Patents

Literature

242results about How to "Solve the lack of flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-leaching non-fouling antimicrobial coatings

InactiveUS20090155335A1Solve the lack of flexibilityPromote adequate mobilityAntibacterial agentsPeptide/protein ingredientsDendrimerFiber

Compositions containing one or more types of membrane-targeting antimicrobial agents immobilized on a substrate with activity in relevant biological environments, and methods of making and using thereof, are described herein. The antimicrobial agents retain their activity in the presence of blood proteins and / or in vivo due to improved molecular structures which allow for cooperative action of immobilized agents and hydrophilic chemistries which resist non-specific protein adsorption. Suitable molecular structures include branched structures, such as dendrimers and randomly branched polymers. The molecule structures may also include hydrophilic tethers which provide both flexibility and resistance to non-specific protein adsorption. The membrane targeting antimicrobial agent coatings can be applied to a variety of different types of substrates including medical implants such as vascular grafts, orthopedic devices, dialysis access grafts, and catheters; surgical tools, surgical garments; and bandages. The substrates can be composed of metallic materials, ceramics, polymers, fibers, inert materials such as silicon, and combinations thereof. The compositions described herein are substantially non-leaching, resistant to non-specific protein adsorption, and non-hemolytic.

Owner:ARROW INT INC

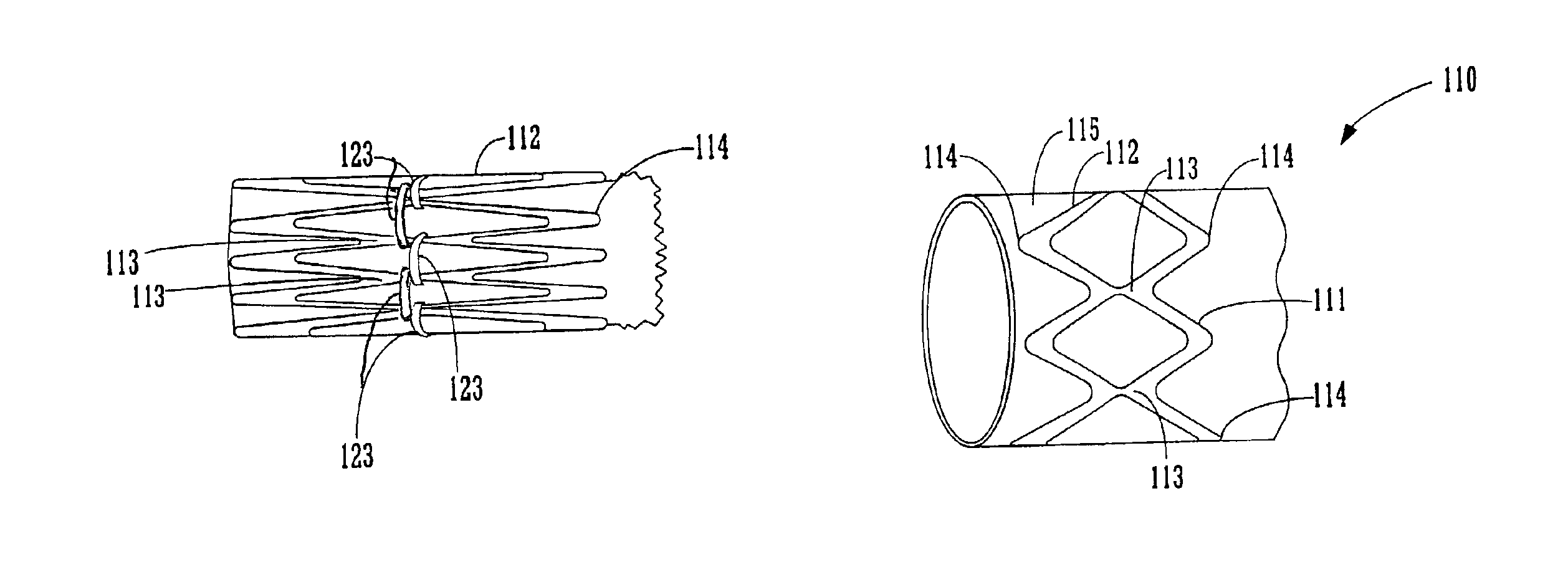

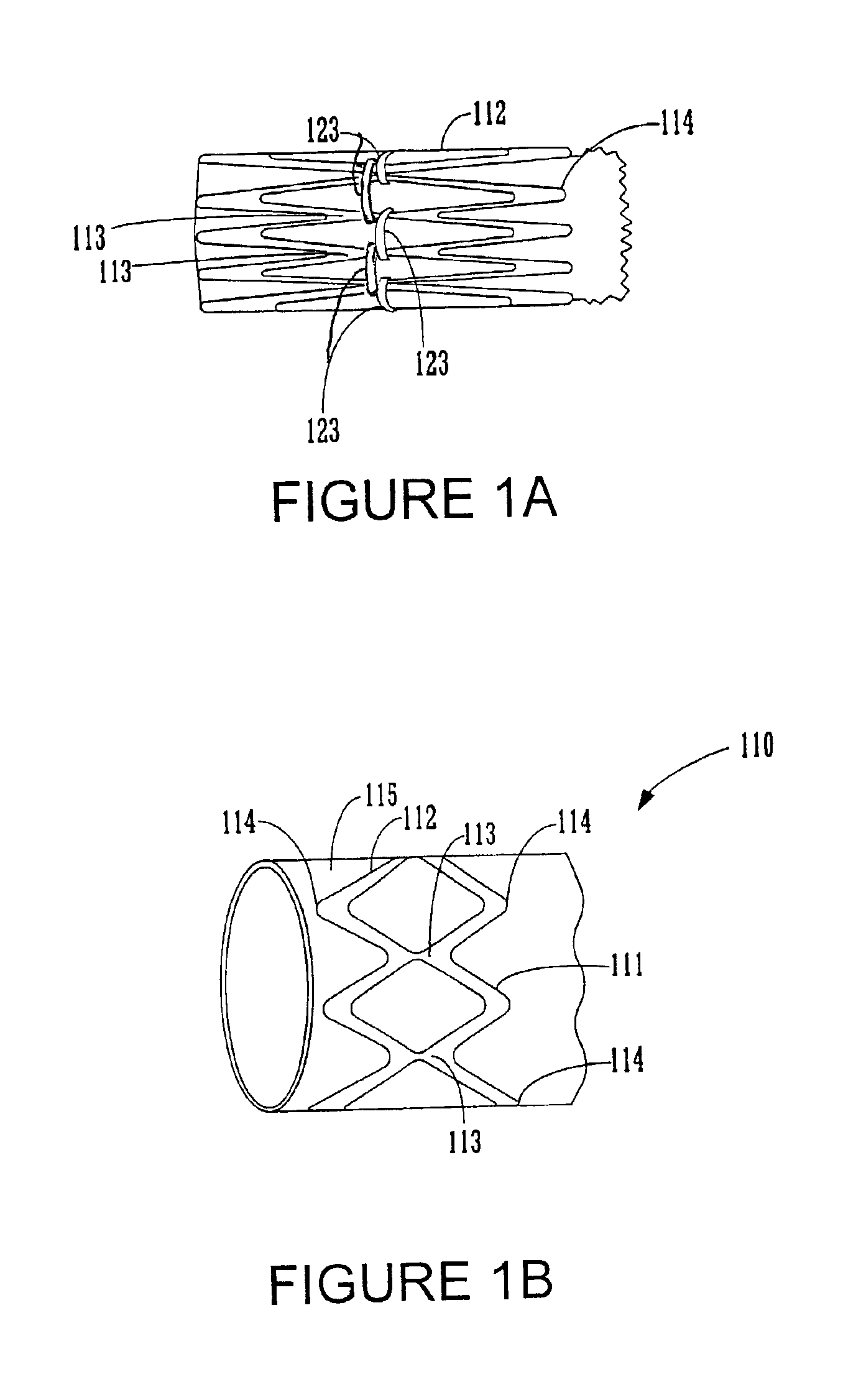

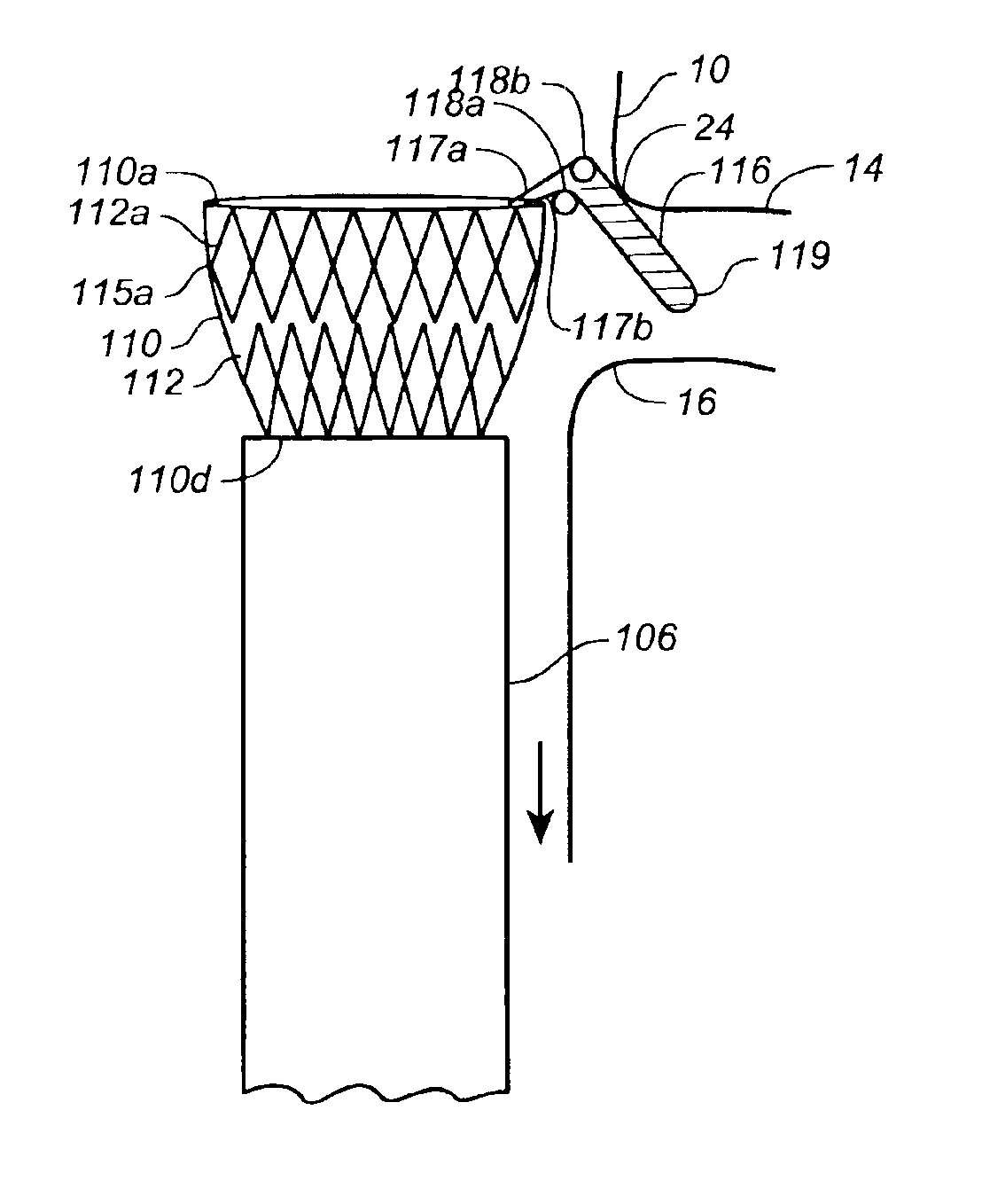

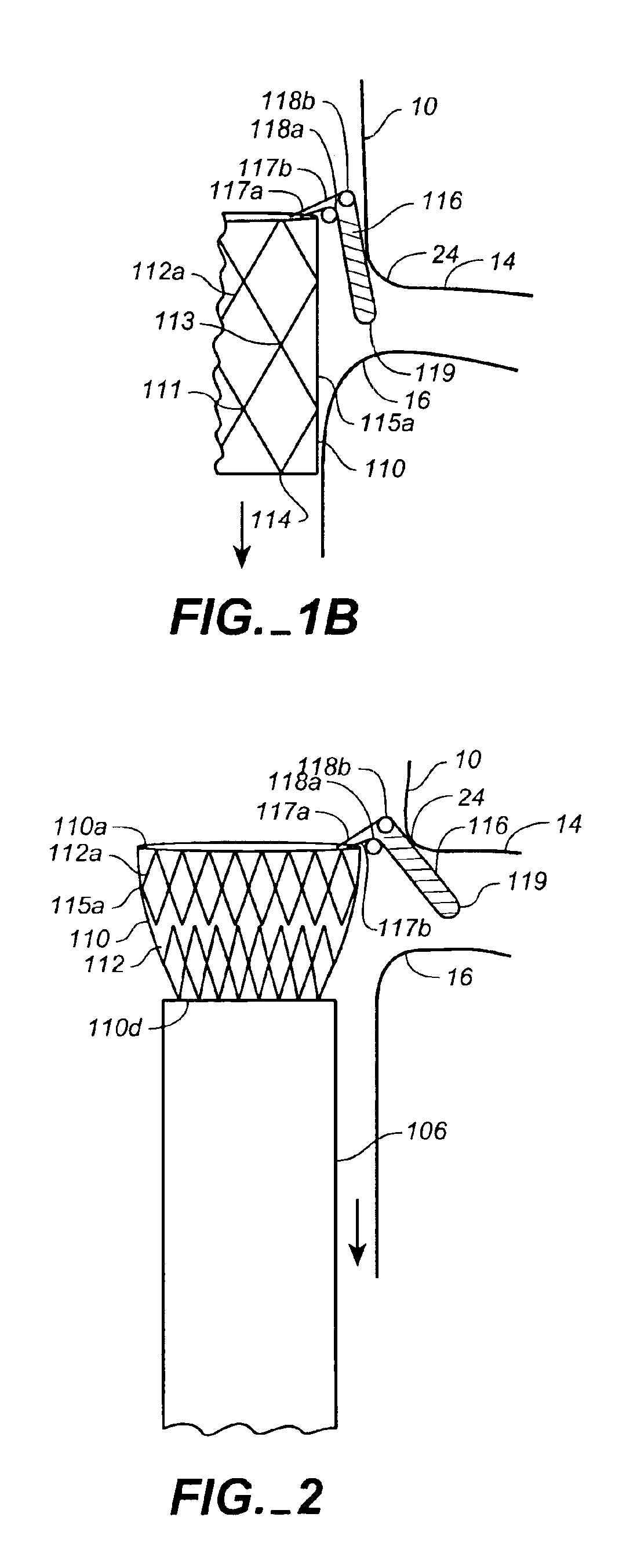

Stent graft loading and deployment device and method

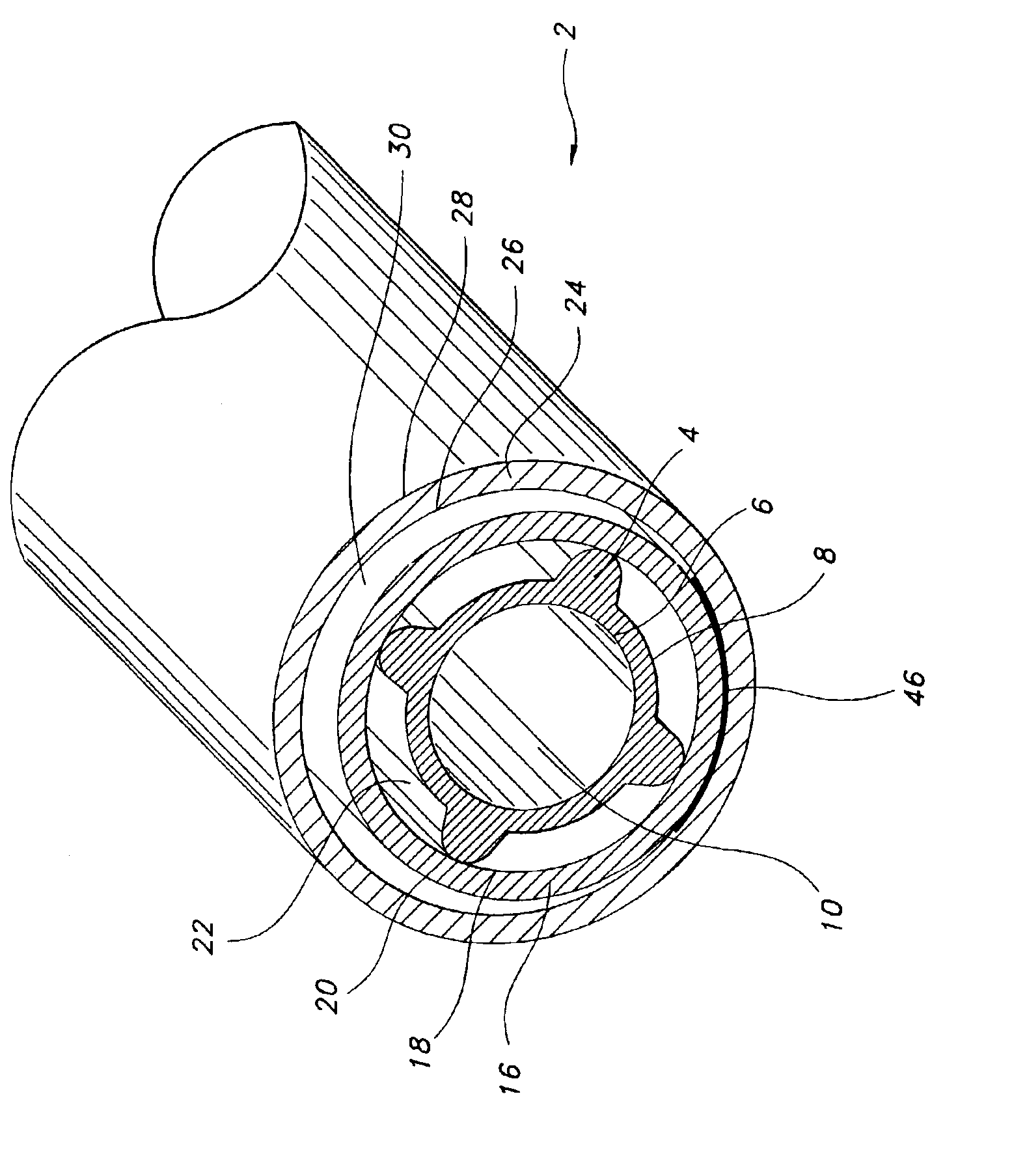

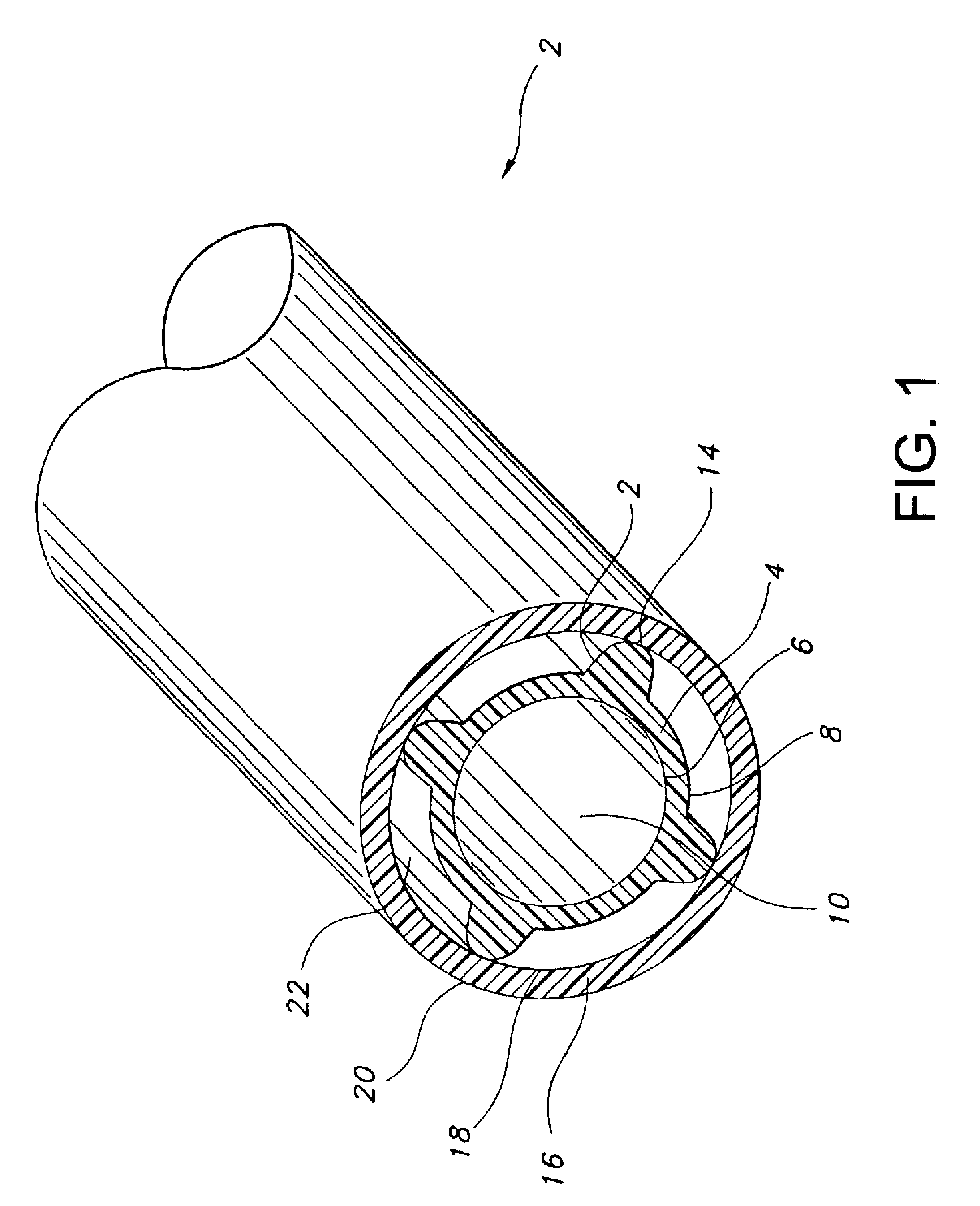

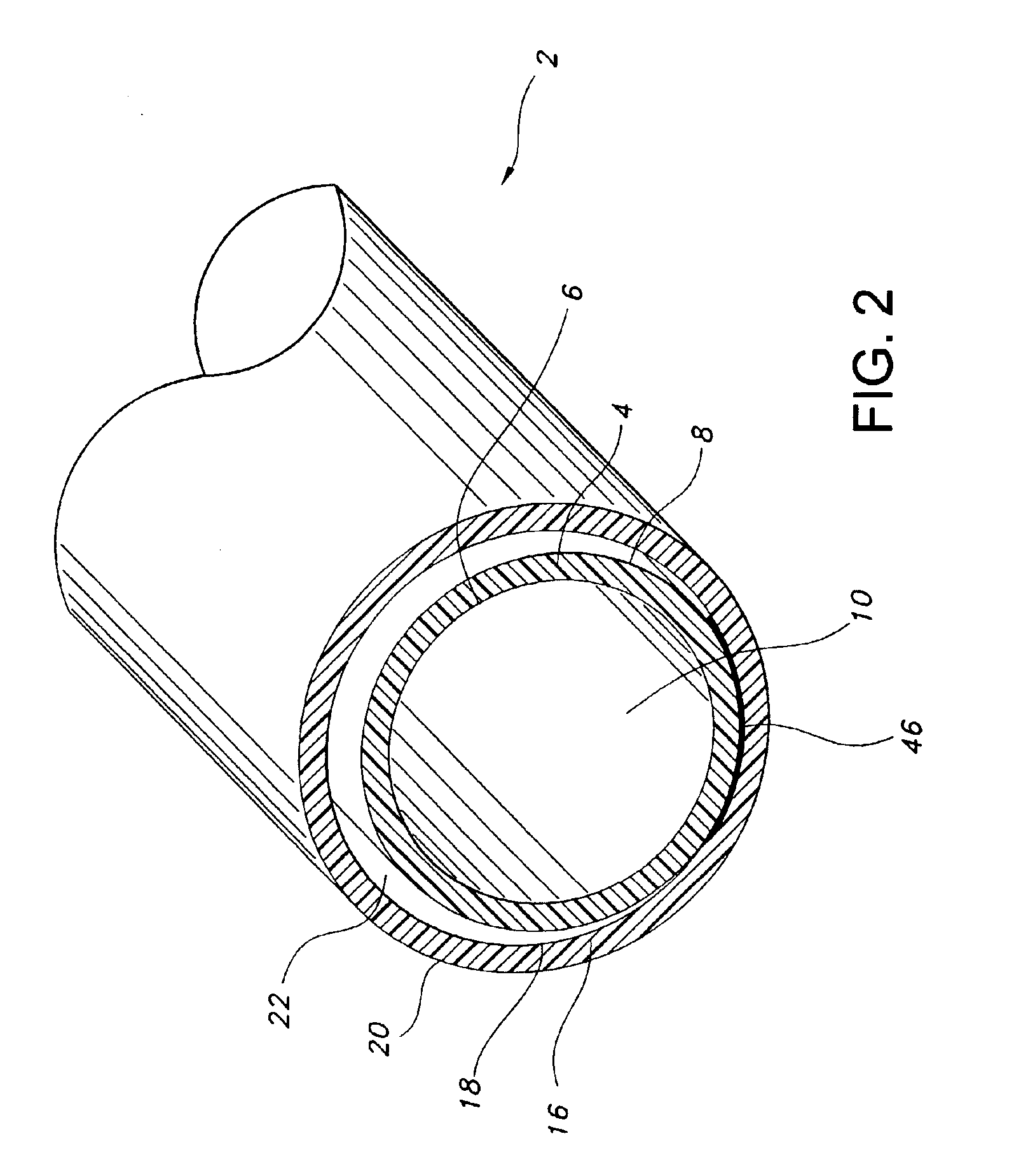

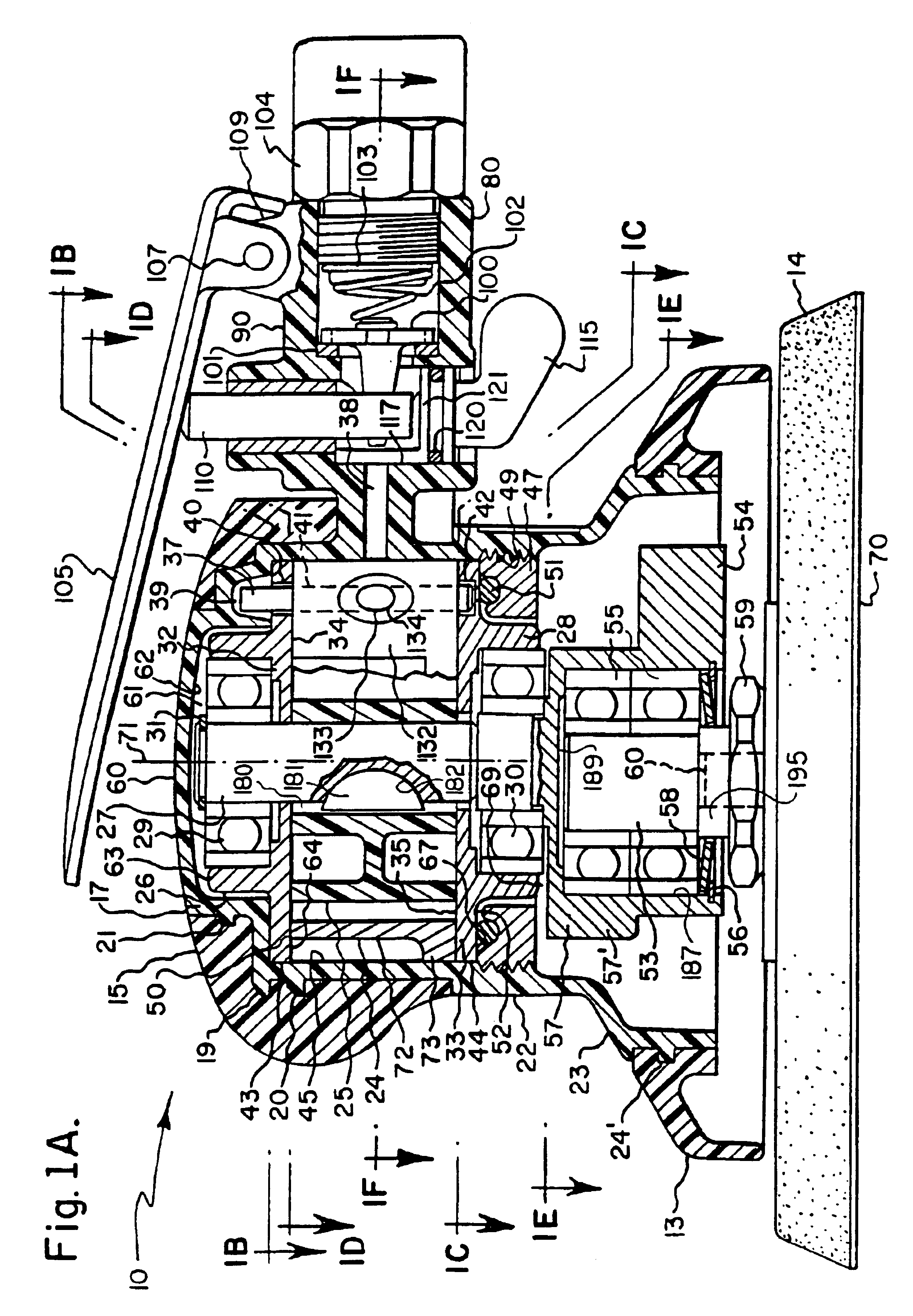

An endoluminal prosthesis includes a tubular graft, an expandable annular support structure and a restraining mechanism restraining the prosthesis in a collapsed configuration in which the annular support structure is compressed to a low profile. The restraining mechanism holds the annular support structures in the collapsed configuration until the prosthesis is positioned for deployment. The restraining mechanism is then released to allow the annular support structures to expand into conforming engagement with the inner wall of a lumen in which the prosthesis is to be deployed. A feature according to the invention provides a balloon catheter onto which the prosthesis is loaded for deployment where the balloon is expanded to provide a radial force to release the restraining mechanism. Another feature provides for a restraining member that breaks upon application of the radial force to release the annular support structure from its constrained configuration. Another feature of the invention provides for independent and / or sequential release of the annular support members. Various types of annular support members attached to tubular grafts in a variety of manners may be used in accordance with the invention. The invention may be used in tubular grafts for endoluminal placement within a body lumen, including blood vessels, and for the treatment of abdominal and other aneurysms.

