Patents

Literature

1972results about "Refuse transferring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

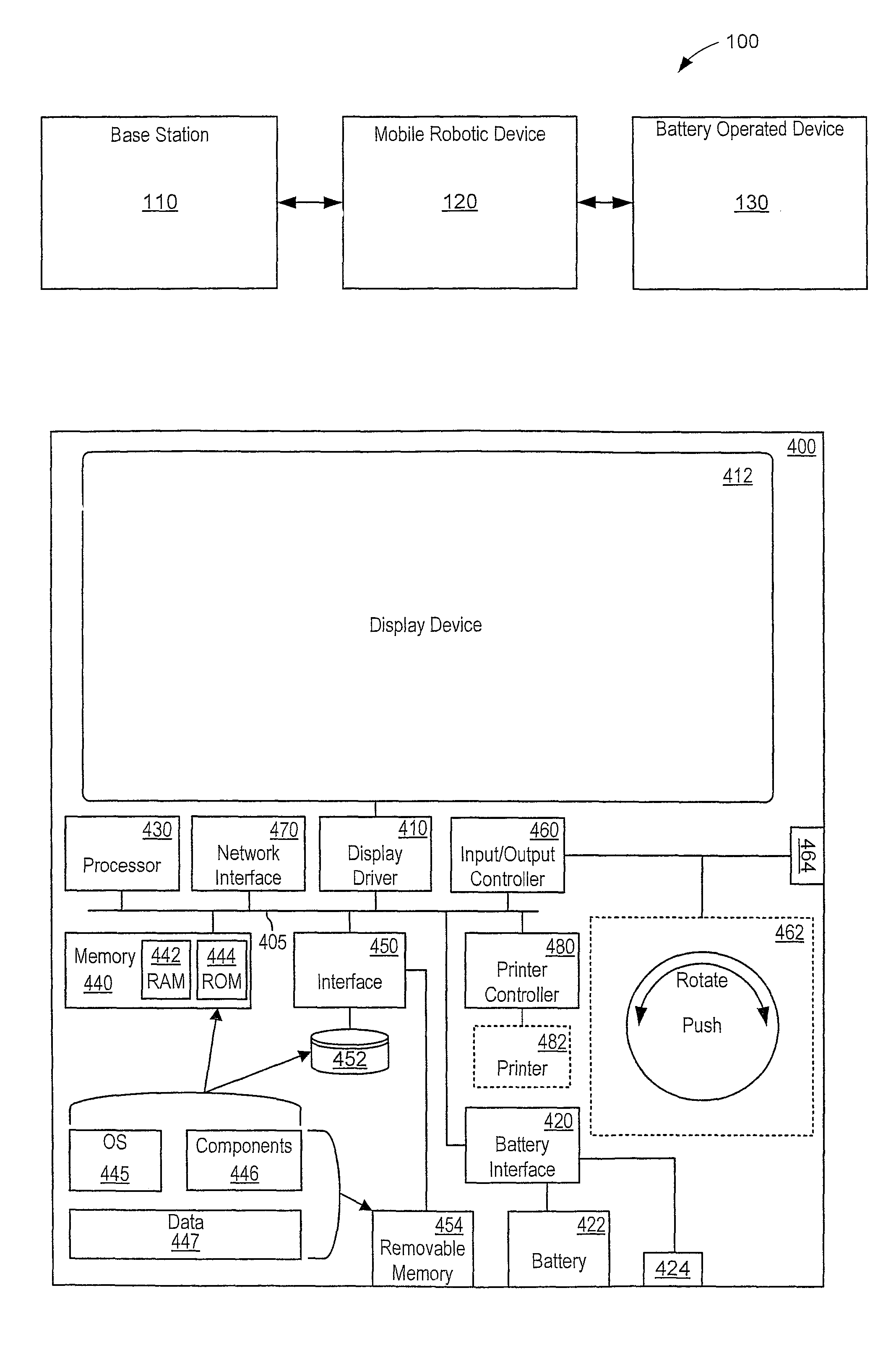

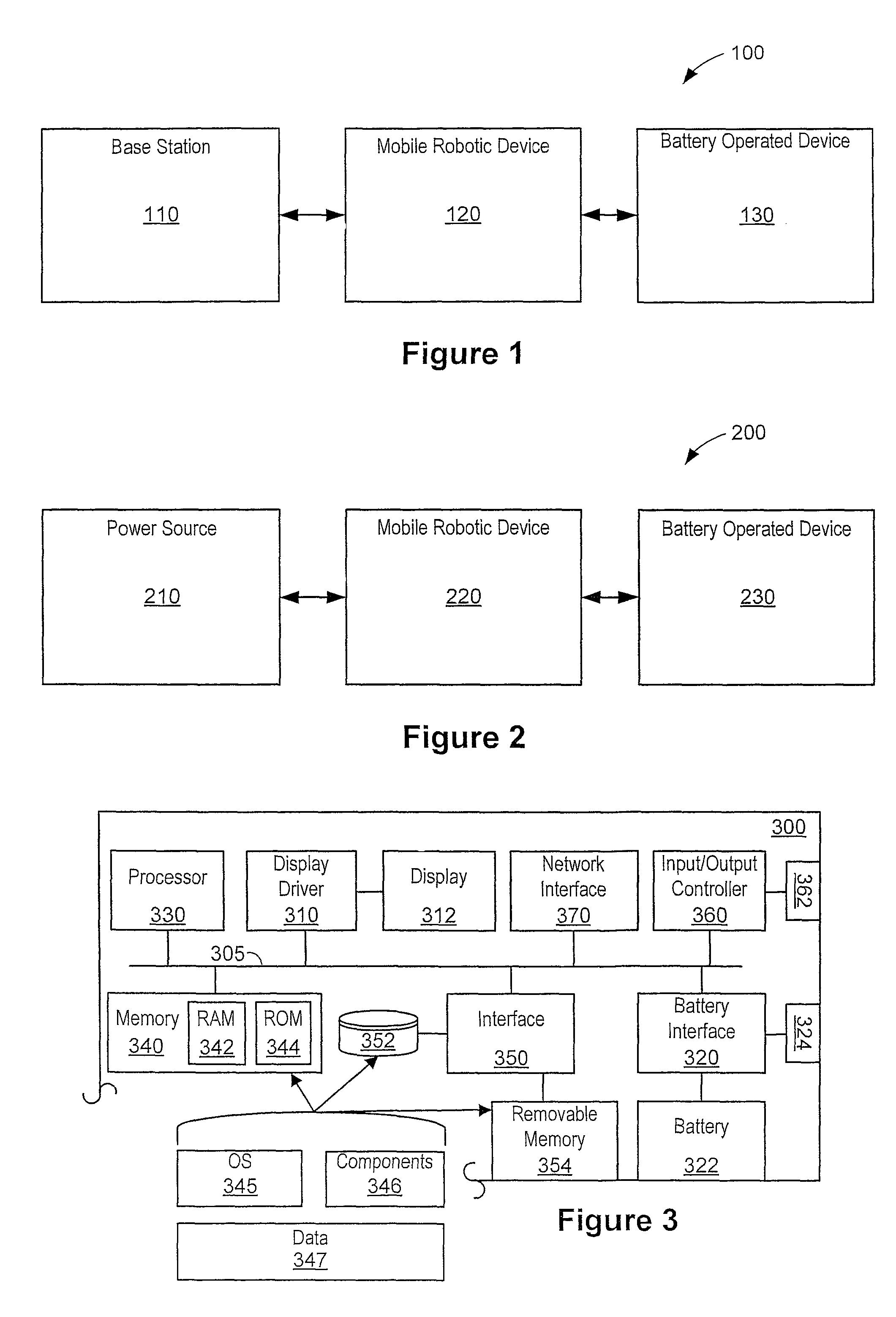

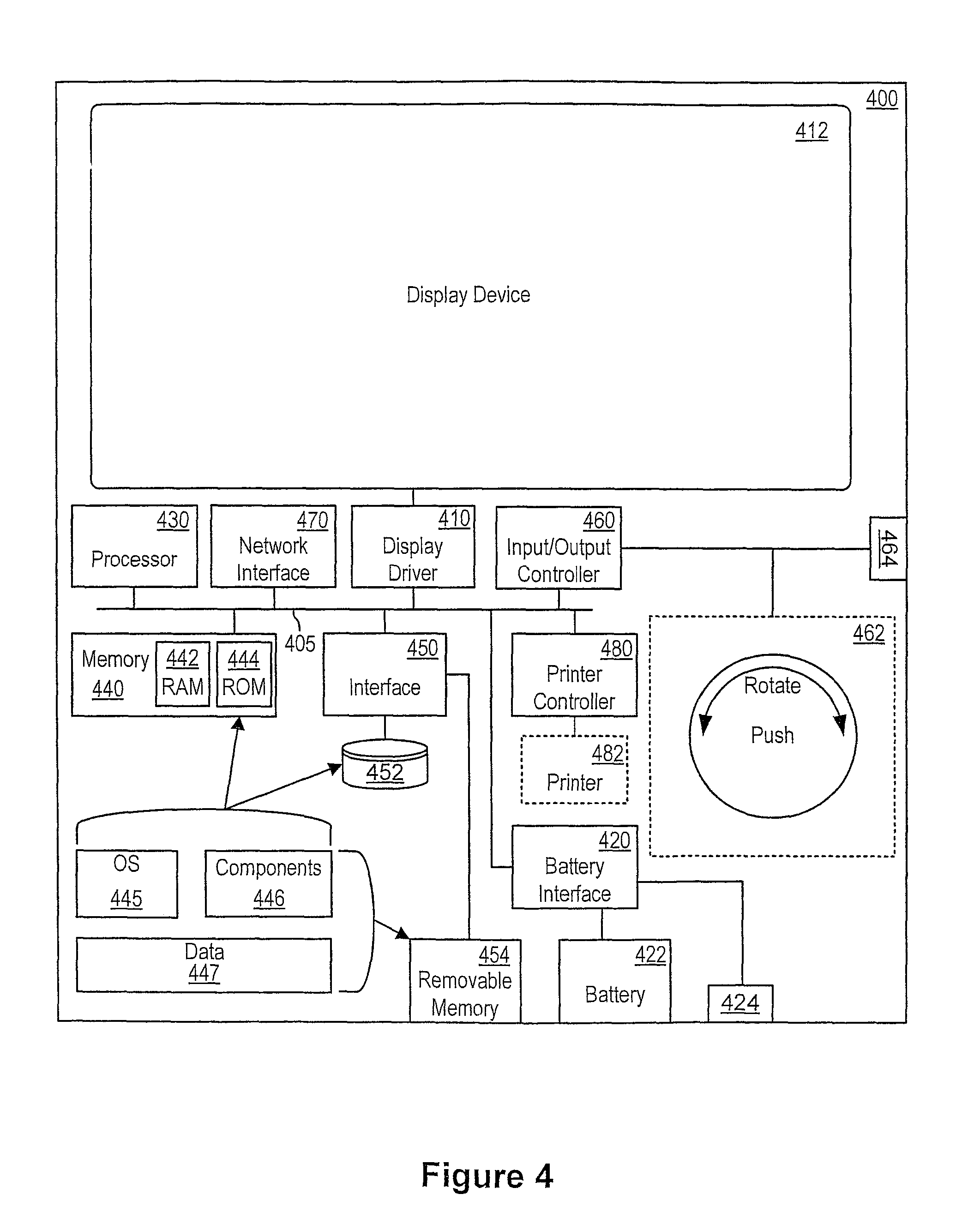

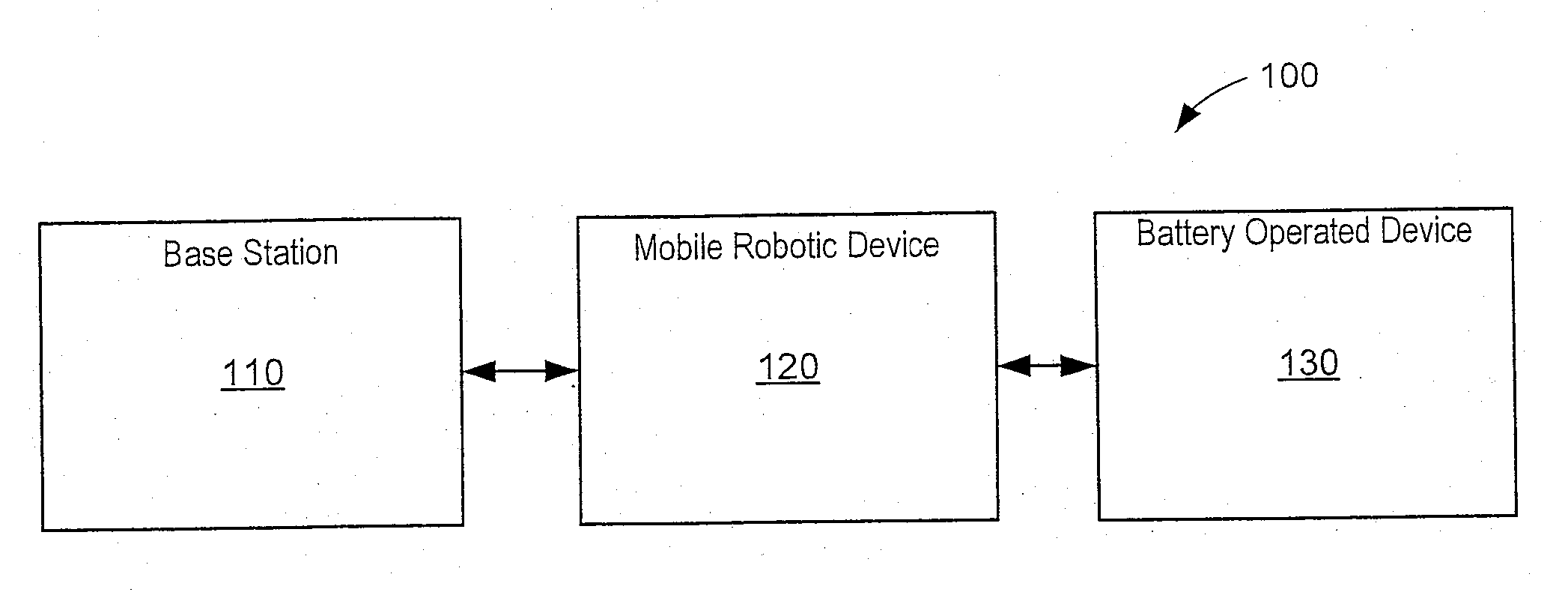

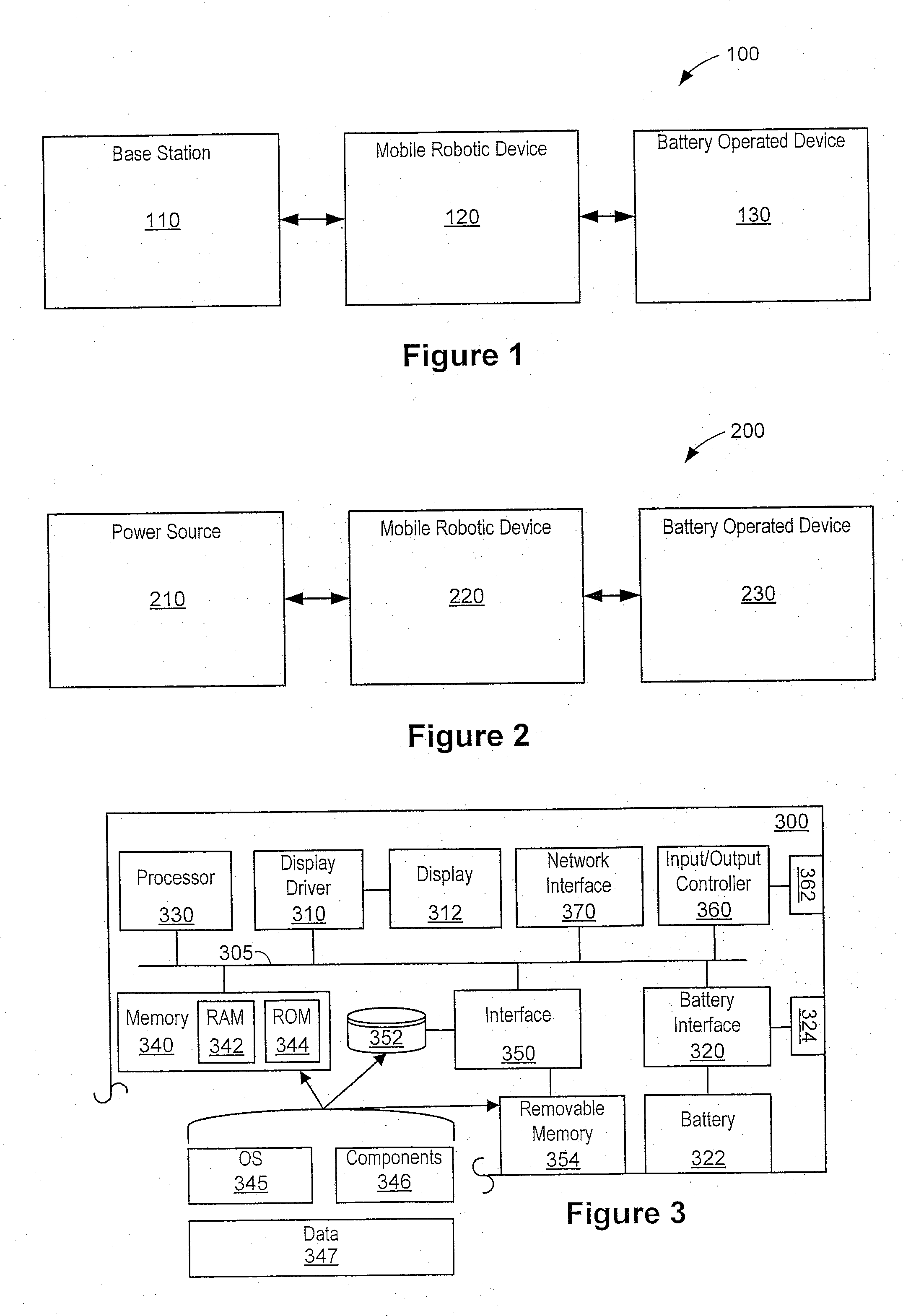

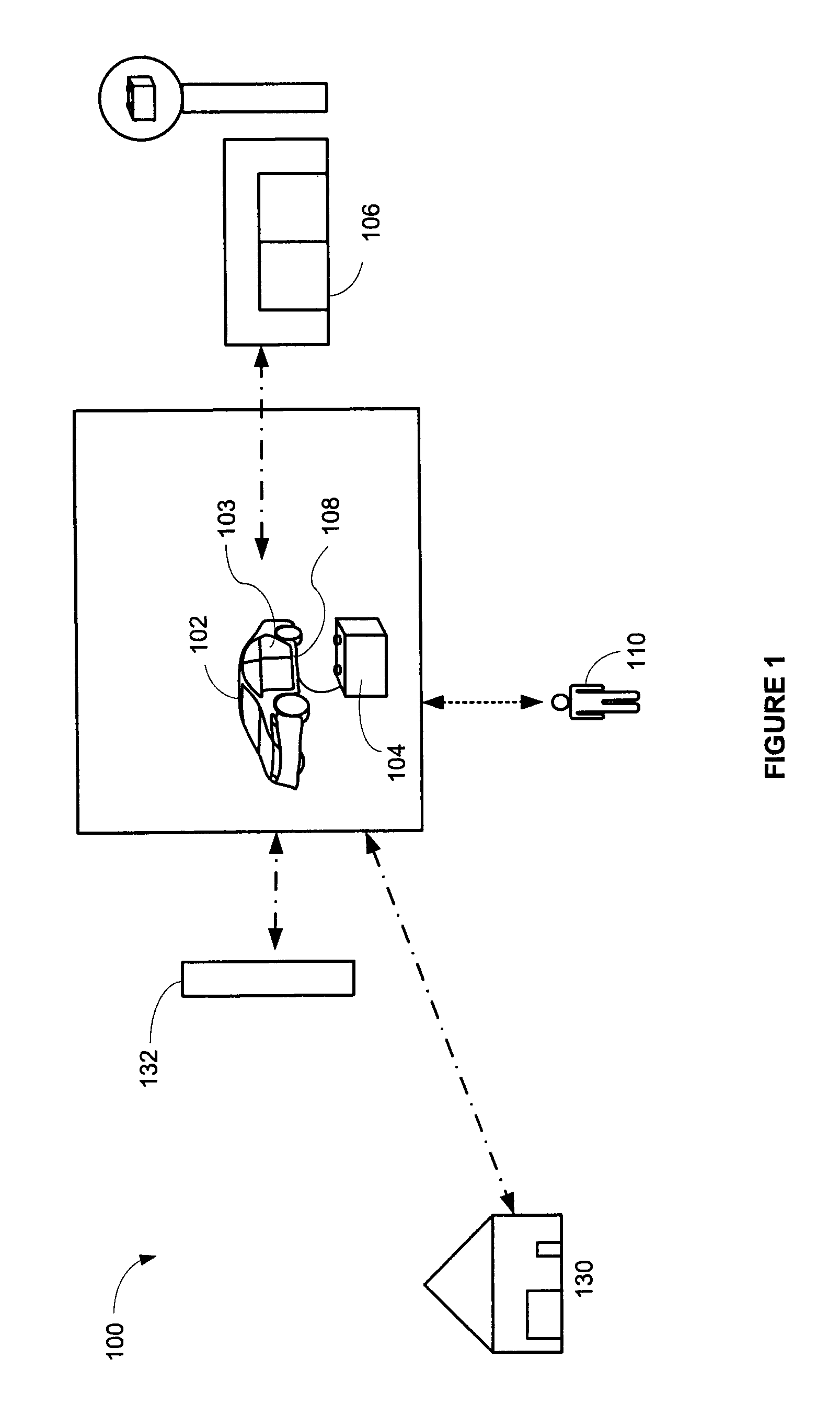

Automated battery and data delivery system

Systems and methods are provided that use a mobile robotic device to transport rechargeable batteries between a base station, which charges the batteries, and a battery operated device, such as battery powered kiosk or signage system, which uses a charged battery as a power source. After traveling to a battery operated device, the mobile robotic device removes any discharged batteries from the battery operated device and installs a charged battery. The mobile robotic device then travels to the base station and attaches the discharged battery to the base station for recharging. The mobile robotic device may be configured to perform other transfers, such as data transfers and paper transfers. In addition, the mobile robotic device may be configured to perform a photographic and spatial survey of the isles, retail shelves, and surrounding environment for various purposes, such as generating three-dimensional store models and remote viewing.

Owner:MACDONALD MURRAY

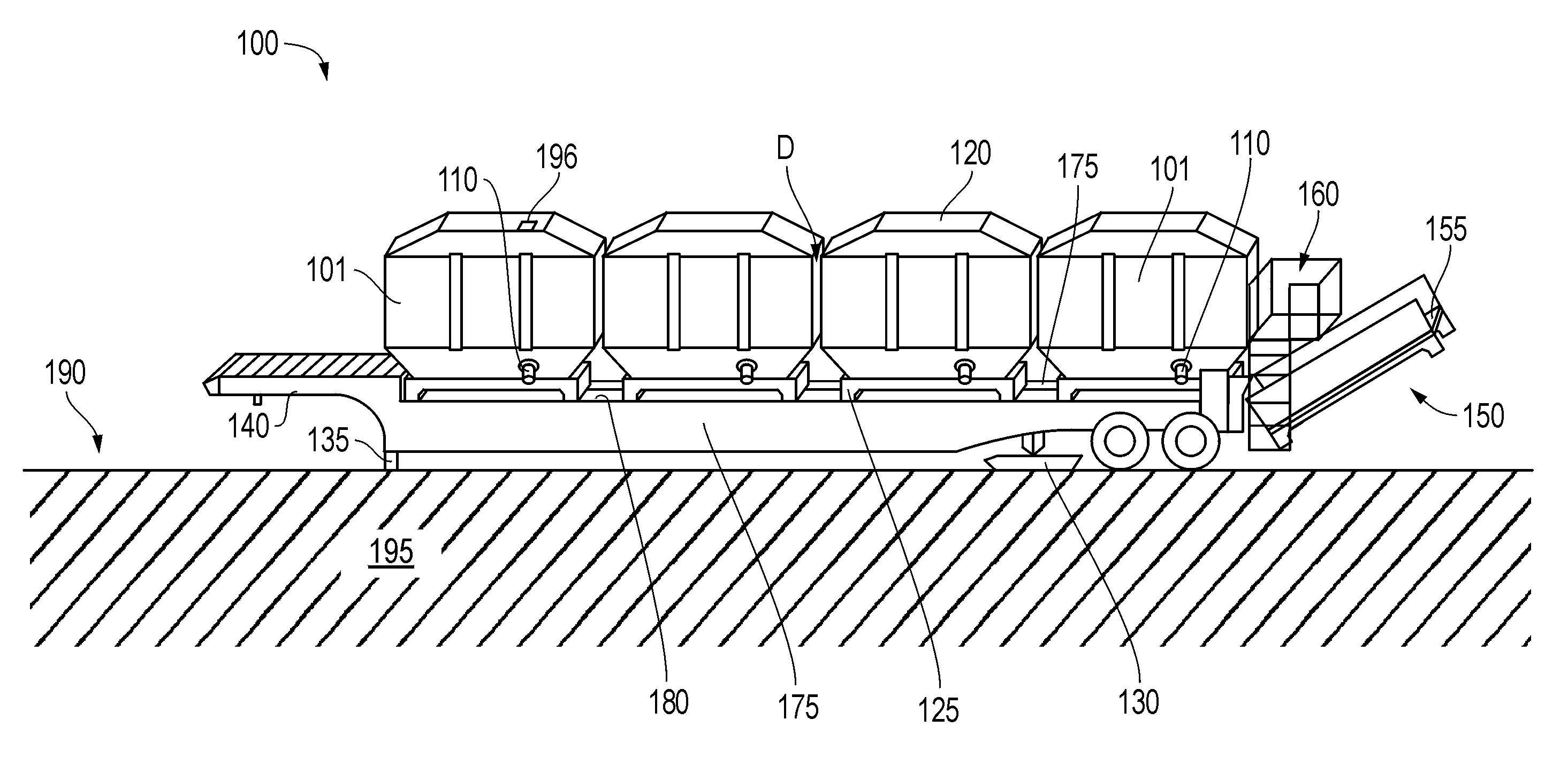

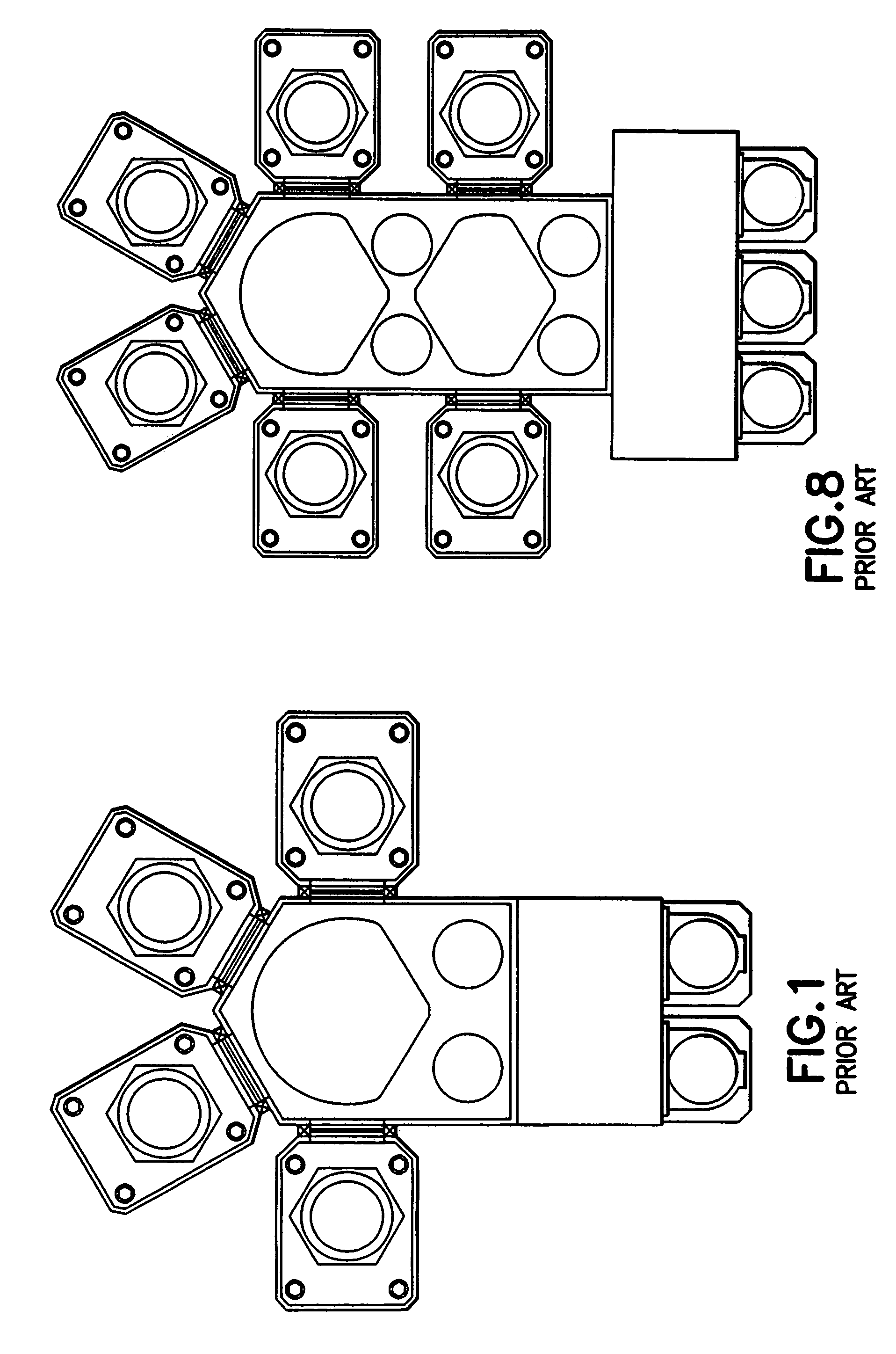

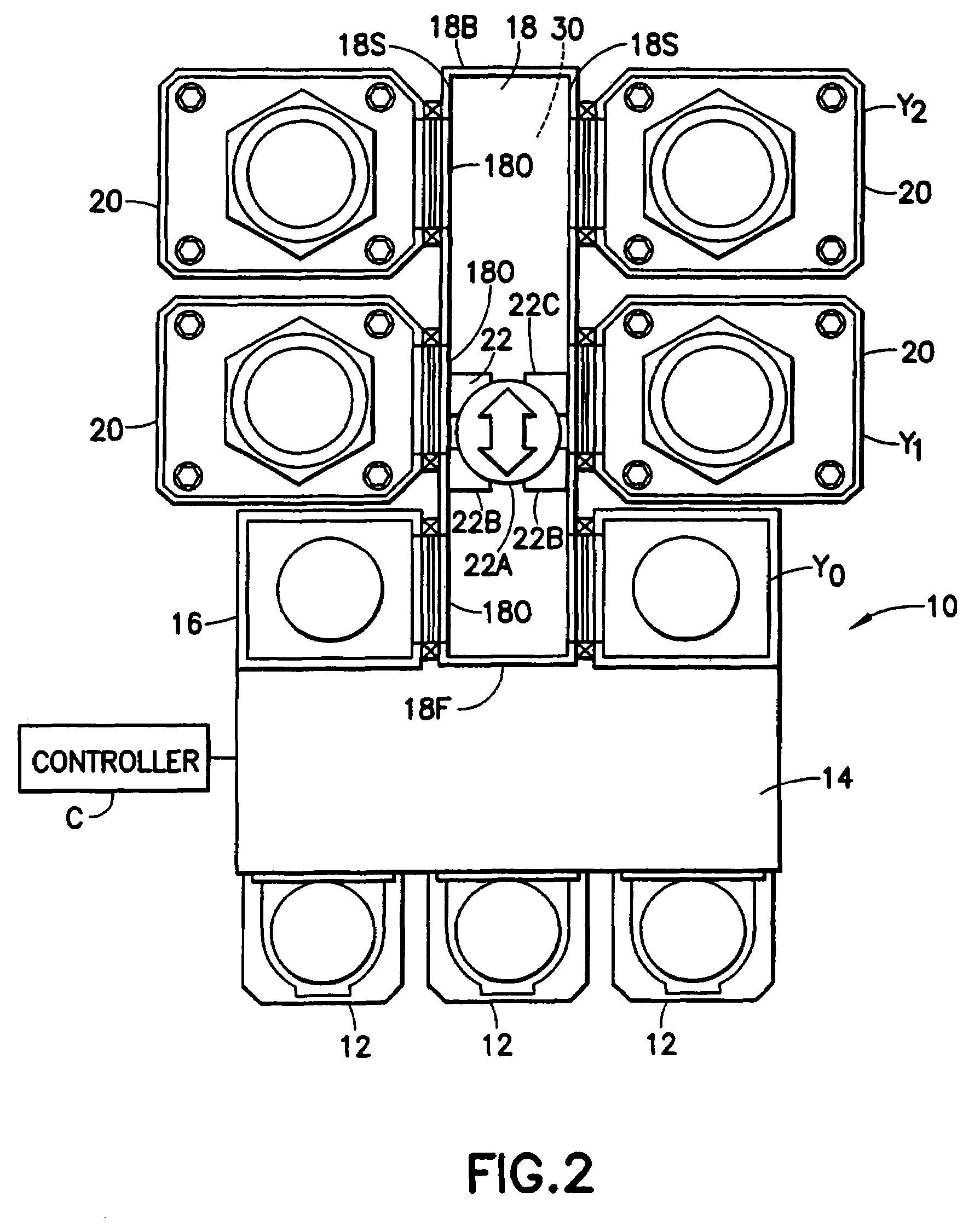

Aggregate Delivery Unit

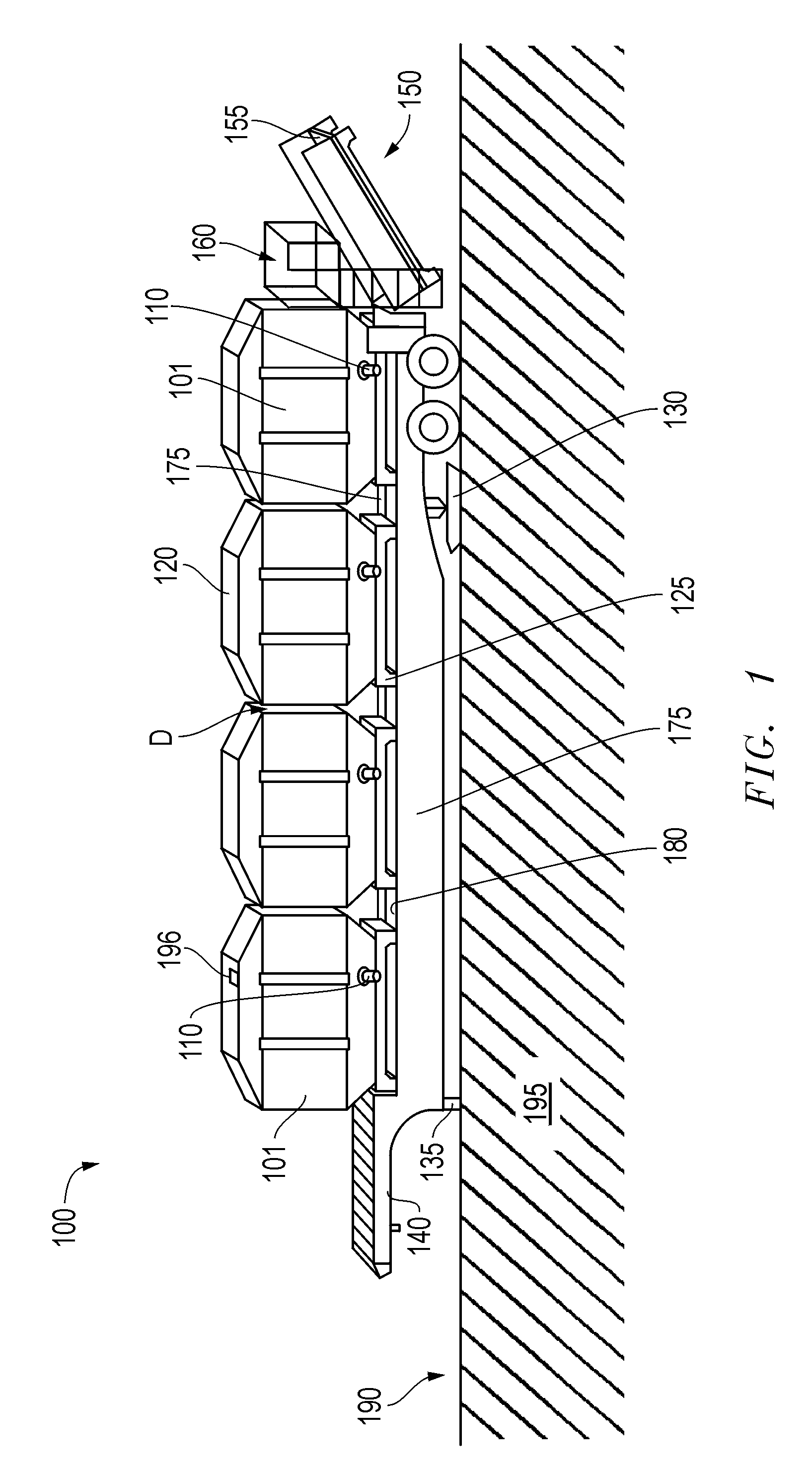

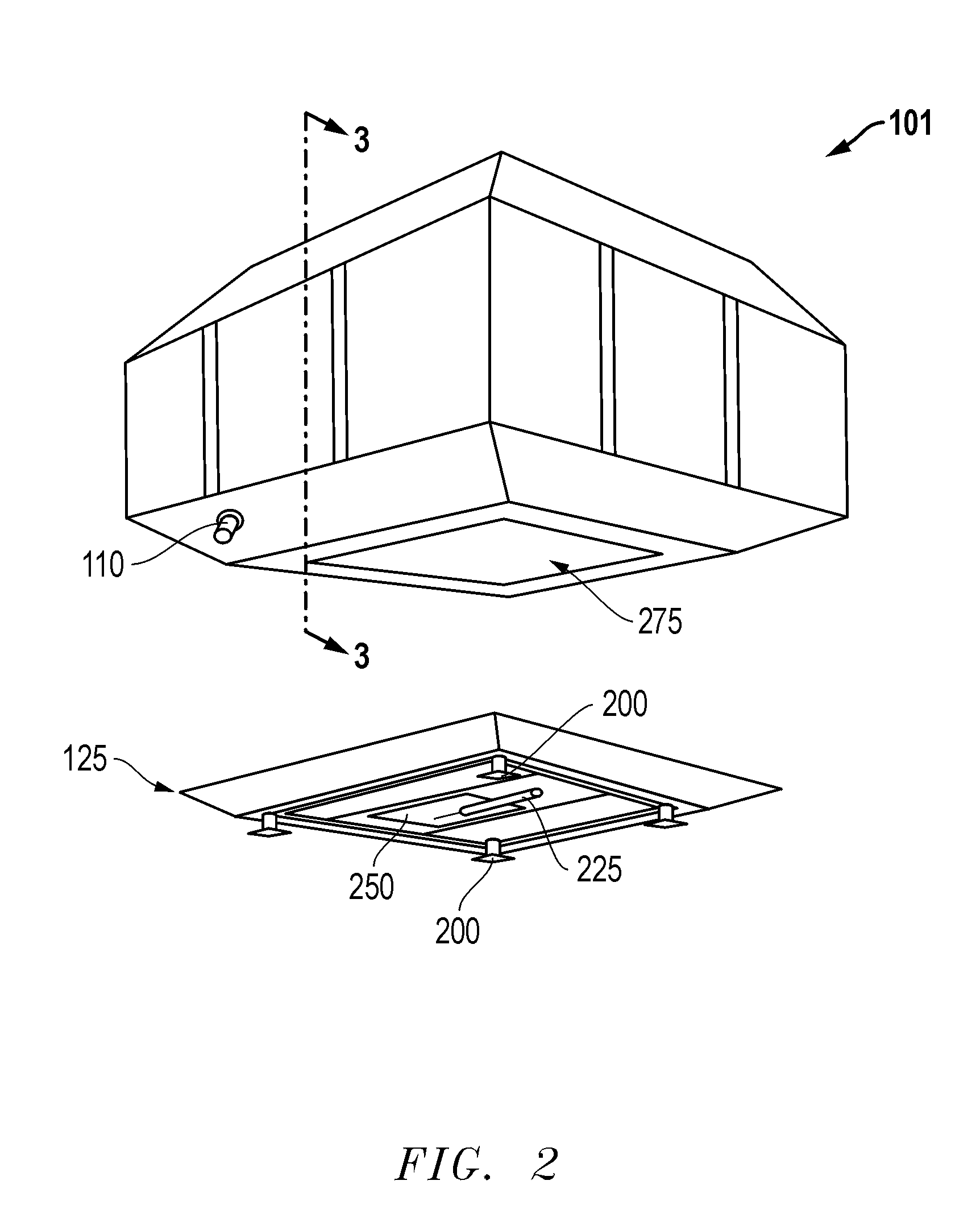

A delivery unit for providing aggregate to a worksite, such as a wellsite location. The unit may include a mobile chassis for accommodating a plurality of modular containers which in turn house the aggregate. As such, a weight measurement device may be located between each container and the chassis so as to monitor aggregate levels within each container over time. The units may be particularly well suited for monitoring and controlling aggregate delivery during a fracturing operation at an oilfield. The modular containers may be of an interchangeable nature. Furthermore, a preferably wireless control device may be provided for monitoring and directing aggregate delivery from a relatively remote location.

