Patents

Literature

585 results about "Product defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A product defect is any characteristic of a product which hinders its usability for the purpose for which it was designed and manufactured.

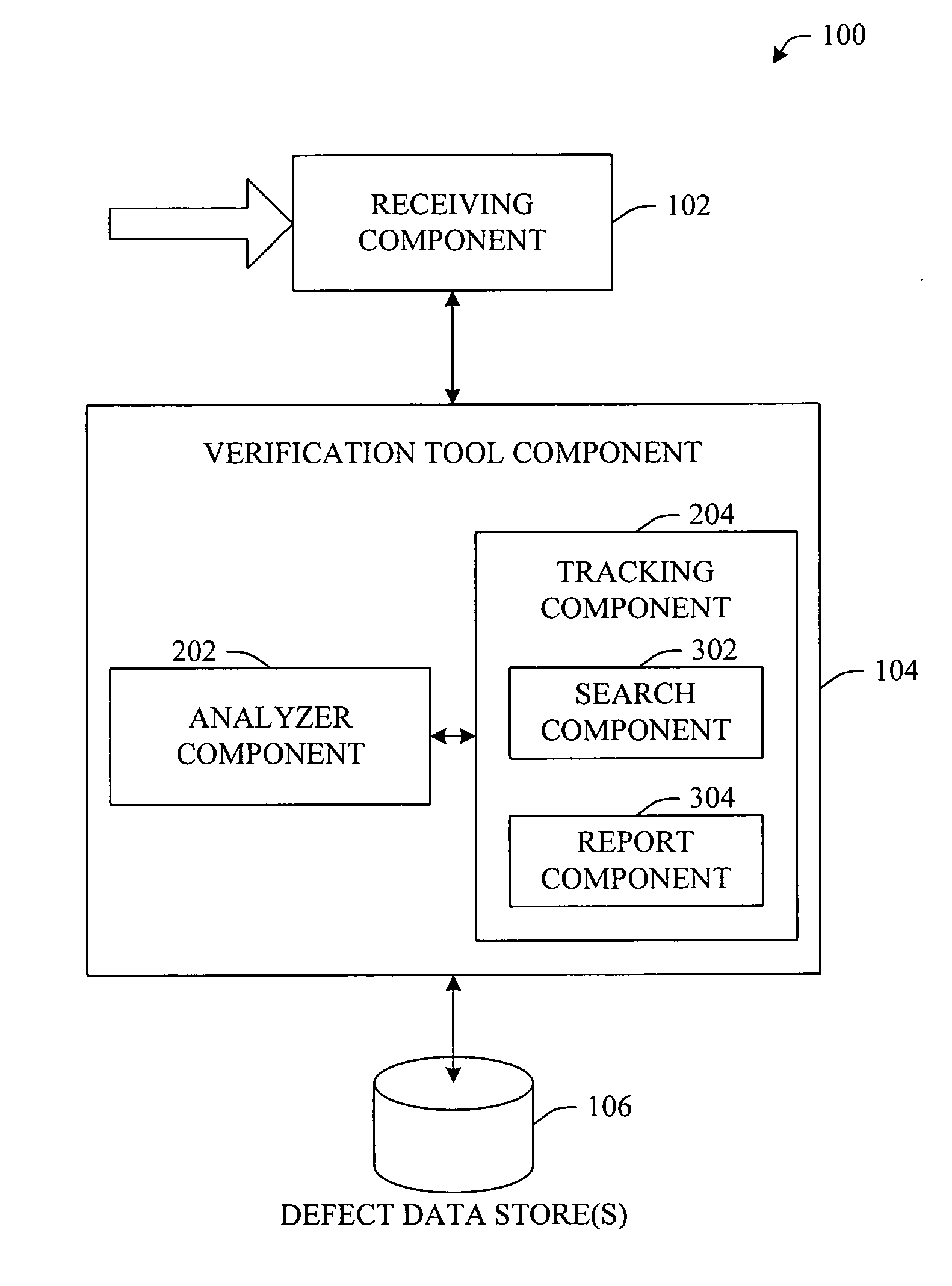

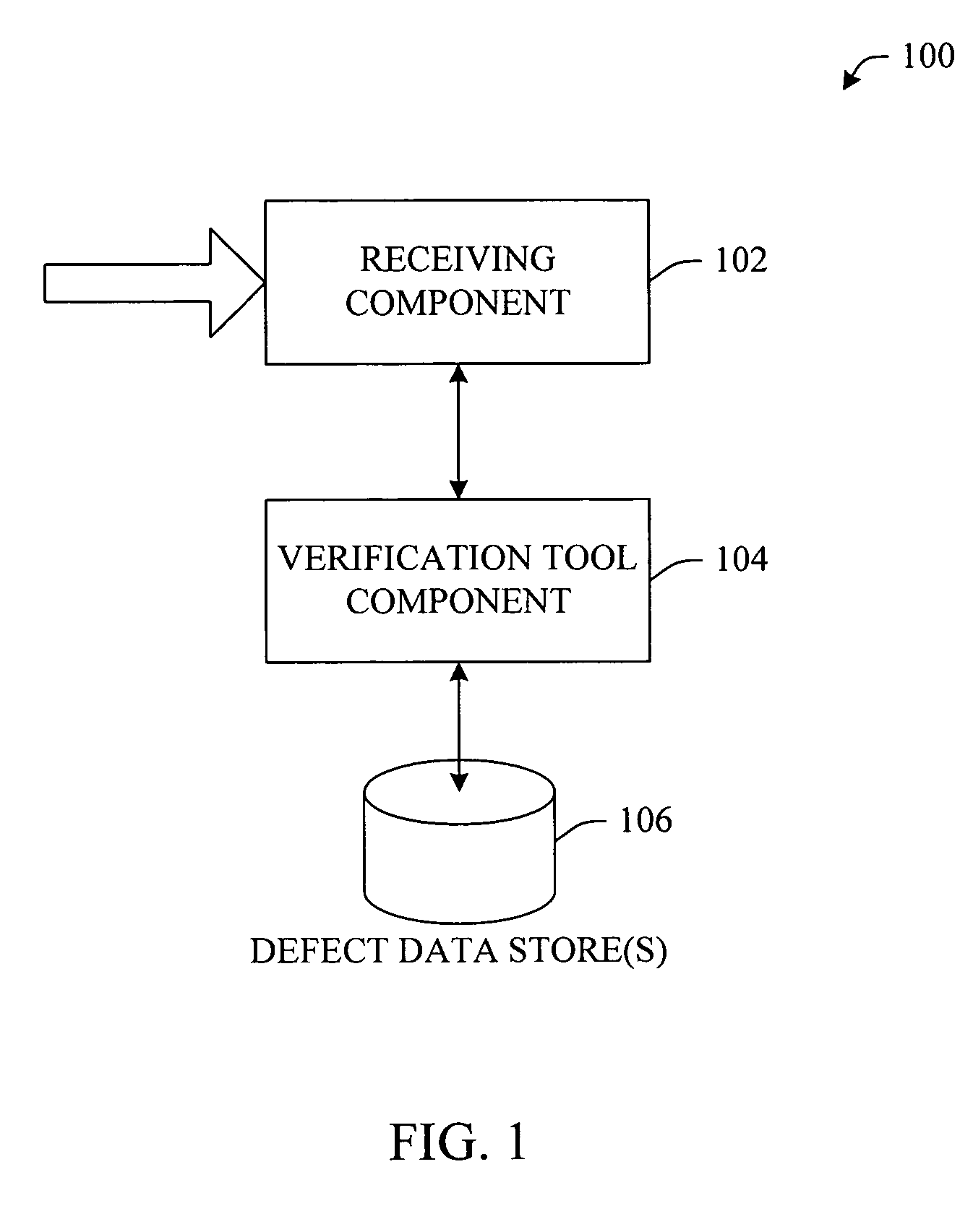

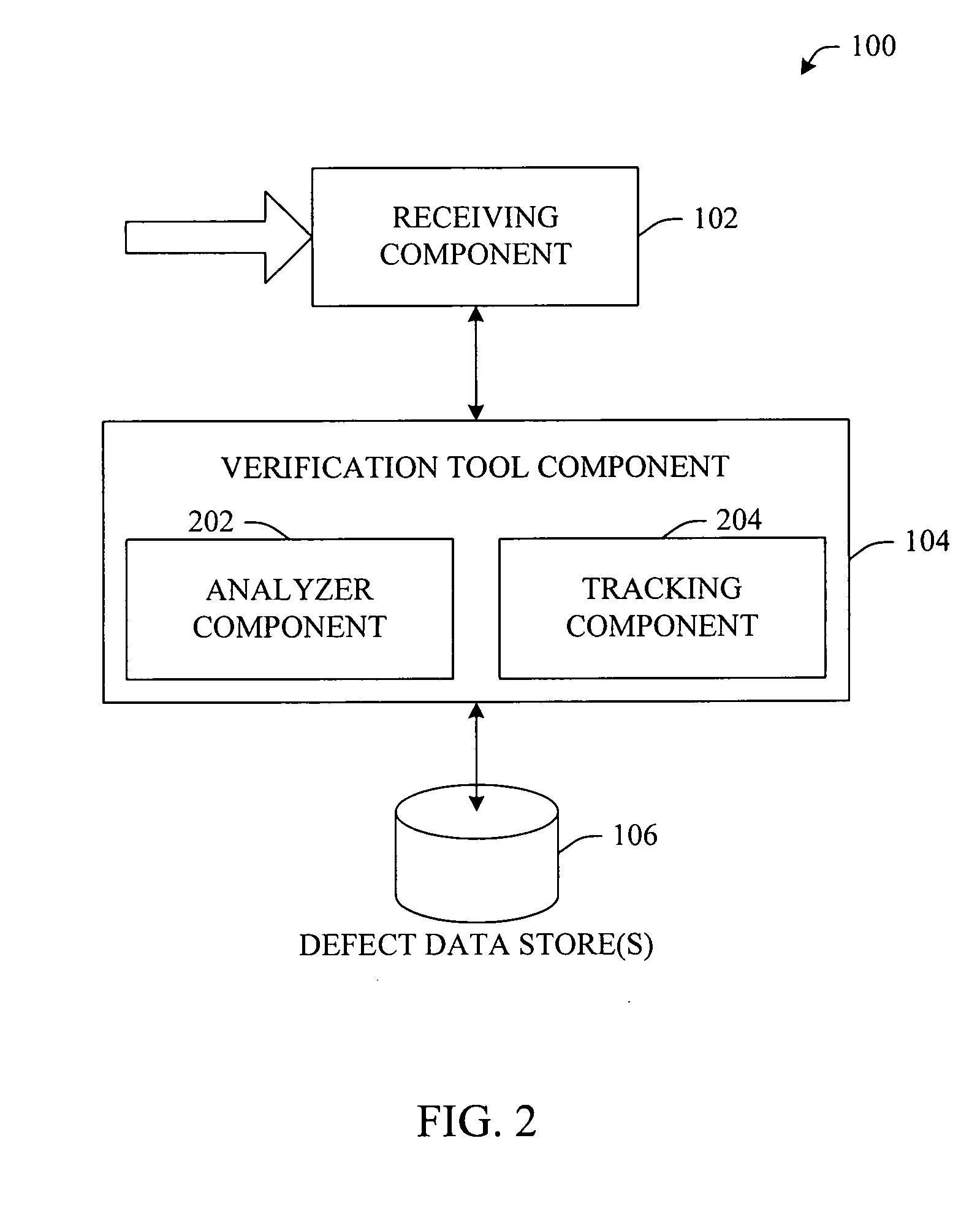

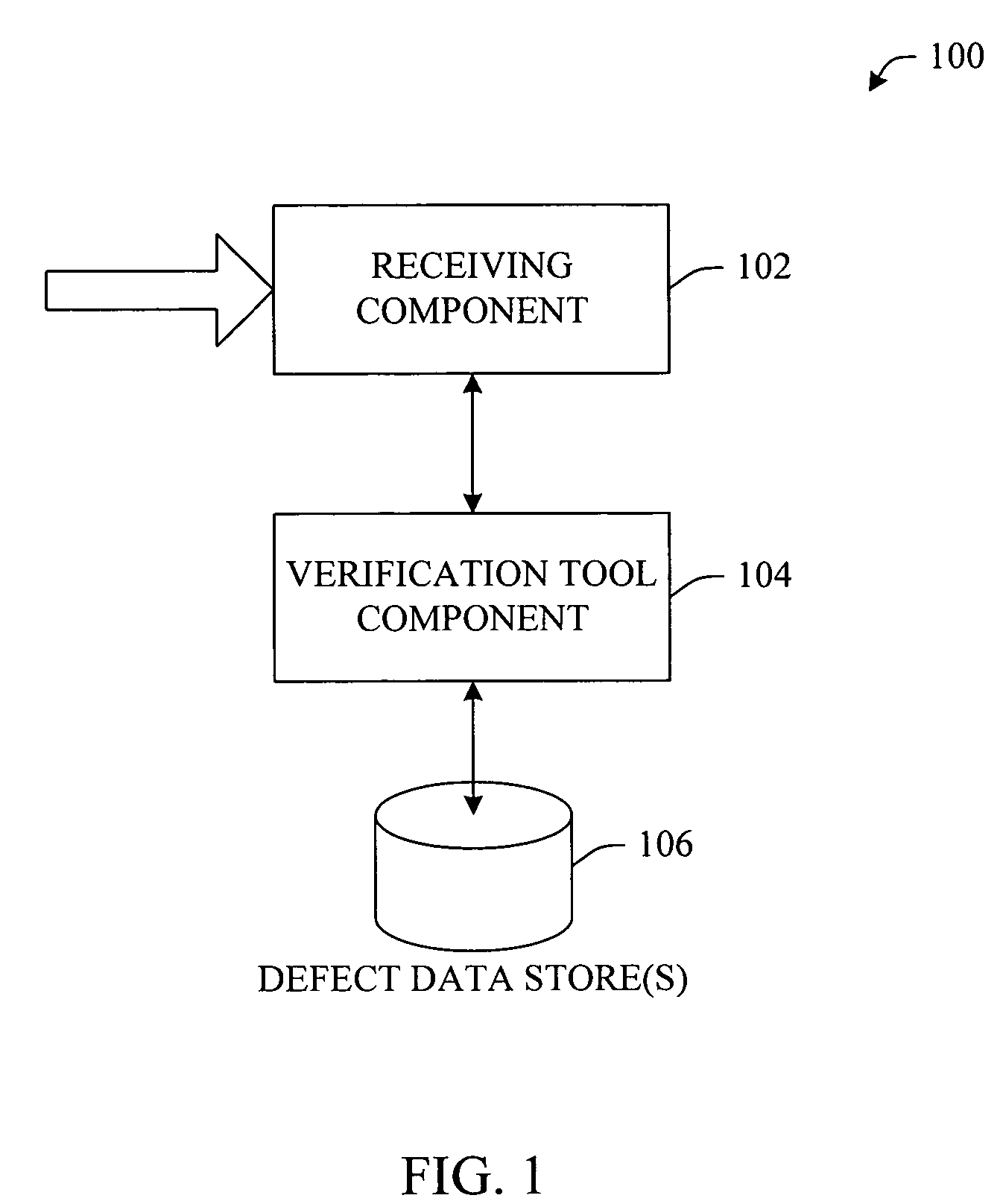

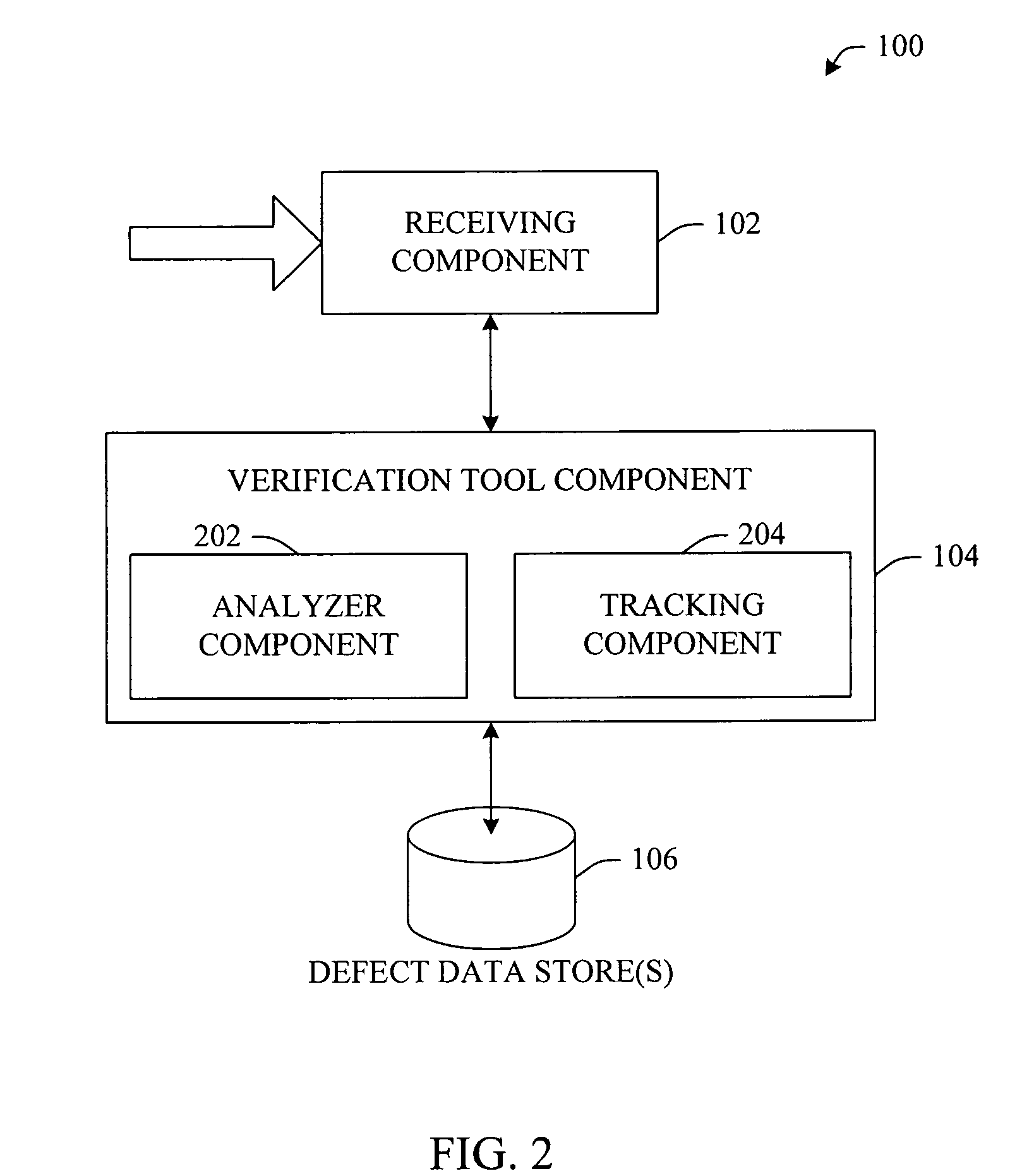

Automated product defects analysis and reporting

InactiveUS20070074149A1Well formedError detection/correctionDigital computer detailsSoftware faultData mining

An automation infrastructure which automatically analyzes software faults and / or bugs related to a product defect is provided. More particularly, the system can automatically analyze and detect symptoms in the forms of crash dump, memory leak, corruption and test issues etc. In accordance therewith, aspects can automatically search for and locate existing defect reports, if such existing reports are available. Moreover, aspects can automatically report new defects in a defect tracking database or other tracking mechanism.

Owner:MICROSOFT TECH LICENSING LLC

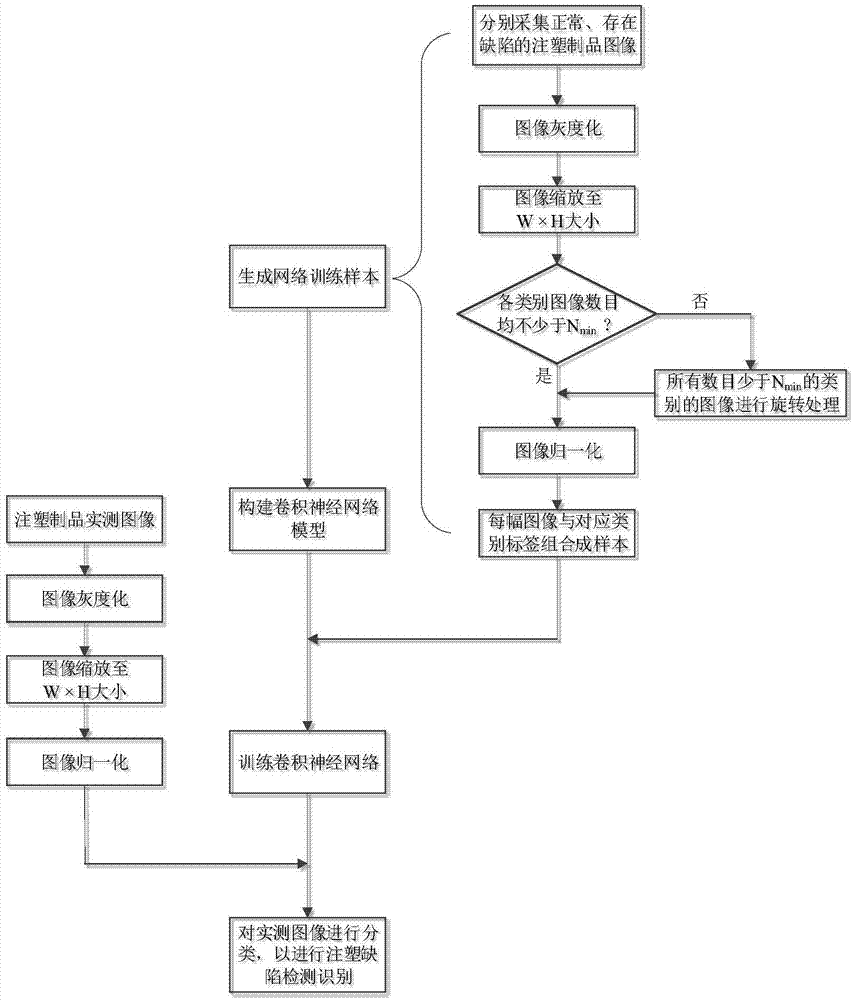

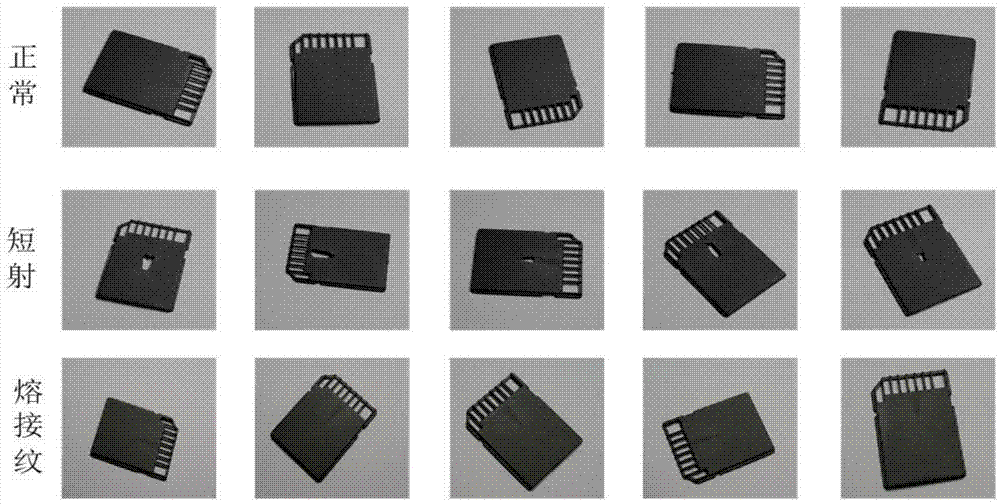

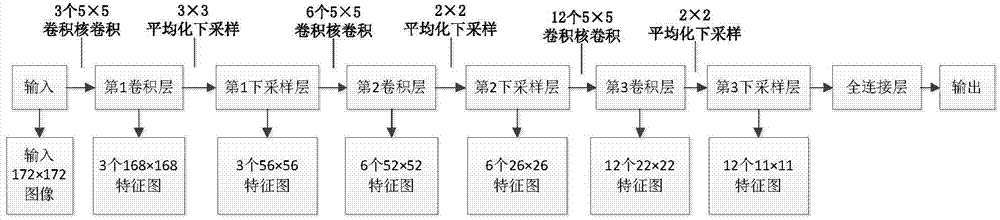

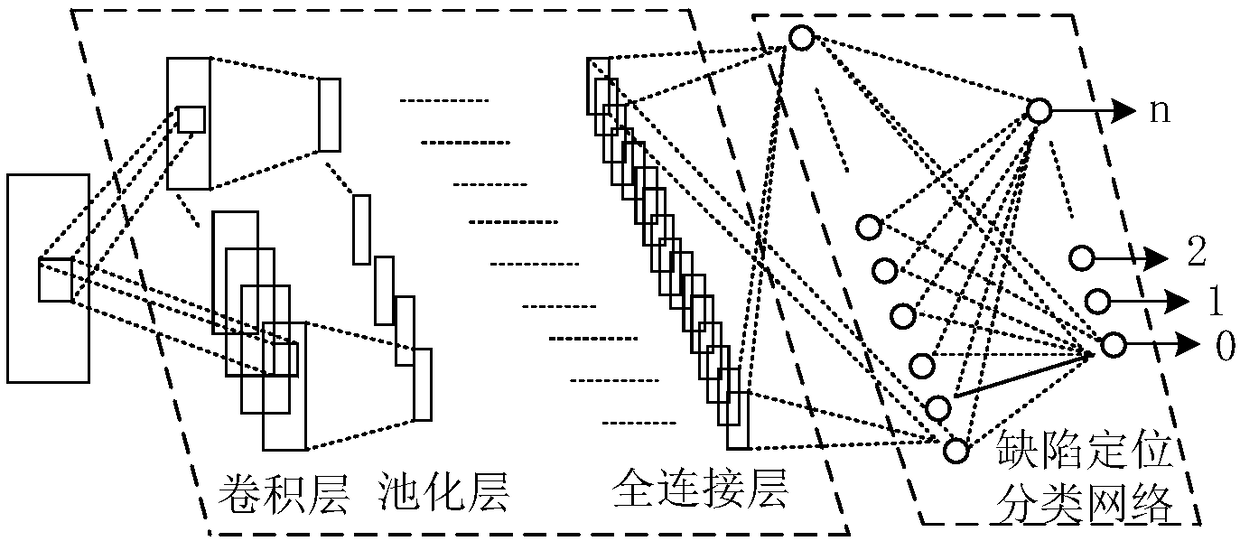

Injection-molded product defect detection and recognition method

ActiveCN104850858AOvercoming requires good prior knowledgeOvercoming selectivityImage enhancementImage analysisFeature selectionProduct defect

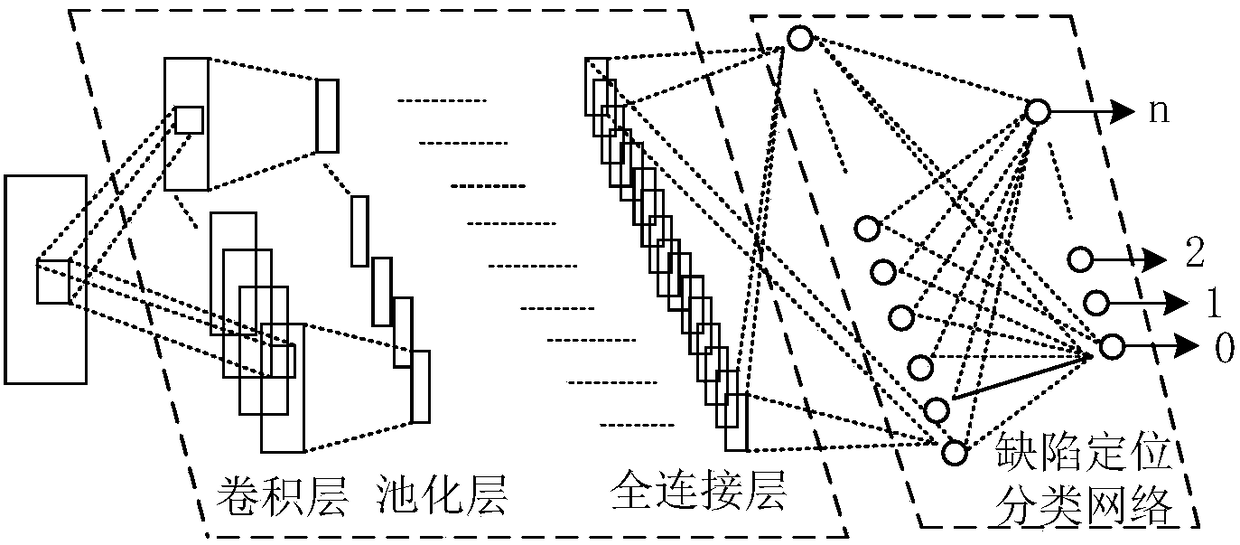

The invention discloses an injection-molded product defect detection and recognition method, which comprises the following steps: 1) images of a normal injection-molded product and a known defect-existing injection-molded product are acquired, and the images are classified and samples are generated; 2) a multi-layer convolutional neural network model is built; 3) the samples in the first step are used for training the convolutional neural network model built in the second step; and 4) the acquired actually-measured injection-molded product images are preprocessed and inputted to the convolutional neural network model after training completion in the third step, the convolutional neural network model carries out classification and recognition on the actually-measured injection-molded product images so as to judge whether injection molding defects exist in the injection-molded product, and if the defects exist, the defect types are classified. The built convolutional neural network model of the invention adopts the same feature selection and extraction mode for various injection-molded defects, is strong in adaptability, and can be used for detection and recognition of various types of defects of the injection-molded product.

Owner:HUAZHONG UNIV OF SCI & TECH

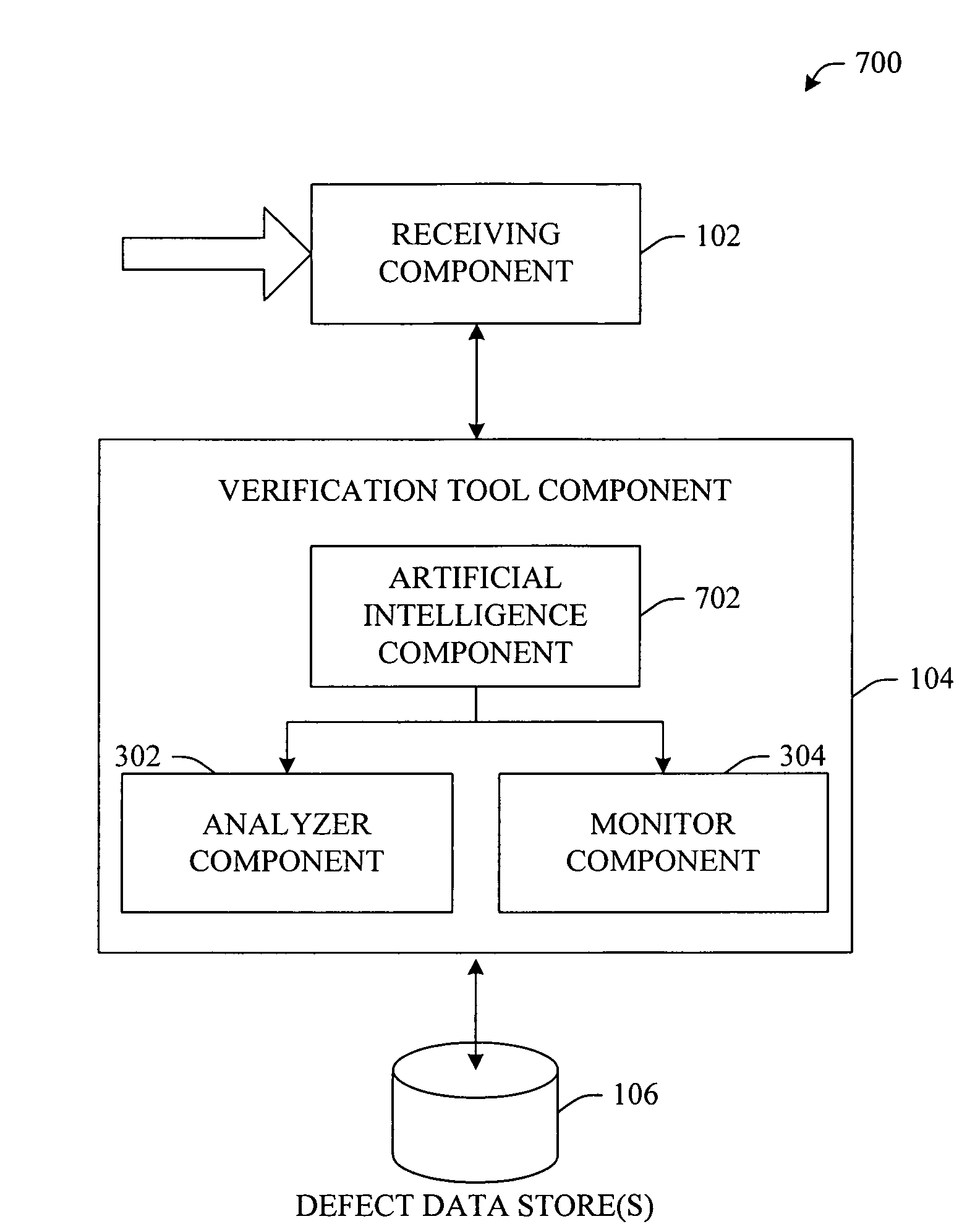

Automated product defects analysis and reporting

An automation infrastructure which automatically analyzes software faults and / or bugs related to a product defect is provided. More particularly, the system can automatically analyze and detect symptoms in the forms of crash dump, memory leak, corruption and test issues etc. In accordance therewith, aspects can automatically search for and locate existing defect reports, if such existing reports are available. Moreover, aspects can automatically report new defects in a defect tracking database or other tracking mechanism.

