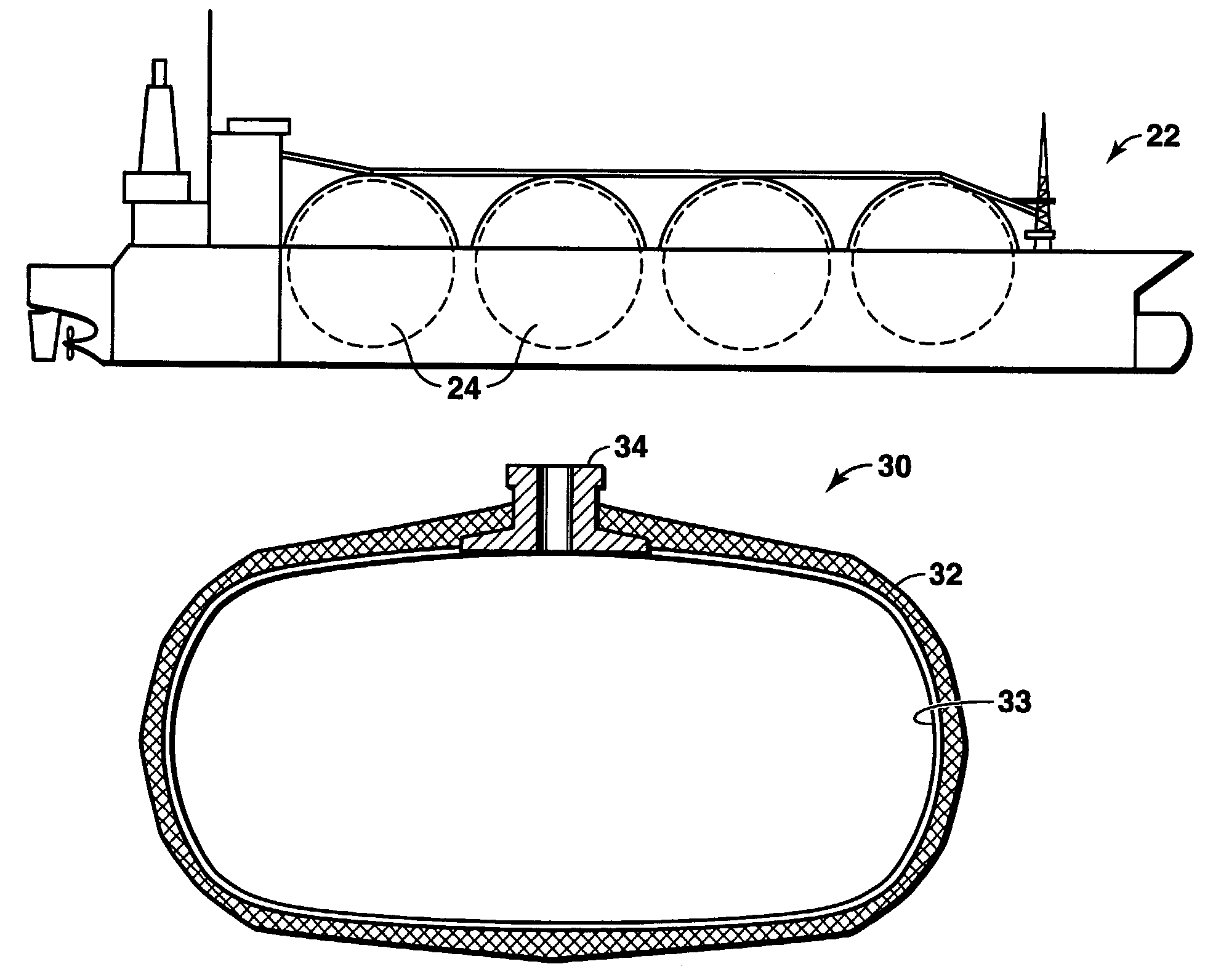

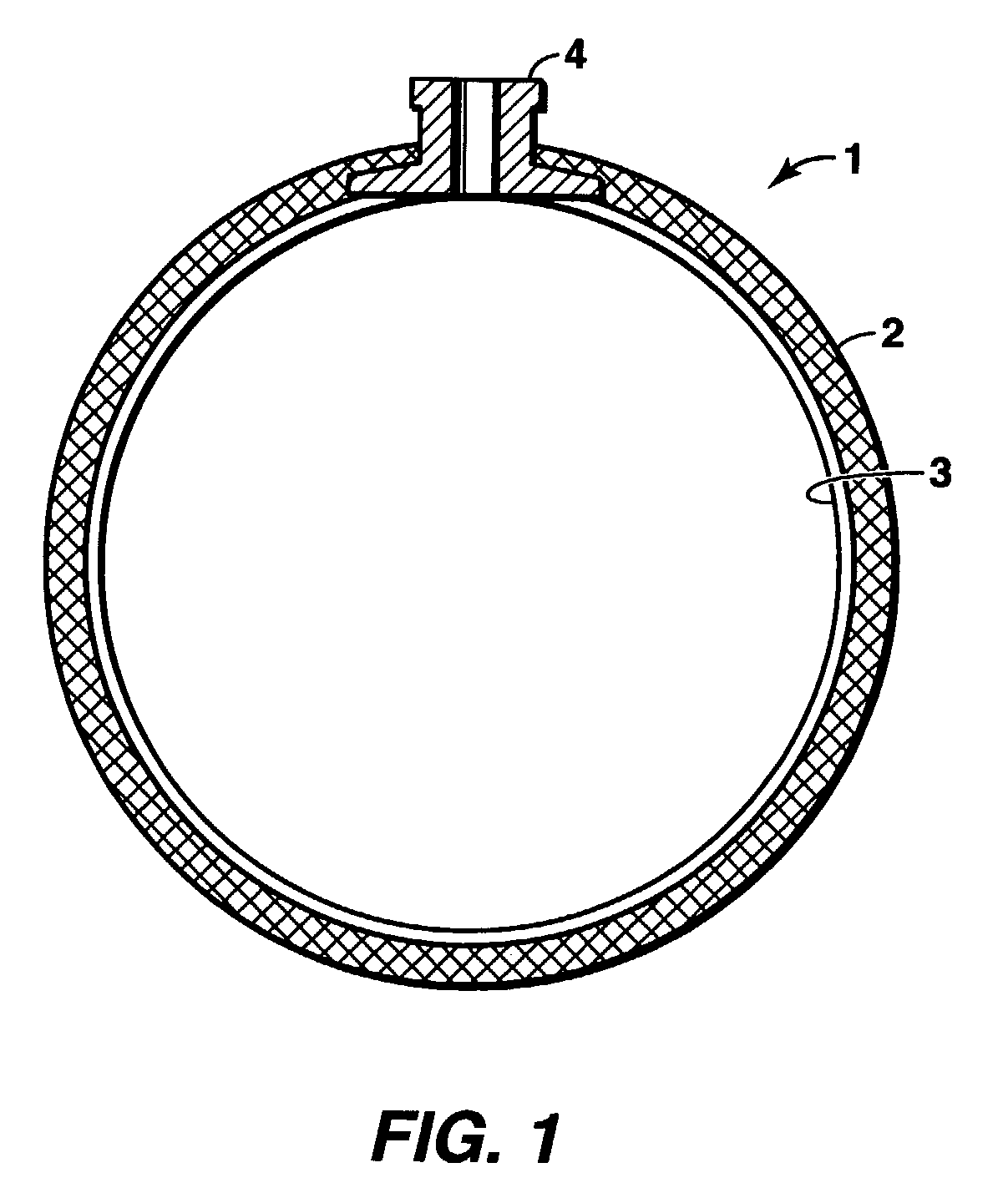

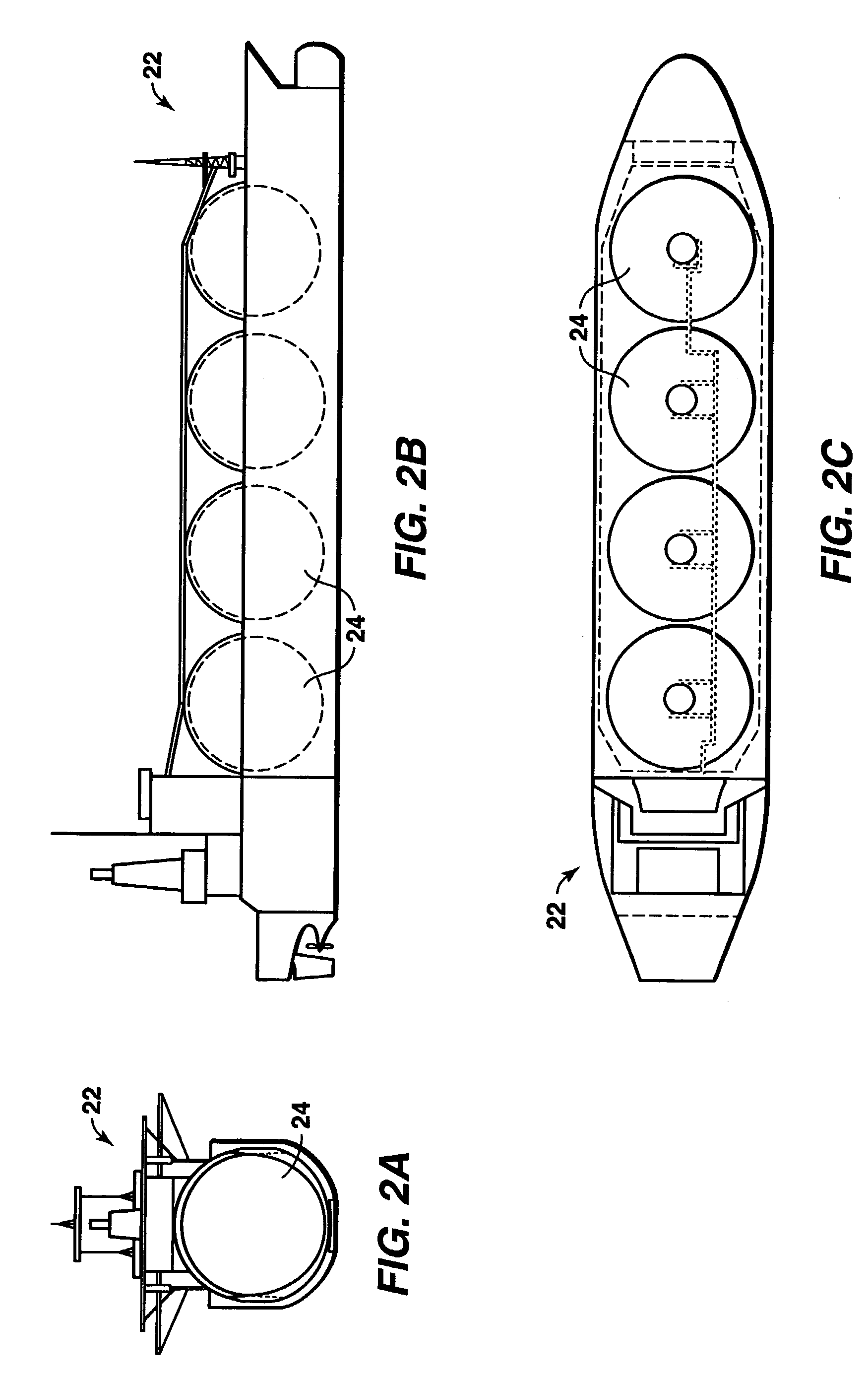

Containers and methods for containing pressurized fluids using reinforced fibers and methods for making such containers

InactiveUS7147124B2Improve creep performanceImprove compactionVessel mounting detailsVessel manufacturingFiberPolymer science

Containers suitable for storing pressurized fluids at cryogenic temperatures of −62° C. (−80° F.) and colder are provided and comprise a self-supporting liner and load-bearing composite overwrap, whereby means are provided for substantially preventing failure of the container during temperature changes.

