Patents

Literature

32758results about How to "High tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

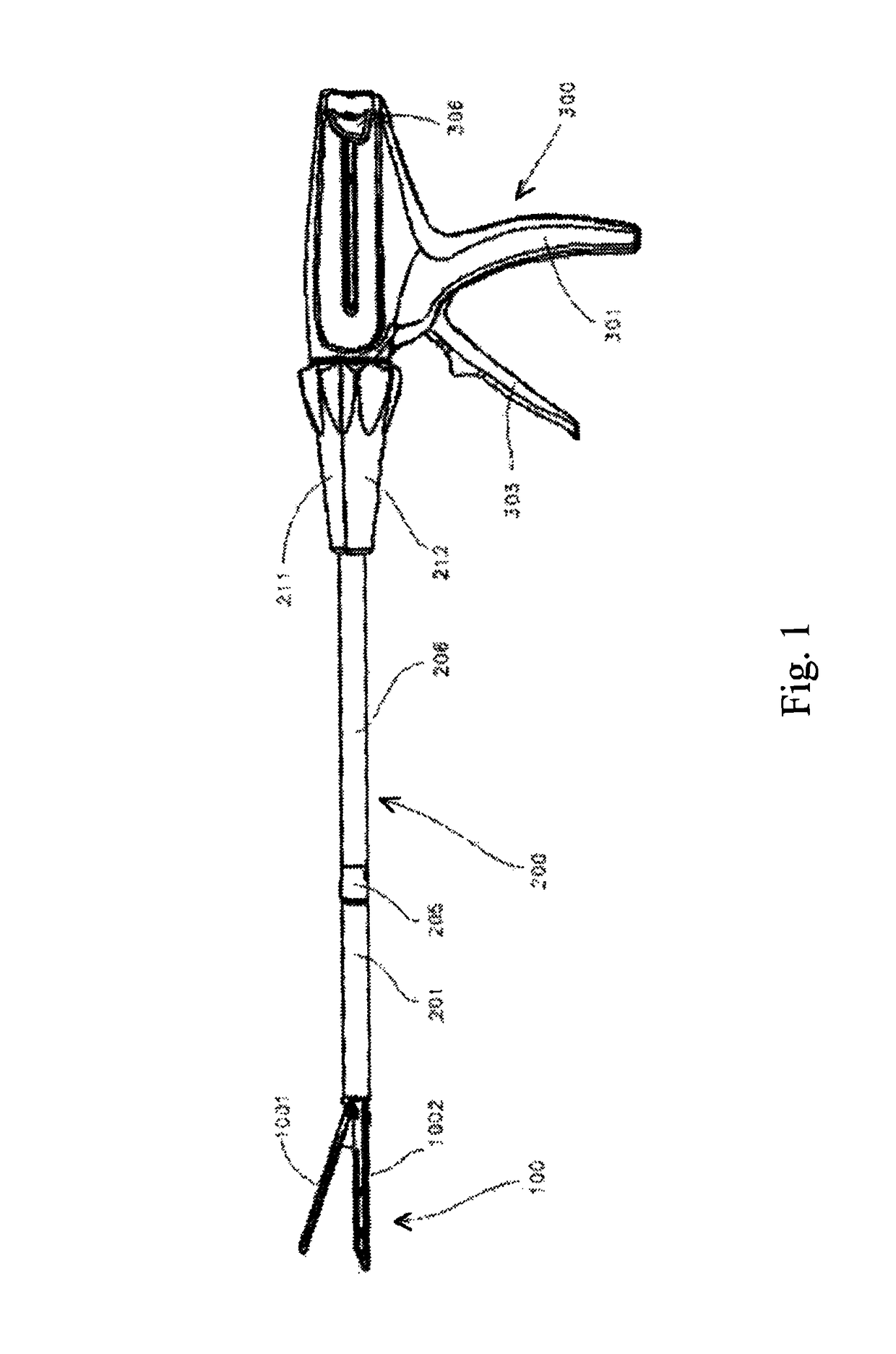

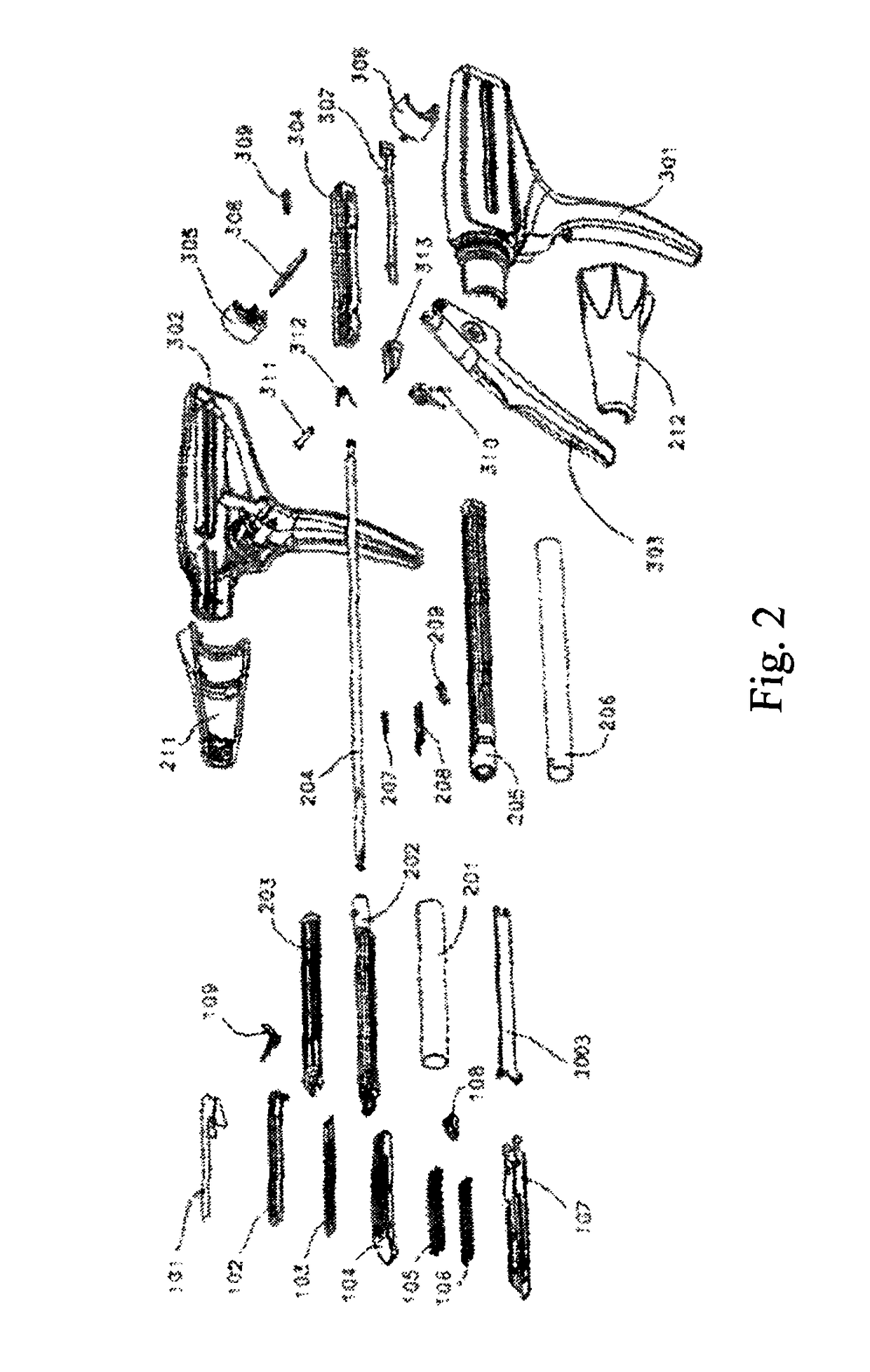

Surgical apparatus actuator

ActiveUS9924945B2Increase the difficultyImprove accuracySurgical staplesEngineeringMechanical engineering

Owner:EZISURG MEDICAL CO LTD

Collagen biofabric and methods of preparation and use therefor

InactiveUS20040048796A1Improved biophysical propertyImprove featuresSenses disorderPeptide/protein ingredientsSurgical GraftWound dressing

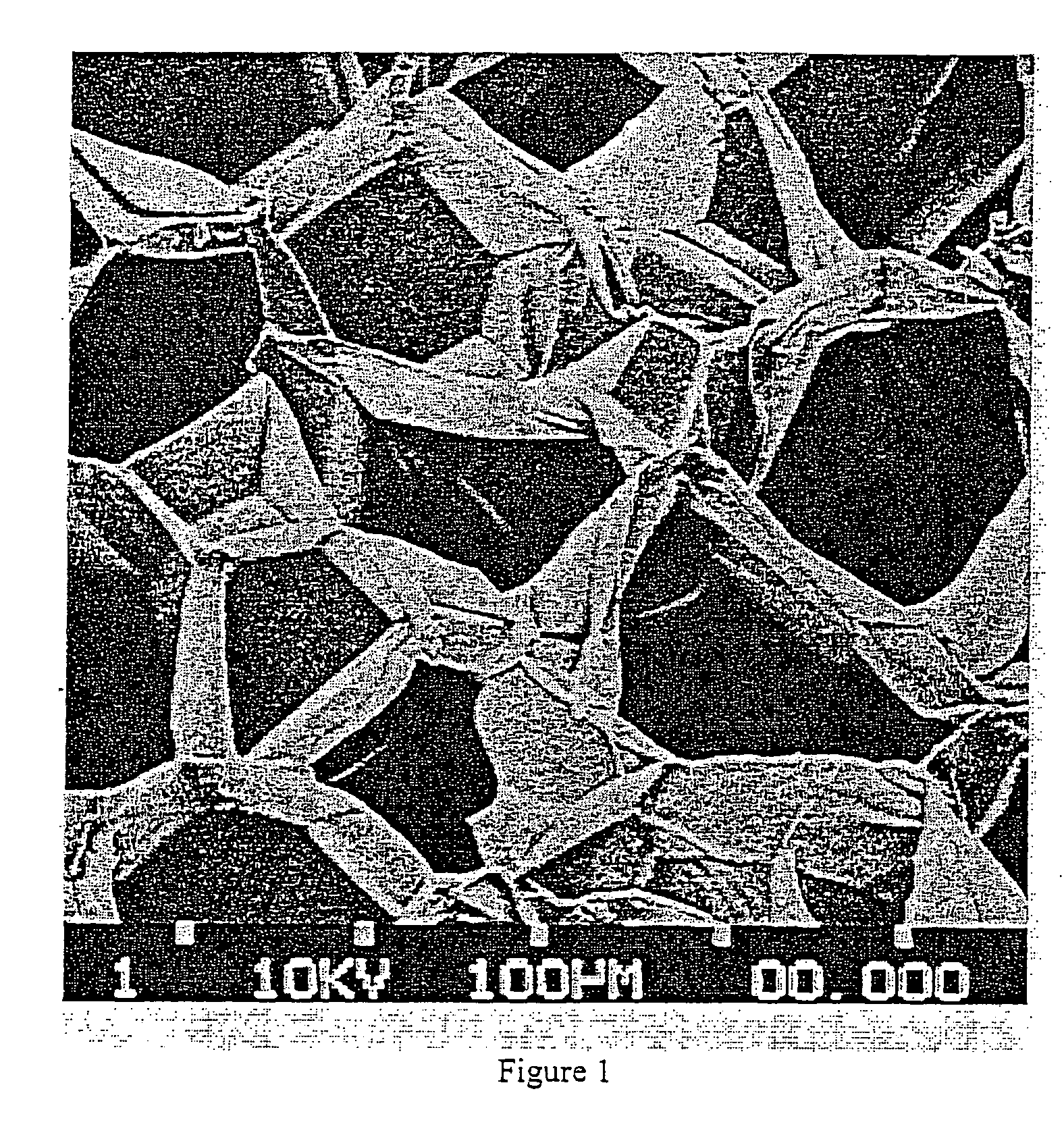

The present invention relates to collagenous membranes produced from amnion, herein referred to as a collagen biofabric. The collagen biofabric of the invention has the structural integrity of the native non-treated amniotic membrane, i.e., the native tertiary and quaternary structure. The present invention provides a method for preparing a collagen biofabric from a placental membrane, preferably a human placental membrane having a chorionic and amniotic membrane, by decellularizing the amniotic membrane. In a preferred embodiment, the amniotic membrane is completely decellularized. The collagen biofabric of the invention has numerous utilities in the medical and surgical field including for example, blood vessel repair, construction and replacement of a blood vessel, tendon and ligament replacement, wound-dressing, surgical grafts, ophthalmic uses, sutures, and others. The benefits of the biofabric are, in part, due to its physical properties such as biomechanical strength, flexibility, suturability, and low immunogenicity, particularly when derived from human placenta.

Owner:CELLULAR THERAPEUTICS DIV OF CELGENE +1

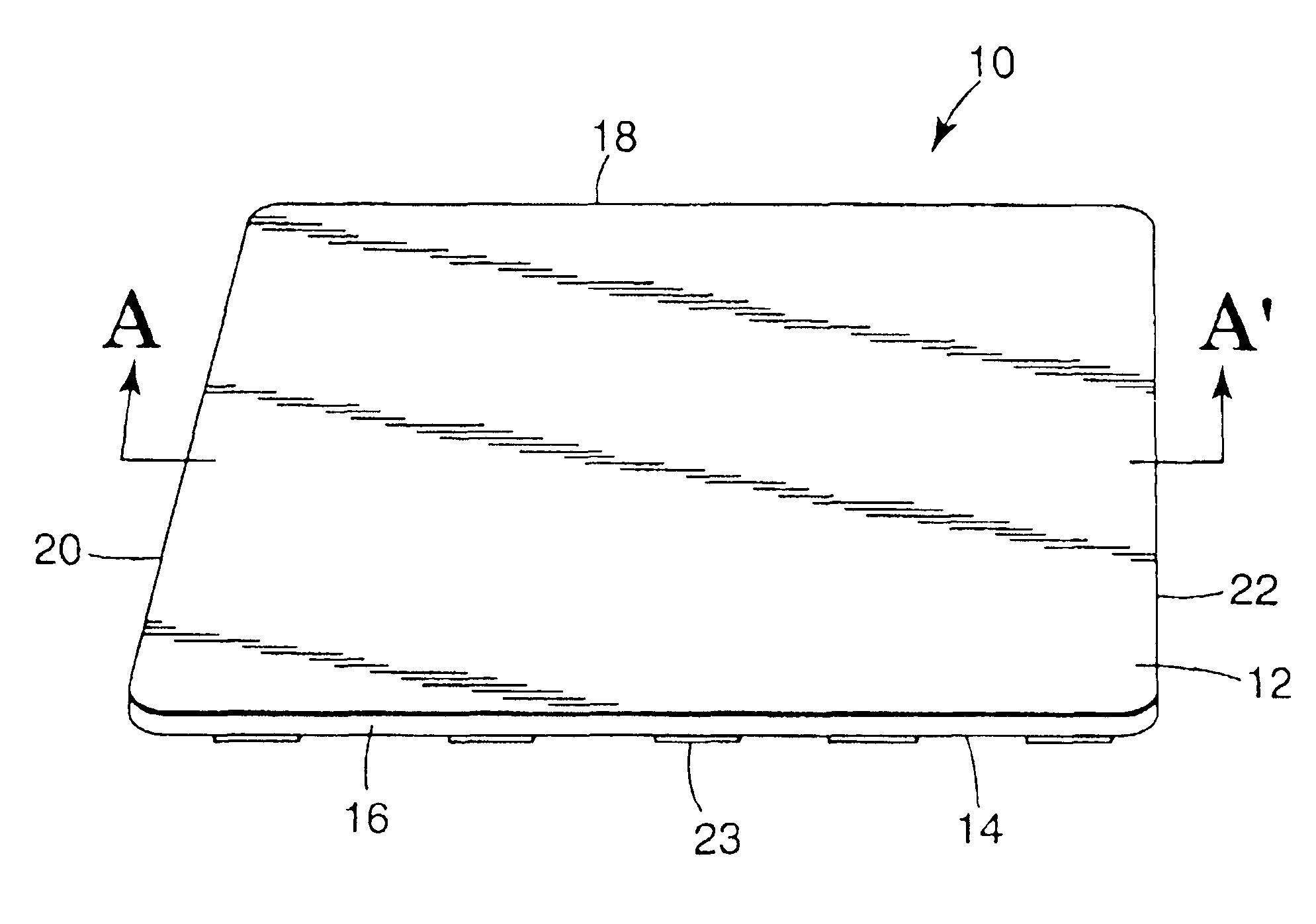

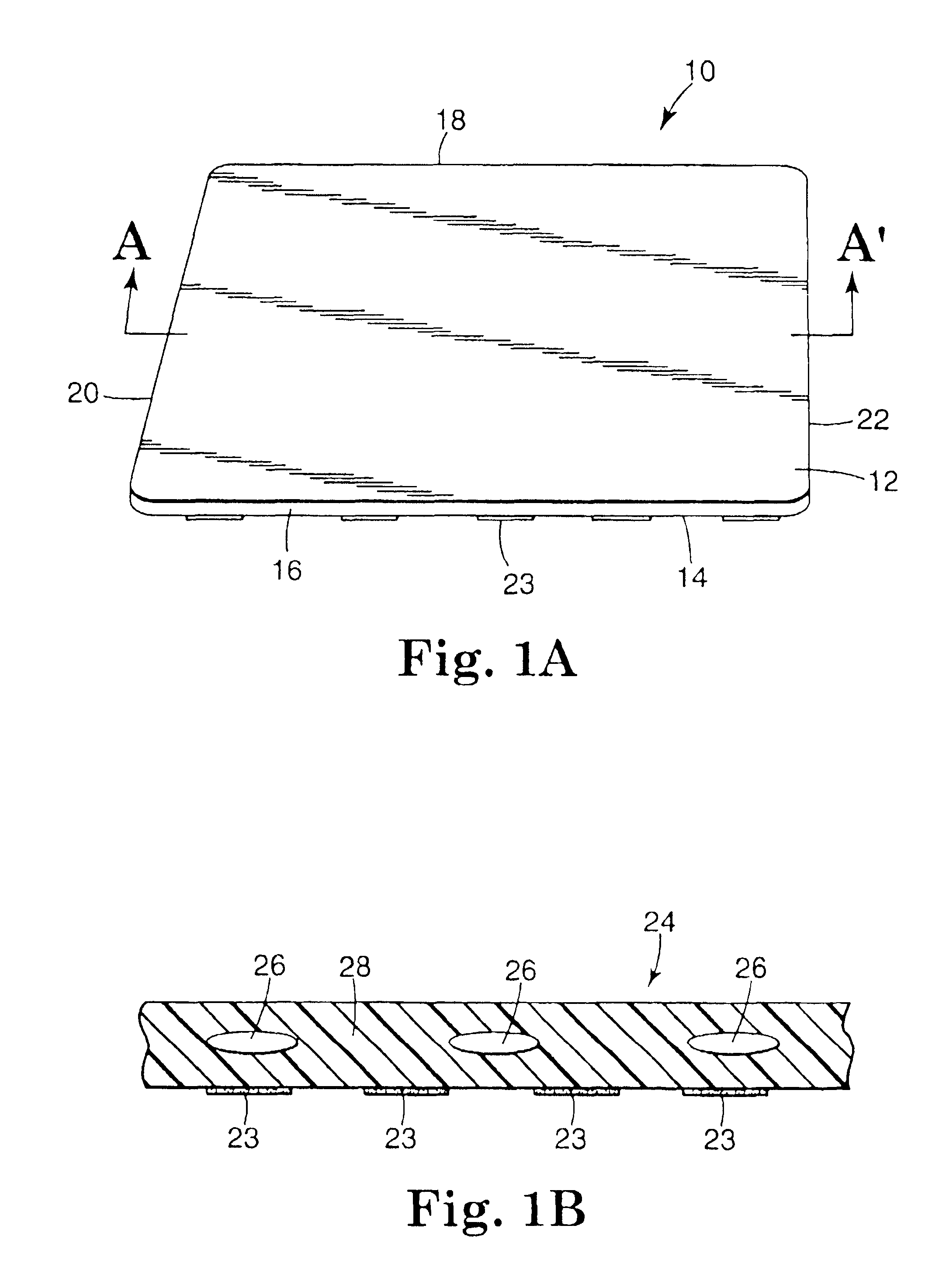

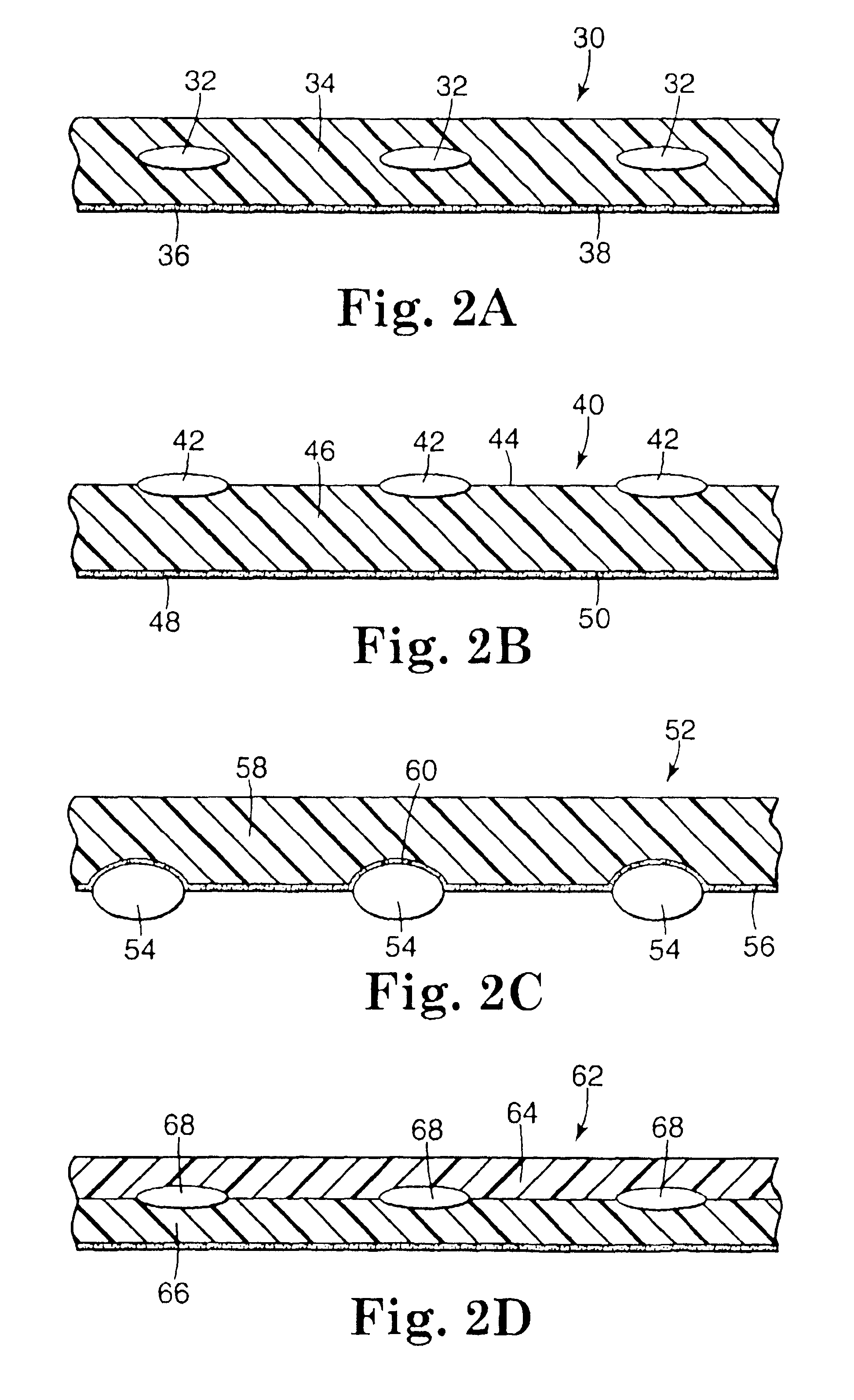

Adhesive composite having distinct phases

InactiveUS6927315B1Increase stiffnessHigh tensile strengthPlastersAdhesive dressingsMoisture vapor transmission rateEngineering

A conformable adhesive article for use as a sterile medical dressing is described. The article includes a breathable polymeric matrix, a plurality of phases, and an adhesive composition positioned on the polymeric matrix. The plurality of phases preferably provide reinforcement and stiffness to the article. The article permits transport of moisture across the breathable polymeric matrix, preferably at an Inverted water moisture vapor transmission rate of at least 300 g / m2 / 24 hours.

Owner:3M INNOVATIVE PROPERTIES CO

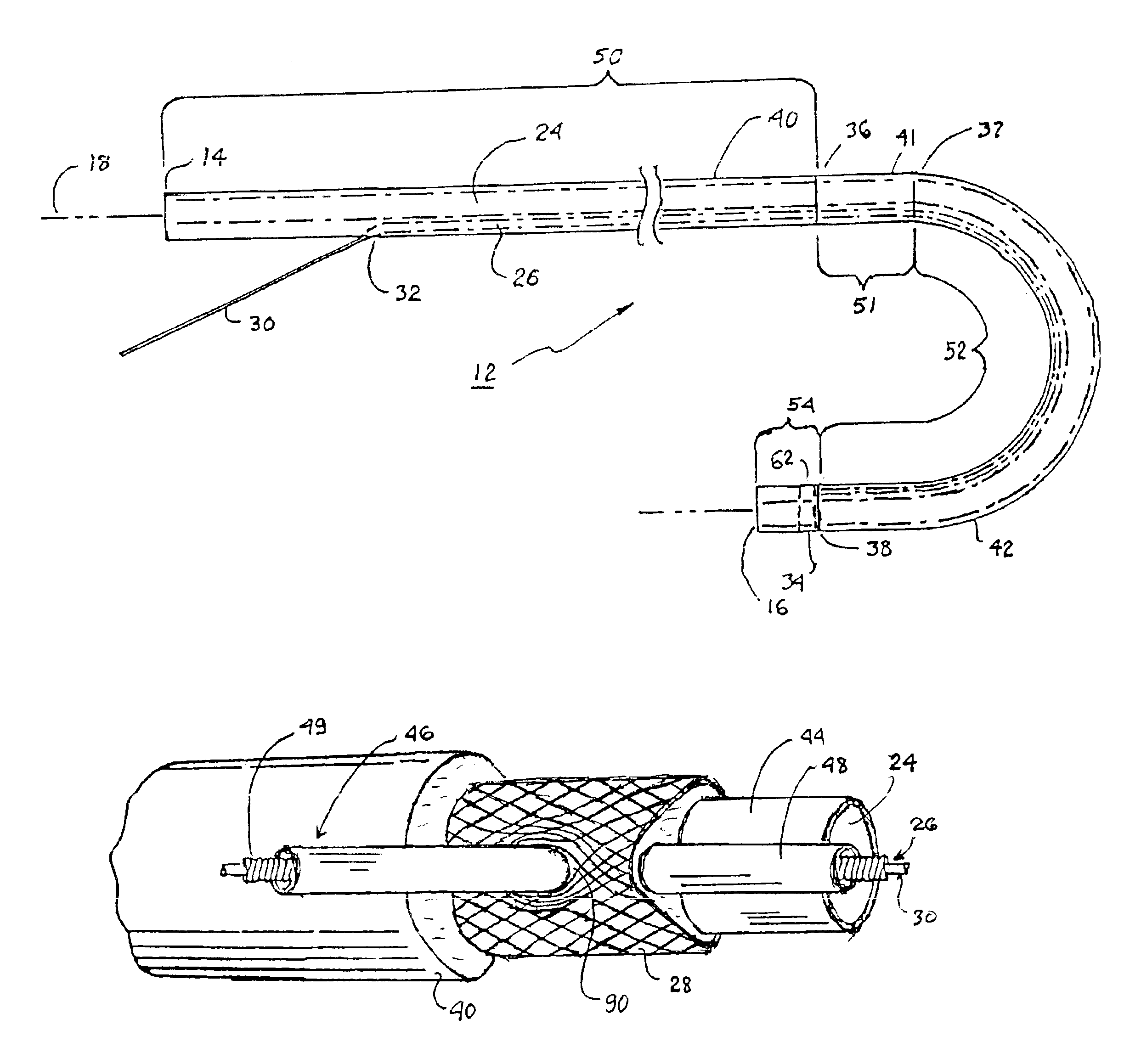

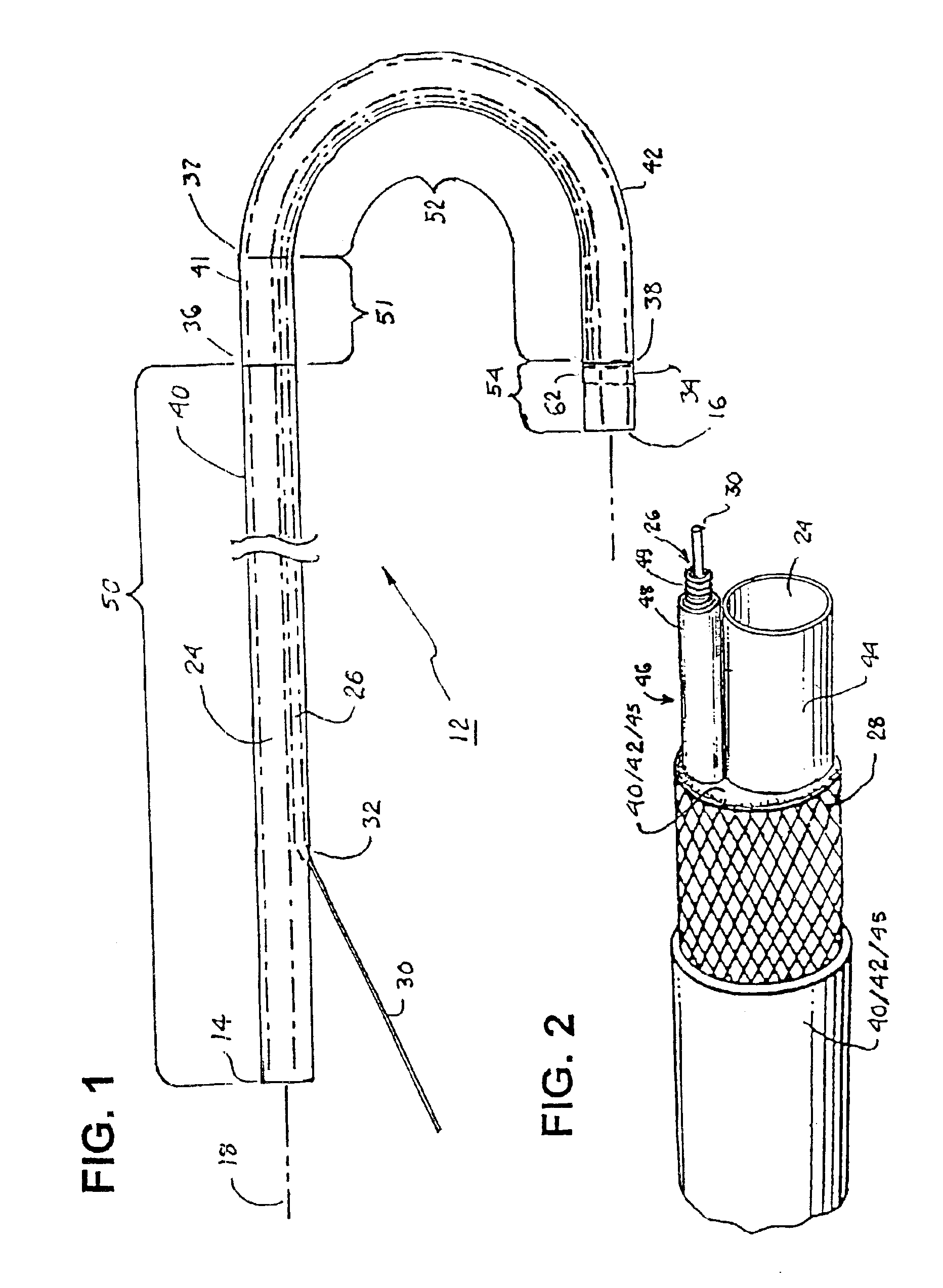

Steerable catheter

InactiveUS6945956B2Easy to insertHigh tensile strengthMulti-lumen catheterMedical devicesDistal segmentCatheter device

A steerable catheter and methods of fabrication including a catheter body formed of a continuous wire braid formed of wires braided over a delivery lumen liner and a pull wire lumen liner distal to a pull wire jacket port, braided around the pull wire jacket port to form a braid port, and over at least a portion of the delivery lumen liner proximal to the pull wire jacket port. A pull wire extends from a pull wire proximal end through the pull wire lumen port and through the pull wire lumen to a pull wire distal end. A band is attached to the pull wire distal end and fitted over a distal segment of the wire braid proximal to the catheter body distal end to fix the pull wire distal end to the catheter body and restrain the wire distal end from flaring away from the delivery lumen liner.

