Patents

Literature

571results about How to "Realize fully automated operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

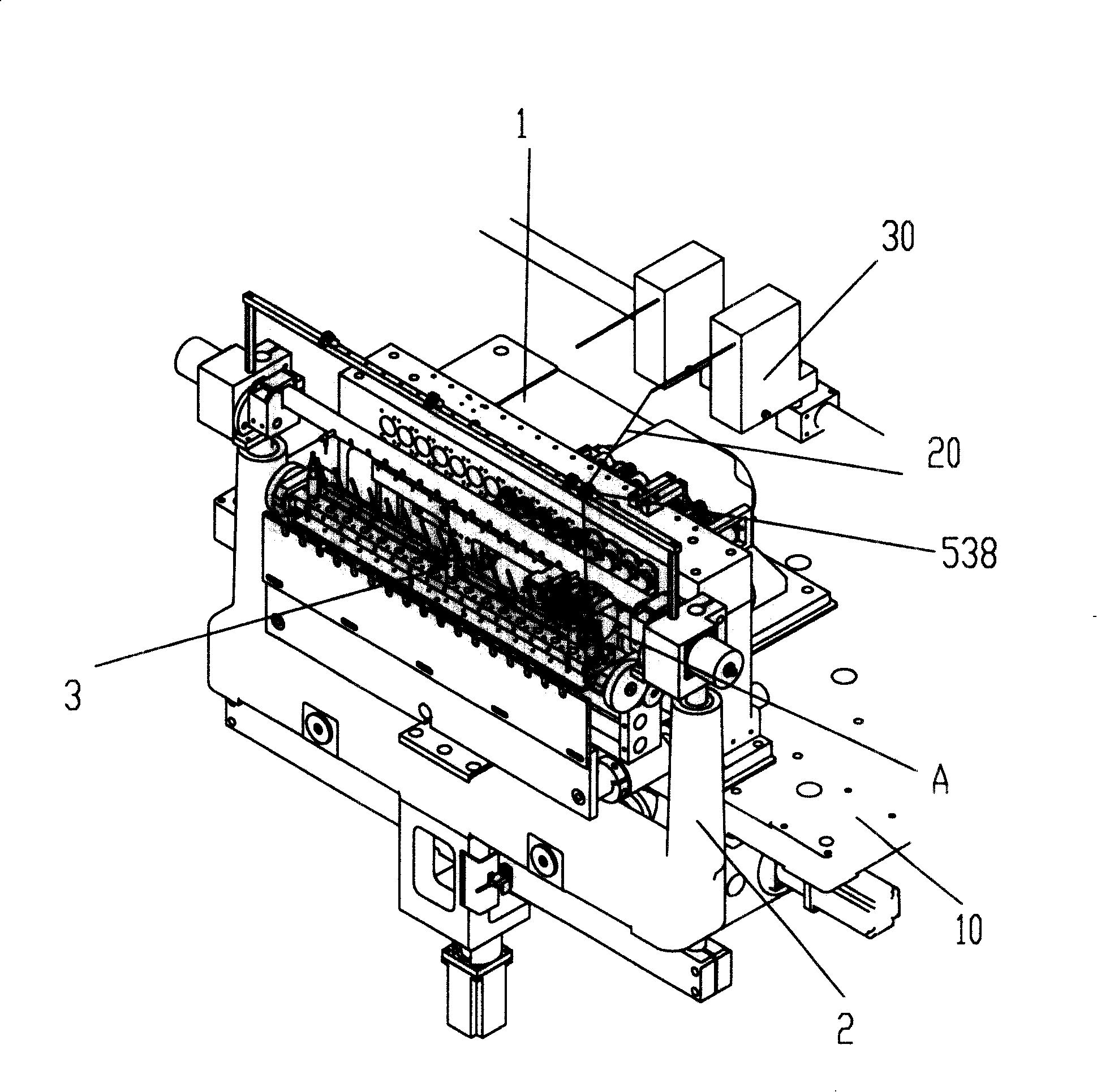

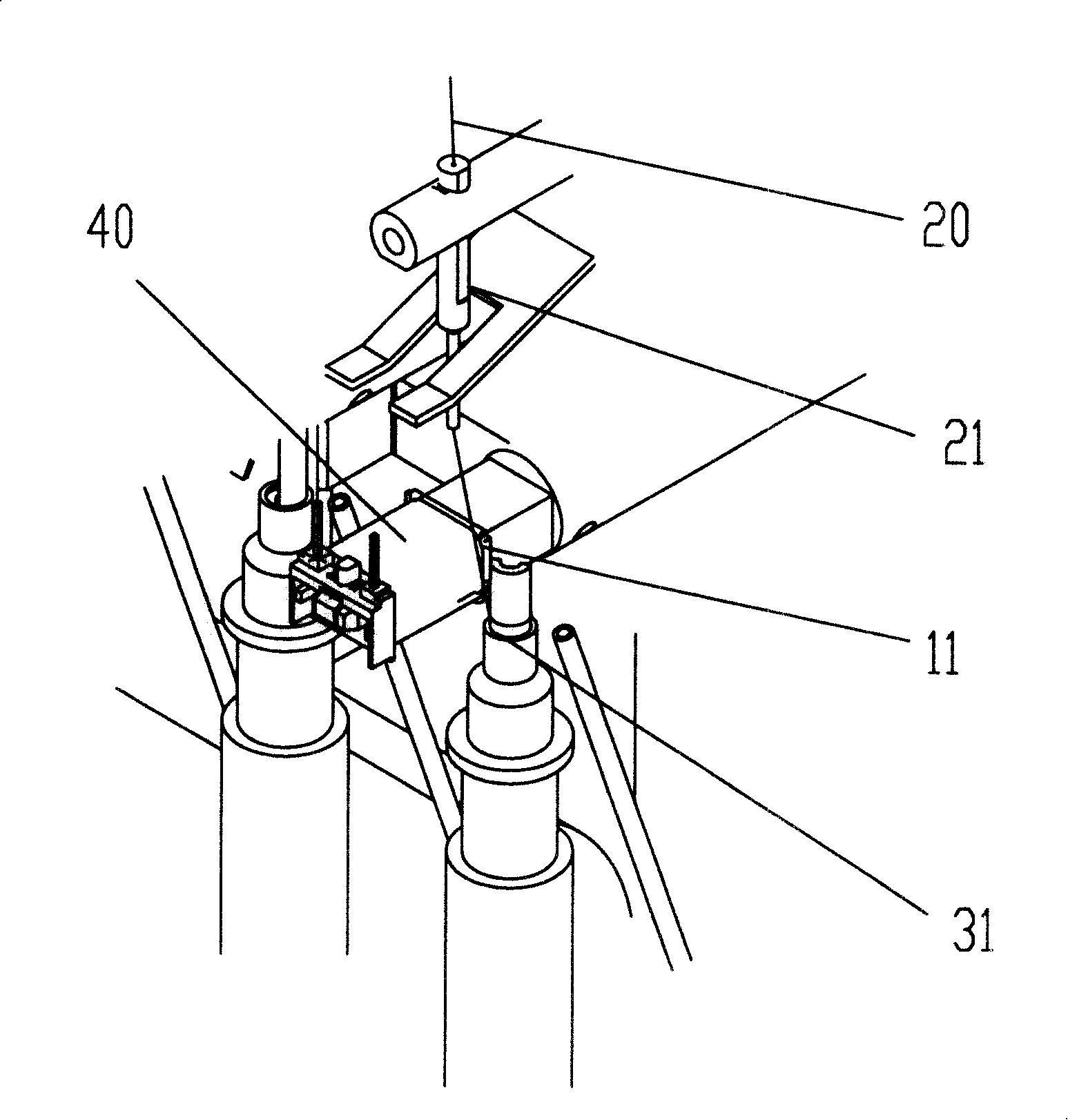

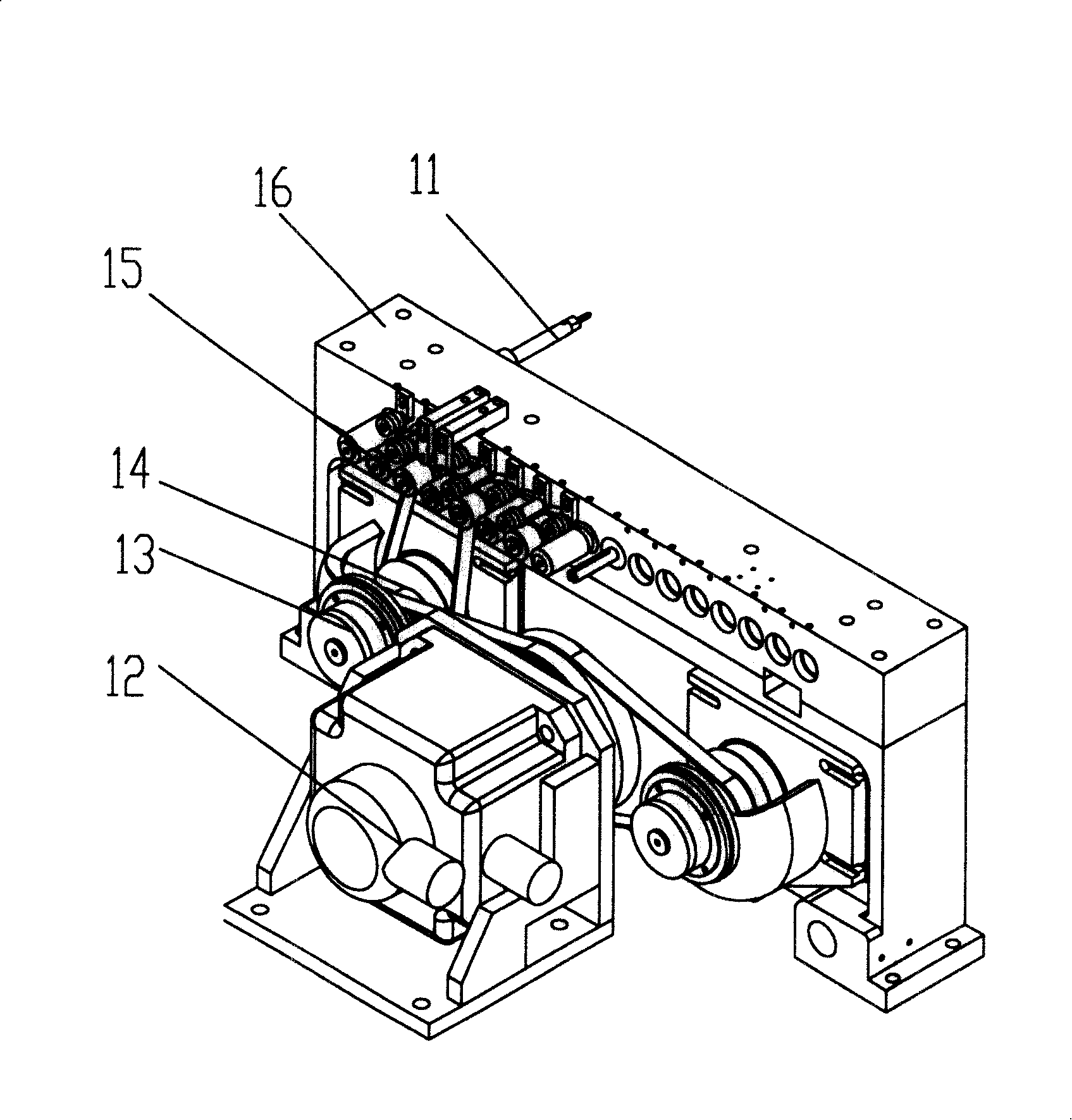

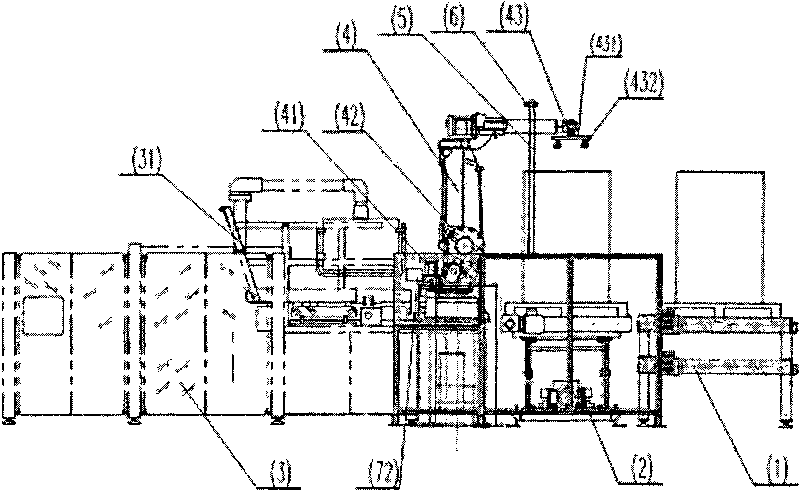

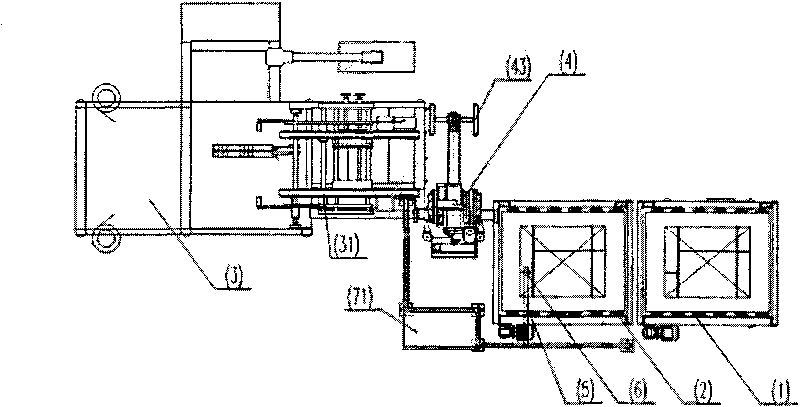

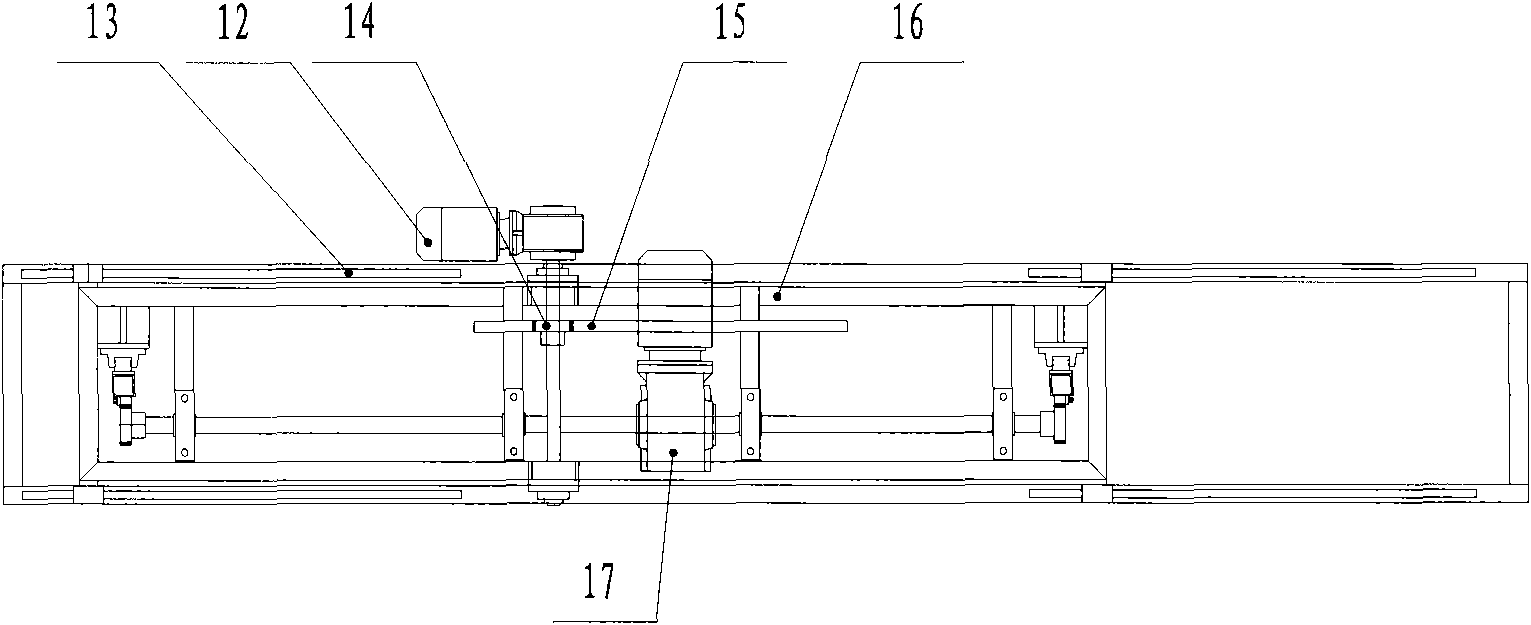

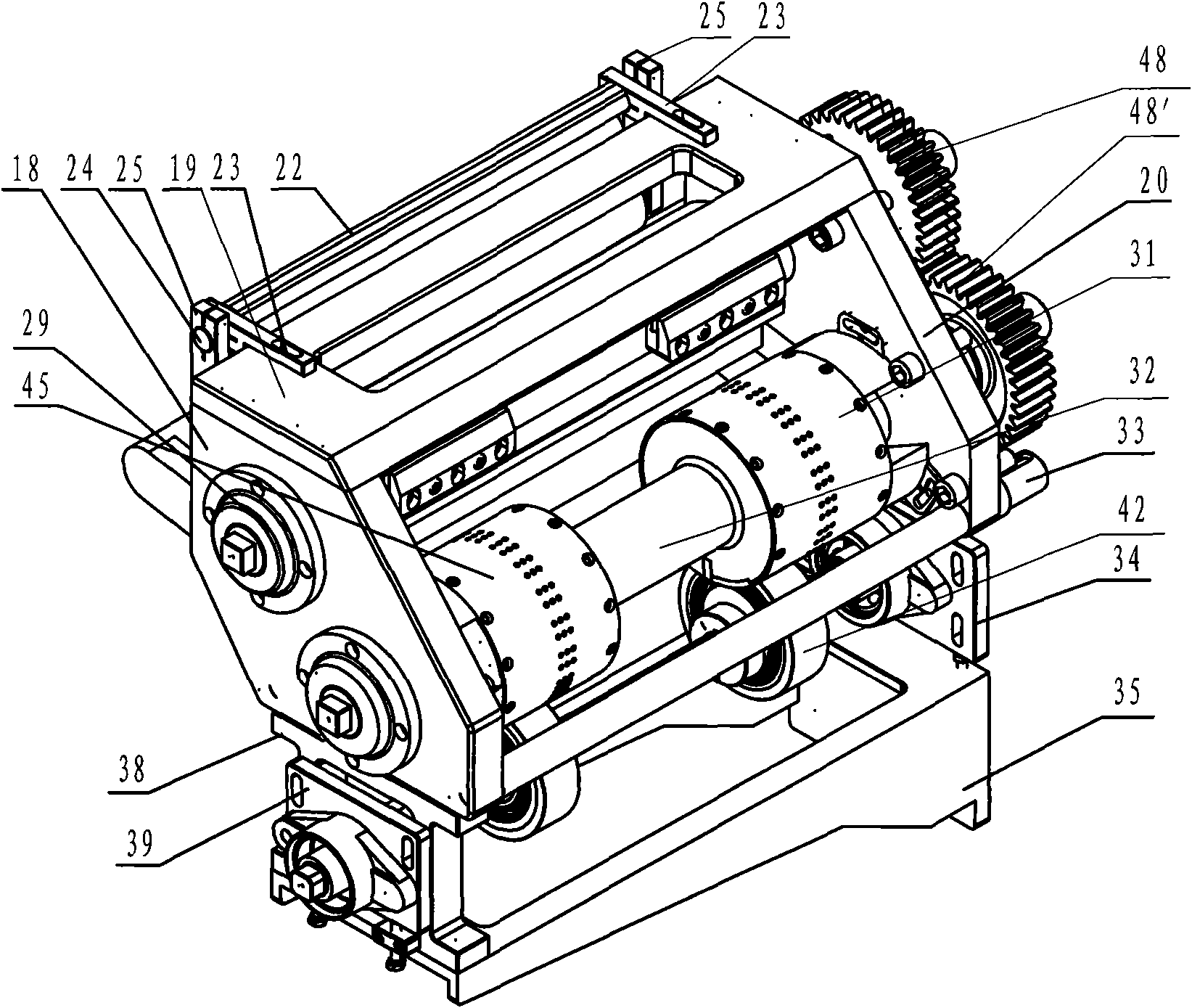

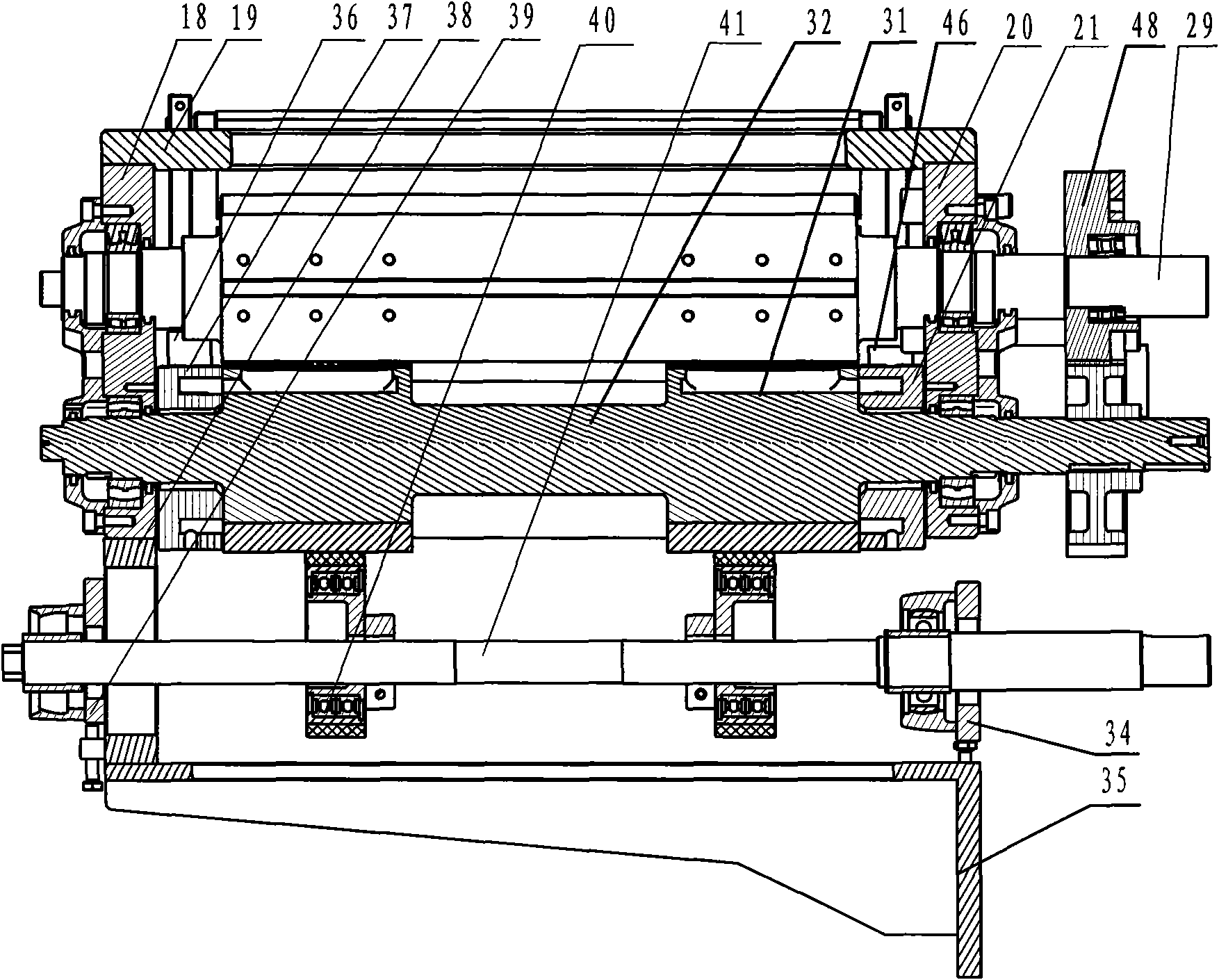

Multiheaded full-automatic wire winder

ActiveCN101211691AImprove motion control response timePrecise positioningCoils manufactureWinding machineElectrical control

The invention discloses a bull full-automatic winding machine, which comprises a main shaft winding mechanism driving a coil frame so as to realize the winding, an automatic line arrangement mechanism for X, Y and Z three axles which can move freely along the transverse, longitudinal and vertical directions so as to realize the winding of the coil frame, a line clamping and cutting mechanism used for realizing clamping the end of the enameled wire at the initiation of the winding and cutting off the outgoing lines of the pins after the pins of the coil frame are wound and an electrical control mechanism used for realizing the control of the main shaft winding mechanism, the automatic line arrangement mechanism for X, Y and Z three axles and the line clamping and cutting mechanism. The invention has the advantages of reasonable structure, high automation degree, extended installation of automatic material loading, material allocating, twisting, flake drip and material unloading systems so as to realize the automation in the entire process, tidy line arrangement, accurate and reliable number of winding rounds, high control accuracy, convenient operation and adjustment, etc.

Owner:XIAMEN HONGFA IND ROBOT CO LTD

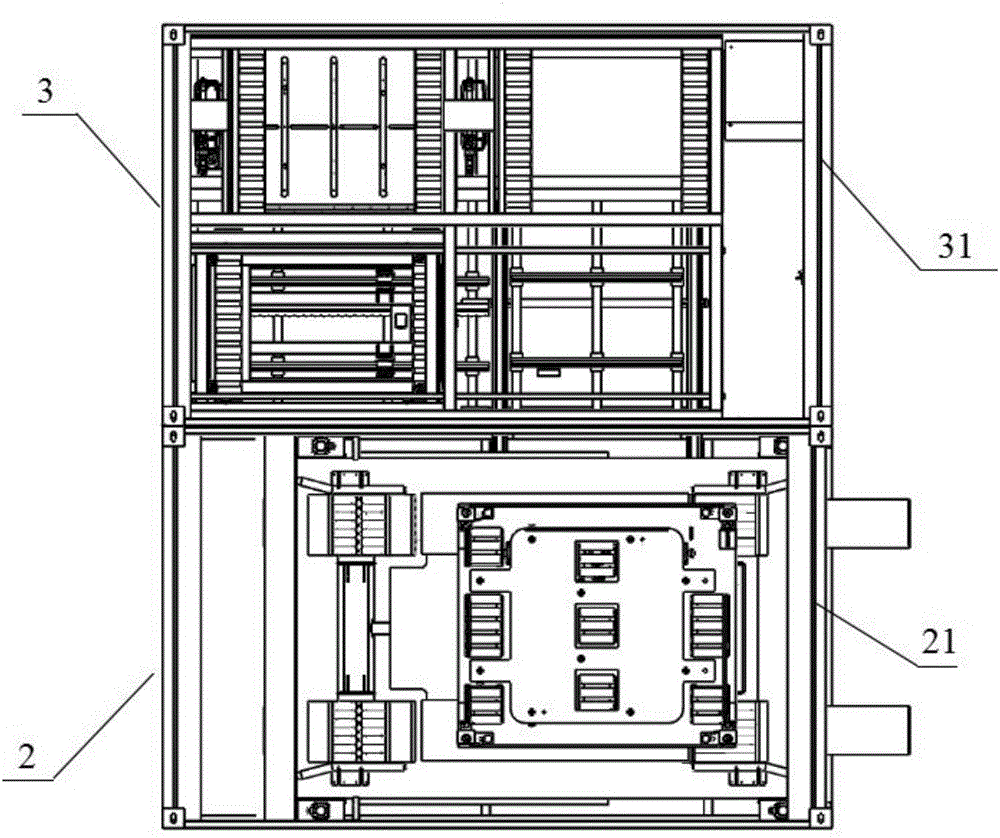

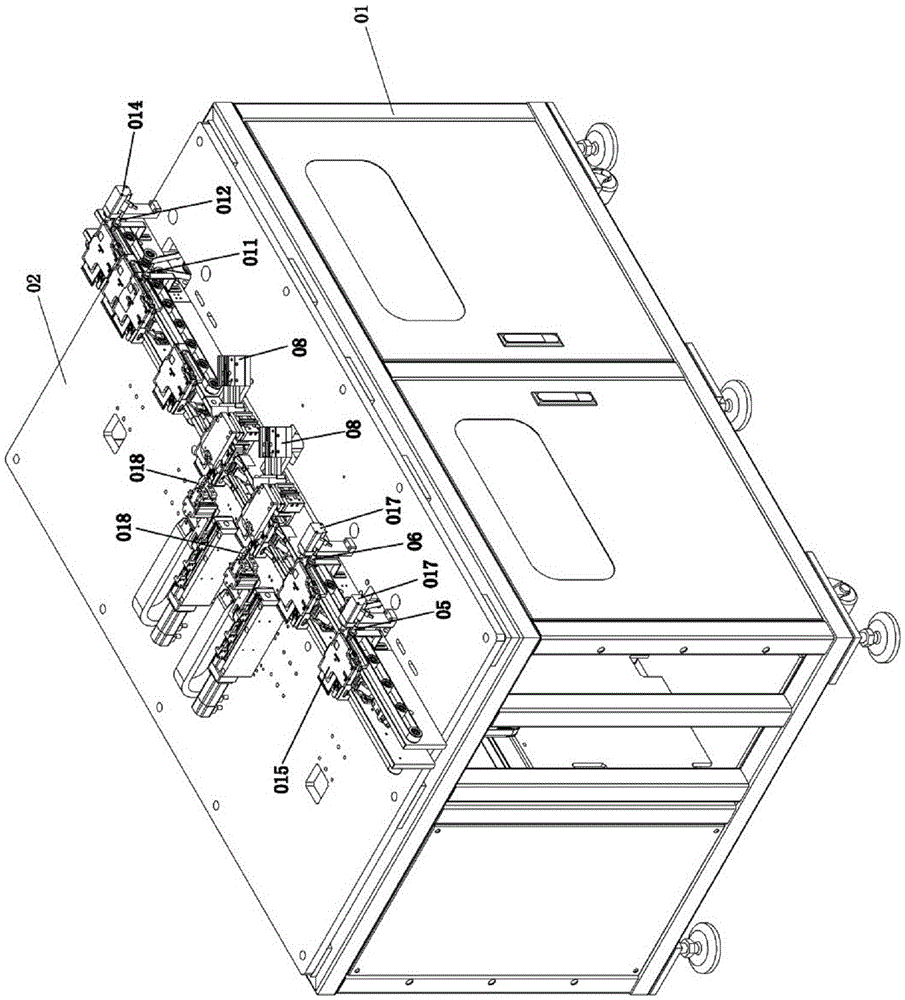

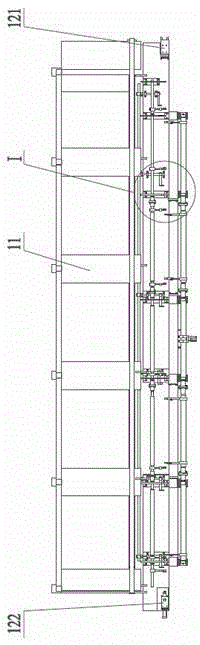

Small-size automatic power exchanging station

InactiveCN106043246ASave internal spaceSmall sizeElectric propulsion mountingVehicle servicing/repairingElectricityControl system

The invention belongs to the field of electric car power distribution and particularly provides a small-size automatic power exchanging station. The small-size automatic power exchanging station aims at solving the problems that an existing power exchanging station is large in land occupation area, civil engineering needs to be conducted, transportation is difficult, and full-automatic power exchanging cannot be conducted. For the purposes, the small-size automatic power exchanging station comprises a battery bin, a power exchanging platform, a power exchanging system and a control system. The battery bin is used for storing a battery and charging the battery. The power exchanging system is used for replacing a battery of an electric car with the battery of the battery bin. The power exchanging platform is used for parking the electric car and lifting the electric car through a lifting device. According to the small-size automatic power exchanging station, the electric car is lifted up through the lifting device, the power exchanging platform and the battery bin are wrapped up through a container at the same time, therefore, any civil engineering does not need to be conducted, the power exchanging station can be overall carried, the position of the power exchanging station can be arranged flexibly, and the size of the power exchanging station can be freely expanded as required.