Owner:EXXONMOBIL UPSTREAM RES CO

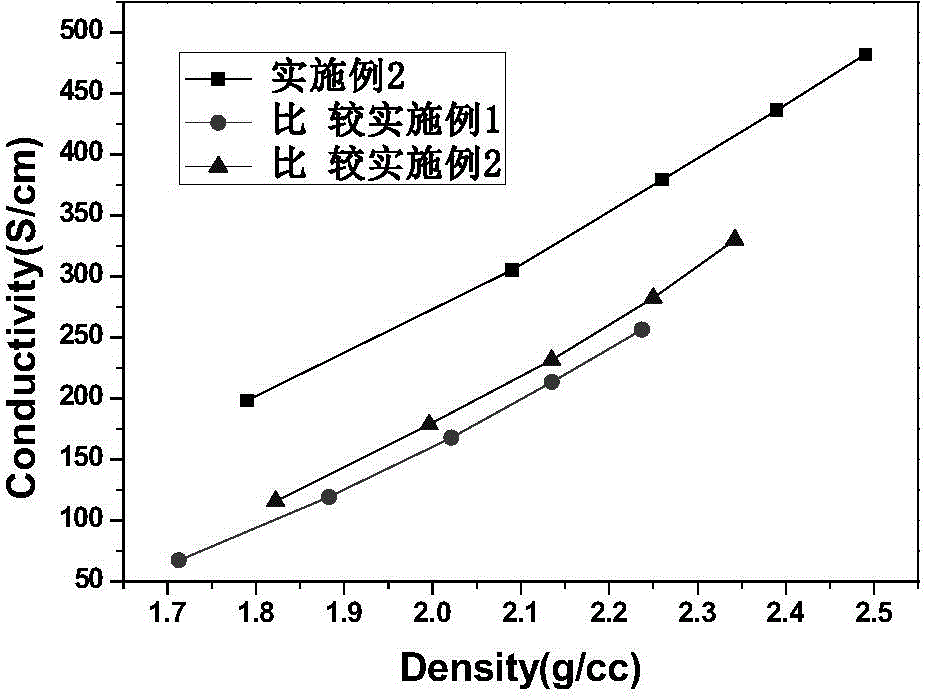

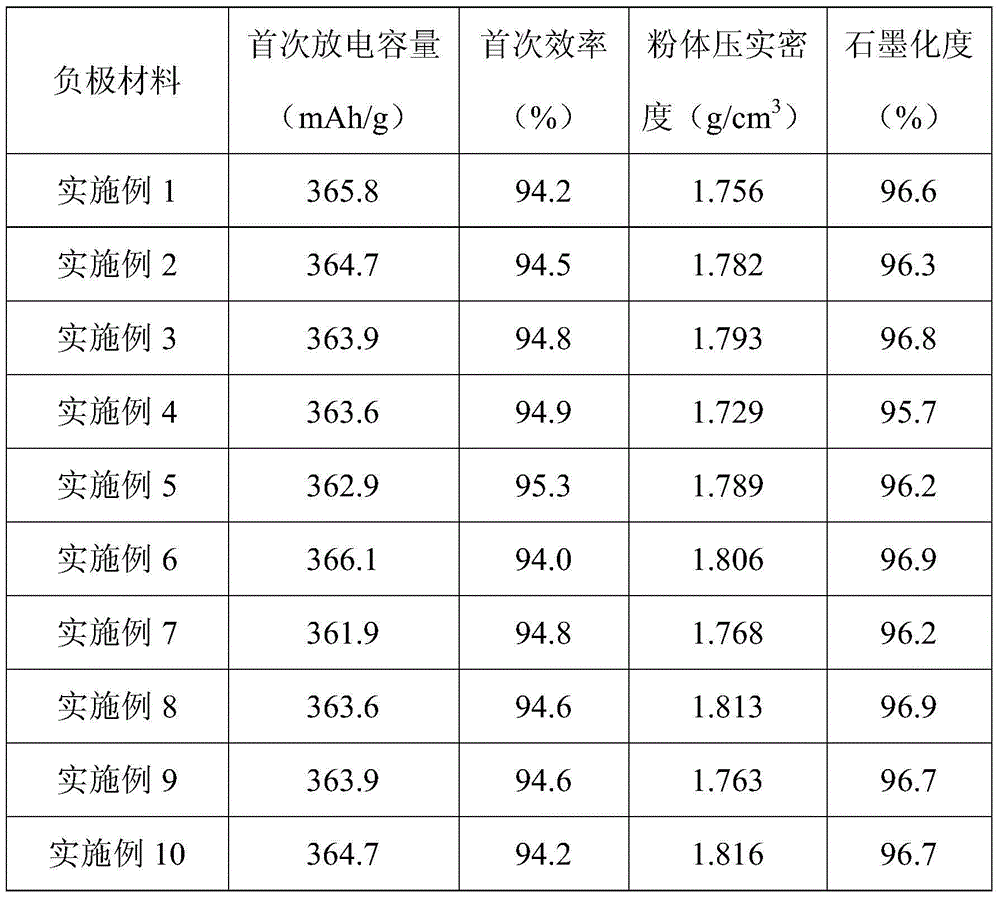

Artificial graphite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN104085883AImprove cycle lifeImprove the degree of graphitizationCell electrodesSecondary cellsCompression moldingAluminium-ion battery

The invention discloses an artificial graphite negative electrode material for a lithium ion battery and a preparation method thereof. The preparation method for the artificial graphite negative electrode material comprises the following steps: preparing powder, adding a binder and / or a crystal nucleus-induced growth additive, kneading, carrying out compression molding, thermally roasting, carrying out nodulizing shaping and / or fusing, carrying out ultrahigh-temperature graphitization, screening, removing magnetism and screening. The preparation method disclosed by the invention is simple to operate, easy to control, lower in production cost and suitable for industrial production. The prepared artificial graphite negative electrode material has high graphitization degree, high compactness, high capacity, high coulombic efficiency, high conductivity and high multiplying power, and can be used for the lithium ion battery.

Owner:贝特瑞(江苏)新材料科技有限公司

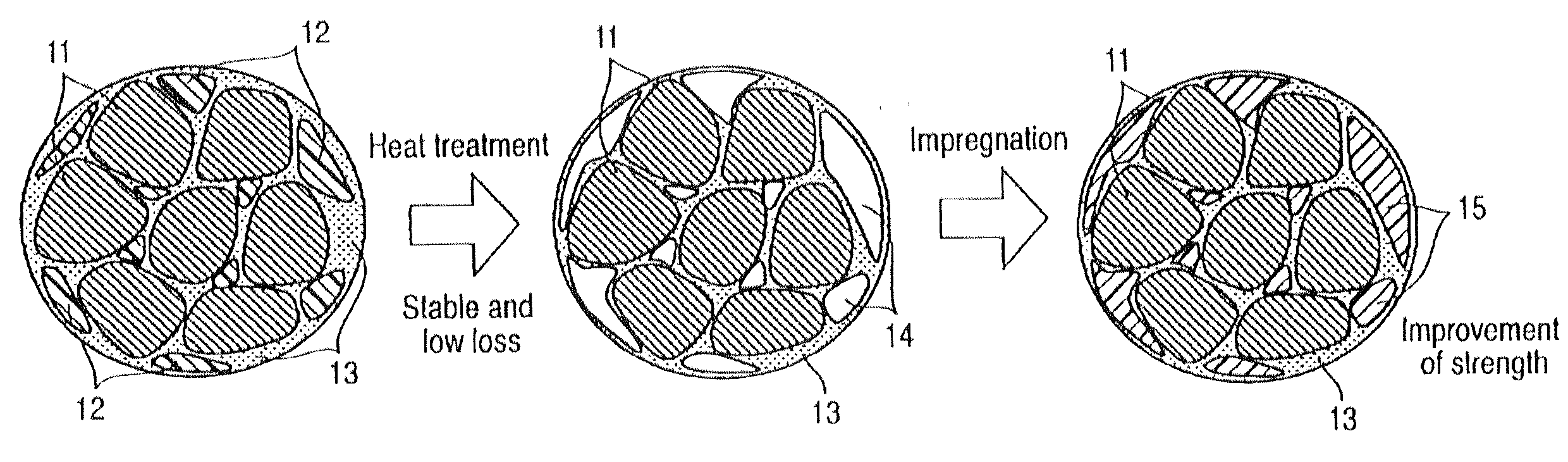

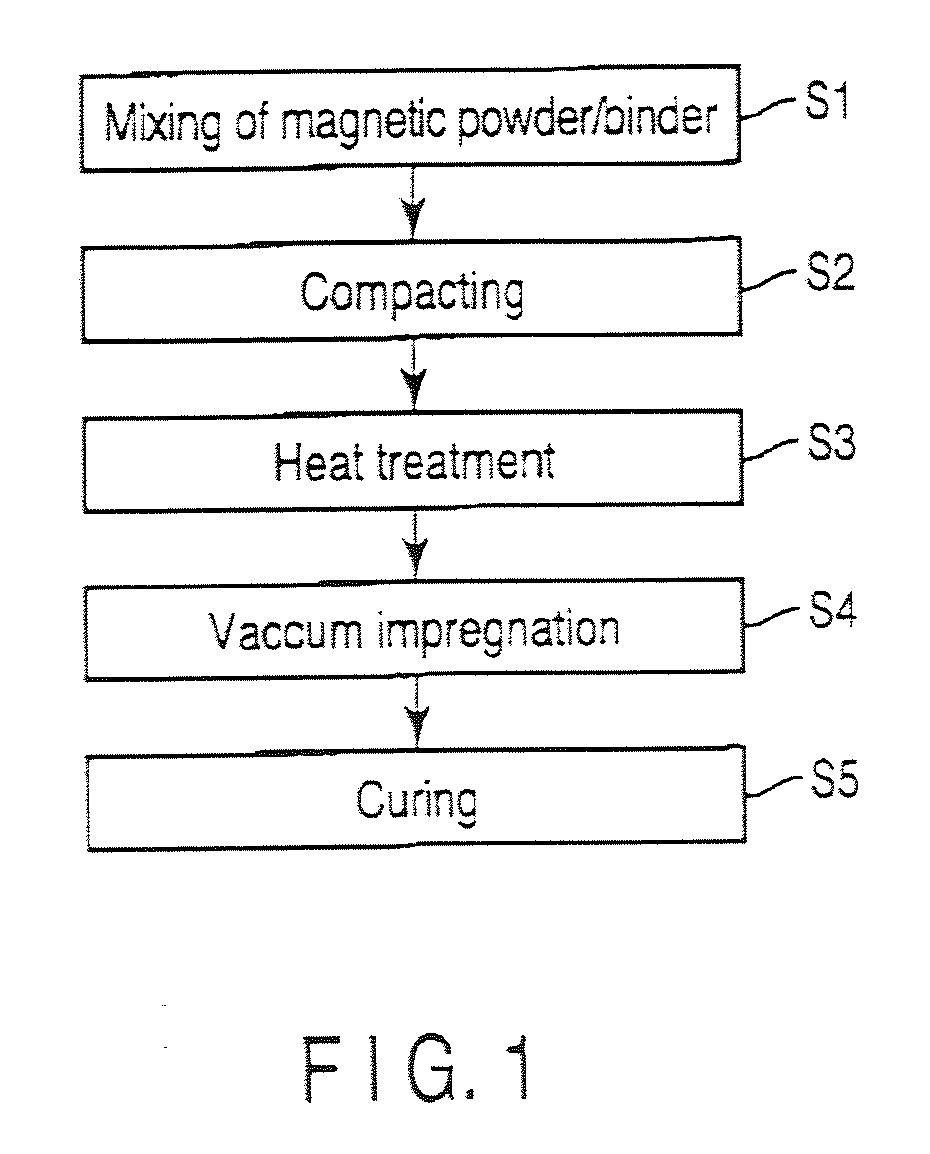

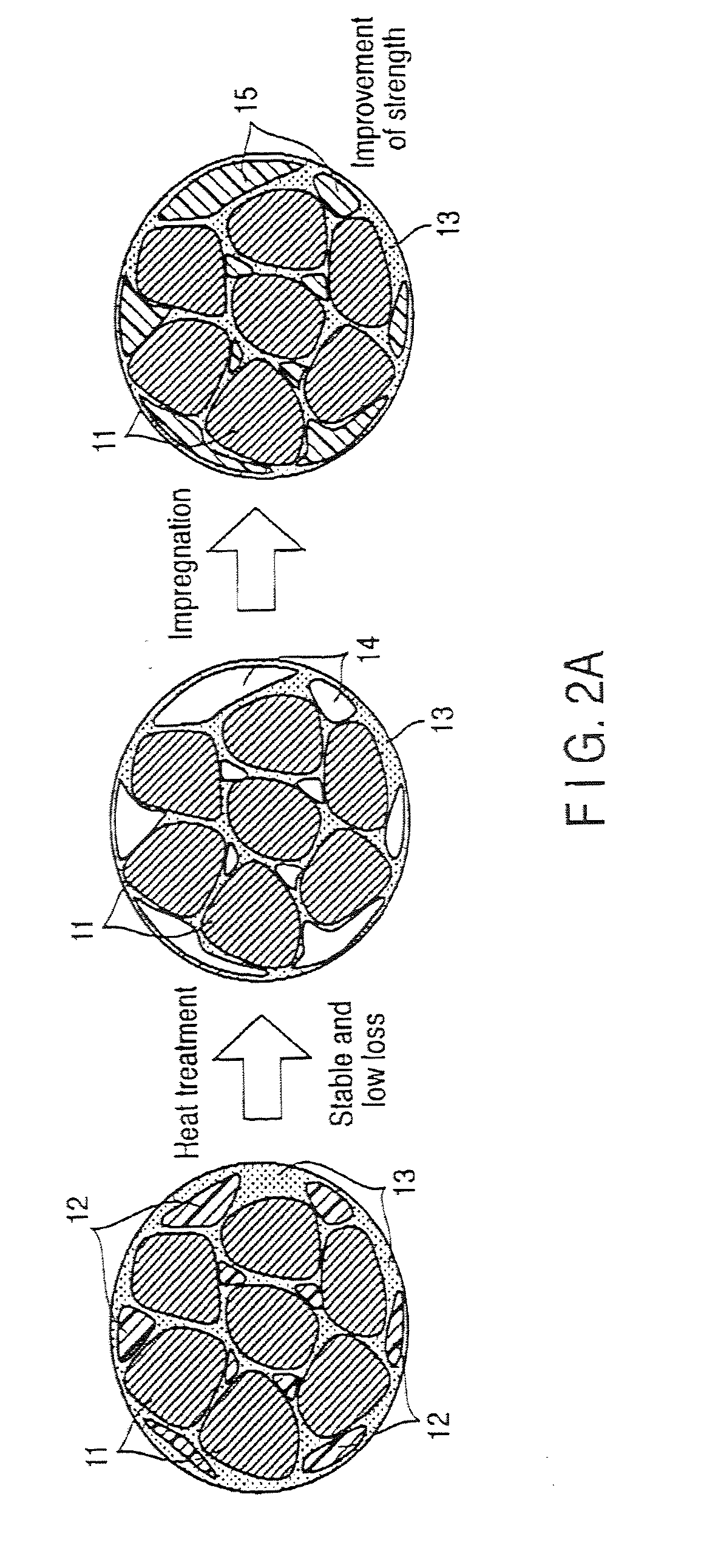

Composite magnetic material and method of manufacturing the same

InactiveUS20110024670A1Good molding effectReduce the amount requiredTransportation and packagingMetal-working apparatusSpherical shapedInductor

Certain embodiments provide a composite magnetic material for an inductor, wherein a non-magnetic material contains a first binder as a compacting additive, and is added to and mixed with the soft magnetic metal powder, and a second binder that is impregnated to a compact as a binder after the heat treatment of the compact obtained by adding the first binder to the soft magnetic metal powder and compacting it, and the soft magnetic metal powder contains 40% by mass or more (including 100%) of spherical particles of which the ratio L2 / L1 between a perimeter L1 of a particle cross-section in the two dimensional plane view and a perimeter L2 of a circle having equivalent cross-sectional area is 0.5 or more.