Owner:MEDTRONIC VASCULAR INC

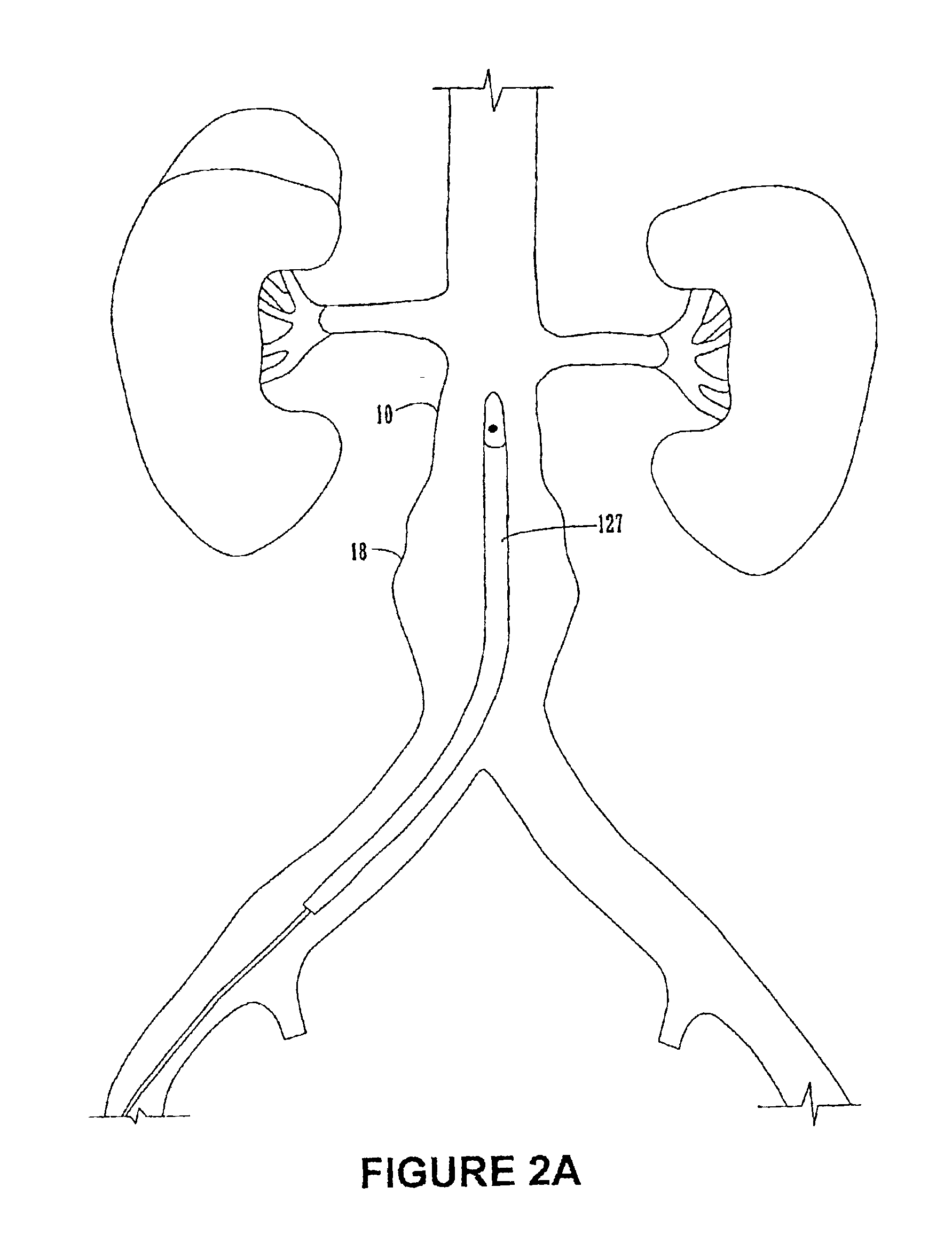

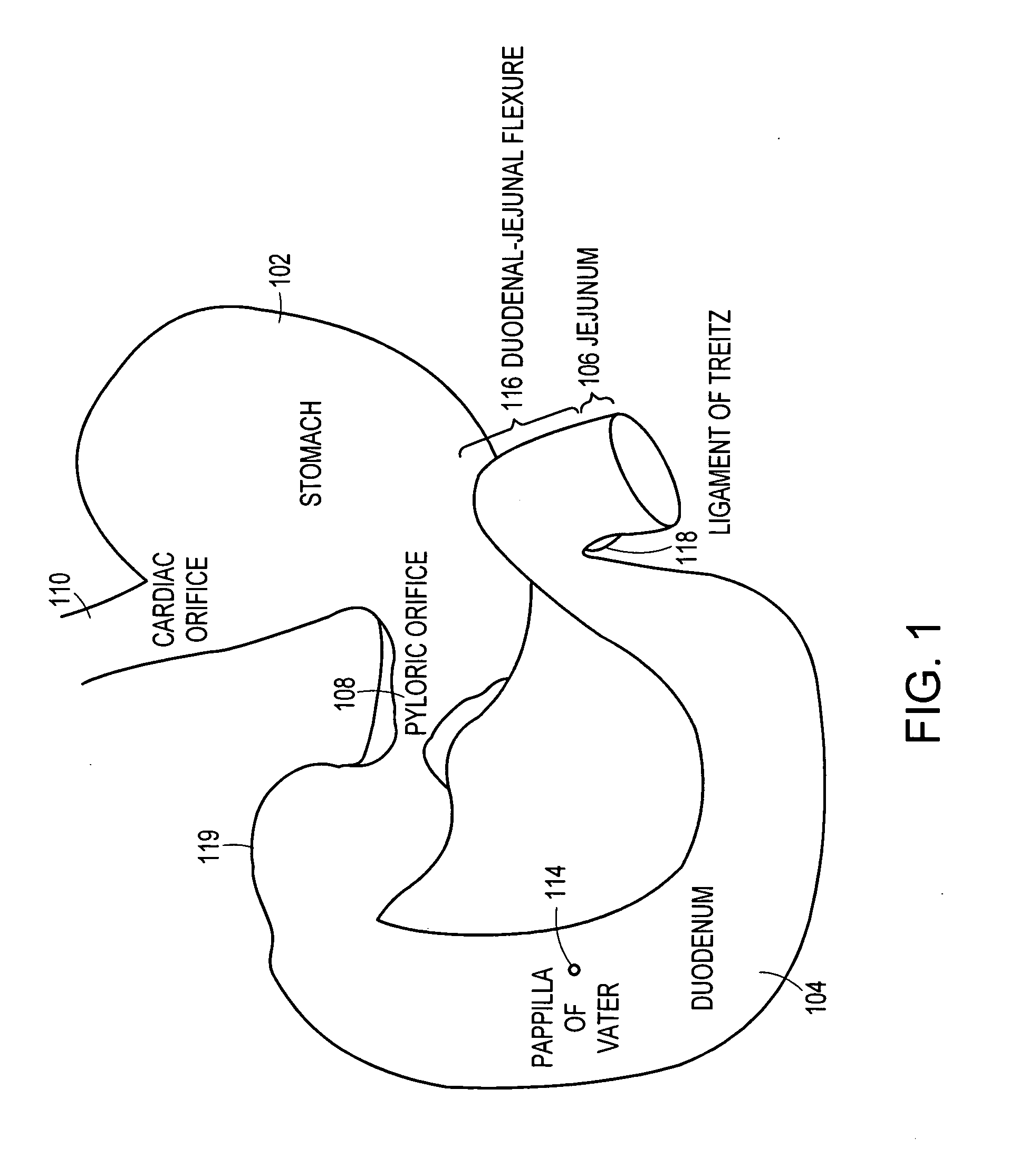

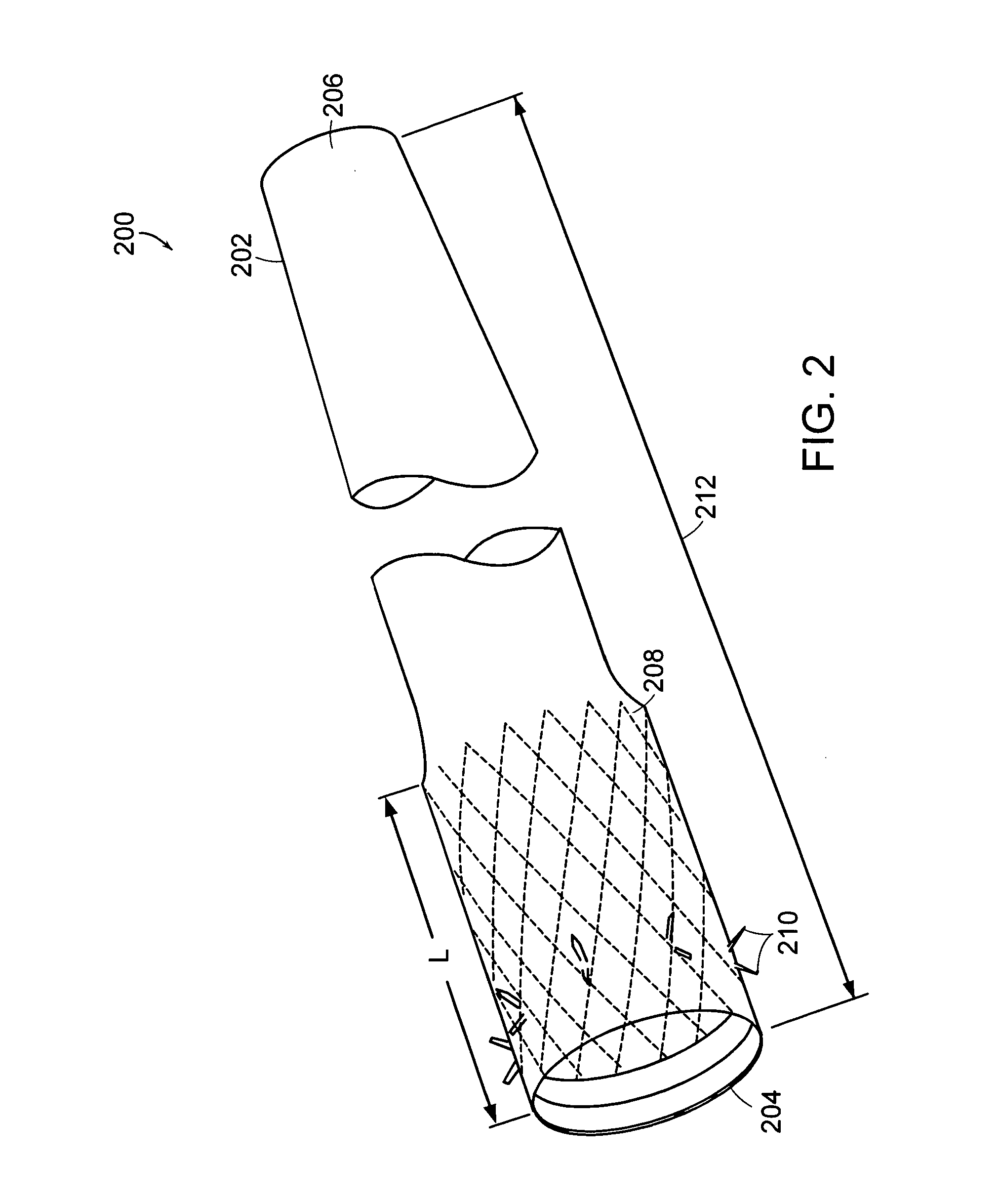

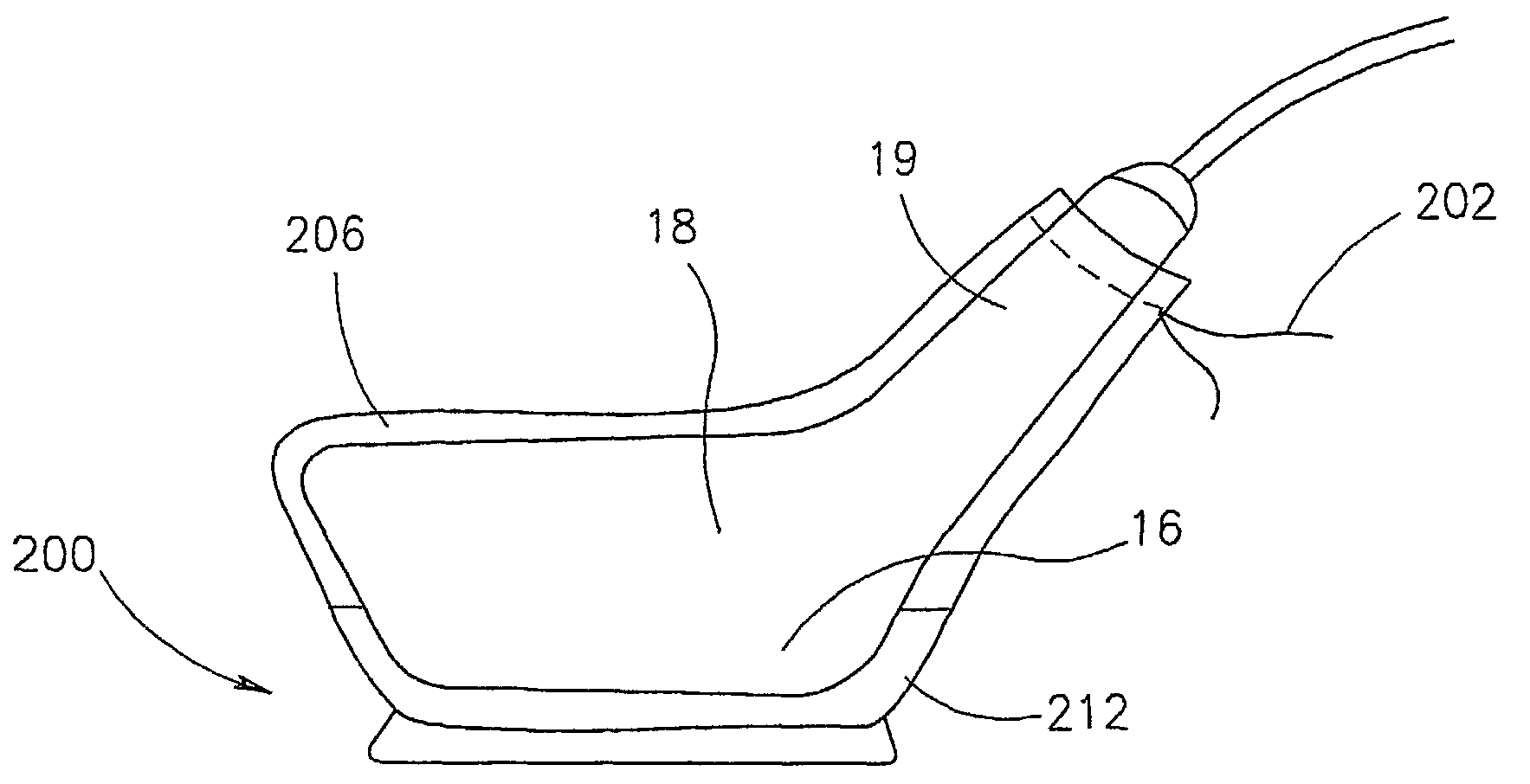

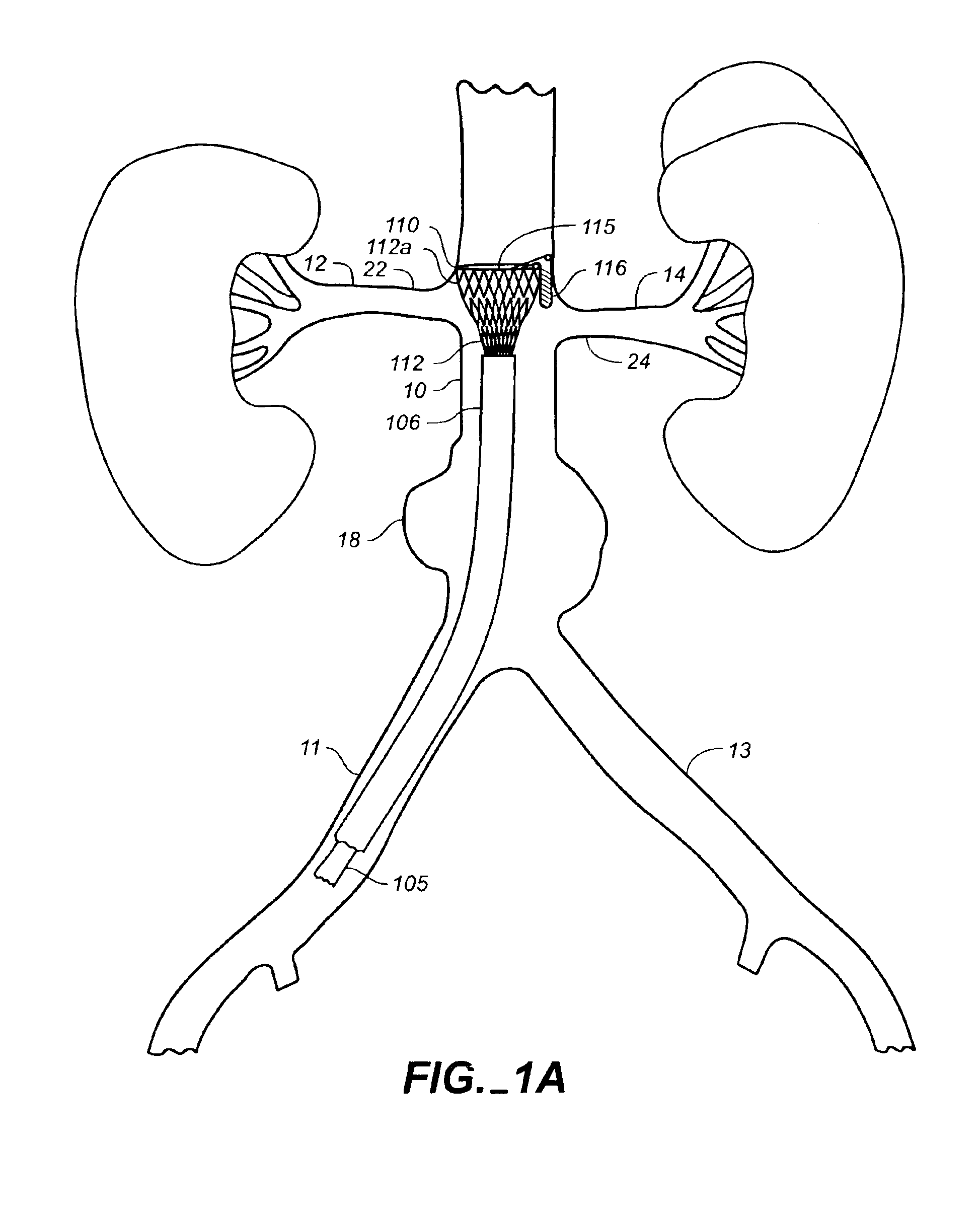

Intestinal sleeve

InactiveUS20060265082A1Reduce twisting and bucklingMinimize traumaSuture equipmentsStentsGastrointestinal deviceInsertion stent

A gastrointestinal implant device is anchored in the duodenum and extends beyond the ligament of Treitz. All food exiting the stomach is funneled through the device. The gastrointestinal device includes an anchor for attaching the device to the duodenum and an unsupported flexible sleeve. The anchor can include a stent and / or a wave anchor and is collapsible for catheter-based delivery and removal.

Owner:GI DYNAMICS

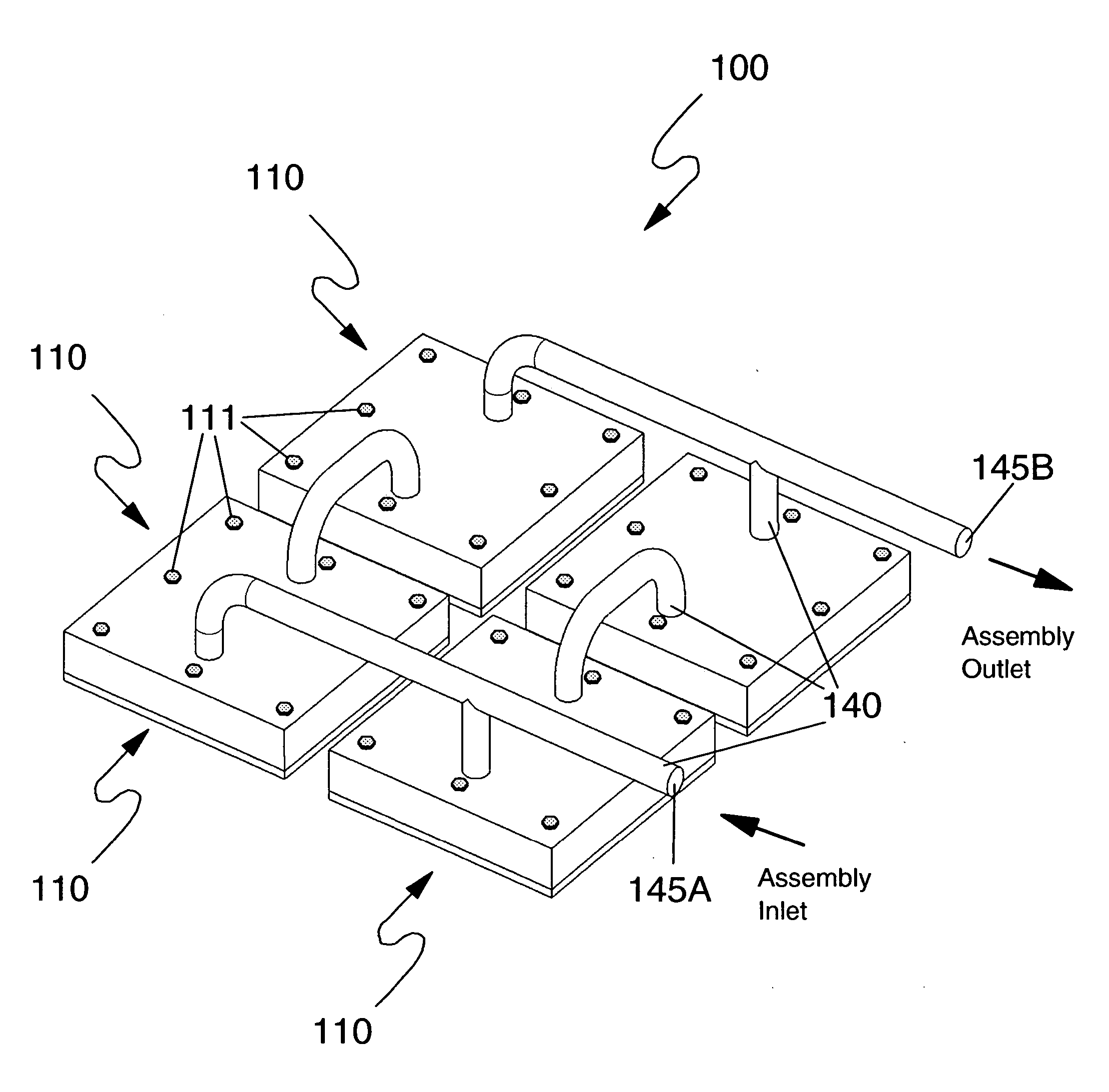

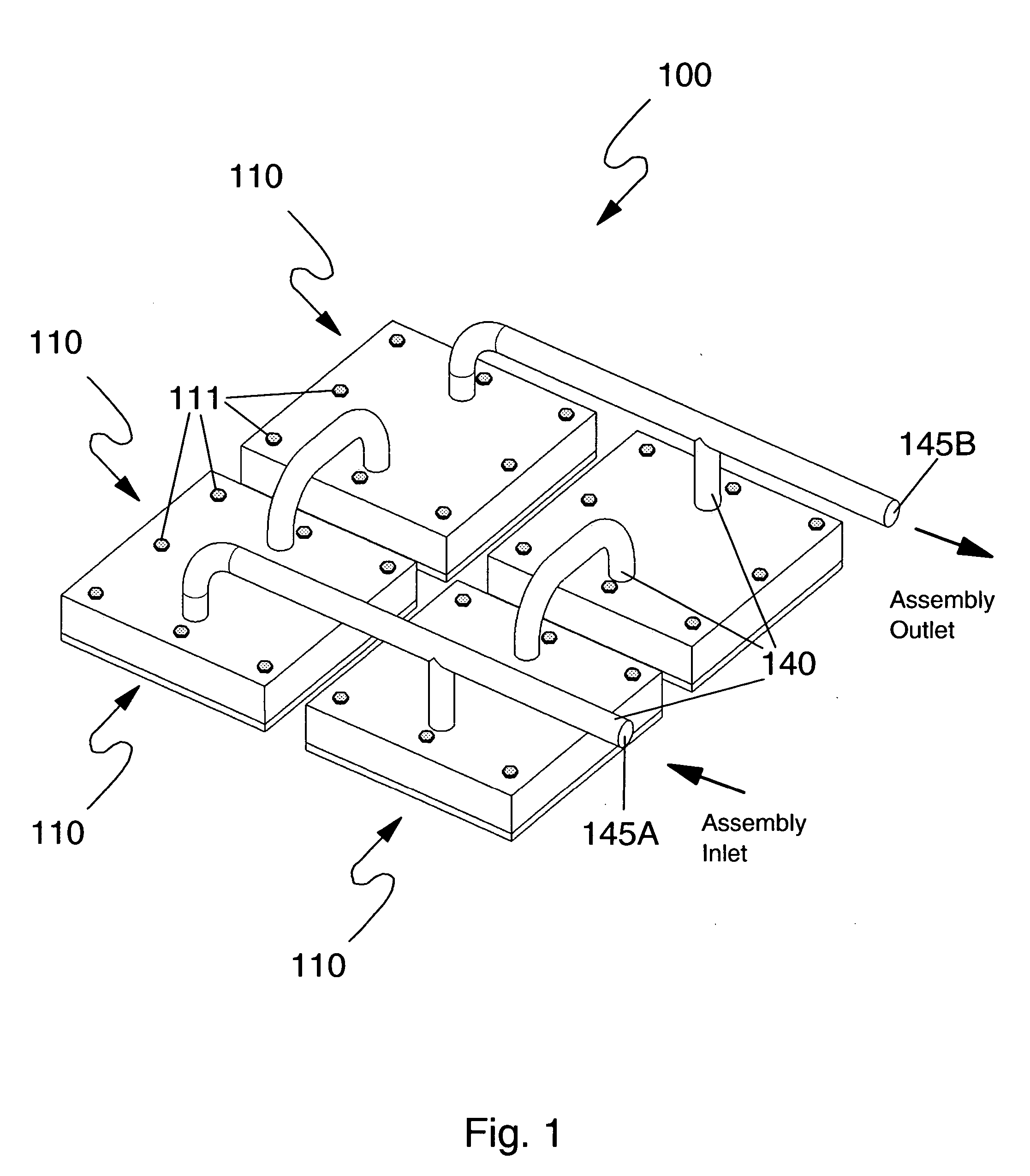

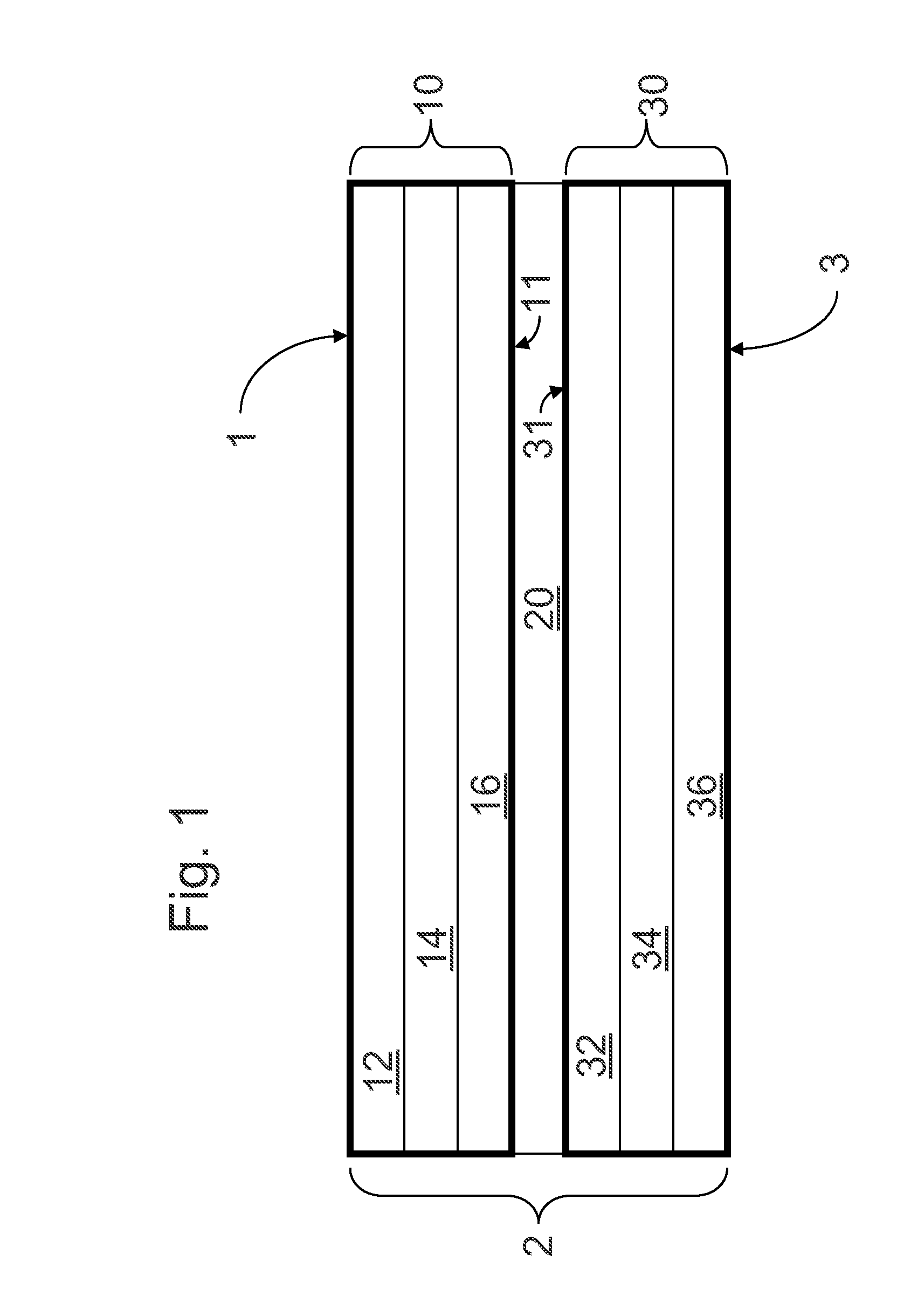

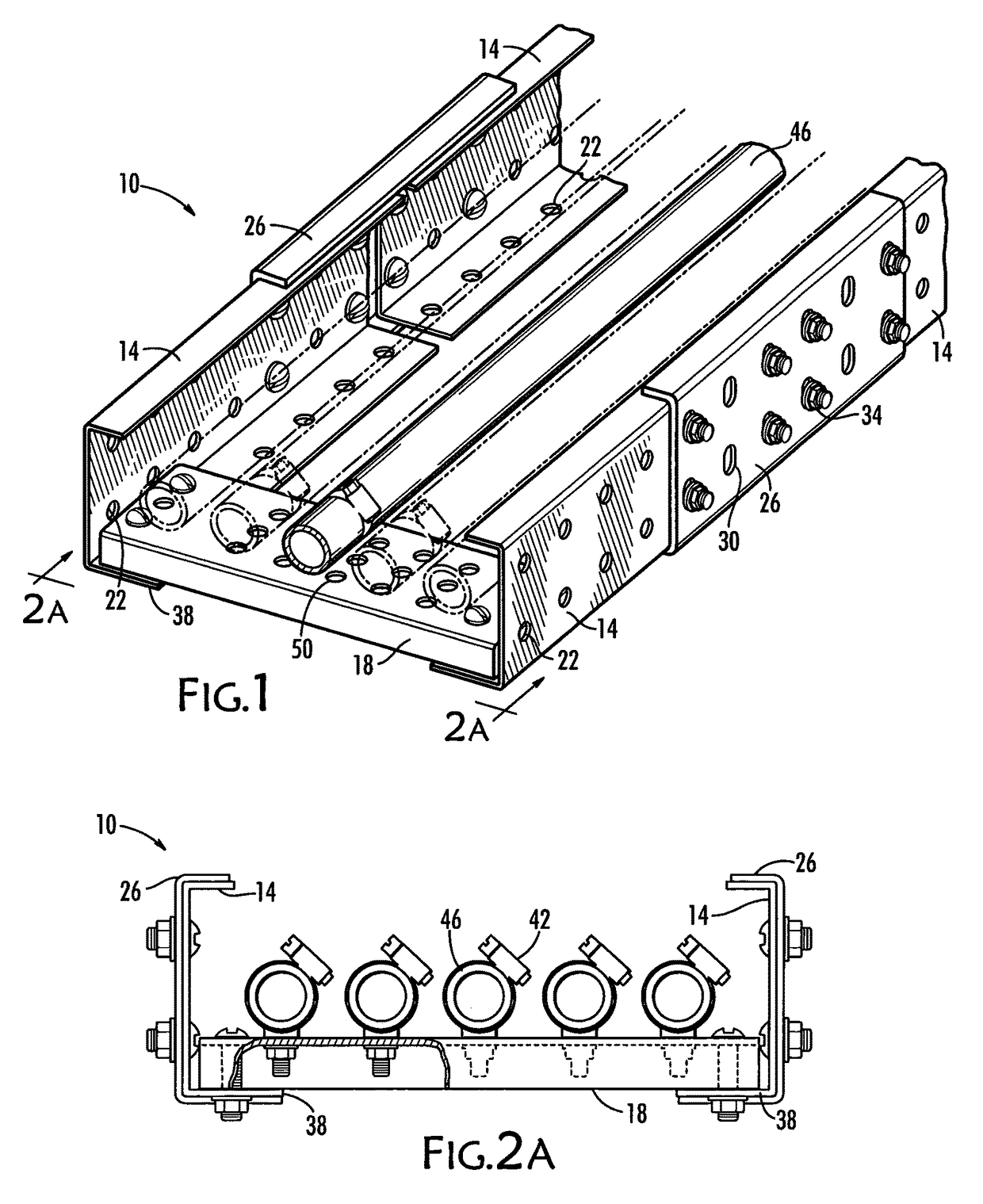

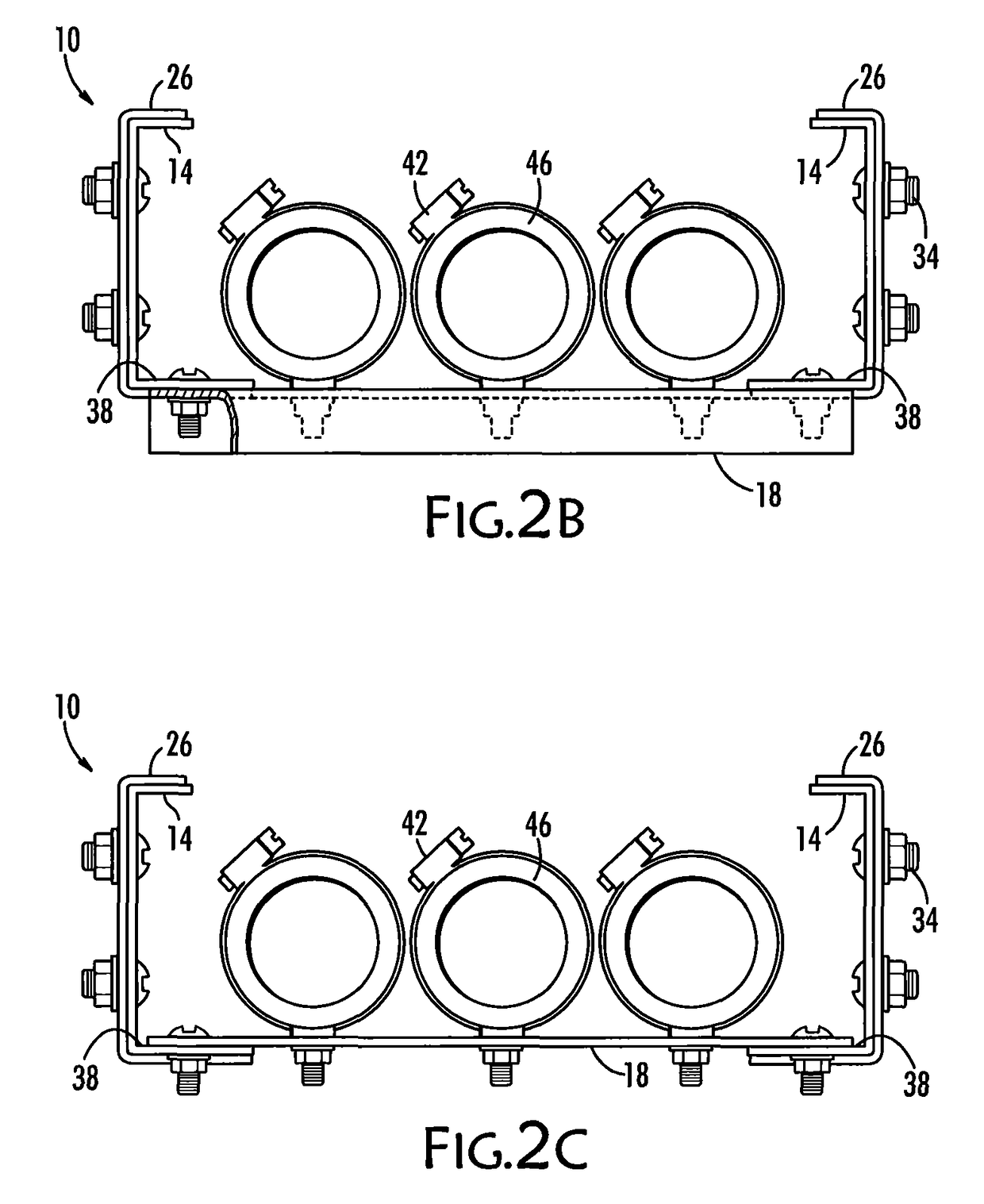

Composite cold plate assembly

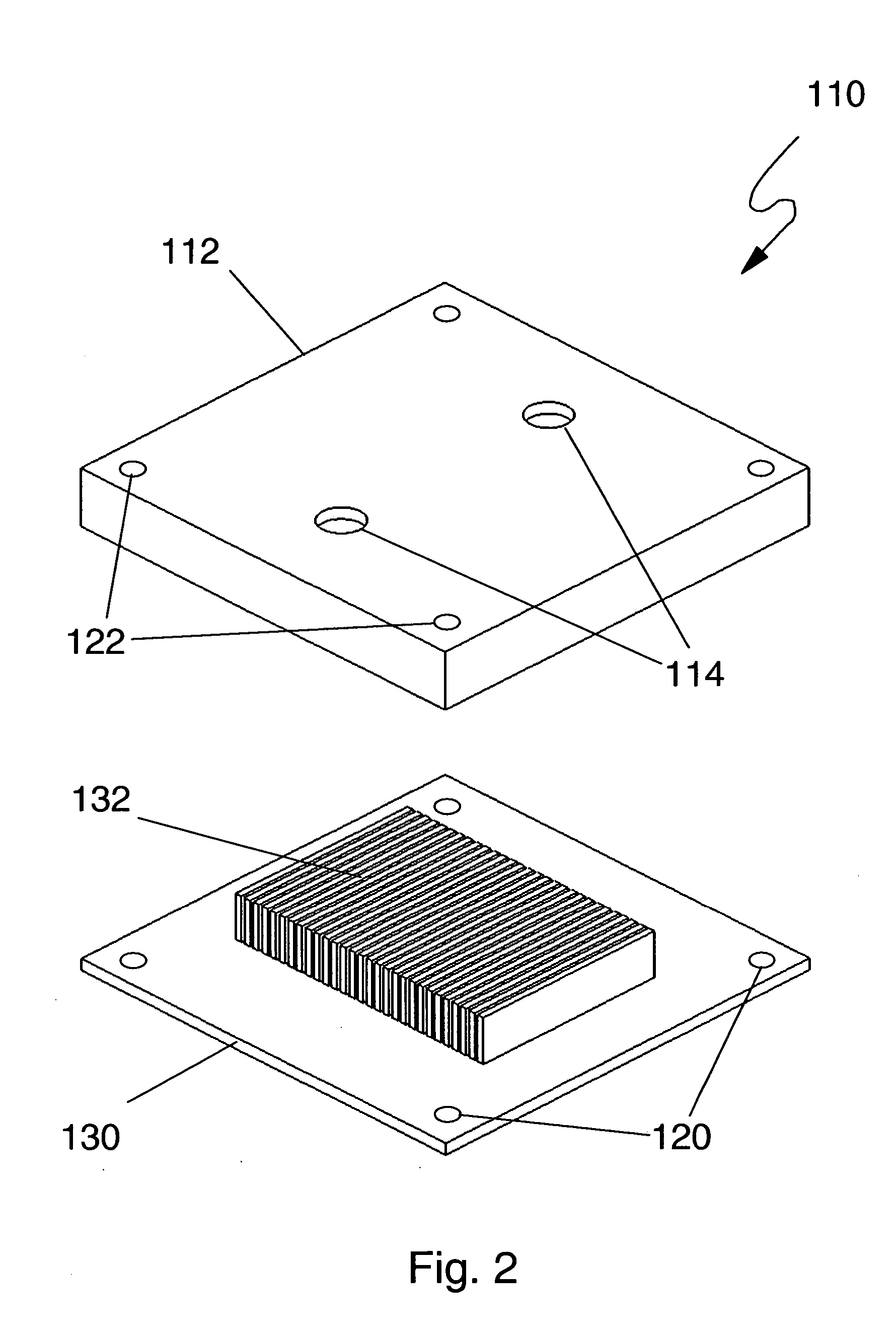

InactiveUS20050128705A1Reduce connectionsSolve the lack of flexibilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringCold plate

A cooling fluid distribution assembly for a plurality of electronic modules, using a composite cold plate structure. One cold plate is associated with each electronic module requiring liquid cooling. Each cold plate includes a high thermal conductivity base sealably fastened to a cover, the cover having at least one fluid inlet and at least one fluid outlet. Cover fluid inlets and outlets are connected via a plurality of flexible, nonmetallic conduits, the conduits being bonded to the cover inlets and outlets. Each cold plate cover is formed of a material that is capable of being bonded to the flexible, nonmetallic conduits, covers are therefore formed of a different material than the material comprising the cold plate base. Cold plate structures preferably include internal fluid distribution structures. The resulting cooling fluid distribution assembly provides reliable fluid connections and is sufficiently flexible to adjust for variances in module height etc.