Owner:SCHLUMBERGER TECH CORP

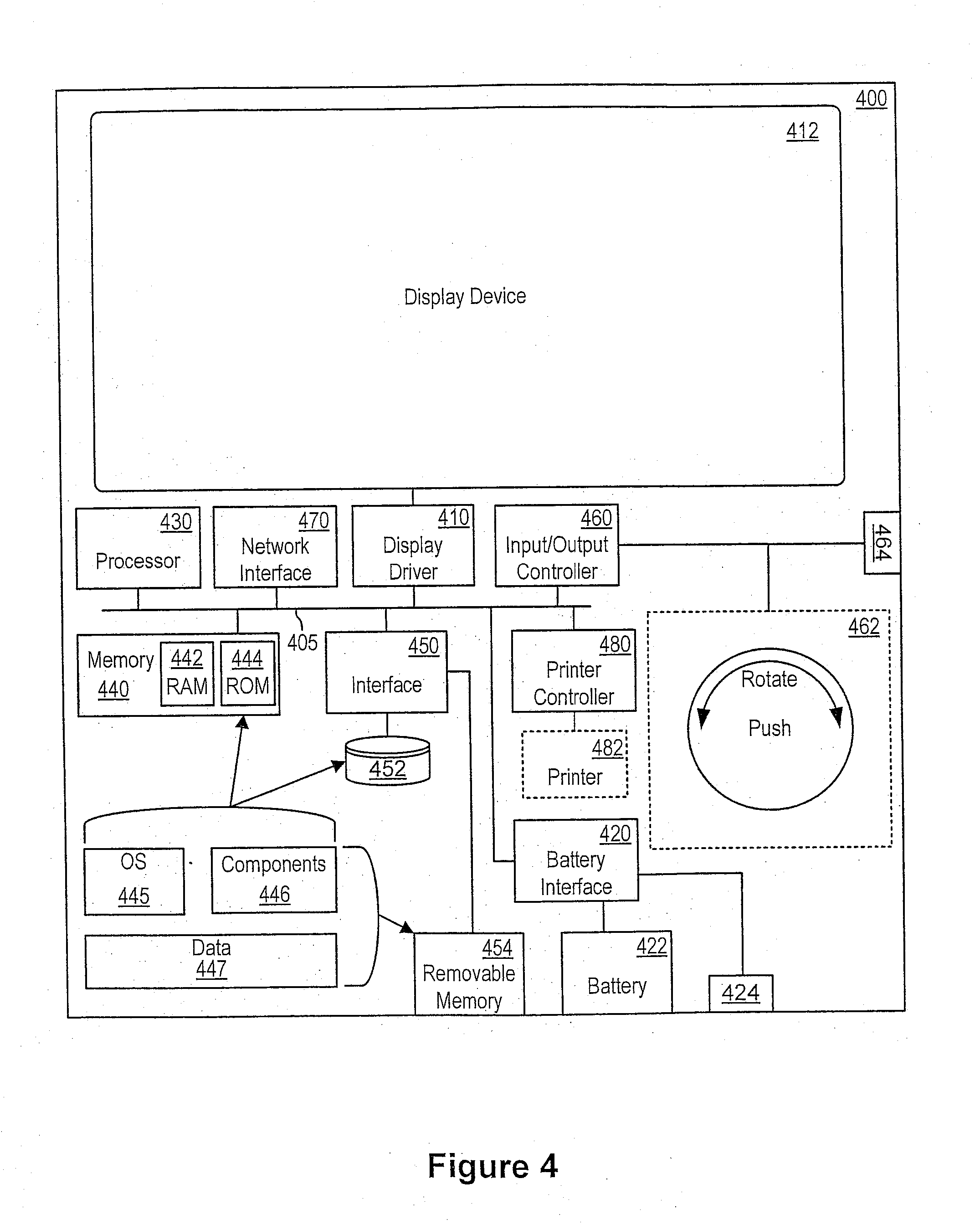

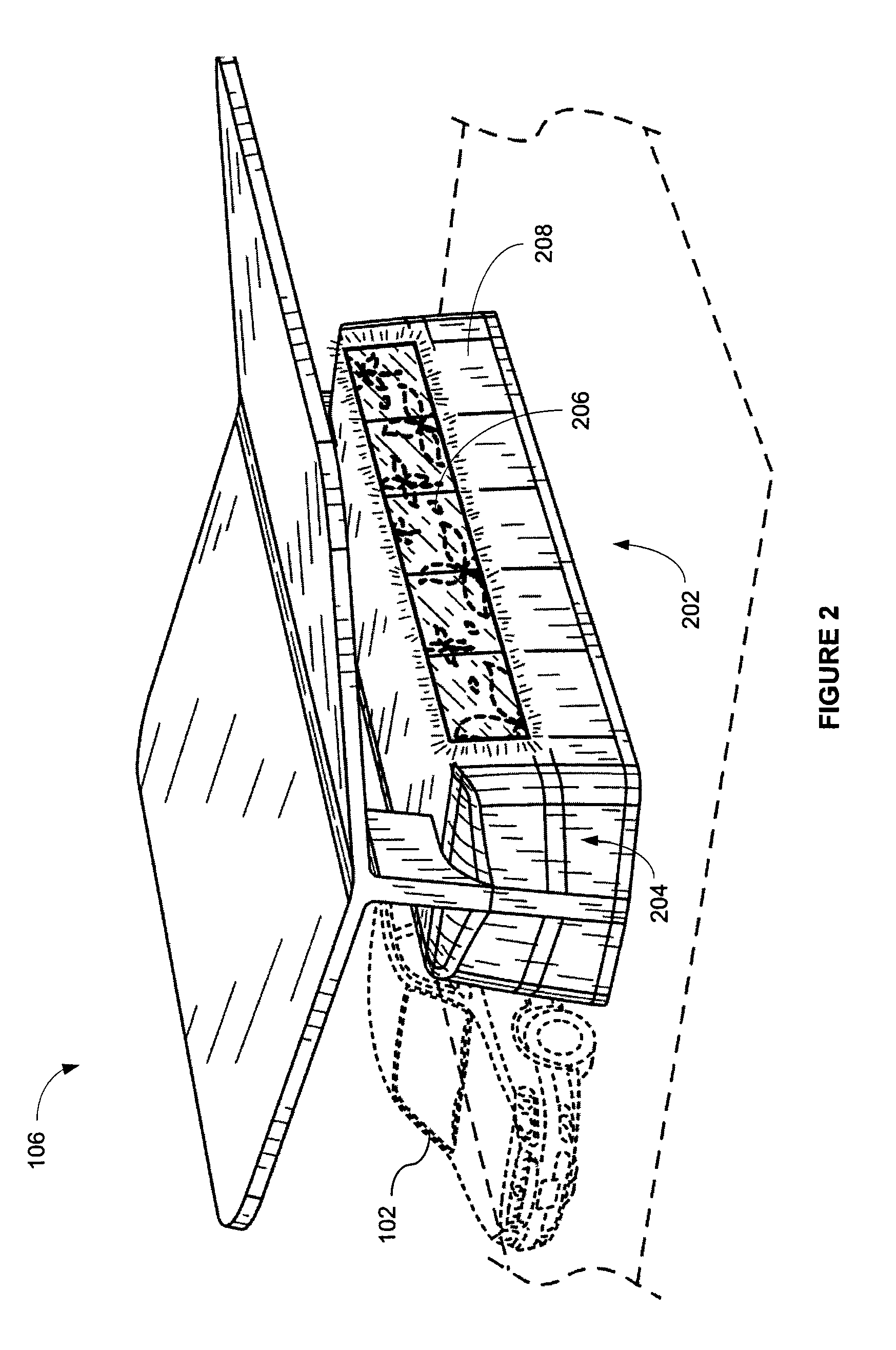

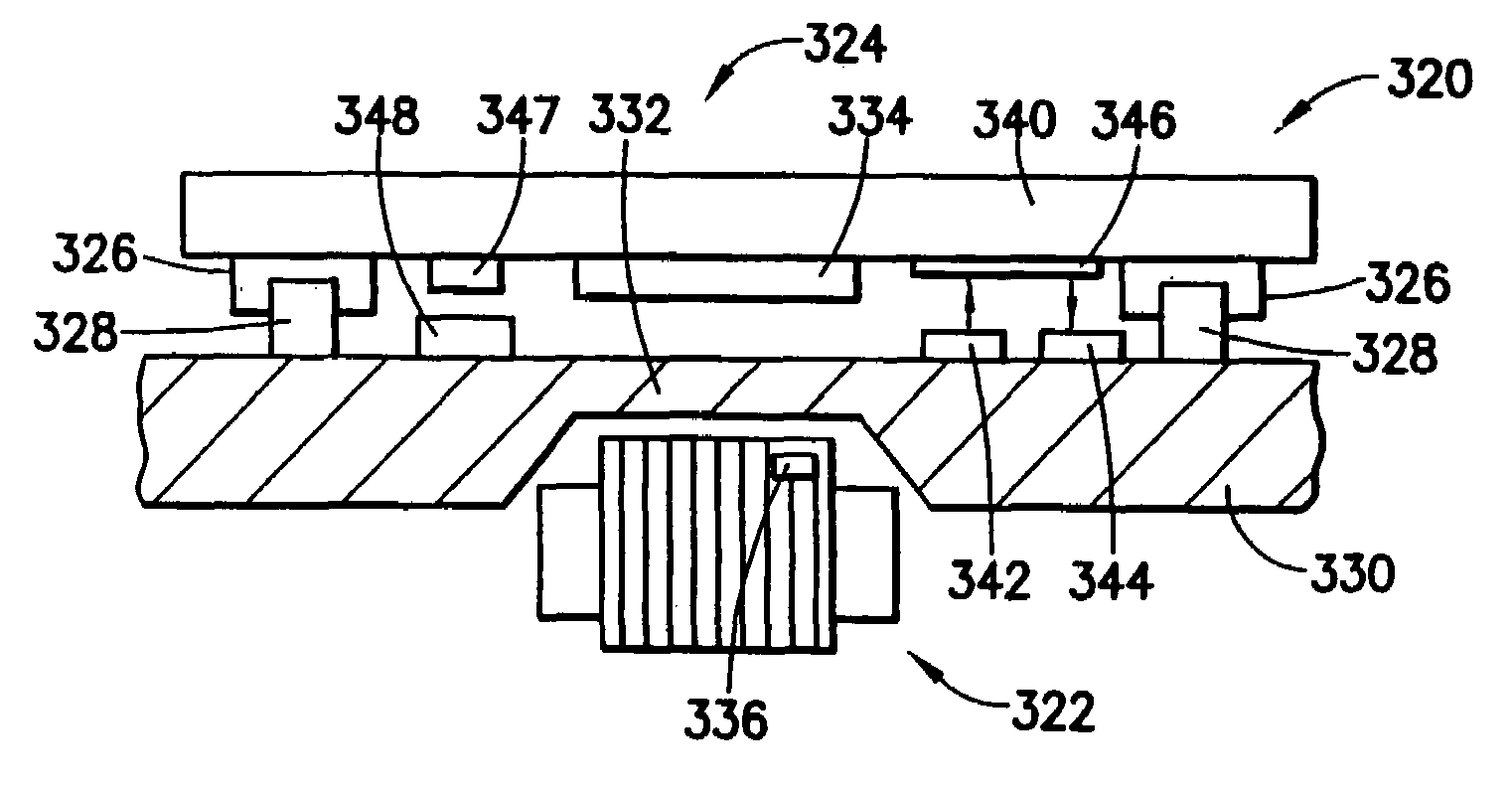

Automated battery and data delivery system

Systems and methods are provided that use a mobile robotic device (120, 220, 800) to transport rechargeable batteries (322, 422, 530, 570, 610, 722) between a base station (110, 600, 700), which charges the batteries, and a battery operated device (130, 230, 300, 400, 500, 550), such as battery powered kiosk (400) or signage system (300), which uses a charged battery as a power source. After traveling to a battery operated device, the mobile robotic device removes any discharged batteries from the battery operated device and installs a charged battery. The mobile robotic device then travels to the base station and attaches the discharged battery to the base station for recharging. The mobile robotic device may be configured to perform other transfers, such as data transfers and paper transfers. In addition, the mobile robotic device may be configured to perform a photographic and spatial survey of the isles, retail shelves, and surrounding environment for various purposes, such as generating three-dimensional store models and remote viewing.

Owner:MACDONALD MURRAY

System for replenishing energy sources onboard different types of automotive vehicles

A service station facility for replenishing various motivational energy sources onboard different types of automotive vehicles is disclosed herein. In one embodiment, the service station facility includes a rack, replaceable fuel tanks, a service module, and an electronic computer control system. The replaceable fuel tanks are stocked on the rack and substantially filled with various fluids, such as hydrogen, which are utile as motivational energy sources within fuel-operated automotive vehicles. The service module is mounted on the rack, and the electronic computer control system is connected in electrical communication with the service module. In this configuration, the service module is controllably operable to receive a depleted replaceable fuel tank from a fuel-operated automotive vehicle and also selectively deliver one of the filled replaceable fuel tanks onboard the automotive vehicle. In another embodiment, the service station facility may also stock replaceable batteries for selective delivery onboard battery-operated automotive vehicles.

Owner:CAPIZZO PETER DAVID

System for replenishing energy sources onboard different types of automotive vehicles

Owner:CAPIZZO PETER DAVID

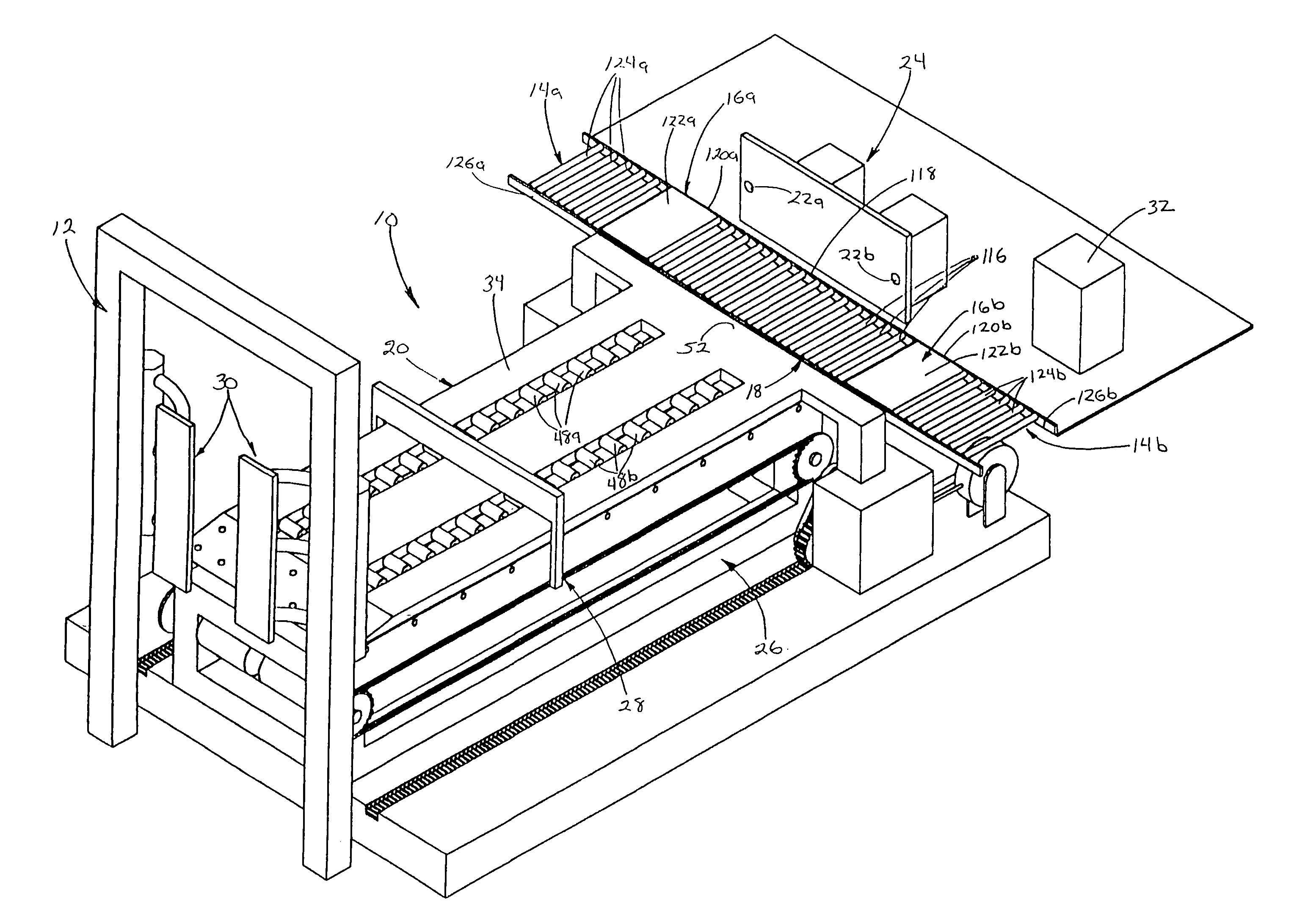

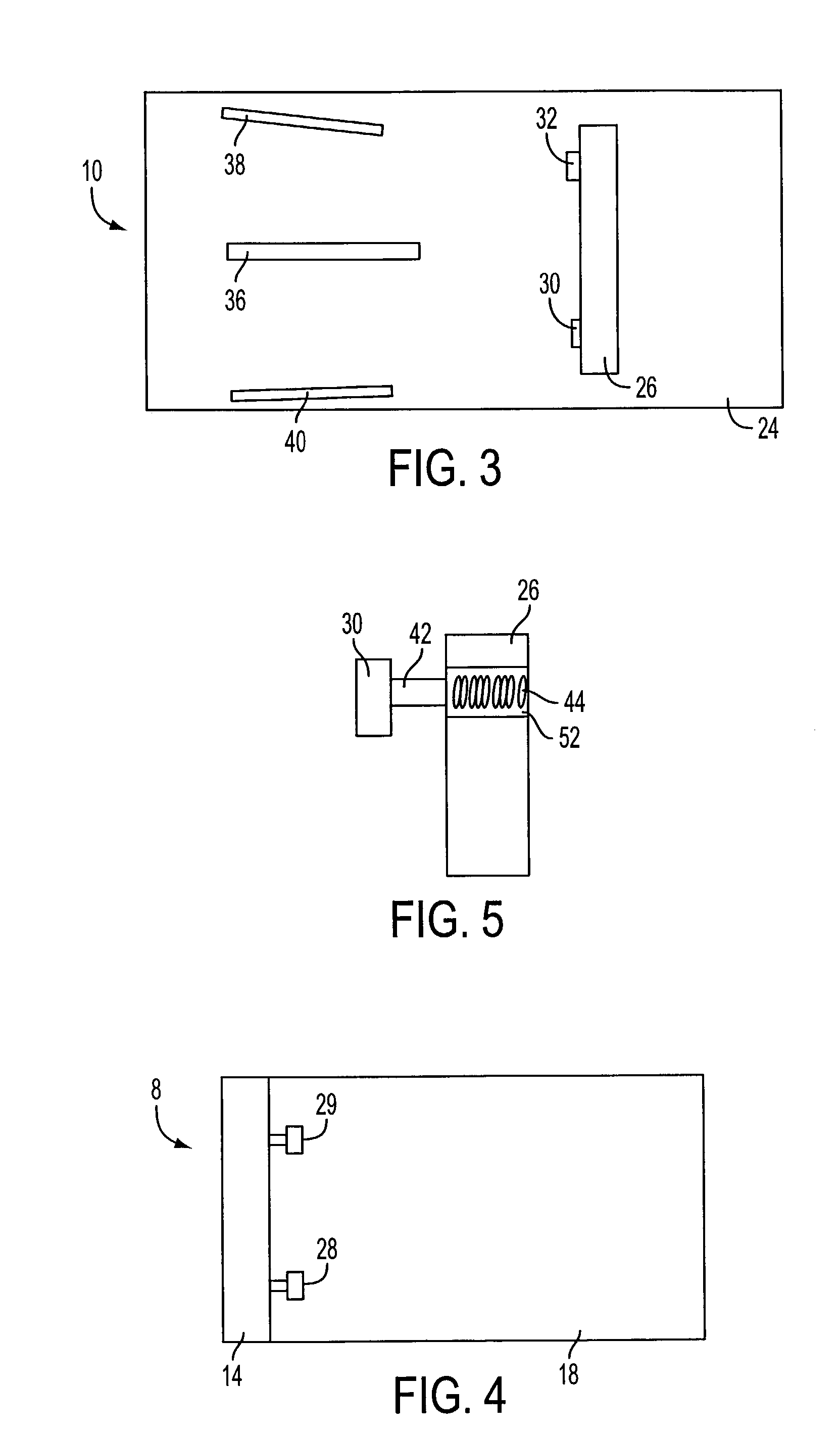

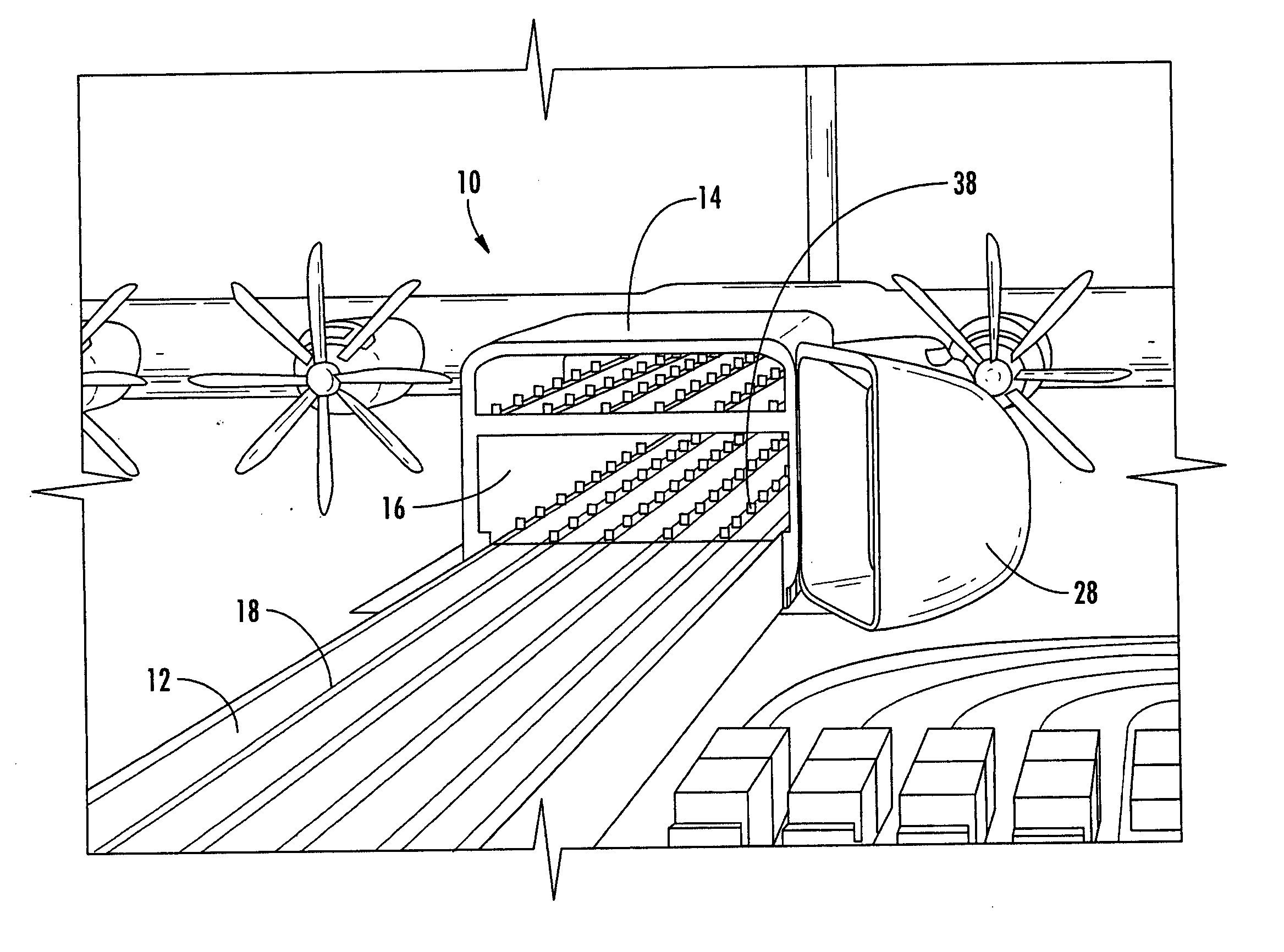

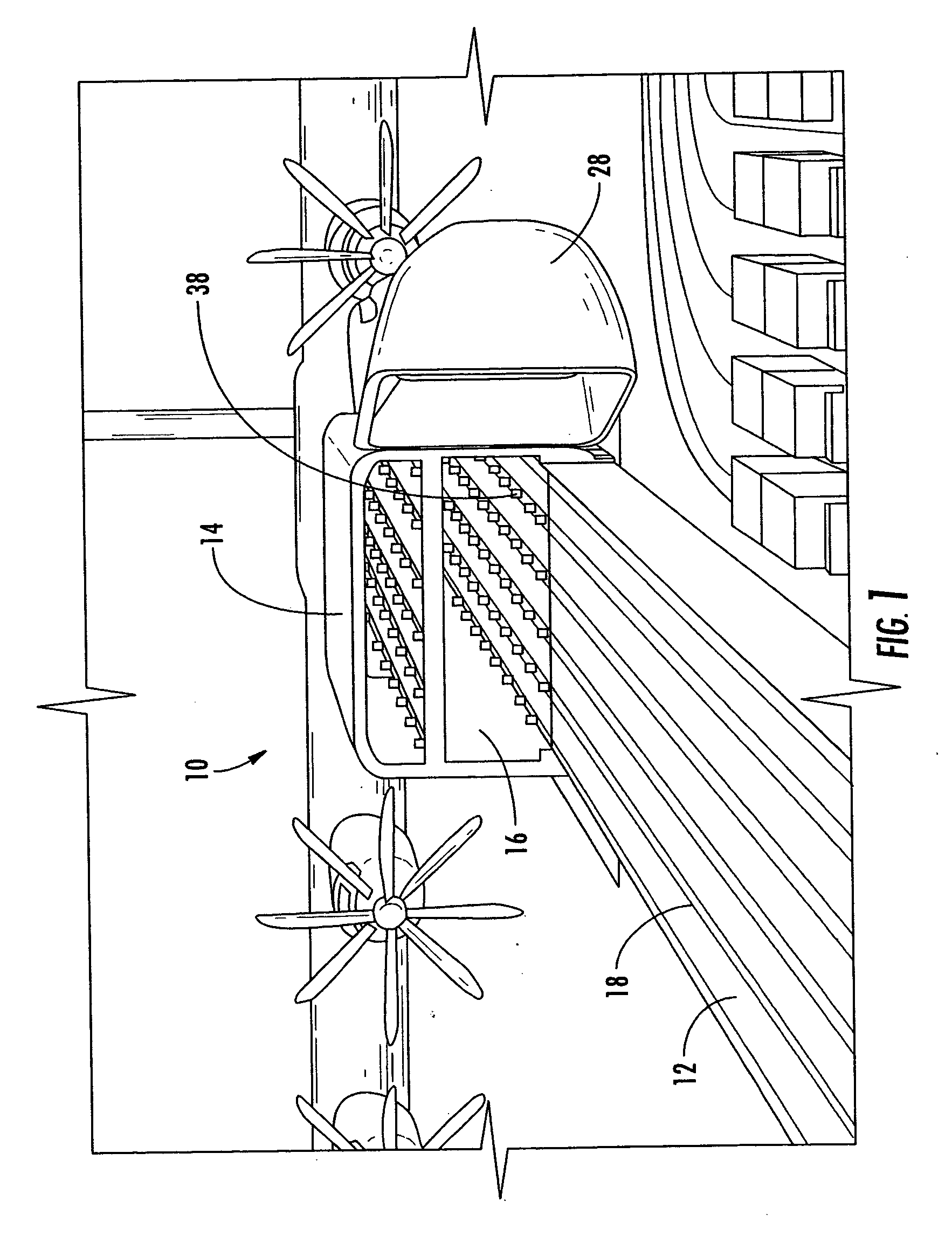

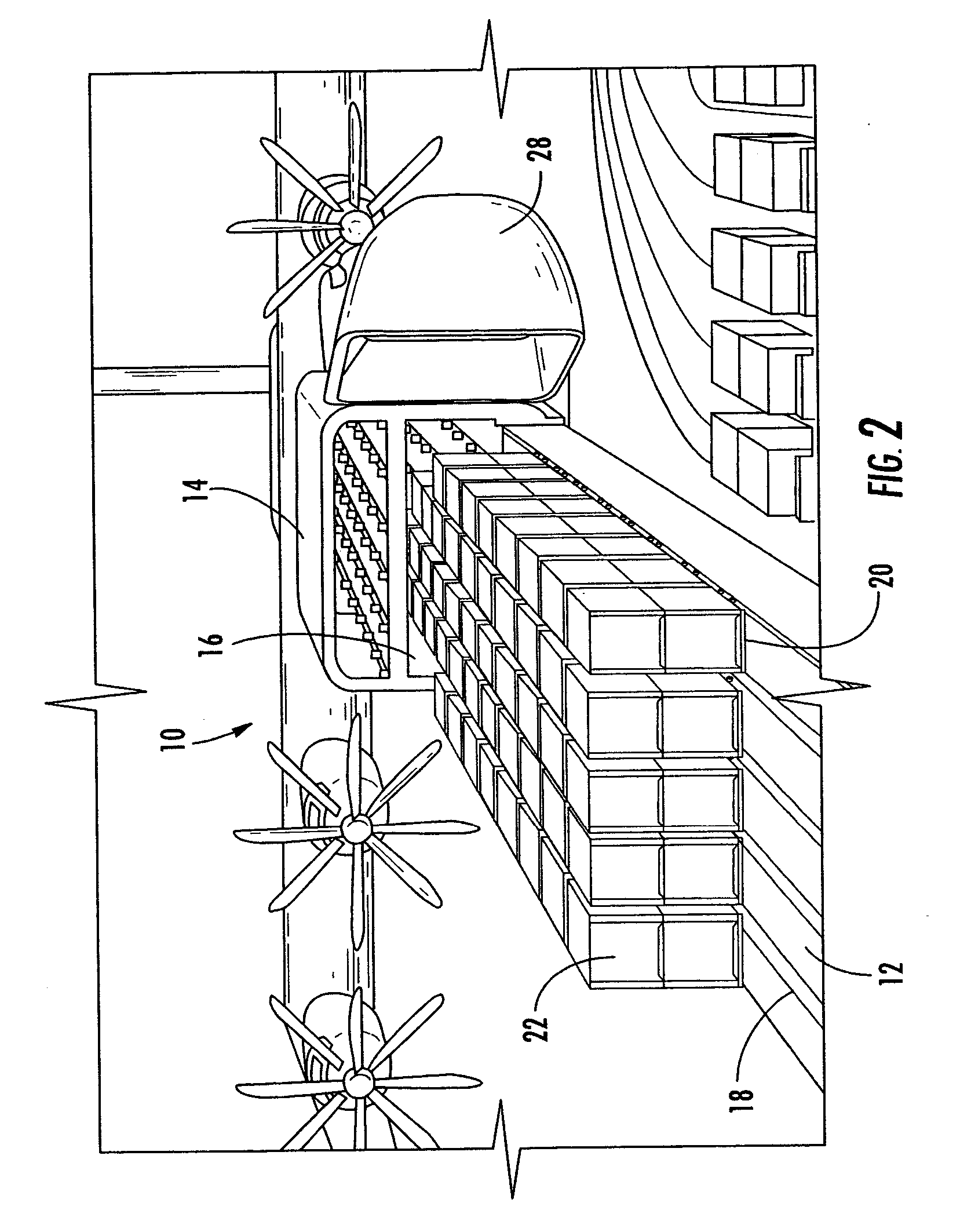

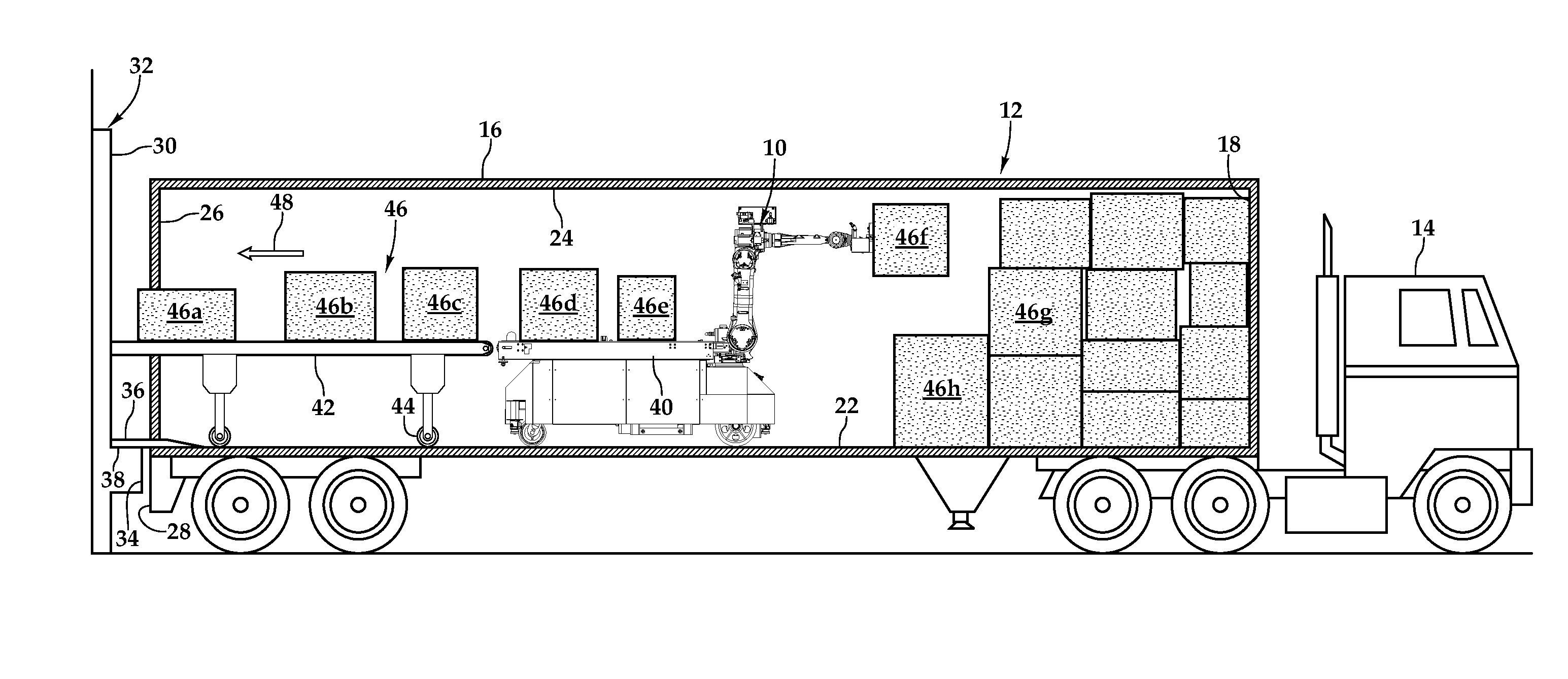

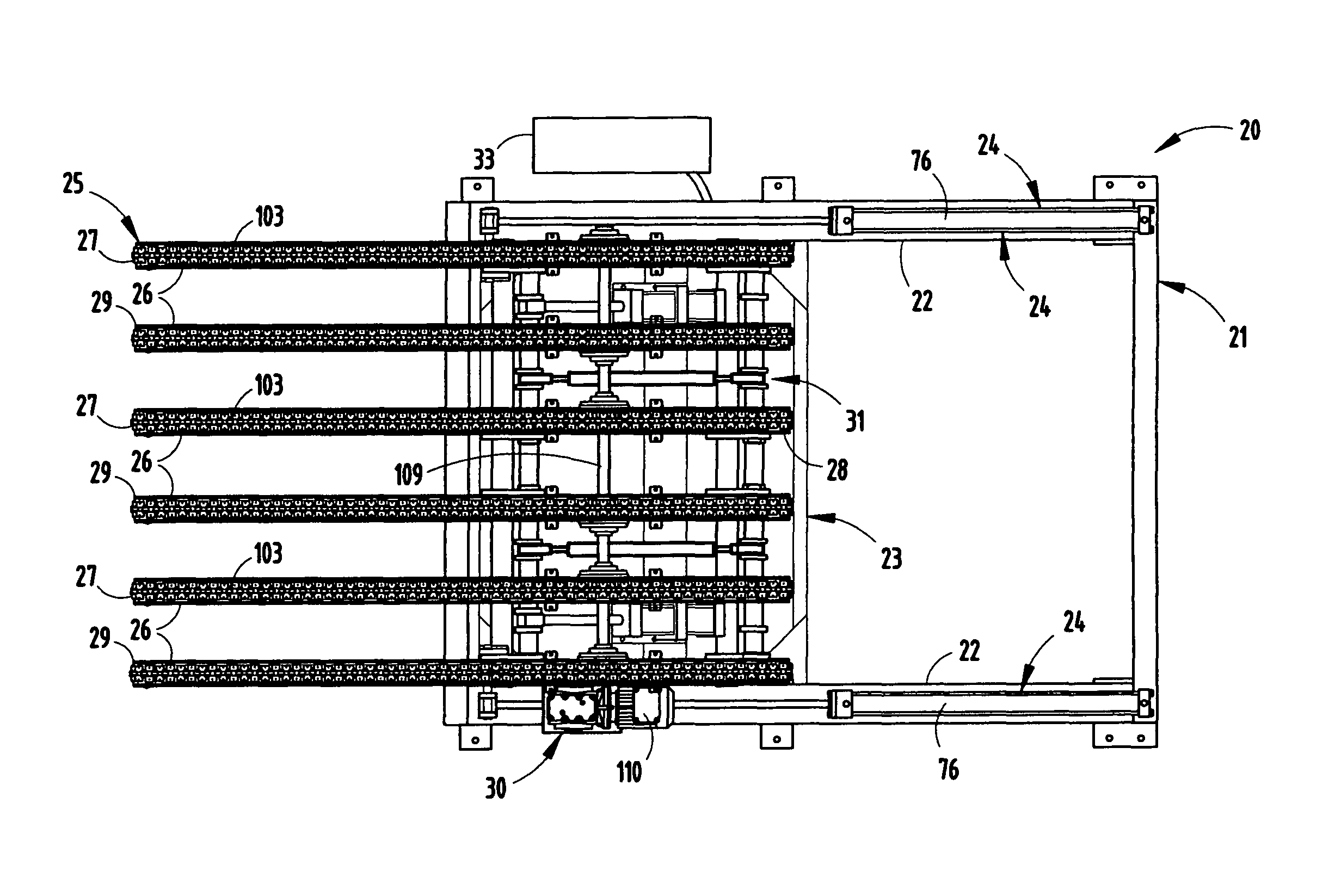

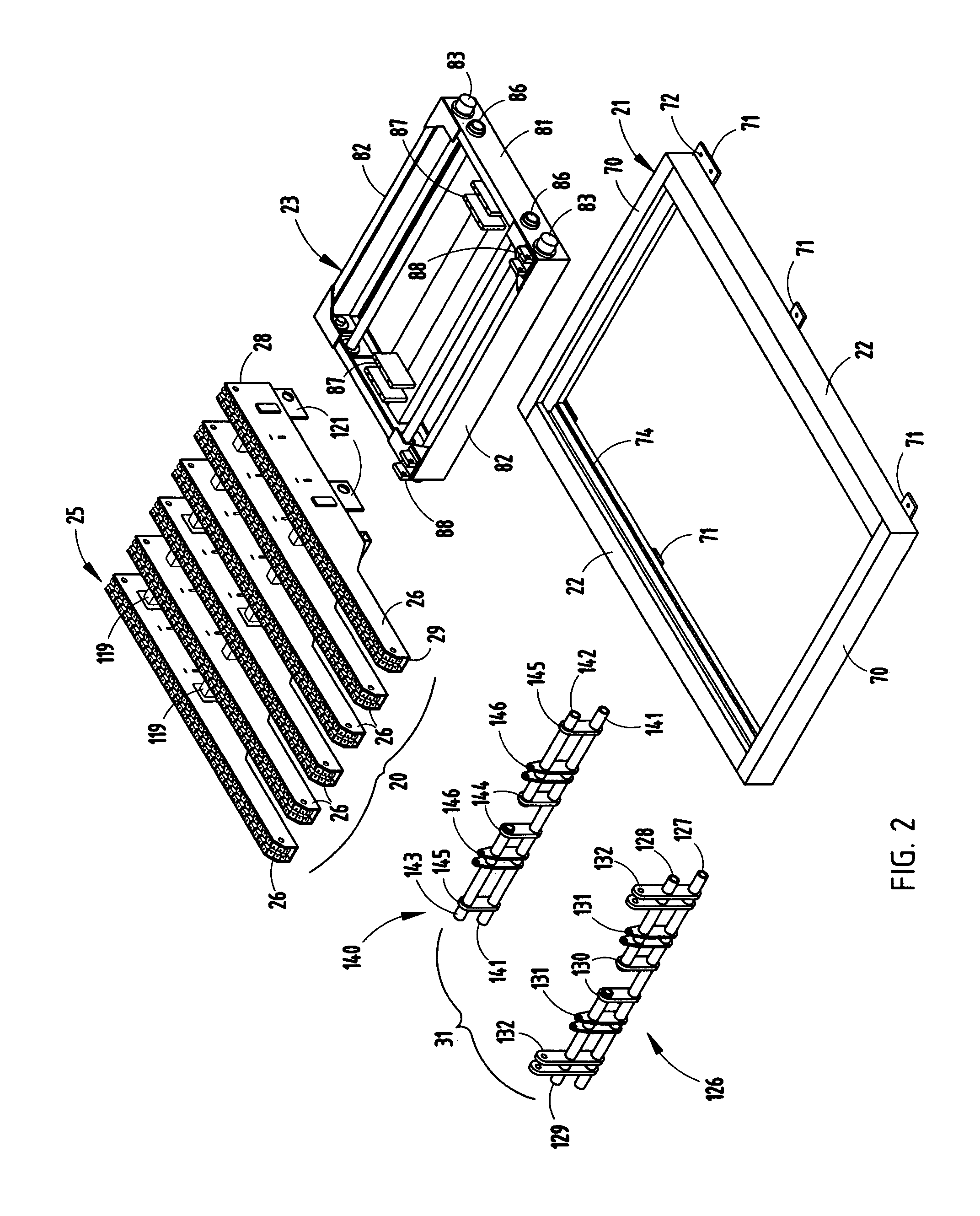

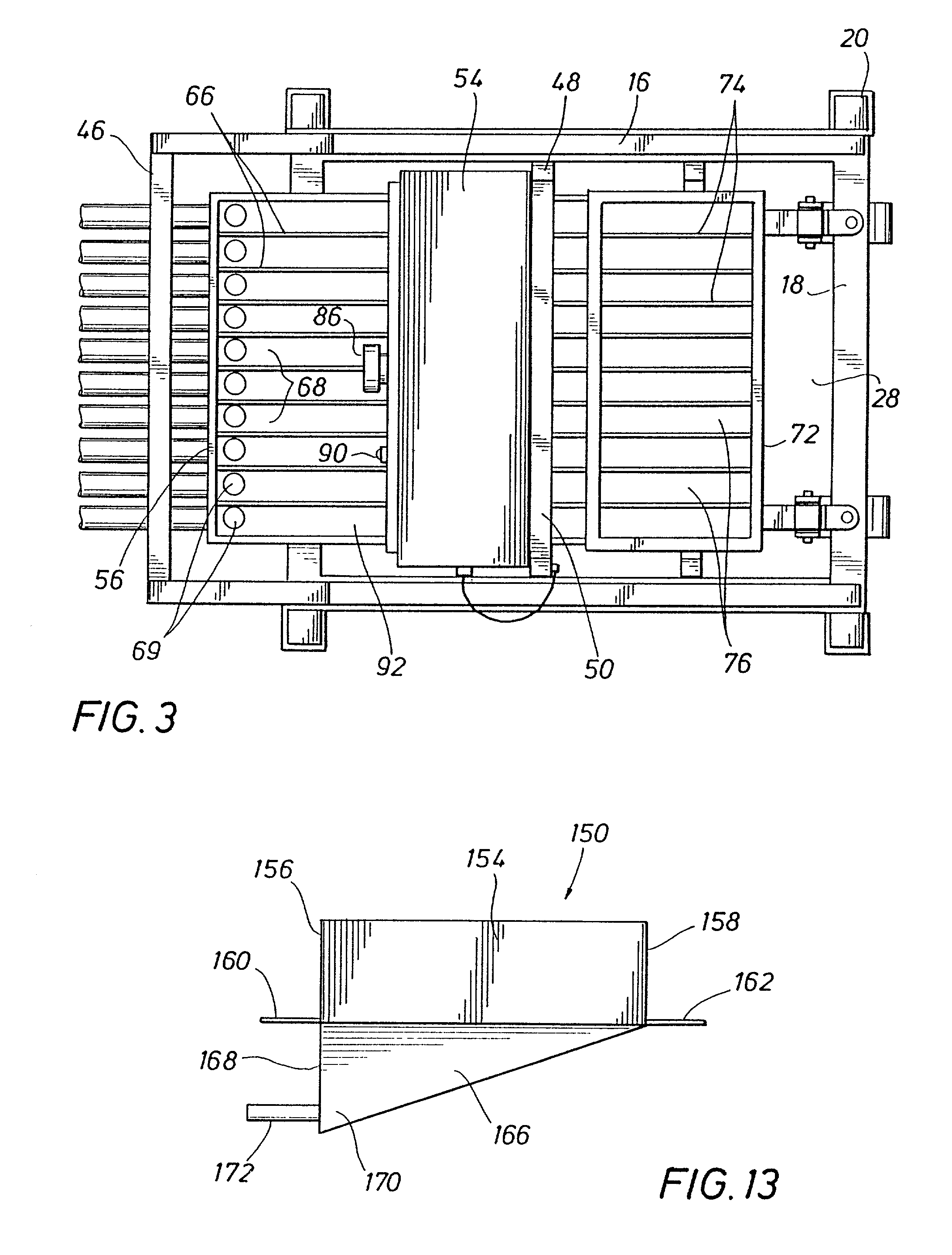

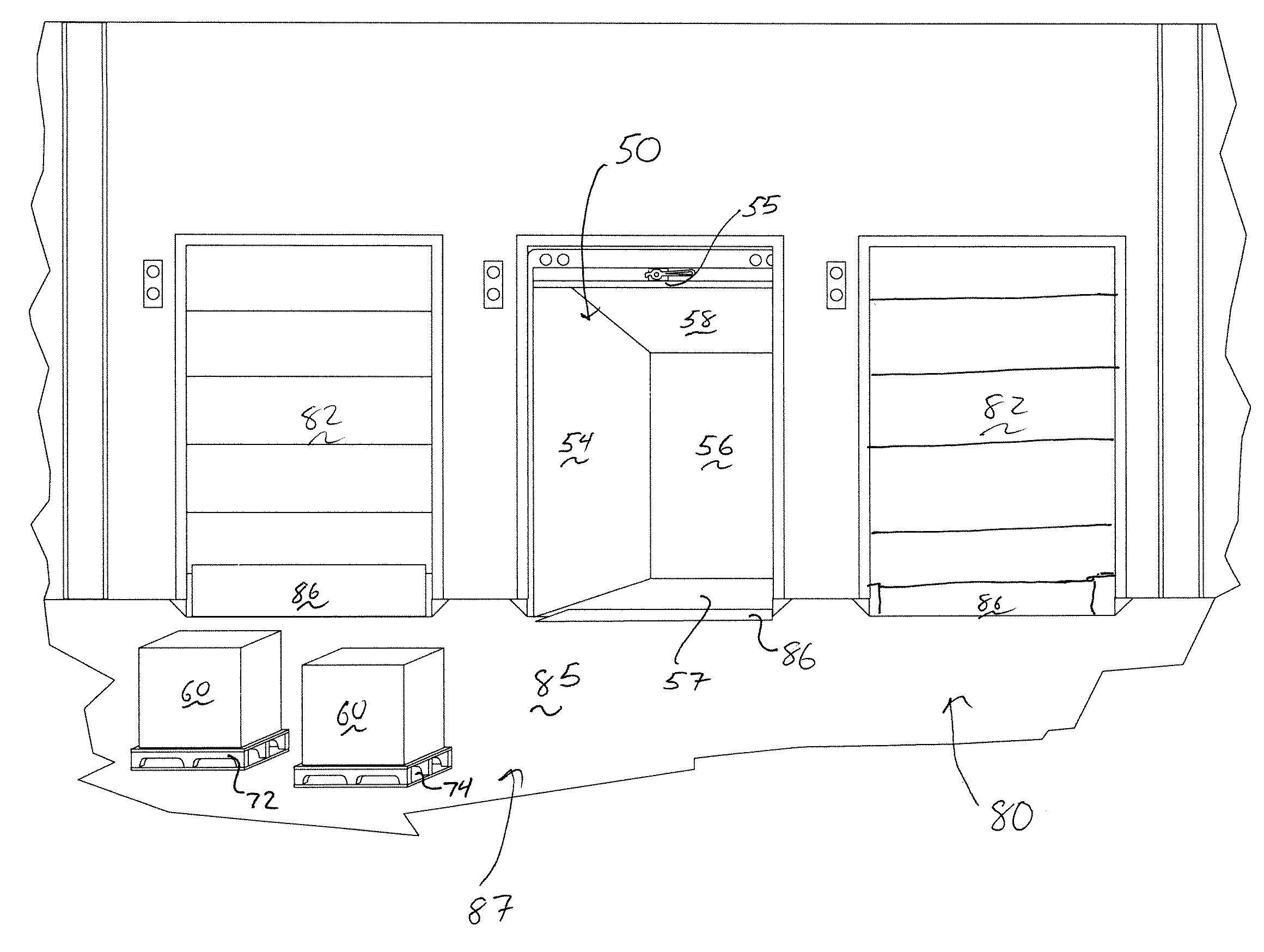

Automated warehousing and cargo loading system

InactiveUS7695235B1Reduce operating costsImprove loading efficiencyLifting devicesRefuse transferringDischarge locationChassis

