Patents

Literature

49results about How to "Reduce incineration costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

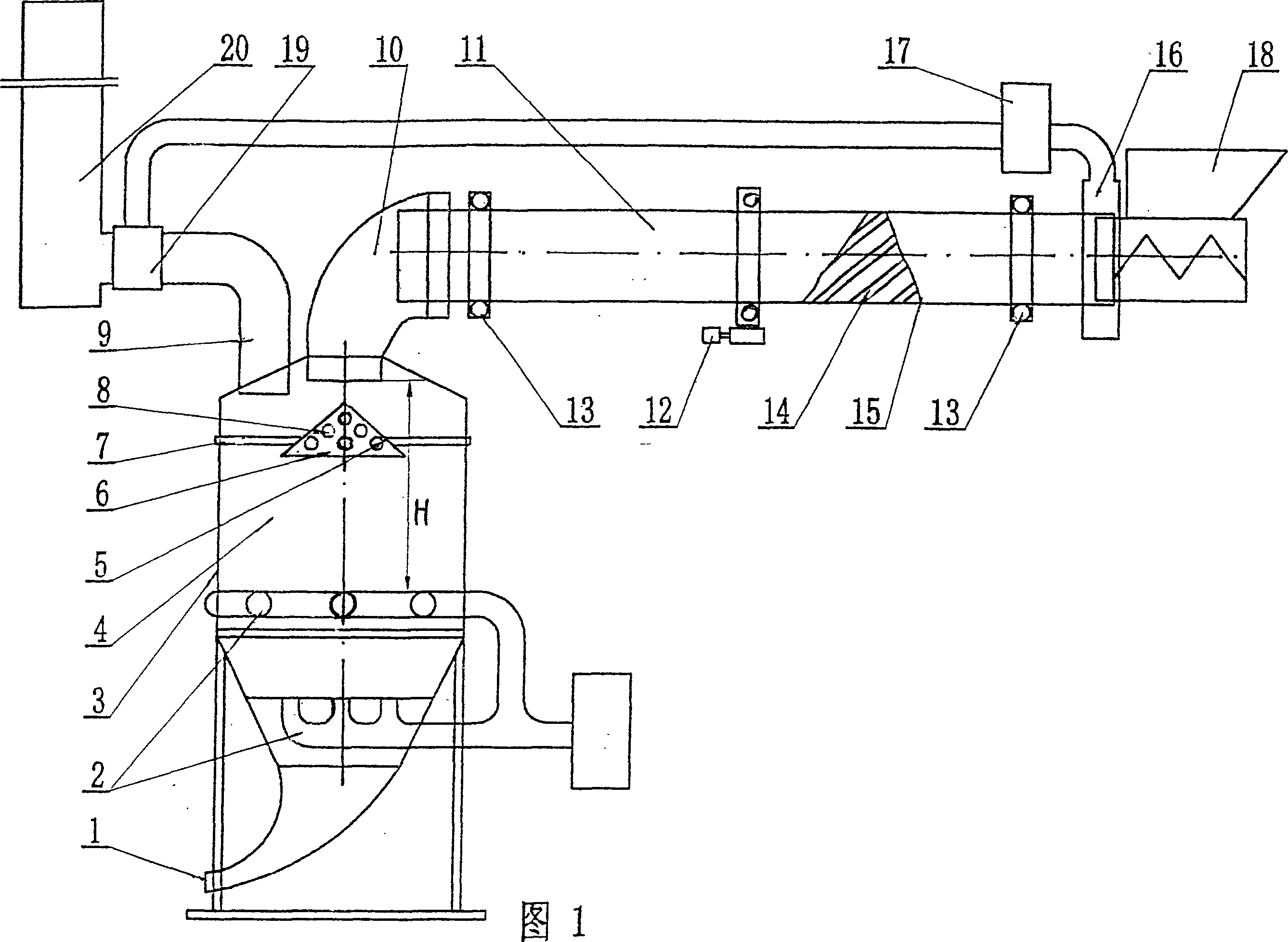

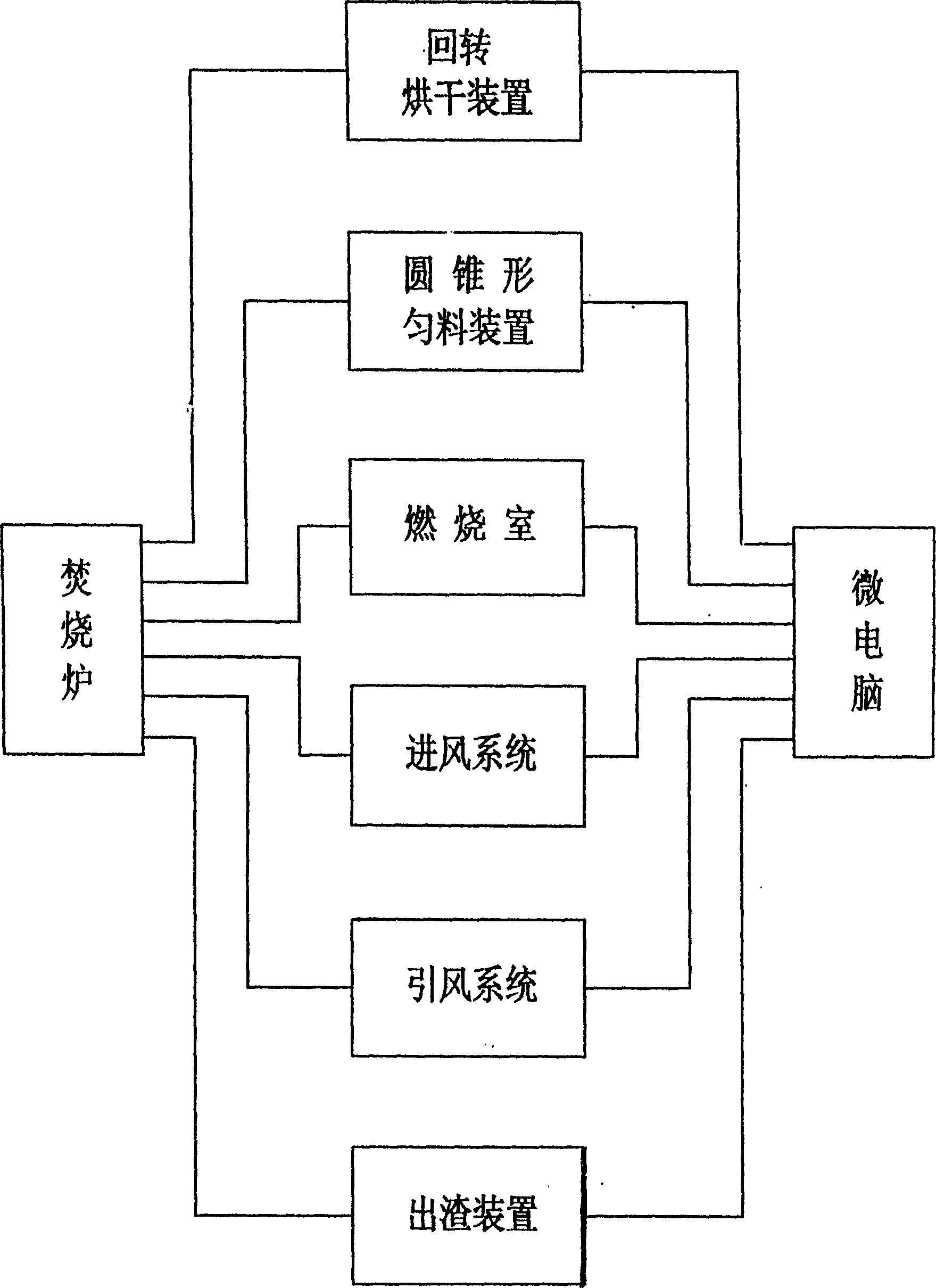

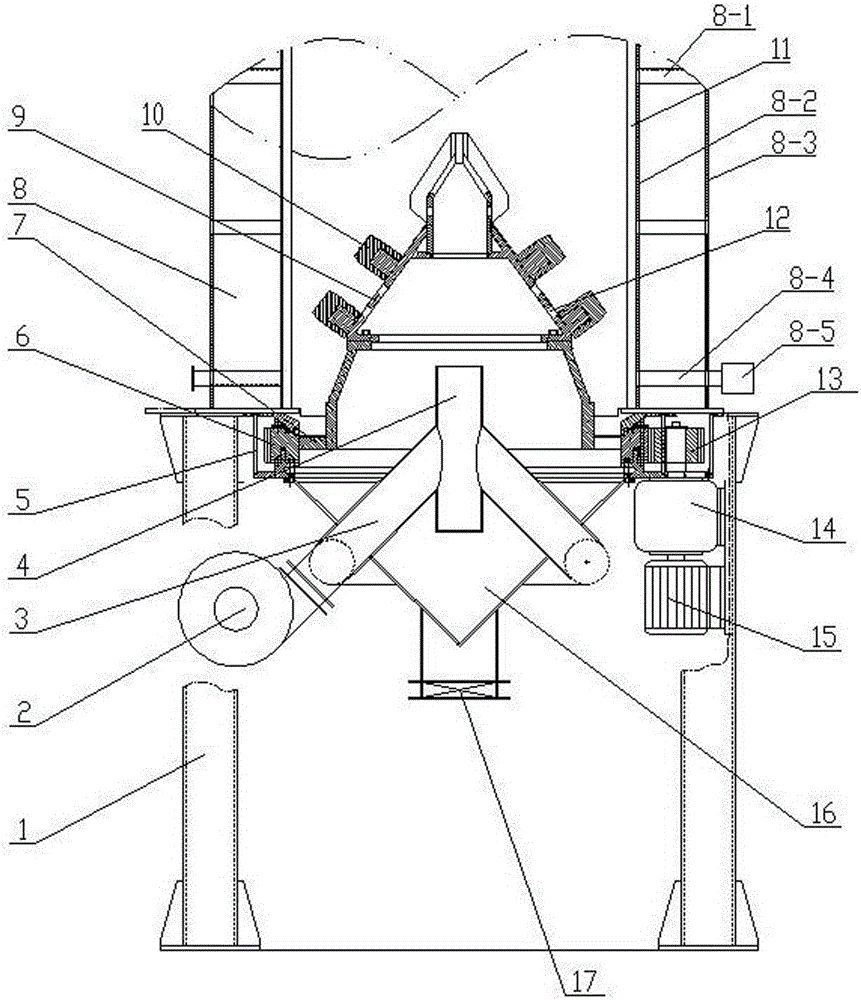

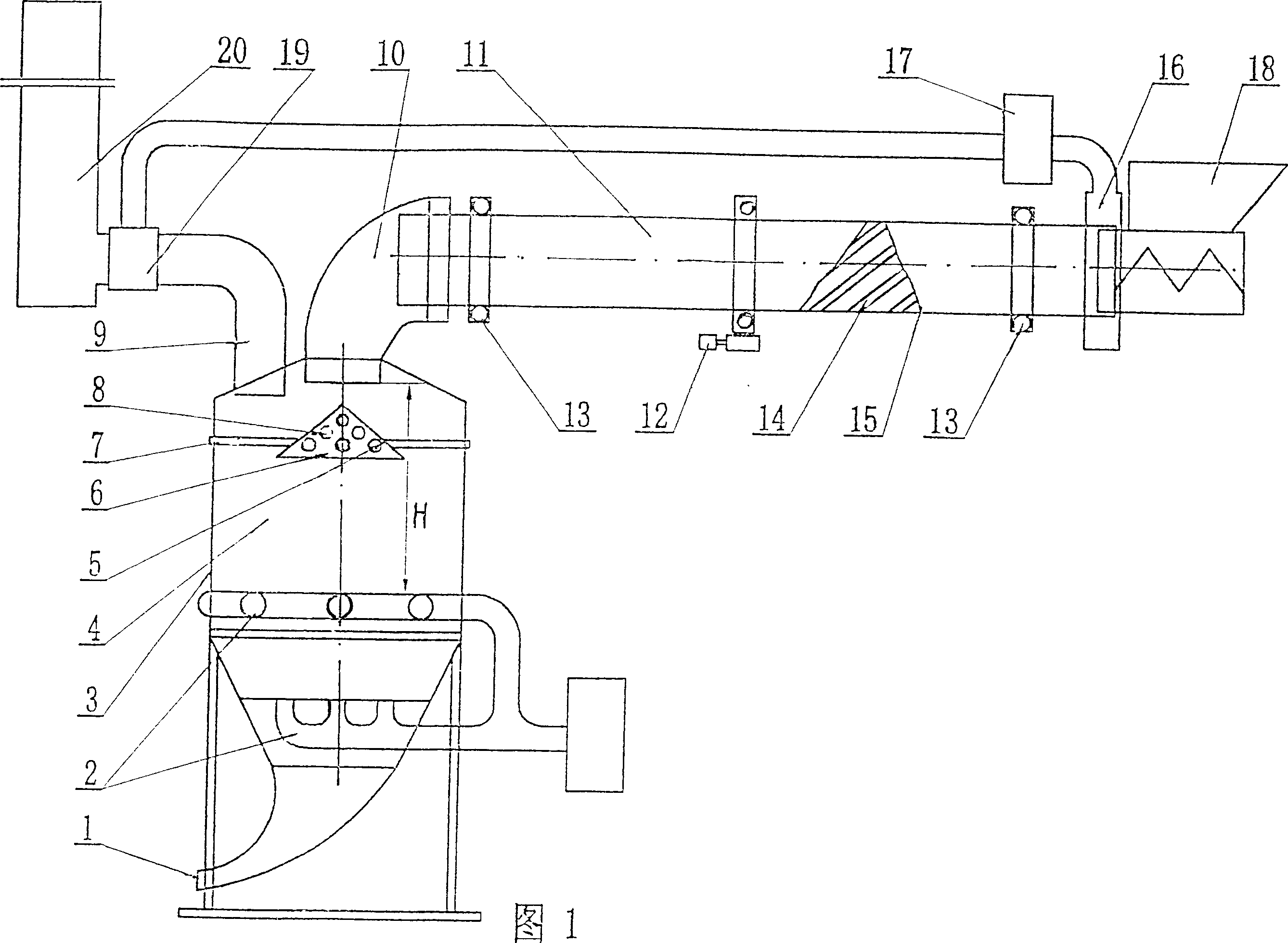

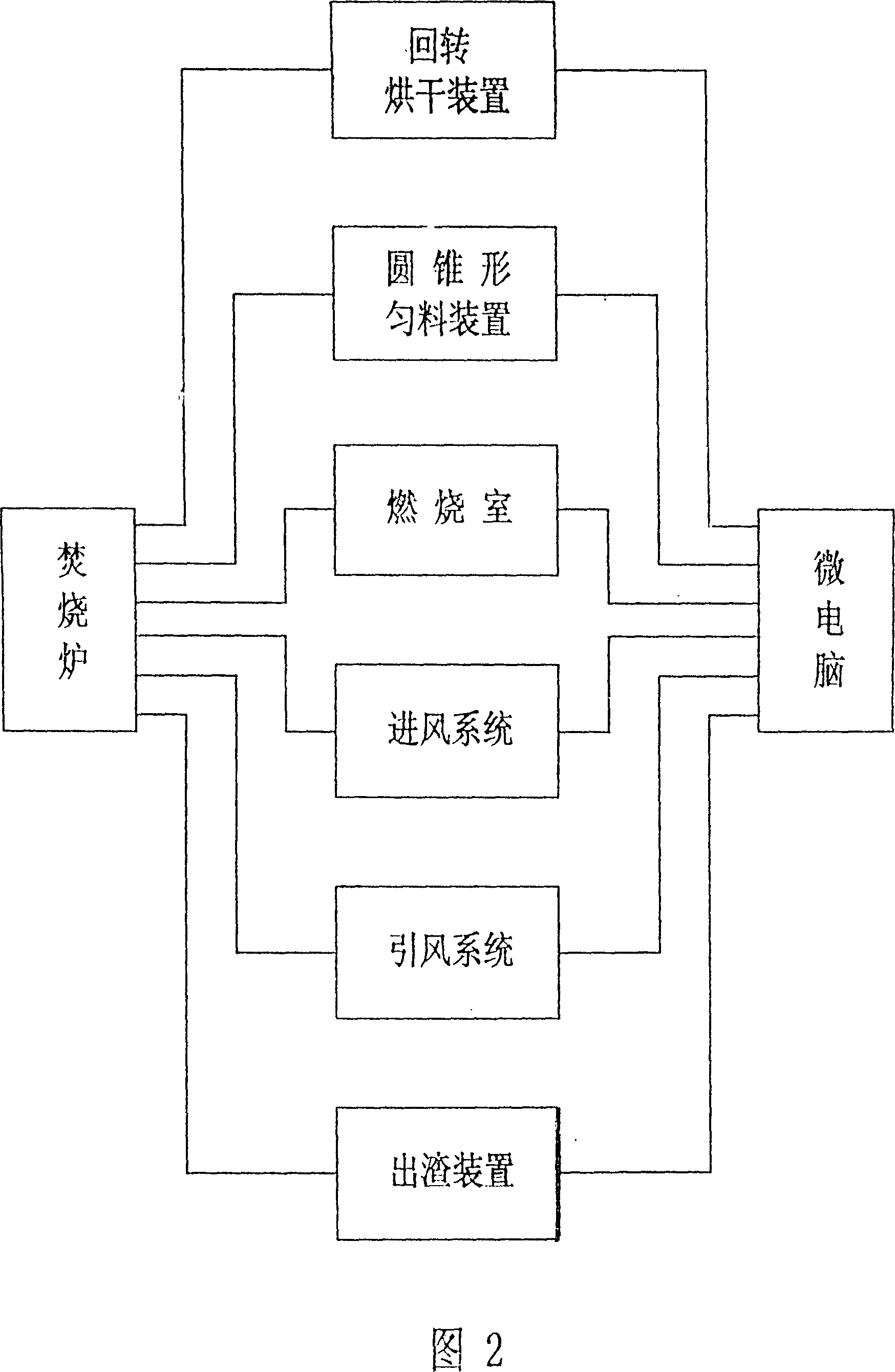

Domestic garbage incinerator

The invention relates to a domestic garbage incinerator that includes furnace body, slewing drying device, cone shaped refining device, burning room, stack nozzle, spoil disposal device, input system, smoke gas process device, chimney, and microcomputer. The feature of the invention is that the slewing drying device is set on the upper of the furnace body that can continuously overturn the domestic garbage and dry to relax garbage sending to furnace body. The laying off elbow of the outlet of the drying device extends into the hearth from the center of the furnace roof. The cone shaped refining device is set in the hearth just inferior of the laying off elbow. The refining device could send the garbage equally and loosely to the hearth burning surface. The incinerator could access to microcomputer and run under the control of the microcomputer. The incinerator could burn the unsorted domestic garbage under the circumstance of not adding assistant fuel, and has high automaticity, high burning output and quantity. The invention is safe, reliable, and low cost.

