Patents

Literature

155 results about "Bubbling fluidized bed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for gas-solid contacting in a bubbling fluidized bed reactor

InactiveUS6894183B2Eliminate and drastically reduce bypassEffective contactThermal non-catalytic crackingCatalytic crackingForming gasSolid particle

Owner:COUNCIL OF SCI & IND RES

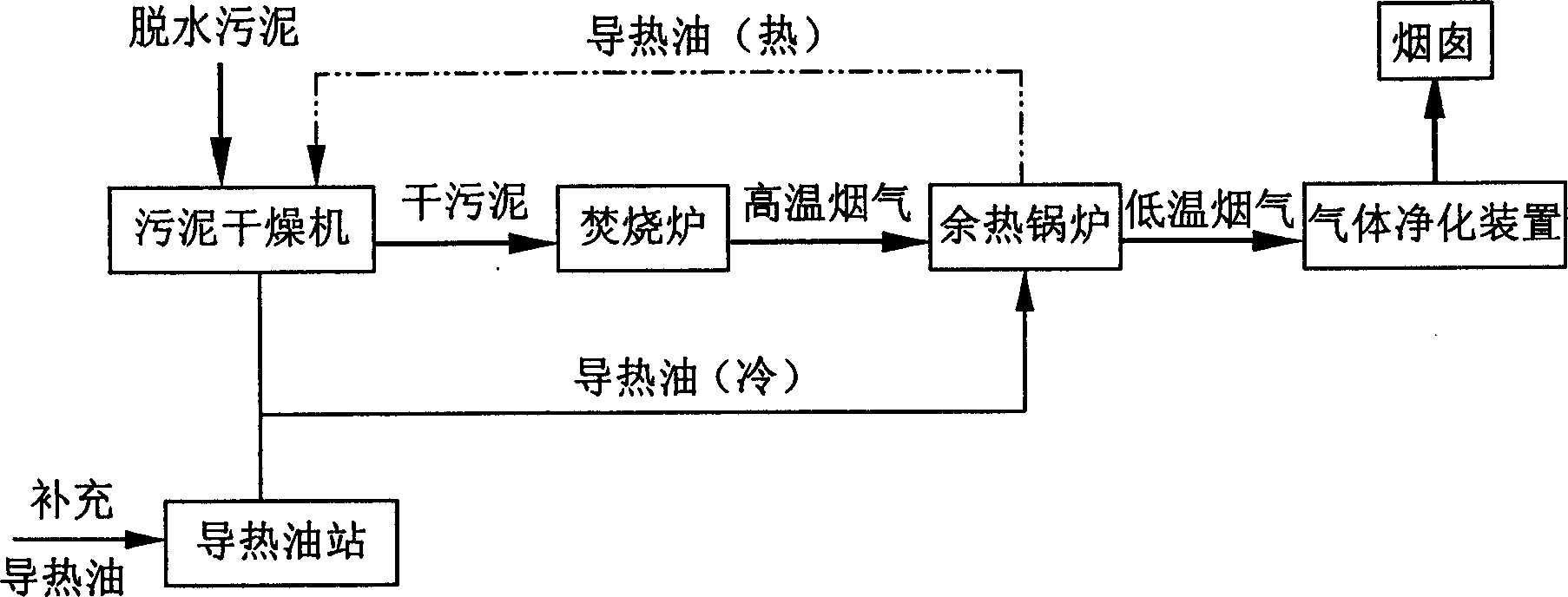

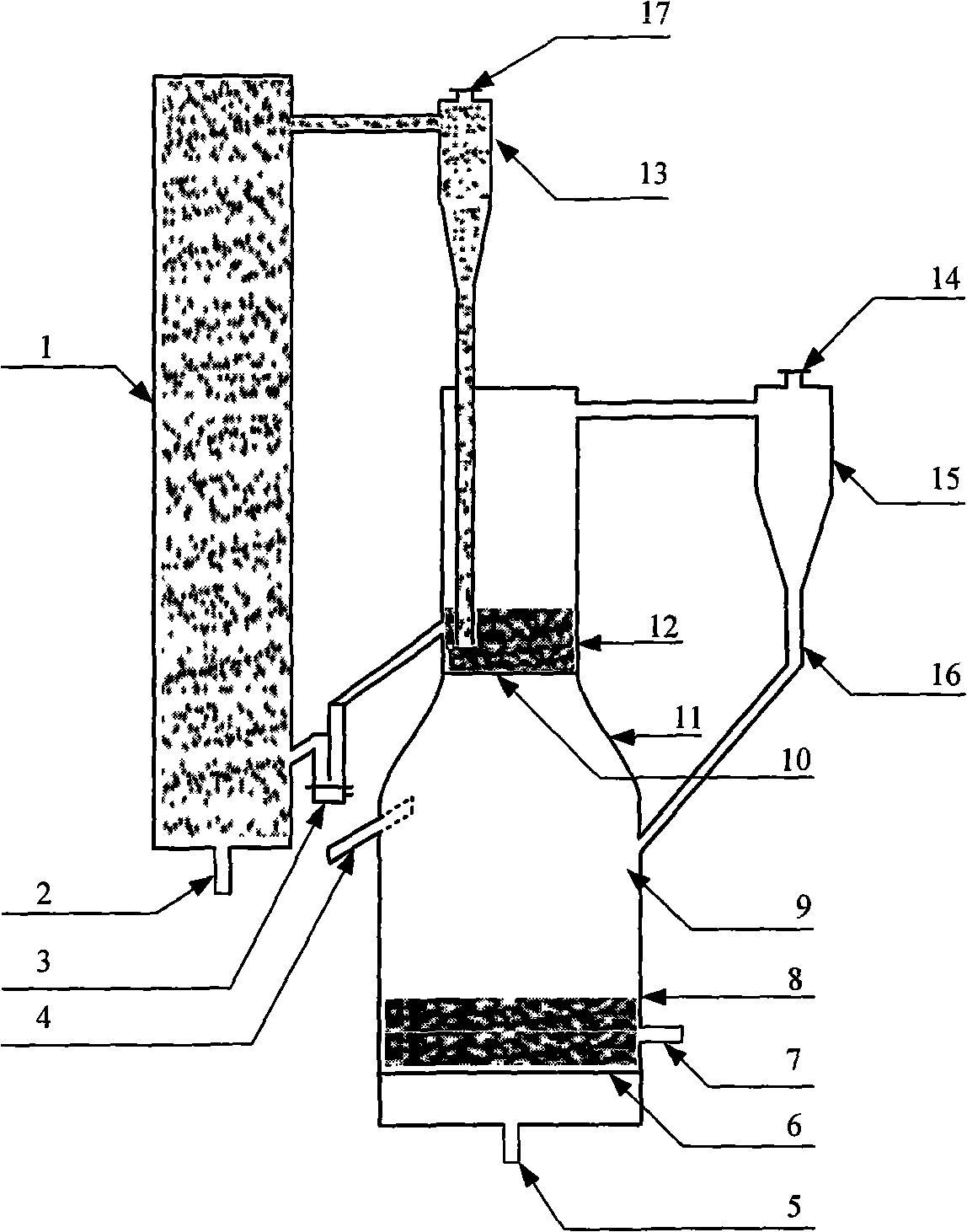

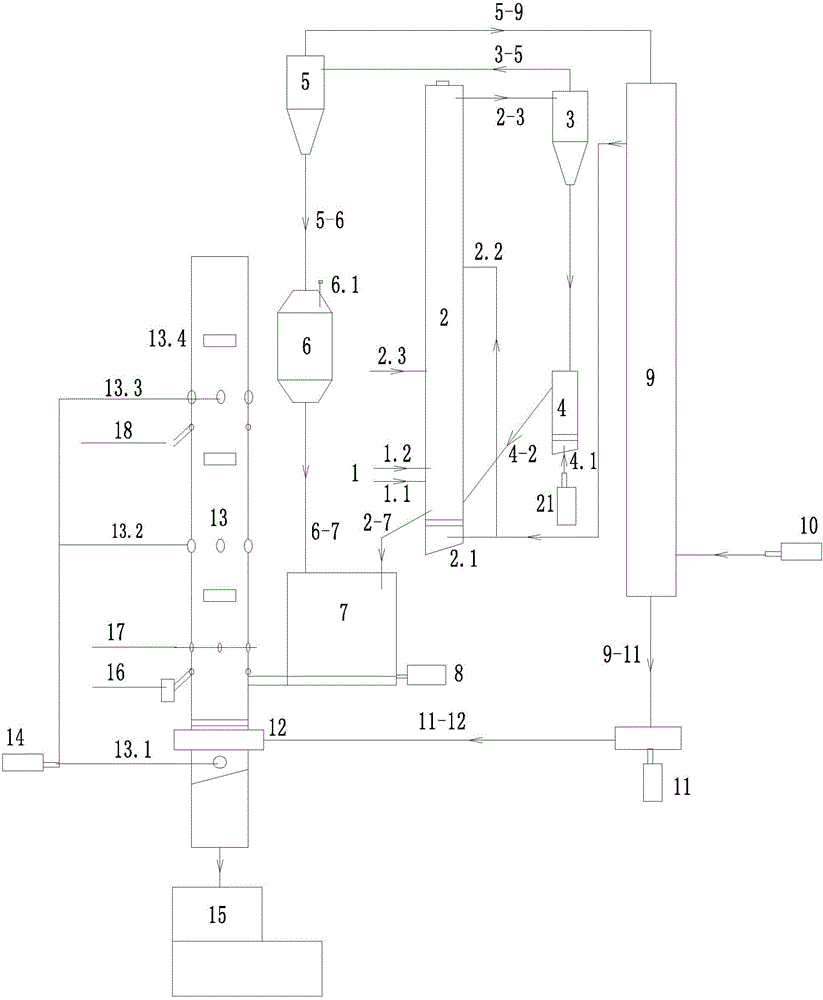

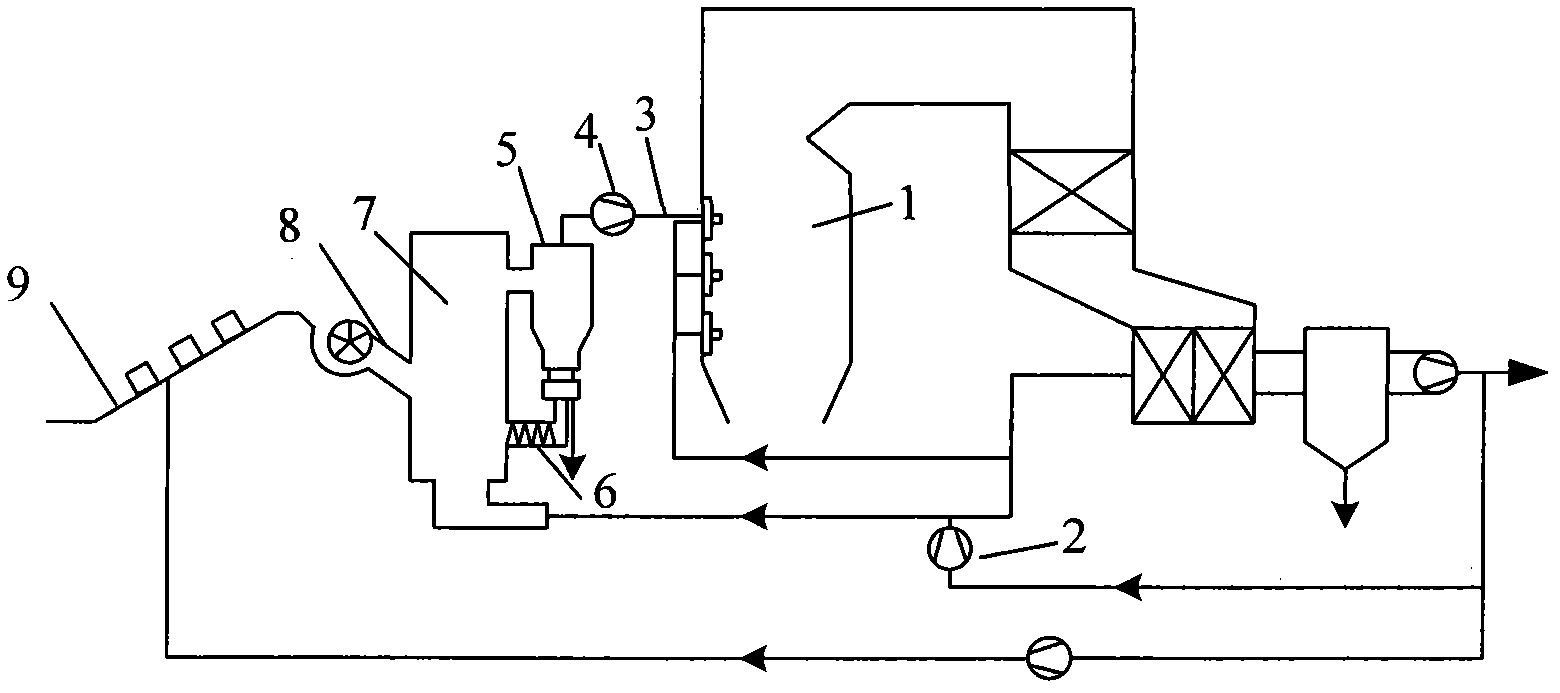

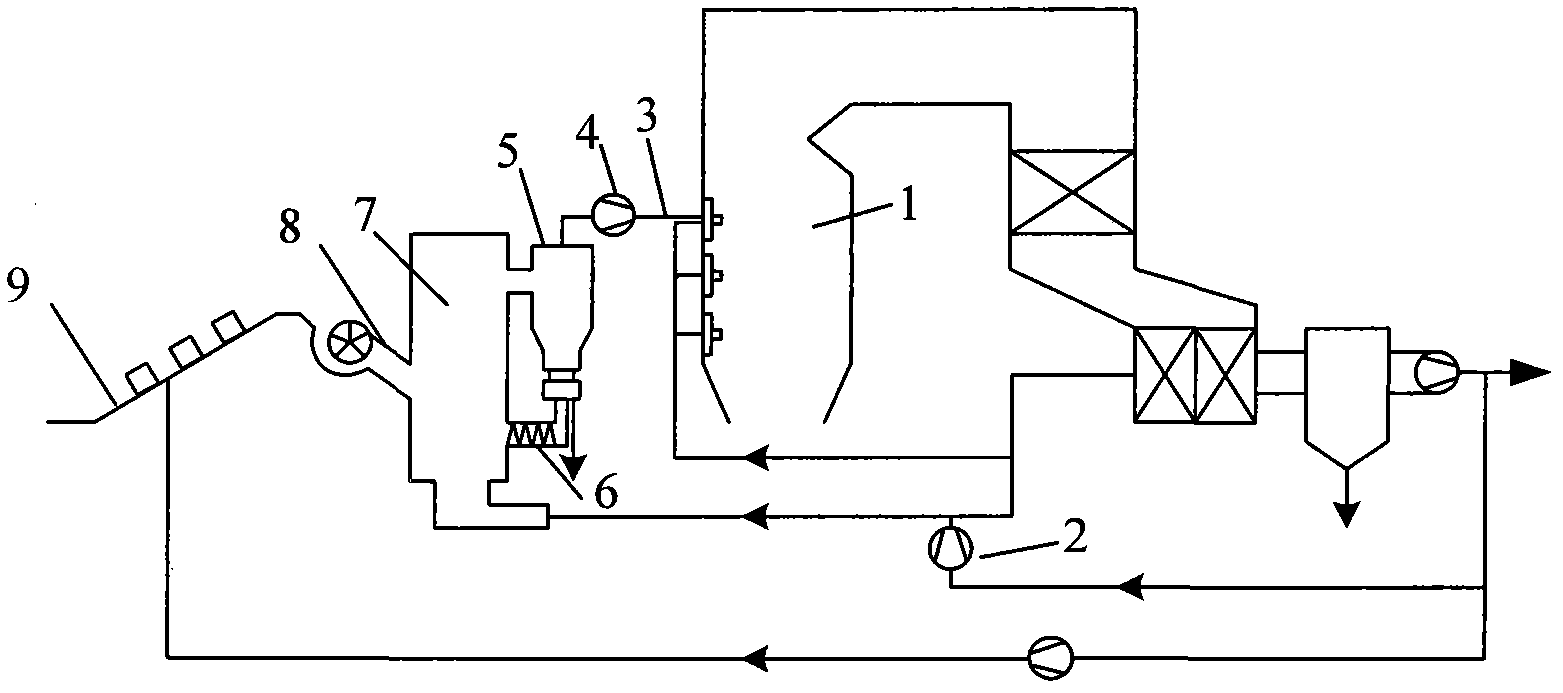

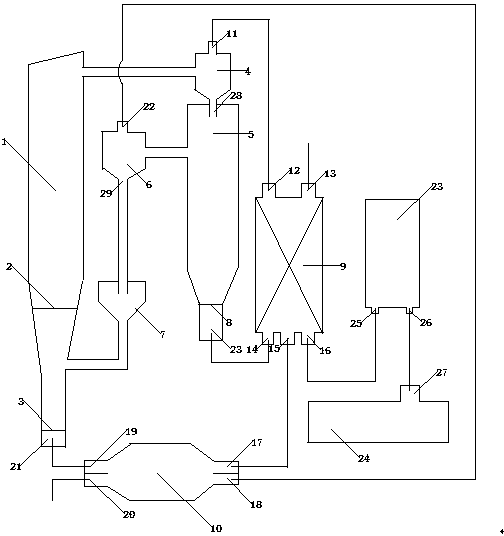

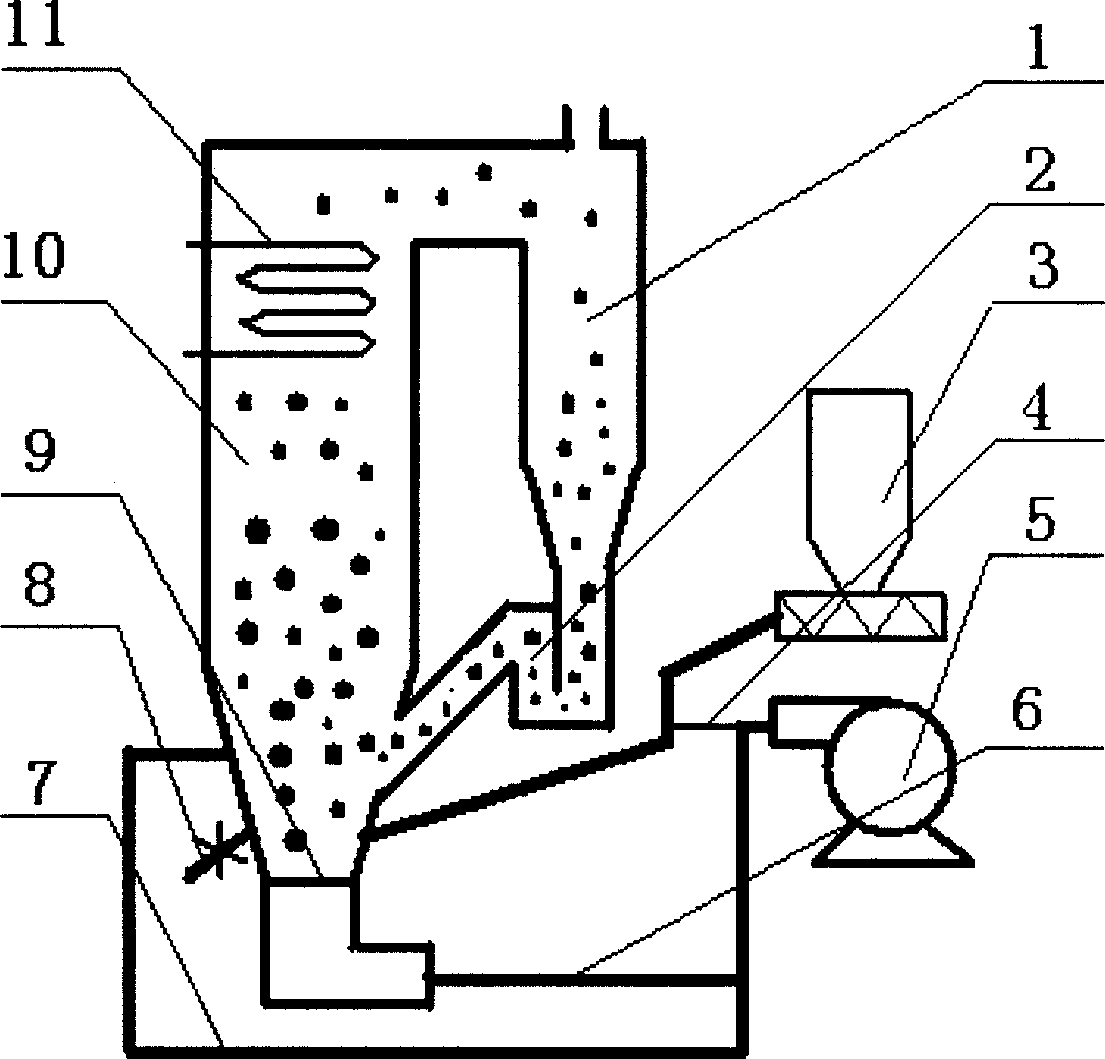

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

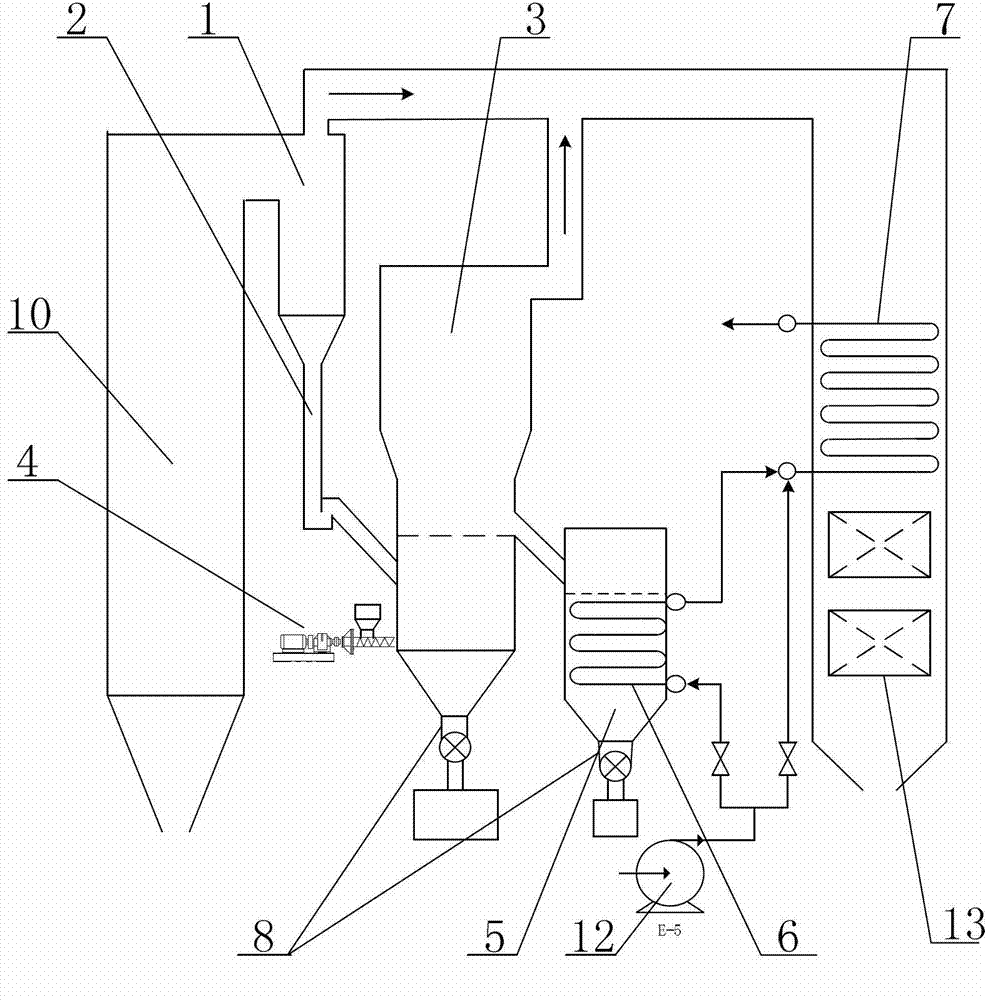

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

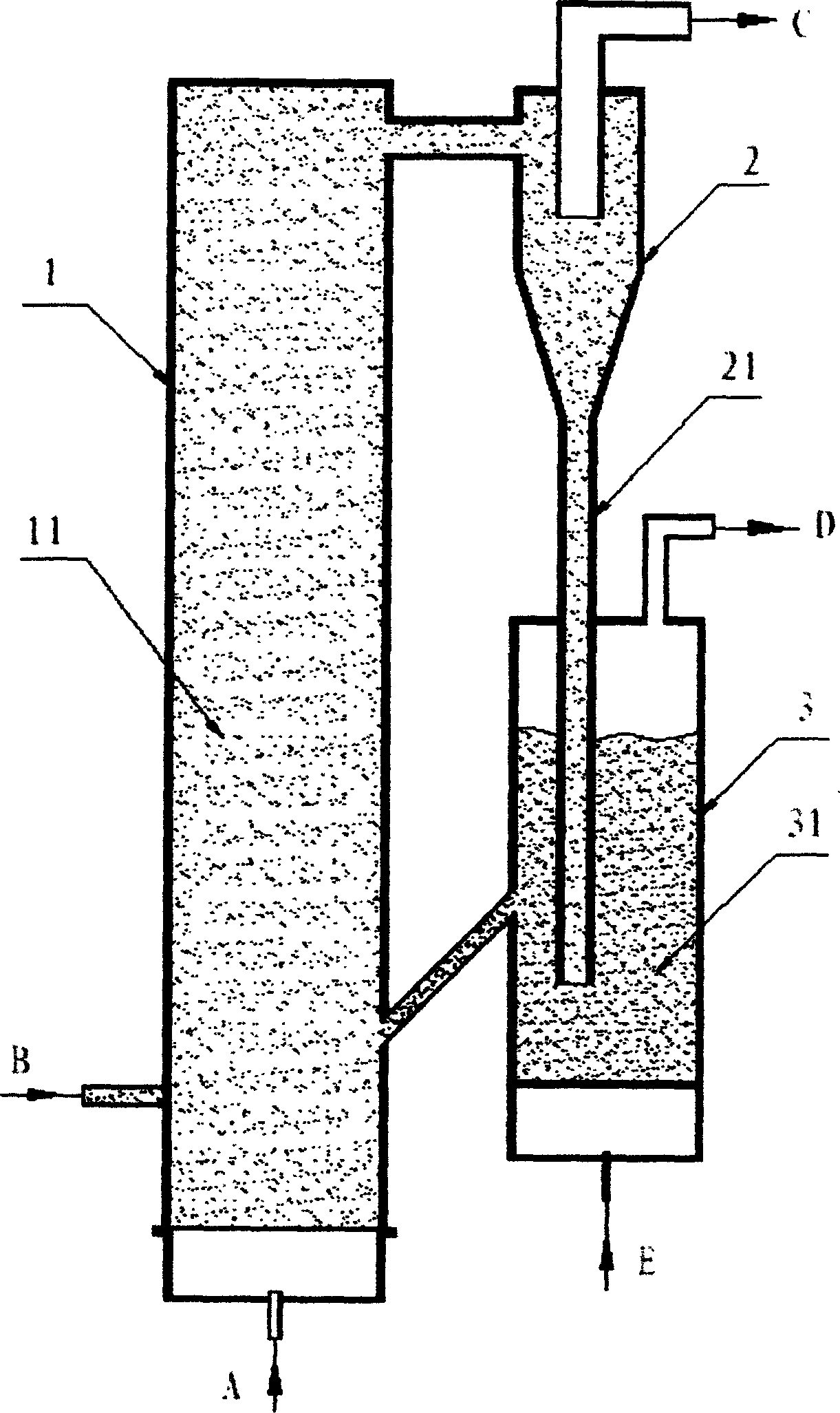

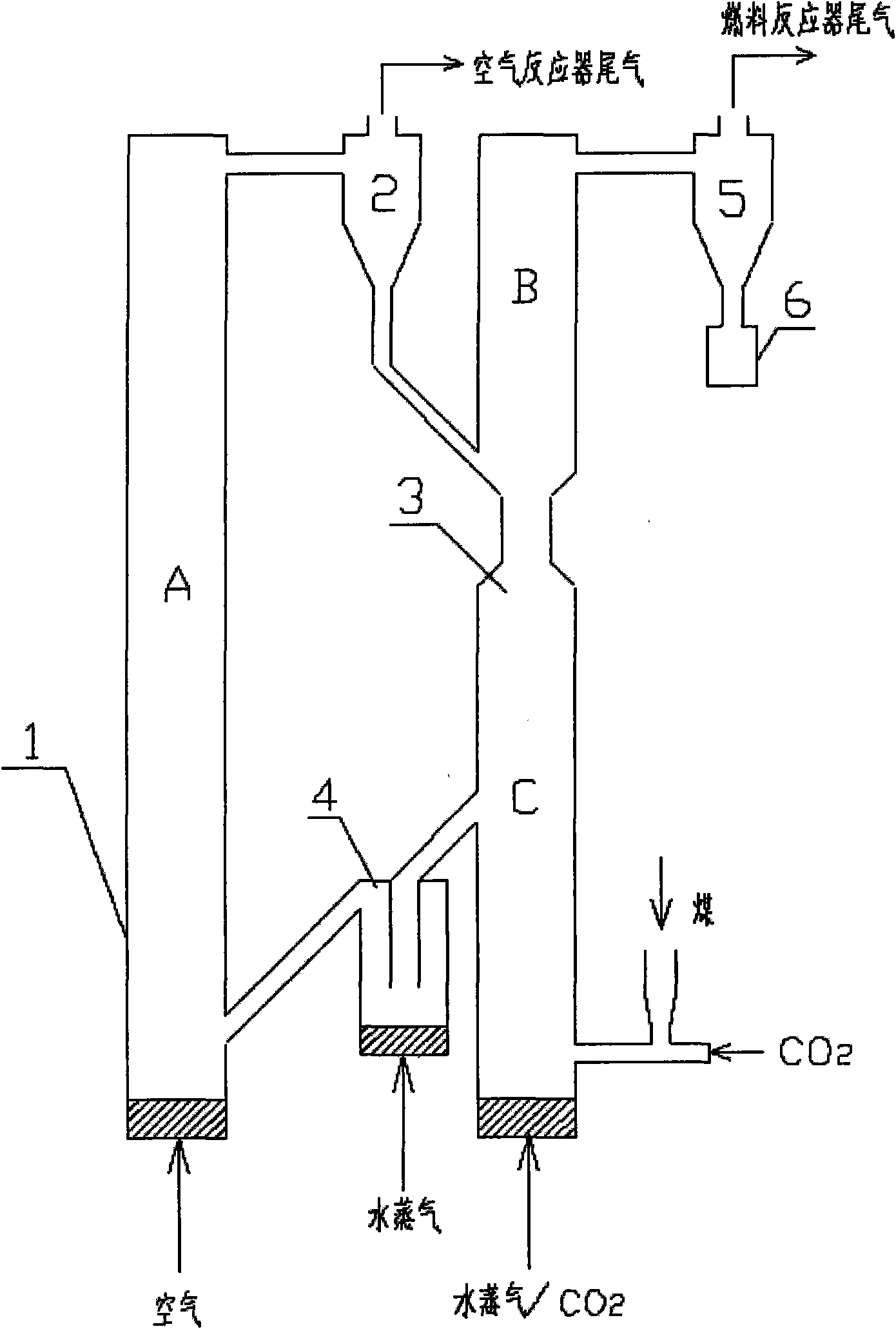

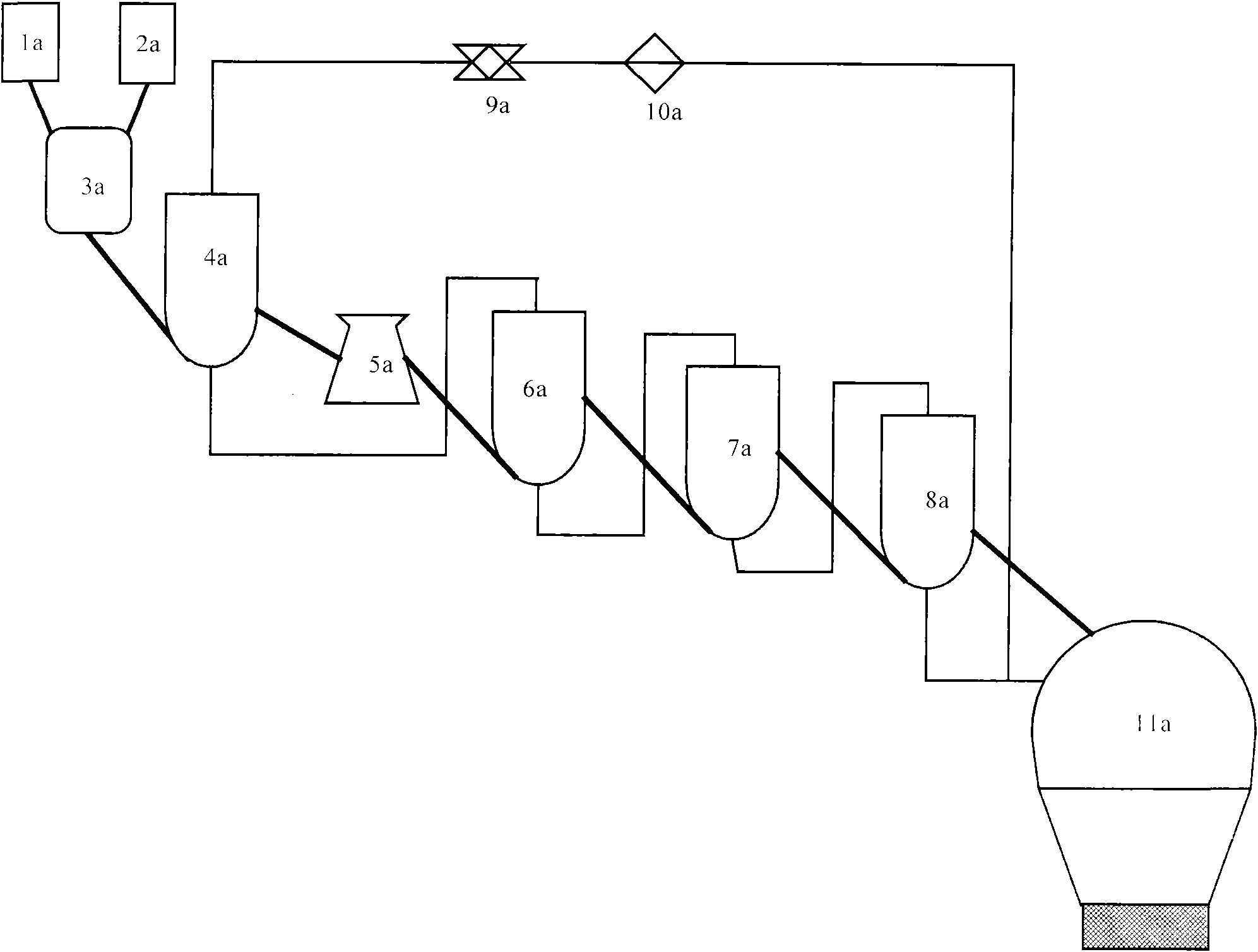

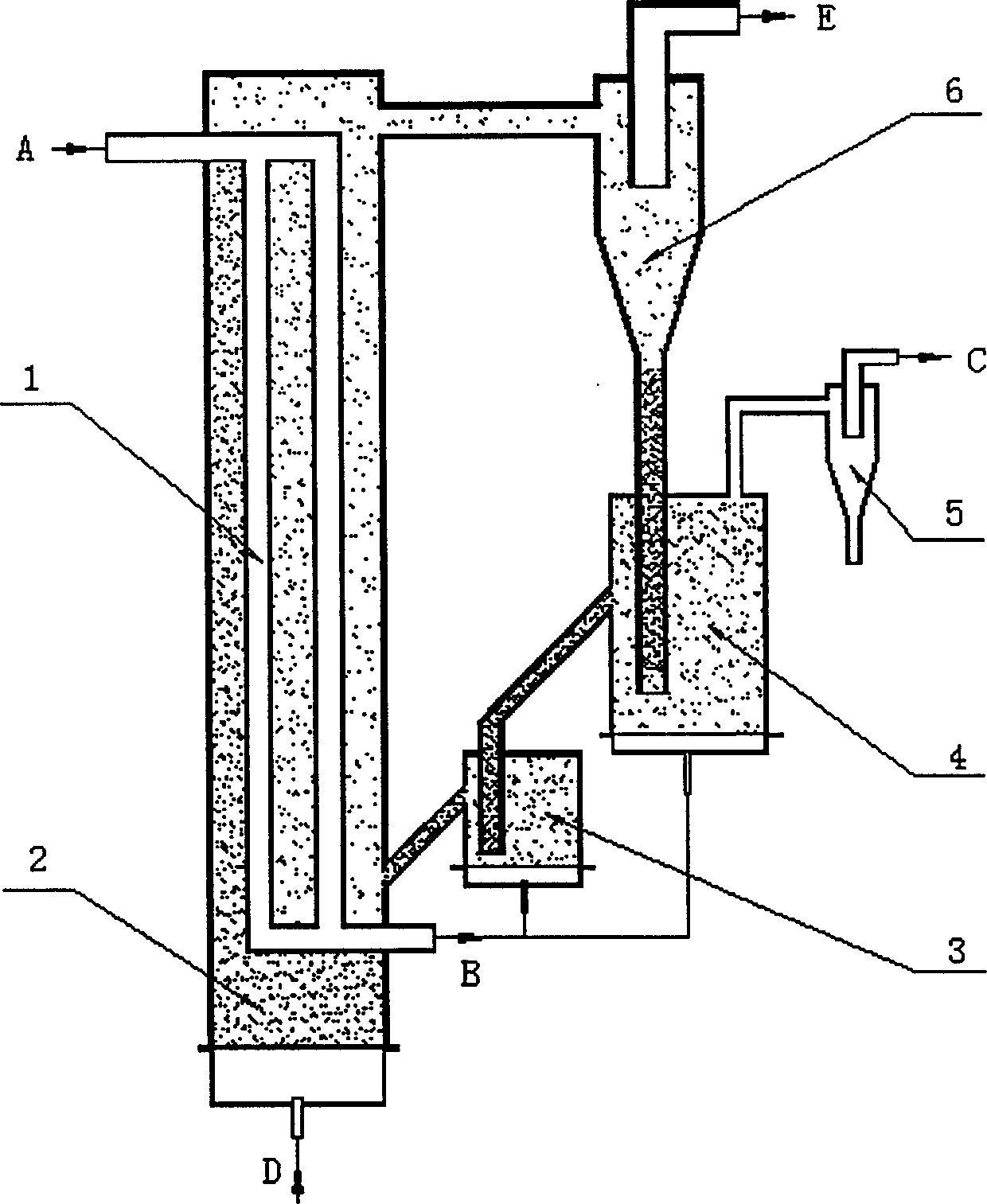

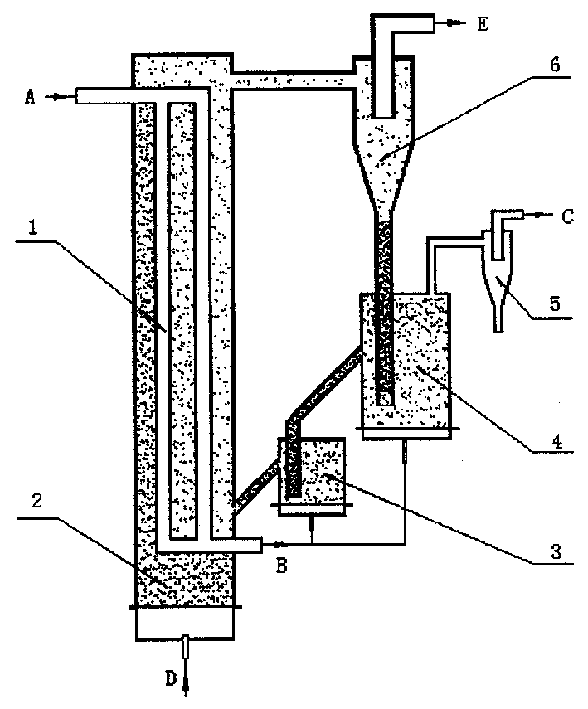

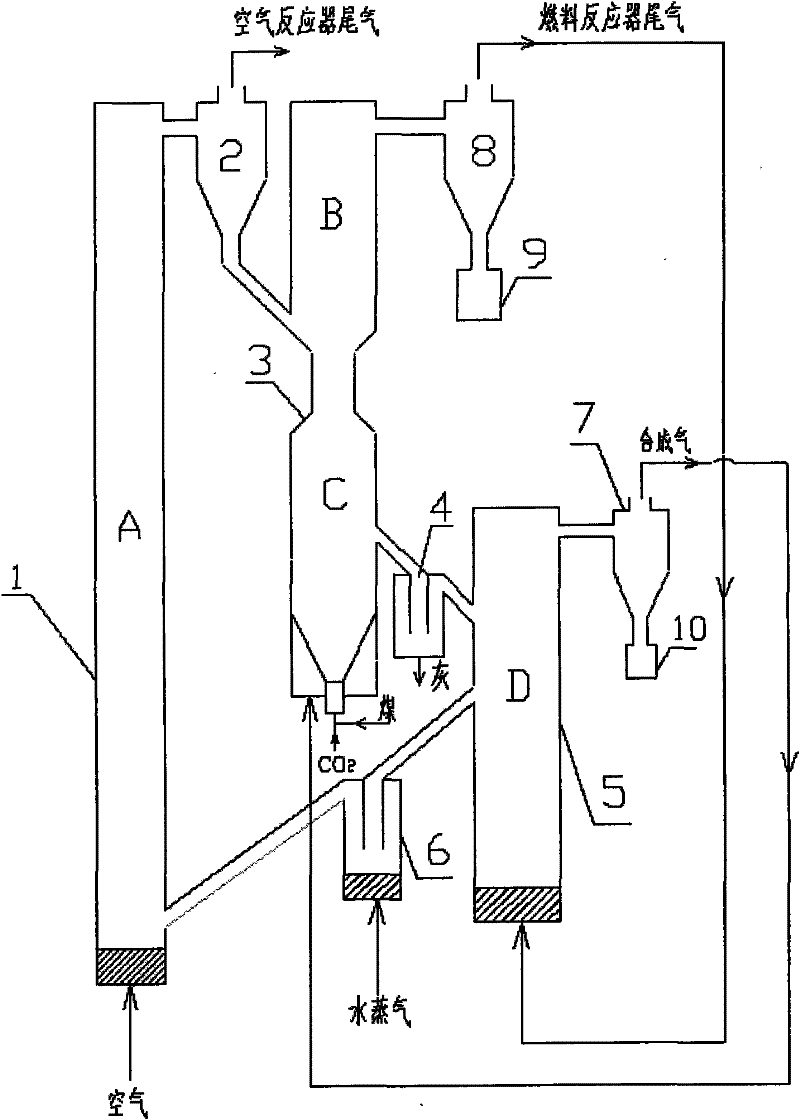

Biomass-gasifying hydrogen generating serial fluid bed apparatus and method

InactiveCN1608972AEfficient hydrogen productionSimple structureHydrogen productionGranular/pulverulent flues gasificationHydrogenDecomposition

The present invention is one method of generating hydrogen via catalytic thermolysis and gasification of biomass. The hydrogen generating apparatus consists of circulating fluidizing bed, cyclonic separator and bubbling fluidizing bed connected serially. The hydrogen generating process the fluidization of biomass with steam in circulating fluidizing bed with catalyst CaO / MgO grains; the catalytic thermolysis and gasification of biomass to produce hydrogen; the fixation reaction of CO2 in gas product with catalyst CaO / MgO grains to form CaCO3 / MgCO3; the separation of CaCO3 / MgCO3 grains and coke grains in cyclonic separator; burning of coke grains to promote the decomposition of CaCO3 / MgCO3 to release CO2 and high temperature CaO / MgO grains; and returning the high temperature CaO / MgO grains to the circulating fluidizing bed as catalyst and heat source.

Owner:SOUTHEAST UNIV

Method for low-severity gasification of heavy petroleum residues

A method for co-producing a sulfur-containing raw synthetic gas and an essentially desulfurized solid residue from a sulfur-containing heavy petroleum residue feedstock, comprising feeding a bubbling fluidized-bed gasification reactor with the feedstock, and converting the feedstock to a raw synthetic gas by a partial oxidation reaction in the presence of water at a temperature at or below about 1000° C. and a pressure at or below about 10 atm, thereby also producing an essentially desulfurized solid residue, while the sulfur components are essentially comprised in the raw synthetic gas; and separately recovering the essentially desulfurized solid residue and the sulfur-containing raw synthetic gas.

Owner:ENERKEM INC

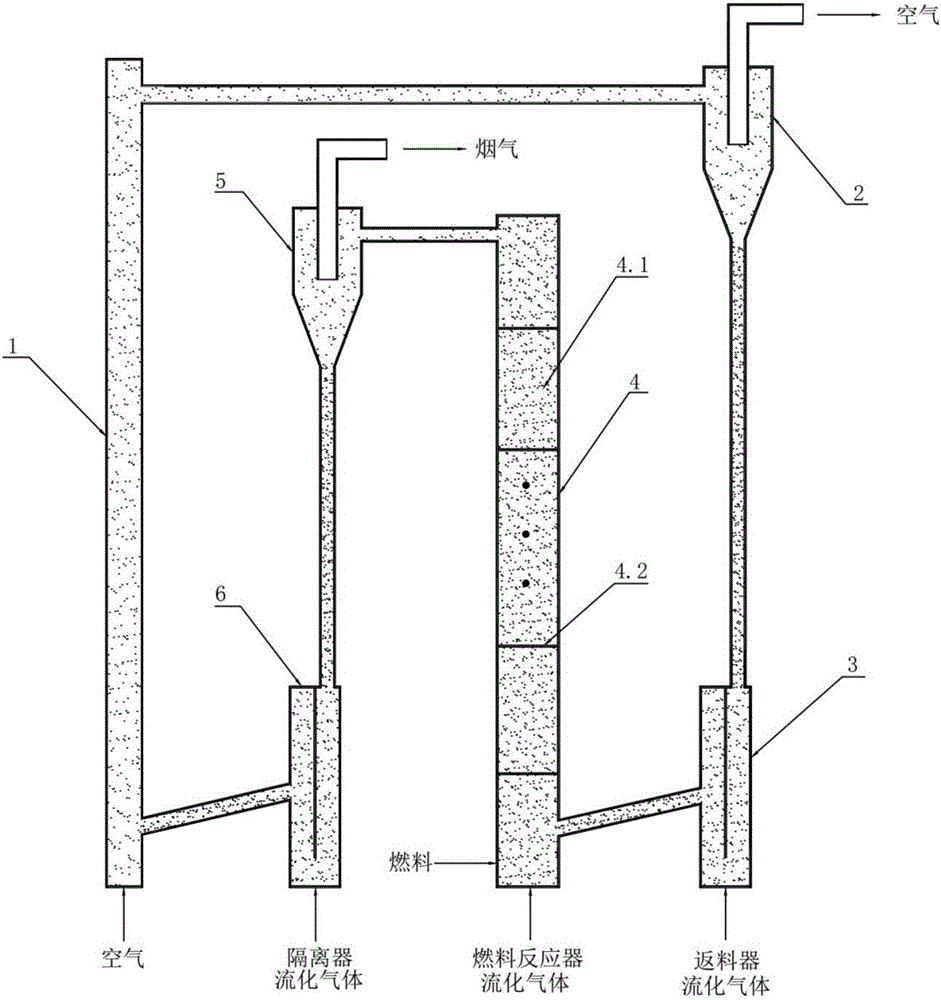

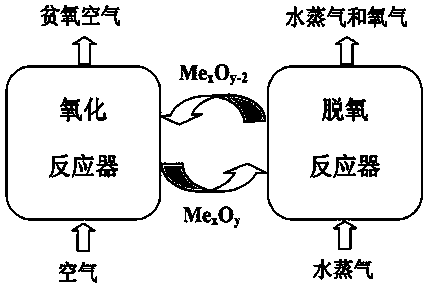

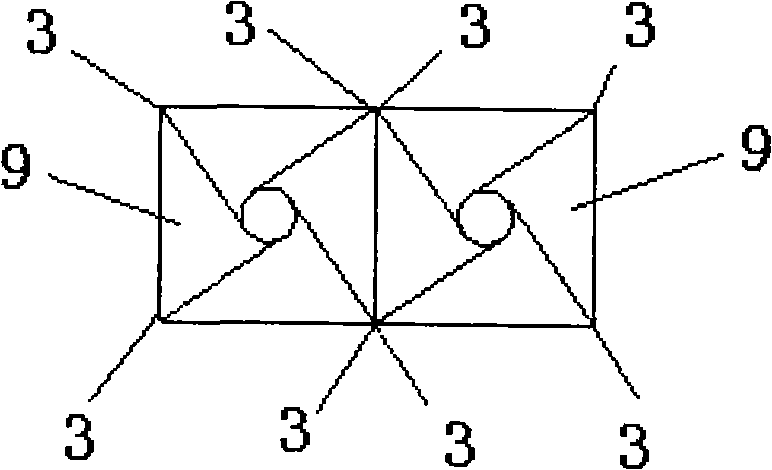

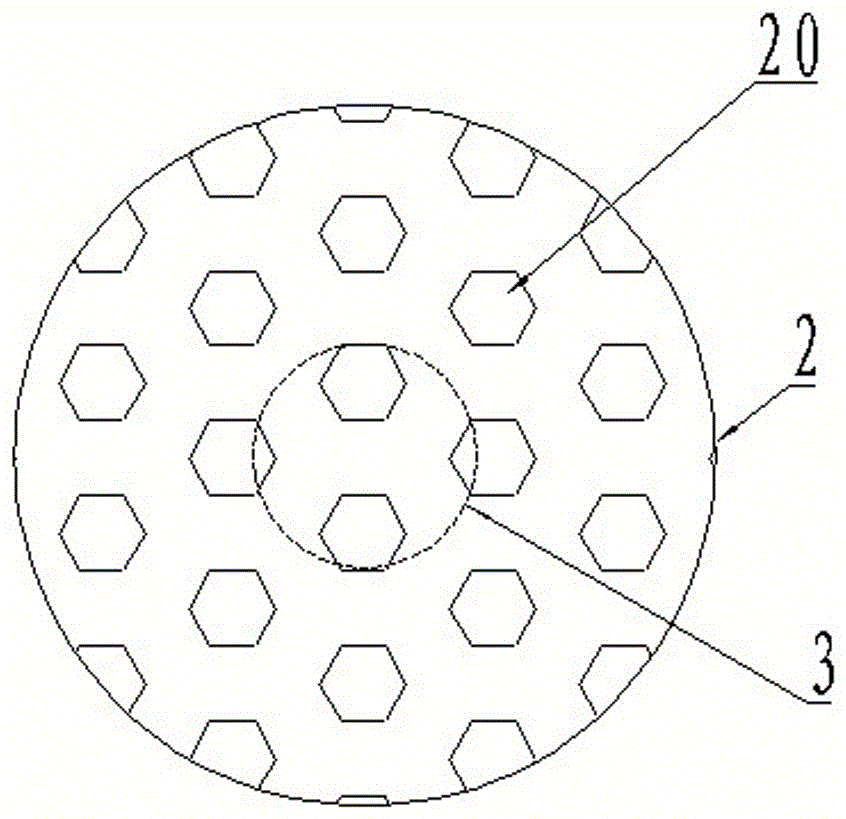

Double distribution plate coal-base serial fluidized-bed chemical chain combustion apparatus

InactiveCN101261010ALow costIncrease profitFluidized bed combustionIndirect carbon-dioxide mitigationDeoxidizationBubbling fluidized bed