Owner:NIO NEXTEV LTD

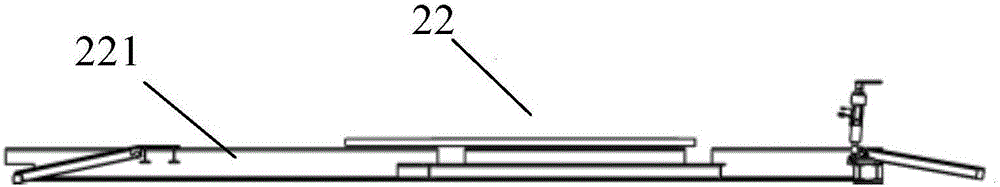

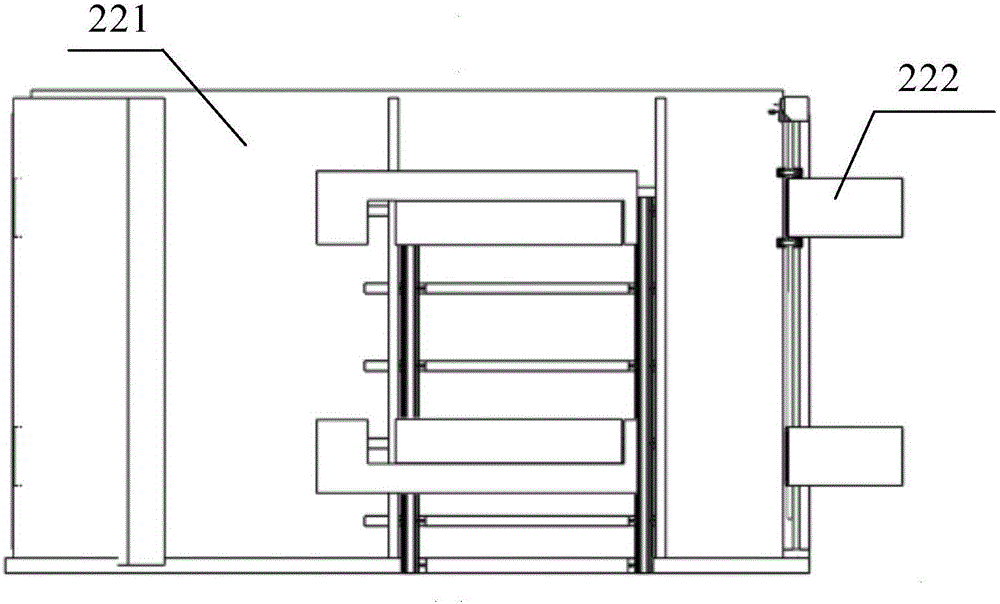

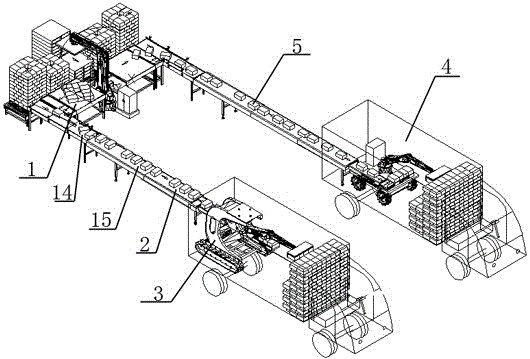

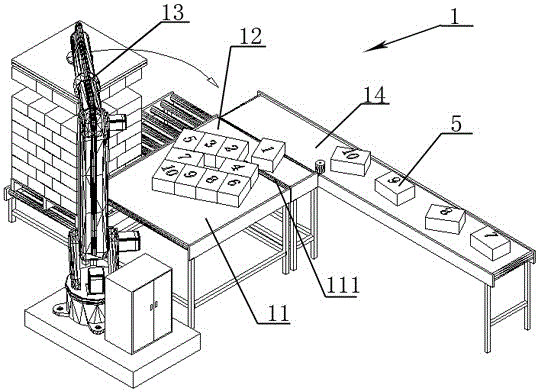

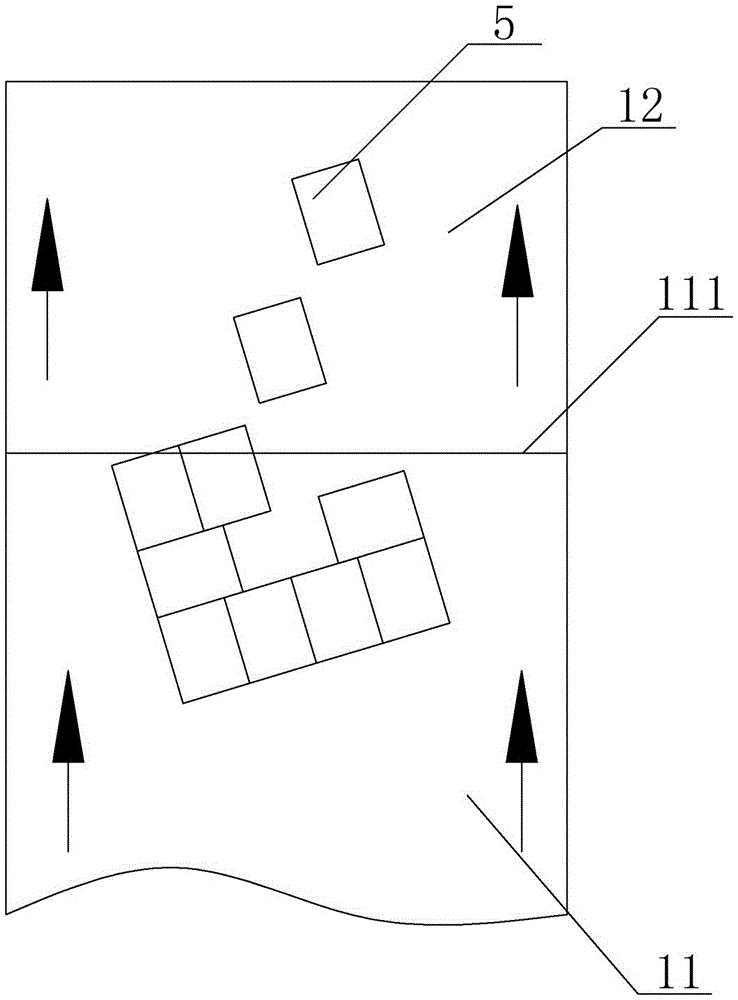

Automatic loading system for articles

ActiveCN105692251AEfficient loadingRealize fully automated operationStacking articlesDe-stacking articlesAutomotive engineeringVision sensor

The invention belongs to the technical field of logistics equipment, and particularly relates to an automatic loading system for articles. The system comprises a destacking device, a stacking robot, a visual system and a general control device. The destacking device comprises a first conveyer belt and a second conveyer belt which are used for successively conveying articles. The destacking device further comprises a first mechanical arm that grasps the articles in a whole layer and puts the articles in the whole layer at a specific angle to the first conveyer belt, wherein the speed of the first conveyer belt is less than that of the second conveyer belt; an article discharging position of the destacking device is connected to the starting end of an extendible conveyer belt; the stacking robot comprises a vehicle body that is connected to the tail end of the extendible conveyer belt; a second mechanical arm is mounted on the vehicle body, and a fixture is mounted at the working end of the second mechanical arm; the visual system comprises a visual sensor for measuring the position of the stacking robot in a compartment and an operational assembly for analyzing position data; the visual sensor is electrically connected to the operational assembly; and the destacking device, the stacking robot and the visual system are electrically connected to the general control device.

Owner:GUAGNZHOU SYL AUTOMATIC CONTROL TECH CO LTD

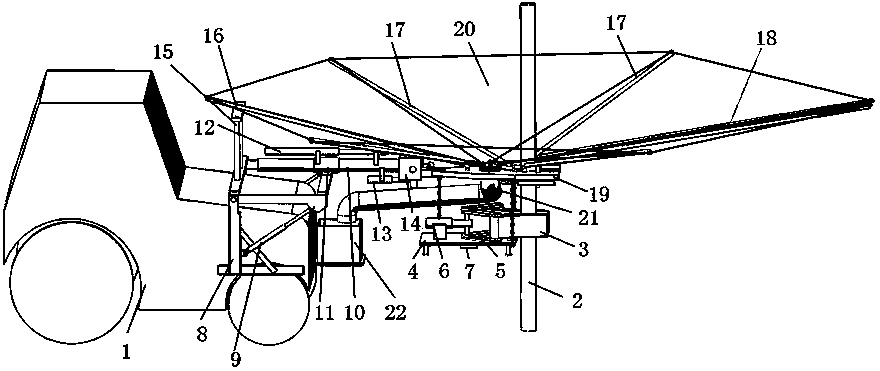

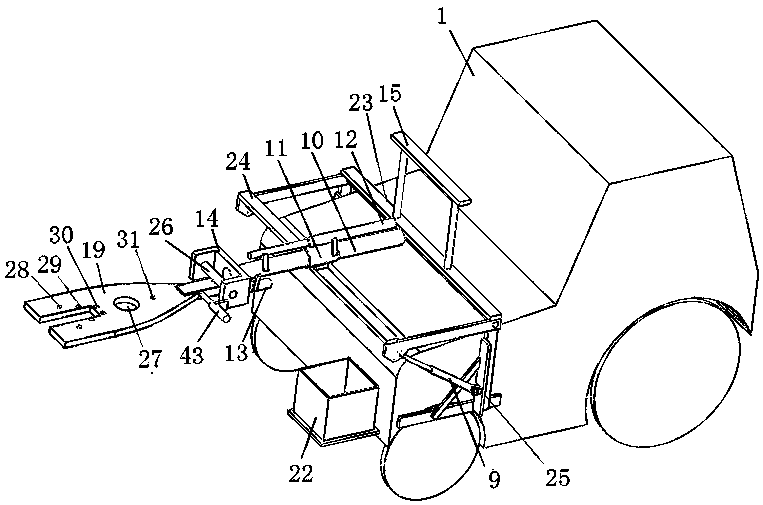

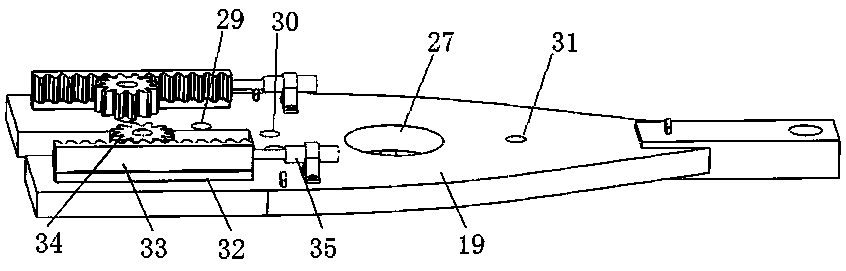

Fruit tree harvesting device

ActiveCN108040607ARealize fully automated operationImprove recovery efficiencyPicking devicesFruit treeEngineering

The invention discloses a fruit tree harvesting device which comprises a clamping and vibrating device, a supporting and adjusting device, an automatic folding / unfolding collecting umbrella, a fruit collecting device and a tractor. The clamping and vibrating device is hung on the supporting and adjusting device through a chain. The supporting and adjusting device is installed on the front side ofthe tractor. The automatic folding / unfolding collecting umbrella is installed on the supporting and adjusting device. The fruit collecting device is fixed to the front side of the tractor, and one endof the fruit collecting device is connected with the supporting and adjusting device. The fruit tree harvesting device can be used for harvesting fruits such as dry fruits, red dates, cherries, apples for juice and citruses and is wide in application range, the full-automatic work of the harvesting process is achieved, and the harvesting efficiency is greatly improved.

Owner:YANGZHOU UNIV

Automatic box feeding machine

ActiveCN101492104ARealize fully automated operationSolve the problems of high labor intensity and low work efficiencyOverturning articlesPackagingCartonFully automatic

The invention provides an automatic box feeding machine, which comprises a machine frame provided with a box inlet and a box outlet. The automatic box feeding machine is characterized in that the machine frame is provided with a lifting device which is connected with the box inlet; and the upper side of the lifting device is provided with a moving and rotating device, and the lower side of the moving and rotating device on one side of the lifting device is provided with a paper box aligning and stacking device which is connected with the box outlet. The automatic box feeding machine can completely achieve automatic box feeding, and overcome the defects of high labor intensity, low work efficiency, and the like, brought by feeding boxes by workers in the prior art. The automatic box feeding machine has the advantages of compact structure, reasonable layout and accurate and quick automatic box feeding, and does not occupy more production spaces. Proper automatic box feeding machine models can be selected according to different box sealing machine layouts of the prior art, so that the automatic box feeding machine also has the advantages of wide application range, convenient installation and investment conversation, and can provide guarantee for cigarette packing to achieve fully-automatic operation.

Owner:东方机器制造(昆明)有限公司

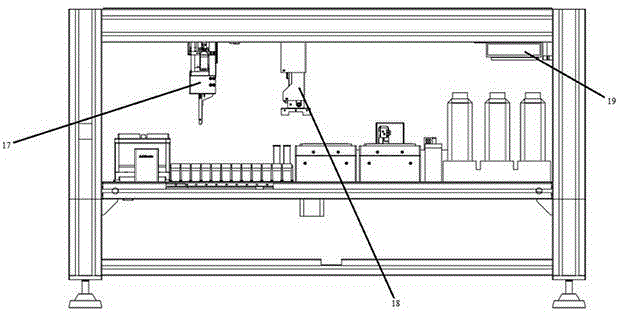

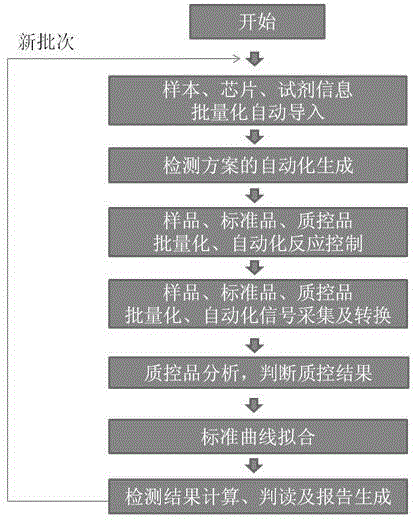

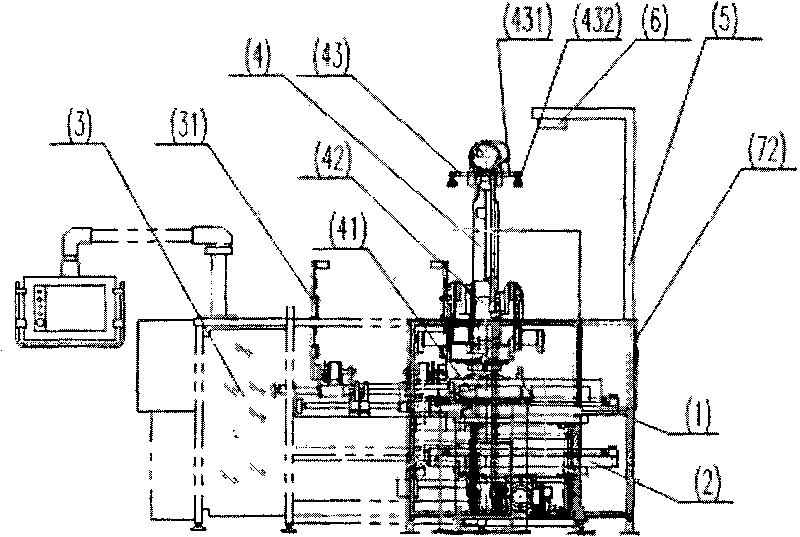

Protein chip fully-automated high-throughput analysis method and protein chip fully-automated high-throughput analysis apparatus

ActiveCN105277726AThe test result is accurateRealize fully automated operationBiological testingComputer hardwareRobotic arm

The present invention discloses a protein chip fully-automated high-throughput analysis apparatus, which comprises a control host machine, a display electrically connected to the control host machine, and a fully-automatic protein chip workstation, wherein the table surface of the fully-automatic protein chip workstation is provided with a sample treatment, a reagent treatment system, a plate washing system and a signal acquisition system, a free mechanical arm and a liquid adding system are added above the table surface of the work station, and the sample treatment system comprises a suction head support frame, a sample support frame, a reagent support frame and a barcode scanner. With the protein chip analysis apparatus of the present invention, the simultaneous detection on the multiple samples, the standard substance and the quality control substance can be achieved, the calculation on the concentration of the current batch of the samples through the current batch of the standard substance and the quality control substance is achieved, and the detection result is accurate and stable; and the multiple samples share the one standard substance or quality control substance so as to achieve the agent saving effect.

Owner:RAYBIOTECH INC GUANGZHOU

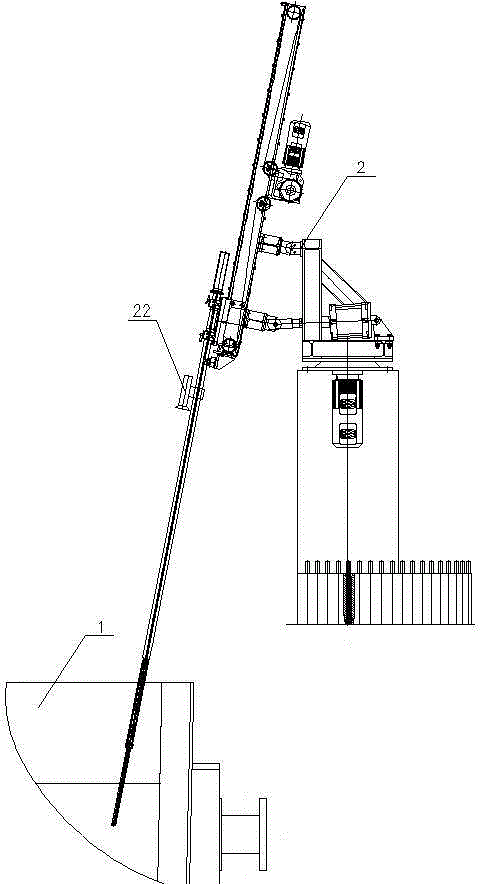

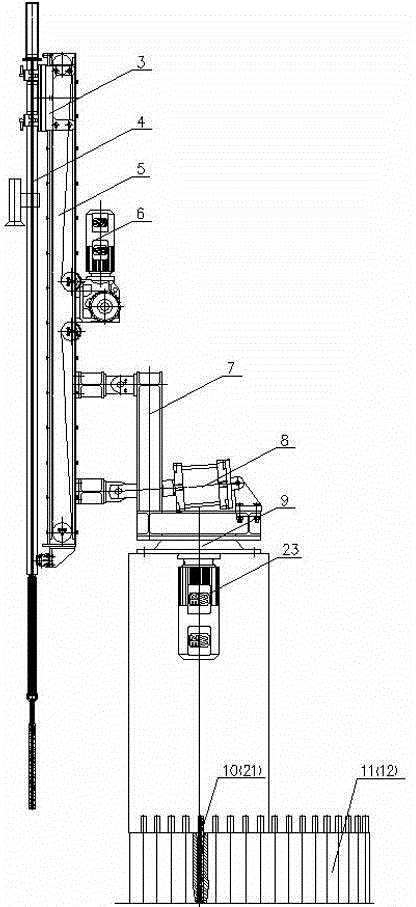

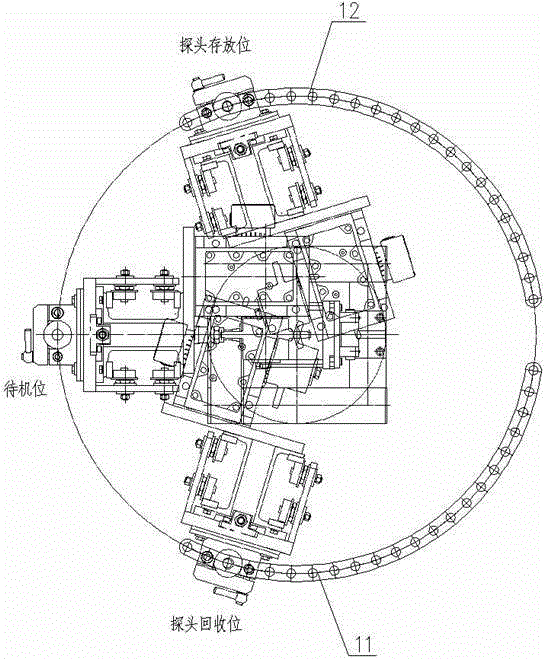

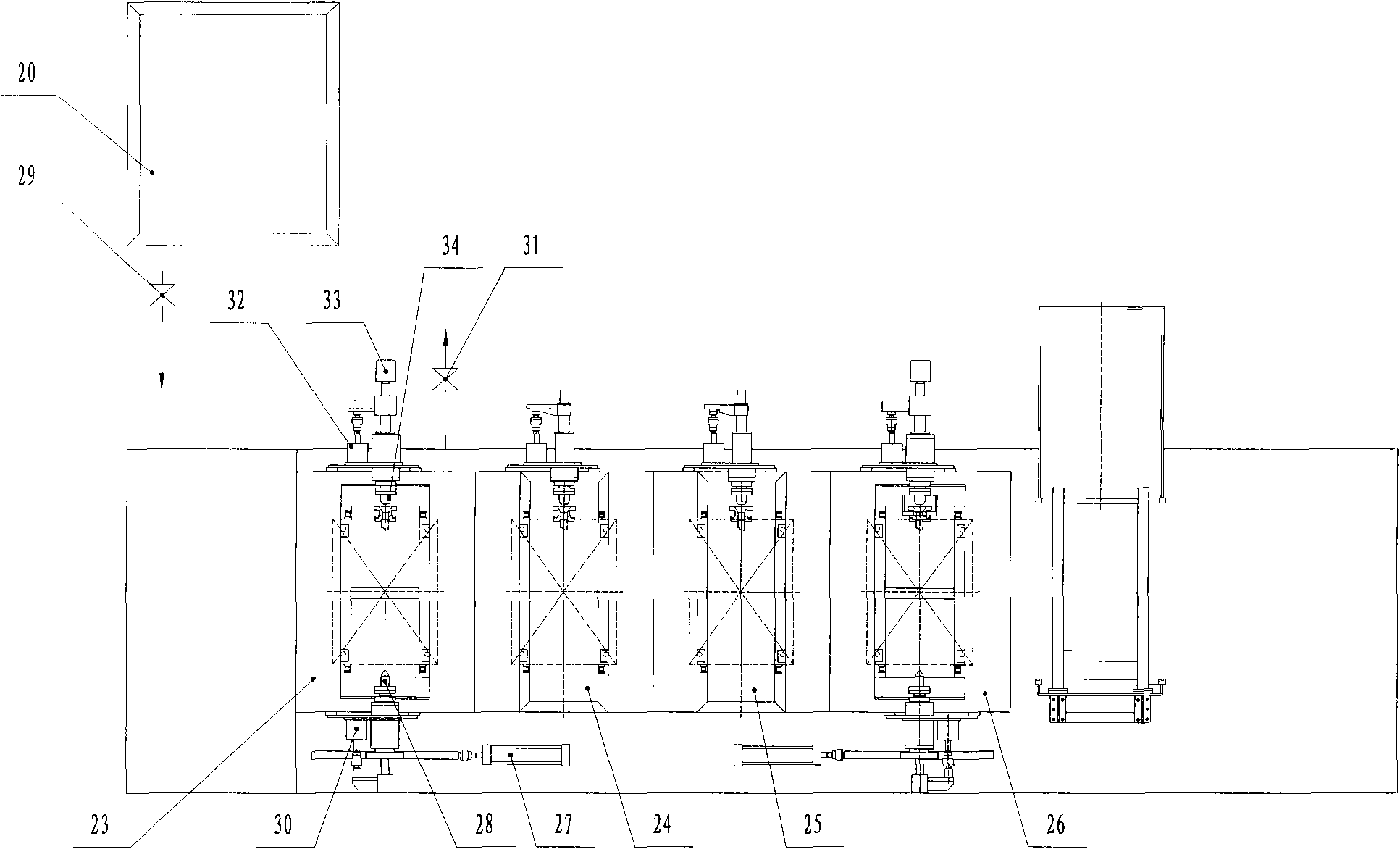

Fully-automatic molten steel temperature measurement and sampling device

ActiveCN104697813ARealize fully automated operationAvoid manual interventionWithdrawing sample devicesThermometer applicationsEngineeringLaser rangefinder

The invention relates to a fully-automatic molten steel temperature measurement and sampling device which comprises a rotating base, a gun rack, a trolley, a gun body, a first motor, a second motor, a laser range finder, storage warehouses, recycling warehouses and a control panel. The trolley is arranged on the gun rack. The first motor is connected with the trolley through a transmission mechanism. The gun rack is connected with the rotating base through a swing mechanism, and the second motor is connected with the rotating base. The gun body is fixed to the trolley and provided with a telescopic gun head. The gun head can be matched with probes. The laser range finder is fixed to the gun body. The storage warehouses and the recycling warehouses are provided with a plurality of storage positions for storing new probes and a plurality of recycling positions for recycling old probes respectively, and the storage positions and the recycling positions are arranged near the rotating base. The first motor, the second motor and the laser range finder are connected with the control panel. The fully-automatic molten steel temperature measurement and sampling device is capable of conducting probe disassembling and assembling automatically and accurately controlling the inserted depth, high in automation degree, high in accuracy, safe to operate and good in working environment.

