Patents

Literature

1482results about How to "Evenly filled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printing liquids for improved print quality

InactiveUS6022908AImprove print qualityReduce bleedingDuplicating/marking methodsInksColoring agentsAnionic polymers

A set of printing liquids is disclosed comprising a first anionic printing liquid comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic printing liquid comprising an aqueous vehicle at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first liquid; a third cationic printing liquid comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic printing liquid comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. More specifically, the present set of printing liquids may find application in ink-jet printing. The set of ink-jet inks provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

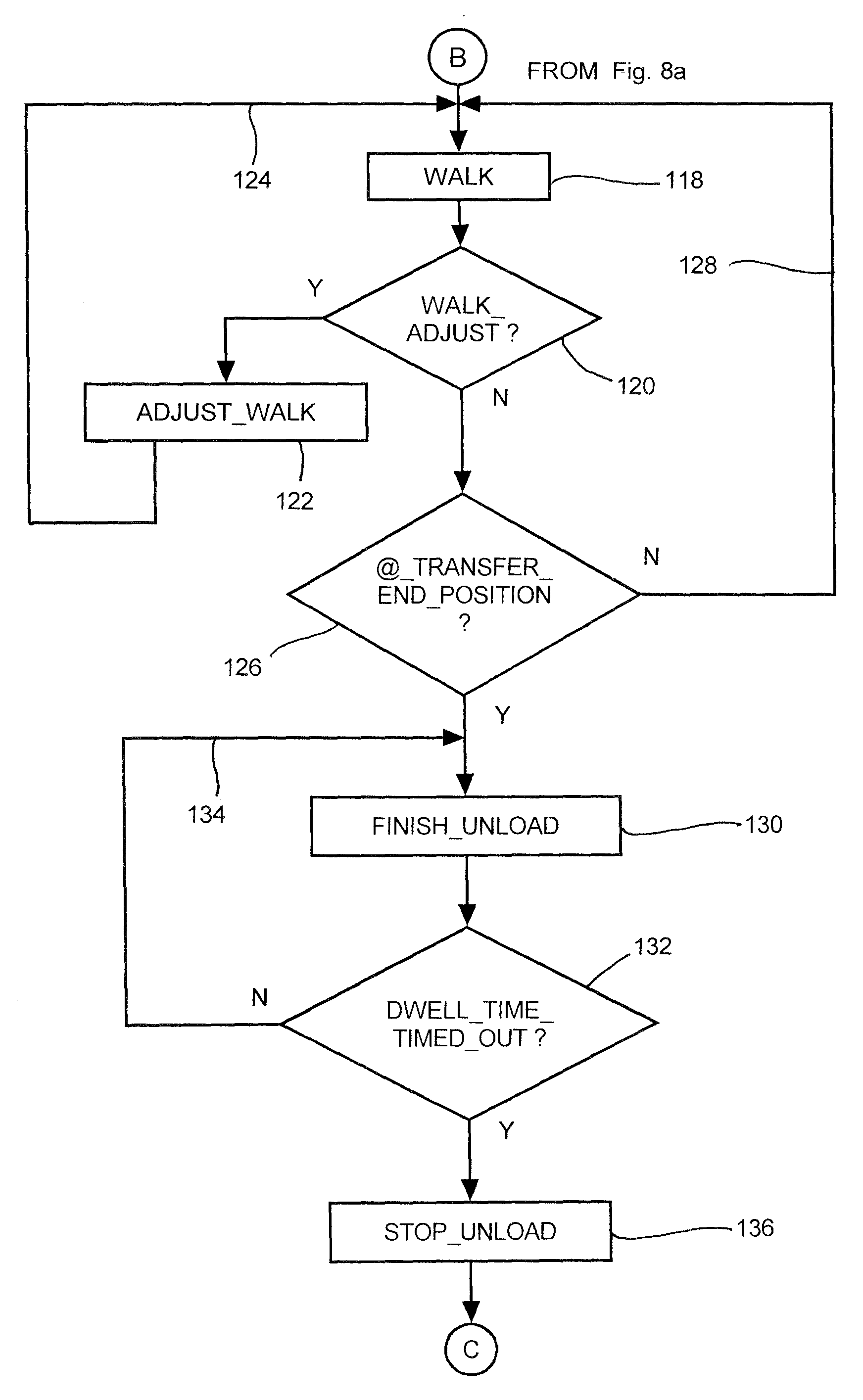

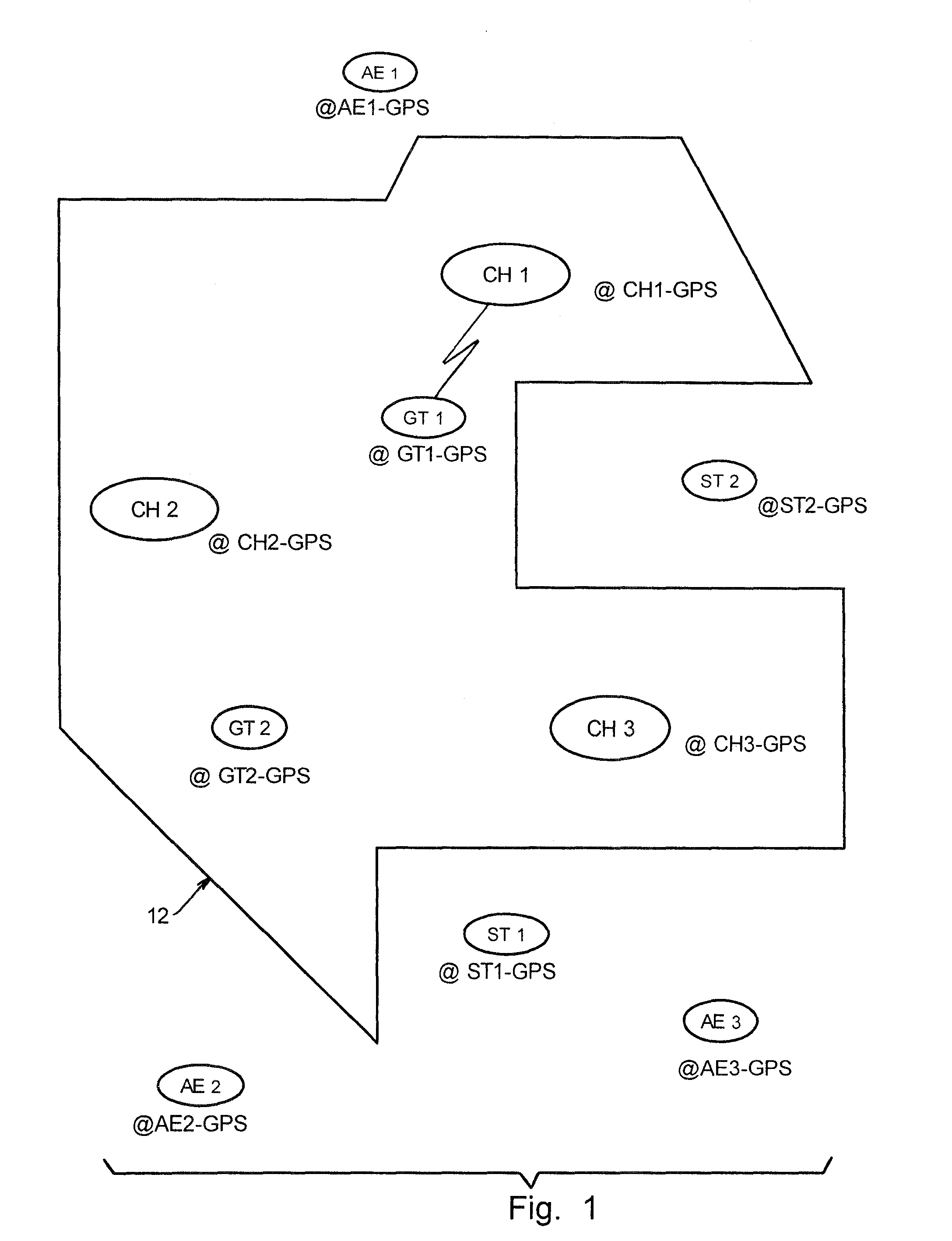

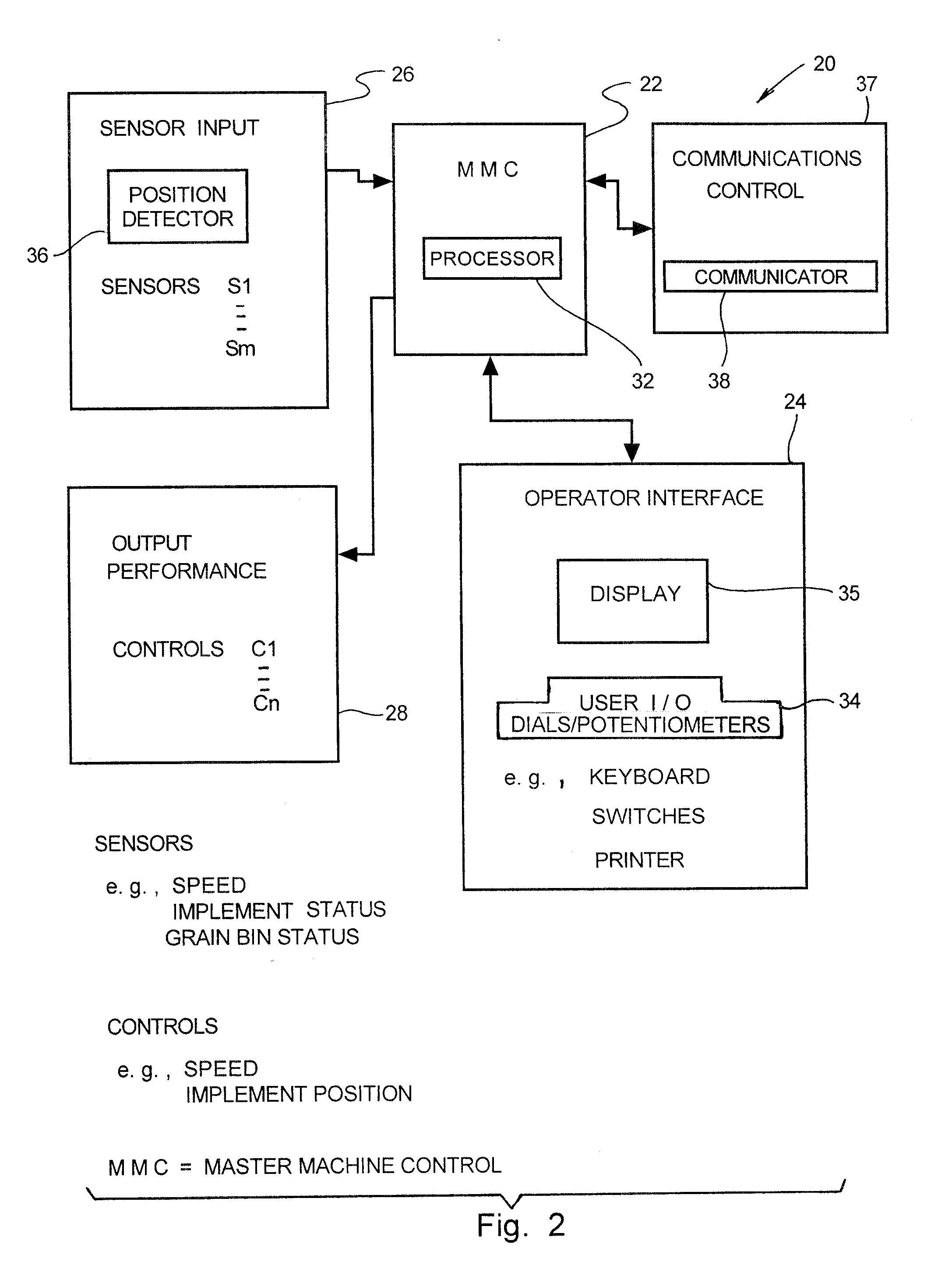

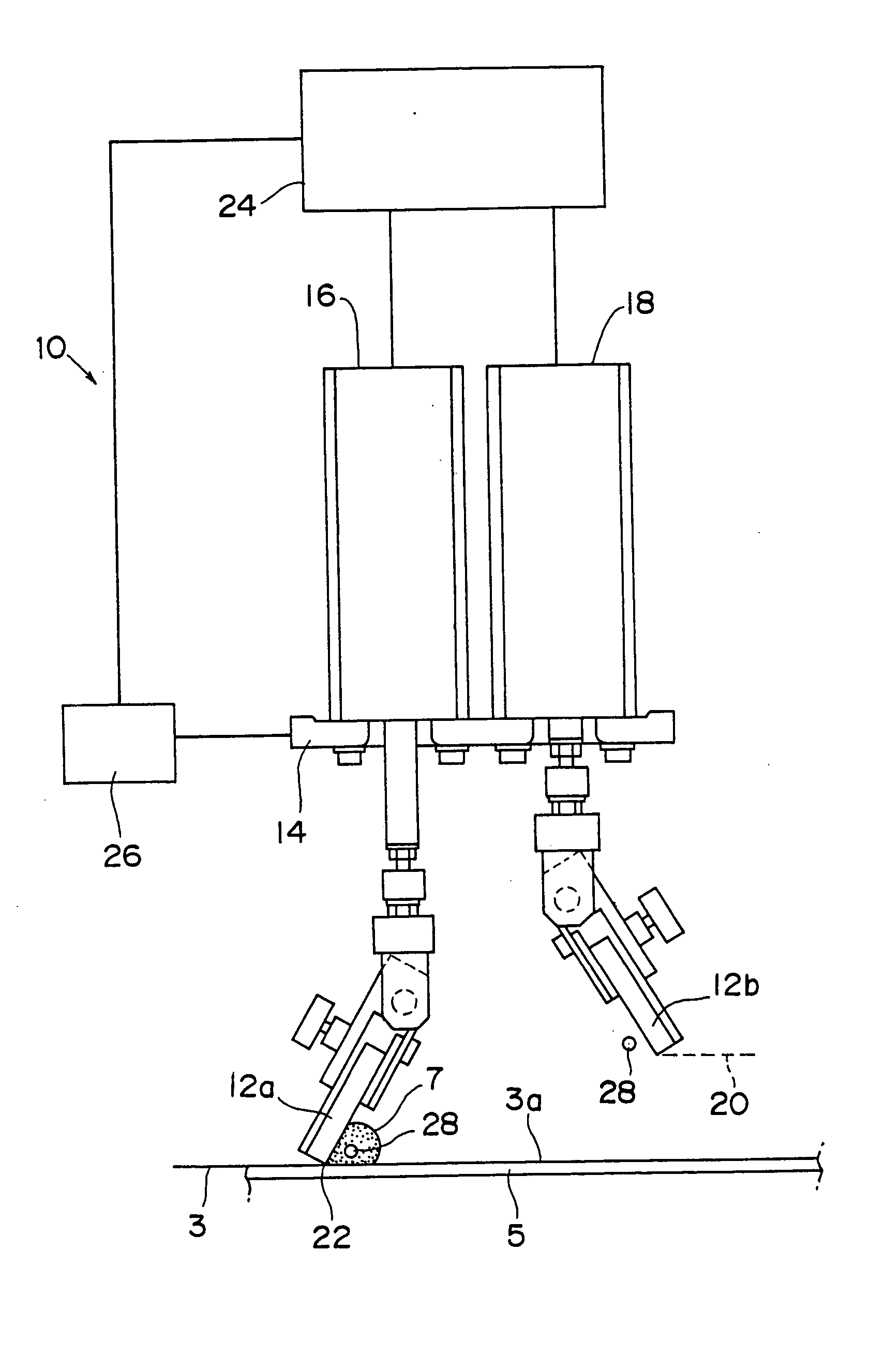

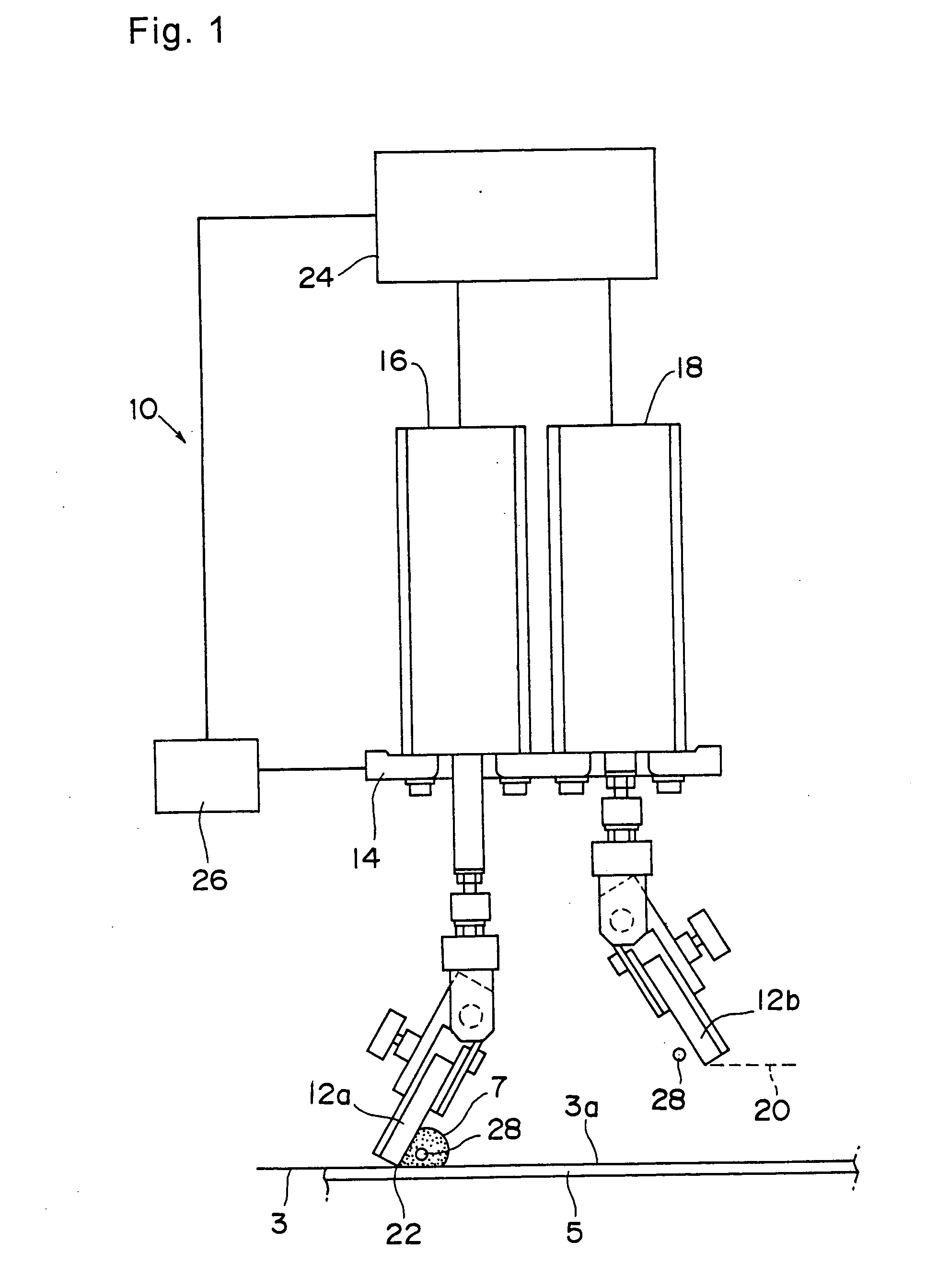

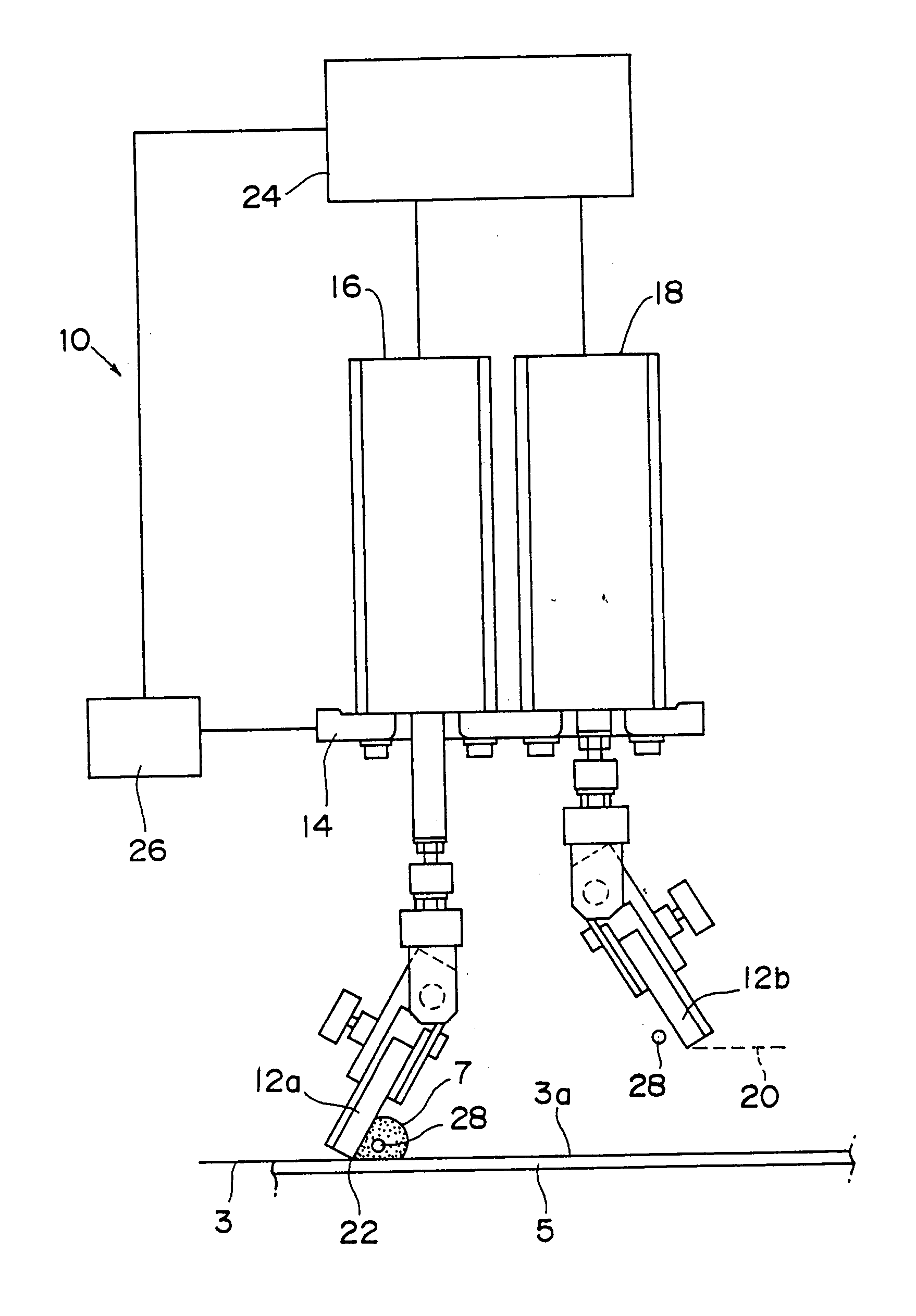

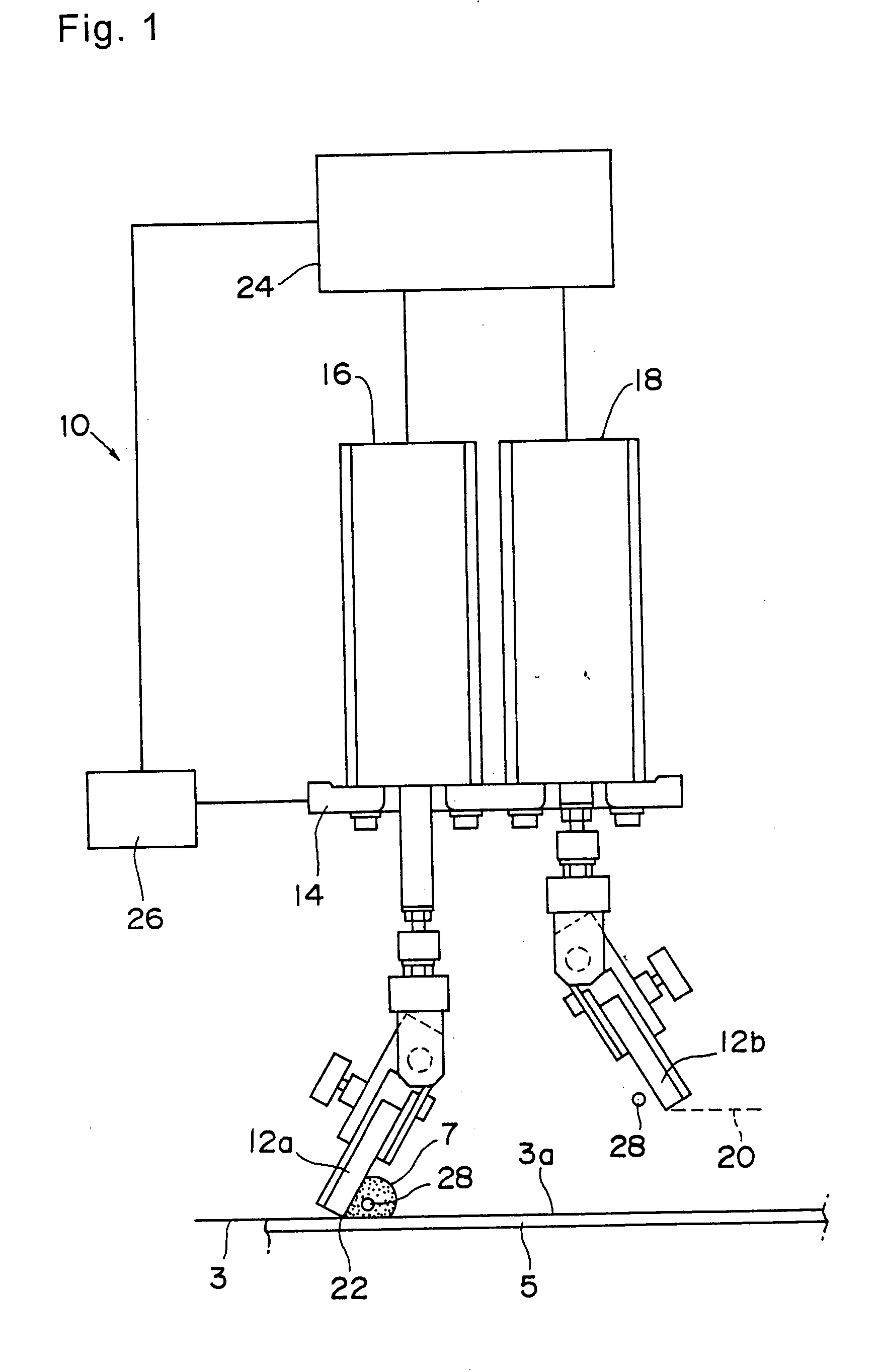

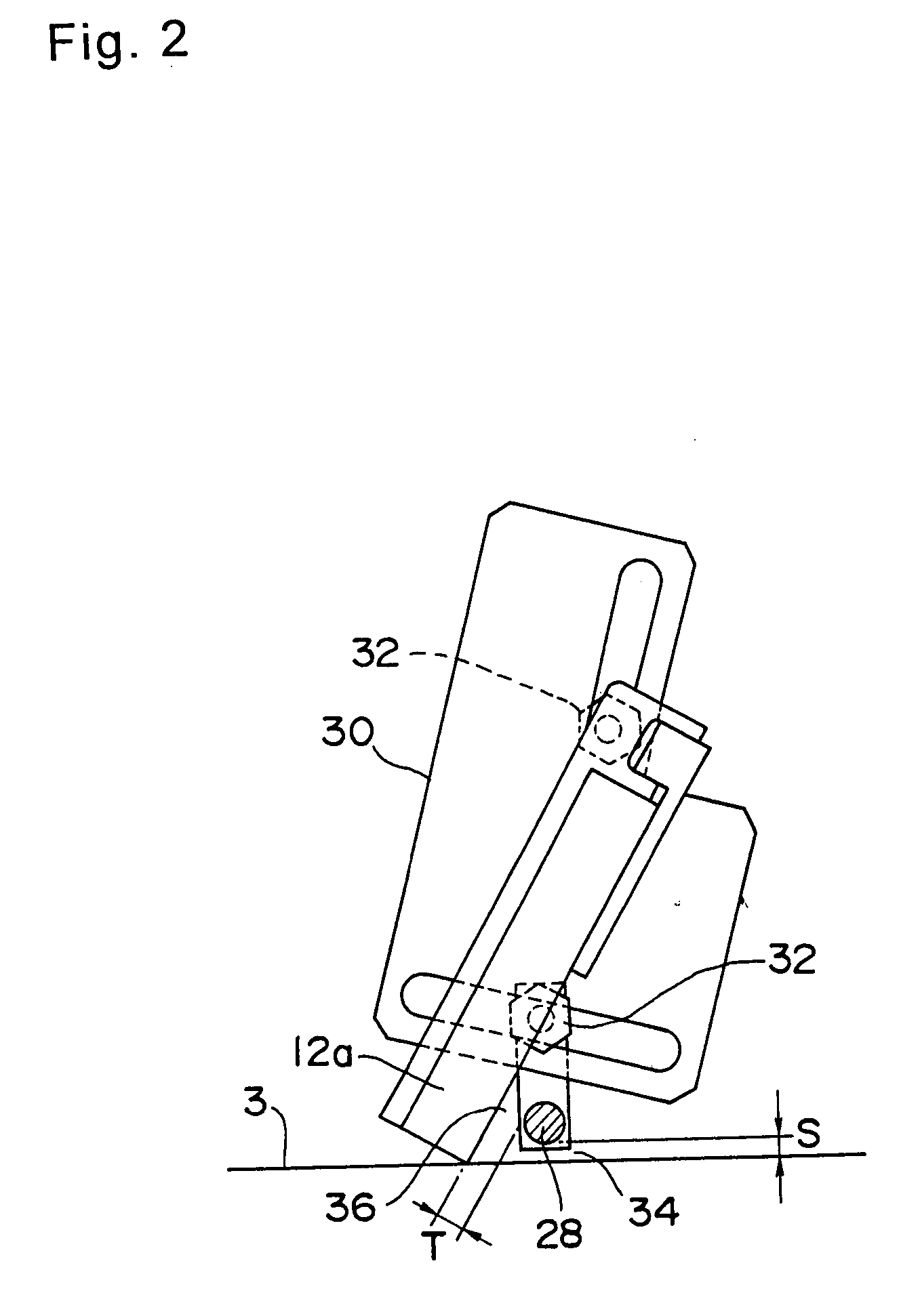

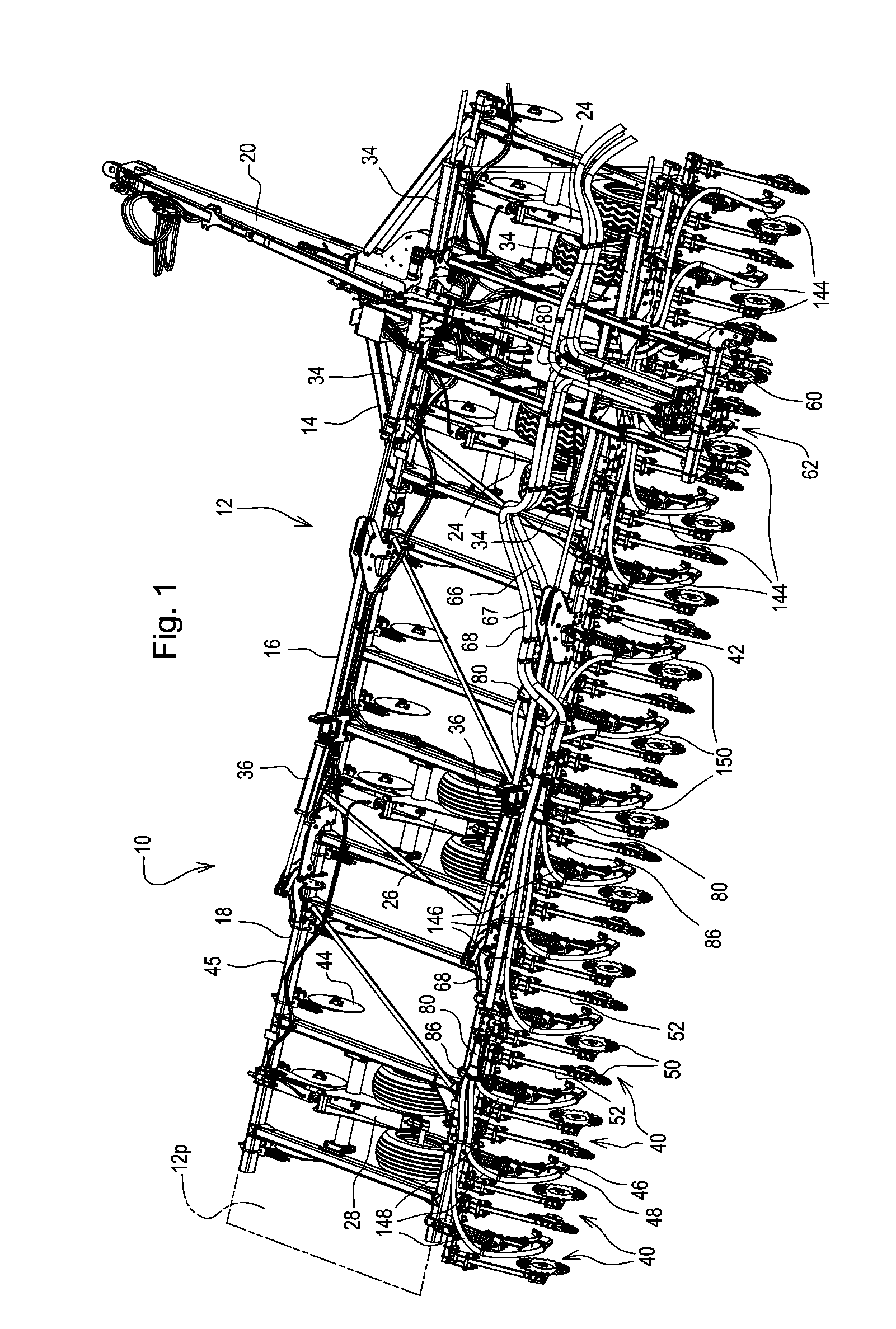

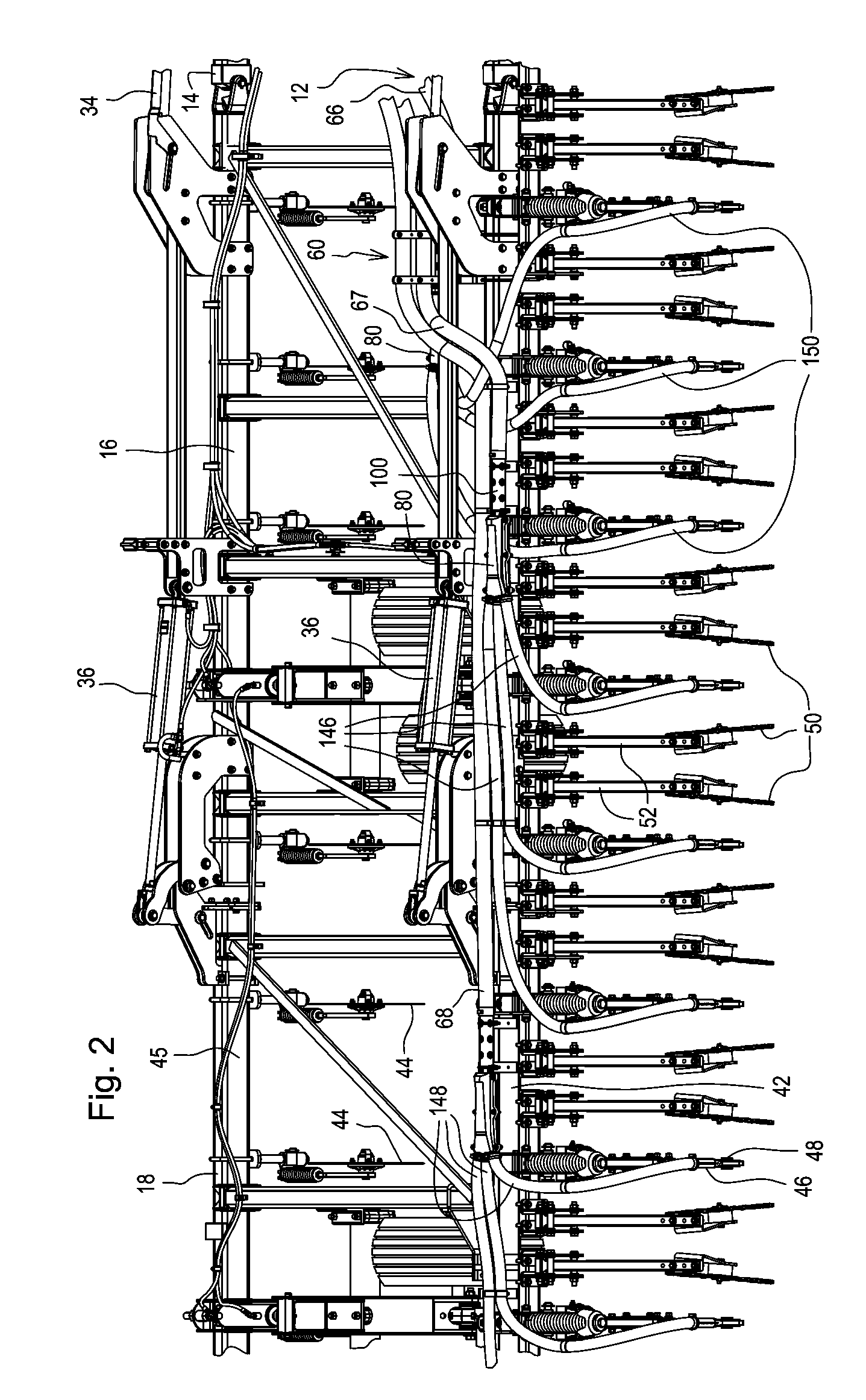

Grain transfer control system and method

ActiveUS20100274452A1Evenly filledDigital data processing detailsRoad vehicles traffic controlAutomatic controlControl system

A grain transfer control system, and method of use thereof, for automatedly controlling the transfer of grain from a mobile transferor-type vehicle, such as a combine harvester, to a mobile transferee-type vehicle, such as a crop transport, by varying the position and speed of the transferor-type and transferee-type vehicles relative to one another during the transfer operation, especially by varying the position and rate of walk of the discharge spout along at least a portion of the length of a grain holding receptacle of the transferee-type vehicle, to effect a generally even fill of the grain holding receptacle of the transferee-type vehicle along the length of the grain holding receptacle.

Owner:BLUE LEAF I P INC

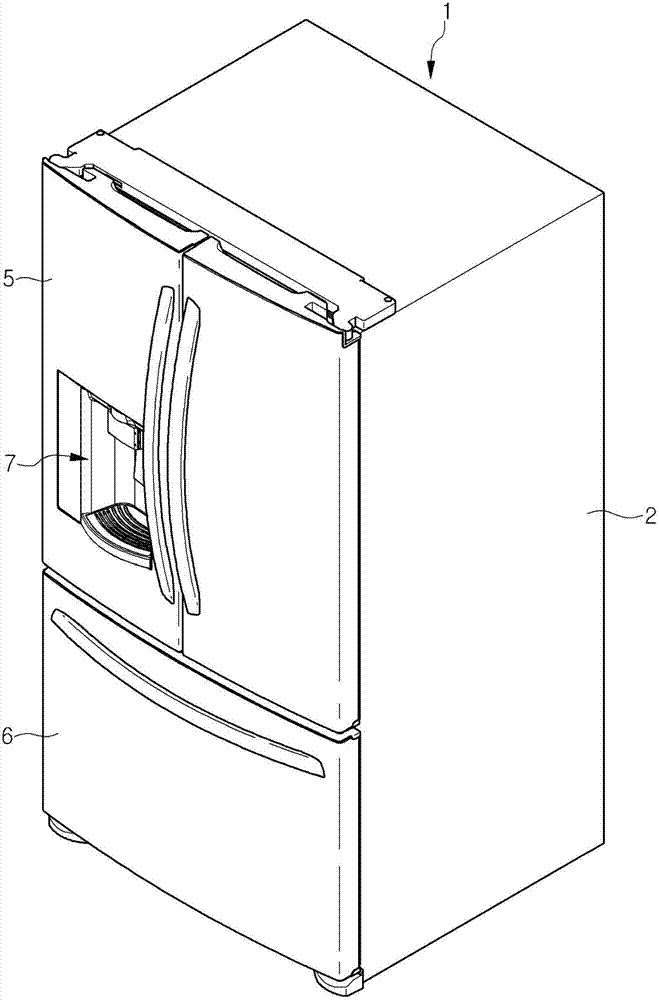

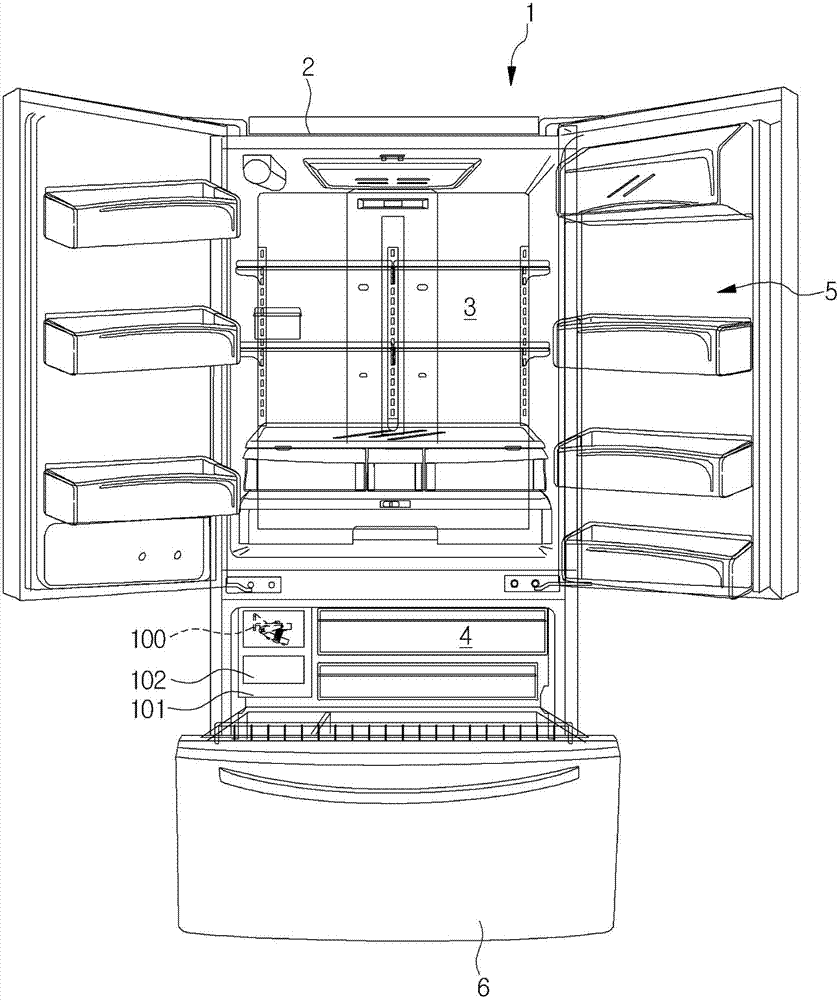

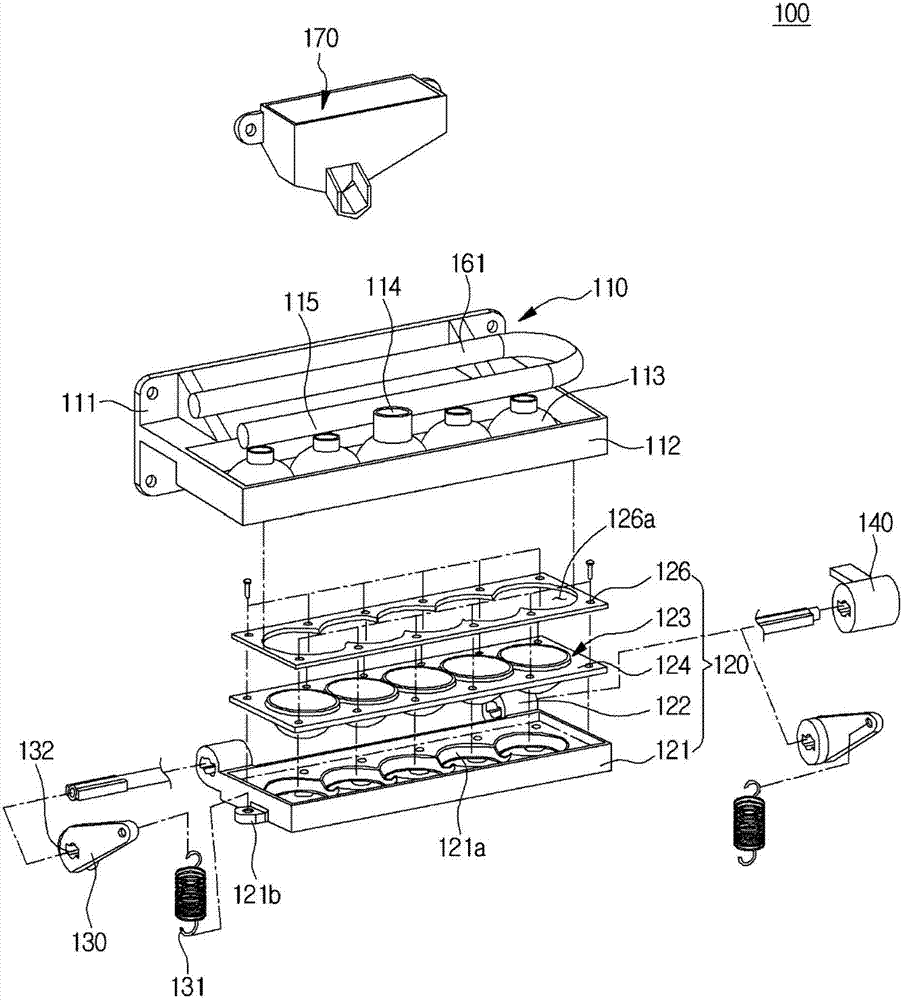

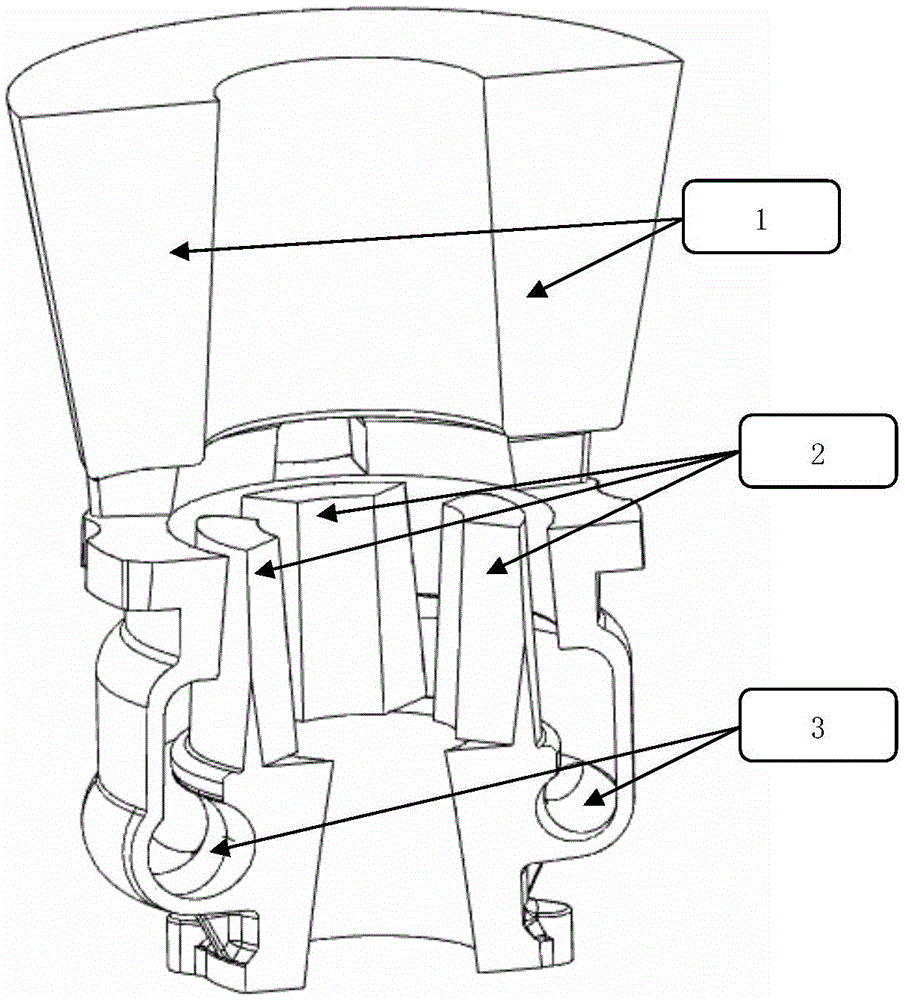

Ice maker

ActiveCN102878743APrevent freezing togetherPrevent freezingLighting and heating apparatusIce productionIcemakerWater supply