Owner:MICROSOFT TECH LICENSING LLC

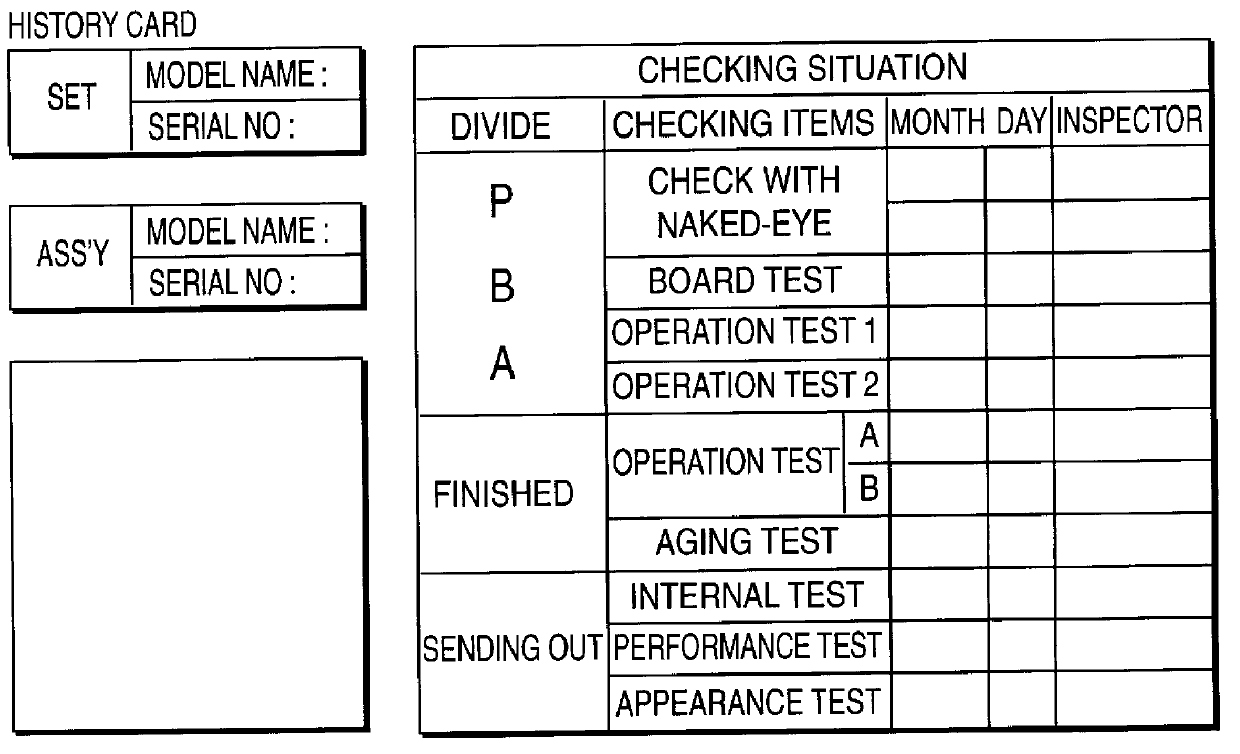

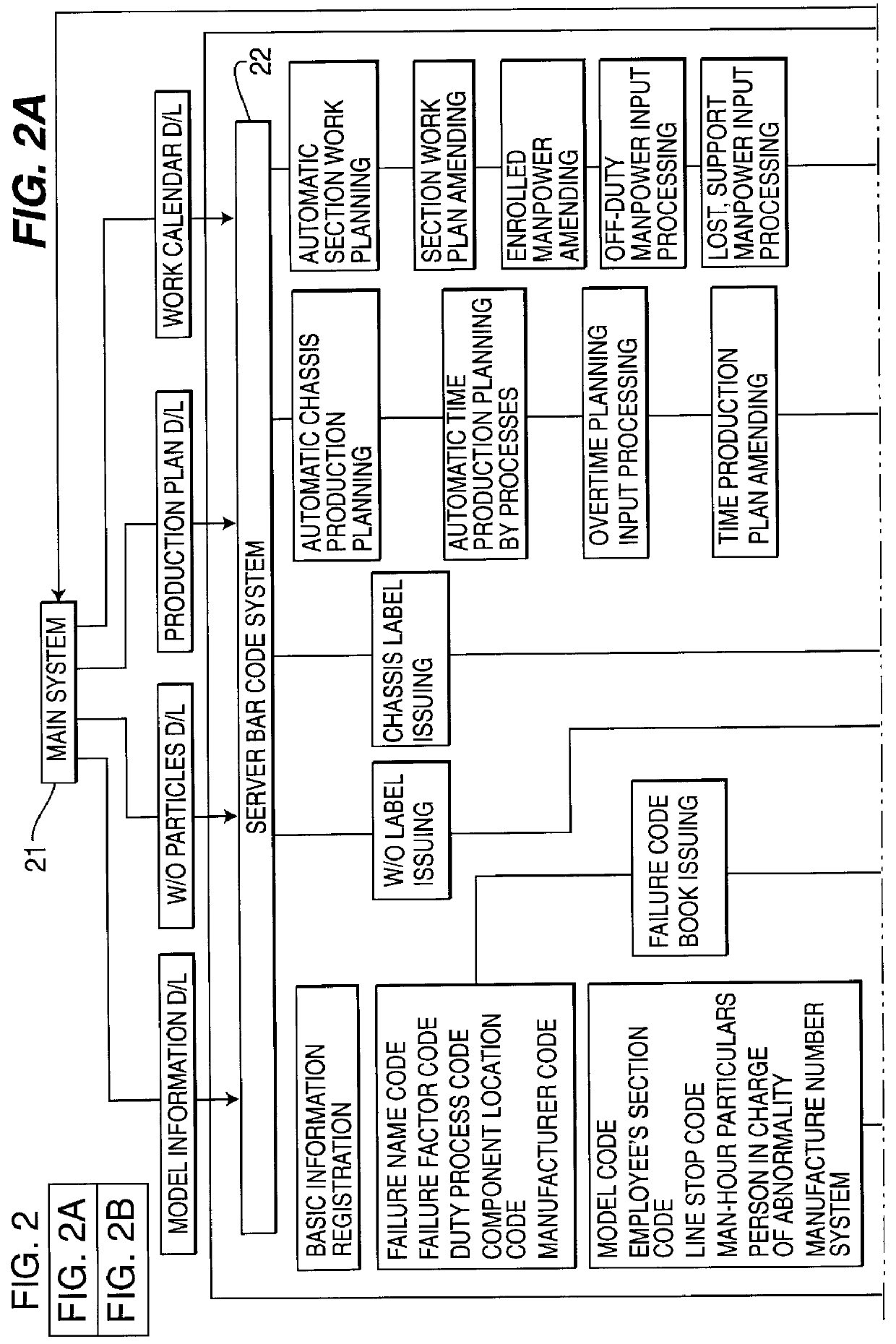

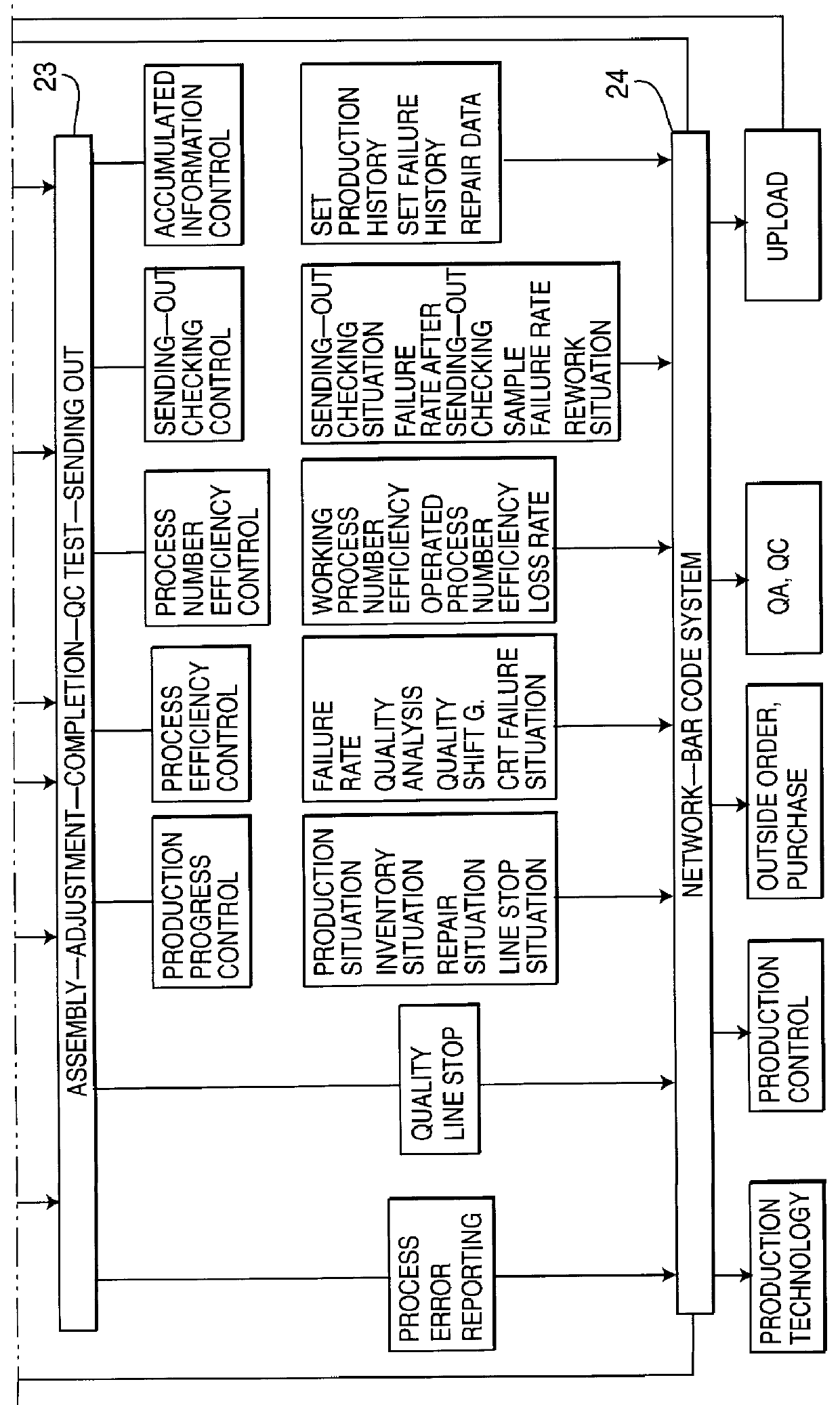

Quality control apparatus and method using a bar code data entry system

InactiveUS6027022AEfficient processingAvoid mistakesElectric testing/monitoringAssembly machinesProduction lineQuality control

A quality control method and apparatus using a bar code data entry system that improves product quality through collection and processing of accurate information in real time by entering the production particulars from a manufacturing process to a sending-out process with the bar code system and storing them in a system control computer so as to prevent defective products from being sent out and avoid repetitive occurrences of the same failure. The bar code system is installed in the production line so as to immediately suspend the production line in case of a situation corresponding to production line stop conditions, thereby preventing repetitive occurrences of the same failure and sending-out of numerous defective products even after some with defects have been sent.

Owner:SAMSUNG ELECTRONICS CO LTD

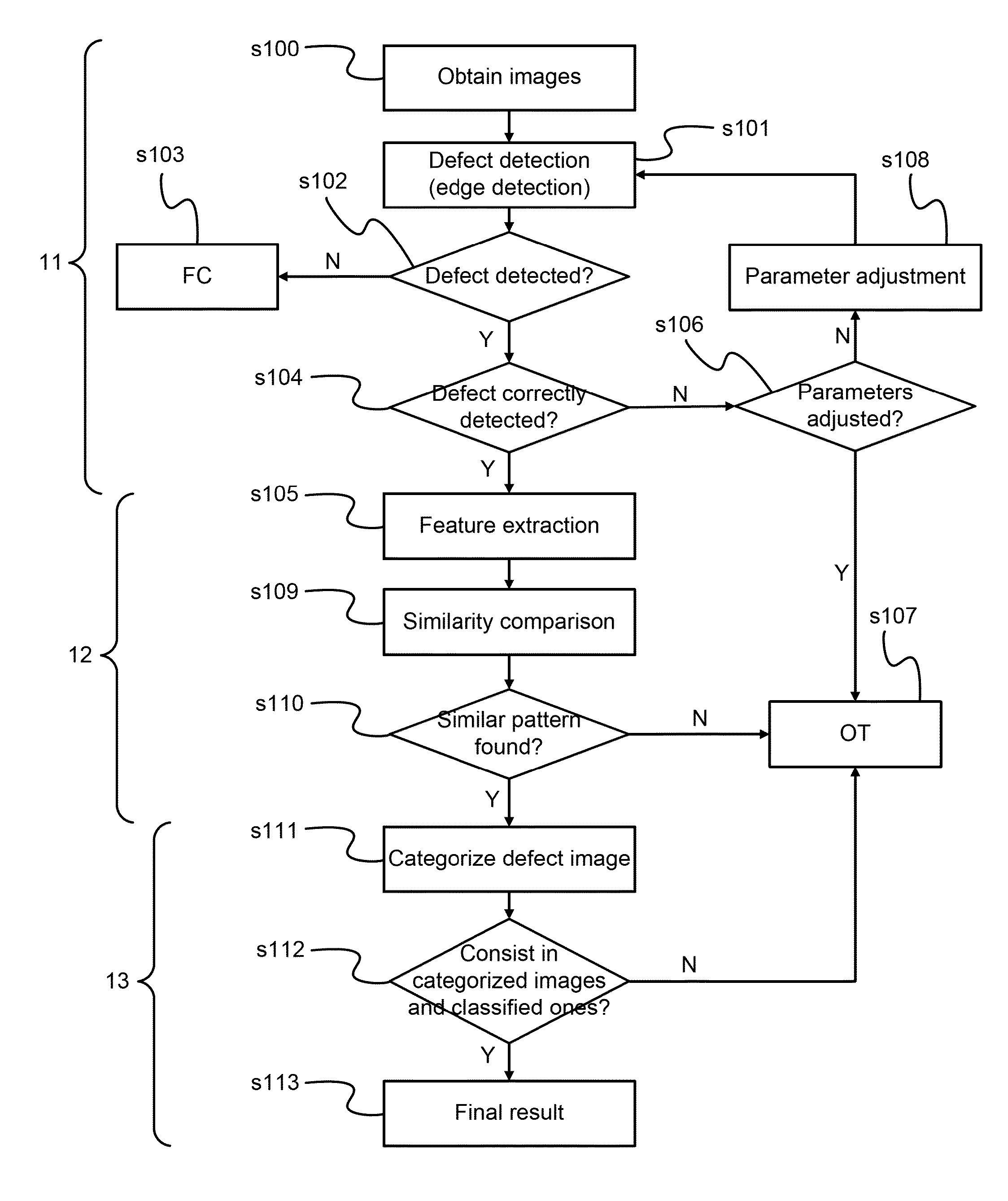

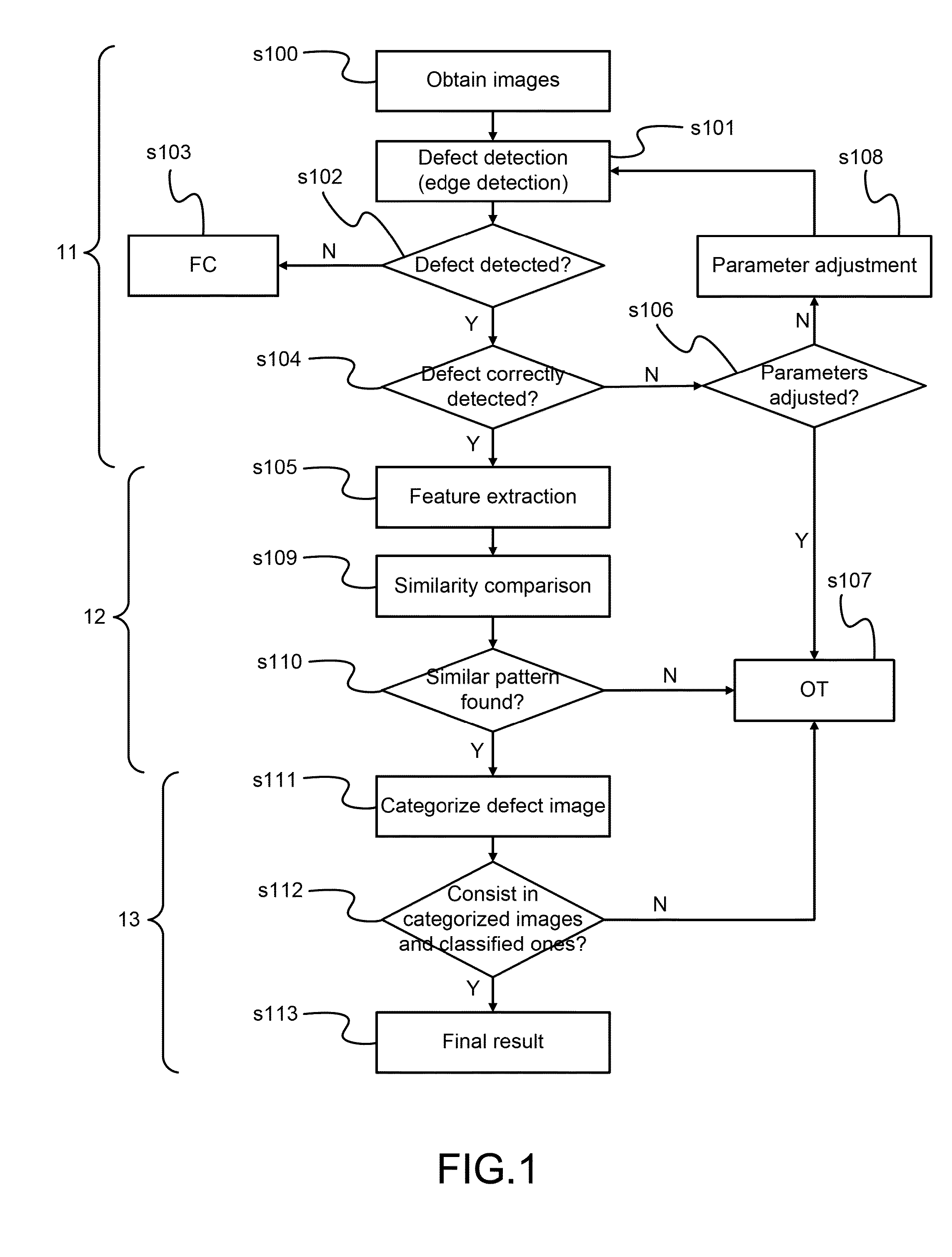

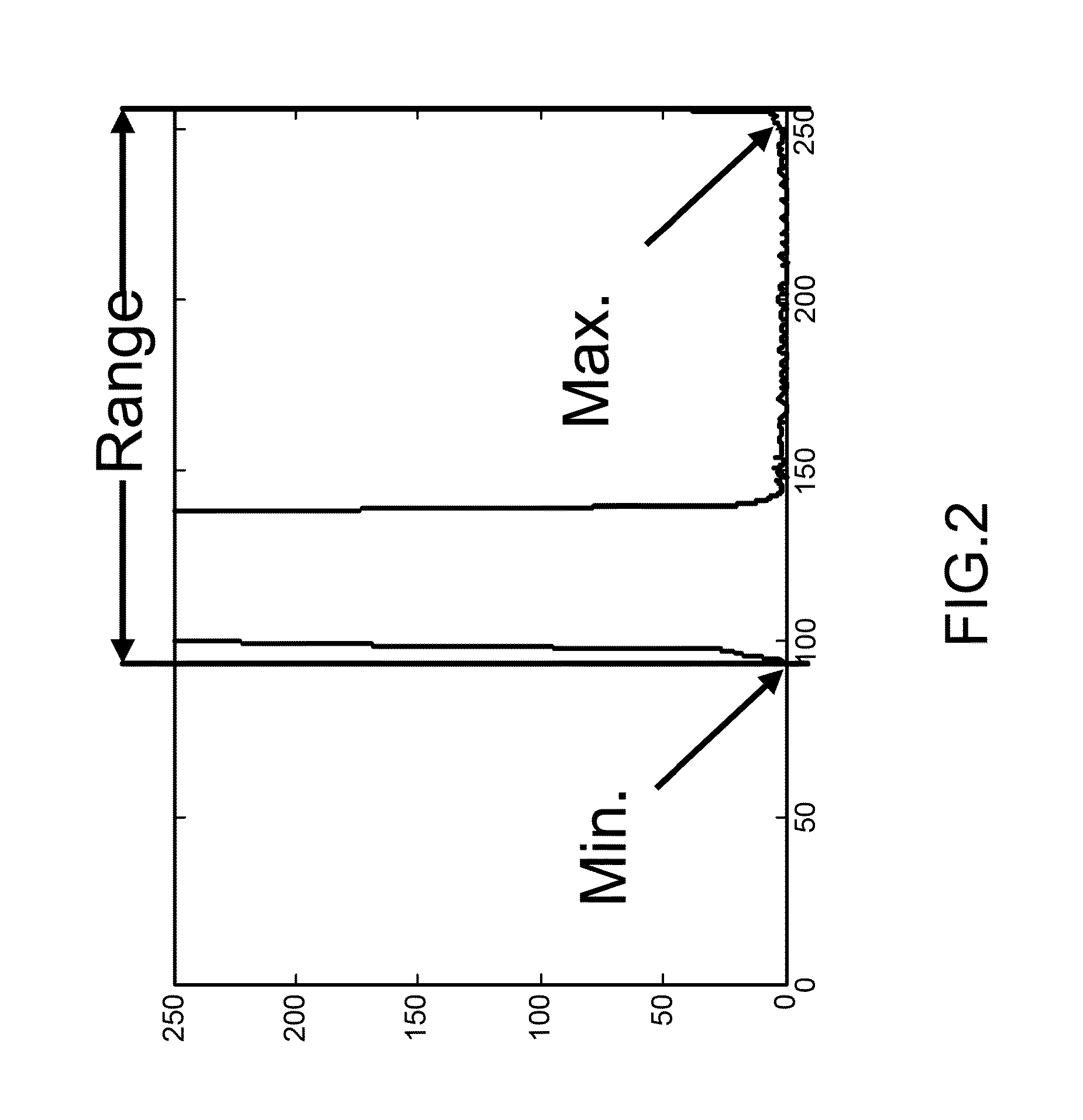

Method of Defect Image Classification through Integrating Image Analysis and Data Mining

InactiveUS20150098655A1Reduce error rateImproved consistency and correctness and reliabilityImage enhancementImage analysisPattern recognitionImaging analysis

A method for classifying defect images is provided. Defect images are processed through an automatic optical detection. The present invention integrates image analysis and data mining. Defects are found on the images without using human eye. The defects are classified for reducing product defect rate. Thus, the present invention effectively enhances performance on finding and classifying defects with increased consistency, correctness and reliability.

Owner:NATIONAL TSING HUA UNIVERSITY

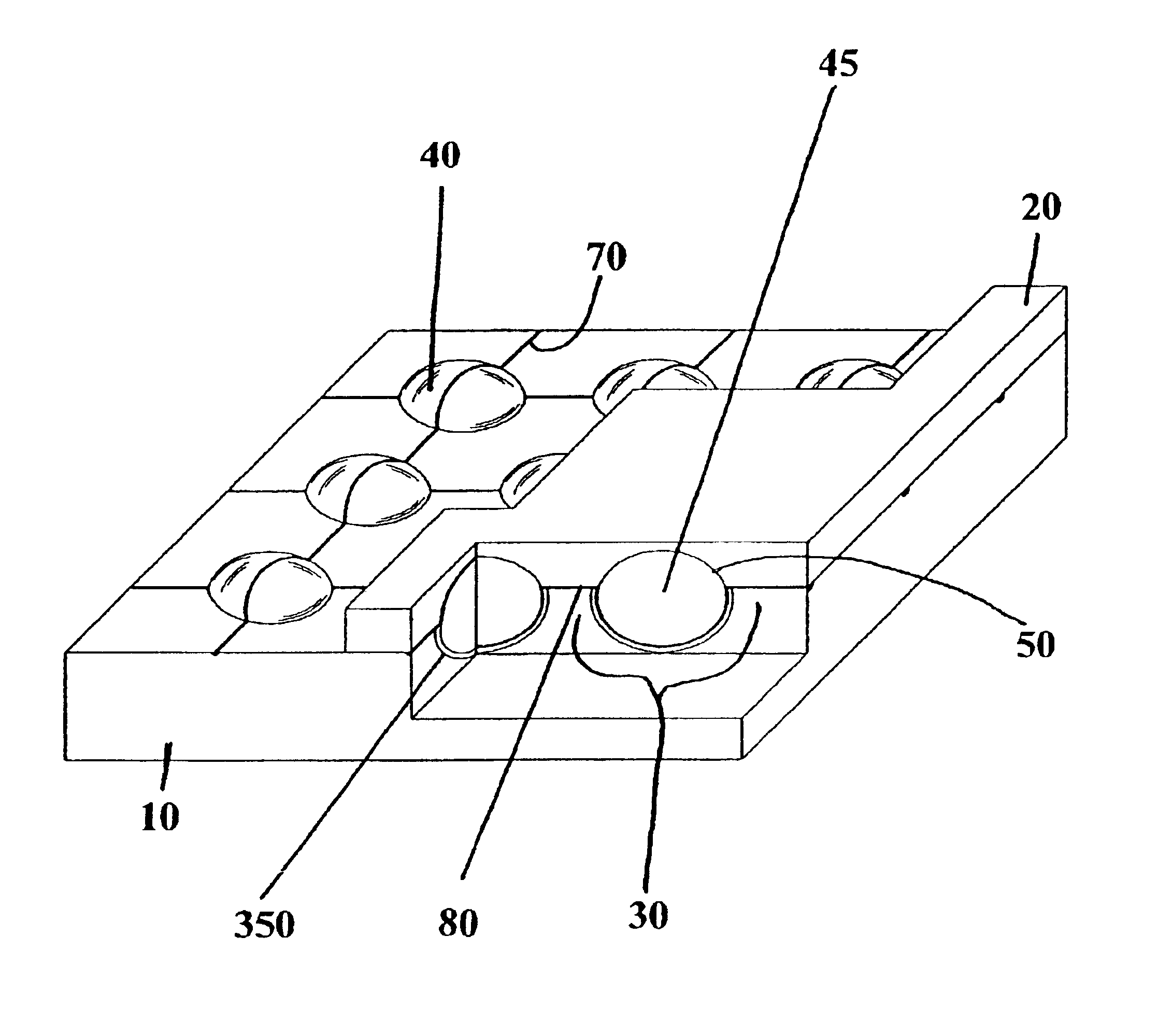

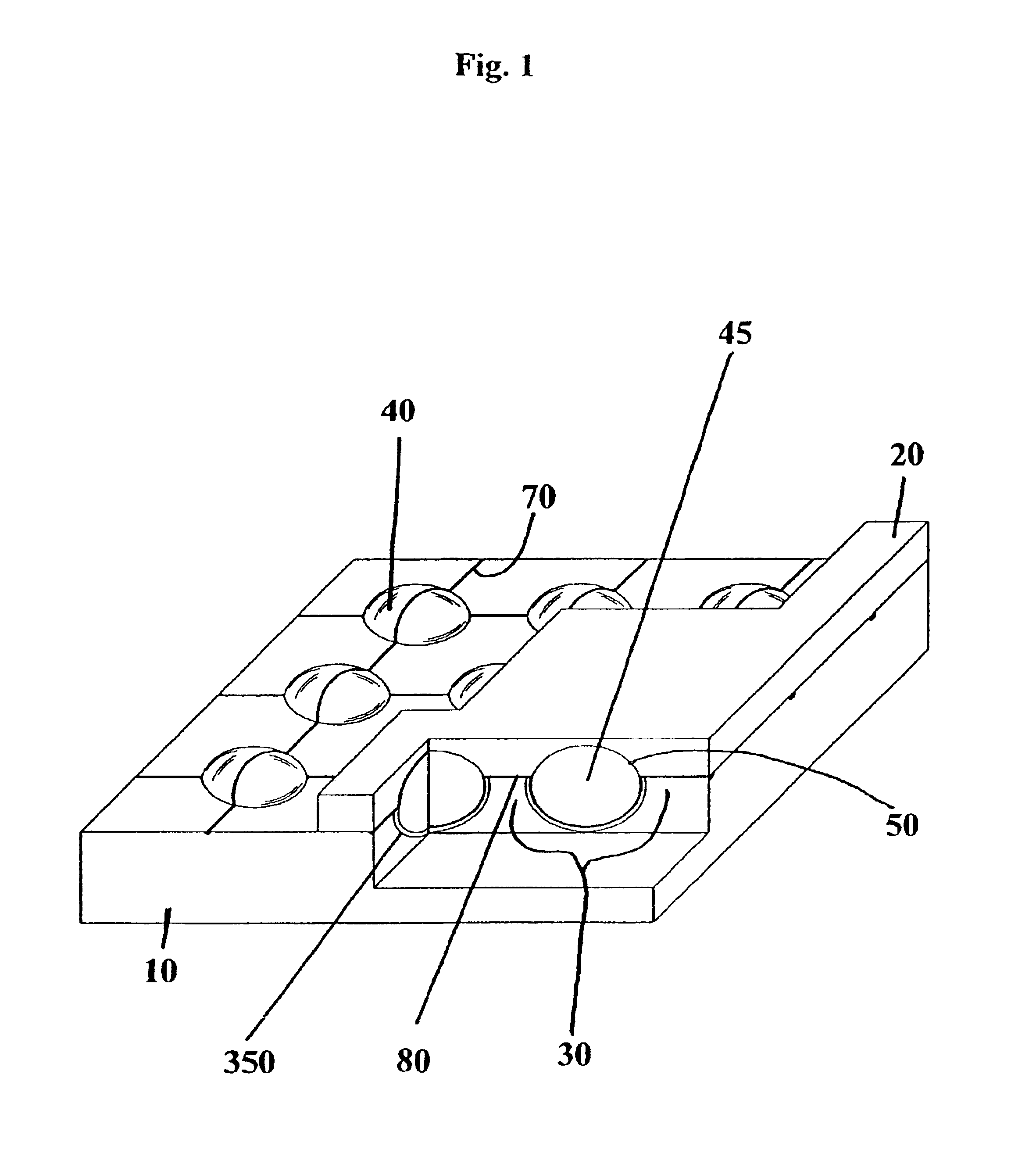

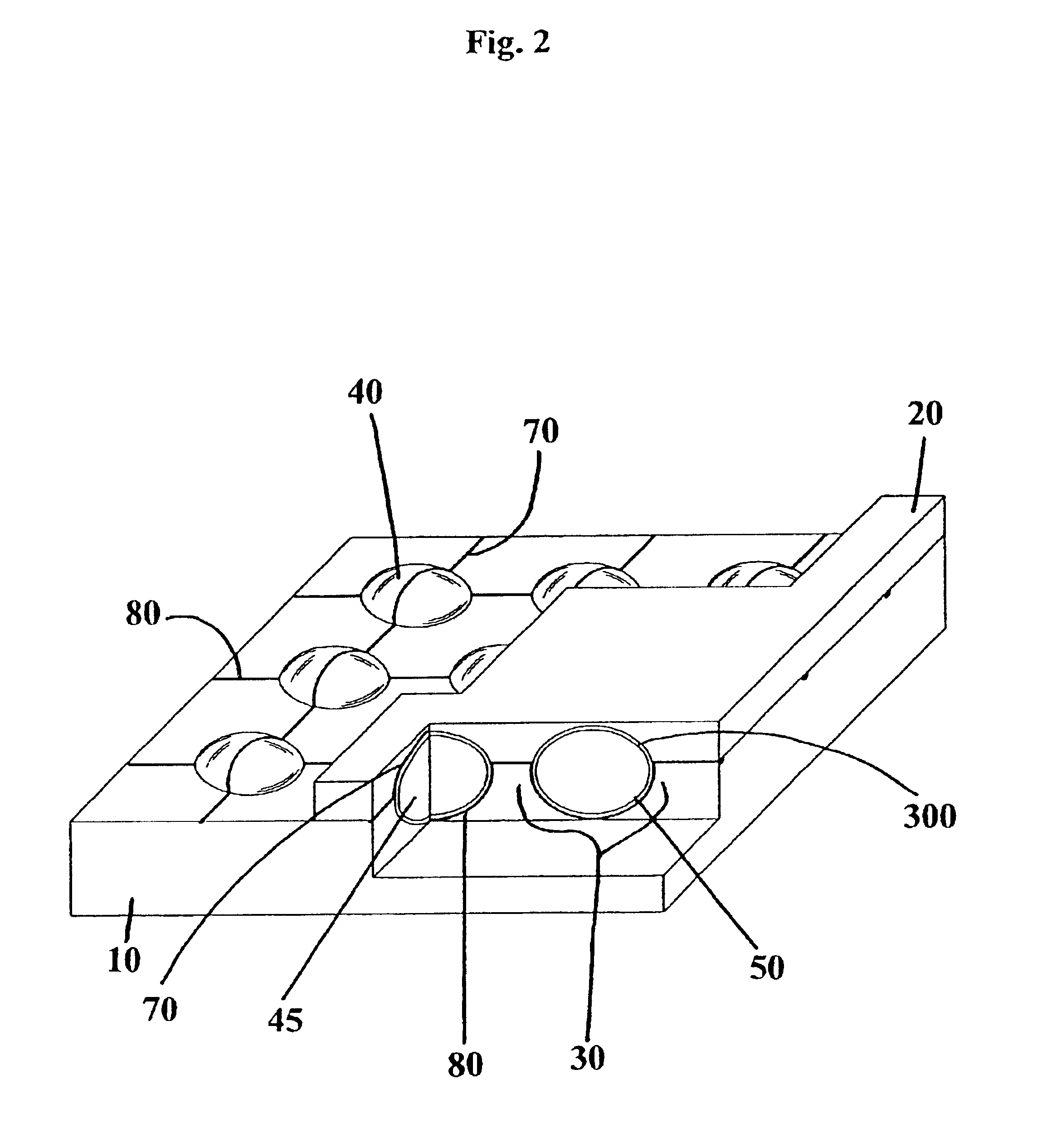

Method for on-line testing of a light emitting panel

InactiveUS6935913B2Sufficient resolutionManufactured very thinSparking plugsStatic indicating devicesEngineeringLight-emitting diode