Owner:WISDRI ENG & RES INC LTD

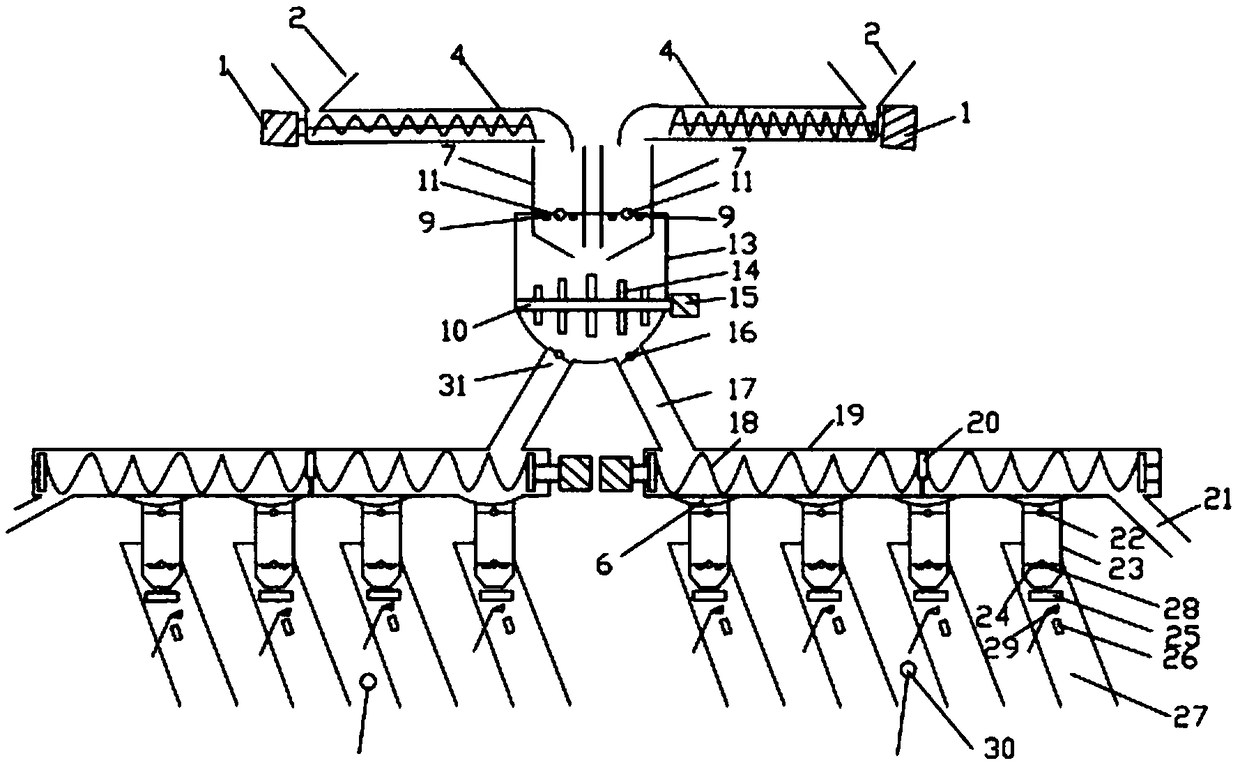

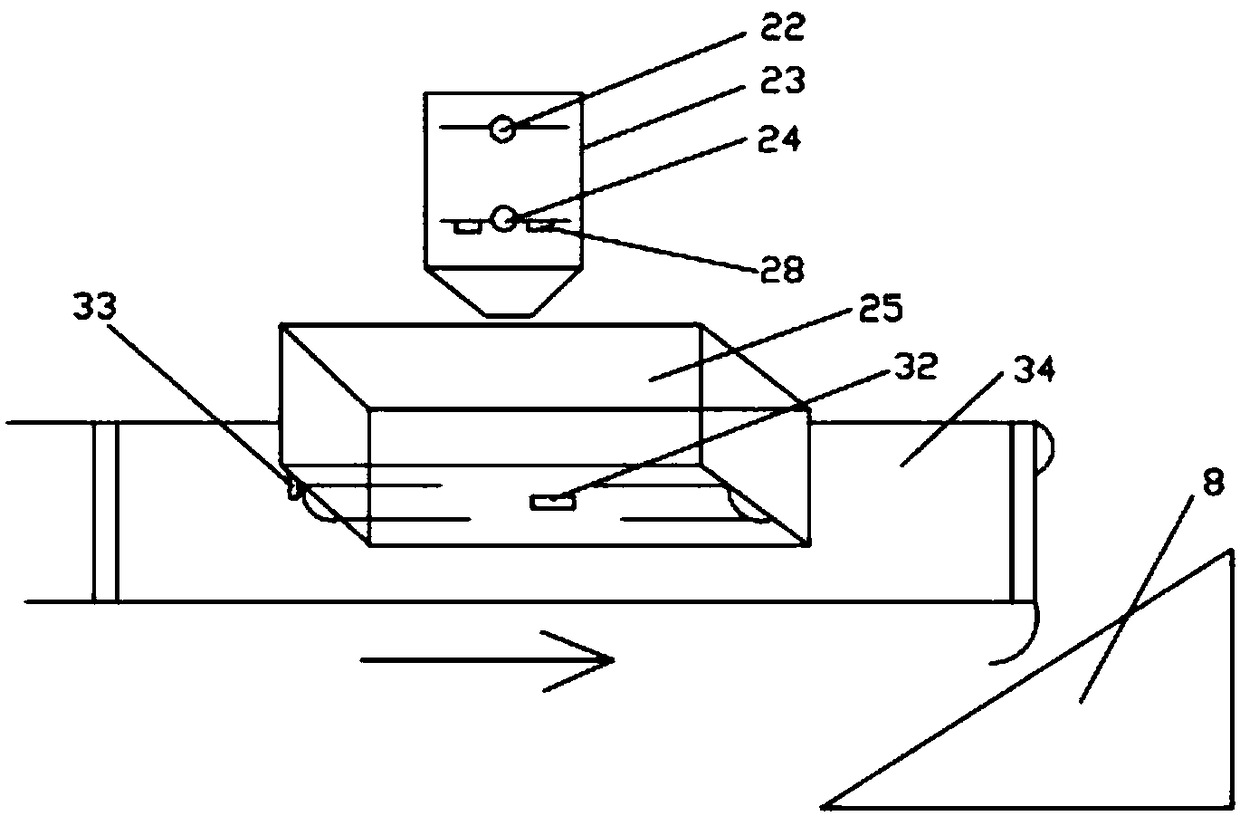

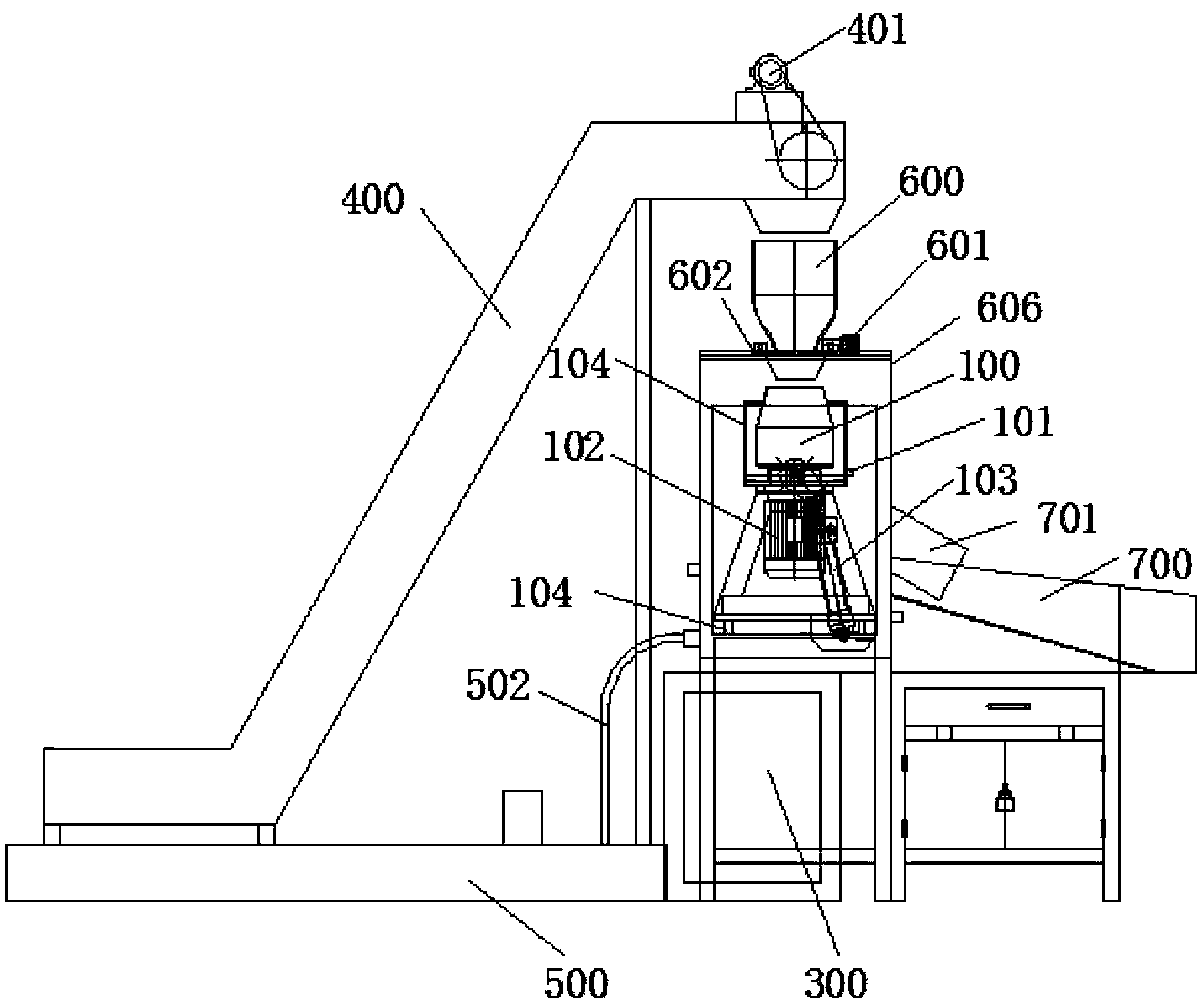

Fine feeding system for pig farm

PendingCN108377924AEfficient recyclingAvoid pollutionAnimal feeding devicesOther apparatusPig farmsEngineering

The invention discloses a fine feeding system for a pig farm. The fine feeding system comprises feed inlet devices, a weighing device, a mixing tank and a distributing device. Input ends of the inletdevices are connected with an input end of the weighing device, an output end of the weighing device is connected with an input end of the mixing tank, an output end of the mixing tank is connected with an input end of the distributing device, and feed can be distributed into feeding troughs in pig raising pigsties by the distributing device via distributing openings of the distributing device. The fine feeding system has the advantages that feed formula proportions can be finely regulated by the aid of the fine feeding system, and feed components can be finely uniformly mixed with one anotherby the fine feeding system; one-time food intake can be set by the aid of RFID (radiofrequency identification) scanning technologies according to individual live pig conditions of live pigs, the one-time feed demand of each single live pig individual can be adjusted in real time, accordingly, refined live pig individual feeding requirements can be met, conditions such as the weights of the live pigs, eating states and epidemic situations can be monitored in real time, and reliable bases can be provided to refined feed feeding; residual feed can be effectively recycled, accordingly, the cost can be saved, and feed contamination can be prevented.

Owner:HUNAN AGRICULTURAL UNIV

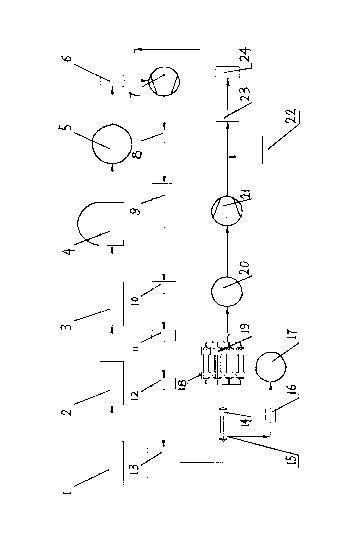

Methane purification system and methane purification technology thereof

InactiveCN103232871AHigh purification rateEfficient removalGaseous fuelsProcess engineeringOil water

The invention discloses a methane purification system and a methane purification technology thereof, solving problems of high investment cost, high operation cost, high fault rate and low purification purity of a conventional system. The system comprises an anaerobic tank (1), a particle filter (2), a drying tower (3), a desulfurizing tower (4), a gasometer (5), a steam-water separation device (6), a low-pressure methane compressor (7), an interception type prefilter (8), a refrigeration drying machine (9), an agglomeration type filter (10), an oil-water separation filter (11), a precise ultimate filter (12), a heater (13), a first CO2 / CH4 efficient separation membrane (14), a second CO2 / CH4 efficient separation membrane (19) and a methane storage tank (20), wherein a methane-enrichment port (15) of the first CO2 / CH4 efficient separation membrane (14) is communicated with a carbon dioxide purification device (16), and a carbon dioxide storage tank (17) is connected with the carbon dioxide purification device (16). The purification technology has high purification rate; and the whole set of technology can realize full-automatic operation.