Owner:IBM CORP

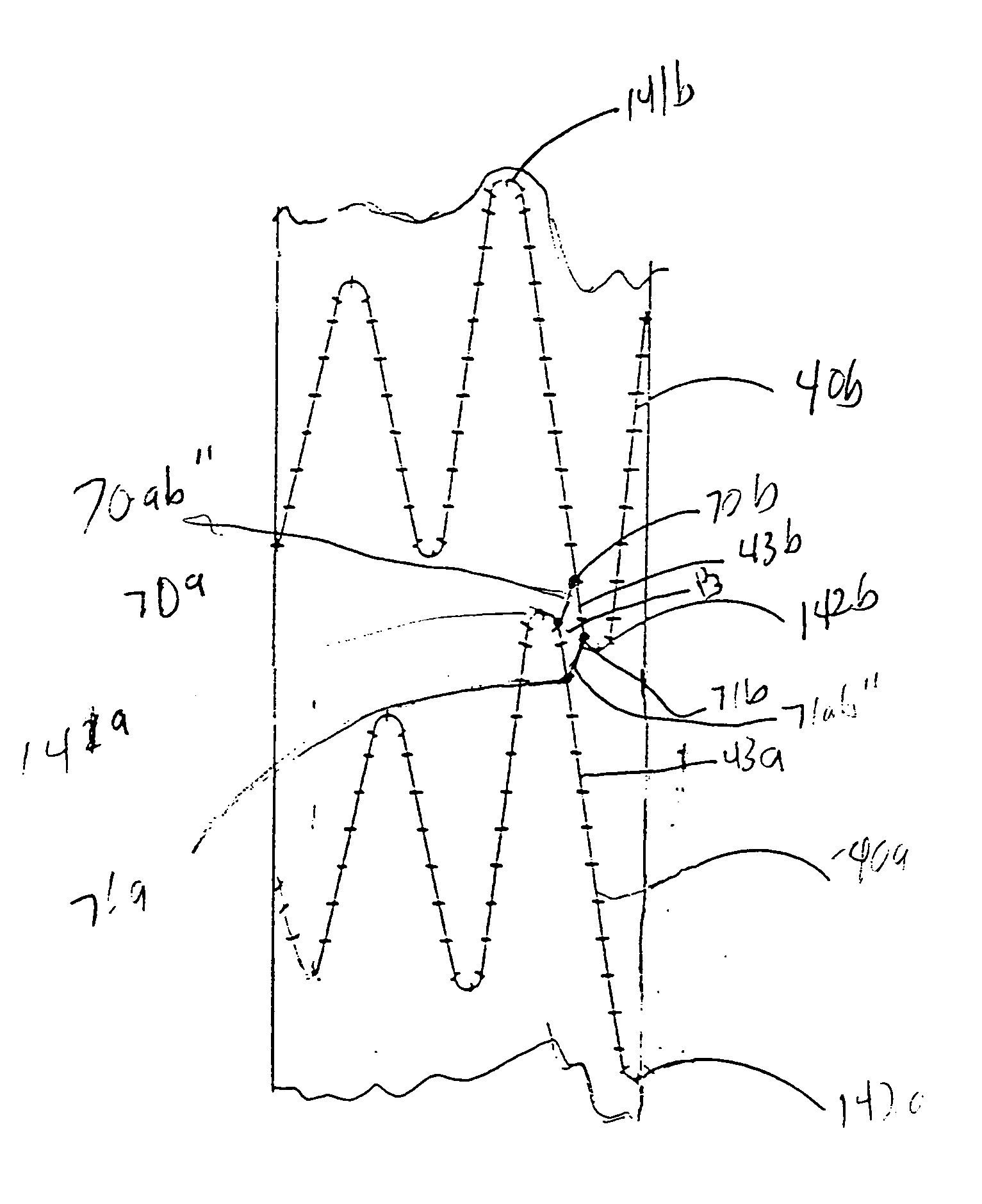

Endoluminal prosthesis

ActiveUS20070055347A1Small pre-deployedSmall collapsed profileStentsBlood vesselsProsthesisUltimate tensile strength

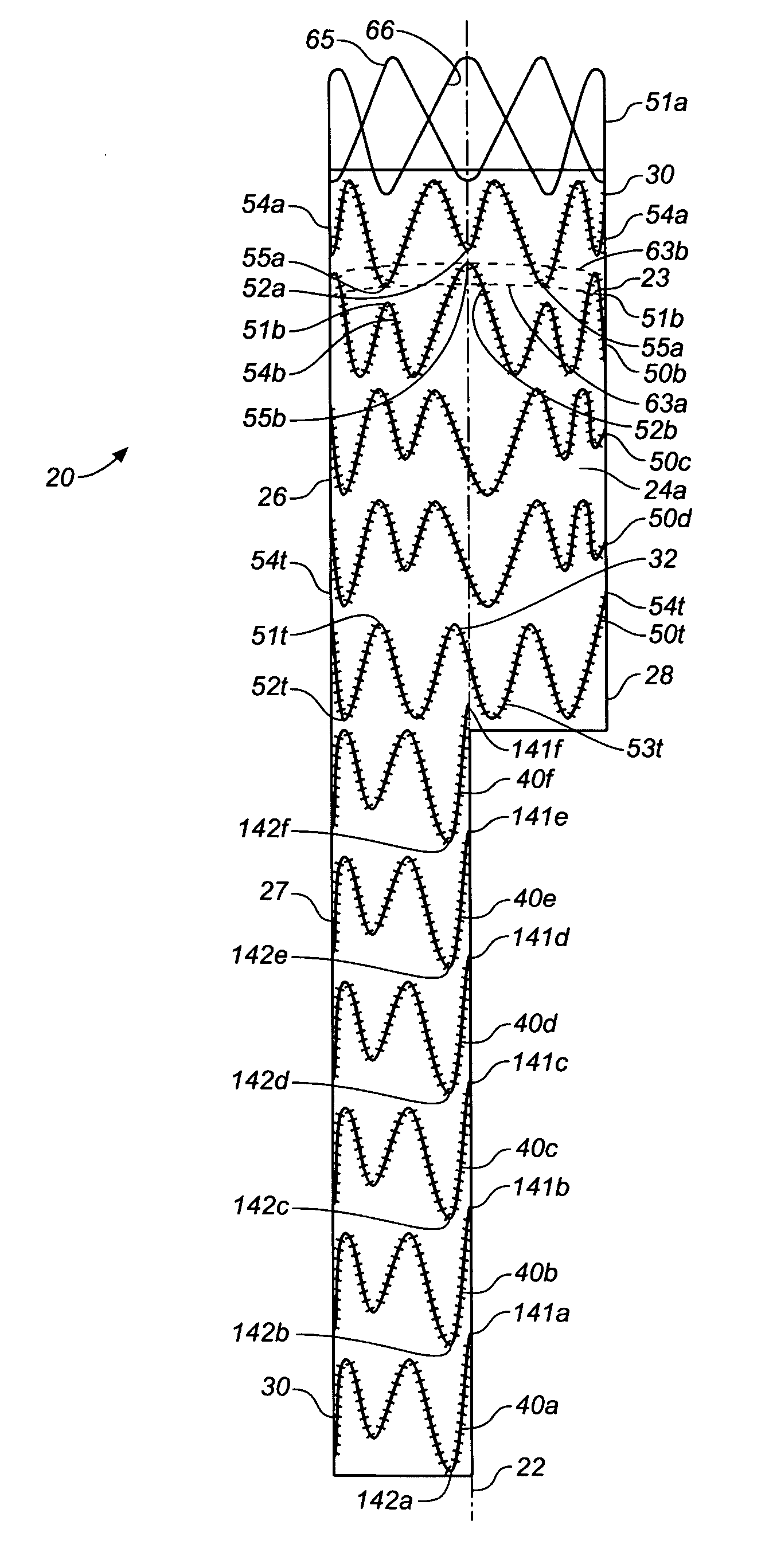

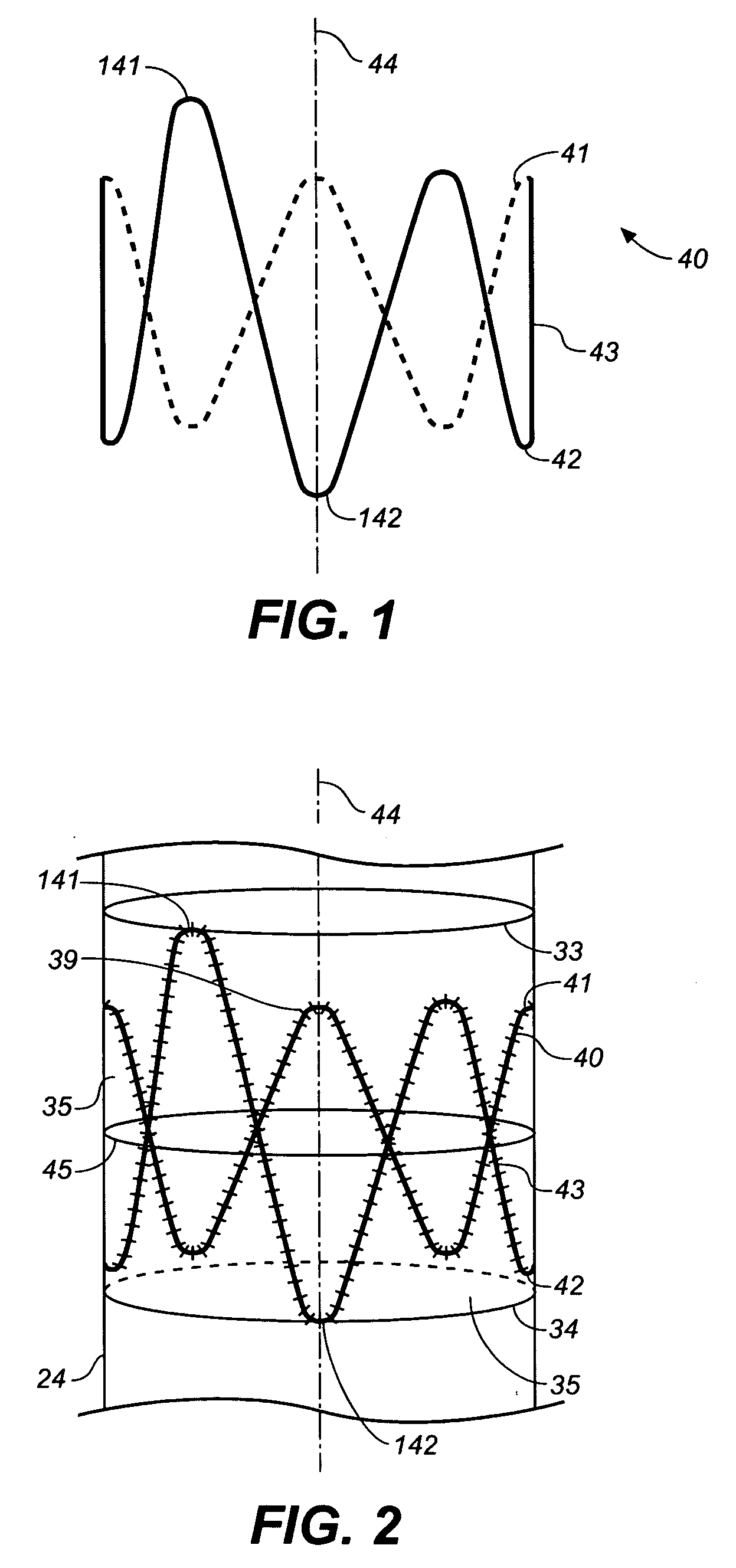

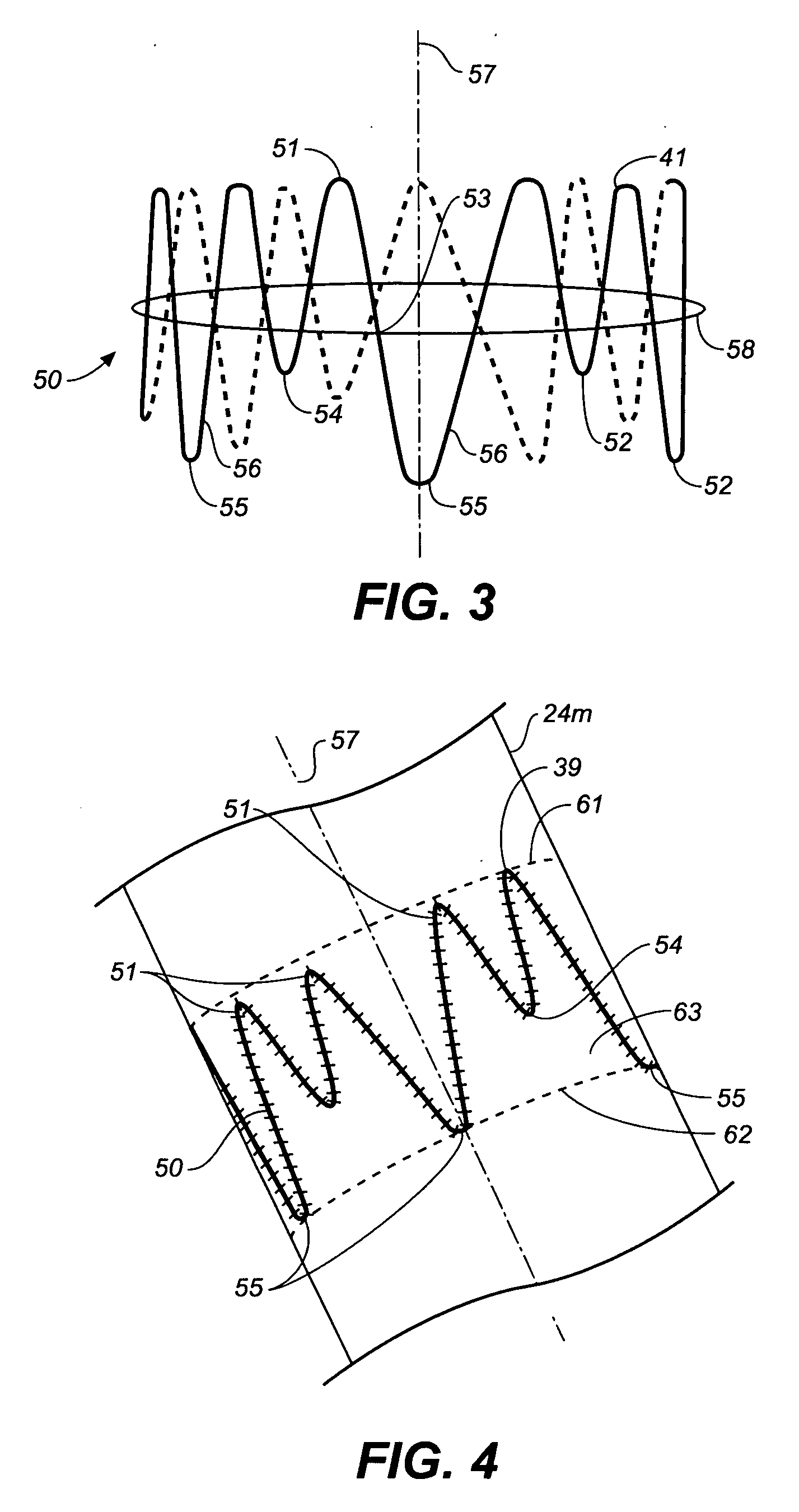

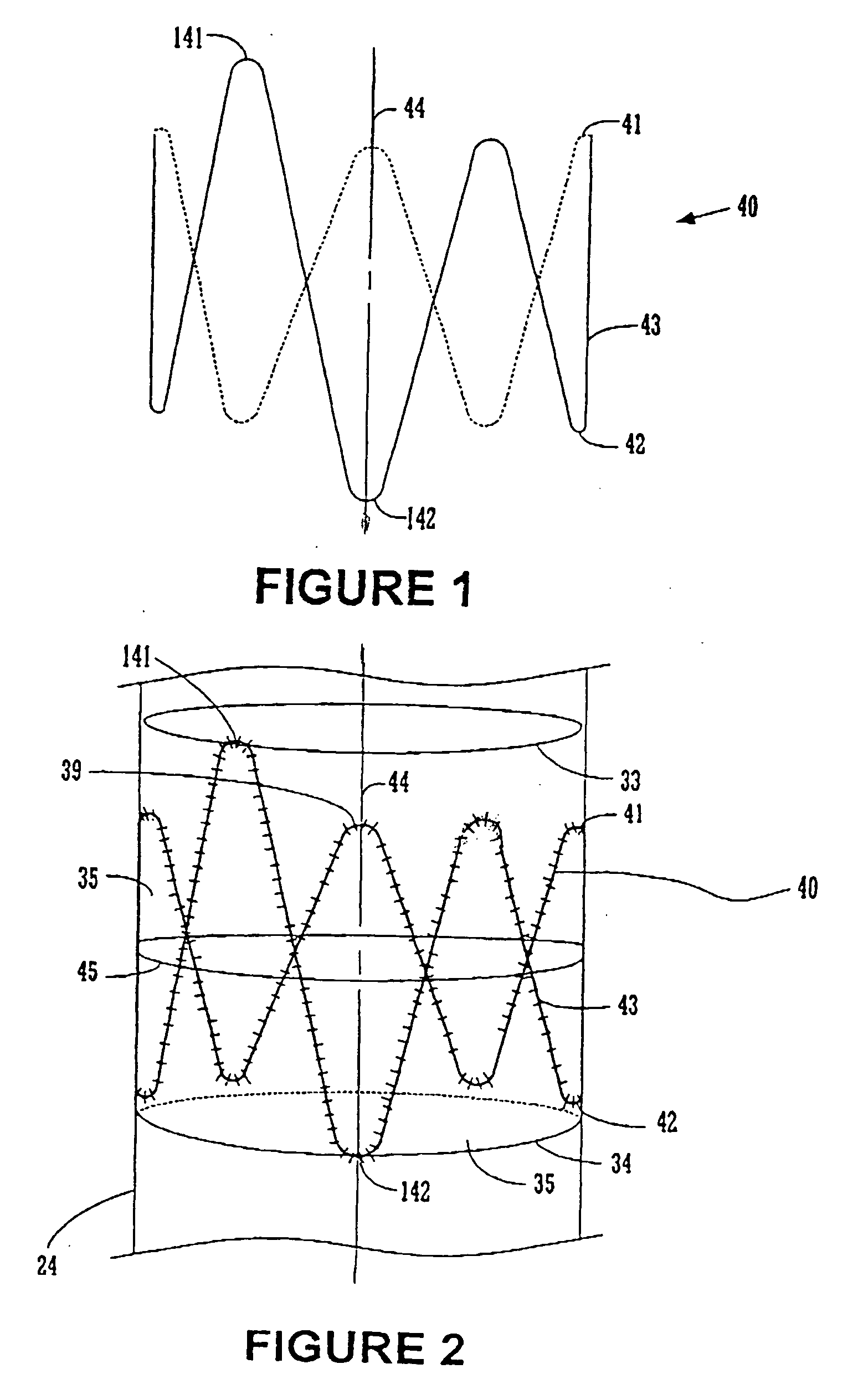

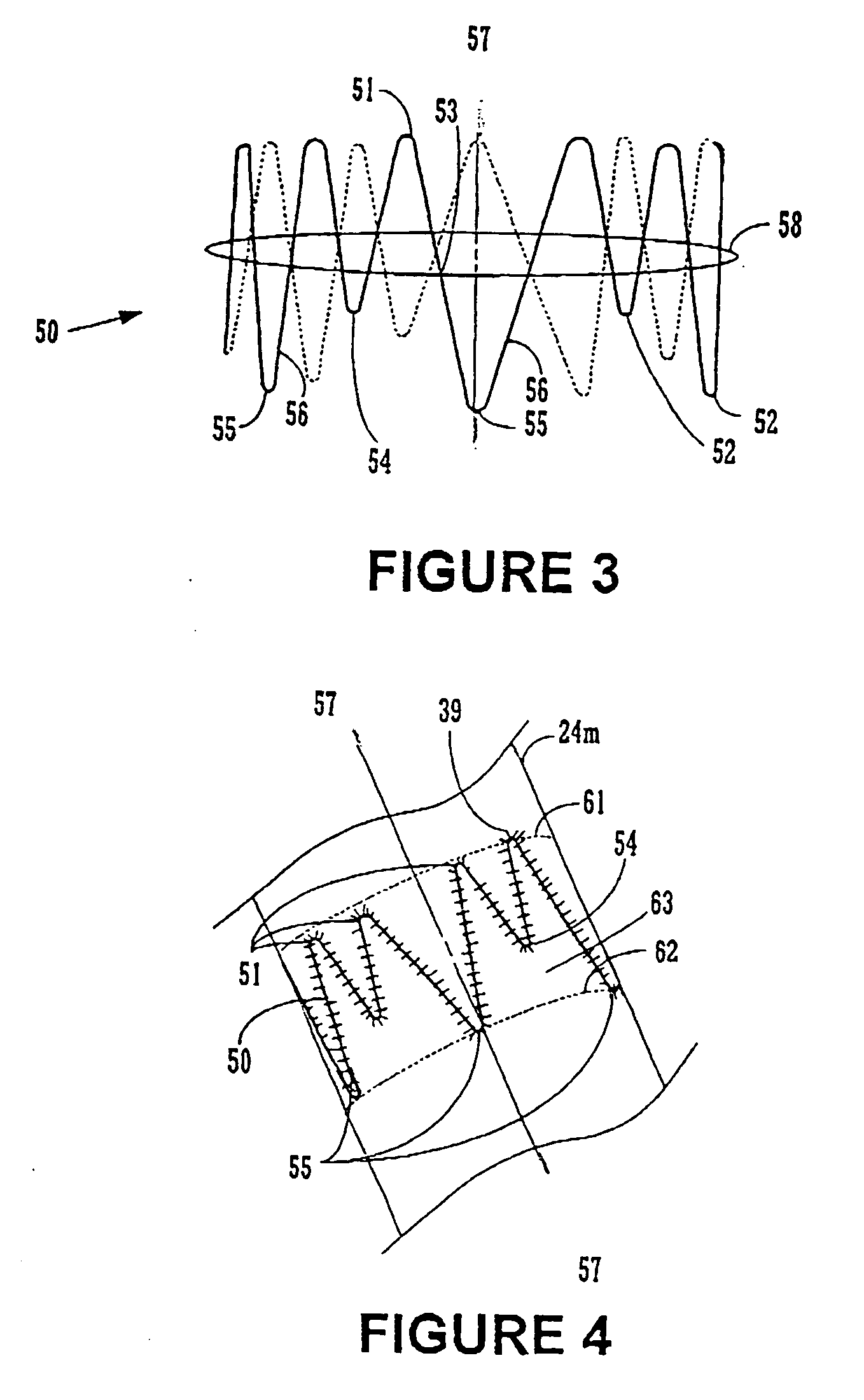

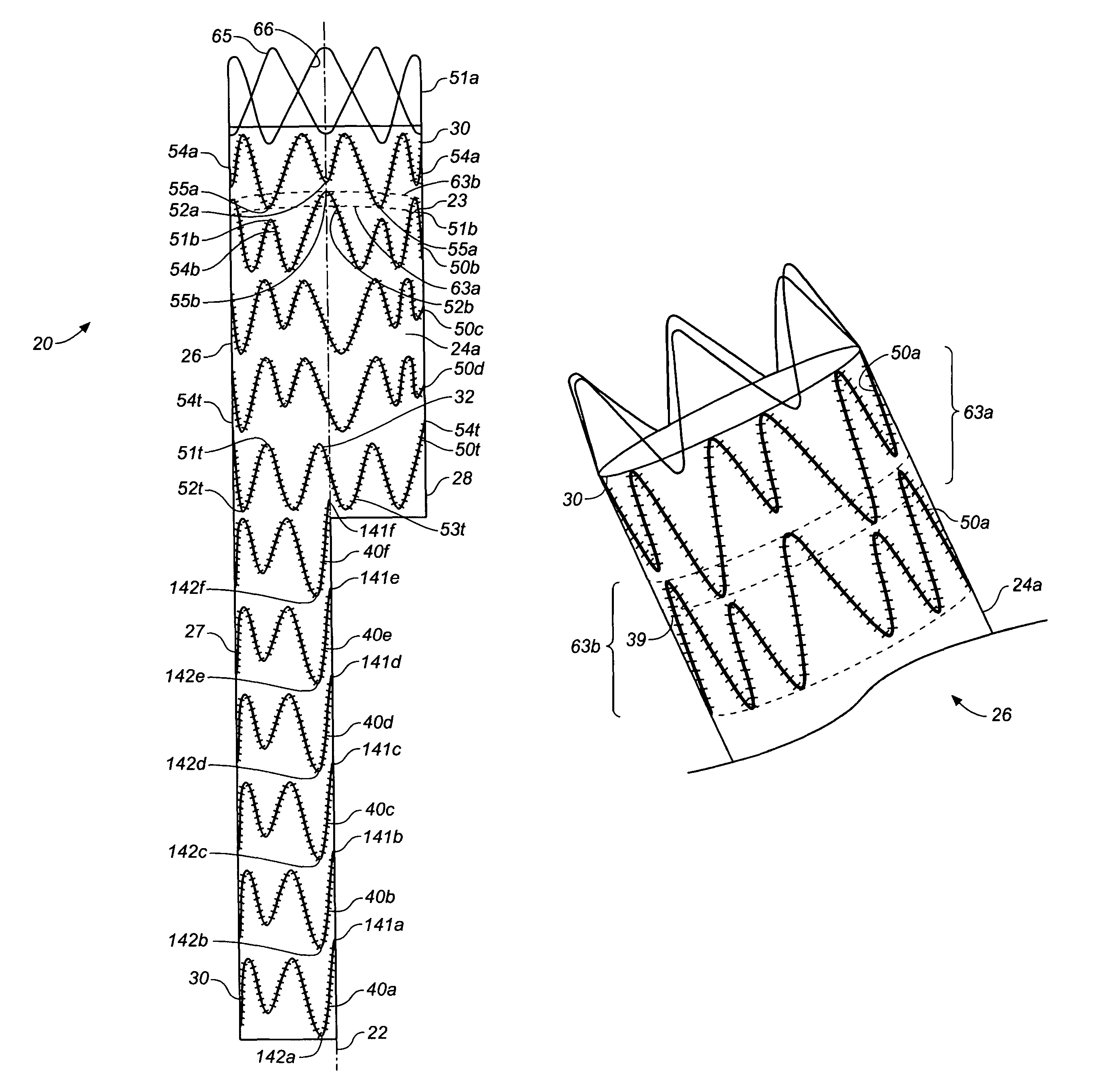

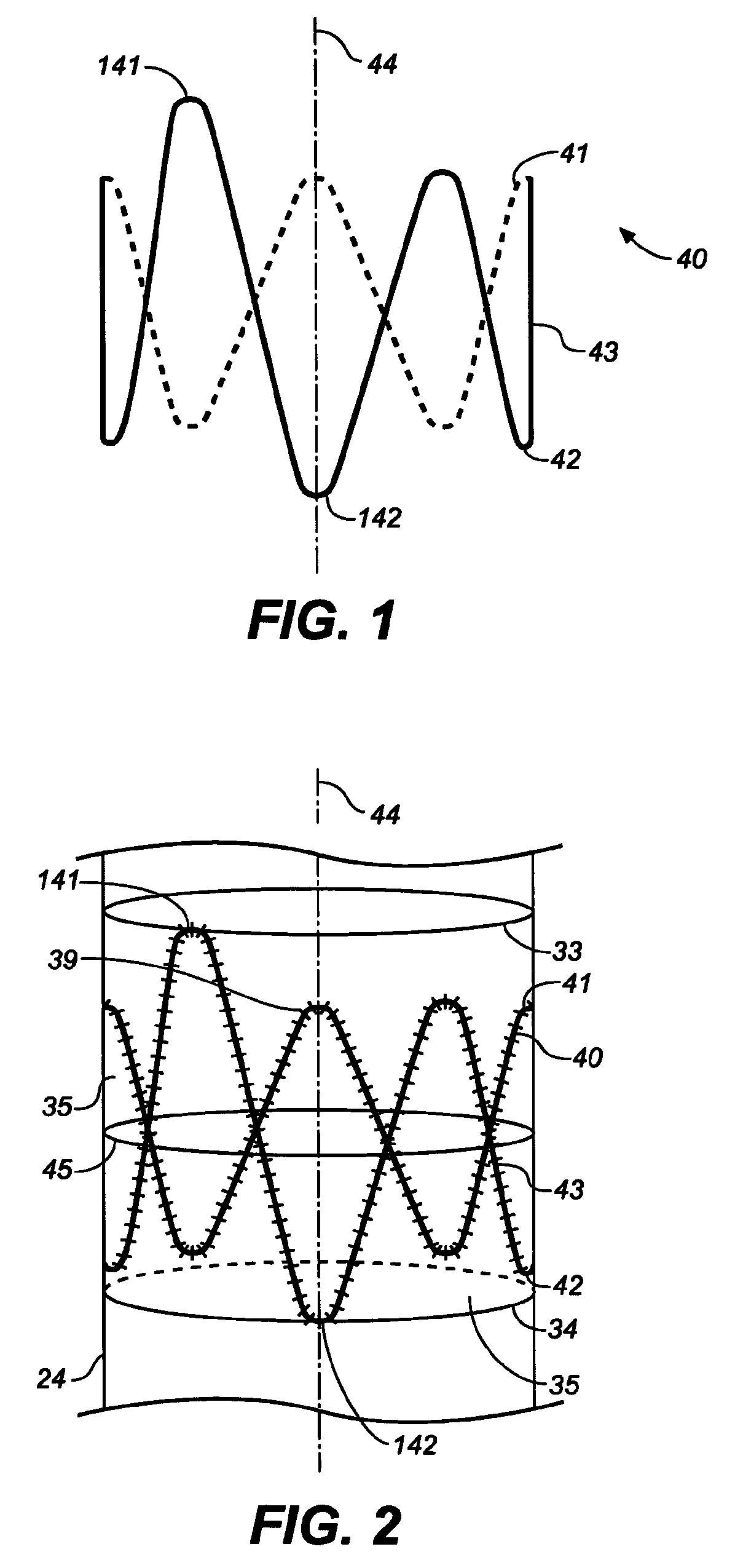

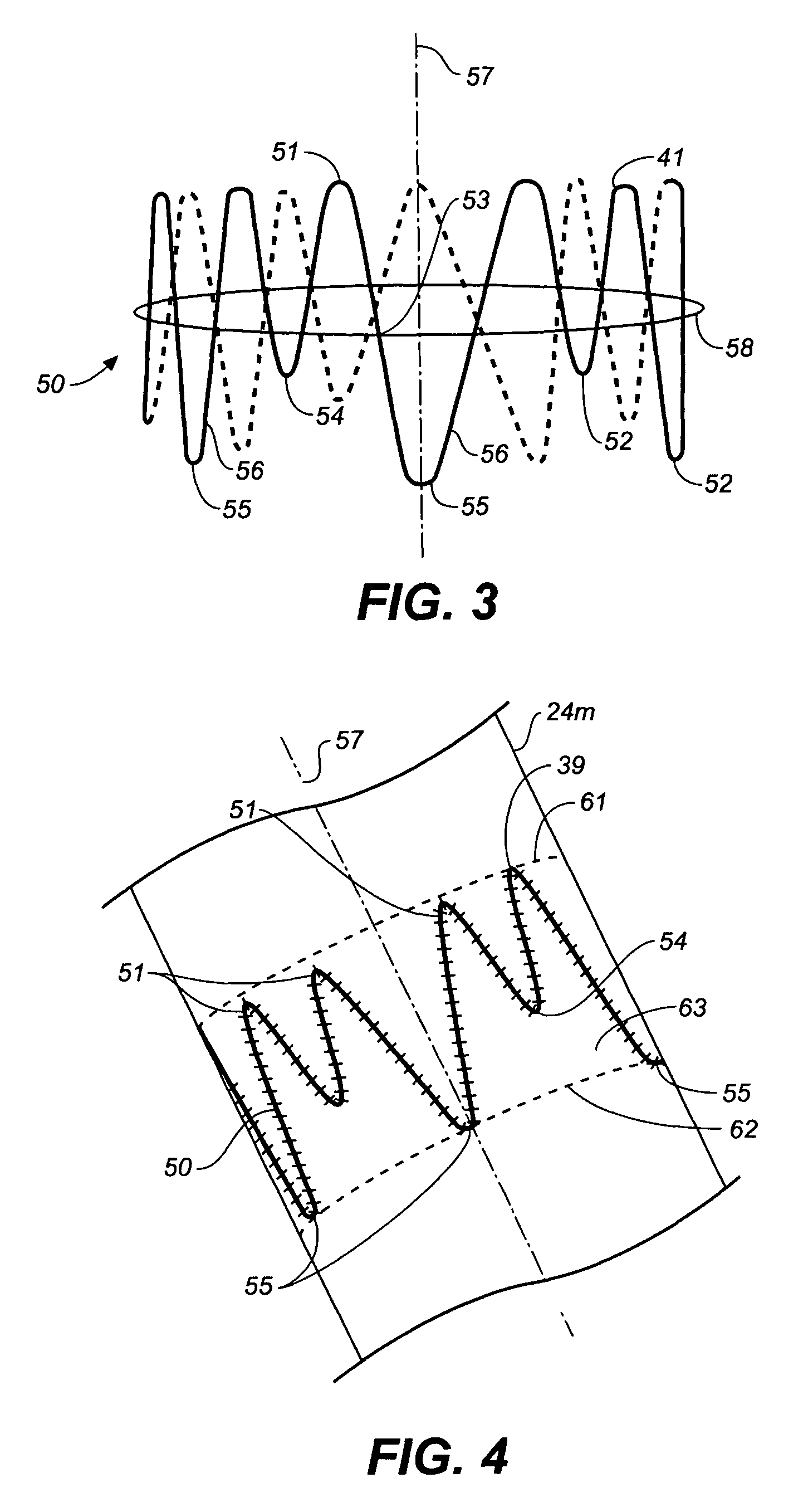

An endoluminal prosthesis is provided that includes a tubular graft and an expandable annular support structure. The annular support structure is coupled to the tubular graft so that the graft and support structure, in combination, provide columnar support while maintaining prosthesis flexibility. The prosthesis has sufficient strength and durability to withstand loads applied during deployment and sufficient flexibility to permit implant in a sealing arrangement within a tortuous body lumen. An embodiment according to the invention provides a plurality of annular structures with staggered, longitudinally overlapping apices of undulating structures. One embodiment relates to tubular grafts for endoluminal placement within a body lumen, including blood vessels, and for the treatment of abdominal and other aneurysms.

Owner:MEDTRONIC VASCULAR INC

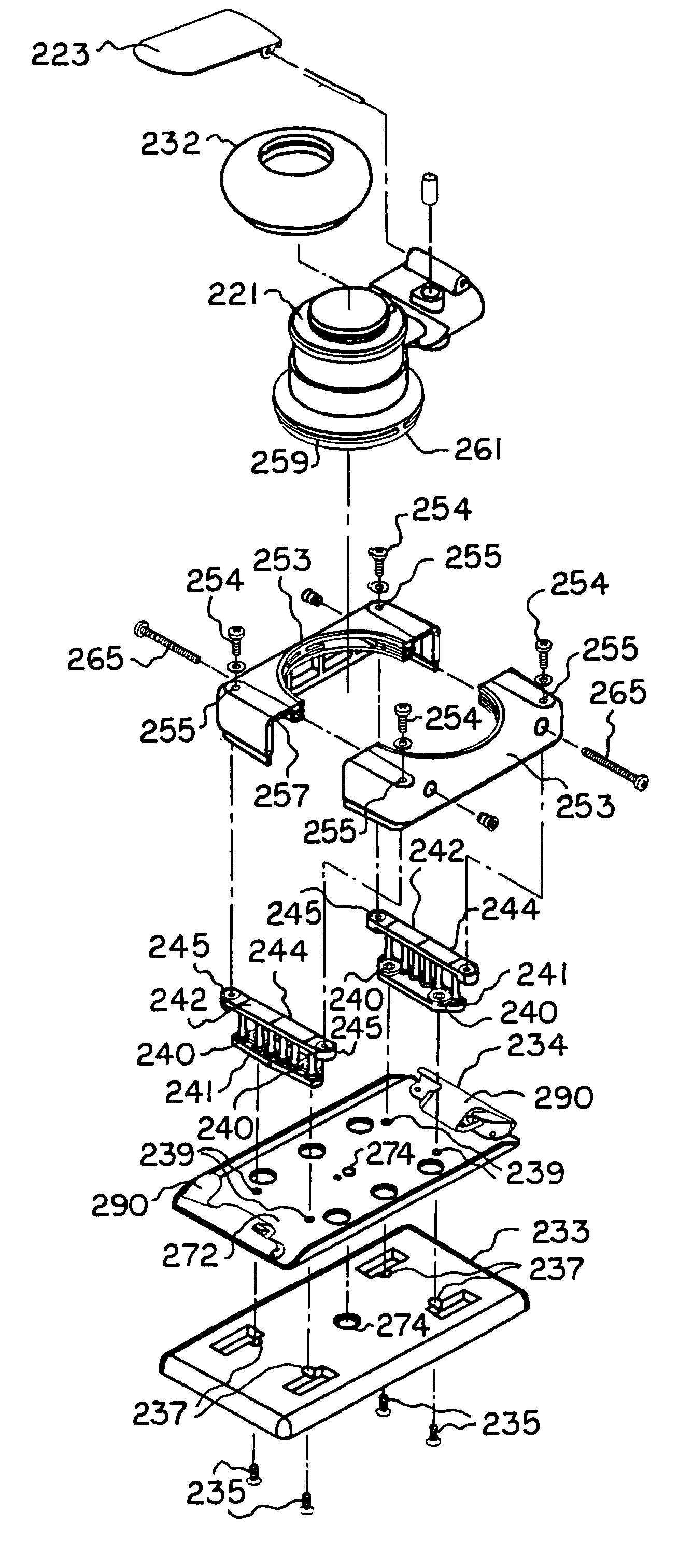

Uniform, disposable, interface for multi-element probe

InactiveUS7162291B1High mechanical strengthAffecting conductivityDiagnostic recording/measuringSensorsBiomedical engineeringMulti element

Owner:TRANSSCAN MEDICAL

Endoluminal prosthesis

ActiveUS20070055345A1Increase flexibilitySmall shapeStentsBlood vesselsWithin blood vesselsProsthesis

An endoluminal prosthesis is provided that includes a tubular graft and an expandable annular support structure for use in a body lumen through which body fluids flow. The annular support structure is coupled to the tubular graft where it is to be sealingly engaged with the inner wall of a body lumen so that the graft and support structure, in combination, provide an improved seal. An embodiment according to the invention provides an annular structure with longitudinally staggered apices providing multiple levels of contact with the inner body lumen wall to provide a seal at multiple levels along the length of the prosthesis. One embodiment relates to tubular grafts for endoluminal placement within blood vessels for the treatment of abdominal and other aneurysms.

