Patents

Literature

97 results about "Hole punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hole punching (or sometimes punch-through) is a technique in computer networking for establishing a direct connection between two parties in which one or both are behind firewalls or behind routers that use network address translation (NAT). To punch a hole, each client connects to an unrestricted third-party server that temporarily stores external and internal address and port information for each client. The server then relays each client's information to the other, and using that information each client tries to establish direct connection; as a result of the connections using valid port numbers, restrictive firewalls or routers accept and forward the incoming packets on each side.

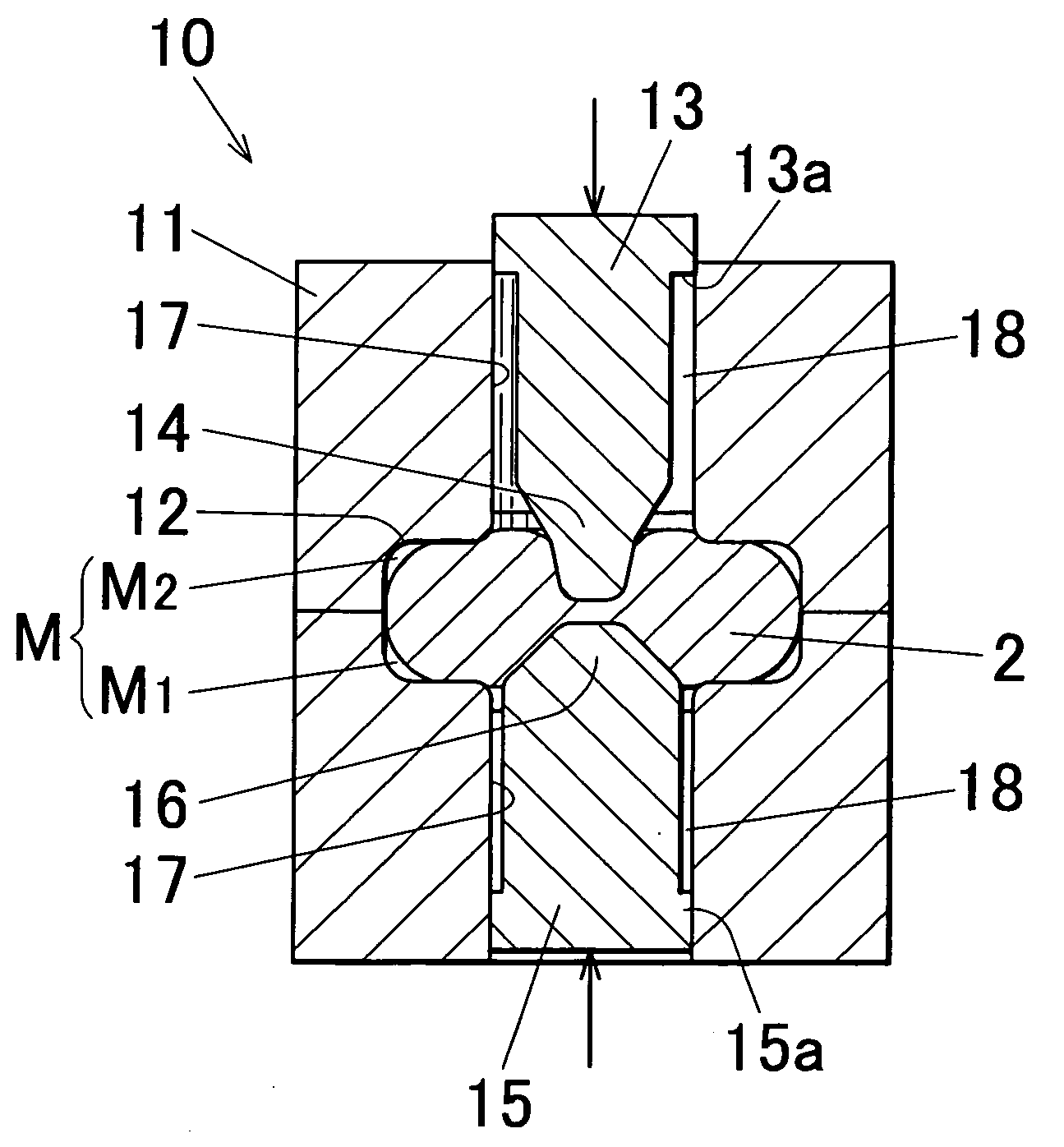

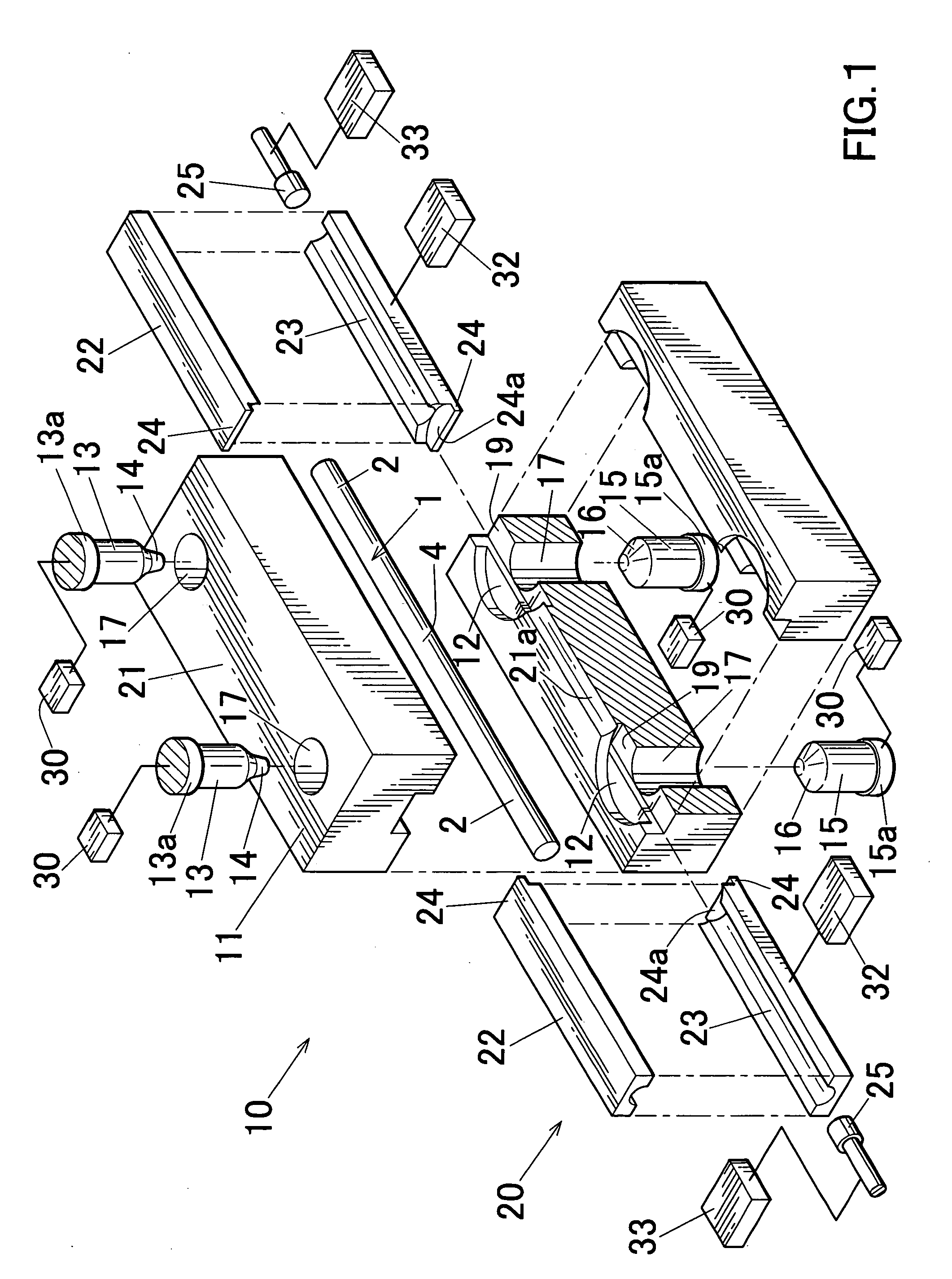

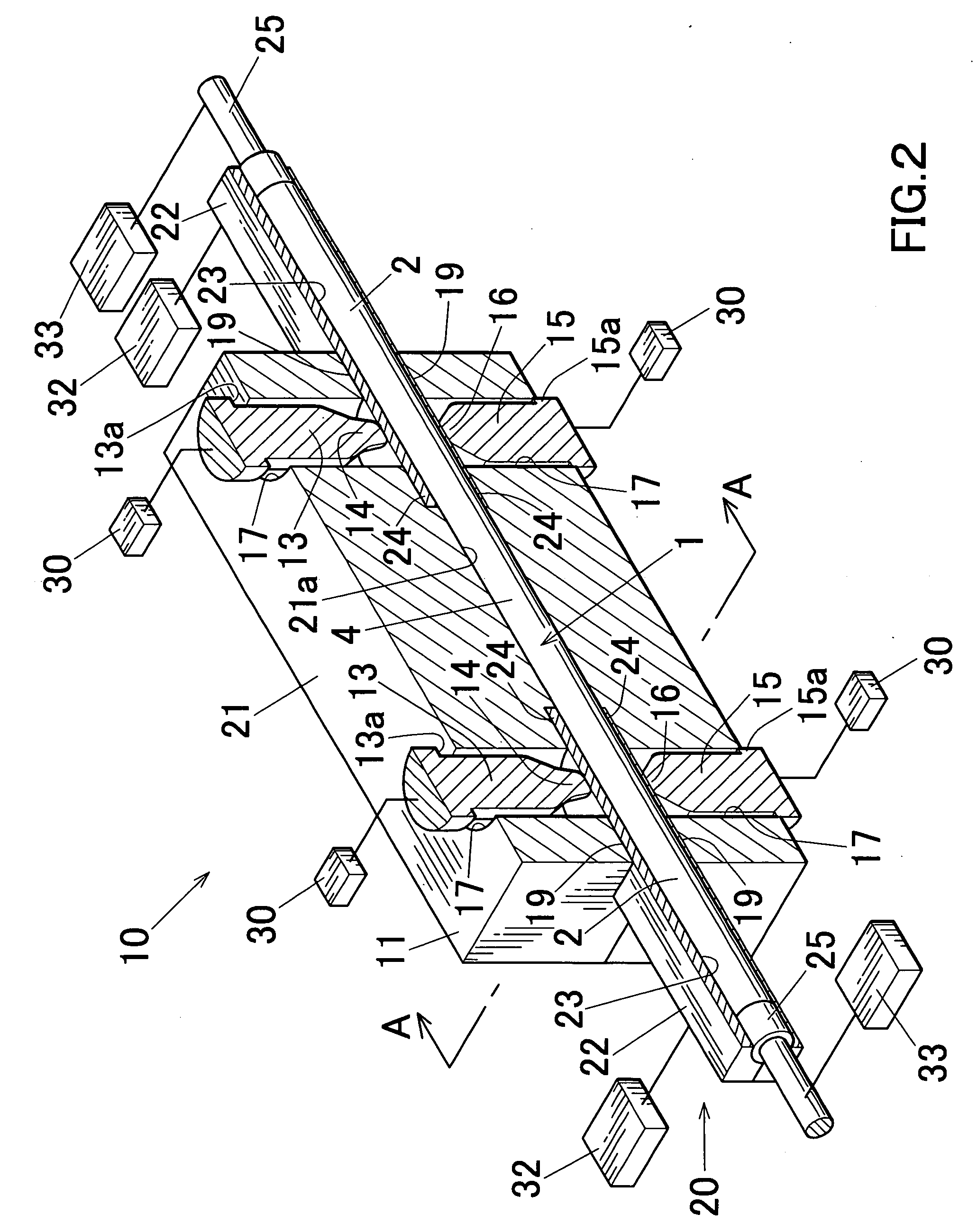

Method and apparatus for hole punching

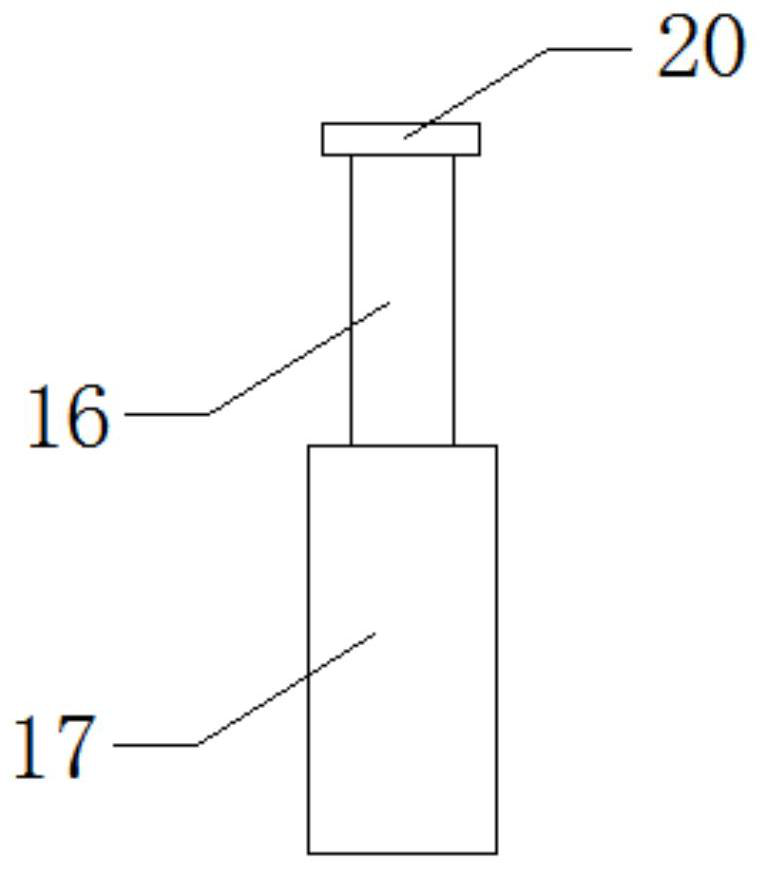

InactiveUS20060288754A1High forming loadLow yieldForging/hammering/pressing machinesLow loadEngineering

A hole punching method capable of executing hole punching with high material yield at a low load and preventing occurrence of underfill is provided. The hole punching method includes a step of expanding a hole punching scheduled portion 2 of a raw material 1 disposed in a cavity 12 of a closed die 11 by pressing the hole punching scheduled portion 2 from opposite sides thereof across the hole punching scheduled portion 2 with a pair of large diameter punch and small diameter punch 13 and 15 different in diameter and arranged to as to face each other so that unfilled portions remain in the cavity, a step of penetrating the small diameter punch 13 into the hole punching scheduled portion 2 of the raw material 1 while releasing or after releasing pressurization by the large diameter punch 15 to the hole opening scheduled portion 2, and a step of penetrating the large diameter punch15 into the hole punching scheduled portion 2 of the raw material 1 while pulling out or after pulling out the small diameter punch 13 penetrated in the hole punching scheduled portion 2 of the raw material 1 from the hole punching scheduled portion 2 of the raw material 1.

Owner:SHOWA DENKO KK

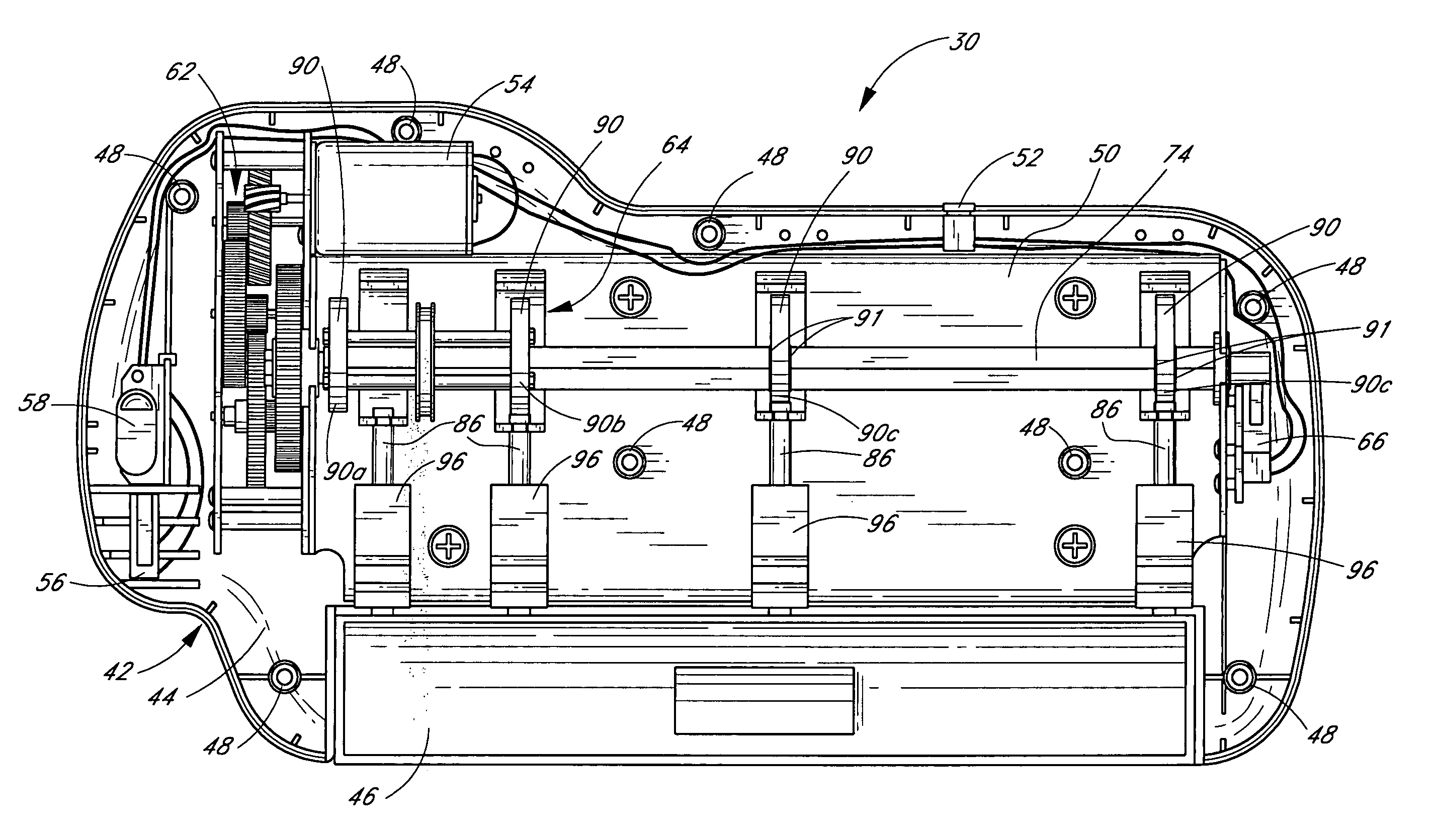

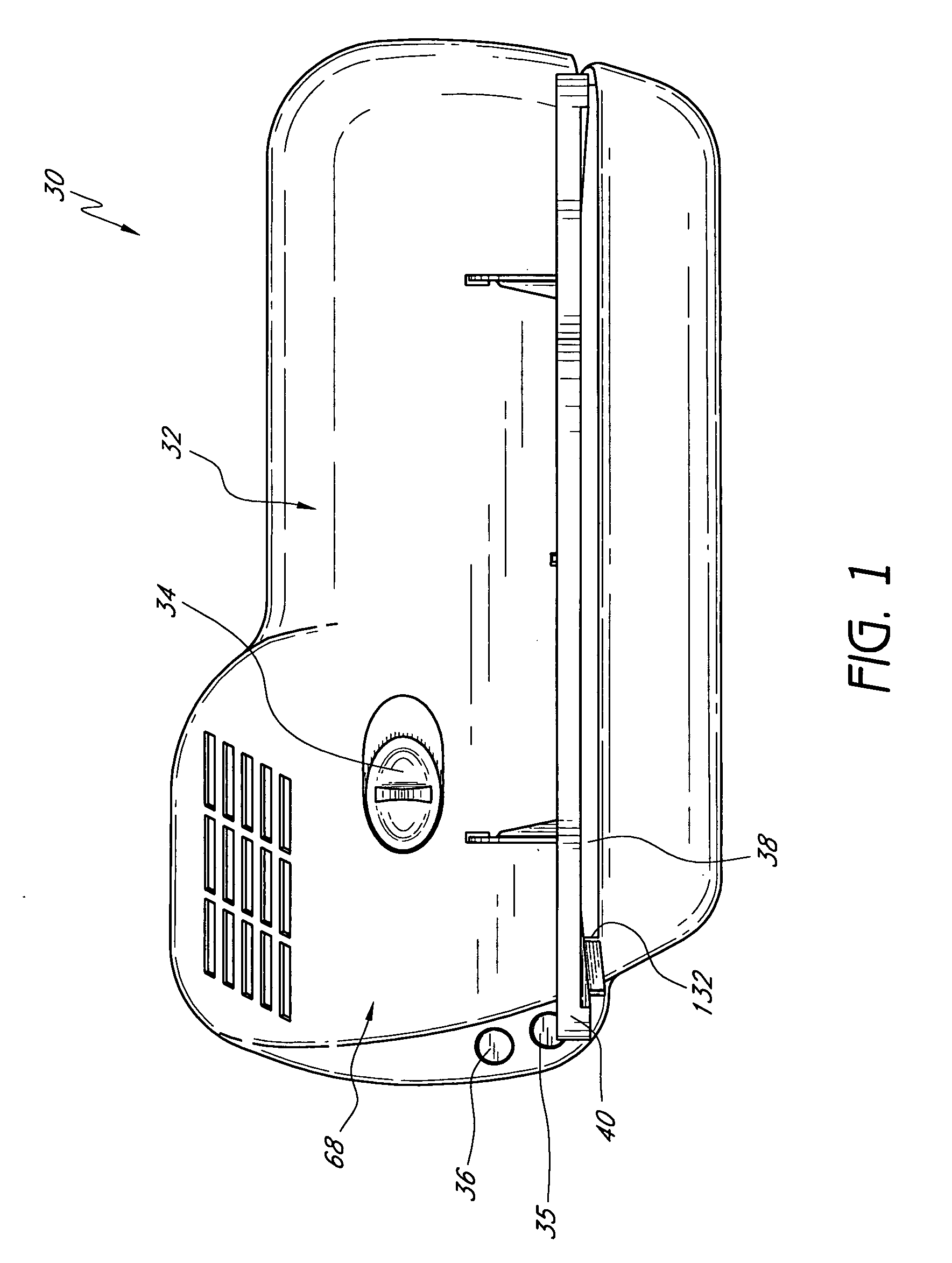

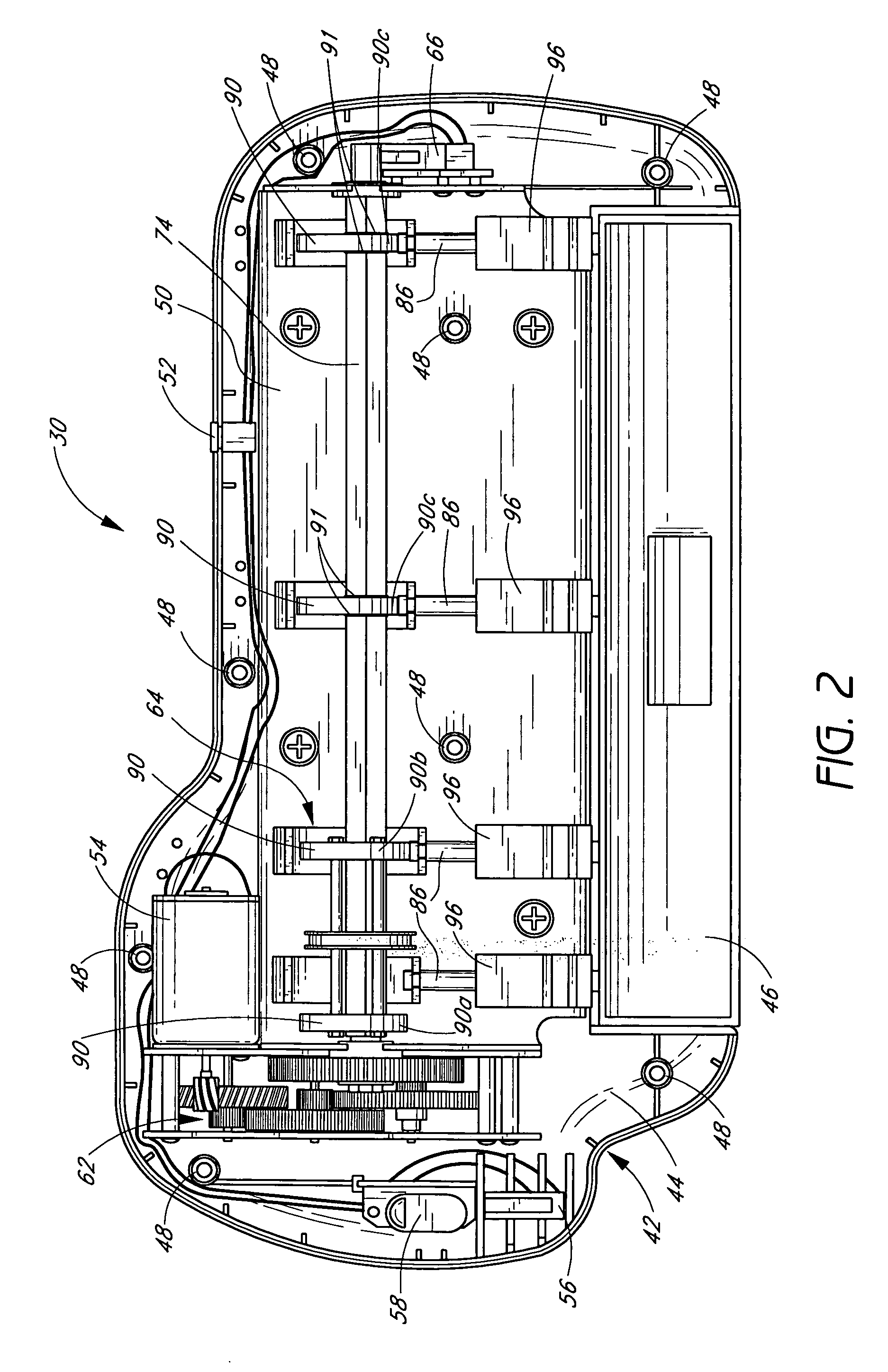

Automatic hole punching devices and methods

An automatic hole punch is disclosed for creating holes in a sheave of sheet material. The automatic hole punch is preferably user-selectable between punching modes, such as two-hole and three-hole modes. A motor is coupled to a camshaft by a gear train. The cam shaft carries a plurality of cams each having an associated punch. As the camshaft rotates, the cams sequentially drive corresponding punches. However, depending on the selected modality, one or more punches may be idle by not being engaged with their respective cams, thus resulting in varying combinations of driven punches resulting in different hole patterns. Finally, a spacer can be inserted into a material receiving slot for adjusting the relative positioning of the material to the punches to properly position the hole pattern along an edge of the material to be punched.