Owner:LEIDOS

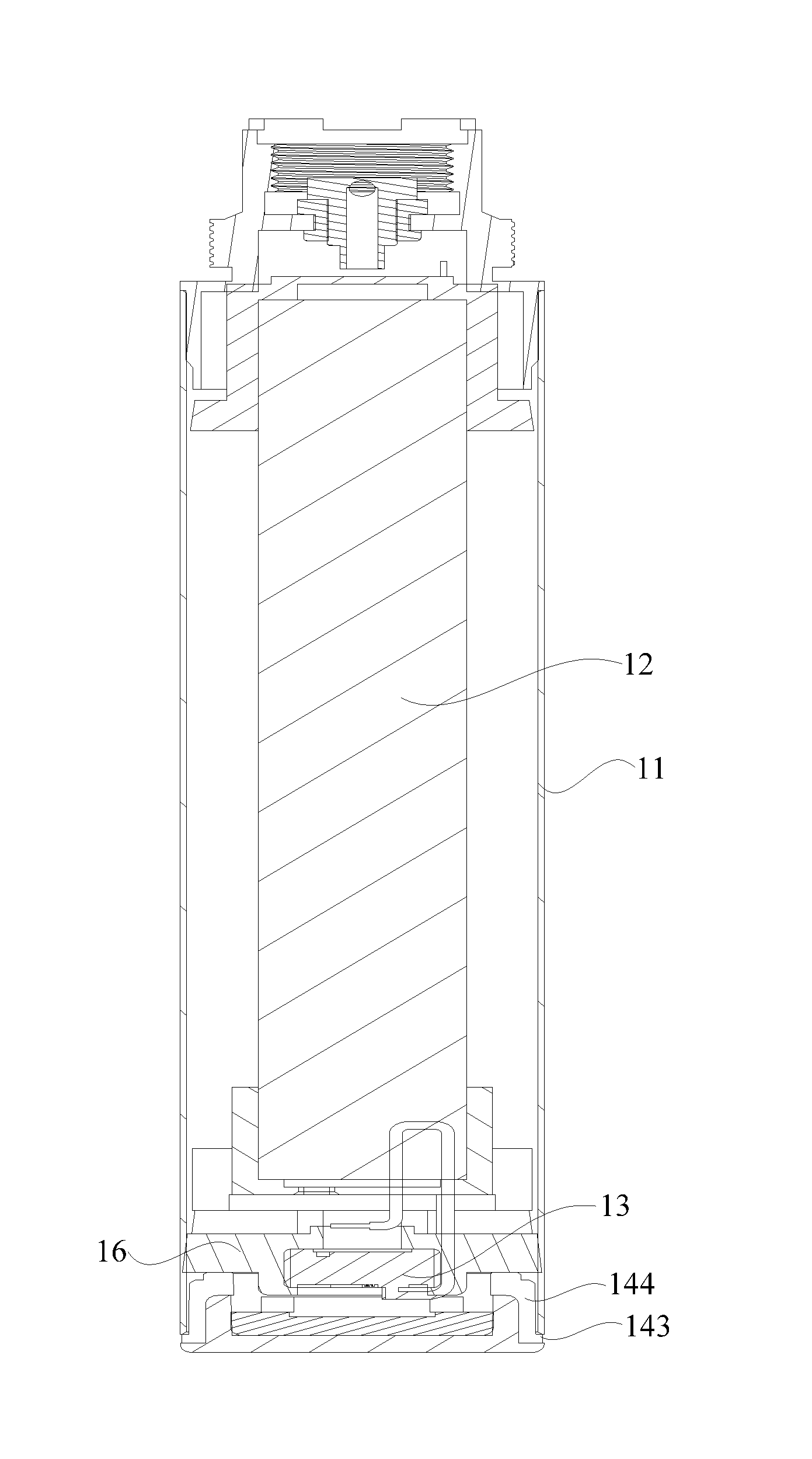

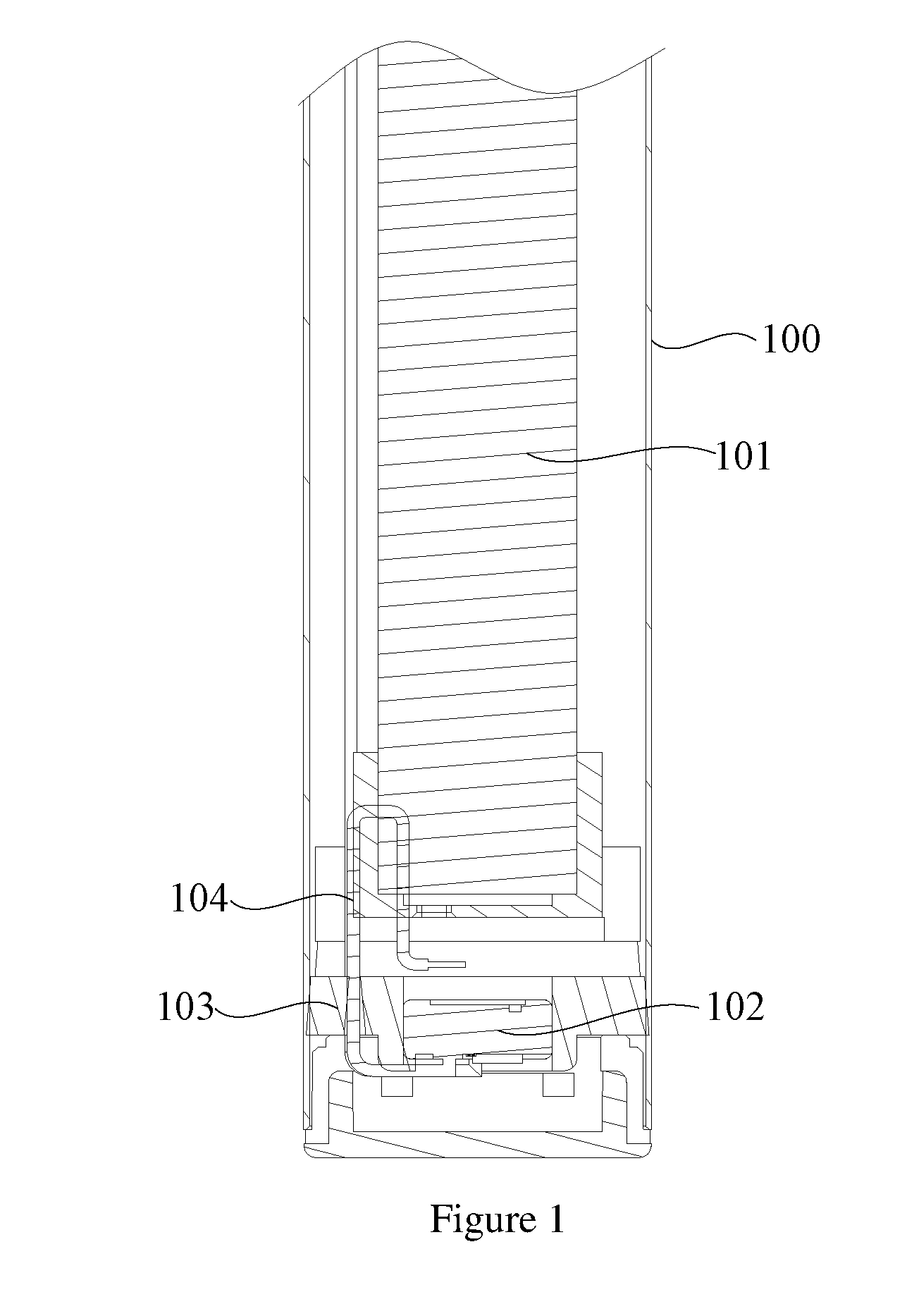

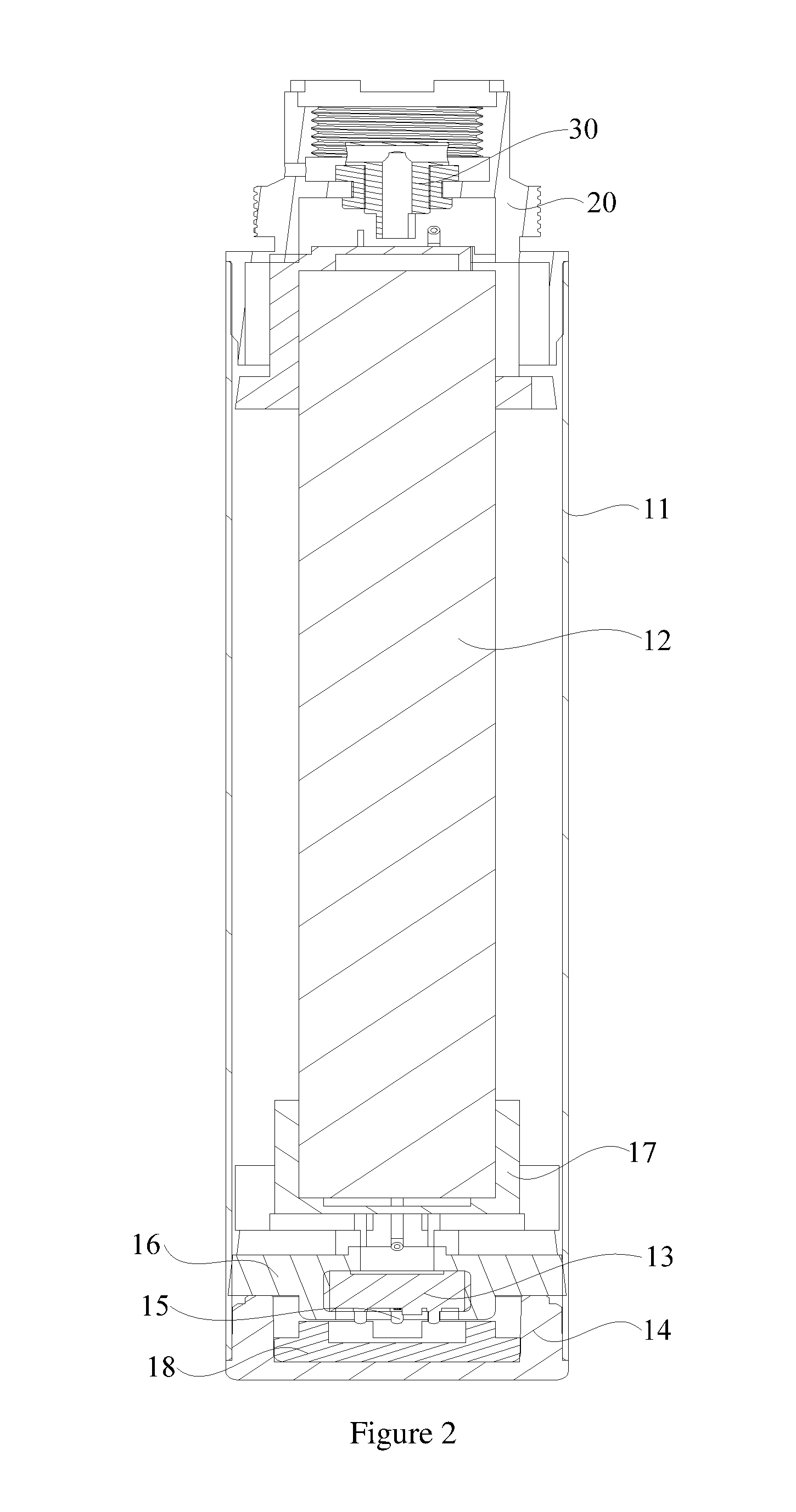

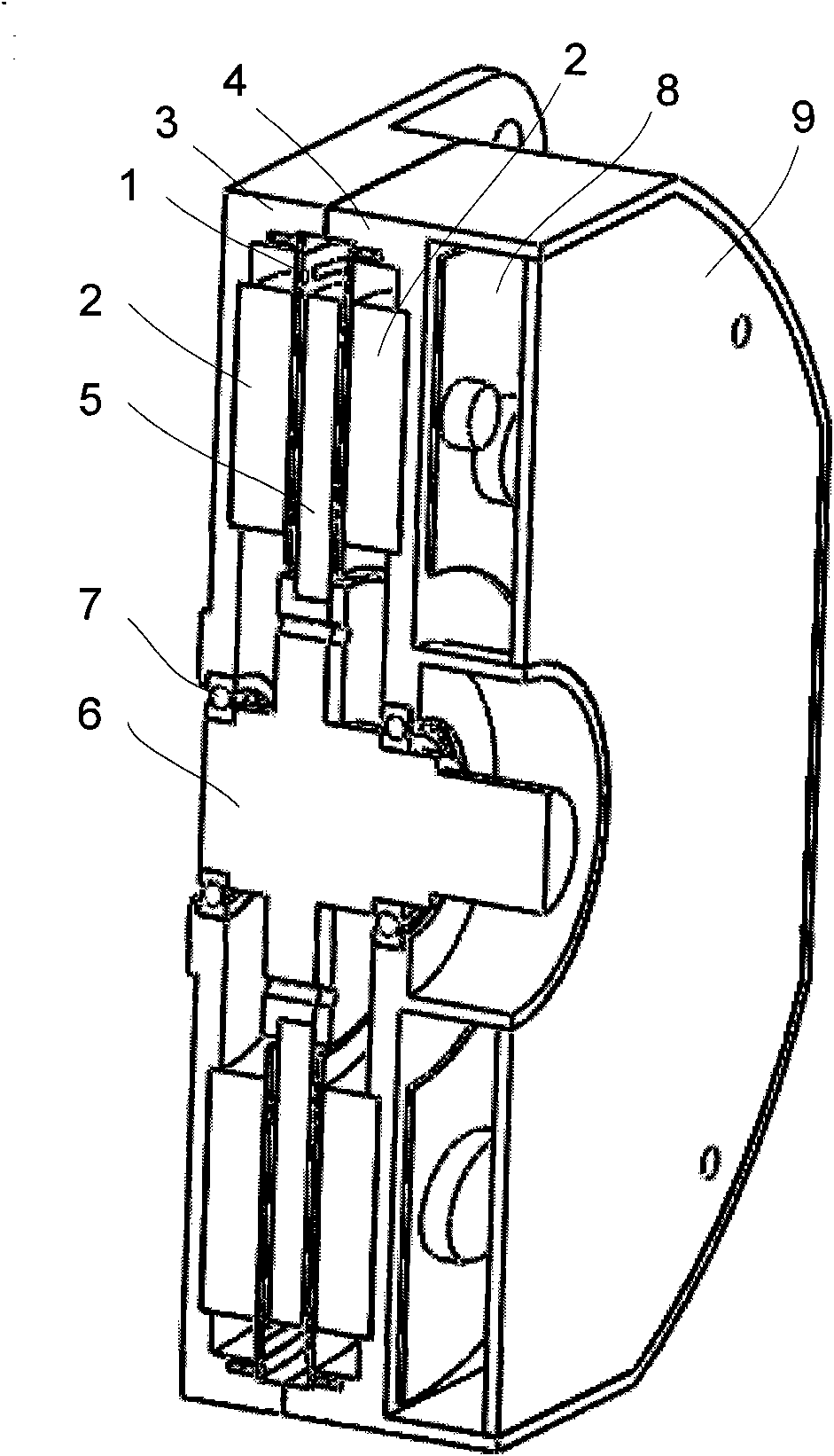

Battery rod and electronic cigarette

InactiveUS20170006920A1Improve sealingHigh sensitivityTobacco devicesOhmic-resistance heatingComputer moduleEngineering

The invention relates to a battery rod and an electronic cigarette. The battery rod comprises a battery casing, a battery, a control module, and an end cover. Wires and an airflow sensor are provided on the control module. An elastic mounting base is provided within the battery casing. The elastic mounting base is provided with a through hole running along the axial direction. The control module is installed in the through hole of the elastic mounting base. An inner peripheral surface of the elastic mounting base elastically abuts against an outer peripheral surface of the control module. The wires penetrate the through hole and parts of the wires are compressed between the control module and the elastic mounting base. Compared to the prior art wherein wires pass through separate holes, the invention has a simple assembly means, reduces the product defect rate, and improves the sensitivity of the electronic cigarette.

Owner:HUIZHOU KIMREE TECH

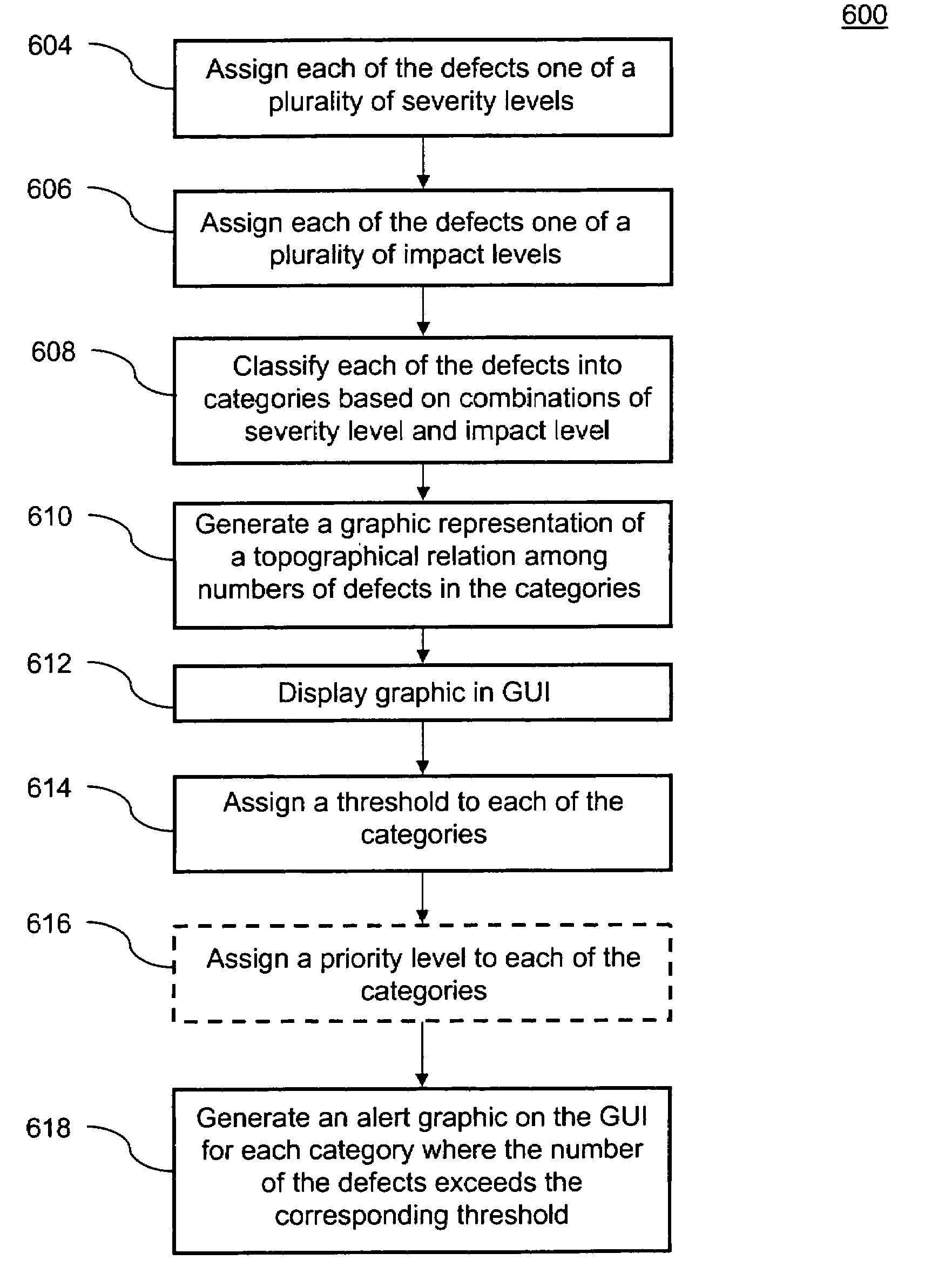

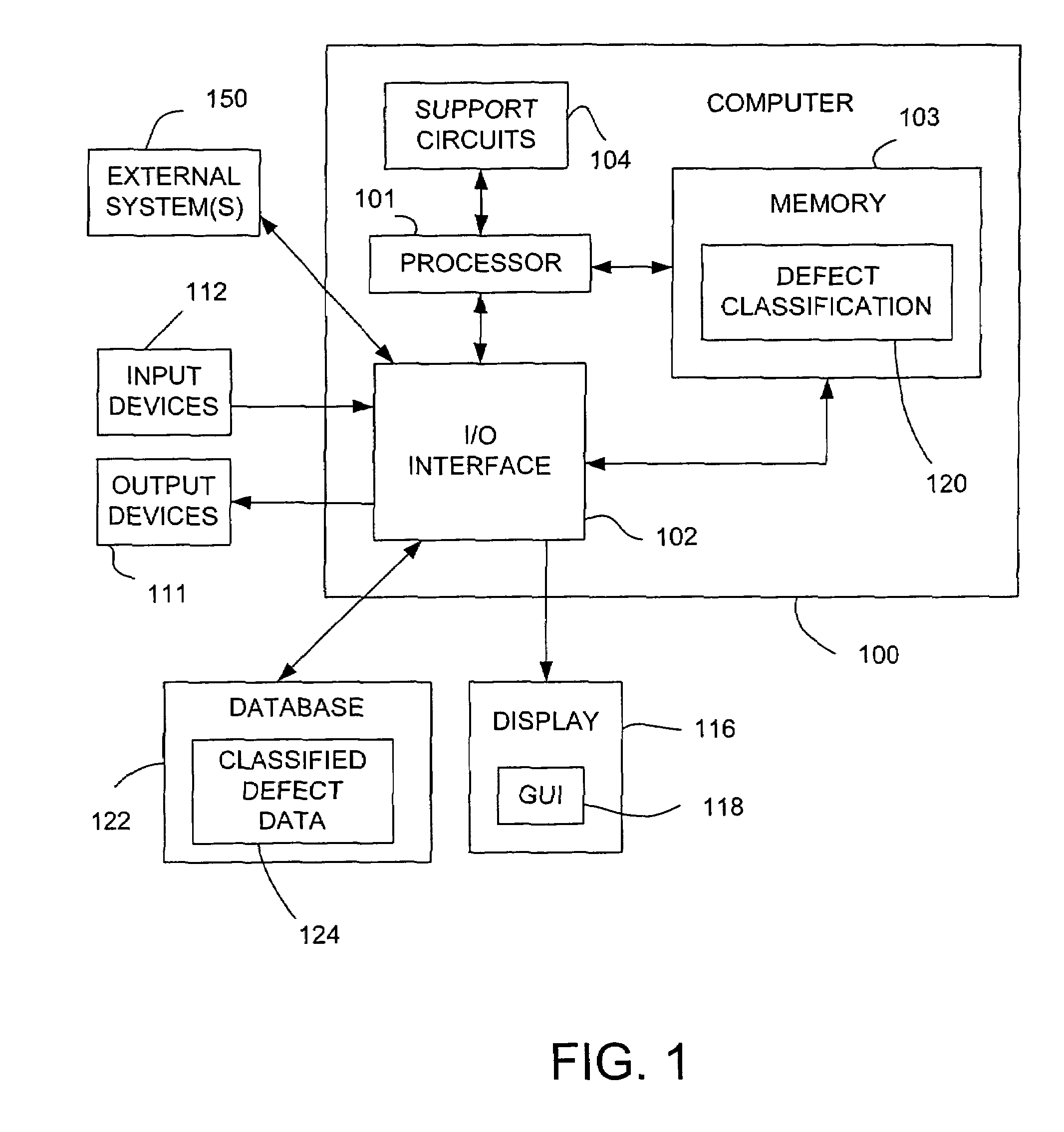

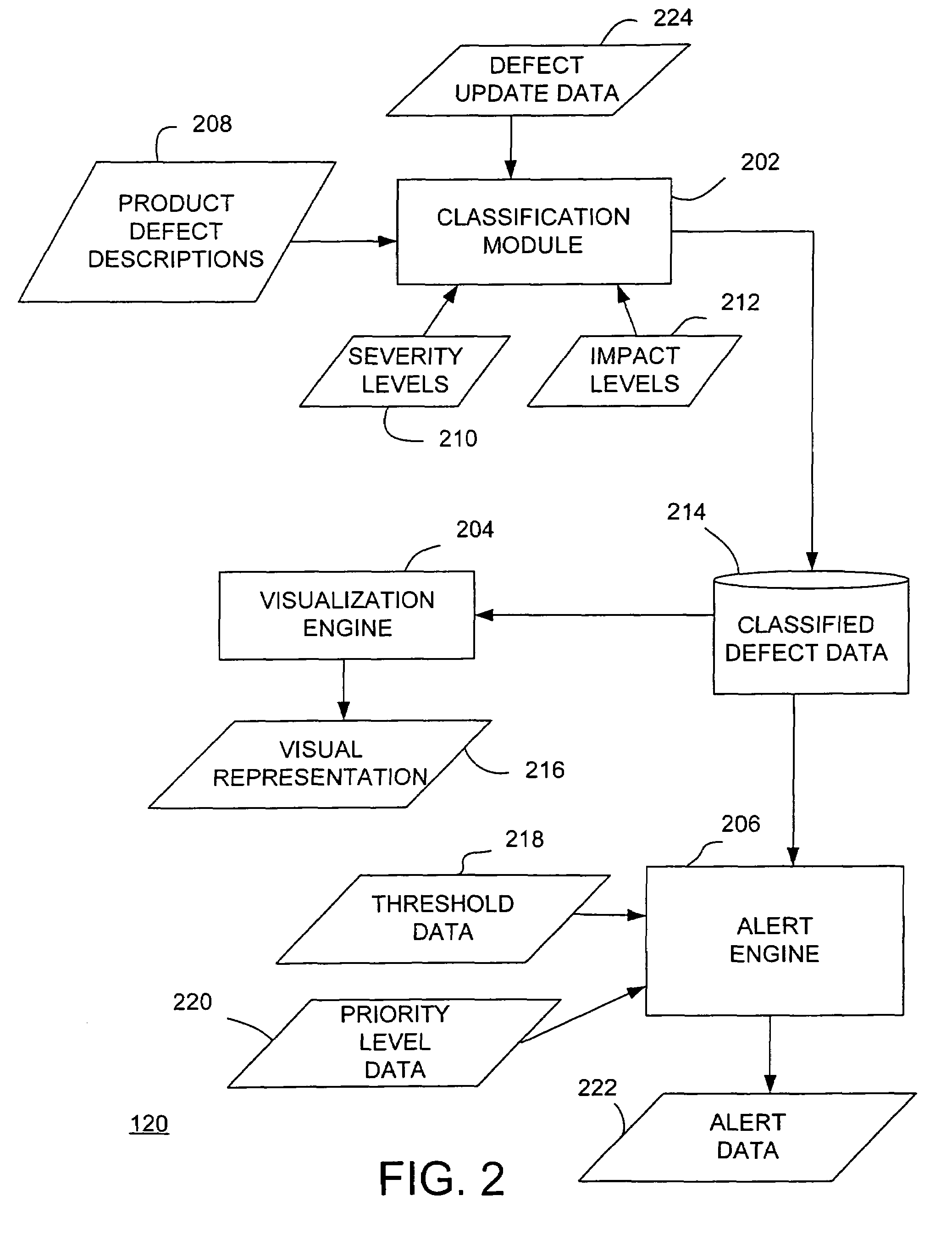

Method and apparatus for product defect classification

Method and apparatus for processing defect data indicative of defects in a product is described. In one example, each of the defects is assigned one of a plurality of severity levels and one of a plurality of impact levels. The defects are classified into categories based on combinations of severity level and impact level. A graphic representative of a topographical relation among numbers of defects in the categories is generated. The graphic is displayed on a graphical user interface (GUI).

Owner:GOOGLE TECH HLDG LLC

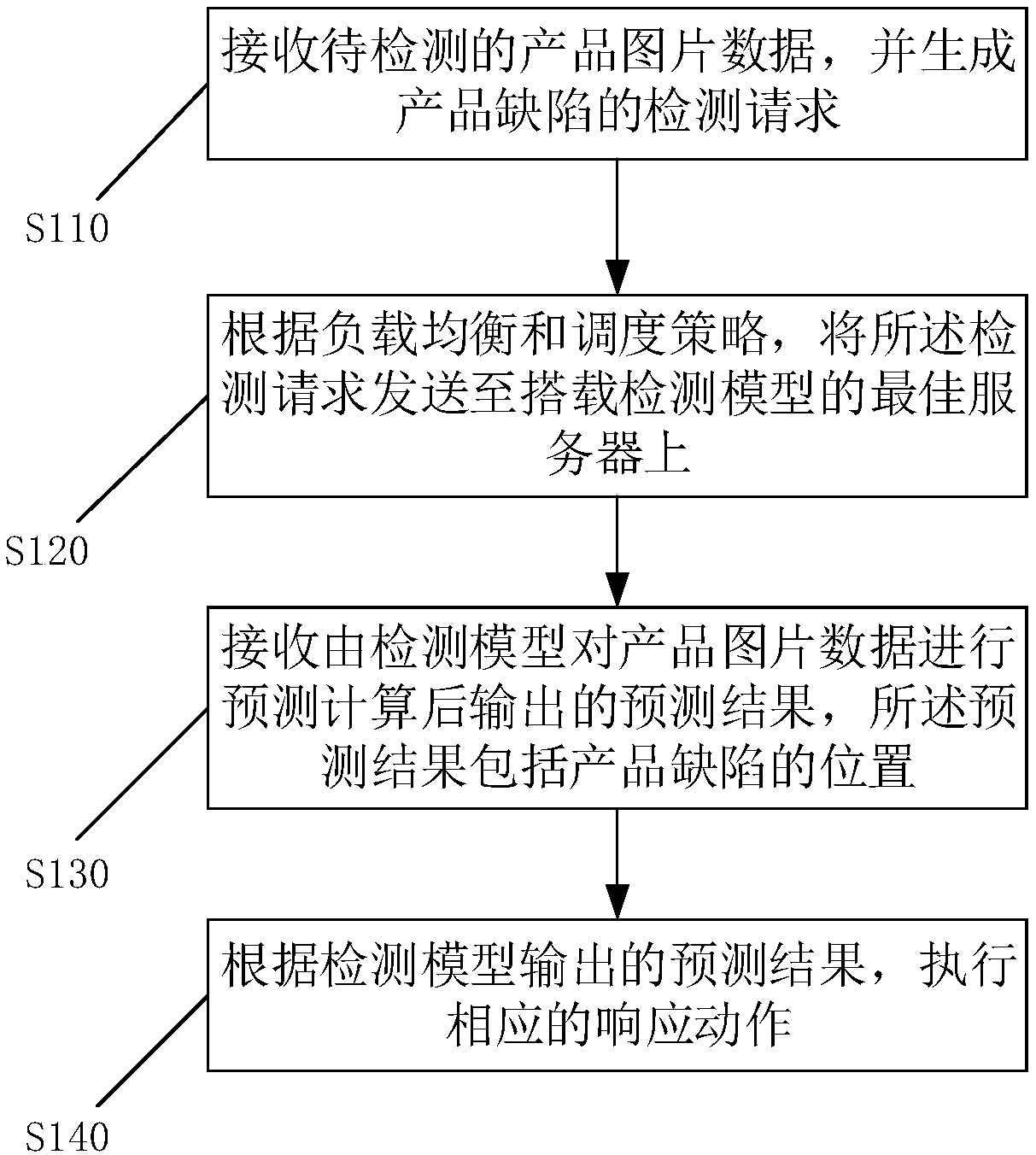

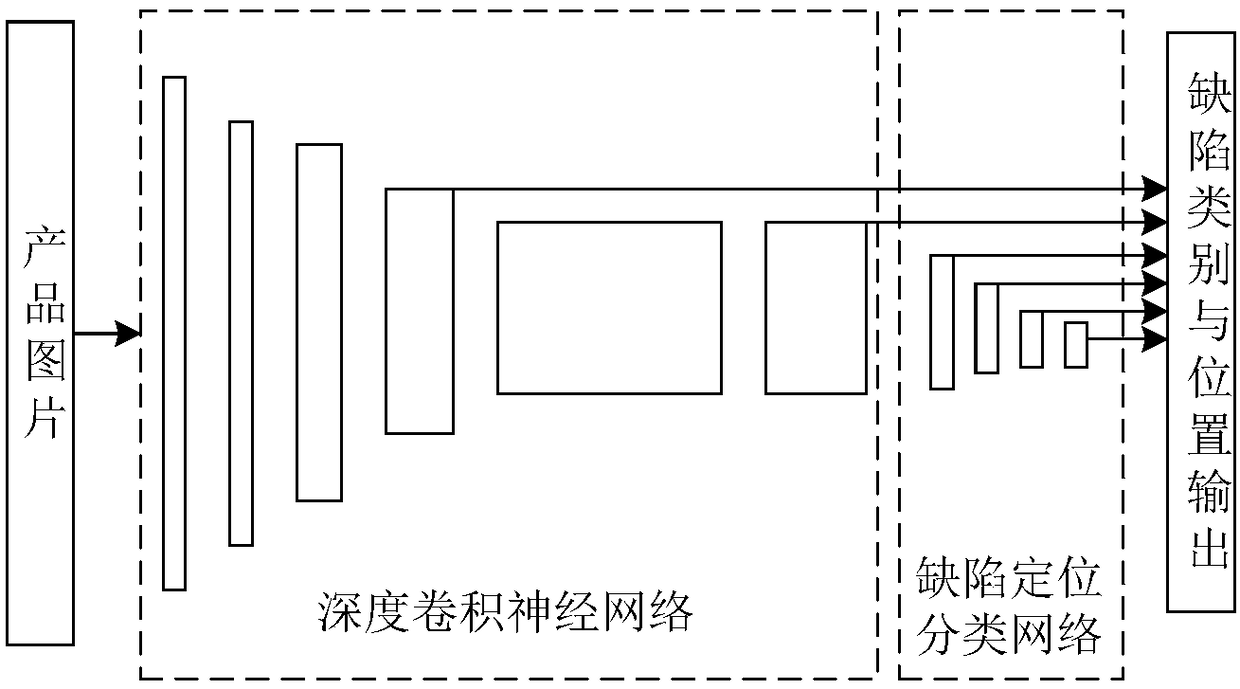

Product defect detection and location method, device and equipment and computer readable medium

InactiveCN108320278AImprove classification accuracyImprove scalabilityImage enhancementImage analysisData miningProduct defect

The invention provides a product defect detection and location method comprising the following steps that the product image data to be detected are received, and a product defect detection request isgenerated; the product image data and the detection request are transmitted to the optimal server loading the detection model according to the load balancing and scheduling strategy; the prediction result outputted after prediction and calculation of the product image data by the detection module is received, wherein the prediction result includes the product defect position; and the correspondingresponse action is performed according to the prediction result outputted by the detection model. The product image acquired in real time is detected and judged and finally the position of the product defect and the category of the product defect can be acquired. Furthermore, iterative updating of the detection model is performed so that the detection model is enabled to be suitable for the latest requirements of the production environment, and the industrial production line can be significantly enhanced in the aspects of classification accuracy, expandability and standardization.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