The invention belongs to the gas-solid fluidized bed reactor field and relates to a dual-distributing plate coal-based serial fluidized bed chemical-chain combustion apparatus suitable for the chemical-chain combustion of burning coal and other solid fuels; the bottom of a bubbling fluidized bed is provided with a gas inlet and a feed port; the inside of the bubbling fluidized bed is divided into three regions by two distributing plates; the bottom of a low gas velocity region and the bottom of a high gas velocity region are respectively provided with a distributing plate; the middle between two regions is provided with a transition region with a reduce section to realize different gas flow velocities in the low gas velocity gasification region and the high gas velocity deoxidization region; the upper part of a bubbling fluidized bed is in tubular communication with the upper part of a cyclone separating device; the top of the cyclone separating device is provided with an exhaust port which is communicated with a gas inlet of the bubbling fluidized bed; the lower part of the cyclone separating device is pumped to the low gas velocity gasification region by a feed leg; the bottom of the high gas velocity deoxidization region is communicated with a circulating fluidized bed by a feed returning device; the bottom of the circulating fluidized bed is provided with an air inlet; the upper part of the circulating fluidized bed is communicated with the cyclone separating device. The dual-distributing plate coal-based serial fluidized bed chemical-chain combustion apparatus has the advantages of low cost, flexible operation, high thermal efficiency, wide application range, etc.

Owner:QINGDAO UNIV OF SCI & TECH

Pulverized coal combustion method and device with function of capturing CO2

InactiveCN101666546AOvercoming many disadvantages such as low utilization efficiencyRealize clean utilizationExothermal chemical reaction heat productionExothermal chemical reactions for heatingCycloneHigh concentration

The invention provides a pulverized coal combustion method with the function of capturing CO2, comprising the steps: CuFe2O4 is decomposed to generate O2 and oxygen vacancy ferrite CuFe2O4-delta (delta is no less than 0 but no more than 2); oxidation reaction is generated between the pulverized coal and the oxygen vacancy ferrite so as to generate CO2, H2O and non-condensed gas, wherein the oxidation reaction is generated between the non-condensed gas and O2 which is obtained by decomposition so as to generate CO2 and steam. The device for achieving the method comprises a loop which is formedby the communication of a fast fluidized bed, a first cyclone separator, a two-stage type bubbling fluidized bed, a U-type flow seal valve and the fast fluidized bed in sequence; and the bubbling fluidized bed is also communicated with a second cyclone separator which is communicated with an ash catching device. The pulverized coal combustion method with the function of capturing CO2 effectively combines a pure oxygen combustion technology of coal with a chemical chain combustion technology, not only lowers the preparation cost of the pure CO2, but also fully realizes the separation of the high-concentration CO2 after the coal reaction.