Owner:TOHO ZINC

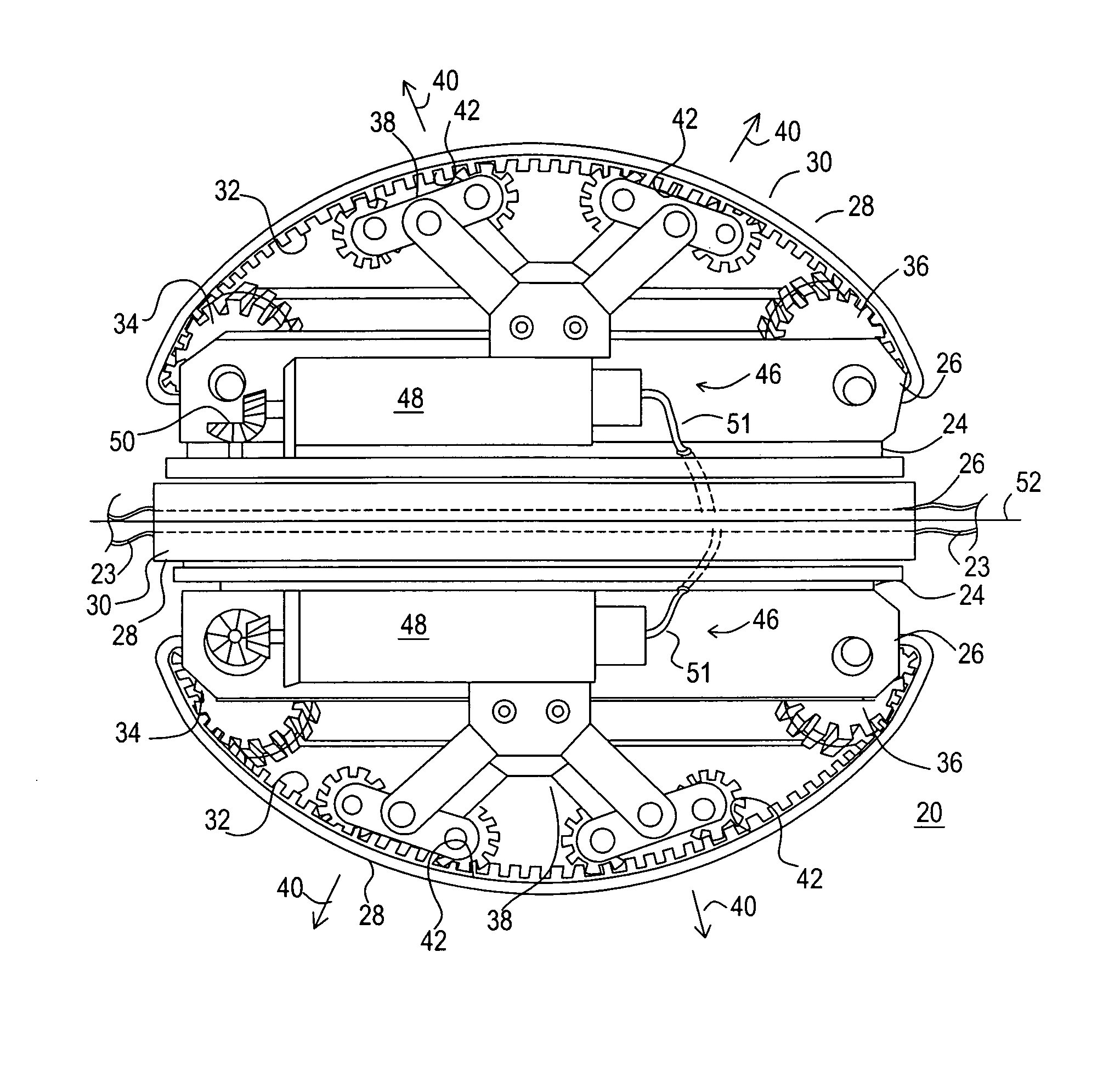

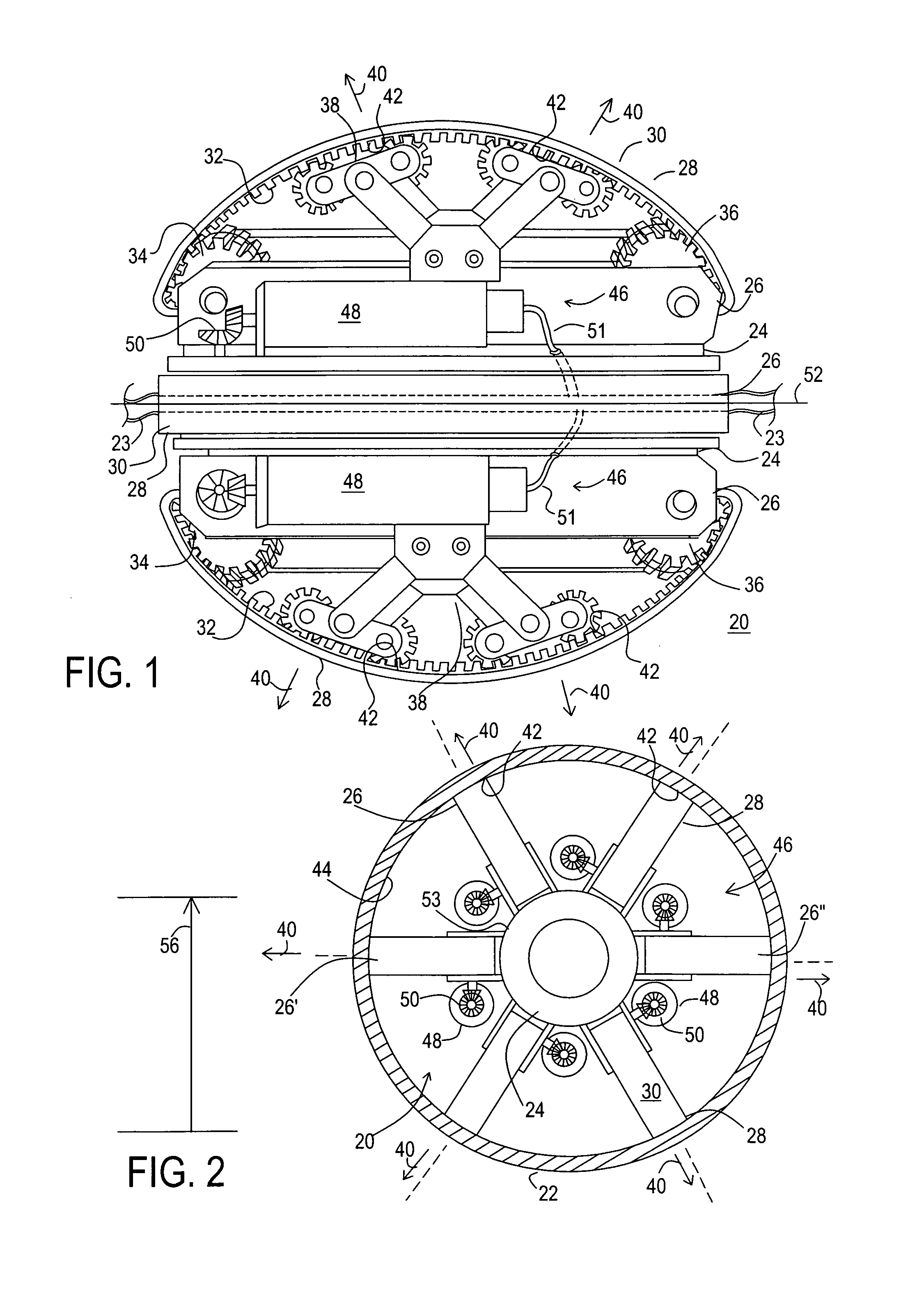

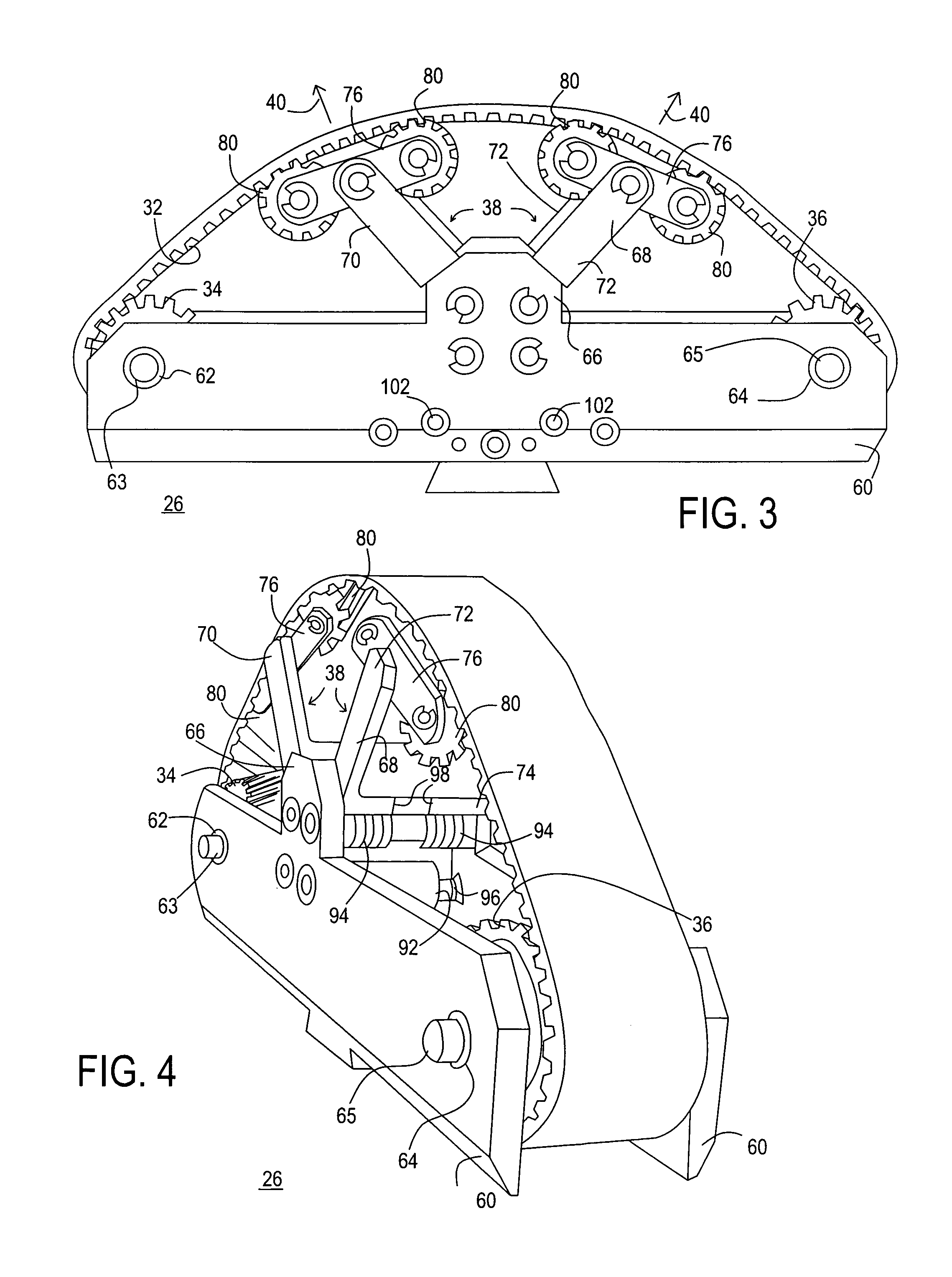

Self-propelled vehicle for movement within a tubular member

InactiveUS7188568B2Sufficient forceEasy to operateRailway tunnelsRailway componentsEngineeringPulley

A self-propelled vehicle (20) for movement within a tubular member (22) includes propulsion mechanisms (28) distributed about a core element (24). Each of the propulsion mechanisms (28) includes a drive belt (28). A first pulley (34), a second pulley (36), and a mid-roller assembly (38) are encompassed by and engage the drive belt (28). The mid-roller assembly (38) is spring-loaded for providing an outwardly-directed force (40) to an underlying portion (42) of the drive belt (28) to press the drive belt (28) against an inner wall (44) of the tubular member (22). A motor arrangement (46), in communication with the propulsion mechanisms (28), actuates one of the first and second pulleys (34, 36) to rotate the drive belt (28) in contact with the inner wall (44) of the tubular member (22) thereby moving the vehicle (20) within the tubular member (22).

Owner:ARIZONA PUBLIC SERVICE

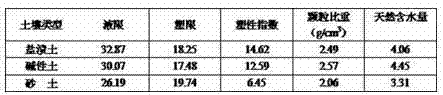

Saline-alkali soil fertilizer

ActiveCN102775250AIncrease productionImprove compactionFertilizer mixturesEscherichia coliAlkali soil

The invention relates a soil improvement fertilizer containing microorganism, inorganic nutrients, organic matters and a water retention agent, specifically aiming at the saline-alkali soil in Binzhou city, Shandong Province. The organic matters and the water retention agent are beneficial to improving the structure of the soil and increasing the water retention ability effectively, thus providing good growing conditions for the growth of microorganism and crops. Through the complementary mutual benefit of the selected nitrogen-fixing bacteria, photosynthetic bacteria, phosphorus-potassium dissolving bacteria and escherichia coli on metabolism, not only can the addition of an inorganic fertilizer be saved, but also the soil quality not easily utilized in soil can be developed. At the same time, adding different proportions of inorganic nutrients depending on the soil composition can not only acquire the basic nutrients for the crops, but also reduce the waste of nutrients. Long-term application of the fertilizer can improve the soil environment fundamentally, thereby achieving the purpose of transforming the saline-alkali soil.