Owner:SHANXI FENXI ELECTROMECHANICAL

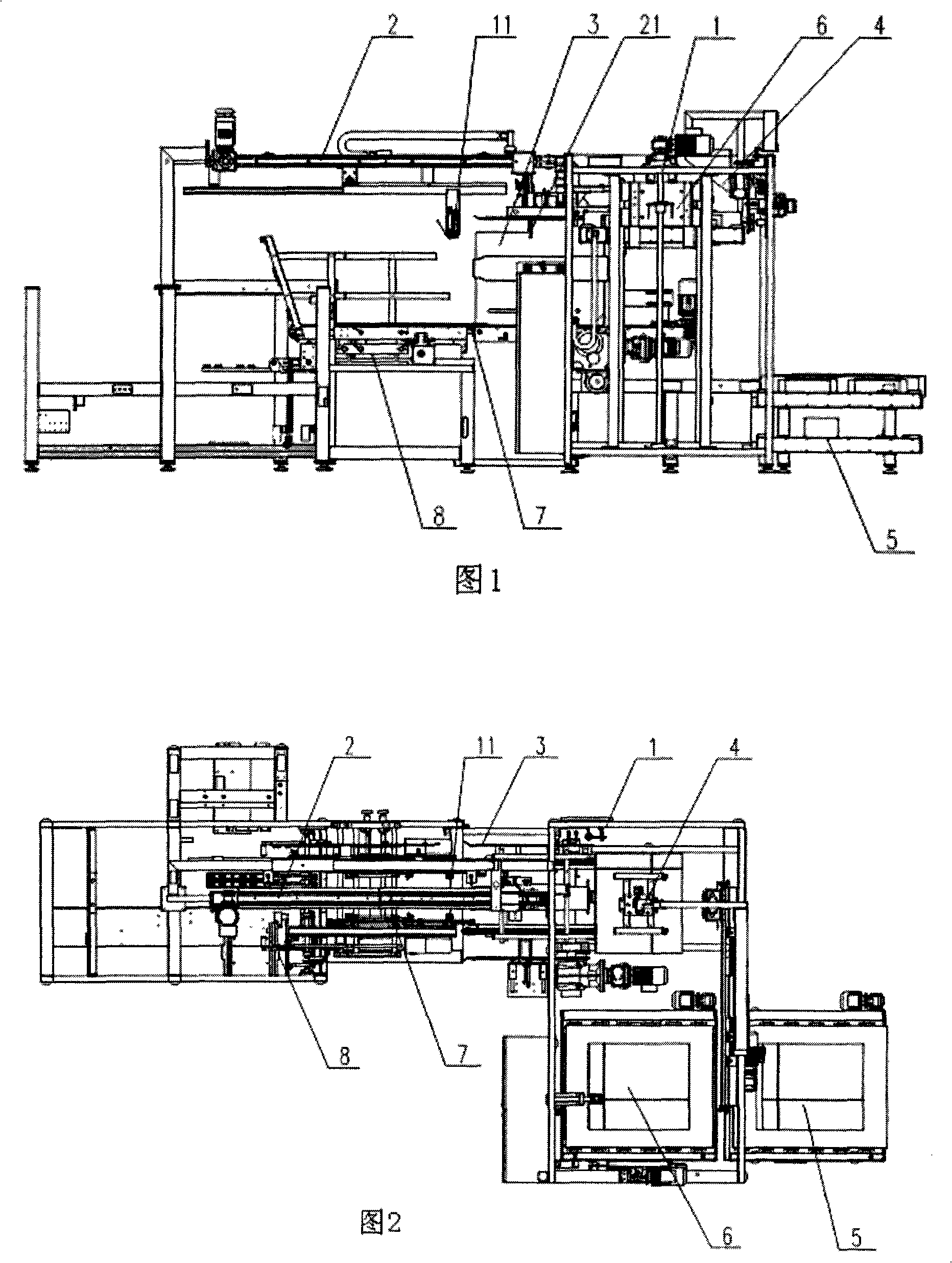

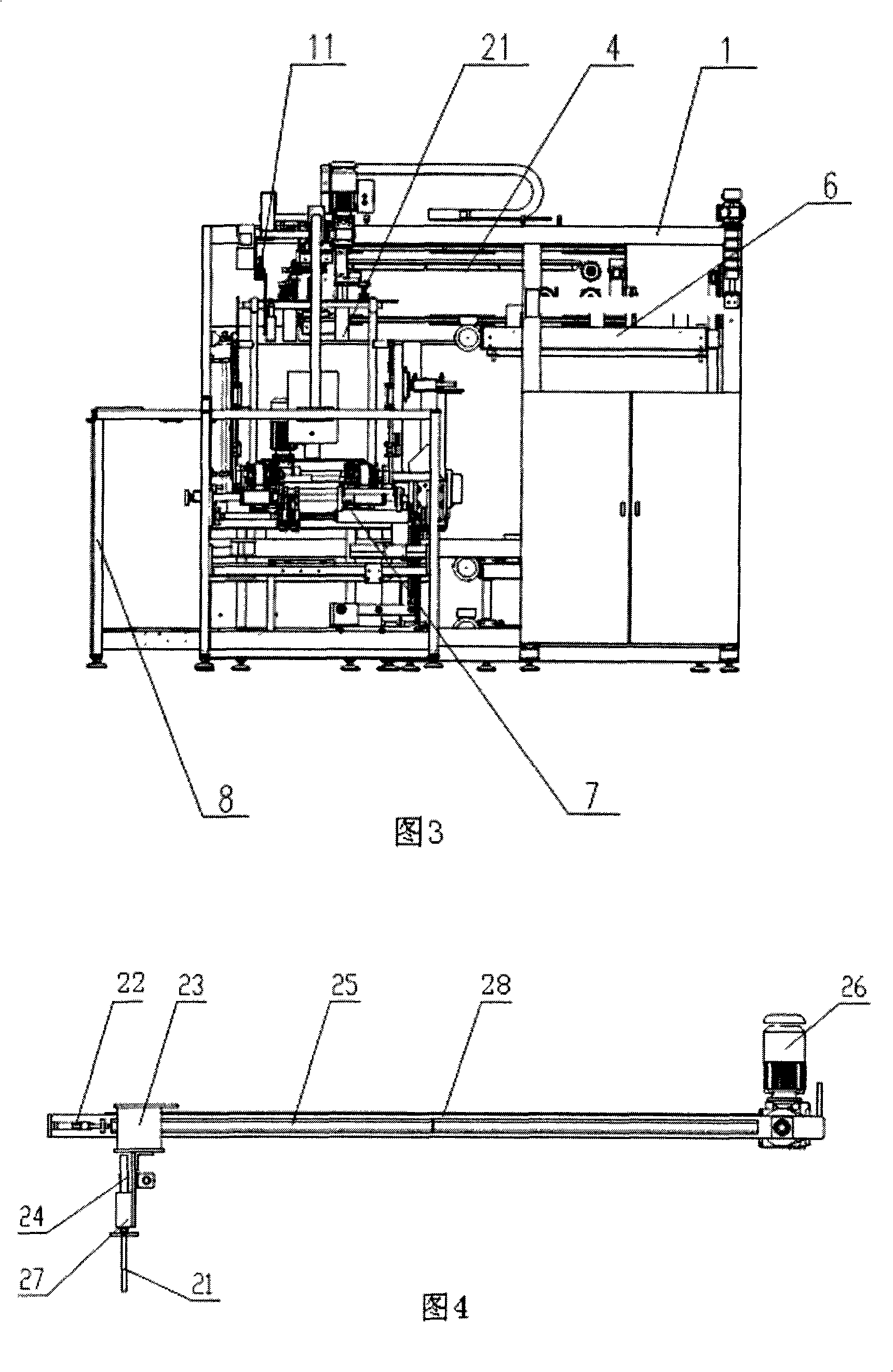

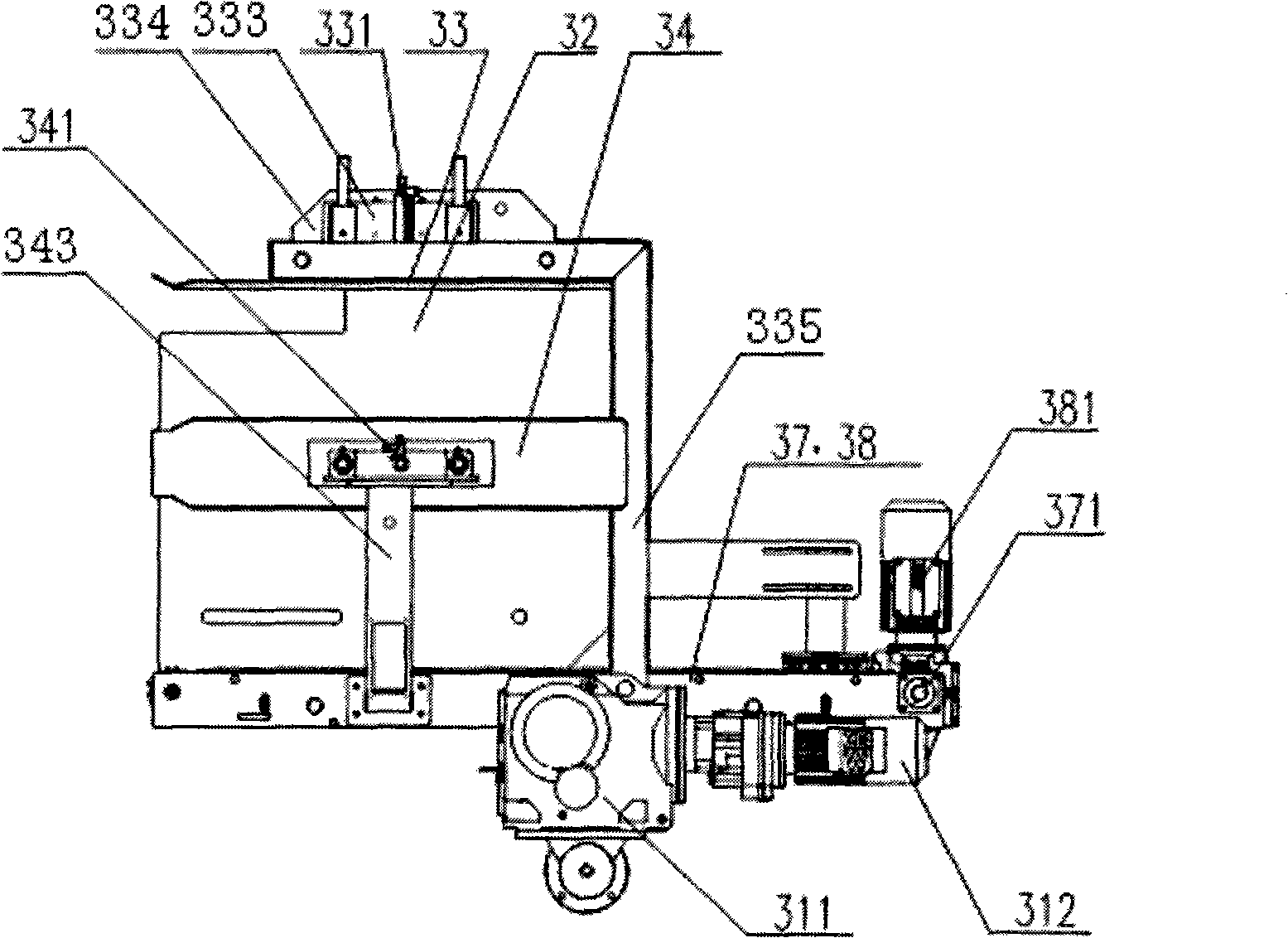

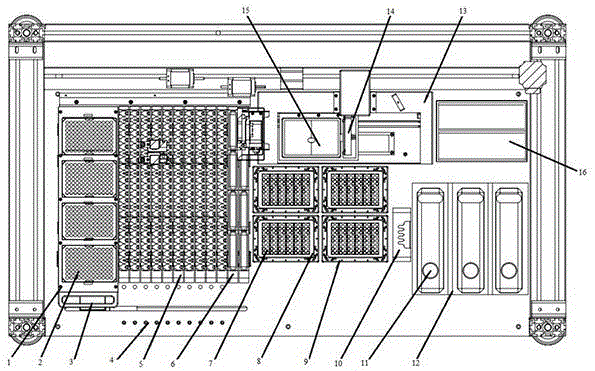

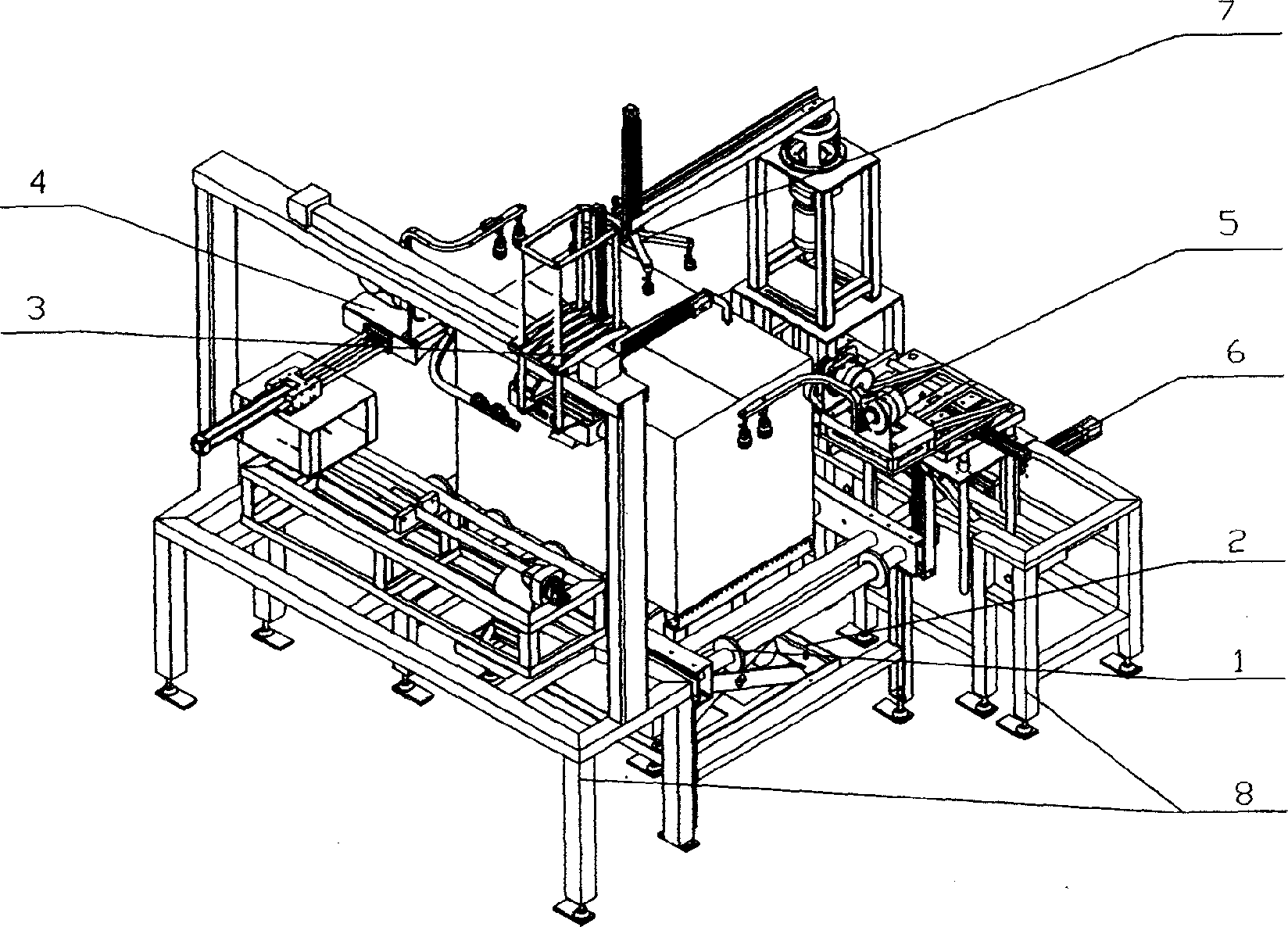

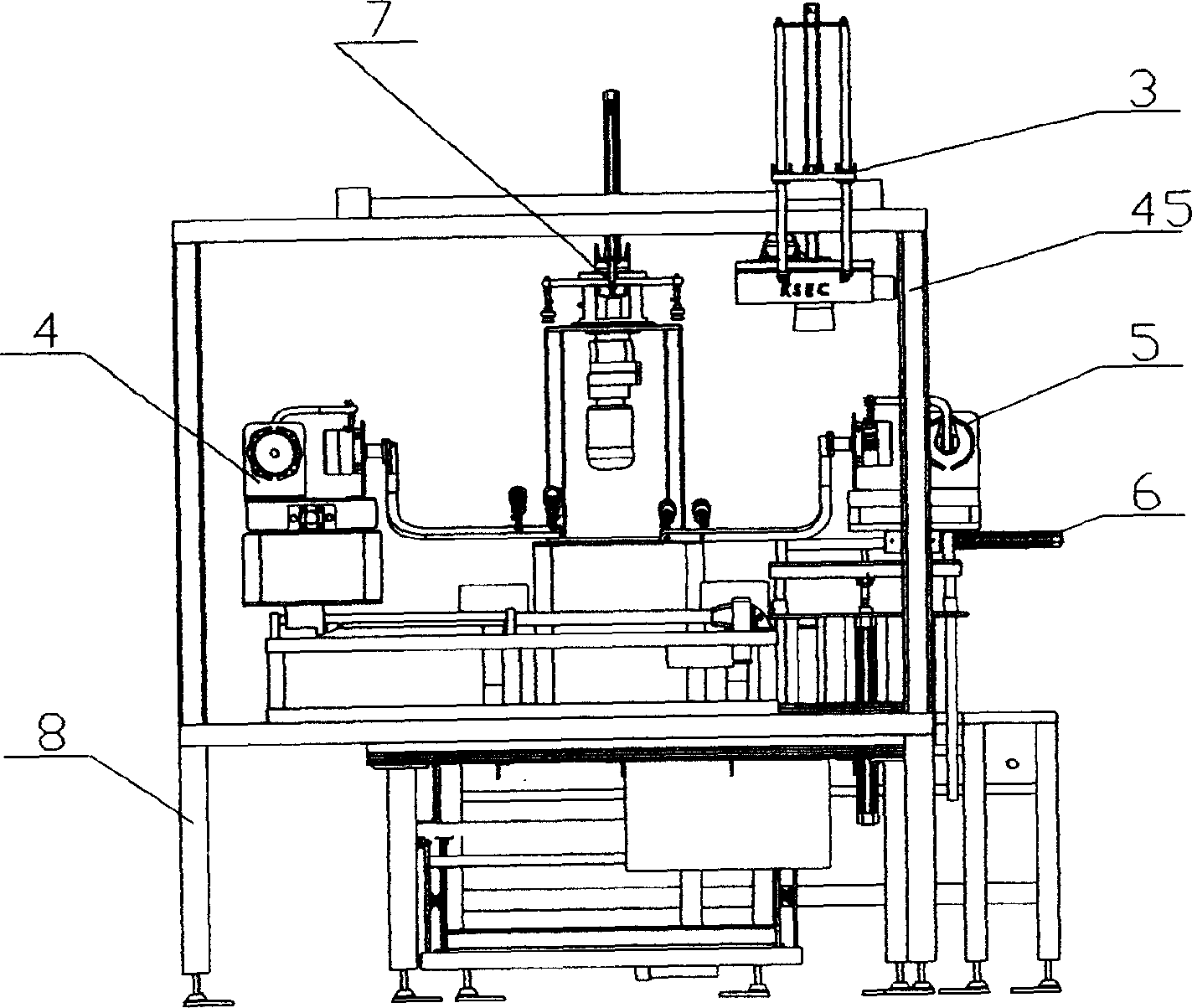

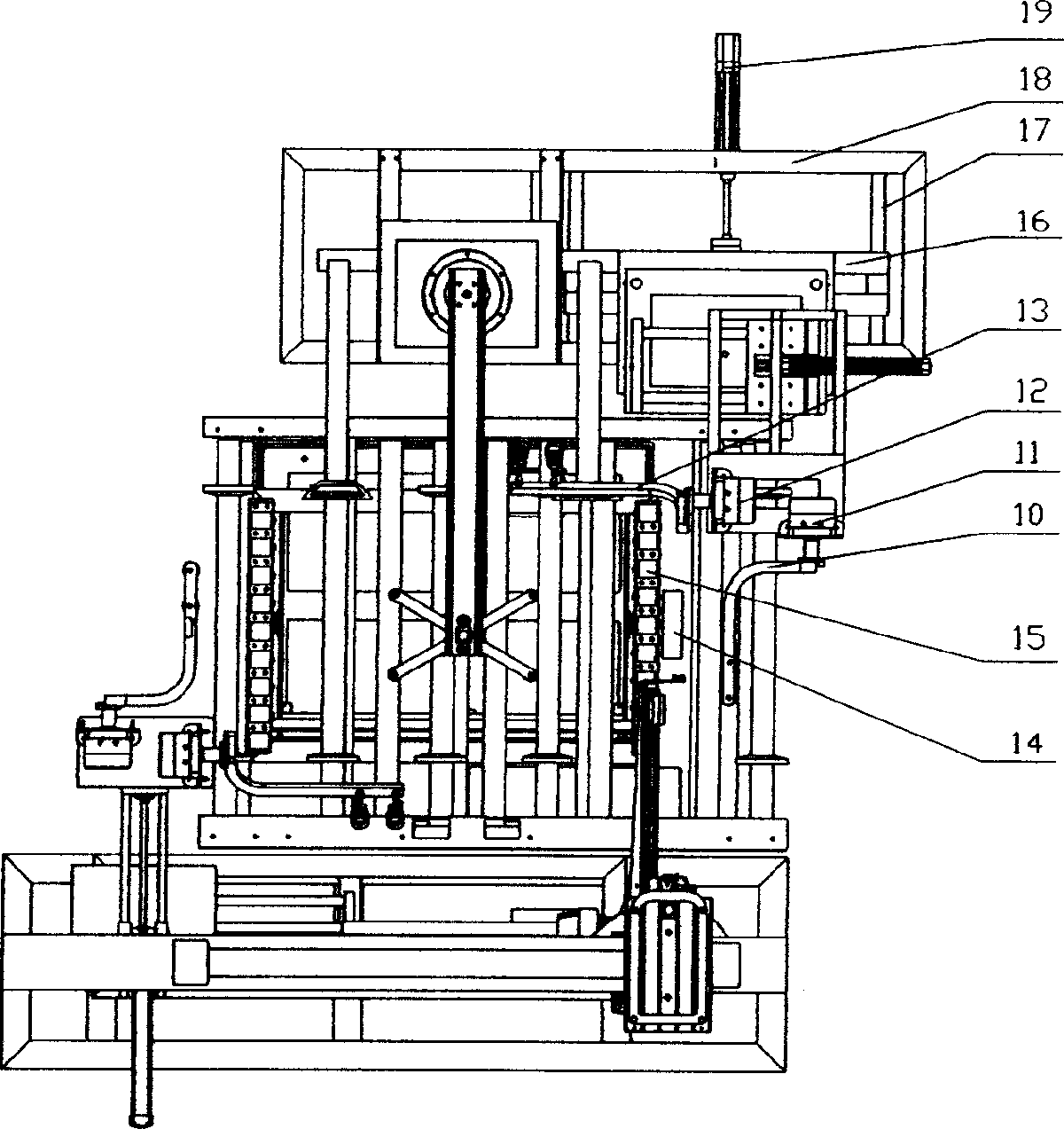

Full automatic opening method and device for paper box

ActiveCN1616305AProcess arrangement is reasonableImprove work efficiencyArticle unpackingCartonPulp and paper industry

The automatic paper box opening process includes the following steps: detecting, dismantling and recovering packing belt on the paper box; and turning the cover. The device used in the said process includes paper box package dismantling and recovering unit, front cover turning unit and back cover turning unit set along the paper box conveying line. The present invention can complete the number detection, locating, shearing and fast recovering of packing belt on the surface of paper box, the turning of paper box cover and removing the upper lining inside the paper box automatically and successively, is suitable for paper boxes of different sizes and has high work efficiency.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

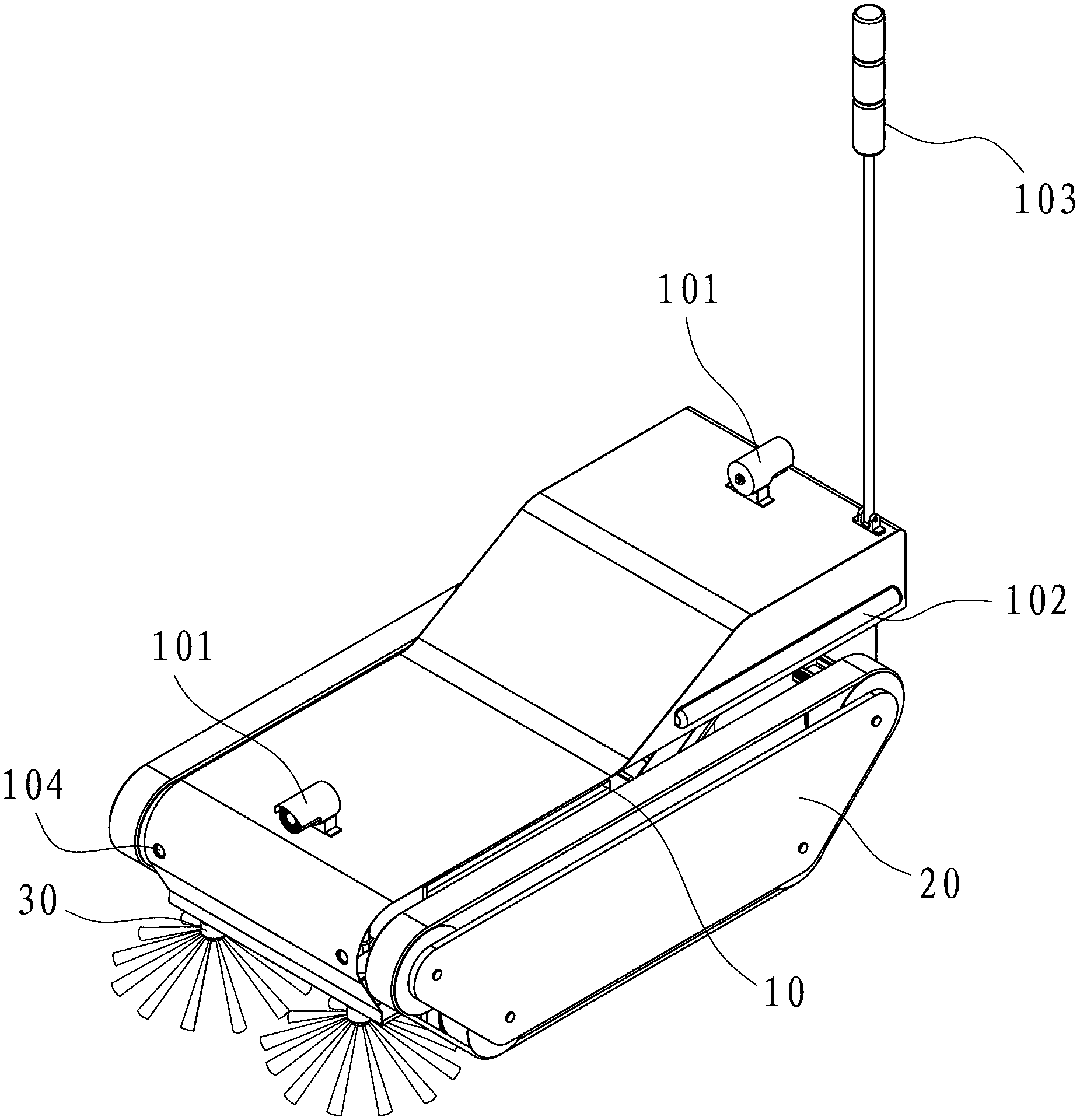

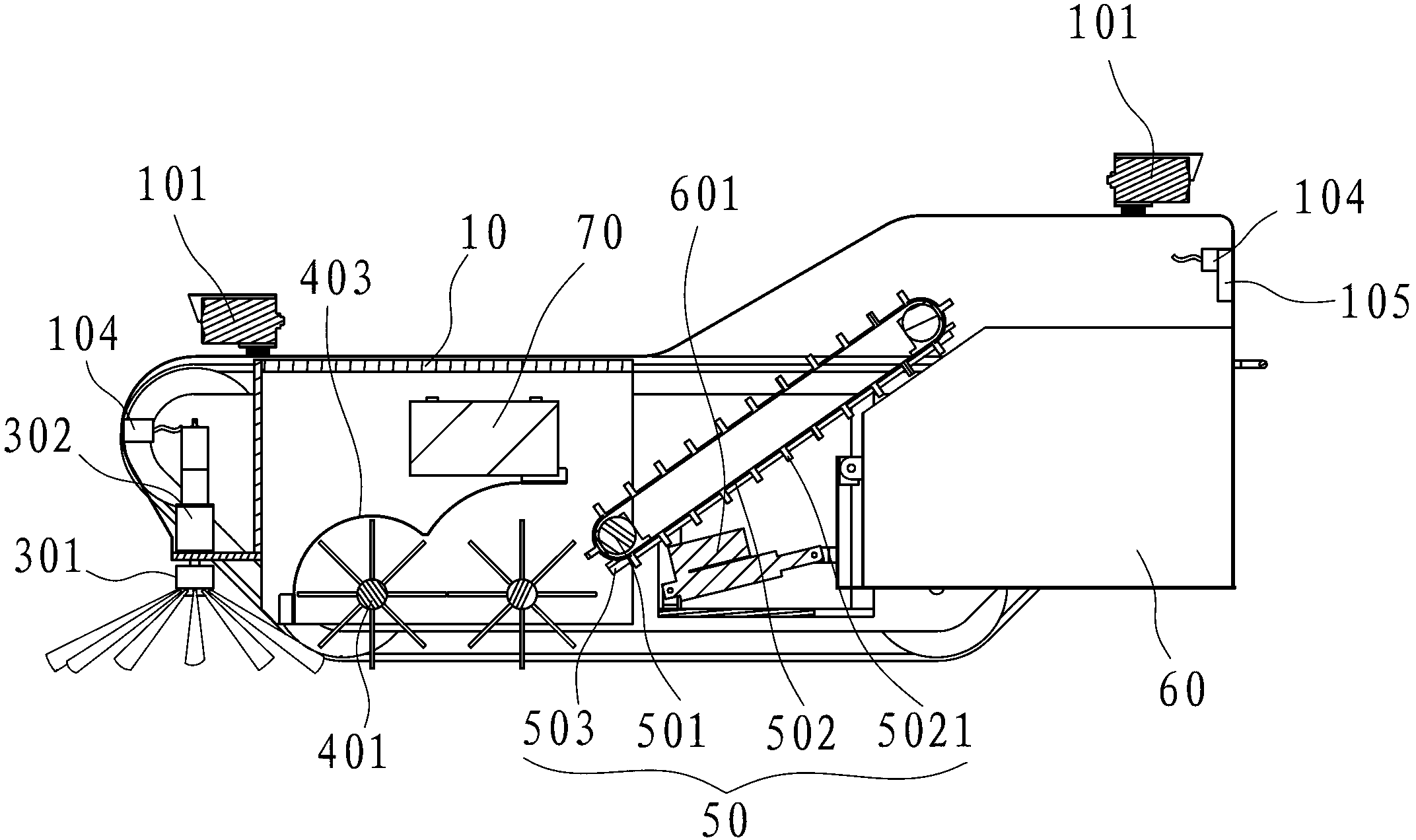

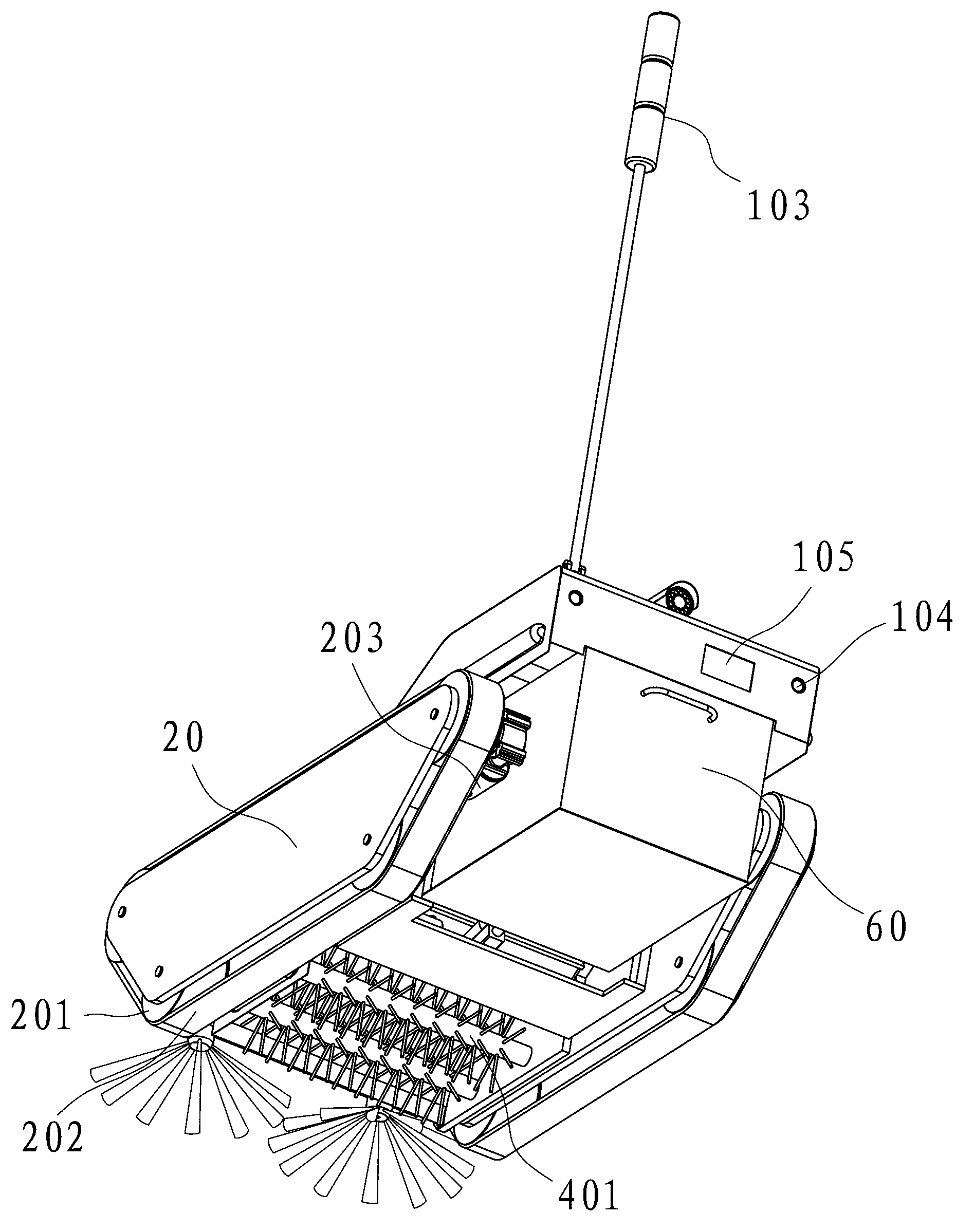

Ground sweeping robot

InactiveCN103225278ARealize automatic cleaningReduce in quantityRoad cleaningEngineeringMechanical engineering

The invention discloses a ground sweeping robot comprising a rack, a first sweeping mechanism, a second sweeping mechanism, a transport mechanism and a dustbin, wherein a walking mechanism is arranged on the rack; the first weeping mechanism comprises a sweeping head and a first drive mechanism for driving the sweeping head to rotate along the axis direction perpendicular to the ground; the sweeping head is arranged at the front end of the rack; the second sweeping mechanism comprises at least one sweeping roll brush and a second drive mechanism for driving the sweeping roll brush to rotate along the axis direction parallel to the ground; the sweeping roll brush is arranged at the middle of the rack; the transport mechanism is arranged in the rear of the sweeping roll brush; and the dustbin is arranged in the rear of the transport mechanism. The ground sweeping robot has the beneficial effects that compared with sanitation workers or dustmen, the ground sweeping robot is higher in work efficiency; in addition, the number of the sanitation workers or the dustmen can be greatly reduced so as to solve the problem of shortage of the sanitation workers or the dustmen; and meanwhile, along with the reduction of the number of the sanitation workers or the dustmen, the labor cost in the sweeping work can be greatly reduced.

Owner:SHENZHEN ZHONGKE DELI INTELLIGENT TECH CO LTD

Robot automatic carton loading machine

ActiveCN101704421ARealize fully automated operationCompact structureGripping headsPackaging automatic controlRobot positionCarton

The invention provides a robot automatic carton loading machine which comprises a carton conveyor and a carton packer, and also comprises a carton lifting conveyor positioned between the carton conveyor and the carton packer, and a robot positioned between the carton lifting conveyor and the carton packer. The robot automatic carton loading machine can completely realize automatic carton loading, fundamentally solves the defects of large labor intensity, low work efficiency and the like caused by manpower loading in the prior art, and has compact structure, reasonable arrangement, is capable of loading carton accurately and rapidly, and does not occupy more production space; according to different carton packer arrangement in the prior art, the suitable machine types of the robot automatic carton loading machine can be selected; and the robot automatic carton loading machine has wide application range, convenient installation and saved investment, and is capable of providing guarantee for cigarette packaging to realize full automatic operation.

Owner:东方机器制造(昆明)有限公司

Top-lifting step conveyance multi-purpose cleaning machine with material frame provided with spray nozzle

ActiveCN101602053AIncrease productivityAchieve cleaningCleaning using liquidsAutomatic controlSpray nozzle

The invention discloses a top-lifting step conveyance multi-purpose cleaning machine with a material frame provided with a spray nozzle. The positioning cleaning or the dry blowing of a workpiece can be realized by using a special material frame, arranging a water and gas inlet pipe on the corresponding central top part of the special material frame and arranging the spray nozzle on a position corresponding to an upper hole of the workpiece; the machine can adapt to different workpieces by changing different material frames; the automatic conveyance and cleaning of the material frames on cleaning positions can be realized by automatic feed and discharge frame devices arranged on both ends of a machine frame and a lifting and conveying mechanism; the actions of turnover cleaning, position cleaning, position rinsing, water pouring and dry blowing, which need to be carried out on the material frames, can be realized by arranging a surging cleaning position, a positioning cleaning position and a rotary water pouring and blowing position to be matched with a rotary water supply device and the rotary driving mechanism; and the whole process adopts program to realize automatic control, and the sequences of actions are electrically interlocked, thereby realizing full-automatic operation, high safety and reliability, and high production efficiency.

Owner:YICHANG ENHANCE ULTRASONIC ELECTRIC

Device and method for processing large square hay bundle into high-density small square hay bundle

InactiveCN102714990AIncrease initial cut-in pressurePrevent loose deformationBalingCuttersHigh densityEngineering

The invention relates to a hay bundle processing machine and a hay bundle processing method, in particular to a device and a method which can be used for cutting a large square hay bundle into hay slices, conducting secondary compression forming after the hay slices are cut into sections and conducting bundling, section cutting and collection operation to the formed hay bundles. A device for processing a large square hay bundle into high-density small square hay bundles comprises a feeding mechanism, a large square hay bundle slicing mechanism, a hay slice separation and conveying mechanism, a hay slice section-cutting mechanism, a secondary compression mechanism, a bundling mechanism, a formed hay bundle section-cutting mechanism and a formed hay bundle collection mechanism. The device and the method have the advantages that the large square hay bundle can be processed into the high-density small square hay bundles, the final products can be tidily collected and the subsequent operation efficiency is improved.

Owner:CHINA AGRI UNIV

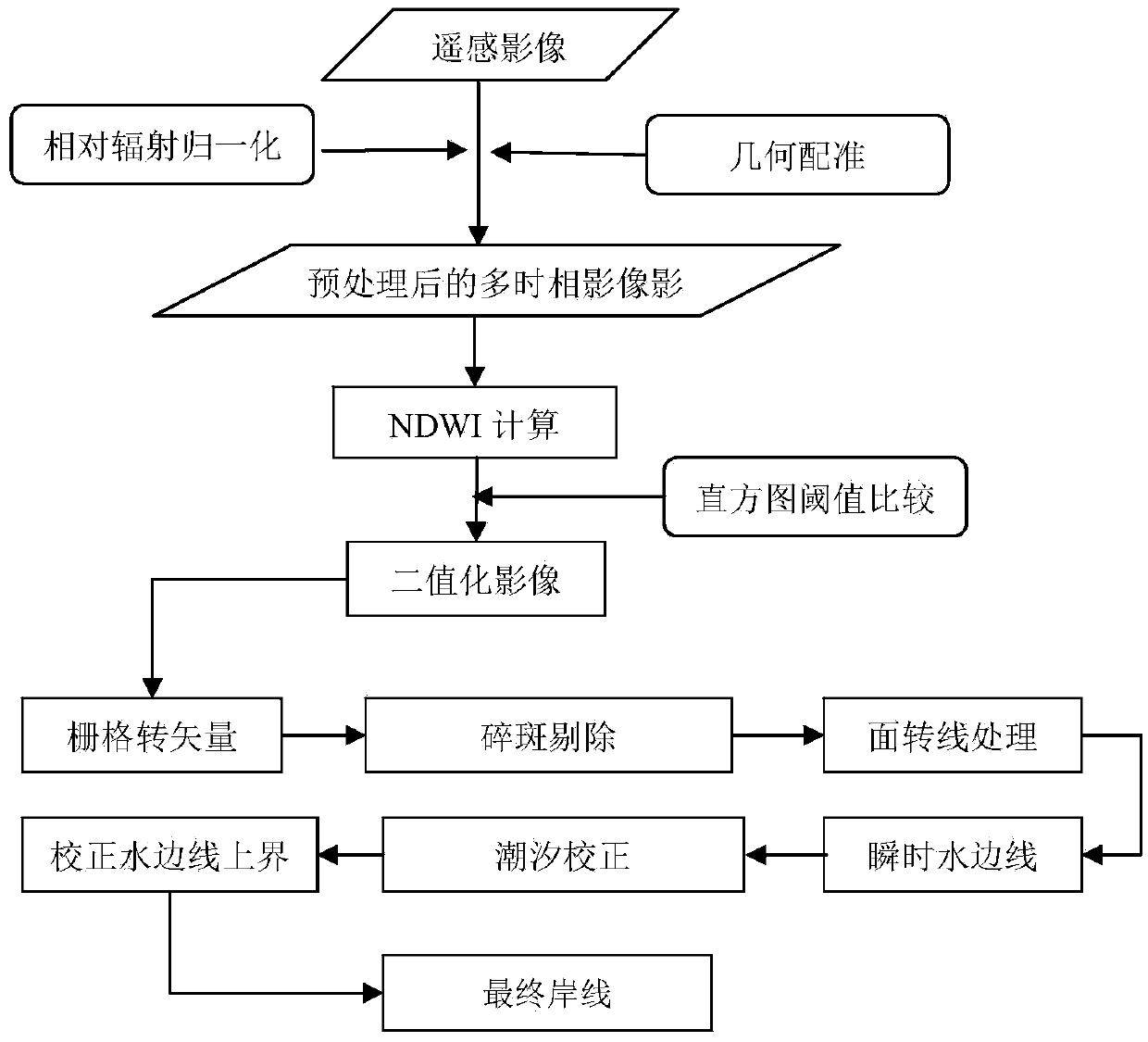

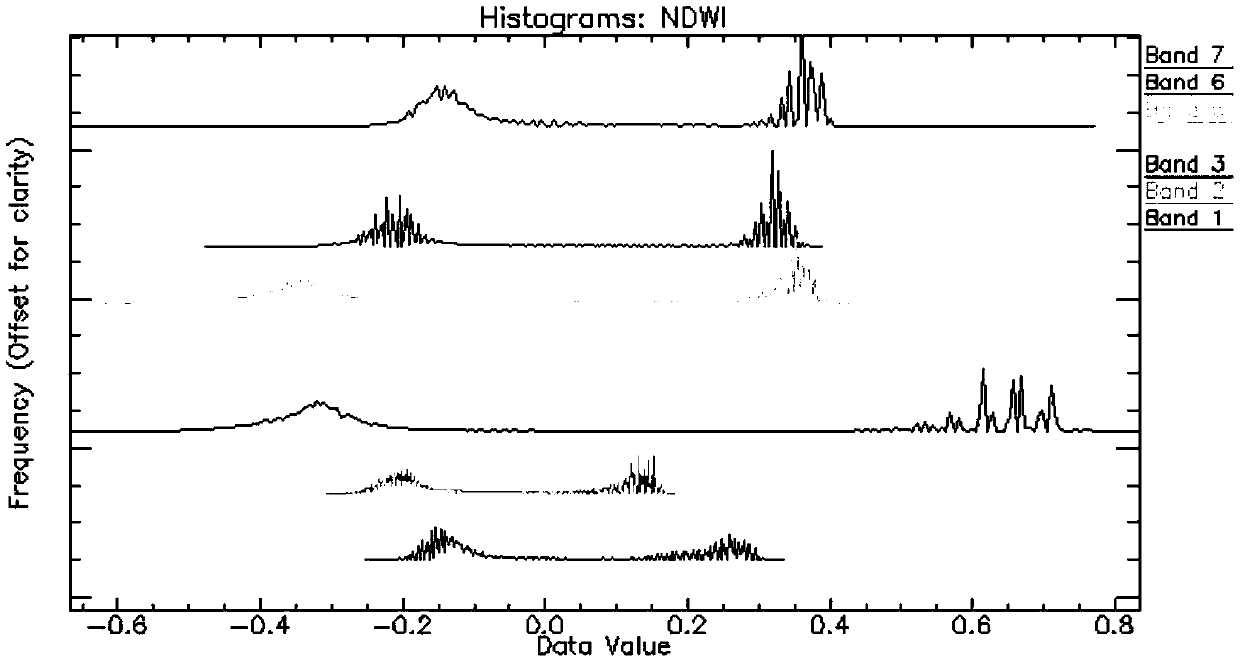

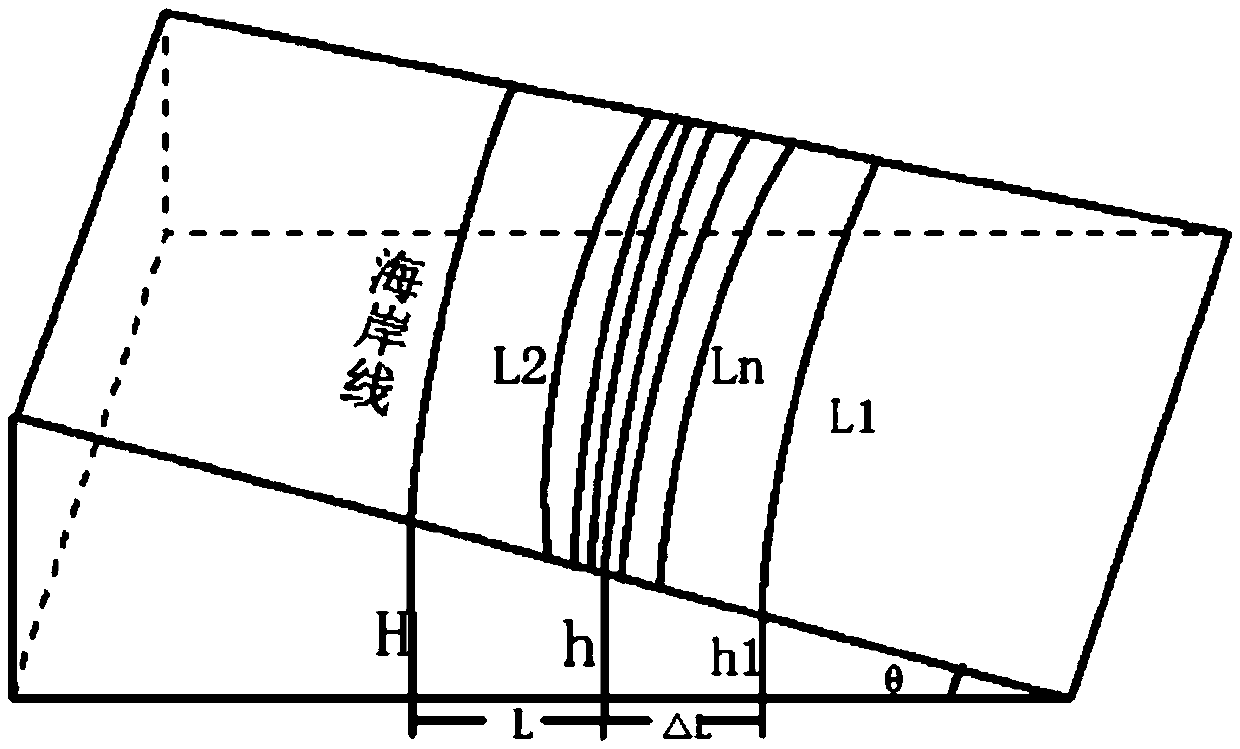

Method of extracting sandy coastline by using multiple periods of remote sensing images