Owner:江苏天目环保科技有限公司

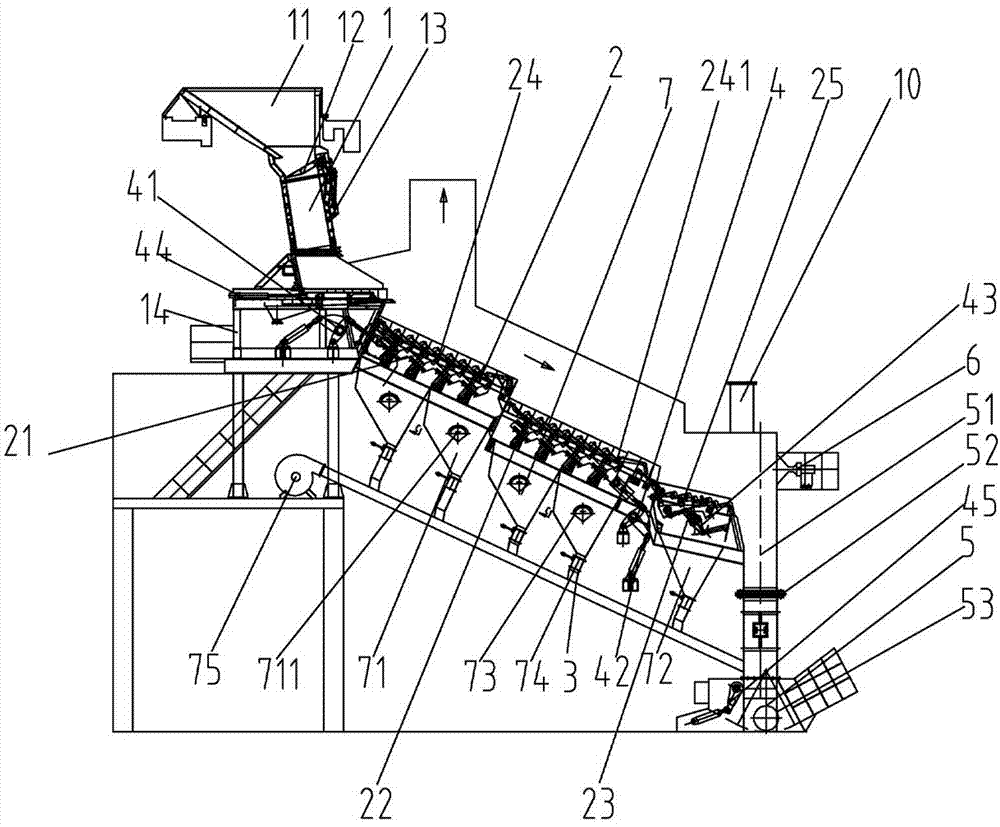

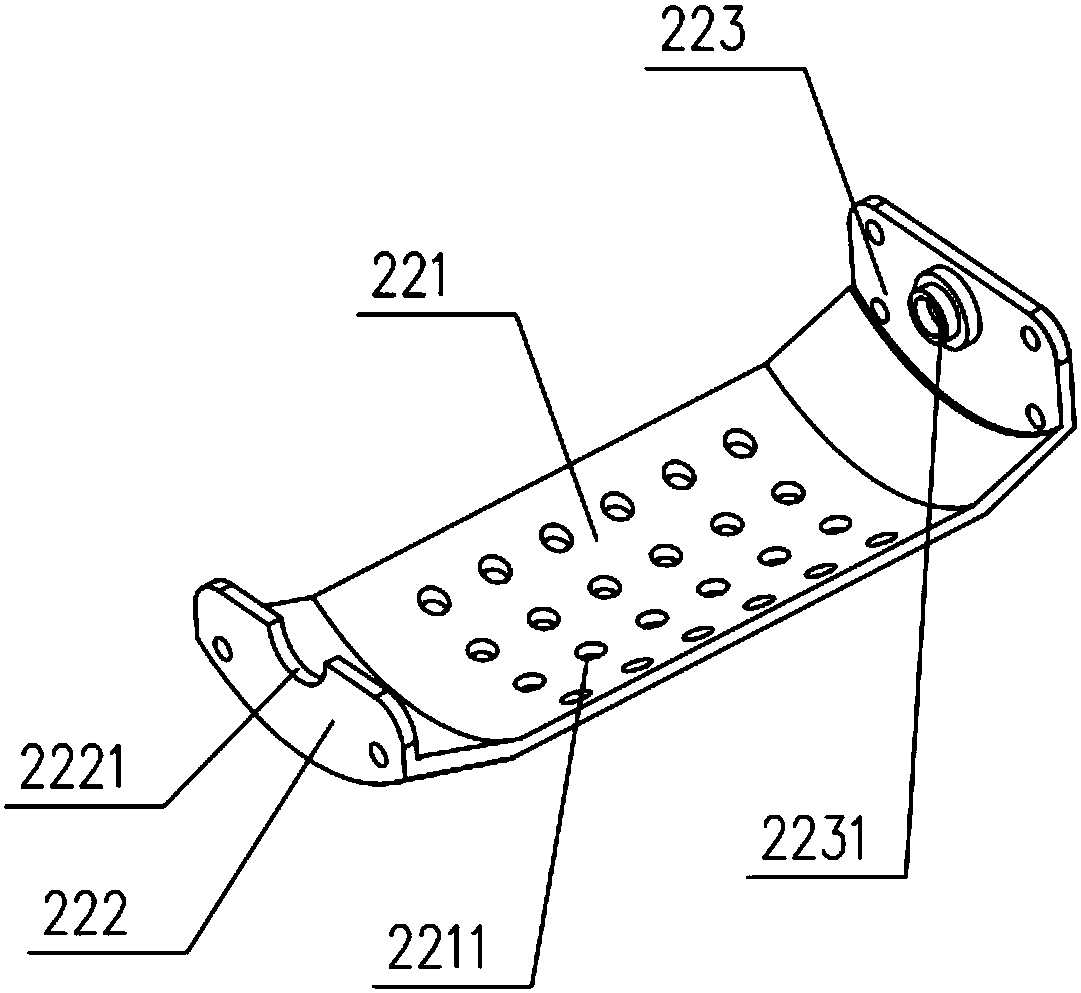

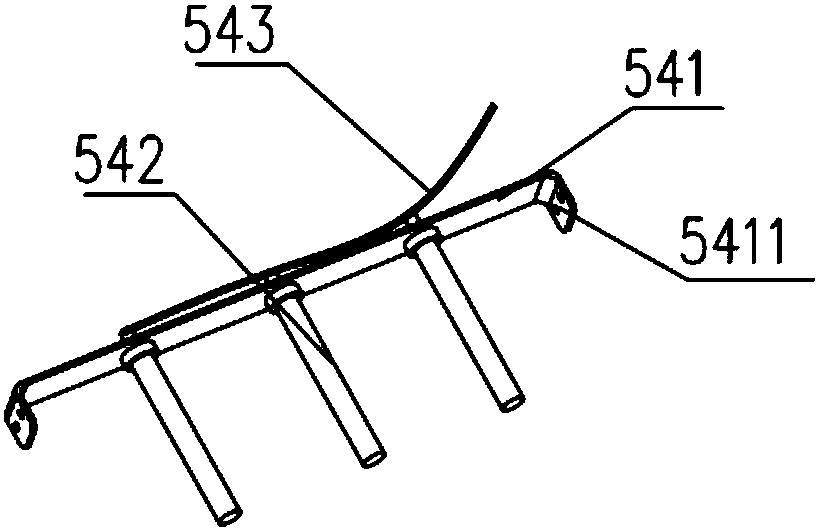

Reciprocating grate furnace with two-section-reverse-acting and one-section-forward-acting grate

InactiveCN102901108AStable combustion conditionsImprove incineration efficiencyIncinerator apparatusCombustionSlag

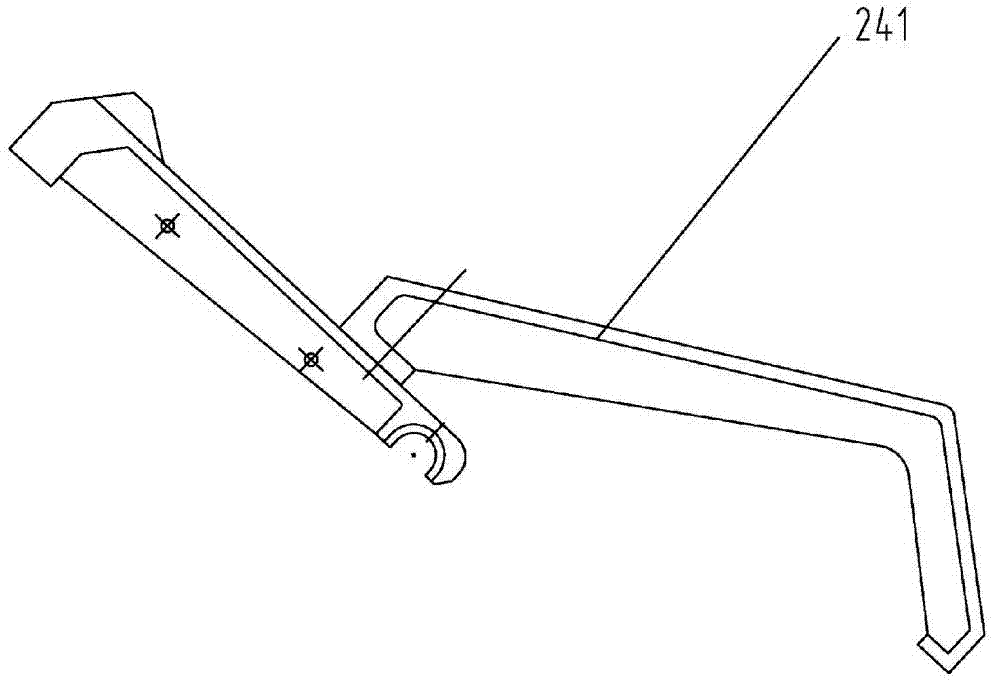

The invention provides a reciprocating grate furnace with a two-section-reverse-acting and one-section-forward-acting grate. The reciprocating grate furnace with the two-section-reverse-acting and one-section-forward-acting grate provided by the invention comprises a feeding system, a hydraulic device, a grate, an automatic grate control system, a slag discharge device, an air chamber and an ash-placing channel, wherein the grate is divided into a drying section, a combustion section and a burnout section in sequence from top to bottom; a height difference is reserved between every two sections; both the grate bodies of the drying section and the combustion section are in a reverse-acting type; and the grate body of the burnout section is in a forward-acting type. By the reciprocating grate furnace adopting a two-section-reverse-acting and one-section-forward-acting grate structure implemented by the invention, the problems that the conventional mechanical grate furnace is inadequate in drying and incomplete in stirring and scattering, and agglomerates are easily formed during drying and combusting can be solved; the waste incineration efficiency can be improved effectively; the incineration cost can be reduced; and the reciprocating grate furnace is applicable to incinerate the waste with high moisture content and a low calorific value.

Owner:福建省丰泉环保控股有限公司

Garbage incinerator

The invention belongs to the field of garbage incineration, particularly relates to a garbage incinerator. The garbage incinerator comprises an incinerator body and an air passage and further comprises an incineration belt used for incinerating garbage; the incineration belt is located inside the incinerator body and further provided with a structure capable of making slag and ashes drop out; anda filter sieve is arranged below the incineration belt. Therefore, the garbage incineration provided by the invention can be used for realizing direct garbage incineration at the same time of timely classifying residual slag during incineration.

Owner:李登平

Method for treating antibiotic dregs by adopting thermophilic microbial agent

ActiveCN103695337AHigh degree of reductionNo secondary pollutionBacteriaSolid waste disposalMicroorganismThermomicrobia

The invention provides a method for treating antibiotic dregs by adopting a thermophilic microbial agent. The thermophilic microbial agent is added into the antibiotic dregs, so that the antibiotic dregs are reduced, and the antibiotic residues in the dregs are reduced. Under an aerobic fermenting condition, the antibiotic dregs are reduced by over 85%, and the removal rate of the antibiotic residues in the dregs reaches over 90%. The method has the advantages that the degree of reducing the antibiotic dregs is high, and the residue removal rate is high. The reduced dregs are then incinerated, so that the incinerating cost is greatly saved. The method is simple, easy to operate, small in occupied area, low in investment cost and free from secondary pollution to the environment, and has the remarkable economical, social and environment-friendly benefits.

Owner:北京绿源科创环境技术有限公司

Consumer waste multipurpose reutilization system

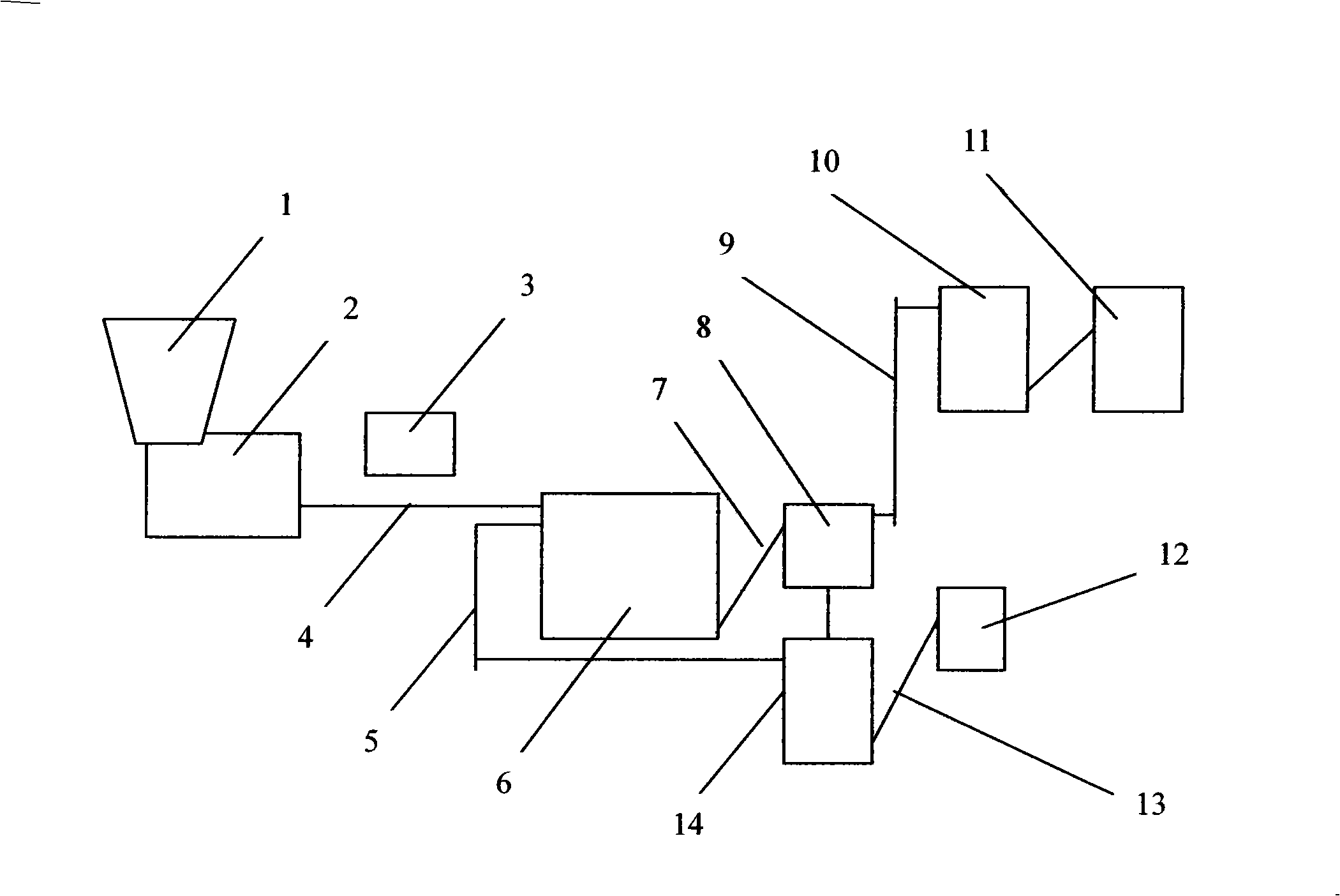

The invention relates to a multifunctional recycling system for living garbage which comprises a cracking device, a firedamp device, a screening equipment and a burning device; the discharge opening of the cracking device is connected with the feeding opening of the firedamp device through a transmission device; the sediment discharge opening of the firedamp device is connected with the feeding opening of the screening equipment through the transmission device; the discharge opening of the matters on the screen of the screening device is connected with the feeding opening of the burning device through the transmission device; the generated materials of big block can be directly recycled; the magnetic materials which are mainly of iron can be directly used as metallurgical materials; the generated firedamp can be used as fuel gas; the generated mud can be used as the materials for preparing fertilizers, soil modifying agents and building materials ; the generated heavy materials can be used as the building materials or as filling materials. The system effectively utilizes various materials and energies in living garbage and is beneficial to save the treatment cost, reduce the environment pollution and is able to obtain useful materials and energies.

