Patents

Literature

1031results about How to "Reduce variance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation shield

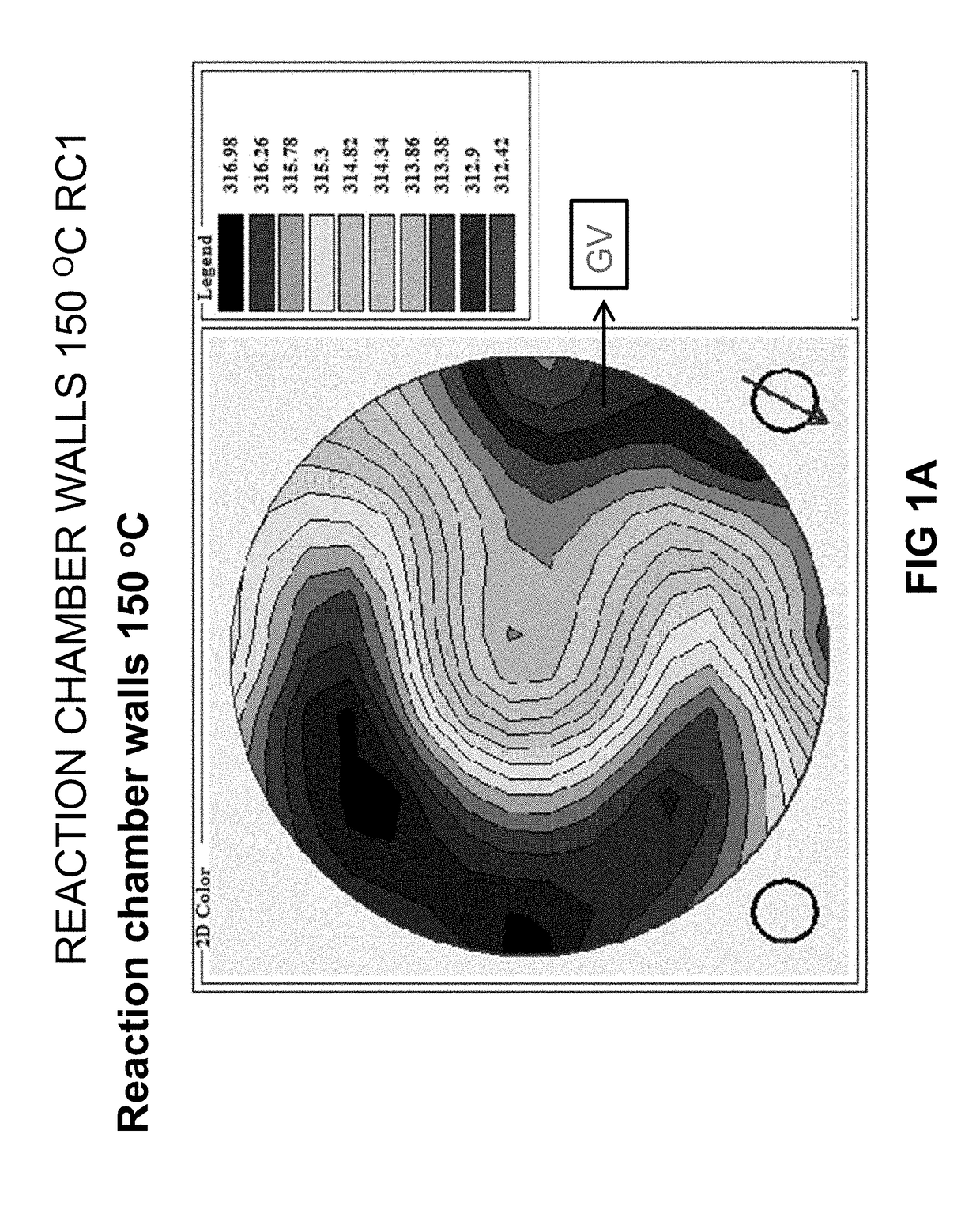

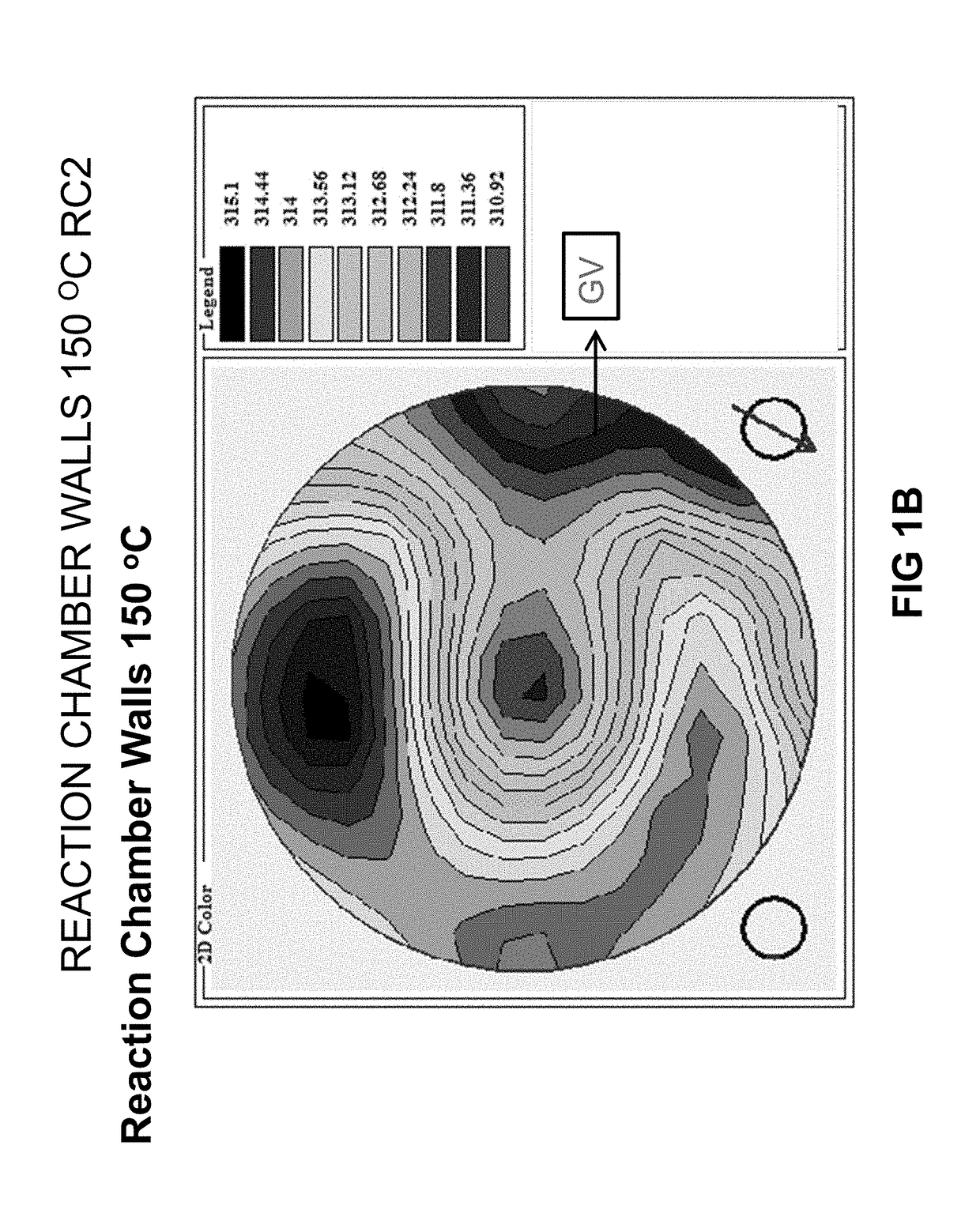

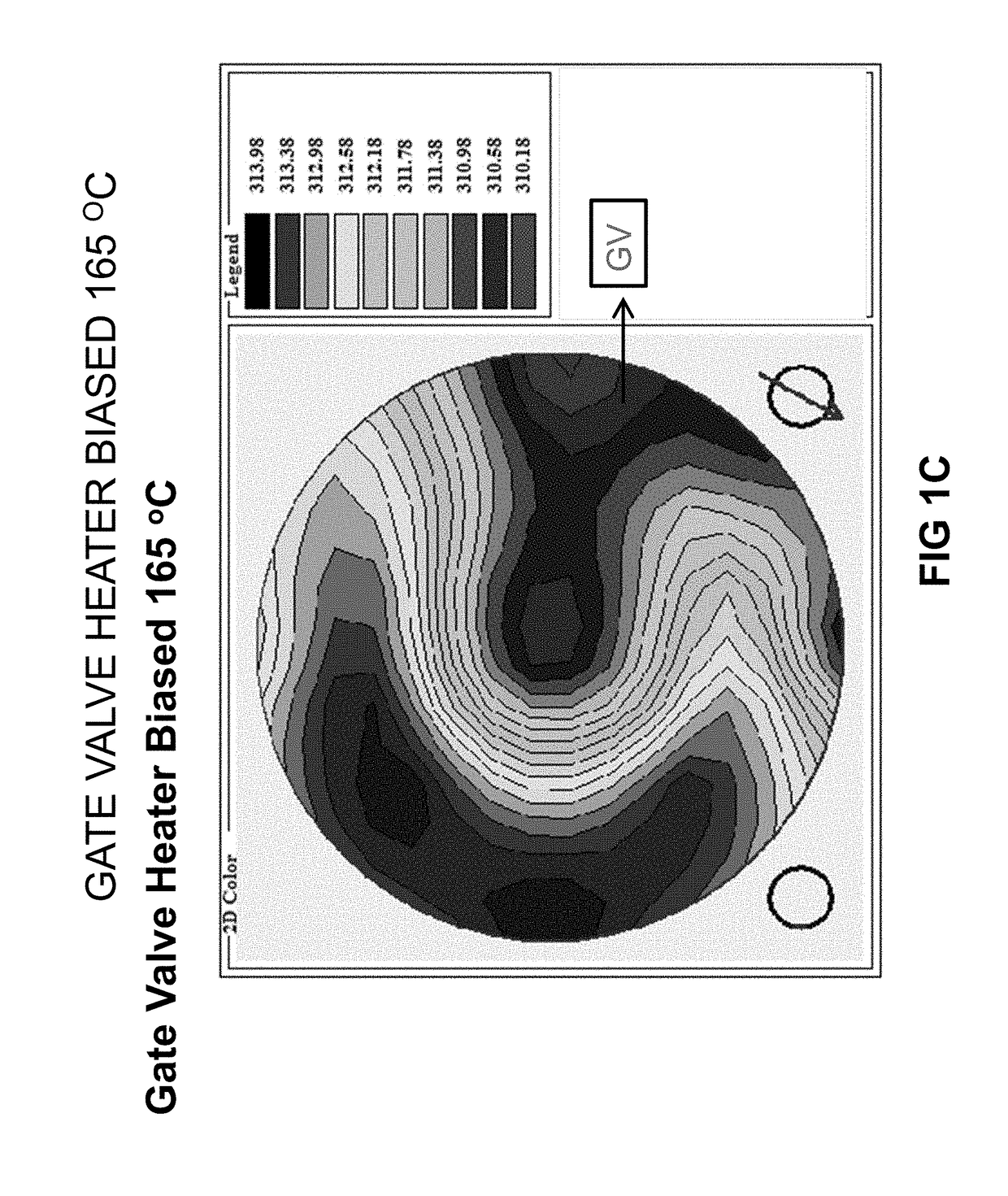

ActiveUS20190051544A1Reduce heat fluxQuality improvementGaseous chemical processesElectric discharge tubesSusceptorHeat flux

A radiation shield and an assembly and a reactor including the radiation shield are disclosed. The radiation shield can be used to control heat flux from a susceptor heater assembly and thereby enable better control of temperatures across a surface of a substrate placed on a surface of the susceptor heater assembly.

Owner:ASM IP HLDG BV

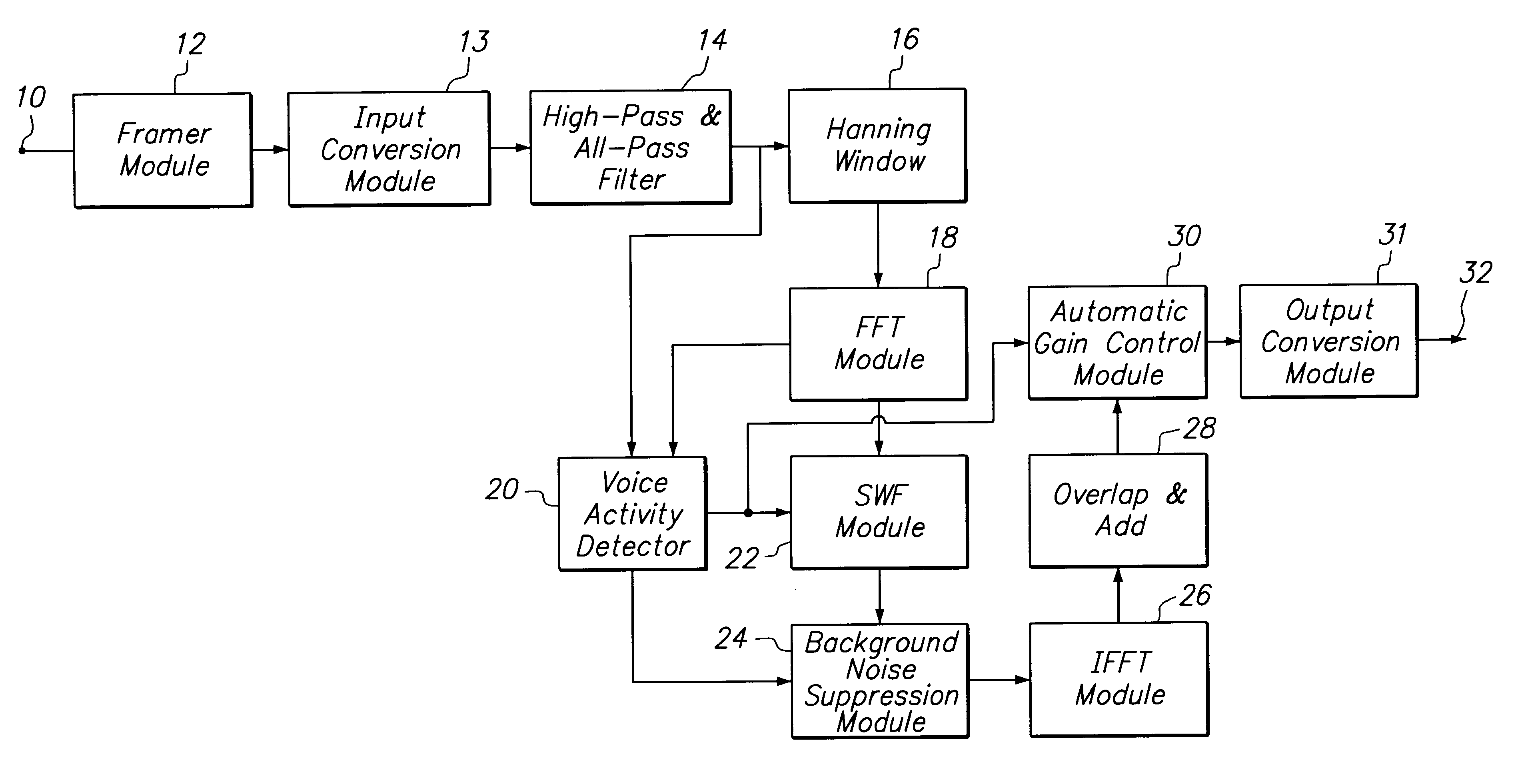

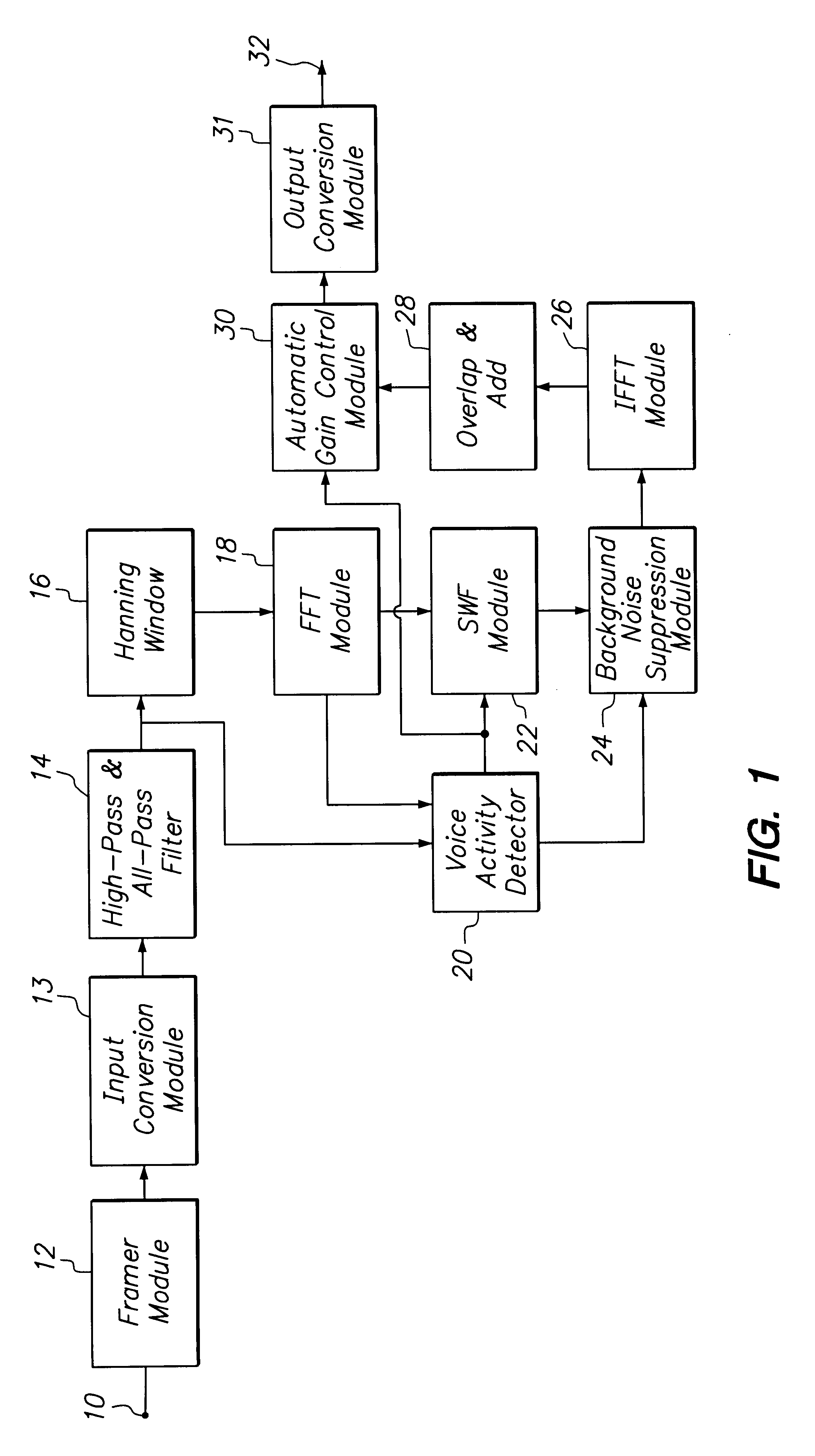

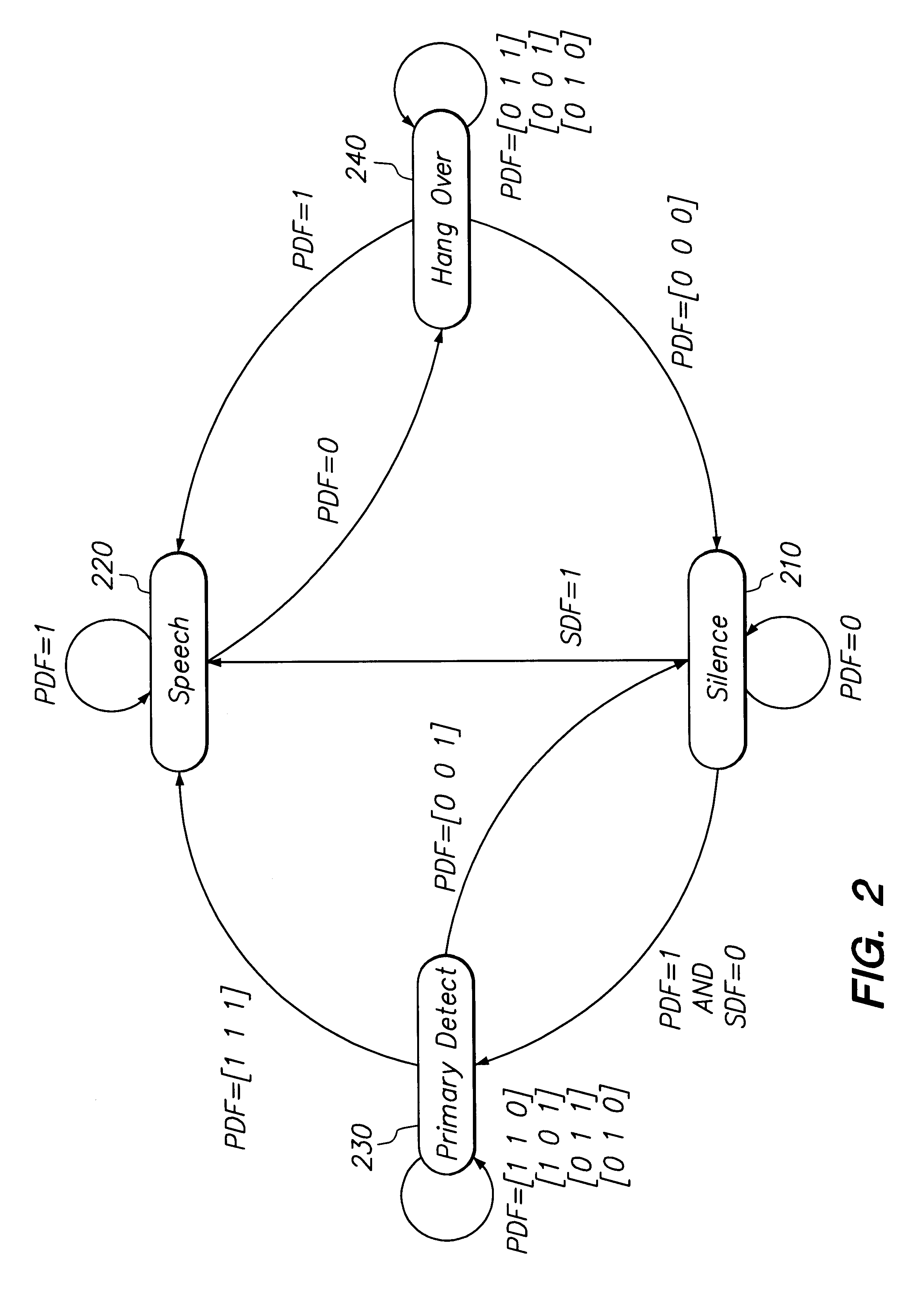

Method and apparatus for enhancing noise-corrupted speech

InactiveUS6415253B1Reduce peakImprove intelligibilitySpeech analysisTransmission noise suppressionTime domainFast Fourier transform

A noise suppression device receives data representative of a noise-corrupted signal which contains a speech signal and a noise signal, divides the received data into data frames, and then passes the data frames through a pre-filter to remove a dc-component and the minimum phase aspect of the noise-corrupted signal. The noise suppression device appends adjacent data frames to eliminate boundary discontinuities, and applies fast Fourier transform to the appended data frames. A voice activity detector of the noise suppression device determines if the noise-corrupted signal contains the speech signal based on components in the time domain and the frequency domain. A smoothed Wiener filter of the noise suppression device filters the data frames in the frequency domain using different sizes of a window based on the existence of the speech signal. Filter coefficients used for Wiener filter are smoothed before filtering. The noise suppression device modifies magnitude of the time domain data based on the voicing information outputted from the voice activity detector.

Owner:META C CORP

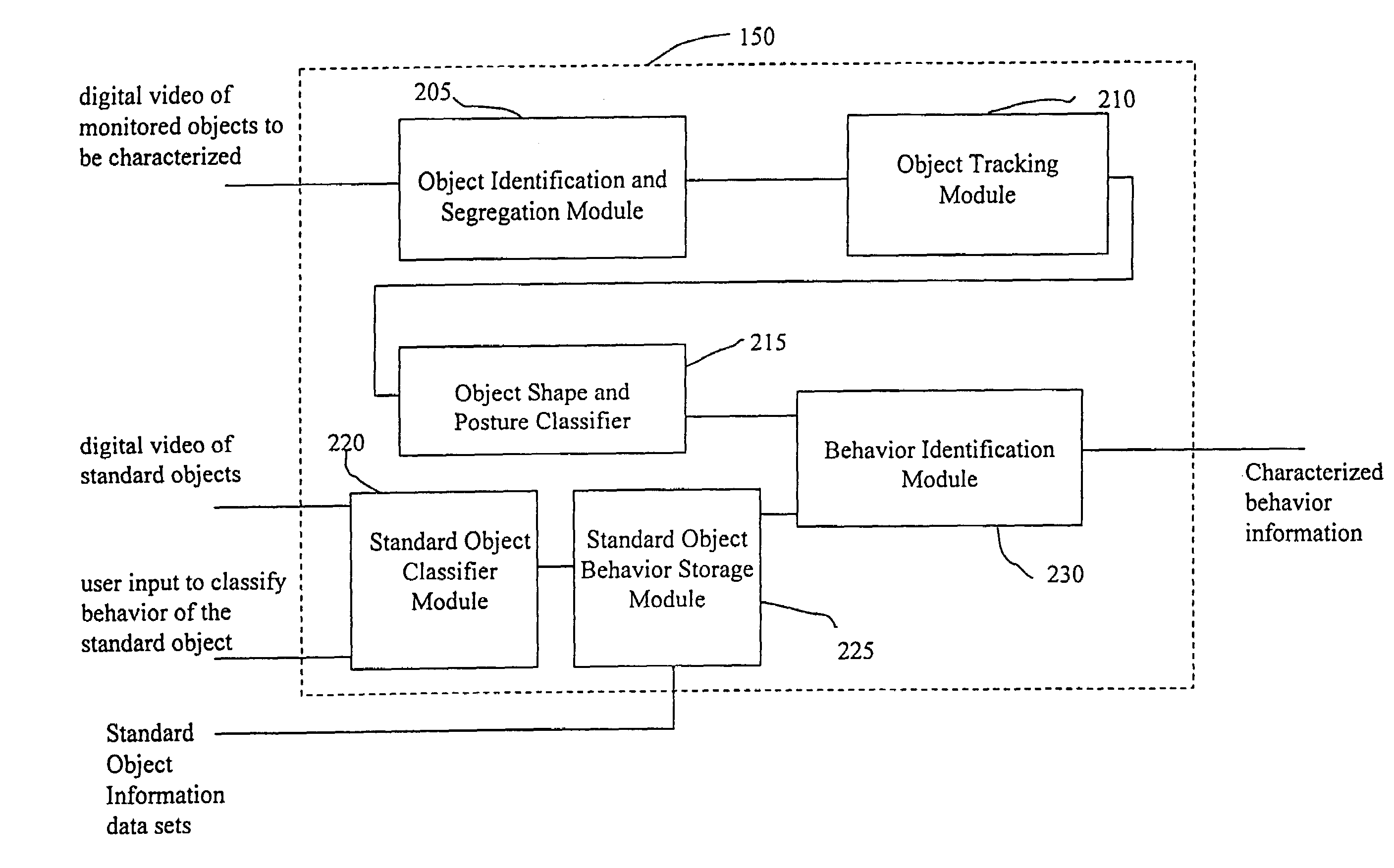

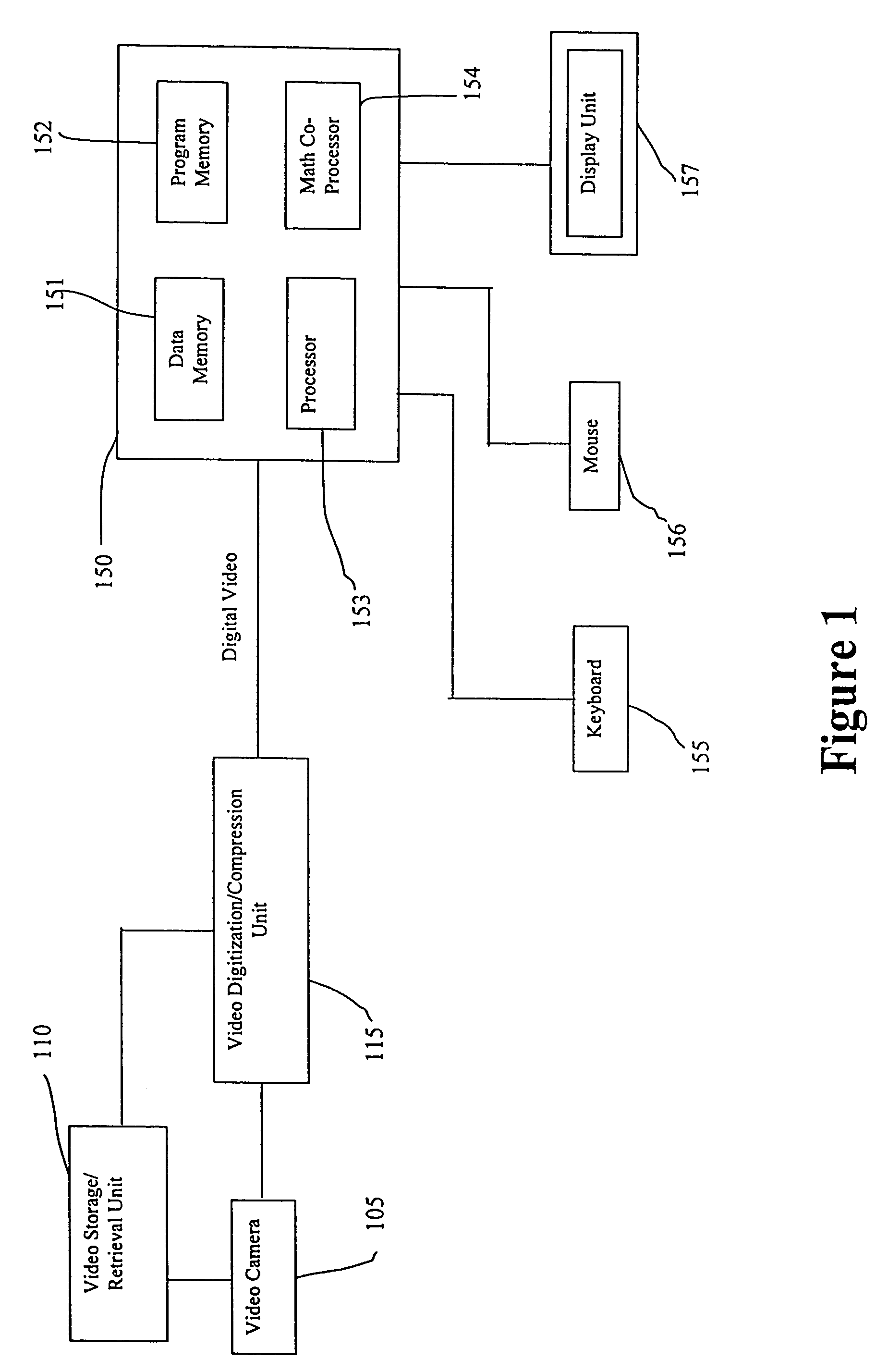

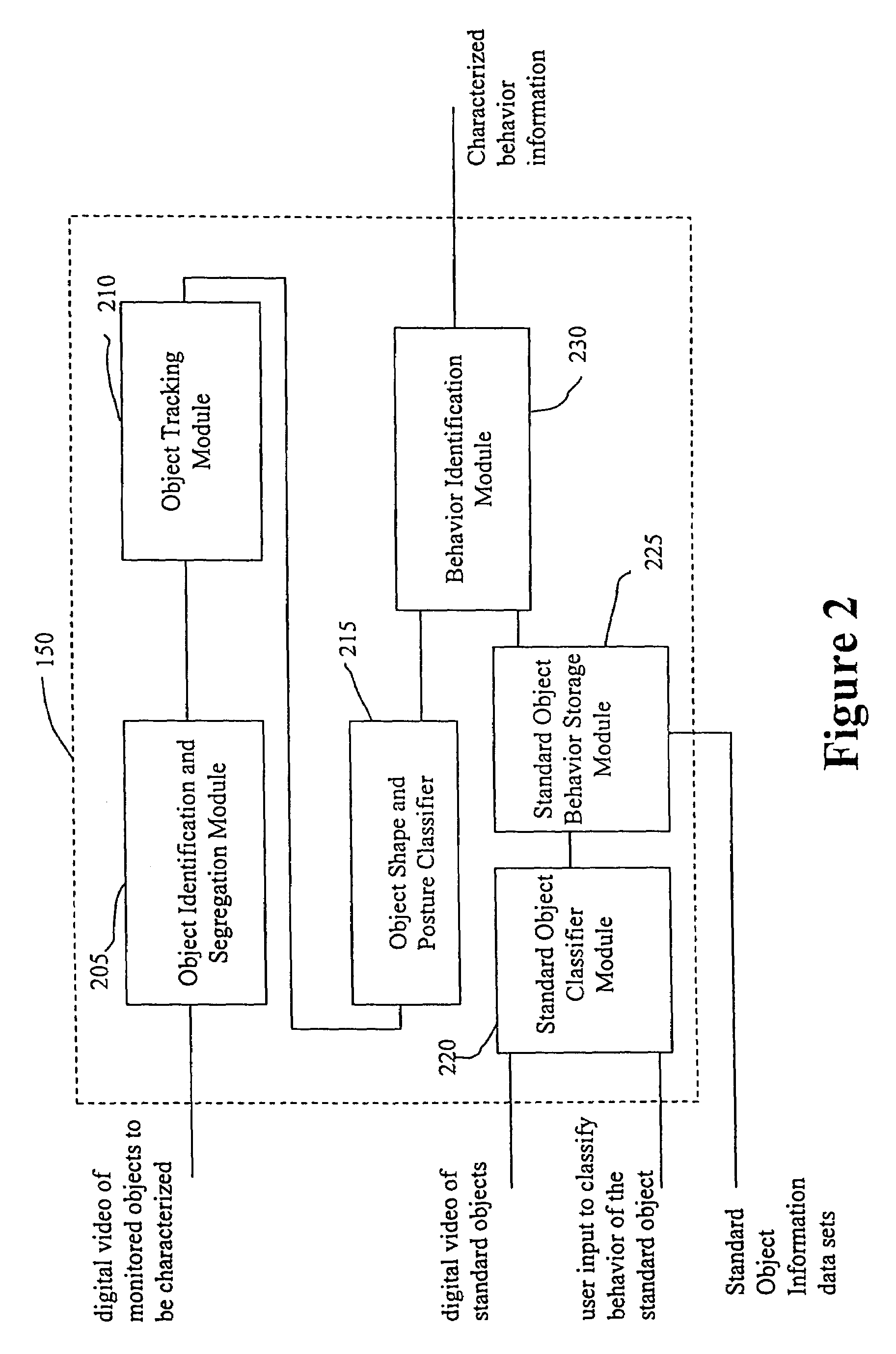

System and method for object identification and behavior characterization using video analysis

InactiveUS7068842B2Accurate identificationEfficient detectionImage enhancementImage analysisProbabilistic methodAnimal behavior

In general, the present invention is directed to systems and methods for finding the position and shape of an object using video. The invention includes a system with a video camera coupled to a computer in which the computer is configured to automatically provide object segmentation and identification, object motion tracking (for moving objects), object position classification, and behavior identification. In a preferred embodiment, the present invention may use background subtraction for object identification and tracking, probabilistic approach with expectation-maximization for tracking the motion detection and object classification, and decision tree classification for behavior identification. Thus, the present invention is capable of automatically monitoring a video image to identify, track and classify the actions of various objects and the object's movements within the image. The image may be provided in real time or from storage. The invention is particularly useful for monitoring and classifying animal behavior for testing drugs and genetic mutations, but may be used in any of a number of other surveillance applications.

