Patents

Literature

3161 results about "Steam pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-phase heat-transfer systems

InactiveUS6866092B1Prevent freezingImprove the overall coefficientLiquid coolingCasingsLiquid jetInternal pressure

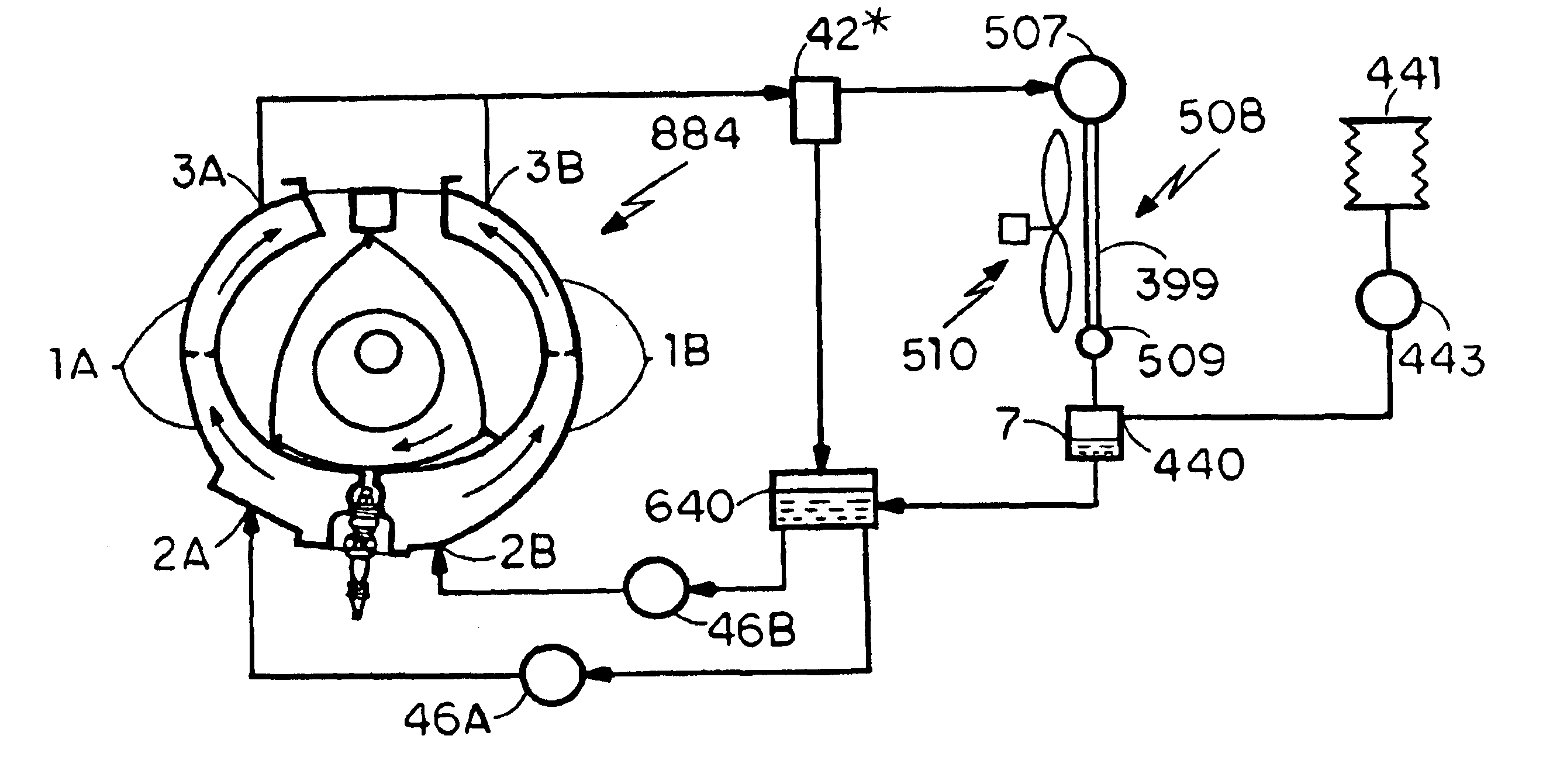

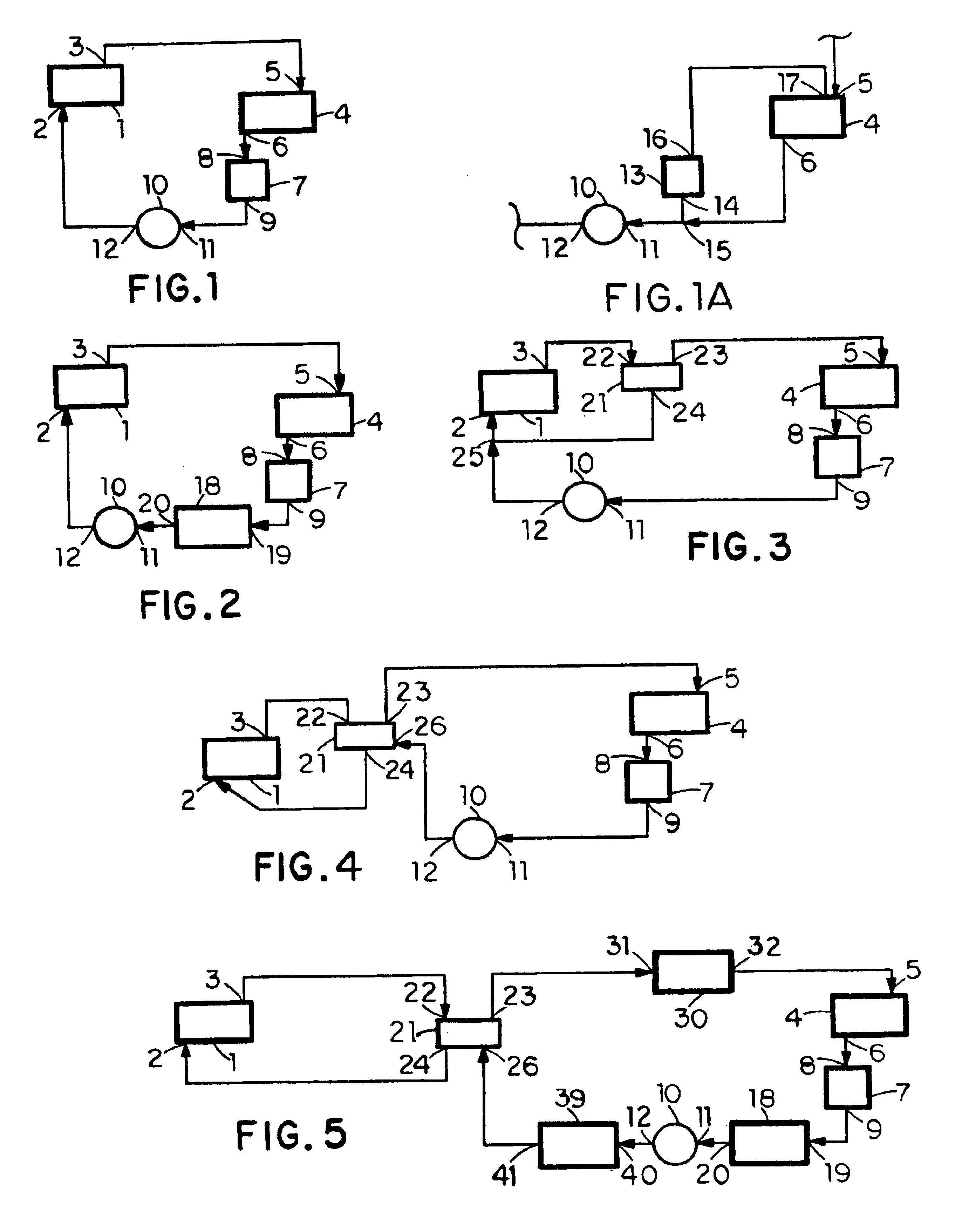

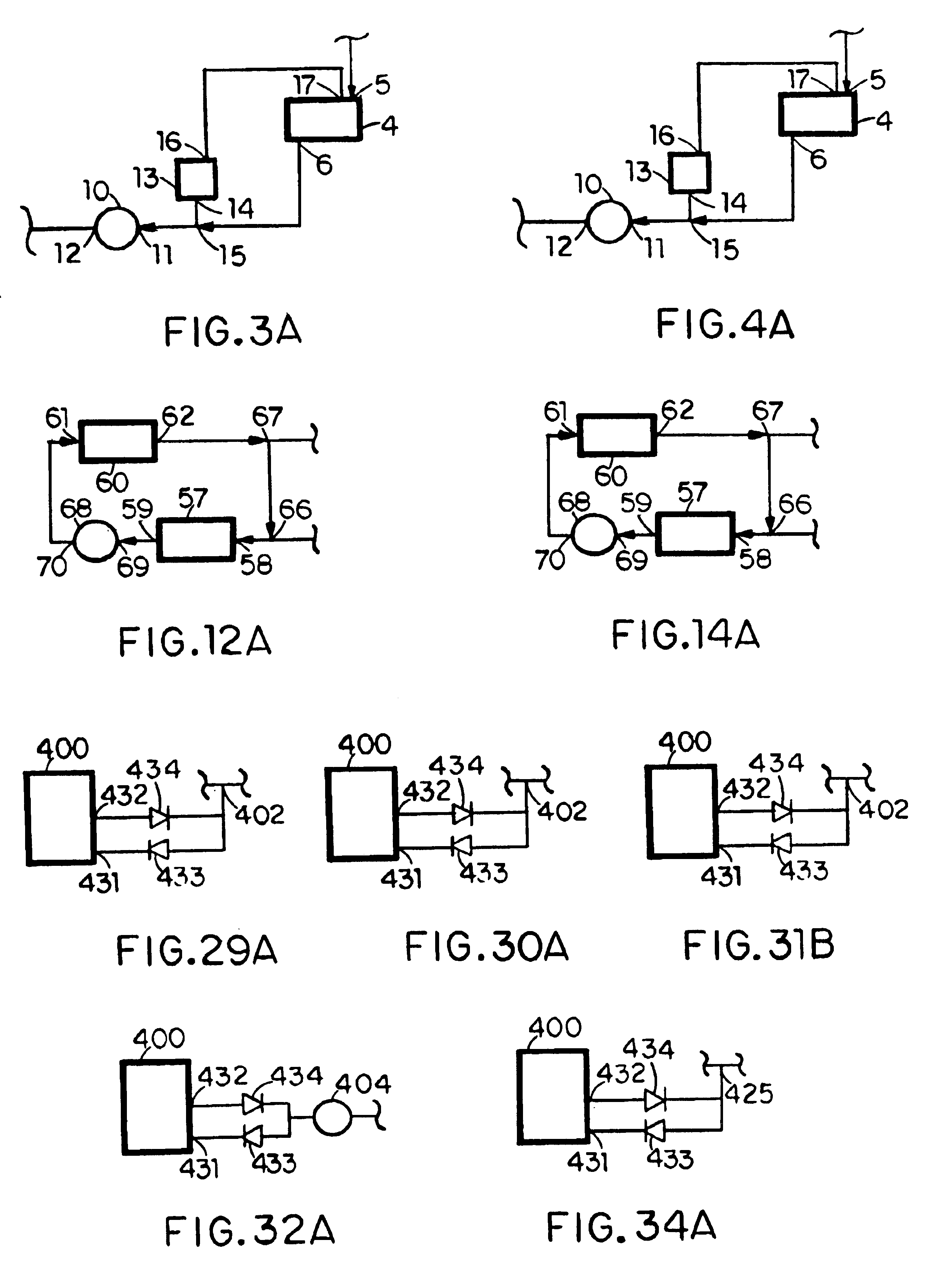

Various techniques are disclosed for improving airtight two-phase heat-transfer systems employing a fluid to transfer heat from a heat source to a heat sink while circulating around a fluid circuit, the maximum temperature of the heat sink not exceeding the maximum temperature of the heat source. The properties of those improved systems include (a) maintaining, while the systems are inactive, their internal pressure at a pressure above the saturated-vapor pressure of their heat-transfer fluid; and (b) cooling their internal evaporator surfaces with liquid jets. FIG. 43 illustrates the particular case where a heat-transfer system of the invention is used to cool a piston engine (500) by rejecting, with a condenser (508), heat to the ambient air; and where the system includes a heat-transfer fluid pump (10) and means (401-407) for achieving the former property.

Owner:MOLIVADAS STEPHEN

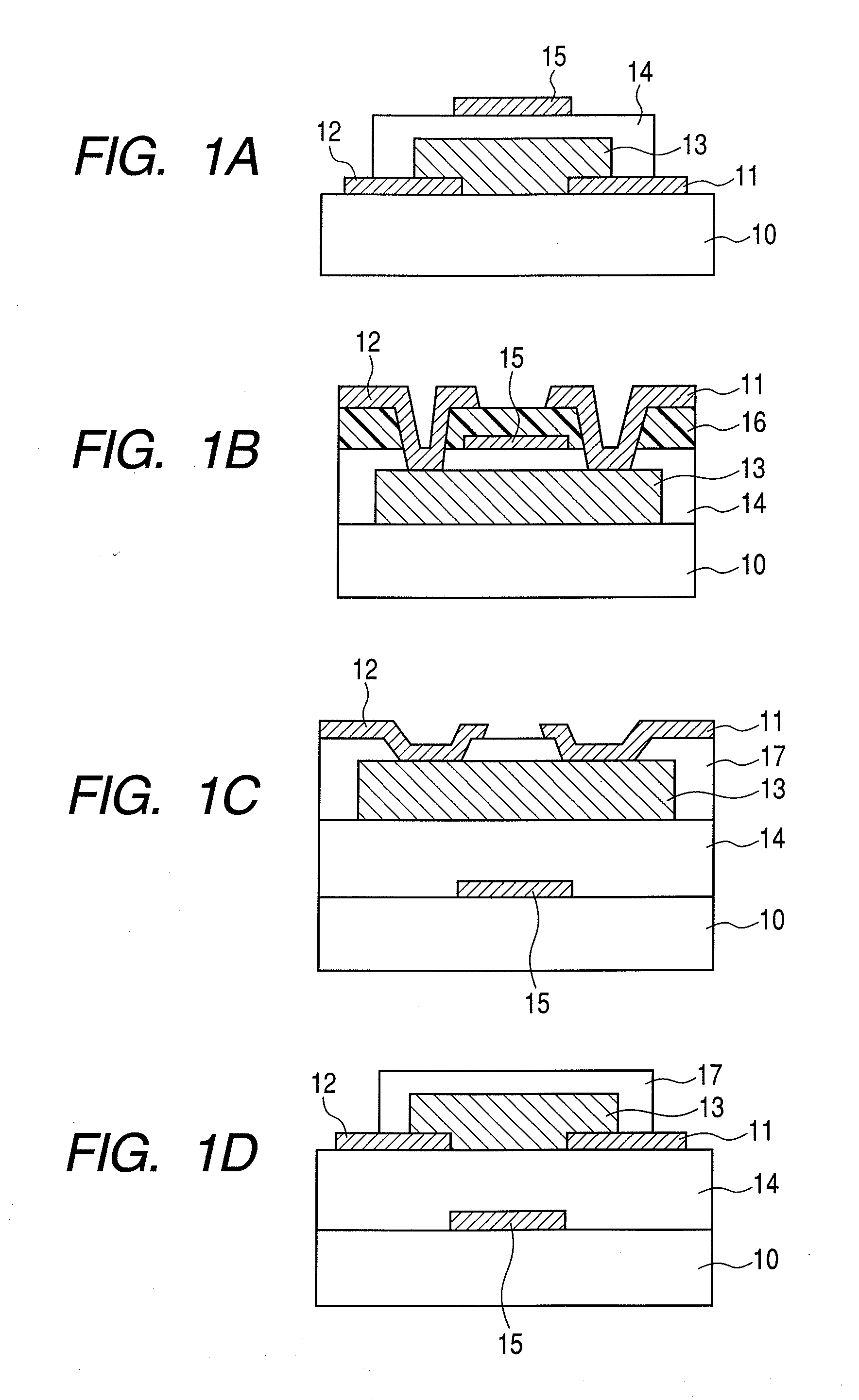

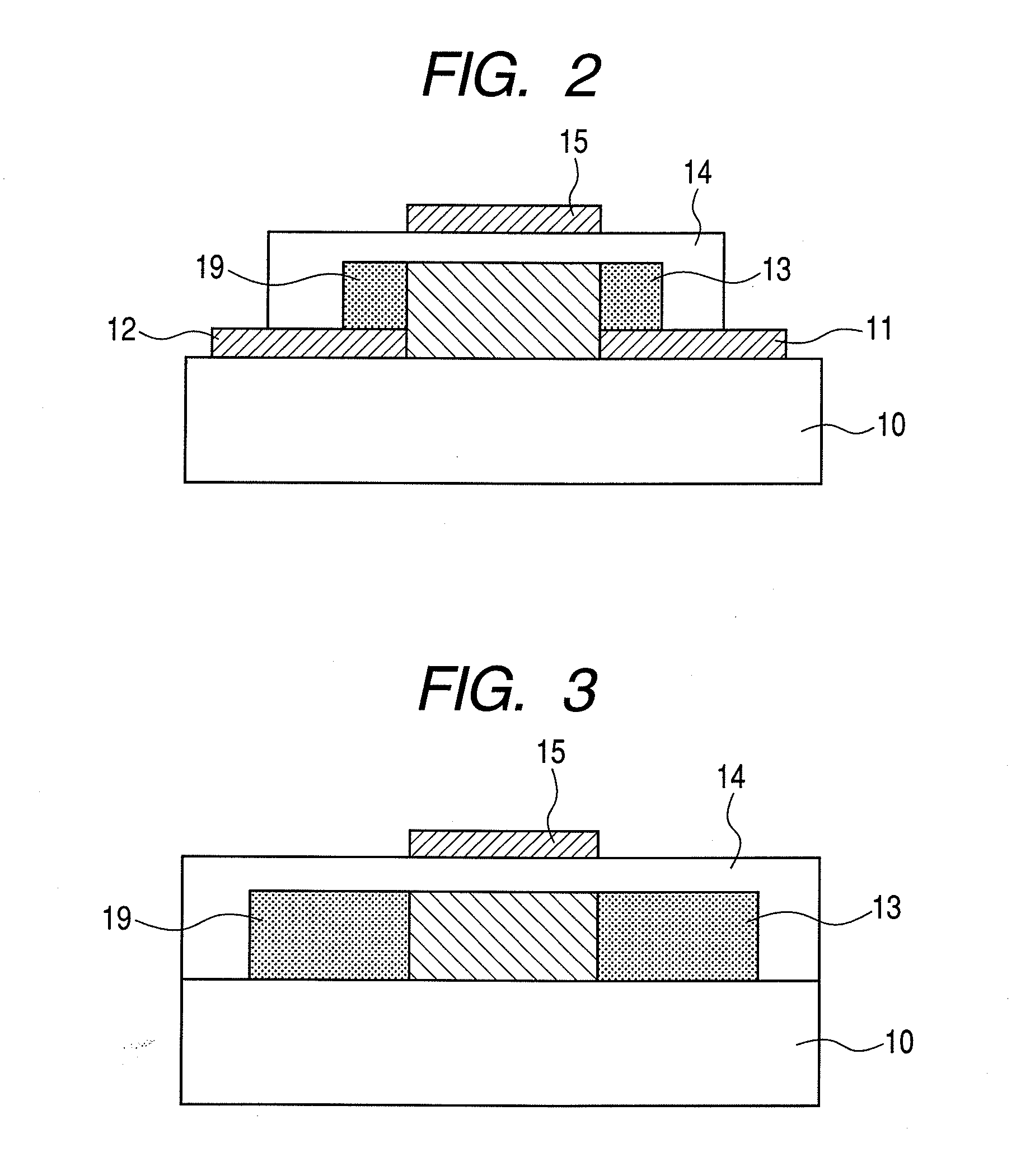

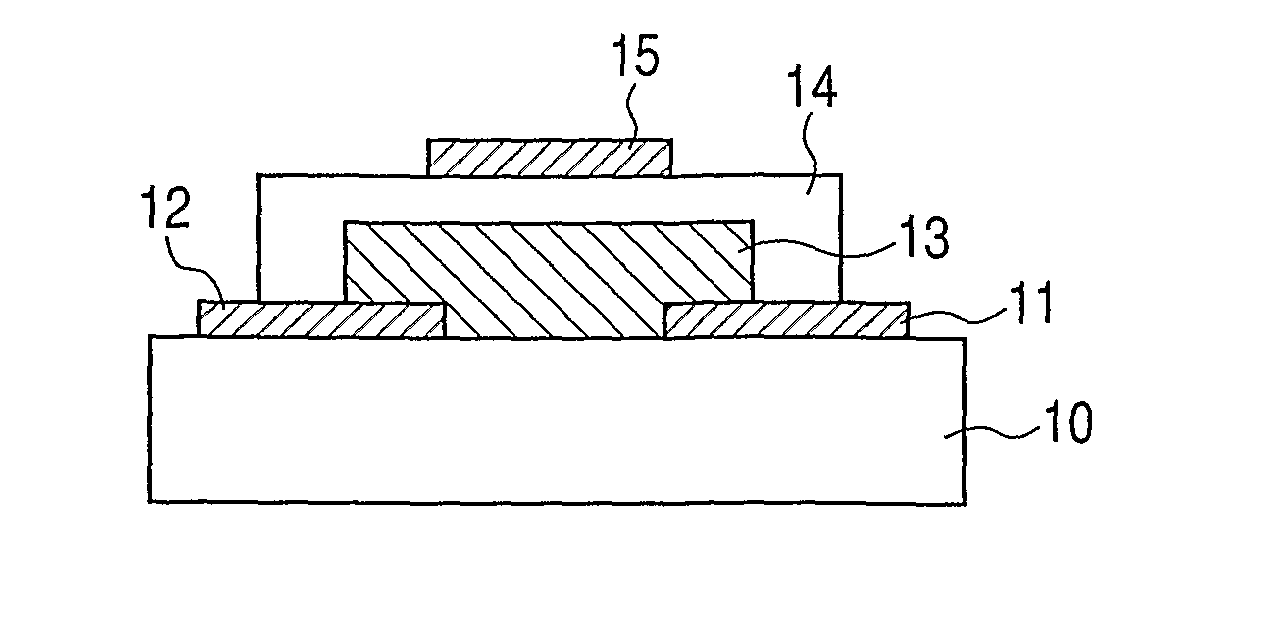

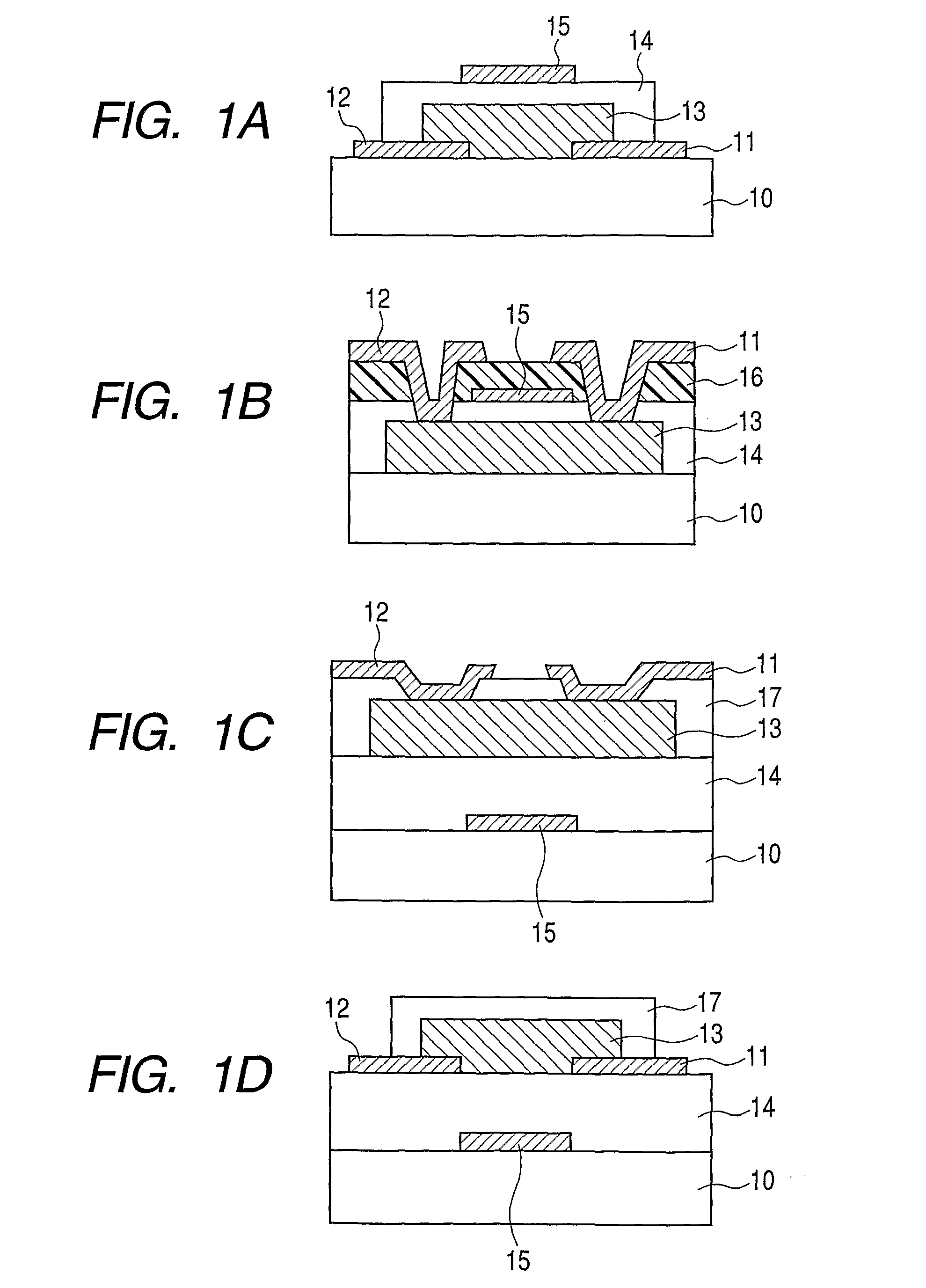

Method for manufacturing field-effect transistor

ActiveUS20100203673A1Improve conductivityImprove featuresSemiconductor/solid-state device manufacturingSemiconductor devicesSteam pressureMetallurgy

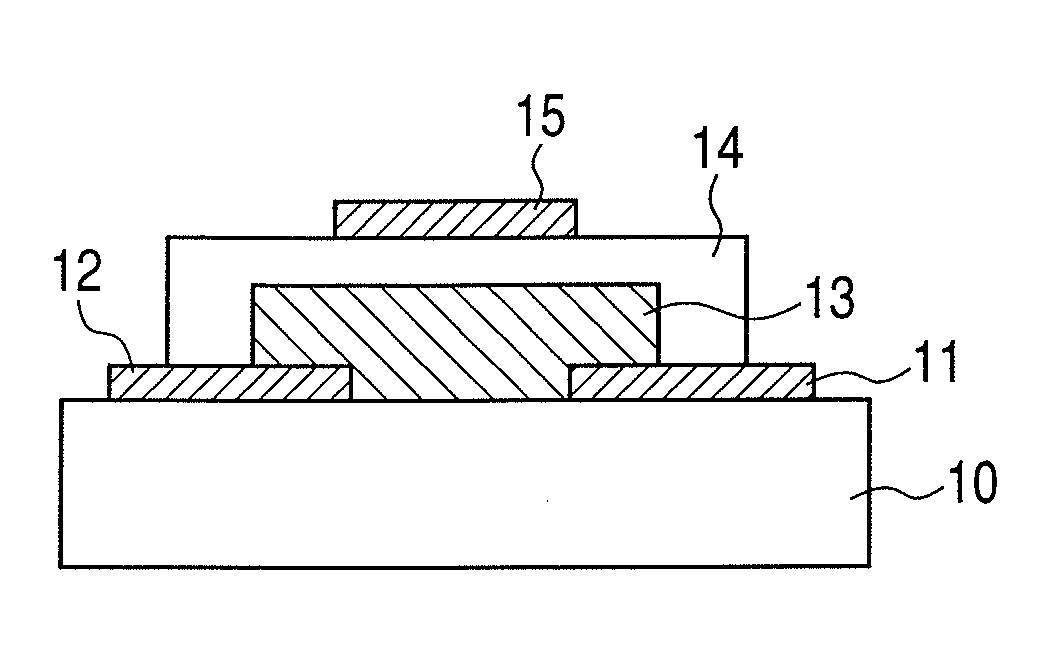

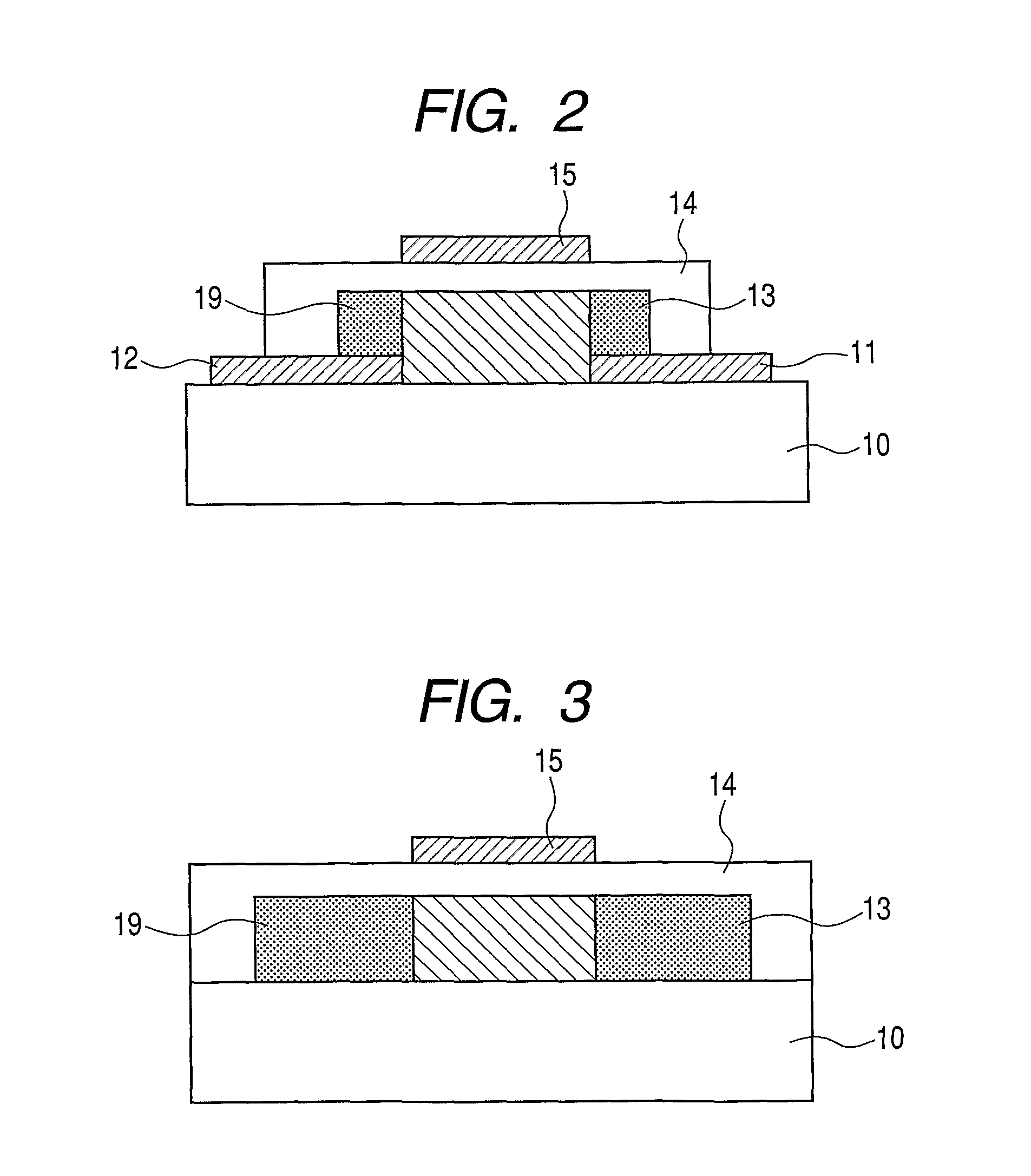

A method for manufacturing a field-effect transistor is provided. The field-effect transistor includes on a substrate a source electrode, a drain electrode, an oxide semiconductor layer, an insulating layer and a gate electrode. The method includes, after forming the insulating layer on the oxide semiconductor layer, an annealing step of increasing the electrical conductivity of the oxide semiconductor layers by annealing in an atmosphere containing moisture. The steam pressure at the annealing step is higher than the saturated vapor pressure in the atmosphere at the annealing temperature.