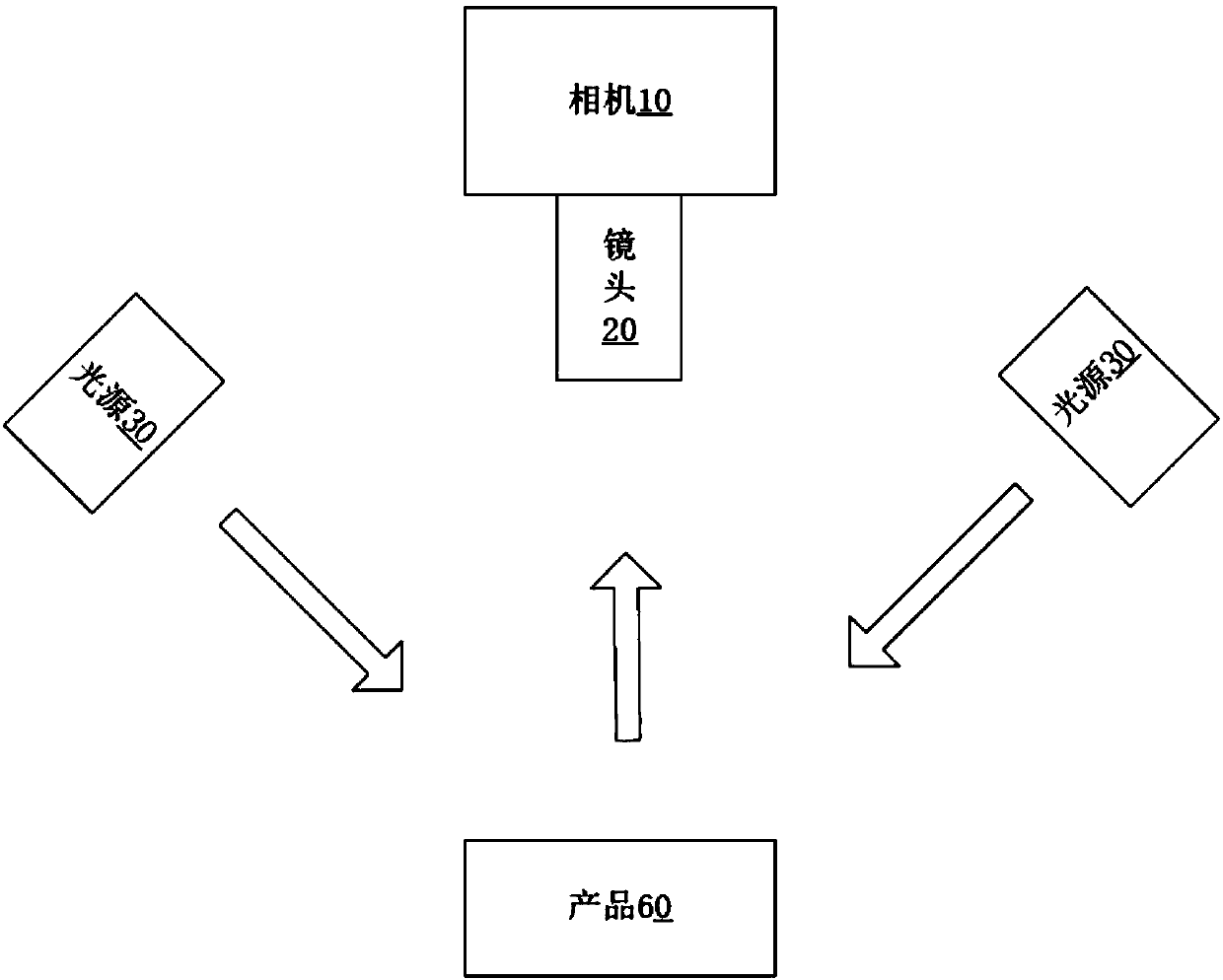

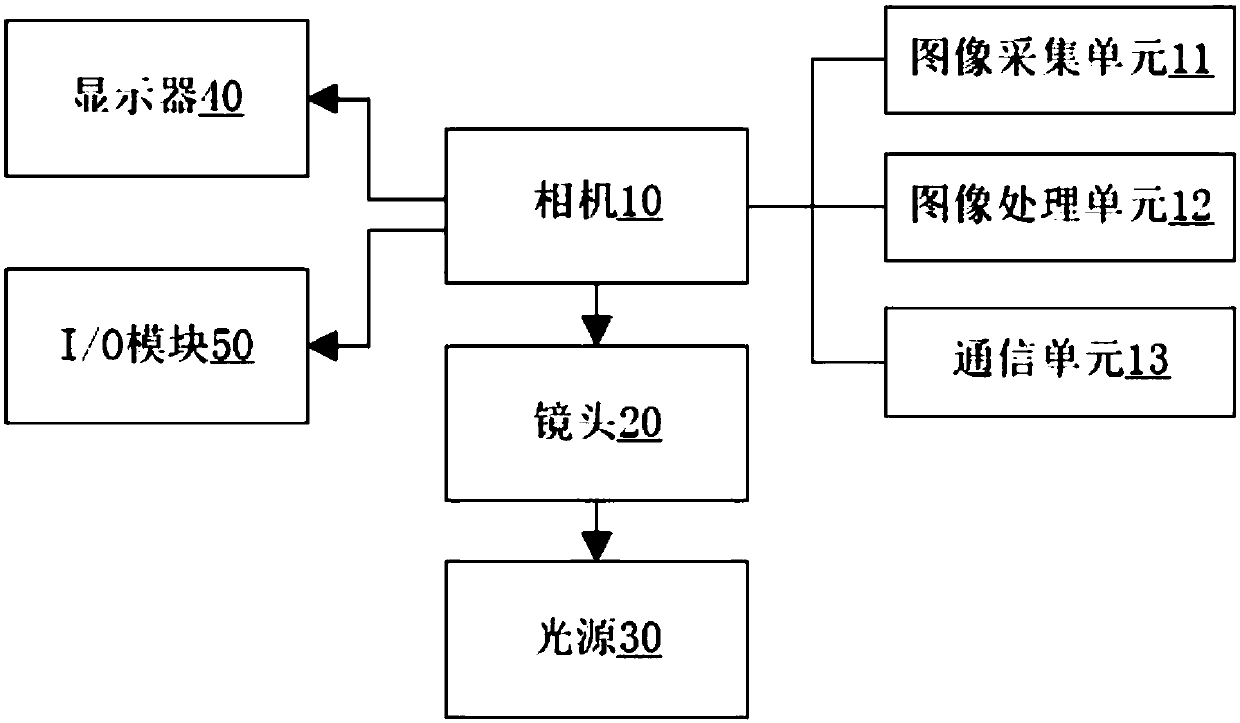

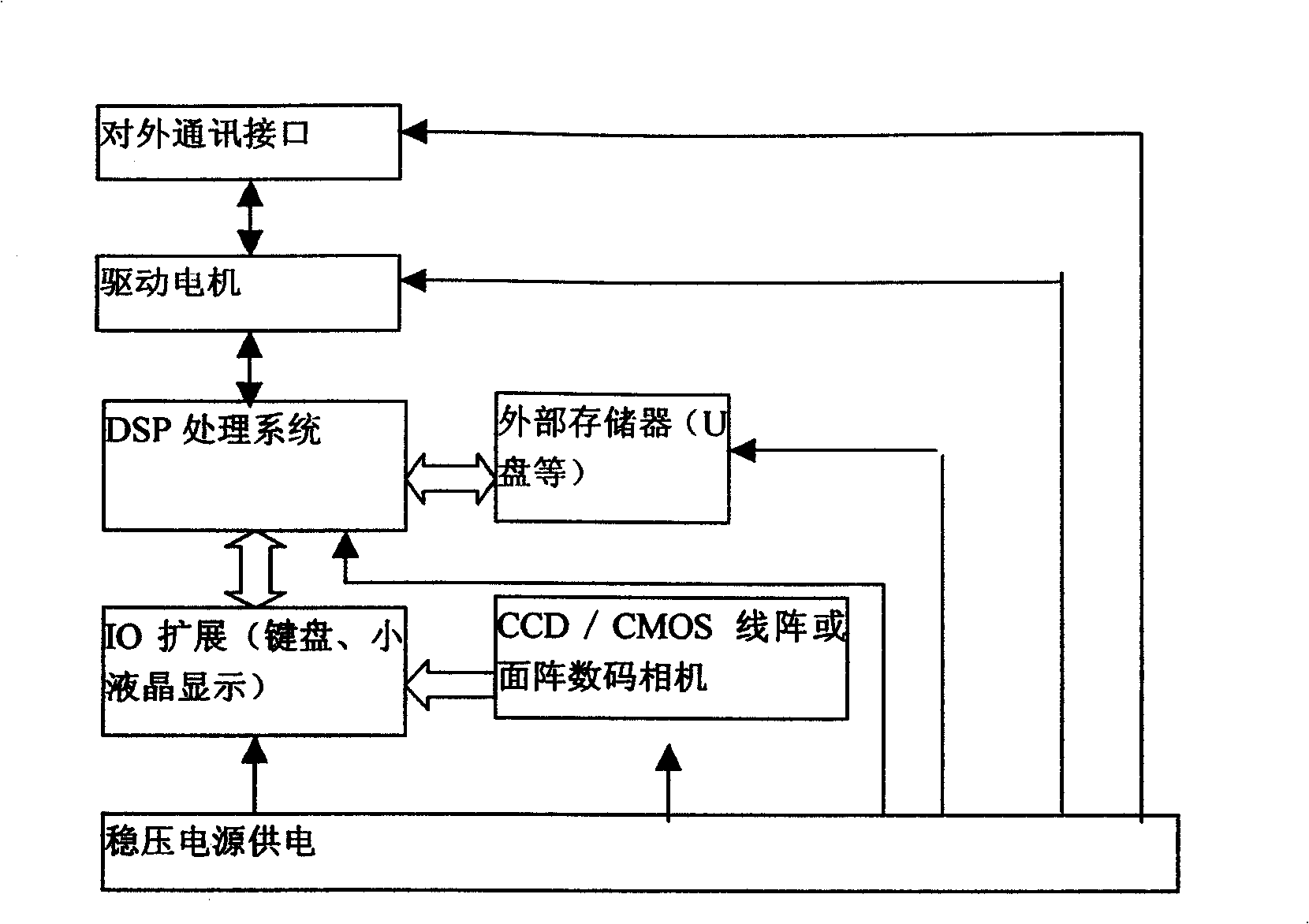

Defect detection control system and method for industrial camera

The invention discloses a defect detection system for an industrial camera. The system comprises a camera, a lens connected with the camera, and multiple light sources, wherein the light sources faceto the front surface of a product at different angles; a main control unit of the camera controls a turn-on sequence of the light sources; an image collection unit of the camera is started to performphotographing to generate multiple images; the camera comprises an image processing unit; and the image processing unit comprises multiple fixed modules formed by packaging algorithms, is used for image processing, and performs synthesis and detection on the images. The system has the beneficial effects that the images shot at multiple angles are synthesized, and product defects are detected out on a synthesized image, so that the problem of incapability of completely detecting out the product defects in conventional single-angle image shooting is solved.

Owner:深圳市创科自动化控制技术有限公司

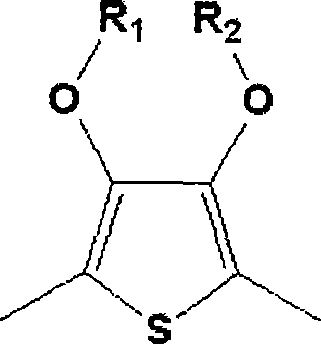

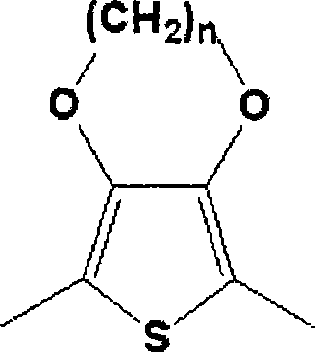

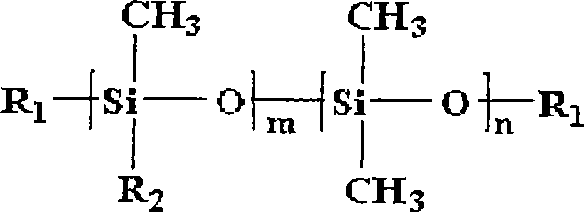

Antistatic silicone release coating films

ActiveCN101421104AReduce pollutionImprove adhesionSynthetic resin layered productsThin material handlingAdhesiveDisplay device

The invention relates to an antistatic silicone release film having a layer coated with an antistatic silicone release composition, and, used for semiconductors, electronics and display devices while addressing problems of static electricity generated when a general release film is separated from adhesive or an adhesive layer, and of contamination by such static electricity that causes critical product defects. The invention also relates to an antistatic silicon release film that can reduce product contamination caused by static electricity in peeling the film from adhesive or an adhesive layer, and achieves close adhesion between a substrate and a coated layer because of no interruption in curing a release layer, and also thereby has a stable release property.

Owner:TORAY ADVANCED MATERIALS KOREA

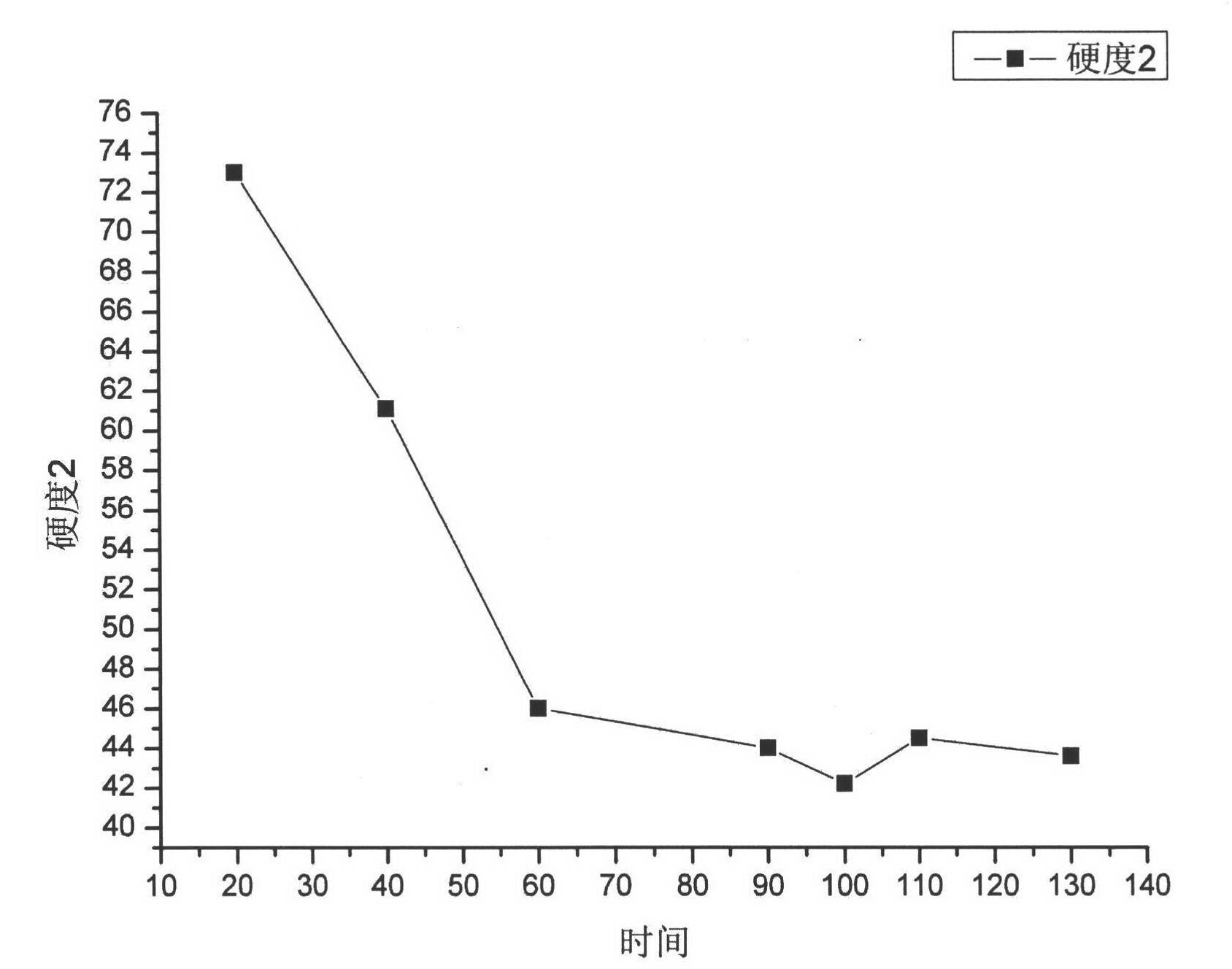

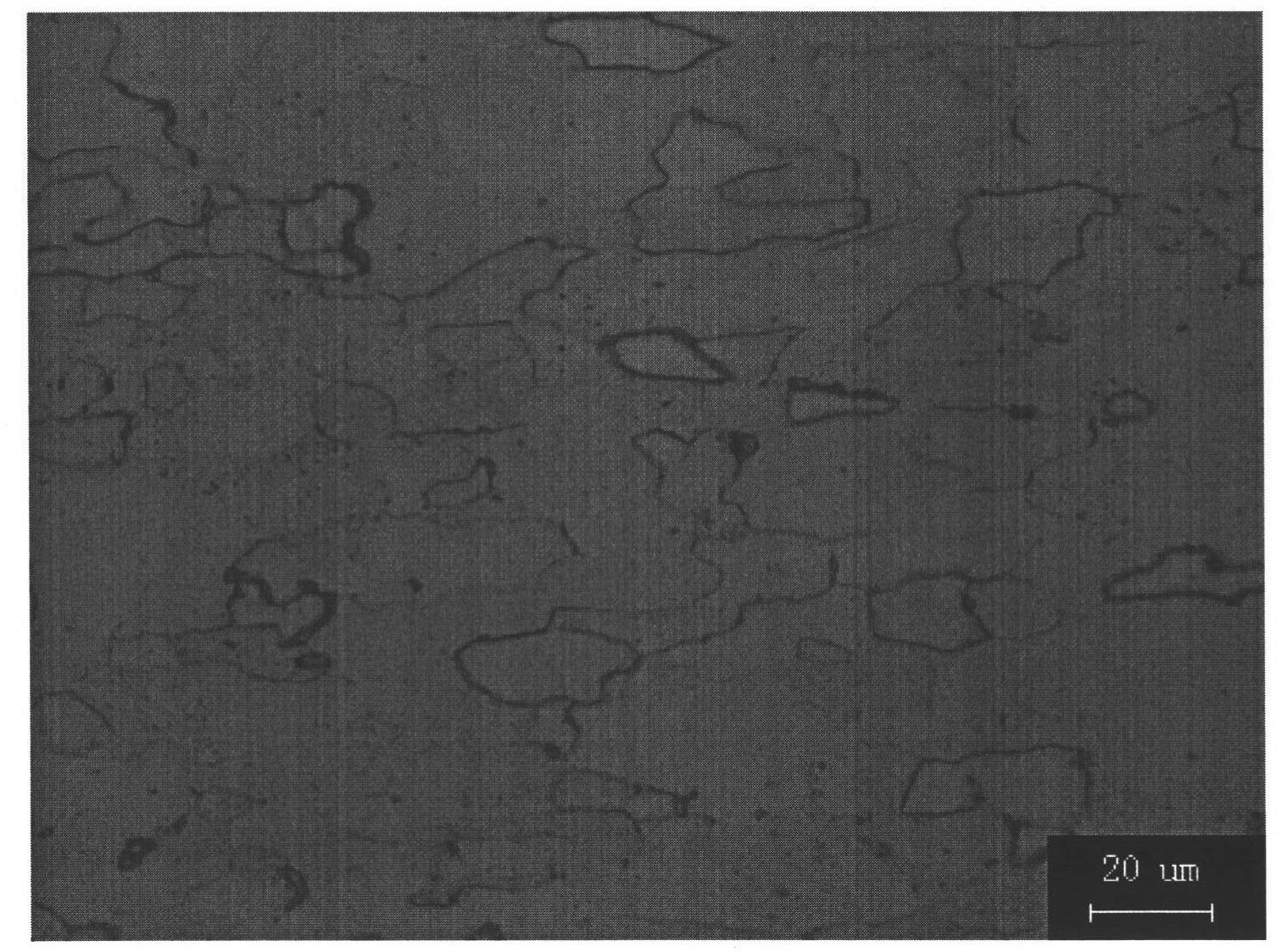

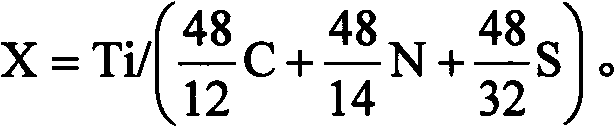

Low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and production method thereof

ActiveCN102653839ALower recrystallization temperatureRealize the structureChemical compositionReduction ratio

The invention relates to a low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and a production method thereof and belongs to the technical field of iron-based alloys. The production method of the cold-rolled steel plate comprises the following steps of: controlling the components of the cold-rolled steel plate in percentage by mass: 0.0005-0.0025% of C, less than or equal to 0.03% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, less than or equal to 0.0025% of O, less than or equal to 0.0025% of N, 0.015-0.050% of Al, 0.03-0.07% of Ti, and the balance of Fe and inevitable mixed elements; and meanwhile, controlling the continuous-annealing temperature of the cold-rolled steel plate to be 710-740 DEG C, and controlling the cold-rolling reduction ratio to be not less than 80%. According to the cold-rolled steel plate and the production method thereof, the reasonable chemical components and the suitable control of cold-rolling reduction are adopted, the recrystallization temperature is lowered, full-old-rolled microstructures are formed, and a lower continuous-annealing temperature can be adapted, so that the equipment cost and energy consumption are reduced, the control difficulty of a production process is reduced, the product defects and production accidents are avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

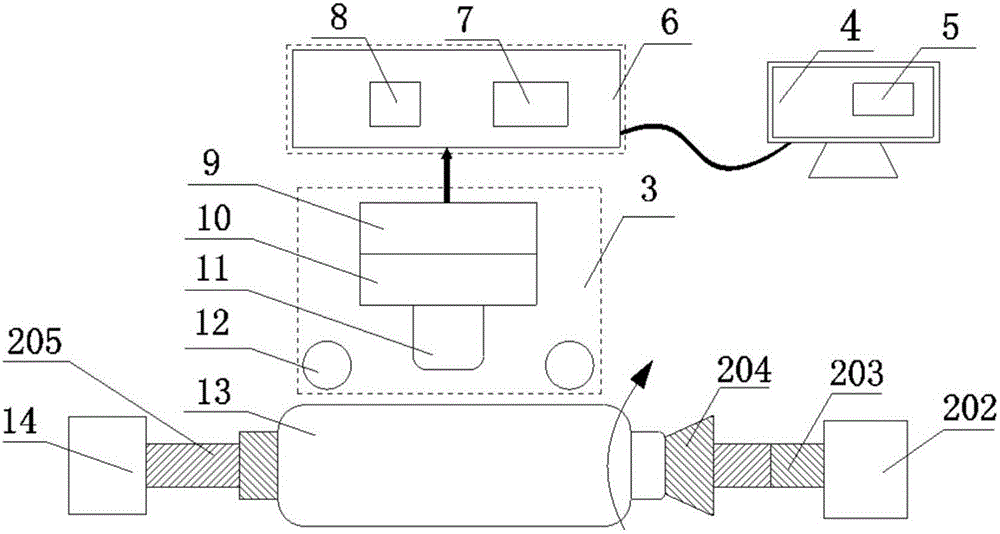

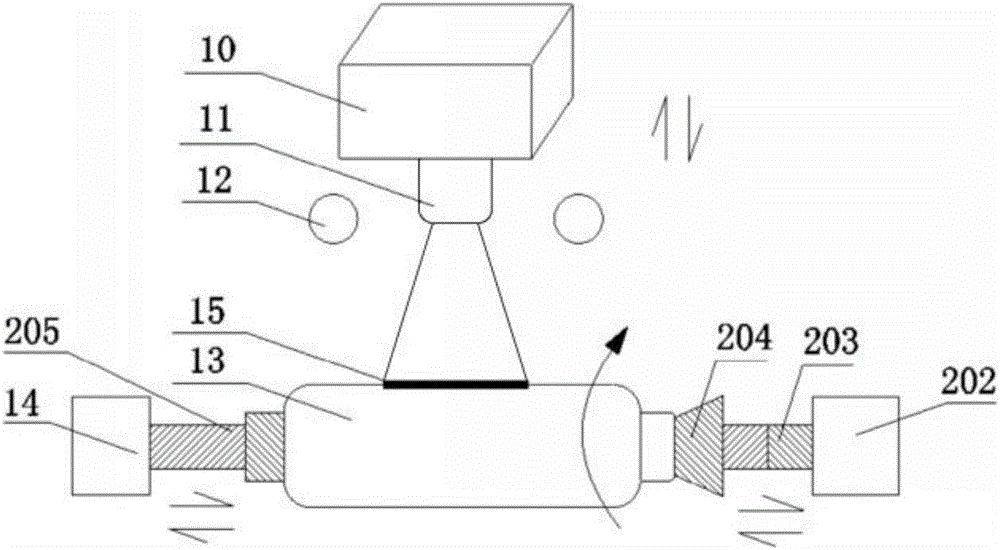

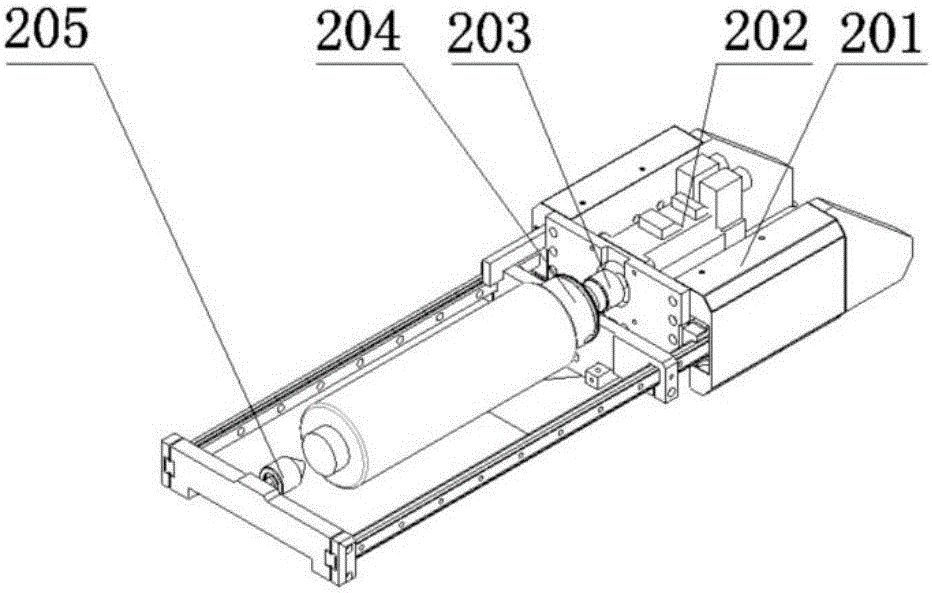

Machine vision based full-automatic rotation printed product defect detection device

InactiveCN106525873AGood quality inspectionOvercome the problem of not being able to detect the defects of printing products on complex curved surfaces of rotary bodiesMaterial analysis by optical meansPrinting press partsSoftware systemEngineering

The invention discloses a machine vision based full-automatic rotation printed product defect detection device which comprises an industrial control computer, supporting facilities of the industrial control computer, an image defect detection software system, a signal transmission unit, an image collection unit, a loading manipulator system, an unloading manipulator system and a product clamping rotation system; the industrial control computer is electrically connected with the image collection unit through the signal transmission unit; the image collection unit is formed by combining an image collection processing card, a CCD industrial camera, an optical lens and a detection light source together; the signal transmission unit is formed by three parts including an I / O (input / output) card, a synchronous card and a rotary encoder; and the product clamping rotation system is mainly used for fixing a product and driving the product to rotate. The machine vision based full-automatic rotation printed product defect detection device has the characteristics of no contact, high detection precision, rapidness, accuracy, high repeatability and high automation degree, relieves the manual detection pressure, solves various problems in manual detection, improves the detection quality, and increases the detection speed.

Owner:广州市申发机电有限公司

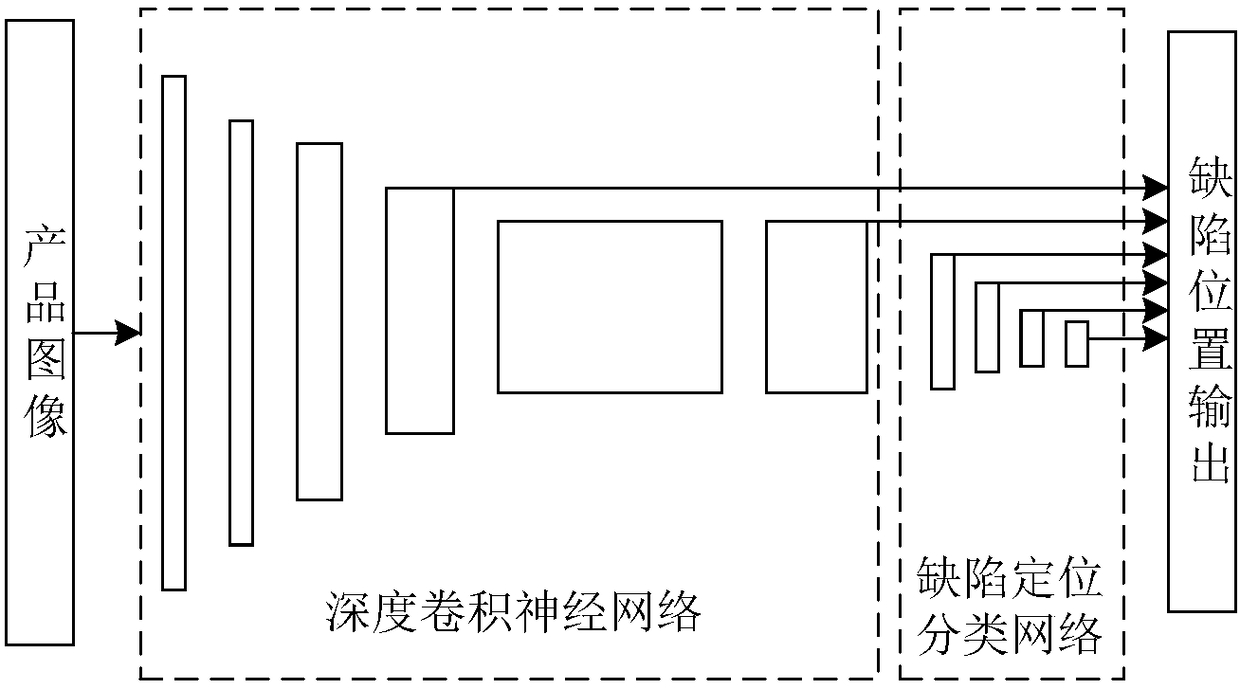

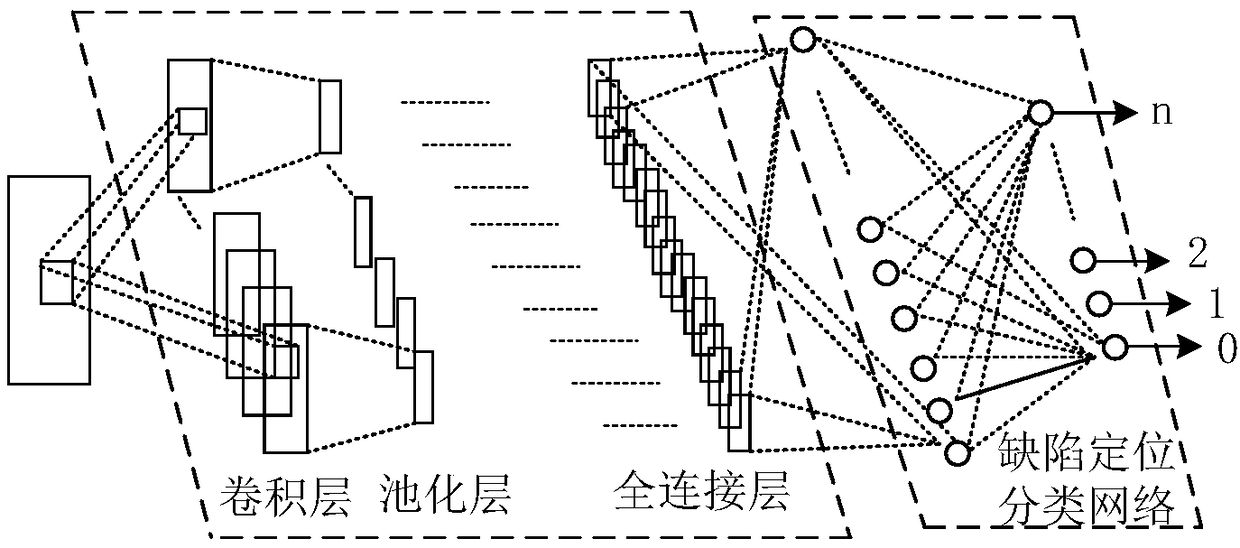

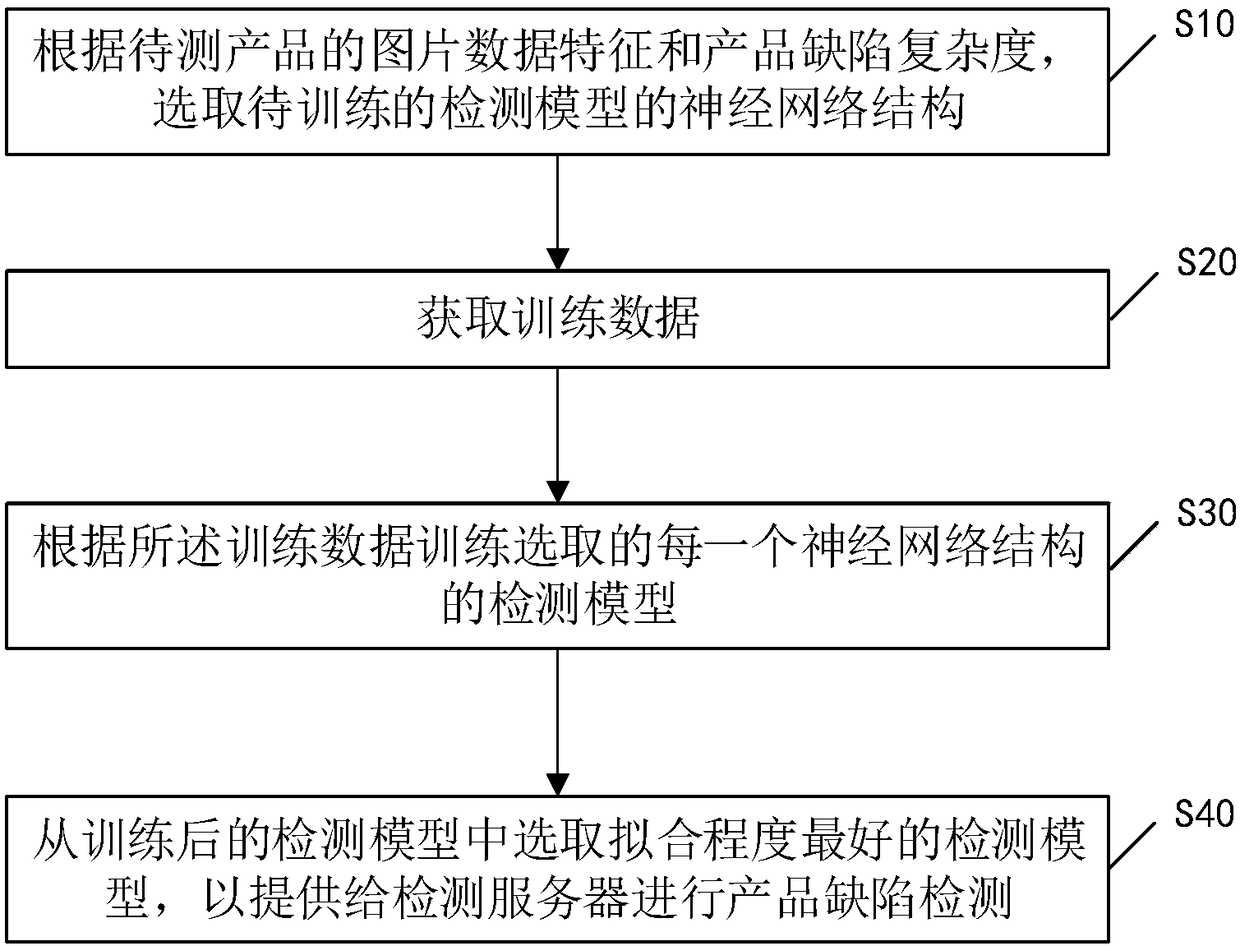

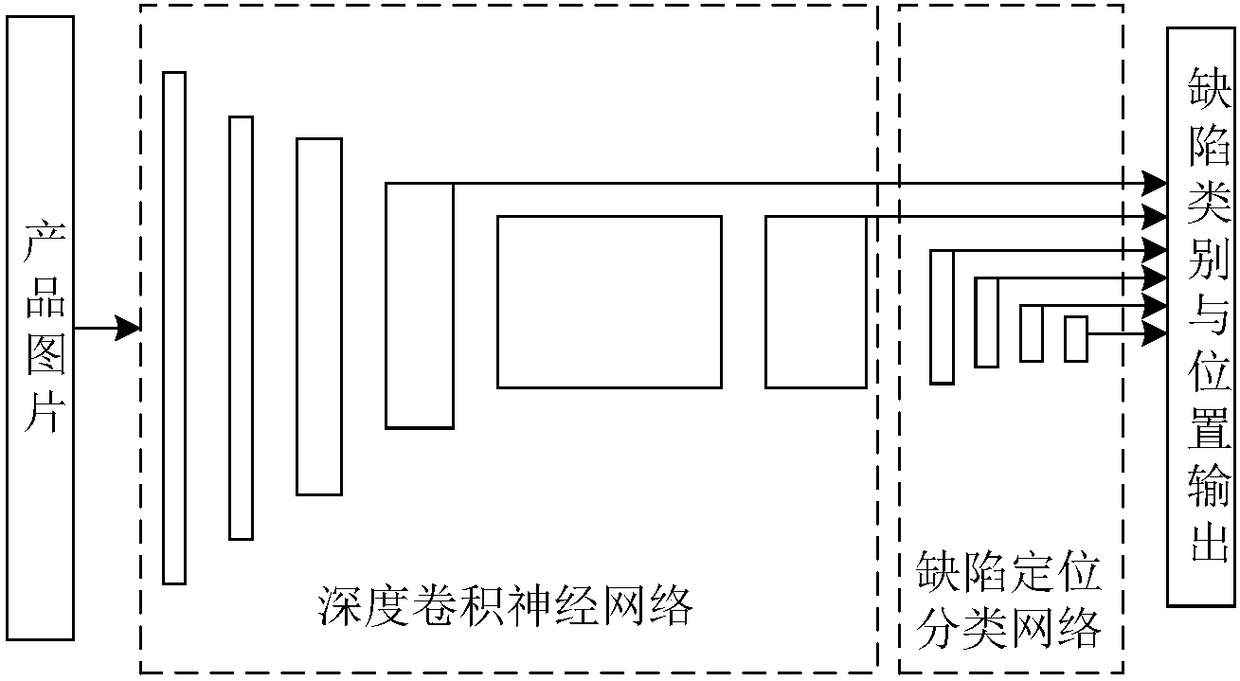

Method, device, storage medium and terminal device for product defect detections and locations