InactiveCN105374041AAvoid underestimationQuick extractionImage enhancementImage analysisImage extractionLandform

The invention discloses a method of extracting a sandy coastline by using multiple periods of remote sensing images. The method comprises the following steps: 1, pretreatment is carried out on remote sensing images acquired via a satellite; 2, an NDWI image is acquired; 3, a binary image with land and water segmentation is acquired; 4, an instantaneous water line is acquired: a raster-vector conversion method is used for converting the binary image into vector data, and through porphyroclast elimination, surface-to-line treatment and false boundary elimination, the instantaneous water line is obtained; 5, tide correction is carried out on the instantaneous water line; and 6, through fusion of multiple periods of corrected water lines, the sandy coastline is acquired. The instantaneous water line is extracted by using the multiple periods of remote sensing images, influences on the coastline position by the tide are also considered, upper lines of multiple water lines through tide correction are fused into an accurate sandy coastline, the coastline extraction process is quick, accurate and fully automatic, and position underestimation of the extracted coastline caused by intertidal zone topografic relief can be effectively avoided.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

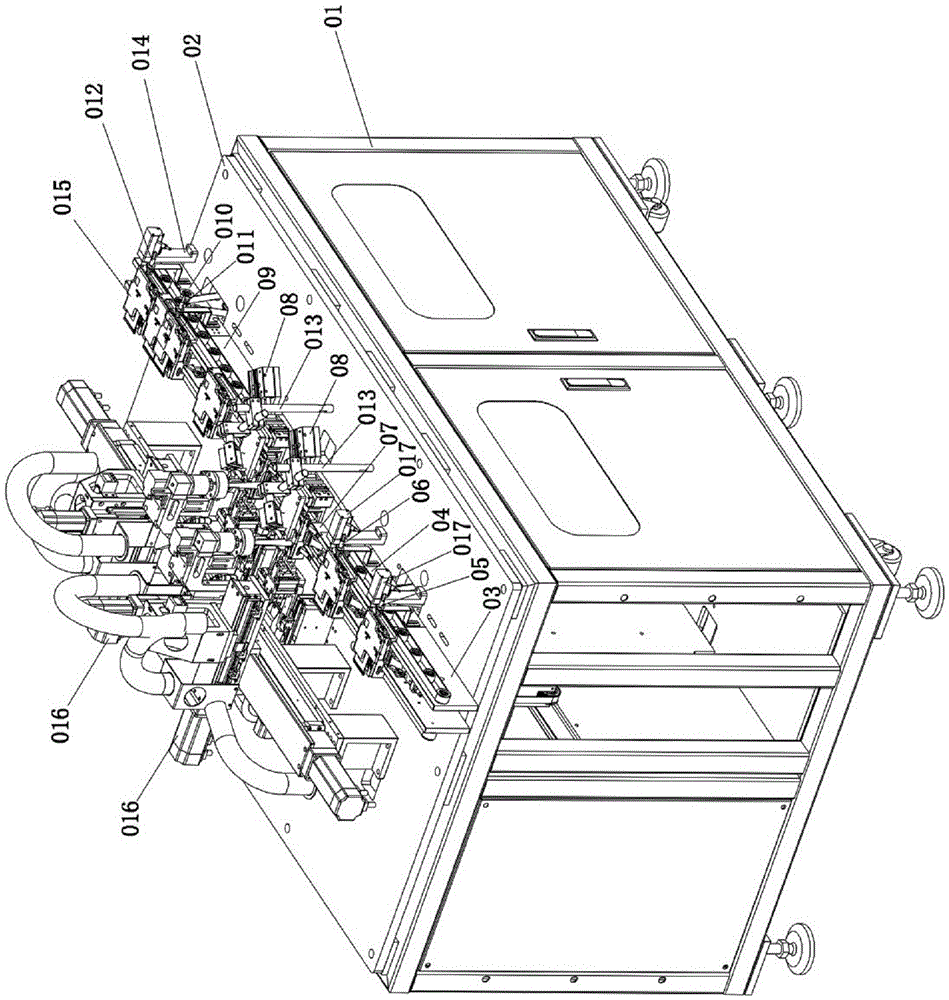

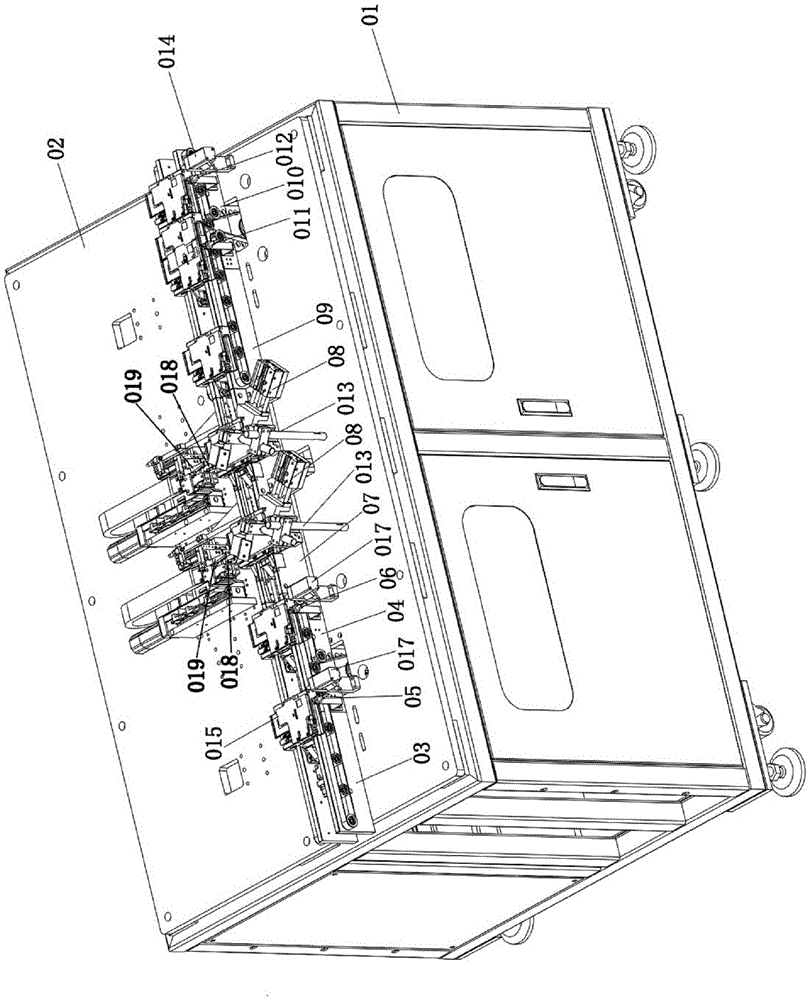

Automatic buckling device used for buckling connection between battery connector and battery test board

ActiveCN105467173AThe connection is compact and reasonableSimplified and smooth action designMeasurement instrument housingMechanical conveyorsElectrical batteryTest board

The invention discloses an automatic buckling device used for buckling connection between a battery connector and a battery test board. The above mentioned device comprises a support, in which is arranged installation space; a device bench disposed on the top part of the support; a tool provided with a battery and a battery test board; a tool shifting mechanism, a battery test board clamping mechanism, a battery flat cable shaping mechanism, and a buckling mechanism, which are disposed on the device bench. The tool can be used to clamp and fasten the battery and the battery test board, and the tool shifting mechanism can be used to move the tool to the working station, and then the battery test board clamping mechanism and a CCD assembly can be used to complete the positioning calibration, and in addition, a flat cable guiding mechanism can be used for the connector flat cable shaping and guiding, and at last the buckling mechanism can be used for the automatic buckling connection between the battery connector and the battery test board, and therefore the automation and the mass production of the battery test can be realized.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

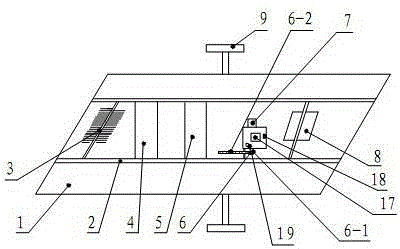

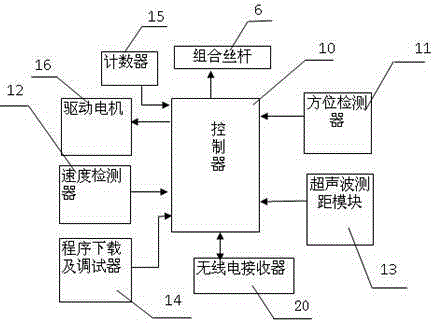

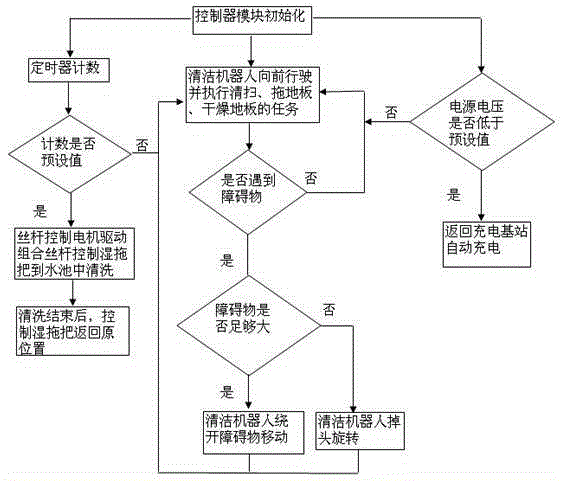

Cleaning robot and control method thereof

InactiveCN105212840AAchieve cleanupEasy to handleCarpet cleanersFloor cleanersState of artVehicle frame

The invention discloses a cleaning robot and a control method thereof and relates to the technical field of automatic control. The cleaning robot comprises a vehicle body with two front wheels, wherein a vehicle frame is mounted in the vehicle body, a broom, a garbage can, a water tank, a wet mop connected with the output shaft of a steering engine and a dry mop are disposed on the vehicle frame, the steering engine is mounted on a fixing plate, the steering engine is connected with the motor of a screw and a controller, and the controller is further connected with a direction detector, a speed detector, an ultrasonic ranging module, a program downloading and debugging device, a counter and a drive motor. The control method includes the steps of A, using the broom to sweep garbage, the web mop to mop a floor and the dry mop to dry the floor when the cleaning robot moves; B, cleaning the wet mop in the water tank after a certain period of time, and returning to an original position to continue mopping after the cleaning; C, by the cleaning robot, automatically returning to a charging base station for charging when the cleaning robot detects that electric quantity is smaller than a preset value. Compared with the prior art, the cleaning robot has the advantage that functions of garbage cleaning, floor mopping and floor drying can be achieved in one step.

Owner:HECHI UNIV

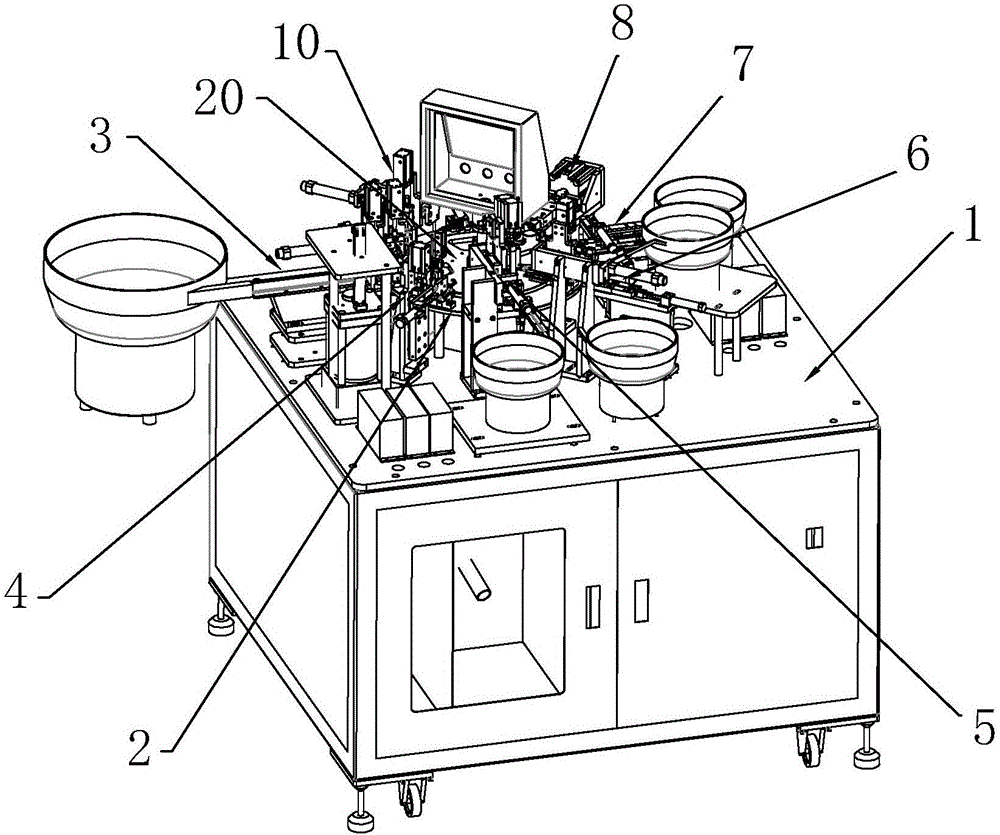

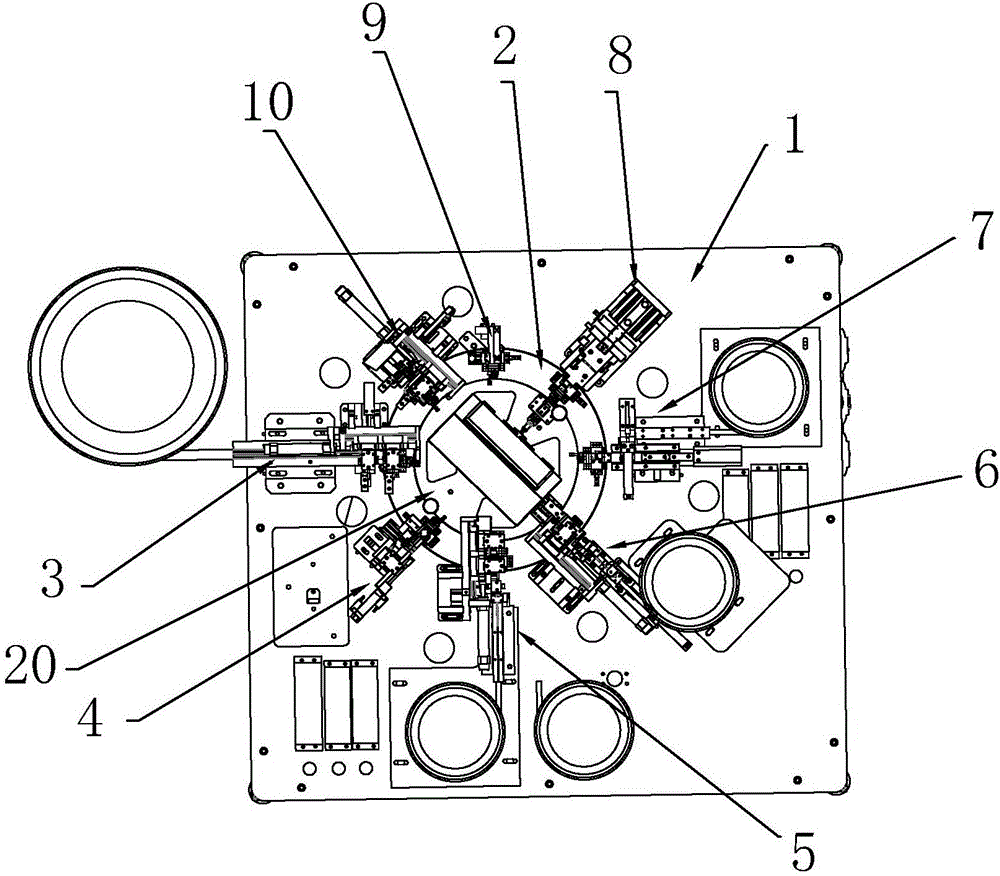

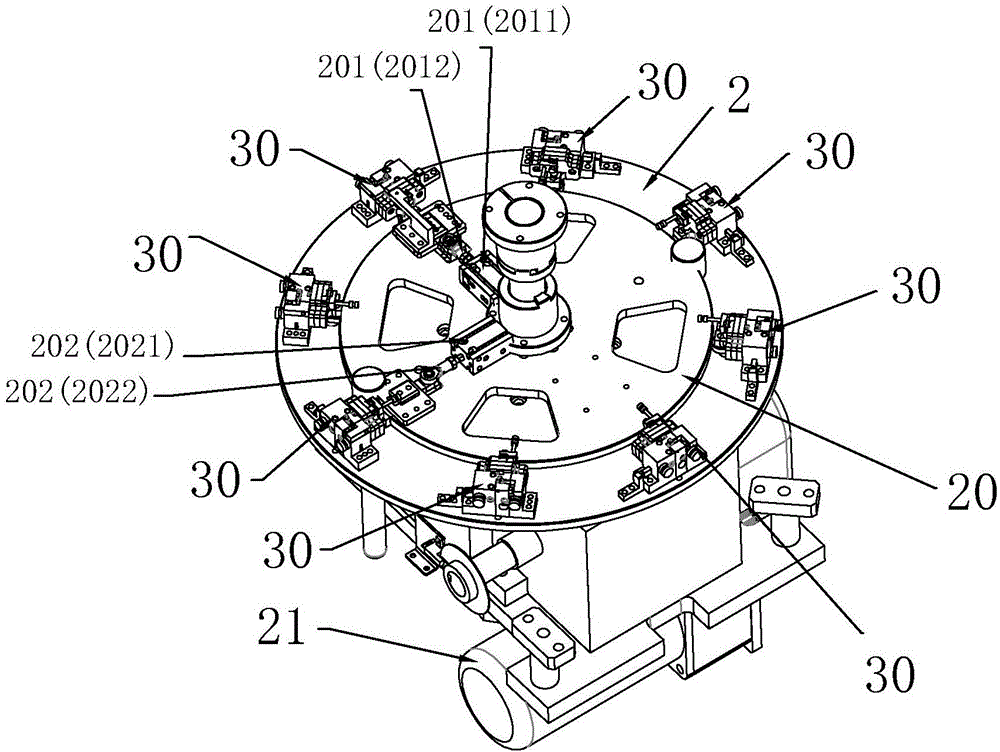

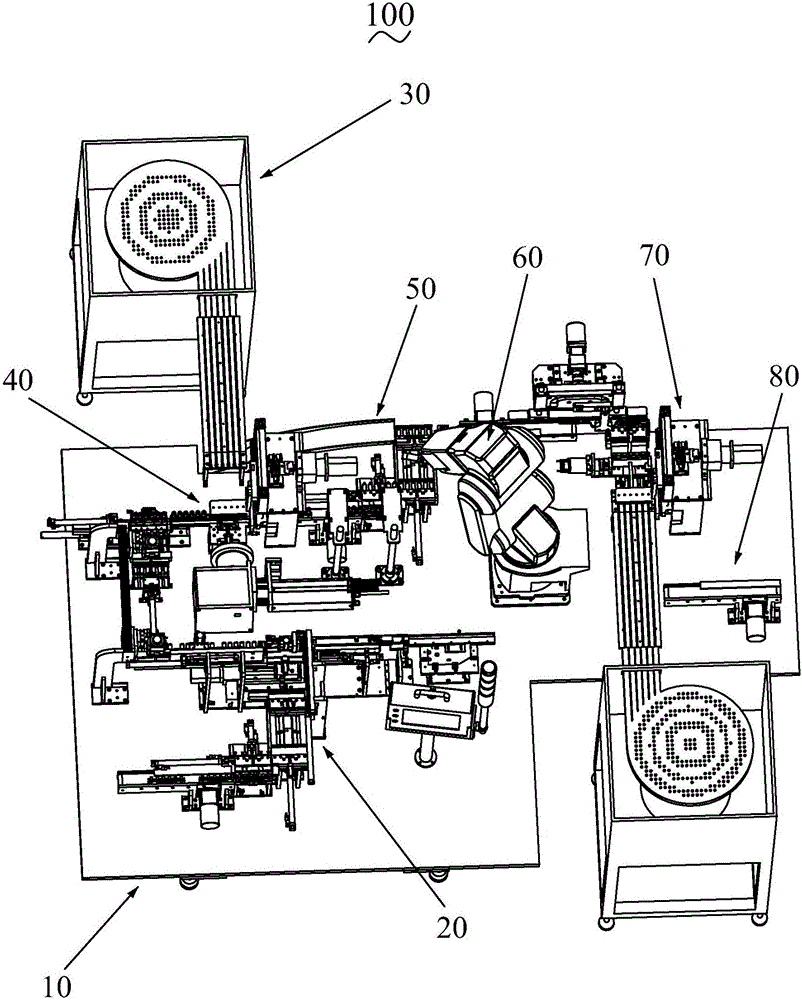

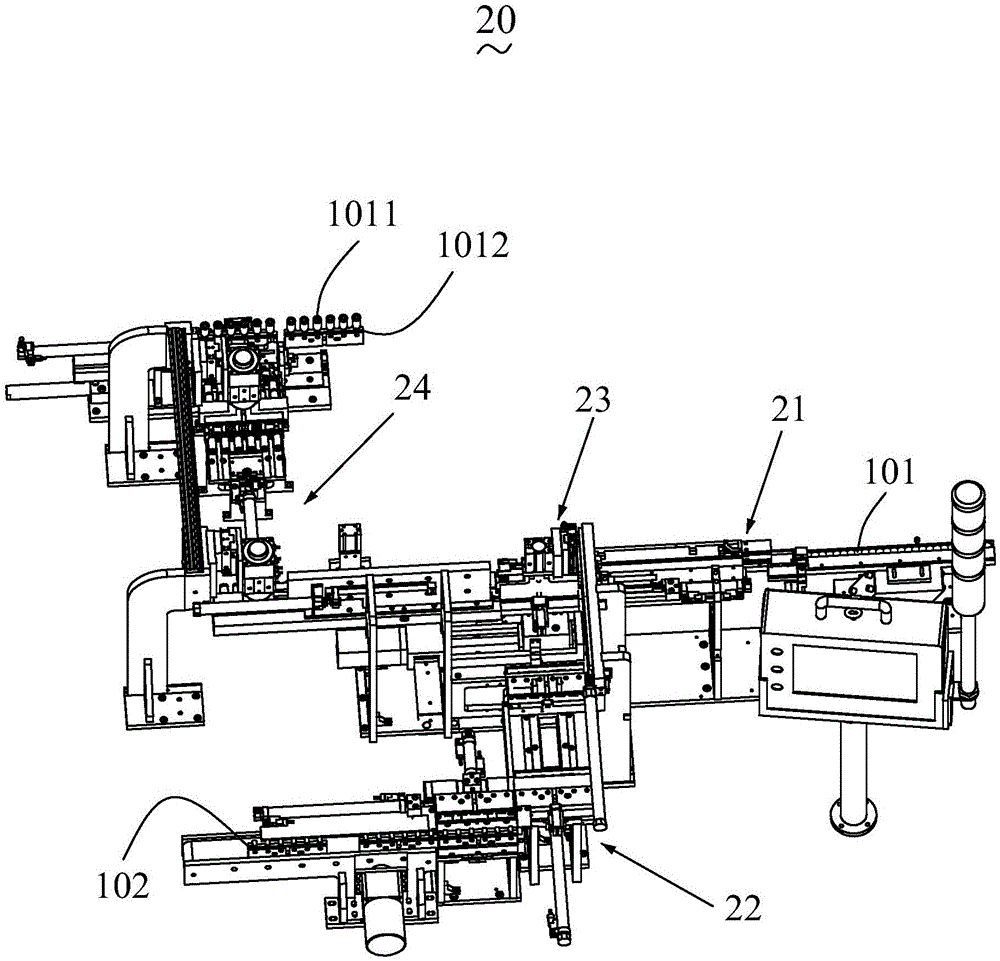

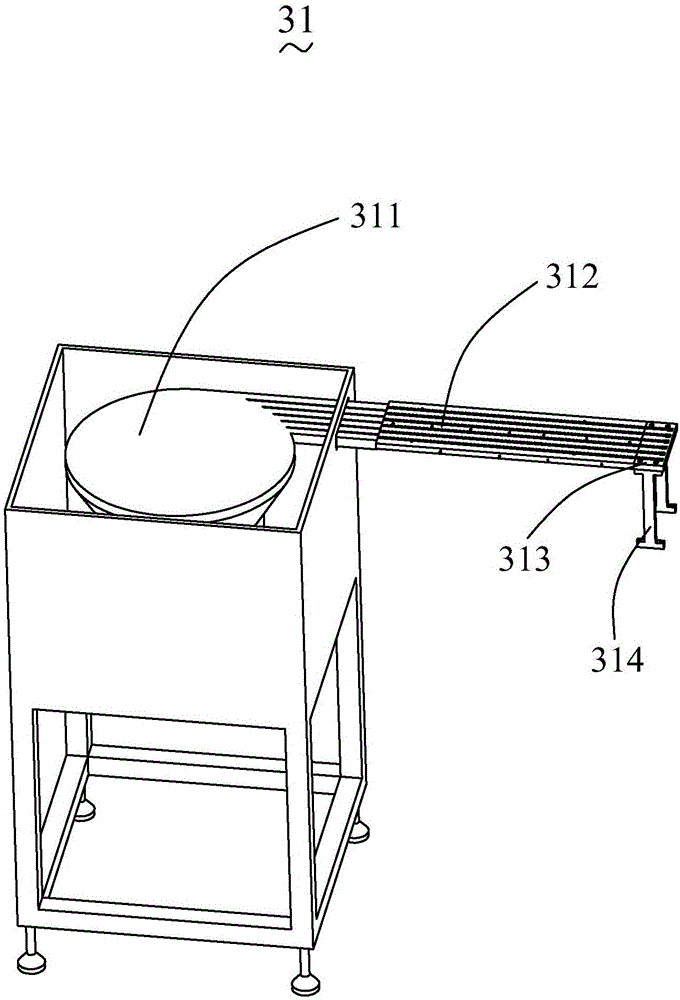

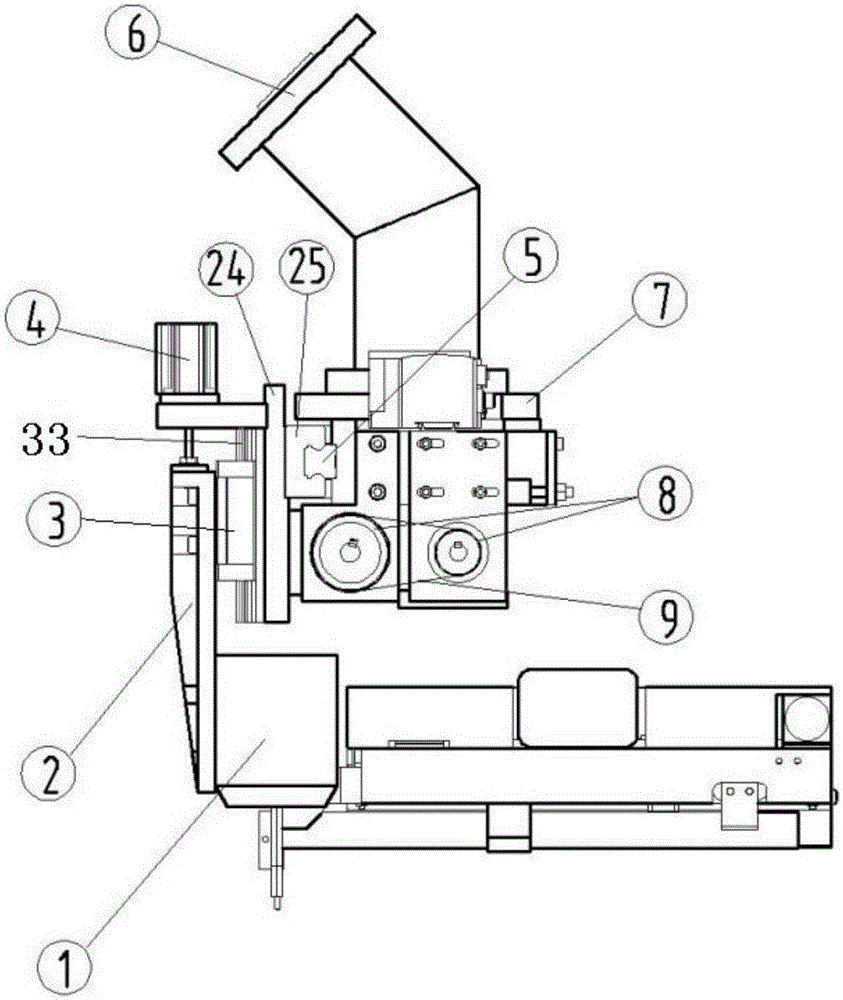

Full-automatic assembler

InactiveCN106217039ARealize fully automated operationImprove assembly efficiencyAssembly machinesProduct testingEngineering

The invention discloses a full-automatic assembler. The full-automatic assembler comprises a frame, a turntable arranged on the frame, and a main feeding device, a spring assembly device, a thimble assembly device, a poking piece assembly device, a pin preinstalling device, a pin riveting device, a finished product testing device and a finished product discharge device arranged around the turntable, wherein a fixed disc is arranged on the turntable, and is provided with a poking piece auxiliary pressing mechanism and a pin auxiliary pressing mechanism; a connecting wire between the poking piece auxiliary pressing mechanism and the poking piece assembly device and a connecting wire between the pin auxiliary pressing mechanism and the pin riveting device are both positioned on a center shaft of the turntable; multiple assembly tools are arranged on the upper surface edge of the turntable around the fixed disc; and a motor is connected to the lower end of the turntable. The full-automatic assembler is reasonable in structure design and high in automation degree, realizes the whole full-automatic assembly process of all parts in products, greatly improves the assembly efficiency, improves the assembly accuracy, and guarantees the product quality.

