Patents

Literature

808results about How to "High reversible capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

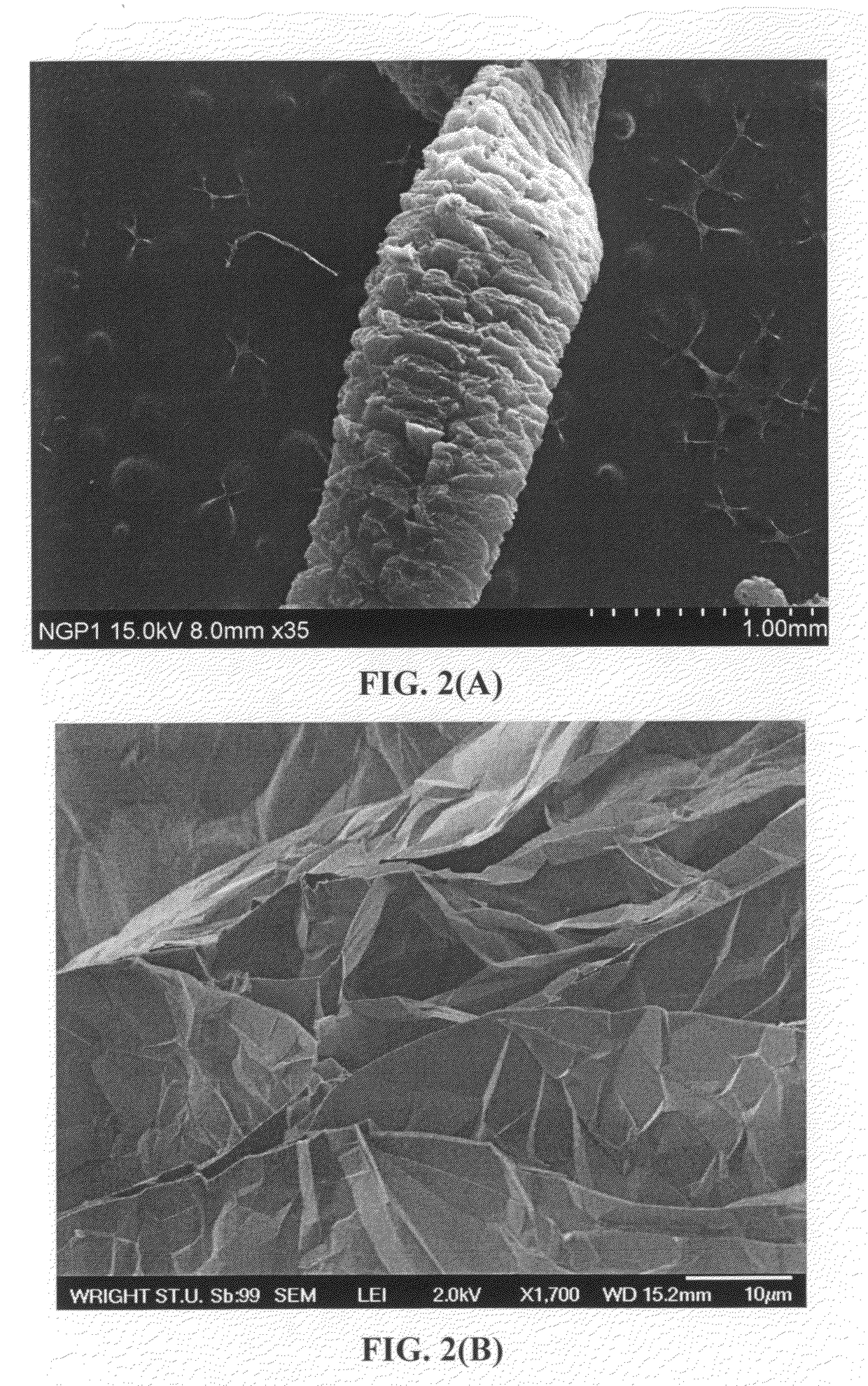

Nano graphene platelet-based composite anode compositions for lithium ion batteries

ActiveUS20090117467A1Improve conductivityLower internal resistanceElectrolytic capacitorsSecondary cellsGraphene flakeGraphite

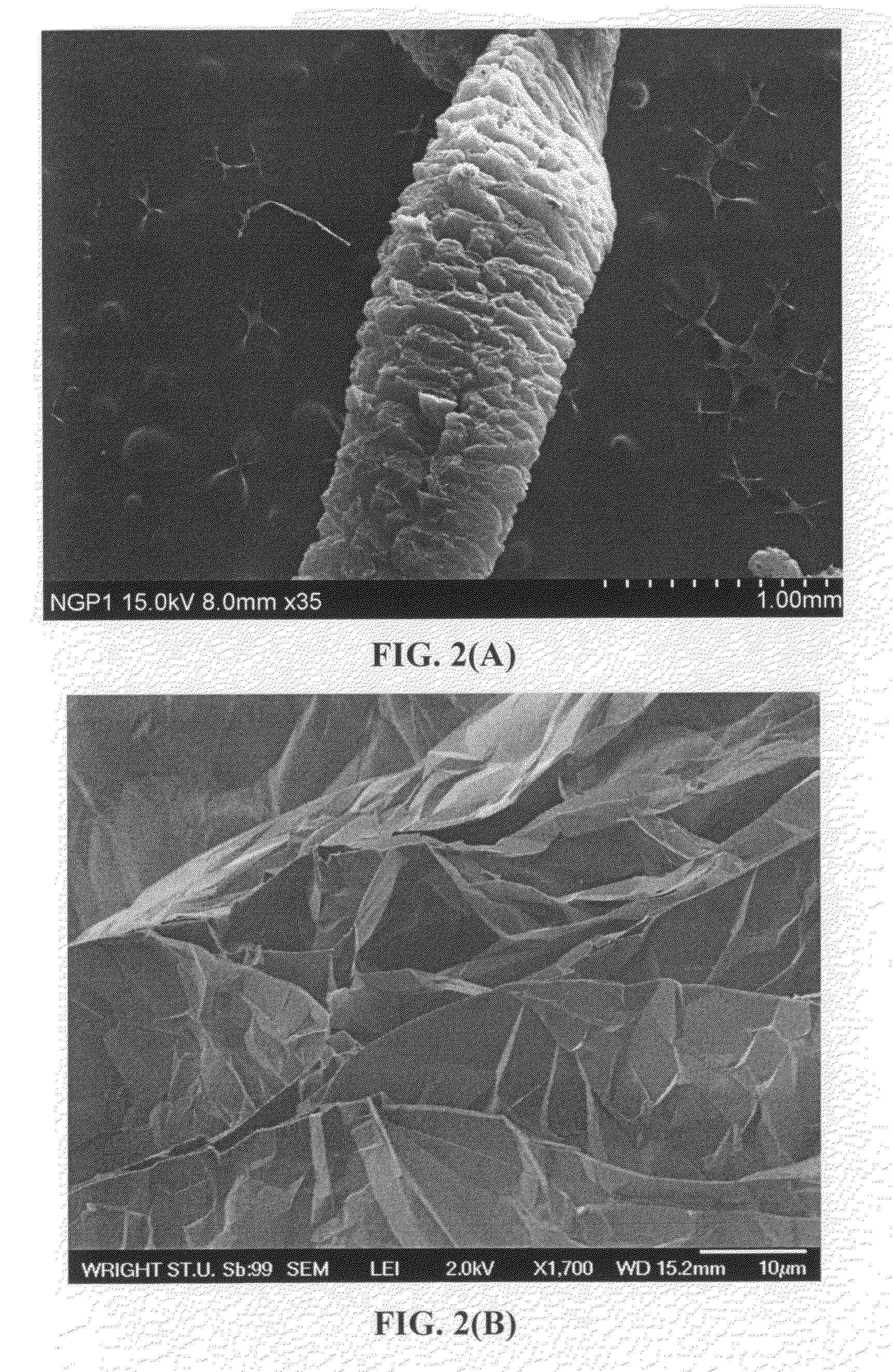

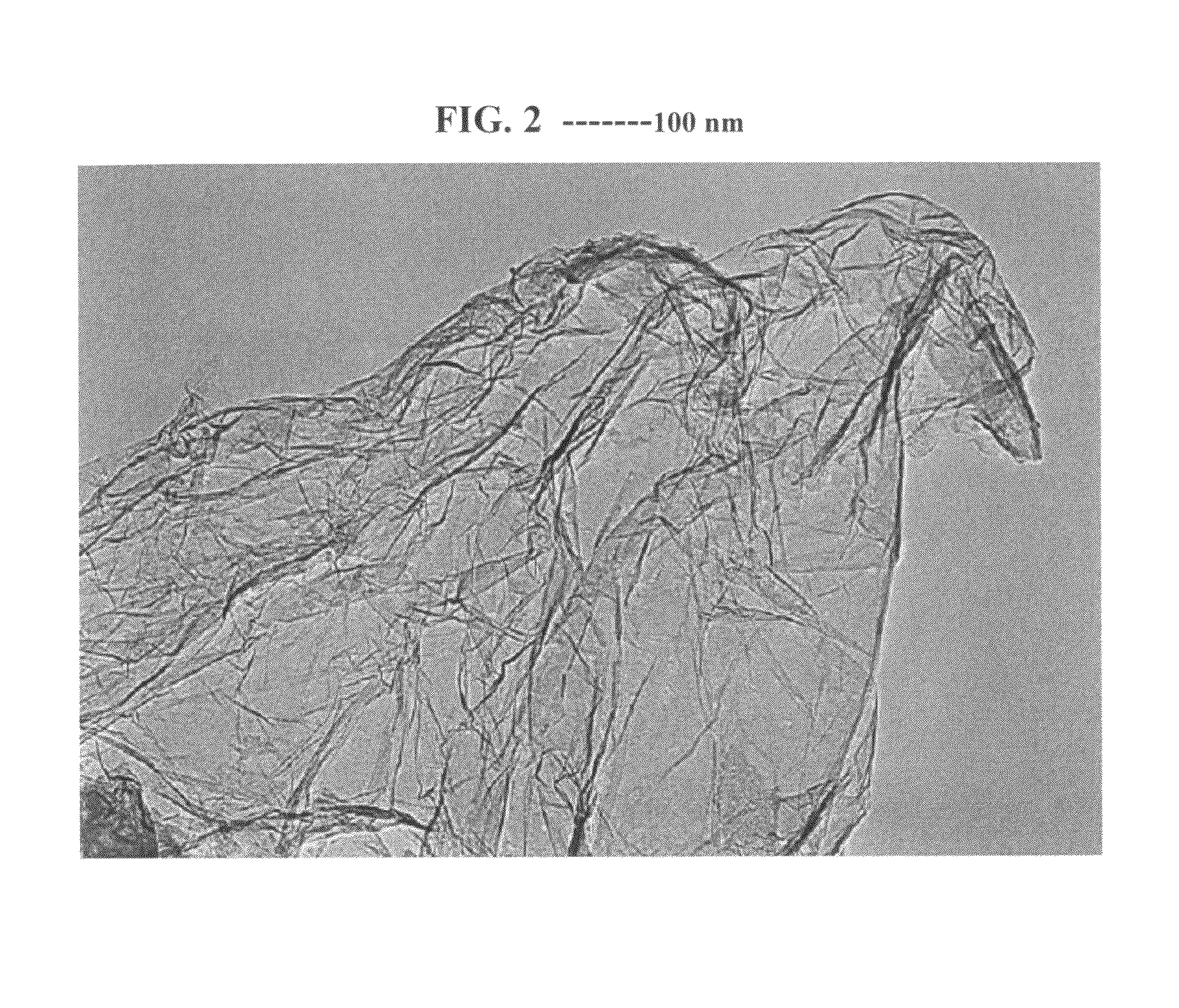

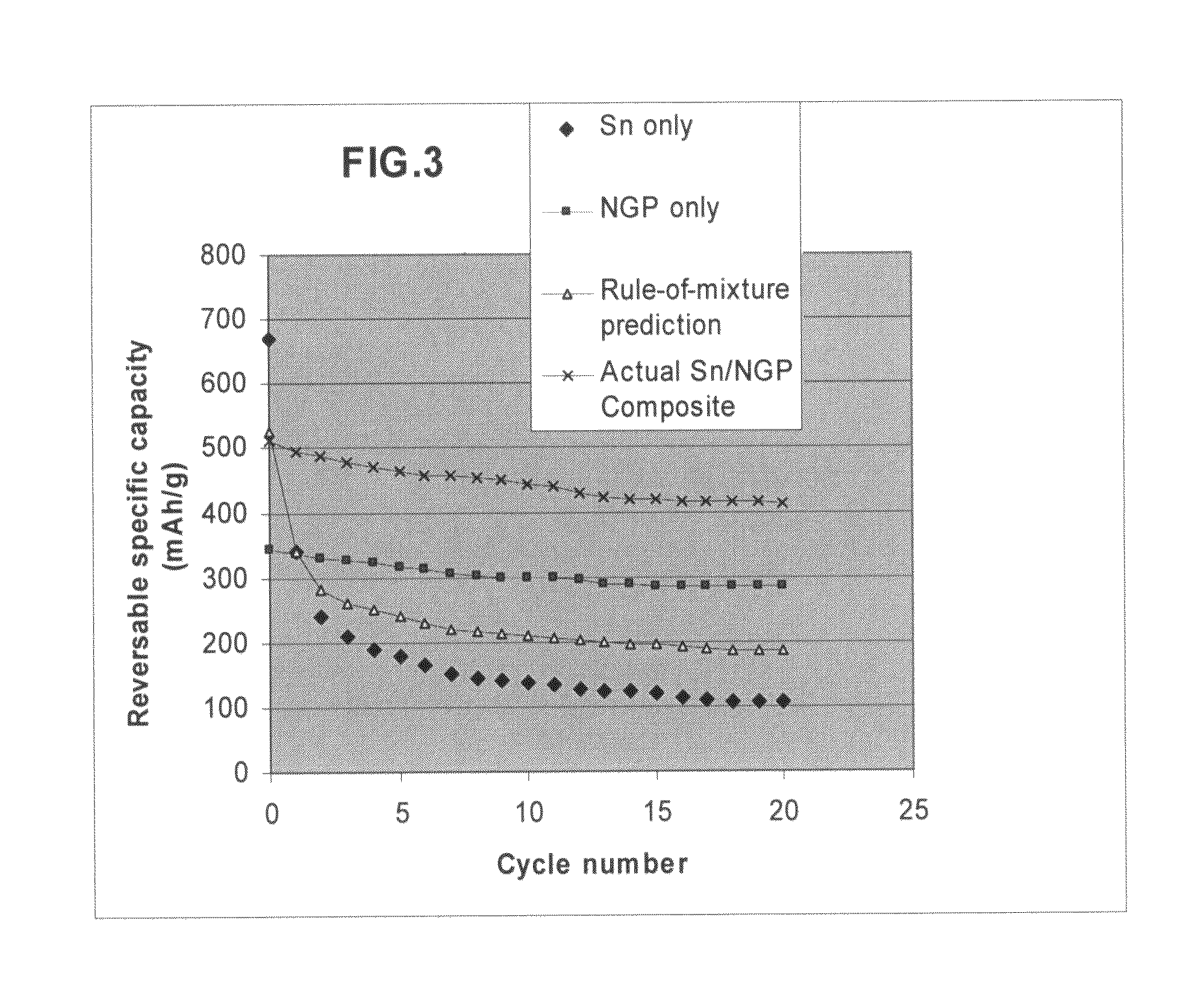

The present invention provides a nano-scaled graphene platelet-based composite material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing lithium ions; and (b) a plurality of nano-scaled graphene platelets (NGPs), wherein a platelet comprises a graphene sheet or a stack of graphene sheets having a platelet thickness less than 100 nm; wherein at least one of the particles or coating is physically attached or chemically bonded to at least one of the graphene platelets and the amount of platelets is in the range of 2% to 90% by weight and the amount of particles or coating in the range of 98% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