Owner:CANON KK

Method for manufacturing field-effect transistor

ActiveUS8110436B2Improve conductivityImprove featuresSemiconductor/solid-state device manufacturingSemiconductor devicesSteam pressureAtmospheric air

A method for manufacturing a field-effect transistor is provided. The field-effect transistor includes on a substrate a source electrode, a drain electrode, an oxide semiconductor layer, an insulating layer and a gate electrode. The method includes, after forming the insulating layer on the oxide semiconductor layer, an annealing step of increasing the electrical conductivity of the oxide semiconductor layers by annealing in an atmosphere containing moisture. The steam pressure at the annealing step is higher than the saturated vapor pressure in the atmosphere at the annealing temperature.

Owner:CANON KK

Real time optimization and control of oxygen enhanced boilers

InactiveUS7401577B2Easy to controlEasy to modifySolid fuel combustionCombustion measurementsCombustion chamberSteam pressure

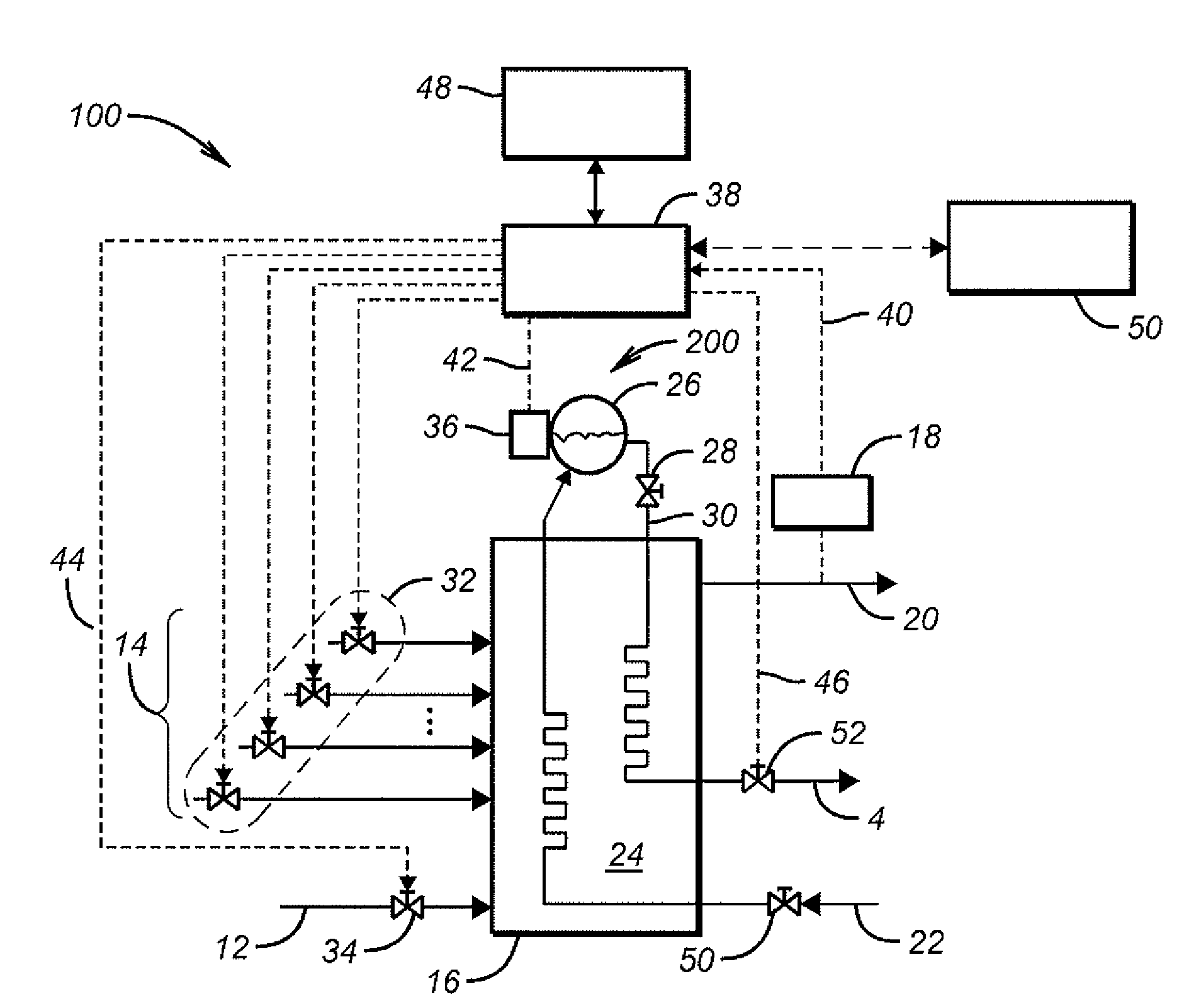

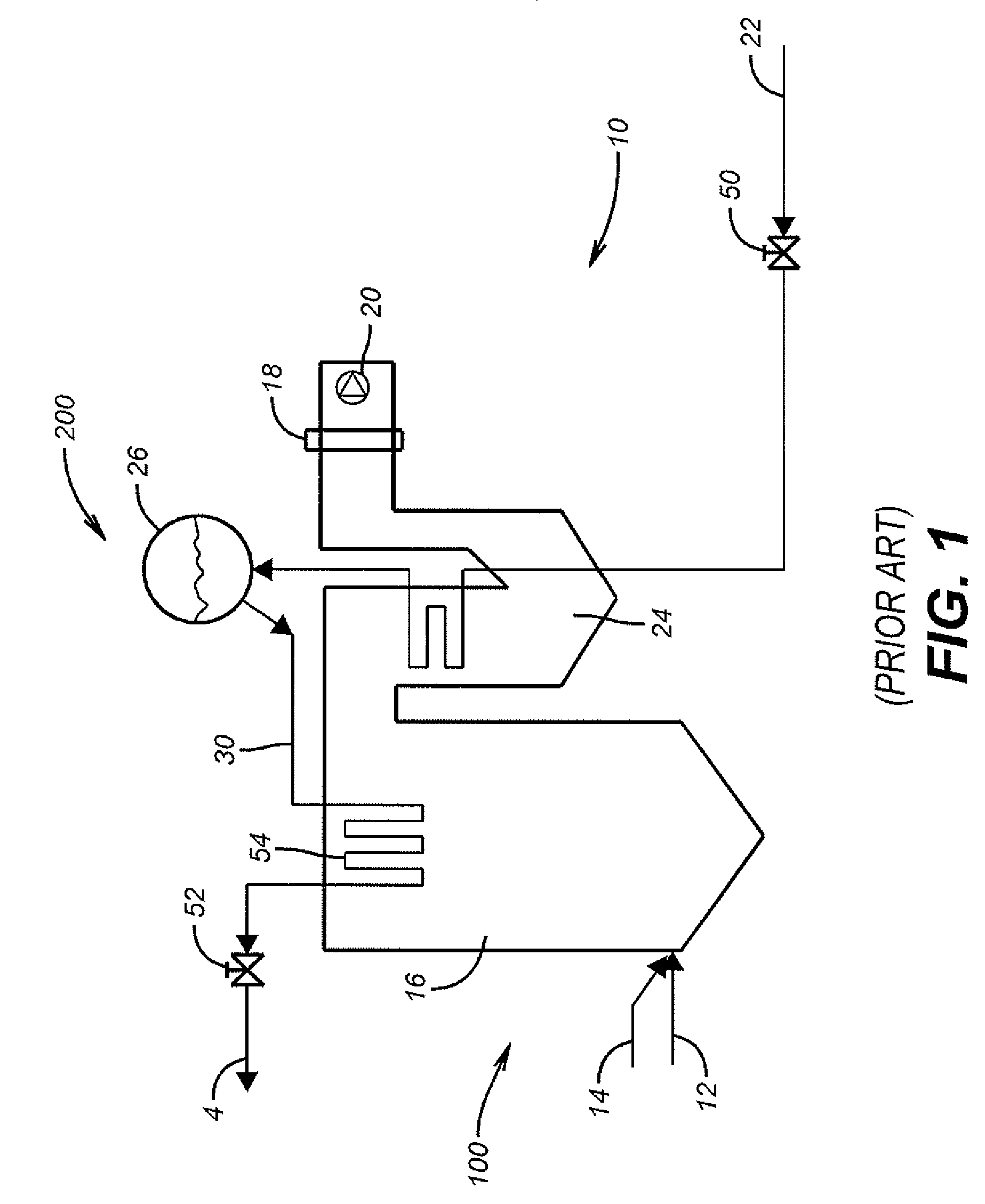

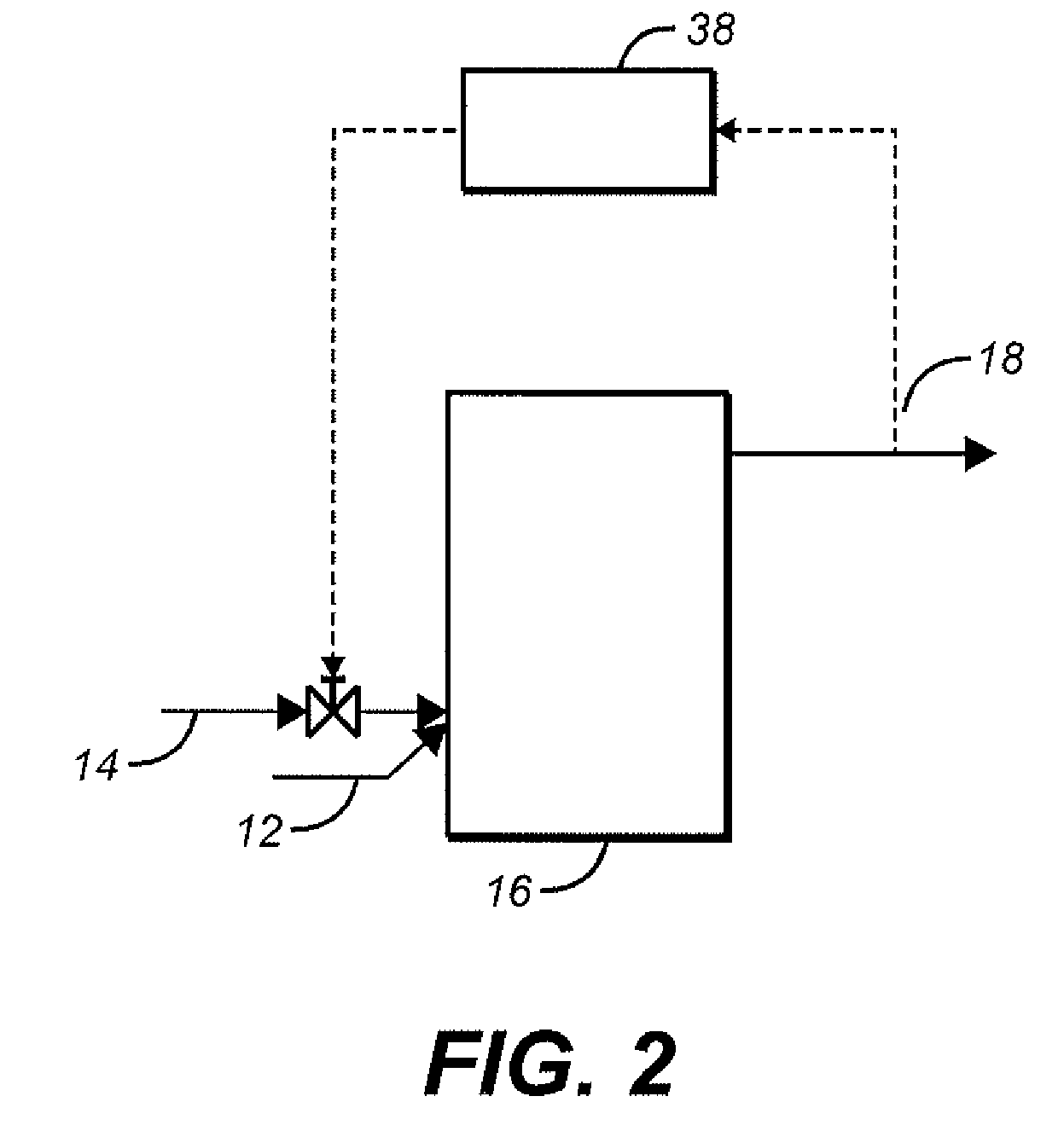

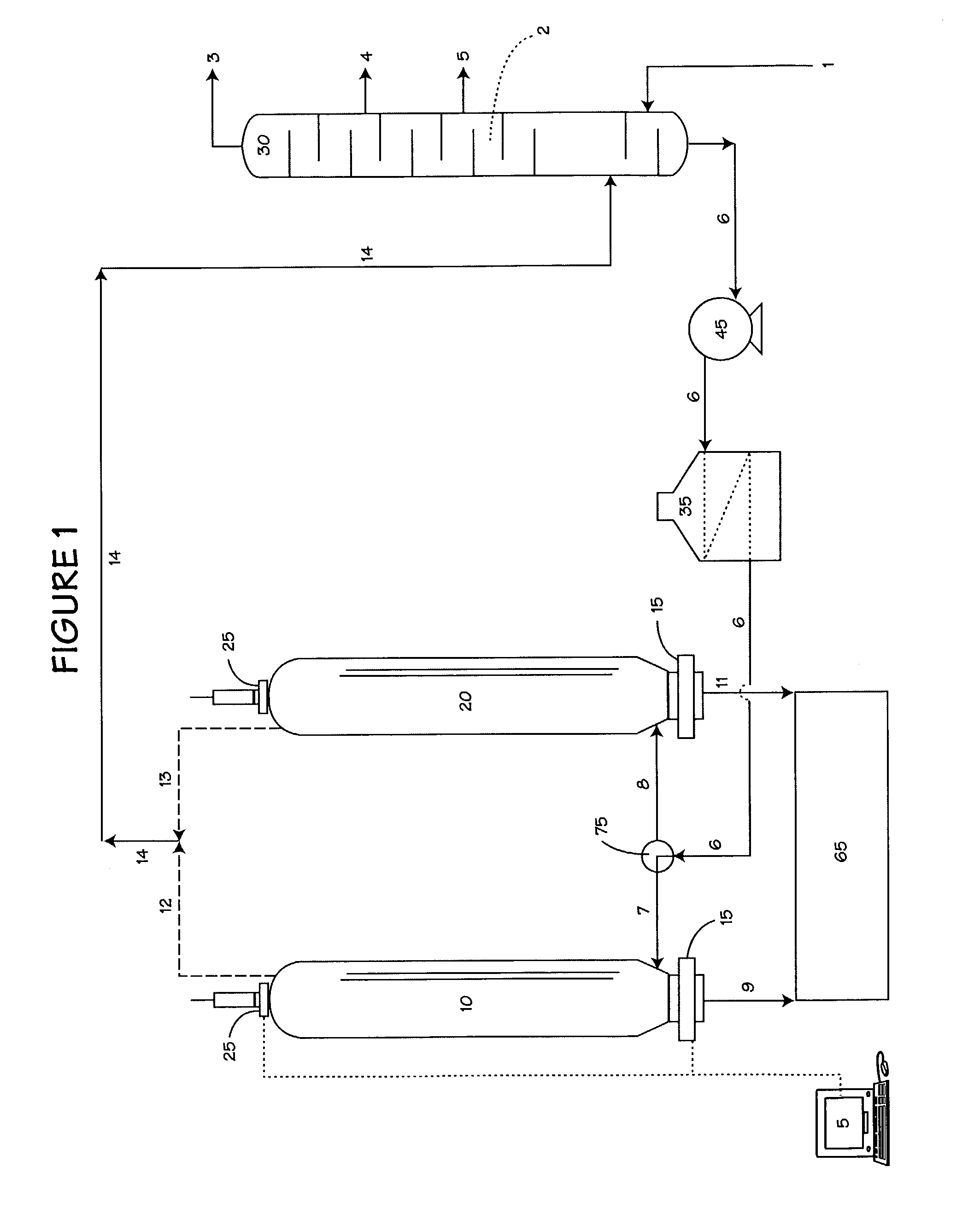

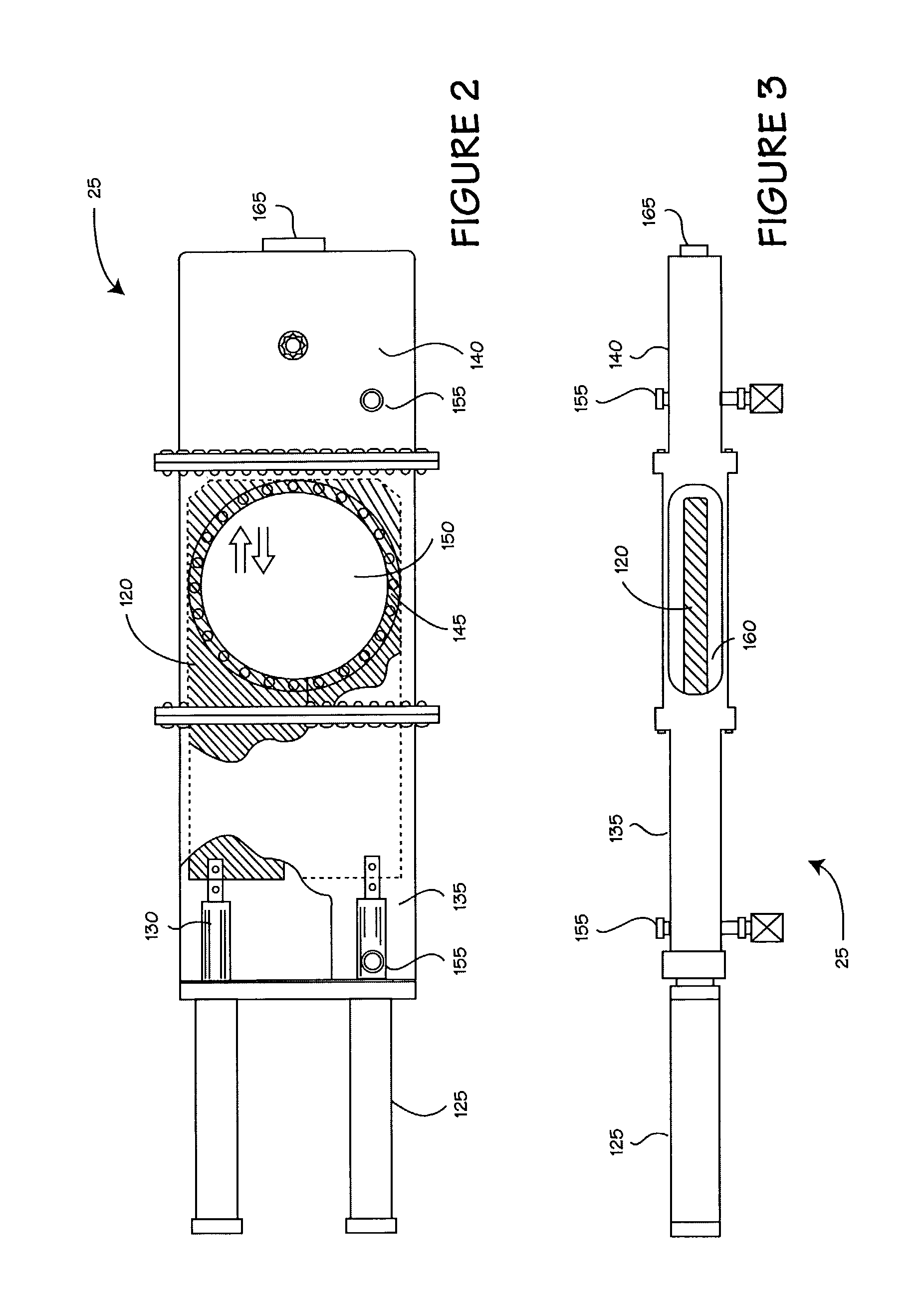

An oxygen enriched boiler having a burner subassembly and a steam subassembly is disclosed. The burner subassembly has a fuel inlet, an oxidant inlet, a combustion chamber, a flue gas composition detector and a flue gas outlet. The fuel inlet provides fuel to the combustion chamber, the oxidant inlet provides an oxygen-enriched inlet stream to the combustion chamber, the combustion chamber burns the fuel and the flue gas composition detector measures at least one characteristic of the flue gas. The steam subassembly has a supply water inlet, a heat exchange zone, a water drum, a steam quality actuator and a steam outlet. The supply water inlet provides feed water to the heat exchange zone, the heat exchange zone transfers heat generated by combustion of the fuel to the water to generate steam, the water drum receives the heated water and steam from the heat transfer zone and maintains the water and steam at a selected steam pressure and water level, and the steam quality actuator regulates at least one characteristic of the steam. Flue gas characteristics, as well as other boiler performance variables, are monitored. At least one controller actuates on the oxidant injections to control combustion. The controller calculates the optimum oxidant distribution in real-time for a series of injection points to minimize undesired flue gas emissions while maintaining the desired steam conditions and boiler operating conditions.