Owner:CLEVER SYS

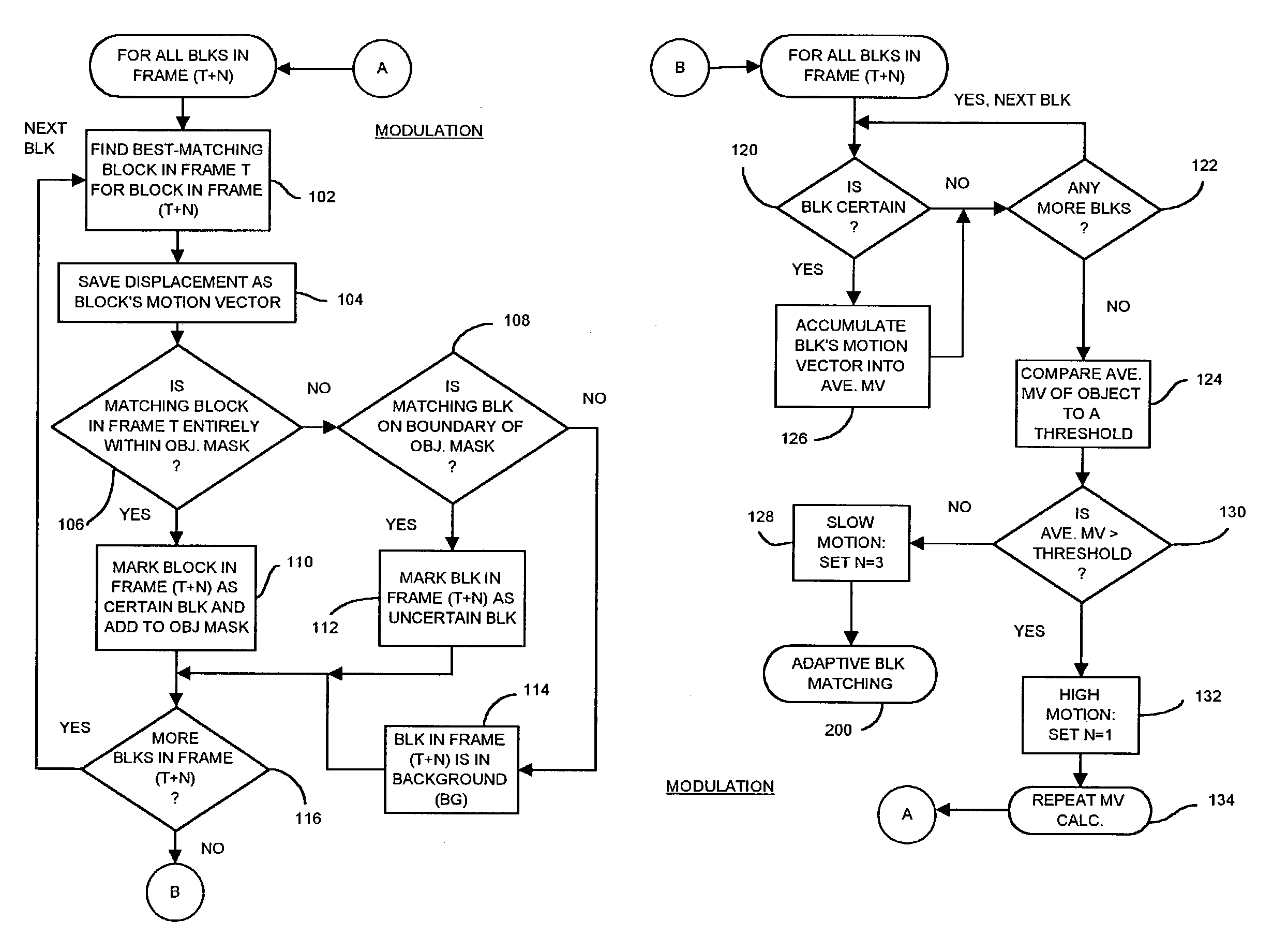

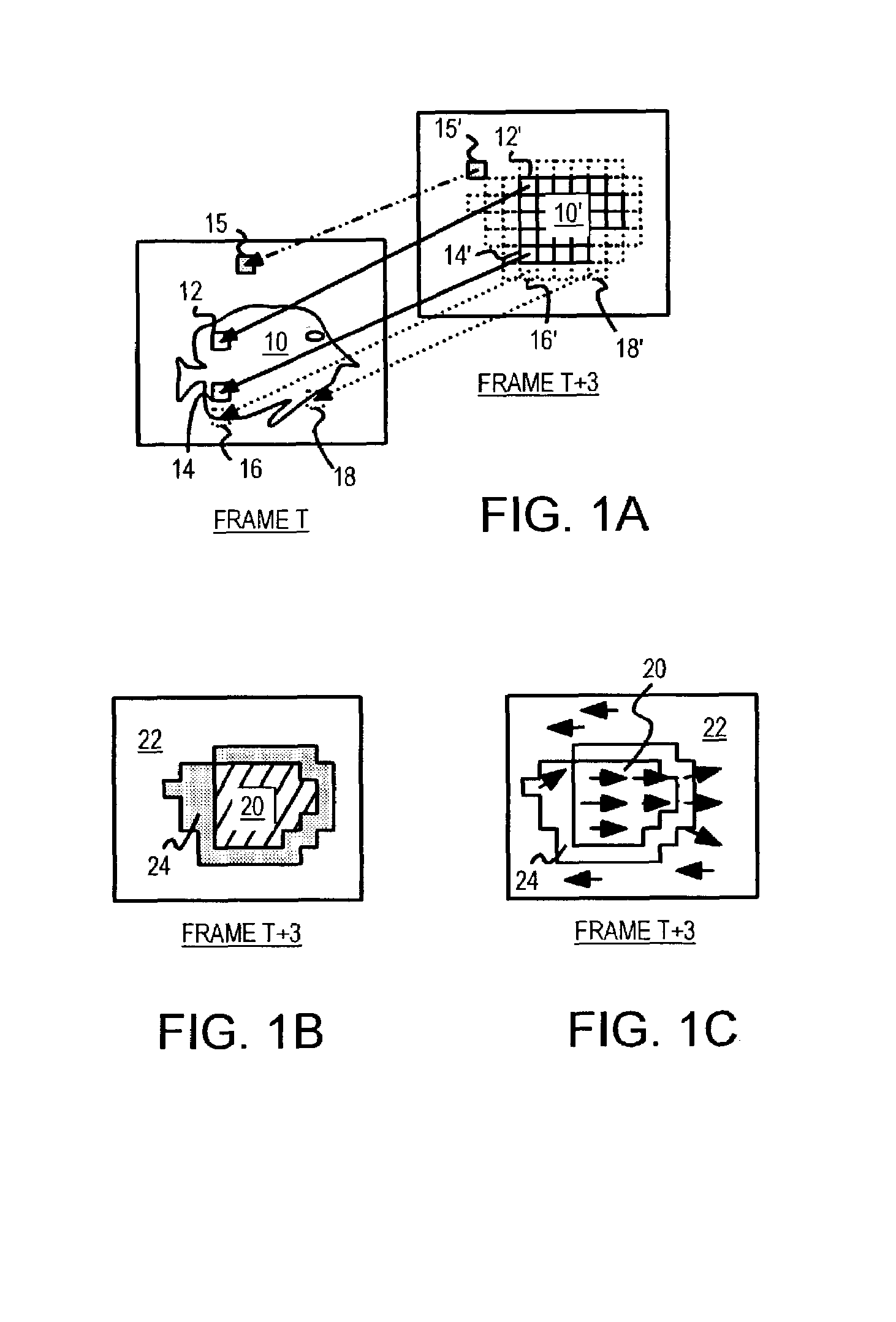

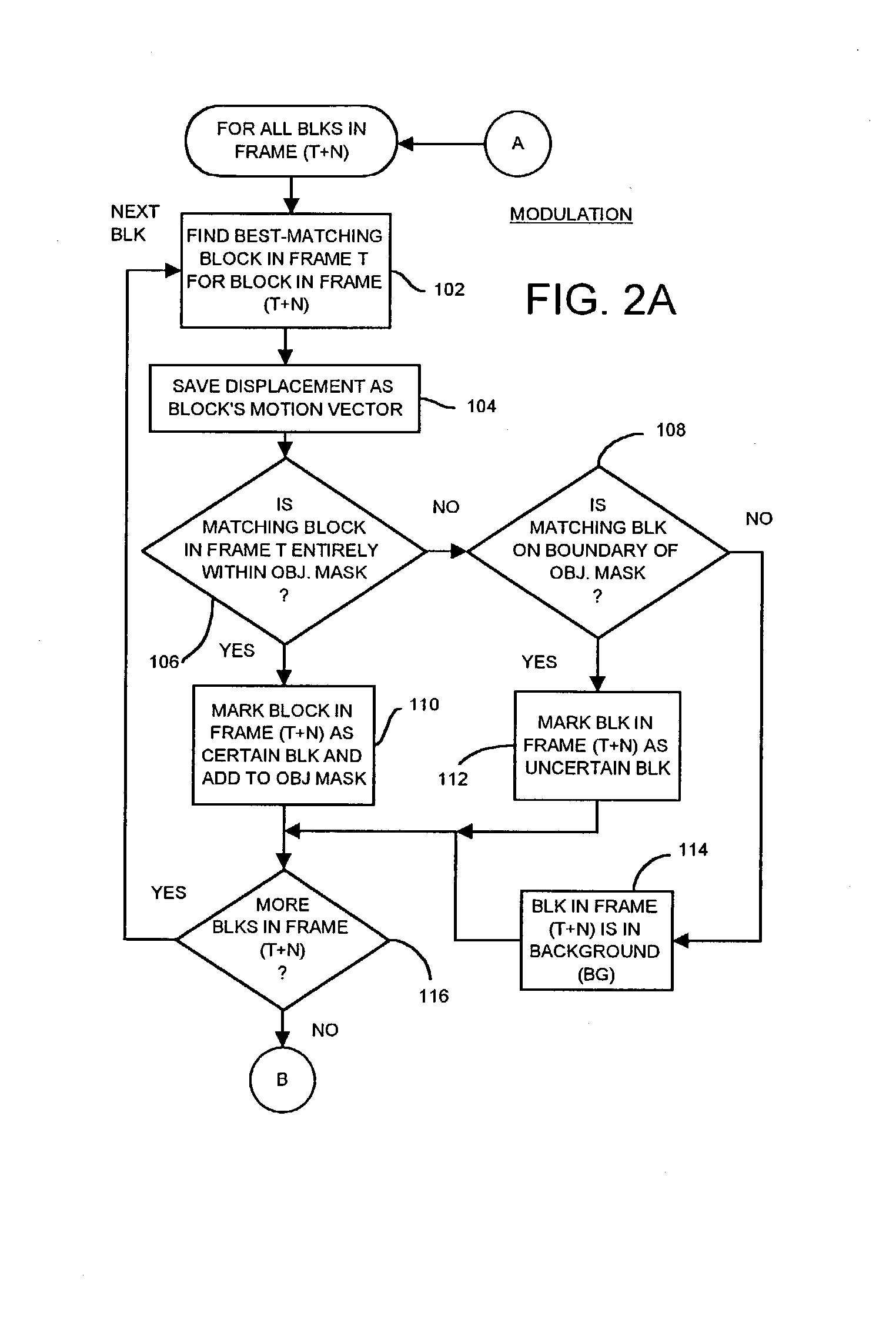

Occlusion/disocclusion detection using K-means clustering near object boundary with comparison of average motion of clusters to object and background motions

ActiveUS7142600B1Reduce varianceAccurate representationColor television with pulse code modulationImage analysisMotion vectorVideo sequence

An object in a video sequence is tracked by object masks generated for frames in the sequence. Macroblocks are motion compensated to predict the new object mask. Large differences between the next frame and the current frame detect suspect regions that may be obscured in the next frame. The motion vectors in the object are clustered using a K-means algorithm. The cluster centroid motion vectors are compared to an average motion vector of each suspect region. When the motion differences are small, the suspect region is considered part of the object and removed from the object mask as an occlusion. Large differences between the prior frame and the current frame detect suspected newly-uncovered regions. The average motion vector of each suspect region is compared to cluster centroid motion vectors. When the motion differences are small, the suspect region is added to the object mask as a disocclusion.

Owner:INTELLECTUAL VENTURES I LLC

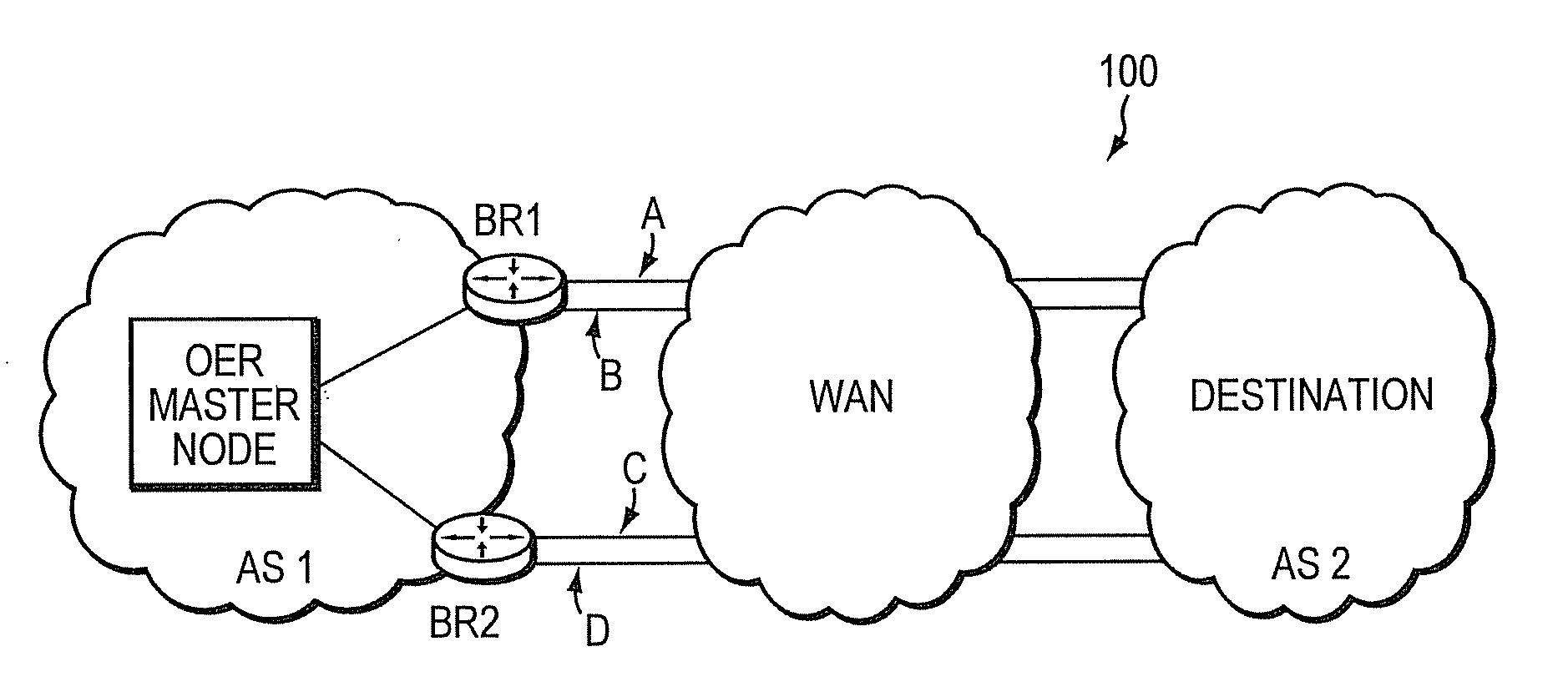

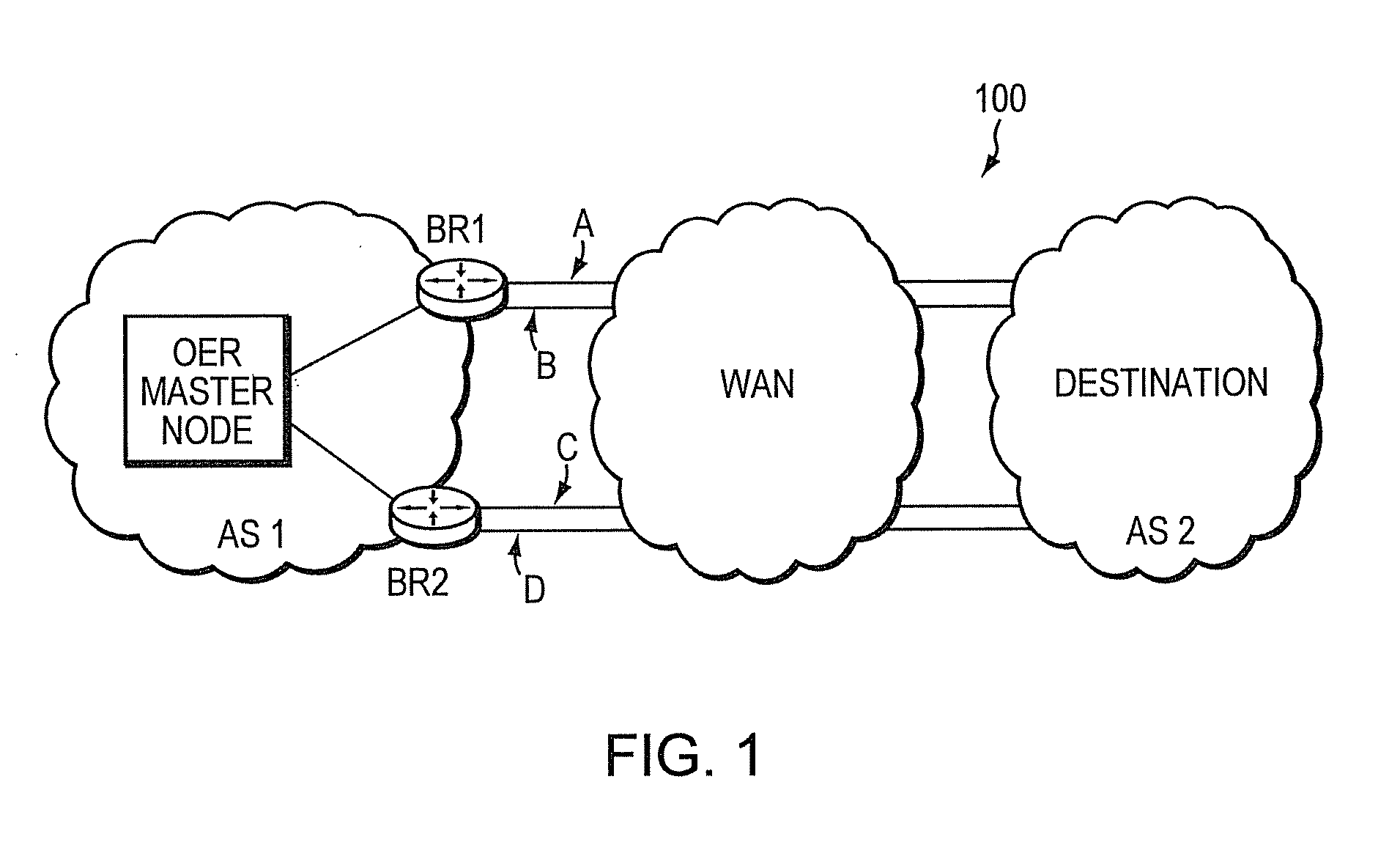

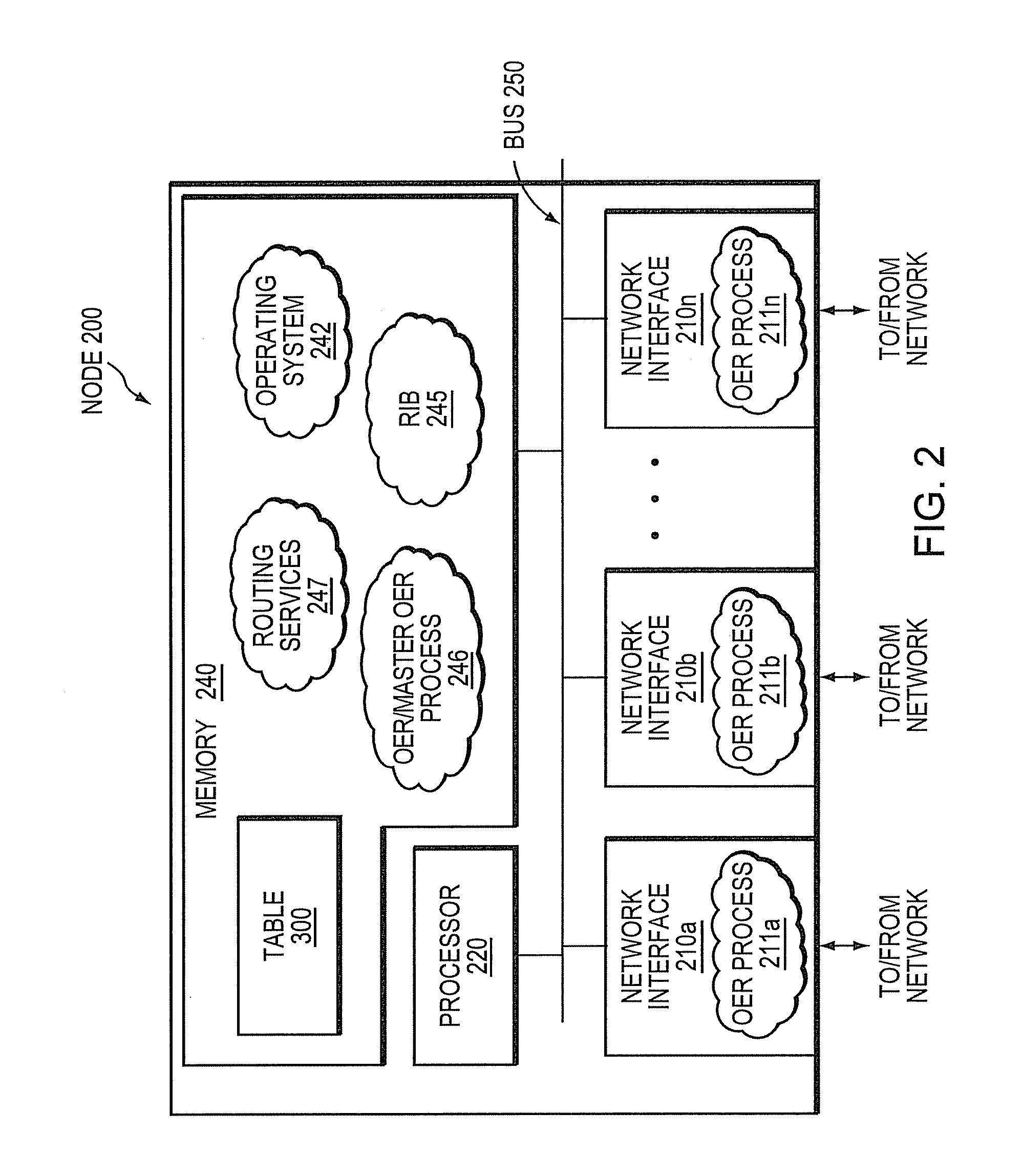

Technique for policy conflict resolution using priority with variance

ActiveUS20100265825A1Reduce varianceError preventionTransmission systemsComputer scienceLower priority

In one embodiment, a value for a option for a particular policy of a plurality of policies that are ranked in a priority order is ascertained. A variance to the value associated with the option for the particular policy is applied to define a range of acceptable values for the particular policy. A determination is made whether one or more other options exist that have values within the range of acceptable values for the particular policy. If no other options exist that have values within the range of acceptable values for the particular policy, the option is selected If other options exist that have values within the range of acceptable values for the particular policy, the ascertaining, applying and determining is repeated for a next lower priority policy of the plurality of policies to consider the other options, the repeating to occur successively until an option is selected.

Owner:CISCO TECH INC

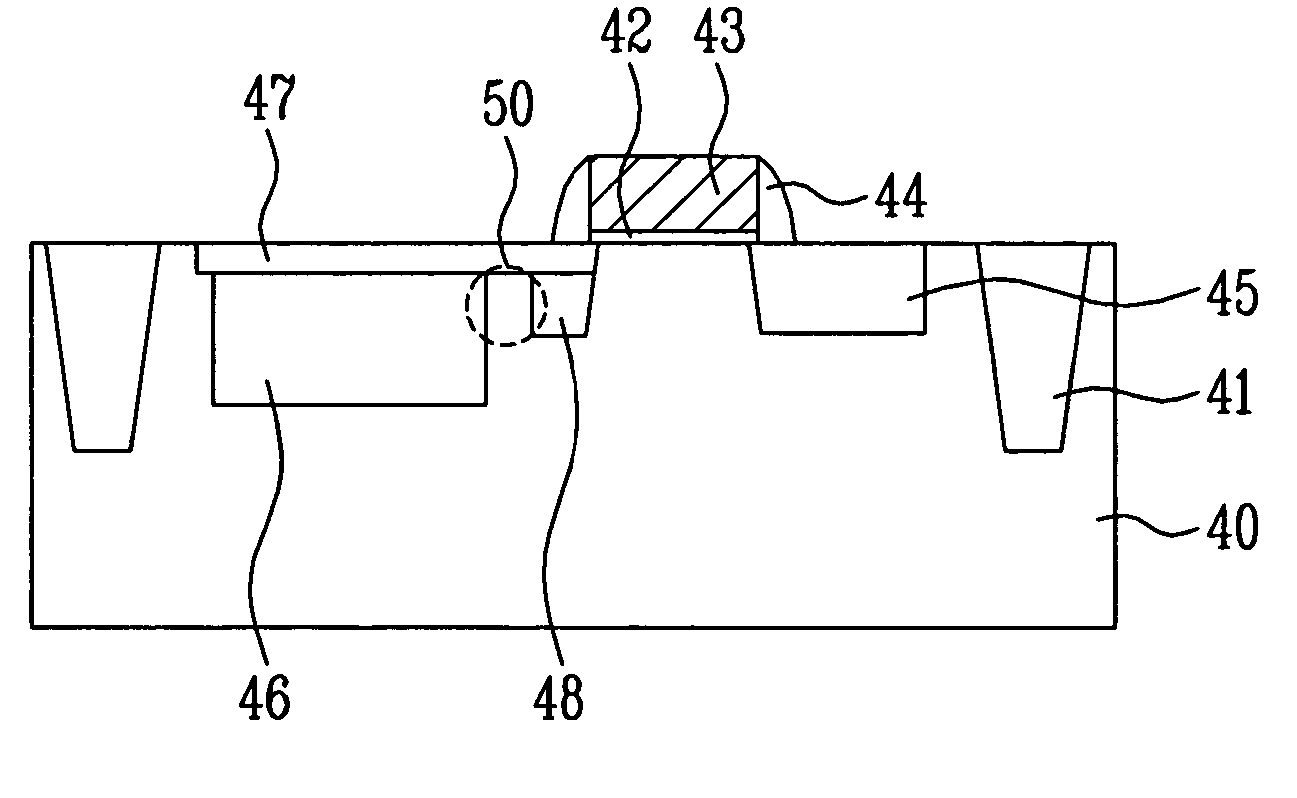

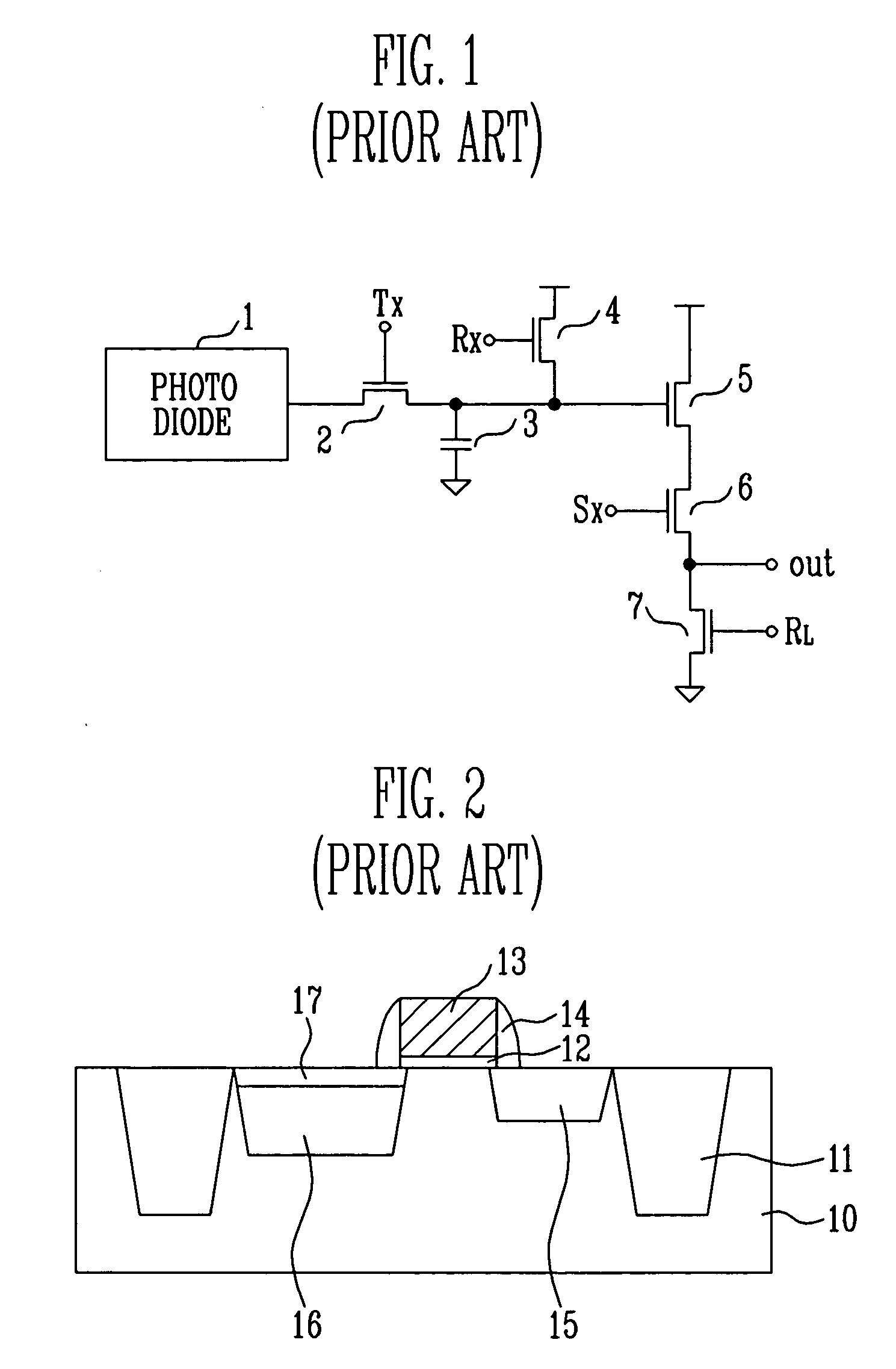

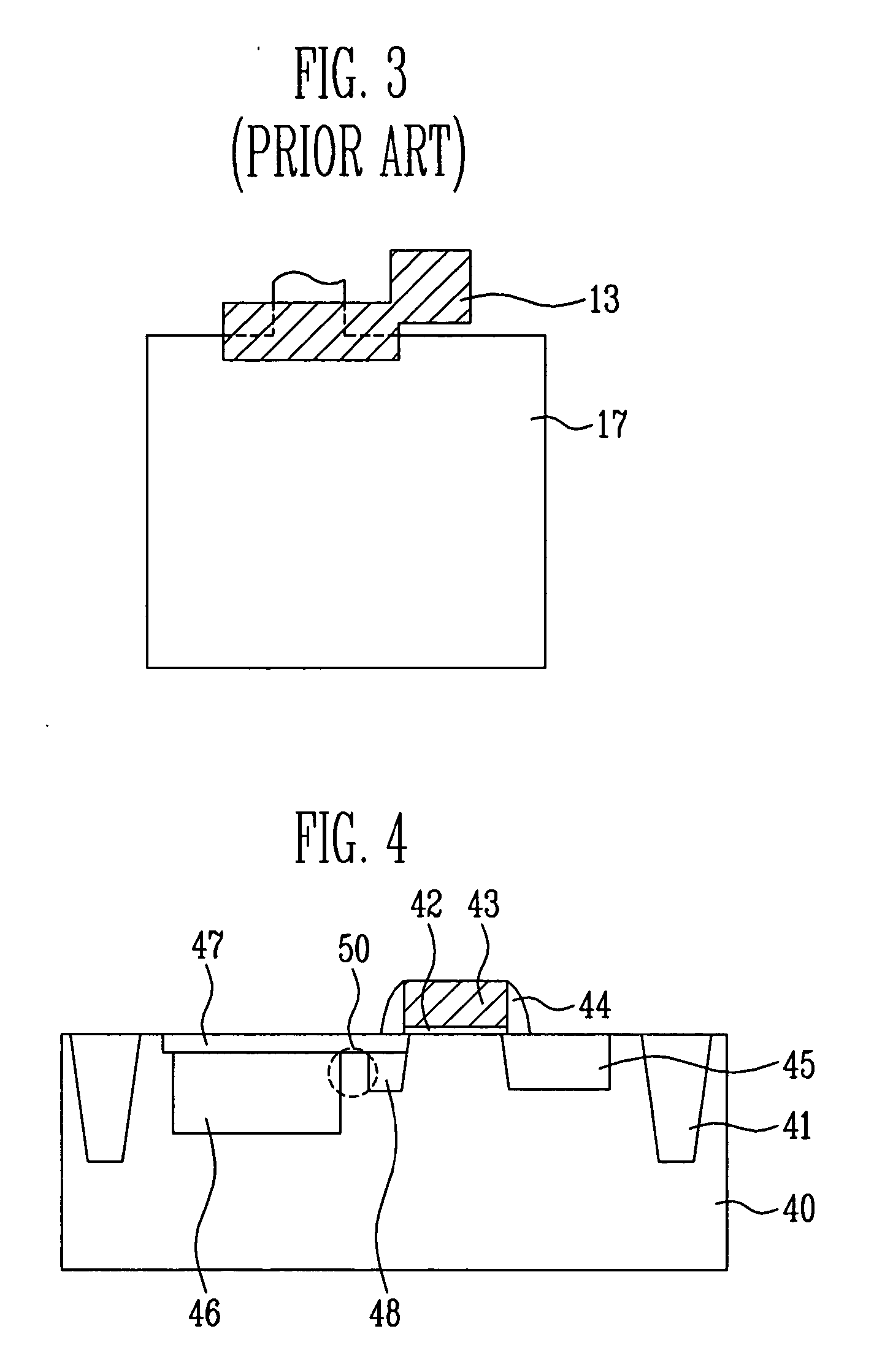

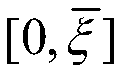

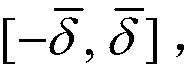

CMOS image sensor

InactiveUS20060108613A1Improve charge transfer efficiencyIncrease signal gainSolid-state devicesRadiation controlled devicesCMOSEngineering

Provided is a CMOS image sensor including a pinned photodiode and a transfer transistor. The CMOS image sensor includes: a substrate; a gate electrode disposed on the substrate and electrically isolated from the substrate by a gate insulating layer; a first floating region disposed in the substrate of one side of the gate electrode; a first impurity region for a photodiode disposed in the substrate of the other side of the gate electrode; a second floating region disposed in the substrate between the first impurity region for the photodiode and the gate electrode; and a second impurity region for the photodiode disposed in a surface portion of the substrate including the first impurity region for the photodiode and the second floating region.

Owner:SONG YOUNG JOO +2

Autonomous underwater vehicle trajectory tracking control method based on deep reinforcement learning

ActiveCN108803321AStabilize the learning processOptimal target strategyAdaptive controlSimulationIntelligent control

The invention provides an autonomous underwater vehicle (AUV) trajectory tracking control method based on deep reinforcement learning, belonging to the field of deep reinforcement learning and intelligent control. The autonomous underwater vehicle trajectory tracking control method based on deep reinforcement learning includes the steps: defining an AUV trajectory tracking control problem; establishing a Markov decision-making process model of the AUV trajectory tracking problem; constructing a hybrid policy-evaluation network which consists of multiple policy networks and evaluation networks;and finally, solving the target policy of AUV trajectory tracking control by the constructed hybrid policy-evaluation network, for the multiple evaluation networks, evaluating the performance of eachevaluation network by defining an expected Bellman absolute error and updating only one evaluation network with the lowest performance at each time step, and for the multiple policy networks, randomly selecting one policy network at each time step and using a deterministic policy gradient to update, so that the finally learned policy is the mean value of all the policy networks. The autonomous underwater vehicle trajectory tracking control method based on deep reinforcement learning is not easy to be influenced by the bad AUV historical tracking trajectory, and has high precision.