Owner:MEDTRONIC INC

Structural and other composite materials and methods for making same

InactiveUS20050281999A1High strength-to-weight ratioEasy to manufactureSynthetic resin layered productsLaminationPolymer scienceHigh intensity

In accordance with the present invention, structural and other composite materials have been developed which have superior performance properties, including high compressive strength, high tensile strength, high shear strength, and high strength-to-weight ratio, and methods for preparing same. Invention materials have the added benefits of ease of manufacture, and are inexpensive to manufacture. The superior performance properties of invention materials render such materials suitable for a wide variety of end uses. For example, a variety of substances can be applied to invention materials without melting, dissolving or degrading the basic structure thereof. This facilitates bonding invention materials to virtually any surface or substrate. Moreover, the bond between invention materials and a variety of substrates is exceptionally strong, rendering the resulting bonded article suitable for use in a variety of demanding applications. Invention materials can be manufactured in a wide variety of sizes, shapes, densities, in multiple layers, and the like; and the performance properties thereof can be evaluated in a variety of ways.

Owner:PETRITECH

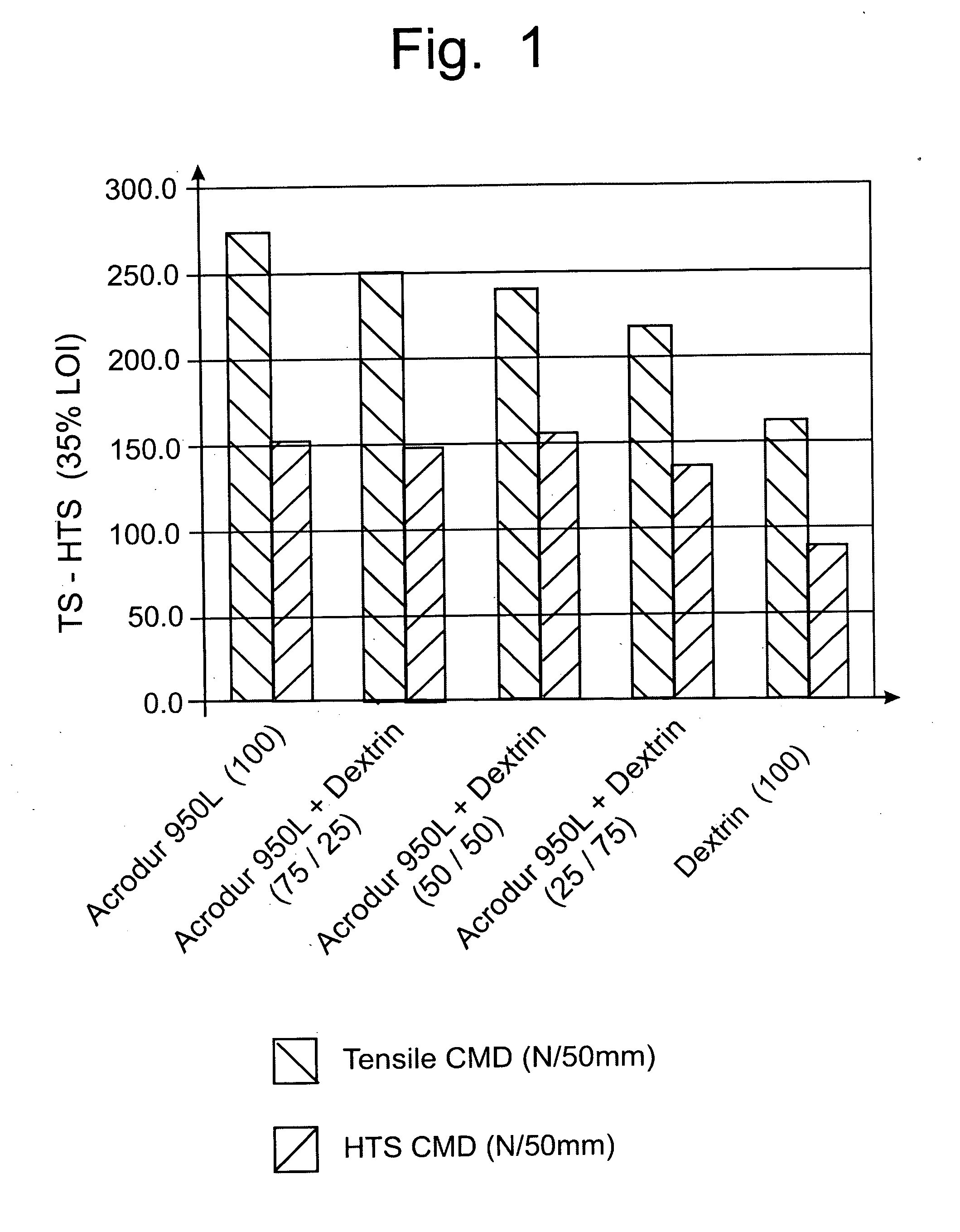

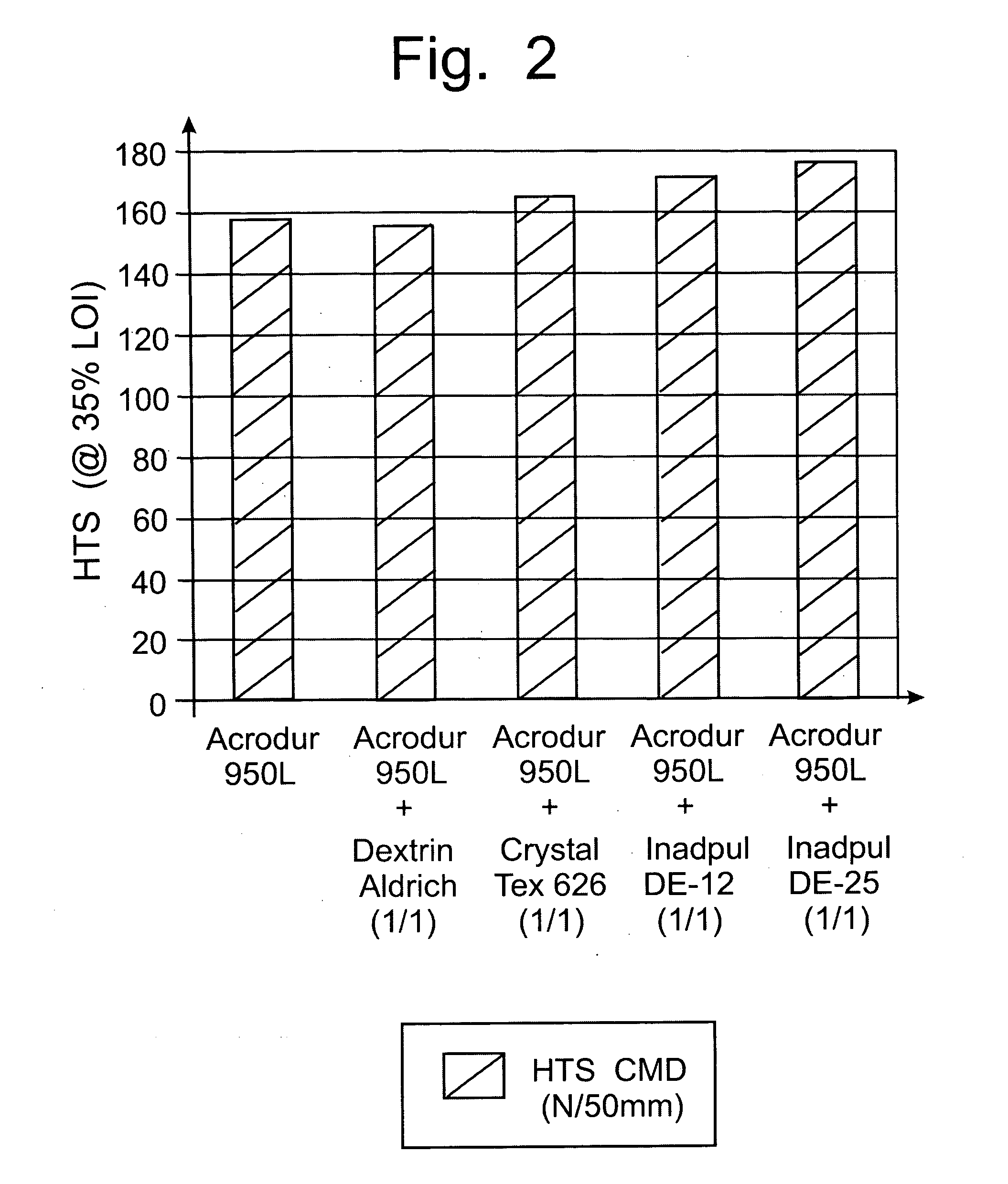

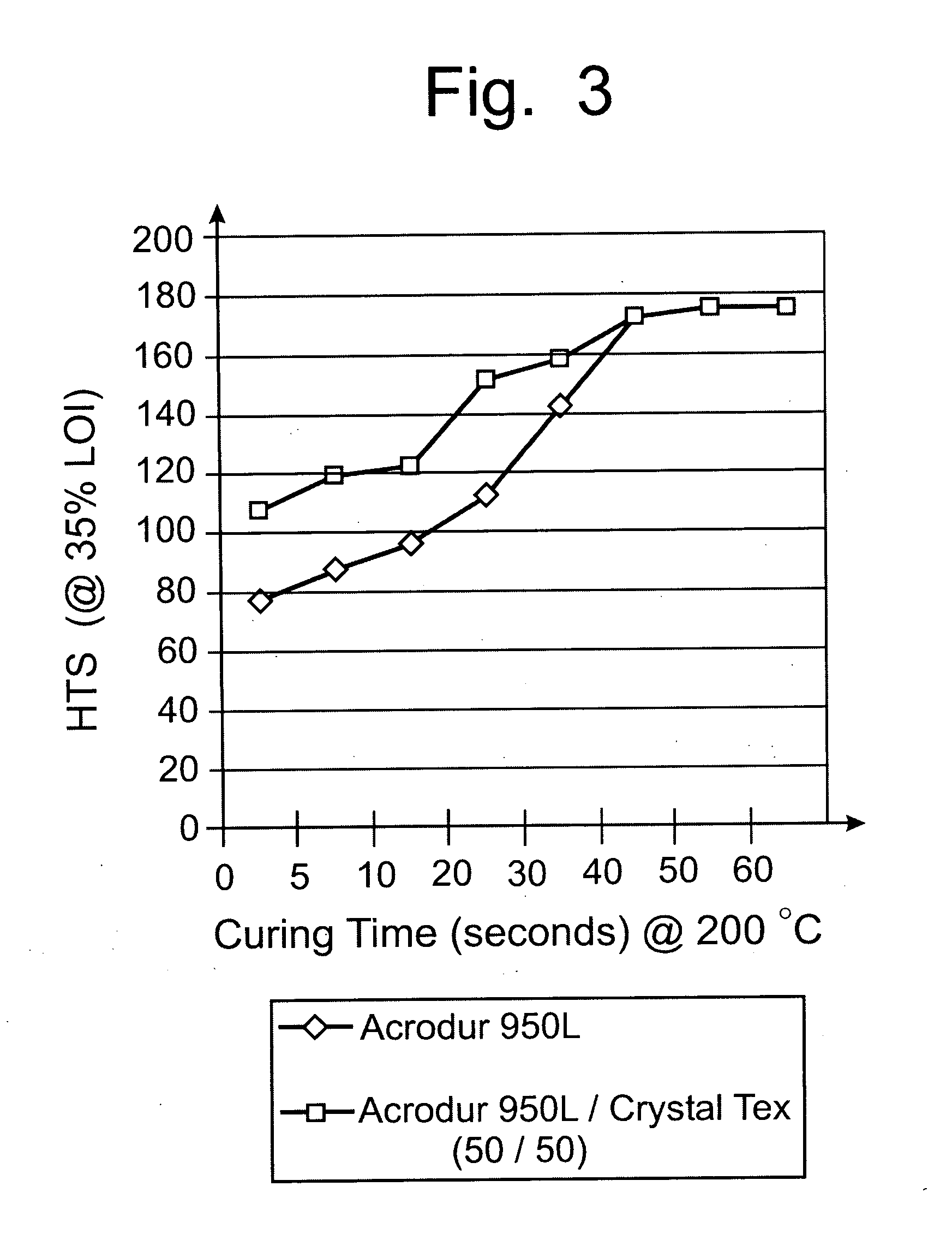

Dextrin binder composition for heat resistant non-wovens

InactiveUS20050215153A1Maintain strengthHigh hot tensile strengthNon-fibrous pulp additionStarch adhesivesPolyolCarboxylic acid

A polycarboxy binder composition that contains a dextrin as a co-binder is provided. The dextrin co-binder may be a dextrin, a modified dextrin, a maltodextrin, or combinations thereof. The dextrin may be chemically modified. A pre-binder composition is formed that contains a polycarboxy polymer, a crosslinking agent, and optionally a catalyst. The polycarboxy polymer may be a homopolymer or copolymer prepared from unsaturated carboxylic acids and may be modified to contain one or more vinyl compounds. The crosslinking agent may be a polyol that contains at least two hydroxyl groups. The pre-binder composition may be formed by admixing the polycarboxy polymer, the crosslinking agent, and optionally, the catalyst, in a mixing device. Dextrin may be added to the pre-binder composition in an amount of from 10-75% of the total binder composition. The dextrin binder composition may have a ratio of from approximately 90:10 to 25:75 pre-binder:dextrin co-binder.