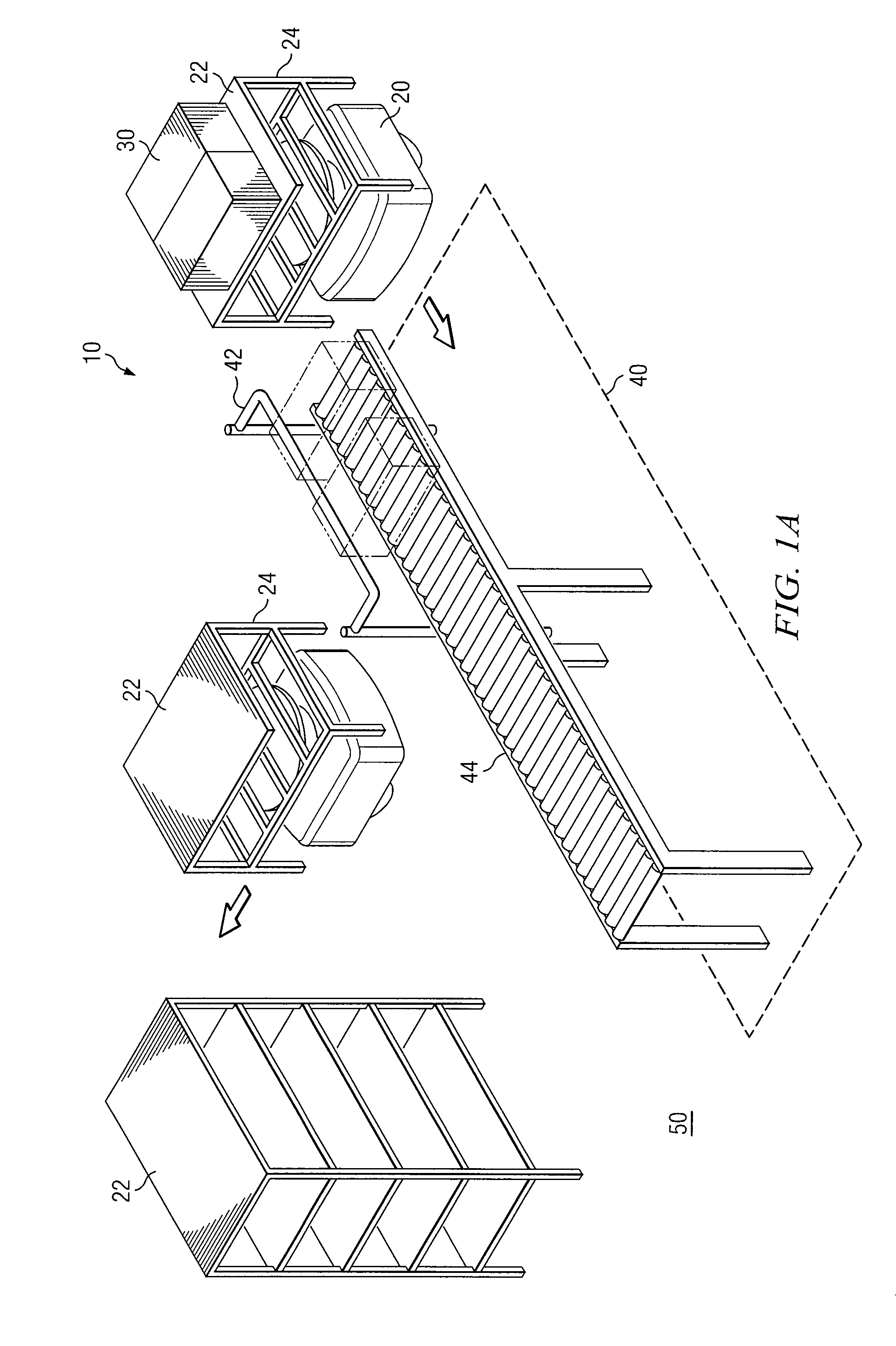

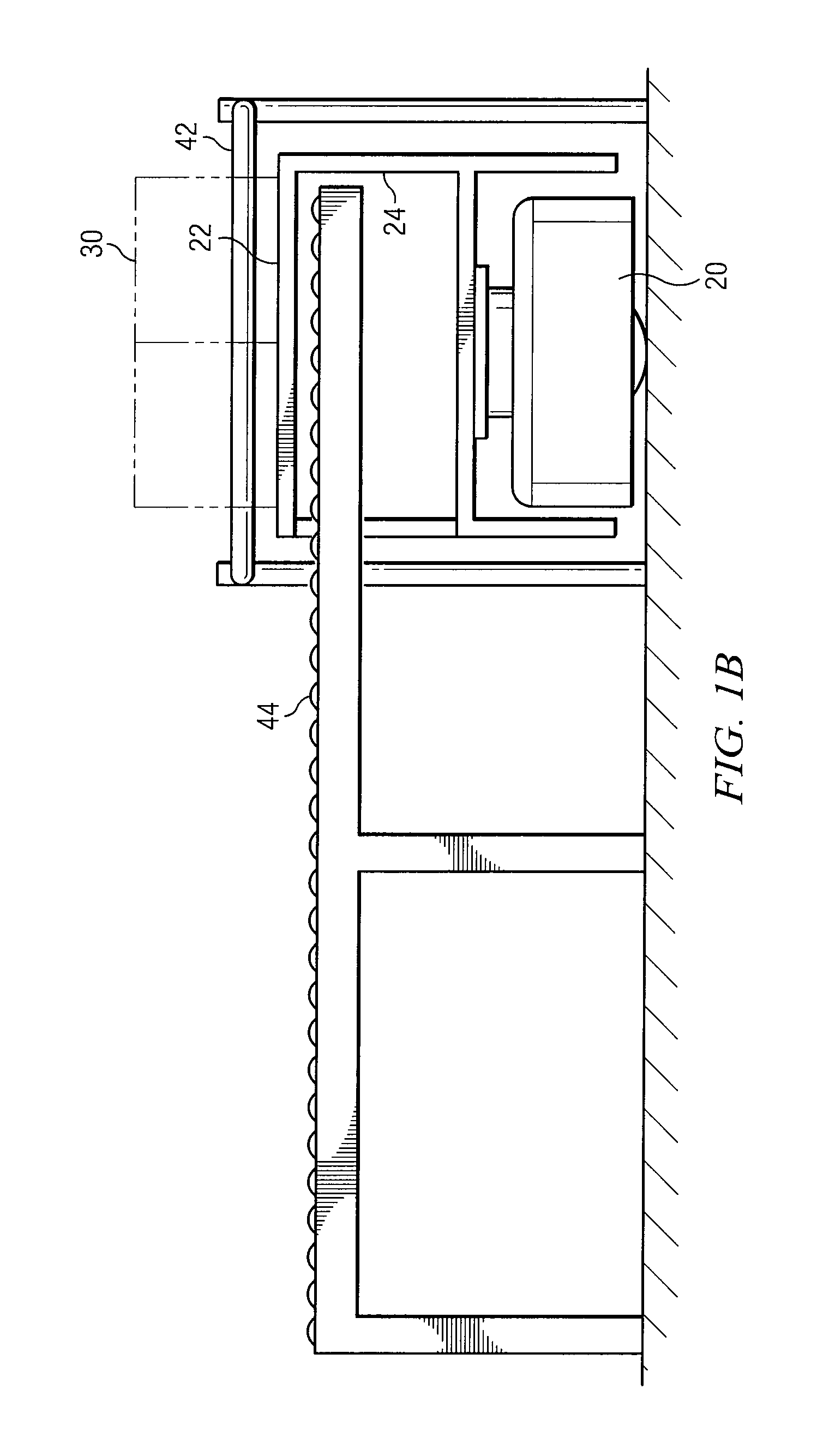

A warehousing system for palletized cargo, and an automated loading / unloading system for use with the same. The warehousing system includes a feed conveyer and a plurality of storage racks. A traveling conveyor carries the cargo from the feed conveyor to the individual racks, and from the racks to a loading / unloading conveyor which carries the cargo to the loading / unloading docks. The traveling conveyor rides on a wheeled chassis that is guided between the receiving and discharge locations on tracks. The storage racks are stackable in tiers, and the traveling conveyor has a deck that raises and lowers to be level therewith. The automated loading / unloading dock includes a rigid, extensible plate having an upper surface for supporting a load of palletized cargo, with a drive mechanism being mounted to the inner end of the plate to translate it in and out of the transport vehicle. The plate carries a load of palletized cargo into or out of the transport vehicle en masse. For loading, restraining doors hold the loaded cargo within the interior of the vehicle as the extensible dock is withdrawn. When unloading, a paddle is deployed above the upper surface of the lock member and is translated towards its inner end so as to push the cargo onto the loading / unloading conveyor.