Owner:AIR LIQUIDE AMERICA INC

Steam pressure cooker

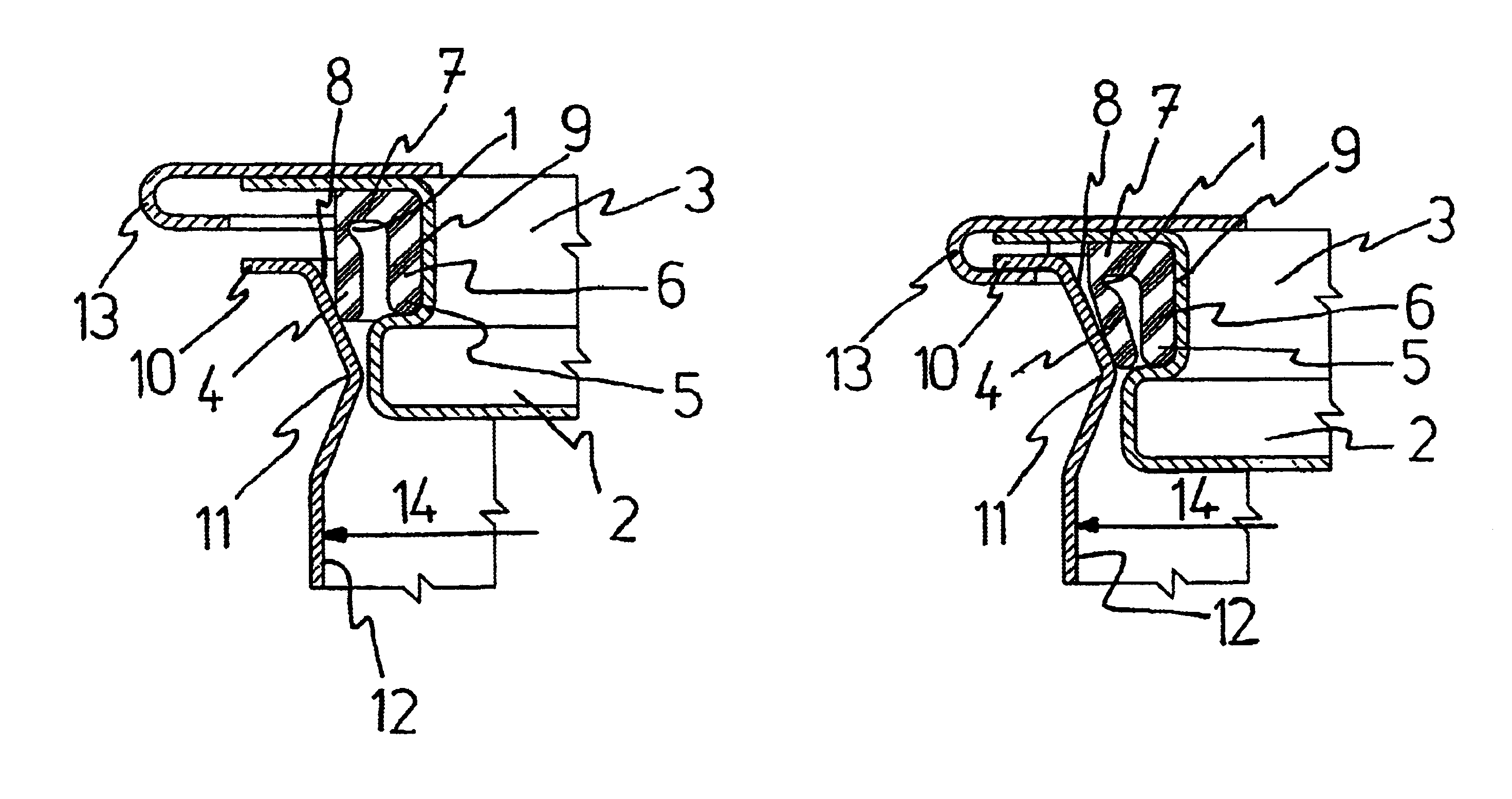

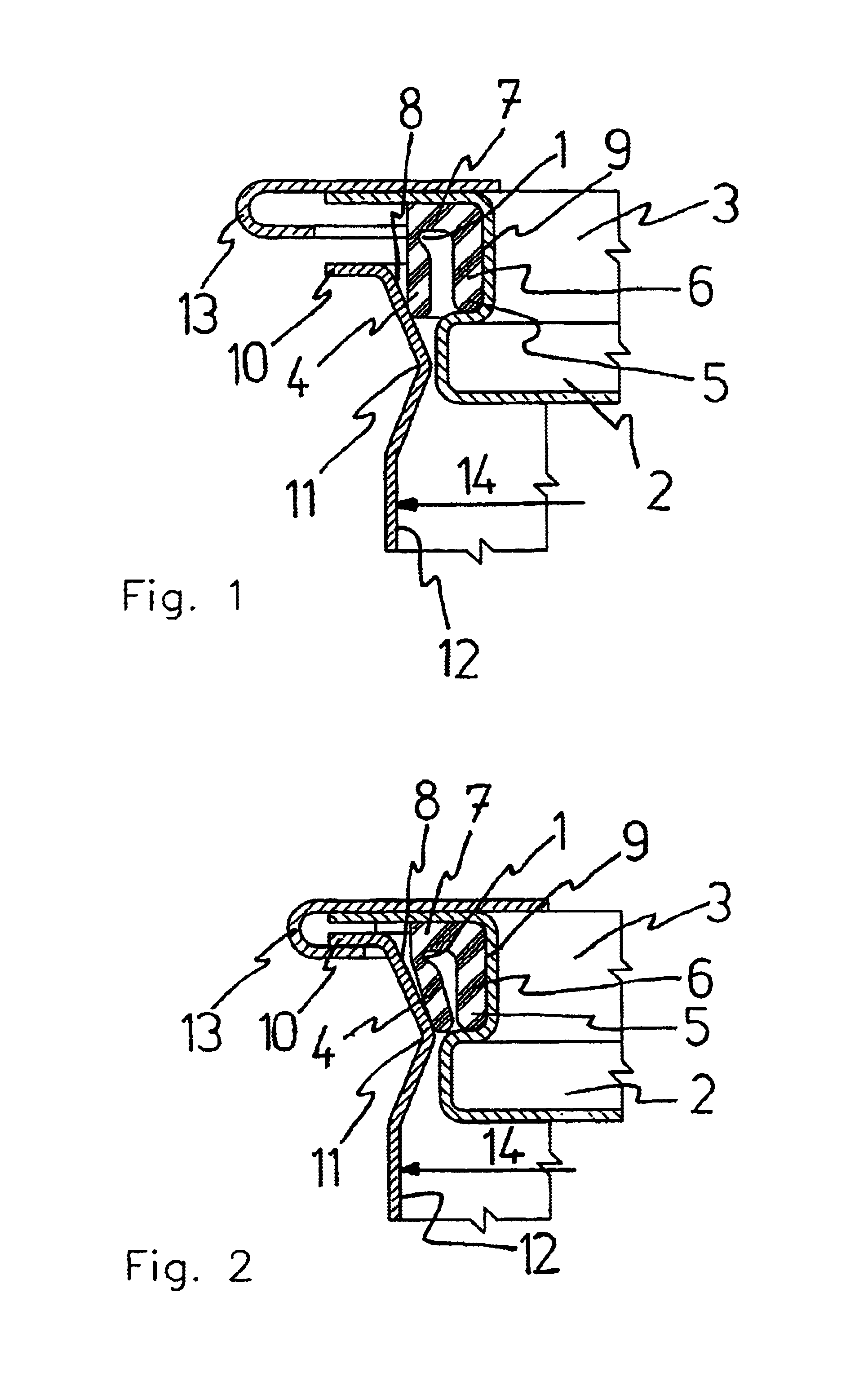

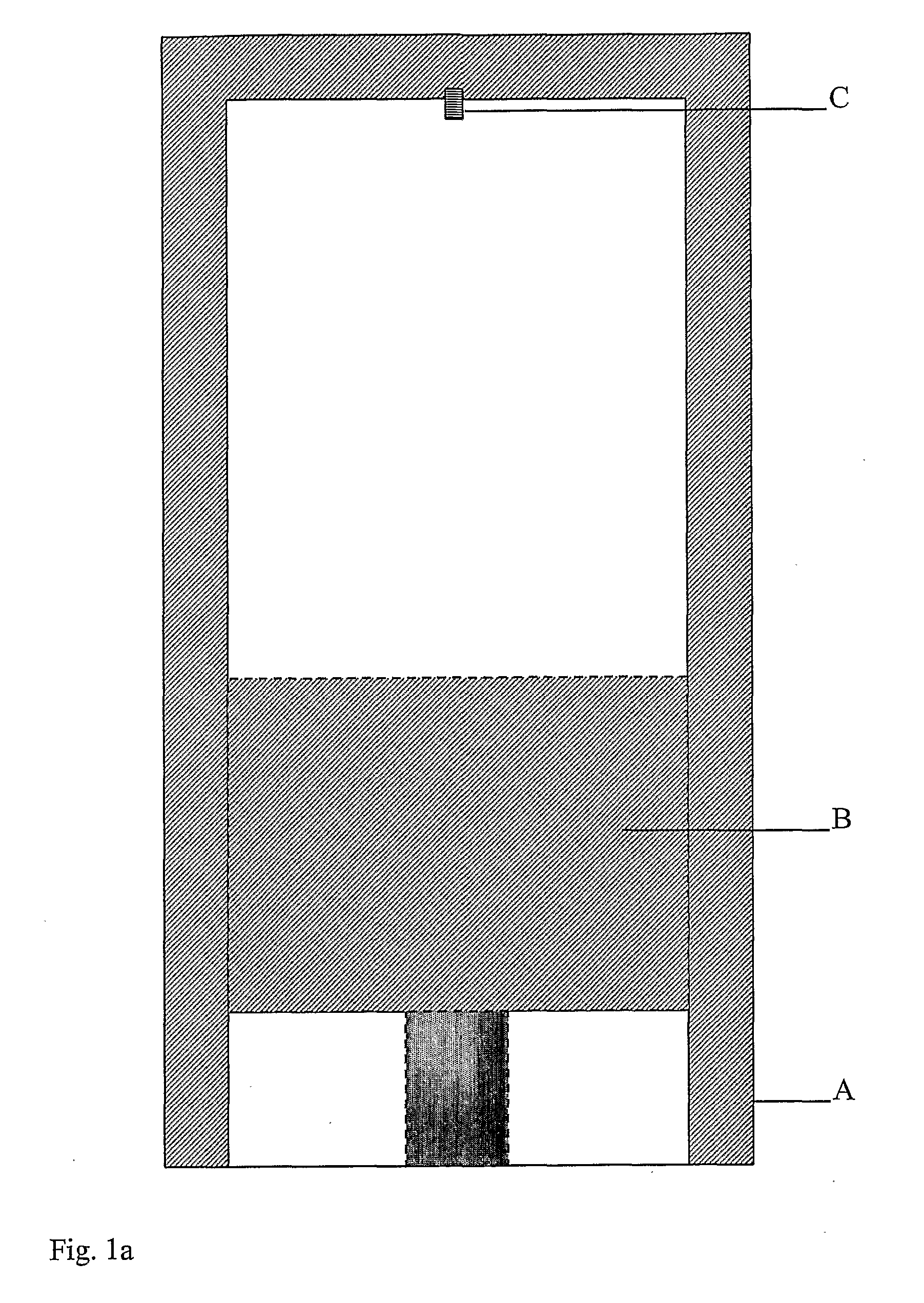

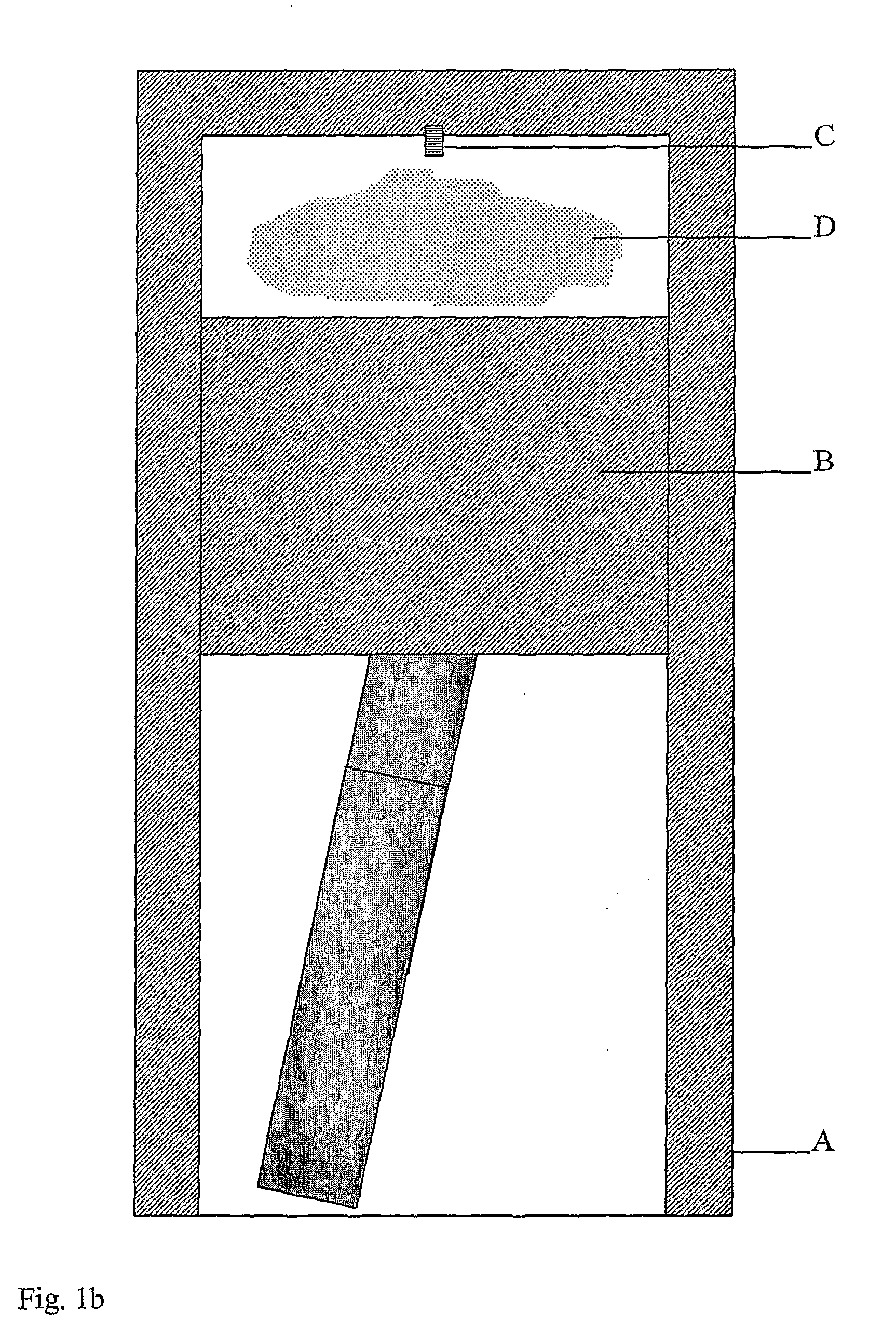

InactiveUS6877633B2Thinner nominal wall thicknessSame strength propertyRefuse receptaclesSealingSteam pressureLocking mechanism

A steam pressure cooker includes a pot having an outwardly directed horizontal pouring rim and formed with a V-shaped circumferential depression which points inwardly to define a conical surface in an upper rim area. A lid can be placed upon the pot for closing and includes a circumferential groove. Positioned between pot and lid is a rubberized elastic sealing element which is held in the circumferential groove. The sealing element has a sealing body of substantially U-shaped configuration to define two sealing lips in coaxial parallel relationship to the vertical pot axis. One sealing lip bears against an inner wall of the pot and interacts with the conical surface of the pot, when the lid is placed upon the pot. A locking mechanism embraces and thereby clamps the lid and the pouring rim, when the steam pressure cooker is closed, and clears the pouring rim, when the steam pressure cooker is opened.

Owner:NIESE URSULA

Autonomous apparatus for cooking food

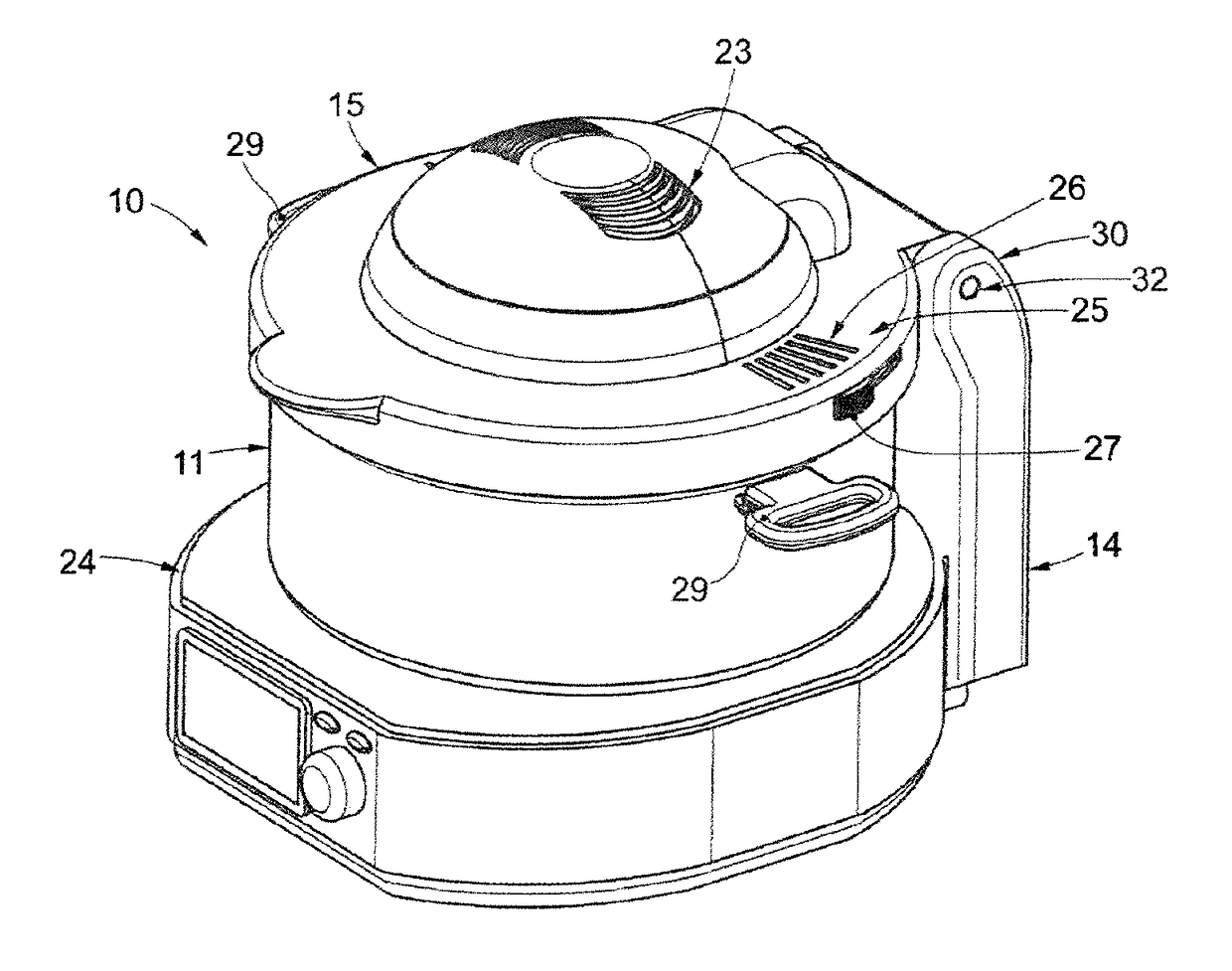

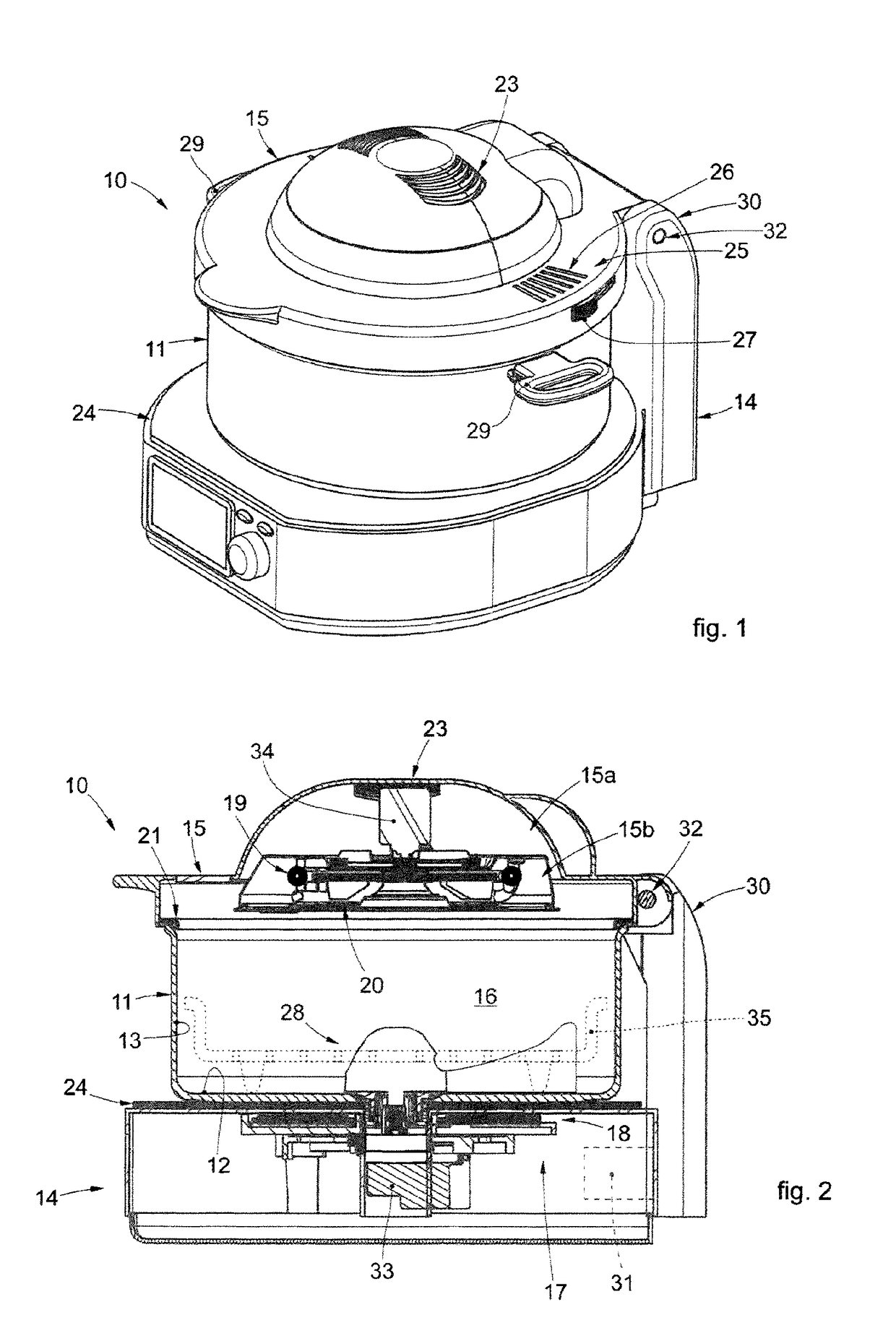

ActiveUS20180325313A1Easy to transformEasy to removeRoasters/grillsVessels with intergral heatingSteam pressureCoupling

An Autonomous apparatus for cooking food having a base body (14) with a main heating element (18), a lid (15) which can be associated with the base body (14) in at least two positions and inside which a secondary heating element (19) is installed and possible heat transfer and / or ventilation means (20), and a mixing device (28). The base body (14) supports and positions one of a removable container (11), said lid (15), and / or said container (11), in correspondence with a respective coupling edge, comprising at least an airtight packing (21) to define a cooking chamber (16) with a desired steam pressure. Said lid (15) has a single size with airtight packings (21) suitable to cooperate with different sizes of the container (11) and / or of one container (11) having different heights with respect to said base body (14).

