Patents

Literature

1282 results about "Fabric structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In architecture, fabric structures are forms of constructed fibers that provide end users a variety of aesthetic free-form building designs. Custom-made fabric structures are engineered and fabricated to meet worldwide structural, flame retardant, weather-resistant, and natural force requirements. Fabric structures are considered a sub-category of tensile structure.

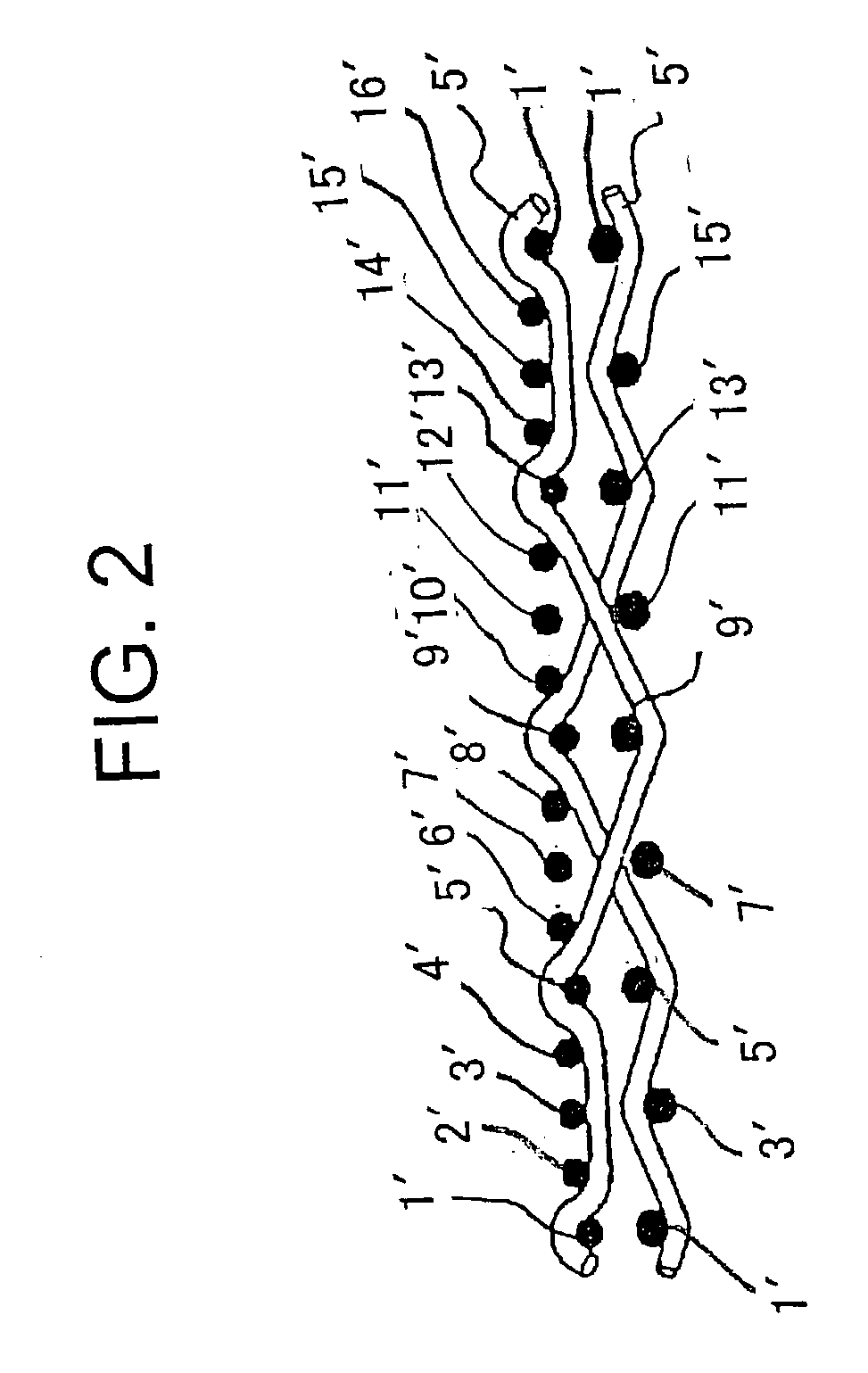

Composite elastic material having multistage elongation characteristics and method of manufacturing the same

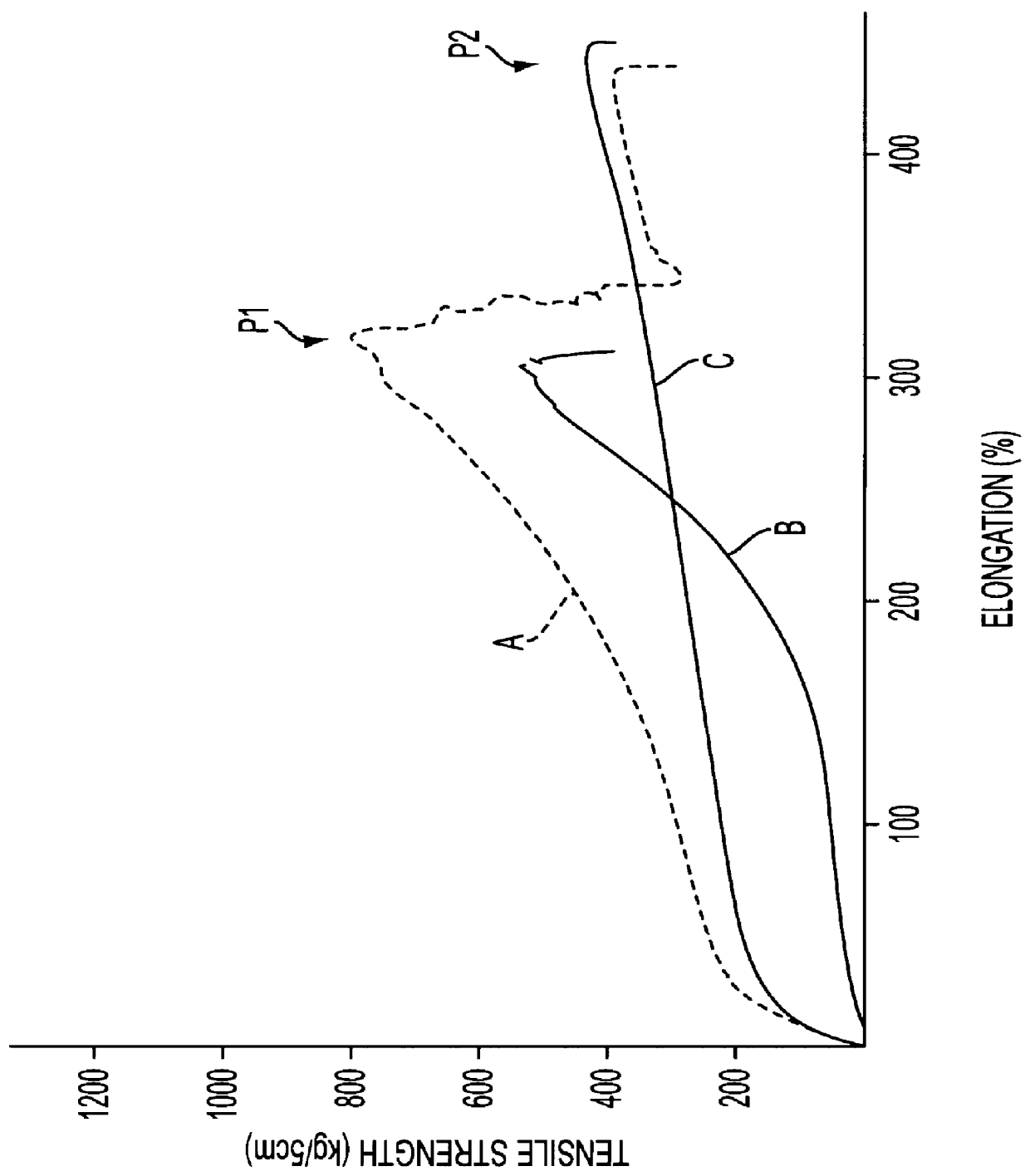

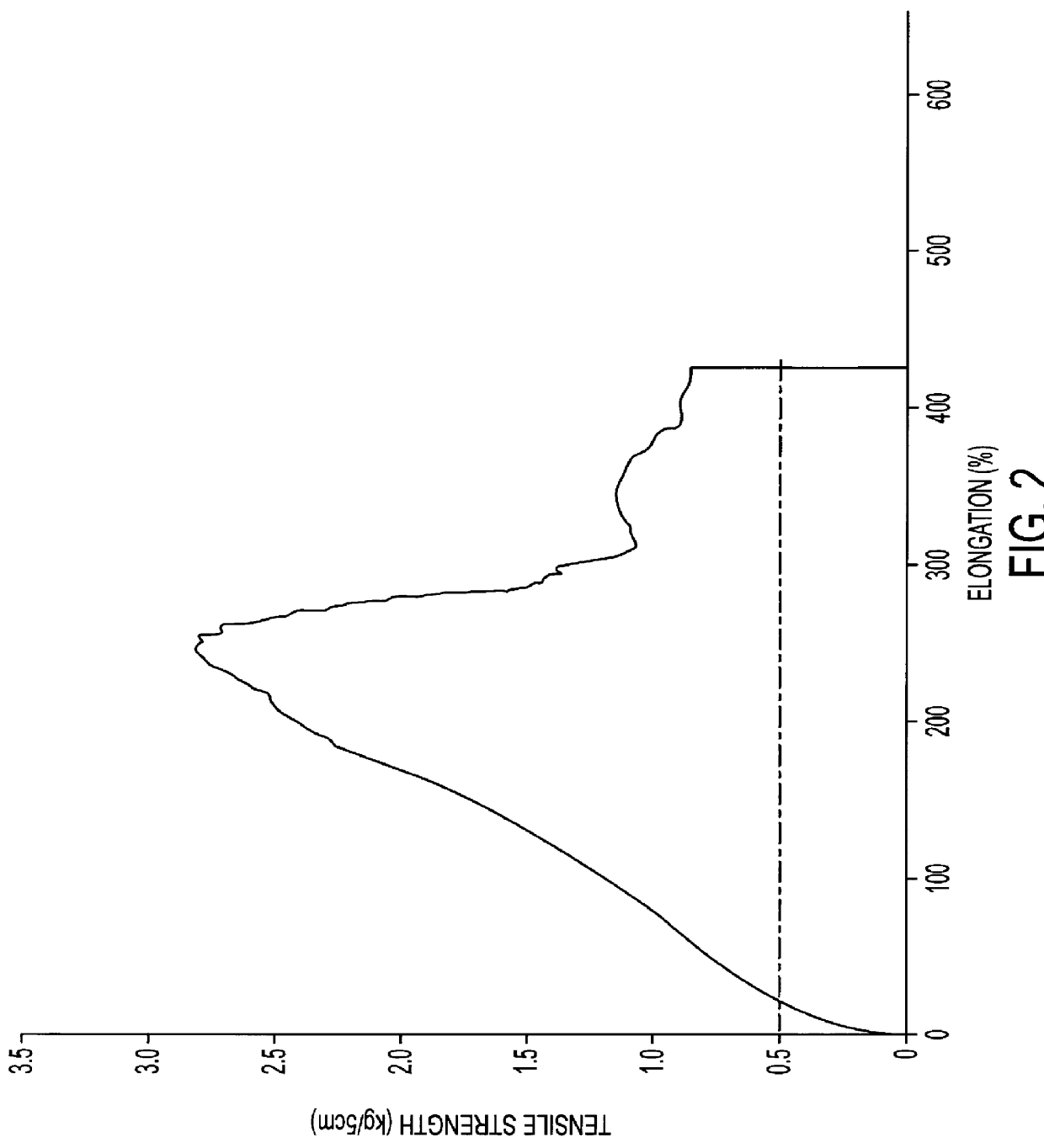

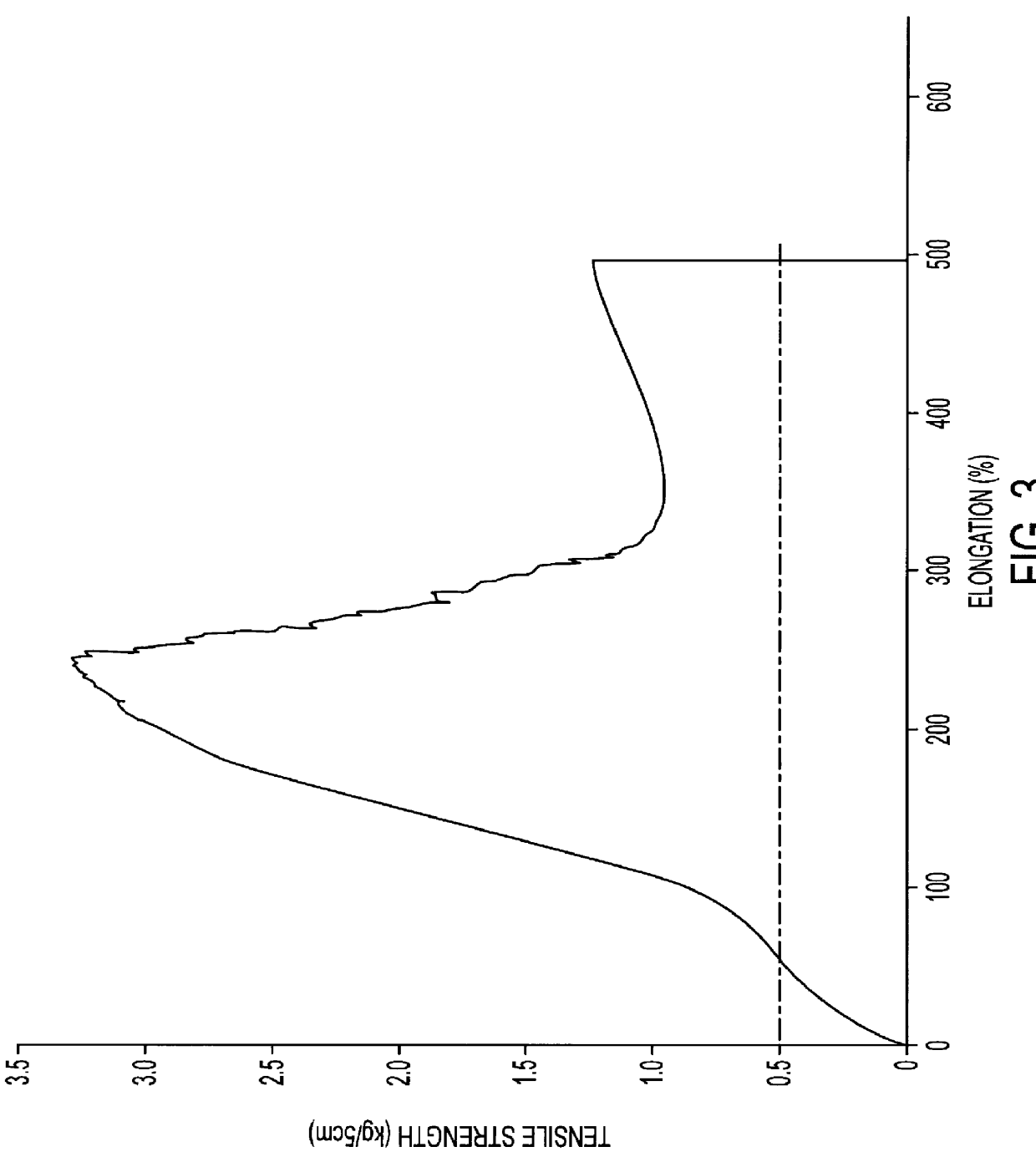

PCT No. PCT / JP96 / 00041 Sec. 371 Date Sep. 16, 1997 Sec. 102(e) Date Sep. 16, 1997 PCT Filed Jan. 12, 1996 PCT Pub. No. WO96 / 21760 PCT Pub. Date Jul. 18, 1996A composite elastic material comprises a non-woven fabric secured to an elastic member. The non-woven fabric is elastically stretchable by about 100% or more. The sheet-like elastic member has an elastic recovery of about 60% or more and a break-down elasticity of about 200% or more. The elastic member and the non-woven fabric are secured together at a plurality of points in the stretchable direction of the non-woven fabric. The composite elastic material has multiple-stage elongation characteristics including a first stress lowering point caused by changes in the structure of the non-woven fabric, and a second stress lowering point occurring at an elongation larger than that of the first stress lowering point, caused by the fracturing of the sheet-like elastic member. The elastic material clearly shows a break-down point when stretched, and increases the flexibility of designing various products.

Owner:PARAGON TRADE BRANDS

Elastomeric balloon support fabric

InactiveUS20020161388A1Promote recoveryHigh degree of stretchOrnamental textile articlesLayered productsYarnBalloon catheter