Owner:OWNS CORNING COMPOSITES

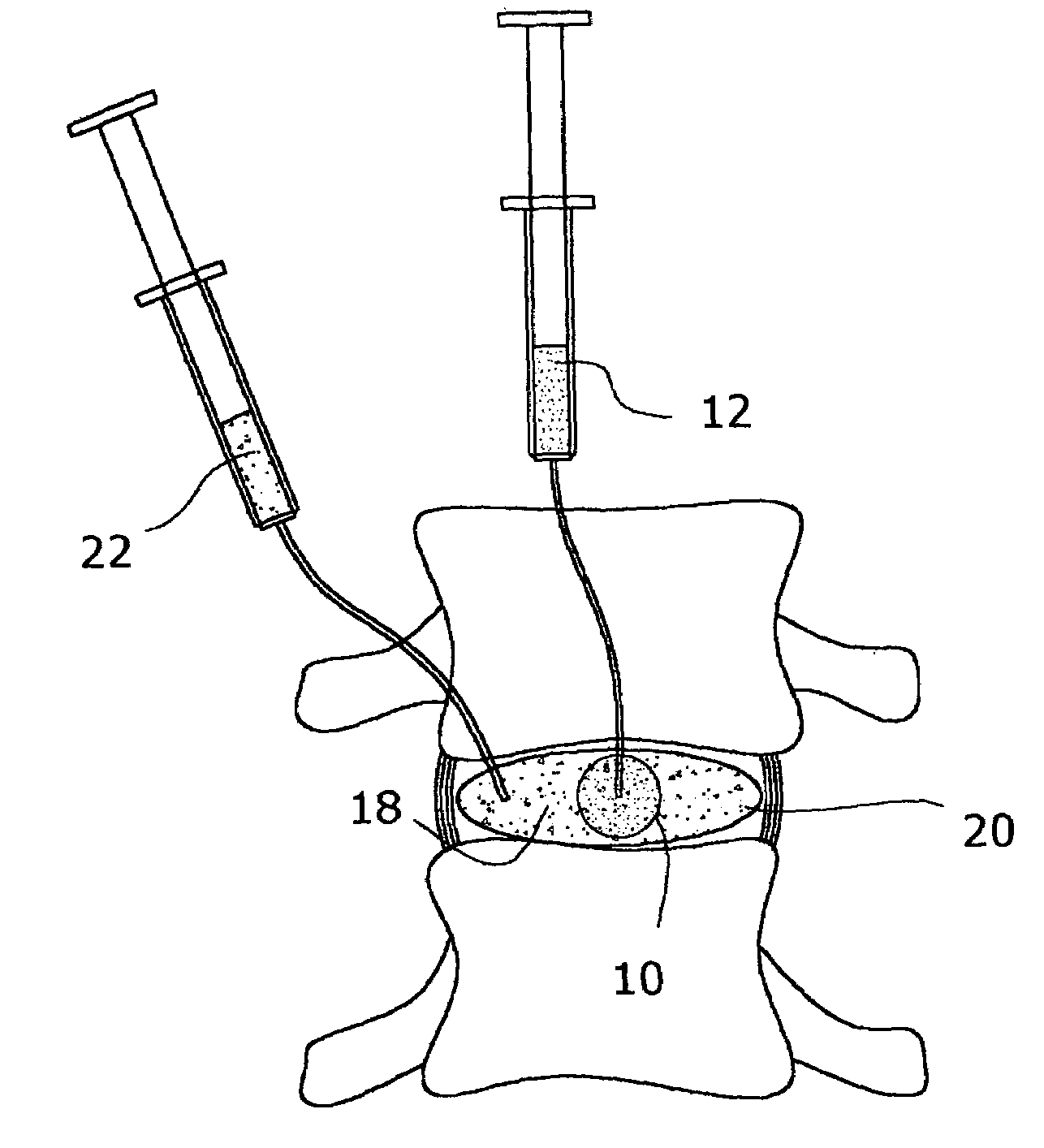

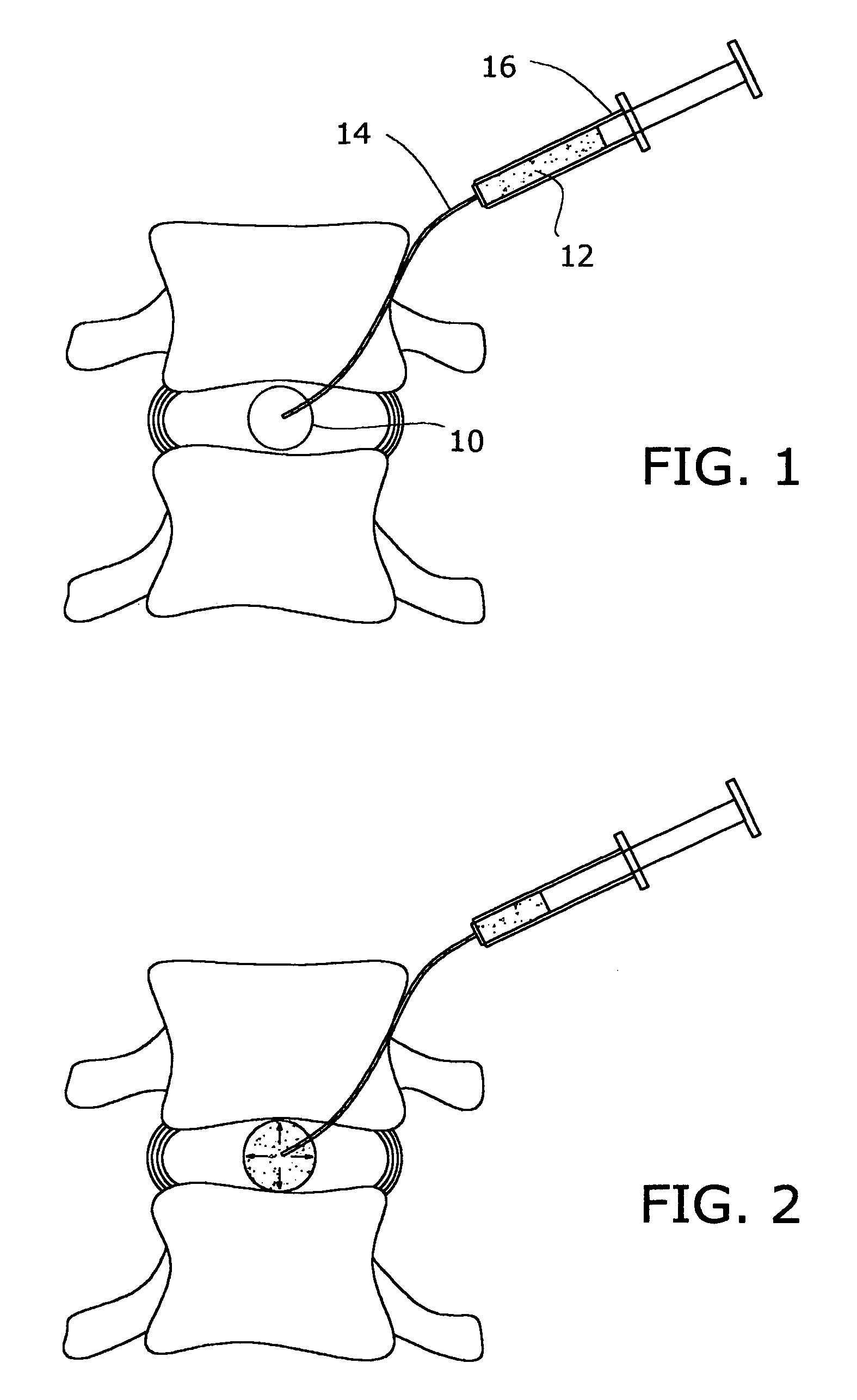

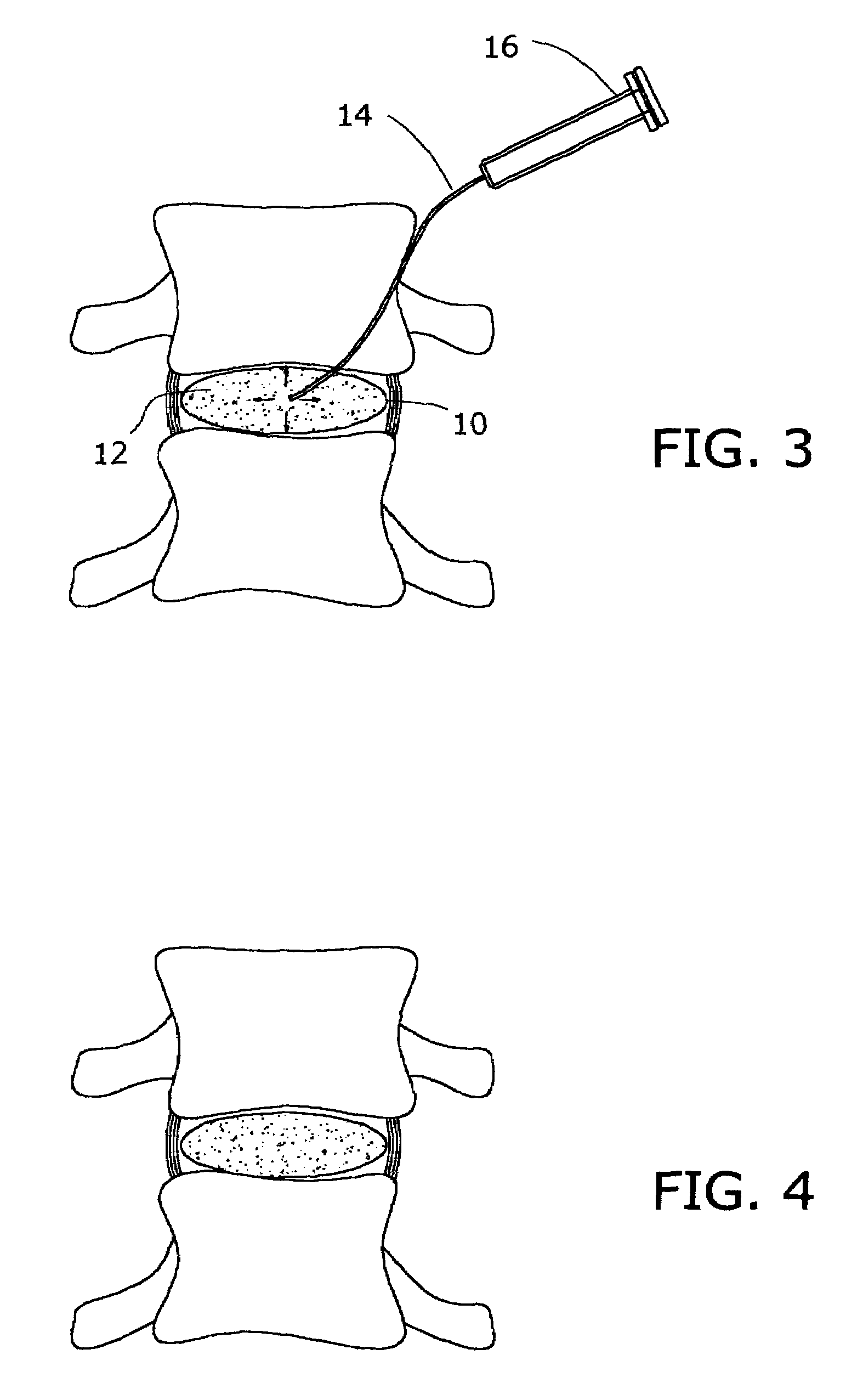

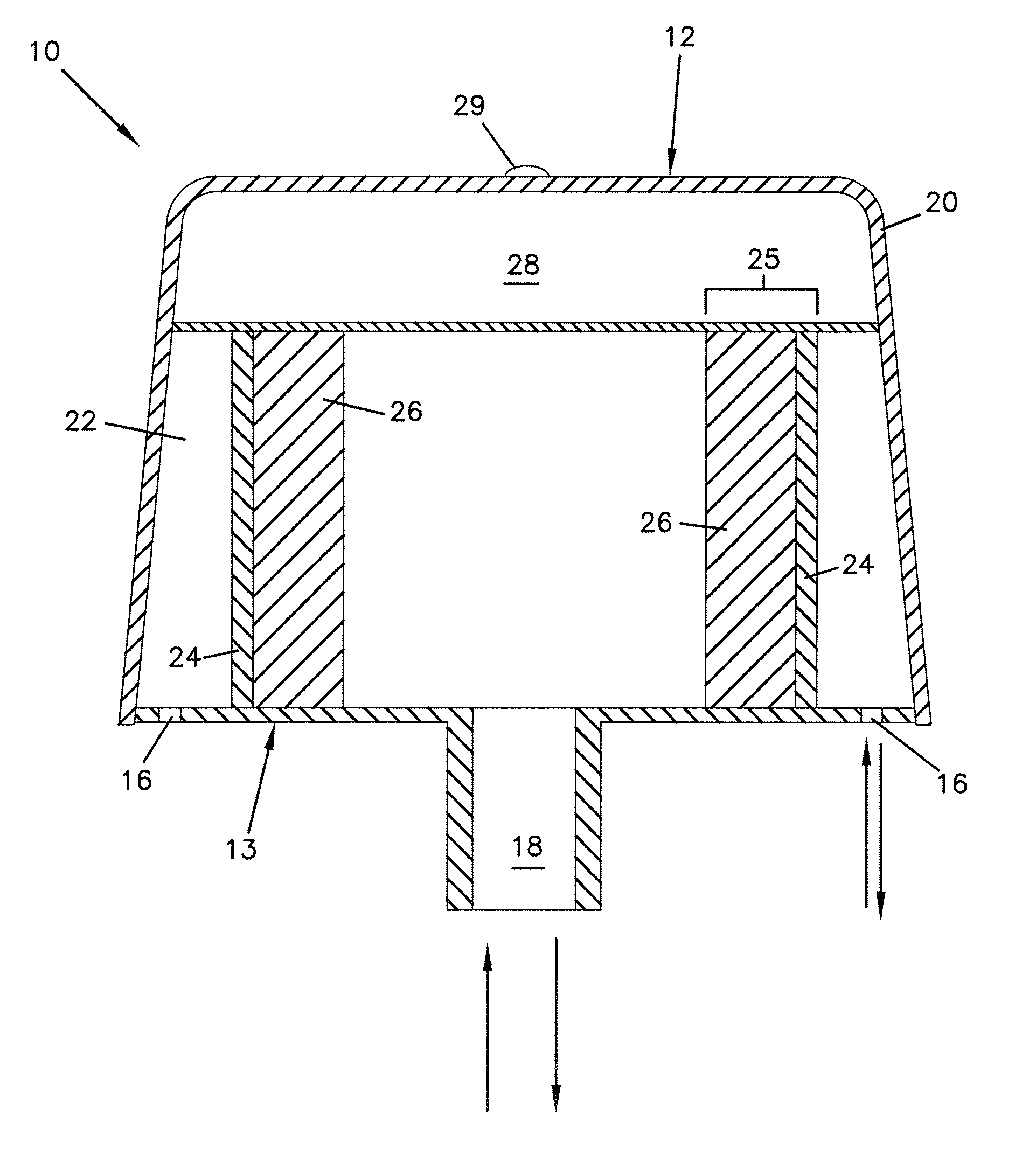

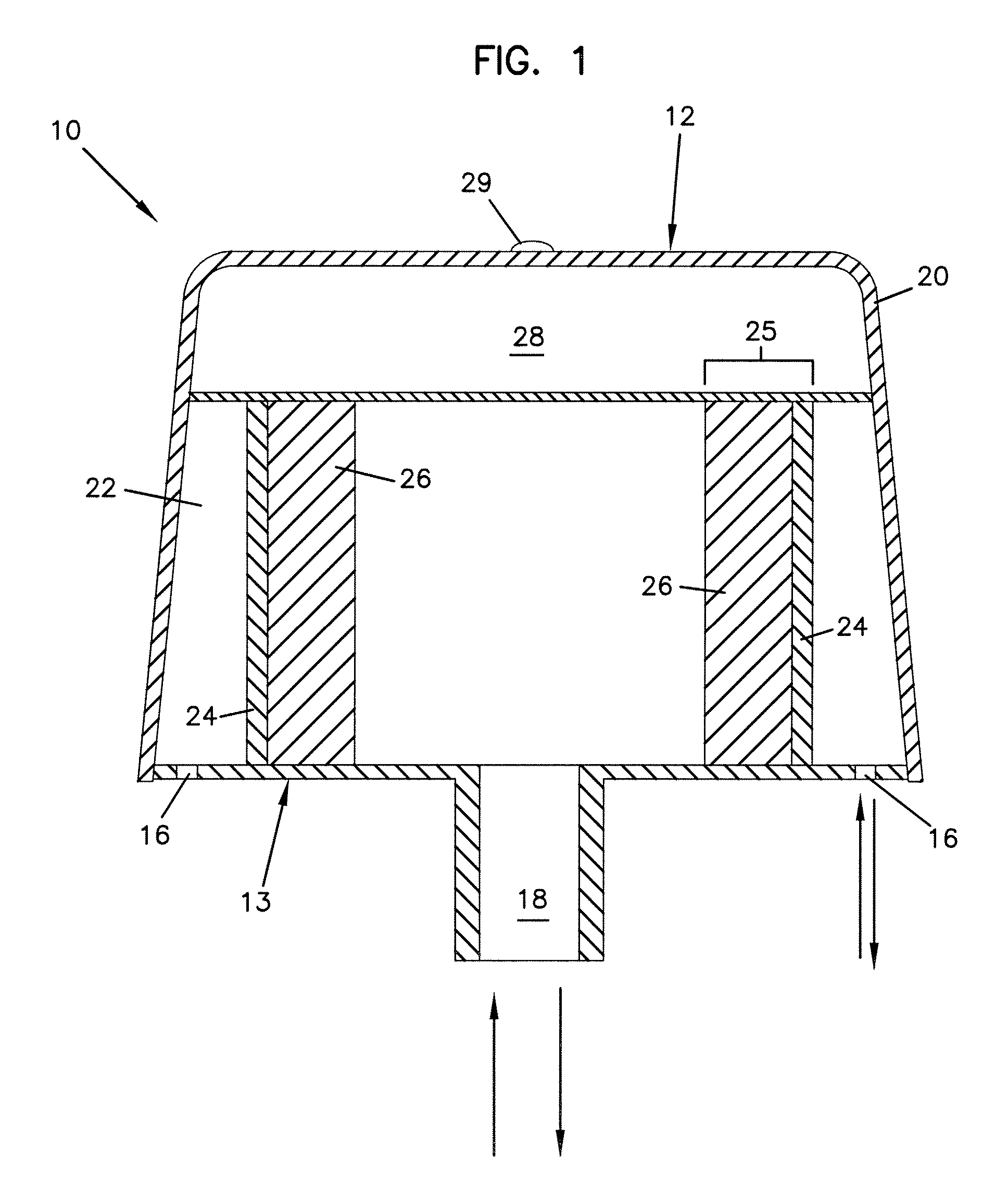

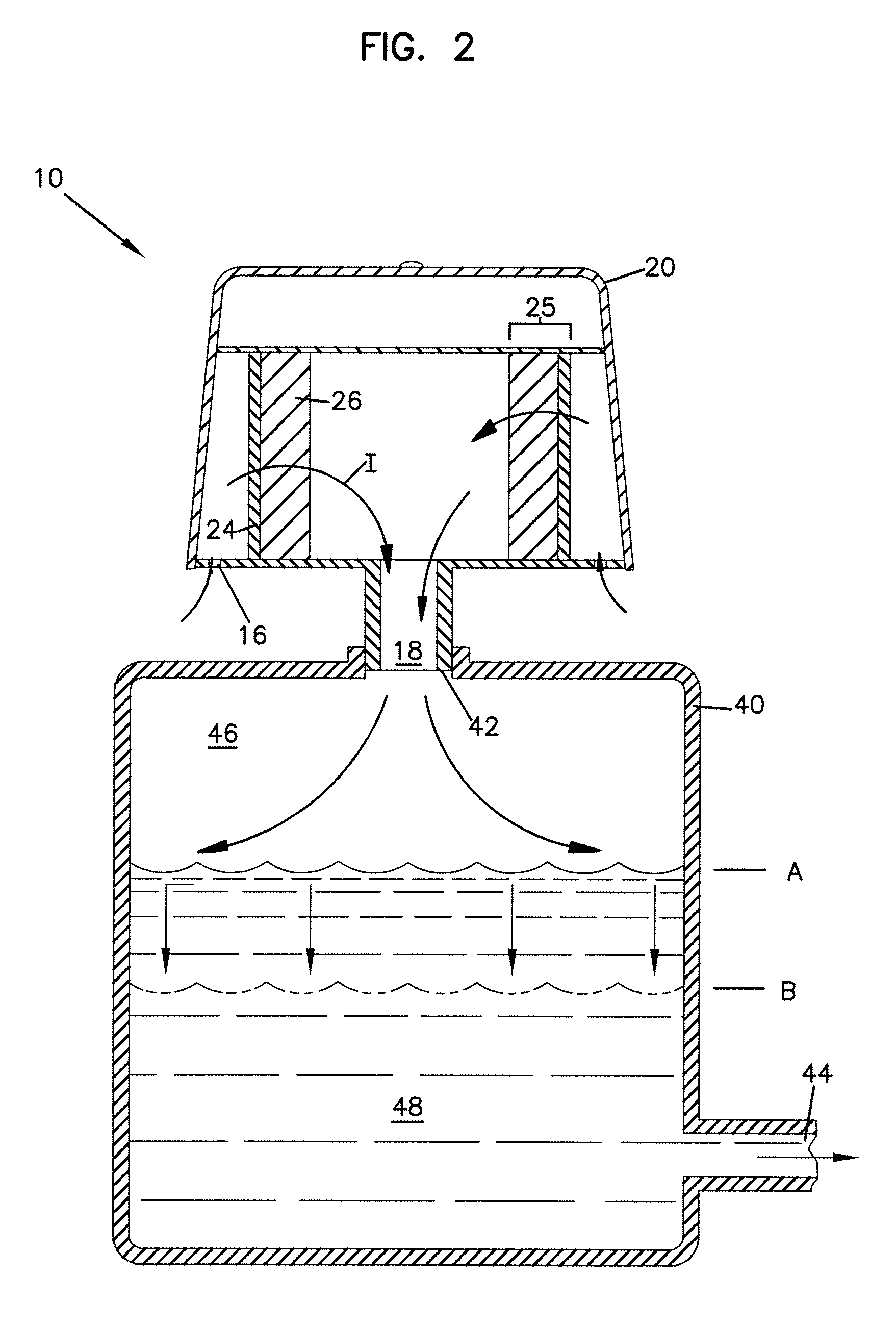

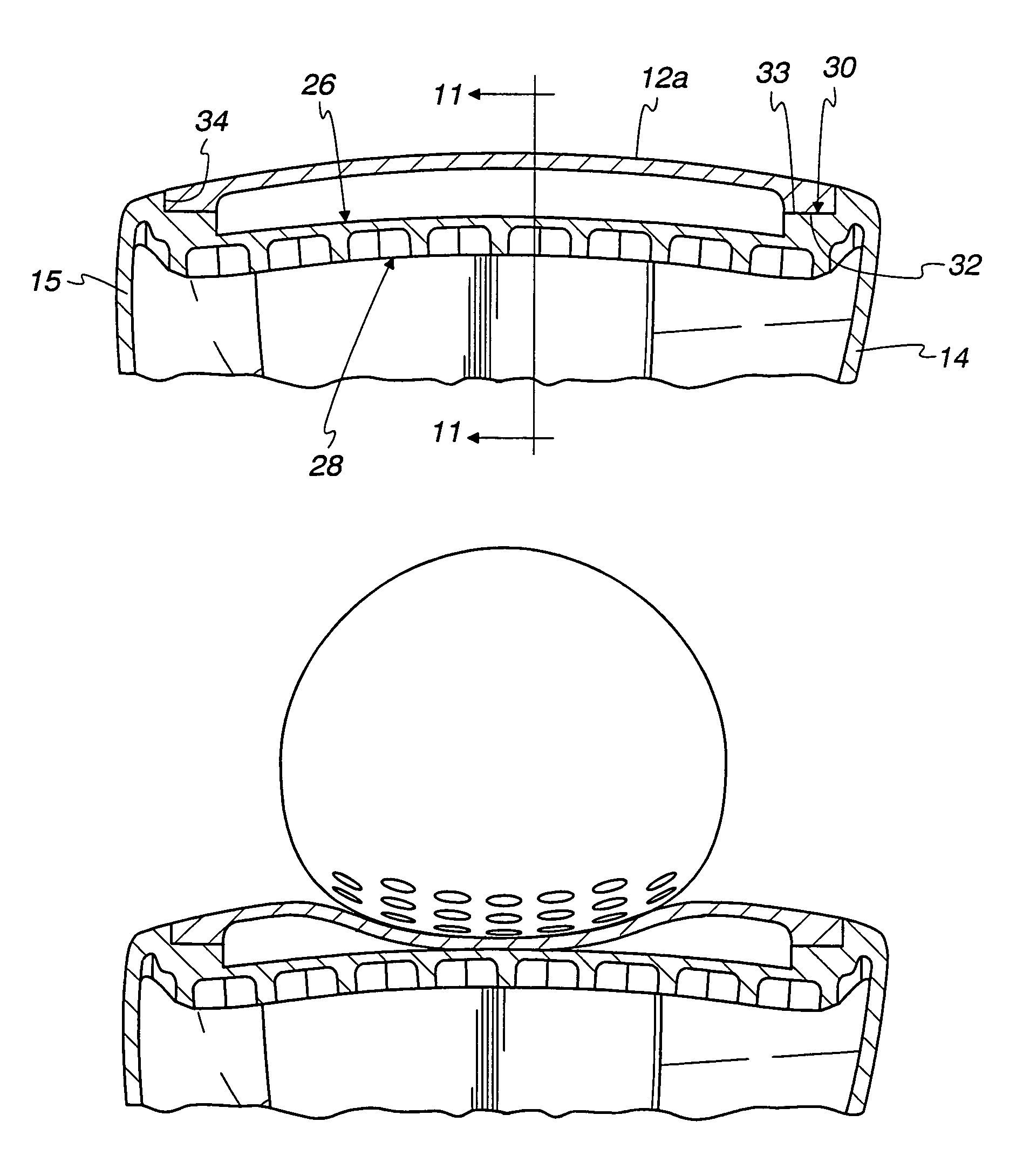

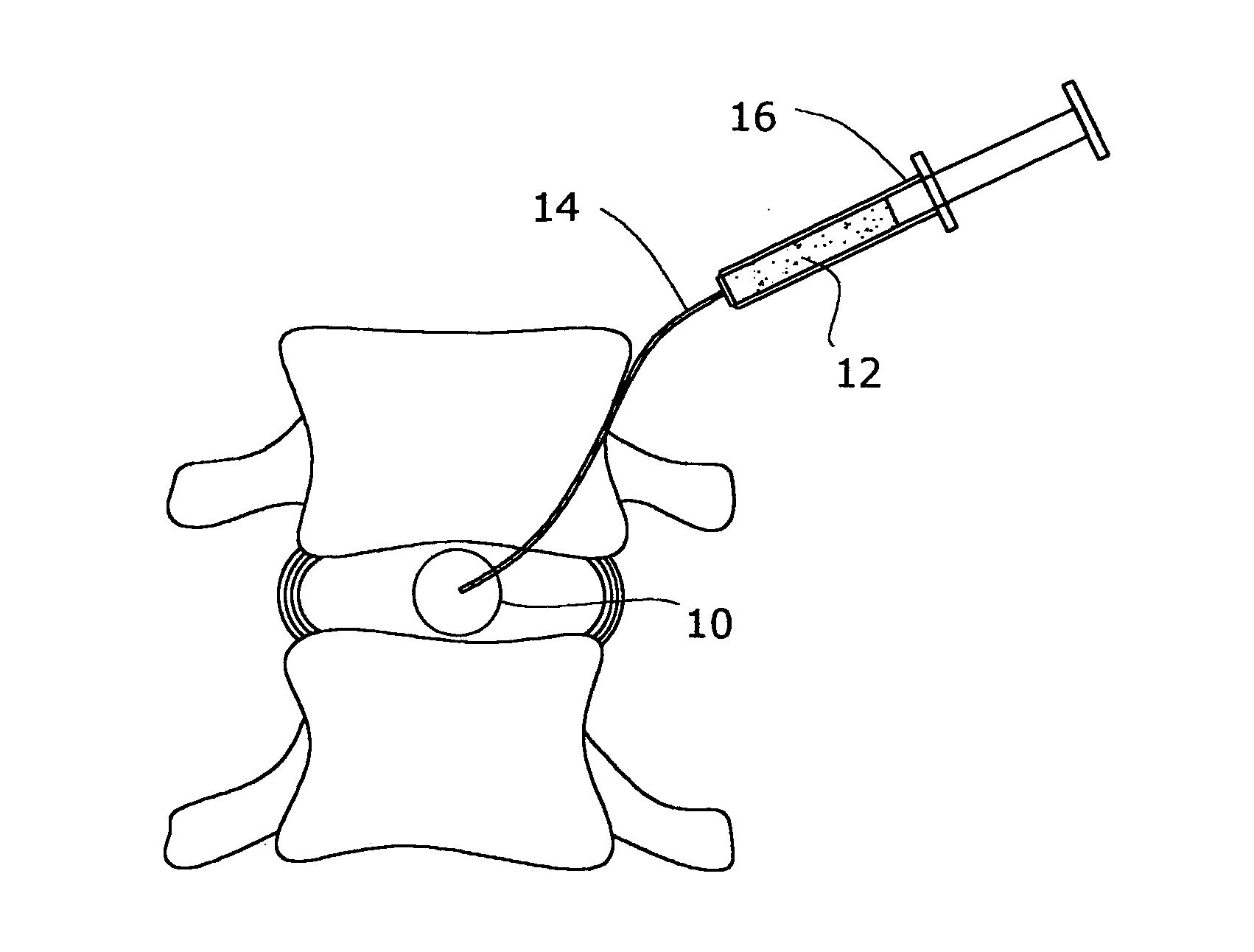

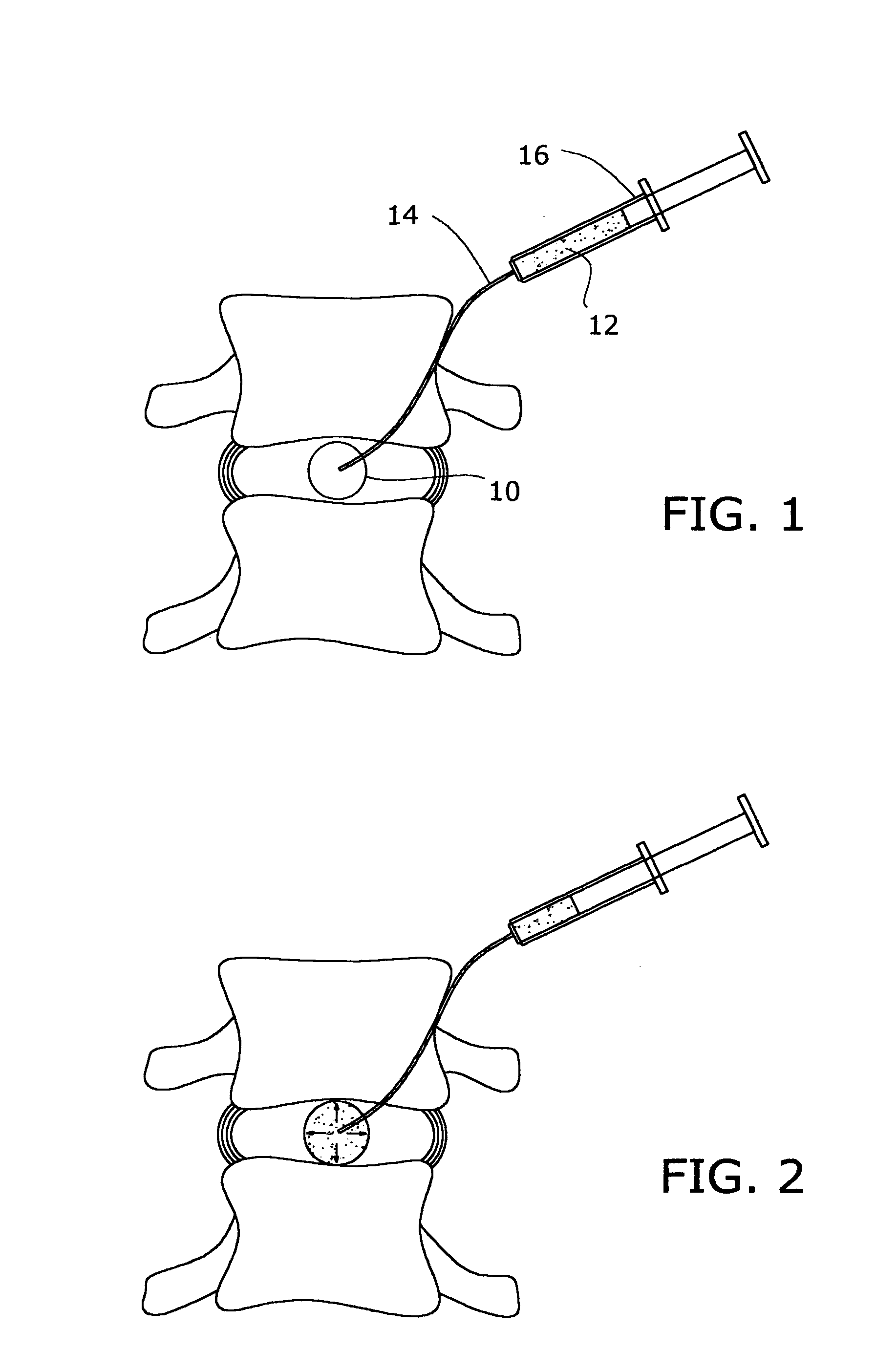

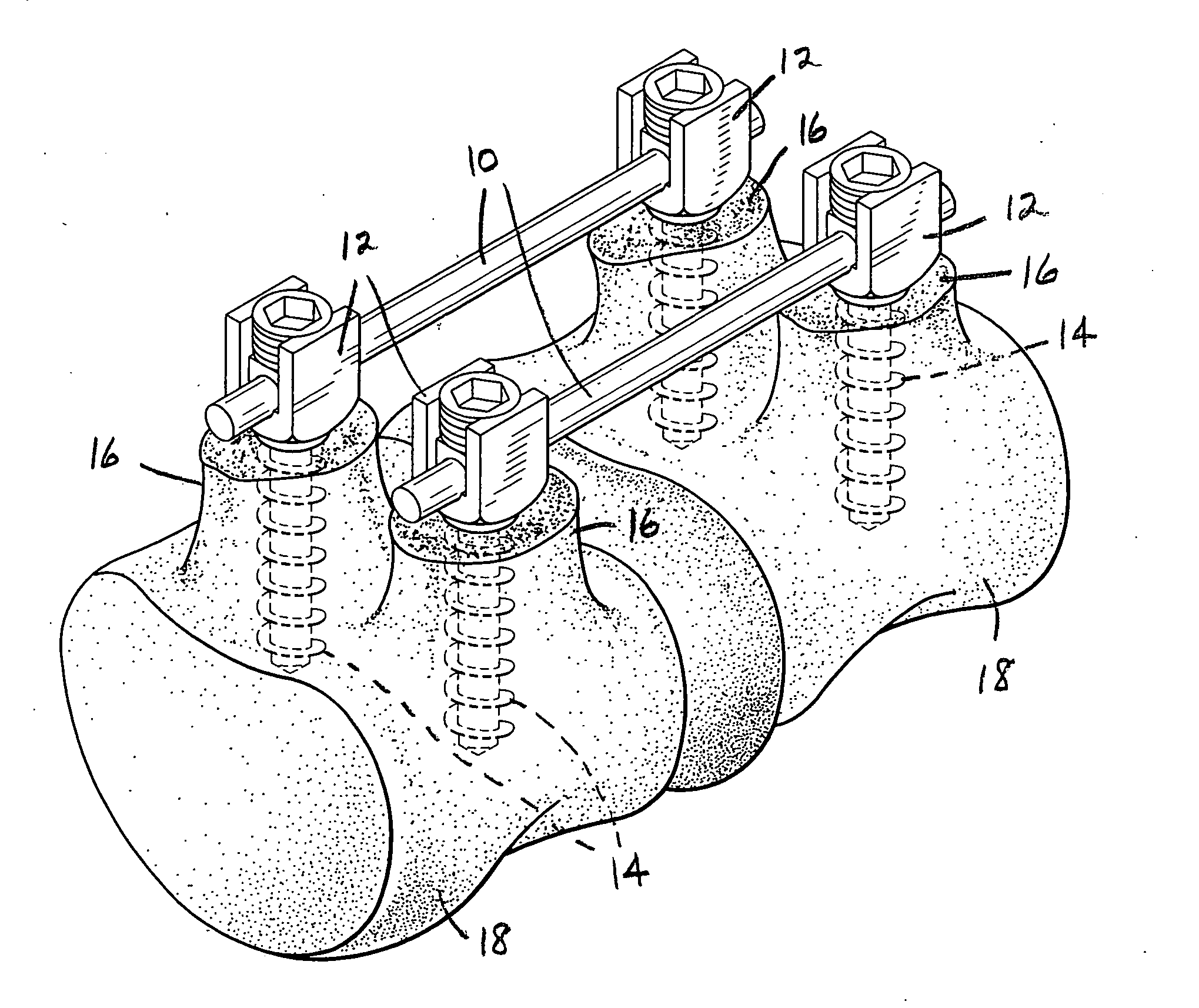

Inflatable nuclear prosthesis

InactiveUS6958077B2Reduce and eliminate abnormal stressSolve the lack of heightJoint implantsSpinal implantsMedicineProsthesis

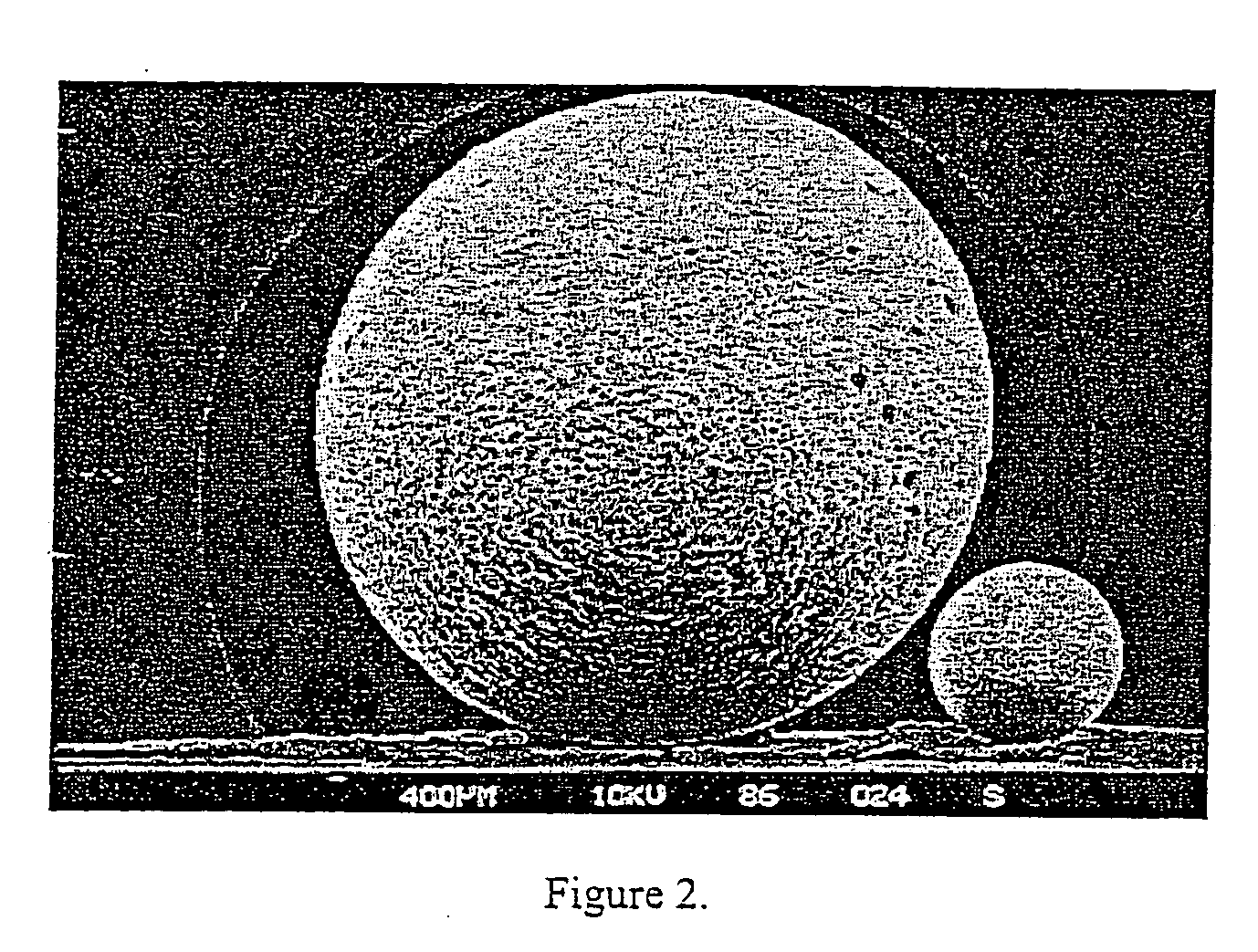

The nucleus of an intervertebral disc is replaced with a construct including a distendable sack or balloon which is inflated with a hardenable material and is detached in situ when the injected material has hardened. Alternatively, two nested balloons may be inserted, and then filled with materials which have different hardnesses when cured, to simulate a natural disc.

Owner:SUDDABY LOUBERT

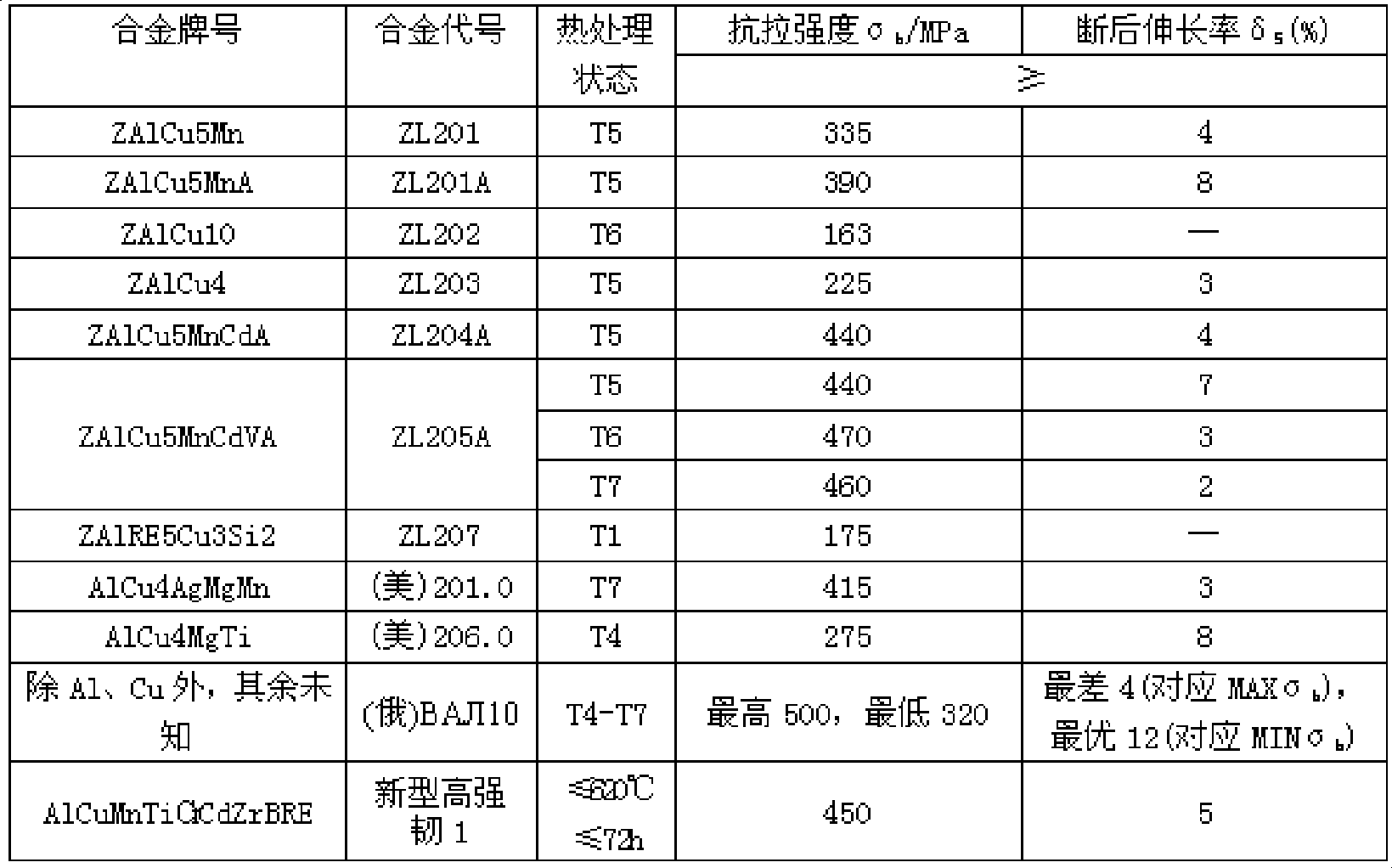

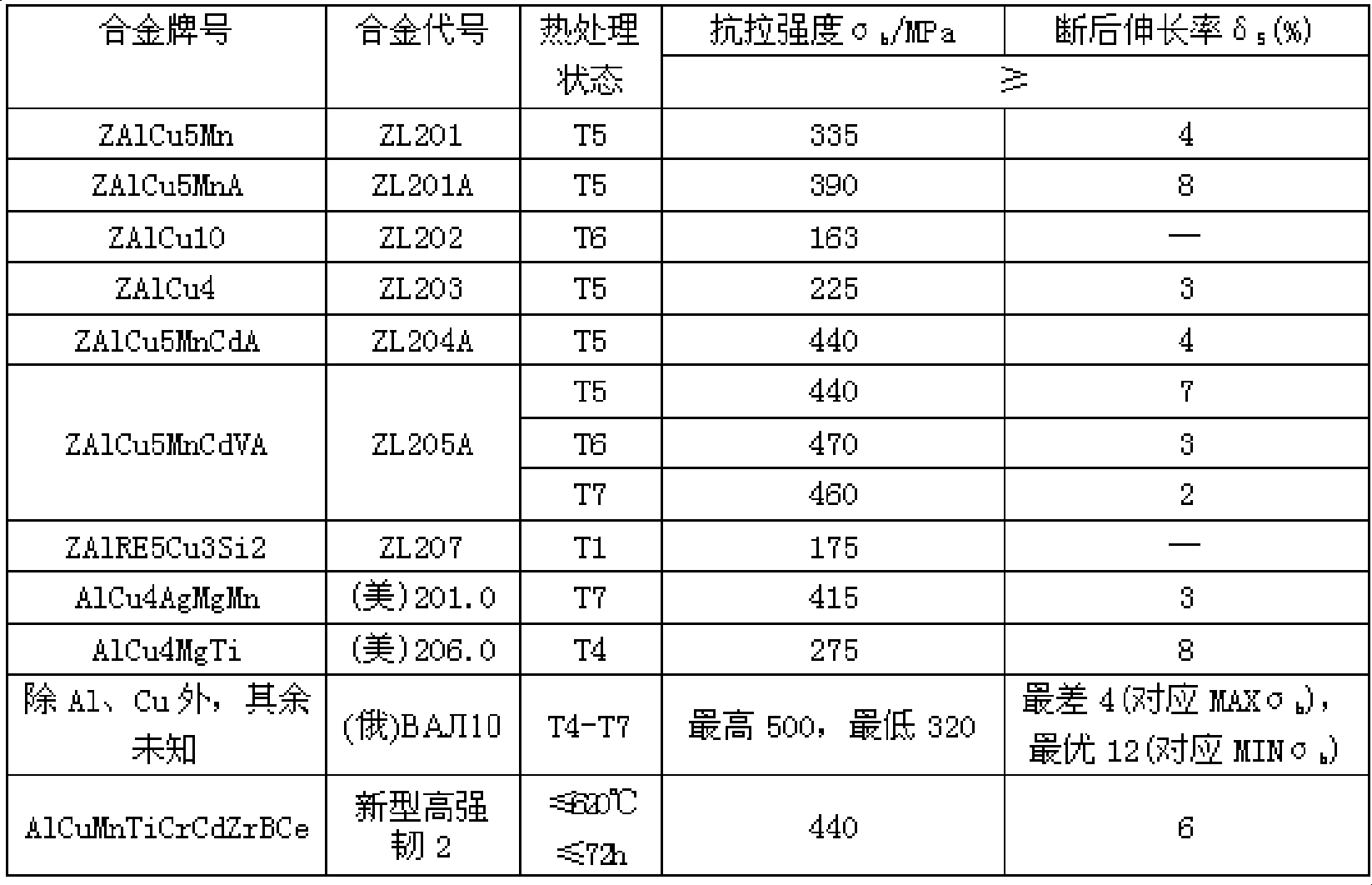

High-strength cast aluminium alloy material

The invention discloses a high-strength cast aluminum alloy material which comprises the following components by weight percentages: 2.0-6.0% of Cu, 0.05-1.0% of Mn, 0.01-0.5% of Ti, 0.01-0.2% of Cr, 0.01-0.4% of Cd, 0.01-0.25% of Zr, 0.005-0.04% of B, 0.05-0.3% of mixed rare earth RE, Al and microimpurity elements. The material adopts the advanced design of alloy components and the microalloying design. Based on the Al-Cu-Mn as the major components, rational microalloy elements (the Ti, the Cr, the B, the Zr, the mixed rare earth, etc.) are found and the ranges thereof are determined, which can realize the function of substituting the precious rare metals Ag, V, and the like, thus lowering the formula cost by 5-10%.