Owner:BEIJING HENGYECUN S&T

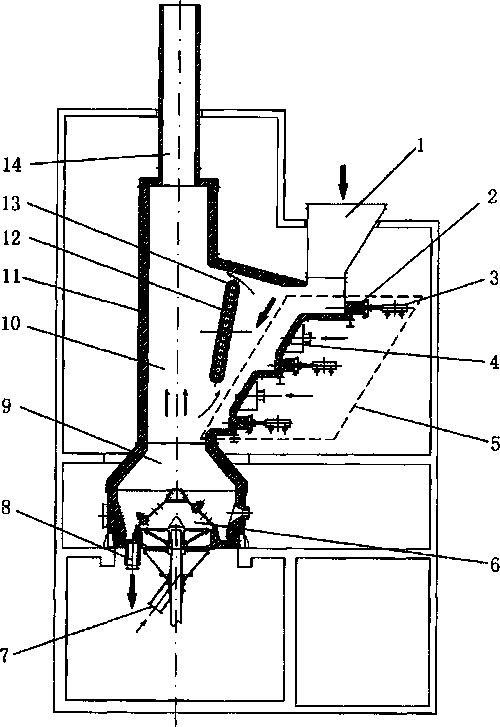

Photothermal medical garbage incinerator

InactiveCN110848710AAchieve the purpose of burningImprove crackingSolar heating energySolar heat collector for particular environmentSlagFuel oil

The invention discloses a photothermal medical garbage incinerator. The photothermal medical garbage incinerator comprises a furnace body and a solar condensing device, the furnace body comprises a furnace shell and a pyrolysis incineration chamber arranged in the furnace shell, a material scattering stand column is arranged at the bottom of the pyrolysis incineration chamber, a spiral buffer material plate is arranged on the material scattering stand column, a solar concentrating port is formed in the bottom of the furnace shell, the solar concentrating port is facing the material scatteringstand column, a solar concentrator is positioned right below the solar concentrating port, a feed port and an exhaust pipe are arranged at the upper part of the pyrolysis incineration chamber, and anair inlet pipe and a slag discharge port are arranged at the lower part of the pyrolysis incineration chamber. According to the method, solar energy is used as a heat source, a medical waste treatmentmethod adopting coal gas and fuel oil as a heat source is replaced, energy consumption is reduced, the photothermal temperature can reach 1600 DEG C instantaneously, waste cracking and incineration speed and completeness are improved, coal gas and fuel oil do not need to be used, and exhaust gas and smoke emission are reduced.

Owner:湖南烁科热工智能装备有限公司

Consumer waste comprehensively processing method

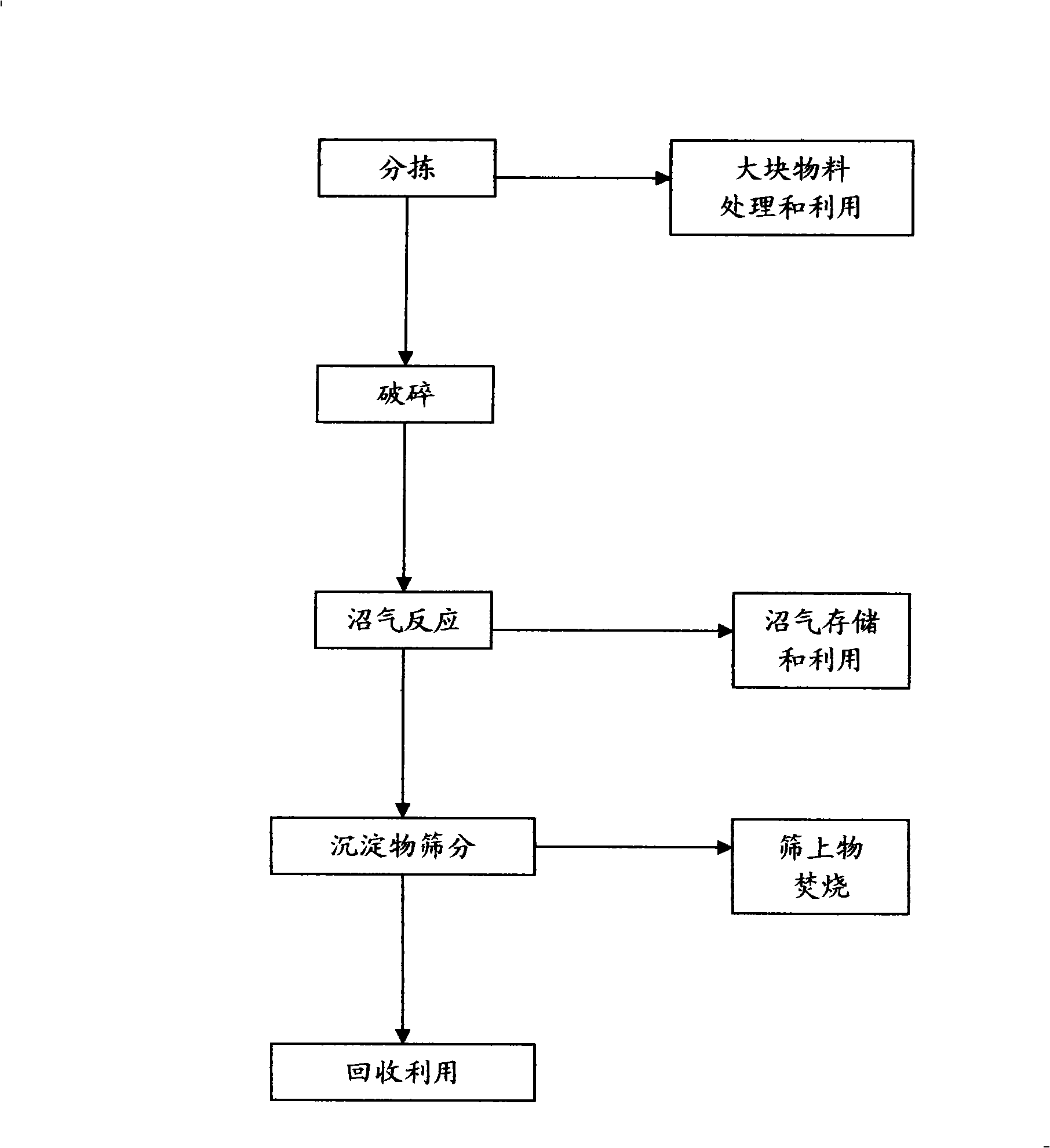

The invention relates to a comprehensive treatment method for living garbage which comprises the following steps: (1) separating: recoverable materials of big blocks and other materials are separated out; (2) cracking: after being separated, the garbage materials are cracked to a granularity that is suitable for a subsequent treatment; (3) feeding to a firedamp device for treatment; (4) screening the sediments in a firedamp pool; (5) burning the matters under a screen. The invention sorts out the materials of big blocks, carries out recycling or other treatments in terms of the properties of various materials and manufactures useful firedamp by using the separated organic, which realizes the reclamation utilization of the energies and materials in garbage materials, reduces the treatment capacity of useless garbage to large extent and reduces the burning treatment cost and the pollution to the atmosphere caused by burning; the method can mainly be applied to treating the living garbage.

Owner:BEIJING HENGYECUN S&T

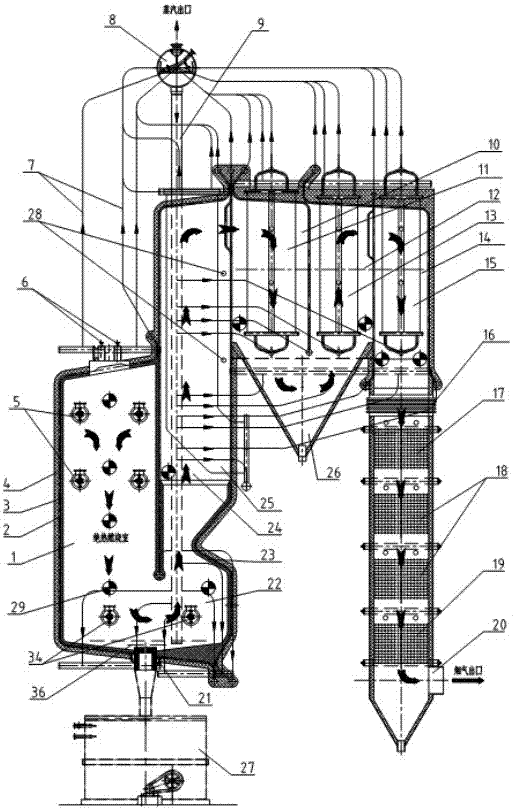

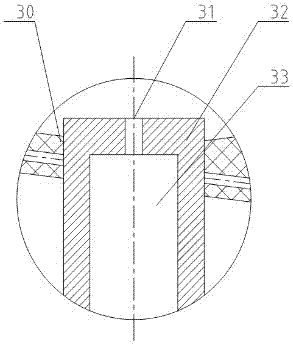

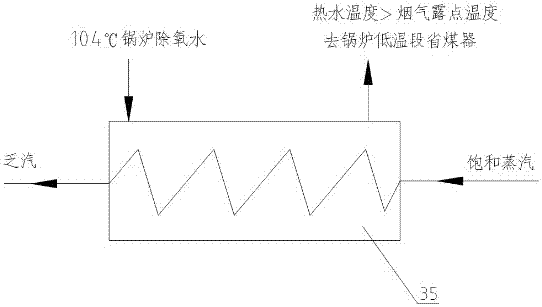

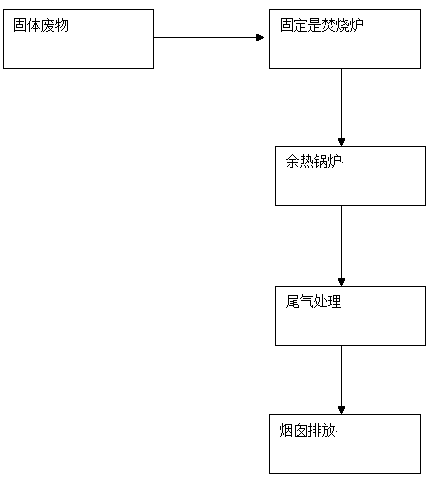

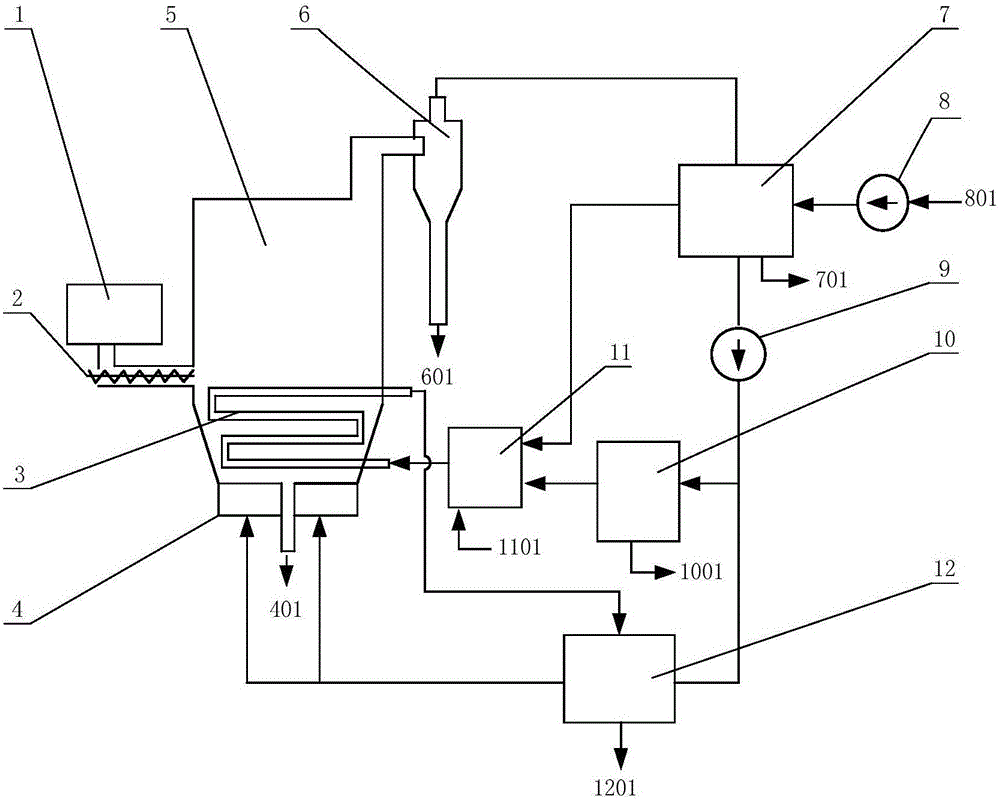

A high-concentration saline organic waste liquid incineration boiler

ActiveCN105240861BReduce incineration costsSimple preparation processChemical industryIncinerator apparatusHigh concentrationCombustion chamber

The invention discloses an incineration boiler for high-concentration salty organic waste liquid. The environment-friendly and energy-saving requirements for harmlessness, reduction and resourcezation of high-concentration salty organic waste liquid are met through high-temperature incineration and waste heat recovery. The incineration boiler structurally and mainly comprises auxiliary combustors, waste liquid spray guns, a thermal insulation hearth combustion chamber, a steering chamber, a radiation cooling chamber, a radiation water-cooling pipe panel, convection current evaporation pipe panels, a steam pocket, a high-temperature economizer, a low-temperature economizer, an ash falling bucket, a flue connection expansion joint and a furnace wall. The thermal insulation hearth combustion chamber is formed by a hearth wall-covering film type water-cooling wall in a defined manner, salty waste liquid is combusted, and recycling is conducted in a salt dissolving tank. High-temperature smoke generated in combustion sequentially enters the thermal insulation combustion steering chamber, a quenching chamber, the multiple stages of convection current evaporation cooling chambers and the economizers to be subjected to heat energy recovery. The incineration boiler has the beneficial effects of being simple in manufacturing process, convenient to maintain, safe and stable in running, and suitable for being used and popularized in high-concentration salty organic waste liquid processing in the industries of chemical engineering, oil refining, papermaking and the like.

Owner:大连科林能源工程技术开发有限公司

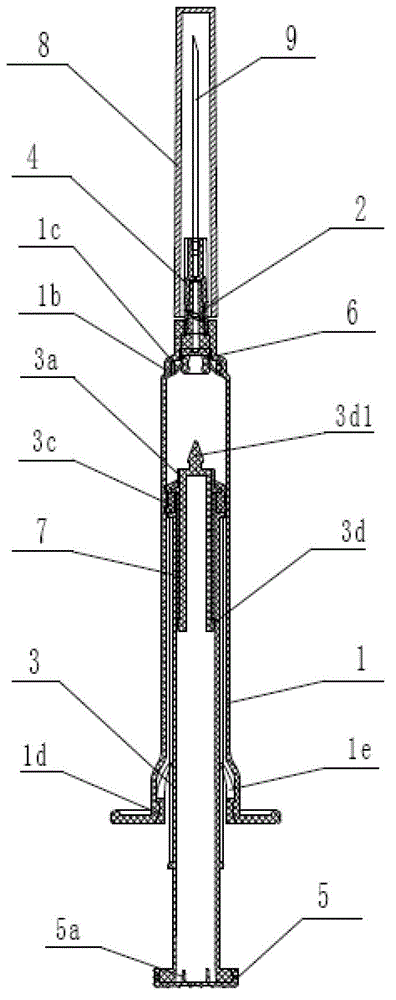

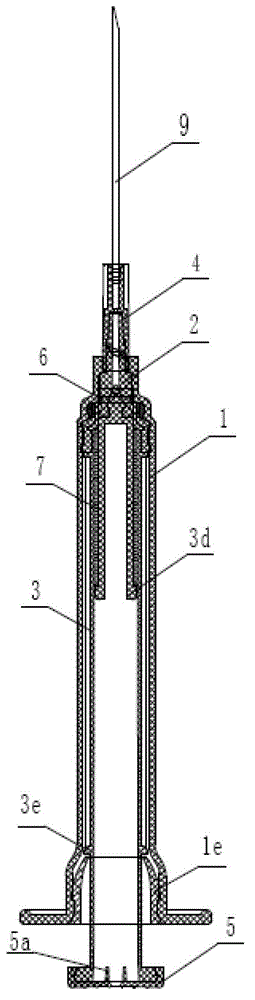

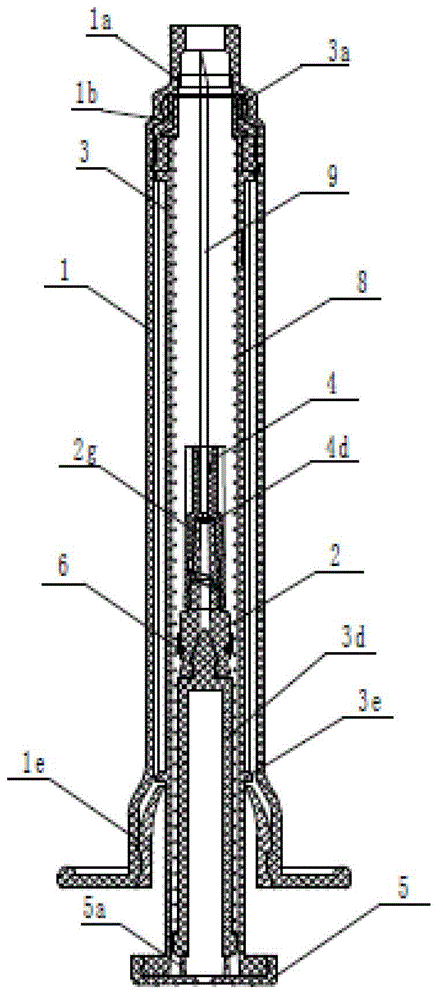

Safe injector

InactiveCN103330976AImprove convenienceImprove reliabilityInfusion syringesIntravenous devicesProduction lineSyringe needle

The invention discloses a safe injector which relates to the technical field of medical instruments, and comprises a needle cylinder (1) and a push rod (3), as well as an injection needle (10) and a connecting tube (2), wherein the injection needle (10) can be replaced as per use requirements. According to the invention, when the safe injector is in use, the traditional operating custom is barely changed, the use is convenient, and the effect is reliable; the injection needle (10) can retract and hide through an automatic retraction mechanism after finishing injecting to ensure that medical staff can be free from the unexpected harm of a contaminated needlepoint; after the injection is completed, the push rod (3) cannot be pulled back as being clamped by clamping rings (1e), so that the push rod cannot be reused, the real disposable injector is realized, and further the cross transmission of blood-borne diseases is avoided; support sheets (1c) are adopted to support the connecting tube (2), and a conical head pulling back rod (3d) is sleeved with a compression spring (7) in a flat pressing annular manner, so that the structural design is more reasonable, the safe injector is more suitable for the automatic assembly production of a production line, the quality is reliable, the qualification rate is high, and the cost is reduced.