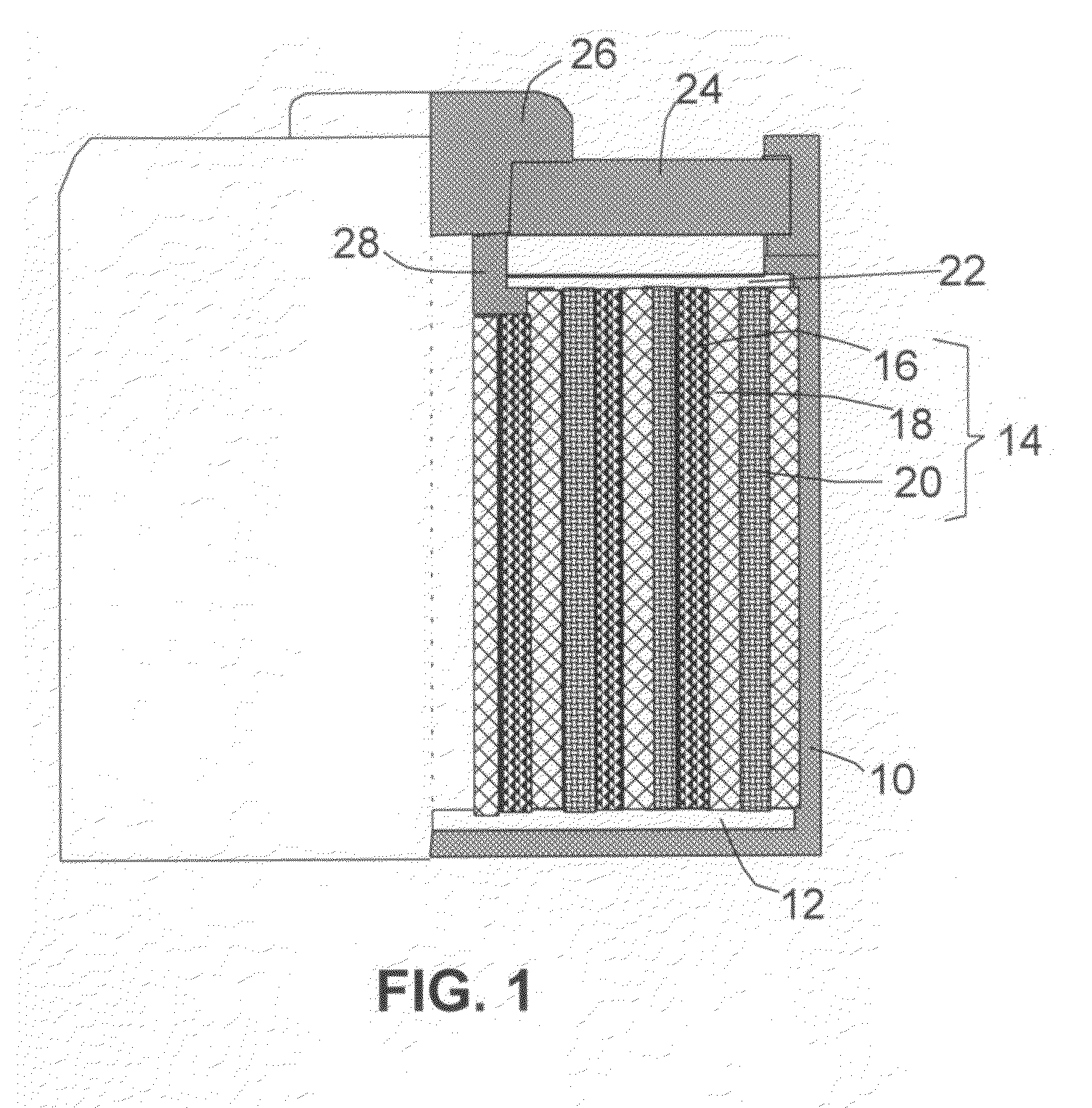

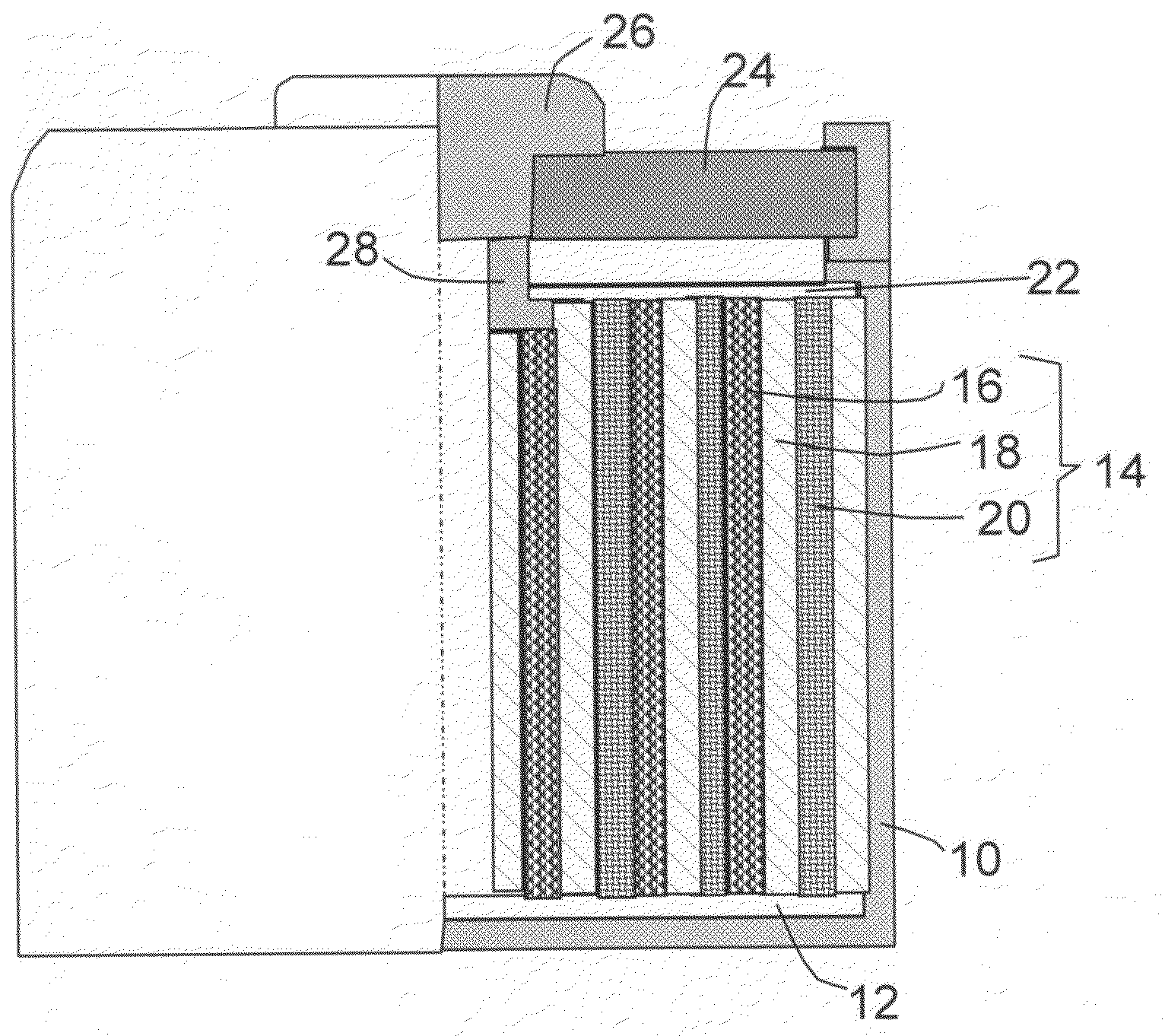

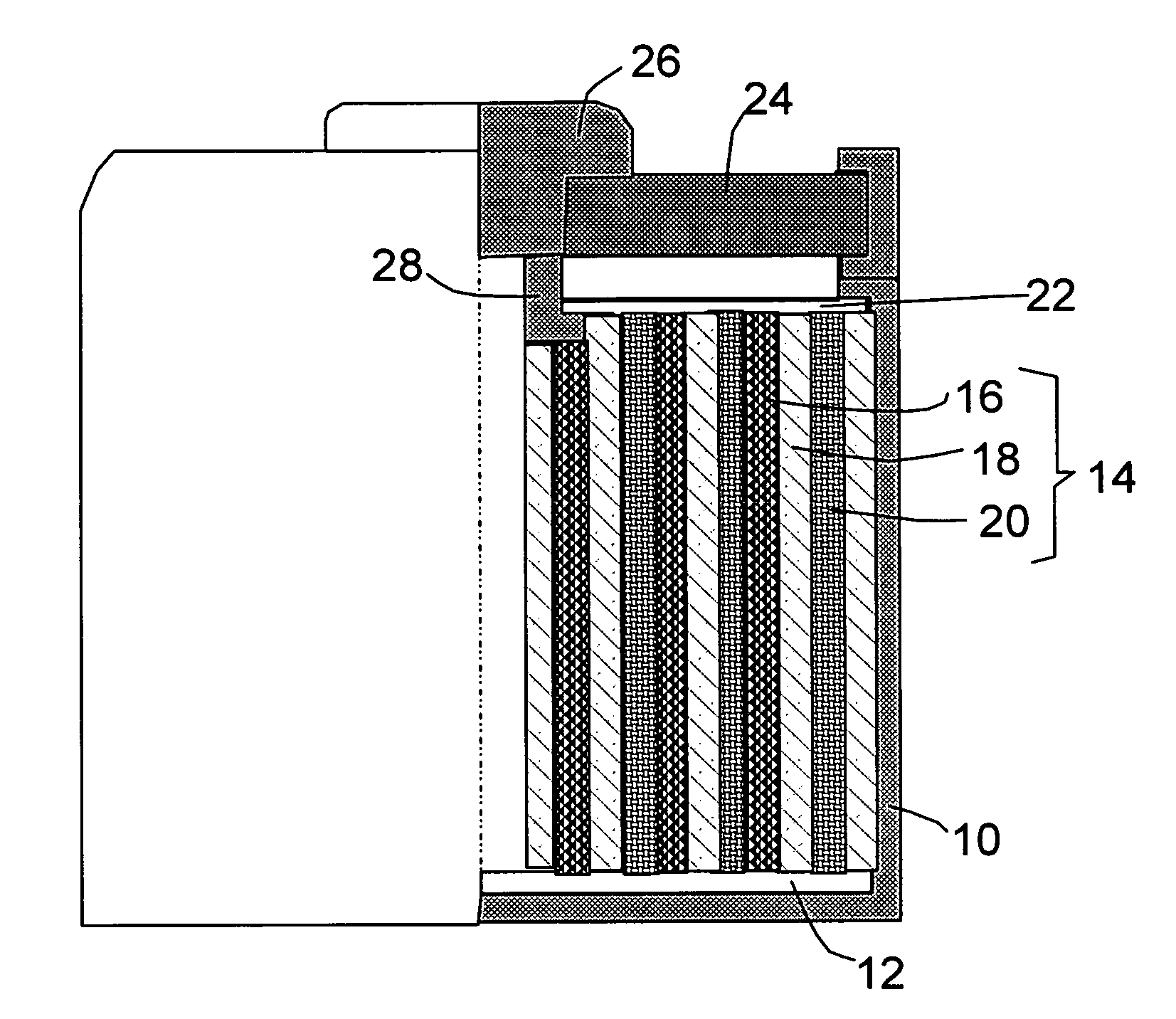

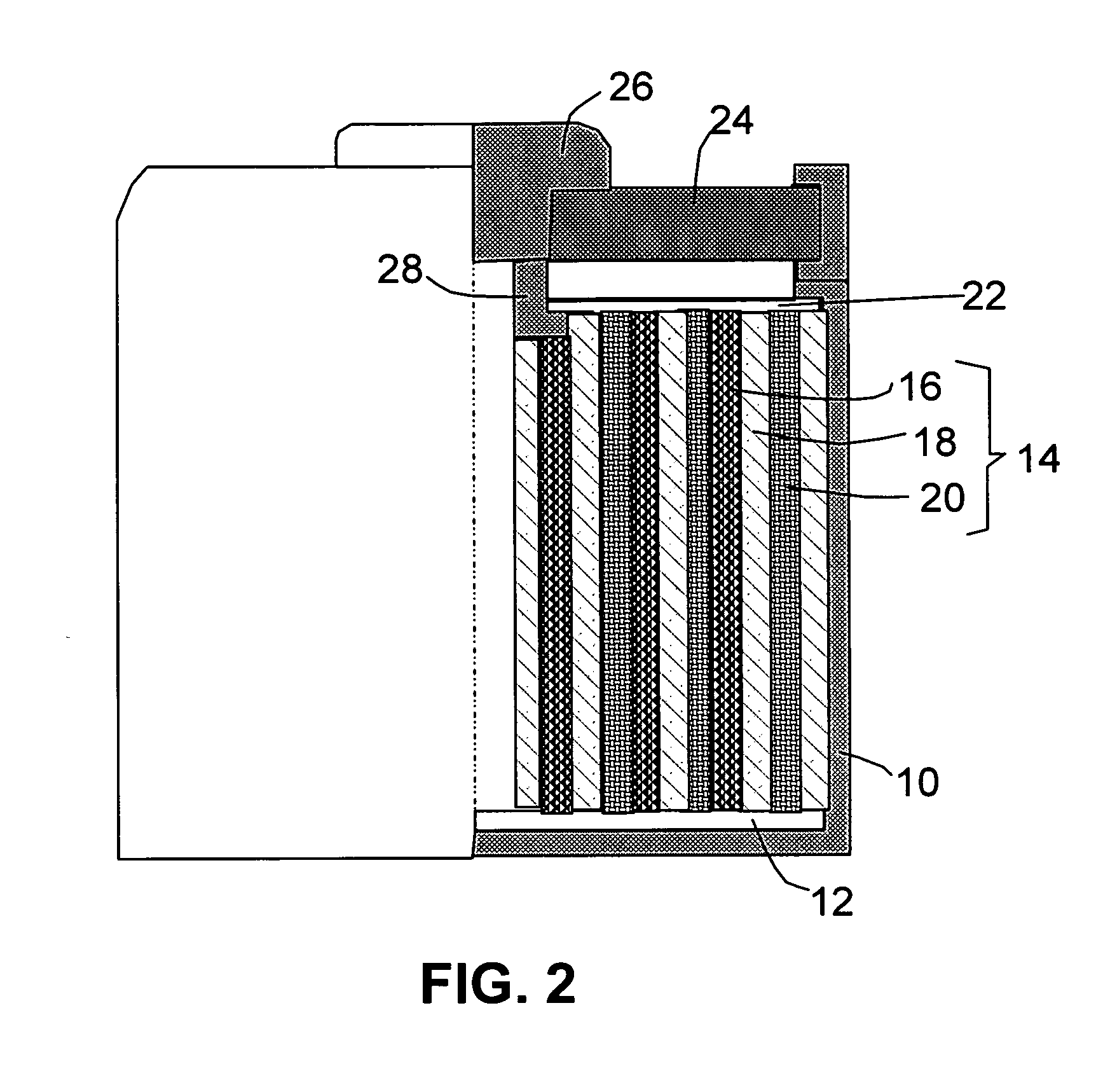

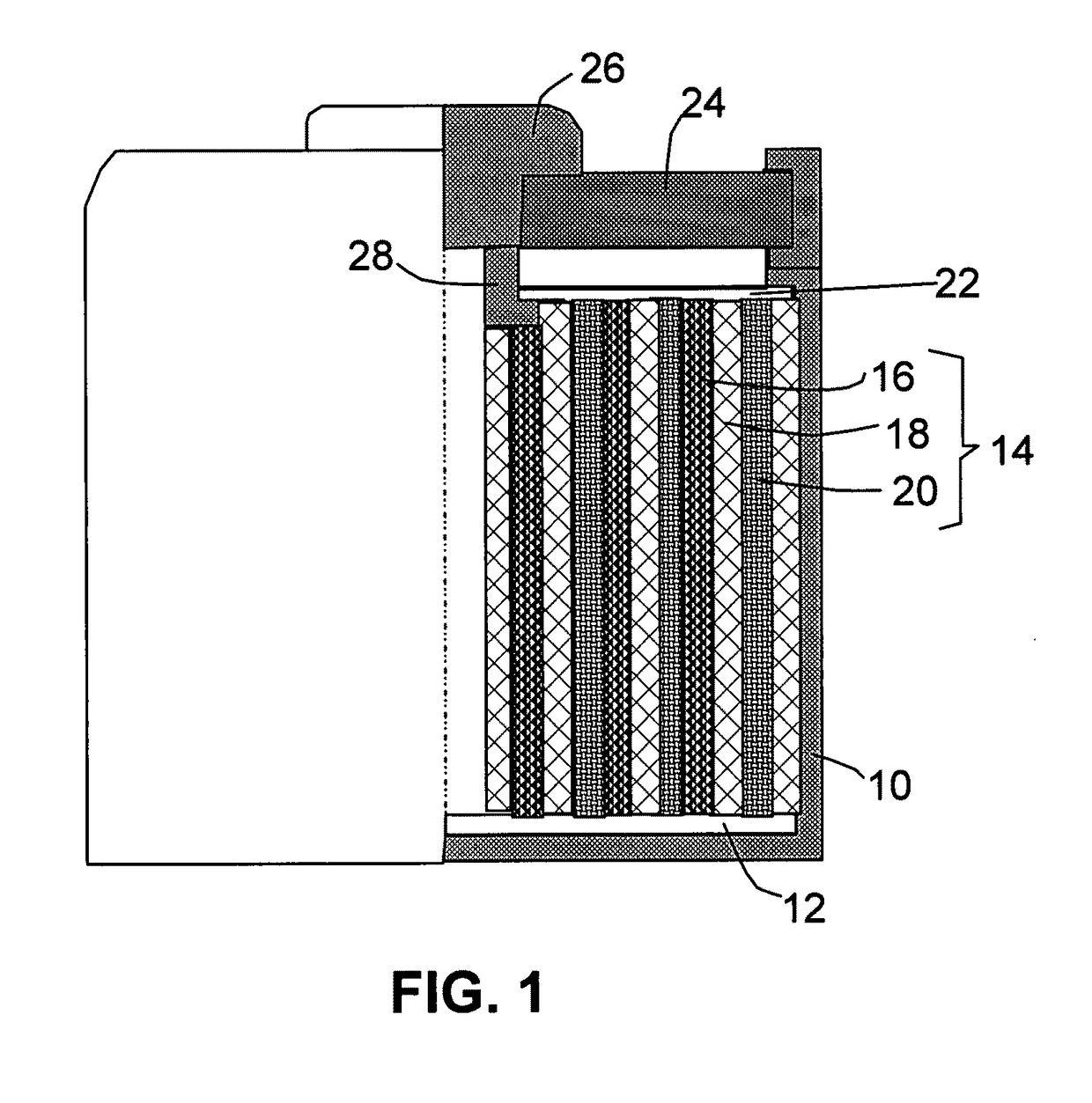

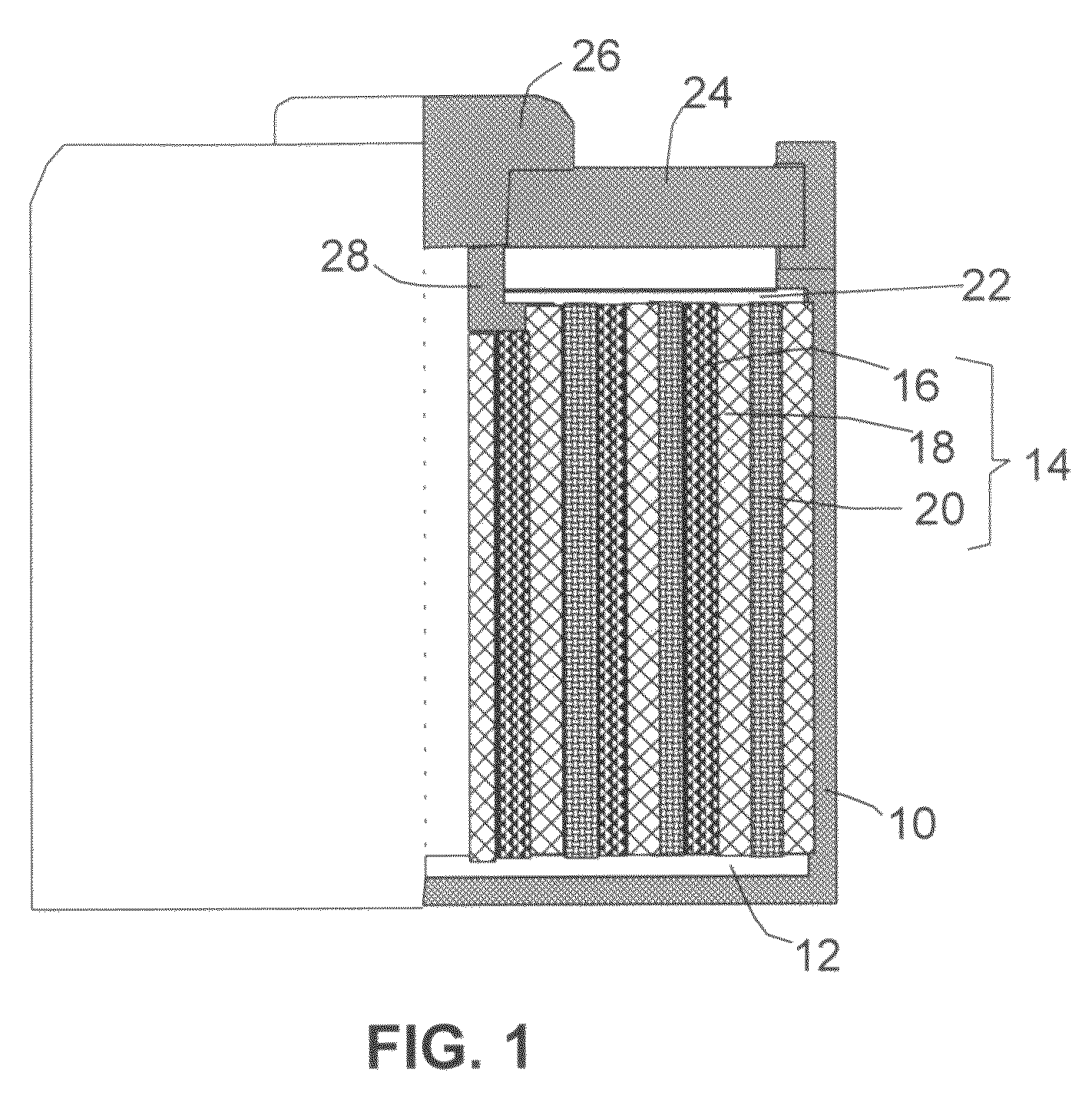

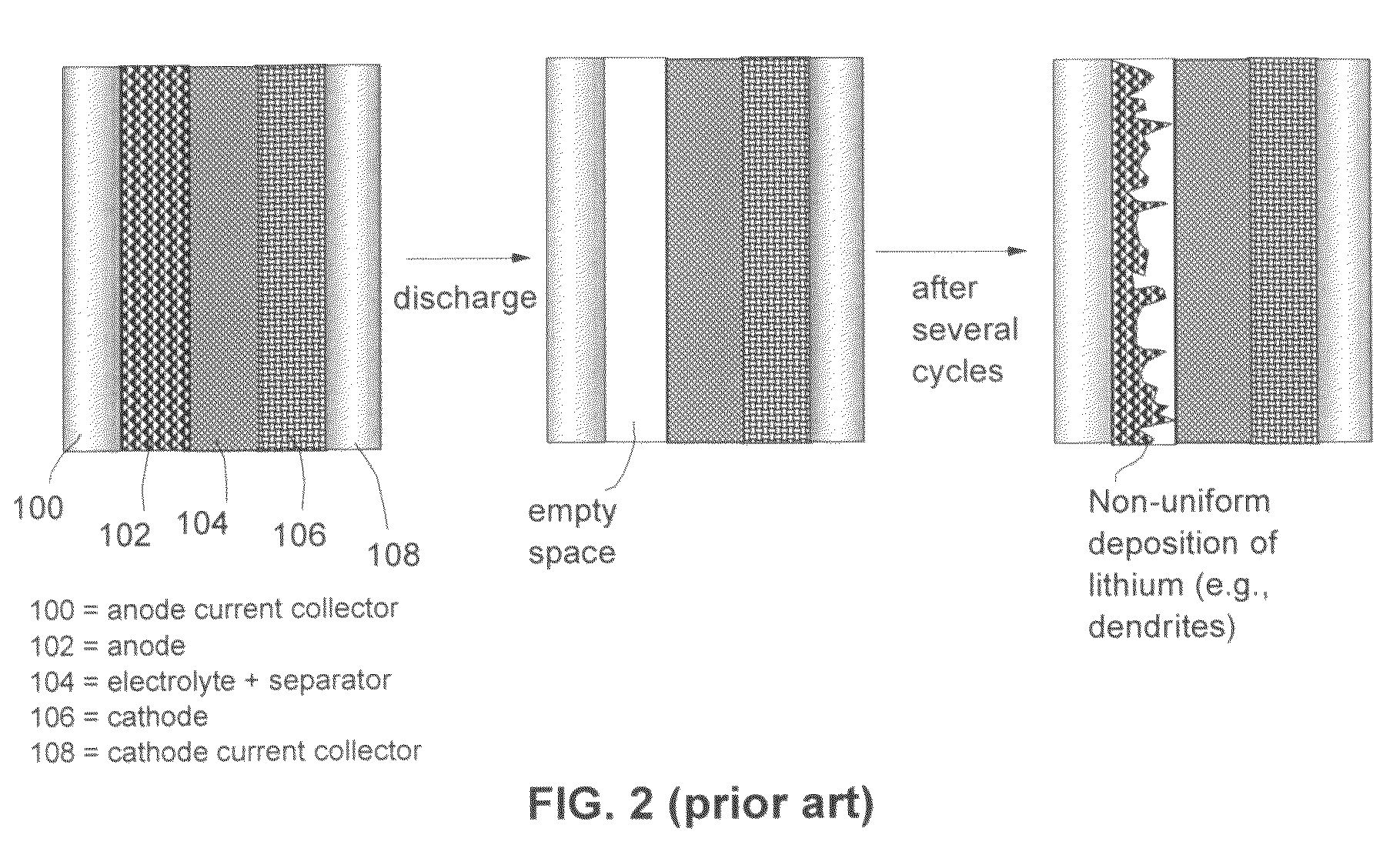

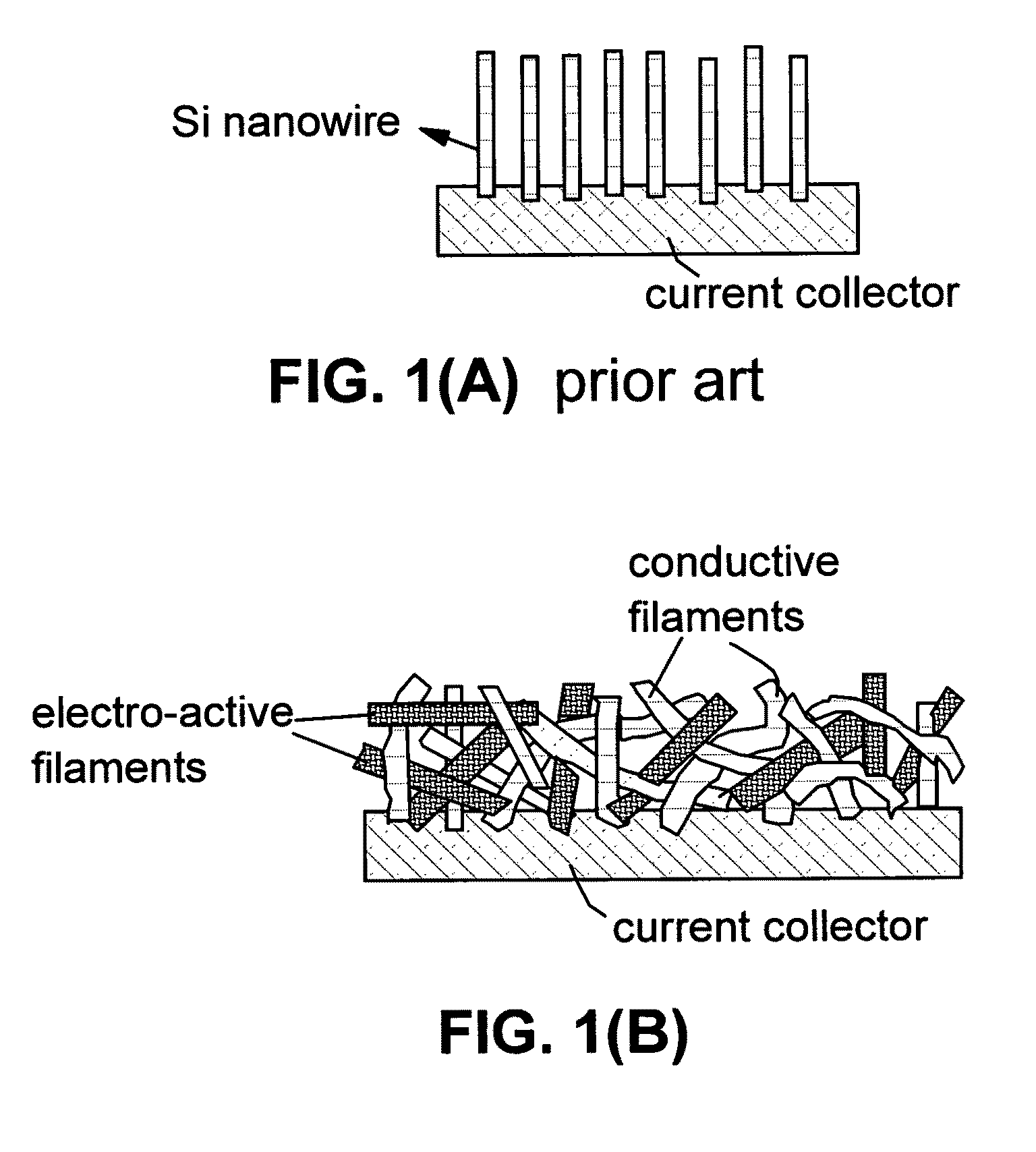

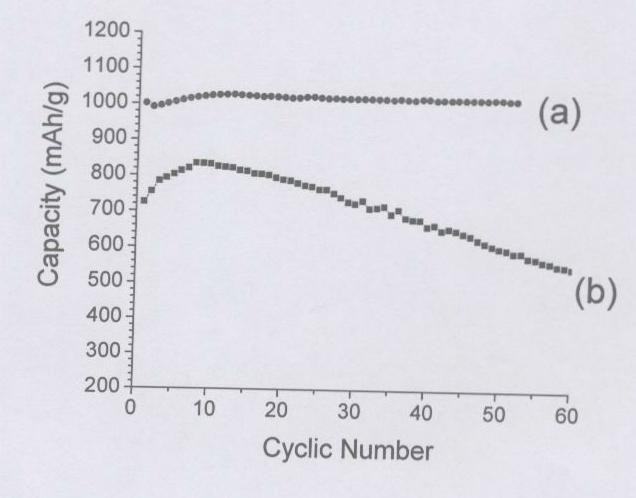

Conductive nanocomposite-based electrodes for lithium batteries

ActiveUS20090305135A1High specific capacityHigh reversible capacityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon layerComposite electrode