Owner:KO JOSEPH Y

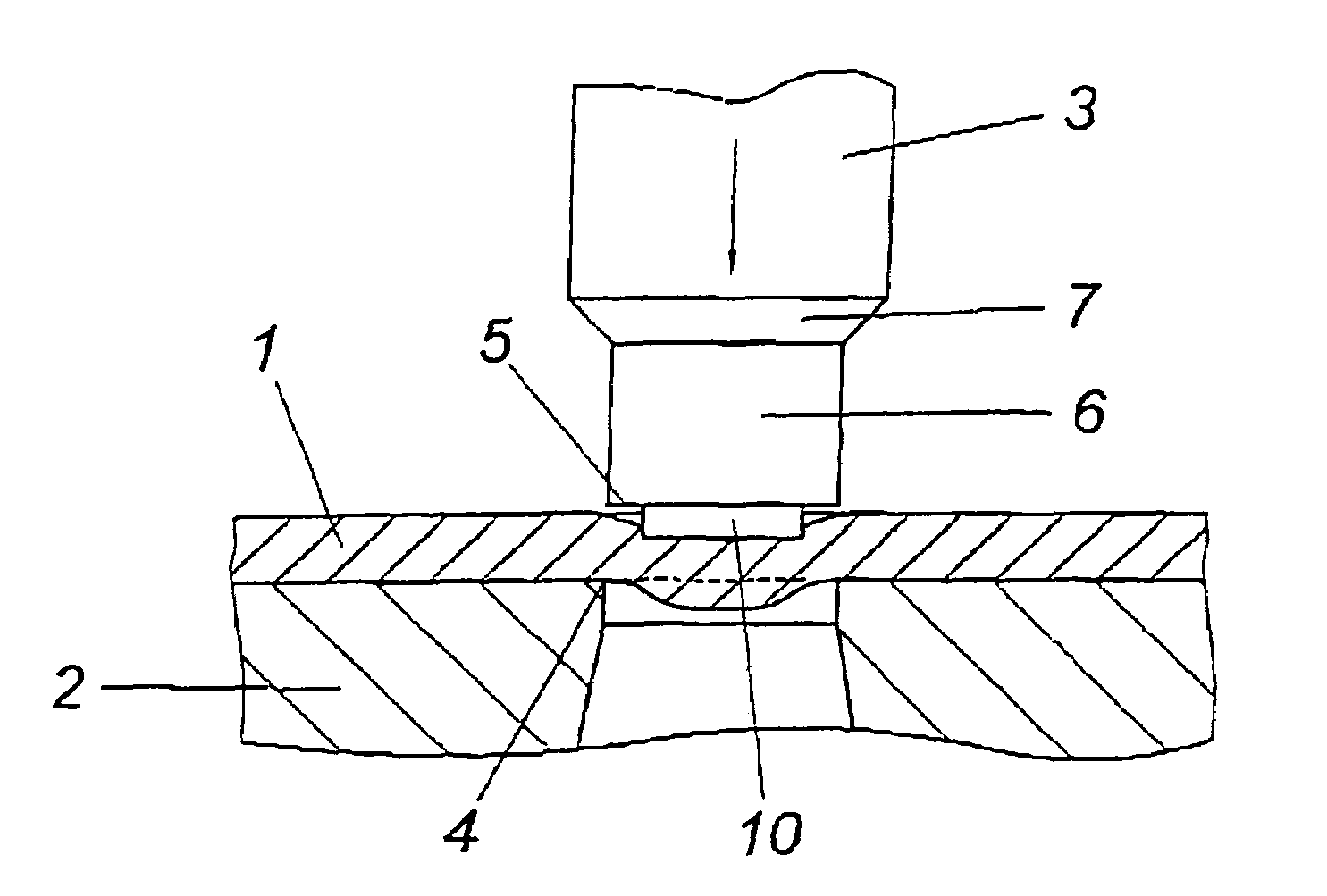

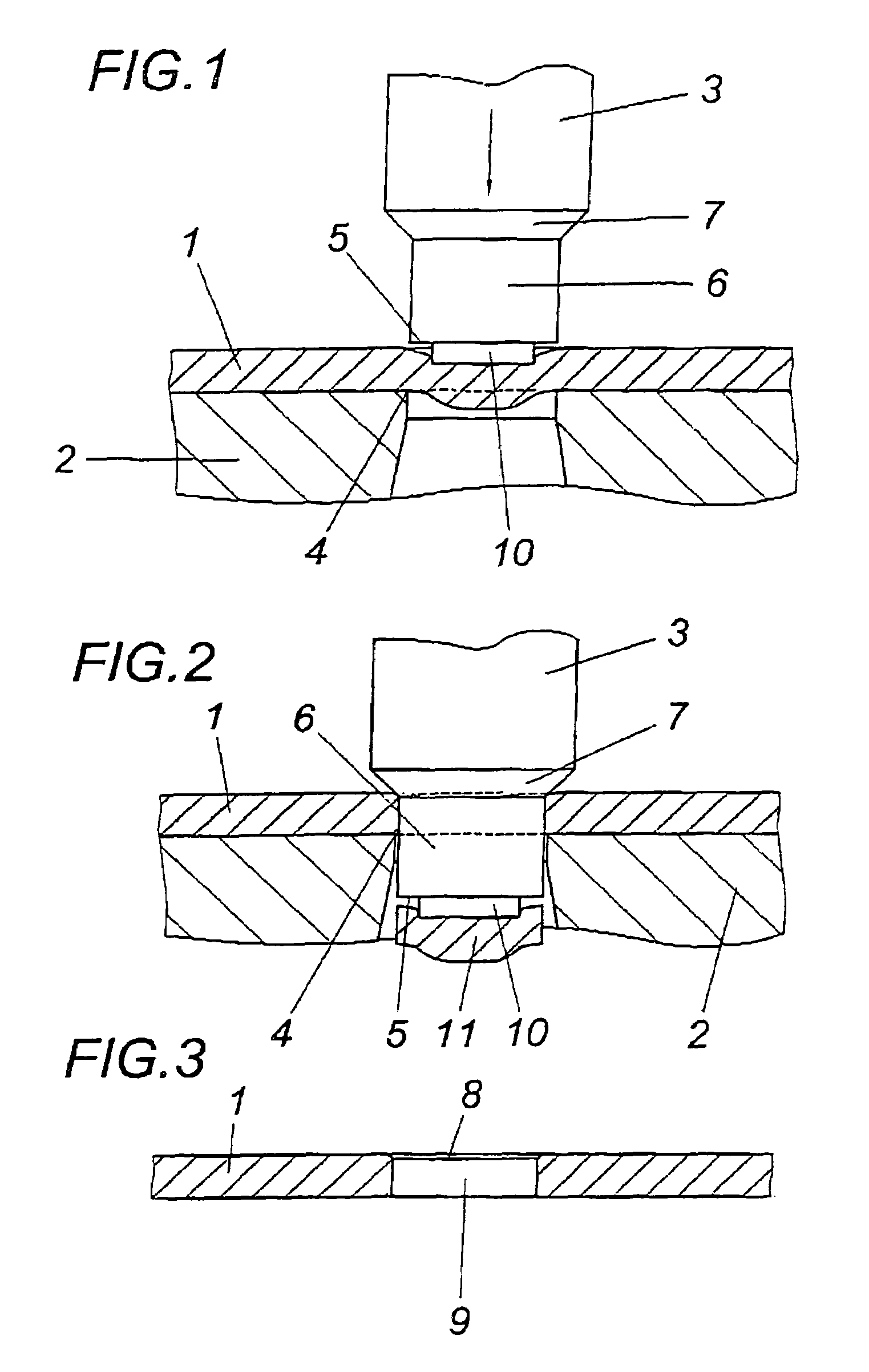

Method for perforating a sheet

A method for perforating a sheet (1) with the aid of a stamp (3) and a matrix (2) is described, the sheet (1) being elongated before the hole punching in accordance with the setpoint diameter in the hole boundary area through bulging of the hole area. In order to be able to stamp flat perforated sheets, it is suggested that the sheet (1) be countersunk through embossing in the hole boundary area on the side diametrically opposite the matrix (2) after the hole punching to equalize internal tensions.

