Cathode of lithium ion secondary battery and lithium ion secondary battery including the same

A secondary battery and lithium-ion technology, applied in secondary batteries, battery electrodes, active material electrodes, etc., to achieve superior battery performance, high battery capacity, and high reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

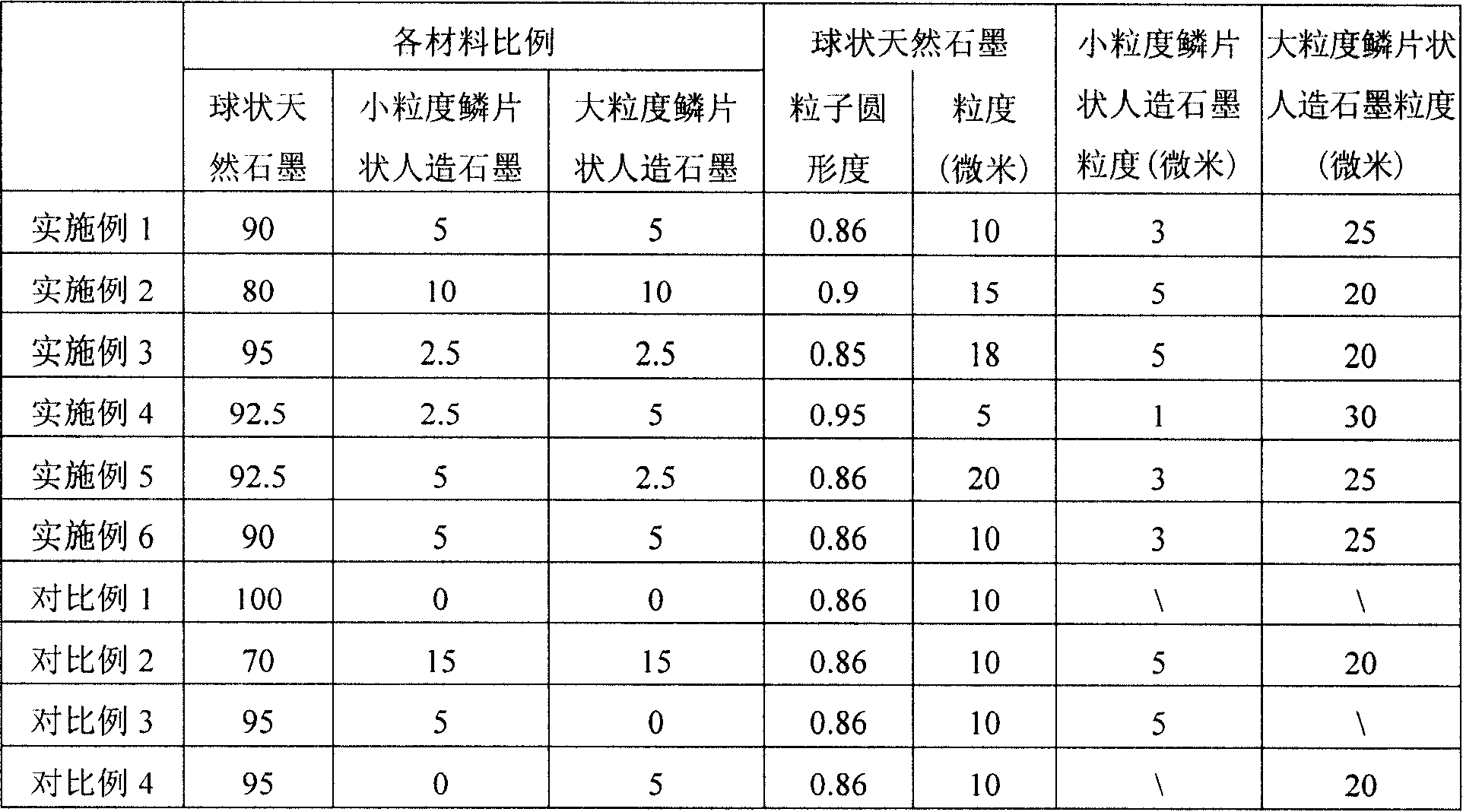

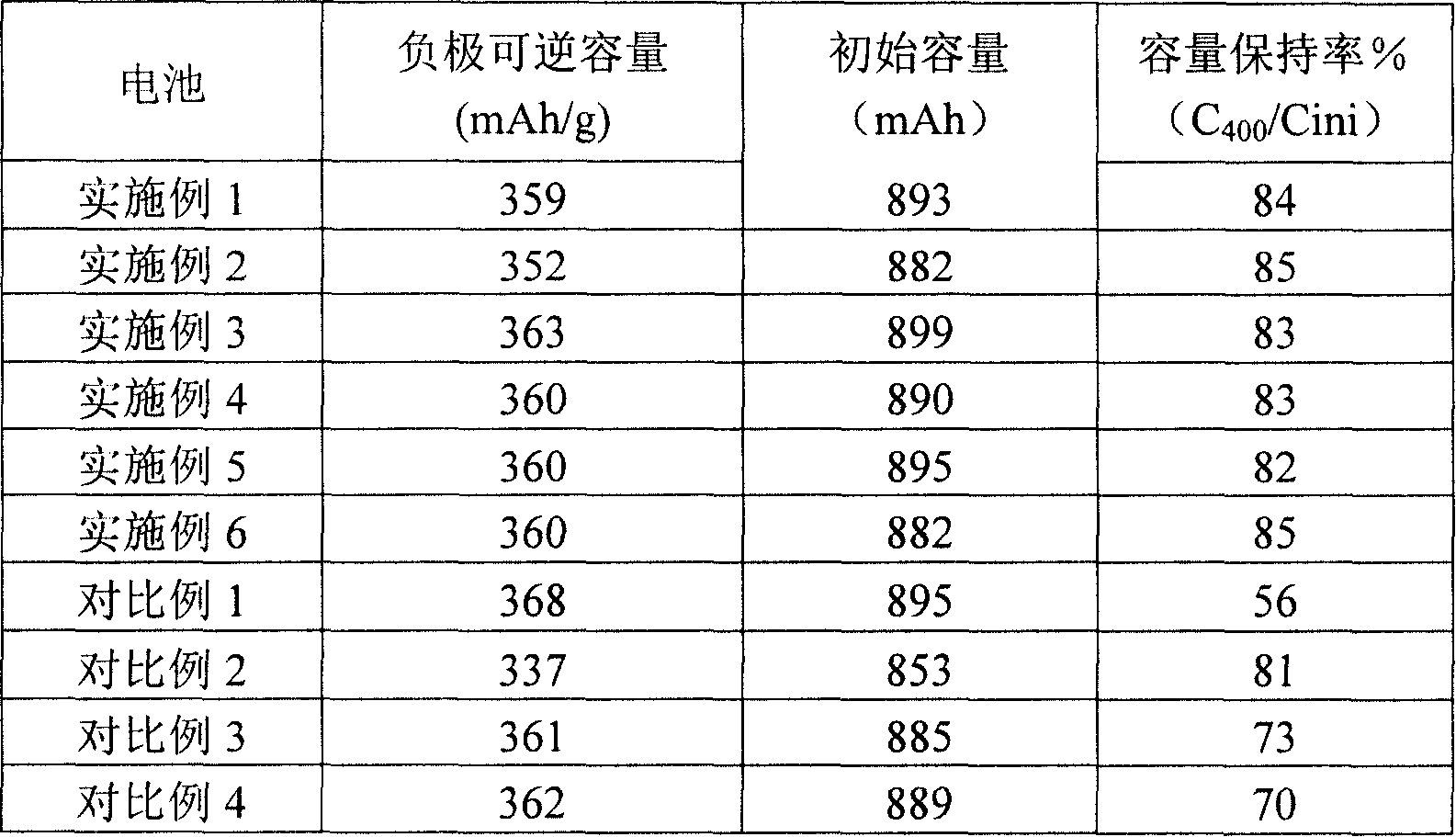

Embodiment 1

[0038] Preparation of spherical natural graphite: 200 grams of flaky natural graphite (graphite powder produced in Qingdao, China) was dissolved in 20 grams of pitch tar, dried at 200 ° C, granulated by mechanical dispersion, and then roasted at a temperature of 1200 ° C for 5 hour, cooling, to obtain spherical natural graphite A, its average particle diameter recorded is 10 microns, and the BET specific surface area is 2.6 meters 2 / g, the particle circularity is 0.86. Interplanar spacing d of (002) plane measured by X-ray diffraction method 002 at 3.357 Angstroms.

[0039] The preparation of negative electrode active material: the spherical natural graphite A of above-mentioned preparation, small particle size flaky artificial graphite (commercially available commodity, brand name is KS6, and its average particle diameter is 3 microns, and BET specific surface area is 6.3 meters 2 / g, the plane spacing d of the 002 plane measured by powder X-ray diffractometry 002 3.3369 ...

Embodiment 2

[0045] Prepare spherical natural graphite according to the same method as embodiment 1, make the average particle diameter D of gained spherical natural graphite by screening 50 15 microns, BET specific surface area is 5 meters 2 / g, the particle circularity is 0.90.

