Rapid multi-hole punching equipment

A kind of equipment and fast technology, applied in drilling/drilling equipment, metal processing equipment, boring/drilling and other directions, can solve the problems of difficult to meet production and processing, high product defect rate, low drilling efficiency, etc. Satisfy production and processing needs, high security, and improve the effect of punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach Image 6 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

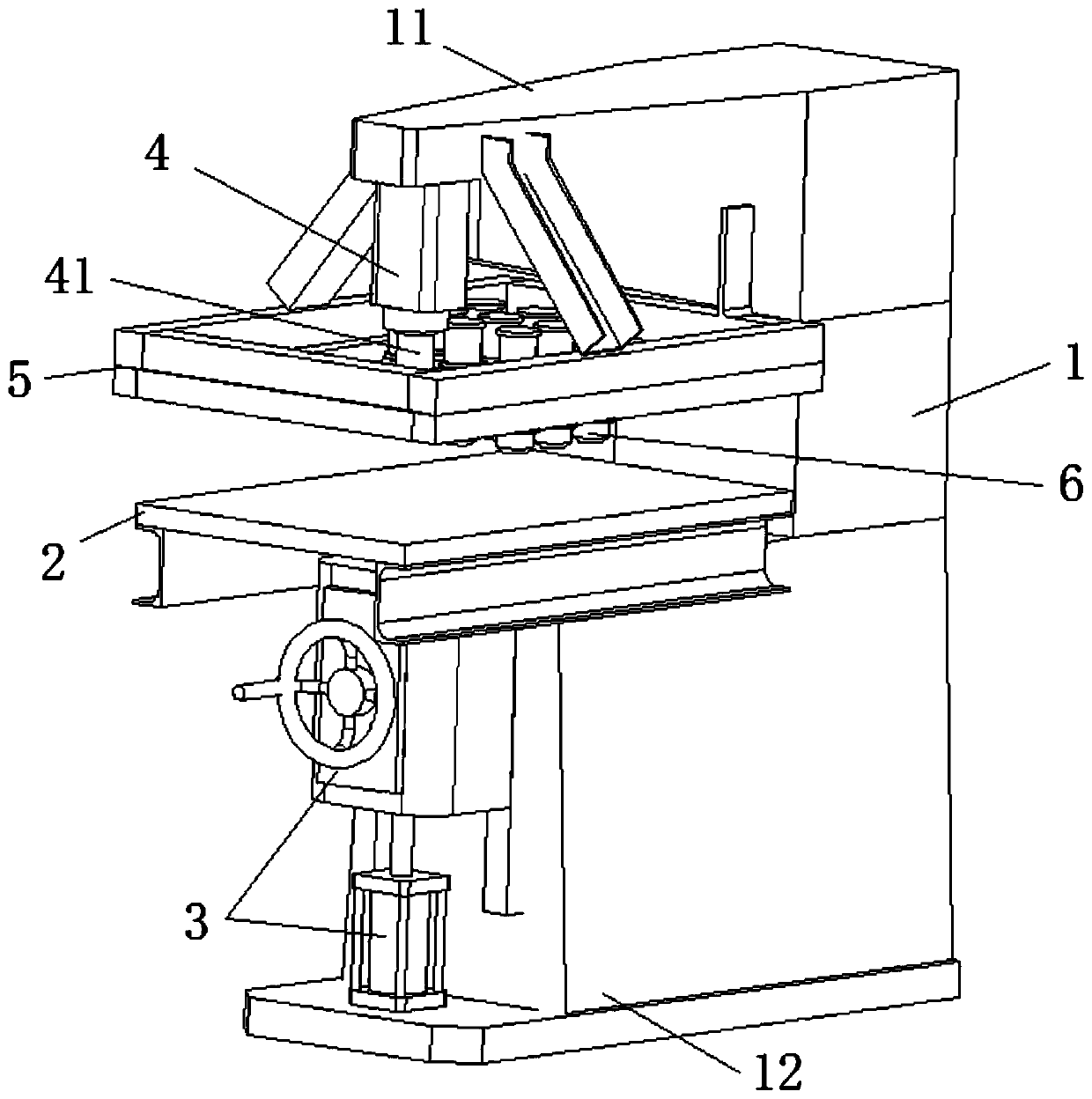

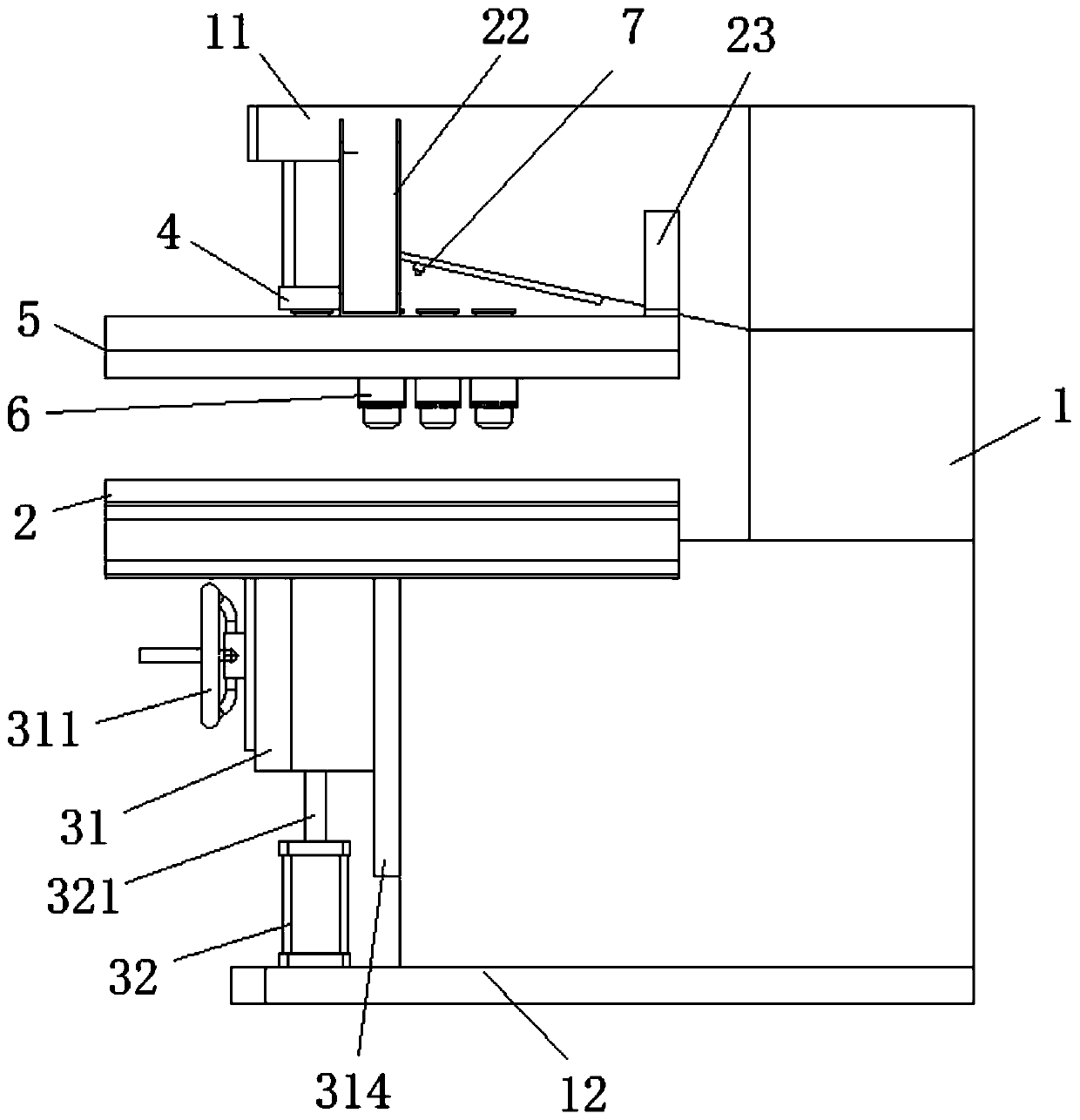

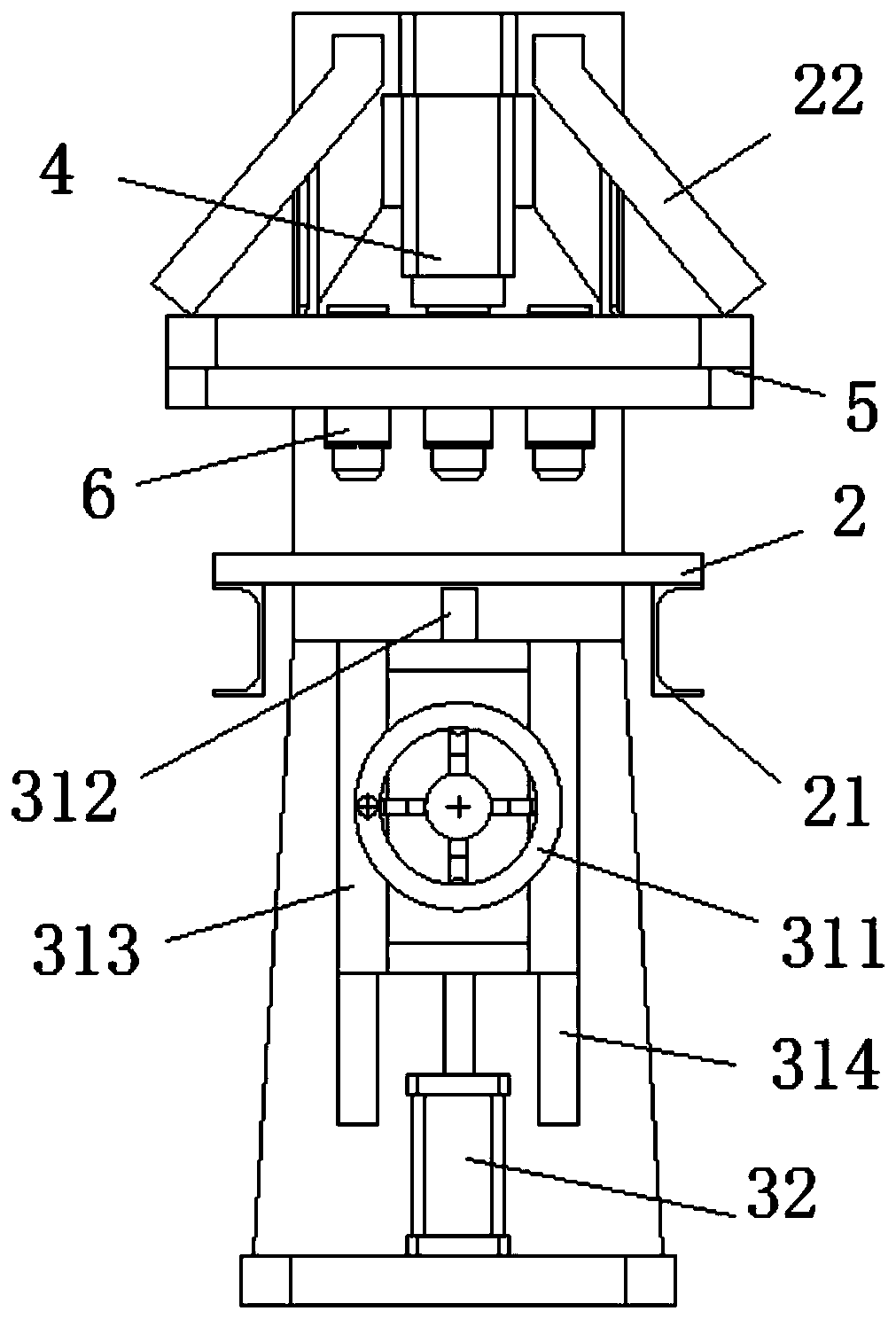

[0035] figure 1 It is a structural diagram of an embodiment of a fast punching device of the present invention; figure 2 It is a structural diagram of a viewing angle of a preferred embodiment of the present invention; image 3 It is a structural diagram of another perspective of a preferred embodiment of the present invention. Such as figure 1 , figure 2 as well as image 3 As shown, the rapid drilling equipment provided in this embodiment includes: frame 1, station table 2, lifting mechanism 3, machine head 4, drill bit installation assembly 5, drill bit installation head 6 and transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com