Owner:黑龙江省东方龙智慧农业发展有限公司

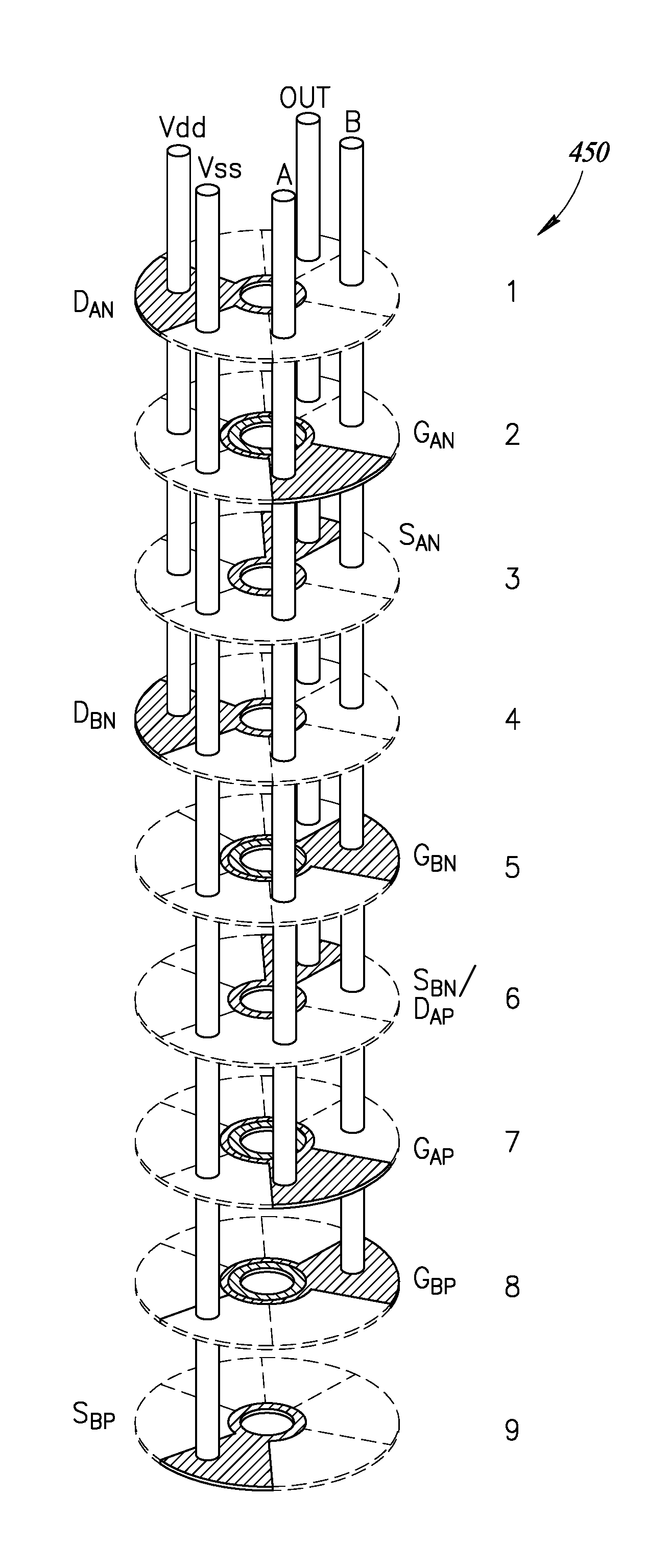

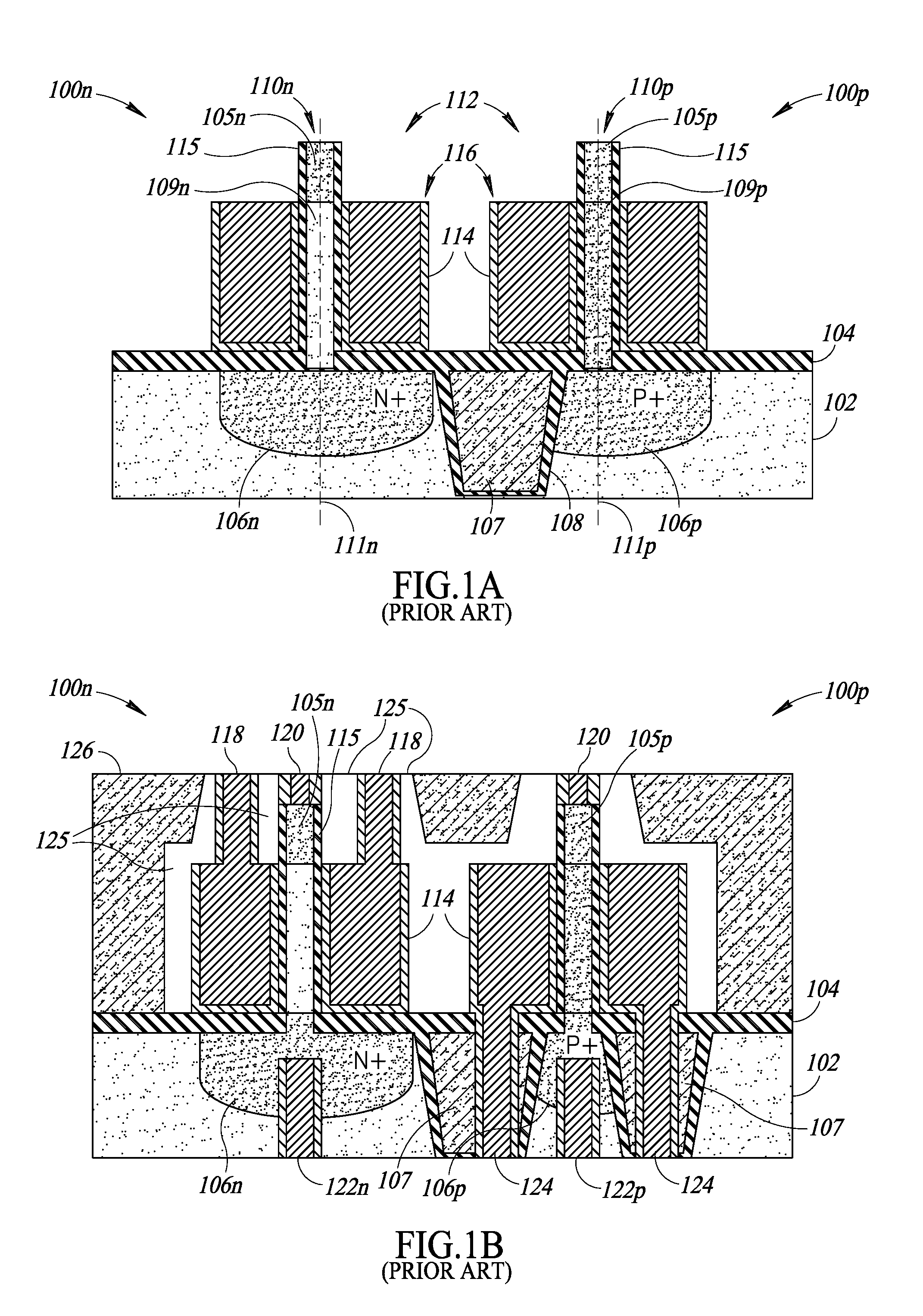

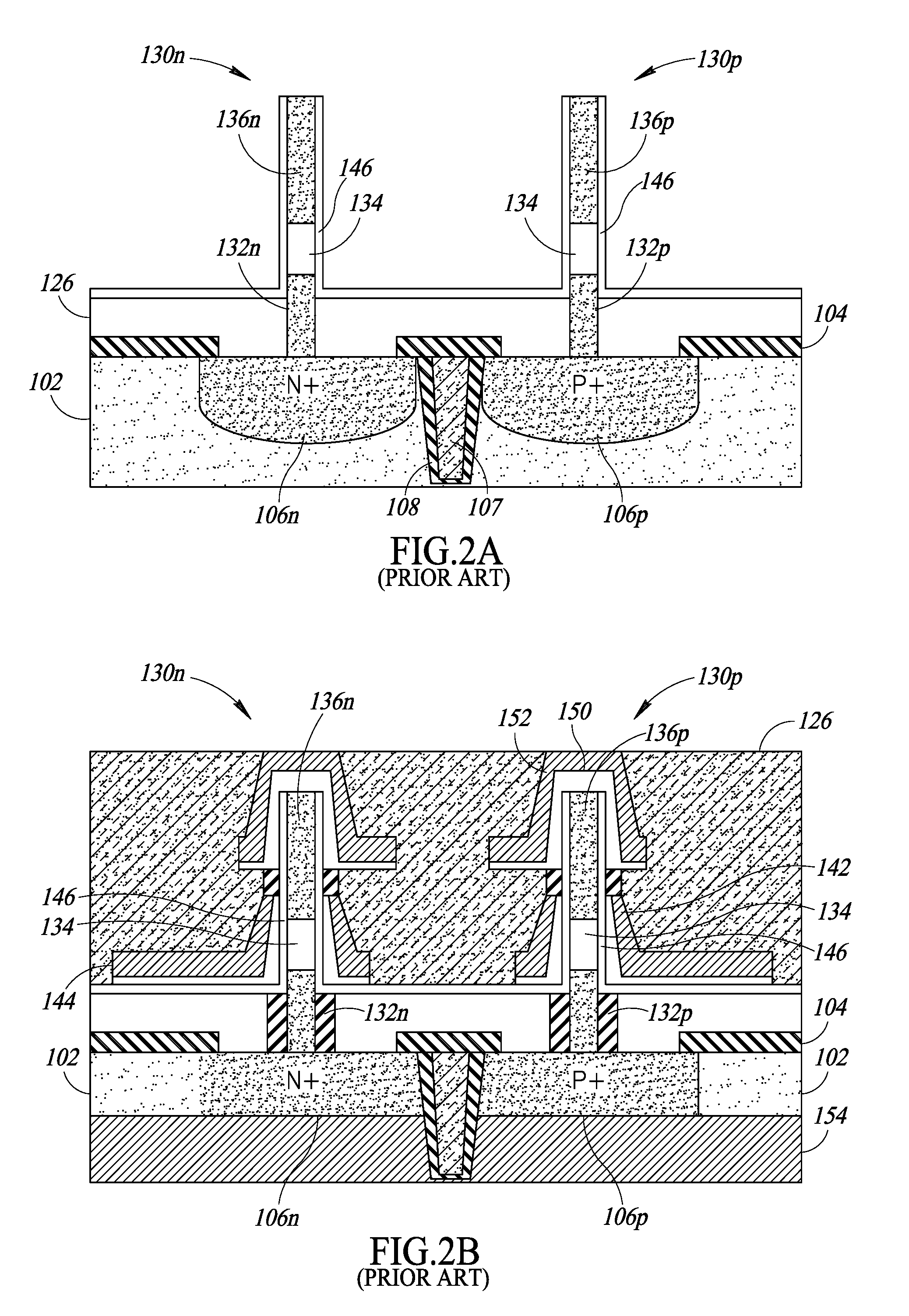

Modular interconnects for gate-all-around transistors

ActiveUS20170005106A1Facilitates building complexImprove compactionTransistorSemiconductor/solid-state device detailsNanowireNOR gate

A modular interconnect structure facilitates building complex, yet compact, integrated circuits from vertical GAA FETs. The modular interconnect structure includes annular metal contacts to the transistor terminals, sectors of stacked discs extending radially outward from the vertical nanowires, and vias in the form of rods. Extension tabs mounted onto the radial sector interconnects permit signals to fan out from each transistor terminal. Adjacent interconnects are linked by linear segments. Unlike conventional integrated circuits, the modular interconnects as described herein are formed at the same time as the transistors. Vertical GAA NAND and NOR gates provide building blocks for creating all types of logic gates to carry out any desired Boolean logic function. Stacked vertical GAA FETs are made possible by the modular interconnect structure. The modular interconnect structure permits a variety of specialized vertical GAA devices to be integrated on a silicon substrate using standard CMOS processes.

Owner:STMICROELECTRONICS SRL

Alkaline soil improver

InactiveCN1664064AImprove compactionThe improved effect is excellentOrganic fertilisersSoil conditioning compositionsCrop cultivationPhosphogypsum

The invention provides a new modifying agent formulation for alkaline soil, which can improve the alkaline soil modifying efficiency by calcium sulfate and phosphogypsum, and the product can be also used in alkali and arid area. The product comprises the following components by weight: calcium sulfate 1,straw 0.5-1.5, urea 0.01-0.08. The important contribution of the invention is that it takes the advantage of straw and mixes with calcium sulfate or with fertilizer industrial waste which combines the chemical modifying with physical modifying, which can improves the soil consolidation essentially, and the modifying effect is obviously better than simple chemical modifying on the condition of not proceeding eluting. The product can not only be used in the ground-crop cultivation proceeding irrigation and draining, but also can be used in forest plantation which not proceeding manual irrigation.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