Owner:HUAZHONG UNIV OF SCI & TECH

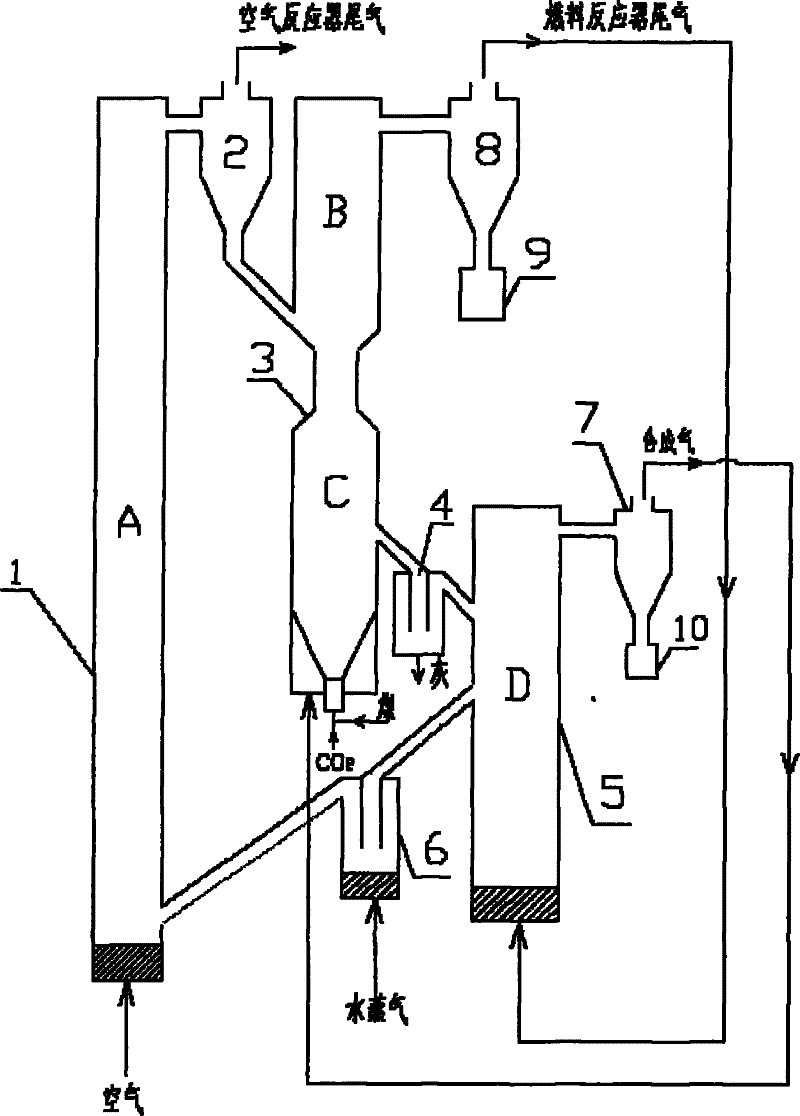

Fuel coal chemical looping combustion CO2 separation method in coupling with pure oxygen gasification

ActiveCN105222129AIncrease temperatureIncrease reaction rateFluidized bed combustionIndirect carbon-dioxide mitigationWater vaporEngineering

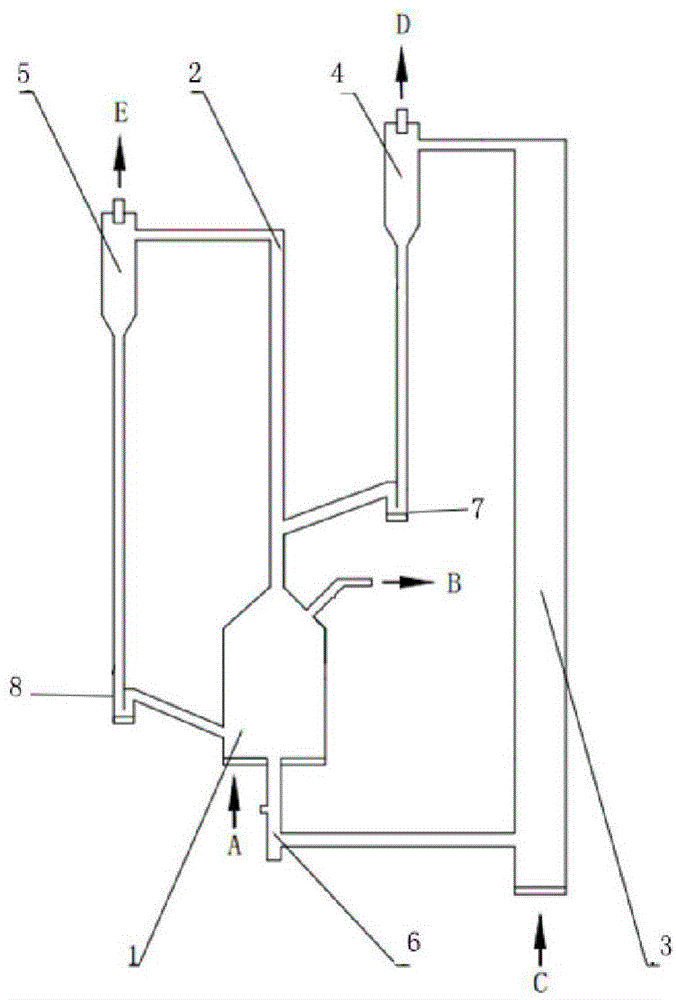

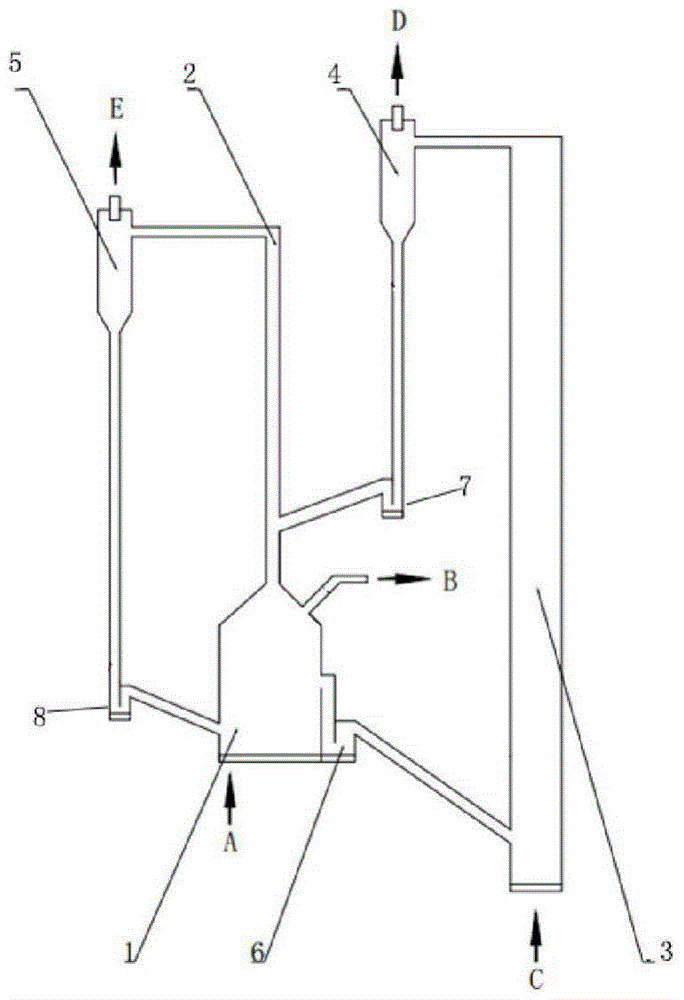

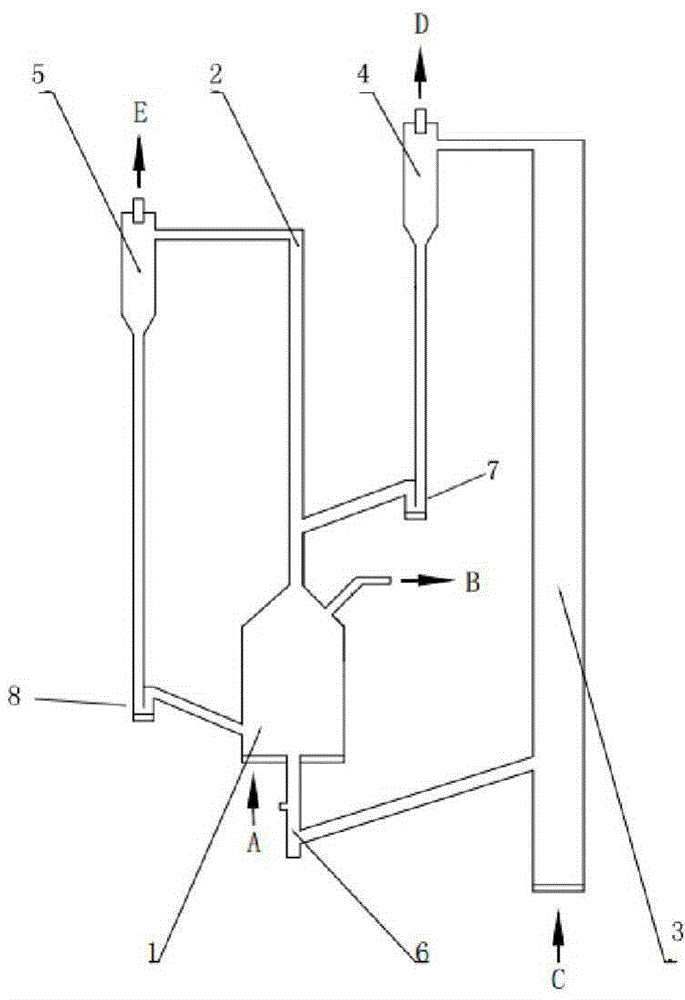

The invention provides a fuel coal chemical looping combustion CO2 separation method in coupling with pure oxygen gasification. In a fuel reactor, a gasification agent (B) composed of water vapor and a small amount of oxygen enters from the bottom of a bed of a bubbling fluidized bed gasification furnace (1), the bed material (C) is coarse-grained inert material and performs fluidization movement under the action of the gasification agent and forms a dense phase zone; fine powdered coal (A) is added into the bubbling fluidized bed gasification furnace (1) from the dense phase zone and performs gasification reaction with the gasification agent (B), so as to form coal gas and unburned carbon (D); oxygen carrier particle (E) enters from the bottom of a lifting pipe (2) and reacts with the combustible components such as CO, H2 and CH4 in the coal gas, so as to generate CO2 and H2O. The flue gas composed of CO2, water vapor, uncompleted burned combustible gas and tiny amount of carbon-containing fine fly ash enters into a reburning chamber (13), wherein the combustible gas and the carbon in the fine fly ash perform combustion reaction with oxygen (J) from an oxygen inlet (14) of the reburning chamber, so as to generate CO2 and H2O.

Owner:SOUTHEAST UNIV

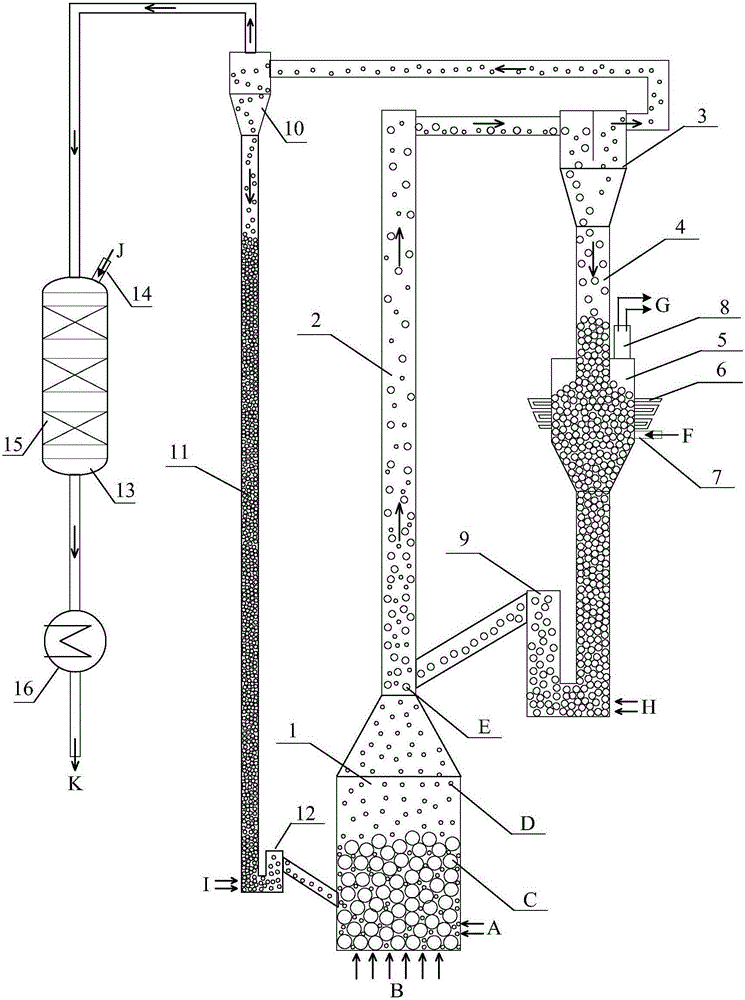

Gas fuel oxygen-carried hydrogen-produced and carbon dioxide separation method and device

ActiveCN101100284AEffective isolationReduce consumptionHydrogenCarbon compoundsHigh concentrationHydrogen

This invention relates to a method for producing hydrogen by using combustible reducing gas as raw material, and using iron / ferrous oxide as oxygen-carrier, during the reaction in a fluidized bed reactor, with coproduct of high concentration carbon dioxide. This invented equipment comprises: a circulation fluidized bed, a moveable bed, a bubbling fluidized bed, a hydrogen separator unit and a carbon dioxide separator. A horn type bucket is used under the bottom of hydrogen separator and connecting the lower part of the bubbling fluidized bed; the bottom of the carbon dioxide separator is connected with horn type bucket; a contraction type bucket is used for connection middle lower part of the bubbling fluidized bed and the moveable bed; the upper part of moveable bed is connected with the middle part of the circulation fluidized bed; the lower ends of the circulation fluidized bed and moveable bed and bubbling fluidized bed are equipped with fluidized steam inlets A and B gas fuel inlet C. This invention has advantages of: simple struction, low cost and high efficiency.