Owner:RALLIS JOHN H

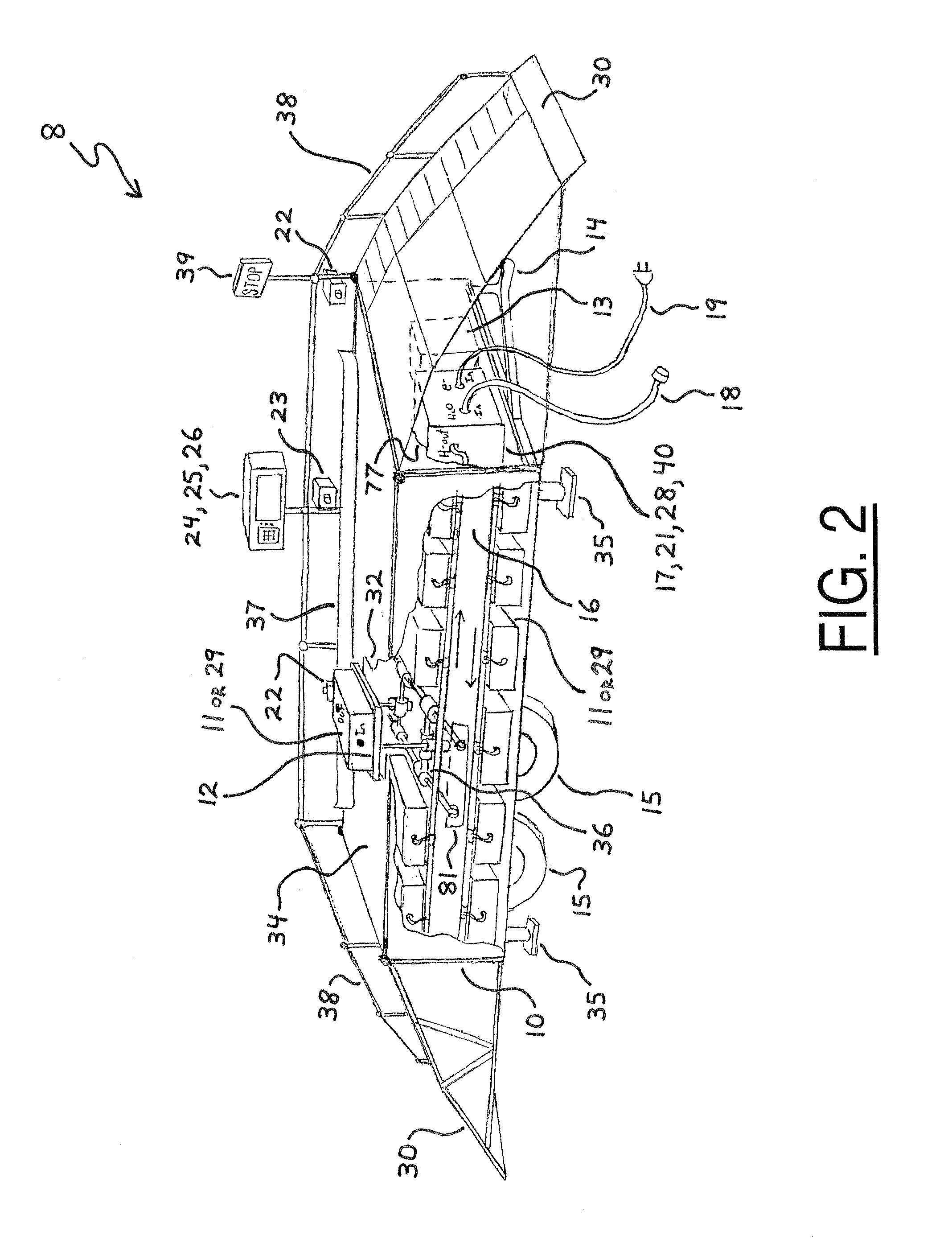

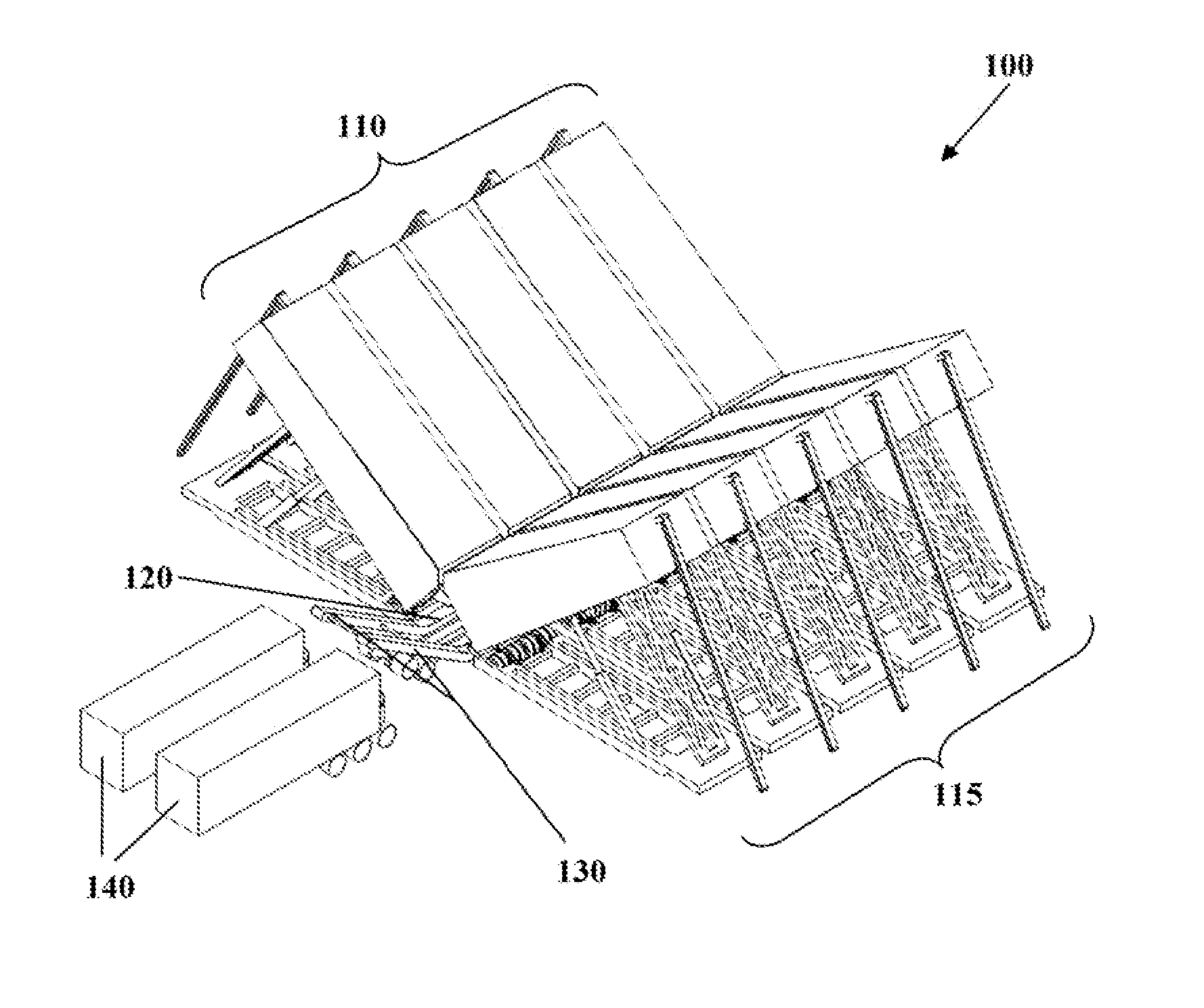

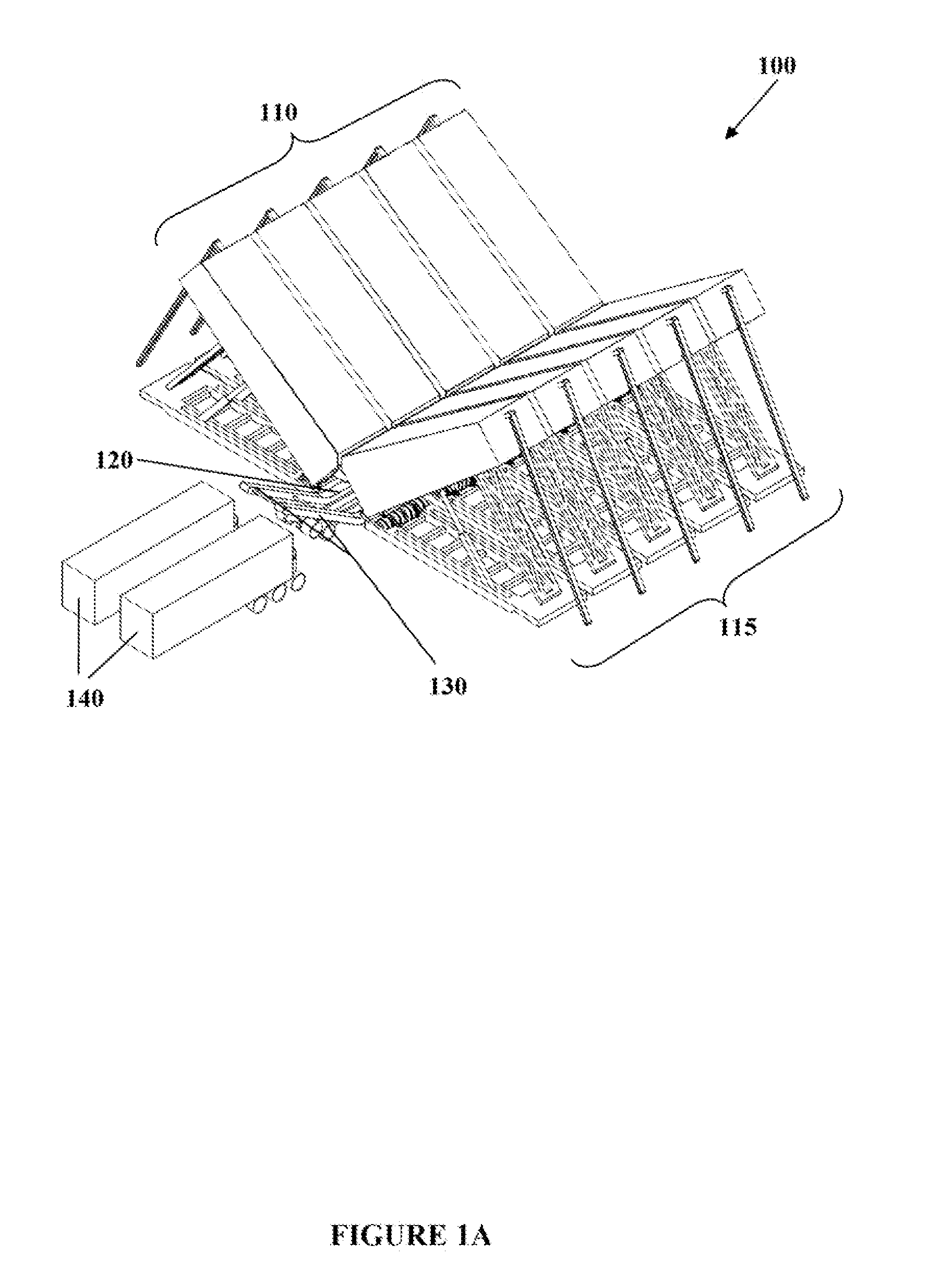

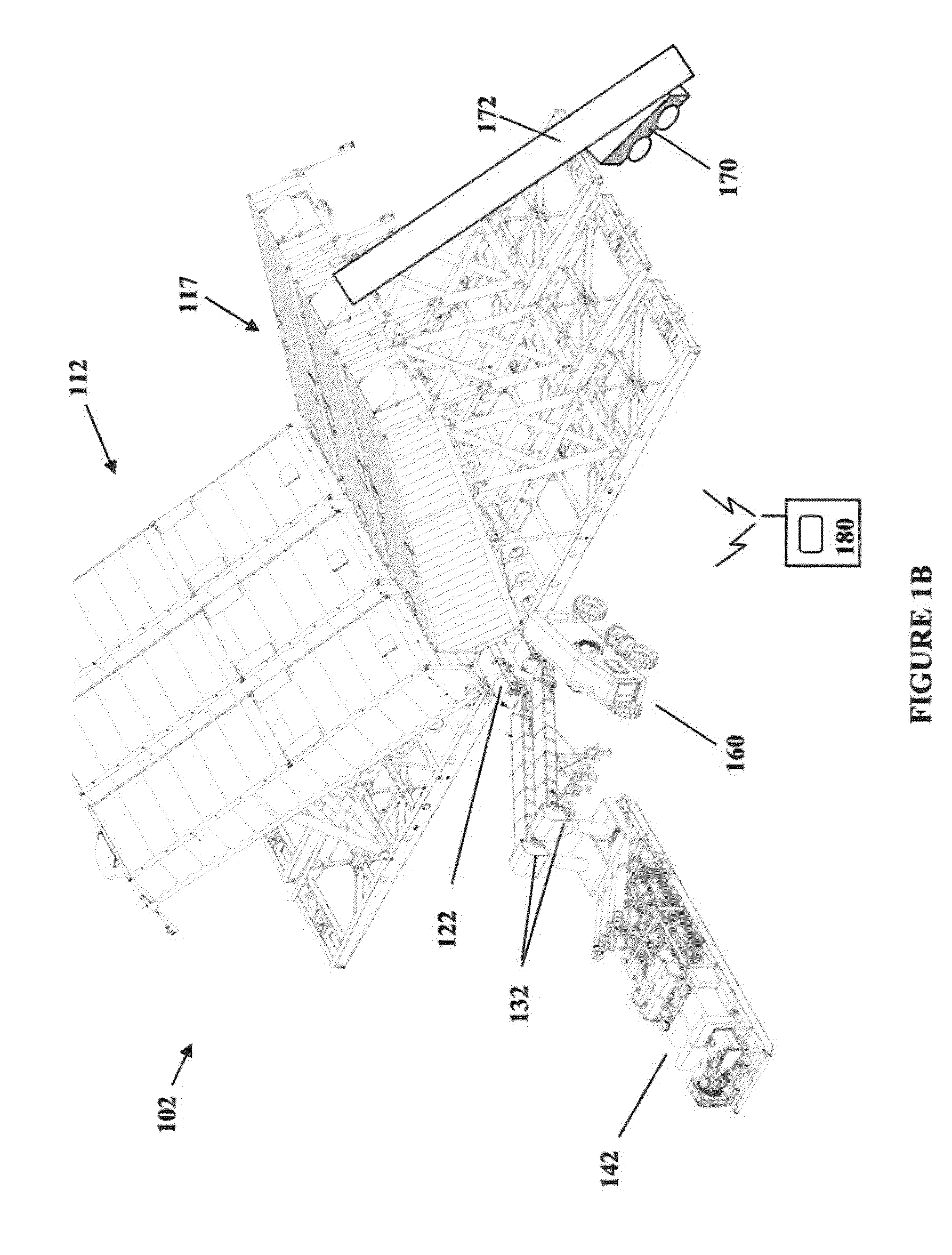

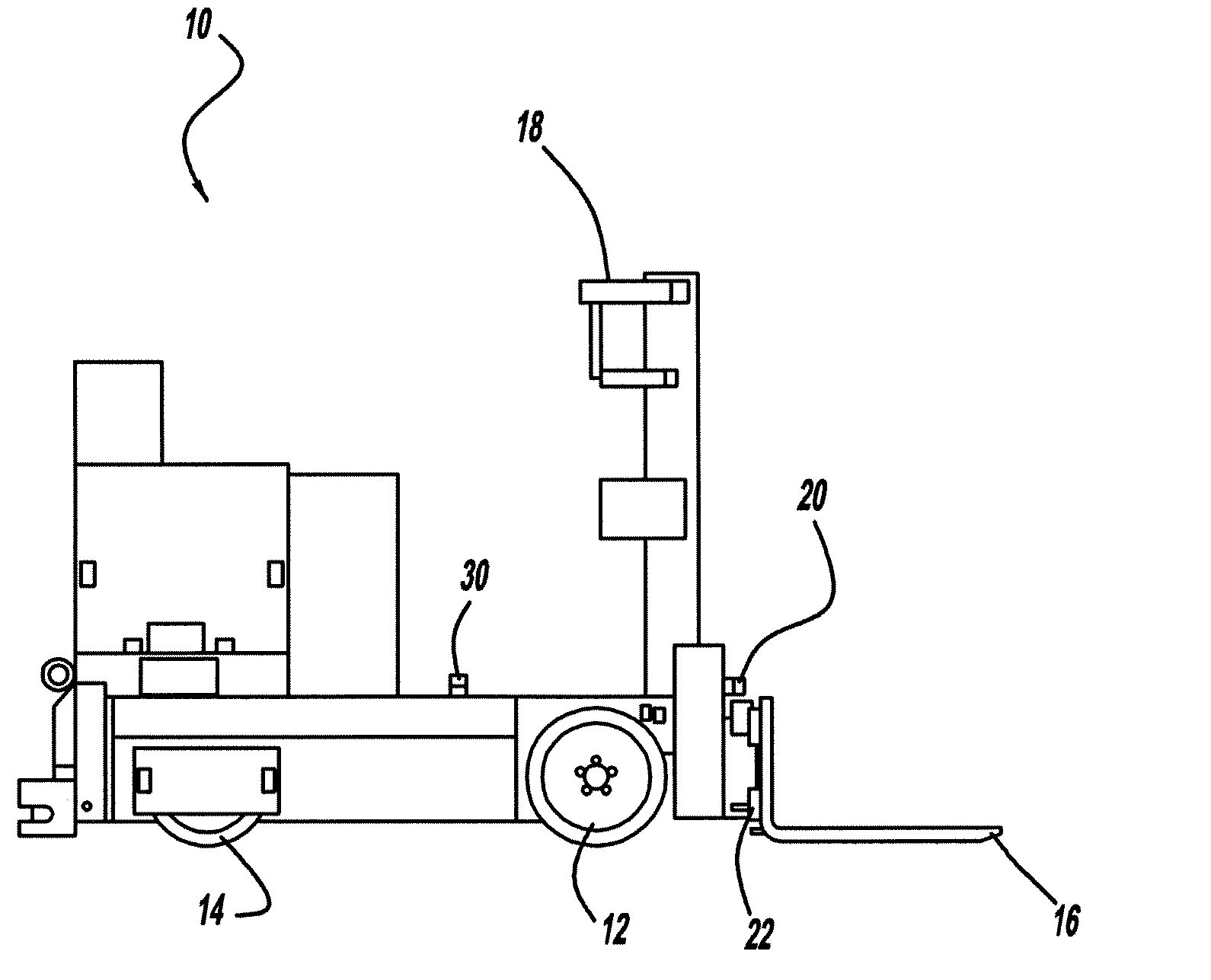

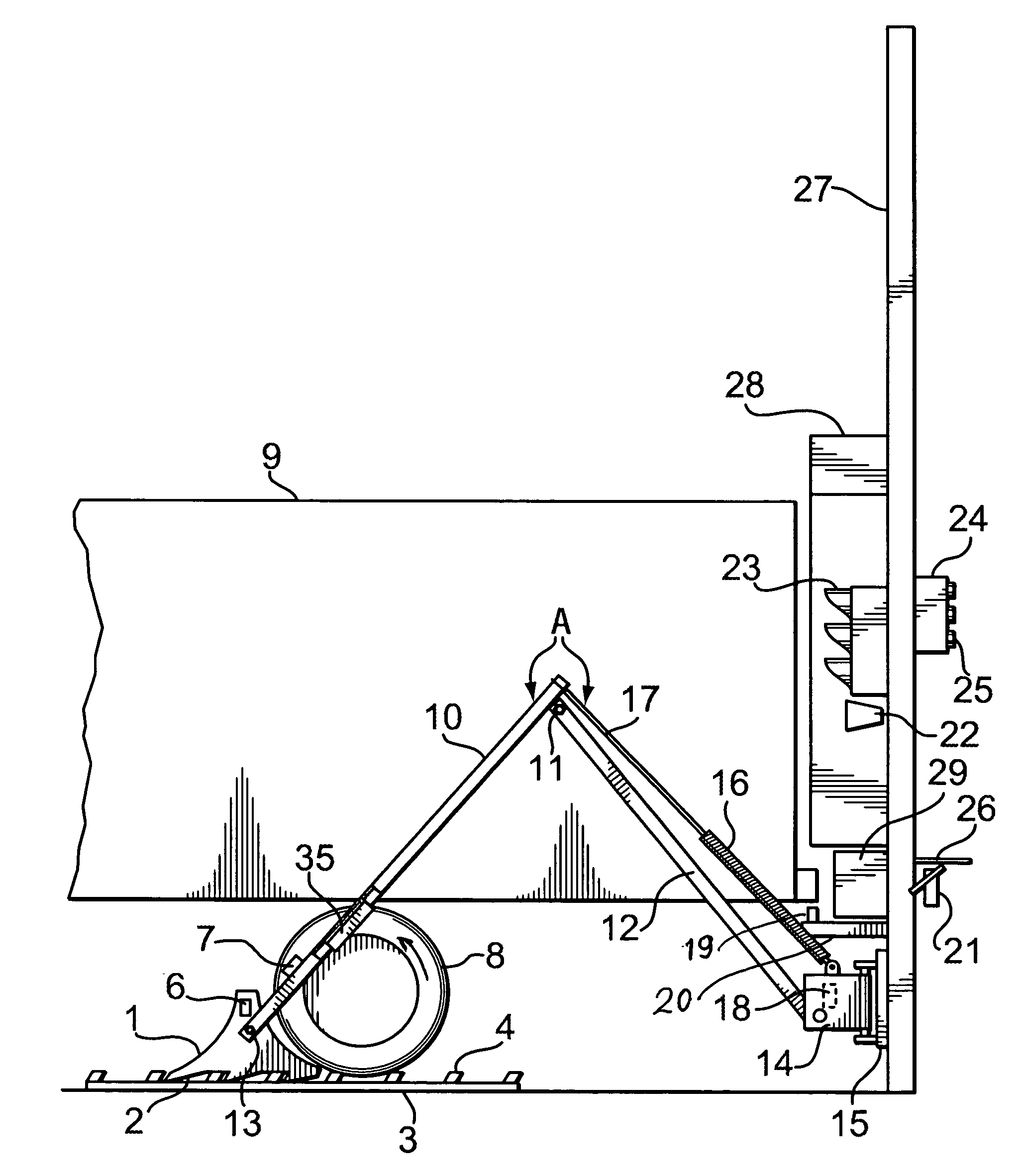

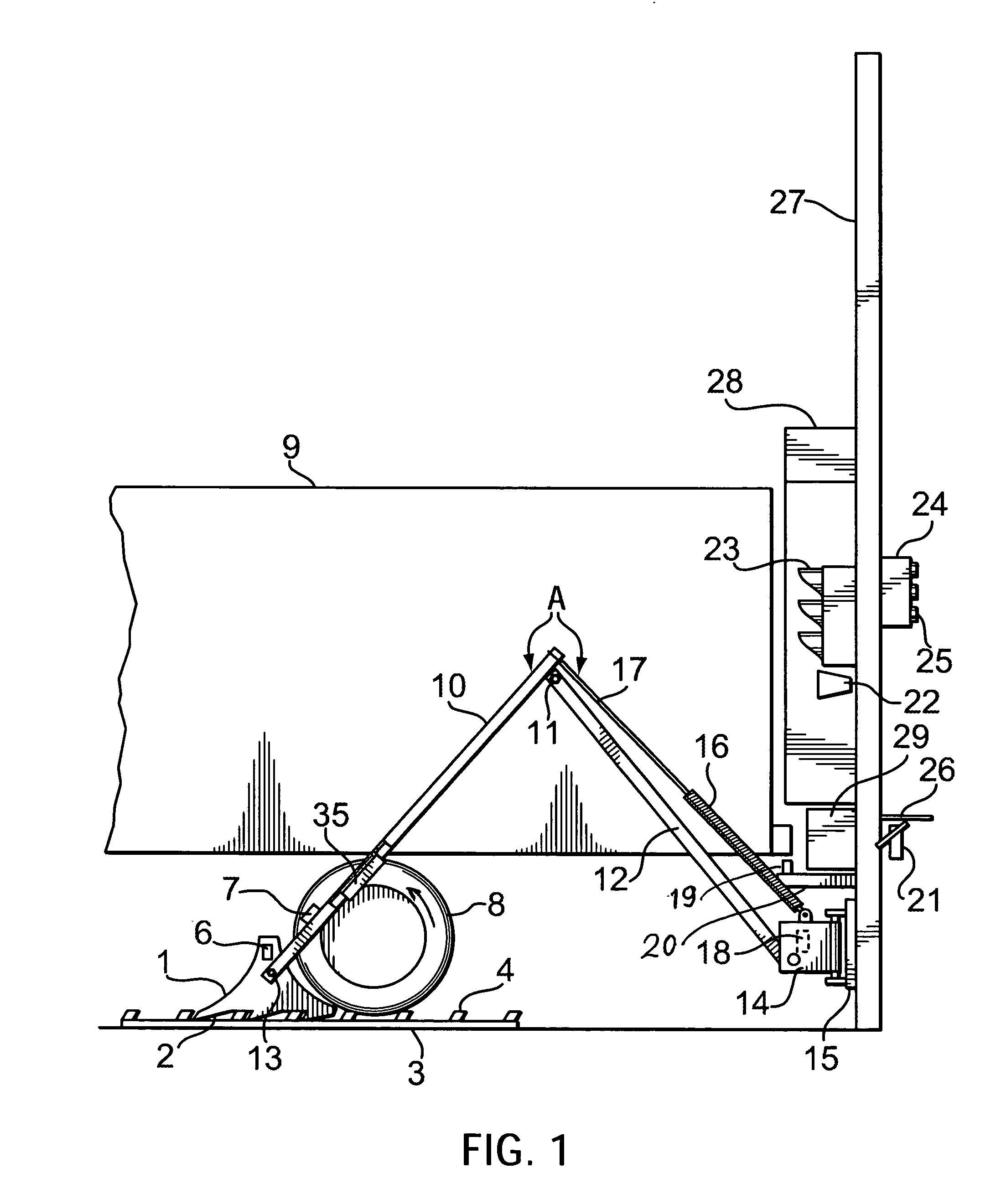

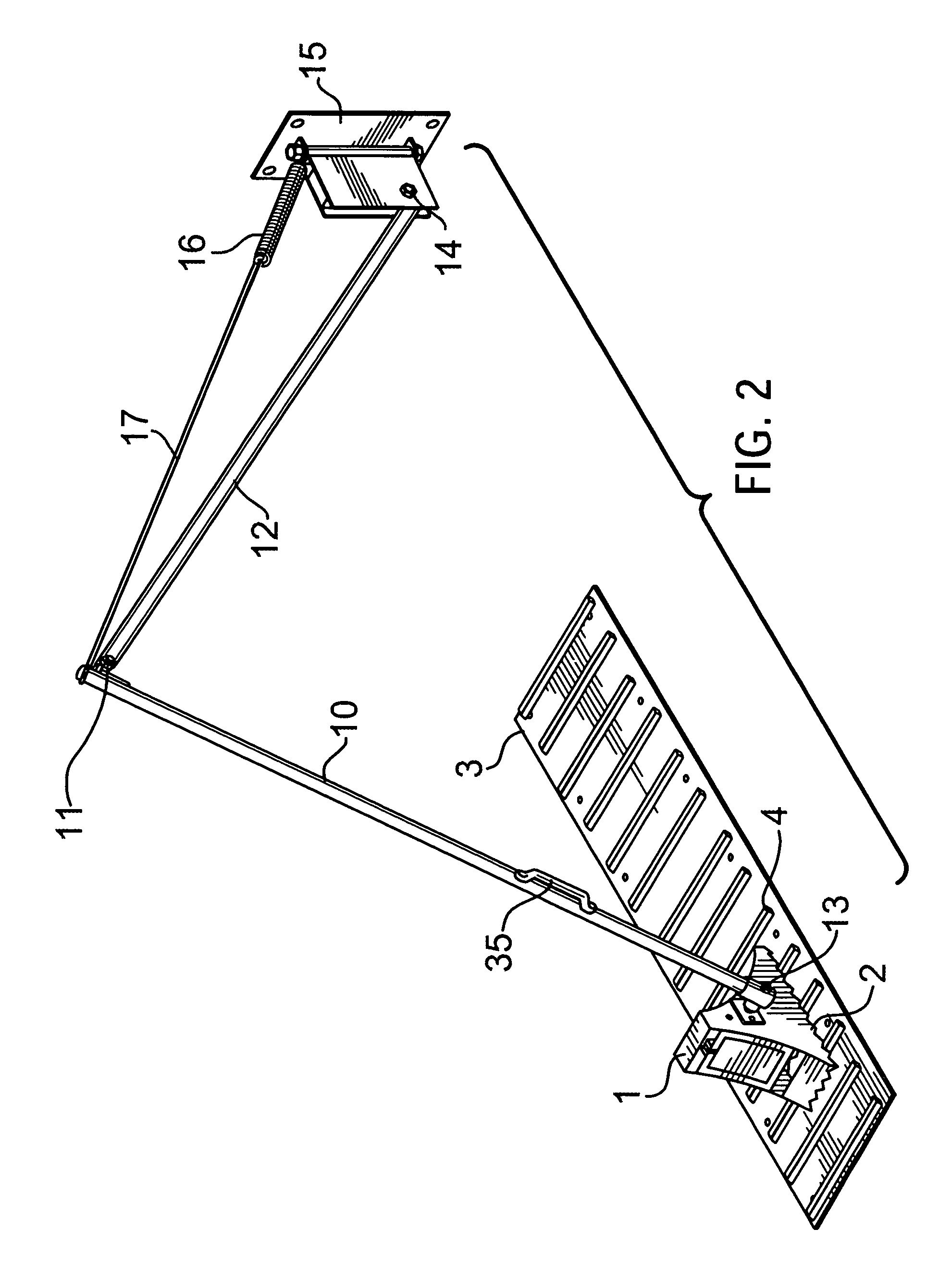

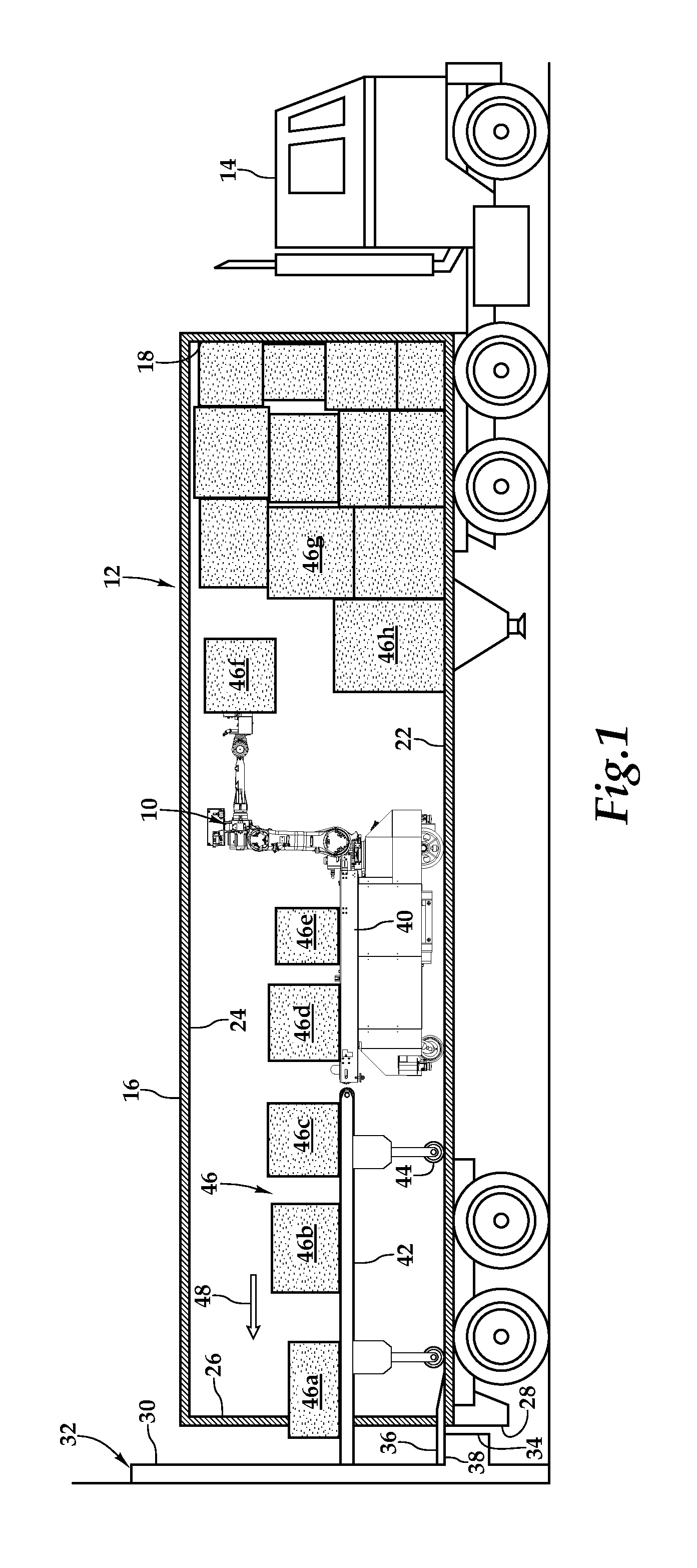

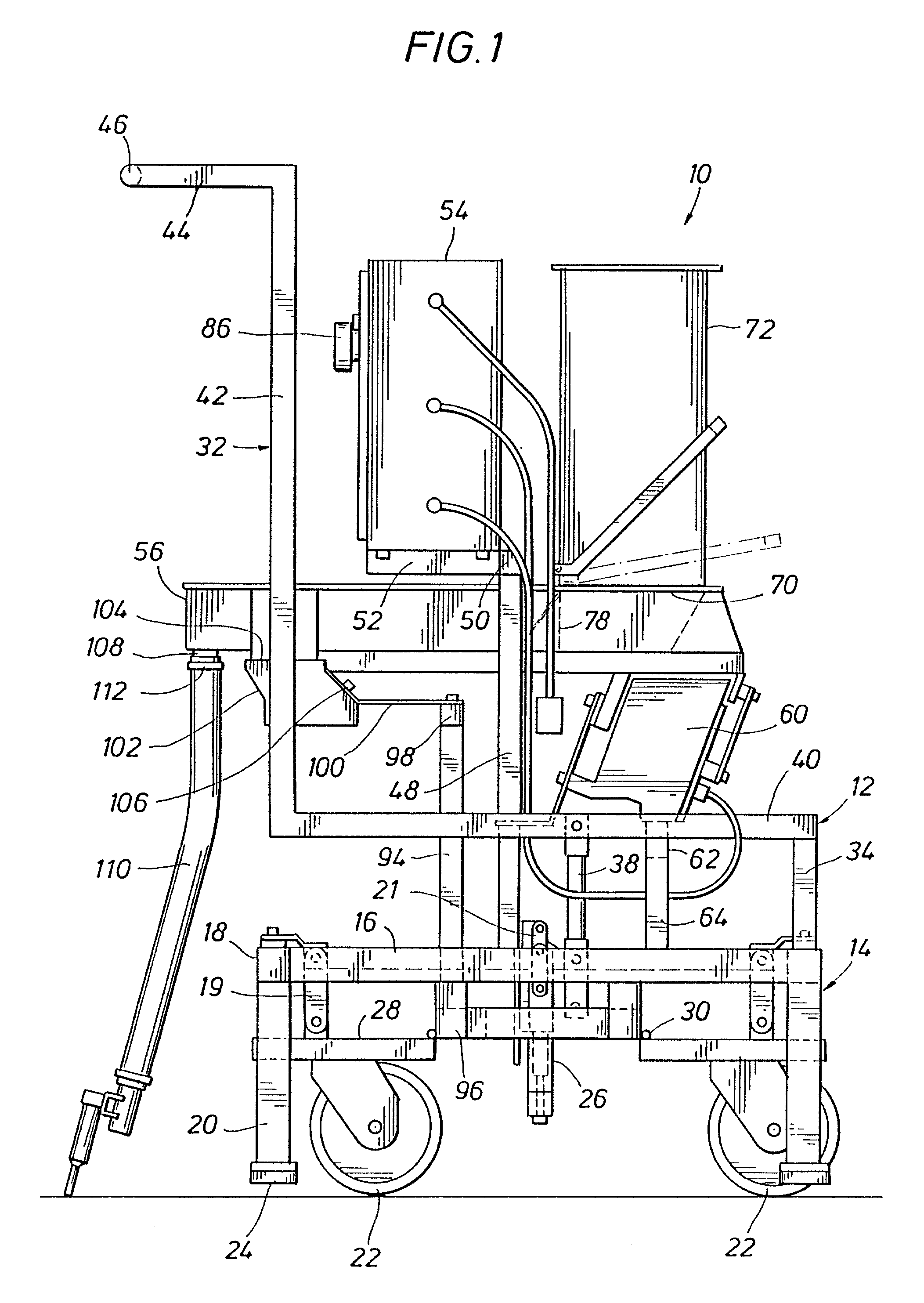

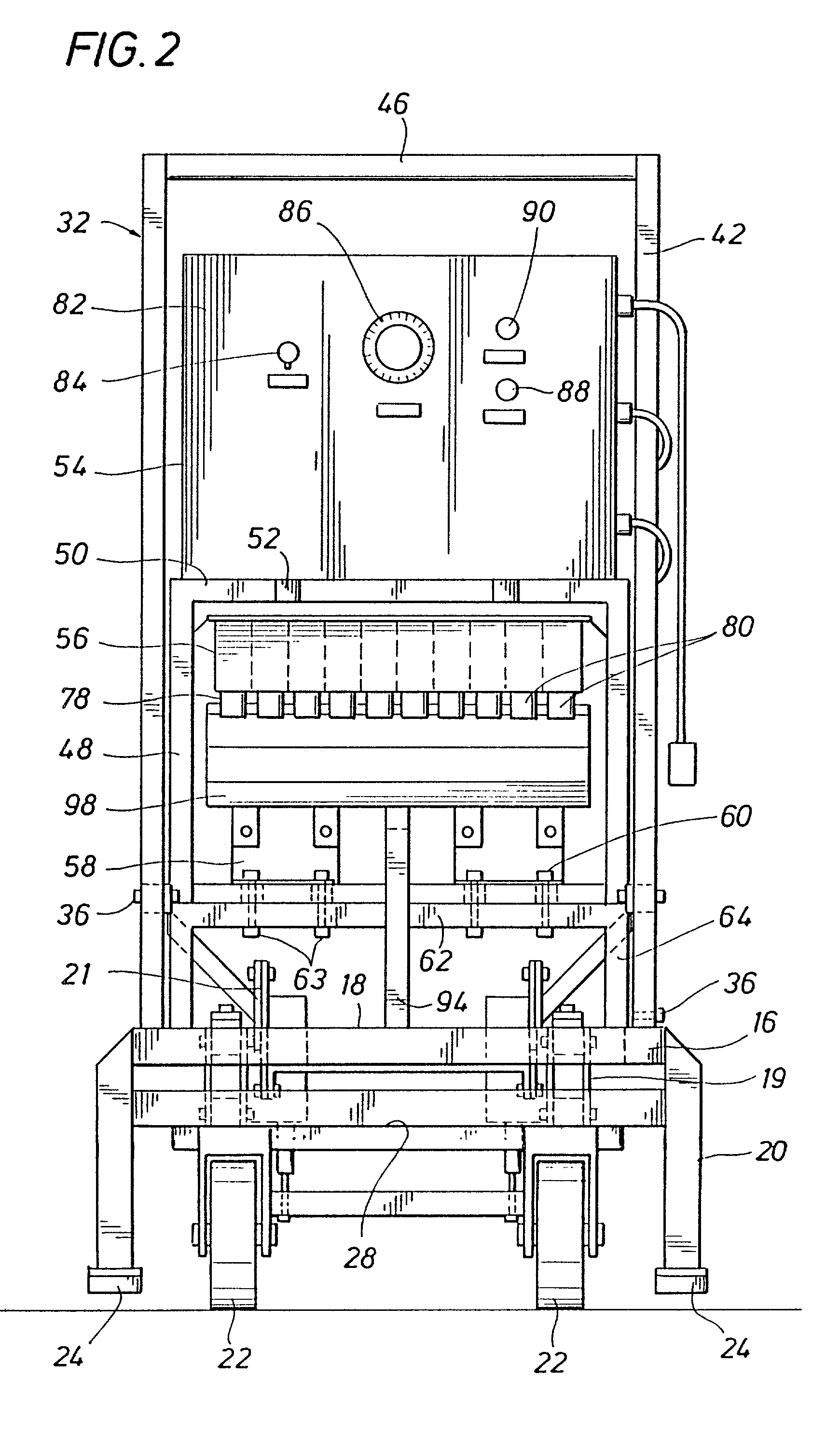

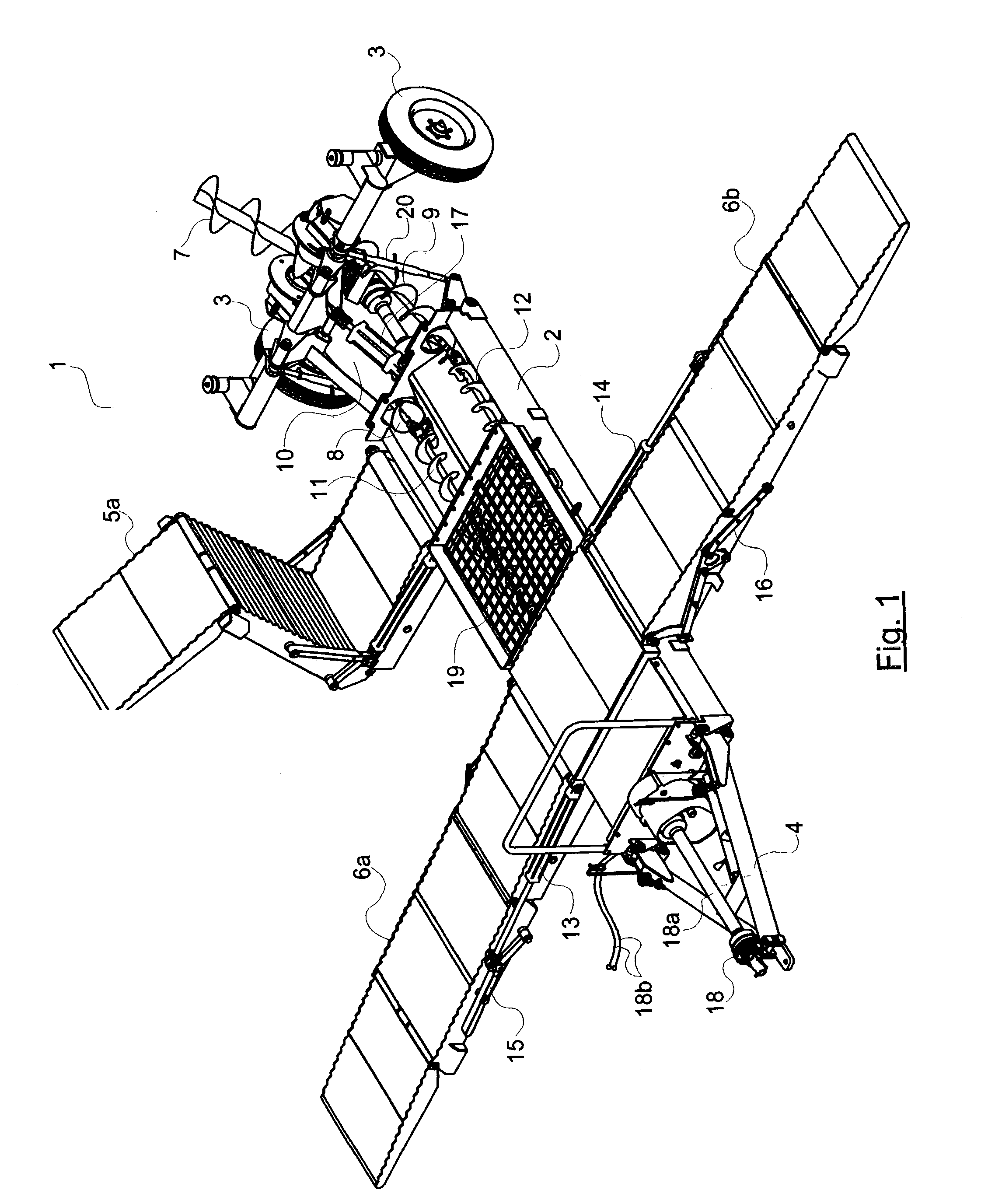

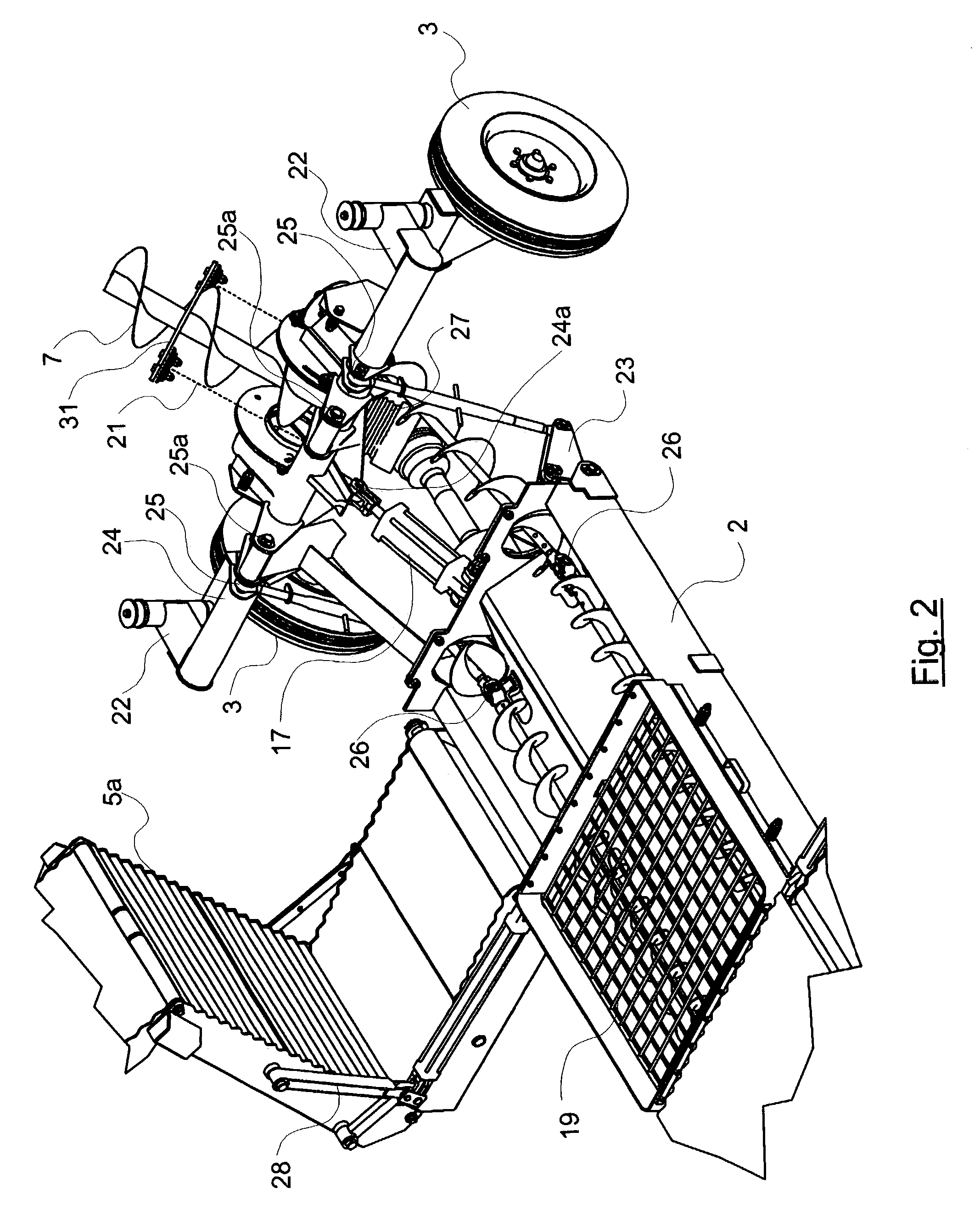

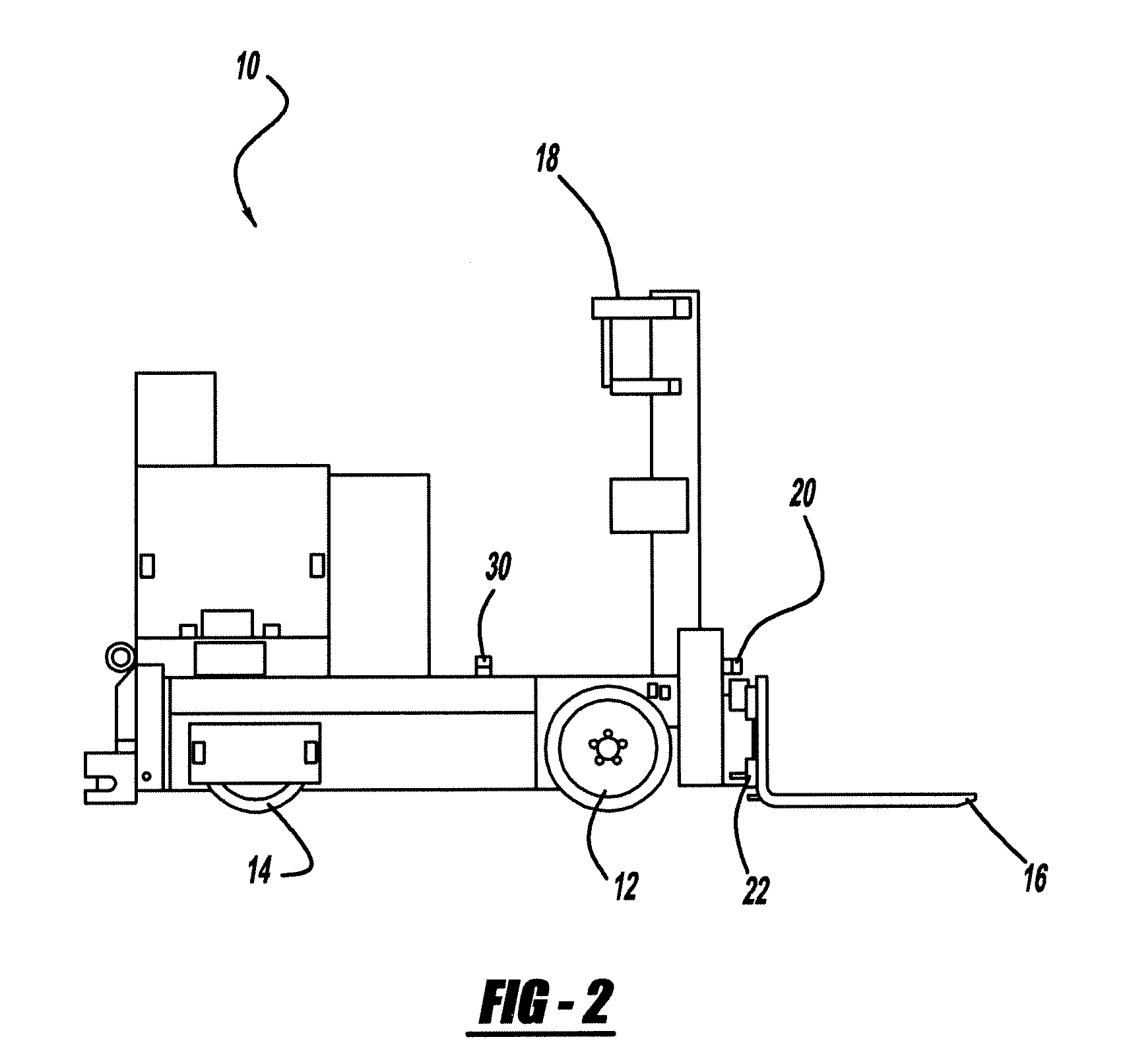

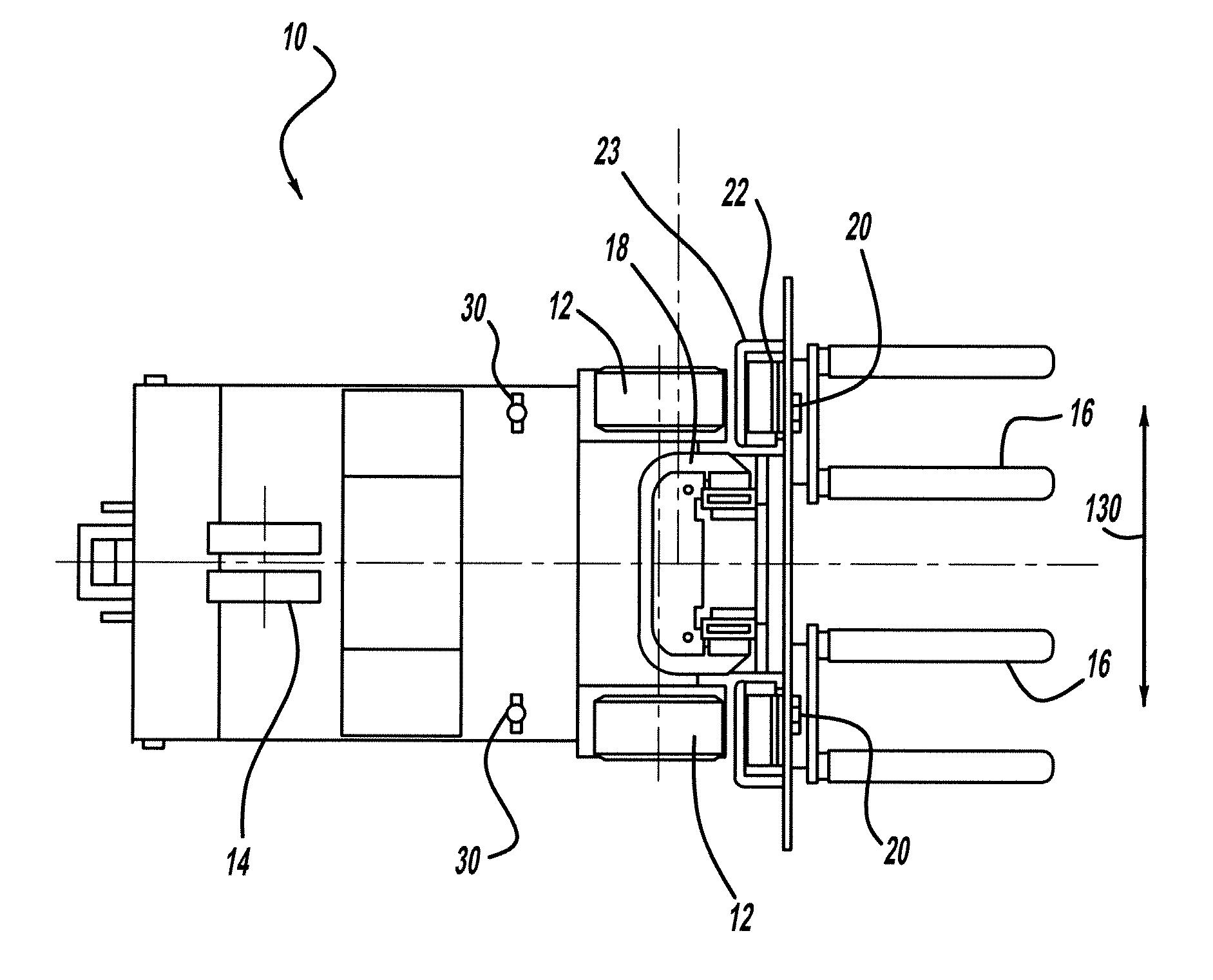

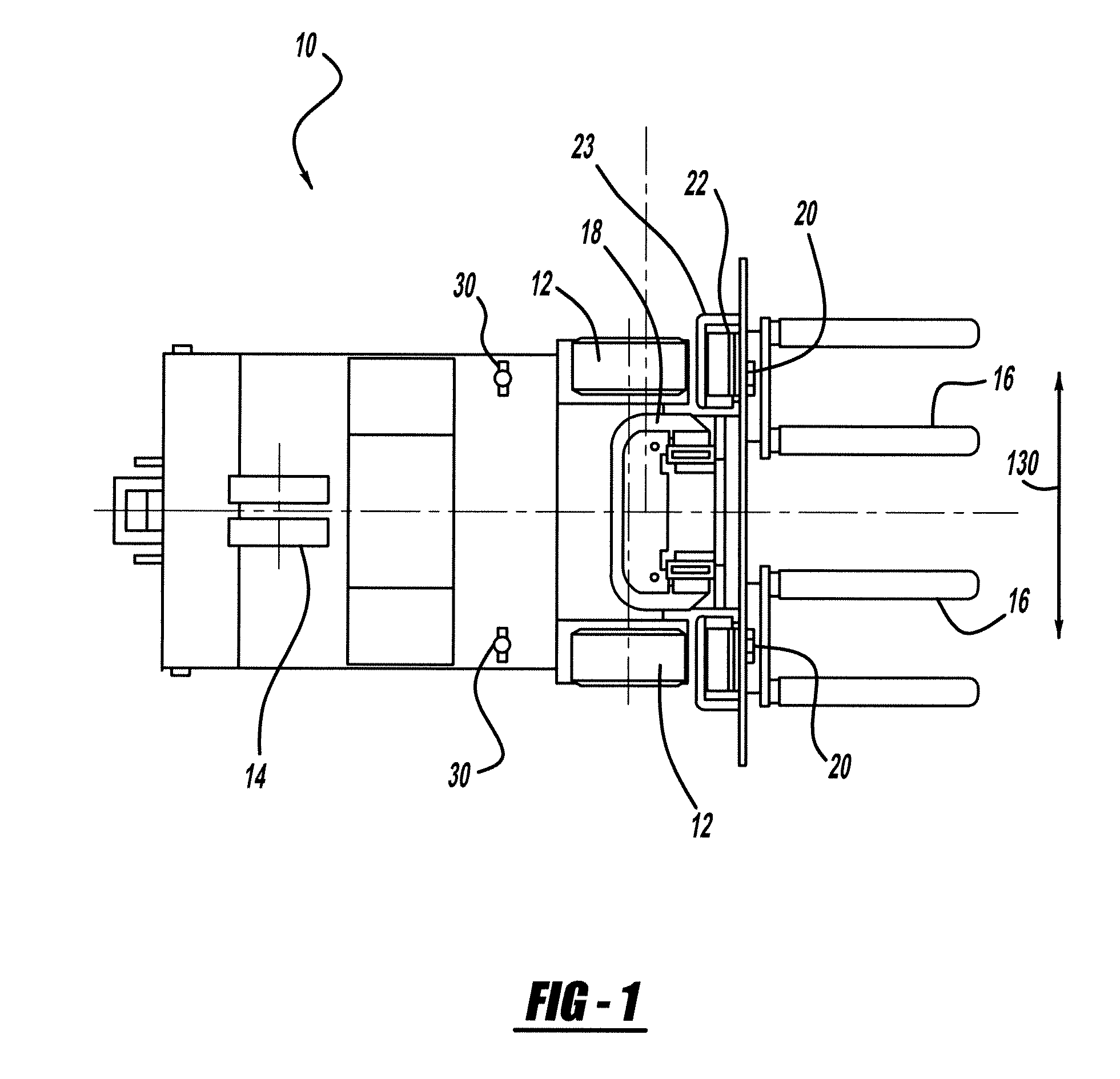

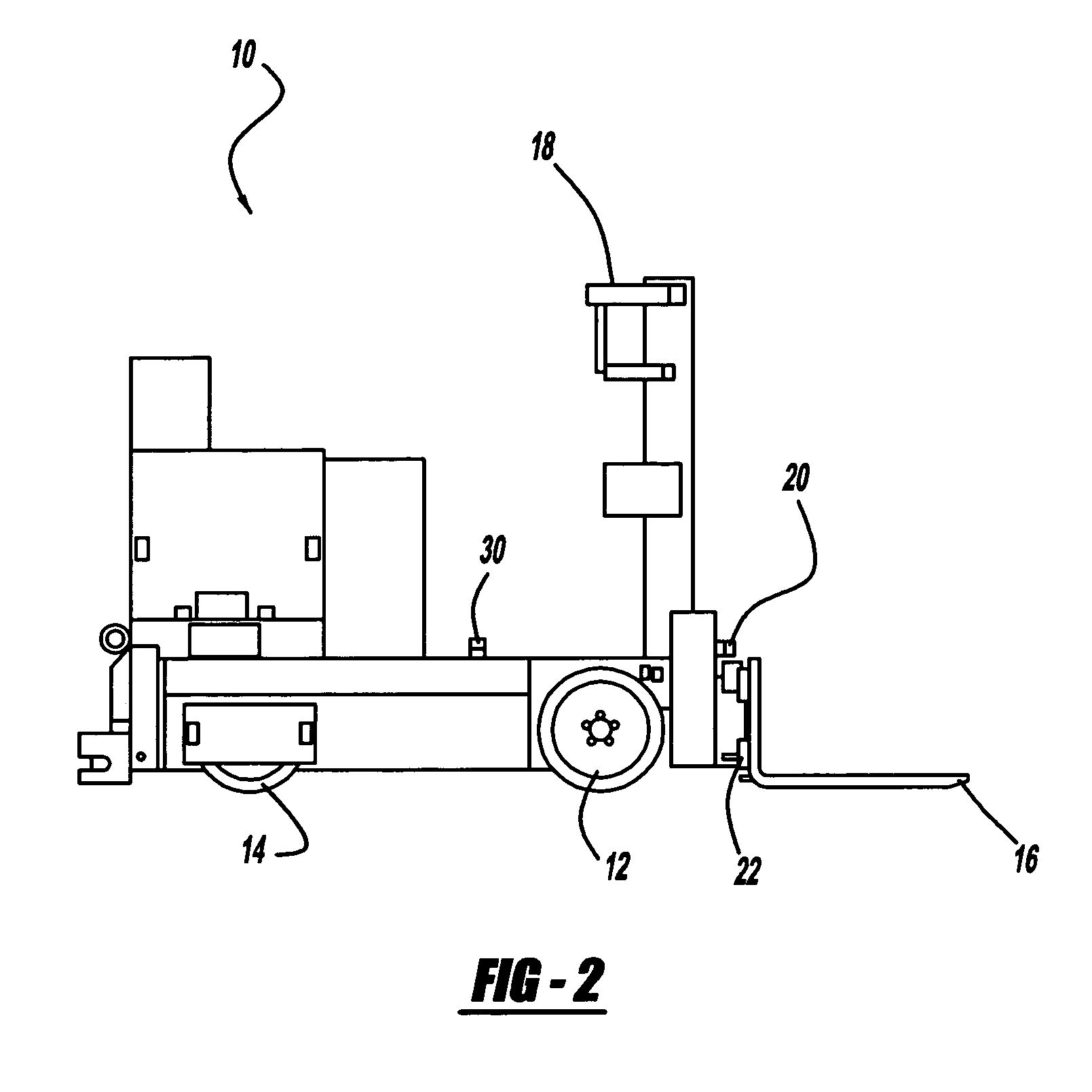

Mobile Material Handling and Metering System

ActiveUS20120219391A1Convenient for centralized processingEasy remote controlLarge containersRefuse transferringWell drillingRemote control

A method and system for handling granular material, such as proppant used in hydraulic fracturing in well drilling, is provided. In an operational configuration, a delivery module having conveyors receives and conveys granular material to a delivery location, and one or more mobile storage modules receive, hold and dispense granular material downward to the delivery module. The mobile storage modules comprise a raised, angular container portion for holding granular material. Each mobile storage module may comprise a rock-over chassis for support against ground. A remote control module provides centralized, remote control of the system. Mobile support unit modules may also be provided as a remotely controlled vehicle capable of providing power, control, heating, and the like to other modules. Mobile in-feed elevator modules may also be provided as a remotely controlled vehicle for feeding granular material to mobile storage modules. In a transportation configuration, each module is separately transportable.

Owner:CONTINENTAL INTERMODAL GRP TRUCKING LLC

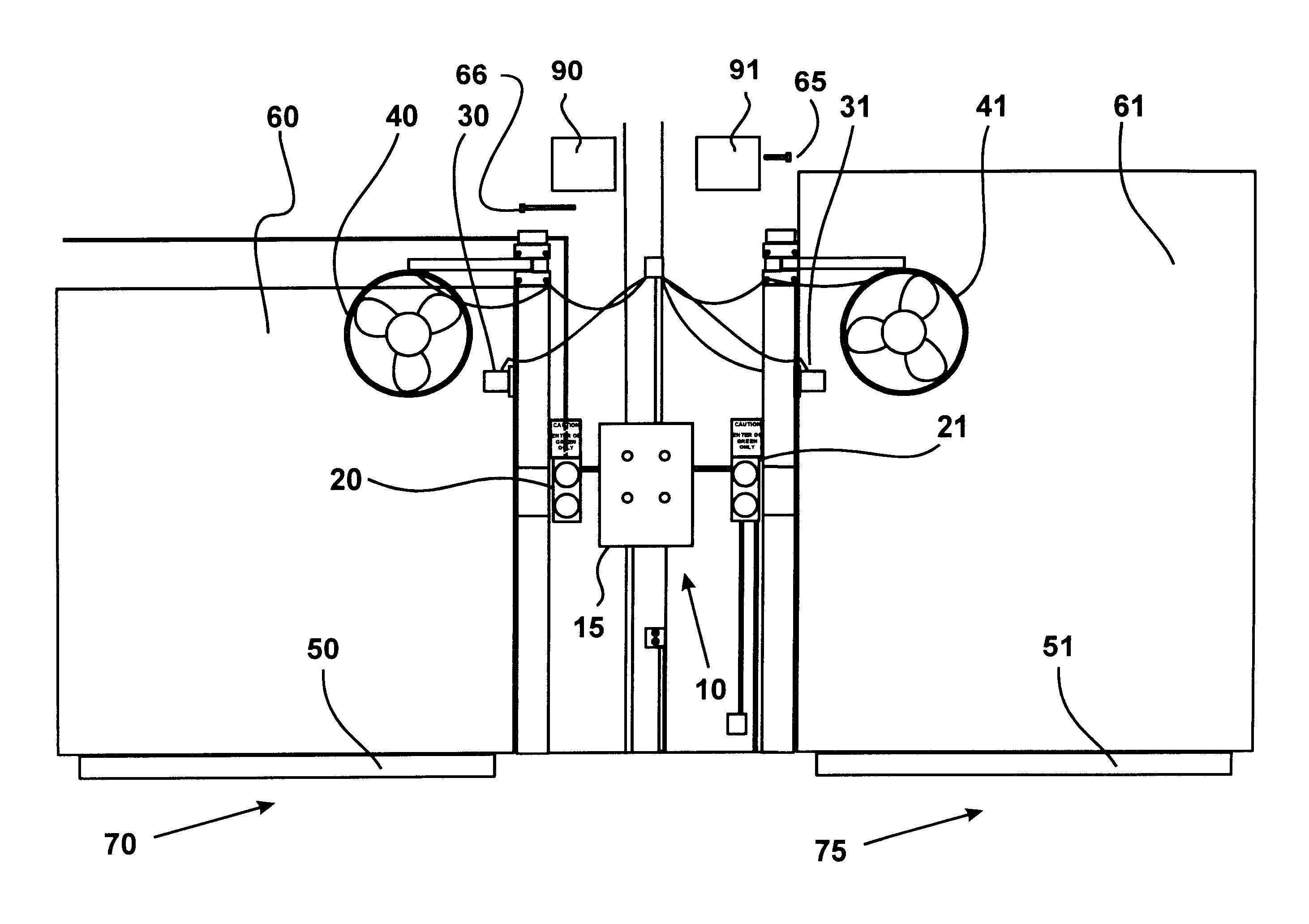

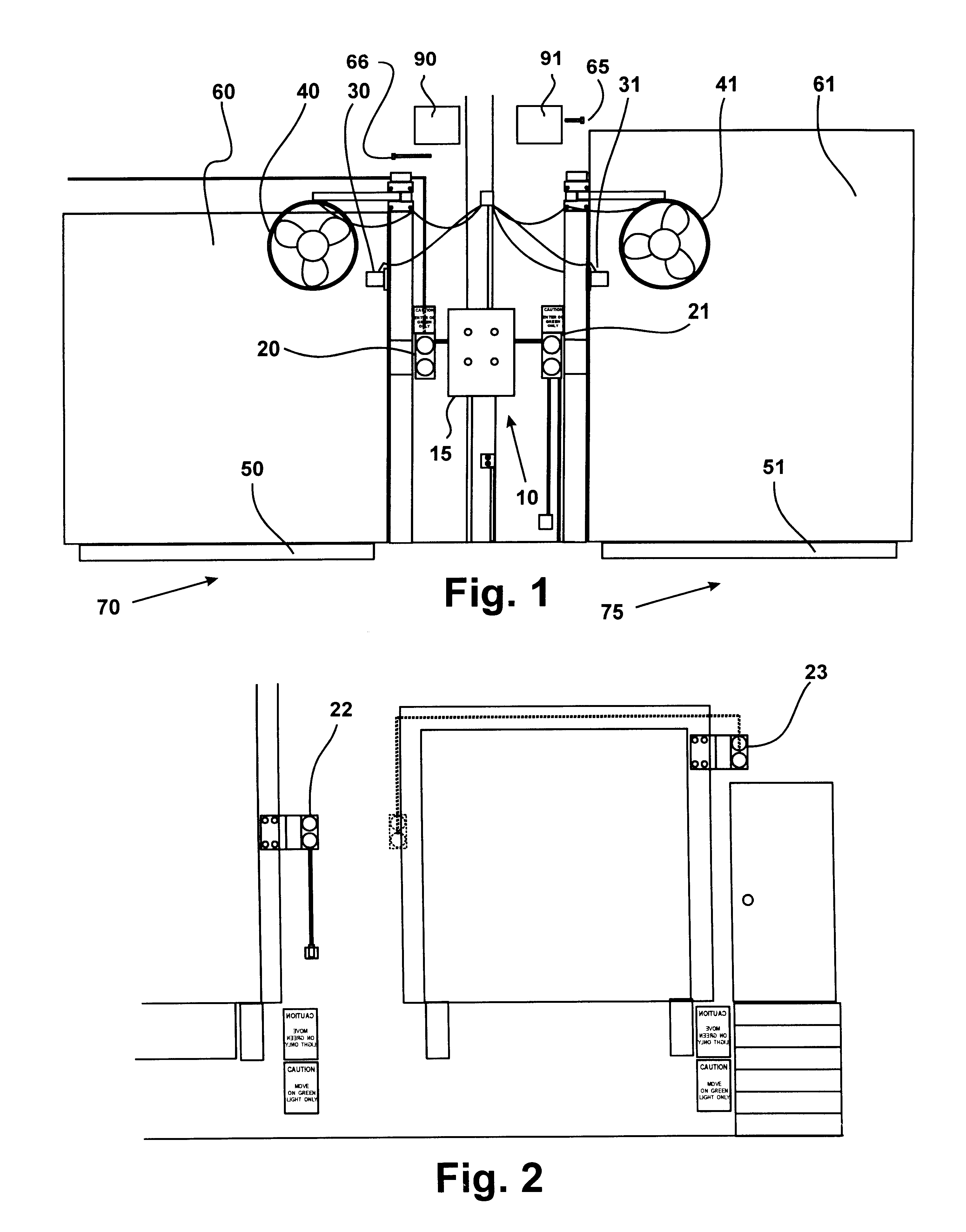

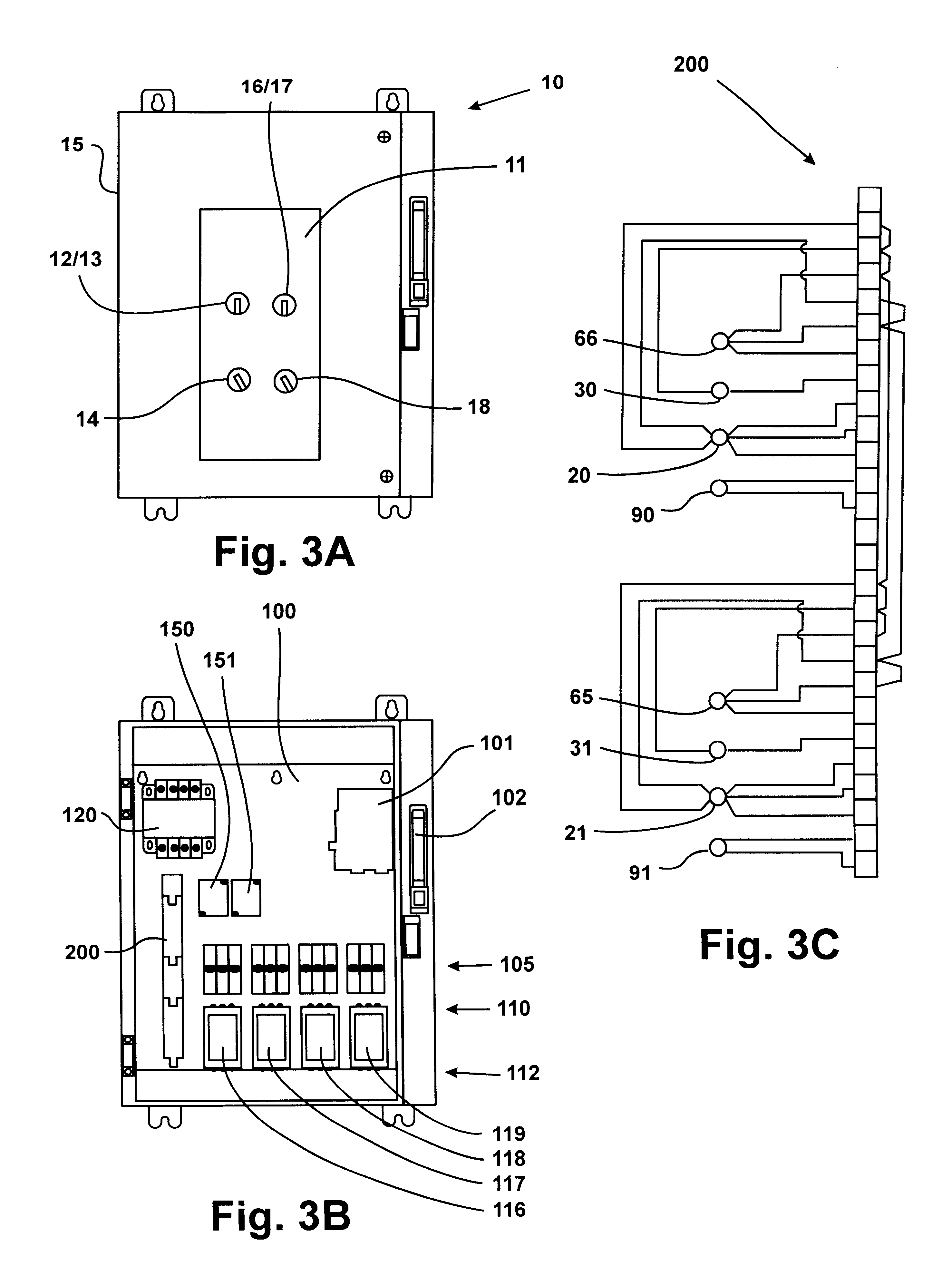

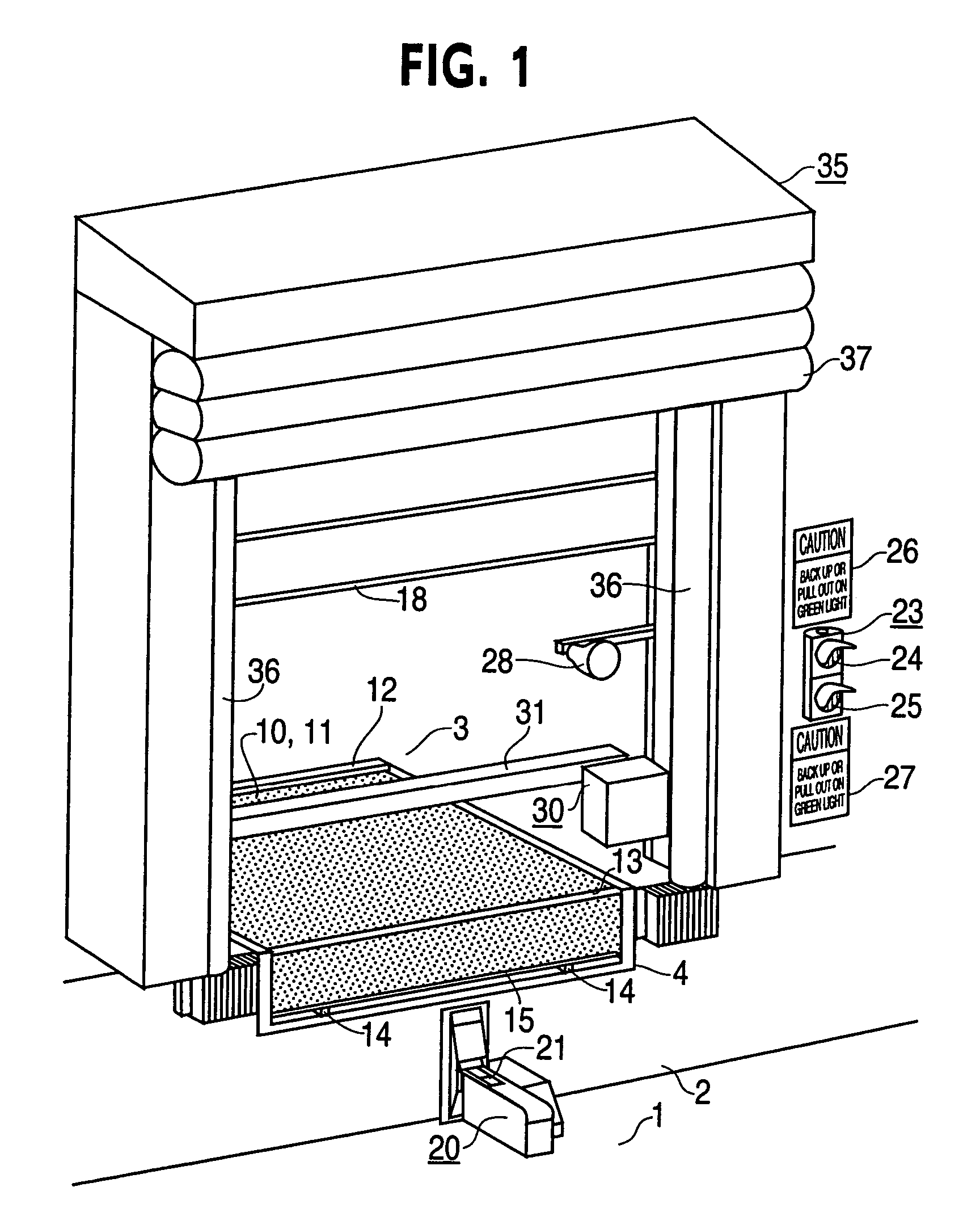

Loading dock traffic automation

The loading dock traffic automation and inventory control system of the present invention automates the loading dock area by controlling a truck control notification automation system, traffic signal dock lights, loading dock spot light, loading dock fan and dock leveler. The manually operated control panel is energized or de-energized with full automation by the movement of the overhead dock door. The device includes a control panel enclosure mounted on the interior wall of the building next to the loading dock door. One control panel enclosure can service one or two loading dock doors.