Owner:江苏富田汇康医疗器械有限公司

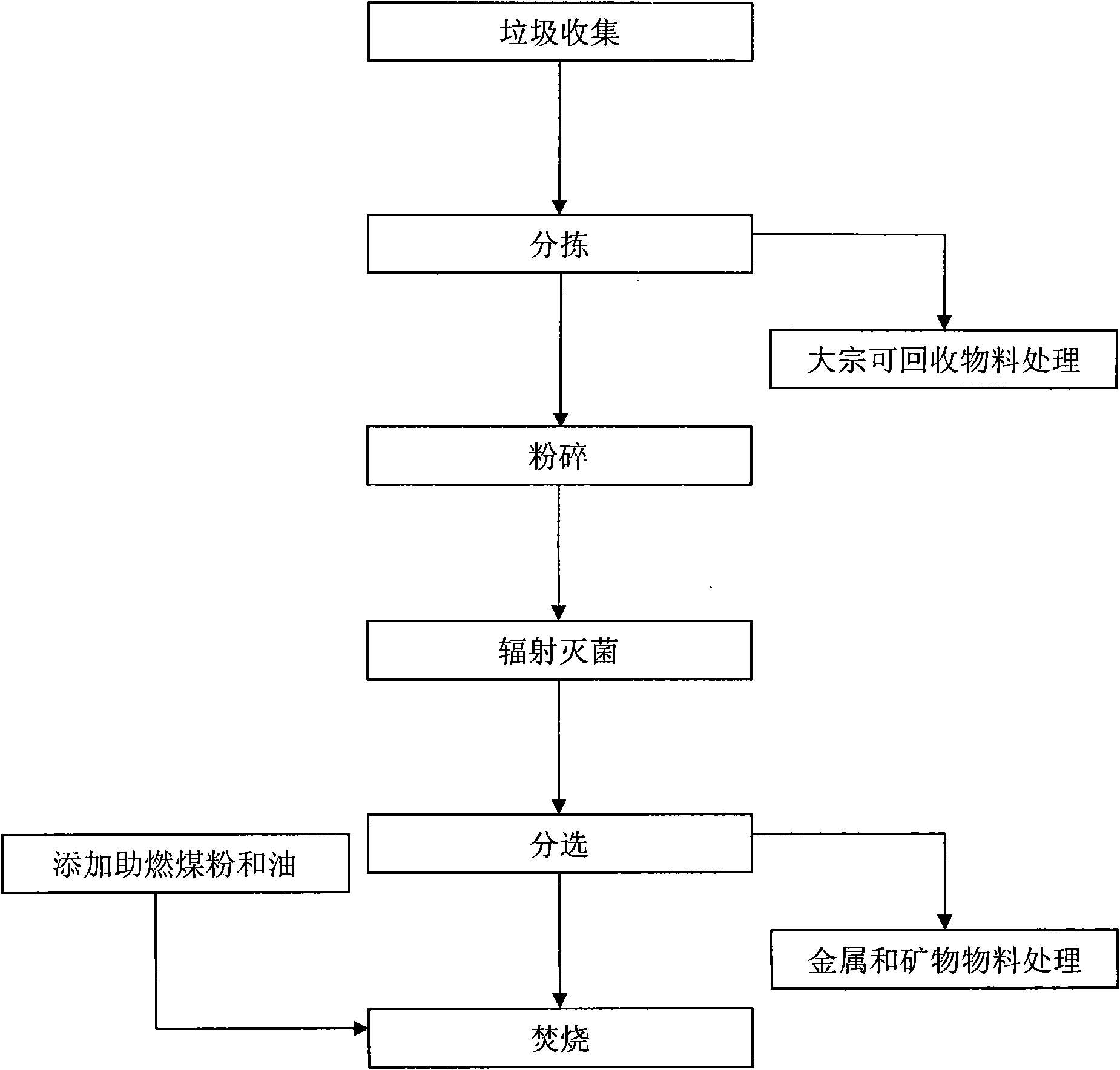

Medical waste separation, recovery, and incineration processing method

InactiveCN101590487AHigh recycling valueNo pollutionSolid waste disposalMedical waste disposalFiberAdditive ingredient

The invention relates to medical waste separation, recovery, and incineration processing method, comprising the following steps: 1. waste collection: collecting by adopting an enclosed way; 2. separation: the chunk material and bulk material which can be recycled separately are separated out; 3. smashing: all the material being processed collectively is smashed under the enclosed condition; 4. sterilization: all the smashed material is sterilized; 5. sorting: the medical waste is divided into two categories in a mechanical way according to the proportion of the material, the first is lighter material with the main ingredients being fiber and other organics, and the second is heavier material with the main ingredients being metal, sandrock and other mineral substances, the lighter material is dried and smashed to form incineration material; and 6. incineration: coal power is added into the incineration material as a combustion accelerator and fuel oil is sprayed into an incineration furnace as a second combustion accelerator. The invention is conducive for reasonable utilization of material in the medical waste and the reduction of energy consumption.

Owner:BEIJING JINAOHUARONG TECH

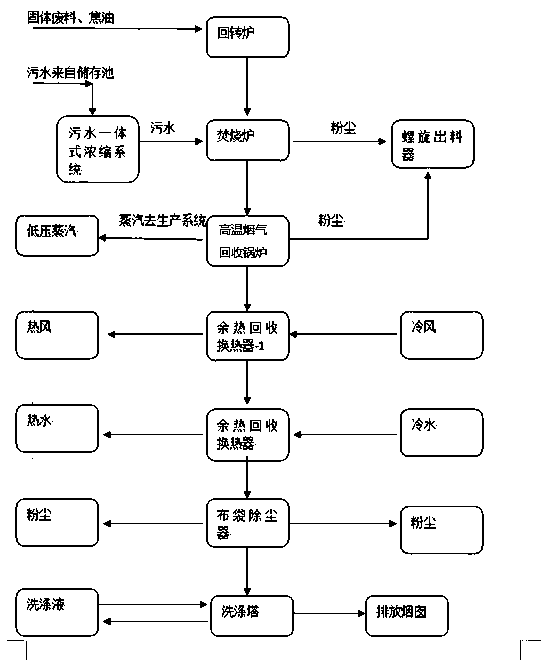

Industrial waste treatment technology and device thereof

PendingCN108726614ANo energy consumptionNo addedWater/sewage treatment by heatingIncinerator apparatusHigh concentrationToxic industrial waste

The invention discloses an industrial waste treatment technology and a device thereof. A method comprises the steps that hazardous waste of tar and the like is subjected to incineration, high-concentration high-salinity sewage is subjected to incineration, the two segments of incineration are combined to form a secondary complete incineration system, hazardous pollutants are removed, and the solidhazardous waste is treated when sewage incineration is conducted; meanwhile, high-temperature waste heat and medium-temperature waste heat are recycled, so that the sewage treatment cost is reduced;an integrated sewage concentration system is adopted, so that the sewage incineration quantity is reduced by 40%-60%, the sewage treatment cost can be saved by 30% or above, the direct cost of sewageincineration is reduced, whole system energy consumption is low, and sewage treatment recycling is achieved.

Owner:PINGYUAN ZHONGDE TAIXING ENVIRONMENTAL PROTECTIONTECH & EQUIP CO LTD

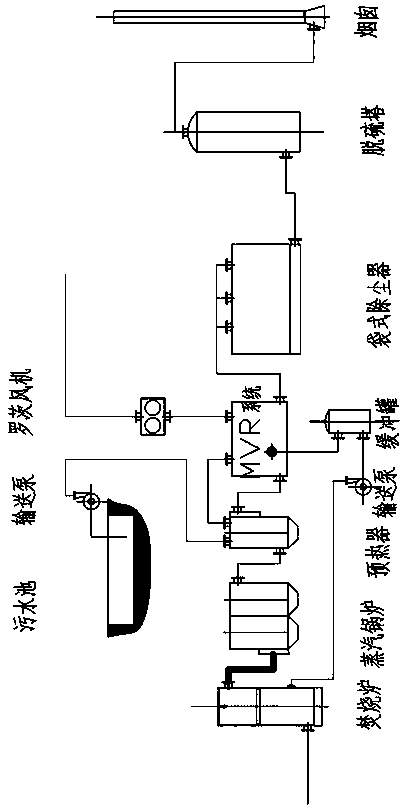

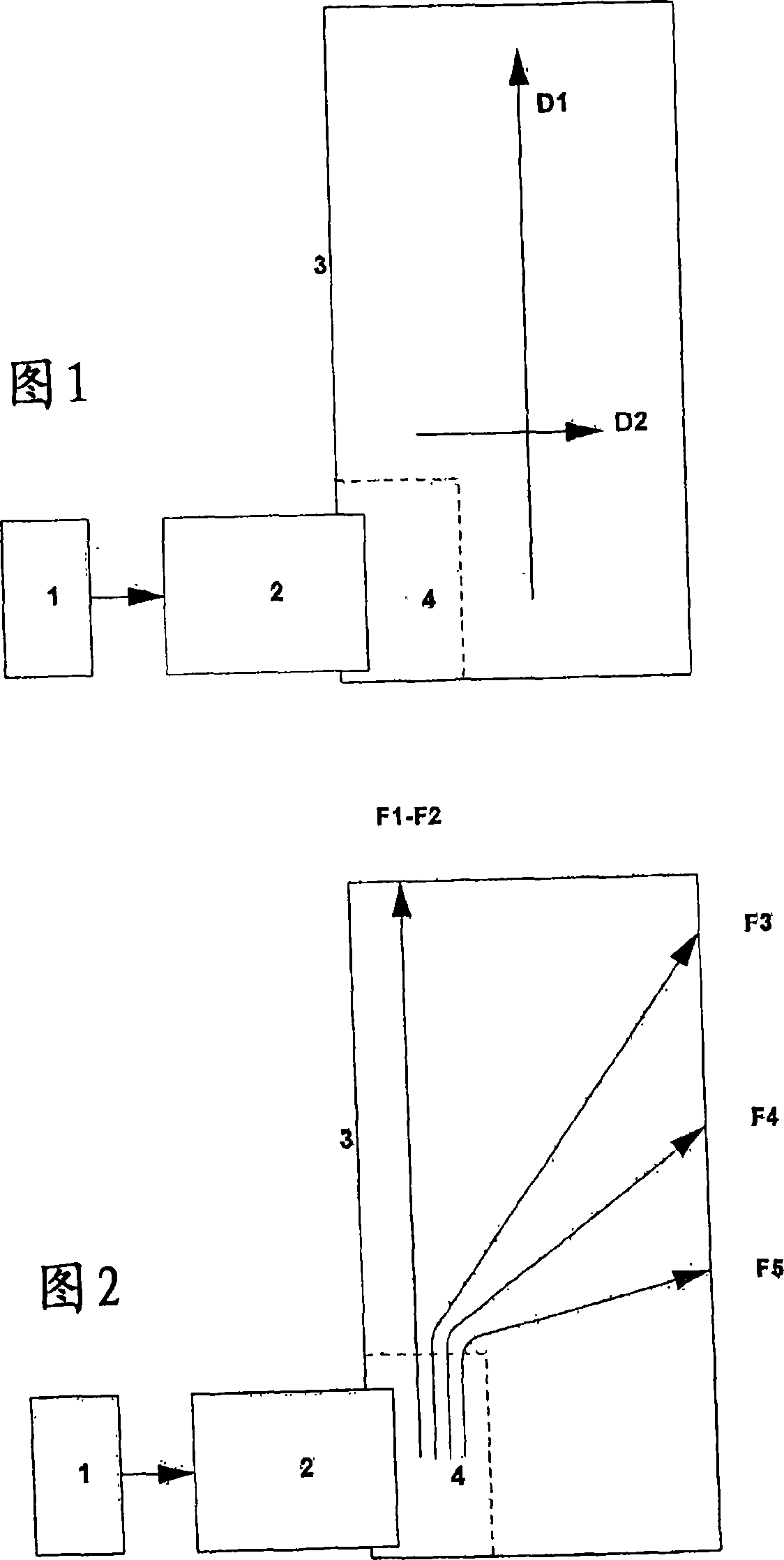

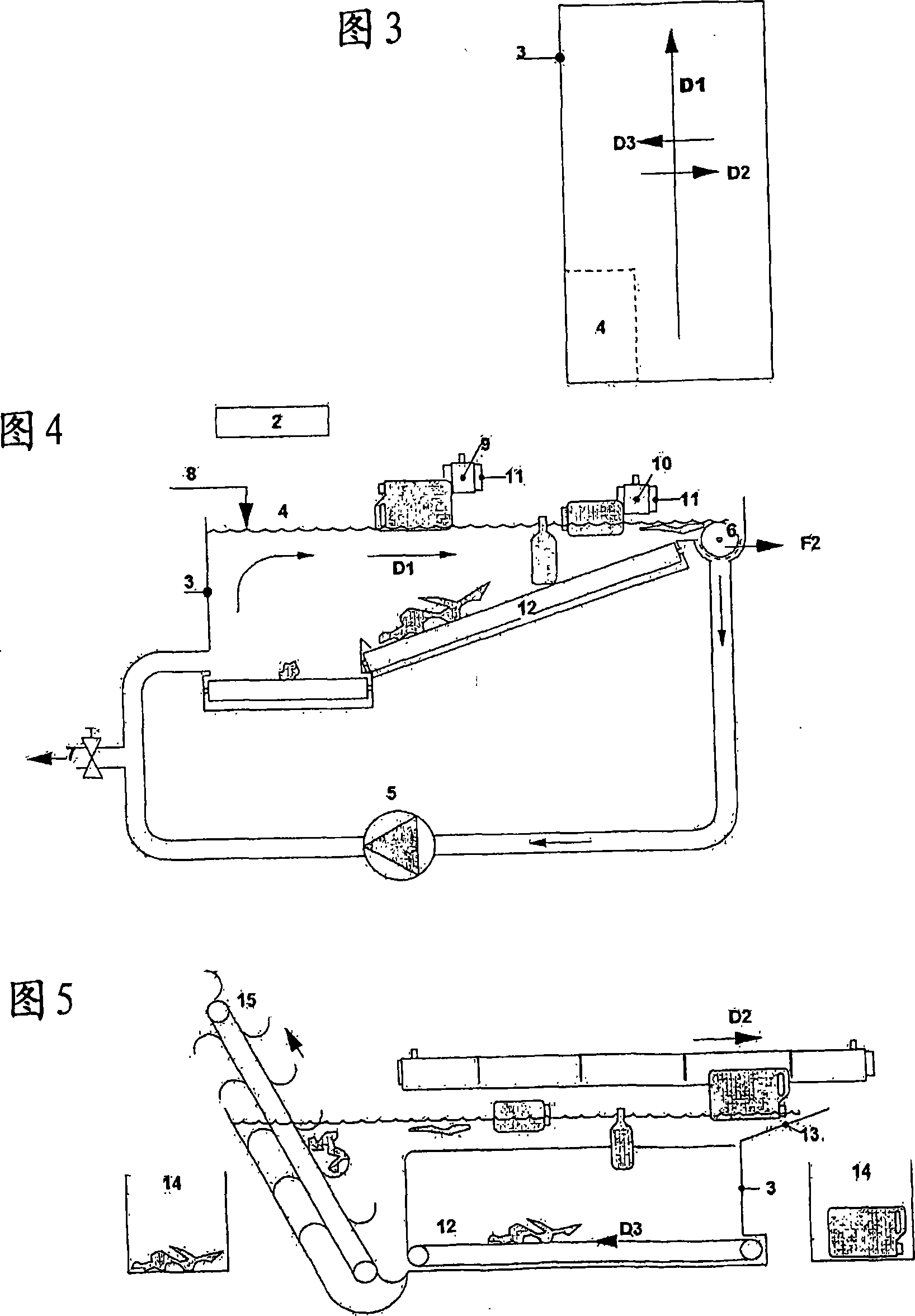

A method for separation of heterogeneous products, including household waste

InactiveCN101111317AReduce incineration costsImprove energy efficiencySeparation devicesMechanical material recoveryHorizontal forceFractionation

A method for separation of heterogeneous products included in household waste (HW) comprises separating the products in a fractionation vessel containing a liquid. The waste includes components, of which at least some are capable of floating in the liquid. The components are exposed to a first essentially horizontal force (P1) in a first direction (D1) enforced by a flow of the liquid in the fractionation vessel and to a second essentially horizontal force (P2) in a second direction (D2), which is substantially different from the first direction (D1). The combined impact of the forces (P1; P2) on the components spreads the components and leads them to at least two collection areas. Products of varying buoyancy may thus be treated separately.

Owner:HOLM CHRISTENSEN BIOSYSTEMER APS

Energy-saving efficient garbage incinerator

InactiveCN106016270AIncrease temperatureAvoid wastingIncinerator apparatusIncinerationGarbage disposal

The invention relates to an energy-saving efficient garbage incinerator which comprises an incinerator body, wherein a base is arranged at the bottom of the incinerator body. A support seat is arranged at the bottom of the inner chamber of the incinerator body. The energy-saving efficiency garbage incinerator is characterized in that the support seat is annular, a tapered fire grate is arranged on the support seat, and the tapered fire grate can rotate around the circumferential direction of the support seat. Stirring teeth are arranged on the outer side face of the tapered fire grate. The cross section of the tapered fire grate and the cross section of the section of incinerator body, corresponding to the height of the tapered fire grate, are both elliptical. The incinerator has an inner layer and an outer layer, a distance is formed between the inner layer and the outer layer, a support rod is arranged in the distance, and two ends of the support rod are respectively connected with the inner layer and the outer layer. Air holes for communicating the inner chamber of the inner layer with the distance are formed in the inner layer. An air inlet is formed in the outer layer, and a second fan is arranged at the air inlet. By adopting the energy-saving efficiency garbage incinerator, garbage disposal cost can be reduced, and waste of energy can be avoided. The energy-saving efficiency garbage incinerator is applicable to incineration disposal of municipal household waste.