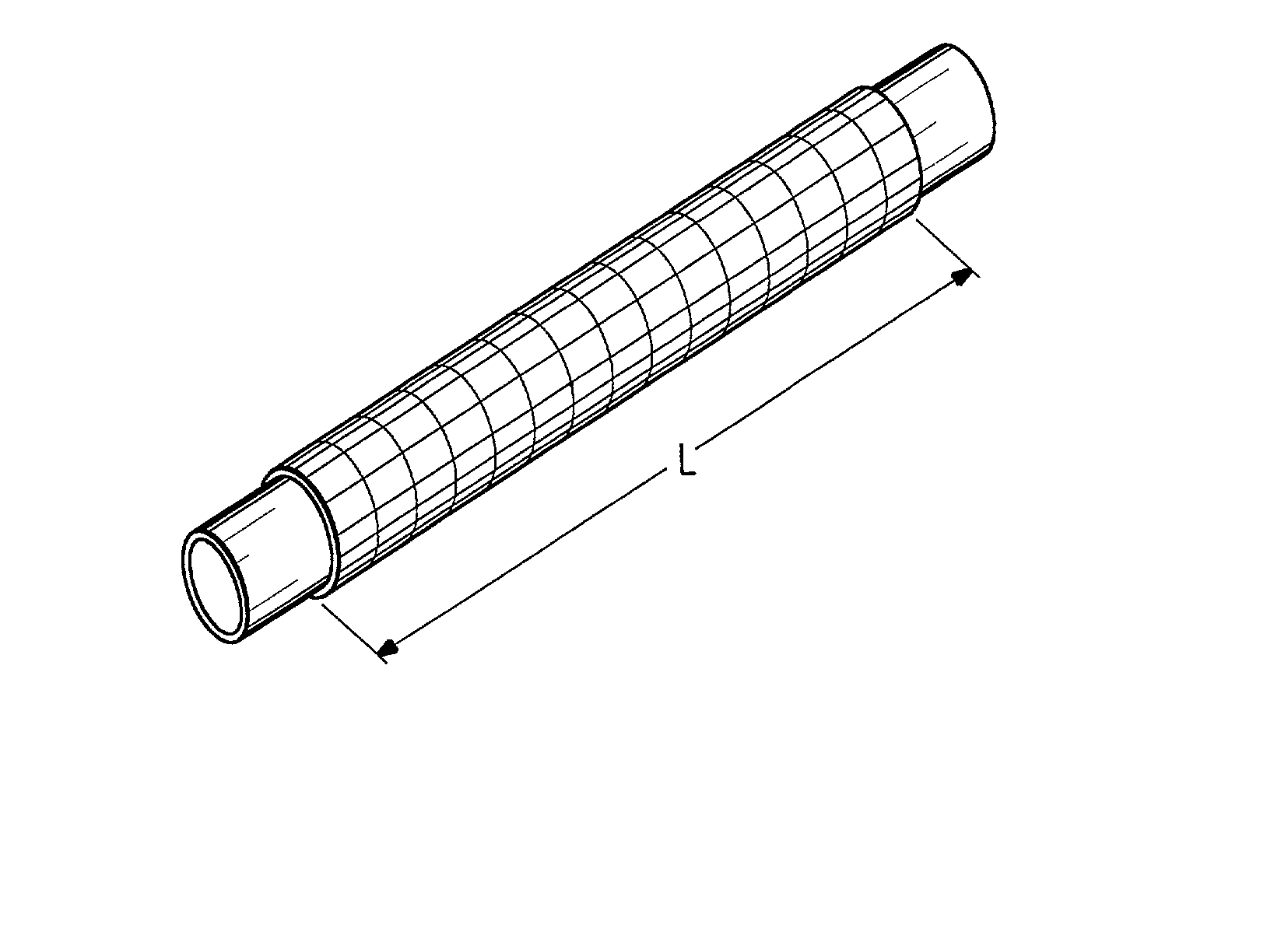

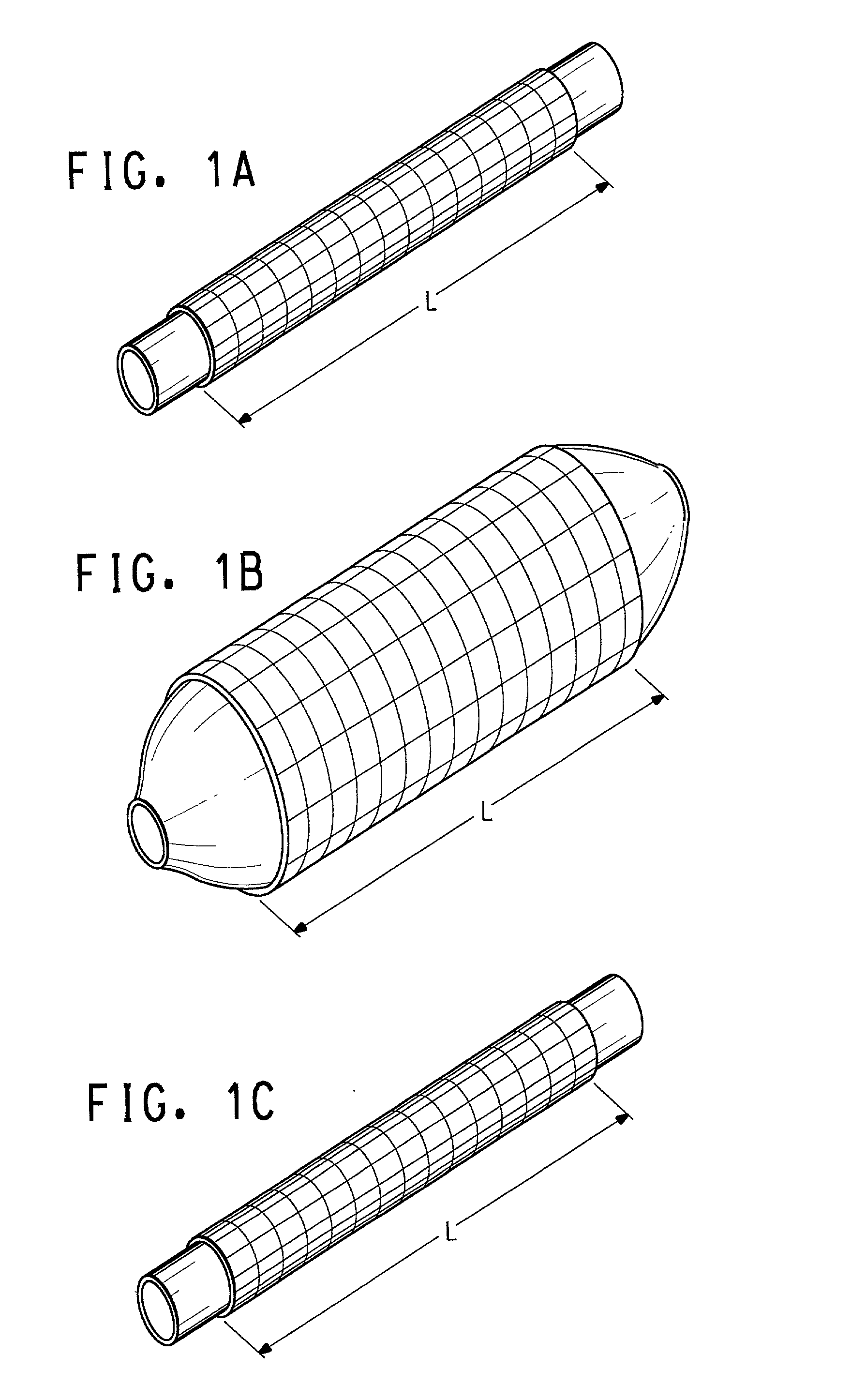

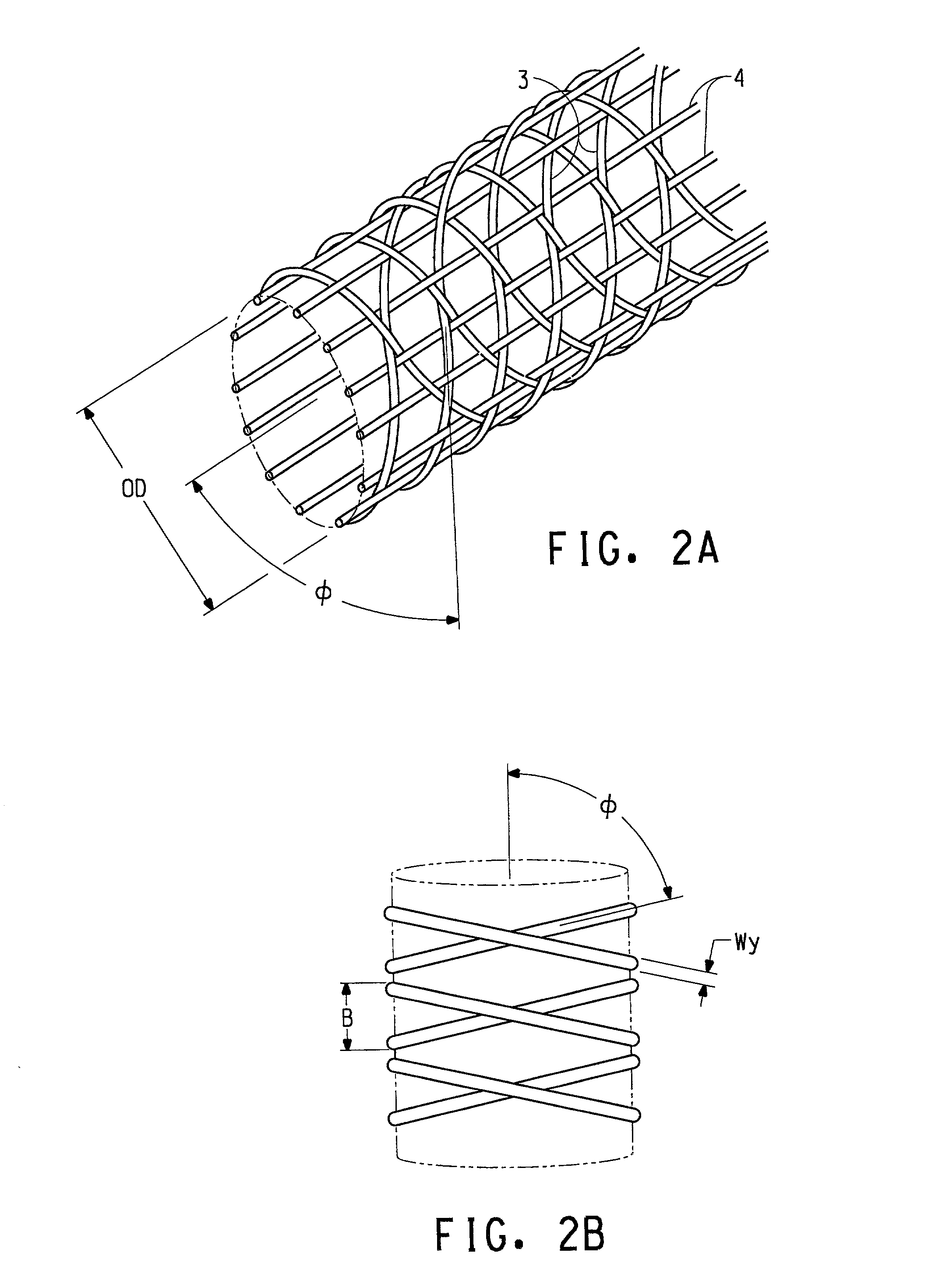

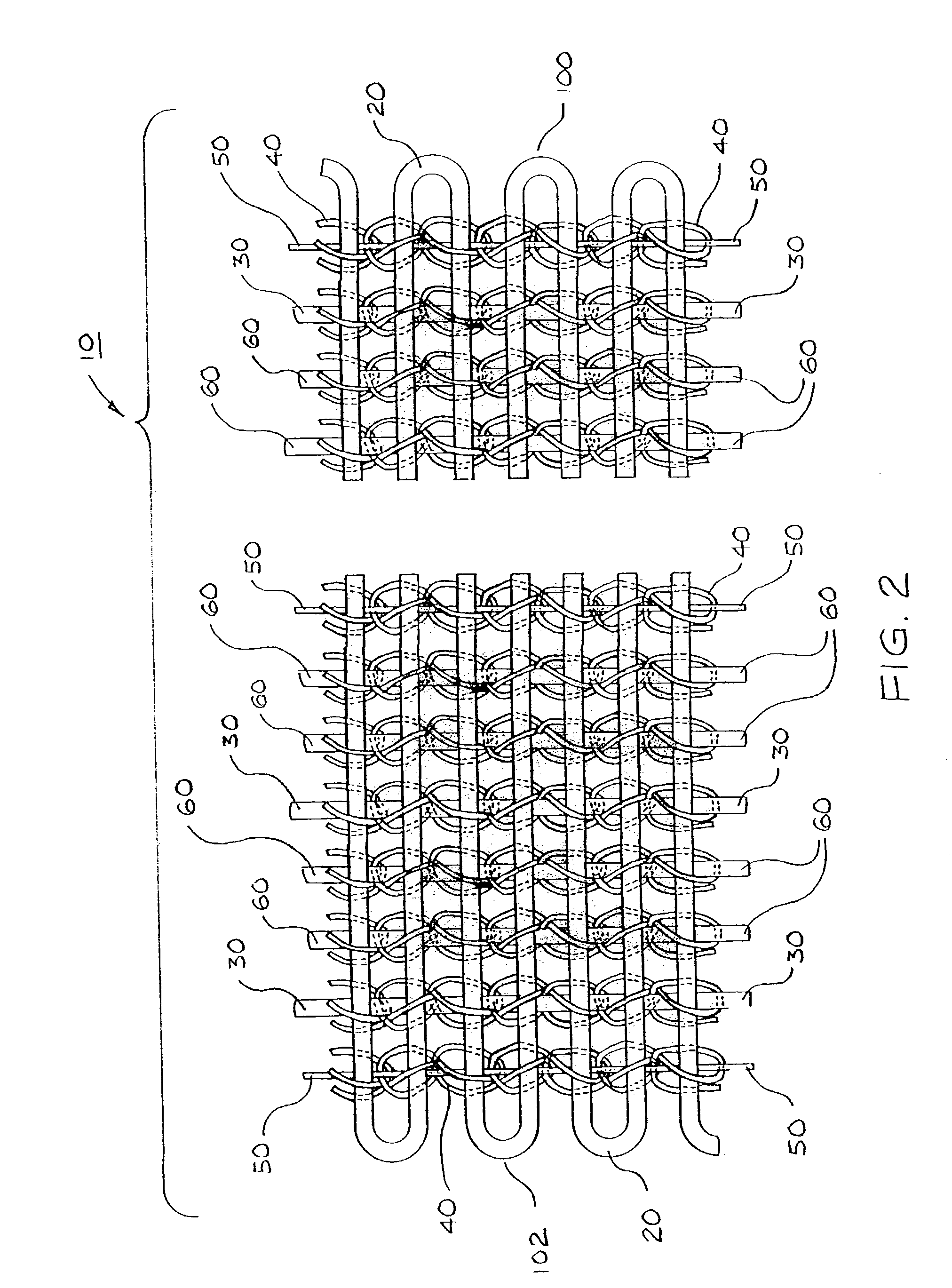

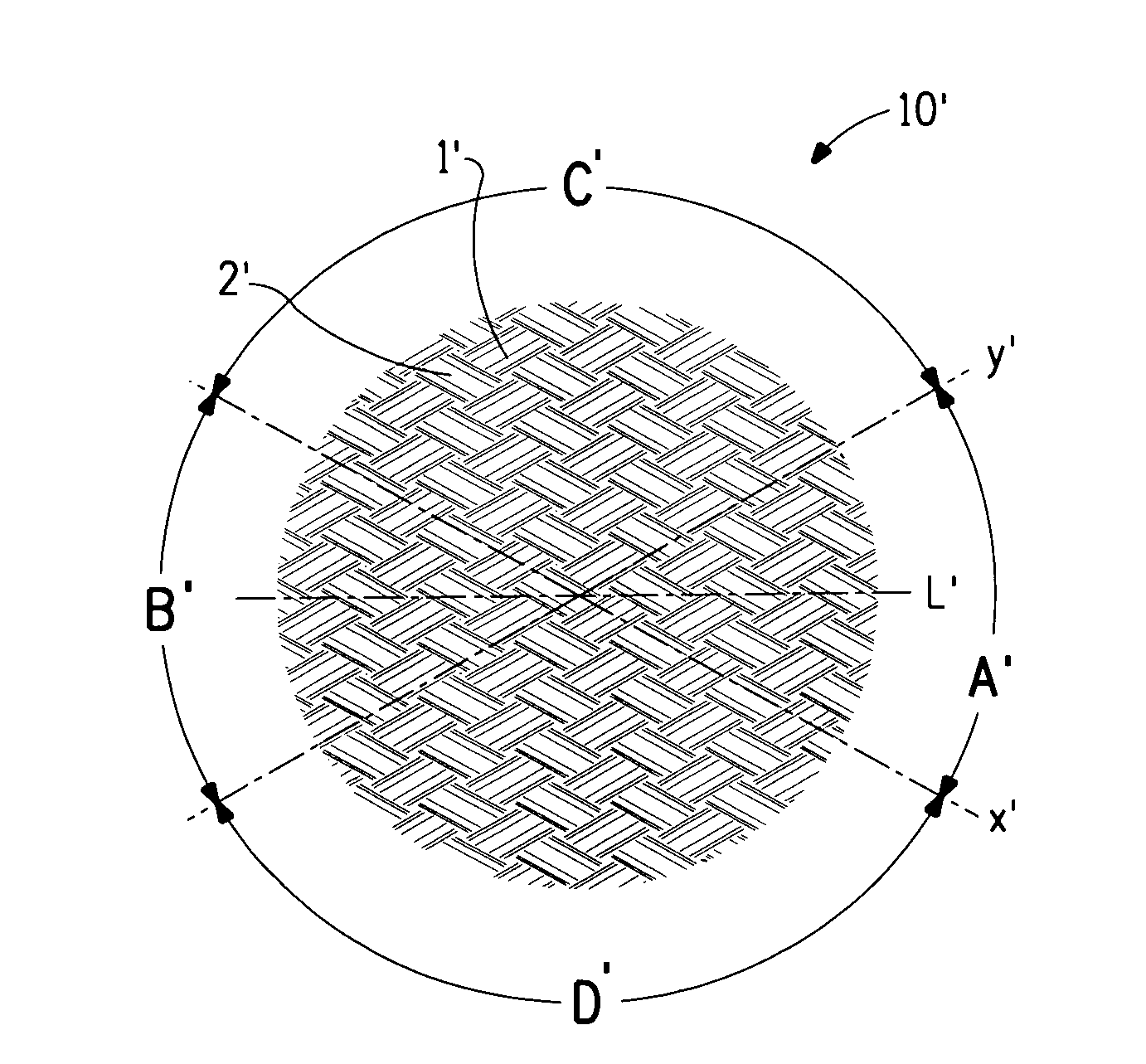

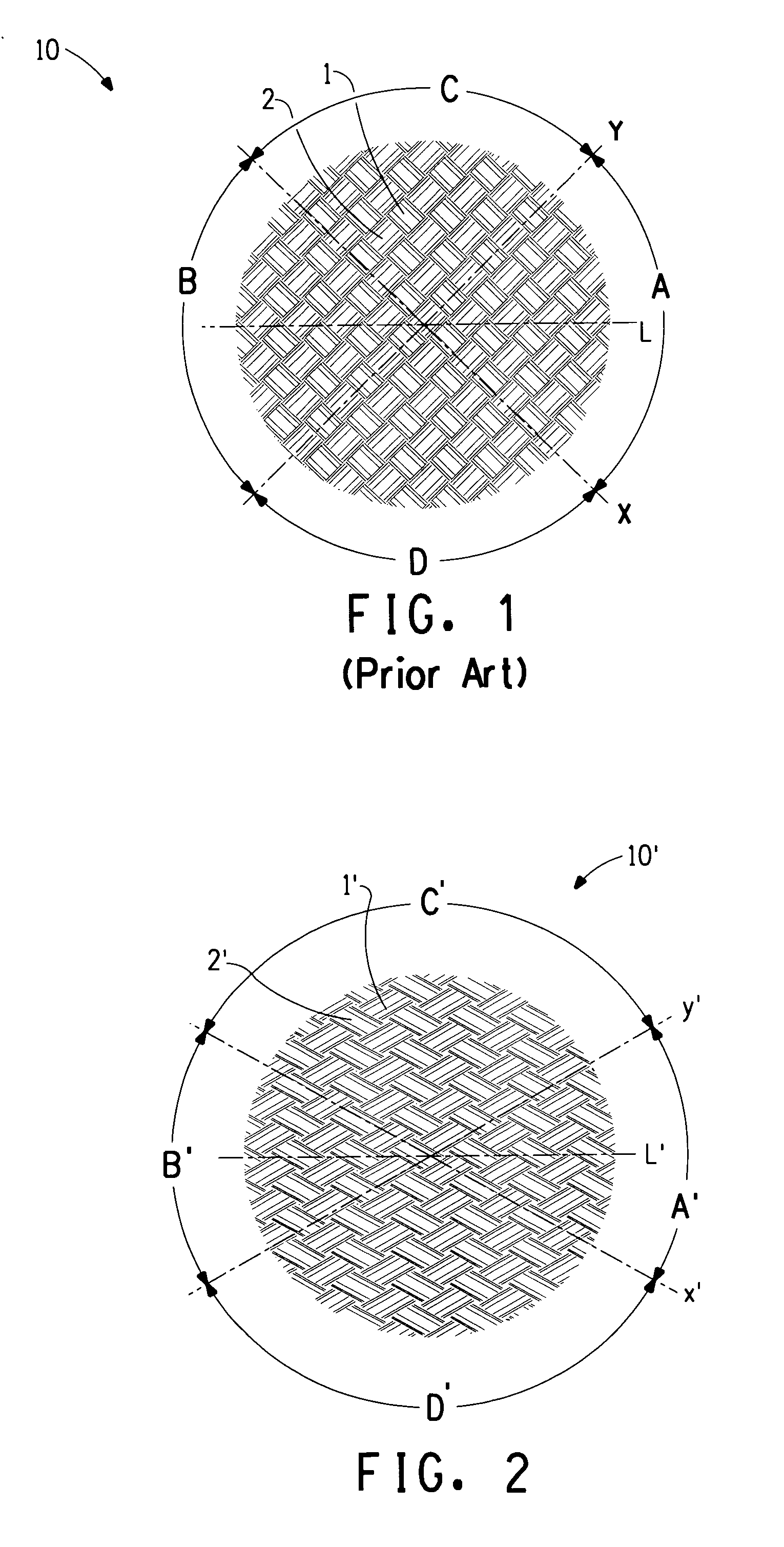

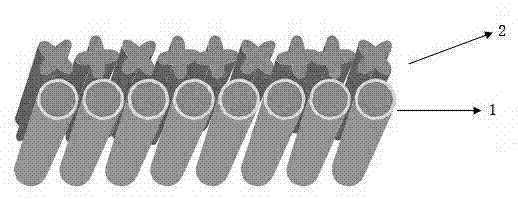

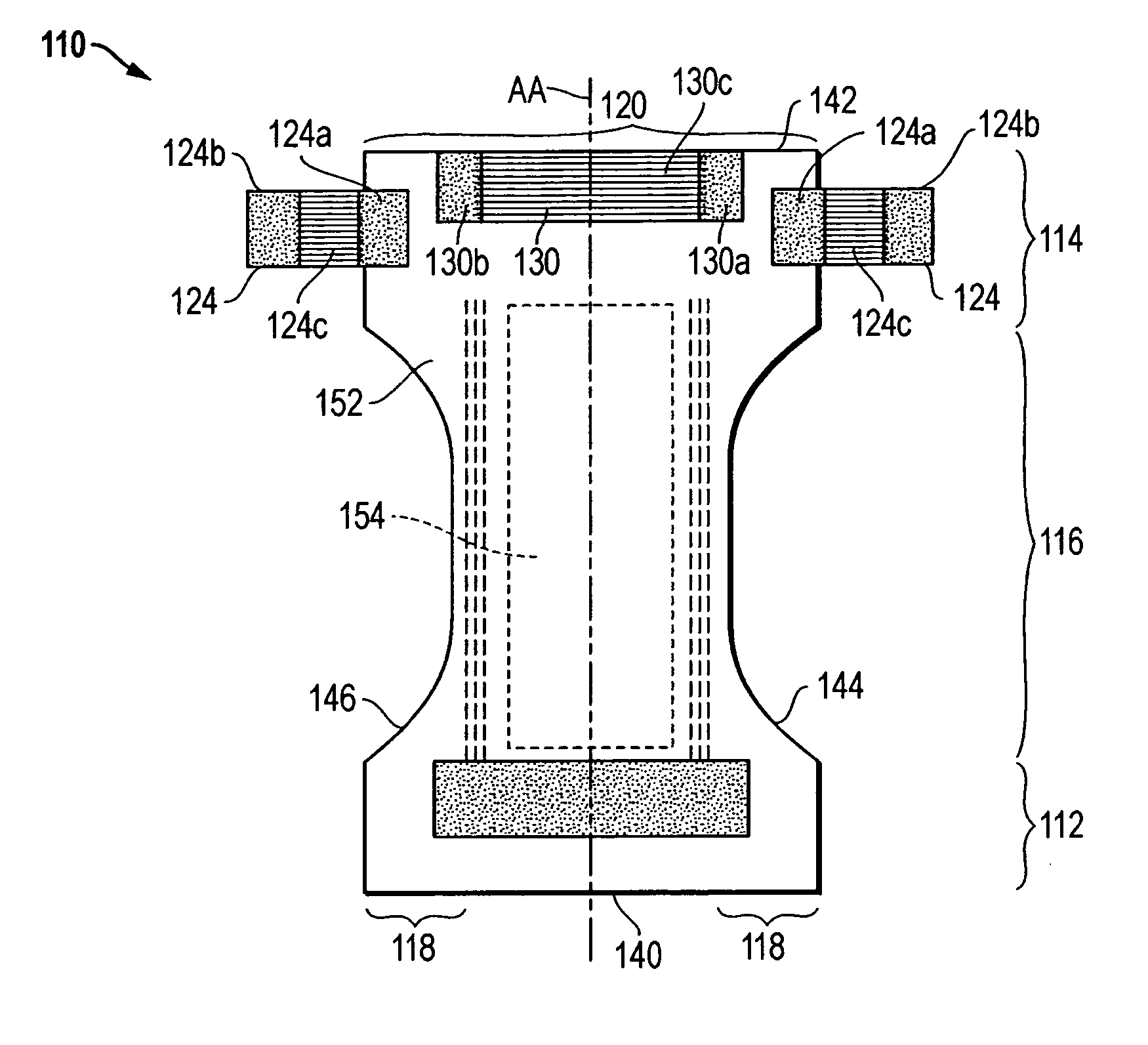

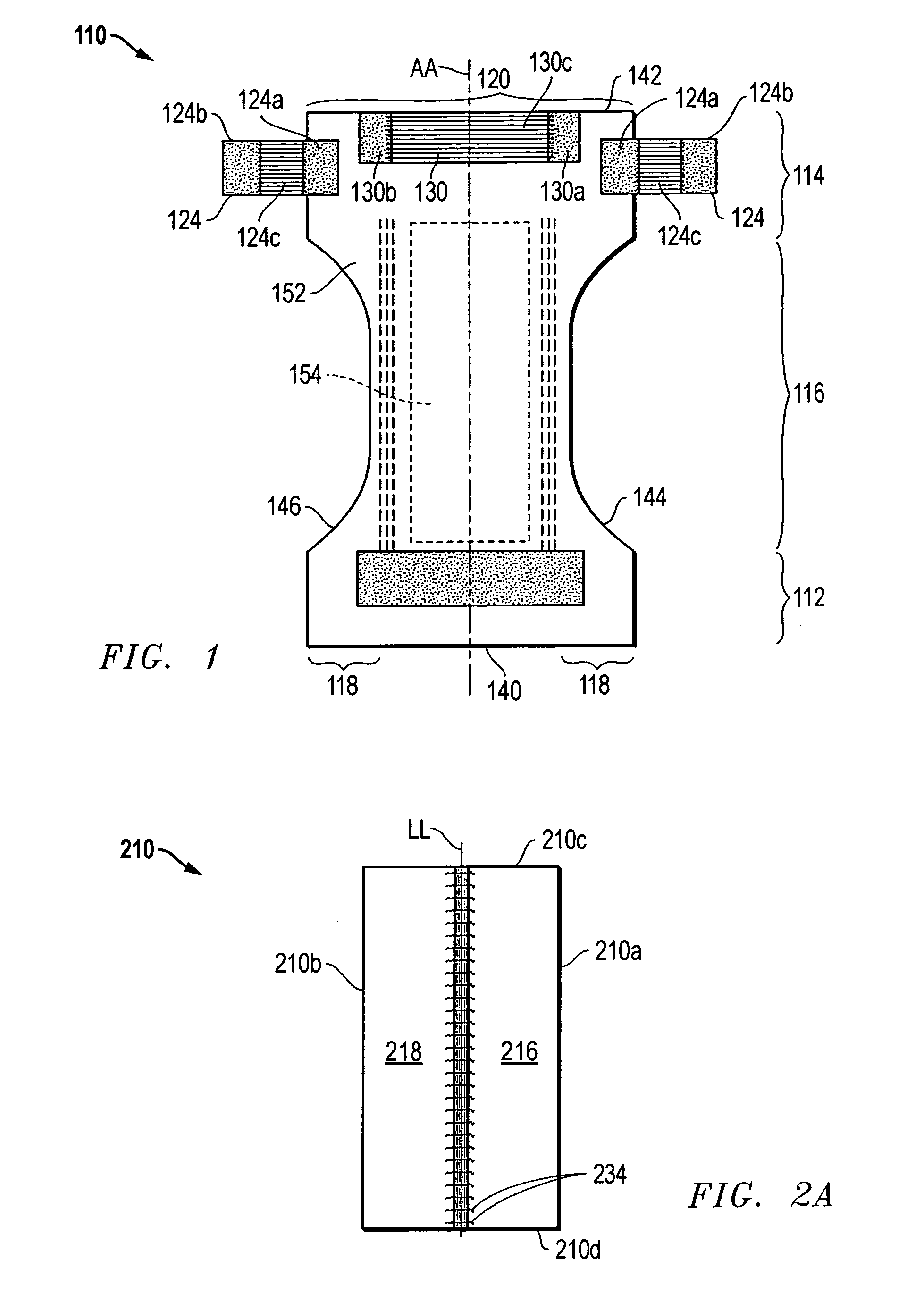

Balloon catheter covers are elastic fabric structures of interconnected yarns, the structure having a high degree of stretch and recovery in the circumferential direction with little change in dimension in the longitudinal direction during multiple pressurization cycles over full range of inflation and deflation of the balloon catheter. The covers have longitudinal yarns positioned at about zero degrees to the balloon axis and reversibly-stretchable, circumferential yarns positioned at a high angle Ø to the axis. A method for making the balloon catheter covers allowing nearly orthogonal placement of circumferential and longitudinal yarns involves triaxial braiding a minimum number of elastomeric braid yarns with multiple axial yarns to provide maximum convergence angle (approaching 90 degrees).

Owner:EI DU PONT DE NEMOURS & CO

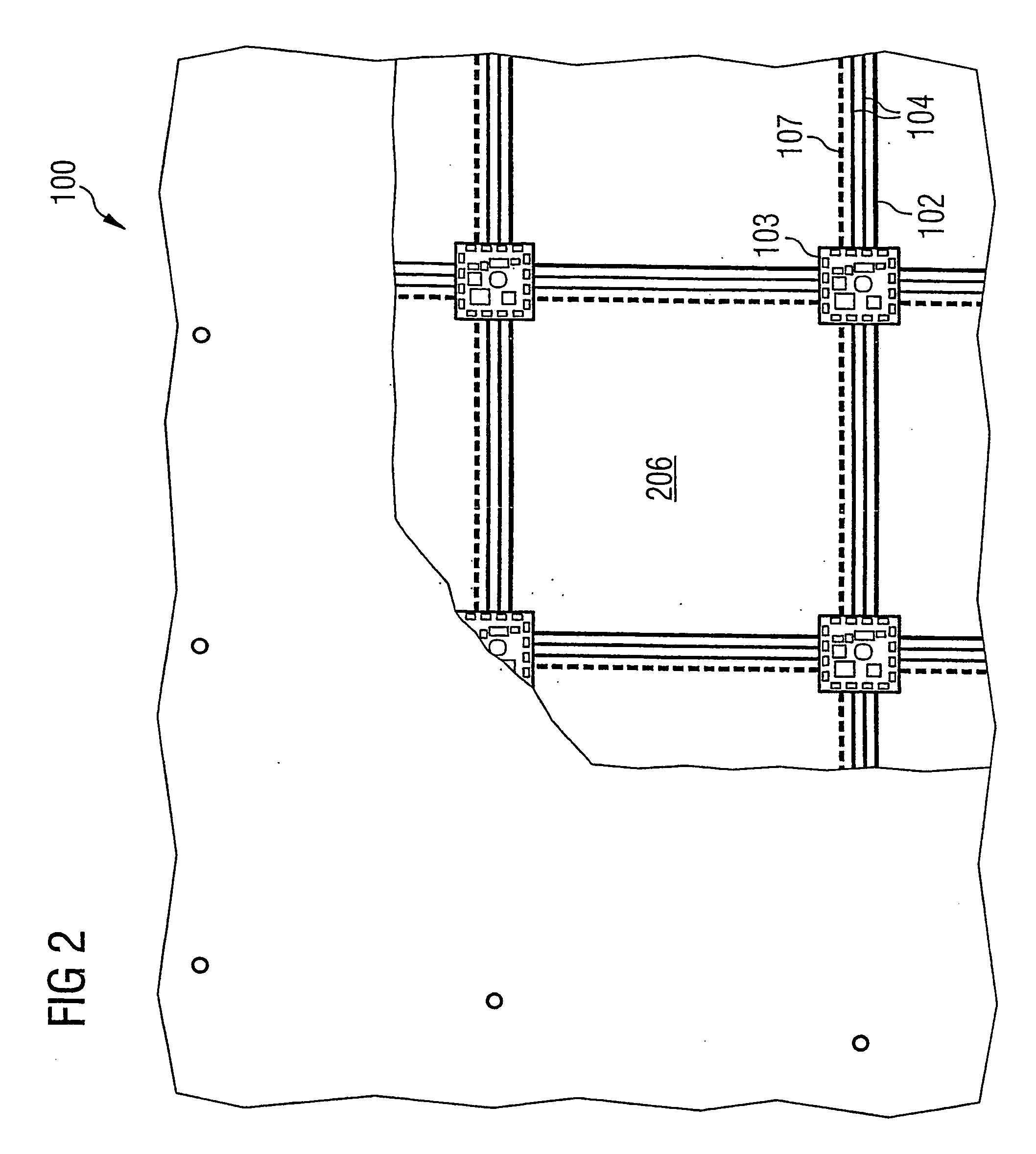

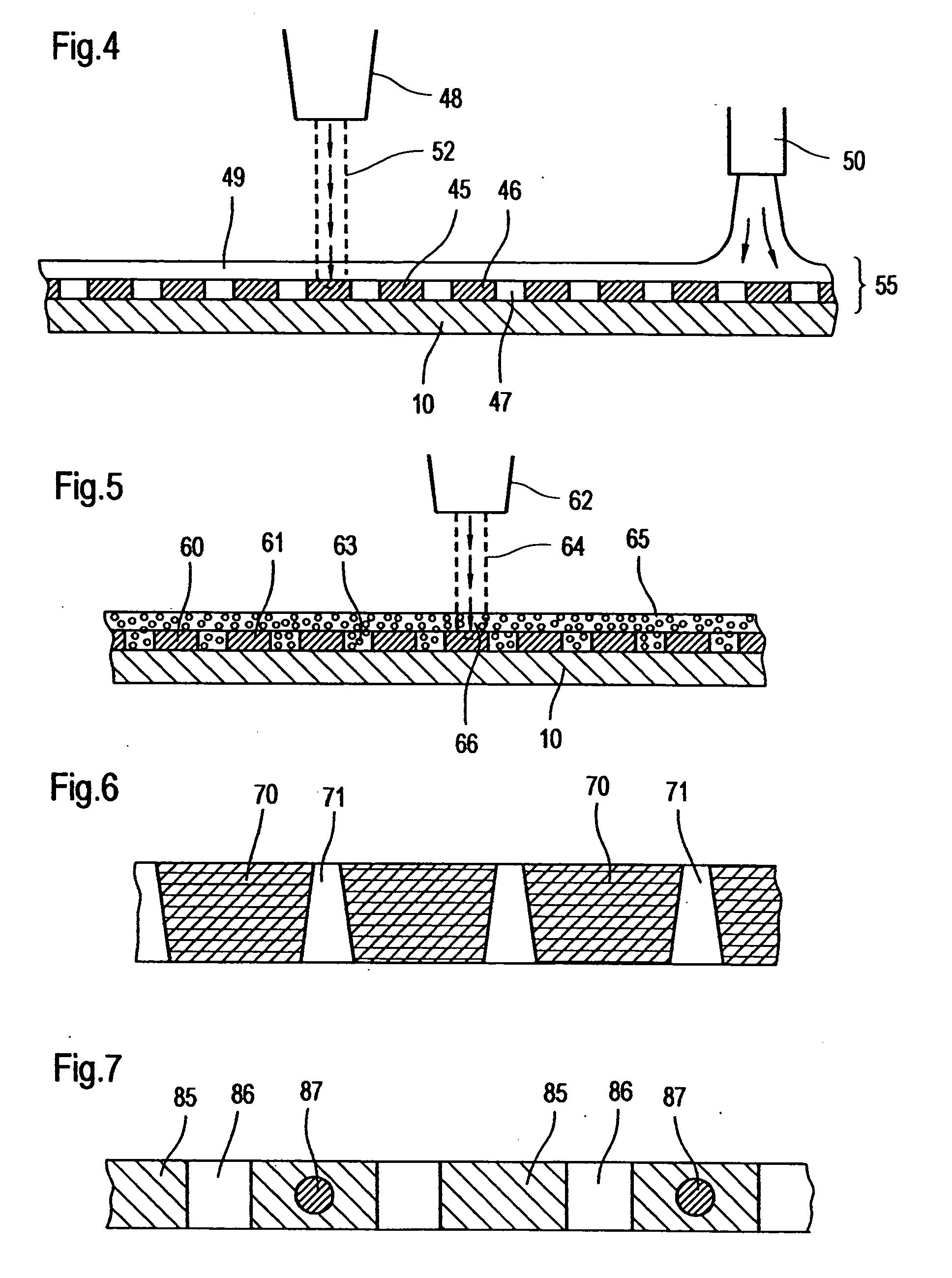

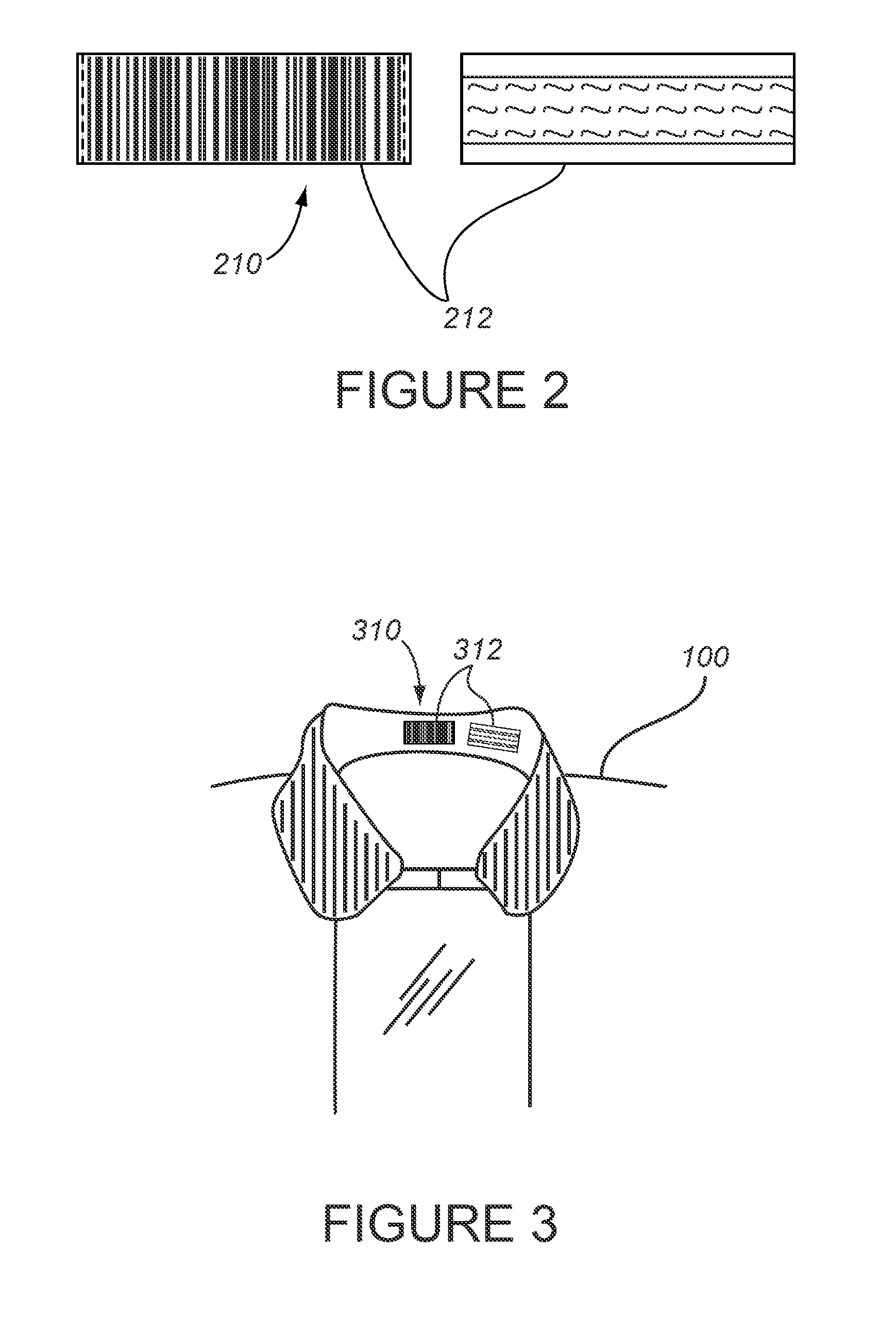

Textile fabric structure

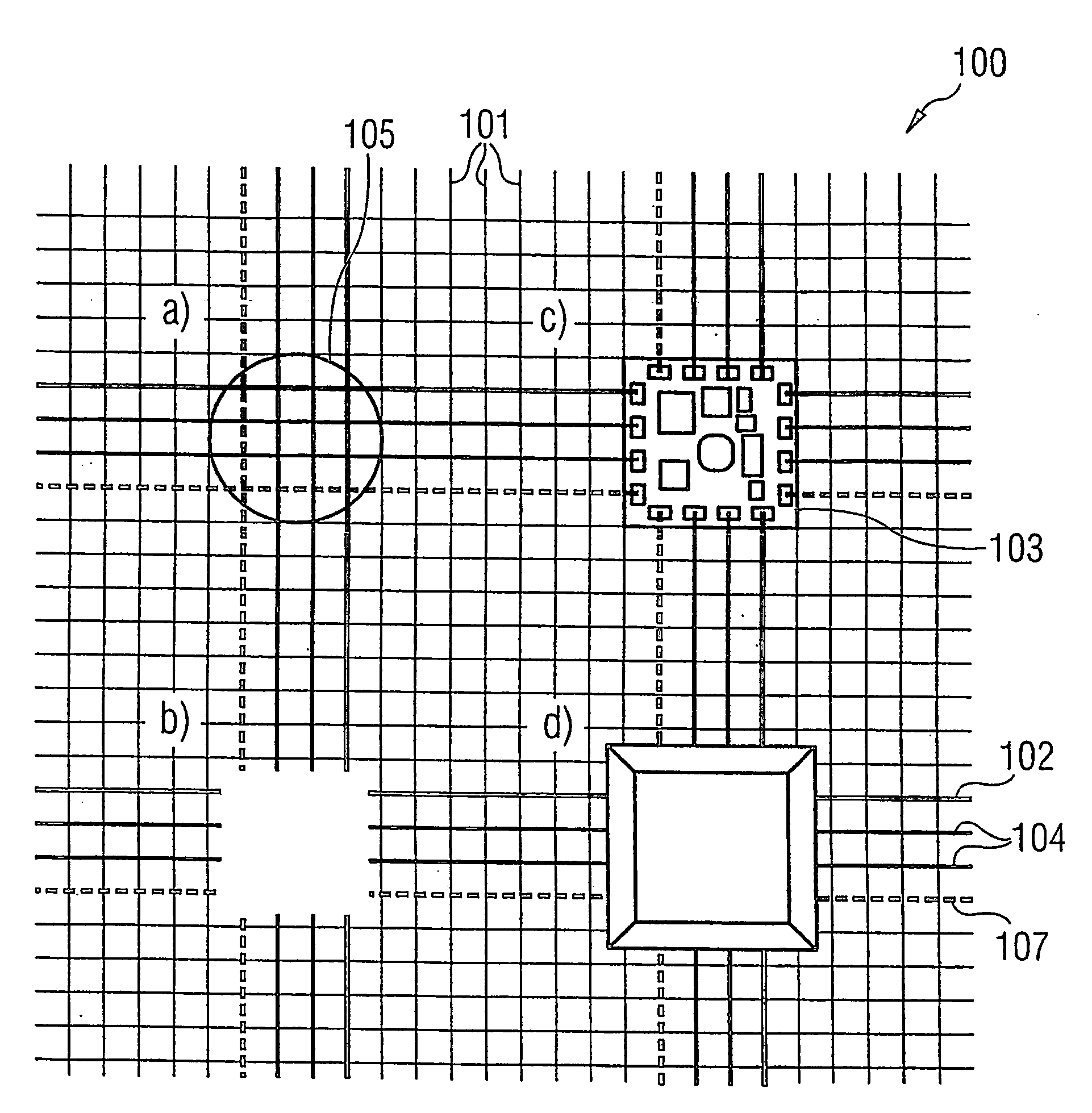

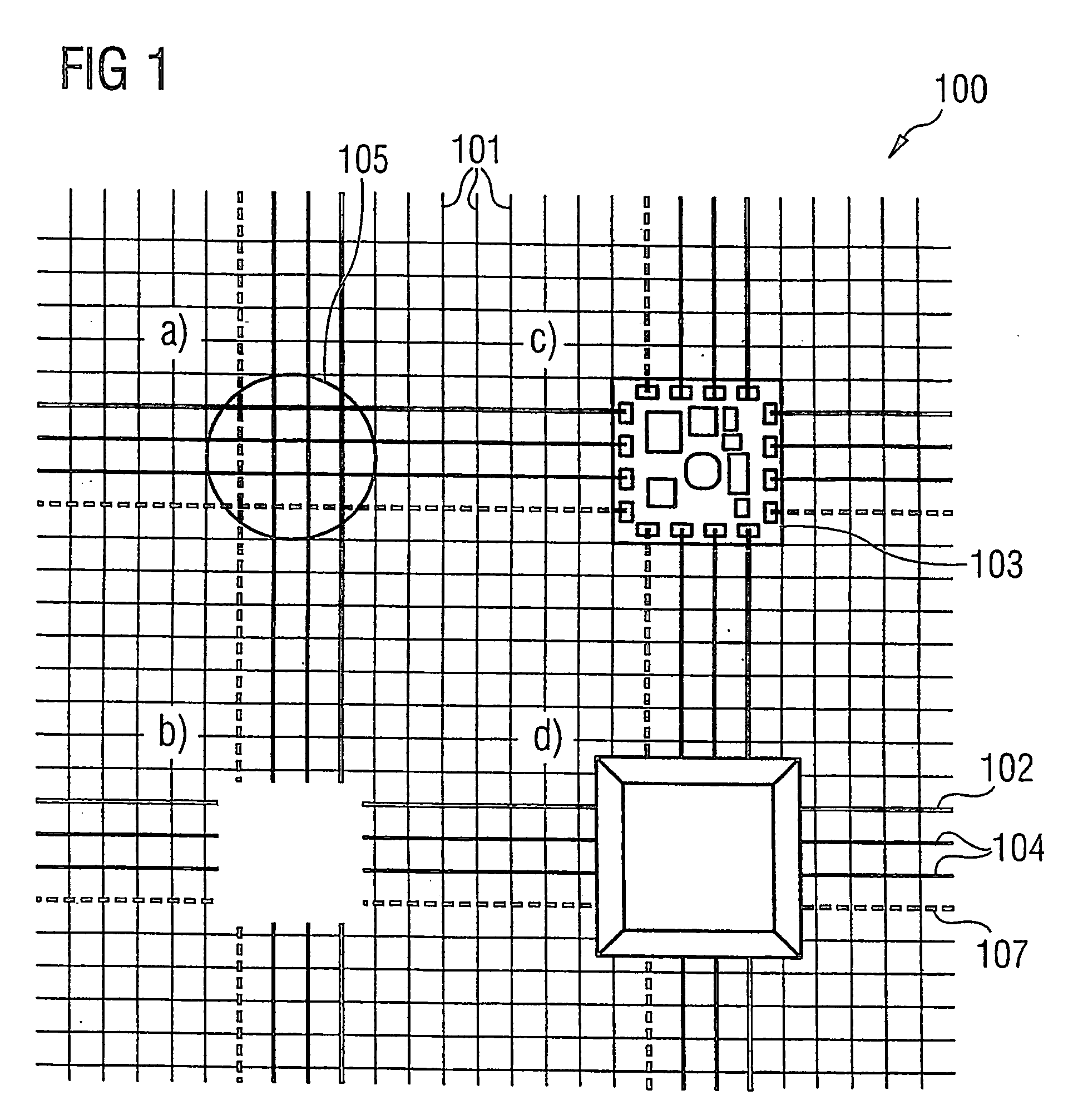

InactiveUS20060035554A1Circuit optical detailsPrinted circuit aspectsData transmissionFabric structure

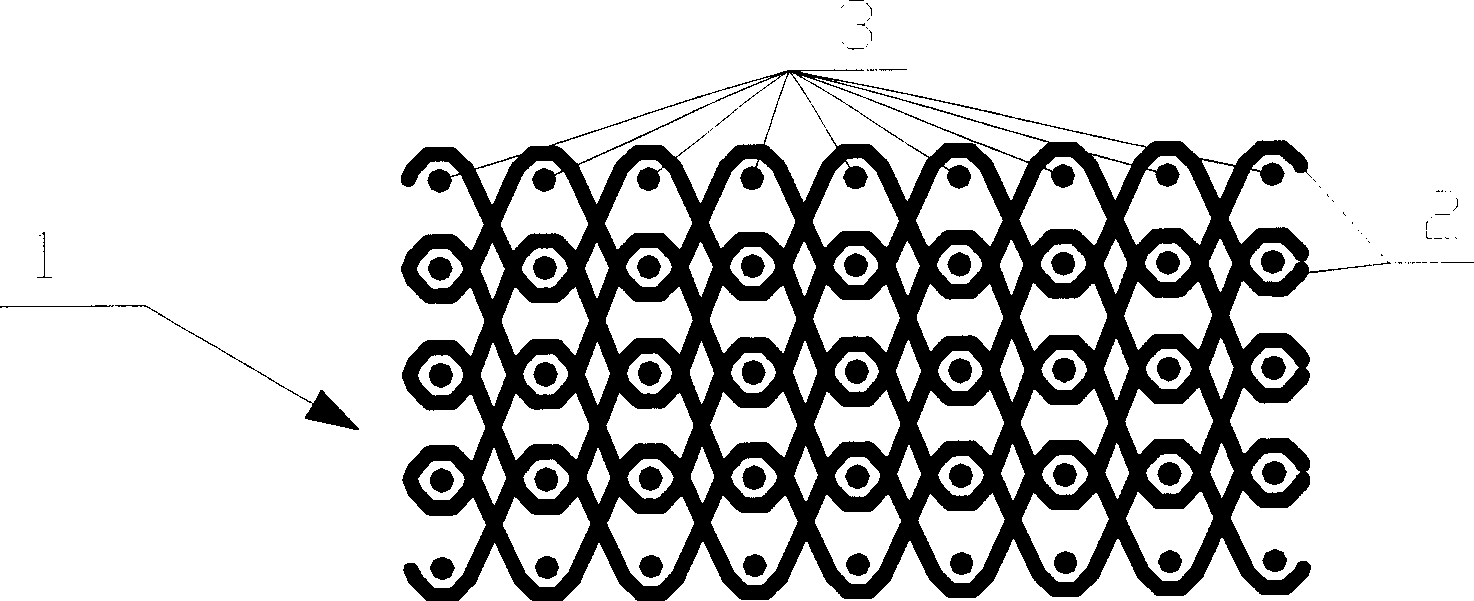

A textile fabric structure having a plurality of microelectronic components, which are arranged in the textile fabric structure, electrically conductive threads, which couple the plurality of microelectronic components to one another, conductive data transmission threads, which couple the plurality of microelectronic components to one another, and electrically nonconductive threads. The conductive threads and the conductive data transmission threads at the edge of the textile fabric structure are each provided with an electric interface and a data transmission interface.