ActiveCN108154508AImprove robustnessDefect Complexity AdaptationImage enhancementImage analysisSoftware engineeringNetwork structure

The invention discloses a method, device, storage medium and terminal device for product defect detections and locations, wherein the method includes: according to the image data characteristics of products to be tested and the product defect complexity, selecting the neural network structure of detection models to be trained; obtaining training data, wherein the training data include training product pictures and standard categories and standard positions of product defects in the training product pictures; according to the training data, training the selected detection models of each neuralnetwork structure; selecting a best fitting detection model from the detection models after training to provide a detection server with the product defect detection, wherein the detection models are used for calculating according to the received product pictures to obtain predicted categories and predicted locations of the product defects in the received product pictures. Adopting the method, device, storage medium and terminal device for product defect detections and locations is capable of improving the accuracy of detecting the product defects.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

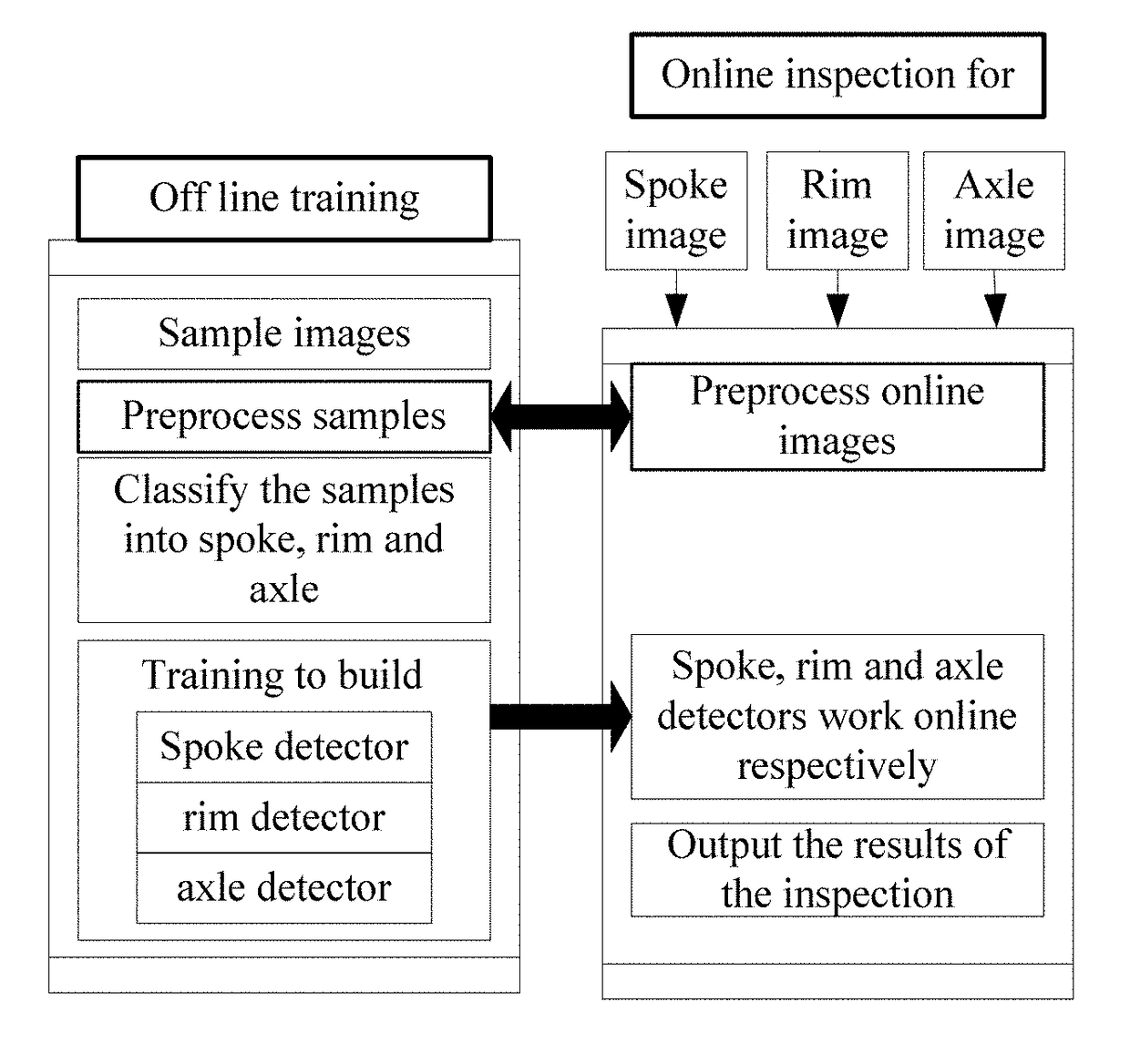

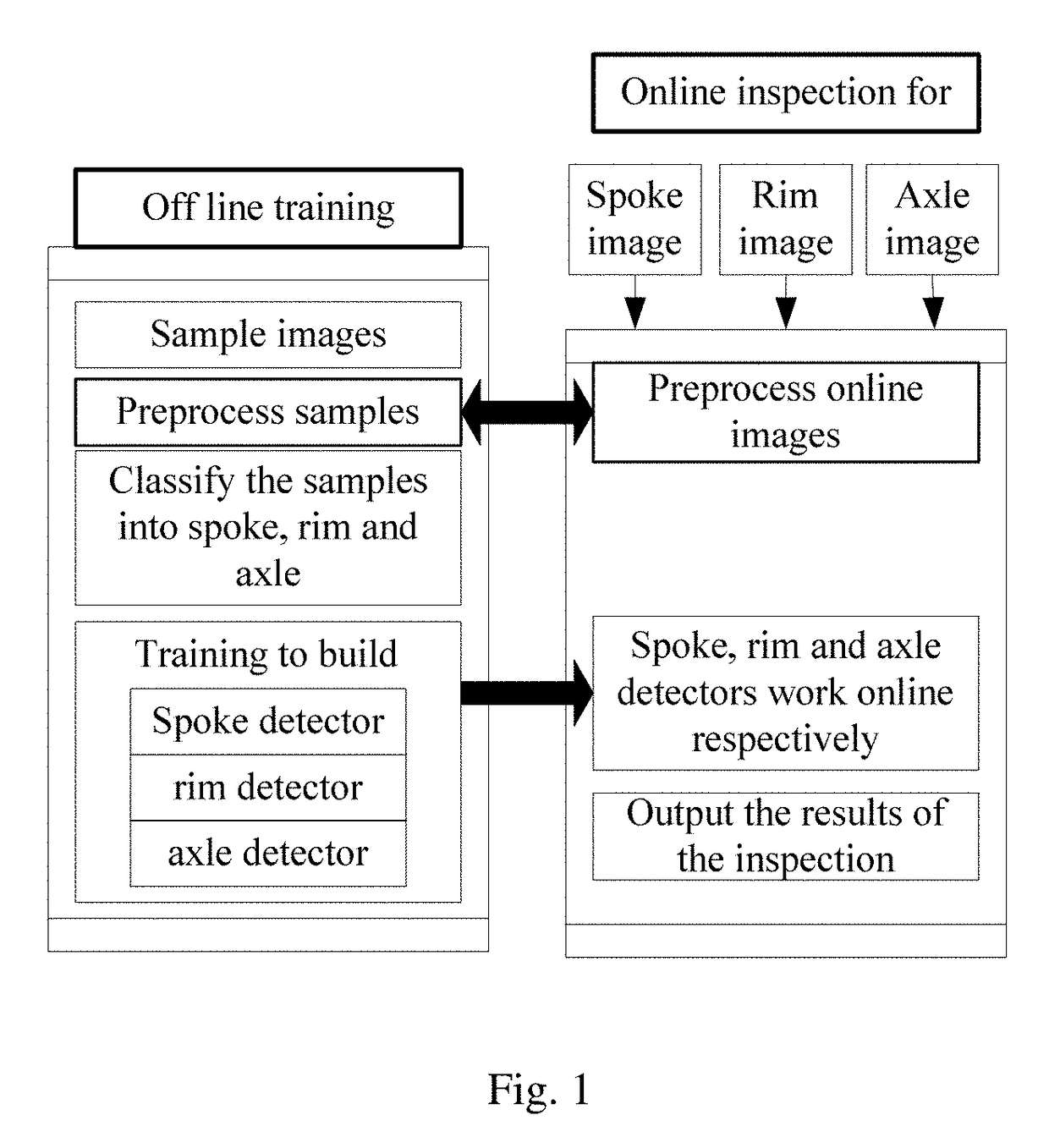

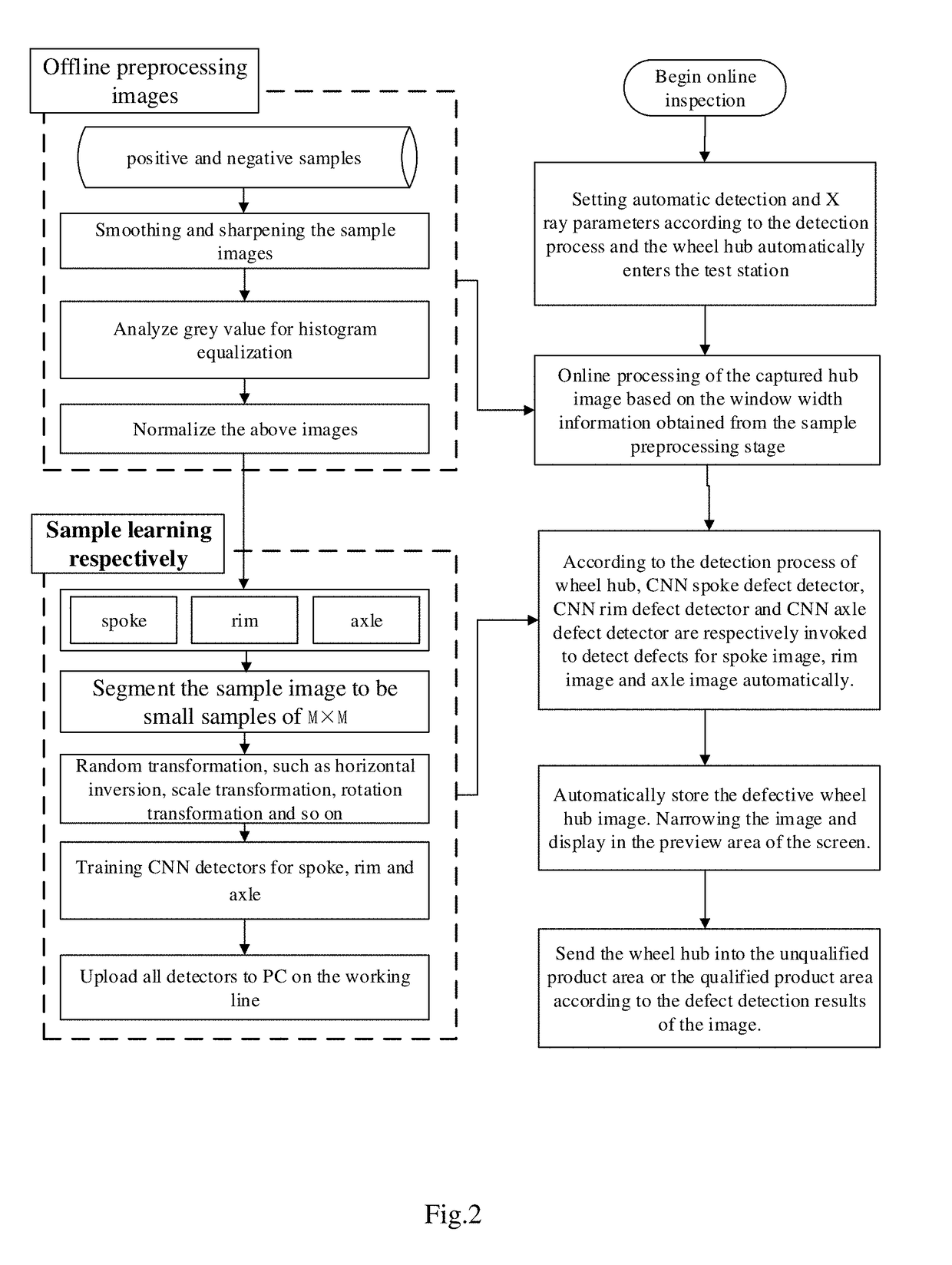

Method for automated detection of defects in cast wheel products

Provided in the present invention is a method for automated detection of defects in cast wheel products, comprising three stages of sample preprocessing, offline training, and online inspection. Specific steps comprise collection of training samples; sample preprocessing; categorization of samples in three major types as spokes, rims and hubs, then processing; by means of the three sample types, spokes, rims and hubs, training a network offline, then generating online detectors for said three sample types respectively; importing the trained CNN spoke defect detector, CNN rim defect detector and CNN hub defect detector to a host computer, and locating same on an automated production inspection line; wholly automated online defect detection; output of identified detected defects by an output mode according to user requirements. The automated inspection method of the present invention is particularly robust in respect of the illumination, angle of photography and positioning that prevail during the inspection process, and, with a high degree of automation, provides accurate defect inspection with no need for the participation of an operator adjusting minor parameters.

Owner:SOUTH CHINA UNIV OF TECH

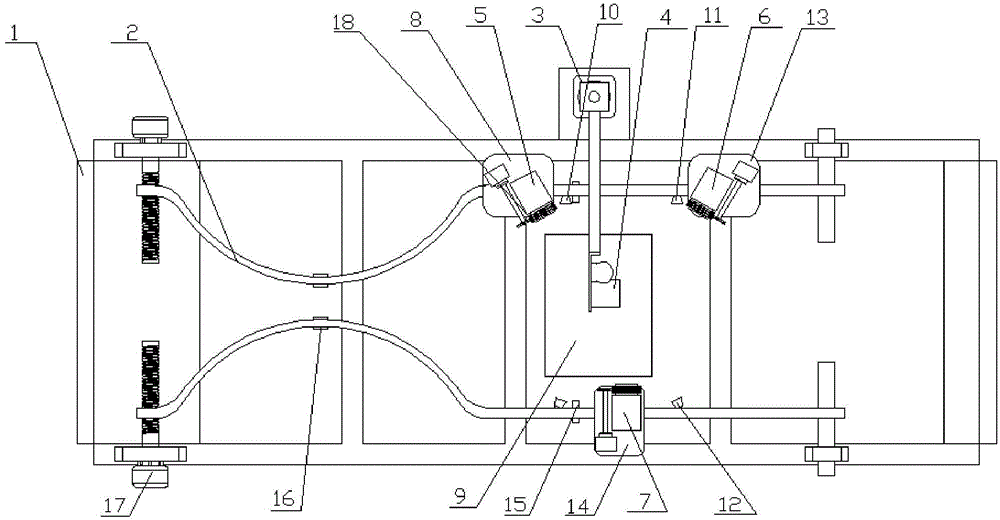

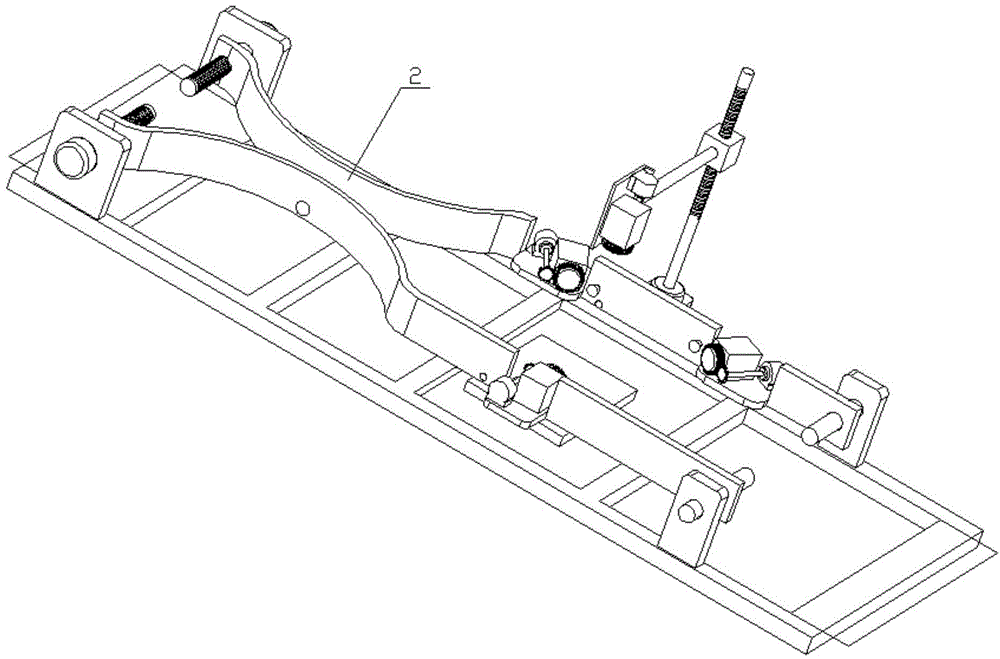

Intelligent detecting device for detecting defects of multi-type irregularly shaped product

InactiveCN104101608AGood shooting effectImprove detection qualityMaterial analysis by optical meansUsing optical meansMaterial resourcesEngineering

The invention discloses an intelligent detecting device for detecting the defects of multi-type irregularly shaped products. The intelligent detecting device comprises a glass sliding table, a bottleneck material passing mechanism and an image collecting system, wherein the glass sliding table is arranged on a rack in an inclining manner relative to a horizontal plane; the bottleneck material passing mechanism comprises two spoon-shaped baffle plates with the same structural size; the spoon mouths of the two spoon-shaped baffle plates are contrary to each other and symmetrically arranged; the image collecting system comprises an overlooking image collecting mechanism, a side-looking collecting system, an image collecting triggering mechanism and an image analyzing system. According to the invention, multi-type products can be detected without a preset database; in addition, a camera and lamplight are designed, so that the photographing effect is enabled to be better, and the detecting quality can be improved; the automation and the intelligence of detecting the defects of the multi-type irregularly shaped products are realized, the labor force and the material resources are greatly saved, and the detecting accuracy is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electronic die cutting material defect detecting implementation method based on machine vision

ActiveCN106770332ARealize the shapeImplement defect identificationOptically investigating flaws/contaminationMaterial defectDimension measurement

The invention discloses an electronic die cutting material defect detecting implementation method based on machine vision. The method comprises the following steps of (a) loading a detection template; (b) transferring a detection object; (c) monitoring through a sensor; (d) capturing an image; (e) identifying an object; (f) processing the image; (g) carrying out binarization processing; (h) carrying out data statistics and detection analysis. The method adopts a non-contact optical sensor system, and adopts a machine to replace human eyes to measure and judge, a system utilizes a CCD (Charge Coupled Device) camera for capturing the image of an objective measuring object, and information such as pixel distribution, brightness and color of the image of the objective measuring object is converted into digital image signals; a project control system operates the signals to extract the characteristics of the measuring object; finally, field equipment is controlled to act according to tolerance and other condition output results so as to meet the core demands on on-line detection of product defects and dimension measurement, so that the measurement precision, the measurement speed, and the reliability under an industrial site environment can be ensured.

Owner:HANGZHOU BYTE INFORMATION TECH CO LTD

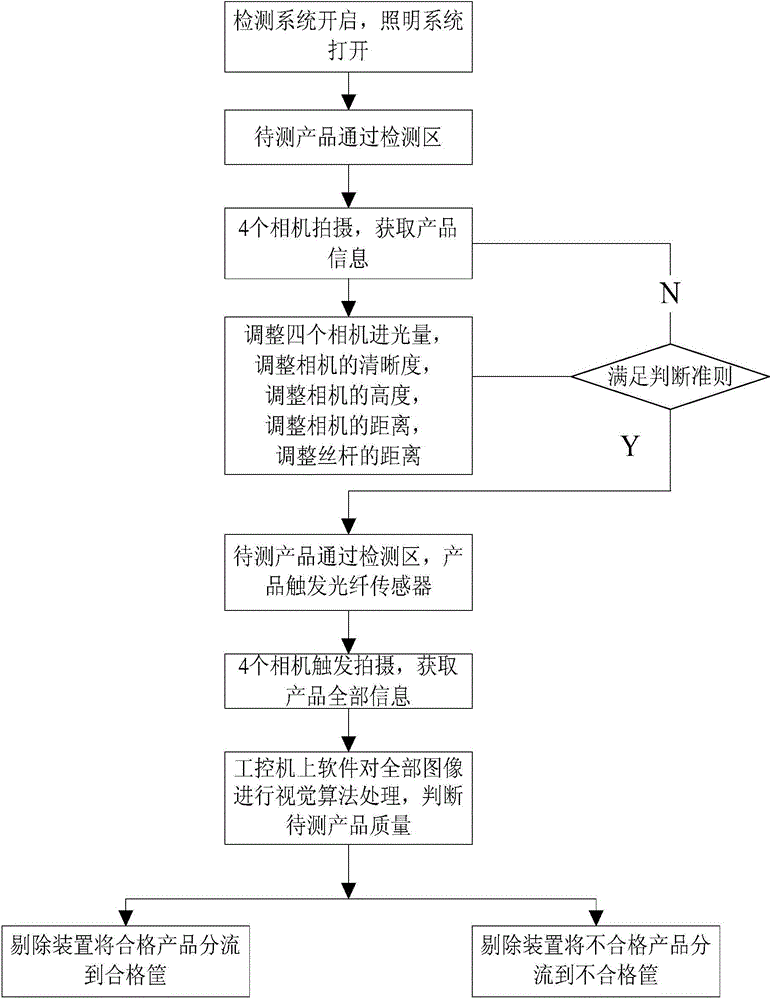

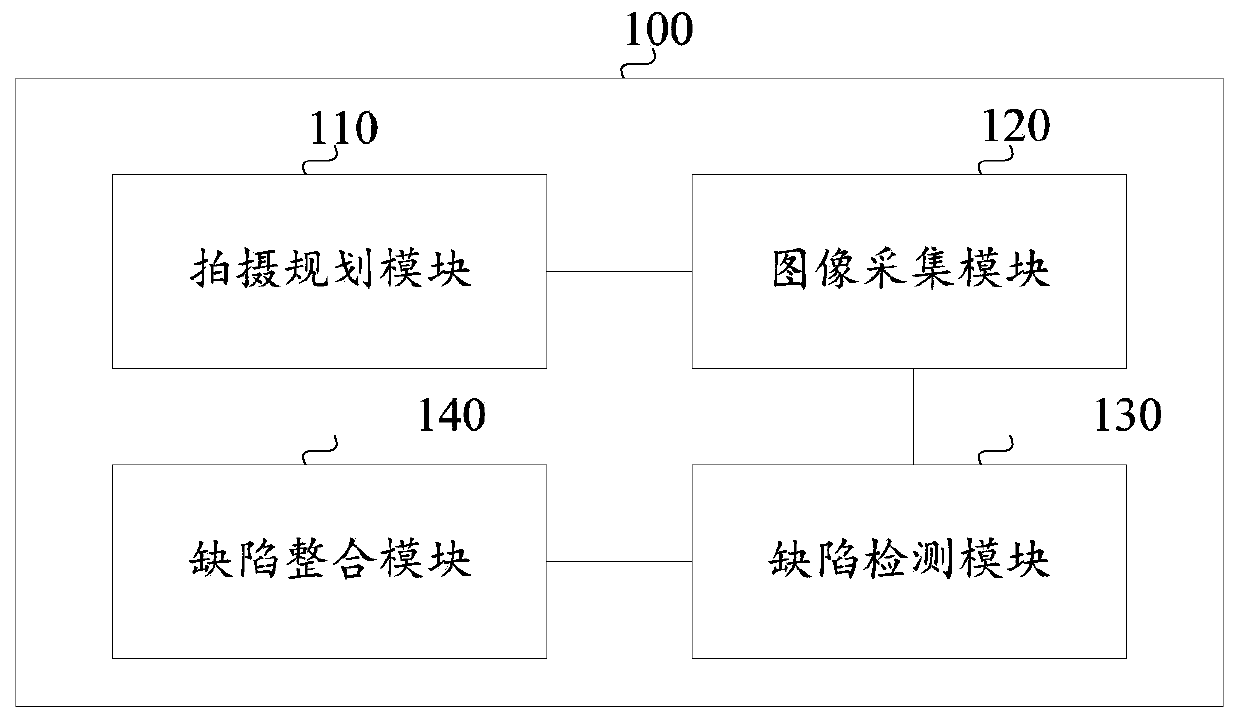

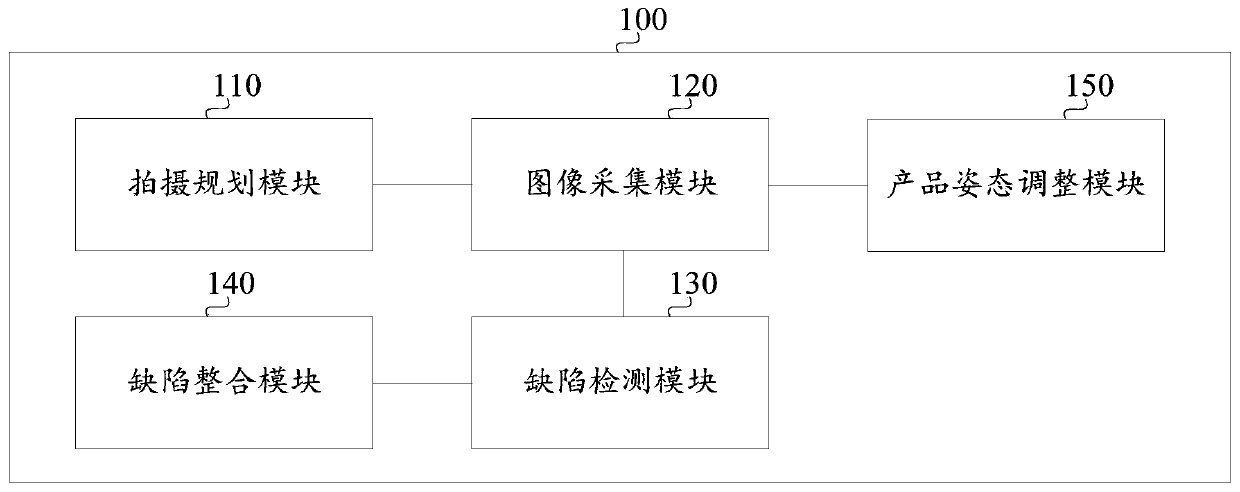

Product defect detection system and method

ActiveCN110609037AImprove detection efficiencyReduced image quality effectsOptically investigating flaws/contaminationAcquisition SchemeProduct defect

The invention discloses a product defect detection system and method. The system comprises a shooting planning module, an image acquisition module, a defect detection module and a defect integration module, wherein the shooting planning module is used for determining an image acquisition scheme of the image acquisition module and sending the image acquisition scheme to the image acquisition module, the image acquisition module is used for performing image acquisition on a to-be-detected product to obtain an image sequence according to the image acquisition scheme and sending the image sequenceto the defect detection module, the image sequence comprises images of the to-be-detected product at different shooting points and under different shooting angles, the defect detection module is usedfor performing defect detection on each image in the image sequence to obtain a defect detection result of each image and sending the defect detection result to the defect integration module, the defect detection result comprises position coordinate and defect type information of defect in the images, and the defect integration module is used for determining defect position and type of the to-be-detected product under the same shooting point according to the defect detection result.

Owner:BEIJING KUANGSHI TECH

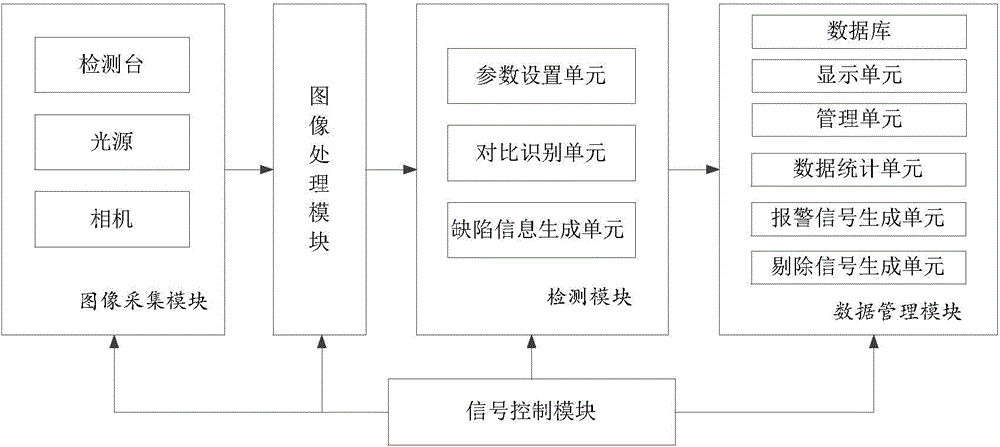

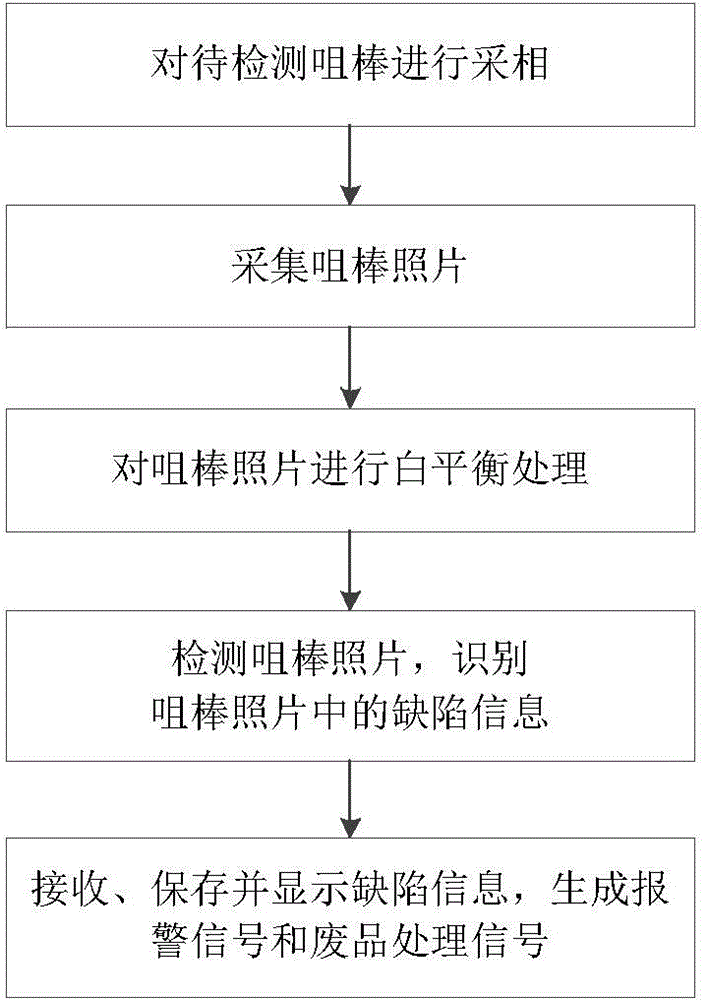

Visual detection system and method for filter

ActiveCN104807829AReliable test resultsTest results are stableOptically investigating flaws/contaminationControl signalVisual perception

The invention relates to a visual detection system and method for a filter. The visual detection system comprises an image acquisition module, an image processing module, a detection module, a data management module and a signal control module, wherein the image acquisition module is used for photo sampling of a filter to be detected; the image processing module is used for performing white balance treatment on the filter photos; the detection module is used for selecting a qualified filter photo as a standard sample and comparing the standard sample with other filter photos to identify product defect types; the data management module is used for receiving, storing and displaying defect information, and meanwhile, generating a warning signal and a waste processing signal; the signal control module is used for input and output control of signals, signal filtering and denoising and / or abnormal signal interference screening. As a machine is adopted for detection, not only is the labor intensity of workers reduced, but also the detection speed and the detection precision are high, the detected products are reliable in quality, and quality management of cigarette material plants is greatly assisted.