Owner:MEDTRONIC VASCULAR INC

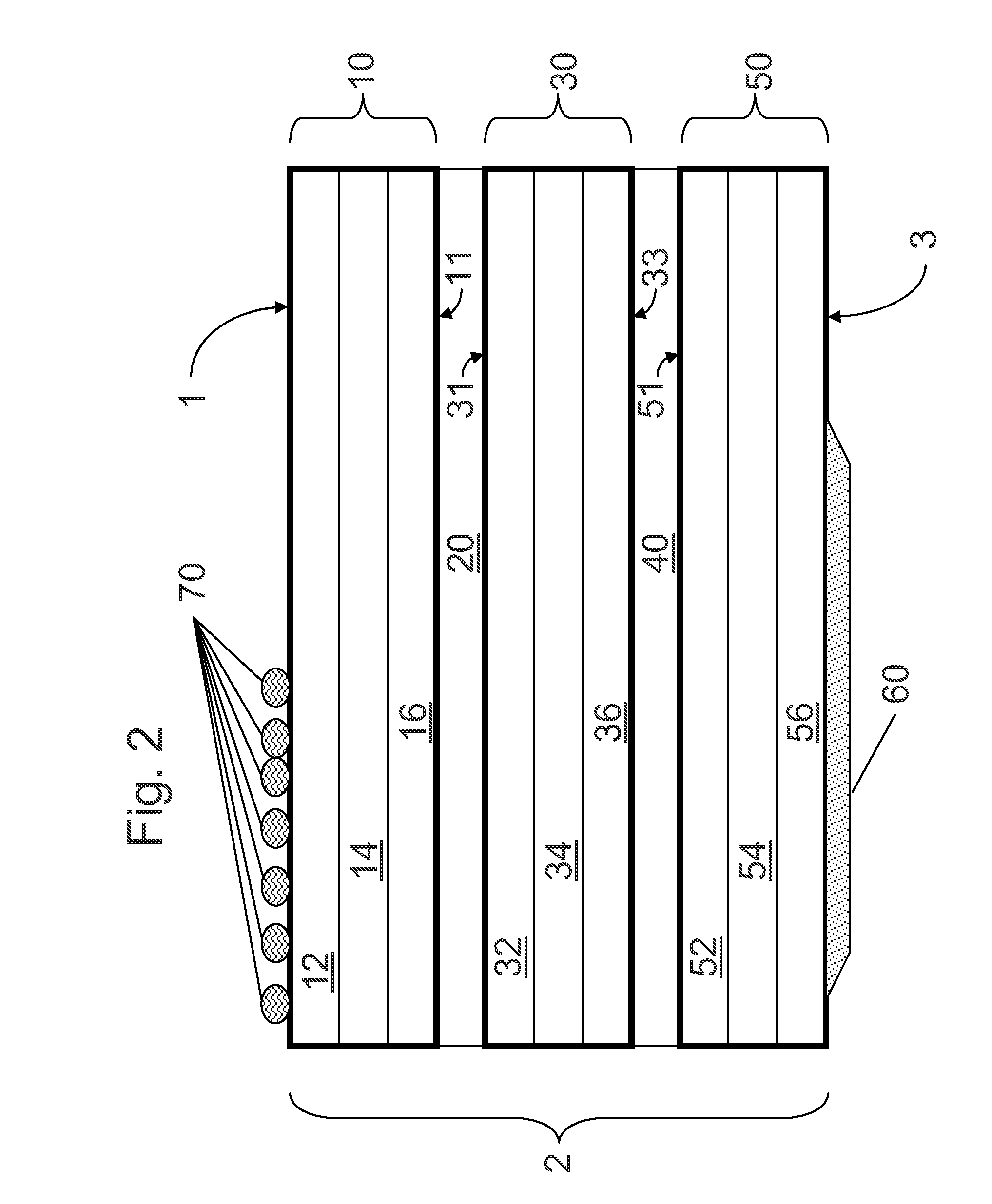

Multi-lumen vascular grafts having improved self-sealing properties

InactiveUS6926735B2Solve Porosity InsufficiencySolve the lack of flexibilityCoatingsBlood vesselsVascular graft

Owner:MAQUET CARDIOVASCULAR LLC

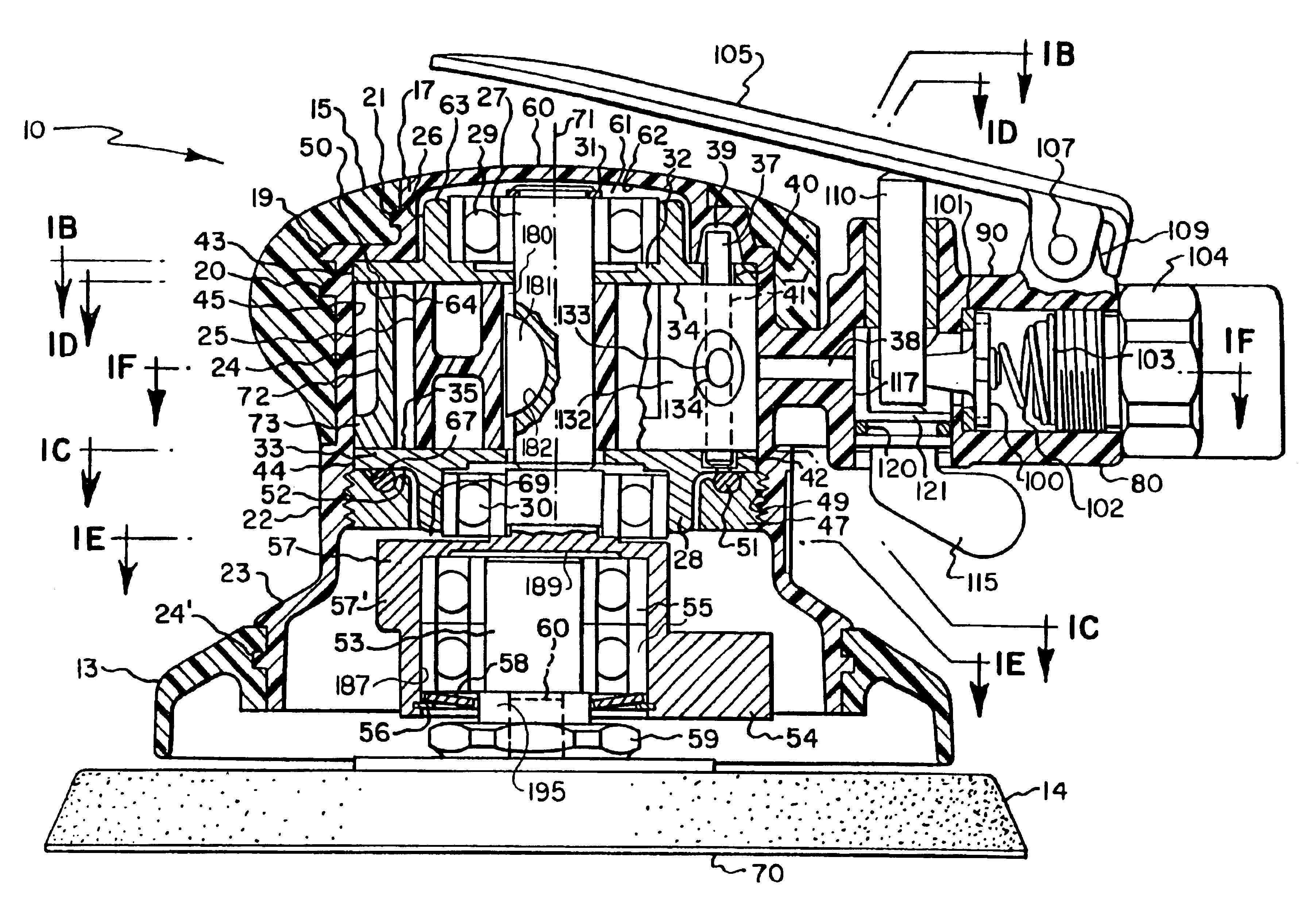

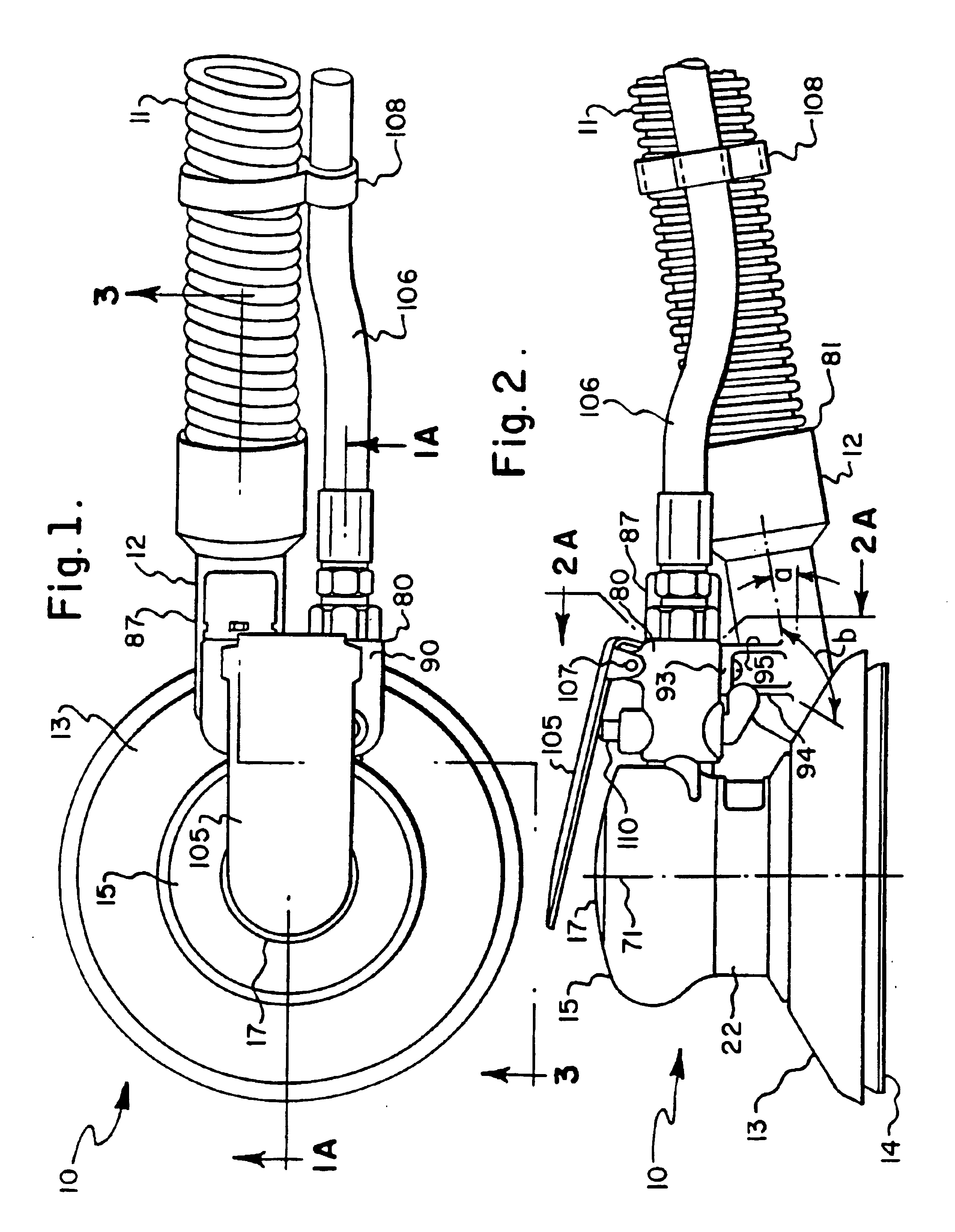

System for transrenal/intraostial fixation of endovascular prosthesis

InactiveUS6918926B2Promote migrationEasy to fixStentsBlood vesselsEndovascular prosthesisBlood vessel

An endoluminal prosthesis is provided with an improved fixation system for coupling the endoluminal prosthesis to an inner wall of a lumen and to reduce distal migration. According to an embodiment of the present invention, a laterally protruding member atraumatically engages the ostium of a side or branch vessel. The protruding member may be fixed to a portion of a prosthesis. In one embodiment the protruding member is provided on a modular fixation device for initial fixation within the body lumen with the finger member within the side or branch vessel. A primary endoluminal prosthesis is then fixed to the modular fixation device to bypass a diseased portion of the anatomy.

Owner:MEDTRONIC VASCULAR INC

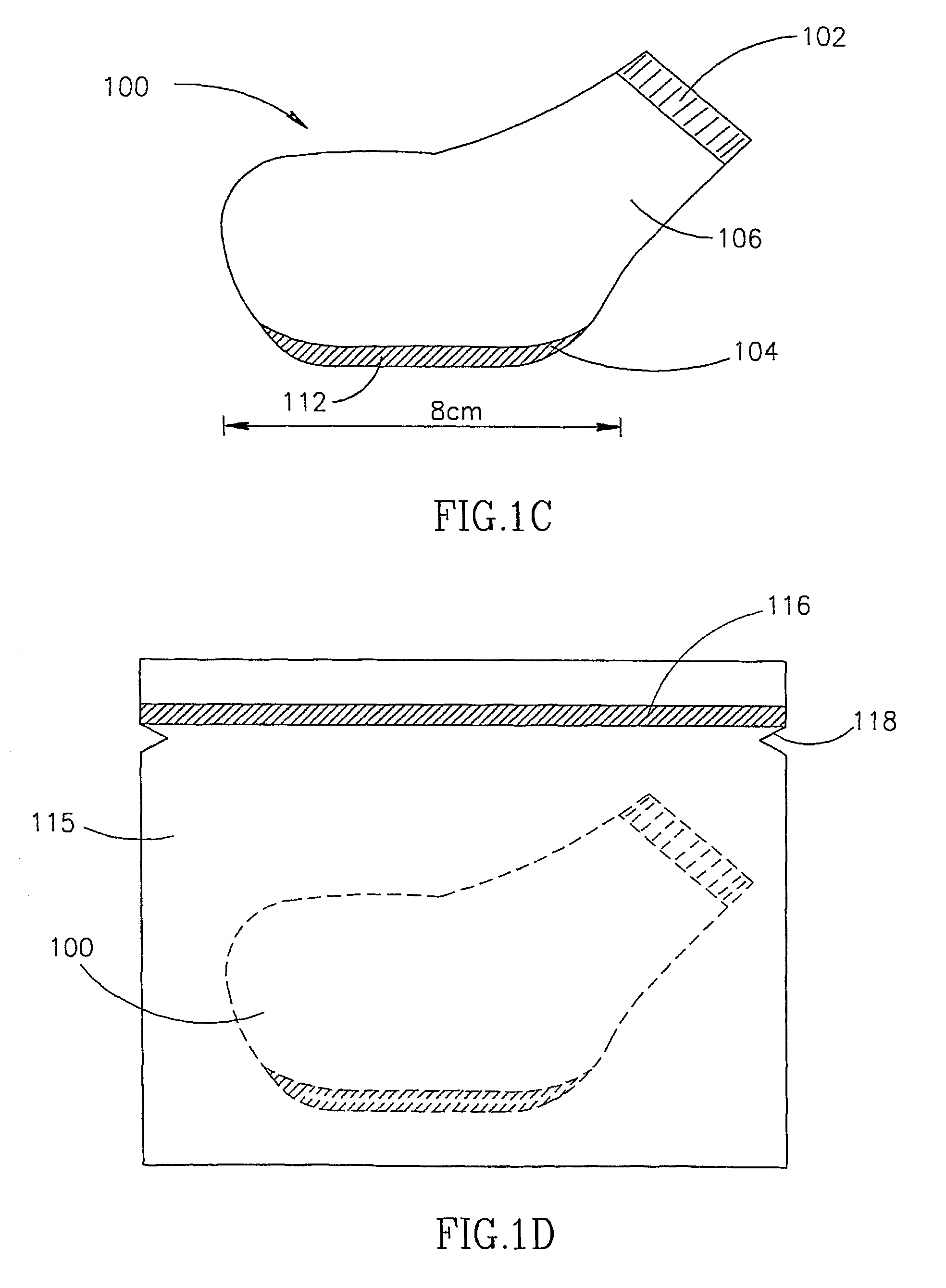

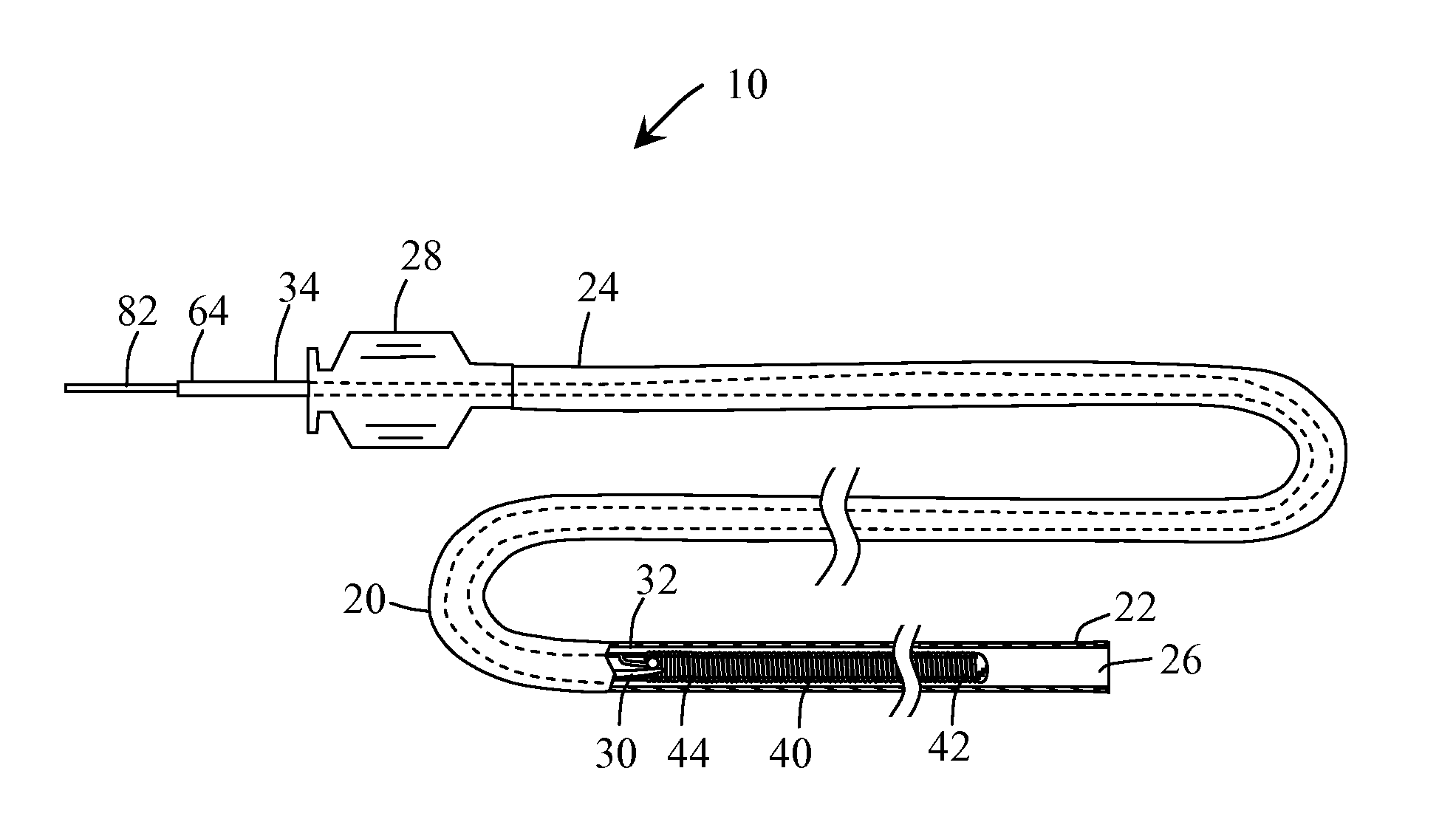

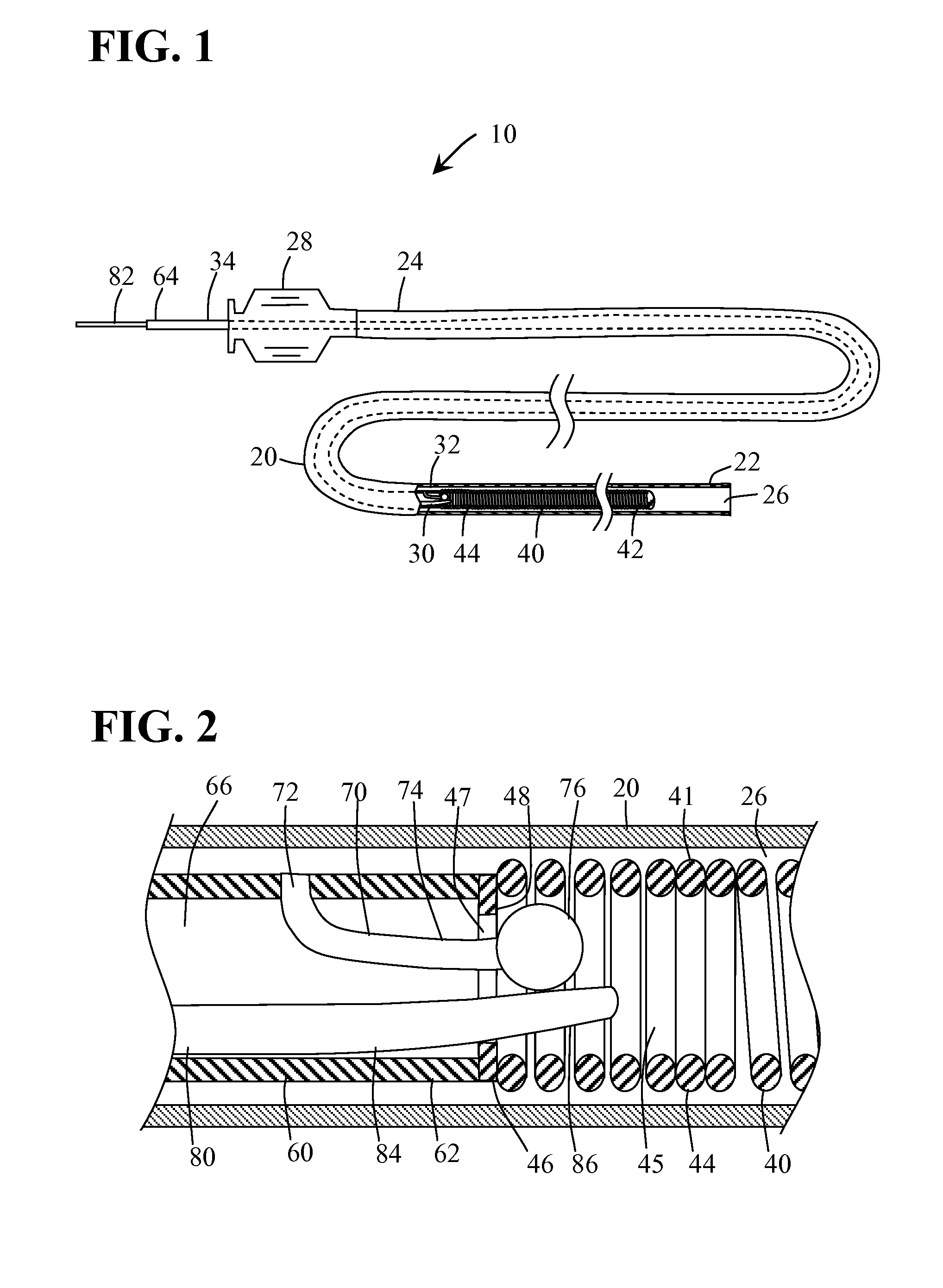

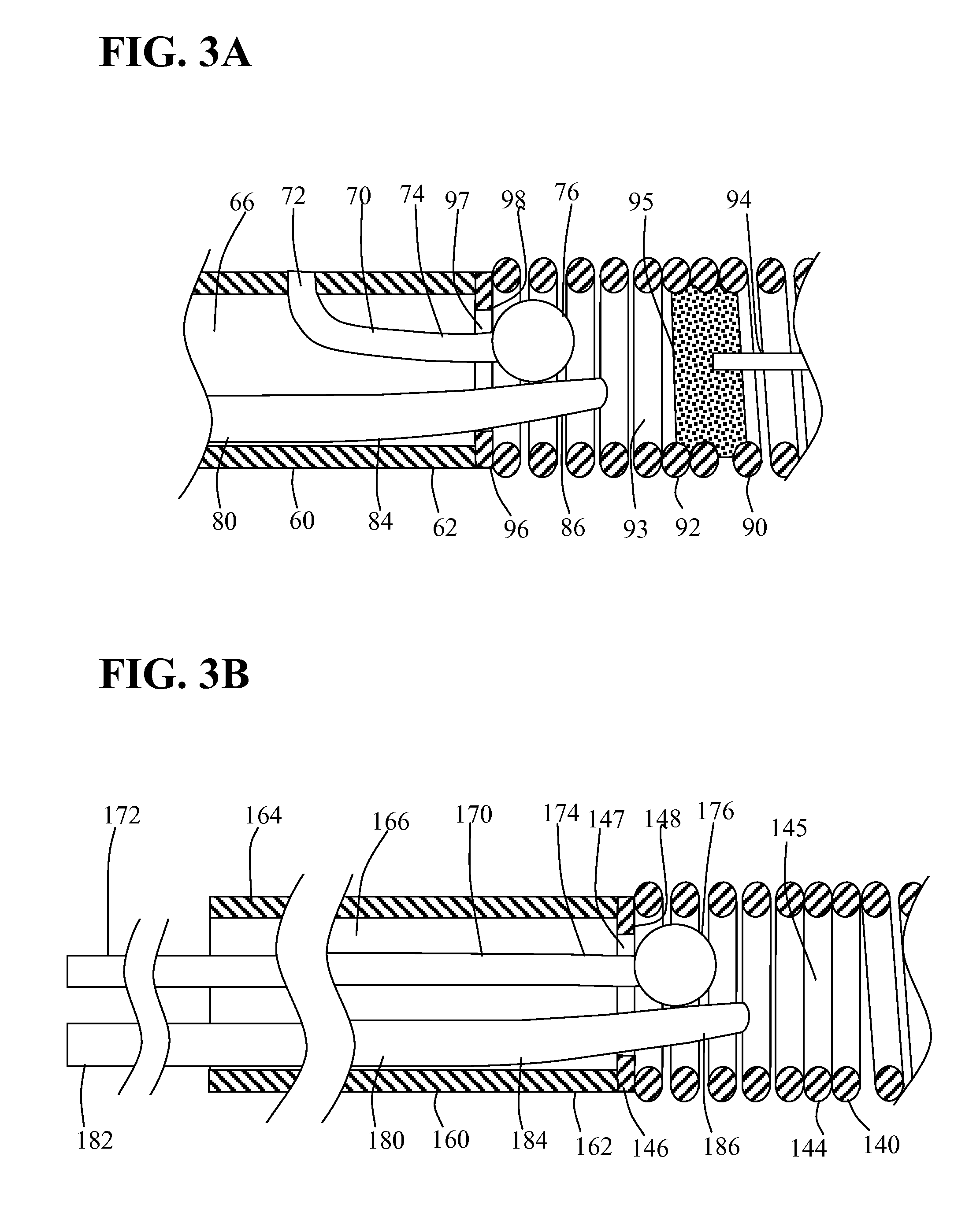

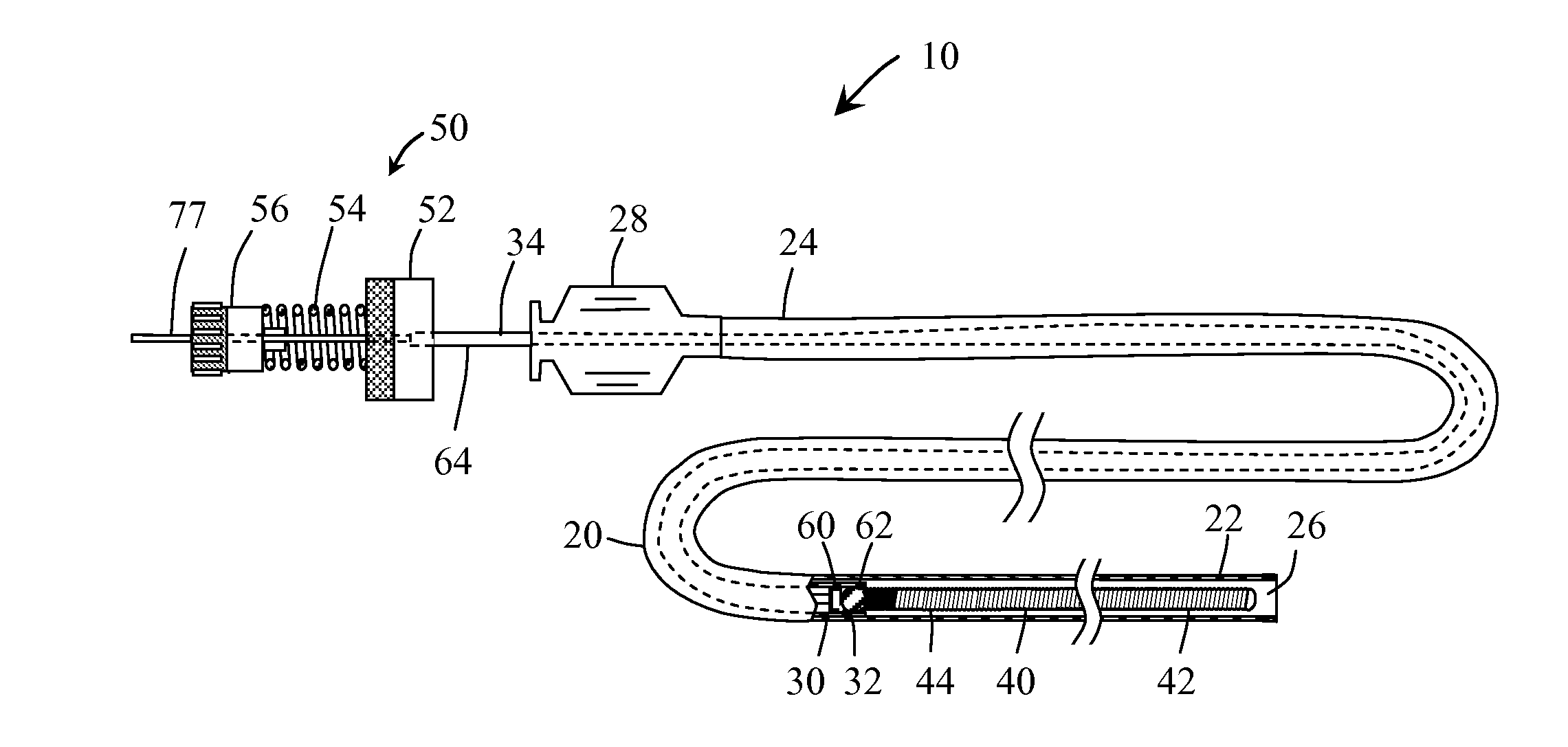

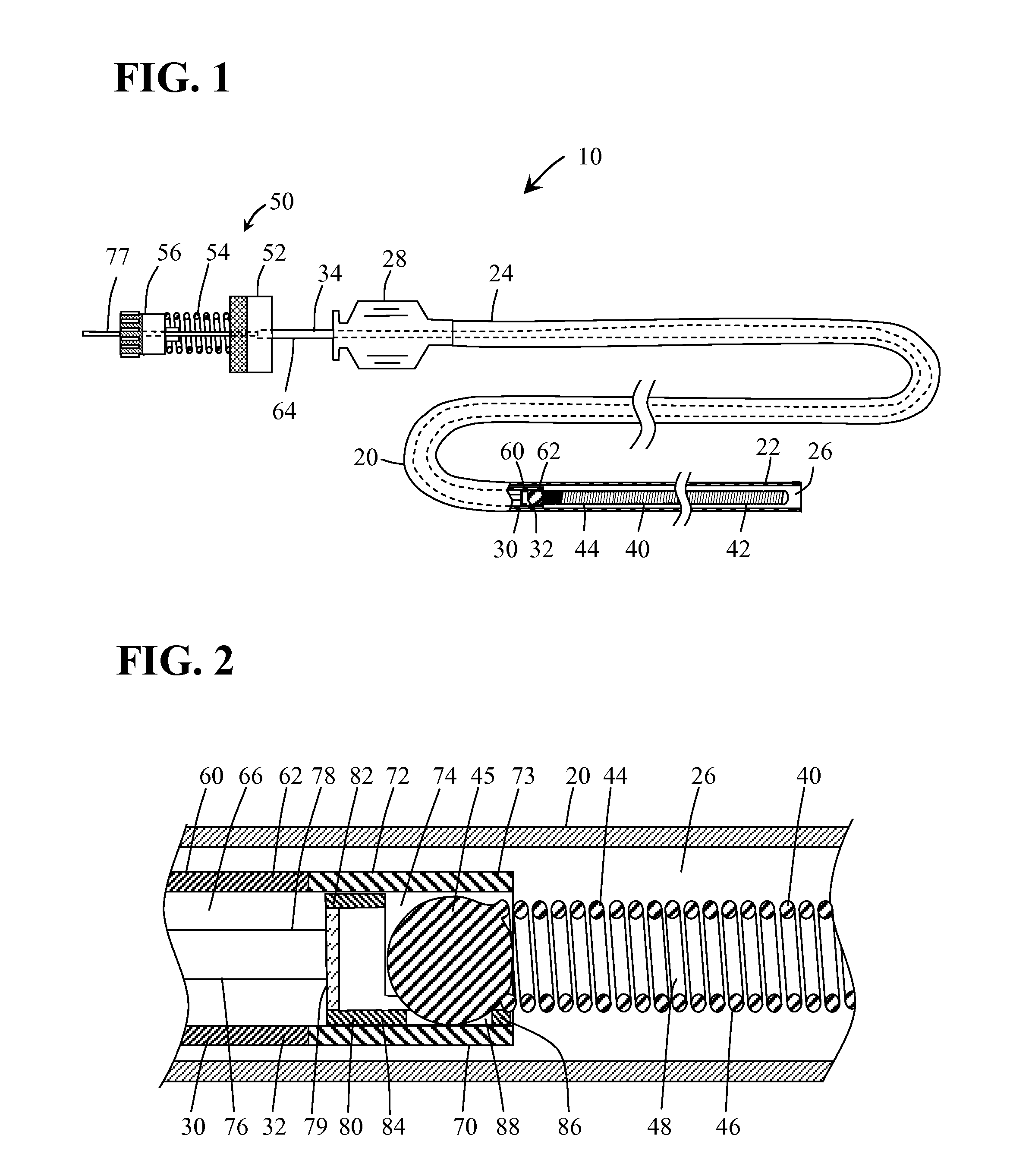

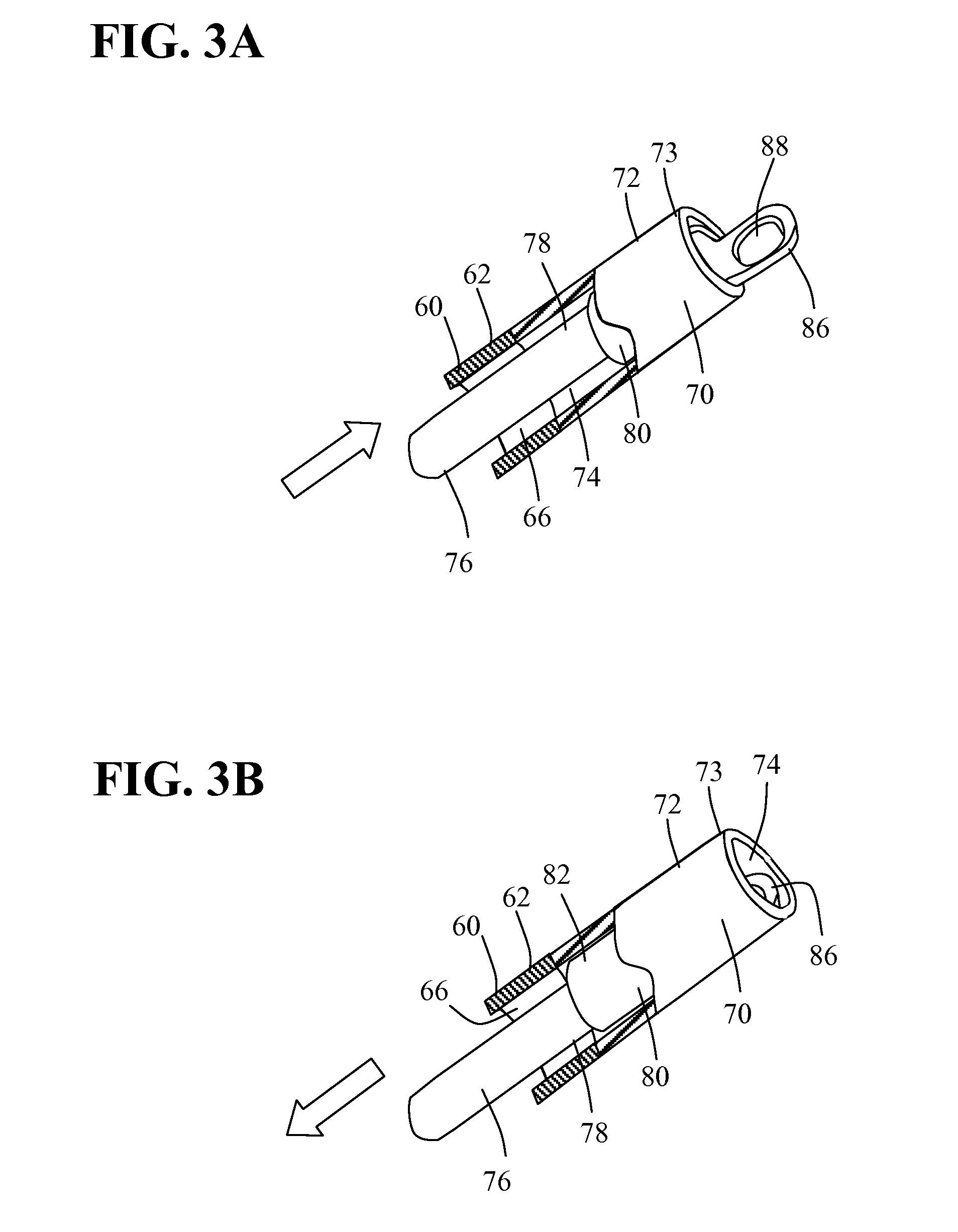

Detachable Coil Release System and Handle System

ActiveUS20150335333A1Sufficient pushabilitySufficient visibilityDilatorsOcculdersProximal pointCoupling

A medical implant deployment system for placing an implant at a preselected site comprising a deployment system that includes a mechanical coupling assembly at the distal end of a delivery member that engages the proximal end of the implant and a release member having an extended configuration in which the release member cooperatively maintains the coupling assembly engagement with the implant proximal end and a retracted configuration where the release member allows the coupling assembly to disengage from the implant proximal end. An attachable handle assembly is provided to place the release member in the retracted configuration allowing the coupling assembly to disengage from the implant proximal end, thereby releasing the implant.