Owner:DELONGHI APPLIANCES S R L CON UNICO SOCIO

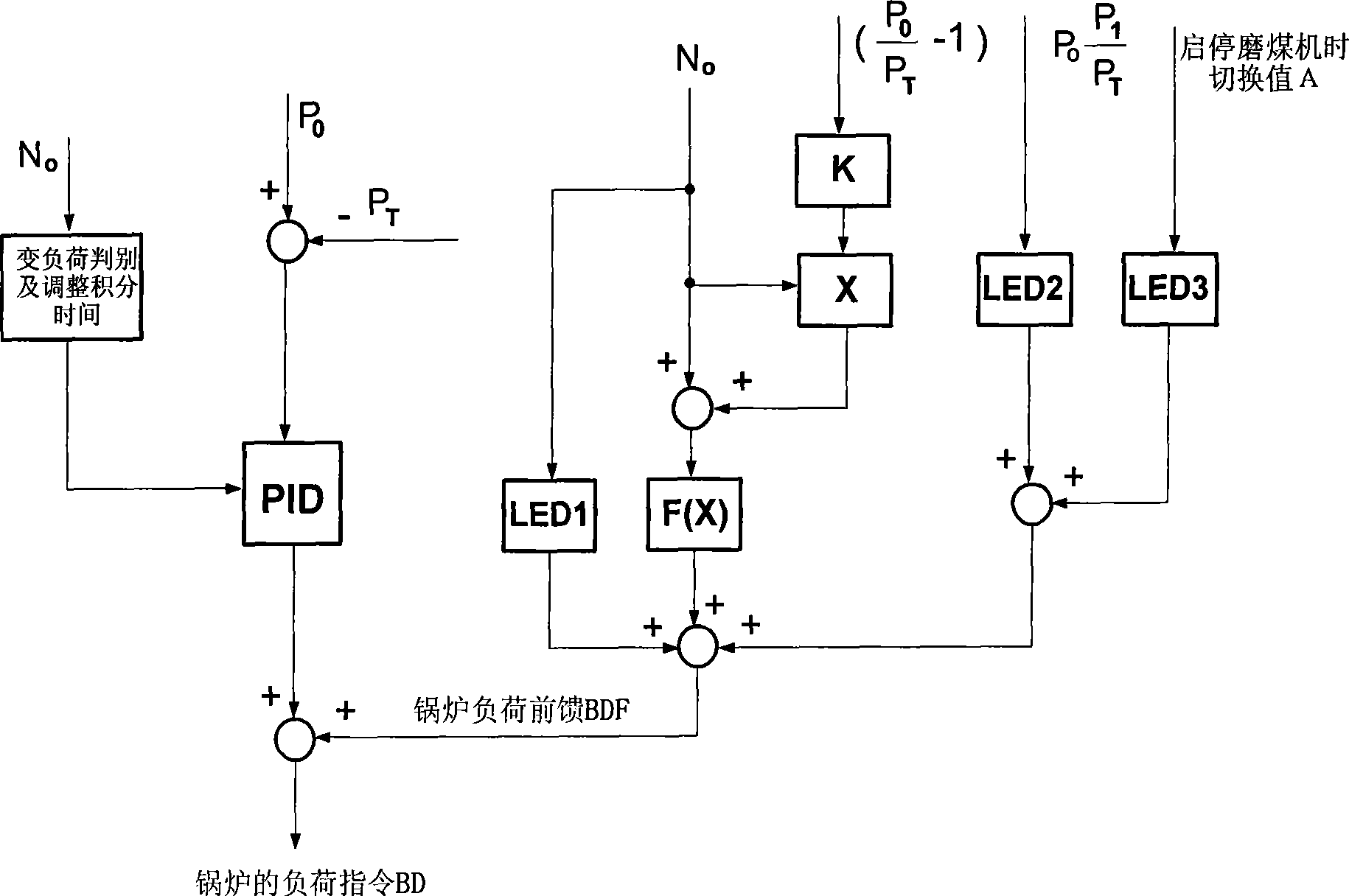

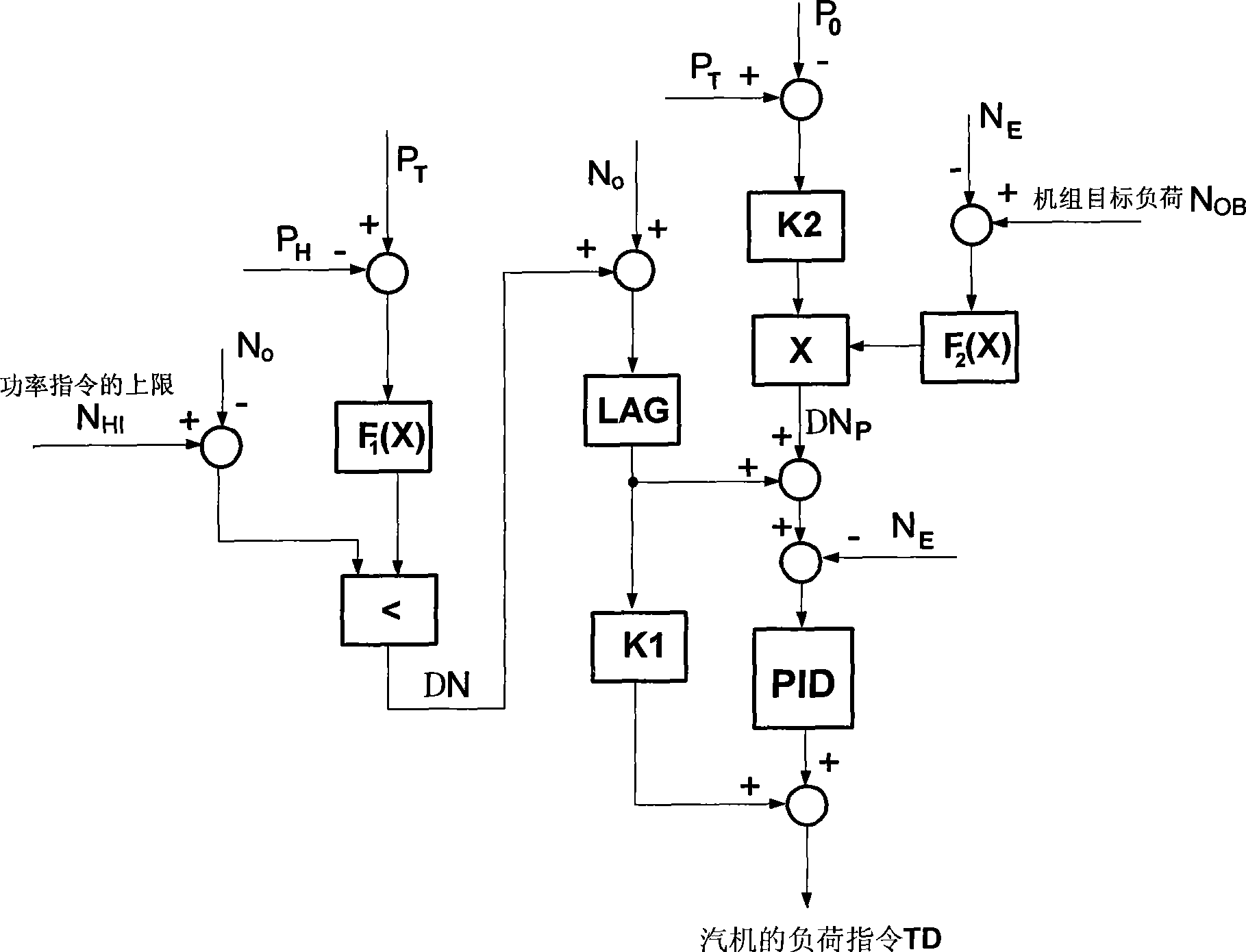

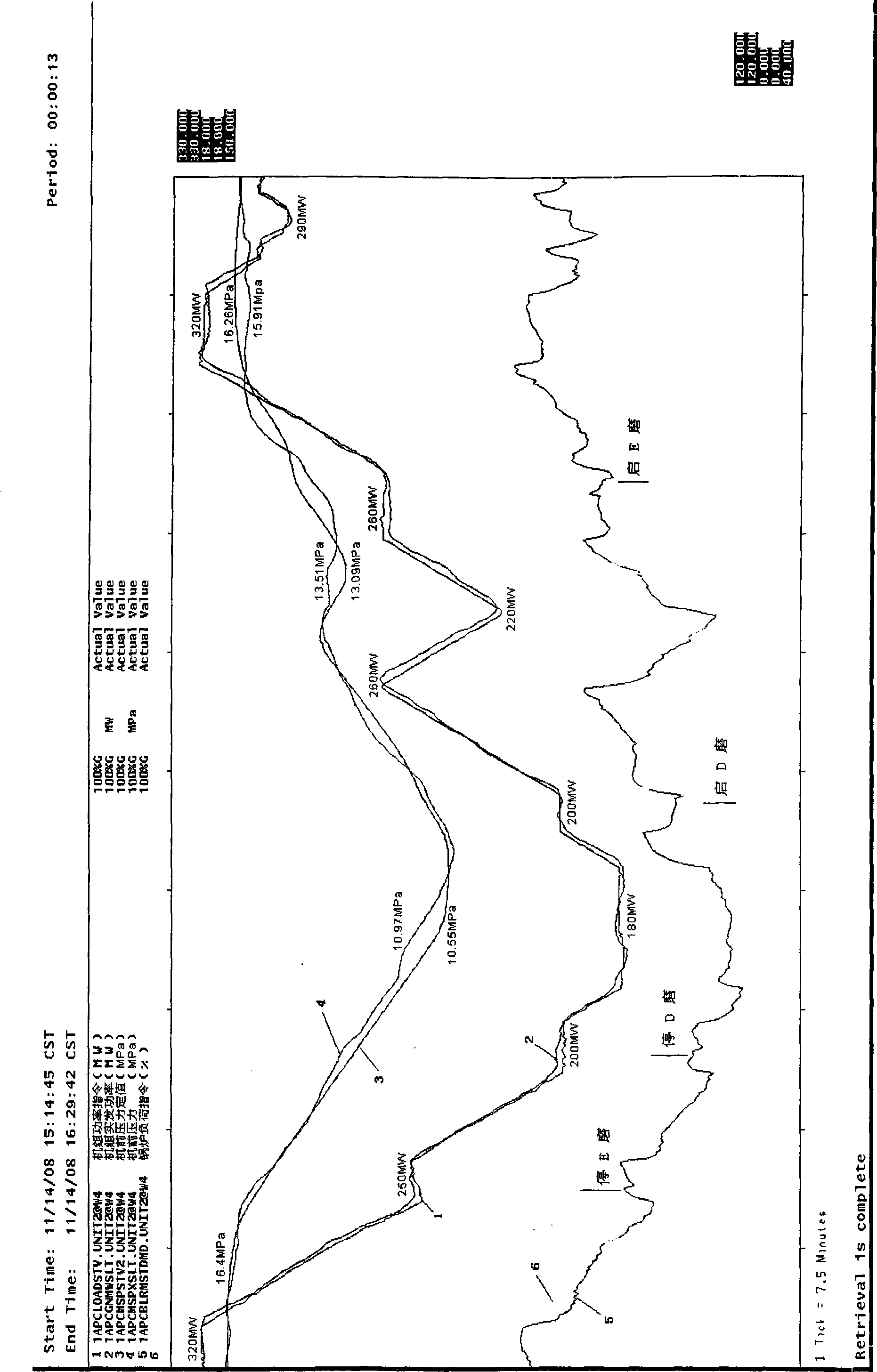

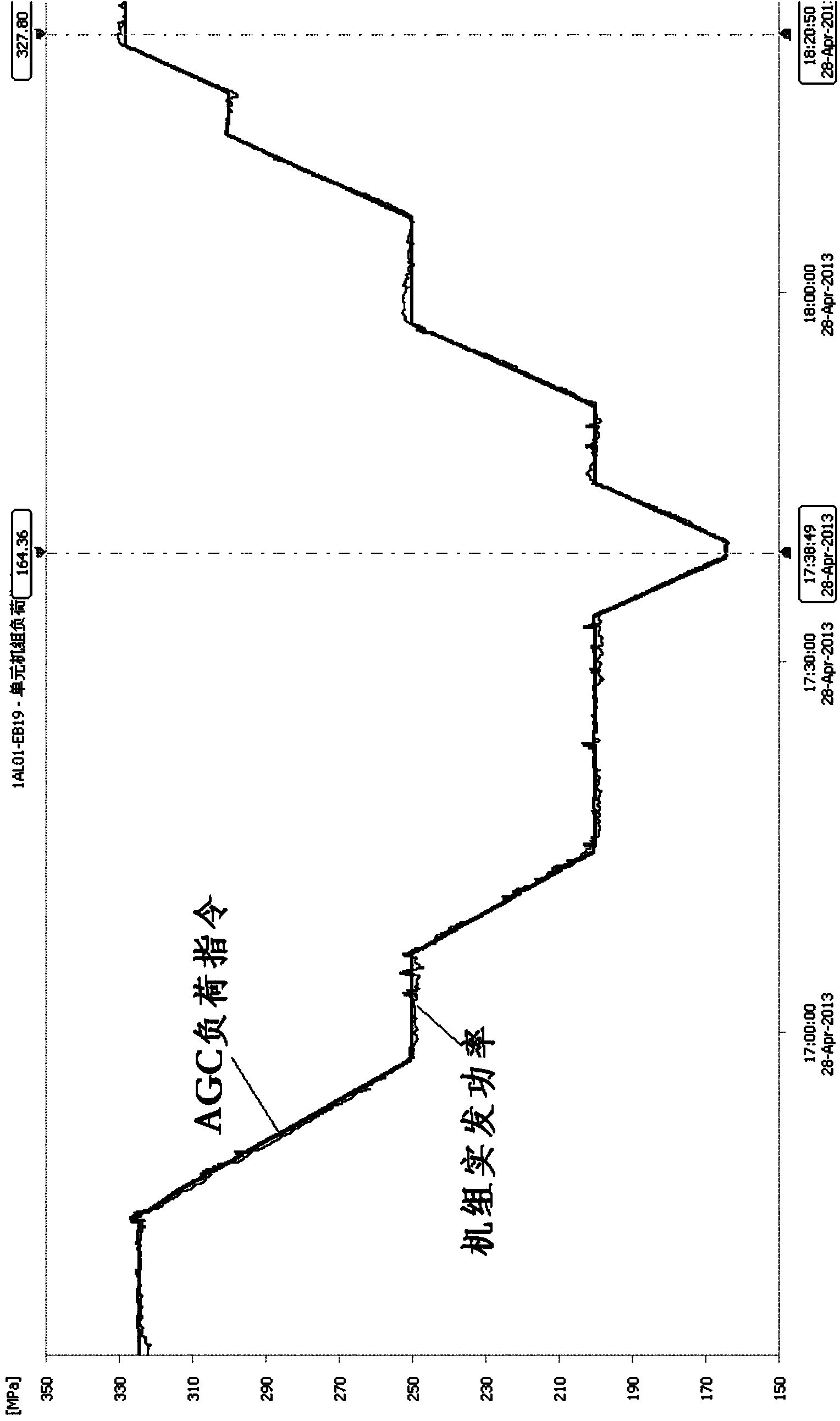

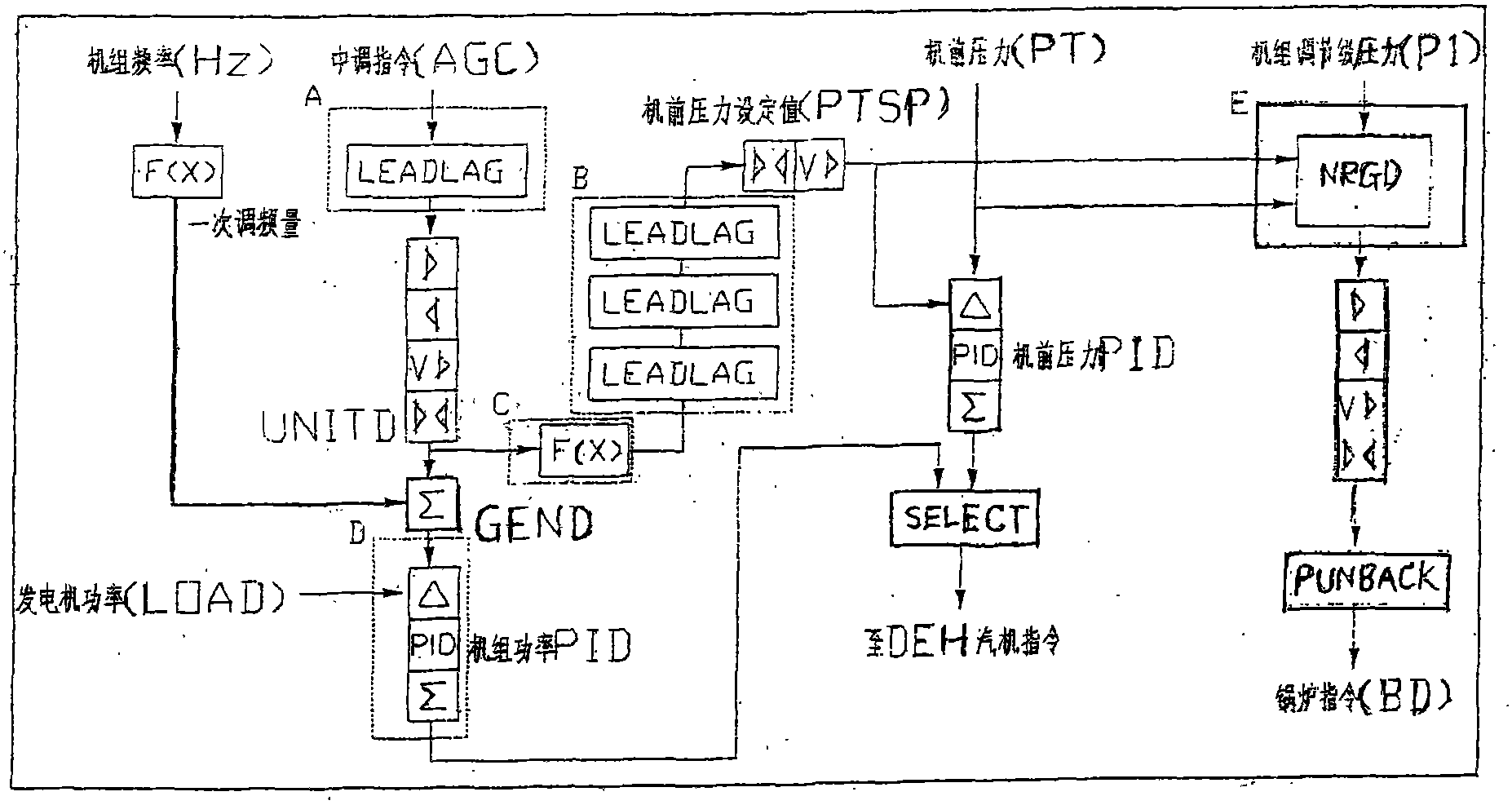

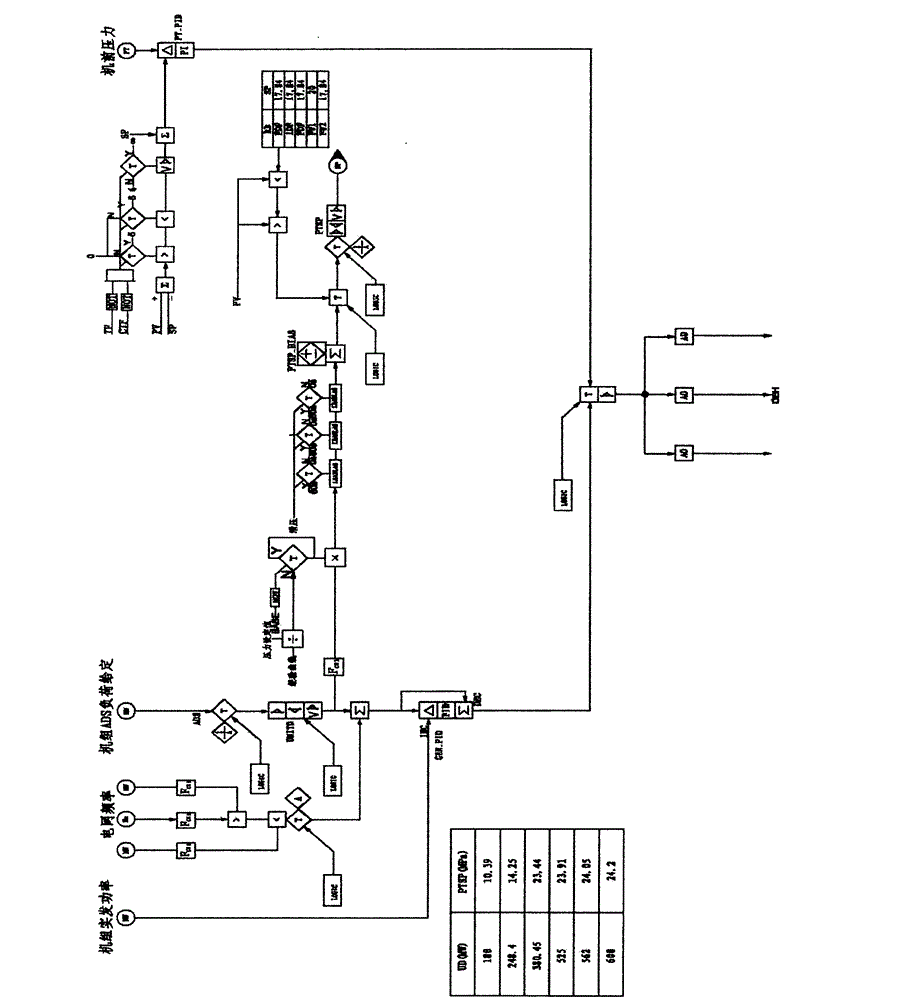

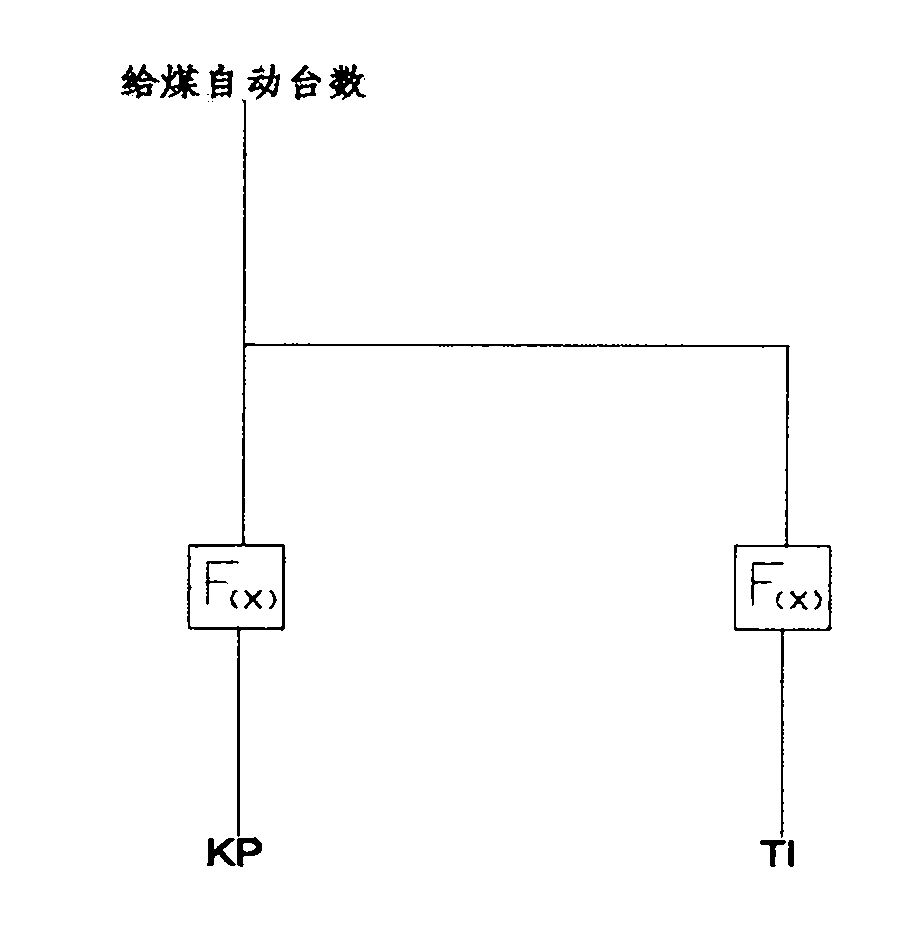

Advanced control method for thermal power unit boiler turbine coordination system

InactiveCN101488022ADecrease in weight coefficientIncreased weight coefficientMachines/enginesEngine componentsUnit loadSteam pressure

The invention provides an advanced control method for a coordination system of a boiler and a steam turbine of a thermal power unit, which applies advanced dynamic feedforward technology to the feedforward design of a main control system of the boiler so as to effectively accelerate governing speed of a boiler load command in a load varying process of the unit. In the load varying process of the unit, oscillation tendency of the main control system of the boiler can be inhibited through reducing integral action of a regulator. In the main control system of the steam turbine, a unit load command N0 is subjected to inertia LAG time-delay, and protection design is carried out on main steam pressure. The method ensures that the boiler and the steam turbine can operate under a more coordinated mode and ensures that the thermal power unit has faster ascending and descending speed of load and more stable variation of the main steam pressure, wherein the ascending and descending speed of the load of the unit reaches 3.0 percent Pe / min in actual application, the main steam pressure is stable without overshoot, and the pressure deviation is in an acceptable range.

Owner:SOUTHEAST UNIV

Method and a system for control of a device for compression

InactiveUS20070151528A1Work lessImprove efficiencyNon-fuel substance addition to fuelInternal combustion piston enginesSteam pressureCombustion chamber

A method of compressing a medium in the combustion chamber of a combustion engine, wherein a liquid spray is introduced into the compression chamber during a compression stroke, the liquid is pressurized and heated before introduction into the compression chamber to such a degree that at least a part of the droplets of the spray explode spontaneously upon entrance in the compression chamber. The pressurized liquid has a steam pressure that is above the pressure in the compression chamber, and the liquid has a temperature that exceeds the boiling point of the liquid for the temperature and the pressure that, at the moment of introduction, exists in the compression chamber, and the heat being water. The liquid is heated to such an extent that, at the moment of introduction, it has a temperature that is below the temperature of the medium at the moment of introduction of the liquid.

Owner:CARGINE ENG AB

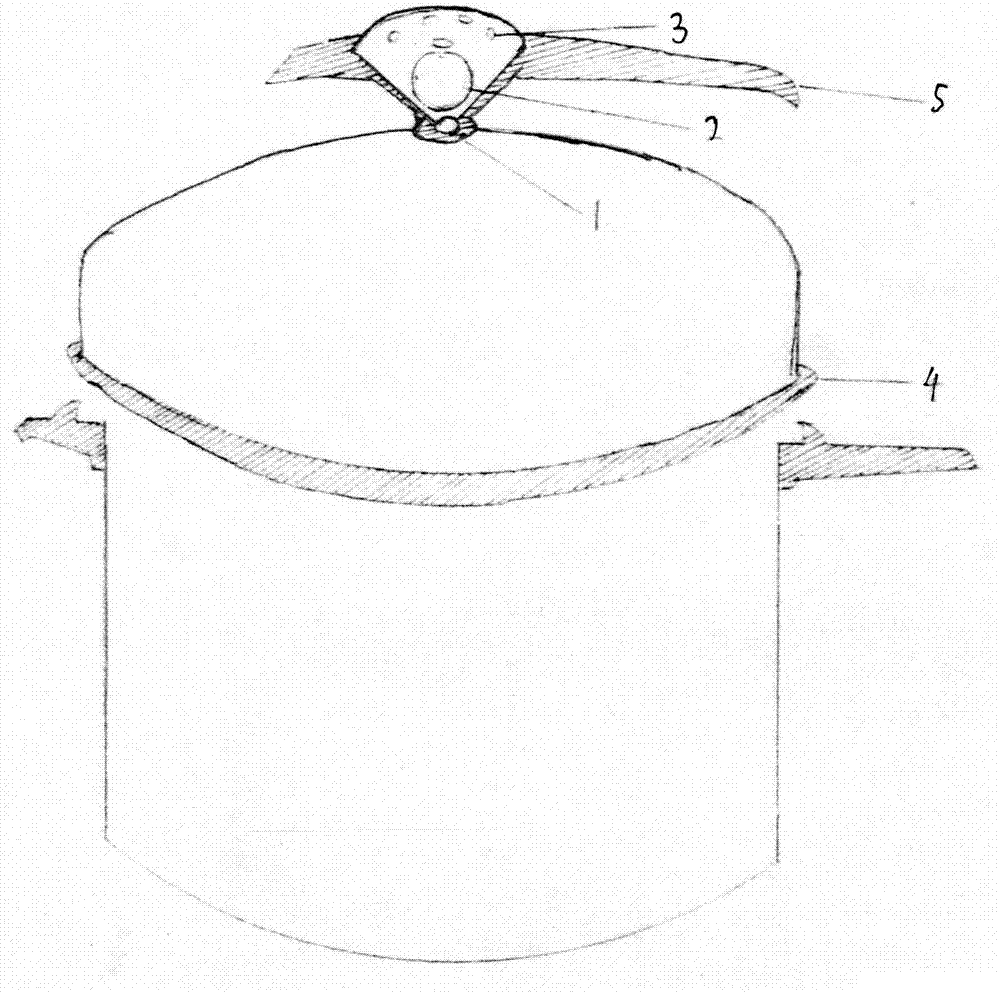

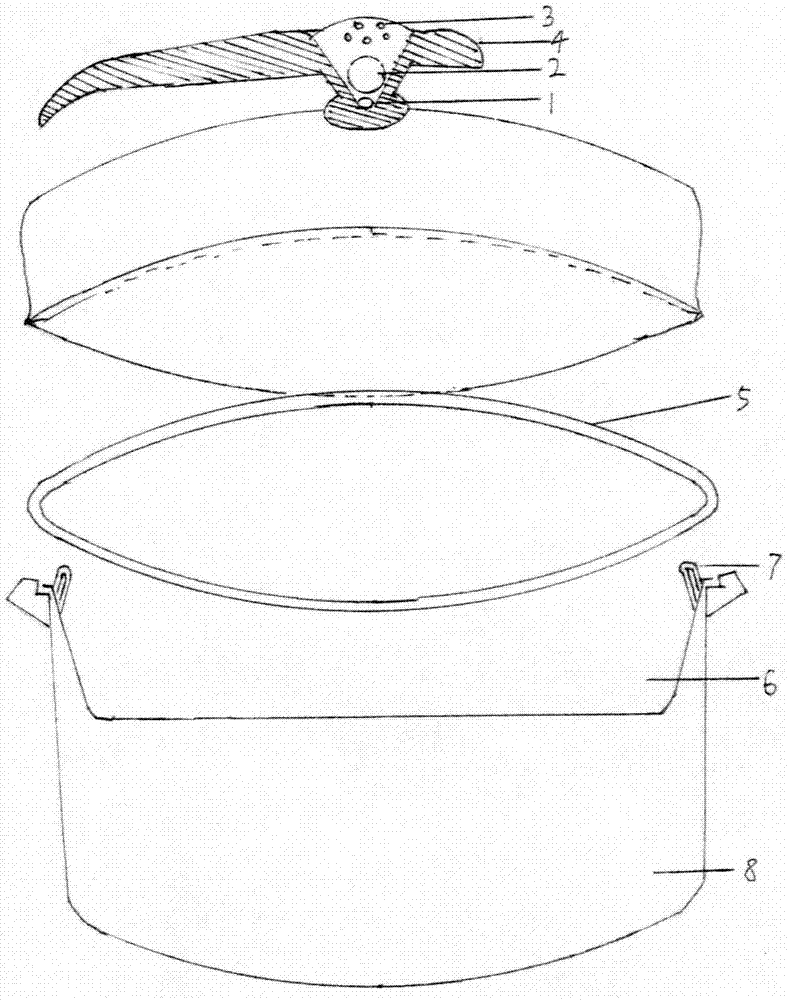

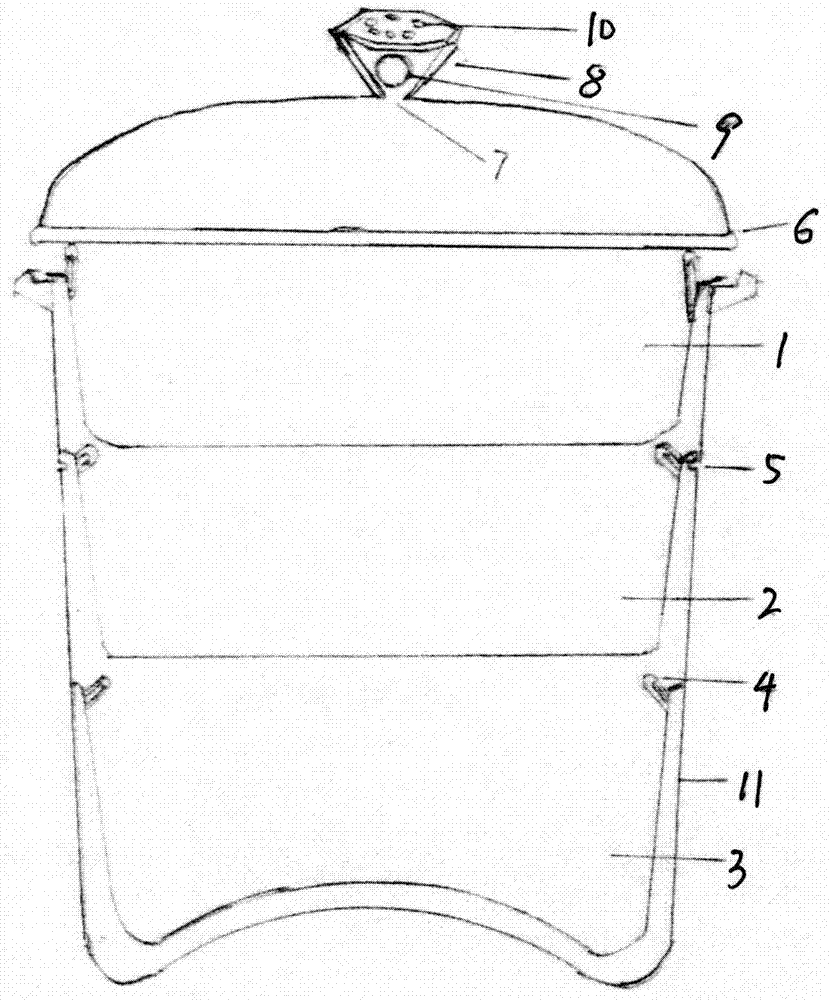

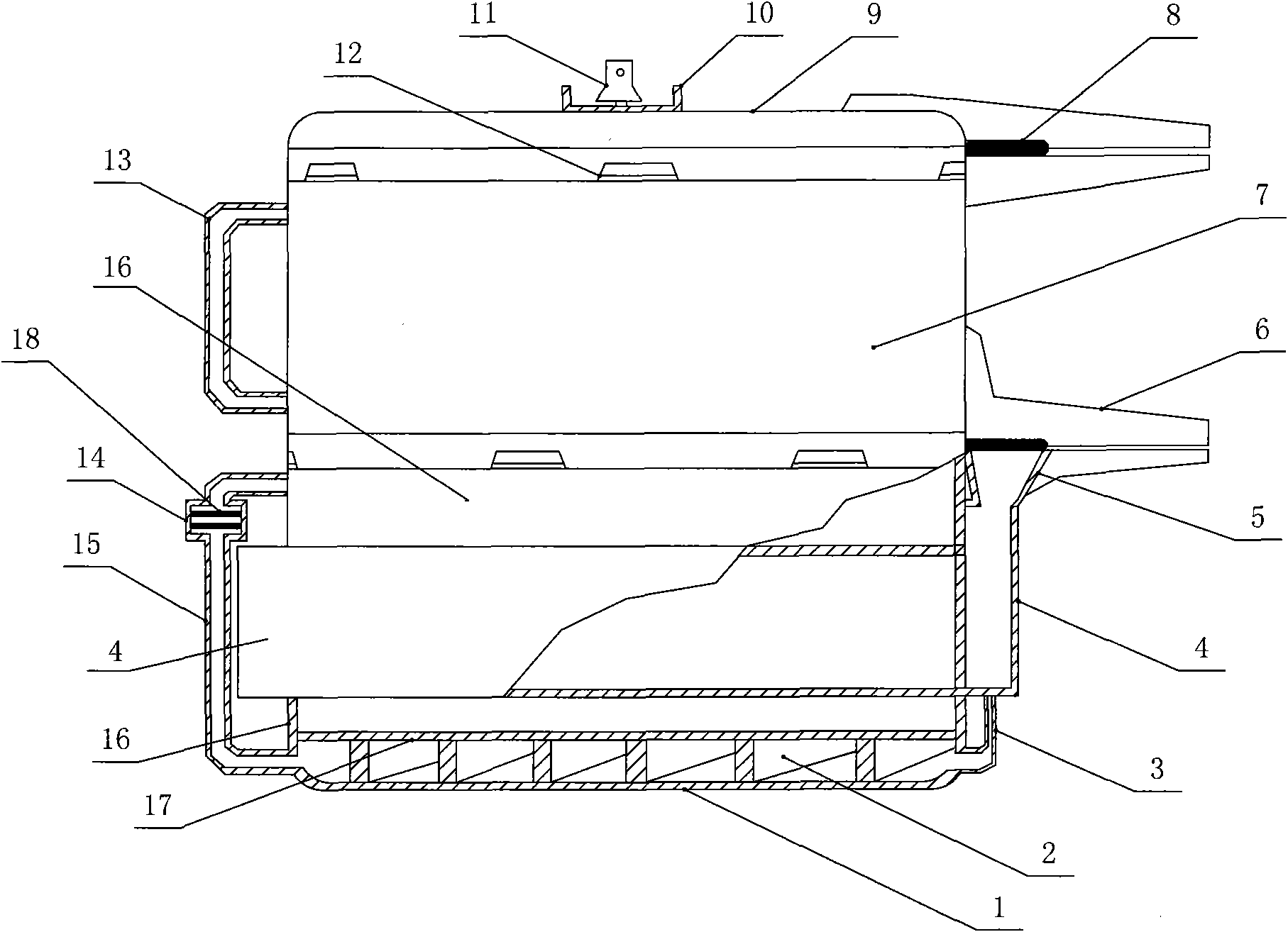

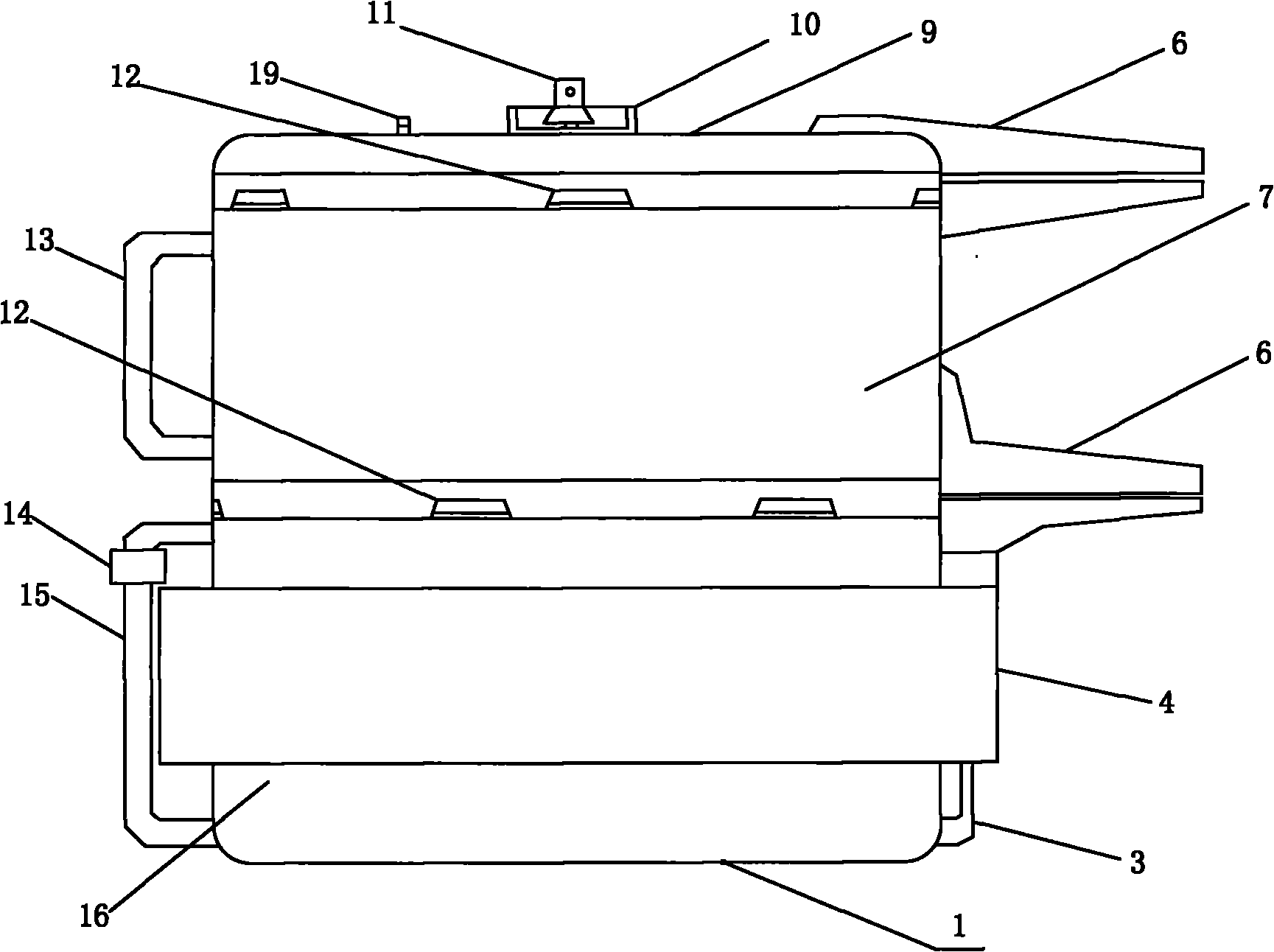

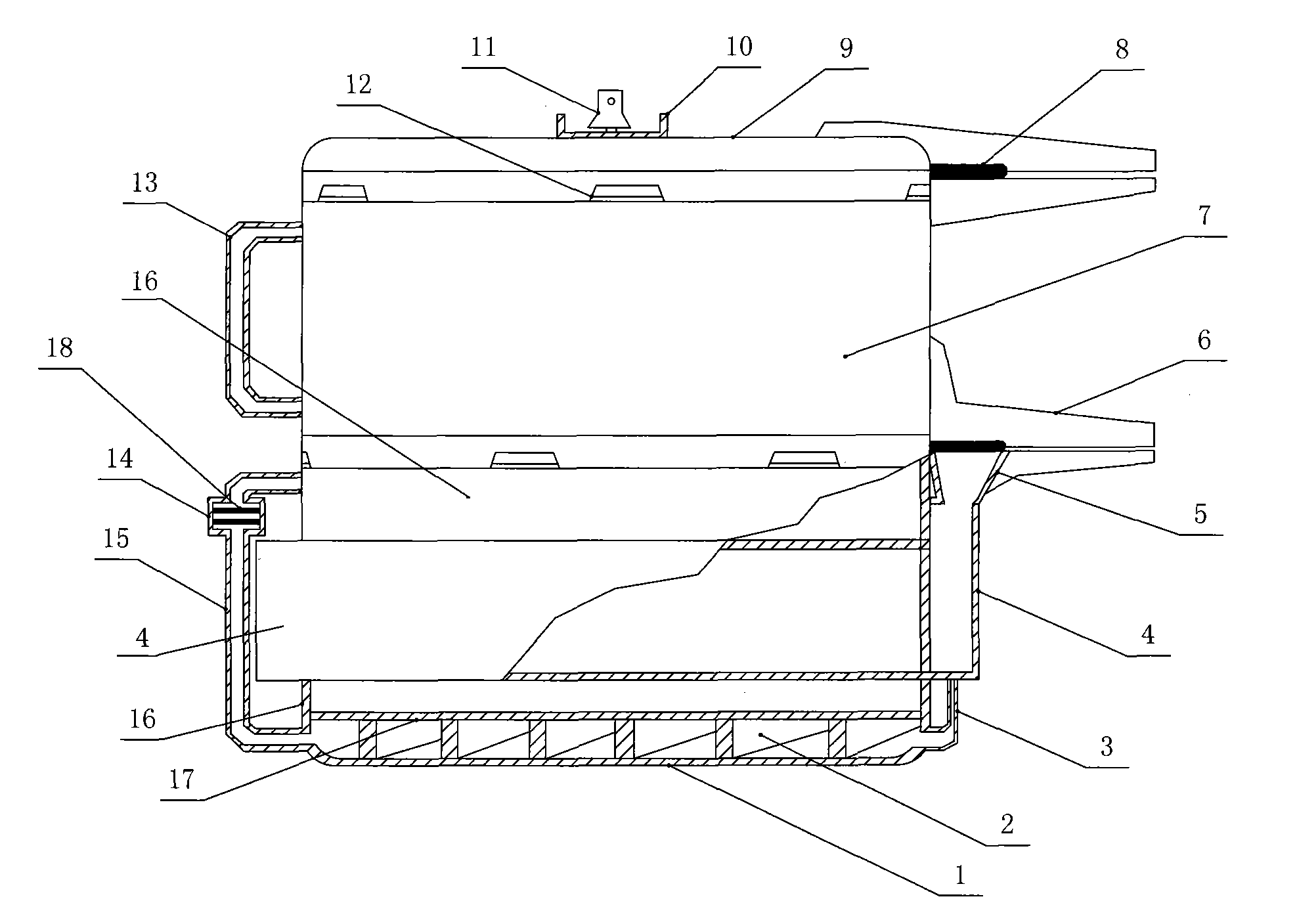

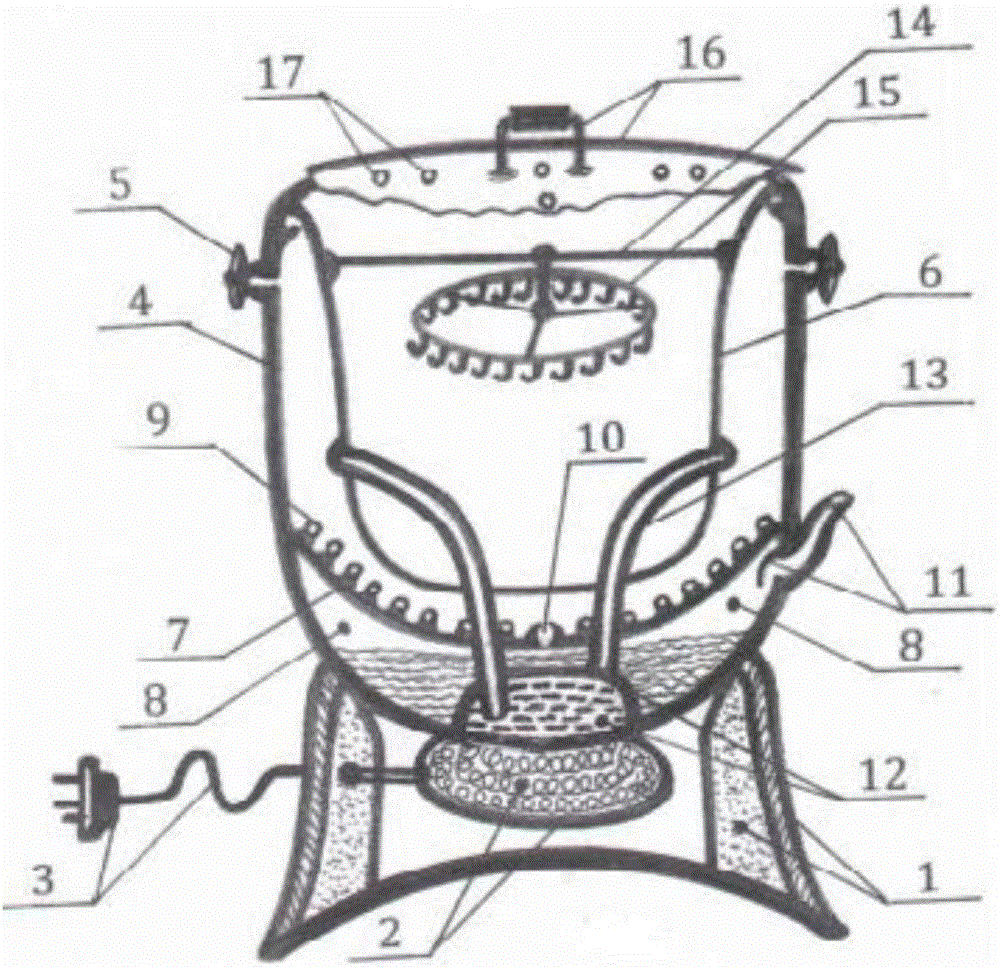

Natural pressure cooker, electric steamed bun cooker and pressure electric cooker adopting natural pressure conduction heating

Natural pressure conduction heating (natural pressure cooker, rice steamed bun cooker, pressure rice cooker) wherein natural pressure conduction heating is a heating method for food. It belongs to the technical field of food cooking. (Natural pressure cooker, electric rice steamed bun pot, pressure electric rice cooker) are pots and electric rice cookers provided by this heating method, belonging to the field of food cooking equipment. It relates to the following as a whole: 1. A pot and an electric rice cooker that use the pot-in-pot to form pressure conduction heating naturally. 2. A pot utilizing a natural pressure relief ball and a sealed pot cover to form pressure. The natural pressure cooker is to block the steam outlet hole of the pot cover with a naturally movable pressure relief ball, and the pressure is set by its proportioning. The steamed rice cooker and the pressure rice cooker use the pot in the pot, and the non-porous steamer naturally forms pressure and conducts heat to make delicious, delicious and nutritious meals. Among them, multi-layer sealing repeatedly produces energy efficiency, so that the energy saving efficiency is more than three times.