Owner:GASSNER GMBH & CO KG

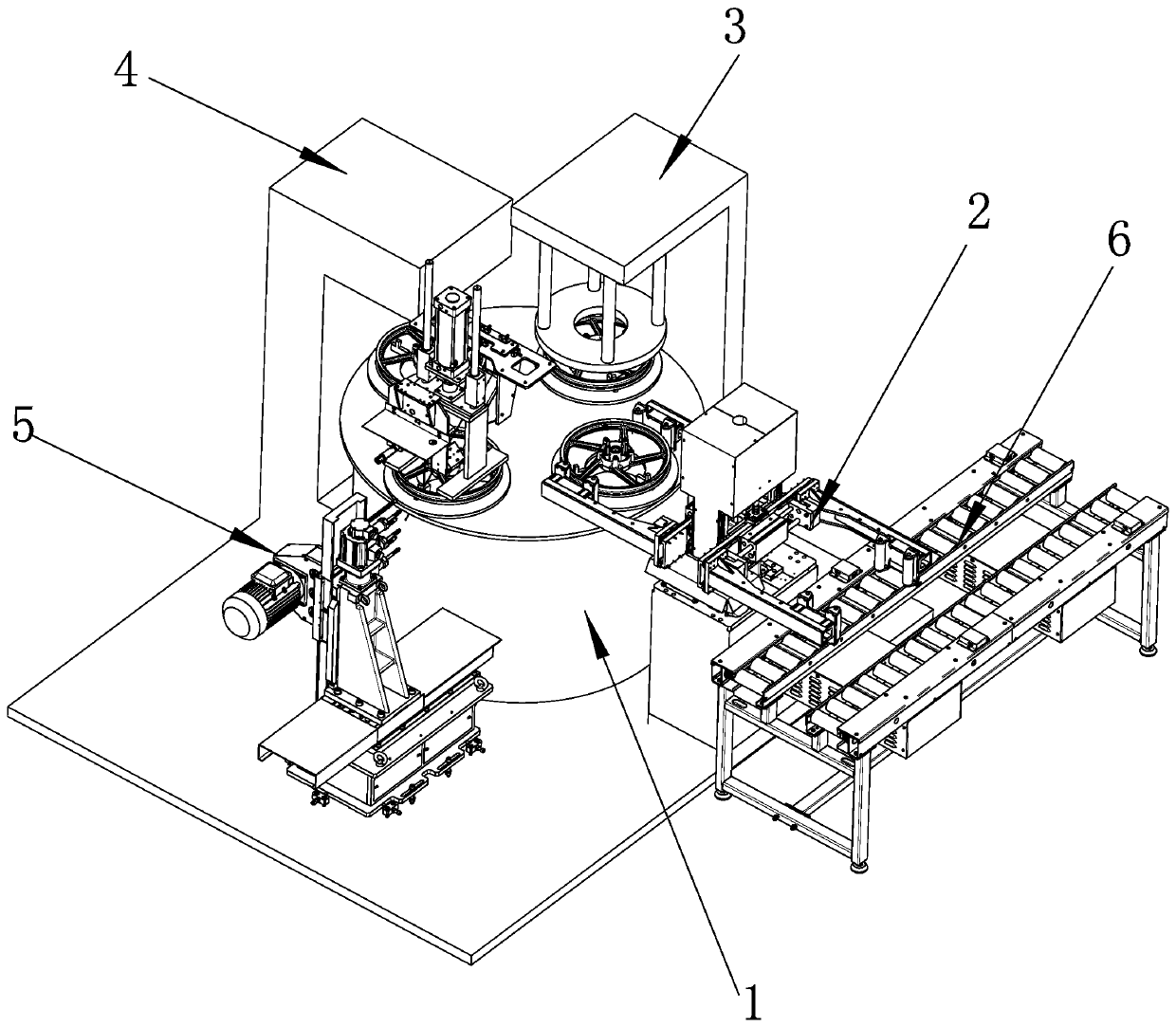

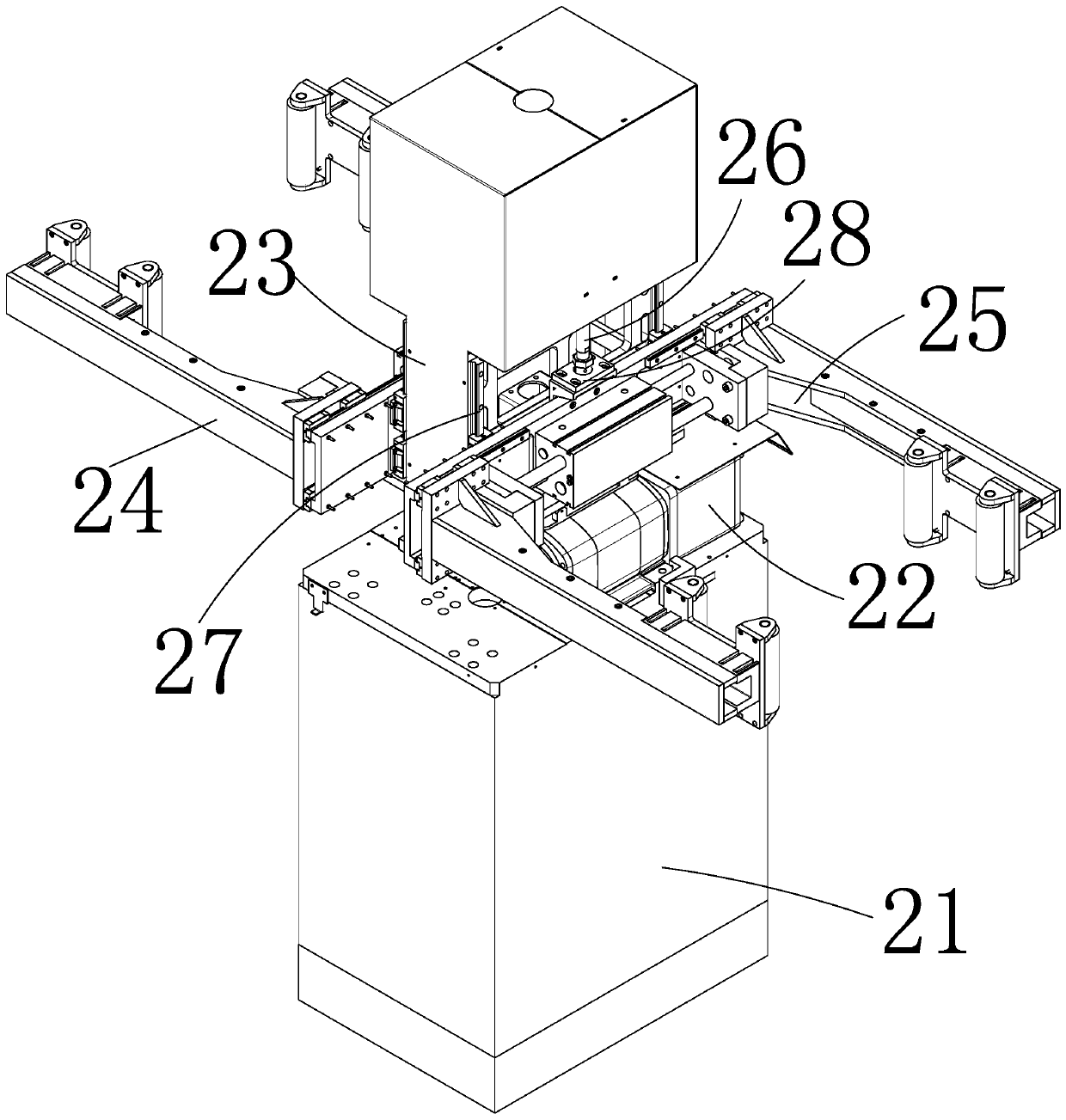

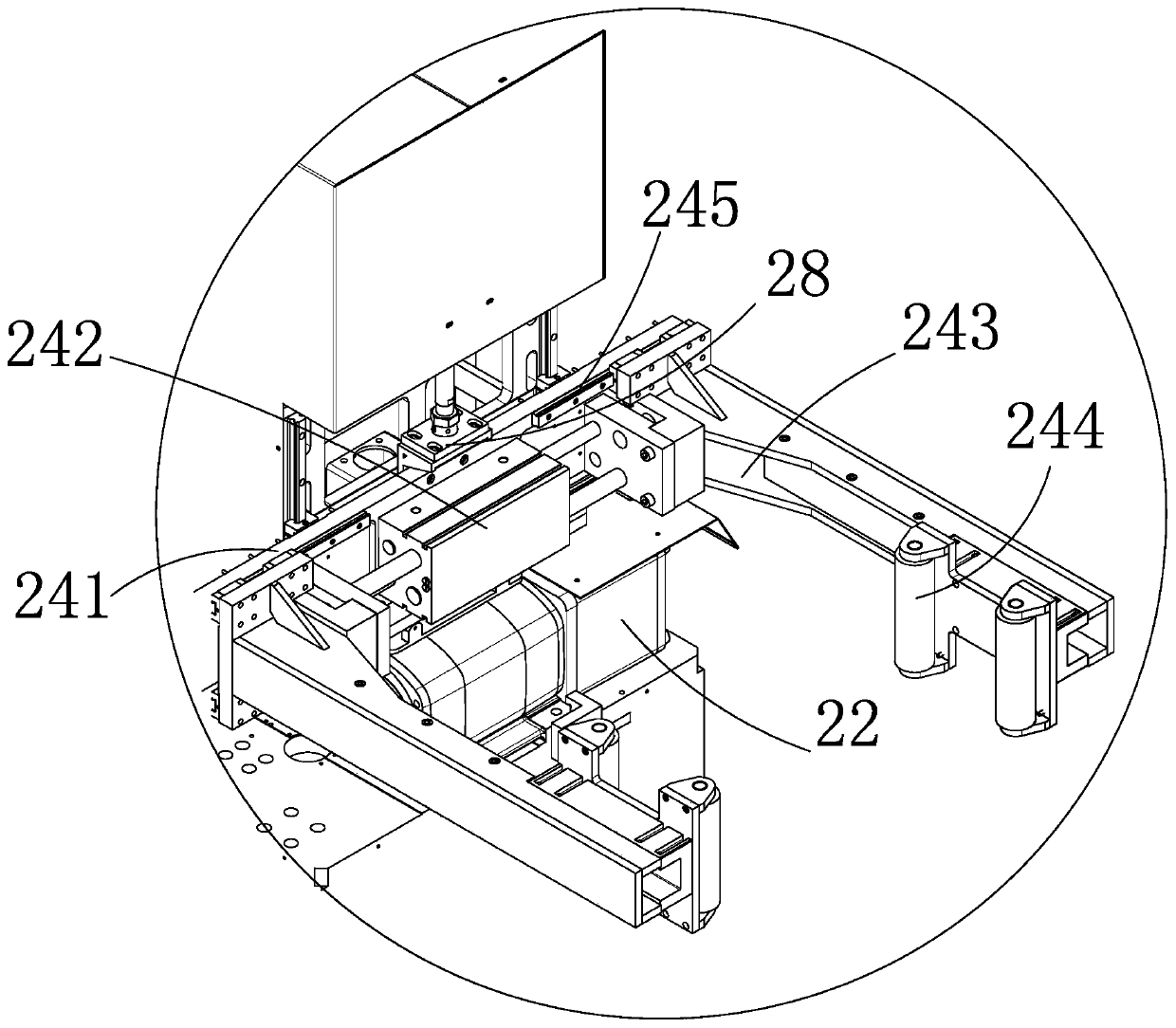

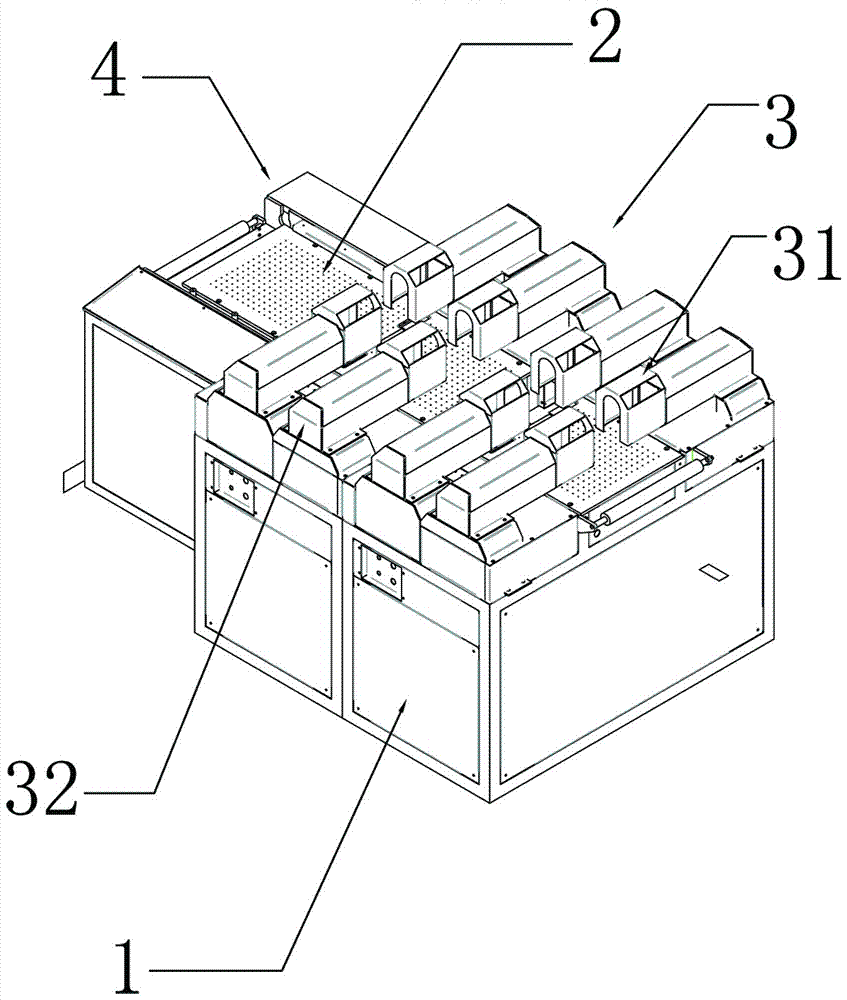

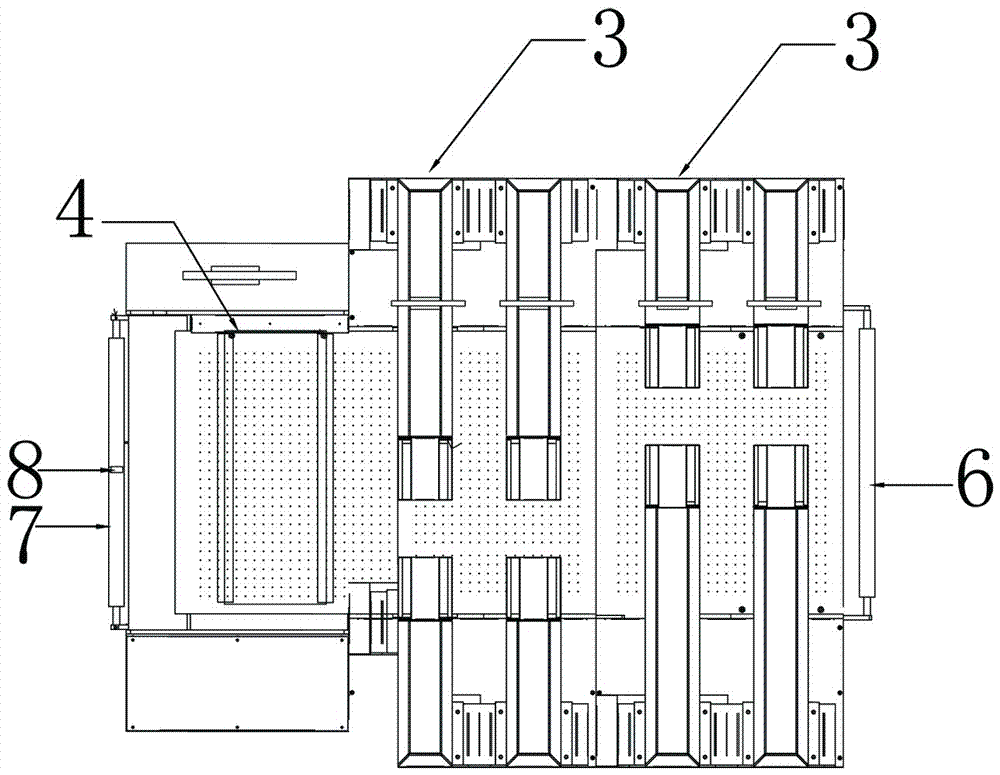

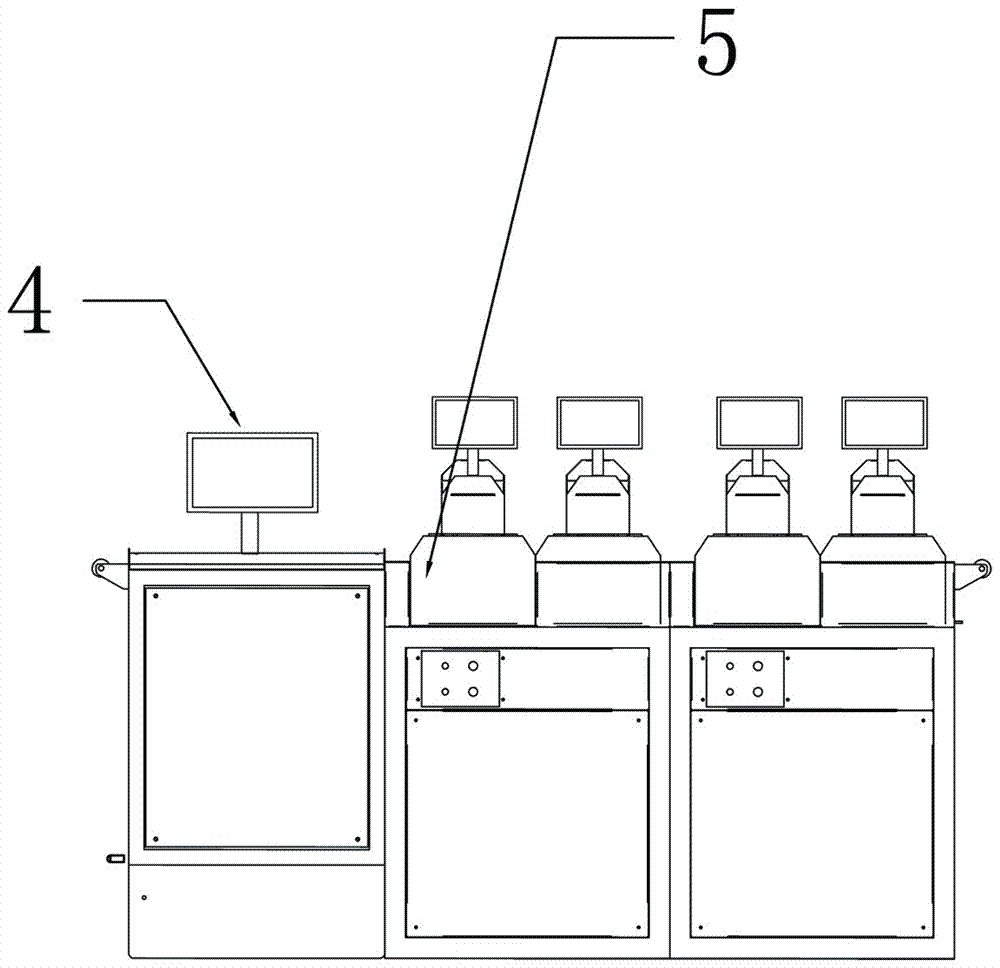

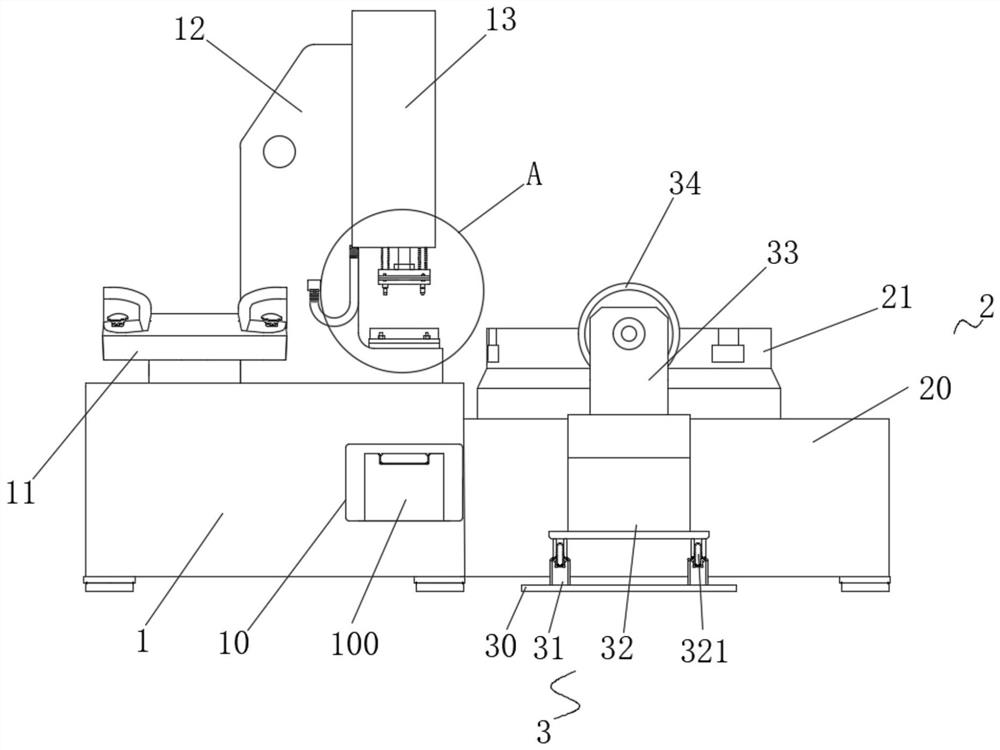

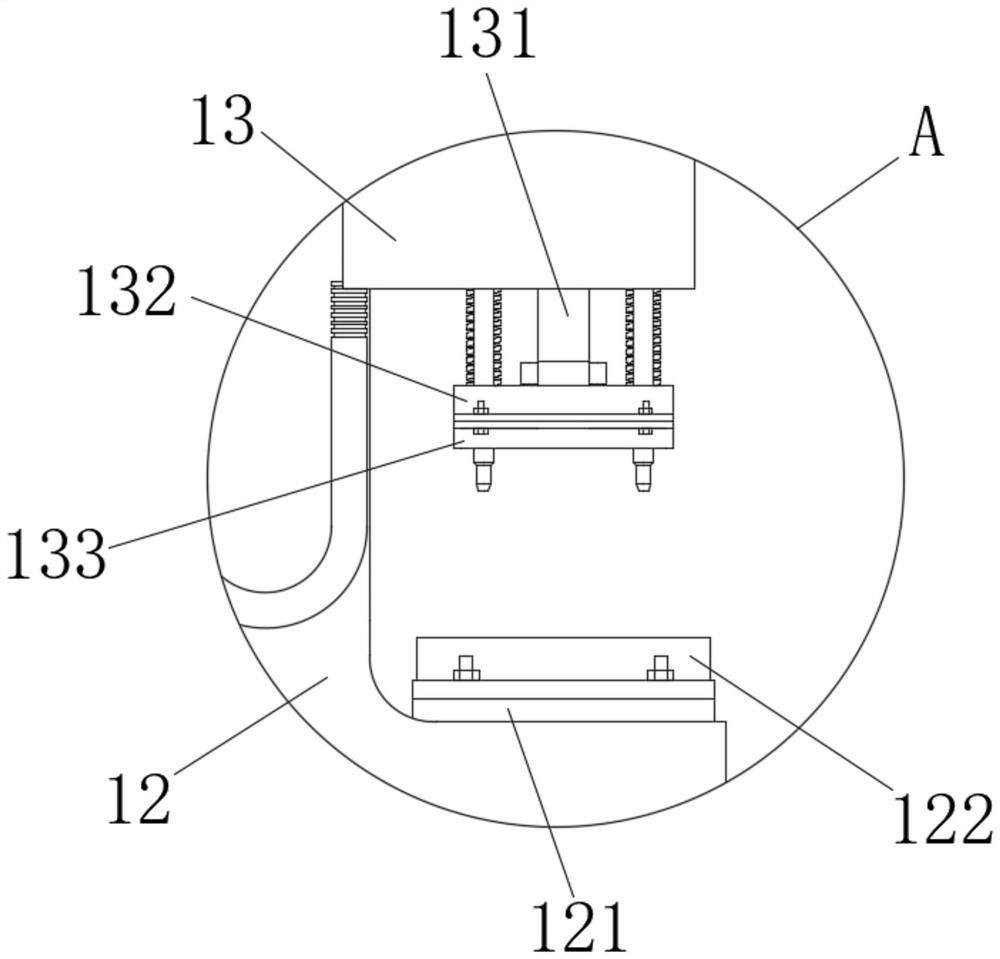

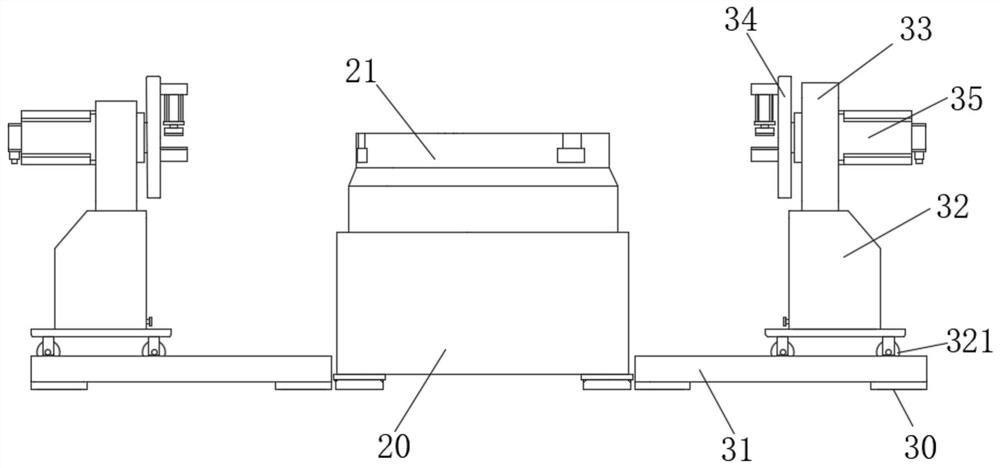

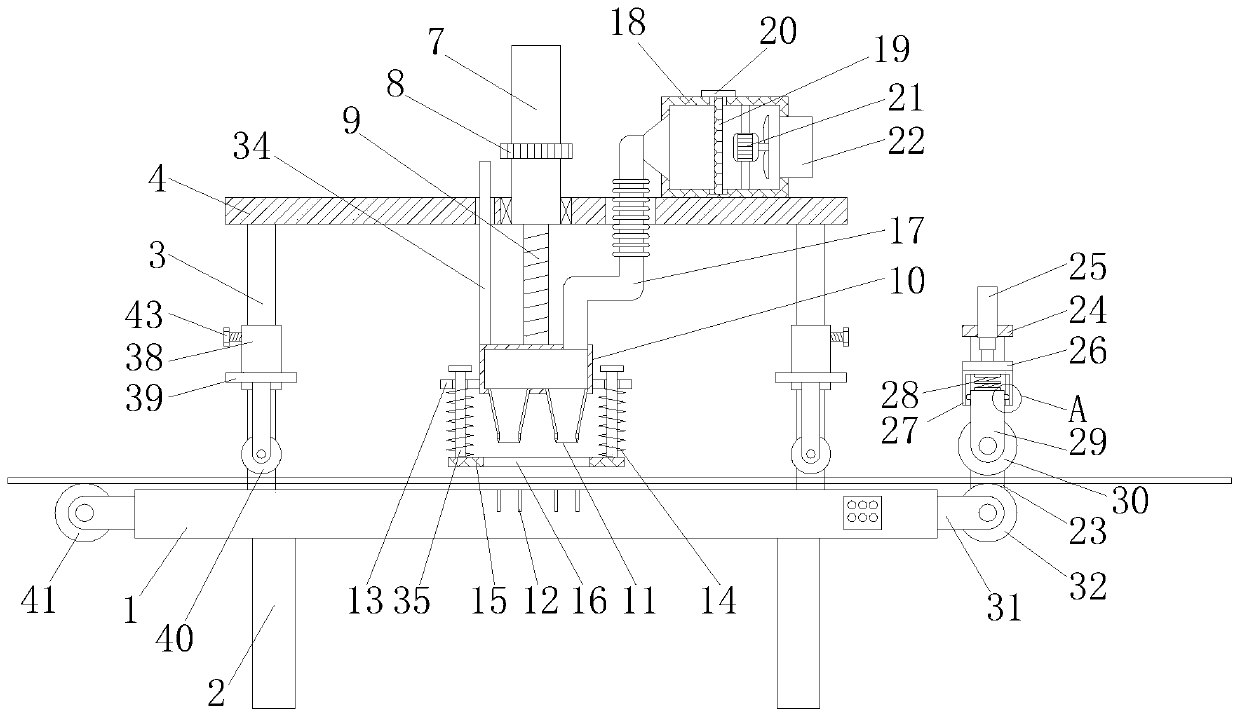

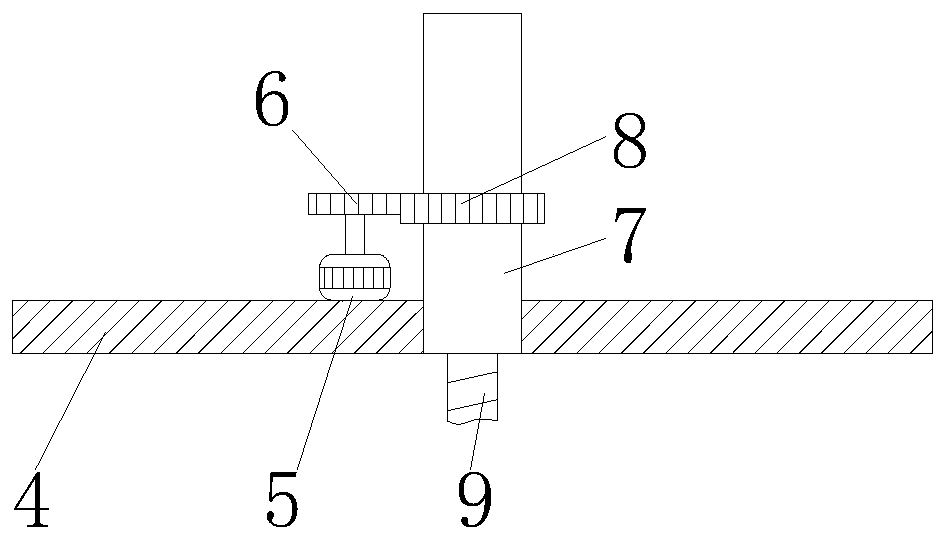

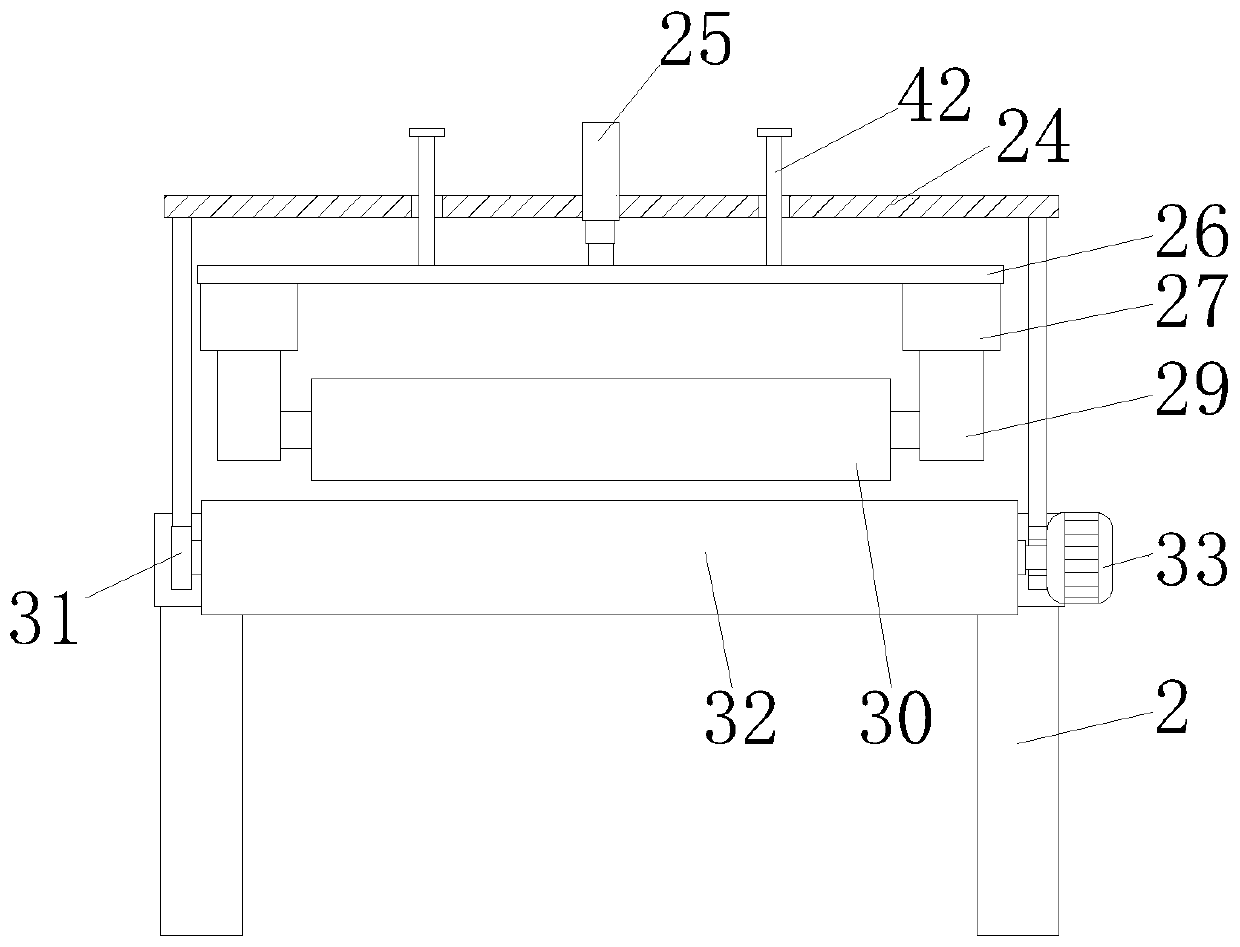

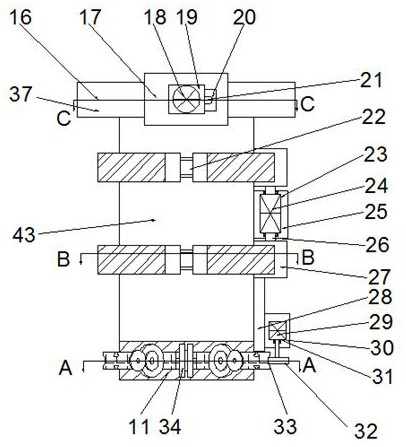

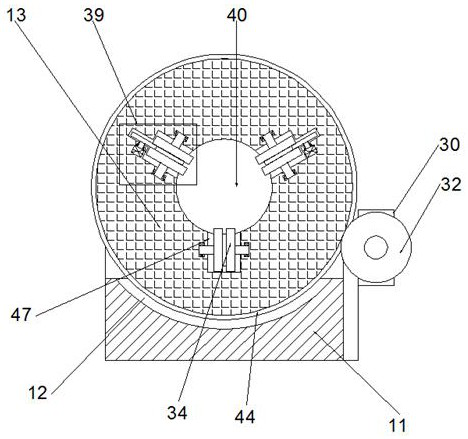

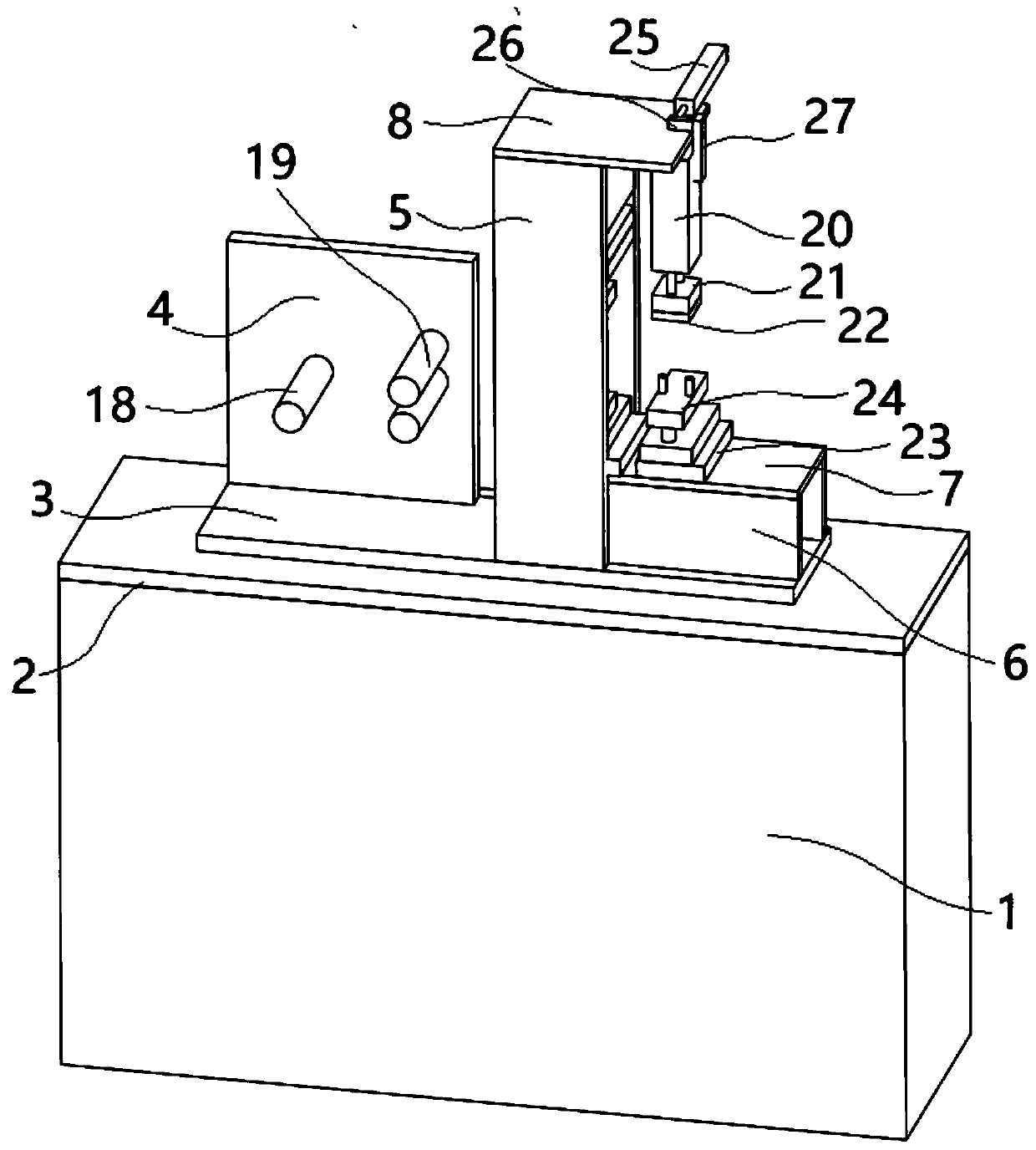

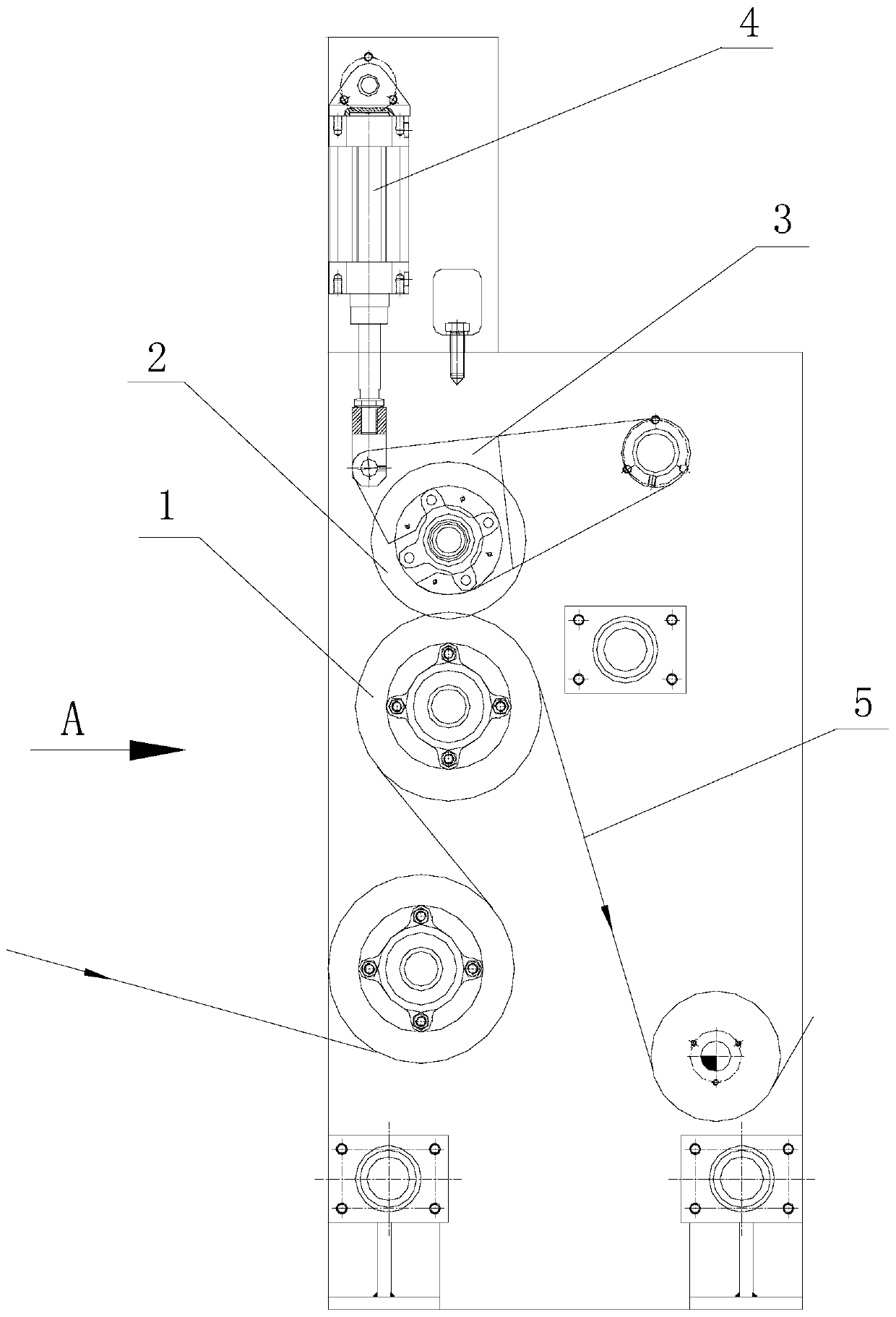

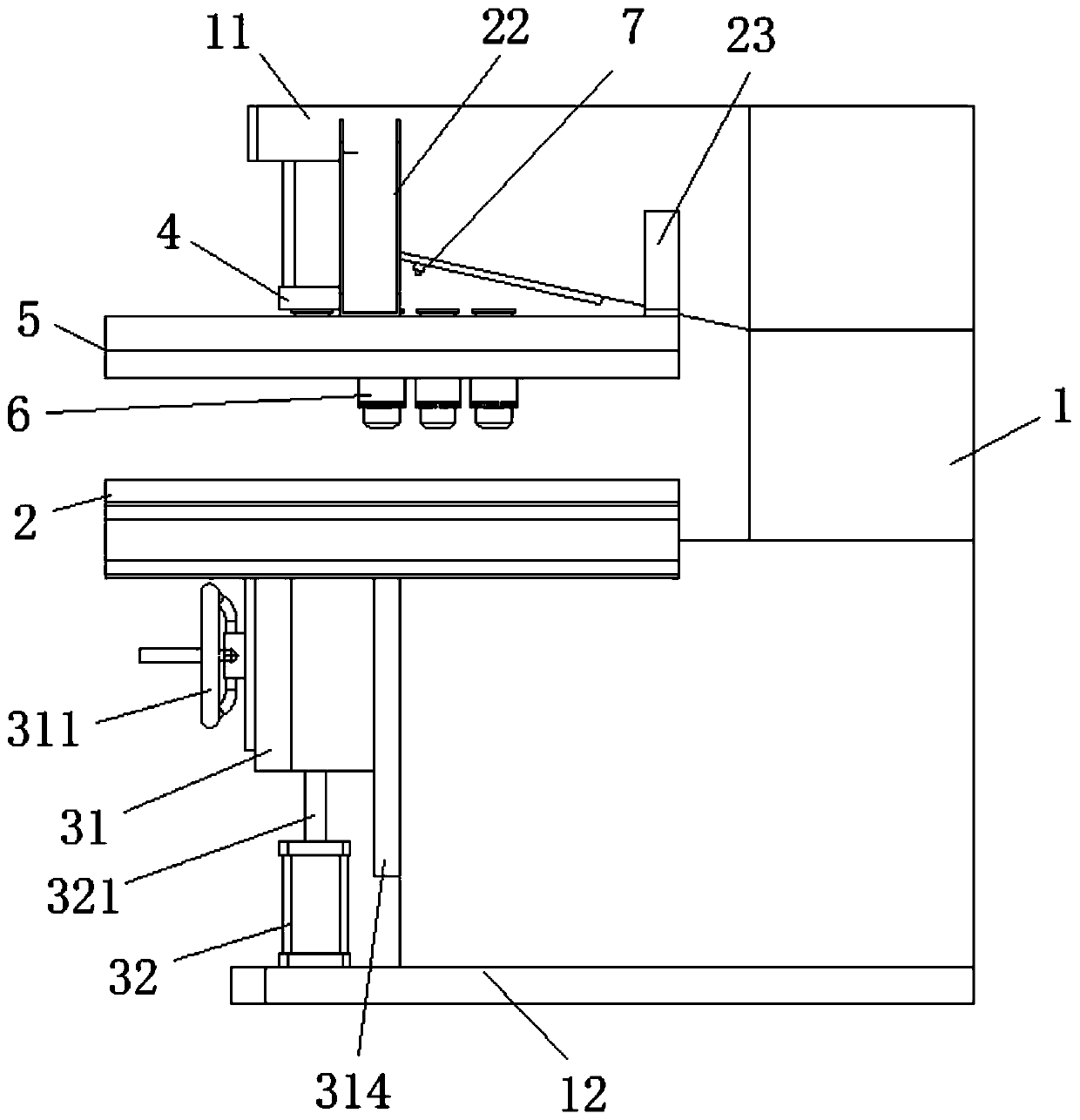

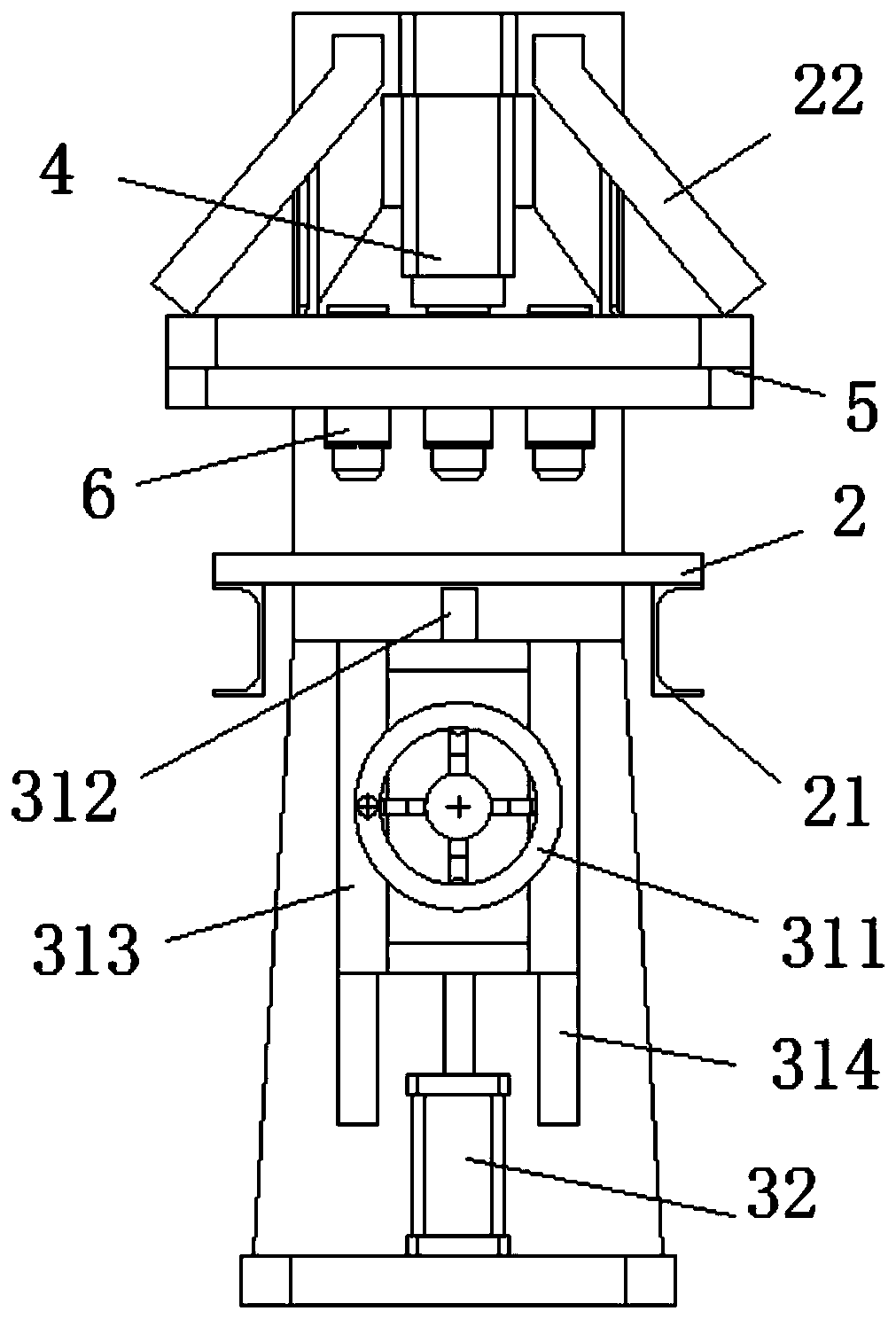

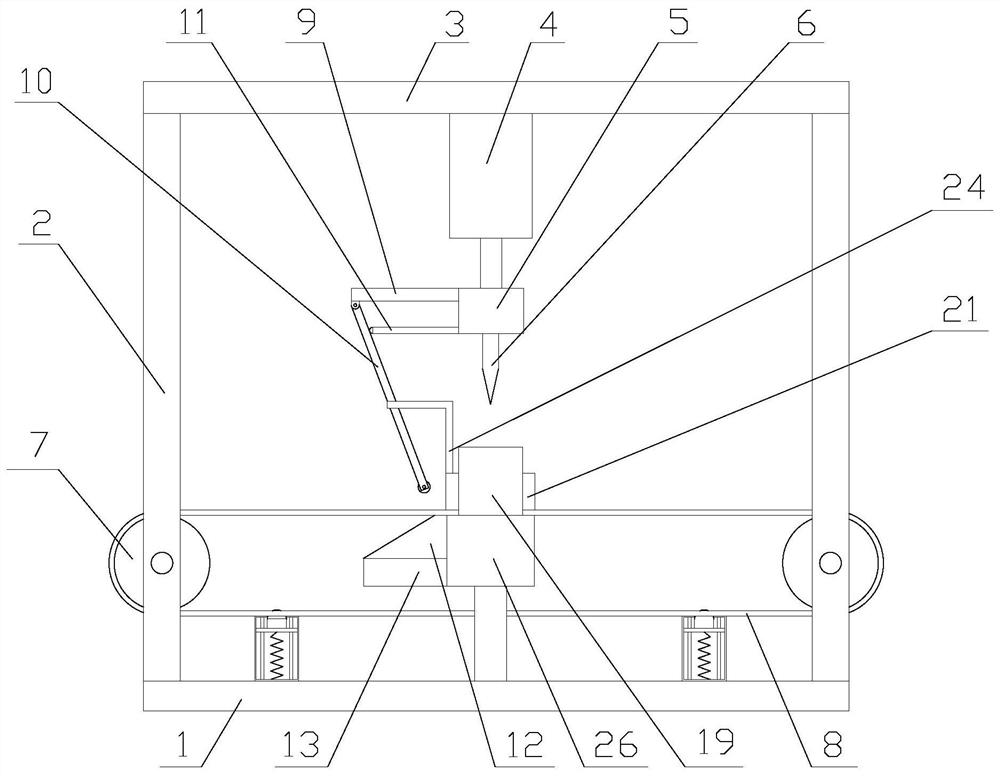

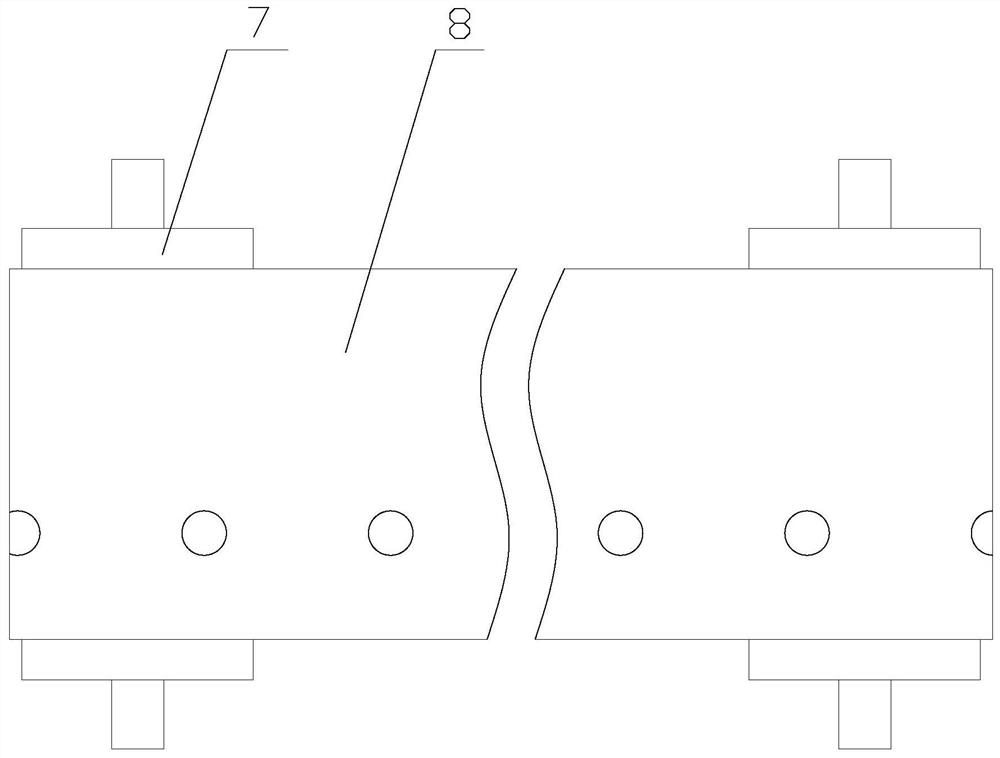

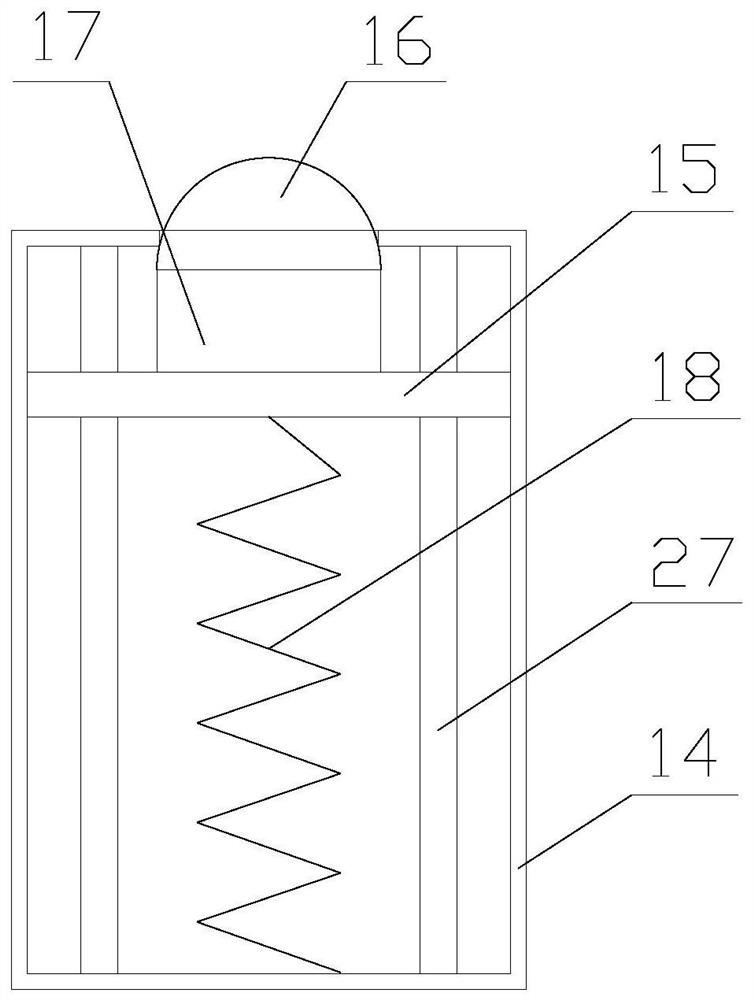

Intelligent processing system for aluminum alloy hub reshaping, base surface turning and valve hole punching