Provided is an ice maker. The ice maker includes an upper tray including a plurality of first recessed parts, each having a hemispherical shape, and a lower tray including a plurality of second recessed parts, each having a hemispherical shape. The ice maker also includes a driving unit that moves at least one of the upper tray and the lower tray to change between an attached orientation in which the upper tray is attached to the lower tray to define a plurality of spherical shells and a separated orientation in which the upper tray is separated from the lower tray. The ice maker further includes a water supply part configured to supply water into the shells and an ejecting unit disposed outside the shells and configured to facilitate separation of ice pieces made in the shells.

Owner:LG ELECTRONICS INC

Packaging film or sheet

InactiveUS6416832B1Good formabilityExcellent gas barrier propertiesFlexible coversWrappersCopolymerPolymer chemistry

The invention provides a single-layer or multi-layer packaging film or sheet having at least one layer formed of a polyamide resin composition, wherein the layer formed of the polyamide resin composition is a layer (A) formed of a polyamide resin composition comprising a copolymer nylon (c) composed of an aliphatic nylon (co)polymer component (1) and an aromatic nylon (co)polymer component (2) in a proportion of at least 5 wt. %.

Owner:KUREHA KAGAKU KOGYO KK

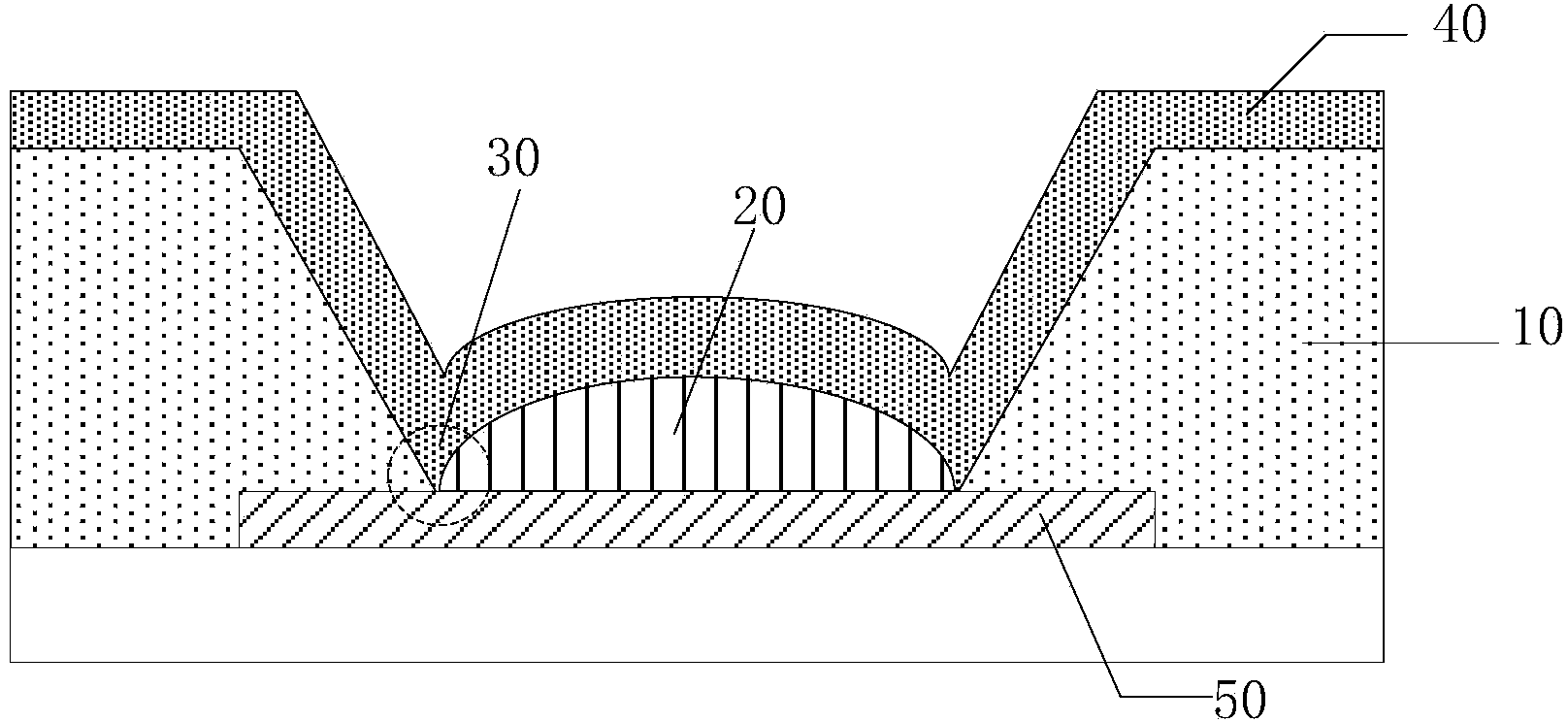

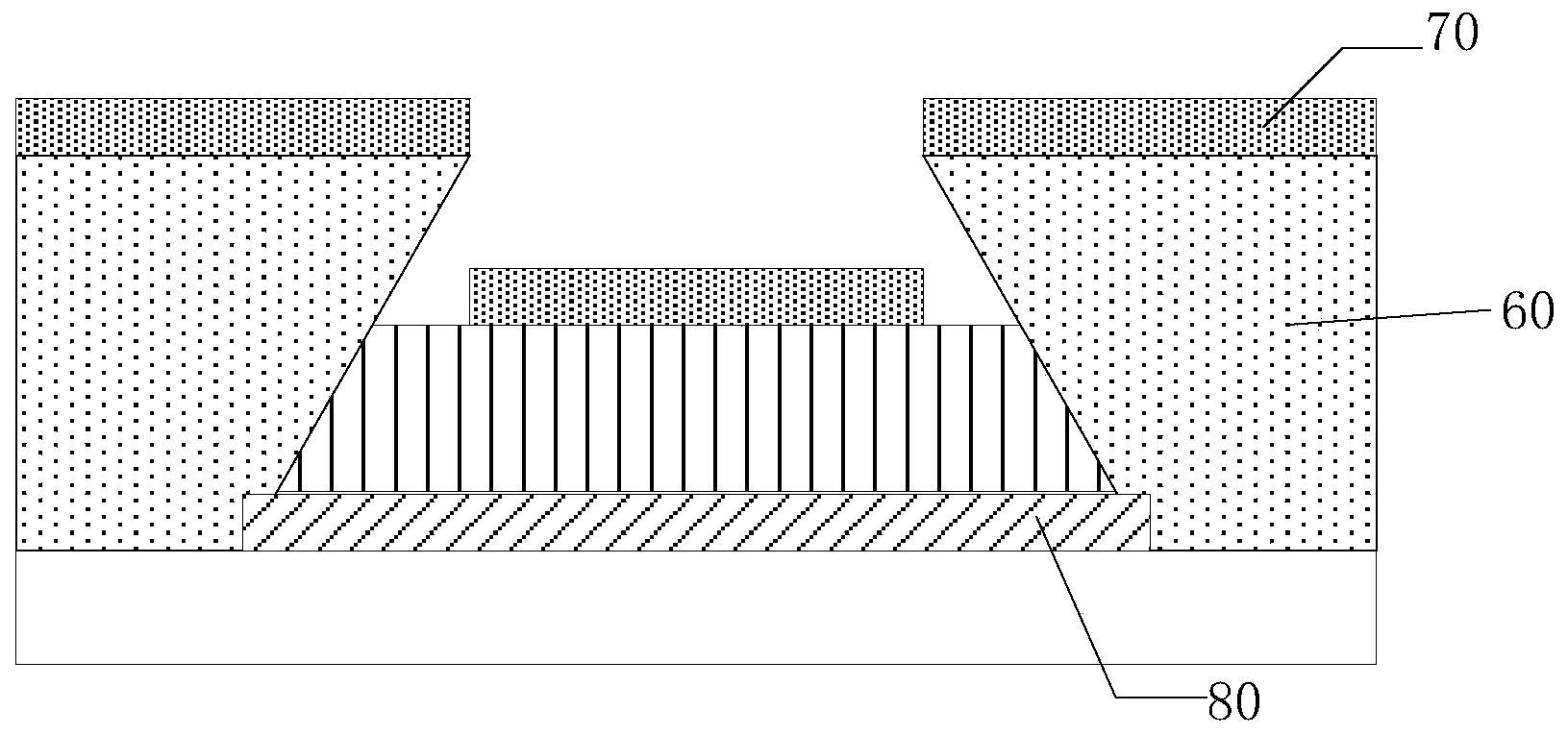

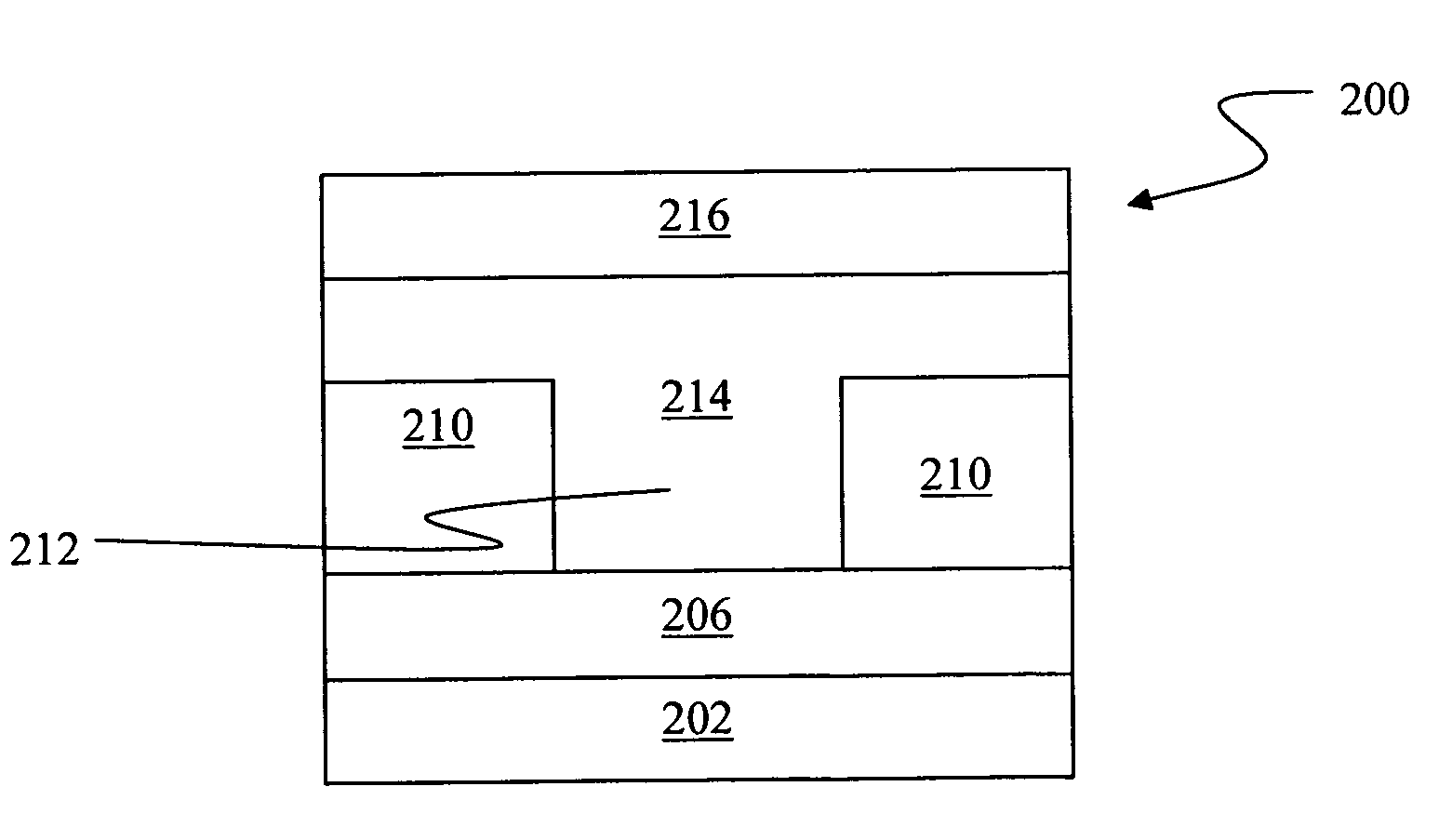

Organic electroluminescent display (OLED), manufacturing method thereof and display device

ActiveCN104167430AImprove luminous performanceAvoid disconnectionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceLuminescent material

The invention discloses an organic electroluminescent display (OLED), a manufacturing method of the organic electroluminescent display (OLED) and a display device. A pixel defining layer arranged in the organic electroluminescent display (OLED) is provided with opening areas corresponding to pixel areas of the OLED, an opening of each opening area is larger than the bottom face of the opening area, and thus the problem that a cathode may break later can be avoided; because the upper surface of the pixel defining layer is made from lyophobic material, and luminescent material with which the pixel defining layer is coated later cannot remain on the upper surface of the pixel defining layer easily, the problem that colors of the adjacent pixel areas are mixed can be avoided; meanwhile, the inclined faces of the corresponding opening areas of the pixel defining layer are made from lyophilic material so that it can be guaranteed that the opening areas are evenly filled with the luminescent material with which the pixel defining layer is coated later. Therefore, according to the OLED, the uniformity of a film layer formed later on the pixel defining layer can be guaranteed, and the luminescence property of the OLED is improved.