Owner:TSINGHUA UNIV

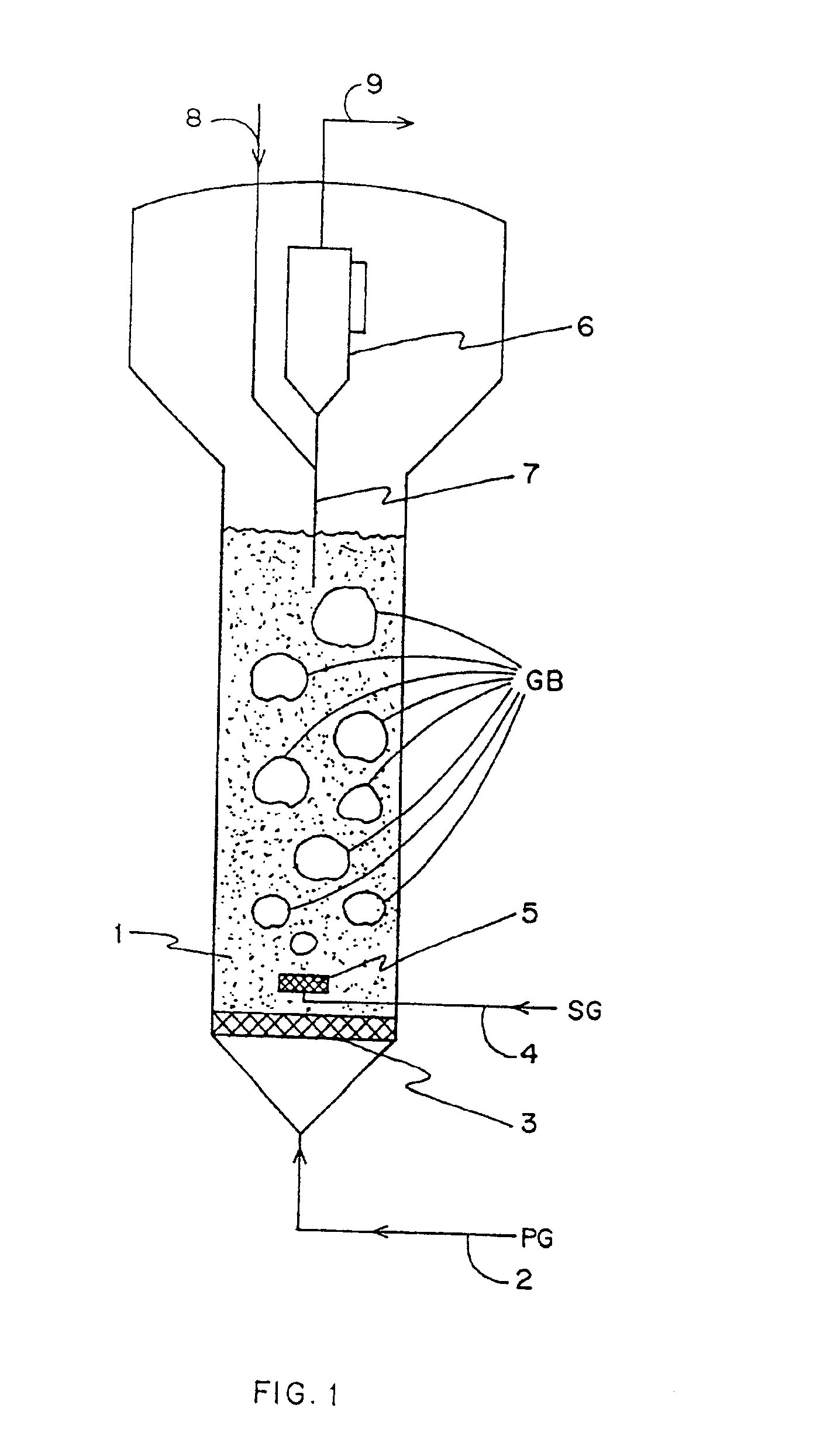

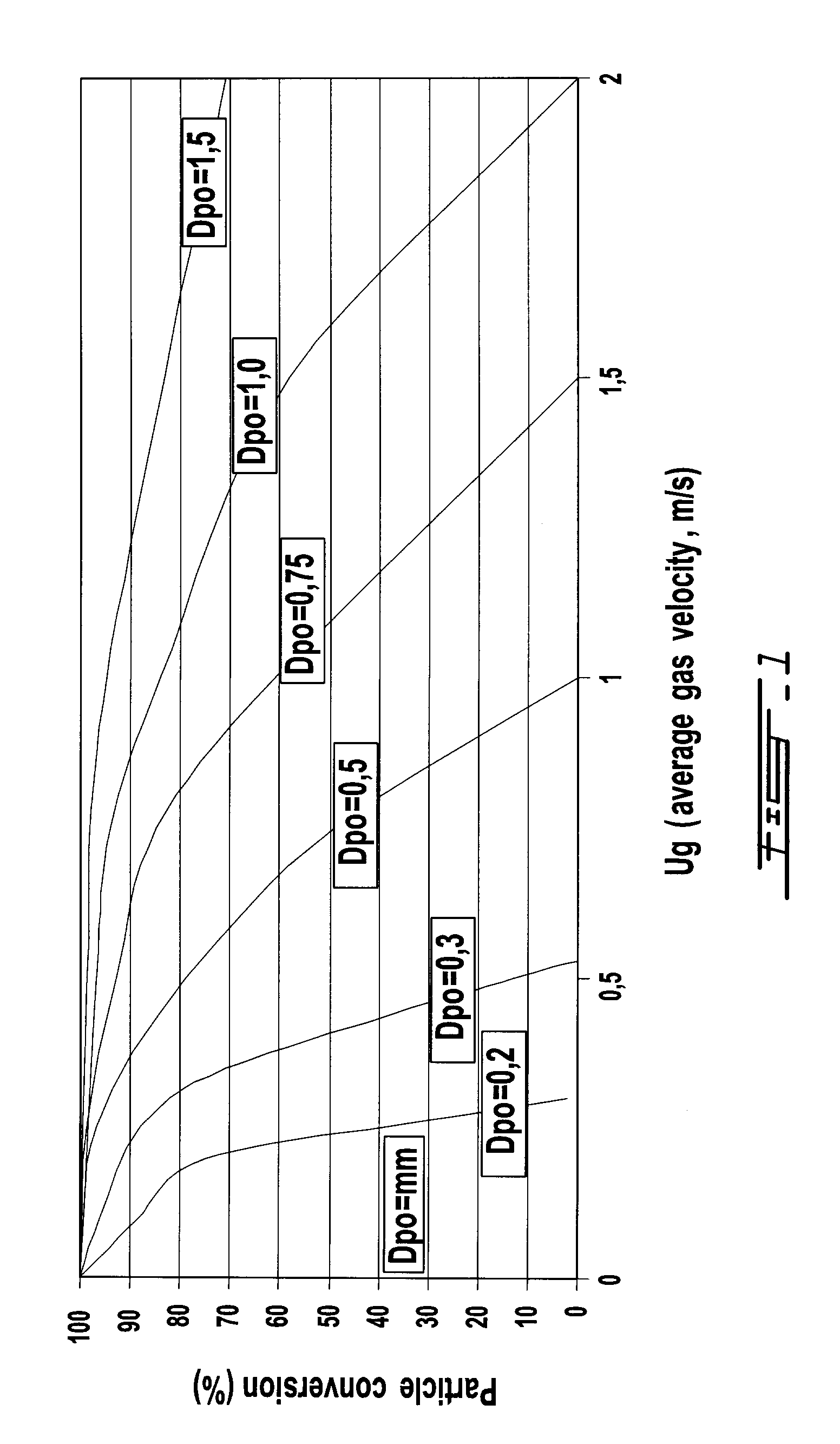

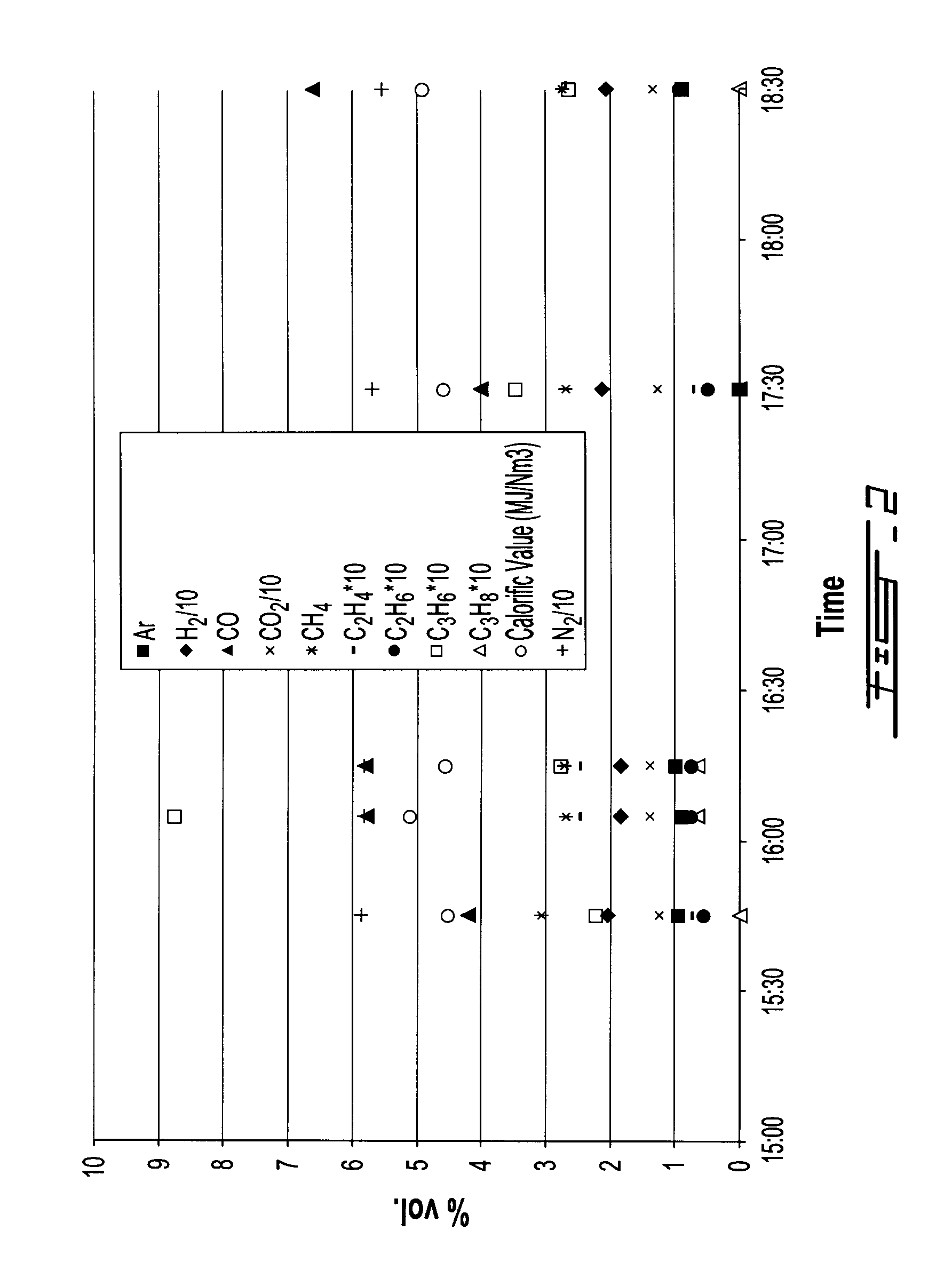

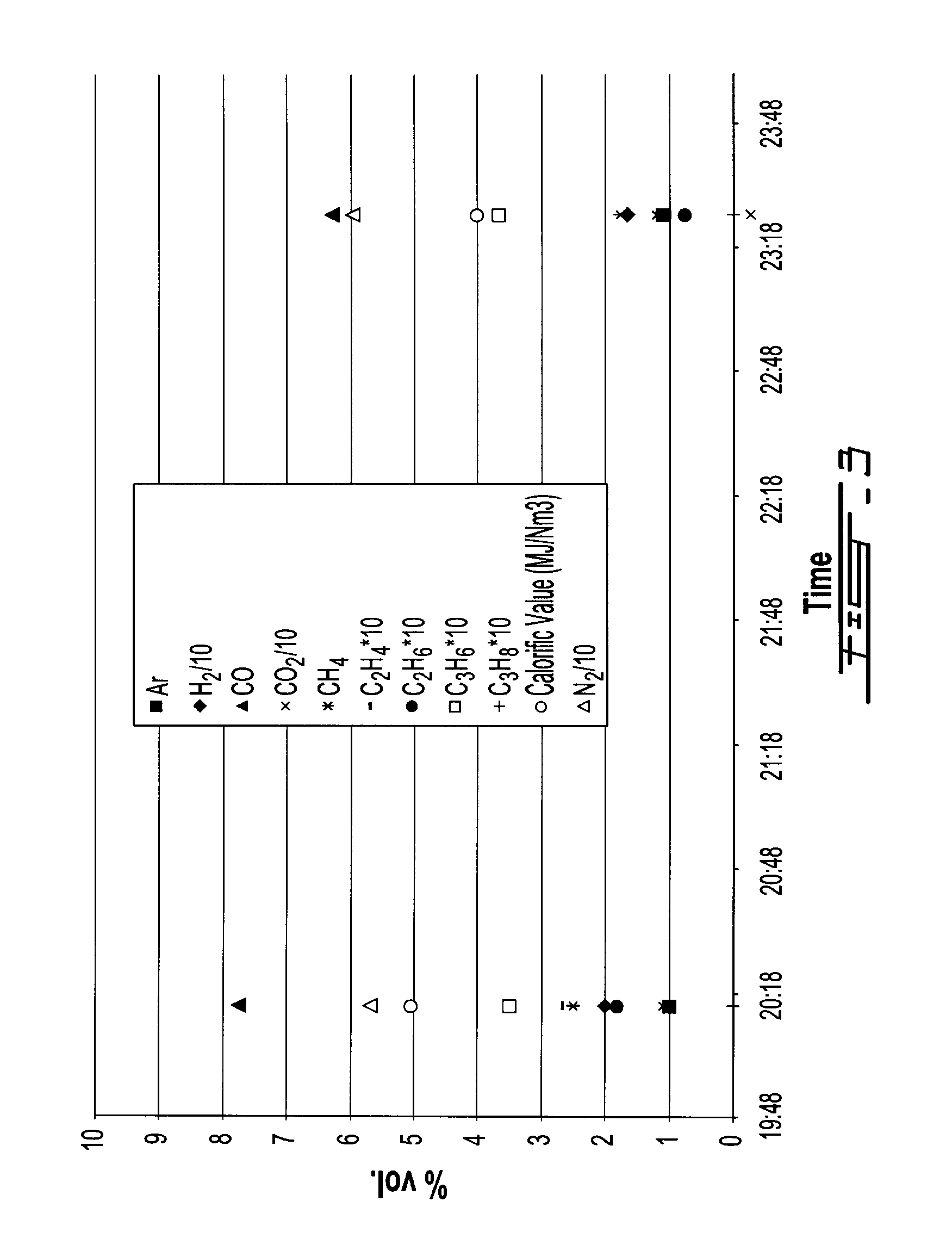

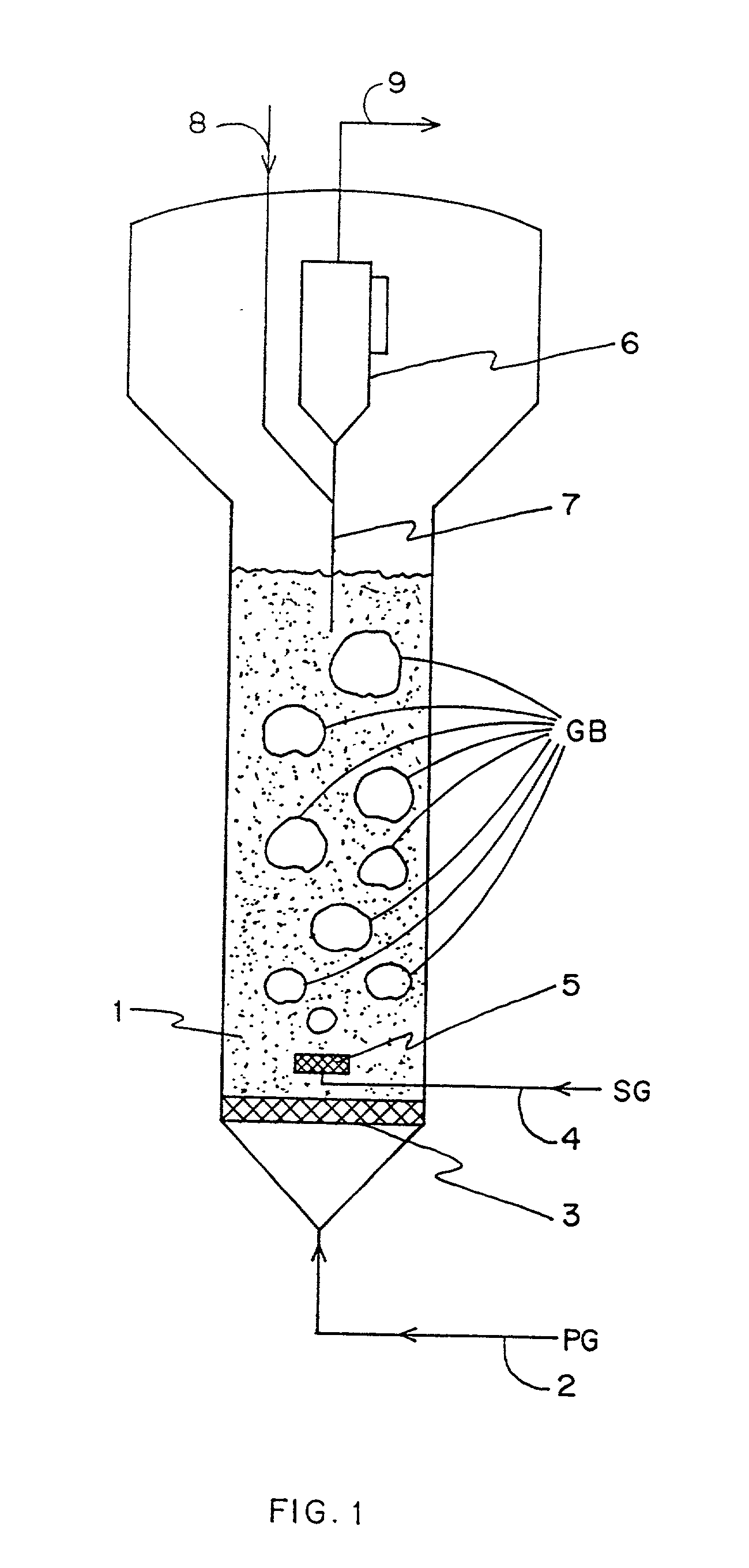

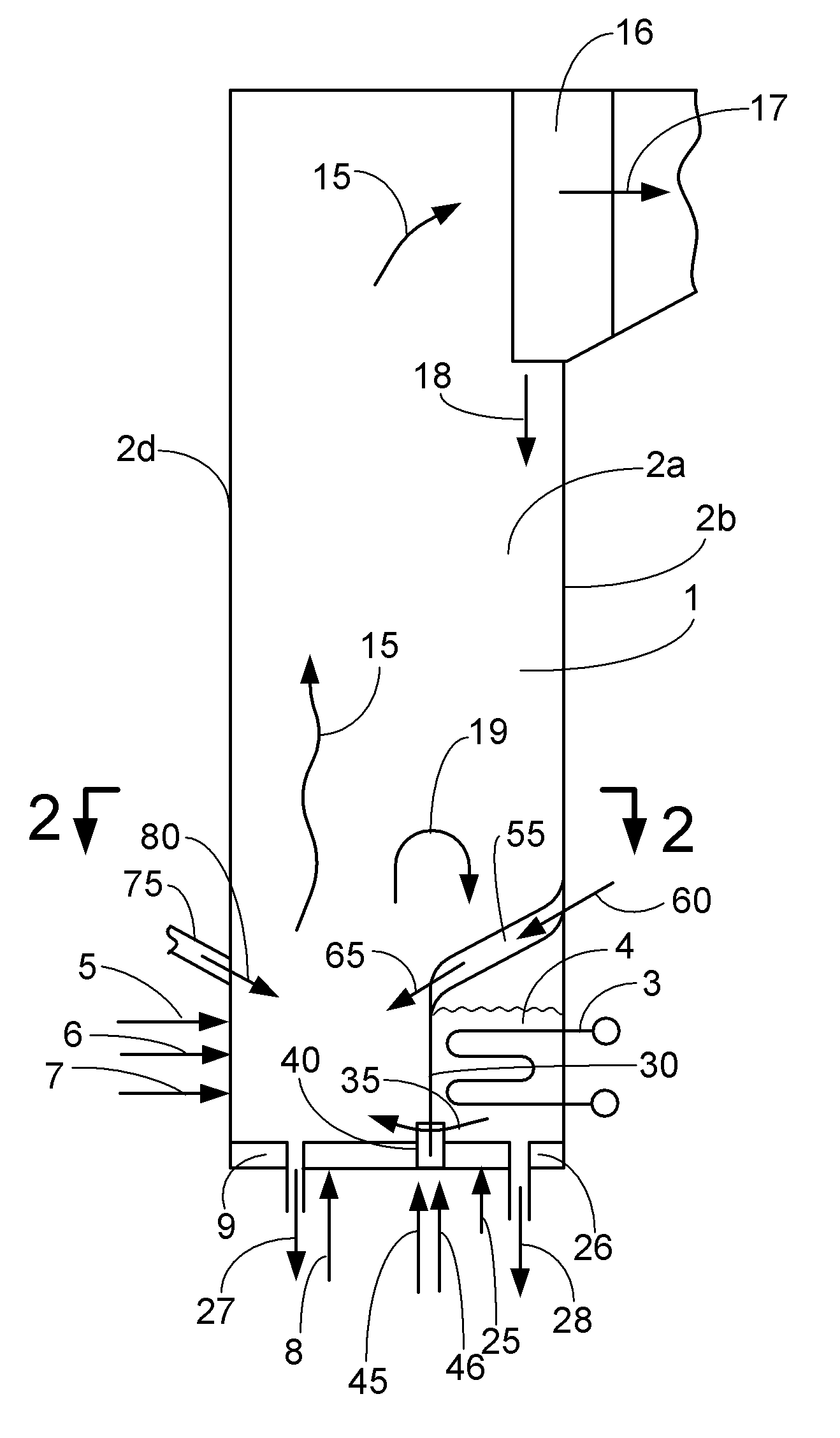

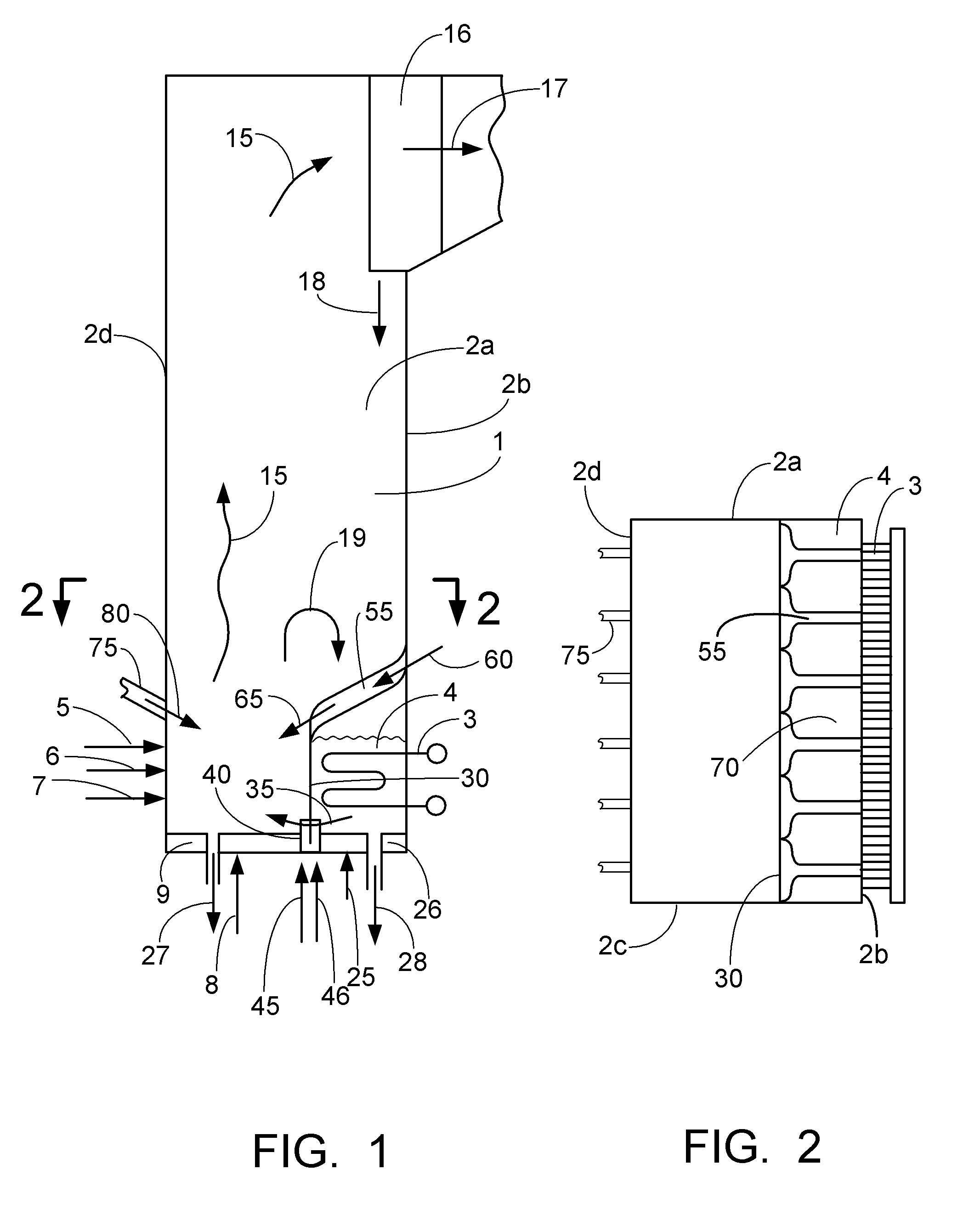

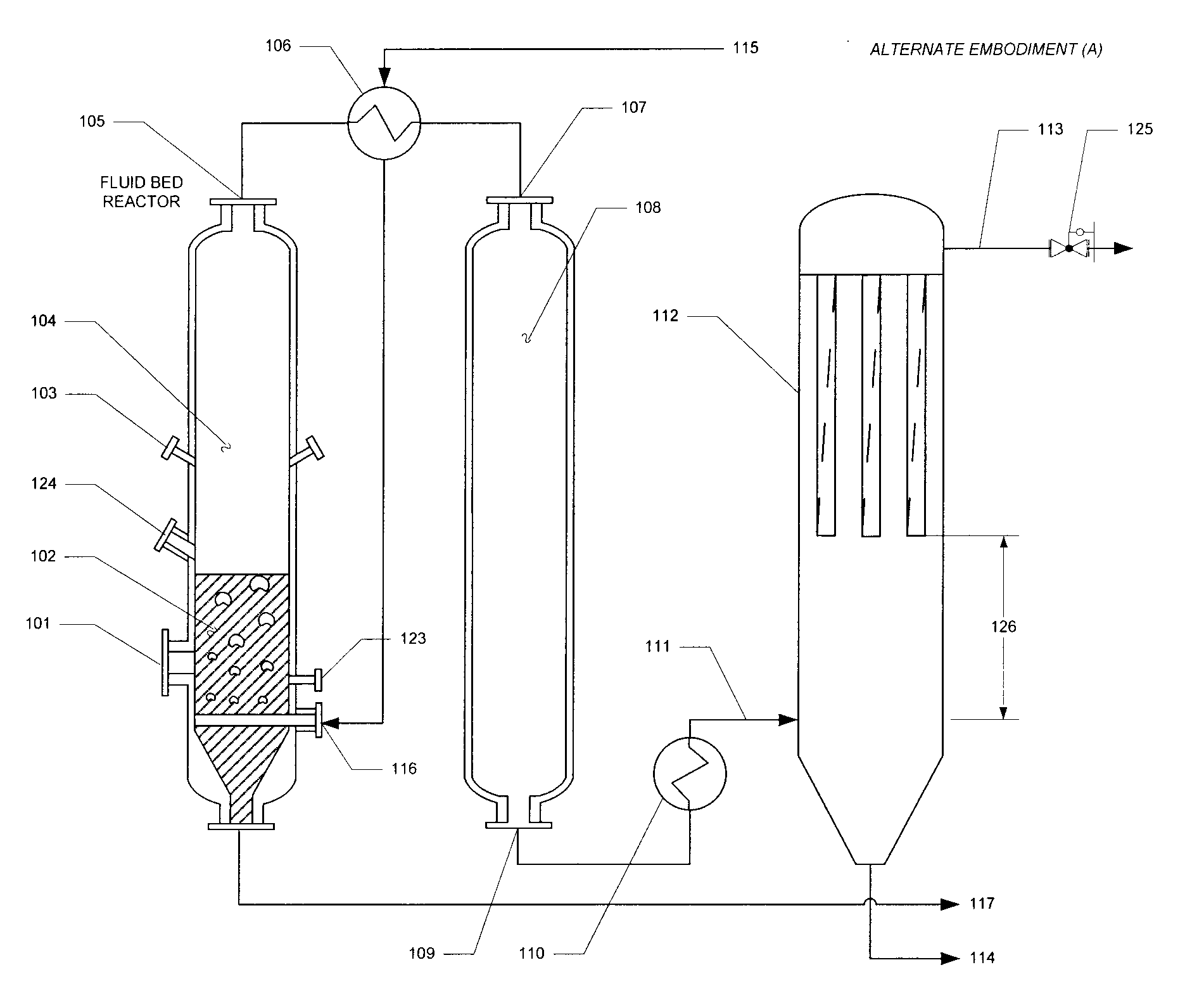

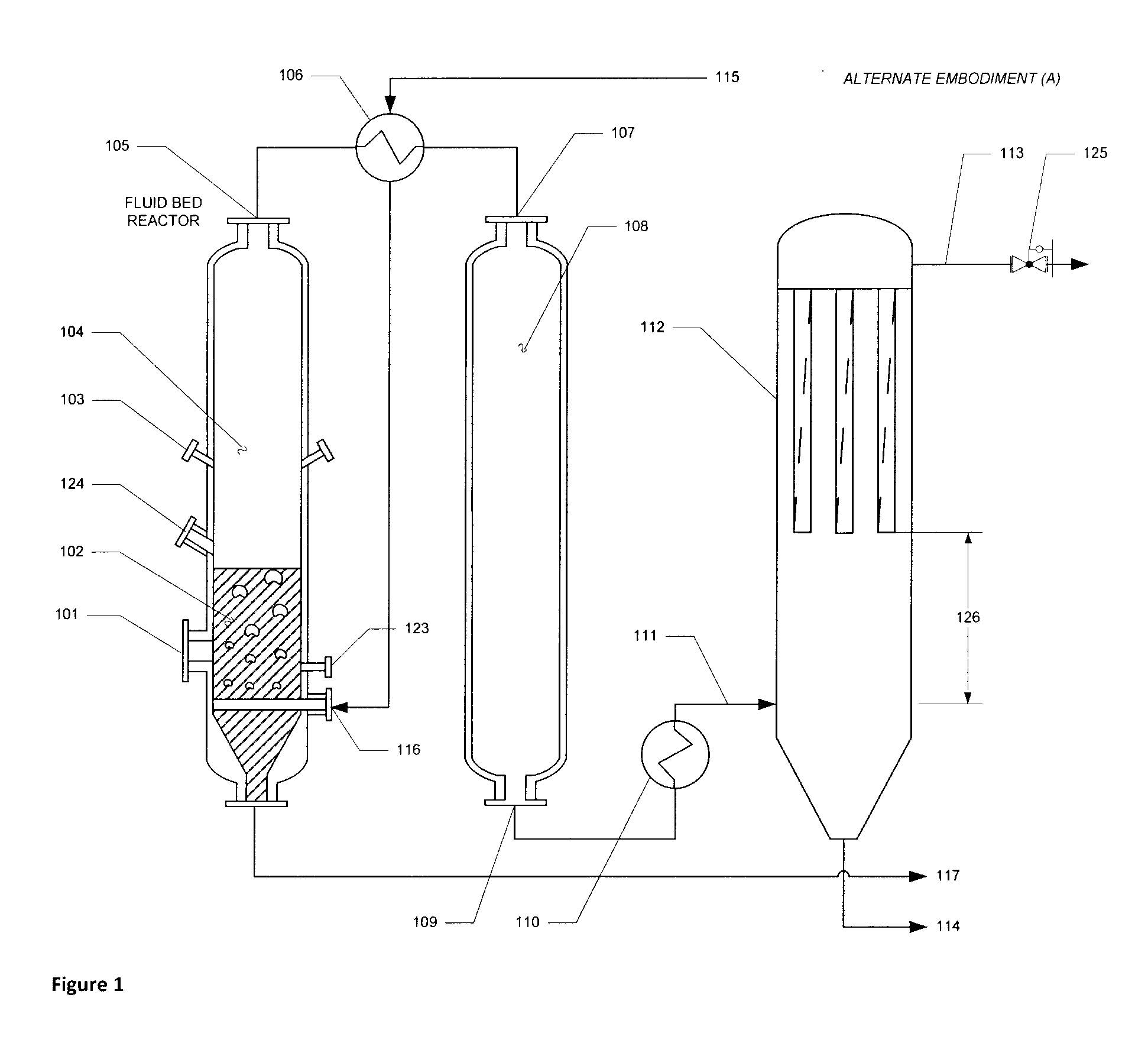

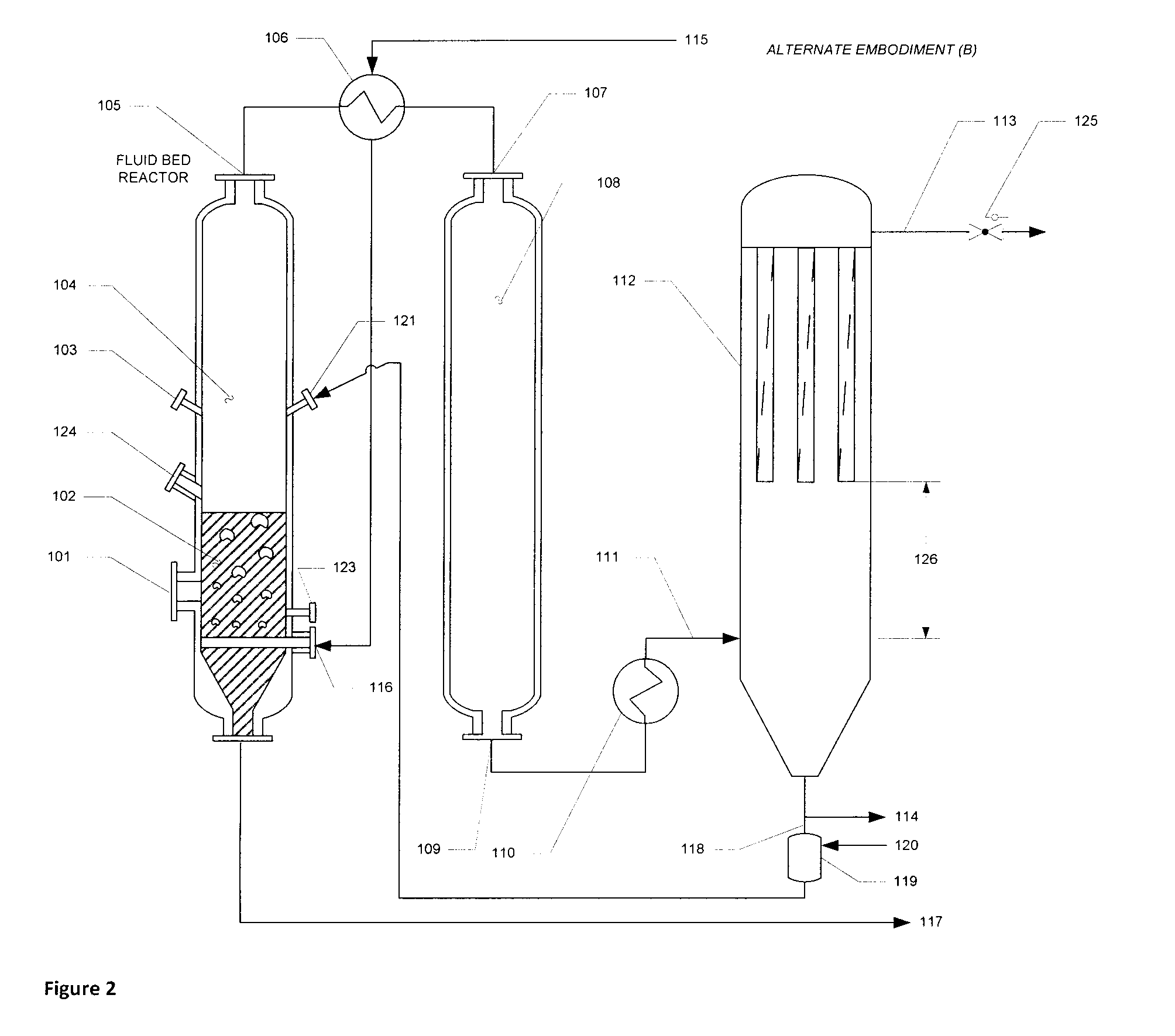

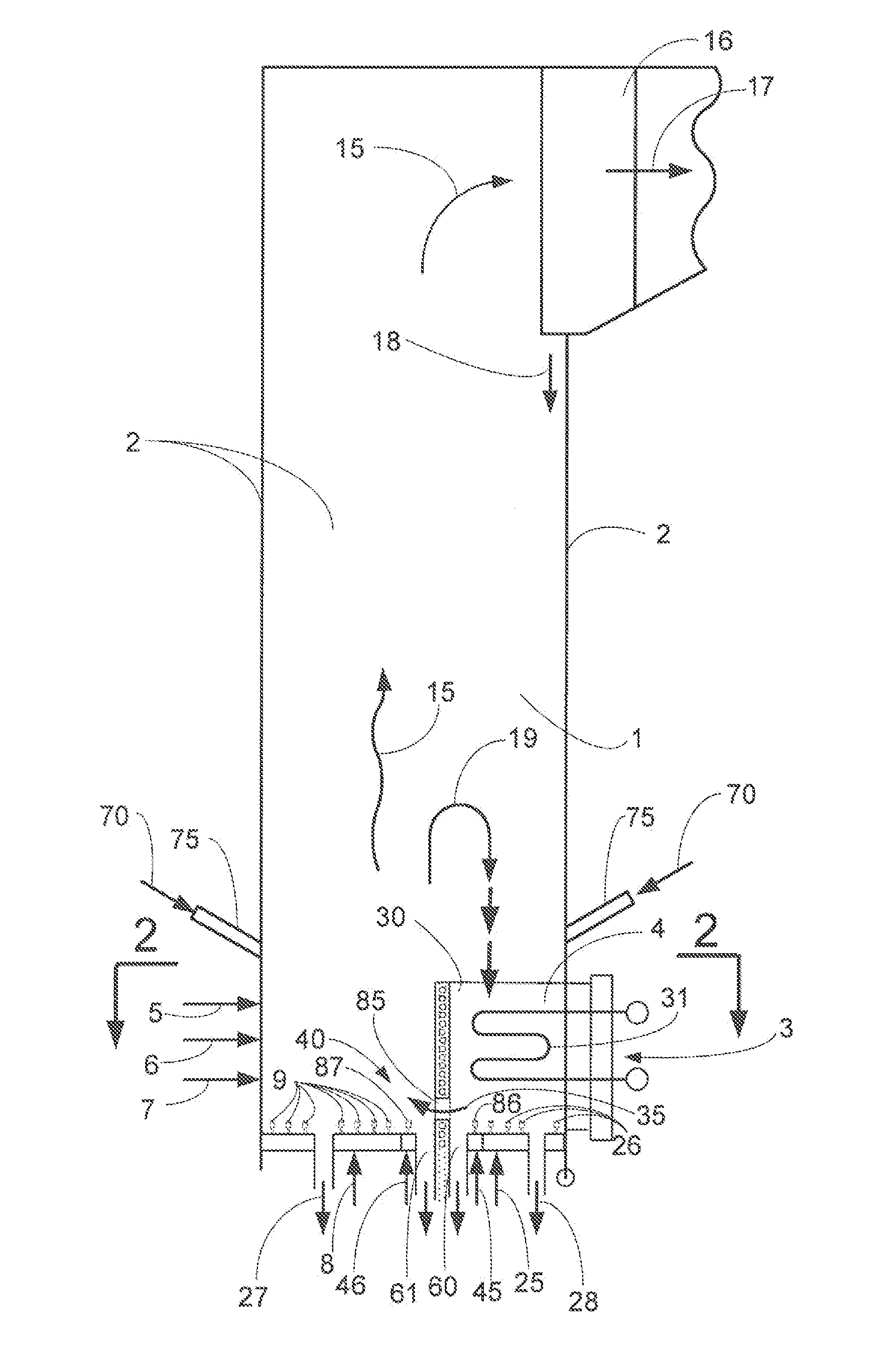

Method for gas - solid contacting in a bubbling fluidized bed reactor

InactiveUS20020179489A1Effective contactSpeed up the conversion processThermal non-catalytic crackingCatalytic crackingForming gasSurface velocity