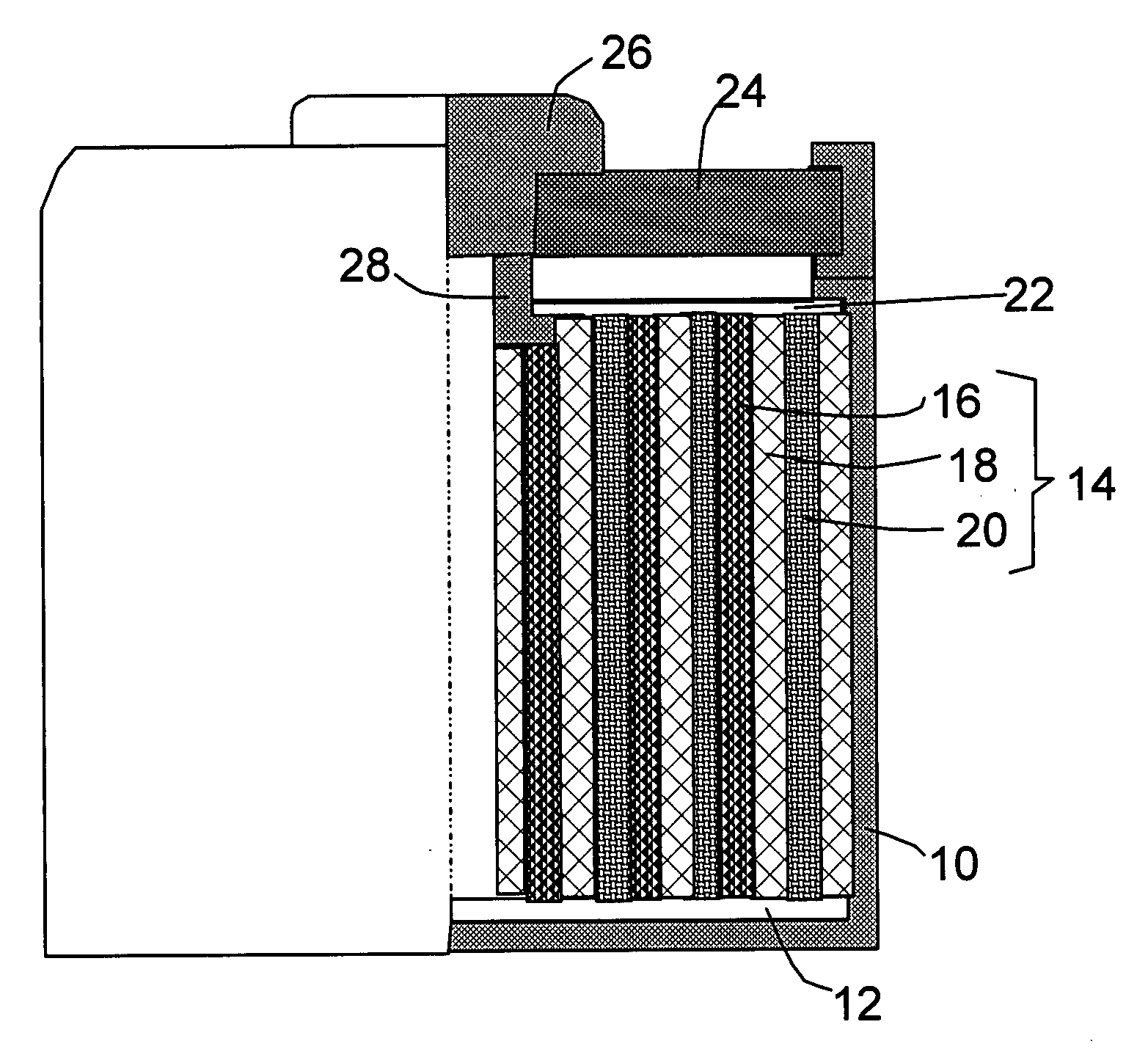

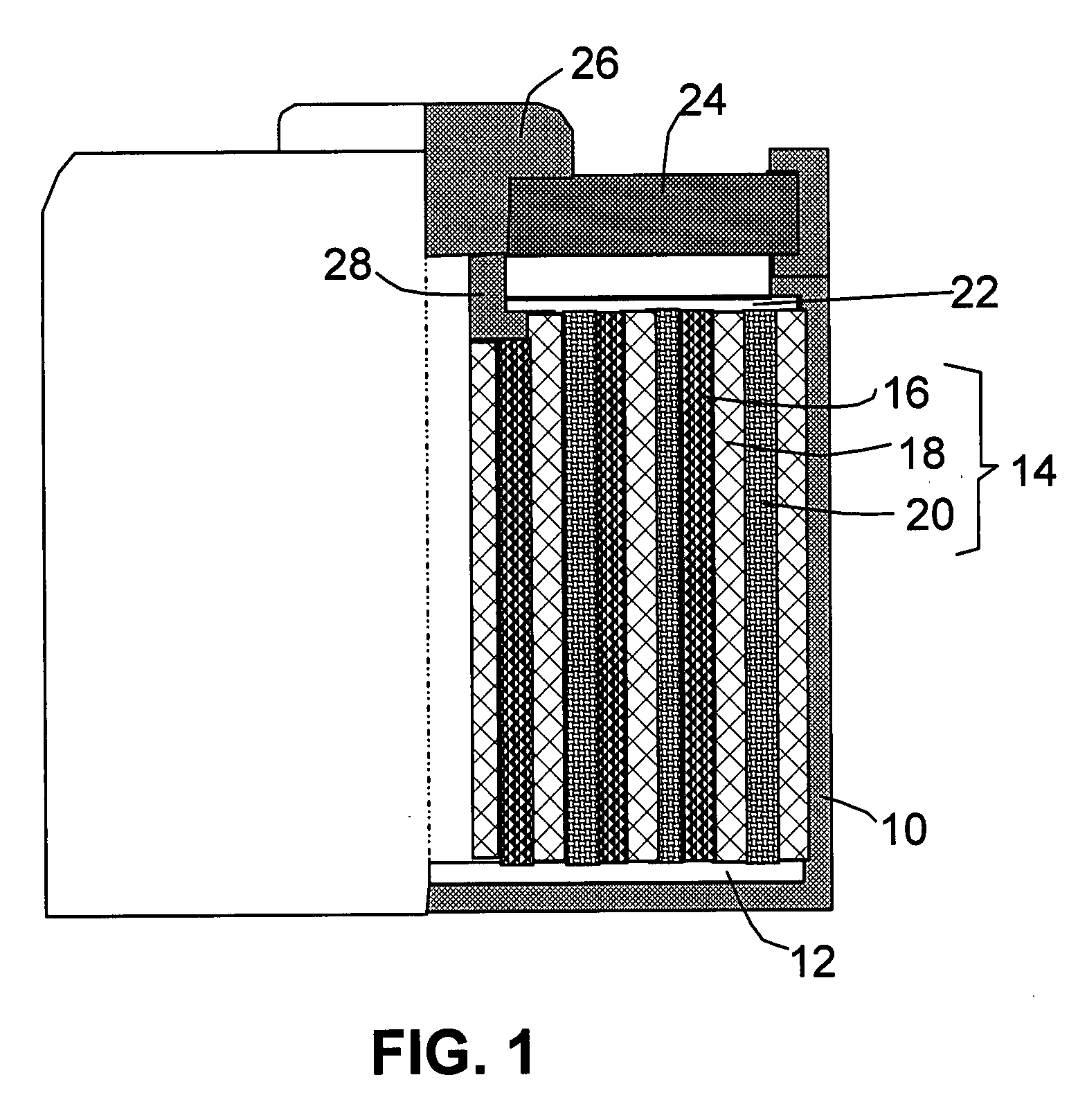

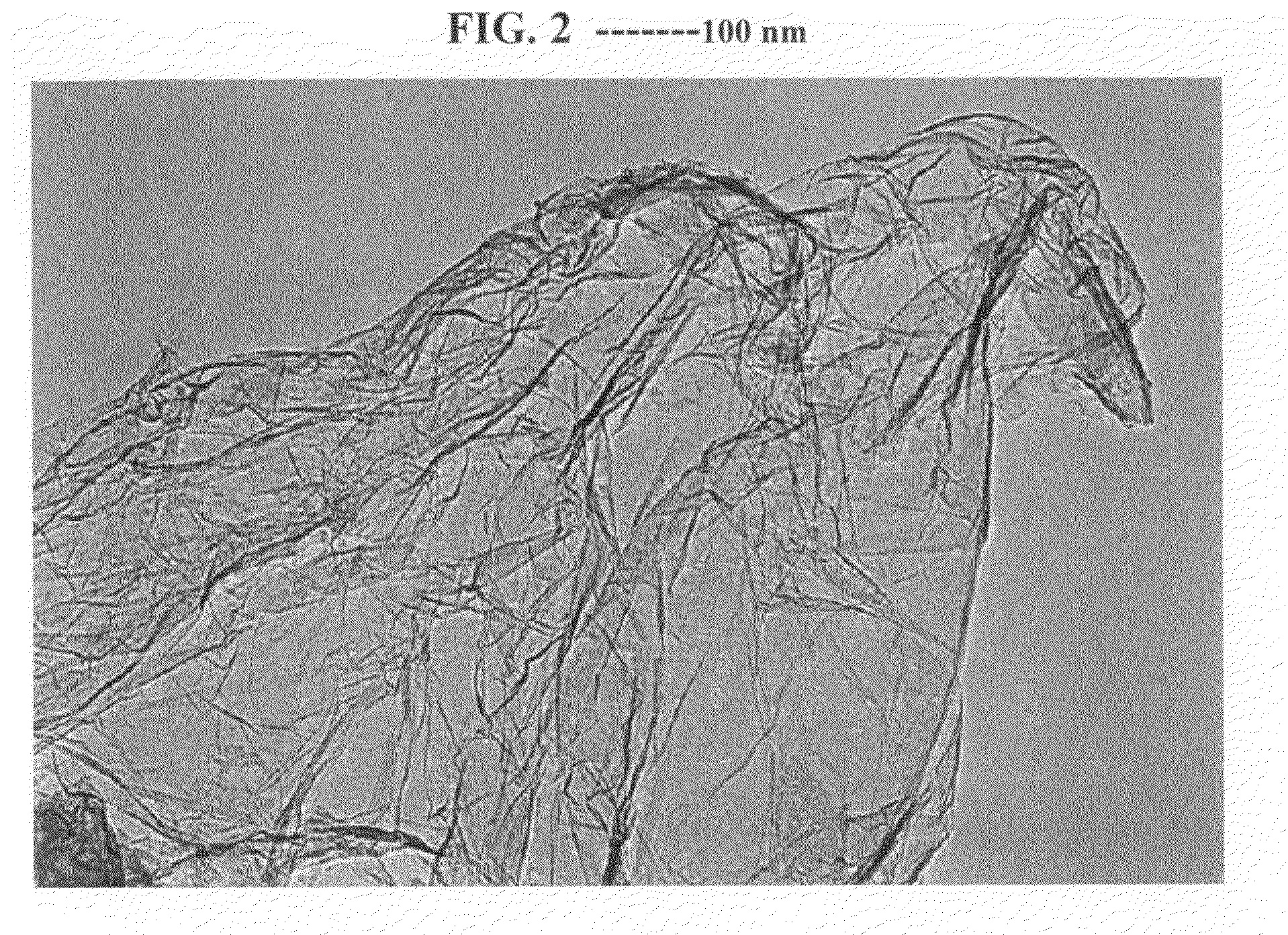

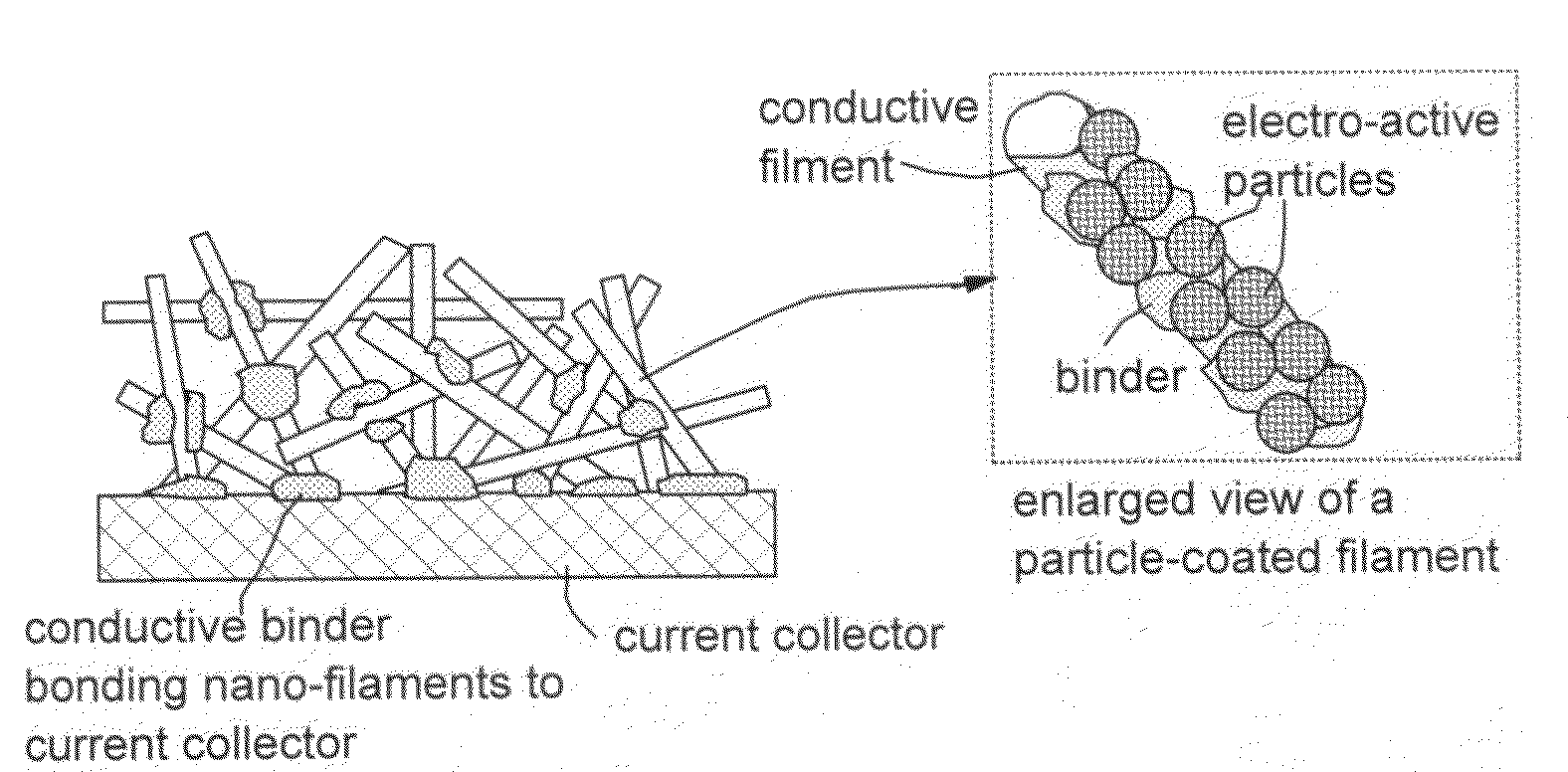

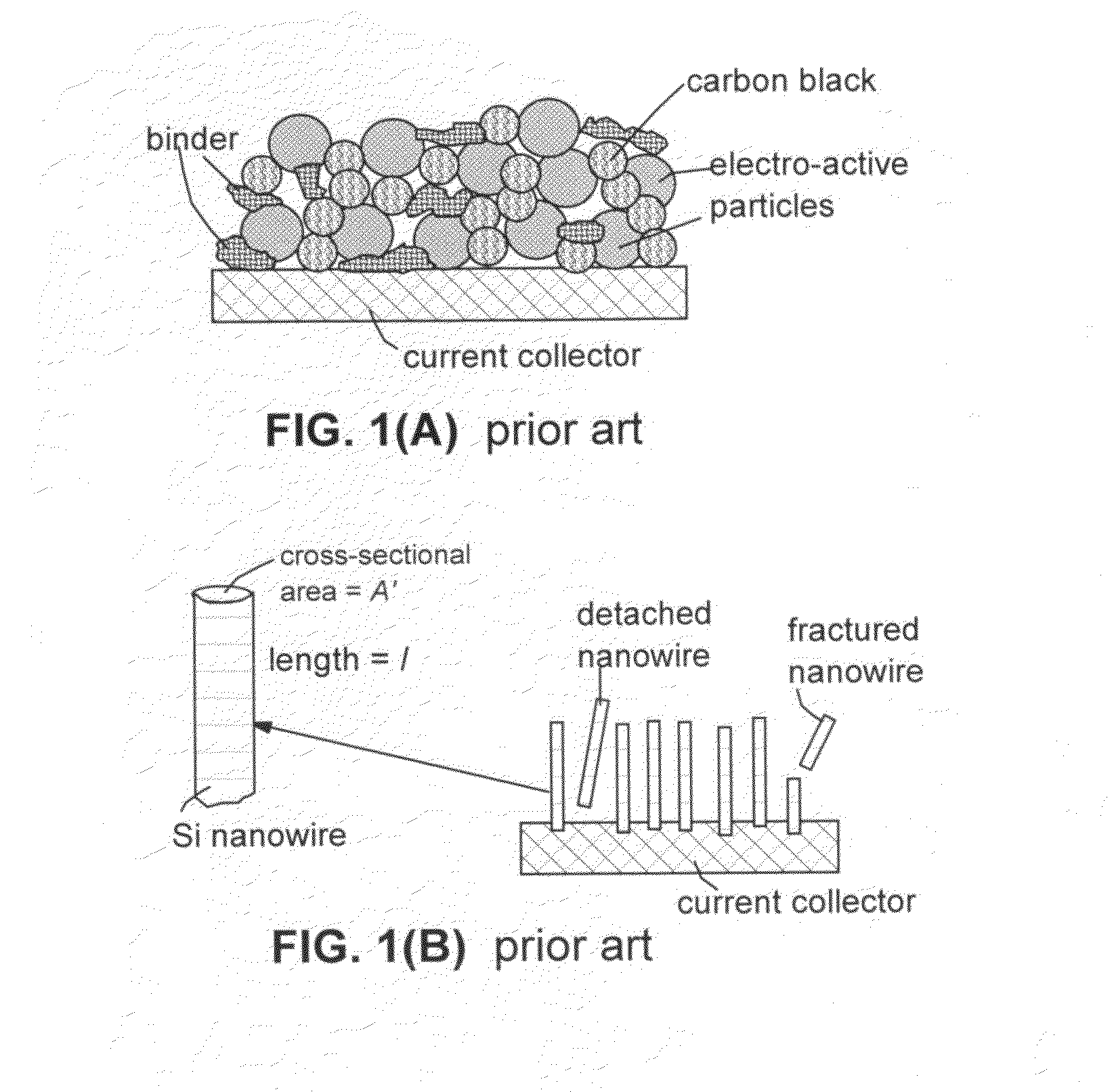

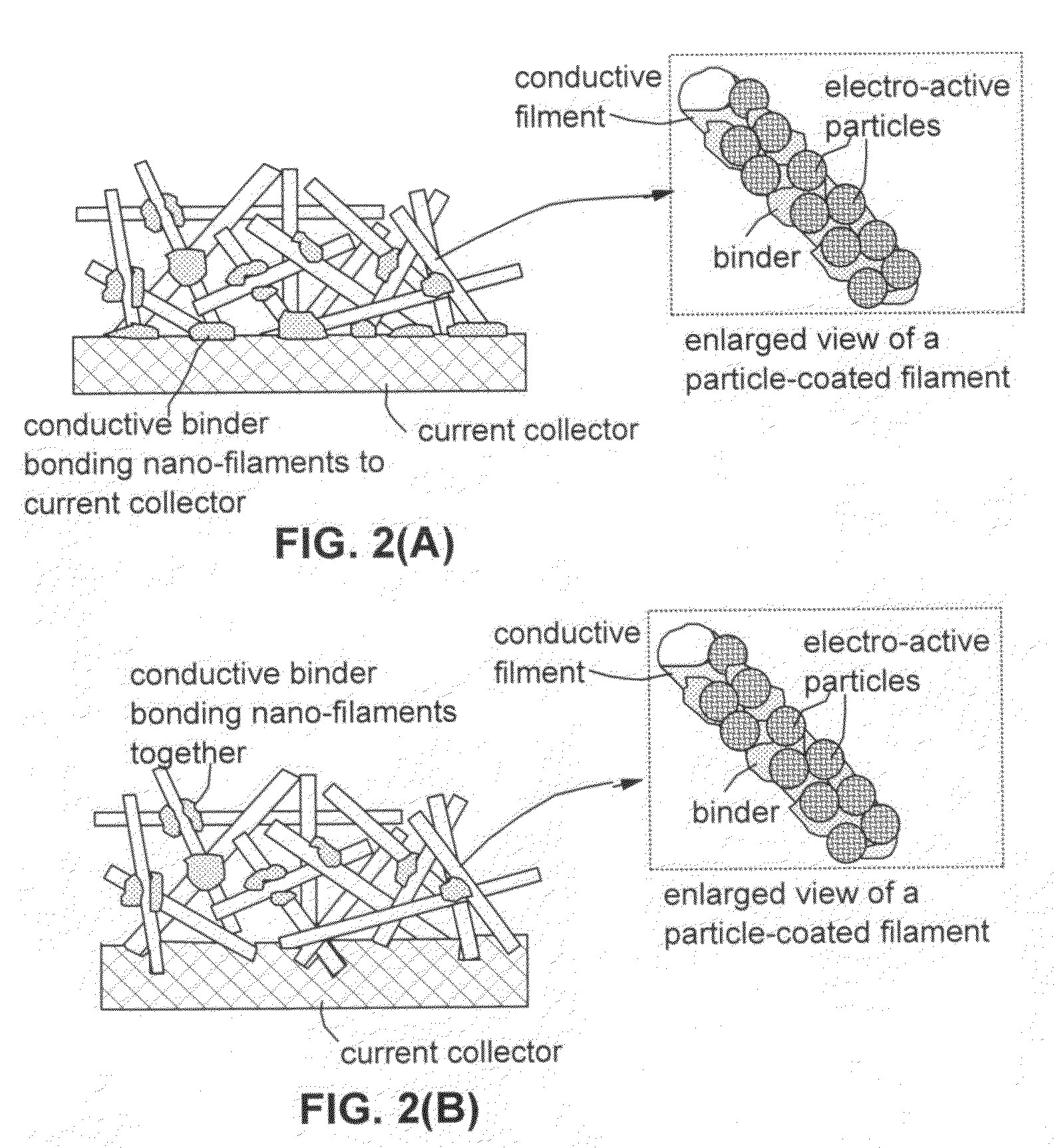

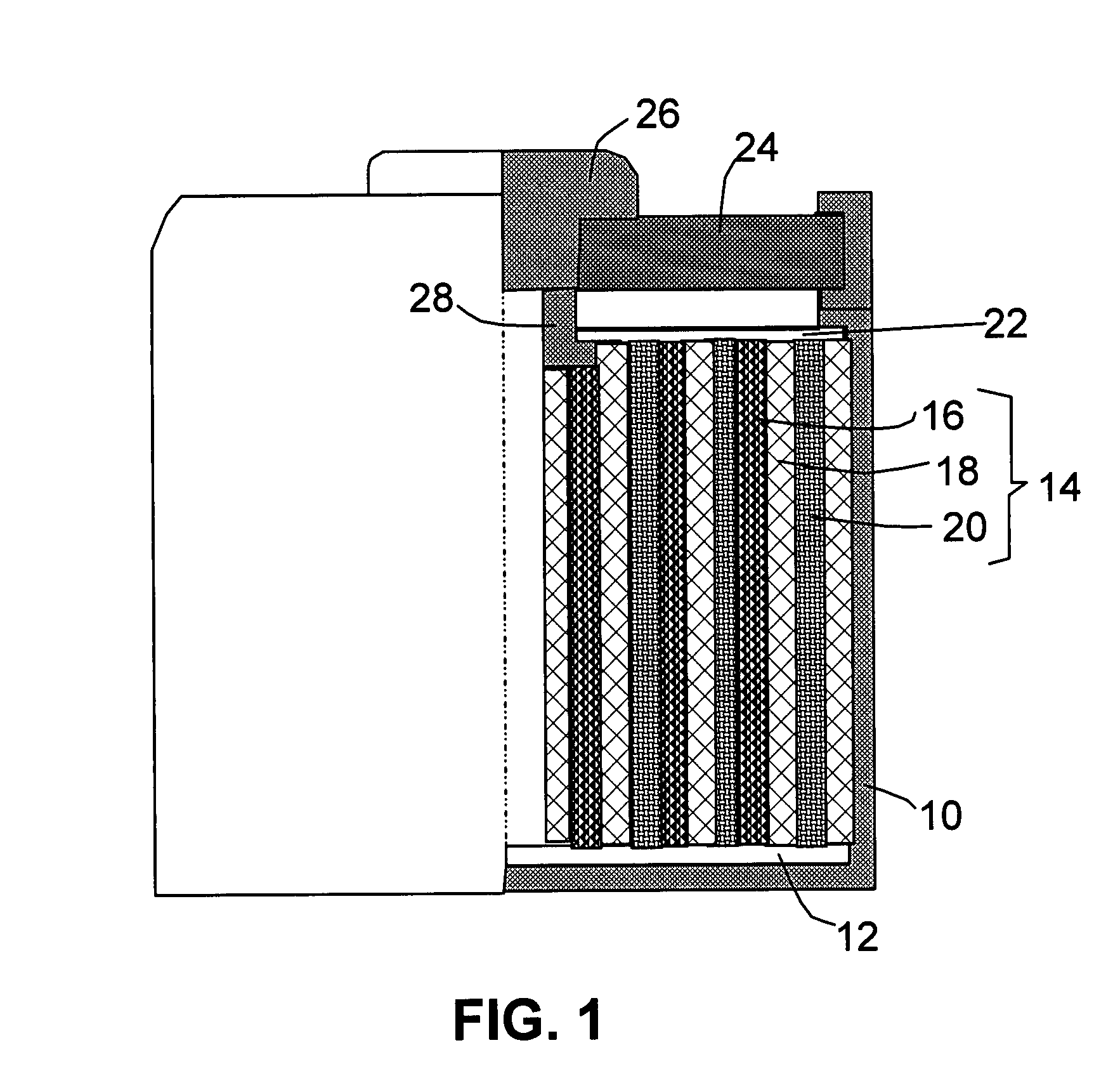

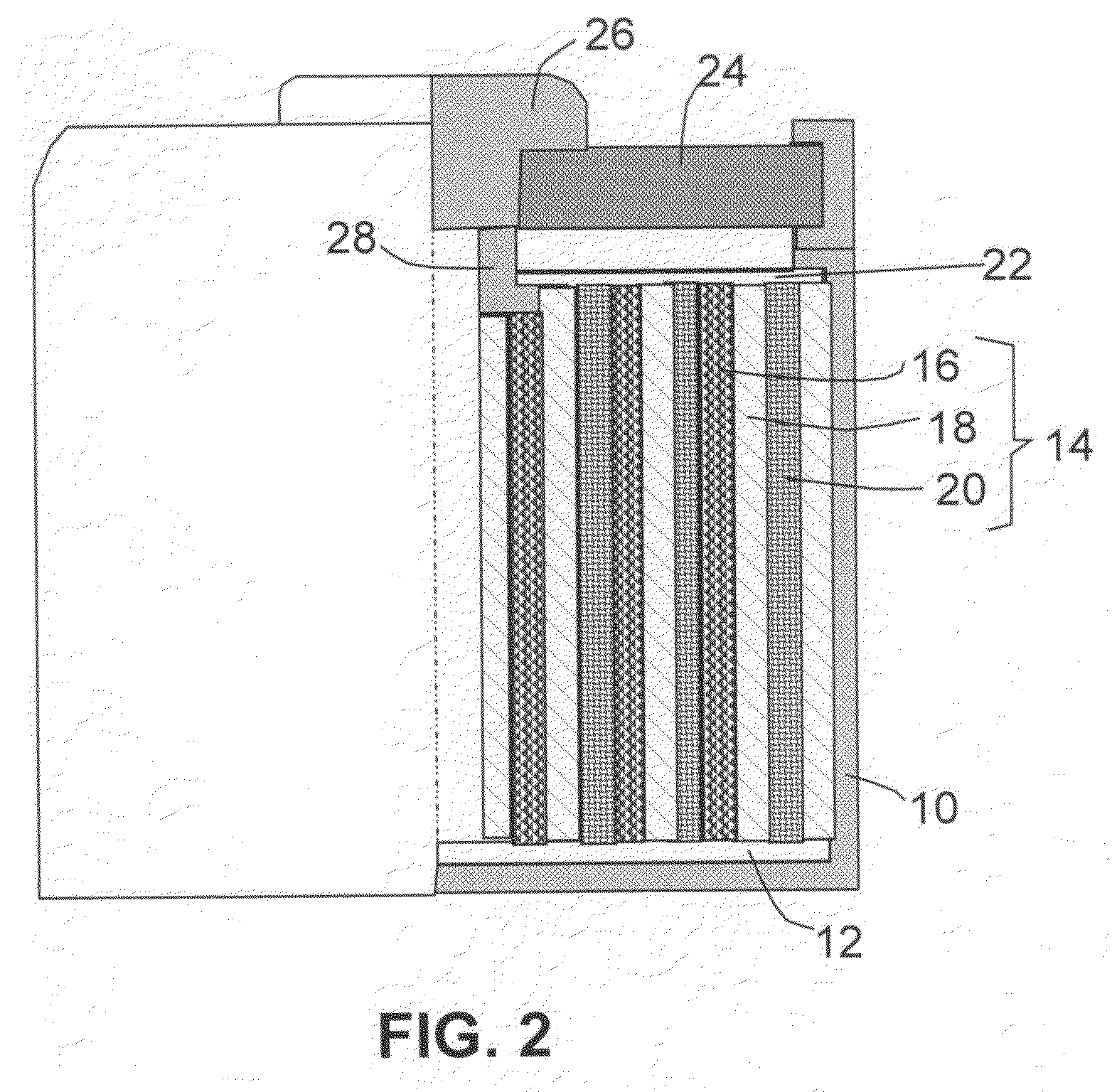

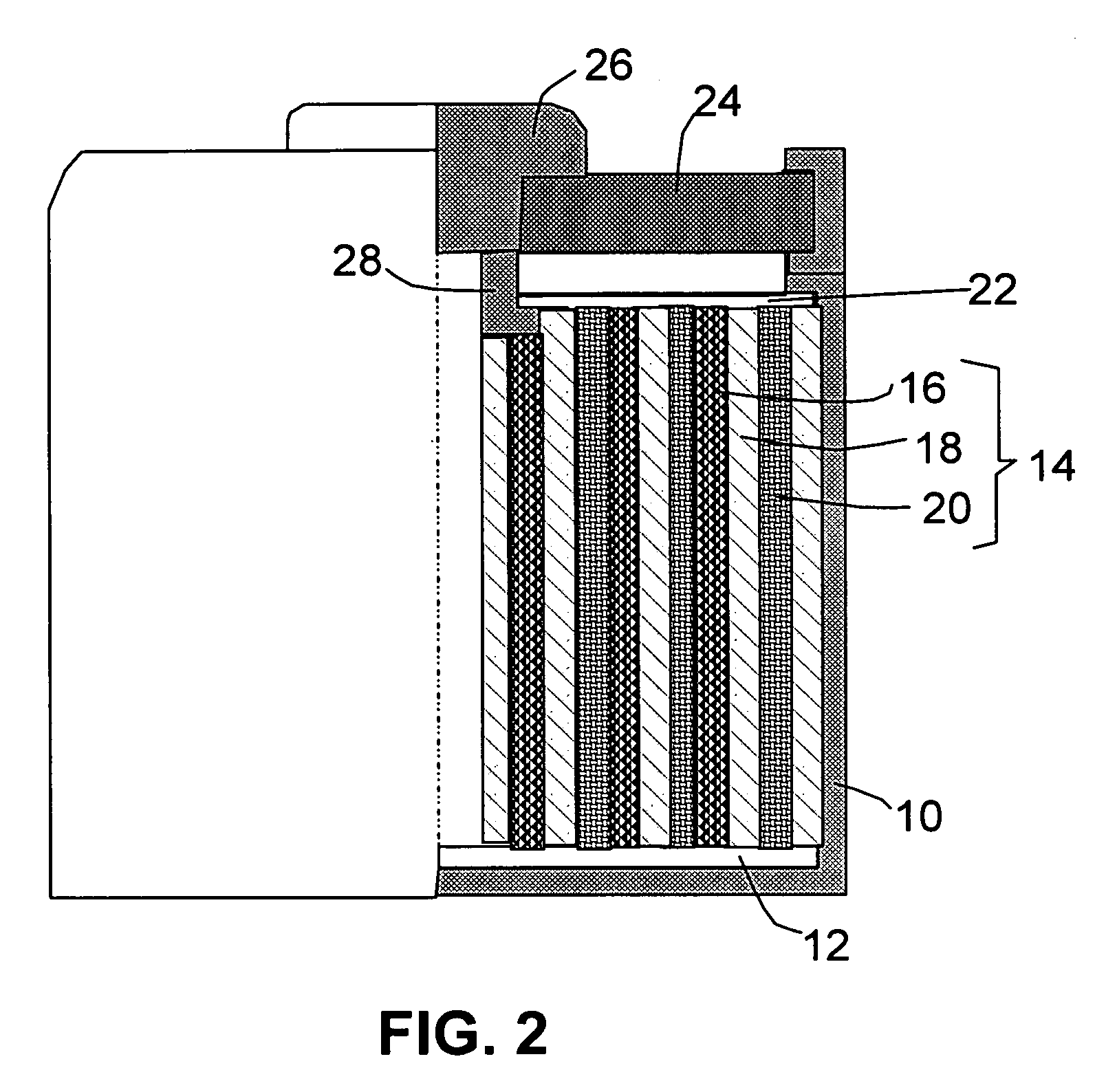

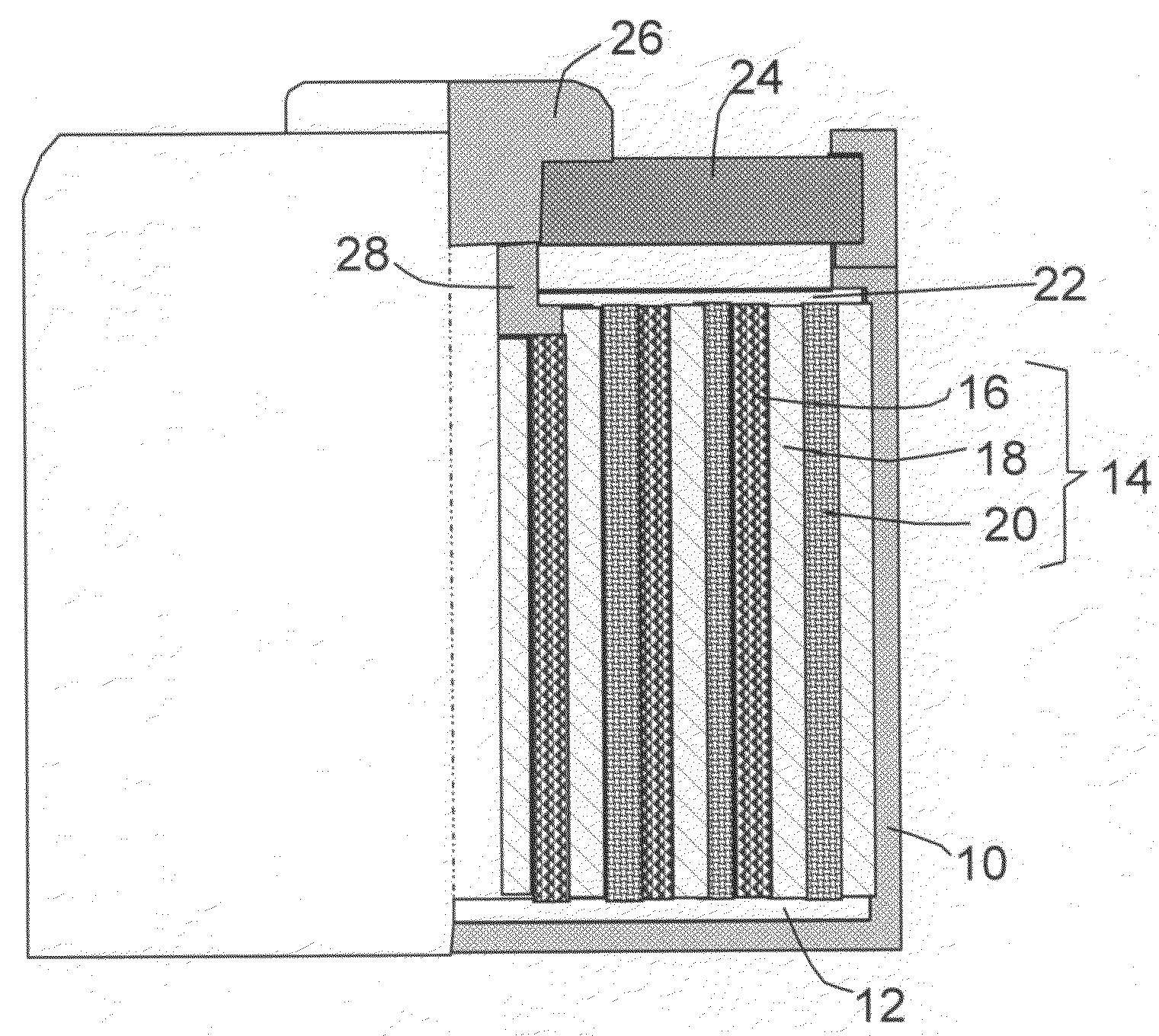

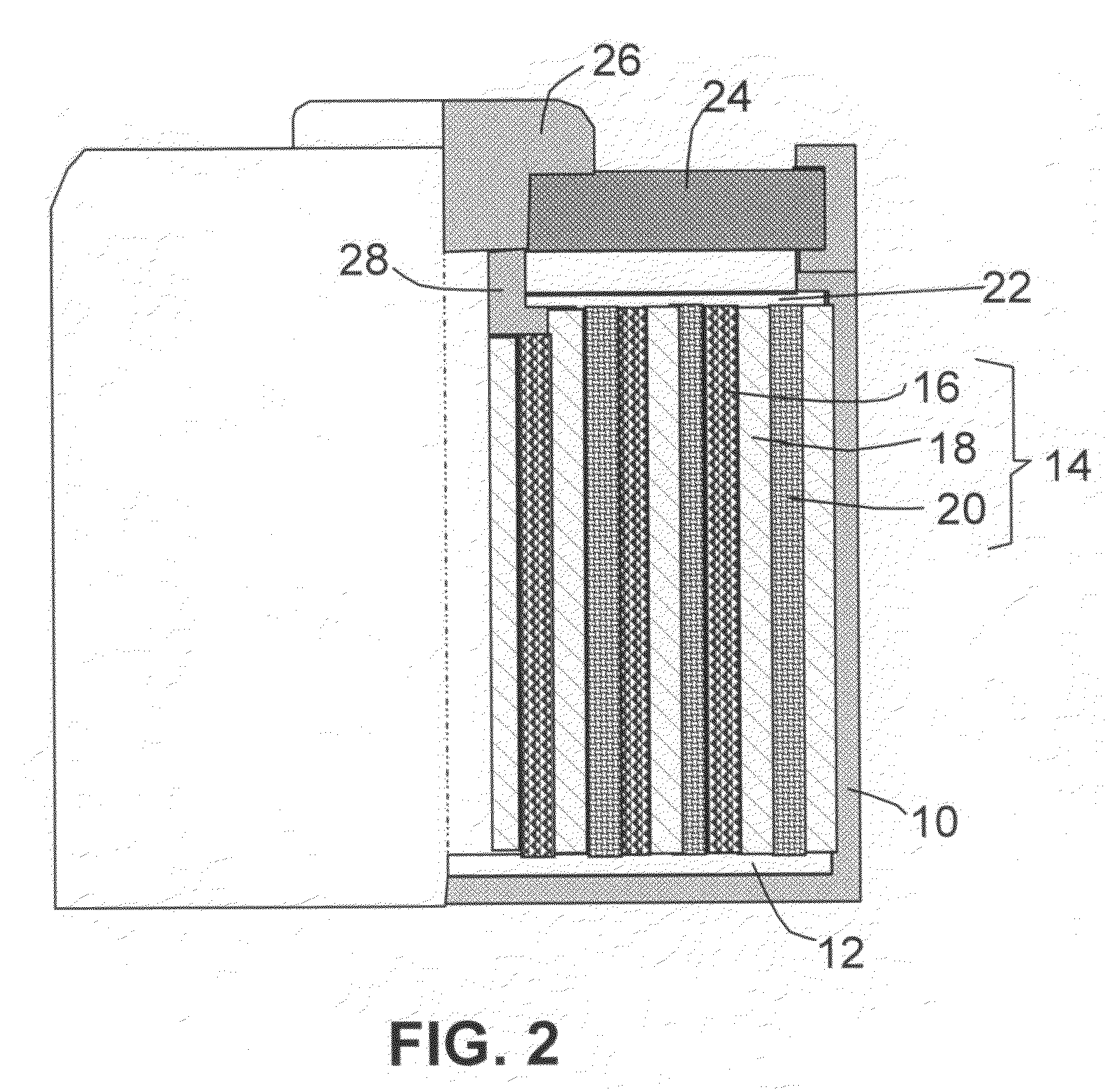

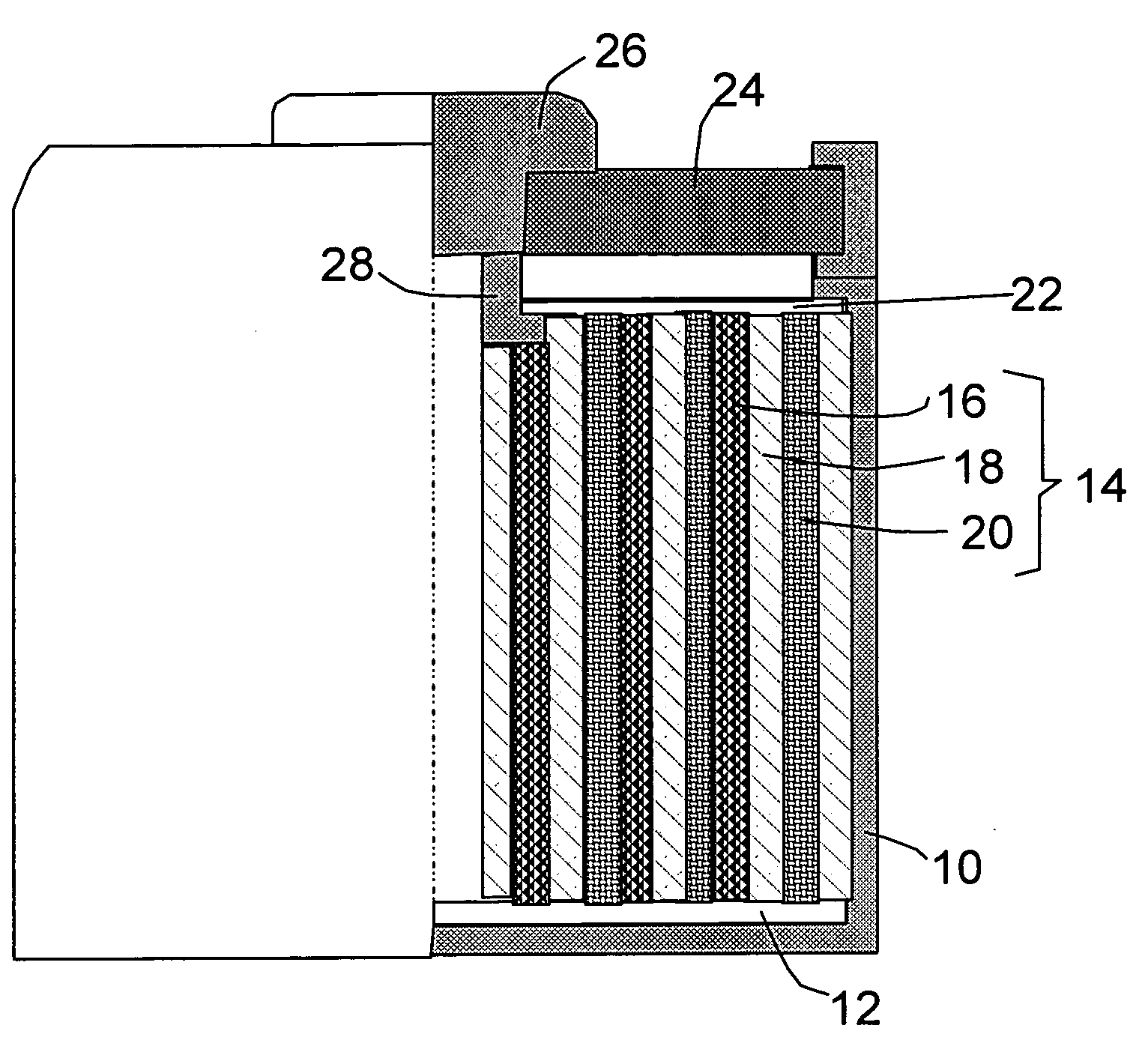

This invention provides a nanocomposite-based lithium battery electrode comprising: (a) A porous aggregate of electrically conductive nano-filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a three-dimensional network of electron-conducting paths, wherein the nano-filaments have a diameter or thickness less than 1 μm (preferably less than 500 nm); and (b) Sub-micron or nanometer-scale electro-active particles that are bonded to a surface of the nano-filaments with a conductive binder material, wherein the particles comprise an electro-active material capable of absorbing and desorbing lithium ions and wherein the electro-active material content is no less than 25% by weight based on the total weight of the particles, the binder material, and the filaments. Preferably, these electro-active particles are coated with a thin carbon layer. This electrode can be an anode or a cathode. The battery featuring such an anode or cathode exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

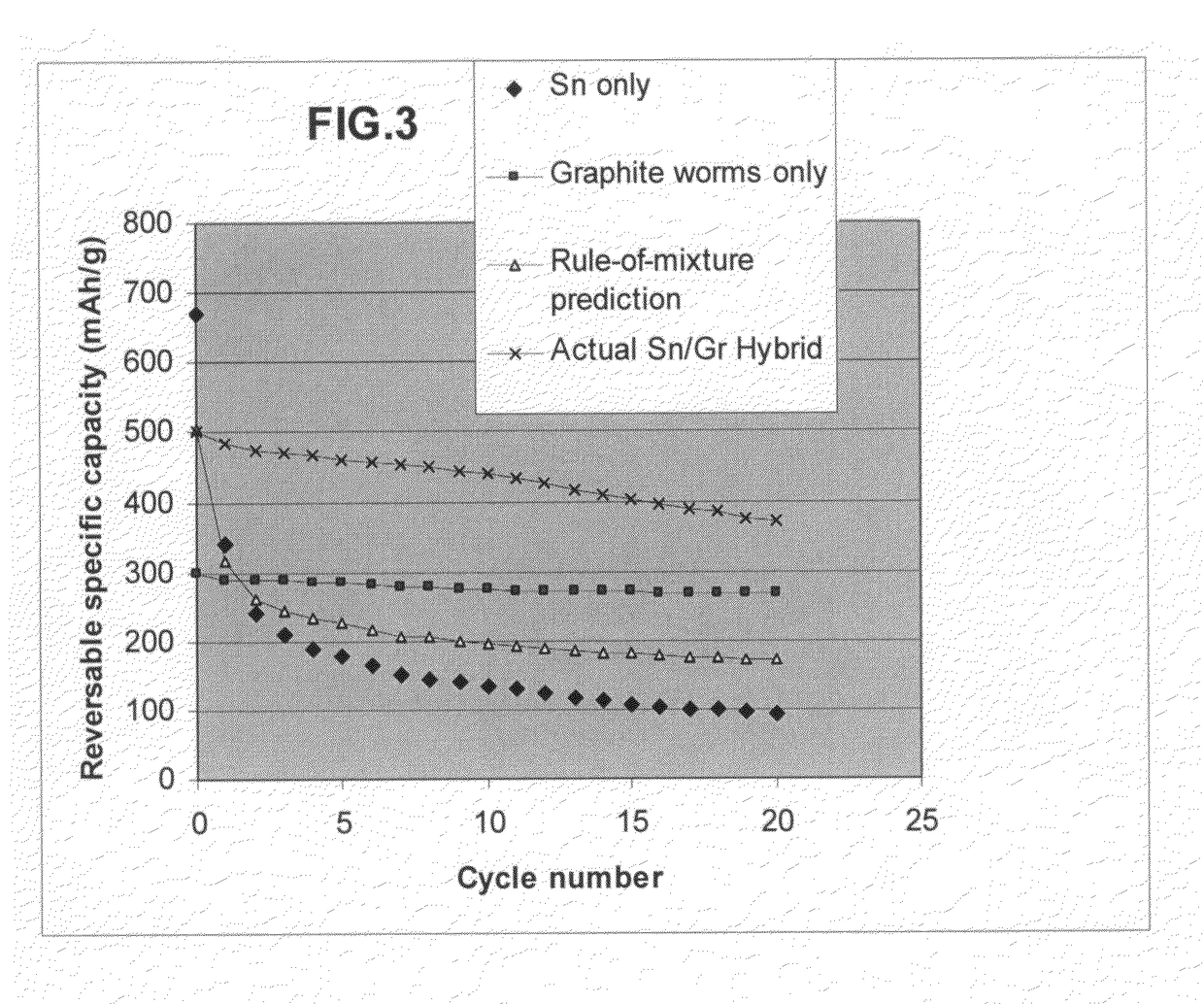

Hybrid anode compositions for lithium ion batteries

ActiveUS20090117466A1Superior multiple-cycle behaviorSmall capacity fadeAlkaline accumulatorsConductive materialHybrid materialSodium-ion battery

The present invention provides an exfoliated graphite-based hybrid material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing alkali or alkaline metal ions (particularly, lithium ions); and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least one of the particles or coating resides in a pore of the network or attached to a flake of the network and the exfoliated graphite amount is in the range of 5% to 90% by weight and the amount of particles or coating is in the range of 95% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, excellent reversible capacity, and long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

Nano graphene platelet-base composite anode compositions for lithium ion batteries

ActiveUS7745047B2Improve conductivityLower internal resistanceAlkaline accumulatorsElectrolytic capacitorsGraphiteGraphene

The present invention provides a nano-scaled graphene platelet-based composite material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing lithium ions; and (b) a plurality of nano-scaled graphene platelets (NGPs), wherein a platelet comprises a graphene sheet or a stack of graphene sheets having a platelet thickness less than 100 nm; wherein at least one of the particles or coating is physically attached or chemically bonded to at least one of the graphene platelets and the amount of platelets is in the range of 2% to 90% by weight and the amount of particles or coating in the range of 98% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

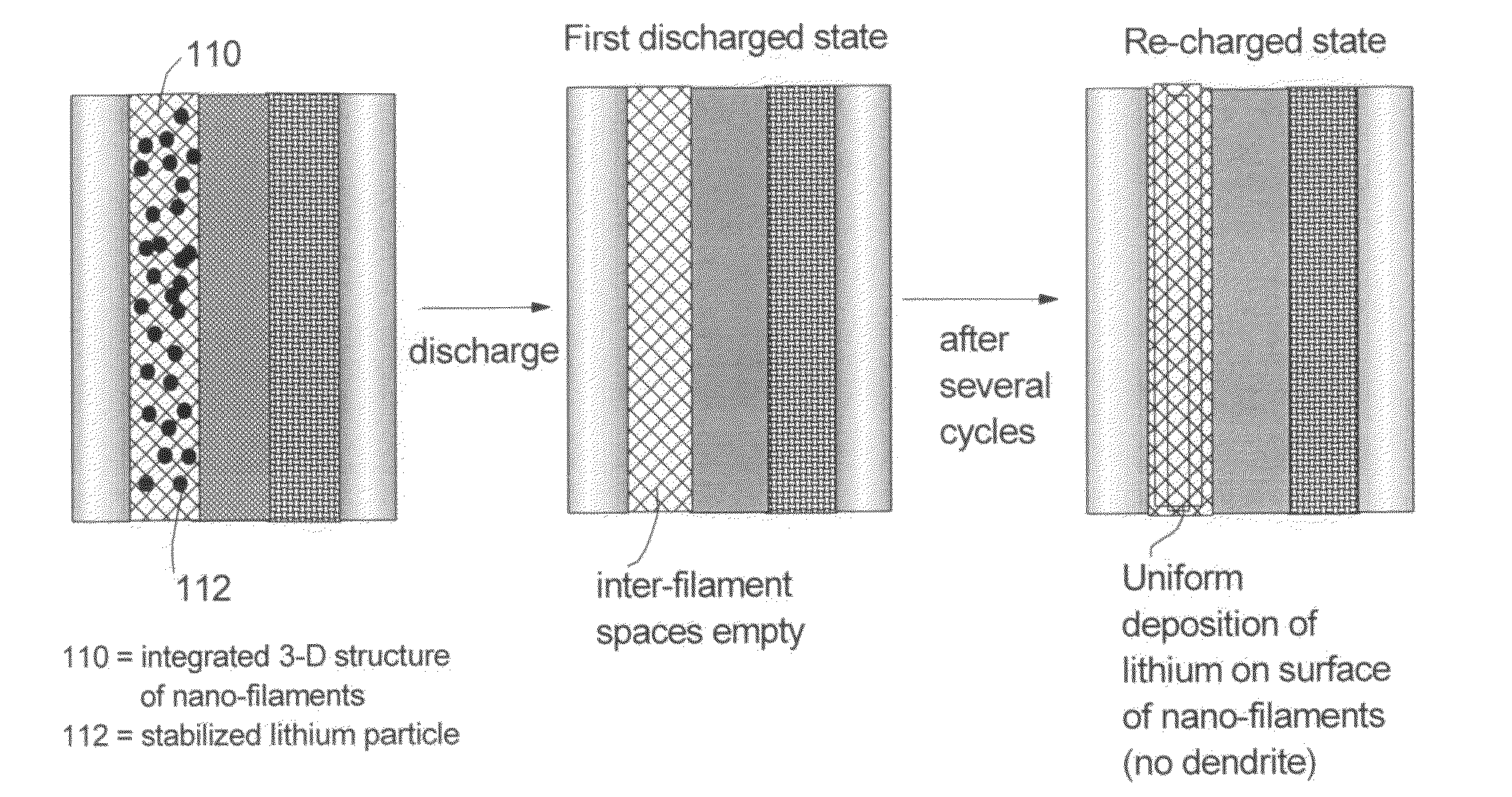

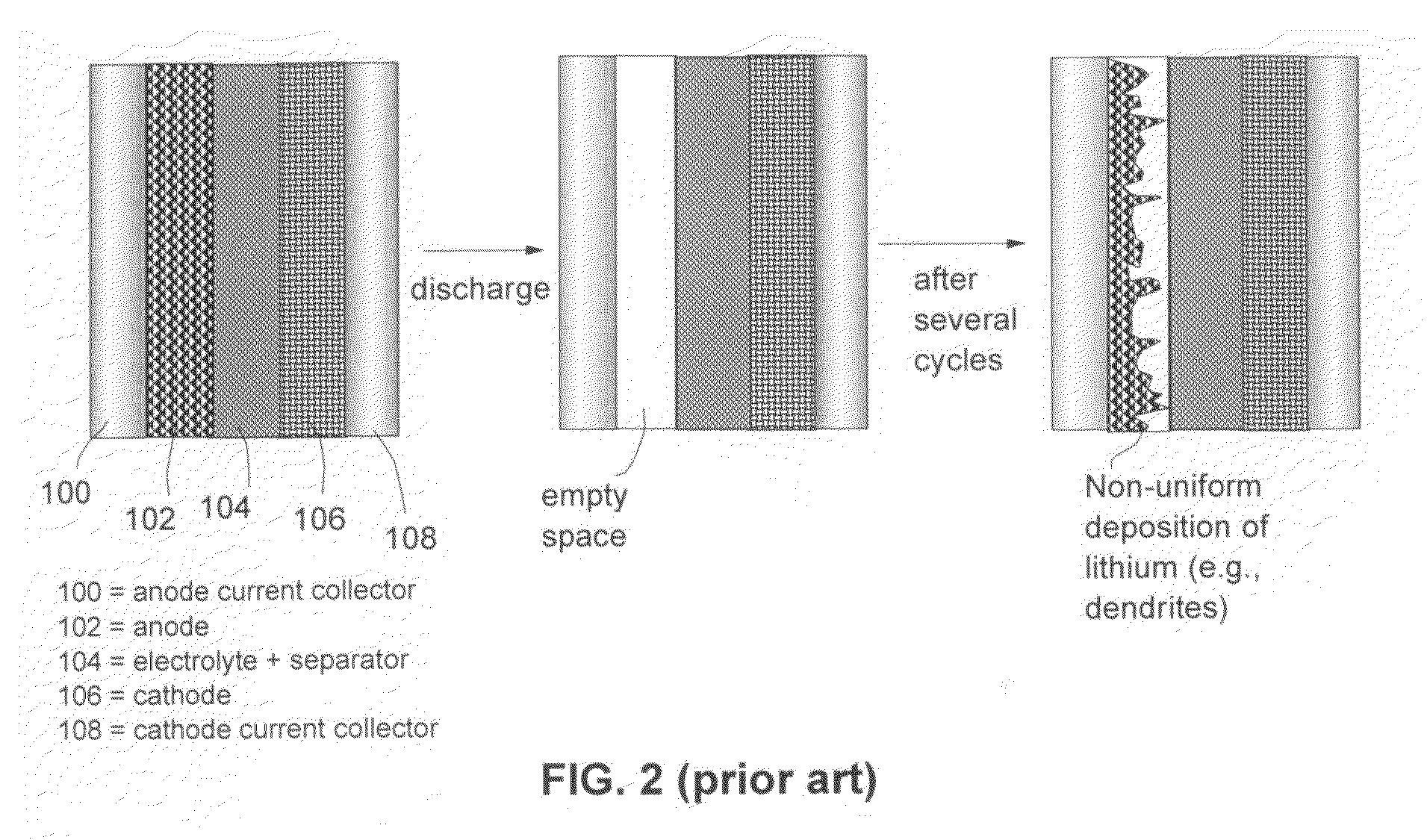

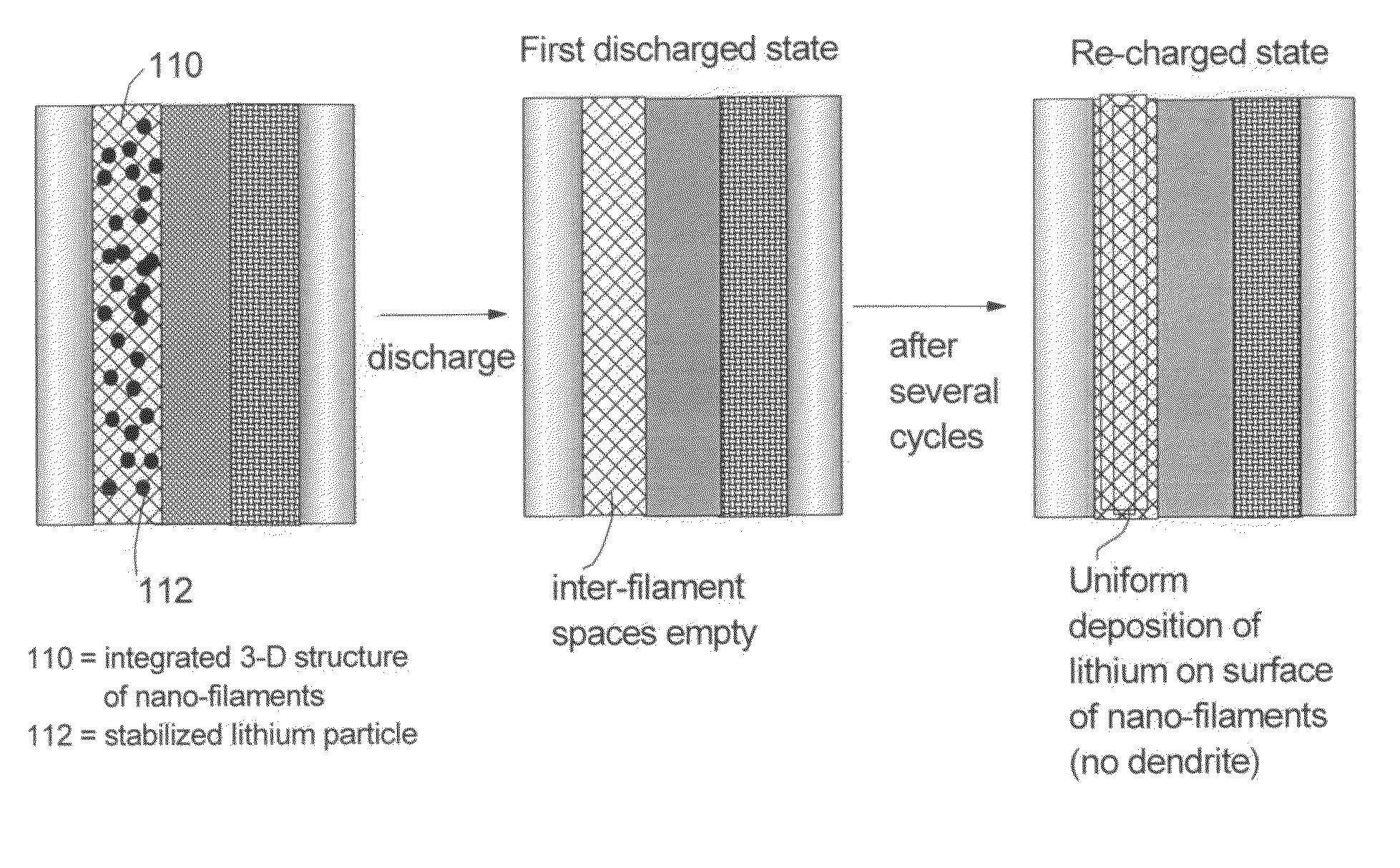

Nano-structured anode compositions for lithium metal and lithium metal-air secondary batteries

ActiveUS20110104571A1High specific capacityHigh reversible capacityFuel and primary cellsConductive materialLithium metalAlloy

This invention provides a nano-structured anode composition for a lithium metal cell. The composition comprises: (a) an integrated structure of electrically conductive nanometer-scaled filaments that are interconnected to form a porous network of electron-conducting paths comprising interconnected pores, wherein the nano-filaments have a transverse dimension less than 500 nm; and (b) micron- or nanometer-scaled particles of lithium, a lithium alloy, or a lithium-containing compound wherein at least one of the particles is surface-passivated or stabilized and the weight fraction of these particles is between 1% and 99% based on the total weight of these particles and the integrated structure together. Also provided is a lithium metal cell or battery, or lithium-air cell or battery, comprising such an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