Owner:TSINGHUA UNIV

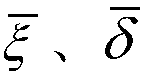

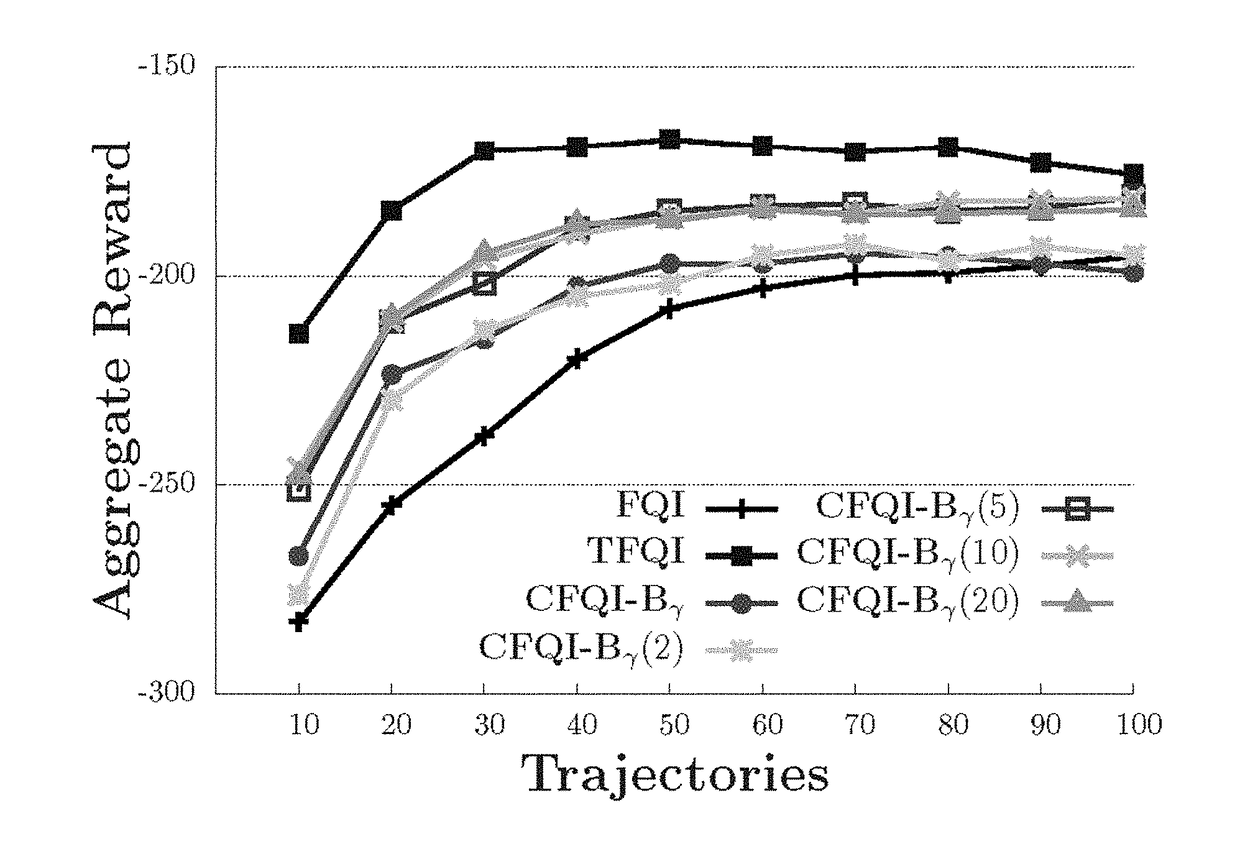

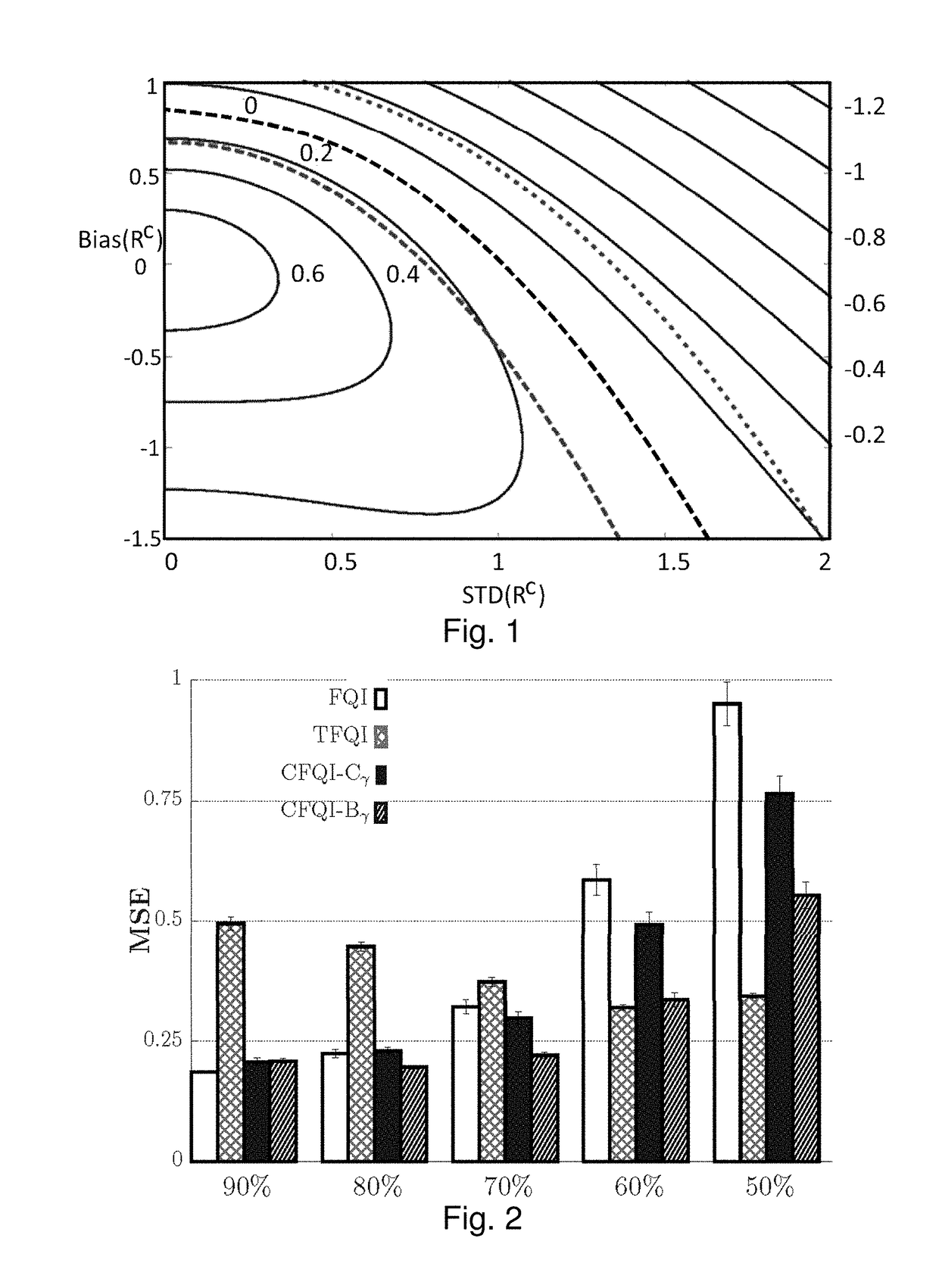

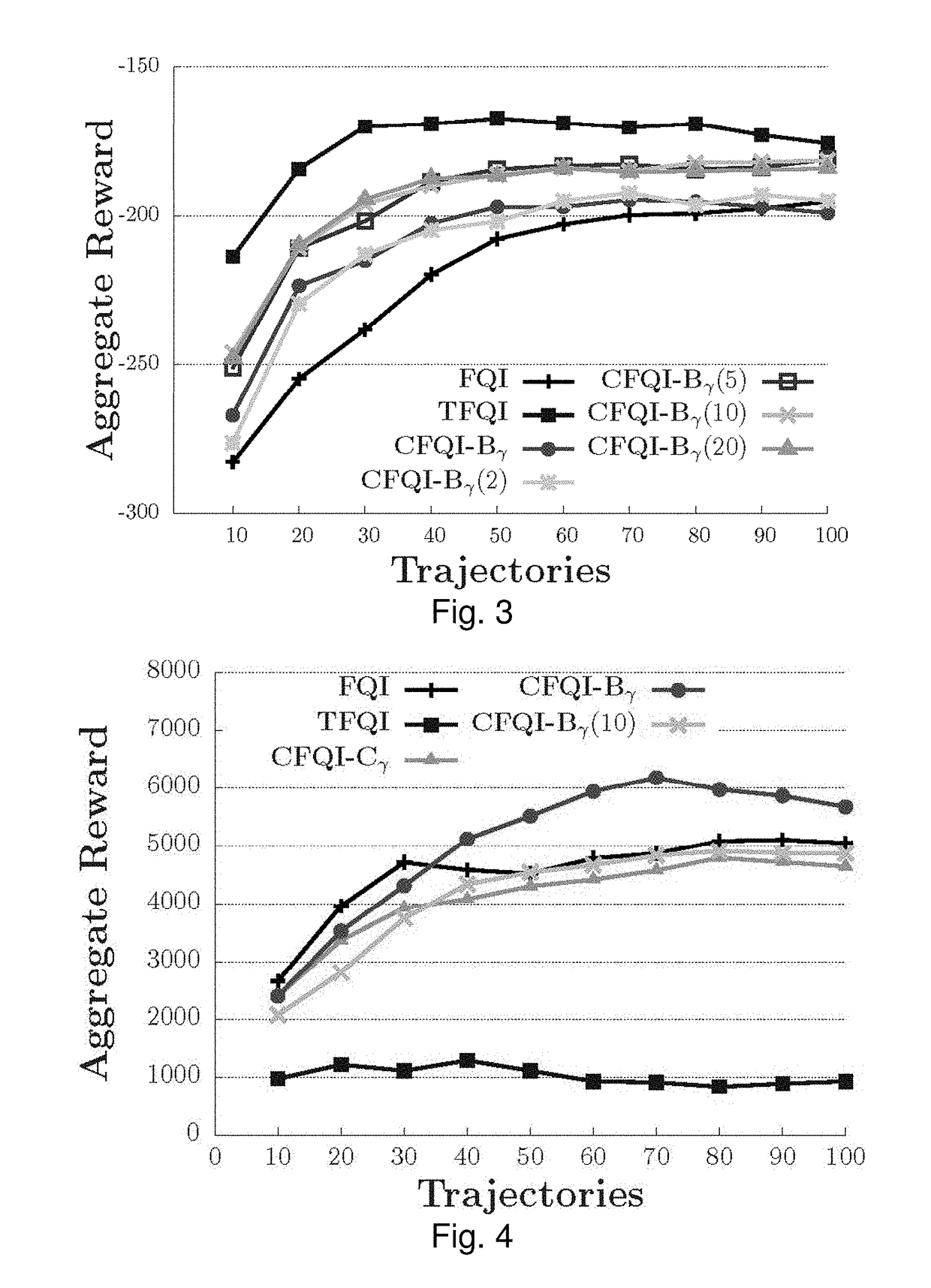

Approximate value iteration with complex returns by bounding

ActiveUS20180012137A1Reduce varianceBetter estimatorComputer controlProbabilistic networksData setControl system

A control system and method for controlling a system, which employs a data set representing a plurality of states and associated trajectories of an environment of the system; and which iteratively determines an estimate of an optimal control policy for the system. The iterative process performs the substeps, until convergence, of estimating a long term value for operation at a respective state of the environment over a series of predicted future environmental states; using a complex return of the data set to determine a bound to improve the estimated long term value; and producing an updated estimate of an optimal control policy dependent on the improved estimate of the long term value. The control system may produce an output signal to control the system directly, or output the optimized control policy. The system preferably is a reinforcement learning system which continually improves.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

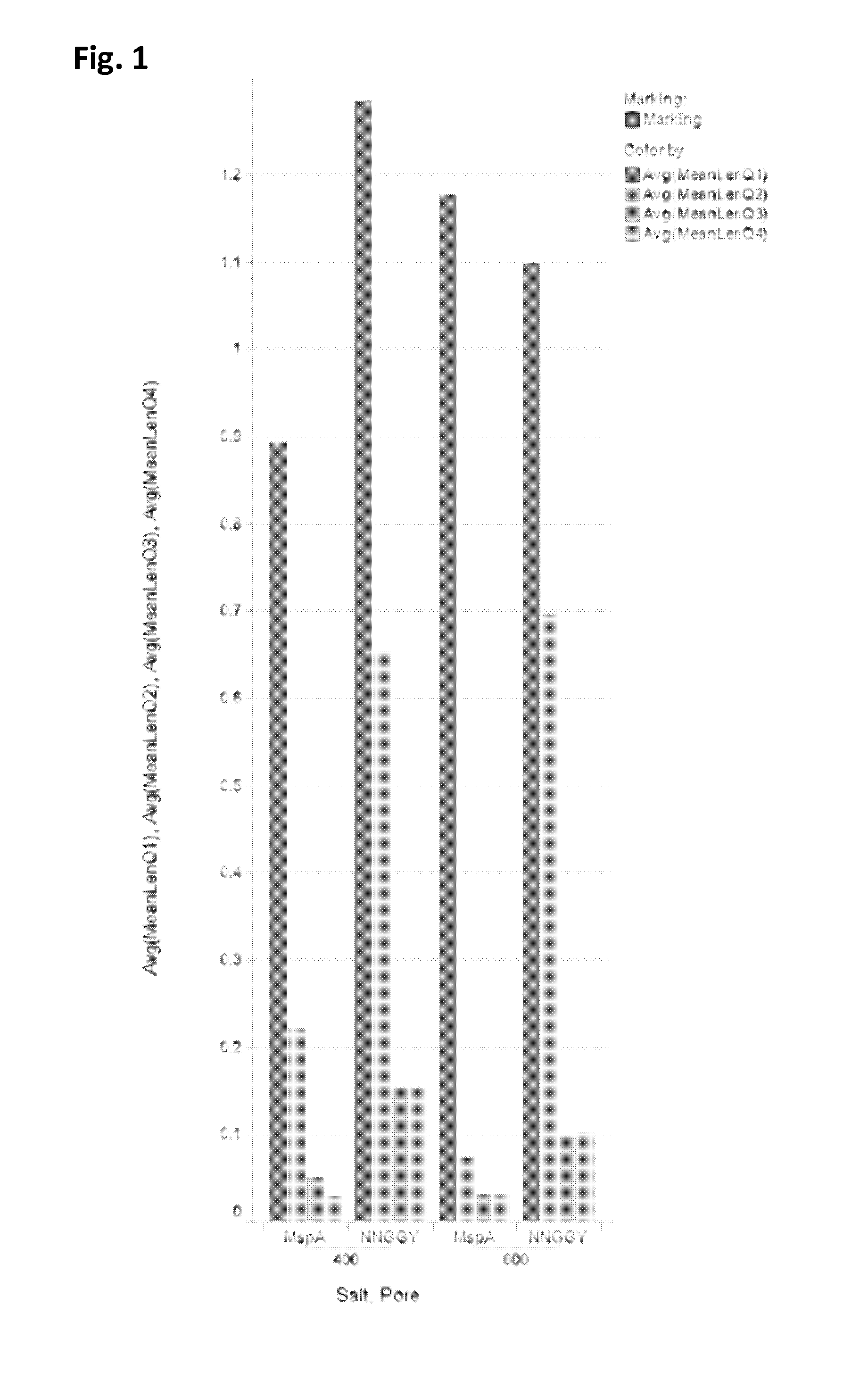

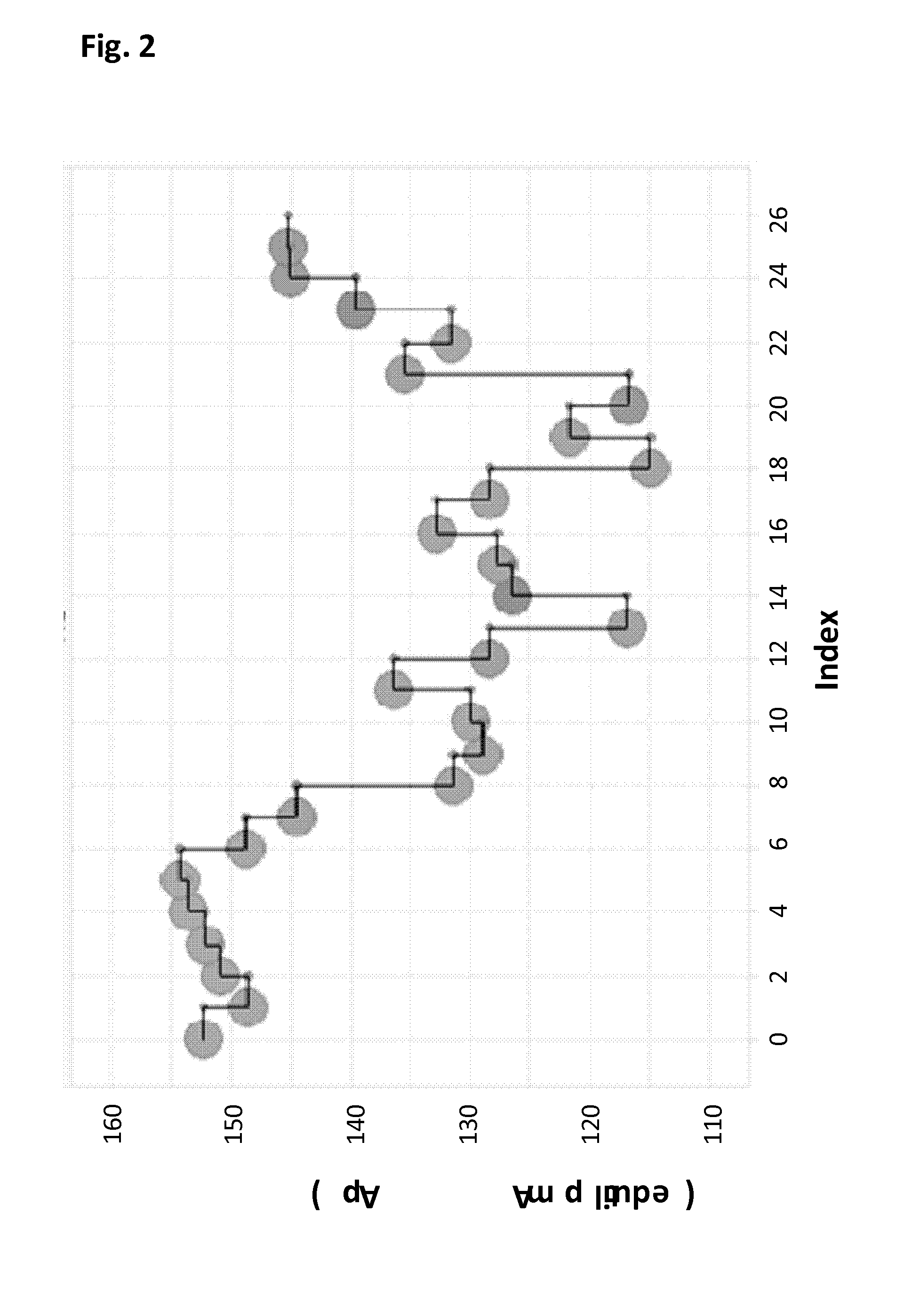

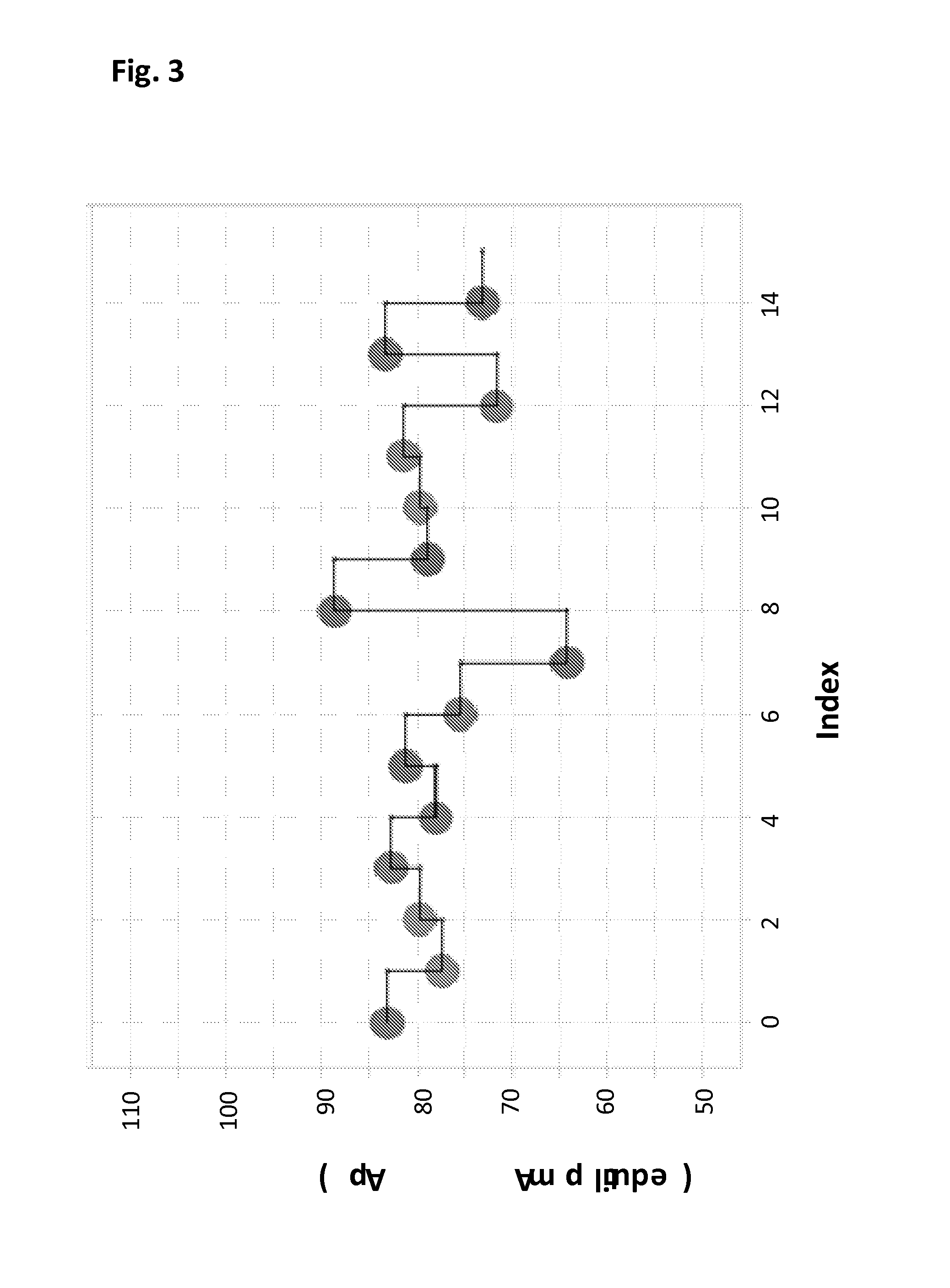

Mutant pores

ActiveUS20140186823A1Easily discriminatedReduce varianceBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acidChemistry

The invention relates to mutant forms of Msp. The invention also relates to nucleic acid characterisation using Msp.

Owner:OXFORD NANOPORE TECH LTD

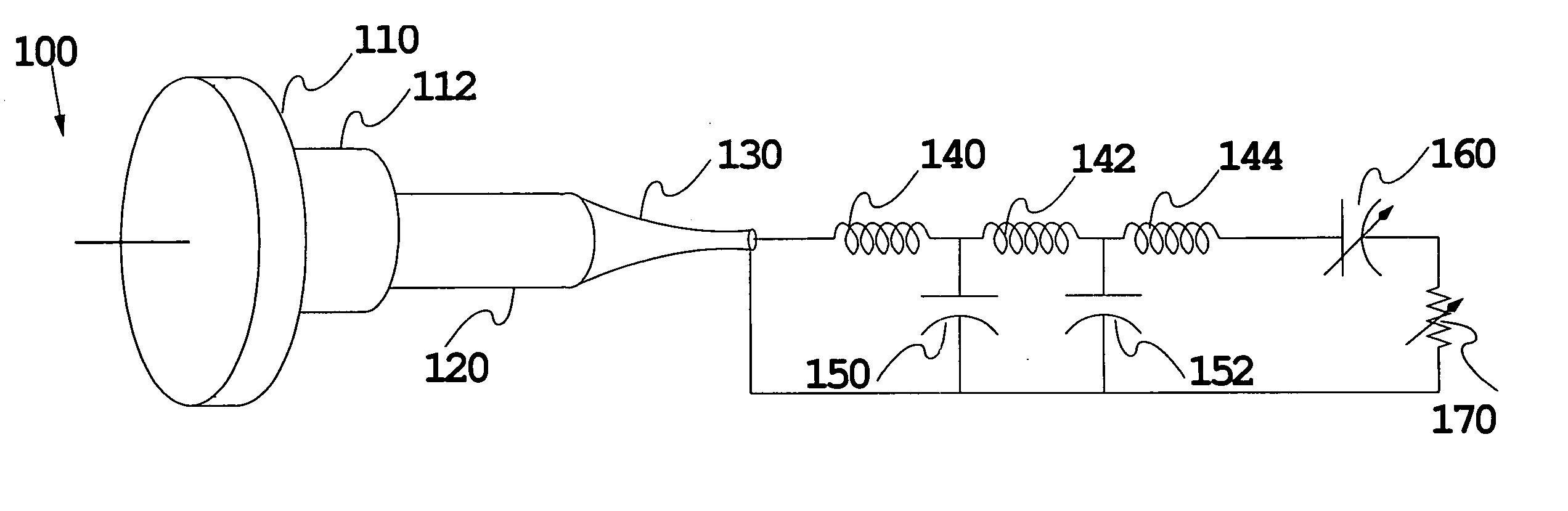

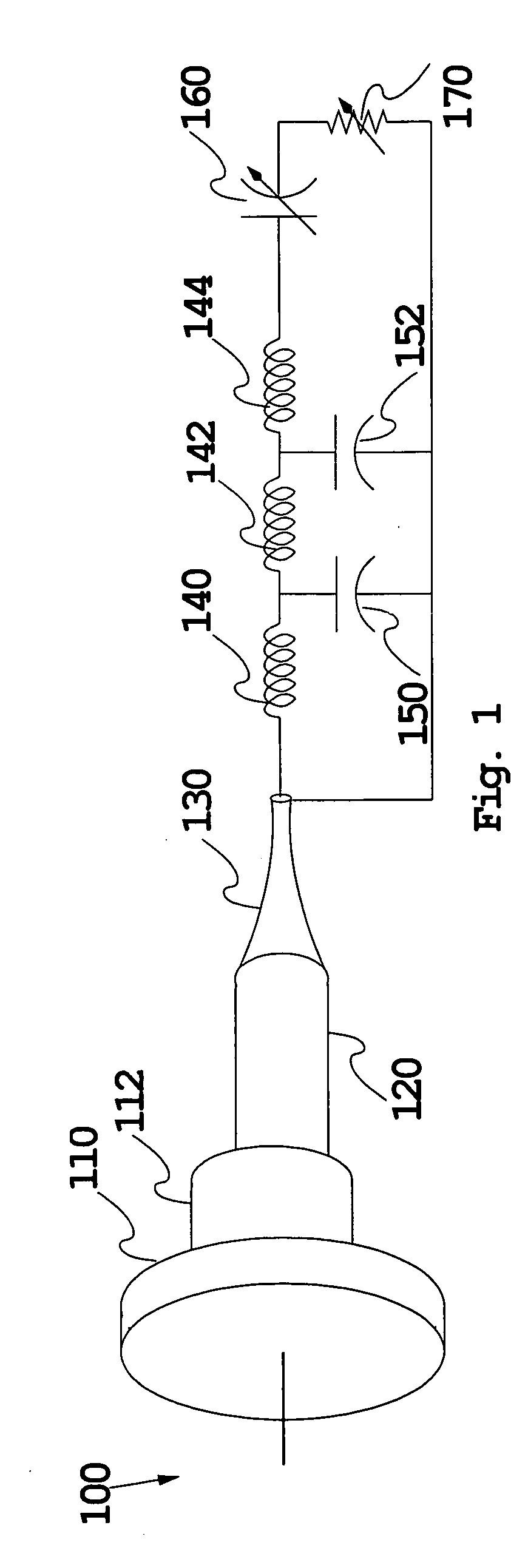

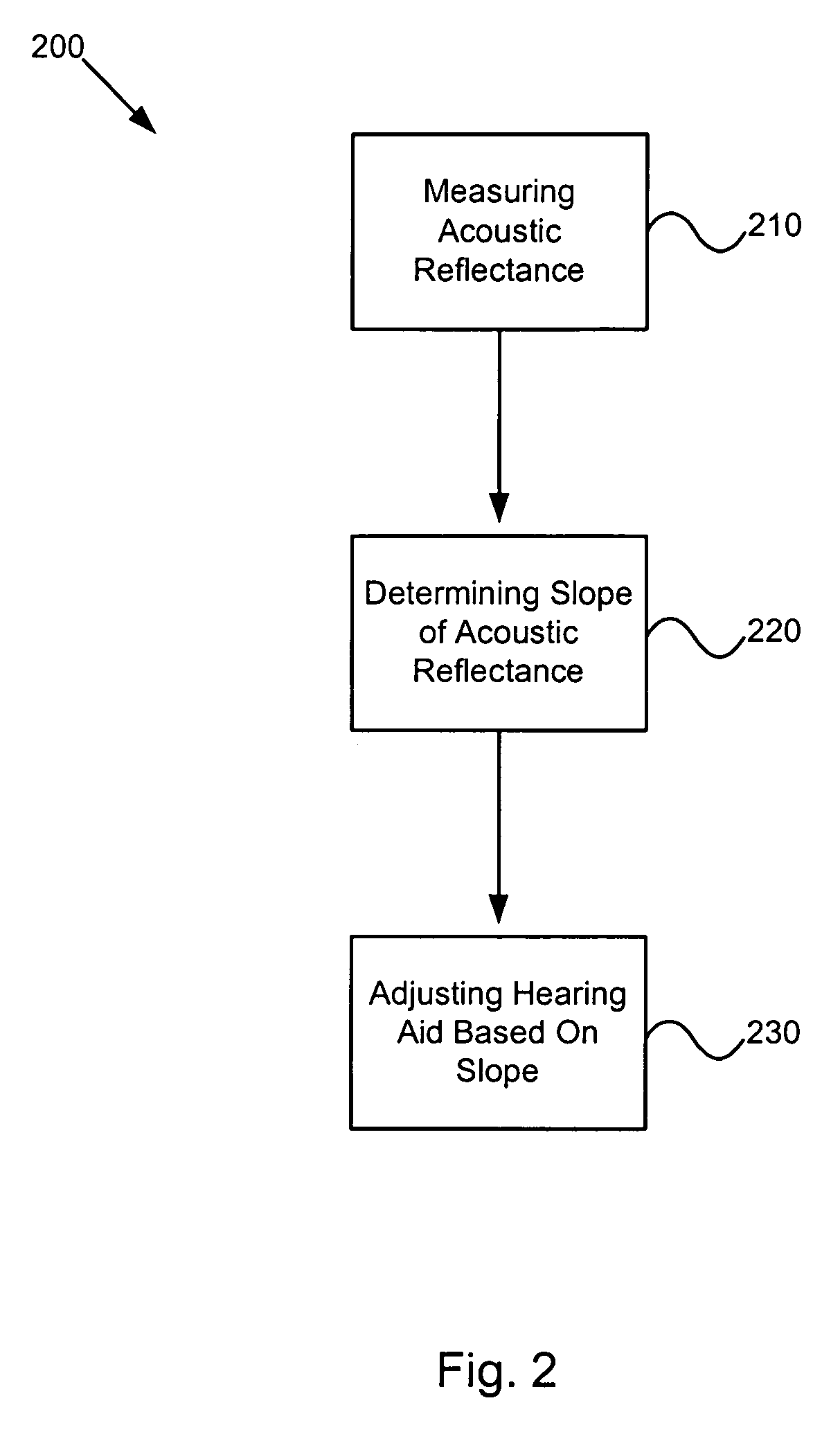

System and method for automatically adjusting hearing aid based on acoustic reflectance

Method and system for automatically adjusting a hearing aid. The method includes measuring an acoustic reflectance associated with an ear canal as a function of an incident pressure and an acoustic frequency, processing information associated with the measured acoustic reflectance, determining a reflectance slope based on, at least, information associated with the measured acoustic reflectance, and adjusting, at least, one parameter associated with the hearing aid based on, at least, information associated with the reflectance slope. The reflectance slope is associated with a reflectance component varying with the incident pressure.

Owner:MIMOSA ACOUSTICS

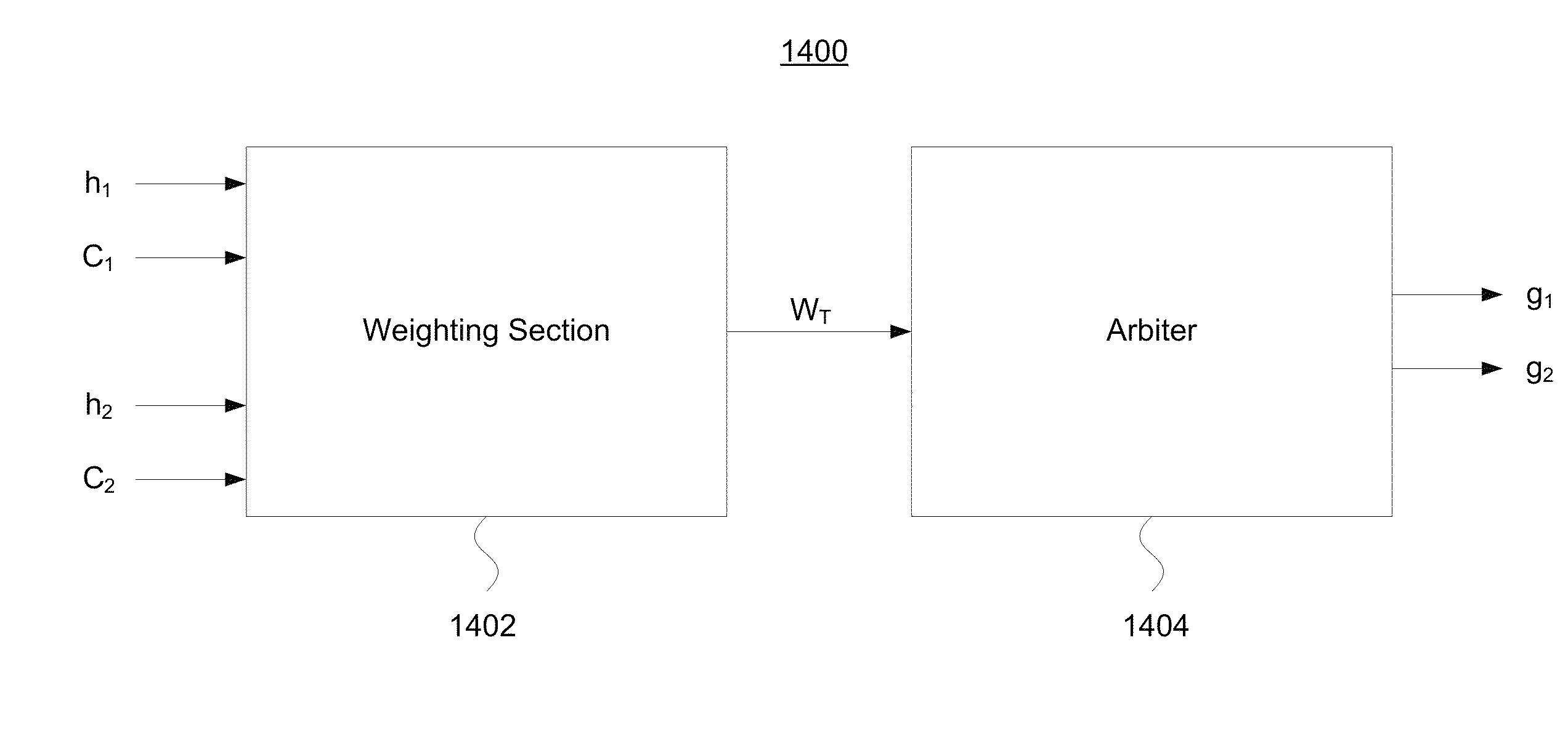

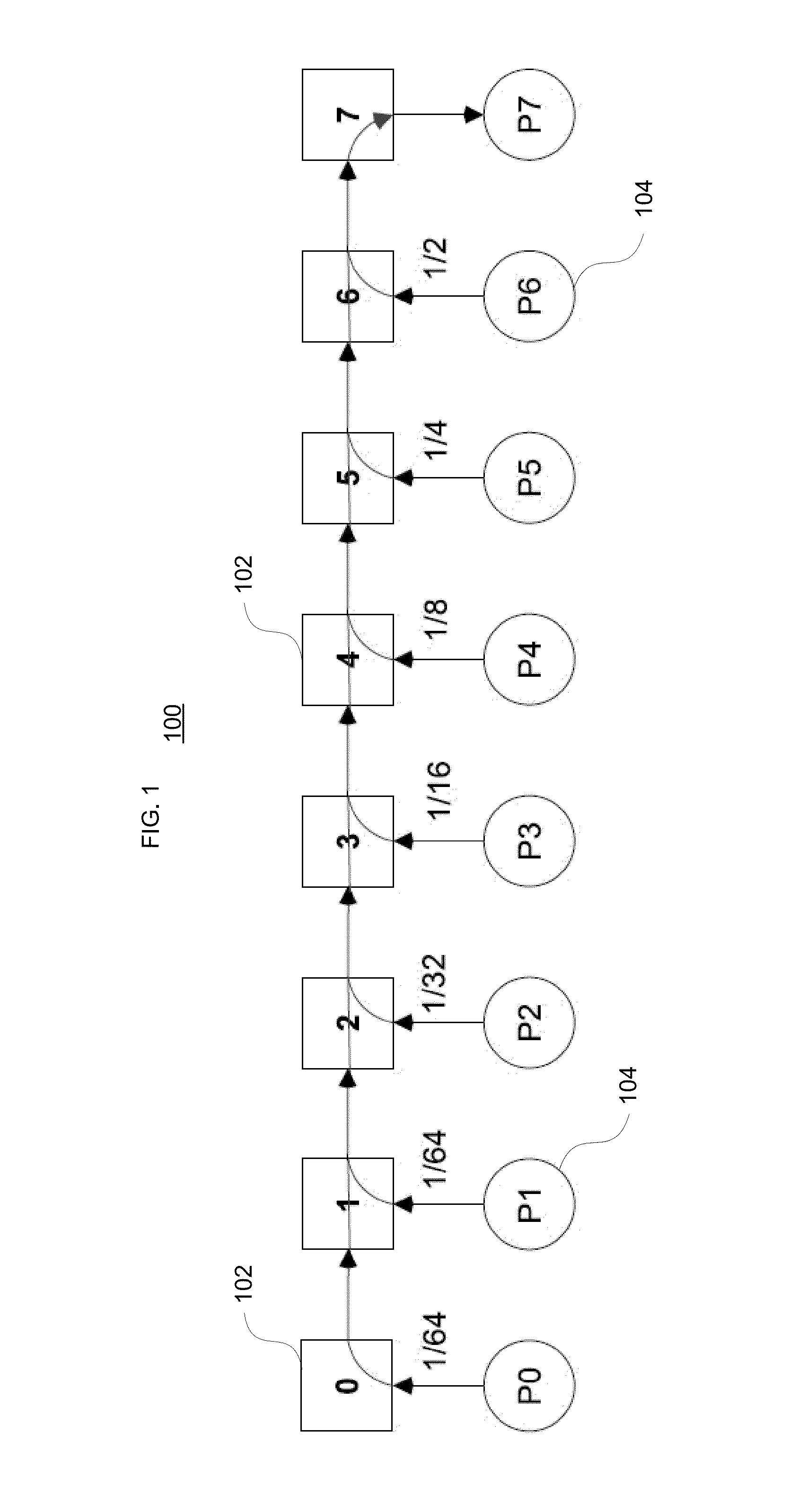

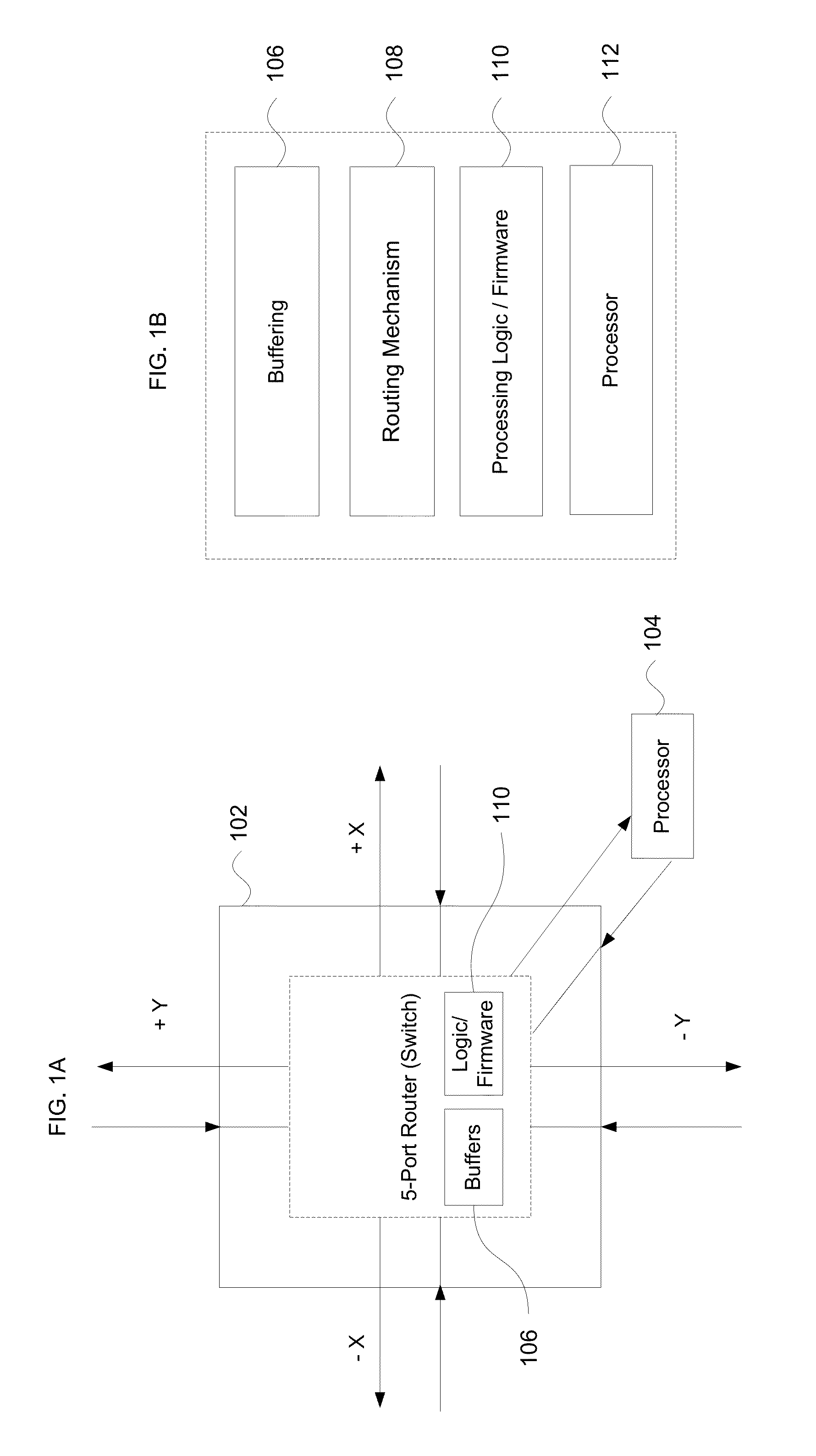

Probabilistic distance-based arbitration

ActiveUS8705368B1Reduce varianceEffective synchronizationMultiplex system selection arrangementsError preventionQuality of serviceInterconnection

Probabilistic arbitration is combined with distance-based weights to achieve equality of service in interconnection networks, such as those used with chip multiprocessors. This arbitration desirably used incorporates nonlinear weights that are assigned to requests. The nonlinear weights incorporate different arbitration weight metrics, namely fixed weight, constantly increasing weight, and variably increasing weight. Probabilistic arbitration for an on-chip router avoids the need for additional buffers or virtual channels, creating a simple, low-cost mechanism for achieving equality of service. The nonlinearly weighted probabilistic arbitration includes additional benefits such as providing quality-of-service features and fairness in terms of both throughput and latency that approaches the global fairness achieved with age-base arbitration. This provides a more stable network by achieving high sustained throughput beyond saturation. Each router or switch in the network may include an arbiter to apply the weighted probabilistic arbitration.

