Patents

Literature

3675results about "Grinding machine components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

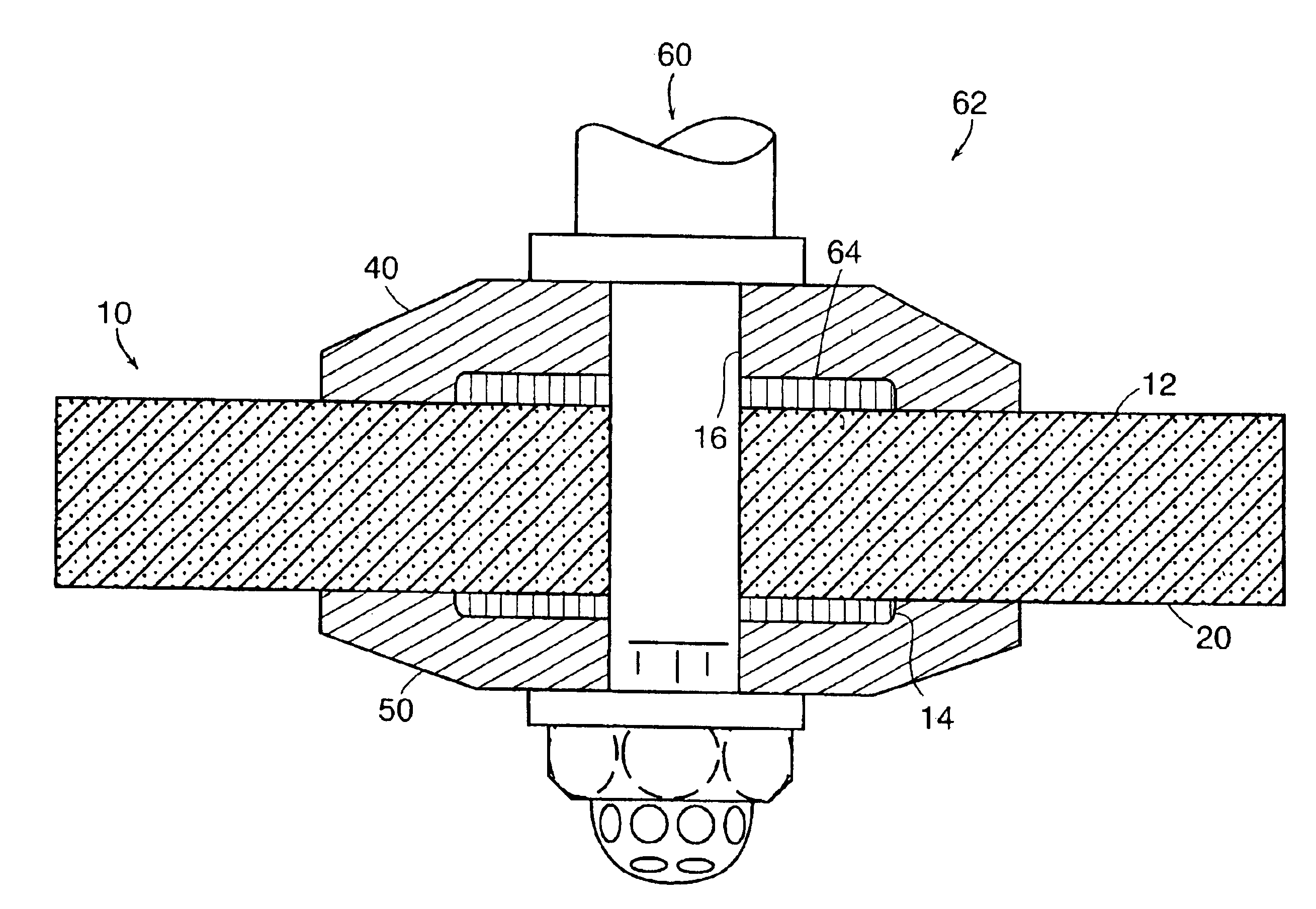

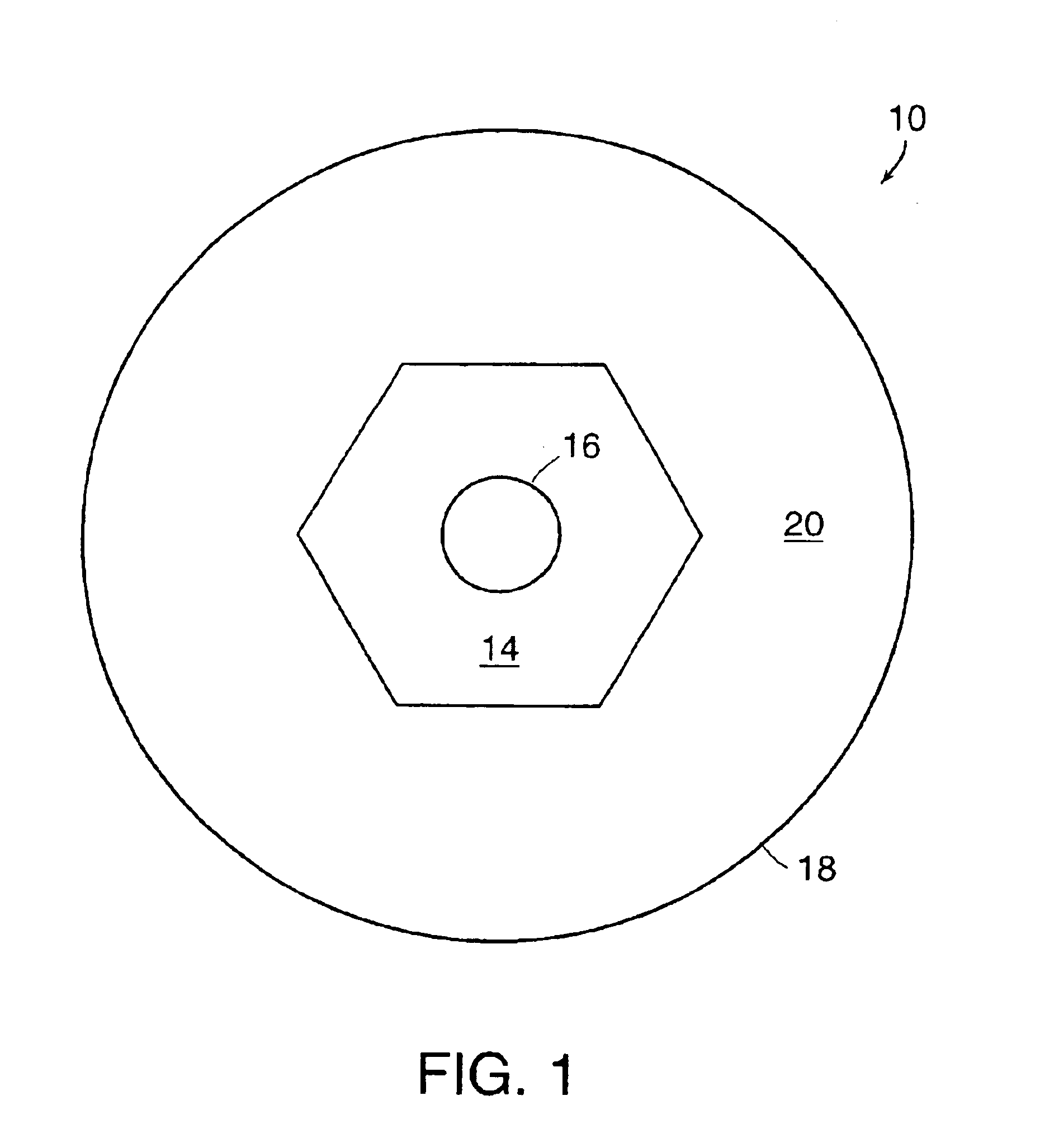

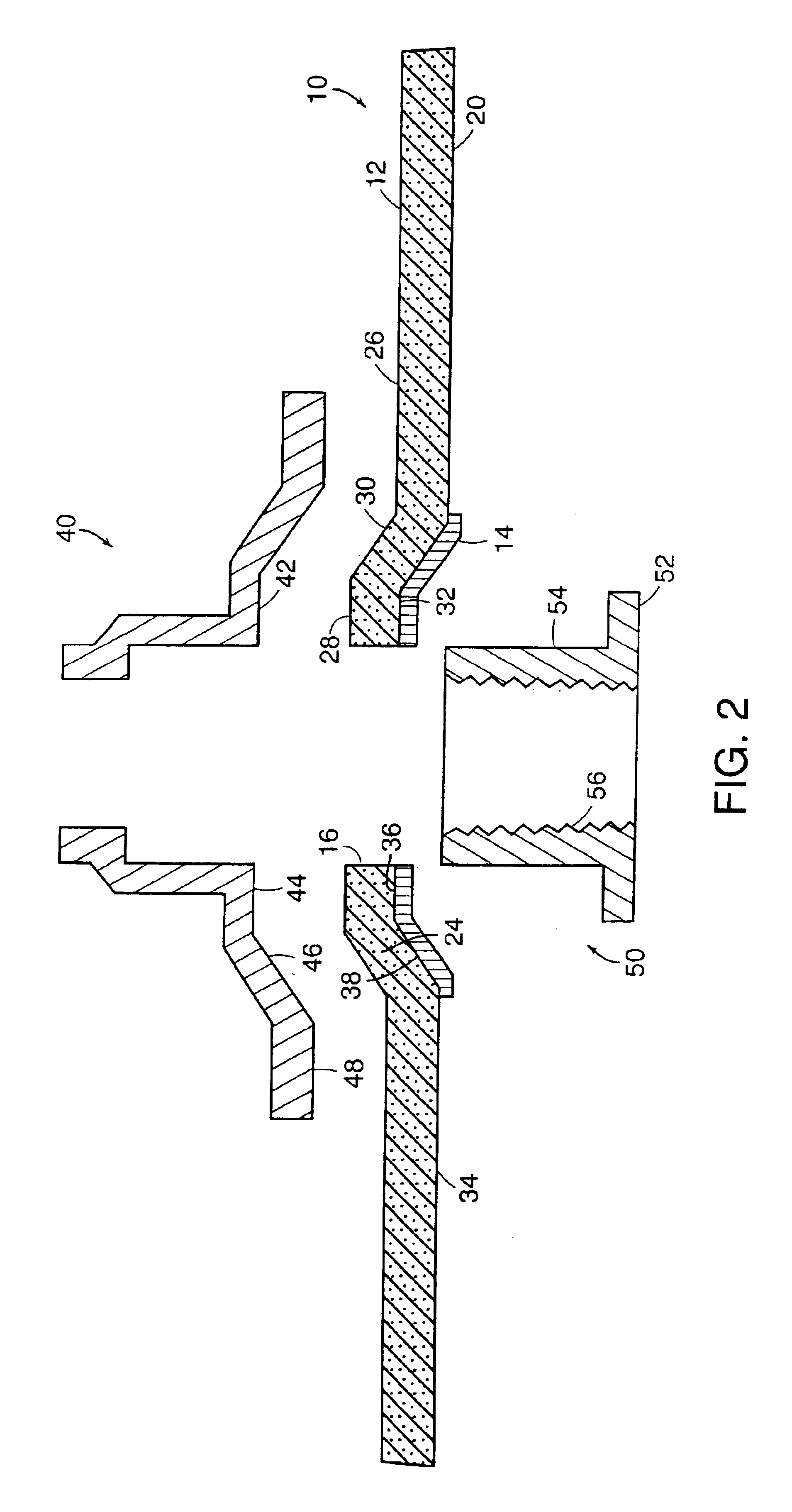