Owner:无锡多灵环保工程设备有限公司

Refining method of ammonia-containing methanol waste liquid

ActiveCN106588571ALower Methanol Price and SalesReduce acid cost and incineration costOrganic compound preparationHydroxy compound separation/purificationAmmonium sulfateChemistry

The invention discloses a refining method of an ammonia-containing methanol waste liquid, the refining method comprises the following steps: (1) inputting of the ammonia-containing methanol waste liquid into a distillation tower; (2) total reflux of the distillation tower; (3) use of an acid pickling tower for absorption of volatilized ammonia in the distillation column and preparation of the ammonia into an ammonium sulfate solution, after the acid pickling tower is saturated by absorption, preparation of a crude ammonium sulphate product from the ammonium sulfate solution by ammonium sulfate drying dehydration equipment; (4) addition of sulfuric acid in the distillation column after the total reflux for neutralization; (5) total reflux of the distillation tower and control of the reflux ratio to 3-10 for direct distillation of the methanol waste liquid in the distillation tower into a high purity methanol finished product, and (6) final discharge of a tower bottom liquid released from the bottom of the distillation tower. The process of the method is simple, and the cost is greatly reduced.

Owner:SHANGHAI TIANHAN ENVIRONMENTAL RESOURCES CO LTD

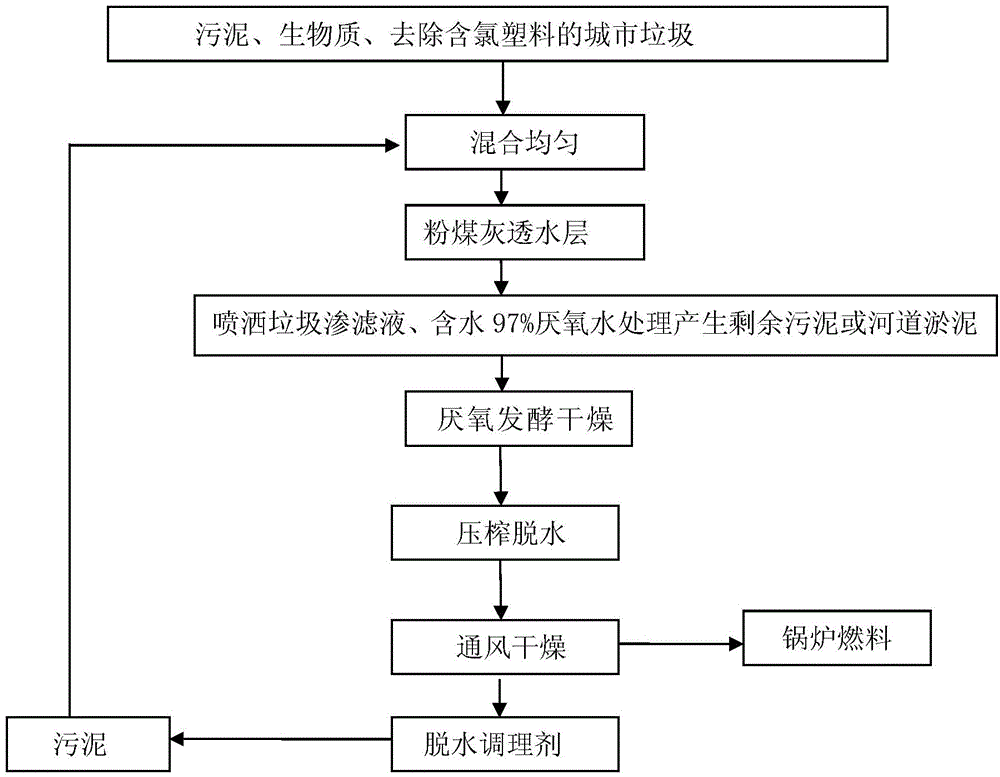

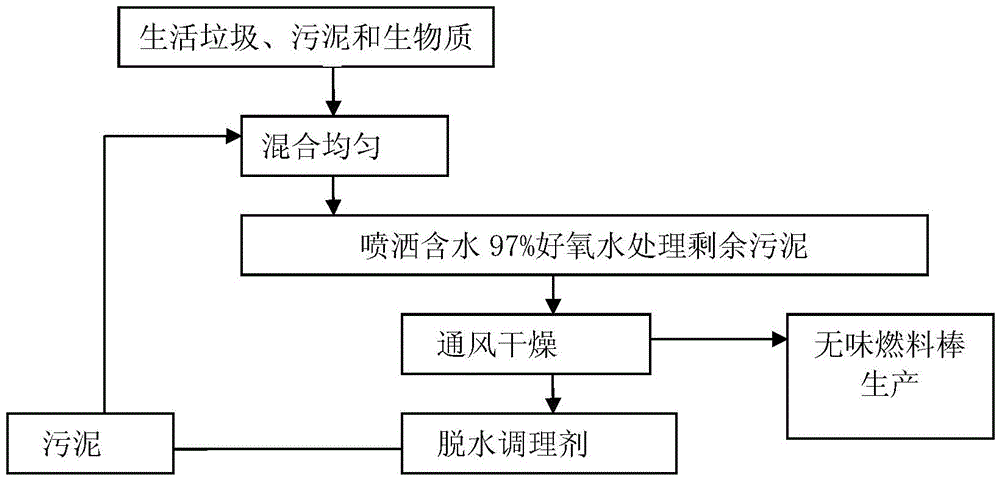

Compound sludge dewatering conditioner adaptable to incineration treatment technology of excess sludge as well as preparation method and application of conditioner

InactiveCN104891776ALow cost of dehydrationCause secondary pollutionSludge treatment by de-watering/drying/thickeningMoistureFermentation

The invention relates to a compound sludge dewatering conditioner adaptable to an incineration treatment technology of excess sludge as well as a preparation method and an application of the conditioner. The conditioner comprises components as follows: 10%-20% of SiO2, 5%-10% of Al2O3, 1%-10% of Fe2O3, 0.5%-10% of CaO and 15%-60% of C. The preparation method comprises steps as follows: fly ash, urban garbage with chlorine-containing plastic removed, sludge, biomass, excess sludge which contains 97% of moisture and is produced by anaerobic water treatment and landfill leachate are evenly mixed in proportion, subjected to anaerobic fermentation for 3-5 days, pressed, dewatered and ventilated for 5-20 days, so that the conditioner is obtained. The compound sludge dewatering conditioner dewaters the sludge with a lysis technology, is non-toxic and harmless and cannot cause secondary pollution to the environment, and the dewatering cost is low; when the conditioner is applied to deep sludge dewatering, the method is simple, the moisture content can be decreased to 5-30%, preparation of sludge boiler fuel rods is facilitated, and the sludge incineration cost is reduced.

Owner:DONGHUA UNIV

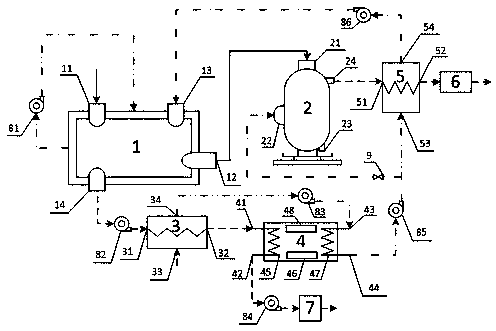

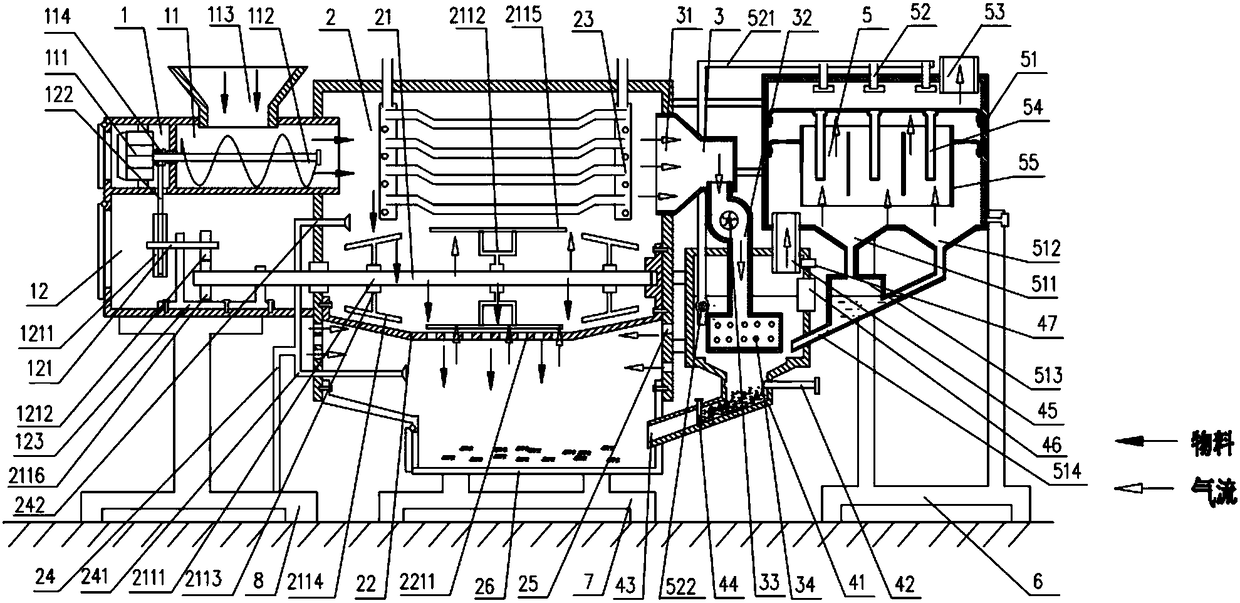

System and method of sludge by using drying incineration heat balance treatment

ActiveCN108800164AReduce incineration costsImprove conversion efficiencyIncinerator apparatusSludgeWater vapor

The invention provides a system and a method of sludge by using drying incineration heat balance treatment. The problem that a self heat balance of the sludge with higher water content and lower dry basis heat value cannot be achieved in a drying incineration treatment process is aimed, a high-temperature stink containing water vapor discharged in the sludge drying process is used for pre-heatingcold air; then an auxiliary heating device is adopted to further heat the pre-heated air; and finally the further heated air is subjected to heat exchange with incineration hot flue gas to form hot air, wherein the heat of the hot air is not lower than the heat required by drying of the sludge. By adopting the method of the sludge by the drying and incineration, the sludge drying incineration heatbalance can be realized.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

Comprehensive utilization method of waste residues generated in refining 1-aminoanthraquinone

The invention provides a comprehensive utilization method of waste residues generated in refining 1-aminoanthraquinone. The dye varieties such as disperse reddish brown, disperse yellow, disperse blue and the like are directly prepared without separating and purifying by taking waste resides generated in the production process of 1-aminoanthraquinone as raw materials, and dye varieties equivalent with the existing commodity dyes such as the traditional products disperse ash, disperse black and the like are prepared after the dye varieties are mixed according to different proportions. The waste residues obtained by using the method are not needed to be treated by processes such as refining, purification and the like, and all components in the waste residues can be utilized, so that not only are the economic values of the waste residues increased, but also the secondary pollution caused by refining and purifying are avoided, and the environmental pollution problem is effectively solved; the comprehensive utilization method has high economic and environment-friendly values.

Owner:JIANGSU YABANG DYE

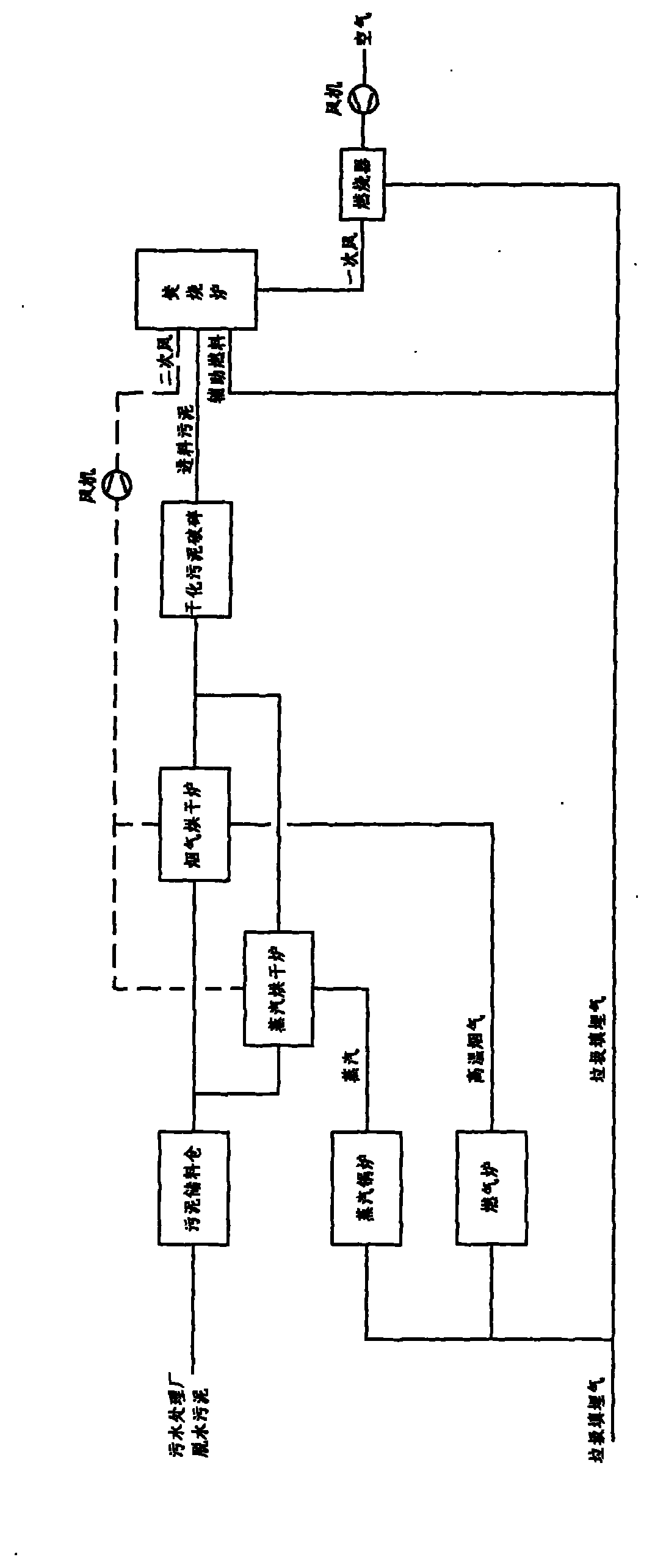

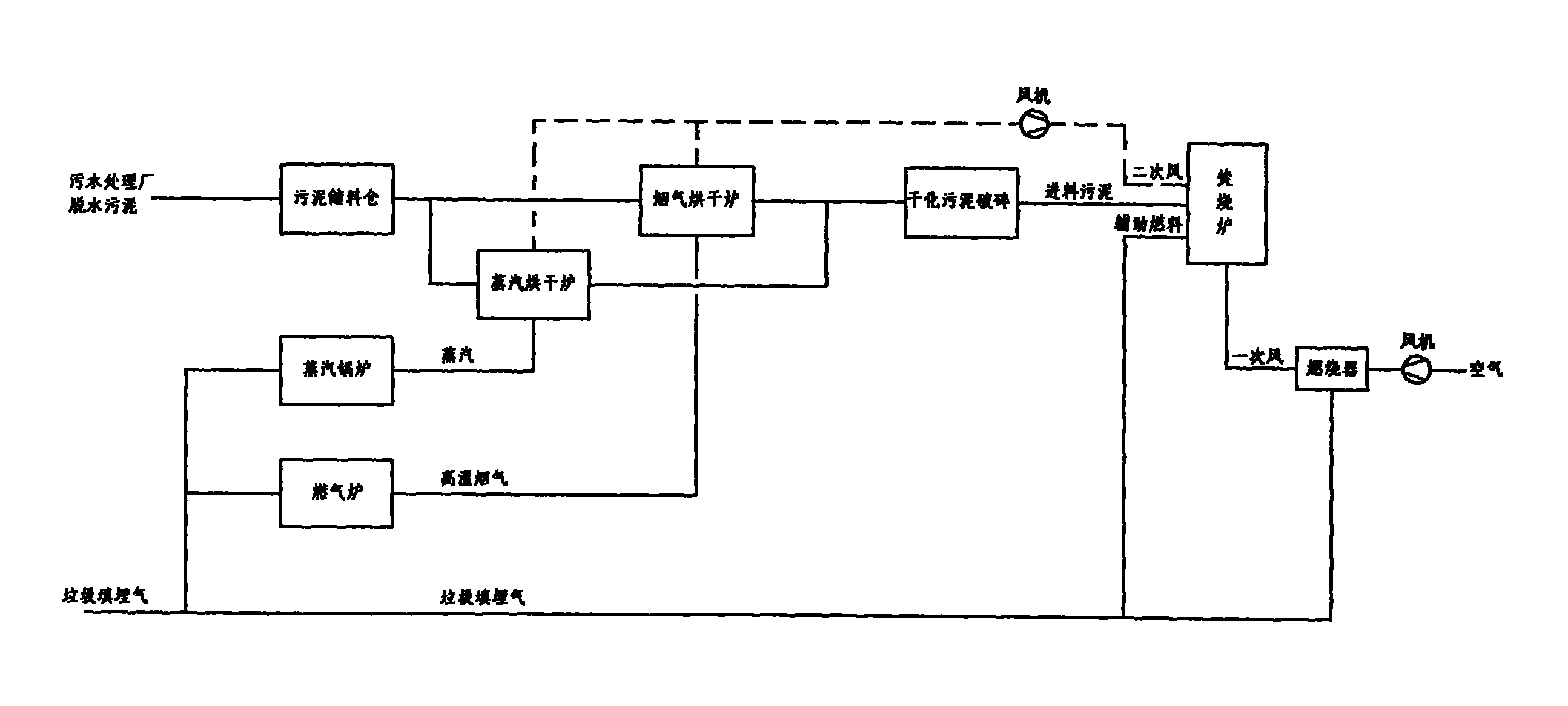

Municipal sludge incinerating system using rubbish landfill gas as auxiliary fuel