Owner:INFINEON TECH AG

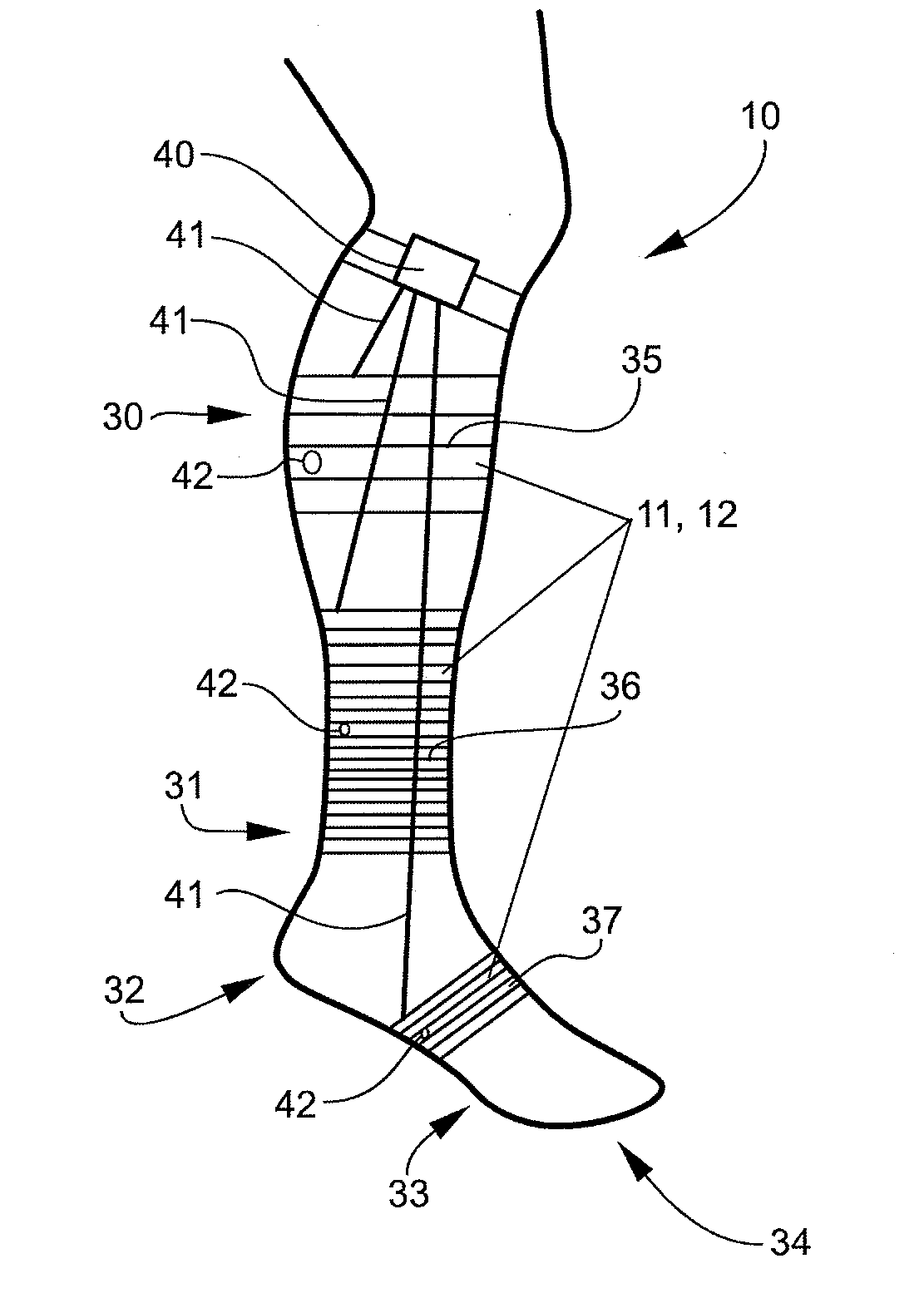

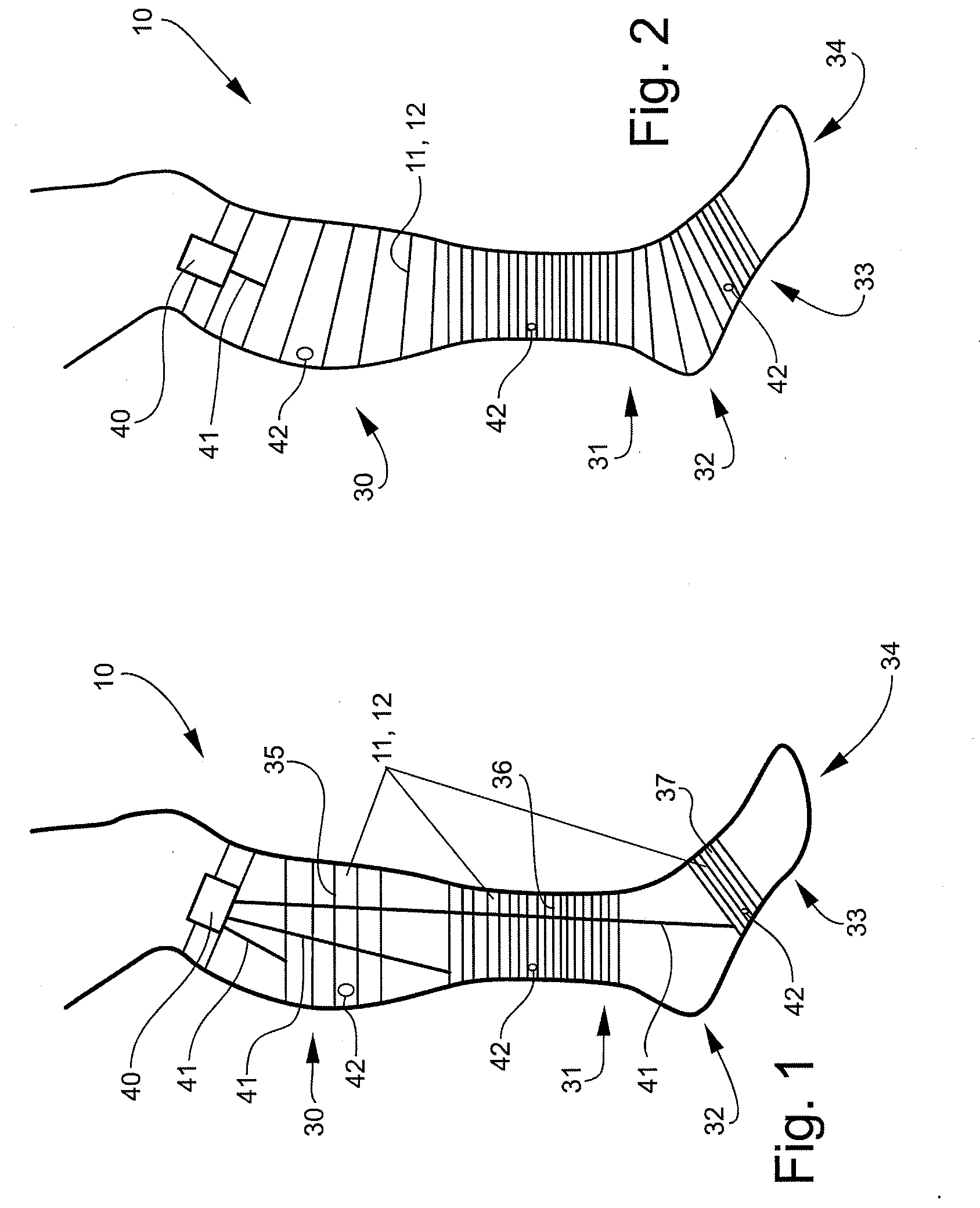

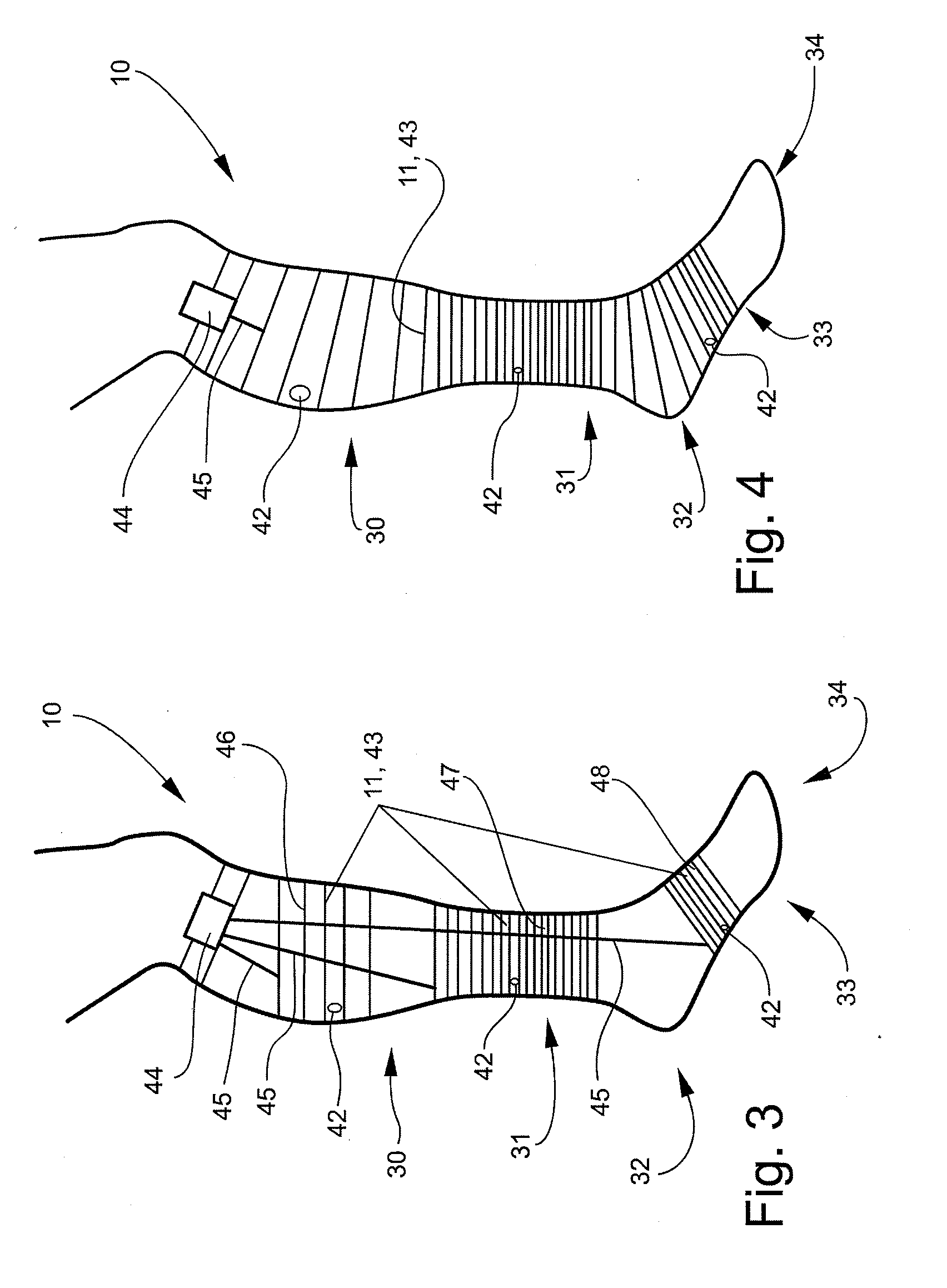

Compression Adjustable Fabric and Garments

A compression adjustable fabric and / or garment, system, and / or method can include a compression element (a) integrated into a fabric structure, (b) having a compressive pressure capability independent from compressive pressure capabilities inherent in the fabric structure, and (c) adjustable to provide various compressive pressures. In such a garment, the compressive pressure provided by the garment can be adjusted in all or part of the garment while the garment is being worn. The compressive pressures in different parts of the garment may be independently adjustable. The compression element can further comprise an inflatable tube and / or an electrically stimulatable yarn. The compression element can be integrated into the fabric structure by being knit into, or laid in, the fabric structure.

Owner:CAROLON

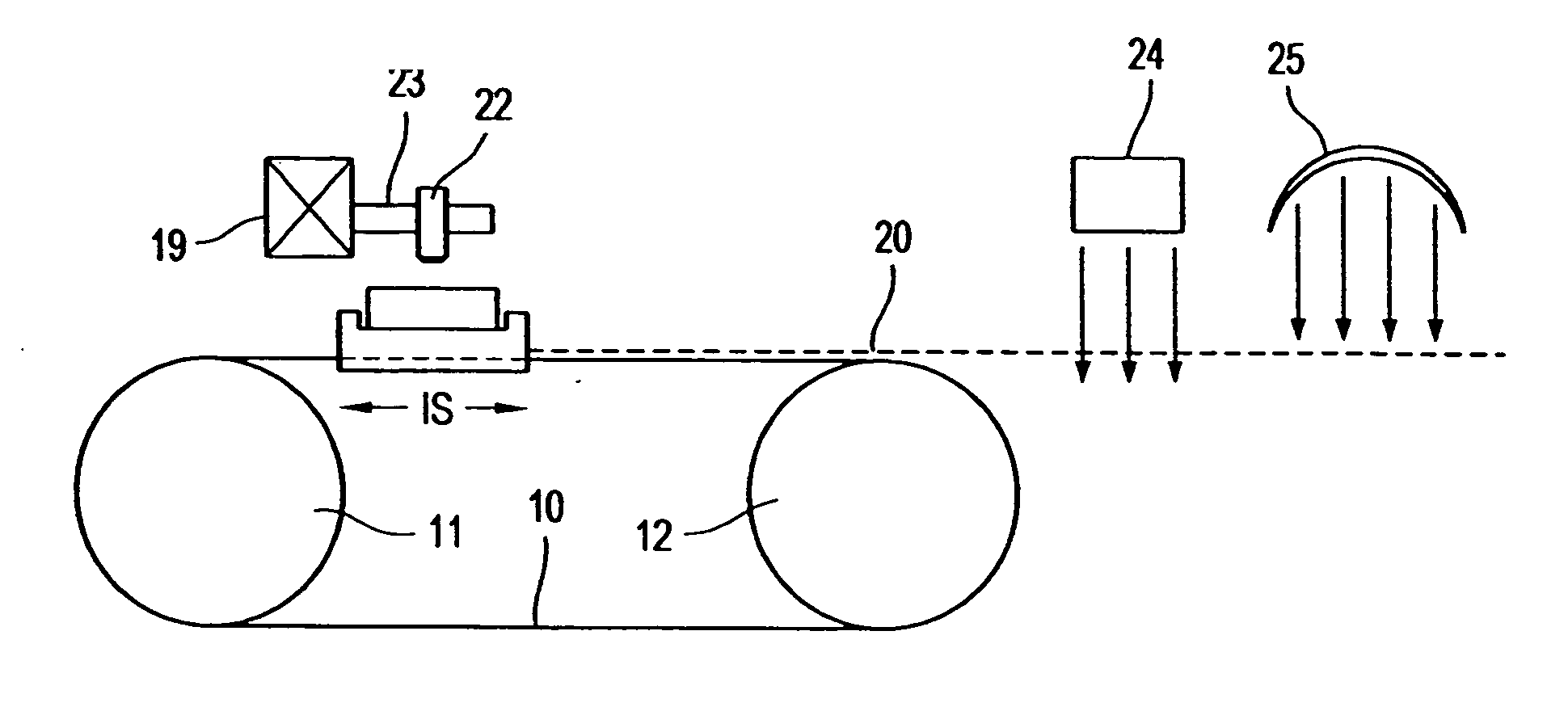

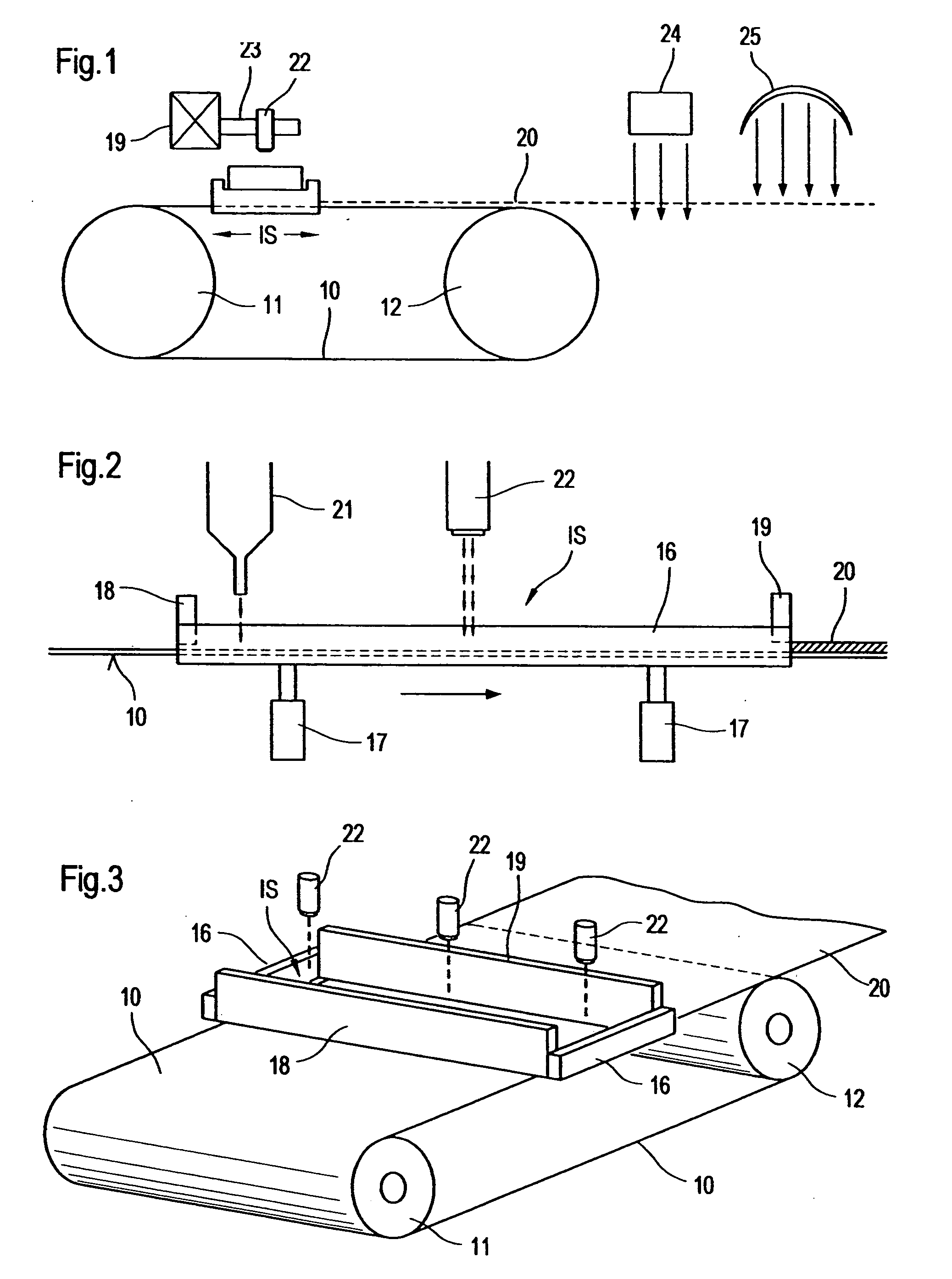

Manufacture of papermachine fabrics

Paper machine clothing method including covering an extended working surface with successive layers of a resultant material. Treating each successive layer with an energy source in accordance with predetermined instructions before adding a next successive layer to build up a three-dimensional fabric structure. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:VOTH FABRICS PATENT GMBH

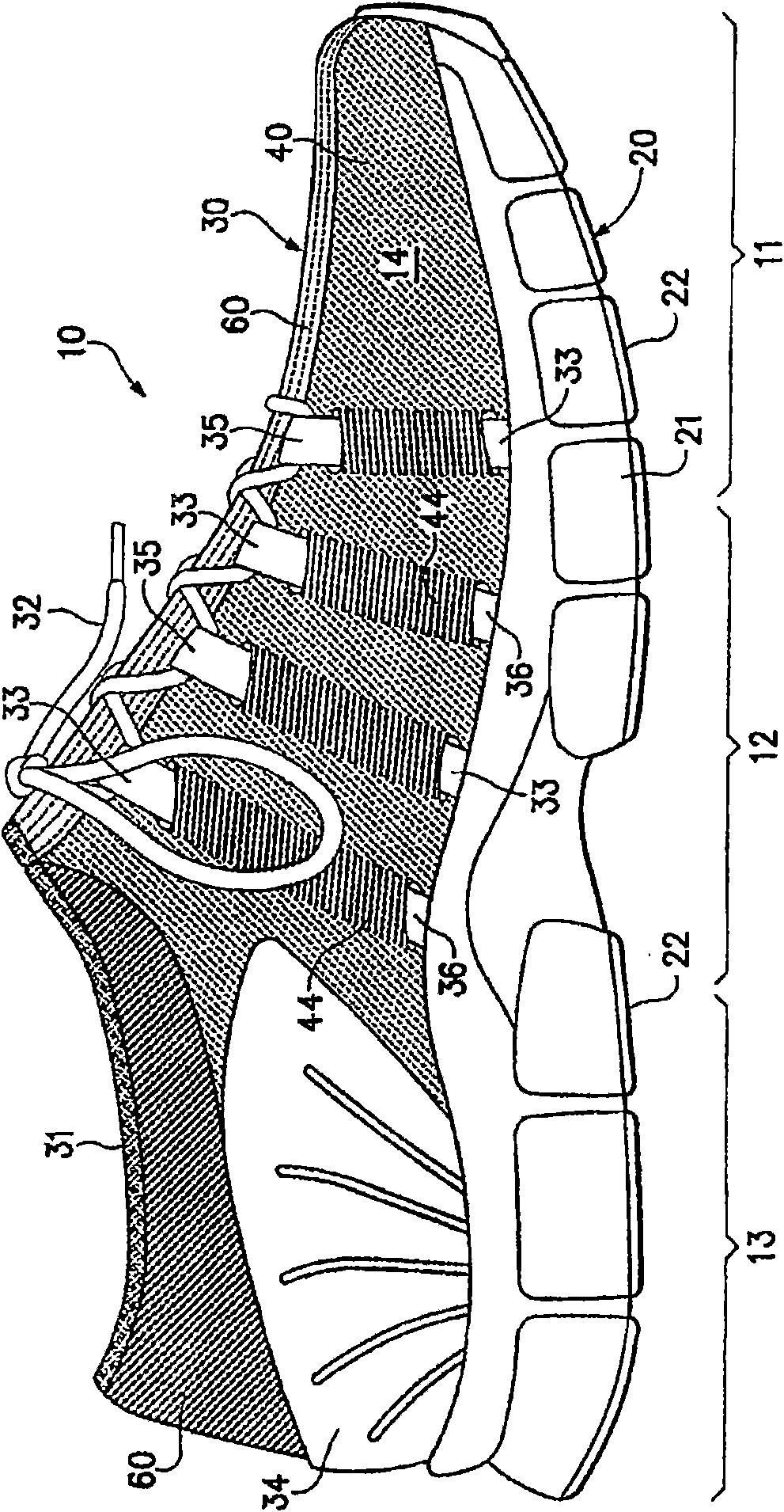

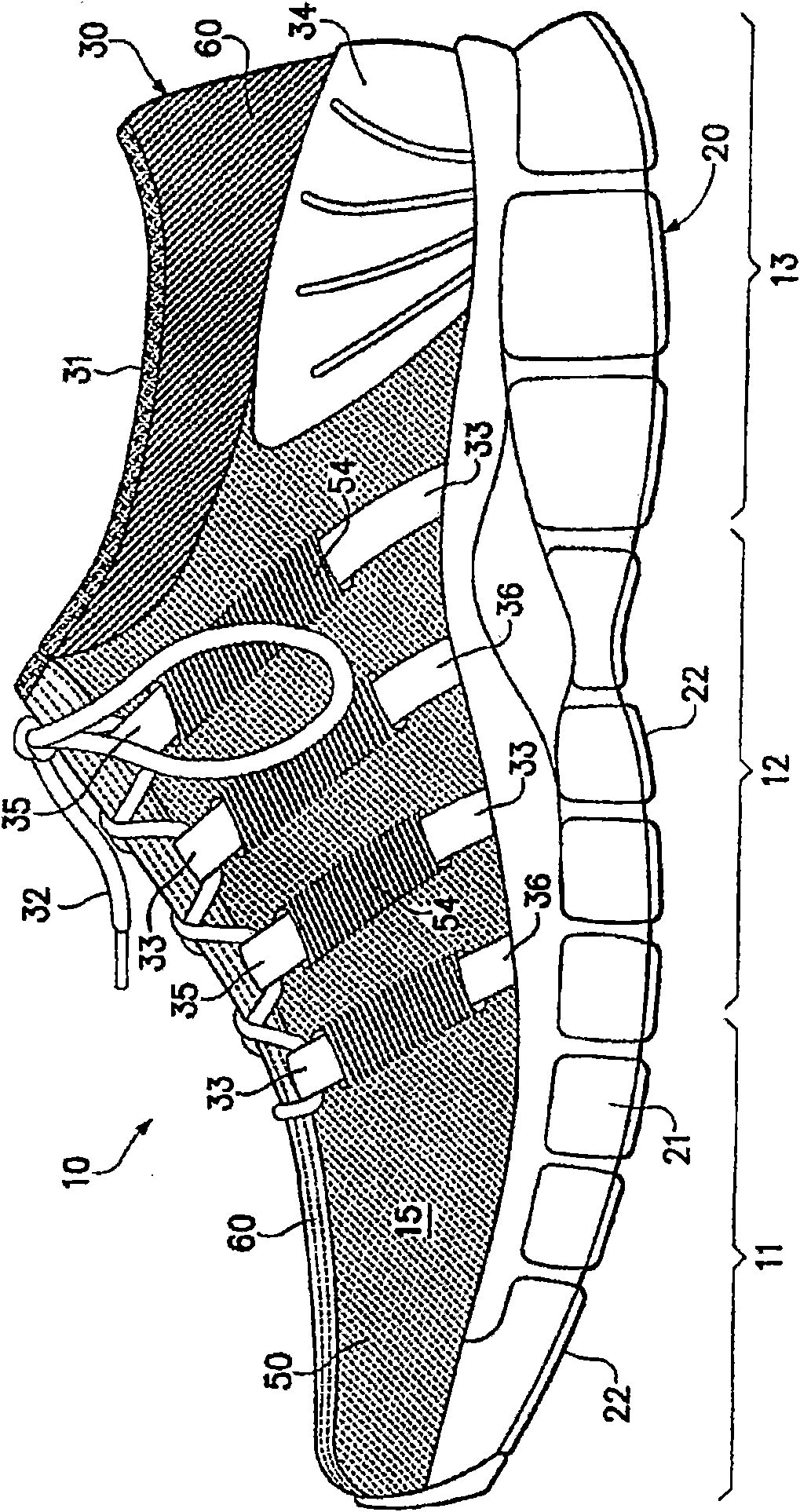

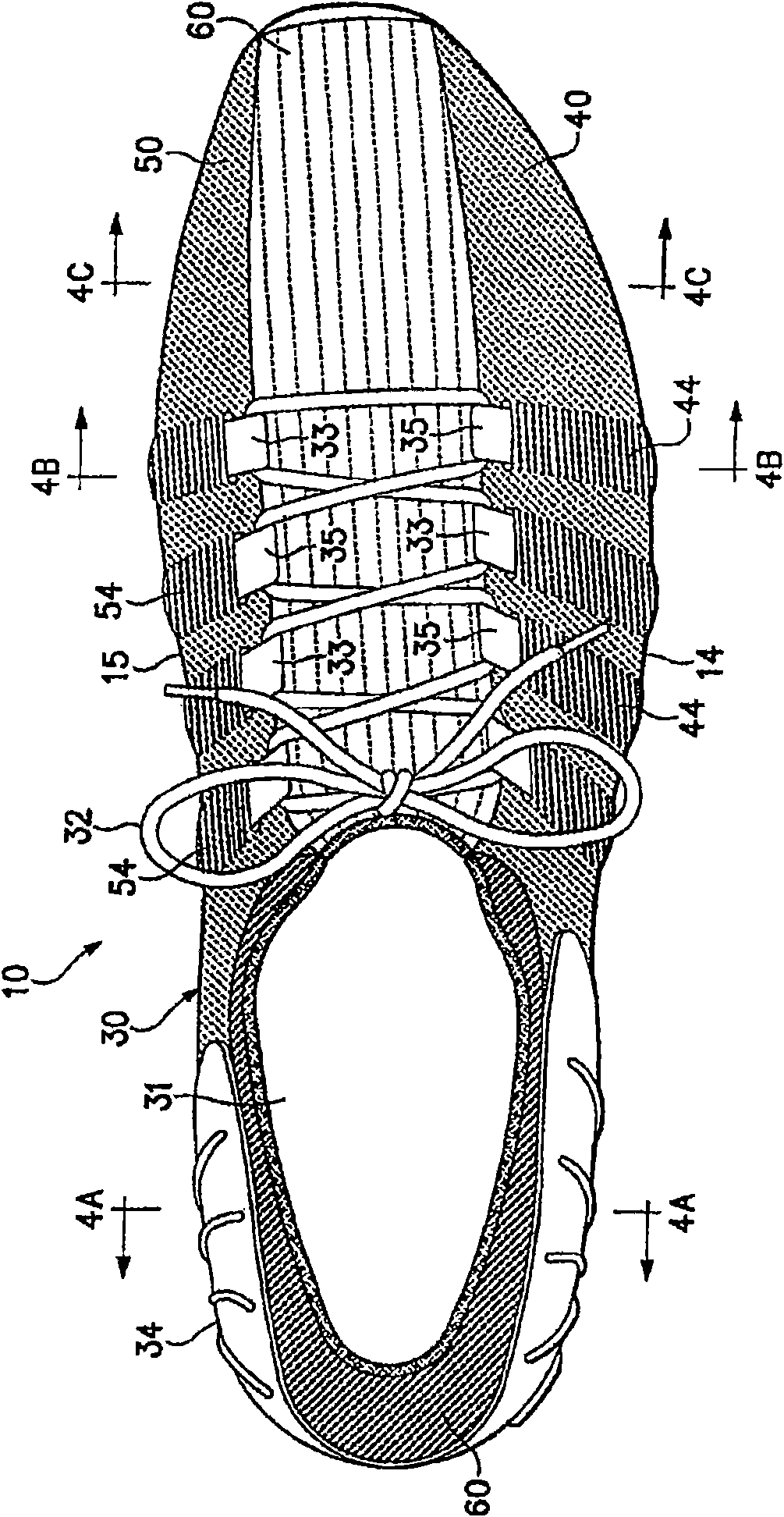

Article of footwear having a flat knit upper construction or other upper construction

Flat knitting allows production of textile structures (e.g., for use in footwear uppers) of a final desired shape such that textile cutting steps can be avoided. Flat knitted elements also can be formed directly in desired three dimensional shapes, which can help avoid the need to use additional support structures (e.g., in footwear construction). By selectively placing multiple different yarns and / or stitch patterns at multiple different locations in the overall structure during the knitting process, flat knitted products may have multiple different physical properties (e.g., different stretchability, different moisture management capabilities, etc.) at multiple different locations or zones within a single, unitary construction (e.g., different properties at different zones or locations within a single footwear structure). Additionally, flat knitting can be used to produce pockets, tunnels, or other layered structures in the final product.

Owner:NIKE INNOVATE CV

Transducer including fibers and outputting and inputting an electric signal

InactiveUS20170029985A1High strengthIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesGeneral purposeFiber

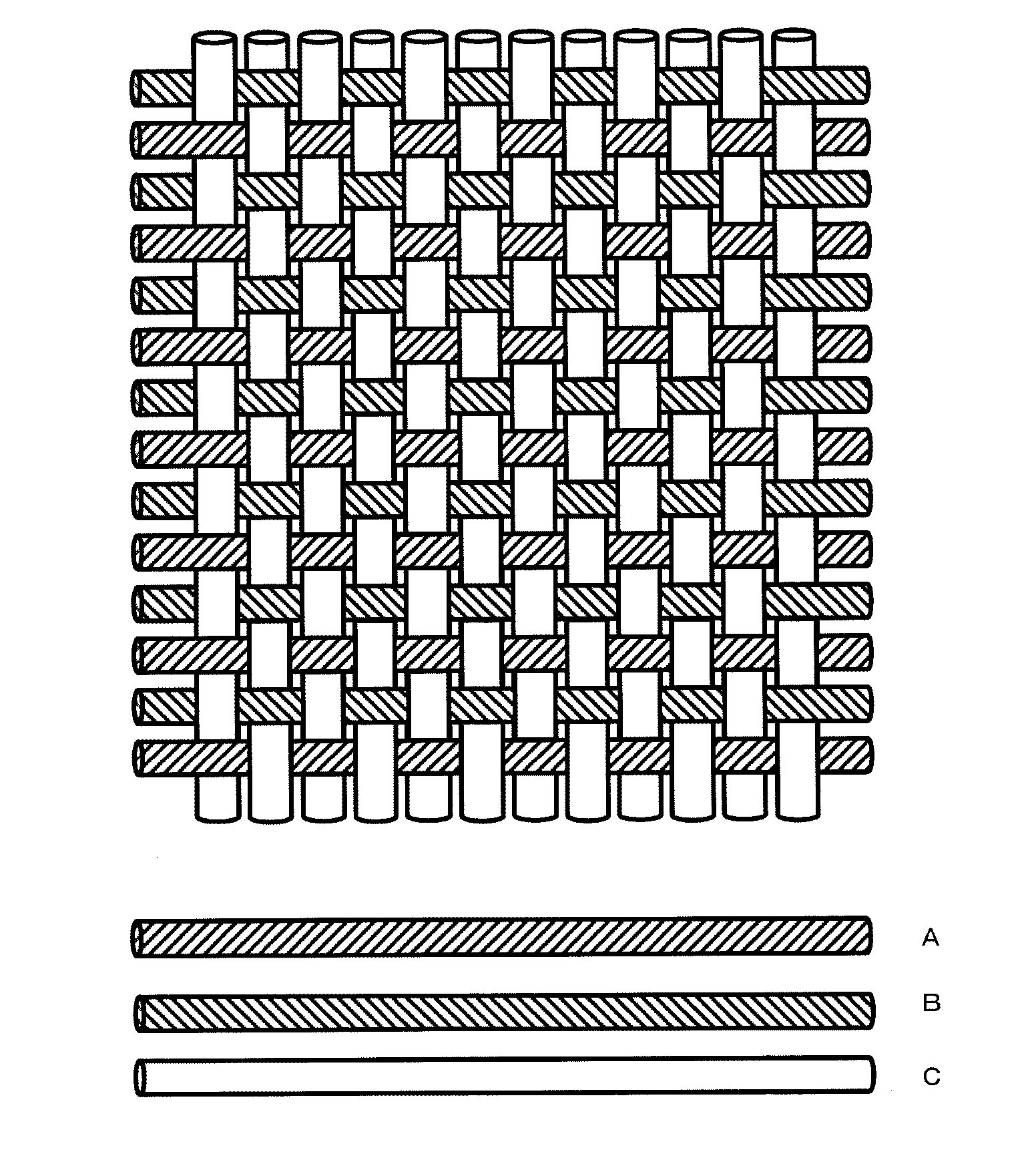

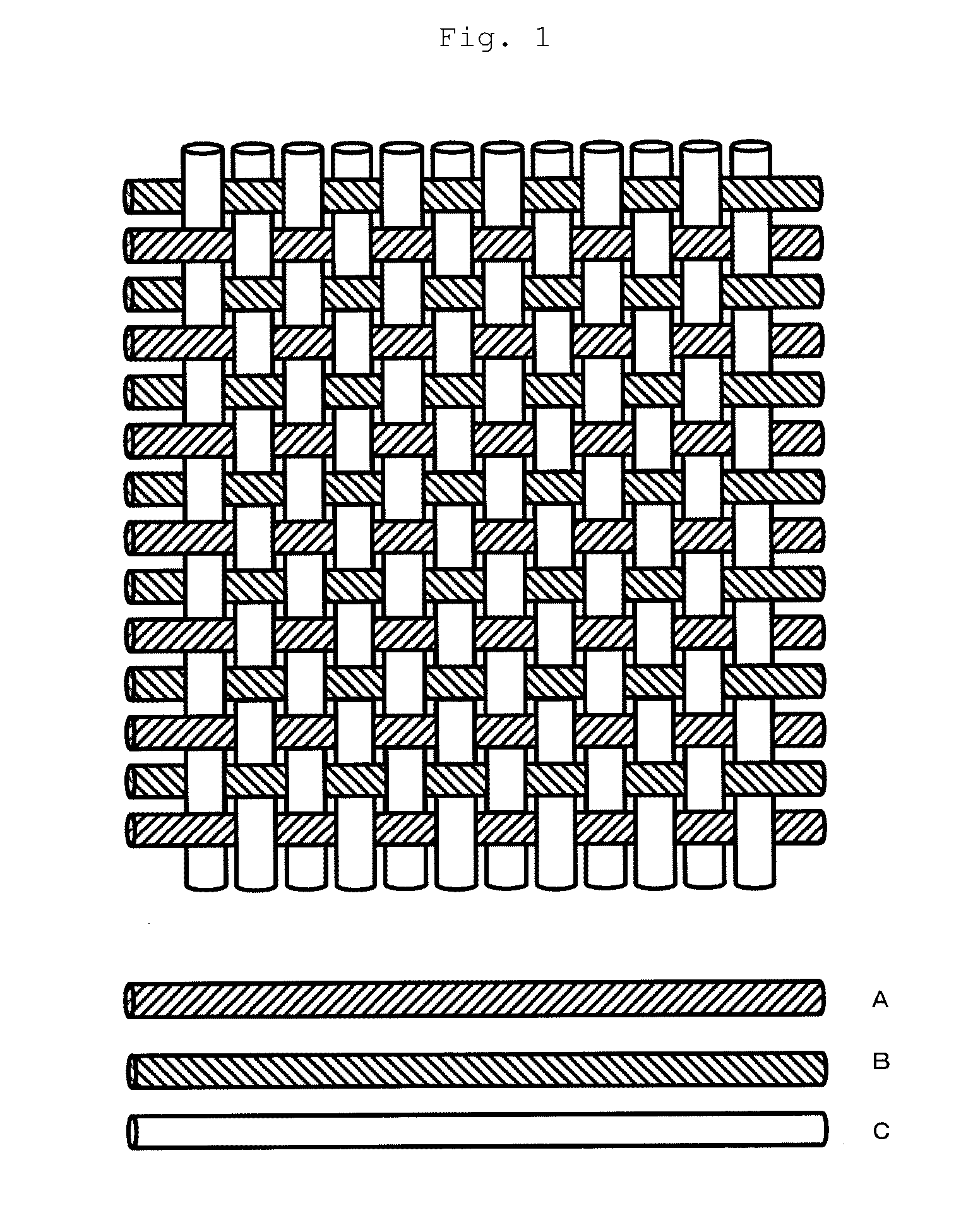

A transducer in the form of cloth having high flexibility obtained by manufacturing a conventional woven or knitted fabric structure using general-purpose fiber materials. The transducer includes piezoelectric units, each including two conductive fibers and one piezoelectric fiber arranged substantially on the same plane in the order of the conductive fiber, the piezoelectric fiber and the conductive fiber, and outputs and inputs an electric signal.