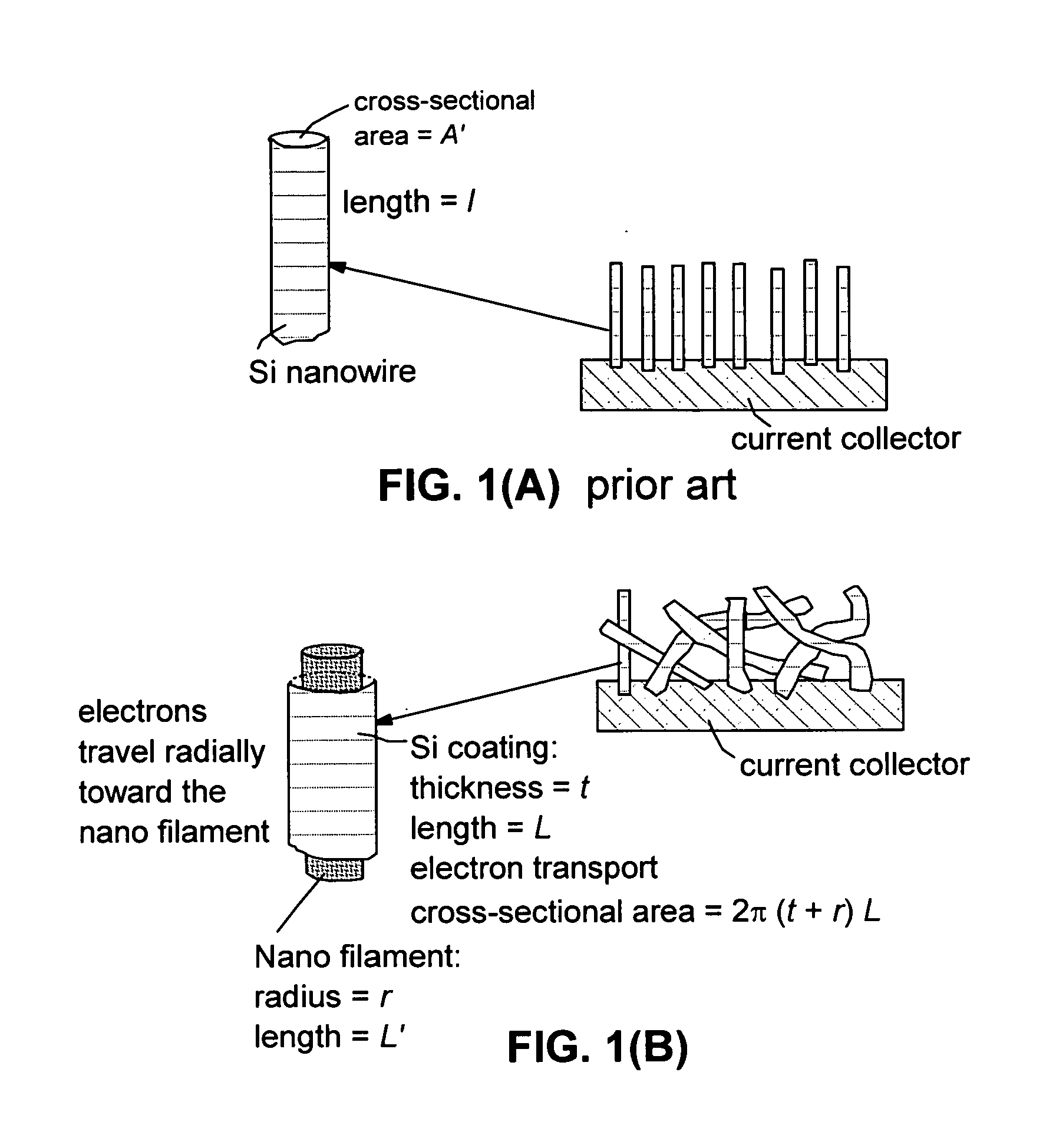

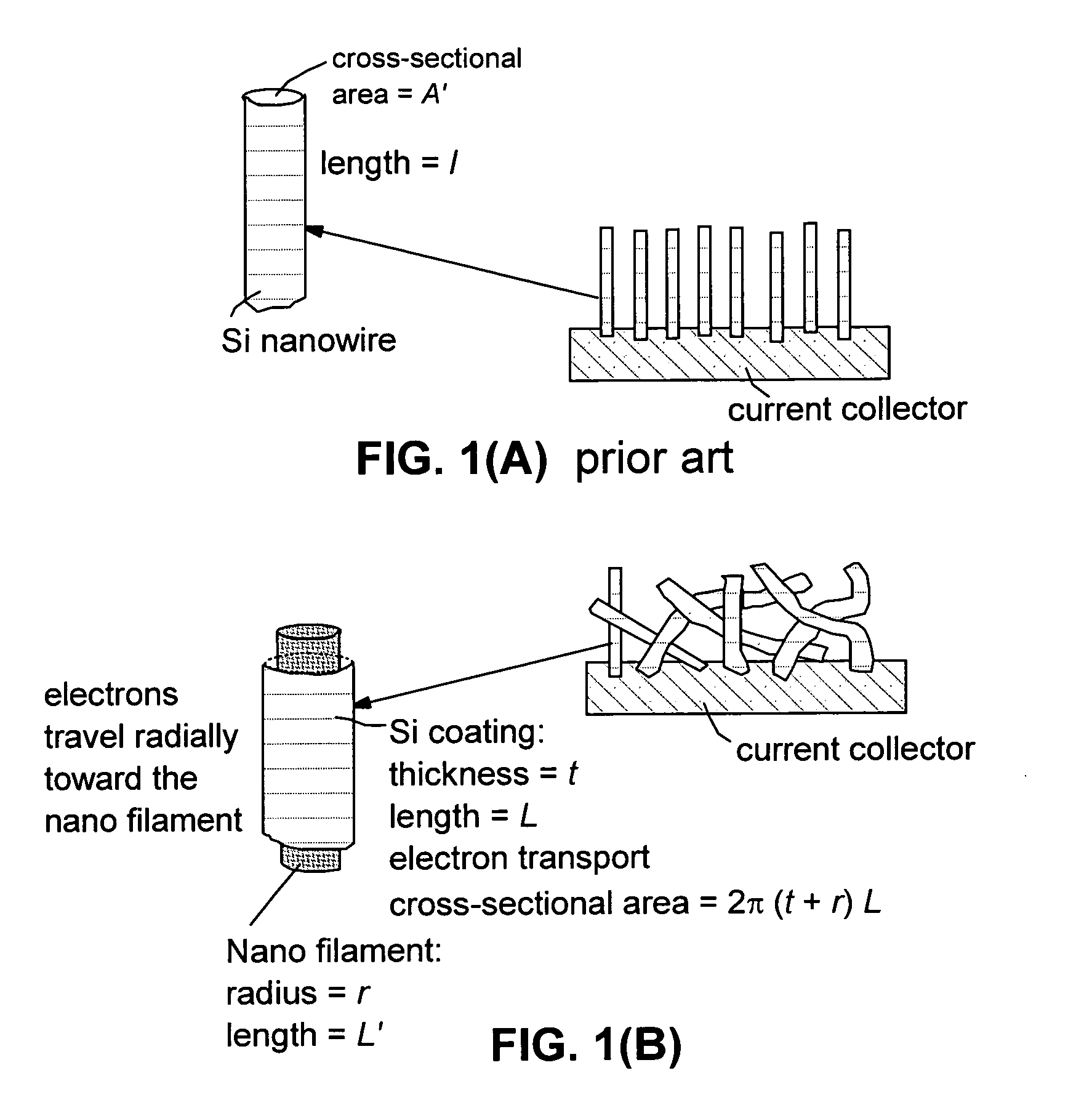

Hybrid nano-filament anode compositions for lithium ion batteries

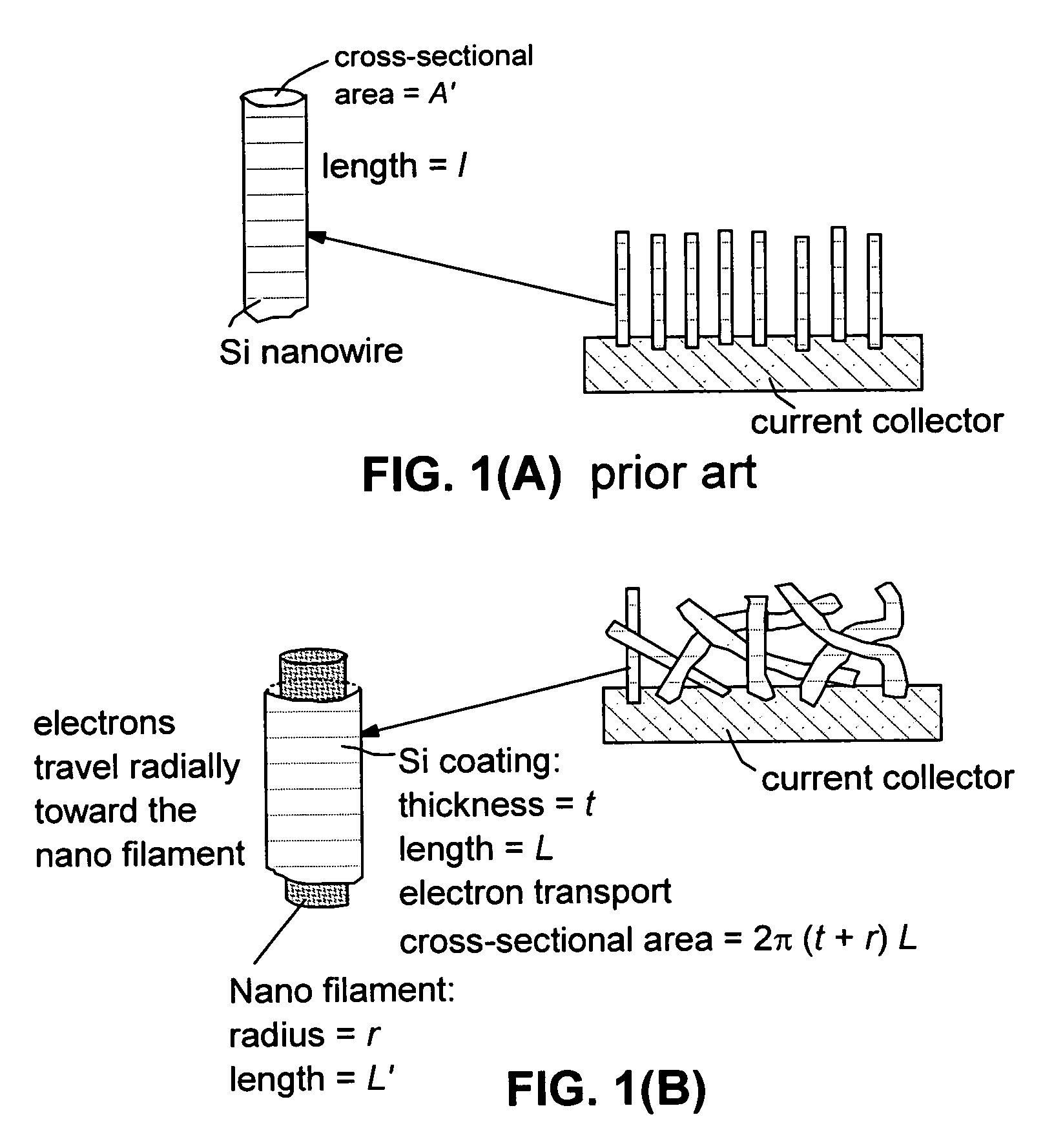

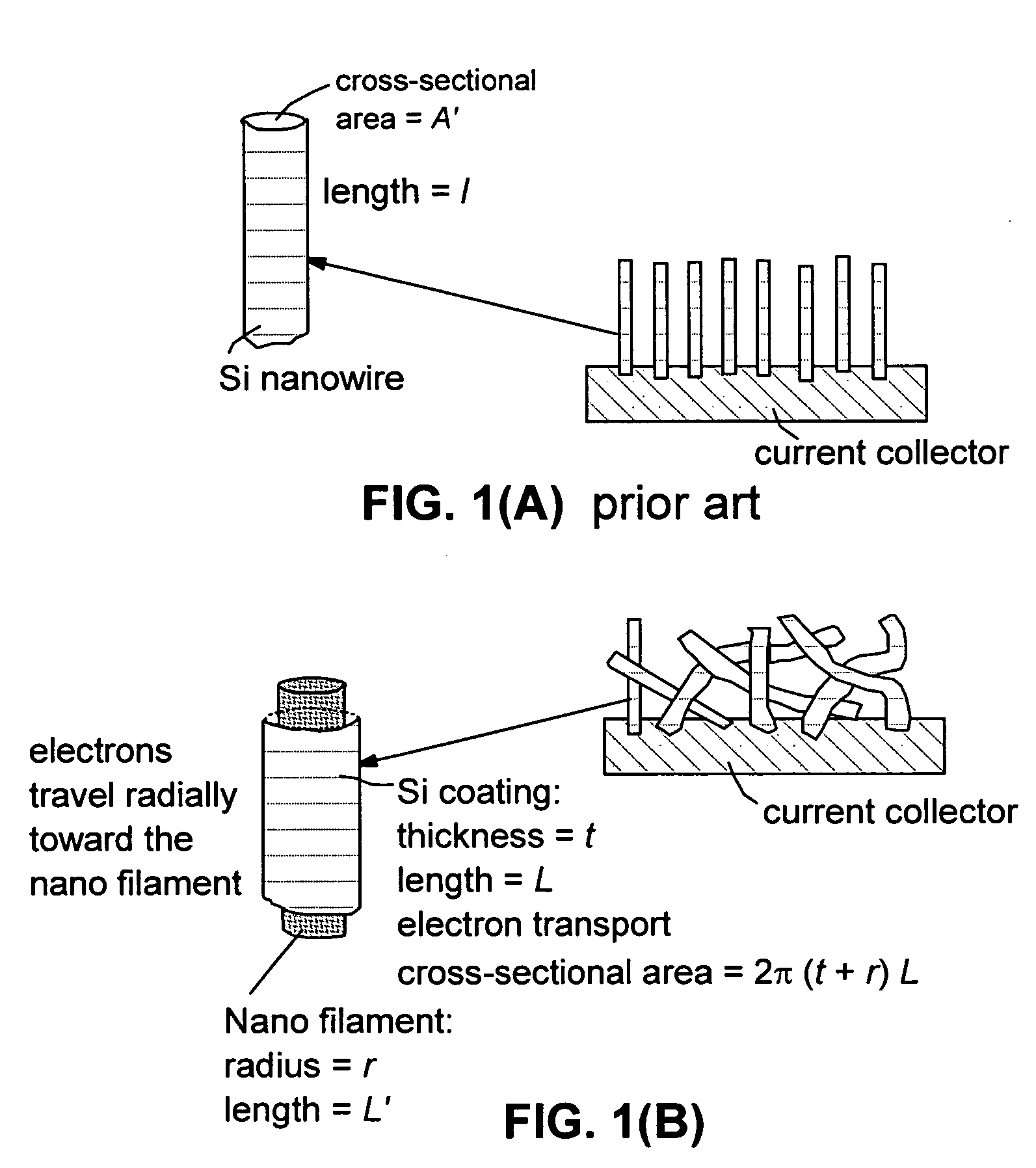

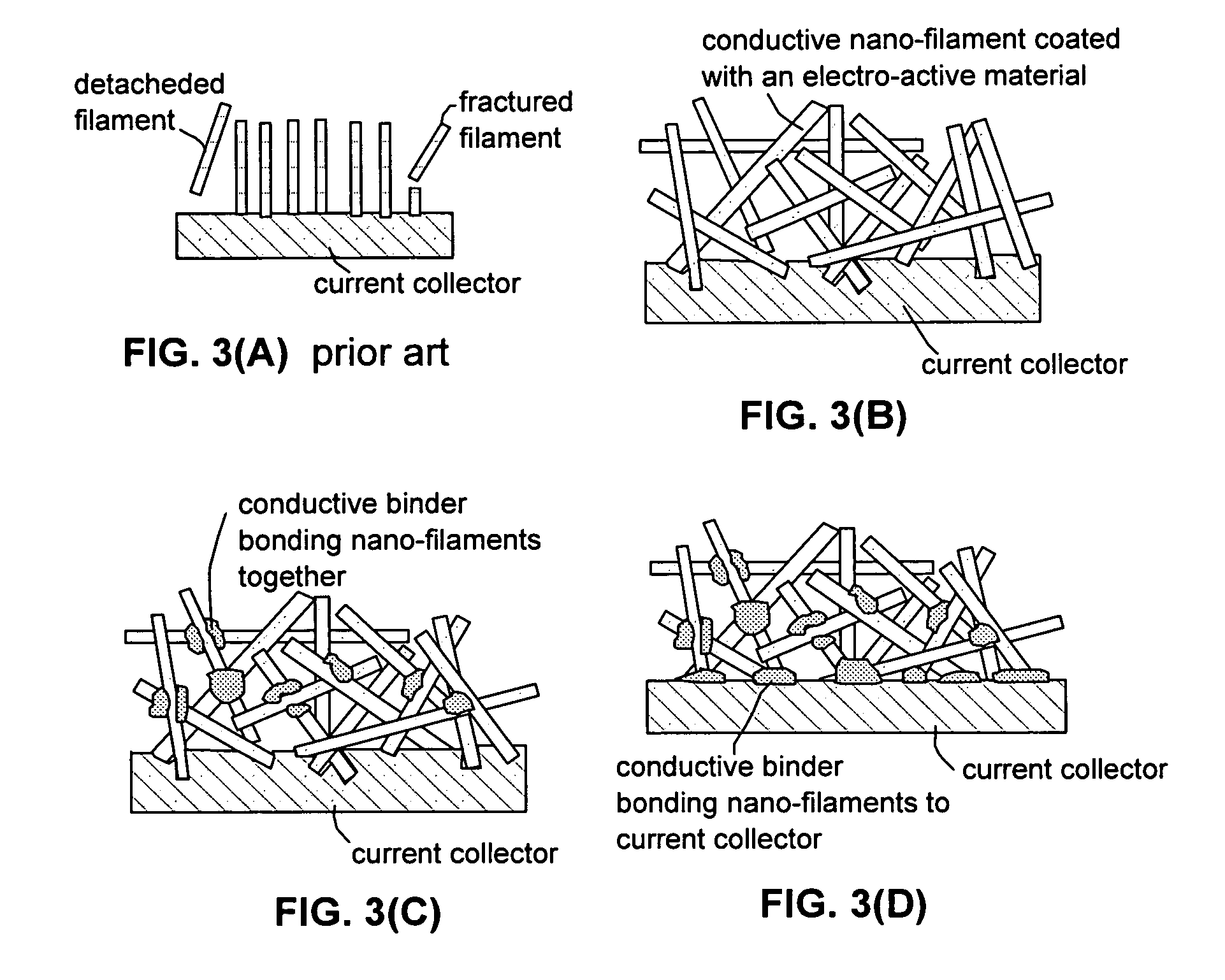

ActiveUS20090169996A1Superior multiple-cycle behaviorImprove cycle lifeElectrochemical processing of electrodesElectrode thermal treatmentLithium-ion batteryNanometre

This invention provides a hybrid nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network comprising substantially interconnected pores, wherein the filaments have an elongate dimension and a first transverse dimension with the first transverse dimension being less than 500 nm (preferably less than 100 nm) and an aspect ratio of the elongate dimension to the first transverse dimension greater than 10; and (b) micron- or nanometer-scaled coating that is deposited on a surface of the filaments, wherein the coating comprises an anode active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 20 μm (preferably less than 1 μm). Also provided is a lithium ion battery comprising such an electrode as an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Process for producing hybrid nano-filament electrodes for lithium batteries

ActiveUS20090269511A1High reversible capacityLower internal resistanceCell electrodesFinal product manufactureNanowireElectrical battery

This invention provides a process for producing a hybrid nano-filament composition for use in a lithium battery electrode. The process comprises: (a) providing a porous aggregate of electrically conductive nano-wires that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the nano-wires have a diameter or thickness less than 500 nm; and (b) depositing an electro-active coating onto a surface of the nano-wires, wherein the electro-active coating is capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm, preferably less than 1 μm. This process is applicable to the production of both an anode and a cathode. The battery featuring an anode or cathode made with this process exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Hybrid nano-filament cathode compositions for lithium metal or lithium ion batteries

InactiveUS20090186276A1Superior multiple-cycle behaviorImprove cycle lifeElectrochemical processing of electrodesSecondary cellsNanometreElectrically conductive

This invention provides a hybrid nano-filament composition for use as a cathode active material. The composition comprises (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network, wherein the filaments have a length and a diameter or thickness with the diameter or thickness being less than 500 nm; and (b) micron- or nanometer-scaled coating that is deposited on a surface of the filaments, wherein the coating comprises a cathode active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm, preferably less than 1 μm and more preferably less than 500 nm. Also provided is a lithium metal battery or lithium ion battery that comprises such a cathode. Preferably, the battery includes an anode that is manufactured according to a similar hybrid nano filament approach. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Mixed nano-filament electrode materials for lithium ion batteries

ActiveUS20090176159A1Improve conductivityEasy to collectActive material electrodesSecondary cellsFiberNanowire

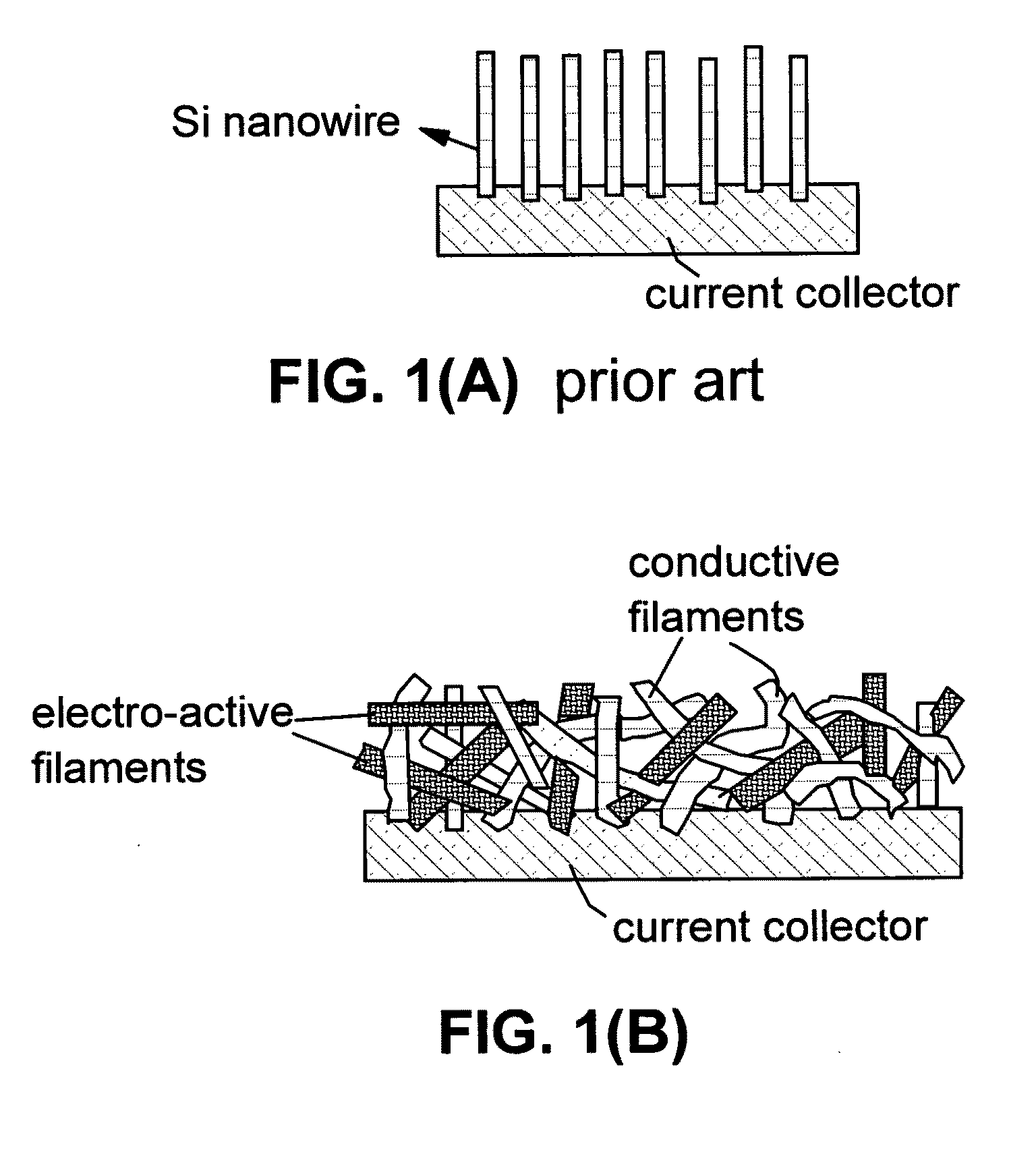

This invention provides a mixed nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network, wherein the filaments have a length and a diameter or thickness with the diameter / thickness less than 500 nm (preferably <100 nm) and a length-to-diameter or length-to-thickness aspect ratio greater than 10; and (b) Multiple nanometer-scaled, electro-active filaments comprising an electro-active material capable of absorbing and desorbing lithium ions wherein the electro-active filaments have a diameter or thickness less than 500 nm (preferably <100 nm). The electro-active filaments (e.g., nanowires) and the electrically conductive filaments (e.g., carbon nano fibers) are mixed to form a mat-, web-, or porous paper-like structure in which at least an electro-active filament is in electrical contact with at least an electrically conductive filament. Also provided is a lithium ion battery comprising such an electrode as an anode or cathode, or both. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Method of producing hybrid nano-filament electrodes for lithium metal or lithium ion batteries

ActiveUS20090169725A1High reversible capacityLower internal resistanceElectrochemical processing of electrodesElectrode thermal treatmentChemical LinkageFiber

Disclosed is a method of producing a hybrid nano-filament composition for use in a lithium battery electrode. The method comprises: (a) providing an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the filaments comprise electro-spun nano-fibers that have a diameter less than 500 nm (preferably less than 100 nm); and (b) depositing micron- or nanometer-scaled coating onto a surface of the electro-spun nano-fibers, wherein the coating comprises an electro-active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm (preferably less than 1 μm). The same method can be followed to produce an anode or a cathode. The battery featuring an anode or cathode made with this method exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Silicon-carbon Composite Anode Material for Lithium Ion Batteries and A Preparation Method Thereof

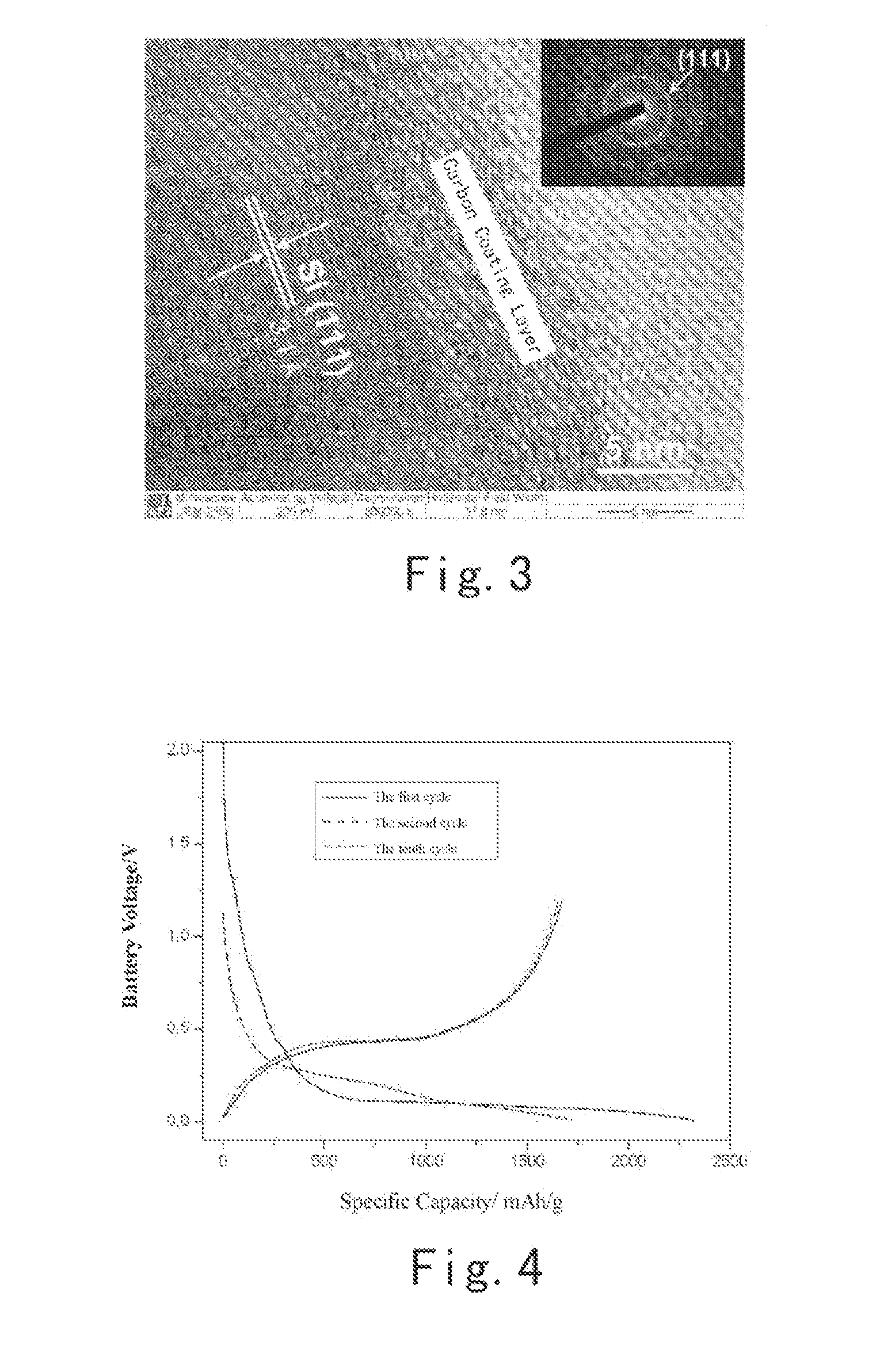

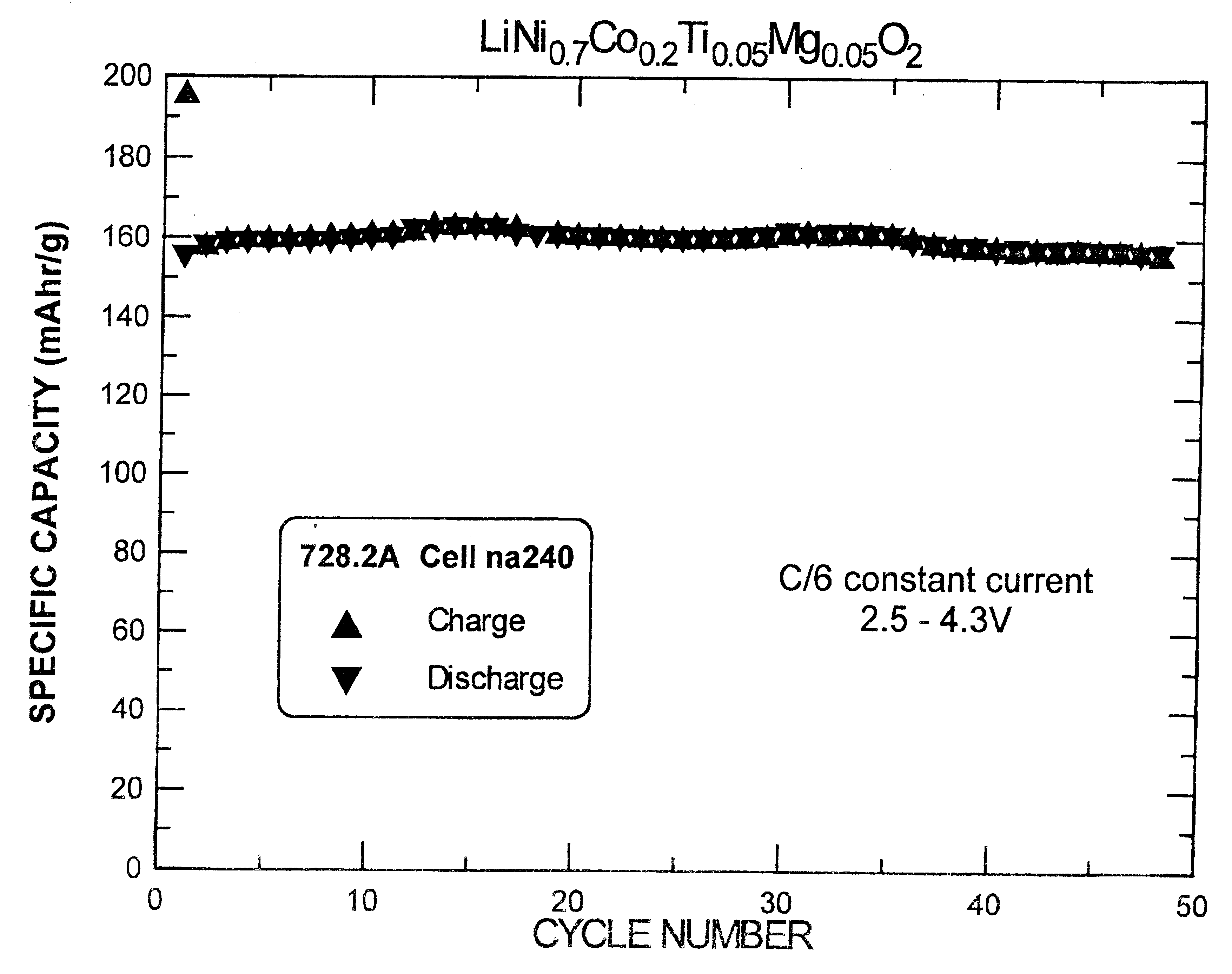

ActiveUS20140147751A1Large capacityImprove cycle stability performanceMechanical vibrations separationLiquid/solution decomposition chemical coatingCarbon compositesCarbon coating

Disclosed in the invention are a silicon-carbon composite anode material for lithium ion batteries and a preparation method thereof The material consists of a porous silicon substrate and a carbon coating layer. The preparation method of the material comprises preparing a porous silicon substrate and a carbon coating layer. The silicon-carbon composite anode material for lithium ion batteries has the advantages of high reversible capacity, good cycle performance and good rate performance. The material respectively shows reversible capacities of 1,556 mAh, 1,290 mAh, 877 mAh and 474 mAh / g at 0.2 C, 1 C, 4 C and 15 C rates; the specific capacity remains above 1,500 mAh after 40 cycles at the rate of 0.2 C and the reversible capacity retention rate is up to 90 percent.