Owner:BOE TECH GRP CO LTD

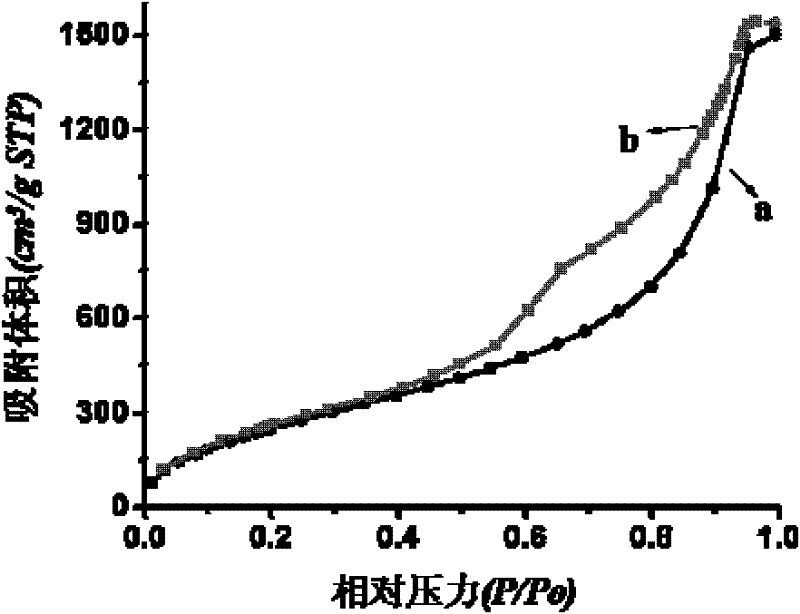

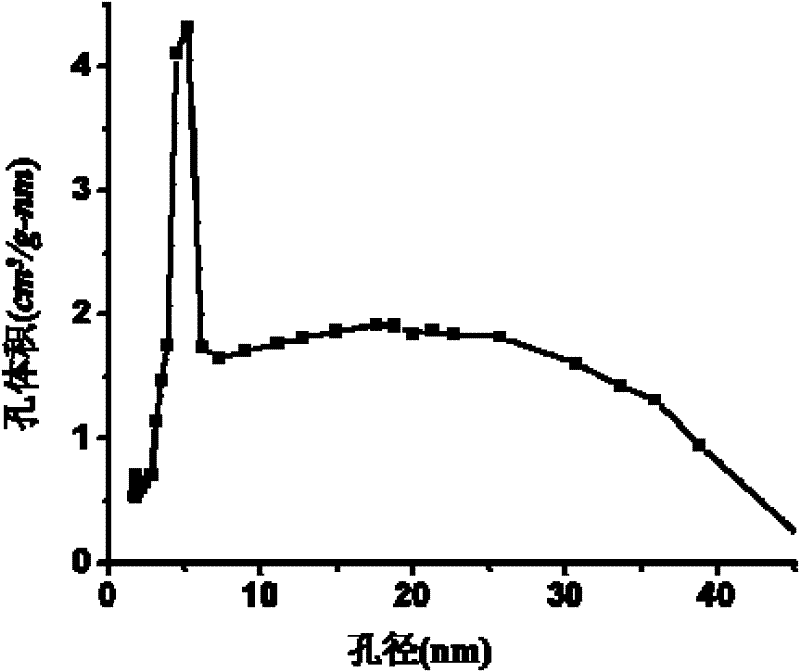

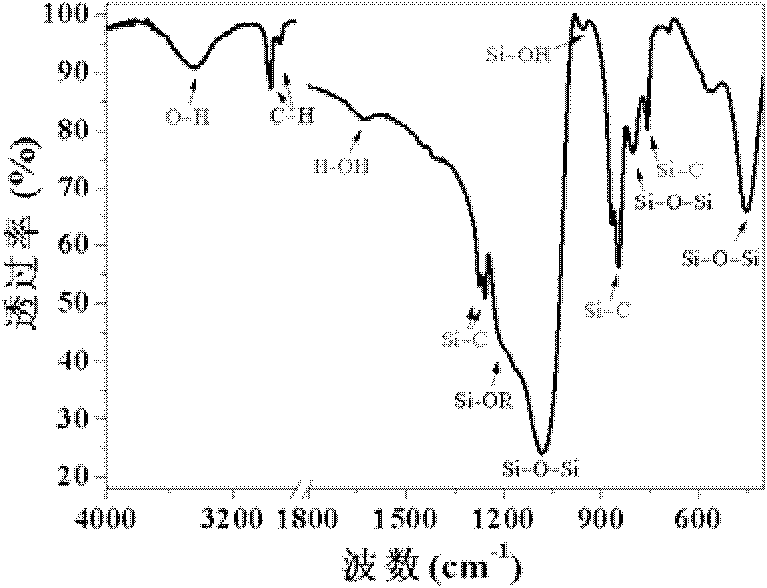

Method for preparing foam material reinforced silica aerogel composite material

The invention discloses a method for preparing a foam material reinforced silica aerogel composite material and relates to silica aerogel. The method comprises the following steps of: preparing silica plural gel and aging the silica plural gel, modifying and drying. Through test, porosity is 80 t o 95 percent, density is 0.15 to 0.5g / cm<3>, the Brunauer-Emmett-Teller (BET) specific surface area is 600 to 1,100m<2> / g, and a water contact angle is 130 to 160 degrees; the foam material reinforced silica aerogel composite material is super hydrophobic; aerogel pore size distribution is relativelycentralized and the pore size of the aerogel is 2 to 50nm; and coefficient of heat conductivity is 0.01 to 0.035 W / (m.K), compression strength is 0.3 to 2Mpa (2 percent deformation), and elastic modulus is 1 to 5 Mpa. Meanwhile, the foam material reinforced silica aerogel composite material has good heat insulation performance, and adsorption performance, environment-friendliness and the other excellent performance. The method is simple, is short in a cycle, low in cost, and high in safety, and contributes to large-scale production; and by the method, excellent performance of the aerogel can be kept and the mechanical property of aerogel can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

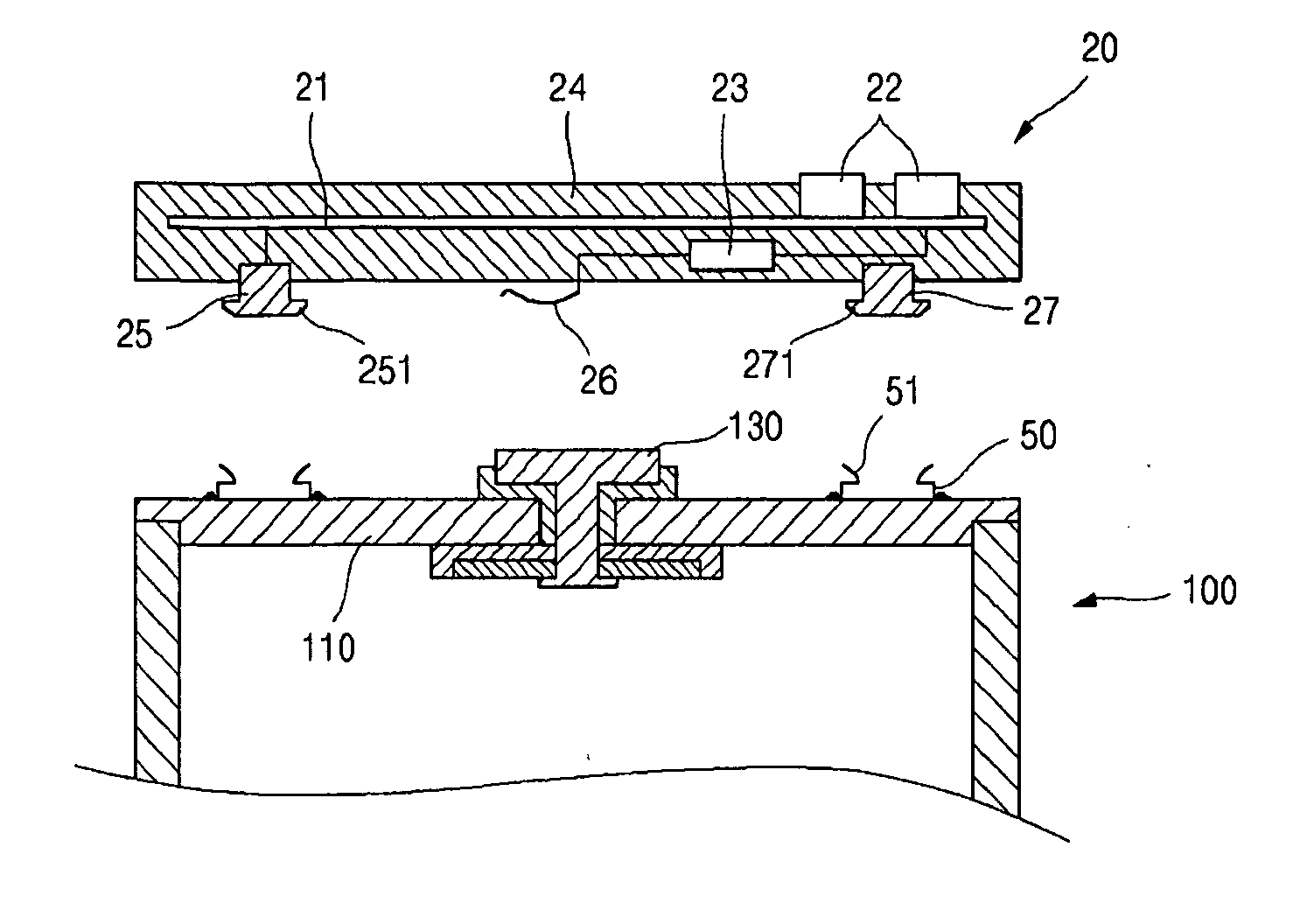

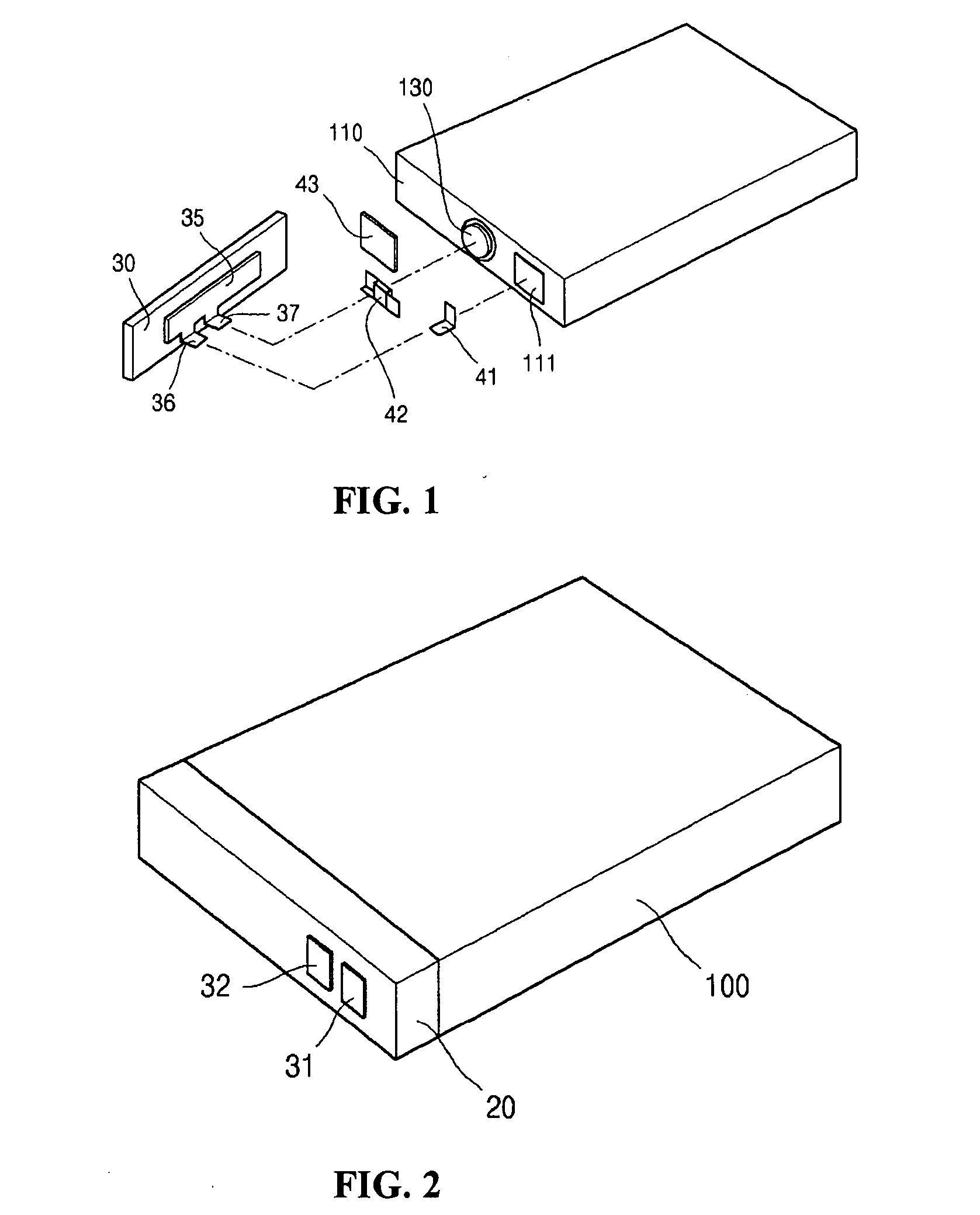

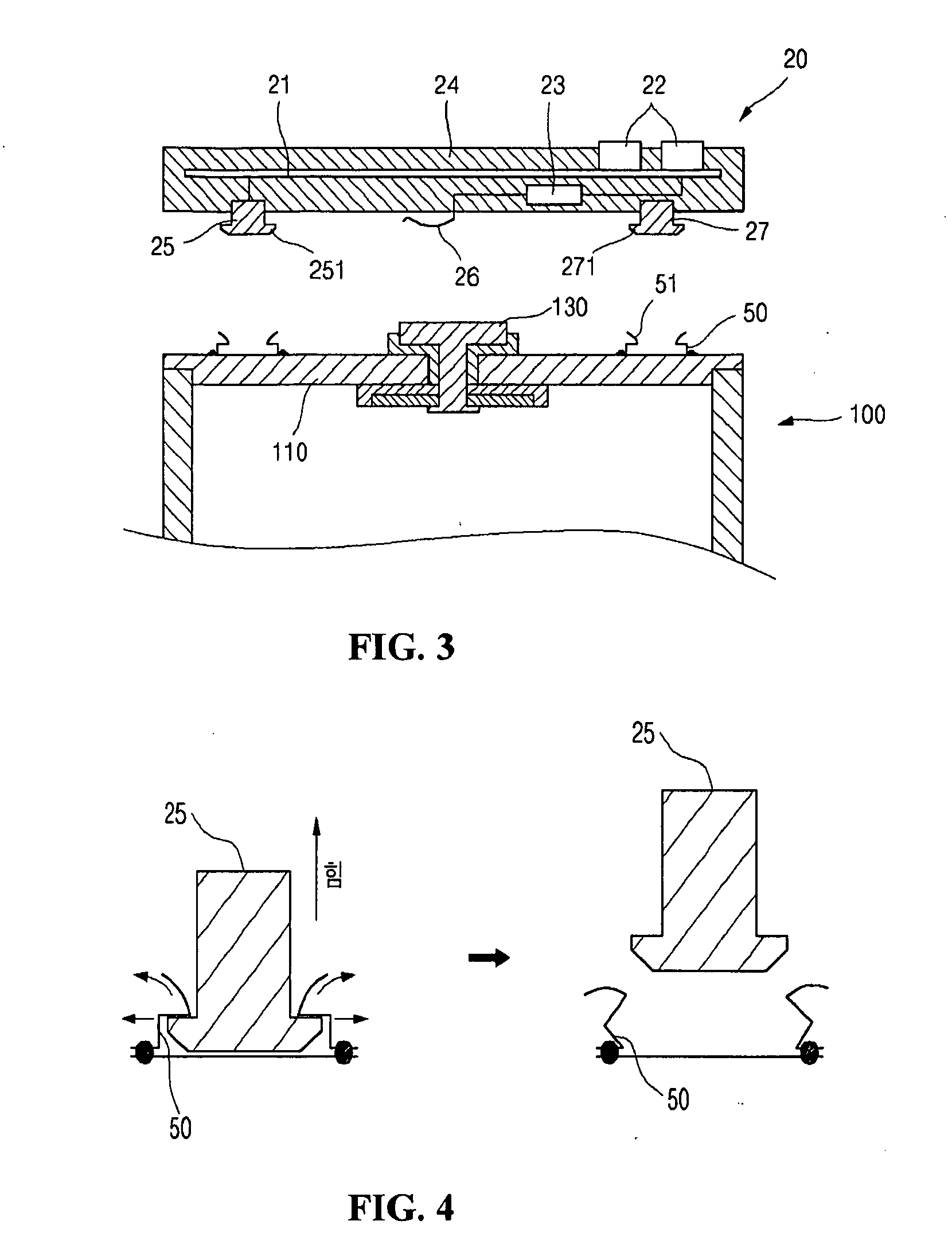

Rechargeable battery

InactiveUS20050175889A1Stable and simple mannerAvoid problemsFinal product manufacturePrimary cellsRechargeable cellMechanical bond

Disclosed is a rechargeable battery including: a bare cell composed of an electrode assembly including a negative electrode, a separator and a positive electrode, a container for housing the electrode assembly and an electrolyte, and a cap assembly for closing an opening of the container; and a safety device electrically coupled to an outer surface of the bare cell, wherein the safety device is coupled to the bare cell by being incorporated into a battery component part, and each of bonding surfaces of the bare cell and the battery component to be bonded to each other has a bonding parts capable of forming a mechanical bonding between the bare cell and the battery component. The rechargeable battery permits a safety device such as a protective circuit board and a bimetal device to be coupled to a bare cell in a stable and simple manner. Additionally, the mechanical bonding parts between the safety device and the bare cell can be separated so that the safety device such as a protective circuit board can be reused.

Owner:SAMSUNG SDI CO LTD

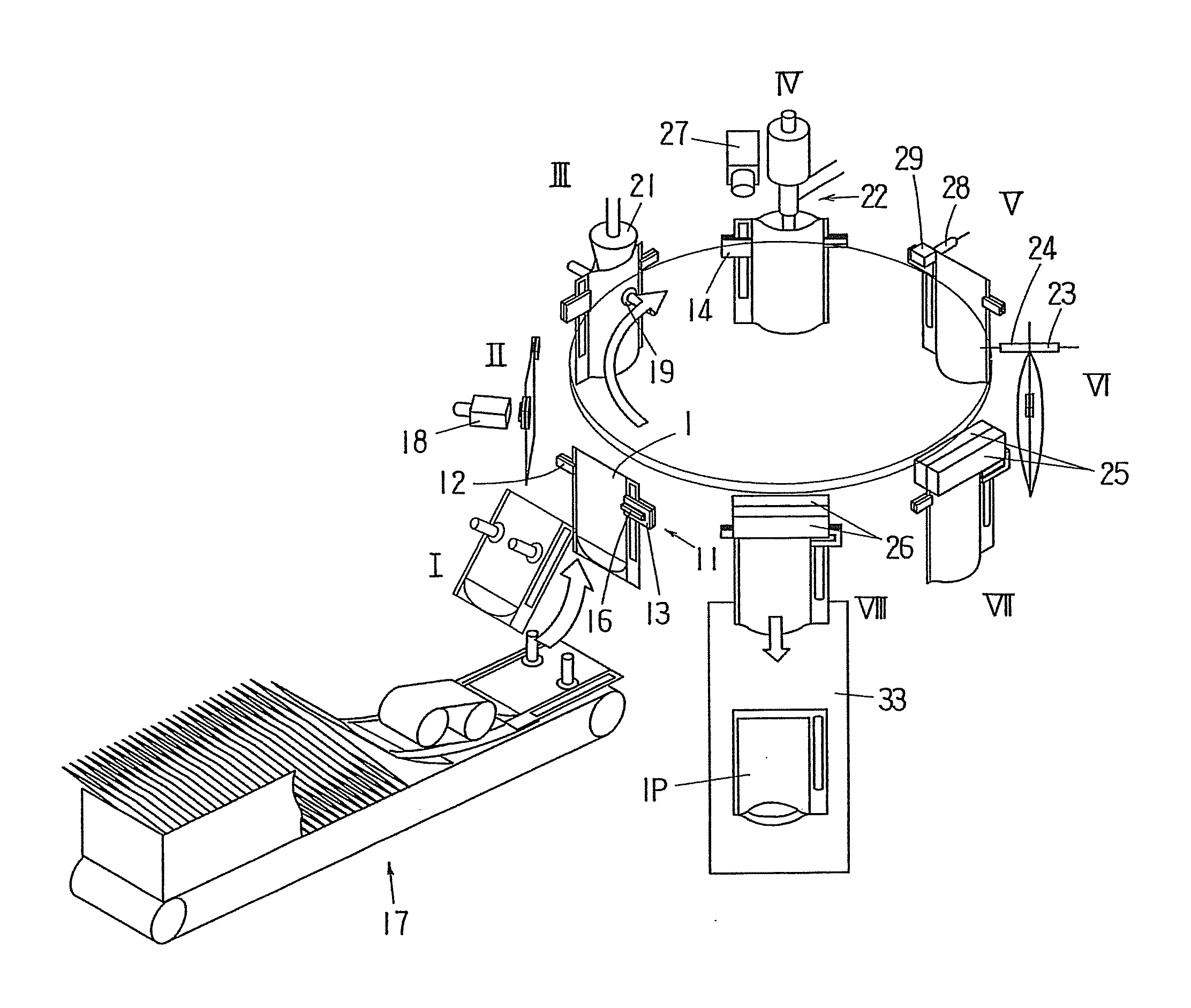

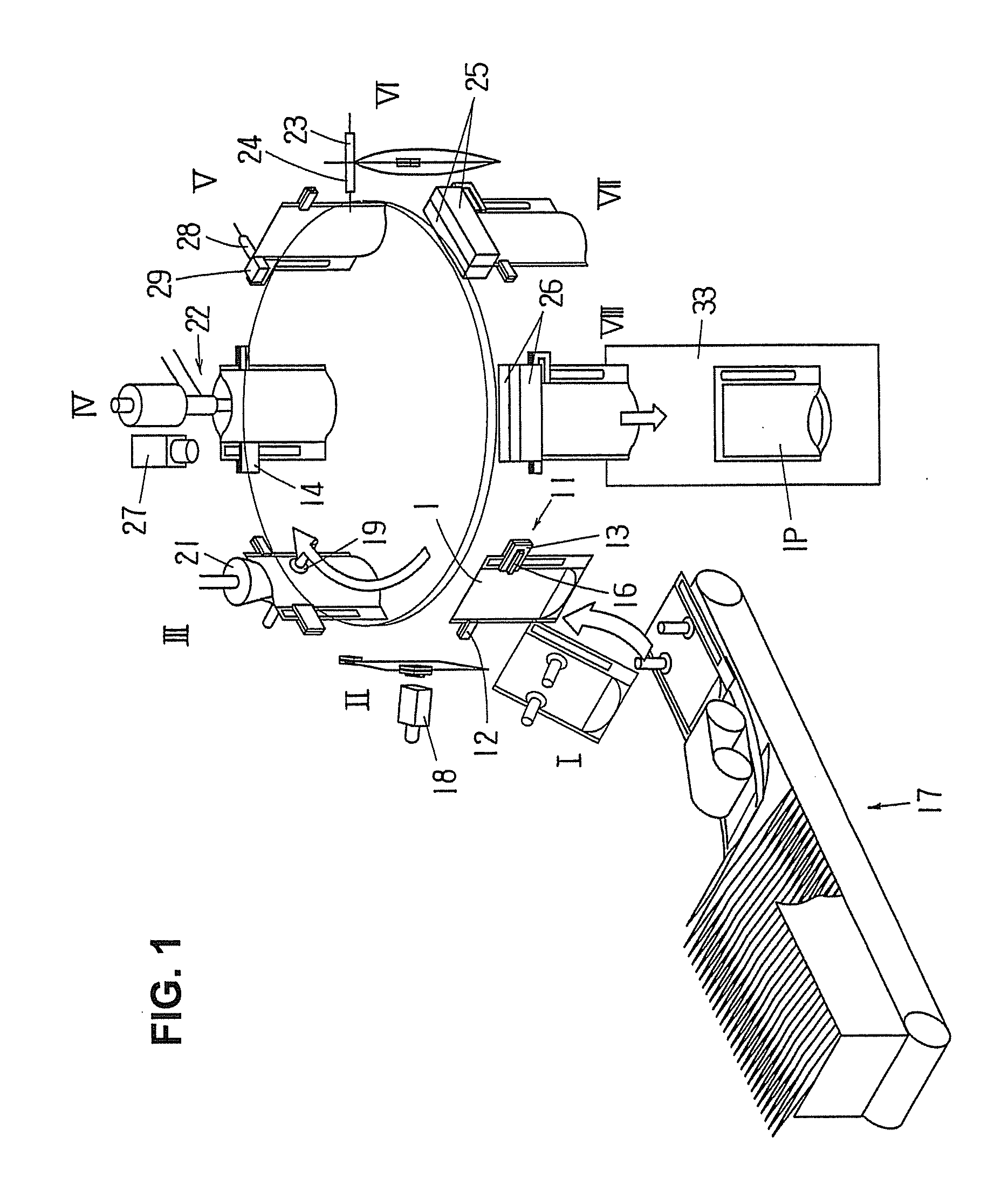

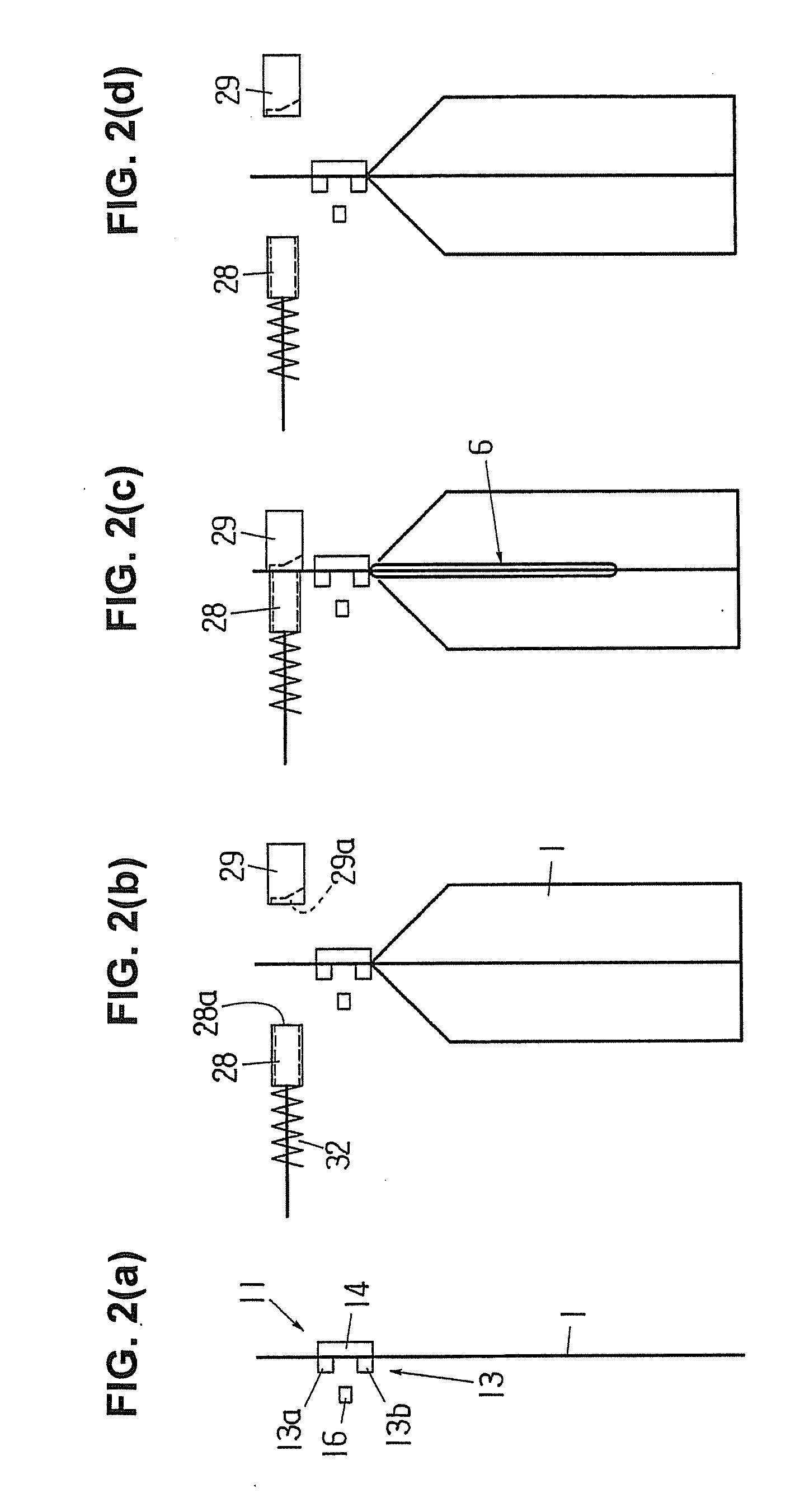

Gas Charging Method and Gas Charging Apparatus for Bag Equipped with Gas Compartment Portion

InactiveUS20140250834A1Evenly filledWithout loss of productivityCapsCap application using vaccuumEngineeringElectrical and Electronics engineering

In a method and apparatus for charging a gas into a gas compartment portion (6) of a bag (1), after a pre-heating step which is performed in stop position (IV) so that the gas compartment portion of the bag is heated by a heated gas-blowing nozzle (27), a preliminary gas injection step for injecting gas into the gas compartment portion is performed by a gas blowing nozzle (28) and a receiving member (29) in stop position (V). Then, a gas filling step is carried out in stop position (VI) by gas injection nozzles (23, 24), and the incision (9) in the gas compartment portion is sealed in stop position (VII). In the following pre-heating step, the front and rear film sheets (7, 8) of the gas compartment portion are softened, and in the preliminary gas injection step, the film sheets are separated and their adhesion is eliminated.