Owner:GUIZHOU UNIV +2

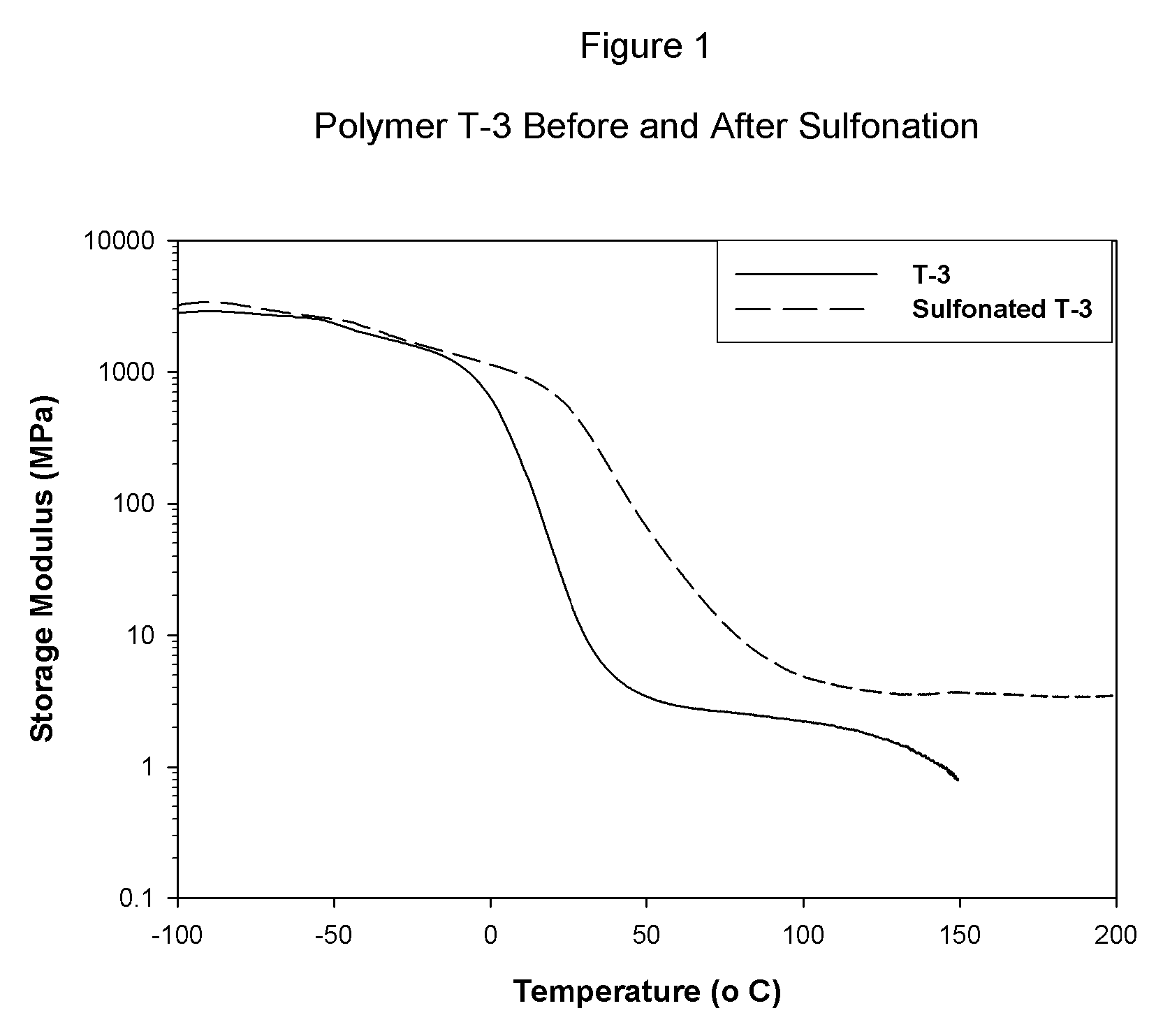

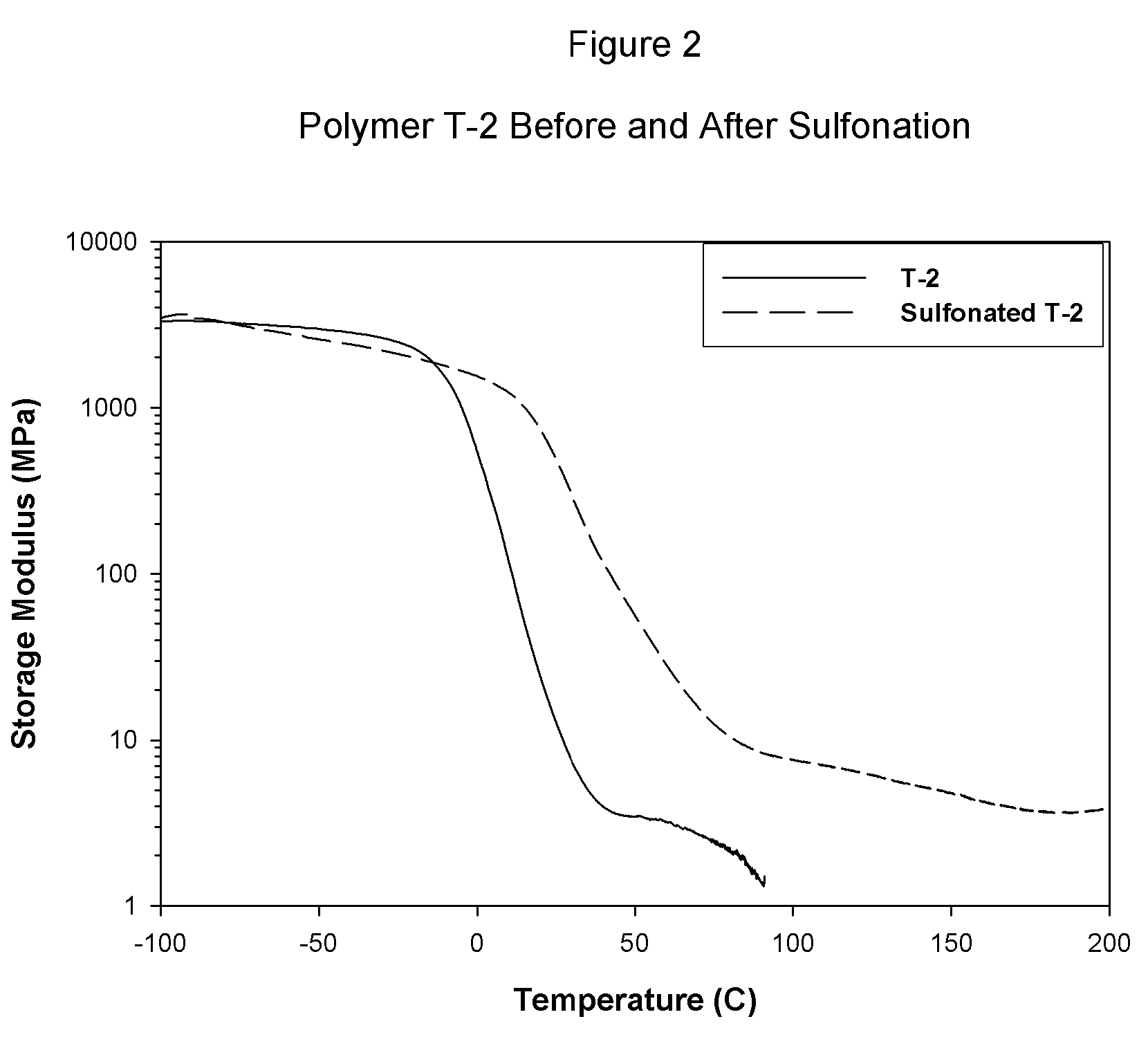

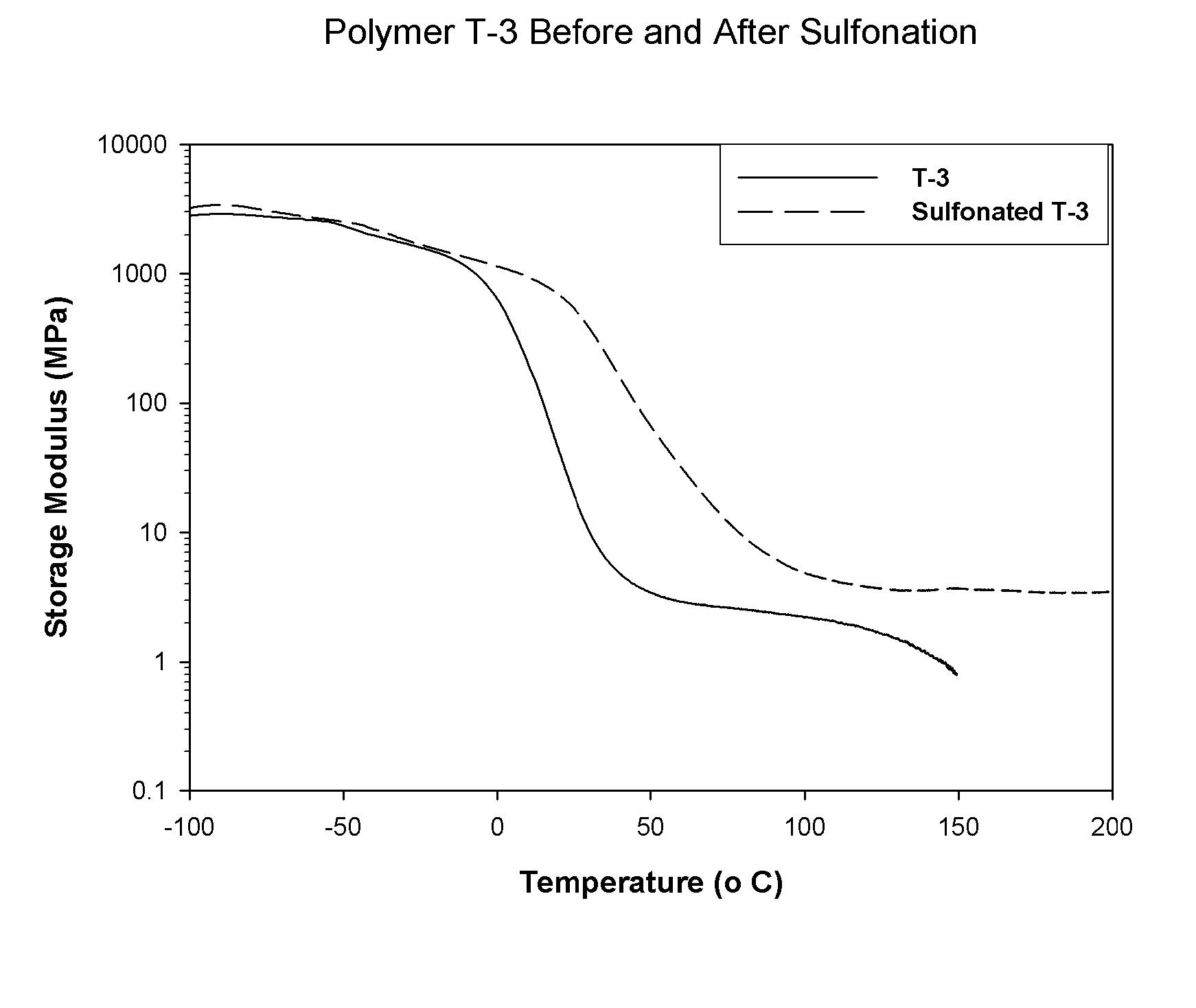

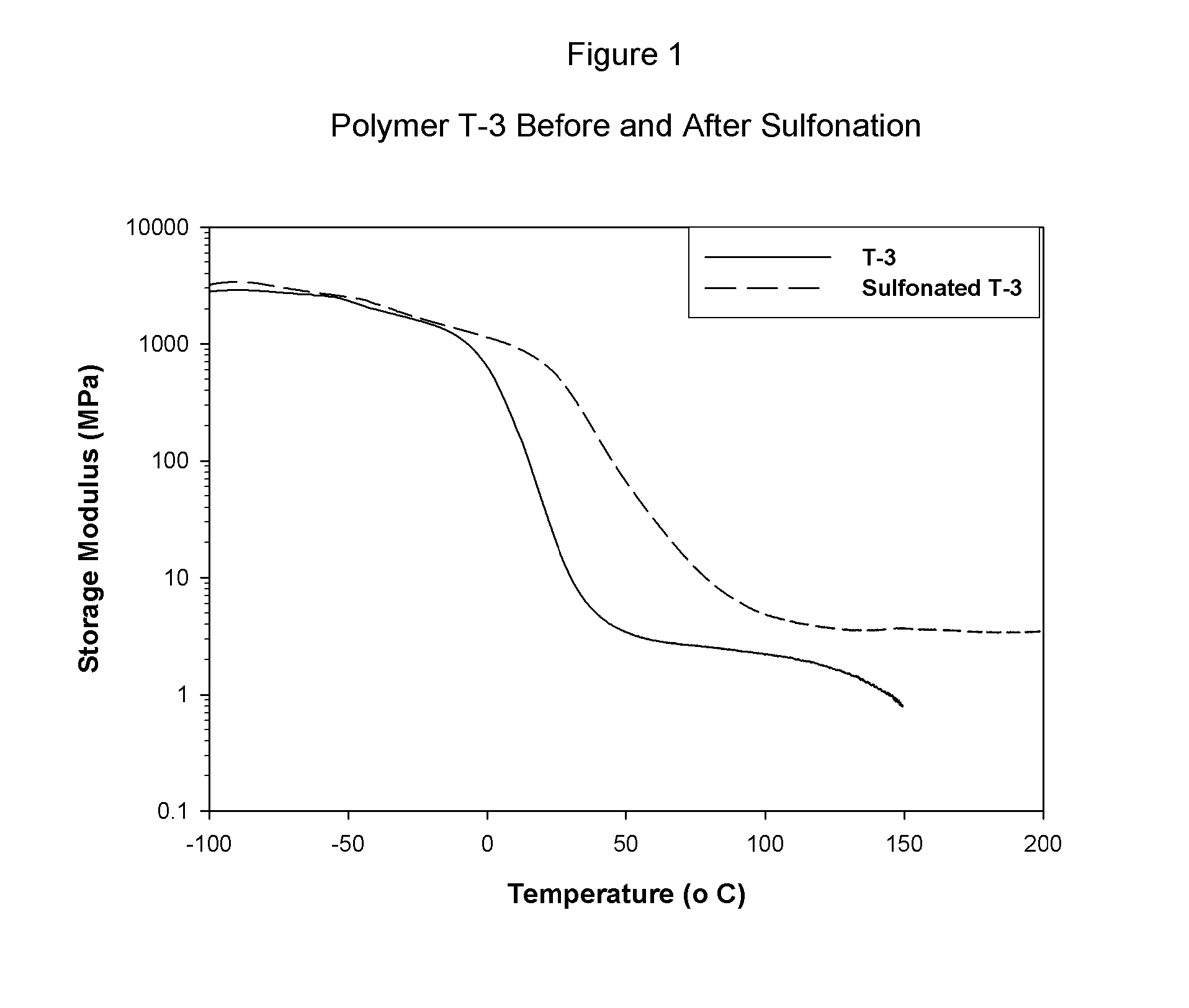

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

ActiveUS7737224B2Reduced responseHigh propertySemi-permeable membranesNegative electrodesMethacrylatePolymer science

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

High-strength cast aluminium alloy material

The invention discloses a high-strength aluminum casting alloy material which comprises the following components by weight percentages: 2.0-6.0% of Cu, 0.05-1.0% of Mn, 0.01-0.5% of Ti, 0.01-0.2% of Cr, 0.01-0.4% of Cd, 0.01-0.25% of Zr, 0.005-0.04% of B, 0.05-0.3% of Ce, Al and other microimpurity elements. The material adopts the advanced design of alloy components and microalloying design. Based on the Al-Cu-Mn as the major components, rational microalloy elements (the Ti, the Cr, the B, the Zr, mixed rare earth, etc.) are found and the ranges thereof are determined, which can realize the function of substituting the precious rare metals Ag, V, and the like, thus lowering the formula cost by 5-10%.