Owner:GOOGLE LLC

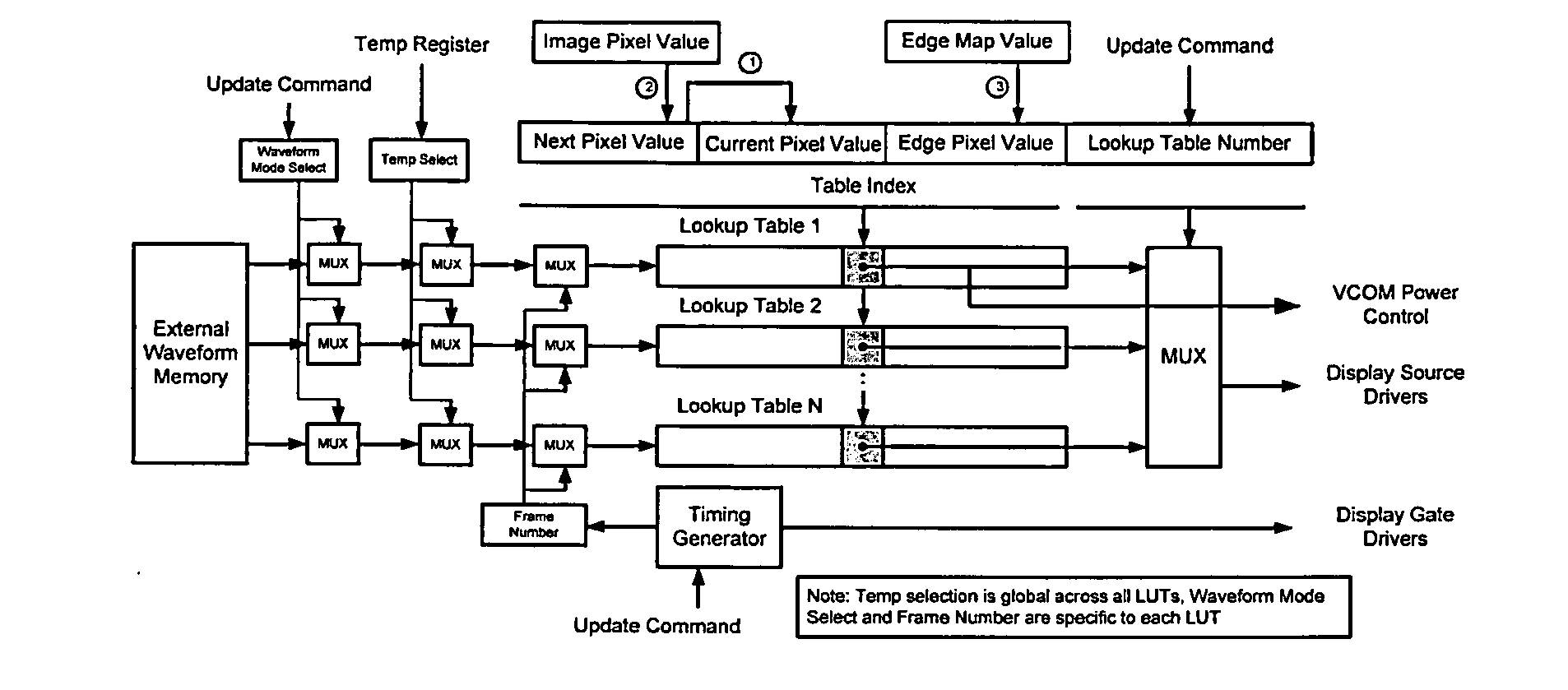

Methods for driving electro-optic displays

ActiveUS20140292830A1Minimize effectEffect be particularly severeCathode-ray tube indicatorsNon-linear opticsEdge effectsDisplay device

Methods for driving electro-optic displays, especially bistable displays, include (a) using two-part waveforms, the first part of which is dependent only upon the initial state of the relevant pixel; (b) measuring the response of each individual pixel and storing for each pixel data indicating which of a set of standard drive schemes are to be used for that pixel; (c) for at least one transition in a drive scheme, applying multiple different waveforms to pixels on a random basis; and (d) when updating a limited area of the display, driving “extra” pixels in an edge elimination region to avoid edge effects.

Owner:E INK CORPORATION

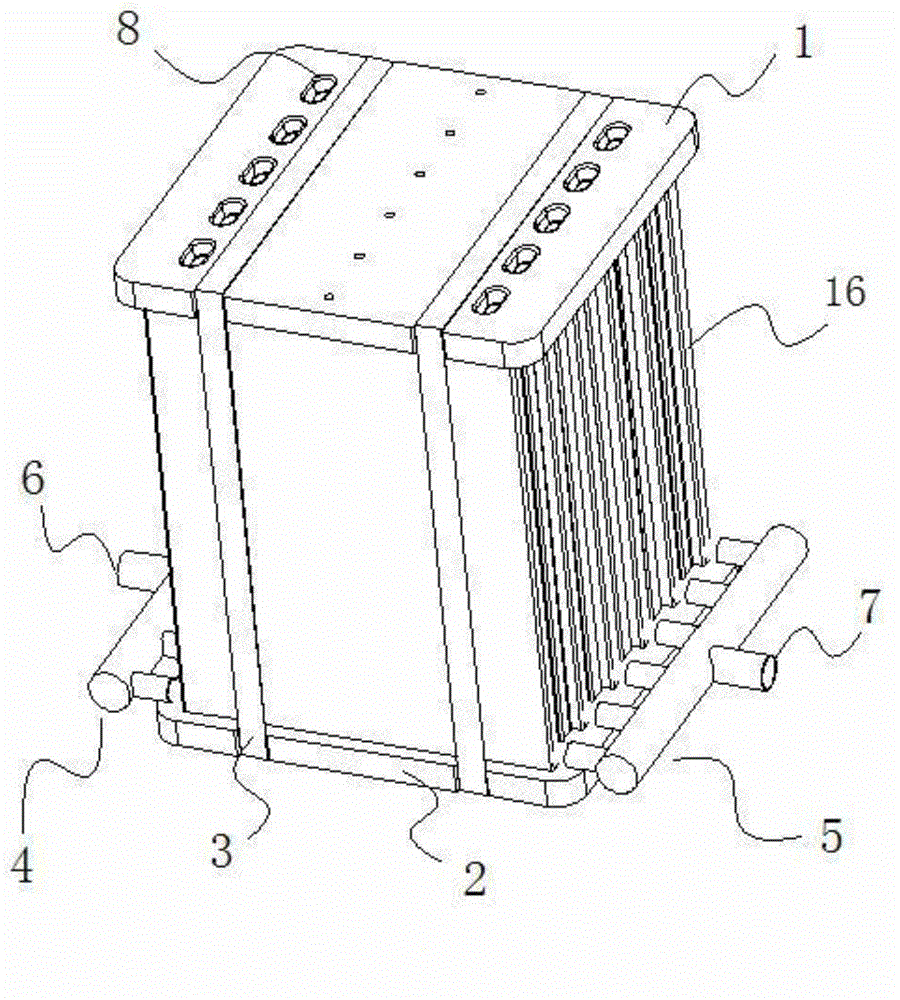

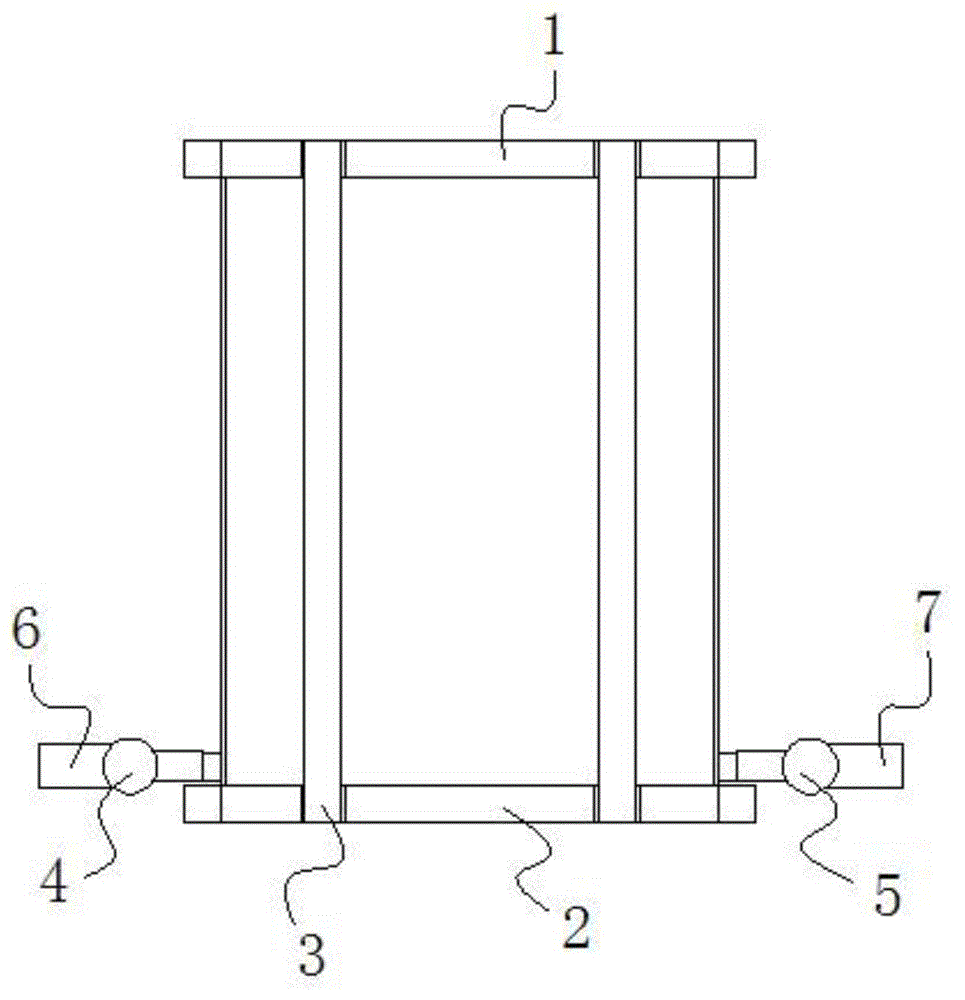

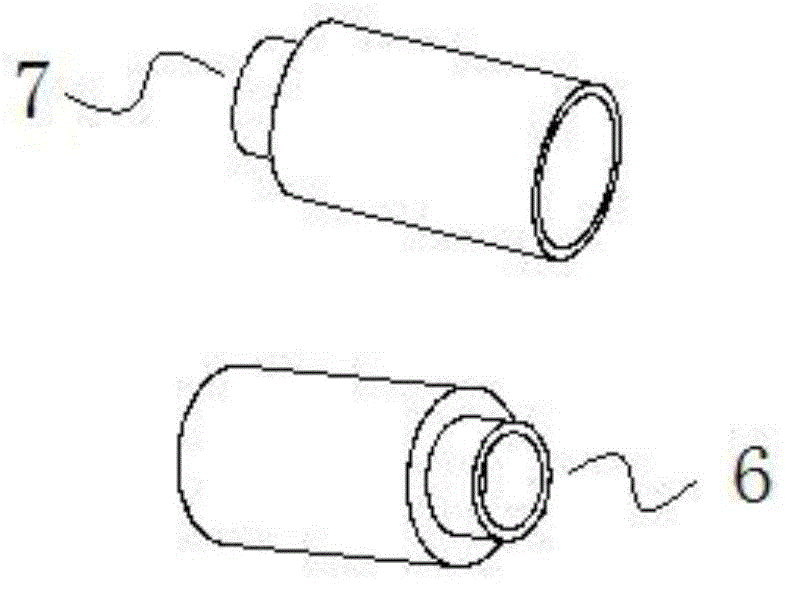

Water-cooled heat management system of electric automobile battery pack

InactiveCN102881959AShorten the timeReduce varianceSecondary cellsPropulsion coolingAutomotive batteryWorking temperature

The invention discloses a water-cooled heat management system of an electric automobile battery pack. A power battery is fixed between an upper fixing baffle and a lower fixing baffle; a cooling separator is arranged tightly against the power battery; a cooling channel is disposed in the cooling separator, two ends of the cooling channel are communicated with a liquid inlet pipe and a liquid outlet pipe; the liquid inlet pipe is connected with a water pump through a liquid inlet connector; the liquid outlet pipe conveys heat transfer working media cooled by the cooling channel to a heat exchanger and a heating insulation water tank through a liquid outlet connector; the cooling separator is provided with a temperature sensor; and a BMS reads temperature data of the temperature sensor and controls the heat transfer working media conveyed to the inner portion of the cooling separator. The water-cooled heat management system solves the control of temperature of the battery pack when the battery is charged or discharged. The water-cooled system which is safe and reliable, has good operational performance, is convenient for maintenance and replacement and is capable of effectively regulating and controlling the working temperature of the battery is provided.

Owner:HUBEI GREEN DRIVING SCI & TECH

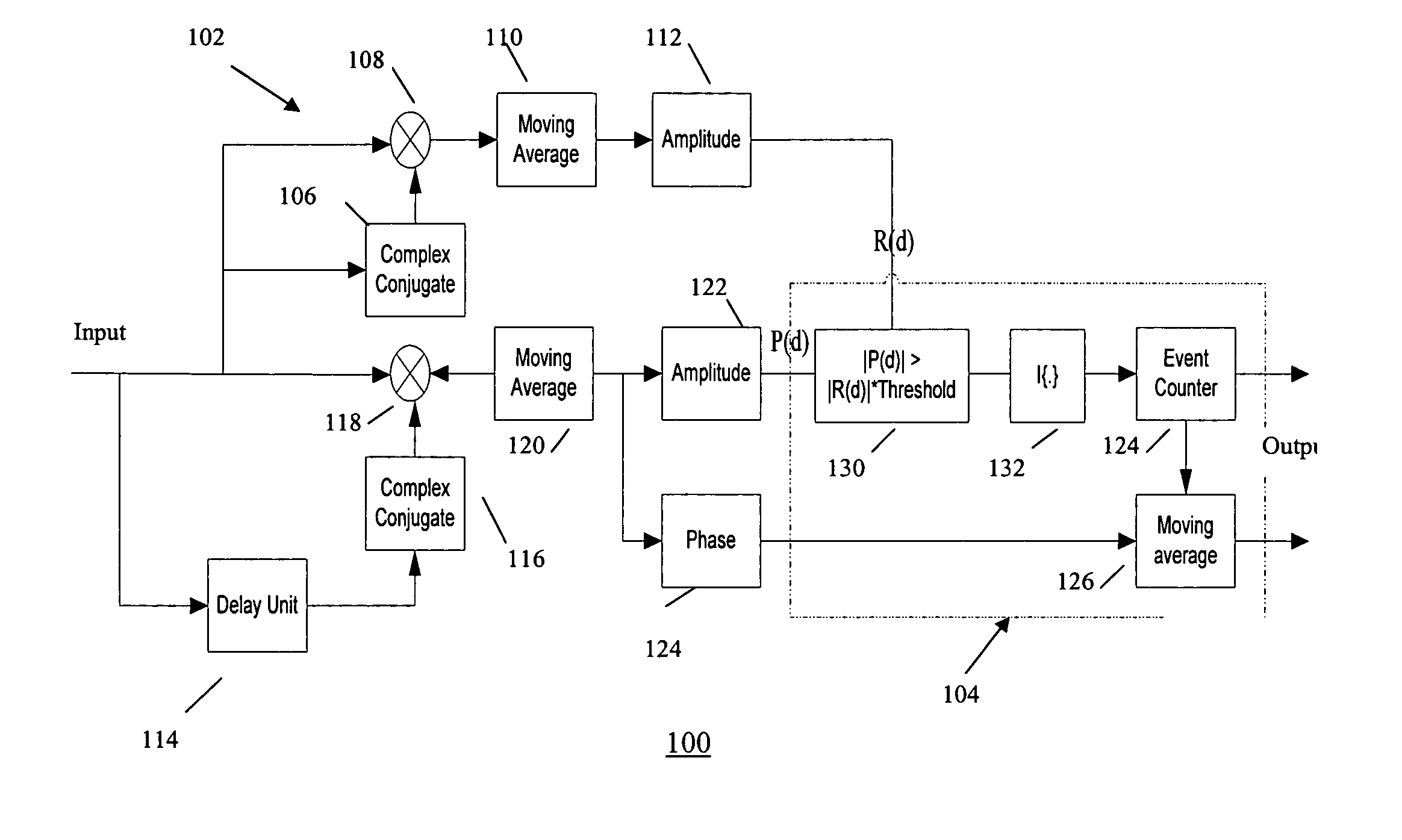

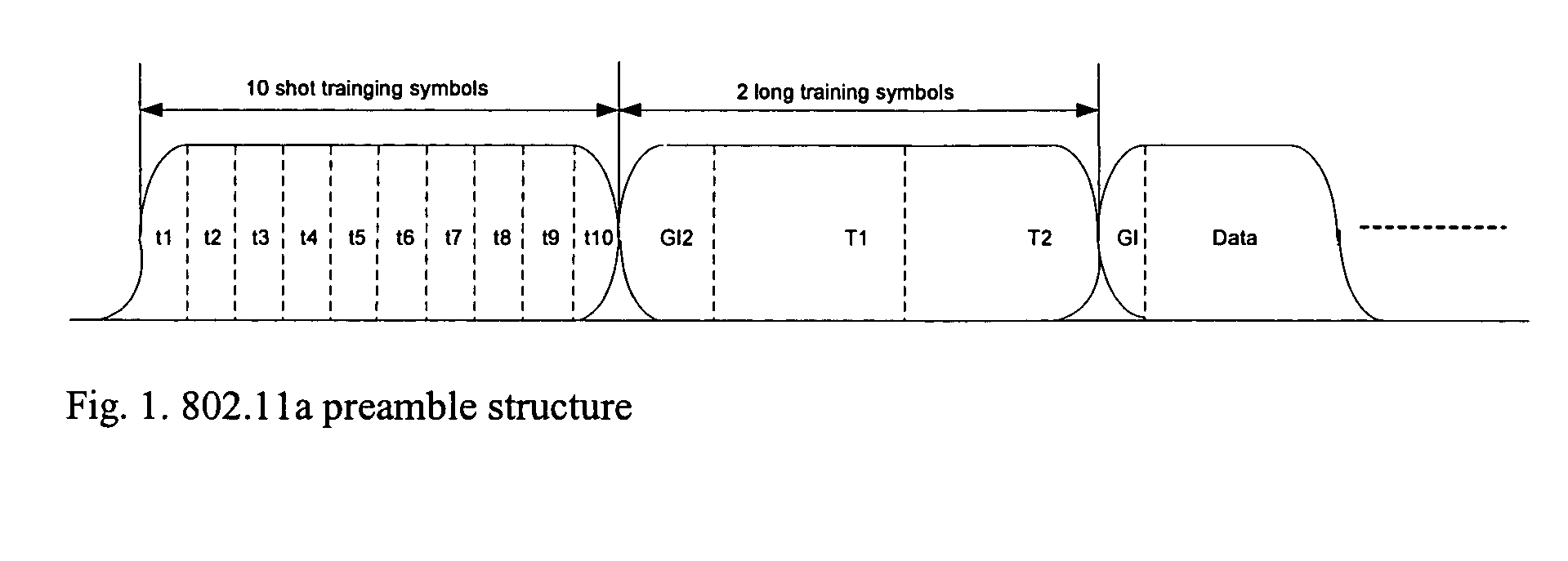

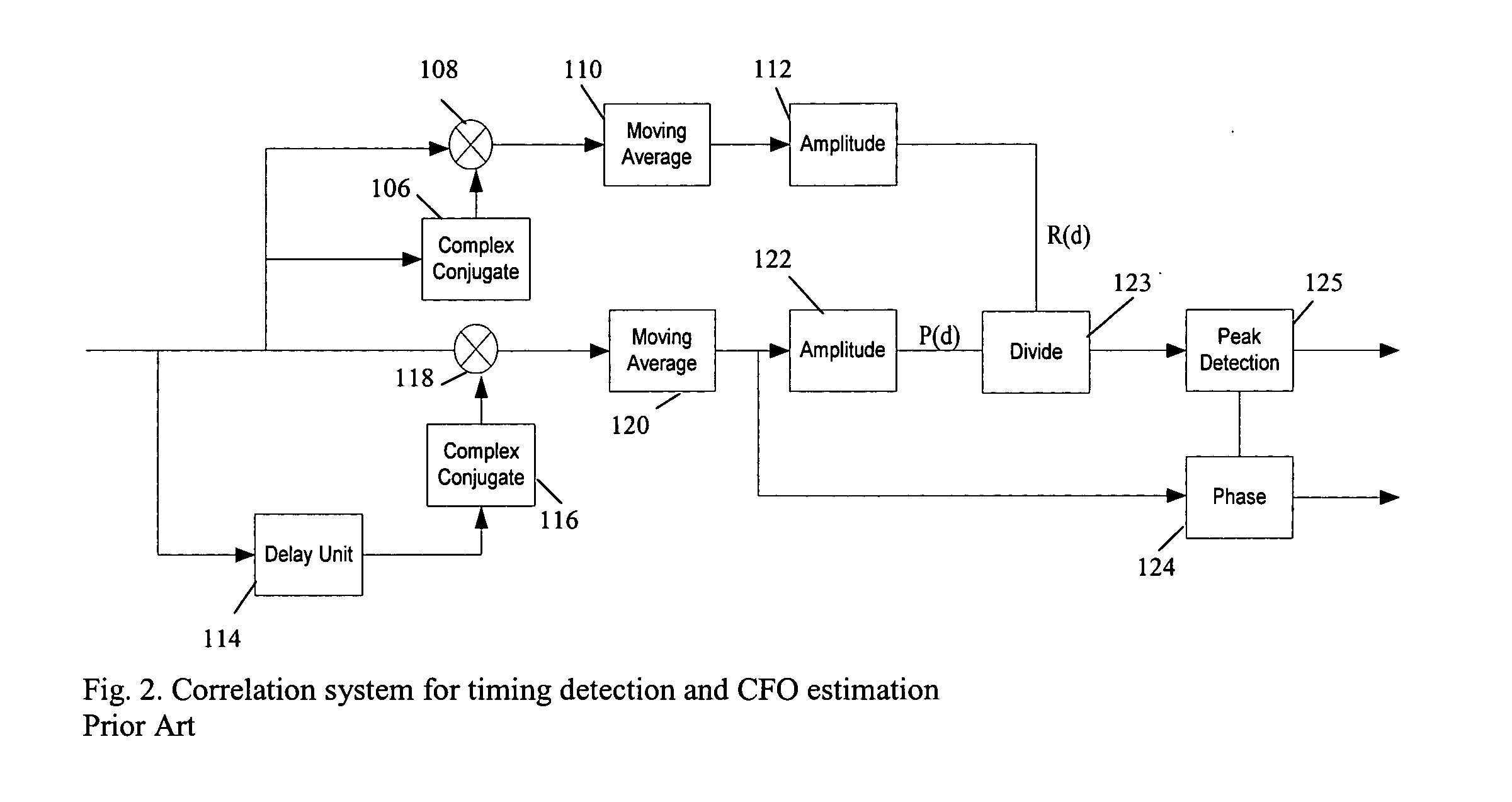

Method of robust timing detection and carrier frequency offset estimation for OFDM systems

InactiveUS20060222095A1Reduce varianceAngle modulationSecret communicationCarrier frequency offsetPeak value

A symbol detector for an OFDM receiver determines the correlation of corresponding samples of at least two received preamble symbol samples, one of the samples delayed a predetermined duration with respect to the other; determines a timing metric based on the correlation results; detects multiple peaks in the timing metric; indicates a symbol detection based on the multiple peaks detected in the timing metric; and gets a refined CFO estimation using averaging the phase information across these multiple peaks.

Owner:SAMSUNG ELECTRONICS CO LTD

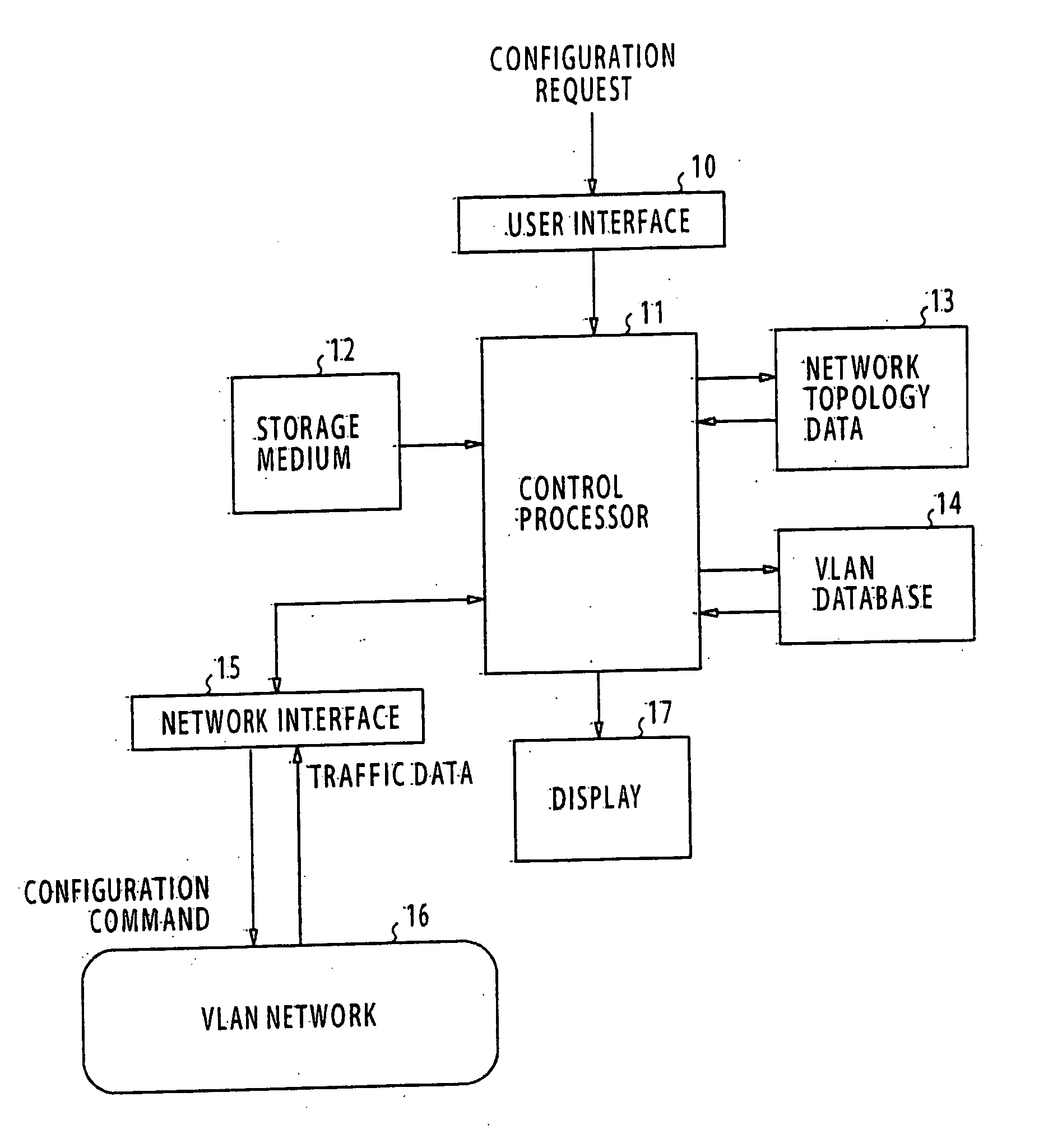

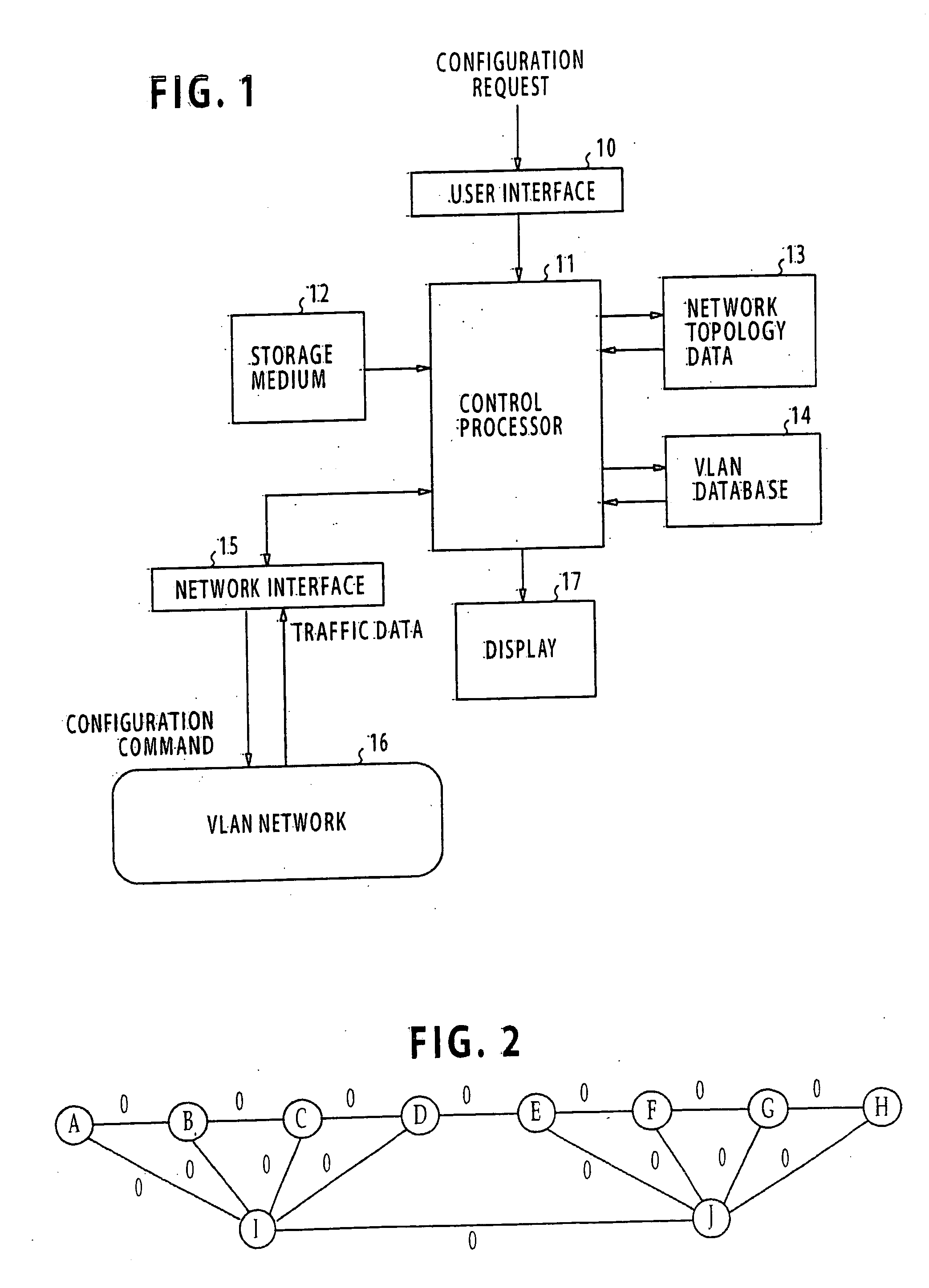

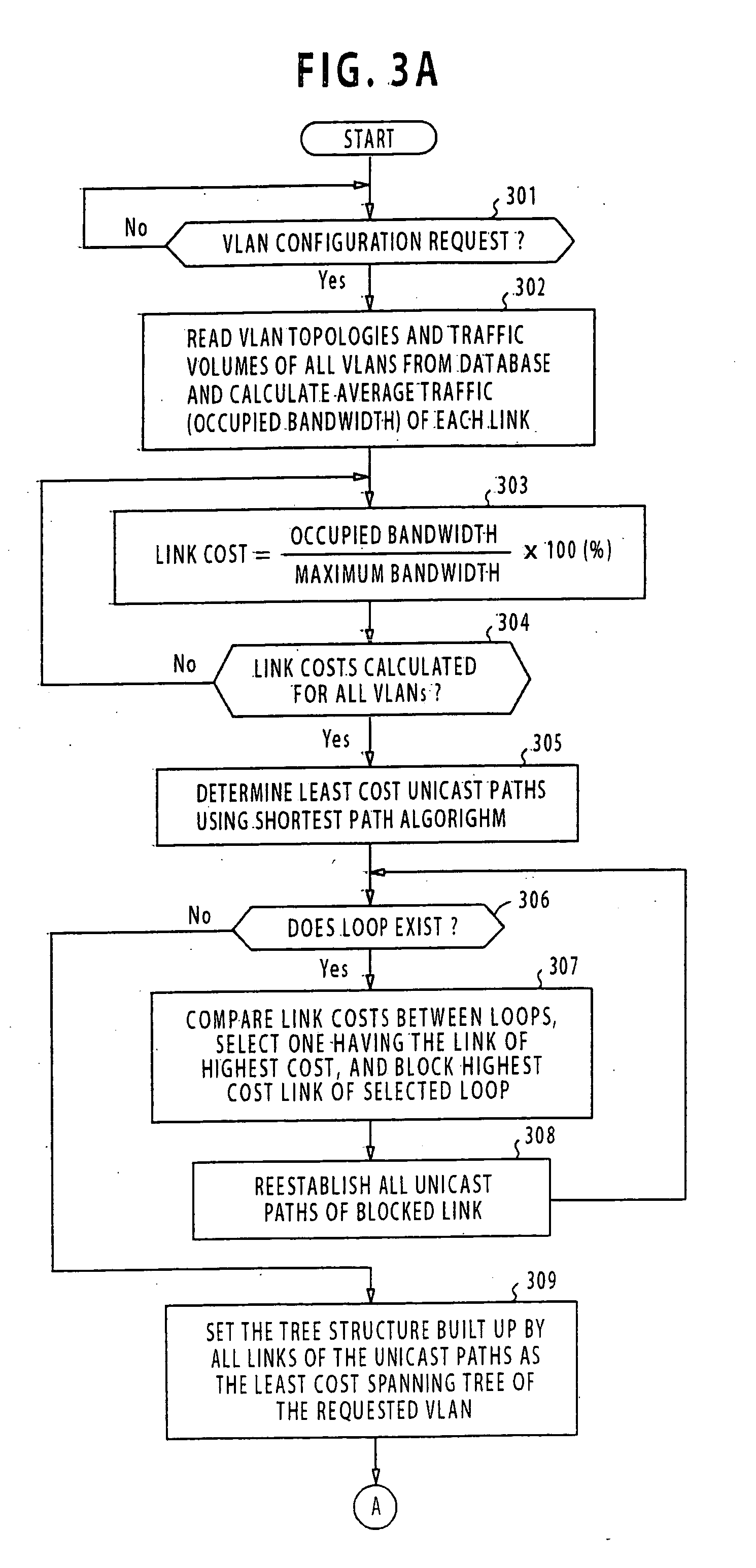

Method and apparatus for designing a spanning tree virtual network

ActiveUS20050063321A1Reduce varianceEvenly dispersedStar/tree networksNetworks interconnectionShort path algorithmLeast cost

An apparatus for designing a virtual VLAN network includes a database containing data representing a plurality of VLAN networks in a spanning tree topology, each of the VLAN networks being formed of a plurality of VLAN member nodes interconnected by links. In response to a network configuration request from a communications network, control circuitry determines the costs of the links, and then determines least cost unicast paths by using a shortest path algorithm. A search is made through the least cost unicast paths for detecting a loop. If at least one loop is detected, a link of highest cost of the loop is blocked. All unicast paths of the blocked link are reestablished through links that circumvent the blocked link. A spanning tree built up with all the links accommodating the least cost unicast paths is established. Configuration command is sent to the network for configuring it according to the established spanning tree.