Owner:TOYO JIDOKI CO LTD

Ink-jet printing system for improved print quality

InactiveUS6247808B1Improve print qualityReduce bleedingMeasurement apparatus componentsDuplicating/marking methodsInkjet printingColoring agents

An ink-jet printing system is disclosed comprising a set of ink-jet inks comprising a first anionic ink comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic ink comprising an aqueous vehicle; at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first ink; a third cationic ink comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic ink comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. The printing system provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

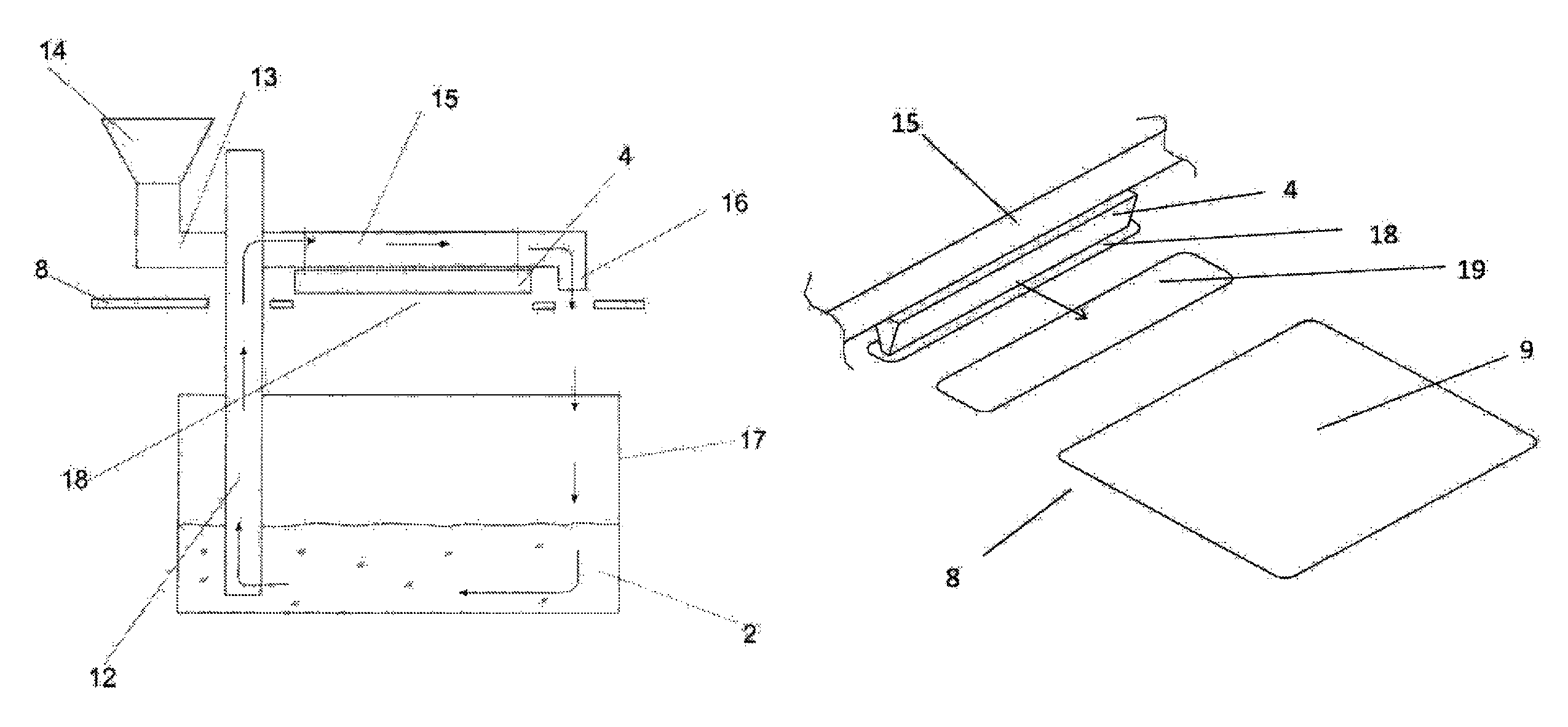

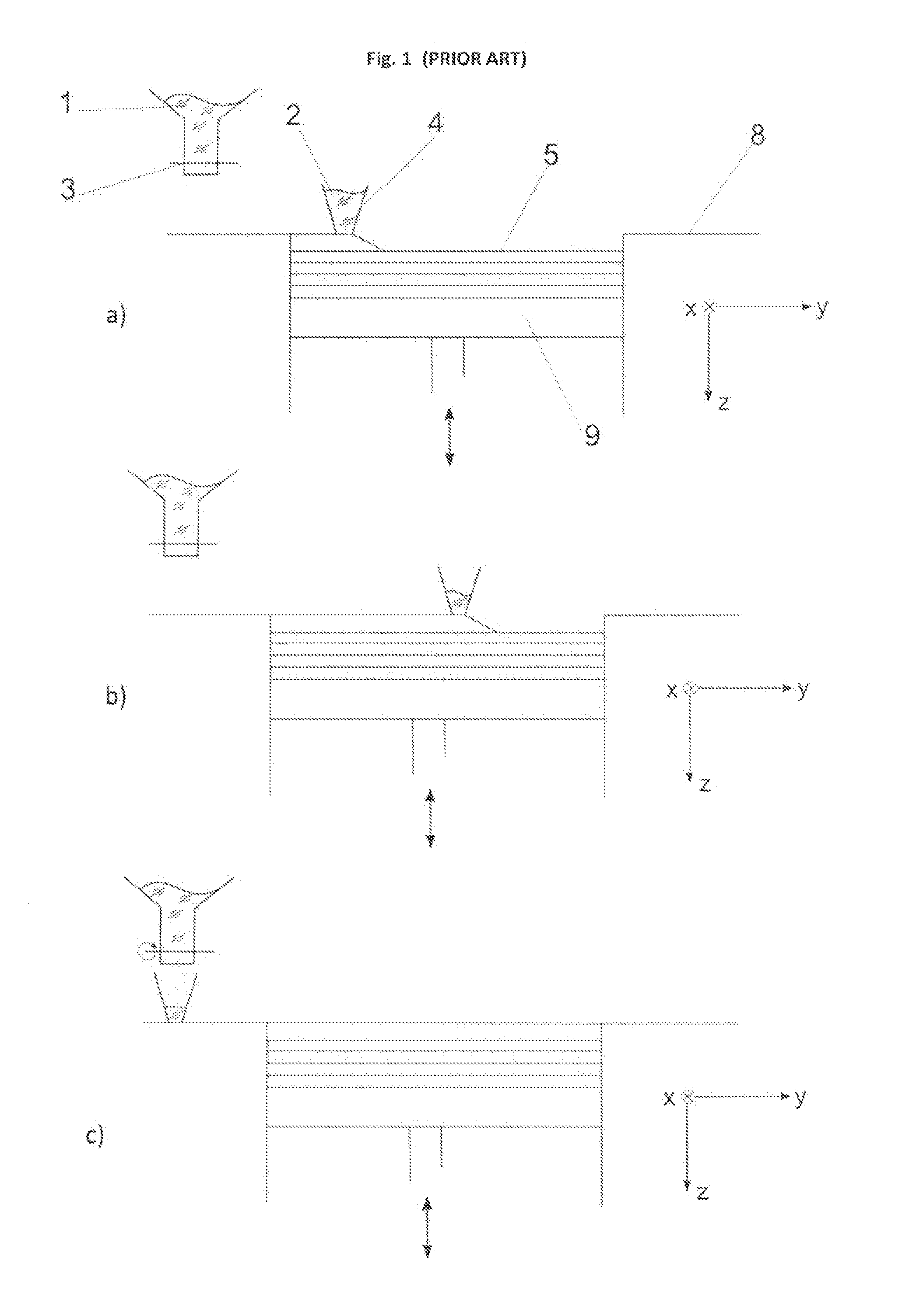

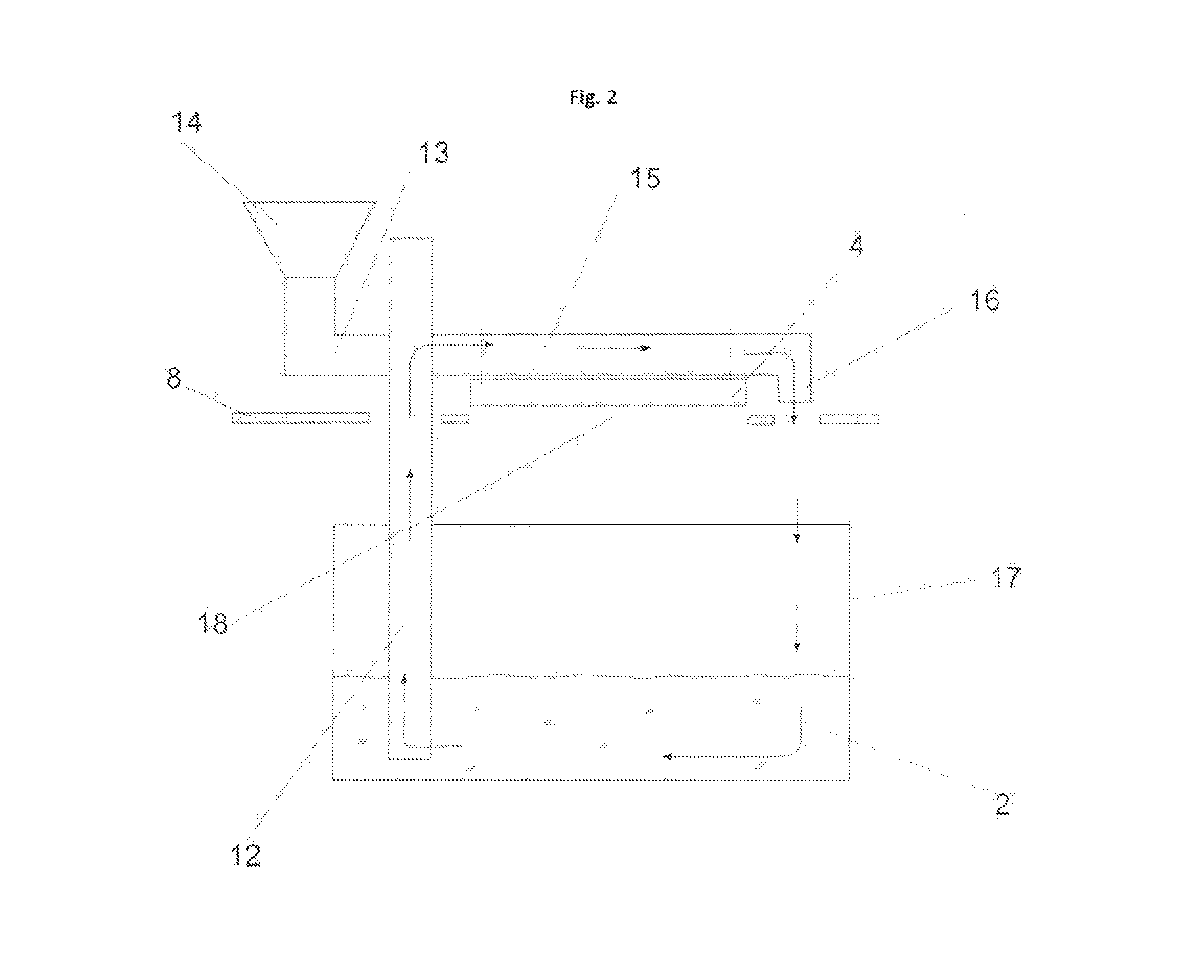

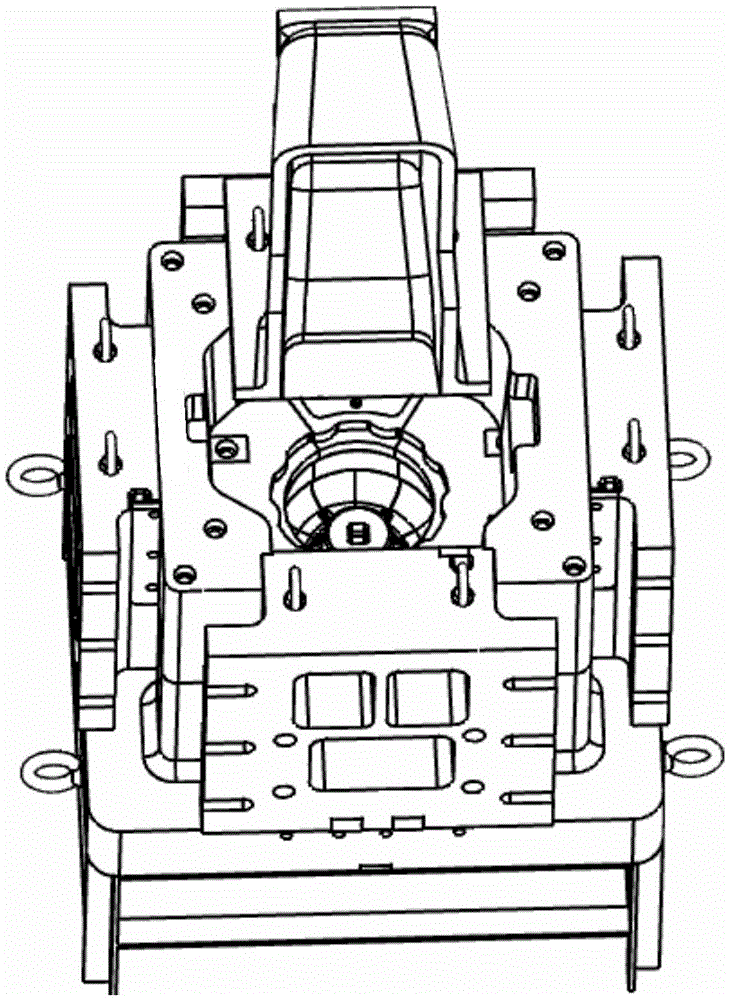

Method and device for conveying particulate material during the layer-wise production of patterns

ActiveUS8727672B2Evenly filledLiquid surface applicatorsAdditive manufacturing apparatusEngineeringMechanical engineering

Owner:VOXELJET AG

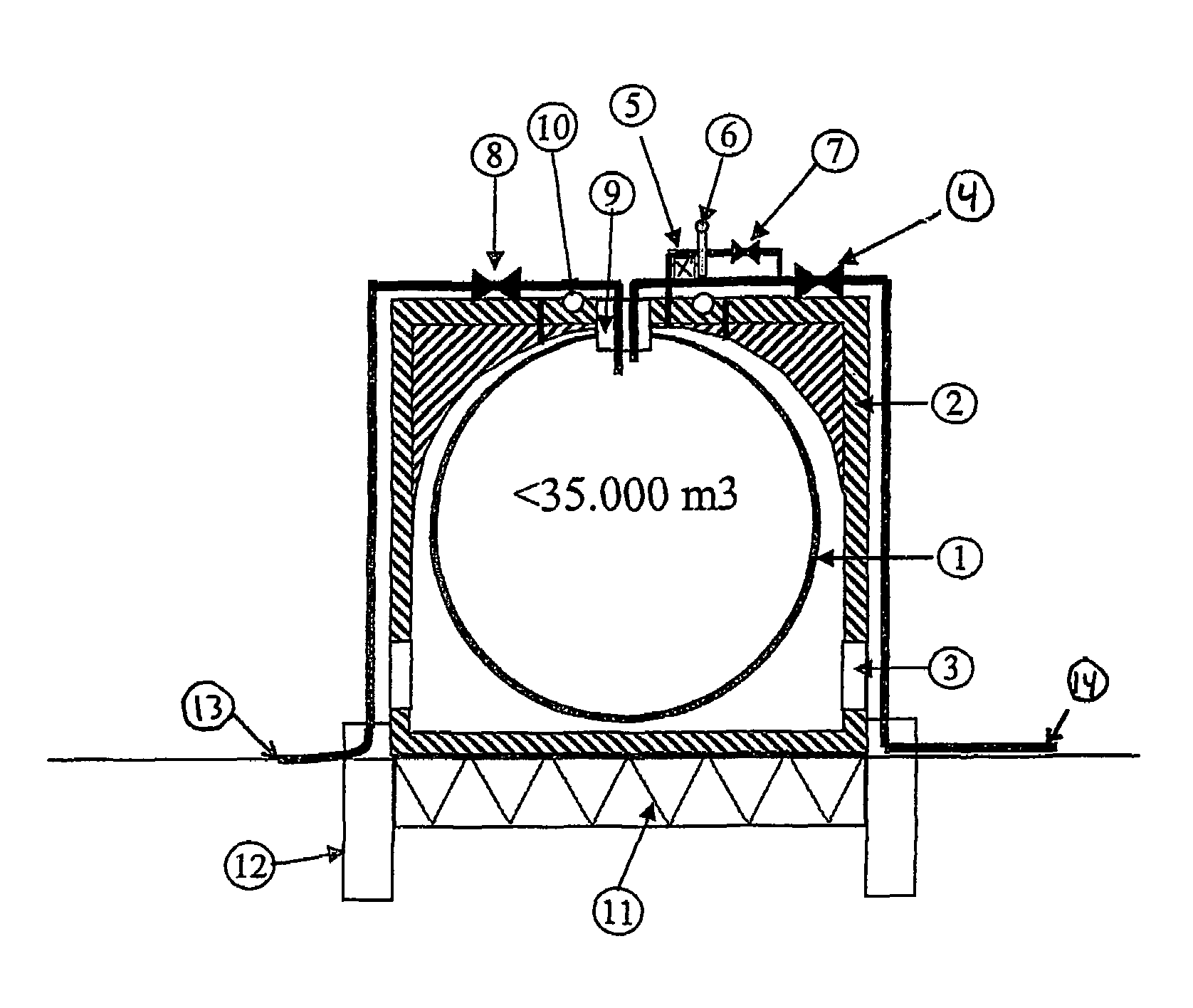

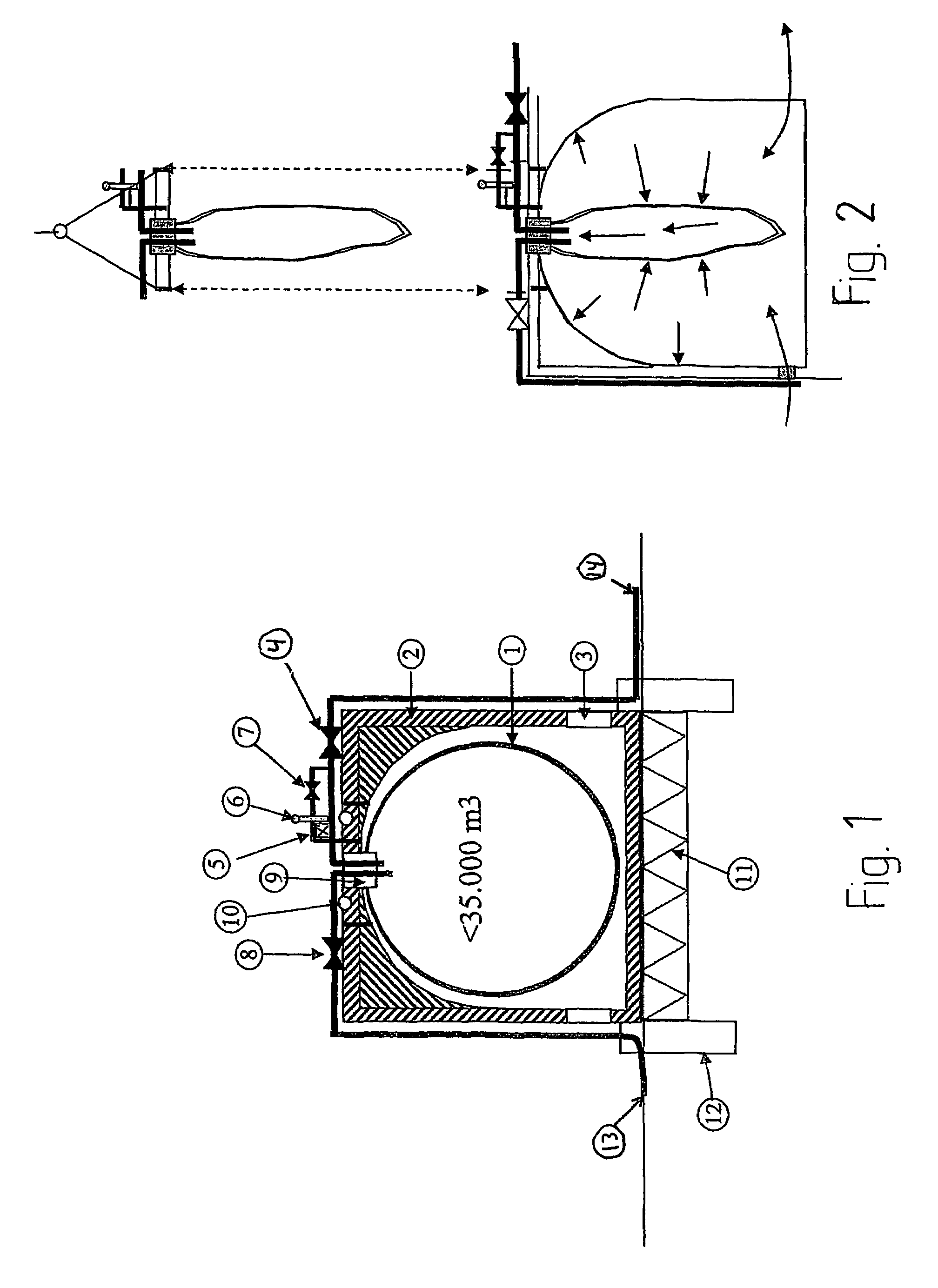

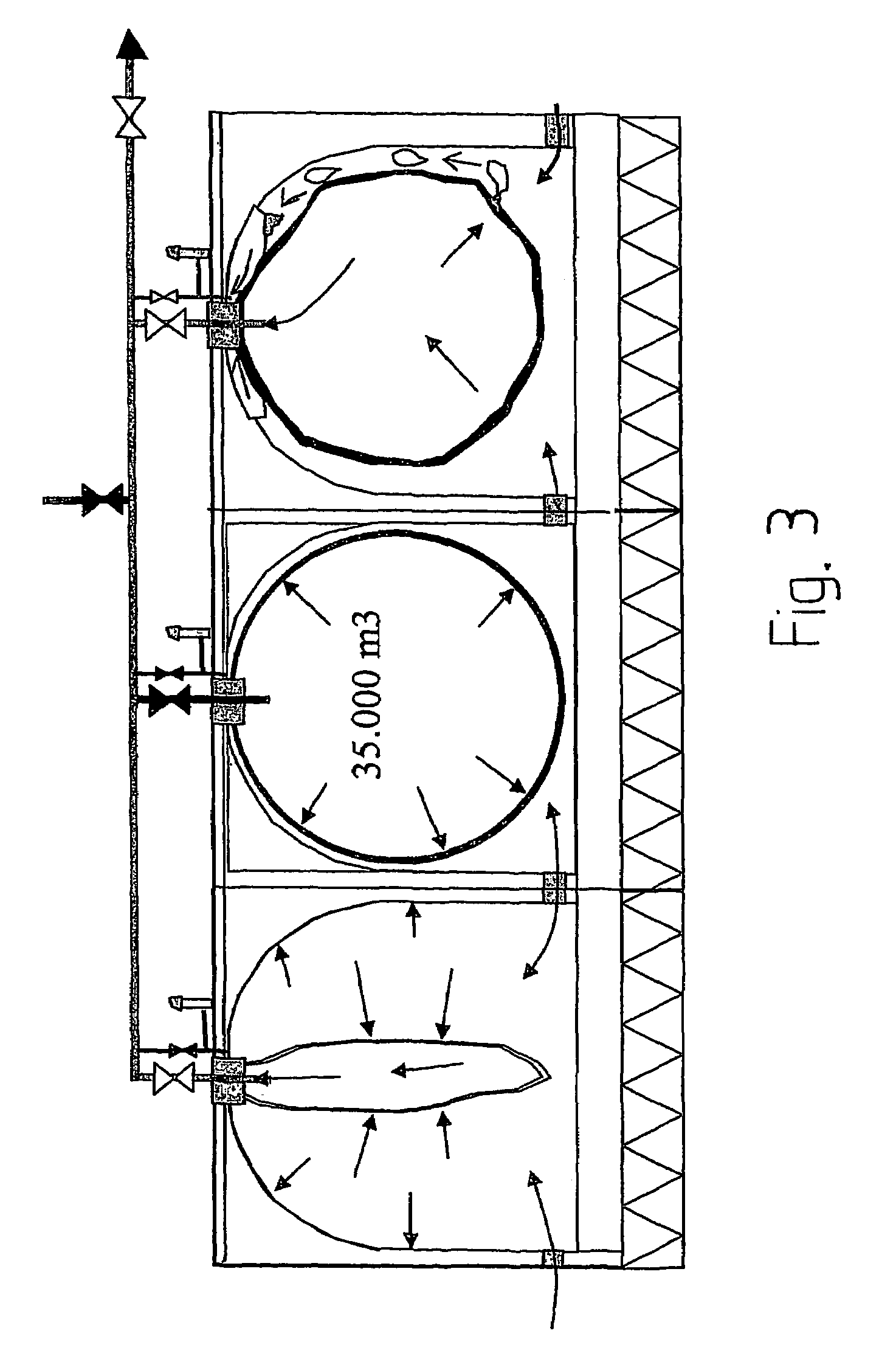

Seabed located storage

Seabed located storage for crude oil or other fluid, distinguished in that it is comprising a storage section in form of an oil and waterproof cloth formed as a flexible balloon that can be filled with, store and emptied for a storage fluid, a structure section formed as an external casing over the storage section, which structure section is closed in the upper part such that an upward close volume of size at least corresponding to the volume of the storage section is formed, but with openings to the surroundings in the lower part, an anchoring section formed as a substructure between the structure section and the seabed, with means for anchoring to or stable placement on the seabed, and a transfer section comprising pipes and valves for loading and unloading of a storage fluid, arranged in substance exterior to the upper part of the storage.

Owner:NOV PROCESS & FLOW TECH AS

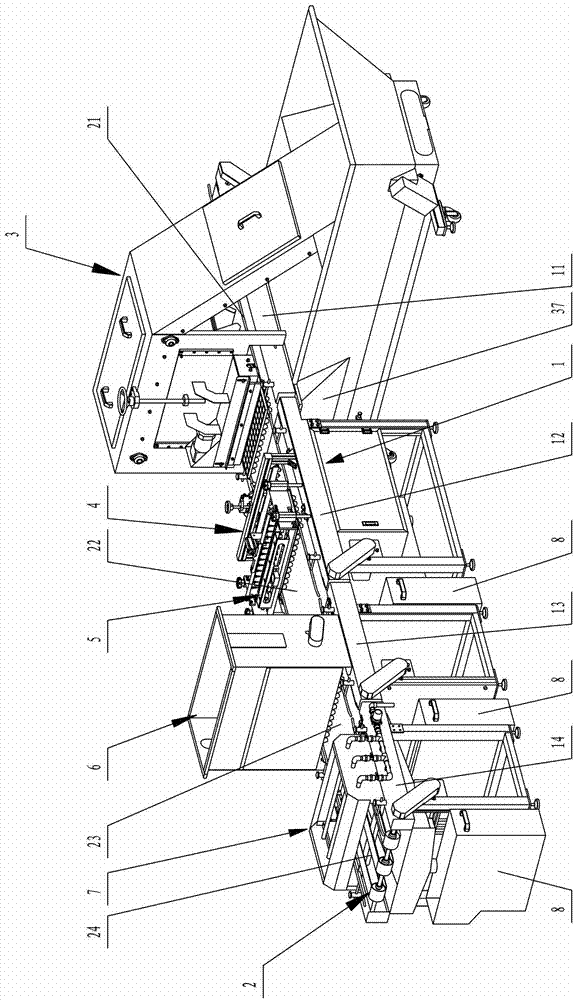

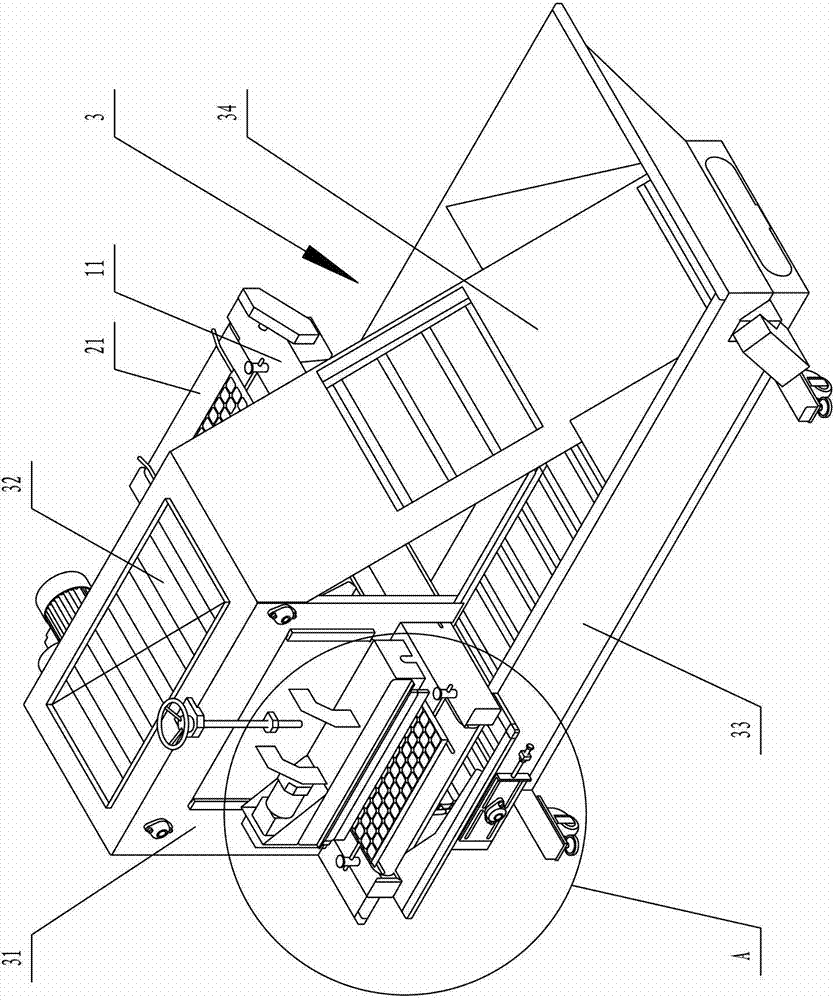

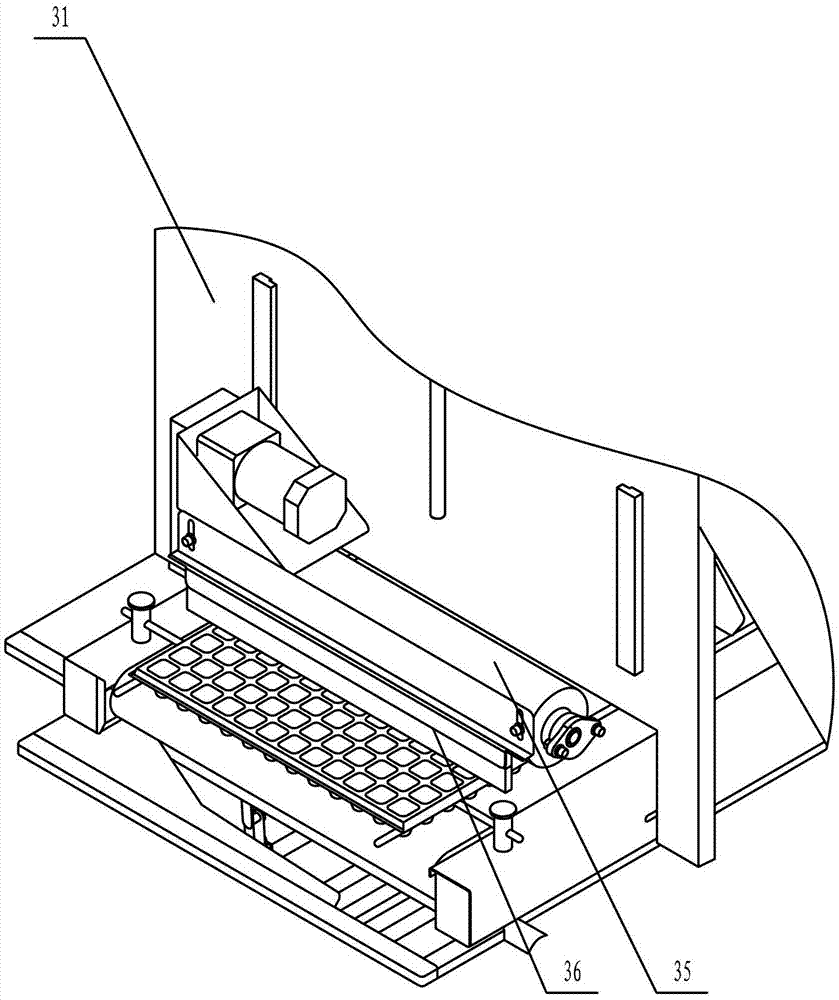

Seedling and seeding machine and seedling and seeding method

ActiveCN102960101AImprove work efficiencyRealize automatic controlCultivating equipmentsSeed depositing seeder partsProduction linePunching

The invention provides a seedling and seeding machine. The seedling and seeding machine comprises a rack, and a conveying device at the top of the rack, wherein a subsoil filling device, a punching device, a needle type tray seeding device, a soil covering device and a watering device are sequentially arranged on the conveying device along the conveying direction of the conveying device. According to the seedling and seeding machine provided by the invention, the subsoil filling device, the punching device, the needle type tray seeding device, the soil covering device and the watering device which are sequentially arranged on the conveying device are used for conveying trays, filling the subsoil, punching, seeding, filling trays and covering the soil, and watering, so that the whole work of seedling and seeding can be carried out on one production line, and as a result, the working efficiency in seedling and seeding can be effectively improved. The invention also provides a seedling and seeding method. The seedling and seeding method comprises the following steps in sequence: conveying trays, filling the subsoil, punching, seeding, filling trays and covering the soil, and watering; and by adopting the method, the working efficiency in seedling and seeding can be effectively improved.