Owner:贵州铝厂有限责任公司 +2

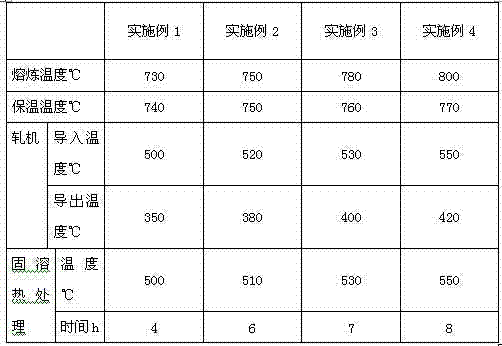

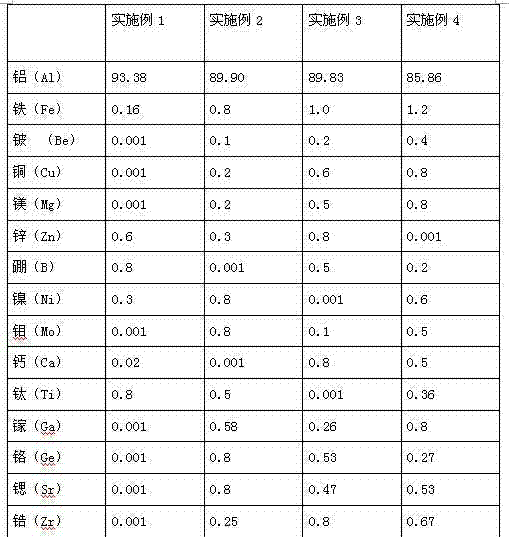

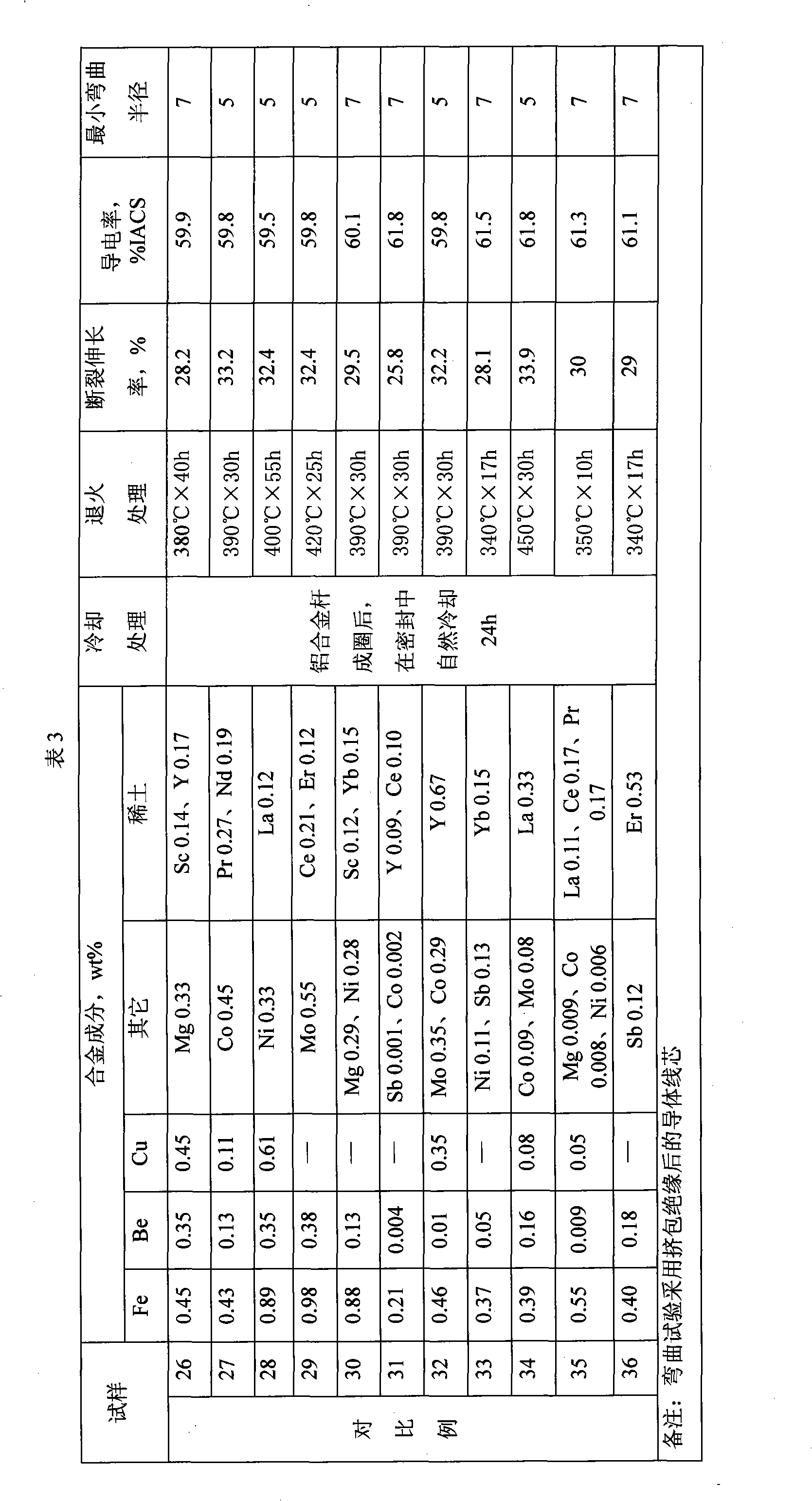

A kind of aluminum alloy material and preparation method thereof

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

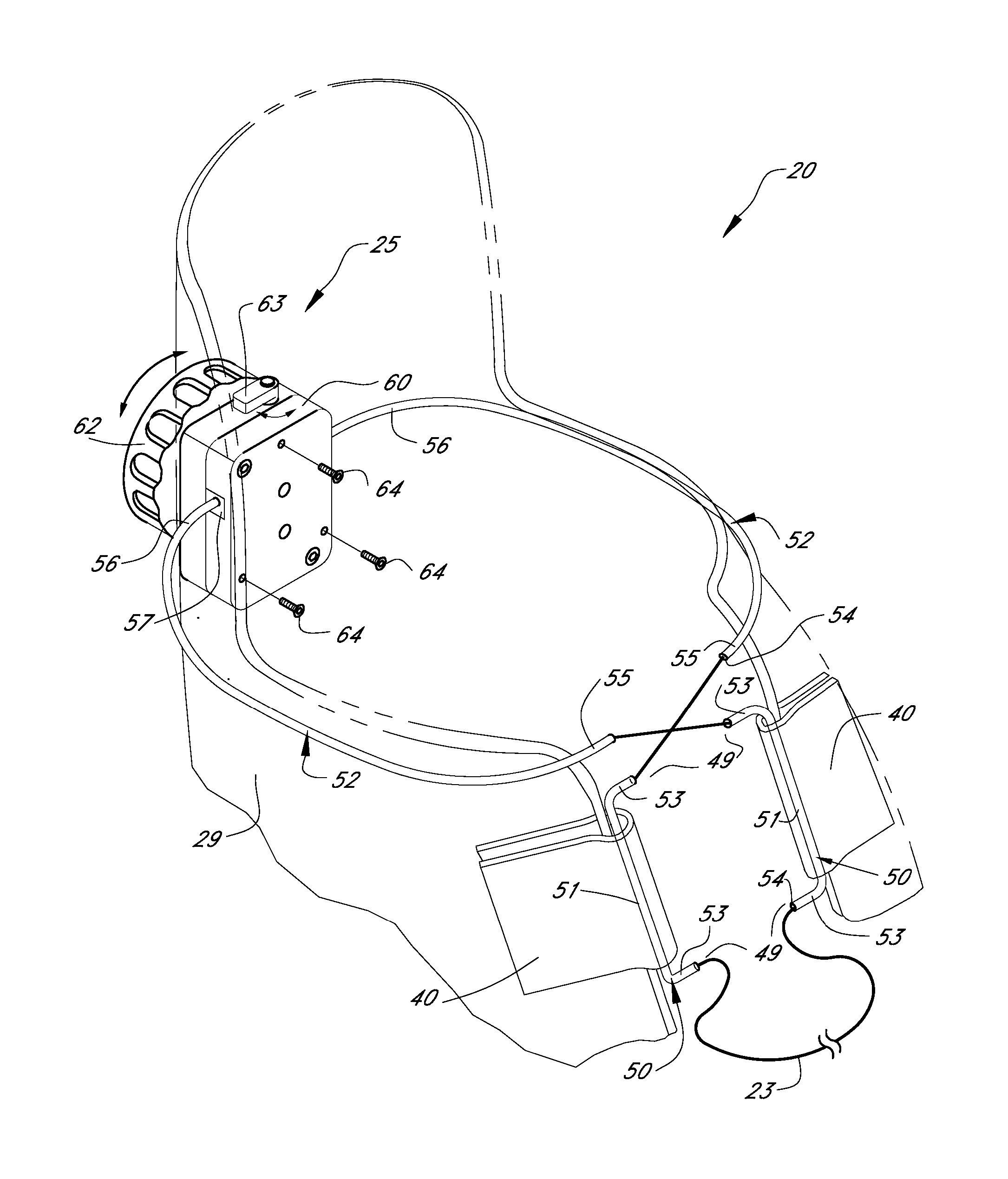

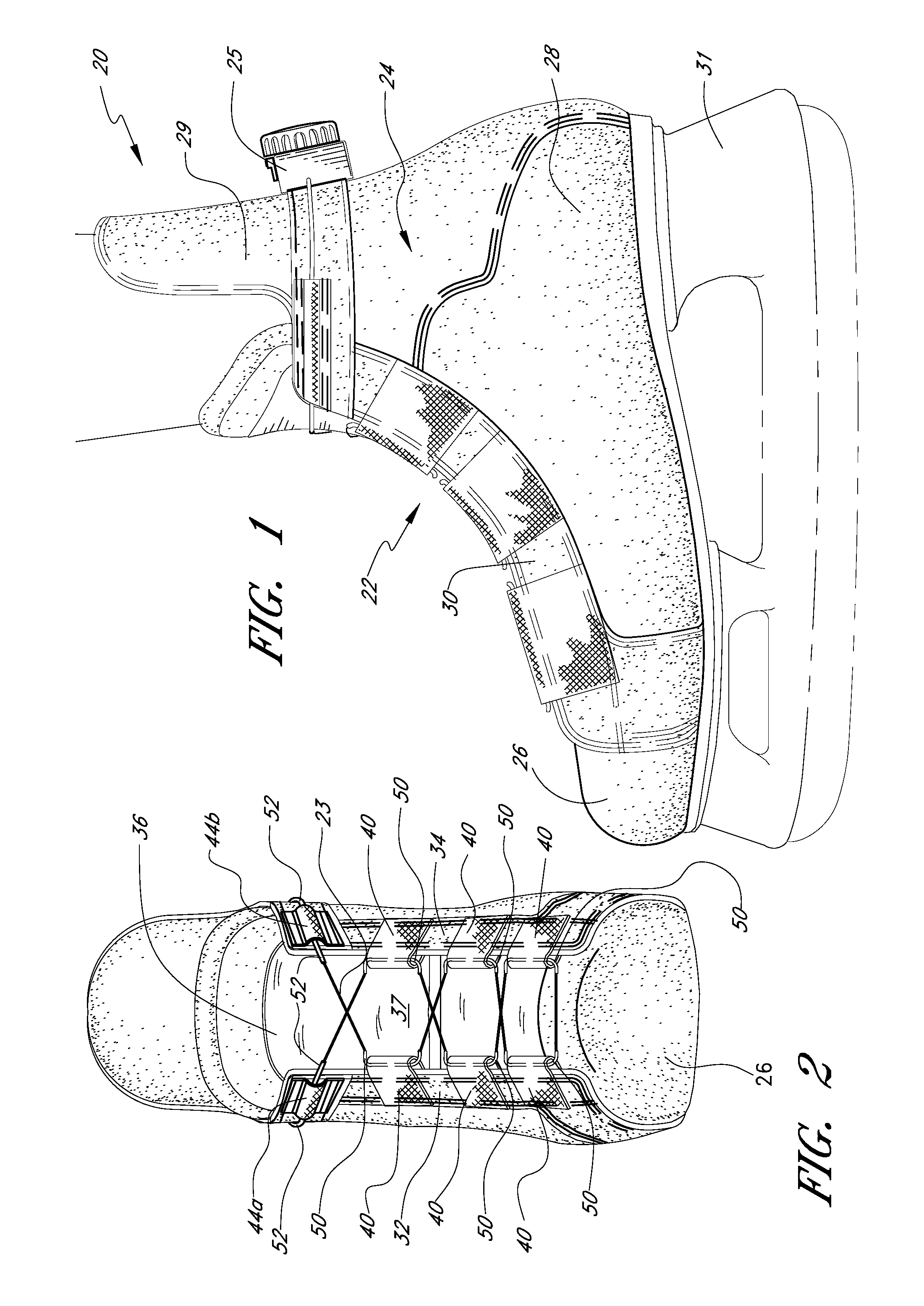

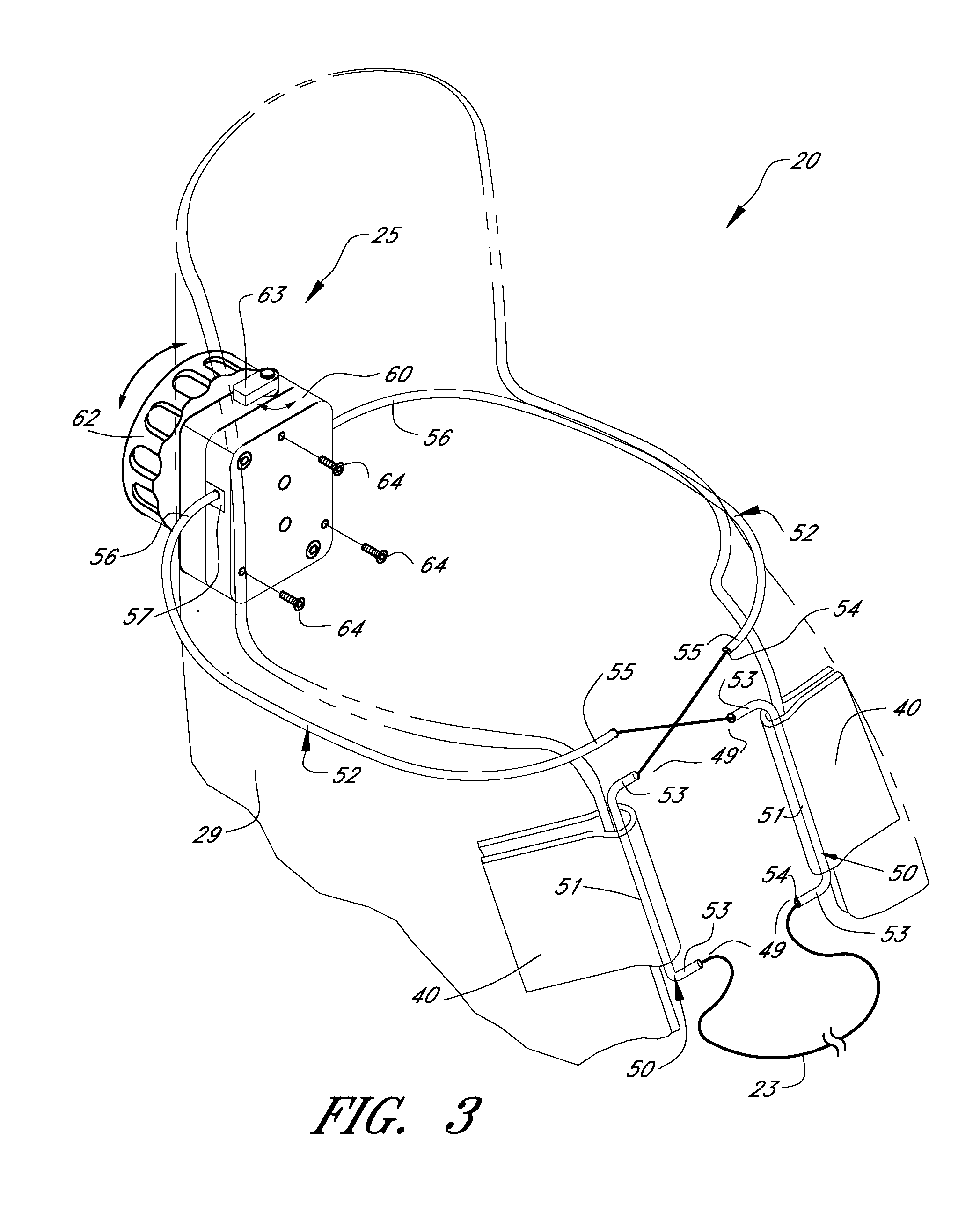

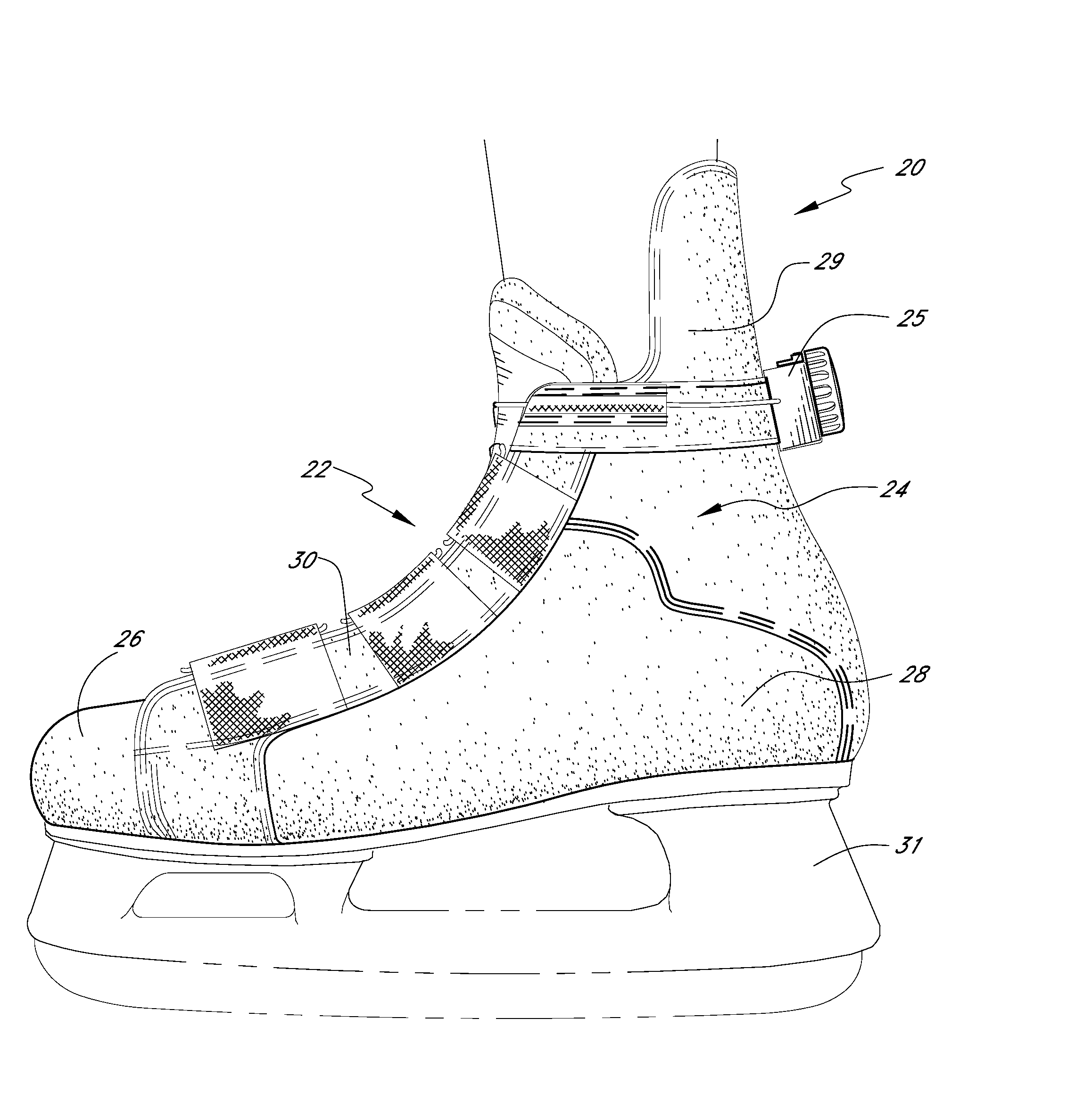

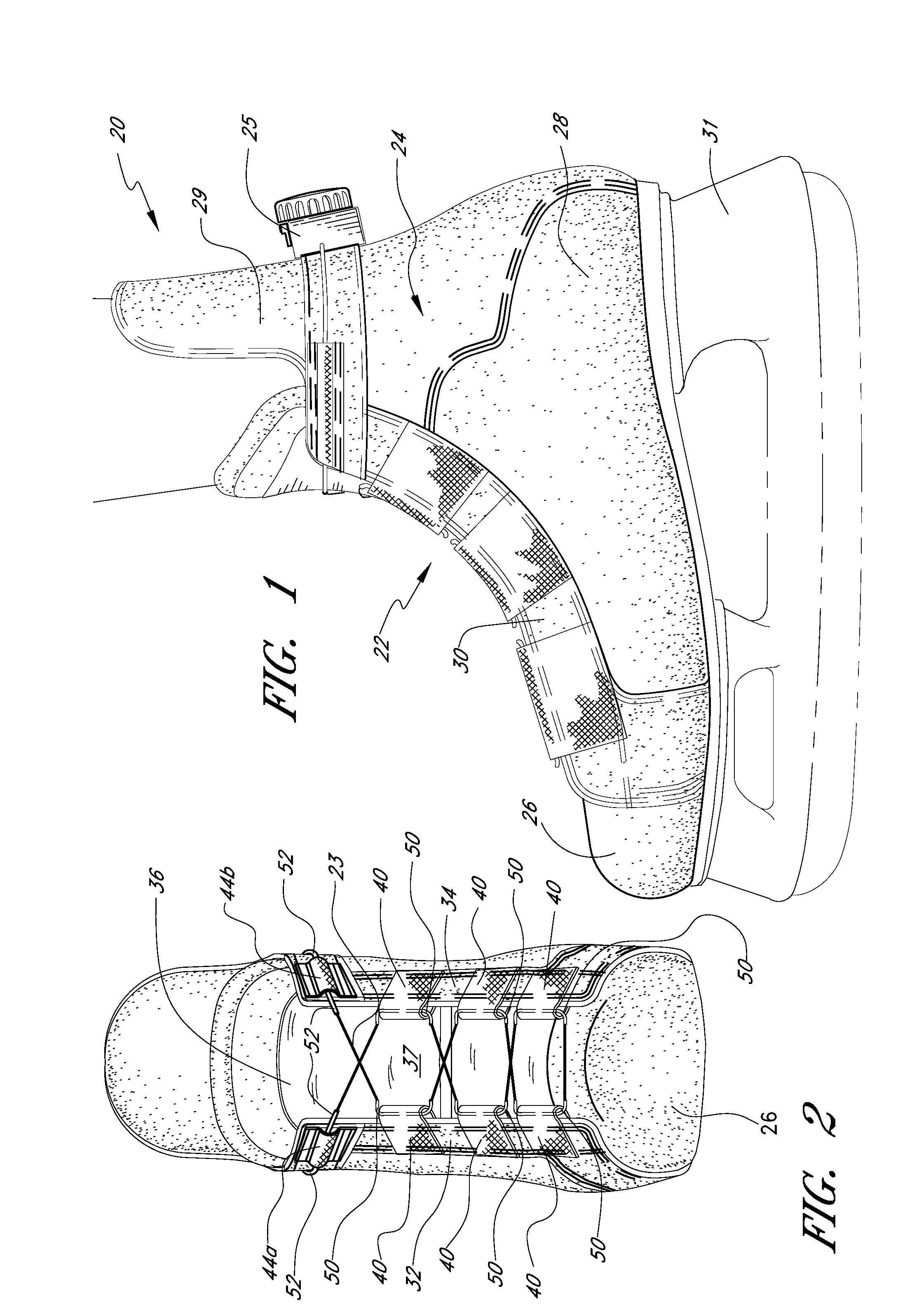

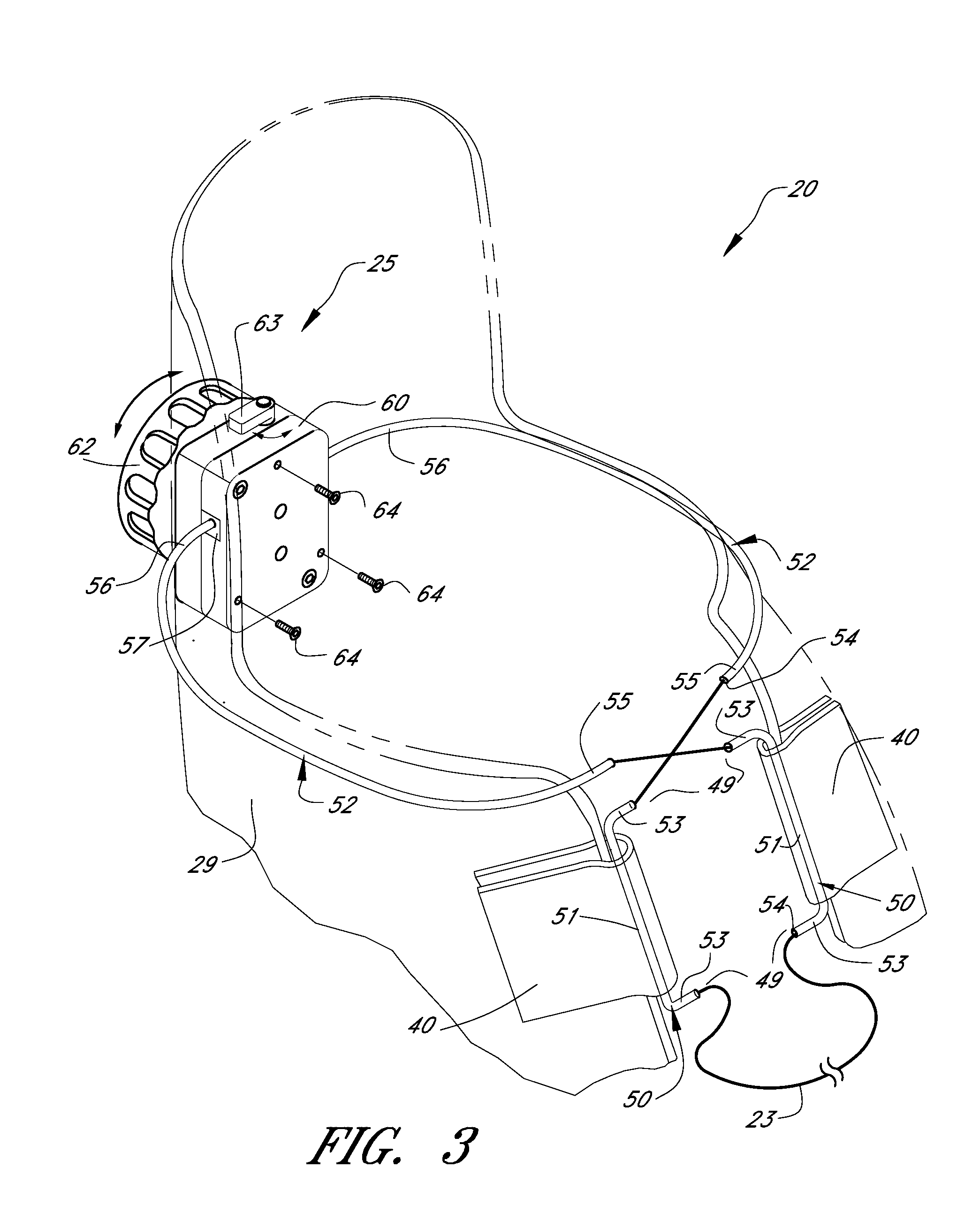

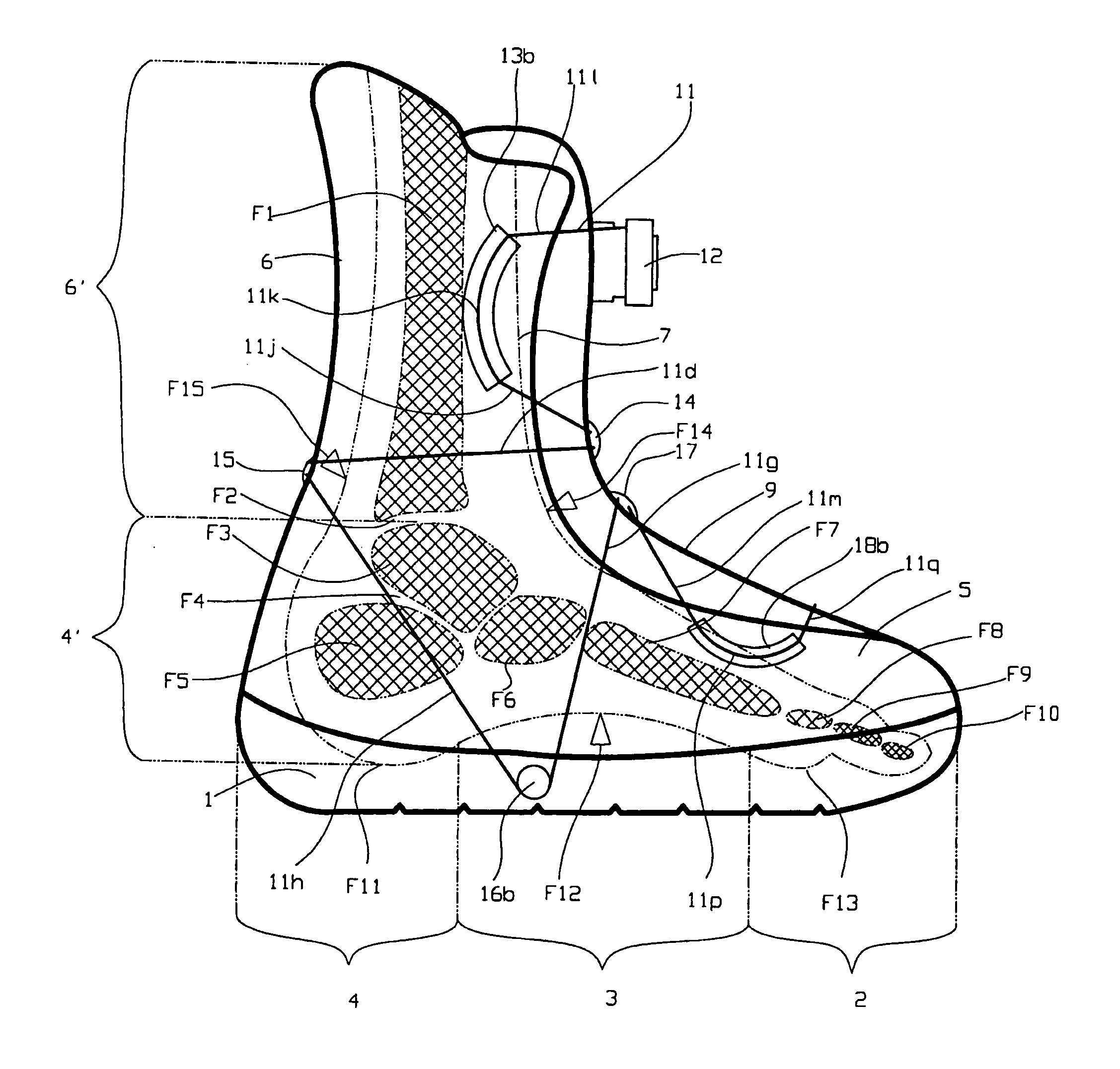

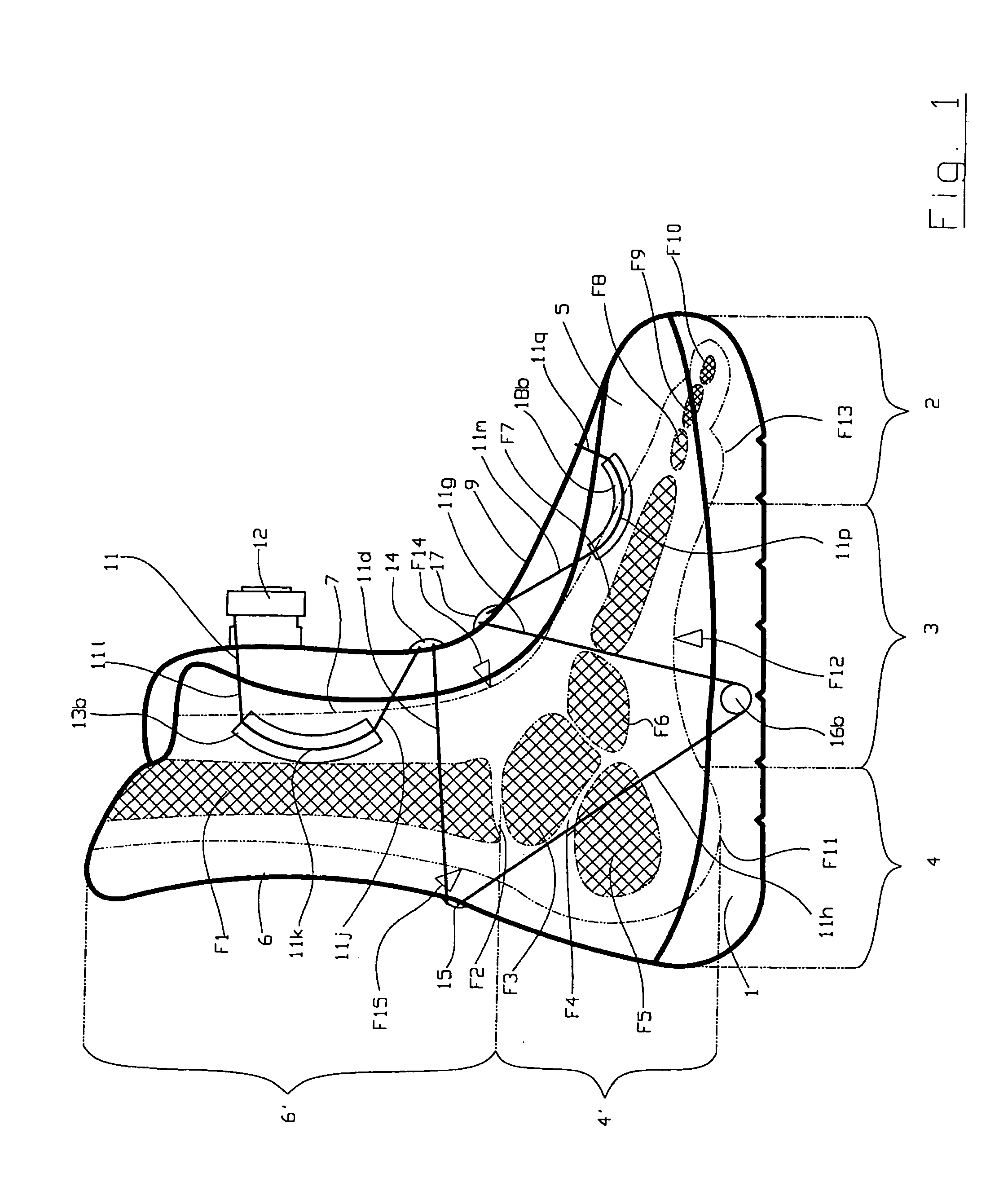

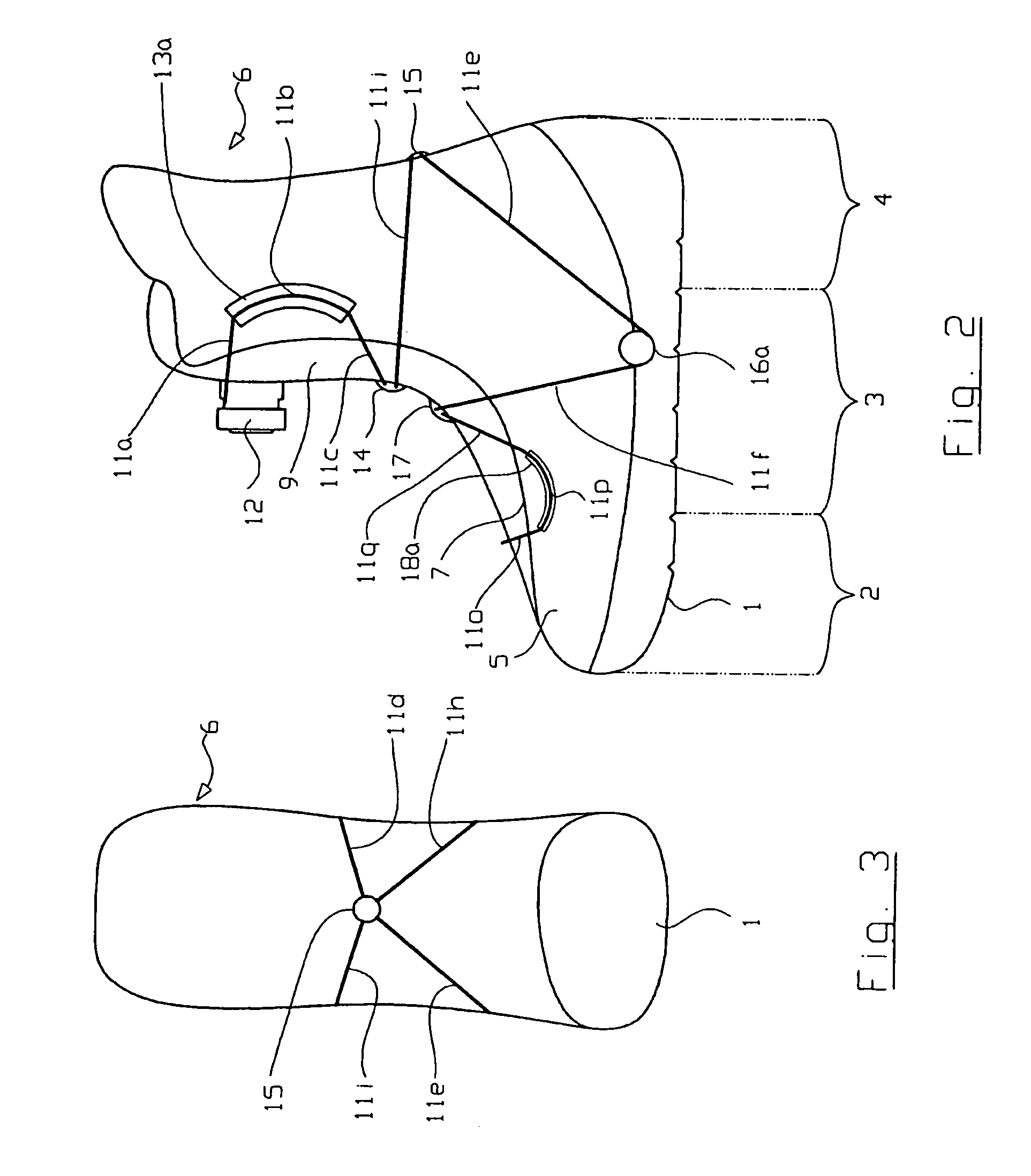

Reel based closure system

InactiveUS20080060167A1Weak elasticityHigh tensile strengthSnap fastenersShoe lace fasteningsEngineeringMechanical engineering

Disclosed is a closure system used in combination in any of a variety of applications including clothing, for example as a footwear lacing system comprising a lace attached to a tightening mechanism. The lace extends through a series of guide members positioned along two opposing footwear closure portions. The lace and guides preferably have low friction surfaces to facilitate sliding of the lace along the guide members so that the lace evenly distributes tension across the footwear member. The tightening mechanism allows incremental adjustment of the tension of the lace. The closure system allows a user to quickly loosen the lace and inhibits unintentional and / or accidental loosing of the lace.

Owner:HAMMERSLAG GARY R +2

Thermoplastic copolymer of tetrafluoroethylene and perfluoromethyl vinyl ether and medical devices employing the copolymer

An improved elastomeric material is described comprising an essentially noncross-linkable amorphous copolymer of tetrafluoroethylene (TFE) and perfluoromethyl vinyl ether (PMVE) which is both a thermoplastic and exhibits exceptional mechanical properties. This material is particularly suitable for use in ultra-clean environments, and particularly for use in an implantable device, since it does not contain contaminants that previous thermoset TFE / PMVE copolymers have required. Among the improved properties of the present invention are excellent biocompatibility, high matrix tensile strength, high clarity, high abrasion resistance, high purity, adequate elasticity, and ease of processing due to the thermoplastic, and noncross-linkable structure of the copolymer. The material of the present invention is also a high strength bonding agent particularly suited for bonding porous PTFE to itself or to other porous substances at room or elevated temperatures.

Owner:WL GORE & ASSOC INC

Sulfonated block copolymers, method for making same, and various uses for such block copolymers

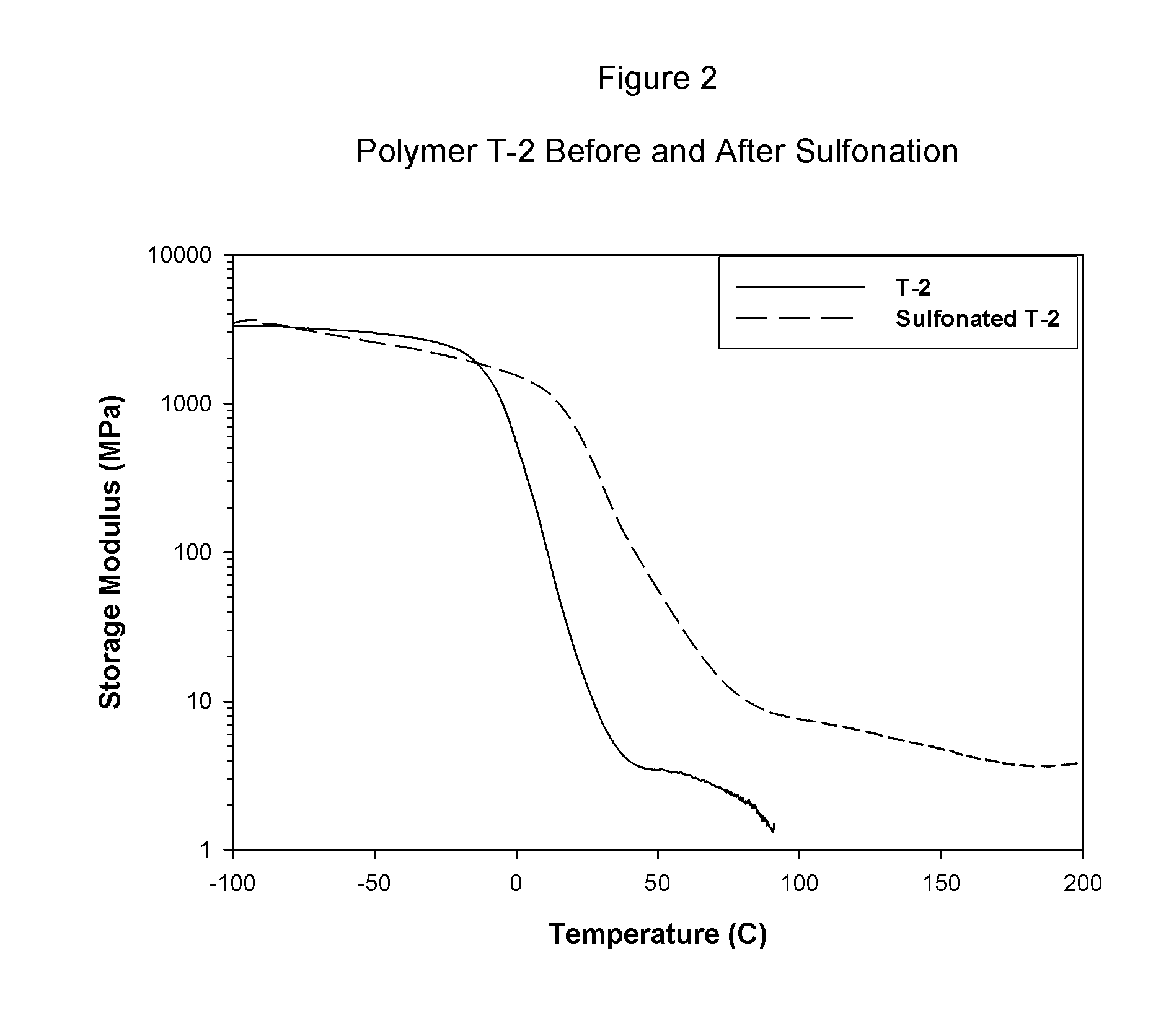

ActiveUS20070021569A1High water transport propertyImprove wet strengthSemi-permeable membranesNegative electrodesMethacrylatePolymer science

The present invention is a, solid block copolymer comprising at least two polymer end blocks A and at least one polymer interior block B wherein each A block is a polymer block resistant to sulfonation and each B block is a polymer block susceptible to sulfonation, and wherein said A and B blocks do not contain any significant levels of olefinic unsaturation. Preferably, each A block comprising one or more segments selected from polymerized (i) para-substituted styrene monomers, (ii) ethylene, (iii) alpha olefins of 3 to 18 carbon atoms; (iv) hydrogenated 1,3-cyclodiene monomers, (v) hydrogenated monomers of conjugated dienes having a vinyl content less than 35 mol percent prior to hydrogenation, (vi) acrylic esters, (vii) methacrylic esters, and (viii) mixtures thereof; and each B block comprising segments of one or more polymerized vinyl aromatic monomers selected from (i) unsubstituted styrene monomers, (ii) ortho-substituted styrene monomers, (iii) meta-substituted styrene monomers, (iv) alpha-methylstyrene, (v) 1,1-diphenylethylene, (vi) 1,2-diphenylethylene and (vii) mixtures thereof. Also claimed are processes for making such block copolymers, and the various end uses and applications for such block copolymers.