Owner:东莞工坊精密模具有限公司

Automatic oil removing machine

InactiveCN103567191AAvoid security issuesRealize fully automated operationCentrifugesCleaning processes and apparatusNumerical controlEngineering

The invention relates to an automatic oil removing machine used for deoiling the surfaces of parts after being processed by a cold header, a numerical control machine tool, an automatic tapping machine and the like or cuttings. The automatic oil removing machine comprises a centrifugal machine, an automatic loading device, a control cabinet and an unloading device, the centrifugal machine comprises a centrifugal basket and a centrifugal motor, the automatic loading device comprises a loading rack and a loading motor, the unloading device comprises a discharge port and a discharge power device, and the control cabinet is connected with the discharge power device, the loading motor and the centrifugal motor respectively through photoelectric control. Through arranging the automatic loading device, mechanical loading processing operation is realized, so that the production efficiency is further improved, and the safety problem of operators is also solved. The control cabinet is used for controlling the discharge power device, the loading motor, the centrifugal motor and a material blocking power device, full automatic operation is realized, and the production efficiency is improved.

Owner:王军林 +1

Full-automatic battery spot welding equipment

PendingCN106624309AContinuous weldingFast solderingResistance welding apparatusButt weldingEngineering

The invention provides full-automatic battery spot welding equipment. The equipment comprises a rack and a battery carrying mechanism, two material charging mechanisms, a spot welding mechanism, a detection mechanism, a transfer mechanism, a butt welding mechanism and a discharging mechanism which are arranged on the rack. According to the full-automatic battery spot welding equipment, full-automatic operation can be achieved, battery charging and transportation, screw / double-screw bolt charging and transportation, screw and battery spot welding, CCD detection, unqualified product screening, double-screw bolt and battery butt welding, product outputting and other operation are integrated, screws and double-screw bolts can be welded to the two ends of a battery continuously and rapidly, batched production is met, and the precision of product machining can be improved.

Owner:OPTIMUM BATTERY CO LTD

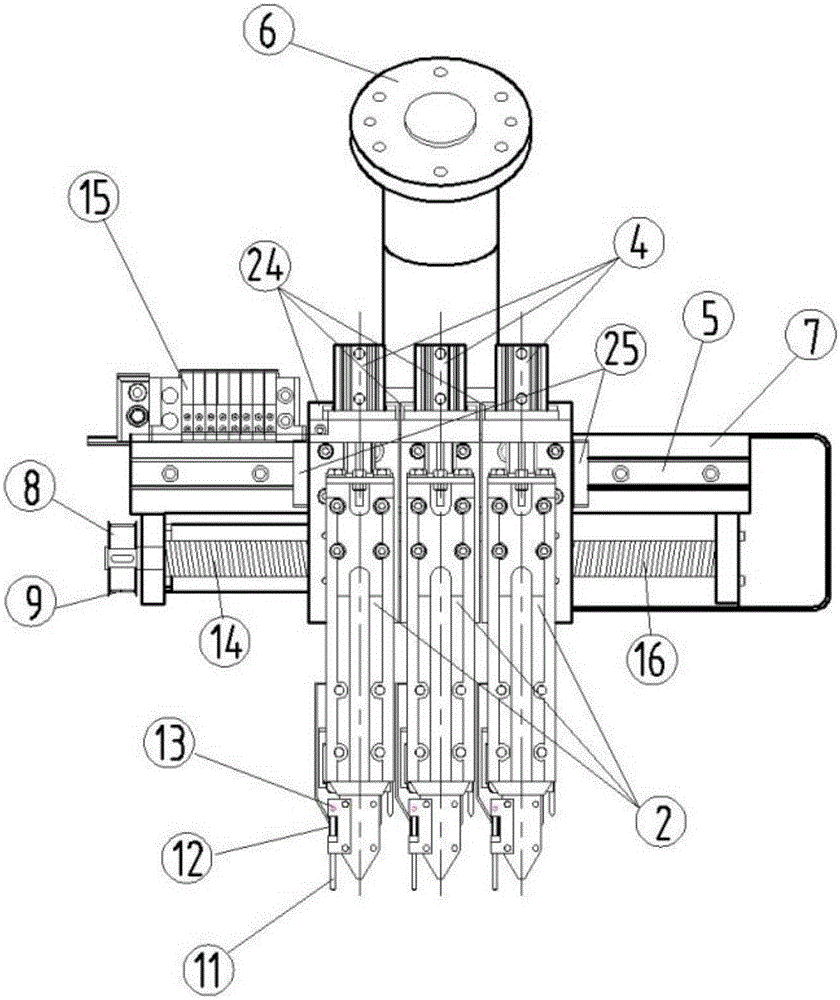

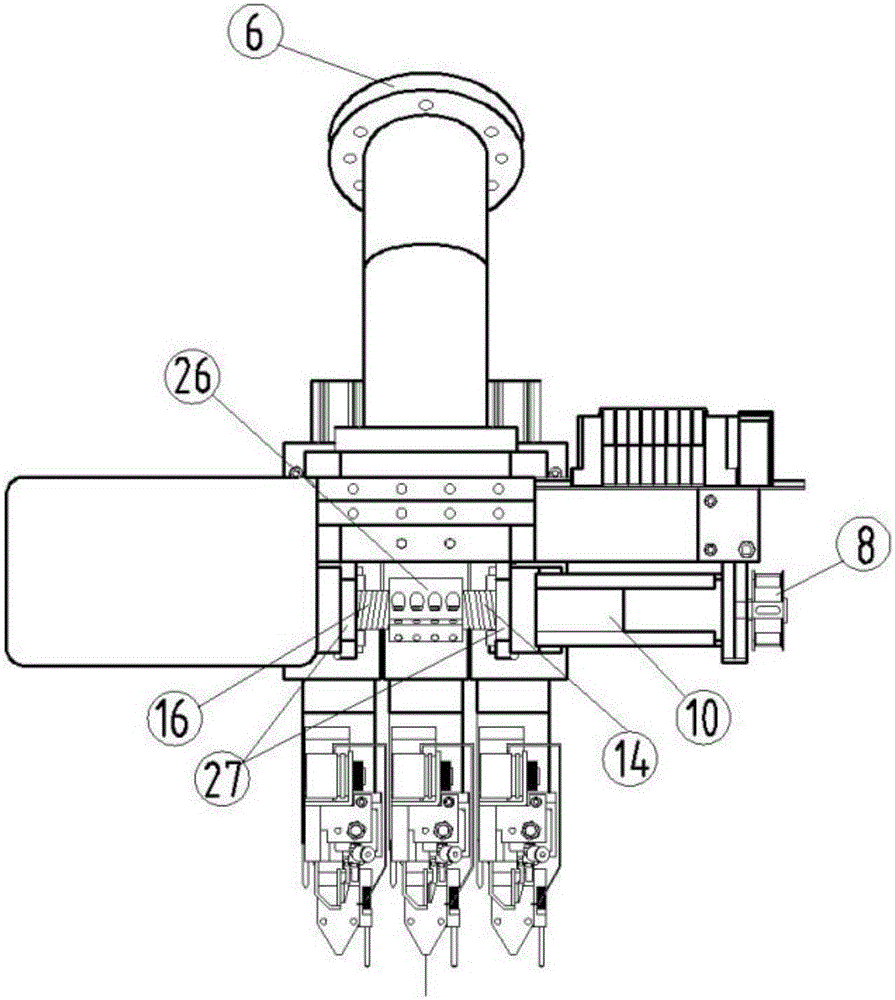

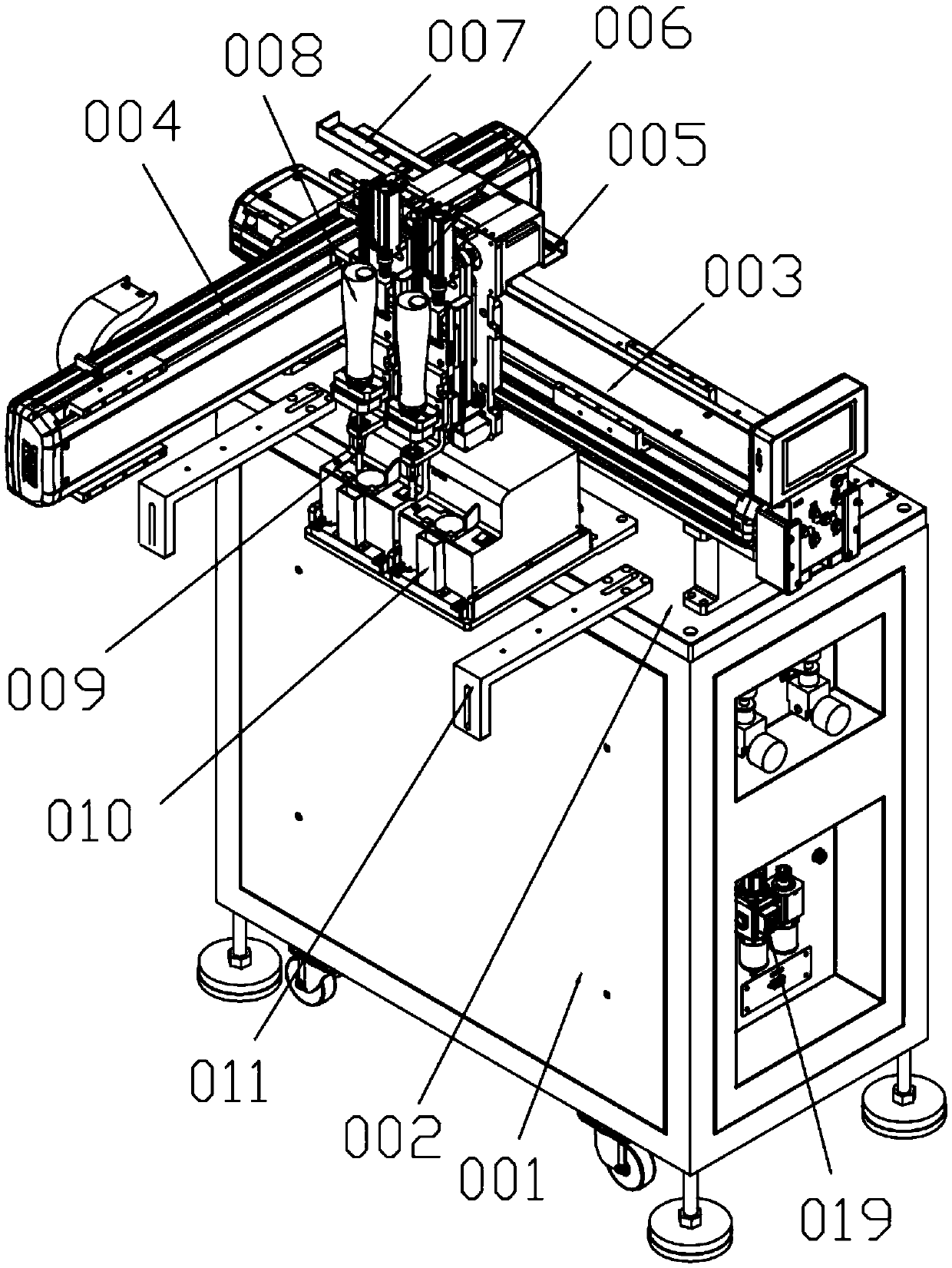

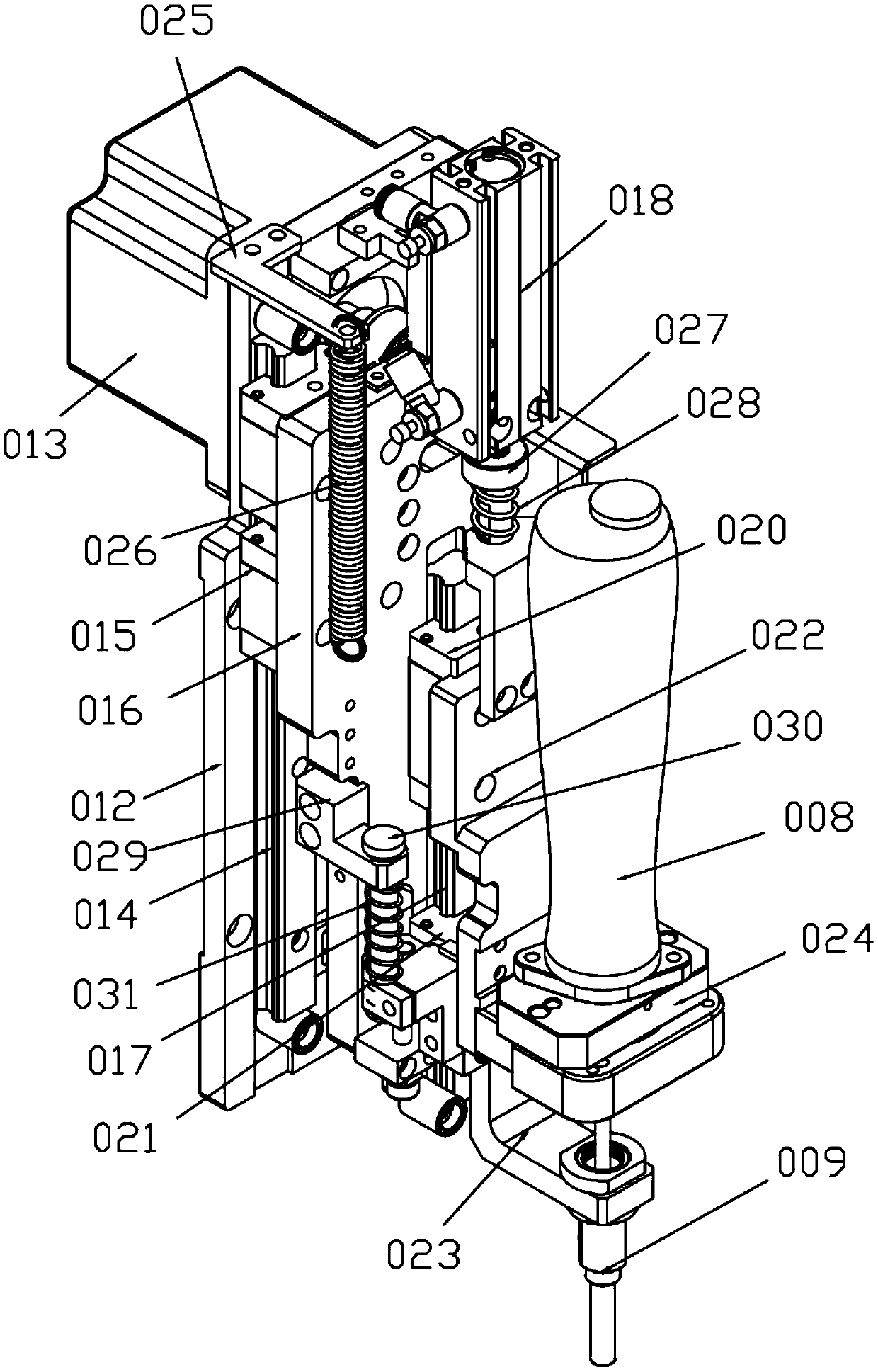

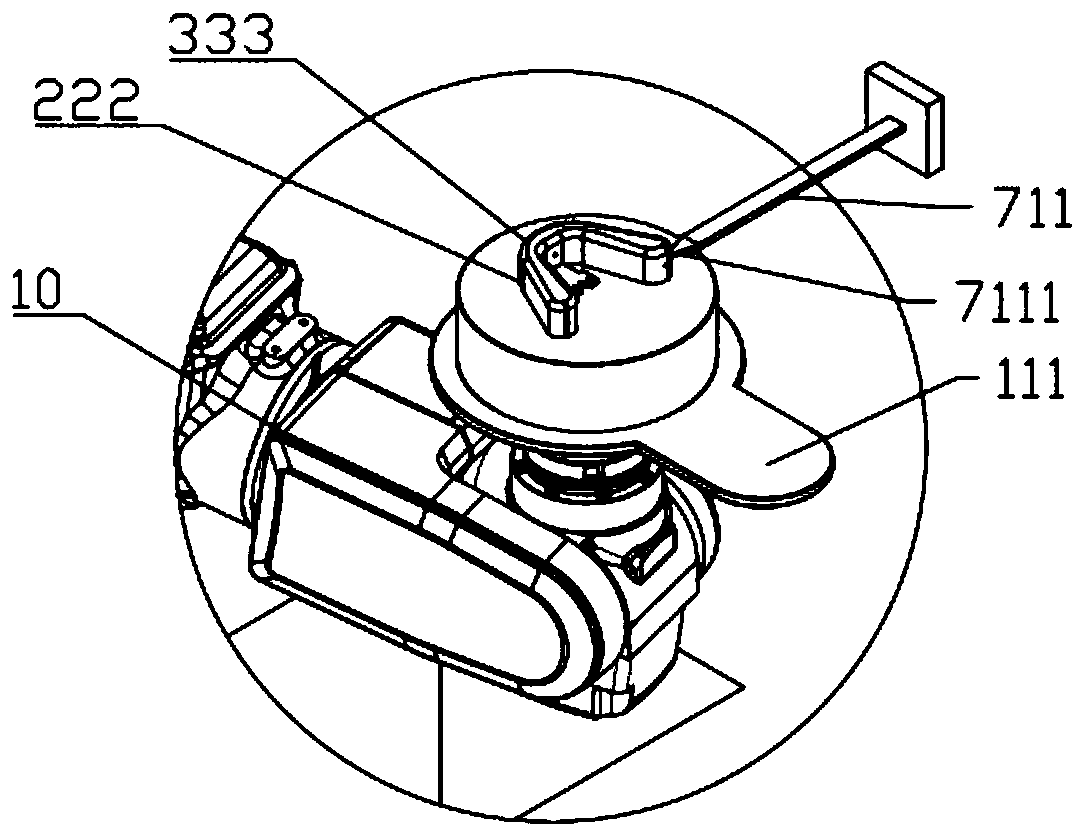

Automatic nail gun operated by robot

ActiveCN105058526AFlexible drivePrecise positioningStapling toolsNailing toolsEngineeringBiomedical engineering

The invention discloses an automatic nail gun operated by a robot. The automatic nail gun comprises nail gun bodies, an electromagnetic valve, a robot connecting flange, a frame, a nail gun body lifting device, a nail gun body distance adjusting device, a nailing triggering device and a nail counting device. The nail gun body lifting device, the nail gun body distance adjusting device, the nailing triggering device and the nail counting device are mounted on the frame. According to the automatic nail gun, nailing positioning precision is improved, and the automatic nail gun has the characteristics of being high in production efficiency and automation degree.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

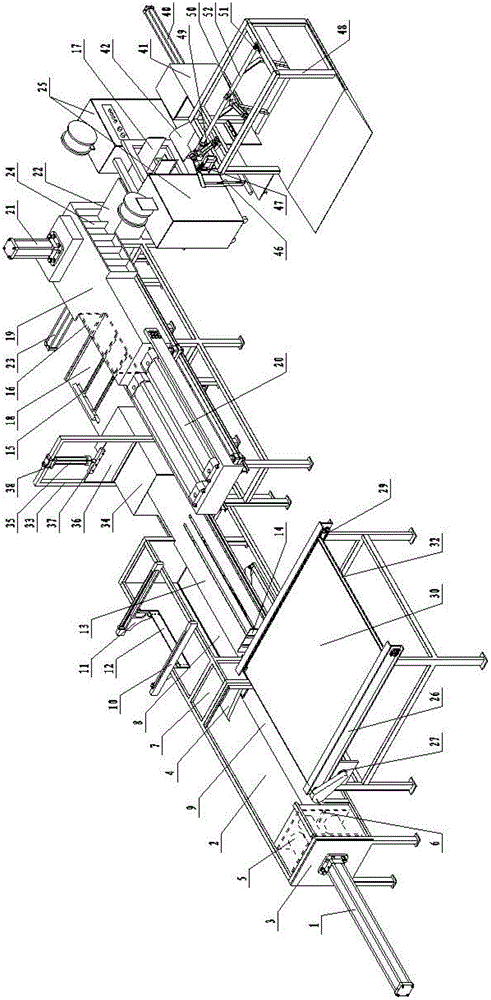

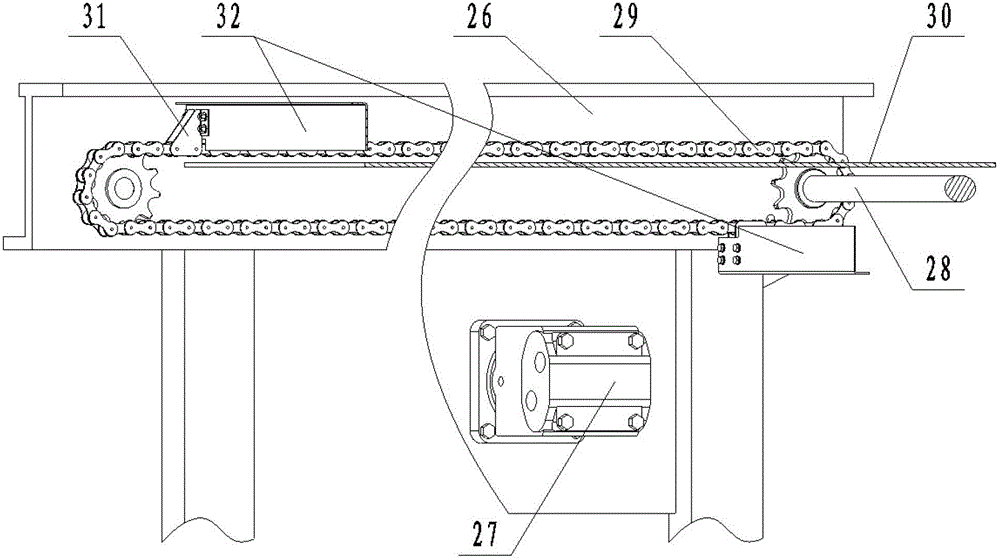

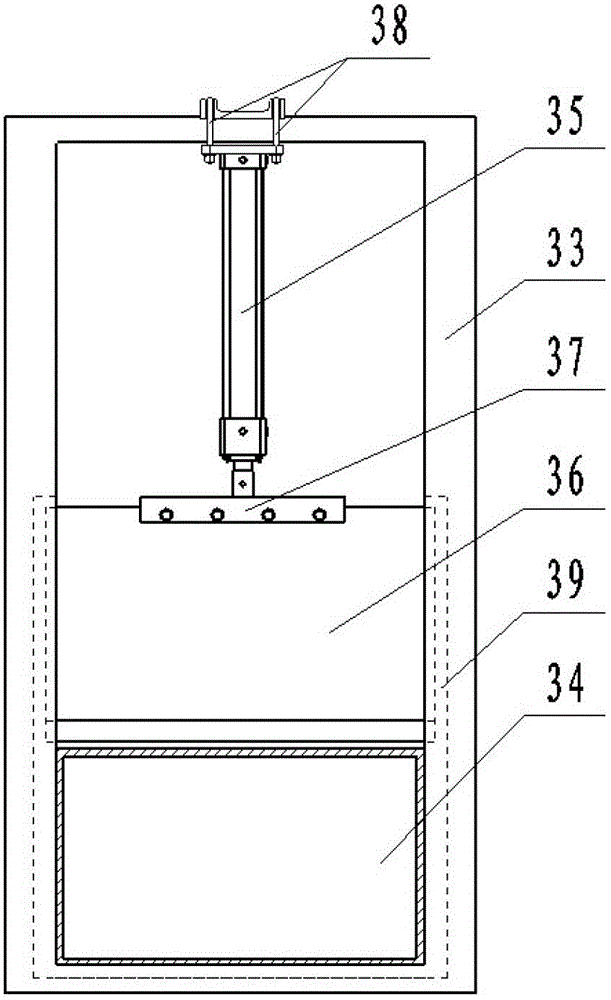

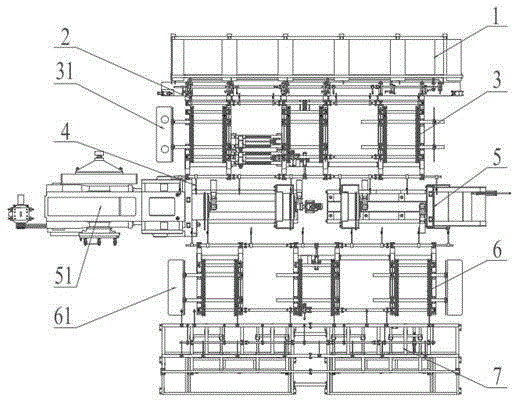

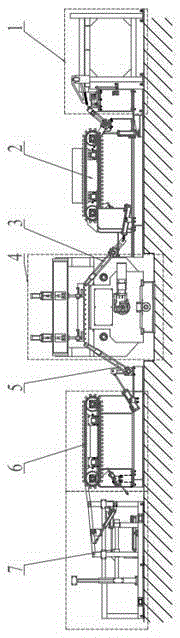

Full-automatic sucker rod forging production line

ActiveCN105397005AReduce manual operationsSave human effortForging/hammering/pressing machinesForging press drivesAutomatic controlEngineering

The invention relates to the technical field of machining equipment and automation, in particular to a full-automatic sucker rod forging production line. The full-automatic sucker rod forging production line comprises a mechanical transmission heating system, a pneumatic system, a lubricating system and a control component, wherein the control component controls the pneumatic system to provide power for the mechanical transmission heating system, and controls the lubricating system to lubricate the mechanical transmission heating system; and the whole production line is fully automatically controlled through the control component. During production, field workers only need to place bars on a beginning part of the production line, and transfer finished sucker rods at the tail end of the production line, the bars are not required to be carried manually in a production process, full-automatic operation of the production process is realized, labor and materials are saved, full-automatic production of the sucker rod forging production line is realized, the technical problem that an existing sucker rod forging production line is relatively low in degree of automation and relatively high in labor and material consumption is solved, and the full-automatic sucker rod forging production line is provided.