Owner:四川川龙拖拉机制造有限公司

Visible casting method

ActiveCN1631579AGood casting processAvoid entrainmentCasting safety devicesMaterial analysis by transmitting radiationSystems designX-ray

Owner:中科西王特钢有限公司

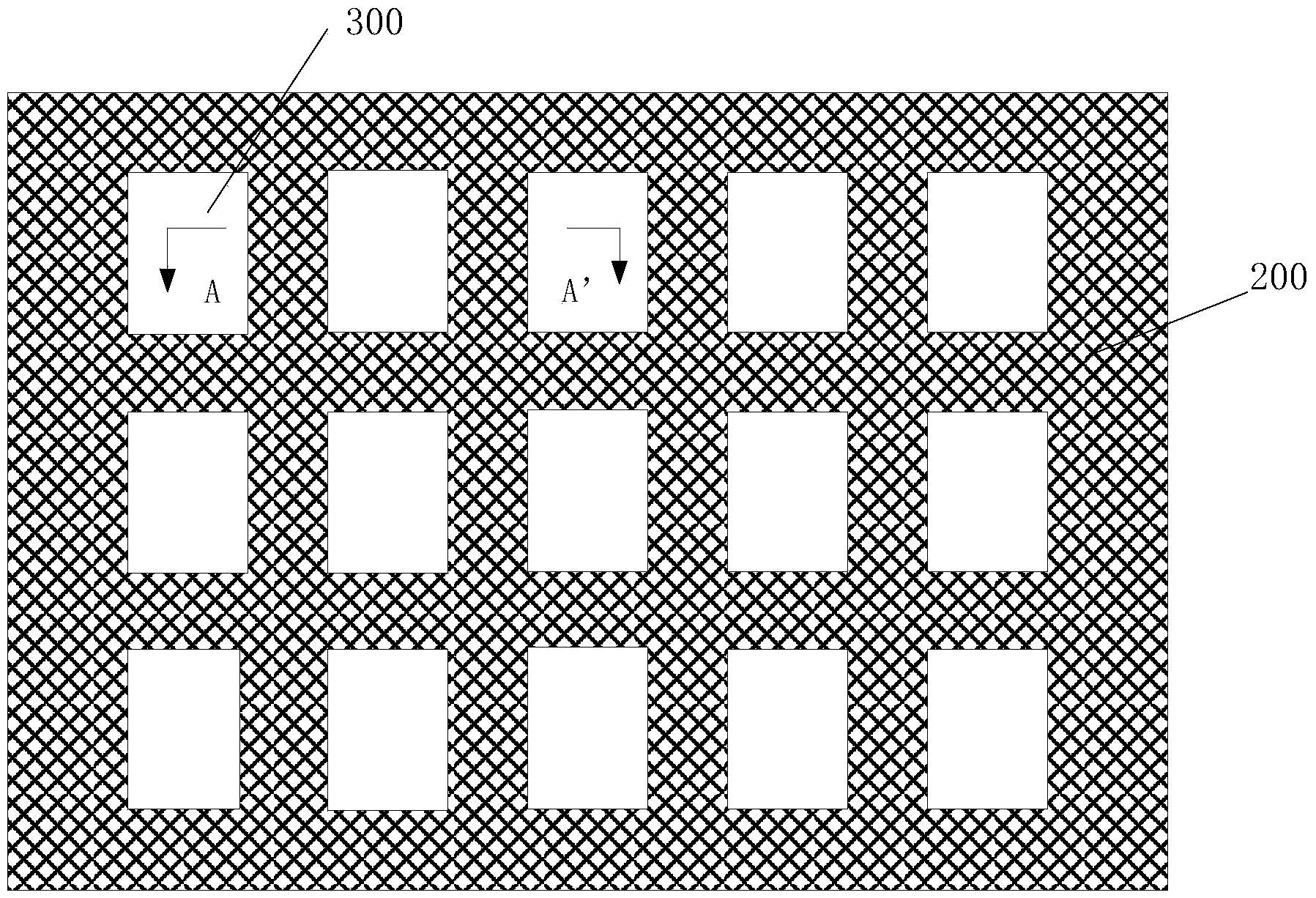

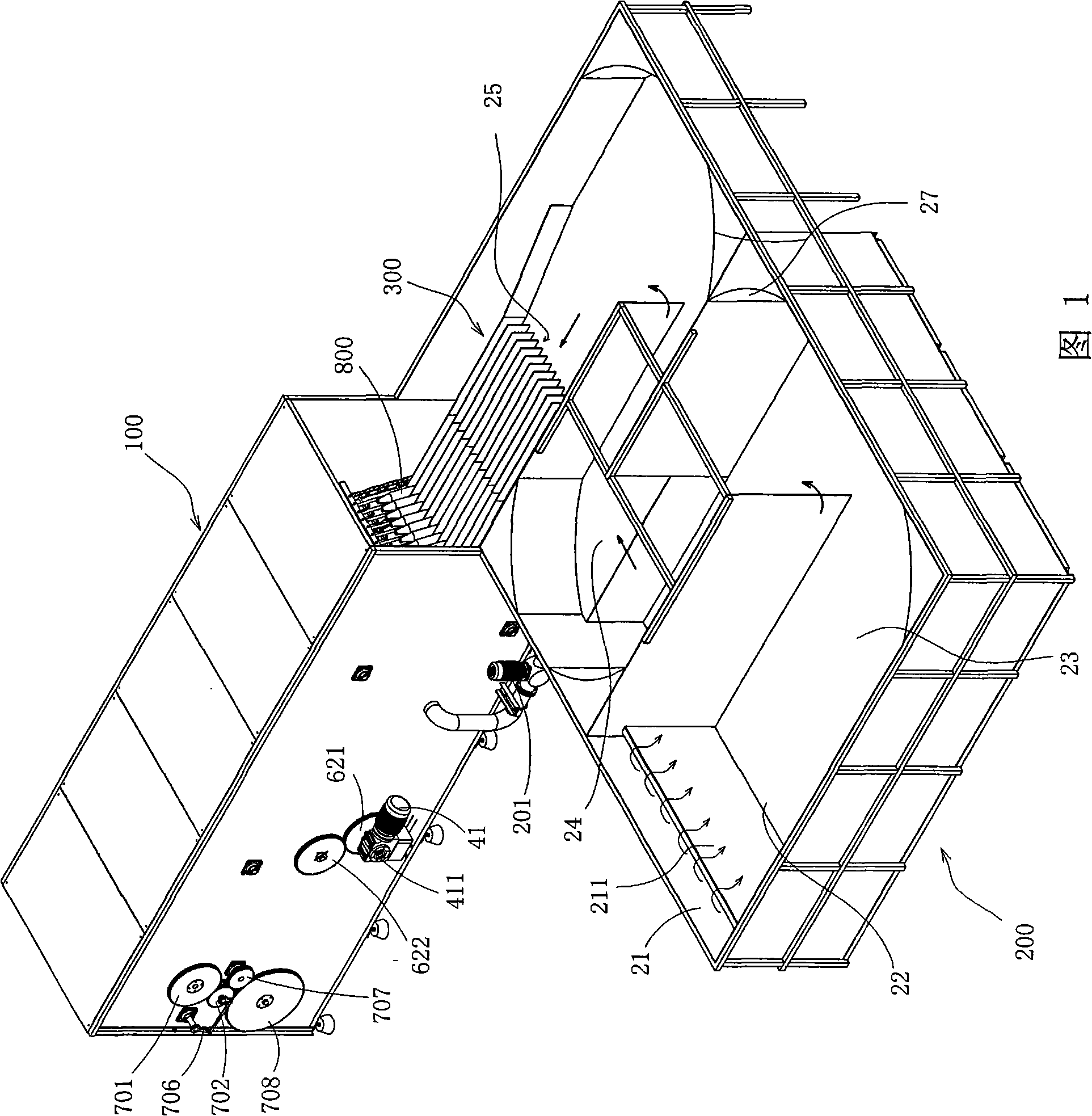

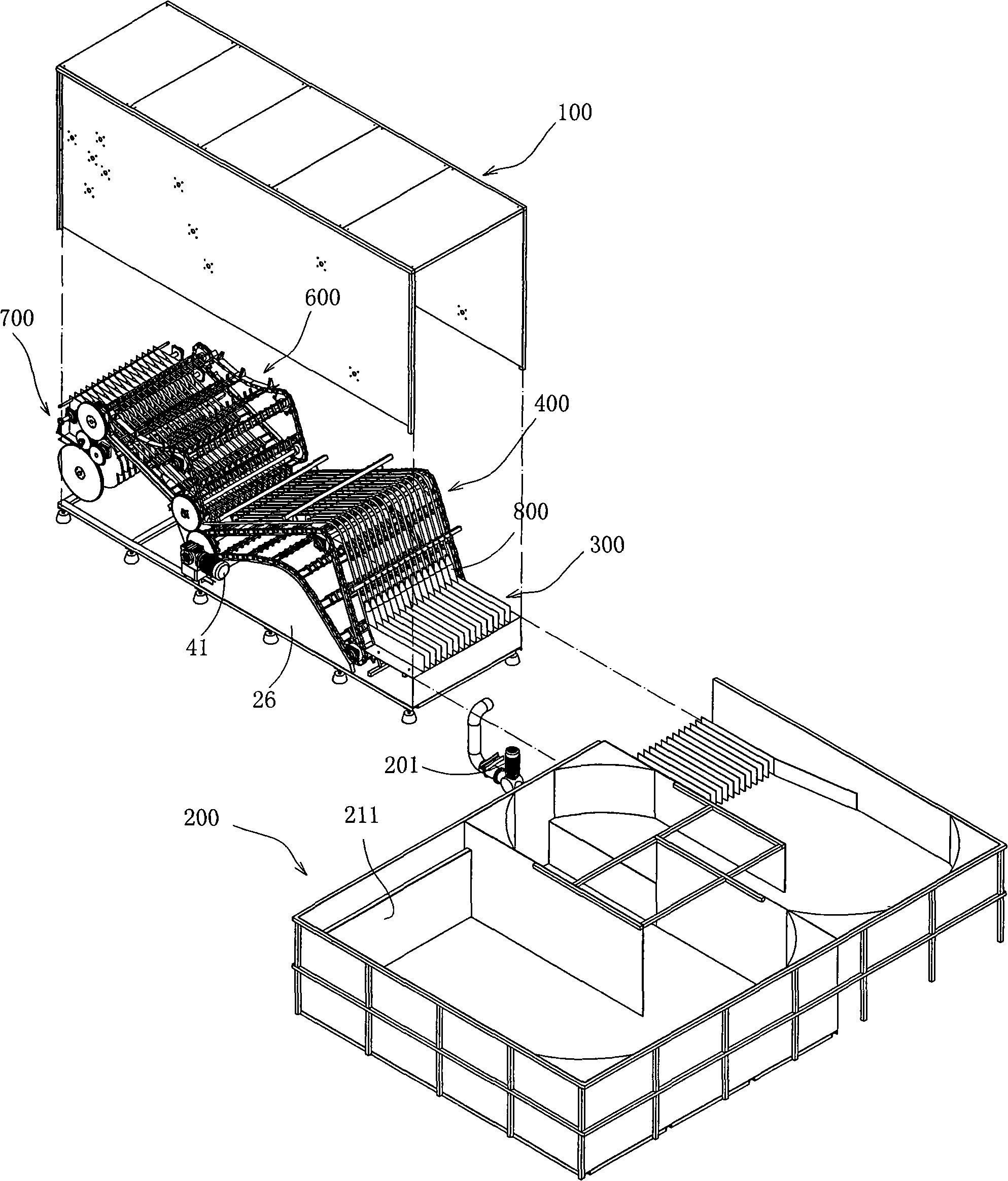

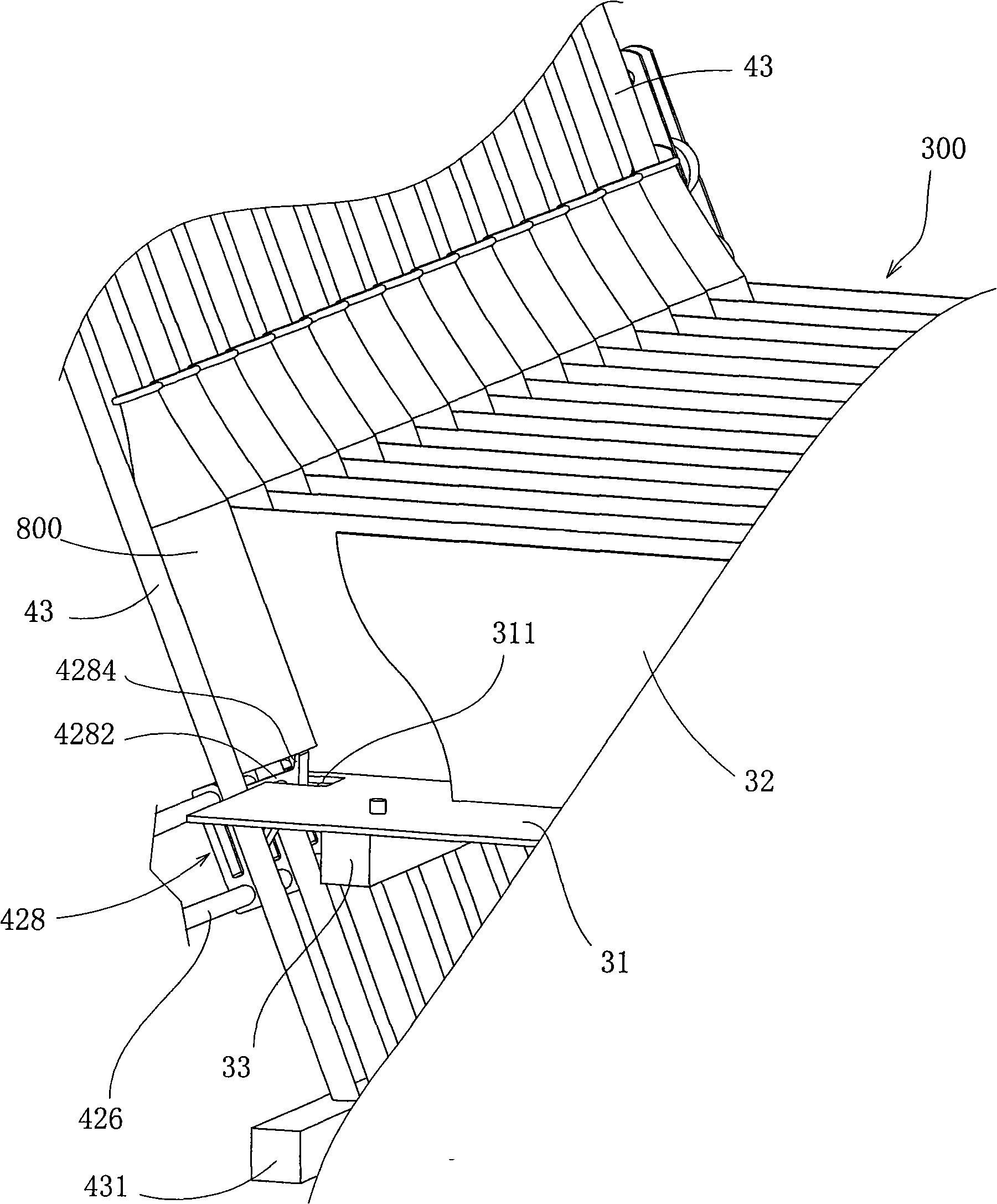

Unscrambling method and unscrambler utilizing the unscrambling method

InactiveCN101284597ASmooth floating motionReduce sinkingLiquid bottlingConveyor partsLiquid cellEngineering

The invention discloses a bottle arranging method and a bottle arranging machine thereof; a pump (201) is used for pumping liquid at the tail part of a liquid cell (200), a conveying pipe is used for conveying the liquid to the front end of the liquid cell for forming circular flowing stable liquid flow in the liquid cell; open-ended glass bottles (800) to be arranged are randomly arranged in theliquid cell; after the glass bottles are poured with certain amount of liquid, bottle openings automatically face up and lead the bottles to float on the liquid, the bottles are carried by the liquidflow to a track lane mechanism (300) and automatically array orderly into a plurality of lines; a bottle raising mechanism (400) raises the bottles from the front end of the track lane mechanism lineby line and carries the bottles to a liquid poring mechanism; the liquid in the bottle is poured out; the glass bottles are reversed to enable the bottle opening to turn vertically or obliquely upwards and vertically fall on a transitional board so as to be linked up with the next working procedure. As stable liquid flow is adopted, the glass bottles can stably float and the liquid pouring is more stable, thus better ensuring the bottle openings to vertically turn upward and float, reducing sinking, avoiding disordered collision of the glass bottles as well as reducing damage; moreover, the labor intensity and the cost are greatly reduced and the efficiency is improved.

Owner:杨晖伟

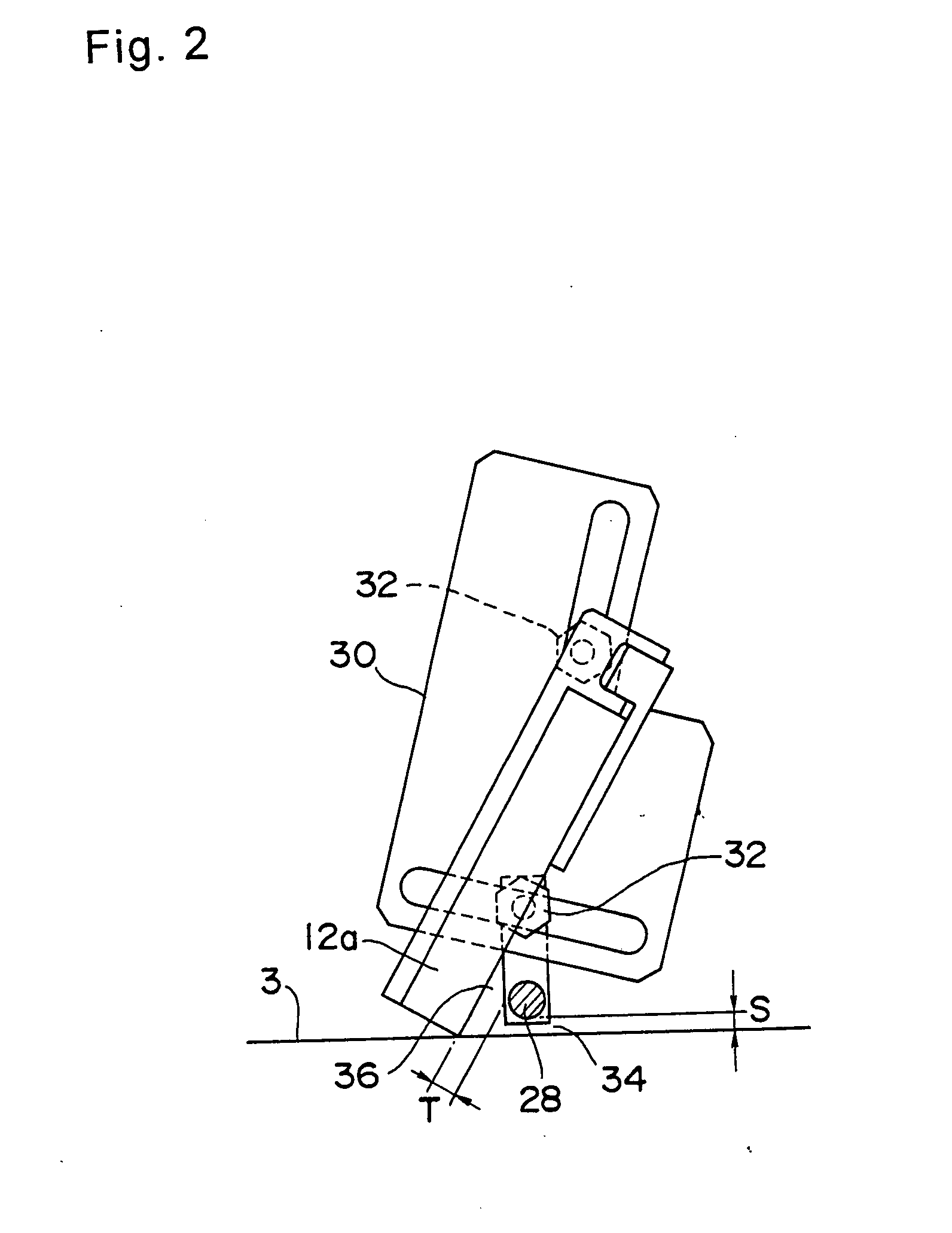

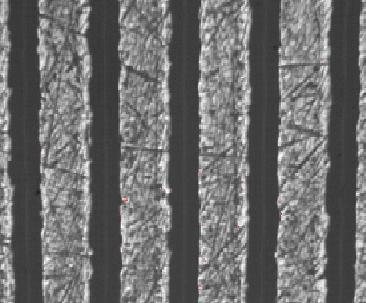

Solder paste printing apparatus and printing method

InactiveUS20040035306A1TakingReduce printing timeMechanical cleaningInking apparatusEngineeringPrinting ink

When solder paste passes through a first gap (34) located between a pressurizing member (28) and a printing mask (3) during solder paste printing, a pressure directed toward the printing mask is applied from the pressurizing member to the solder paste.

Owner:PANASONIC CORP

Solder past printing apparatus and printing method

InactiveUS20040108368A1Evenly filledTakingLiquid surface applicatorsScreen printersEngineeringSolder paste

When solder paste passes through a first gap (34) located between a pressurizing member (28) and a printing mask (3) during solder paste printing, a pressure directed toward the printing mask is applied from the pressurizing member to the solder paste.

Owner:PANASONIC CORP

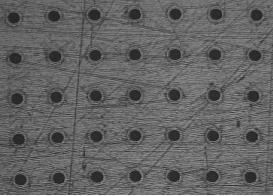

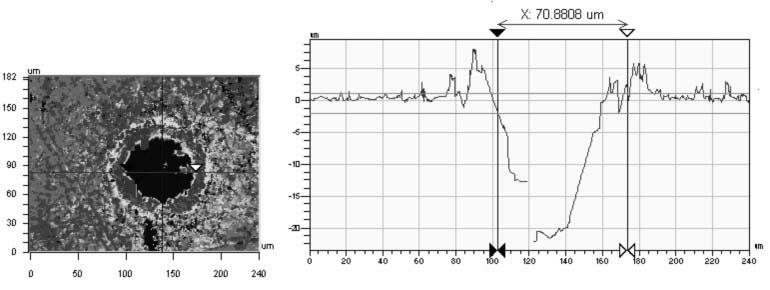

Micro-embedded self-lubricating texture on surfaces of gear and cam and preparation method thereof

InactiveCN102628544AImprove adaptabilityImprove lubrication and anti-wear performancePortable liftingBase-materialsLaser processingHexagonal boron nitride

The invention discloses a micro-embedded self-lubricating texture on the surfaces of a gear and a cam and a preparation method thereof. The preparation method comprises the following steps of: performing micro texture processing on the surfaces of the gear and the cam by an Nd: YAG laser processing technology; and embedding a solid lubricant into the micro texture on the surfaces of the gear and the cam by a molding bonding technology of a self-lubricating composite material. The self-lubricating composite material comprises the following formula components in percentage by mass: 15 to 85 percent of polyimide (PI), 0 to 85 percent of polytetrafluoroethylene (PTFE), 10 to 40 percent of MoS2, 0 to 15 percent of WS2, 0 to 16 percent of graphite fluoride, 5 to 15 percent of graphite, 0 to 12 percent of PbO, 0 to 6 percent of antimony trioxide, 0 to 10 percent of CaF2 or BaF2, 0 to 15 percent of hexagonal boron nitride, 0 to 15 percent of nano lubricant and 0 to 5 percent of additive. According to the micro-embedded self-lubricating texture, the self-lubricating texture is subjected to micro embedding on the surfaces of the gear and the cam to ensure that the solid lubricant on the friction surface is stably supplied and uniformly coated, so that the lubrication and anti-wear properties of friction pairs such as the gear and the cam under complicated and harsh operating conditions are improved.

Owner:JIANGSU UNIV

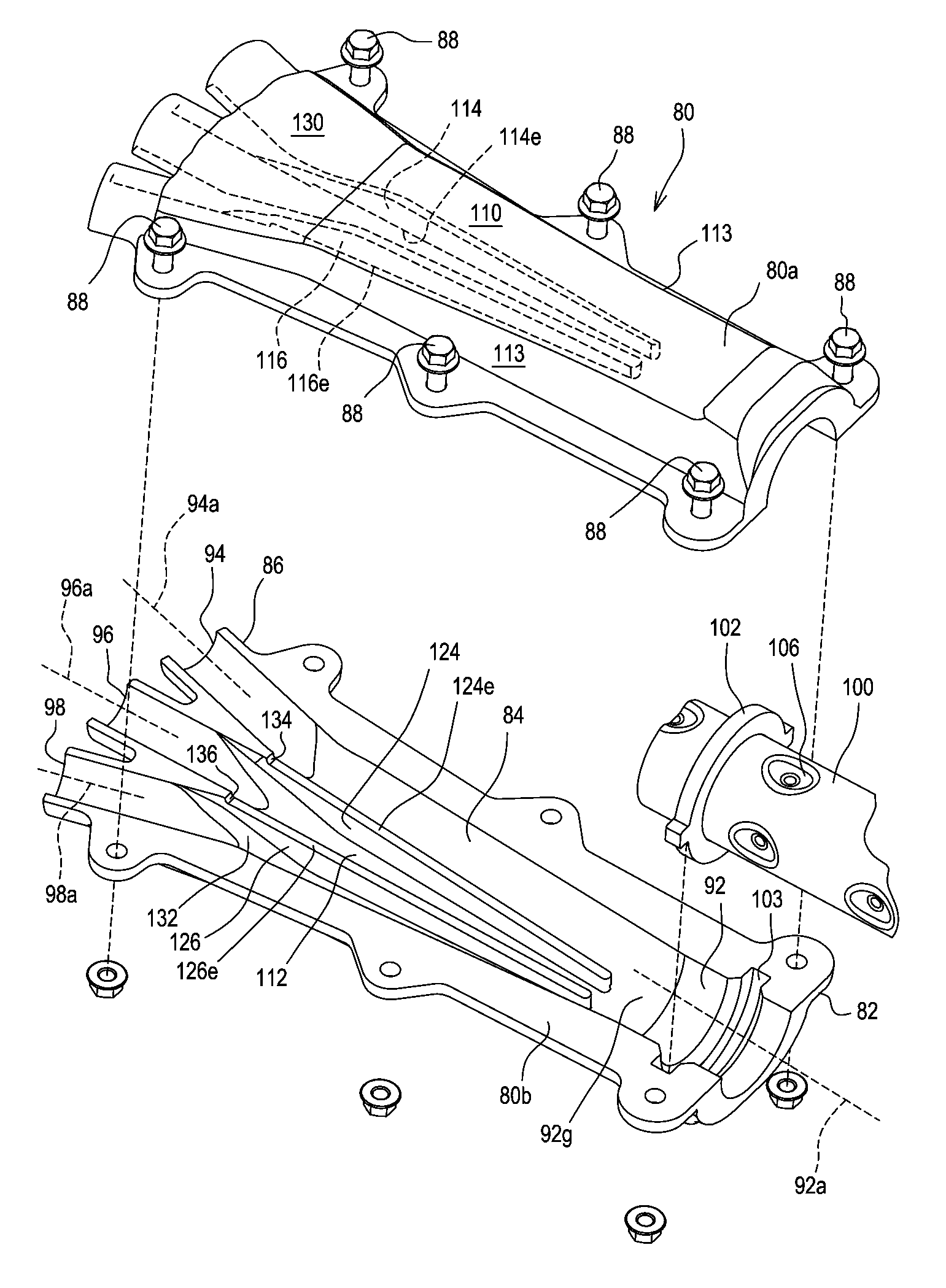

Commodity Splitter for an Air Delivery System

ActiveUS20110311322A1Streamline in appearanceEasily mountSowingPotato plantersAirflowPressure balance

Owner:DEERE & CO

Method for preparing low temperature solder sheets

ActiveCN107486651AImprove uniformityHigh strengthWelding/cutting media/materialsSoldering mediaLiquid stateMixed states

The invention discloses a method for preparing low temperature solder sheets. The method comprises the following steps: firstly, carrying out chemical cleaning on stains and oxide films on the surface of a foam metal skeleton; filling metal foam with low-melting point solder in an infiltration way; and finally heating the metal foam filled with the low-melting point solder to a solid-liquid mixed state and rolling to obtain composite sheets with certain thicknesses. According to the method disclosed by the invention; the foam metal-reinforced solder is rolled in the solid-liquid mixed state, so that the problems that the foam metal skeleton is stretched to form a thin strip-type fiber structure and is fractured during normal temperature rolling are effectively solved; meanwhile, during rolling in the solid-liquid mixed state, low-melting point metal which is in a liquid state is good in fluidity and can be uniformly filled in the foam metal skeleton, so that the mass percentage of the foam metal skeleton can be increased, the porosity of the foam metal is reduced and the uniformity and the strength of the foam metal-reinforced low melting point solder are increased.