Owner:EMPIRILON TECH

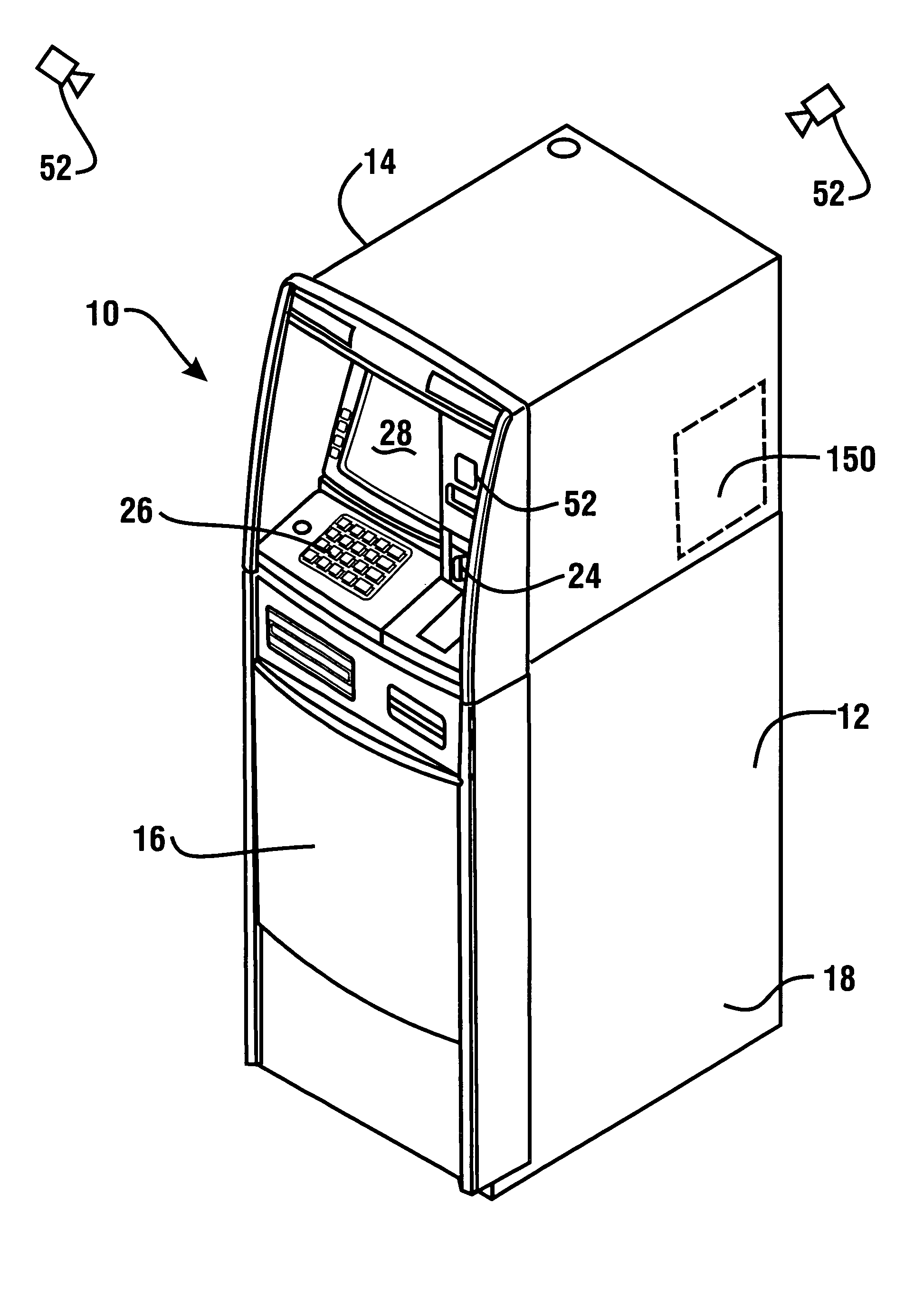

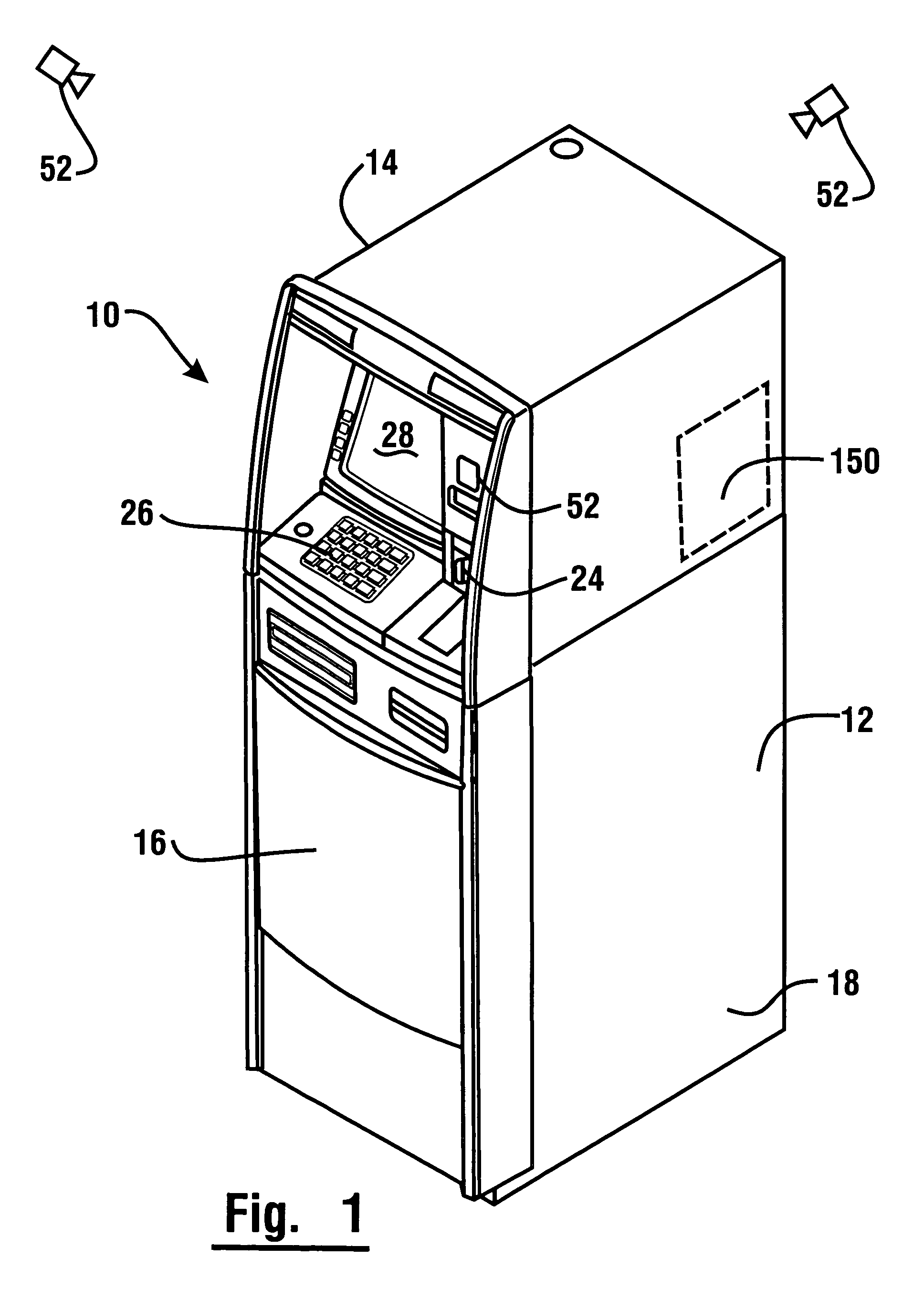

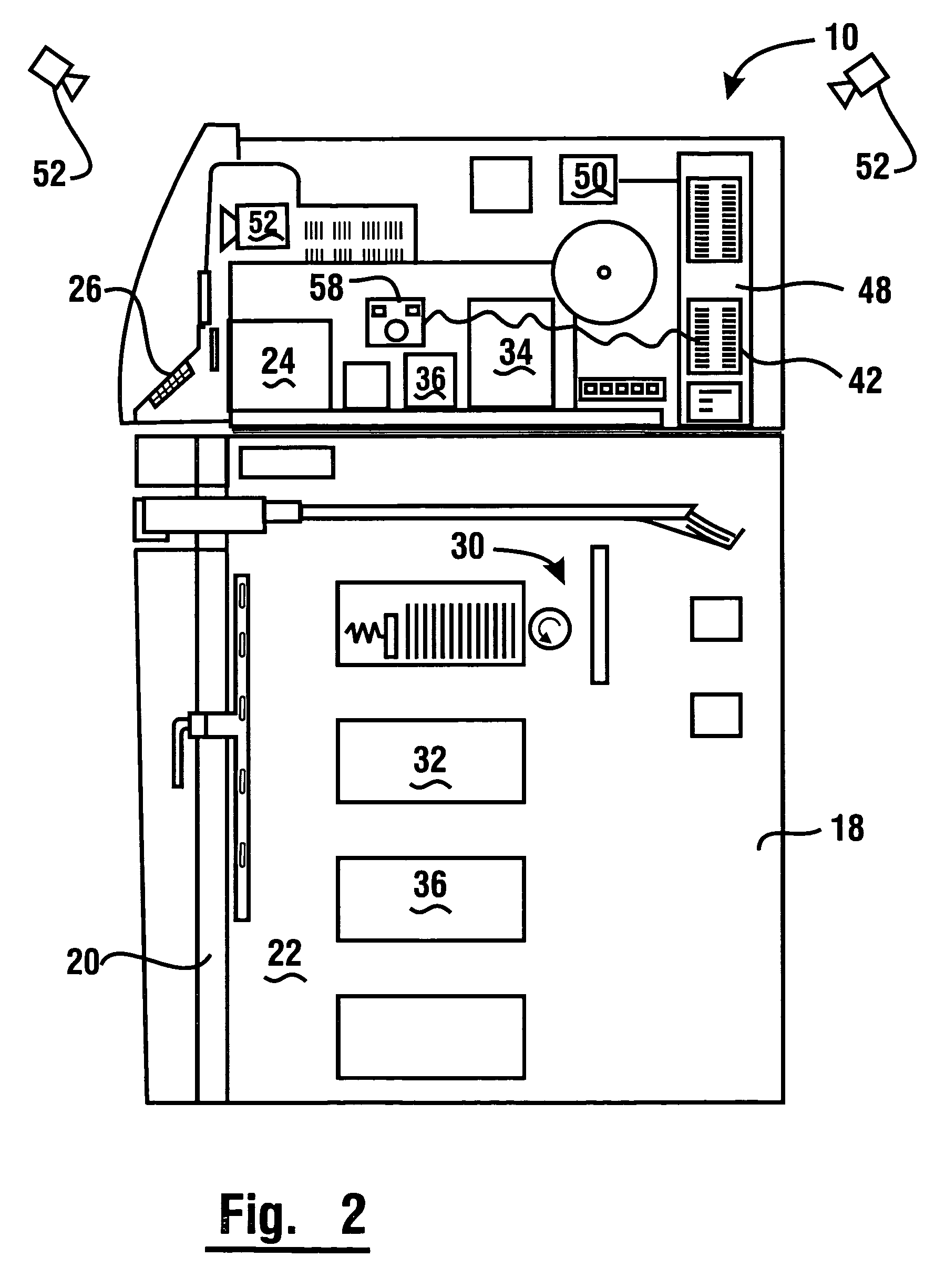

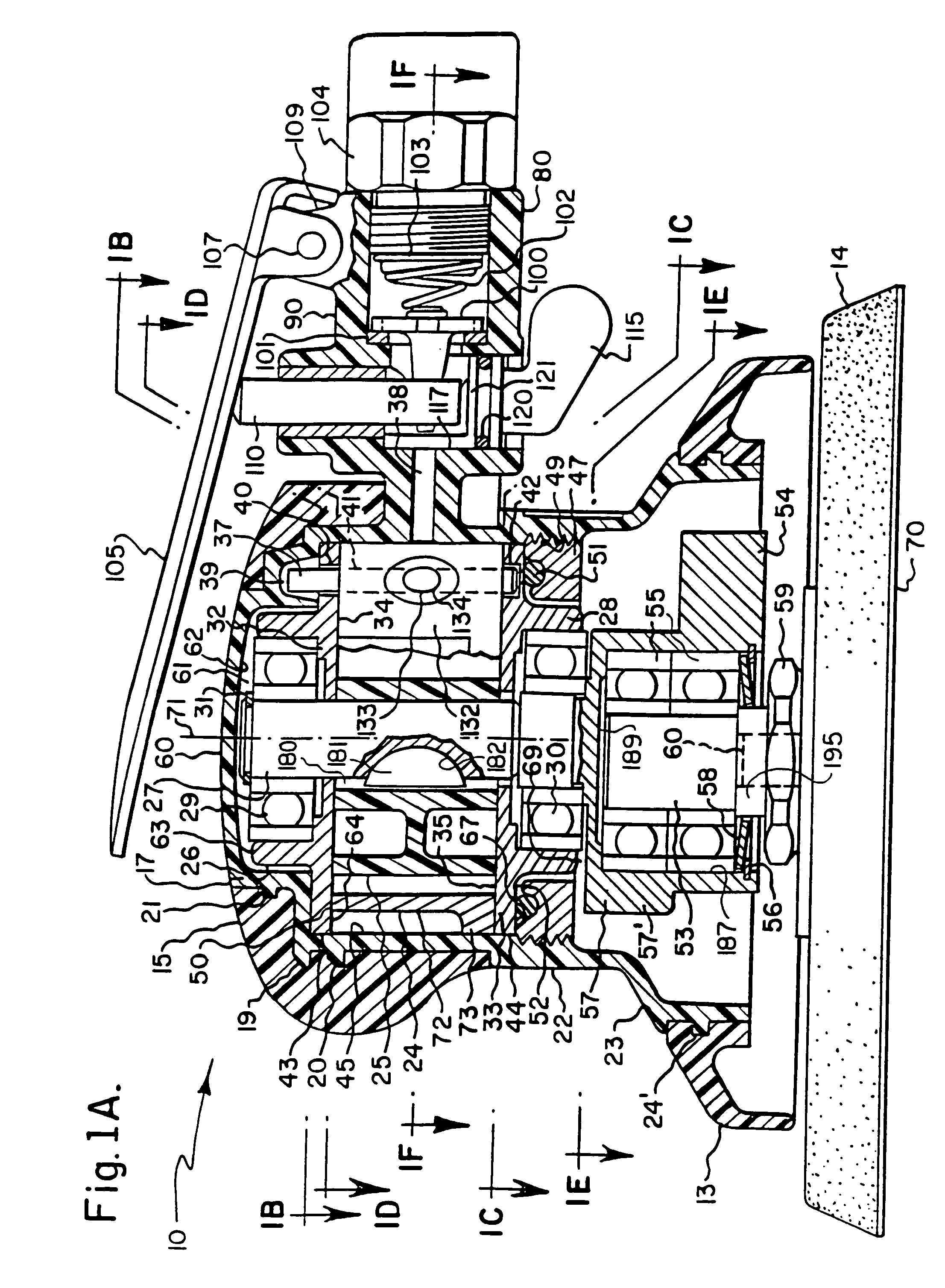

Automated banking system controlled responsive to data bearing records

ActiveUS7959072B1Improved operating and servicingSolve the lack of flexibilityPayment architectureSpecial data processing applicationsFinancial transactionCard reader

An automatic banking machine operates responsive to data bearing records. The machine includes a card reader for reading user cards, and at least one of a note acceptor and a cash dispenser. The automated banking machine carries out financial transfers related to user accounts based on information read from cards. The automated banking machine provides a printed receipt for transactions conducted. The machine carries out transactions when operatively connected to a source of power and a transaction network. The machine also carries out functions to control the power status of devices in the machine.

Owner:DIEBOLD SELF SERVICE SYST DIV OF DIEBOLD NIXDORF INC

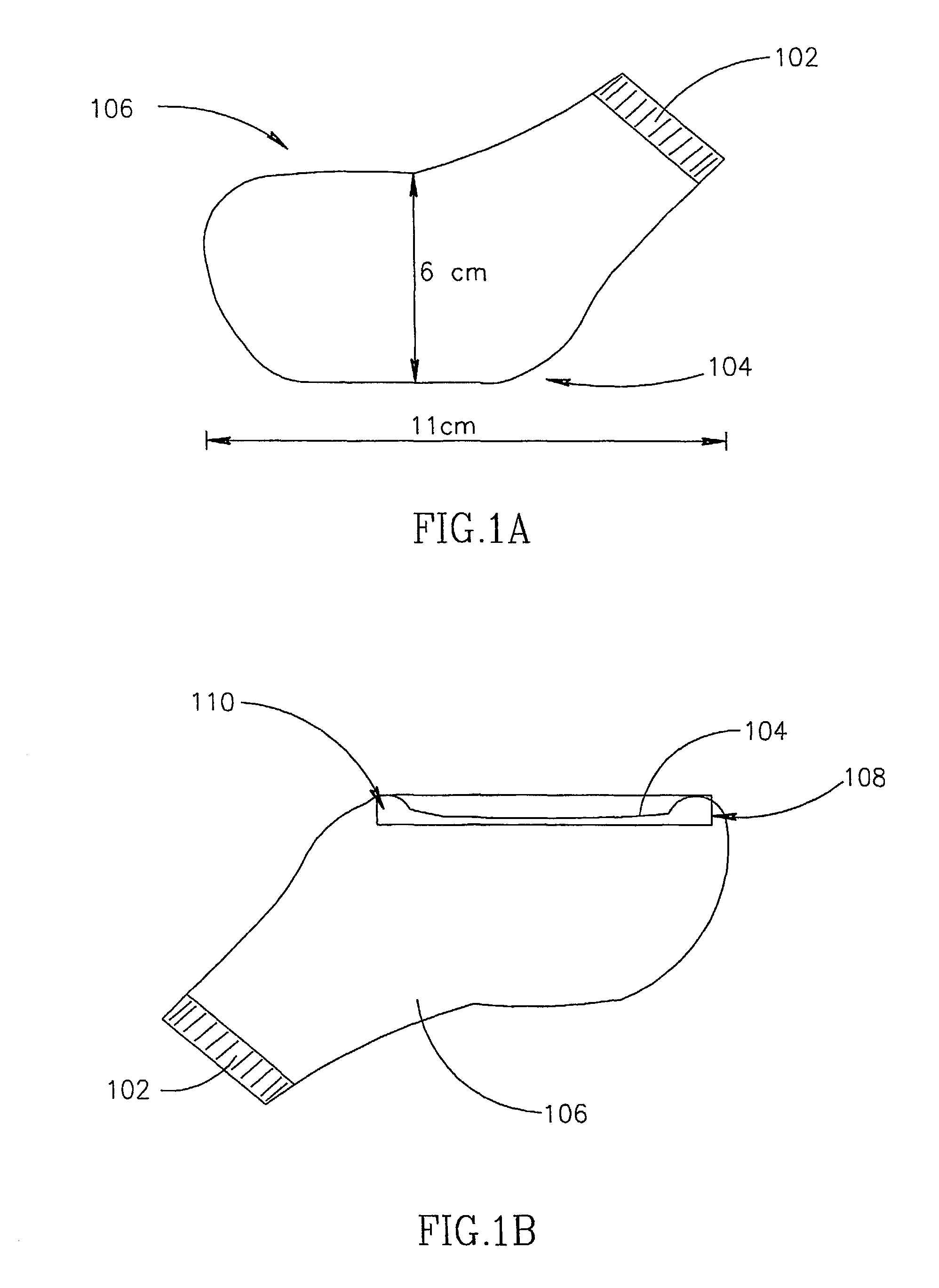

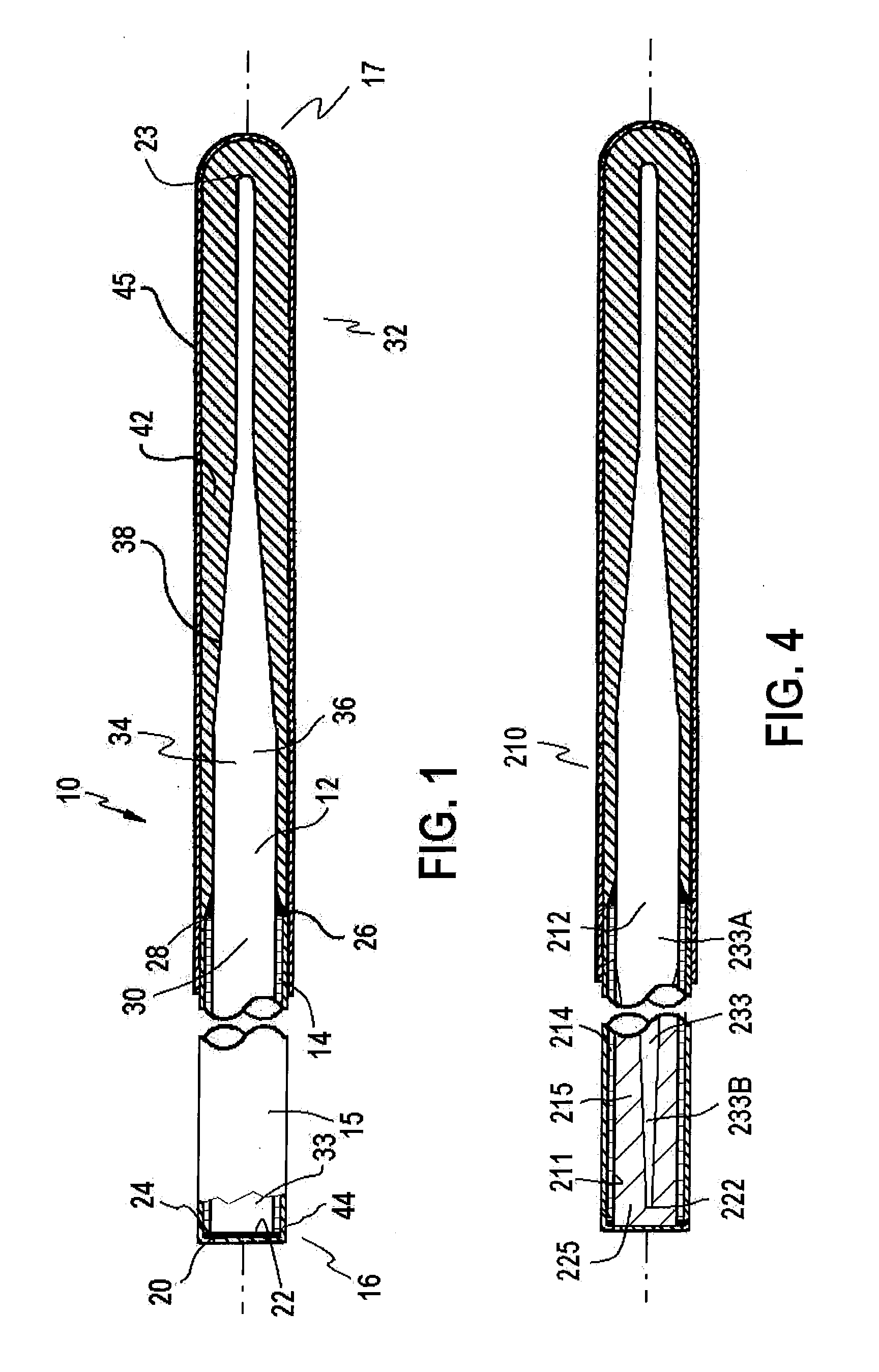

Intravaginal devices containing progesterone for estrus synchronization and related proceses

InactiveUS6939558B2Solve the lack of flexibilitySolving the Insufficiency of ElasticityAnimal reproductionPharmaceutical delivery mechanismMedicineEstrus synchronization

Embodiments of the present invention generally relate to devices and processes related to estrus synchronization. Particular embodiments of devices and processes of the present invention slowly release progesterone over a period of time for estrus synchronization.

Owner:AKZO NOBEL NV

Intravaginal devices containing progesterone for estrus synchronization and related proceses

InactiveUS20050021009A1Solve the lack of flexibilitySolving the Insufficiency of ElasticityAnimal reproductionFemale contraceptivesMedicineEstrus synchronization

Embodiments of the present invention generally relate to devices and processes related to estrus synchronization. Particular embodiments of devices and processes of the present invention slowly release progesterone over a period of time for estrus synchronization.

Owner:AKZO NOBEL NV

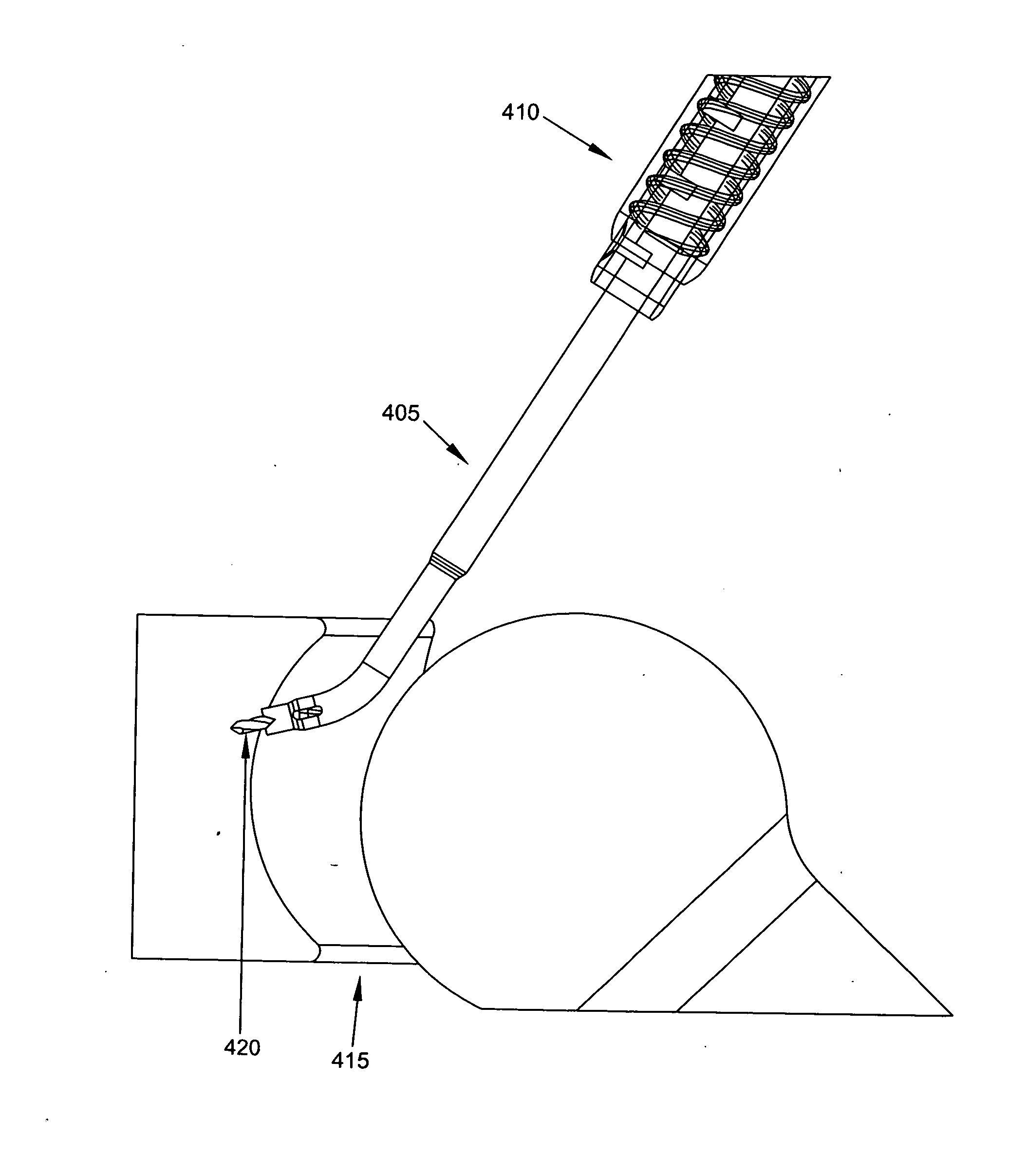

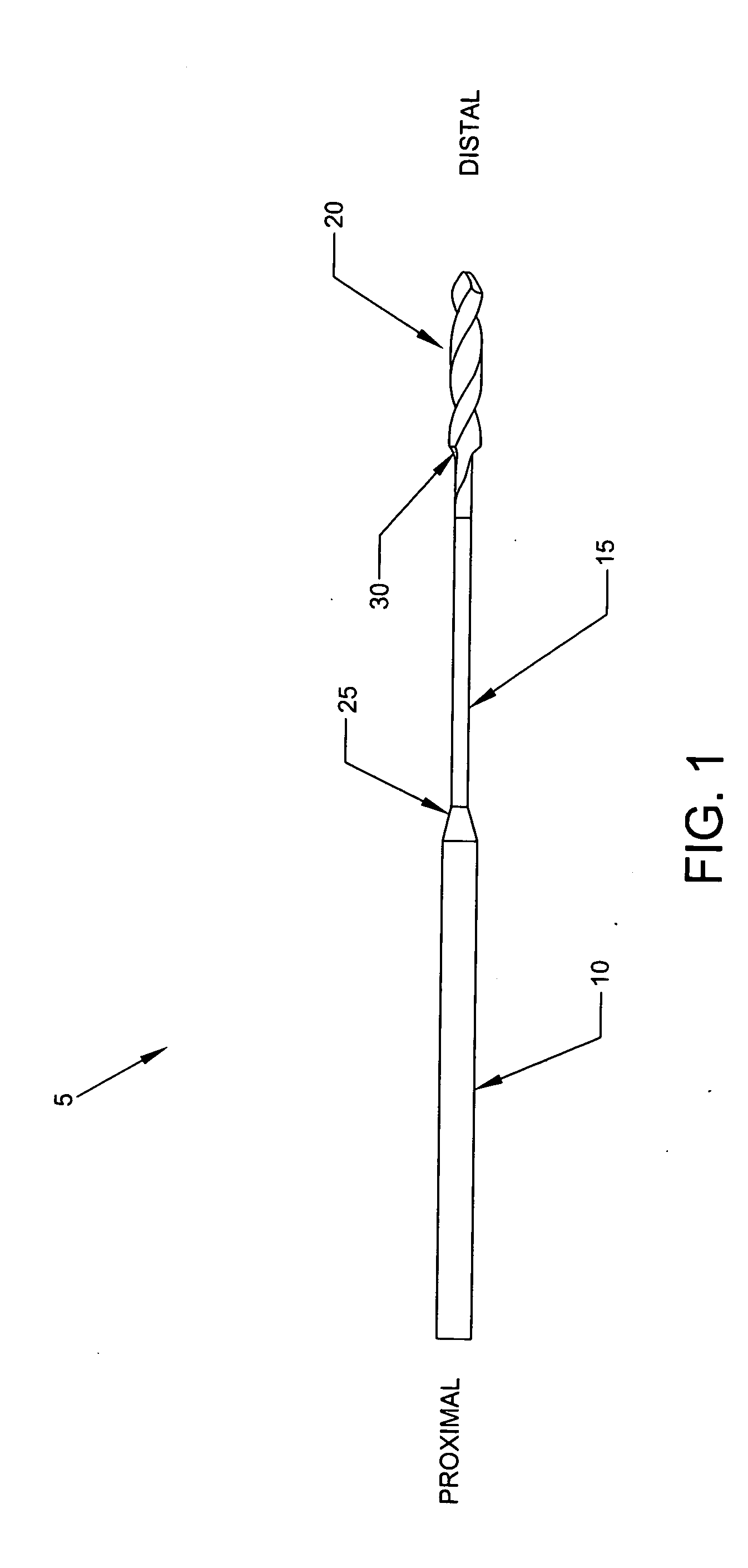

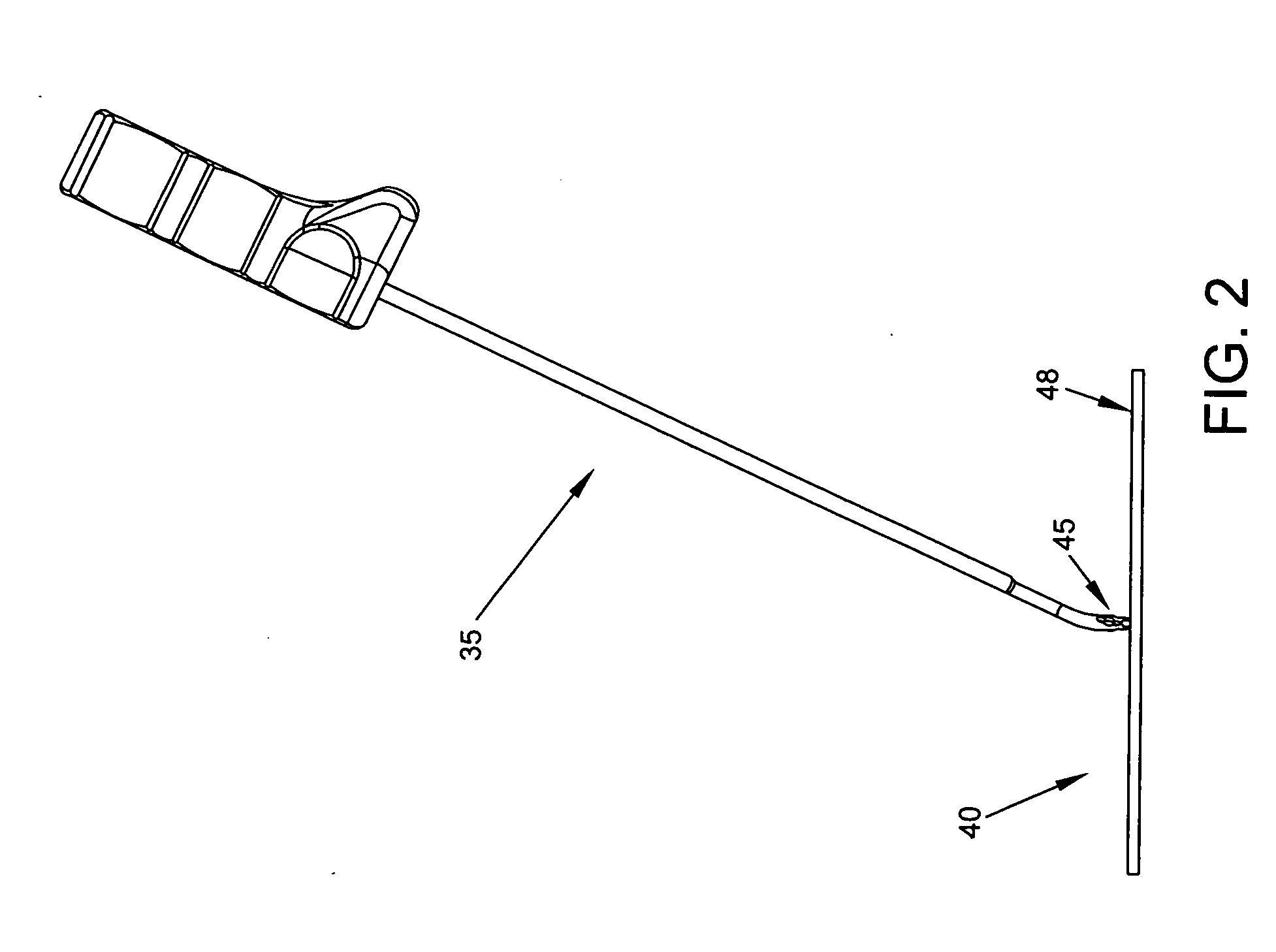

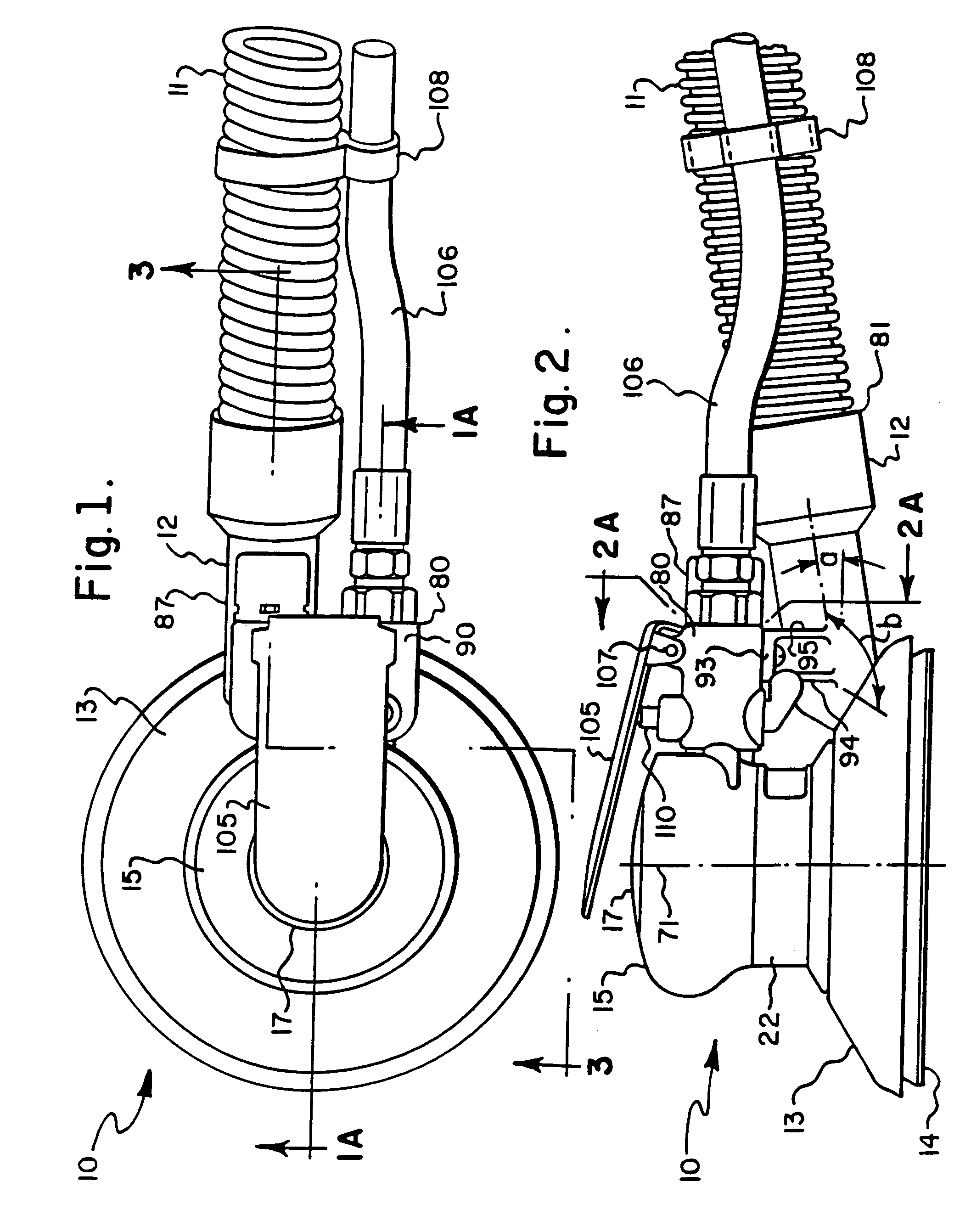

Flexible drill bit and angled drill guide for use with the same

ActiveUS20130296864A1Effectively narrowing lumenSolve the lack of flexibilityDiagnosticsProsthesisEngineeringBiomedical engineering

Apparatus for drilling a hole in material, the apparatus comprising:an angled drill guide comprising a curved distal section, a less-curved proximal section, and a lumen extending therebetween, wherein the less-curved proximal section comprises a flat extending therealong for reducing the effective diameter of the less-curved proximal section so as to minimize interference between the angled drill guide and the side wall of an access cannula.