Owner:BOSCH CHINA INVESTMENT

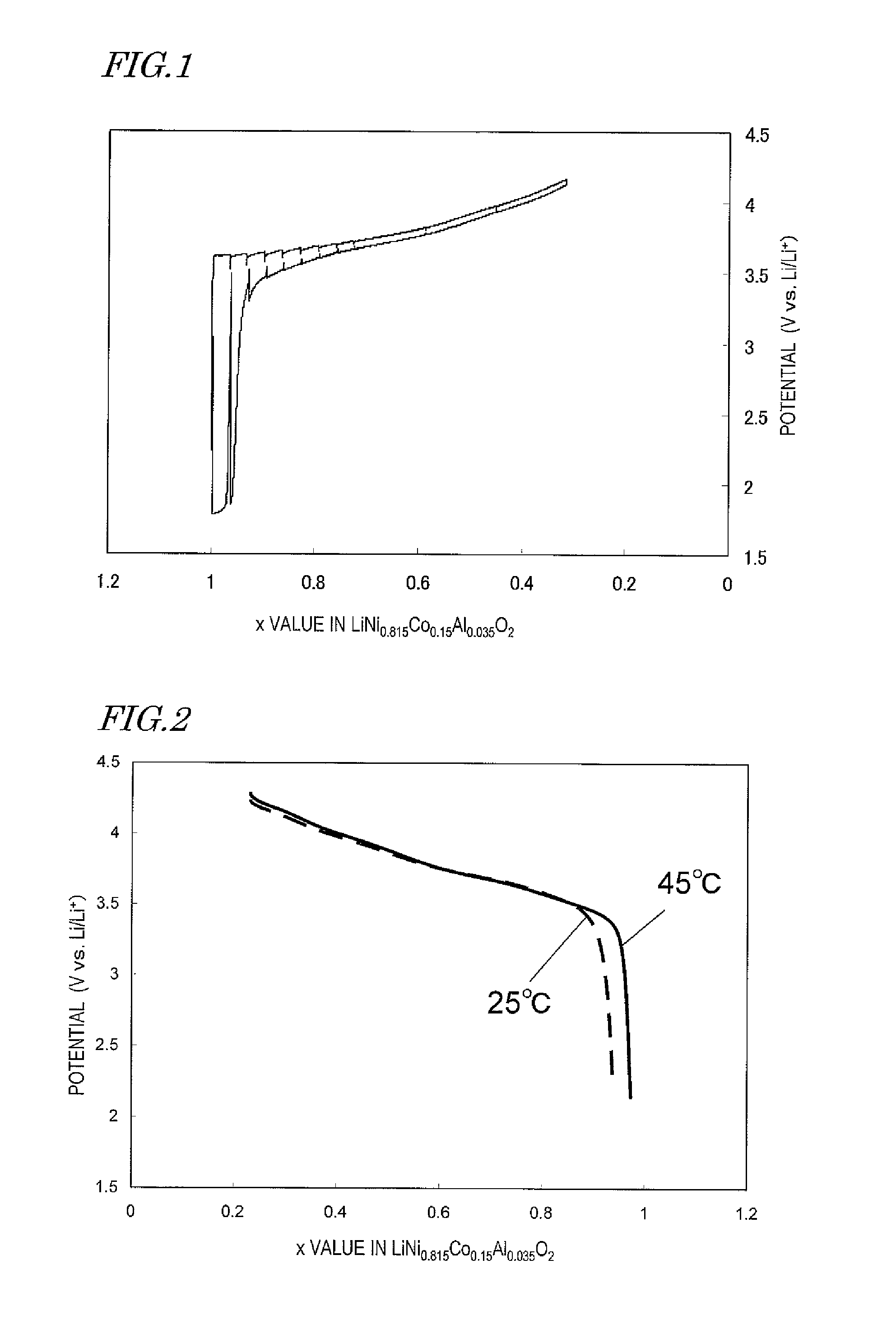

Lithium metal oxide containing multiple dopants and method of preparing same

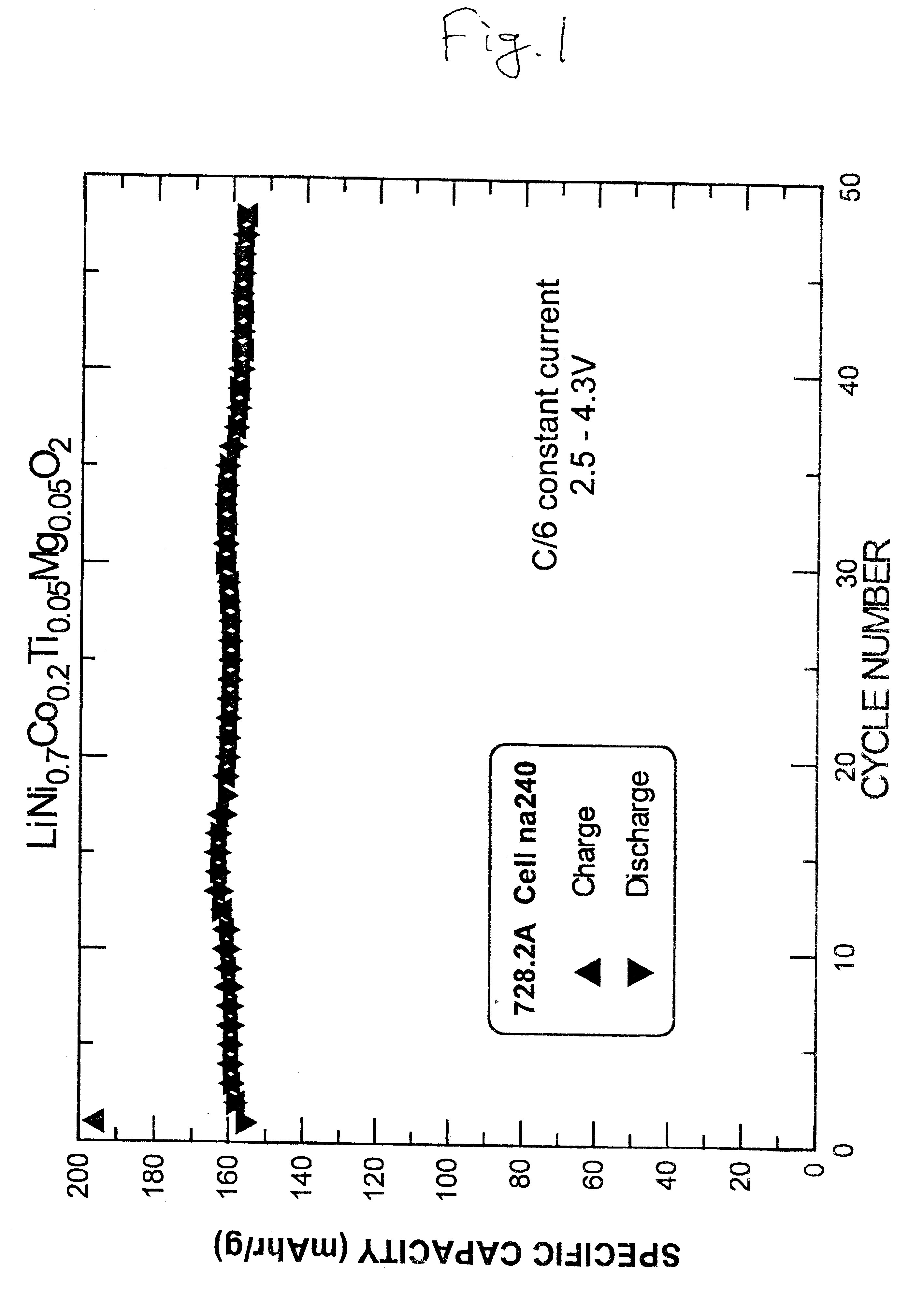

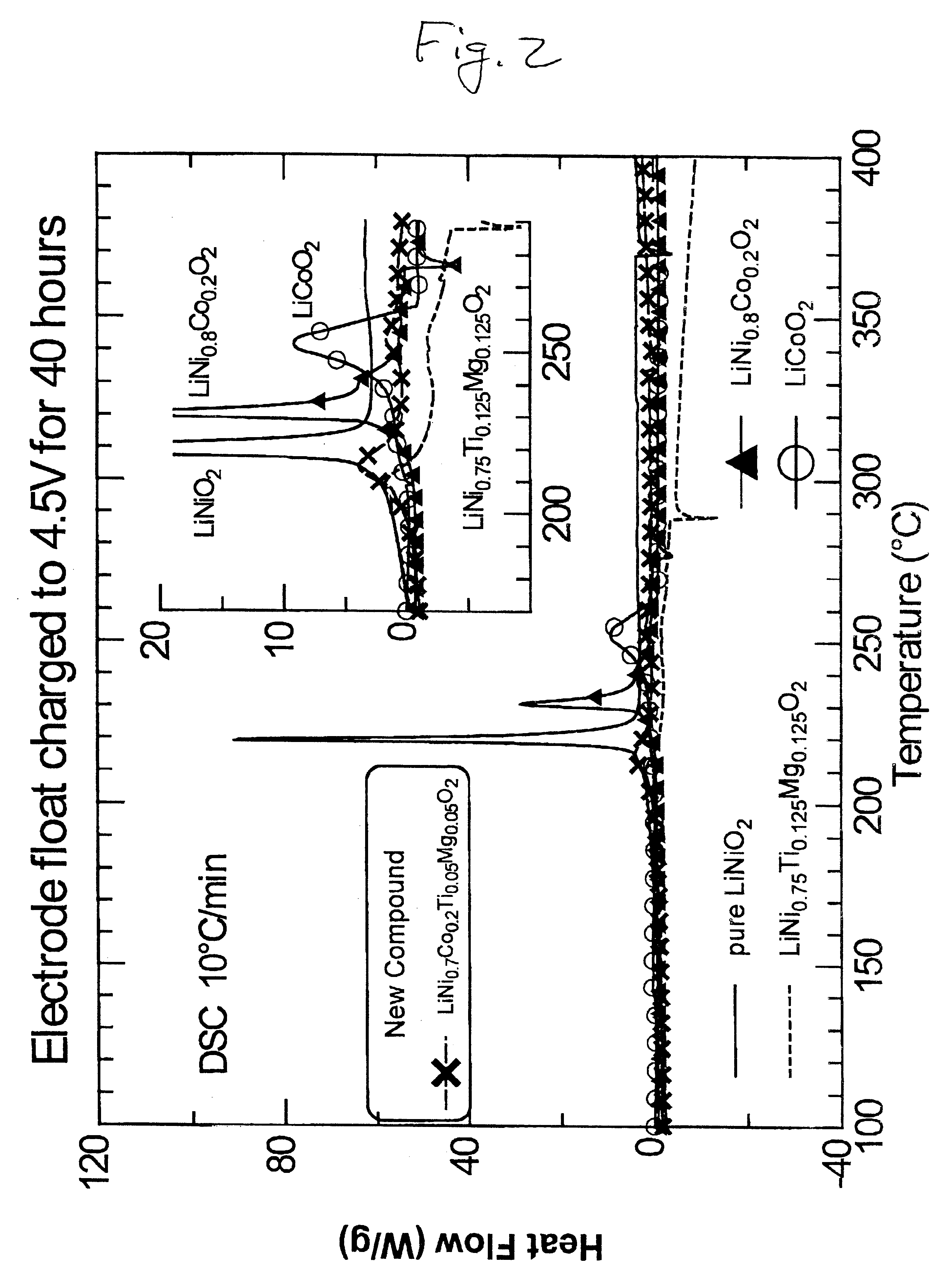

InactiveUS6277521B1Reduce irreversible capacityHigh reversible capacityCobalt compoundsNon-aqueous electrolyte accumulator electrodesOxideLithium electrode

The present invention provides a multiple-doped lithium metal oxide and a method of preparing same for use in the positive electrodes of lithium and lithium ion batteries. The intercalation compound of the invention has the formula LiNi.sub.1-x Co.sub.y M.sub.a M'.sub.b O.sub.2, wherein M is selected from the group consisting of Ti, Zr, and combinations thereof, and M' is selected from the group consisting of Mg, Ca, Sr, Ba, and combinations thereof. The elements in the compounds are present such that x=y+a+b, x is from greater than 0 to about 0.5, y is from greater than 0 to about 0.5, a is from greater than 0 to about 0.15, and b is from greater than 0 to about 0.15.

Owner:UMICORE AG & CO KG

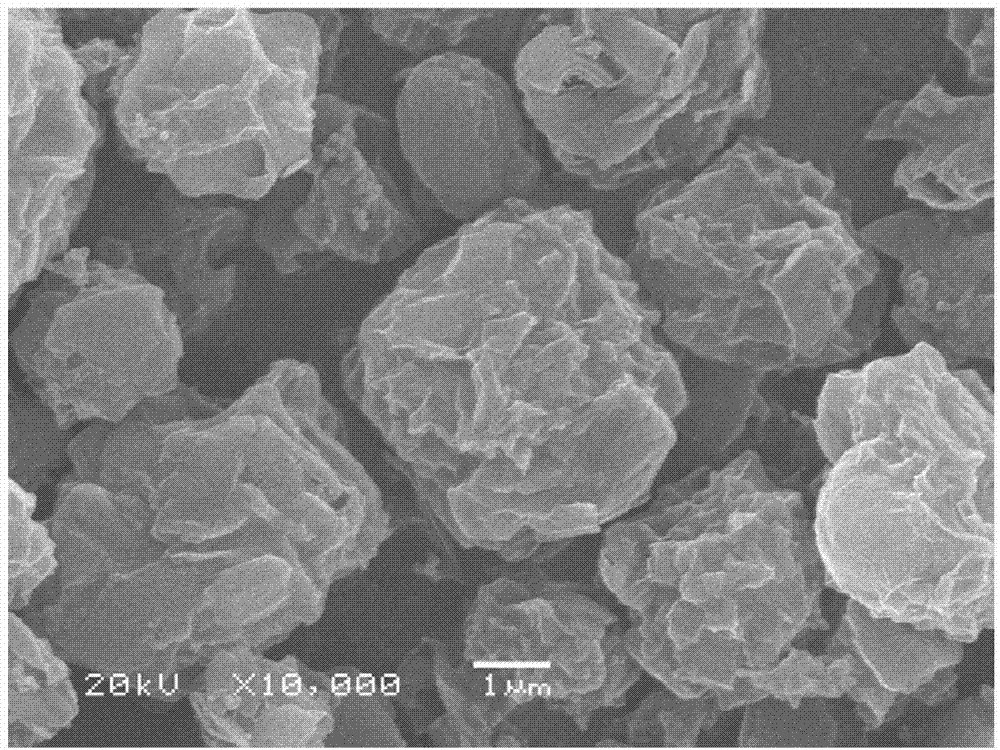

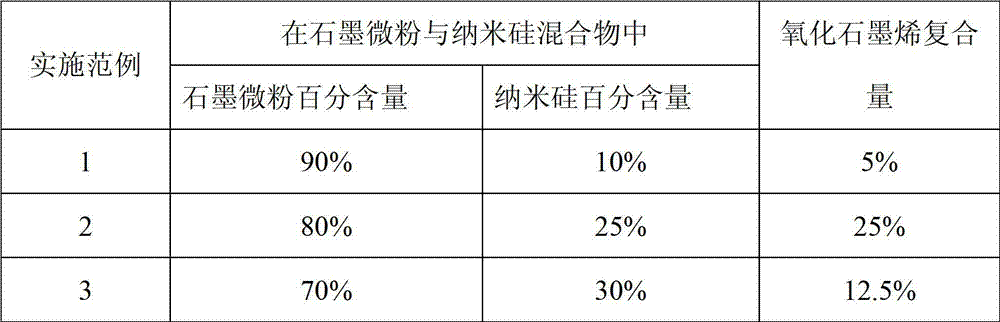

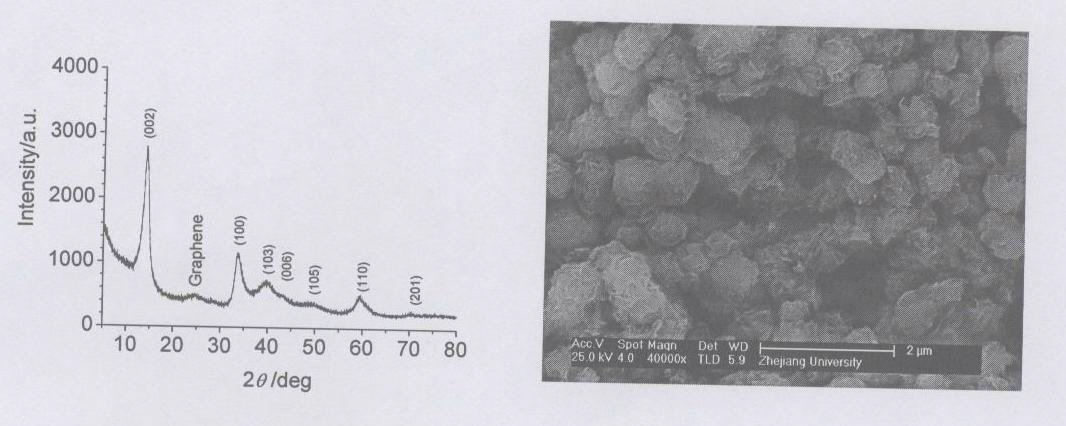

Preparation method of silicon and carbon-coated graphene composite cathode material

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

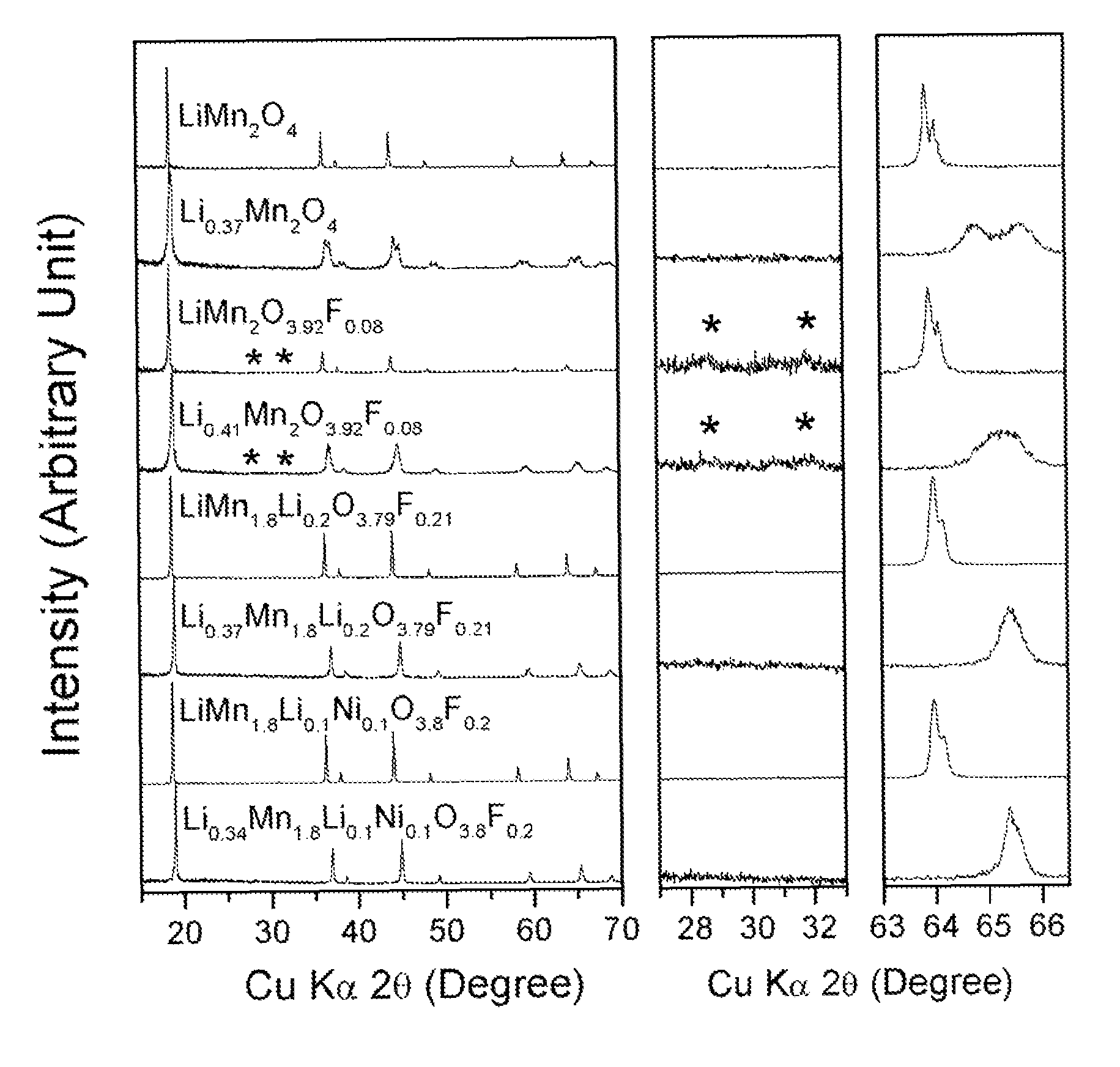

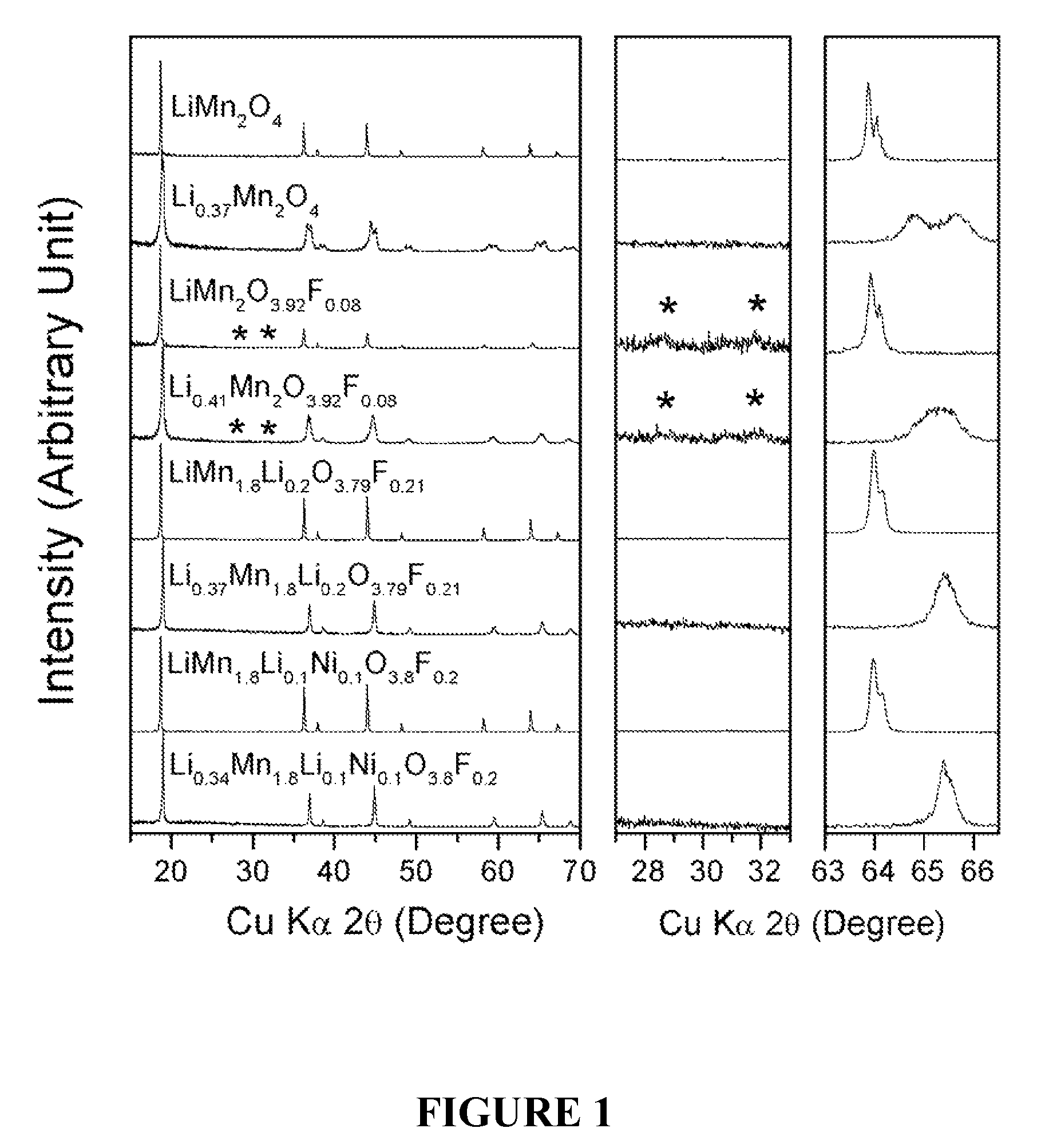

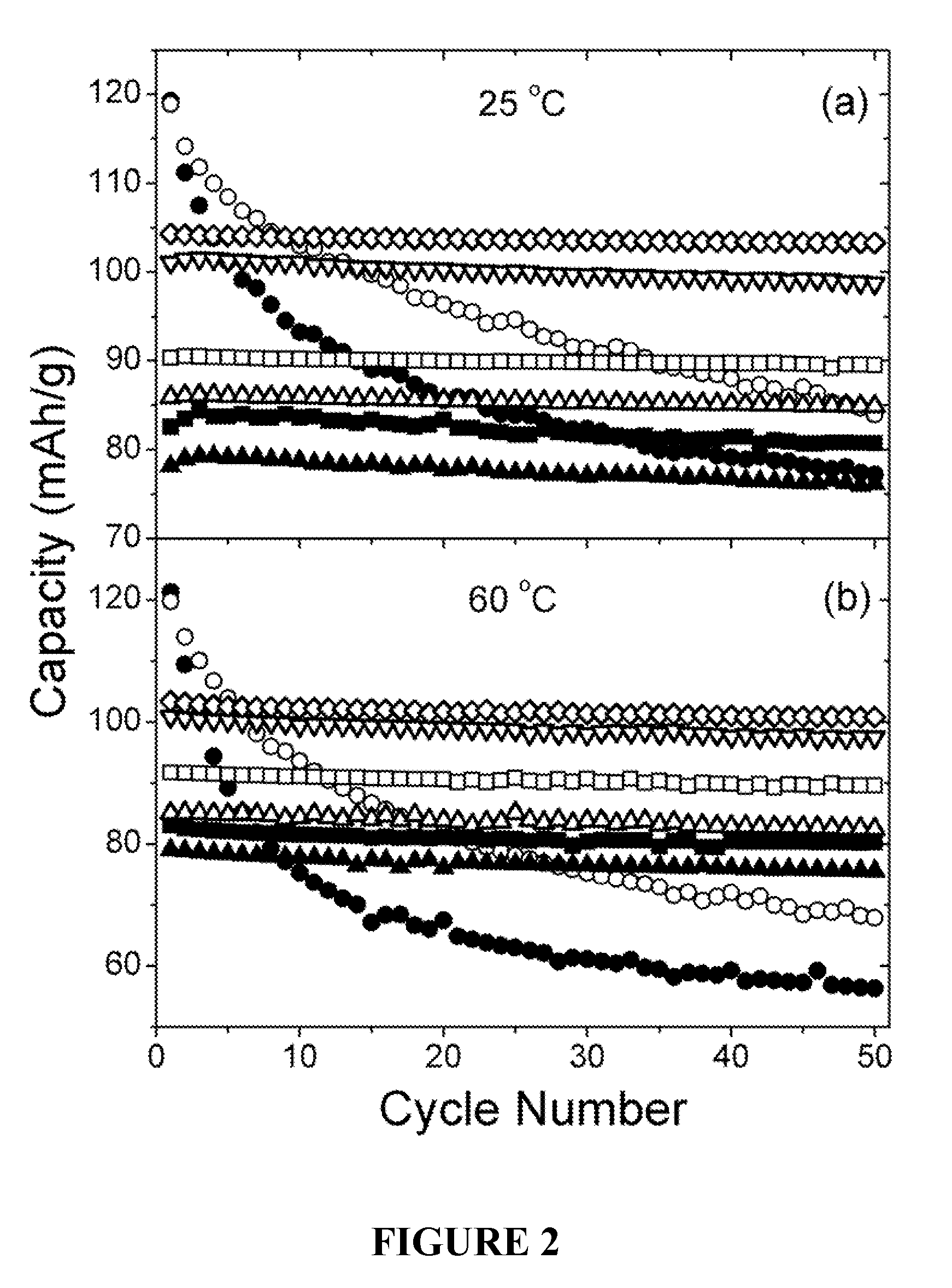

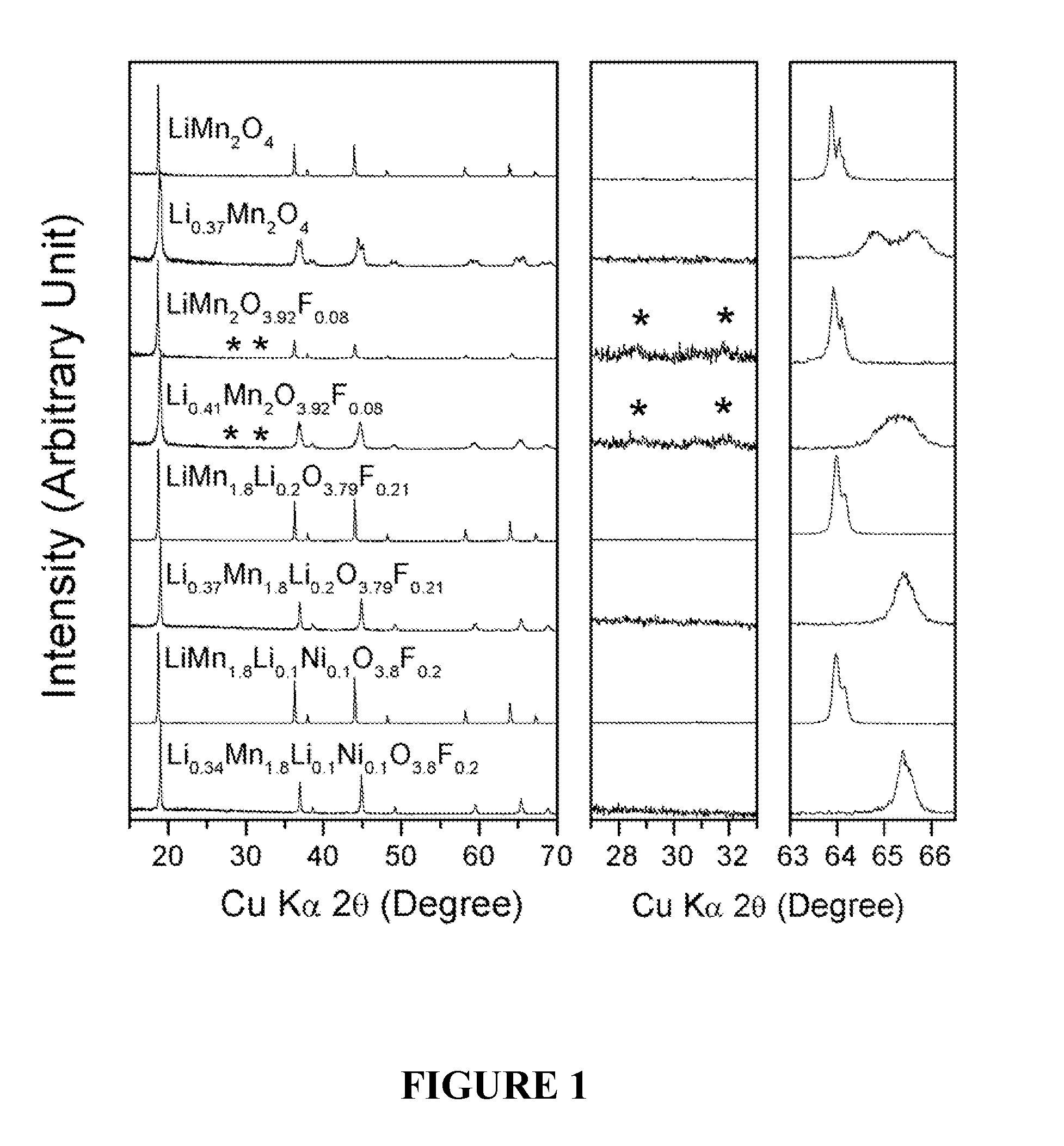

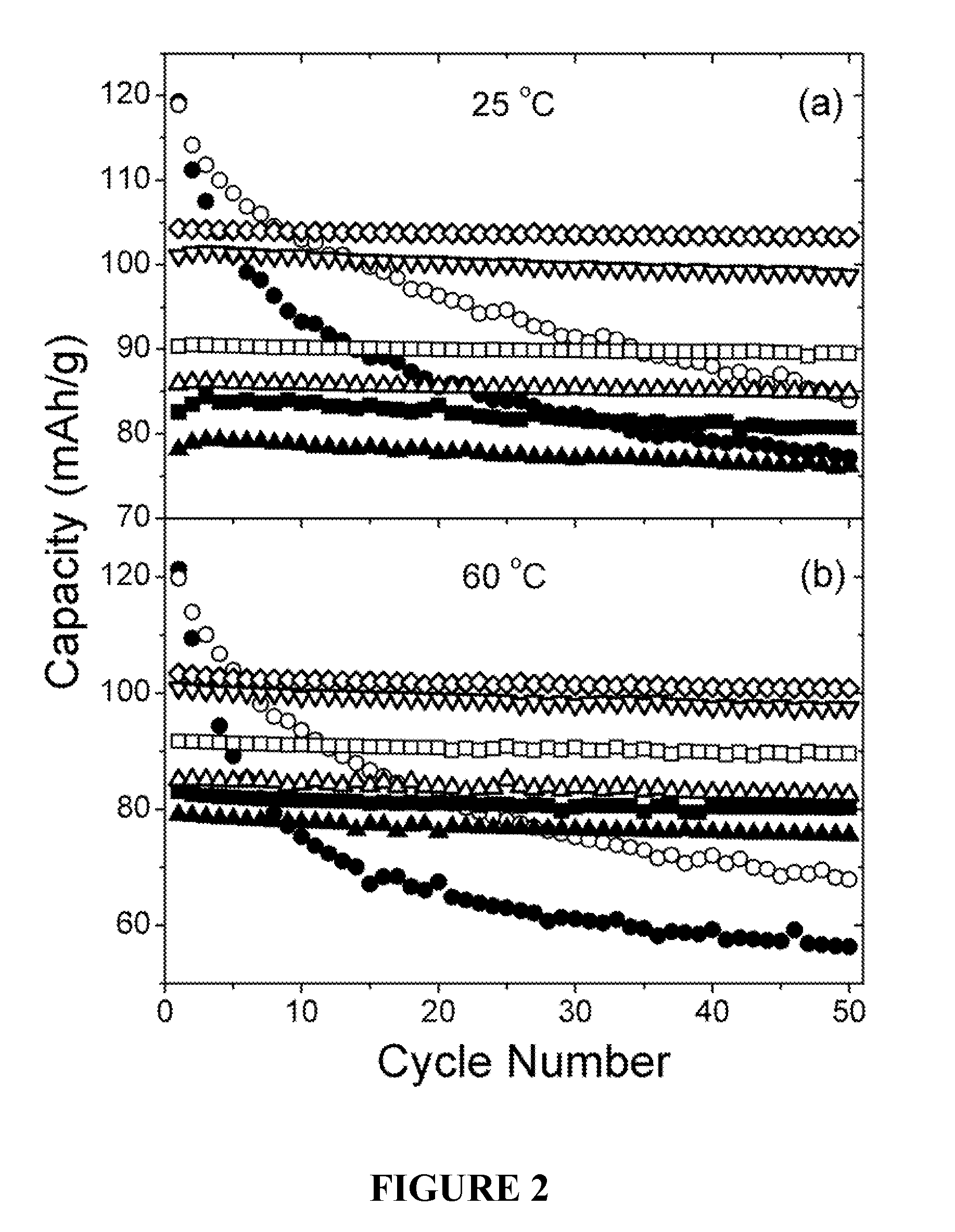

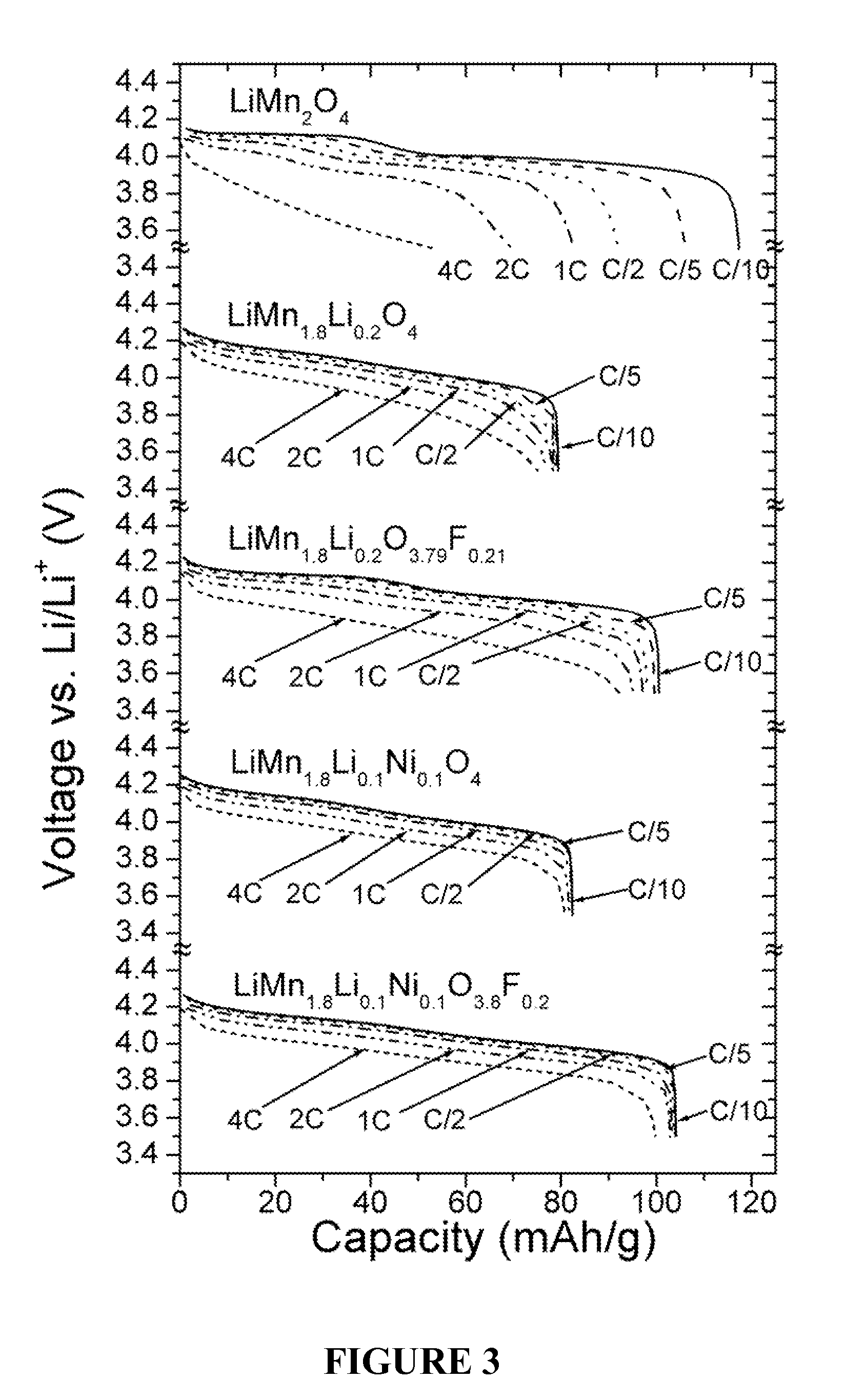

Cation-substituted spinel oxide and oxyfluoride cathodes for lithium ion batteries