Owner:DEYANG ZHONGLIAN MACHINERY MFG CO LTD

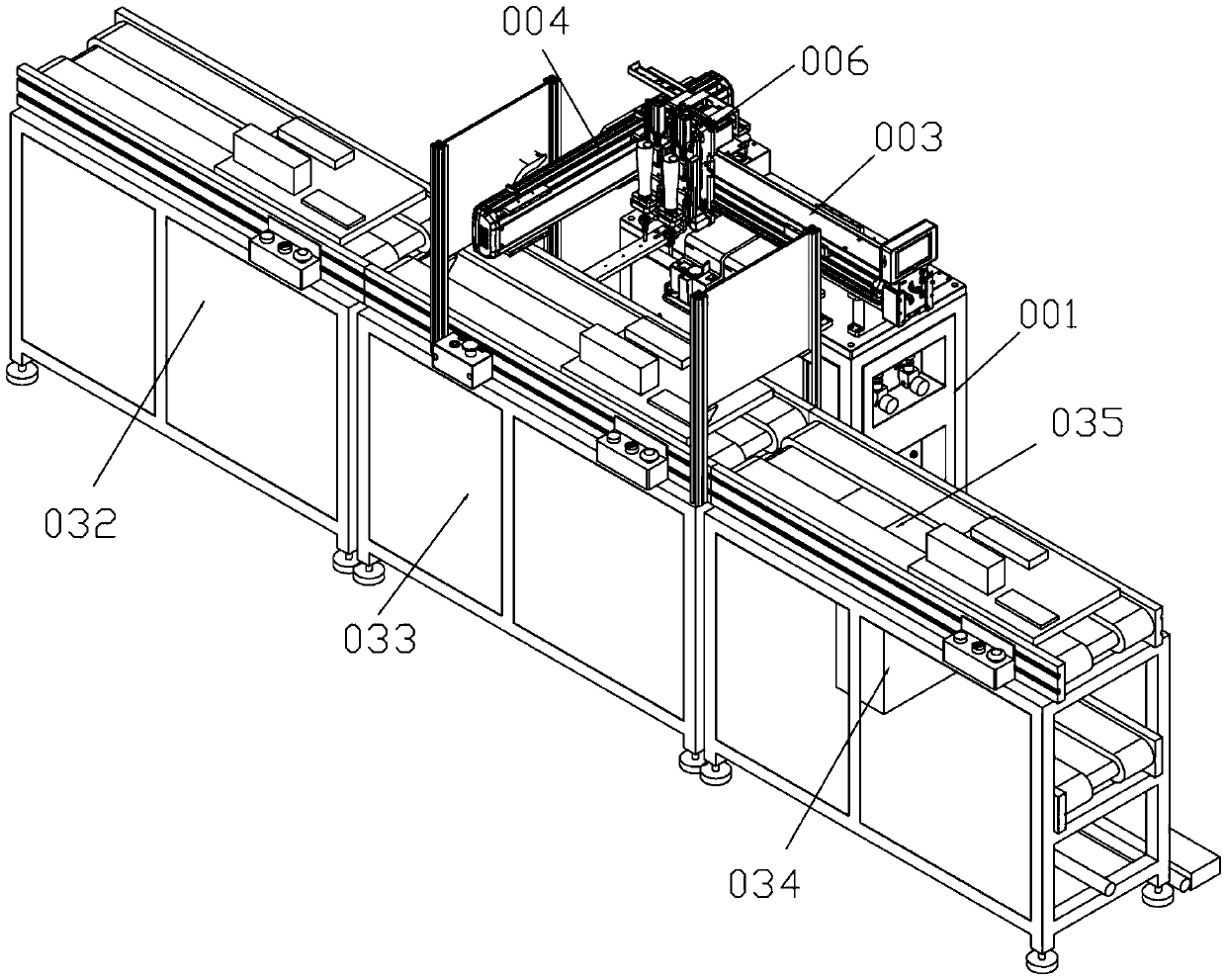

Online screw locking machine

InactiveCN105522373AShorten the work scheduleRealize fully automated operationConveyorsSpannersWorking range

The invention discloses an online screw locking machine. The online screw locking machine comprises a frame; a counterweight is arranged in the frame; a working platform is arranged at the upper end part of the frame; an X-axle module is transversely arranged on the working platform, and is connected with a Y-axle module longitudinally arranged; the assembly positions of the X-axle module and the Y-axle module are perpendicularly arranged; the front end part of the Y-axle module extends to the front side, and is positioned out of the working platform; the Y-axle module is connected with a connecting plate; two adjacent Z-axle modules in the same direction are arranged on the connecting plate; each Z-axle module is connected with an electric screwdriver and a sucker; a screw feeder is arranged on the working platform, and is arranged in a working range of the Z-axle modules; and a fixed frame extending to the front side of the frame is arranged on the working platform. The online screw locking machine can realize automatic operation, improves the working efficiency, reduces the production cost, adopts a half-suspension mode to shorten the operation travel of the electric screwdriver, is more reasonable in structure, and is more stable in work.

Owner:NEW ROAD MARK AUTOMATION TECH

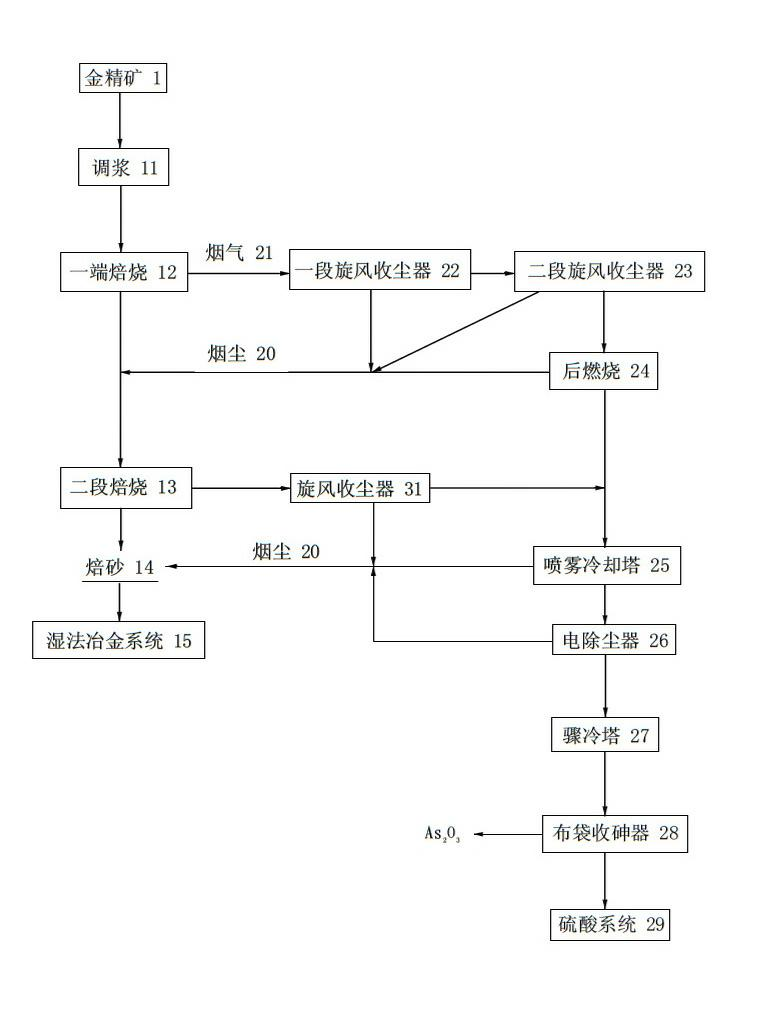

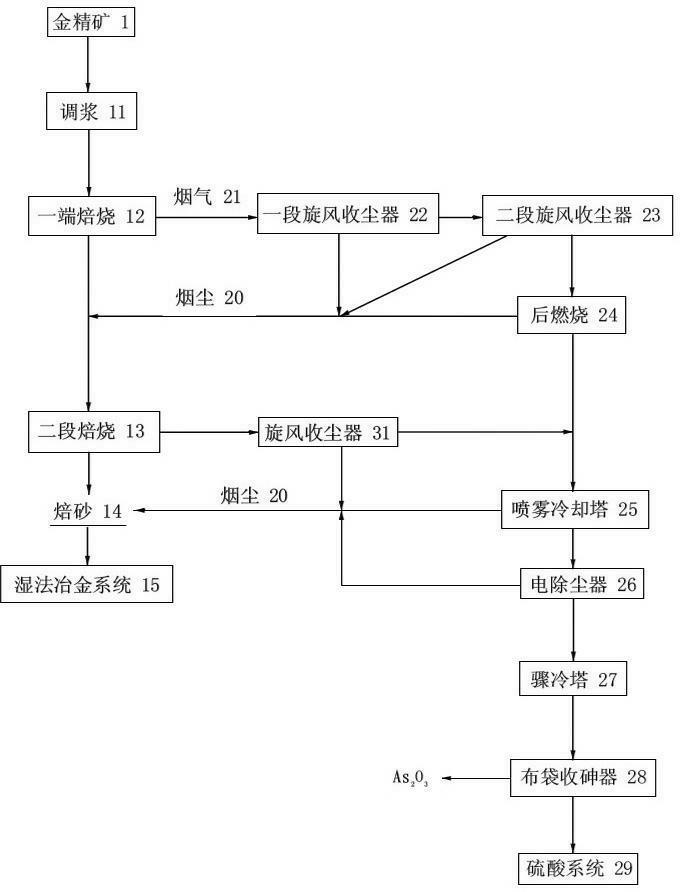

Arsenic removal process containing post-combustion technology

InactiveCN102560084ASmooth production processAdvanced process indicatorsProcess efficiency improvementChemistryPrecious metal

The invention relates to an arsenic removal process containing a post-combustion technology and belongs to the technical field of a gold and silver extraction method for precious metal smelting. The arsenic removal process comprises the following steps of: treating gold concentrate containing arsenic by adopting a two-stage roasting process, removing the arsenic as well as sulphur and changing an ore structure, generating porous roasted ore to facilitate next cyaniding operation and improve the leaching rate of gold, and recovering valuable elements in the concentrate; through controlling the air quantity, removing the arsenic and the sulphur in the first-stage roasting under the anoxic roasting atmosphere, carrying out sulfatizing roasting in the second-stage roasting under the oxygen atmosphere; and after flue gas generated by roasting is subjected to arsenic removal, producing sulfuric acid and generating the arsenic into thick white arsenic for sales. The arsenic removal process has the beneficial effects that a traditional process is improved, a post-combustion process is increased on the basis of the traditional process, the problems of initial sulfur condensation and non-arsenic trioxide (As2S3) compound deposition caused by incomplete combustion of roasted flue gas are solved, and the effects of smooth production process and advanced process index are achieved.

Owner:长春黄金设计院有限公司

Full-automatic traditional Chinese medicine mortar device

ActiveCN104772182ARealize fully automated operationLow costGrain treatmentsMedicineTraditional Chinese medicine

The invention relates to a mortar device and in particular relates to a full-automatic traditional Chinese medicine mortar device. The full-automatic traditional Chinese medicine mortar device comprises an upper cylinder, a lower cylinder, a grinding motor, a grinding head and a medicine bowl, wherein the upper cylinder and the lower cylinder are arranged on a rack, the grinding motor is arranged right below the upper cylinder and the lower cylinder, the grinding motor is connected with the upper cylinder and the lower cylinder, the grinding head is arranged right below the grinding motor and is connected with the grinding motor, the medicine bowl is arranged right below the grinding head and is matched with the grinding head, the medicine bowl is arranged on the rack, a material receiving cylinder is arranged right below the medicine bowl and is arranged on a tray in a separated manner, the tray is connected with a left cylinder and a lower cylinder, and the left cylinder and the right cylinder are arranged on the rack. According to the full-automatic traditional Chinese medicine mortar device, full-automatic operation is realized, the operation is time-saving and labor-saving, the grinding effect is good, and the full-automatic traditional Chinese medicine mortar device is sanitary and clean, has a simple structure, can be used conveniently and can be maintained easily.

Owner:山西宝泰药业有限责任公司

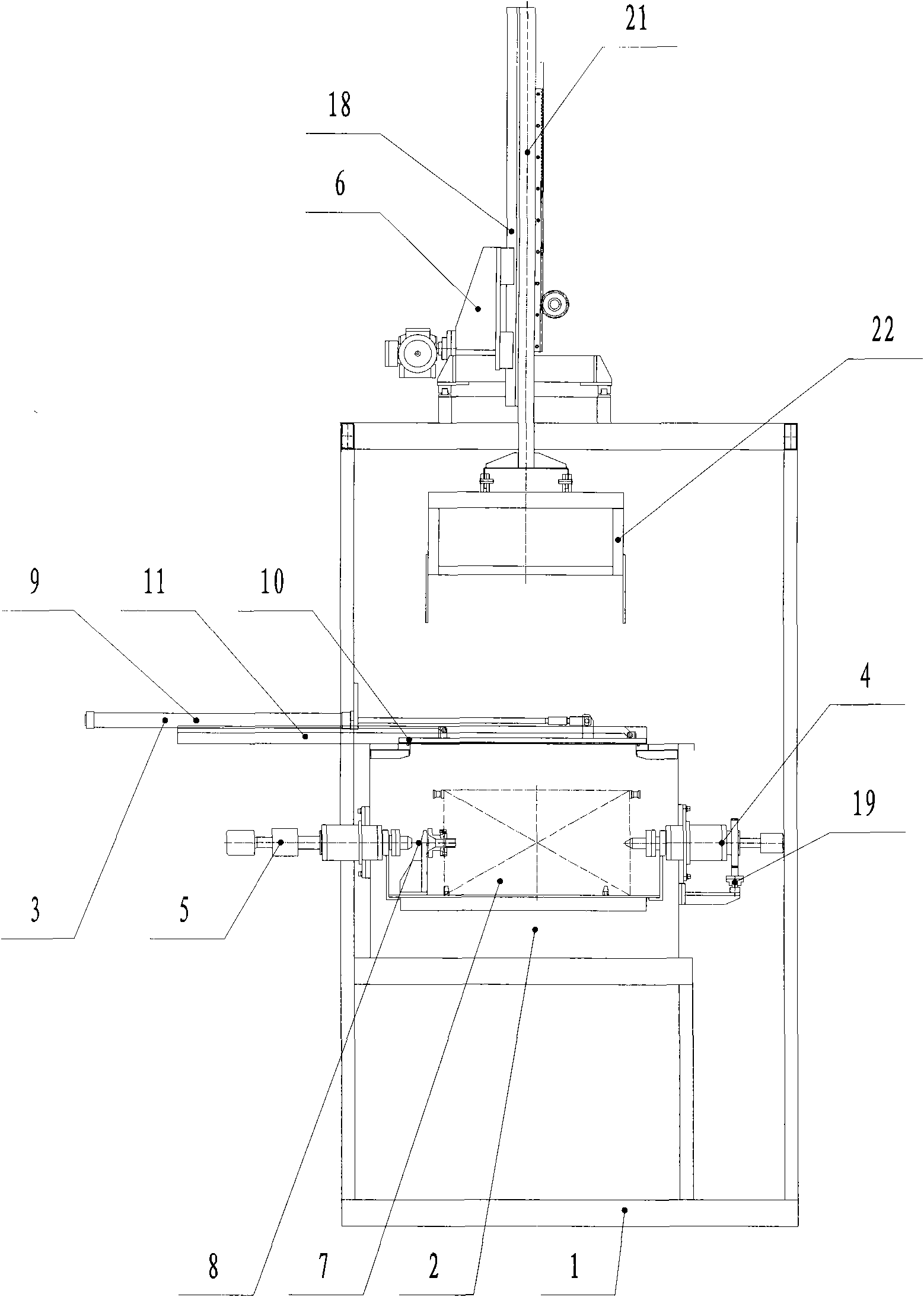

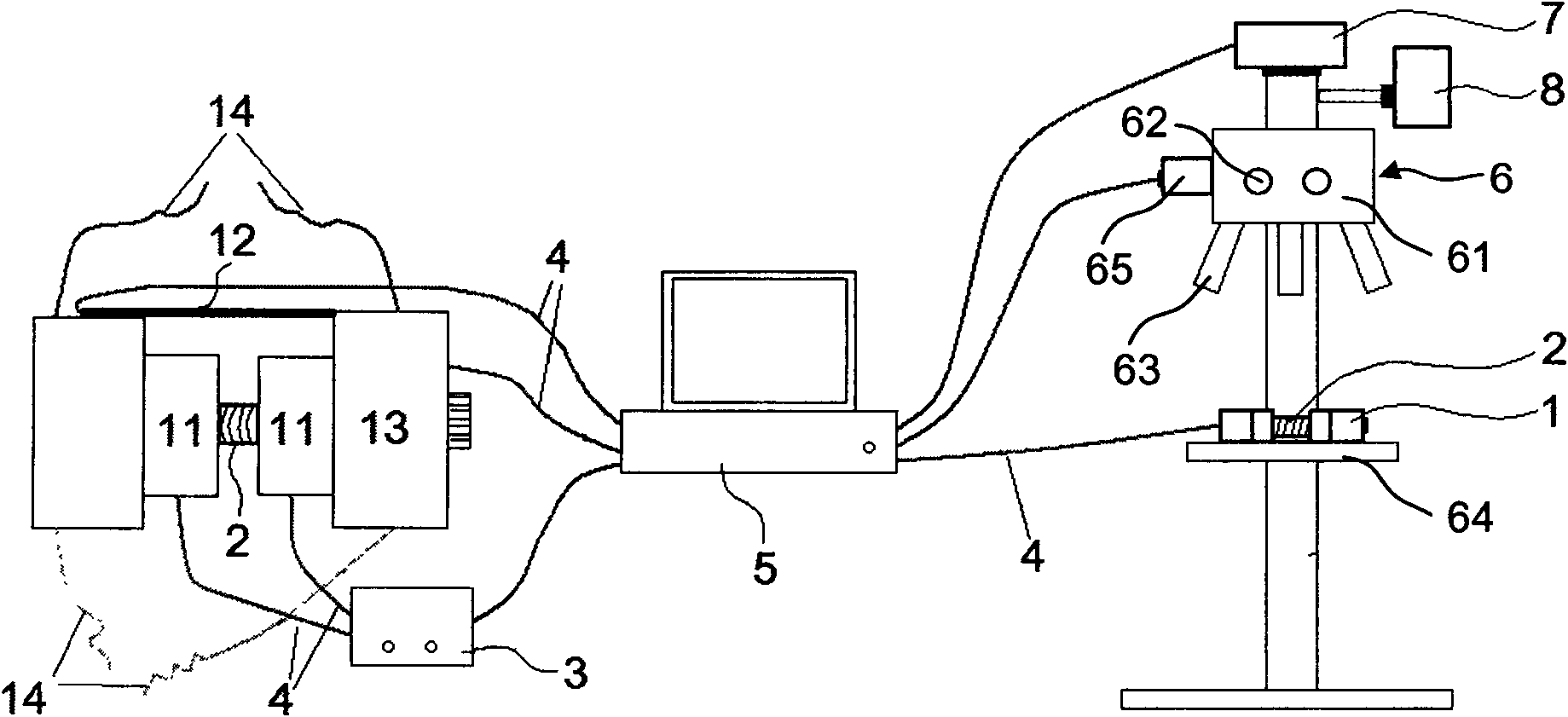

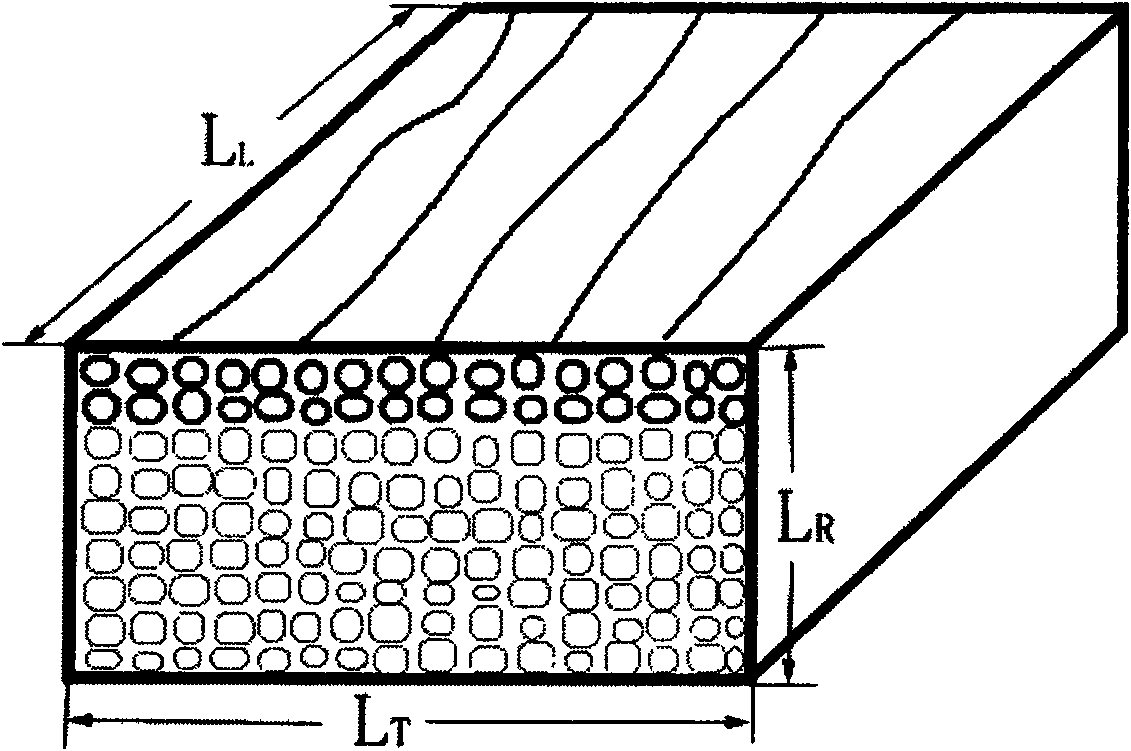

Real-time detection system for wood microstructure characteristic changes

ActiveCN101603820AReal-time reflection of mechanicsReal-time reflection characteristicsUsing optical meansStrength propertiesImaging processingMicroscopic scale

The invention discloses a real-time detection system for wood microstructure characteristic changes, which comprises a loading unit, a microscopic unit, an image acquisition unit and an image processing unit, wherein the loading unit is used to stretch, compress, bend, twist or cut to-be-detected wood; the microscopic unit is used to magnify a to-be-detected area of the wood; the image acquisition unit is used to acquire surface image information of the area magnified through the microscopic unit; and the image processing unit is used to receive image information acquired by the image acquisition unit, calculate and obtain the micro-area strain information and the real-time microstructure change results of the to-be-detected wood. The system can measure micro-area tissue and cell strain to realize micro-area deformation quantization, and can monitor micro-area defects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

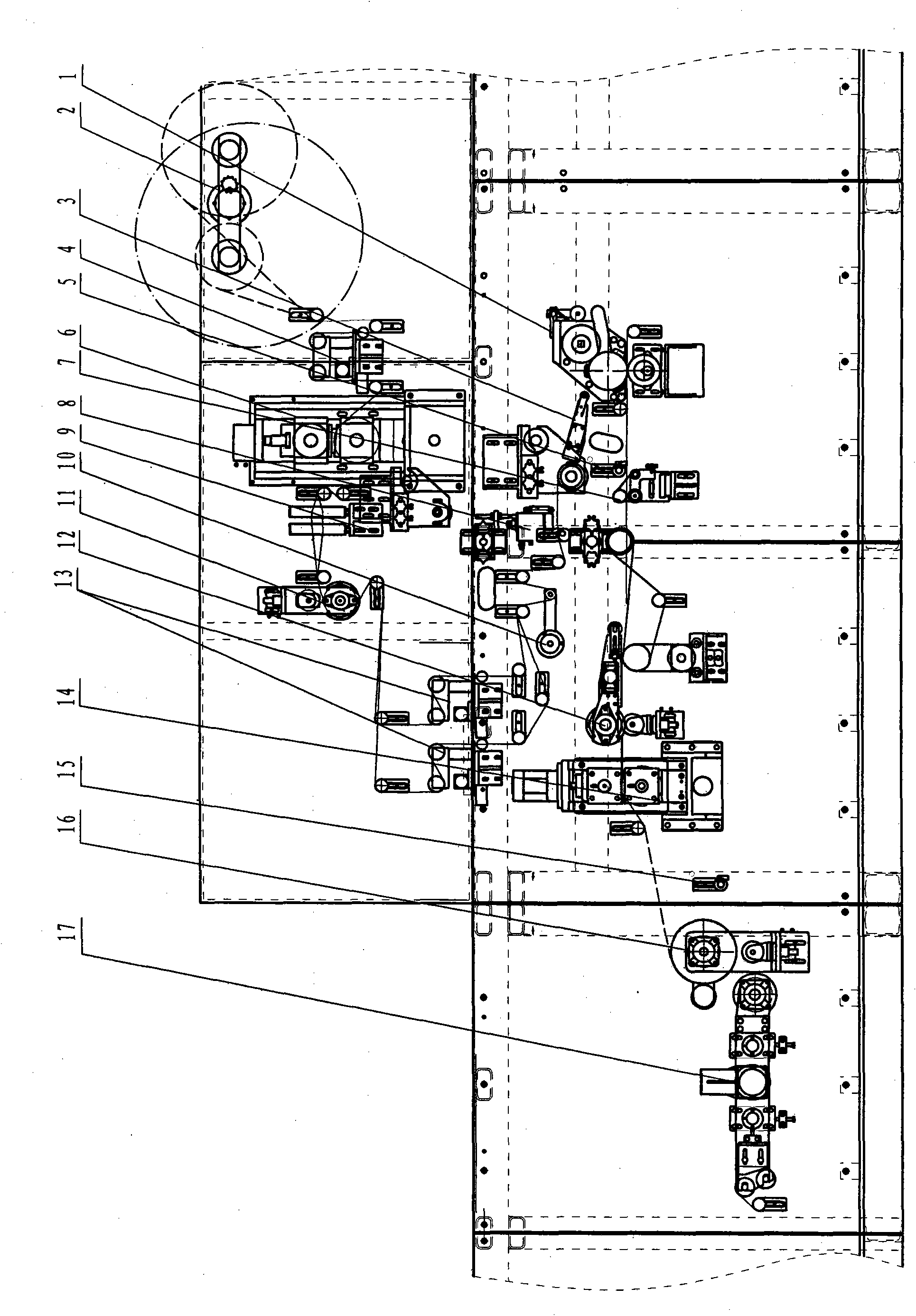

Waist tape cutting and positioning compound device for disposable hygienic product production line

ActiveCN102078239AReasonable designHigh speedAbsorbent padsBaby linensSocial benefitsProduction line

The invention discloses a waist tape cutting and positioning compound device for a disposable hygienic product production line. The device provided by the invention comprises four mechanism components as follows: a first component, namely a cutting compound component which comprises a waist tape gluing gun, a waist tape negative pressure conveyer, a waist tape cutting assembly and a waist tape detection optical hole; a second component, namely a pulling conveying component which comprises a waist tape pulling mechanism, a dragging mechanism, a corrector and a small waist tape cutting and positioning swinging rod; a third component, namely a forming component which comprises a waist tape rotating material rack, a corrector and a magic bent hook cutting assembly; and a fourth component, namely a folding pressing component which comprises a waist tape pressing mechanism, a waist tape folding mechanism, a waist tape pressing point assembly, a shifting wheel and a waist tape detection optical hole. According to the technical scheme of the invention, the problem of high rejection rate is solved, the compound function of cutting and positioning a waist tape is more stable, the positioning precision is high, the production rate of the machine and the product percent of pass are increased, and more economic benefits and social benefits are created.