Owner:WUHAN EASY VIEW SCI & TECH CO LTD +1

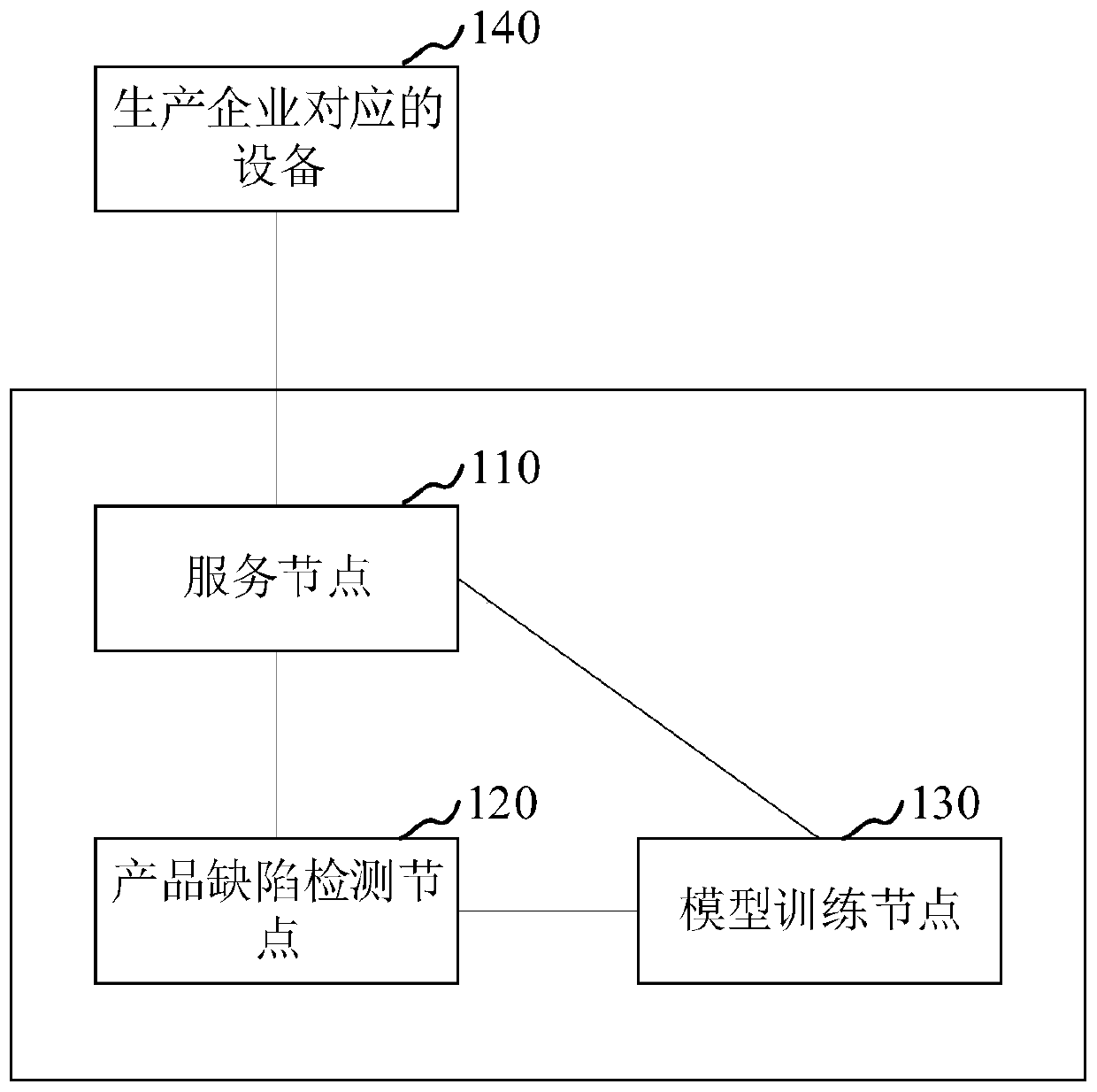

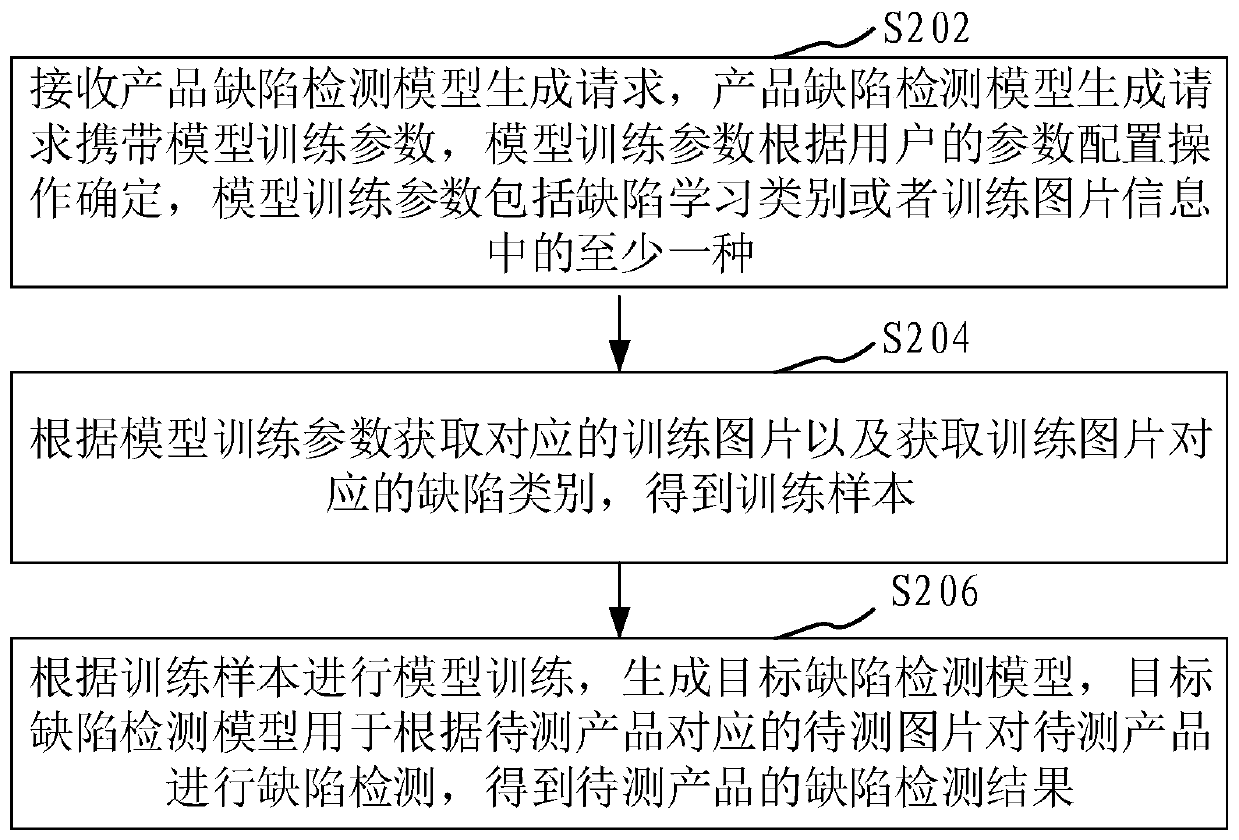

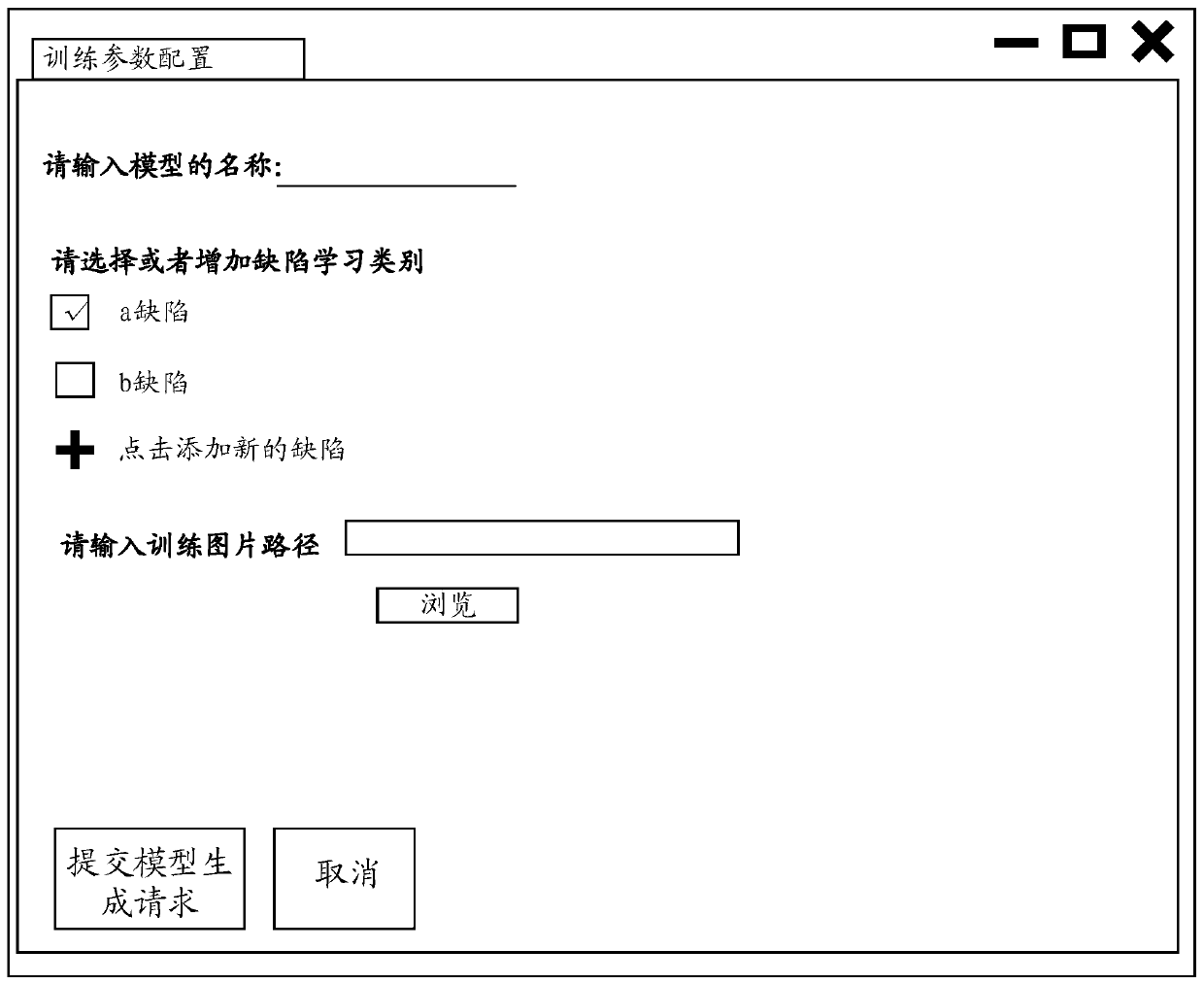

Product defect detection data processing method, device, system and equipment

ActiveCN110554047AImprove efficiencyIncrease flexibilityCharacter and pattern recognitionOptically investigating flaws/contaminationAlgorithmProduct defect

The invention relates to a product defect detection data processing method, device, system and equipment. The method comprises the steps of receiving a product defect detection model generation request, wherein the product defect detection model generation request carries model training parameters, the model training parameters are determined according to parameter configuration operation of a user, and the model training parameters comprise at least one of defect learning categories or training picture information; obtaining a corresponding training picture according to the model training parameters and obtaining a defect category corresponding to the training picture to obtain a training sample; and carrying out model training according to the training sample to generate a target defectdetection model, the target defect detection model being used for carrying out defect detection on the to-be-detected product according to a to-be-detected picture corresponding to the to-be-detectedproduct to obtain a defect detection result of the to-be-detected product. The model obtained by the method is high in product defect detection efficiency and high in flexibility.

Owner:TENCENT TECH (SHENZHEN) CO LTD

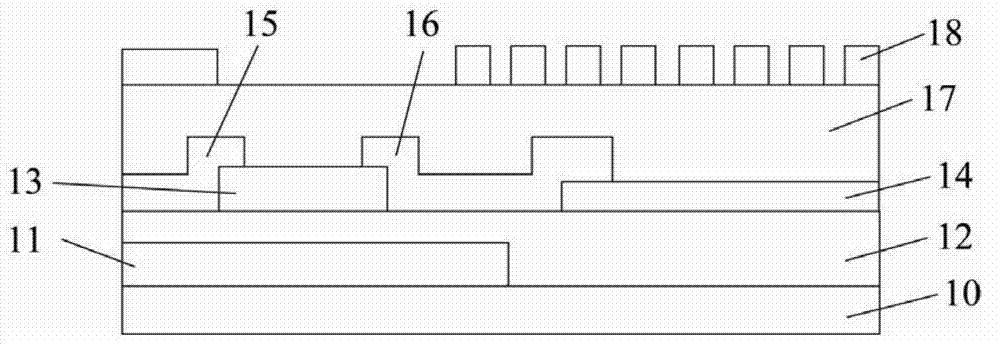

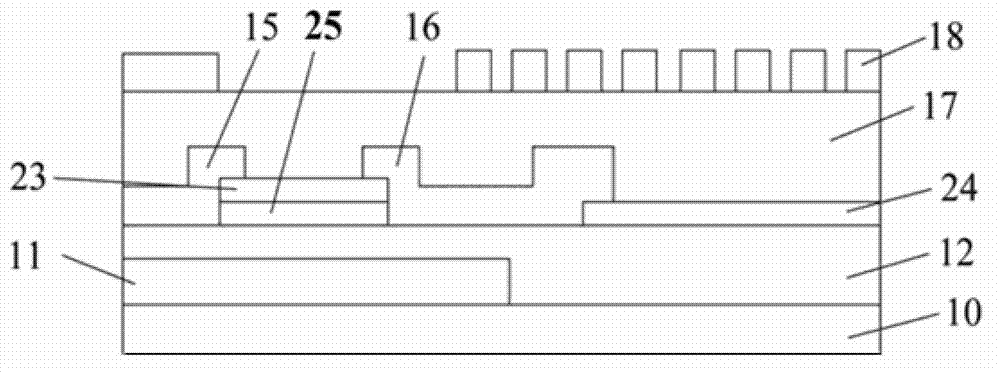

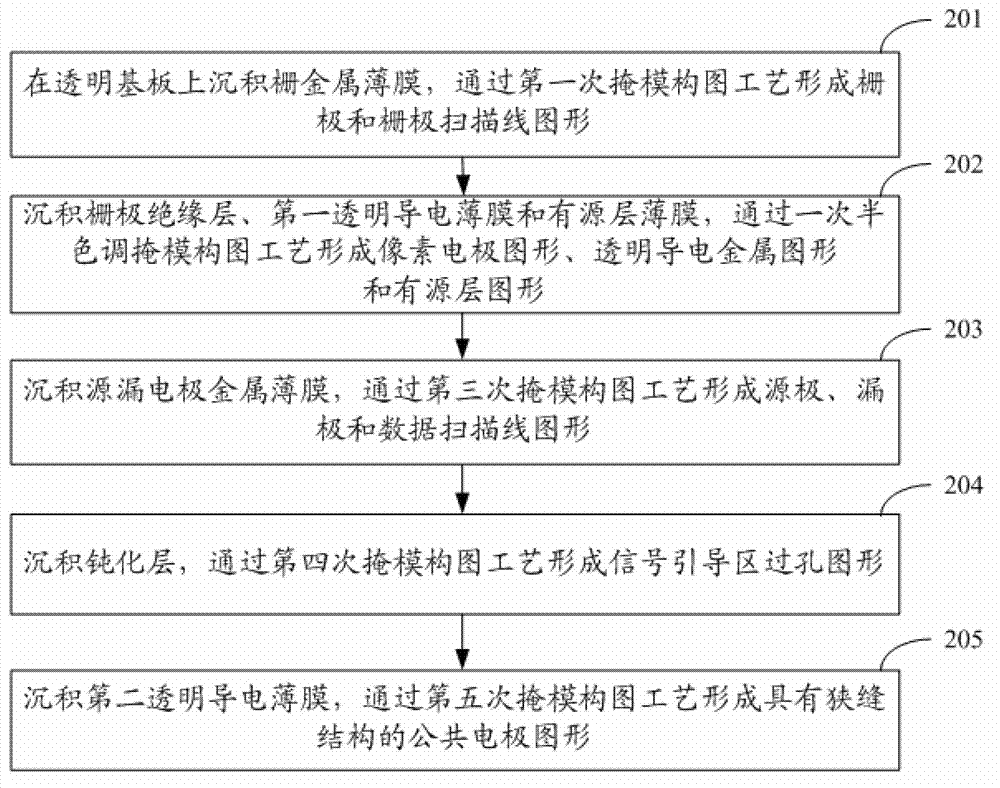

Array substrate, display panel and array substrate manufacturing method

ActiveCN102881688AMask patterning process eliminatesSimple production processTransistorSolid-state devicesProduct defectTransistor

The invention discloses an array substrate, a display panel and an array substrate manufacturing method. The array substrate includes a plurality of pixel units; each pixel unit includes a thin film transistor, a transparent conductive metal layer and a pixel electrode; and the thin film transistor includes a grid electrode, an active layer, a source electrode and a drain electrode, wherein the active layer is located above or below the grid electrode, and contacted with the transparent conductive metal layer in a stacked manner, the source electrode and the drain electrode form a channel of the active layer, and the drain electrode is connected to the pixel electrode. According to the invention, as the transparent conductive metal and the active layer are contacted in a stacked manner, a pixel electrode pattern and an active layer pattern can be formed only by performing half-tone mask patterning process at once after a transparent conductive thin film and an active layer film are deposited during manufacturing the array substrate, so that the production process is greatly simplified, the potential product defects brought by the mask patterning process are reduced at the same time, thereby greatly improving the production capacity.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

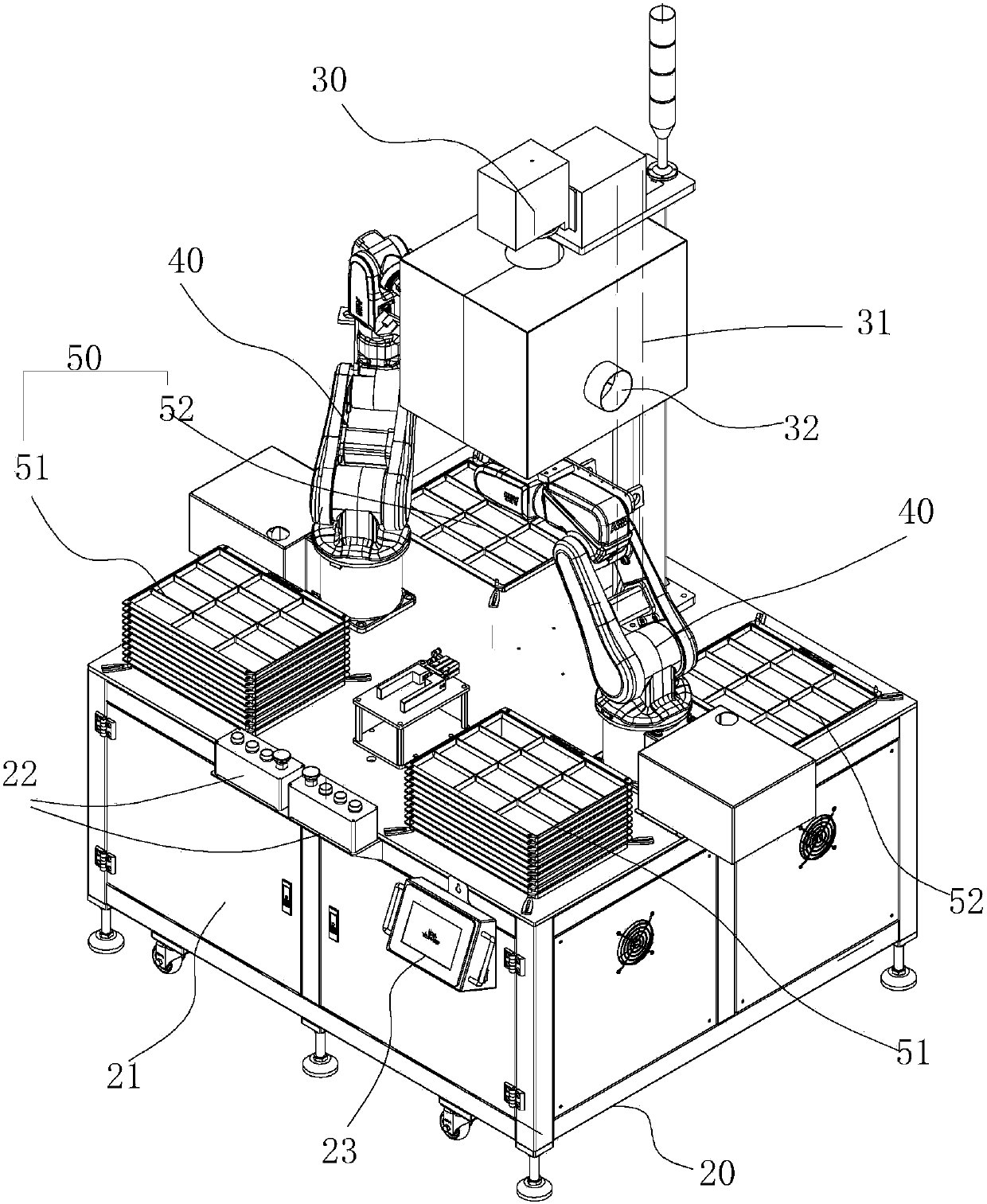

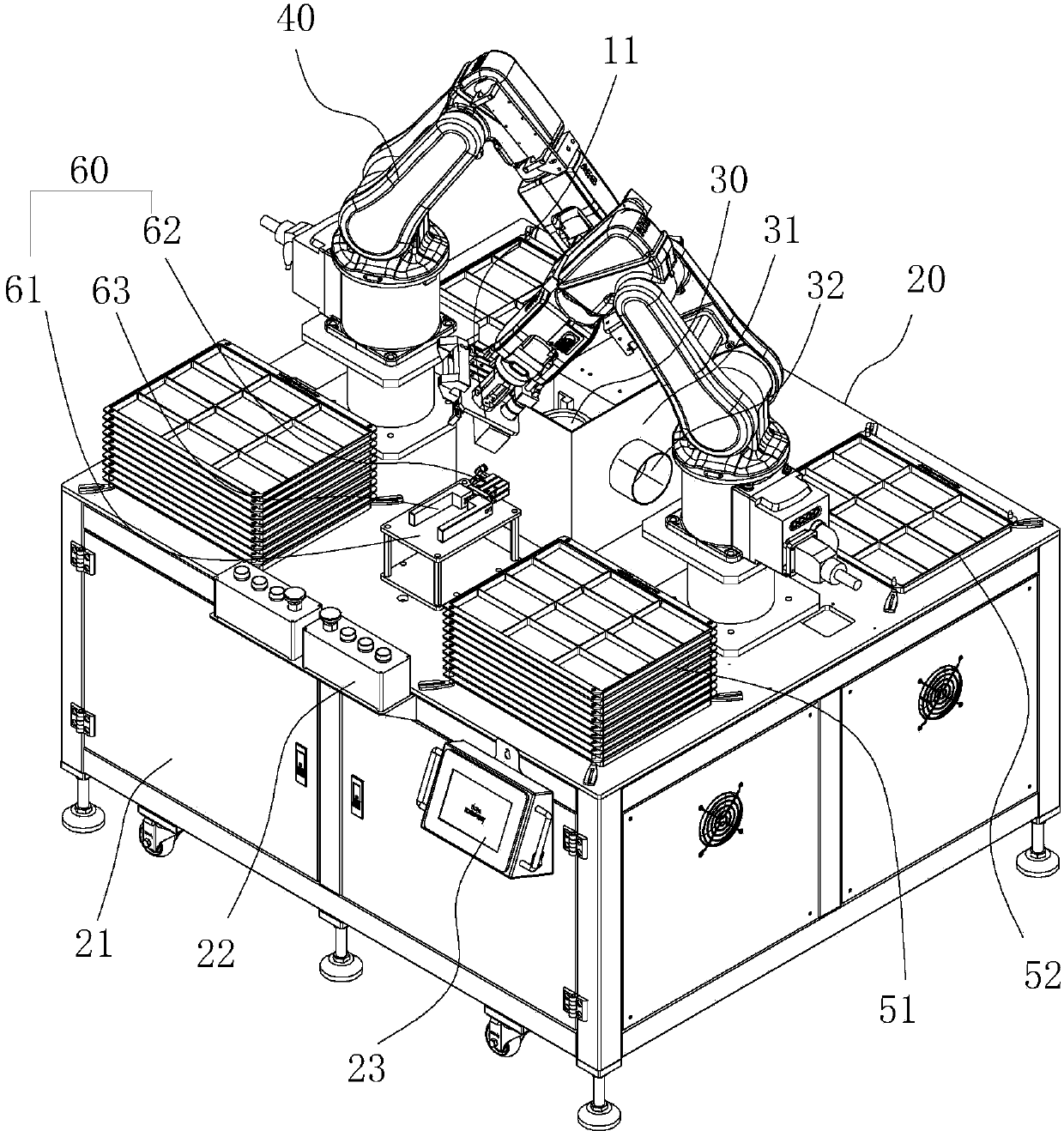

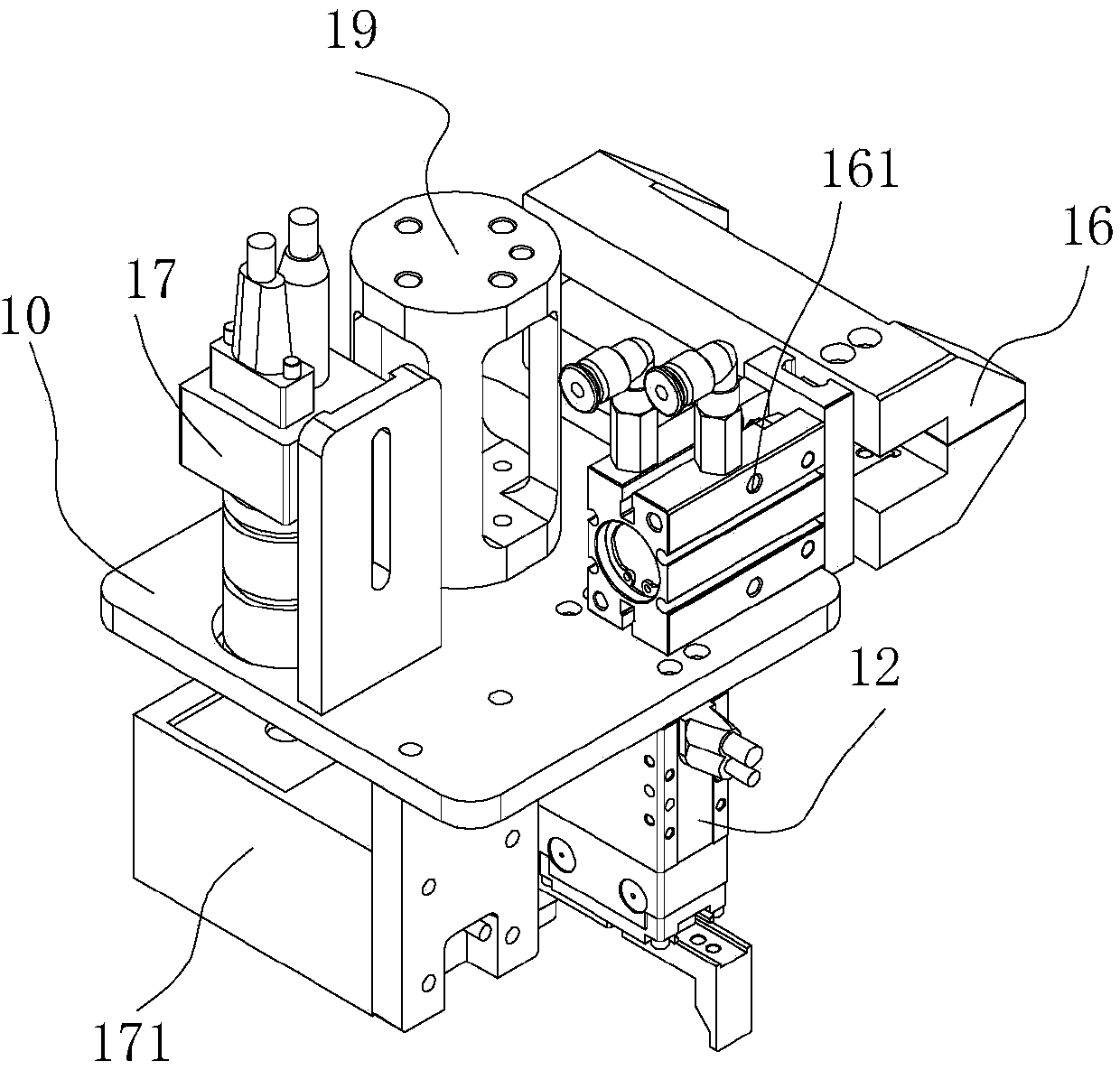

Laser method and laser equipment adopting robot

InactiveCN104175008ARealize fully automated operationPrecise positioningProgramme-controlled manipulatorGripping headsEngineeringProduct defect

The invention discloses a laser method and laser equipment adopting a robot. The laser equipment comprises a base and a laser machine arranged on the base, and the robot and a material area used for storing workpieces are further arranged on the base; a free end of the robot is provided with a clamp structure used for clamping the workpieces to move between the material area and a laser area; the clamp structure is provided with a clamping portion used for clamping the workpieces; the laser equipment further comprises a positioning mechanism used for positioning the workpieces. The robot is adopted for moving materials from a feeding area to the laser area of the laser machine and further moving the materials to a discharging area after laser operation is finished, full-automatic operations of the workpieces in the laser process are realized, and accordingly production efficiency is improved, and product defects resulted from manual operations are reduced; by the aid of the positioning mechanism, precision in workpiece positioning during clamping is realized to further realize precision laser of the workpieces.