PendingCN111300062ASave spaceLow costOther manufacturing equipments/toolsMetal working apparatusControl systemEngineering

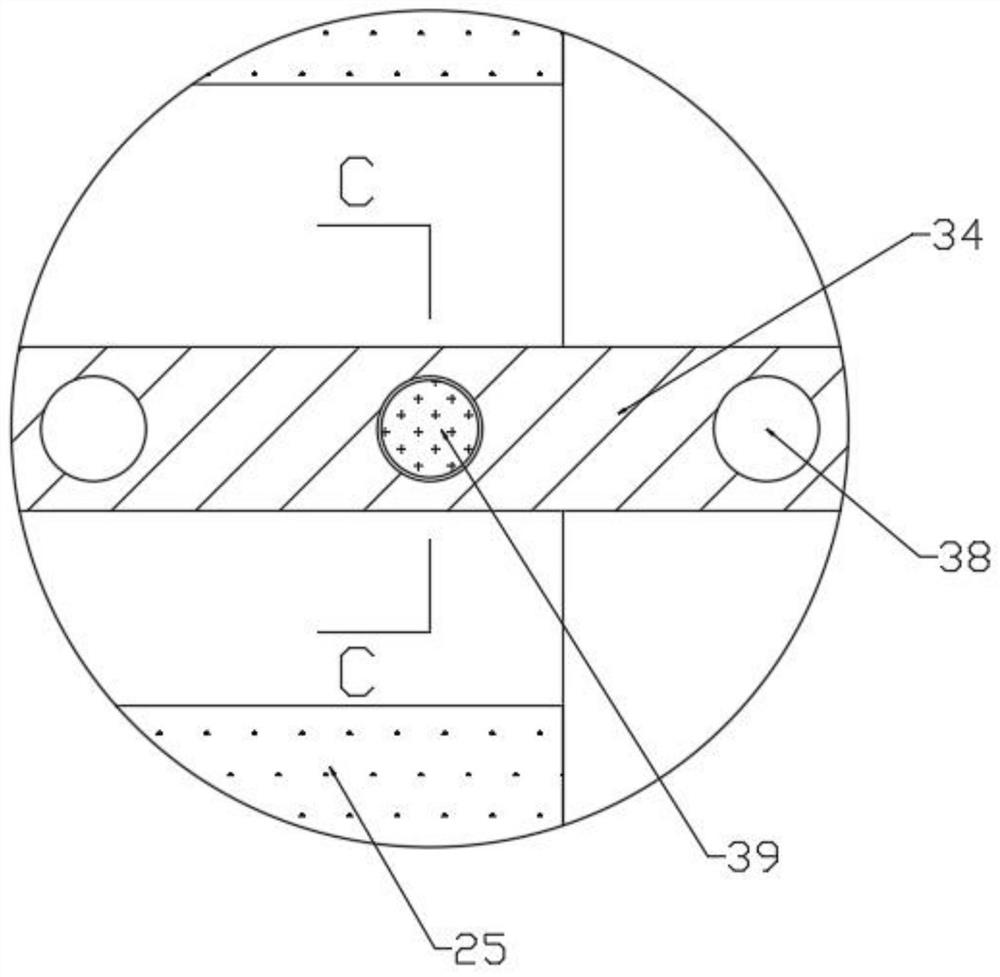

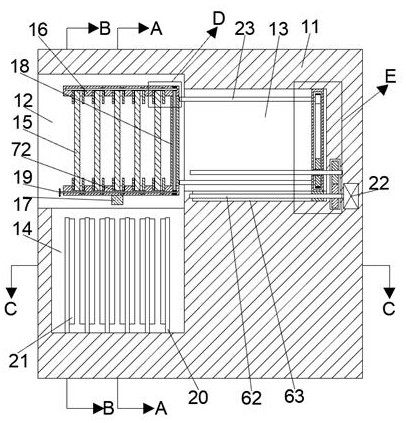

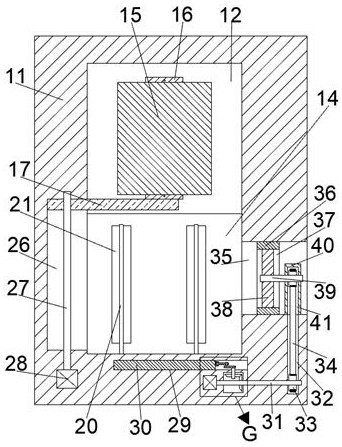

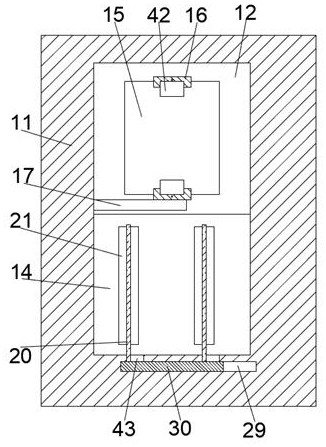

The invention discloses an intelligent processing system for aluminum alloy hub reshaping, base surface turning and valve hole punching. The intelligent processing system comprises a rotary disc mechanism as well as a hub transporting mechanism, a hub reshaping mechanism, a hub base surface turning mechanism and a valve core punching mechanism which are arranged around the periphery of the rotarydisc mechanism, wherein a plurality of centering stations are arranged on the rotary disc mechanism; the hub transporting mechanism is used for loading and unloading; the rotary disc mechanism rotatesto drive to-be-processed hubs on the centering stations to sequentially pass through the hub reshaping mechanism, the hub base surface turning mechanism and the valve core punching mechanism; the valve core punching mechanism comprises a visual identifying device and a drilling mechanism; the visual identifying device is used for acquiring hub position data and transmitting the hub position datato a PLC control system; and the PLC control system controls the drilling mechanism to drill. The intelligent processing system can realize quickly switching hubs among the stations, accomplishes processing of the hub according to the process flow, solves the problem workpieces in an existing production process are quickly rotated for processing, is intensive in process, is automatic in processing, and improves working efficiency.

Owner:XIANGNONG INTELLIGENT TECH CO LTD

Flexible circuit board punching machine

ActiveCN107454748ASolve easy deviationTroubleshoot issues causing downtimePrinted circuit manufactureElectronic waste recyclingFlexible circuitsStructural engineering

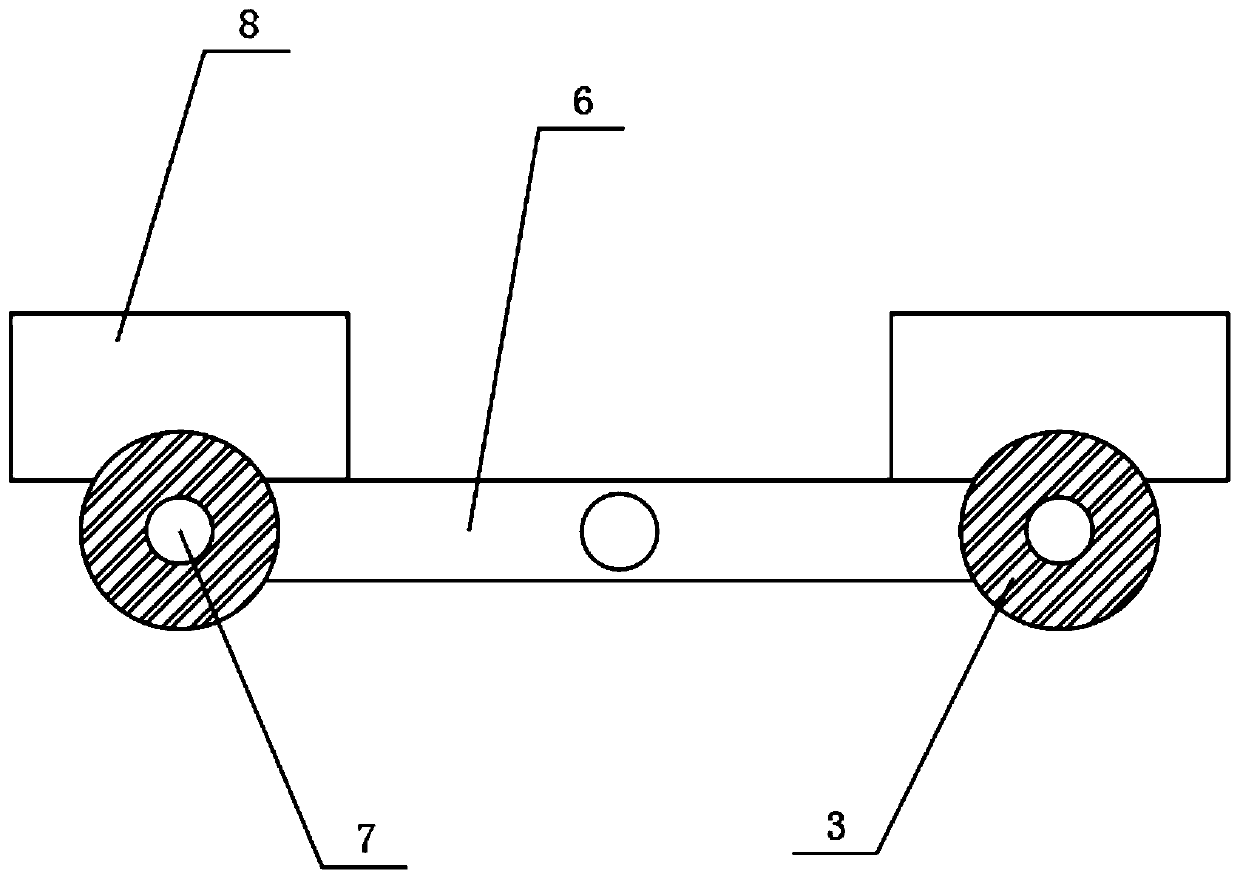

The invention relates to the technical field of printed circuit boards, and particularly relates to a flexible circuit board locating hole punching machine comprising a rack and a conveyor belt which is arranged on the rack. Multiple punching devices are arranged above the conveyor belt. The flexible circuit board locating hole punching machine also comprises a rectification device which is arranged before multiple punching devices. The rectification device comprises a rectification frame which is arranged above the conveyor belt. The rectification frame comprises two side plates which are oppositely arranged at the two sides of the conveying belt and a top plate which is arranged above the conveying belt and connects the two side plates. The internal side of the side plates and the top plate is provided with multiple flexible stop strips. The flexible circuit board locating hole punching machine has the rectification function and can perform rectification before hole punching of the flexible circuit board so that the problem of deviation of the flexible circuit board to be processed can be solved, and the machine has the advantages of being high in hole punching efficiency and stable and reliable.

Owner:MLS

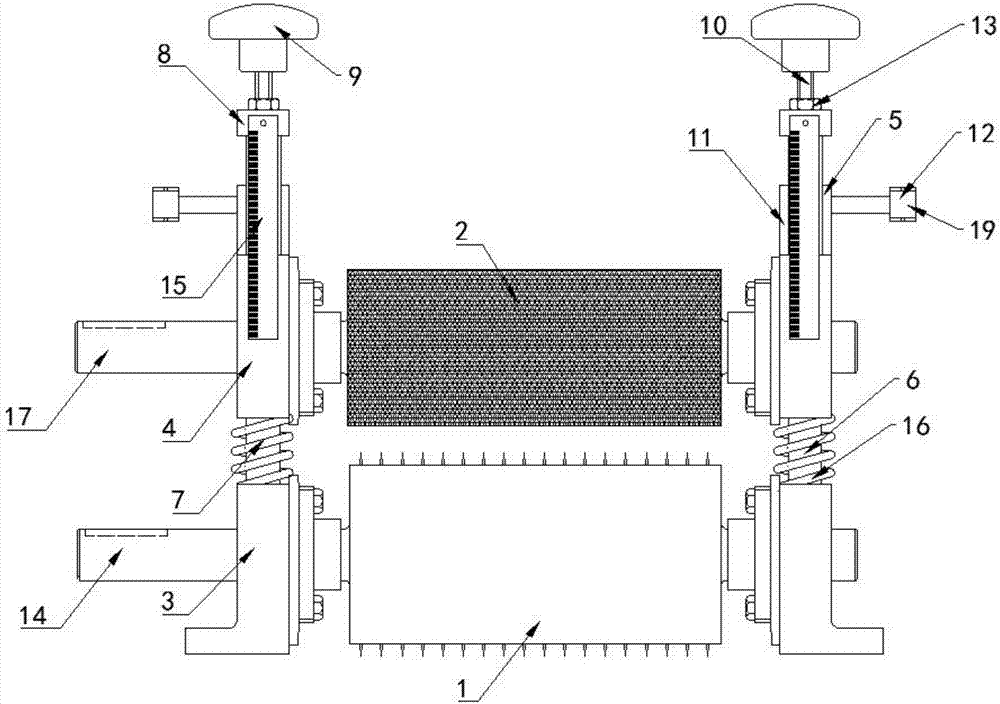

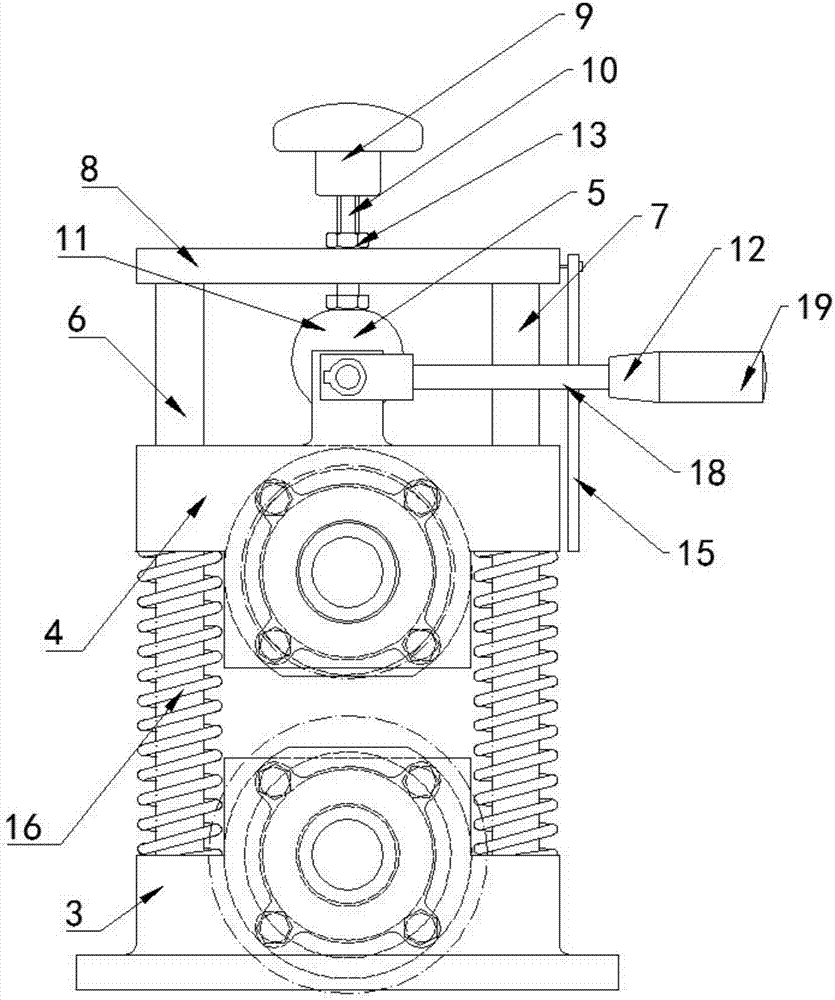

Novel hole puncher

ActiveCN107244098AEasy to operateEasy to adjustBag making operationsPaper-makingPlastic packagingElectric machinery

The invention relates to the field of plastic packaging bag production machinery, and discloses a novel hole puncher. The novel hole puncher comprises a cold pin roller, a rubber roller, lower bearing blocks, upper bearing blocks and height adjusting devices. Springs used for supporting the upper bearing blocks are arranged between the upper bearing blocks and the lower bearing blocks. Each height adjusting device comprises a fixed handle, a screw, a cam mechanism and an adjusting handle, wherein the cam mechanism is fixedly connected with the corresponding upper bearing block. One end of one of the lower bearing blocks is provided with a first motor used for driving the cold pin roller to rotate. According to the novel hole puncher, when a large gap needs to be changed, coarse adjustment can be conducted through the height adjusting devices, then fine adjustment is conducted through the cam mechanisms, large displacement can be met, in addition, adjustment can be more accurate through fine adjustment, and the hole punching quality of the novel hole puncher is guaranteed; and the springs can support the upper bearing blocks, the situation that gravity of the upper bearing blocks is borne only by nuts is avoided, the service life is prolonged, in addition, the springs can support the upper bearing blocks upwards, and thus, the cam mechanisms can be applied to the novel hole puncher.

Owner:斯图尔特针钉制品(郑州)有限公司

Stainless steel plate hole punching device

The invention discloses a stainless steel plate hole punching device which comprises a main machine body. A main arm is arranged in the middle of the upper portion of the main machine body, an operation table is arranged on one side of the main arm, a punching button is arranged on the operation table, a cantilever and a lower base are arranged on one side of the main arm, the cantilever is located over the lower base, a punching air cylinder is arranged below the cantilever, an upper base is arranged at the stretching-out end of the punching air cylinder, a punching die is arranged below the upper base, a supporting die is arranged above the lower base, the punching die and the supporting die can be replaced according to the type and the diameter of a hole needing to be punched, and the requirement for hole punching of a stainless steel plate is met; and a turning assembly is arranged on one side of the main machine body, turnover assemblies are symmetrically arranged on the two sides of the turning assembly, the turning assembly cooperates with the turnover assemblies so that when the stainless steel plate is subjected to hole punching operation, the stainless steel plate can rotate in the direction, holes can be punched in the two faces of the stainless steel plate, the applicability is wide, and multiple hole punching requirements are met.

Owner:安徽华汇电力设备有限公司

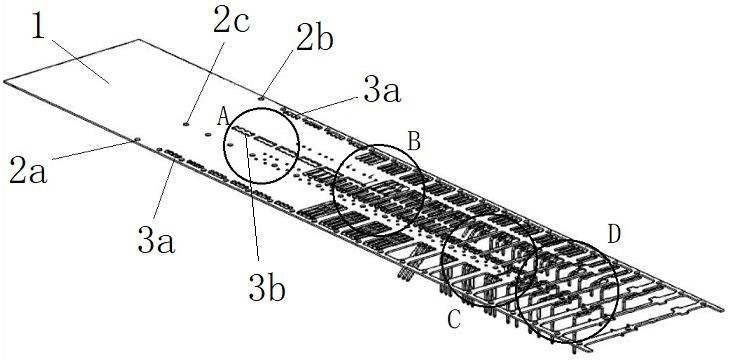

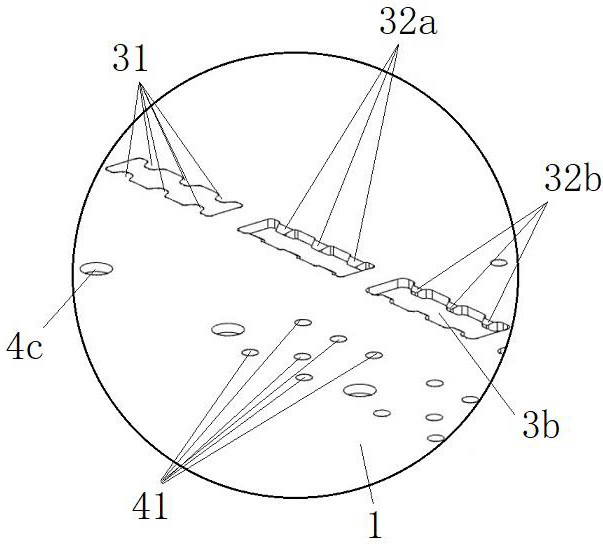

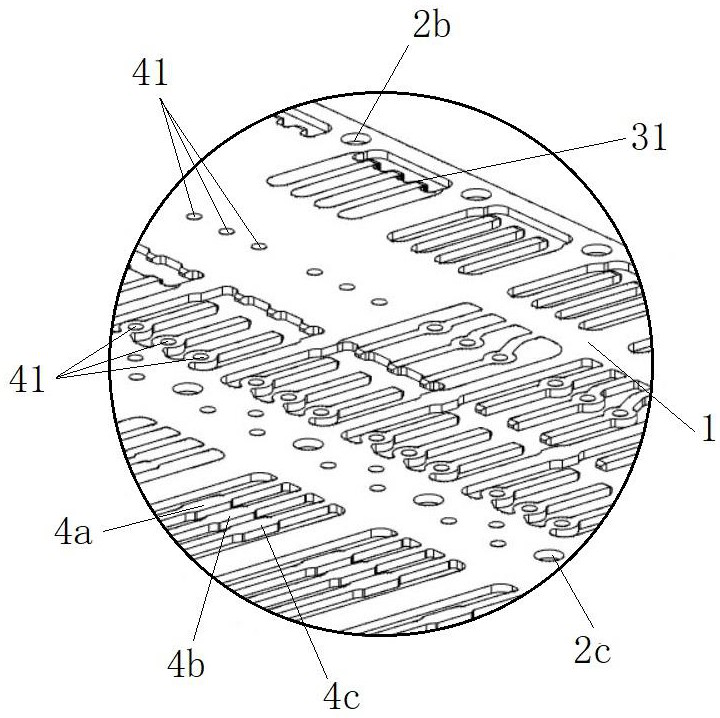

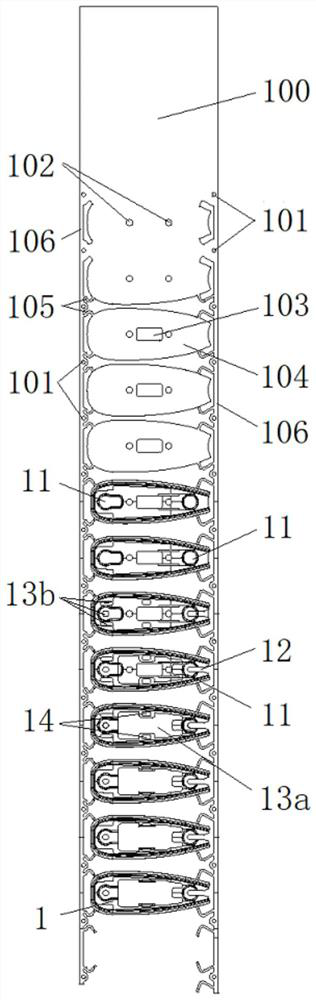

Continuous forming method for thin terminal

ActiveCN113560427AGuaranteed structural accuracyMeet the precision requirementsContact member manufacturingMetal-working feeding devicesStructural engineeringMachining process

The invention belongs to the technical field of stamping machining, and relates to a continuous forming method for a thin terminal. The continuous forming method comprises the steps of (1) positioning hole punching, (2) tail end pre-cutting, (3) tail end chamfering, (4) tail end finishing, (5) edge cutting, and (6) blanking. In the step (2), a plurality of pre-cutting holes are cut in a product forming area with a positioning hole as the benchmark, the pre-cutting holes comprise side pre-cutting holes close to the side edge position of a metal material belt, the outlines of the side pre-cutting holes comprise a plurality of side-by-side protruding structures, the protruding height of the protruding structures does not exceed 2mm, and edge cutting is carried out after chamfering and finishing are carried out on the protruding structures. According to the method, the two ends of the terminal with the small size can be pre-formed into chamfering parts, then the rest outlines of the terminal are punched, the process is continuous, the structural precision of terminal chamfering is ensured, and the precision requirement of a client is met.

Owner:苏州铭峰精密机械有限公司

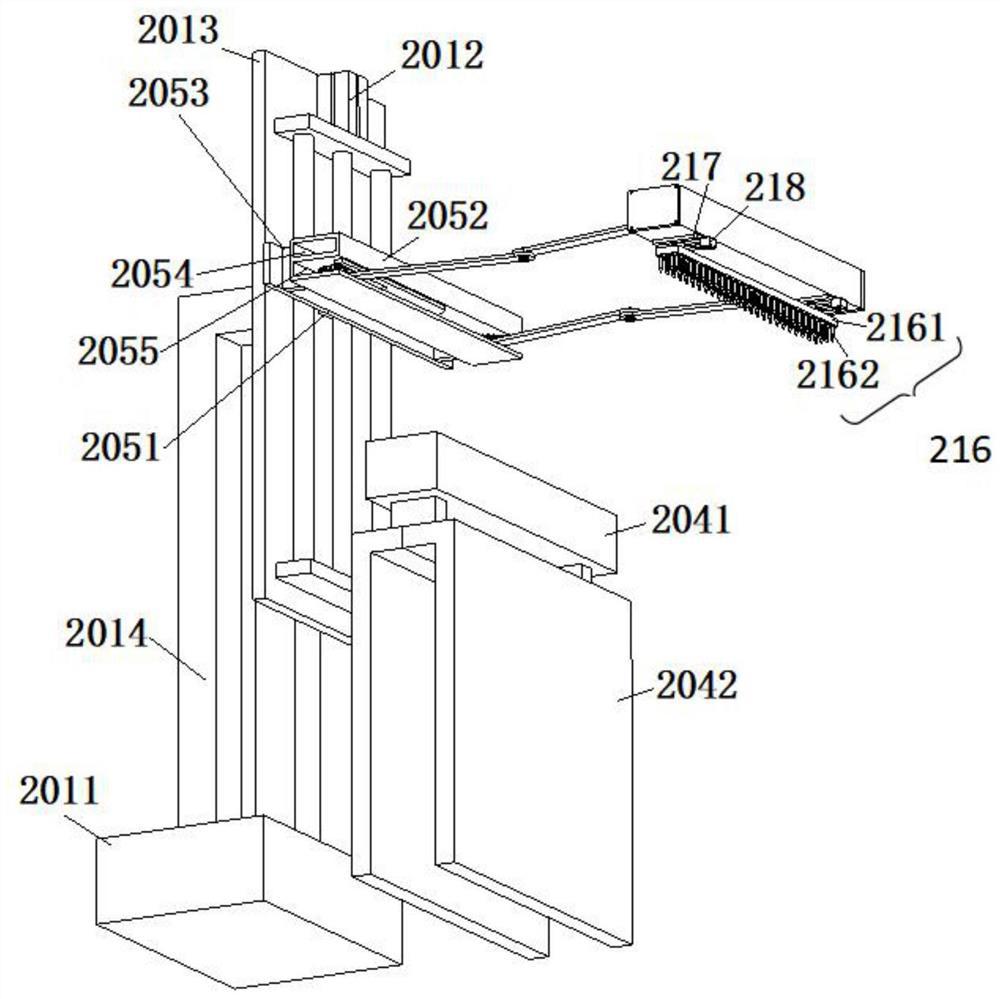

A circuit board processing equipment

ActiveCN111405764BResidue reductionAvoid affecting the final effect of punchingInsulating layers/substrates workingStructural engineeringHole punching

The invention relates to the technical field of circuit board processing, in particular to a circuit board processing equipment, comprising a circuit board conveying device and a positioning punching device, wherein the positioning punching device is arranged on the side of the circuit board conveying device, and the positioning punching device The hole device includes a bearing driving part, a transverse driving part, a bearing punching part and a hole punching cleaning part, the transverse driving part is drivingly connected with the bearing driving part, and the bearing punching part is installed on the output end of the transverse driving part, so The punching and cleaning component is installed between the carrying driving component and the circuit board conveying device, and the output end of the carrying punching component is butted with the top of the circuit board conveying device. The invention realizes the positioning and cleaning operation of the bearing and punching parts through the punching and cleaning parts, reduces the residual residue on the bearing and punching parts, and avoids the inaccuracy of the punching precision during the secondary punching operation, which affects the final effect of the punching. .