[0046] The preparation of negative electrode active material: the spherical natural graphite of above-mentioned preparation, small particle size scaly artificial graphite (average particle diameter is 5 microns, BET specific surface area is 2.82 meters 2 / g, the plane spacing d of the 002 plane measured by powder X-ray diffractometry 0020.3365 angstroms), large-scale flaky artificial graphite (average particle size is 25 microns, BET specific surface area is 3 meters 2 / g, the plane spacing d of the 002 plane measured by powder X-ray diffractometry 002 0.3367 angstroms) in a weight ratio of 80:10:10 by means of ball mill mixing, thoroughly mixed and then vacuum-dried at 200° C., and the resulting mixed graphi...

Embodiment 3

[0051] Preparation of negative electrode active material: spherical natural graphite (GP802, Hitachi powder metallurgy commodity, average particle size 18 microns, specific surface 2.6 meters 2 / g, the particle circularity is 0.85, and the plane spacing d of the 002 plane measured by powder X-ray diffraction method 002 0.3359 angstroms), small particle size flaky artificial graphite (GP-895F, Hitachi powder metallurgy commodity, its average particle size is 5 microns, and the BET specific surface area is 6 meters 2 / g, the plane spacing d of the 002 plane measured by powder X-ray diffractometry 002 0.3369 angstroms), large-grained flaky artificial graphite (GP-895G, Hitachi powder metallurgy commodity, average particle size is 20 microns, BET specific surface area is 6 meters 2 / g, the plane spacing d of the 002 plane measured by powder X-ray diffractometry 002 0.3368 angstrom) in a ratio of 95:2.5:2.5 by ball milling, thoroughly mixed uniformly, and then vacuum-dried at 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com