InactiveUS7718319B2Cyclability at elevated temperaturesImprove rendering capabilitiesElectrode carriers/collectorsConductive materialSpinelGraphite

The present invention includes compositions and methods of making cation-substituted and fluorine-substituted spinel cathode compositions by firing a LiMn2−y−zLiyMzO4 oxide with NH4HF2 at low temperatures of between about 300 and 700° C. for 2 to 8 hours and a η of more than 0 and less than about 0.50, mixed two-phase compositions consisting of a spinel cathode and a layered oxide cathode, and coupling them with unmodified or surface modified graphite anodes in lithium ion cells.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Hybrid anode compositions for lithium ion batteries

ActiveUS8119288B2Improve conductivityLower internal resistanceAlkaline accumulatorsConductive materialPhysical chemistryHybrid material

The present invention provides an exfoliated graphite-based hybrid material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing alkali or alkaline metal ions (particularly, lithium ions); and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least one of the particles or coating resides in a pore of the network or attached to a flake of the network and the exfoliated graphite amount is in the range of 5% to 90% by weight and the amount of particles or coating is in the range of 95% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, excellent reversible capacity, and long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

Negative electrode active material and use of secondary lithium battery

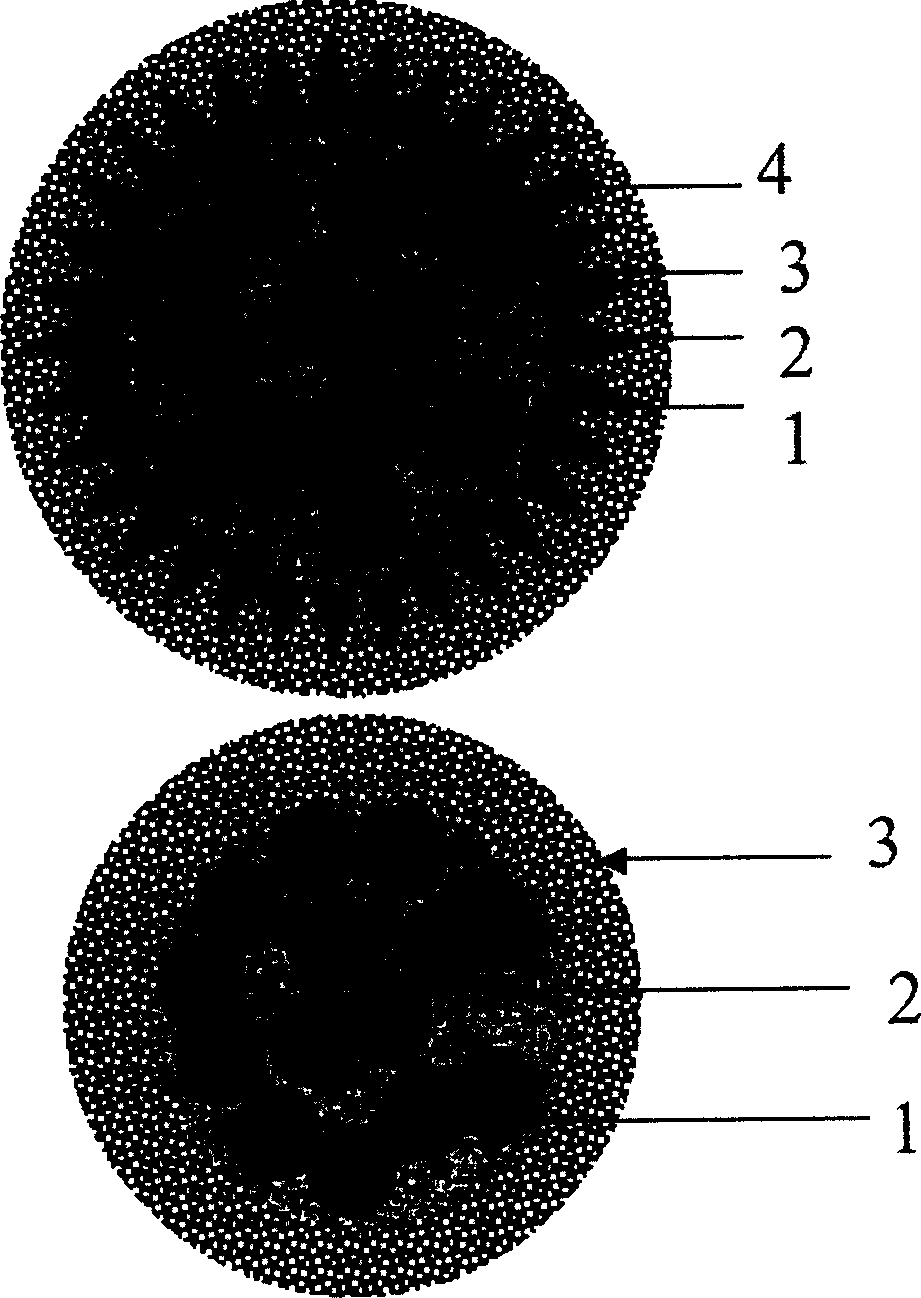

The invention has a grain structure with an outer shell and several inner cores. The grain size is from 100 nanometers to 100 microns. The inner cores are compound grain that includes active substance and conducting additive. The outer shell is a carbon layer. The active substance takes 20-95wt% of total cathode active material, and is mixture of one or several transition metallic compound selected from silicon and lithium storage whose thermodynamic equilibrium potential is less than 1.5v. The cathode material can be made by using mechanical process or thermal method, and can be directly used as cathode material or used with other existing cathode material.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

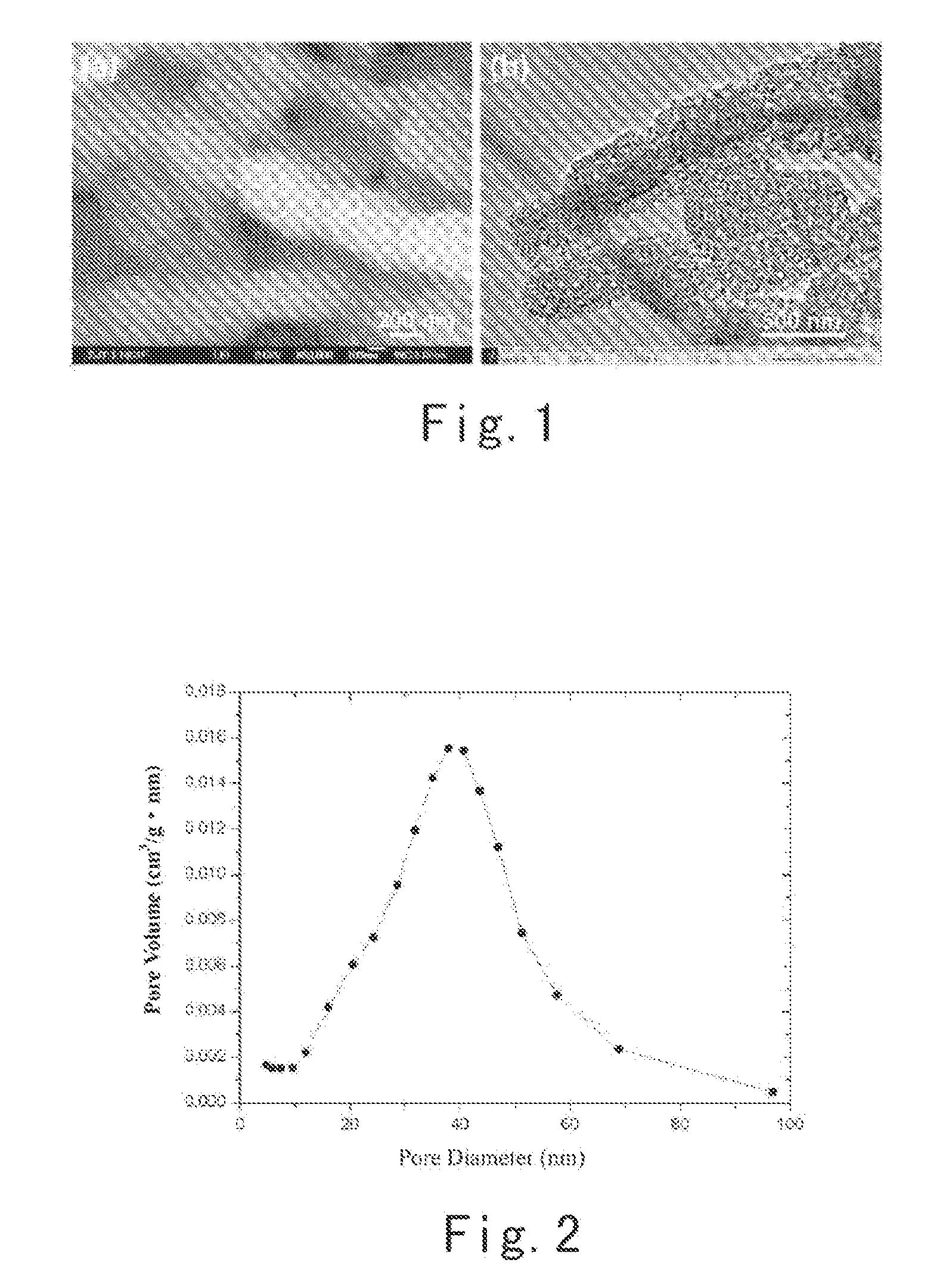

Silicon-carbon composite material with nano micropores and preparation method as well as application thereof

ActiveCN103305965AImprove lithium storage performanceImprove electrochemical performanceCell electrodesFilament/thread formingCarbon compositesCarbon fibers

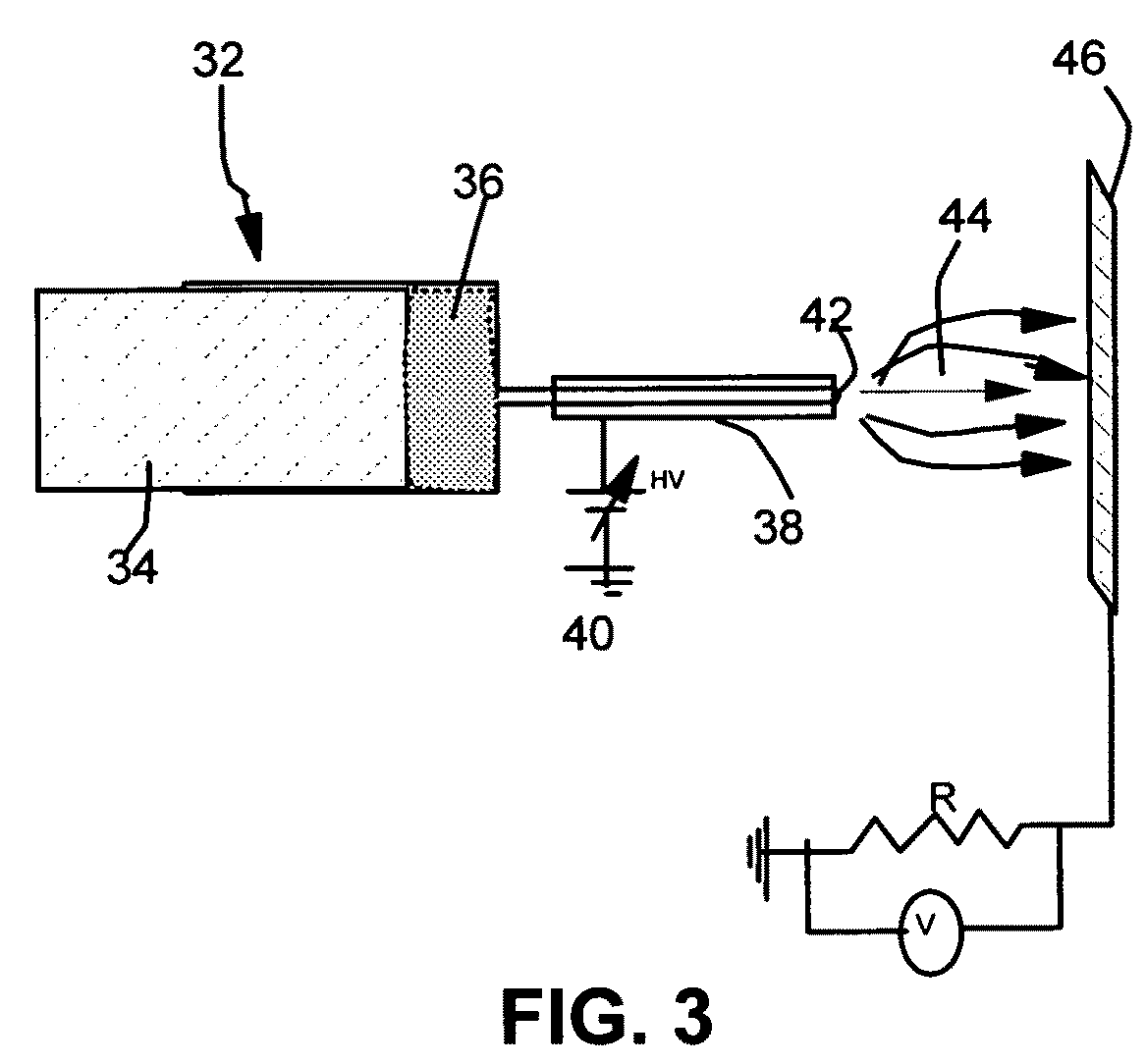

The invention discloses a silicon-carbon composite material with nano micropores and a preparation method as well as application thereof. The material comprises nano-silicon (Si) particles and a carbon nanofiber matrix, wherein the nano-silicon particles are dispersed in the carbon nanofiber matrix; and nano pores and micropores communicated with the nano pores are distributed in the carbon nanofiber matrix. The method comprises the steps of dissolving the nano-Si particles and polyacrylonitrile (PAN) in a solvent to prepare a mixed spinning solution, then carrying out electrostatic spinning on the mixed spinning solution, and curing spinning trickles in a coagulating bath to obtain a porous PAN-Si composite nanofiber; and then carrying out oxidation and carbonization treatment in sequence to obtain the silicon-carbon composite material with a nano micropore structure. The silicon-carbon composite material is applied to preparation of lithium ion battery cathode materials. Compared with the prior art, the silicon-carbon composite material ensures the overall electron transport capacity of the material while reserving buffer space for expansion of the nano-Si particles.

Owner:深圳石墨烯创新中心有限公司

Nano-structured anode compositions for lithium metal and lithium metal-air secondary batteries

ActiveUS8236452B2High specific capacityHigh reversible capacityFuel and primary cellsConductive materialNano structuringLithium metal

This invention provides a nano-structured anode composition for a lithium metal cell. The composition comprises: (a) an integrated structure of electrically conductive nanometer-scaled filaments that are interconnected to form a porous network of electron-conducting paths comprising interconnected pores, wherein the nano-filaments have a transverse dimension less than 500 nm; and (b) micron- or nanometer-scaled particles of lithium, a lithium alloy, or a lithium-containing compound wherein at least one of the particles is surface-passivated or stabilized and the weight fraction of these particles is between 1% and 99% based on the total weight of these particles and the integrated structure together. Also provided is a lithium metal cell or battery, or lithium-air cell or battery, comprising such an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

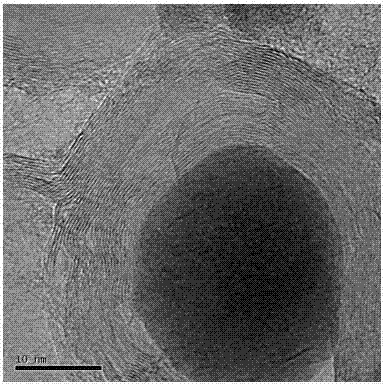

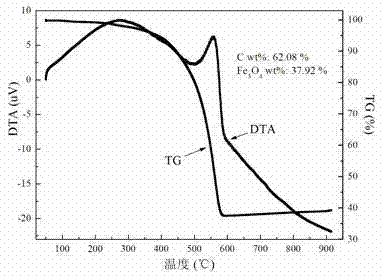

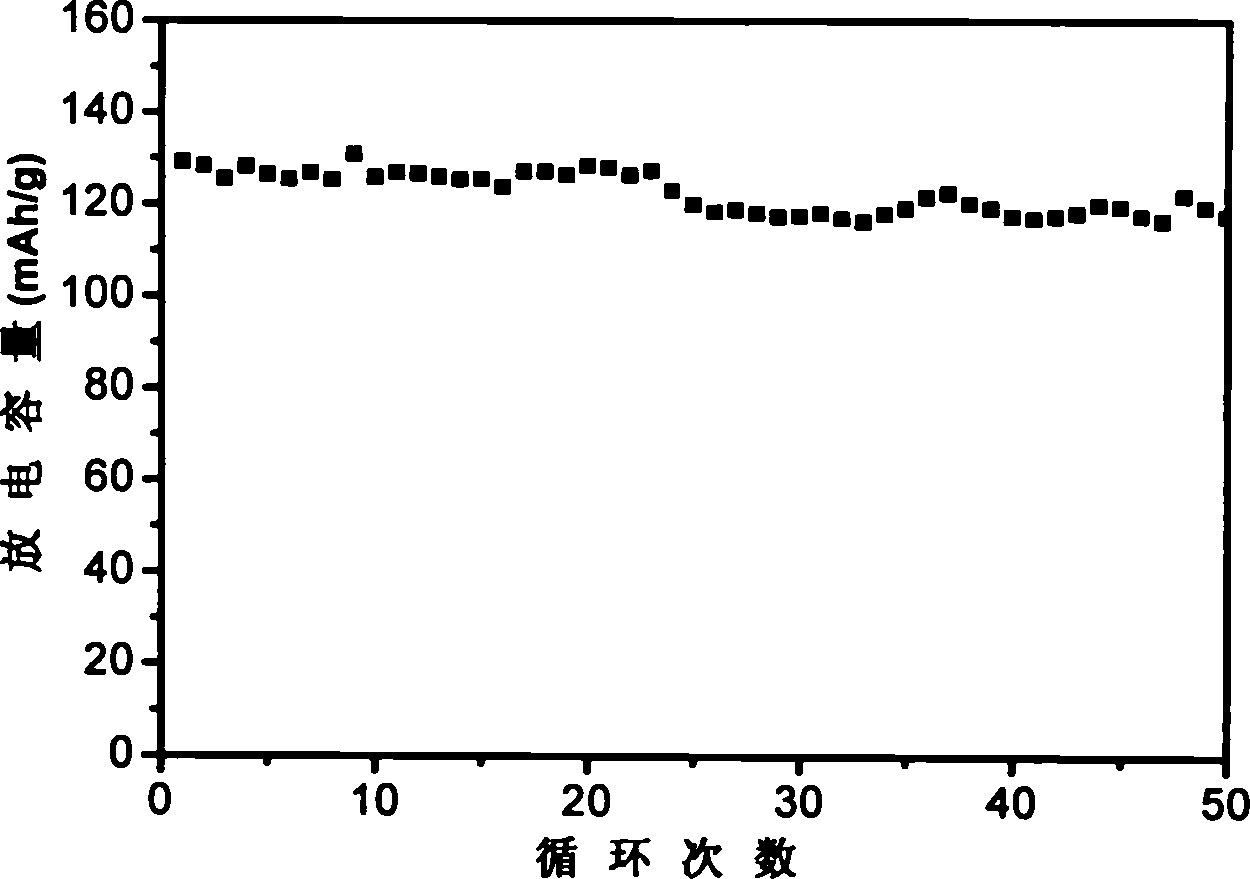

Carbon cladded ferriferrous oxide negative electrode material of lithium ion battery and preparation method thereof

InactiveCN102790217AHigh degree of graphitizationLarge specific surface areaCell electrodesSolid carbonButton battery

The invention discloses a carbon cladded ferriferrous oxide negative electrode material of a lithium ion battery and a preparation method thereof. The negative electrode material is a carbon cladded Fe3O4 composite material and has a particle size in a range of 1 to 100 nm. The preparation method comprises the following steps: with NaCl used as a dispersing agent and a supporter, fully mixing NaCl with a metal oxide source and a solid carbon source; drying an obtained mixed solution under vacuum to obtain a mixture; placing the mixture into a tubular furnace for calcination in an inert atmosphere so as to obtain a calcined product; and rinsing and grinding the calcined product to obtain carbon cladded metal oxide nanometer particles. The method is safe and non-toxic and is simple to operate; during charging and discharging tests of a lithium ion button cell made of the carbon cladded ferriferrous oxide negative electrode material, discharge specific capacity can be maintained at 620 to 900 mAh / g after 30 cycles of charging and discharging at a current of 0.1C (with current density being 92 mA / g), and discharge specific capacity can be maintained at 600 to 760 mAh / g after 50 cycles of charging and discharging at a current of 1C (with current density being 920 mA / g); and the negative electrode material of the lithium ion battery has high reversible capacity and good cycling stability.

Owner:TIANJIN UNIV

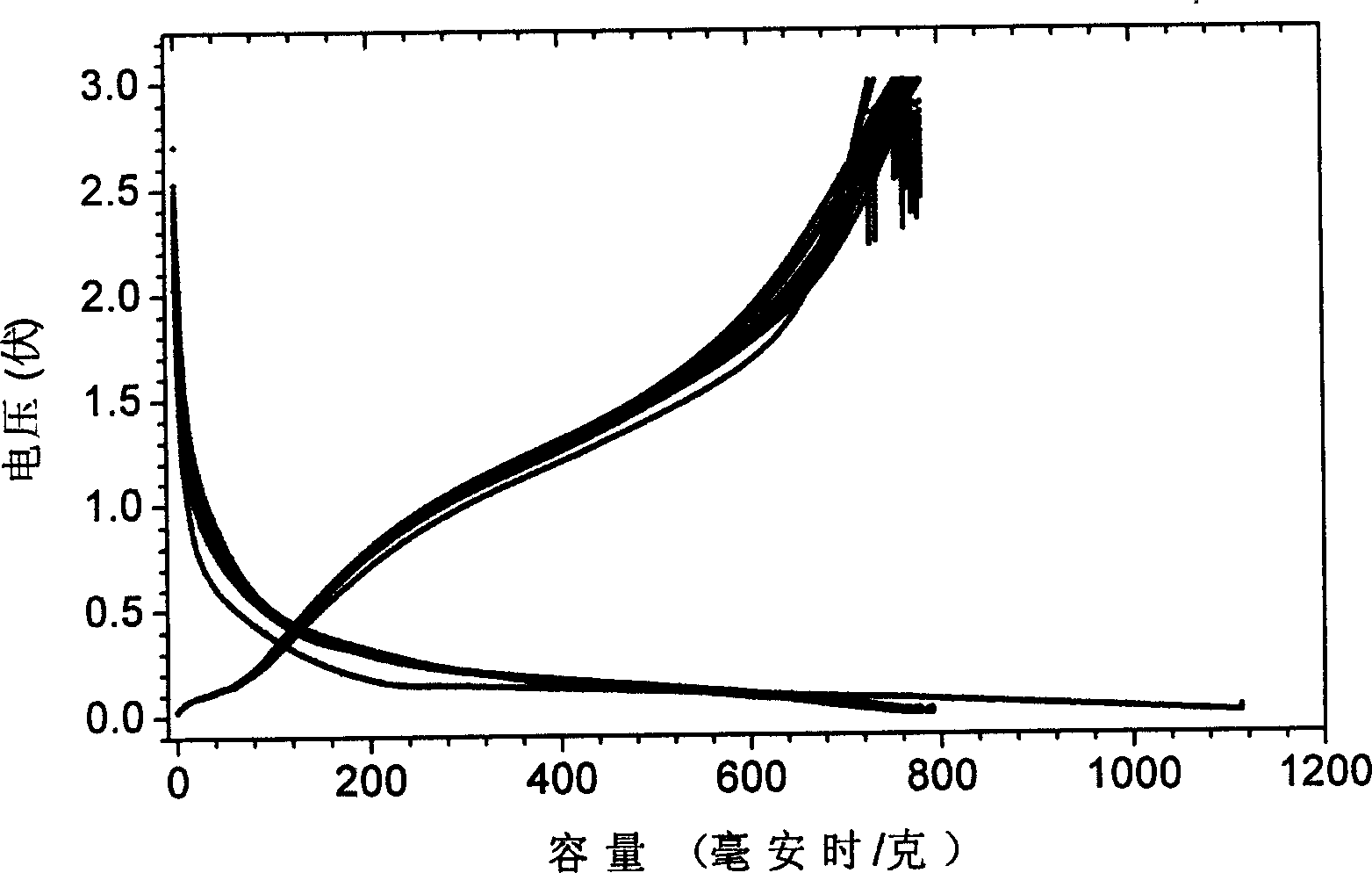

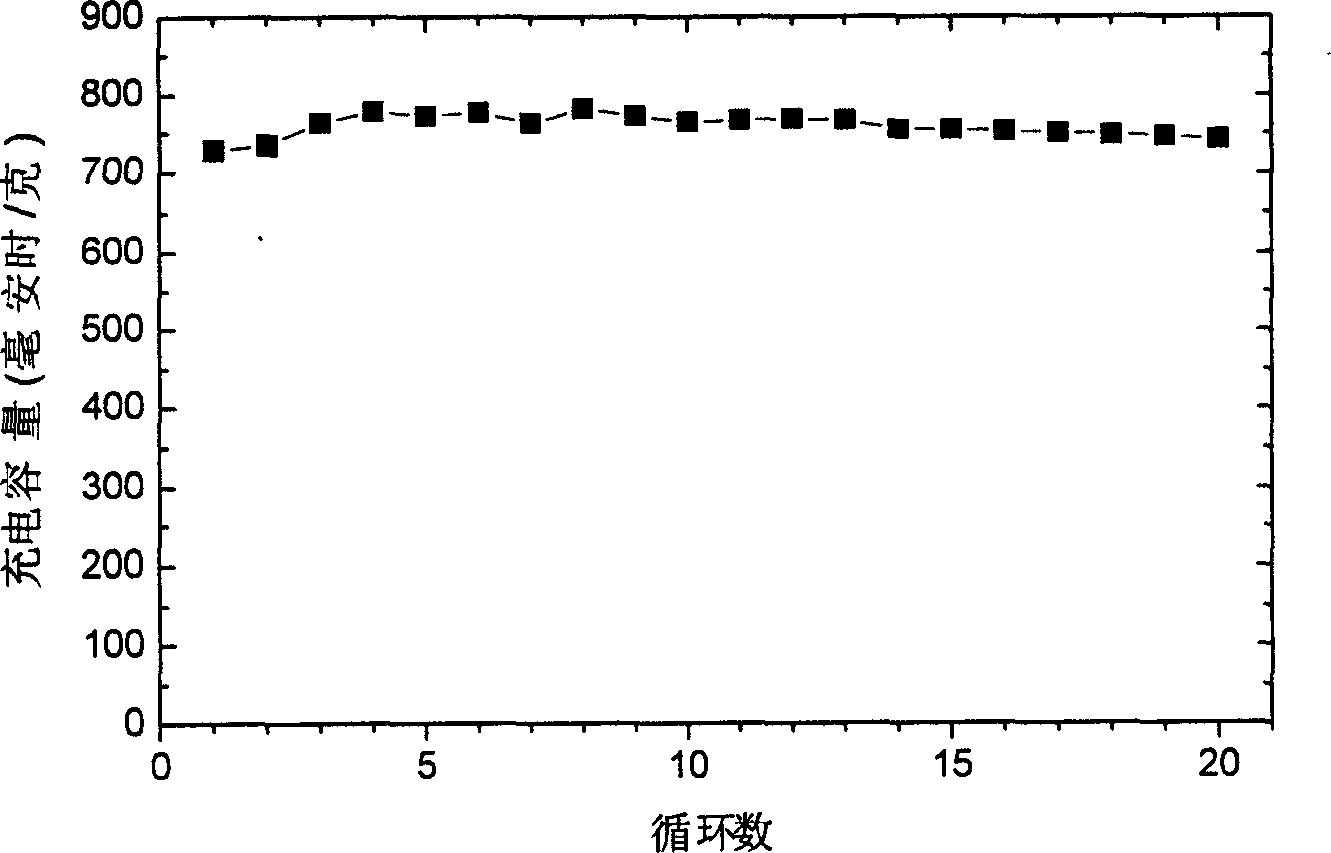

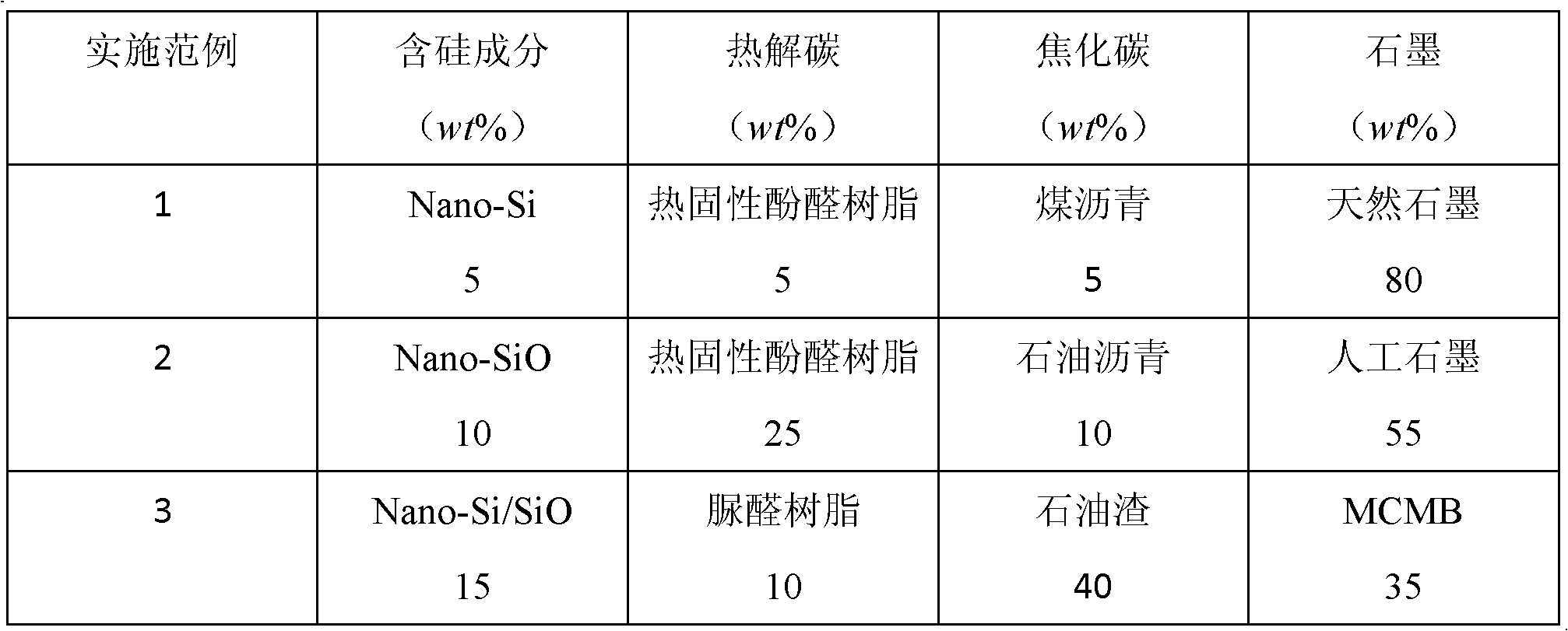

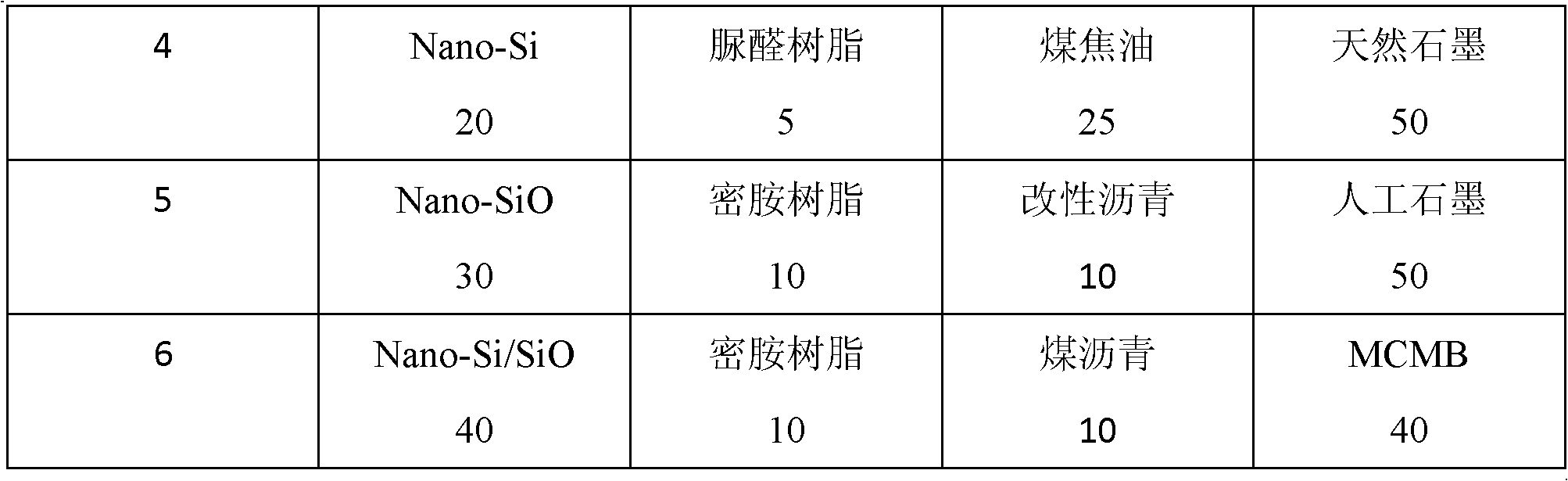

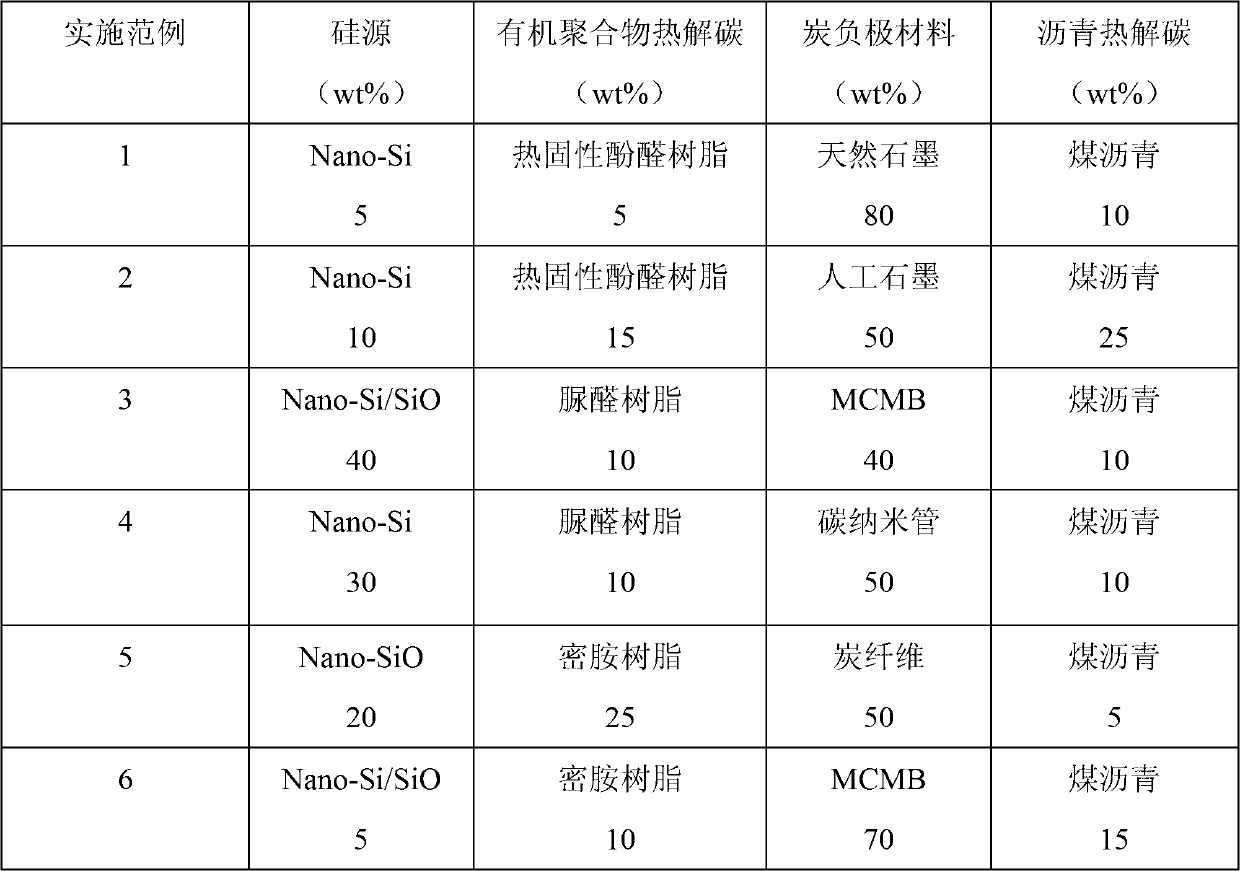

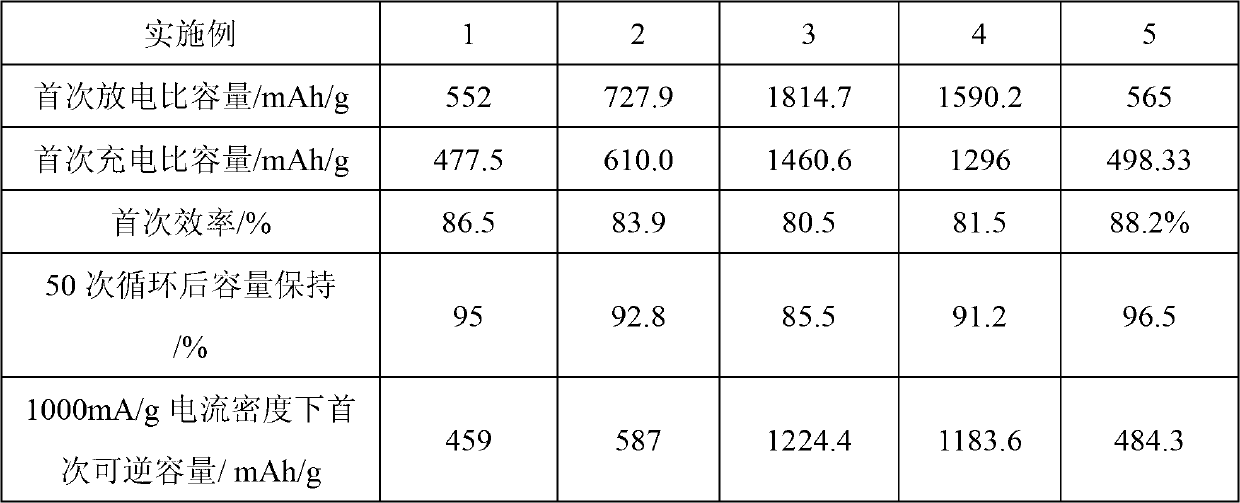

Preparation method for composite cathode material of lithium ion battery

The invention discloses a preparation method for a composite cathode material of a lithium ion battery by means of spray drying pyrolysis treatment. The preparation method includes the steps: dissolving a first type of binder organic carbon source into solvent of a proper quantity, adding a silicon source, a second type of binder and a dispersing agent, dispersing uniformly, adding graphite, dispersing for a certain time, subjecting uniformly dispersed suspension to spray drying, and using the first type of binder organic carbon source to bond the silicon source, the graphite and the second type of binder particles into spherical or spherical-like forms to obtain a composite precursor; and transferring the precursor into a shielding atmosphere for sintering, heating the second type of binder to a certain temperature to be melted into a liquid crystal state, bonding the particle silicon source and the graphite into cores, subjecting the organic carbon source to pyrolysis at the high temperature to form a coating, and furnace cooling to obtain the carbon-silicon composite cathode material of the lithium ion battery. The preparation method is simple, easy in implementation and high in practicality. The carbon-silicon composite prepared by the method has the advantages of high reversible capacity, designable capacity, high circulating performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