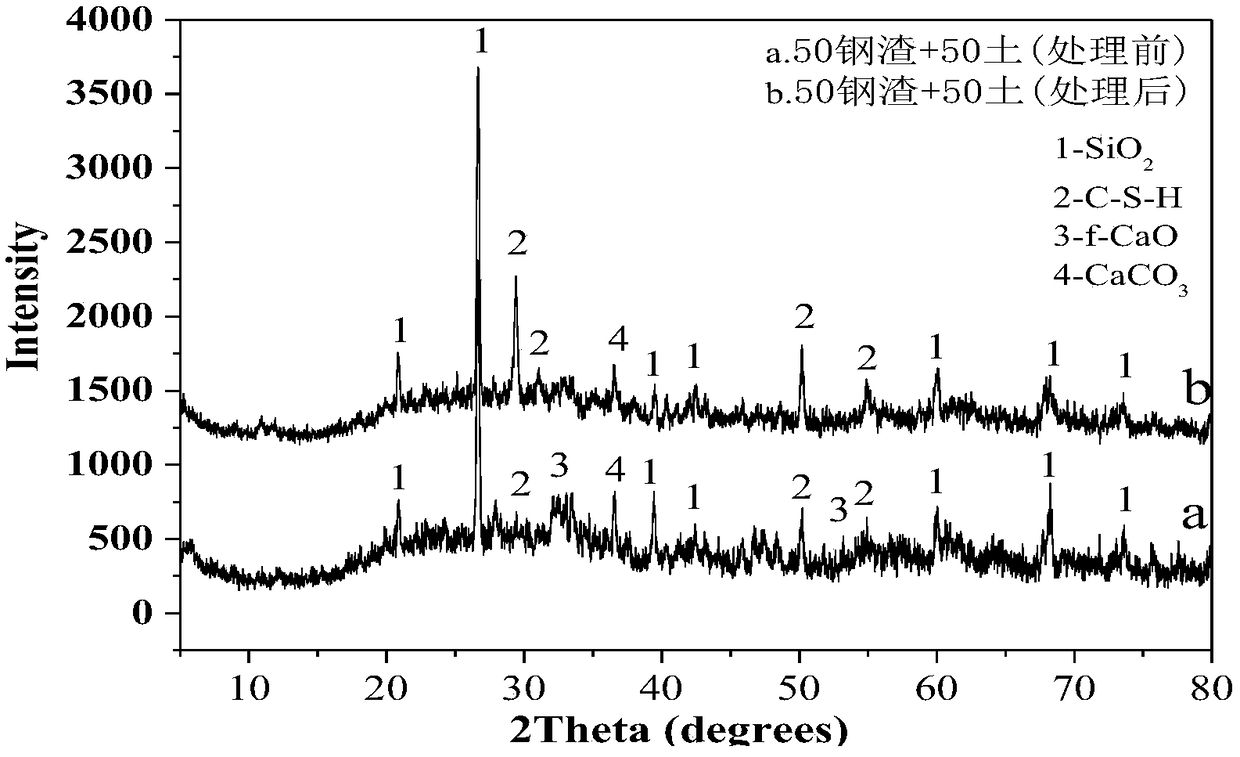

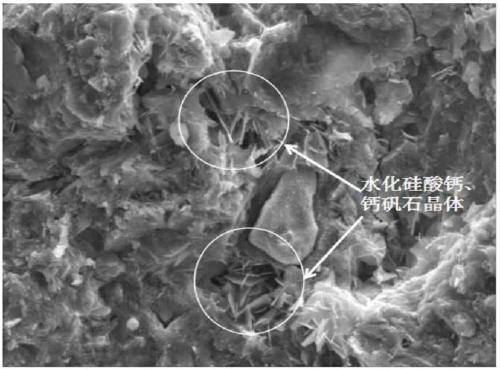

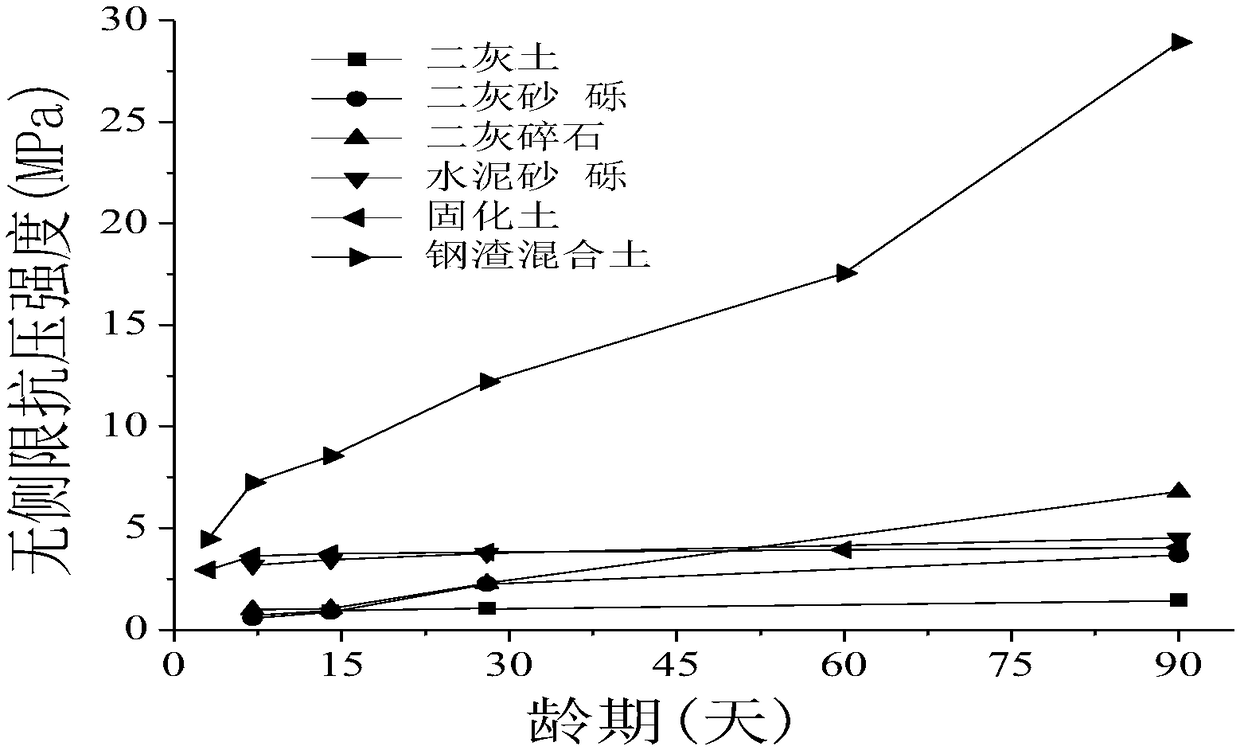

Novel steel slag composite soil road base material and preparation method thereof

The invention discloses a steel slag composite soil road base material and a preparation method thereof. The steel slag composite soil road base material contains the following materials in parts by weight: 0-15 parts of water, 40-80 parts of common soil, 20-60 parts of steel slag without ageing treatment, 5-25 parts of complexing agent, 1-5 parts of cement, and 0.01-0.05 part of modifying agent.The preparation method comprises the following steps: mixing the steel slag, the soil, the cement and the complexing agent and then performing a compaction test, and testing to obtain an optimal watercontent; smashing the steel slag; spraying tap water accounting for 50% of the total water amount, and sufficiently blending the steel slag with the complexing agent, to obtain a slag-powder mixture;spraying the modifying agent to the common soil and doping the redundant tap water, to obtain modified soil; blending and compacting the slag-powder mixture, the modified soil and Portland cement, toobtain a road base material. The steel slag composite soil road base material and the preparation method can sufficiently realize recycling of metallurgic solid water resource, and reduce pollution to the environment in the steel slag stacking and ageing process; also can effectively save the sandstone material, and avoid destruction of the ecological environment caused by sandstone material mining, and has remarkable economical and social benefits.

Owner:安徽马钢嘉华新型建材有限公司 +1

Manganese residue compound fertilizer and preparation method thereof

ActiveCN102674965ARealize resource utilizationImprove void structureFertilizer mixturesSulfateManganese

The invention relates to a manganese residue compound fertilizer and a preparation method thereof. Manganese ore leached residue is used as the main raw material, a carbonate-containing fertilizer is added to convert calcium sulfate in the manganese residue into calcium carbonate, and the manganese residue compound fertilizer is prepared from the manganese residue containing the calcium carbonate, the lignin-containing additive, and one or more of nitrogen fertilizer, phosphate fertilizer and potash fertilizer. The carbonate-containing fertilizer and the lignin-containing additive can effectively prevent soil from packing together, keep the acid-base balance in soil, and enhance the fertilizer efficiency. The invention can effectively utilize abundant manganese residue generated in electrolytic manganese industry, and provides an effective way for recycling manganese residue.

Owner:CENT SOUTH UNIV

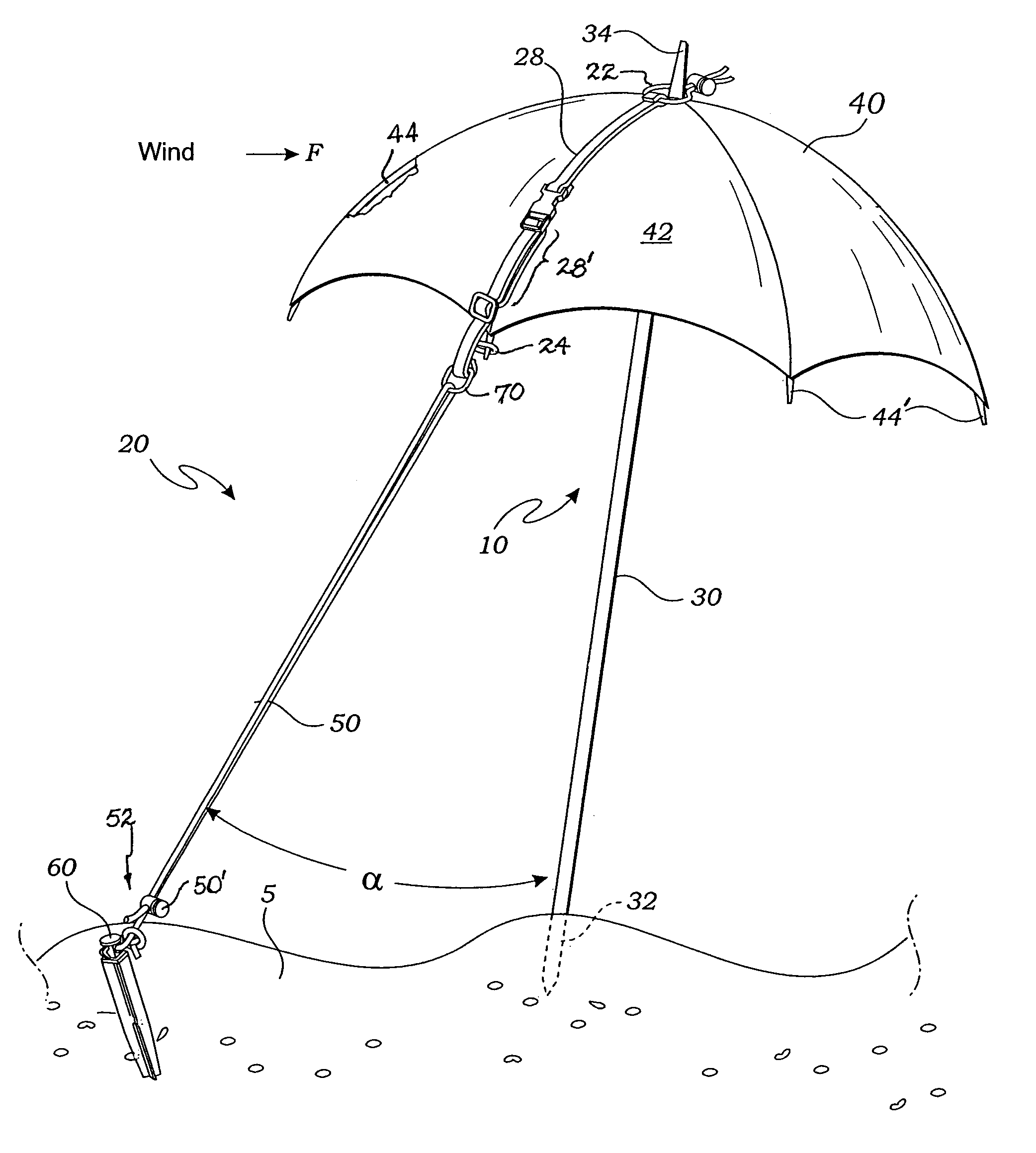

Tie-down for a beach umbrella

InactiveUS6964277B2Improve compactionEasy to foldWalking sticksApparel holdersEngineeringMechanical engineering

A beach umbrella provides an elongated support shaft having a pointed distal end inserted into a soft surface, and a proximal folding canopy positioned below an upper terminal end of the support shaft. The folding canopy provides a fabric panel stretched over a plurality of ribs engaged with the support shaft and extending radially from it to form a downwardly convex external surface. A flexible strap is attached over the upper terminal end of the support shaft and an opposing eyelet engaged with the tip of one of the ribs of the umbrella. A securing line is fixed at a distal end to a stake driven into the surface so the line forms a downwardly divergent angle with the support shaft. The flexible strap lies in contact with the external surface of the fabric panel and is joined at its upper end with the strap. Strap and line are arranged to point upwind to counter wind forces so that the umbrella cannot be blown over.

Owner:NABER MICHAEL JOHN

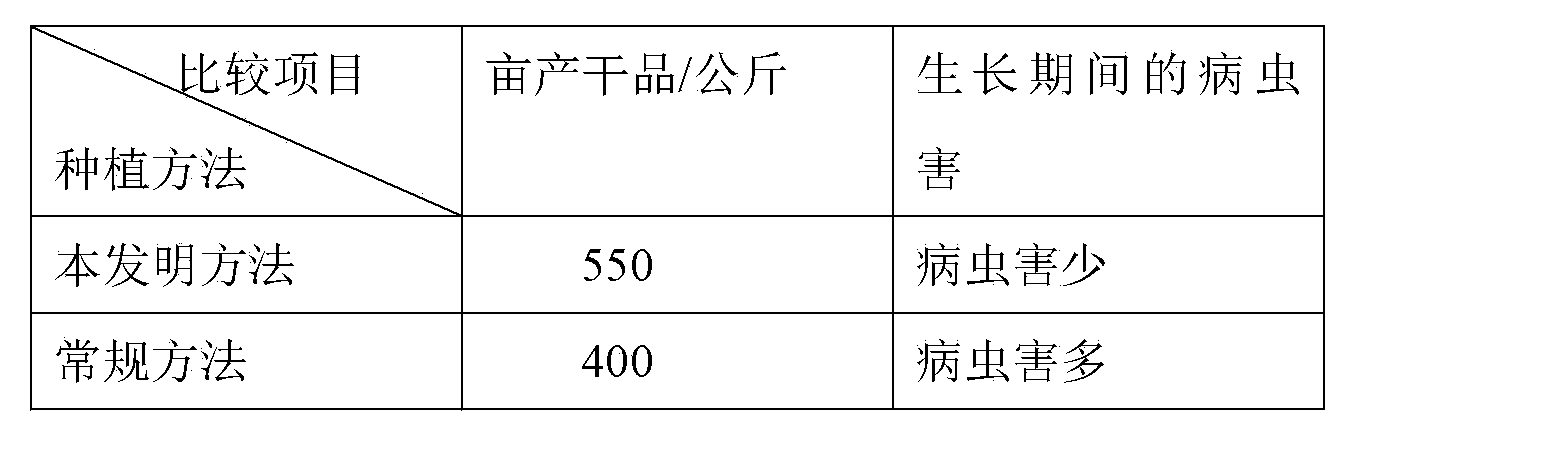

Method for planting Chinese angelica

InactiveCN103430723AImprove compactionImprove crispnessSoil lifting machinesHorticultureHydrogenSoil conditioner

The invention discloses a method for planting Chinese angelica. The method comprises the steps of seedbed finishing, seeding, land preparation of a large field, transplantation, field management, disease and pest prevention and harvesting and processing. A seeding matrix is paved on a seedbed field, and a soil conditioner is added into the soil of a transplantation field, so that the potential of hydrogen of the soil is improved, and the fertilizer quantity is increased. The Chinese angelica planted by using the method is high in mu yield, high in quality and small in disease and pest damage.