Owner:东莞市鹏诚电子有限公司

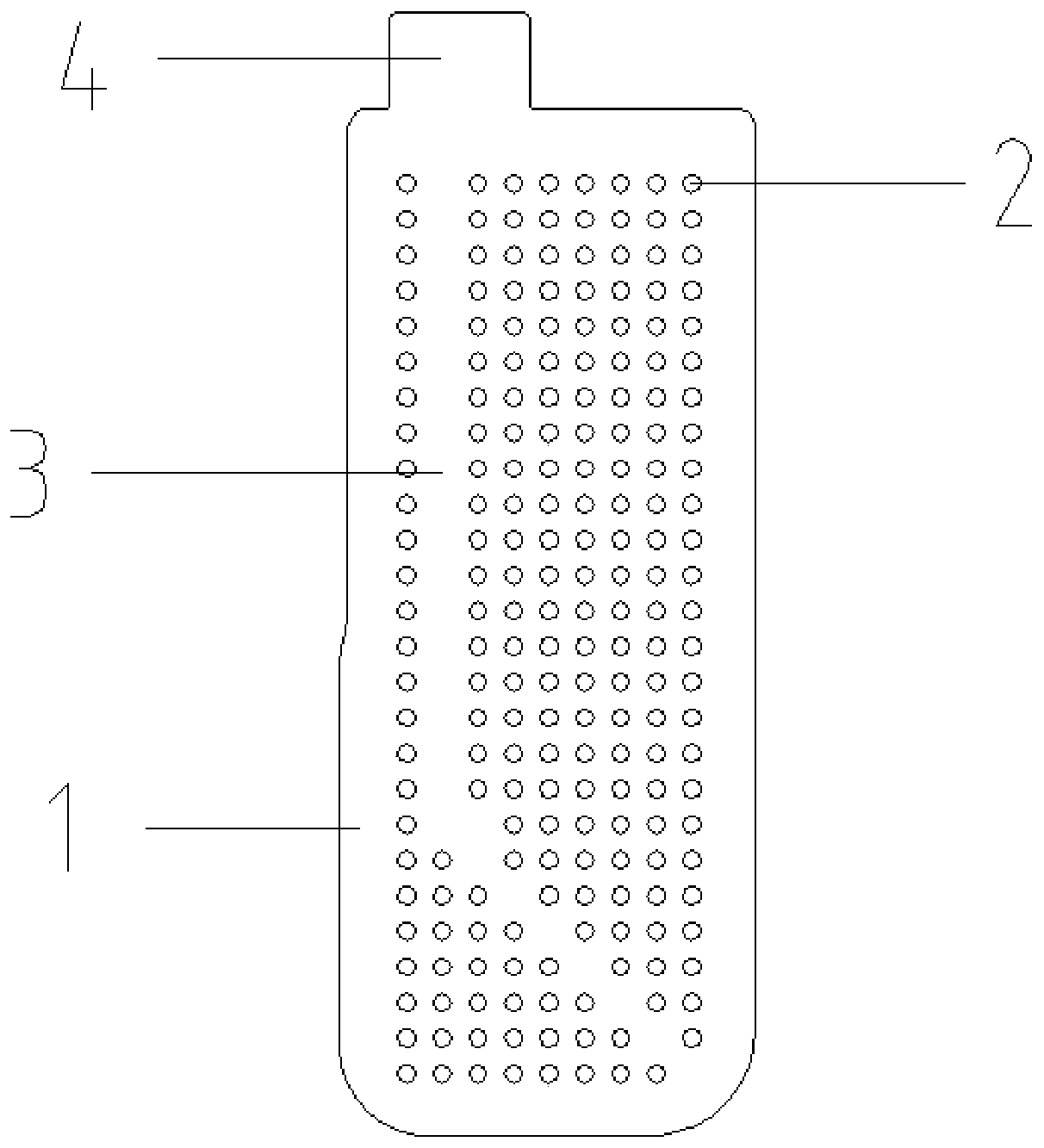

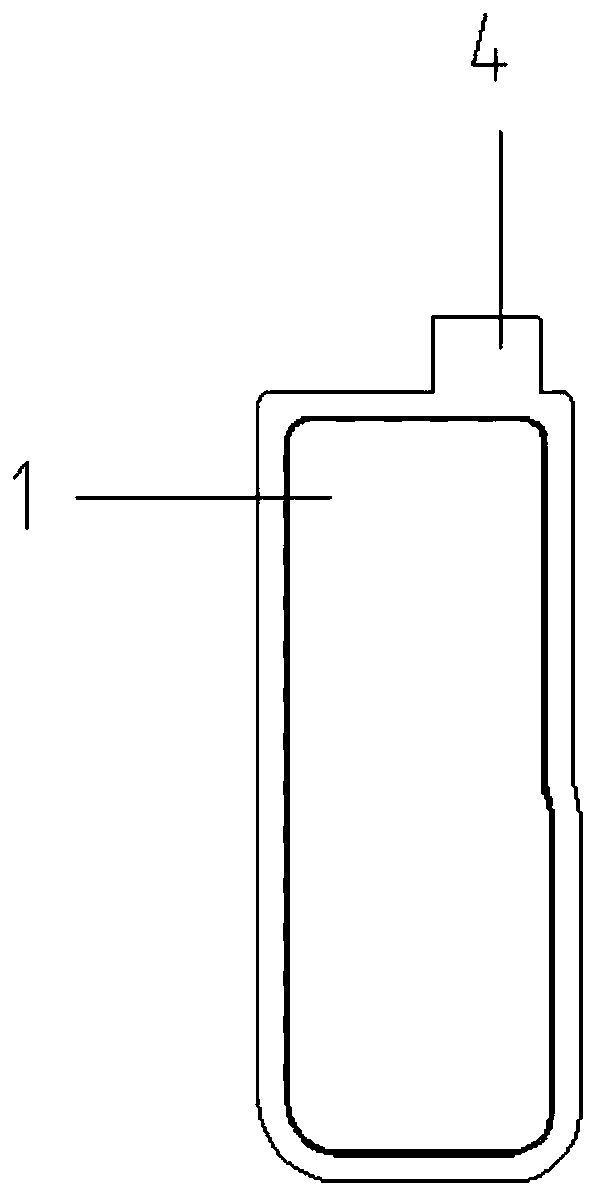

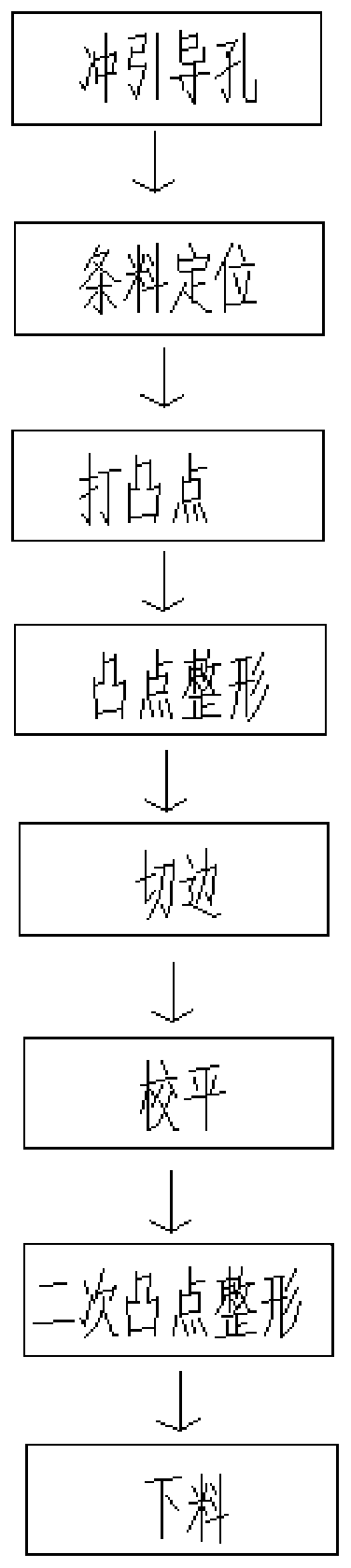

Electronic equipment stamping hardware piece and production process thereof

PendingCN110280677AGuaranteed circulationGuaranteed cooling areaShaping toolsHeat exchange apparatusHeat sinkUltimate tensile strength

The invention provides an electronic equipment stamping hardware piece which is of a sheet-like structure. One surface of the sheet is a smooth plane, and the other surface of the sheet is uniformly provided with outward protruding convex points. A production process of the electronic equipment stamping hardware piece comprises the steps of guide hole punching, strip positioning, convex point forming, convex point shaping, trimming, leveling, secondary convex point shaping and blanking. Radiating fins are formed in a stamping mode, so that the thickness of the radiating fins reaches 0.07mm-0.09mm, meanwhile, convex points are stamped and formed on the back surfaces of the radiating fins, the uniformly-distributed convex points play a role of supporting stress, and the strength of the radiating fins is increased. Meanwhile, due to the design of the radiating convex points, circulation of air is guaranteed, the radiating area is guaranteed, and the radiating effect is better achieved.

Owner:吴义友

Hole punching equipment for facial mask processing and using method

InactiveCN111230993AEasy to sendEasy to move verticallyMetal working apparatusWebs handlingThreaded pipeWorking environment

The invention discloses hole punching equipment for facial mask processing and a using method. The equipment comprises a table plate, supporting legs are fixedly connected to the four corners of the bottom of the table plate, square rods are fixedly connected to the four corners of the top of the table plate, a transverse plate is fixedly connected to the tops of the square rods, a first motor isfixedly connected to the rear side of the top of the transverse plate, the top of a rotating shaft of the first motor is fixedly connected with a first gear, a threaded pipe penetrates through the topof the transverse plate, and the bottom of the threaded pipe penetrates through the transverse plate and is movably connected with the transverse plate. The equipment and the method have the advantages of collecting waste after punching and conveniently conveying facial mask paper, and solve the problems that according to existing facial mask hole punching processing equipment, the waste cannot be conveniently collected, the waste is driven to be conveyed together in the facial mask conveying process, the waste is scattered to all places, and the working environment is polluted, and meanwhile, the facial mask paper cannot be conveniently tensioned and conveyed, the phenomenon that the facial mask paper stagnates is prone to occurring, and facial mask paper processing is not facilitated.

Owner:黄文开

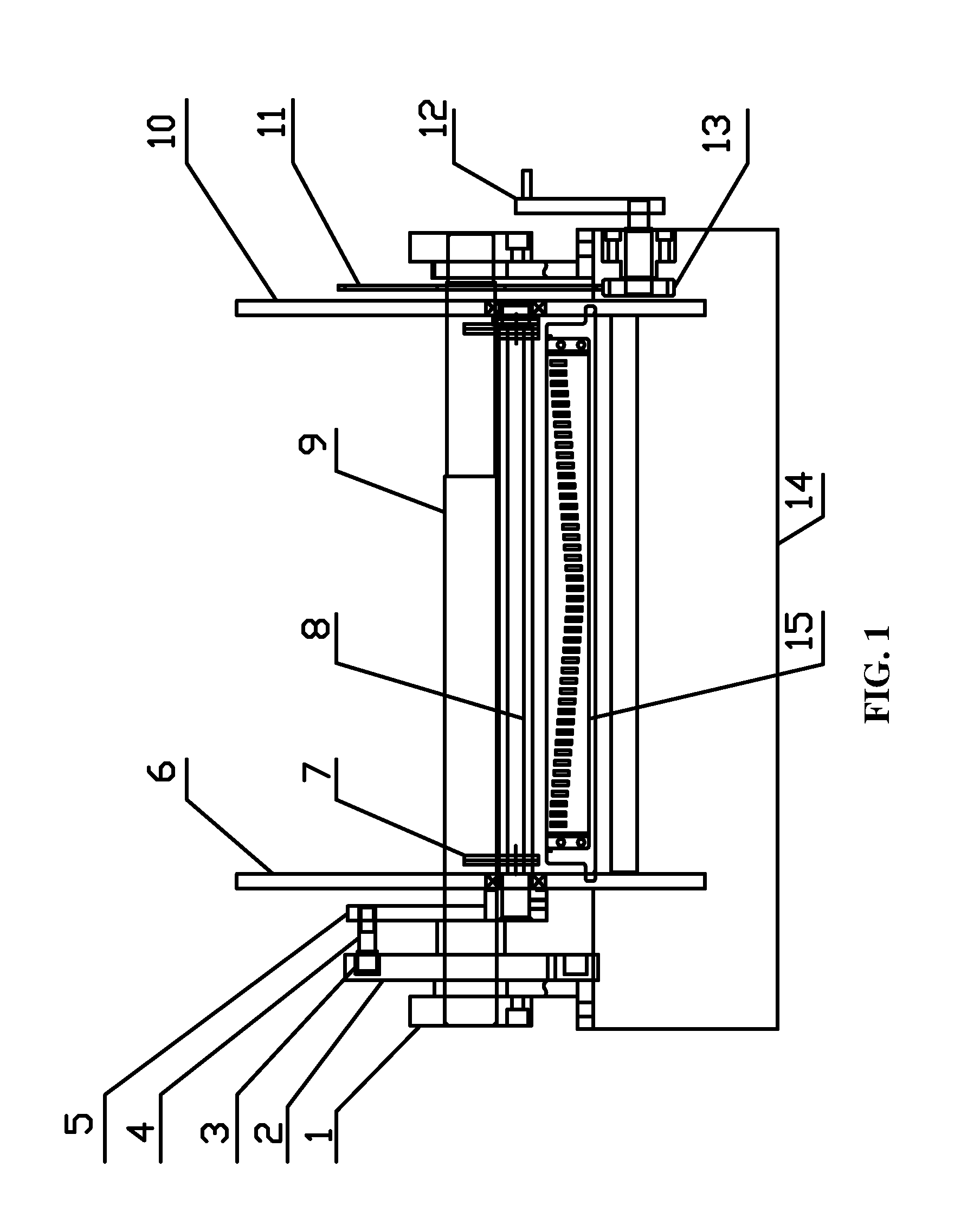

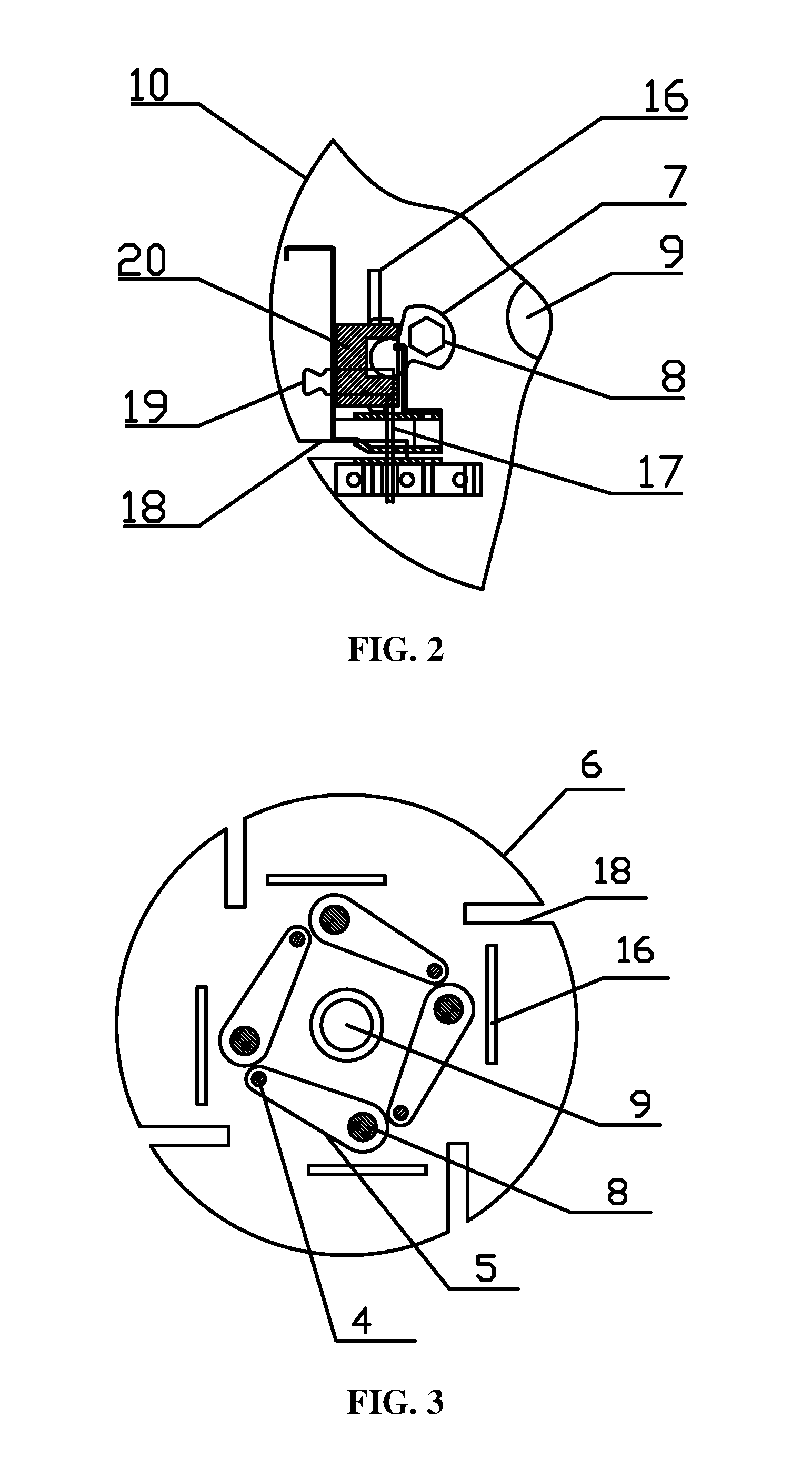

Full-automatic hole punching machine for building steel pipes

InactiveCN112170896AFully automatedEnsure safetyFeeding apparatusPositioning apparatusGear wheelConstruction engineering

The invention discloses a full-automatic hole punching machine for building steel pipes. The full-automatic hole punching machine for building steel pipes comprises a base and a drilling device, wherein a low base is fixedly mounted at the lower end of the base; a main slideway, of which an opening is located in the forward direction, is arranged at the front end of the low base; a rotatable sleeve is mounted in the main slideway in a sliding manner; an outward sleeve gear cavity is formed in the circumferential position of the rotatable sleeve; and a sleeve gear is fixedly mounted in the sleeve gear cavity. According to the full-automatic hole punching machine for the building steel pipes disclosed by the invention, through combination of a conveying mechanism and a hole punching mechanism, automation of hole punching for the building steel pipes is realized, a large quantity of manpower and material resources can be saved, the massive working efficiency is improved, and the manual operation is reduced; and moreover, a hole punching angle can be adjusted, manual steering is not needed, the refined mounting degree and efficiency are ensured, accident incidence ratios caused by themanual operation are also reduced, and the safety of workers is ensured.

Owner:JINHUA KAISEN INTELLIGENT TECH CO LTD

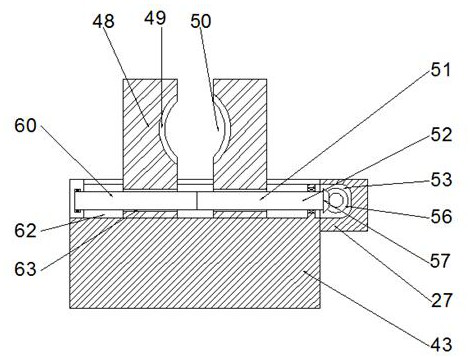

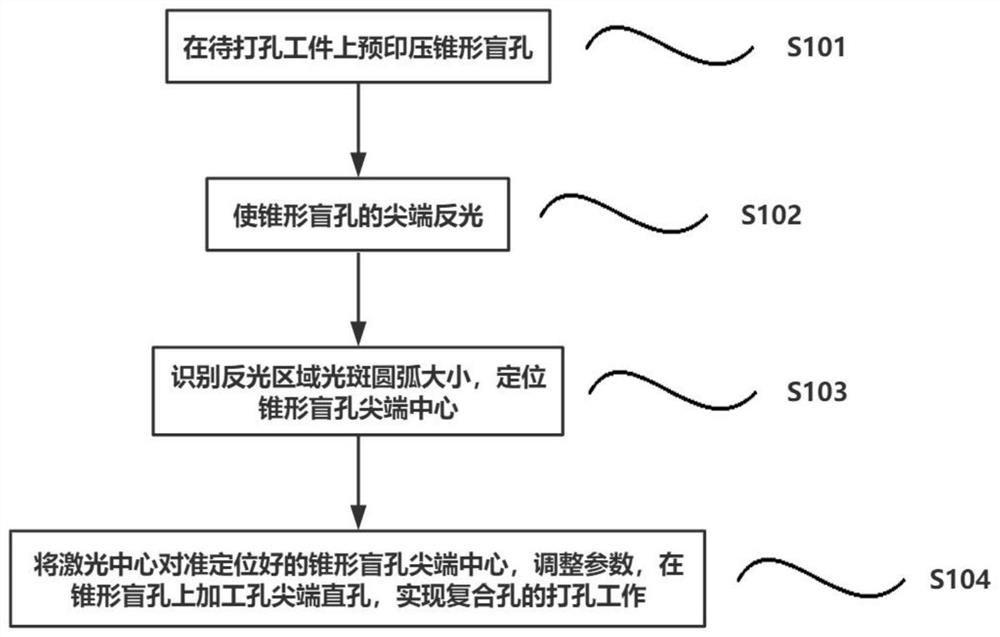

Composite hole laser punching method based on tip bright point guide

ActiveCN111774741ASolve positioningSolve the problem of not being able to precisely punch compound holesLaser beam welding apparatusLight spotEngineering

The invention is applicable to the technical field of composite punching, and provides a composite hole laser punching method based on tip bright point guide. The composite hole laser punching methodbased on tip bright point guide comprises the following steps that a conical blind hole is printed and pressed on a workpiece to be punched; the tip of the conical blind hole reflects light, the sizeof an arc of a light reflecting area light spot can be recognized, and the geometric center of the light spot can be positioned; the geometric center of the light spot is the tip center of the conicalblind hole; and the laser center is aligned with the tip center of the positioned conical blind hole, parameters are adjusted, a hole tip blind hole is machined in the conical blind hole, and punching work of a composite hole can be achieved. The bright point guide effect of the conical blind hole tip is used for positioning, the tip blind hole is machined in the tip center, the needed compositehole is obtained, the problems that during composite hole laser punching, the conical hole tip is difficult to position, and the composite hole punching cannot be precisely carried out can be effectively solved, and the advantages of being convenient, rapid, and accurate are achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

Combination hole punching and book binding machine

A combination hole punching and book binding machine having a worktable and an electric motor disposed fixedly thereon, a left changeover panel and a right changeover panel being symmetrically disposed on the worktable, a press knife assembly being disposed between the left changeover panel and the right changeover panel. By driving the left changeover panel and the right changeover panel, the press knife assembly can be combined as needed. Meanwhile, the quantity of the press knives is regulated, and thereby the number, pass, and pitch of holes is adjusted.

Owner:HANGZHOU SUPU BUSINESS MACHINE +1

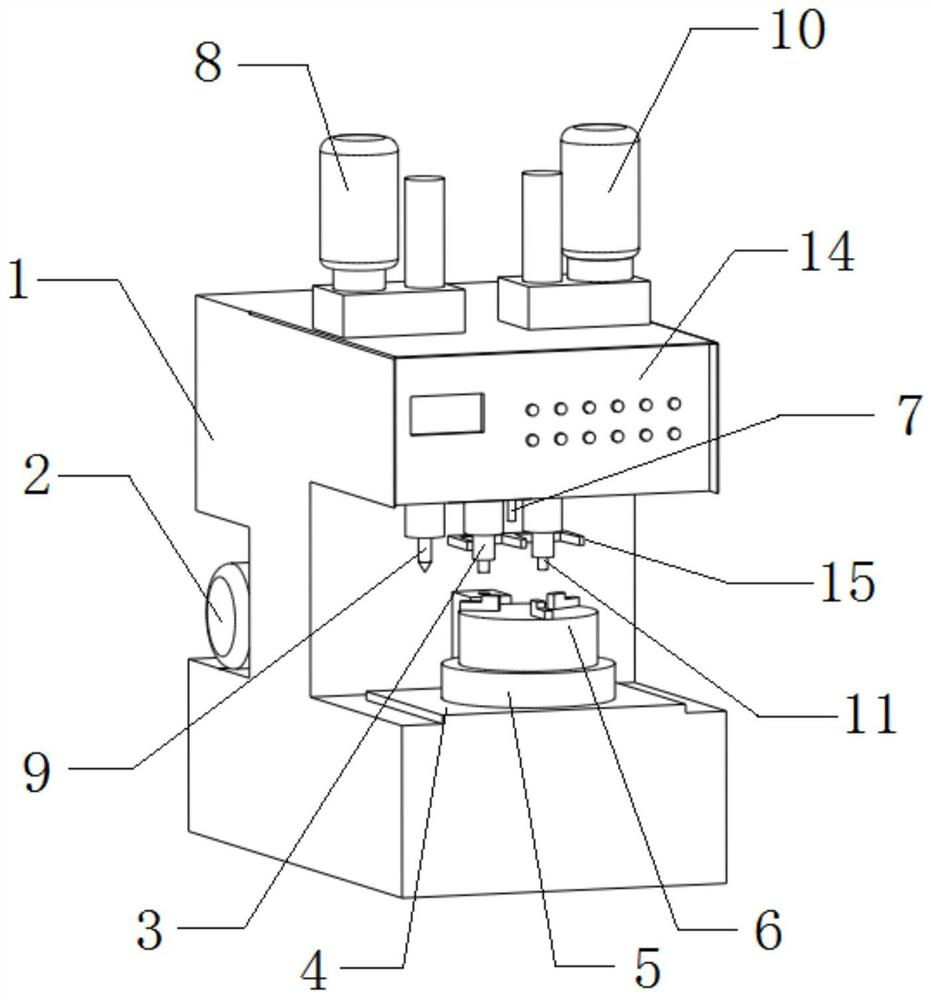

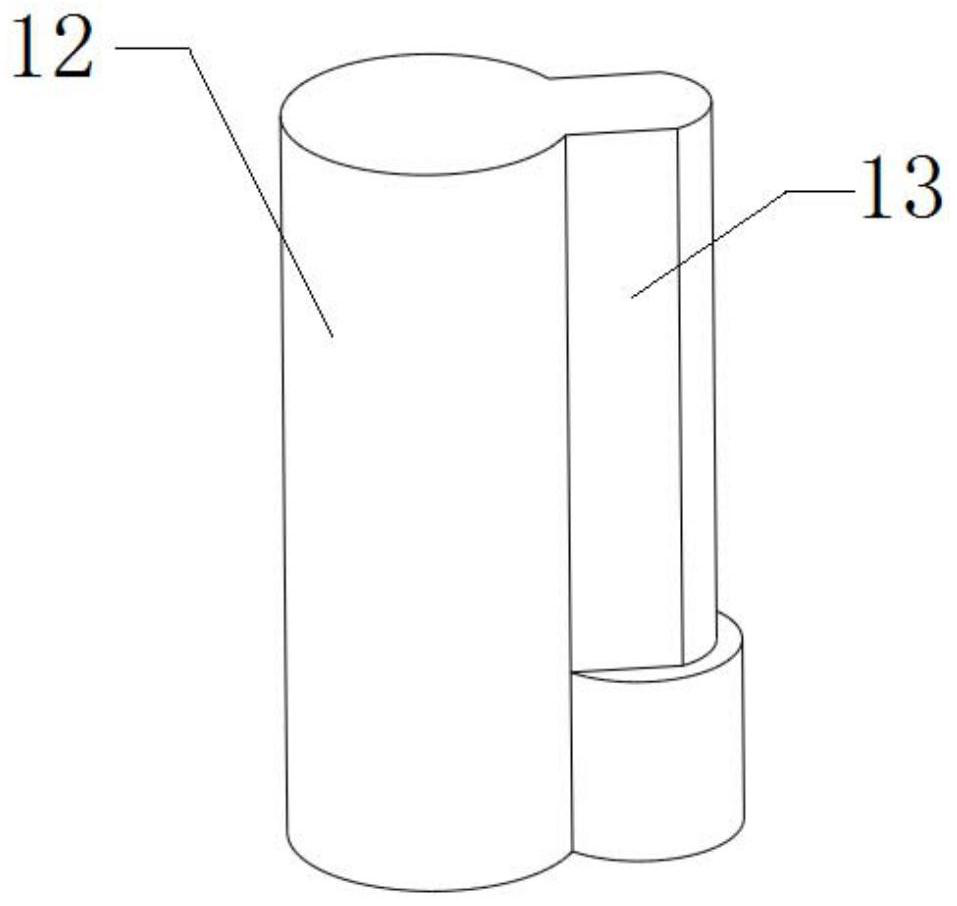

Drilling, punching and tapping all-in-one machine for square and round flange end plates

PendingCN112809383ALabor savingLow input costOther manufacturing equipments/toolsNumerical controlElectric machinery

The invention discloses a drilling, punching and tapping all-in-one machine for square and round flange end plates. The all-in-one machine comprises a numerical control punching machine, a punching knife fixing rod, a drilling assembly, a tapping assembly and a motion sensor, wherein a punching head, a numerical control index plate and a chuck are detachably arranged on the punching knife fixing rod, the drilling assembly comprises a drilling driving motor and a drill bit, the tapping assembly comprises a tapping driving motor and a screw tap, the punching head comprises a large hole punch and a rib passing hole punch which are integrally arranged, and the drill bit, the large hole punch, the rib passing hole punch and the screw tap are transversely arranged or arranged in an arc shape with the center of the numerical control dividing plate as the circle center. According to the machine, the four machining steps of drilling, large hole punching, rib passing hole punching and tapping are integrated, the four machining steps are completed through one machine, the labor force is relieved, the equipment input cost is lowered, and the machine has the advantages of high speed, high efficiency, high precision, low machining noise, low maintenance cost and fast die replacement and specification replacement and is suitable for popularization.

