Combustion process multivariable control method for CFBB (circulating fluidized bed boiler)

A circulating fluidized bed, multi-variable control technology, applied in the direction of fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve the multi-variable process that does not exert predictive control, and does not solve the multi-variable process well Coupling problems and other problems to achieve strong robustness, inaccurate solutions, and excellent decoupling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

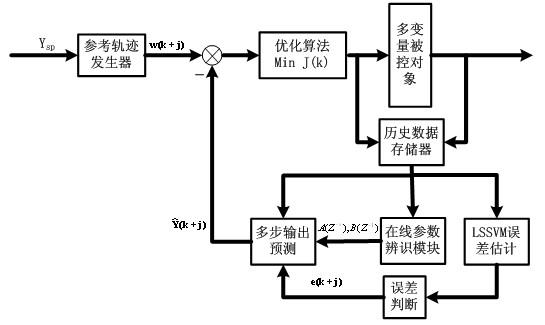

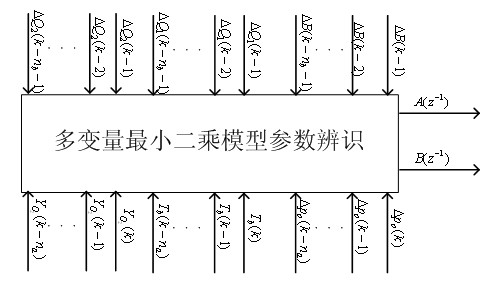

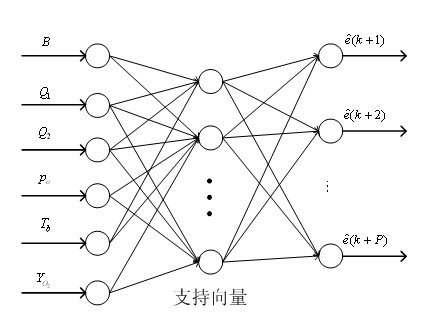

[0015] The multi-variable generalized predictive control system of the circulating fluidized bed boiler combustion process of the present invention is as follows: figure 1 As shown, in this control system, the data memory stores several groups of real-time data of boiler operation through data acquisition equipment: main steam pressure, material bed temperature, flue gas oxygen content, coal feed rate, primary air volume, and secondary air volume. The model online parameter identification module reads the historical data in the data memory, and identifies the CARIMA model suitable for control online. The error judgment module calculates the error between the model prediction output and the actual output of the process, and chooses whether to enable the error based on the least squares support vector machine. Compensation, based on the historical operation data, CARIMA model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com