Owner:刘九金

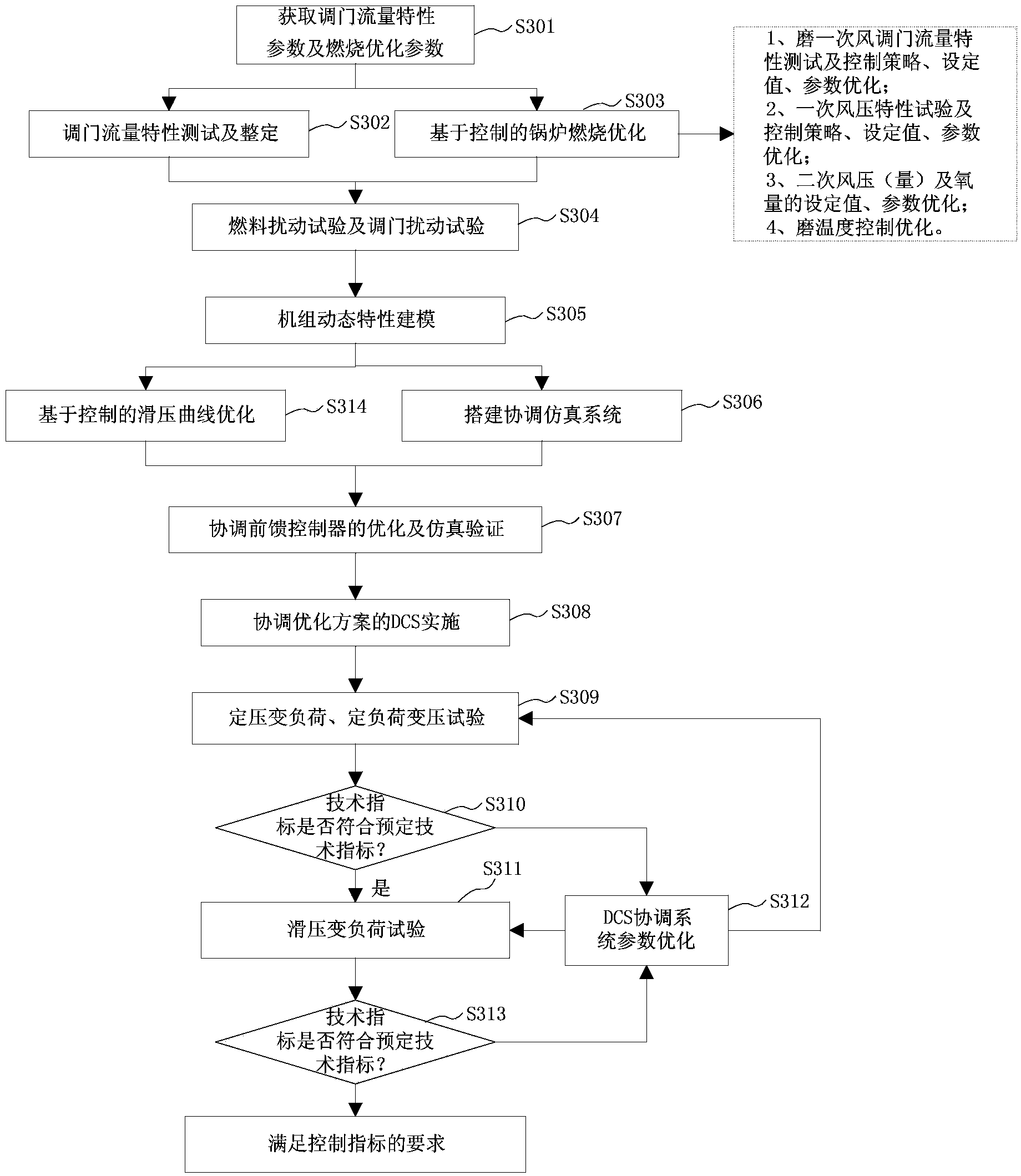

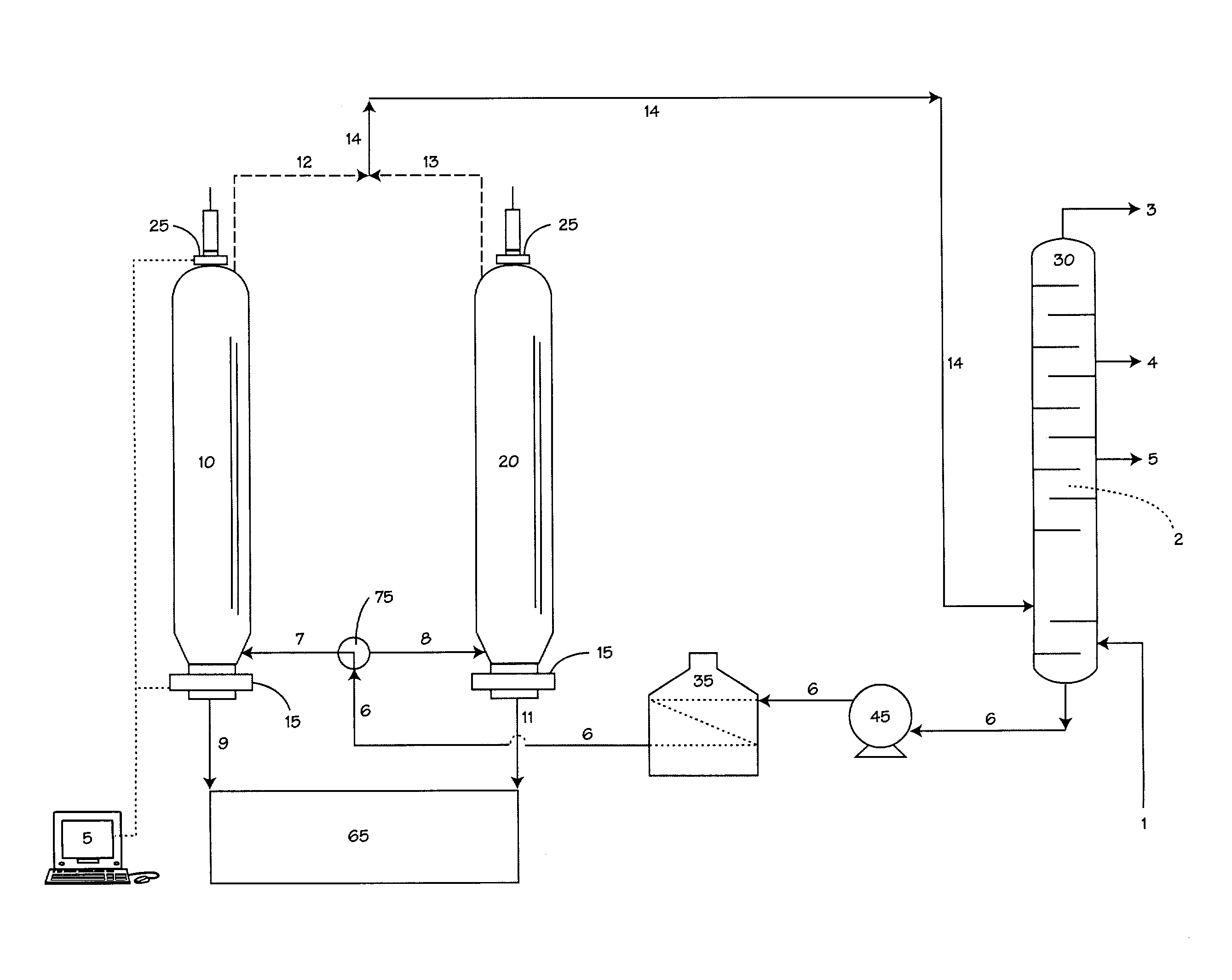

Integral optimization method and system for automatic power generation system of coal-fired unit

ActiveCN103513640AImprove variable load capacityImprove adaptabilityProgramme total factory controlSteam pressureDynamic models

The invention provides an integral optimization method and system for an automatic power generation system of a coal-fired unit. The method comprises the steps of carrying out control valve flow characteristic test and adjustment according to control valve flow characteristic parameters, carrying out combustion optimization on a wind and smoke subsystem and a combustion subsystem, carrying out a fuel disturbance test and a control valve disturbance test to generate typical test parameters, using the typical test parameters to generate a dynamic unit model, constructing a coordinating simulation system according to a coordinating controller and the dynamic unit model, using the dynamic unit model to optimize a feedforward controller and carry out simulation verification on the coordinating simulation system simultaneously, carrying out DCS configuration and parameter debugging in the simulation system, carrying out a constant-voltage slide-voltage variable-load test and a constant-load voltage-transformation test to generate technical indexes of the variable-load rate, the variable-load accuracy, variable-load response time and the main steam pressure accuracy, judging whether the technical indexes meet the preset technical indexes, and if on yes judgment, carrying out a slide-voltage variable-load test to enable the coal-fired unit to operate normally.

Owner:STATE GRID CORP OF CHINA +1

Steam pressure cooker

The invention relates to a household drinking appliance, in particular to a steam pressure cooker, which comprises a main pot body. The upper end of the main pot body is connected with a selective laminated pot body and a pot lid, the bottom of the main pot body is connected with a steam-heating plate, and the shell of the main pot body is connected with a water accumulation core and a handle; and the water accumulation core is connected with one end of the steam-heating plate through a water supply pipe, the steam-heating plate can boil water through an external heating source to generate steam, and one end of the steam-heating plate is also connected with an air delivery pipe and an anti-spillage box and extends into the main pot body. The invention has the advantages that the drink-steaming speed is high, the adoption of the steam-heating plate can realize the water boiling within a short term due to the clearance cooking in the small space, and the generated heat can be used for steaming and cooking food; and the thermal energy transmitted from a heat source can be utilized more completely and more directly due to the fin type heat transfer block of the steam-heating plate technology.

Owner:戴文育

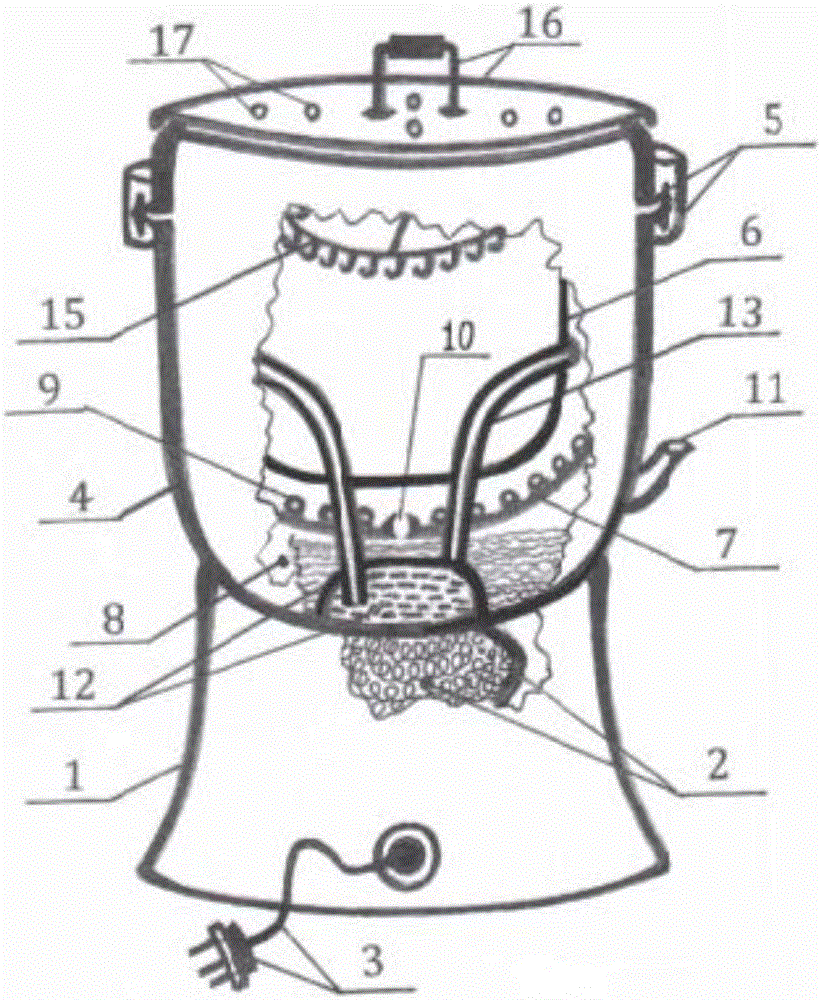

Double-heat-source steaming type barbecue grill

A double-heat-source steaming type barbecue grill comprises a base, a shell and an inner container. The bottom of the shell is arranged on the base. A heating disc is arranged at the position, close to the bottom of the shell, of the base. The inner container is arranged in the shell. A cavity is formed between the inner wall of the shell and the outer wall of the inner container. A steam pressure reducing plate is arranged between the position, above the bottom of the shell, in the cavity and the position, below the bottom of the inner container, in the cavity, a steam water tank is formed by the steam pressure reducing plate and the bottom of the shell, and steam nozzles are evenly distributed on the steam pressure reducing plate. A steam accumulated water circulating hole is formed in the middle of the steam pressure reducing plate, and a secondary heat source heat conducting oil tank is arranged at the position, in the middle of the bottom of the shell, of the steam water tank. A circulating oil pipe penetrates through the steam pressure reducing pipe and is wound around the outer wall of the inner container, and the two ends of the circulating oil pipe are connected with the secondary heat source heat conducting oil tank. According to the double-heat-source steaming type barbecue grill, it is unnecessary that open fires are used for directly baking food, double indirect heat sources are adopted for baking, and therefore the baked food contains no harmful matter, and is healthy to eat.

Owner:定远县创新科技服务园

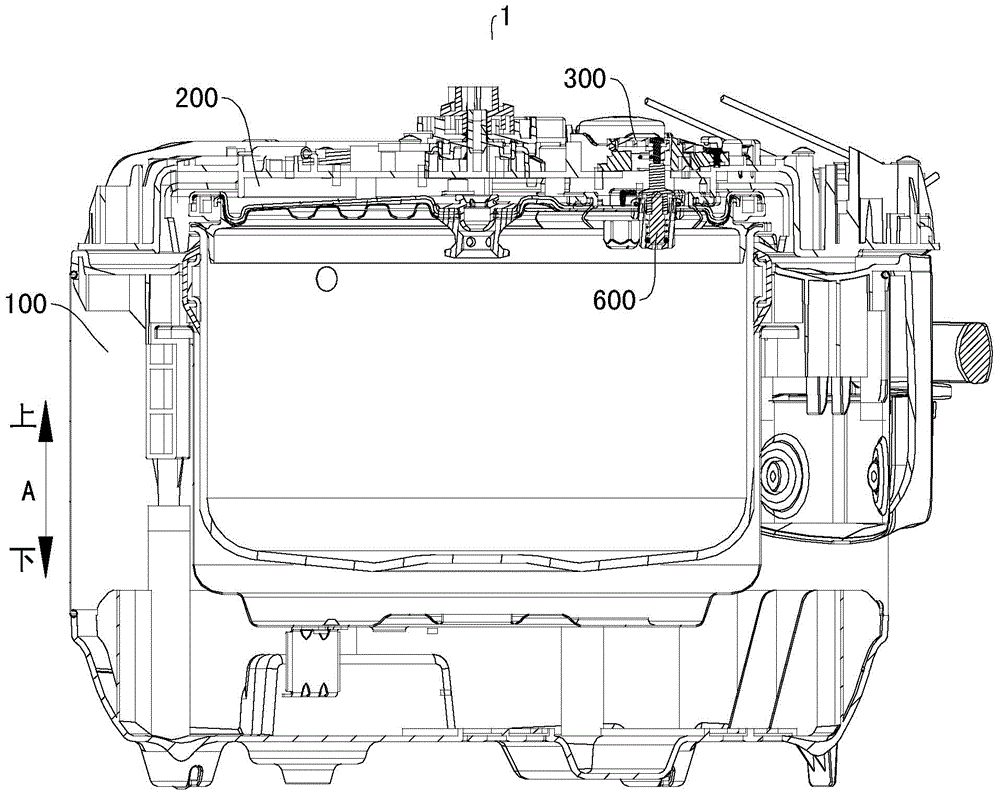

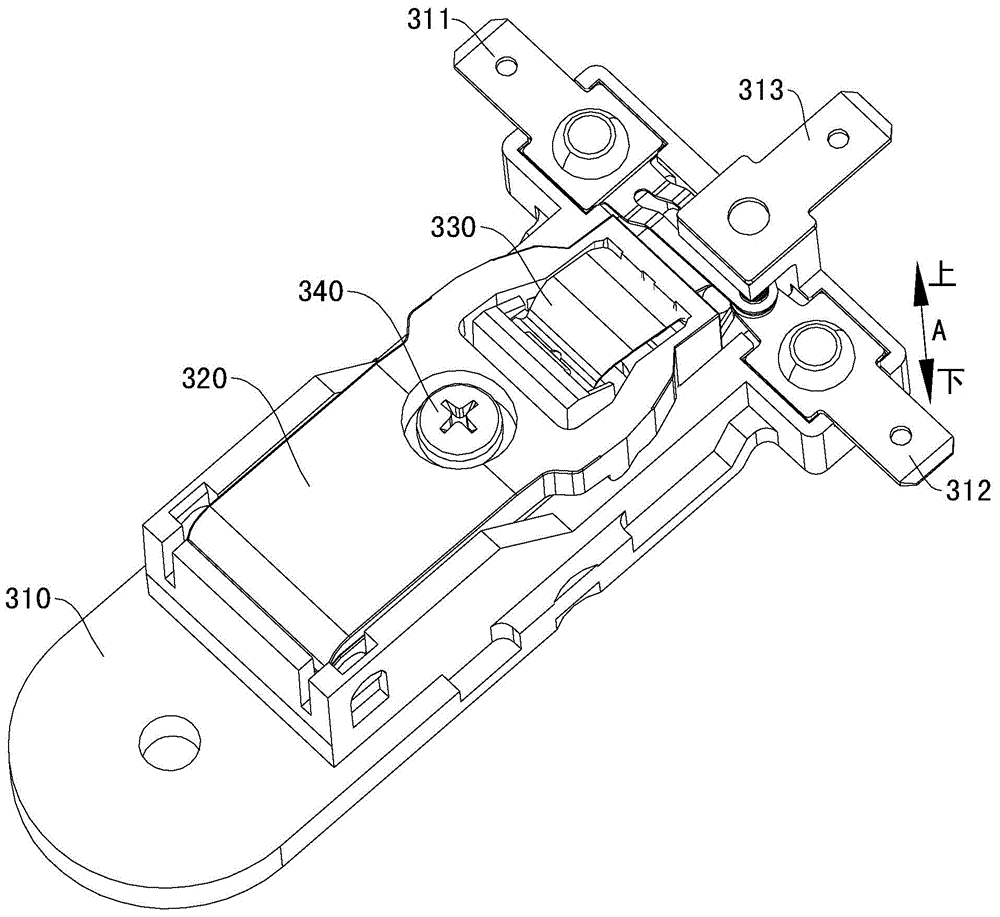

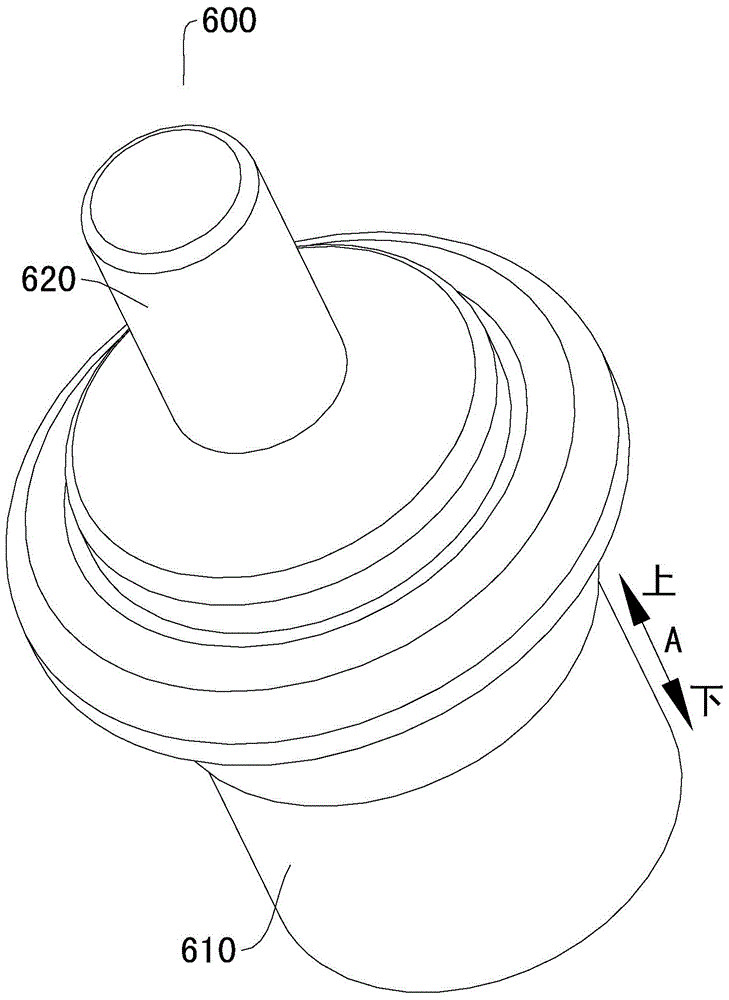

Pressure cooker

The invention discloses a pressure cooker. The pressure cooker comprises a cooker body, a cooker cover, an on-off switch, a controller, a pressure reduction device and a pressure detection device, wherein the cooker cover is arranged on the cooker body; the on-off switch is arranged on the cooker body or the cooker cover and provided with an input terminal, a first output terminal and a second output terminal, and the input terminal is connected with a power supply and also connected with the first output terminal; the controller is connected with the first output terminal and the power supply respectively; one end of the pressure reduction device is connected with the second output terminal and the controller, and the other end of the pressure reduction device is connected with the power supply; and the pressure detection device is arranged on the cooker body or the cooker cover and connected with the on-off switch, and the pressure detection device controls the input terminal to be disconnected with the first output terminal and connected with the second output terminal when pressure in the cooker body is higher than the predetermined value. The pressure cooker according to the embodiment of the invention can realize overflow-free steam pressure reduction in case of excess pressure, and therefore, has the advantages of high security, good cleanliness and sanitariness and the like.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

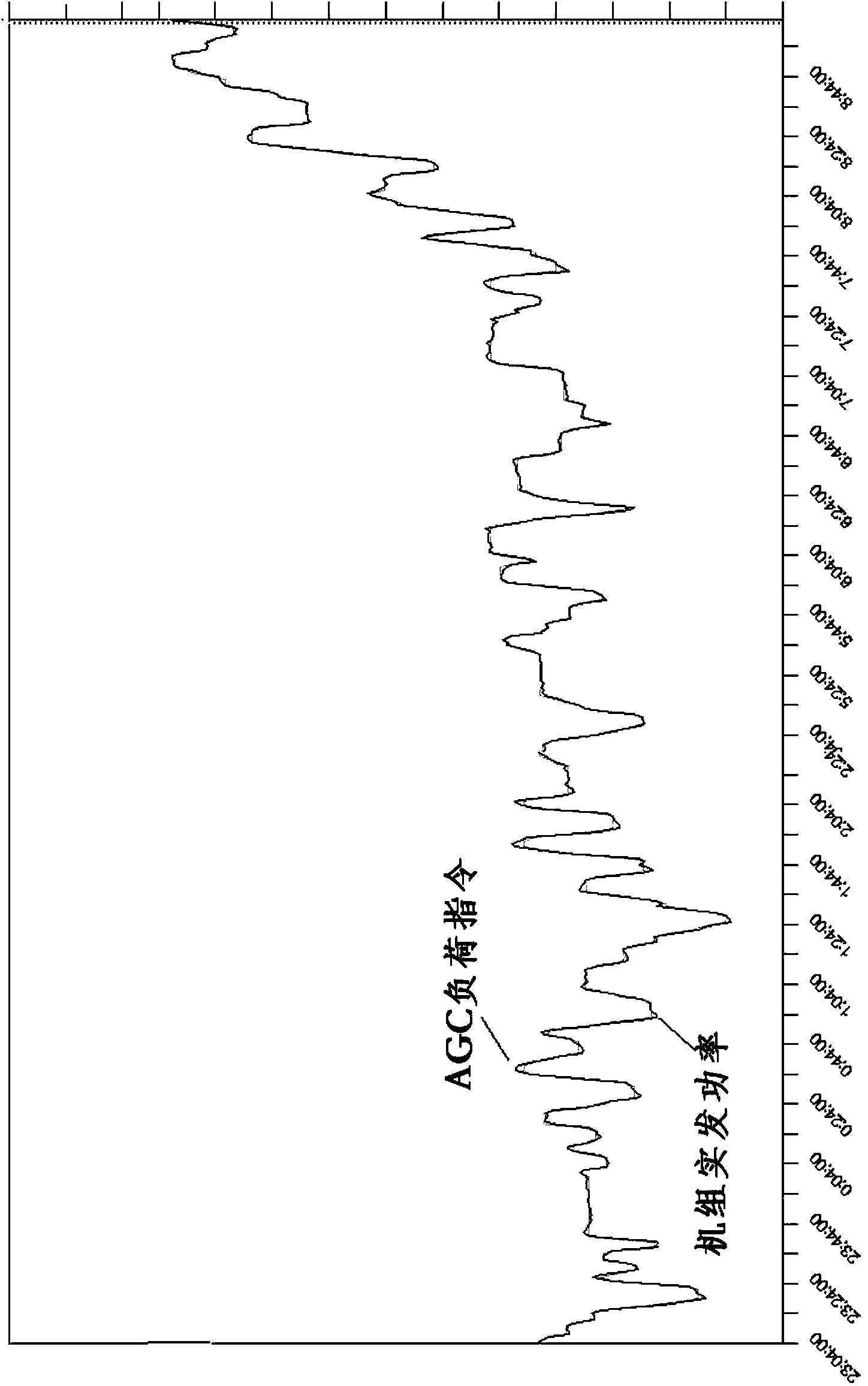

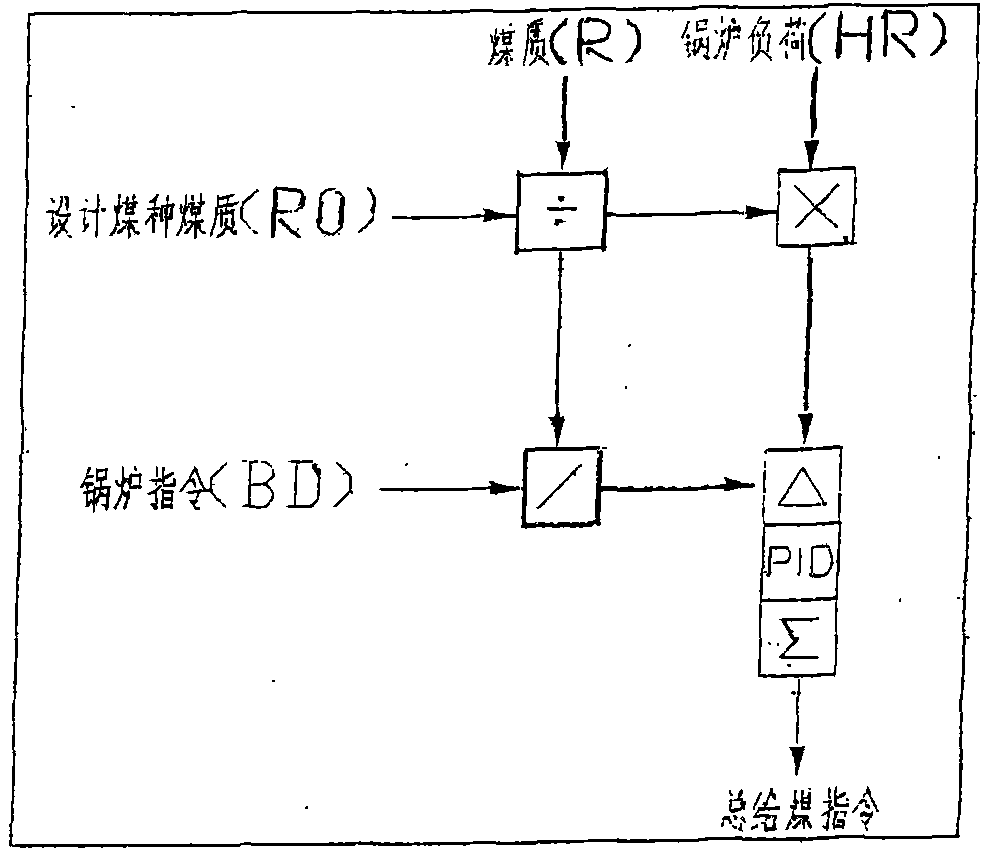

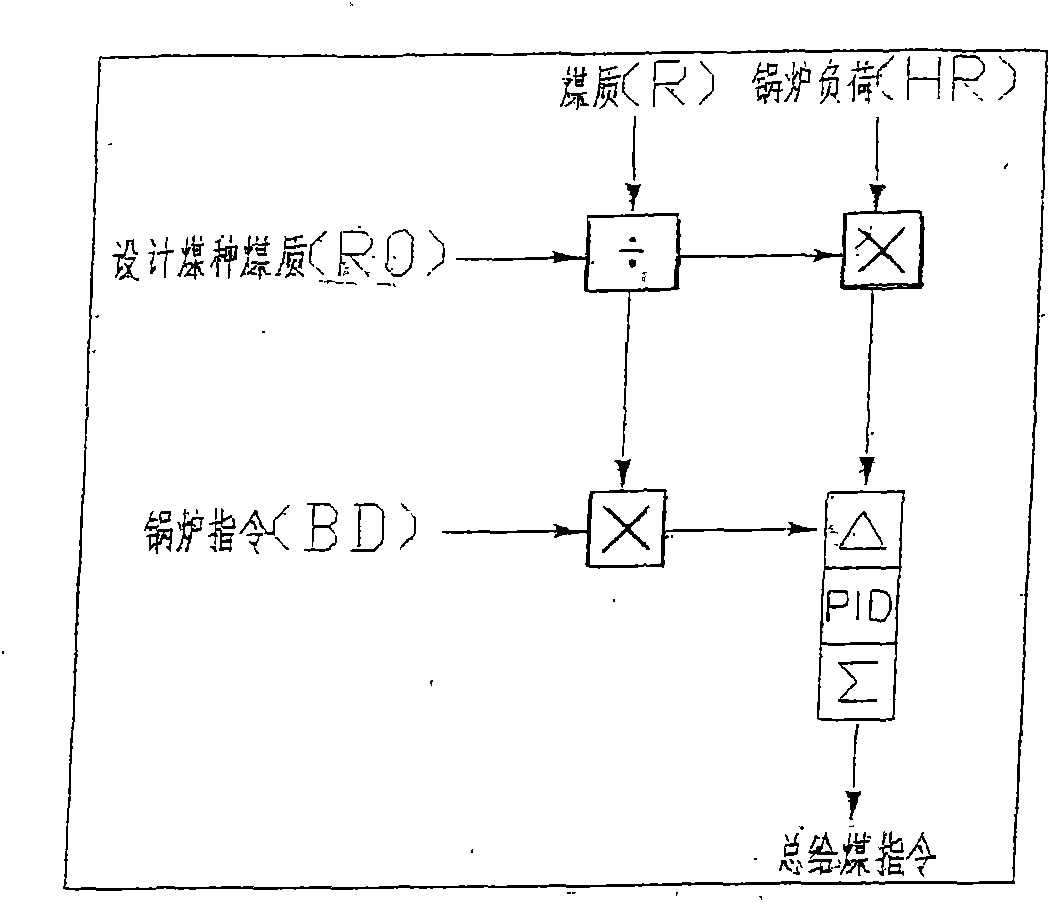

Control method for coordination and automatic power generation of coal quality self-adaptive thermal power generating unit

InactiveCN101788155AEnsure coordinationGuaranteed AGC control indicatorsFuel supply regulationSteam pressureAir volume

The invention provides a control method for coordination and automatic power generation of a coal quality self-adaptive thermal power generating unit. The method comprises the following steps of: 1, compressively determining the coal quality according to parameters including first-level pressure of a steam engine, drum pressure, coal feed, unit load and the like; 2, by the determined coal quality, performing the coal quality self-adaptive control over main control systems of fuel, coordination, air delivery and the like; 3, by core control strategies of boiler load commands, main steam pressure settings, a coal quality self-checking positive load upper limit and the like, realizing the control over the coal quality self-adaptive coordination and automatic power generation of the thermal power generating unit; and 4, realizing the automatic safe operation of the thermal power generating unit by improving safety locking conditions of the thermal power generating unit. The method has the following obviously advantages that: under a fluctuating condition of the coal quality of the thermal power generating unit, the automatic power generation and the coordination control of the thermal power generating unit are unnecessarily intervened by people, and the scheduling requirements are still met; and compared with the conventional control method, the control method of the invention has the advantages that: the accuracies of the main controlled parameters of the thermal power generating unit are further improved; and simultaneously, the automatic power generation control indexes and the safety and the economy of the thermal power generating unit are enhanced.