Owner:王运海

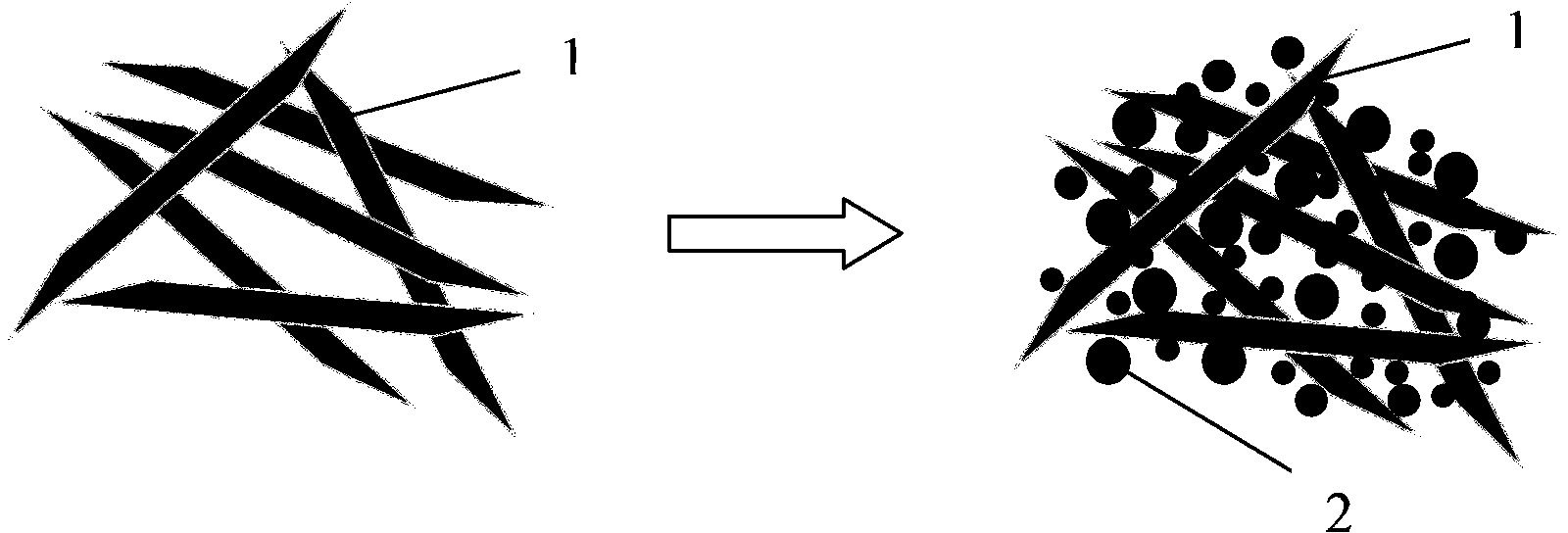

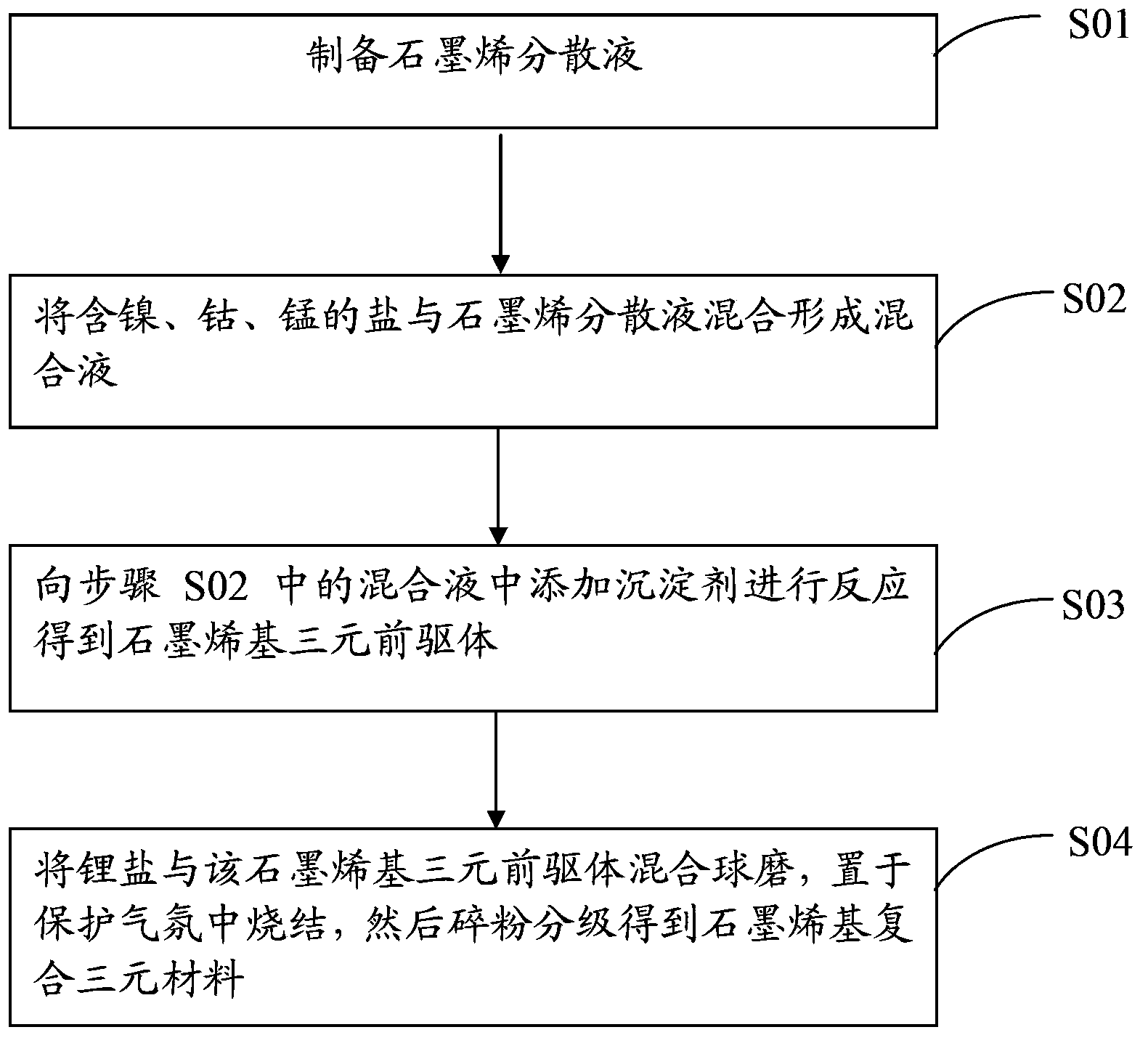

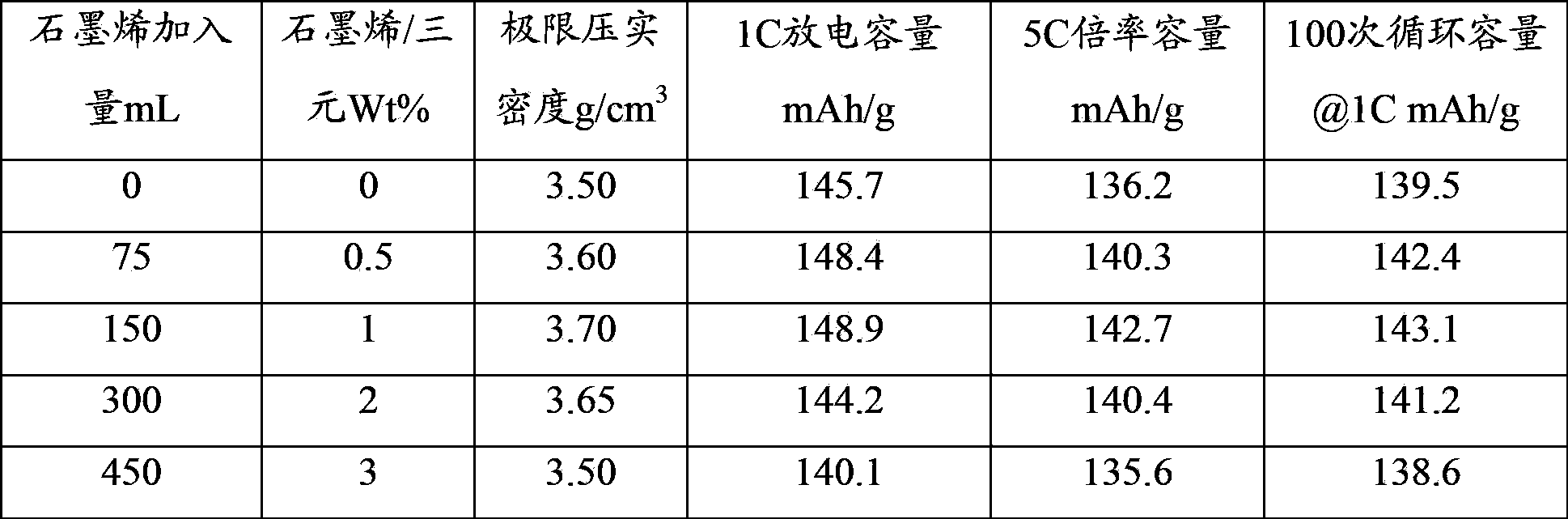

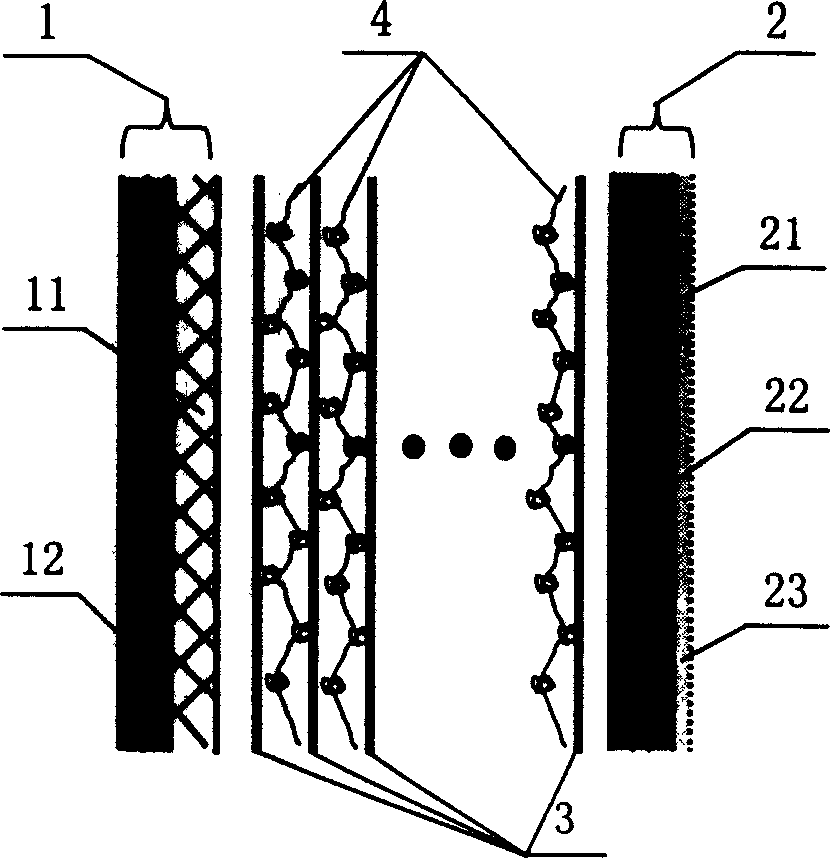

Graphene-based composite ternary material, preparation method thereof, and lithium ion battery

ActiveCN103904330AIncrease compaction densityReduce breakageMaterial nanotechnologyCell electrodesManganeseCobalt

The invention provides a graphene-based composite ternary material. The ternary material comprises graphene and a nickel-cobalt-manganese ternary material, wherein the graphene is prepared by sintering oxidized graphene, is composed of single-layered graphene slices or multi-layered graphene slices whose layer number is less than 10, and accounts for 0.1% to 10.0% of the total weight of the composite ternary material; and the nickel-cobalt-manganese ternary material has a primary particle structure or a secondary particle structure, has a molecular formula of Li(Ni<x>Co<y>Mn<z>)O2, wherein the sum of x, y, and z is equal to 1, and x, y, and z are all in a range of 0 to 1, and accounts for 90.0% to 99.9% of the total weight of the composite ternary material. The graphene slices are freely stacked in the graphene, thus conductive nets and cavities are formed, and the nickel-cobalt-manganese ternary material particles are embedded into the cavities between the nano graphene layers through a chemical precipitation method. The invention also provides a preparation method of the graphene-based composite ternary material.