Owner:NEC CORP

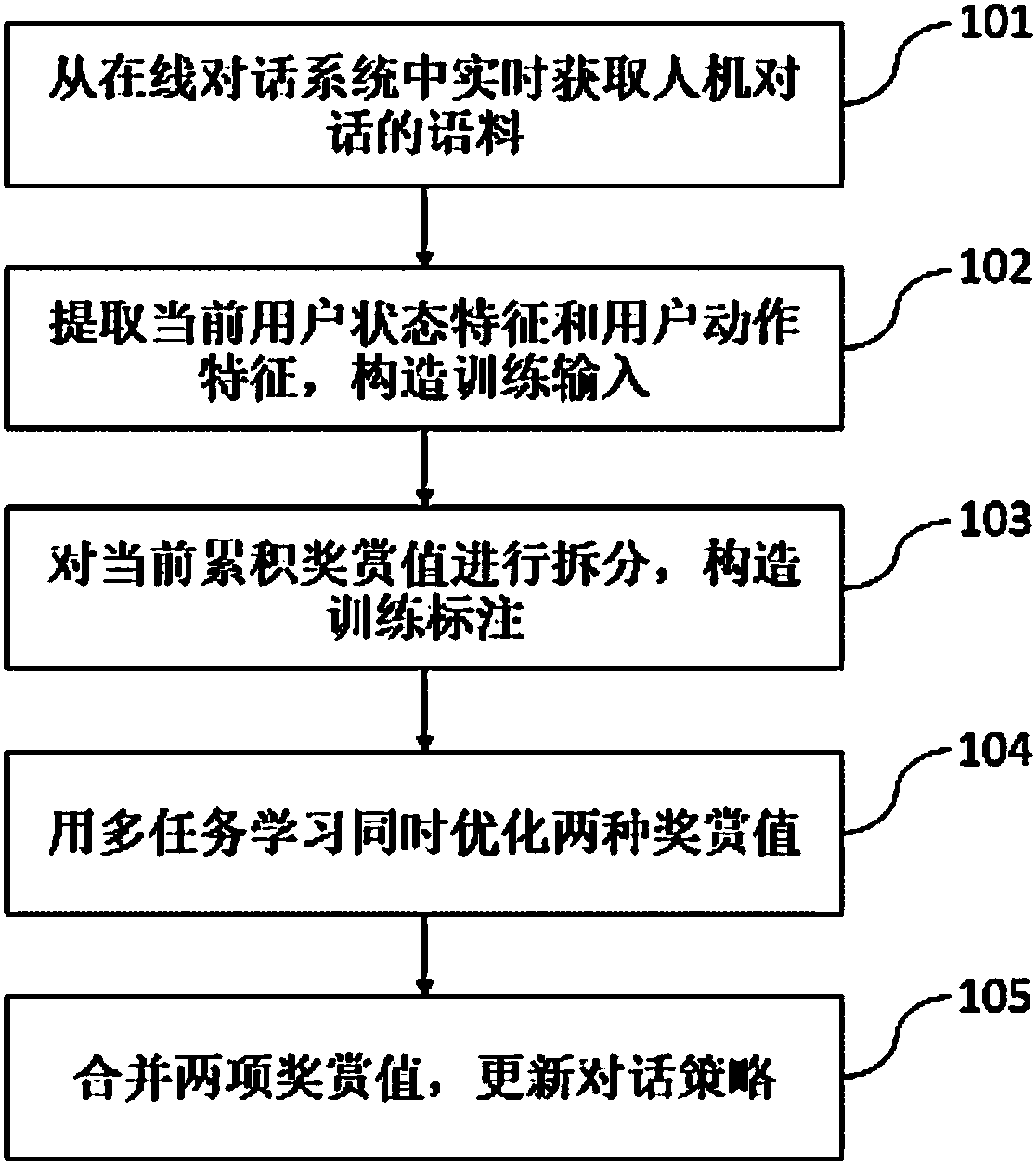

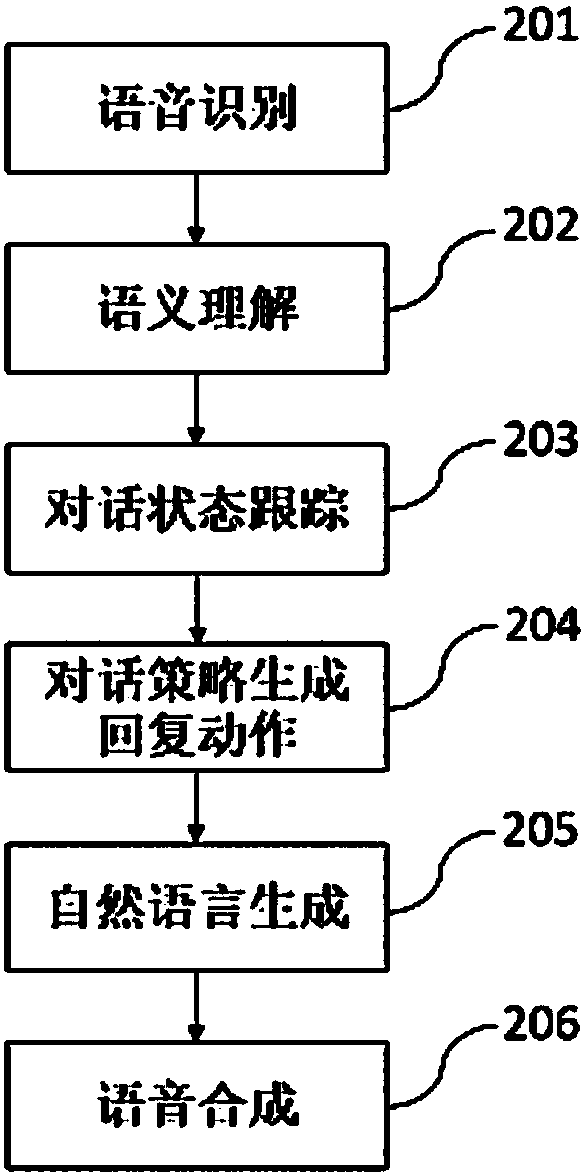

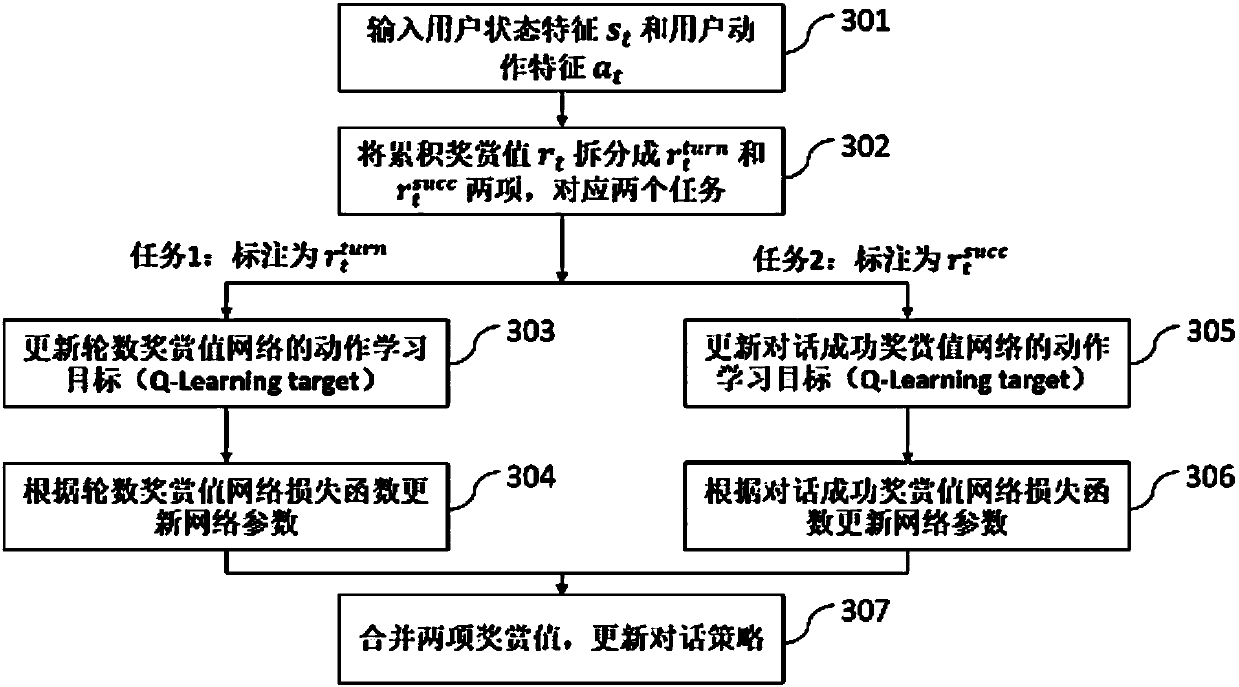

Dialog strategy online realization method based on multi-task learning

ActiveCN107357838AAvoid Manual Design RulesSave human effortSpeech recognitionSpecial data processing applicationsMan machineNetwork structure

The invention discloses a dialog strategy online realization method based on multi-task learning. According to the method, corpus information of a man-machine dialog is acquired in real time, current user state features and user action features are extracted, and construction is performed to obtain training input; then a single accumulated reward value in a dialog strategy learning process is split into a dialog round number reward value and a dialog success reward value to serve as training annotations, and two different value models are optimized at the same time through the multi-task learning technology in an online training process; and finally the two reward values are merged, and a dialog strategy is updated. Through the method, a learning reinforcement framework is adopted, dialog strategy optimization is performed through online learning, it is not needed to manually design rules and strategies according to domains, and the method can adapt to domain information structures with different degrees of complexity and data of different scales; and an original optimal single accumulated reward value task is split, simultaneous optimization is performed by use of multi-task learning, therefore, a better network structure is learned, and the variance in the training process is lowered.

Owner:AISPEECH CO LTD

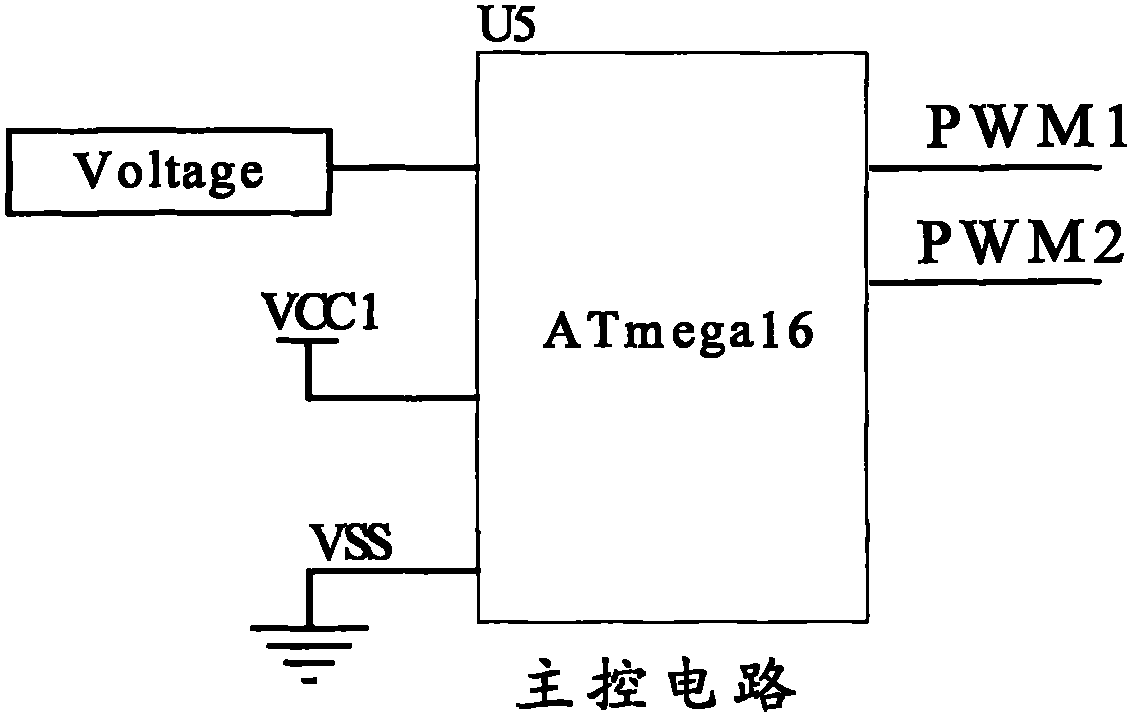

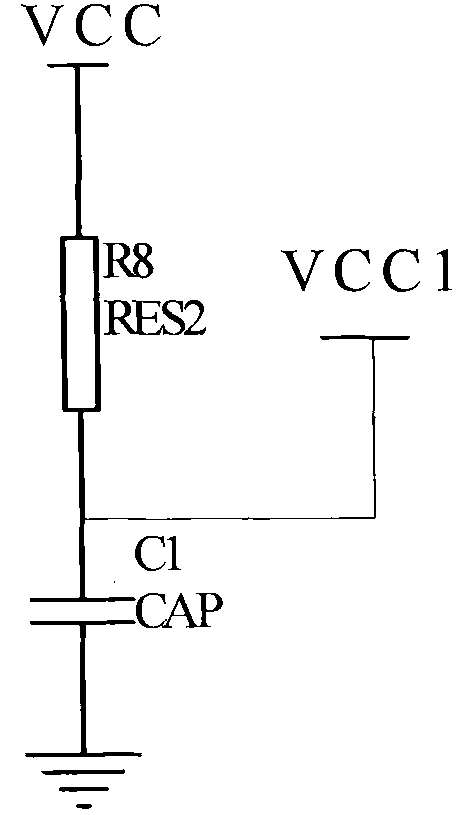

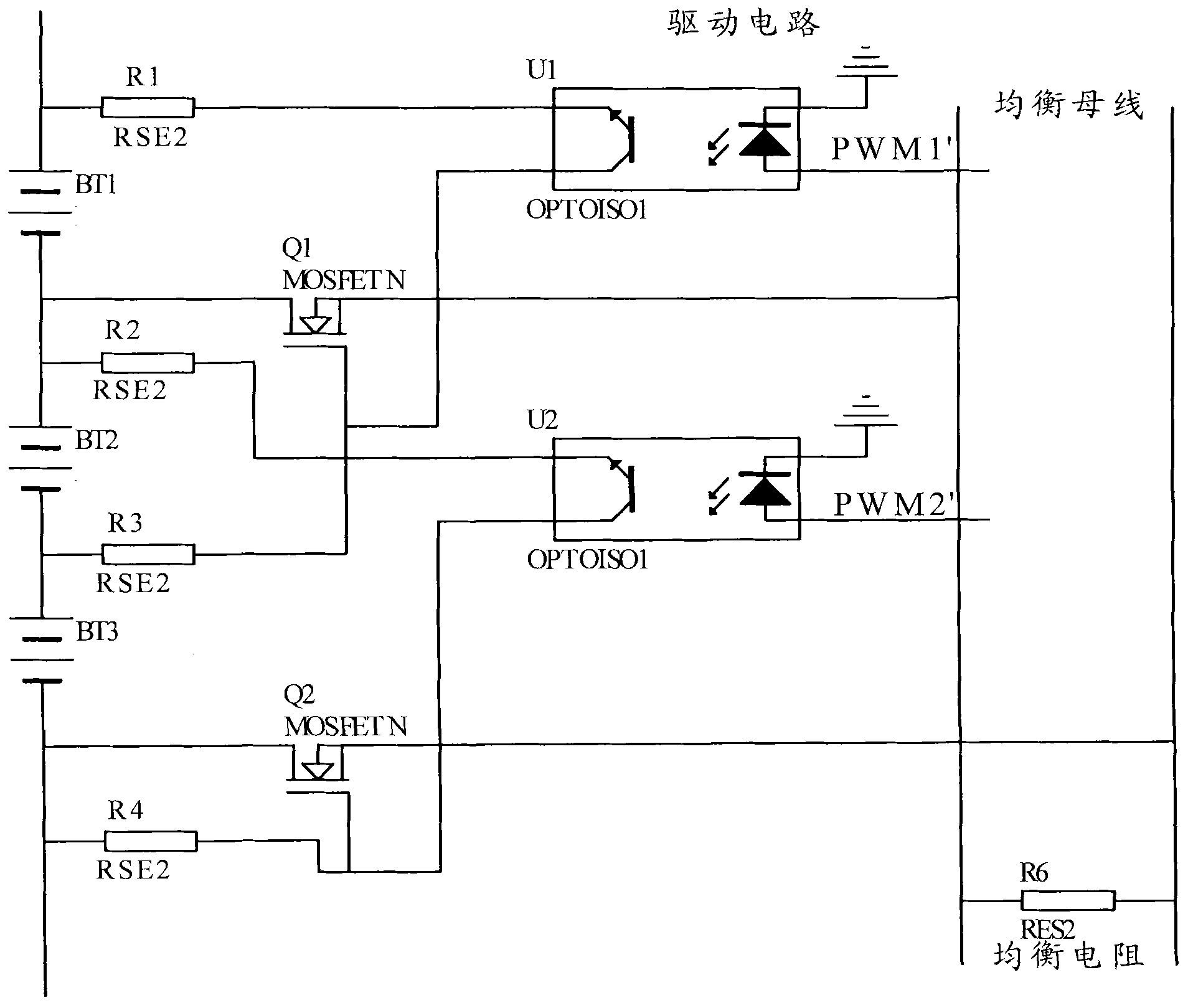

Battery equalizing device

ActiveCN101986508AReduce varianceBatteries circuit arrangementsElectric powerElectricityElectrical resistance and conductance

The invention discloses a battery equalizing device used for equalizing multiple battery units in a battery pack by utilizing an equalizing resistance, which comprises a controller, a resistance switching circuit and the equalizing resistance, wherein the resistance switching circuit is used for connecting the battery units specified by the equalizing resistance and the controller in parallel under the control of the controller; and the controller is used for collecting the voltage value of each battery unit in the multiple battery units, determining the residual electricity quantity of each battery unit according to the collected voltage and controlling the resistance switching circuit to connect the equalizing resistance with the battery unit in parallel under the circumstance that one battery unit meets the switching conditions, wherein the switching condition is as follows: the residual electricity quantity of the battery unit is higher than the specified value of the average residual electricity quantity of the multiple battery units. The battery equalizing device can intelligently equalize the battery units, effectively reduce the difference between the battery units and cansave the volume and the cost of equipment.

Owner:力高(山东)新能源技术股份有限公司

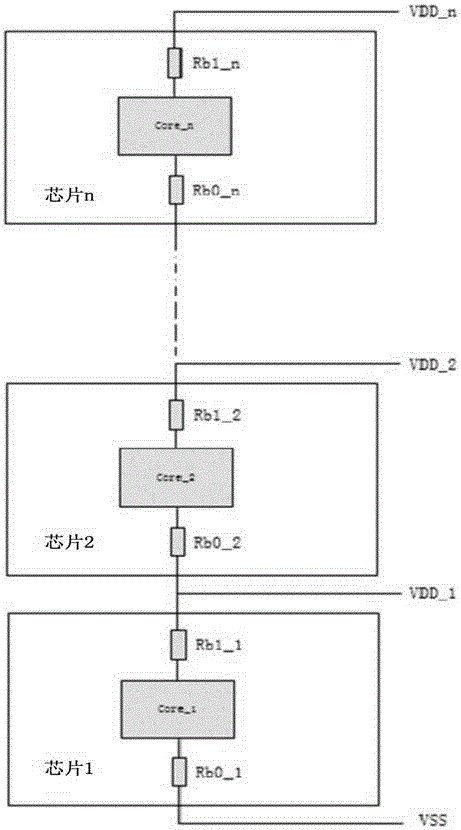

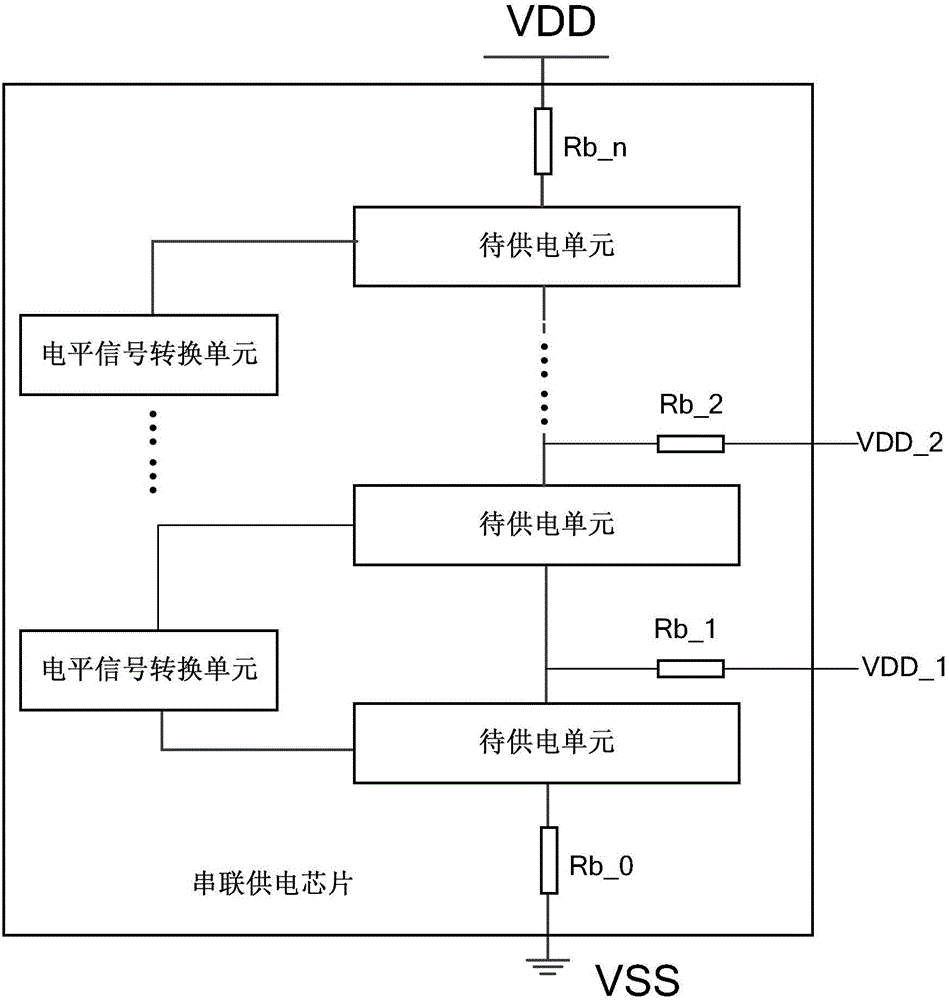

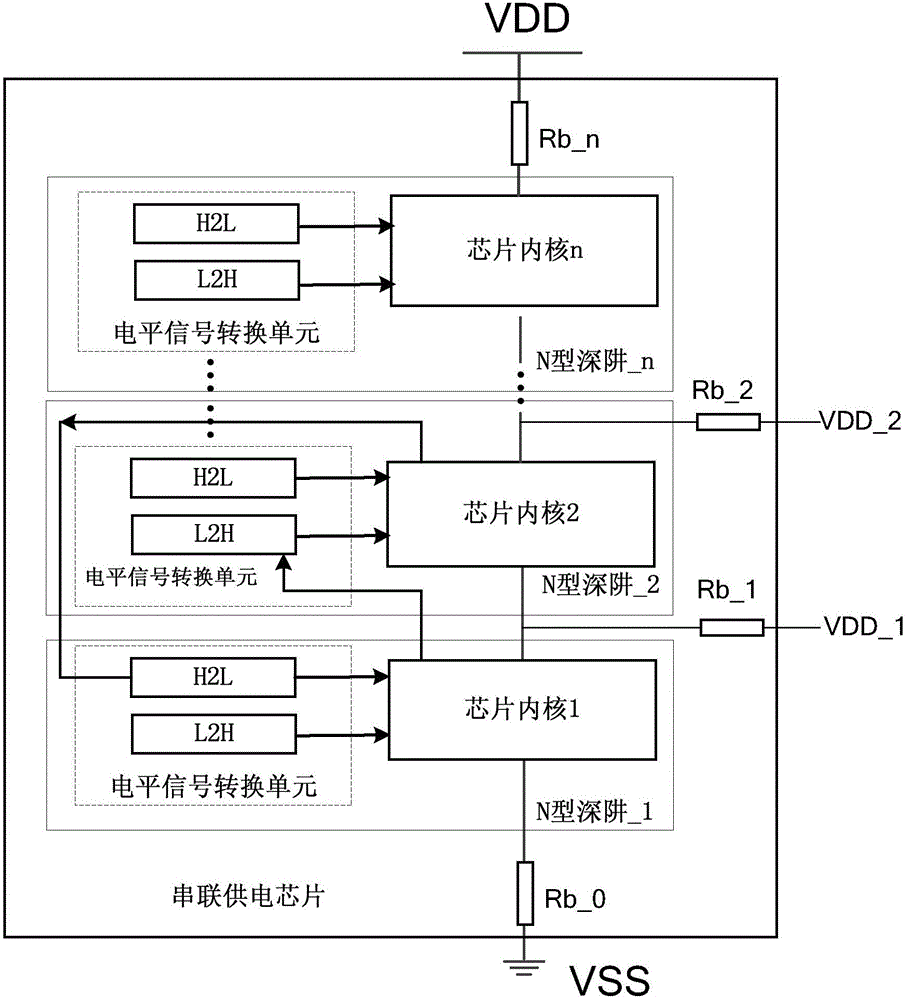

Serial-connection power supply chip, serial-connection power supply system, virtual digital currency mining machine and server

PendingCN106774767AImprove work performanceImprove overall work performanceVolume/mass flow measurementPower supply for data processingPower unitEngineering

An embodiment of the invention discloses a serial-connection power supply chip, a serial-connection power supply system, a virtual digital currency mining machine and a server. The serial-connection power supply chip comprises n serial-connection to-be-powered units which are powered in a serial connection manner, a voltage domain is formed in every to-be-powered unit, and voltage of a power source of the serial-connection power supply chip forms n-stage serial-connection voltage domains, wherein n is an integer more than 1; a signal level conversion unit is serially connected between every two adjacent to-be-powered units and used for communication signal level conversion between every two adjacent to-be-powered units. The serial-connection power supply chip has the advantages that the work performance of the to-be-powered units and the whole work performance of the chip are improved, and the whole production cost is reduced.

Owner:BEIJING BITMAIN TECH LTD

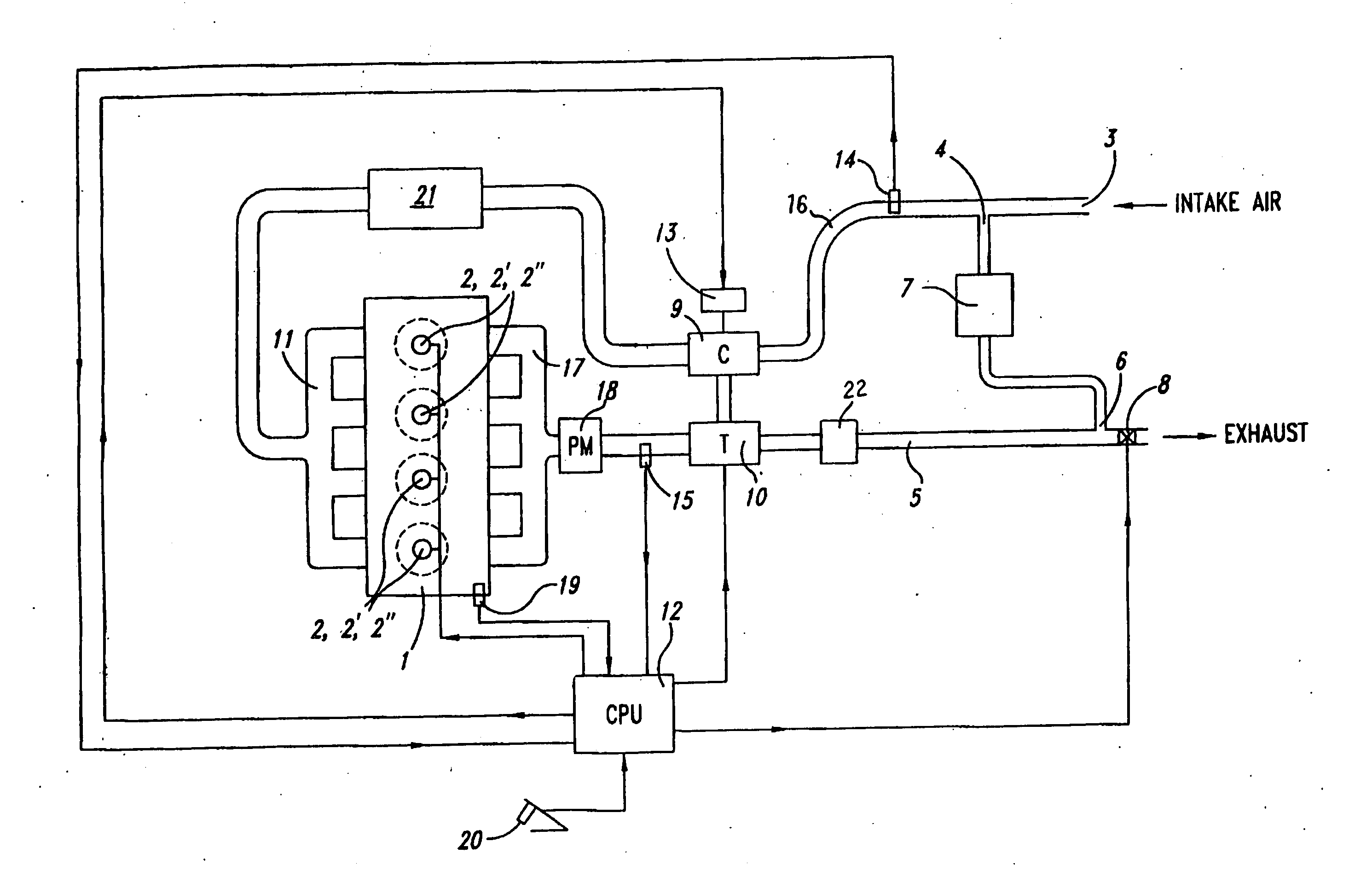

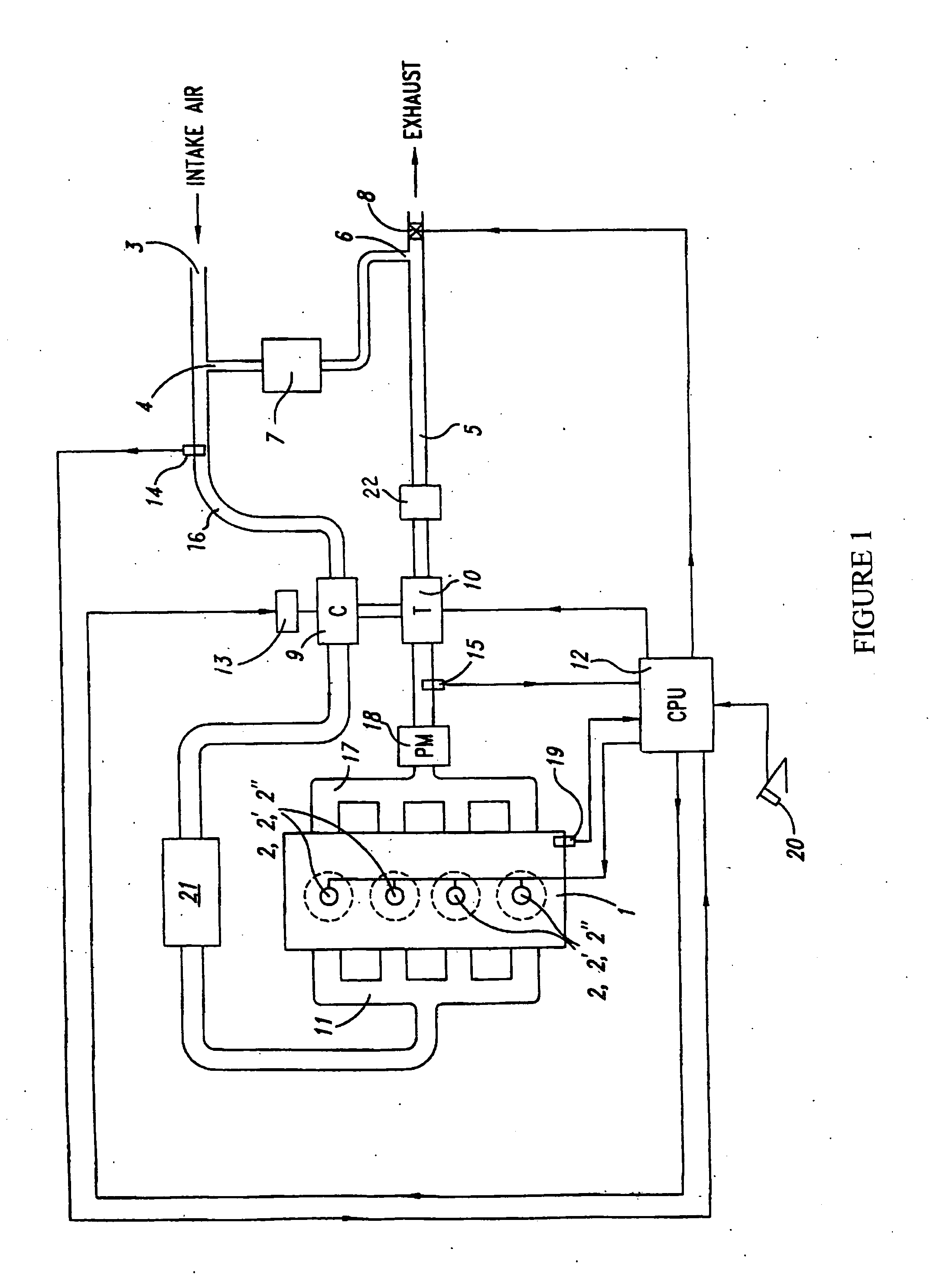

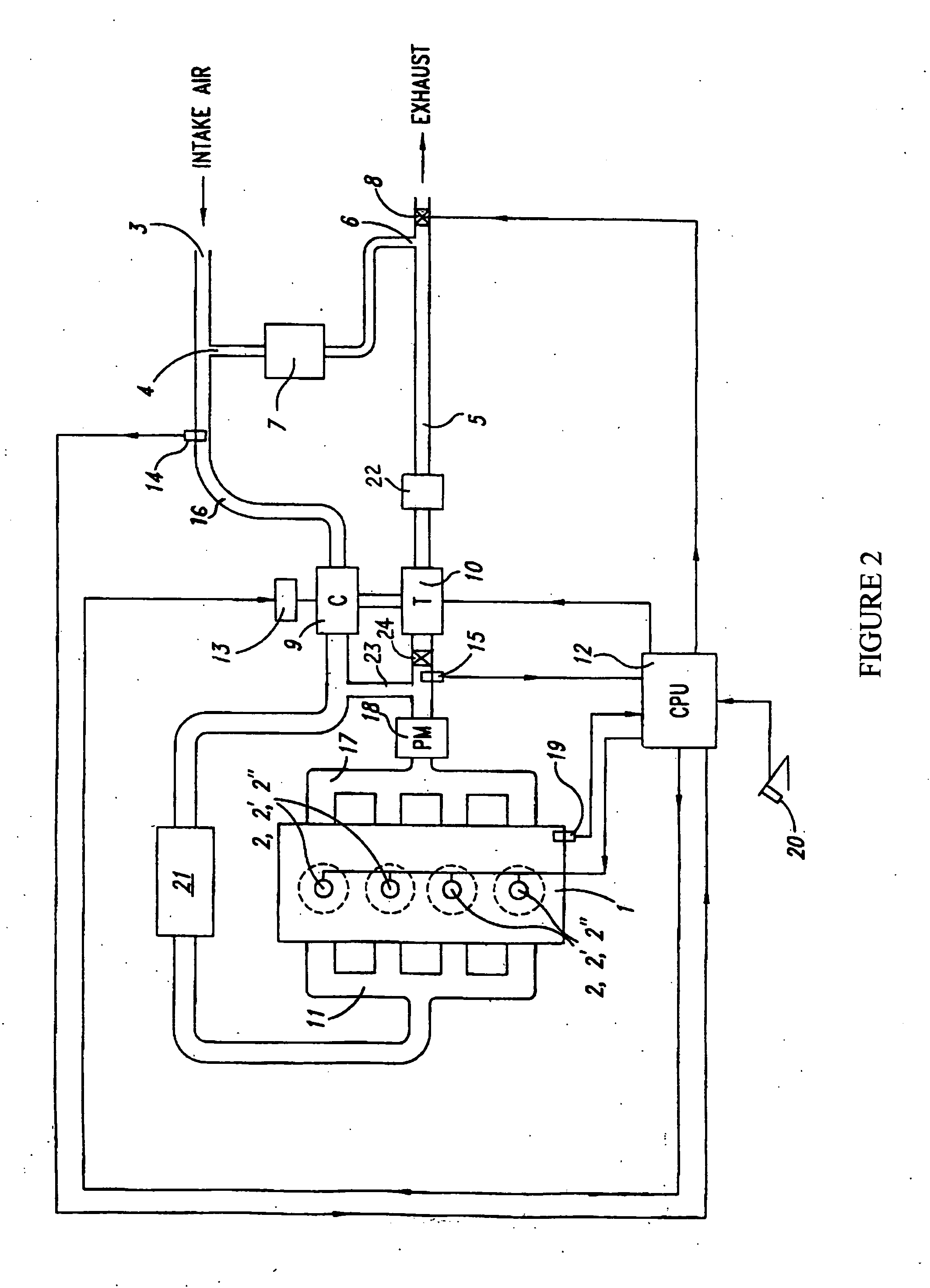

Control methods for low emission internal combustion system

InactiveUS20070220864A1Reduce the formation of nitrogen oxidesImprove transient response timeElectrical controlInternal combustion piston enginesCombustion systemEngineering

Improved transient response times are obtained while maintaining low emissions with a low pressure EGR system through methods for quickly obtaining a desired oxygen concentration for charge-air to be used for combustion. Under a first method, fuel quantity in the main combustion event is controlled in the combustion process to produce exhaust around a relatively constant target exhaust oxygen concentration value. By keeping the exhaust oxygen concentration levels at a relatively constant value, lag time in waiting for low pressure EGR valve adjustments during transients may be avoided, and the system's air handling response to meet transients may be paced solely by adjusting the mass of air to be supplied (i.e. boost response). Under a second method, a multiple-stage combustion process is utilized, in which fuel feed is controlled in a small, preliminary HCCI-type combustion event in order to produce a target oxygen concentration of charge-air to be used for the second, main combustion event. Under a third method, exhaust rebreathing is used to produce a target oxygen concentration of charge-air to be used for combustion.