Owner:SHENZHEN RAPOO TECH

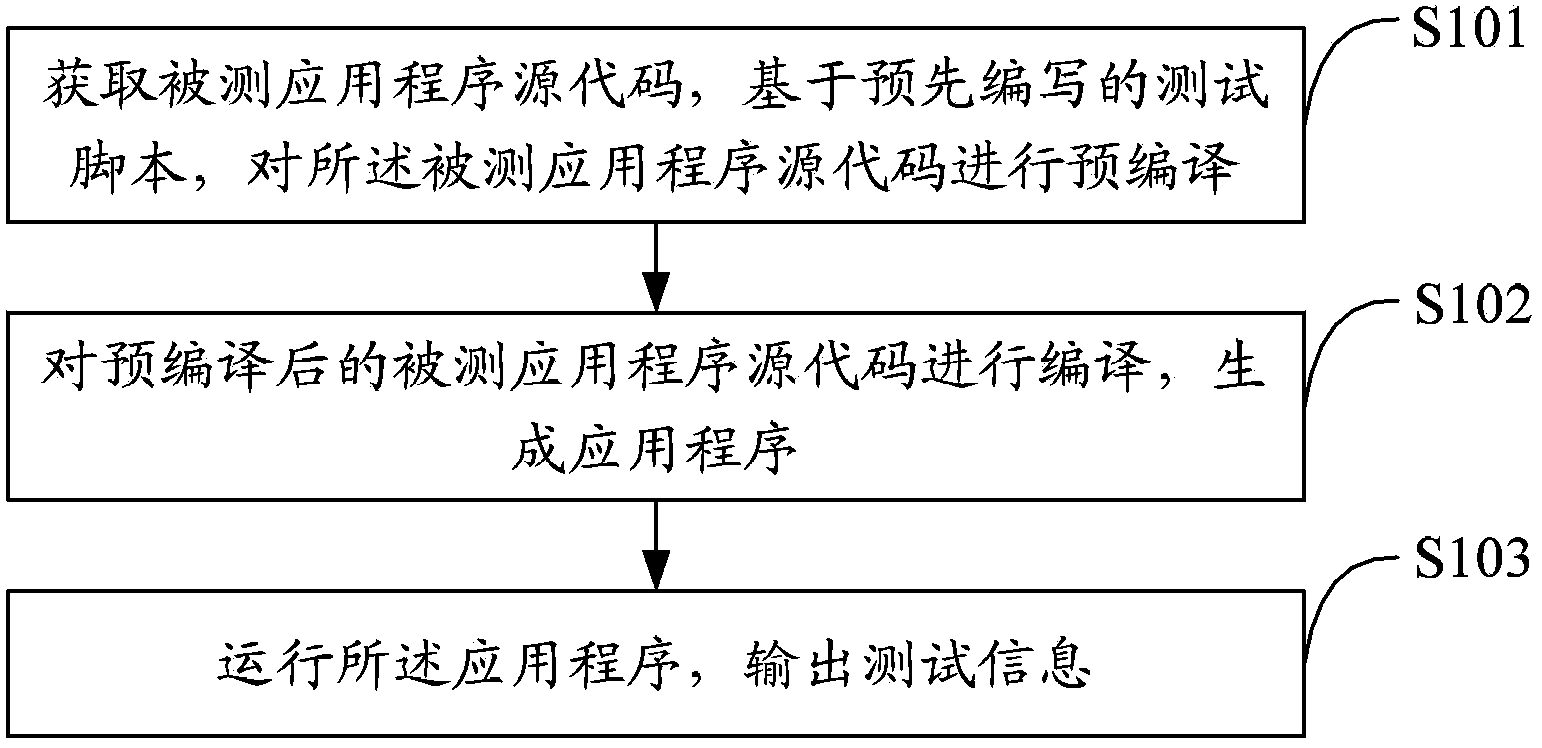

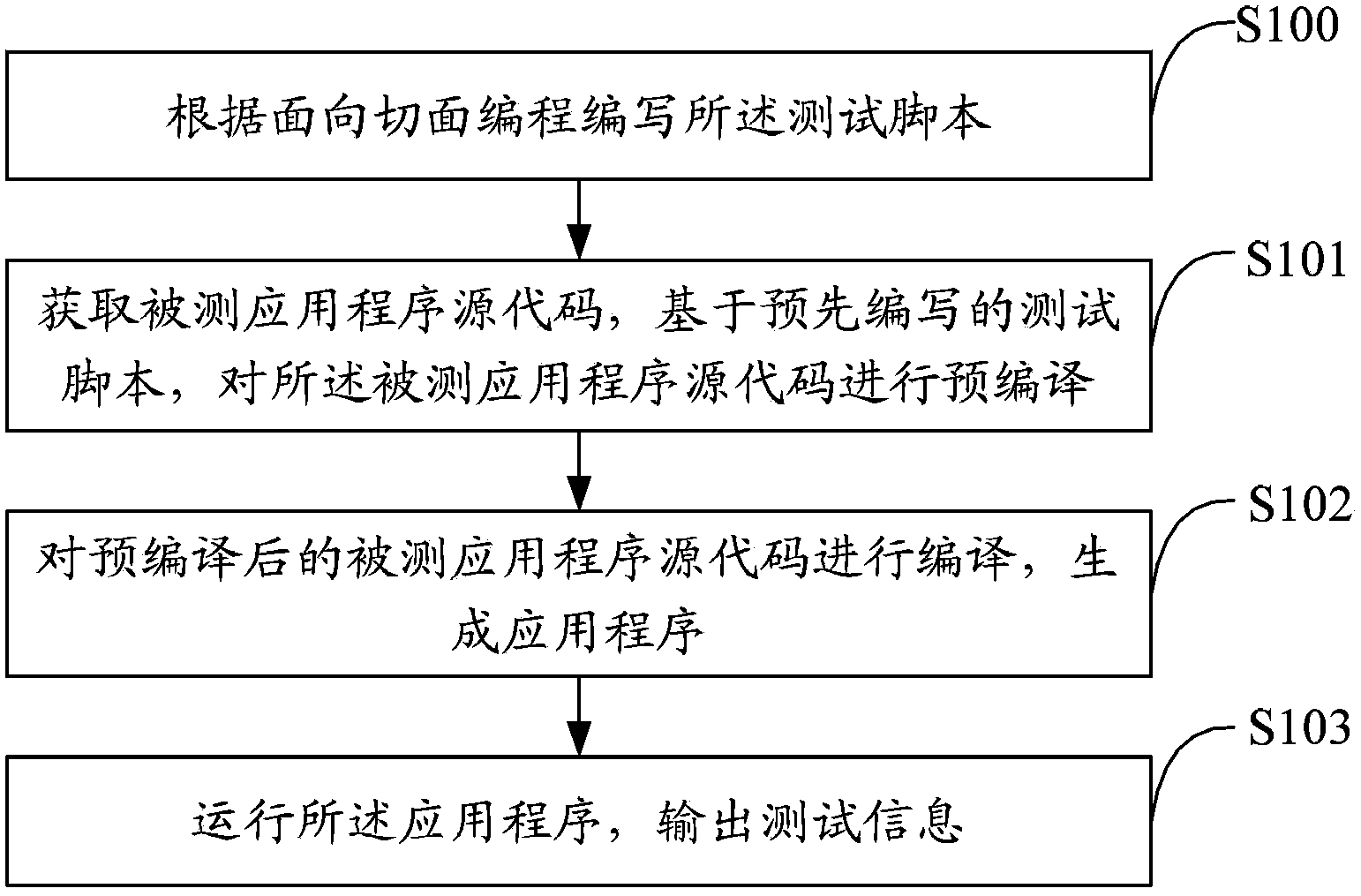

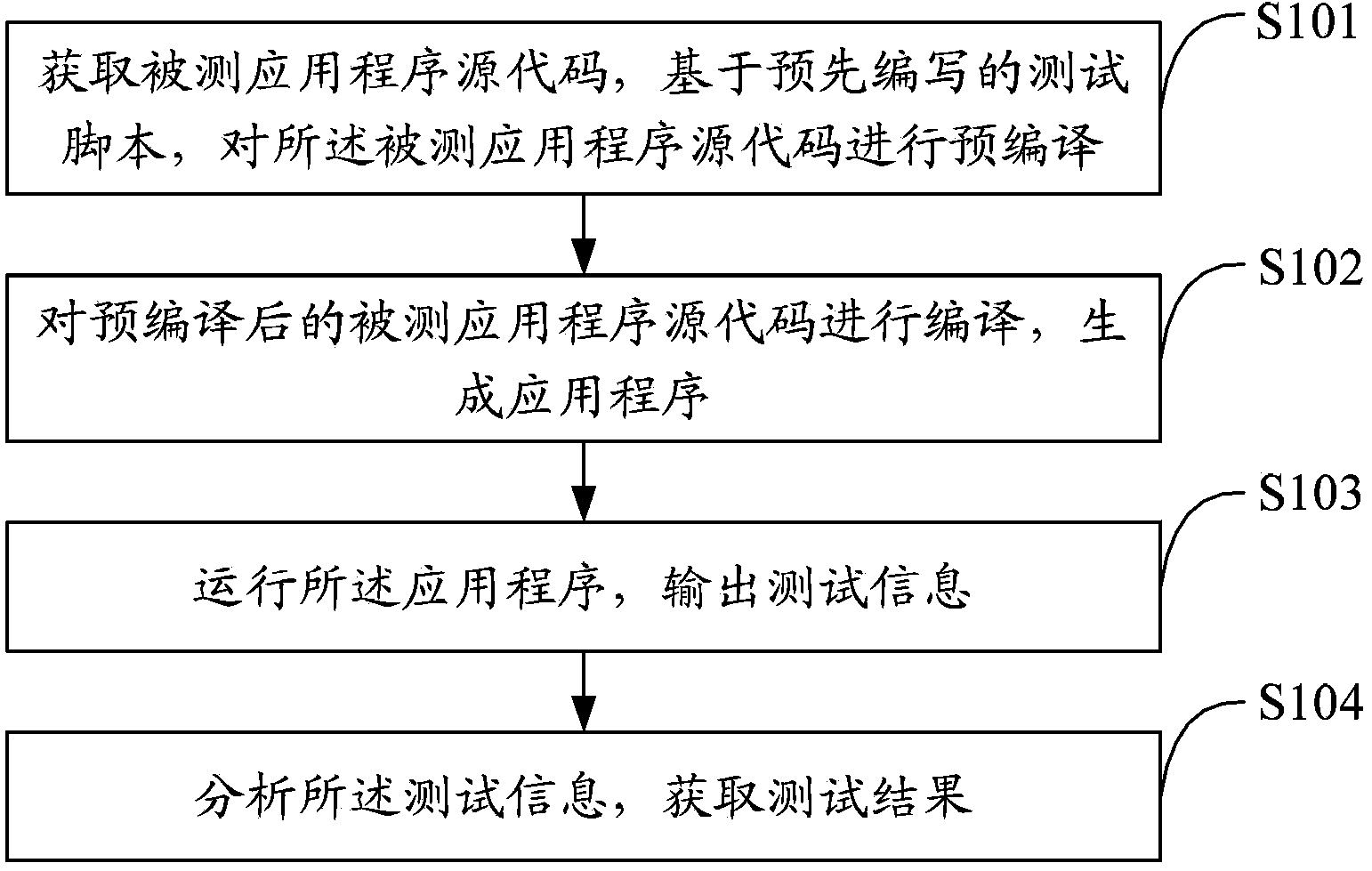

Method and device for testing application program

ActiveCN104102574AValid testWill not cause defectsSoftware testing/debuggingTest scriptMaintainability

The invention relates to a method and a device for testing an application program. The method for testing the application program comprises the following steps: acquiring a source code of the application program under test, and precompiling the source code of the application program under test on the basis of a test script complied advance; compiling the source code of the precompiled application program under test to generate an application program; running the generated application program, and outputting test information. According to the method and the device provided by the invention, during precompiling, according to the test script of aspect oriented programming, a debugging code for test is dynamically inserted into the source code of the application program under test; when the application program is run, the test information is output on the basis of the debugging code, and therefore, location and quality measurement can be performed on the bug of the application program according to the test information; as the source code of the application program under test does not need to be modified, the product defect and performance risk of the application program cannot be caused; while the validity test of the application program is realized, the maintainability of the code under test is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

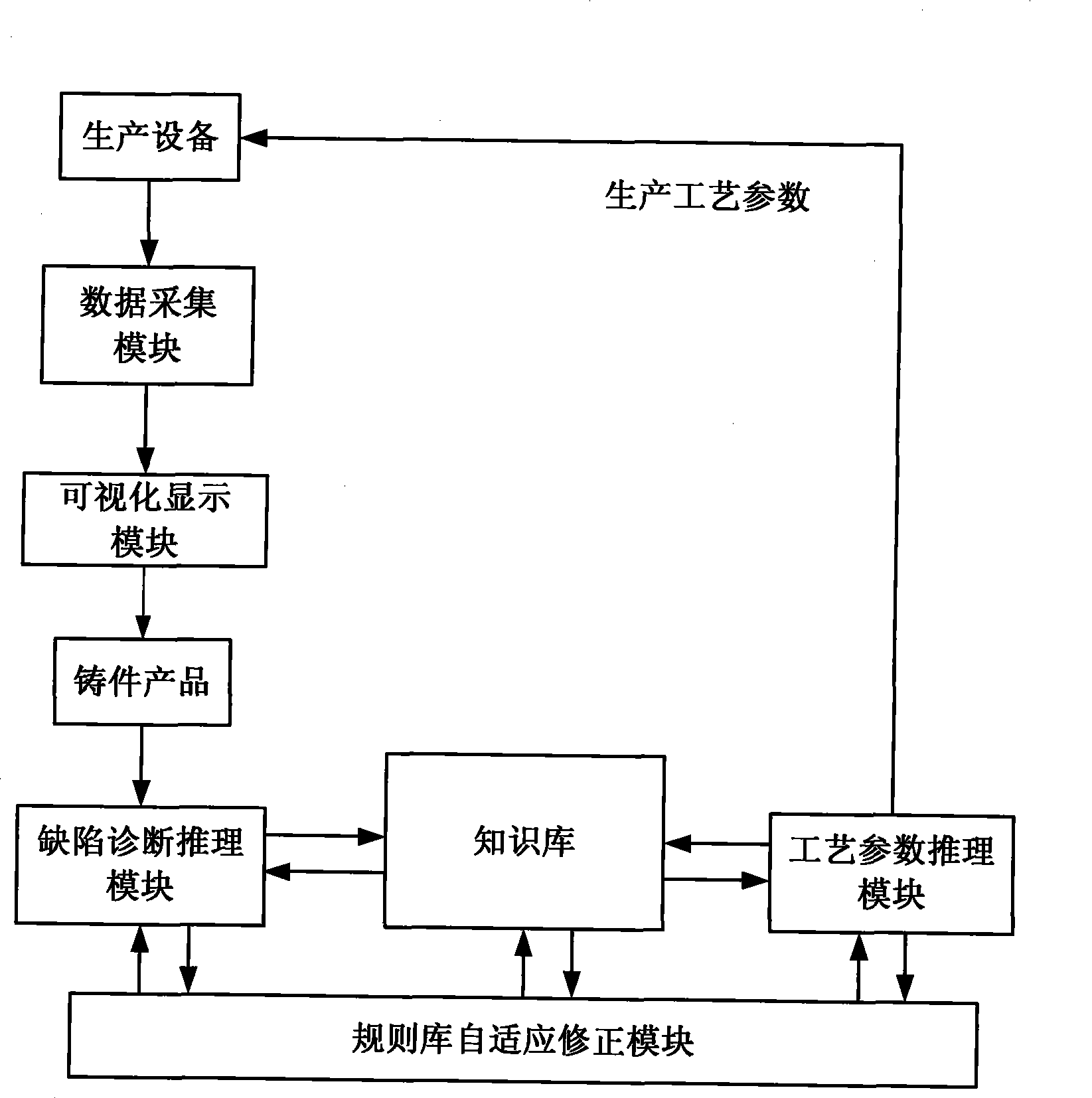

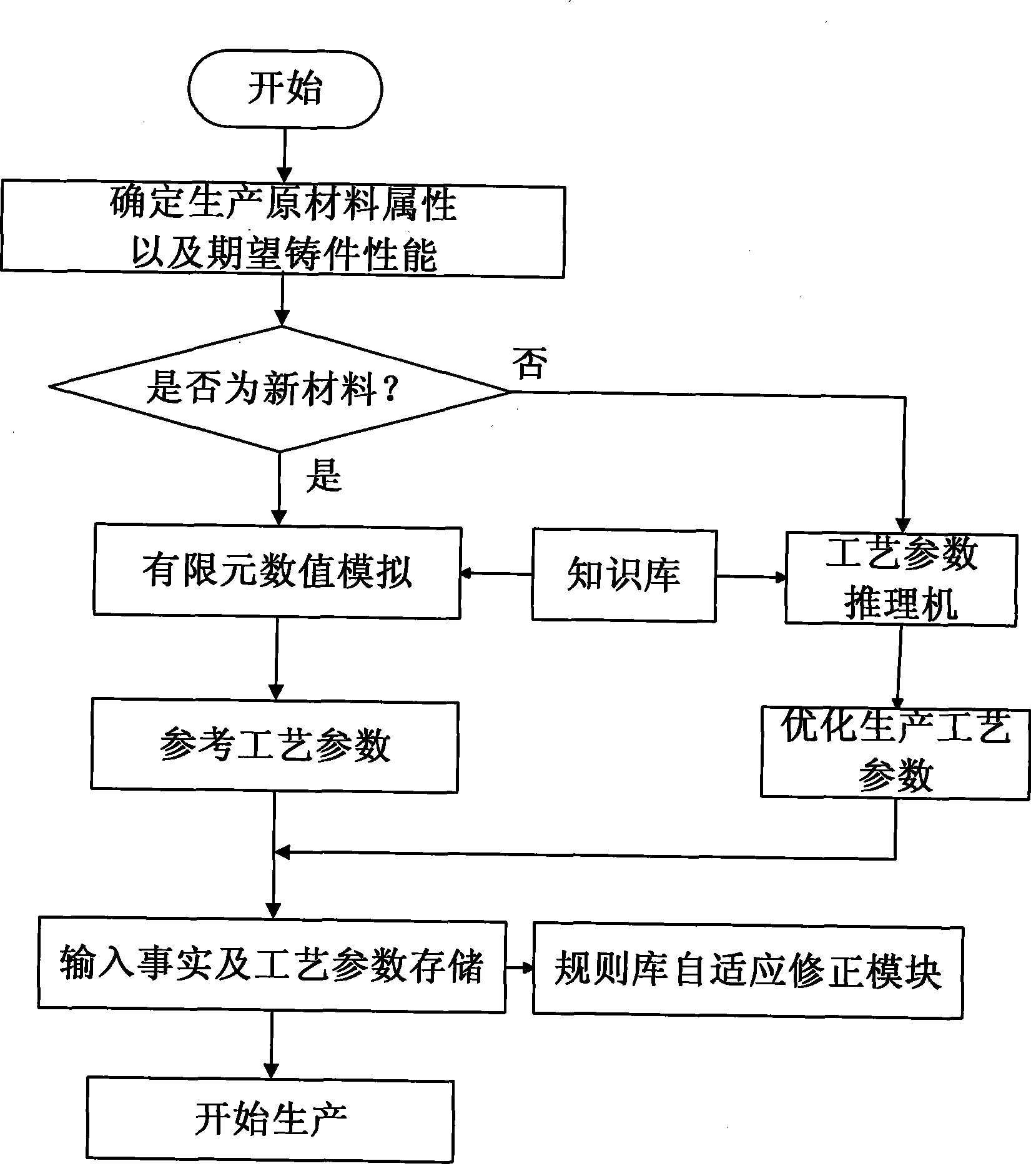

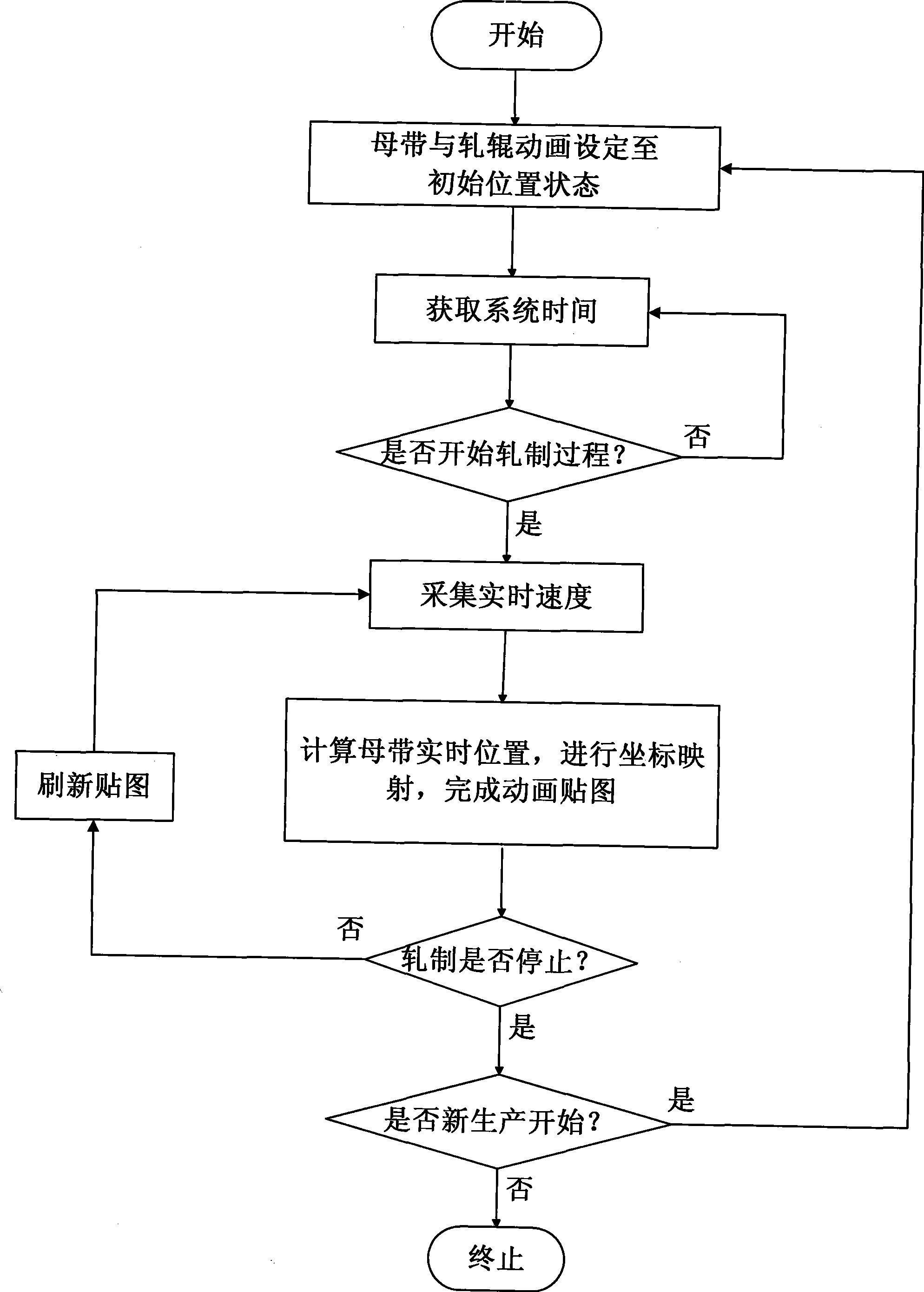

System and method suitable for quality control of reverse solidification technique

The invention discloses a system and a method suitable for quality control in an inverse solidification process. The system mainly comprises a data acquisition module, a visualized display module, and an adaptive expert system, wherein the adaptive expert system comprises a defect diagnostic reasoning module, a processing parameter reasoning module, an adaptive rule base correcting module, and a knowledge base. The processing parameter reasoning module reasons and provides optimized processing parameters before production, the data acquisition module and the visualized display module carry out data acquisition and visualized animation display on a detected production process, the defect diagnostic reasoning module analyzes performance and defects of products, and the adaptive rule base correcting module extracts defect analysis result of the products and the processing parameters re-correct rule to be fed back and applied to the processing parameter reasoning module so as to carry out a new production process. The system and the method can remarkably improve combination quality of a motherboard solidification layer in the inverse solidification process, accumulate processing experience, reduce defect, and save experiment expense.

Owner:BEIHANG UNIV

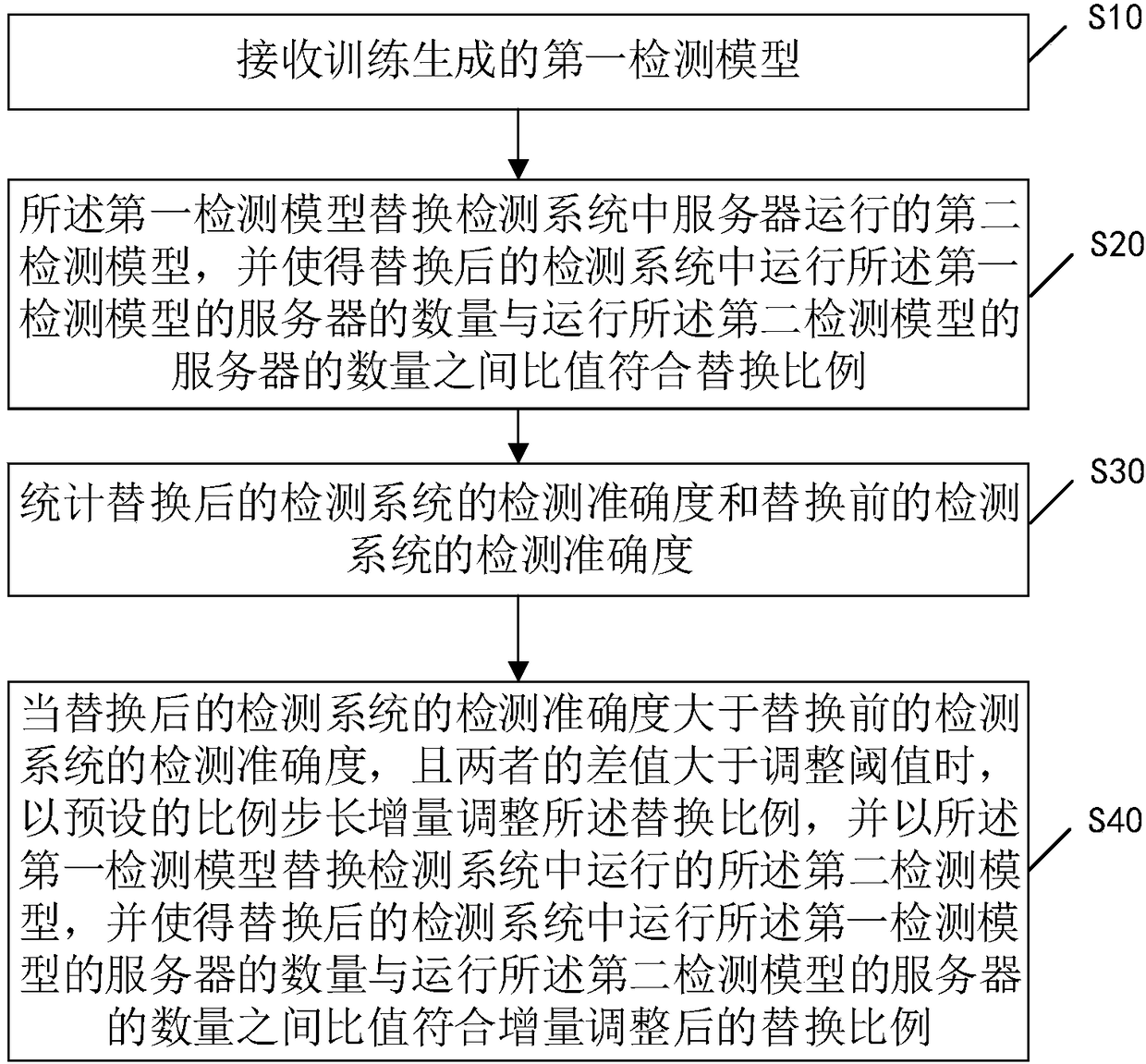

Method and device for updating product defect detection model, storage medium and terminal equipment

ActiveCN108257121AImprove applicabilityImprove detection accuracyImage enhancementImage analysisTerminal equipmentComputer terminal

The invention provides a method and a device for updating a product defect detection model, a storage medium and terminal equipment. The method comprises the following steps: receiving a first detection model generated by training; replacing the second detection model in a detection system with the first detection model, and making the ratio of the number of servers running the first detection model to the number of servers running the second detection model in the detection system after replacement conform to a replacement proportion; calculating the detection accuracy of the detection systembefore replacement and the detection accuracy of the detection system after replacement; and if the detection accuracy of the detection system after replacement is higher than the detection accuracyof the detection system before replacement and the difference is greater than an adjustment threshold, adjusting the replacement proportion based on a preset proportional step size increment, replacing the second detection model in the detection system with the first detection model, and making the ratio of the number of servers running the first detection model to the number of servers running the second detection model in the detection system after replacement conform to the replacement proportion after incremental adjustment. According to the invention, the applicability and detection accuracy of the detection model can be improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

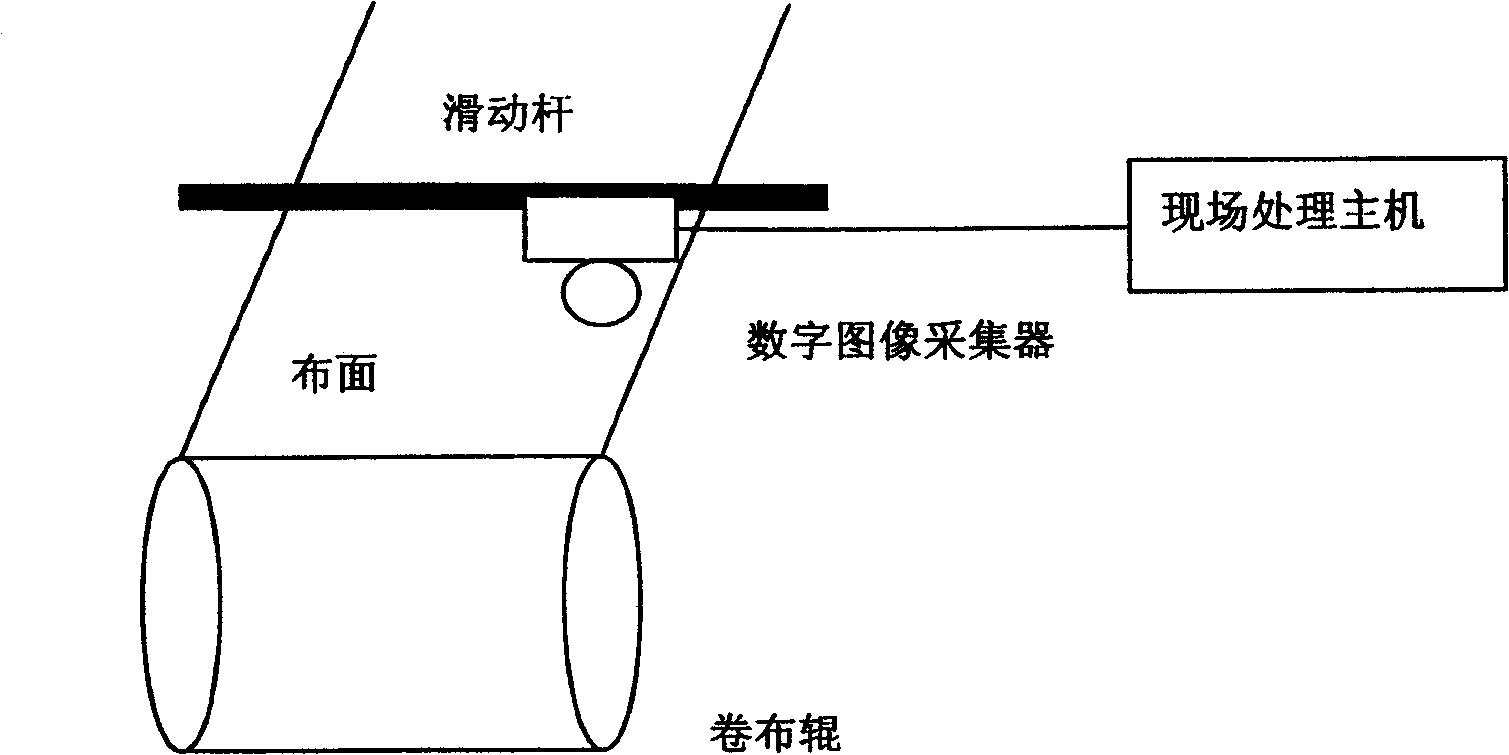

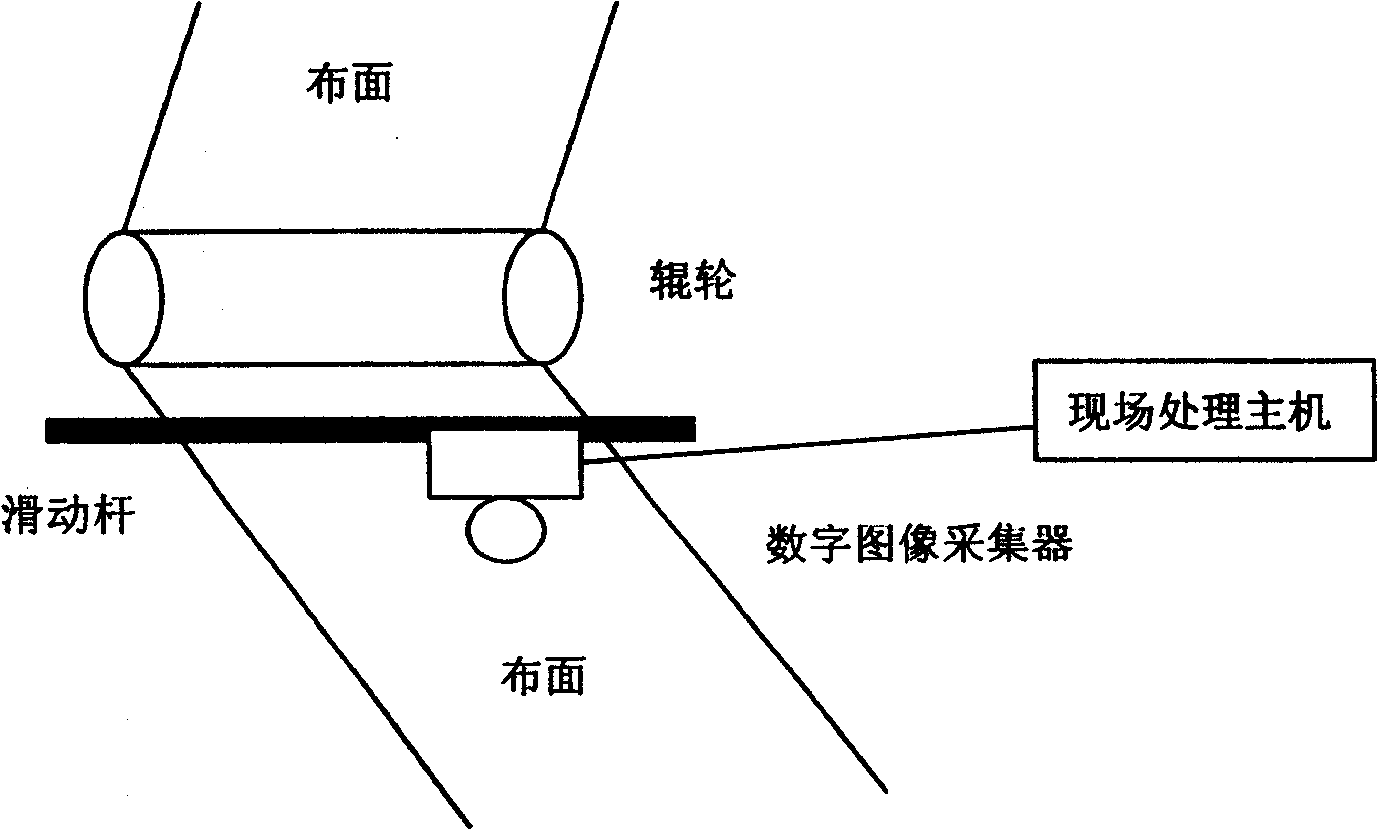

Dyeing and printing products on-line quality monitoring method based on computer pattern recognition principle

InactiveCN101334367AReduce generationReduce usageInspecting textilesTextile testingSites treatmentReciprocating motion

The invention relates to an online quality monitoring method of dyed products that is based on the computer graphic identification principle, adopts a digital image collector which is arranged and fixed on a slide rod above a rolling wheel or a cloth roller that are related to each technique in the dyeing, a camera shot side of the camera faces to a cloth surface, uninterrupted photographing of the moving cloth surface is implemented according to the set shooting frequency in unit time and repeated motion speed on the slide rod, and collected digital linear array or area array images are transmitted to an in-site processing host in real time; the in-site processing host is internally arranged with a standard cloth sample library and a defect library and implements fabric defect judgment, once a defect is determined, an alarming signal is emitted and leads the machine to halt, defect type on the fabric piece goods is reported, and concrete defect position is computed and indicated. The online quality monitoring method of the invention can implement the uninterrupted quality inspection of the products during the device running process, judge the product defects and indicate the defect type and the defect position.