Cation-Substituted Spinel Oxide and Oxyfluoride Cathodes for Lithium Ion Batteries

InactiveUS20080157027A1Decrease in reversible capacity valueImproved cyclabilityConductive materialElectrode carriers/collectorsLithium electrodeOxide

The present invention includes compositions and methods of making cation-substituted and fluorine-substituted spinel cathode compositions by firing a LiMn2-y-zLiyMzO4 oxide with NH4HF2 at low temperatures of between about 300 and 700° C. for 2 to 8 hours and a η of more than 0 and less than about 0.50, mixed two-phase compositions consisting of a spinel cathode and a layered oxide cathode, and coupling them with unmodified or surface modified graphite anodes in lithium ion cells.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

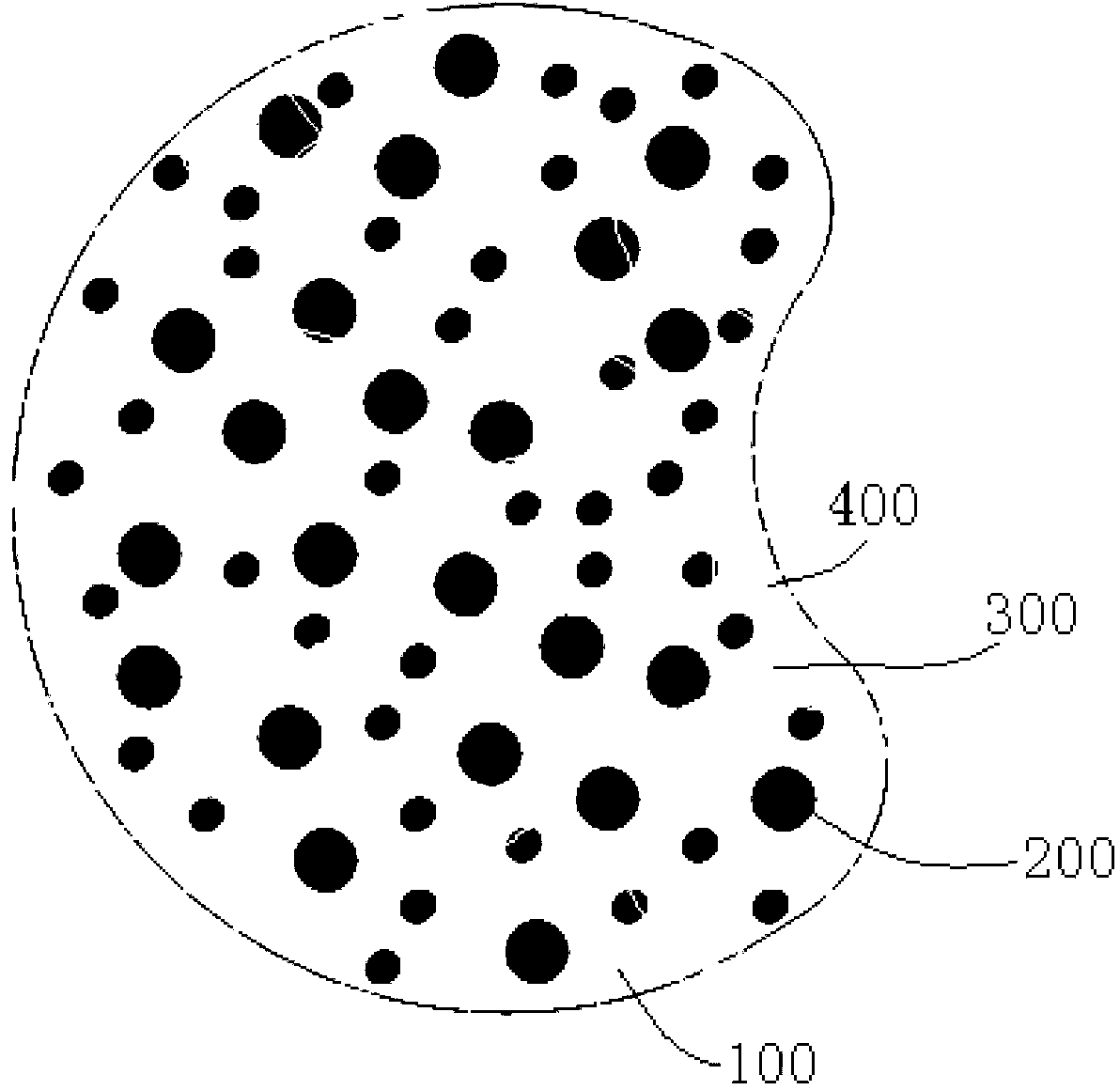

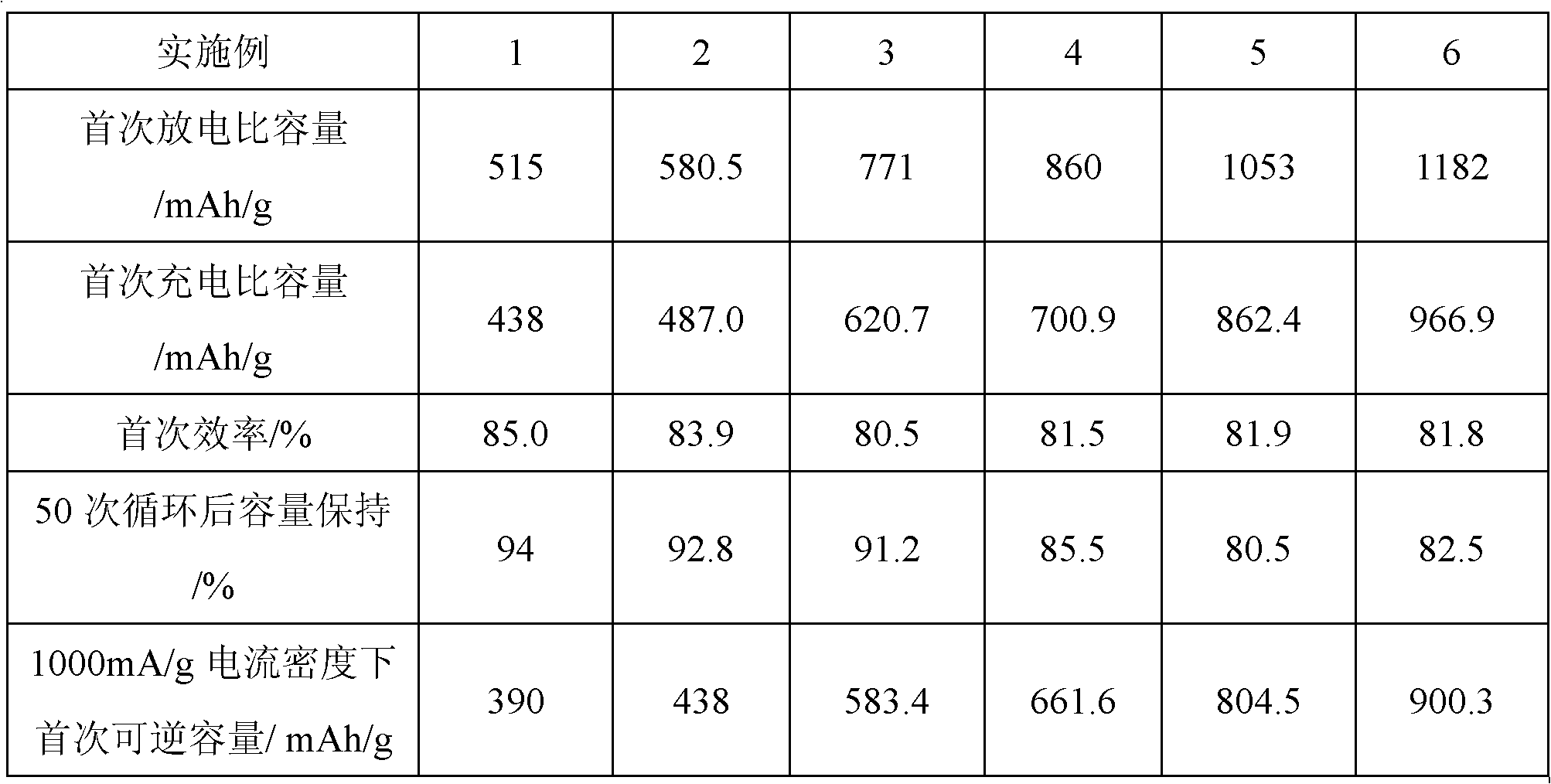

Multi-core core-shell-structure silicon carbon composite negative pole material and preparation method thereof

The invention relates to a multi-core core-shell-structure silicon carbon composite negative pole material and a preparation method thereof. The preparation method comprises the following steps: 1. preparation method of high-dispersivity multi-core porous spheres; 2. preparation of high-dispersivity asphalt suspension; and 3. preparation of multi-core core-shell-structure silicon carbon composite negative pole material: adding the porous spheres prepared in the step 1 into the high-dispersivity asphalt suspension prepared in the step 2, carrying out ultrasonic dispersion, heating and drying by distillation while intensely stirring to remove the solvent, transferring the powder particles into a protective atmosphere, and holding at low temperature so that the asphalt liquid enters the inside of the porous spheres to enhance the binding strength between the silicon source and the conducting carbon mesh, carry out secondary coating on the silicon source, overcome the defects in the coating in the step 1 and enhance the capacity performance of the silicon; and carrying out high-heat treatment. The invention is simple and easy to implement, and has the advantage of high practicality. The prepared silicon carbon composite material has the advantages of high reversible capacity, designable capacity, favorable cycle performance, favorable heavy-current discharge capacity, high tap density and the like.

Owner:CENT SOUTH UNIV

Mixed nano-filament electrode materials for lithium ion batteries

ActiveUS8435676B2Improve conductivityEasy to collectSecondary cellsActive material electrodesFiberNanowire

Owner:GLOBAL GRAPHENE GRP INC

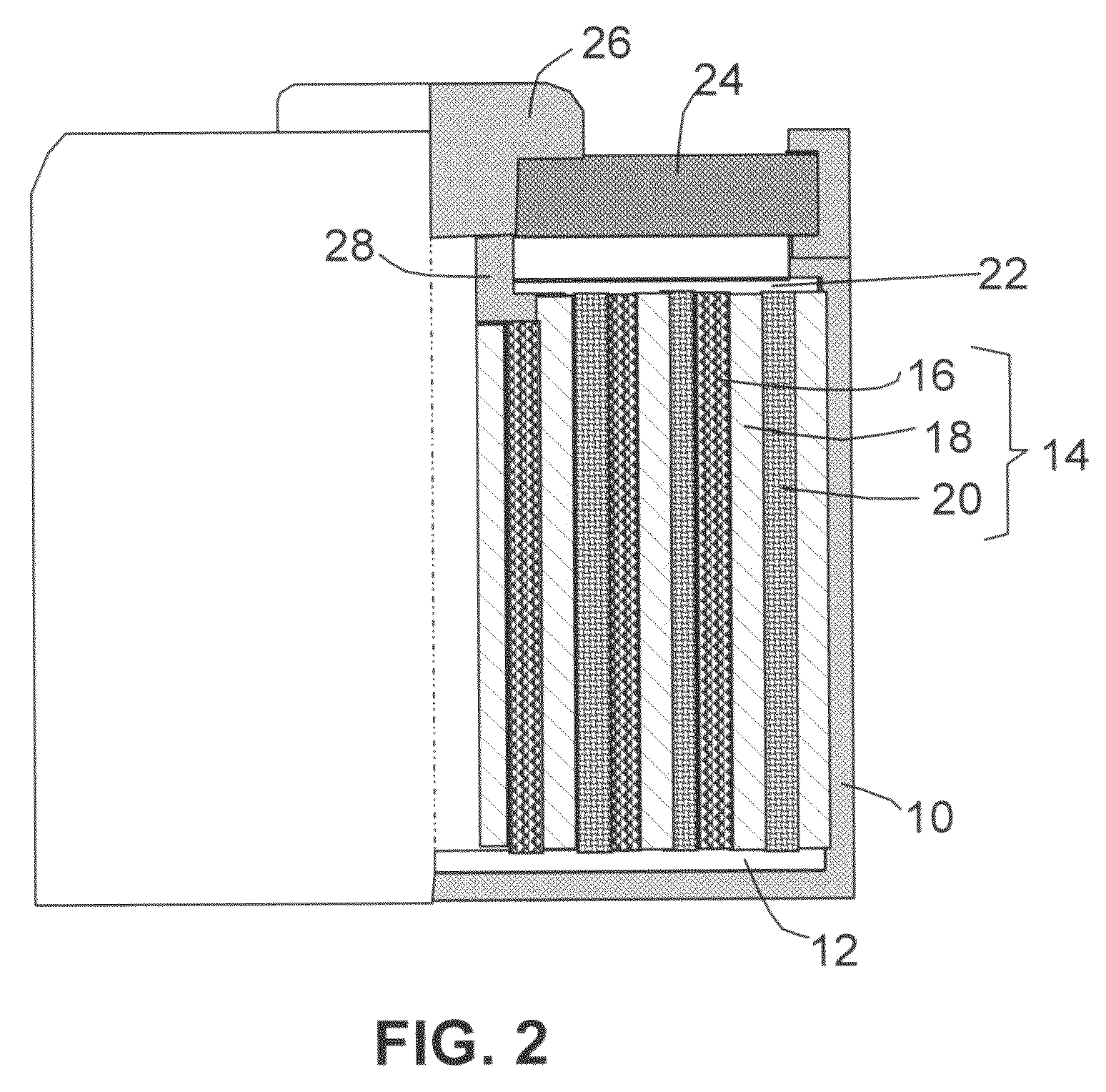

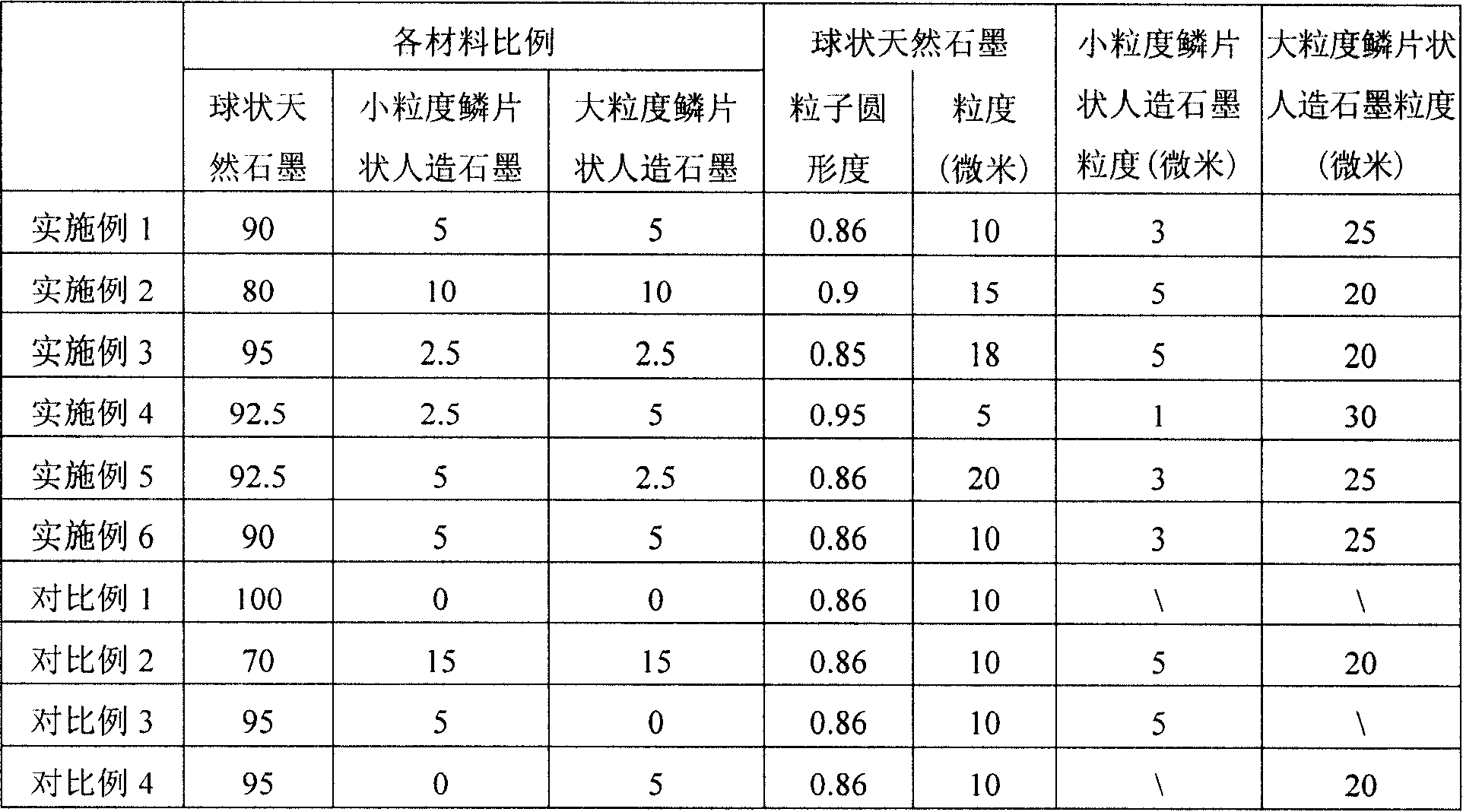

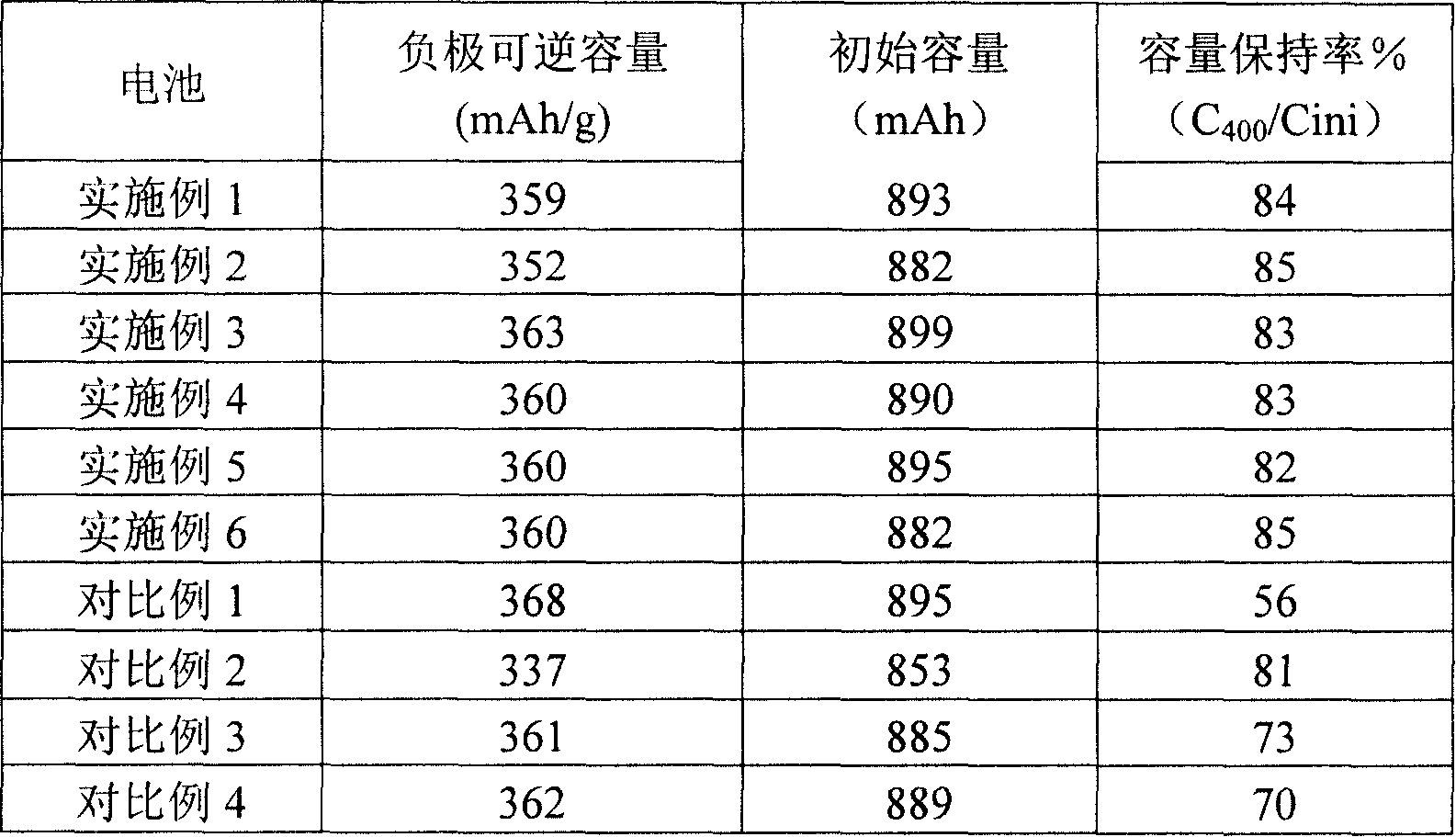

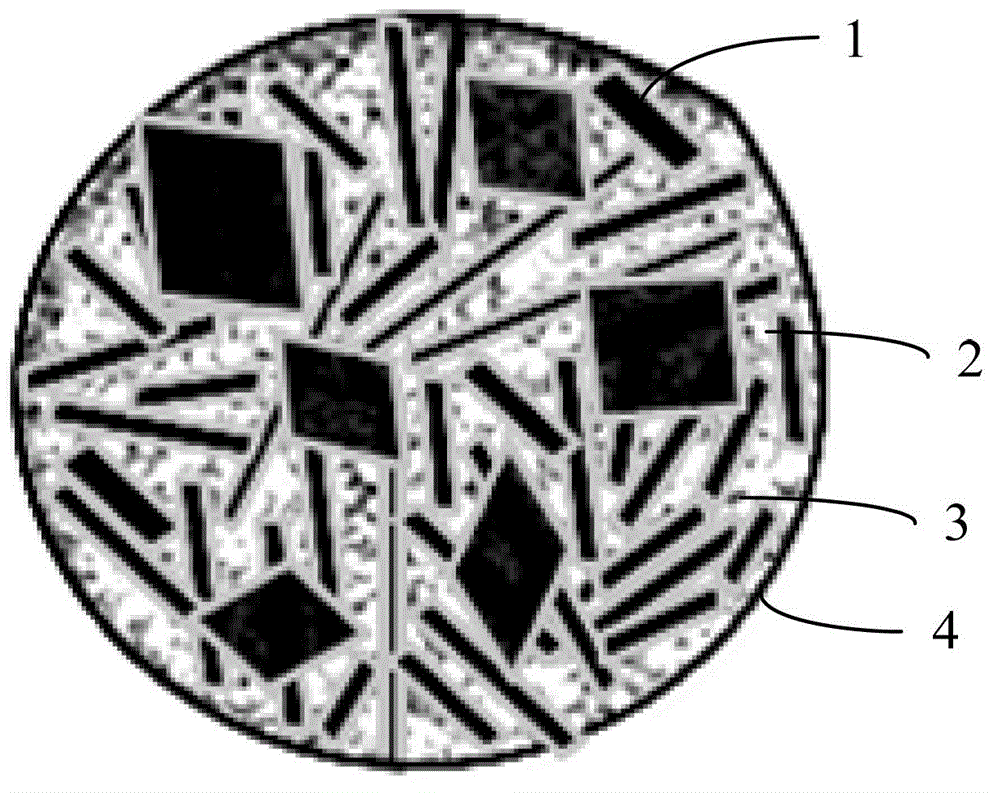

Cathode of lithium ion secondary battery and lithium ion secondary battery including the same

ActiveCN101174683AIncrease battery capacityHigh reversible capacityActive material electrodesSecondary cellsIonLarge capacity

The present invention relates to a cathode of a lithium-ion, which comprises a cathode collecting body and a cathode material layer that is coated on the collecting body; the cathode material layer comprises a cathode active substance and an adhesion agent, the cathode active substance comprises a spherical-shaped natural graphite and a squamiform artificial graphite, wherein, the squamiform graphite comprises a large-granularity squamiform artificial graphite and a small-granularity squamiform artificial graphite, the average granularity D50 of the large-granularity squamiform artificial graphite is 20 to 35 micron, the average granularity D50 of the small-granularity squamiform artificial graphite is 1 to 5 micron; adopting the total quantity of the mixing graphite of the spherical-shaped natural graphite, the large-granularity squamiform artificial graphite and the small-granularity squamiform artificial graphite as the standard, the content of the spherical-shaped natural graphiteis 75 percent to 98 percent, the content of the large-granularity squamiform artificial graphite is 1 percent to 20 percent, and the content of the small-granularity squamiform artificial graphite is1 percent to 20 percent. Even the density of the cathode using the cathode active substance reaches 1.8 g / cm<3>, the cathode still has higher capacity and good cycling service life.

Owner:BYD CO LTD

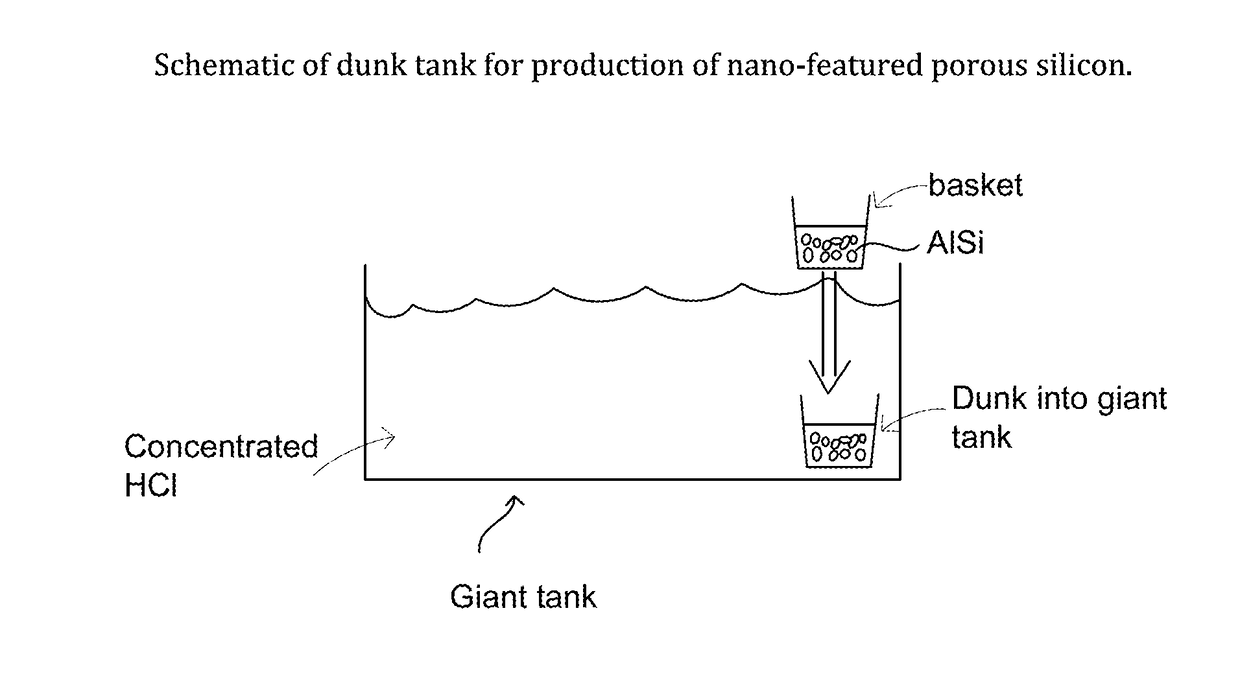

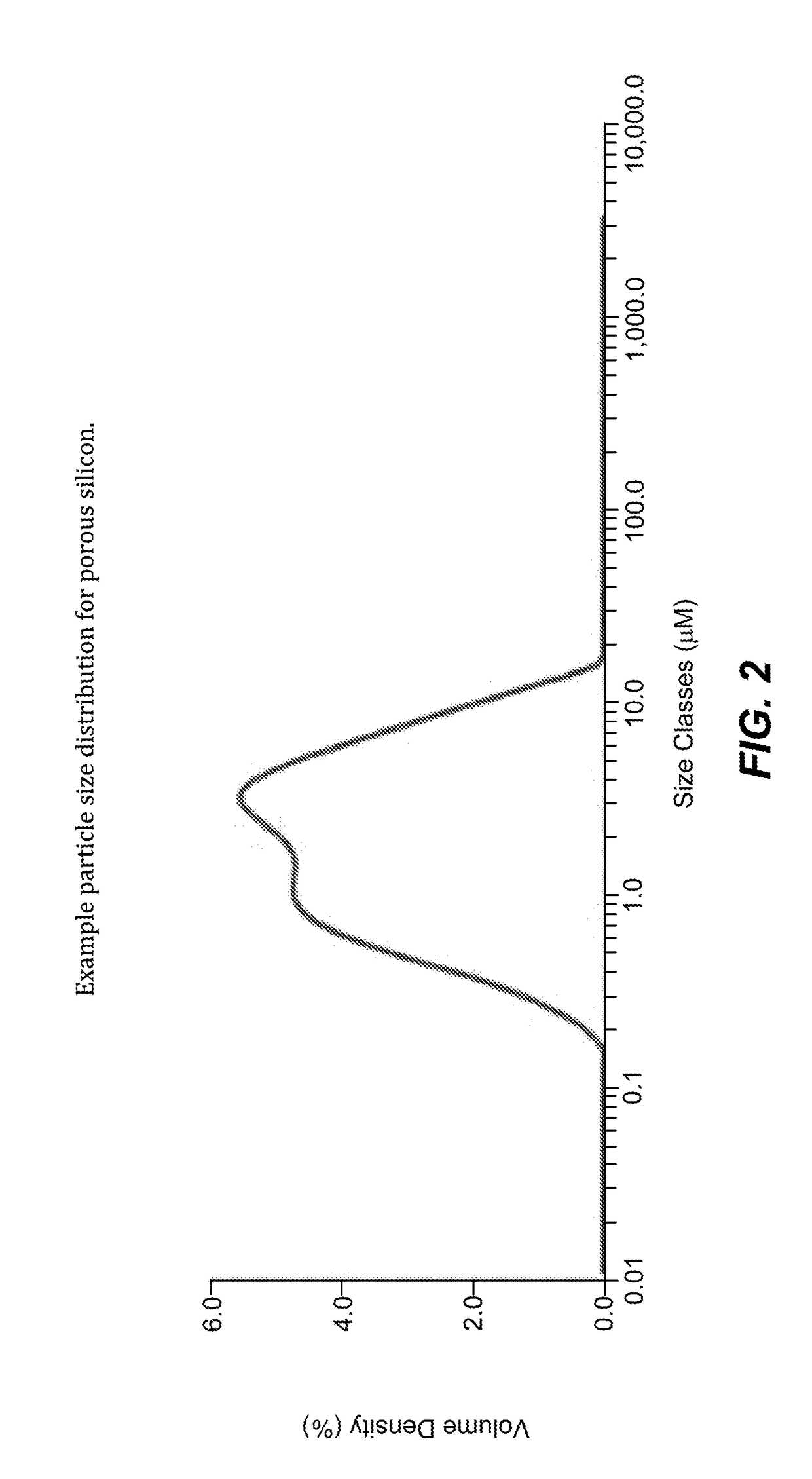

Nano-featured porous silicon materials

ActiveUS20180331356A1Optimized lithium storageOptimized utilization propertyTransportation and packagingNegative electrodesCarbon particleEnergy storage

Porous silicon and methods for preparation and use of the same are disclosed. The porous silicon materials have utility either alone or in combination with other materials, for example, combined with carbon particles for energy storage applications.