Owner:US EPA OFFICE OF GENERAL COUNSEL UNITED STATES OF AMERICA THE

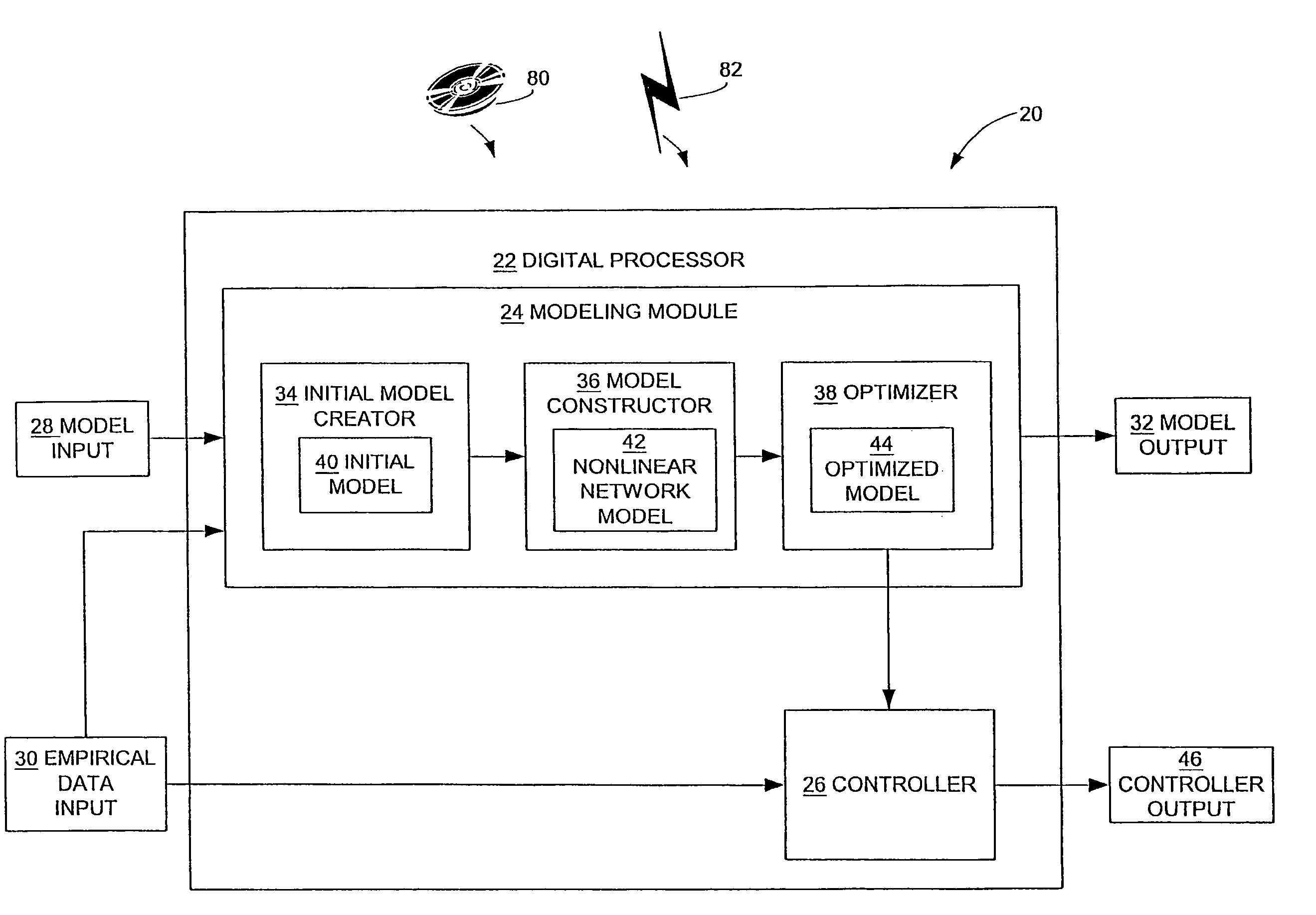

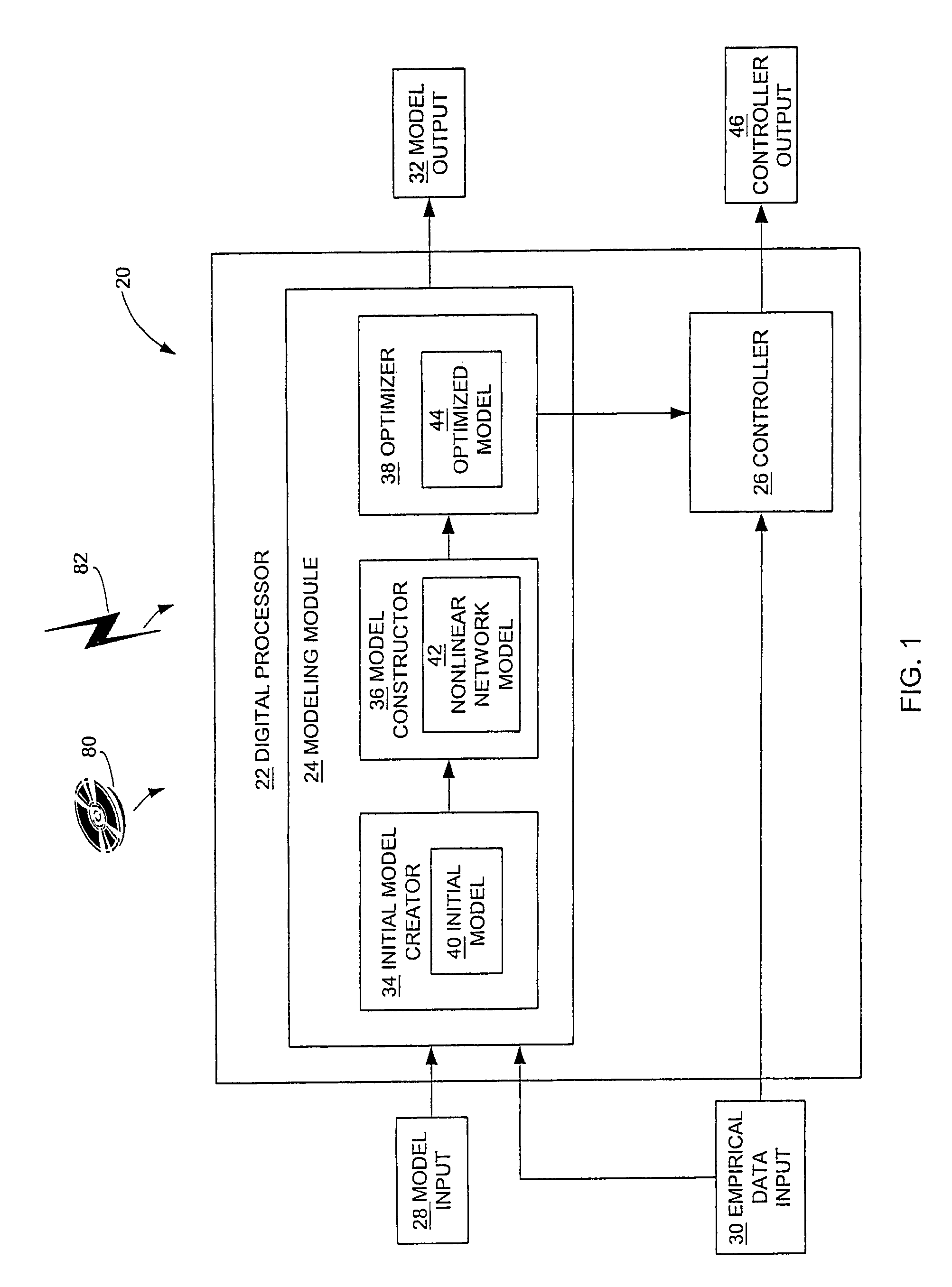

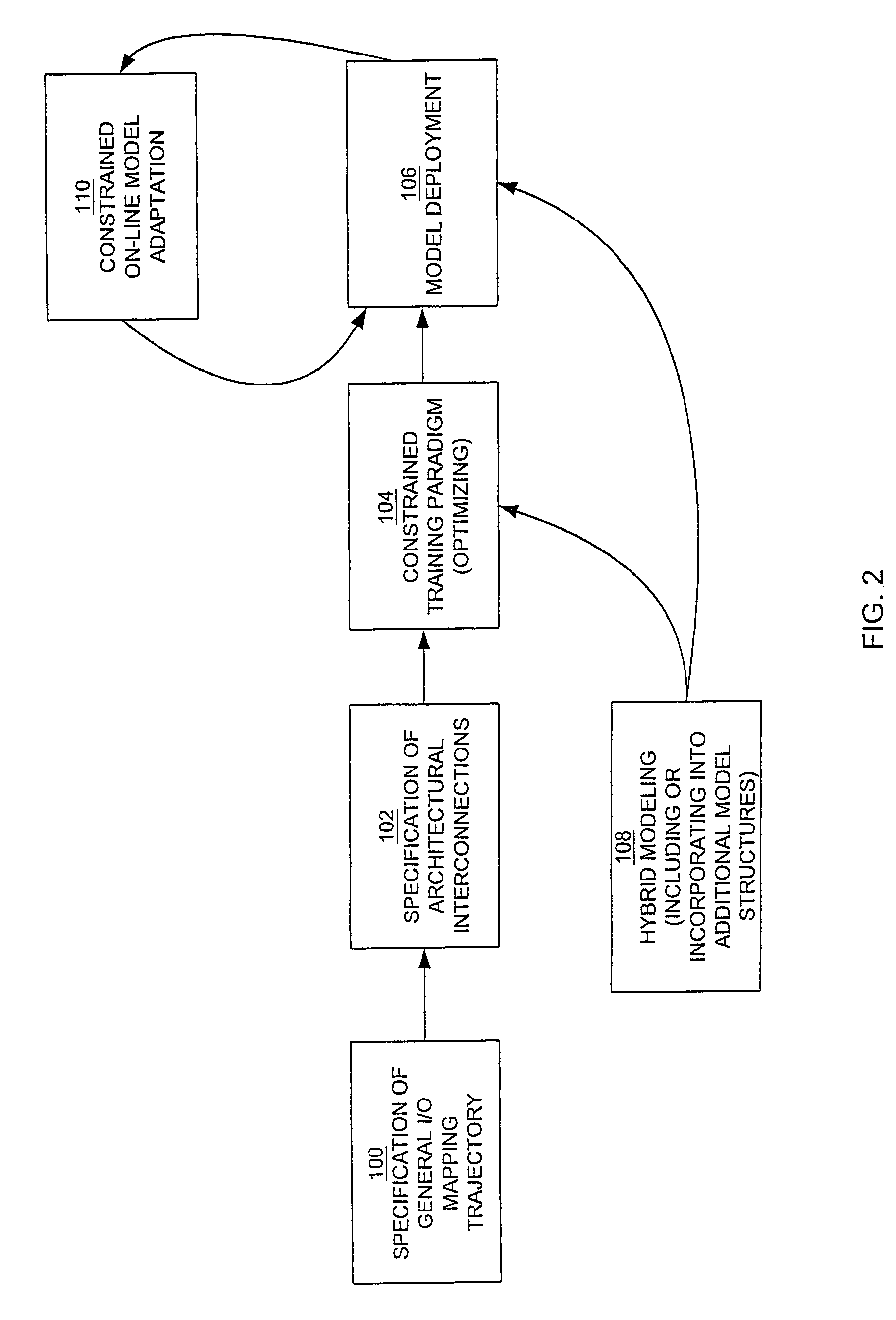

Computer method and apparatus for constraining a non-linear approximator of an empirical process

InactiveUS7630868B2Predict and controlReduce varianceSimulator controlAnalogue computers for electric apparatusNonlinear approximationGraphics

A constrained non-linear approximator for empirical process control is disclosed. The approximator constrains the behavior of the derivative of a subject empirical model without adversely affecting the ability of the model to represent generic non-linear relationships. There are three stages to developing the constrained non-linear approximator. The first stage is the specification of the general shape of the gain trajectory or base non-linear function which is specified graphically, algebraically or generically and is used as the basis for transfer functions used in the second stage. The second stage of the invention is the interconnection of the transfer functions to allow non-linear approximation. The final stage of the invention is the constrained optimization of the model coefficients such that the general shape of the input / output mappings (and their corresponding derivatives) are conserved.

Owner:ASPENTECH CORP

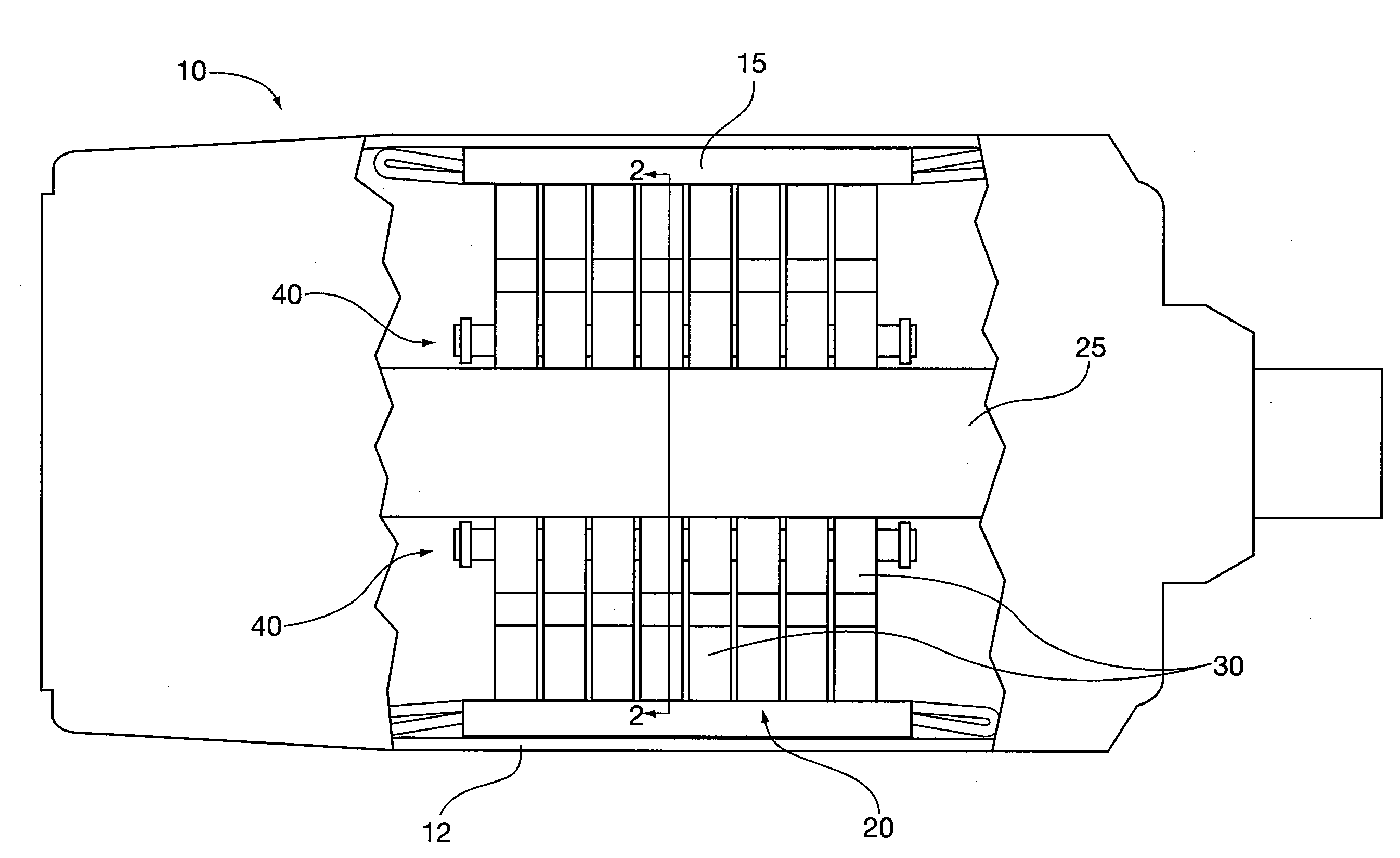

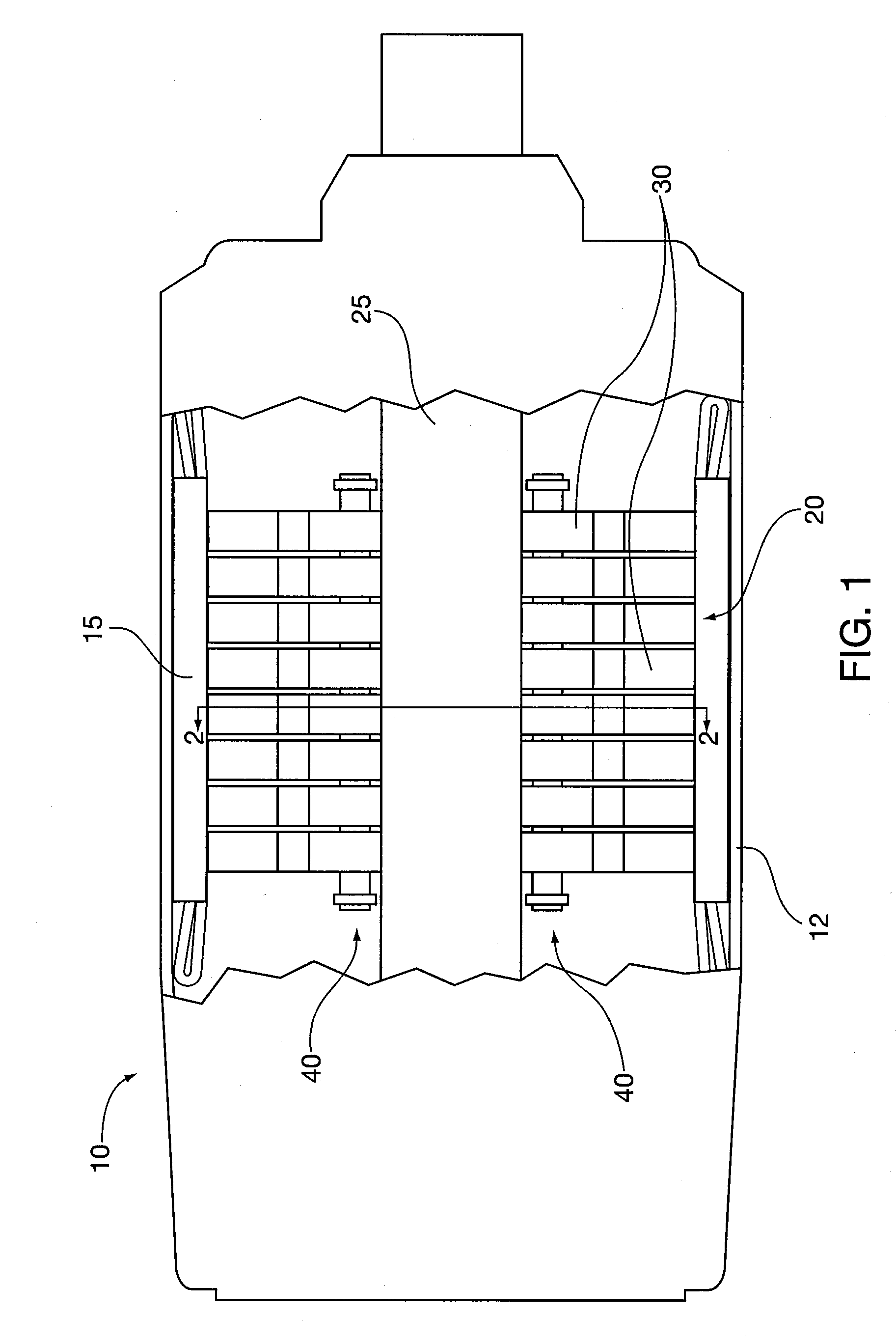

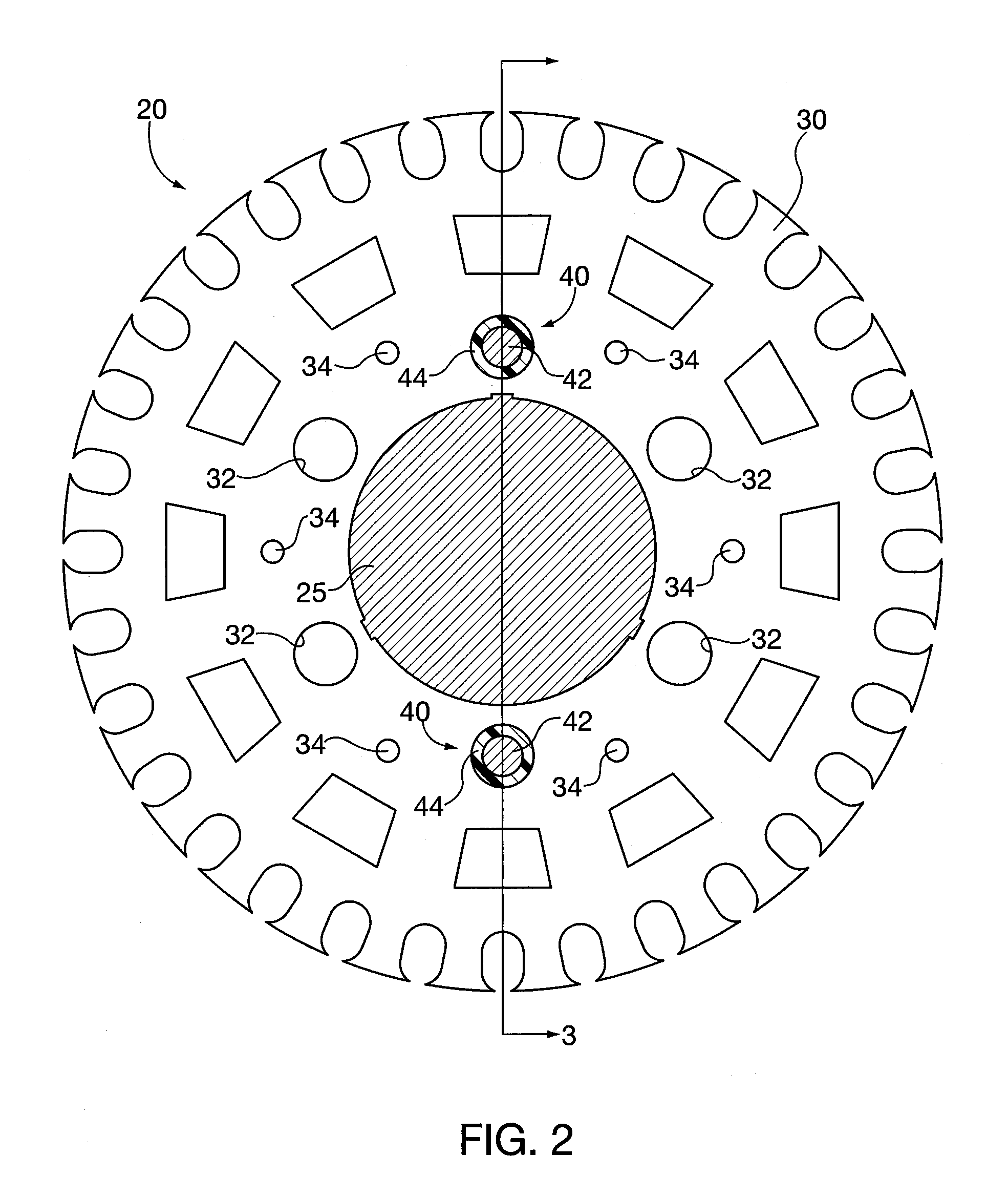

Method of Tuning Bending and Torsion Stiffness of Ducted Rotor Core of An Induction Motor

ActiveUS20110074242A1Change stabilityMotor critical vibration speed can be alteredMagnetic circuit rotating partsStatic/dynamic balance measurementInduction motorMotor vibration

Electrodymamic machine rotating mass, including for example induction motor rotors, stiffness tuning methods include selective orientation and compression of modular tie rod assemblies into through bores formed in the rotor lamination core outboard of the rotor shaft during motor manufacture, repair or refurbishment. Stiffness tuning enables a motor manufacturer to tune a rotor's rotordynamic stability, and hence the assembled motor's critical vibration speed. Electrodynamic machine rotating mass tuning can be adjusted in response to machine physical design, operational application and manufacturing variation attributes that impact the assembled machine's critical vibration frequency. Thus the present invention offers a systematic, holistic approach to motor vibration refinement through use of a simple kit of modular tie rod assemblies oriented and tightened in a selected array. Rotor stiffness tuning can be tested virtually on computer work stations. Additional actual rotor stiffness tuning can be performed during manufacture.

Owner:INNOMOTICS LLC

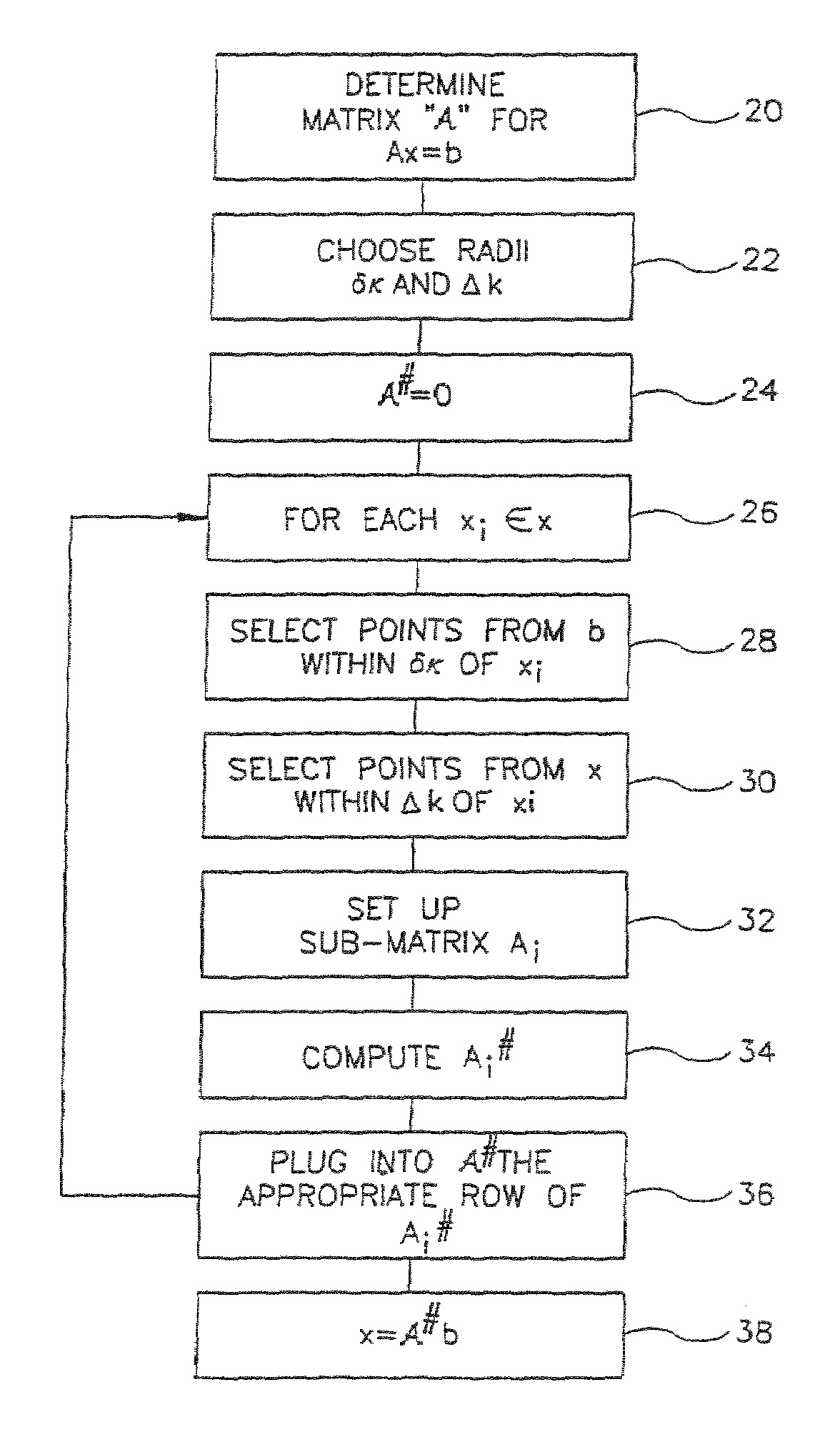

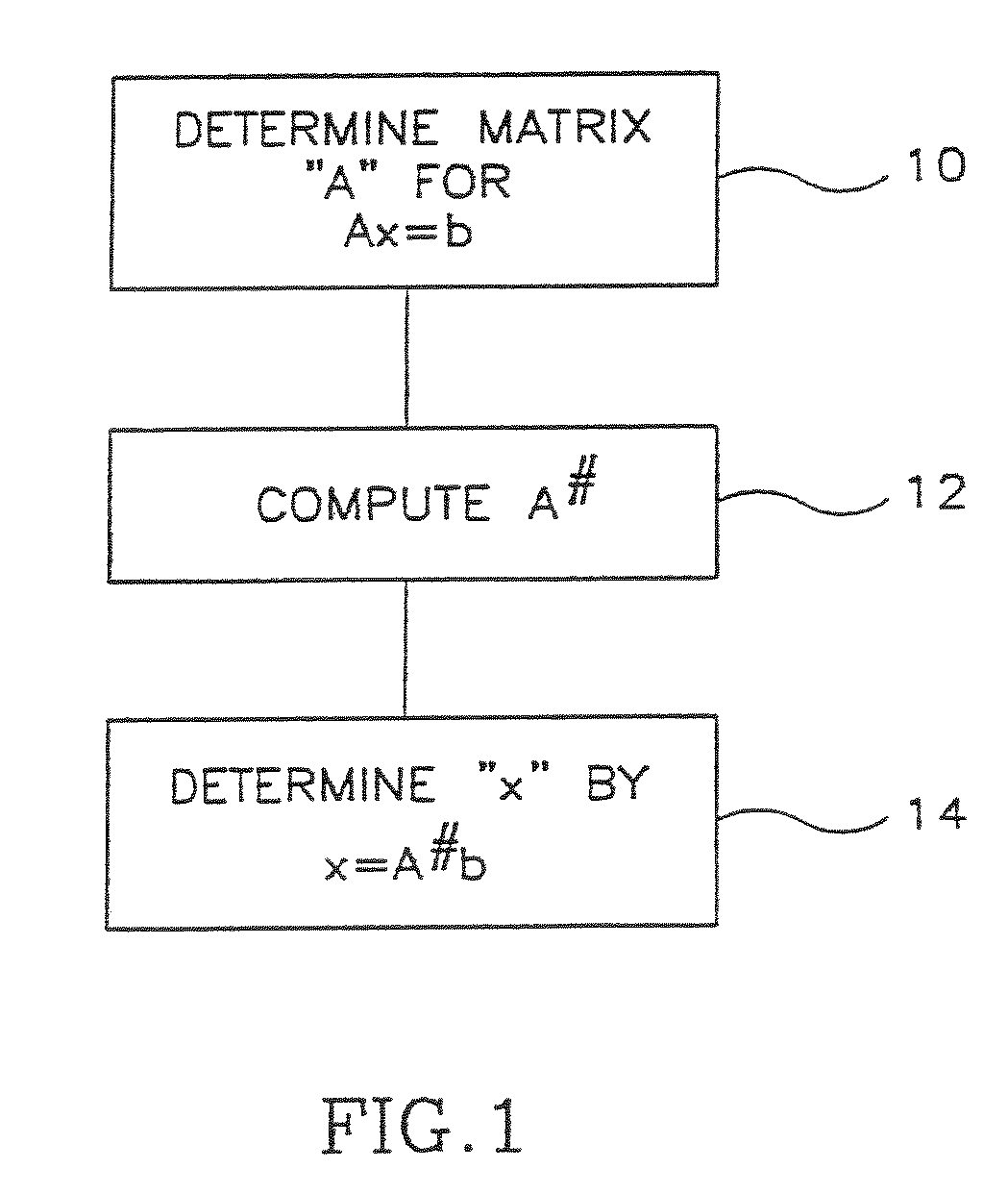

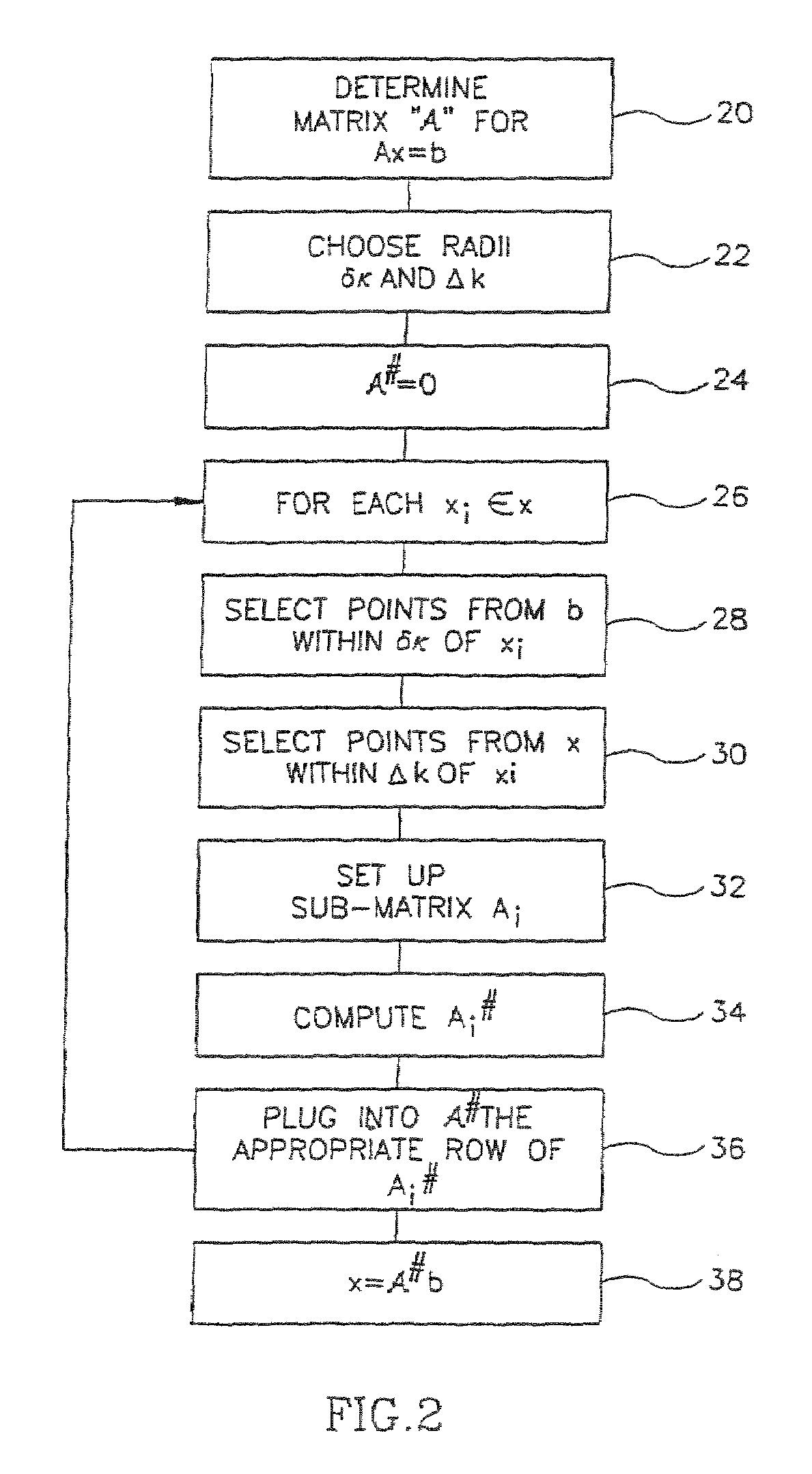

Algebraic reconstruction of images from non-equidistant data

InactiveUS7076091B2Computationally efficientReduce errorsGeometric image transformationCharacter and pattern recognitionMedical imaging dataComputer science

A method of resampling medical imaging data from a first spatial distribution of data points onto a second spatial distribution of data points, including determining a matrix of reverse interpolation coefficients for resampling data from said second spatial distribution onto said first spatial distribution, inverting a matrix based on said reverse interpolation matrix to determine forward resampling coefficients for resampling data from said first spatial distribution to said second spatial distribution, and resampling data from said first spatial distribution onto said second spatial distribution using said forward resampling coefficients.