ActiveCN101539296BImprove incineration efficiencyReduce incineration costsSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeBubbling fluidized bed

Owner:南京碳环生物质科技有限公司

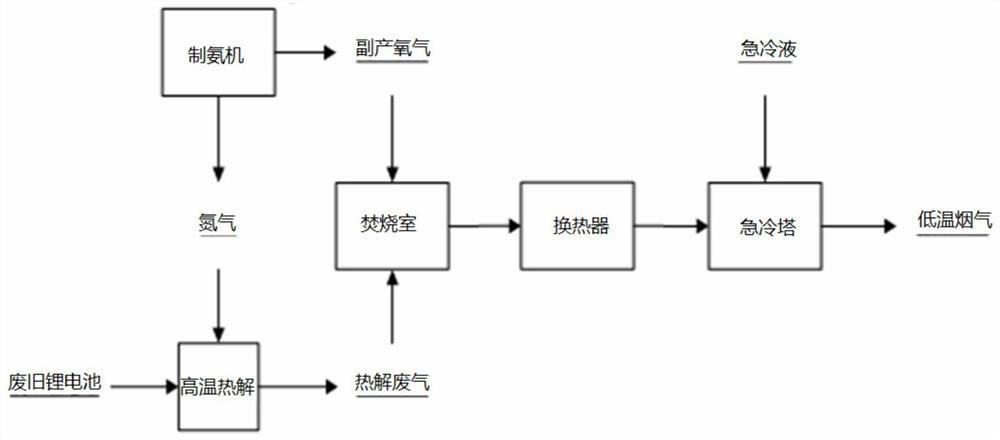

Method for preventing and treating dioxin in waste lithium battery pyrolysis process

PendingCN114353091AInhibitionBreak down toIndirect carbon-dioxide mitigationIncinerator apparatusNitrogen generatorFlue gas

The invention provides a method for preventing and treating dioxin in a waste lithium battery pyrolysis process. In the pyrolysis process of the waste lithium battery, inert gas is introduced to enable the pyrolysis process to be in an oxygen-deficient state, then waste gas generated by pyrolysis is sprayed into an incineration chamber, natural gas is sprayed to support combustion, the combustion temperature is controlled to be 850-1100 DEG C, meanwhile, oxygen-enriched gas is sprayed to form flame vortex with the pyrolysis waste gas, and the oxygen-enriched gas and the pyrolysis waste gas are fully mixed in the incineration chamber to generate oxidation reaction; and dioxin generated by pyrolysis is decomposed. And then flue gas discharged from the incineration chamber passes through a heat exchanger, the temperature is reduced to 600-700 DEG C, then the flue gas is introduced into a quench tower to be quenched, the flue gas is quenched to 200 DEG C or below, the quenching time is shorter than 1 second, and regeneration of dioxin is restrained. According to the method, the nitrogen making machine is used for producing nitrogen, meanwhile, the byproduct oxygen-enriched gas is produced, dioxin generated in the pyrolysis process of the waste lithium batteries is decomposed through oxygen-enriched combustion, the use amount of natural gas is reduced, the cost is relatively low, and the method is suitable for large-scale recycling of the waste lithium batteries.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