Owner:ANCEL THOMAS A

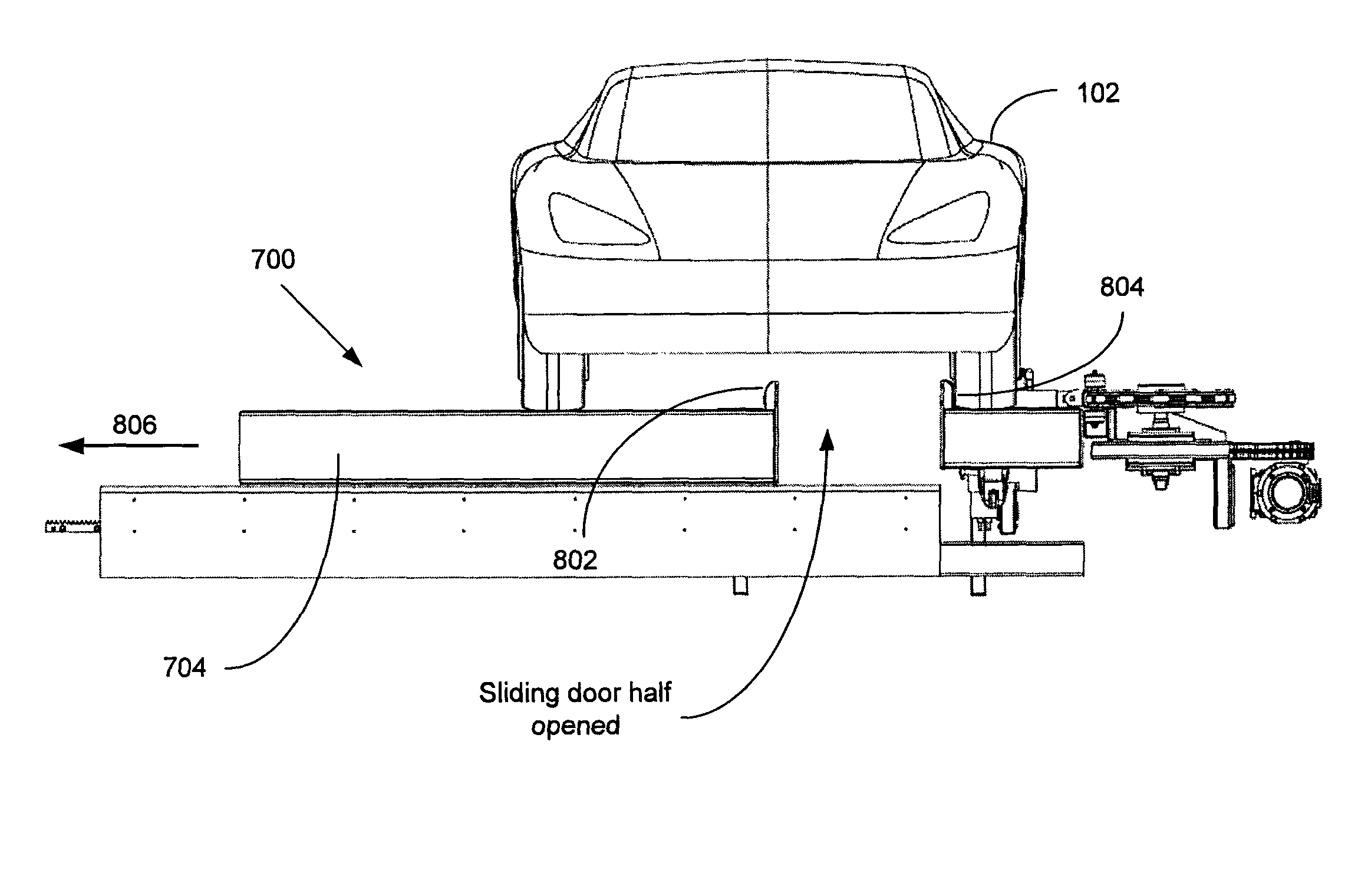

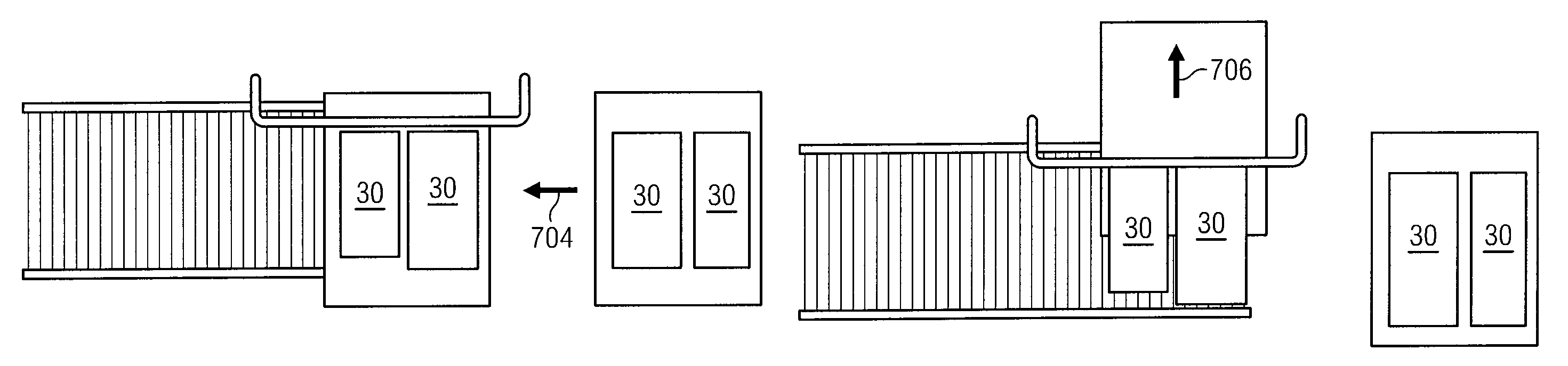

Battery exchange station

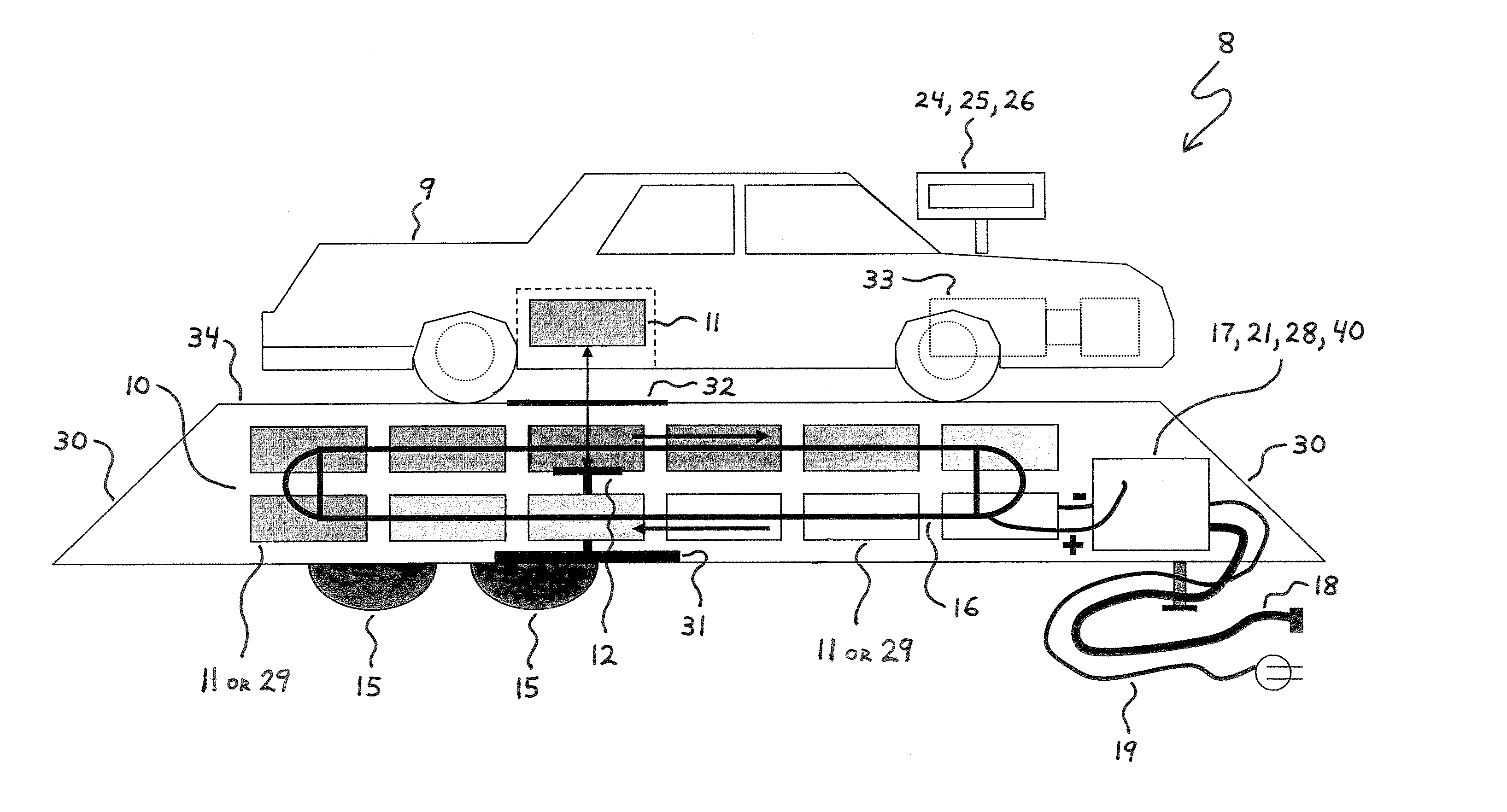

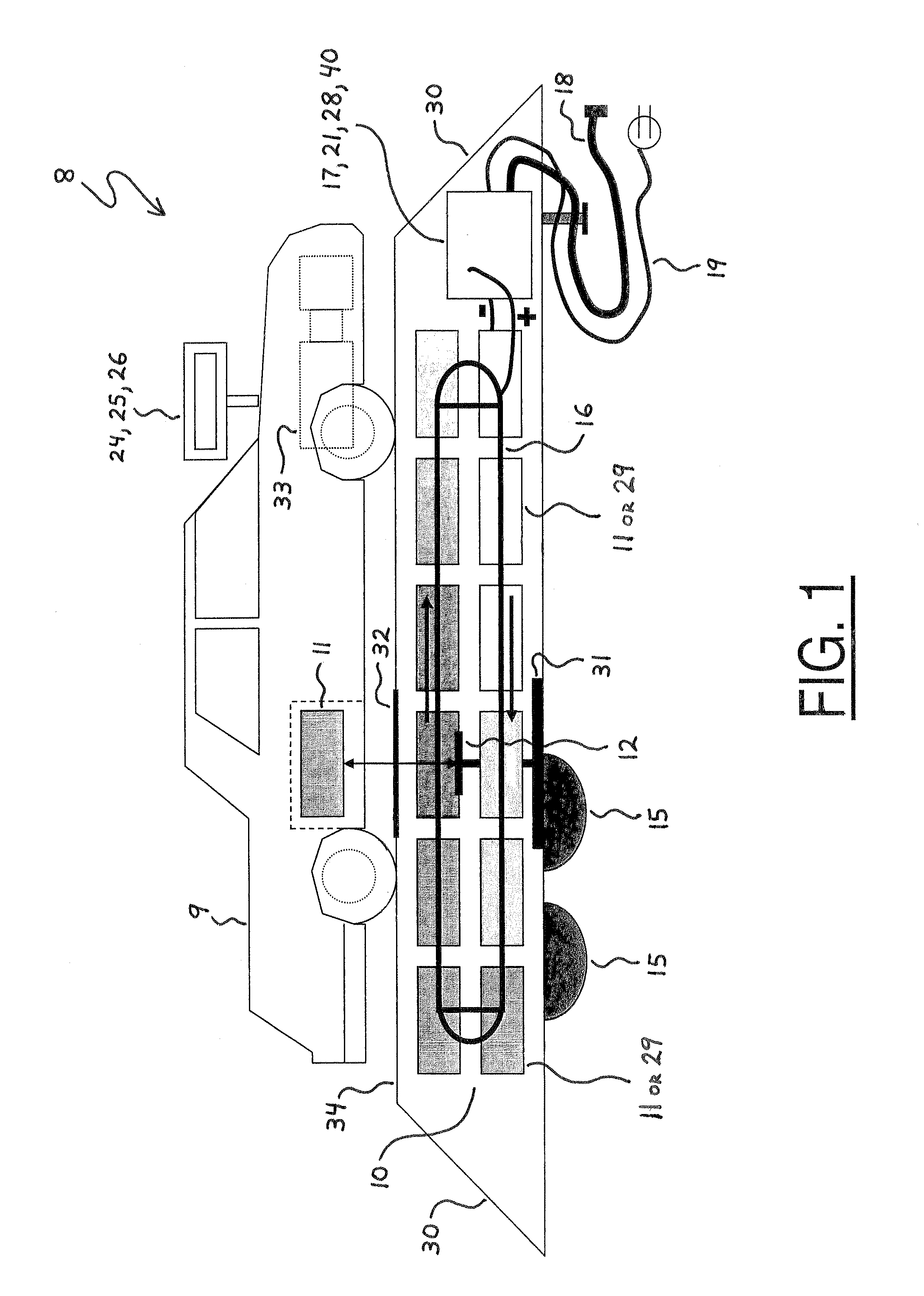

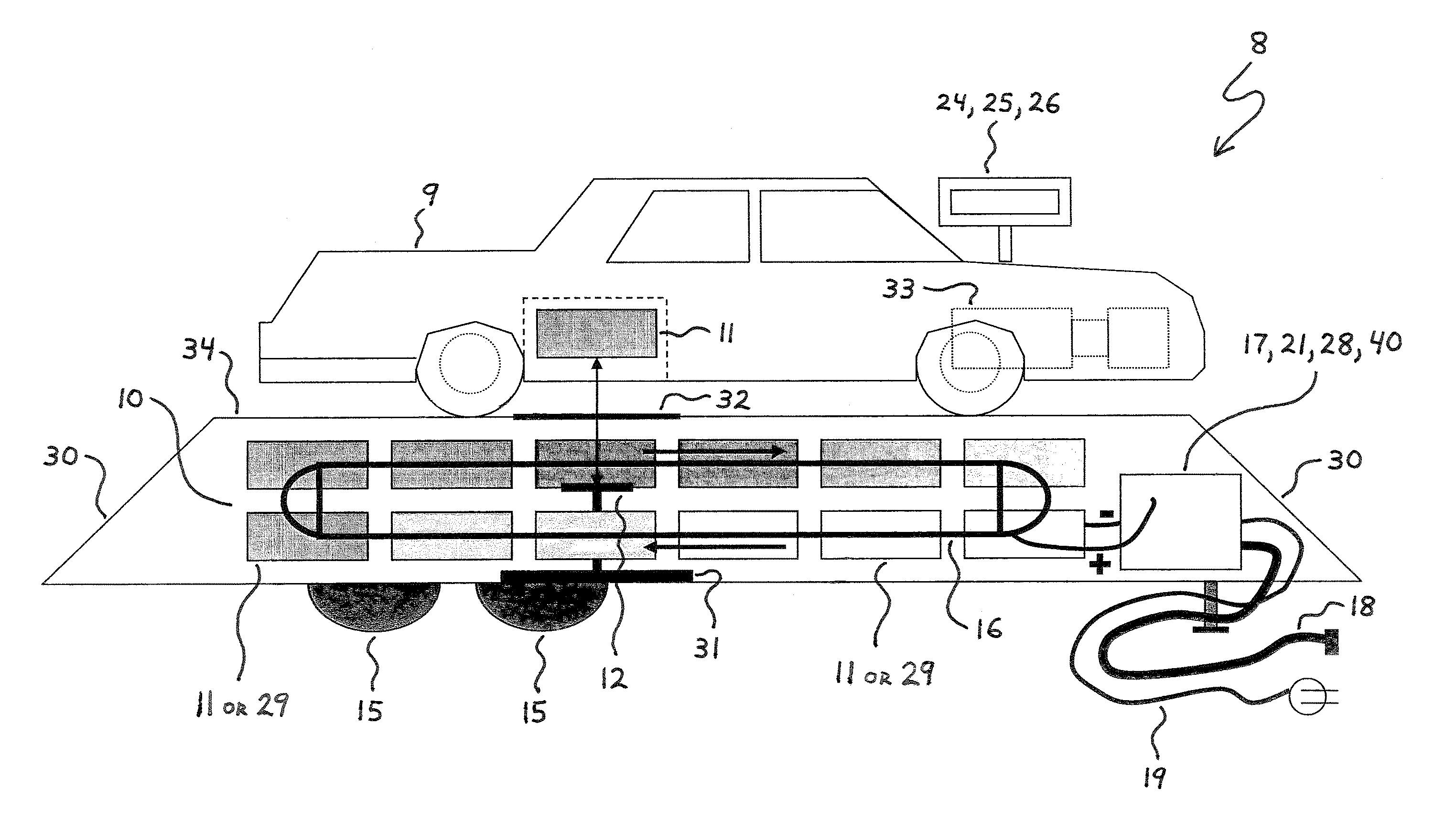

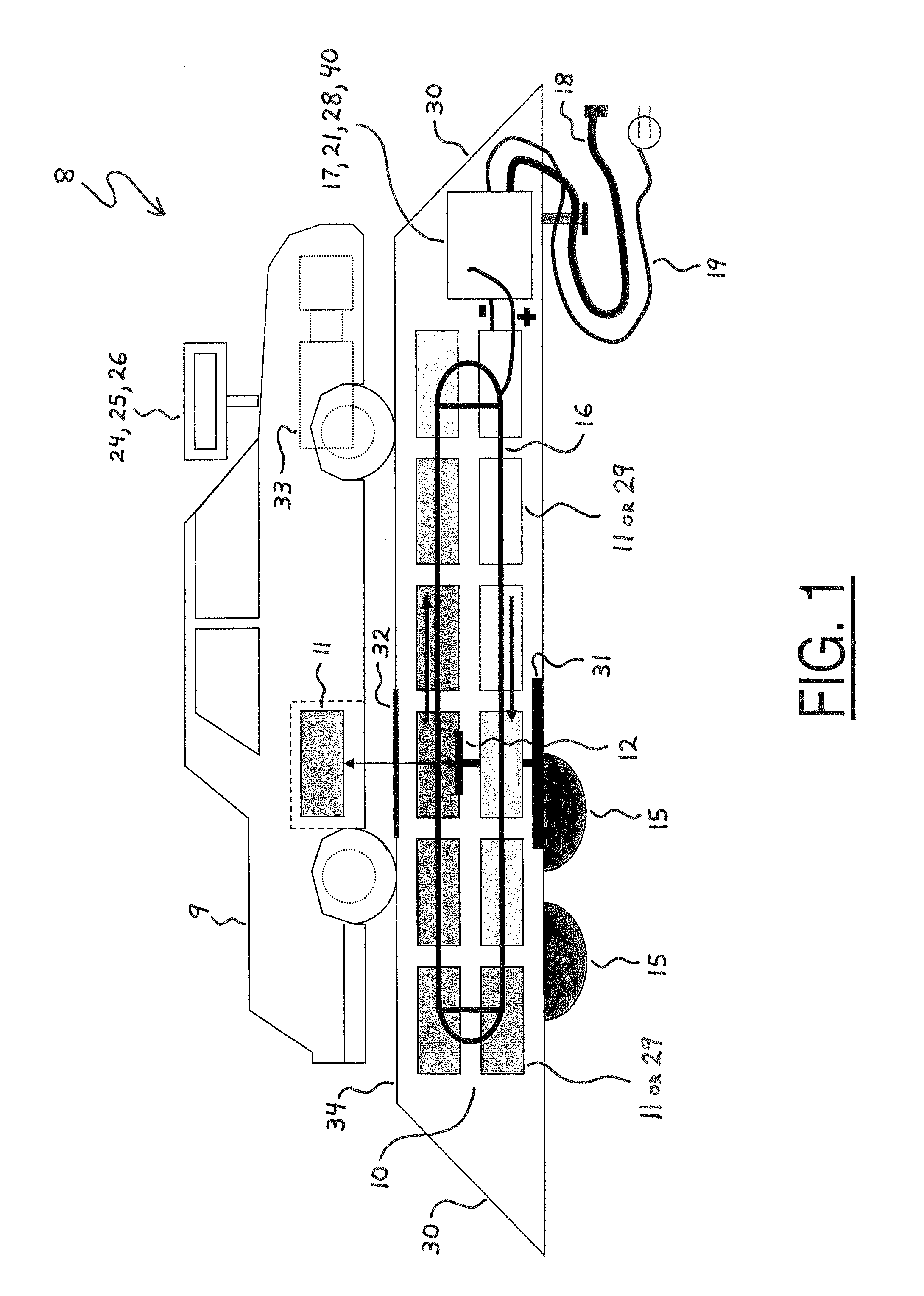

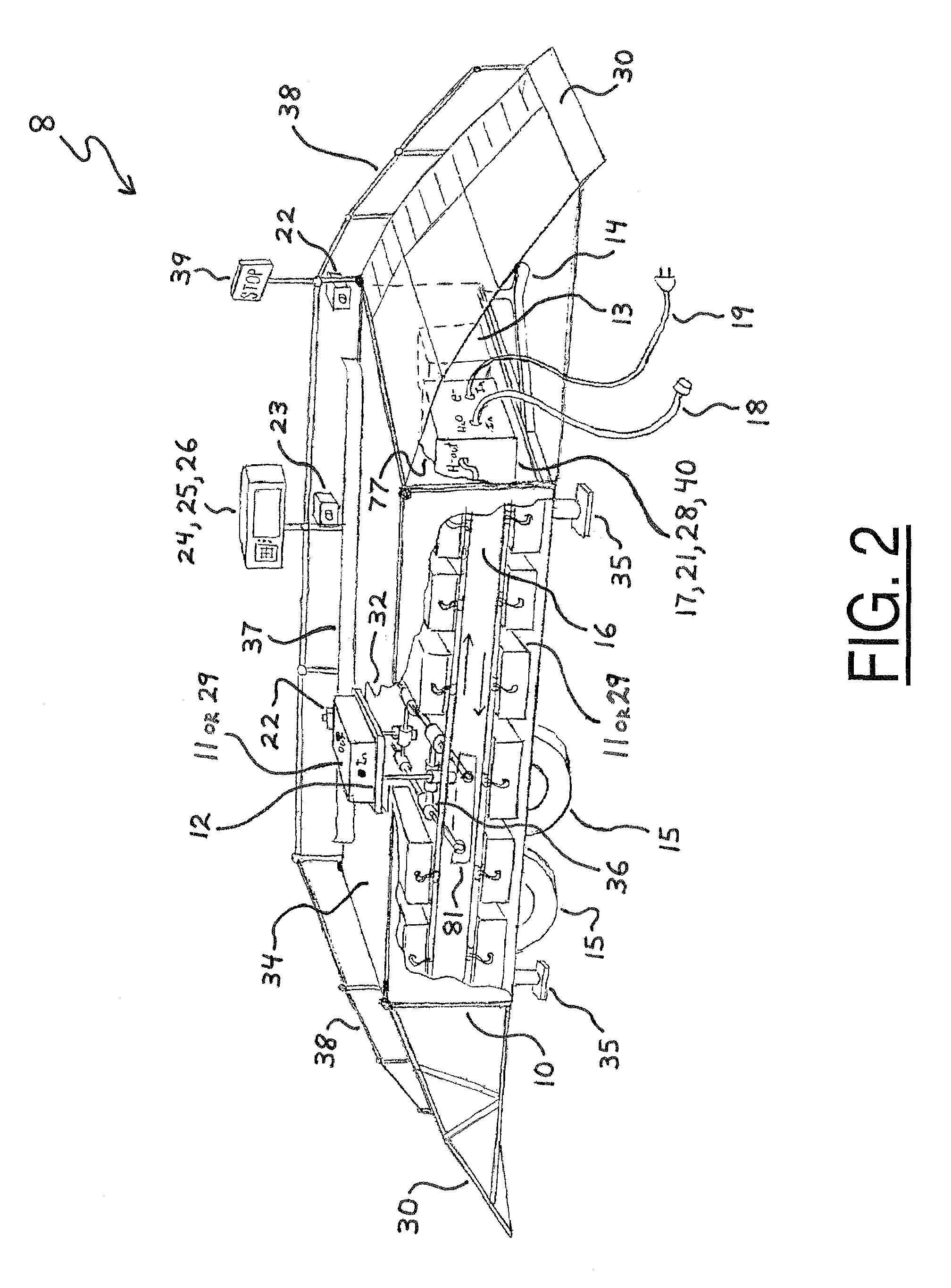

ActiveUS8013571B2Keep for a long timeReduce dependenceRailway vehiclesRefuse receptaclesElectrical batteryElectric vehicle

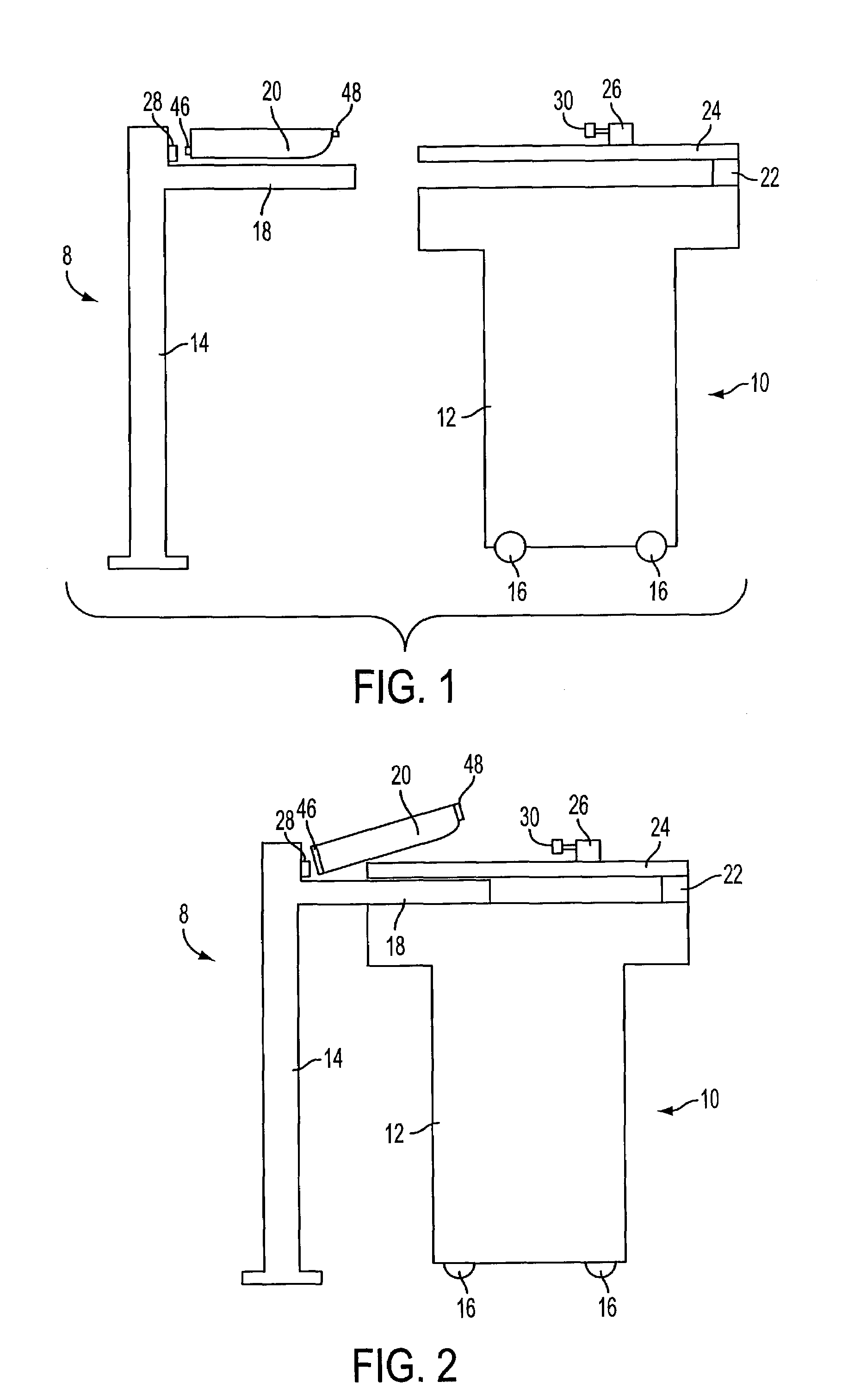

At the battery exchange station a discharged battery is removed and a charged battery is inserted into an electric vehicle. The battery is inserted and removed along a vertical axis, i.e., into and out of the bottom of the vehicle. The battery exchange system is located in a service bay under the vehicle. A sliding door system creates an opening above the service bay. A vehicle is received over the sliding door system, such that at least one wheel of the vehicle rests on the conveyor system. The door slides in a first direction while allowing the conveyor system to slide in a direction opposite the first direction. The conveyor system also supports the at least one wheel of the vehicle while the door and conveyor slide in opposite directions. The sliding of the door and the sliding of the conveyor system occur at least partially simultaneously.

Owner:CHARGE PEAK

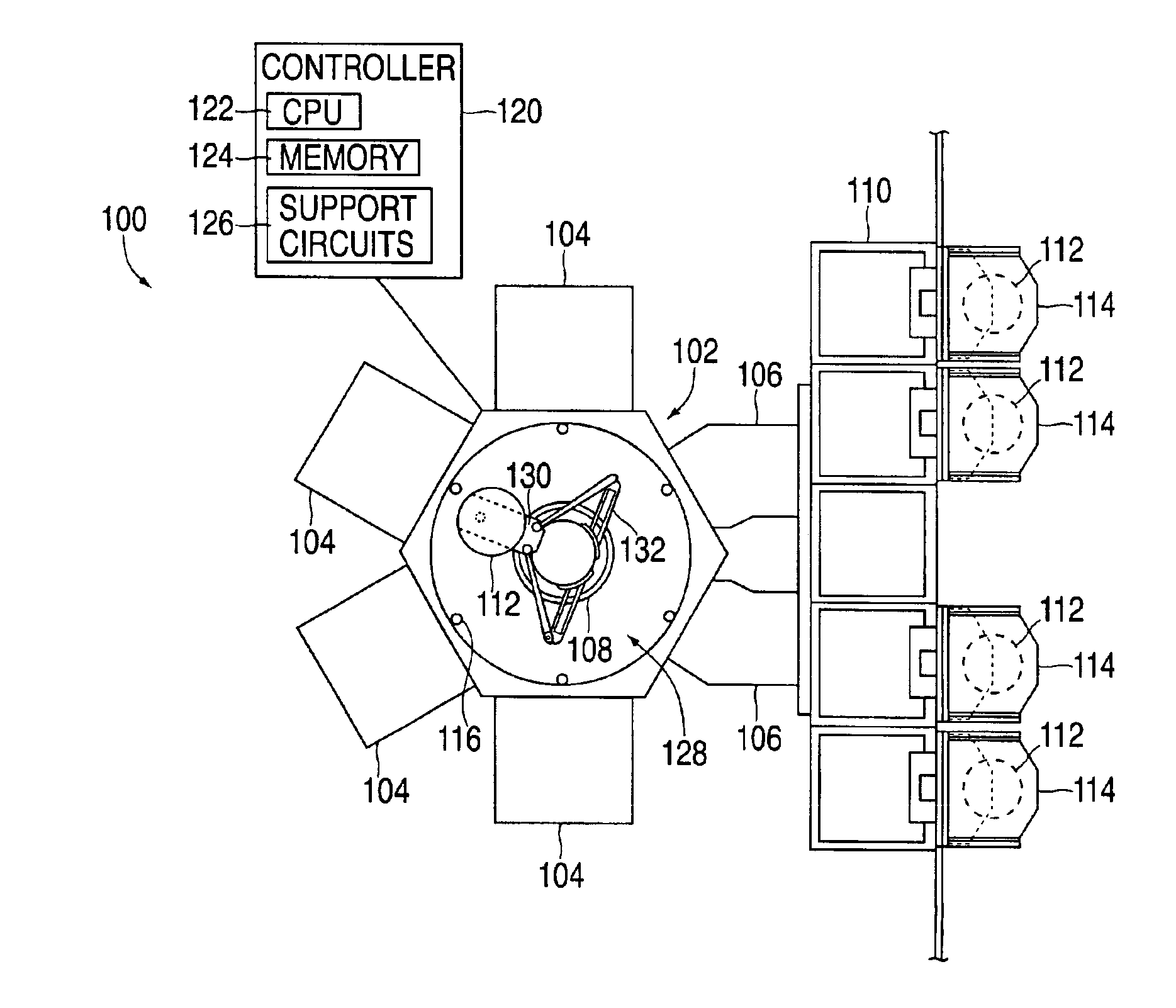

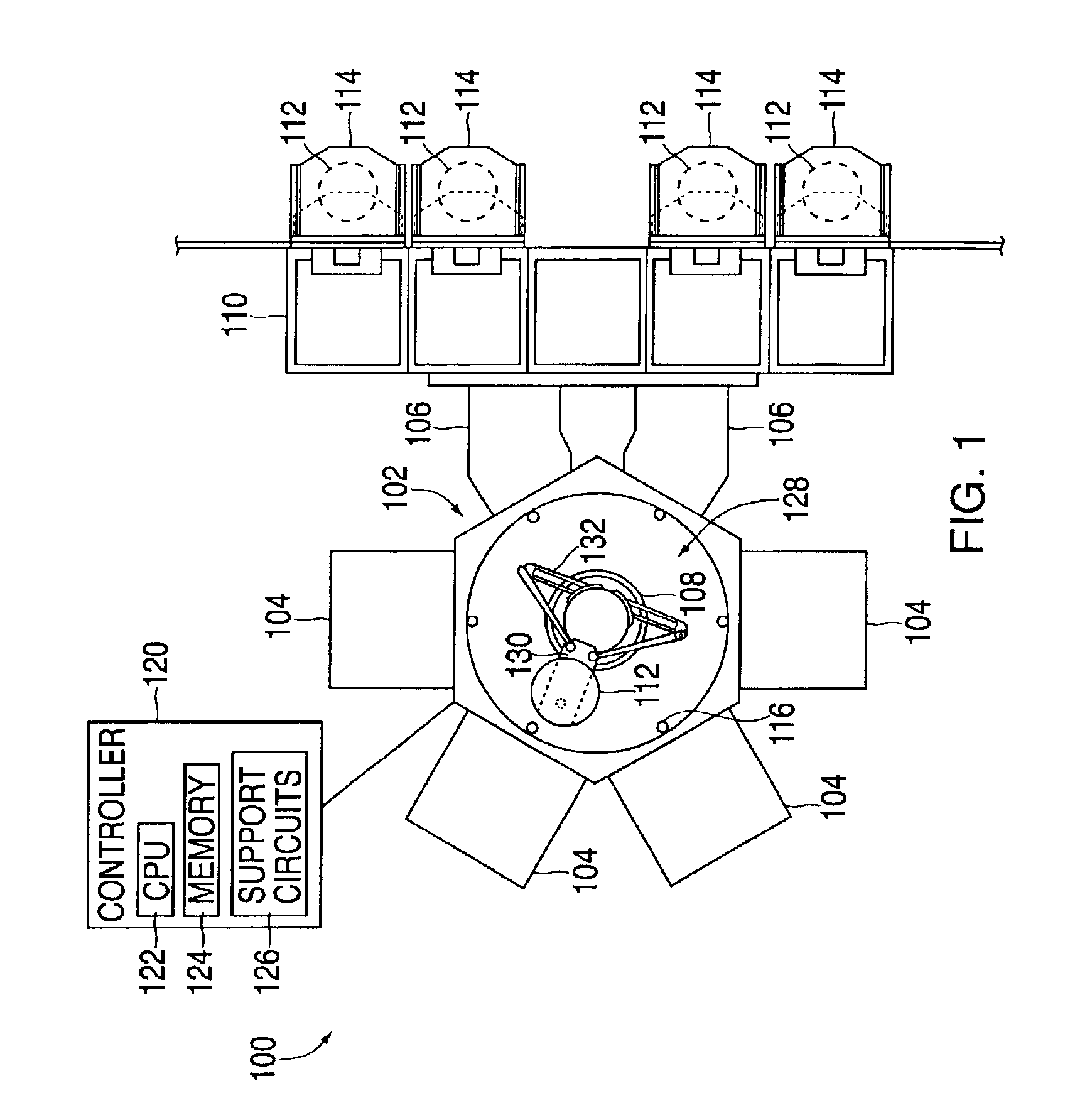

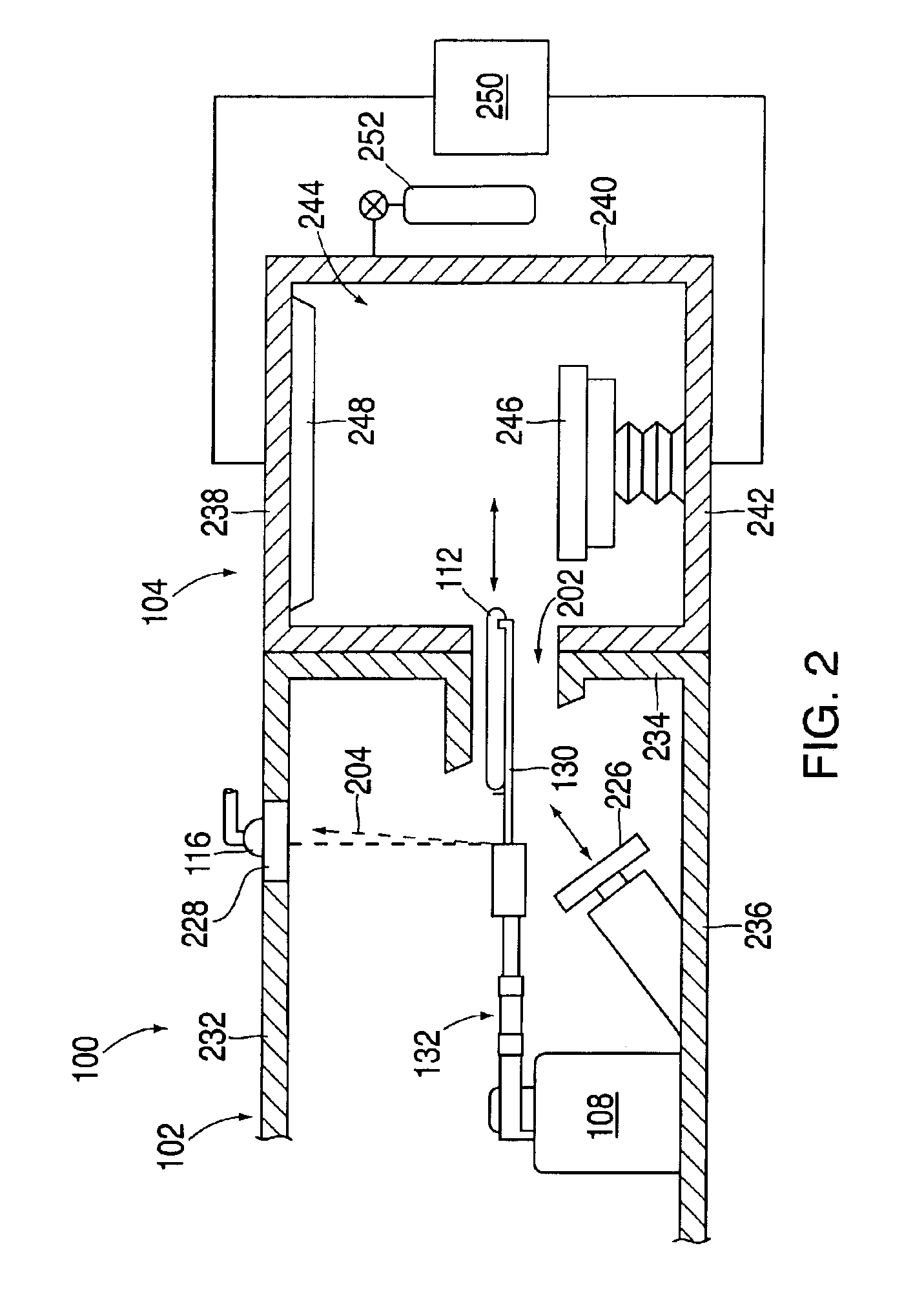

Substrate processing apparatus

A semiconductor workpiece processing apparatus having a first chamber, a transport vehicle, and another chamber. The first chamber is capable of being isolated from an outside atmosphere. The transport vehicle is located in the first chamber and is movably supported from the first chamber for moving linearly relative to the first chamber. The transport vehicle includes a base, and an integral semiconductor workpiece transfer arm movably mounted to the base and capable of multi-access movement relative to the base. The other chamber is communicably connected to the first chamber via a closable opening of the first chamber. The opening is sized to allow the transport vehicle to transit between the first chamber and the other chamber through the opening.