Owner:云南电力试验研究院(集团)有限公司

Safe and automatic method for preparation of coke for removal from a coke vessel

InactiveUS7037408B2Prevent leakageReduces and eliminates dangerousThermal non-catalytic crackingDirect heating destructive distillationSteam pressureDrill

A safe, efficient and repetitively operable coke vessel decoking system is disclosed. In a preferred embodiment the closed system comprises a coker vessel pressure-tightly sealed to a top head system, which includes a closure housing with a laterally moveable horizontal closure member therein and a cutting head enclosure, which further comprises a drill stem guide, an access door, and a cutting assembly mounted therein. A novel feature of the invention is a steam purge / blocking system whereby steam pressure is maintained in the closure housing during the coking cycle to maintain seal integrity. Personnel safety during decoking operations is greatly enhanced by eliminating dangerous manual tasks associated with the prior art such as unbolting and removing top head devices. The system can be remotely and repetitively operated through numerous coking / decoking cycles without removal of any system element.

Owner:CHEVROU USA INC

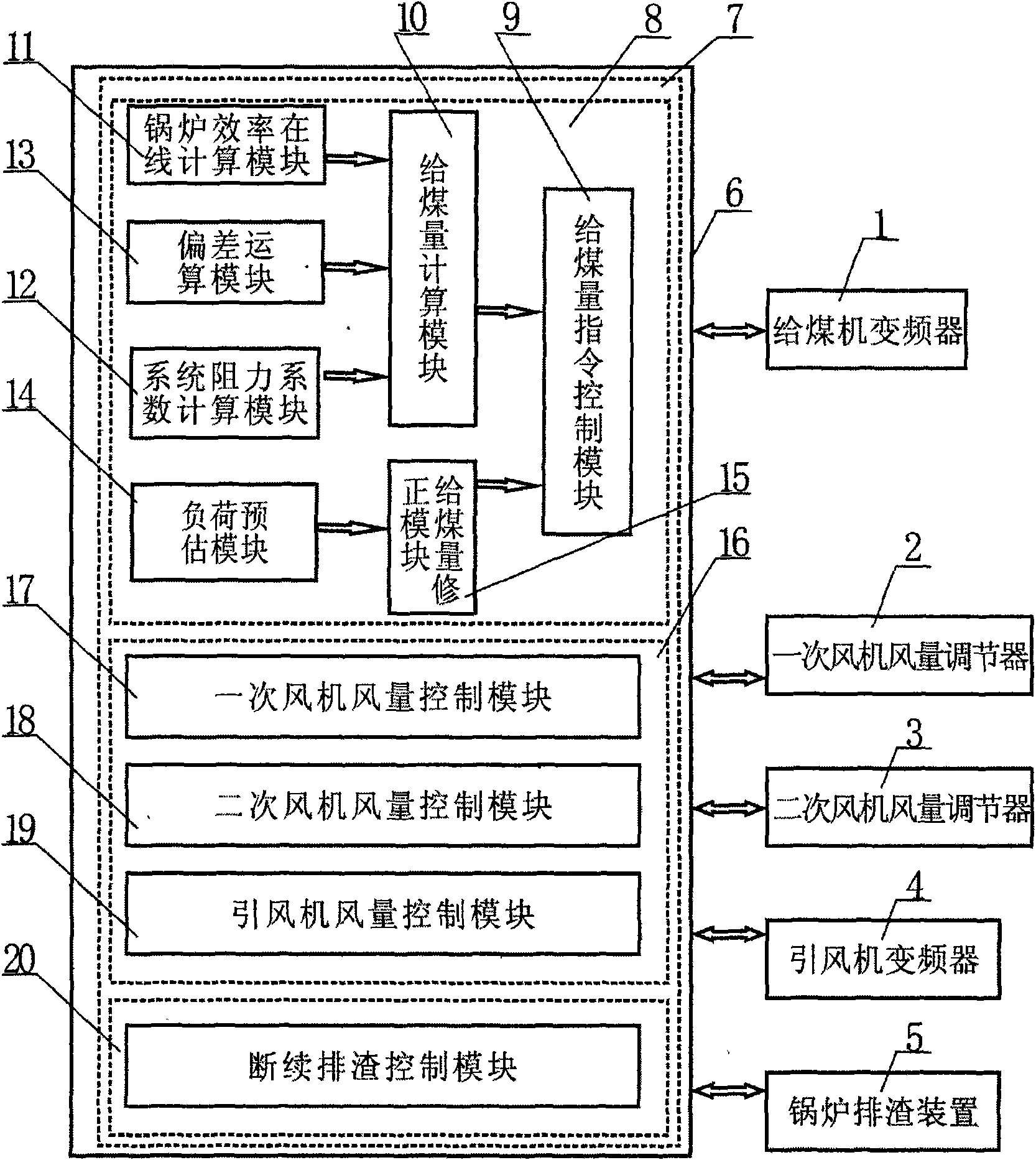

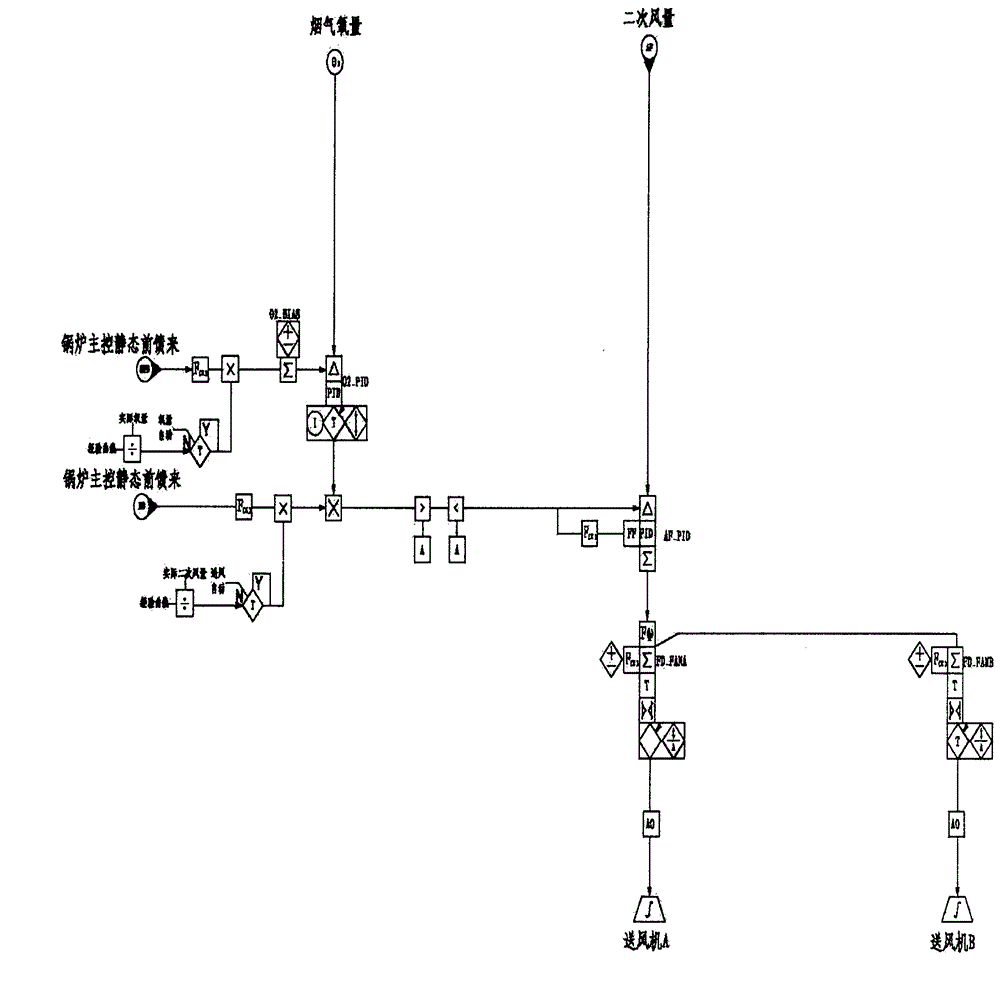

Automatic boiler combustion control system of circulating fluid bed

ActiveCN101551103AAdvanced and reasonable designImprove combustion efficiencyFluidized bed combustionProgramme control in sequence/logic controllersSteam pressureAir volume

The invention discloses an automatic boiler combustion control system of a circulating fluid bed, which is applied to machine sets for coal-fired power generation, heat supply or combined heat and power generation. The system comprises hardware and control program software, wherein the control program software comprises a fuel control part, an air volume control part and a deslagging control part, and the control program software can automatically and timely control the input quantity of boiler fuel, the oxygen content in the boiler and the boiler deslagging device. The combustion control system is applicable to all sorts of complicated operating conditions, has consistently correct and reliable reaction, advanced and reasonable algorithm design as well as good control effect, is safe and effective, has the capabilities of improving boiler combustion condition, increasing boiler combustion efficiency and reducing unburned carbon in flue dust, leads main steam pressure control to be stable, enhances the capability of tracking the change in load of the boiler and greatly improves the running safety performance, leads main steam temperature control precision to be effectively improved, avoids temperature excursion of an overheater, reduces the danger of steam turbine water slug caused by low-temperature steam, and improves the thermal efficiency and automation control degree of the steam turbine.

Owner:DONGGUAN TEXWINCA HLDG

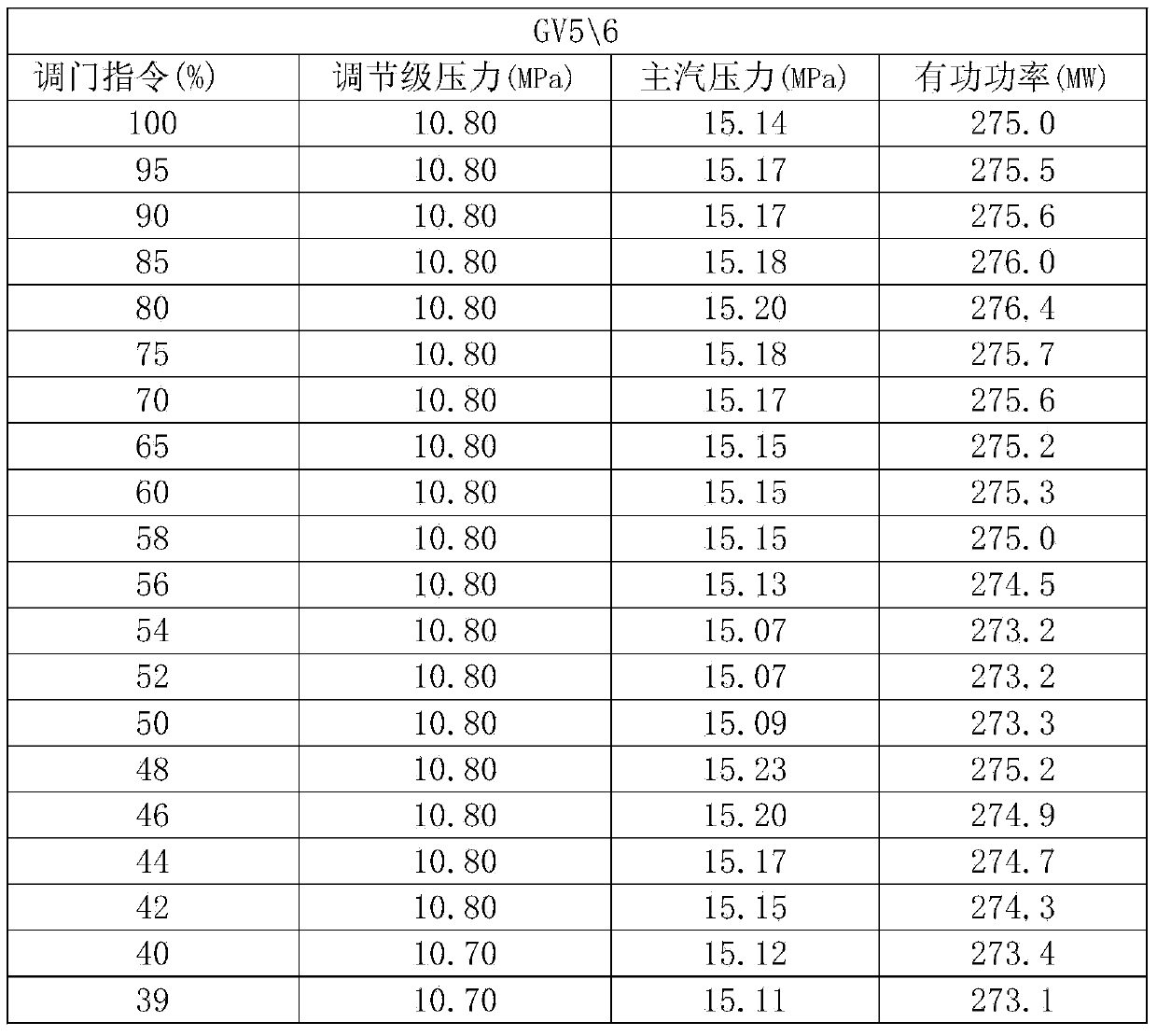

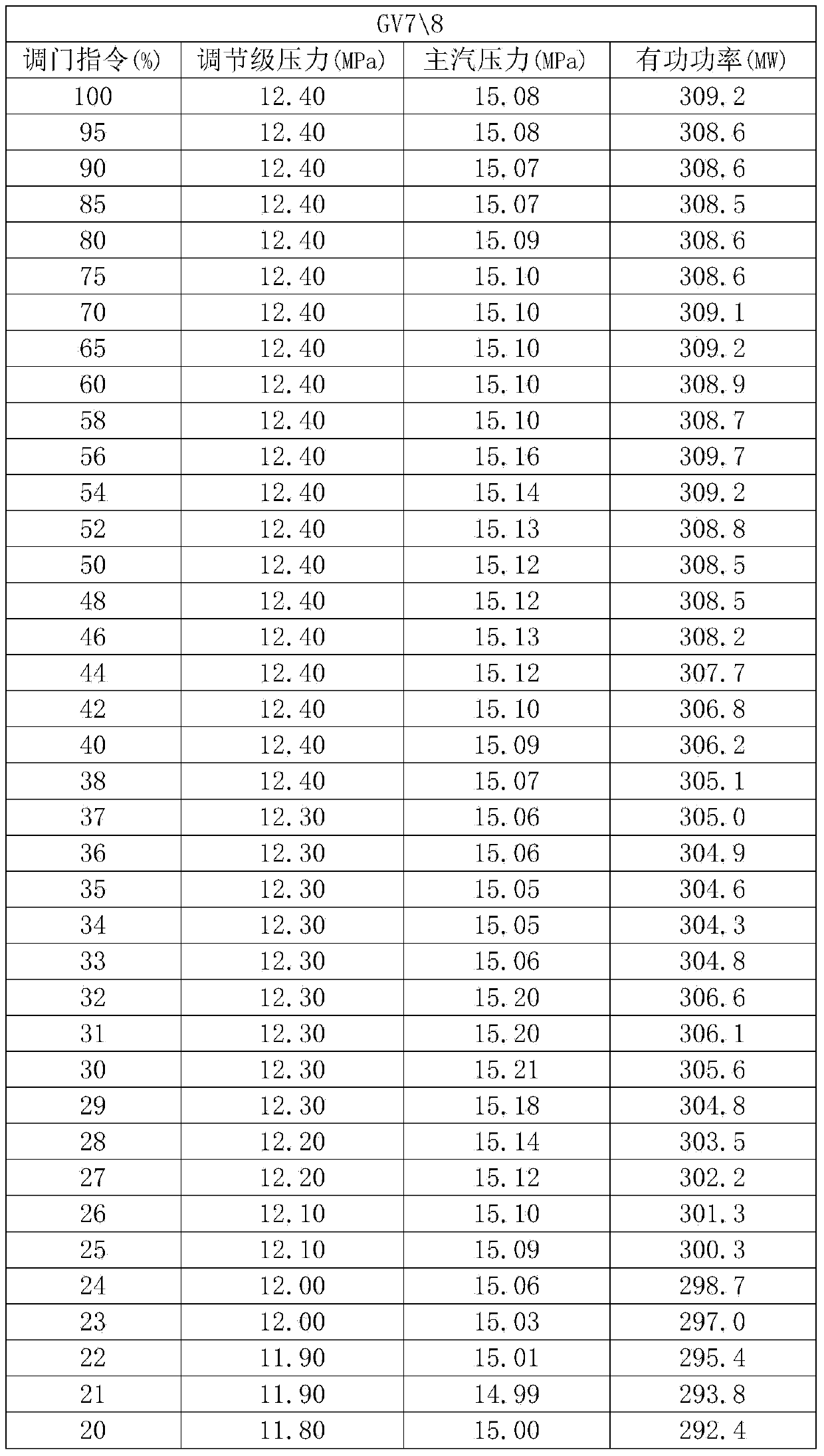

Turbine DEH system high-pressure regulating valve flow characteristic testing and setting method

ActiveCN103743560AImprove control qualityImprove efficiencyMachine part testingSteam pressurePerformance index

The invention discloses a turbine DEH system high-pressure regulating valve flow characteristic testing and setting method, which comprises the steps: relieving the AGC and the primary frequency modulation control method of a DEH system high-pressure adjusting valve, and recording the main steam pressure of a unit; relieving the coordination control method and the DEH remote control method of the DEH system high-pressure adjusting valve, and switching in a DEH valve control method and main steam pressure constant pressure automation; forcedly closing the high-pressure adjusting valve by an instruction according to a specified rule, and recording data; forcedly opening the high-pressure adjusting valve by an instruction according to a specified rule, and recording data; determining a flow characteristic correction curve of the high-pressure adjusting valve according to experimental result data. The testing and setting method has the beneficial effects that the unit efficiency and whole performance indexes are improved, the automation control level is improved, the operation efficiency of the unit is improved, and primary energy is saved.

Owner:STATE GRID CORP OF CHINA +1

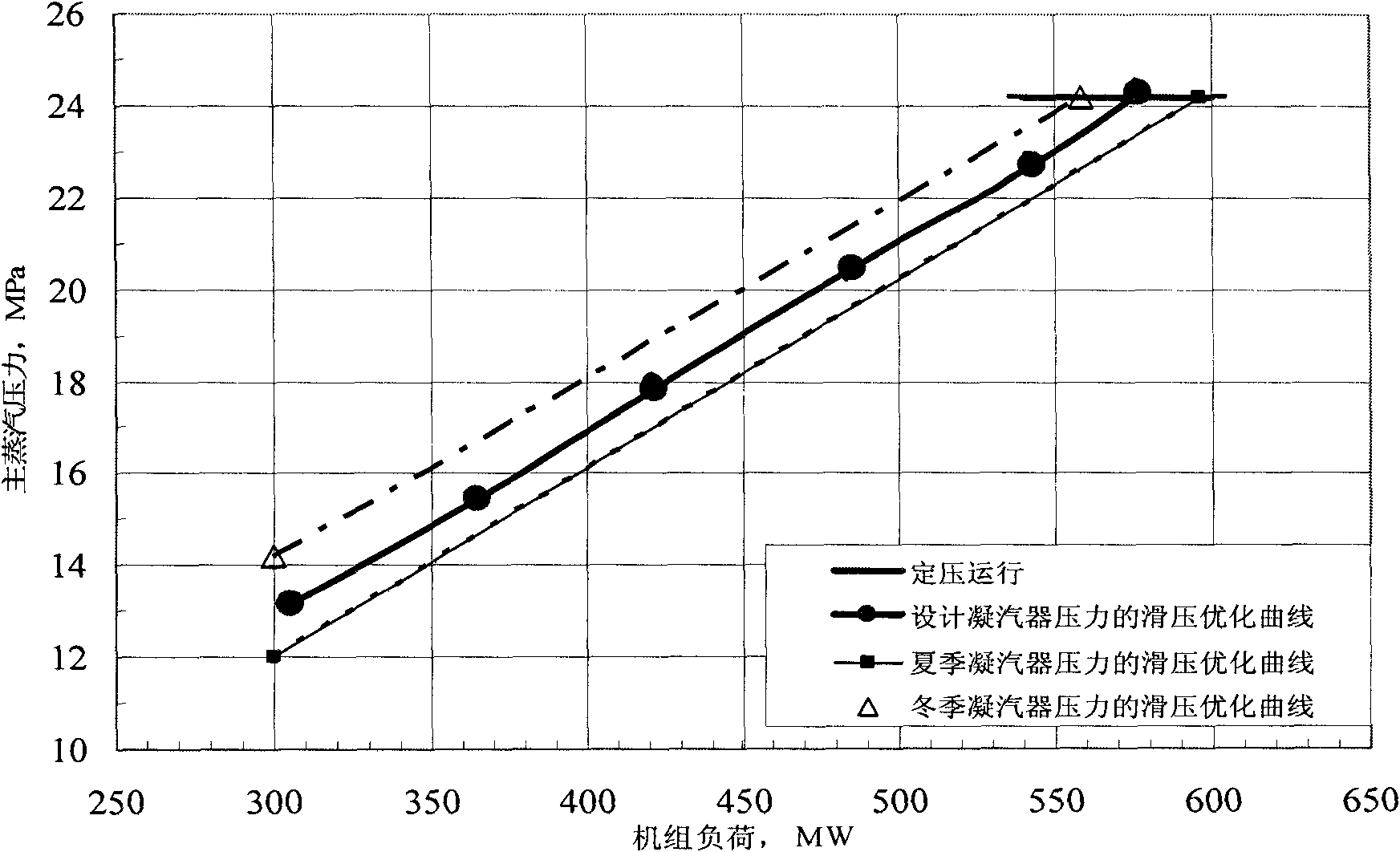

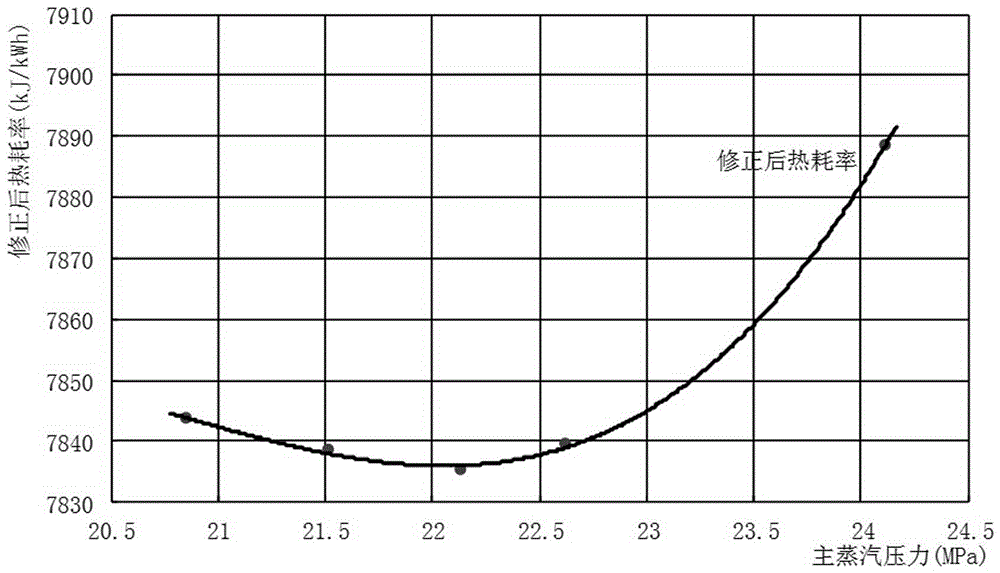

Correction method for optimization of sliding pressure of large steam turbine

ActiveCN101864994ABest sliding pressure operation modeImprove operational efficiencyMachines/enginesEngine componentsSteam pressureLow load

The invention discloses a correction method for optimization of sliding pressure of a large steam turbine generator set of a power plant. The current research on optimization of the sliding pressure of the large steam turbine generator set operating under the low load to ensure that the generator set can operate with excellent performance under the sliding pressure during the low-load operation has great significance in improvement of the operating efficiency of the generator set. The correction method is characterized in that correction factors are adopted to correct the sliding pressure control curve of the generator set, that is, the relevance relation of the load of the generator set, the main steam pressure and the opening of the high-pressure regulating valve is expressed as Cn*Ng varies as Cp*P0*Cv. Since the specific correction factors are introduced for control elements, the load of the generator set and the main steam pressure of the control curve of the generator set under the sliding pressure in the sliding pressure deviation factor correction method, the invention ensures that the steam turbine generator is in the mode of operating under the best sliding pressure, andcan maintain the high operating efficiency of the generator set all the time.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

Method for coordinating and controlling quality change of coal in supercritical once-through boiler unit

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER

Full-mixed pellet feed for mutton sheep and production method thereof

InactiveCN102550861AImprove palatabilityEliminate nutritional imbalancesAnimal feeding stuffFeed conversion ratioSteam pressure

The invention relates to full-mixed pellet feed for mutton sheep and a production method thereof. The feed is composed of the following raw materials by weight percentage: 30% to 50% of maize straw, 5% to 15% of alfalfa, 5% to 10% of beet pulp, 5% to 10% of dry brewer's grains, 15% to 25% of corn, 5% to 10% of bran, 5% to 10% of bean pulp, 5% to 10% of cotton seed meal, 1% to 5% of molasses and 1% to 2% of premixed feed. The production method comprises kneading, smashing and mixing the raw materials with the mixing uniformity within 5%, and after mixing evenly, using a special feed pellet pressing machine to pelletize with steam pressure of 0.3 MPa to 0.4 MPa, temperature of 70 DEG C to 75 DEG C and ring die diameter of 6mm to 12mm. The feed has the advantages of being rich in nutrition for all growth stages of mutton sheep, good in palatability, appropriate in concentrate-roughage ratio, favorable for relative stability of potential of hydrogen (pH) in rumen of mutton sheep and capable of effectively preventing digestion from disordering to greatly improve feed conversion rate. Daily gain of mutton sheep having the feed can be improved by more than 10%, and feed cost is reduced by more than 5%.

Owner:包头北辰饲料科技股份有限公司

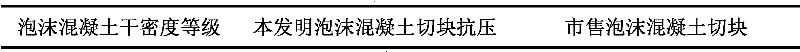

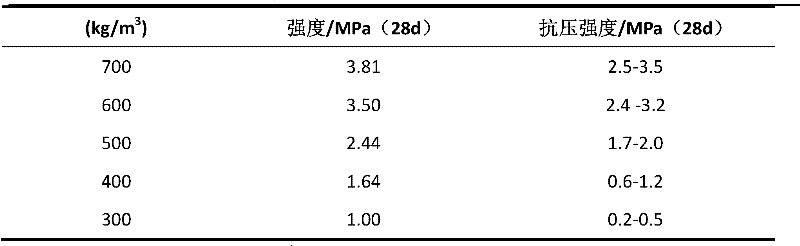

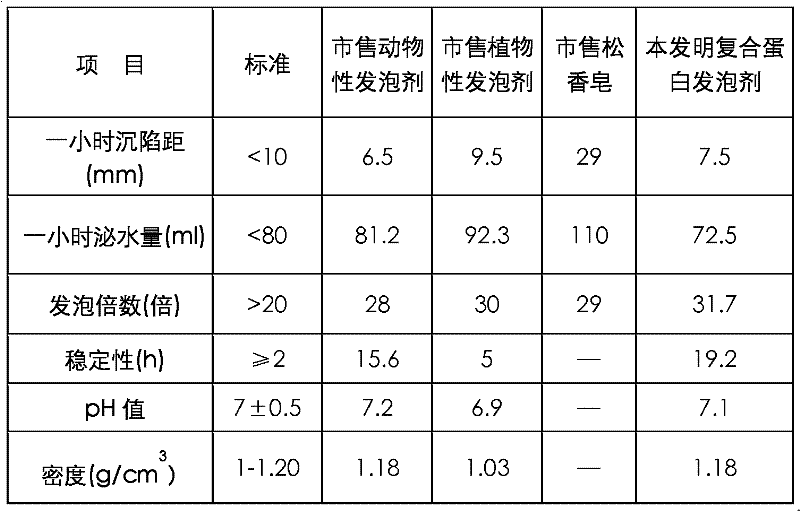

Method for preparing light foam concrete by using compound protein foaming agent

ActiveCN102515827AImprove foam stabilityNo autoclaving requiredCeramicwareFoam concreteActivated sludge

The invention relates to a method for preparing light foam concrete by using a compound protein foaming agent. The light foam concrete comprises 1-10 weight parts of foaming agent, 20-50 weight parts of concrete, 25-60 weight parts of fly ash, 1-10 weight parts of lime, 1-5 weight parts of gypsum, 0.5-2 weight parts of additive, and 27-40 weight parts of water, wherein the foaming agent comprises2.5-25 weight parts of activated sludge protein with a mass concentration 15-25 %, 0.1-1 weight parts of vegetable protein with a mass concentration of 20-40 %, 0.1-0.5 weight parts of stabilizing agent, and 73.5-97.3 weight parts of water. According to the invention, the compound protein foaming agent uses activated sludge protein and vegetable protein as the main components, and the stabilizingagent is used for modification, thus the foam stability of the protein foaming agent is raised. The preparation method has no need of steam pressure curing.