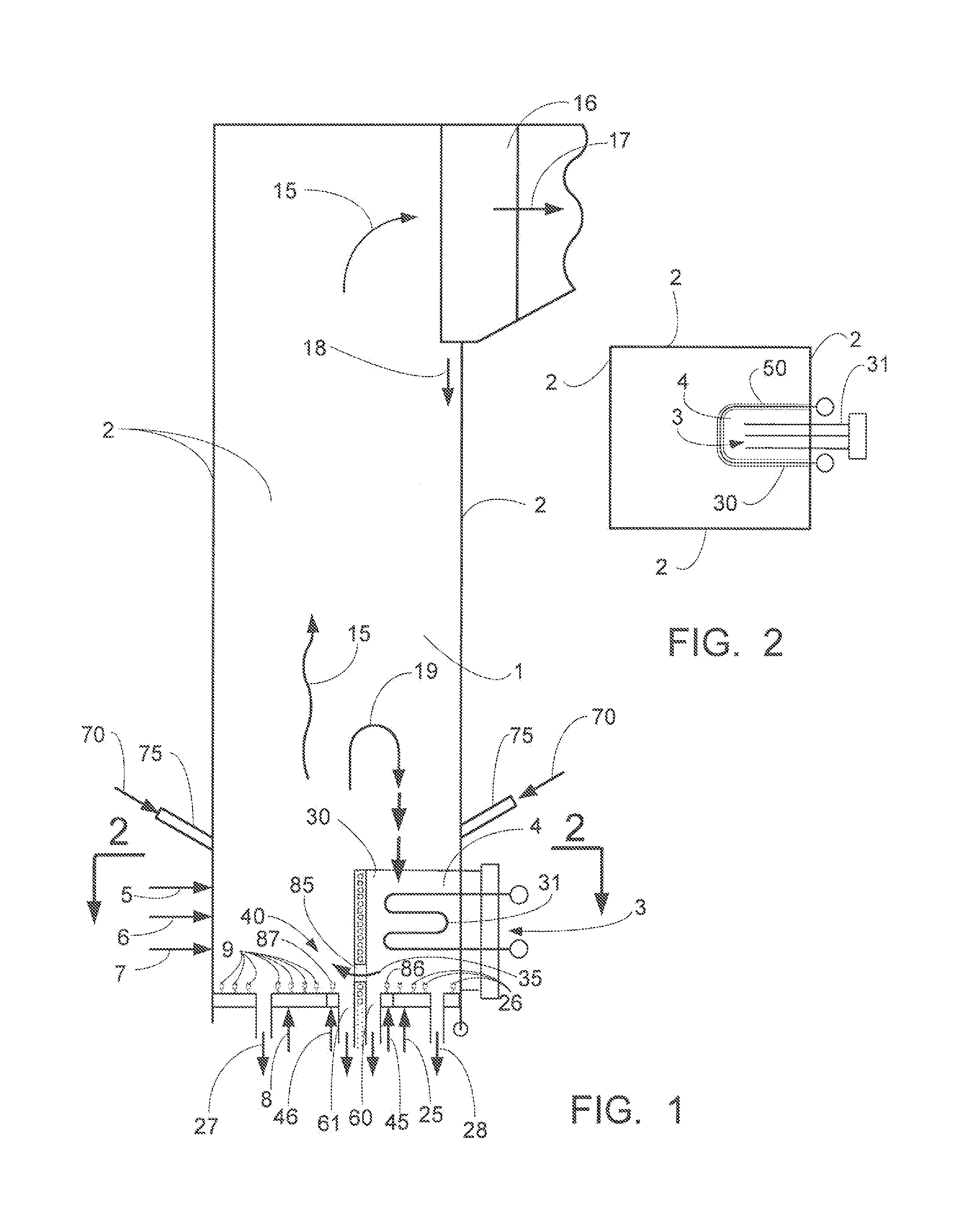

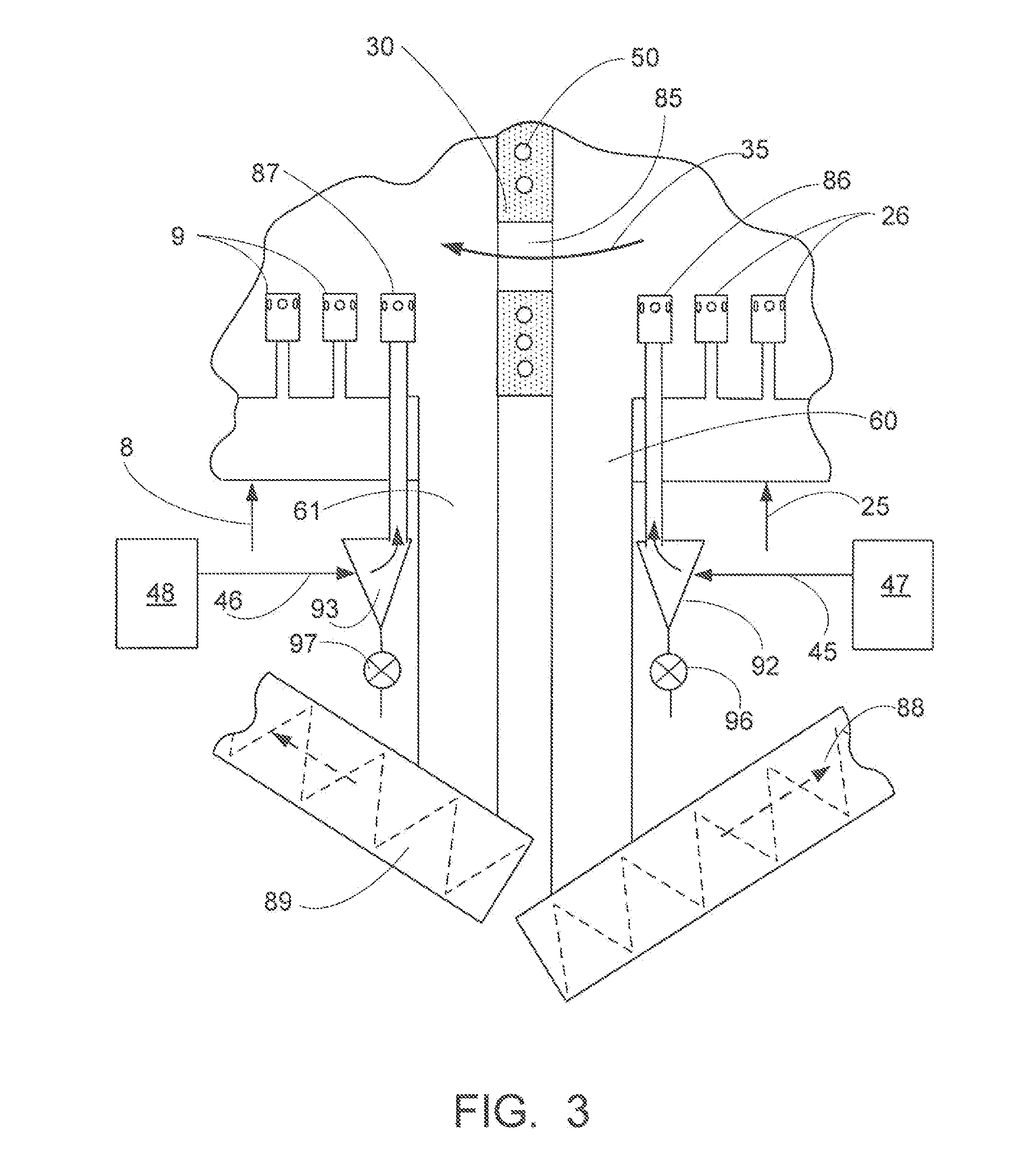

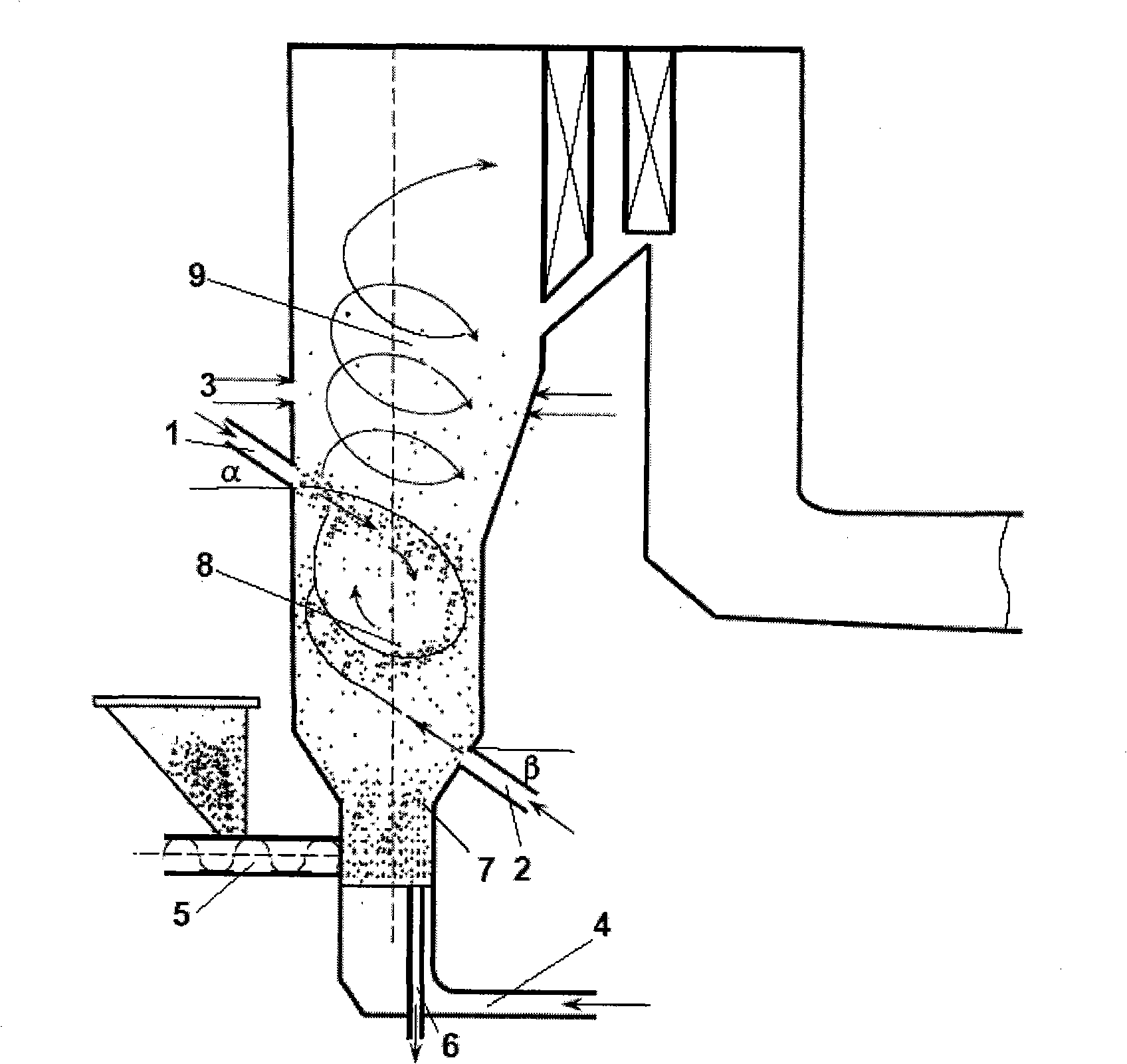

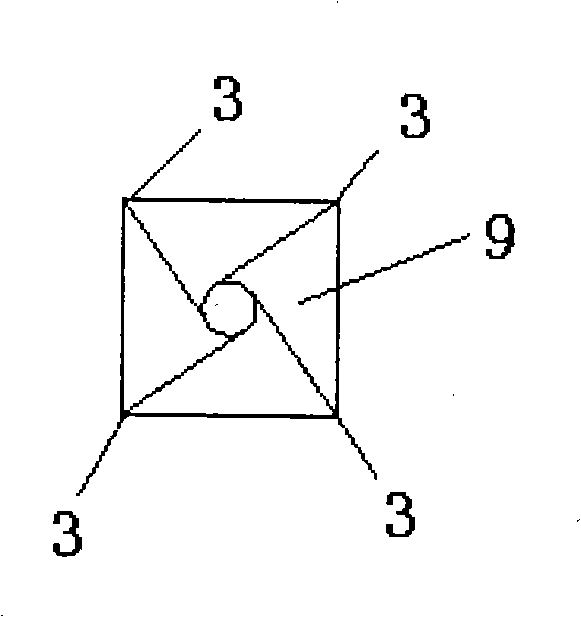

The present invention relates to a method for gas-solid contacting in a bubbling fluidized bed reactor by: (a) introducing into a reactor with bed length to bed diameter ratio below about 5.0, a primary gas consisting essentially of reactant(s) of the reaction to be carried out in the bed of solid particles through a primary gas distributor located at the reactor bottom at a superficial gas velocity Up, which is very close or equivalent to the minimum fluidization velocity Umf, required for achieving the incipient fluidization of the solid particles in the bed to obtain an emulsion phase consisting essentially of the solid particles and the primary gas with little or no formation of gas bubbles to achieve incipient fluidization or liquid-like behavior of fluidizable solid particles; (b) forming gas bubbles in the incipiently fluidized bed by introducing through a secondary gas distributor located immediately above the primary gas distributor a secondary gas, selected from one of the reactants which is used in excess of that required for the reaction stoichiometry, steam, an inert or a mixture of two or more thereof at a superficial gas velocity, Us, which is related to the superficial velocity of the primary gas such that a ratio of the superficial velocity of the secondary gas to the superficial velocity of the primary gas Us / Up, is in the range from about 0.5 to about 10.0, preferably from about 1 to about 5.

Owner:COUNCIL OF SCI & IND RES

Process for refining molten iron by directly using low-grade iron ores

InactiveCN101660017AReduce block making processReduce cooling effectFluidised-bed furnacesSmelting processLower grade

The invention provides a process for refining molten iron by directly using low-grade iron ores. The process comprises the following steps that: 1, low-grade iron ores are magnetically roasted in a fluidized bed reactor to obtain iron ores with stronger magnetism; 2, the fine ores obtained after roasting enter a hot magnetic separator to obtain hot iron ores with higher grade by hot magnetic separation; 3, the high-quality hot iron ores, which are obtained by magnetic separation, are added into a pre-reduction multi-stage fluidized bed to obtain pre-reduction iron ores with a higher reductiondegree, wherein the pre-reduction multi-stage fluidized bed is combined by a 2 to 4-stages circulating fluidize bed and a bubbling fluidized bed reactor, and after being reduced by the pre-reduction multi-stage fluidized bed, the metallization rate of the fine ores is over 60 percent; and 4, the pre-reduced iron ores are directly injected in a final reduction furnace or fusion gasification furnaceby a hot-pressed block for final reduction refining so as to obtain the molten iron. In the process, the refining process of the low-grade iron ores is completed by fully using energy in the technological process and the low-grade iron ores avoids repeated heating and cooling when being refined into the molten iron, so the energy consumption is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Treatment technology for biomass solid waste and hazardous waste

ActiveCN104990084AEasy to handleImprove carbon conversionIncinerator apparatusBubbling fluidized bedBurn out

The invention discloses the treatment technology for biomass solid waste and hazardous waste. Materials are sequentially subjected to pretreatment, loading, pyrolysis and gasification, and combustion and steam making, and the generated tail gas is subjected to the fuel gas treatment. The combustion temperature of a pyrolysis and gasification furnace is controlled at 700-900 DEG.C when the pyrolysis and gasification furnace treats the solid waste such as mushroom dregs, so that a problem that a static bed is liable to coke is avoided. The whole operation is performed in the reduction environment, NOx can be effectively prevented from generating, the disturbance of the materials in the whole bed is high, and the whole gas output and the factor of created gas are stable. Waste liquid and ash output by a pyrolysis and gasification bed can be fully combusted and burned out through the fuel gas output by the pyrolysis and gasification bed, so that carbon residue in the ash can be further reduced, and the waste liquid can be thoroughly eliminated. A bubbling fluidized bed combustion tower employs pyrolysis and gasification bed ash as the bed material, and the fluidization of the materials in the furnace can be promoted after the air enters the combustion tower.

Owner:山东知周环境科技有限公司

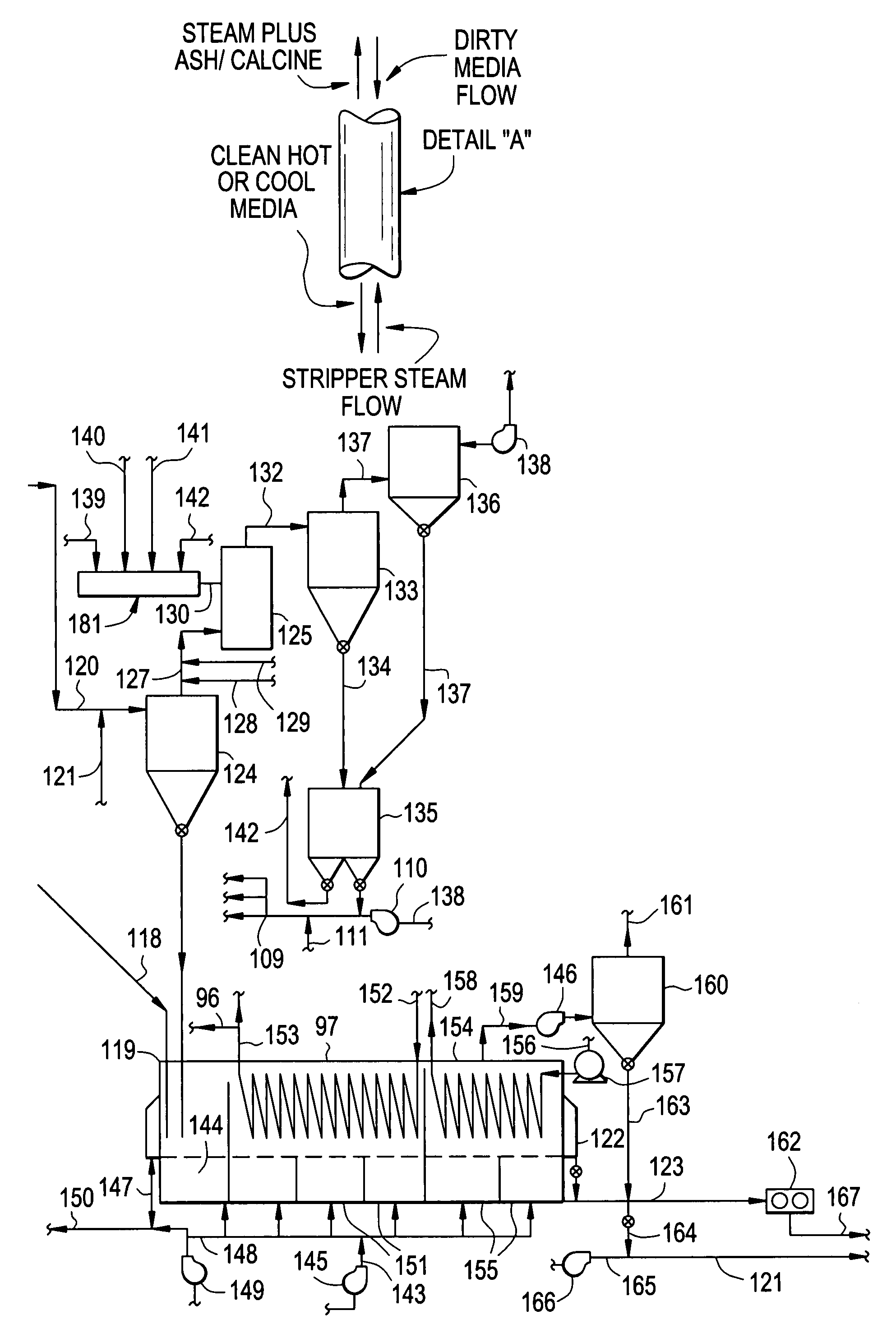

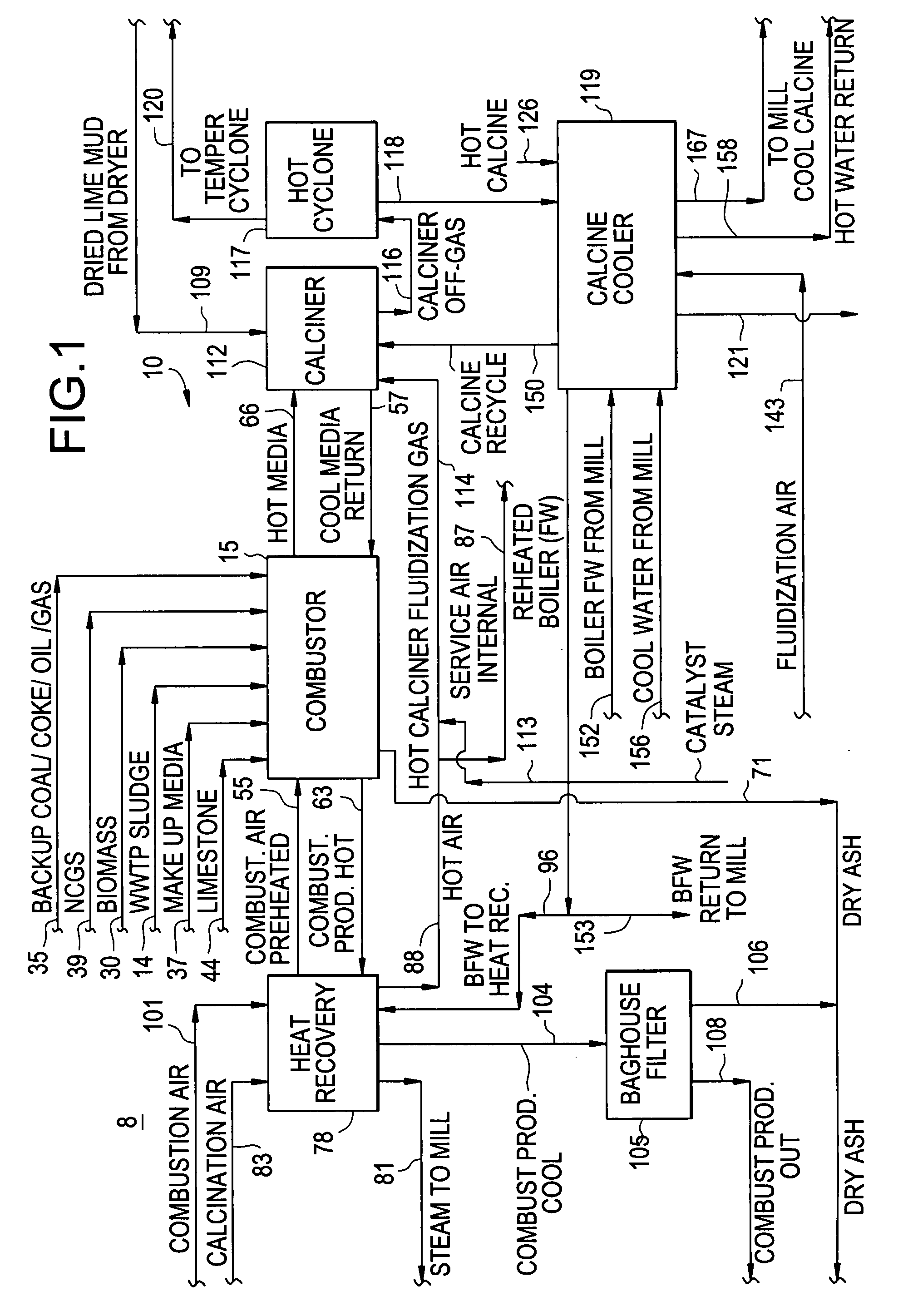

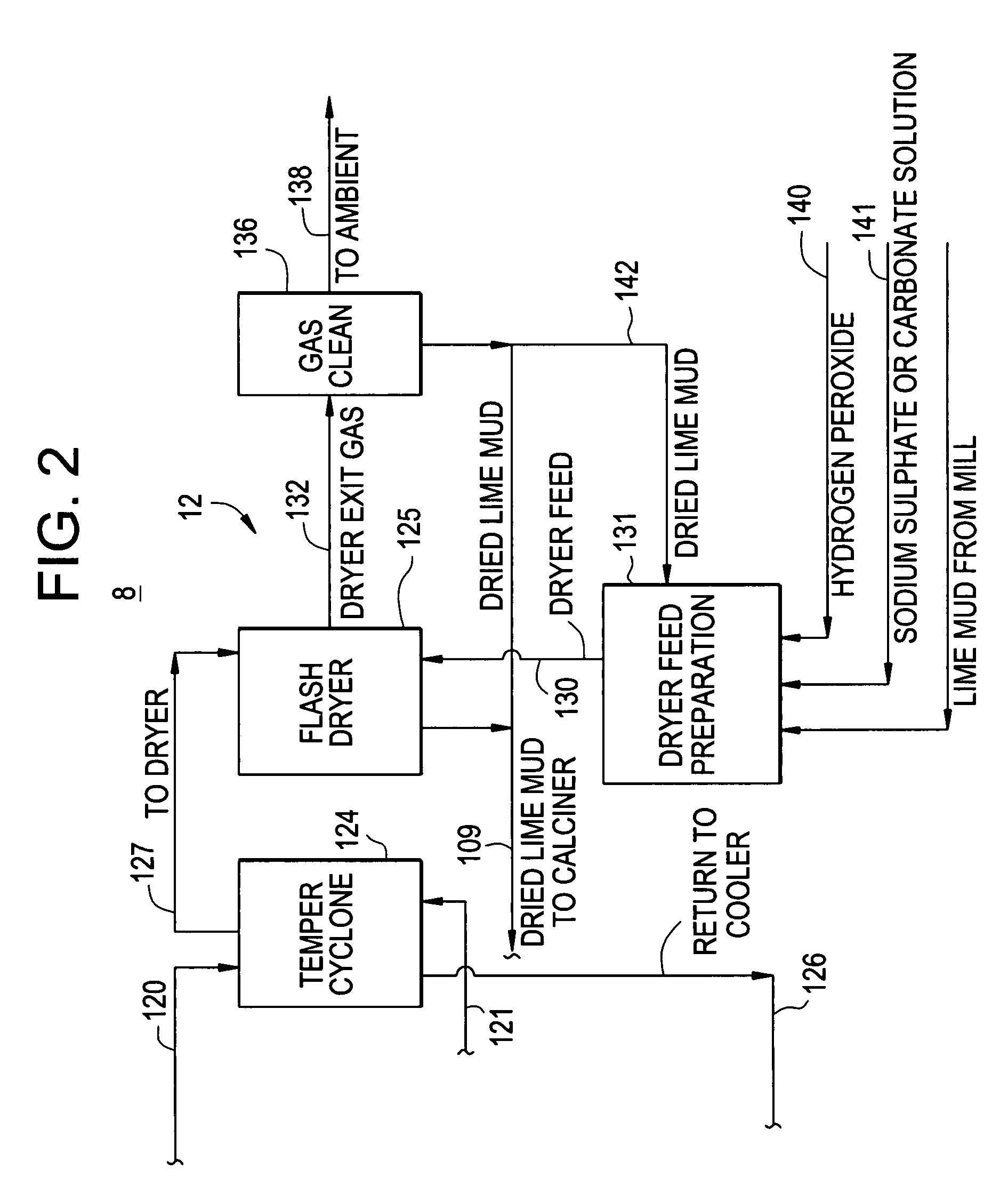

Process and system for calcination of high solids kraft paper pulp mill lime mud

InactiveUS20090114352A1High melting pointMitigate calciner scaling and fouling and unwanted gaseous emissionsCarbon compoundsDryer sectionSludgeSolid particle

The invention features methods and systems for calcining wet calcium carbonate lime mud produced in a re-causticizing manufacturing operation, for instance, Kraft pulp mill lime mud (“lime mud”) and converting it to re-burned lime by (a) feeding wet lime mud obtained from a re-causticizing manufacturing process into a flash dryer and then feeding the dried lime mud into a bubbling fluid bed calciner thermally linked by moving media heat transfer (MMHT) utilizing solid particulate media to a circulating fluid bed combustor wherein the MMHT provides heat input for calcination and drying; (b) recycling the media being from said calciner to said combustor wherein said combustor receives mill WWTP sludge, or precipitated lignins, or biomass, or NCGs as fuels to re-heat the solid particulate media; and (c) recovering calcined “soft-burned” lime mud from the fluid bed calciner. Steam and heated boiler feed-water are also generated and exported to the mill's steam distribution and generation system as well as hot process water for use in the mill's boiler house and manufacturing operation. The system for calcining calcium carbonate lime mud produced from a re-causticizing manufacturing operation and converting it to re-burned lime comprises a calciner and a combustor linked by a moving media heat transfer MMHT system or apparatus. The MMHT system or apparatus thermally links separate fluid bed combustion (exothermic) and calcination (endothermic) stages. The system further comprises a flash dryer or spray dryer that utilizes exhausted heat from the calcination stage.