Owner:BOOKS AUTOMATION US LLC

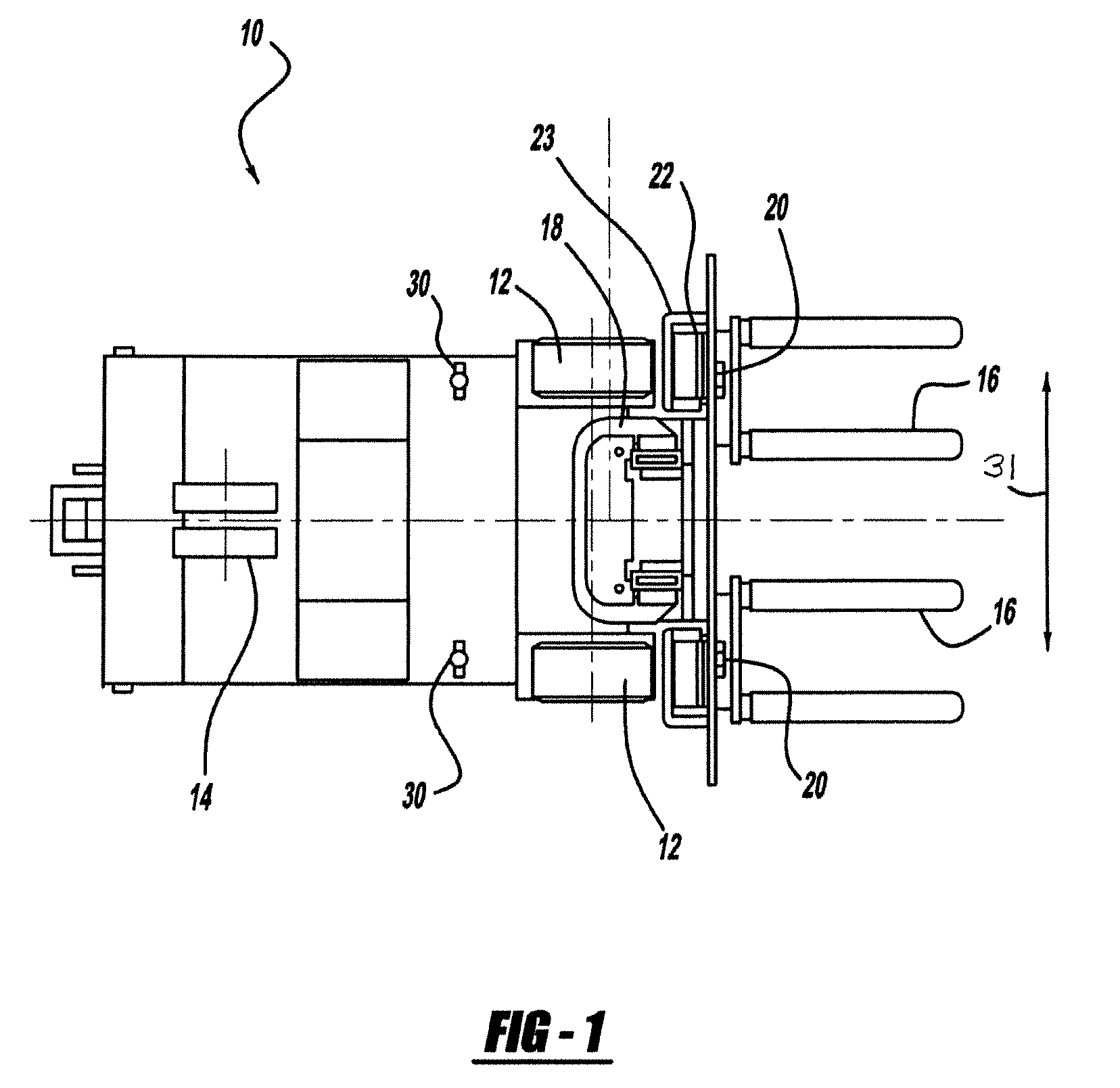

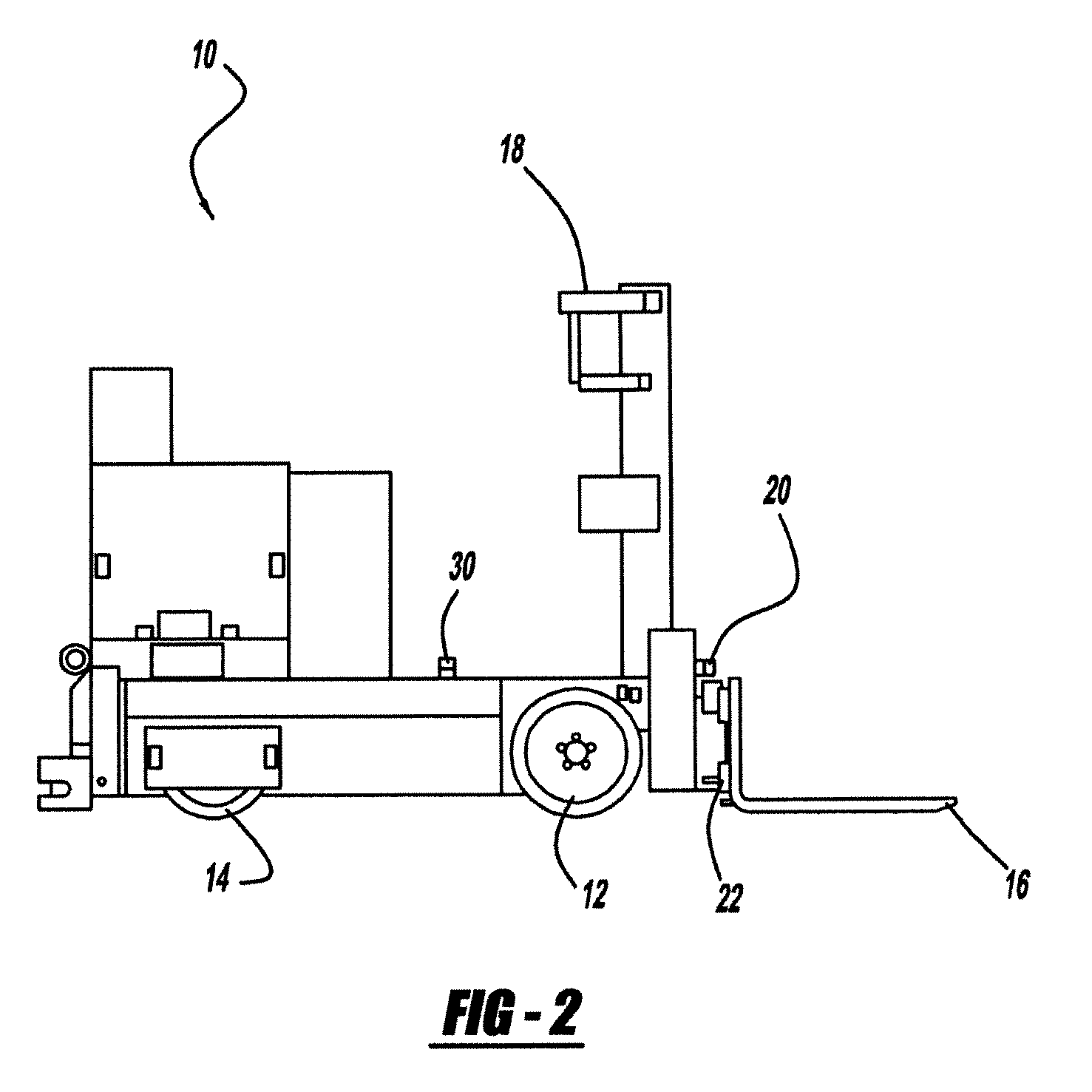

Automatic transport loading system and method

ActiveUS20070269299A1Efficient and effectiveSpeed controllerRailway vehiclesGuidance systemTransport engineering

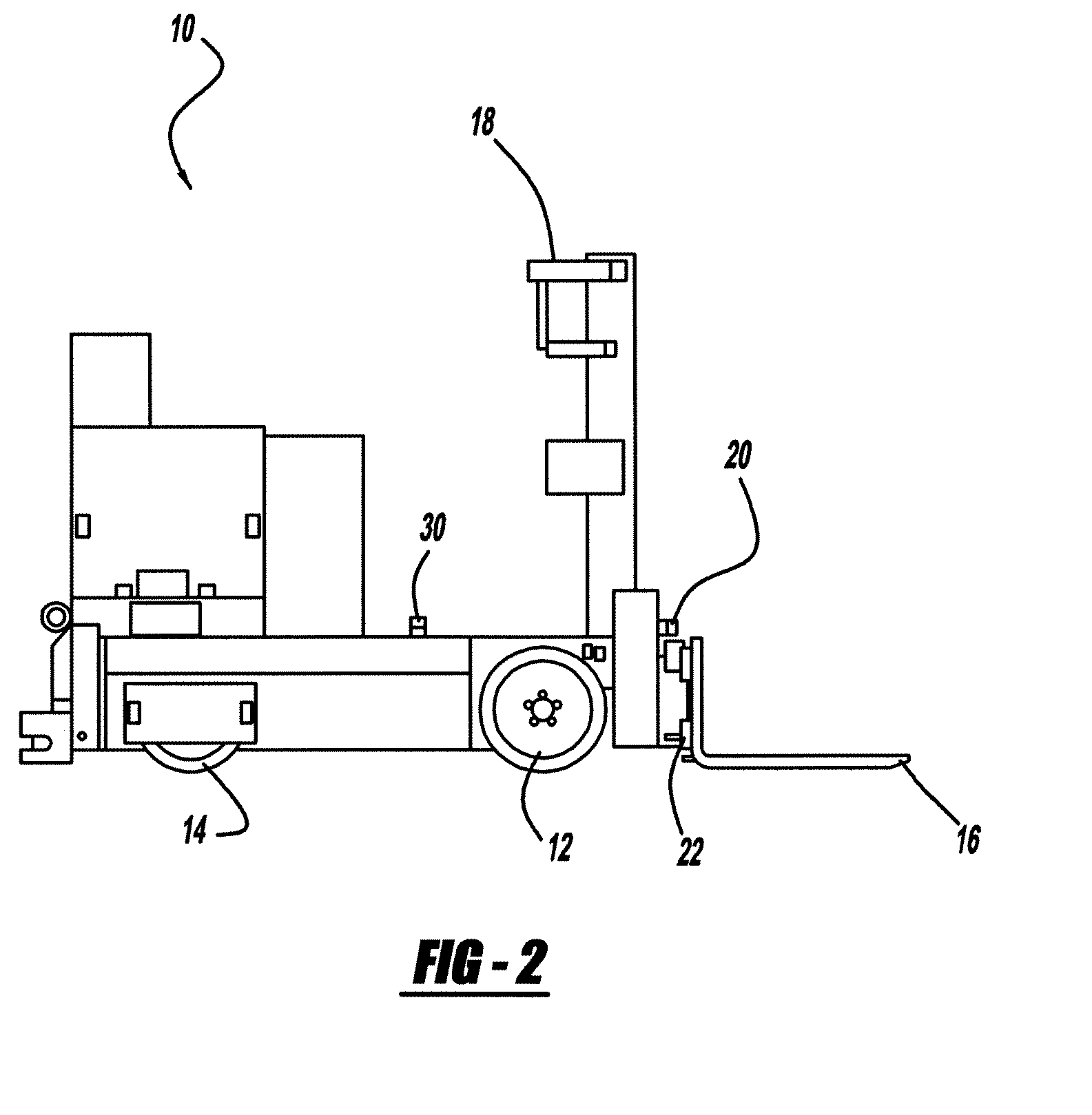

A method and system for automatically loading and unloading a transport is disclosed. A first guidance system follows a travel path to a position near the transport and then a sensor profiles a transport so that a transport path is determined for an AGV to follow into the transport to place a load and for exiting the transport upon placement of the load.

Owner:JERVIS B WEBB INT CO

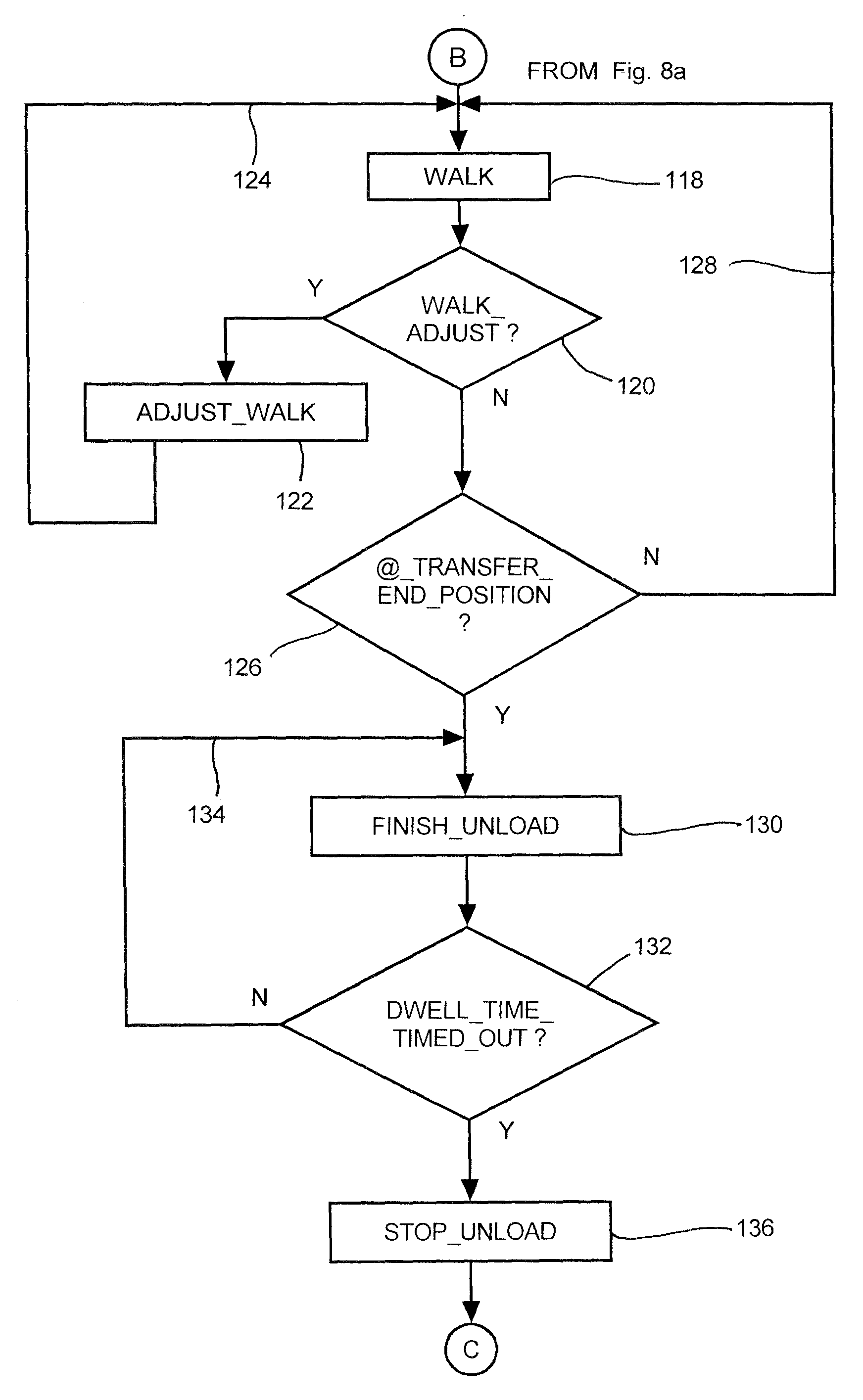

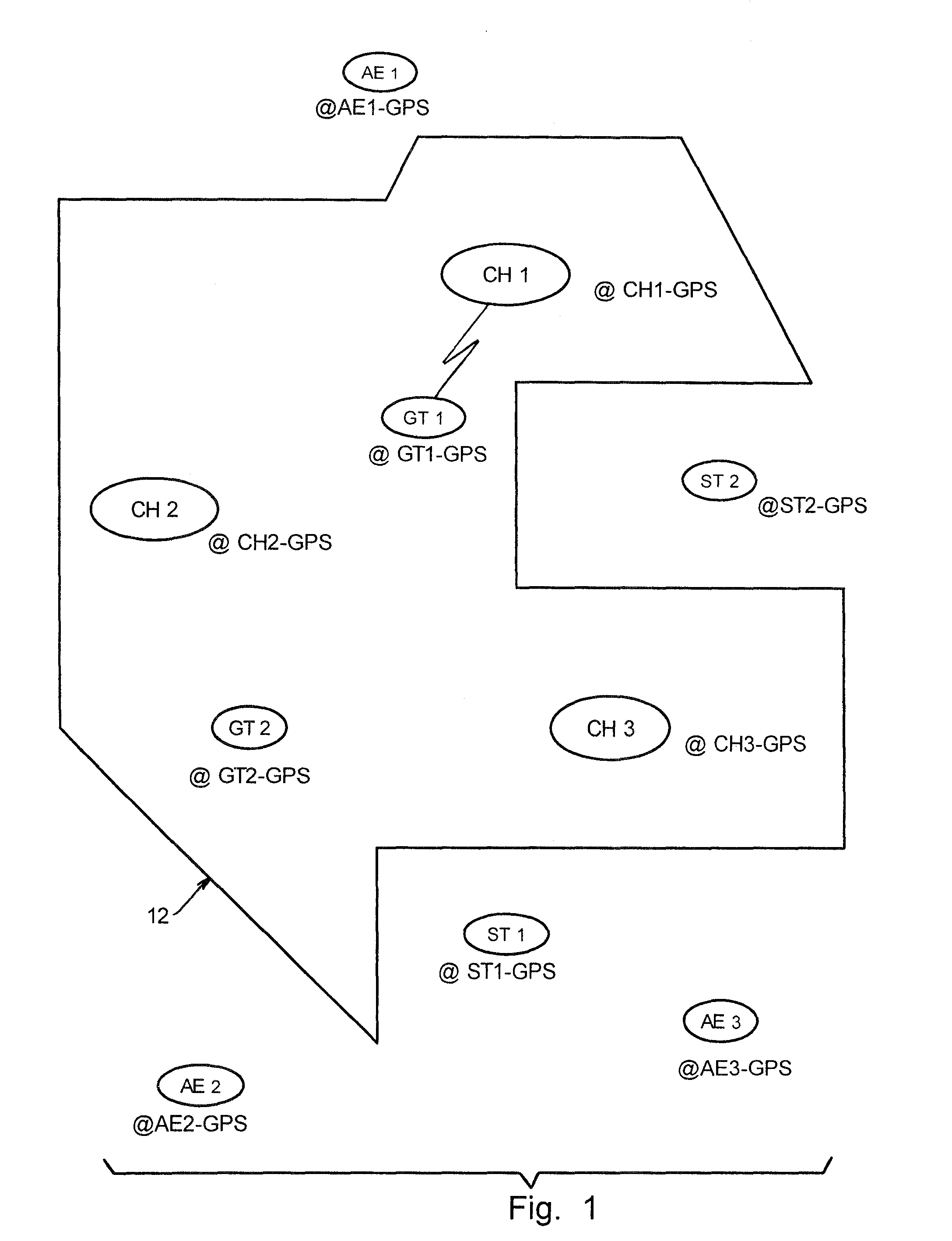

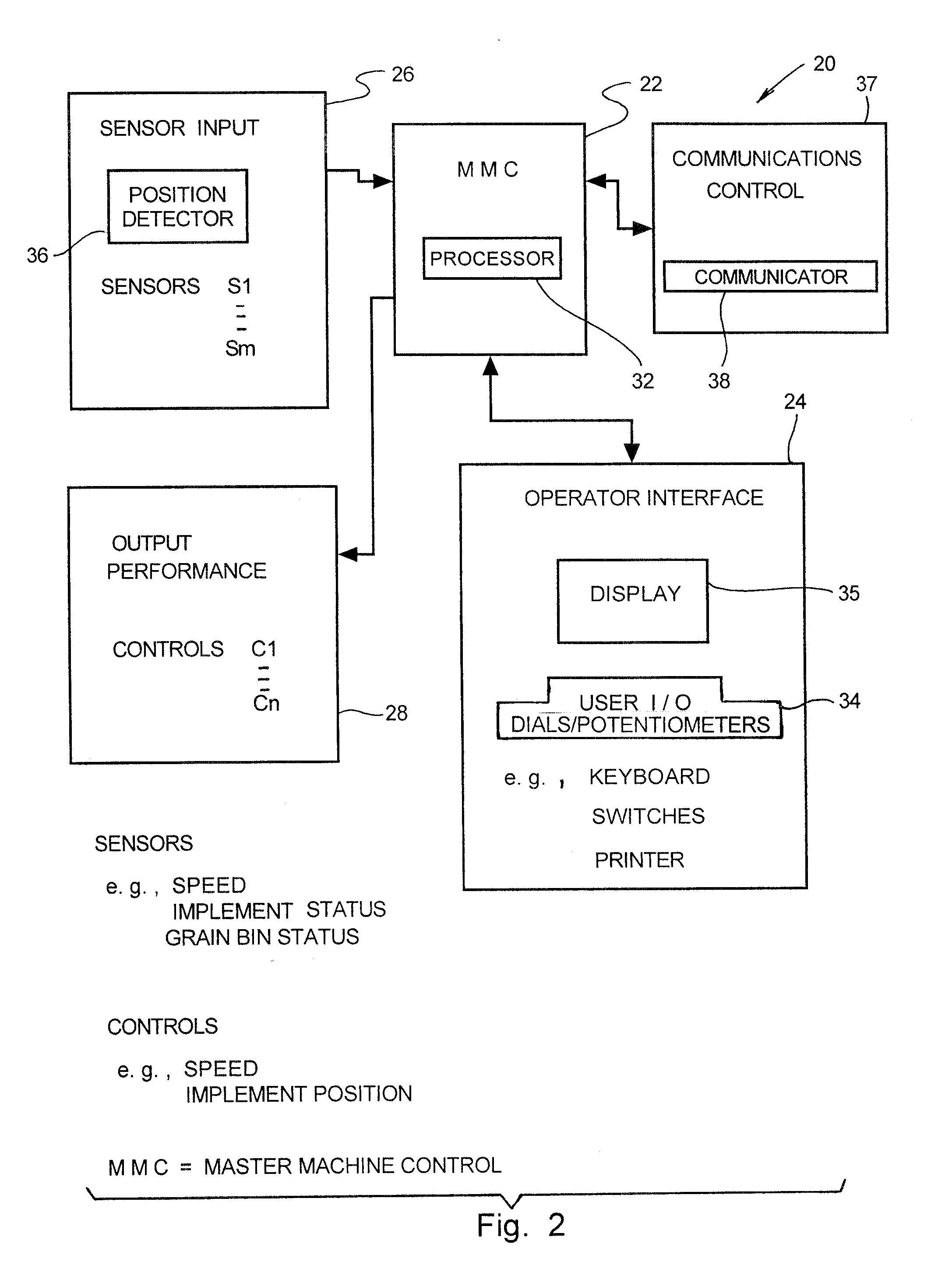

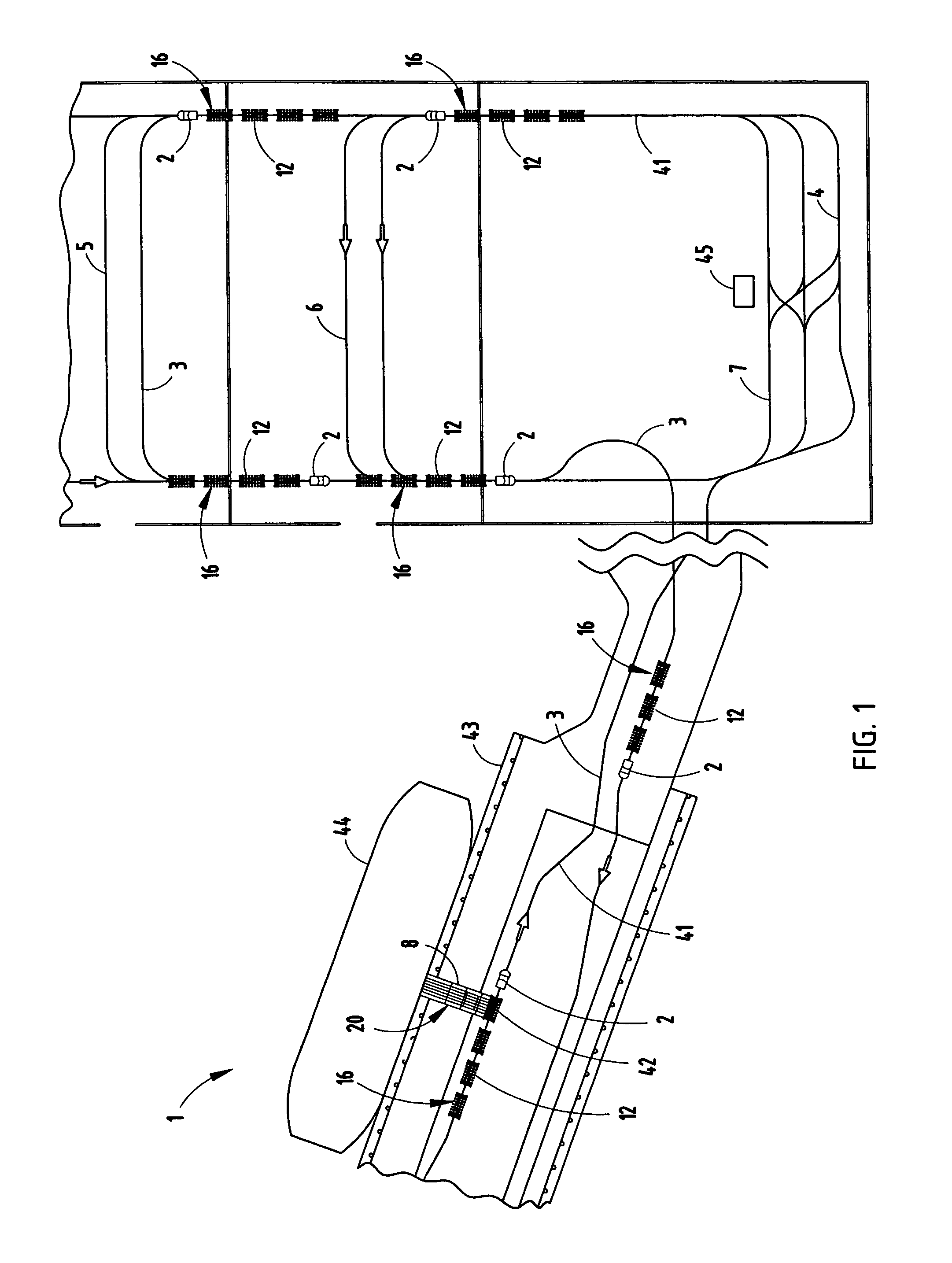

Grain transfer control system and method

ActiveUS20100274452A1Evenly filledDigital data processing detailsRoad vehicles traffic controlAutomatic controlControl system

A grain transfer control system, and method of use thereof, for automatedly controlling the transfer of grain from a mobile transferor-type vehicle, such as a combine harvester, to a mobile transferee-type vehicle, such as a crop transport, by varying the position and speed of the transferor-type and transferee-type vehicles relative to one another during the transfer operation, especially by varying the position and rate of walk of the discharge spout along at least a portion of the length of a grain holding receptacle of the transferee-type vehicle, to effect a generally even fill of the grain holding receptacle of the transferee-type vehicle along the length of the grain holding receptacle.

Owner:BLUE LEAF I P INC

Wheel chock restraint system

InactiveUS7032720B2Simple methodEliminate the problemPortable braking systemRail brake actuationMechanical engineeringWheel chock

Wheel chock restraint system comprising a wheel chock, a supporting element mounted on the ground in vicinity of a loading dock and a wheel chock support assembly connected by one end to the wheel chock and by another end in vicinity of the loading dock. A base portion of the chock is provided with first engagement elements and the supporting elements are provide with corresponding second engagement elements. The first engagement elements are adapted to cooperate with the second engagement elements, thus creating a retention force directed away from the loading dock and preventing the chock from sliding away from the wheel of a vehicle making an attempt to depart prematurely from the loading dock. Wheel chock support assembly is adapted to ensure a secure positioning of the chock under the wheel of the vehicle during loading and unloading operation by creating an engagement force directed towards the loading dock and pressing the chock against the wheel. The first engagement elements comprise a plurality of teeth extending downwardly from the base portion of the chock under a predetermined angle and the second engagement elements are a plurality of stoppers extending upwardly from the supporting element.

Owner:9172 9863 QUEBEC

System and method for unloading items

ActiveUS8444369B2Disadvantages and reduced eliminatedInventory reduced eliminatedSemiconductor/solid-state device manufacturingRefuse transferringEngineeringMechanical engineering

A method for unloading inventory items includes storing an inventory item on an inventory holder and moving the inventory holder toward an unloading station with a mobile drive unit. Additionally, the method includes moving the inventory holder past a barrier of the unloading station. The method further includes preventing the inventory item from moving past the barrier as the mobile drive unit moves the inventory holder past the barrier.

Owner:AMAZON TECH INC

Robotic pick up and delivery system

InactiveUS7261511B2High retention strengthHigh strengthRefuse transferringStorage devicesMobile robotEngineering

A pick up and delivery system for use with mobile robots which have a body with a horizontal upper surface and at least one vertical side. The robot has at least one shelf, each of which contains a stop bar containing a retaining device. The system further uses multiple stations, each of which contain at least one pallet retaining surface to contain at least two pallets. The pallet retaining surfaces are provided with a holding device at the pick up area and a holding device at the delivery area. Pallets are used to retain the items being transferred with each of the pallets having a securing device that interacts with the holding device and retaining device. The strength of the holding device at the pick up area is less than the holding device at the delivery area, with the robot's retaining device having a strength between the strength of the holding devices. The mobile robot picks up a pallet from a first station, and delivers the pallet to a second station.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Cargo container handling system and associated method

InactiveUS20070025832A1Efficiently and effectively transportingPrecise alignmentVehicle with removable loadingLoad accommodationEngineeringHandling system

A system and method for cargo handling is provided. The system includes a transport vehicle including a cargo bay capable of housing a plurality of cargo containers, and a loading dock for coupling to the cargo bay. The system also includes at least one railcar and pylons positioned along a floor of the cargo bay. A predetermined number of pylons are operable to elevate and lower a cargo container within the cargo bay. The present invention also provides a railcar for transporting cargo containers, as well as an apparatus for positioning at least one cargo container within a transport vehicle. The present invention also provides a system for aligning a loading dock and a transport vehicle that includes a mechanism for adjusting the height of the transport vehicle or loading dock, or a plurality of engagement members that are capable of aligning the loading dock and transport vehicle.

Owner:THE BOEING CO

Method for determining a position of a robot

InactiveUS7039501B2Programme-controlled manipulatorDigital data processing detailsRobot positionThermal expansion

Generally, a method of determining a position of a robot is provided. In one embodiment, a method of determining a position of a robot comprises acquiring a first set of positional metrics, acquiring a second set of positional metrics and resolving the position of the robot due to thermal expansion using the first set and the second set of positional metrics. Acquiring the first and second set of positional metrics may occur at the same location within a processing system, or may occur at different locations. For example, in another embodiment, the method may comprise acquiring a first set of positional metrics at a first location proximate a processing chamber and acquiring a second set of positional metrics in another location. In another embodiment, substrate center information is corrected using the determined position of the robot.

Owner:APPLIED MATERIALS INC

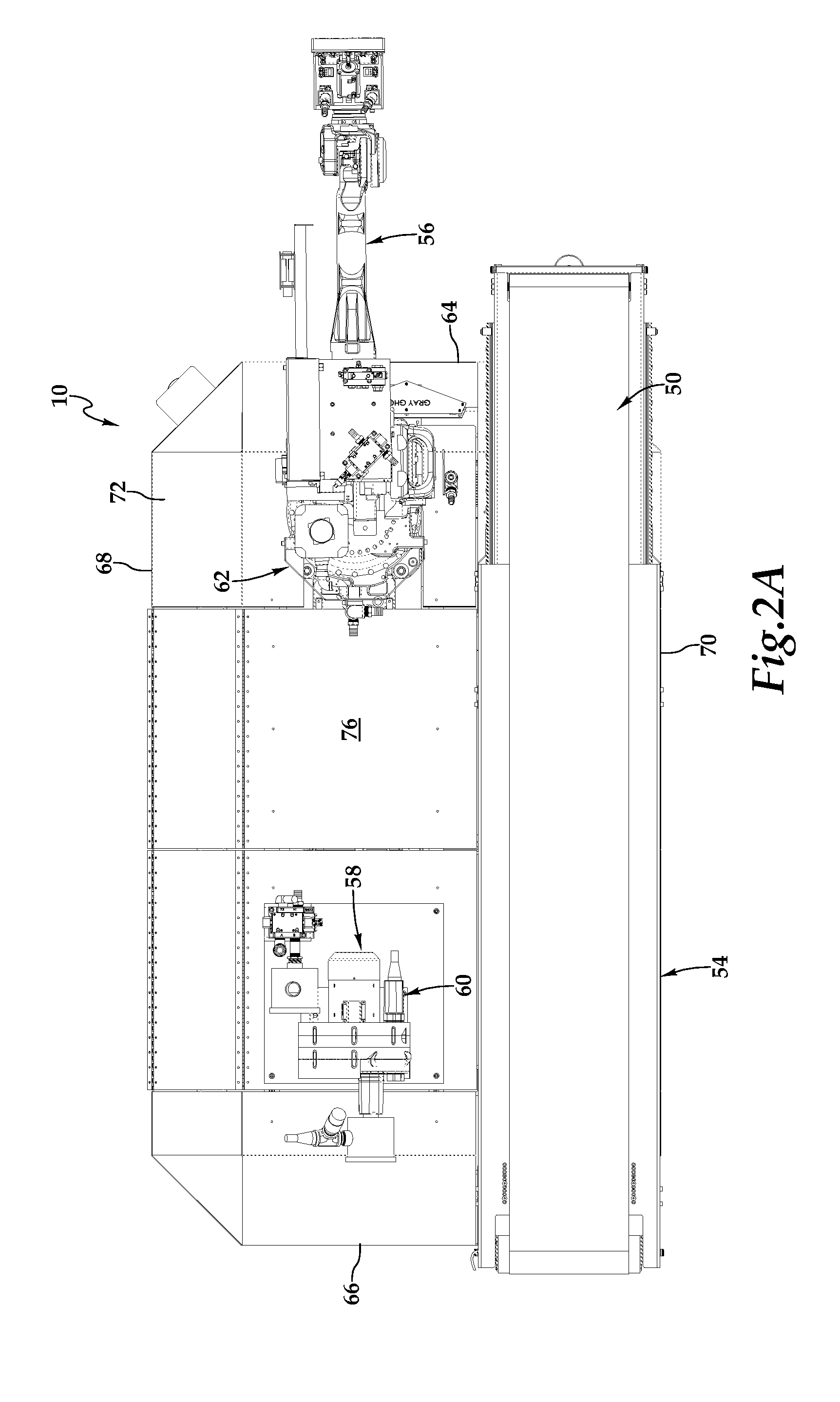

Automated Truck Unloader for Unloading/Unpacking Product from Trailers and Containers

ActiveUS20140205403A1Quantity maximizationProtect and extend lifeProgramme controlProgramme-controlled manipulatorEngineeringBiological activation

An automatic truck unloader for unloading / unpacking product, such as boxes or cases, from trailers and containers is disclosed. In one embodiment, a mobile base structure provides a support framework for a drive subassembly, conveyance subassembly, an industrial robot, a distance measurement subassembly, and a control subassembly. Under the operation of the control subassembly, an industrial robot having a suction cup-based gripper arm selectively removes boxes from the trailer and places the boxes on a powered transportation path. The control subassembly coordinates the selective articulated movement of the industrial robot and the activation of the drive subassembly based upon the distance measurement subassembly detecting objects, including boxes, within a detection space, and dimensions of the trailer provided to the control subassembly.