Owner:TEIJIN LTD +1

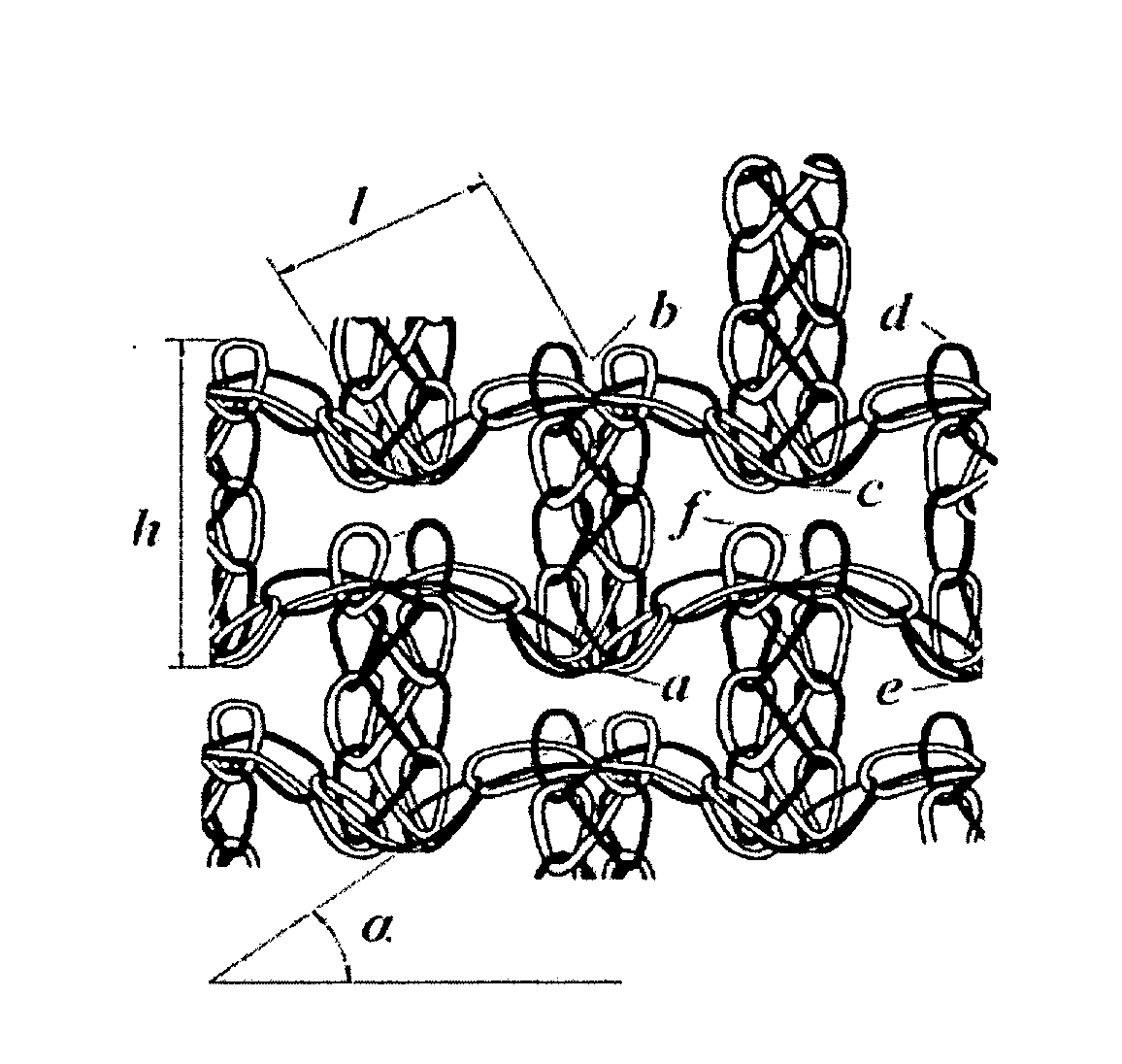

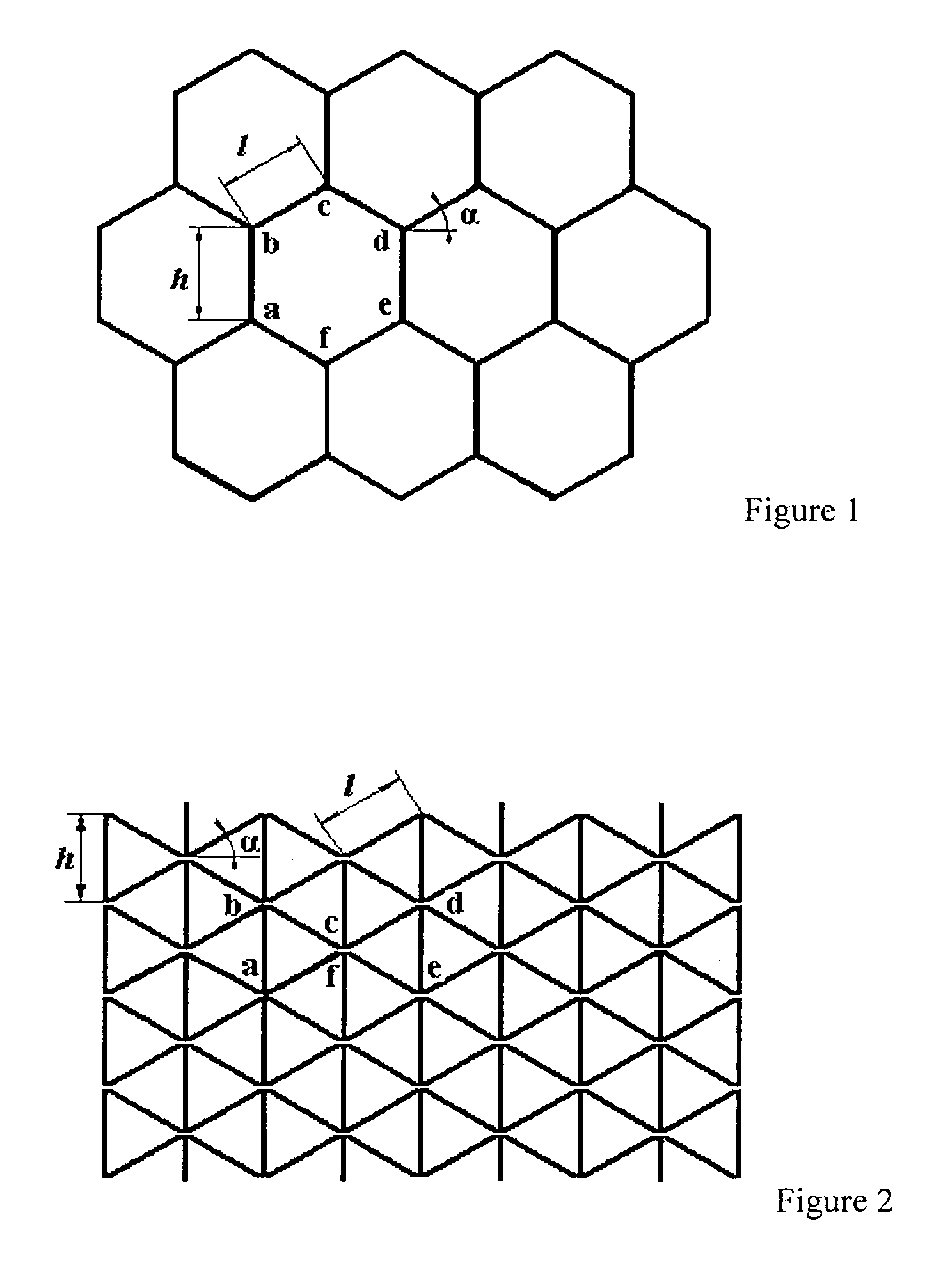

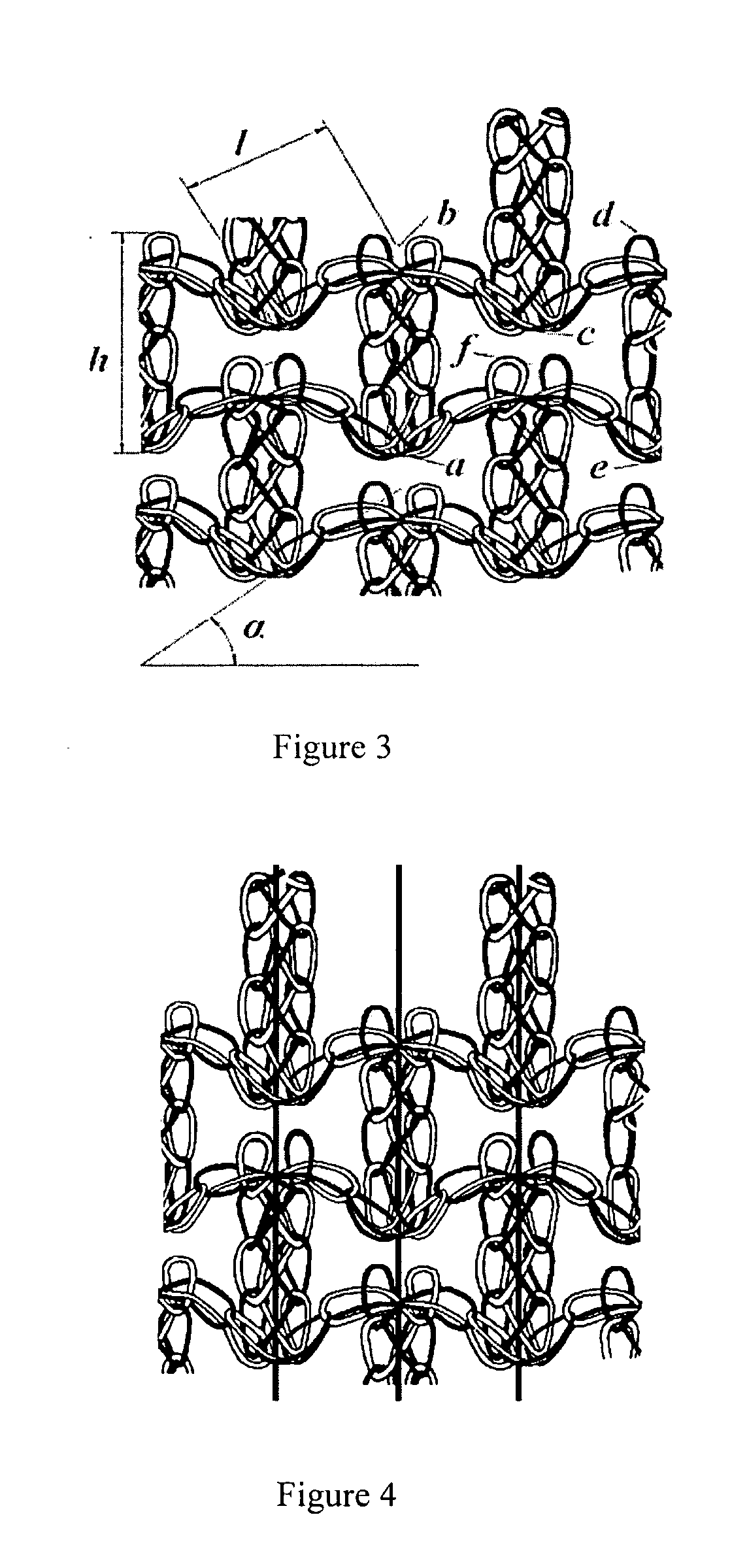

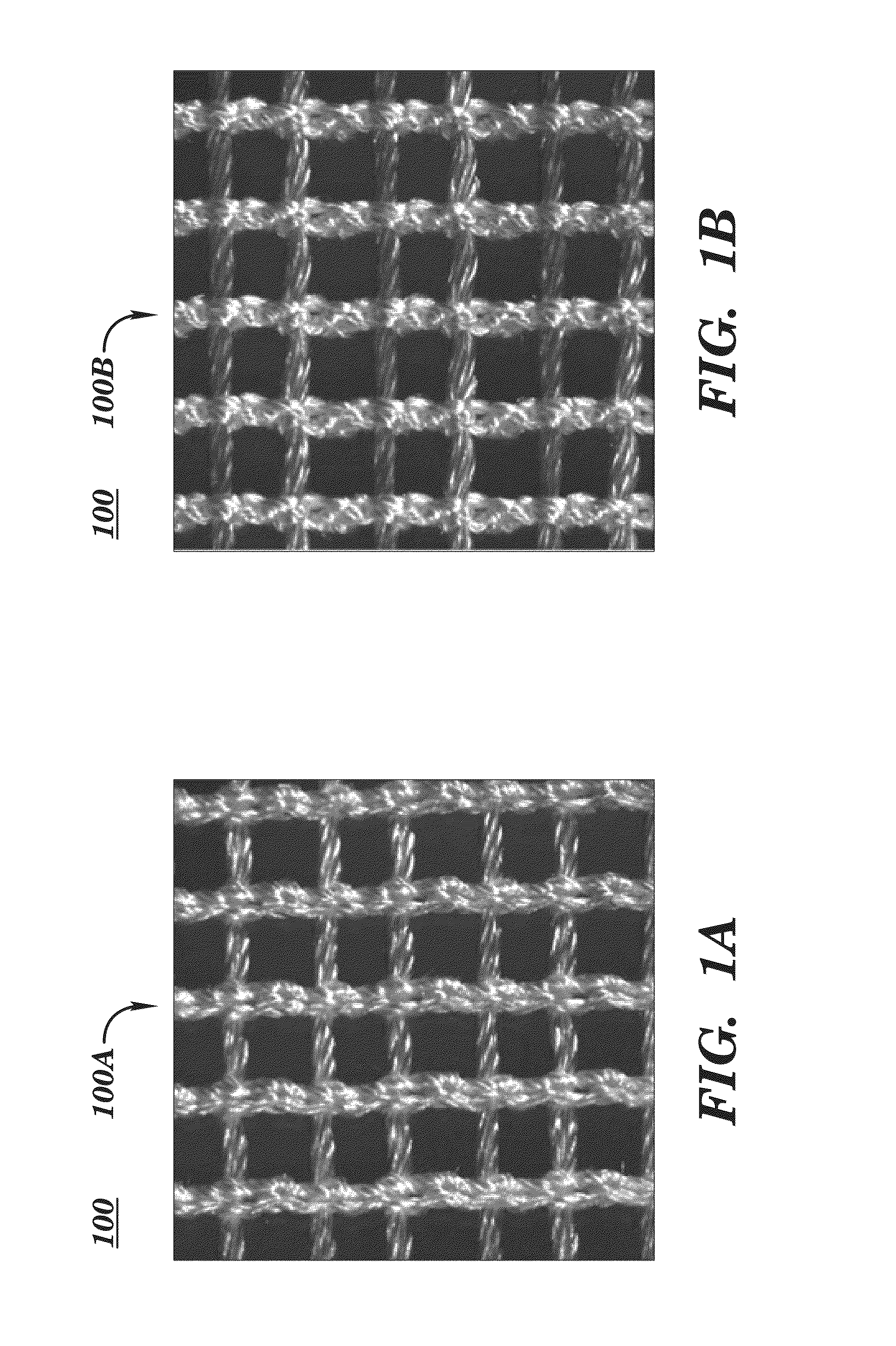

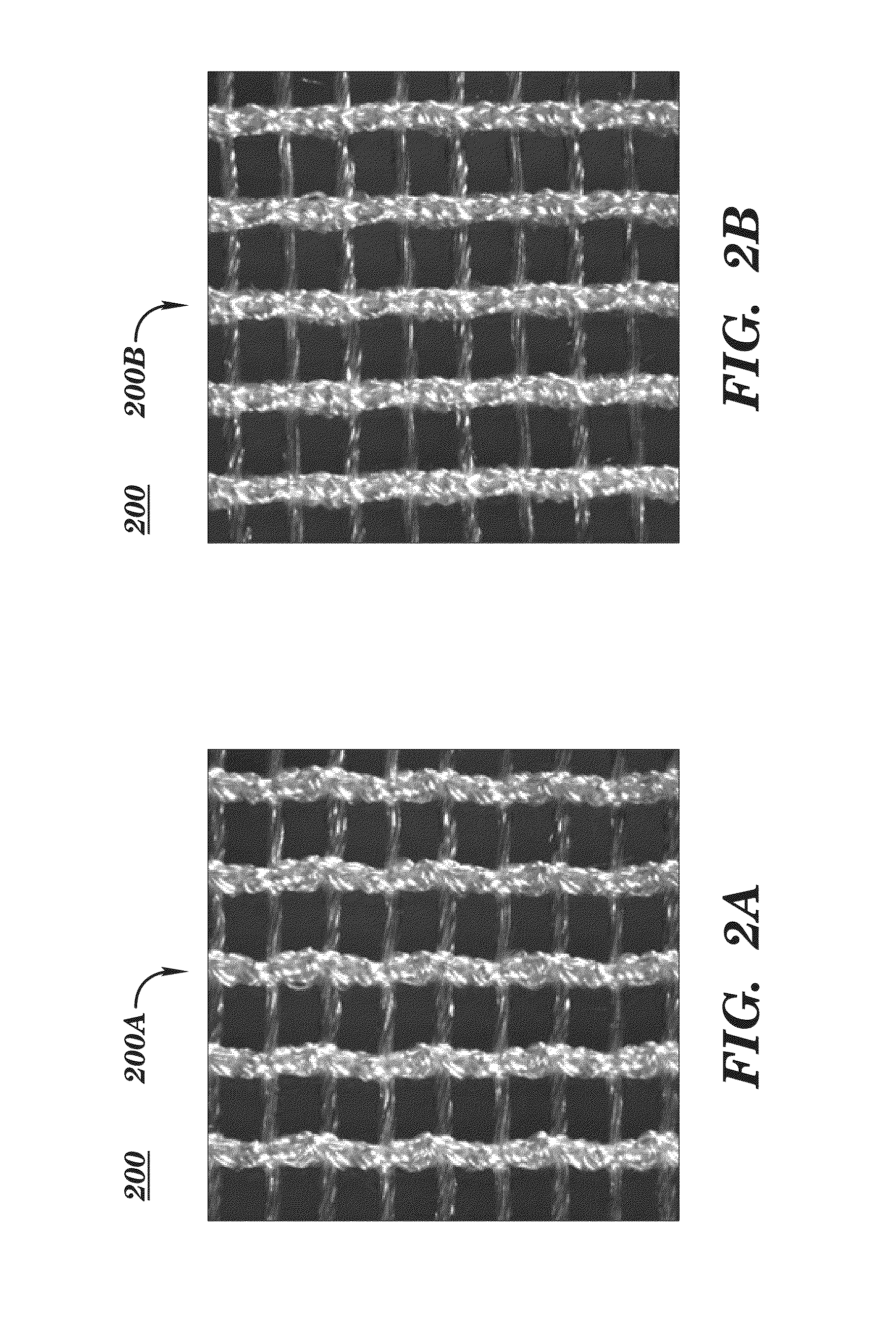

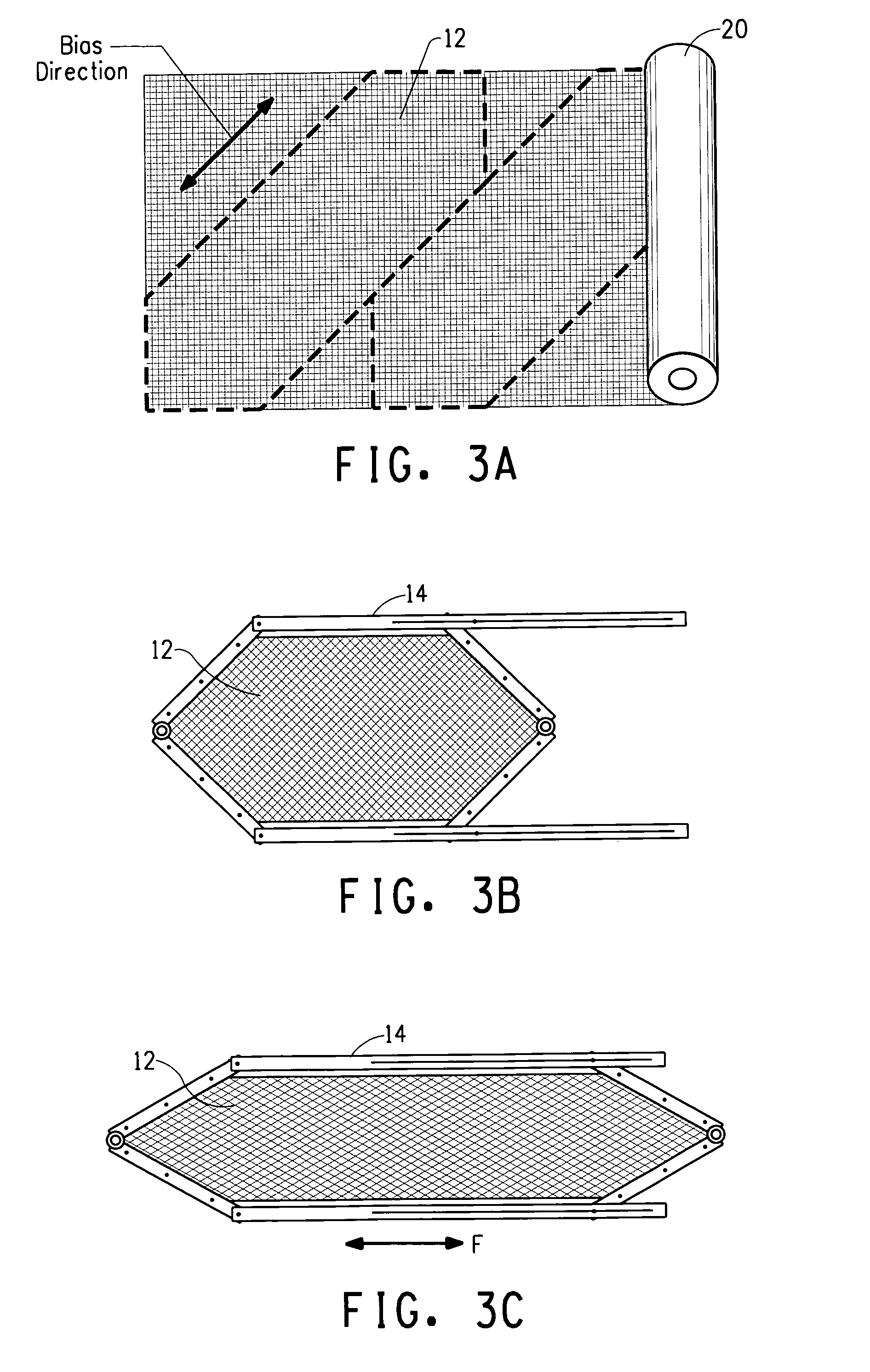

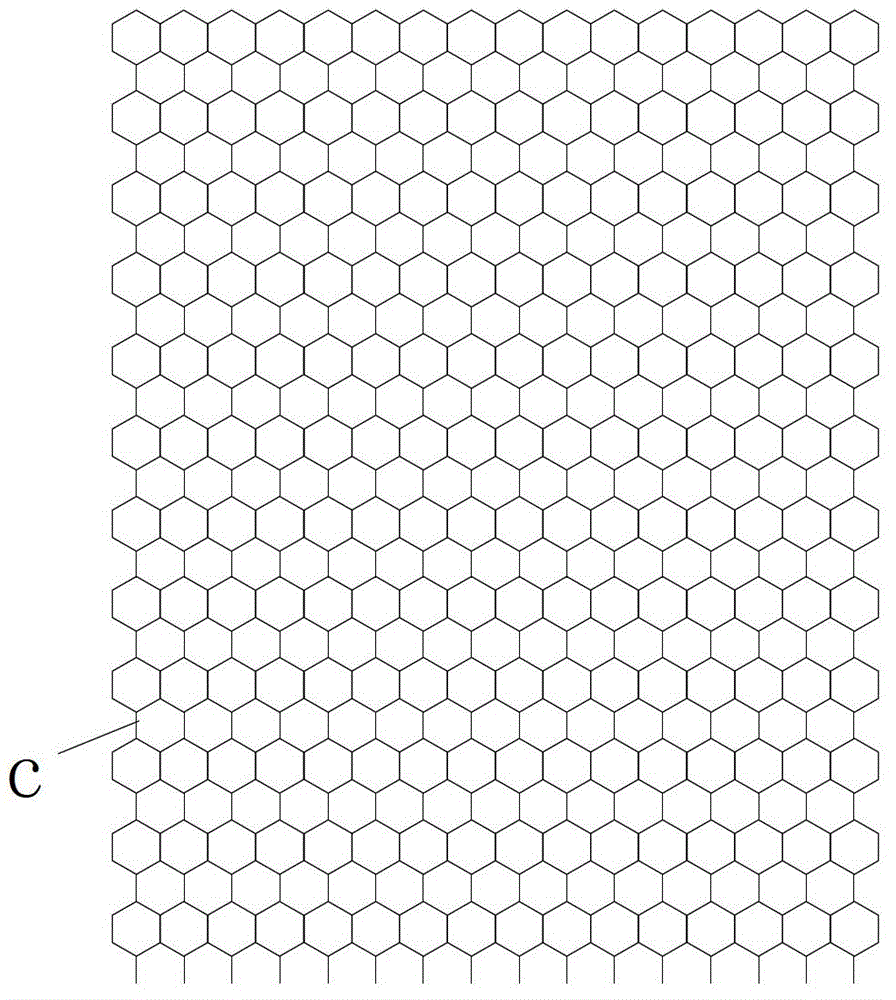

Auxetic Fabric Structures and Related Fabrication Methods

Owner:UNIV OF MASSACHUSETTS

Plastic floor covering and method for obtaining same

InactiveUS20040102120A1Retention characteristicImprove featuresClosuresLayered productsThermoplasticEngineering

The invention concerns a floor covering produced by coating and comprising a thermoplastic-based structure, in particular plasticized PVC, reinforced with a textile reinforcement, optionally combined with a foam backing and whereof the visible surface consists of a surface coating providing decoration and wear resistance to the product. The invention is characterised in that the back surface designed to be in contact with the floor, consists of a textile web, the bonding between the textile structure and the supporting back surface being produced by means of an additional plastisol layer, which penetrates over a minor part the thickness of the textile structure and which, after gelling, bonds said textile to the thermoplastic substrate back surface.

Owner:GERFLOR

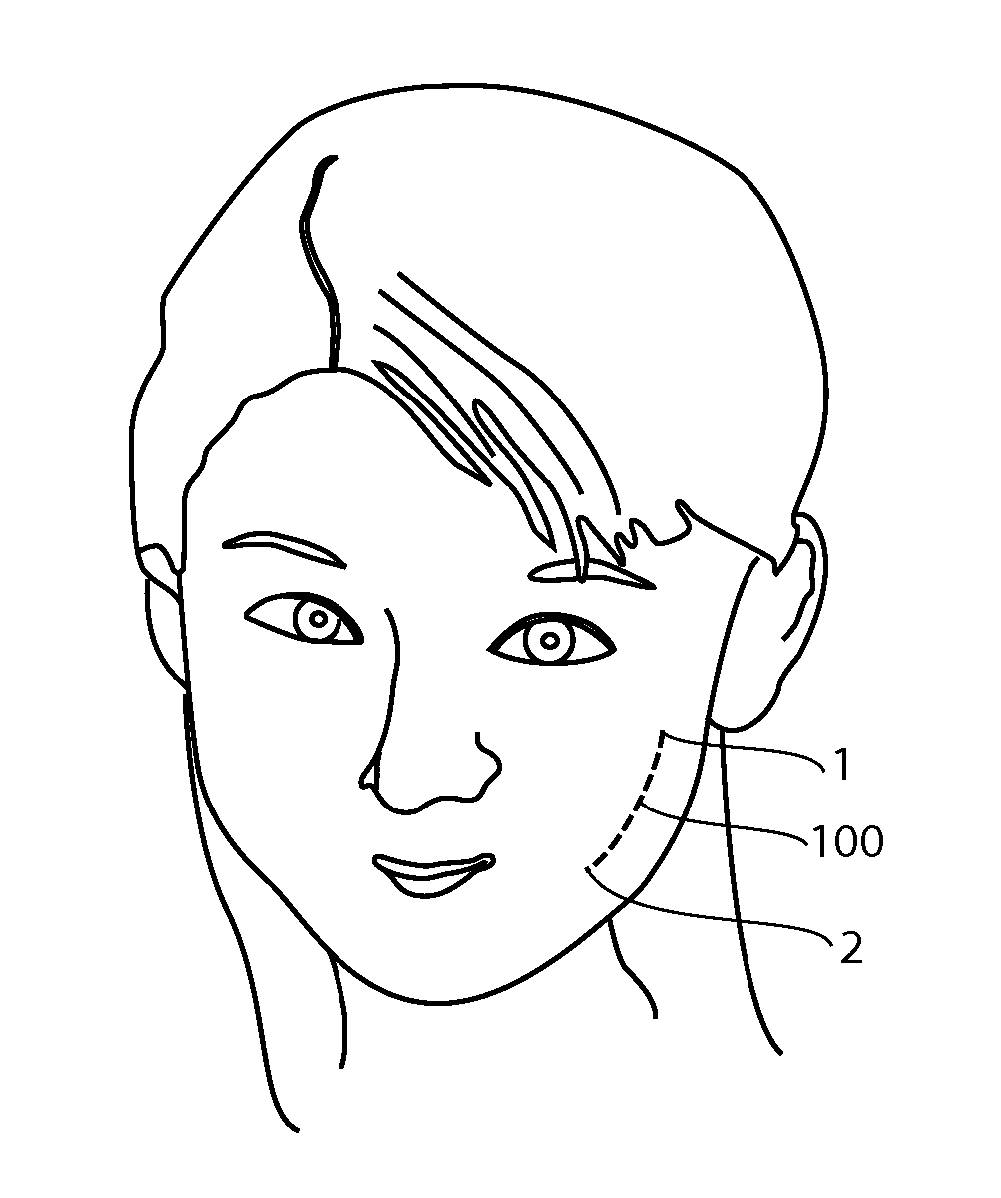

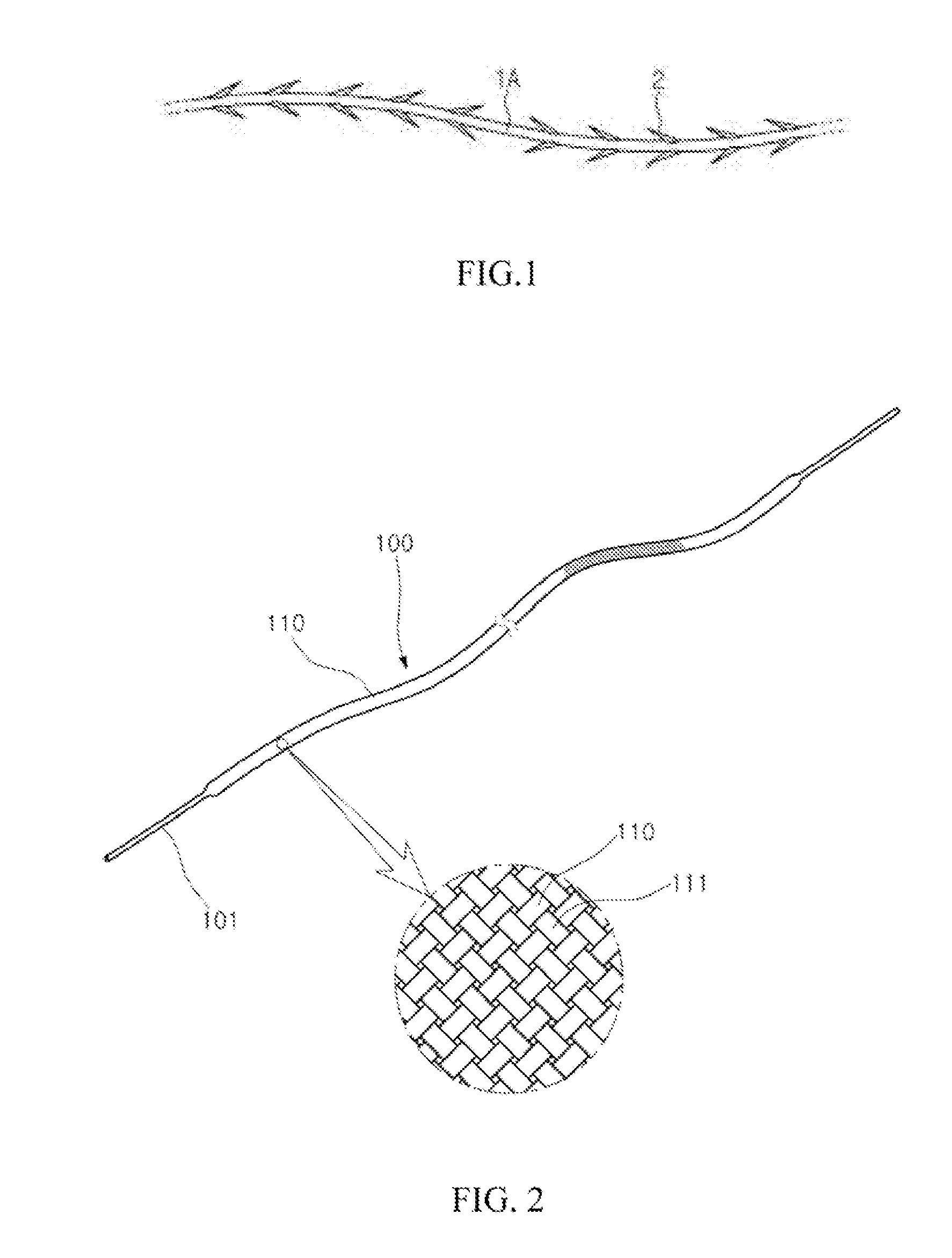

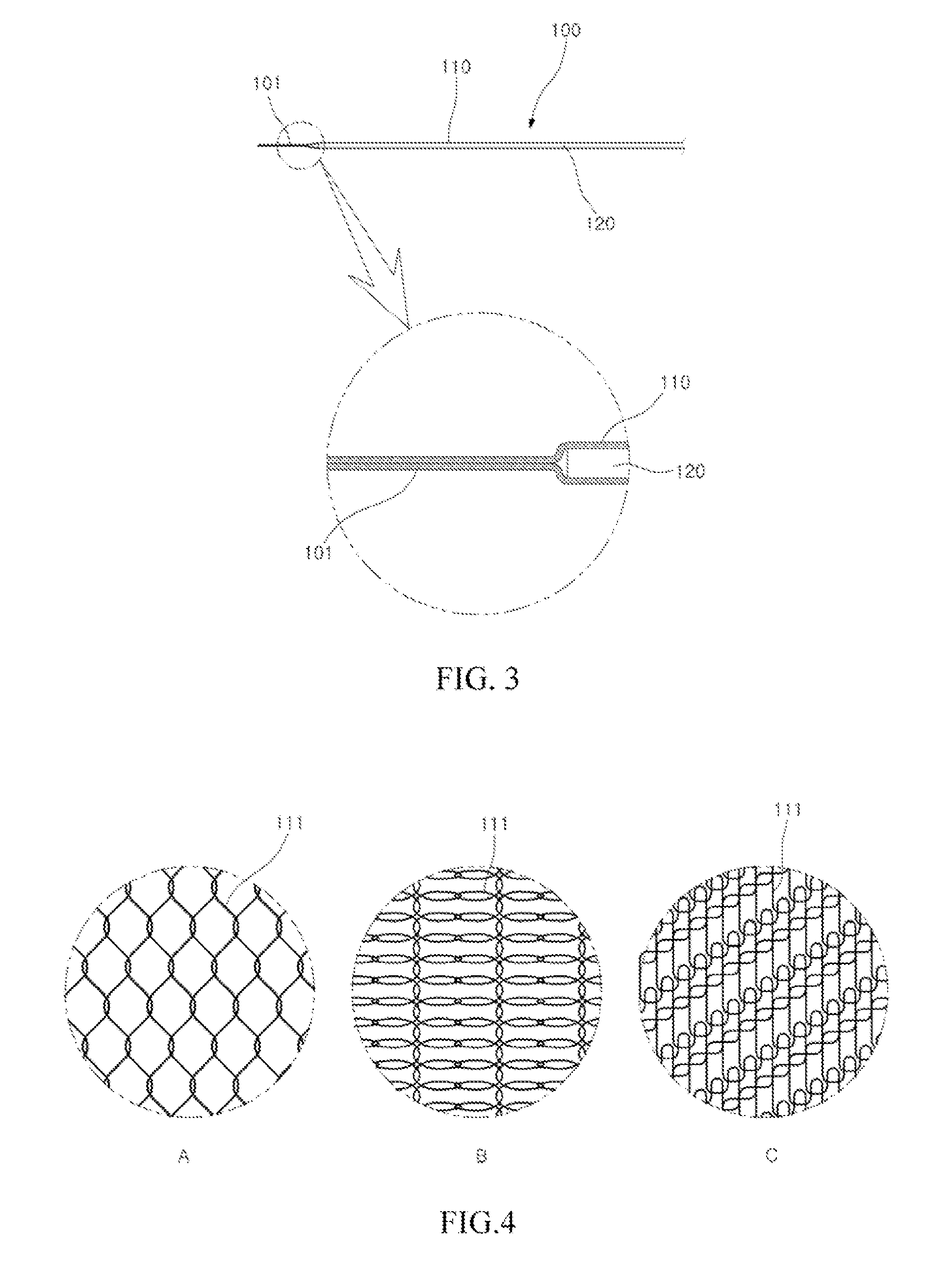

Linear tension material for plastic surgery

InactiveUS20080046094A1High strengthAvoid fatigueSuture equipmentsCosmetic implantsWrinkle skinFiber

The present invention relates to a linear tension material for surgery used to pull skin tissue. An object of the present invention is to provide a linear tension material for plastic surgery which prevents permanent deformation due to excessive elongation and fatigue and of which a portion besides united portions is uniformly and properly united with body tissue. According to an aspect of the present invention, there is provided a linear tension material for plastic surgery which is provided to pull a predetermined site inside skin tissue of the body in a state of tensile load so as to smooth out wrinkles and pull the tissue to tighten a saggy portion, the linear tension material including: a core material in a code shape, which is made of a flexible resin including polyorganosiloxane; and a covering material which covers an outside of the core material to be united with the core material, shrinks together with the core material, and has a fiber textile structure formed by weaving a number of fiber threads.