Owner:ROSSI ROBERT A

Method for generating power by gasifying integrated straws in supercritical coal-fired generator set

InactiveCN102010757AEasy to storeSmall footprintInternal combustion piston enginesEnergy inputBiomass gasifierBubbling fluidized bed

The invention discloses a method for generating power by gasifying integrated straws in a supercritical coal-fired generator set. The method comprises the following steps of: packing and forming biomass straws serving as a gasification raw material of a gasifier of a bubbling fluidized bed, wherein primary wind-heat air surplus in a power station and tail gas fume of a boiler are used as gasifying agents. A biomass gasifier is effectively integrated by simply modifying the conventional supercritical unit to make biomass gasified, combusted and generate power, so that the defect that the biomass is directly blended and combusted is effectively overcome, the influence of biomass ash on fly ash is avoided, and the problem that the conventional auger feeding equipment is easy to damage is solved; therefore, biomass energy can be efficiently utilized and pollutant emission of coal-fired power stations is further reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

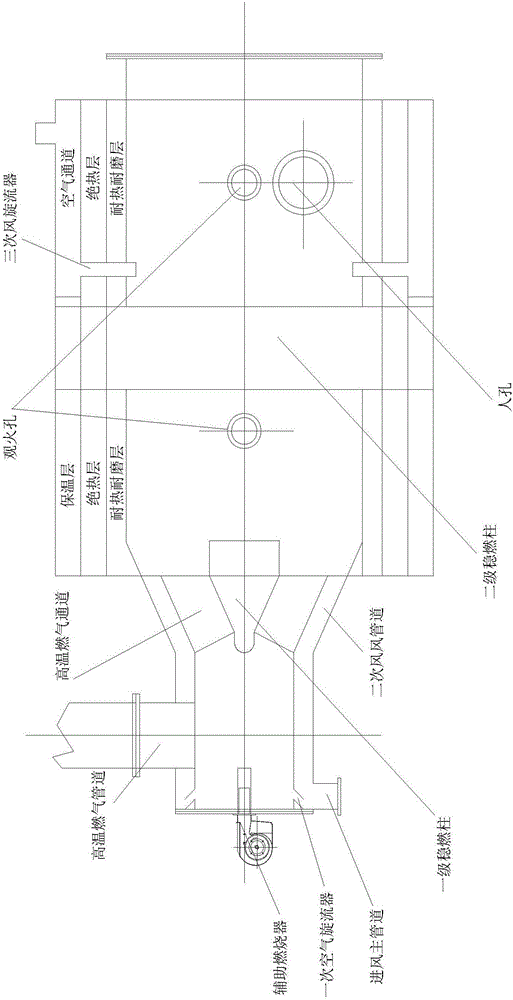

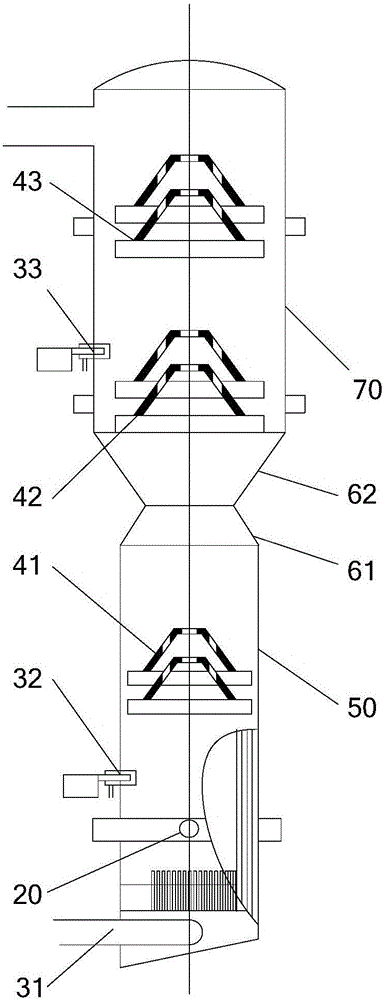

Chemical looping combustion device and method based on tower bubbling fluidized bed fuel reactor

ActiveCN106247323AImprove conversion efficiencyGuaranteed uptimeFluidized bed combustionIndirect carbon-dioxide mitigationCycloneOxidation state

The invention provides a chemical looping combustion device and method based on a tower bubbling fluidized bed fuel reactor. The device is a circulating loop composed of an air reactor, an air cyclone separator, a return feeder, the tower fuel reactor, a fuel cyclone separator and an isolator. The method includes the steps that fuel in the tower fuel reactor sequentially upward passes through small chambers divided by multiple independent air distribution partition boards in the height direction to be subjected to deep oxidation reaction with oxidation state oxygen carriers, the mixture is converted into CO2 and H2O to be discharged, reduction state oxygen carriers enter the air reactor through the fuel cyclone separator and the isolator for oxygen carrier regenerative reaction to generate oxidation state oxygen carriers, and the oxidation state oxygen carriers are separated through the air cyclone separator and then enter the fuel reactor through the return feeder; solid fuel is subjected to gasification reaction in the small chamber on the lower portion of the fuel reactor and then is subjected to oxidation reaction. By means of the device and method, the air-solid flow state in the fuel reactor can be effectively improved, and chemical looping combustion efficiency is improved.

Owner:SOUTHEAST UNIV

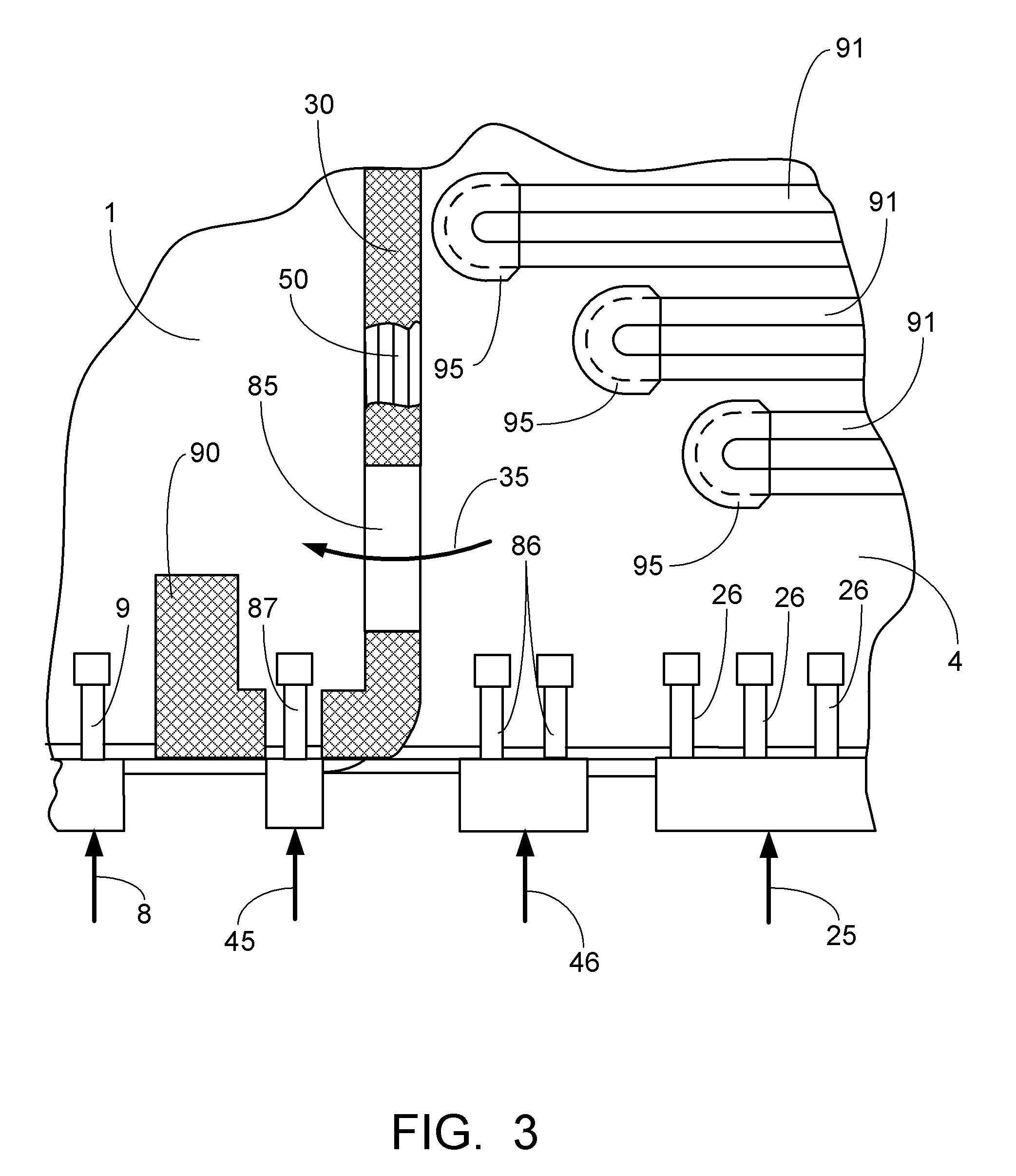

In-bed solids control valve

InactiveUS20110073049A1Easy to operateImprove reliabilityFluidized bed combustionIncinerator apparatusBubbling fluidized bedControl valves

A circulating fluidized bed (CFB) boiler comprising a reaction chamber. A bubbling fluidized bed (BFB) is contained within an enclosure within the lower portion of the reaction chamber and contains an in-bed heat exchanger (IBHX) that occupies part of the reaction chamber floor. At least one non-mechanical valve, which includes an opening between the CFB and BFB and independently controlled fluidizing means located both upstream and downstream of the opening, is used to control the heat transfer to the IBHX by controlling the solids discharge from the BFB to the CFB. The elevation of the bottom of the opening is at or above the elevation of the fluidizing means. A flow control barrier may be located downstream of the opening.

Owner:THE BABCOCK & WILCOX CO

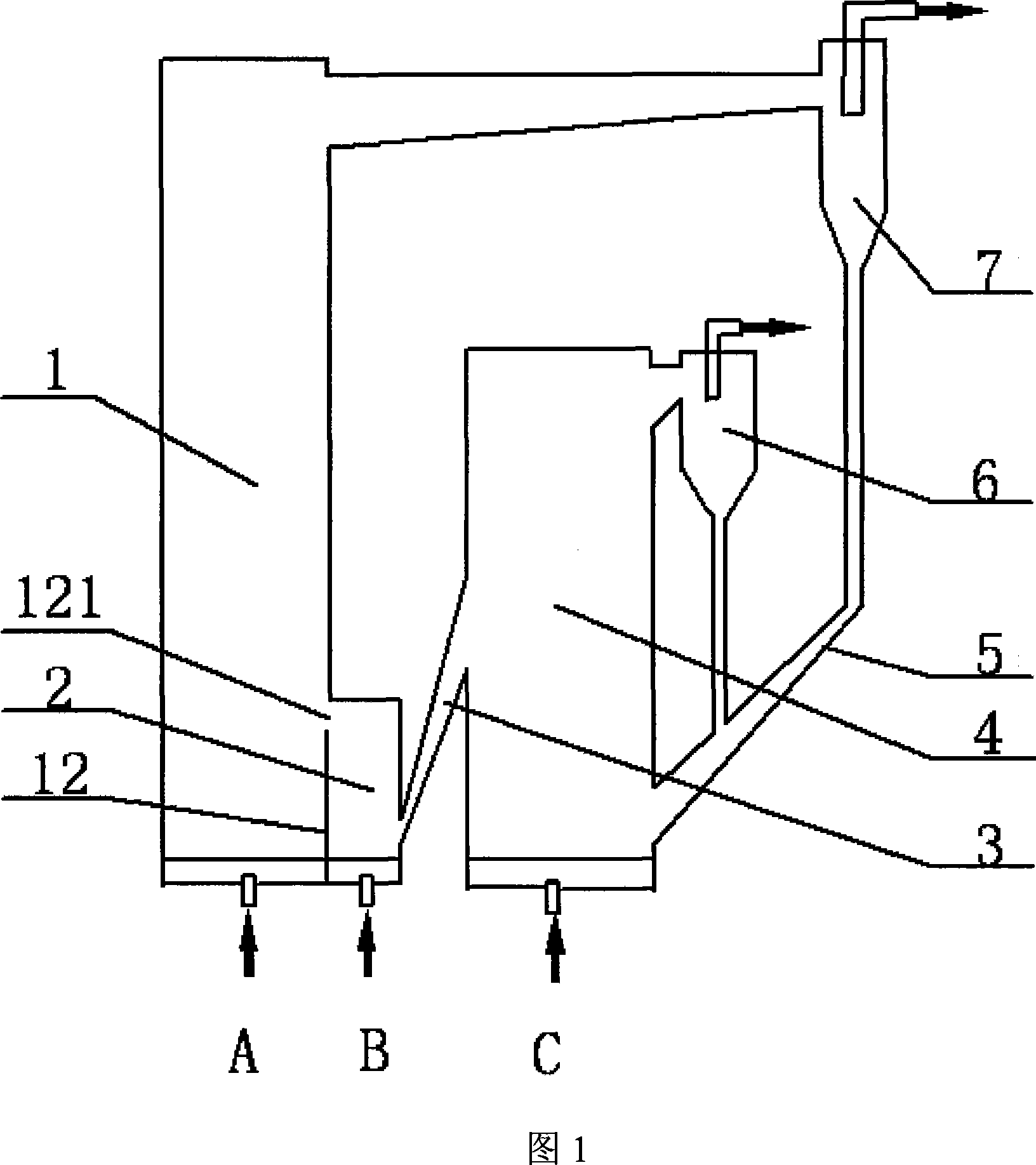

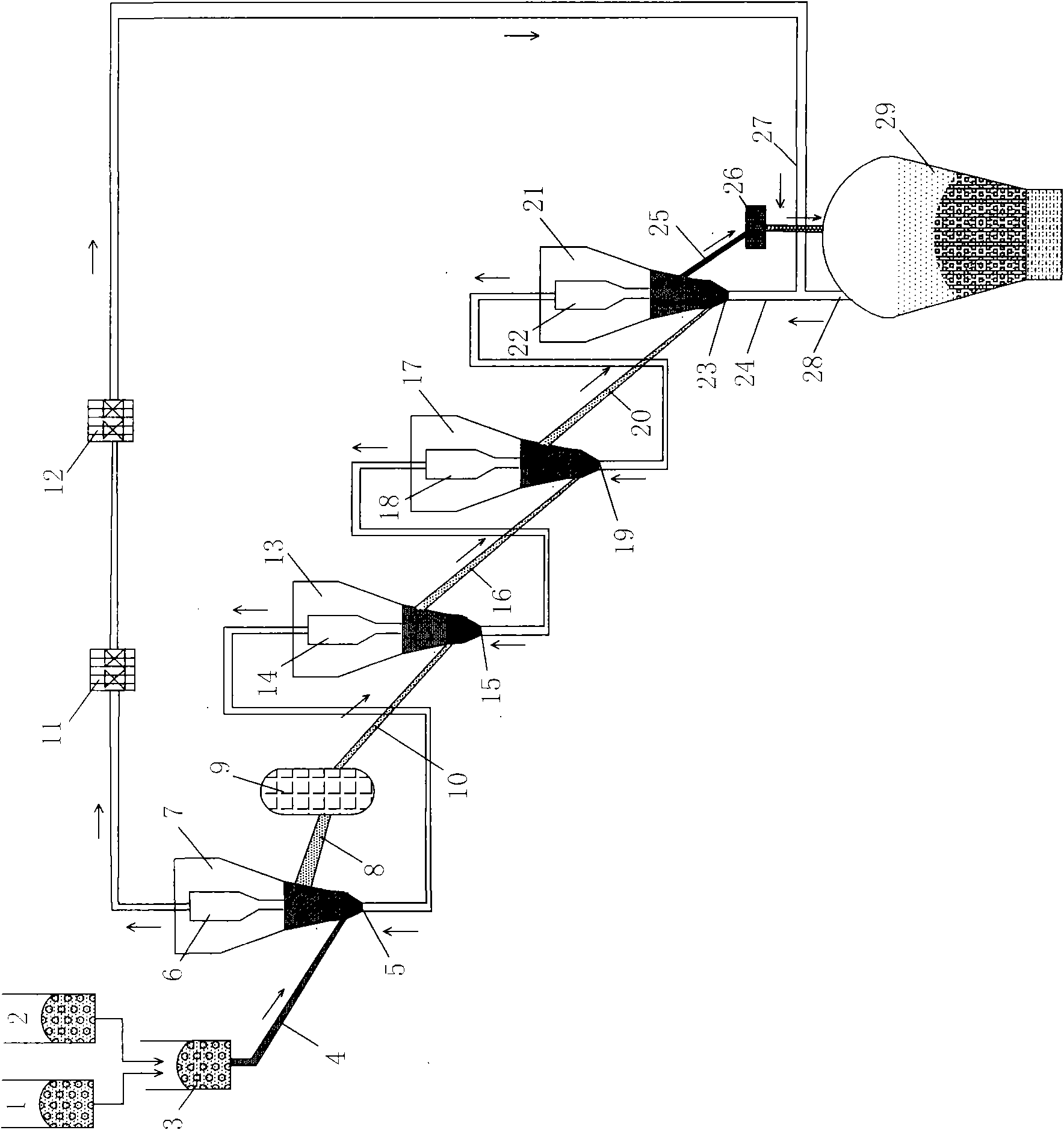

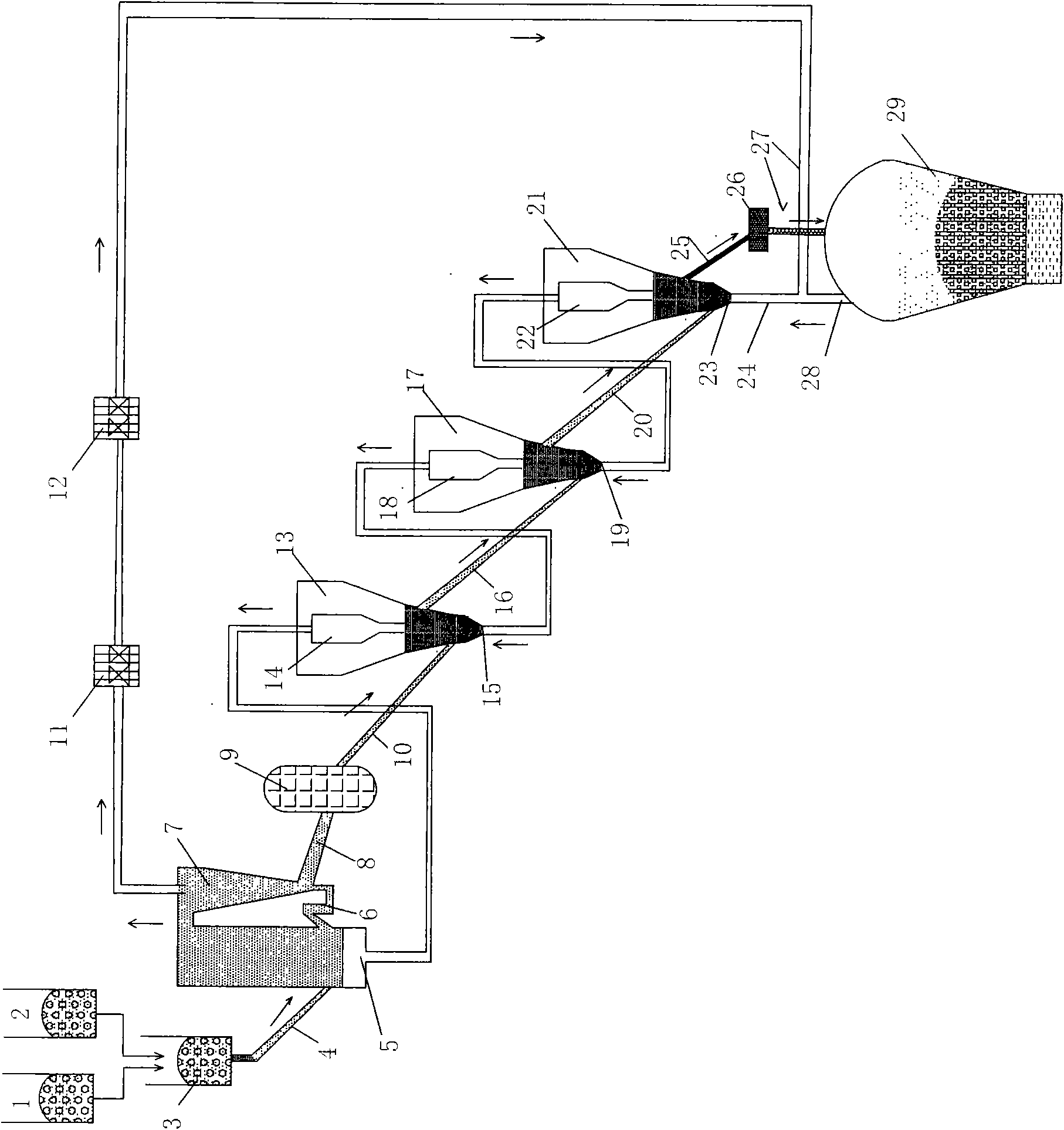

Coal fired serial fluidized bed indirect burning device and method

InactiveCN1493814AIndirect combustion achievedExtensive social benefitsFluidized bed combustionApparatus for fluidised bed combustionCycloneCombustion

An indirect combustion apparatus with serially connected fluidized beds for burning coal is composed of circulating fluidized-bed air reactor, bubbling fluidized-bed fuel reactor, moving fluidized-bed gas isolator, and cyclone separator, all of which are serially connected. Its combustion method includes mixing powdered coal with water, delivering the mixture to the water-coal slurry gasifying reactor, feeding the resultant gas in bubbling fluidized-bed fuel reactor and moving fluidized-bed gas isolator, oxidizing reaction between air and metal in said circulating fluidized-bed air reactor and separating by cyclone separator to obtain metallic oxide, reaction between said metallic oxide and said resultant gas in the bubbling fluidized-bed fuel reactor to reduce it into metal, returning back to said air reactor for regenerating metallic oxide, and reacting with water-coal slurry in fuel reactor to generate Co2 and H2O.