Owner:WYNRIGHT CORP

Automatic load transfer device and method for automated material handling systems

InactiveUS8047756B2Efficiently and reliably transport loadHigh uptime reliability and durabilitySpeed controllerOperating modesMaterial handlingWaste management

Owner:SAVANT AUTOMATION

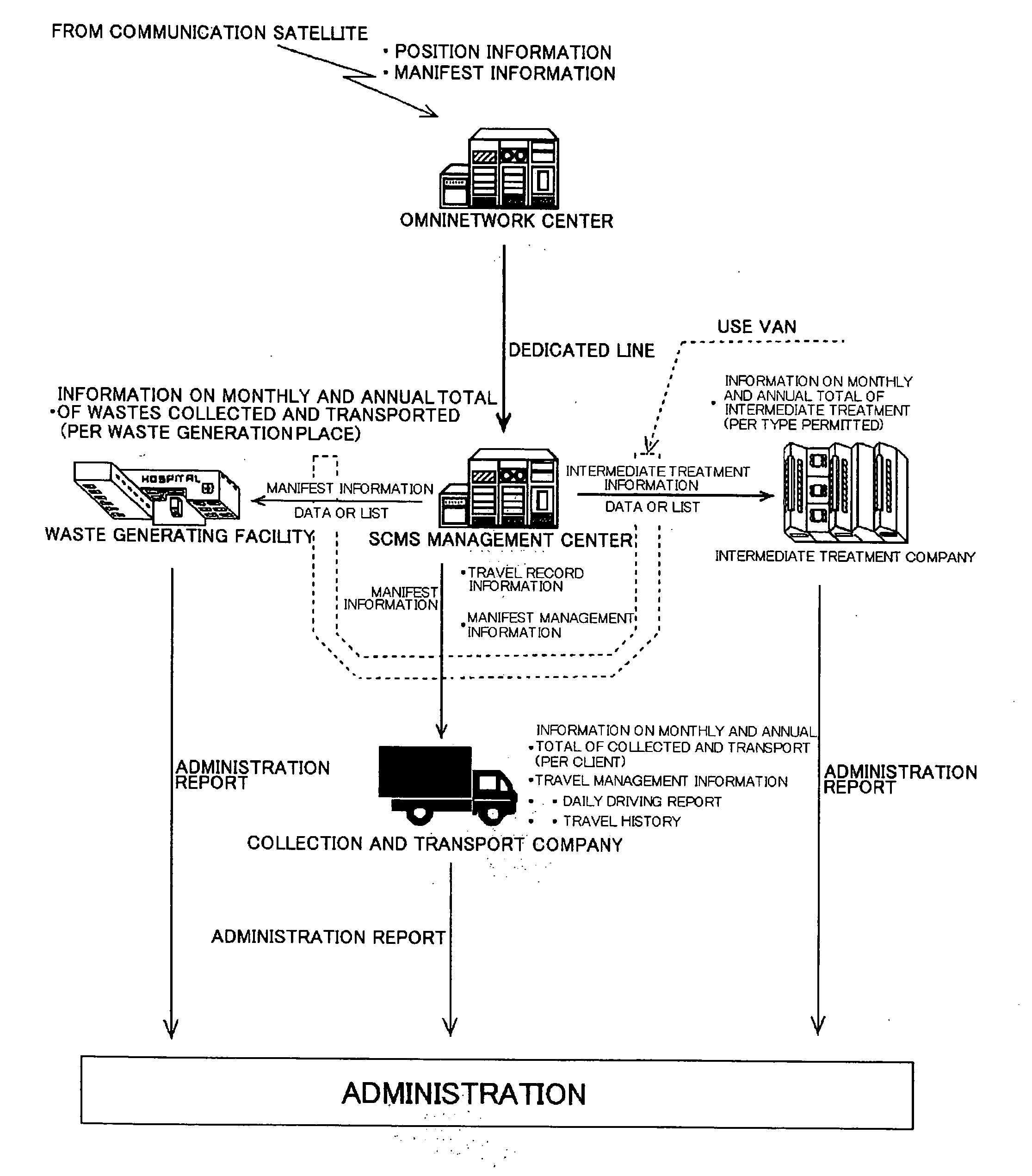

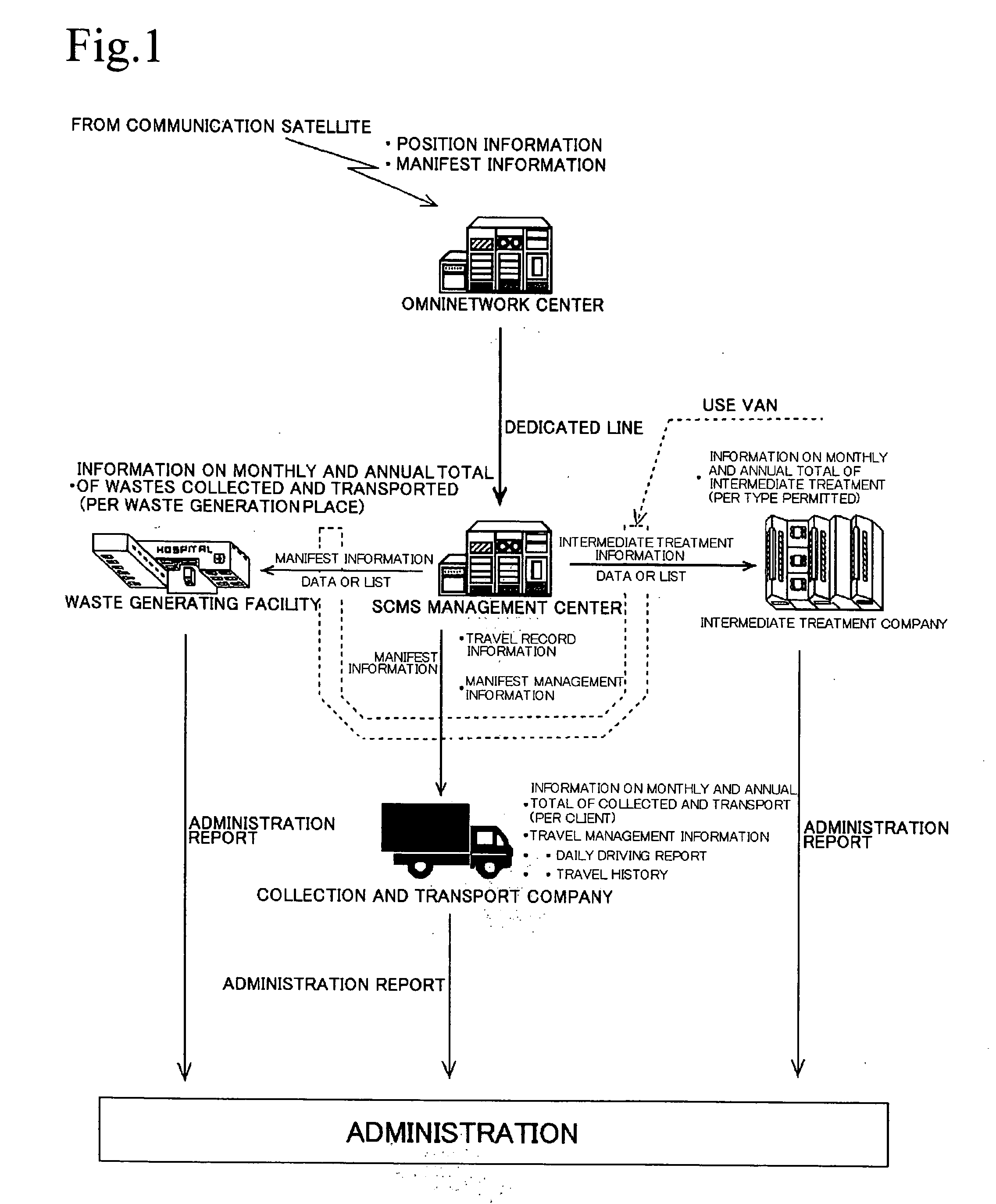

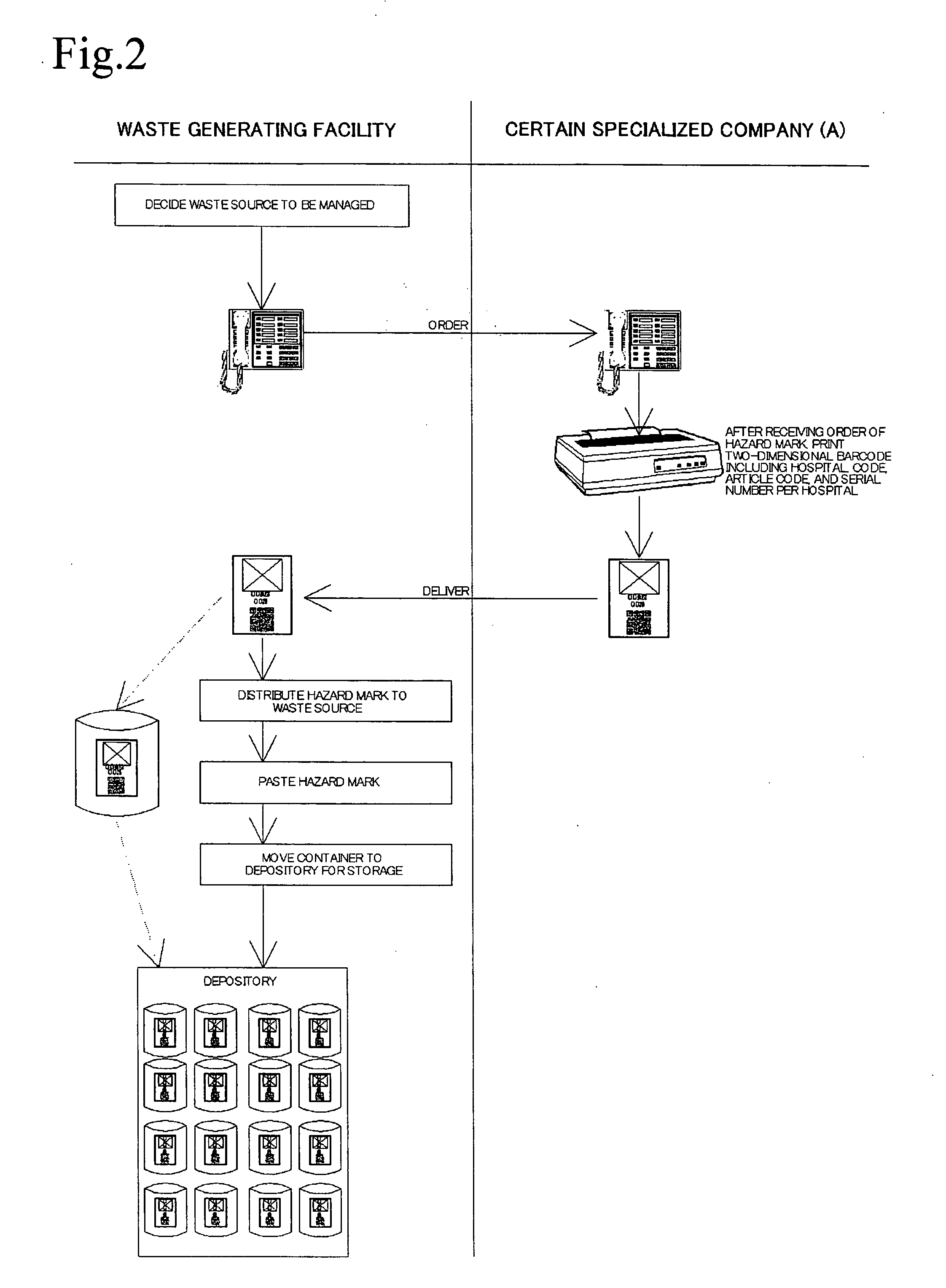

Waste treatment information management system

InactiveUS20050209825A1Improve reliabilitySuppress improper treatmentError detection/correctionSolid waste disposalBarcodeWaste treatment

Individual management with a high reliability is performed on a container for wastes under special control or a vehicle carrying the container so as to suppress improper treatment, such as loss of the container by a mistake or illegal disposal, during transportation of the wastes under special control, and to exactly and promptly detect and cope with false treatment if occurs. A waste treatment information management system collects information on the flow of waste treatment using satellite communication, thereby enabling management of the waste treatment among a waste generating facility, a waste collecting company, and a waste treating company, and thereby rapidly preparing and providing necessary information from the information collected. The system is characterized by use of combination of a two-dimensional barcode label and a cargo bill where necessary items are described according to the related information including the two-dimensional barcode, which has been input to a terminal for the satellite communication.

Owner:NISSCOM CORP

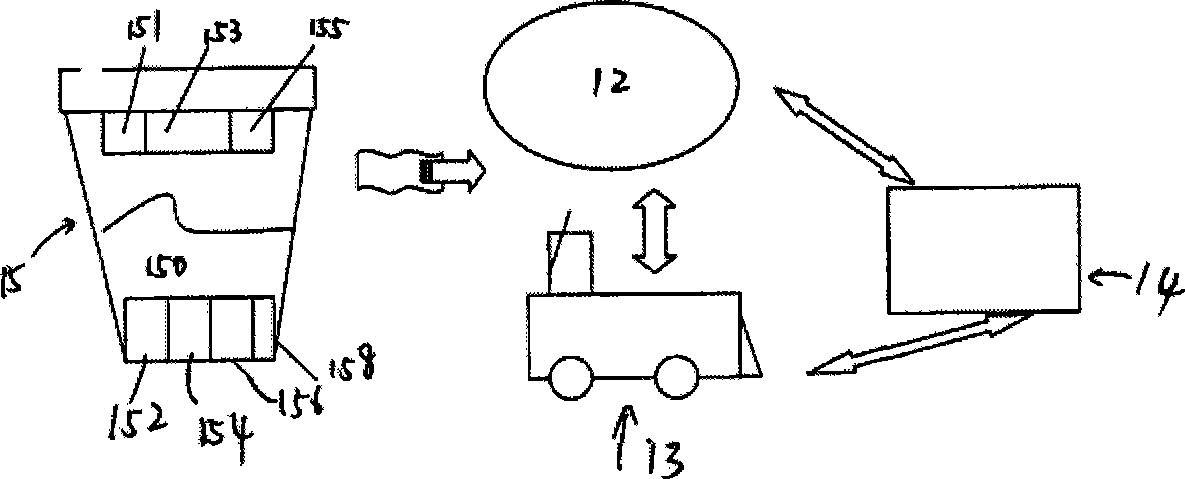

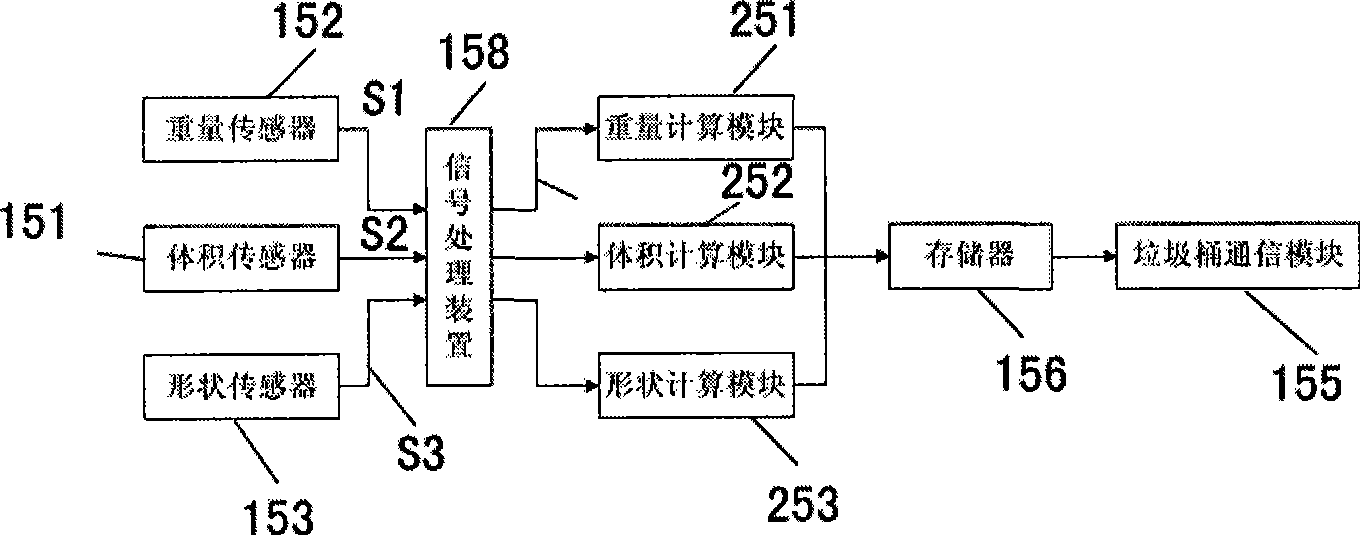

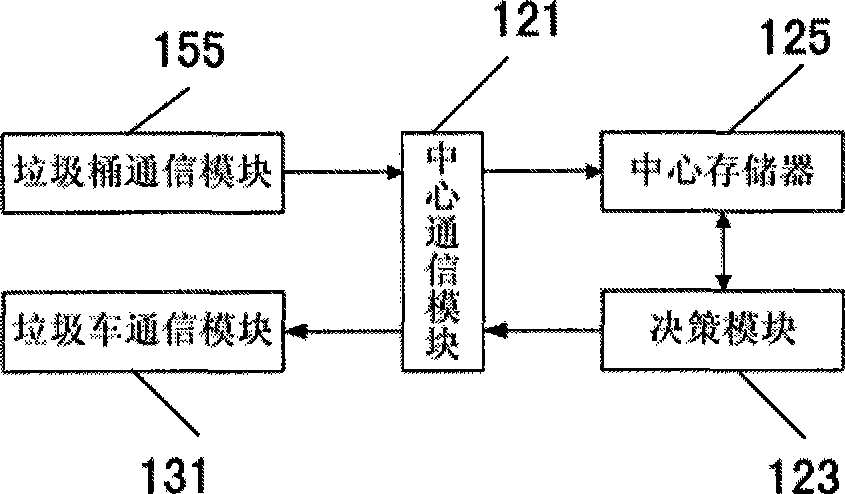

Garbage bin and garbage collection and transportation system

InactiveCN101482742AEasy to collect and transportReduce shipping costsRefuse receptaclesRefuse transferringLitterComputer module

A garbage receiving and conveying system comprises a garbage bin, a control center and a garbage truck. The garbage bin is installed with a sensor, a signal processing module, a garbage bin communication module and a power source. The sensor is used for detecting the physical characteristic of garbage in the garbage bin and outputting characteristic signal. The signal processing module is coupled with the sensor, receives a first characteristic signal, obtains and outputs the characteristic parameter. The calculating module is coupled with the signal processing module, receives the characteristic parameter and calculates the characteristic value data of physical characteristic. The garbage bin communication module is used for transmitting characteristic value data. The control center comprises a central communication module and a decision module. The central communication module is wirelessly connected with the garbage bin communication module and receives characteristic value data. The decision module is coupled with the central communication module and outputs a signaling signal to the central communication module according to the characteristic value data. The garbage truck comprises a garbage truck communication module which is wirelessly connected with the central communication module and receives command signal.

Owner:阿尔伯托·罗贝塔 +1

Substrate processing apparatus

A semiconductor workpiece processing apparatus having a first chamber, a transport vehicle, and another chamber. The first chamber is capable of being isolated from an outside atmosphere. The transport vehicle is located in the first chamber and is movably supported from the first chamber for moving linearly relative to the first chamber. The transport vehicle includes a base, and an integral semiconductor workpiece transfer arm movably mounted to the base and capable of multi-access movement relative to the base. The other chamber is communicably connected to the first chamber via a closable opening of the first chamber. The opening is sized to allow the transport vehicle to transit between the first chamber and the other chamber through the opening.