Owner:KRATON POLYMERS US LLC

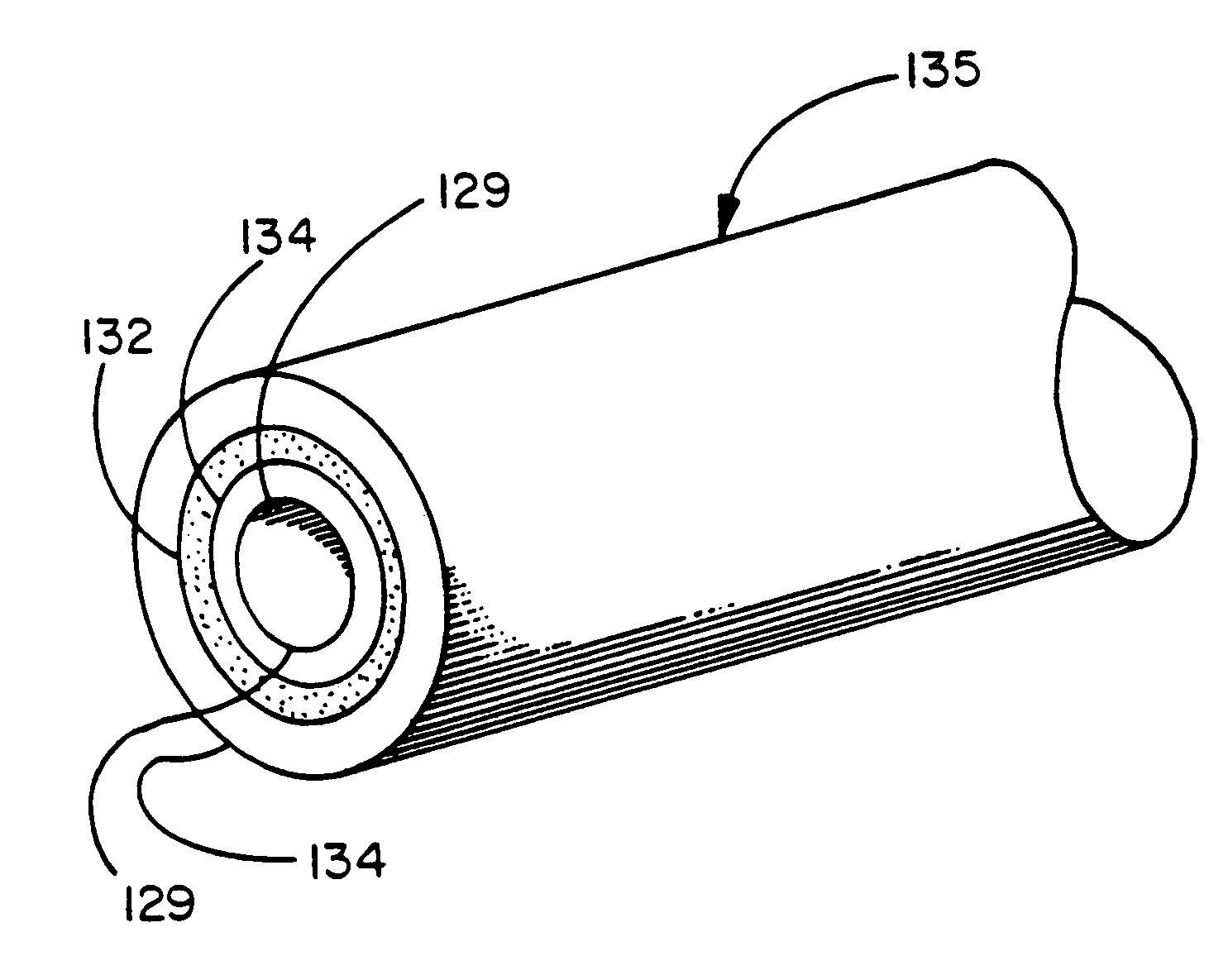

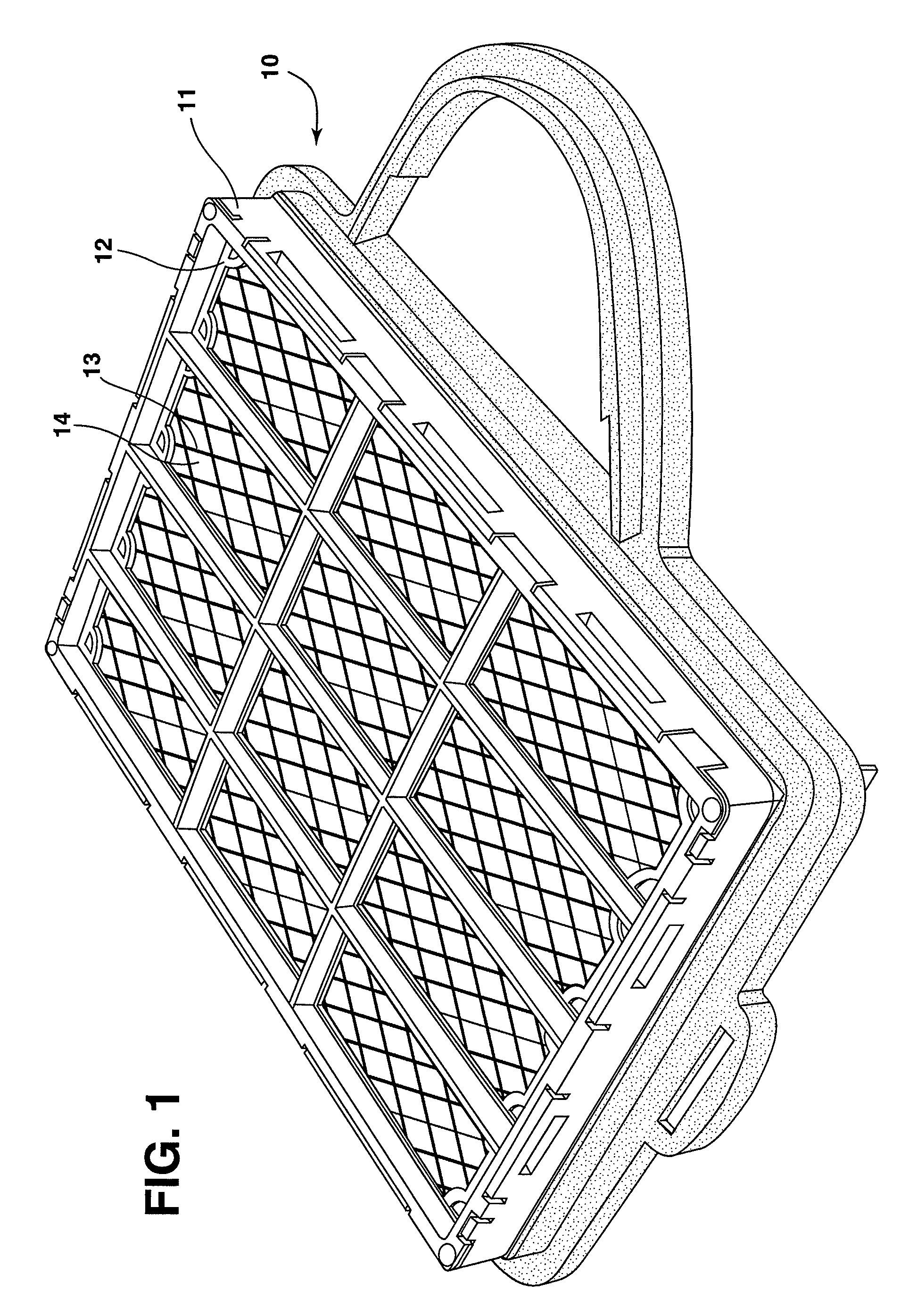

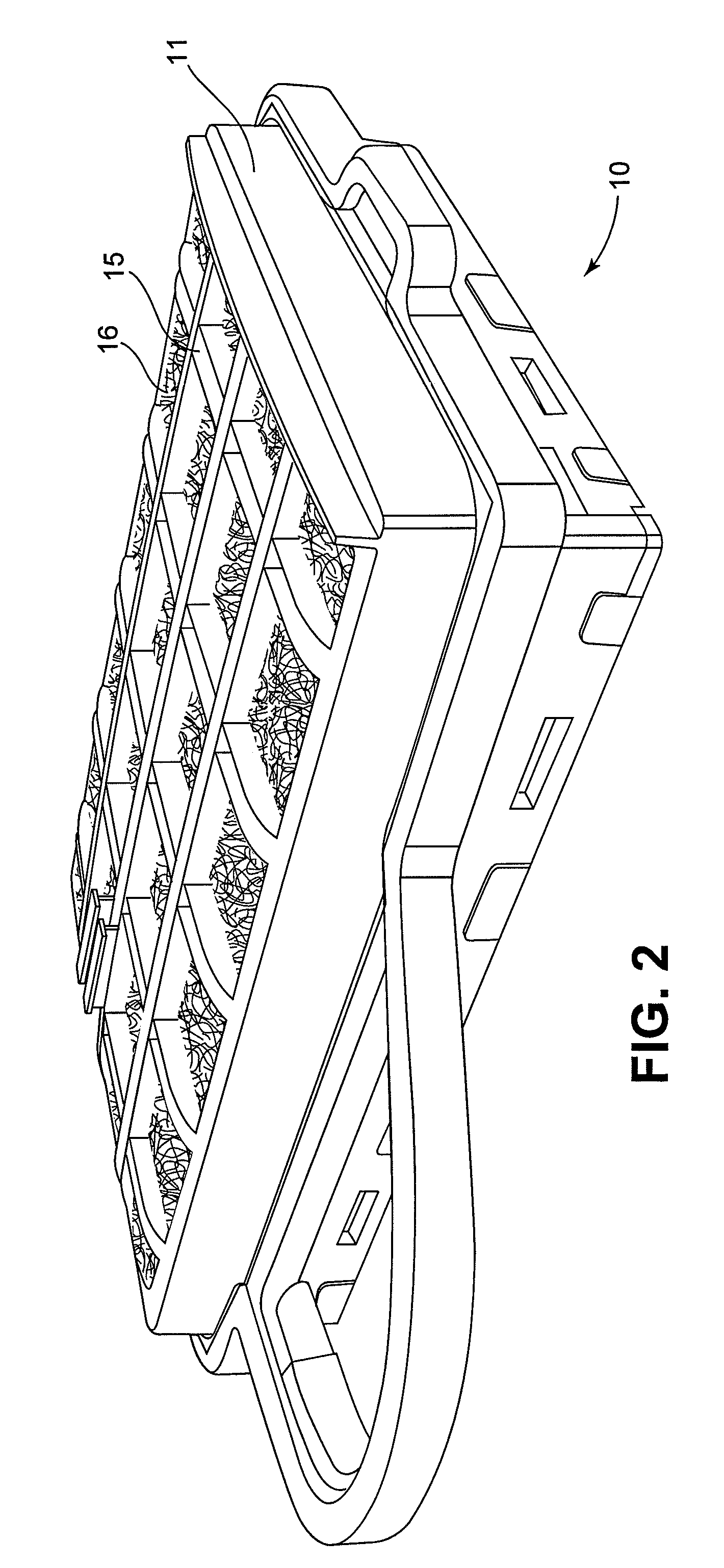

Filter medium and structure

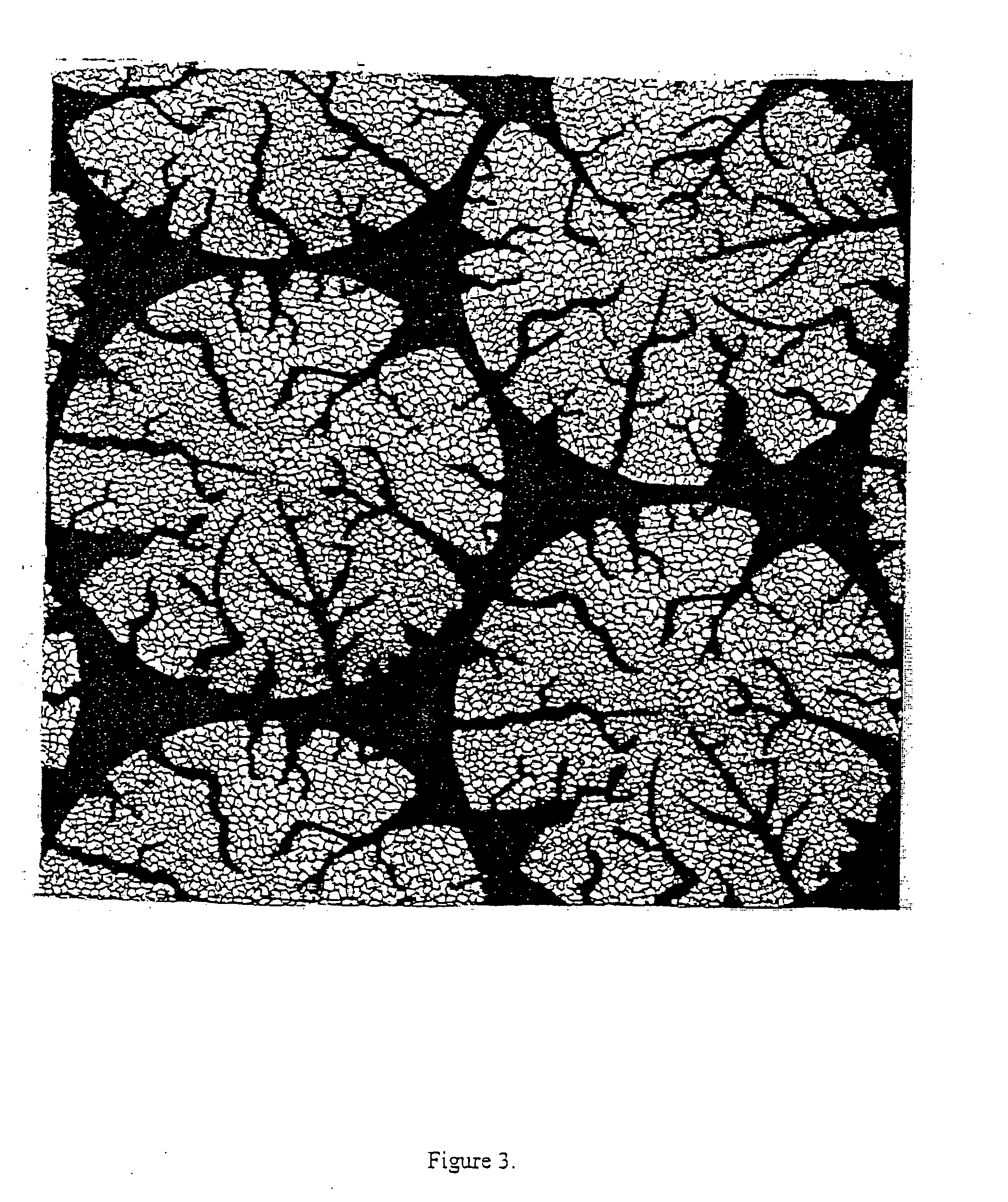

ActiveUS20060096263A1Efficient removalHigh strengthDispersed particle filtrationTransportation and packagingFiberParticulates

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

Filter medium and breather filter structure

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units, such as breather caps. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate and / or fluid mist load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

Reel based closure system

ActiveUS20100299959A1Weak elasticityHigh tensile strengthSnap fastenersShoe lace fasteningsEngineeringMechanical engineering

Disclosed is a closure system used in combination in any of a variety of applications including clothing, for example as a footwear lacing system comprising a lace attached to a tightening mechanism. The lace extends through a series of guide members positioned along two opposing footwear closure portions. The lace and guides preferably have low friction surfaces to facilitate sliding of the lace along the guide members so that the lace evenly distributes tension across the footwear member. The tightening mechanism allows incremental adjustment of the tension of the lace. The closure system allows a user to quickly loosen the lace and inhibits unintentional and / or accidental loosing of the lace.

Owner:BOA TECHNOLOGY

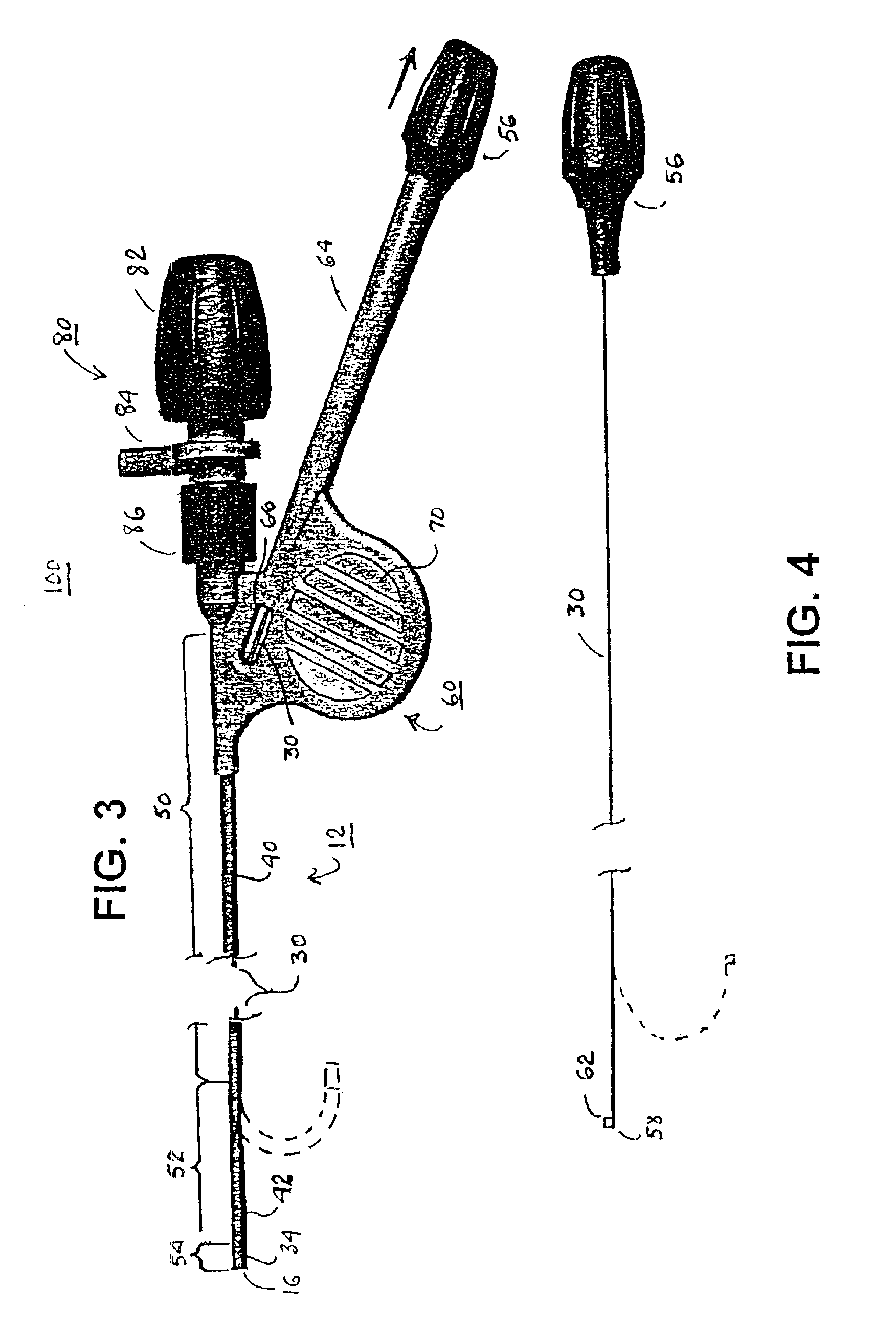

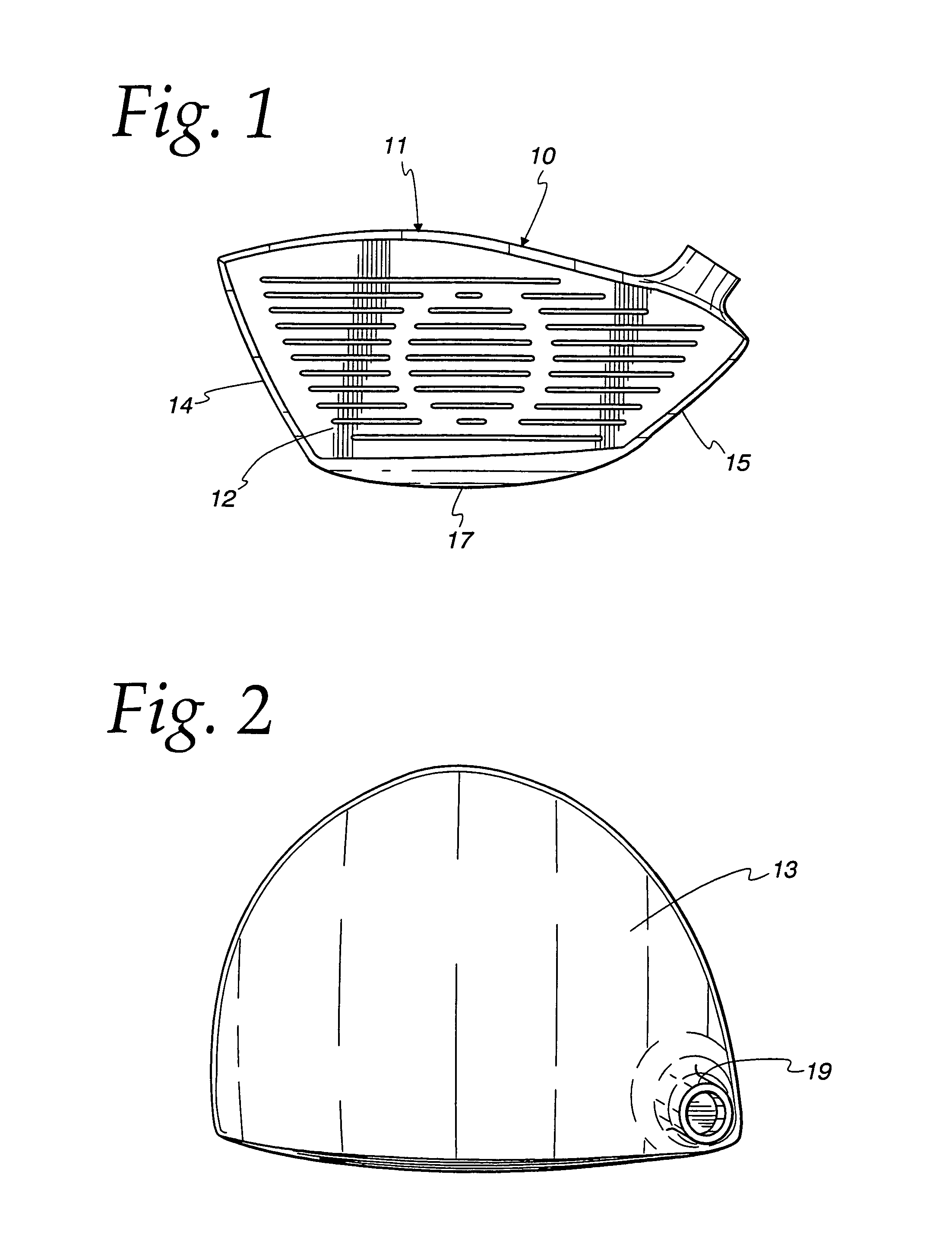

Golf club face flexure control system

InactiveUS6979270B1High modulusImprove energy transferGolf clubsRacket sportsControl systemGolf Ball

An improved line of golf clubs tailored to the golfer. The face wall firstly is designed so that the face wall modulus of elasticity increases from a low modulus for the low swing speed range to progressively higher modula for the higher swing speed ranges. Face modulus can be altered by a variety of techniques including face wall thinning, material selection and heat treatment or a combination thereof. In each of the swing speed range clubs, the face has a first modulus of elasticity determined by the face itself and after the face deflects to a predetermined value, the face modulus is significantly increased by a secondary wall parallel to and closely spaced behind the face wall.

Owner:KARSTEN MFG CORP

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

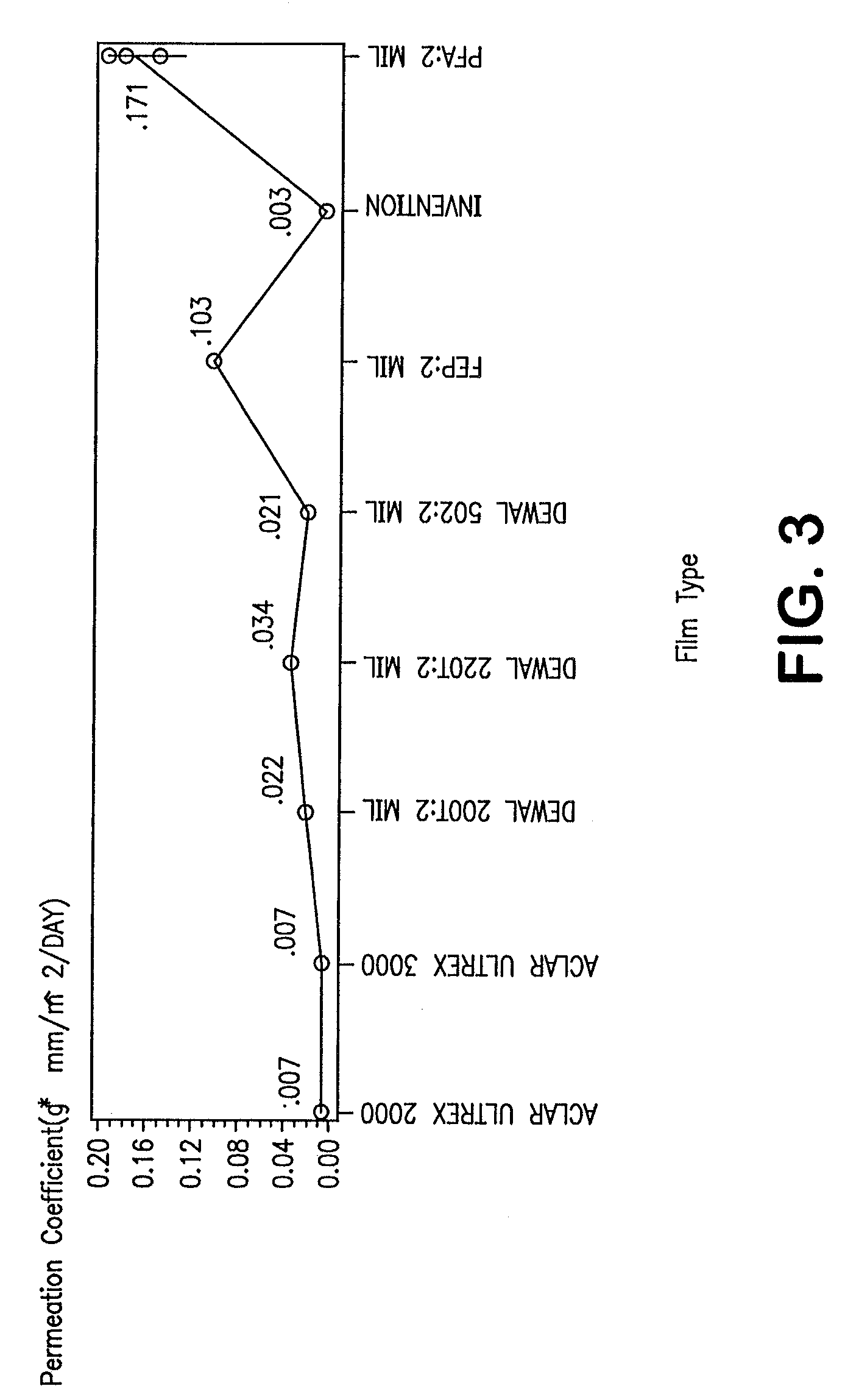

Fluoropolymer barrier material

InactiveUS7521010B2Improve barrier propertiesImprove permeabilitySynthetic resin layered productsCeramic shaping apparatusPolymer scienceWater vapor permeability

A novel densified fluoropolymer article is described which has a water vapor permeation of about 0.015 g-mm / m2 / day or less, and preferably has a matrix tensile strength of at least 10,000 psi in two orthogonal directions. The articles are made by compressing expanded porous PTFE at pressures, temperatures and times which result in elimination of the pores, and subsequent stretching above the crystalline melt temperature.

Owner:WL GORE & ASSOC INC

Laced boot

A laced boot having a boot lace and sections of the boot lace run in a continuous one-piece manner as follows: a first section runs from the metatarsal area of the sole over the instep of the boot; a second section runs from the metatarsal area of the sole around the outside of the upper above a heel area of the boot; and a third section runs from the same position of the upper to the instep and back to the cited position of the upper and the three named sections form a triangle, viewed from the side of the boot that covers the ankle joints of the foot.