Owner:GENERAL ELECTRIC CO

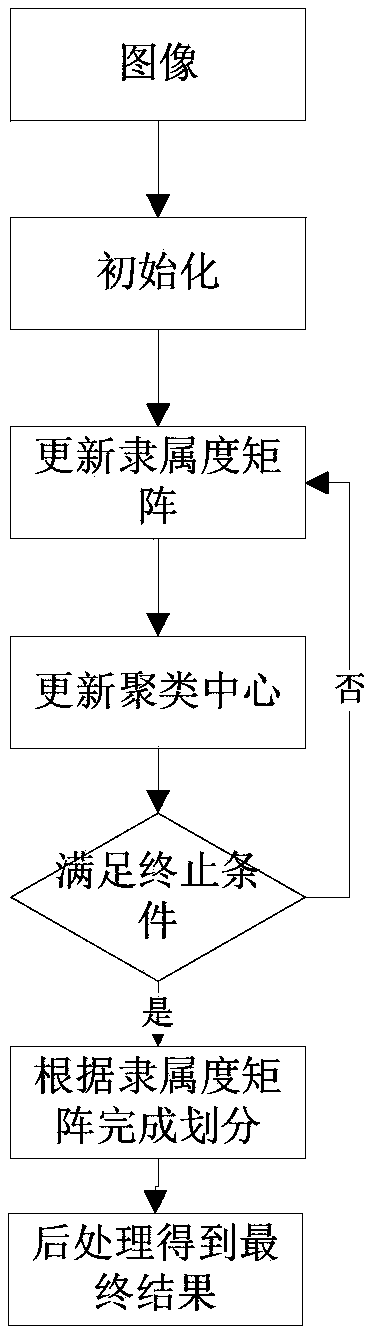

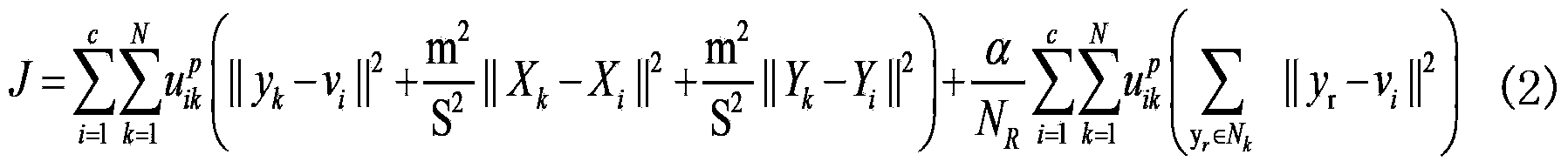

Superpixel segmentation method based on fuzzy theory

ActiveCN103353987AGood welt performanceImprove robustnessImage analysisCluster algorithmPattern recognition

The invention relates to a superpixel segmentation method based on the fuzzy theory. The superpixel segmentation method improves fitness of superpixel edges and original image edges, and segmented superpixels have an undiversified internal structure and uniform gray scale. The superpixel segmentation method comprises steps of 1) processing images and initializing cluster centers; 2) adding coordinate distances of pixel points into the fuzzy C-means clustering algorithm and establishing an objective function; 3) updating a membership matrix; 4) updating cluster centers with gray scale values and coordinates included; 5) repeating steps 3) and 4) until a termination condition that the change amount of the cluster center gray scale values is smaller than an artificially set threshold value or iteration times are larger than some artificially set value; 6) completing initial superpixel division based on the finally obtained membership matrix; and 7) performing post-processing to complete the final superpixel division by combining sets of points ,which are isolated and unavoidably exist in superpixels generated after the above six steps, with adjacent superpixels which have the maximum similarity.

Owner:山东幻科信息科技股份有限公司

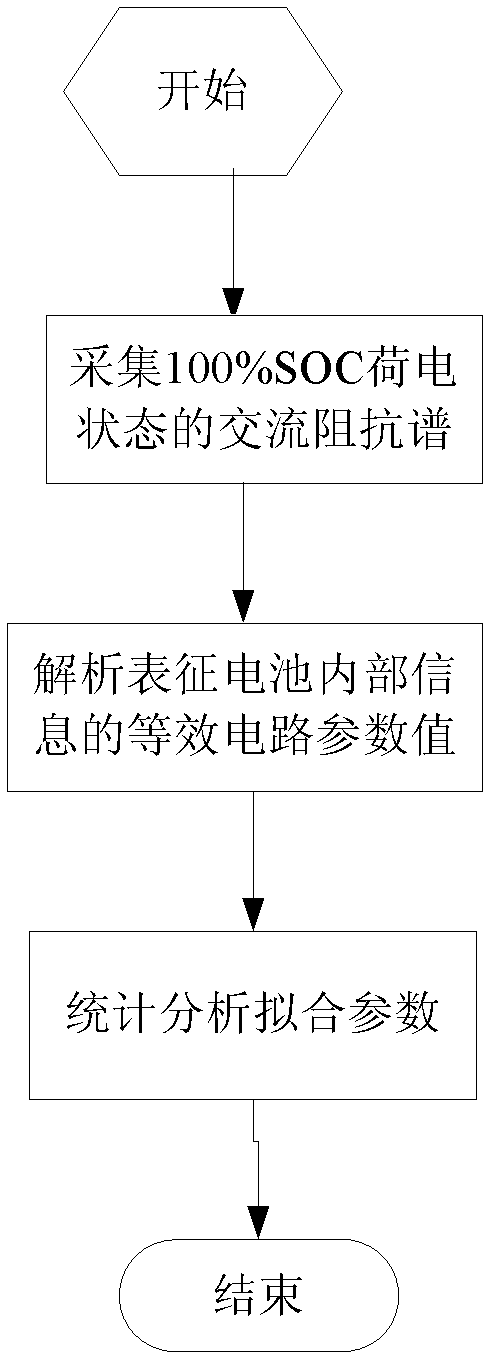

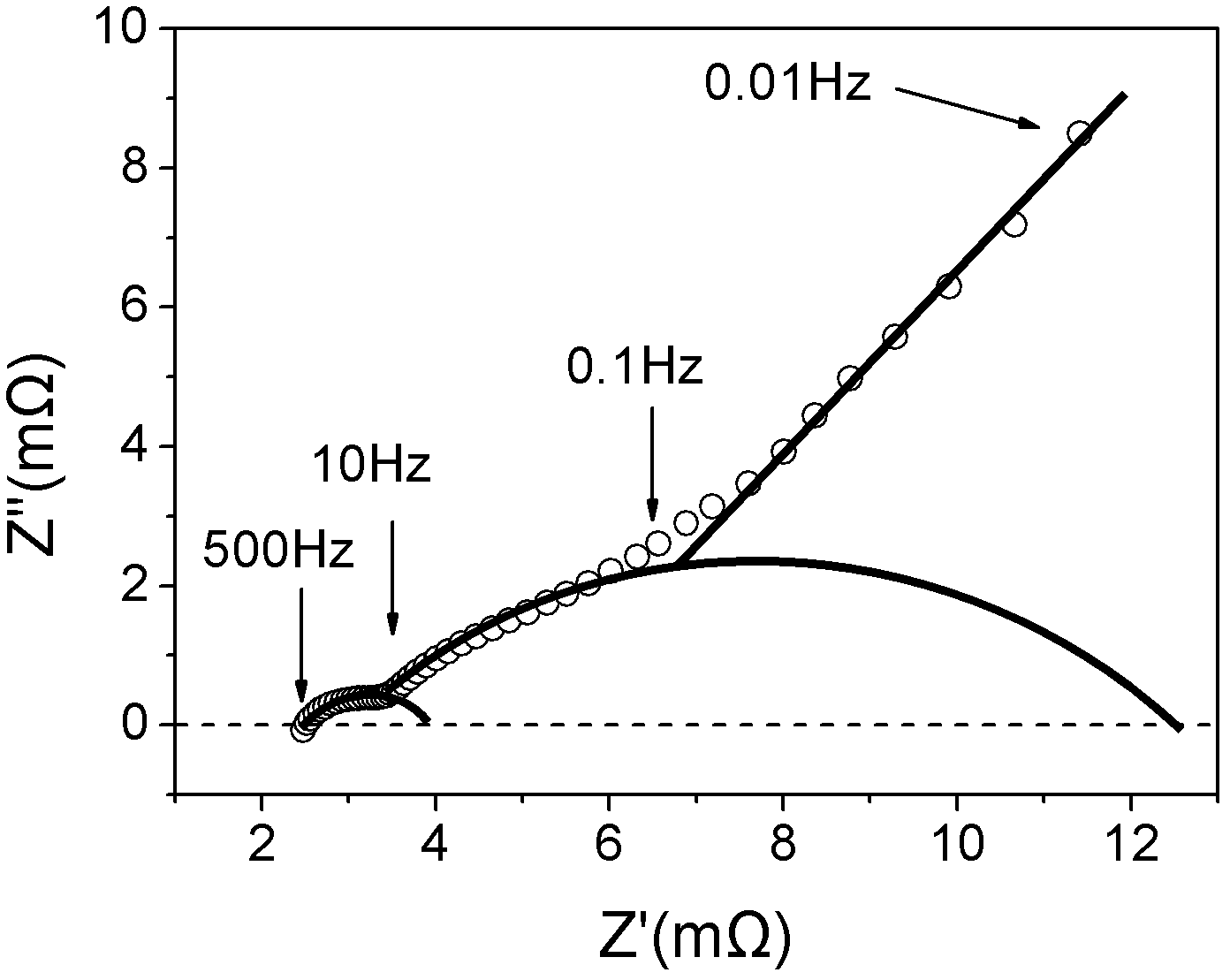

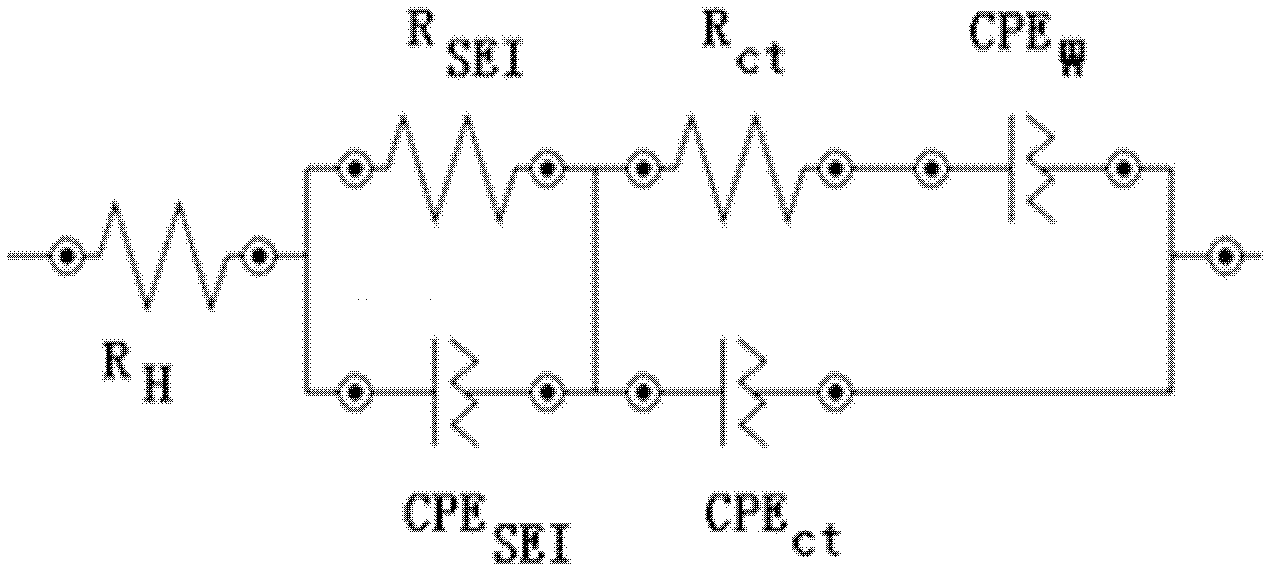

Battery sorting method based on alternating-current impedance spectrum

ActiveCN102553838AAccurate reflection of healthAccurately reflects electrolyte concentrationSortingLithiumElectrical battery

The invention relates to a lithium ion secondary battery, in particular to a sorting method based on an alternating-current impedance spectrum. The method comprises the steps of (1) acquiring the alternating-current impedance spectrum; (2) analyzing equivalent-circuit parameters; and (3) conducting statistic analysis on the equivalent-circuit parameters. In the method provided by the invention, an electrode structure inside a battery system can be detected without damaging a battery, the inner information such as health condition of the battery, the electrolyte concentration, diaphragms and SEI (Solid Electrolyte Interface) membranes are accurately reflected; and according to the information, the coefficient of concordance is calculated by utilizing the principle of statistics, so that the consistency of the inner structure of the sorted battery can be ensured sufficiently, the differences of the sorted batteries are reduced obviously, and the defects of a sorting method in prior arts can be overcome.

Owner:许昌许继电科储能技术有限公司

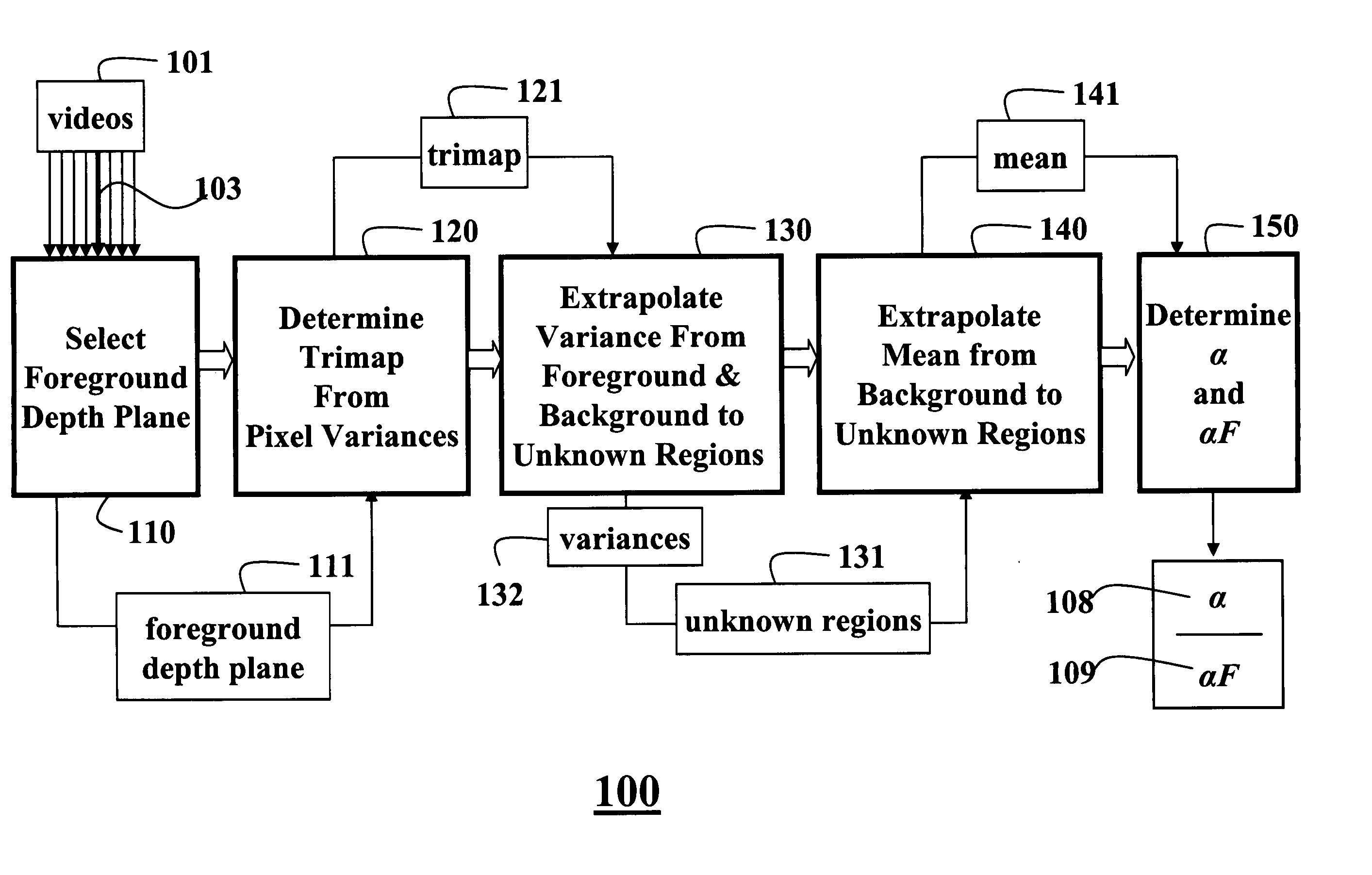

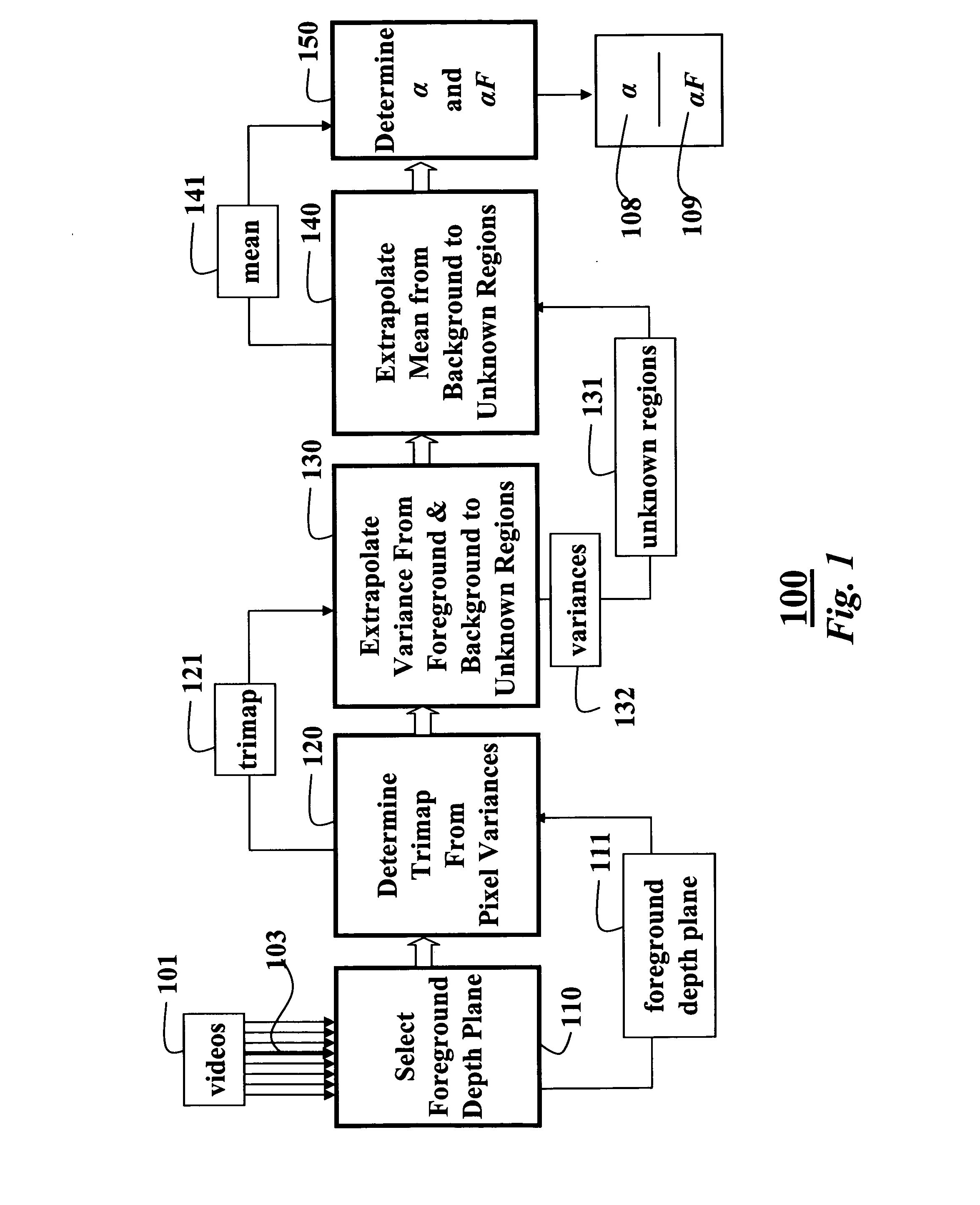

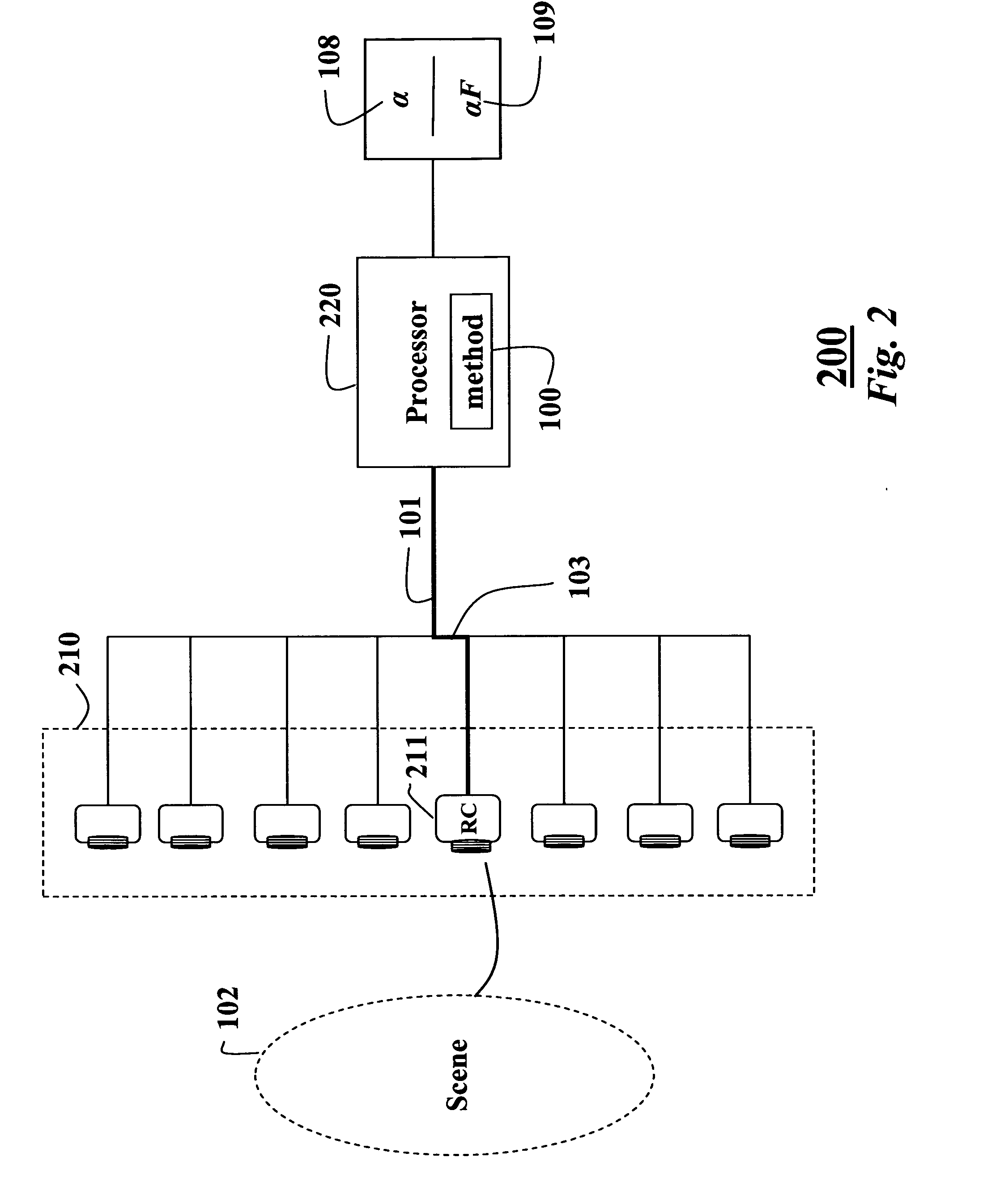

Video matting using camera arrays

InactiveUS20070070200A1High-qualityReduce varianceTelevision system detailsCharacter and pattern recognitionDepth planeCamera array

A method and system for determining an alpha matte for a video is presented. A set of videos is acquired by an array of cameras. A centrally located camera in the array is designated as a reference camera and acquires a reference video. A foreground depth plane is selected from the set of videos. A trimap is determined from variances of pixel intensities in each image. Variances of the intensities of pixels labeled as background and pixels labeled as foreground are extrapolated to the pixels labeled as unknown in the trimap. Means of the intensities of the pixels labeled as background are extrapolated to the pixels labeled as unknown to determine an alpha matte for the reference video.

Owner:MITSUBISHI ELECTRIC RES LAB INC

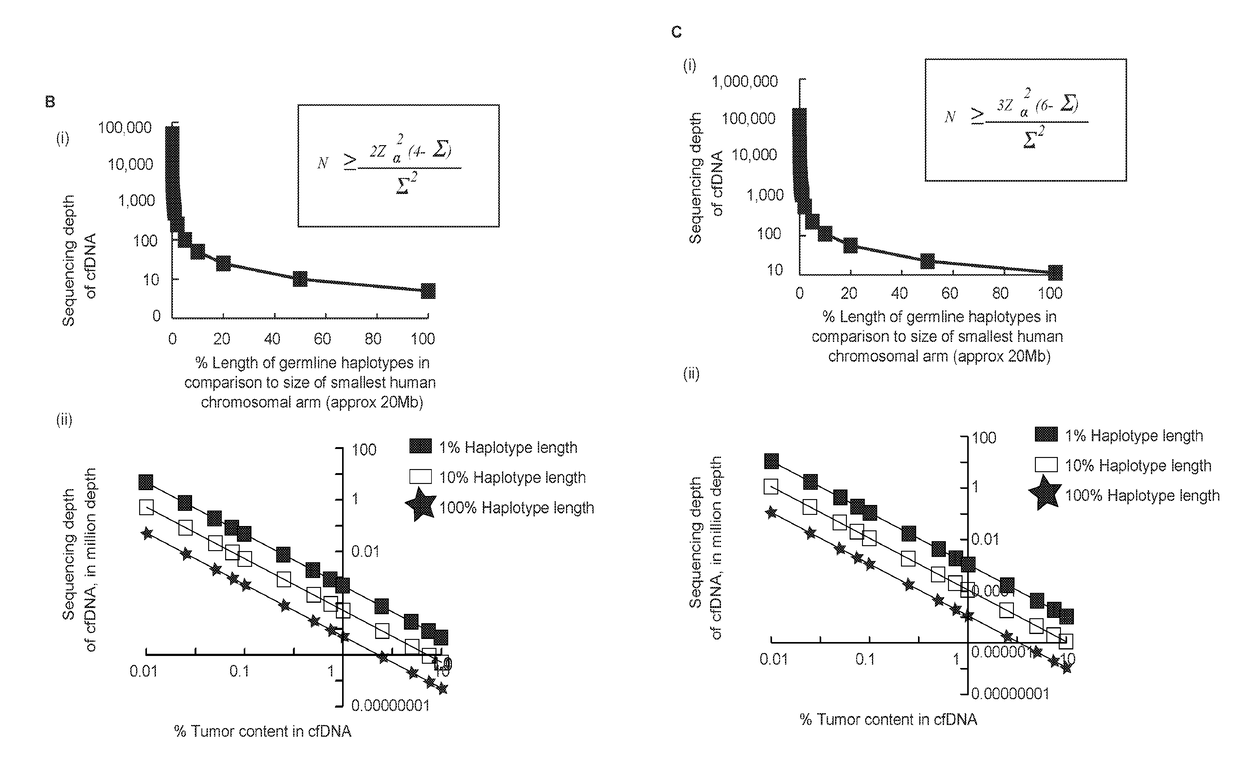

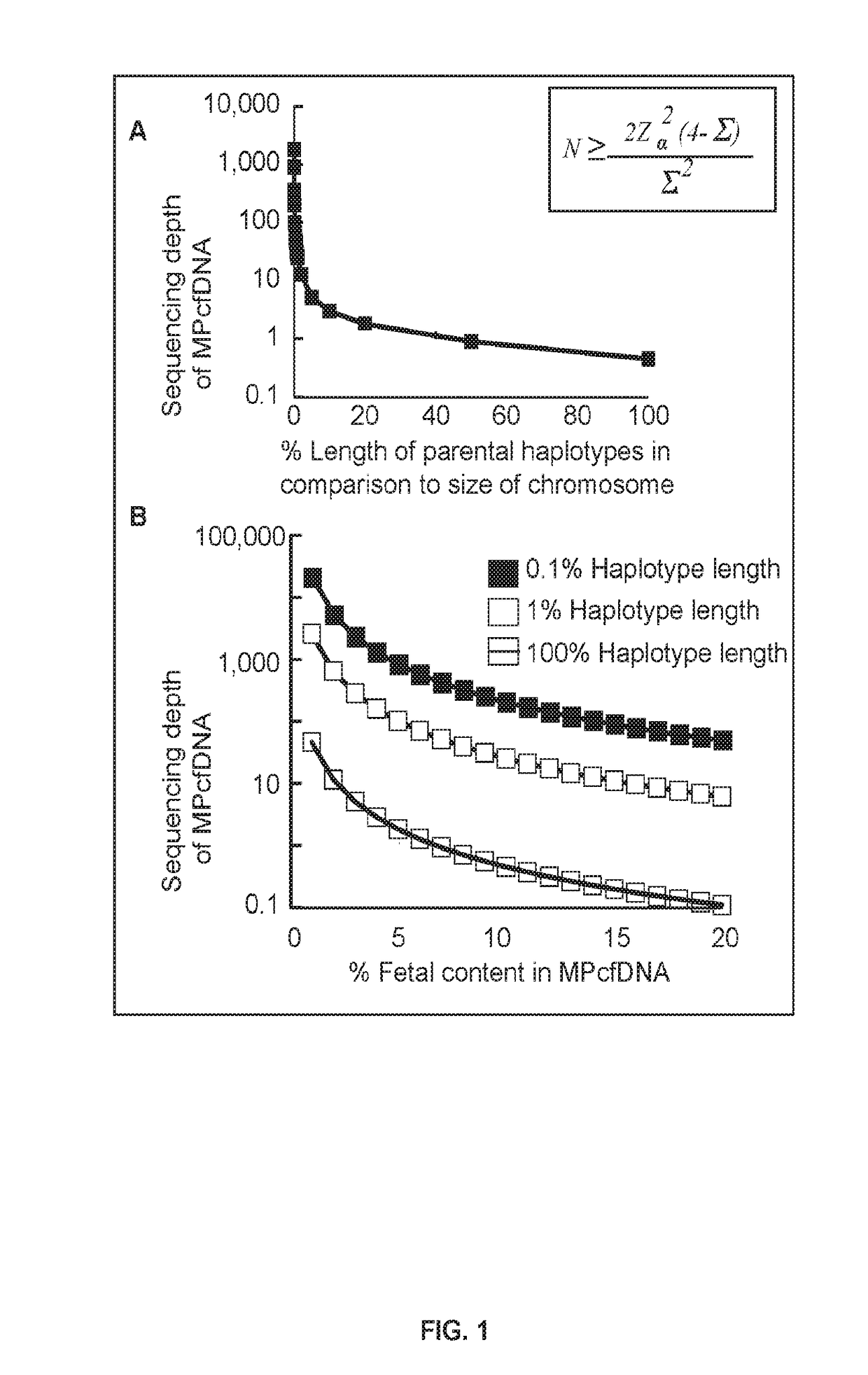

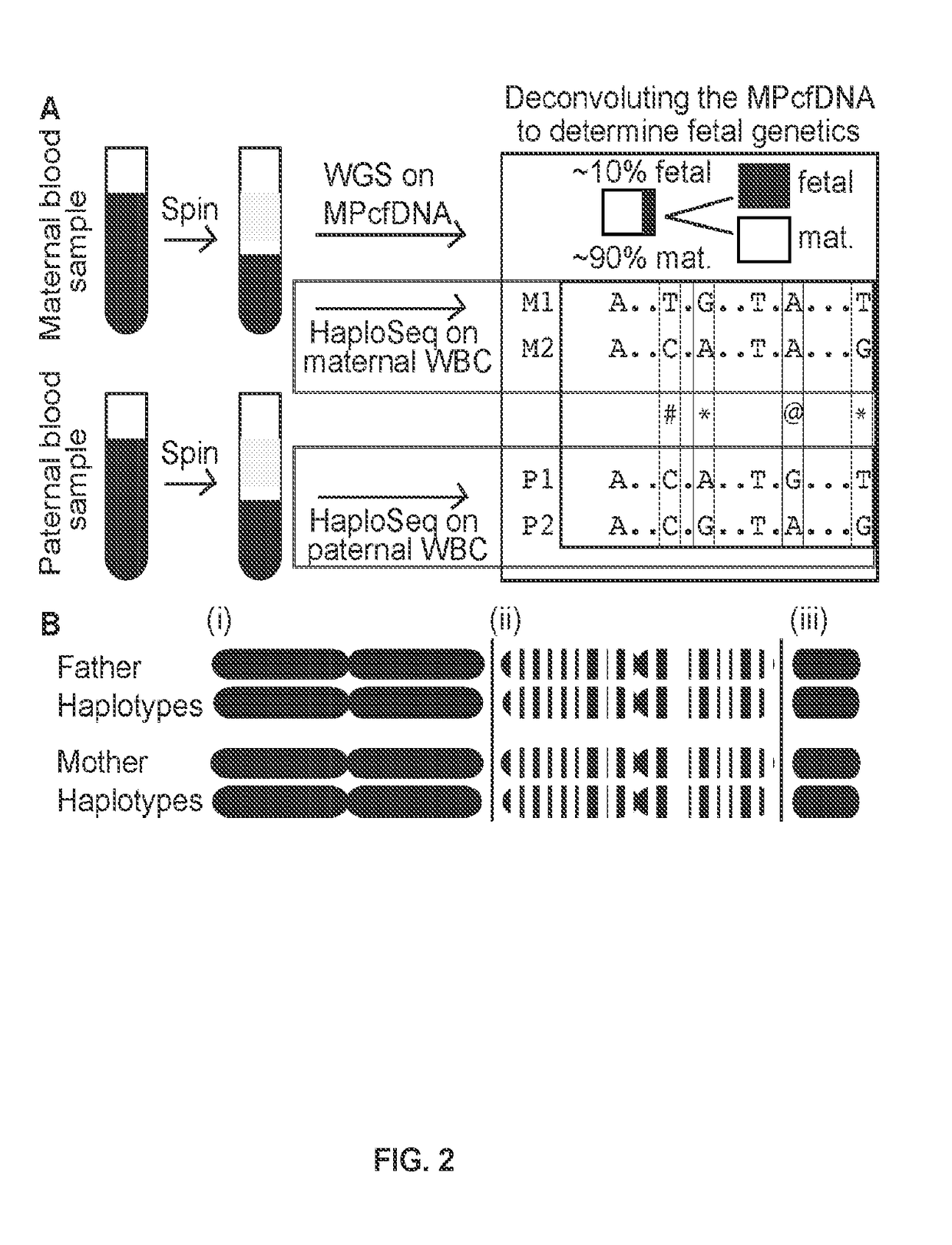

Accurate molecular deconvolution of mixture samples

PendingUS20180187241A1Reduce varianceAccurate deconvolutionMicrobiological testing/measurementBiostatisticsNon invasiveBlood plasma

The present disclosure relates to methods to deconvolute a mixture sample of genetic material from different origins or sources. The disclosed methods can be used in various applications, including, the non-invasive determination of a fetal genome, a fetal -ome (e.g. exome). or other targeted fetal locus from cell-free nucleic acids in maternal plasma or other body fluids; the de-termination of cancer-associated mutations from cell-free nucleic acids in a body fluid sample that contains a mixture of nucleic acids from normal cells and tumor cells; and quantification of donor cell contamination using a body fluid from a transplantation recipient to monitor and / or predict the outcome of a transplantation procedure.