Owner:BOOKS AUTOMATION US LLC

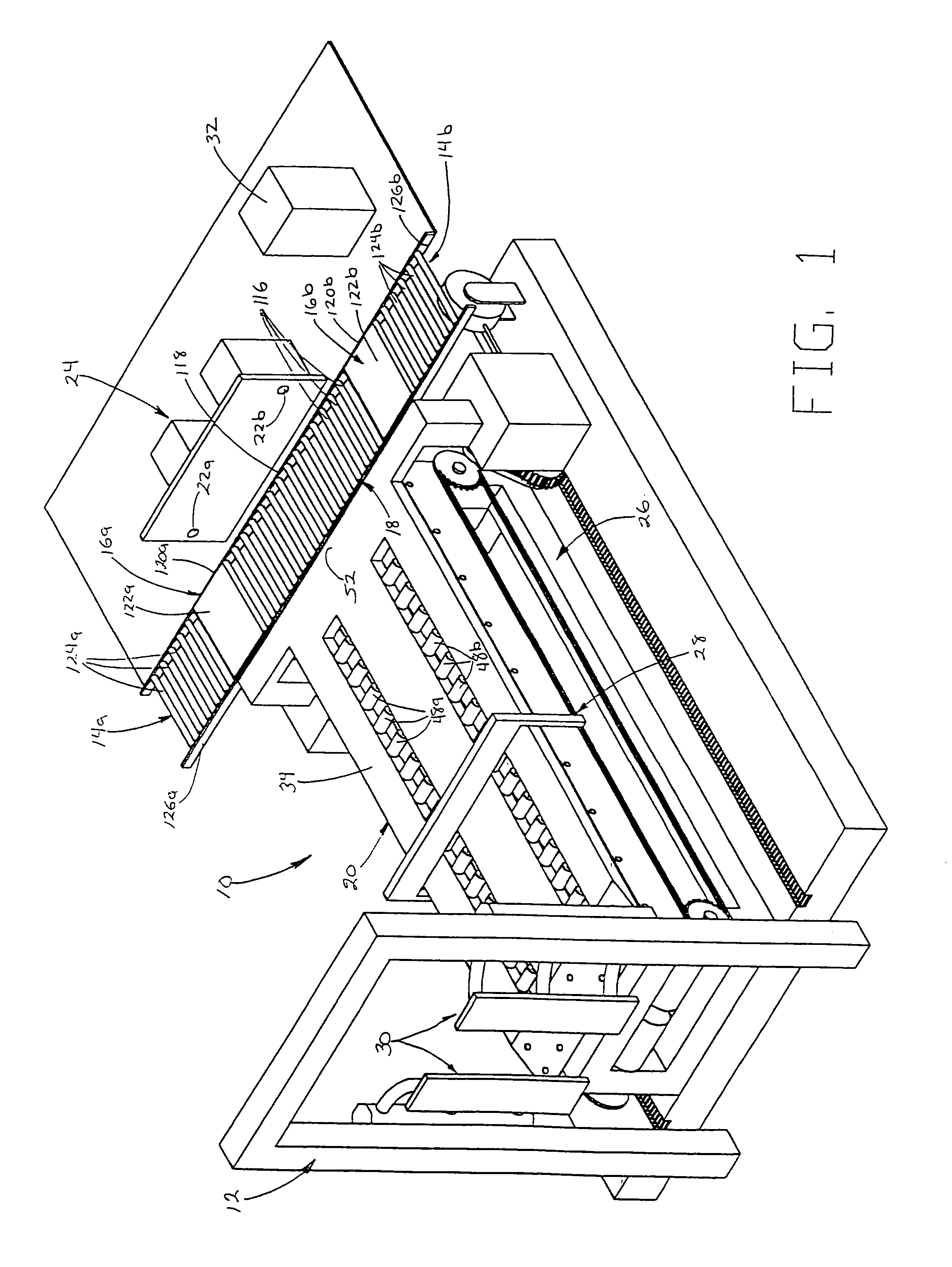

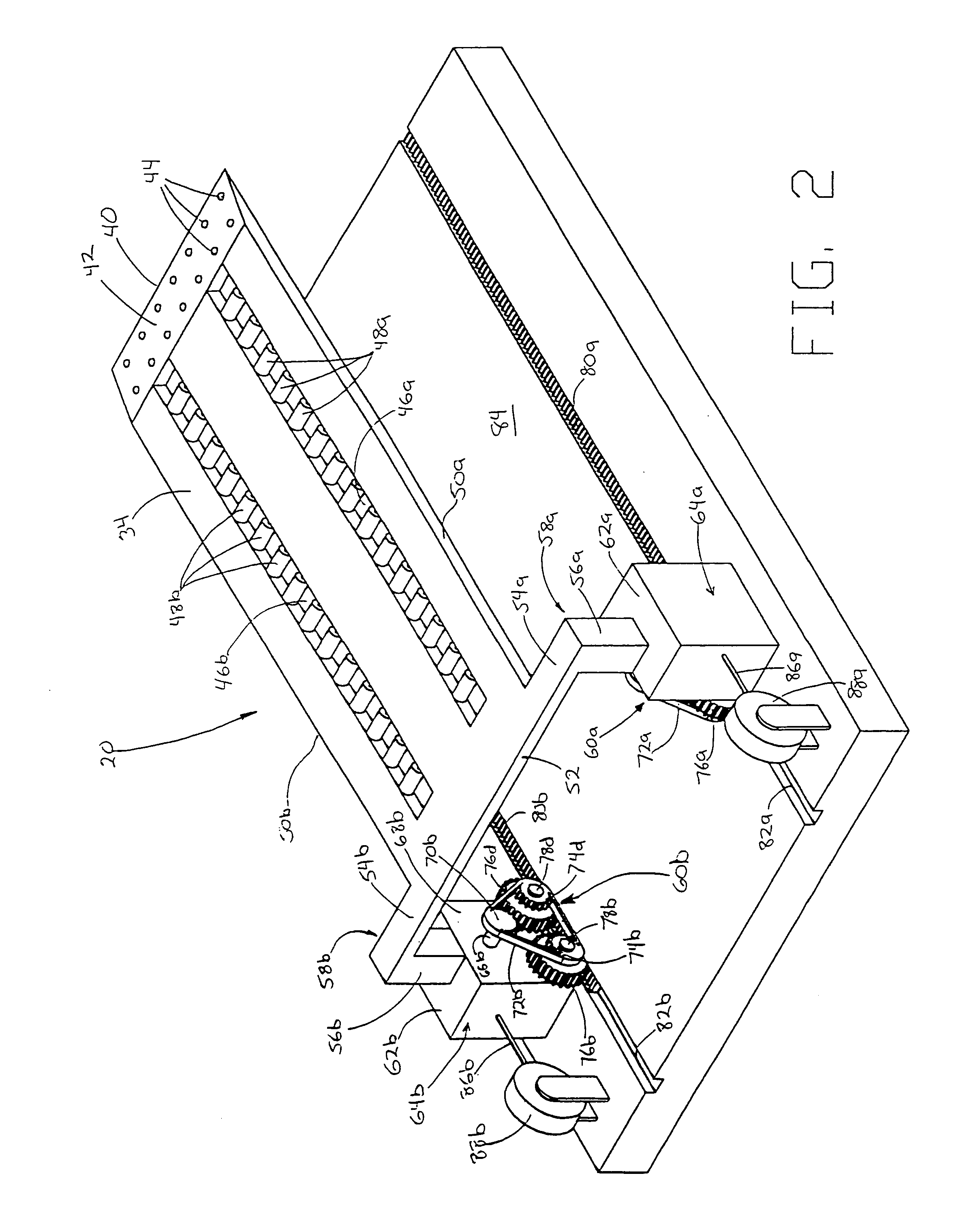

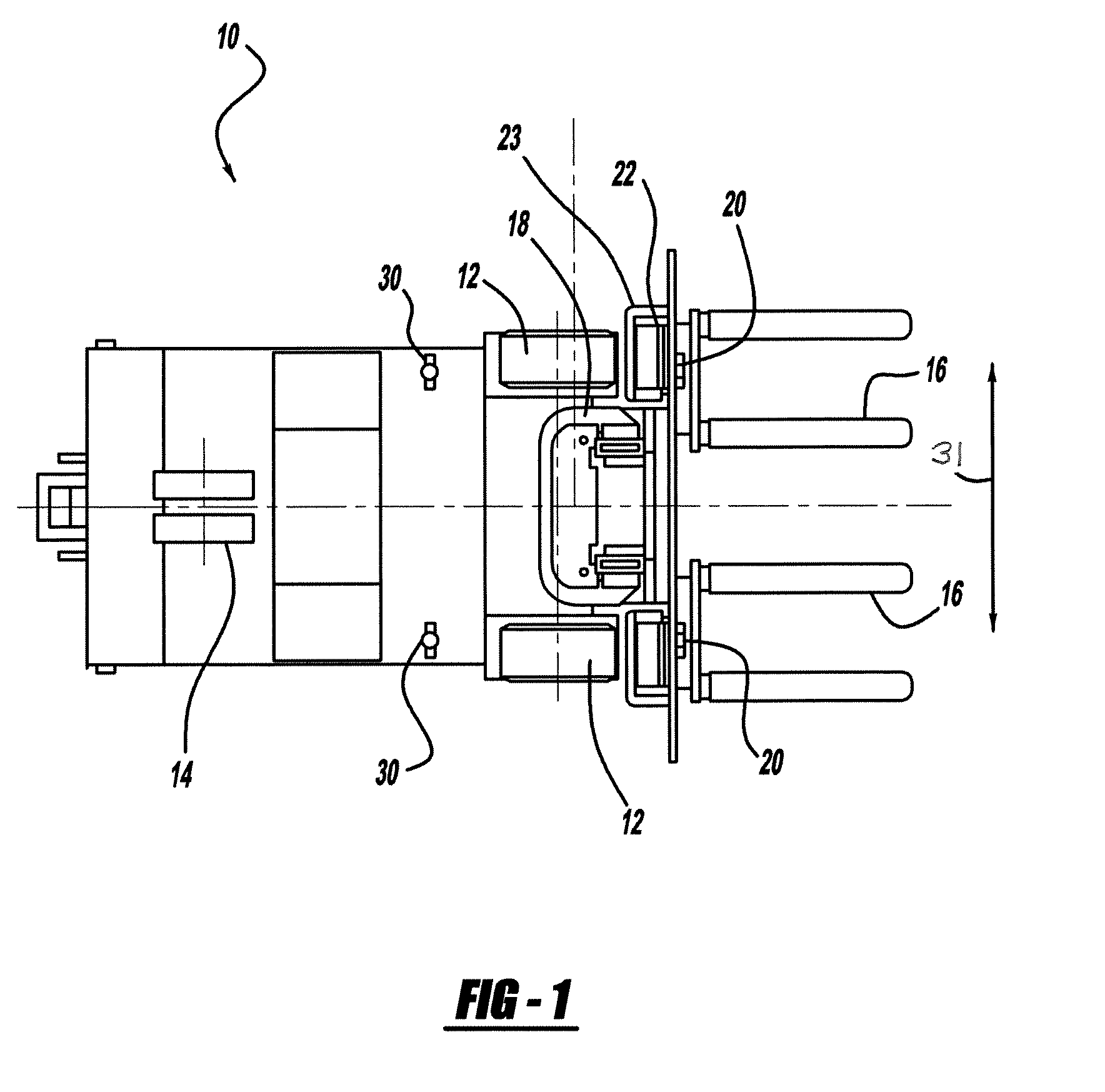

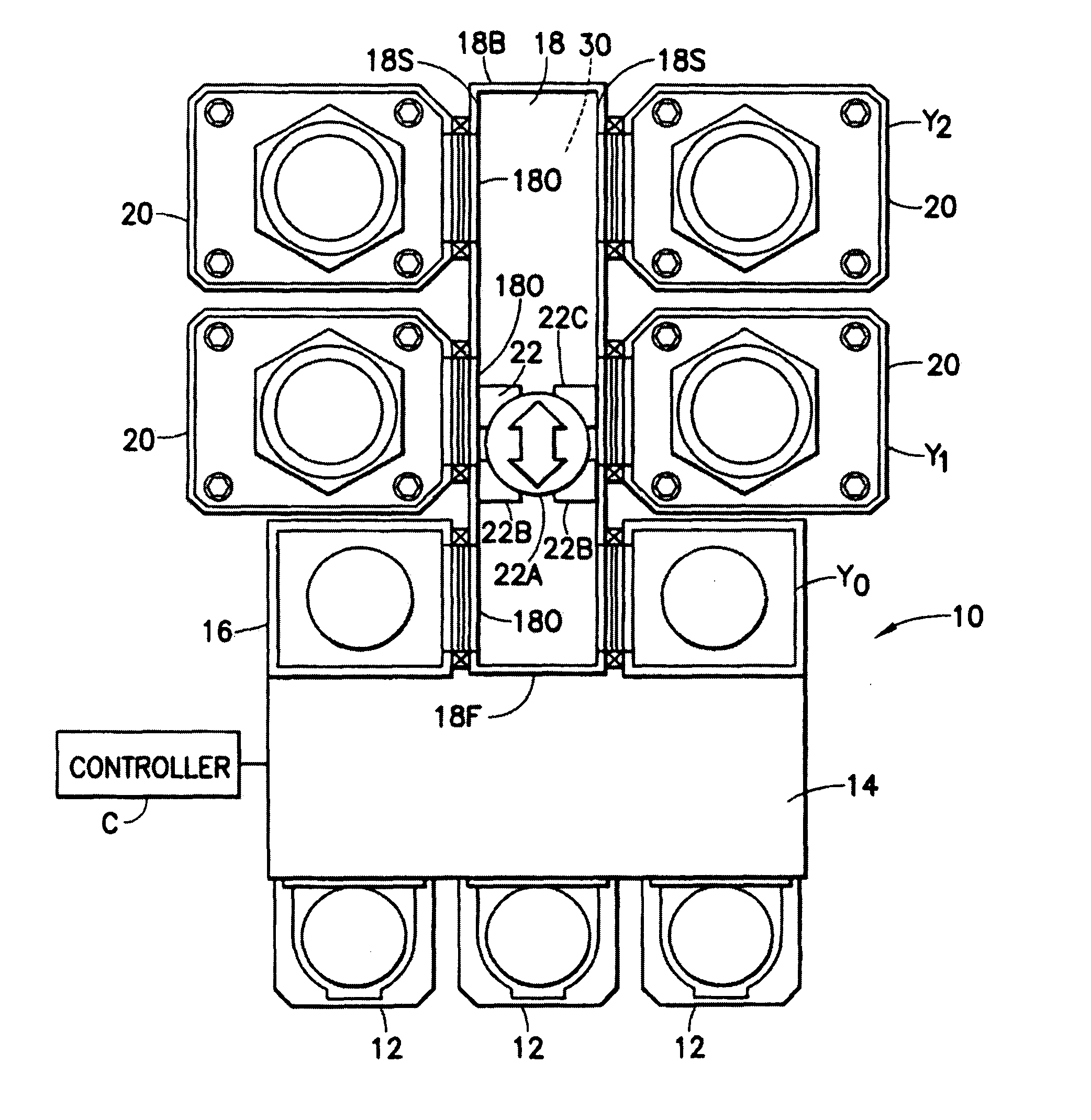

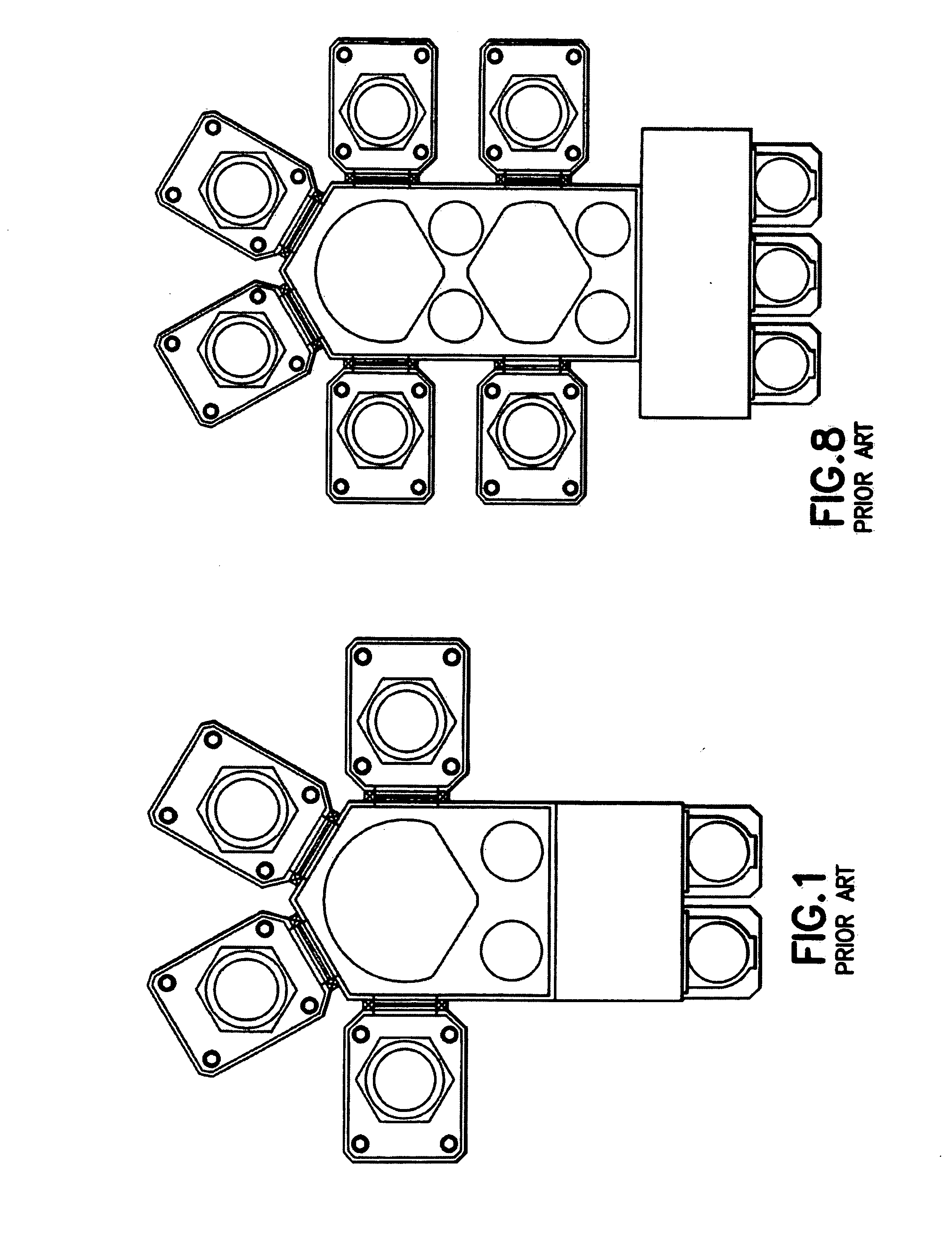

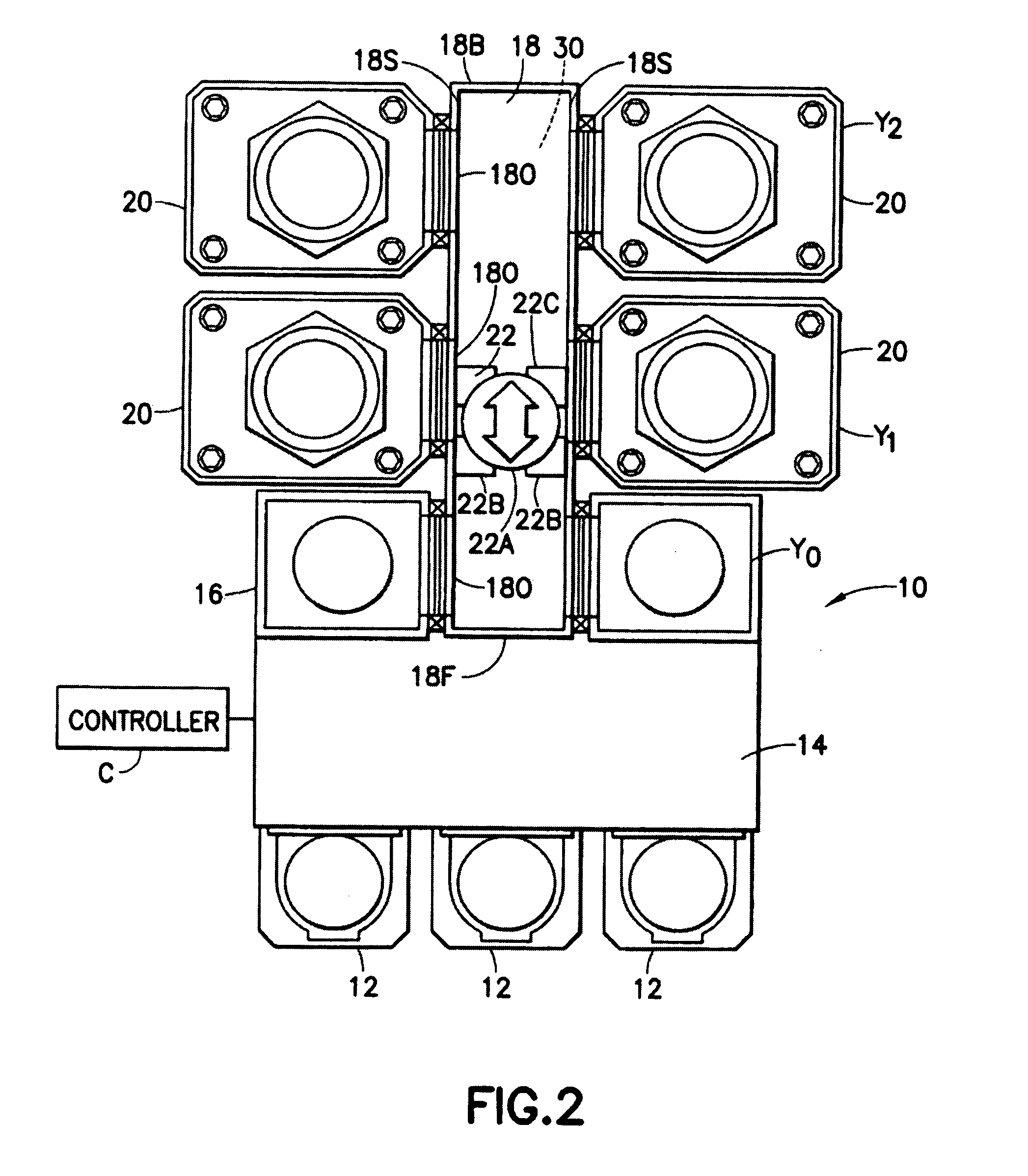

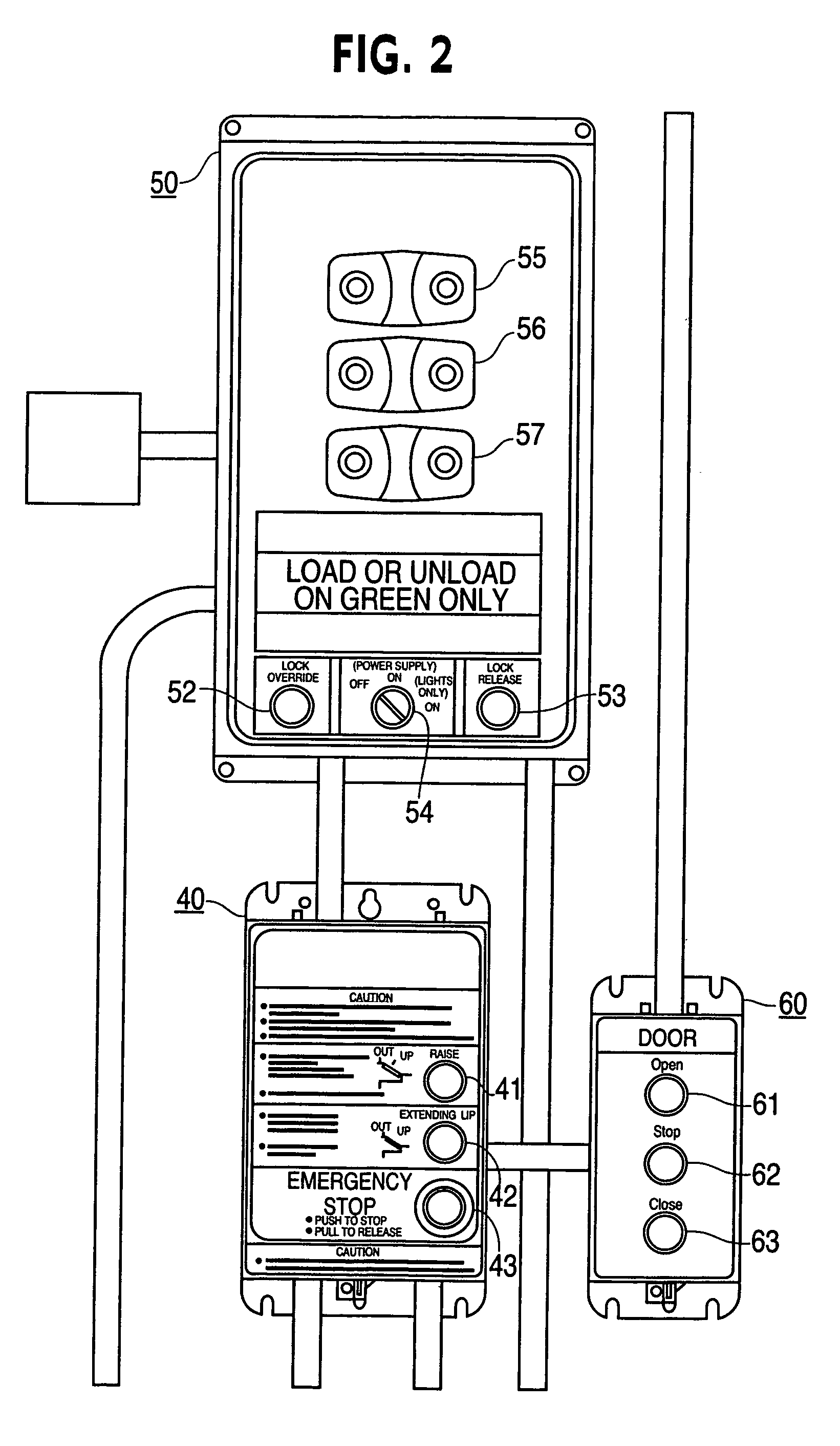

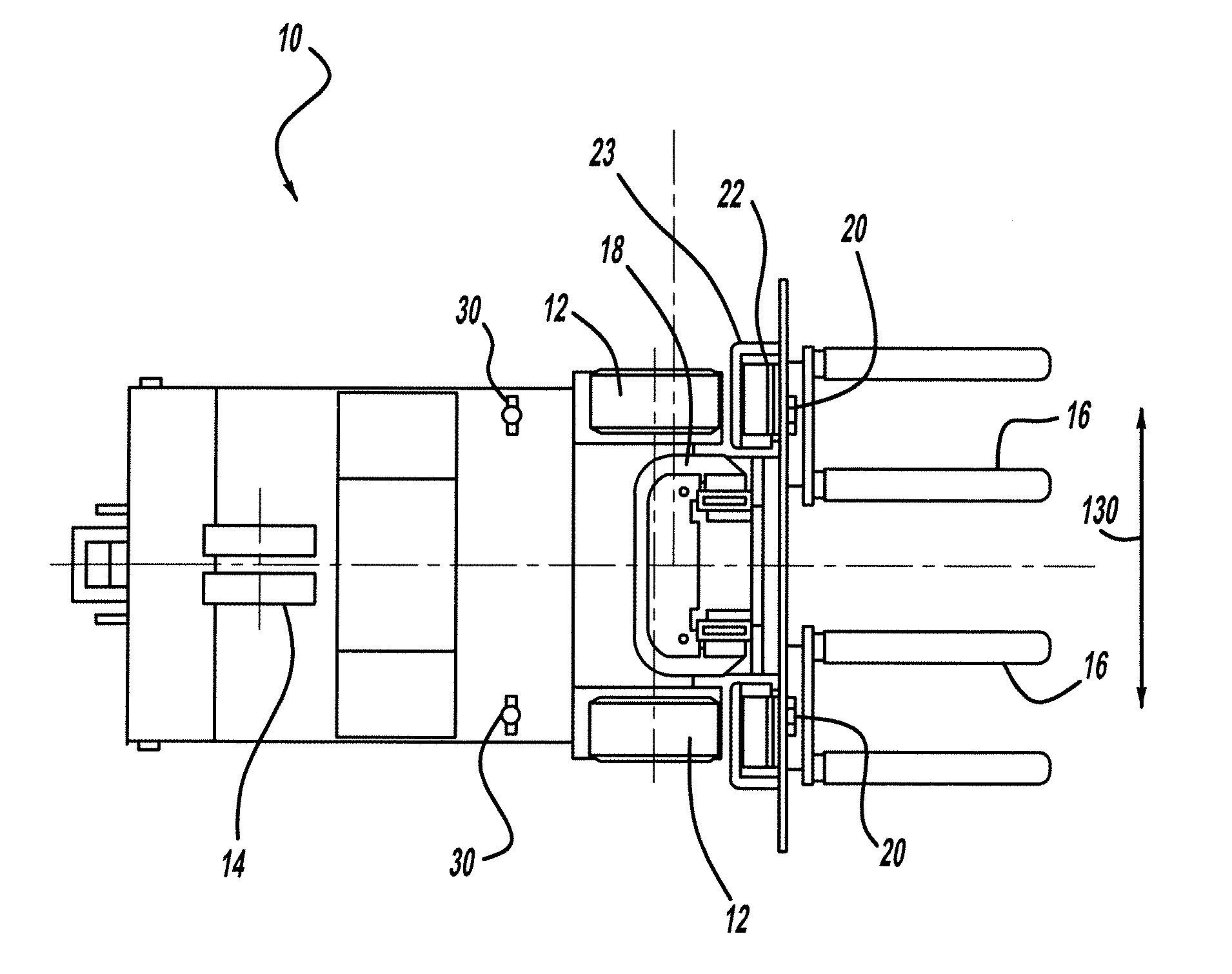

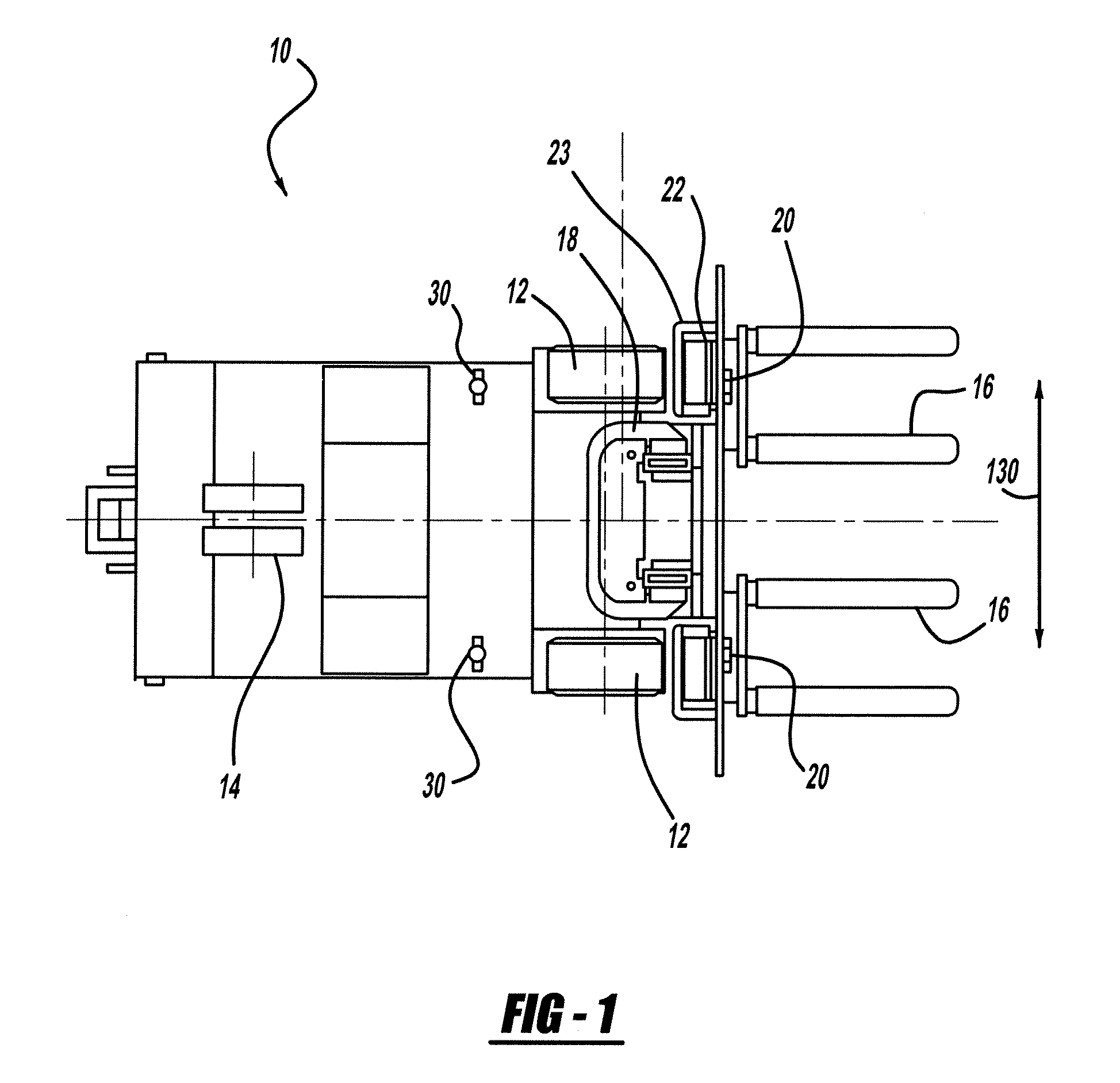

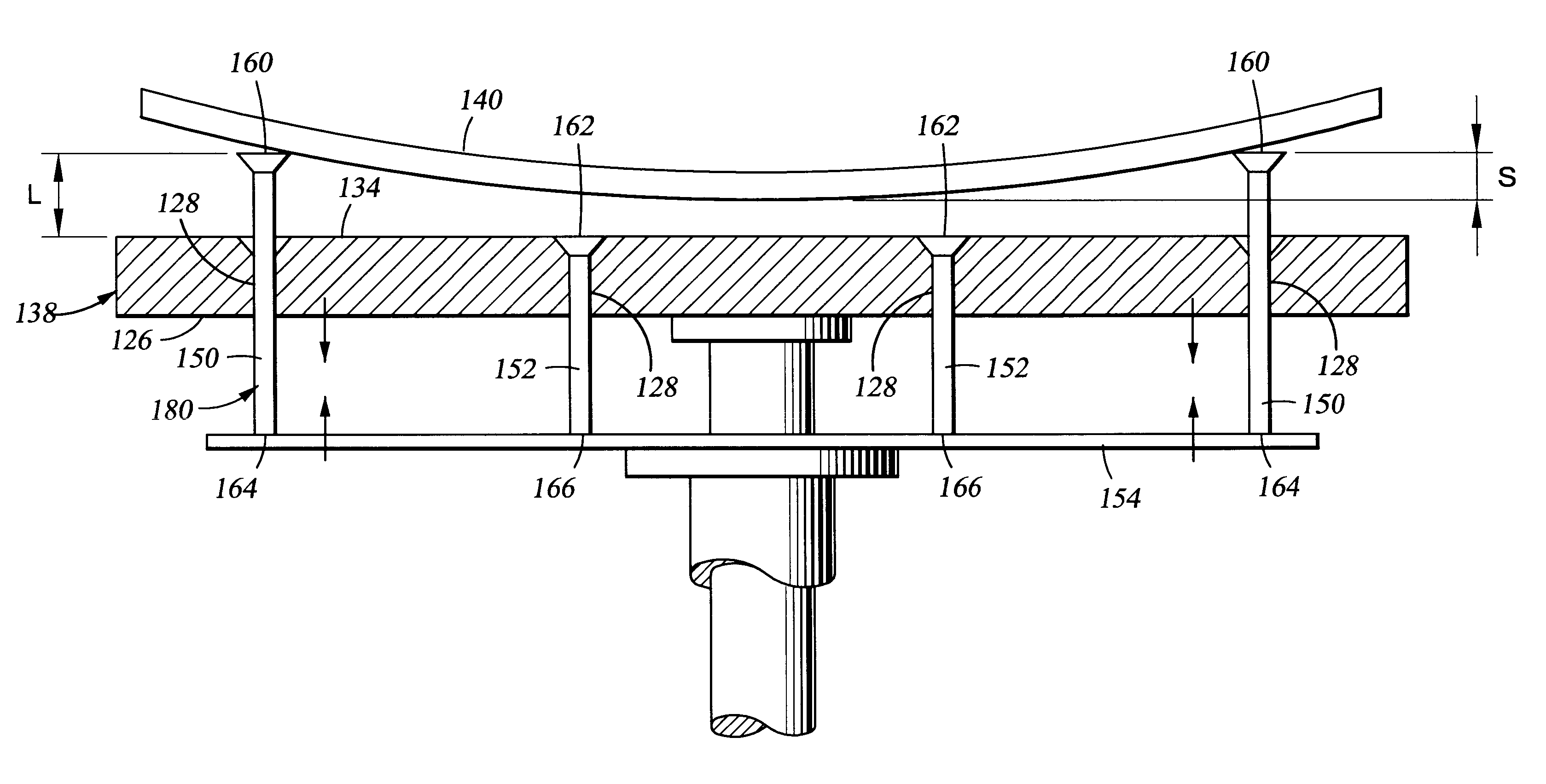

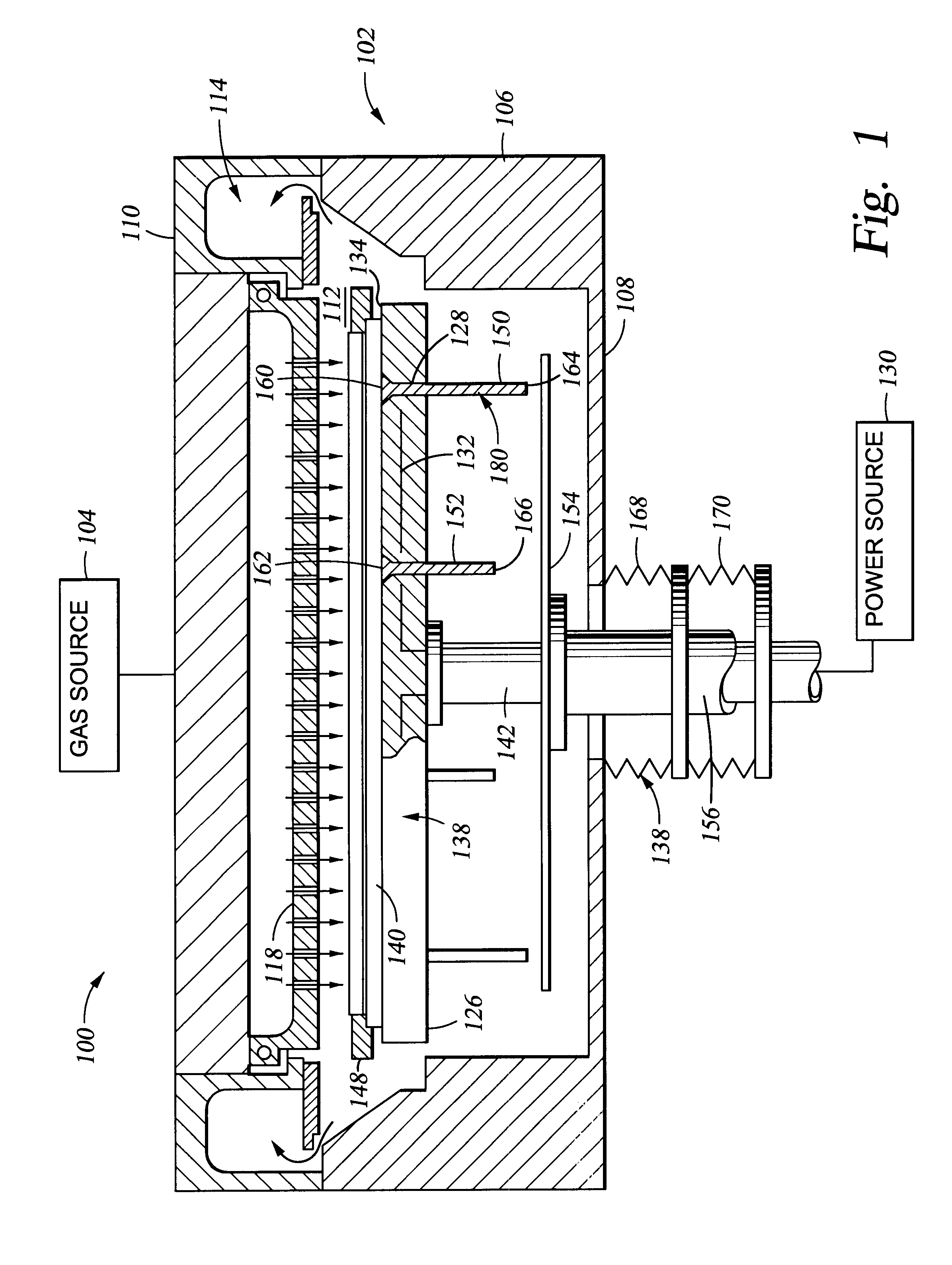

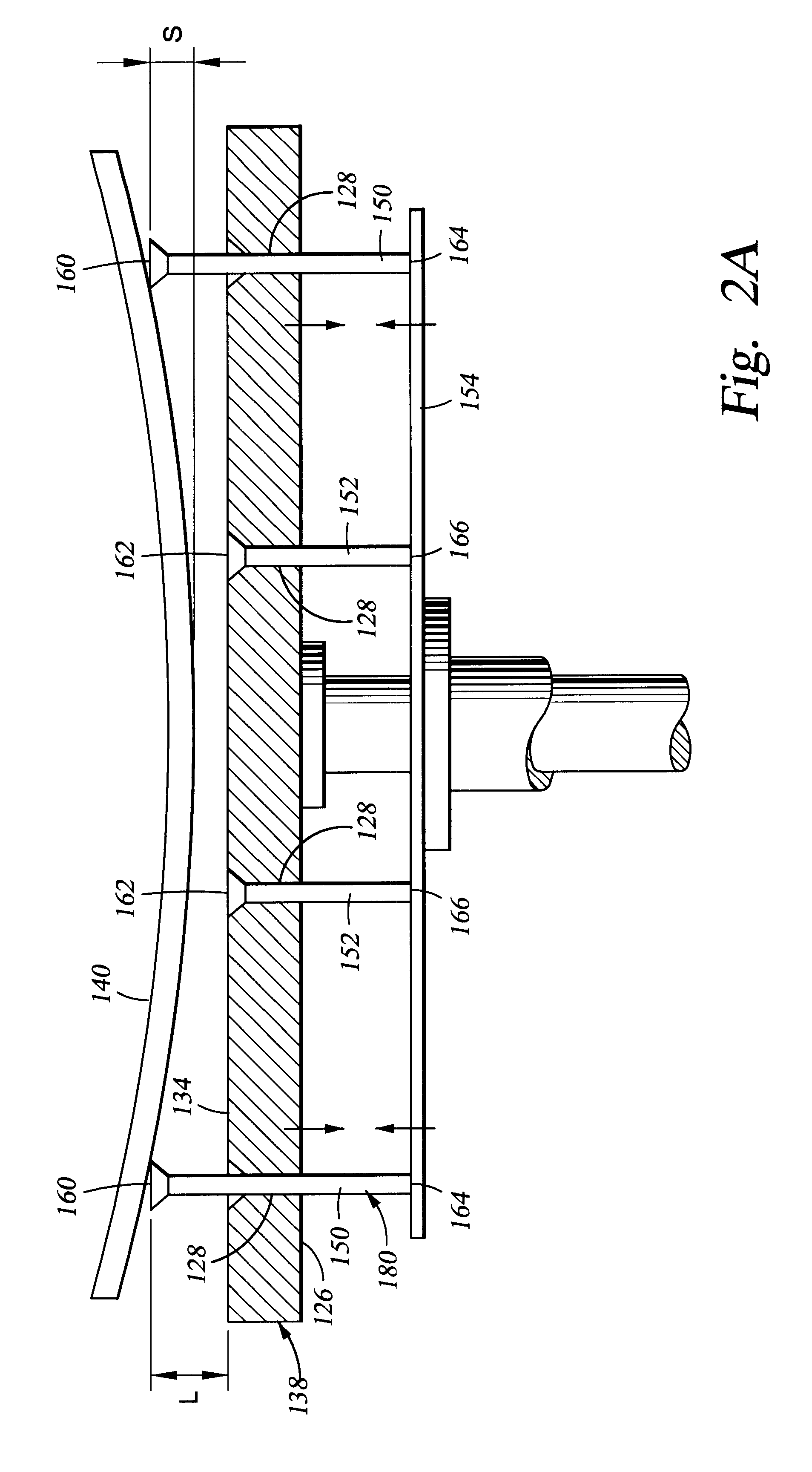

Catalytic reactor charging system and method for operation thereof

InactiveUS20010041117A1Permit accuracyPermit efficiencyTank vehiclesBell-and-hopper arrangementPtru catalystControl system

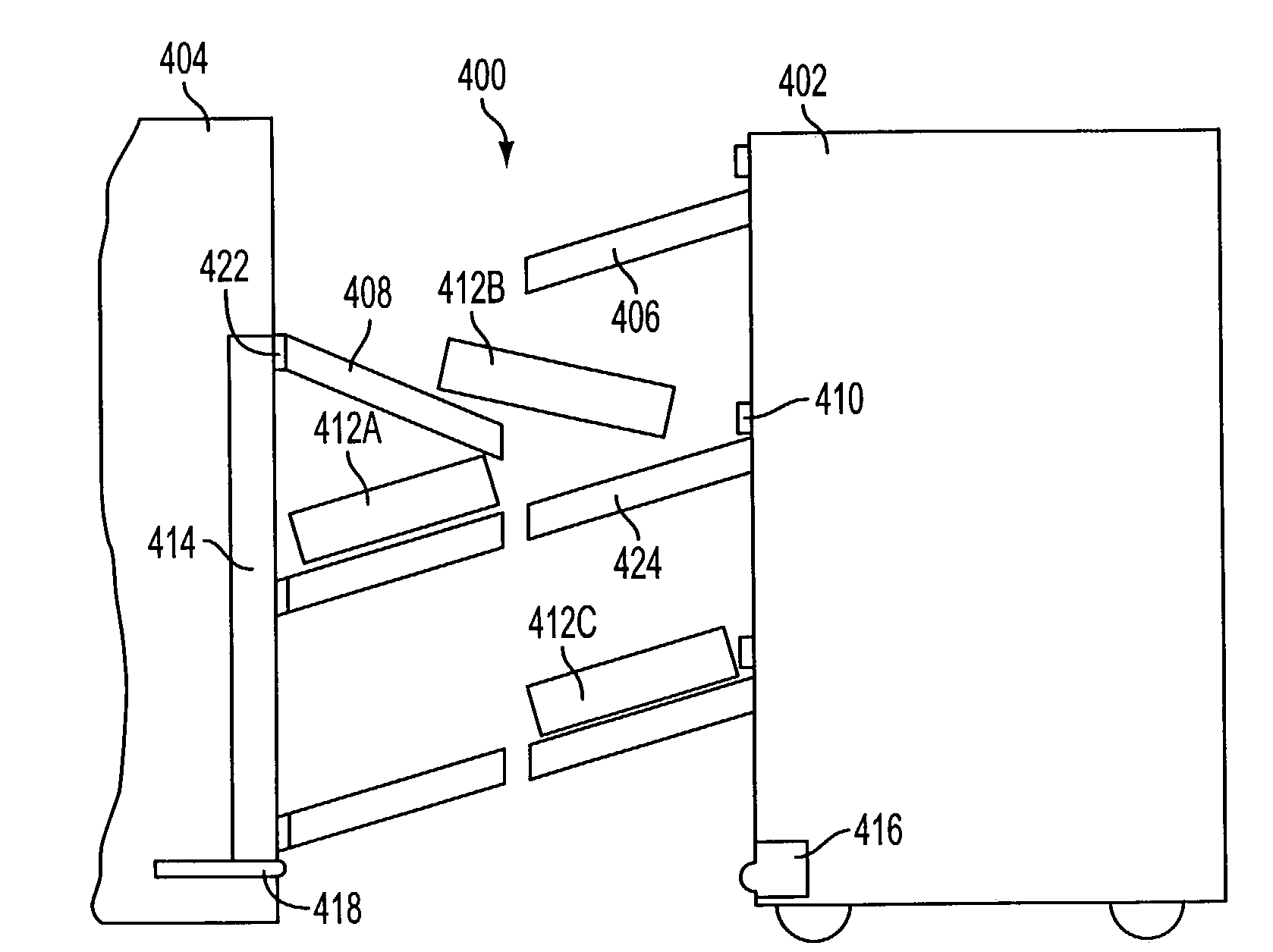

A catalyst loading system for utilizing catalyst from a bulk supply located adjacent but not on the upper tube sheet of a catalytic reactor and for mechanized measuring of multiple identical quantities of catalyst and for mechanized loading of catalyst pellets into the reaction tubes of the reactor to achieve even drop rate, compaction and outage of the reaction tubes. From the bulk supply, multi-compartment catalyst charging hoppers are individually filled in rapid and accurately measured fashion by mechanized filling equipment having a predetermined sequence of operation that ensures accuracy of volumetric catalyst measurement. The charging hoppers are used for delivery of measured volumes of catalyst of a reactor tube loading mechanism which may take the form of a mobile cart framework being selectively positionable relative to the upper tube sheet and reaction tubes of a catalytic reactor to be charged with catalyst pellets. A pair of electronic vibrators are mounted to the cart framework and provide for support and vibratory movement of a vibratory tray having a catalyst feed hopper adapted to feed catalyst pellets to a plurality of generally parallel catalyst transfer troughs along which catalyst pellets are moved by vibration of the vibratory tray to a plurality of drop tubes. A compartmented hopper is fixed to the vibratory tray and controllably feeds catalyst pellets into respective catalyst transfer troughs. A plurality of charging tubes are connected to respective drop tubes by a plurality of elongate flexible tubes and are maintained in fixed, spaced relation by a structural element so as to define a charging manifold for simultaneous, timed delivery of catalyst pellets into a plurality of reactor tubes. The charging manifold has locator pins which are inserted into selected reactor tubes for orienting the charging tubes of the charging manifold with respect to a selected group of reaction tubes. A system is also provided for raising and lowering the charging manifold for efficiency of reactor tube charging operations. An electronic control system is effective for controlling the vibrators to achieve even drop rate from each of the catalyst transfer troughs and to control the vibrators responsive to catalyst weight to achieve even catalyst drop rate during an entire catalyst charging cycle.

Owner:COMARDO MATHIS P

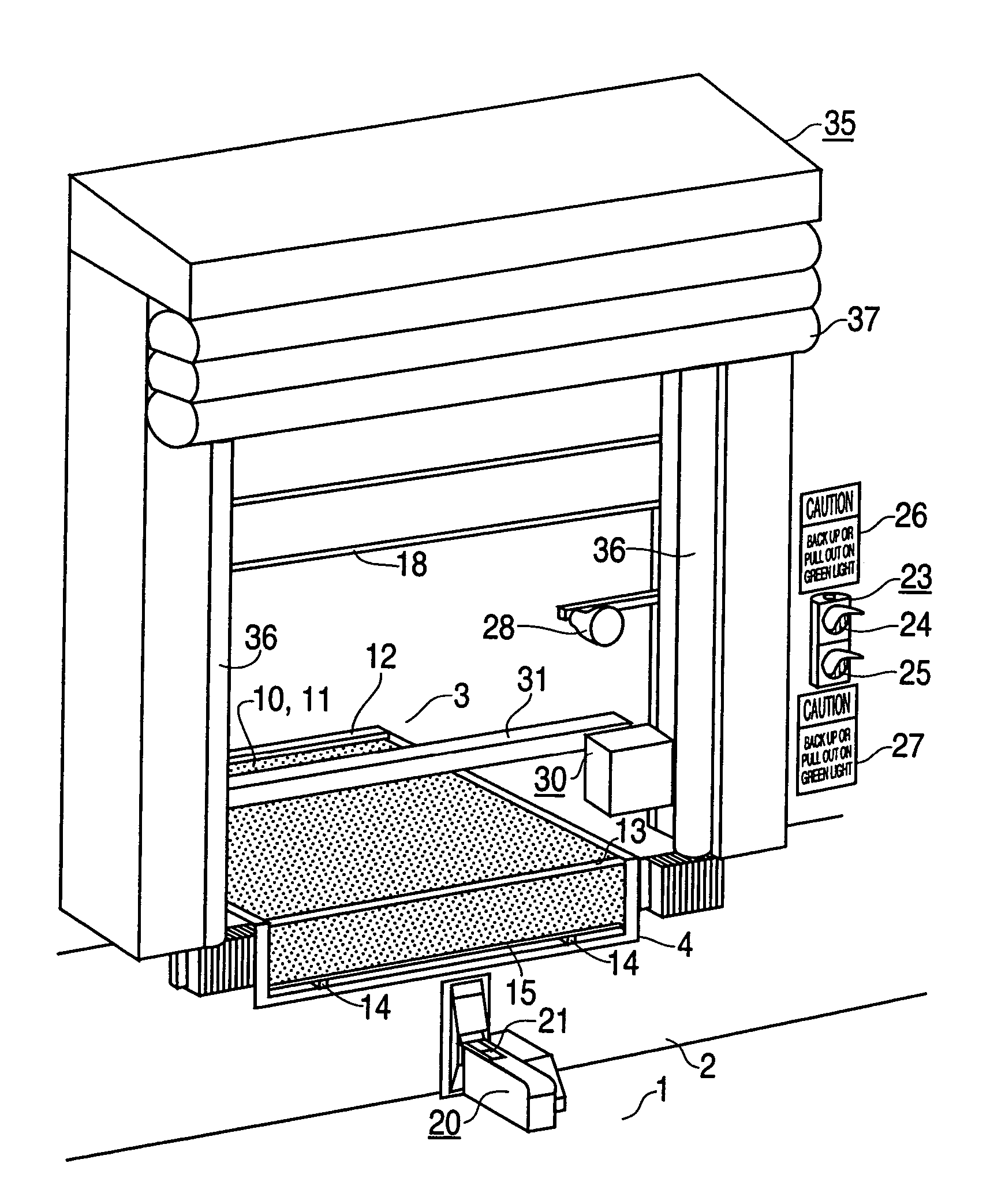

Zone specific remote master control panel for loading dock equipment

InactiveUS7274300B2Compact spaceInexpensive to installElectric controllersRefuse transferringRemote controlEmbedded system

A loading dock apparatus remote control is provided. Some embodiments of the invention include a zone specific remote control for loading dock apparatus. Some optional embodiments include a selector switch to select which apparatus the single set of controls will control. Other optional embodiments automatically select the apparatus to be controlled by the single set of controls. A method of operating loading dock apparatus using a remote control is also provided.

Owner:4FRONT ENGINEERED SOLUTIONS

Automatic transport loading system and method

ActiveUS20100266381A1Effectively and efficiently and accurately usEasy to moveLifting devicesRefuse transferringGuidance systemTransport engineering

A method and system for automatically loading and unloading a transport is disclosed. A guidance system follows a travel path to a position near the transport and then a sensor profiles a transport so that a transport path is determined for an AGV to follow into the transport to place a load and for exiting the transport upon placement of the load.

Owner:JERVIS B WEBB INT CO

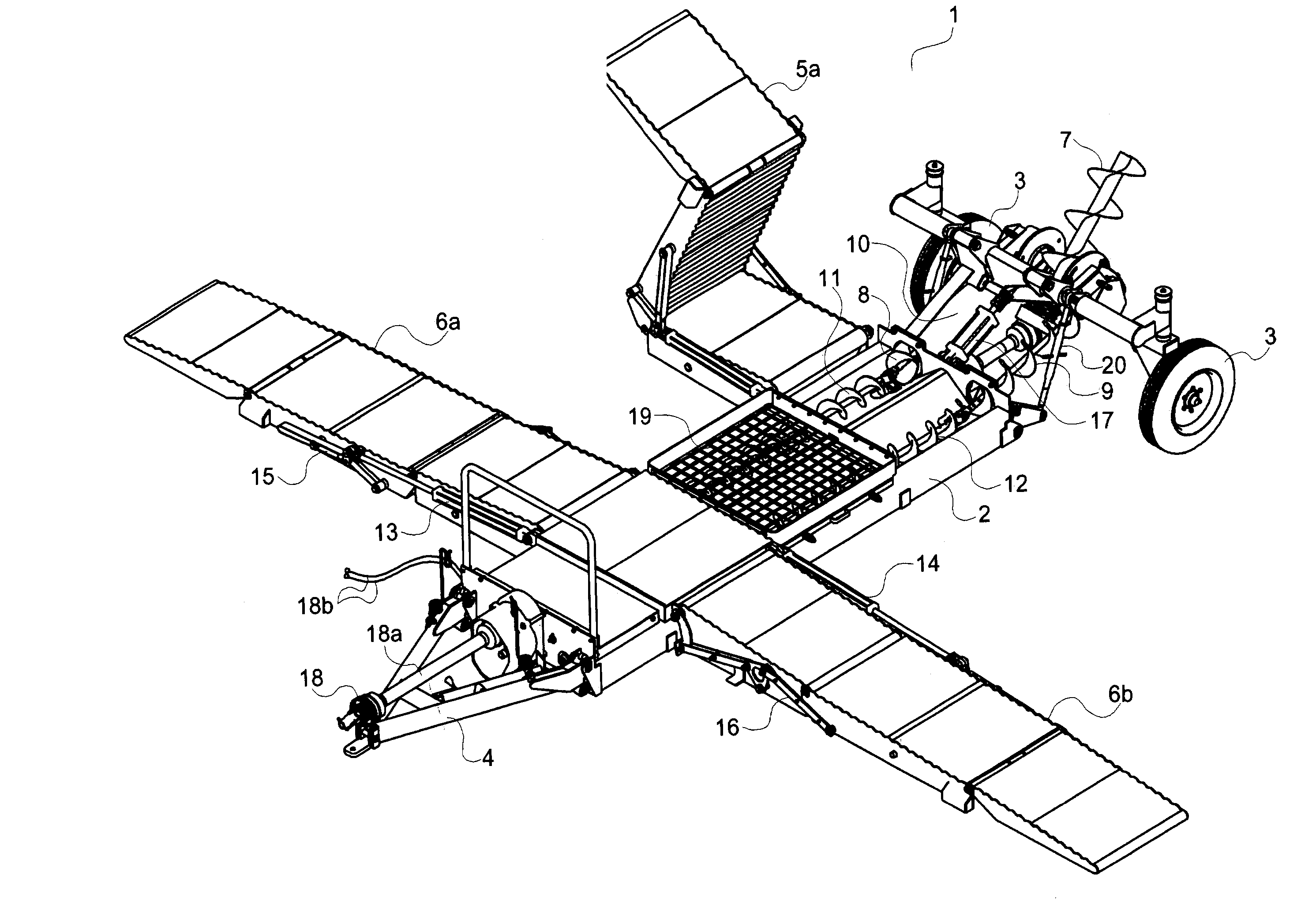

Unloading system for particulate material

InactiveUS7090066B2Precise positioningLoadersRefuse transferringAgricultural engineeringParticulate material

This invention concerns a new grain unloading system using an integrated ramp, horizontal transfer conveyor and elevating system. The unit is towed, positioned and powered by an agricultural tractor.

Owner:BOURGAULT INDS

Automatic transport loading system and method

InactiveUS20080189005A1Efficient and effectiveSpeed controllerRailway vehiclesGuidance systemEngineering

A method and system for automatically loading and unloading a transport is disclosed. A first guidance system is used to travel near the transport and a second guidance system is used to travel on the transport.

Owner:JERVIS B WEBB INT CO

Automatic transport loading system and method

A method and system for automatically loading and unloading a transport is disclosed. A first guidance system is used to travel near the transport and a second guidance system is used to travel on the transport.

Owner:JERVIS B WEBB INT CO

Method and apparatus for dechucking a substrate

InactiveUS6676761B2Semiconductor/solid-state device manufacturingRefuse transferringEngineeringSupport surface

A substrate support assembly and method for dechucking a substrate is provided. In one embodiment, a support assembly includes a substrate support having a support surface, a first set of lift pins and one or more other lift pins movably disposed through the substrate support. The first set of lift pins and the one or more lift pins project from the support surface when the pins are in an actuated position. When in the actuated position, the first set of lift pins project a longer distance from the support surface than the one or more other lift pins. In another aspect of the invention, a method for dechucking a substrate from a substrate support is provided. In one embodiment, the method includes the steps of projecting a first set of lift pins a first distance above a surface of a substrate support, and projecting a second set of lift pins a second distance above the surface of the substrate support that is less than the first distance.

Owner:APPLIED MATERIALS INC

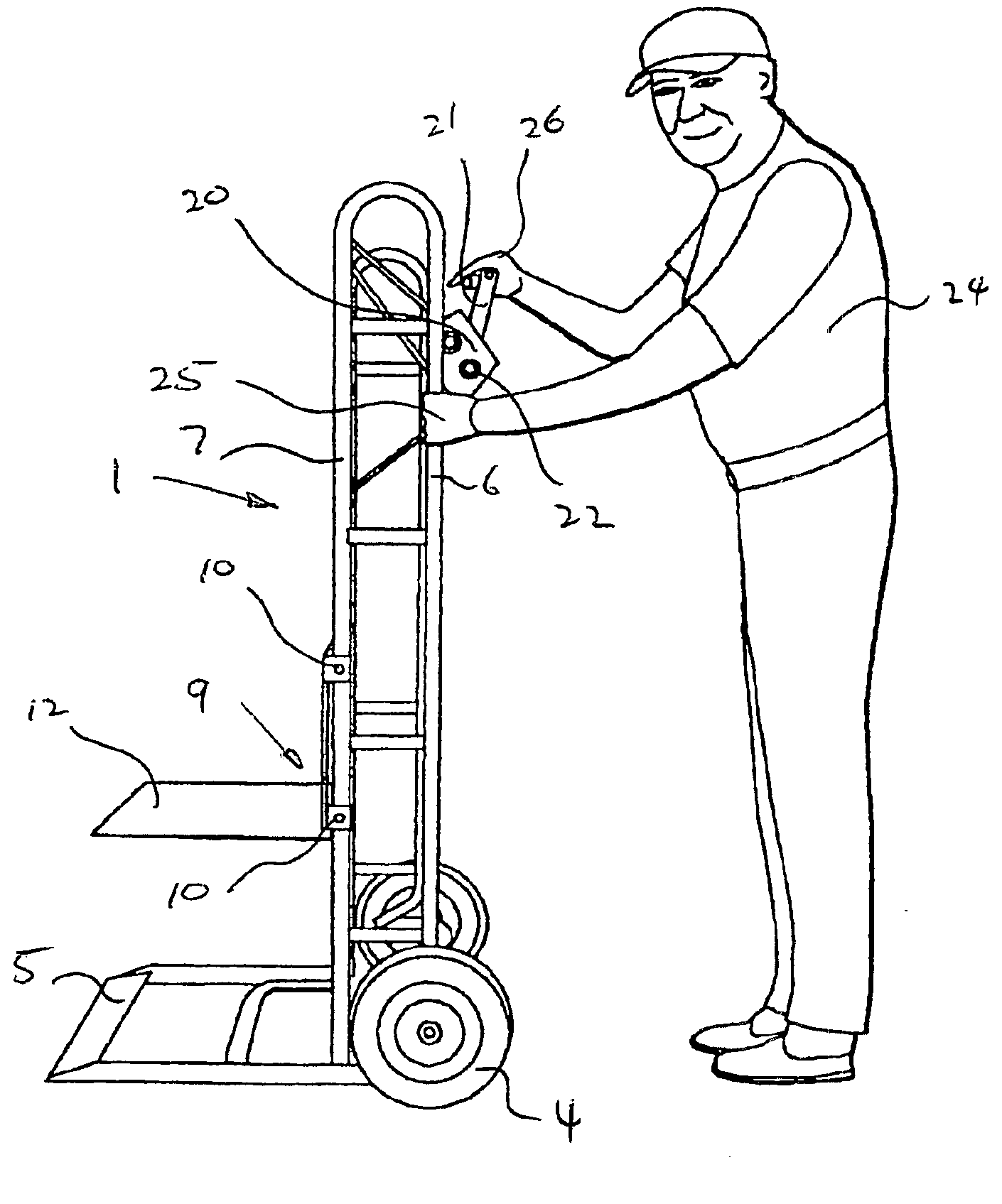

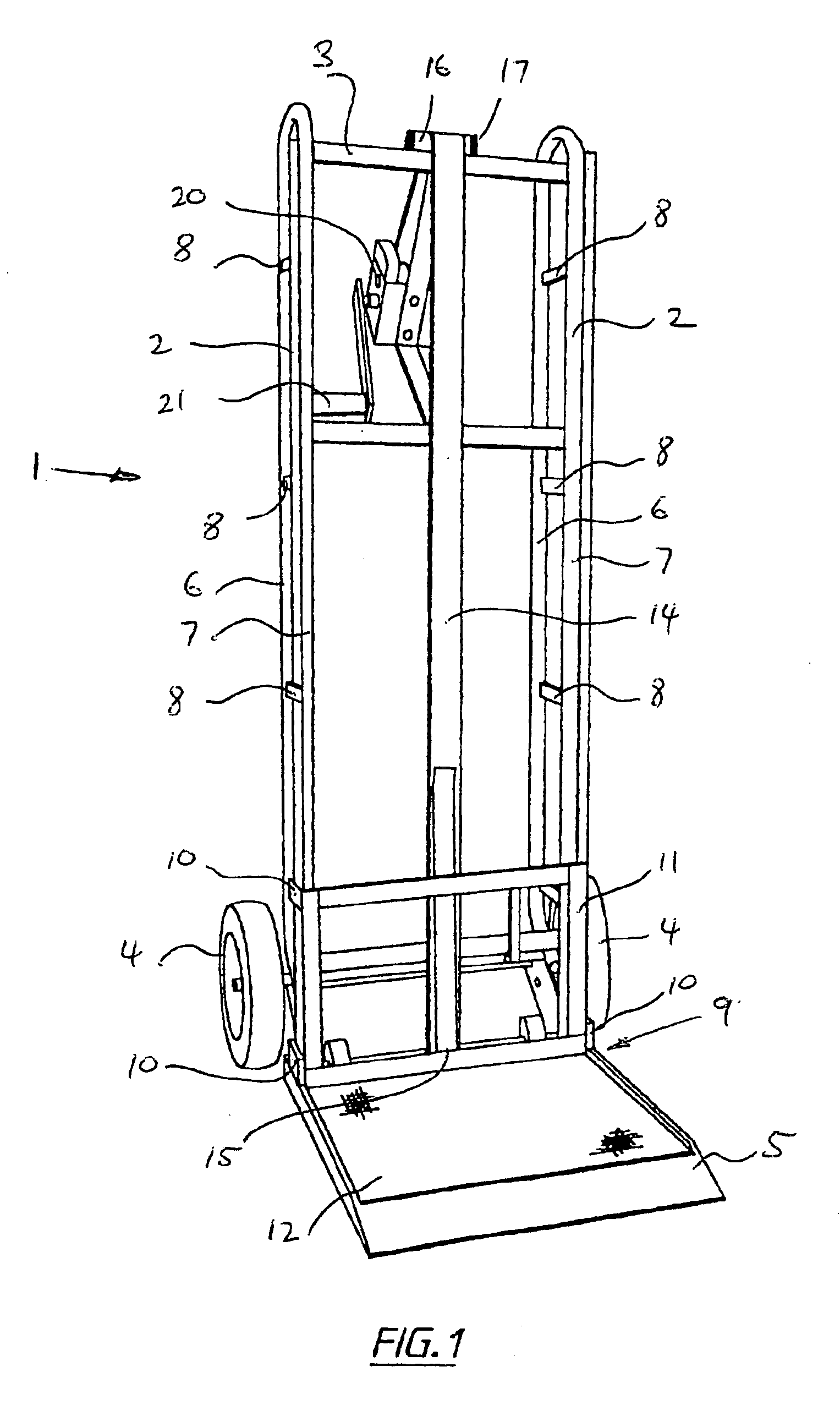

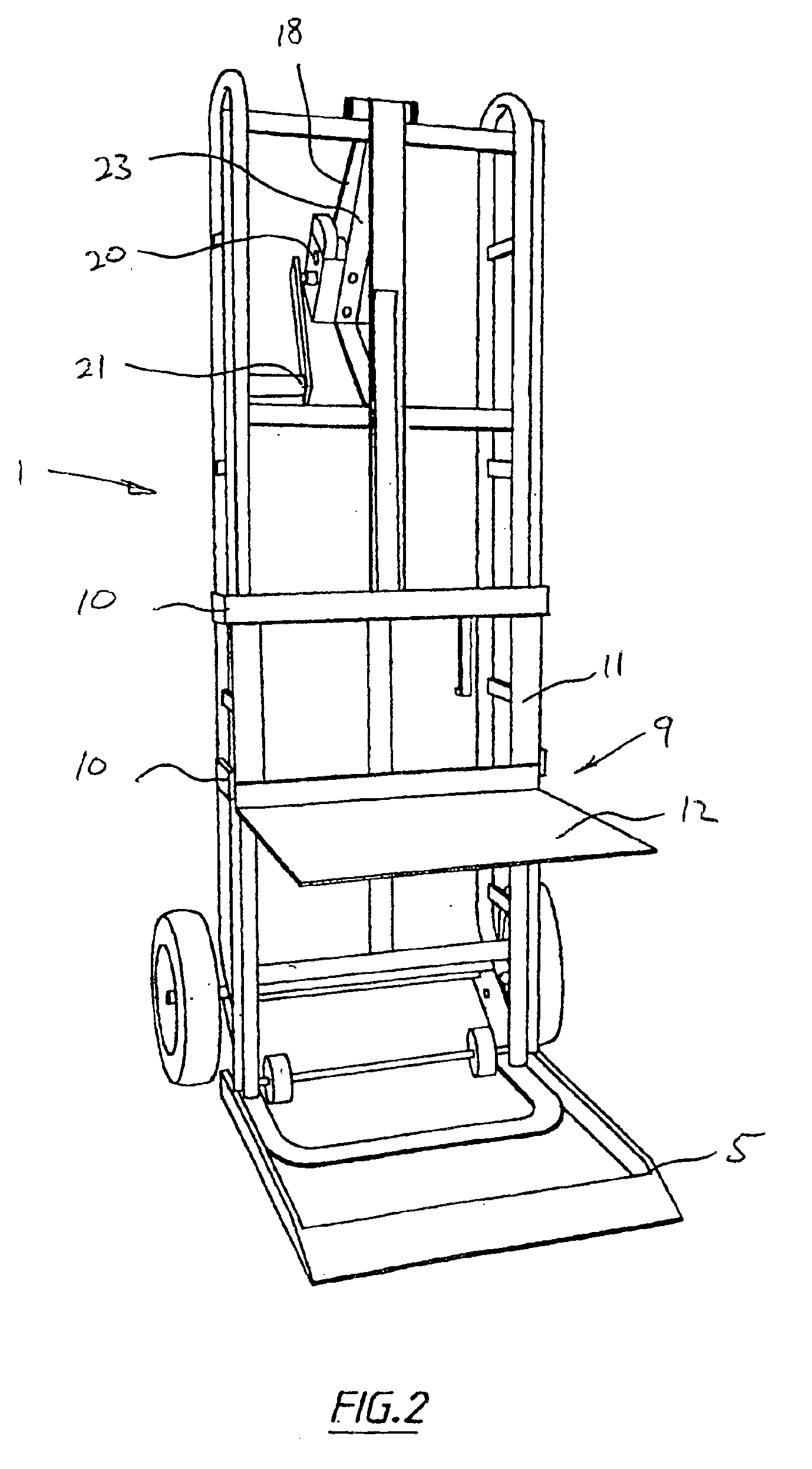

Hand trolley with winch operated lifting carriage

InactiveUS6921095B2Clear wellFacilitate ergonomically sound movementWinding mechanismsElevatorsCarriageWinch

A hand trolley includes a chassis formed from side frames comprising parallel frame members, wheels and a base platform provided with a load lifting carriage having a lifting surface. The carriage can be raised from a low position on the base platform to an elevated position by operating a hand cranked winch with a crank handle rotatable about an axle located proximate to a hand grip on the chassis rails and parallel to the axis of the wheels. The positioning and orientation of the crank handle allows correct ergonomic use by an operator who can grip the trolley chassis with one hand while controlling and operating the crank handle in an ergonomically sound position.

Owner:MIDDLEBY ROBERT J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com