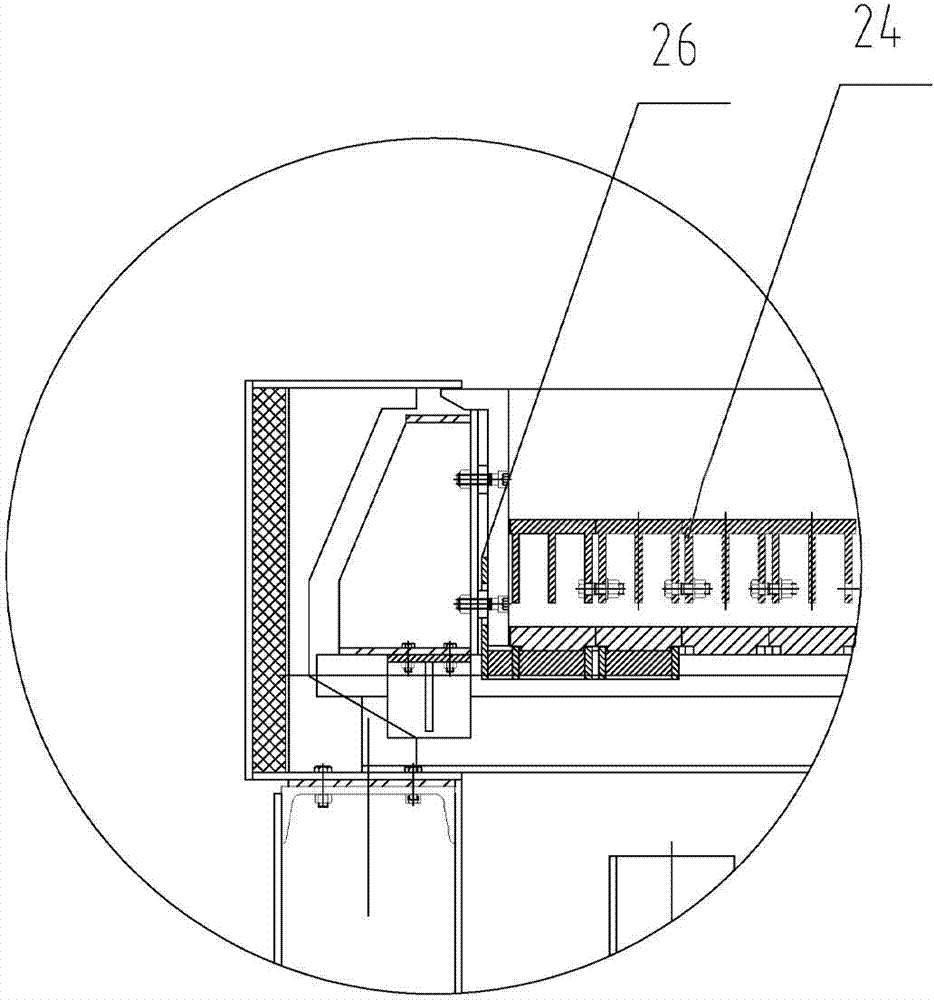

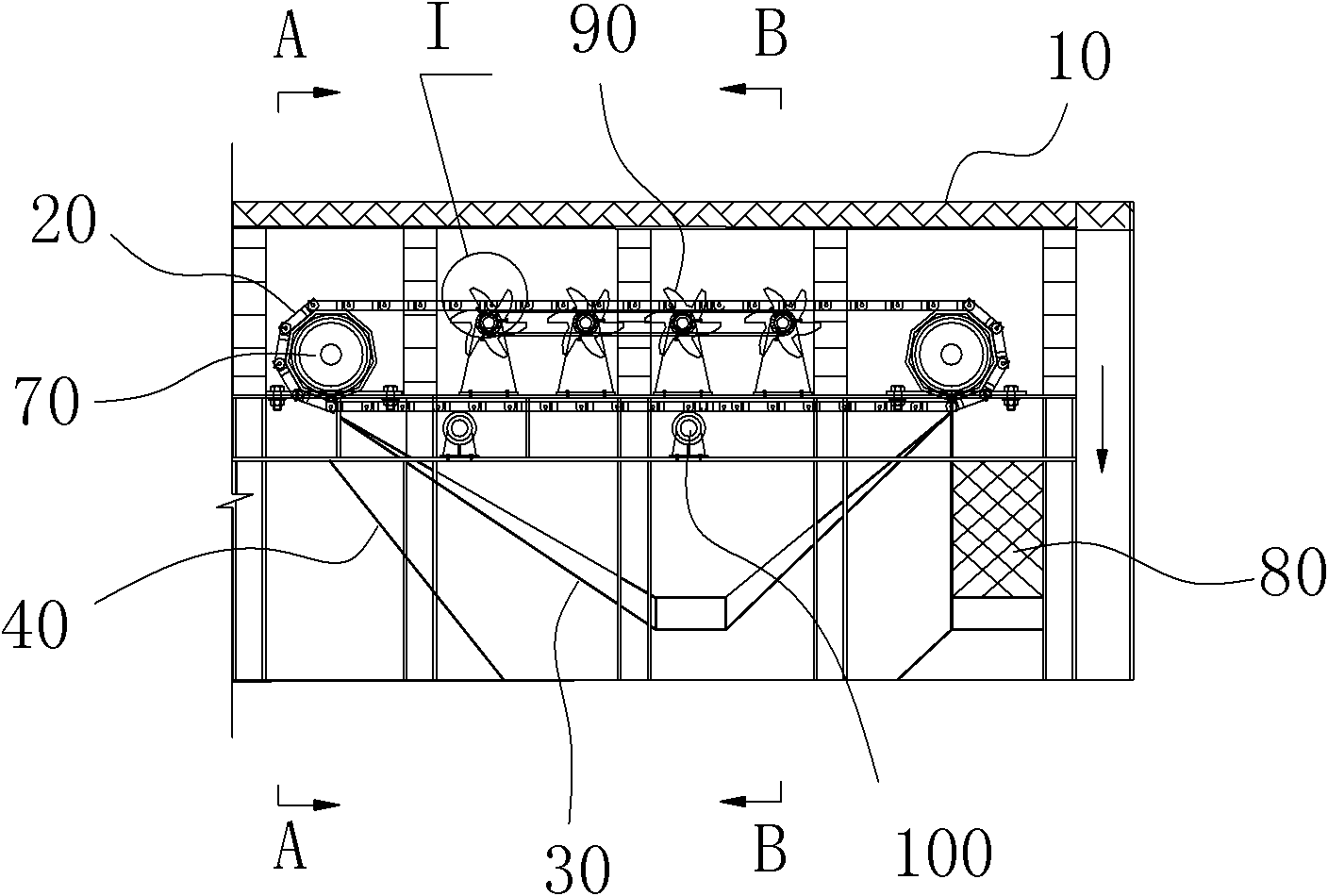

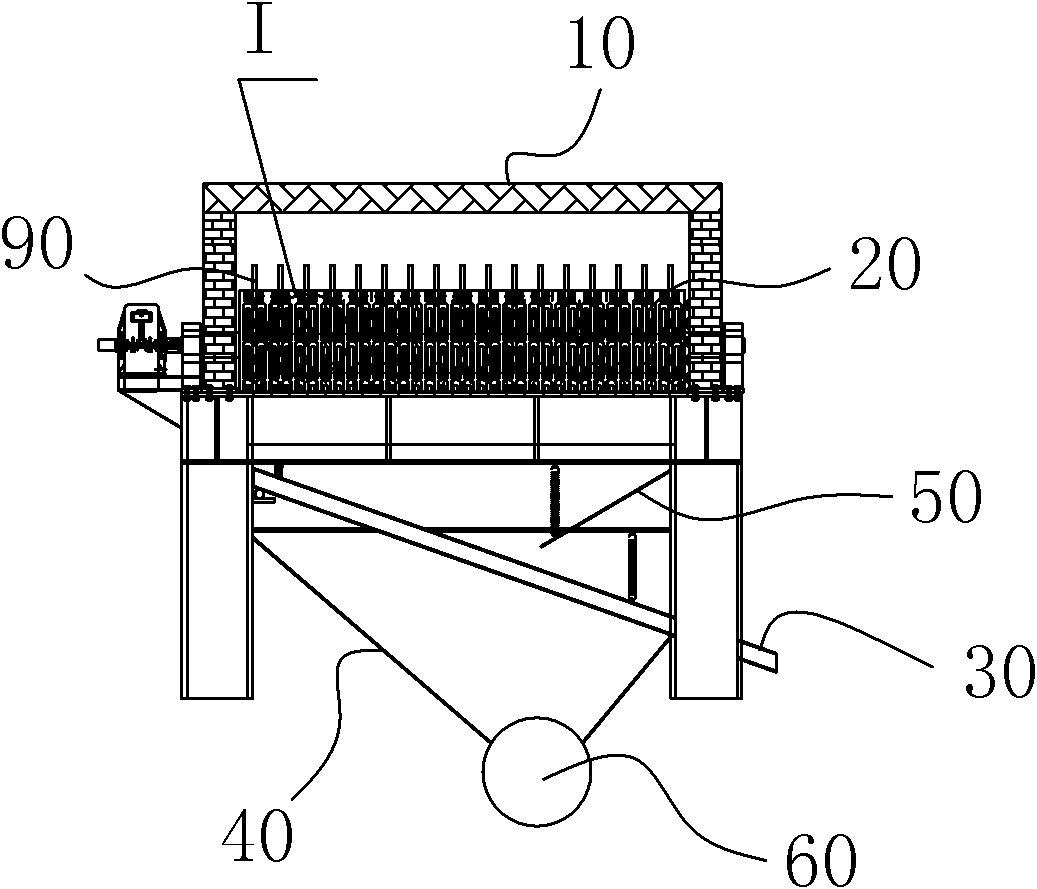

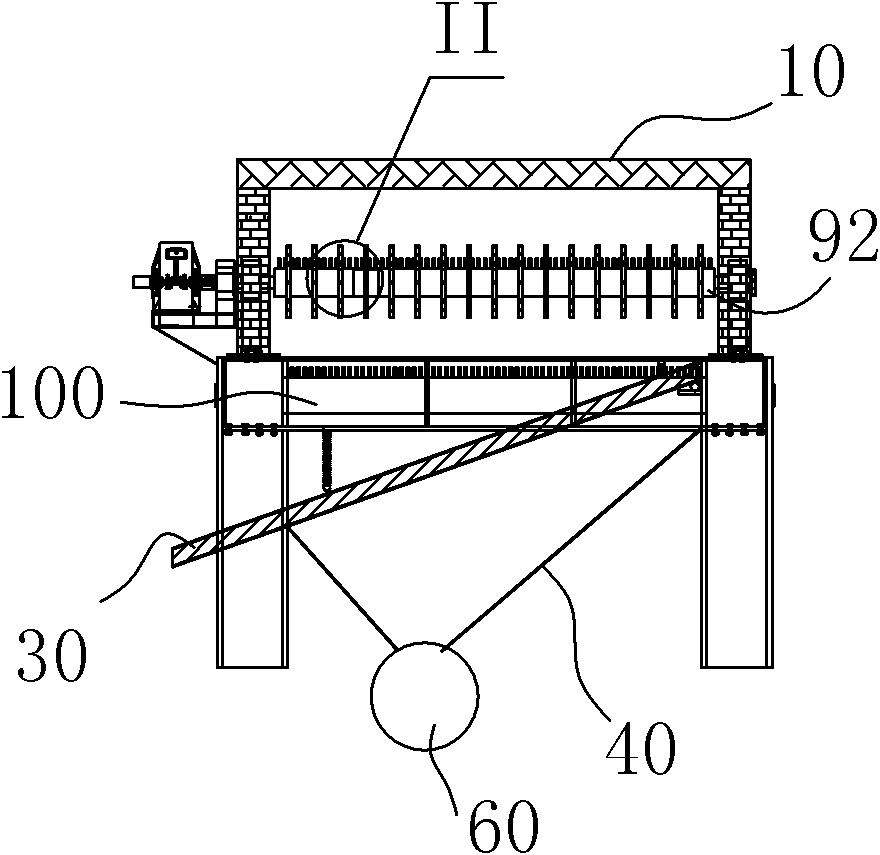

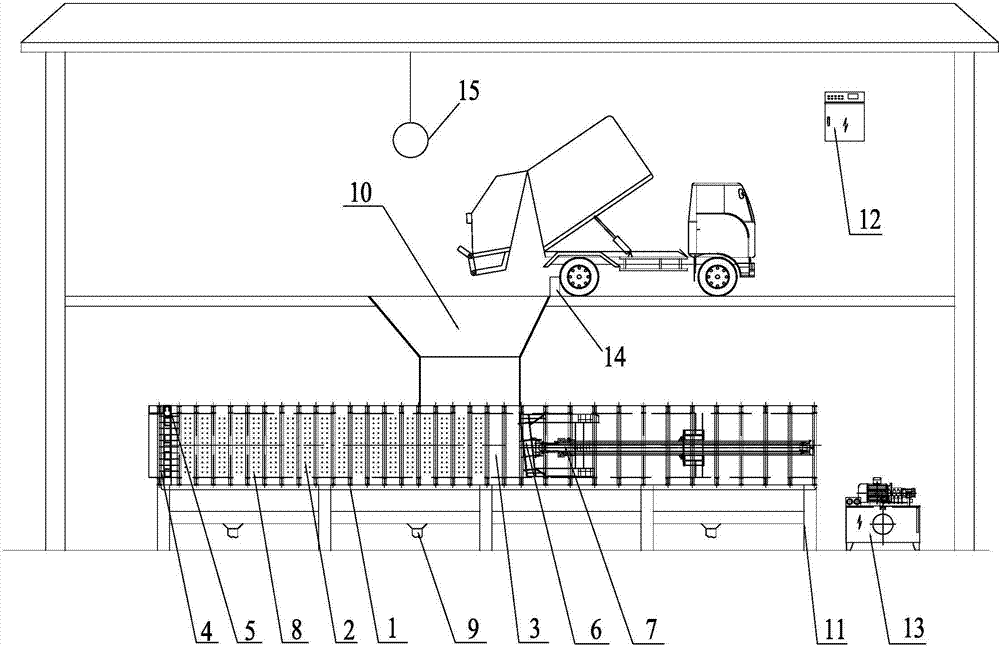

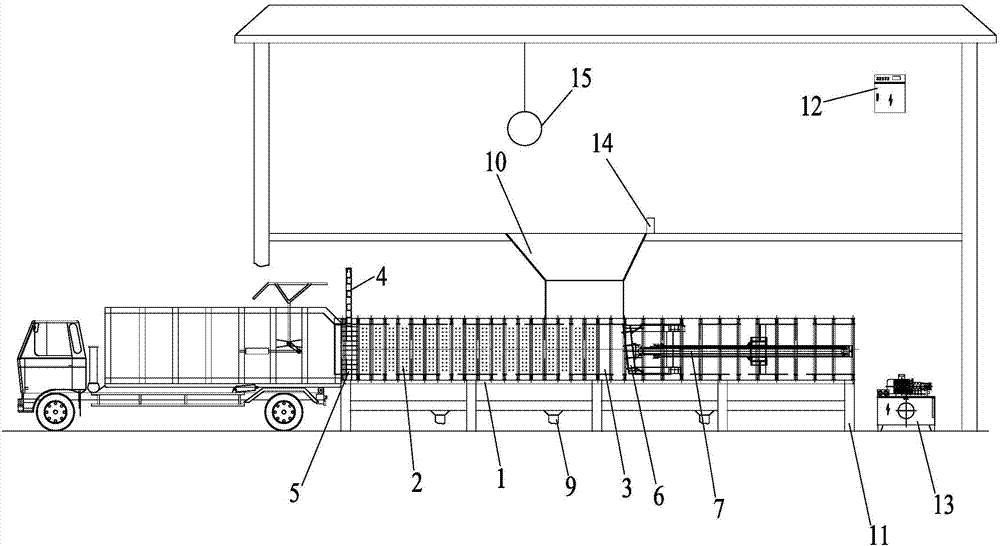

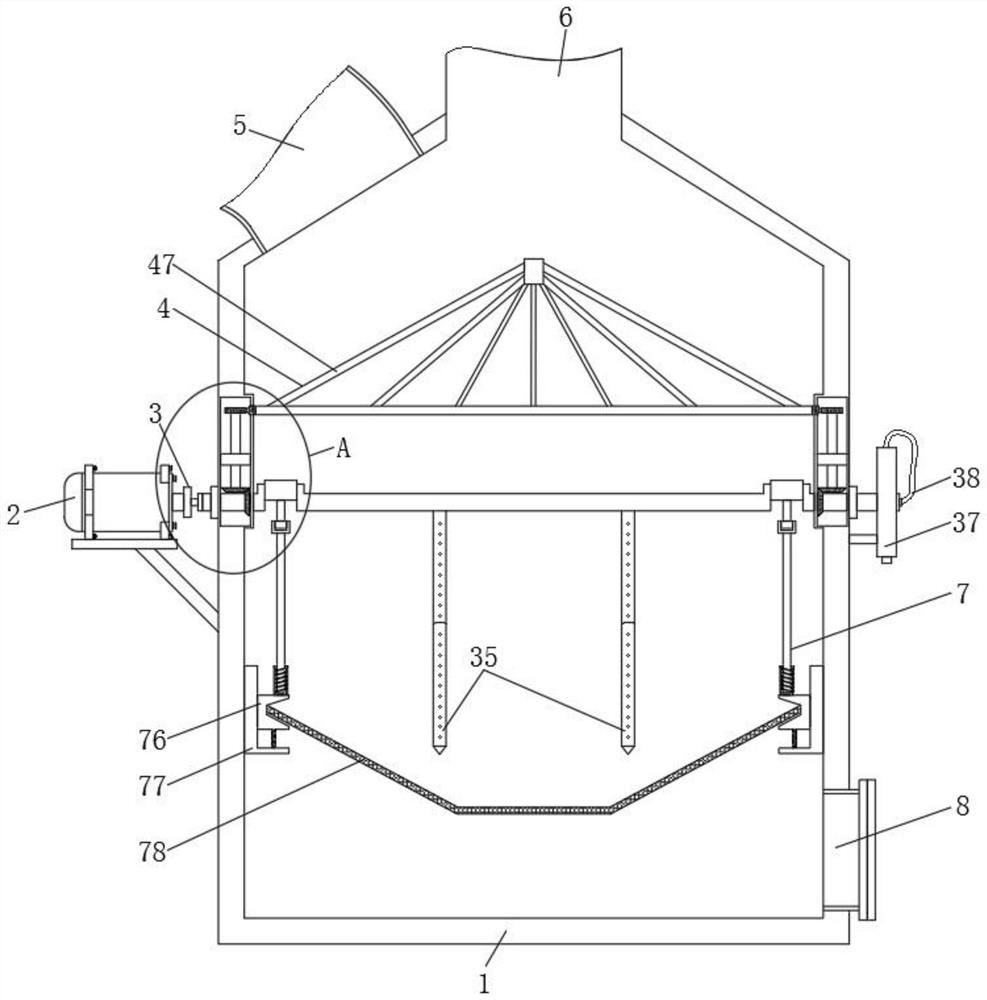

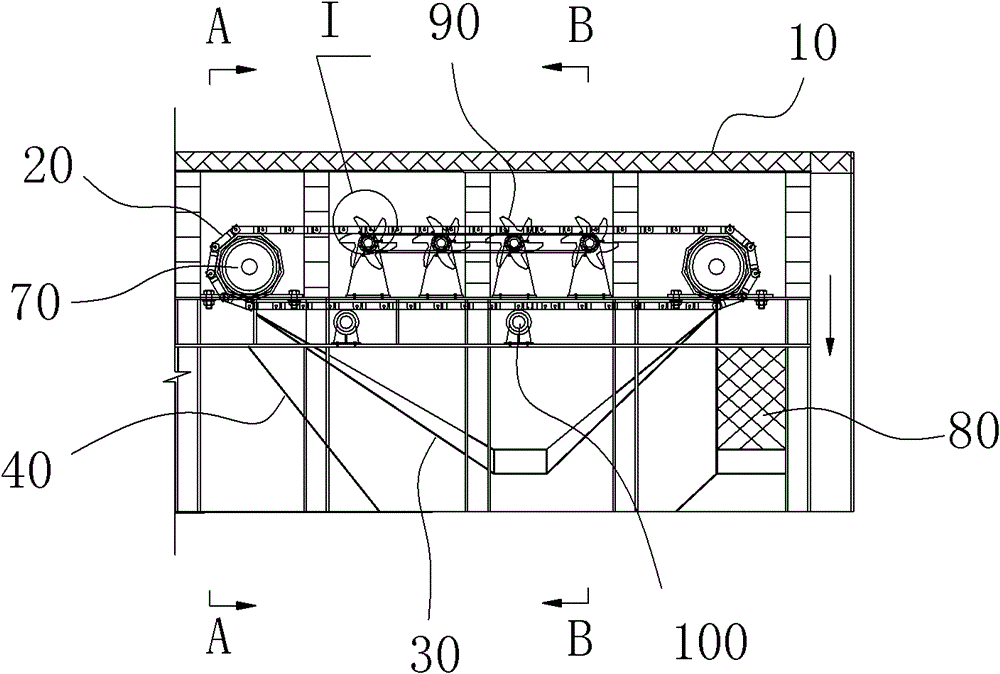

High-strength compression dehydration garbage station

InactiveCN106865080AEffective weight lossReduce incineration costsRefuse transferringLoading/unloadingReciprocating motionDrain tube

The invention belongs to the technical field of environmental-friendly equipment and relates to a high-strength compression dehydration garbage station which comprises a rack placed on a first layer of the garbage station. A box body is arranged on the rack; a compression bin and a garbage receiving bin which mutually communicate are arranged on the box body; and a garbage receiving hopper is arranged on the top of the box body and communicates with the garbage receiving bin. A pushing head is arranged in a cavity of the box body, conducts reciprocating movement along an inner cavity of the cavity and controls the size of space of the garbage receiving bin and the compression bin. The top end of the garbage receiving hopper extends to the position of a bottom plate of a second layer of the garbage station. A front gate is arranged at the end, away from the pushing head, on the box body, achieves lifting movement through a front gate oil cylinder arranged on the box body and controls opening and closing of the front end of the compression bin. A plurality of water outlets are formed in the bottom of the compression bin and communicate with a water collecting hopper at the bottom of the box body, and drainage pipelines are arranged at the bottom of the water collecting hopper. In the using process of the garbage machine, garbage can be effectively subjected to weight reducing operation, then freight and garbage incineration costs are reduced, and economic benefits are considerable.

Owner:无锡市中旺环保机械设备有限公司

Domestic garbage incinerator

Owner:江苏天目环保科技有限公司

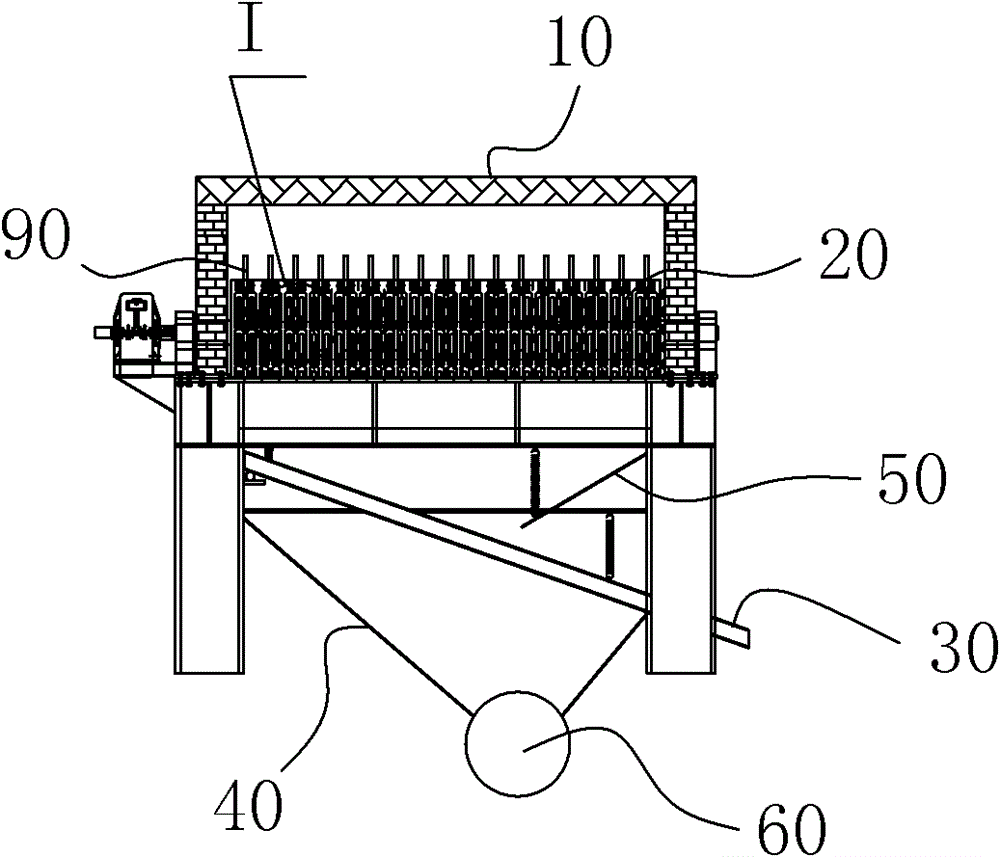

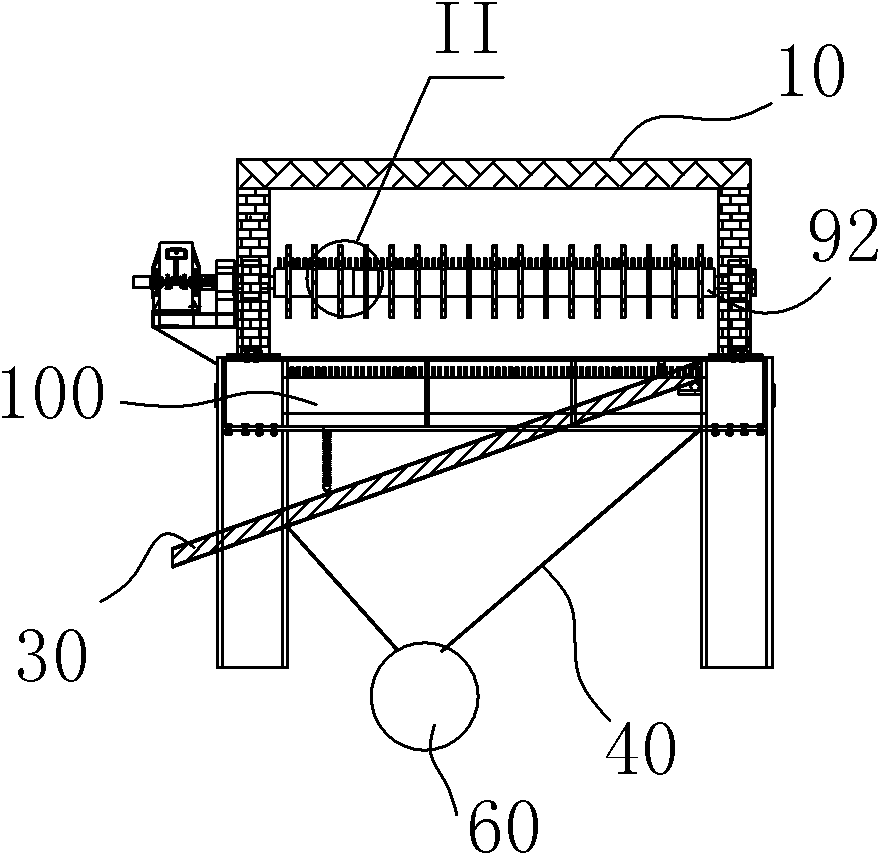

Garbage incinerator with double grates

InactiveCN108050521APromote combustionReduce incineration costsRevolving grateRocking grateCombustion chamberFlue gas

The invention discloses a garbage incinerator. The garbage incinerator comprises an incinerator body (11), a garbage feeding hopper (1), an incinerator grate and a flue gas outlet (14); the incinerator grate is composed of a stepped fire grate (5) and a rotary fire grate (6), wherein the rotary fire grate (6) is positioned at the bottom part of the incinerator body, and the stepped fire grate (5)is positioned on one side of the portion, above the rotary fire grate, of the incinerator body; the garbage feeding hopper (1) is positioned above the stepped fire grate, and the part, above the rotary fire grate, of the cavity of the incinerator body (11) is provided with a primary combustion chamber (9) and a secondary combustion chamber (10) from bottom to top; and a retaining wall (12) is arranged between the stepped fire grate (5) and the secondary combustion chamber (10), and gaps are reserved between the retaining wall (12) and the stepped fire grate (5) and between the retaining wall (12) and the inner wall of the portion, above the retaining wall (12), of the incinerator body. The garbage incinerator has the advantages that incineration cost can be reduced, the incineration efficiency is improved, and the garbage incinerator is particularly suitable for incinerating garbage with the high water content and the low garbage heat value.

