Seedling and seeding machine and seedling and seeding method

The technology of a seeder and a seeding device, which is applied to the parts of the seeder, sowing, and interval quantitative sowing machinery, can solve the problems of low automation, low work efficiency, and a large amount of labor, so as to achieve automatic control and reduce labor costs. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

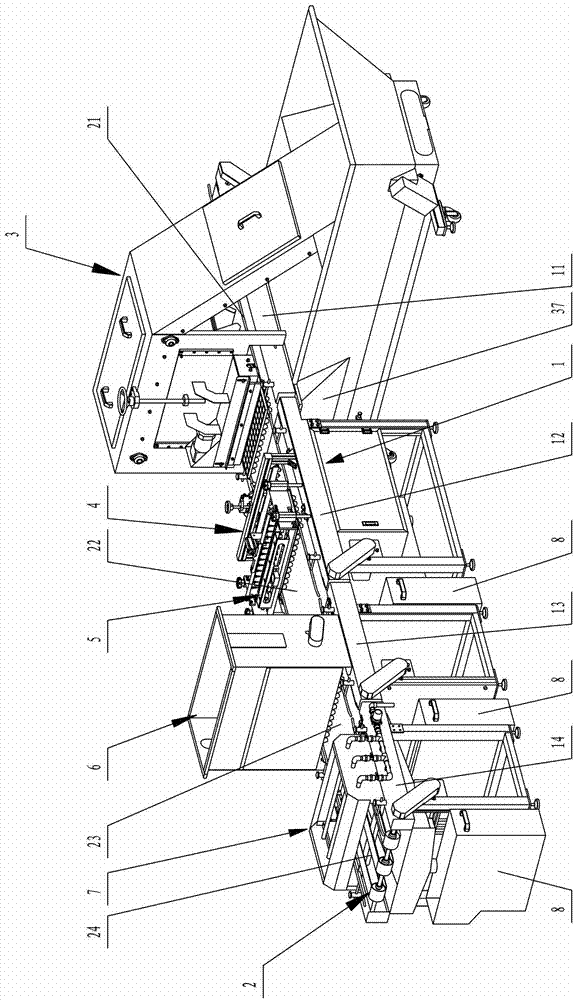

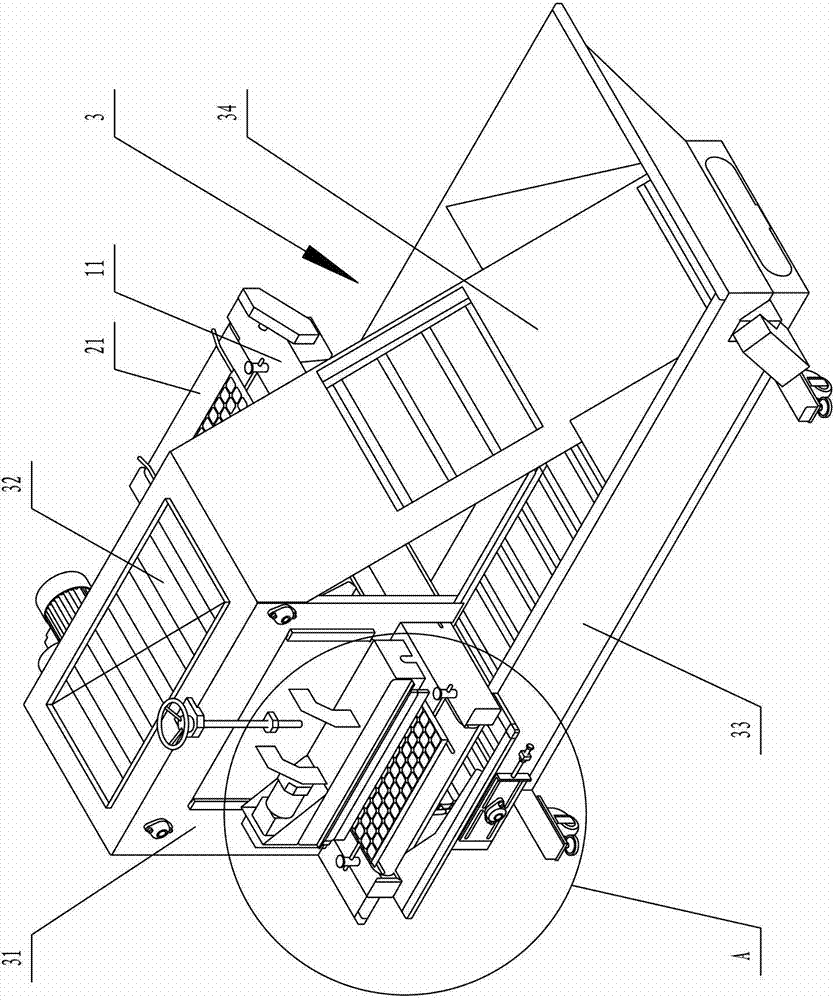

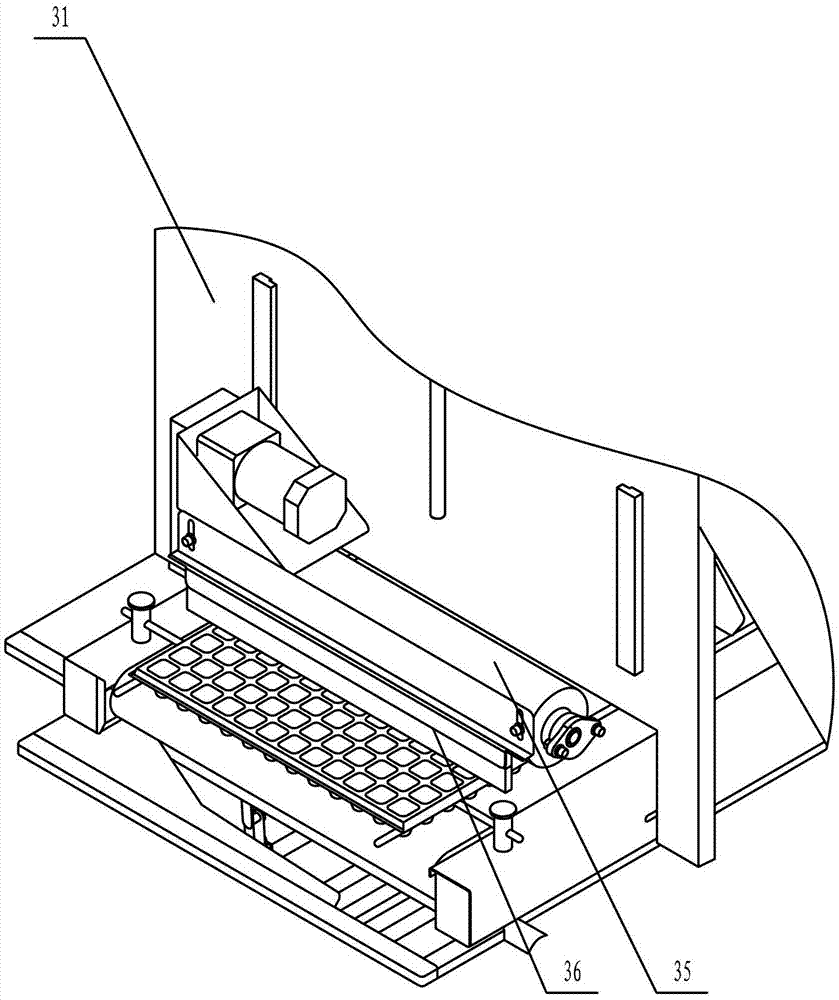

[0058] Such as figure 1 As shown, the seedling planter provided in this embodiment includes a frame 1 and a conveying device 2, the conveying device 2 is arranged on the top of the frame 1, and the conveying device 2 is successively provided with subsoil filling along the conveying direction of the conveying device 2 Device 3 , punching device 4 , needle-type hole tray seeding device 5 , soil covering device 6 and sprinkler device 7 .

[0059] Its specific working process is:

[0060] The tray is placed on the conveying device 2, and the conveying device 2 drives the tray to pass through the subsoil filling device 3, the hole punching device 4, the needle tray seeding device 5, the soil covering device 6 and the sprinkler device 7 in sequence. When the hole plate passes through the subsoil filling device 3, the subsoil falls from the subsoil filling device 3 and falls into the hole plate; then when the hole plate passes through the hole punching device 4, the hole punching de...

Embodiment 2

[0086] Such as Figure 7 Shown, the seedling seeding method provided in the present embodiment, concrete steps are:

[0087] 201. Place the tray on the conveying device.

[0088] 202. Fill the plug with subsoil.

[0089] 203. Drill holes in the subsoil in the plug trays to form pits.

[0090] 204. Sow seeds into each hole in the plug tray.

[0091] 205. Carry out soil covering to the hole tray after sowing seeds.

[0092] 206. Sprinkle water on the hole tray after covering with soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com