Waist tape cutting and positioning compound device for disposable hygienic product production line

A sanitary product and composite device technology, applied in the field of machinery, can solve problems such as waste products, poor positioning accuracy, long and short waist stickers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

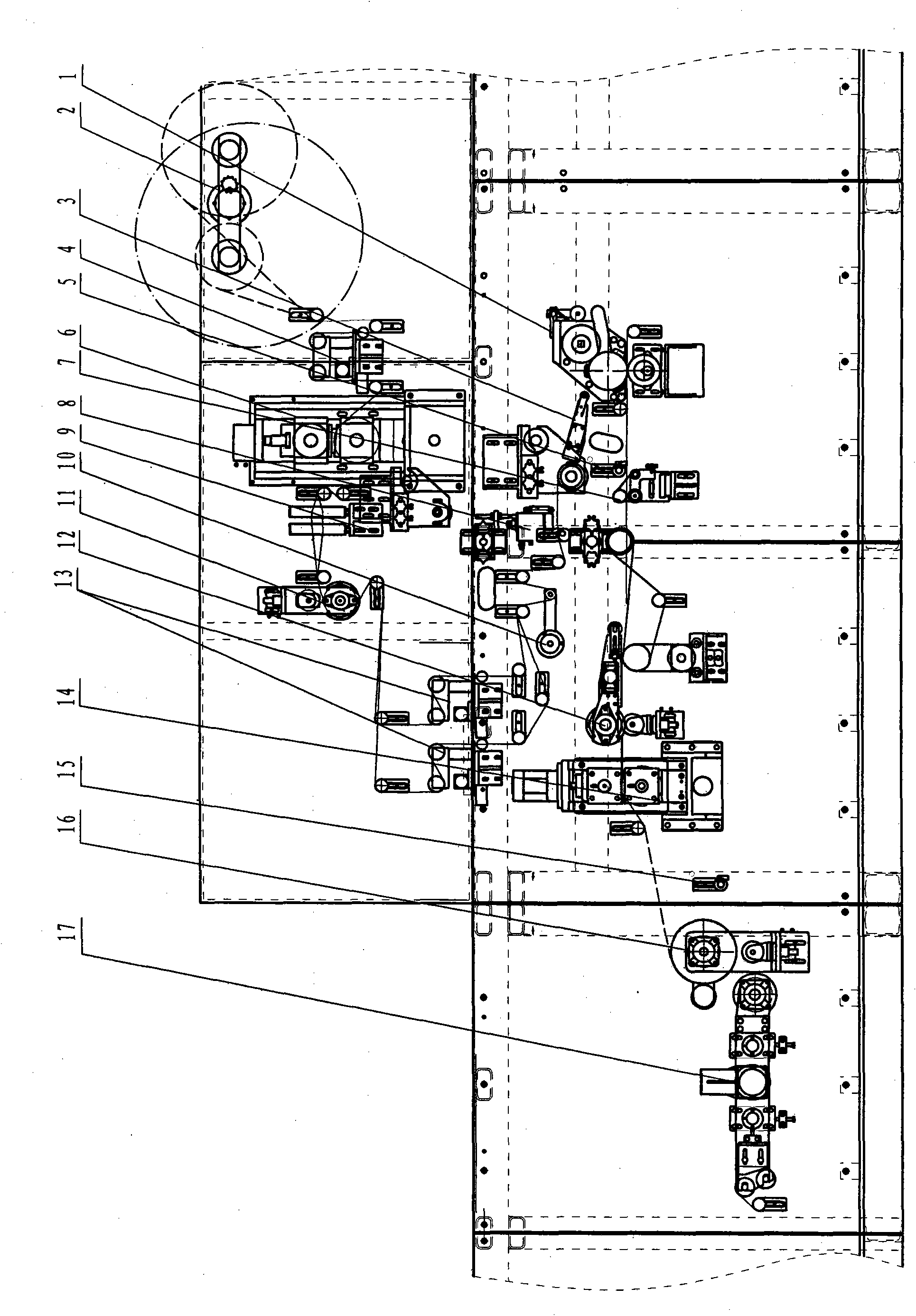

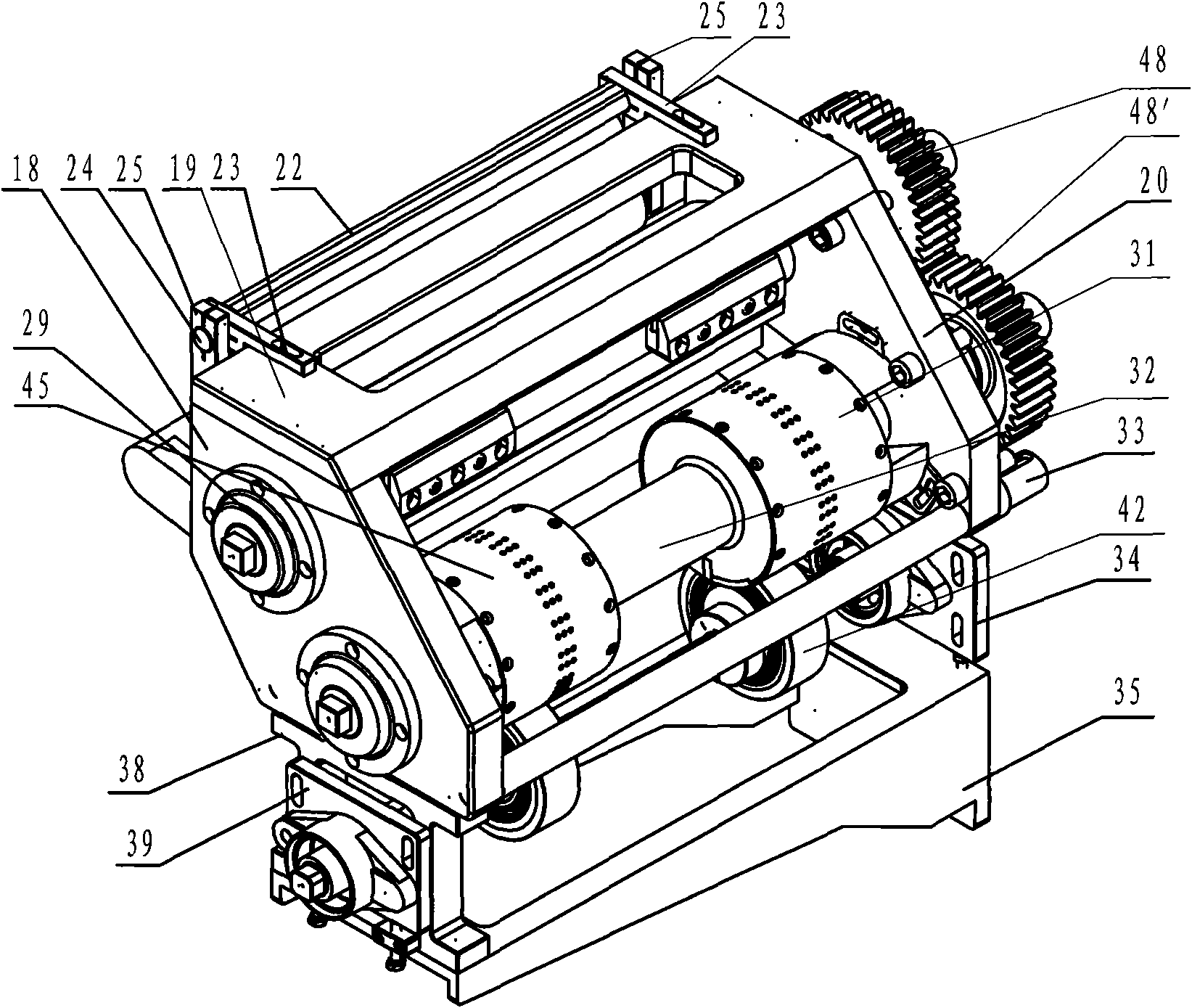

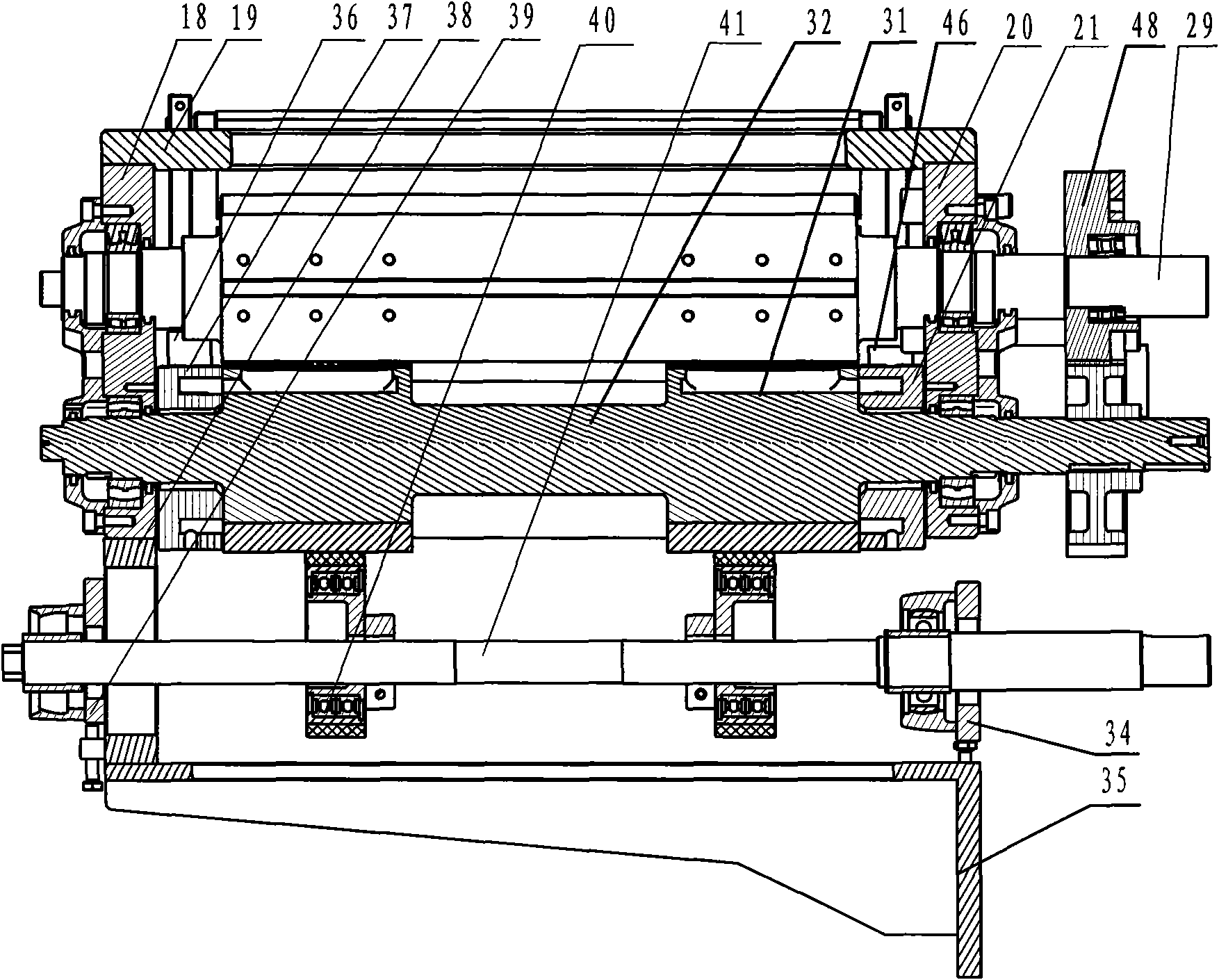

[0035] The following is a detailed description of the waist tape slitting positioning composite device of the disposable sanitary product production line of the present invention with reference to the accompanying drawings:

[0036] The waist sticker slitting and positioning composite device of the disposable sanitary product production line of the present invention includes an unwinding component, a tension adjusting component, a traction component, a slitting component, a steering component, a conveying component (two servo motors), a correction component, and a folding component And detection components.

[0037] See figure 1 , The waist tape slitting and positioning compound device of the disposable sanitary product production line includes waist tape cutting assembly 1, waist tape rotating material rack 2, waist tape negative pressure conveying device 3, corrector I 4, waist tape detection optical eye I 5. Magic hook slitting assembly 6, Waist stick creasing mechanism 7, Waist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com