Owner:徐凯

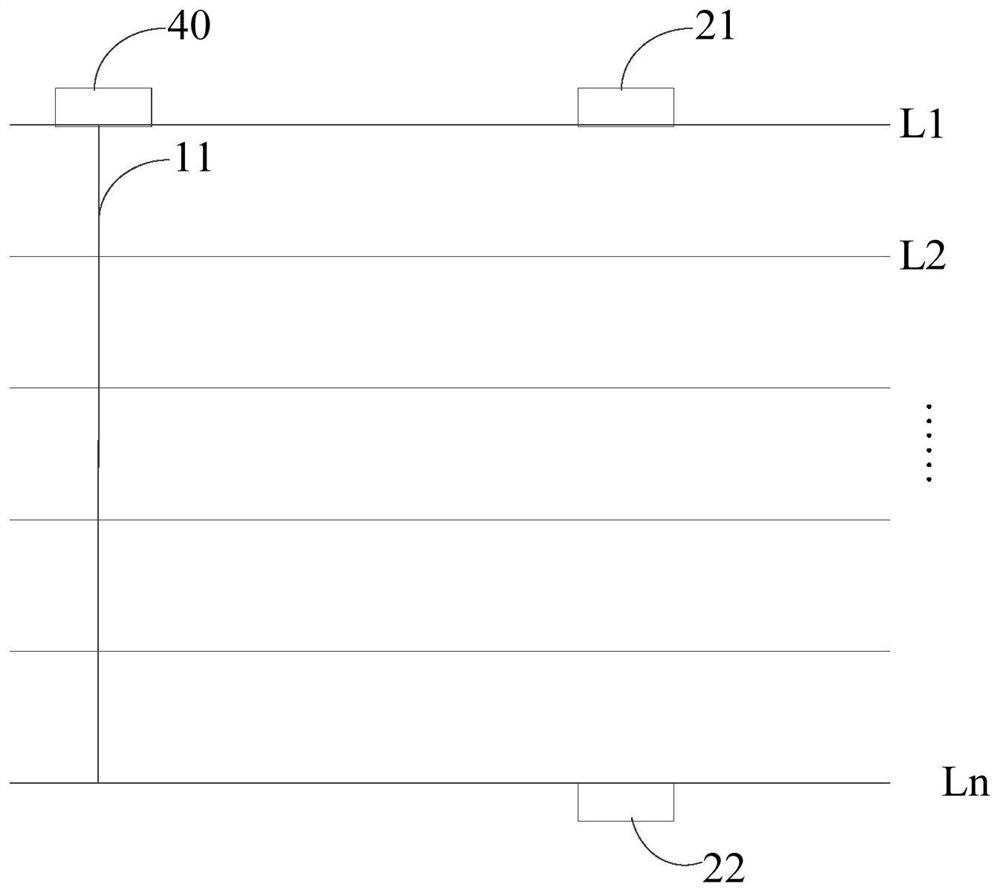

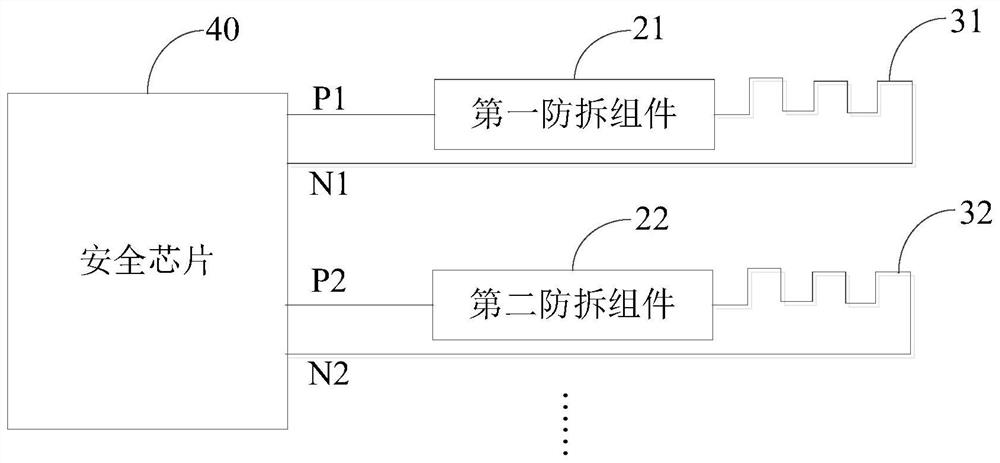

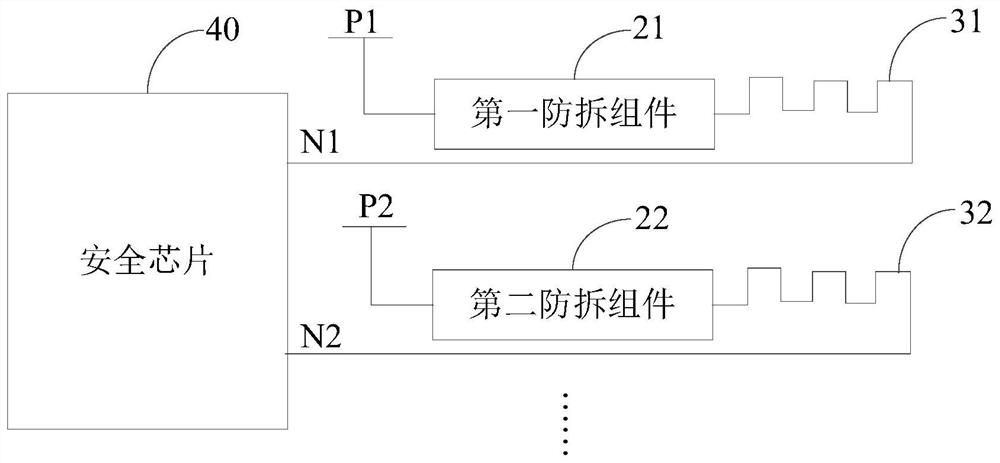

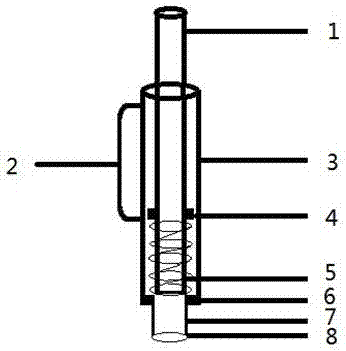

Anti-disclosure structure and electronic equipment

PendingCN112566357ATo achieve the purpose of leak preventionReduce design costCircuit security detailsCAD circuit designEngineeringEmbedded system

The invention provides an anti-disclosure structure and electronic equipment. The anti-disclosure structure comprises a circuit board, at least one anti-disassembly assembly, at least one safety signal line and a safety chip, wherein a through hole is formed between outer layers, and the safety signal line winds the outer layers of the circuit board or winds inner layers of the circuit board through the through hole according to the demands, thereby forming an anti-disassembly region; and the safety signal line is correspondingly connected with the anti-disassembly switch and the safety chip,and when the anti-disassembly switch or the safety signal line is damaged, the level on the safety signal line is changed, so that the safety chip is triggered to erase sensitive information. By adopting the through hole punching method, the purposes of preventing secret disclosure, reducing the design cost and simplifying a safety scheme are achieved at the same time.

Owner:PAX COMP TECH SHENZHEN

Computer case heat dissipation hole punching device

ActiveCN111745041AGuaranteed accuracyGuaranteed yieldShaping toolsPerforating toolsEngineeringChanging equipment

The invention discloses a computer case heat dissipation hole punching device. The punching device is characterized in that when heat dissipation hole of a computer case are punched, the indenting operation of the heat dissipation holes of the computer case is firstly realized by utilizing the mutual press fit between an upper punching die and a lower punching die, then a punching lifting air cylinder is used for driving the upper punching die to punch the indented heat dissipation holes of the computer case, in this way, due to the fact that the indenting operation is carried out firstly, theproblems of breakage, cracks and the like occurring in the subsequent punching process can be effectively solved, the punching accuracy and yield are guaranteed, meanwhile, reclamping is not needed between indentation and punching, in this way, the accuracy of mutual correspondence of indentation and punching can be guaranteed, equipment does not need to be replaced, even a punch and an indentation head do not need to be replaced, indentation and punching operation can be completed through the same indentation head, efficiency is high, reliability is high, the corresponding capacity of indentation and punching is effectively guaranteed, and the punching precision and quality are improved.

Owner:浙江机电职业技术学院

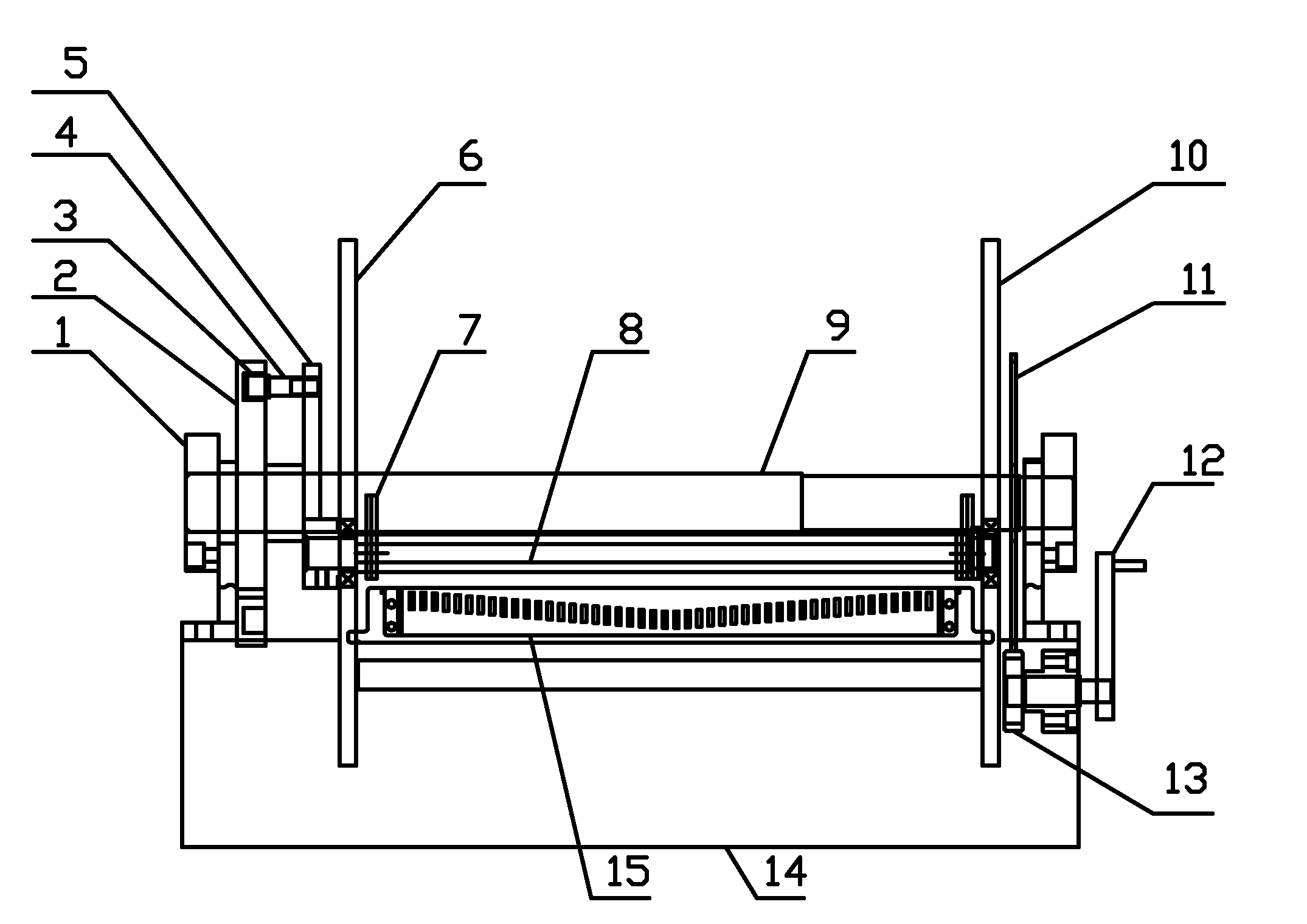

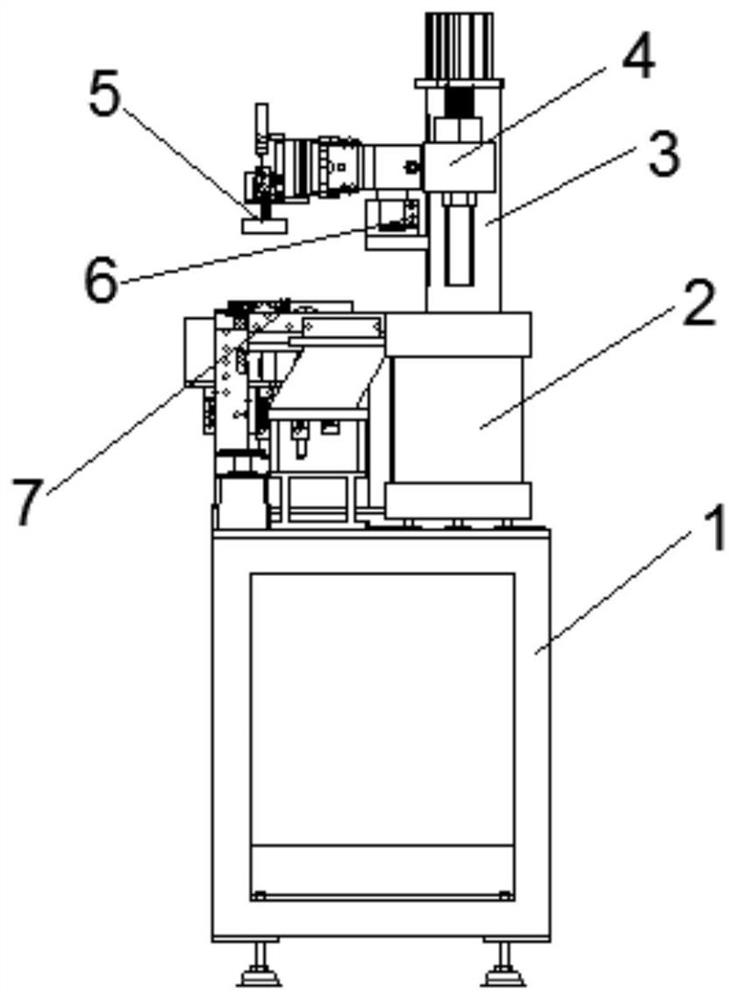

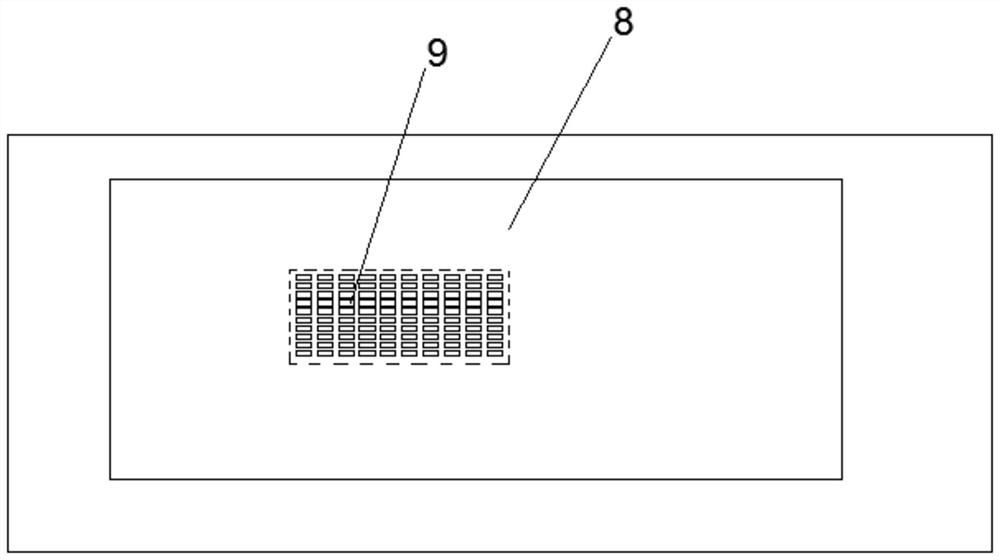

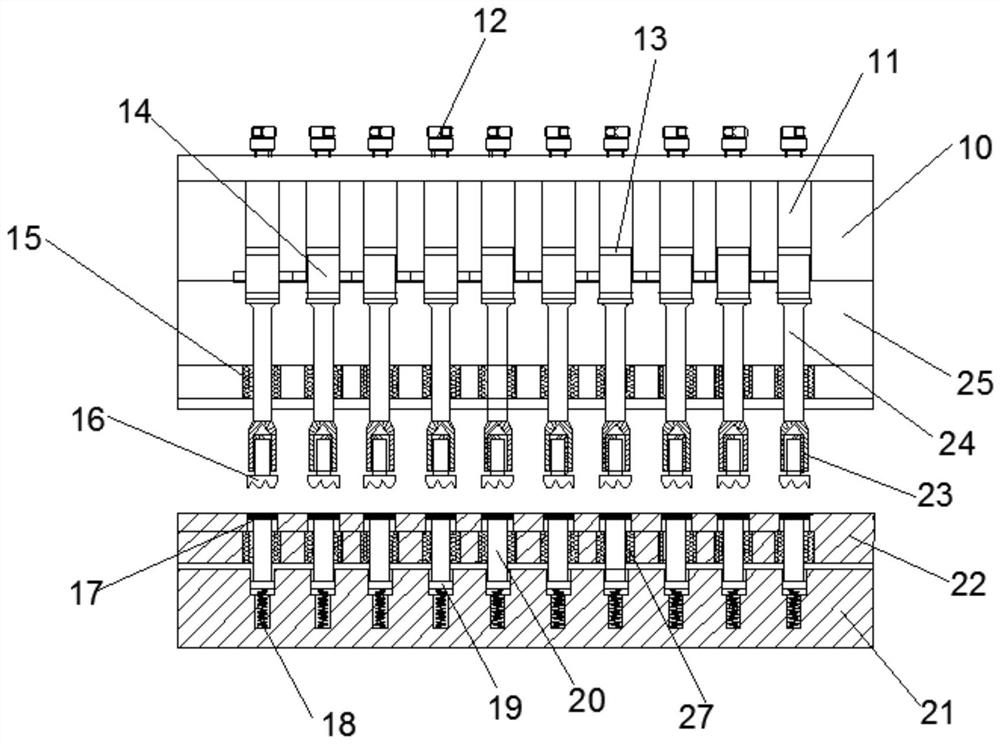

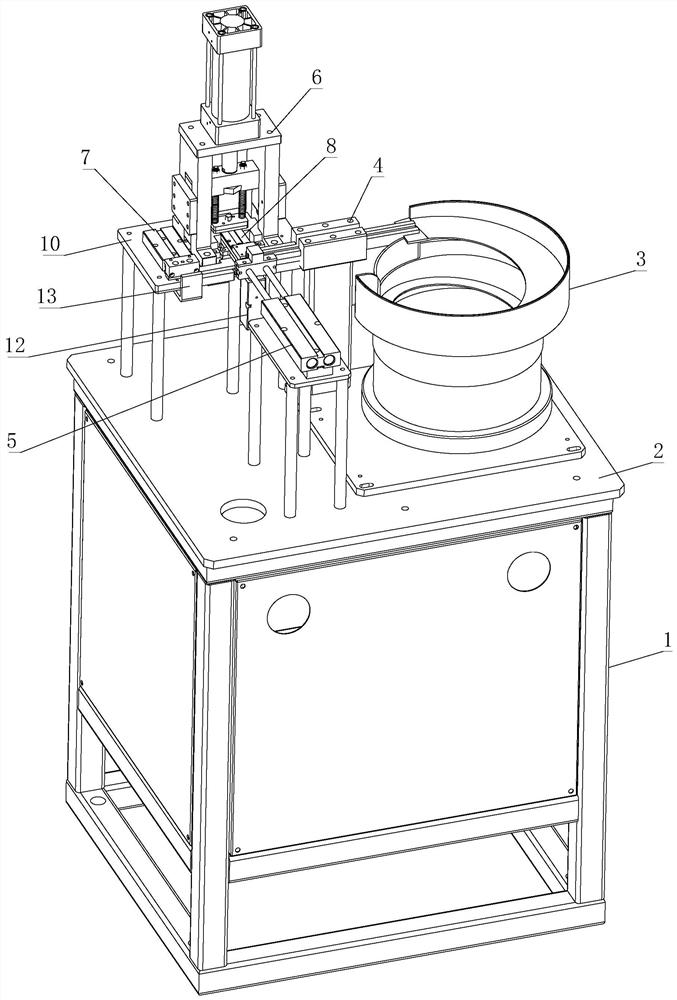

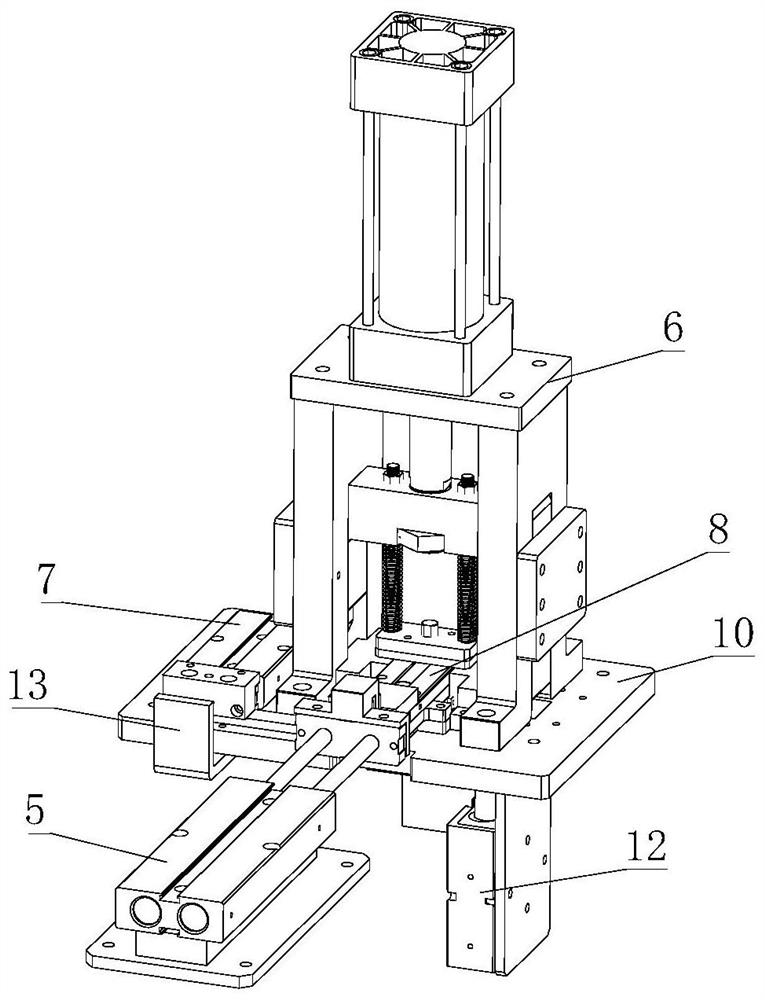

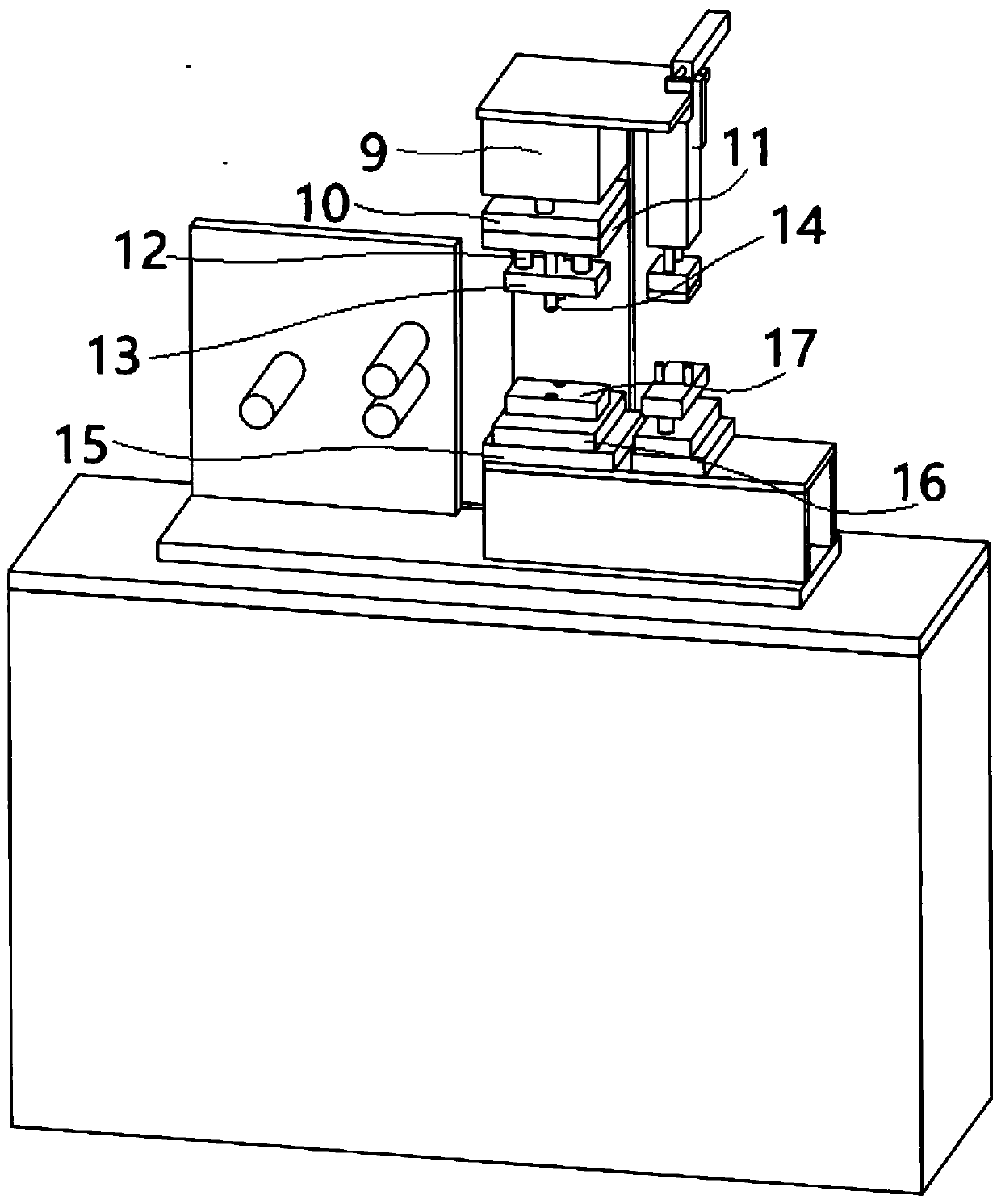

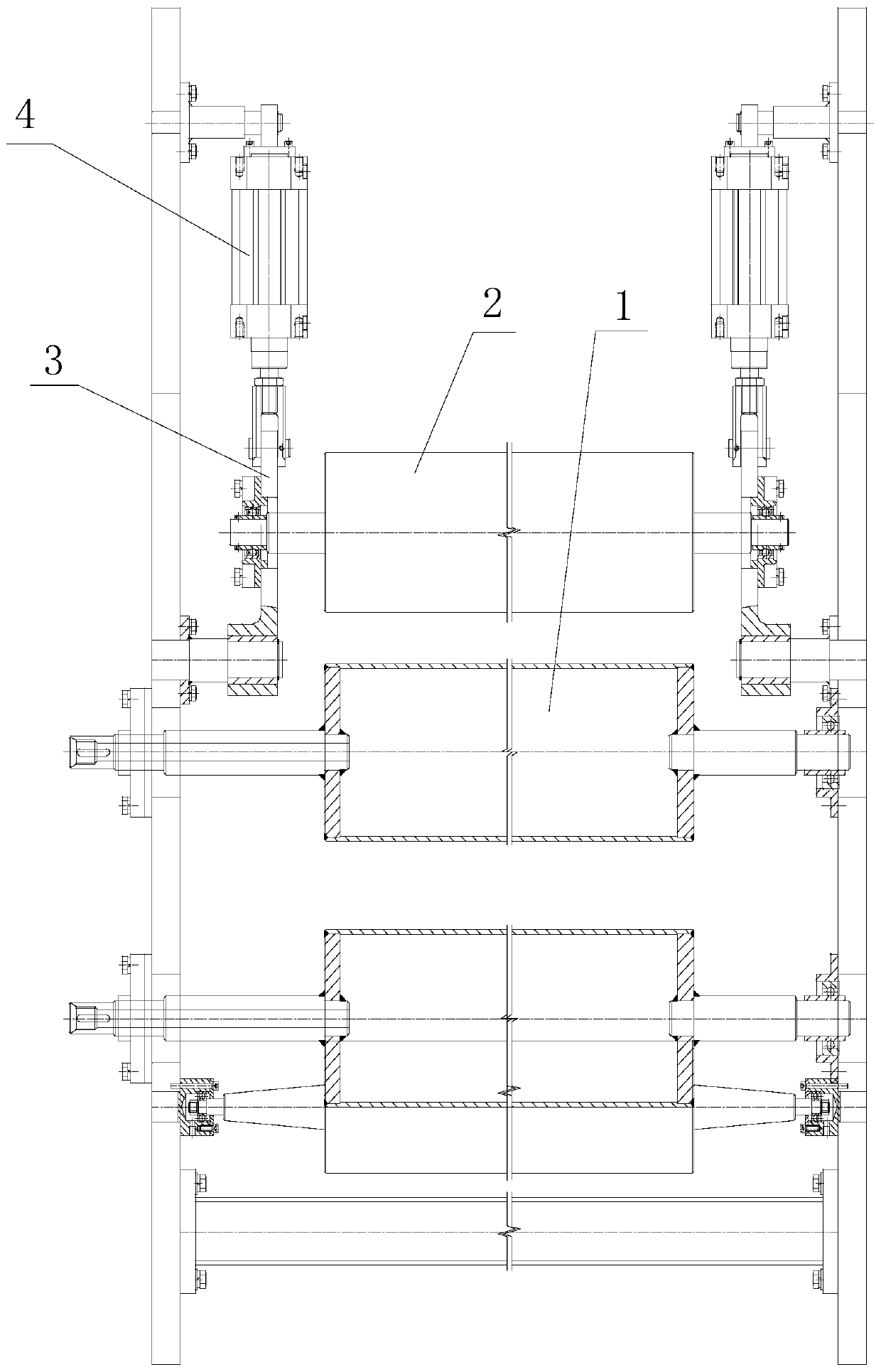

Automatic punching machine for radial hole of thin-wall annular part

ActiveCN112246965ASimple processReduce labor intensityPerforating toolsMetal-working feeding devicesSmall footprintWorkbench

The invention discloses an automatic punching machine for a radial hole of a thin-wall annular part, and belongs to the technical field of punching equipment. The punching machine comprises a workbench and a fixing plate, a feeding assembly and a pushing assembly are arranged on the workbench, the fixing plate is arranged above the workbench, a driving part is arranged on the fixing plate, a baseplate is arranged on the fixing plate and located on the inner side of the driving part, and a material guiding assembly is arranged on the base plate; and a feeding port of the material guiding assembly is connected with a discharging port of the feeding assembly, a material returning assembly and a male die assembly are arranged on the fixing plate, and a female die assembly is arranged at the bottom of the fixing plate. The punching machine has the beneficial effects that automatic feeding, material loading, radial hole punching and material returning are achieved, radial holes can be automatically punched in thin-wall annular parts or thin-wall pipe parts, and the punching machine has the advantages of being simple in process, low in labor intensity, high in production efficiency, small in occupied area, easy to maintain and the like.

