Special-shaped three-dimensional knitted fabric and manufacturing method thereof

A special-shaped three-dimensional, manufacturing method technology, applied in the field of knitted fabrics, can solve the problems of not being able to meet the requirements, not being able to produce concave-convex fabrics, and not being able to meet real-time adjustments, etc., and achieve the effect of good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

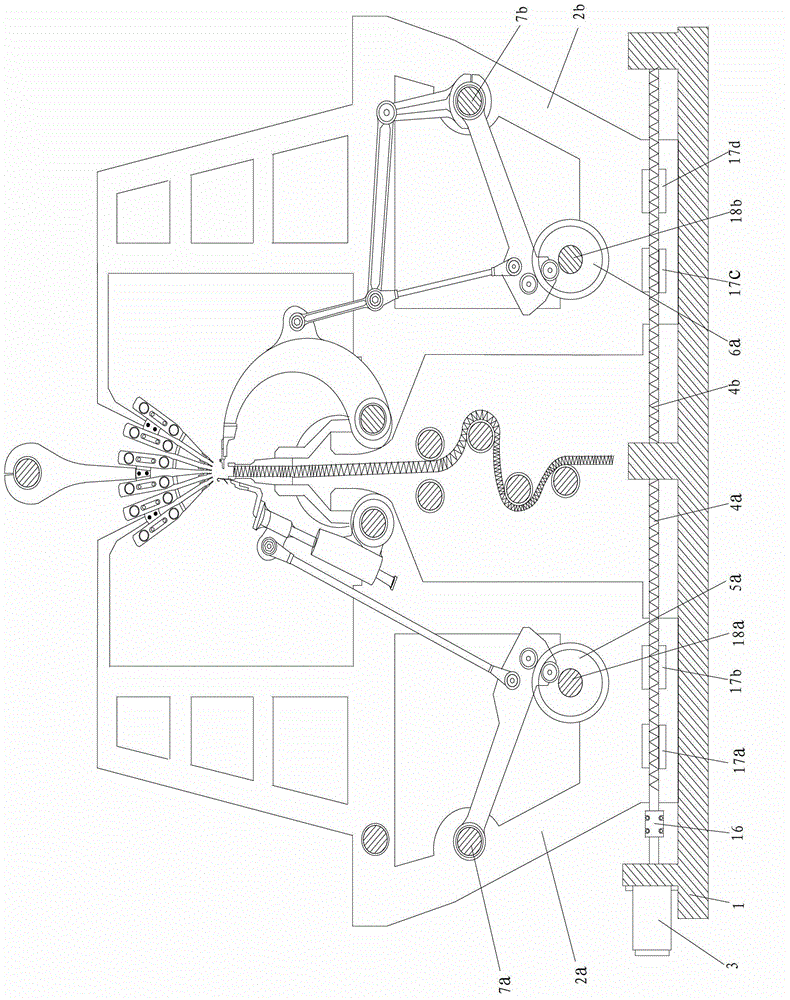

[0030] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

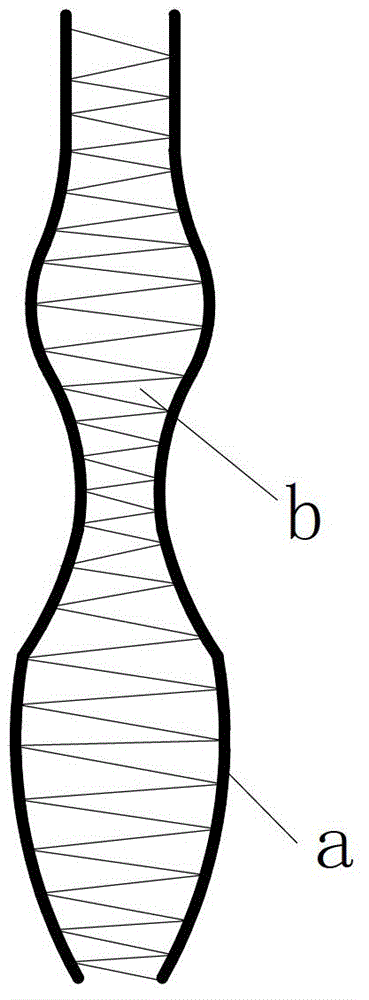

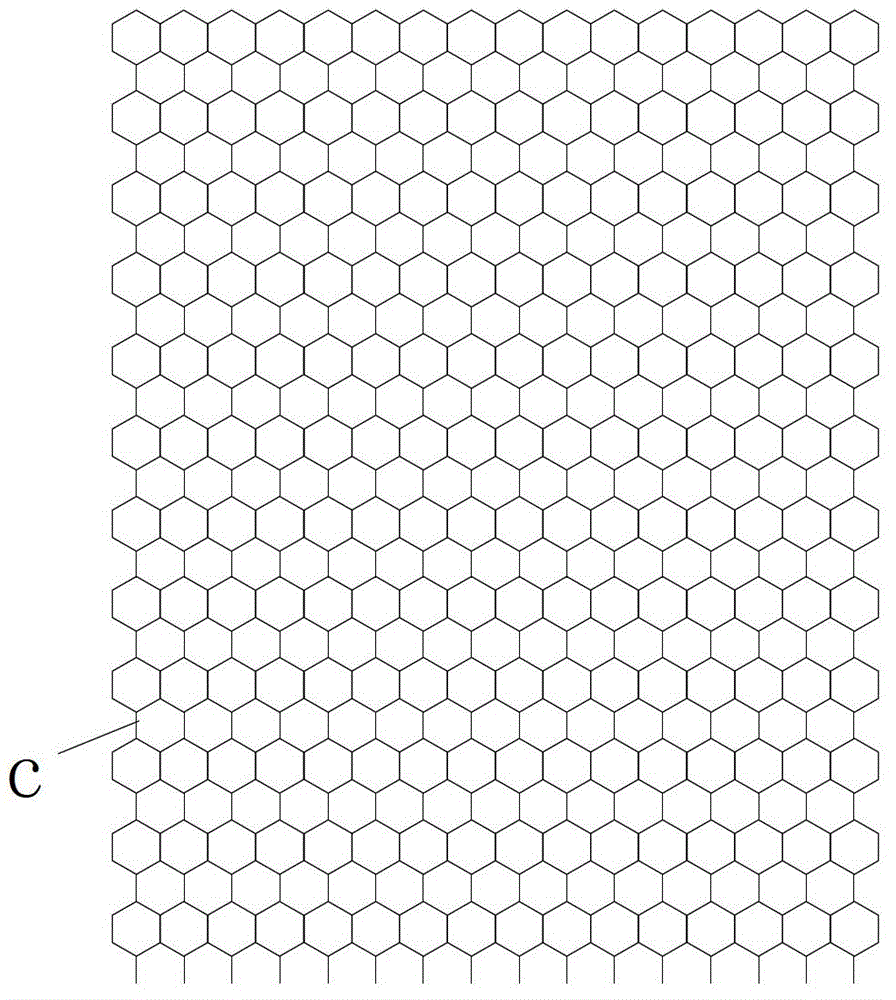

[0031] The knitting machine of special-shaped three-dimensional three-dimensional knitted fabric has double-sided needle beds, and the gauge (number of knitting needles within 1 inch) can be 6~22. The distance between the needle beds of the machine can be adjusted freely within the range of 6~65mm, and the parallel center plane of the two needle beds can be any regular curved surface during adjustment.

[0032] Due to the change of the needle bed spacing, the front and rear swings of the bar during the yarn laying process also need to be adjusted accordingly according to the change of the needle bed spacing.

[0033] The knitting method of the above-mentioned knitted fabric is to adjust the distance between the two needle beds through the electronic control device according to the requirements of the thickness of the fabric during the weaving process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com