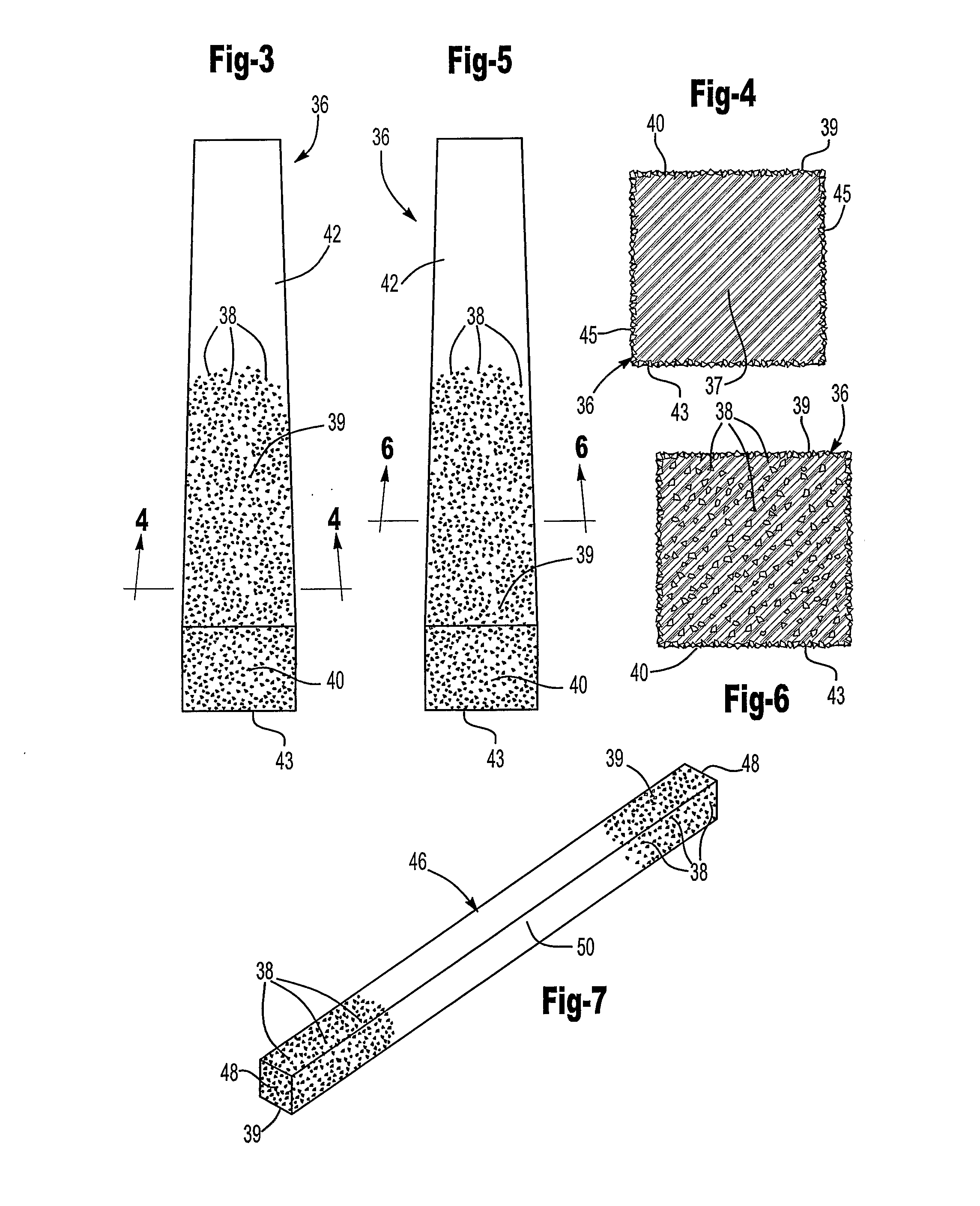

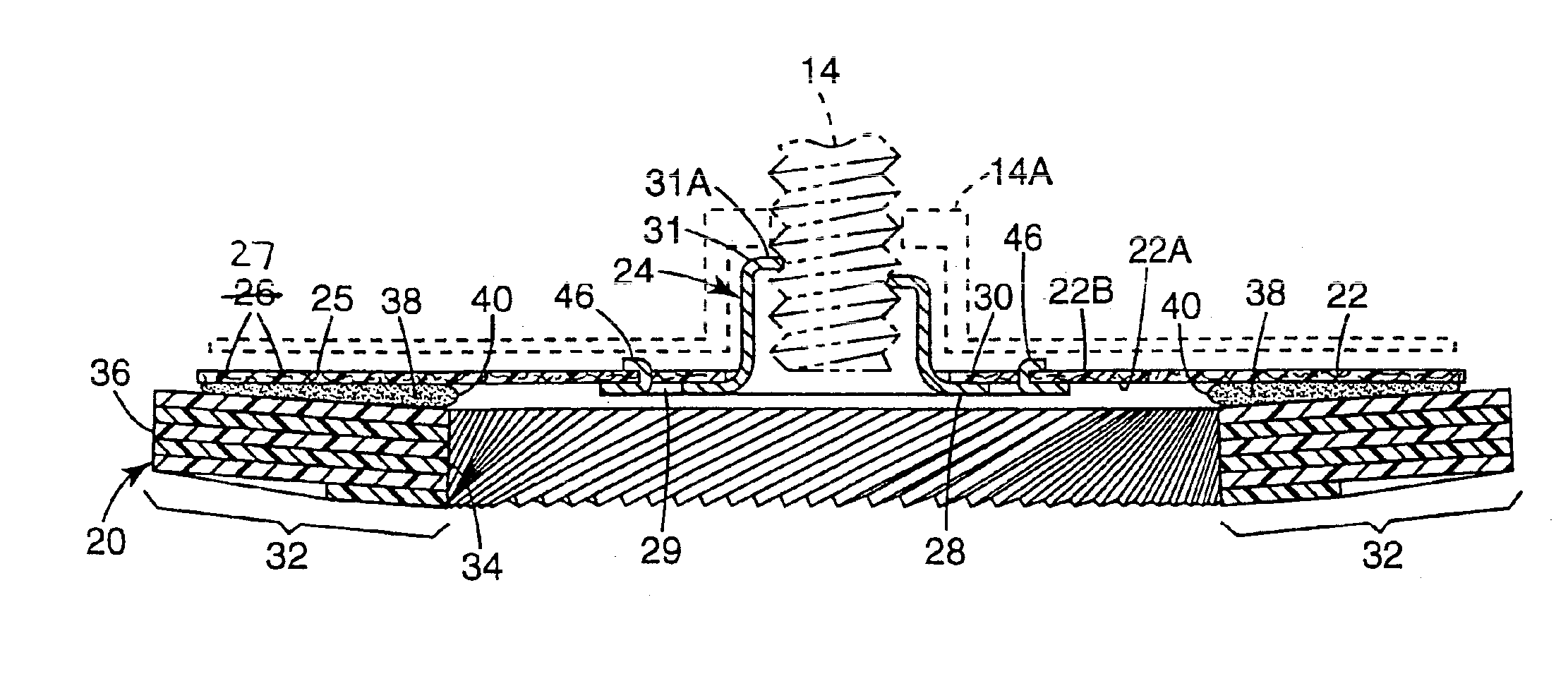

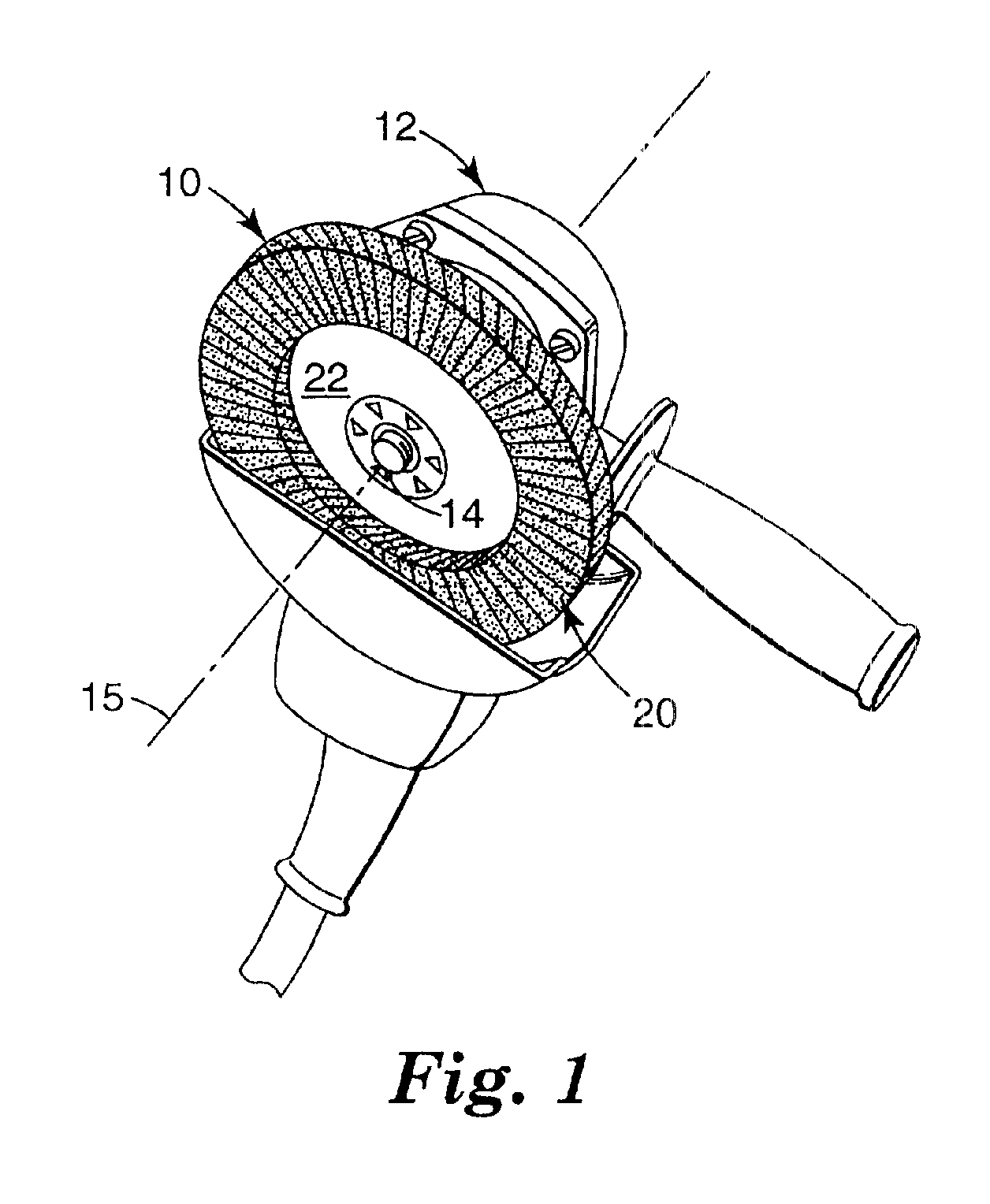

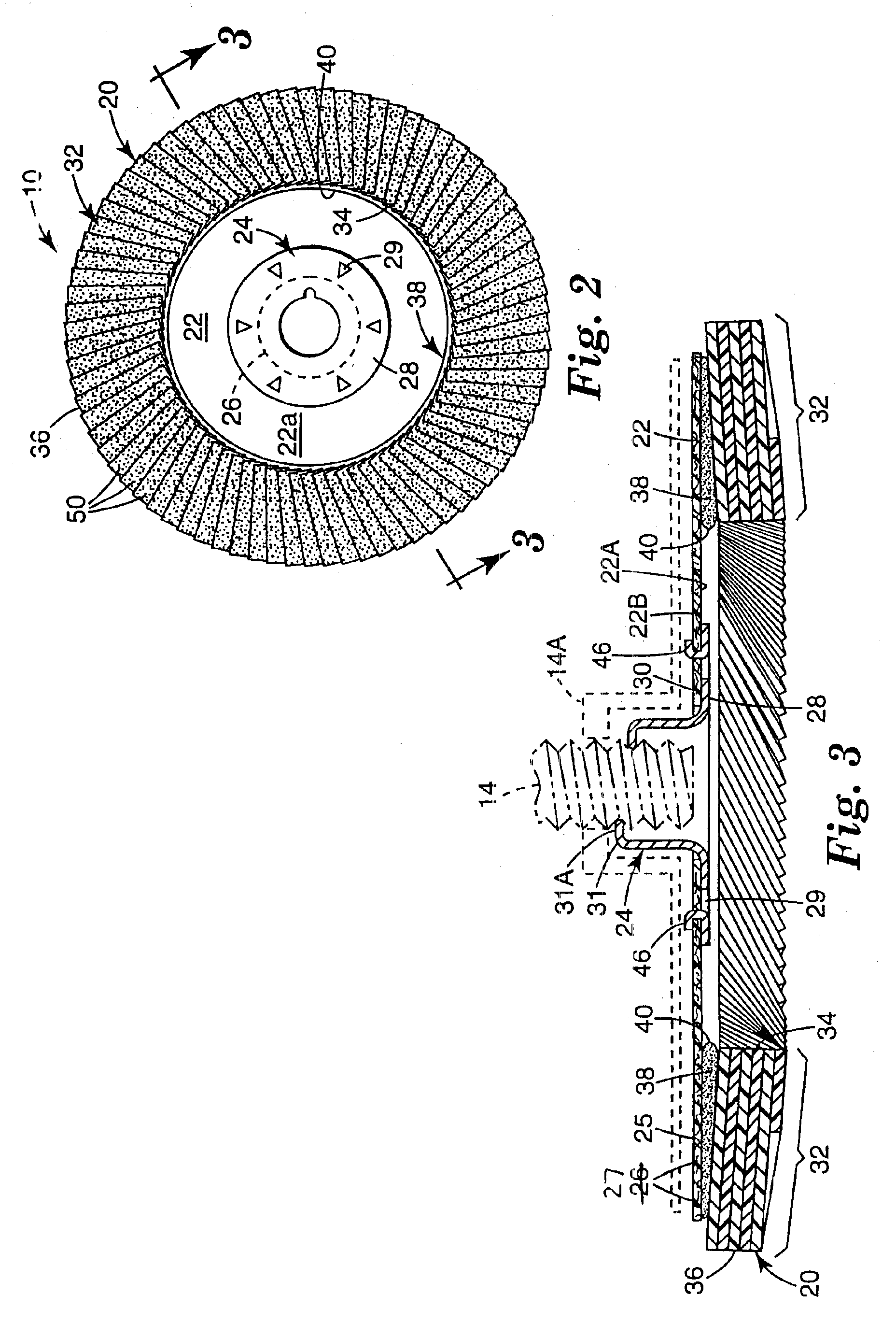

Reinforced abrasive wheels

InactiveUS6942561B2Minimize empty spaceSaving in layer materialGrinding machine componentsRevolution surface grinding machinesGlass fiberEngineering

In a depressed-center abrasive wheel assembly a reinforcement layer of polygonal shape is located between a front face of the abrasive wheel and a front flange. The reinforcement layer is dimensioned to entirely cover the depressed center portion of the wheel. An example of polygonal reinforcement layer has a hexagonal shape and is made of fiberglass cloth. A polygonal shape reinforcement layer can also be employed between the front flange and the front face in an abrasive flat wheel assembly that employs a wheel without internal reinforcement.