Owner:GUIZHOU ZHENHUA HUALIAN ELECTRONICS

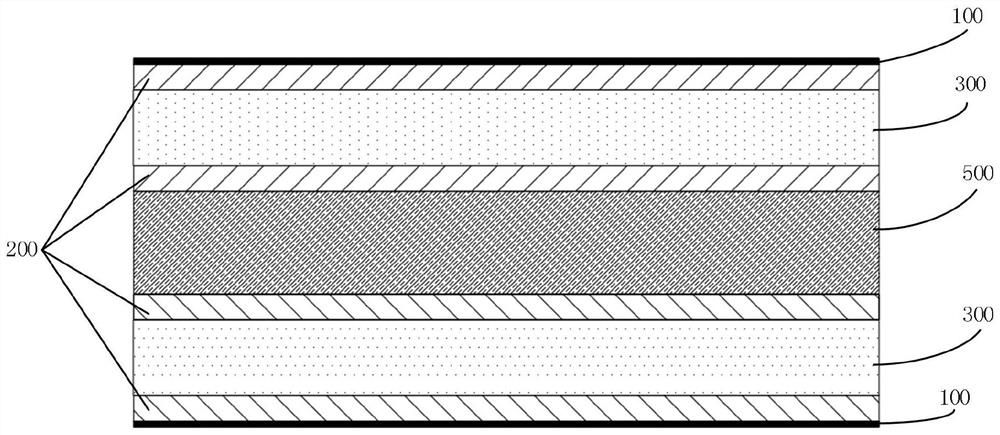

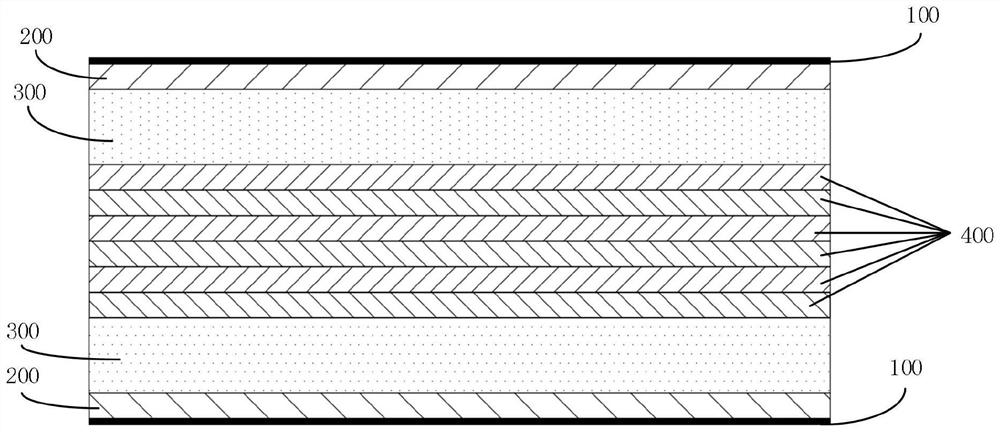

PCB and pressing method thereof

PendingCN114340228AShort processSimple processing technologyPrinted circuit detailsMultilayer circuit manufactureEngineeringCopper foil

The invention relates to the technical field of printed circuit boards, in particular to a PCB and a pressing method thereof. The invention provides a pressing method of a PCB. The pressing method comprises the following steps of S01, cutting a substrate into a preset size, and performing inner layer pattern manufacturing on the substrate; s02, detecting and repairing the substrate by adopting an automatic optical detector; s03, performing hot melting positioning hole punching on the substrate; s04, carrying out browning treatment on the substrate; s05, cutting the first prepreg, and drilling; s06, placing the first prepreg between the substrates and carrying out hot melting; s07, a second prepreg is pre-stacked outside each of the two layers of substrates; s08, cutting the copper foil; s09, typesetting the copper foil, the second prepreg and the substrate; and S10, carrying out press fit. The invention provides a PCB (printed circuit board) and a laminating method thereof, which are used for solving the technical problems of large interposer deviation, low production efficiency and serious production pollution in the existing PCB laminating mode.

Owner:广东和鑫达电子股份有限公司

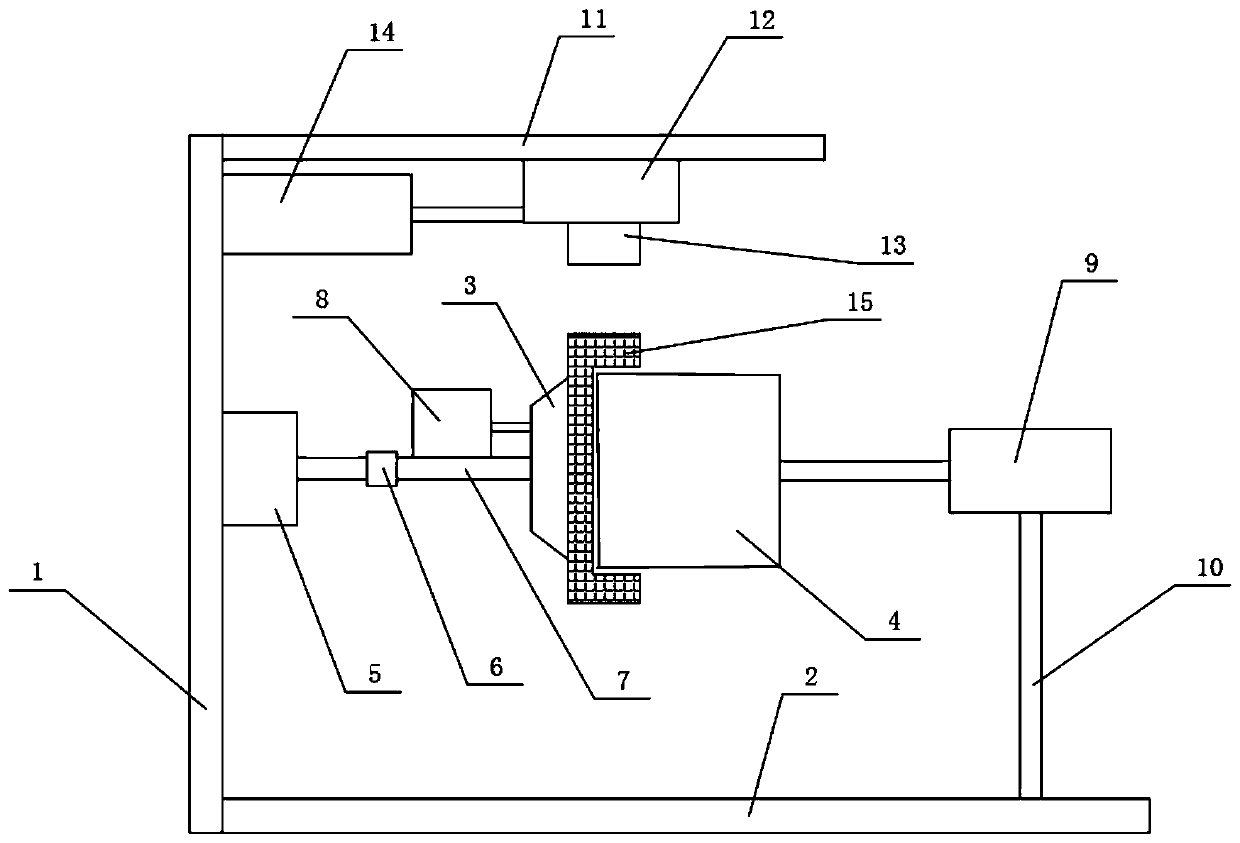

Punching device

InactiveCN110918774AEnsure safetyEasy maintenanceMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The invention discloses a punching device. The punching device includes a machine case. A bottom plate is fixed to the machine case, and a base plate is fixed to the bottom plate. A mounting plate isfixed to the left end of the upper side of the base plate, and a feeding component is arranged on the front side surface of the mounting plate. Two side plates oppositely arranged front and back are further fixed to the upper side of the base plate, and second side plates are further arranged on the inner sides of the first side plates. A flat plate is fixed to the second side plates, and the first side plates and the second side plates are located on the right side of the mounting plate. A top plate is fixed to the two first side plates, and a hole punching component is arranged on the lowerside surface of the top plate. According to the punching device, manual feeding in a dangerous area is not required for the punching device in the punching process through the arrangement of the feeding component, the safety of operators is ensured, the situation that only old staff can perform fast operation is avoided, and the processing efficiency cannot be affected in the personnel replacementprocess; and the punching device is small in size, and later maintenance or replacement of parts is convenient.

Owner:嘉善卓润五金制品有限公司

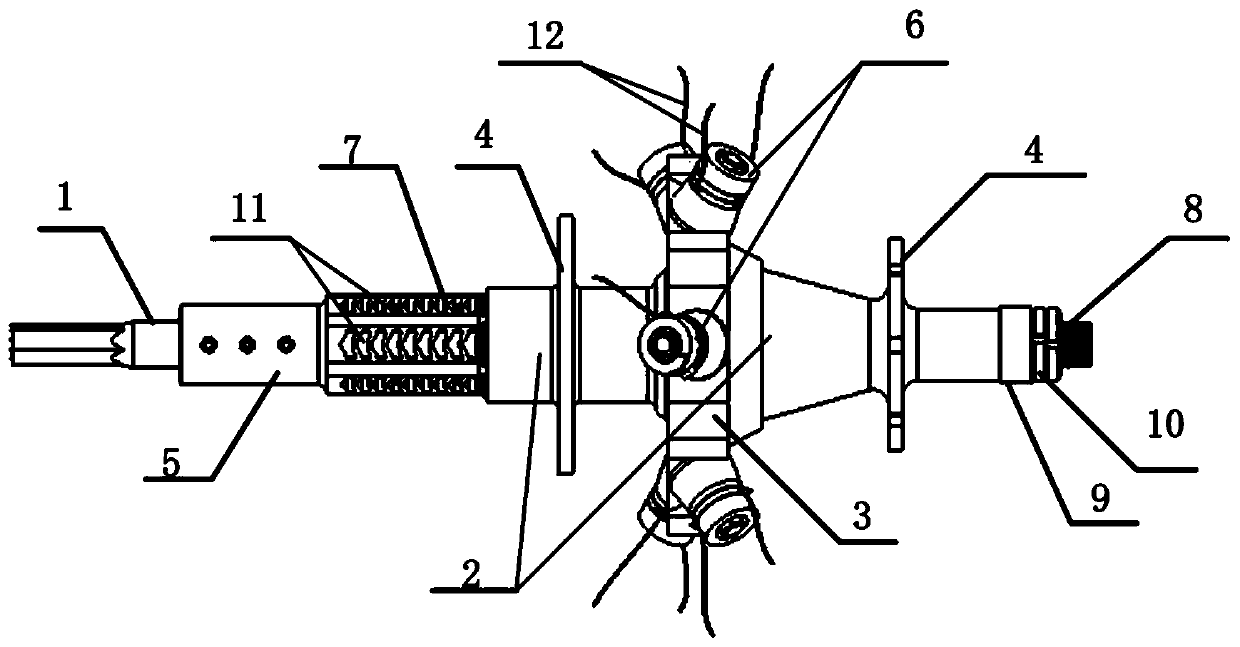

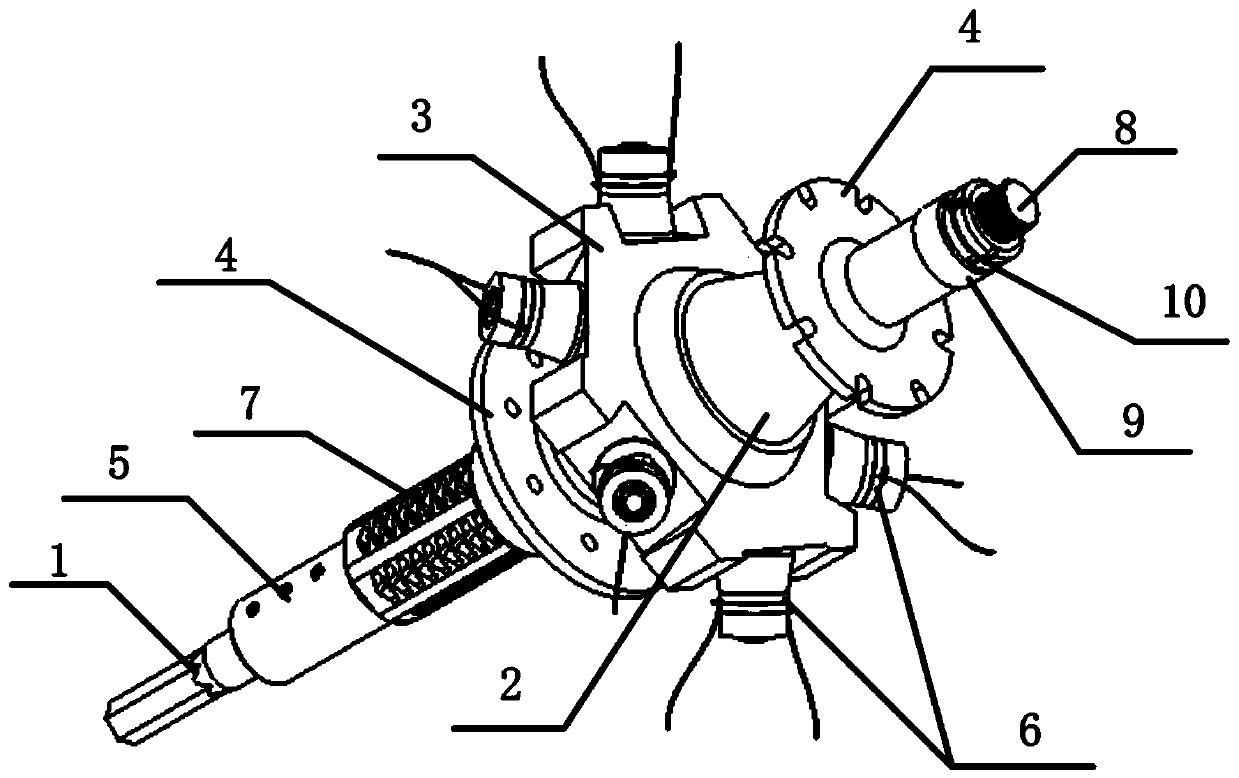

R-L longitudinal bending composite vibration special-shaped hole punching system

PendingCN111036758AImprove molding efficiencyReduce processing difficultyMechanical vibrations separationVibration amplitudeEngineering

The invention discloses an R-L longitudinal bending composite vibration special-shaped hole punching system. According to the R-L longitudinal bending composite vibration special-shaped hole punchingsystem, an R-L composite vibration disc and a longitudinal bending composite vibration amplitude-change pole are arranged, a plurality of vibration transducers are arranged on an outer ring of the vibration disc, and the transducers are driven by a high-frequency power source to generate vibration; the vibration energy of the multiple transducers is gathered through the R-L composite vibration disc and converted into longitudinal vibration, the longitudinal vibration amplitude is amplified through the longitudinal bending vibration amplitude-change pole, the longitudinal vibration is convertedinto longitudinal bending composite vibration, and the tool head is driven to act the composite vibration on a workpiece. Meanwhile, in combination with the feeding motion of the machine tool platform, the rapid forming of a special-shaped hole is achieved. Due to the fact that the vibration of the high-frequency energy converter can reach a very high frequency, the forming efficiency of the special-shaped hole can be effectively improved. Simultaneously, through the electromechanical control, the main device of the R-L longitudinal bending composite vibration special-shaped hole punching system can generate longitudinal bending alternating vibration rotating around the axis on the premise of no main shaft rotation, a punching tool head with a complex section shape can be normally pushedinto a workpiece in the feeding direction of a machine tool, the machining efficiency is further improved, and the machining difficulty of the complex special-shaped hole is reduced. Therefore, compared with a traditional special-shaped hole rotary punching forming device, the R-L longitudinal bending composite vibration special-shaped hole punching system has the advantages that the structure isgreatly simplified, the adaptability is higher, and the cost is further reduced.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

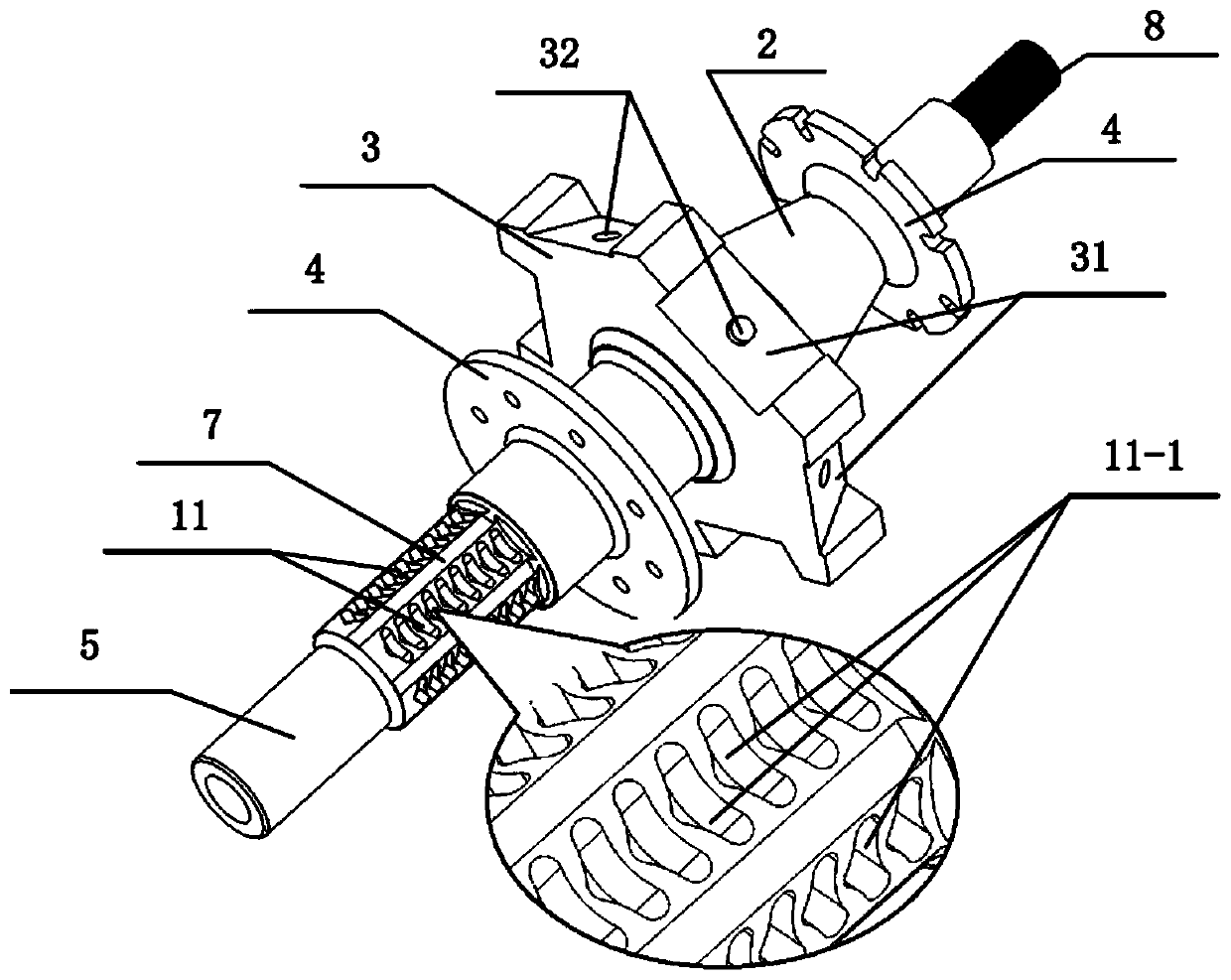

Hole punching device and method for efficiently manufacturing plant leaf discs

The invention provides a hole punching device and method for efficiently manufacturing plant leaf discs. The device comprises an operation rod, an operation handle, a shell, a leaf disc shaping hole, a leaf disc temporary storage cavity and a spring; the operation handle and the shell are connected into one body, the operation rod is arranged in the shell, the spring is arranged on the lower portion of the operation rod, and the operation rod can penetrate through the spring; a leaf disc shaping tube is arranged under the spring, the inner cavity of the tube is the leaf disc temporary storage cavity, and an upper spring bayonet and a lower spring bayonet are arranged on the portions, on the upper portion and the lower portion of the spring, of the shell respectively. The device is used according to a certain application method. By means of the hole punching device and method, the problems that contamination is easy to cause, the adhesion phenomenon easily occurs in the manufacturing process, and the efficiency is low are solved, and a technical support is provided for large-scale genetic transformation of the agrobacterium tumefaciens mediated plants.

Owner:CHINA TOBACCO YUNNAN IND

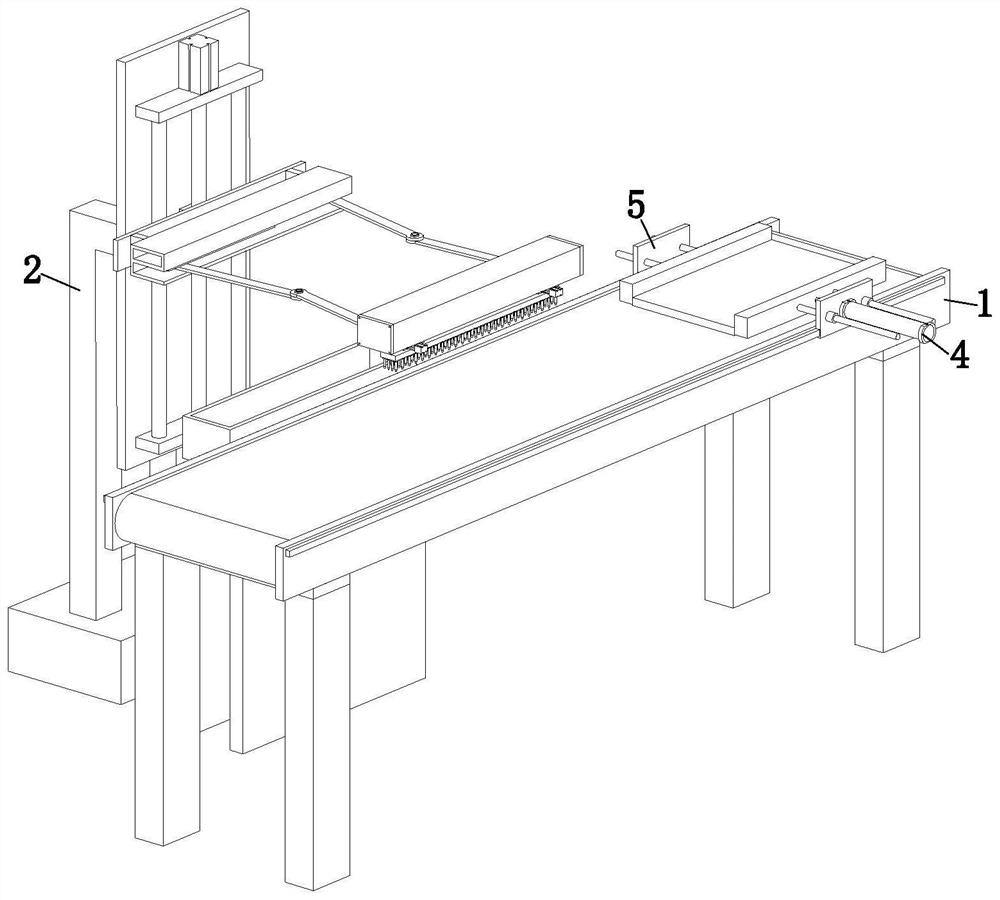

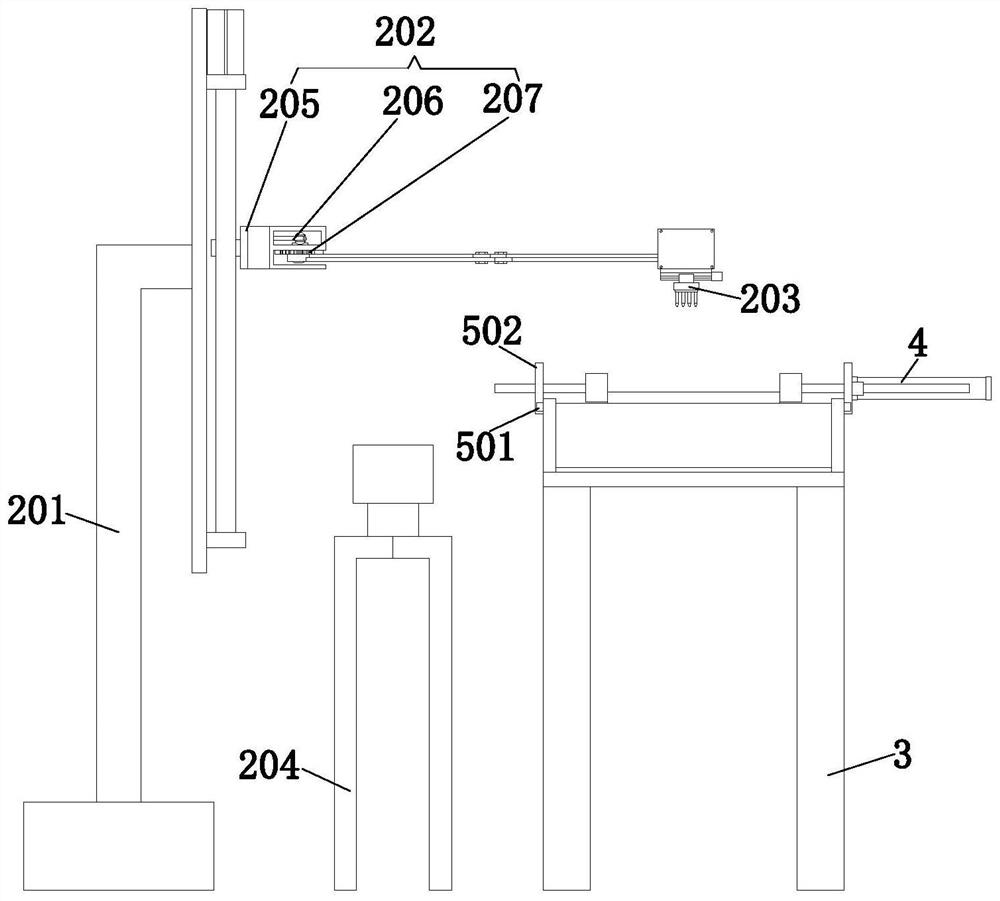

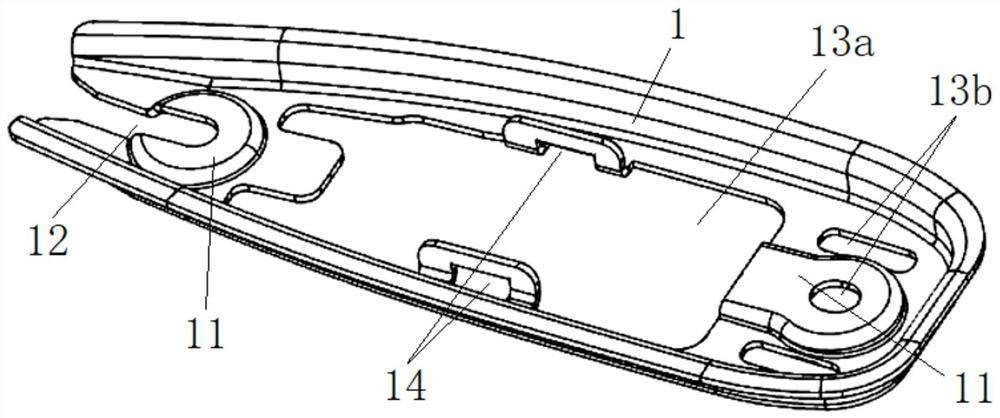

Automobile antenna support forming method

ActiveCN113634680AGuaranteed accuracy requirementsInternal combustion piston enginesVehicle componentsStructural engineeringMachining

The invention belongs to the technical field of stamping machining, and relates to an automobile antenna support forming method which comprises the steps of positioning hole punching, outer trimming, preformed hole punching, convex hull punching, groove punching, buckle hole punching, inner trimming, flanging and blanking. By means of the method, deformation machining of an automobile antenna support can be completed continuously and rapidly, and the precision requirement of each position can be met.