Owner:ANQING HENG CHANG MACHINERY

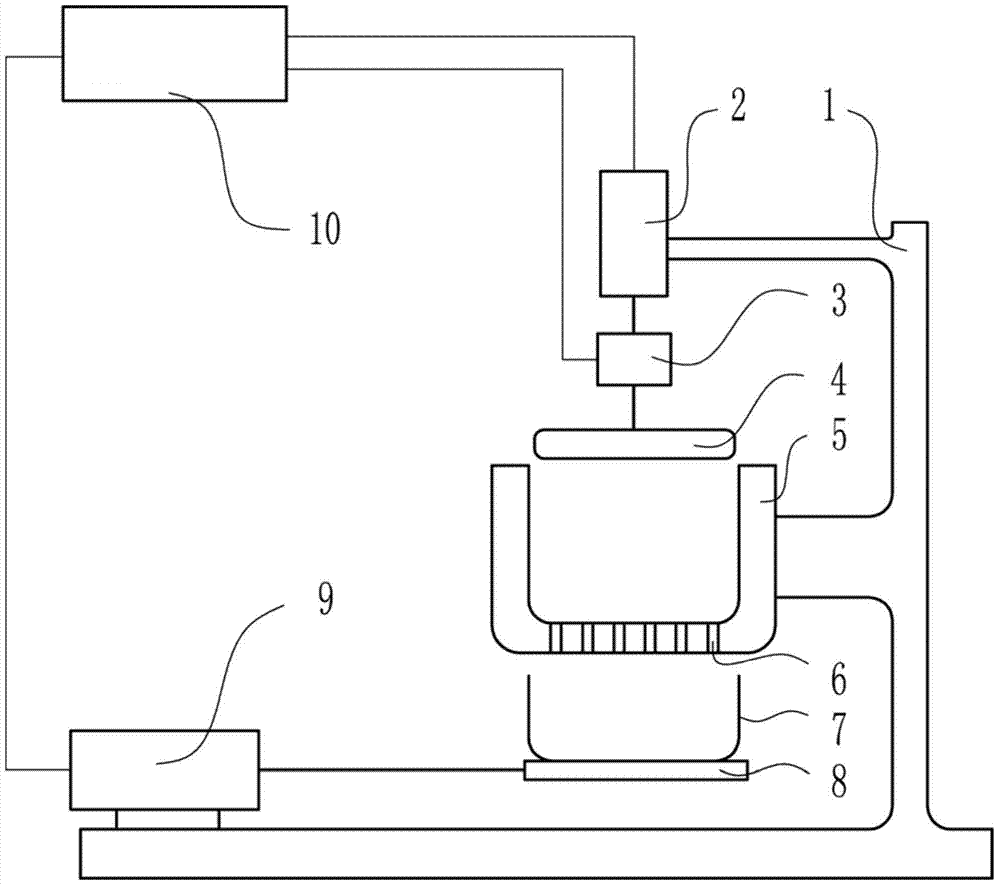

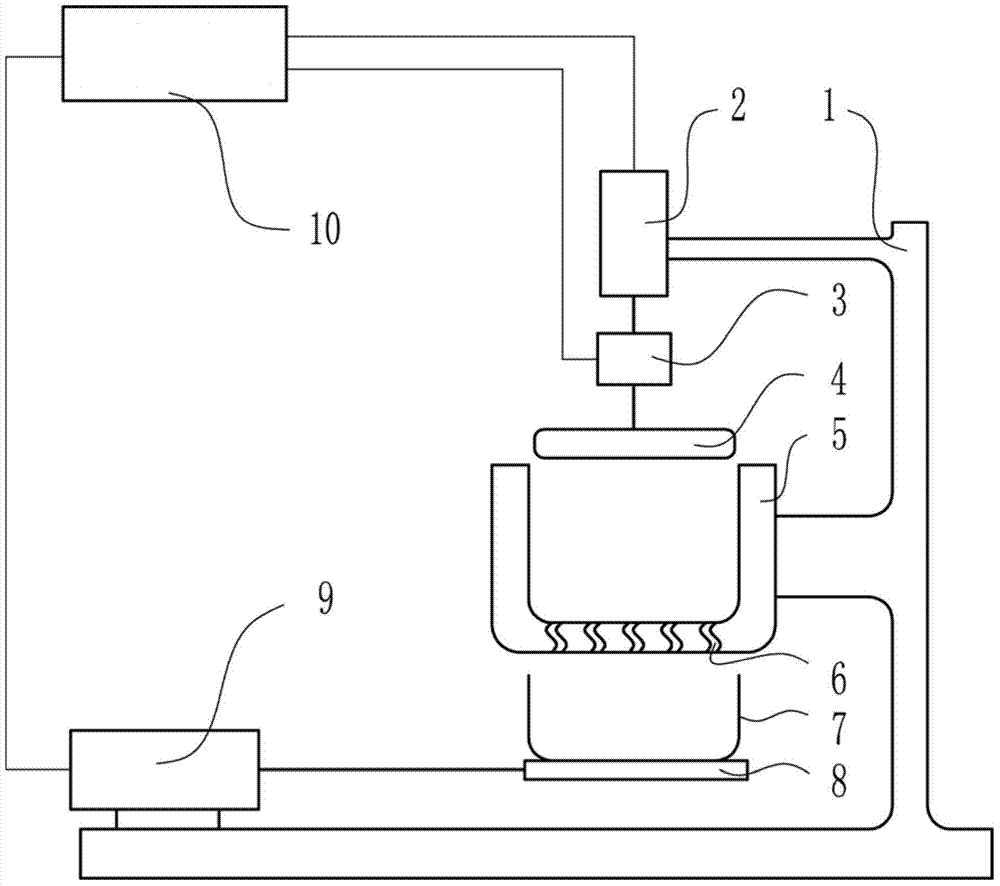

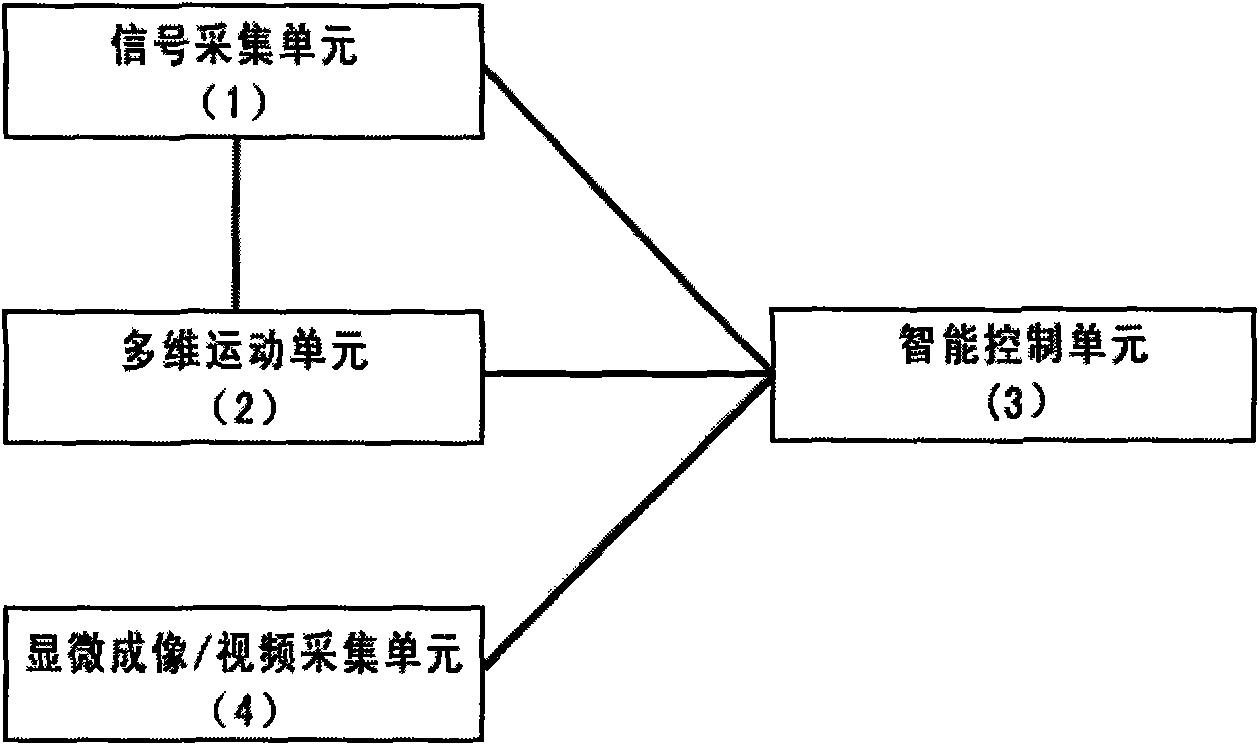

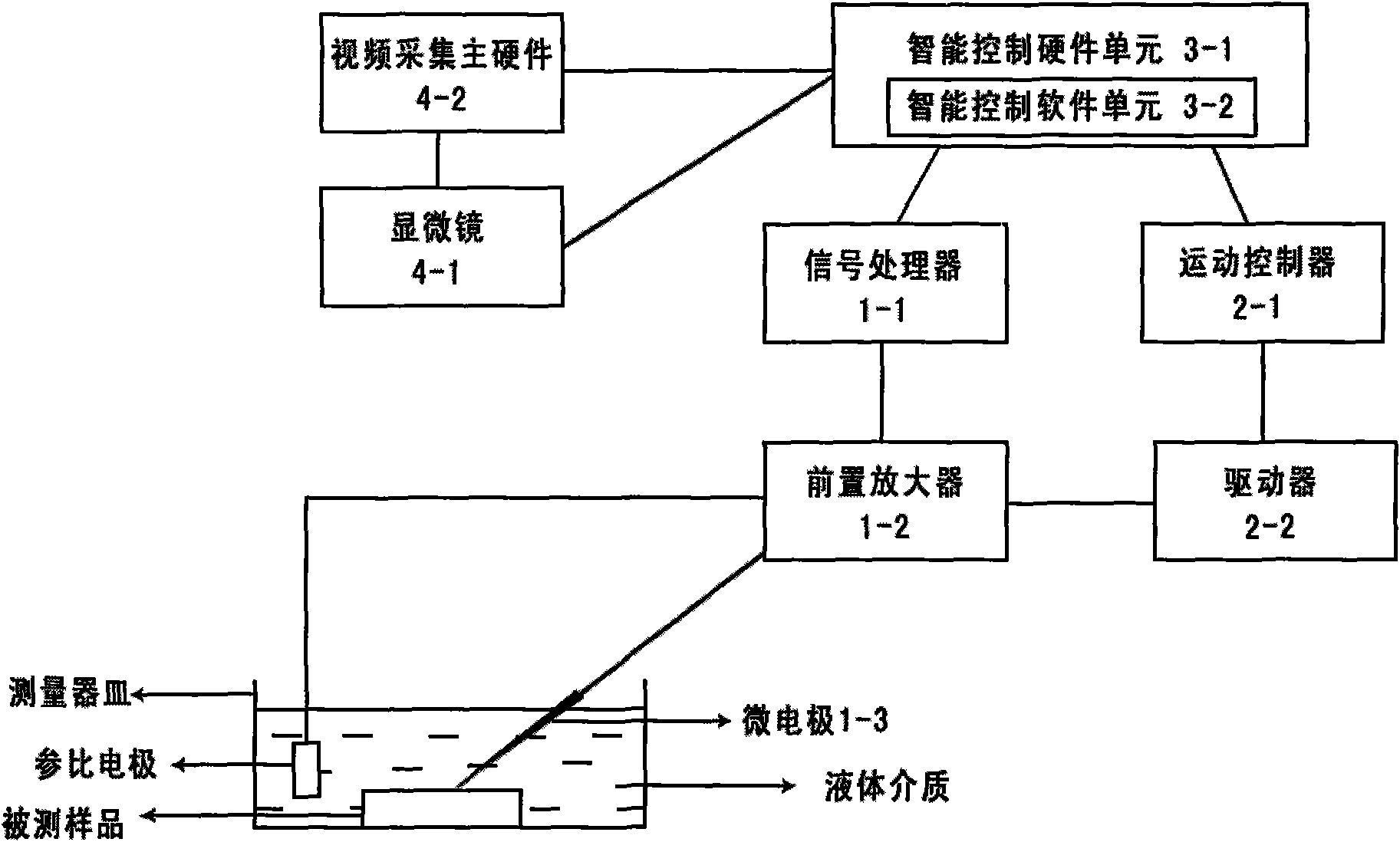

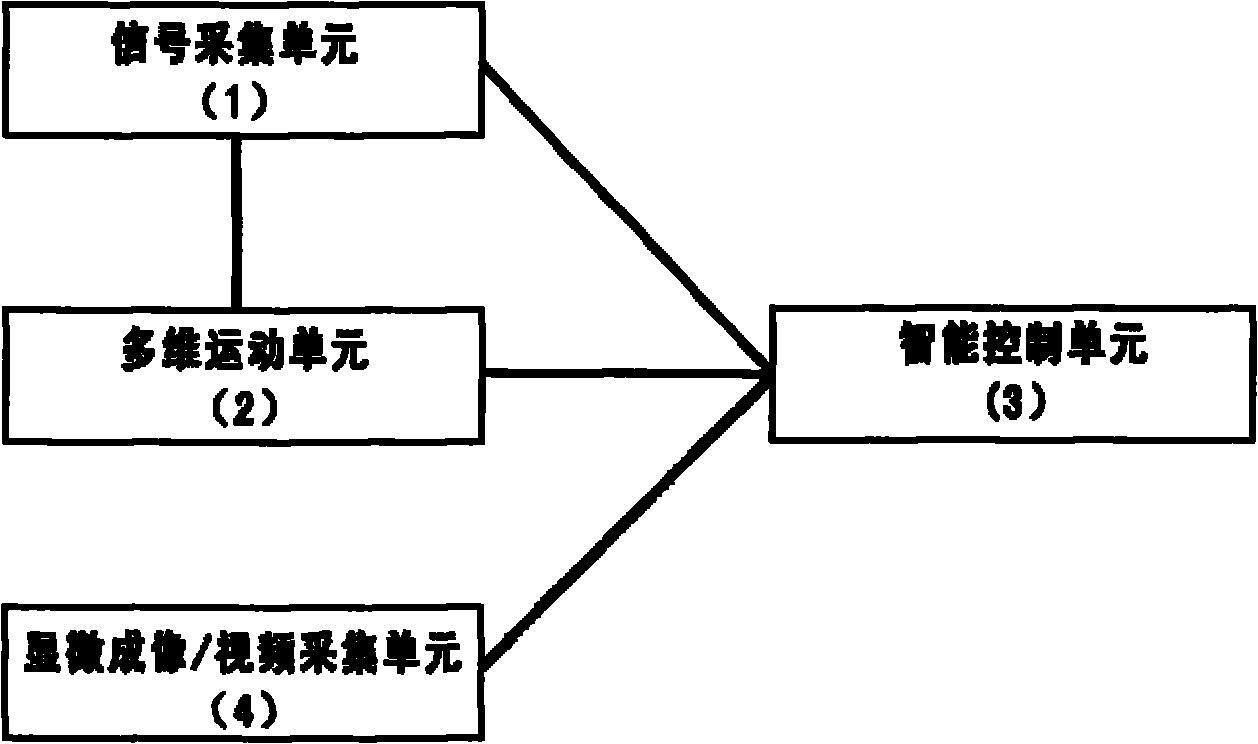

Full-automatic non-invasive micro-test technology

ActiveCN101988914ARealize fully automated operationGood application effectMaterial electrochemical variablesMicro imagingLocal current

The invention provides a method for fully automatically controlling a microelectrode to approach a sample for testing and non-invasively acquiring ion and molecule concentration, flow rate and flow direction of the incoming and outgoing samples, and sample microcell information such as sample surface local current information and the like. The method involves a signal acquisition unit (1), a multidimensional motion unit (2), an intelligent control unit (3) and a micro-imaging / video acquisition unit (4). The intelligent control unit (3) sends a control command to the multidimensional motion unit (2) and the micro-imaging / video acquisition unit (4) by analyzing a signal transmitted by the signal acquisition unit (1) and the micro-imaging / video acquisition unit (4), controls the motion of the microelectrode and the measured sample, and realizes full-automatic information acquisition of the measured sample by the microelectrode. The method causes no damage to the measured sample, the operating process is fully automatic and independent of man-made operating factors, and the acquired data is steady and reliable. The method can be applied to biological living body, non-organism and other samples.

Owner:XUYUE BEIJING

Automatic plate shearing machine

InactiveCN106424892AAutomate operationRealize automatic feedingMetal-working feeding devicesShearing machinesControl systemEngineering

The invention provides an automatic plate shearing machine. The automatic plate shearing machine comprises a feeding device, a shearing device and a material collection device, wherein the feeding device comprises a conveyer belt bracket, an upper conveyer belt, a lower conveyer belt, driving rollers, a motor and a variable frequency controller; the shearing device comprises a rack, a plate shearing platform, a pressing device, a movable limiting device, a control system, a shearing mechanism and a driving mechanism; and the material collection device comprises a material collection disc, slide rails and a material collection disc limiting device. The automatic plate shearing machine has the beneficial effects that the automation degree is high, the steel plate shearing precision is high, and the qualification rate of a finished product is high.

Owner:TIANJIN YUTENG HENGTAI STEEL PROD

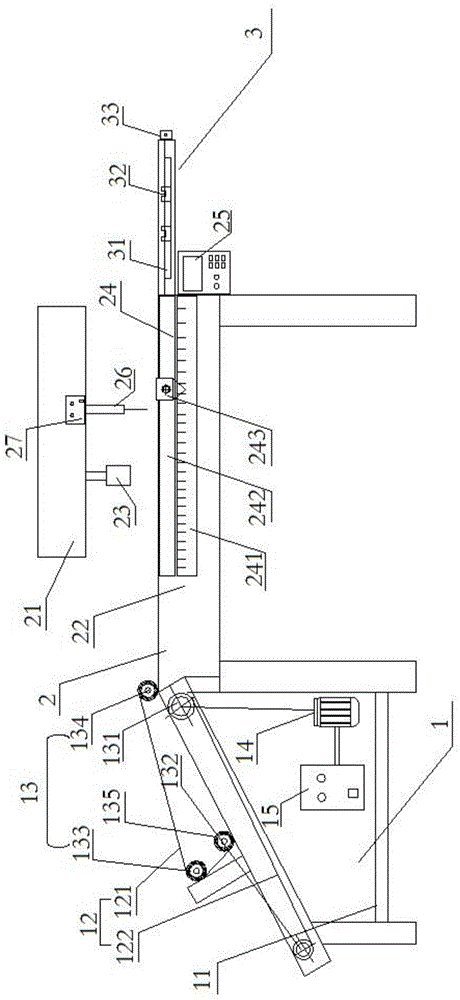

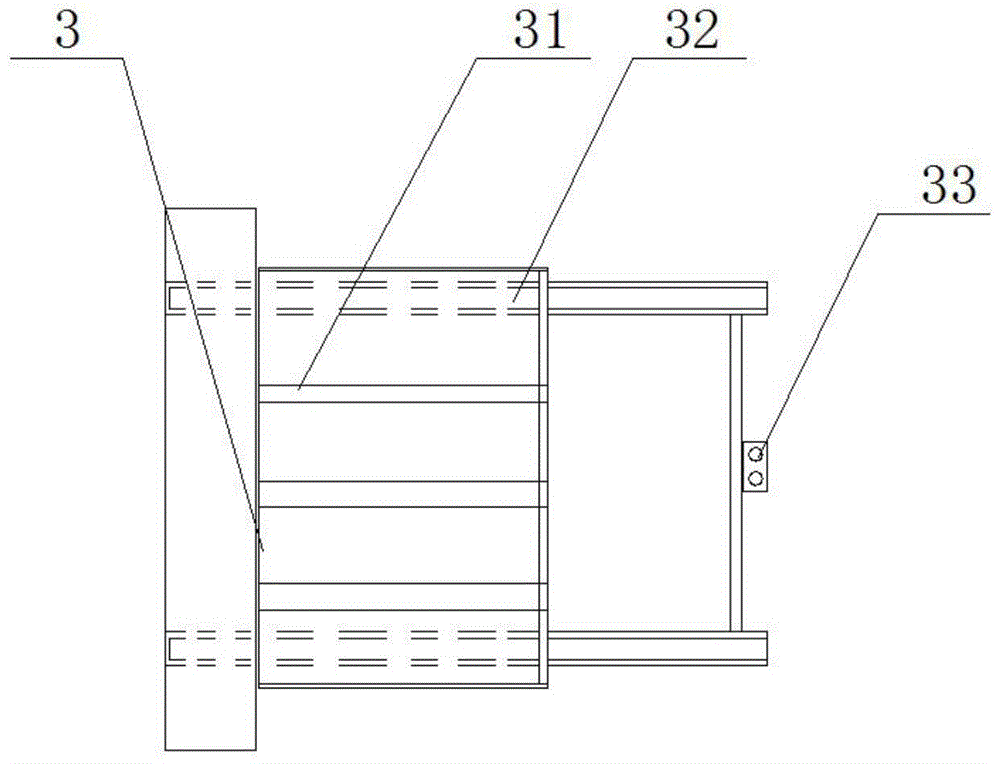

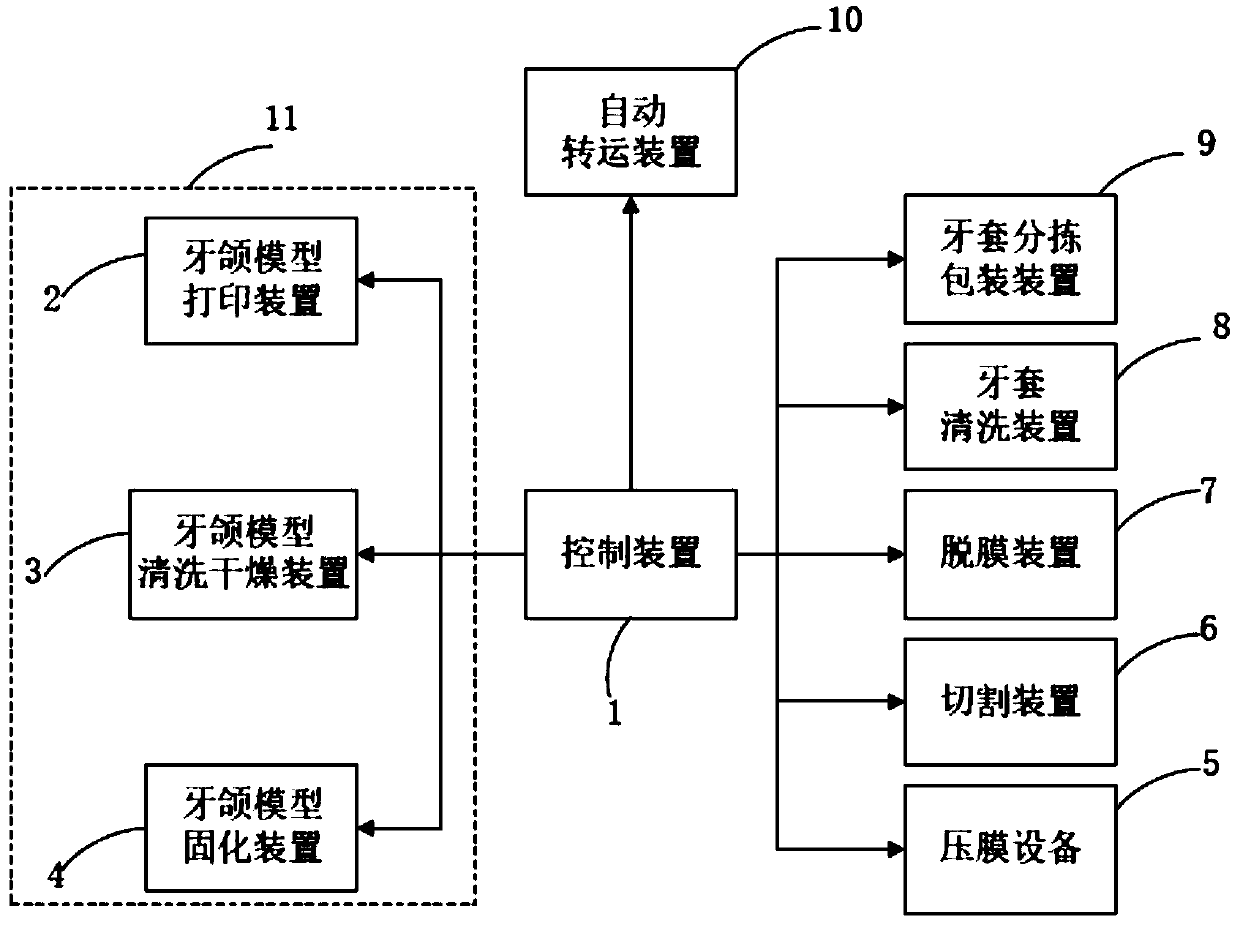

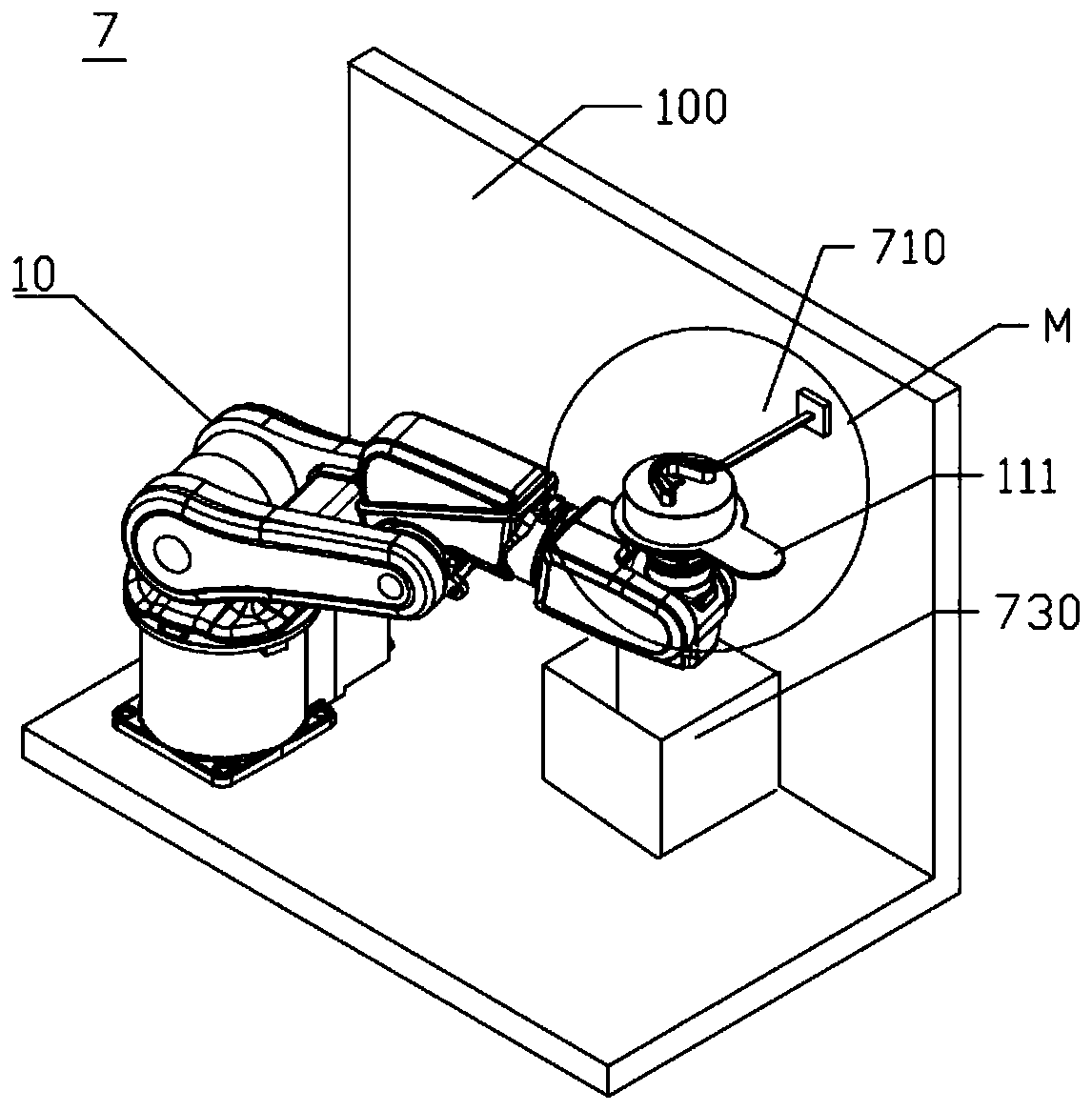

Membrane stripping device, membrane stripping method and one-stop tooth socket production system

PendingCN109808157AQuality assuranceAvoid exposure to contaminationDrying gas arrangementsDental articulatorsEngineeringDental Models

The invention discloses a membrane stripping device which comprises a control device, an automatic transfer device, a transmission tray arranged at the free end of the automatic transfer device and amembrane stripping module. The membrane stripping module is provided with a membrane prying part which is provided with a membrane prying end, the transmission tray can be loaded with a dental model with a tooth socket to be subjected to membrane stripping, the control device controls the automatic transfer device to move to enable the open end of the tooth socket loaded on the automatic transferdevice to make contact with the membrane prying end, the control device controls the automatic transfer device and the membrane prying part to move relatively to produce membrane prying force to pry the tooth socket from the dental model, and automatic stripping of the tooth socket from the dental model is achieved. The invention further discloses an automatic membrane stripping method adopting the membrane stripping device and a one-stop tooth socket production system with the membrane stripping device. The membrane stripping device and the membrane stripping method achieve automatic membranestripping in tooth socket production, and the one-stop tooth socket production system achieves integrated layout of tooth socket production and lays a foundation to chair side manufacturing and immediate delivery.

Owner:浙江正雅齿科股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com