Owner:ARIMA GENOMICS INC

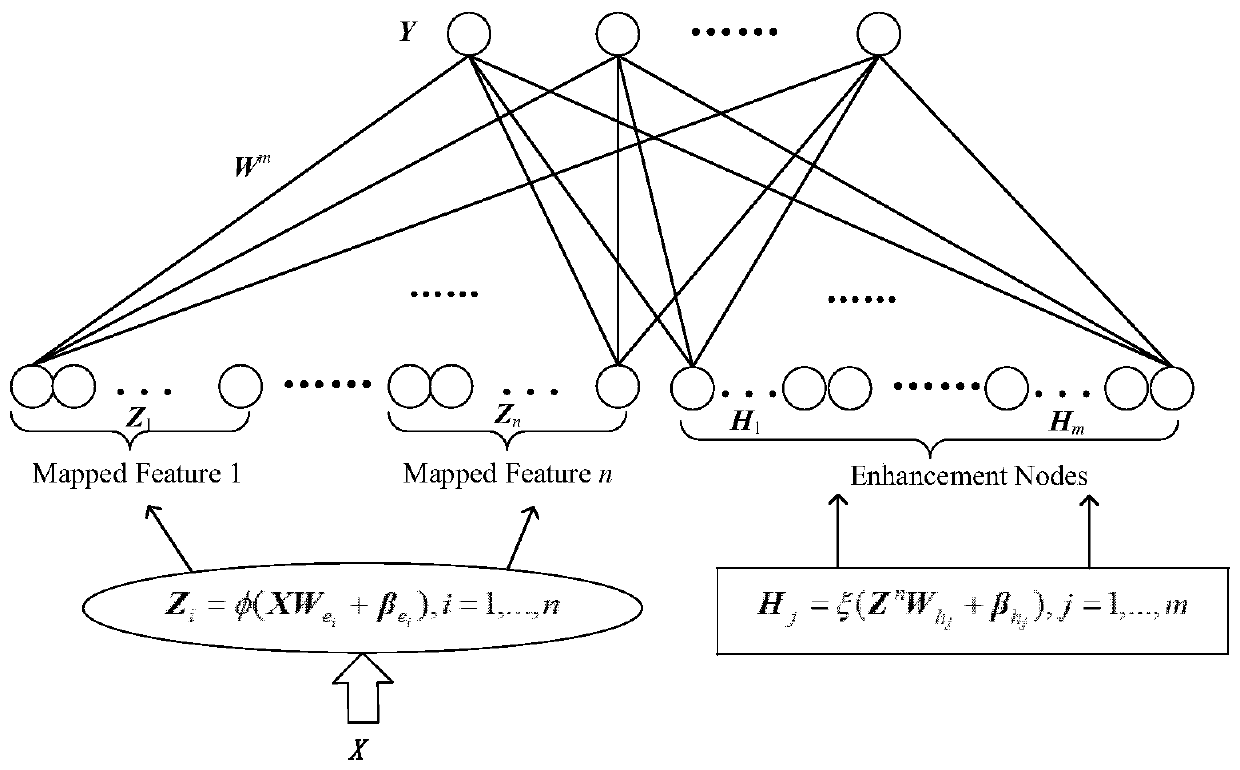

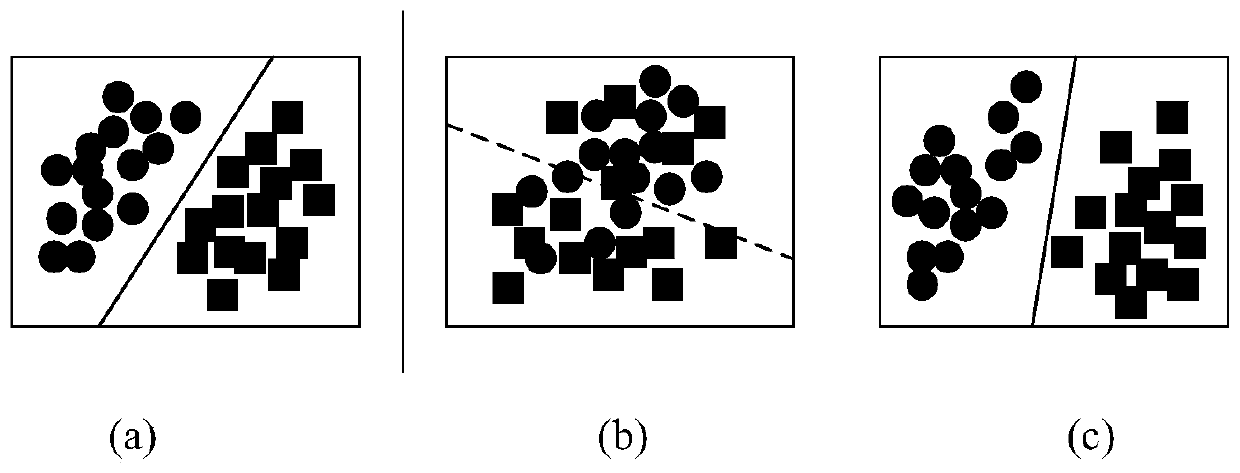

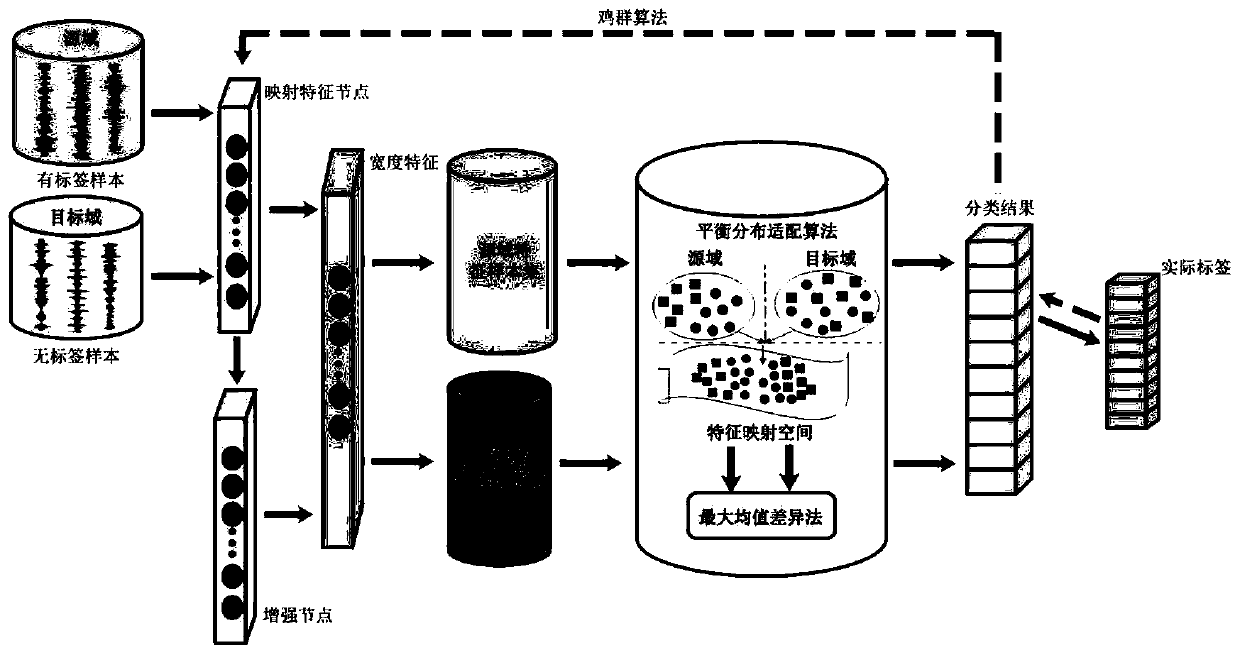

Width transfer learning network and rolling bearing fault diagnosis method based on same

ActiveCN110849627ASimple network structureFast trainingMachine part testingMachine learningMachine learningNetwork model

The invention discloses a width transfer learning network and a rolling bearing fault diagnosis method based on the same, and belongs to the technical field of bearing fault diagnosis. The invention provides a novel width transfer learning network and a rolling bearing intelligent diagnosis method based on the same, and aims to solve the problems of scarcity of vibration data with mark informationof a rolling bearing under a variable load, large distribution difference between source domain data and target domain data in the same state, unbalanced distribution of multi-state data and low diagnosis accuracy and model training efficiency. According to the invention, a width learning system is utilized to extract features of source domain data and target domain data and construct a sample set, and on the basis, a balanced distribution adaptation method in transfer learning is adopted to reduce the difference between a source domain and a target domain. A chicken swarm algorithm is introduced to optimize width transfer learning network parameters and establishing a width transfer learning network model. The proposed network model is applied to rolling bearing fault intelligent diagnosis under the variable load, and an experimental result verifies the high efficiency and accuracy of the proposed method.

Owner:HARBIN UNIV OF SCI & TECH

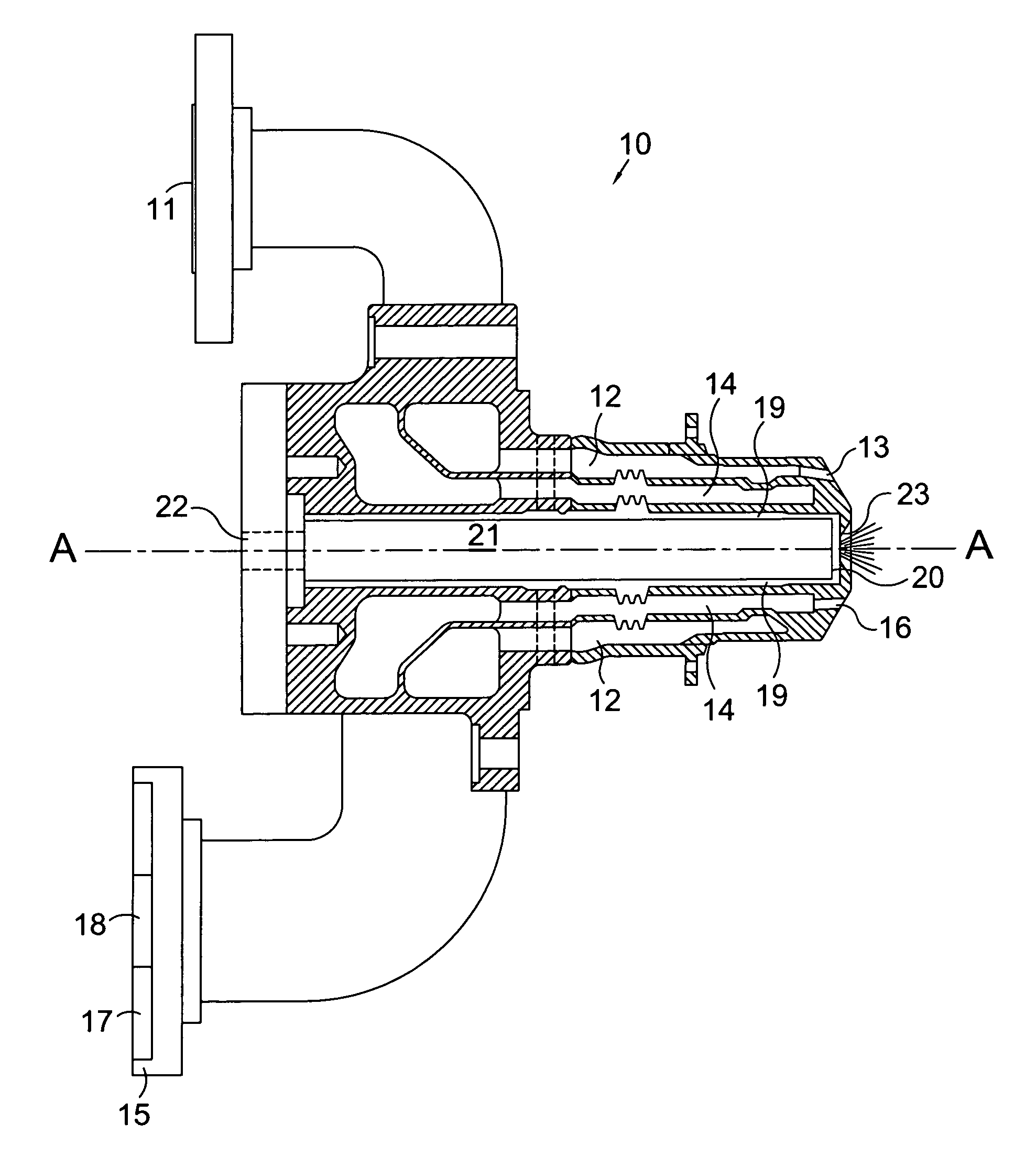

Apparatus and method for improving combustion stability

InactiveUS7104069B2Reduce varianceReduce combustion dynamicBurnersContinuous combustion chamberGas turbinesEngineering

A fuel nozzle for use in a gas turbine combustor is provided having the capability of injecting multiple fuel types as well as steam for NOx reduction. Combustion dynamics within a combustor due to the mal-distribution of steam are controlled by the placement of a meterplate at the steam inlet, such that the meterplate reduces steam velocity and increases steam pressure drop. A higher pressure drop reduces the sensitivity of the combustion process to upstream steam supply variations. A method for providing uniform steam flow to a plurality of fuel nozzle assemblies about a gas turbine engine is also disclosed.

Owner:ANSALDO ENERGIA IP UK LTD

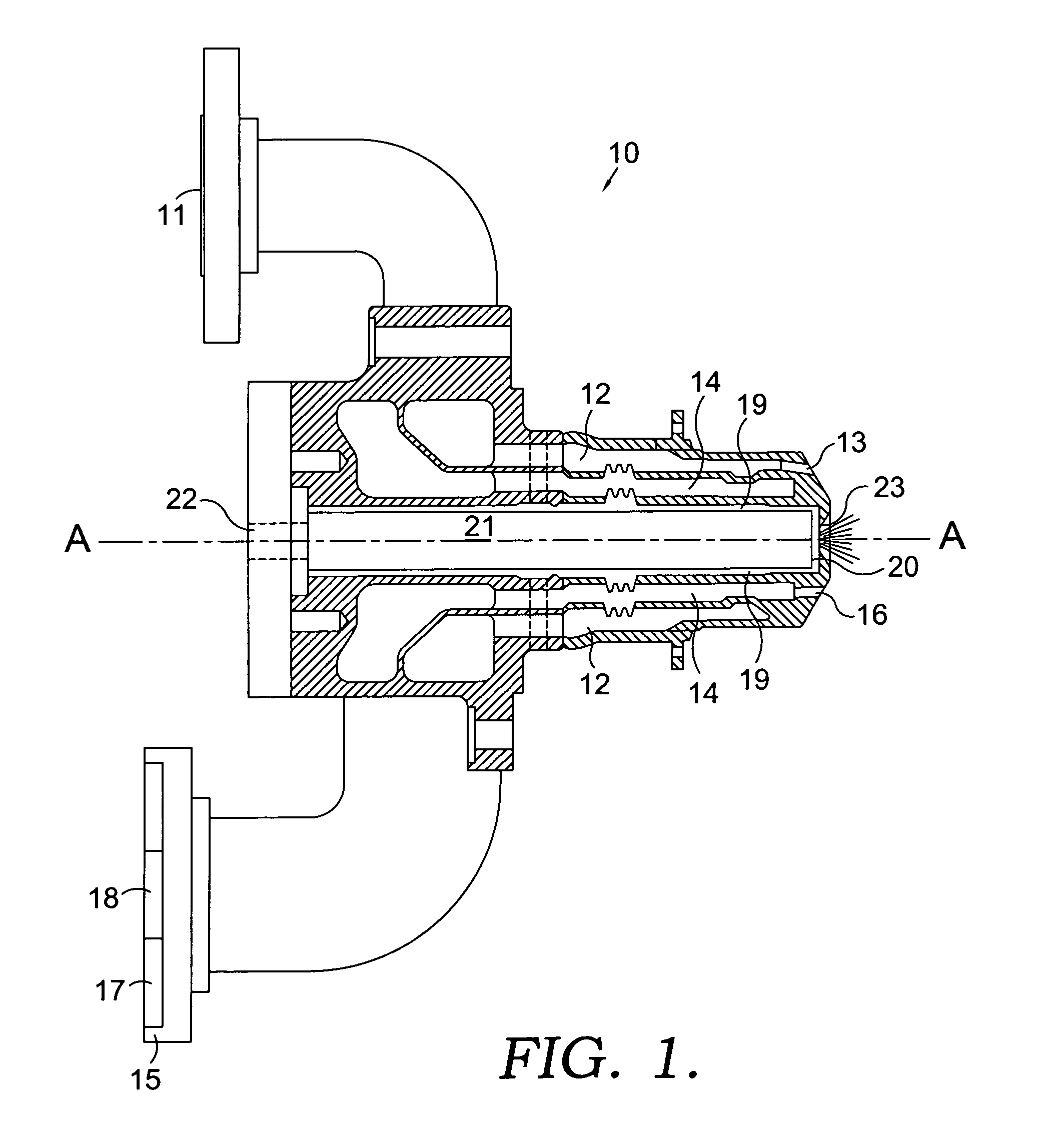

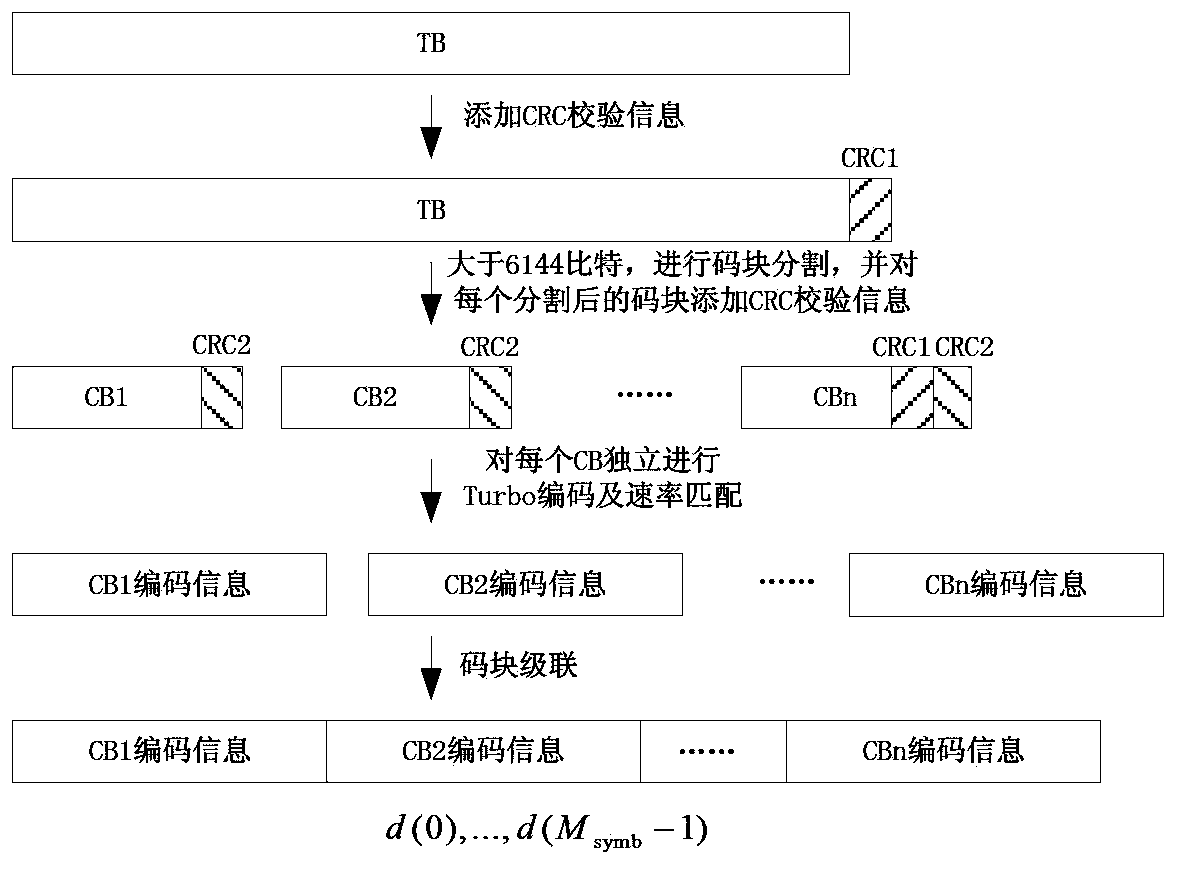

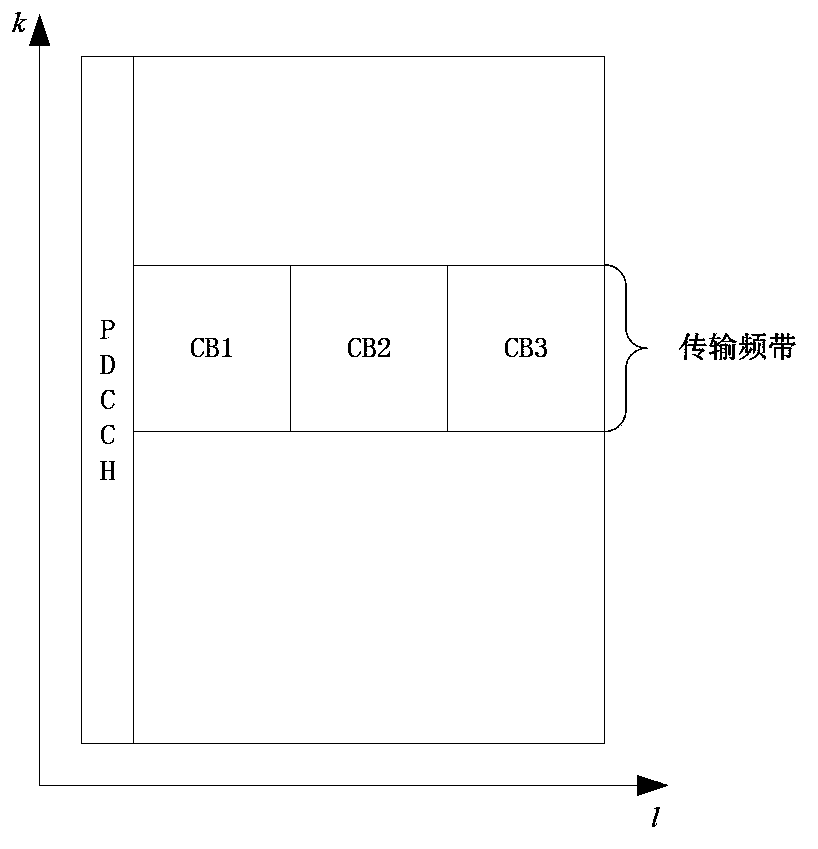

Data transmission method and device

ActiveCN104283630AInterference equalizationReduce varianceForward error control useData transmissionCoding block

The embodiment of the invention discloses a data transmission method and device, and relates to the field of wireless communication. The data transmission method and device are used for improving data coding performance of receiving end equipment. According to the scheme, when conducting cascade connection on coding information of all coding blocks (CB) correspondence to a transmission block (TB), sending end equipment conducts interleaving cascade connection on information bit segments contained by the coding information of all the CBs, so that information bits in the coding information of all the CBs are distributed in coding information of the TB in an interwoven mode; in this way, when the modulated coding information of the TB is later mapped to physical resources, the coding information of all the CBs can be evenly distributed in the whole physical channel resources. Accordingly, the effect, caused by the situation that different CBs have different coding properties, on the coding property of the TB is reduced, and the data coding property of the receiving end equipment is improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

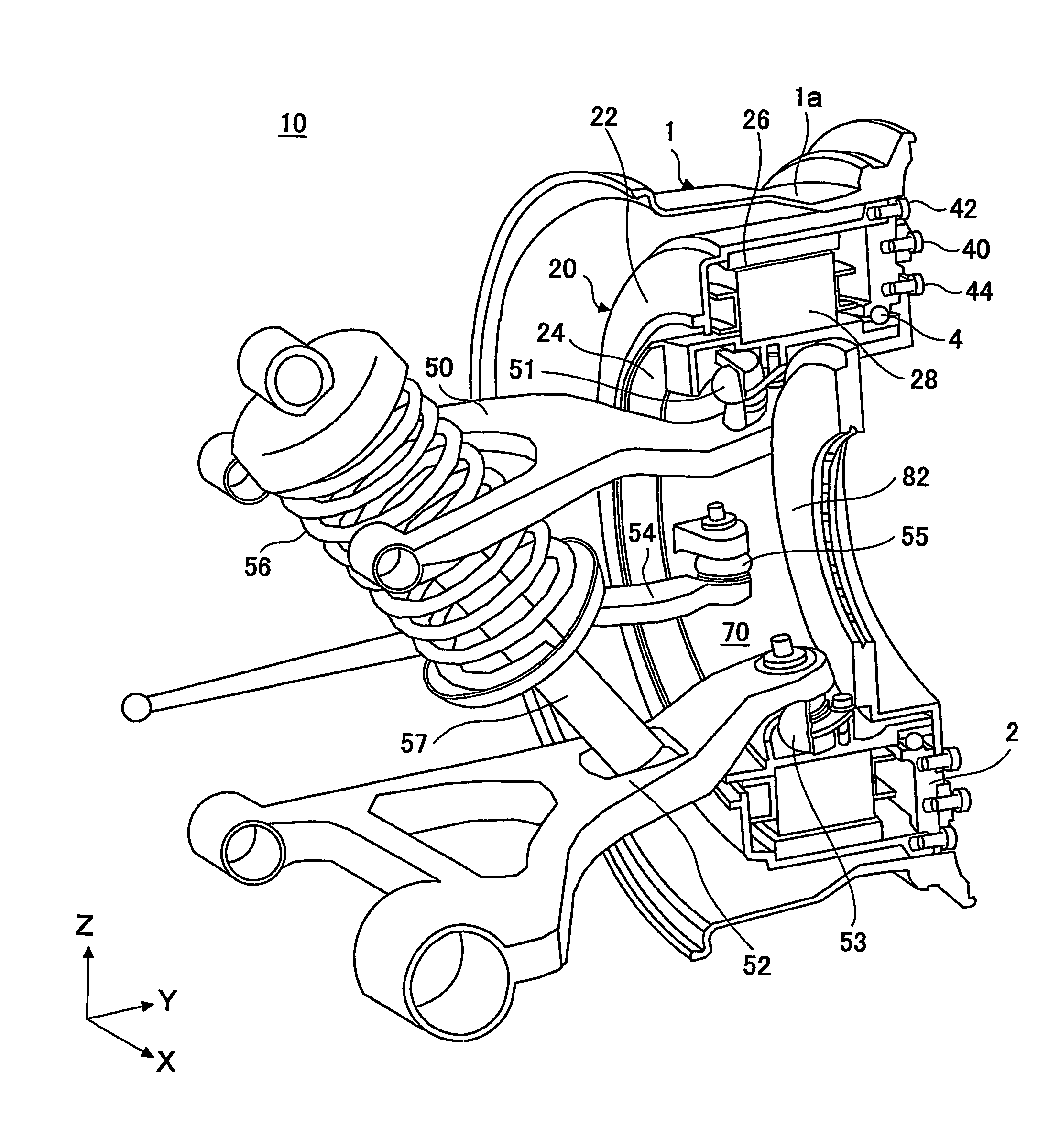

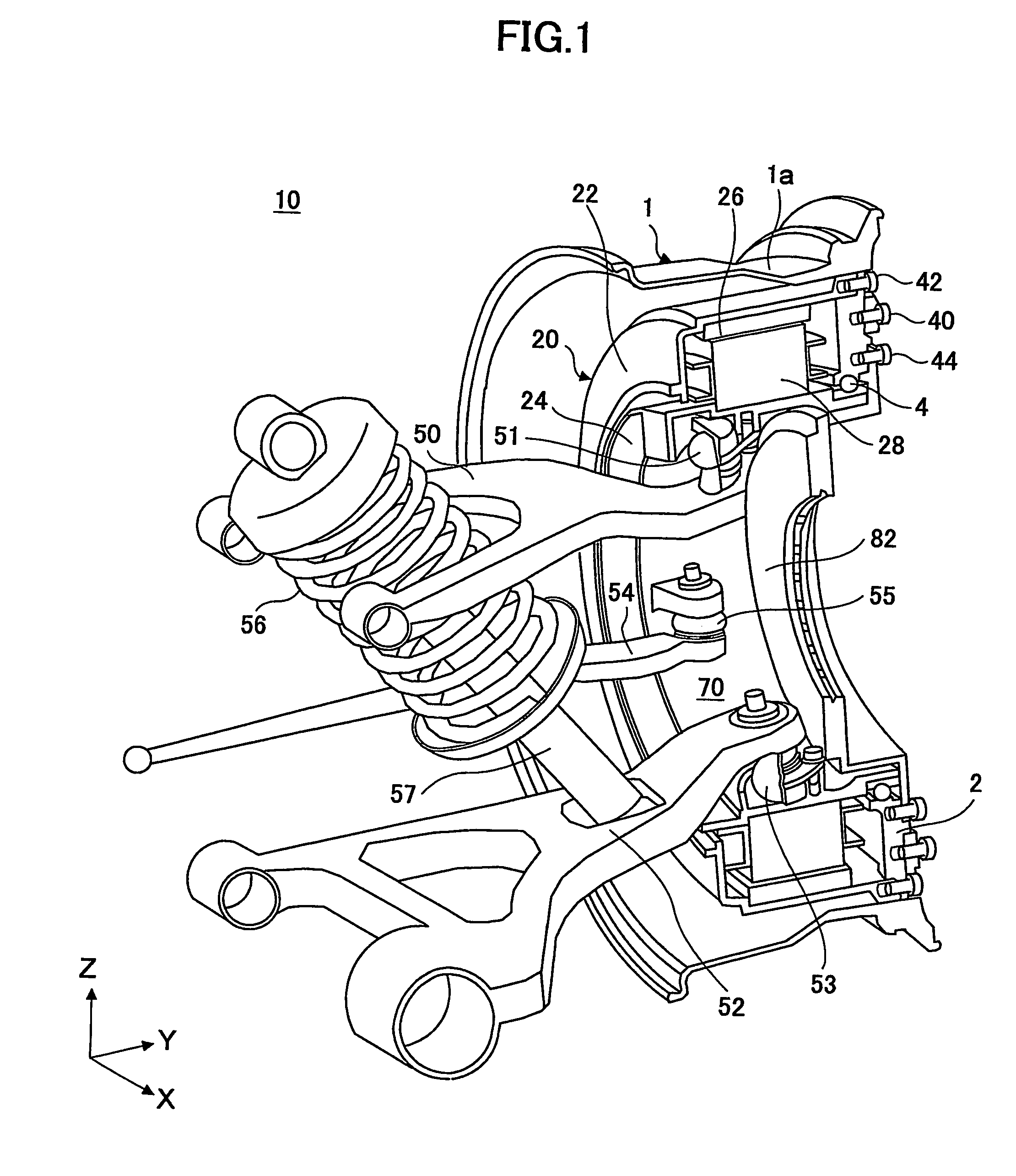

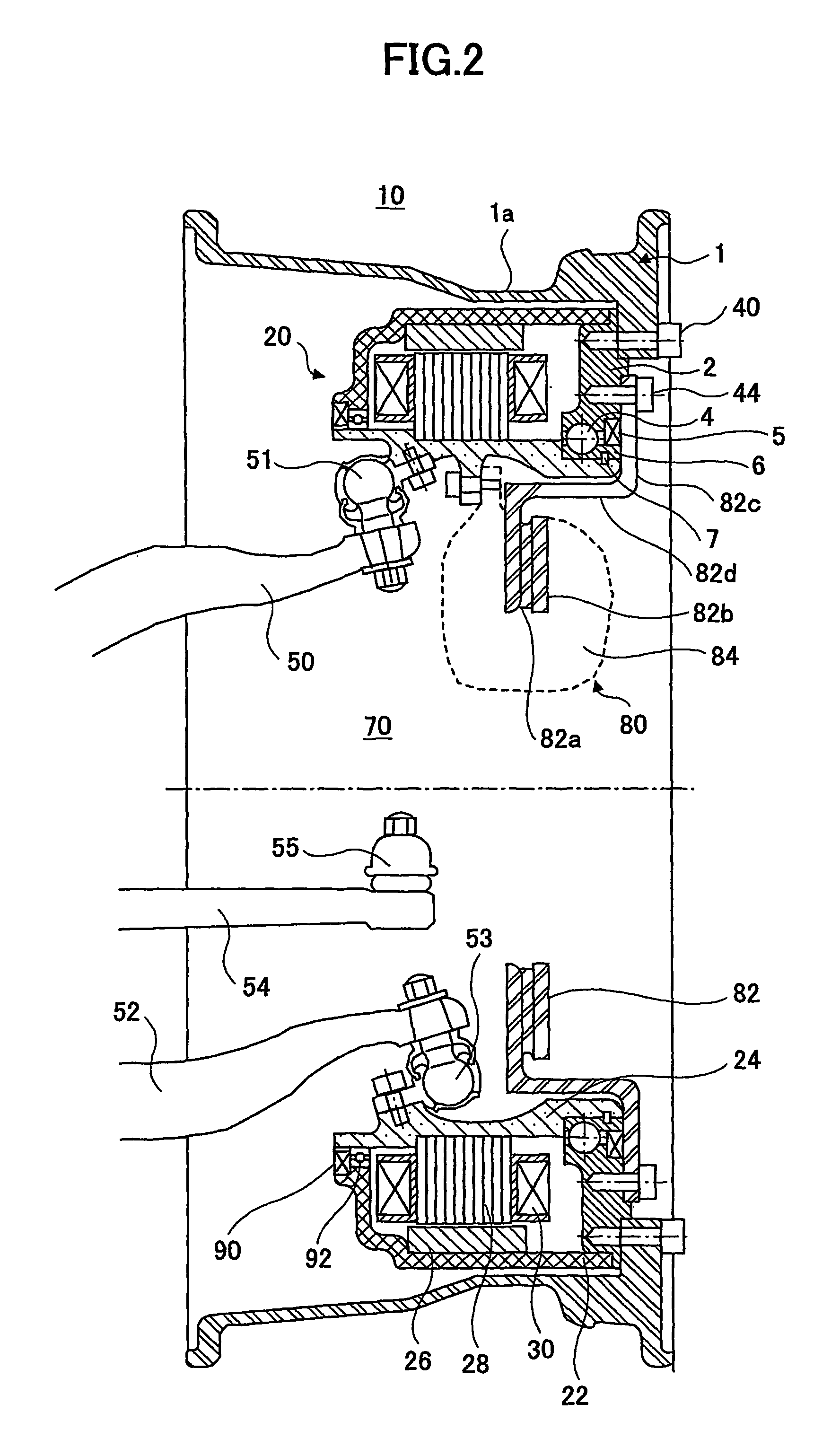

Suspension system for suspending a wheel having a motor therein

InactiveUS7735588B2Increase flexibilityLength minimizationElectric devicesAxially engaging brakesEngineeringElectric motor

A suspension system 10 for a vehicle for suspending a wheel 1 is disclosed. An outer rotor type motor 20 is provided within the wheel 1. The motor 20 has a stator (28, 30) provided on an outer surface of a cylindrical member 24 that defines space 70 open to at least an inboard side of the vehicle, and a rotor (22,26) rotatably supported by the cylindrical member 24. The wheel 1 receives the motor 20 and is connected to the rotor (22,26). The mounting portions of suspension arms (50,52,54) are provided on an inner surface of the cylindrical member 24.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com