Owner:苏州铭峰精密机械有限公司

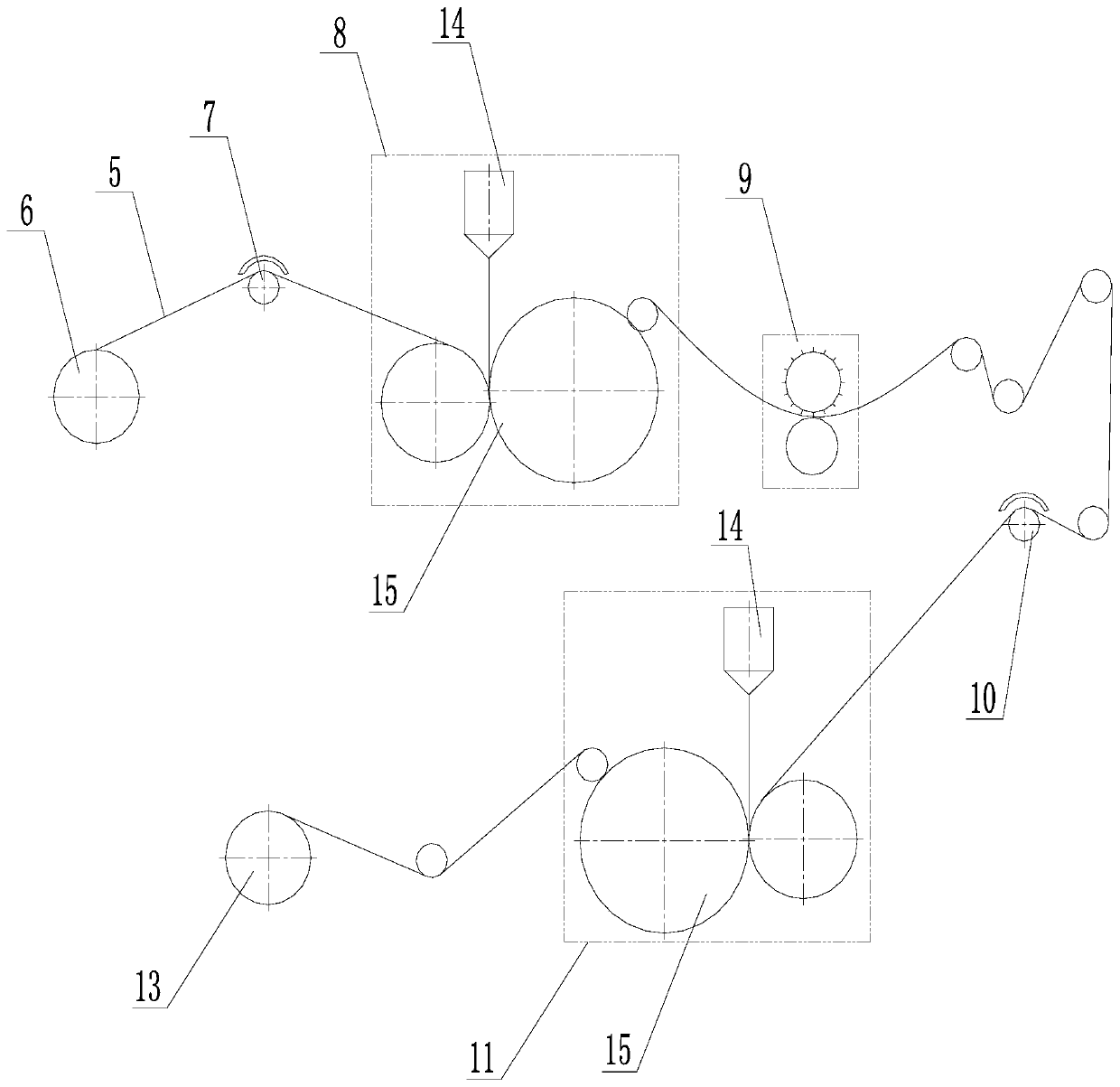

High efficient energy-saving coating technology and equipment of double side coated release paper

InactiveCN110846929AImprove stabilityImprove product qualityPaper/cardboardMetal working apparatusIsolation layerEngineering

The invention discloses a high efficient energy-saving coating technology and equipment of a double side coated release paper. According to the technology, an isolation layer is formed on one side ortwo sides of a substrate, then the isolation layer on one side of the substrate is punched to form a hole by a hole punching device so that a release agent can be painted on the isolation layer on theother side, and after the isolation layer on the other side is painted, the substrate is reeled by a reeling mechanism. The equipment comprises following components, which are sequentially connectedalong the substrate delivery direction: an unreeling direction, a front corona device, a front coating device, a hole punching device, a rear corona device, a rear coating device, a silicon painting device, and a reeling device; or comprises following components, which are sequentially connected along the substrate delivery direction: an unreeling mechanism, a front corona device, a front coatingdevice, a rear corona device, a rear coating device, a hole punching device, and a reeling device. The product quality is guaranteed, the drying step is eliminated, the production energy consumption and equipment cost are reduced, and the goals of environmentally friendly production, high efficiency and energy saving are realized.

Owner:HUILONG PLASTICS MACHINERY

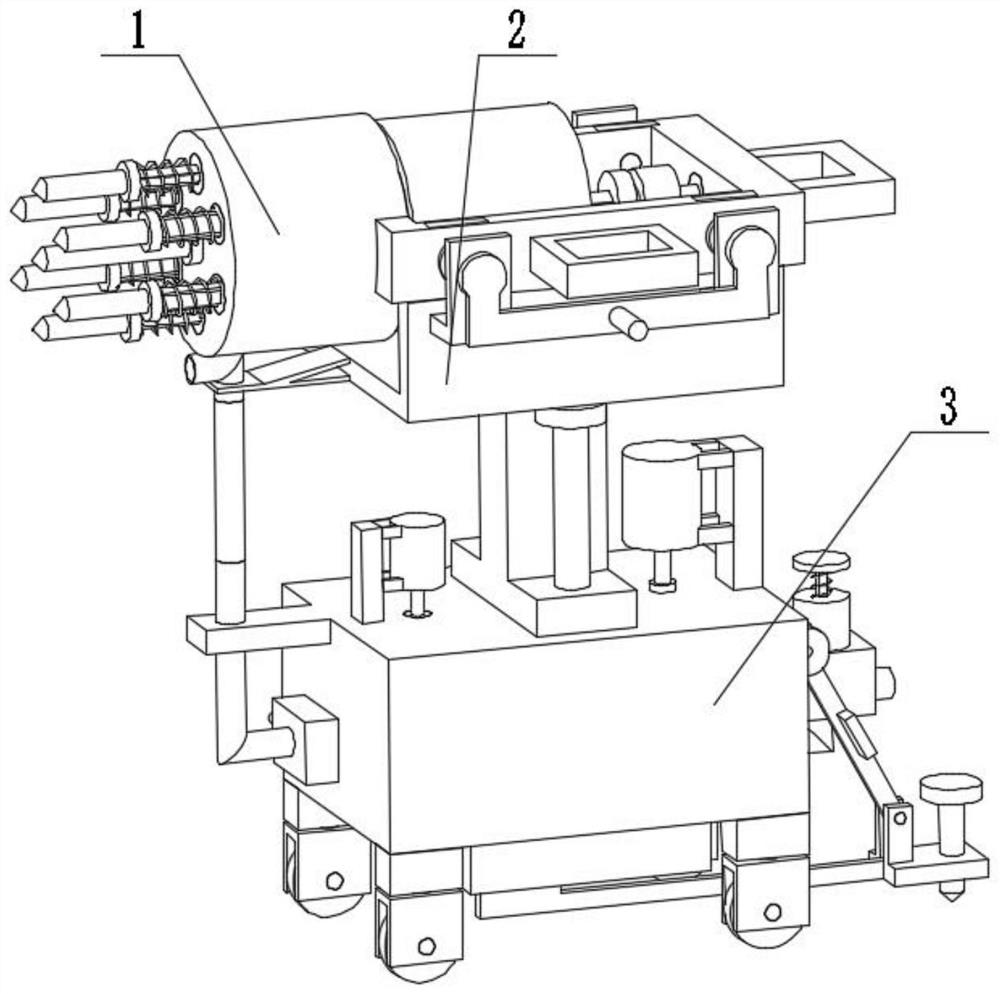

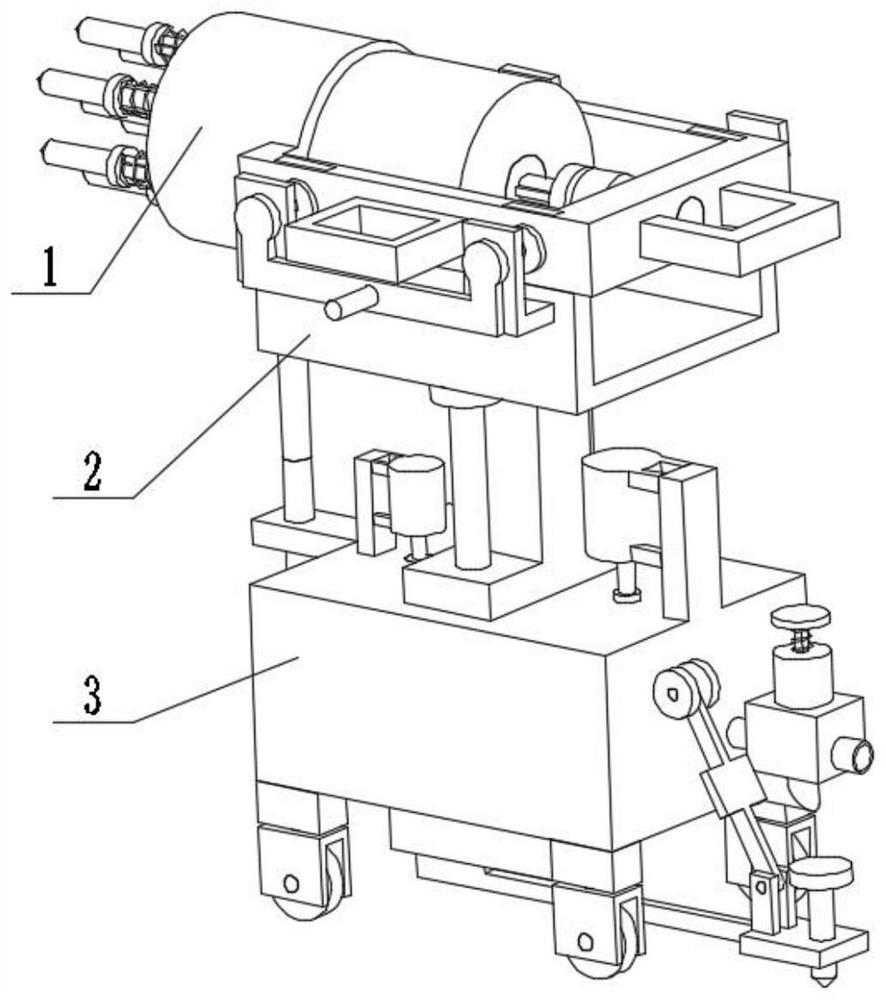

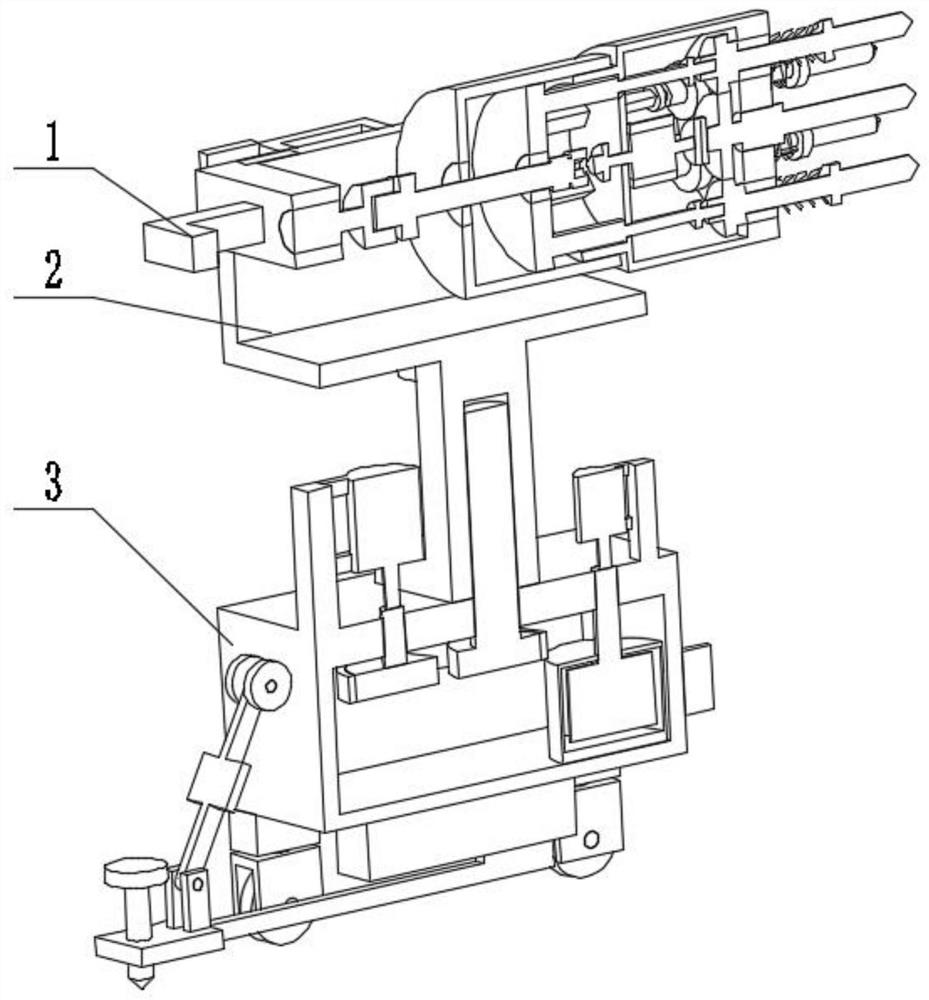

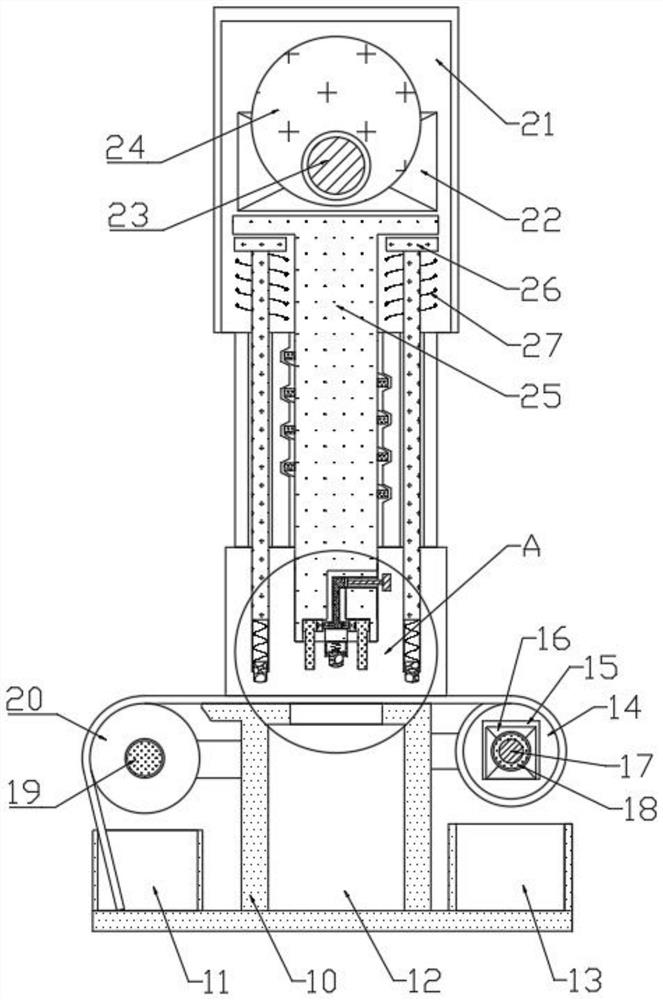

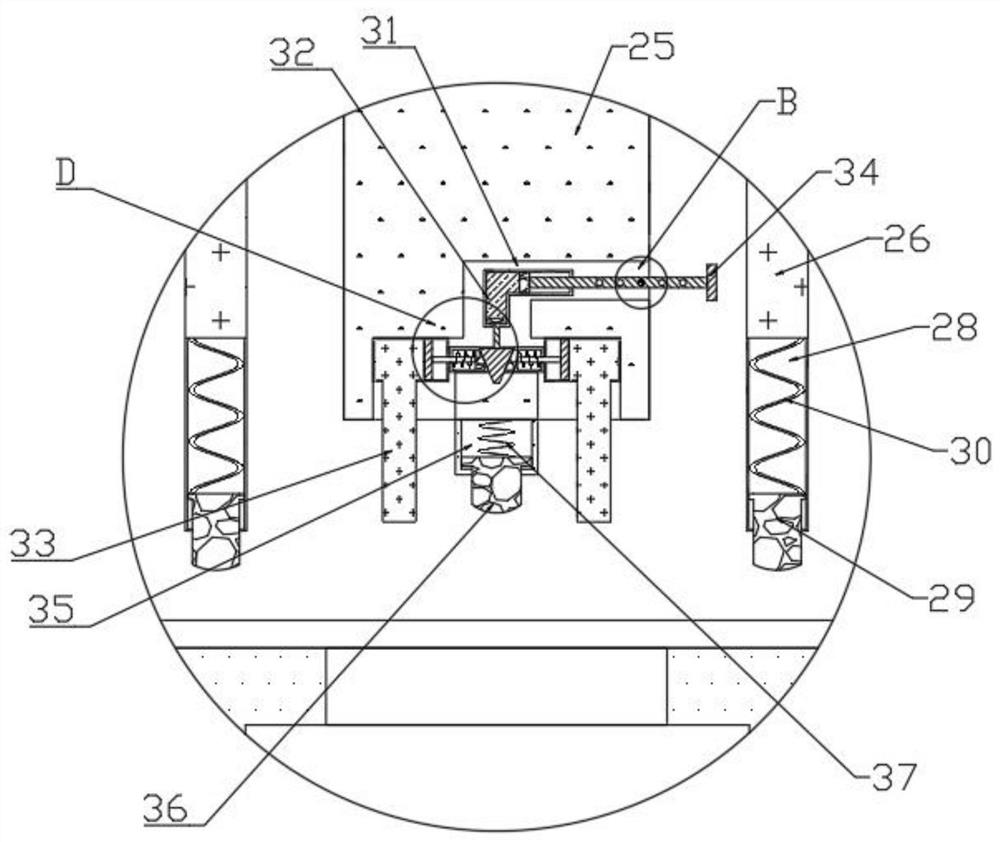

Explosive pre-buried hole punching equipment for building blasting

The invention relates to punching equipment, in particular to explosive pre-buried hole punching equipment for building blasting. The equipment comprises a detachable punching device, a height-variable support mechanism and a vehicle body mechanism, wherein the equipment can punch a plurality of holes at the same time, can be switched into a single-hole mode, can be detached for use, can reduce dust and can assist in punching, the detachable punching device is connected to the height-variable support mechanism, and the height-variable support mechanism is connected to the vehicle body mechanism.

Owner:王得娣

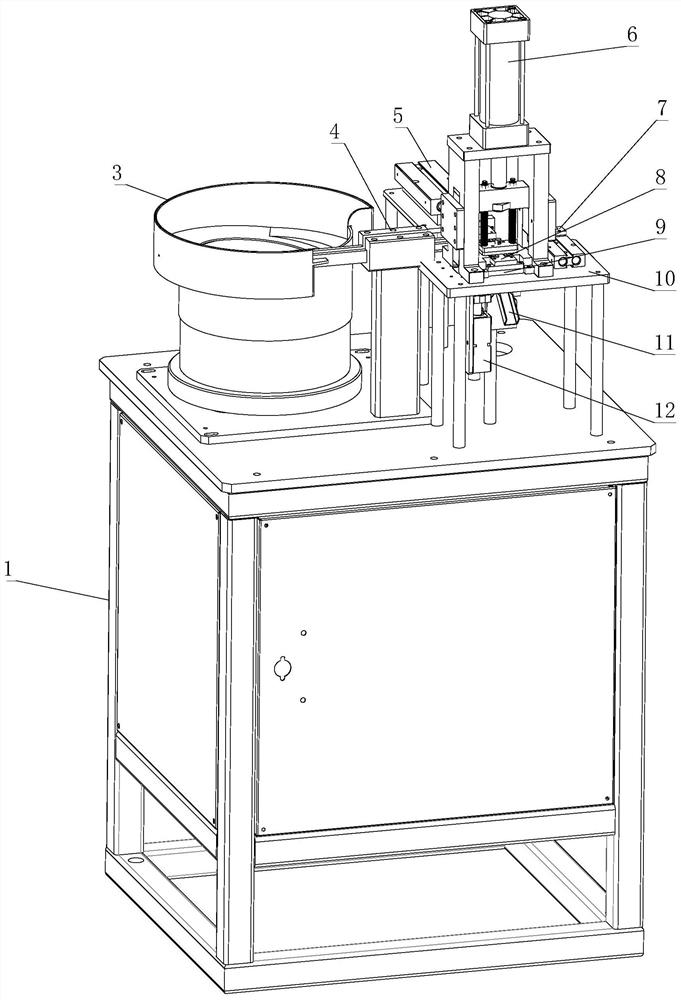

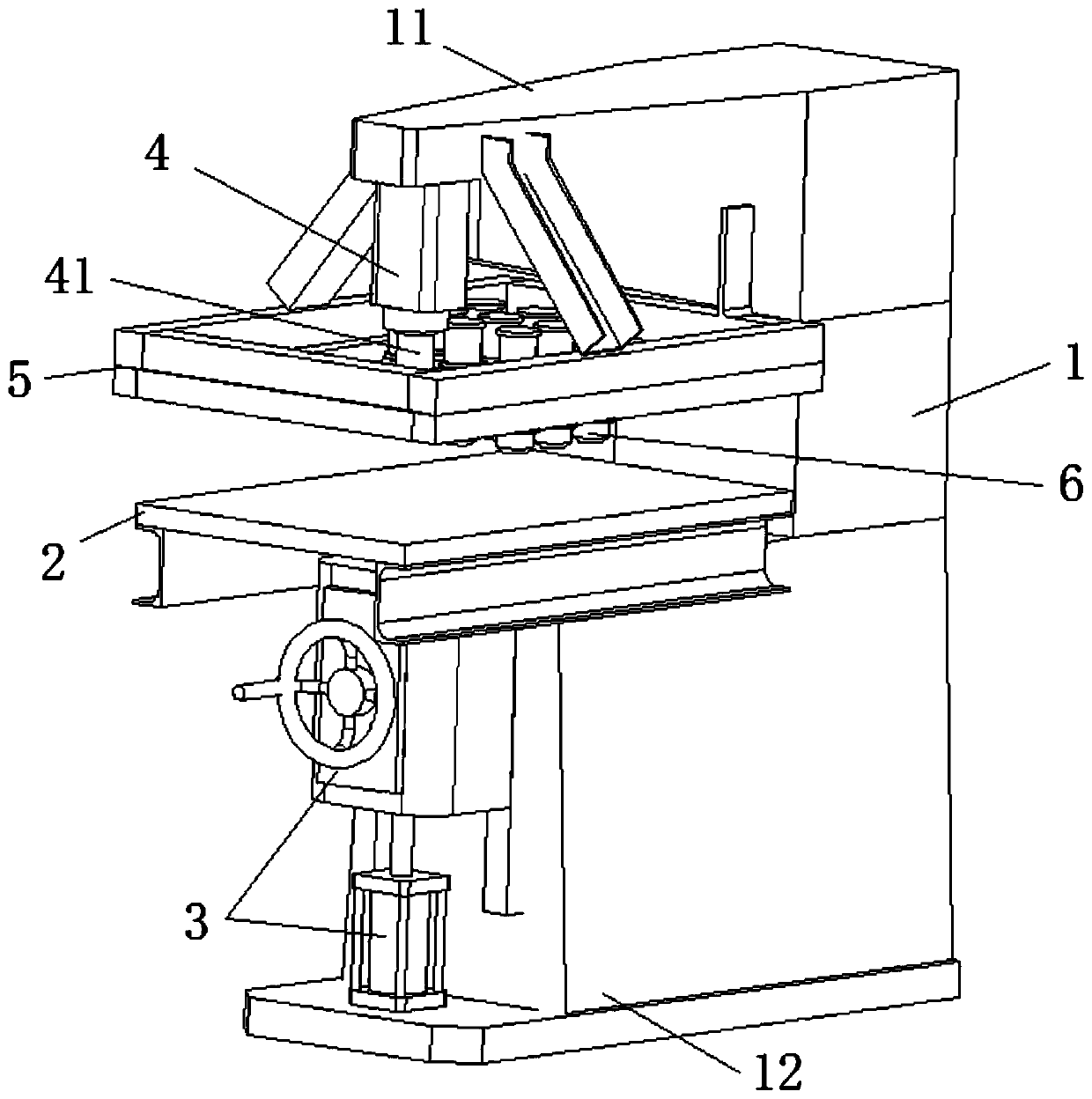

Rapid multi-hole punching equipment

ActiveCN111570841AGuaranteed accuracyPrevent installation offsetCleaning using gasesCleaning using liquidsStructural engineeringMachine

The invention provides rapid multi-hole punching equipment, and belongs to the technical field of automatic punching processing. The rapid multi-hole punching equipment comprises a frame, a workbench,a lifting mechanism, a machine head, drill bit mounting assemblies, a drill bit mounting head and a driving belt. According to the rapid multi-hole punching equipment, the machine head and the workbench are arranged on the upper part and the lower part of the frame respectively, the drill bit mounting assembly is detachably connected to the frame. Meanwhile, a plurality of drill bit mounting heads which are in power transmission with the machine head are detachably arranged on the drill bit mounting assembly, and mounting of drill bits is realized through the drill bit mounting heads, so thatcorresponding drill bit mounting assemblies can be replaced and drill bit mounting heads of different quantities and positions can be arranged according to actual machining demands; simultaneous machining of a plurality of holes in workpieces is realized; the problems of repeated clamping and replacement of the drill bits due to repeated machining are solved; the machining efficiency and machining accuracy are improved; the product quality is ensured; and the production and machining demands of enterprises are met better.

Owner:宁波格林工艺玩具有限公司

Hole punching equipment for textiles

InactiveCN112249791AAdjustable sizeImprove versatilityMetal working apparatusArticle deliveryHole punchingStructural engineering

The invention discloses hole punching equipment for textiles. A feeding assembly is arranged on a first support and provided with a first power assembly, the first power assembly provides power for the feeding assembly, a hole punching assembly for punching holes in a fabric is arranged on the upper side of the feeding assembly, a second power assembly is arranged on the upper side of the hole punching assembly and provides power for the hole punching assembly, and a stabilizing assembly is arranged on the lower side of the second power assembly and used for extruding and stabilizing the fabric when the hole punching assembly punches holes in the fabric. According to the hole punching equipment, double knives symmetrically arranged on the center line rotate to cut downwards to punch holes,the distance between the double knives is adjustable, and the fabric generated by hole punching is collected in the hole punching process.

Owner:HANGZHOU MUYE MASCH TECH CO LTD

Circuit board mounting hole punching device with dust removal function

InactiveCN111873062AAvoid interferenceImprove work efficiencyDirt cleaningCleaning using toolsDust controlEngineering

The invention discloses a circuit board mounting hole punching device with a dust removal function. The circuit board mounting hole punching device comprises a machine body, wherein a punching cavitywith a leftward opening is formed inside the machine body, the lower side of the punching cavity is provided with a dust removal cavity in a communicating mode, the punching cavity and the rear side of the dust removal cavity are jointly provided with a lifting cavity in a communicating mode, a lifting plate capable of sliding up and down is arranged inside the lifting cavity, a front end of the lifting plate extends into the punching cavity, a lower fixing plate is fixedly arranged on the upper end surface of the lifting plate, a connecting rod is fixedly arranged on the right side of the upper end surface of the lower fixing plate, and an upper fixing plate right opposite to the lower fixing plate is fixedly arranged on the upper end surface of the connecting rod. According to the circuit board mounting hole punching device, a plurality of circuit boards can be clamped and fixed at the same time, then mounting hole punching is carried out on four corners of the circuit boards at thesame time through punching drill bits, and the working efficiency is high; and the device can automatically clear dust left on the surfaces of the circuit boards and generated by punching, so that interference of the dust on use of the circuit boards is avoided.

Owner:东阳坎层电子科技有限公司

Continuous hole punching device with high precision

InactiveCN111745173AHigh precisionImprove stabilityFeeding apparatusMetal working apparatusTransmission beltLinkage (mechanical)

The invention relates to a continuous hole punching device with high precision. The continuous hole punching device with high precision comprises a support frame, a hole punching mechanism, a positioning mechanism, a transmission mechanism and a clamping mechanism, wherein the hole punching mechanism is arranged on a transverse rod; the transmission mechanism is arranged on support rods; the clamping mechanism is arranged right under the hole punching mechanism; and the positioning mechanism comprises a moving assembly and a position clamping assembly. The continuous hole punching device withhigh precision has the advantages that the hole punching is realized through the hole punching mechanism; the transmission mechanism is positioned through the positioning mechanism, so that positioning on workpieces on a transmission belt is realized; clamping on the workpieces is realized through the clamping mechanism; and the hole punching precision is improved. Compared with an existing hole punching device, the continuous hole punching device with high precision has the advantages that through one output source, the linkage of hole punching, transmission and clamping of the workpieces isrealized; and the energy sources are saved. Compared with an existing positioning mechanism, the positioning mechanism uses a pure mechanical structure, avoids the use of a sensor, prolongs the service life, and improves the mechanism stability.

Owner:GUANGZHOU SONGBIN ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com