Owner:HUAWEI TECH CO LTD

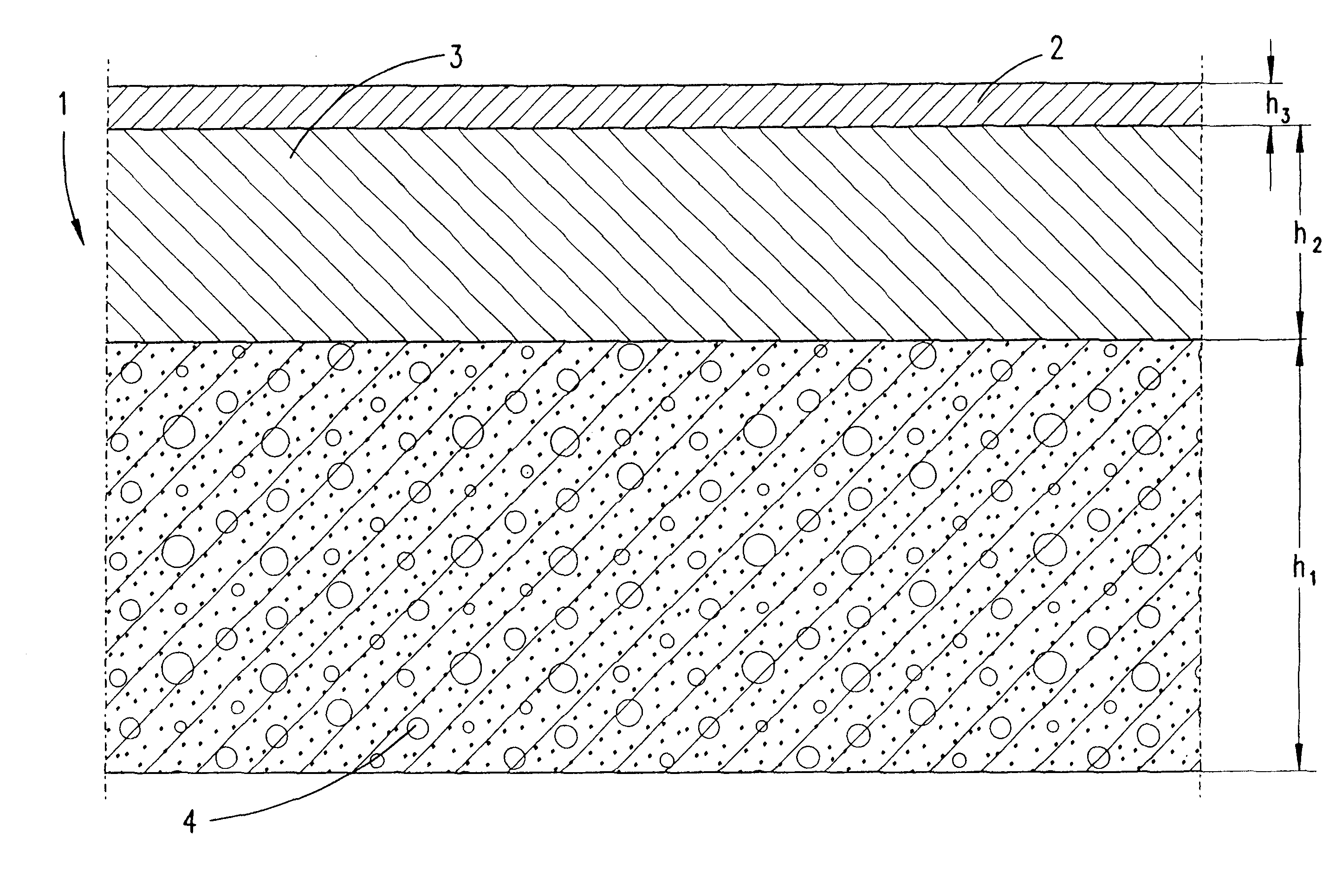

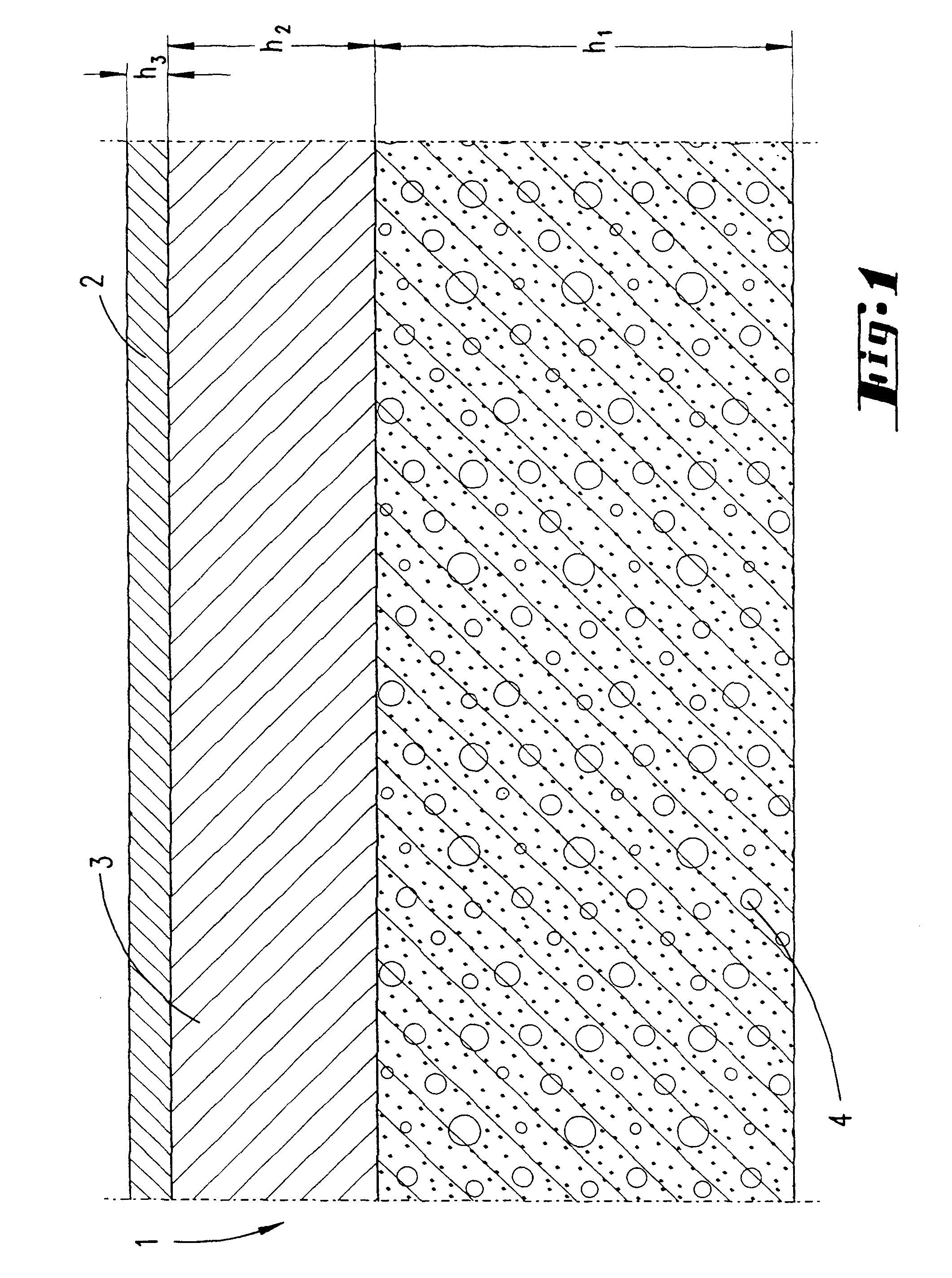

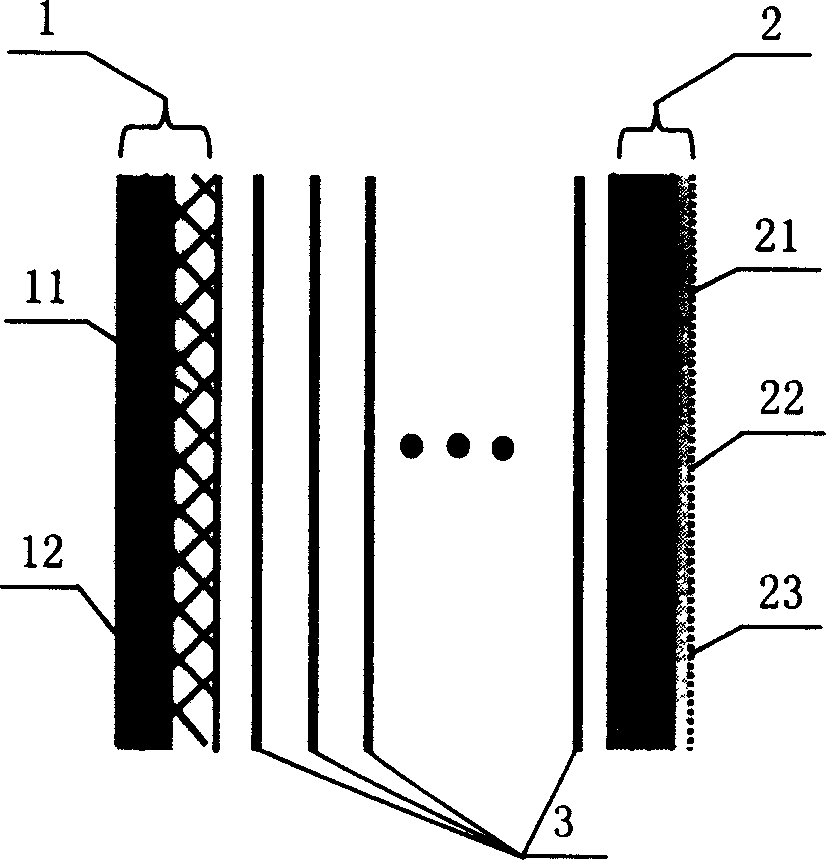

Heat insulation soft thin composite fabric, preparing method and its use

InactiveCN1586884ASimple compositionWell formedSynthetic resin layered productsProtective garmentComposite effectRoom temperature

The present invention relates to the composite fabric structure with one side capable of bearing high temperature, low temperature or composite effect of high temperature and low temperature, and the other side maintained at room temperature state of 5-35 deg.c. The fabric structure has heat and cold resisting high performance coated fabric in one side; soft, comfortable, antifrosting and condensation-preventing fabric in the other side; and composite fabric of heat insulating polymer and compounded metal film as the middle layer, which may have also net lining fabric with stable thickness and size. The composite fabric has natural thickness of 3-12 mm, practical densified thickness of 1-3 mm and unit area weight of 150-550 g / sq m, may be adhered and sawn, and is completely sealed suitable for use as heat insulating protecting material in the environment condition from -130 deg.c to 120 deg.c.

Owner:DONGHUA UNIV

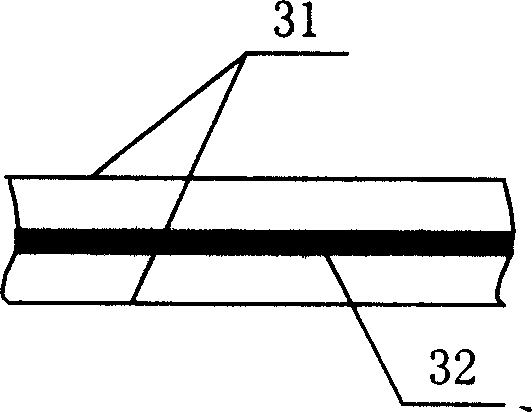

Method for preparing stalk charcoal and stalk vinegar liquid form stalks of cropper

InactiveCN1563277AImprove fertilizer efficiencyImprove compactionBiofuelsPyroligneous acid productionCombustion chamberProduct gas

A method for preparing straw charcoal and straw vinegar liquid includes placing agricultural straw into retort for pyrolytic reaction of 4-12 h. at 300-600 deg.C under condition of oxygen being isolated or being provided with limitation; obtaining straw charcoal from solids through drying, precharring, charring and calcining; obtaining straw vinegar liquid and combustible gas by arrying out gas-liquid separation of pyrolysis gas and sending combustible gas back to combustion chamber as heating source.

Owner:NANJING FORESTRY UNIV

Soil conditioner with marine organisms

InactiveCN101275078AEfficient use ofRaw materials are easy to getOrganic fertilisersSoil conditioning compositionsFiberOyster

The present invention provides a soil conditioner containing marine organisim, composed of 10-40 (weight)% shell powder, 10-60 (weight)% oyster shell powder, 1-5 (weight) % chitosan powder, 10-50 (weight) % stem vegetable and fruit powder or leavening having strong fibre, and or marine organisim powder or leavening. The waste marine organisim is a main raw material, the raw material is easy to get, having low cost, and the waste is effectively utilized, beneficial to environmental protection. The soil conditioner improves soil hardening, increasing soil permeability and activity, eliminating residual in the soil of the decomposition chemical fertilizer. The soil conditioner enhances the fertilizer utilization ratio, also exciting cropper root growth and enhancing cropper immunocompetence.