Owner:CHINA NAT ELECTRIC APP RES INST

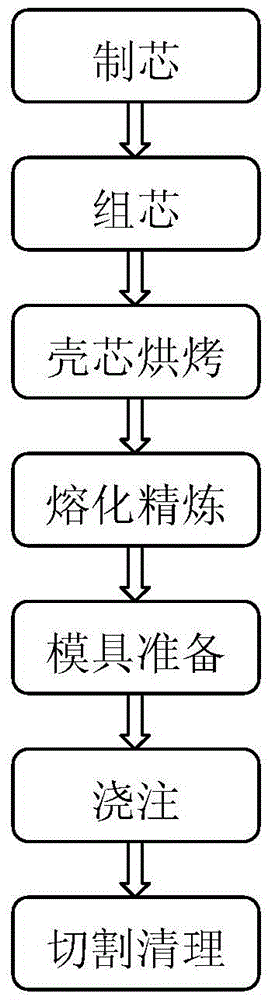

Casting method of turbine housing

ActiveCN105458182AIncrease productivityEffective control of solidification sequenceFoundry mouldsFoundry coresSlagTurbine

The invention provides a casting method of a turbine housing. The casting method includes the following steps of firstly, core manufacturing, secondly, core assembly, thirdly, shell core baking, fourthly, smelting and refining, fifthly, mold preparation, sixthly, casting and seventhly cutting and cleaning. In the core manufacturing process, a riser sand core mold is arranged on a core shooting machine, the core shooting machine is powered on to heat the mold, a layer of precoated sand is cured on a cavity of the riser sand core mold, and a riser sand core is obtained after mold opening. In the core assembly process, the riser sand core and a turbine housing core are assembled and bonded. In the shell core baking process, shell cores painted with coatings are put into a baking kiln. In the smelting and refining process, raw materials are added to a melting and heat preservation furnace, and the melting and heat preservation furnace is powered on for melting. In the casting process, the shell cores are put in a mold, and tilt casting is conducted after mold combination. In the cutting and cleaning process, a casting is cut, the riser is cast, and burrs and fins of the casting are ground and cleaned. The metal tilt casting method of an aluminum alloy turbine housing body can solves the problems of shrinkage porosities and cavities and slag holes in a big flange face of the aluminum alloy turbine housing; open risers and blind risers are arranged, in combination with the riser sand core, an ideal temperature field is formed after the casting is cast, and solidification can be conducted from the casting to the risers in sequence.

Owner:XIAN AERO ENGINE CONTROLS

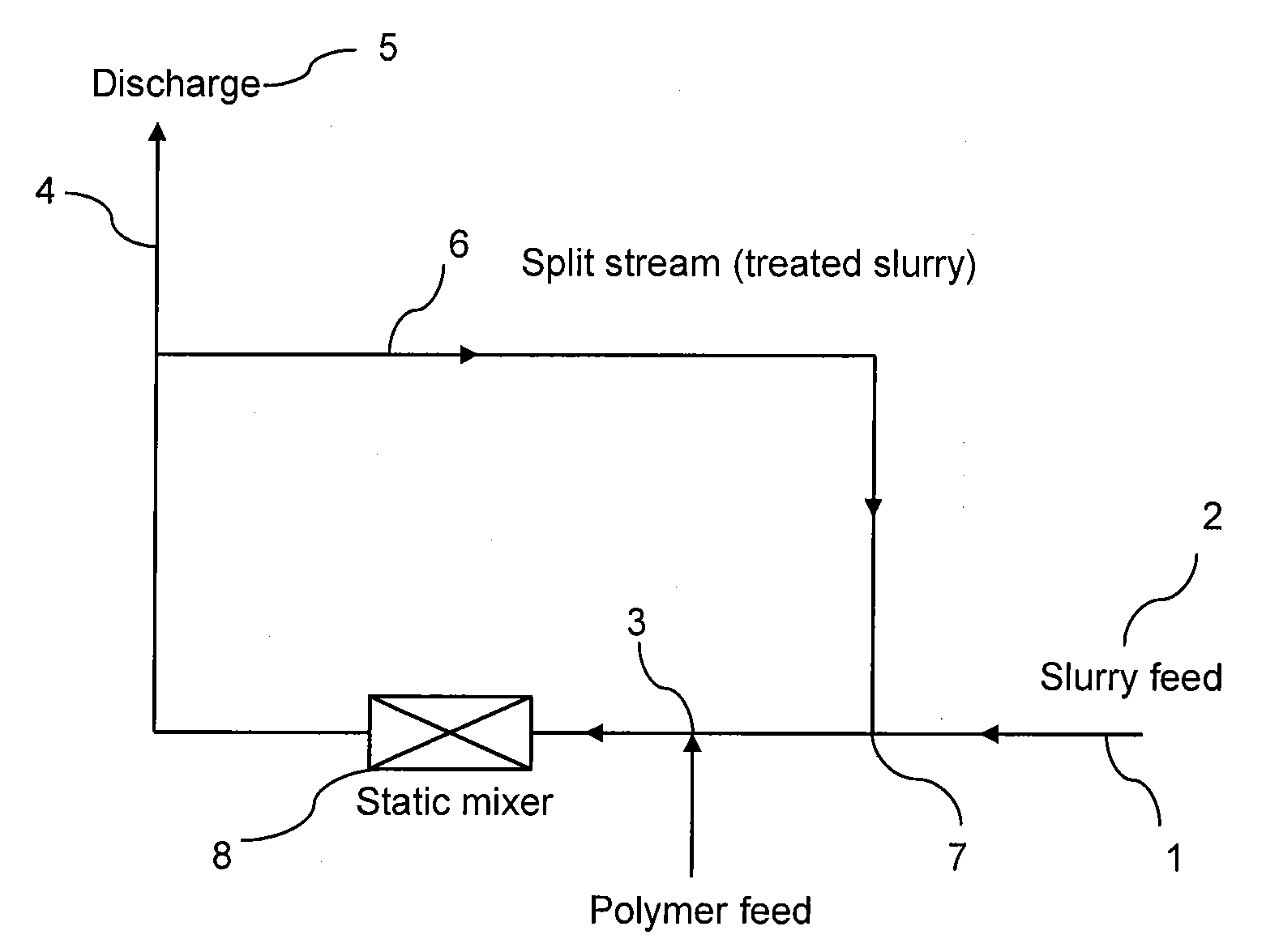

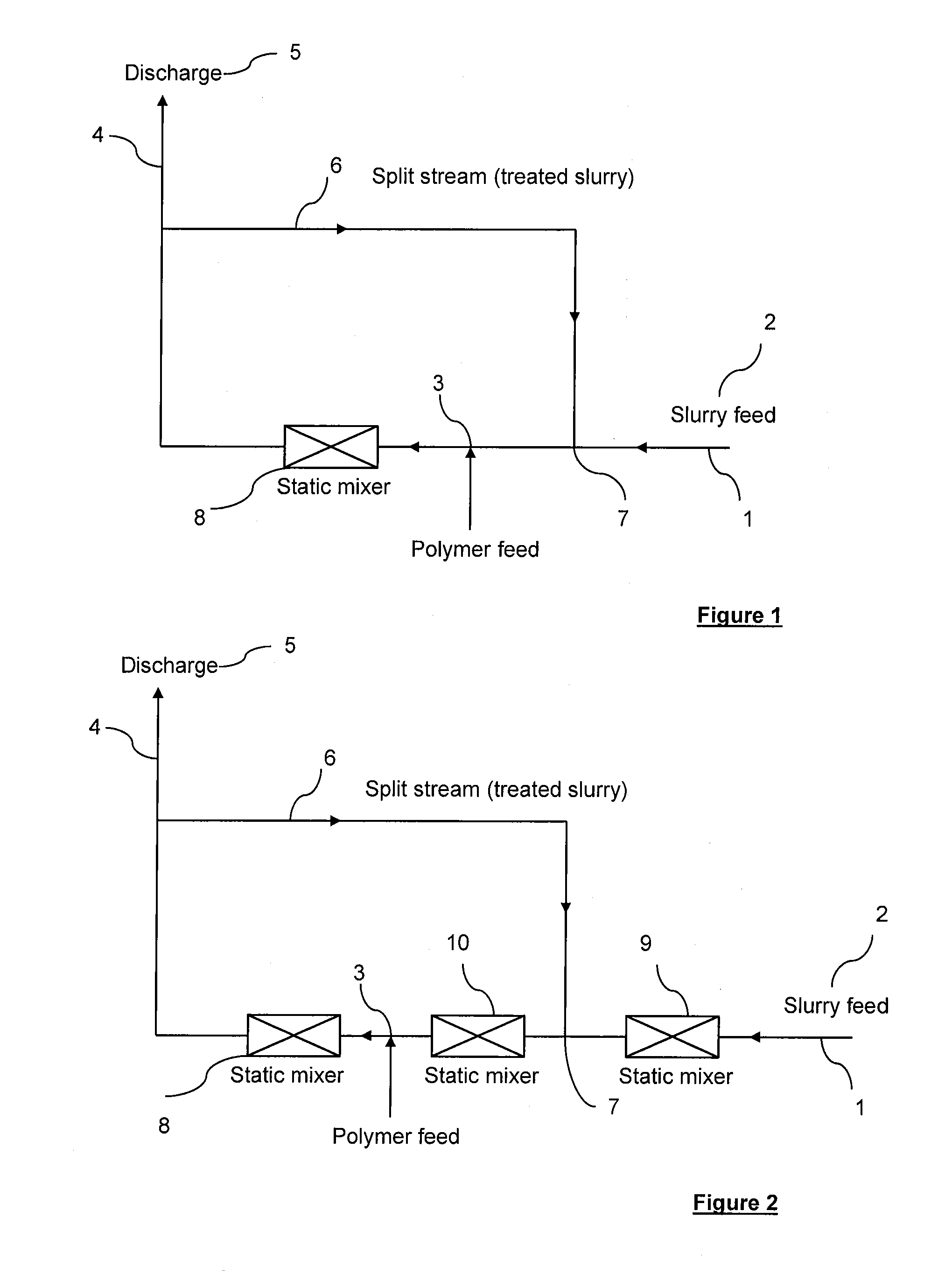

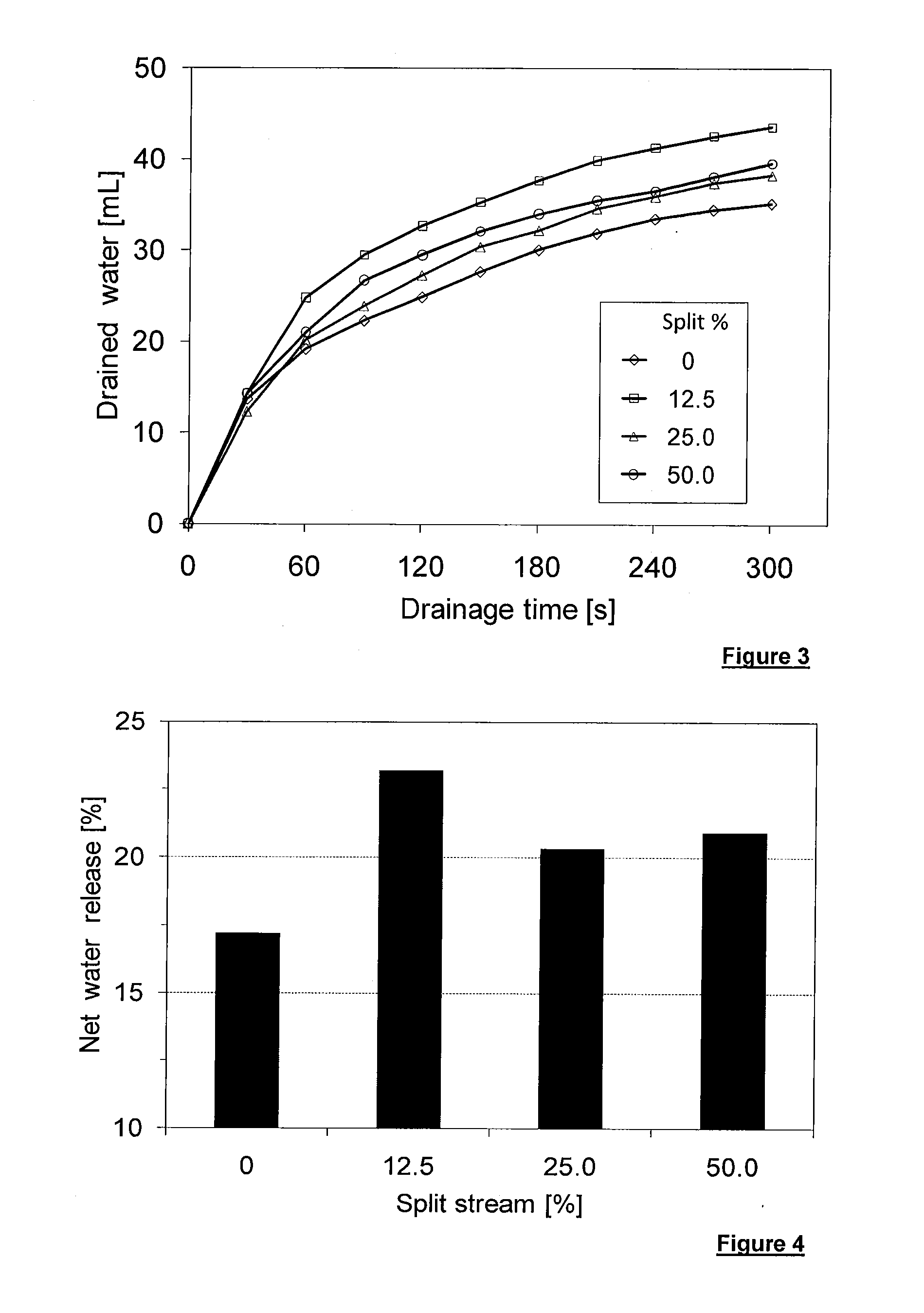

Process for improving inline tailings treatment

InactiveUS20120138542A1Improve processing efficiencyEasily improve performanceTransportation and packagingSolid waste disposalFlocculationPolymer science

A process for improving inline mineral slurries treatment comprises successively: providing an in-line flow of slurries in a main stream; introducing at least one polymer into the main stream through at least one polymer injection point to cause dispersion of the polymer and to start the coagulation and / or the flocculation of slurries to produce treated slurries; and splitting the main stream containing treated slurries into two streams respectively: a discharge stream which directly transfers a part of treated slurries to the deposit area, and a split stream which reintroduces the other part of treated slurries into the main stream through at least a reinjection point in a location prior to the at least one polymer injection point.

Owner:S P C M SA

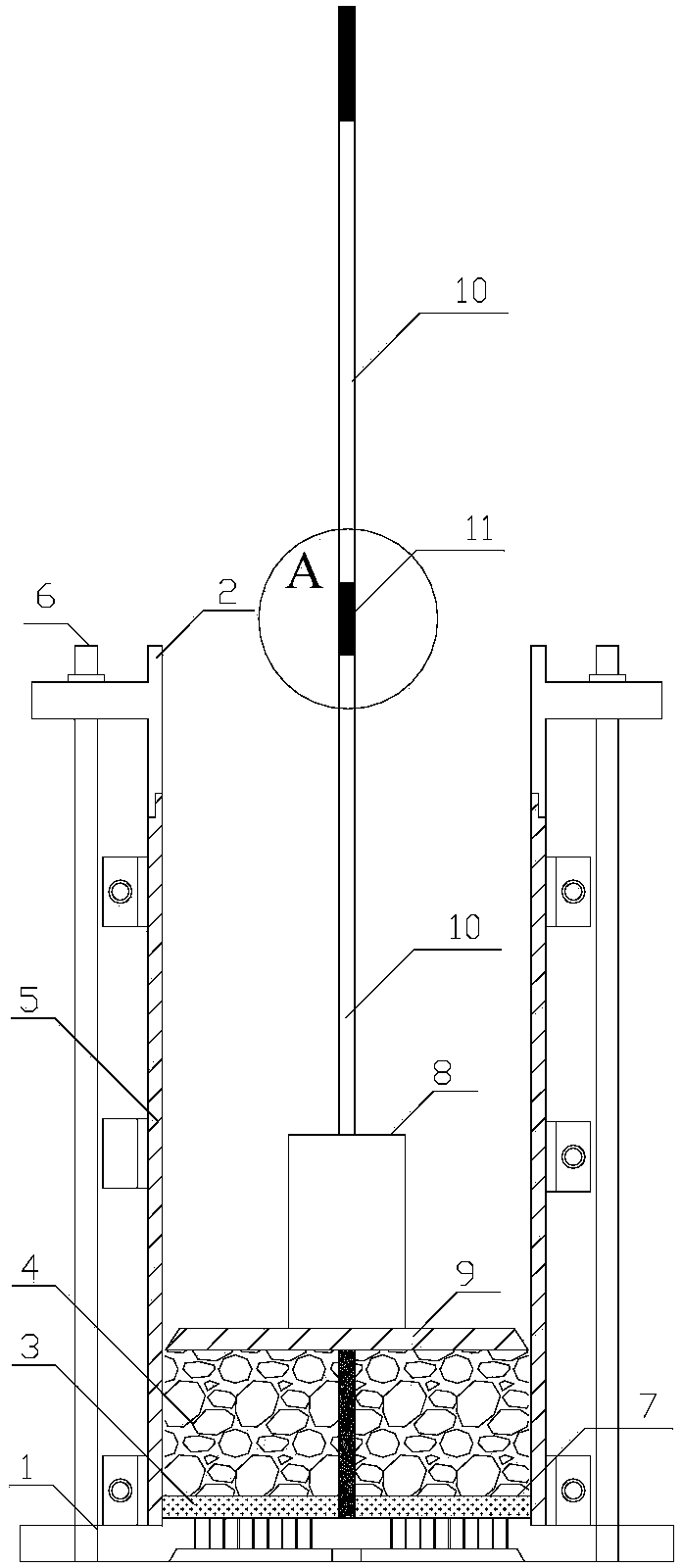

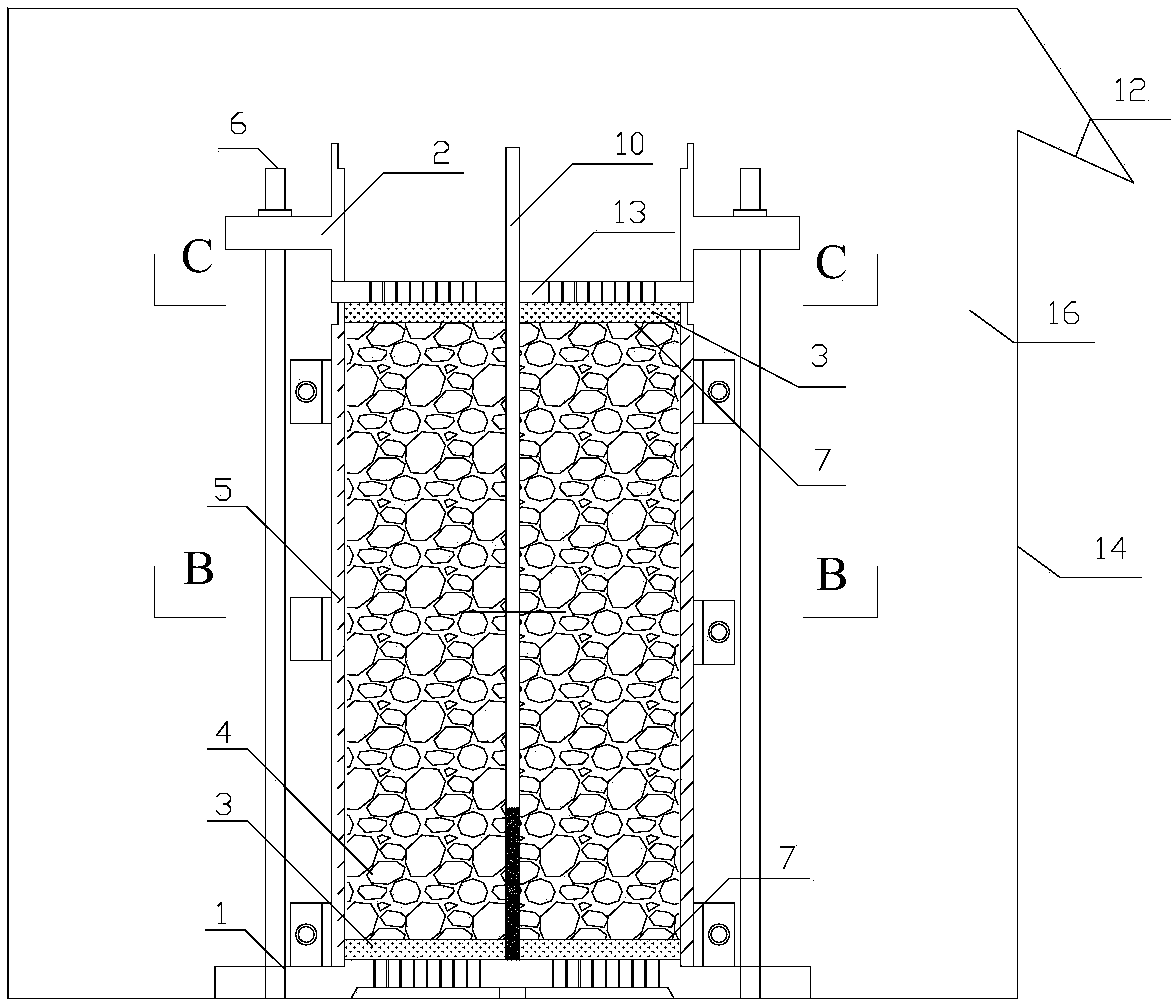

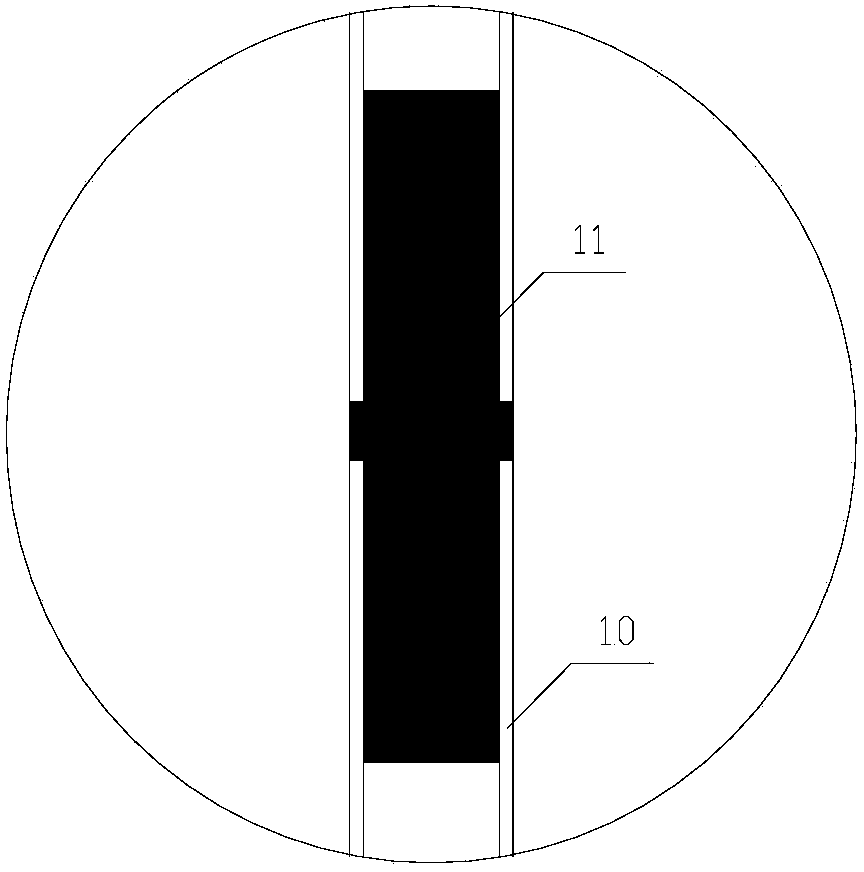

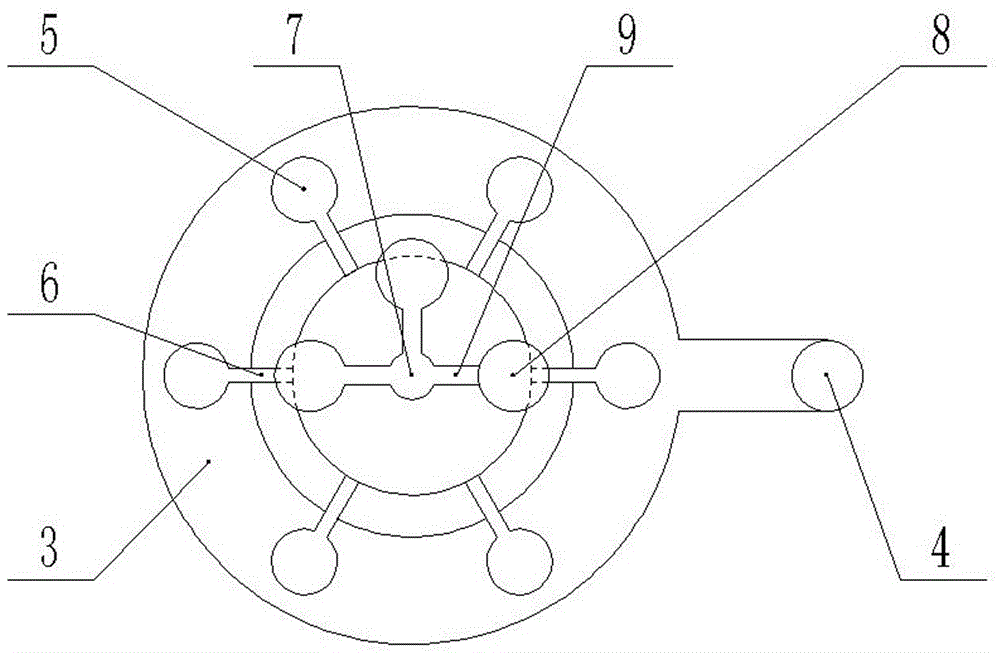

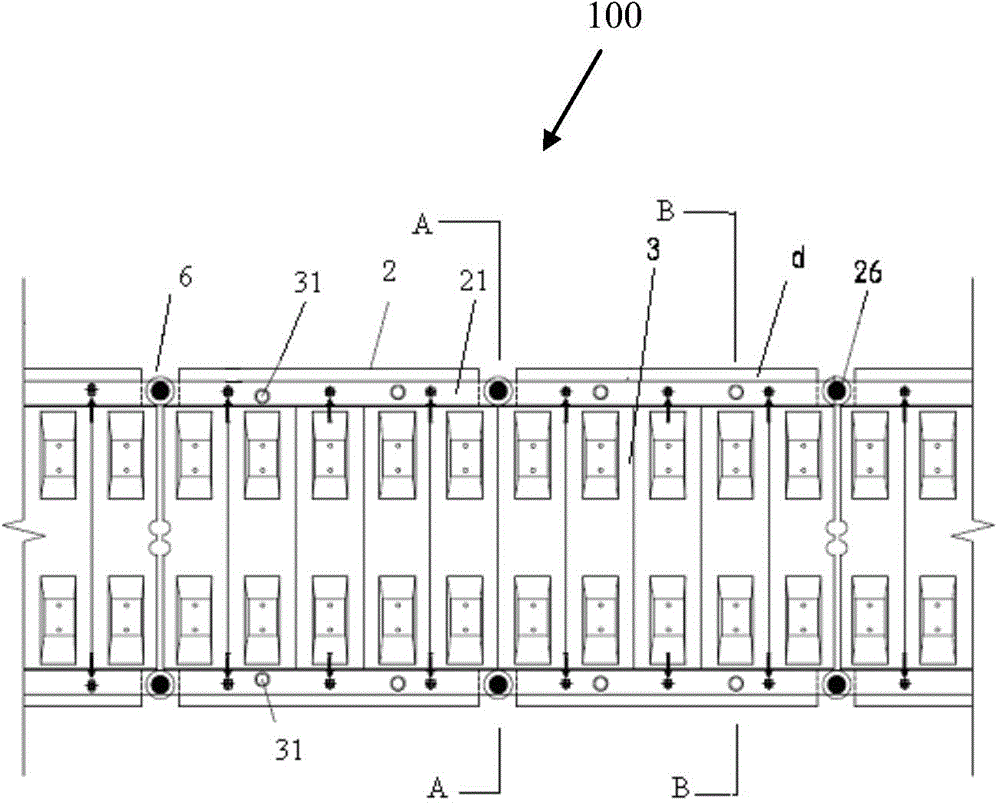

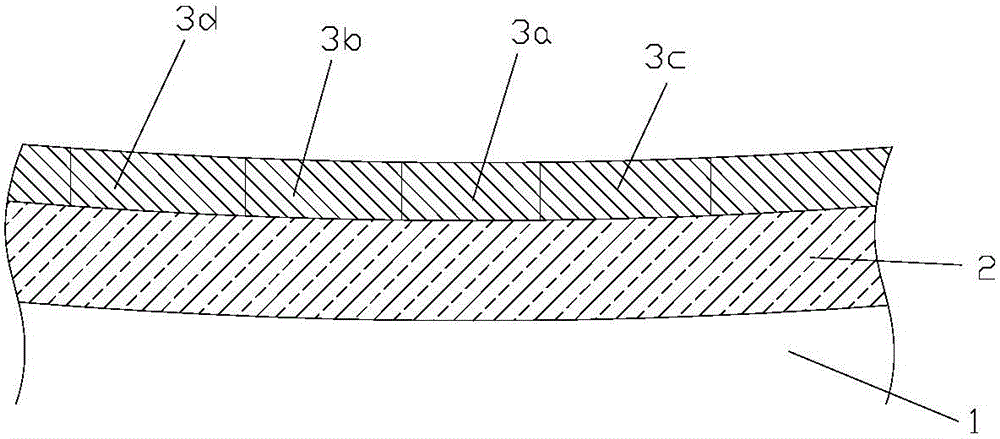

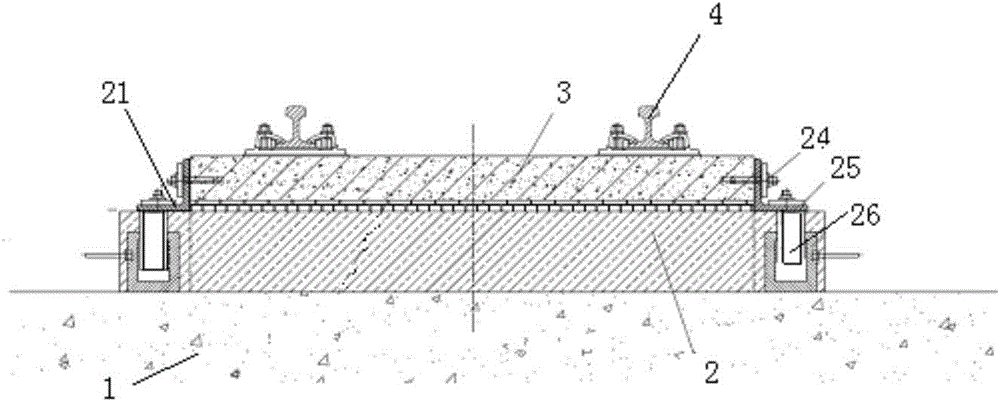

Coarse-grained soil polymer slip casting triaxial test sample kit and using method thereof

ActiveCN103837385AEasy to separateEvenly filledPreparing sample for investigationTest sampleEngineering

The invention discloses a coarse-grained soil polymer slip casting triaxial test sample kit and a using method thereof. The sample kit comprises a sample kit assembly and a compaction device, wherein the sample kit assembly comprises a split cavity and a base and a porous disc supporting the split cavity; the compaction device comprises a plastic sleeve, a compaction hammer and a compaction gasket positioned below the compaction hammer; one end of the plastic sleeve is inserted into a circular hole in the middle of the porous disc; the compaction device is used for compacting coarse-grained soil in the split cavity; a top cover is arranged above the compacted coarse-grained soil; the top cover is pressed on the split cavity through a pressing device. The using method of the sample kit comprises the steps of fixing the split cavity, compacting coarse-grained soil, immersing the sample kit and carrying out slip casting on polymer. The sample kit is compact in structure, the split cavity can be disassembled conveniently, the volume of the grout amount can be measured by the water discharge of a water tank, and whether the inside slip casting is complete is judged by combining the initial porosity of the sample. The using method of the sample kit is simple and convenient and easy to operate.