Owner:HAN KWANG HEE +1

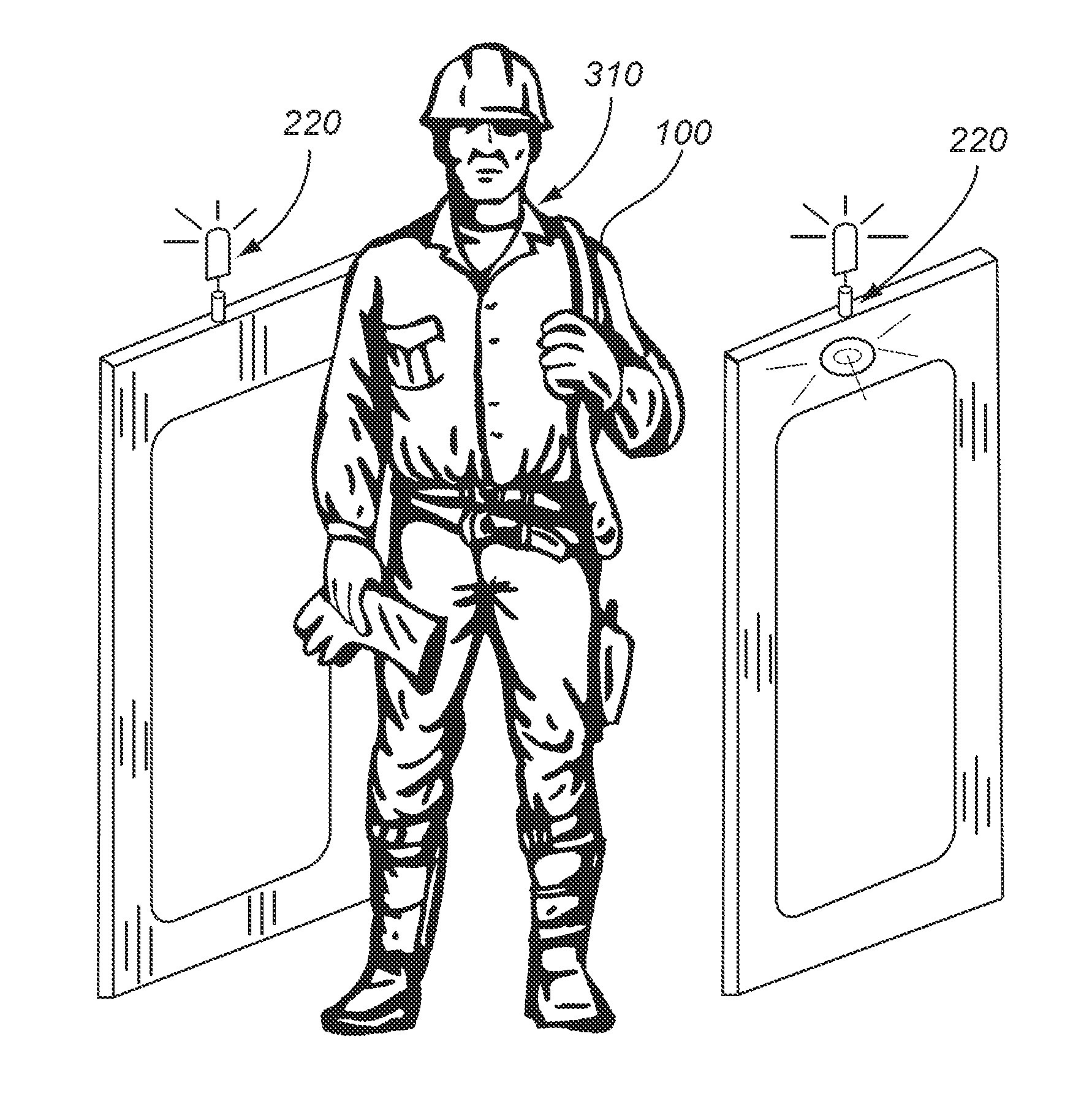

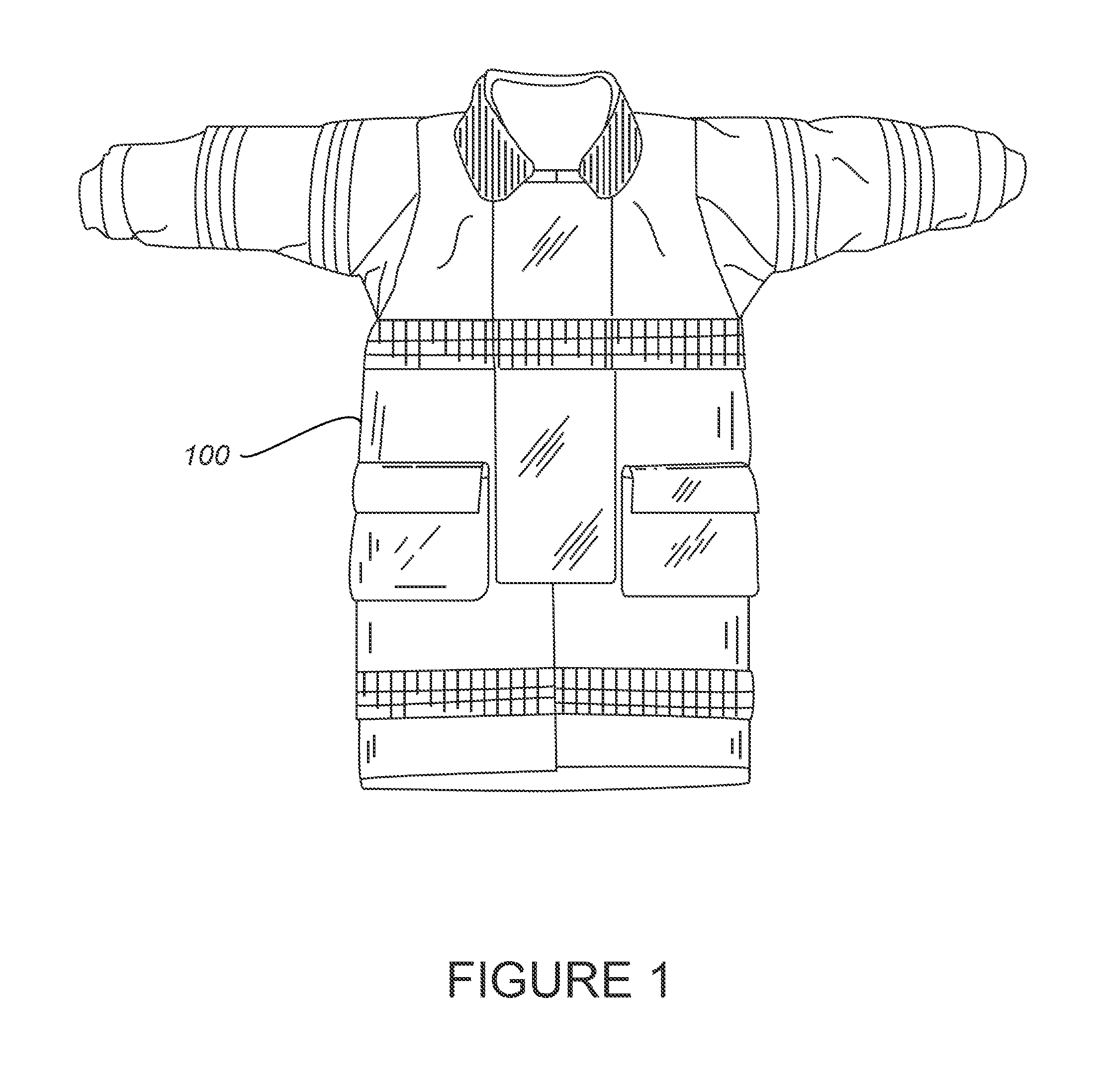

Protective Fabrics and Garments

Fabrics with a knit construction using an air jet spun yarn and ring spun yarn that provide electric arc protection are disclosed. Garments made from the fabrics are also disclosed. In addition, devices, systems, and methods are disclosed that are useful for tracking for the purpose of monitoring and alerting the user of a garment and / or others regarding the safety, health, environmental, and security aspects of the garment, user, and / or the environment in which the user is present.

Owner:DRIFIRE

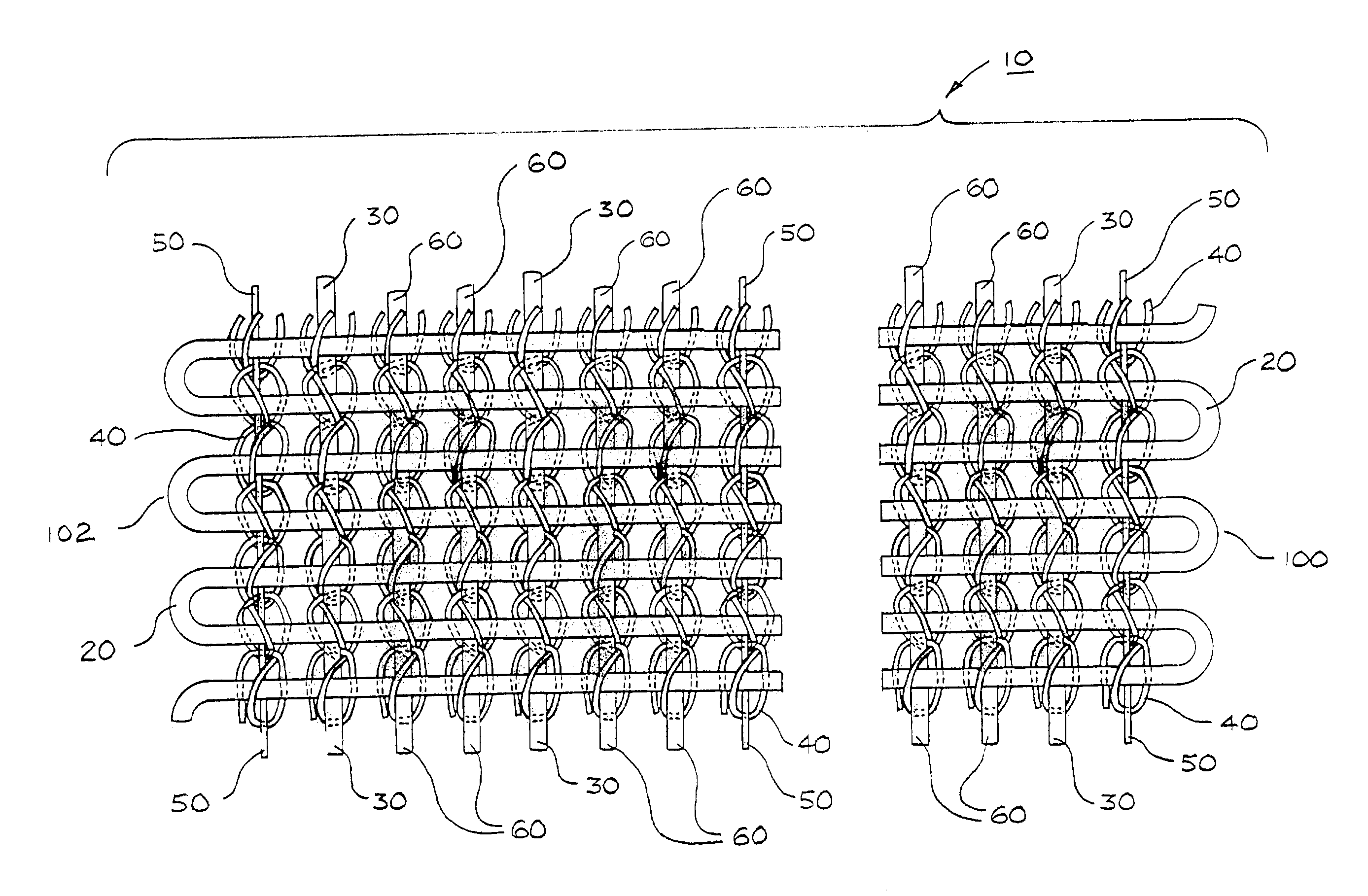

Wire-reinforced elastic webbing

InactiveUS6984596B2Limited elongationEvenly distributedOrnamental textile articlesWire networkYarnPolyester

A wire-reinforced webbing material is disclosed for use in furniture, bedding and the like. The webbing includes a flat knitted fabric comprised of substantially elastic yarns such as polyester. A plurality of reinforcement wires are integrally knitted into the fabric structure in a lengthwise direction. The wires may be thin-gauge titanium or titanium alloy wires. Elastomeric yarns or cards may also be integrally knitted into the fabric structure parallel to the reinforcement wires. The reinforcement wires and elastomeric cords combine with the knitted fabric to yield a webbing material having both a high tensile strength and a resilient responsiveness to applied external loads.

Owner:HICKORY SPRINGS MFG

Electroconductive woven and non-woven fabric and method of manufacturing thereof

ActiveUS20070054577A1Improve adhesionUniform and stableNanotechPhysical treatmentEngineeringBiological activation

The invention relates to an electroconductive textile material and method of preparation thereof. The method consists mainly of two stages: 1) special pretreatment of the fabric substrate for activation and making it suitable for subsequent application and strong attachment of a conductive coating with the use of a layer-by-layer technique (LBL); 2) subsequent application and strong attachment of a conductive coating by means of a layer-by-layer technique. The first stage may be carried out thermally, thermochemically, by treating in hot solutions, or plasma-chemically by plasma treatment. The pre-treatment may be performed, e.g., for swelling and / or for the formation of unsaturated chemical bonds or uncompensated charges in the fabric material. The pretreatment is needed to ensure more efficient penetration of chemical components into the fabric structure during subsequent LBL applications of treatment solutions that contain nano-particles and that determine the density of the molecular layer. The types and amounts of the nano-particles determine their charge density (solution pH is very important for charge density) in the sublayer. Such a pretreatment increases bonds of the applied layers with the substrate material.

Owner:EEONYX CORP

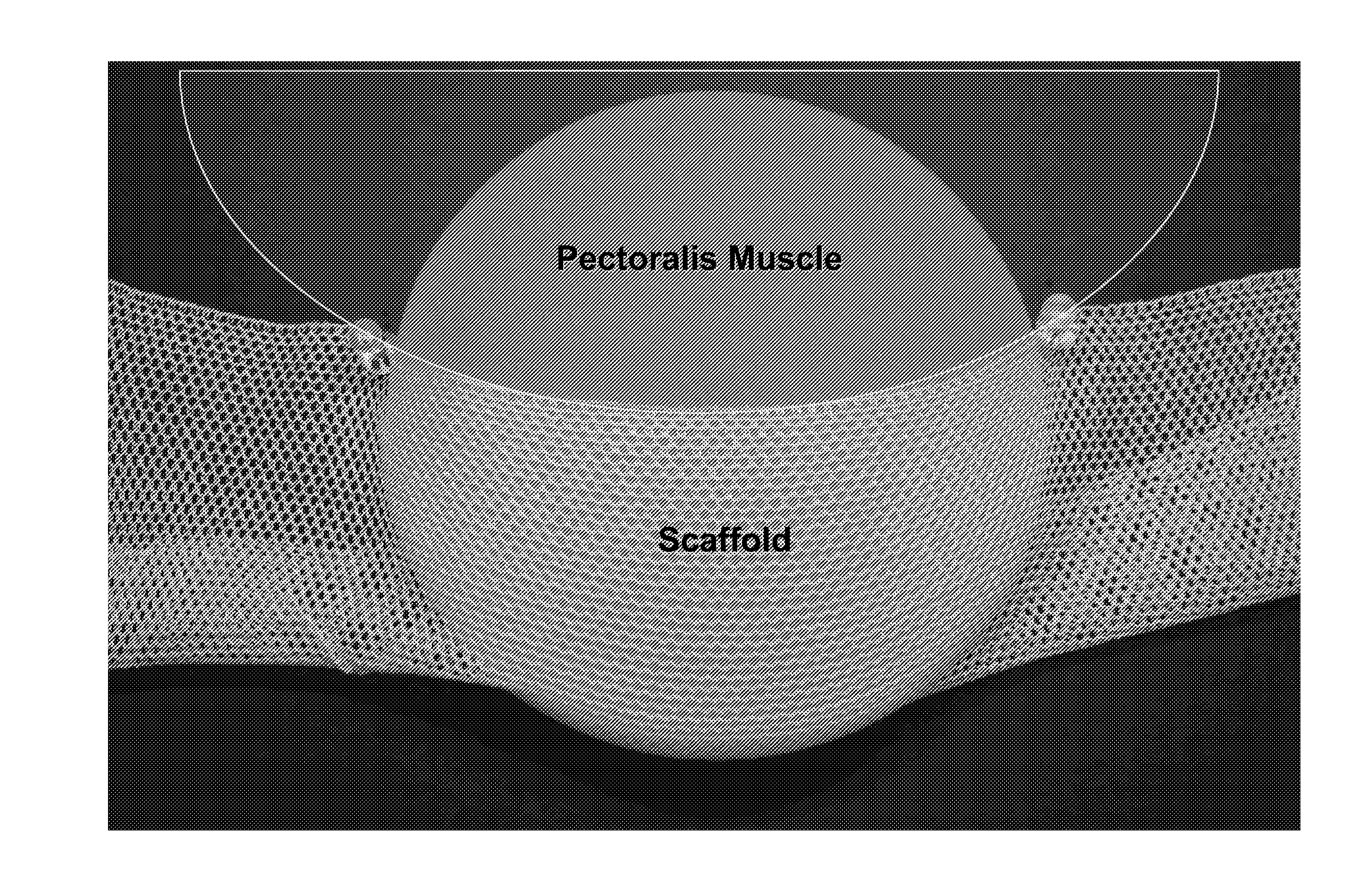

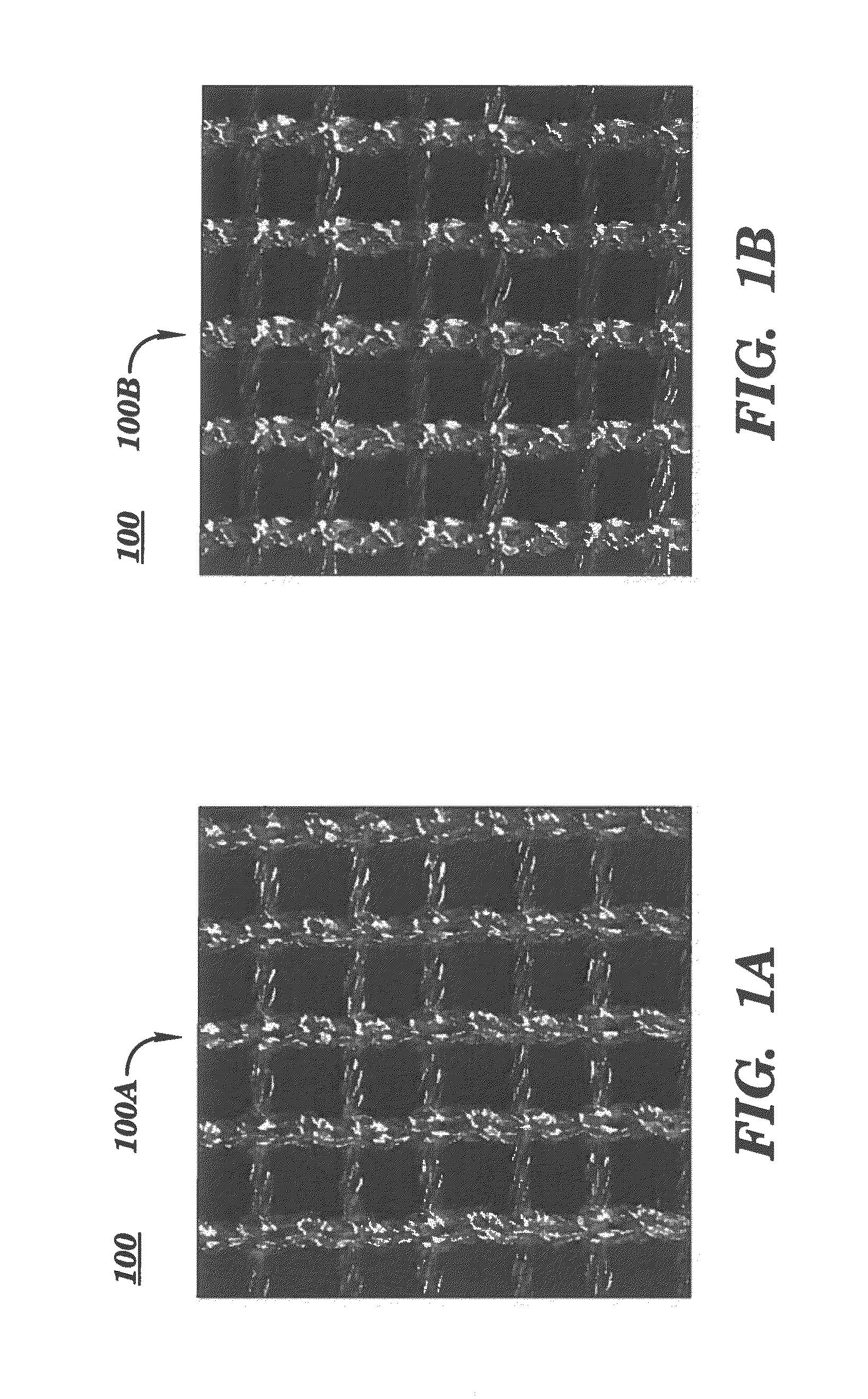

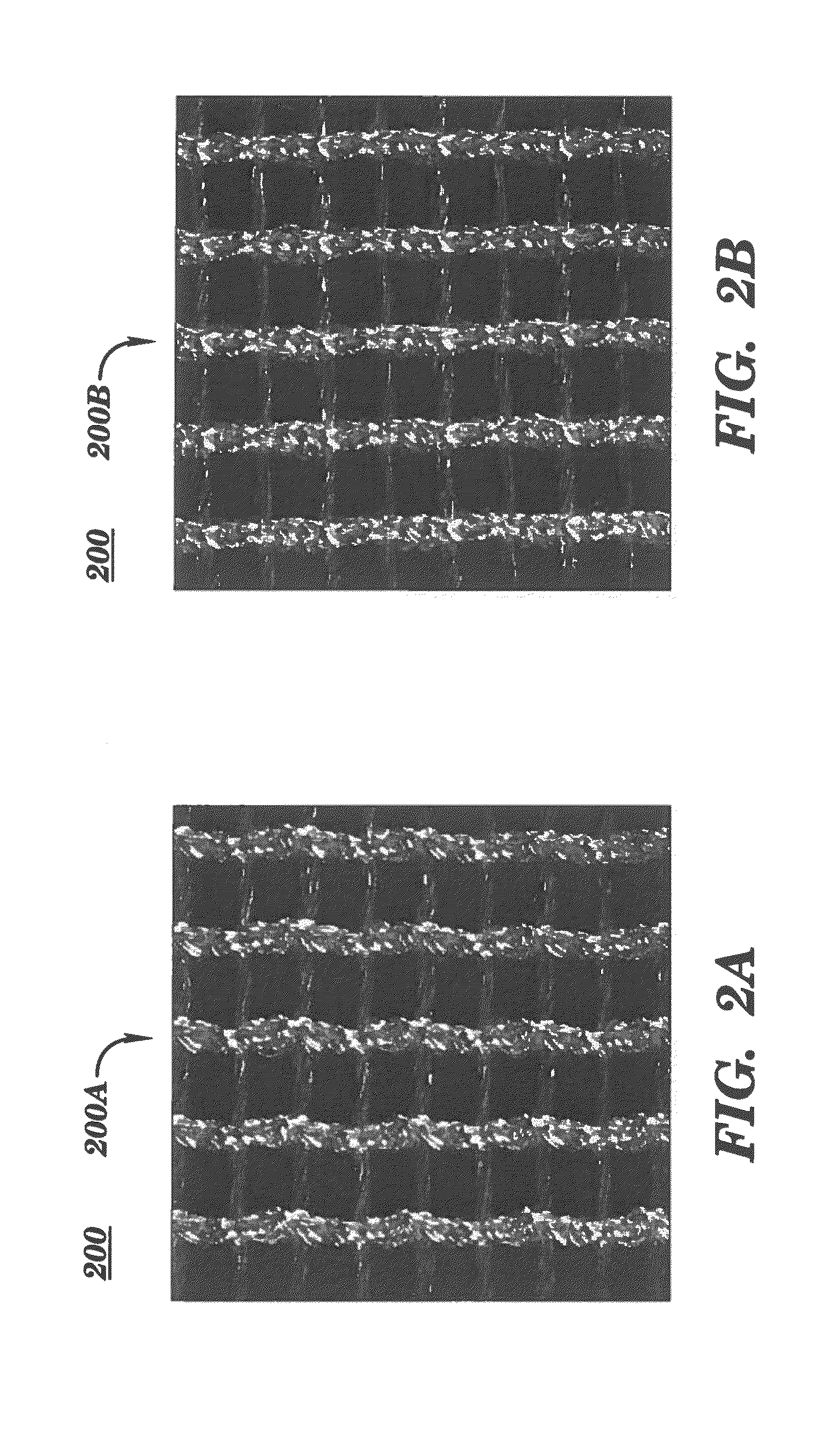

Silk medical device for use in breast augmentation and breast reconstruction

A three-dimensional fabric structure in a form of a pocket for use in a breast reconstruction surgical procedure such as single-stage or two-stage breast reconstruction. The silk scaffold employs a knit pattern that substantially prevents unraveling and preserves the stability of the mesh or scaffold device, especially when the mesh or scaffold device is cut. An example scaffold device employs a knitted mesh including at least two yarns laid in a knit direction and engaging each other to define a plurality of nodes.

Owner:ALLERGAN INC

Fabric and Fabric Laminate

InactiveUS20100255270A1Feel goodImprove gripNatural cellulose pulp/paperPretreated surfacesYarnFiber

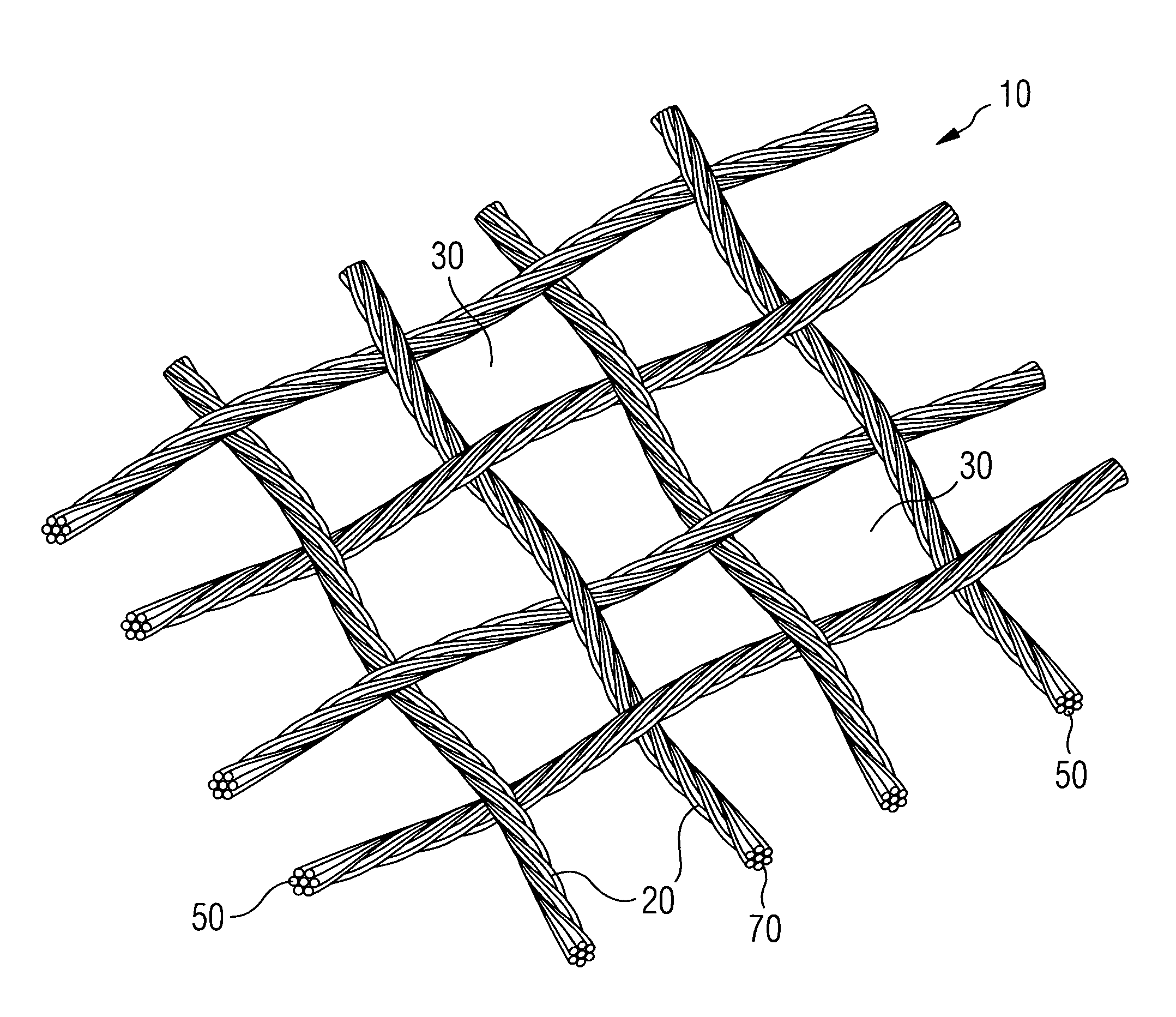

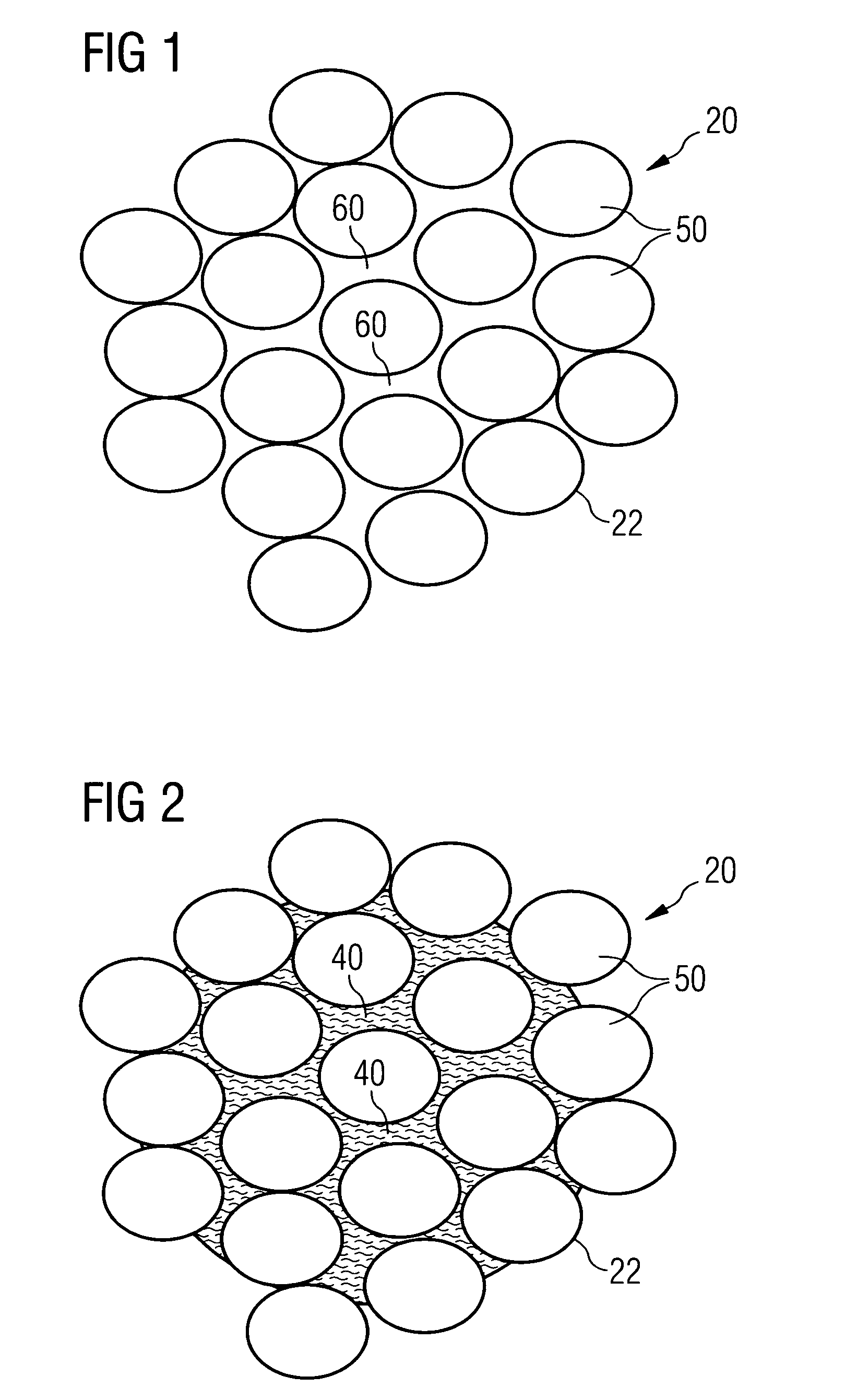

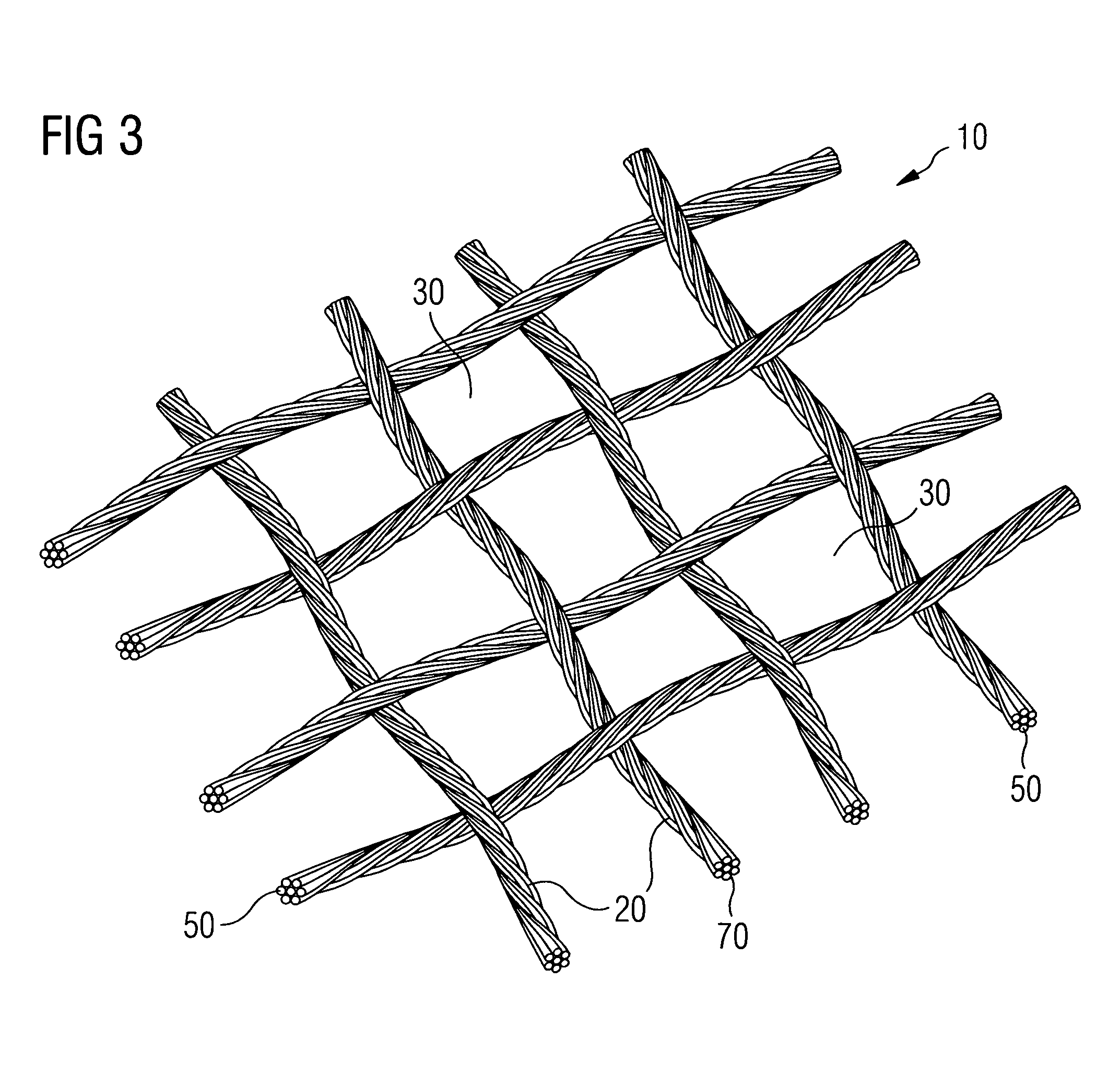

The present invention provides a fabric and a fabric structure made of yarns with reduced water absorption. The fabric comprises yarns and interstices between the yarns, the interstices between the yarns having an average width of greater than 100 μm. At least one of the yarns is comprised of multiple fibers. Said at least one yarn has voids between the fibers wherein the voids are filled up with a polymer material. The interstices remain open and the size of the interstices is the same as before the treatment. The filling of the voids between the fibers with the polymer material prevents the absorption of water into said voids and therefore leads to reduced water absorption of the fabric. The polymer material is substantially only located within the voids of the yarn and has embedded the fibers within the outer surface of said yarn.