Owner:SOUTHEAST UNIV

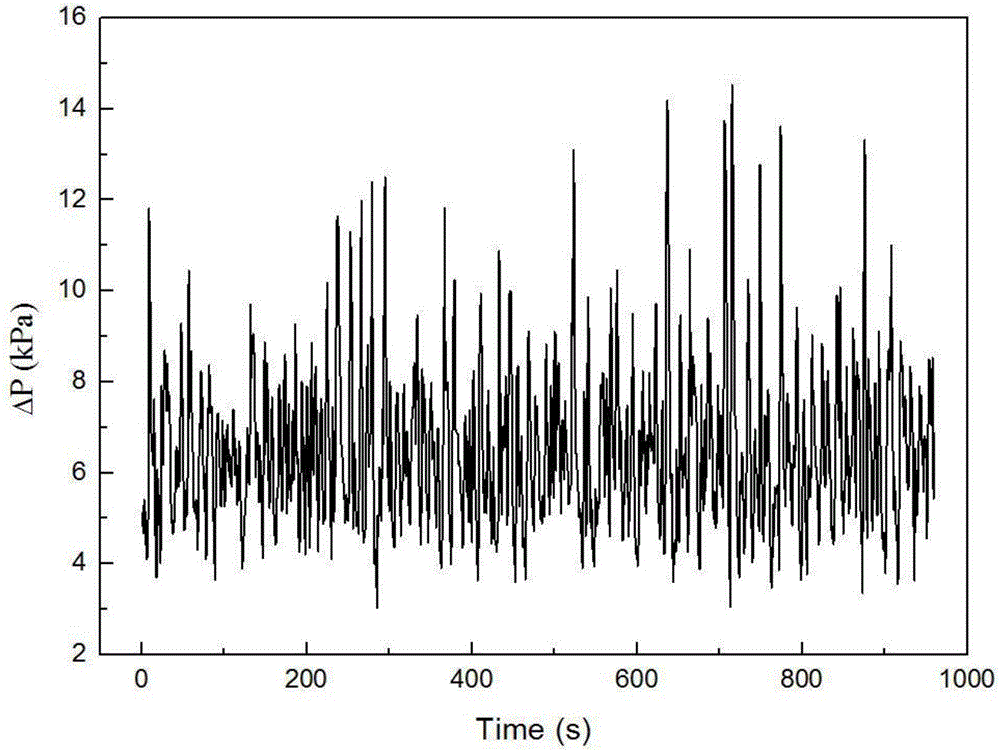

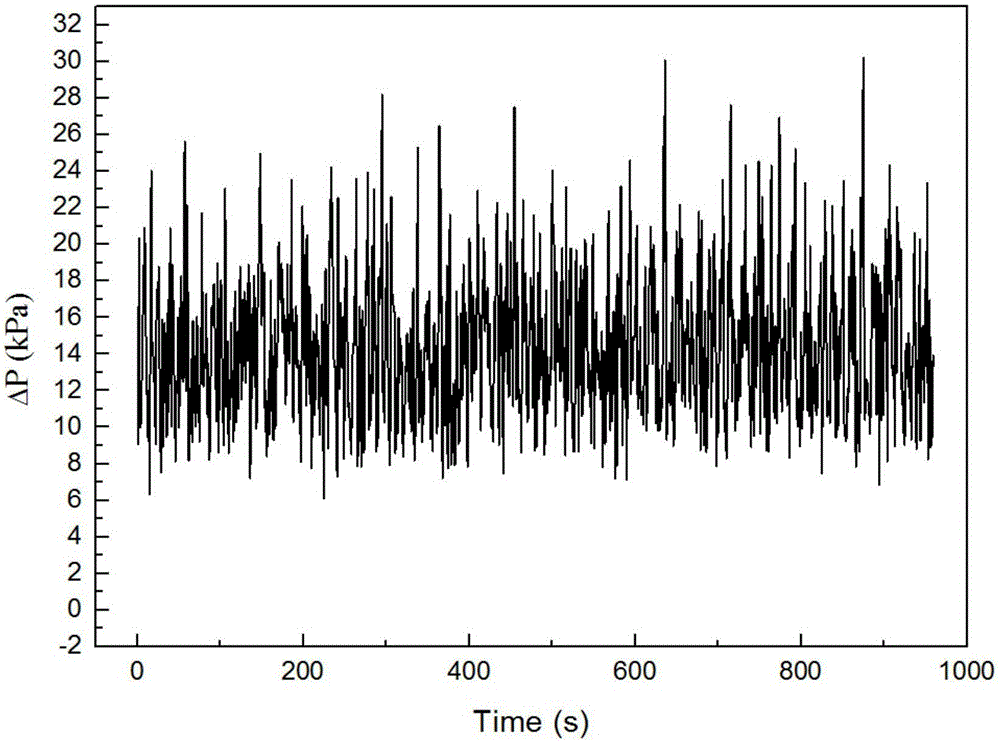

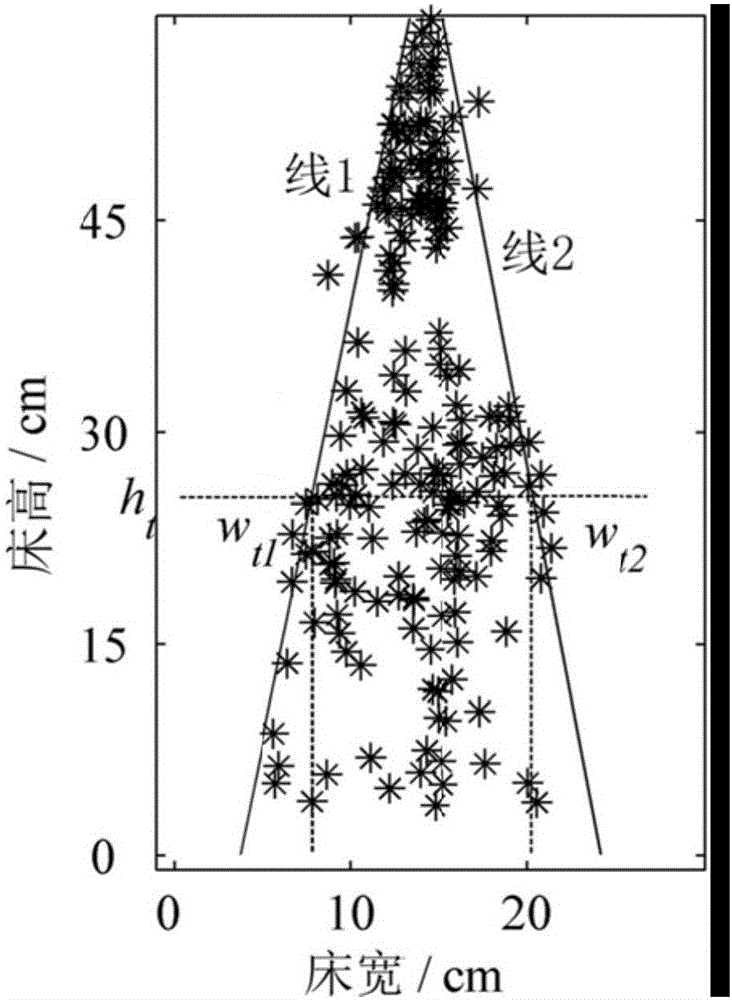

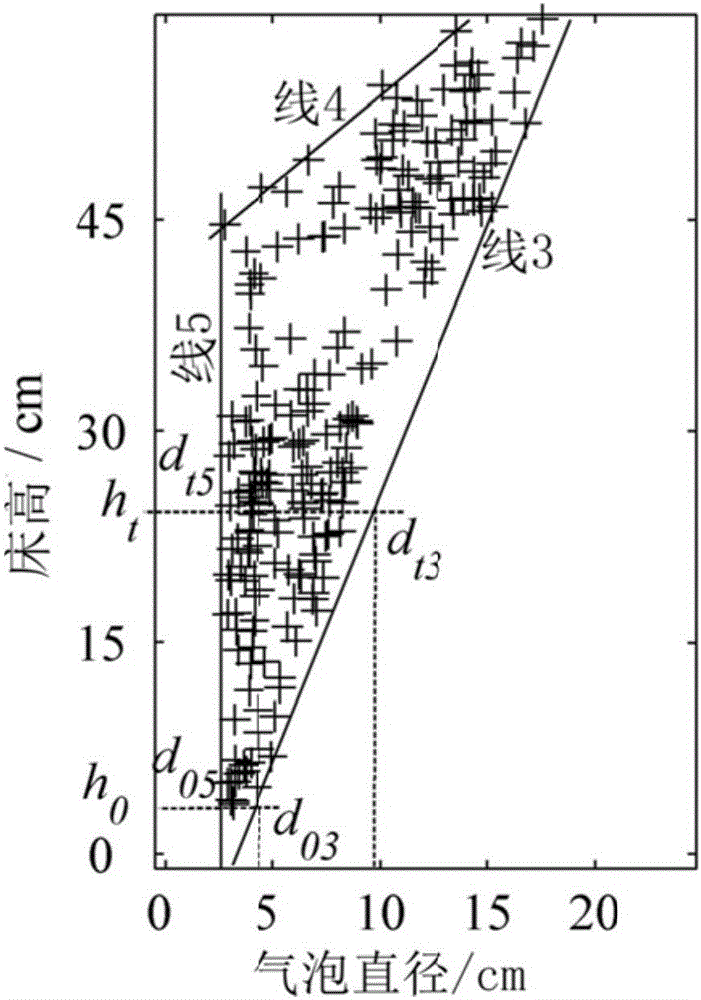

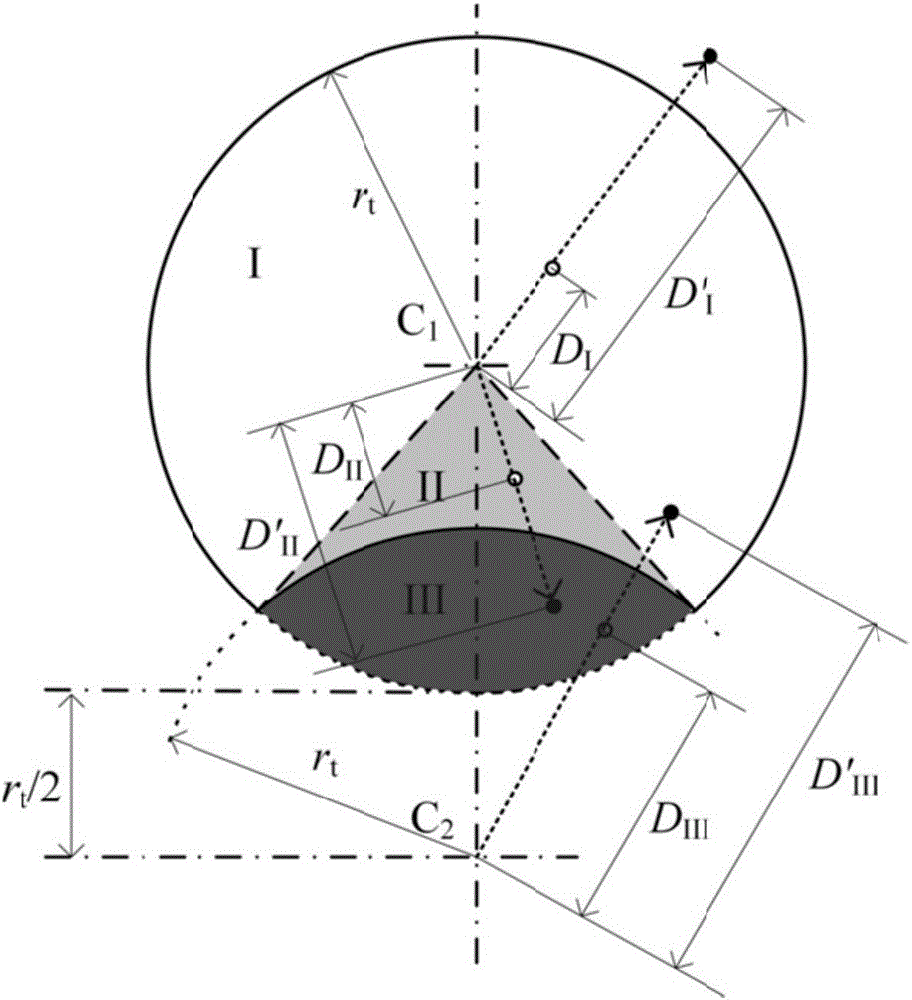

Modelling method for bubbling fluidized bed based on random motion of bubbles and particles

InactiveCN106021638AGuaranteed calculation accuracyAvoid mechanical propertiesSpecial data processing applicationsMarkov chainModel method

The invention discloses a modelling method for a bubbling fluidized bed based on random motion of bubbles and particles. The method comprises the steps that (1) statistics for particle motion rules of the bubbling fluidized bed computed by CFD-DEM is carried out, and a Markov chain random model of a particle phase is established; (2) image identification is carried out to an instant distribution map of the bubbling fluidized bed particles computed by the CFD-DEM, statistics is carried out to rules for generation, motion and growth of the bubbles, and a bubble random development model is established; and (3) a baseball cap model of bubble shapes is used to couple the particle-phase Markov course with the bubble random model, and a random model of the particle motion of the bubbling fluidized bed is established. The method disclosed by the invention has the advantages that the defect that a single particle-phase Markov course cannot reflect bubble information and influences of the information on the particle motion can be solved; and computation loads are greatly reduced, and a computation speed is increased on the premise of guarantee of accuracy of the bubbling fluidized bed particle motion.

Owner:SOUTHEAST UNIV

Device and method for preparing oxygen by virtue of chemical looping air separation

InactiveCN103864021ASimple structureSimple and fast operationEnergy inputOxygen preparationCycloneSeparation technology

The invention discloses a device and a method for preparing oxygen by virtue of chemical looping air separation. The device comprises a bubbling fluidized bed reactor, a distribution plate, a first air distribution plate, a first cyclone separator, a fast fluidized bed reactor, a second cyclone separator, a returning mechanism, a second air distribution plate, a condenser, a waste heat boiler, an oxygen purifier and a gas bottle, all of which are connected together. The device and the method are used for preparing oxygen by virtue of the principle of the chemical looping air separation technology, and have the advantages of high efficiency, low energy consumption, simple operation and high produced oxygen purity.

Owner:NANJING UNIV OF SCI & TECH

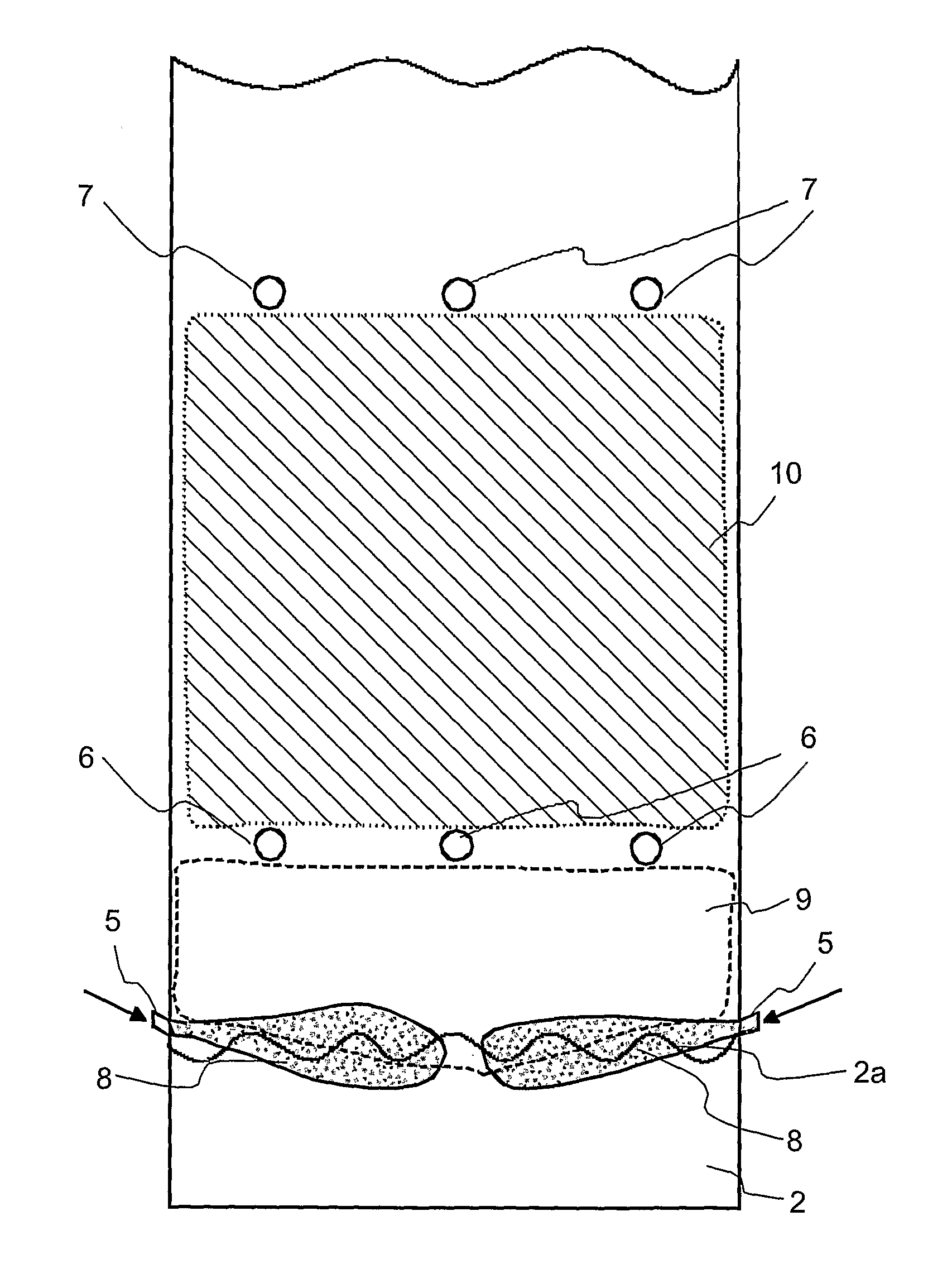

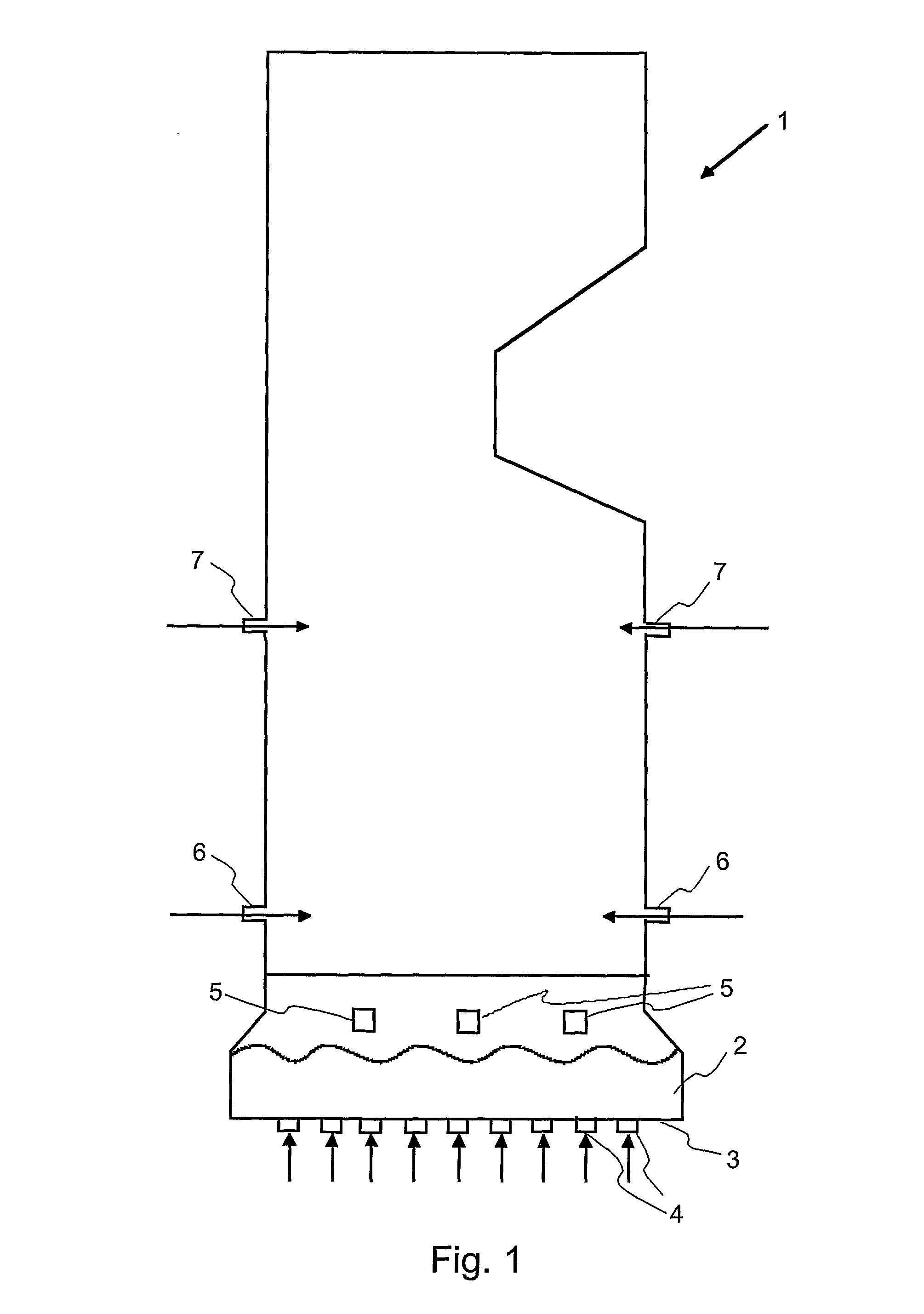

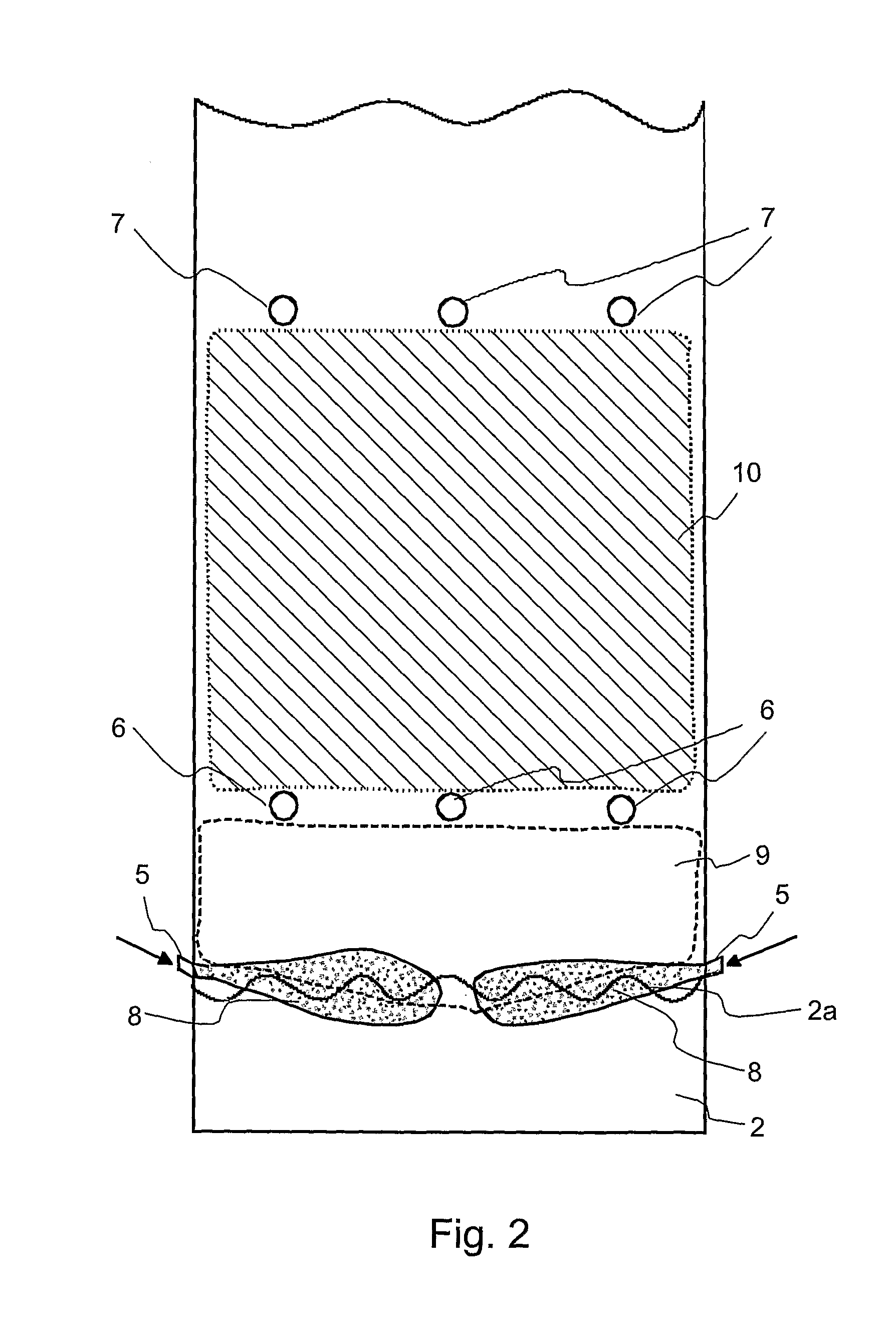

Method For Reducing Nitrogen Oxide Emissions of a Bubbling Fluidized Bed Boiler and an Air Distribution System of a Bubbling Fluidized Bed Boiler

InactiveUS20080149012A1Reduce nitrogen oxide emissionsMaximizes creationFluidized bed combustionStaged combustionFluidized bed dryingBiofuel

A method for reducing nitrogen oxide emissions of a bubbling fluidized bed boiler burning biofuel and an air distribution system for a bubbling fluidized bed boiler biofuel. A fluidized bed is arranged in a lower part of a furnace of the boiler. The bed is fluidized by fluidizing gas that includes primary air. Fuel is fed to the fluidized bed, which dries and pyrolizes into pyrolysis gas including volatile matter of the fuel. The gas rises upwards in the furnace and burns. Secondary air is supplied above the fluidized bed from secondary air nozzles, and tertiary air is supplied above the secondary air nozzles. A part of primary air is supplied in connection with fuel feeding such that the fuel is forced substantially on the surface of the fluidized bed, thus pyrolizing entirely, and at least a part of the pyrolysis gases formed in the pyrolysis is burned by primary air such that the air coefficient in relation to the volatile matter of fuel in the pyrolysis gases is in the substoichiometric area.

Owner:METSO POWER OY

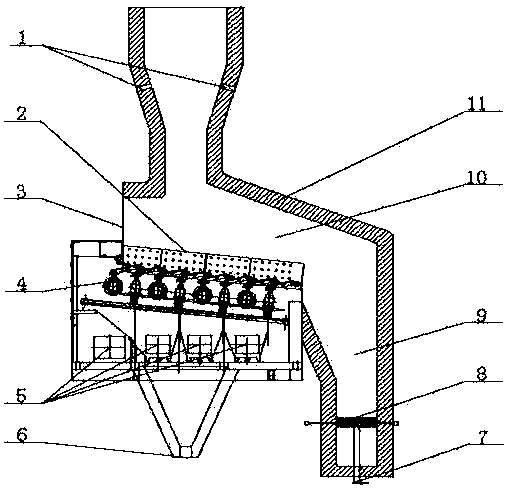

Apparatus and method of optimized acid gas and toxic metal control in gasifier produced gases

ActiveUS20110277639A1Maximize uptakeLess-effective utilization of sorbent-aIsotope separationSolid fuel combustionRefuse-derived fuelSorbent

An apparatus and method is presented for removing acid gases and other trace contaminants to very low levels in combustible gases generated from thermal gasification of biomass or refuse-derived fuels. The invention includes optimization of geometric variables, temperature and pressure set points via use of a pressurized bubbling fluidized bed reactor to convert granular raw (non-activated) sorbents and auto-generated biochar sorbents) into activated, highly dispersed, and ideally sized particles for removing acid gases and toxic metals. The system can incorporate a generated gas cooler, a gas-sorbent contact chamber or zone, and a novel filter (with or without additional gas cooling and residence time stages).

Owner:FRONTLINE BIOENERGY

Composite type solid-waste gasifying device

InactiveCN103468321AImprove fluidizationRapid fluidizationGranular/pulverulent flues gasificationSlagEngineering

The invention discloses a composite type solid-waste gasifying device. The composite type solid-waste gasifying device is characterized in that a reciprocating grate and a bubbling fluidized-bed reactor structure are combined, waste is firstly dried, pyrolyzed and gasified on the front-section reciprocating grate, and the rear-section fluidized bed device is used for pyrolysis of residual waste and suspended combustion of gasified slag. The reciprocating grate adopts a plurality of sections of high-temperature air distribution to dry, pyrolyze and gasify the waste so as to provide partial heat, and a long rear arch maintains high temperature under high-temperature flue gas, and is used for increasing radiant heat on the grate and providing energy for pyrolyzing and gasifying the waste with low calorific value. The high-temperature flue gas generated by combustion of a fluidized bed maintains high-temperature environment of the wall surface of the rear arch of the grate, and the slag is discharged by a slag discharging hole at the middle part of an air distributing plate of the fluidized bed. The composite type solid-waste gasifying device disclosed by the invention has the beneficial effects that the advantages of the traditional grate and the traditional fluidized-bed reactor are integrated; due to the radiation of a long high-temperature rear arch, the content of tar in gasified gas can be effectively reduced; full burning out of bottom slag is realized by the fluidized bed, so that high-efficiency gasification of low-grade waste is realized.