Owner:天津市裕川环境科技有限公司

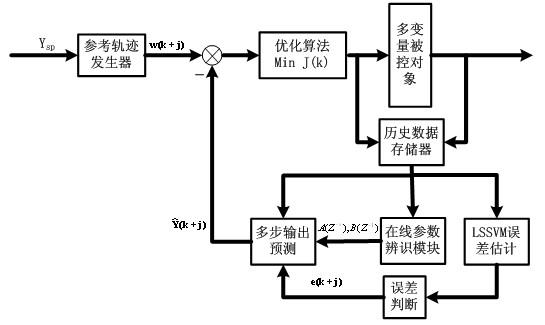

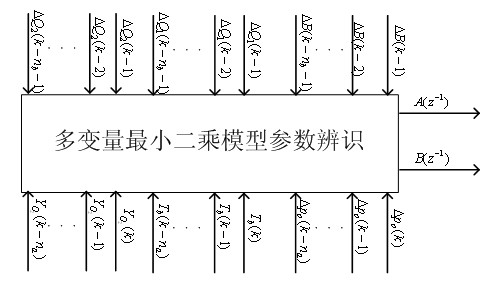

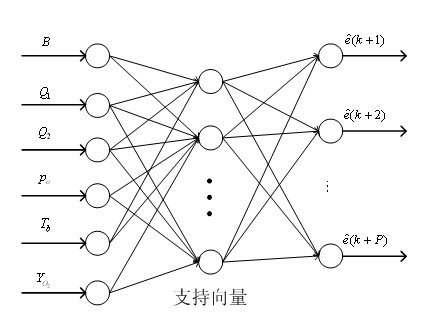

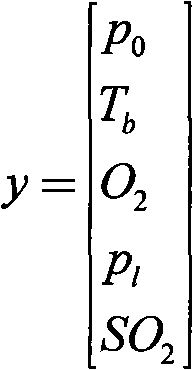

Combustion process multivariable control method for CFBB (circulating fluidized bed boiler)

InactiveCN102494336AImprove robustnessSolving time-varying problemsFluidized bed combustionApparatus for fluidised bed combustionSteam pressureData acquisition

The invention discloses a combustion process multivariable control method for a CFBB (circulating fluidized bed boiler), which is realized in the following procedures: in each control period, collecting operational parameters of the boiler through data collecting equipment and storing the operational parameters in a data storage module; utilizing the history data in a memorizer to on-line identify the CARIMA model and present P step future moment predominant values such as process output variable main steam pressure, material bed temperature and flue gas oxygen content through a model on-lineparameter identification module of GPC (generalized prediction control); performing error compensation to the process future moment prediction output through an error estimation module of an LSSVM (least square support vector machine); and referring the reference trace obtained by a trace generator, performing rolling optimization in GPC for the process future moment prediction output, and calculating through the optimized algorithm to enable the process actual output to reach the set value. The method provided by the invention solves the time varying problem of the model parameter, and enables the control system to have stronger robustness.

Owner:ZHEJIANG UNIV

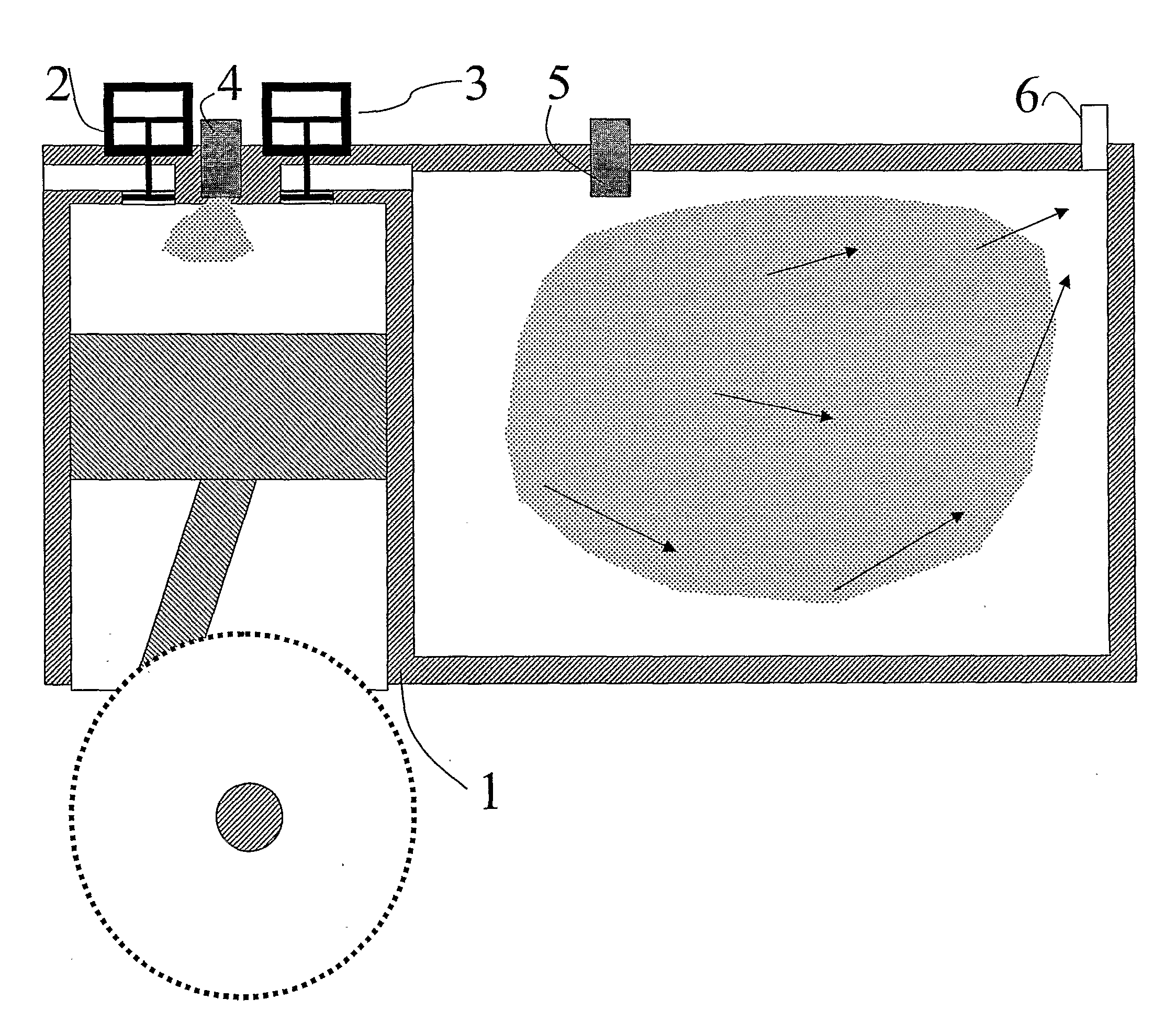

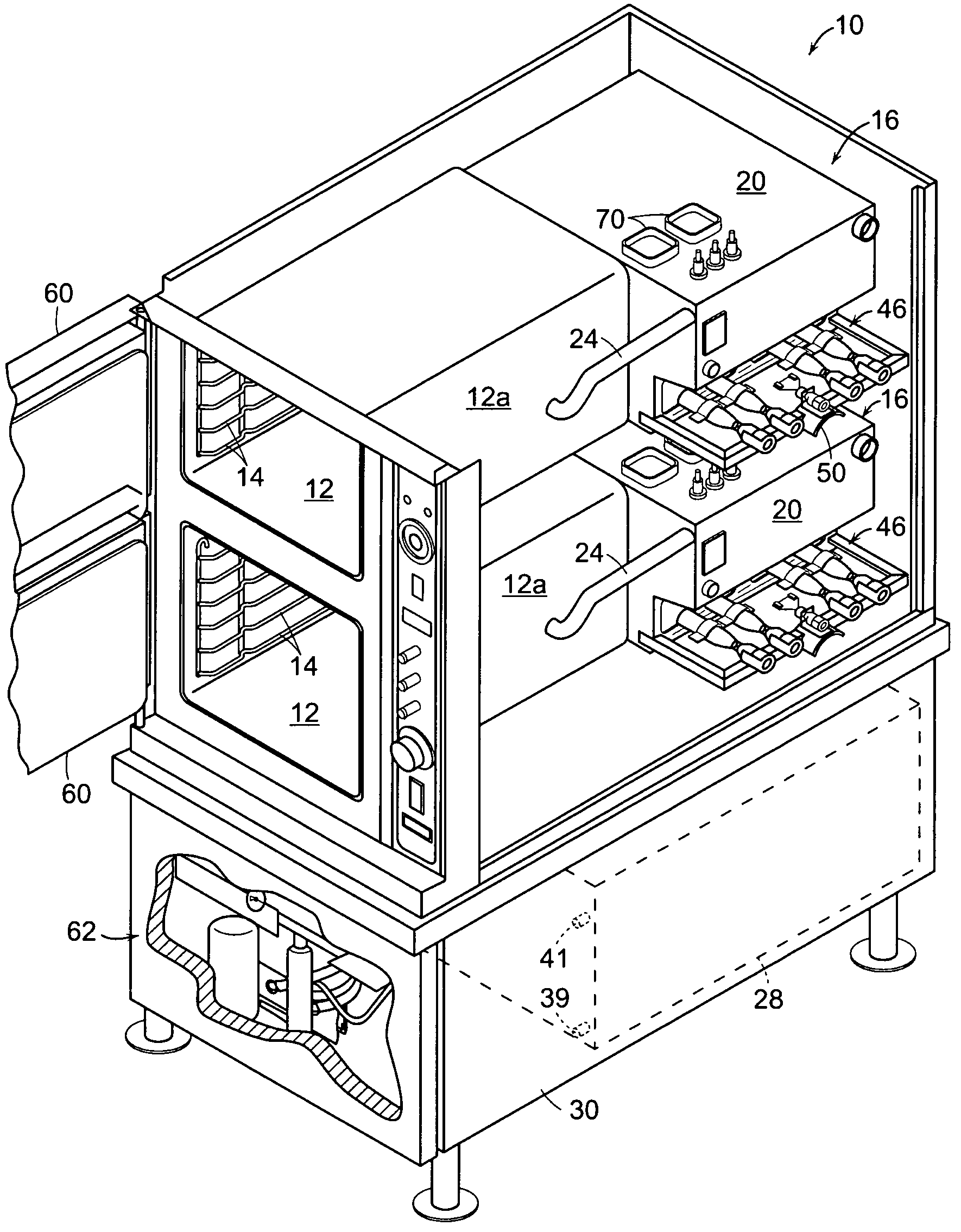

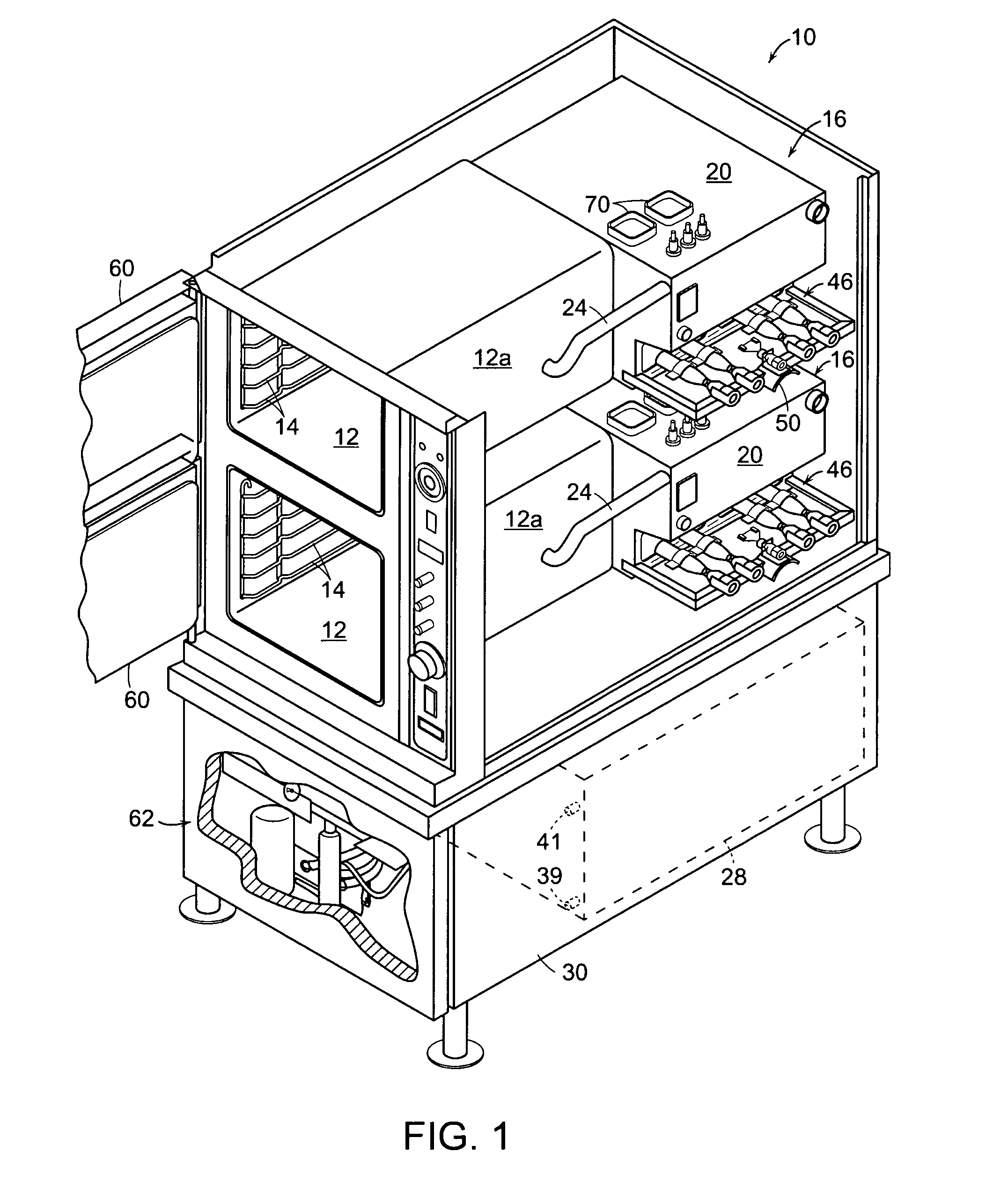

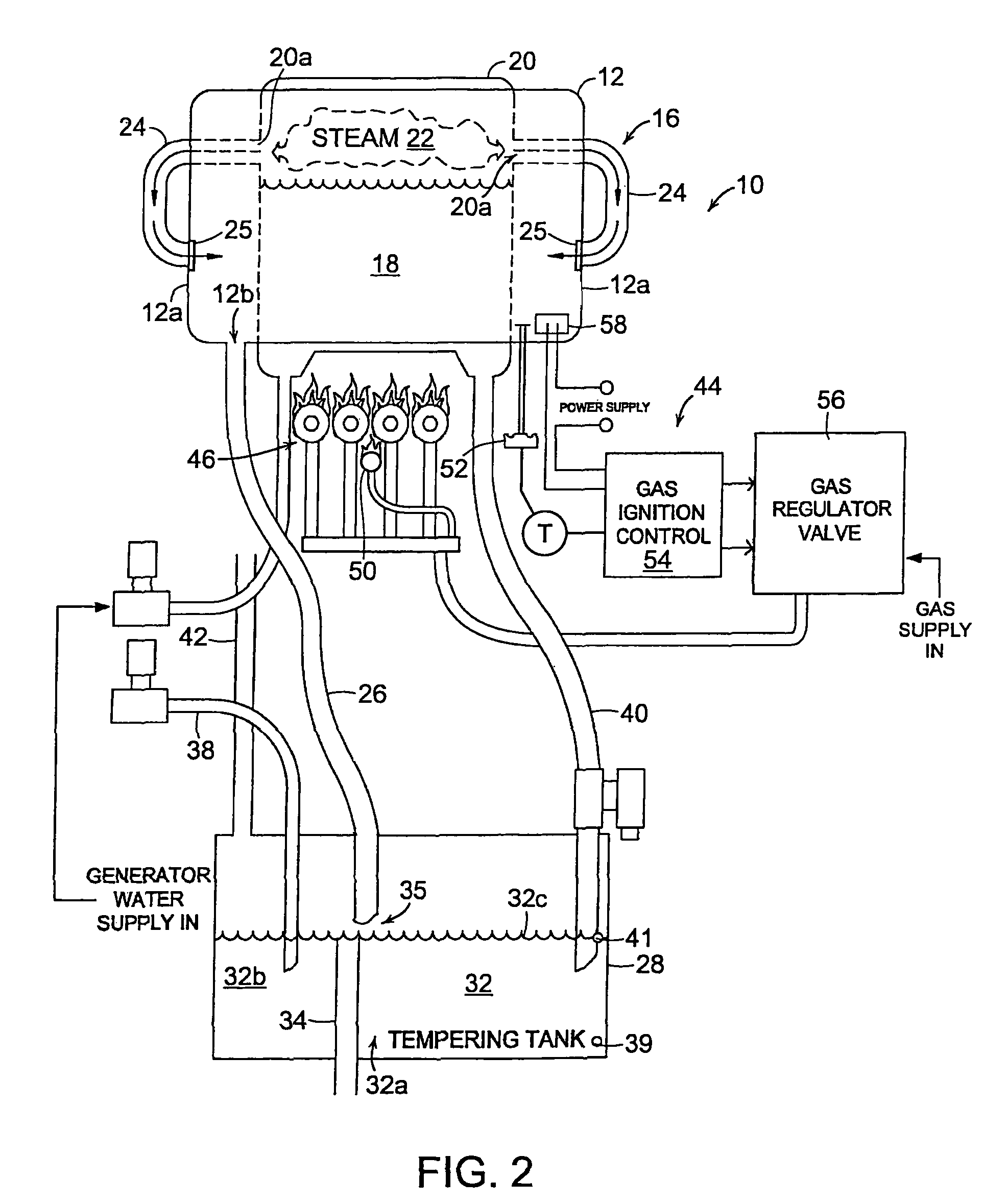

High efficiency atmospheric steamer

ActiveUS7810488B2Temperature control without auxillary powerDomestic stoves or rangesSteam pressureFiltration

A pressureless or atmospheric steamer for cooking food with a high cooking efficiency has a cooking compartment with an outlet for steam and condensate that feeds to a tempering tank via an outlet conduit. The outlet conduit is spaced closely from the controlled water level in the tempering tank, and is in fluid communication with the atmospheric vent to create an open steam cooker. A steam generator is adjacent the cooking compartment and has a water reservoir, a heat exchanger secured within the reservoir in a heat-transferring relationship at an exterior surface of the heat exchanger with the water held in the reservoir, and a heater that supplies heat to the interior of the heat exchanger. The tempering tank has a drain and level controls for a water supply held in the tempering tank. A pressure-sensitive device is disposed to measure the steam pressure in the cooking compartment and to generate electrical output signals indicative of minimum and maximum pressure values to control the operation of the heater to maintain the steam pressure in the cooking compartment within that operating range. The steamer has an in-built water filtration system for water supplied to the water reservoir.

Owner:MARKET FORGE INDS

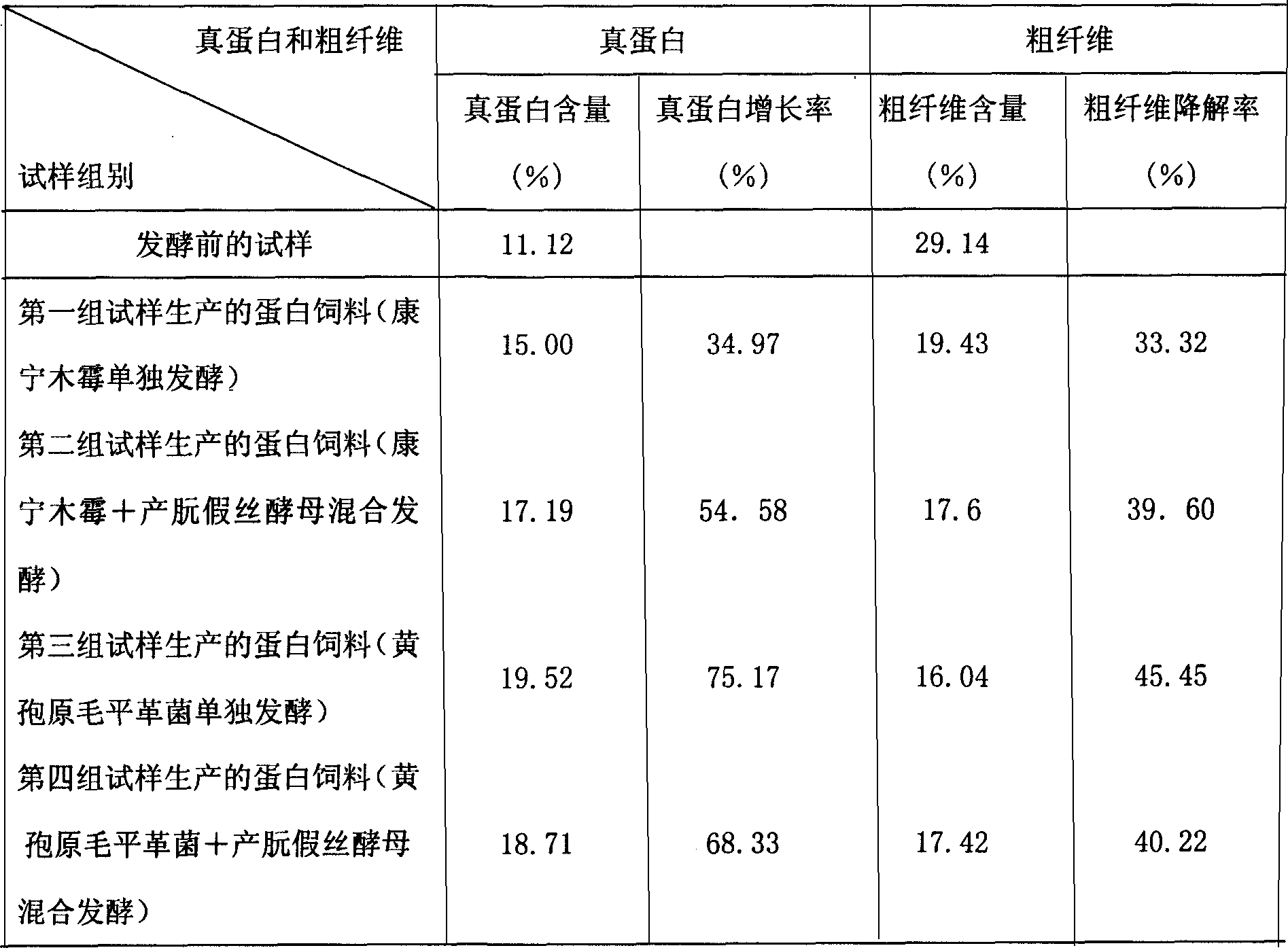

Process for producing protein feed stuff by traditional Chinese medicine slag

InactiveCN1907083ALow costReduce pollutionAnimal feeding stuffAccessory food factorsSteam pressureSlag

TTThe invention discloses a protein fodder preparing method through traditional Chinese medicine slag, which comprises the following steps: (1) predisposing traditional Chinese medicine slag through drying and grinding; (2) allocating solid material and water at 1: 1-1: 3; blending; blending 2-4% nitrogen source and 0.5-1.2% phosphoric source evenly; blending the allocated solution with traditional Chinese medicine slag evenly; controlling pH value at 4.5-6.0; (3) sterilizing; setting steam pressure at 1atm and temperature at 121 deg.c for at least 30 min; (4) fermenting; seeding 10-20% bacteria; fermenting under normal pressure at 30-37 deg.c with 4-7 d as one period; (5) drying to obtain the product.

Owner:SICHUAN UNIV

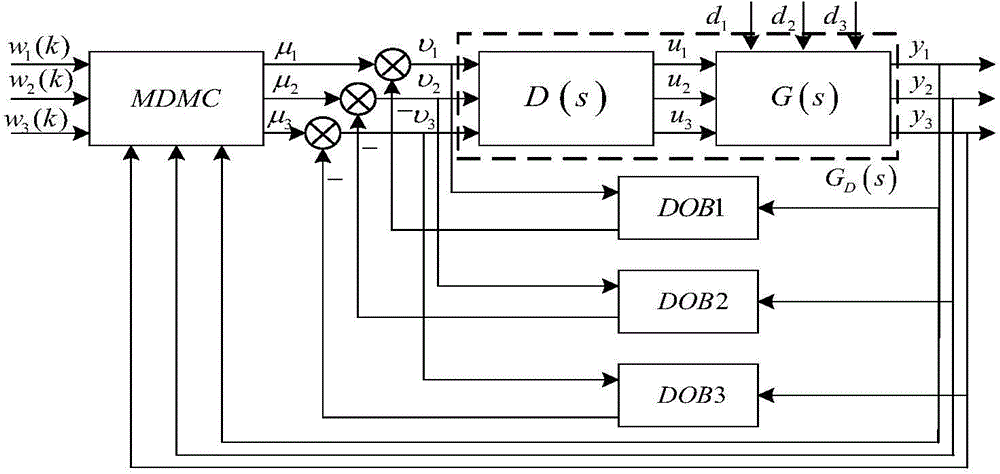

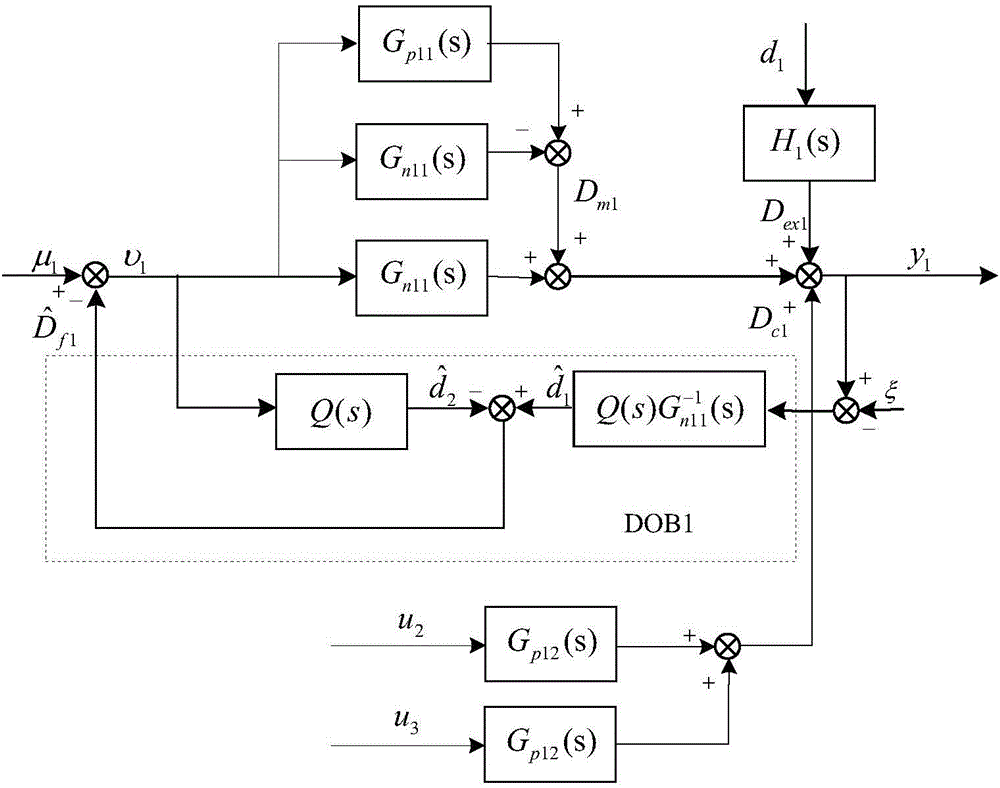

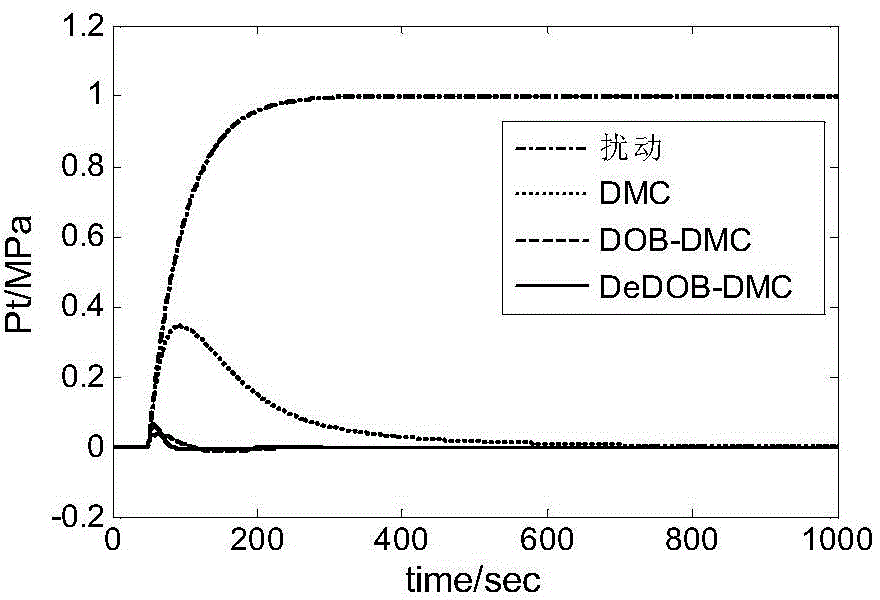

Predictive control method for supercritical set based on decoupling and disturbance observation

The invention discloses a predictive control method for a supercritical set based on decoupling and disturbance observation. According to the method, a supercritical thermal power generating set is adopted as a controlled object, the fuel amount, the water supply amount, and the openness of an adjusting valve of a steam turbine are adopted as inputs, the main steam pressure, the middle point temperature, and the loads of the set are adopted as outputs, the controlled object is enabled to be similar to decoupling through a feedforward compensator, and then disturbance is observed through disturbance observers which are respectively arranged at channels, so that the multivariate predictive control to the controlled object is realized, the problem of poor control effects caused by the disturbance influences of a coordinative control system of the supercritical set is solved, the external influence that the disturbance cannot be measured can be effectively inhibited, and besides, the internal disturbance caused by the coupling between input varies can be inhibited, so that the control property of the coordinative control system of the supercritical set is improved.