Owner:STUEBIGER WERNER

Fabric architectures for improved ballistic impact performance

A woven fabric from yarn for use in the manufacture of ballistic projectile or puncture resistant articles where the fabric has a first plurality of parallel oriented yarns within the plane of the fabric interwoven with a second plurality of parallel oriented yarns within the plane of the fabric having a direction / orientation within the plane of the fabric different from that of the first plurality and where the crossing of any fiber yarn from the first plurality with a fiber yarn from the second plurality forms a pair of acute vertical angles having an angular measurement less than 90 degrees.

Owner:EGRES JR RONALD G

Polyester filament woven fabric for air bags

InactiveUS20060252322A1Pedestrian/occupant safety arrangementSynthetic resin layered productsEngineeringFabric structure

A polyester plain weave fabric construction wherein said fabric has a basis weight of between 150 to 300 g / m2 with tongue tear strength equal to or better than nylon fabrics of the same construction and weight. The present invention relates to both coated and uncoated polyester filament woven fabric. The uncoated fabric is useful for industrial purposes wherein the fabric has a warp tongue tear resistance of at least 0.75 N / g / m2, when the fabric basis weight is between 150 to 300 g / m2 The preferred uncoated polyester filament yarn has a linear density of between about 200 to about 800 dtex, a tenacity of at least 65 cN / tex, a tensile index of at least 350. The fabrics can be coated with chloroprene, neoprene, polyurethane, silicone or other organic coatings to reduce air permeability. The fabric of the present invention may also be constructed with the warp and / or filling yarn having an aspect ratio between 1.2 and 6.

Owner:INV PERFORMANCE MATERIALS LLC +1

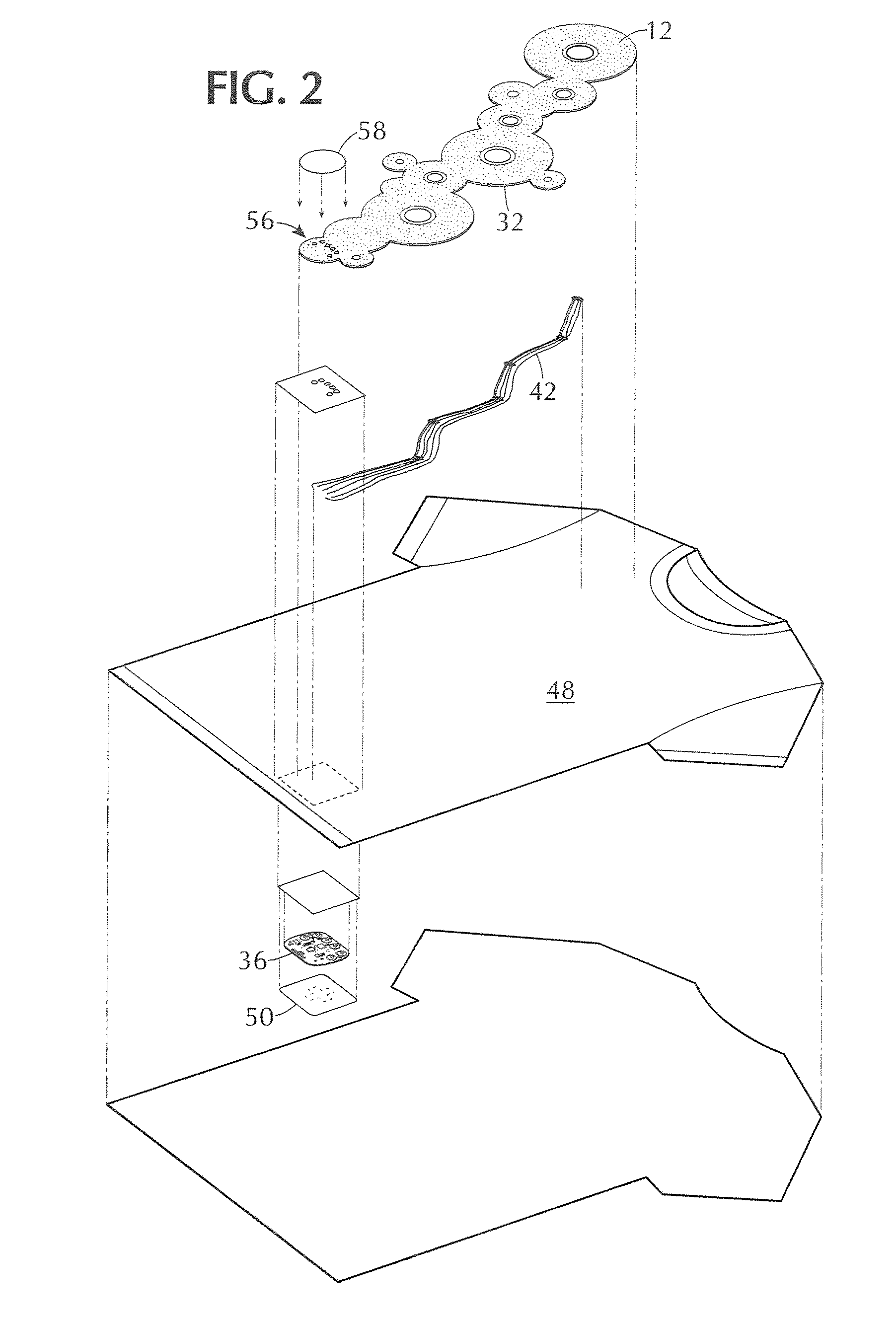

Fabric constructions with sensory transducers

ActiveUS20110119812A1Easy to disassembleLine/current collector detailsPoint-like light sourceTransducerEngineering

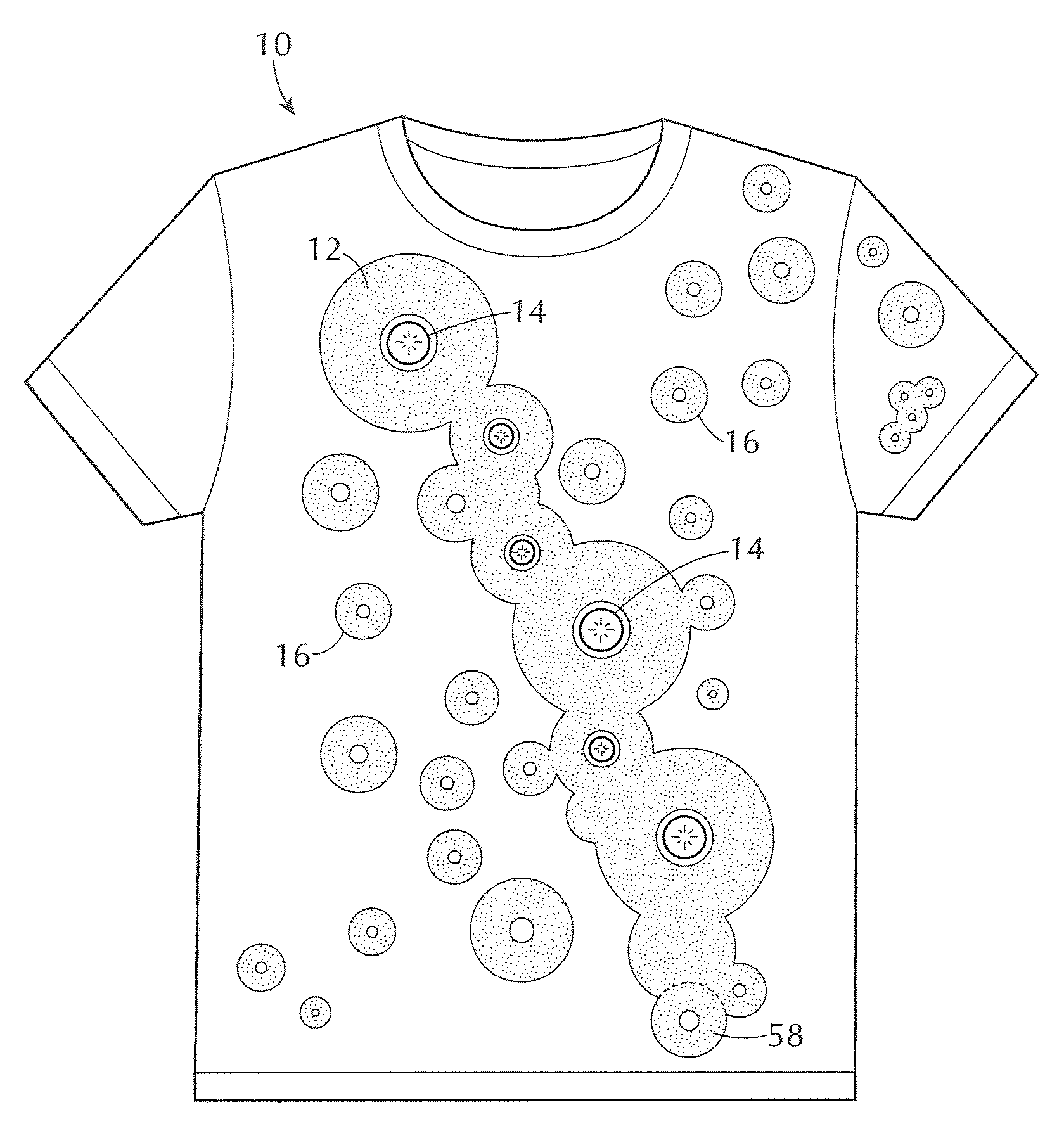

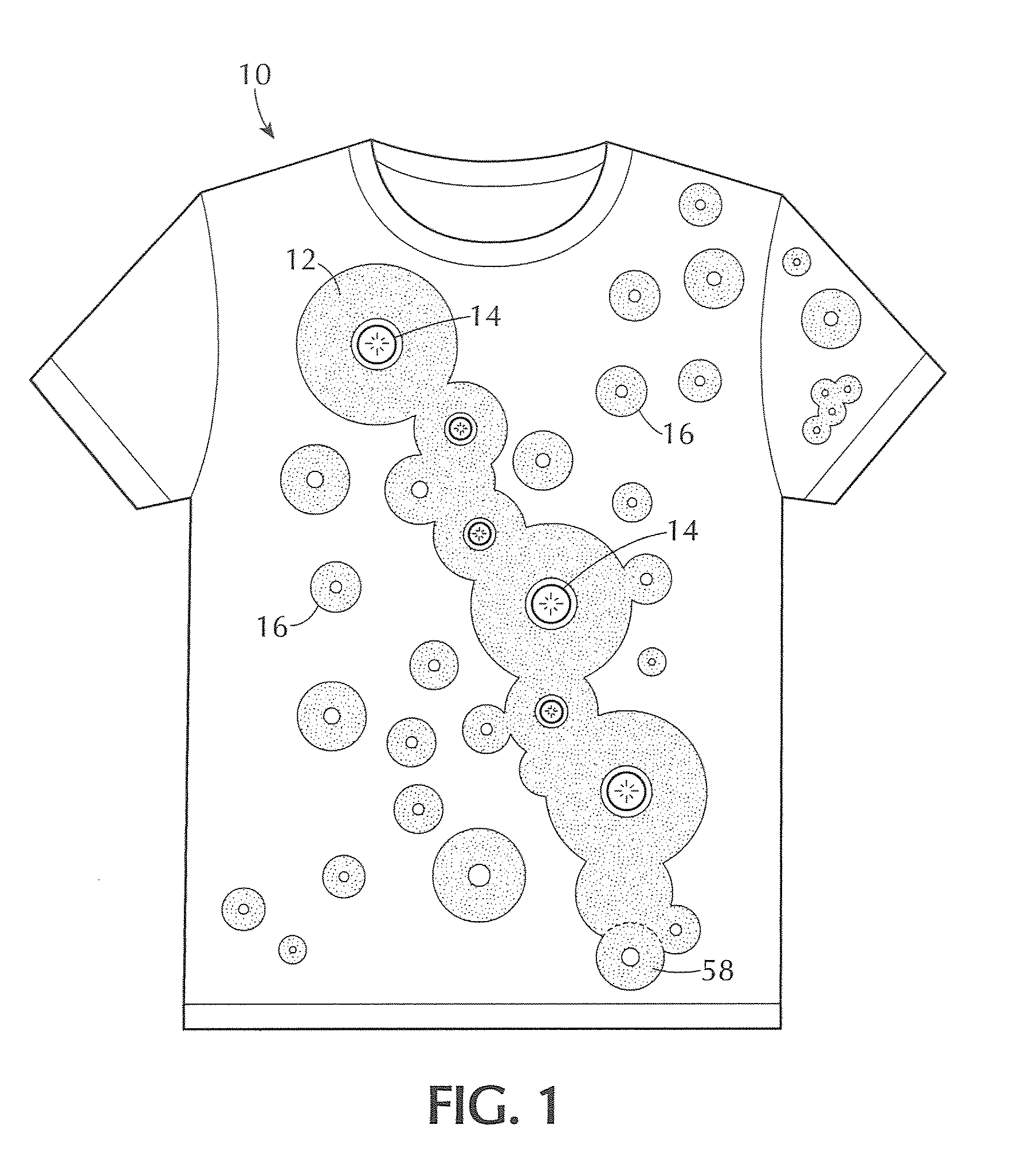

A fabric construction includes sensory transducers, such as light-emitting diodes, for sensory effects while maintaining the look and feel of a conventional fabric item. The construction is especially adapted for implementation as a garment. The construction has a fabric layer and an appliqué on a front surface of the fabric layer. A plurality of electrical sensory transducers are arranged in a desired pattern with an electrical harness electrically interconnecting the sensory transducers to a drive and control circuit. The transducers and harness are located between a rear surface of the appliqué and a front surface of the fabric layer, while the drive and control circuitry is positioned at a rear surface of the fabric layer. The fabric layer and appliqué are bonded together to seal the transducers and harness in place. Releasable connectors extend through the fabric layer to operatively connect the harness to the drive and control circuit.

Owner:GENZ RYAN T +1

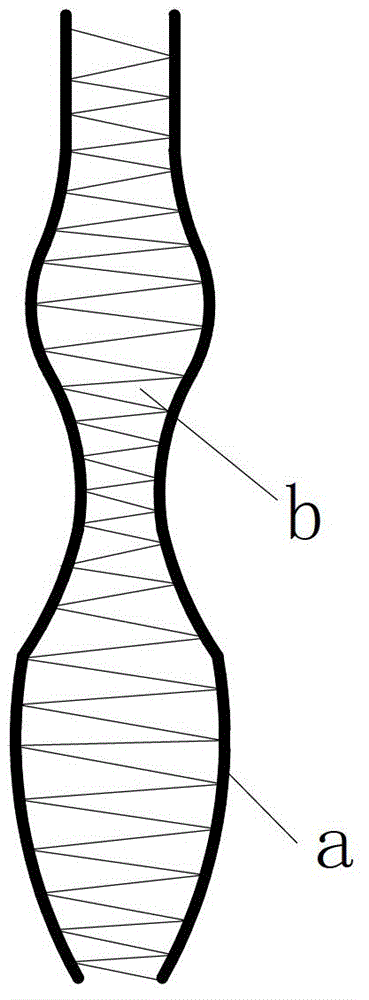

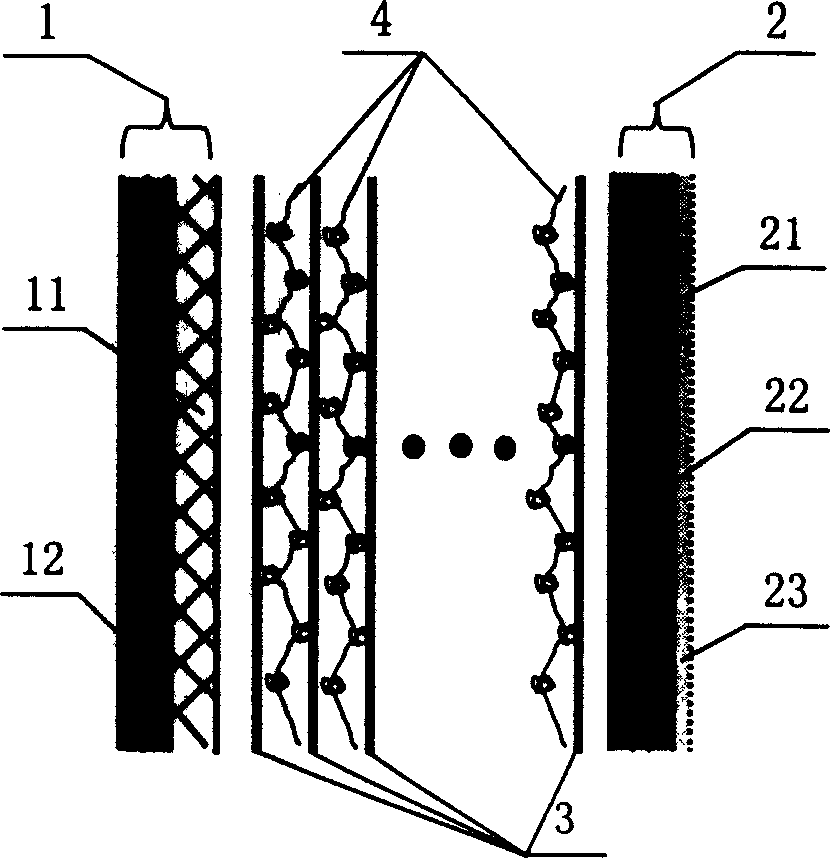

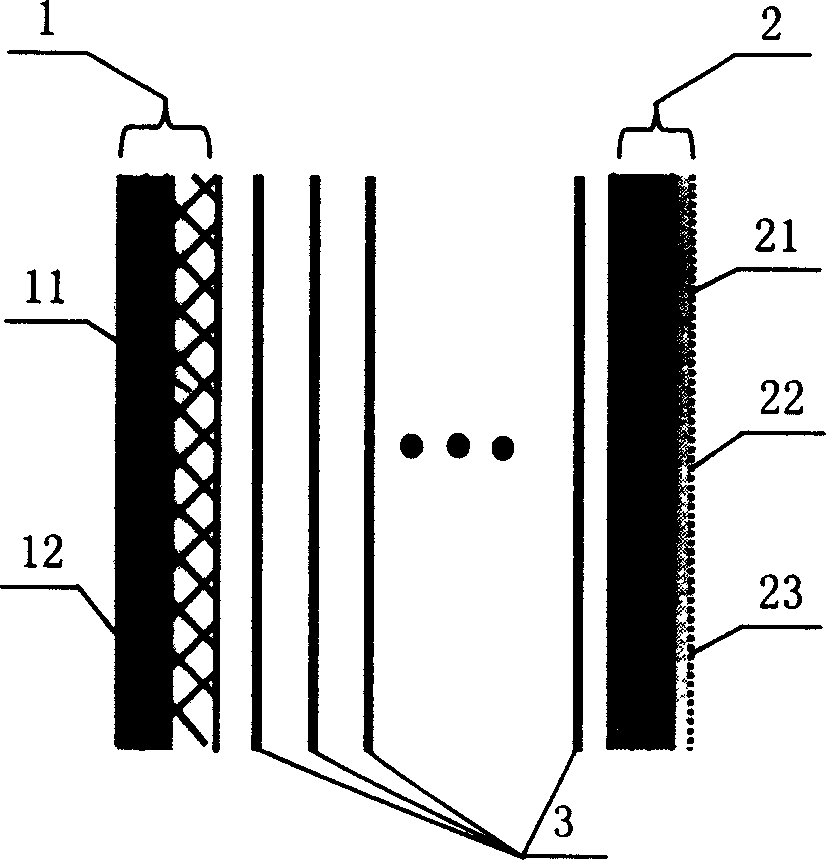

Special-shaped three-dimensional knitted fabric and manufacturing method thereof

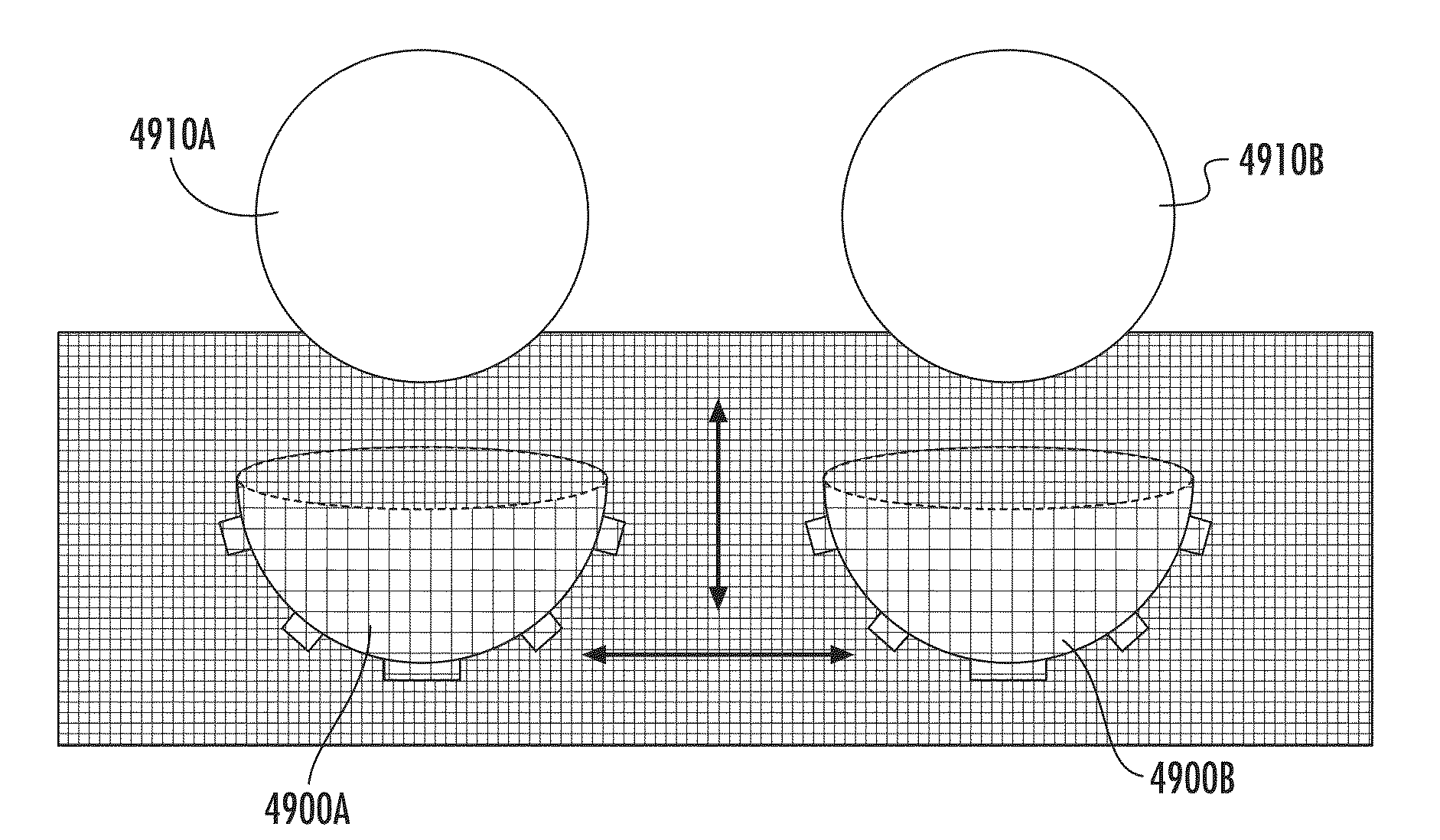

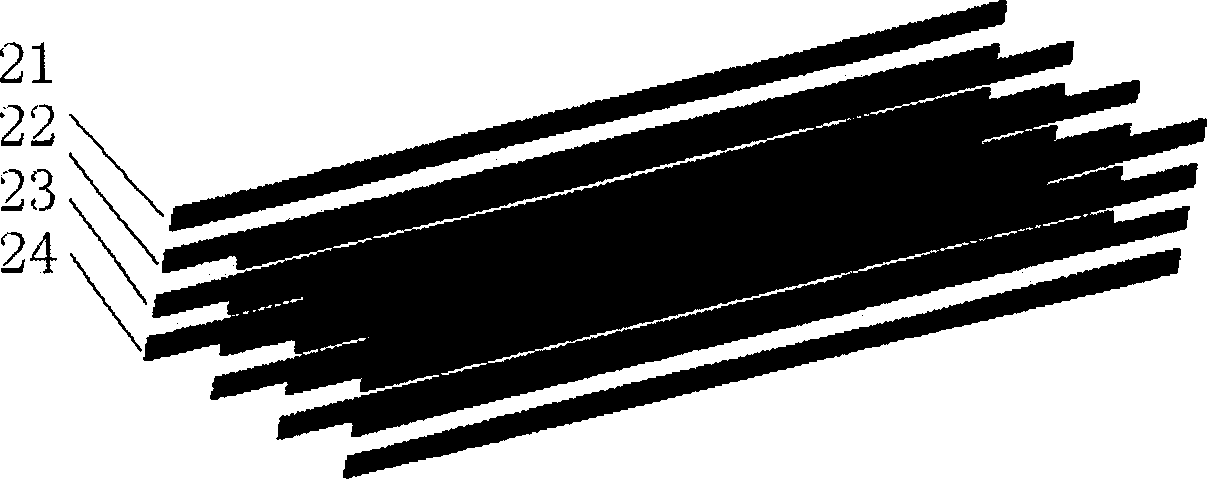

The invention relates to a special-shaped three-dimensional knitted fabric and a manufacturing method thereof, which relate to the knitted fabric. The special-shaped three-dimensional knitted fabric with at least one of an upper surface and a lower surface being a concave-convex special-shaped curved face, and favorable air permeability, support performance and shearing resistance, and the manufacturing method thereof are provided. The special-shaped three-dimensional knitted fabric comprises an upper fabric layer, a middle fabric layer and a lower fabric layer, wherein the upper fabric layer or / and the lower fabric layer is / are provide with a concave-convex curved face(s) in a knitted longitudinal direction(s); and the middle fabric layer is formed by connecting yarns with flexural rigidity. According to a fabric structure and a texture requirement, required materials of the upper fabric layer, the required lower fabric layer and the middle fabric layer are selected; according to structural features of the fabric, the yarns are sewed on a guide bar; according to special-shaped structural features of the fabric, warp run-in of the fabric is set, and a distance between two needle beds can be adjusted in real time when the fabric is knitted in different horizontal lines according to variation in thicknesses of the different horizontal lines of the fabric; and a drawing device draws the knitted textile from the needle beds when knitting is carried out simultaneously.