Owner:HOHAI UNIV

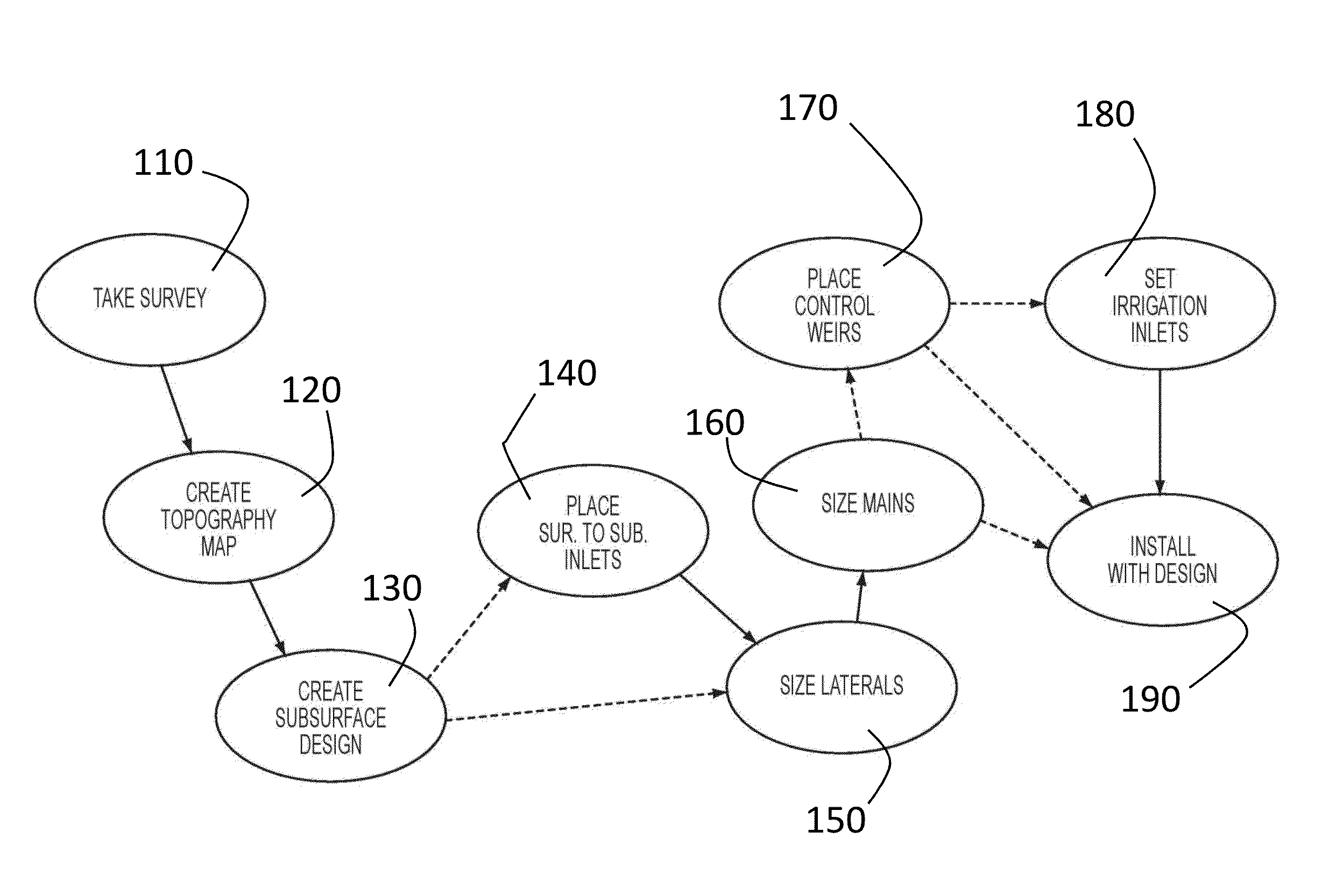

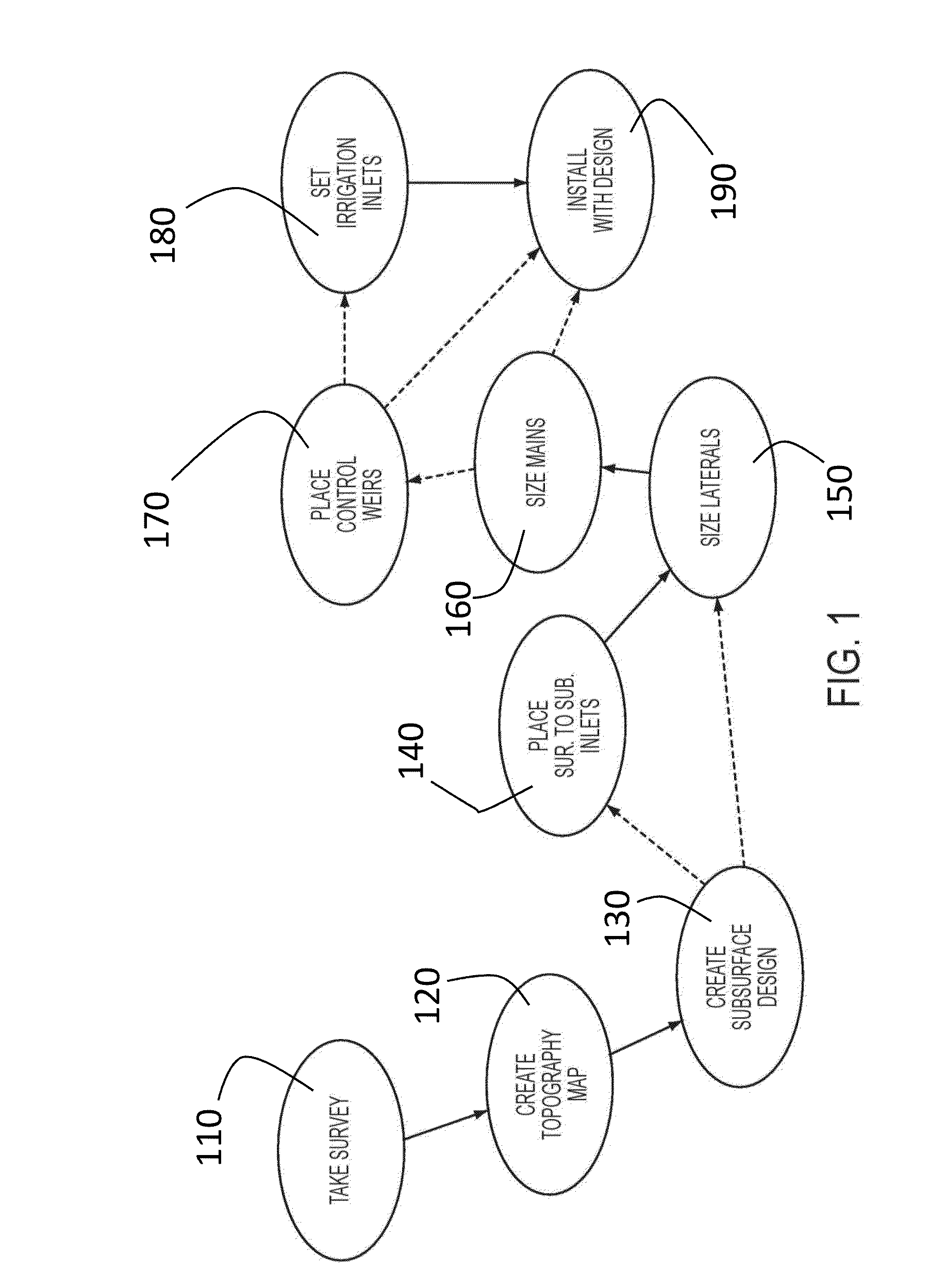

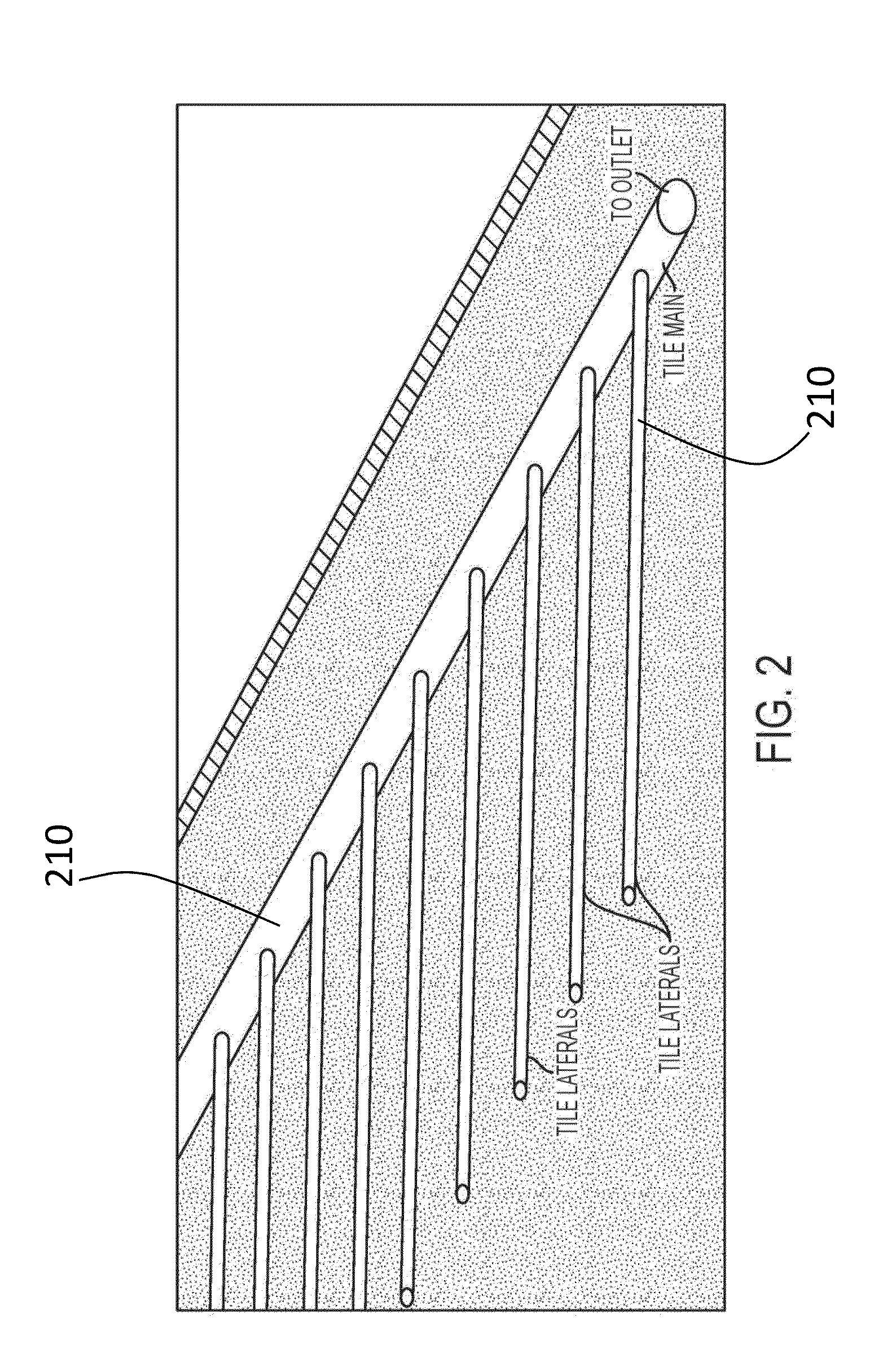

System And Method For Design Of Subsurface Drainage Systems Incorporating Control Weirs, Surface To Subsurface Inlets, And Irrigation Inlets

InactiveUS20130311144A1Minimize changesKeep distanceGeometric CADSpecial data processing applicationsSubsurface drainagePipeflow

A method for the creation of subsurface water management systems that place subsurface drainage lines at a consistent grade and within defined elevation bounds throughout a field with topographical undulation and inconsistent slopes, incorporate control weirs for dividing the subsurface into elevation and acreage zones, place and size surface to subsurface, size and determine inside surface of drainage mains and laterals according to the desired coefficient of the subsurface system, and determine the amount of water required at irrigation inlets in order to deliver a determined amount of water into the subsurface system for purposes of irrigation.

Owner:MEINERS CHAD R +2

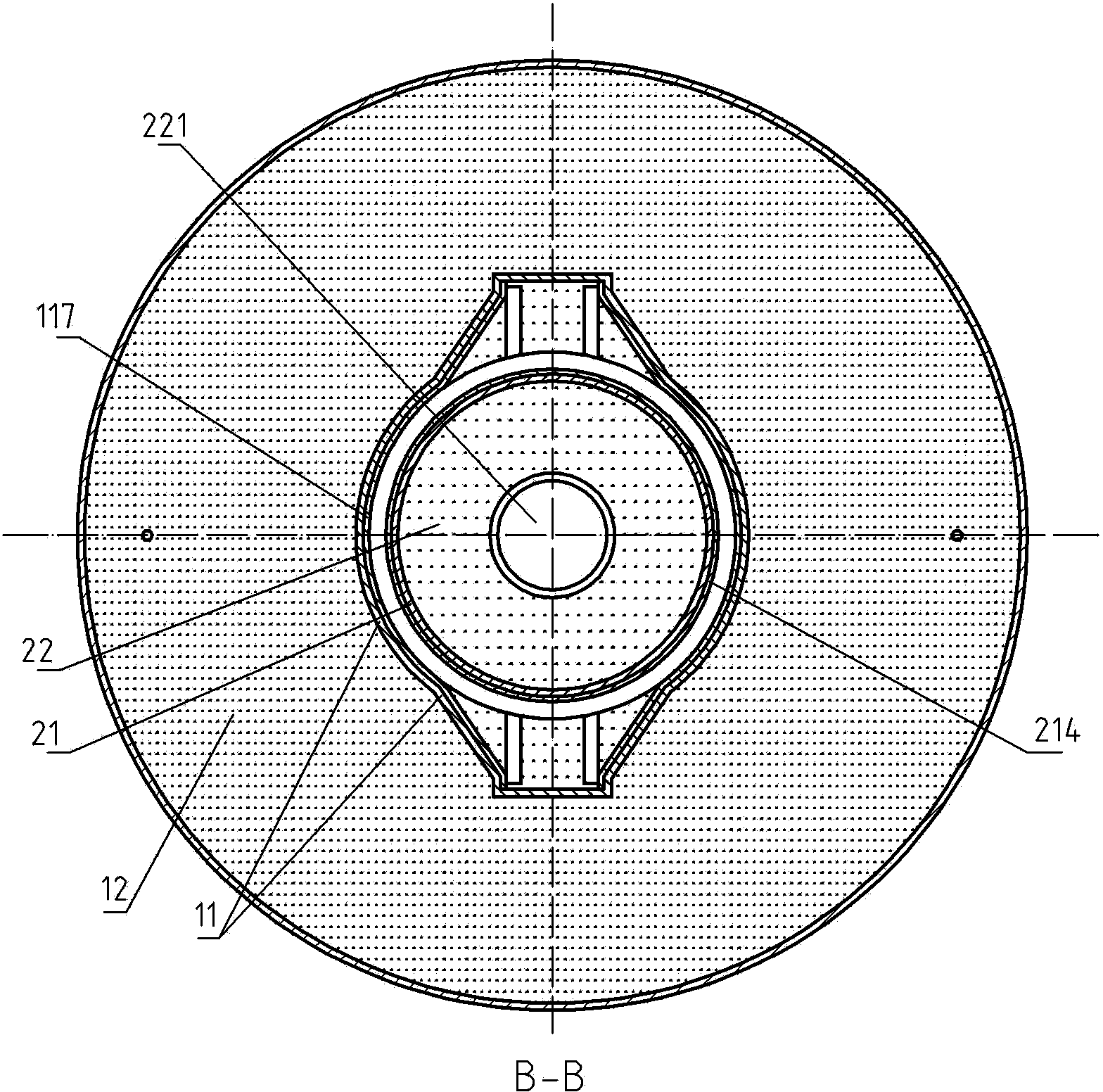

Solidification and feeding method for complicated annular thin-wall shell steel casting

The invention discloses a solidification and feeding method for a complicated annular thin-wall shell steel casting. By means of the solidification and feeding method, the problem that in the casting process of existing complicated annular thin-wall steel castings, shrinkage porosity, shrinkage cavities and crack defects are prone to occur is resolved. The solidification and feeding method comprises the following steps that a, steel casting sand mold cavity is made; b, annular transverse runners and a straight runner are made on the steel casting sand mold cavity, slag collecting cylinders are arranged on the upper surfaces of the annular transverse runners, gap inner runners are arranged between the slag collecting cylinders and the outer wall of the steel casting sand mold cavity, a feeding auxiliary sprue and top risers are arranged on the upper portion of the steel casting sand mold cavity, and a gap auxiliary runner is arranged between each top riser and the feeding auxiliary sprue; c, during pouring, the film forming pouring temperature of molten metal is 1500 DEG C-1520 DEG C; and d, when the molten metal level reaches the upper portions of the top risers, melt metal pouring is stopped on the straight runner, and the molten metal enters the steel casting sand mold cavity through the feeding auxiliary sprue until pouring is completed. The whole mold filling process is stable, no disturbance exists, and the phenomena of pores and dreg inclusion defects are avoided.

Owner:SHANXI PINGYANG IND MACHINERY

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

Repair method for ballastless track foundation settlement

InactiveCN104452484AControl extensionControl Lifting AccuracyBallastwayTrack maintainenceEngineeringRepair method

The invention relates to a repair method for ballastless track foundation settlement. The method includes the first step of lifting a supporting layer of a settlement area to make a corresponding track board lifted by a preset rising amount, the second step of conducting grouting and compacting on the lower portion of the lifted supporting layer, and the third step of finishing grouting and completing repair. By means of the method, the lifting accuracy can be accurately controlled.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

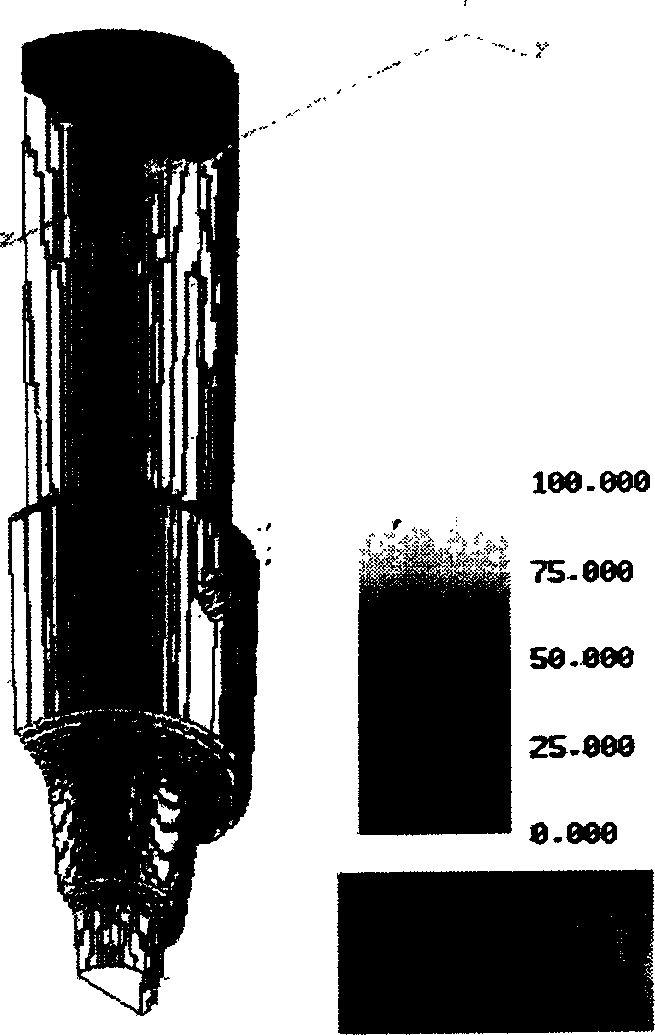

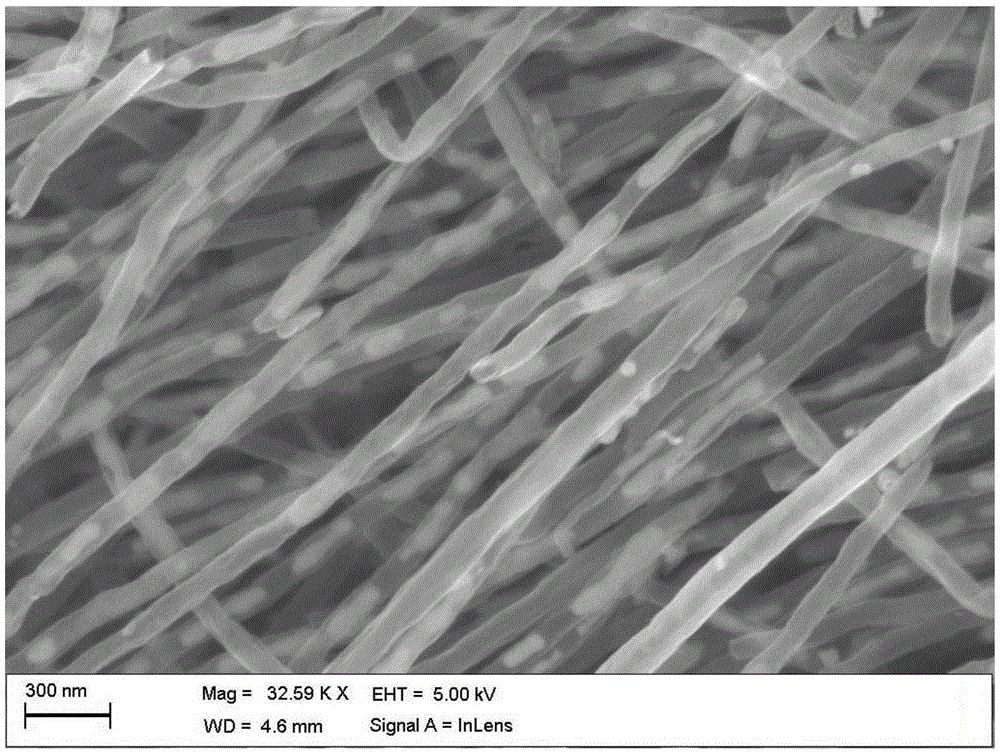

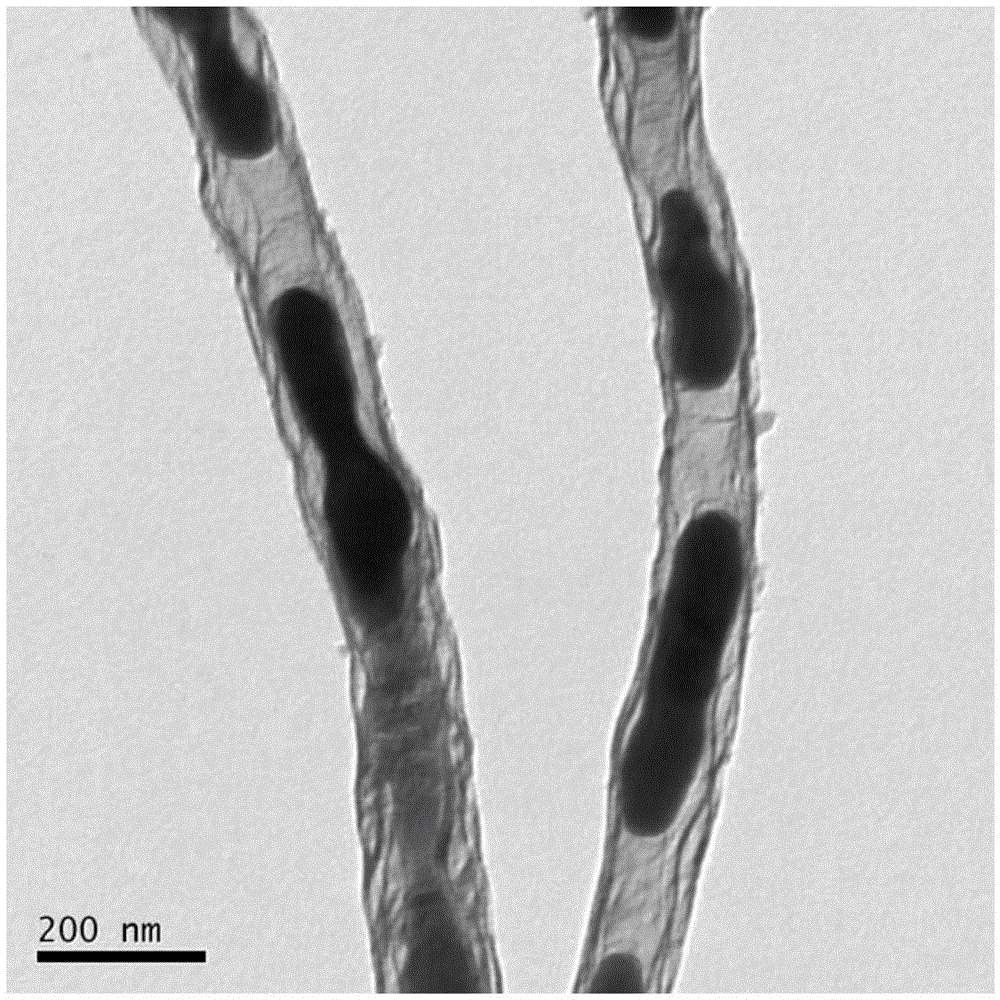

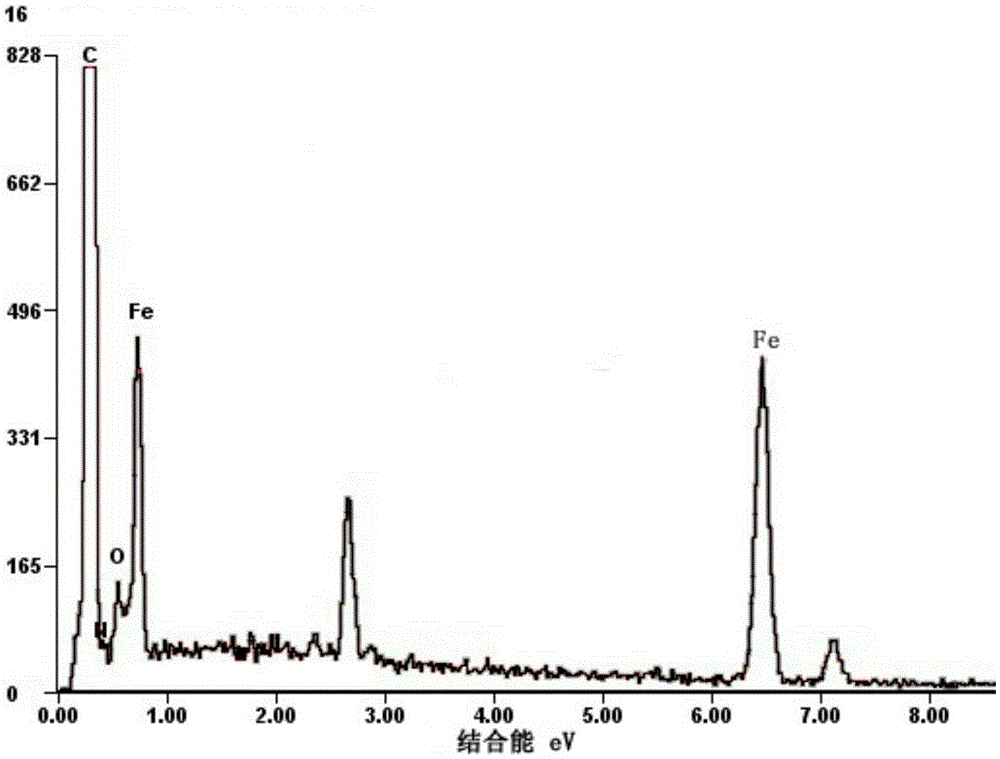

Method for in-situ preparation of iron carbide filled doped carbon nanotube

InactiveCN105271229AHigh iron filling rateIncrease productionMaterial nanotechnologySimple Organic CompoundsTube furnace

The invention discloses a method for in-situ preparation of an iron carbide filled doped carbon nanotub. The method includes: mixing an iron salt, a cyanamide nitrogenous organic compound precursor and a doping precursor evenly, then conducting high temperature pyrolysis in a tube furnace, and carrying out pickling to remove impurities, thus obtaining the iron carbide filled doped carbon nanotub. Compared with the traditional method, the method provided by the invention uses cheap precursor, reaches high utilization ratio, lower equipment requirement, improves the safety of the preparation process, and can be used for large-scale preparation, The prepared iron carbide filled doped carbon nanotub has uniform size, iron carbide is filled evenly, the filling content is high, and the product yield is high.