Owner:王志斌

Garbage incinerator

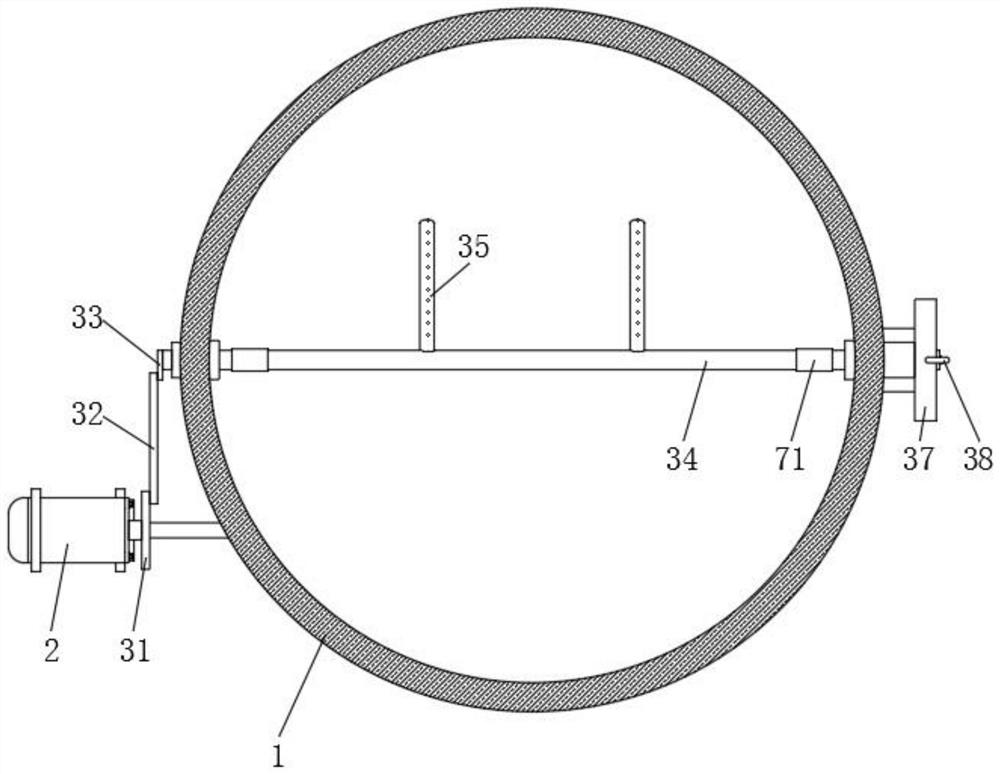

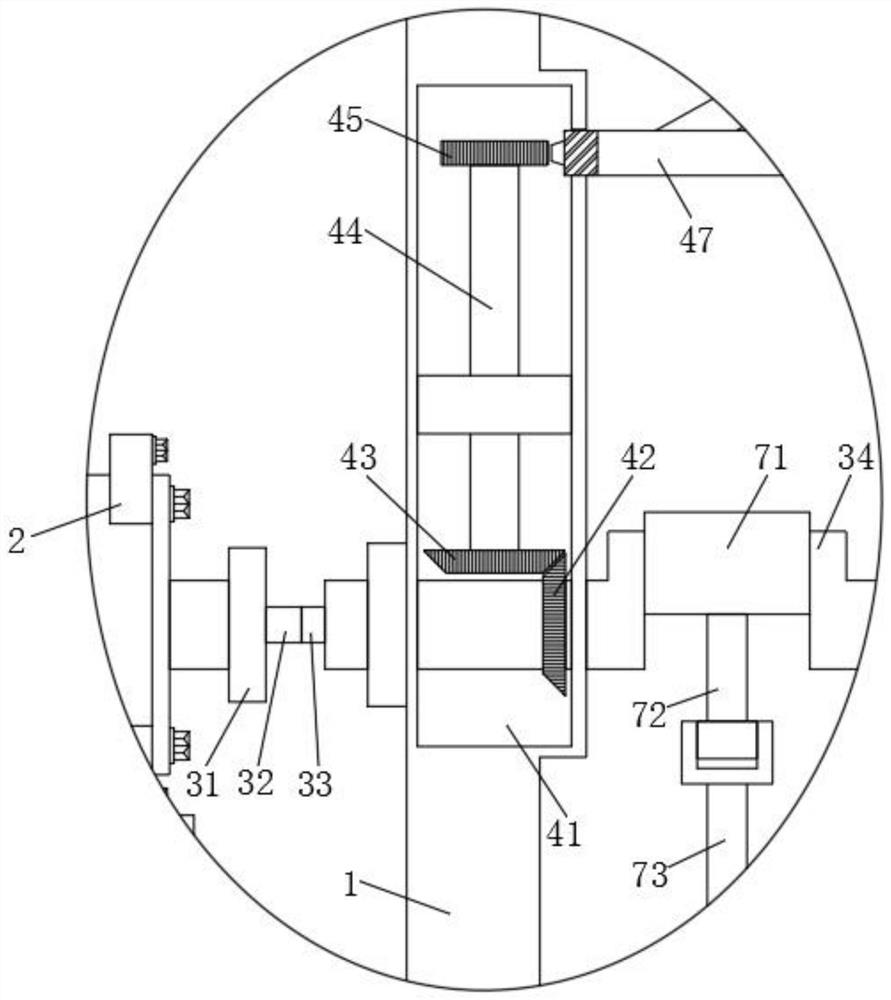

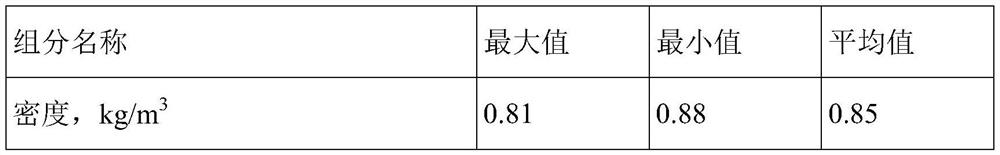

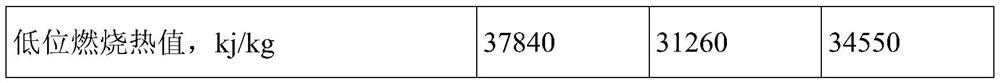

InactiveCN114593430AImprove incineration efficiencyAvoid it happening againIncinerator apparatusCombustionElectric machine

The invention relates to the technical field of garbage treatment, and discloses a garbage incinerator which comprises an incinerator body, a motor is fixedly installed at the middle section position of the left side of the incinerator body, the motor is fixedly connected with a turning mechanism, an anti-extinguishing mechanism is arranged at the upper end of the turning mechanism, and a feeding port is formed in the upper left end of the anti-extinguishing mechanism; a flue is arranged on the right side of the feeding port, a vibration mechanism is arranged on the upper side of the bottom end of the furnace body, and an ash outlet is formed in the right side of the bottom end of the vibration mechanism. According to the garbage incinerator, through the arranged turning mechanism, garbage combustion is more thorough, the combustion efficiency is higher, harmful gas is prevented from being generated due to incomplete garbage combustion, the body health of workers is prevented from being damaged, and through the arranged extinguishing prevention mechanism, the situation that the garbage directly falls to cover the combusting garbage, flames are prone to being extinguished, and the temperature in the incinerator body is unstable is effectively prevented; incineration efficiency is improved, and incineration cost is saved.

Owner:李绍亭

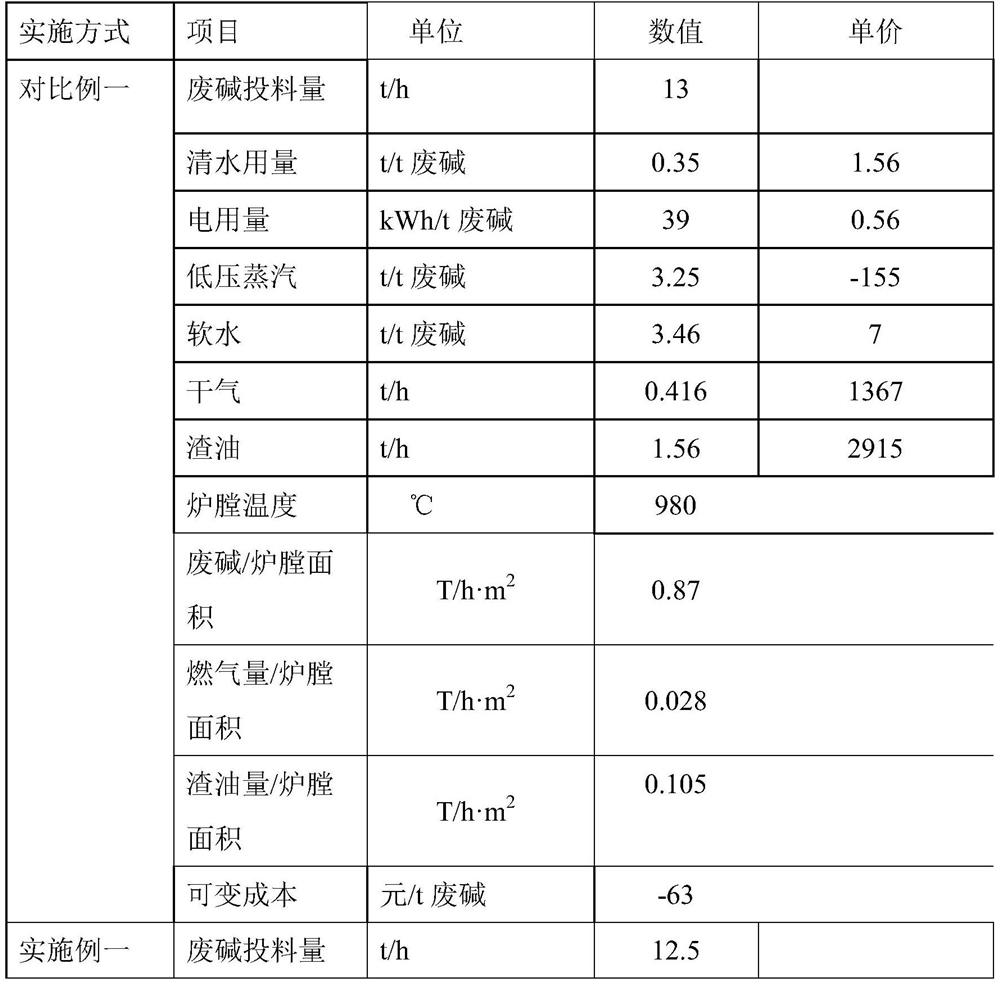

A method for burning petrochemical waste liquid based on gas and oily liquid mixed fuel

ActiveCN108870413BReduce incineration costsAvoid pollution and even stalled parking problemsIncinerator apparatusCombined combustion mitigationProcess engineeringPetrochemical

The invention discloses a method for incinerating petrochemical industry waste liquid based on mixed fuel of gas and oily liquid. The method comprises the steps of spraying the petrochemical industrywaste liquid into a combustion area of a spent caustic incinerator in an atomized manner, using fuel gas and oily liquid as combustion-supporting fuel, and carrying out combustion on the condition ofblowing in gas with oxygen while controlling the temperature of the combustion area to range from 800 DEG C to 1, 200 DEG C, wherein the material input of petrochemical industry waste liquid, and thematerial input of the fuel gas and the oily liquid simultaneously meet the requirements that the ratio of petrochemical industry waste liquid quantity per hour to spent caustic incinerator combustionarea hearth cross sectional area ranges from 0.7 to 1.0 t / h.m2, the ratio of fuel gas quantity per hour to spent caustic incinerator combustion area hearth cross sectional area ranges from 0.05 to 0.09 t / h.m2, and the ratio of oily liquid quantity per hour to spent caustic incinerator combustion area hearth cross sectional area ranges from 0.03 to 0.08 t / h.m2. With the method for incinerating petrochemical industry waste liquid based on mixed fuel of gas and oily liquid, it can be achieved that the combustion load is reasonable, the processing cost is reduced, damage caused by overhigh combustion load to a device is reduced, and it is beneficial for a waste liquid incineration technology to be promoted and applied to industries.

Owner:CHINA PETROLEUM & CHEM CORP +1

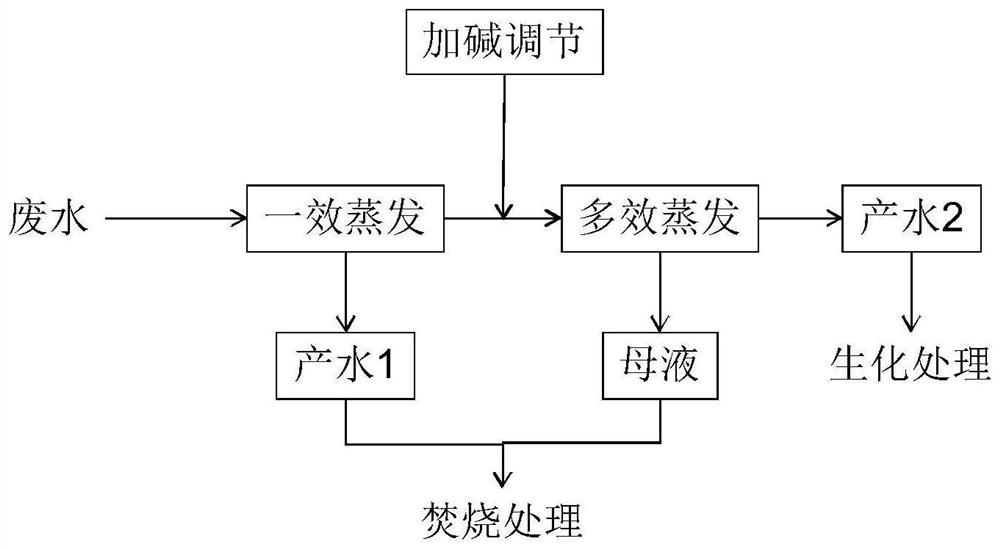

Acrylate production wastewater treatment process method

PendingCN114394707AReduce COD productionReduce consumptionMultistage water/sewage treatmentNature of treatment waterProcess engineeringTreatment costs

The invention discloses a treatment process of acrylic ester production wastewater. A traditional acrylic ester production wastewater treatment method is incineration treatment, the treatment cost of the method is extremely high, and the treatment cost of each ton of water can reach more than 600 yuan. The acrylic ester production wastewater is subjected to concentration and decrement treatment by using a multi-effect evaporation treatment technology, the incineration treatment amount of the wastewater can be effectively reduced, the treatment cost is reduced, and the distilled water has the characteristics of low COD (Chemical Oxygen Demand) content and good biochemical effect.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

A device and method for resource utilization of oily solid waste

InactiveCN104748130BImprove resource yieldPyrolytic distillation speeds upIncinerator apparatusAir preheaterCombustor

The invention discloses an oil-bearing solid waste resource utilization device and method. The device comprises a hopper, a feeding device, a fluidized bed pyrolytic reaction distiller, a dust collector, an air pre-heater, a booster fan, a combustor, a buried pipe heat exchanger, a condenser, a fluidizing air pre-heater and an air chamber. The method includes the steps that oil in solid waste is pyrolyzed and distilled, pyrolyzed and distilled gas serves as an inert circulating medium, pyrolytic gas is cooled and liquefied in the air pre-heater and the condenser and separated to obtain fluid oil, reclamation is achieved, and noncondensing gas serves as pyrolytic fuel; after fresh air is heated in the air pre-heater, the fresh air, the noncondensing gas and make-up fuel combust and become high-temperature gas to provide heat for the fluidized bed pyrolytic reaction distiller. According to the device, oil in the oil-bearing solid waste is separated, solid waste resource utilization is achieved, and the effects of reducing environmental pollution and improving solid waste reclamation are achieved at the same time.

Owner:SOUTHEAST UNIV

Compound sludge dewatering conditioner adaptable to technology for preparation of odorless fuel rods from excess sludge as well as preparation method and application of conditioner

InactiveCN104891775ALow cost of dehydrationSimple methodSludge treatment by de-watering/drying/thickeningBiomassPulverised fuel ash

The invention relates to a compound sludge dewatering conditioner adaptable to a technology for preparation of odorless fuel rods from excess sludge as well as a preparation method and an application of the conditioner. The conditioner comprises components in percentage by mass as follows: 1%-20% of SiO2, 5%-10% of Al2O3, 1%-10% of Fe2O3, 0.5%-10% of CaO, 15%-50% of C and 0.6%-2% of N. The preparation method comprises steps as follows: fly ash, municipal solid waste, sludge, biomass and excess sludge which contains 97% of moisture and is produced by anaerobic water treatment are mixed and ventilated for 7-20 days, and the conditioner is obtained. The conditioner has the advantages that sludge is dewatered with a lysis technology, the conditioner is non-toxic and harmless and cannot cause secondary pollution to the environment, the dewatering cost is low and the like; when the conditioner is applied to deep sludge dewatering, the method is simple, the dewatering rate can be adjusted according to comprehensive utilization application of the sludge, the moisture can be decreased to be lower than 30%, preparation of the odorless sludge fuel rods is facilitated, and the sludge incineration cost is reduced.

Owner:DONGHUA UNIV

Garbage incinerator

Owner:李登平

Exhaust gas wet dust removal garbage incineration device

ActiveCN108413405AAchieving stirringImprove incineration efficiencyEmission preventionIncinerator apparatusCombustion chamberLitter

The invention discloses an exhaust gas wet dust removal garbage incineration device which comprises a feeder, a combustion chamber, a gas collecting device, a gas washing chamber and a dust remover, wherein the combustion chamber is formed in the right side of the feeder; a gas pipeline comprises a main heater and an ignition heater; the main heater is inserted in the combustion chamber and is positioned below a combustion grid; the ignition heater is inserted in the combustion chamber and is positioned above a stirring device; the gas collecting device is connected with a position above the right side wall of the interior of the combustion chamber; a gas collecting hood is inserted in the right side wall of the combustion chamber and is connected with a gas guiding pipe; an induced air wind wheel driven by a motor is arranged in the gas guiding pipe; the lower part of the gas guiding pipe is inserted in the gas washing chamber; the part, below the internal liquid level of the gas washing chamber, of the gas guiding pipe is provided with a gas discharging cylinder; the dust remover is positioned above the gas washing chamber; and the air in the gas washing chamber enters the dust remover through a first connecting pipe. Through arranging the wet dust remover, the exhaust gas wet dust removal garbage incineration device can realize purifying treatment of exhaust gas after garbage incineration and is flexible and convenient to operate, excellent in purifying effect, high in treatment efficiency and suitable for being widely used in garbage incineration.

Owner:江苏蓝电环保股份有限公司

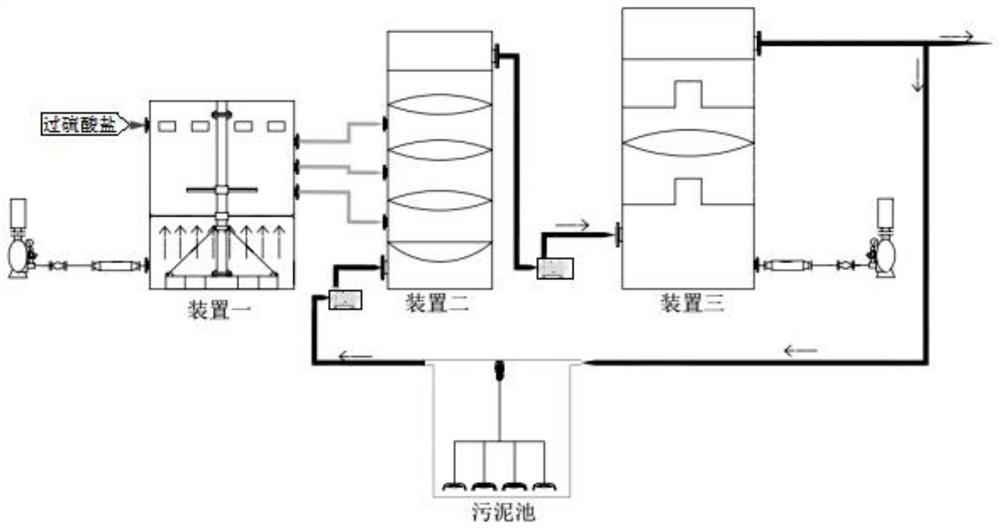

Method for treating active microorganisms in sewage

ActiveCN113788517AImprove mixing efficiencyDissolve fastSludge treatment by de-watering/drying/thickeningWater aerationActivated sludgeMicroorganism

The invention discloses a method for treating active microorganisms in sewage, which comprises the following steps: I, ultrasonic treatment is conducted on a persulfate aqueous solution by using an ultrasonic converter to obtain aerosol; II, the generated aerosol enters a three-dimensional catalytic reactor and is subjected to a catalytic reaction with activated sludge in a three-dimensional catalytic reactor; III, the degraded homogeneous activated sludge enters a catalytic oxidation reactor, and the activated sludge is further destroyed and degraded; and VI, one part of treated activated sludge is filtered, supernate is directly fed into a biochemical sludge tank to be used as a nutrient solution, and the other part of the treated activated sludge is discharged. The treatment effect of the method is obviously better than that of other treatment methods, the sludge reduction effect is obvious, and the method has important significance for reducing the sludge treatment cost.

Owner:WEIHAI COSCO SHIPBUILDING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com