Owner:SOUTHEAST UNIV

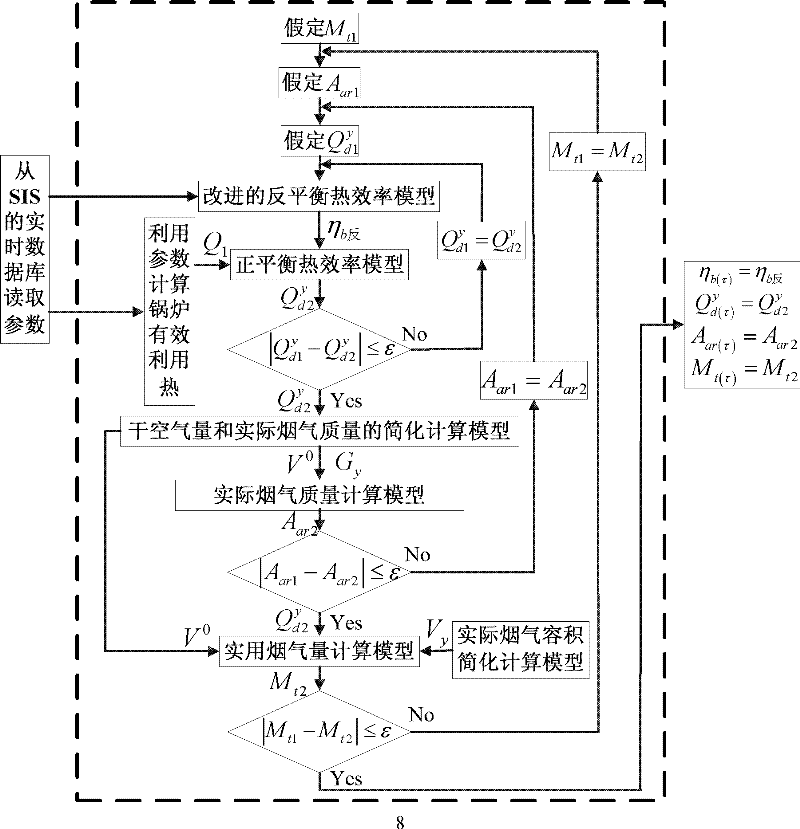

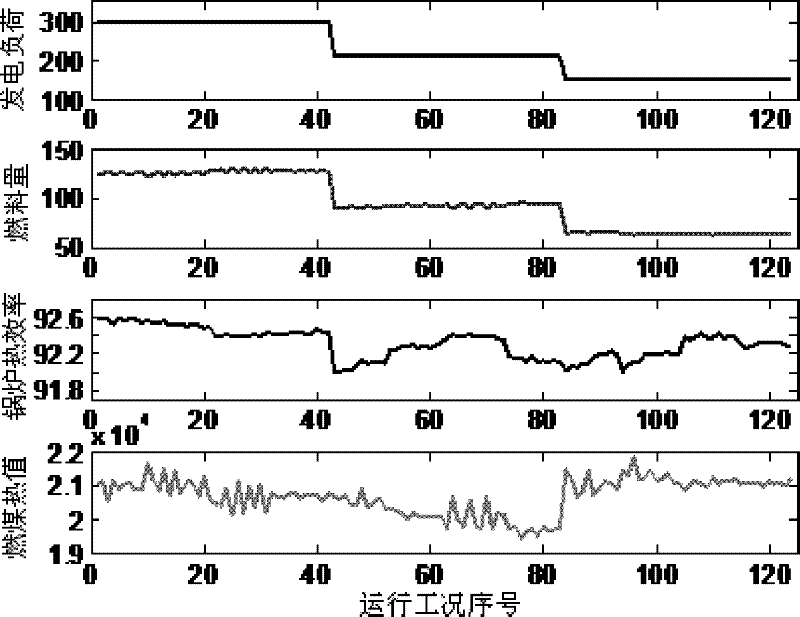

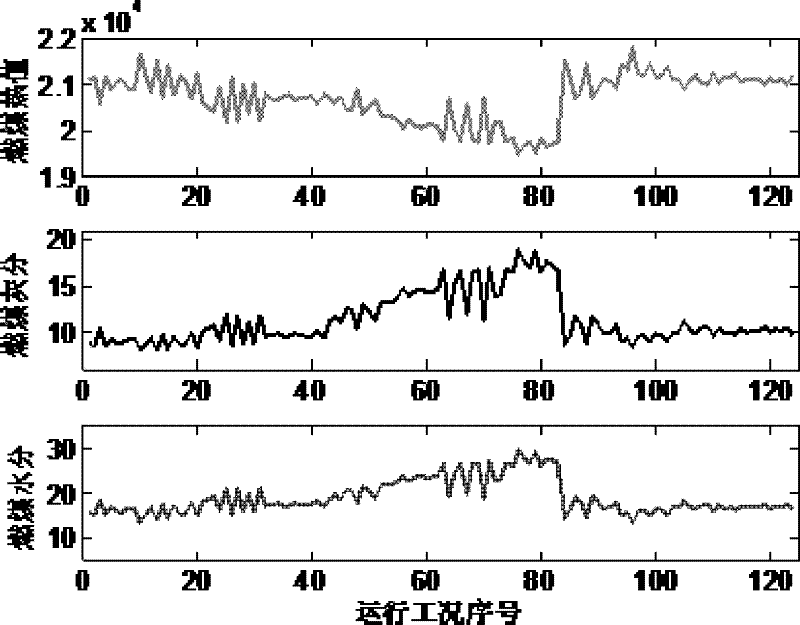

Synchronous reckoning method of utility boiler efficiency and coal heat value as well as ash content and moisture content

InactiveCN102494714AVerify correctnessImprove calculation accuracyStructural/machines measurementSteam pressureEvaporation

The invention relates to a synchronous reckoning method of utility boiler efficiency and coal heat value as well as ash content and moisture content, wherein air supply temperature, smoke exhaust temperature, smoke exhaust oxygen content, carbon content in fly ash, boiler-fed fuel content, boiler evaporation amount, assembly electric generating load, main steam pressure temperature, reheated steam inlet / outlet pressure temperature, water supply pressure temperature and flow rate, steam drum pressure, reheater temperature lowering water jet amount and steam extraction pressure temperature of each heater of high pressure cylinder are read through a plant-level supervisory information system (SIS) of a thermal power plant; and the parameters as the water temperature and drainage temperature of the inlet / outlets of different-level heaters of the high pressure cylinder are synchronously reckoned by hypothesizing the initial values of the coal heat value, the coal ash content and the coal moisture content, utilizing a boiler anti-balance heat efficiency model, a dry air amount required for theoretical combustion and actual smoke quality simplified calculating model, an actual smoke quality calculating model, an actual smoke volume calculating model, an actual smoke amount calculating model, a boiler positive-balance heat efficiency model and a boiler effective utilized heat model, and establishing prediction and rectification methods.

Owner:SOUTHEAST UNIV

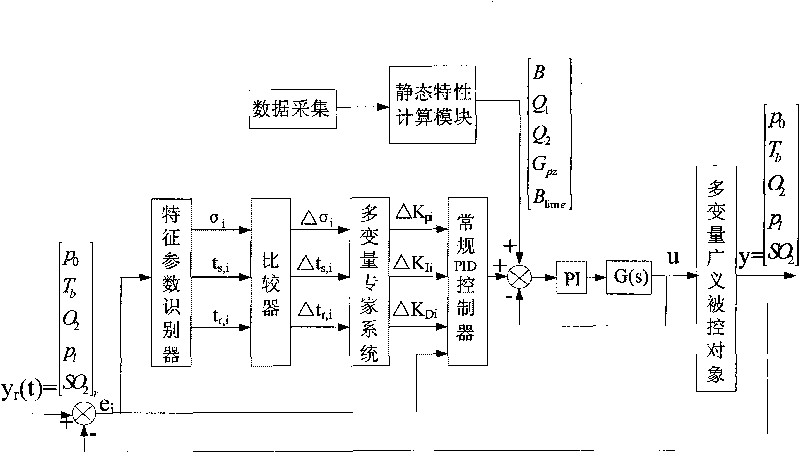

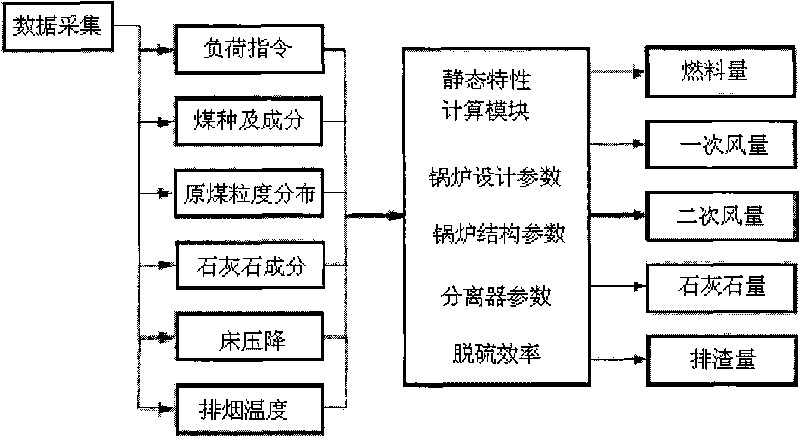

Control method of combustion system of circulating fluidized bed boiler

InactiveCN101713536AReal-time and accurate adjustment commandRealize combustion automatic controlFluidized bed combustionApparatus for fluidised bed combustionAir volumeAutomatic control

The invention relates to a control method of a combustion system of a circulating fluidized bed boiler, which adopts multivariable expert intelligent self-calibration PID control and is provided with an on-line calculation module for the static characteristics of the circulating fluidized bed boiler. The on-line calculation module for the static characteristics of the circulating fluidized bed boiler calculates the coal supply quantity, the limestone quantity and the deslagging quantity for realizing the optimizing combustion of the boiler under different loads, the primary air quantity and the secondary air quantity are optimized and proportioned and are used as load feedforward signals which are applied to a main steam pressure control loop, a limestone quantity control loop, a bed pressure drop control loop, a bed temperature control loop and an oxygen quantity control loop, and each control loop adopts an expert intelligent self-calibration PID controller to form a multivariable combustion control system of a CFB boiler. The invention is provided with the calculation module for the static characteristics of the circulating fluidized bed boiler, which can accurately send out each regulation quantity instruction at real time and realize automatic control; the multivariable expert system is in consideration of the nonlinearity and the strong-coupling property of the combustion system of the boiler and ensures the performance robustness of the control system; and meanwhile, the PID parameters are automatically regulated according to the change of the characteristics of a controlled object, so the automatic combustion control system of the circulating fluidized bed boiler has stable robustness.

Owner:TAIYUAN UNIV OF TECH

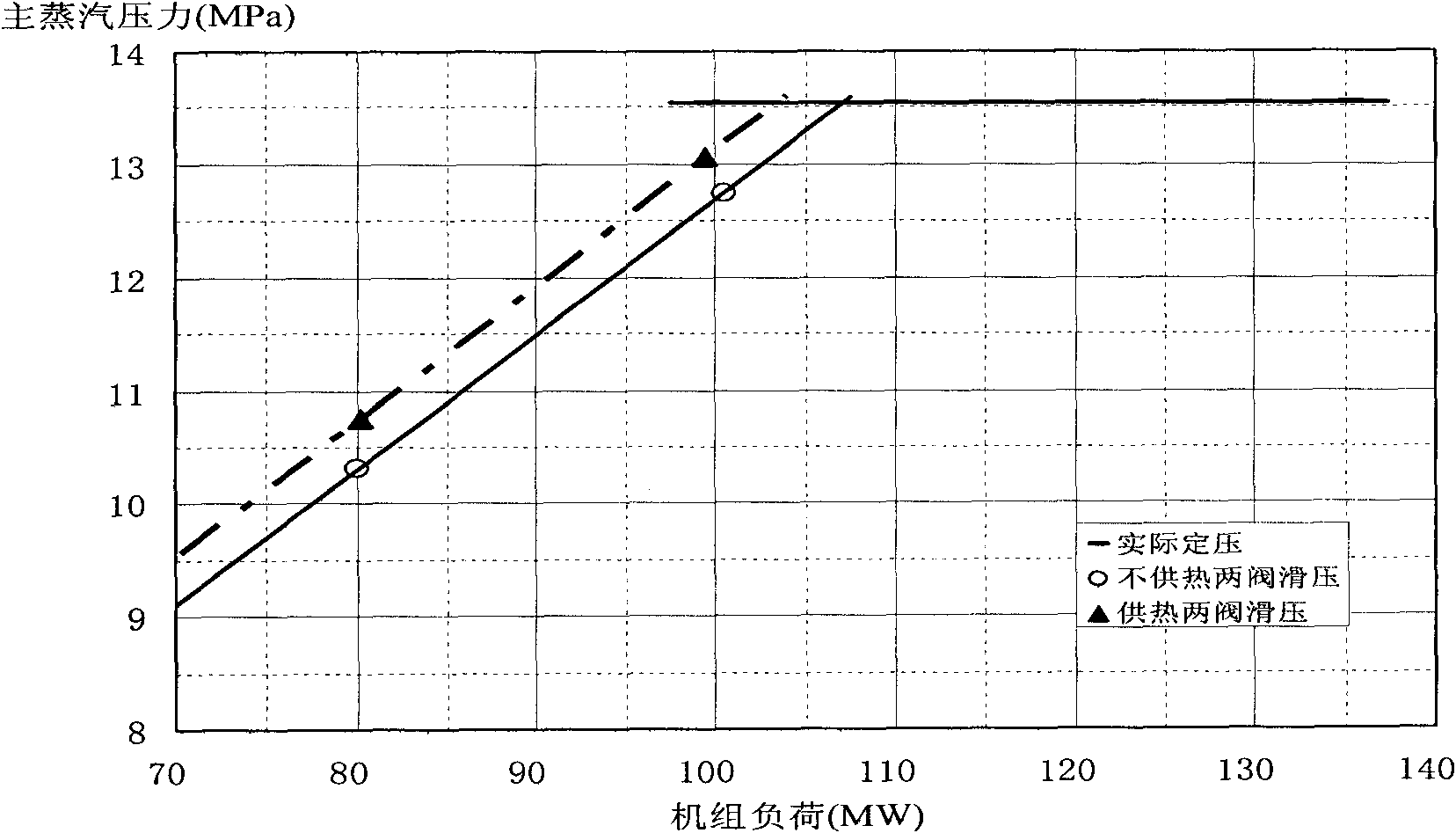

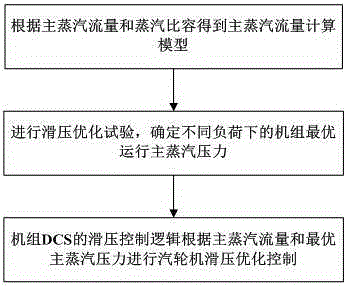

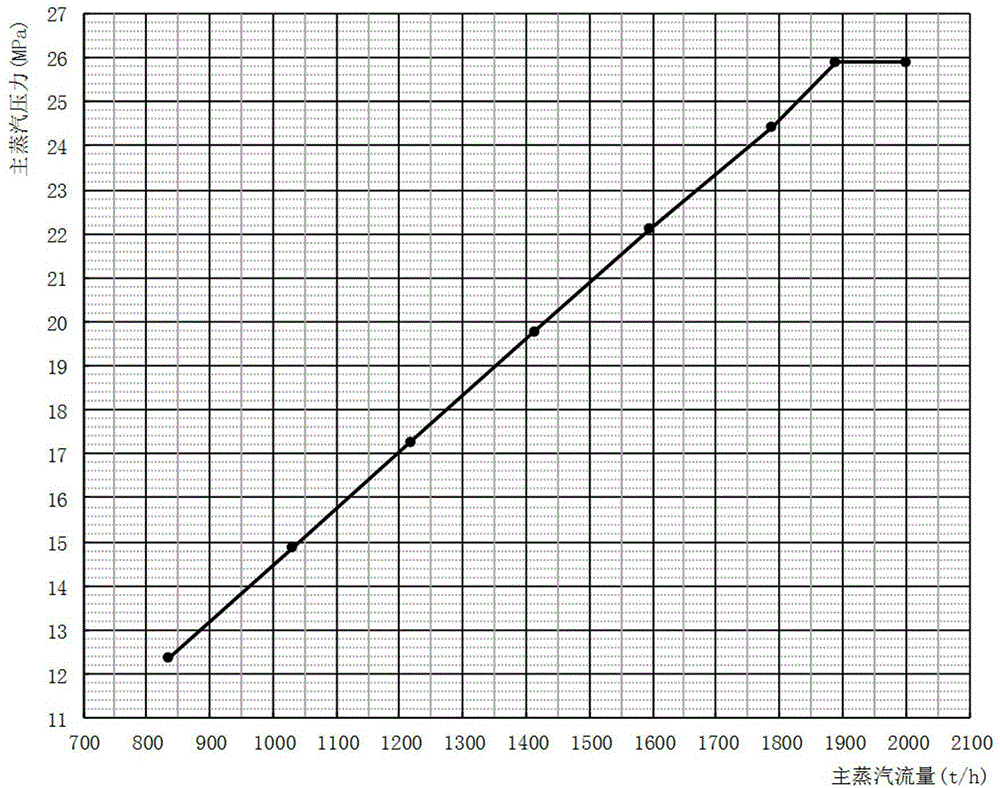

Main-steam-flow-based steam turbine sliding pressure optimization control method

ActiveCN105201564ATap into energy-saving potentialImprove operating economyMachines/enginesEngine componentsSteam pressureEngineering

The invention discloses a main-steam-flow-based steam turbine sliding pressure optimization control method which comprises the following steps: 1. obtaining a main steam flow calculation model according to the main steam flow and steam specific volume; 2. carrying out sliding pressure optimization testing to determine the optimal operation main steam pressure of the set under different loads; and 3. carrying out steam turbine sliding pressure optimization control by set DCS sliding pressure control logic according to the main steam flow and optimal main steam pressure obtained by the formula (3) and formula (5). In order to solve the problem that the changes of back pressure, main reheated steam temperature, heat supply and other factors influence the economical efficiency of the set in the steam turbine sliding pressure operation process, the invention provides a main-steam-flow-based steam turbine sliding pressure optimization control method, so that the steam turbine can still keep the optimal operating mode when the influencing factors change, thereby further exploring the energy conservation potential of the set.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

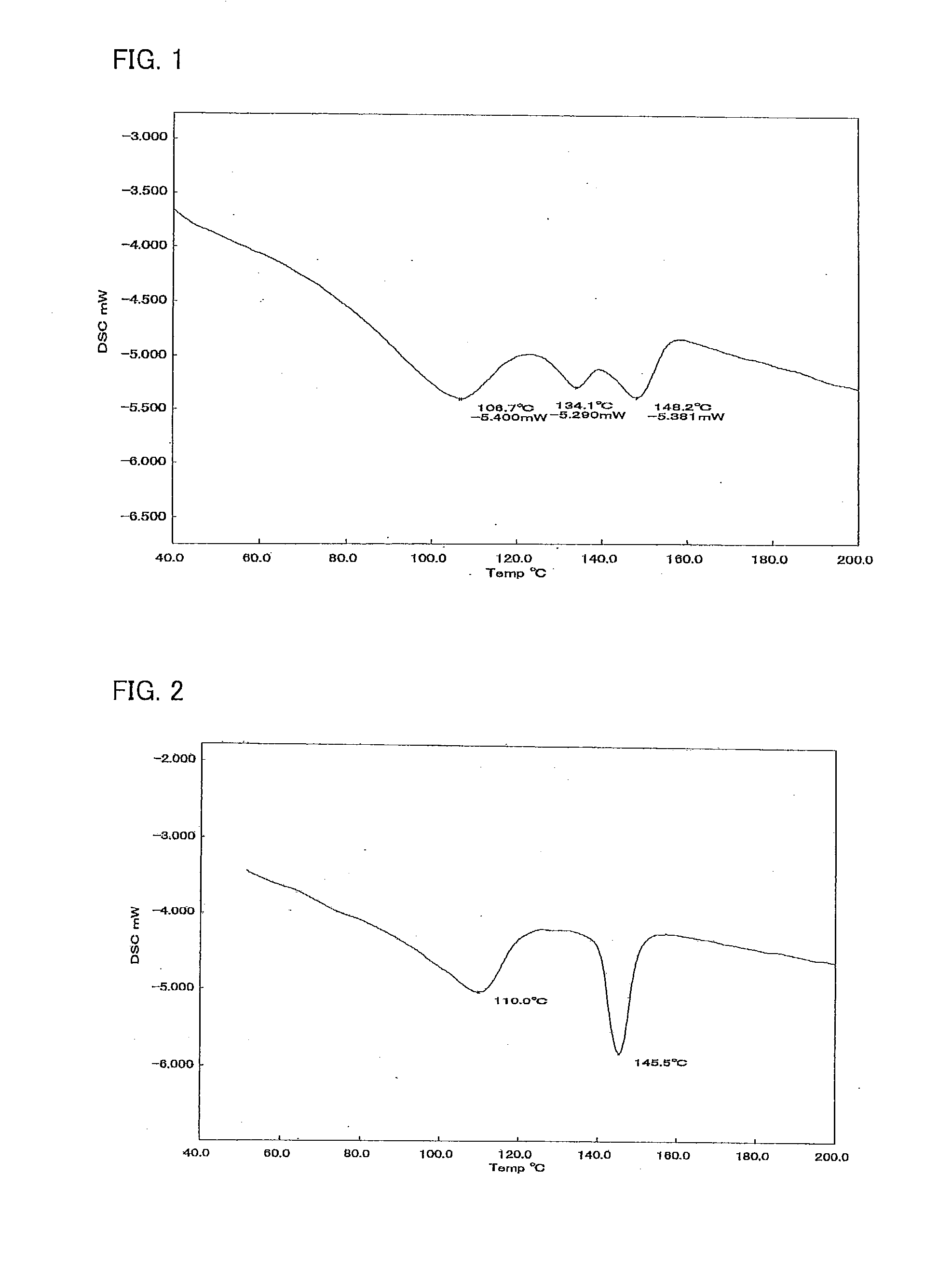

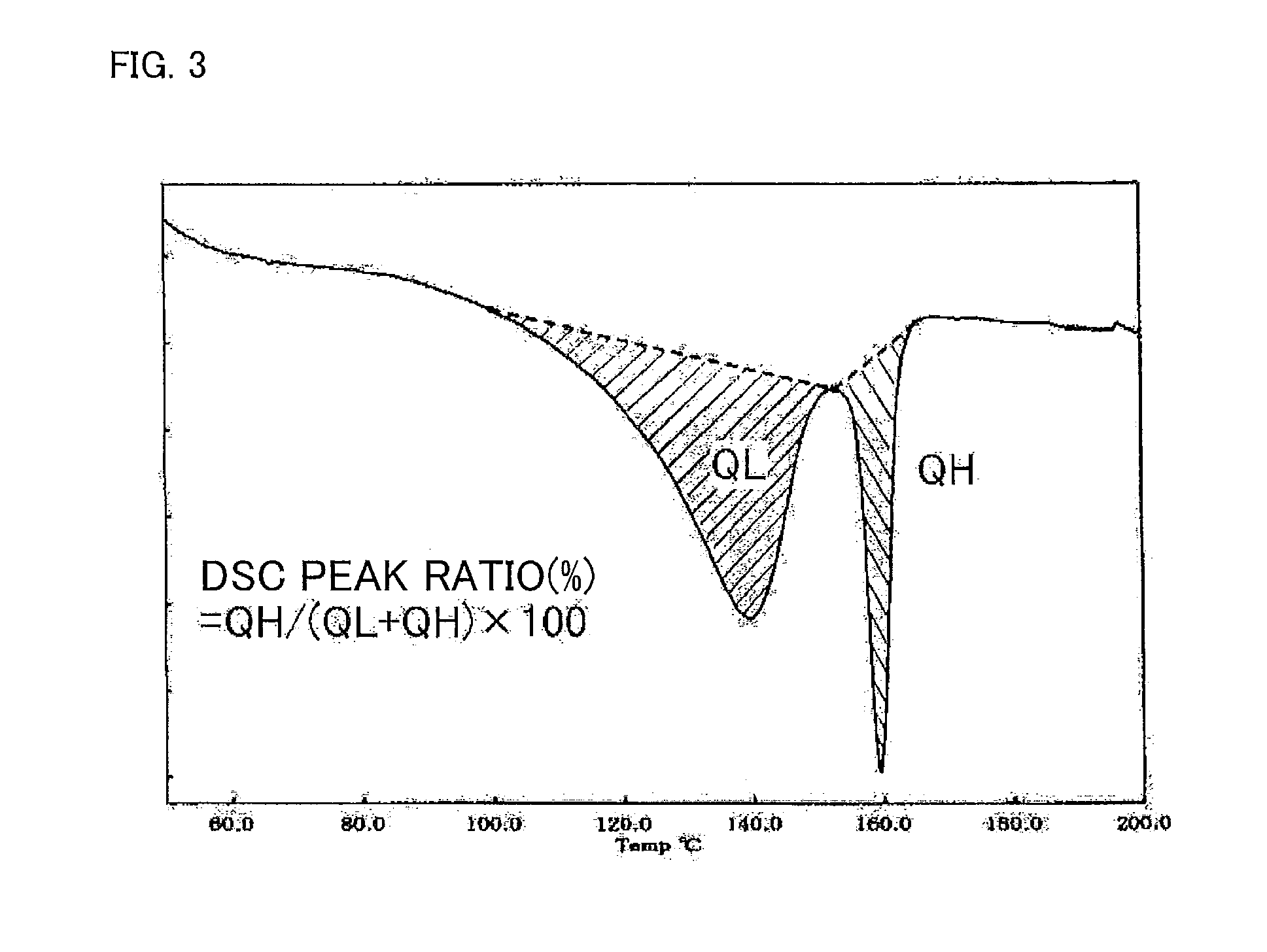

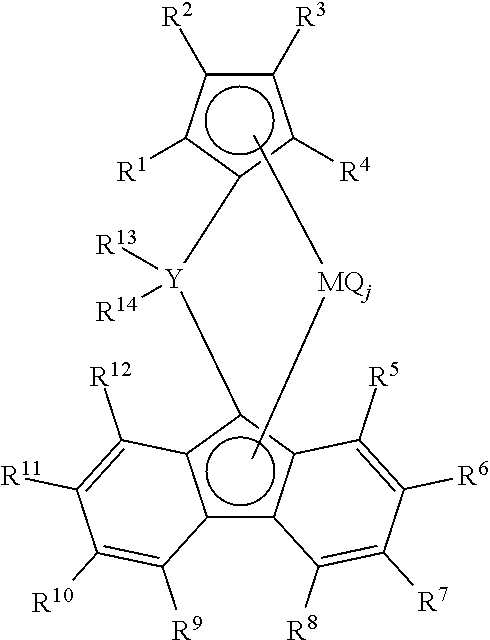

Polypropylene resin expanded particles and polypropylene resin in-mold foaming molded body

ActiveUS20120214890A1Wide range of heating conditionSatisfactory moldabilityLow distortionSteam pressure

Polypropylene resin expanded particles include polypropylene resin as base material resin having at least two melting peaks on a DSC curve, the at least two melting peaks including (i) a lowest-temperature melting peak of 100° C. or more but 130° C. or less and (ii) a highest-temperature melting peak of 140° C. or more but 160° C. or less, so that the expanded particles: produce an in-mold foaming molded product at a very low mold heating steam pressure; exhibit low distortion, low shrinkage, and a wide range of heating condition for molding, even if the mold heating steam pressure is increased; have satisfactory moldability when the expanded particles are molded by using a mold having a complicated shape or a large mold; and maintain properties such as compressive strength, substantially unimpaired, when the expanded particles make the in-mold foaming molded product.

Owner:KANEKA CORP

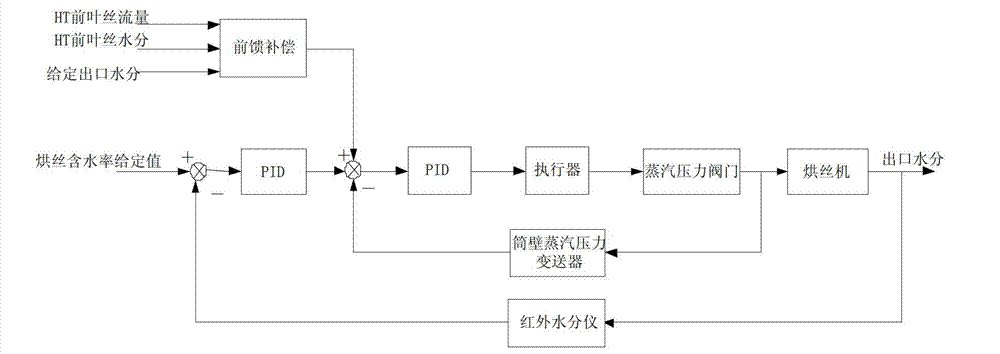

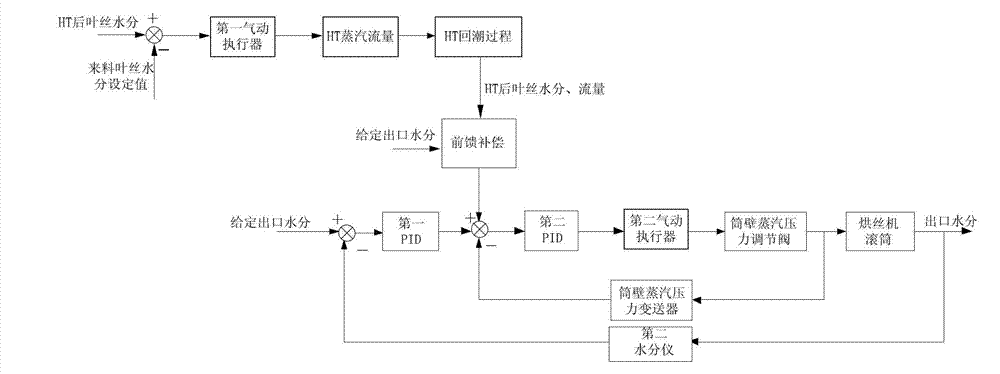

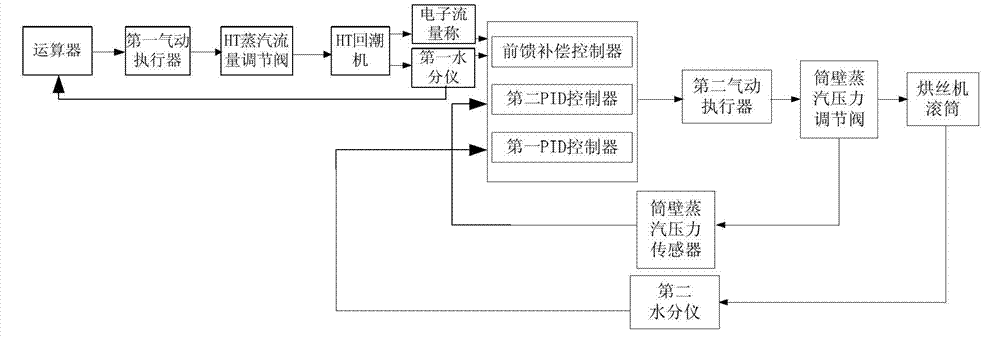

Cut lamina drying control method and cut lamina drying system based on feedforward and feedback of HT moisture compensation

ActiveCN103202528AStable drying process parametersImprove processing quality stabilityTobacco preparationTobacco treatmentSteam pressureControl system

The invention discloses a cut lamina drying control method and a cut lamina drying system based on feedforward and feedback of HT moisture compensation. By the cut lamina drying control method, steam flow of an HT damping machine is adjusted to compensate HT incoming material moisture fluctuations, cut lamina moisture stability at an inlet of a rolling cylinder is maintained to the utmost extend, influence to a rolling cylinder drying process by the material moisture fluctuations is obviously reduced, dry process parameter stability is maintained, and process processing quality stability is improved; and cut lamina moisture and cut lamina flow at the inlet port of the rolling cylinder are added into a feedback control system through the feedforward, and accuracy of moisture adjustment in the rolling cylinder drying process is improved. The cut lamina drying control system based on the feedforward and feedback of the HT moisture compensation comprises a controller unit, two pneumatic actuators, two moisture meters, an electronic flow scale, a calculator and a cylinder wall steam pressure sensor. The control system is simple in structure, low in cost and easy to promote.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com