Top-lifting step conveyance multi-purpose cleaning machine with material frame provided with spray nozzle

A technology of stepping conveying and cleaning machines, which is applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of increased investment, poor equipment versatility, and inability to effectively guarantee the cleaning quality. The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

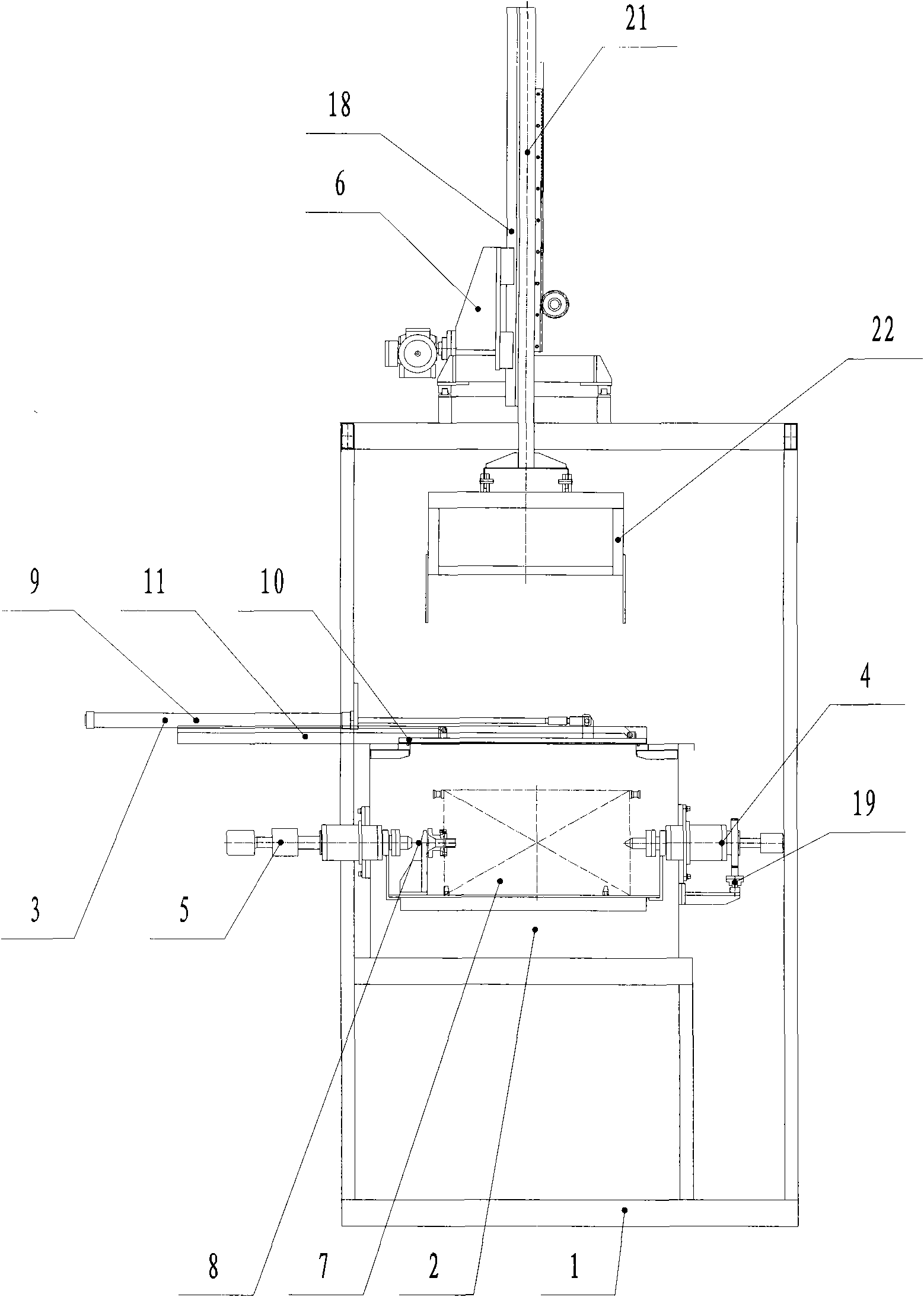

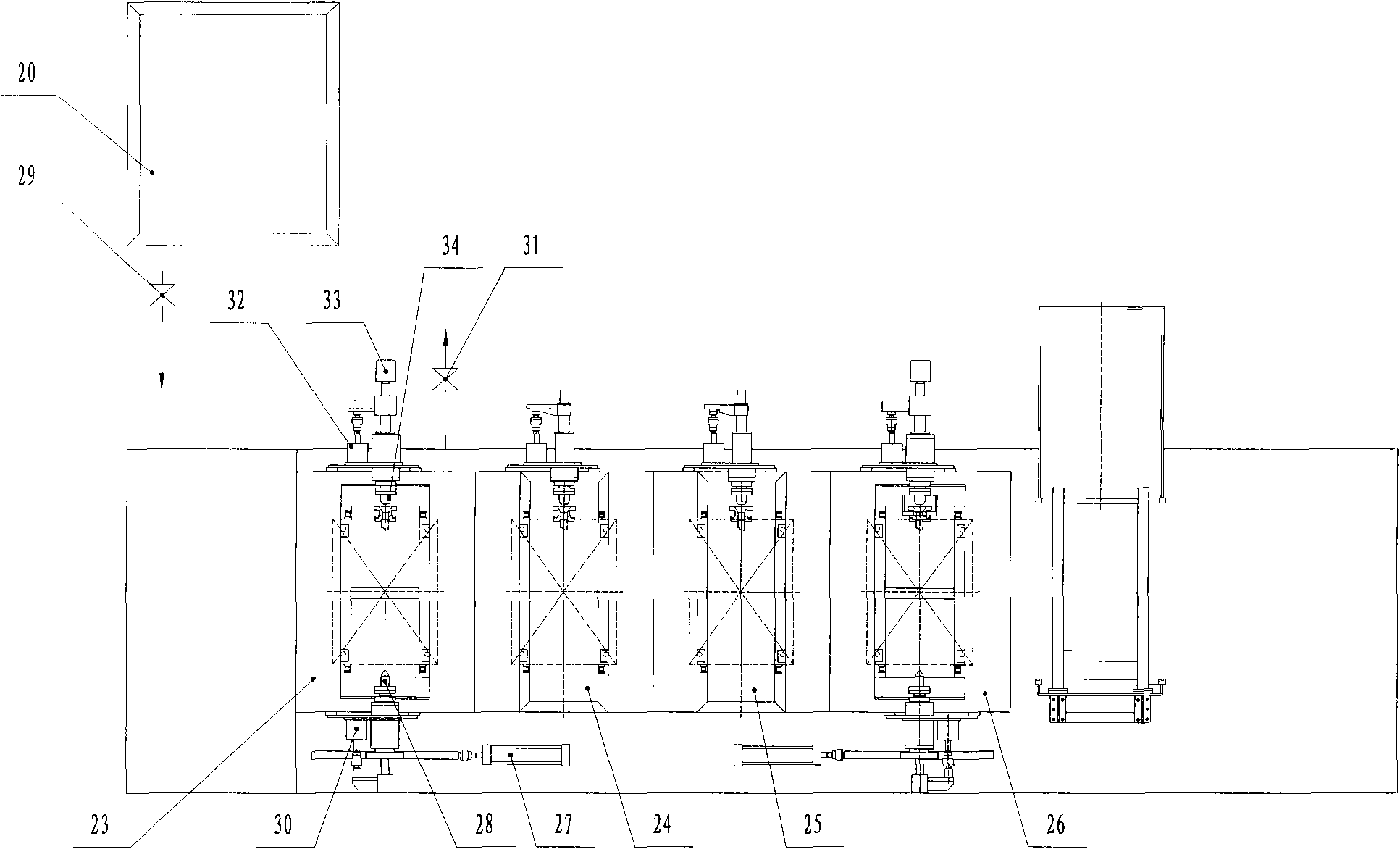

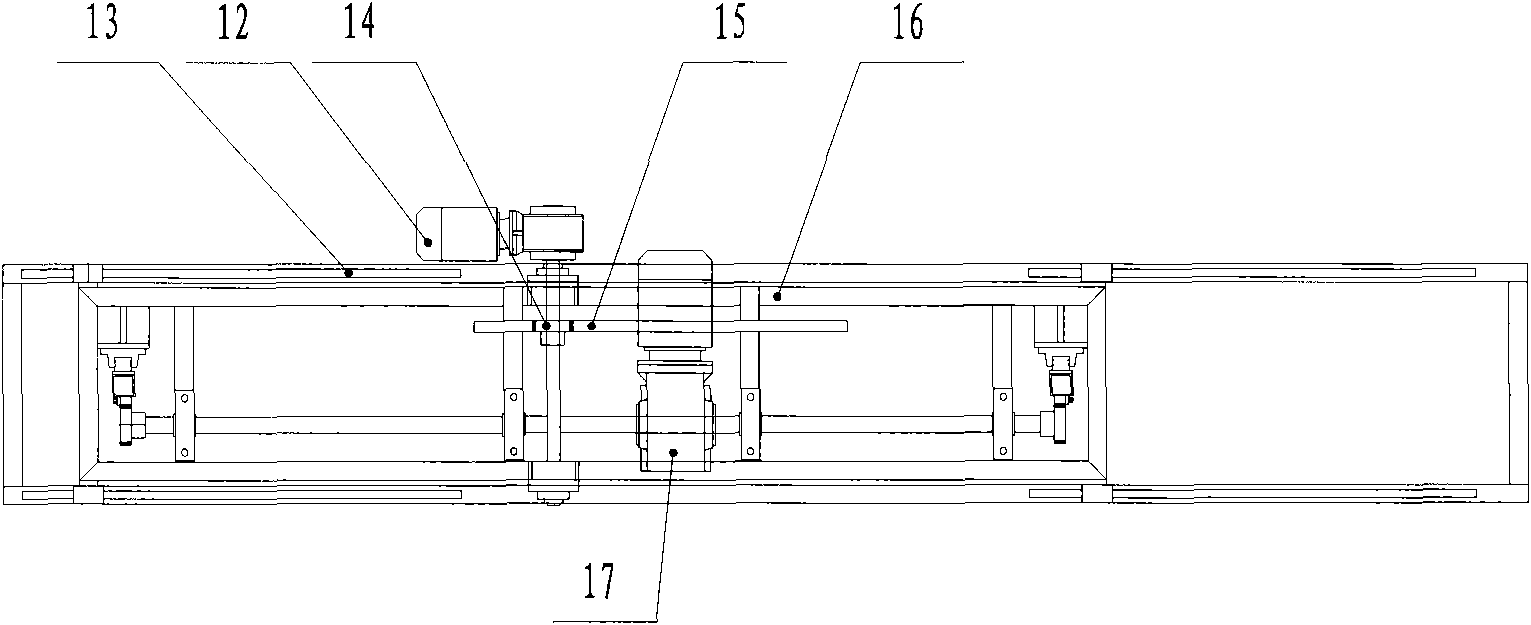

[0027] The power source of the driving device adopted in this example is a pneumatic pump, the workpiece is put into the special material frame 7, and the special material frame 7 is provided with a nozzle at the corresponding hole of the workpiece, and the nozzle is connected with the water inlet and the air intake pipe 8. The material frame 7 enters the surge cleaning station 23 through the automatic feeding frame device, the discharge valve 29 is opened, the cleaning liquid in the high-level water tank 20 is discharged into the surge cleaning station 23, and the driving device 9 in the pneumatic sealing cover plate 3 is the cylinder action, drive the cover plate 10 to run along the cover plate guide rail 11 to cover the surge cleaning station 23.

[0028] The driving device 32 in the rotary water supply device 5 acts to drive the center top 34 to communicate with the water inlet and air inlet pipe 8 on the special material frame 7, and the rotary joint 33 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com