Owner:ZHEJIANG UNIV

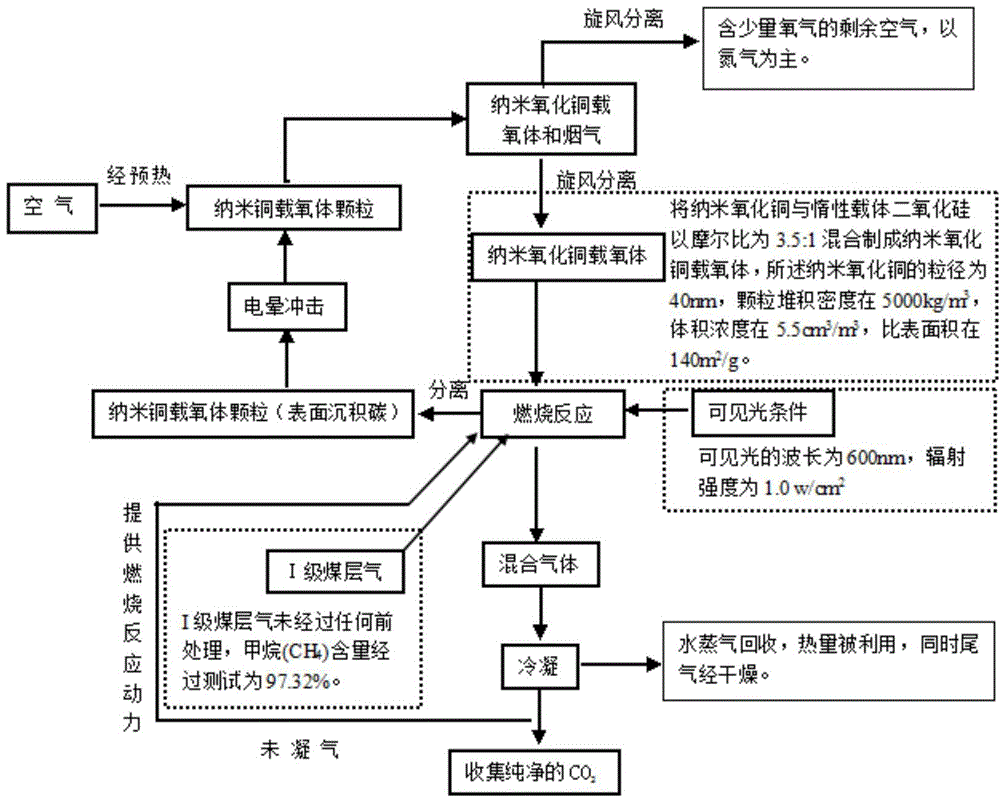

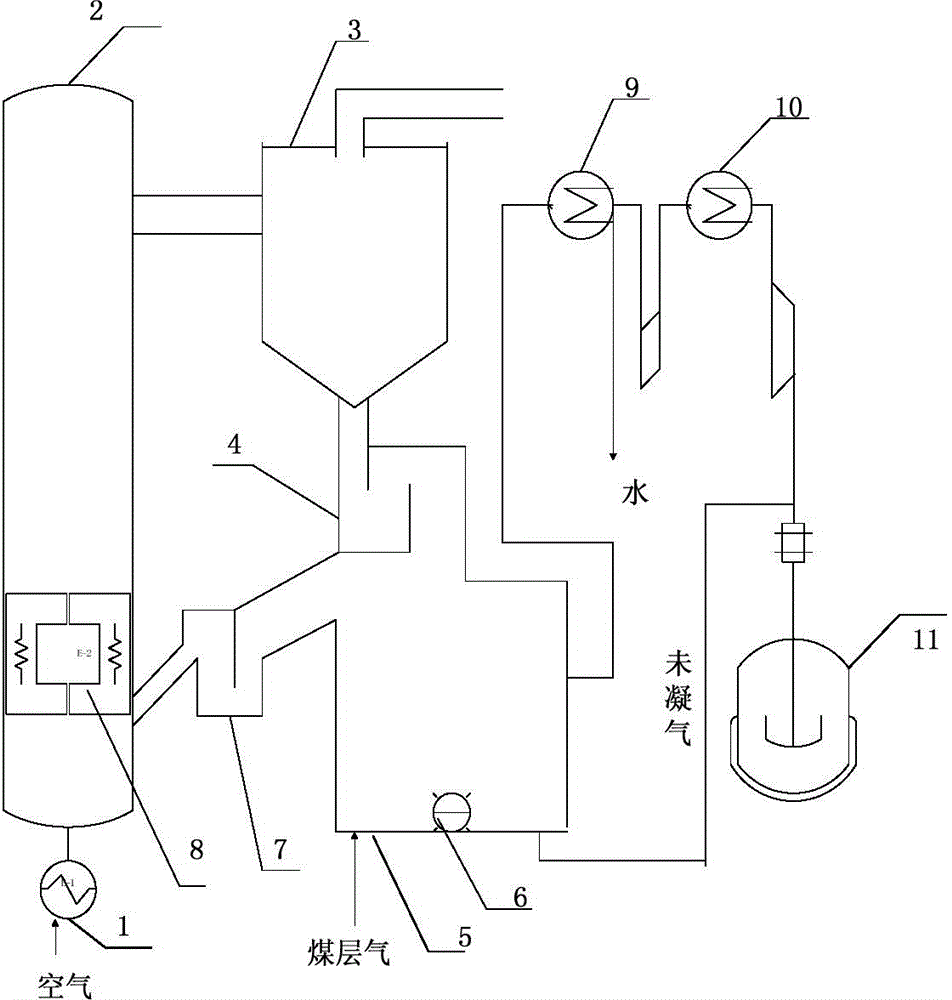

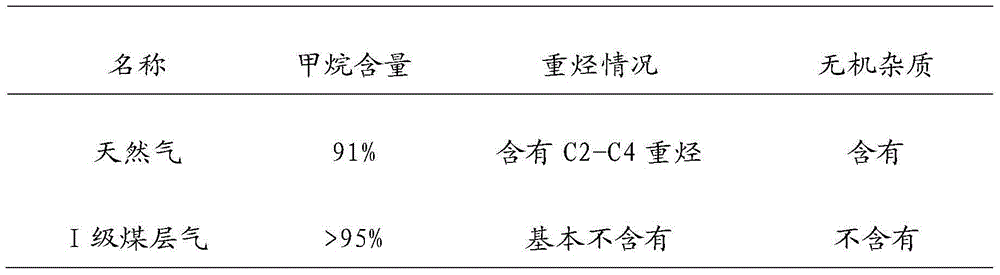

Chemical chain combustion method for coalbed methane, and interconnected fluidized bed system

ActiveCN104456544AImprove catalytic performancePromote degradationFluidized bed combustionIndirect carbon-dioxide mitigationCombustionFlue gas

The invention provides a chemical chain combustion method for coalbed methane and an interconnected fluidized bed system. The method comprises the following steps: carrying out oxidization reaction on preheated air and a nanocopper oxygen carrier to generate nano CuO oxygen carrier particles and flue gas; then carrying out combustion reaction on nano CuO oxygen carrier particles and coalbed methane under lighting to generate a mixed gas and a nanocopper oxygen carrier; enabling the nanocopper oxygen carrier to repeat the steps; condensing and collecting the mixed gas, wherein the nanocopper oxygen carrier is formed by mixing nano CuO and inert carriers according to the ratio of (1.5-3.5) to 1, and the particle size of the nano CuO is 20-40nm. The system comprises an air heating device, a high-speed lifting fluidized bed, a cyclone separator, a first overflowing device, a bubbling fluidized bed, a heat recovery device and a CO2 collector which are sequentially connected, and an illumination device is arranged in the bubbling fluidized bed. The circulating times of the oxygen carrier can be increased by 23%, and the oxidization rate of surface deposits on the oxygen carrier is increased to 44.23%-75.11%.

Owner:INNER MONGOLIA UNIVERSITY

In-bed solids control valve with improved reliability

InactiveUS20140102342A1Reduce and stop flowLower levelFuel supply regulationFluidized bed combustionBubbling fluidized bedControl valves

A non-mechanical valve arrangement for use with circulating fluidized bed (CFB) boilers has a CFB reaction chamber and a bubbling fluidized bed (BFB) within an enclosure in the lower portion of the CFB reaction chamber, the BFB containing an in-bed heat exchanger (IBHX). Solids flowing from the BFB enclosure to the CFB reaction chamber may be controlled using one or more non-mechanical valves. Each non-mechanical valve is independently controlled using independently controlled fluidizing means. The non-mechanical valve has collectors to collect solids backsifting into the fluidizing means of the valve. Agglomerates are removed which could block the valve. Channel walls parallel to the direction of solids flow through the valve opening may be provided to reduce external interference with local fluidization to maintain the proper functionality of the non-mechanical valve.

Owner:THE BABCOCK & WILCOX CO

Fluidization-suspension combined combustion boiler

ActiveCN101280920ACost savingsSave running costsFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberHazardous substance

The present invention provides a liquefaction-suspension combined combustion boiler comprising a vertical combustion chamber arranged in routine boiler, the combustion chamber has a bubble fluidized-bed combustion section equipped with a feeder, fluidized bed slag discharge opening on bottom; the combustion chamber has a low-temperature reducing property main combustion section on lower portion and a high temperature oxidation combustion section on upper portion. The main combustion section on lower part of the combustion chamber comprises a primary air nozzle and auxiliary air ejector nozzle arranged on walls on opposite sides of the combustion chamber for mixture of primary air-fuel entering into the combustion chamber. The high temperature oxidation combustion section on upper portion of the combustion chamber has at least one layer of secondary air nozzle arranged above the primary air nozzle. The primary air-fuel mixture nozzle and the oppositely arranged auxiliary air ejector nozzle form a strong rotation-circulation flow field at lower part of the combustion chamber, which implements combustion of majority of fuel in main low-temperature and reducing property combustion section, uncombusted particle and fuel gas are combusted on upper portion of the combustion chamber. The invention has advantages of high combustion efficiency, low harmful substance discharge, simple structure, safe and reliable operation.

Owner:EASTERN BOILER CONTROL CO LTD

Process for preparing sulfur dioxide by roasting troilite in circulating fluidized bed

InactiveCN1884049AImprove temperature uniformityHigh concentration of sulfur dioxideSulfur compoundsTroiliteBubbling fluidized bed

The invention discloses a preparing method of sulfur dioxide to sinter troilite through circulated bed in the chemical raw material preparing technological domain, which is characterized by the following: adopting ferric oxide with 40-50 um even particle diameter as bed material; making inner bed material lie rapid fluidization condition through adjusting fluidization wind quantity; heating bed material at 845-855 deg.c; improving evenness of inner bed temperature and composite gas-solid as well as one-set product; guaranteeing enough reacting time for fine particle separated from circulated fluidization bend reactor; allocating separating system and return system; separating fine particle from gas; sending the separated material to reactor continuously.

Owner:铜陵有色金属集团控股有限公司铜冠冶化分公司

Method and device for zero emission of CO2 from burning coal

The invention provides a method for zero emission of CO2 from burning coal. The method comprises the following steps: MFe2O4 (M stands for any of Cu, Ni, Mn and Co) oxygen carrier is decomposed to generate oxygen deficient ferrite MFe2O4-delta (delta is more than or equal to 0 and is less than or equal to 2) and O2, the oxygen deficient ferrite and coal gasified products carry out reduction reaction to generate CO2, H2O and noncondensable gas, wherein the noncondensable gas and the O2 which is obtained by decomposition carry out oxidation reaction to generate CO2 and steam; and the generated CO2 and steam and the reduced oxygen deficient ferrite carry out reduction reaction to generate synthetic gas consisting of CO and hydrogen, thus realizing zero emission of CO2. The invention also provides a device for realizing the method, and main components of the device are a rapid fluidized bed, a two-section spouted-fluidized bed and a bubbling fluidized bed. The method and the device realize efficient and clean use of the burning coal and true zero emission of CO2, avoid energy and cost consumption of long-distance transmission of CO2 and have wide application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

Apparatus for preparing synthetic gas with adjustable H2/CO proportion by methane-rich gas and method thereof

InactiveCN104401938AAvoid secondary adjustmentsFacilitate the subsequent synthesis processNitrogen purification/separationCarbon compoundsCycloneSyngas

The invention discloses an apparatus for preparing synthetic gas with adjustable H2 / CO proportion by methane-rich gas and a method thereof. The apparatus comprises a fuel reactor, an air reactor, a first cyclone separator, a second cyclone separator, a material returning valve 1, a material returning valve 2 and a material returning valve 3; a bubbling fluidized bed is arranged at bottom of the fuel reactor, a lifting pipe is arranged at upper part of the fuel reactor; the bubbling fluidized bed is connected to the air reactor through the material returning valve 1, the upper part of the air reactor is connected to the first cyclone separator, a blanking tube of the first cyclone separator is connected to the lifting pipe through the material turning valve 2, the upper part of the lifting pipe is connected to the second cyclone separator, and the blanking tube of the second cyclone separator is connected to the lower part of the bubbling fluidized bed through the material turning valve 3. By adjusting the circulation volume of oxygen carrier and stay time in the bubbling fluidized bed, the reduction depth of the oxygen carrier in the bubbling fluidized bed can be controlled, proportion of H2 / CO at a synthetic gas outlet can be adjusted, subsequent synthesis technology is convenient, CO2 can be instantly separated and captured, and separating step can be avoided.

Owner:SOUTHEAST UNIV

Flying ash processing device of fluidized bed incinerator

ActiveCN102901106AEfficient captureEffective sensible heatIncinerator apparatusResource utilizationEngineering

The invention relates to a flying ash processing device of a fluidized bed incinerator. The flying ash processing device comprise a cyclone separator, a flying ash conveying system, a bubble fluidized bed device and a moving bed ash cooler; the cyclone separator is arranged between the fluidized bed incinerator and a tail part flue and is communicated with the bubble fluidized bed device through the flying ash conveying system at the same time; the moving bed ash cooler is communicated with the bubble fluidized bed device; a buried tube heat exchanger is further arranged inside the moving bed ash cooler; the input end of the buried tube heat exchanger is connected with a water feeding pump of the fluidized bed incinerator; and the output end of the buried tube heat exchanger is connected with a coal economizer of the fluidized bed incinerator. With the adoption of the flying ash processing device, the flying ash is effectively captured before the pollutants are accumulated to the surface of the flying ash, and the sensible heat of the flying ash is effectively absorbed, so that the discharge quantity and the processing cost of the flying ash are greatly reduced, the accumulated ash, the abrasion and the corrosion to the heated plane at the tail part of the fluidized bed incinerator are reduced, the resource utilization of the flying ash is realized, the defects that a traditional method is large in capacity-increase and high cost are made up, the sensible heat of the flying ash is effectively used, and the heat economy of the system is improved.

Owner:WUXI GUOLIAN ENVIRONMENTAL SCI & TECH

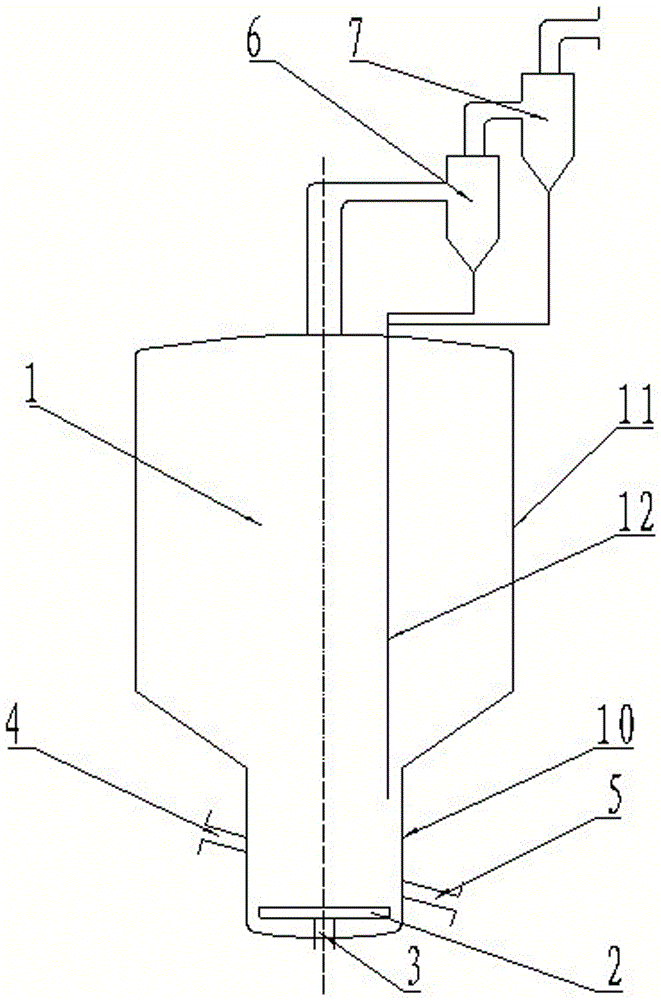

Industrial slag salt bubbling fluidized bed incineration harmless treatment device and method

InactiveCN106196097AHigh purityConducive to subsequent secondary useIncinerator apparatusCycloneSlag

The invention provides an industrial slag salt bubbling fluidized bed incineration harmless treatment device. The device can be used for conducting batched harmless treatment on industrial slag salt, the purity of obtained salt particles is high, and the treatment technology is simple. The device comprises a vertically-arranged incinerator. The lower portion of the incinerator is provided with a dense-phase incineration area, and the upper portion of the incinerator is provided with a dilute-phase incineration area. The diameter of the dense-phase incineration area is smaller than that of the dilute-phase incineration area. A distribution plate is arranged at the bottom of the dense-phase incineration area, and an air inlet pipeline is connected to the distribution plate. One side of the dense-phase incineration area above the distribution plate is connected with a feeding pipe, and the other side of the dense-phase incineration area above the distribution plate is connected with a discharging pipe. An inlet of the feeding pipe is arranged above an inlet of the discharging pipe. The top of the incinerator is in pipeline connection with a single-pipe cyclone separator A which is in pipeline connection with a single-pipe cyclone separator B.

Owner:安徽今朝环保科技有限公司

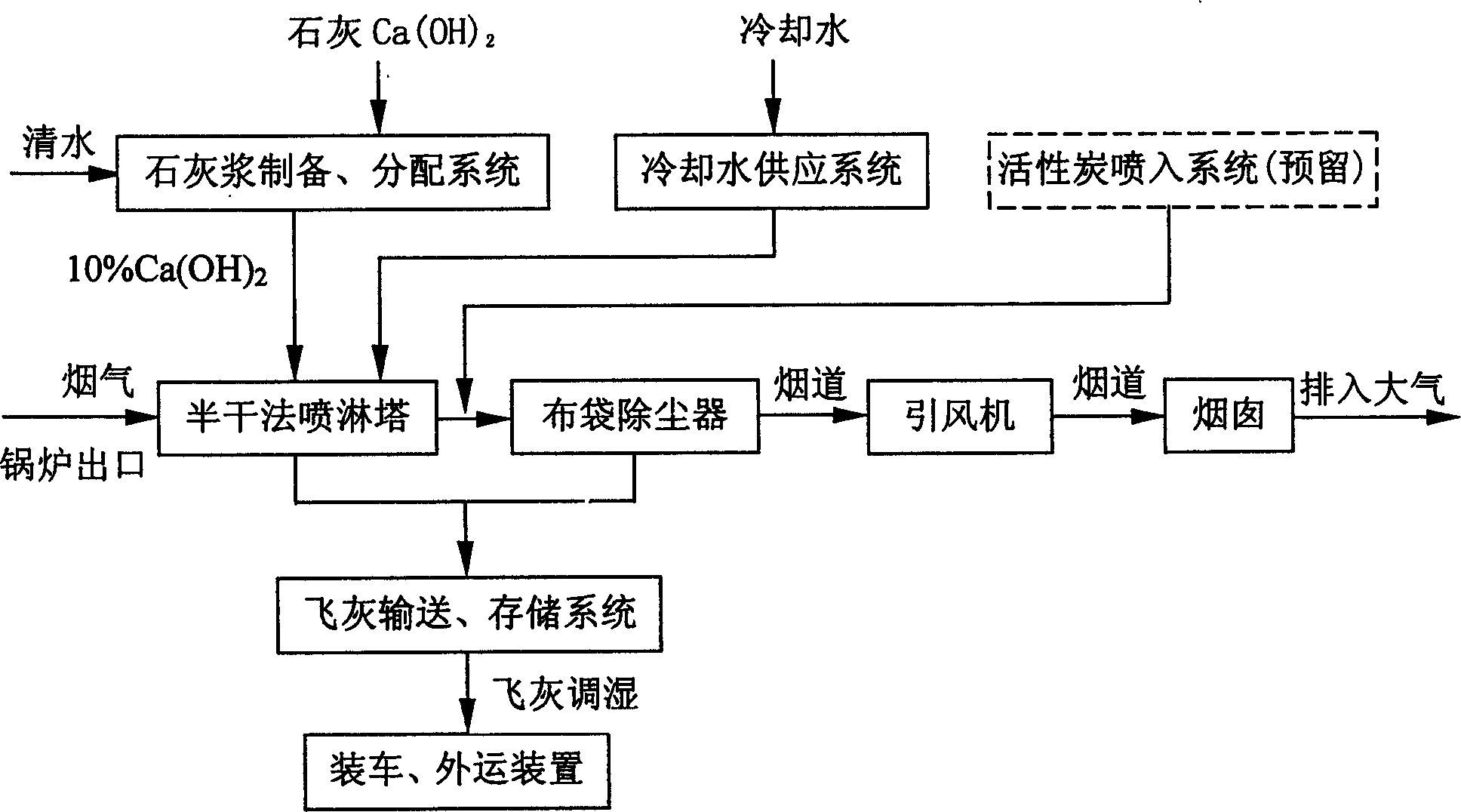

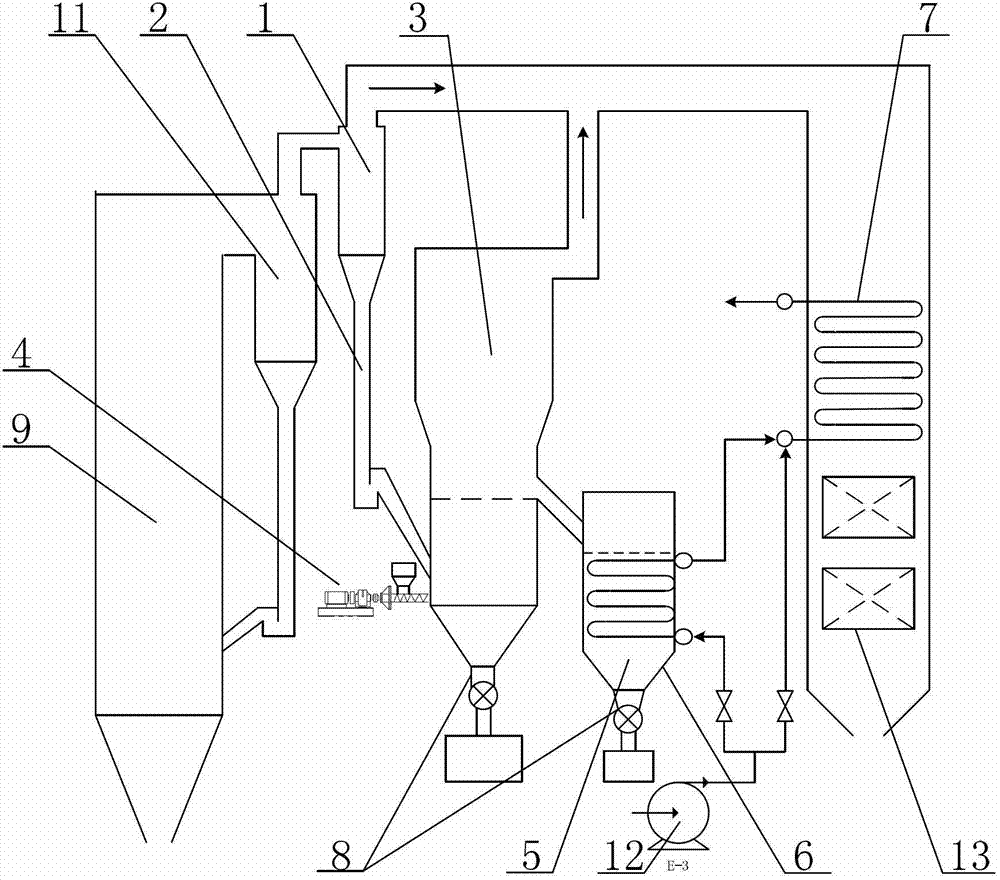

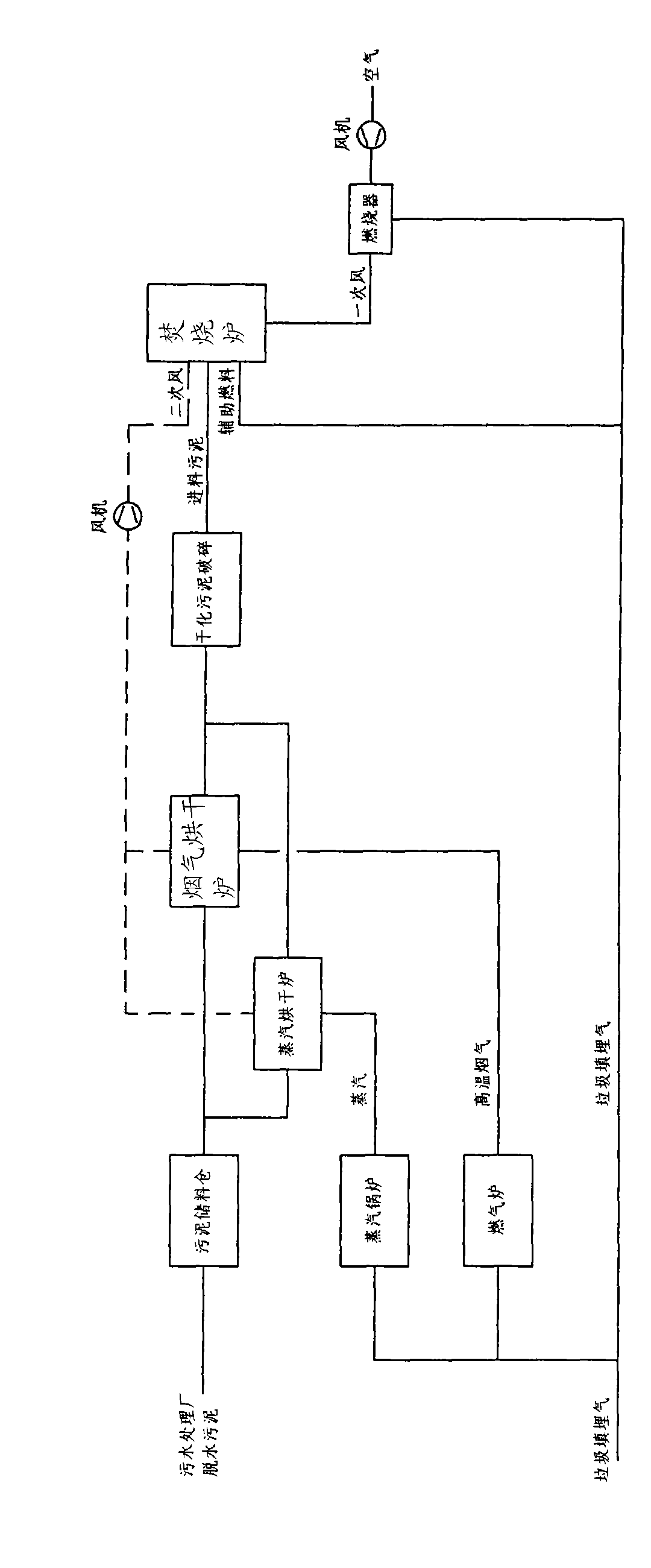

Municipal sludge incinerating system using rubbish landfill gas as auxiliary fuel

ActiveCN101539296AImprove incineration efficiencyReduce incineration costsSludge treatment by de-watering/drying/thickeningIncinerator apparatusThermal energyLitter

The invention provides a municipal sludge incinerating system using rubbish landfill gas as auxiliary fuel. Dehydrated municipal sludge is incinerated after being dried and smashed, an incinerator used for incineration adopts a bubbling fluidized bed incinerator, primary air combusted and heated by the rubbish landfill gas is blown into and the rubbish landfill gas is led into to be used as the auxiliary fuel so as to maintain the temperature of a fluidized bed in the sludge incinerator. The invention greatly improves the incineration efficiency of the municipal sludge, fully utilizes the heat energy of the rubbish landfill gas, lowers the incineration treating cost of the municipal sludge, and achieves the purposes of treatment of a waste by another waste, energy saving and environment protection and remarkable economic benefit.

Owner:南京碳环生物质科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com