Owner:GOODWELL INT

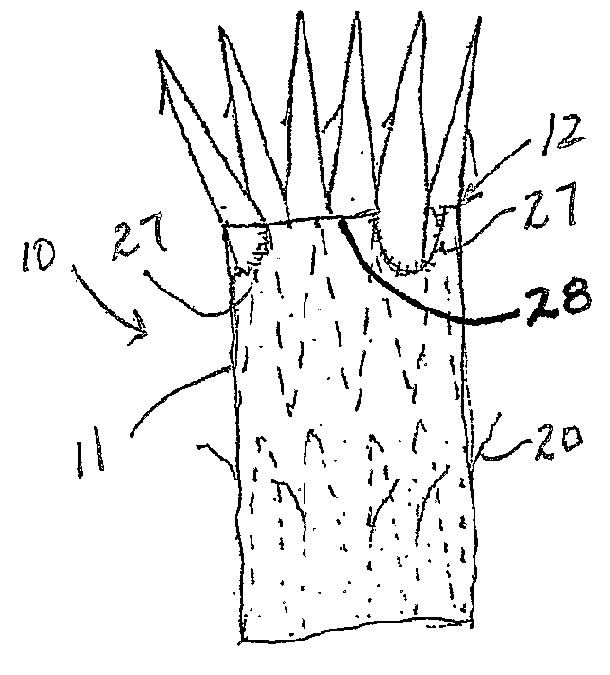

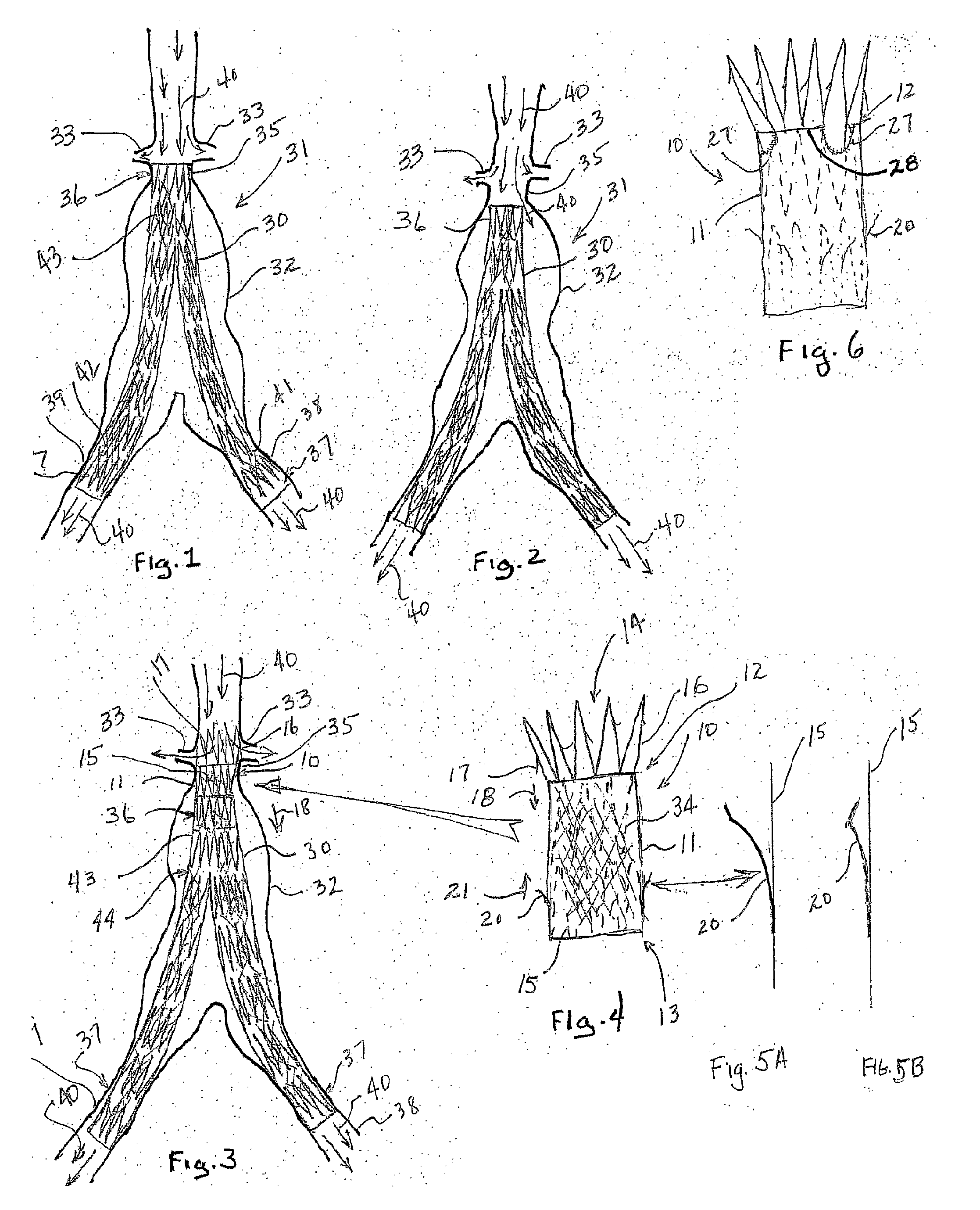

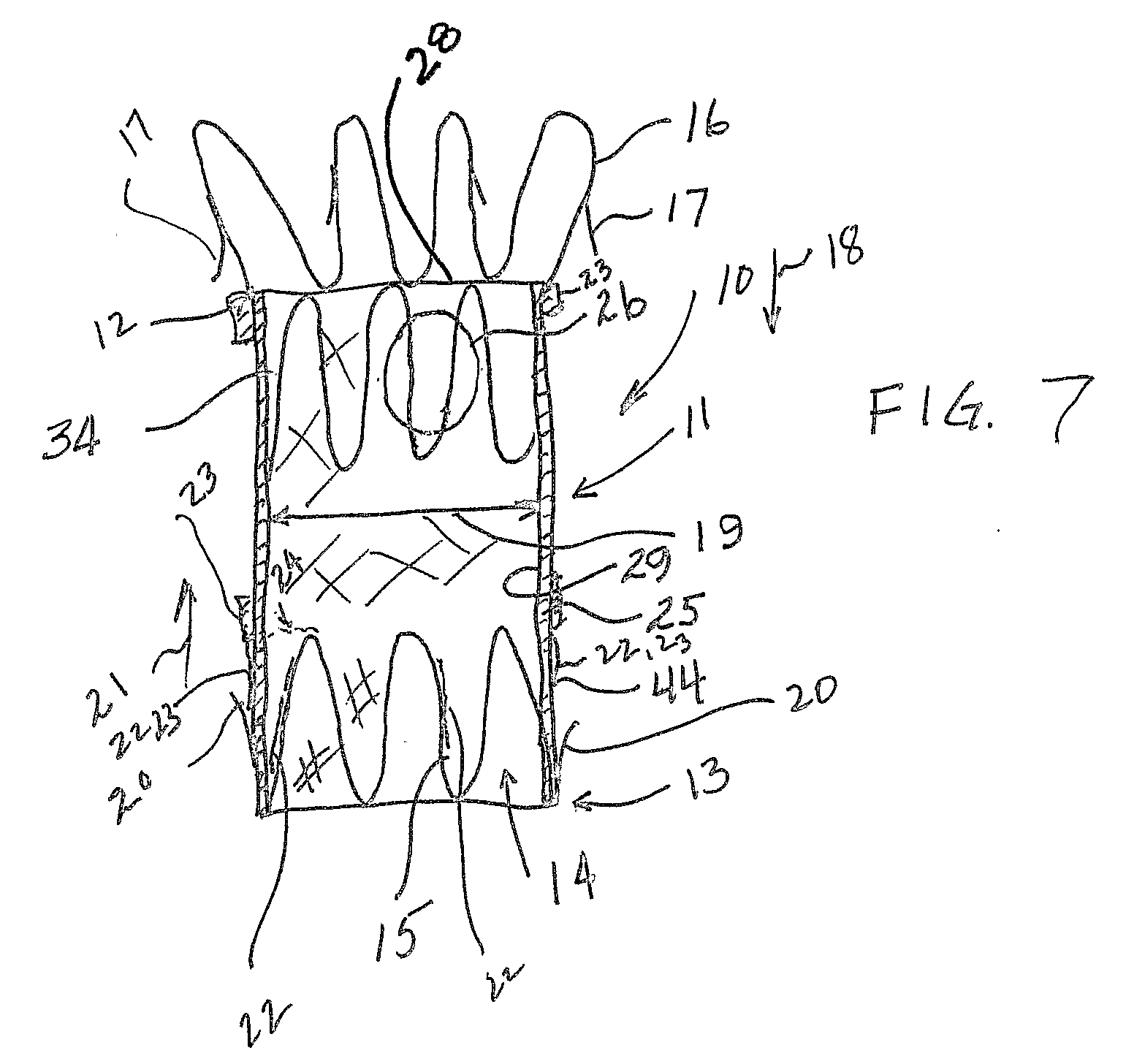

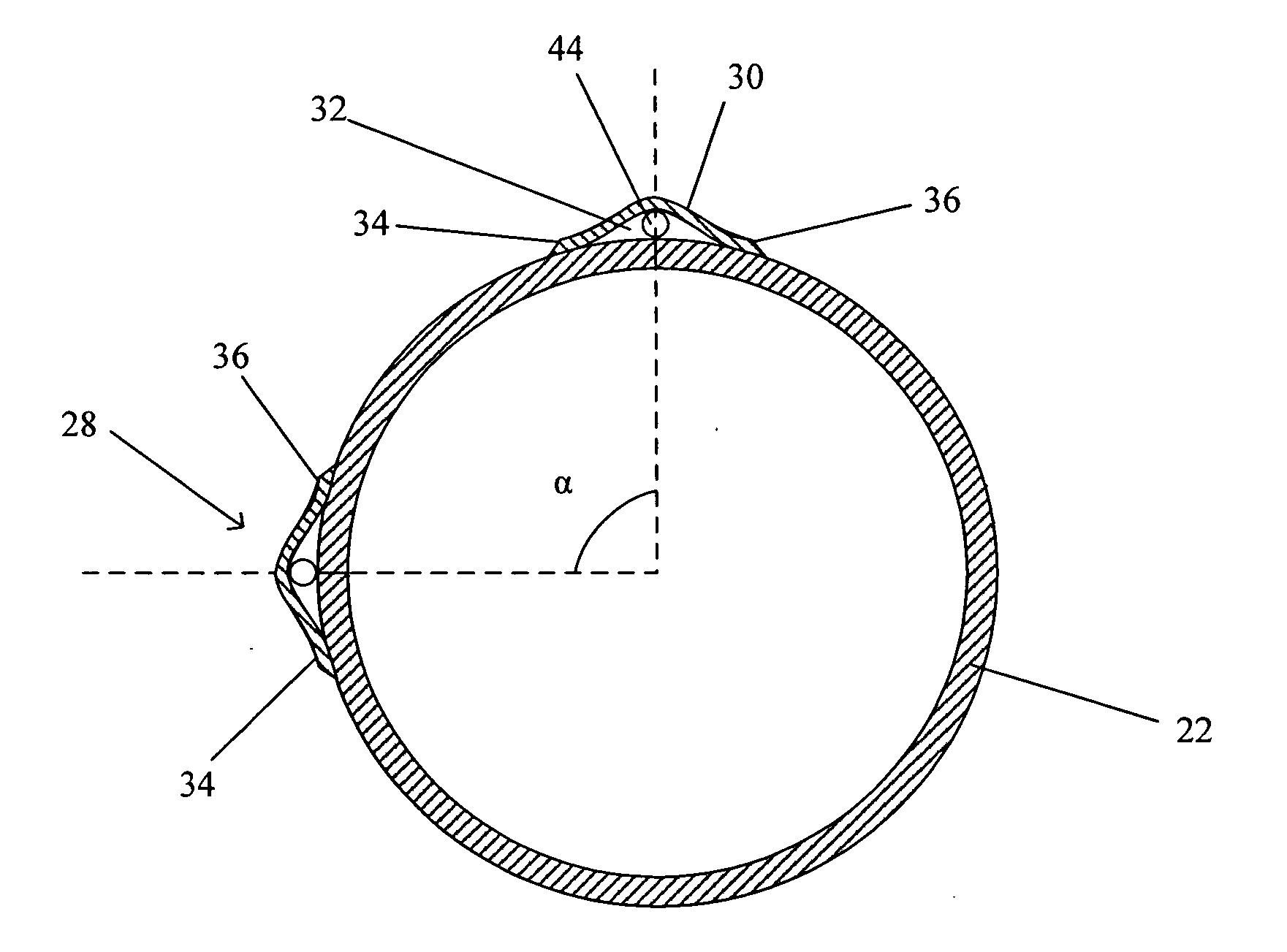

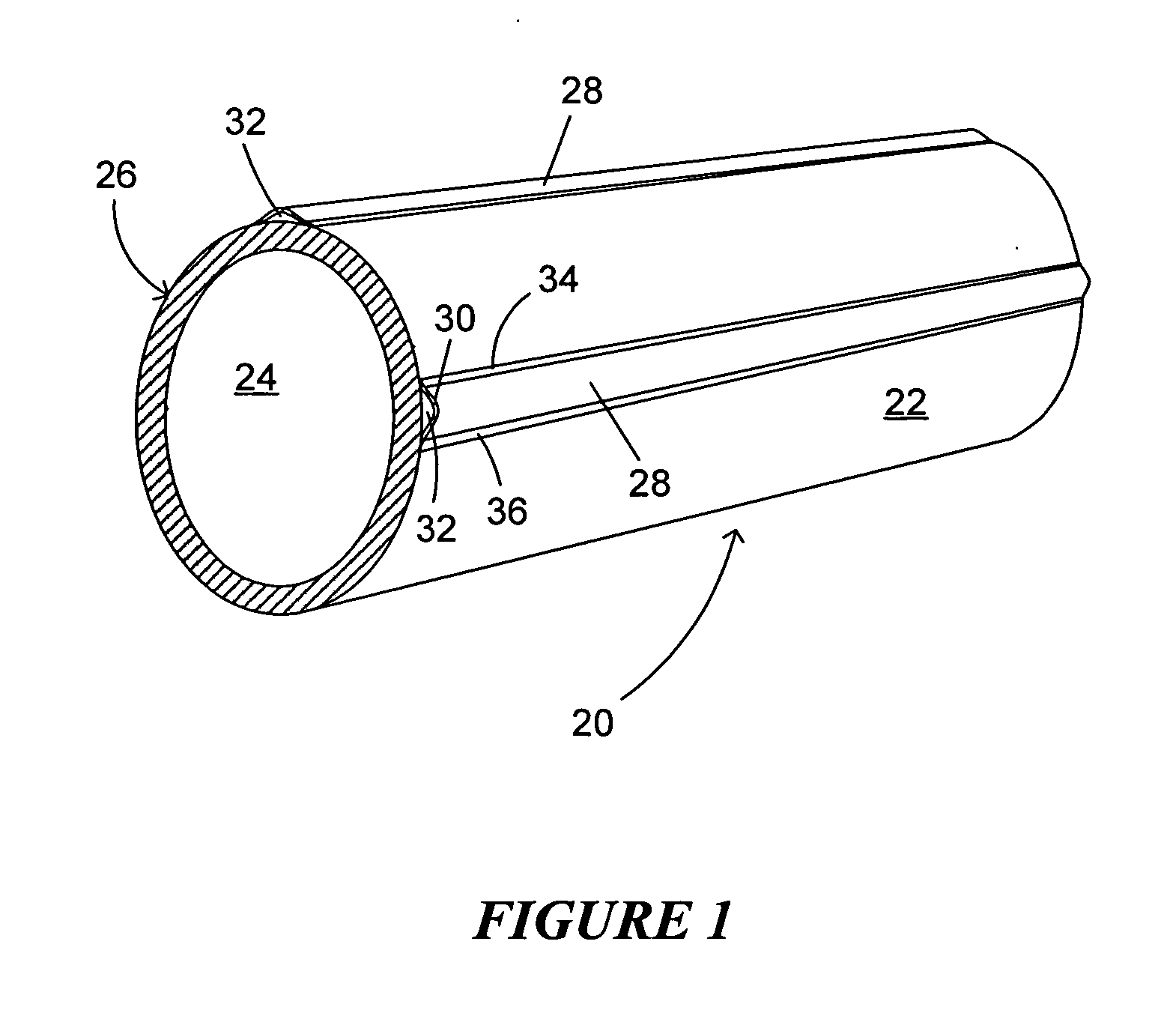

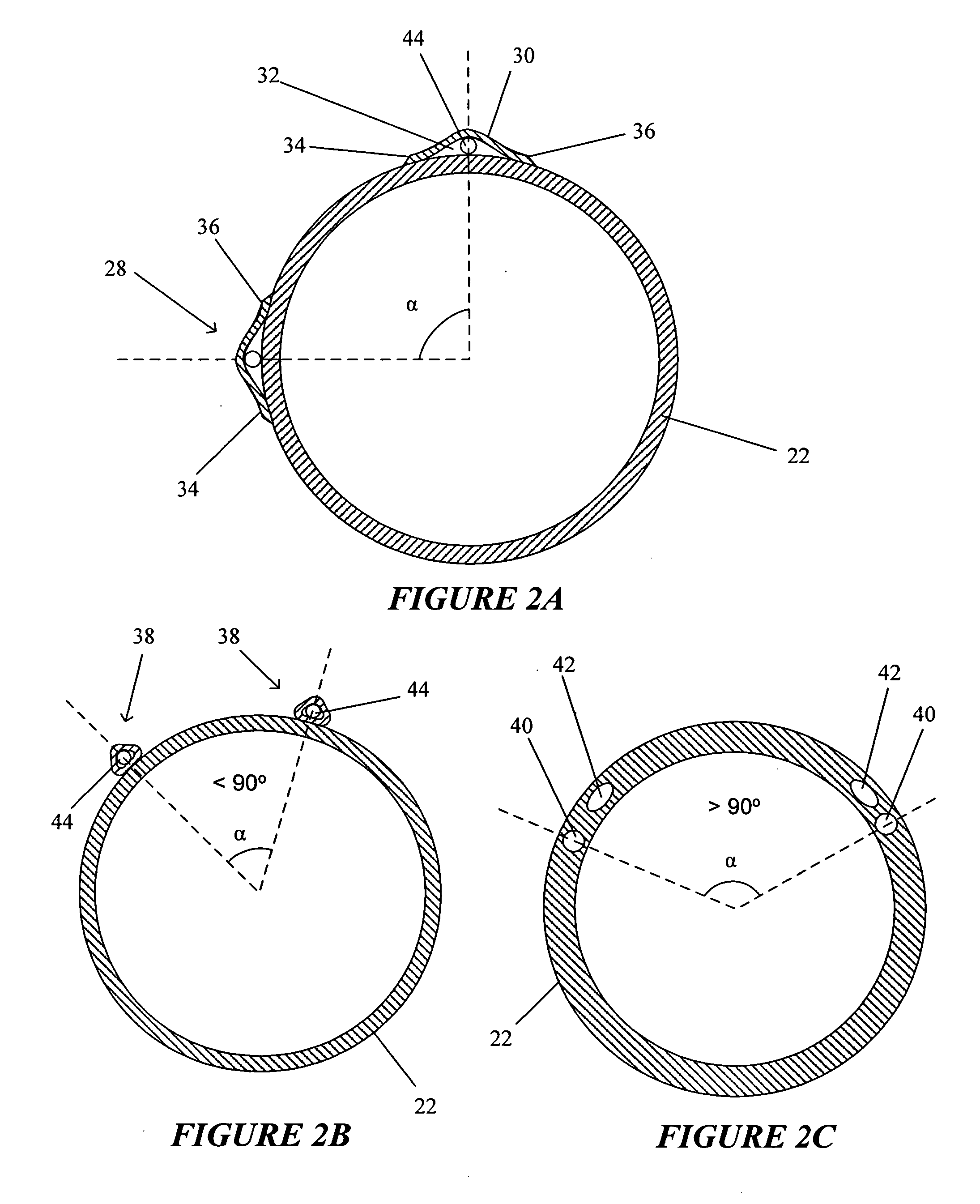

Stent Graft Repair Device

ActiveUS20070219620A1Avoid possibilityHigh tensile strengthStentsBlood vesselsStent graftingInsertion stent

A repair device (10) for affixing a migrating stent graft (30) to the interior surface of a vessel wall (31). The repair device includes tubular graft (11) with a bare or uncovered stent (16) affixed to the proximal end (12). The bare stent includes a plurality of distally pointed barbs (17) for securing the repair device to a vessel wall. A second stent (15) is positioned in the passage (14) of the tubular graft to expand the graft against the interior surface of the migrating stent graft (30). Proximally pointing barbs (20) are affixed to the struts of the second stent and extend through the graft material for securing the repair device to the migrating stent graft. Biological glue (22) and other sealing material (23) can be applied to the tubular graft and / or stents for sealing the repair device against the vessel wall and / or the interior of the migrating stent graft.

Owner:COOK MEDICAL TECH LLC

Inflatable nuclear prosthesis

ActiveUS20050027358A1Restores sufficient disc space heightRestore mobilityJoint implantsSpinal implantsMedicineProsthesis

The nucleus of an intervertebral disc is replaced with a construct including a distendable sack or balloon which is inflated with a hardenable material and is detached in situ when the injected material has hardened. Alternatively, two nested balloons may be inserted, and then filled with materials which have different hardnesses when cured, to simulate a natural disc.

Owner:SUDDABY LOUBERT

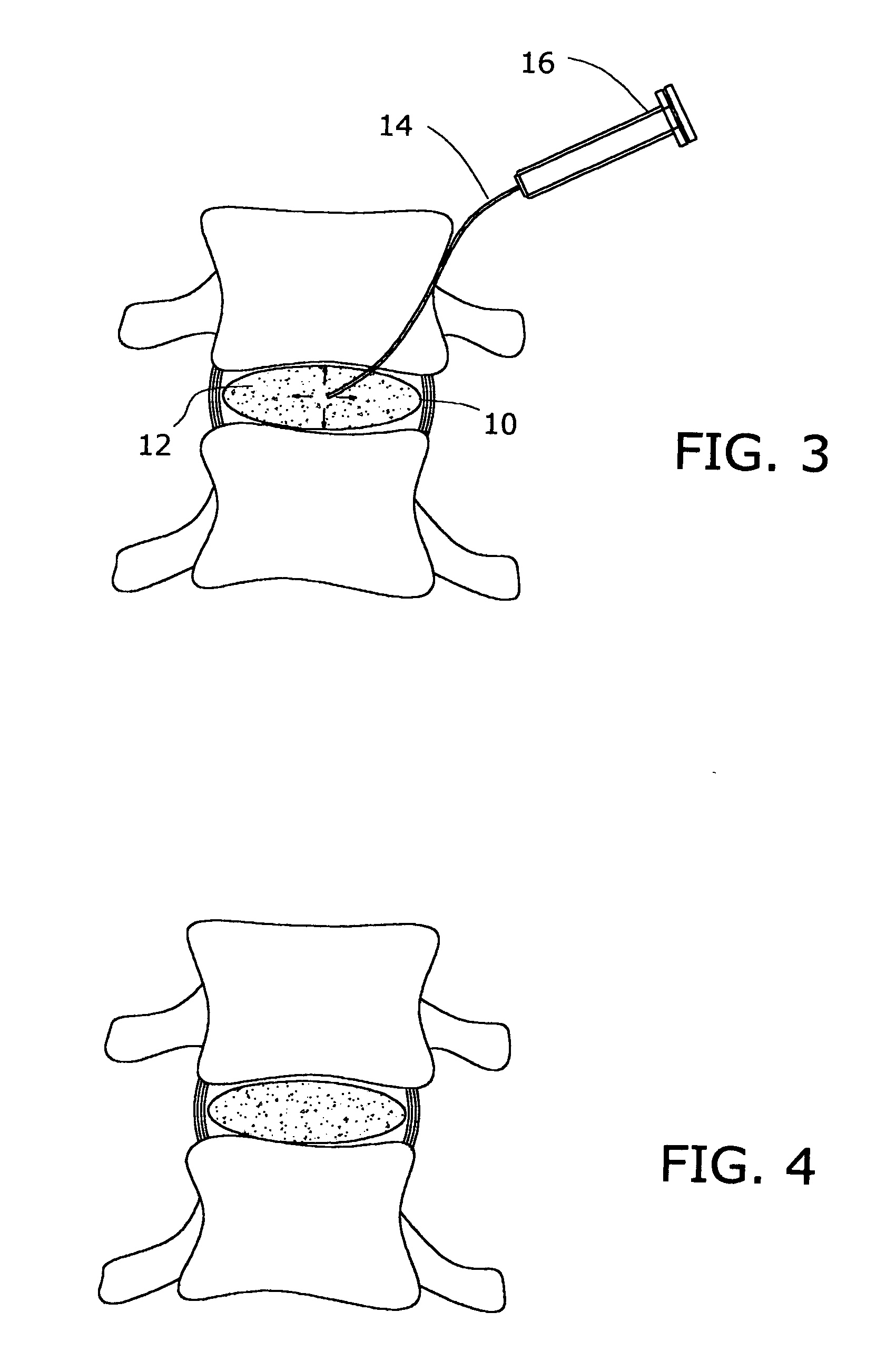

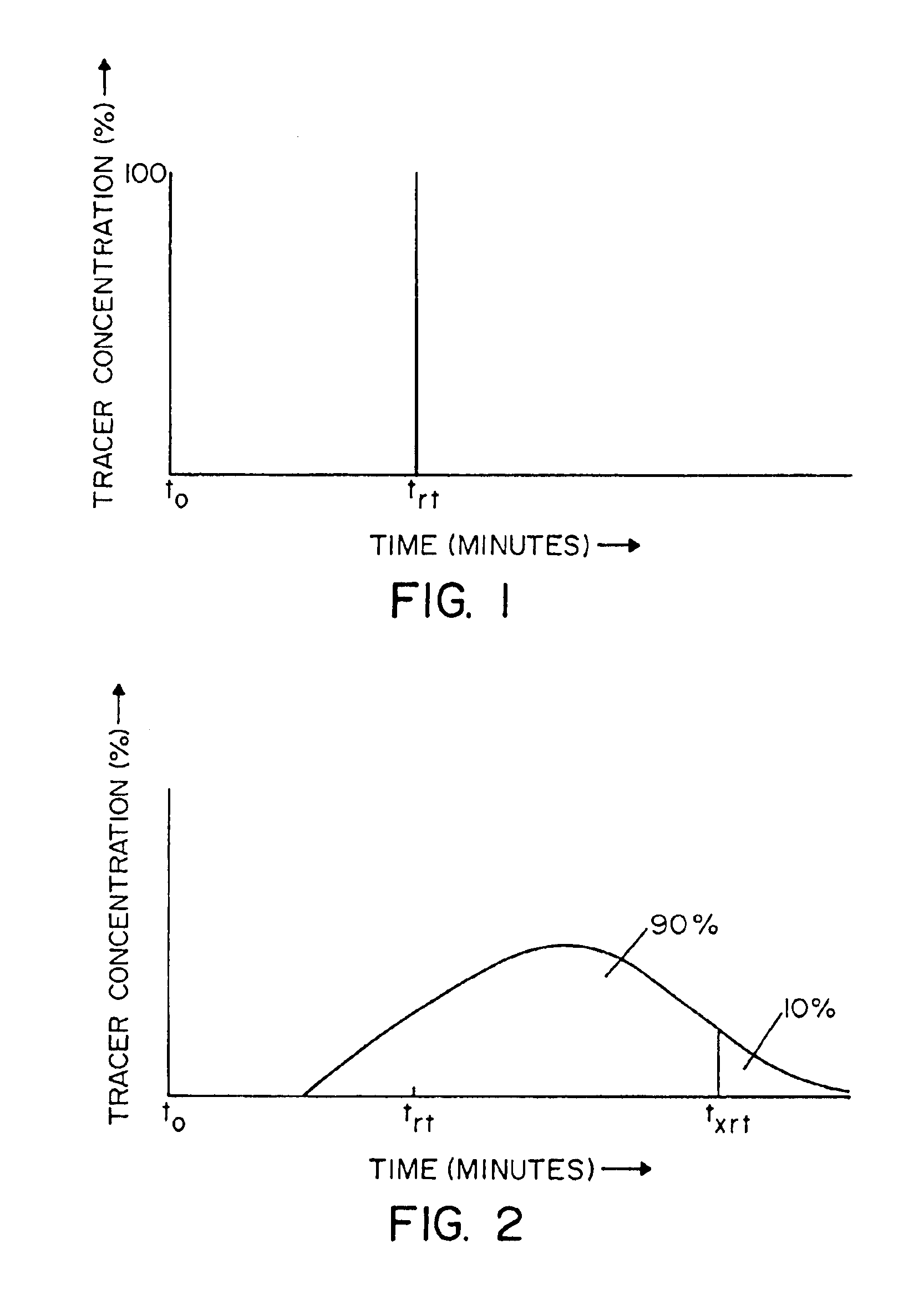

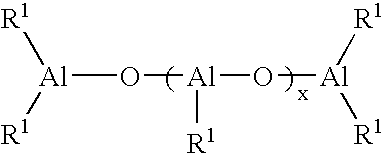

Continuous process for the production of conjugated diene polymers having narrow molecular weight distribution and products therefrom

InactiveUS6897270B2Narrow molecular weight distributionImprove responseHydrocarbon solventsContinuous reactor

A continuous process for producing conjugated diene polymers comprising the steps of contacting, within an hydrocarbon solvent and within a continuous reactor, conjugated diene monomer and a catalyst composition prepared by combining: (a) a lanthanide compound, (b) an alkylating agent, and (c) a halogen-containing compound, and maintaining a non-ideal flow pattern within the continuous reactor so that 10% of the reagents entering the reactor at a reference time t0 are still present within the continuous reactor at a time t0+xtrt, where trt is the residence time corresponding to ideal flow within the continuous reactor and x is a numeral greater than 1.5.

Owner:BRIDGESTONE CORP

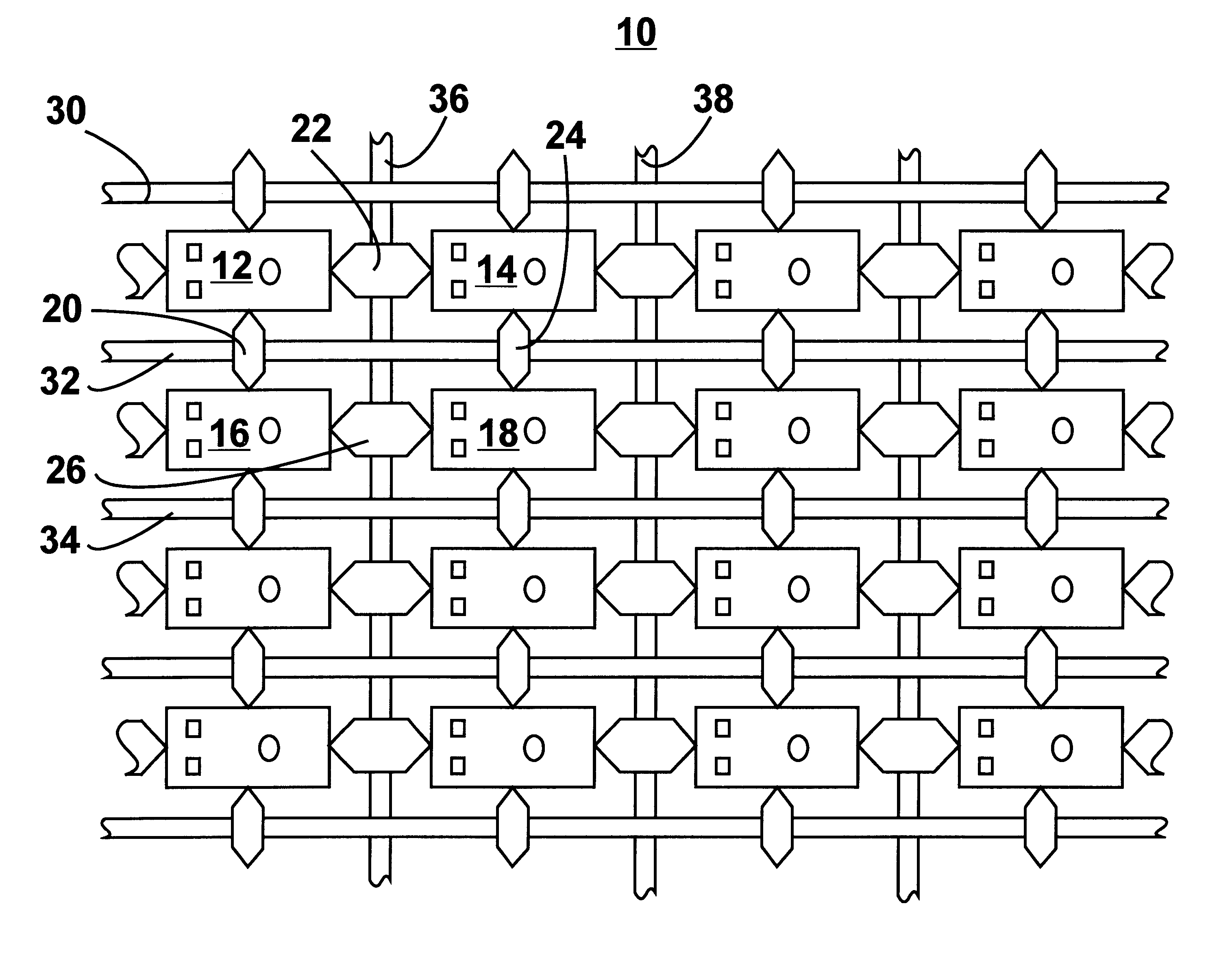

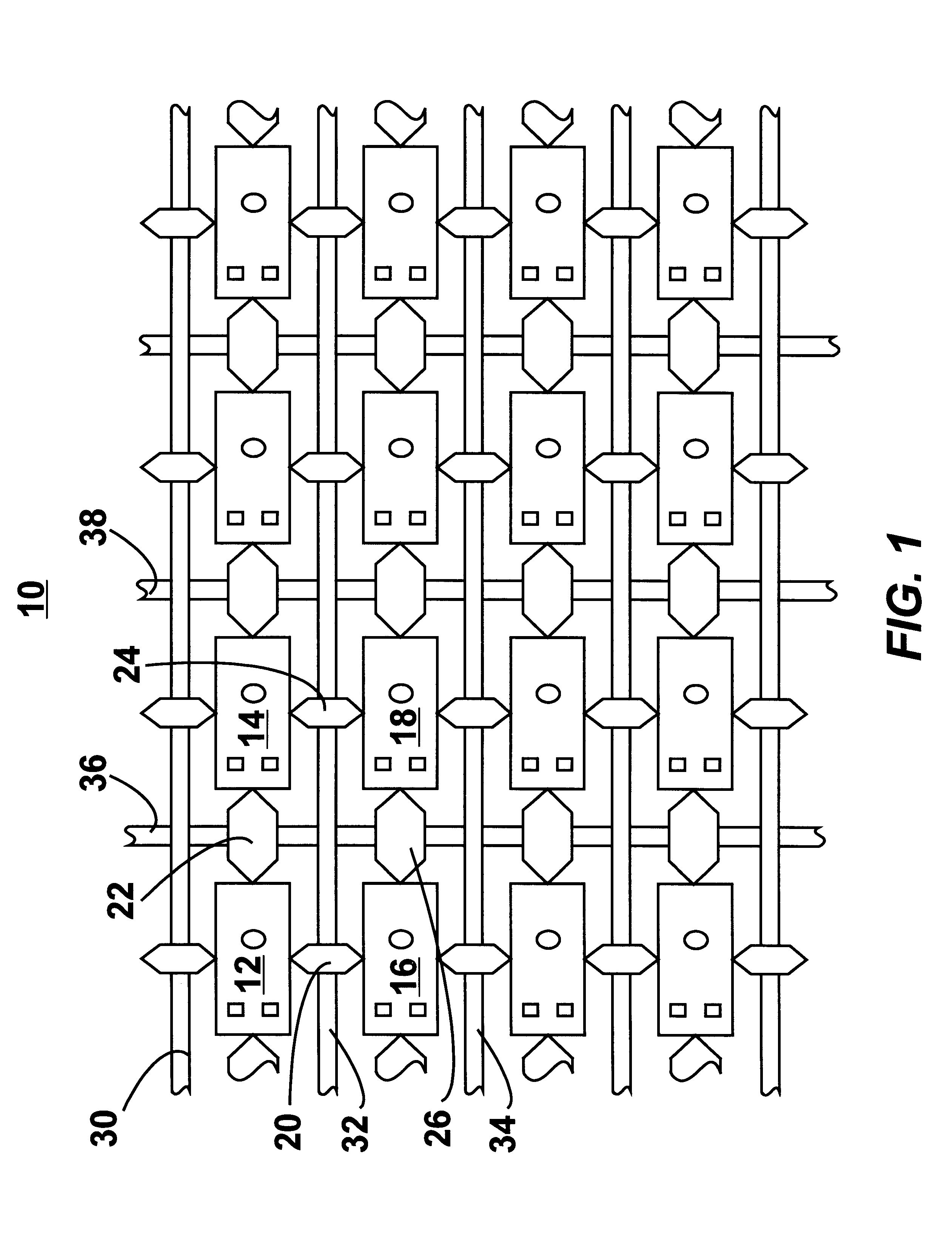

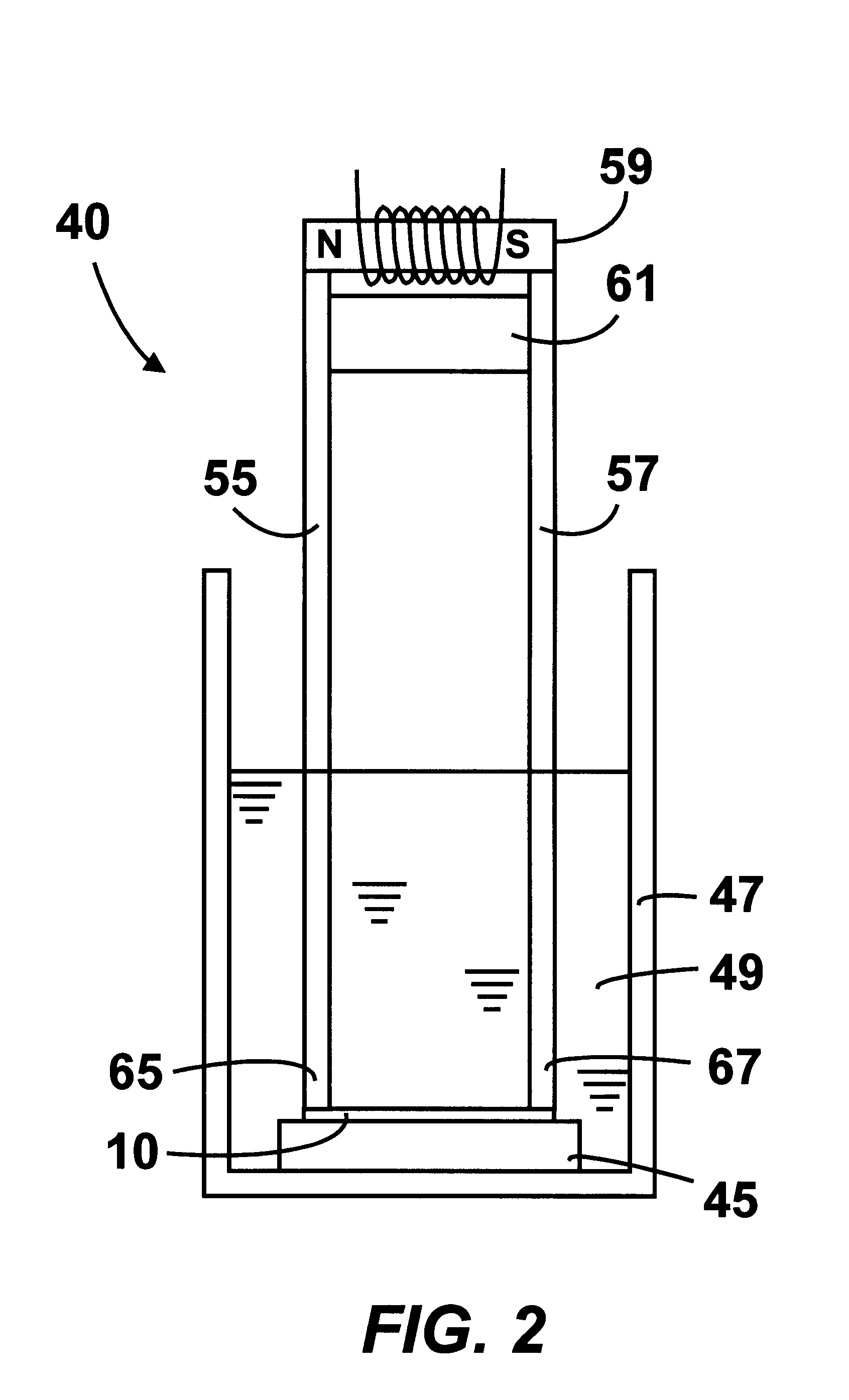

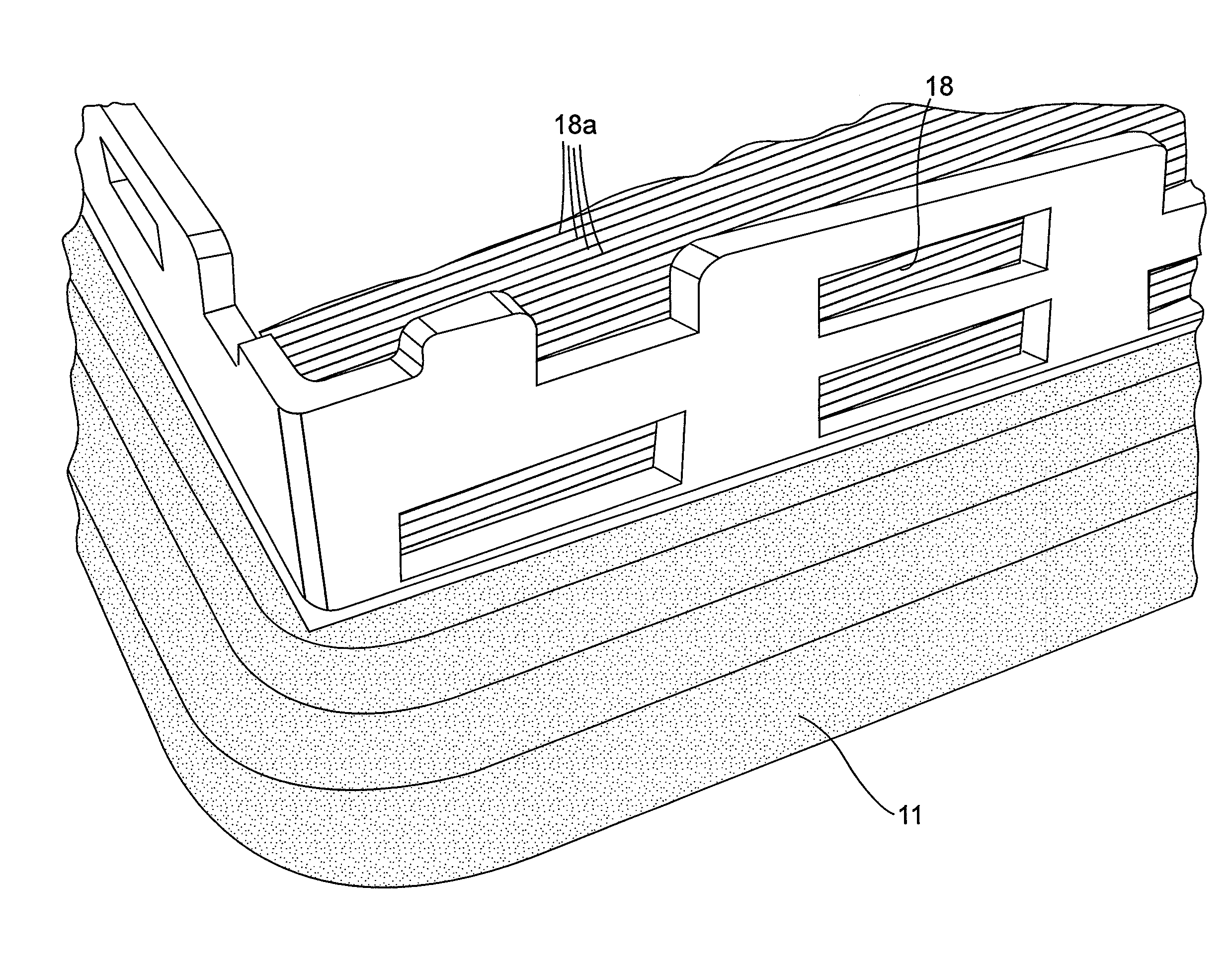

Method and tool for handling micro-mechanical structures

InactiveUS6255721B1High tensile strengthEasy to moveTransistorSemiconductor/solid-state device detailsMicro devicesEngineering

A method of forming and handling an array of micro-devices such as thin film devices that enables simultaneous mass handling and processing of these thin film devices. A plurality of micro-devices and links are simultaneously formed on a wafer, with the links interconnecting the micro-devices for maintaining a unitary array structure. A matrix of magnetic strips is then formed to impart added overall tensile strength to the array. The magnetic strips are secured to the links and form a planar support grid therewith. The array of micro-devices is then released from the wafer and lifted therefrom by means of a magnetic pick-up tool. Using the pick-up tool, the array is transferred onto a magnetic chuck which securely retains the array. Conductive wires are bonded to a row of micro-devices which are then separated from the array into individual micro-devices.