Owner:SOUTH CHINA UNIV OF TECH

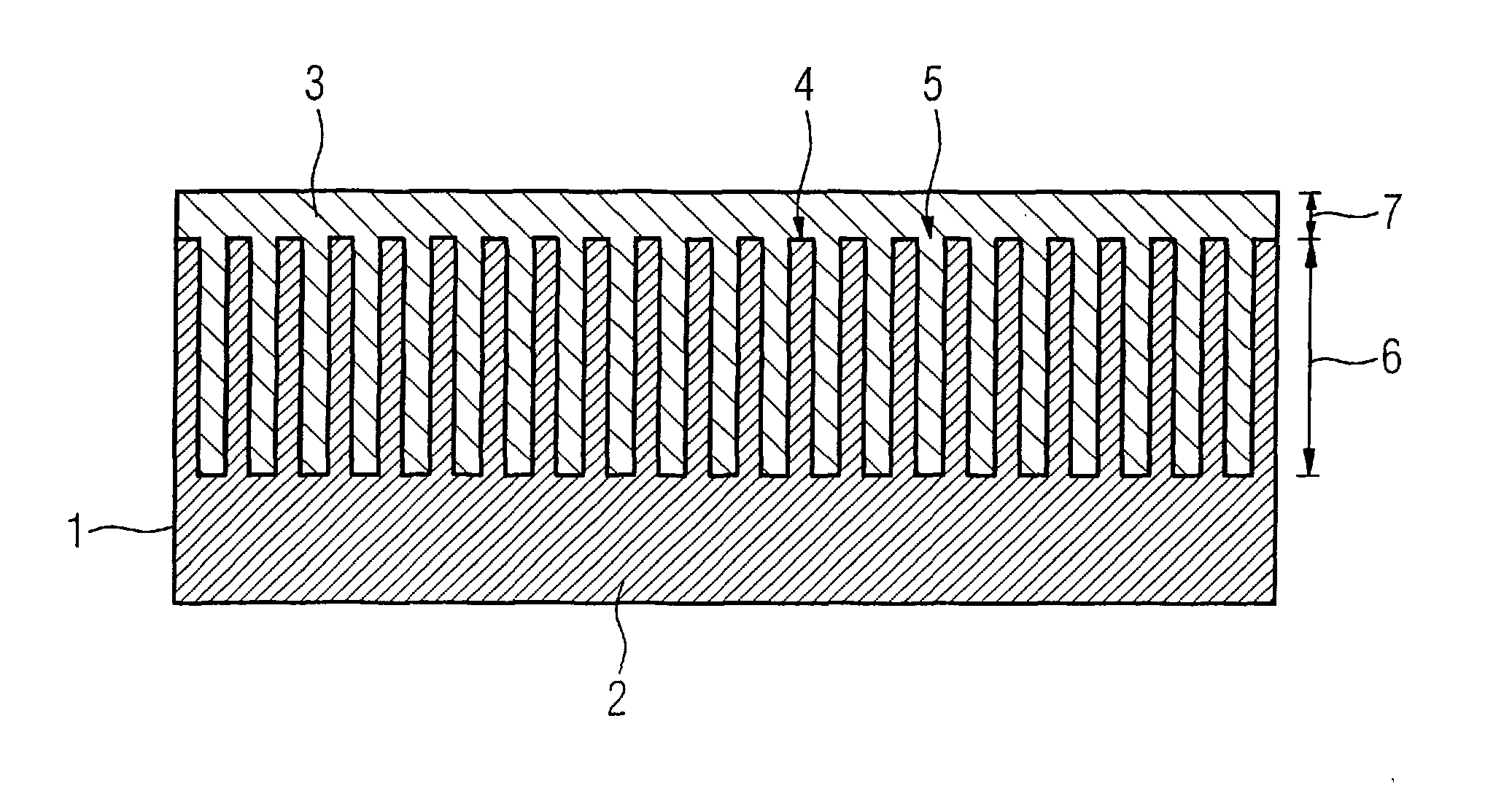

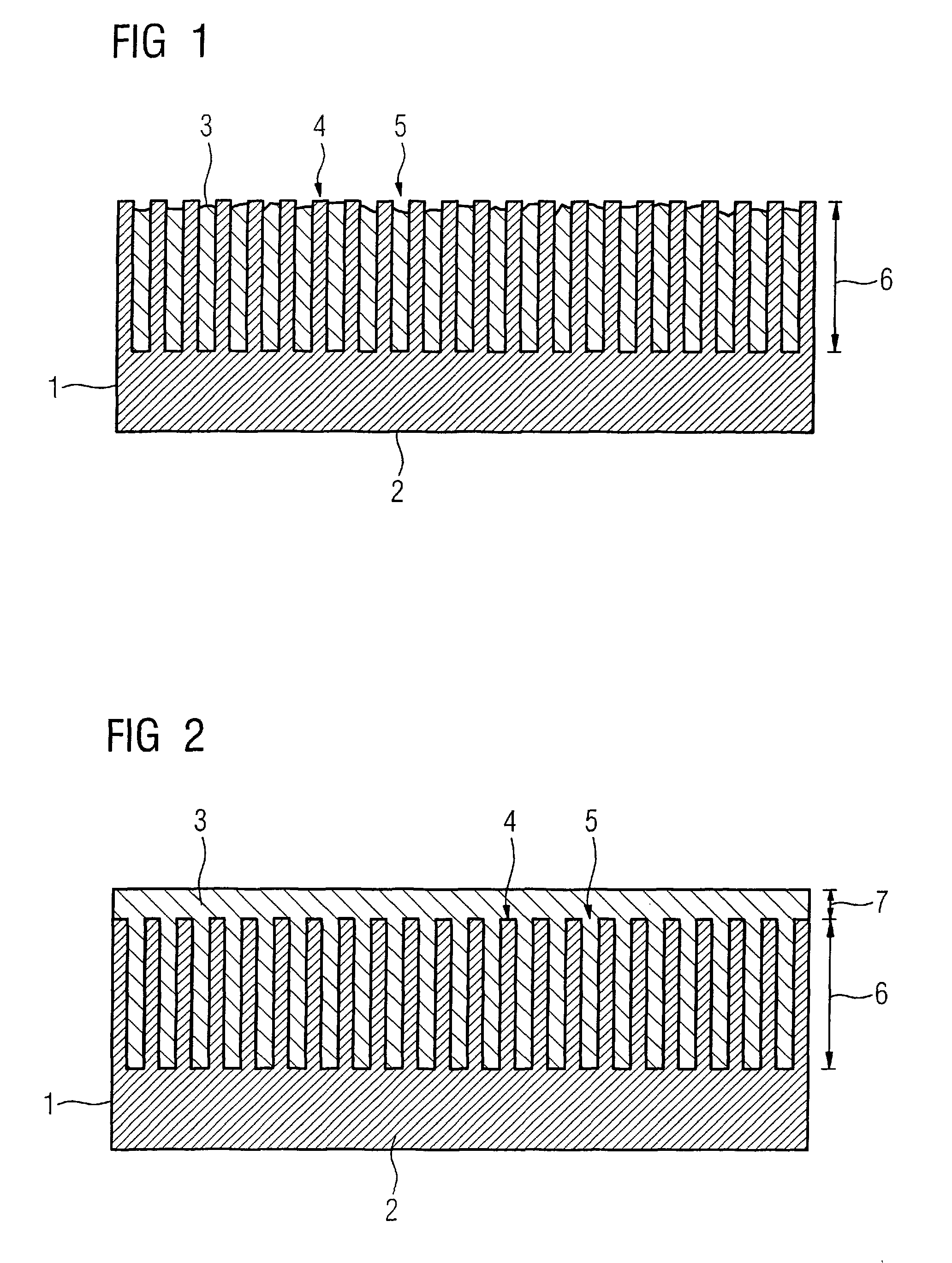

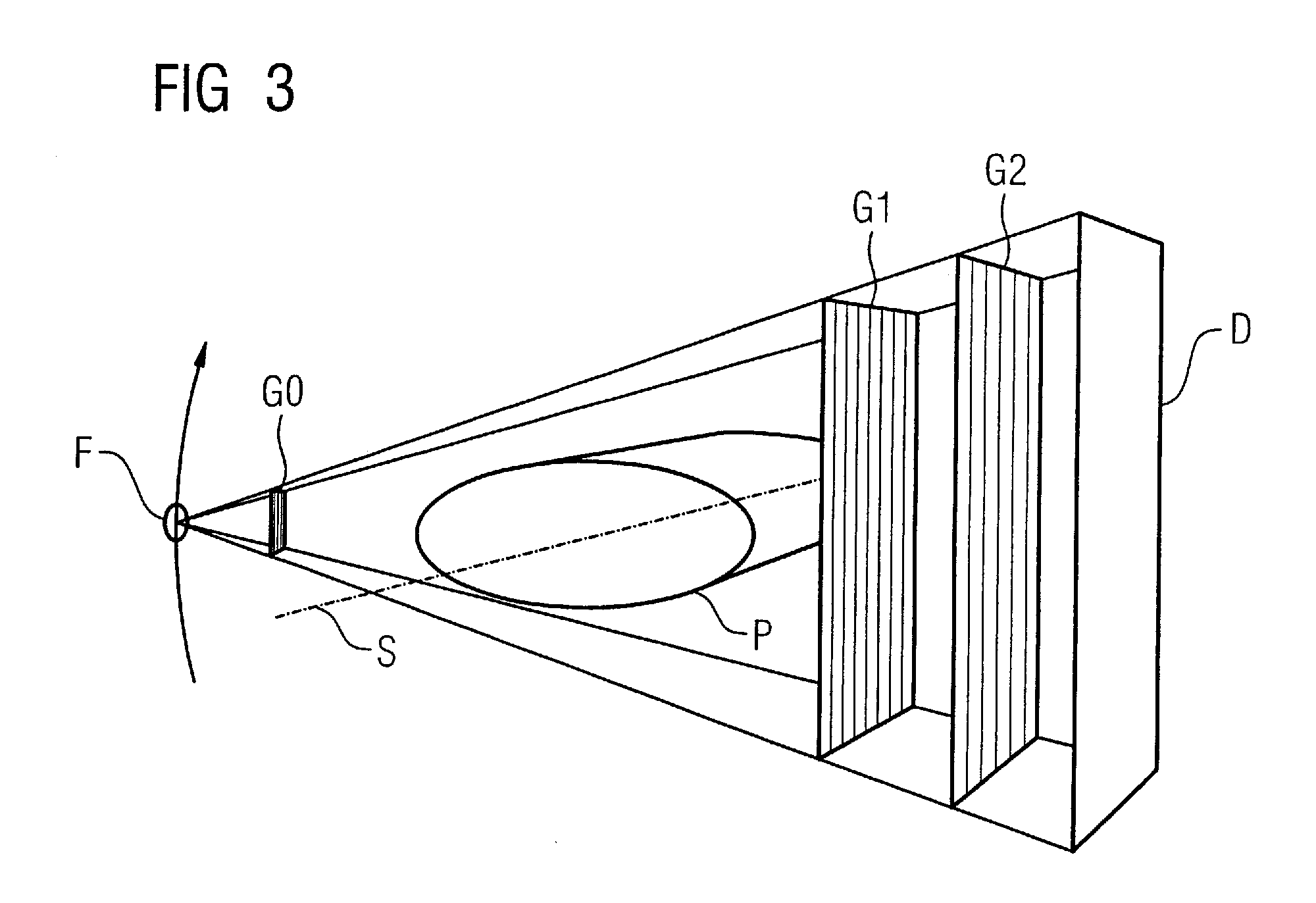

X-ray optical grating and method for the production thereof, and X-ray detector embodying same

InactiveUS8165270B2Maintain qualityEvenly filledImaging devicesHandling using diffraction/refraction/reflectionSoft x rayGrating

In a method for the production of x-ray-optical gratings composed of a first material forming of periodically arranged grating webs and grating openings, a second material is applied by electroplating to fill the grid openings. The electroplating is continued until a cohesive layer of the second material with uniform height is created over the grating webs with this layer having a large absorption coefficient, the absorption properties of the grating structure of the grating are homogenized, so an improvement of the measurement signals that are generated with this grating is improved. Moreover, the mechanical stability of gratings produced in such a manner is improved.

Owner:PAUL SCHERRER INSTITUT +1

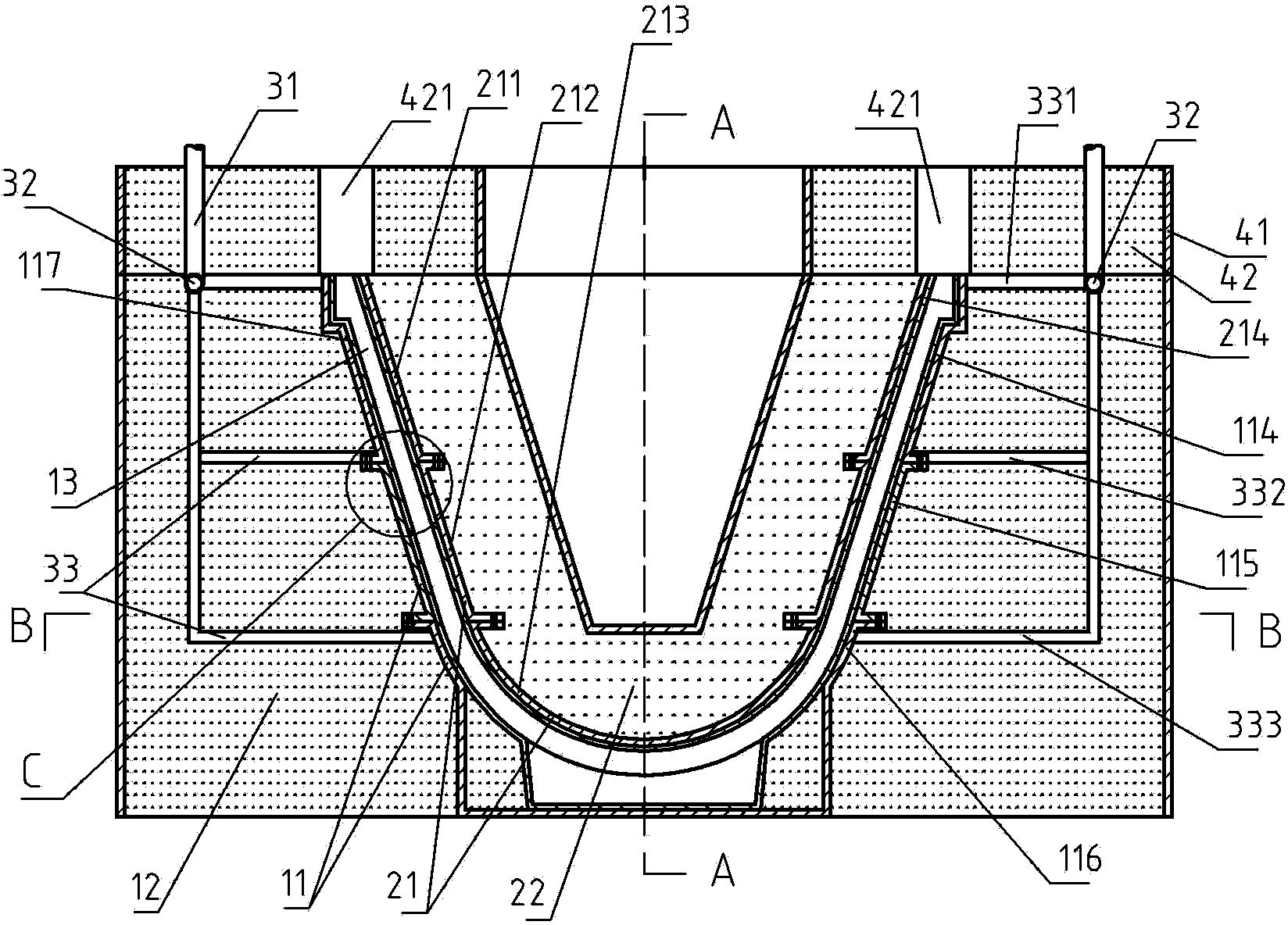

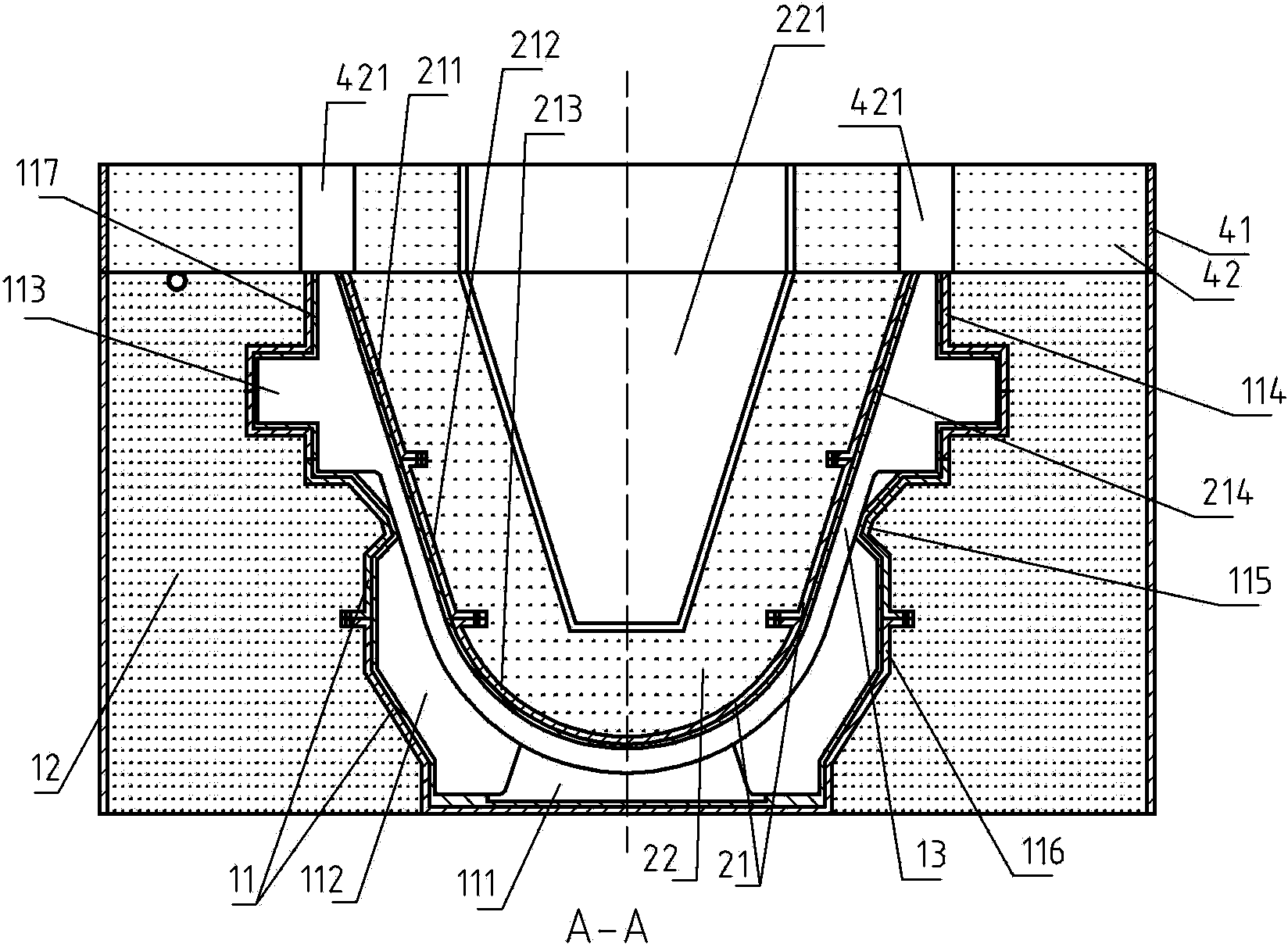

Casting method of slag ladle and casting mold

InactiveCN104226916ANo shrinkage porosity defectsHigh yieldMelt-holding vesselsMolten metal pouring equipmentsSlagCasting mold

The invention discloses a casting method of a slag ladle and a dedicated casting mold for implementing the method. The method comprises the following technical steps: 1. manufacturing the casting mold: (1) designing a pit: designing and manufacturing a casting pit; (2) manufacturing a casting external mold of the slag ladle and a pouring gate system, preparing an external wall cold mold (11) of the slag ladle, connecting the pouring gate system well, and filling an outer sand mold (12); (3) manufacturing a casting inner mold of the slag ladle and a feed head mold, manufacturing an inner wall cold mold (21) of the slag ladle, installing the inner wall cold mold (21) of the slag ladle in the outer wall cold mold (11) of the slag ladle, and defining a slag ladle casting cavity (13) between the inner wall cold mold and the outer wall cold mold, wherein the outer wall cold mold (11) of the slag ladle and the inner wall cold mold (21) of the slag ladle are both made of iron; (4) drying of the mold: drying the mold with hot air till dry; 2. pouring: pouring the casting liquid in the slag ladle casting cavity (13), cooling, and at last obtaining the slag ladle.

Owner:衡阳中钢衡重铸锻有限公司

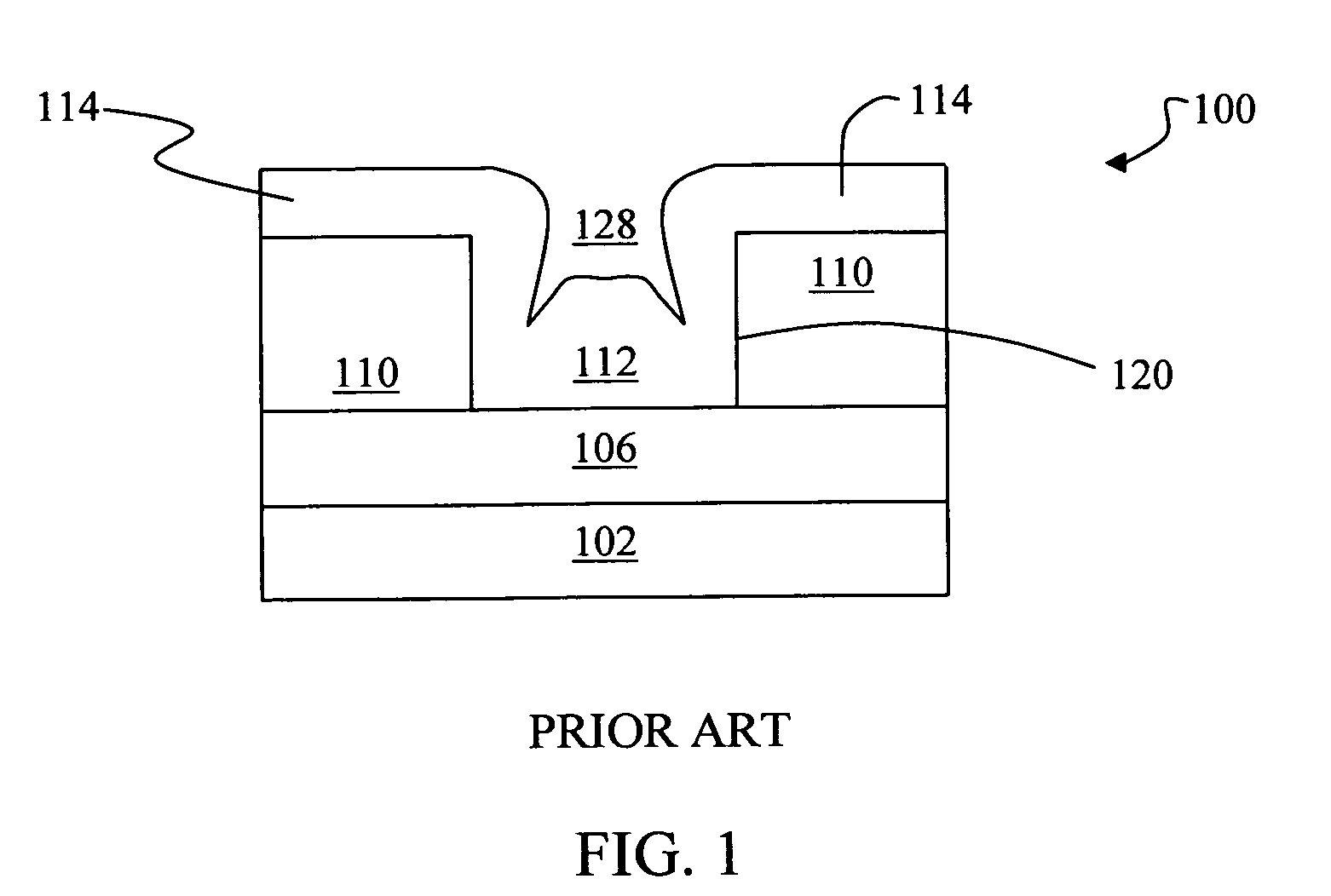

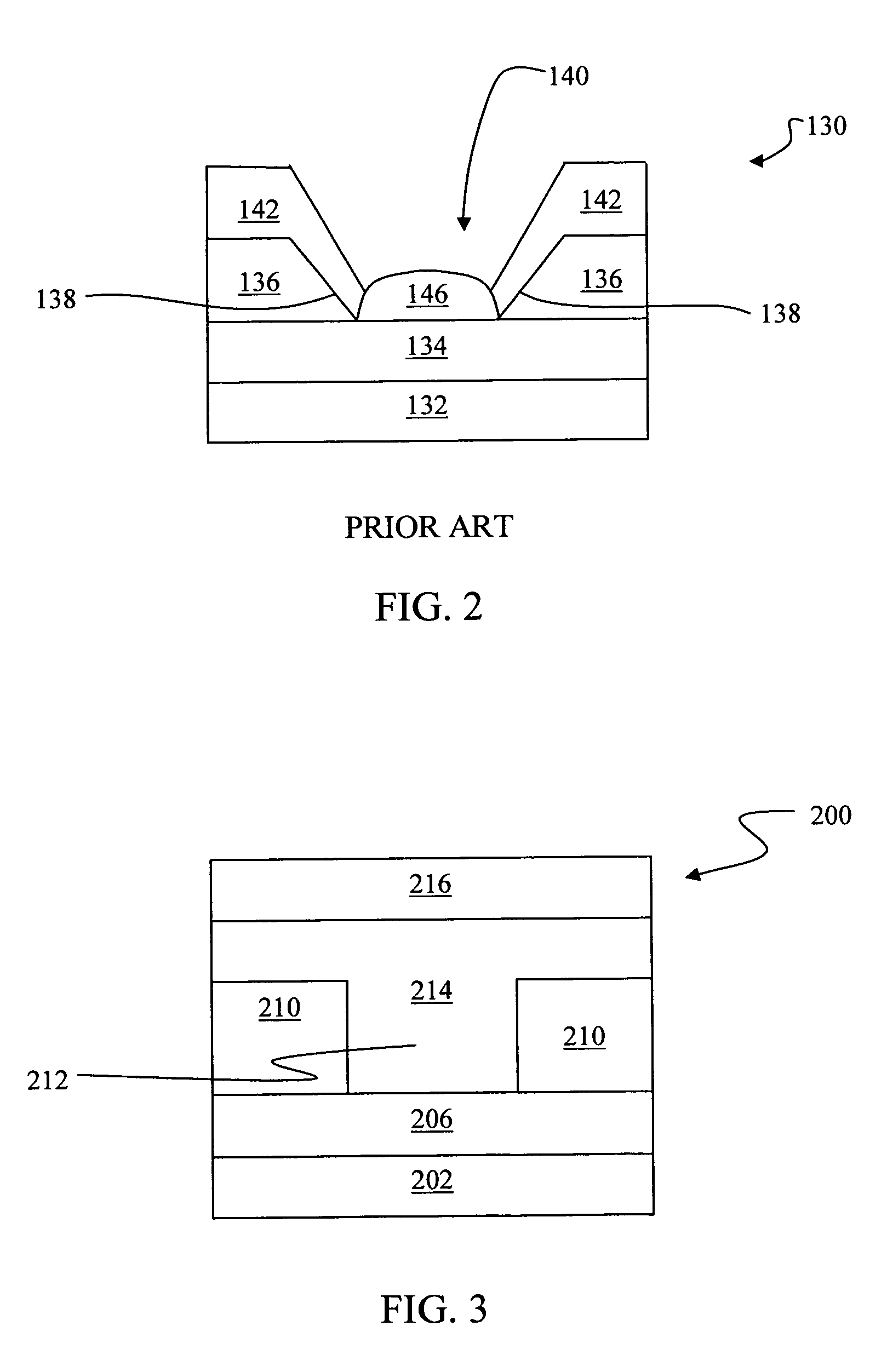

Pressure extrusion method for filling features in the fabrication of electronic devices

InactiveUS20090226603A1More consistentReduce structureElectrical apparatusCoatingsAspect ratioPhase-change material

A method of filling high aspect ratio features with active electronic or conductive materials. In one method, high pressure extrusion is used to urge the as-deposited active or conductive material into an incompletely filled opening. In another method, a rapid thermal anneal process is used to induce reflow of the as-deposited active or conductive material into an incompletely filled opening. Both methods are also effective in densifying active or conductive materials within openings by collapsing voids that arise in the as-deposited state. The instant methods provide for more uniform and consistent filling of openings and minimize the variability and impairment of electrical characteristics of active material devices. Active materials include phase-change materials, chalcogenide materials, switching materials, and programmable resistance materials.

Owner:OVONYX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com