Owner:STRYKER PUERTO RICO LLC

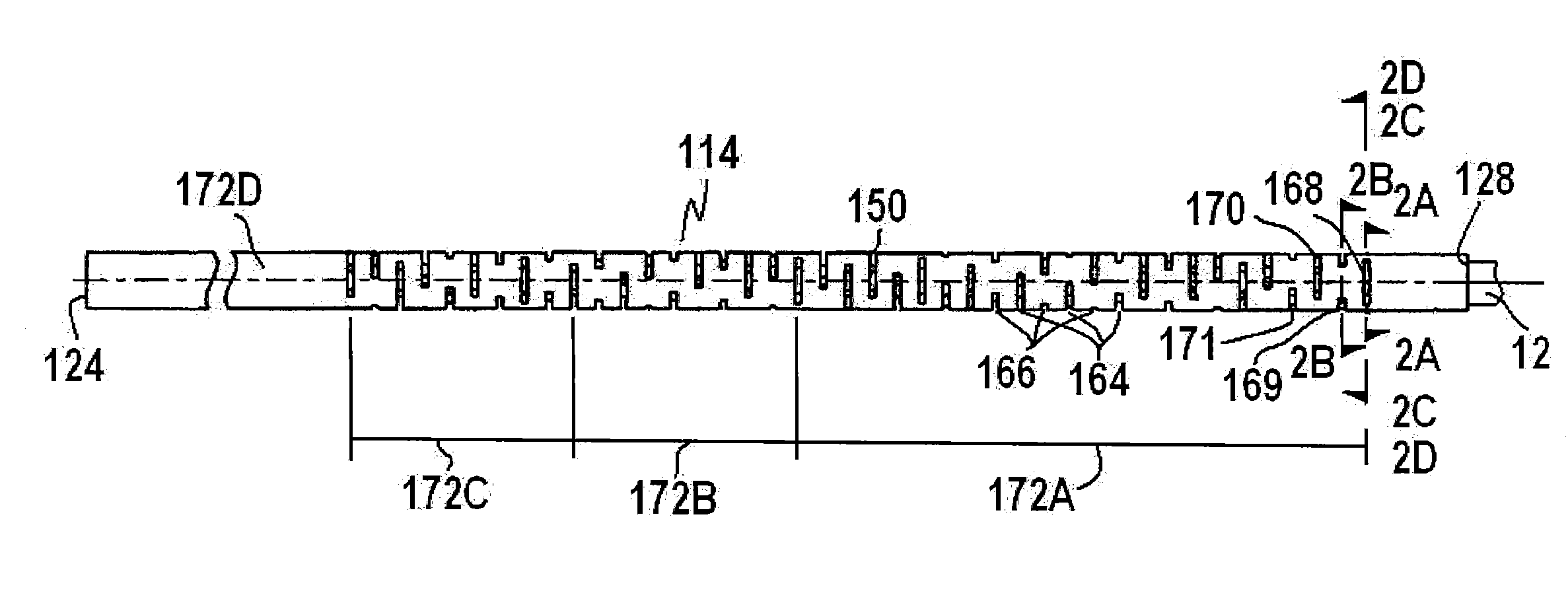

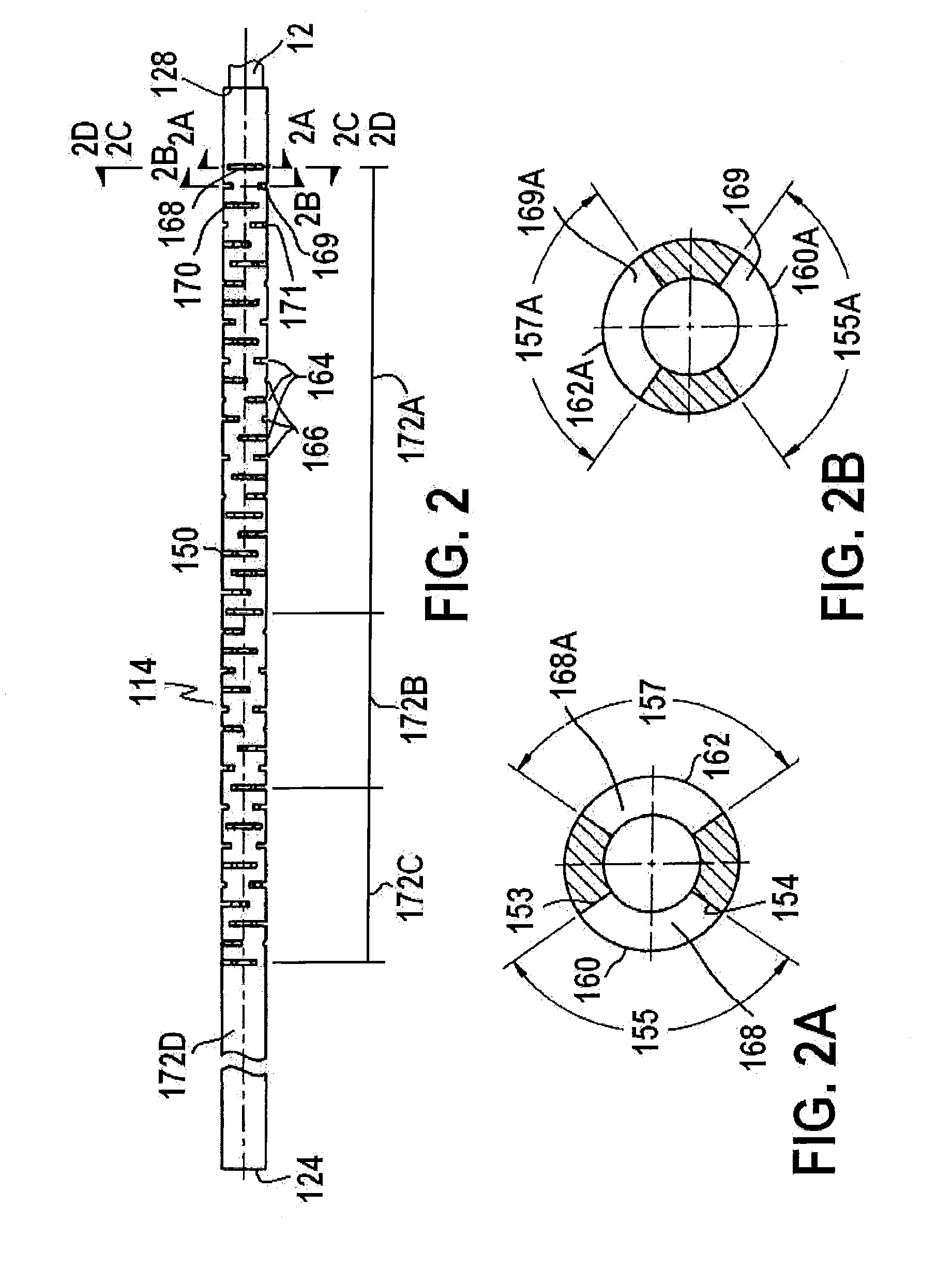

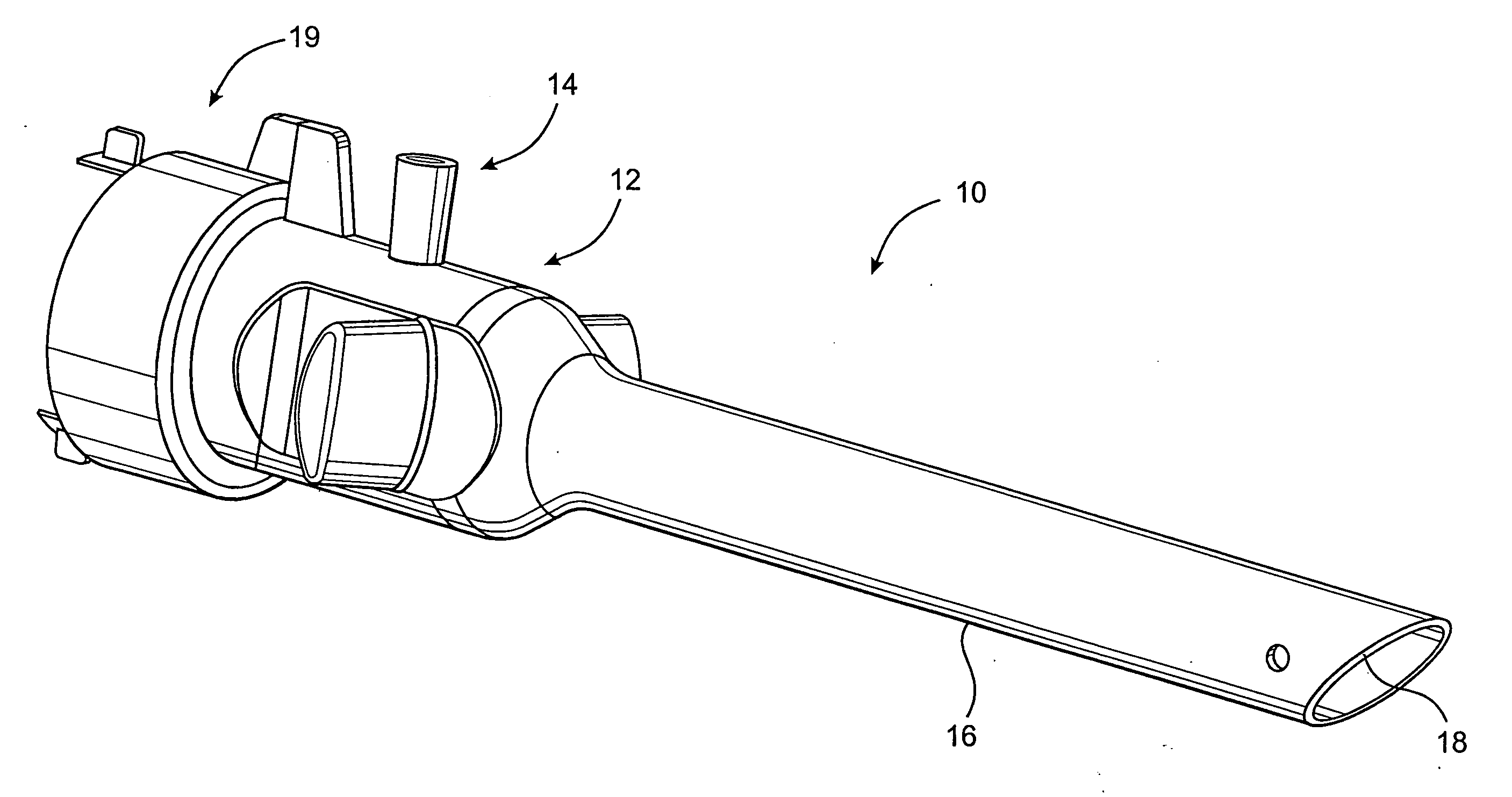

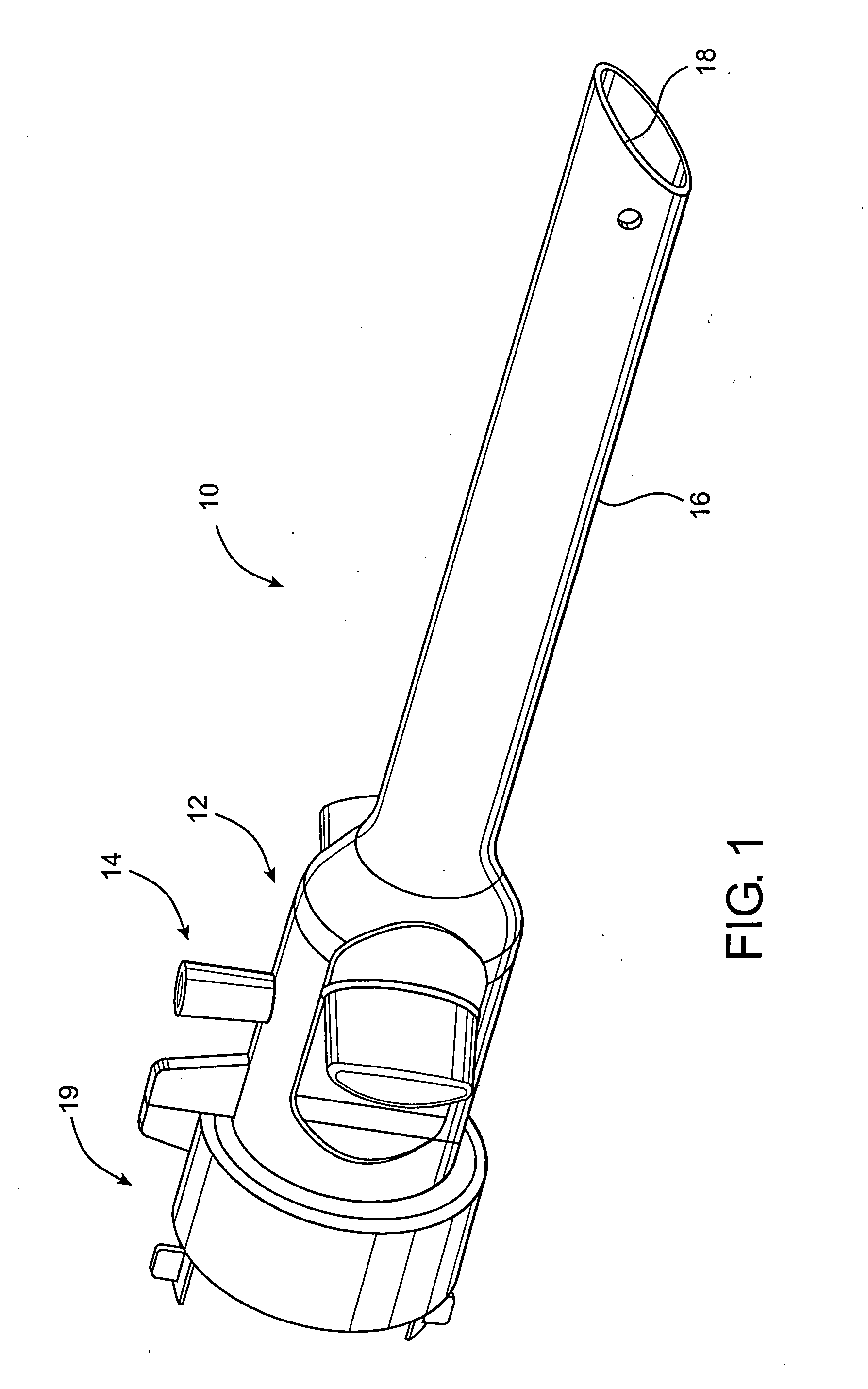

Wire guide with cannula

InactiveUS20110160680A1Solve the lack of flexibilitySolve the lack of resistanceGuide wiresAbsorbent padsMedical treatmentSurgical device

The present invention generally relates to a medical surgical device and specifically a wire guide for percutaneous placement within a body lumen. The wire guide includes an elongated mandrel having sufficient flexibility and kink resistance and a cannula having a stiffness greater than the mandrel stiffness for sufficient pushability. The mandrel extends through the cannula and has a portion extending distal thereto to form a distal tip of the wire guide. The wire guide can further include a slotted cannula to improve the flexibility of the wire guide at the proximal portion of the wire guide. The slots can be arranged in various patterns for increased flexibility along the longitudinal length of the cannula, as well as increased circumferential flexibility along the wire guide. The mandrel may also have a proximally tapered portion to improve the flexibility of the wire guide at the proximal portion of the wire guide.

Owner:COOK INC

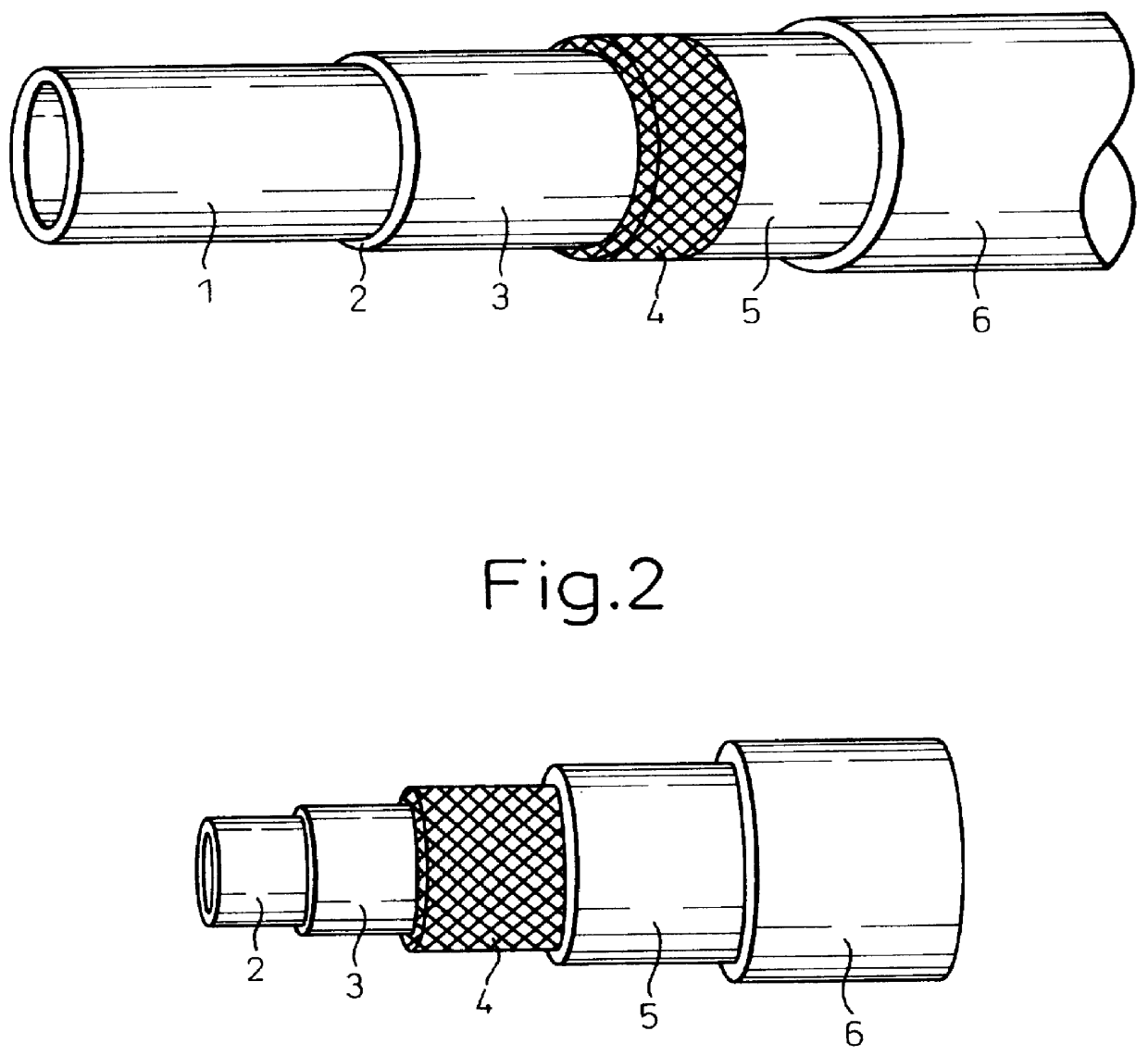

Thermoplastic elastomer composition, hose comprising thermoplastic elastomer composition and process of production thereof

InactiveUS6166143AImprove compatibilitySolve the lack of flexibilityClosuresClosure using stoppersThermoplasticCross-link

PCT No. PCT / JP97 / 03987 Sec. 371 Date Jul. 2, 1998 Sec. 102(e) Date Jul. 2, 1998 PCT Filed Oct. 31, 1997 PCT Pub. No. WO98 / 20068 PCT Pub. Date May 14, 1998A thermoplastic elastomer composition containing a component (A) (thermoplastic polyolefin resin), component (B) (epoxy-group-containing ethylene acrylic ester copolymer rubber), and component (C) (acid-modified polyolefin resin) comprising a continuous phase of the component (A) in which the component (B) is dispersed as a dispersed phase and is cross-linked by a peroxide; a thermoplastic elastomer composition comprising a continuous phase of a thermoplastic polyolefin resin (A) and a dispersed phase of an epoxy-group-containing ethylene-acrylic ester copolymer rubber component (B) and acrylonitrile butadiene rubber component (C), which is dynamically cross-linked; and a hose having an inner tube, at least one reinforcing layer, and an outer cover, wherein the inner tube and the outer cover contain a thermoplastic elastomer composition comprised of a thermoplastic resin in which is blended an at least partially cross-linked elastomer component, the reinforcing layer is a brass-plated wire, and the reinforcing layer and inner tube and the reinforcing layer and outer cover have between them a maleic-acid-modified polyolefin thermoplastic resin.

Owner:YOKOHAMA RUBBER CO LTD

Implant delivery and release system

InactiveUS20140058435A1Minimal resistanceFacilitate couplingDilatorsOcculdersBiomedical engineeringMedical treatment

A medical implant deployment system for placing an implant at a preselected site within a vessel, duct or body lumen of a mammal comprising a reloadable deployment system includes a mechanical coupling assembly at the distal end of a delivery member, having an extended configuration in which the coupling assembly is adapted to receive or release the implant proximal end and a retracted configuration where the coupling assembly distal end is interlockingly engaged with the implant proximal end. Once the implant is properly positioned the coupling assembly is actuated, thereby releasing the implant at a desired position within the body.

Owner:JONES DONALD K +1

Ergonomically friendly orbital sander construction

InactiveUS6855040B2High strengthSufficient lateral flexibilityGrinding machine componentsRotary piston pumpsMotor shaftAcute angle

A random orbital sander including a housing, a motor having a vertical axis in the housing, a pad coupled to the motor, a face on the pad extending substantially perpendicularly to the vertical axis, a shroud surrounding the pad, an opening in the shroud, and a dust discharge tube having an inner end in communication with the opening and an outer end on the dust discharge tube end extending at an acute angle to the face of the pad. An orbital sander wherein the pad is supported from the sander housing by columnar units located on opposite sides of the motor. A bore in the motor shaft conducts compressed air through the chamber housing the bearings which support the spindle which mounts the pad.

Owner:CHAO HAO CHIEN

Endoluminal prosthesis

ActiveUS8702787B2Increase flexibilitySmall shapeStentsBlood vesselsProsthesisUltimate tensile strength

An endoluminal prosthesis is provided that includes a tubular graft and an expandable annular support structure. The annular support structure is coupled to the tubular graft so that the graft and support structure, in combination, provide columnar support while maintaining prosthesis flexibility. The prosthesis has sufficient strength and durability to withstand loads applied during deployment and sufficient flexibility to permit implant in a sealing arrangement within a tortuous body lumen. An embodiment according to the invention provides a plurality of annular structures with staggered, longitudinally overlapping apices of undulating structures. One embodiment relates to tubular grafts for endoluminal placement within a body lumen, including blood vessels, and for the treatment of abdominal and other aneurysms.

Owner:MEDTRONIC VASCULAR INC

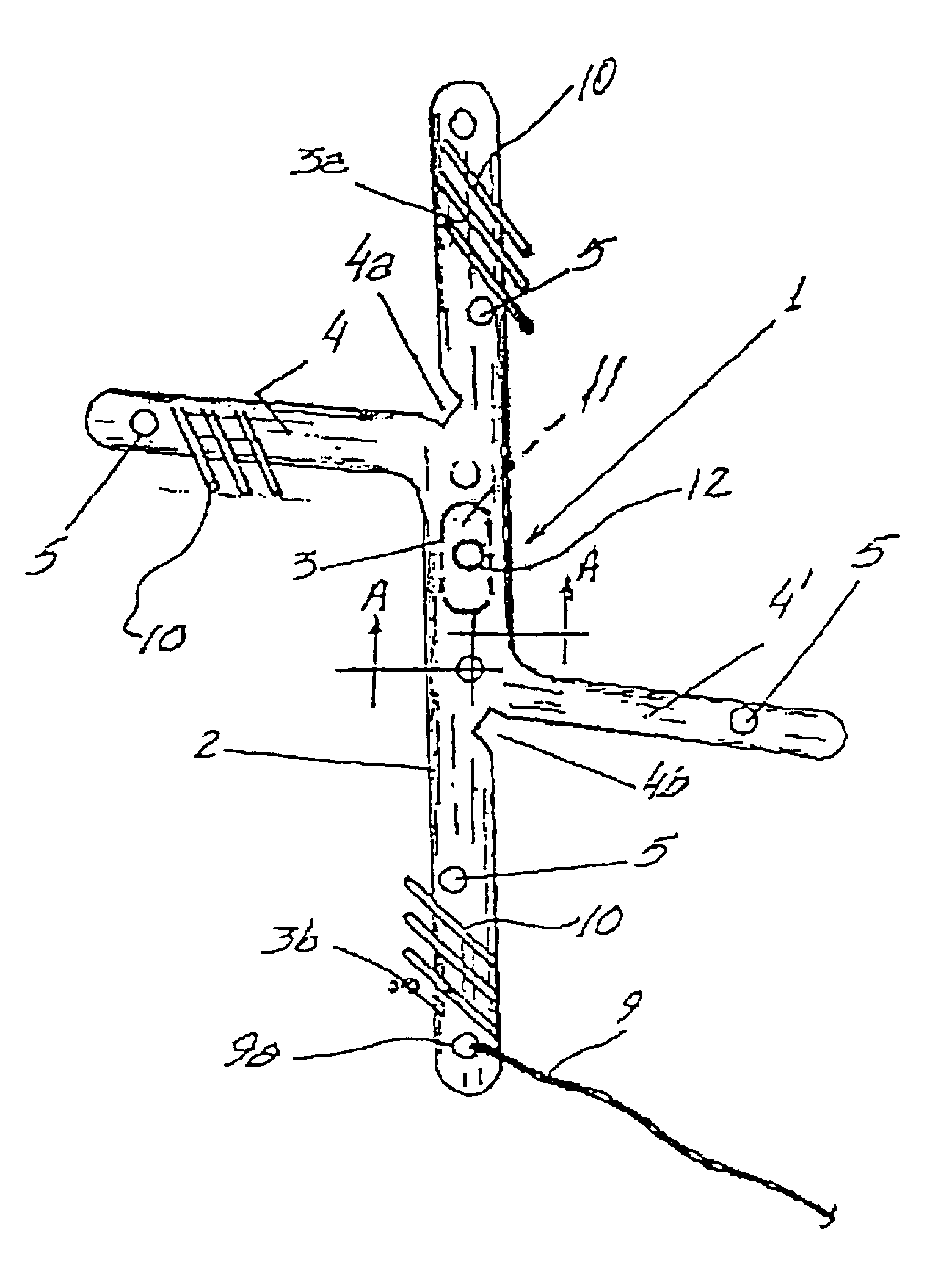

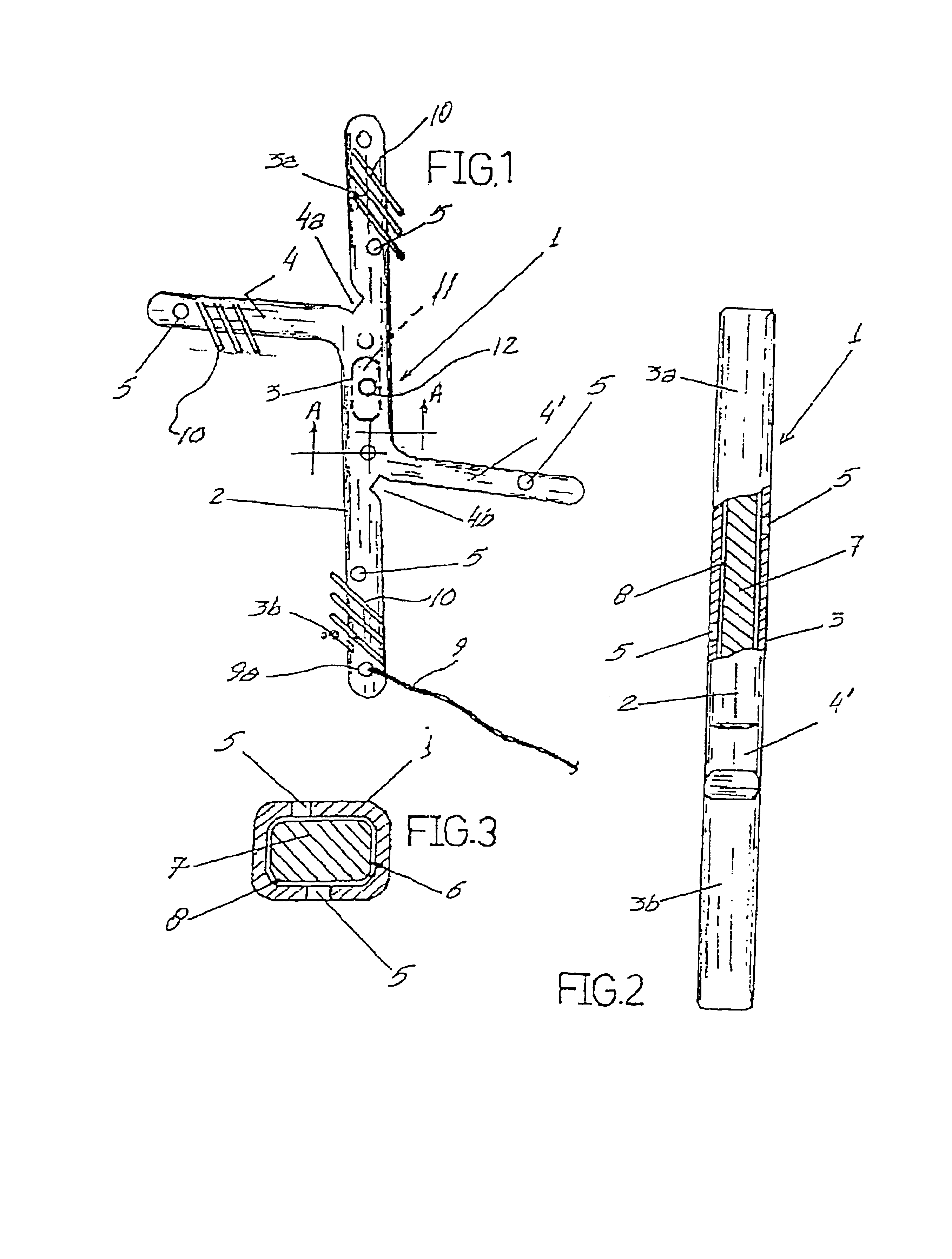

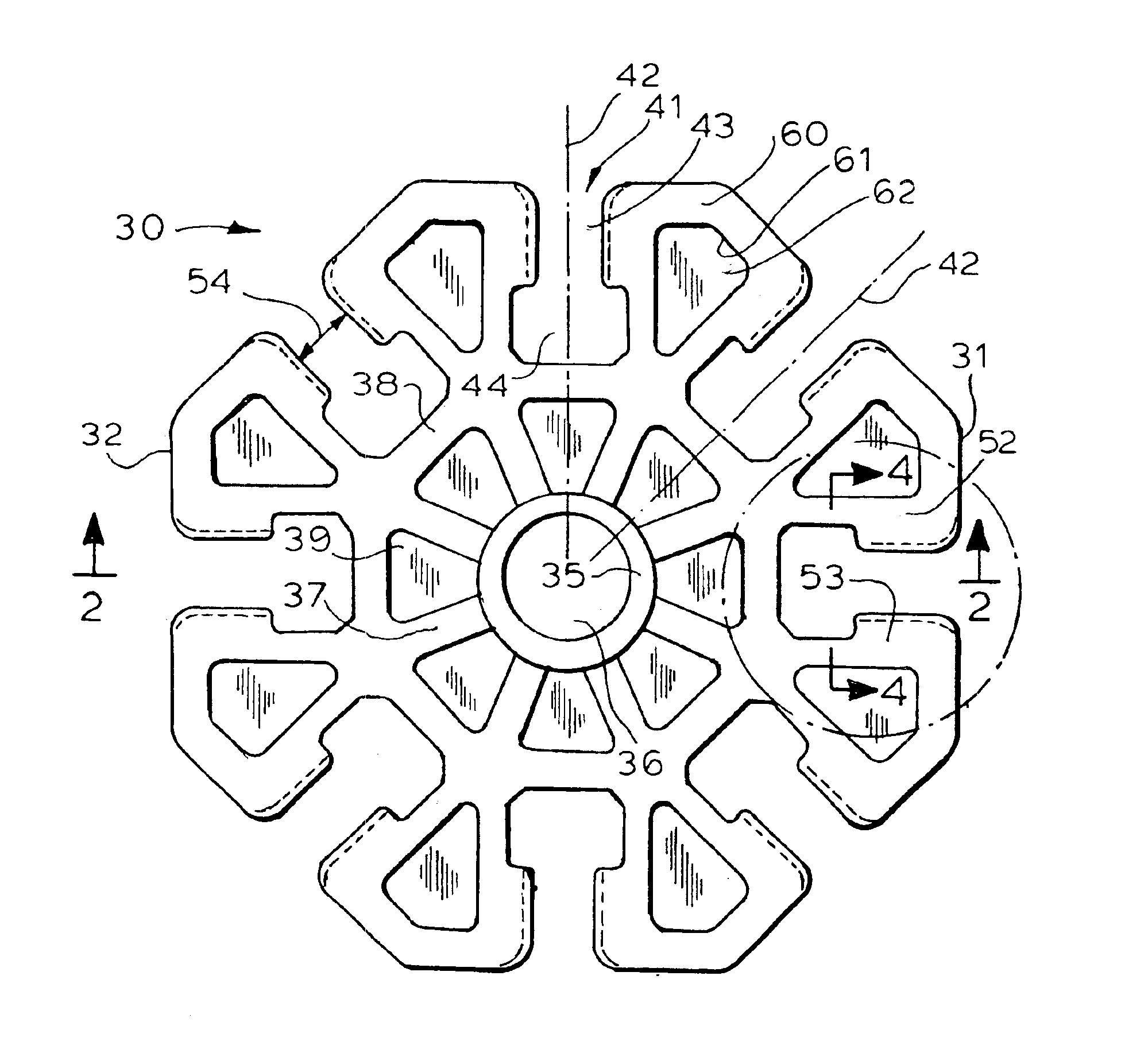

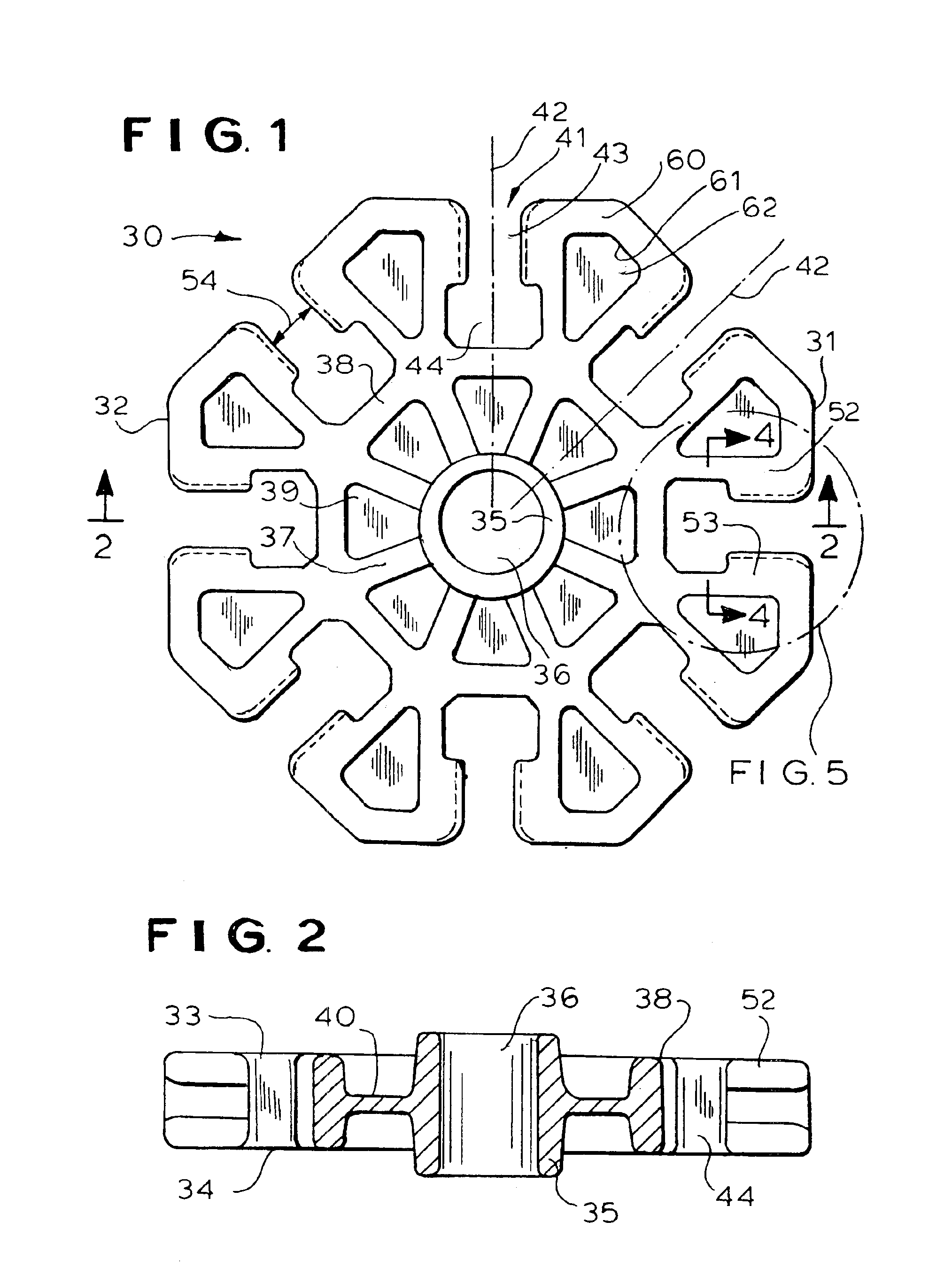

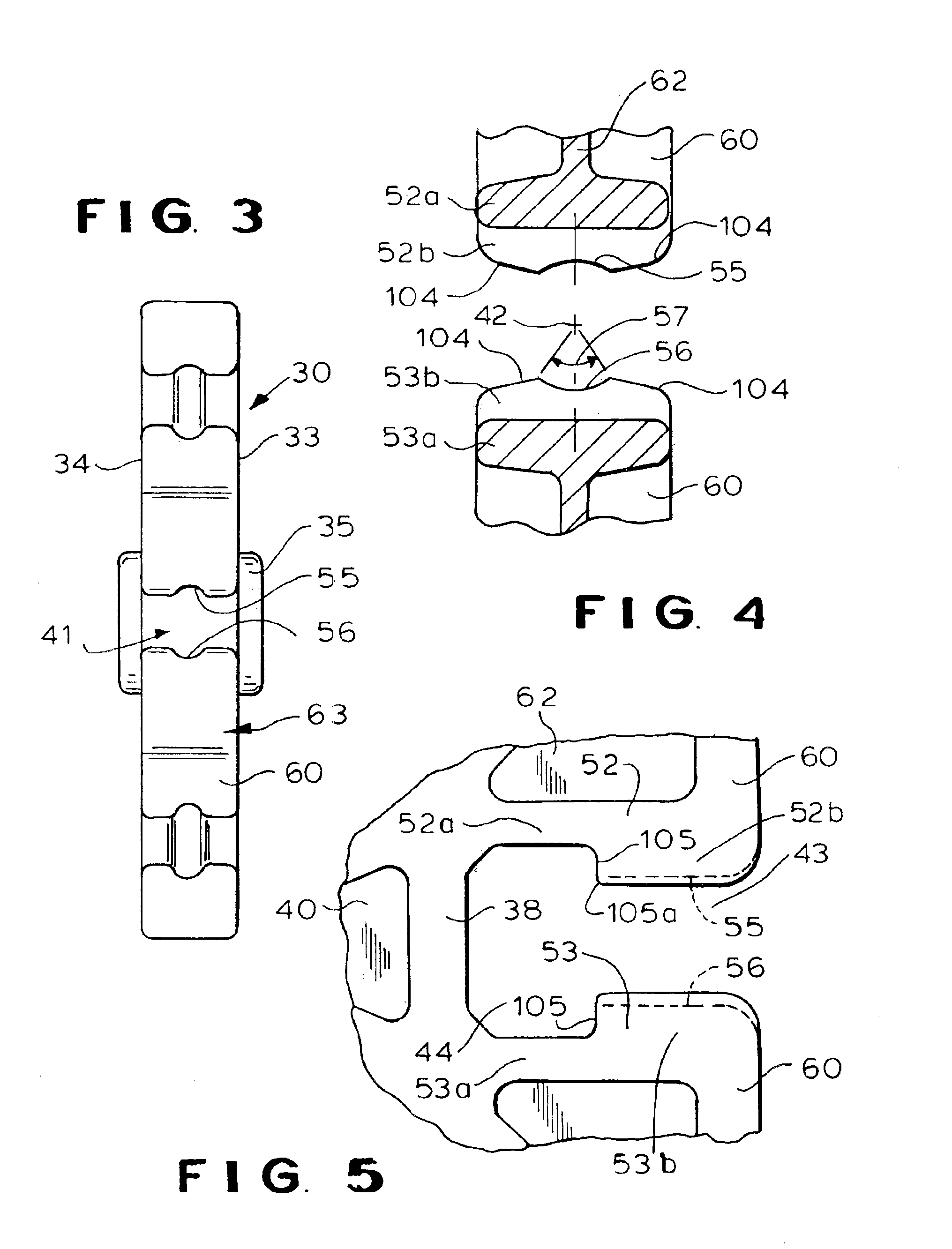

Rod and connector toy construction set

A rod and connector toy construction set, especially for use by young children. Connector elements, are formed with one or more rod-gripping sockets arranged radially with respect to a hub. The sockets are open at opposite sides, enabling lateral insertion and removal of rods. The connector elements, which are relatively large for easy handling by small children, are formed of a soft and pliant plastic material, to facilitate assembly and disassembly of rods with the connector elements by small hands. The rods generally are formed of a plastic material harder and stiffer than the connector material to accommodate easy handling of the rods during assembly and disassembly and to provide adequate strength in an assembled structure. The rods include enlarged, generally cylindrical end portions and adjacent neck portions of reduced diameter. The connector sockets include inner portions, configured to receive and closely confine the rod end portions, and outer portions arranged to receive and snuggly grip the rod neck portions, such that rods are held in axial alignment with the connector sockets.