Owner:福建福联精编有限公司

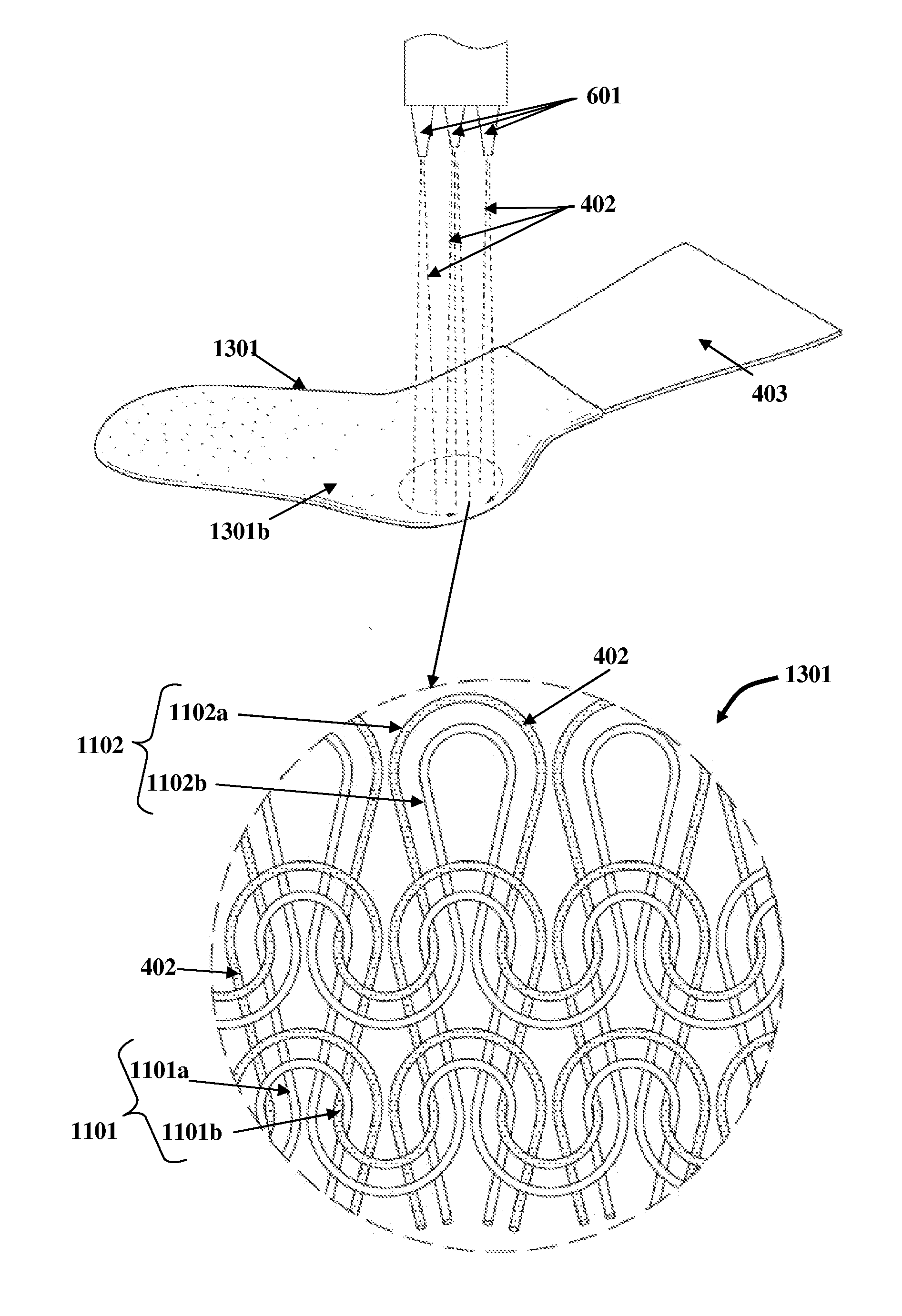

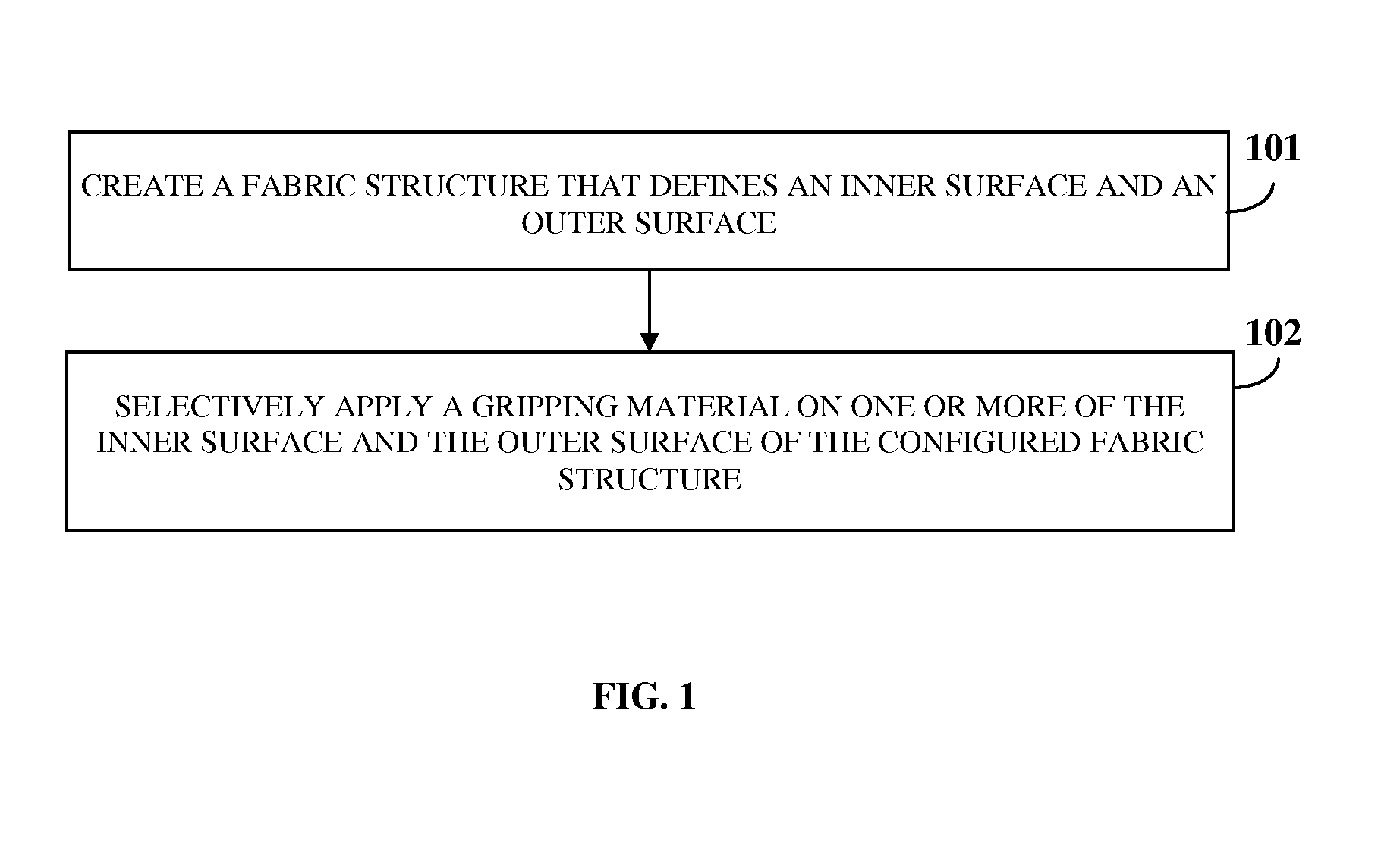

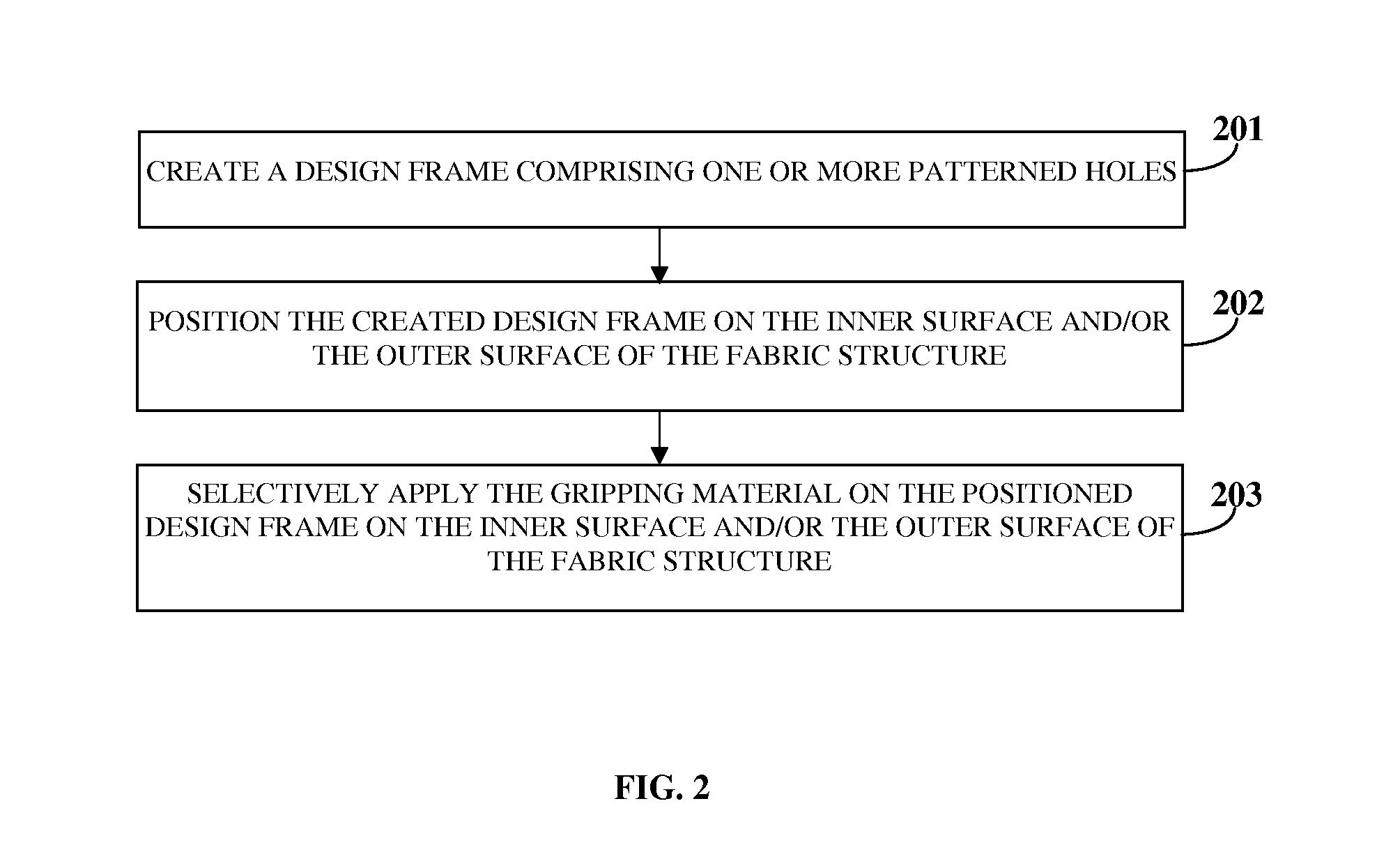

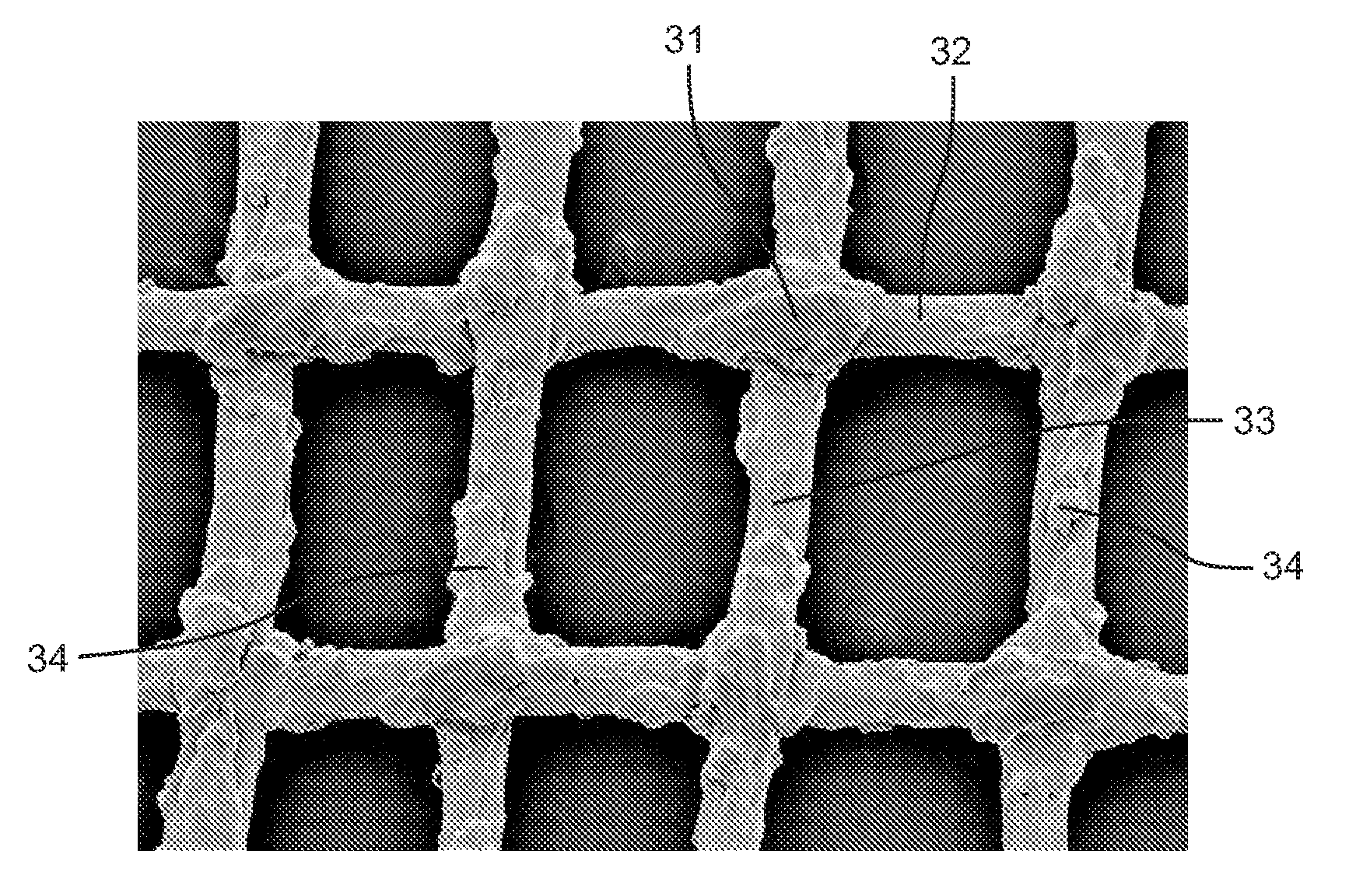

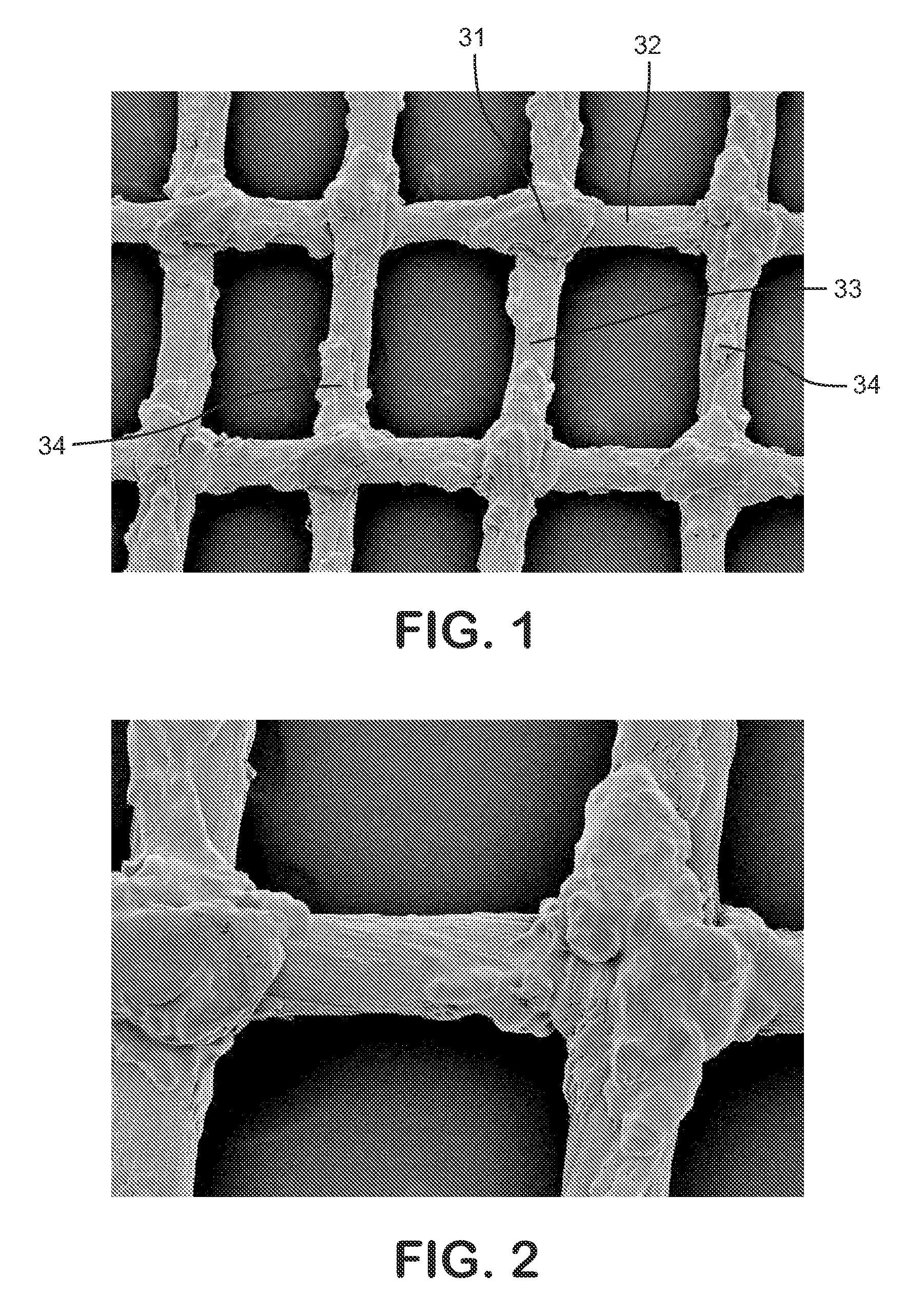

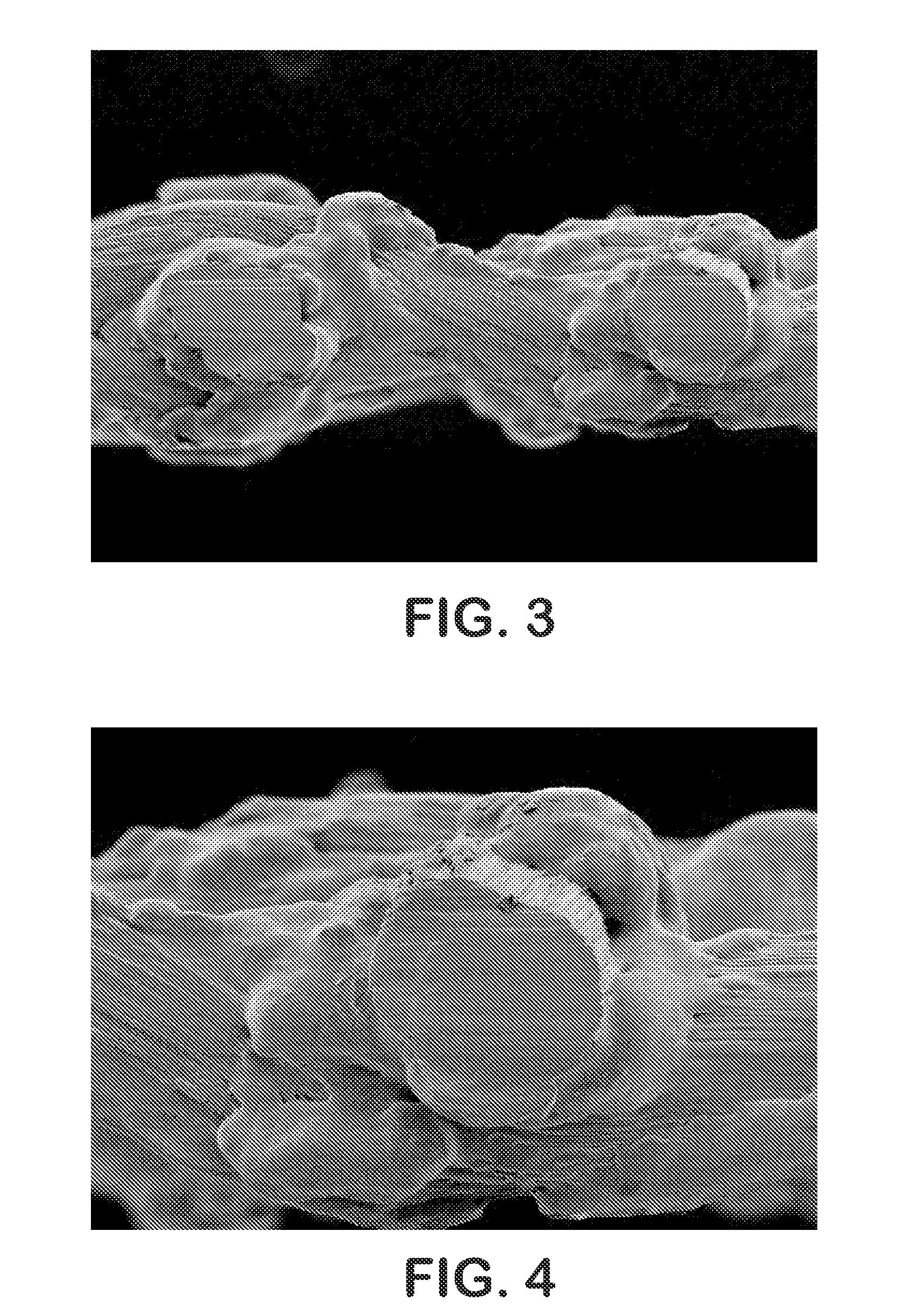

Construction Of A Gripping Fabric

ActiveUS20120058316A1Prevent slippingImprove gripDecorative surface effectsWarp knittingEngineeringFabric structure

A gripping fabric and method for construction thereof is provided. A fabric structure that defines an inner surface and an outer surface is created. The fabric structure or the gripping fabric is configured to conform to a user's body part for constructing a garment, for example, a sock. The inner surface is proximal to a user contact surface and distal to an external contact surface. The outer surface is proximal to the external contact surface and distal to the user contact surface. A gripping material is selectively applied on the inner surface and / or the outer surface of the fabric structure. The gripping material on the inner surface and the outer surface of the fabric structure adheres to the user contact surface and the external contact surface respectively, thereby providing grip between the user contact surface and the fabric structure, and grip between the fabric structure and the external contact surface.

Owner:TRUSOX LLC

Knitted fabric with unidirectional moisture conducting function and processing technology thereof

The invention provides a new knitted fabric with a unidirectional moisture conducting function, solving the following problems: the existing knitted fabrics with a unidirectional moisture conducting function are mostly modified processed products, the unidirectional moisture conducting function has poor durability, the processing technology of the fabrics is complex and the processing efficiency is low. The new knitted fabric has a layer structure and is characterized in that the knitted fabric has a double-layer fabric structure; the double-layer fabric structure comprises inner hydrophobic fibers and outer hydrophilic fibers; and the inner hydrophobic fibers are polypropylene fibers. The invention also provides a processing technology of the knitted fabric with a unidirectional moisture conducting function. The processing technology comprises the steps of gray fabric weaving, gray fabric pre-processing, dyeing, reduction clearing and setting.

Owner:WUXI HANUO TEXTILE TECH

Capping three-dimensional fabric, and its knitting method

The invention relates to the peak enveloping three dimensional textiles and the producing process. The fabric possesses the crest and the body which are plaited on time by the longitude yarn and the abb, it is the three dimensional whole fabric without the layer. The said plaiting method plaits the crest of the peak enveloping three dimensional textile: the obligate longitude yarn is fixed in advance according to the fabric frame needing, the obligate length abb are inducted into the said obligate length longitude yarn according to the fabric frame needing using the beeline citing latitude method, they are interlaced, the said obligate length abb is installed in advance, the cycle is performed according to the process to finish the plaiting of the fabric crest; the without interlacing part of the said obligate length longitude yarn and the abb on the fabric crest can be used to be the yarn of the body of the peak enveloping three dimensional textile, the plaiting of the body can be performed using the method of machine plaiting or knitting, so the fabric whole plaiting can be finished.

Owner:TIANJIN POLYTECHNIC UNIV

PTFE Fabric Articles and Method of Making Same

ActiveUS20100159171A1Minimizing movementMinimizing slippageDecorative surface effectsWarp knittingBiomedical engineeringPTFE fiber

Owner:WL GORE & ASSOC INC

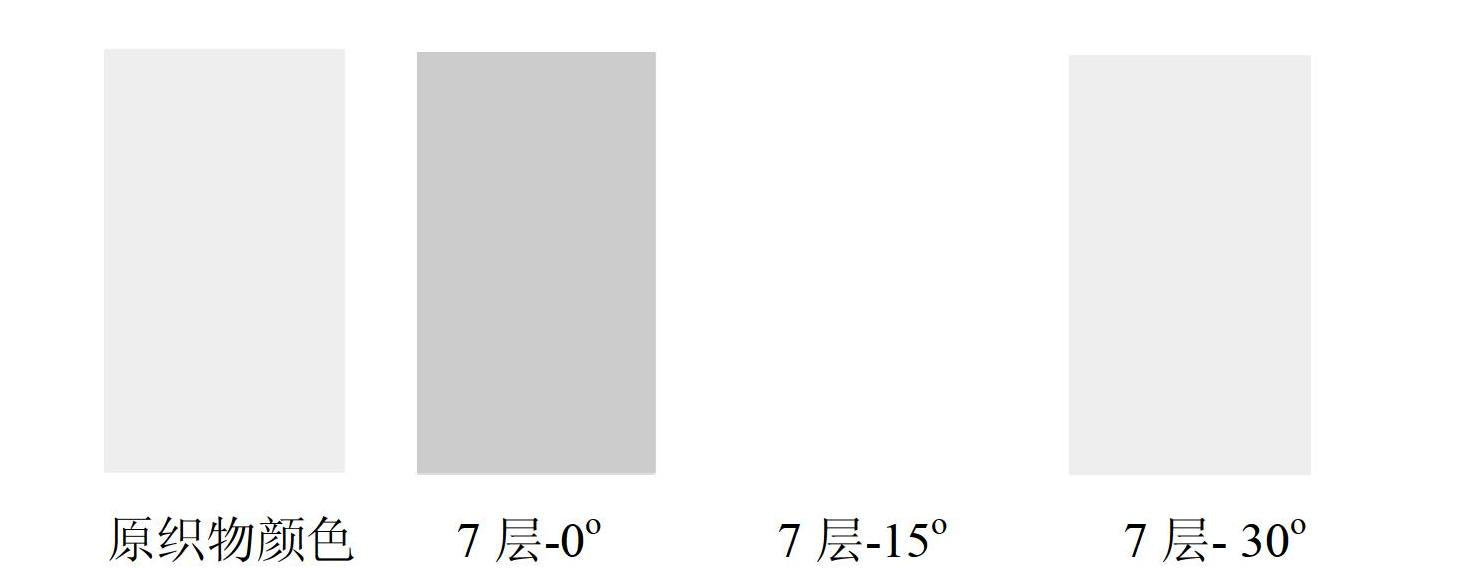

Method for preparing one-dimensional photonic crystal film on fabric surface to realize structural color

The invention relates to a method for preparing a one-dimensional photonic crystal film on the fabric surface to realize a structural color. The method comprises preparation of titanium sol and silica sol and alternate forming of a titanium dioxide film layer and a silicon dioxide film layer on the fabric surface. The structural color can be formed on the fabric surface by adopting the method. The results show that variation of the surface color of the fabric treated by the method can be observed from different angles and the structural color effect is generated. The synthetic method and required production equipment are simple, are easy to realize industrial production and have great reference significance in reducing the environmental pollution of the dyeing industry. The prepared fabric dispenses with any dye to realize the structural color and has excellent optical property and good application prospect.

Owner:DONGHUA UNIV

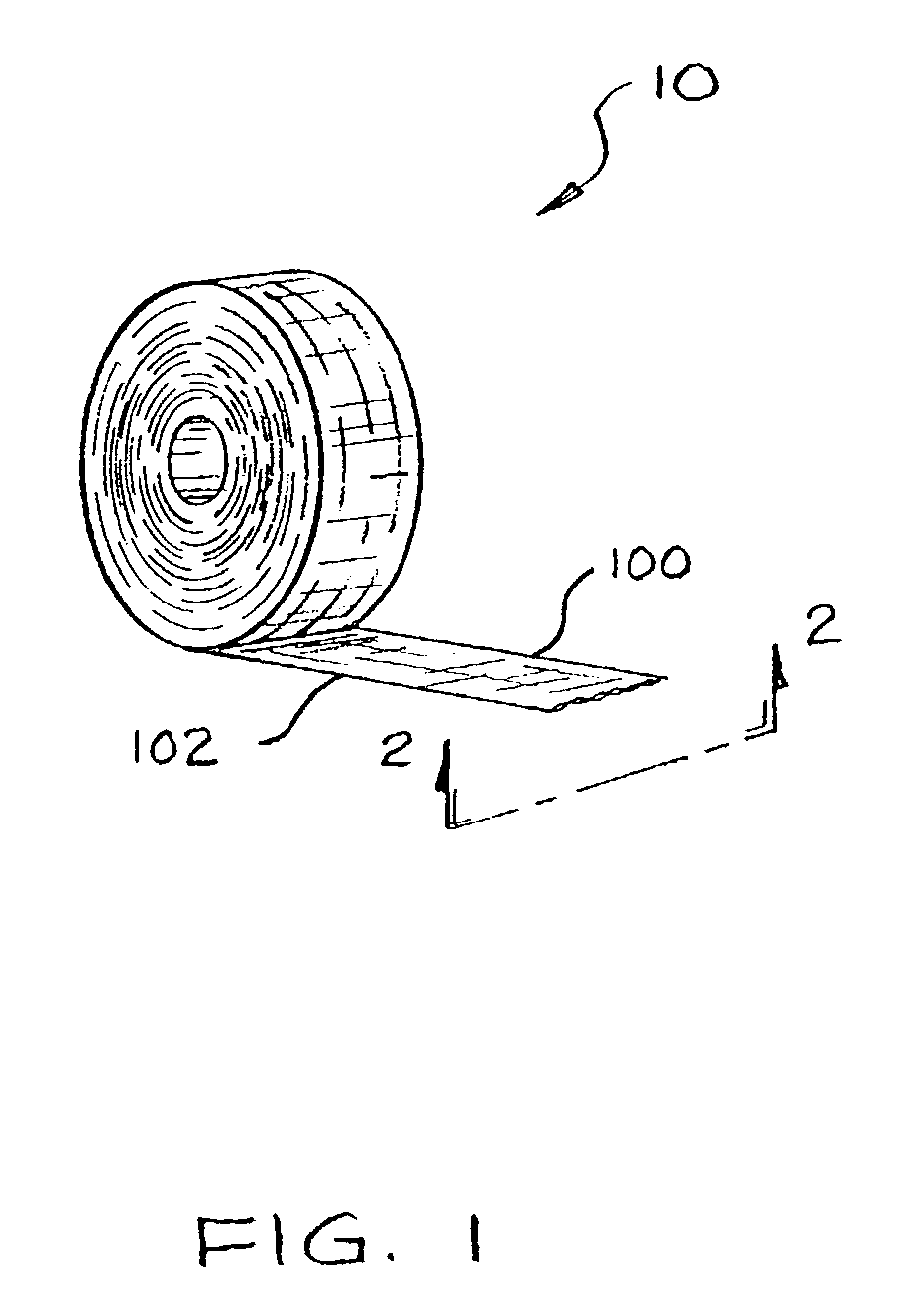

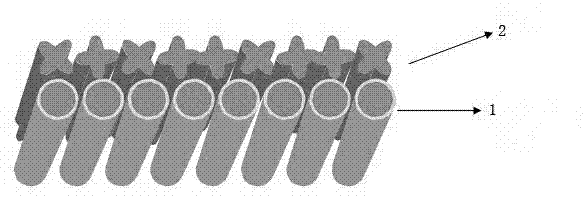

Elastic composite, and a system and method for making the elastic composite

A method of making an elastic composite is provided. The method entails conveying a first web of material along a web plane path. The method also entails applying a first section of a first elastic strand onto the first web and generally transversely to the web plane path and applying a second section of a second elastic strand onto the first web and generally transversely to the web plane path. These applying steps are repeated while performing the conveying step, thereby arranging a plurality of first and second elastic elements on the first web, in generally parallel relation to one another. The resultant composite is suitable for incorporation into a disposable absorbent garment, textile or fabric structure, and the like.

