Three-axial magnetometer correcting method and three-axial magnetic gradient correcting method

A calibration method and three-axis magnetic technology, applied in the direction of the size/direction of the magnetic field, instruments, measuring devices, etc., can solve the problems of excessive site area requirements, small site area requirements, background magnetic field errors, etc., and achieve small site area requirements , low equipment requirements and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] a. Compensate the background magnetic field in the working area: Compensate the magnetic field in the center of the homogeneous area of the triaxial Helmholtz coil to a level where the magnetic field value is less than 1nT. According to the current level of compensation technology, the residual magnetic field of each component of the three-axis coil can be kept at a level less than 1nT in a short period of time (10 minutes).

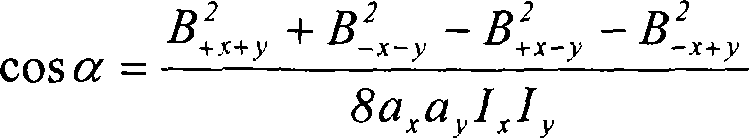

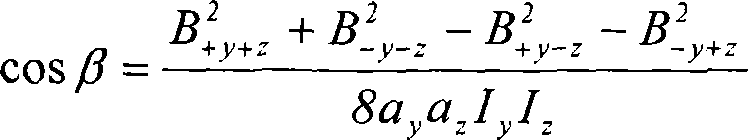

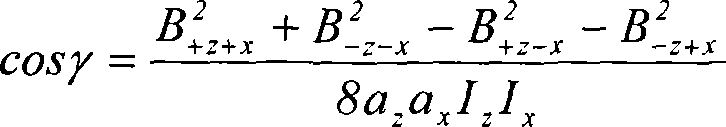

[0040] b. Test the coil constants of the three axes of the magnetic field coil: taking the X axis as an example, apply a current value of 60A in the positive and negative directions of the same direction to the X axis of the three axis coil in step a. Record the applied current value and the corresponding output value of the scalar magnetometer placed in the center of the uniform area of the above-mentioned three-axis coil, and calculate the coil constant on each axis of the above-mentioned three-axis coil, and divide the sum of these two outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com