Owner:BASIC FUN

Latex emulsions and coating compositions formed from latex emulsions

ActiveUS9181448B2Simple processSolve the lack of adhesionLinings/internal coatingsCoatingsEmulsionStrong acids

Latex emulsions are disclosed which can be used in the formation of coating compositions that are not water sensitive, have good blush resistance and retortability. In some embodiments, the coating compositions are used to coat substrates such as cans and packaging materials for the storage of food and beverages. Coating compositions of the invention may be prepared by polymerizing at least one ethylenically unsaturated monomer component, a stabilizer comprising a strong acid and an initiator in a carrier to form an emulsion, polymerizing the emulsion with at least one different ethylenically unsaturated monomer component to prepare the composite latex emulsion, and reacting the composite latex emulsion with a neutralizer to form the coating composition. Methods of coating substrates with the coating compositions, and substrates coated with the coating compositions are also disclosed.

Owner:AKZO NOBEL COATINGS INT BV

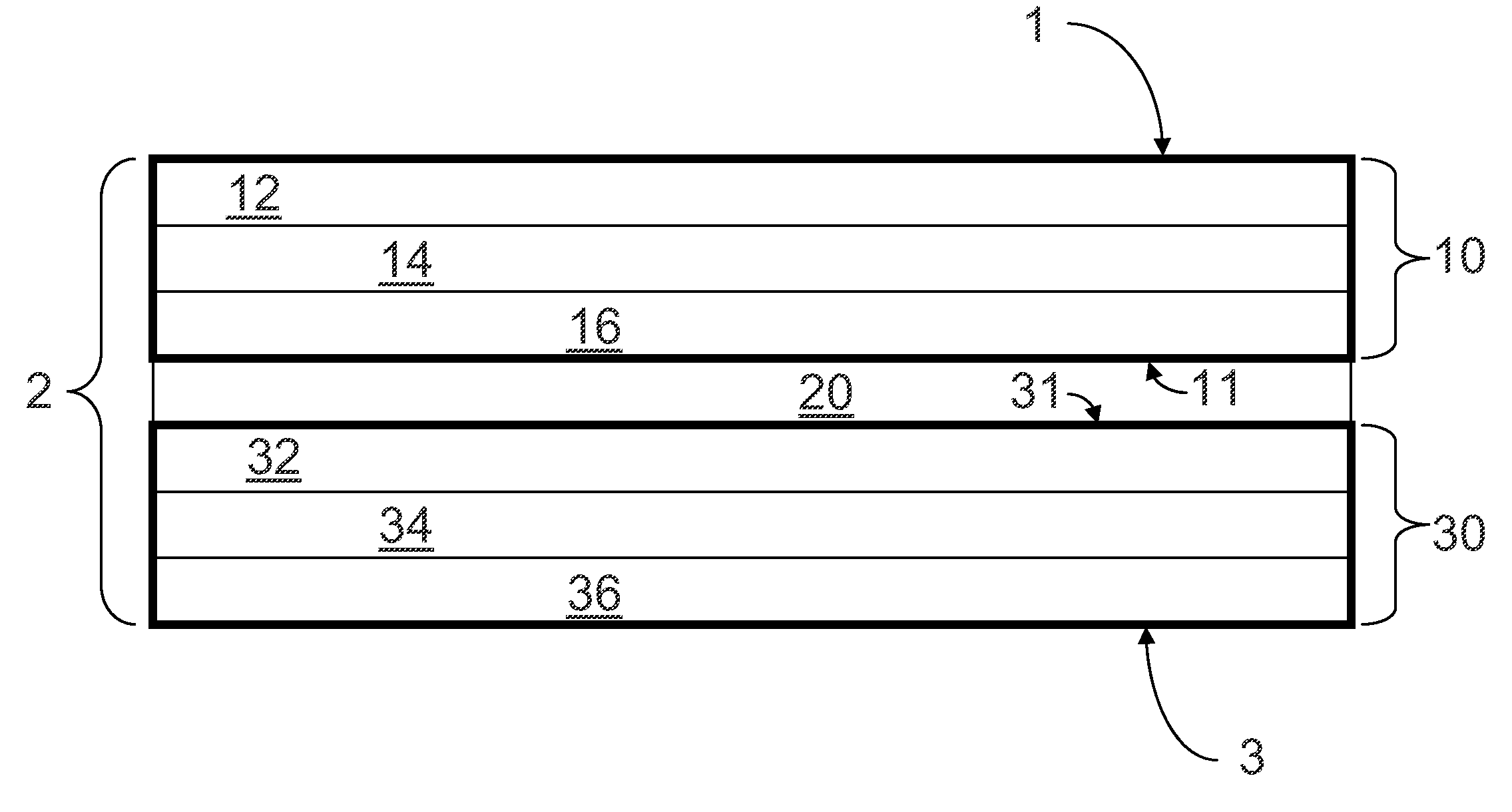

Barrier Film for Use in Multilayer Thermoformable Materials and Shaped Articles and Containers Made Therefrom

InactiveUS20130142975A1Inhibits short-term permeationLower surface energySynthetic resin layered productsGlass/slag layered productsInter layerPermeation

The disclosure relates to a laminated, thermoformable barrier film useful as a peelable surface liner, such as in containers and other shaped articles. The laminated film includes at least two layers, including a distal layer and a medial layer. The medial layer includes an odor-resistant polymer barrier layer that inhibits passage of gases and odors therethrough. The distal layer includes a polymer layer that inhibits permeation of a liquid through to distal layer from a contact face thereof to the barrier layer. Optionally, the distal layer can include a scratch resistant layer. The laminated film can also include a proximal layer that includes a layer of a pliable polymer. The laminated film can be included as a surface liner, or stack of surface liners, on a thermoformed article or on a sheet that can be thermoformed. The laminated sheets have multiple uses, including as liners for food service containers. In such containers, the barrier layer of the laminated sheets can inhibit penetration of the liner by odors or tastes from food items contained therein and can also prevent liquid saturation of the barrier layer of the sheets, which could otherwise limit the odor-resistant properties of the sheets.

Owner:CONVERTER MFG LLC

Ergonomically friendly orbital sander construction

InactiveUS6979254B1High strengthSufficient lateral flexibilityRotary piston pumpsPortable grinding machinesSanderAcute angle

A random orbital sander including a housing, a motor having a vertical axis in the housing, a pad coupled to the motor, a face on the pad extending substantially perpendicularly to the vertical axis, a shroud surrounding the pad, an opening in the shroud, and a dust discharge tube having an inner end in communication with the opening and an outer end on the dust discharge tube end extending at an acute angle to the face of the pad. An orbital sander wherein the pad is supported from the sander housing by columnar units located on opposite sides of the motor. A bore in the motor shaft conducts compressed air through the chamber housing the bearings which support the spindle which mounts the pad.

Owner:CHAO HAO CHIEN

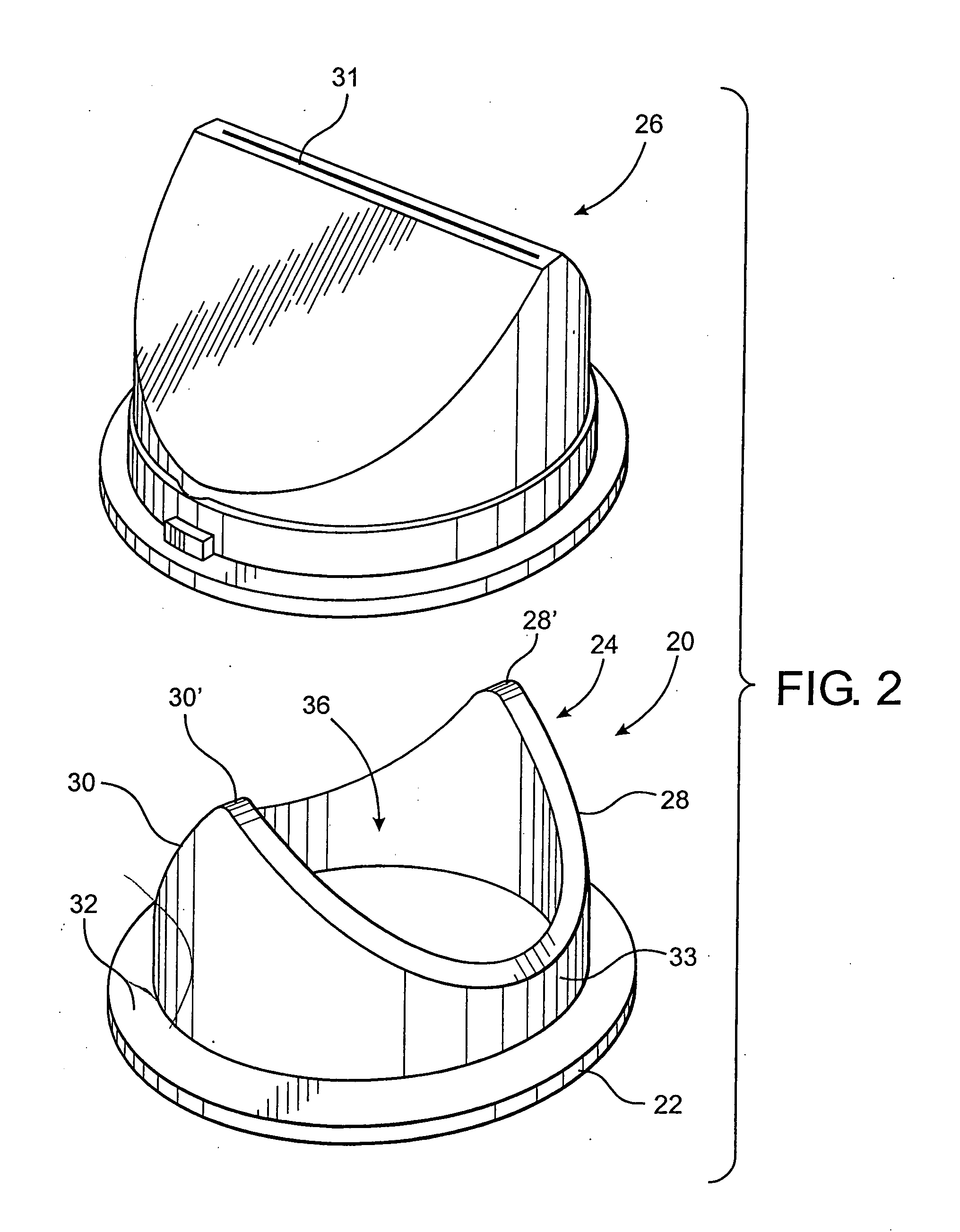

Seal positioning assembly

ActiveUS20050113757A1Reduce frictional contactExhaust fastOperating means/releasing devices for valvesCannulasPERITONEOSCOPEEngineering

An assembly structured to selectively orient a seal between an open position and a closed position. The assembly includes an expander structure disposable into a seal open or a seal closed orientation by being rotated or otherwise movable into and out of forced engagement with predetermined portions of the seal structure. The seal open orientation disposes the seal structure out of engagement with an instrument passing there through and may also facilitate a rapid venting of insufflation gas from an inflated body cavity, such as when the seal positioning assembly is used with a trocar assembly involved in the performance of laprascopic or like surgery. A biasing assembly may be connected to the seal structure to bias it in a normally closed position in the absence of an instrument disposed within the seal structure.

Owner:TELEFLEX MEDICAL INC

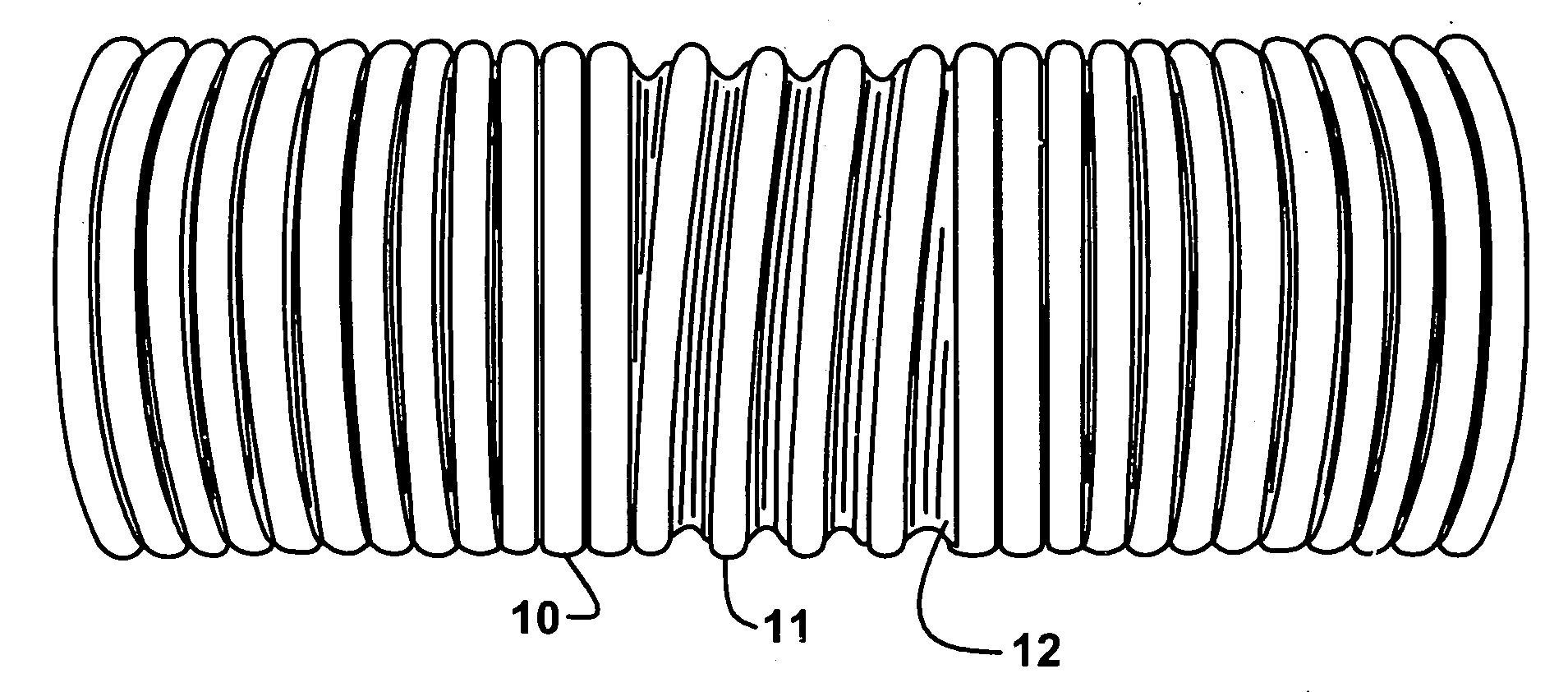

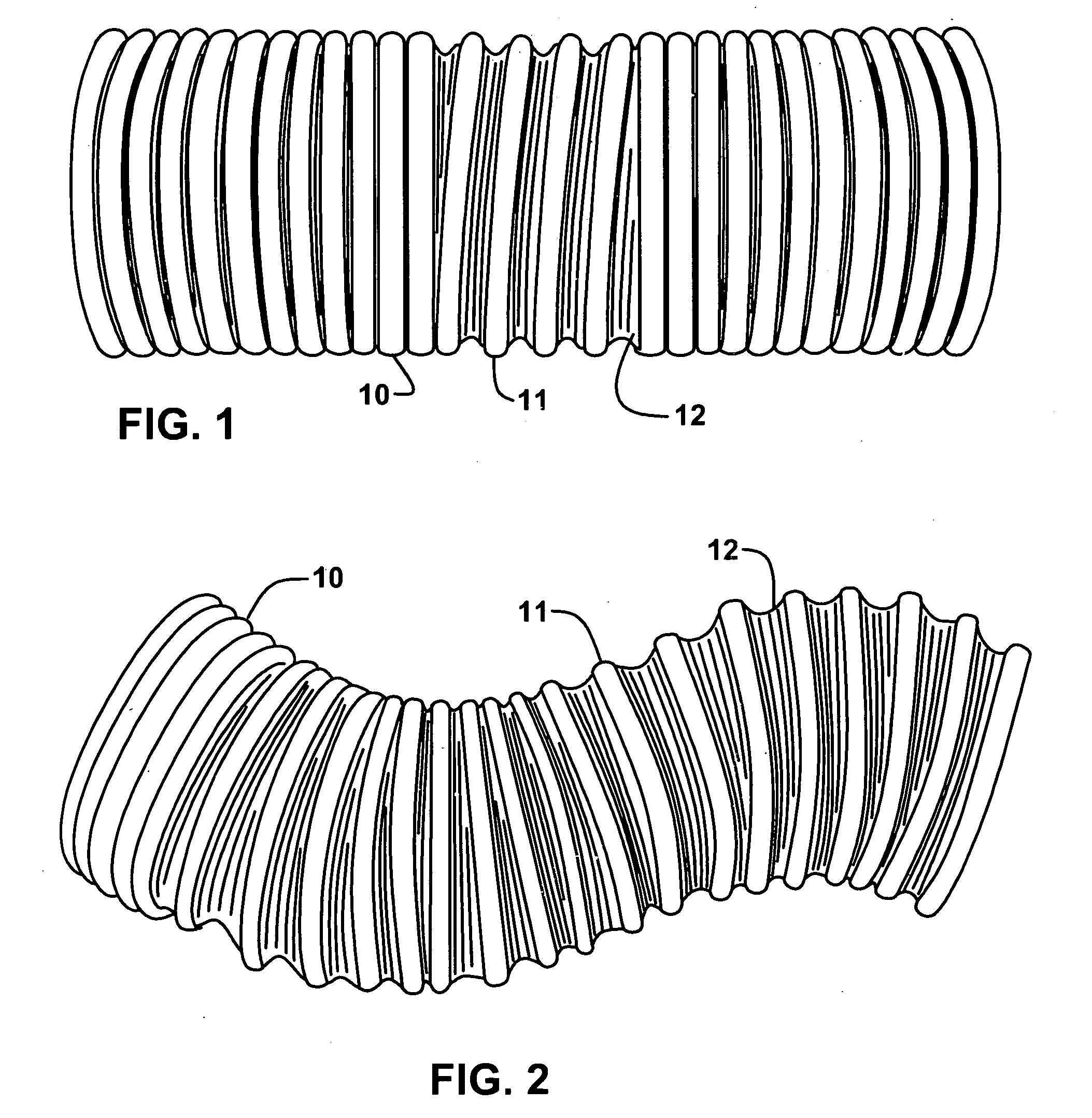

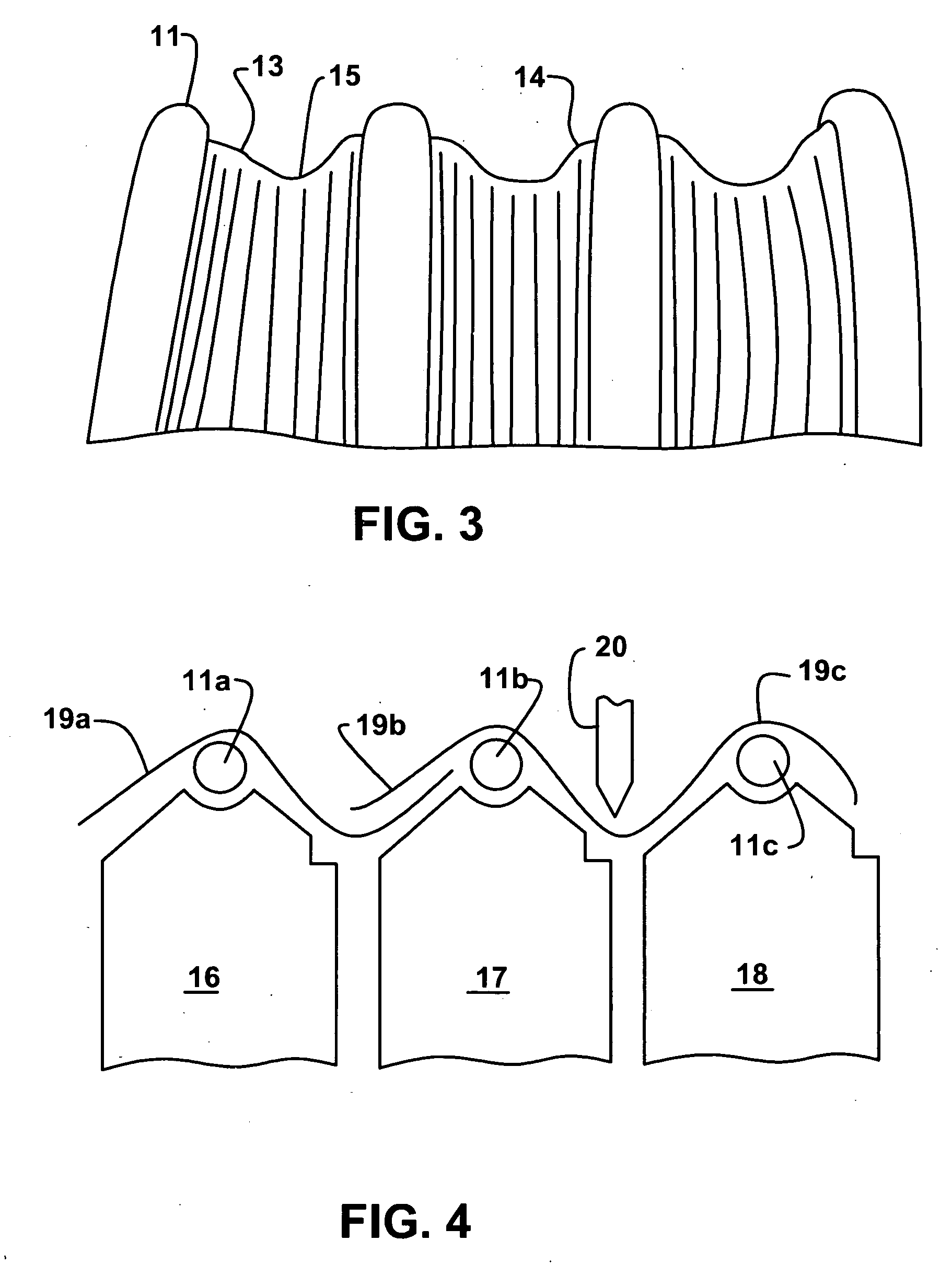

Crush resistant stay put hose

InactiveUS20100108170A1Improve wear resistanceImprove efficiencyFlexible pipesTubular articlesLiving hingeBiomedical engineering

A crush resistant and stay put hose is provided. There is a helical member having a plurality of coils and a wall surface of one or more thermoplastic polymer layers. The layers extend from one coil to the next and the wall surface between the coils has at least one living hinge. When one portion of the hose is in an extended condition, the hose remains in the extended condition without reverting to the unextended condition. Methods of making the hose are also disclosed.

Owner:FLEXIBLE TECH INC

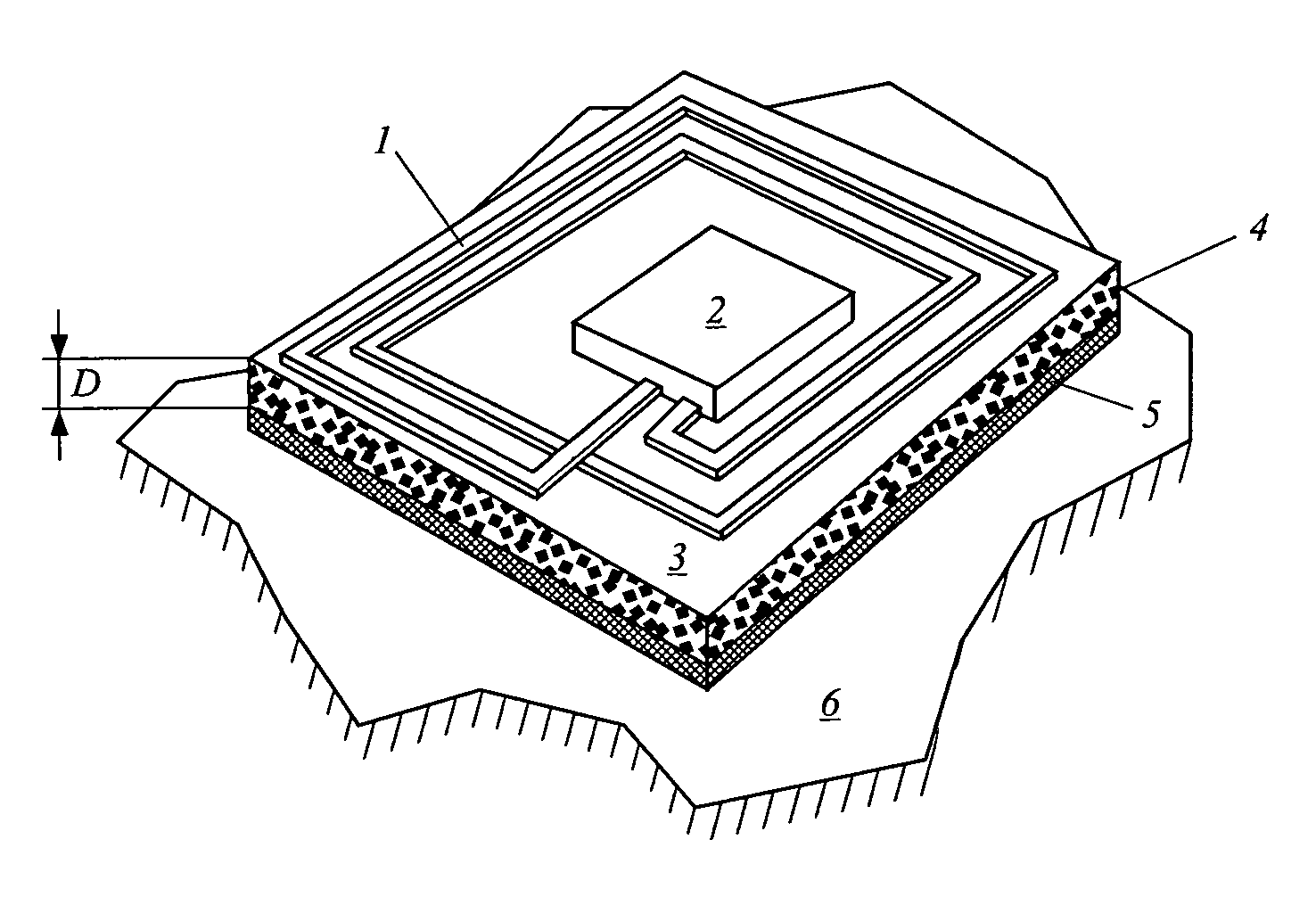

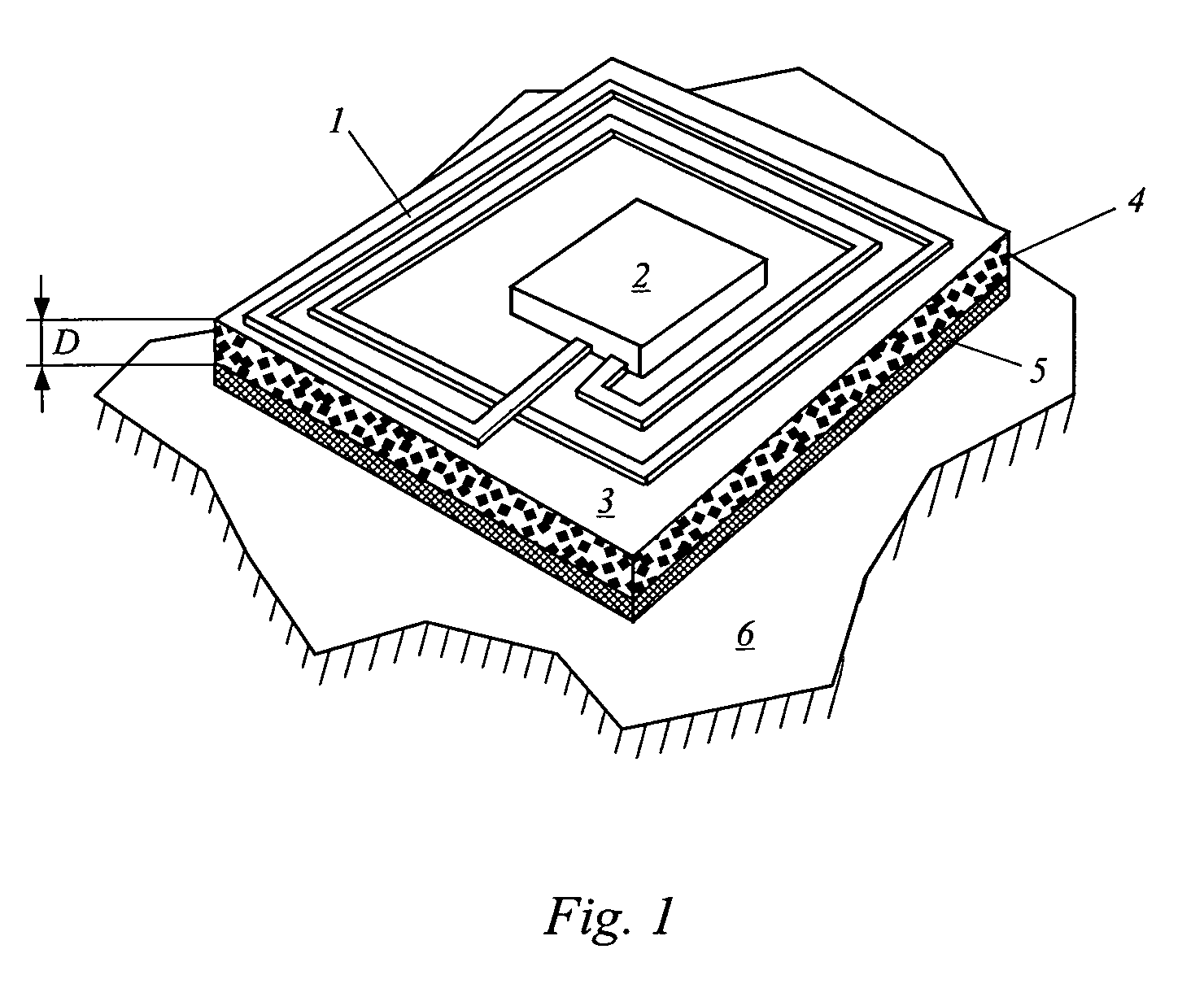

Flexible transponder label which is readable on conductive surfaces

ActiveUS7205899B2Good protectionSolve the lack of flexibilityRecord carriers used with machinesBurglar alarm by hand-portable articles removalElectrical resonanceSemiconductor chip

A transponder label includes an antenna coil, a semiconductor chip, and a single layer film, which acts both as a carrier film and as a shield against the induction of counter magnetic fields in the metallic base layer. The semiconductor chip acts both as a capacitor element of the transponder resonant circuit and as a memory component. The film is a flexible matrix including embedded ferrite particles, which give the film soft magnetic characteristics. The permeability value of the film is adapted to its thickness and the material of the base layer, the value being higher for a reduced thickness. The resonant frequency of the transponder resonant circuit formed from the antenna coil and semiconductor chip lies within a narrow target frequency range, once the label has adhered.

Owner:SCHREINER GRP GMBH & CO KG

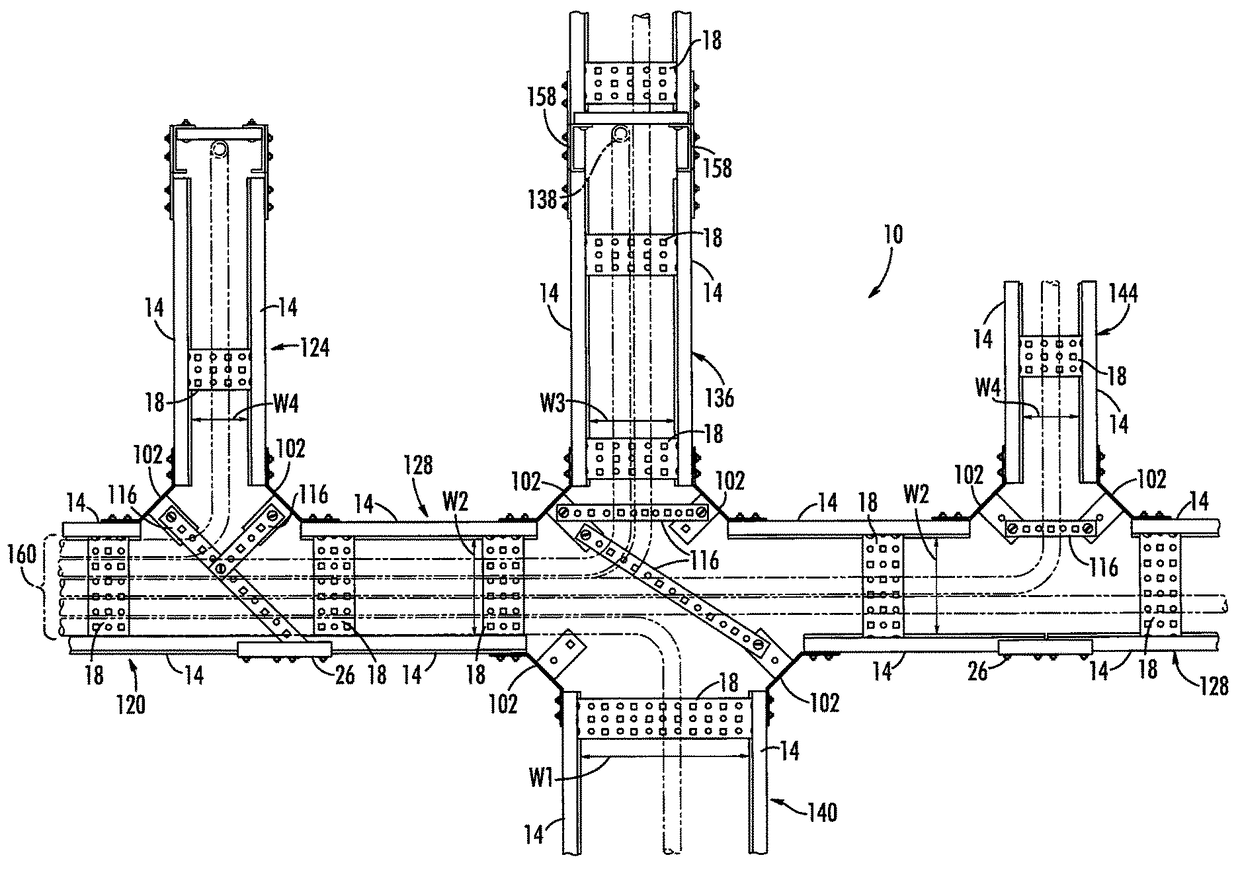

Cable tray system

ActiveUS9841123B1Sufficient capabilitySolve the lack of flexibilityPipe supportsElectrical apparatusCable trayModularity

A collection of components for a cable tray system provide the components and basic hardware for assembling and installing a cable tray that can change direction in three dimensions to avoid obstacles or other cables' trays while negotiating a designated space. Components of the cable tray system may be modular, that is, pre-configured for ease of assembly, such as vertical kits and horizontal bend kits, while others are supplied in lengths for cutting them to fit jobsite requirements, such as rails and rungs. Both components provide an inherent framework that facilitates conceptualization and construction of a cable tray system at the jobsite with flexibility and simplicity to allow the present cable tray system to be employed more efficiently and accurately.