Owner:DSG TECH HLDG

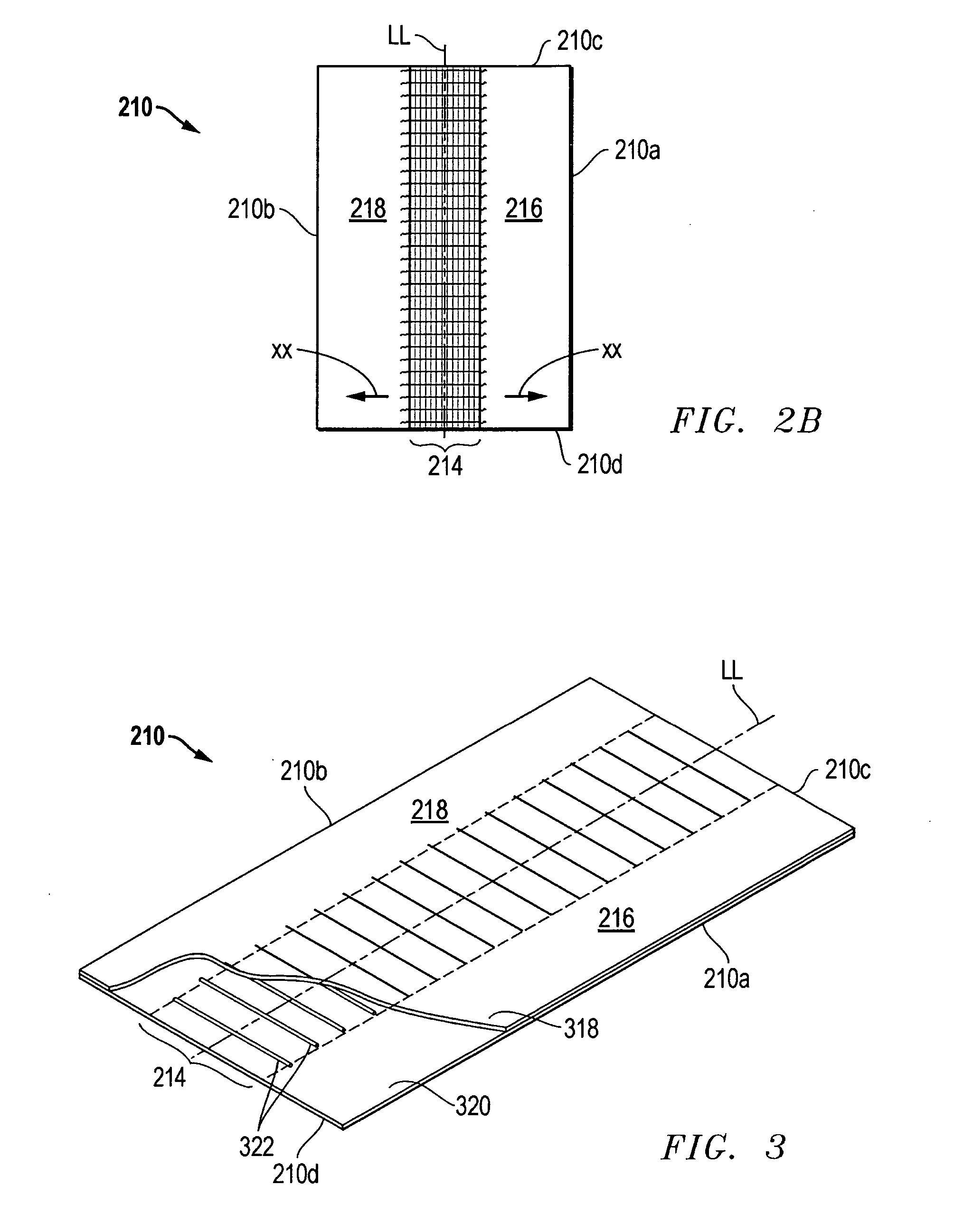

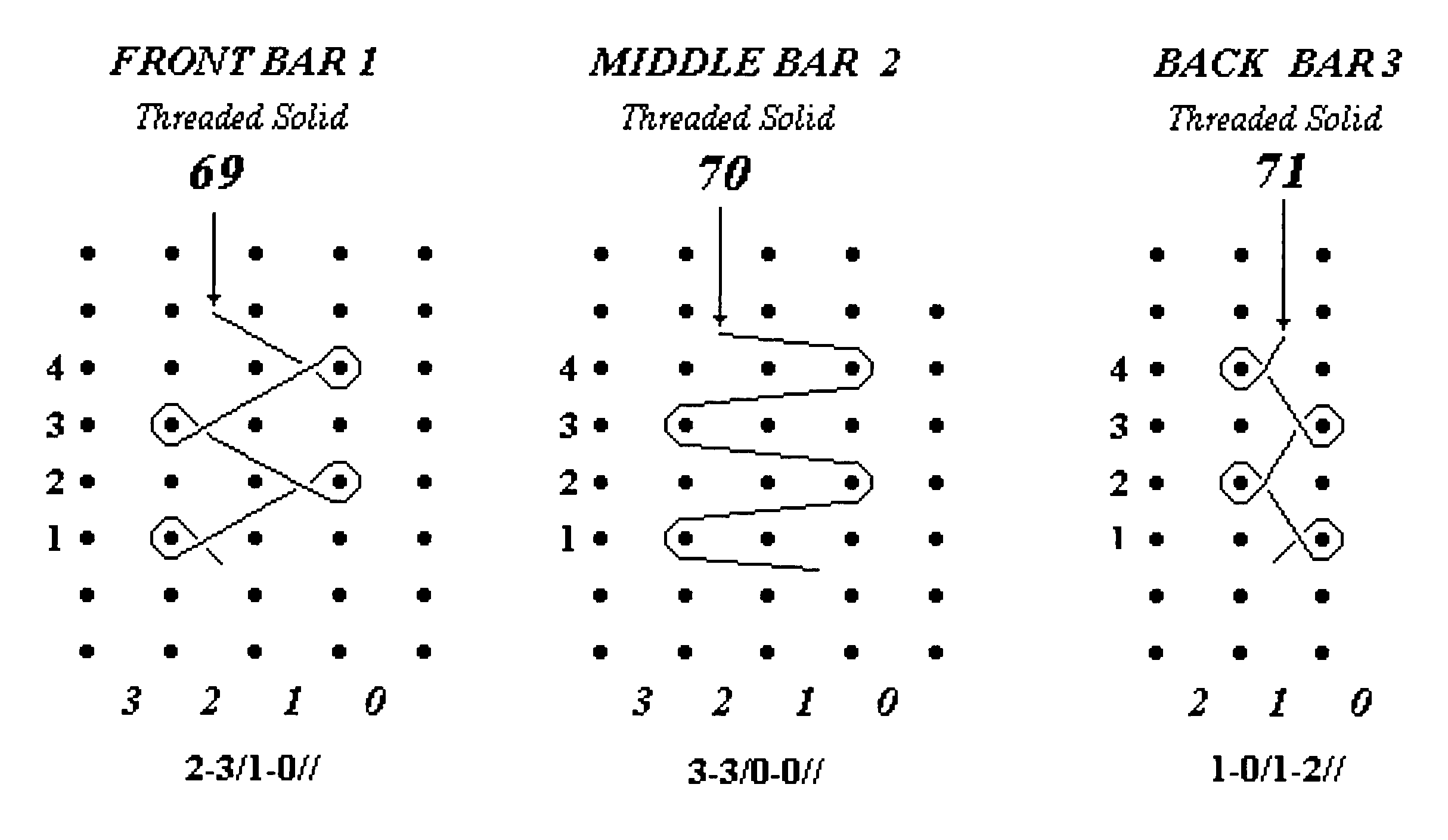

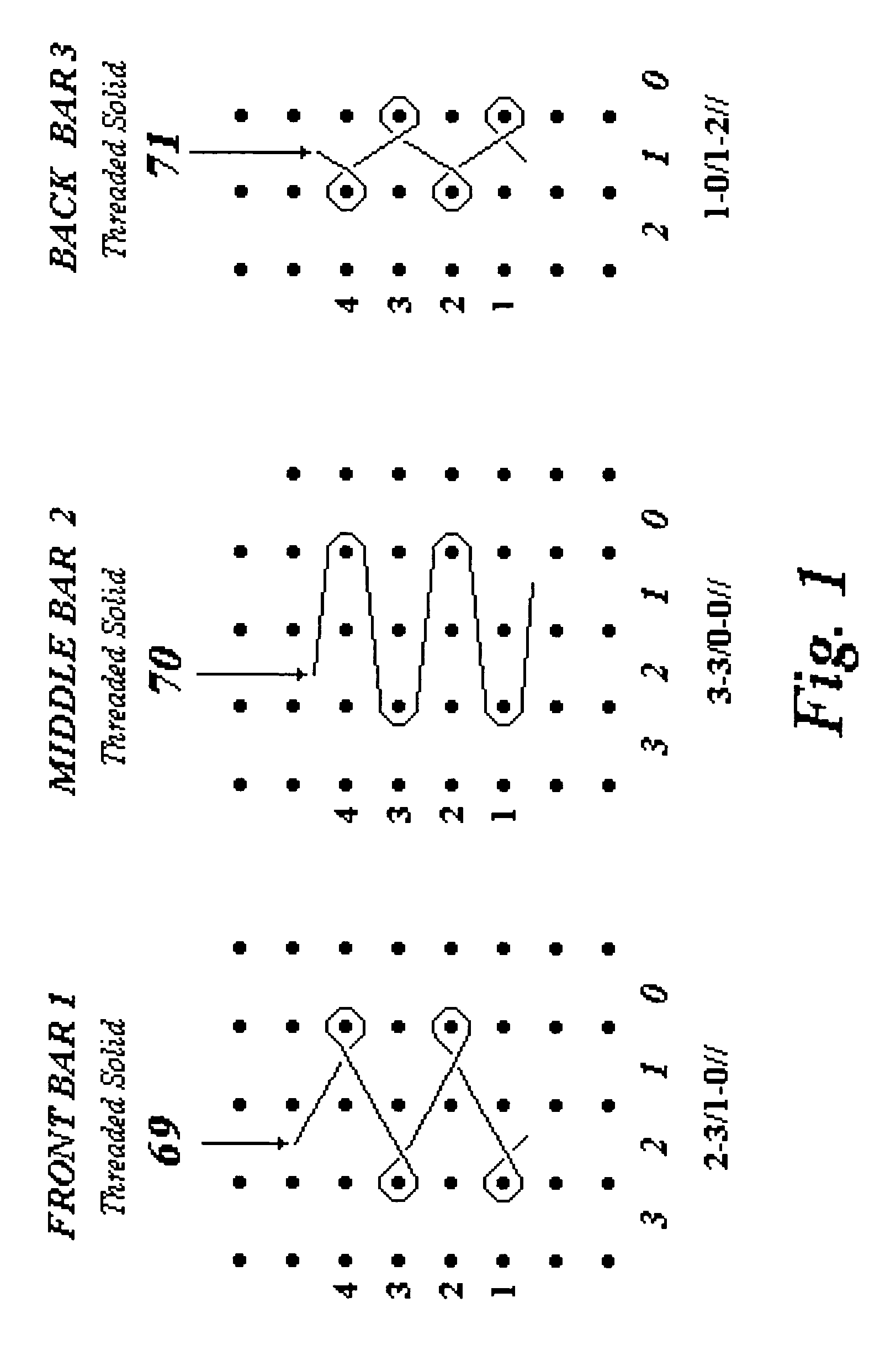

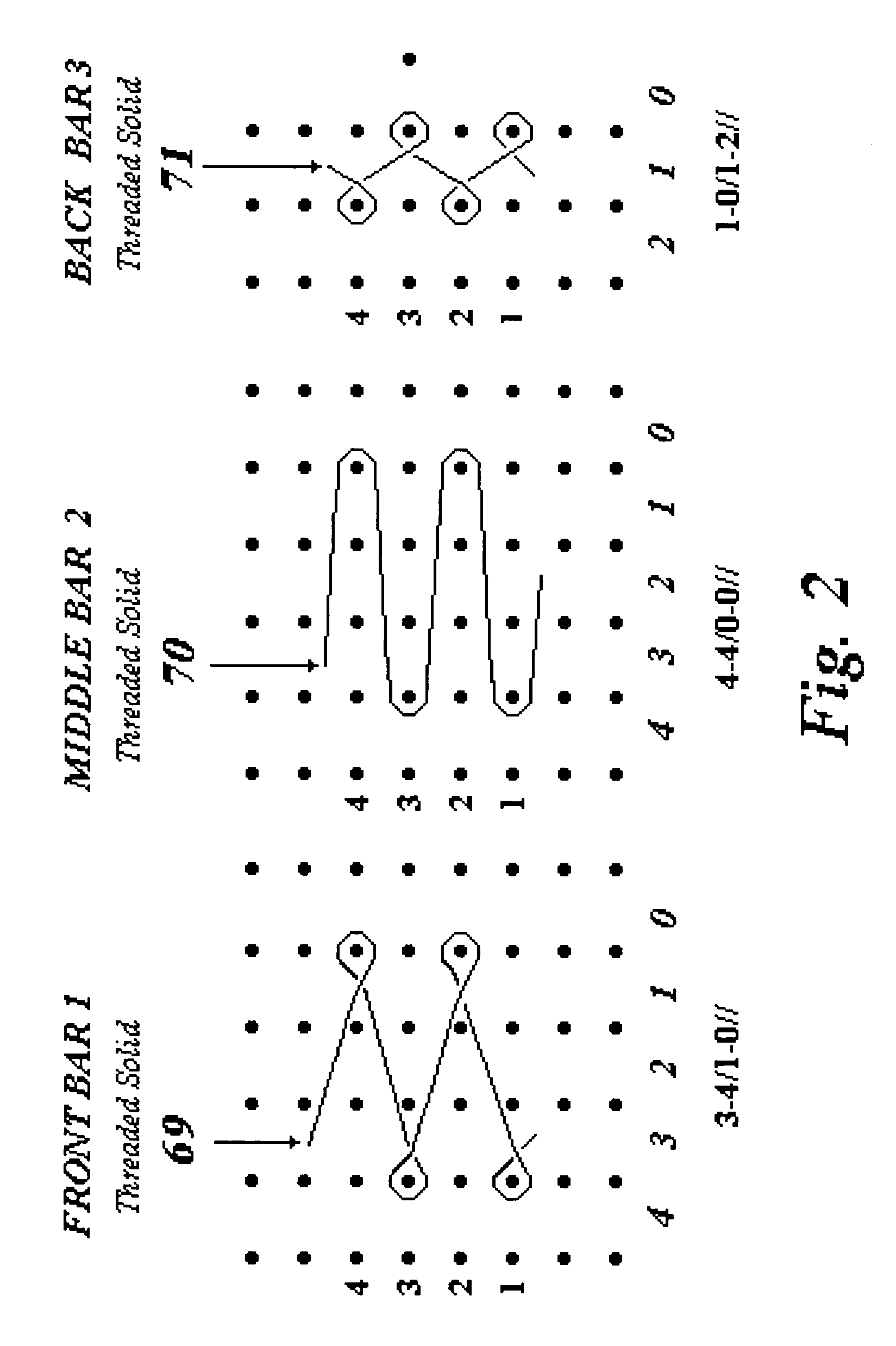

Functional double-faced performance warp knit fabric, method of manufacturing, and products made there from

ActiveUS7465683B2Optimized moisture wick ability functionHigh propertyOrnamental textile articlesSynthetic resin layered productsEngineeringFabric structure

An integrally formed stretch warp knit fabric structure formed using at least three guide bars, a fully or partly threaded first front guide bar, a second fully or partly threaded middle guide bar and third fully or partly threaded back guide bar that are knitted to form one single layer fabric having a definitive two-sided qualities; and a method of making the fabric; and articles using said fabric.

Owner:MCMURRAY BRIAN L

Silk medical device for use in breast augmentation and breast reconstruction

InactiveUS20150351899A1Process stabilitySmooth transferMammary implantsWeft knittingYarnSingle stage

A three-dimensional fabric structure in a form of a pocket for use in a breast reconstruction surgical procedure such as single-stage or two-stage breast reconstruction. The silk scaffold employs a knit pattern that substantially prevents unraveling and preserves the stability of the mesh or scaffold device, especially when the mesh or scaffold device is cut. An example scaffold device employs a knitted mesh including at least two yarns laid in a knit direction and engaging each other to define a plurality of nodes.

Owner:ALLERGAN INC

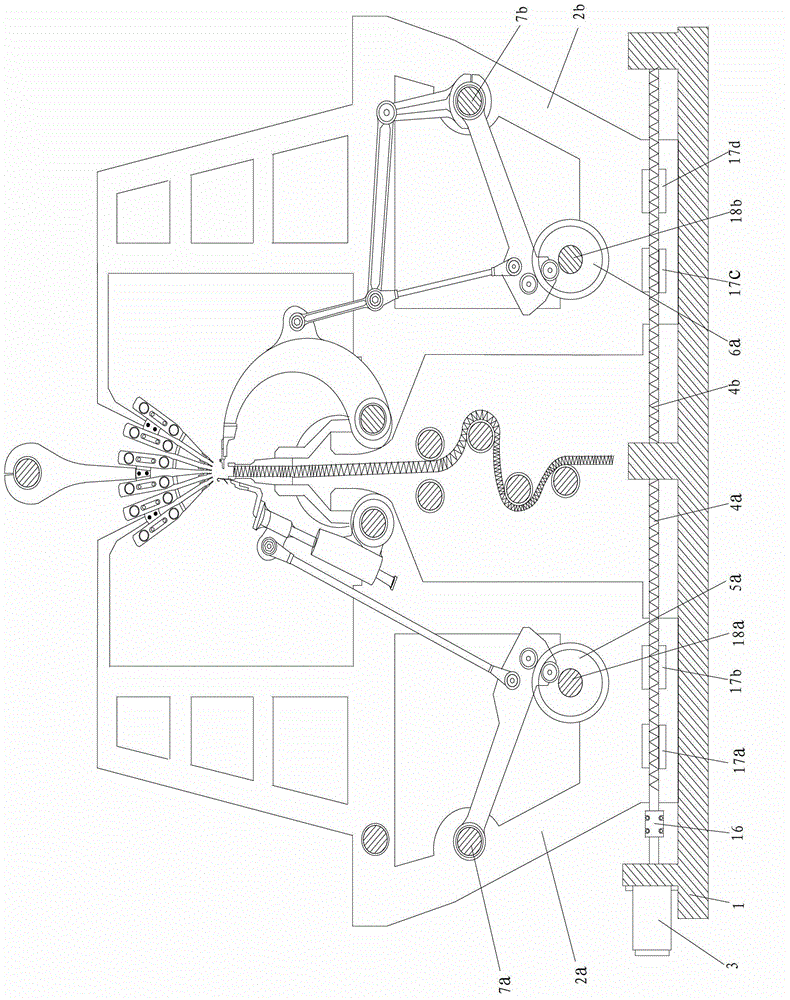

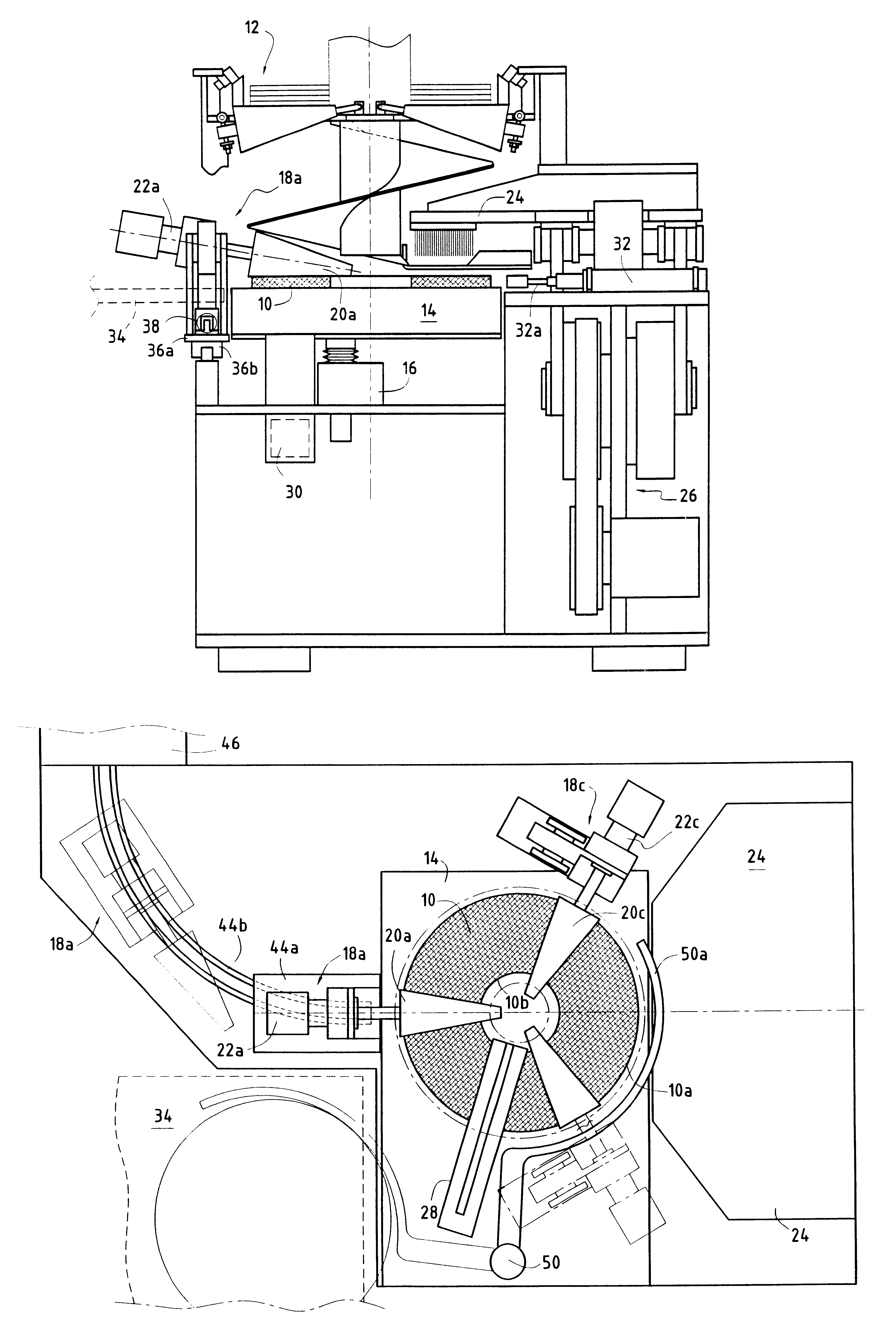

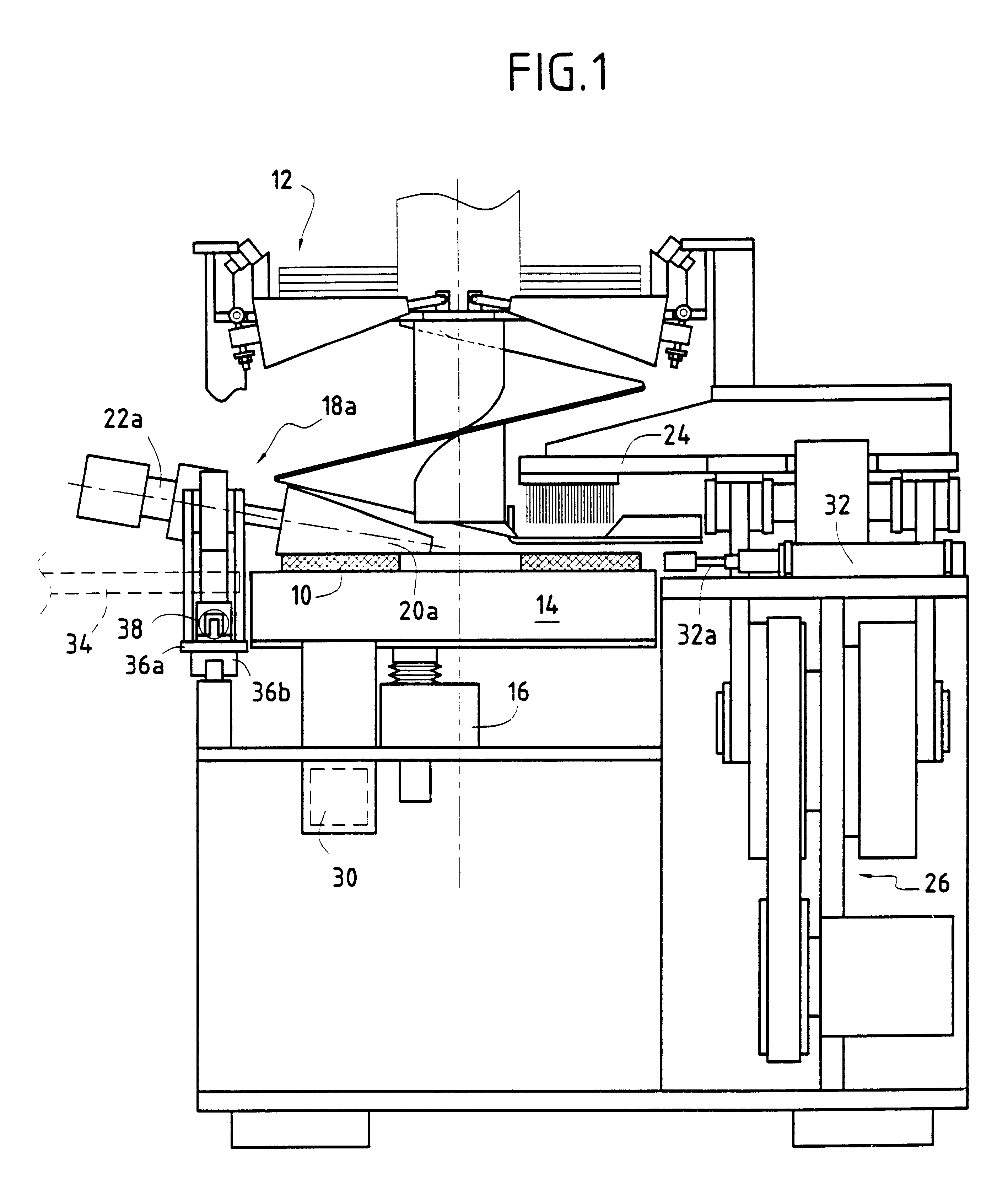

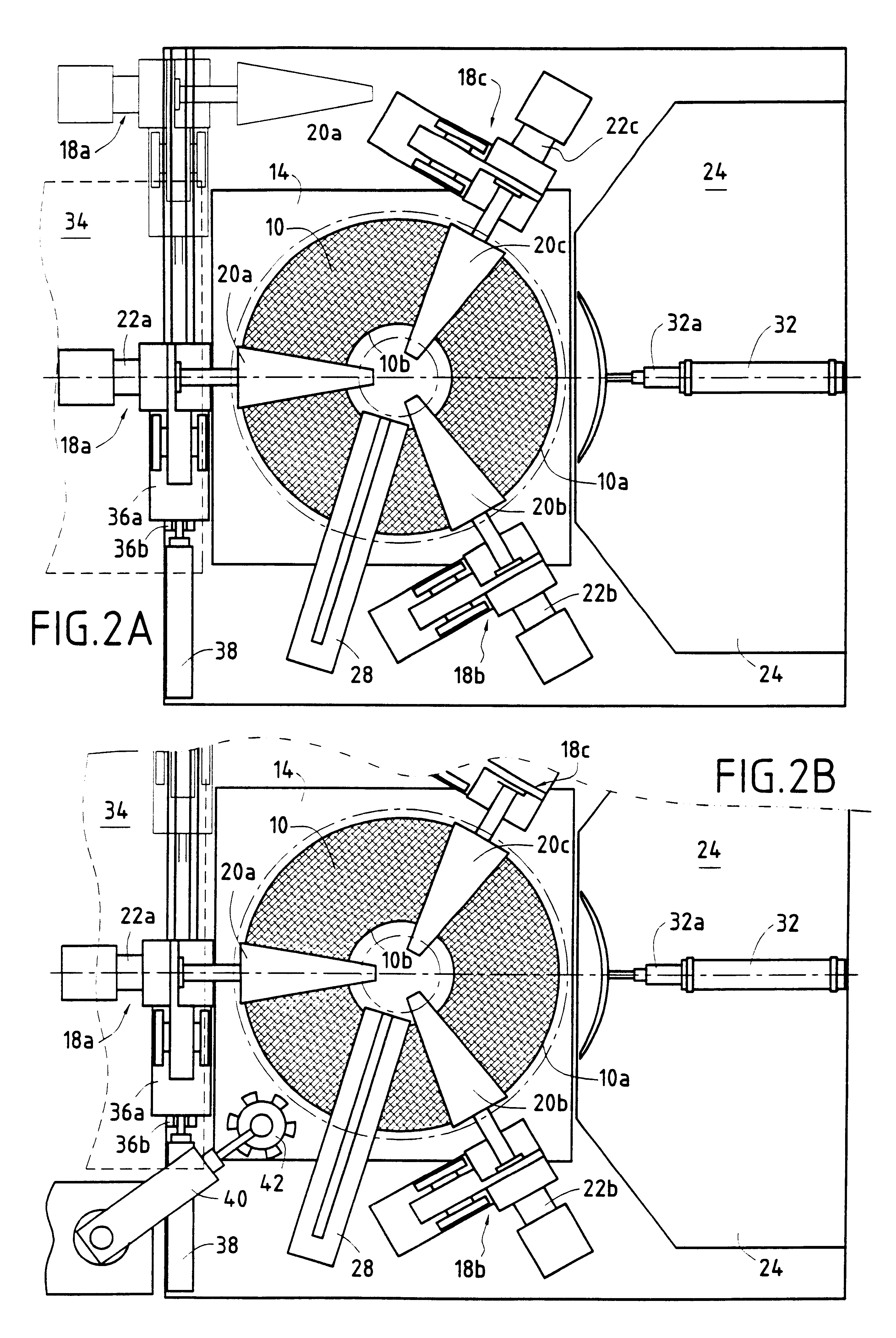

Circular needling machine provided with a device for automatically removing preforms

InactiveUS6347440B1Removed easily and automaticallyLayered productsNeedling machinesEngineeringFabric structure

A machine for needling a textile structure built up from a helical strip delivered by strip supply means, said machine comprising a needling table, a needling head, cutting means for cutting the helical strip, and conical roller drive means for rotating said strip on the needling table, at least a fraction of said conical roller drive means being retractable so as to release an empty space on said needling table enabling ejector means to remove the textile structure from the needling table.

Owner:SAFRAN LANDING SYSTEMS

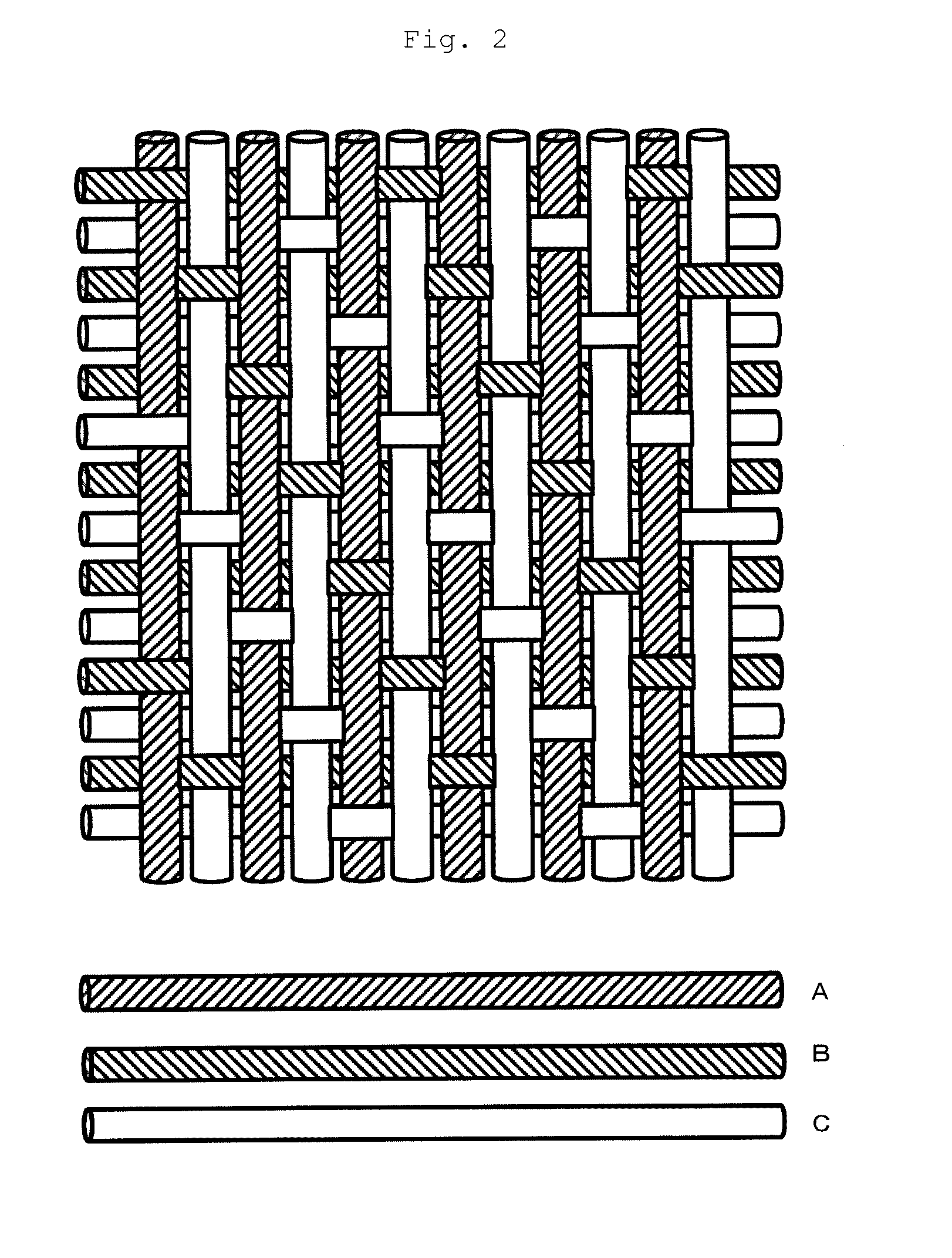

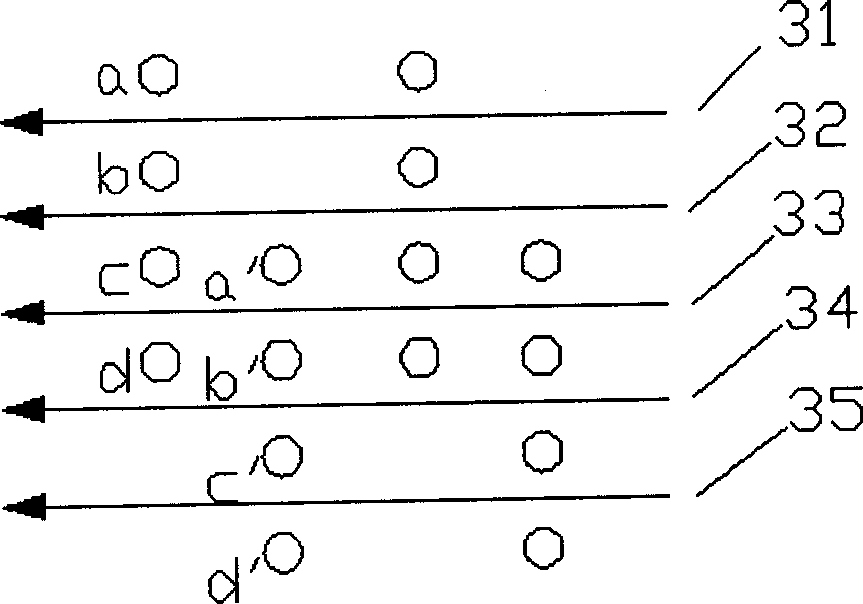

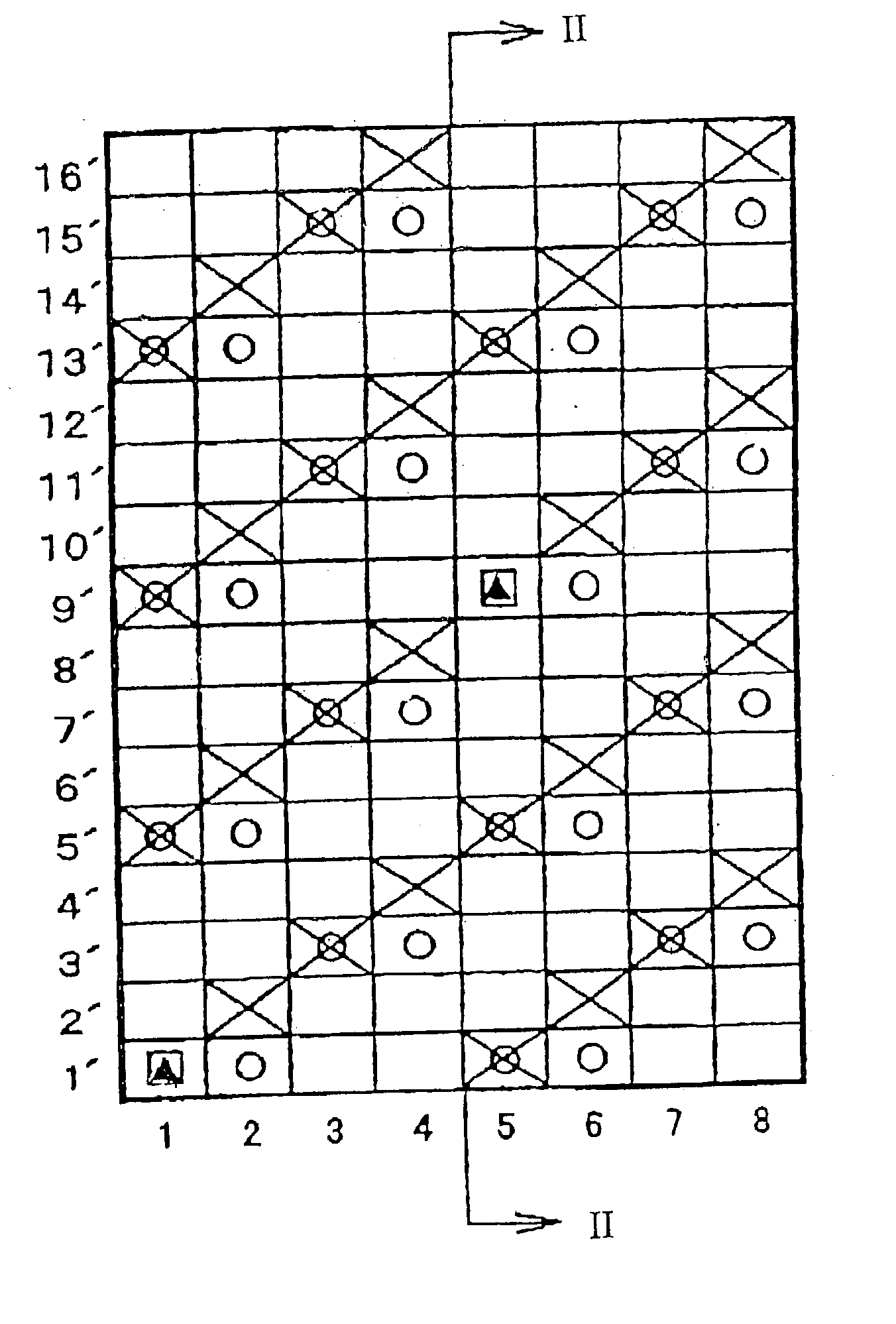

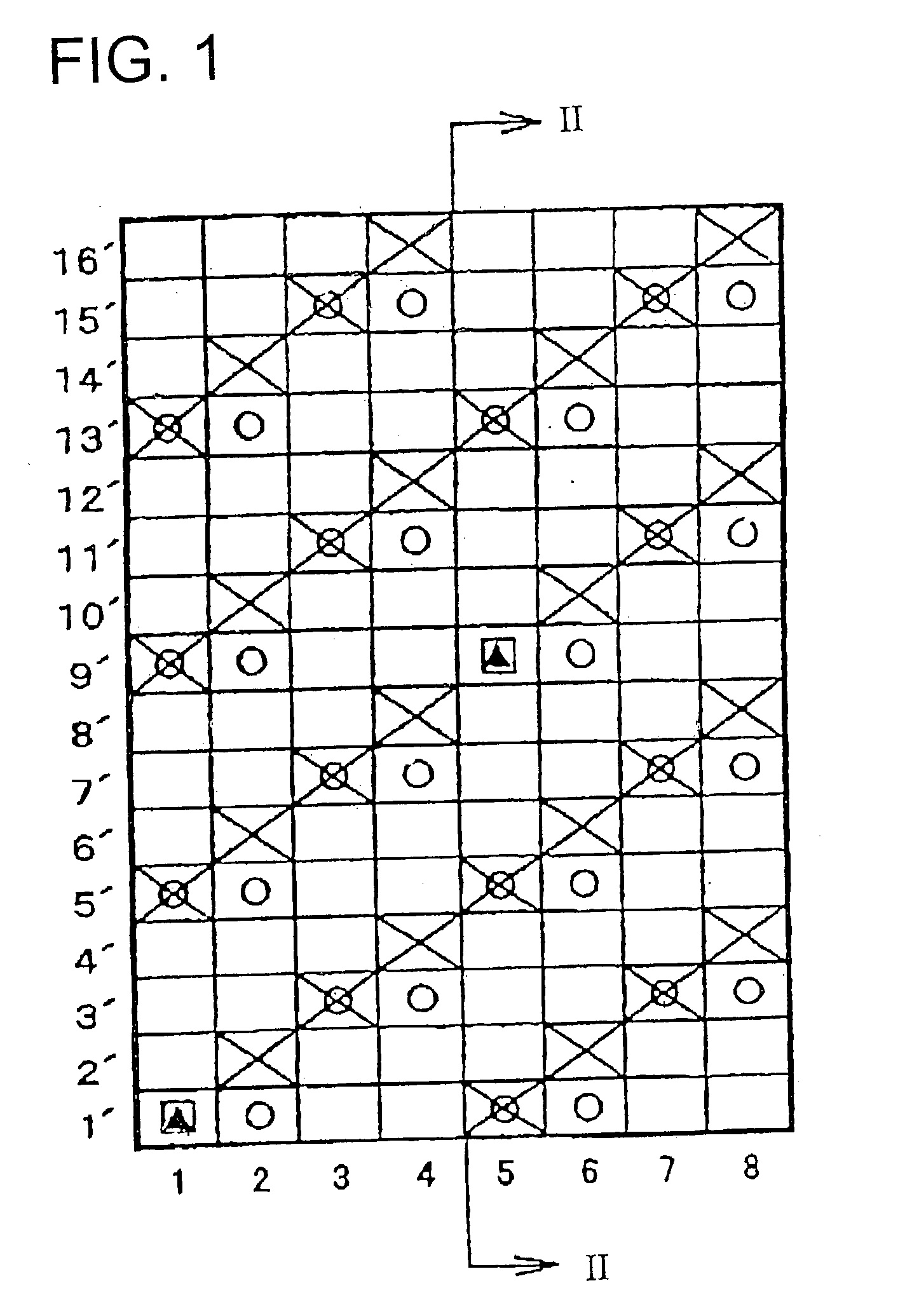

Industrial two-layer fabric

An industrial two-layer fabric comprises an upper layer fabric having upper surface side warps and upper surface side wefts and a lower layer fabric having lower surface side warps and lower surface side wefts. The upper layer fabric and the lower layer fabric are bound at least one spot in a repeating unit where an upper surface side warp weaves a lower surface side weft without weaving an upper surface side weft which should have been woven by the upper surface side warp based on the fabric structure, and where a lower surface side warp weaves the upper surface side weft which should have been woven by the upper surface side warp, without weaving the lower surface side weft which should have been woven by the lower surface side warp.

Owner:NIPPON FILCON

Heat insulation soft thin composite fabric, preparing method and its use

InactiveCN1586884ASimple compositionWell formedSynthetic resin layered productsProtective garmentComposite effectRoom temperature

The present invention relates to the composite fabric structure with one side capable of bearing high temperature, low temperature or composite effect of high temperature and low temperature, and the other side maintained at room temperature state of 5-35 deg.c. The fabric structure has heat and cold resisting high performance coated fabric in one side; soft, comfortable, antifrosting and condensation-preventing fabric in the other side; and composite fabric of heat insulating polymer and compounded metal film as the middle layer, which may have also net lining fabric with stable thickness and size. The composite fabric has natural thickness of 3-12 mm, practical densified thickness of 1-3 mm and unit area weight of 150-550 g / sq m, may be adhered and sawn, and is completely sealed suitable for use as heat insulating protecting material in the environment condition from -130 deg.c to 120 deg.c.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com