Owner:何峰

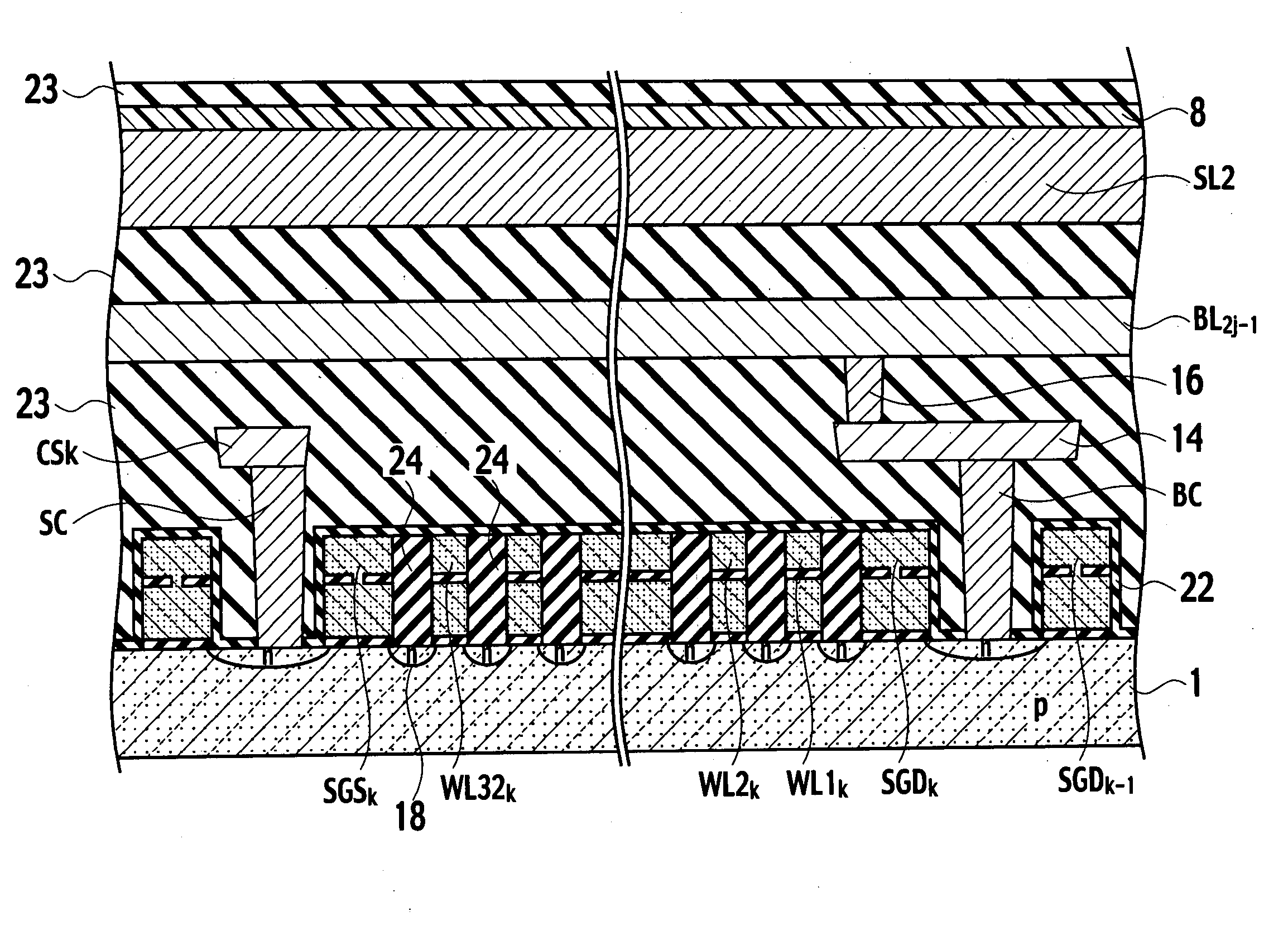

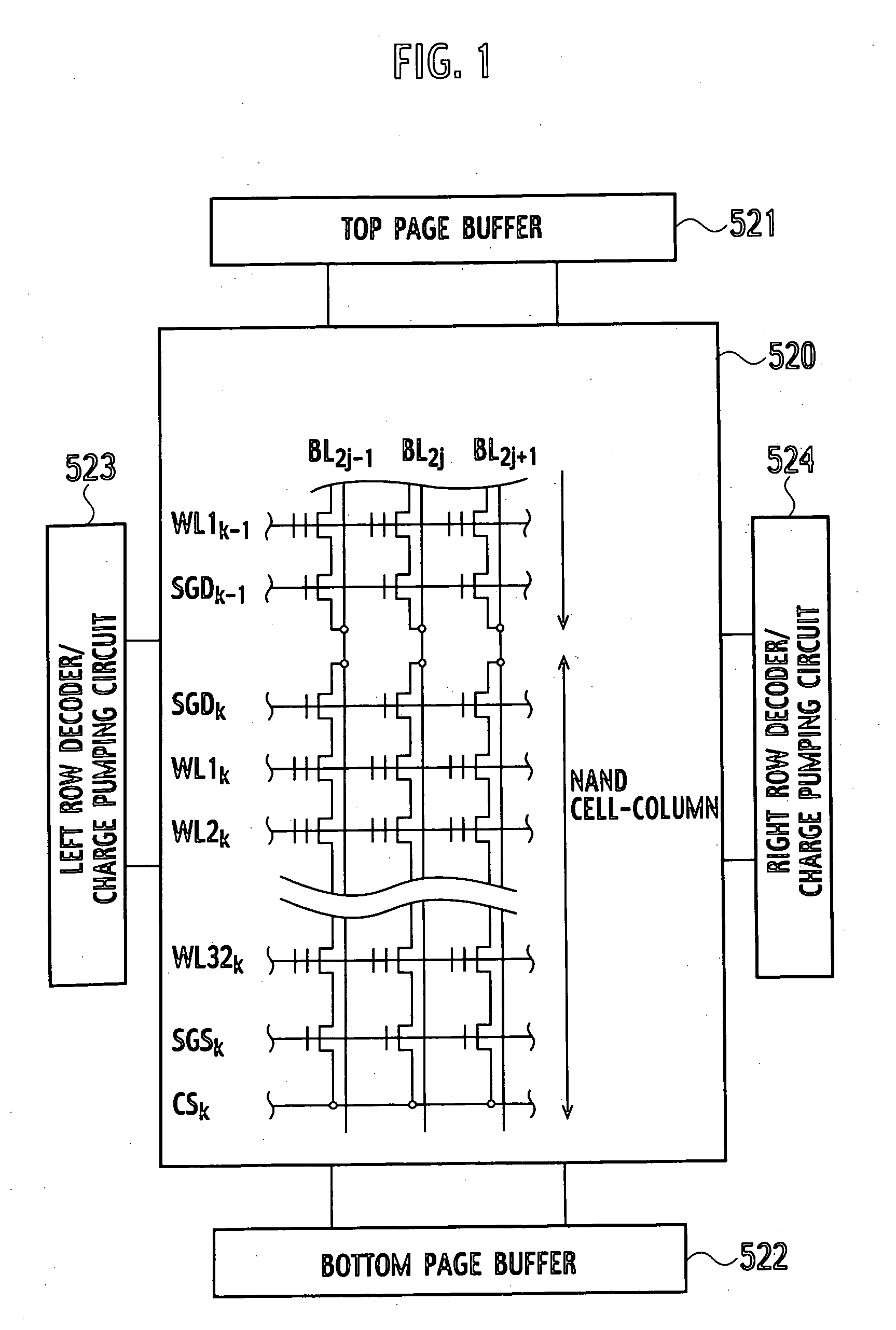

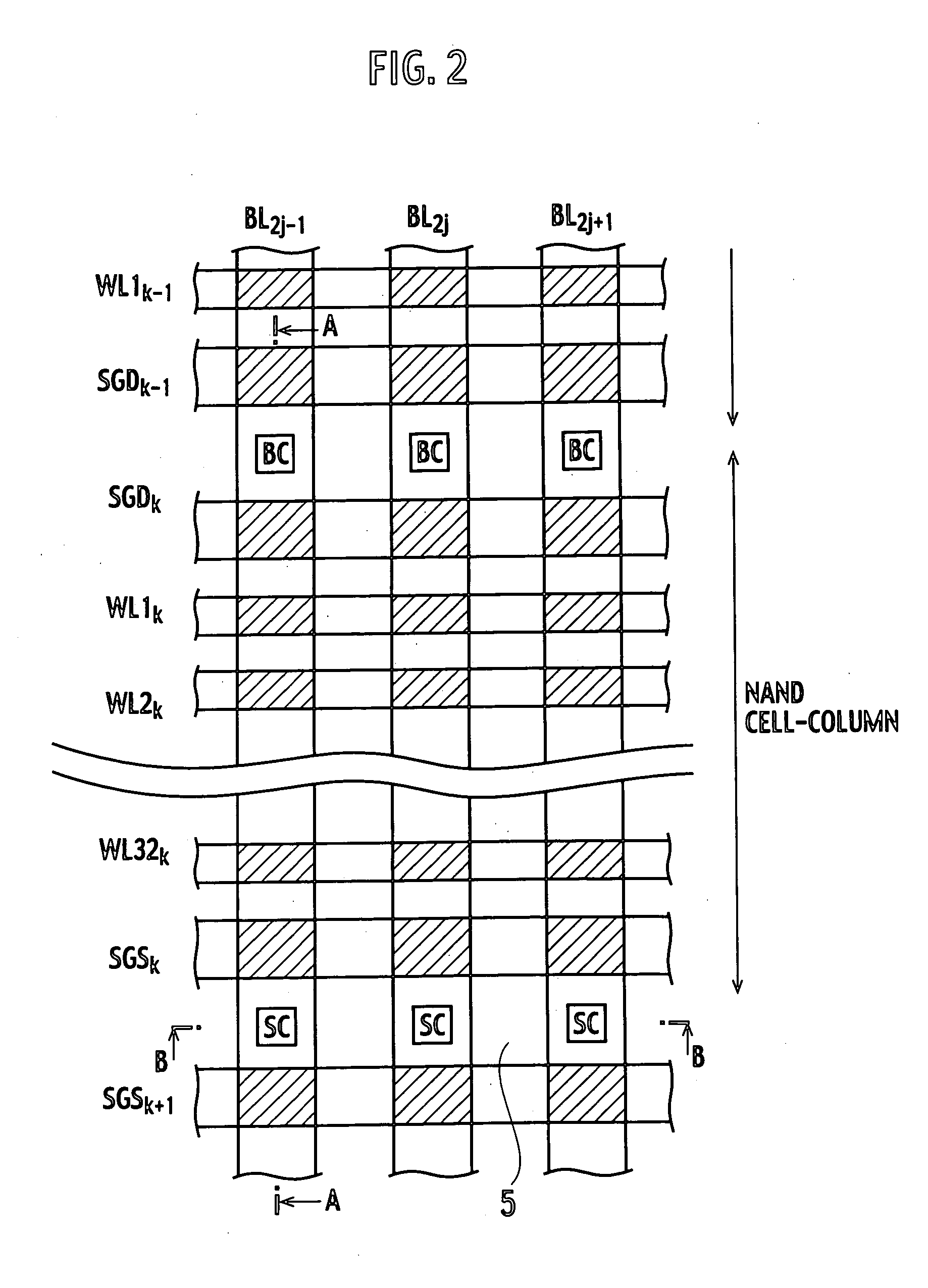

Method for manufacturing industrial products and combination of masks for manufacturing the same

InactiveUS20060166384A1Semiconductor/solid-state device testing/measurementSolid-state devicesElectricityProduct defect

A method for manufacturing an industrial product encompasses: forming a intermediate product pattern, which implements a part of a intermediate product of the industrial product by a sequence of processes corresponds to a part of a procedure for manufacturing the industrial product; forming an interconnect-changing insulator on the intermediate product pattern; boring sampling contact holes in the interconnect-changing insulator so as to make bare a part of the intermediate product pattern to define sampling sites; delineating evaluation interconnects on the interconnect-changing insulator so that each of the evaluation interconnects can electrically connected to at least one of the sampling sites of intermediate product pattern; and measuring an electrical resistance between subject sampling sites through the evaluation interconnects so as to detect a product defect in the intermediate product pattern.

Owner:KK TOSHIBA

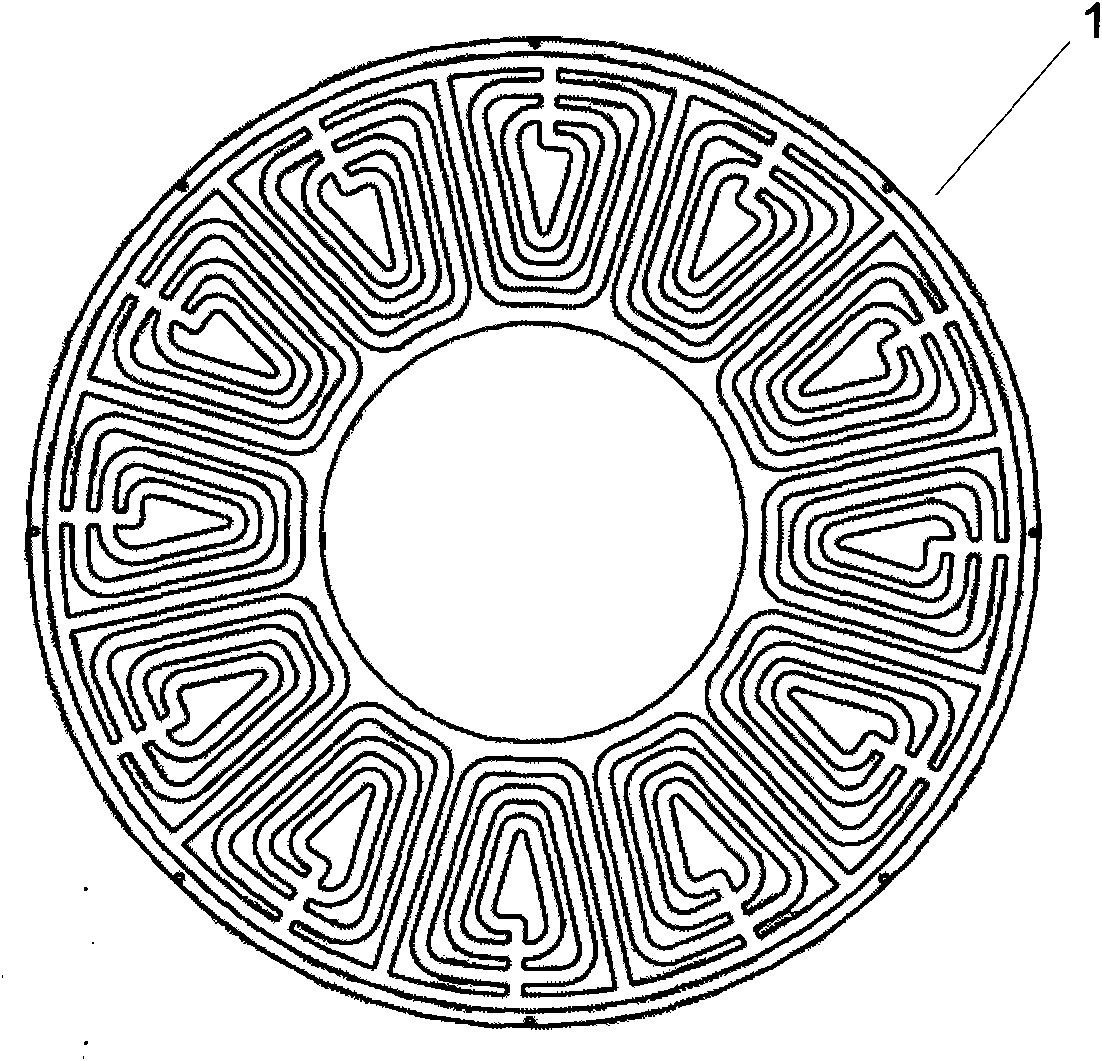

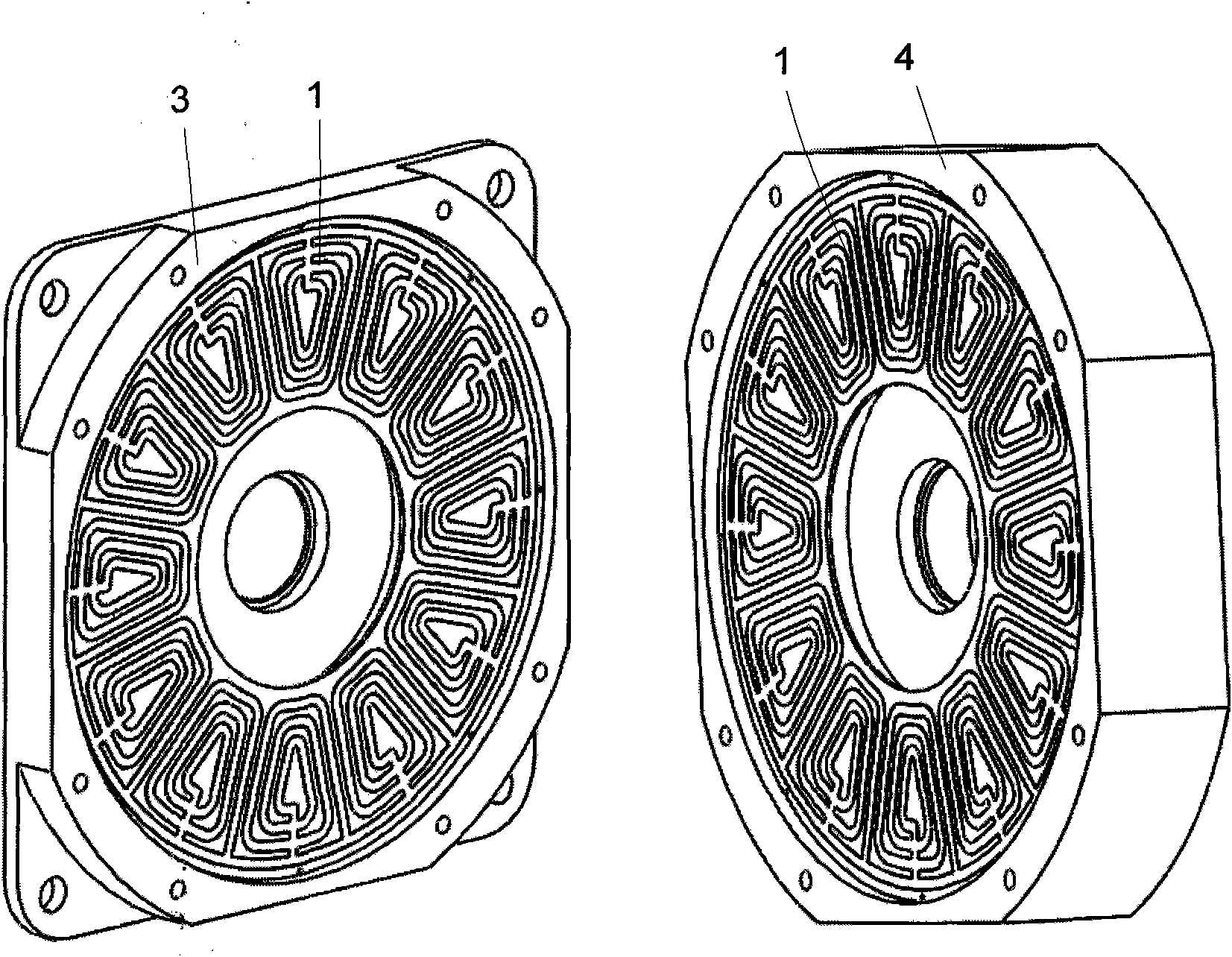

Disc type permanent magnet motor comprising winding in printed circuit board structure

InactiveCN102130563AEasy to installSave man hoursDynamo-electric machinesFailure rateHigh volume manufacturing

The invention provides a novel disc type permanent magnet motor against the defects in the existing production and manufacturing process of an armature of the disc type permanent magnet motor, which is characterized in that a stator component is in a slotless structure or a coreless structure; an armature winding for generating electrical excitation is fixed on a stator, and a stator winding is in a printed circuit board structure; a magnetic pole of a rotor is made of permanent magnet material; and the motor does not comprise an electric brush and a commutator. By adopting the technical scheme, not only the production and manufacturing process of an iron core can be simplified, but also the processes, such as winding, paying off, wire connecting and the like can be simultaneously saved, thereby simplifying the manufacturing process of the armature of the disc type permanent magnet motor, which is complex originally, and bringing convenience to automatic mass production by using a machine. The disc type permanent magnet motor has the advantages of being convenient to mount, saving working time, being high in production efficiency, being firm in structure, being low in failure rate, reducing product defects caused by human factors, being applicable to mass production and being low in cost.

Owner:刘行

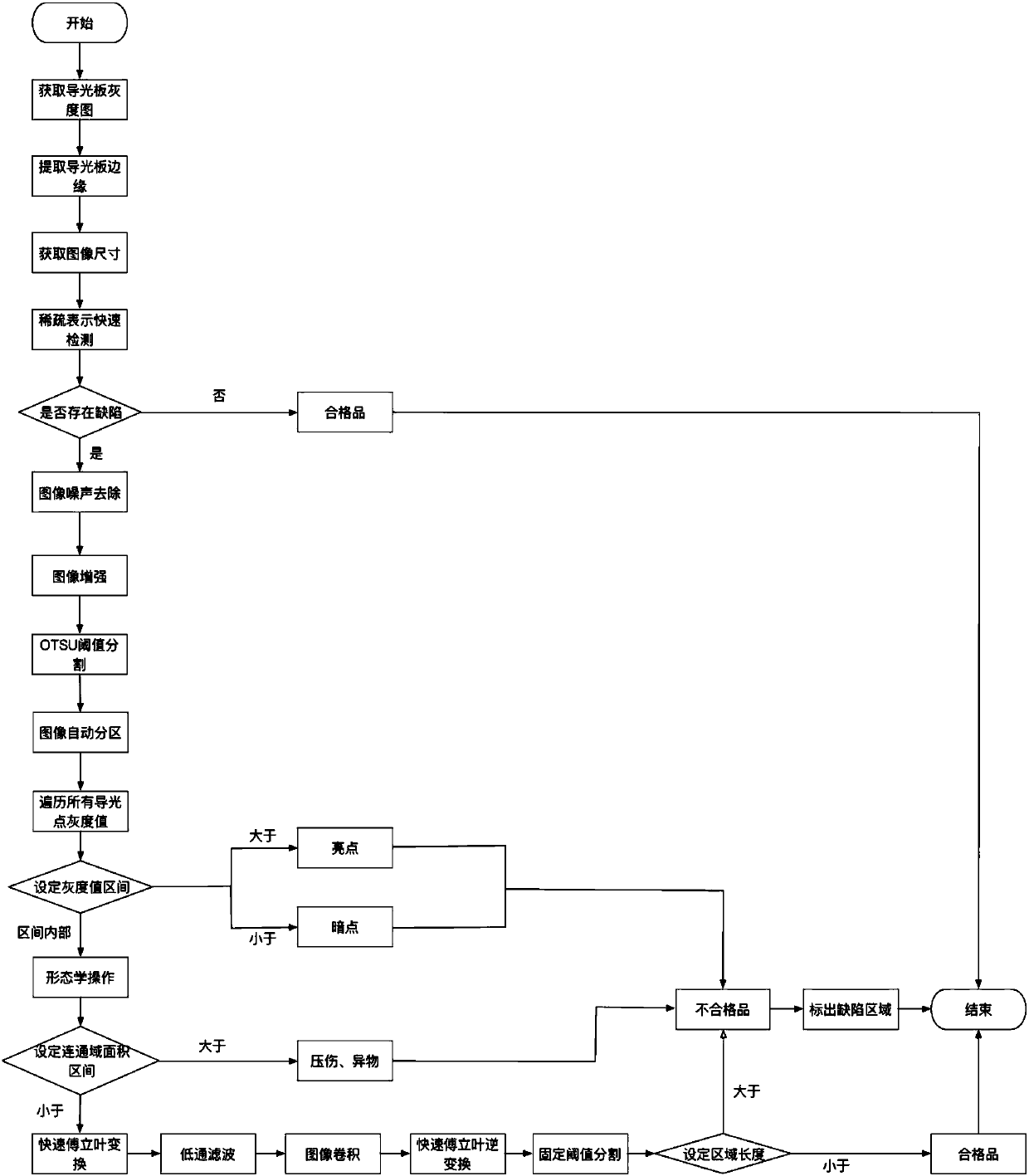

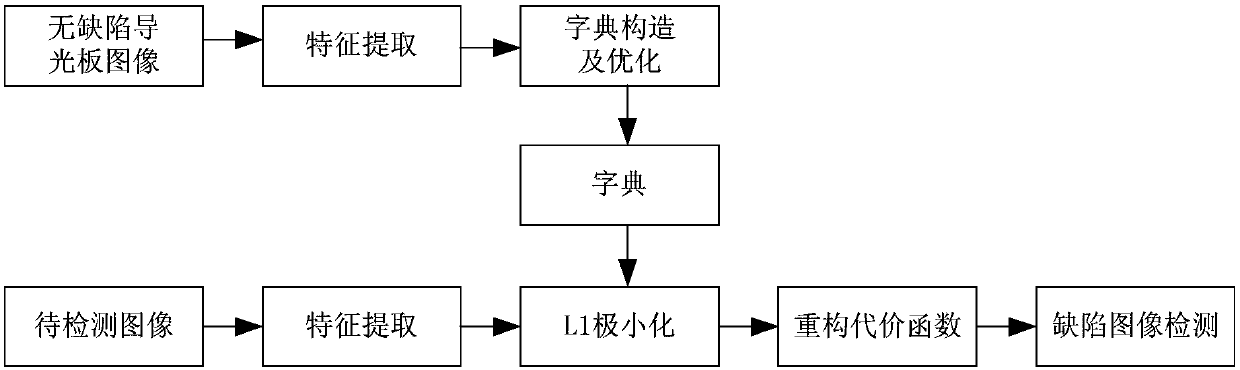

Single-side light-entering-type light guide plate defect extraction method

ActiveCN108346141AImprove operational efficiencyImprove accuracyImage enhancementImage analysisForeign matterAlgorithm

The invention provides a single-side light-entering-type light guide plate defect extraction method. The method comprises the following steps of acquiring a light guide plate image; extracting a lightguide plate body image; acquiring a width M and a height N; carrying out rapid defect detection; rapidly detecting whether a defect exists; removing a noise interference; carrying out gray scale transformation, OTSU threshold segmentation and automatic partition detection; traversing the gray scale range of light guide point area pixels; determining whether a light guide plate has bright and darkpoints; carrying out morphological processing; determining whether a pressing damage or a foreign matter exists; carrying out image segmentation; and determining whether a guide scratch defect existsand extracting an unaccepted product defect area. By using the exploited light-guide-plate adaptive automatic partitioning algorithm, according to the density of surface light guide holes, the different detection areas are automatically divided, a detection algorithm is automatically adjusted and defect extraction is realized. The operation efficiency and the accuracy of the algorithm are high, the stability and the robustness are high, the common defect can be identified and a high detection capability is possessed for an uncommon small defect.

Owner:杭州衡眺科技有限公司

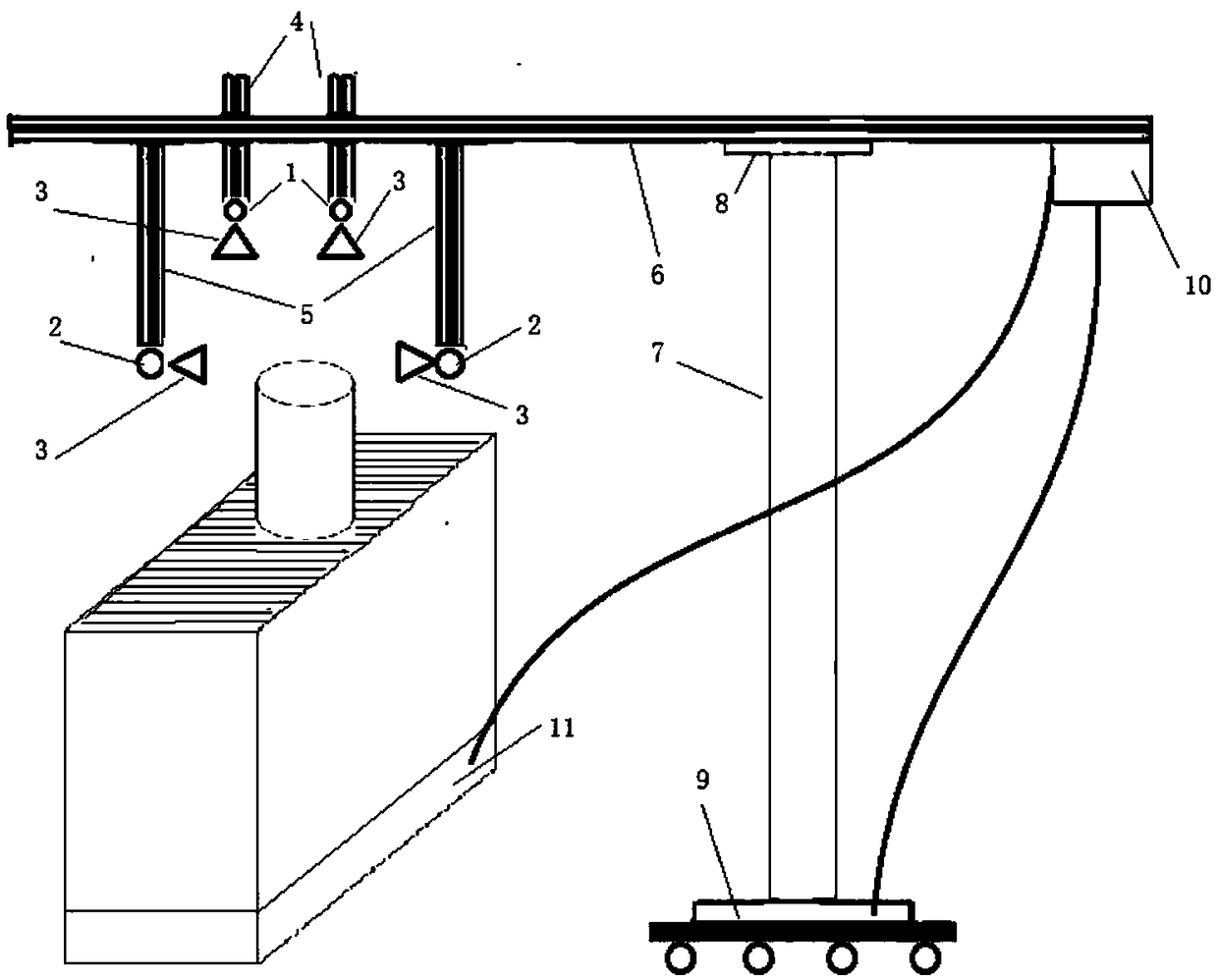

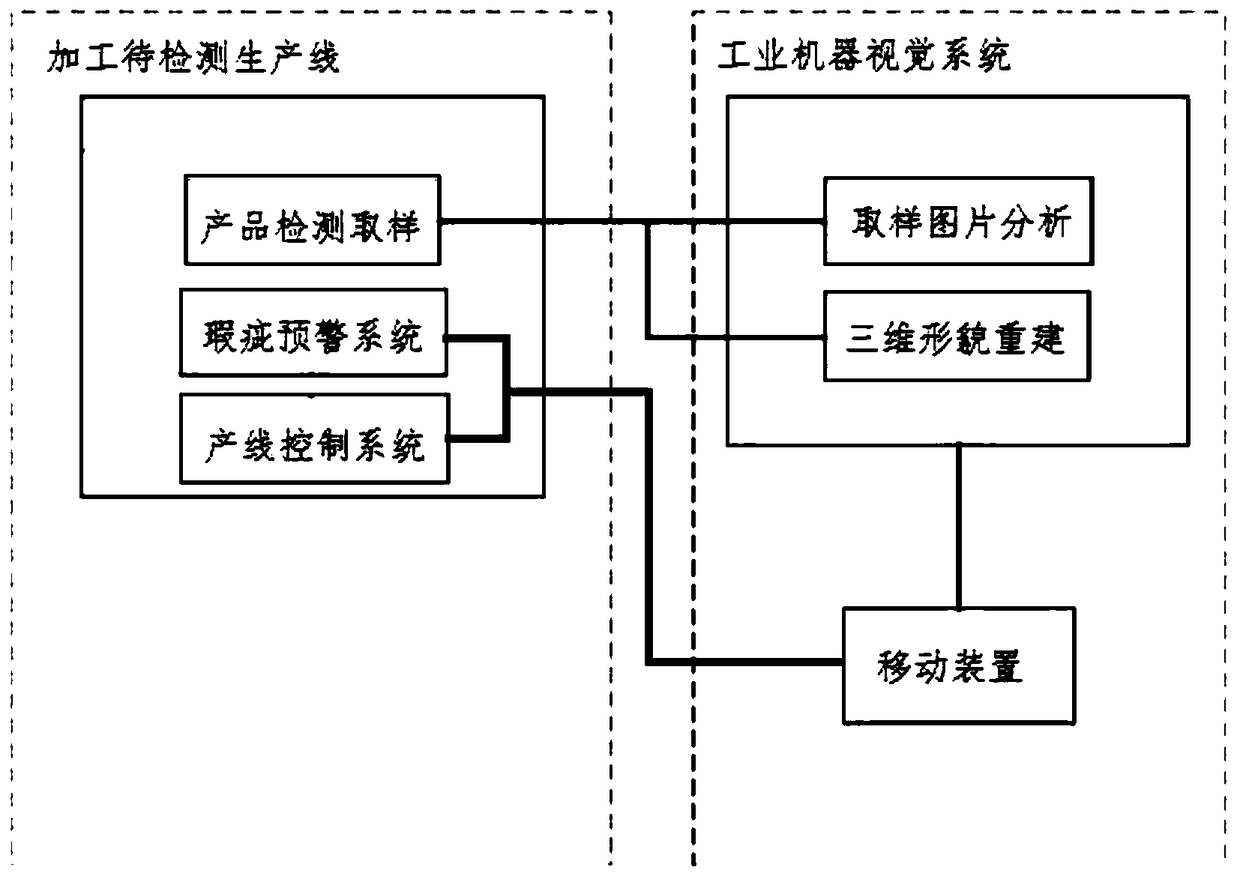

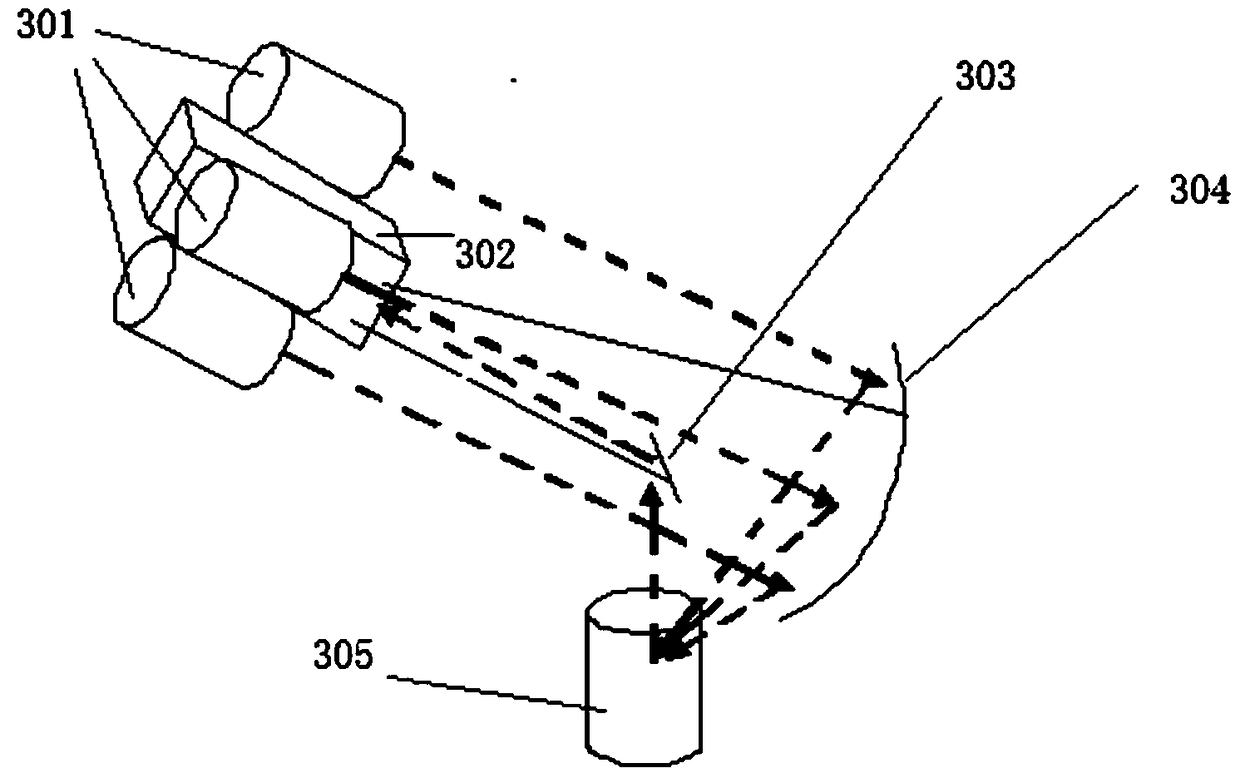

Industrial machine vision system image processing method

PendingCN109375573AMonitor Process AccuracyImage enhancementImage analysisProduction lineMeasurement device

The invention discloses an industrial machine vision system image processing method. The method is based on an industrial machine vision system hardware architecture which comprises a sampling and viewfinding system, a displacement device and a feedback linkage system which are set in data transmission and control transmission connection. According to the method, a high-precision measurement device based on light reflection is internally provided with a plurality of light sources, and the three-dimensional shape of a defective product is reconstructed by images in different illumination modes.The high-precision measurement device based on light reflection is embedded, and whether a micro pipeline or a small side characteristic inner hole has a product defect is determined according to collected high-precision image feedback. According to the invention, by a viewfinding component and a displacement device, the systems integrally move following the process sequence of an industrial processing production line to be detected, the processing precision of the processing line is monitored, the reverse early warning or correction of production line action is carried out, and the problemsgenerated in a production process are adjusted.

Owner:NANTONG SCI & TECH VOCATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com