Owner:JAMES C WHITE CO INC

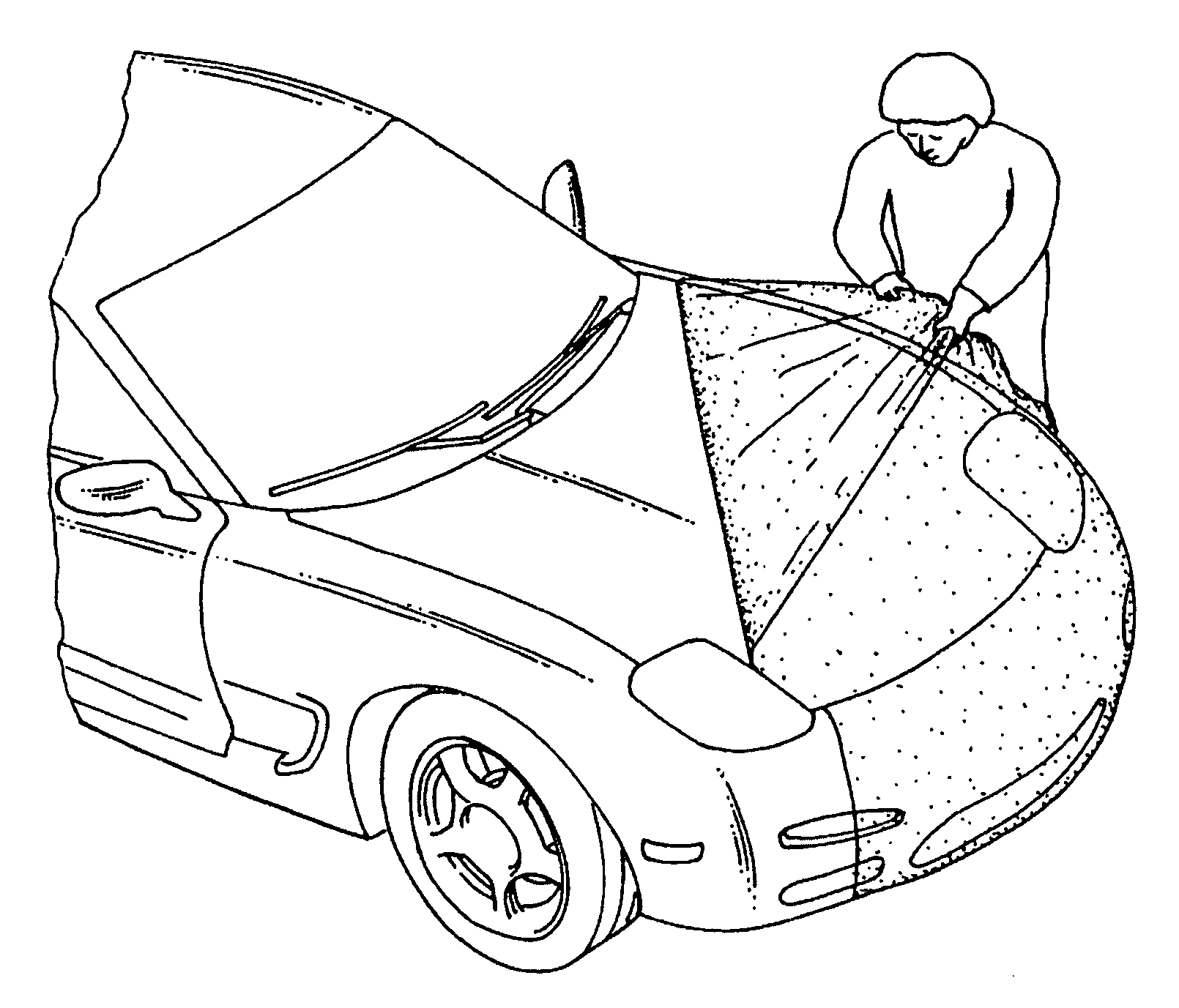

Peel-off coating compositions

ActiveUS8263231B2Easy to disassembleLow costNon-fibrous pulp additionAlkaline-earth metal silicatesEmulsionAcid rain

Methods and compositions are provided for protecting exterior surfaces of automobiles and other products, or components of products, against abrasion, abrasive dust, water, acid rain, etc. The methods involve applying to a surface a protective coating composition comprising a polyvinyl butyrate emulsion and a relatively inert extender. The emulsion is dried to form a water-resistant protective coating that can be removed from the underlying surface by peeling when no longer desired.

Owner:CAL WEST SPECIALTY COATINGS

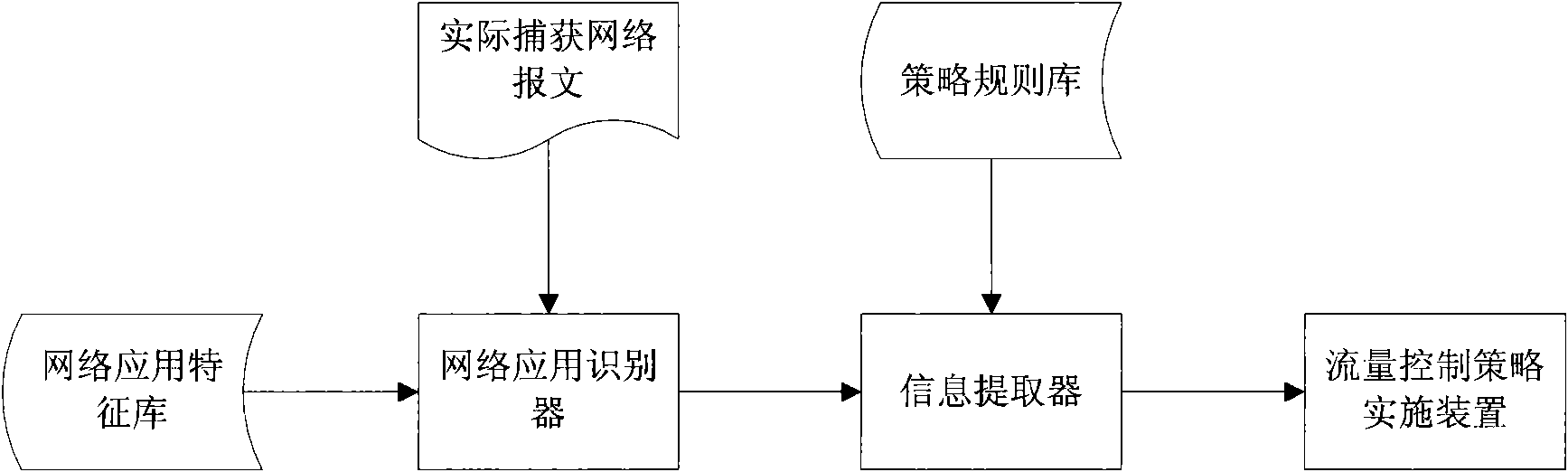

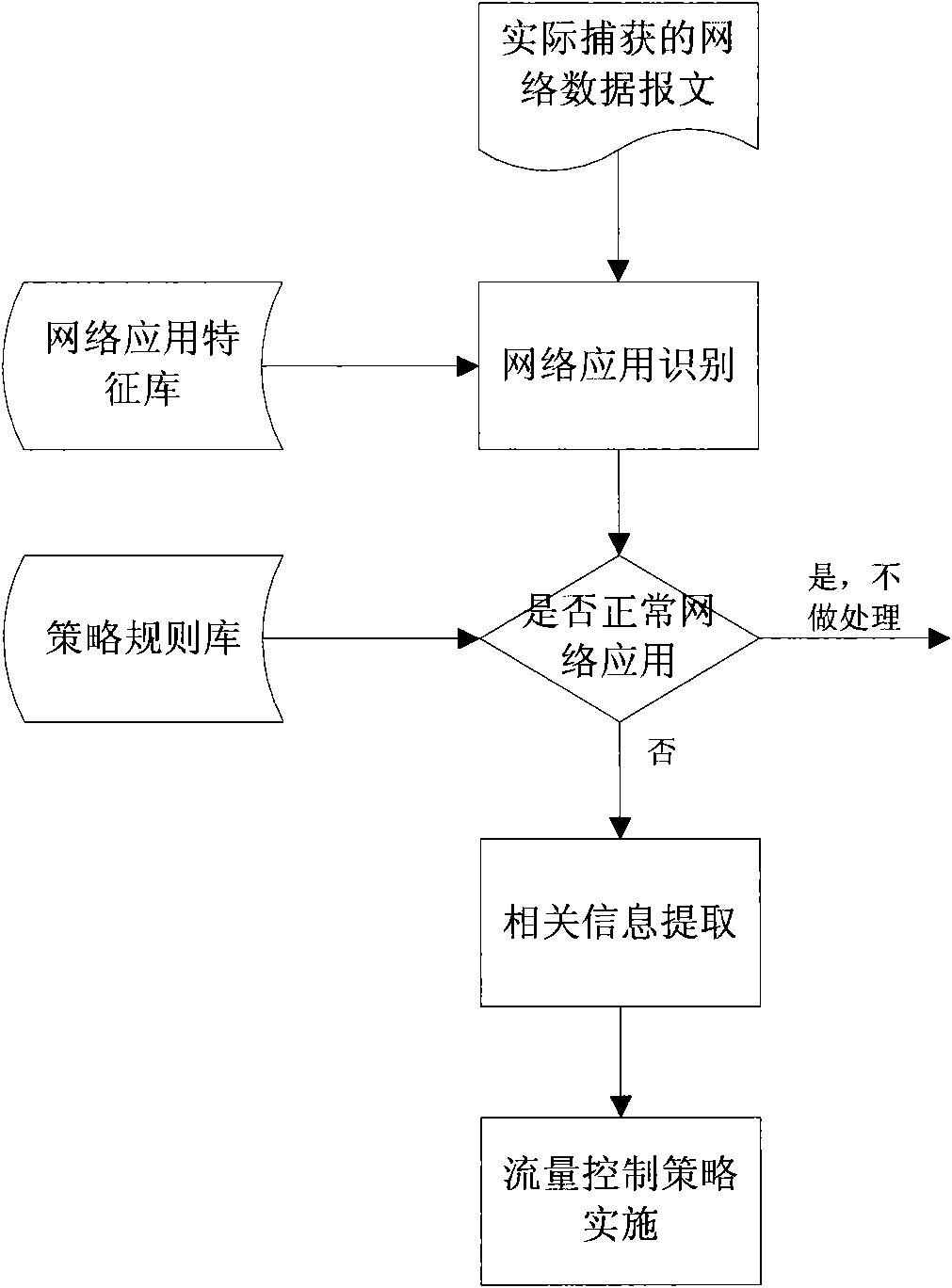

Universal traffic control method and system

InactiveCN101562560ASolve the lack of flexibilityAvoid wastingData switching networksTraffic capacityAutomatic control

The invention relates to a universal automatic control method of network application traffic and a system thereof. The system comprises a network application feature base, a network application identifier, a policy rule base, an information extractor and a traffic control policy implementation device. Operation of the system comprises the following steps: a network application identification step, a related information extraction step and a traffic control policy implementation step. The system solves a problem that a traditional product is short of flexibility for network application traffic control, realizes real-time implementation of corresponding traffic control policy according to different rules in an actual network environment, can establish and implement proper traffic management policies according to actual requirements of user network condition, and has the characteristics of high speed, high accuracy and the like.

Owner:BEIJING VENUS INFORMATION TECH

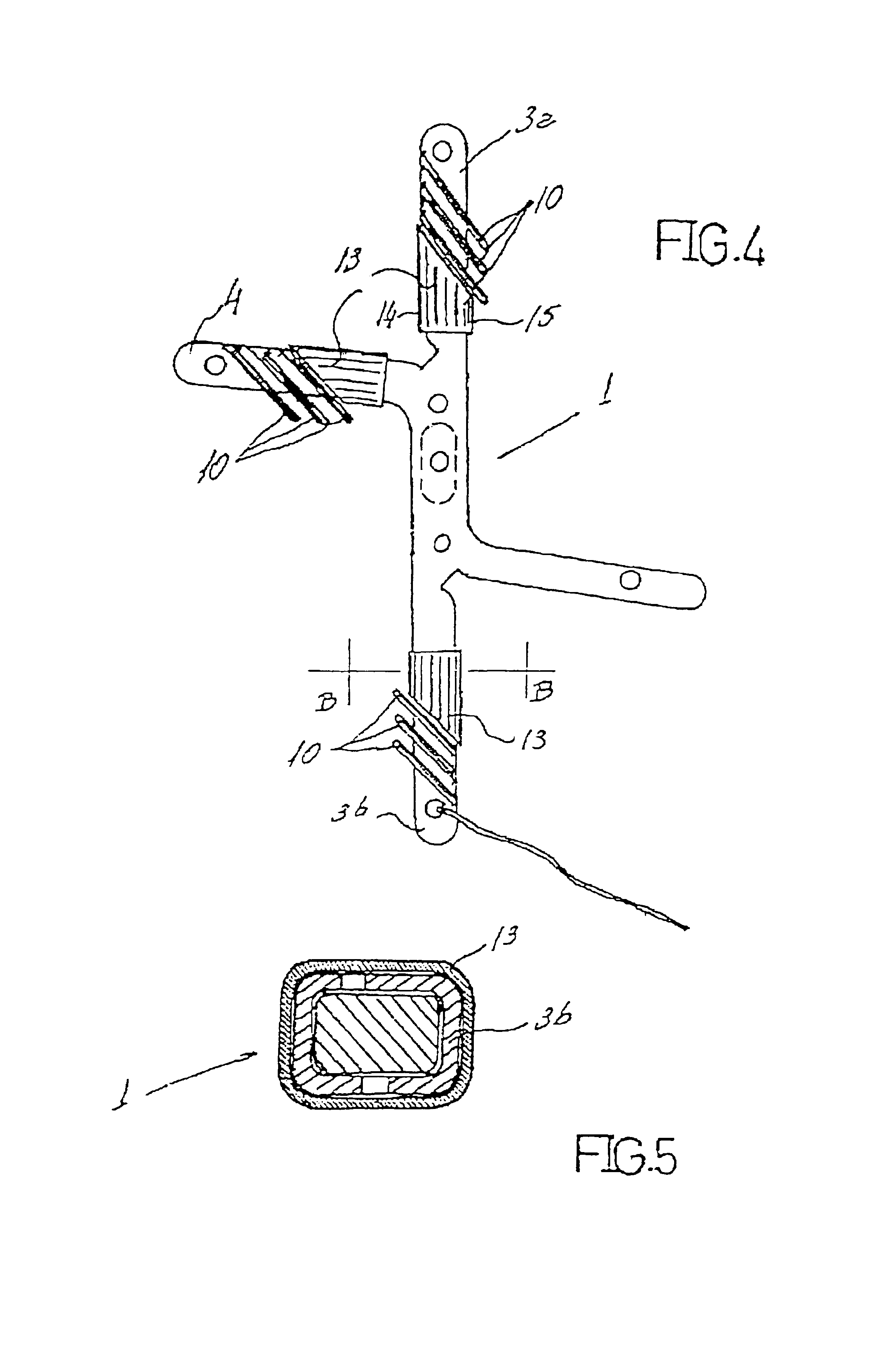

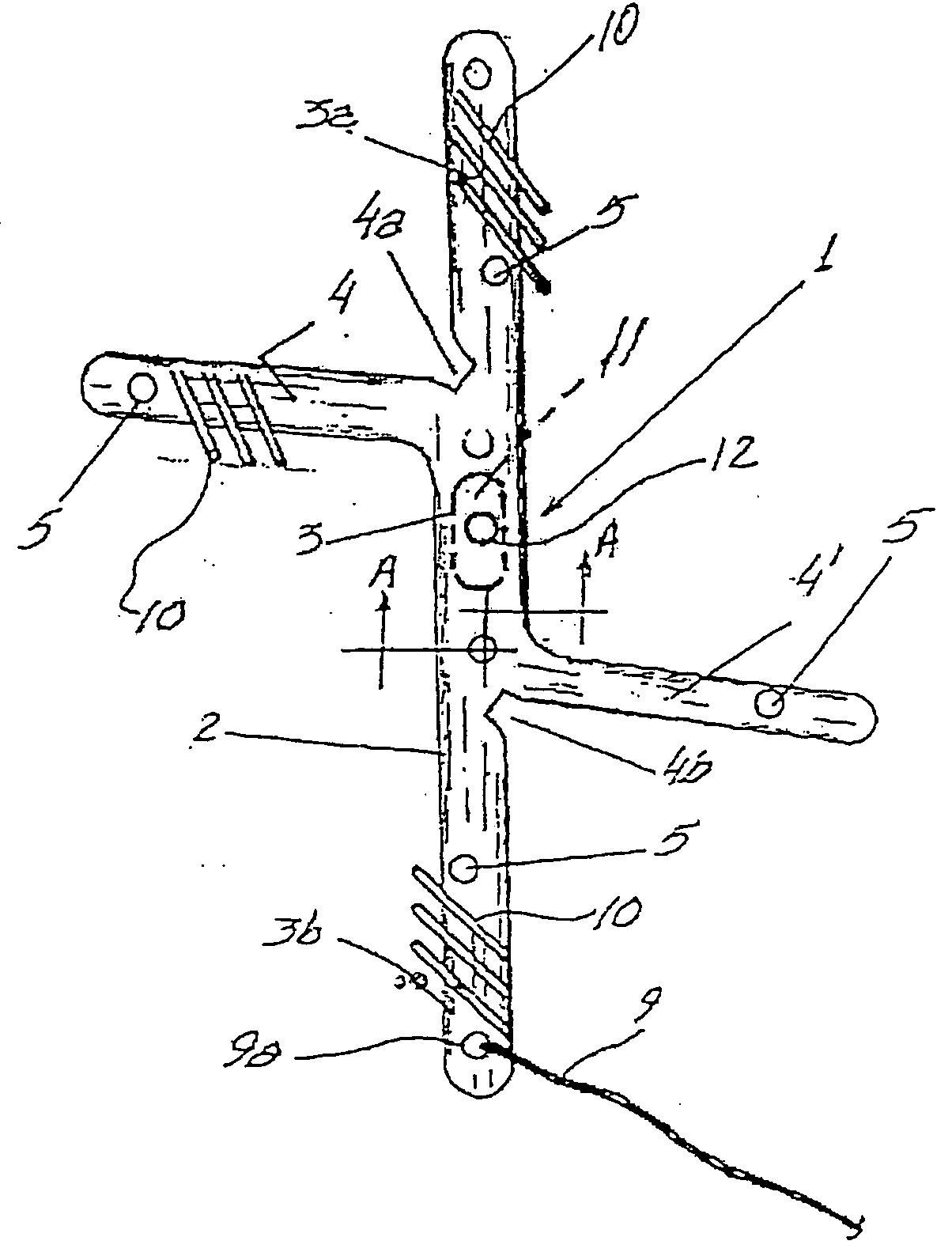

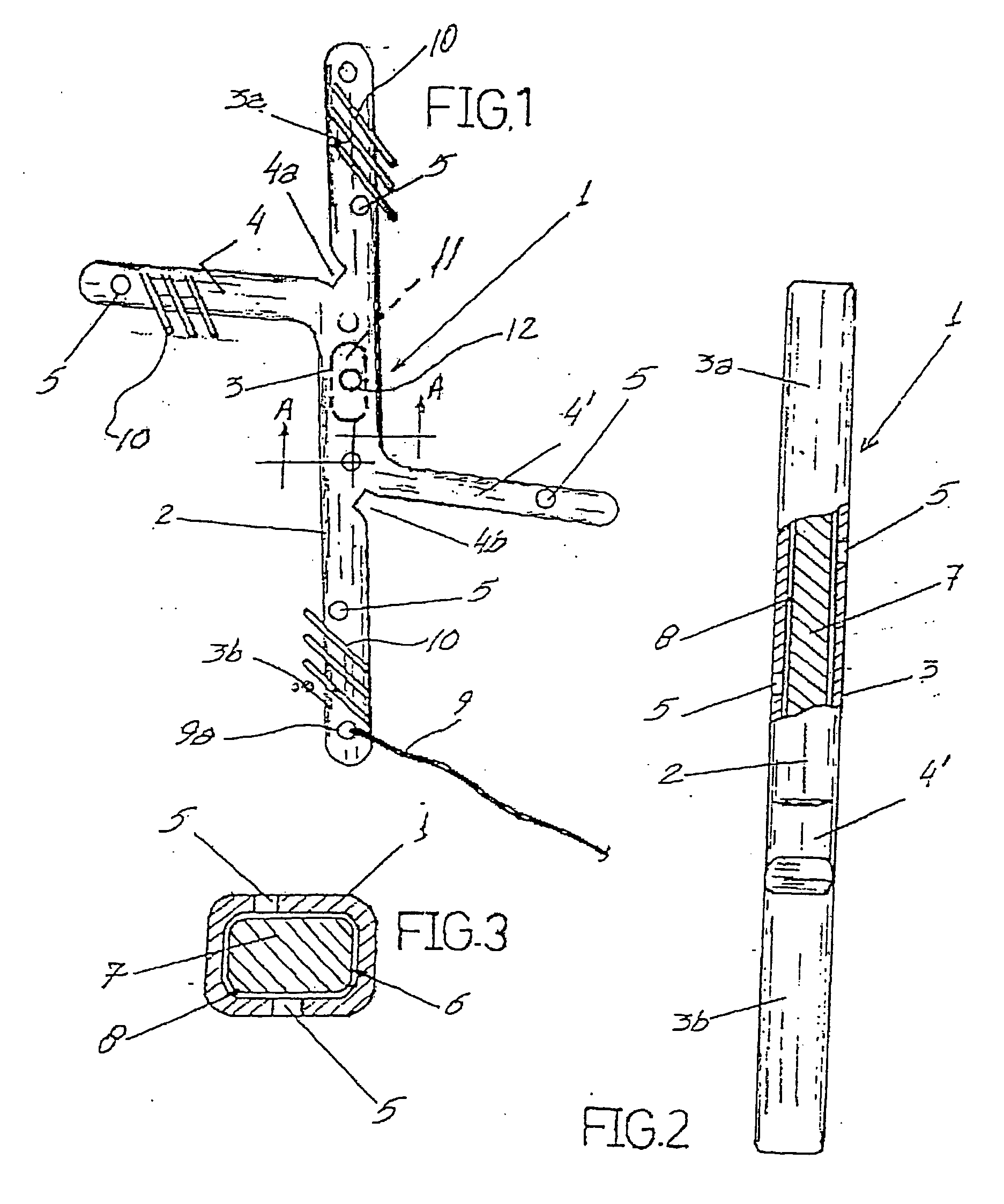

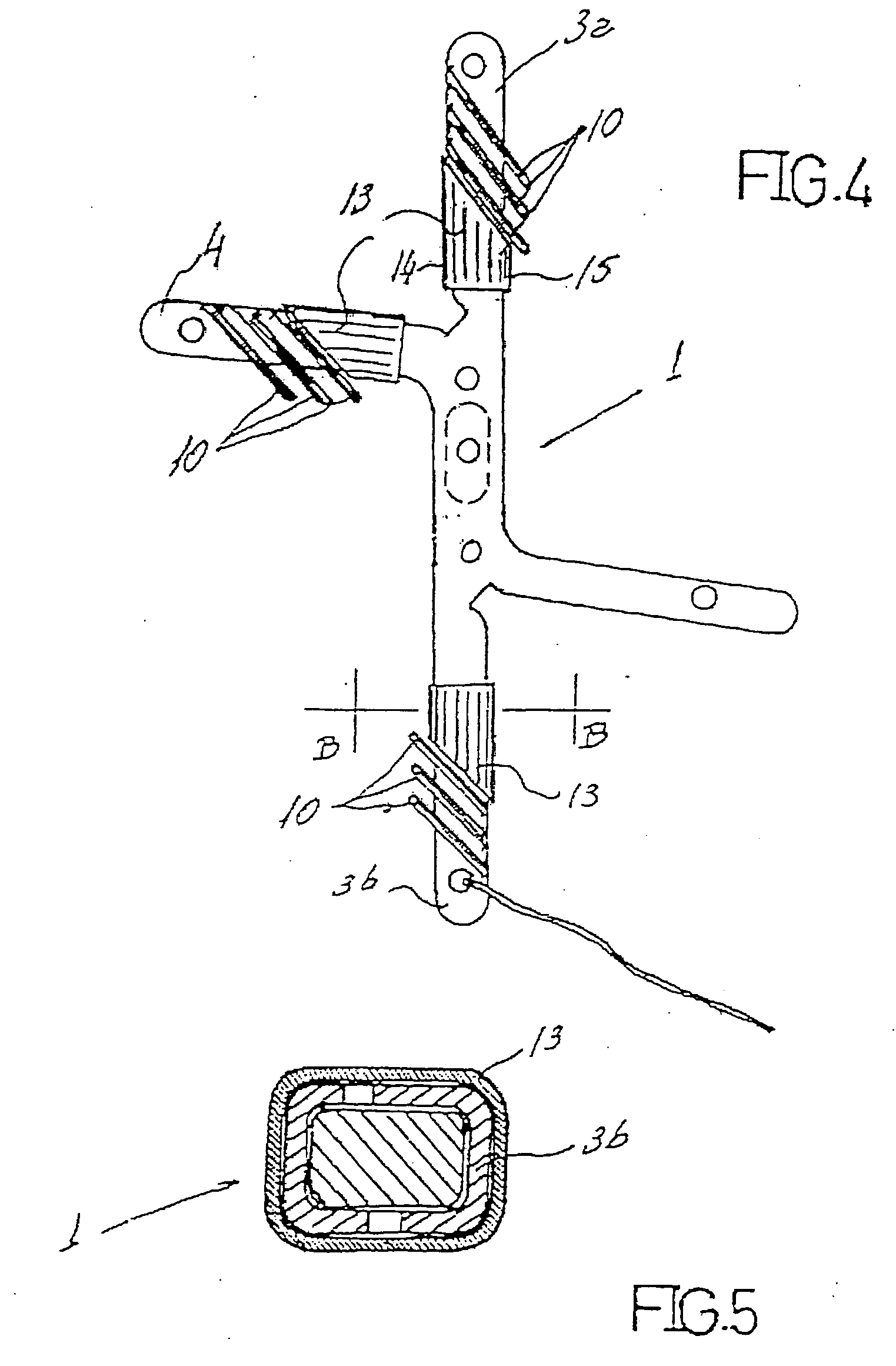

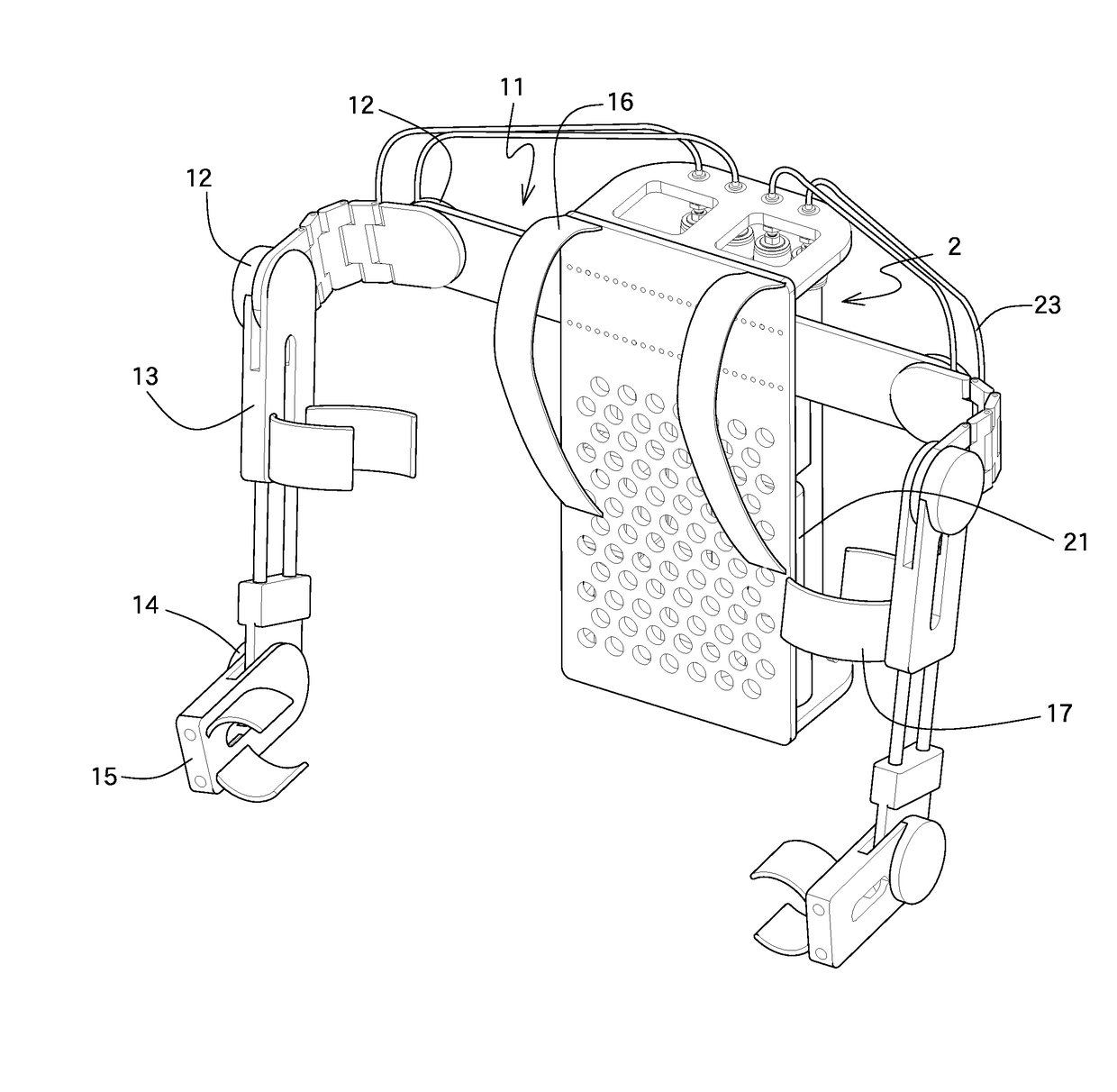

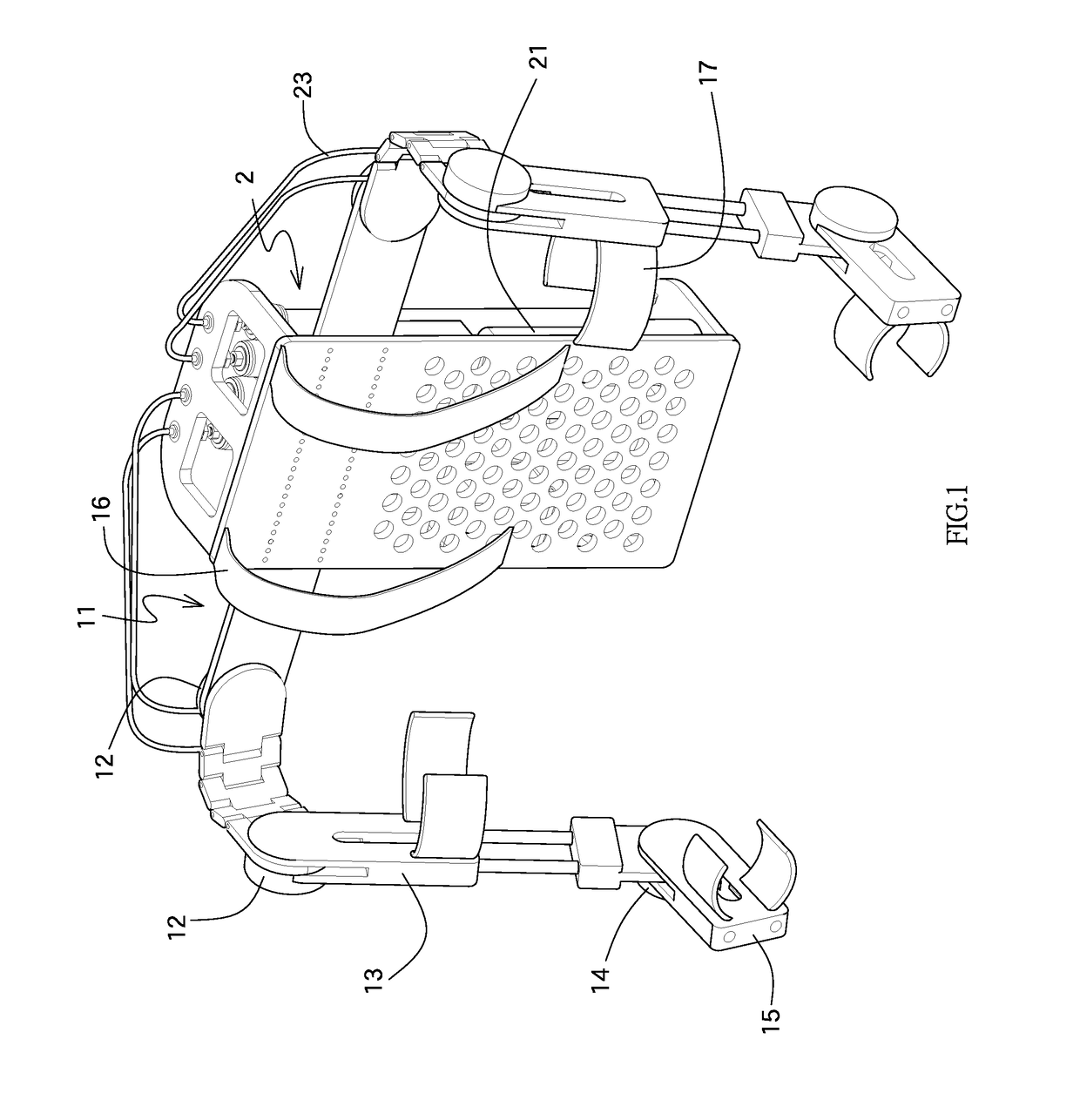

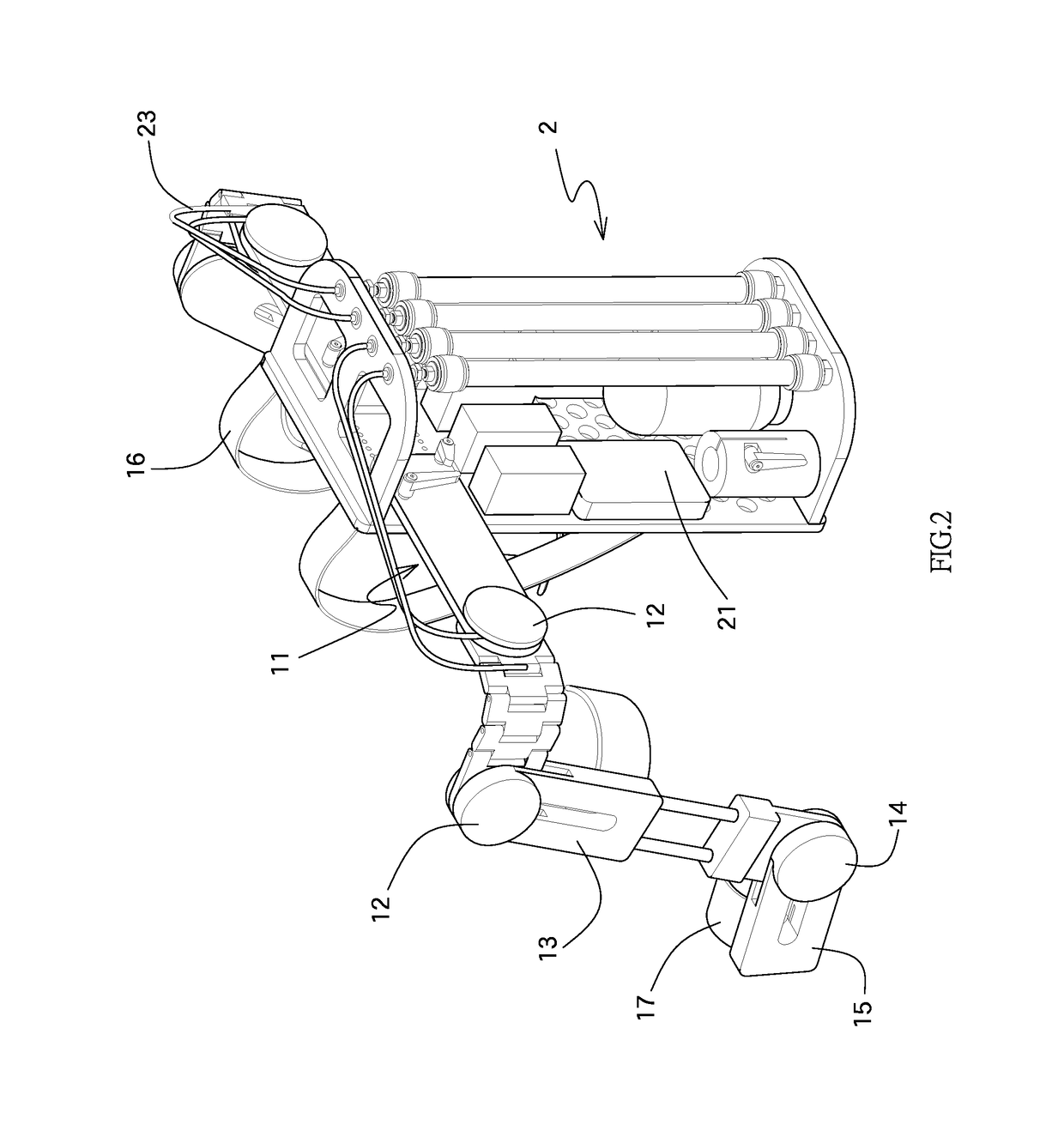

Exoskeleton apparatus driven by pneumatic artificial muscle with functions of upper limb assist and rehabilitation training

ActiveUS20170296418A1Action providedSolve the lack of flexibilityProgramme-controlled manipulatorChiropractic devicesPressure senseEngineering

An exoskeleton apparatus driven by a pneumatic artificial muscle with functions of upper limb assist and rehabilitation training includes an upper limb frame, a shoulder joint mechanism, and an elbow joint mechanism which are driven by utilizing a processing unit, a first angle sensing unit, a second angle sensing unit, a first proportional pressure valve, a pressure sensing unit and a pneumatic muscle device. The exoskeleton apparatus can be independently used as an upper limb exoskeleton assistive device or can be combined to form an upper limb exoskeleton rehabilitation training system to simulate the upper limb movements in daily life through the upper limb frame to assist with the movements of the wearer's upper limbs, accomplishing the rehabilitation training of each upper and lower arm joint and neurological function.

Owner:LUNGHWA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com