Owner:WESTERN DIGITAL TECH INC

Filter element and method

InactiveUS20090044702A1Life of element can be lengthenedIncrease capacityCombination devicesNon-fibrous pulp additionMultiple formsParticulates

A filter element having multiple formed layers of filtration media is disclosed. The media are layered so as to form a pore size gradient. The filter element is capable of removing both solid and liquid particulates from a moving fluid stream. The filter element has high strength and compressibility. The layers can be supported on a porous or perforate support to provide mechanical stability during filtering operations. The filtration media layers can be formed into various filter element forms such as panels, cartridges, inserts, and the like.

Owner:DONALDSON CO INC

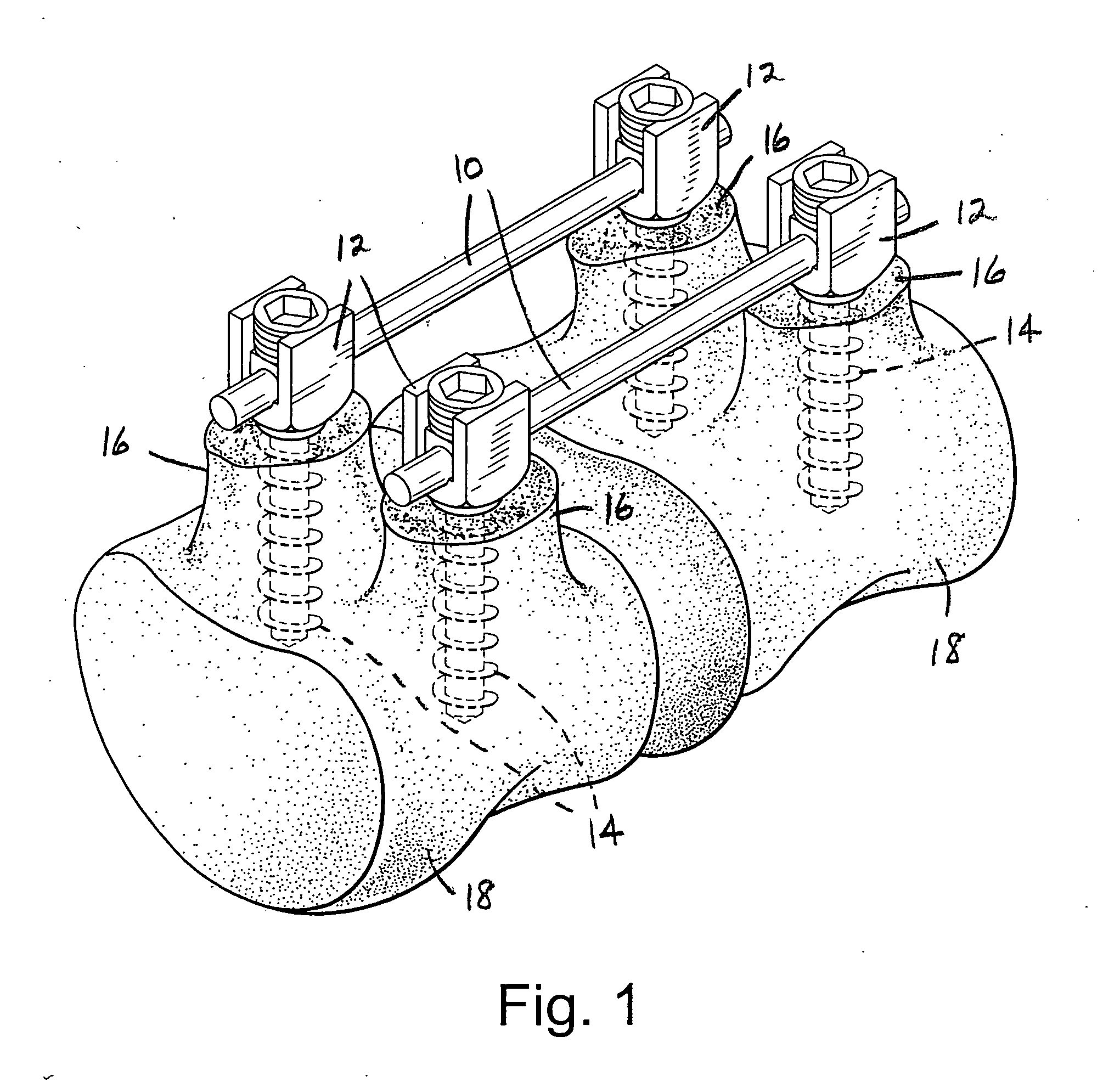

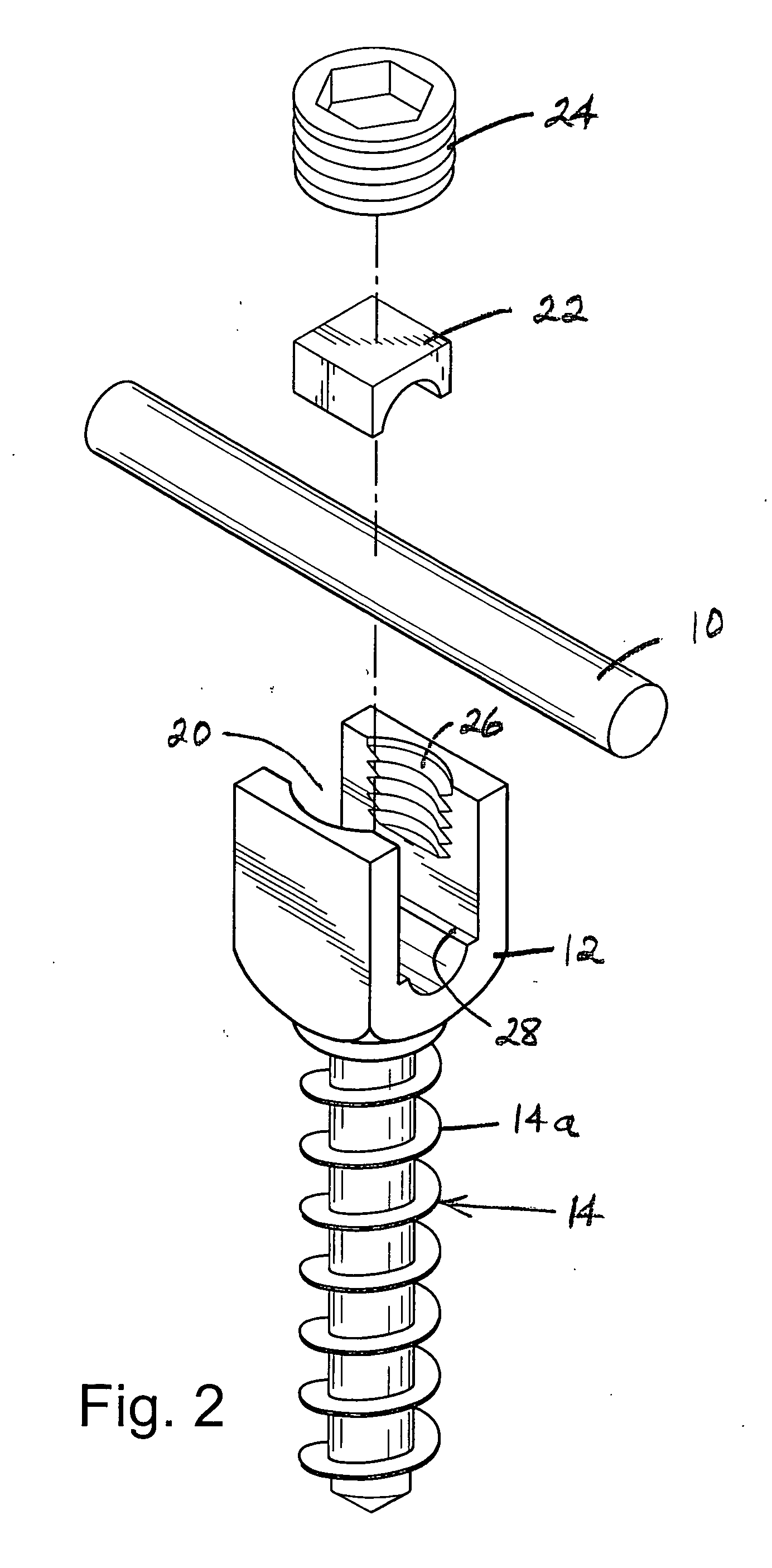

Apparatus and method for flexible spinal fixation

InactiveUS20070233064A1High tensile strengthReduce stretchInternal osteosythesisJoint implantsPlastic materialsUltimate tensile strength

Apparatus for connecting and stabilizing adjacent vertebral segments, comprising a flexible composite connecting rod extending between the segments, and connection devices for connecting the rod to the vertebral segments. The rod comprises a rod member formed of a flexible plastic material having a predetermined compression strength, and a high tensile strength, low stretch, flexible reinforcing element extending longitudinally through the entire length of the rod member and being bonded thereto. The reinforcing element may be in the form of a single cord, rope, braid or monofilament, a plurality of substantially parallel cords, ropes, braids or monofilaments, or a tubular cord, rope or braid extending through the rod member.

Owner:HOLT DEV

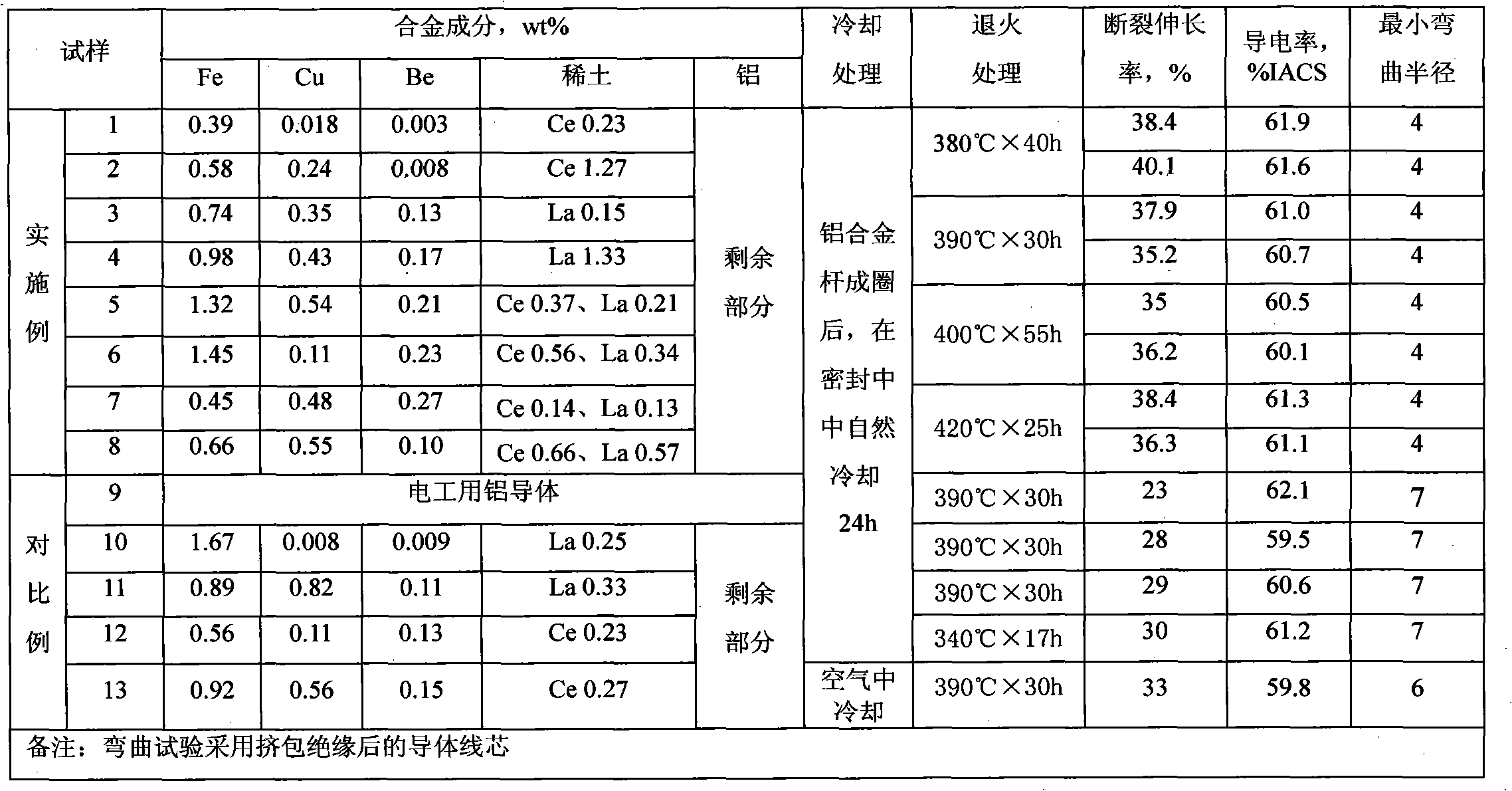

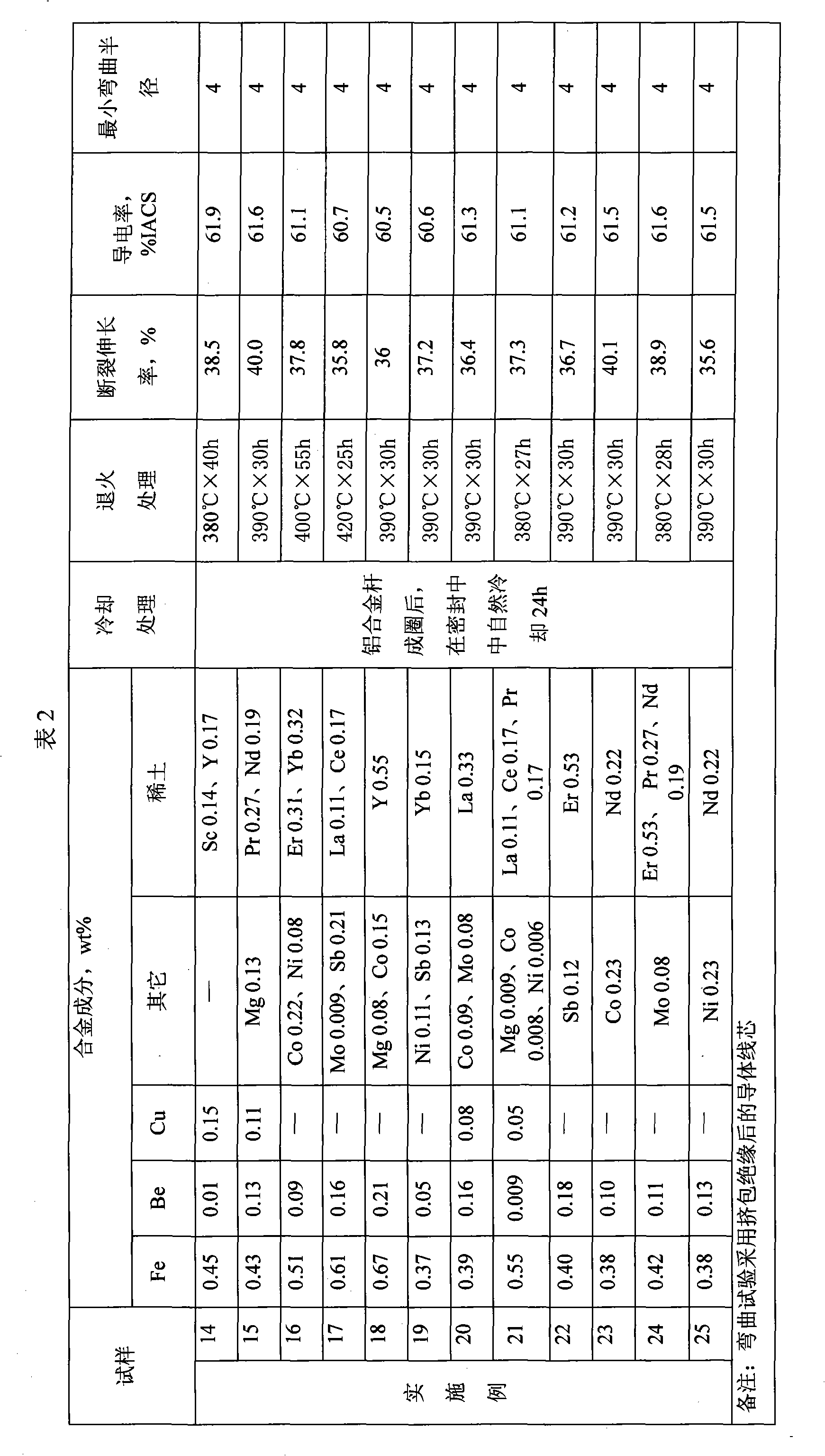

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

Catheters having stiffening mechanisms

InactiveUS20060264907A1Solve the lack of flexibilitySufficient pushabilityCatheterVariable stiffnessShape change

Catheters having selectively insertable or selectively activatable and releasable stiffening mechanisms are provided. In general, the catheter is inserted, navigated and withdrawn from a subject in a relaxed, flexible condition and stiffening mechanisms are deployed to prevent the catheter from shifting during placement or operation of an accessory device or tool through the catheter. Stiffening members(s) may be inserted into and removed from one or more longitudinal channel(s) provided in proximity to the catheter wall and generally coaxial with the primary catheter lumen to change the stiffness properties of the catheter. The properties, configuration and size of the stiffening members and channels may be varied to vary the stiffness properties of the catheter and stiffening members may be constructed from materials having shape change properties or materials that change conformation or stiffness with application of heat, current or electrical field. Stiffening mechanisms may also employ energy absorbing and viscoelastic polymer materials having variable stiffness properties depending on ambient conditions.

Owner:PULSAR VASCULAR

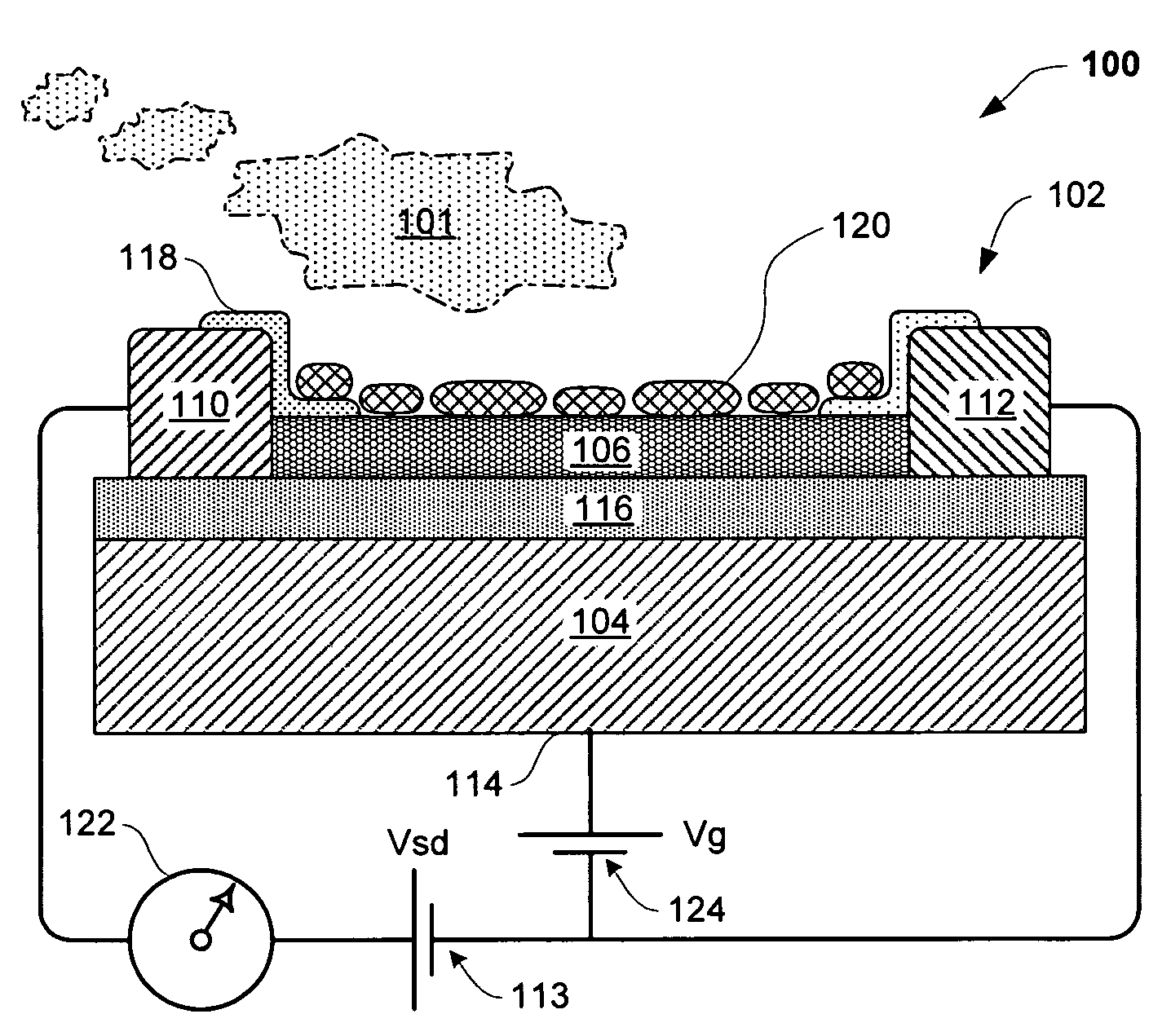

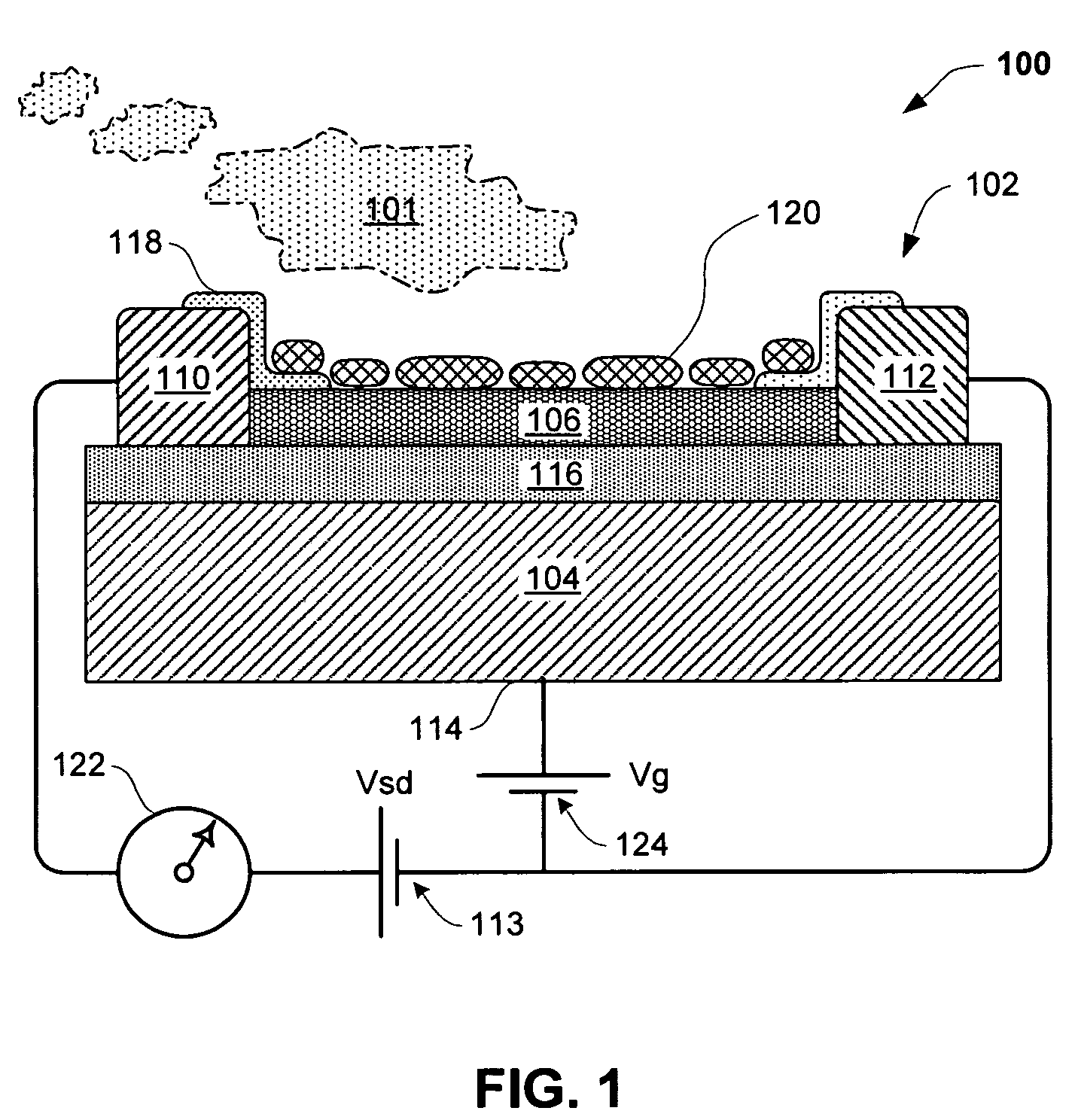

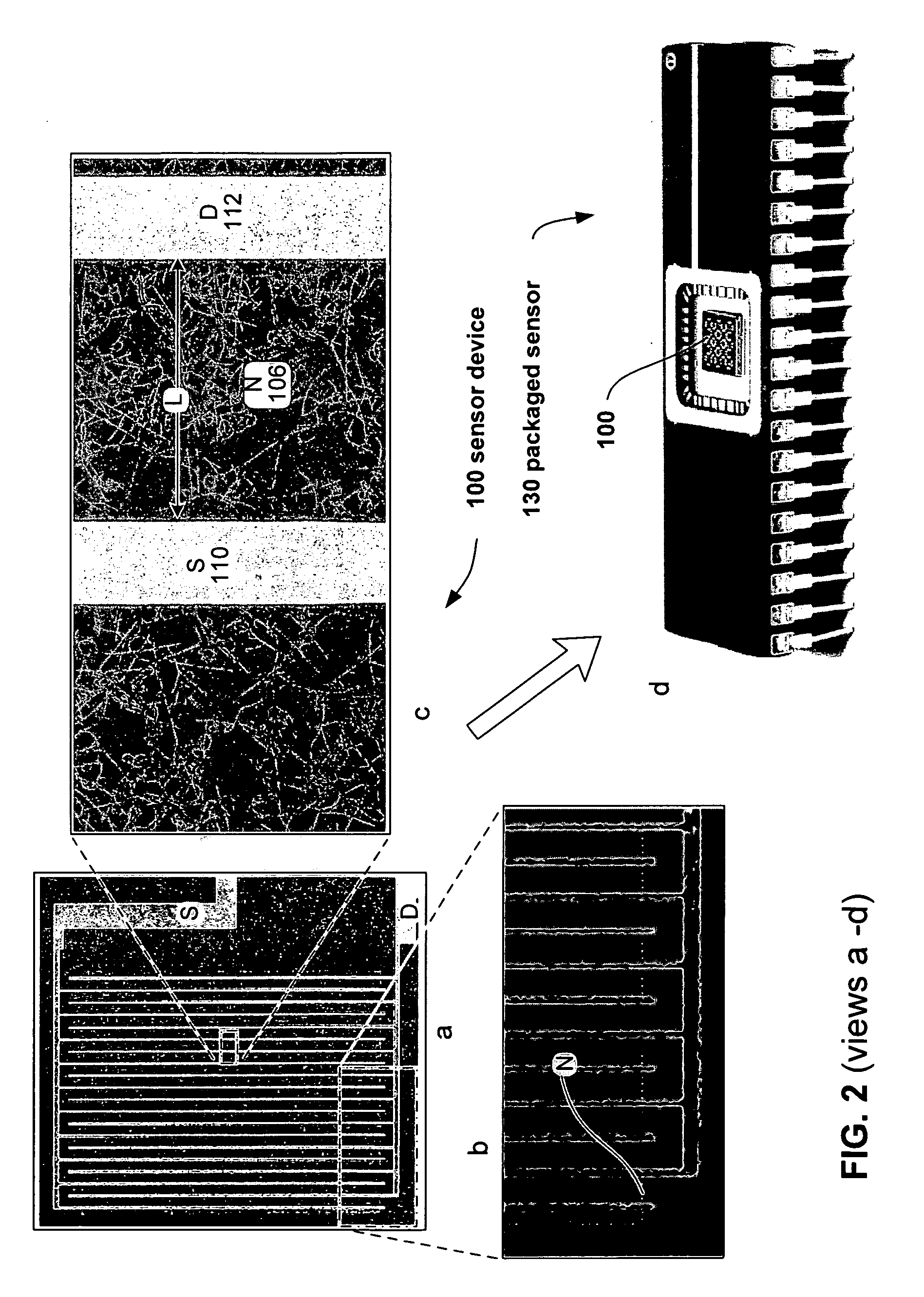

Sensor having a thin-film inhibition layer, nitric oxide converter and monitor

ActiveUS20080221806A1High sensitivityLarge dynamic rangeMaterial nanotechnologyTemperatue controlDiseaseVolatiles

Sensors and detection systems suitable for measuring analytes, such as biomolecule, organic and inorganic species, including environmentally and medically relevant volatiles and gases, such as NO, NO2, CO2, NH3, H2, CO and the like, are provided. Certain embodiments of nanostructured sensor systems are configured for measurement of medically important gases in breath. Applications include the measurement of endogenous nitric oxide (NO) in breath, such as for the monitoring or diagnosis of asthma and other pulmonary conditions.

Owner:NANOMIX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com