Owner:SHENZHEN XIASHI HALOBIOS TECH

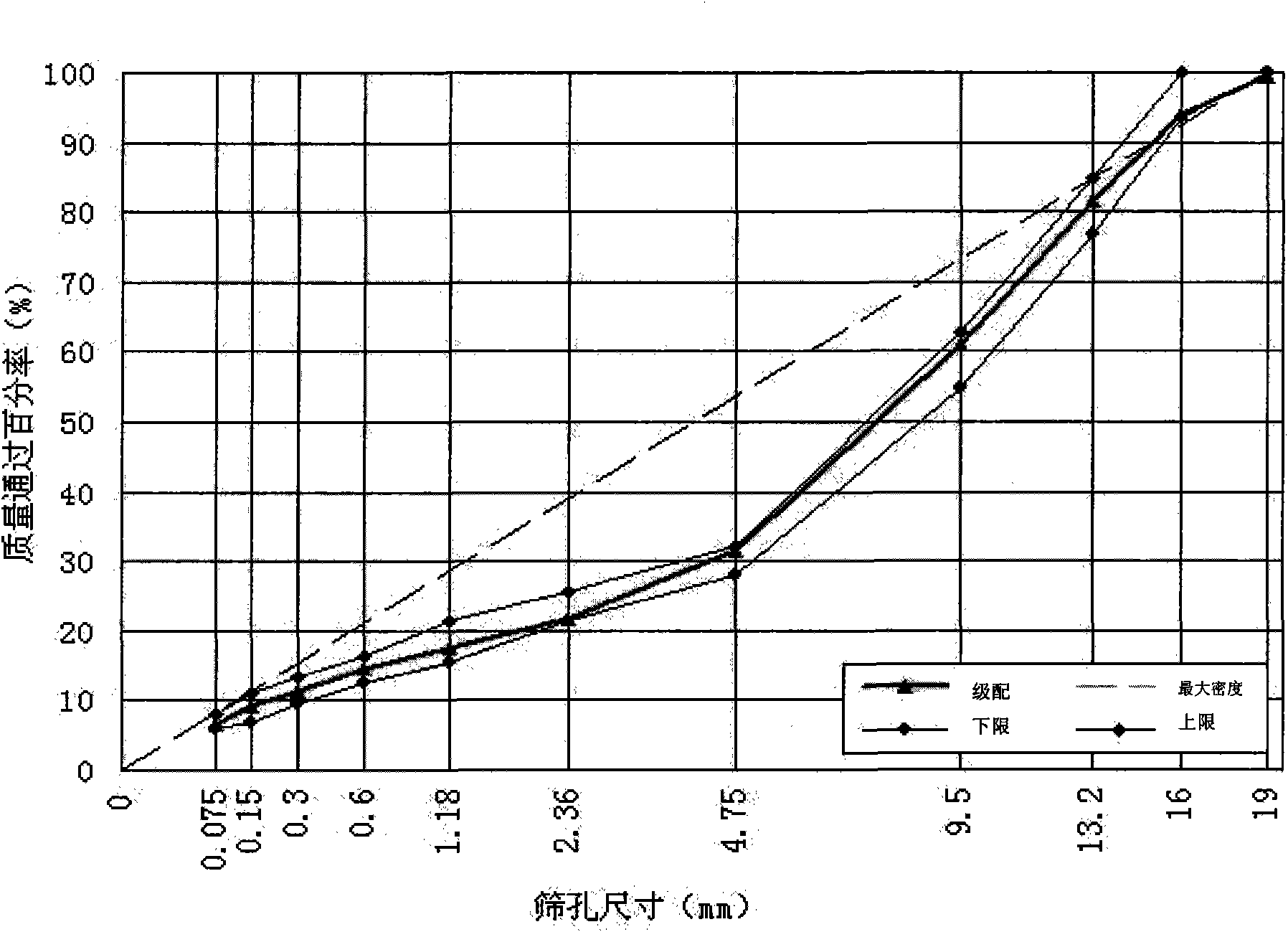

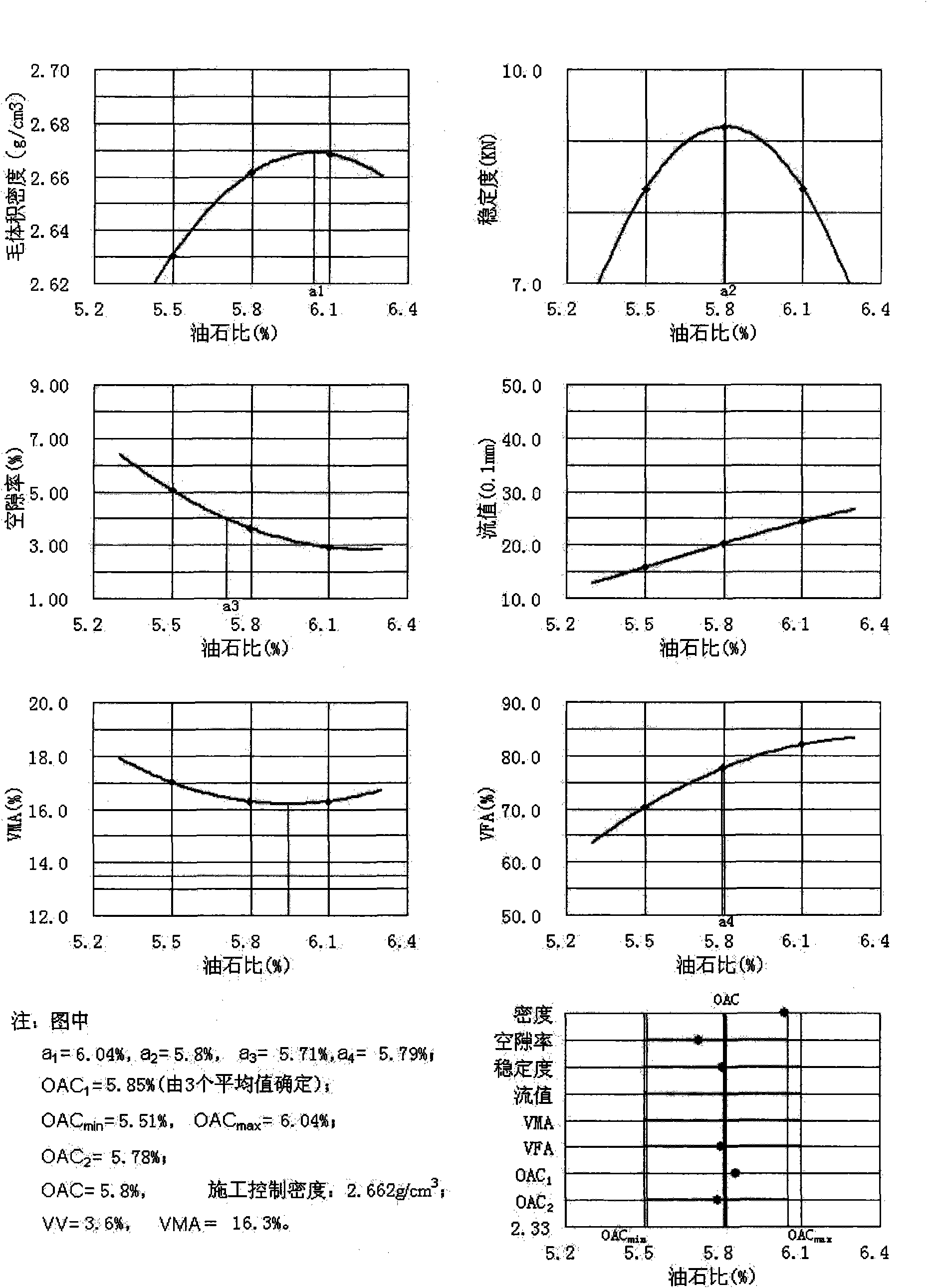

Steel slag and rubber asphalt concrete and preparation method thereof

The invention provides a steel slag and rubber asphalt concrete and a preparation method thereof. In the concrete, the steel slag is selected as a coarse aggregate and rubber asphalt is selected as a binder, and the concrete further comprises a fine aggregate and a filler; the mineral aggregate of the asphalt mixture is graded to form a coarse aggregate gap gradation framework solid type; the ratio of the rubber asphalt to the mineral aggregate is comprehensively determined through a Marshall compacting experiment to determine the range via the volume parameter of a Marshall test piece and verification on the road properties such as high-temperature rutting resistance and water damage resistance; when the rubber asphalt and the mineral aggregate are mixed and stirred, the heating temperature of the rubber asphalt is 175-180 DEG C and the heating temperature of the mineral aggregate is 10-30 DEG C higher than that of the rubber asphalt; moreover, the dry mixing time of the mineral aggregate is 15-20 s and the wet mixing time of the mineral aggregate is 35-40 s; and the ex-factory temperature of the steel slag and rubber asphalt concrete formed after the mixing and the stirring is 175-185 DEG C. The invention replaces the mineral aggregate by the steel slag, and can recycle the waste materials, save the stone resources, and reduce the destruction from the stone mining to the environment.

Owner:RES INST OF HIGHWAY MIN OF COMM

Gasket material

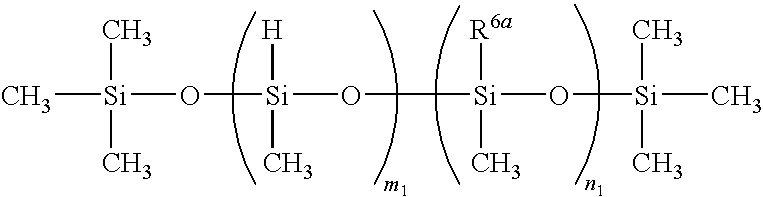

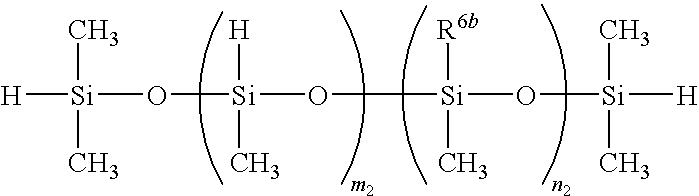

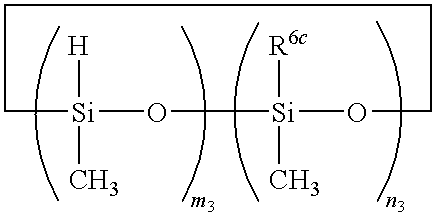

InactiveUS20090322040A1Avoid Insufficient SealingGood removal effectDomestic sealsEngine sealsPolymerChemistry

The present invention provides a gasket material to be placed between two opposing faces to provide a tight closure between them. The gasket material of the present invention, wherein an adhesive layer comprised of a cured product obtained by reacting a polyoxyalkylene polymer having at least one alkenyl group in each molecule with a compound containing two or more hydrosilyl groups on average in each molecule is formed on both surfaces of a substrate sheet, is superior in elasticity and compaction property, shows superior adhesion to various materials, does not cause cohesive failure during detachment and is superior in removability. Therefore, a superior sealing effect lasts for a long time, the gasket material can be removed without leaving residues of the adhesive layer on an adherend after removal, and workability including removal of the gasket material can be improved.

Owner:NITTO DENKO CORP

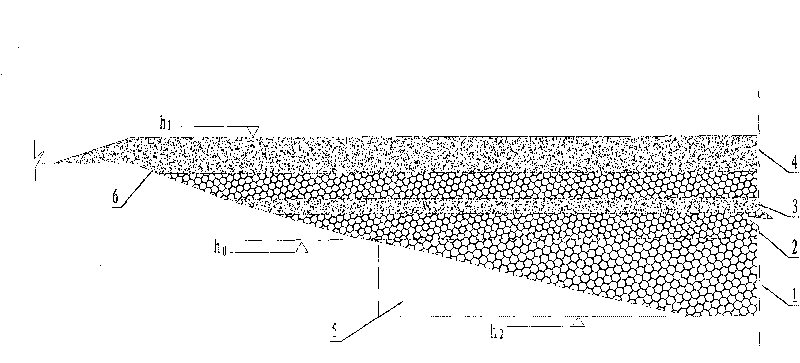

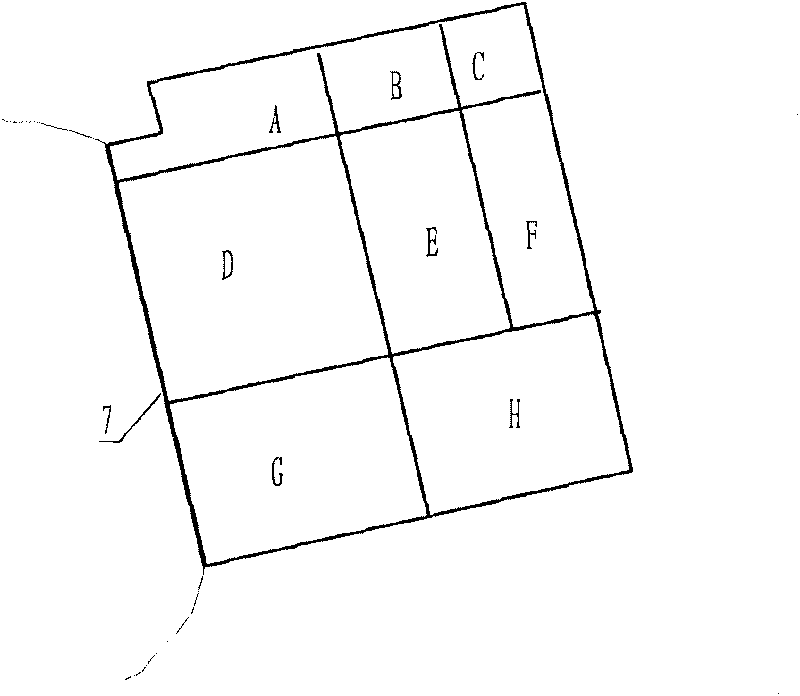

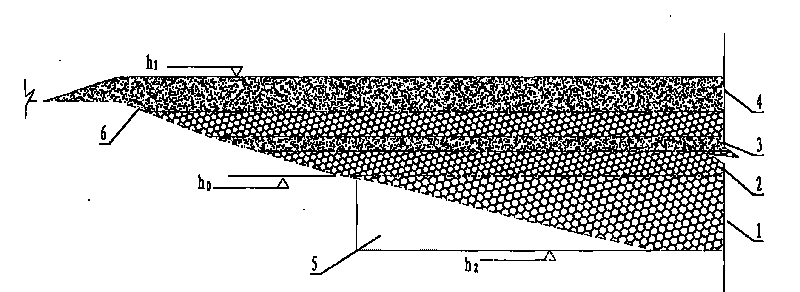

Filling-reclaiming method for building land in coal mining subsidence areas

InactiveCN101713291AEase the growing tensionSave the occupied landUnderground miningSurface miningSpontaneous combustionPorosity

The invention provides a filling-reclaiming method for building land in coal mining subsidence areas, which belongs to the technical field of mining and is used to solve the problem of developing and utilizing coal gangue. The invention adopts a technical scheme that the method is implemented according to the following steps: a, draining accumulated water in reclamation areas and clearing silt; b, striping and stockpiling surface soil; c, determining the thickness and density of coal gangue for hierarchical backfilling through a vibration pressure test; and d, performing hierarchical backfilling compaction on the coal gangue and soil. The method has the following main advantages that: 1, the ways of utilizing the coal gangue are expanded, and environmental pollution caused by stockpiling the coal gangue on ground is reduced; 2, the situation that building land is increasingly short is alleviated by reclaiming subsidence land to be the building land; and 3, the treatment for coal gangue for large-area hierarchical backfilling by a hierarchical vibration-compaction method is economical, reasonable and ideal in compaction effect, can improve the compactness and bearing capacity of coal gangue layers, and can prevent the spontaneous combustion or efflorescence of coal gangue foundations and the separation of harmful substances from polluting local environment because hierarchical compaction greatly reduces porosity and isolates air.

Owner:煤炭科学研究总院唐山研究院

Phosphogypsum water hard road base, road base material and preparation method thereof

The invention discloses a phosphogypsum water hard road base, a road base material and a preparation method thereof, relating to the field of road engineering construction. The preparation method of the road base material comprises the following steps: weighing 85-92 percent of phosphogypsum and 15-8 percent of ordinary portland cement, uniformly mixing and stirring, thereby obtaining a preliminary mixture; weighing 99.7-99.95 percent of preliminary mixture and 0.3-0.05 percent of a phosphogypsum water hard curing agent, uniformly mixing and stirring, thereby obtaining a premix; controlling the moisture content of the premix to be 14-18 percent, thereby obtaining a base material, wherein the phosphogypsum water hard curing agent is prepared by mixing the following components in percentage by mass: 40-60 percent of elastic styrene-acrylic emulsion, 30-20 percent of nanometer alumina sol and 30-20 percent of nanometer silica sol. The road base is prepared from the road base material according to a standard road base construction method. The road base material is produced by utilizing phosphogypsum, the environmental pollution is reduced, and wastes are changed into valuable materials; and moreover, the formed road base is high in crack resistance, difficult to corrode and long in service life.

Owner:黄菁华 +2

Saline-alkali soil conditioner and preparation method thereof

InactiveCN101659867AMiao QiSeedlings turn green quicklyAgriculture tools and machinesOther chemical processesChemistryAlkali soil

The invention relates to a saline-alkali soil conditioner and a preparation method thereof. The saline-alkali soil conditioner is constituted by glacial acetic acid, citric acid, oxalic acid and tap water. The preparation method comprises the following steps: weighing the tap water, citric acid and oxalic acid according to weight ratio and placing in a reaction kettle; starting stirring, warming up to 40 DEG C to 60 DEG C for 0.5 hour to 1 hour; weighing the glacial acetic acid according to weight ratio and placing in the reaction kettle; stirring, warming up to 50 DEG C to 60 DEG C for 0.5 hour to 1 hour; cooling down to 25 DEG C to 40 DEG C; carrying out measurement packaging after the samplings pass the inspection to obtain the finished product of saline-alkali soil conditioner. The saline-alkali soil conditioner in the invention is simple in manufacturing process, low in raw materials and production cost, and can realize the improvement of soil physicochemical property, inhibit theascending of saline matter and neutralizing the alkalinity of the soil.

Owner:路振国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com