Owner:GRP 14 TECH INC

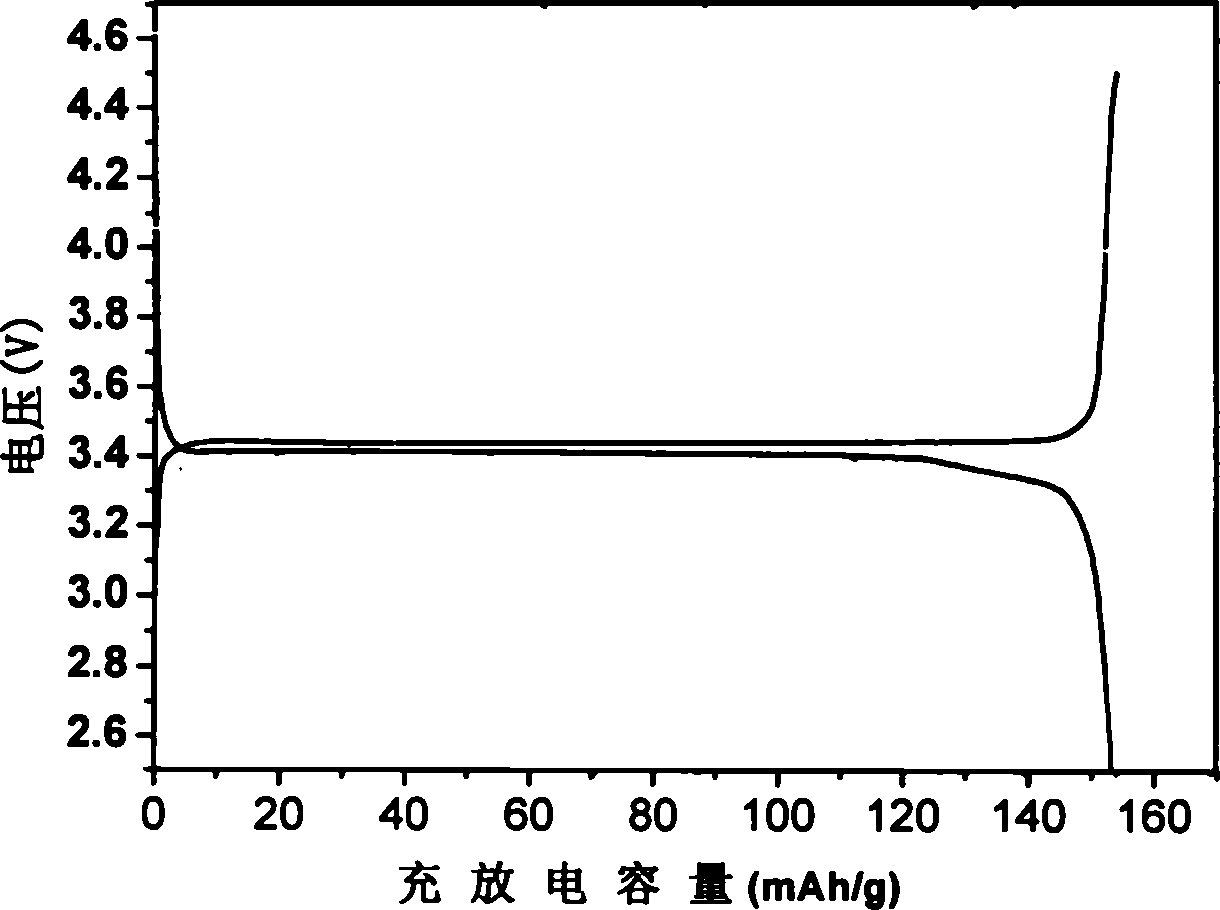

Process for solid phase synthesis of lithium iron phosphate anode materials under high pressure

InactiveCN1884053ALow reaction temperatureReduce manufacturing costCell electrodesPhosphorus compoundsAir atmosphereLithium iron phosphate

The invention discloses a synthesizing method of anode material of high-pressure solid-phase ferric-lithium phosphate, which comprises the following steps: blending lithium salt, ferric salt and phosphate according to 1:1:1 proportion evenly; grinding the material into ball for 6-24 h to obtain priority; disposing priority for 2-10 h at 200-350 deg.c in the air environment; cooling naturally; grinding to obtain powder material; adding carbon material in the powder material with weight percentage of carbon material at 1-20 percent; grinding again for 6-24 h; disposing for 4-24 h at 450-1000 deg.c in the 1-15 Mpa inert environment; cooling naturally to obtain the product.

Owner:SOUTH CHINA UNIV OF TECH

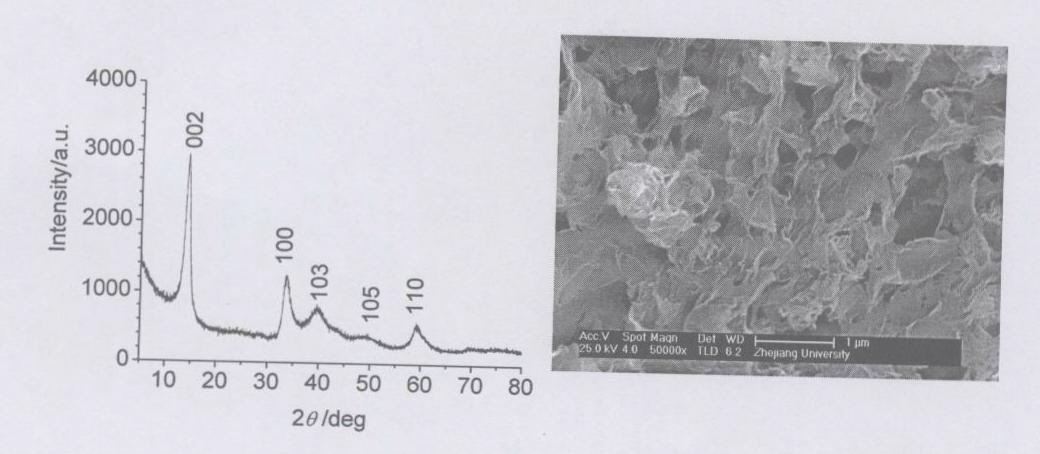

High capacity and stable cyclic performance lithium ion battery electrode and preparation method thereof

ActiveCN102142541AInhibition of agglomerationEasy to passCell electrodesMass ratioLithium-ion battery

The invention discloses a high capacity and stable cyclic performance lithium ion battery electrode and a preparation method thereof. The invention is characterized in that: the electrode comprises the following components in percentage by mass: 75 to 85 percent of graphene nano slice / molybdenum disulfide (MoS2) compound nano material serving as an active substance, and 5 to 10 percent of acetylene black and 5 to 15 percent of polyvinylidene fluoride; and the mass ratio of the graphene nano slice to the MoS2 compound nano material in the compound nano material active substance is (1 to 1)-(4 to 1). The preparation method for the electrode comprises the following steps of: preparing an oxidized graphite nano slice by using graphite as a raw material by a chemical oxidization method; synthesizing by a one-step hydrothermal in-situ reduction method in the presence of the oxidized graphite nano slice to obtain a graphene nano slice / MoS2 compound nano material; and finally, preparing the electrode by using the graphene nano slice / MoS2 compound nano material as the active substance. The electrode has high electrochemical lithium storage reversible capacity and cyclic stabilization performance, and can be widely applied to new generation lithium ion batteries.

Owner:ZHEJIANG UNIV

Silicon-carbon composite anode material, preparation method thereof and lithium ion battery

InactiveCN104103807ANot prone to the problem of electrochemical agglomerationReduce the effects of volume expansionMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

An embodiment of the invention provides a silicon-carbon composite anode material which includes a shell and an active and conductive material which is accommodated in the shell. The active and conductive material includes a silicon nano-material, a graphite material and carbon nano-tubes, wherein the silicon nano-material, the graphite material and the carbon nano-tubes are blended according to a weight ratio of 10-30:15-35:1-5. The shell is a cracked carbon layer. The silicon nano-material is silicon nano-sheets or silicon nano-belts with a length-width size being 50-5000 nm and a thickness being 10-500 nm. Surfaces of the silicon nano-sheets or silicon nano-belts are provided with Si-N-Si composite layers and Si-N-C composite layer. The silicon-carbon composite anode material is high in reversible capacity, is high in first-time charging-discharging efficiency, is good in circulating performance, can finally increasing a system capacity of a lithium ion battery and prolongs a cyclic service life of the lithium ion battery. The embodiment of the invention also provides a preparation method of the silicon-carbon composite anode material and the lithium ion battery containing the silicon-carbon composite anode material.

Owner:HUAWEI TECH CO LTD

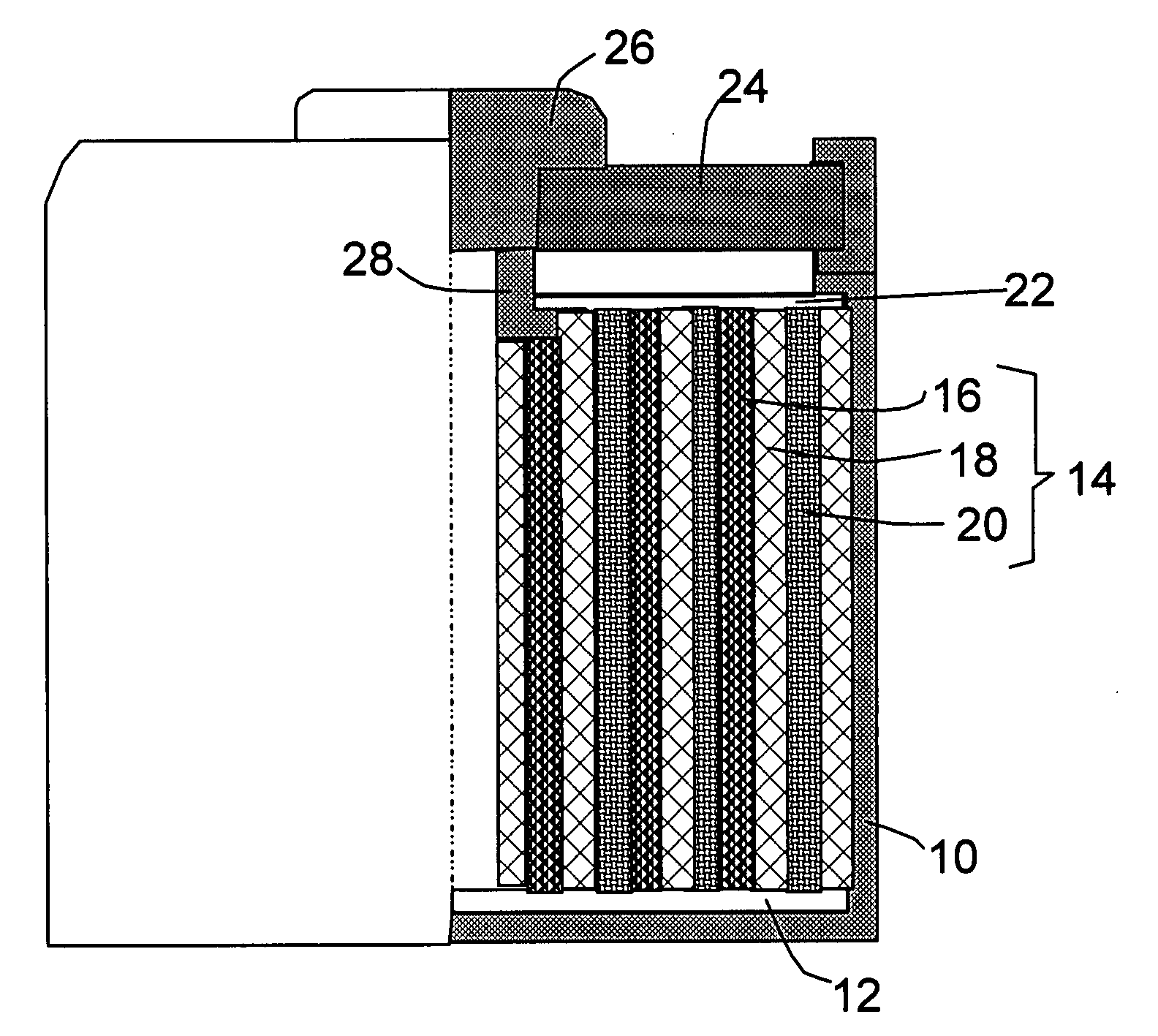

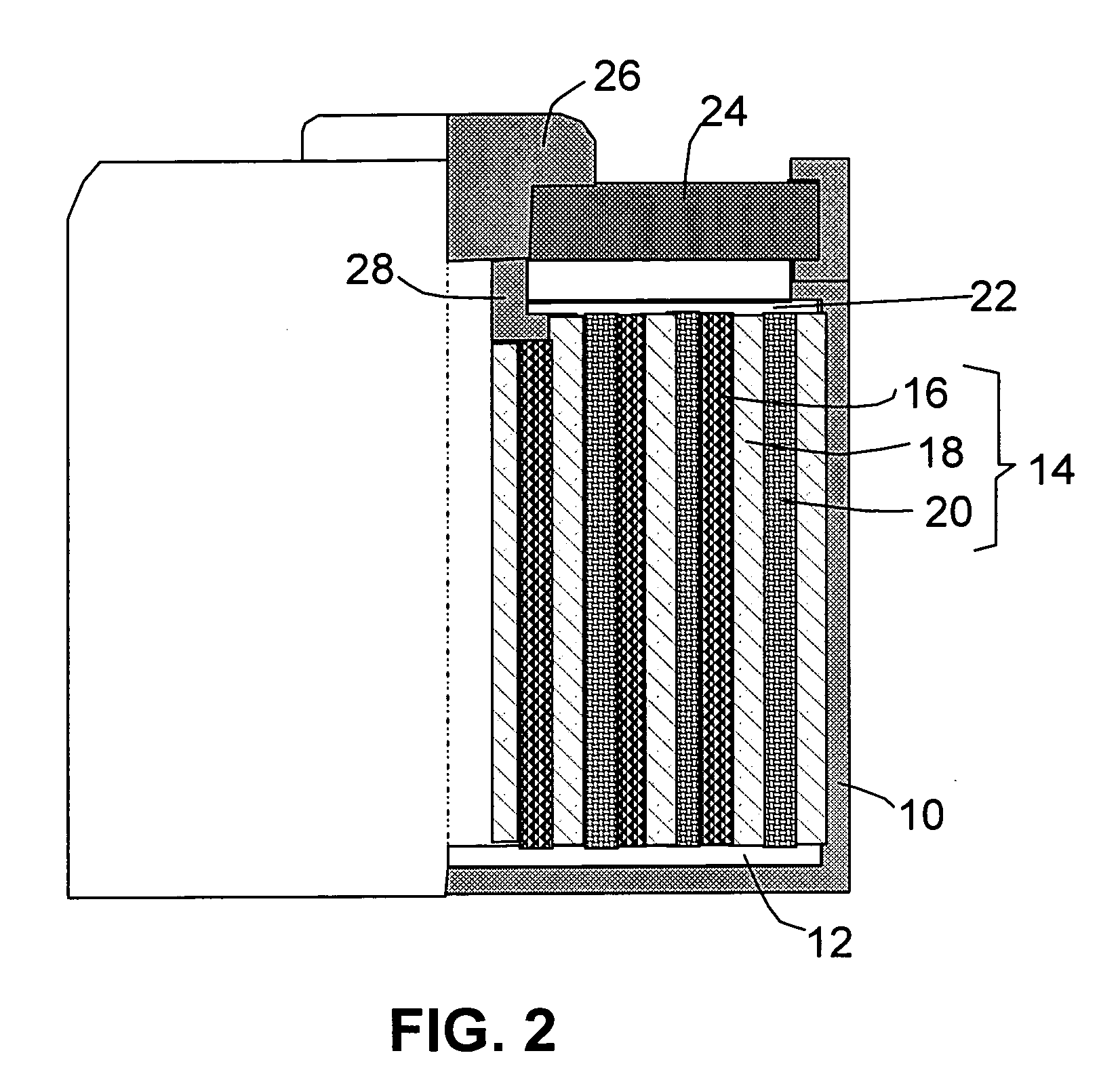

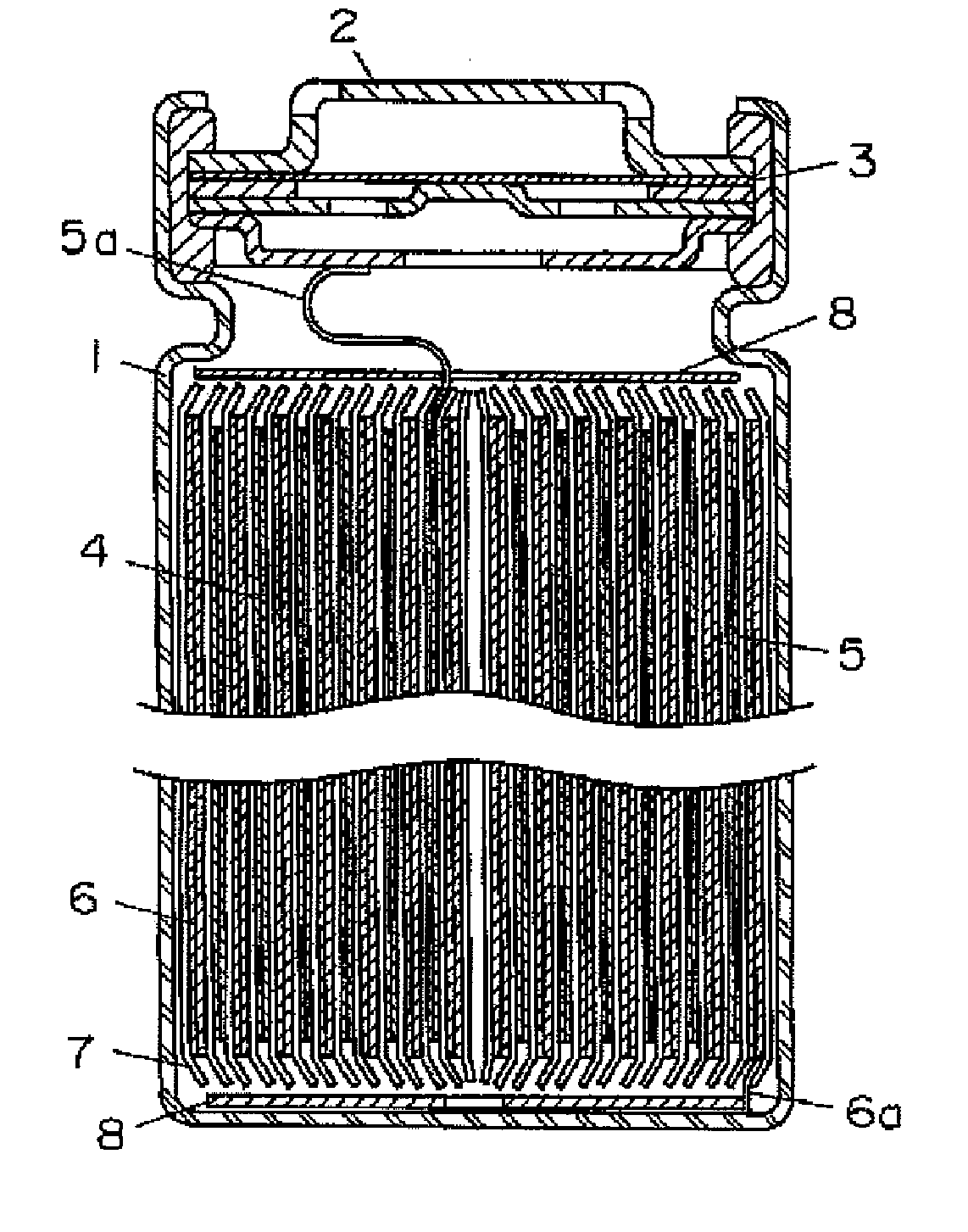

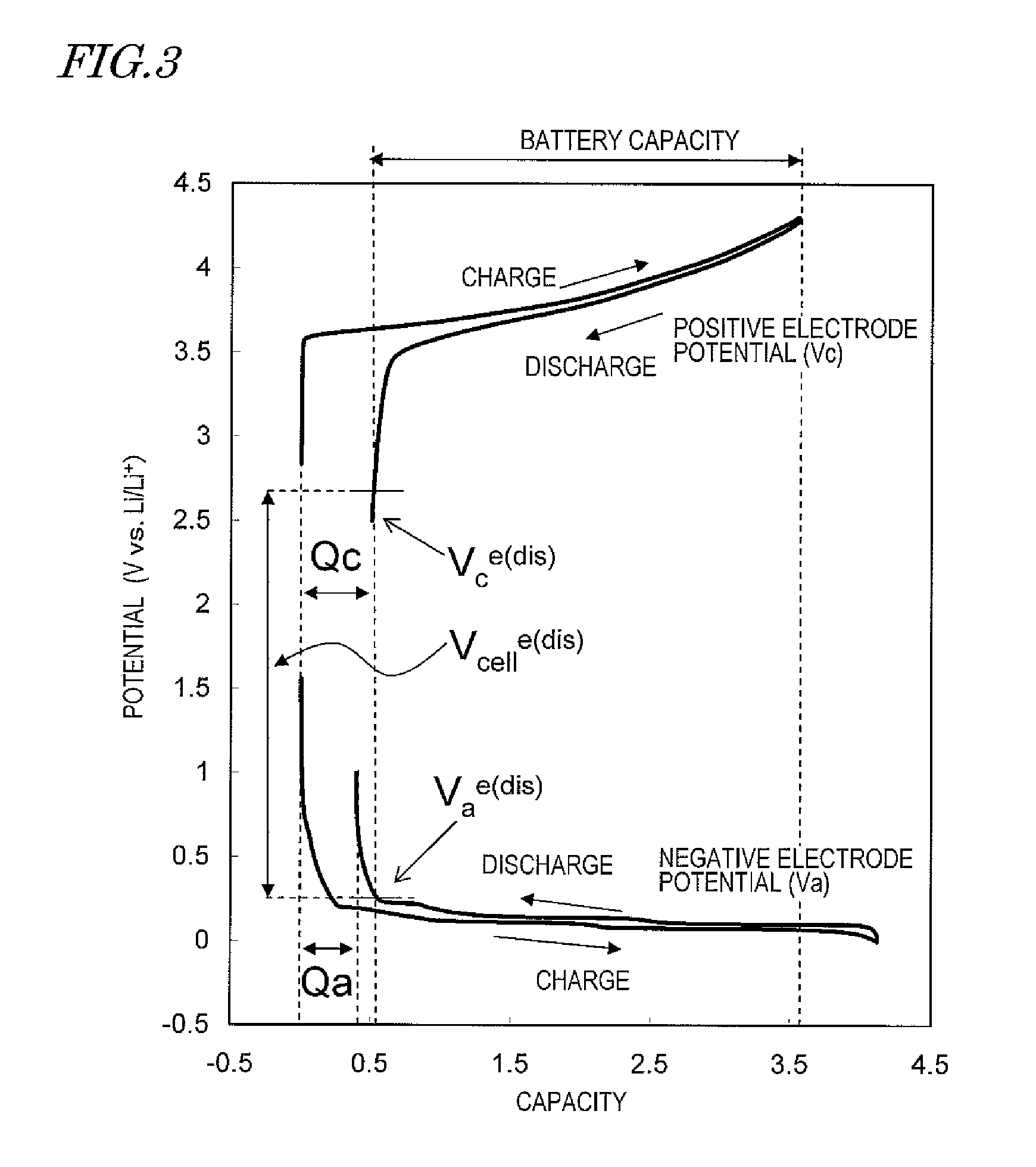

Lithium secondary battery

ActiveUS20120208087A1Reduce capacityImprove featuresElectrode carriers/collectorsSecondary cellsCharge dischargeGraphite

A lithium secondary battery according to the present invention includes: a positive electrode having a positive-electrode active material capable of occluding and releasing lithium ions; a negative electrode having a negative-electrode active material capable of occluding and releasing lithium ions; a separator interposed between the positive electrode and the negative electrode; and an electrolyte having lithium-ion conductivity. The positive-electrode active material contains a nickel-type lithium-containing complex oxide. The negative-electrode active material contains a graphite-type material having a reversible capacity of 350 mAh / g or more and an irreversible capacity of 30 mAh / g or less. A ratio Qc / Qa between an irreversible capacity Qc per unit area in a portion of the positive electrode that opposes the negative electrode and an irreversible capacity Qa per unit area in a portion of the negative electrode that opposes the positive electrode is equal to or greater than 0.50 but less than 1.13. As a result, the charge-discharge cycle characteristics can be improved while ensuring a high capacity.

Owner:PANASONIC CORP

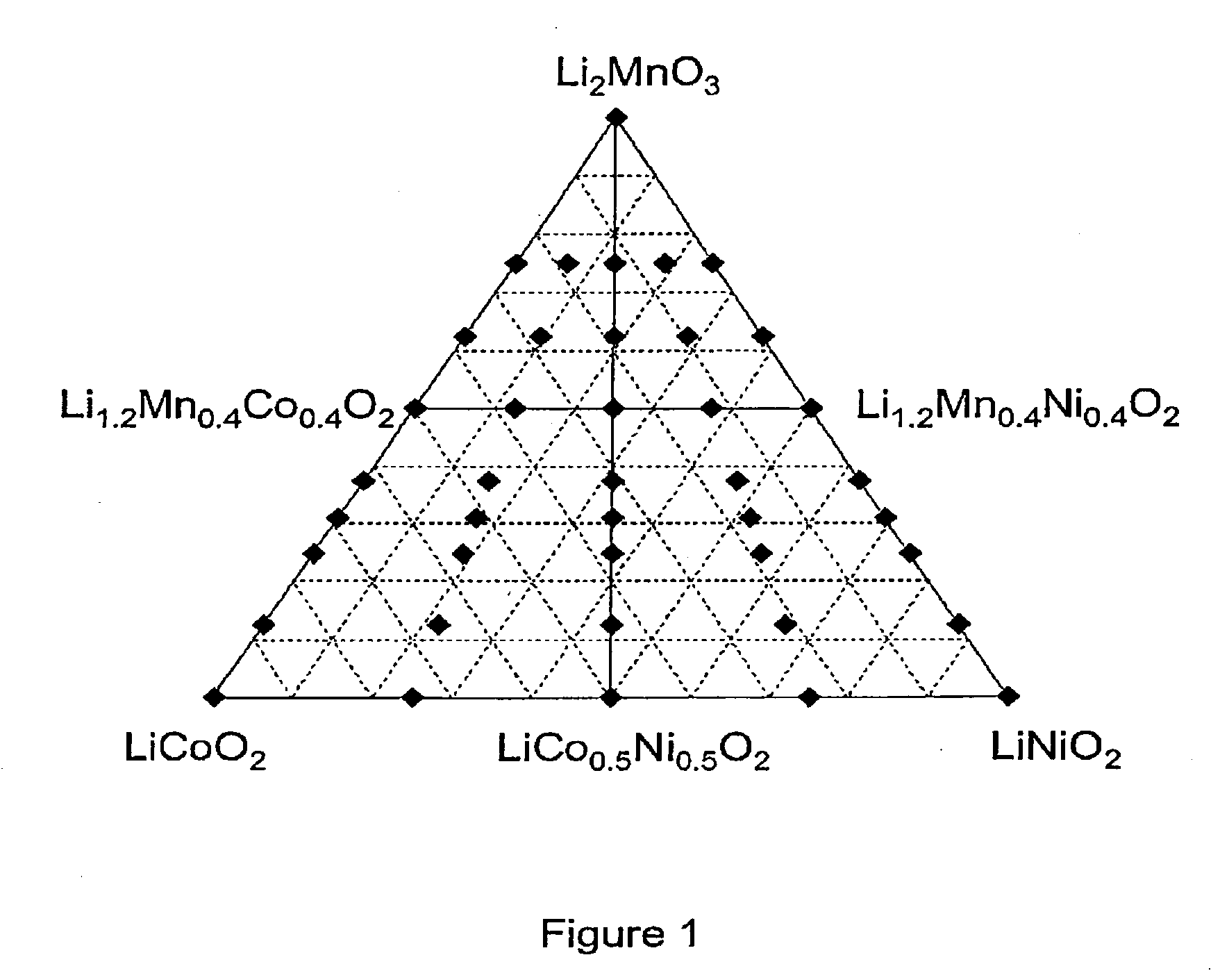

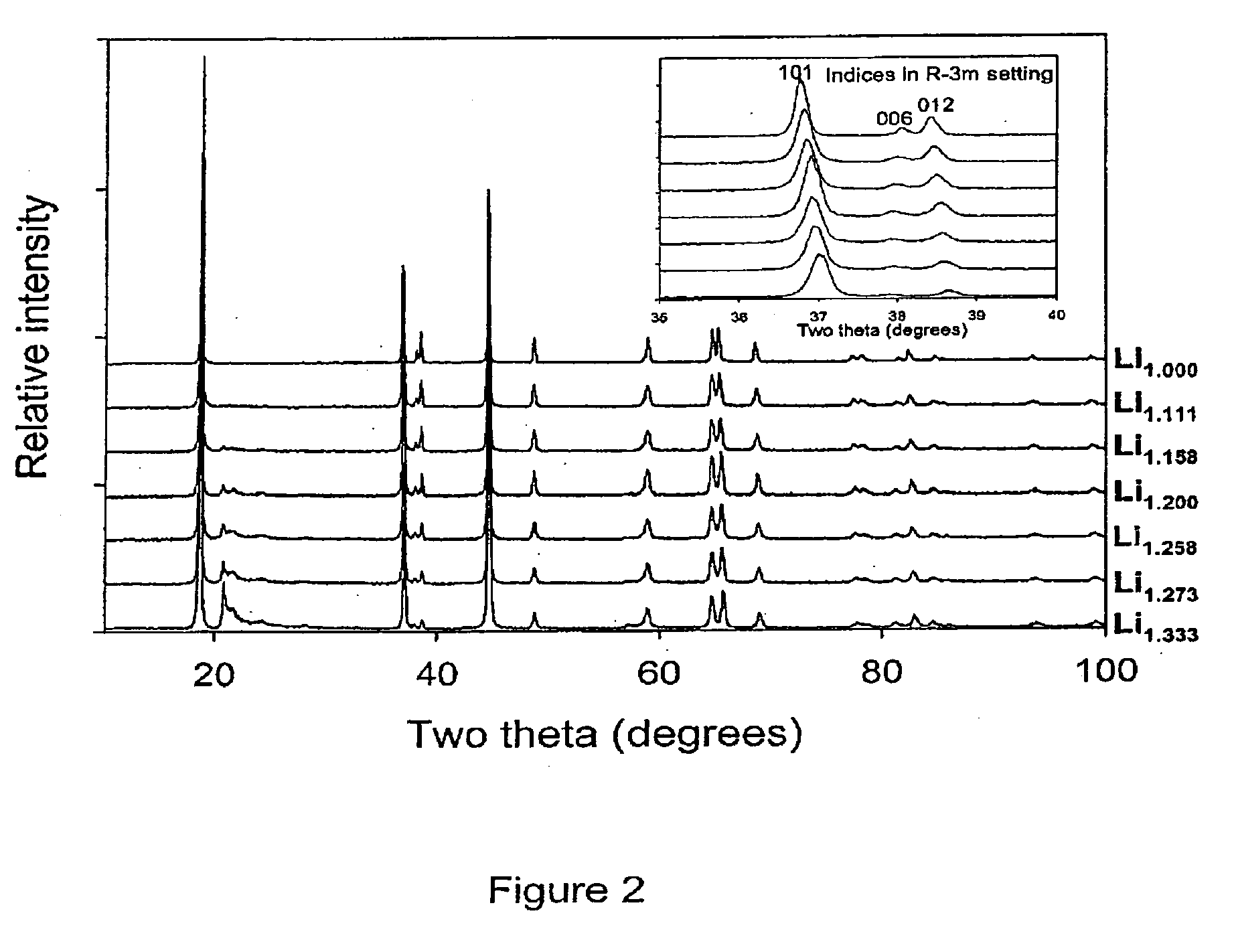

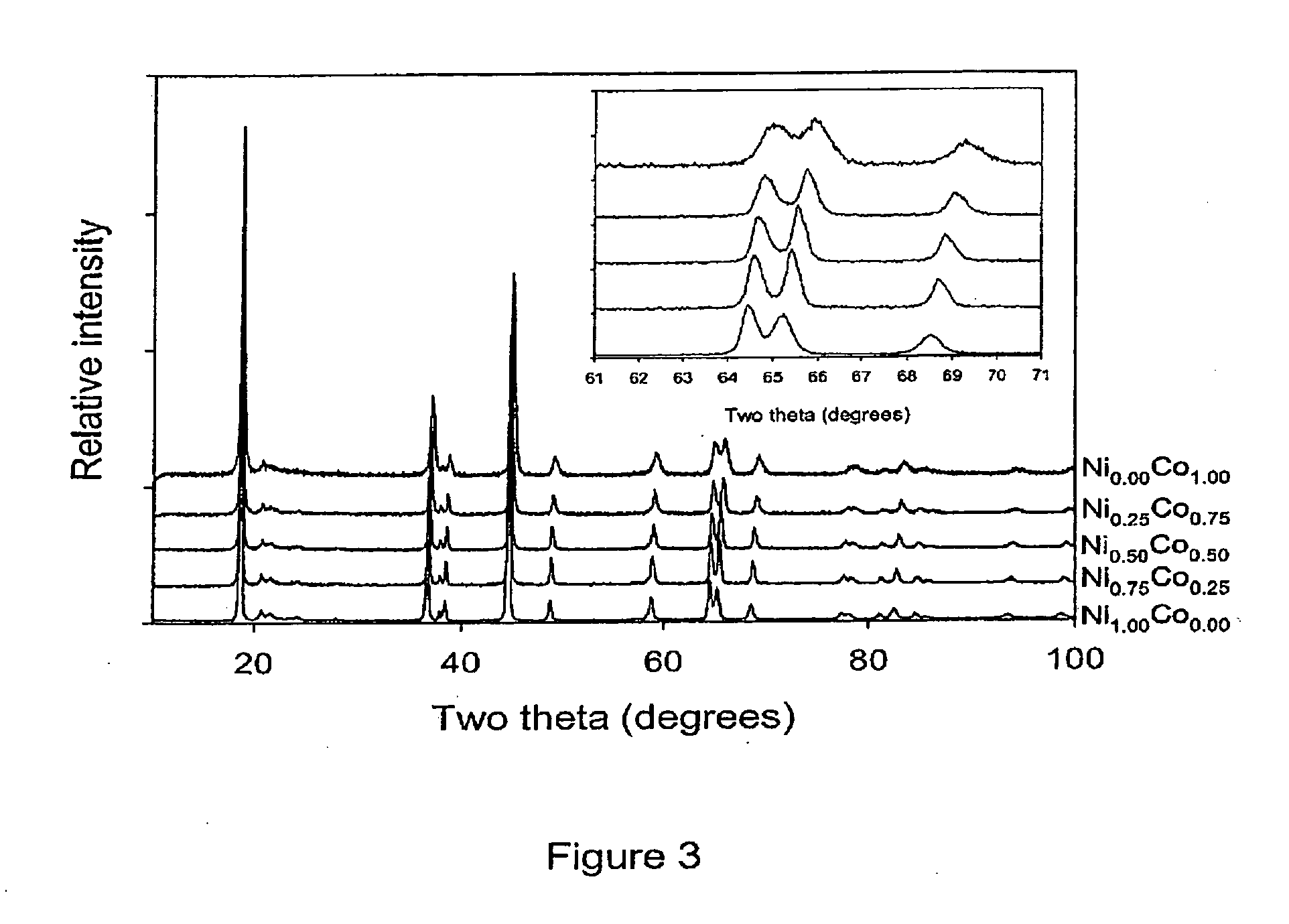

Lithium metal oxide compositions

InactiveUS20090127520A1Large reversible capacityLarge capacityCell electrodesConductive materialLithium metalManganese

The invention disclosed is a composition of a single-phase solid solution of LiMnO2 and LiMO3 having a Li2MnO3-type crystallographic structure and the general formula Lii+y / 3Mn2y / 3M(1−y)O2, wherein 0<y<1, manganese is in the 4+ oxidation state, M is one or more transition metal or other cations which have an appropriate ionic radii to be inserted into the structure without unduly disrupting it, but not solely Ni or Cr, e.g. one or more the first row transition metals: Ti, V, Cr, Mn, Fe, Co, Ni or Cu, or other specific other cations: Al, Mg, Mo, W, Ta, Si, Sn, Zr, Be, Ca, Ga, and P, and M has an average oxidation state of +3. Also disclosed are compositions and structures of the materials e.g in the form of a positive electrode for a non-aqueous lithium cell or battery.

Owner:WHITFIELD PAMELA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com