Owner:SAINT GOBAIN ABRASIVES INC

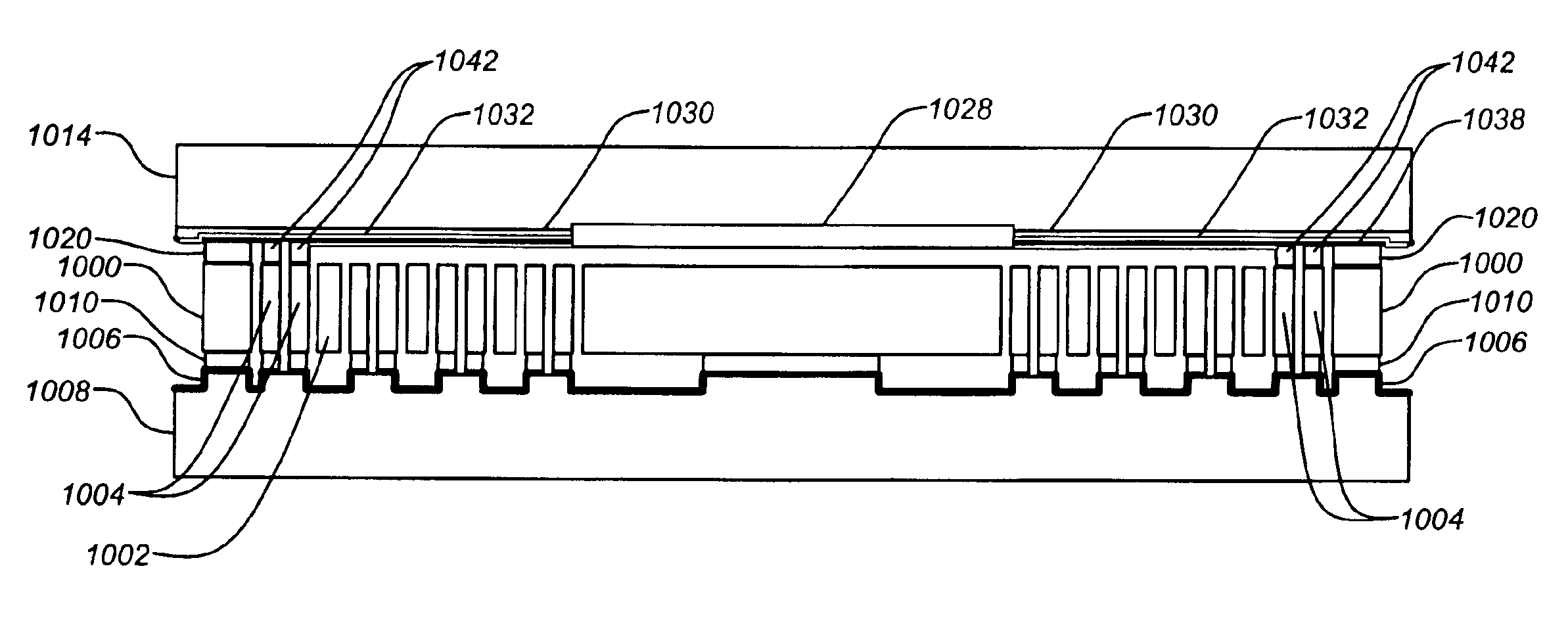

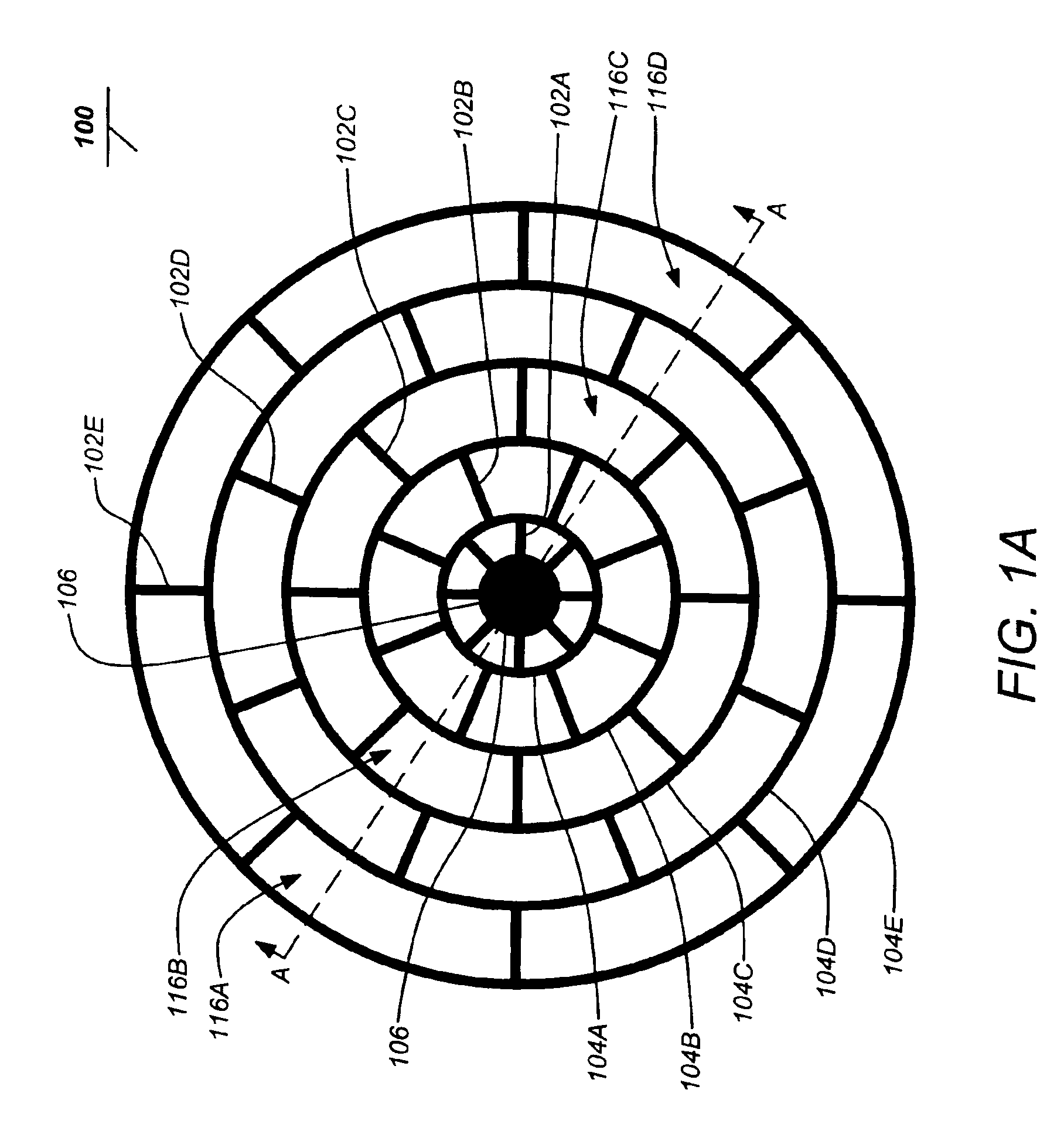

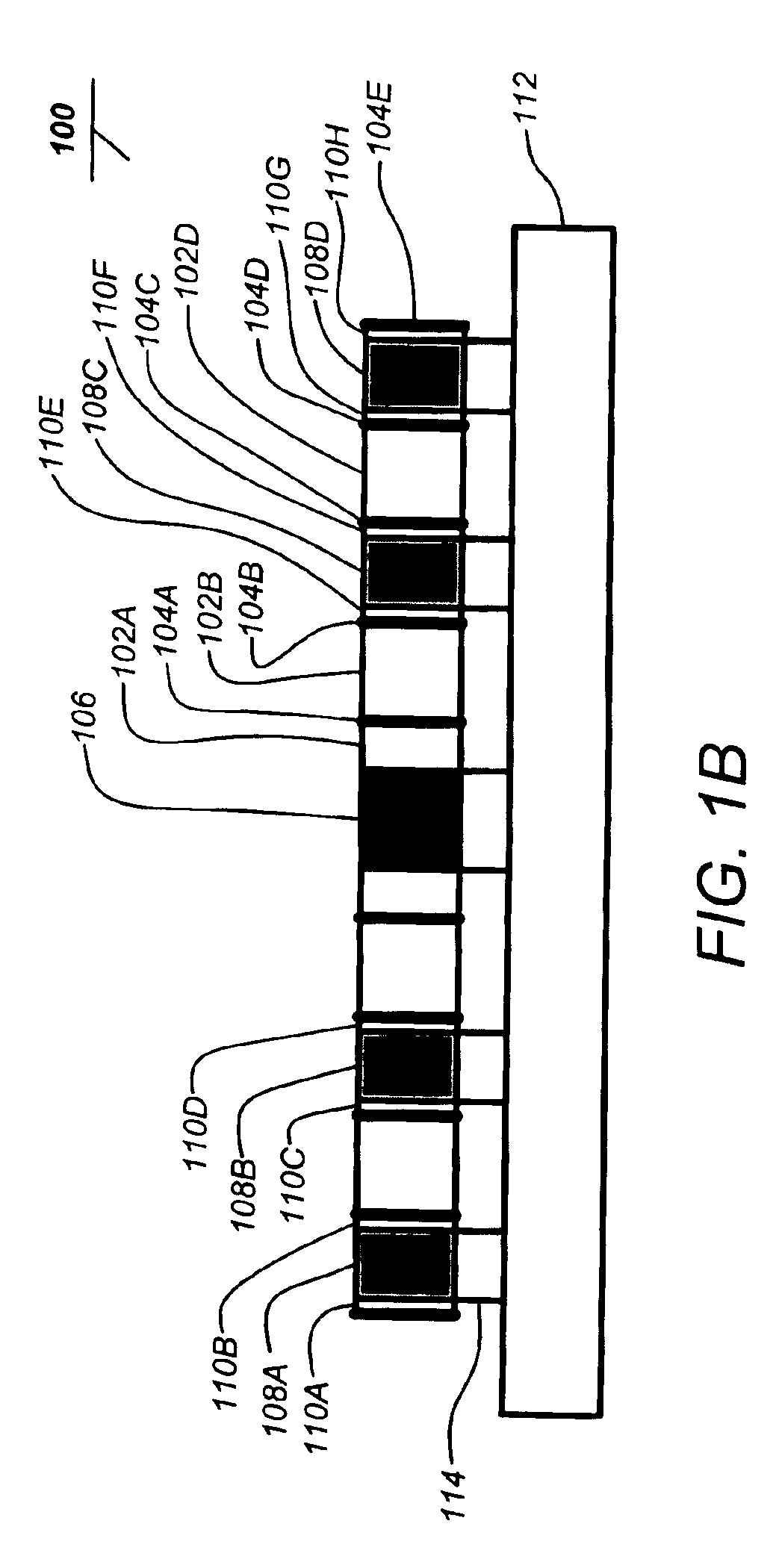

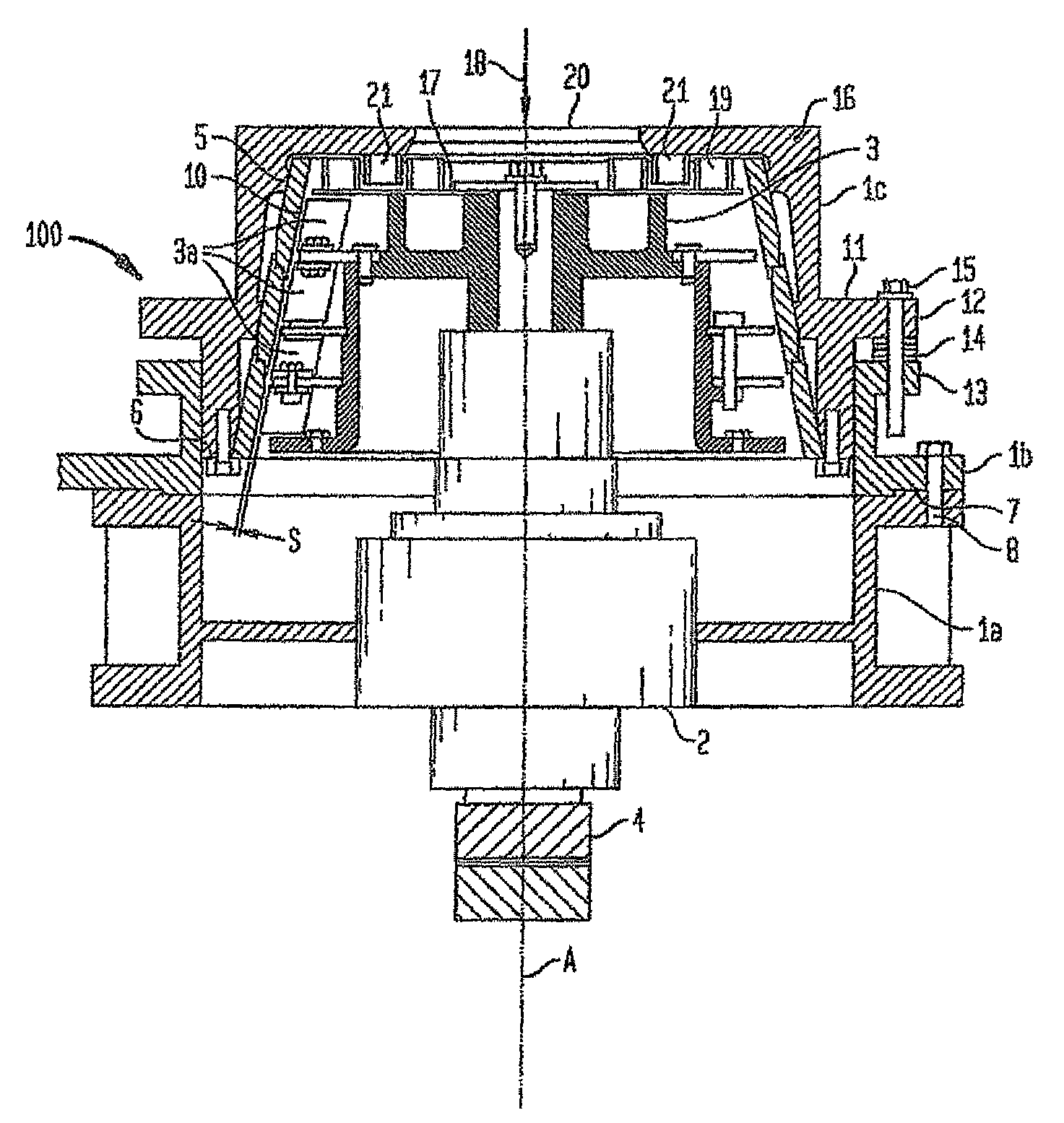

Method of producing an integral resonator sensor and case

InactiveUS6944931B2Improve Sensing PerformanceIncrease the areaGrinding machine componentsWave amplification devicesAcousticsResonator

The present invention discloses an inertial sensor having an integral resonator. A typical sensor comprises a planar mechanical resonator for sensing motion of the inertial sensor and a case for housing the resonator. The resonator and a wall of the case are defined through an etching process. A typical method of producing the resonator includes etching a baseplate, bonding a wafer to the etched baseplate, through etching the wafer to form a planar mechanical resonator and the wall of the case and bonding an end cap wafer to the wall to complete the case.

Owner:CALIFORNIA INST OF TECH +1

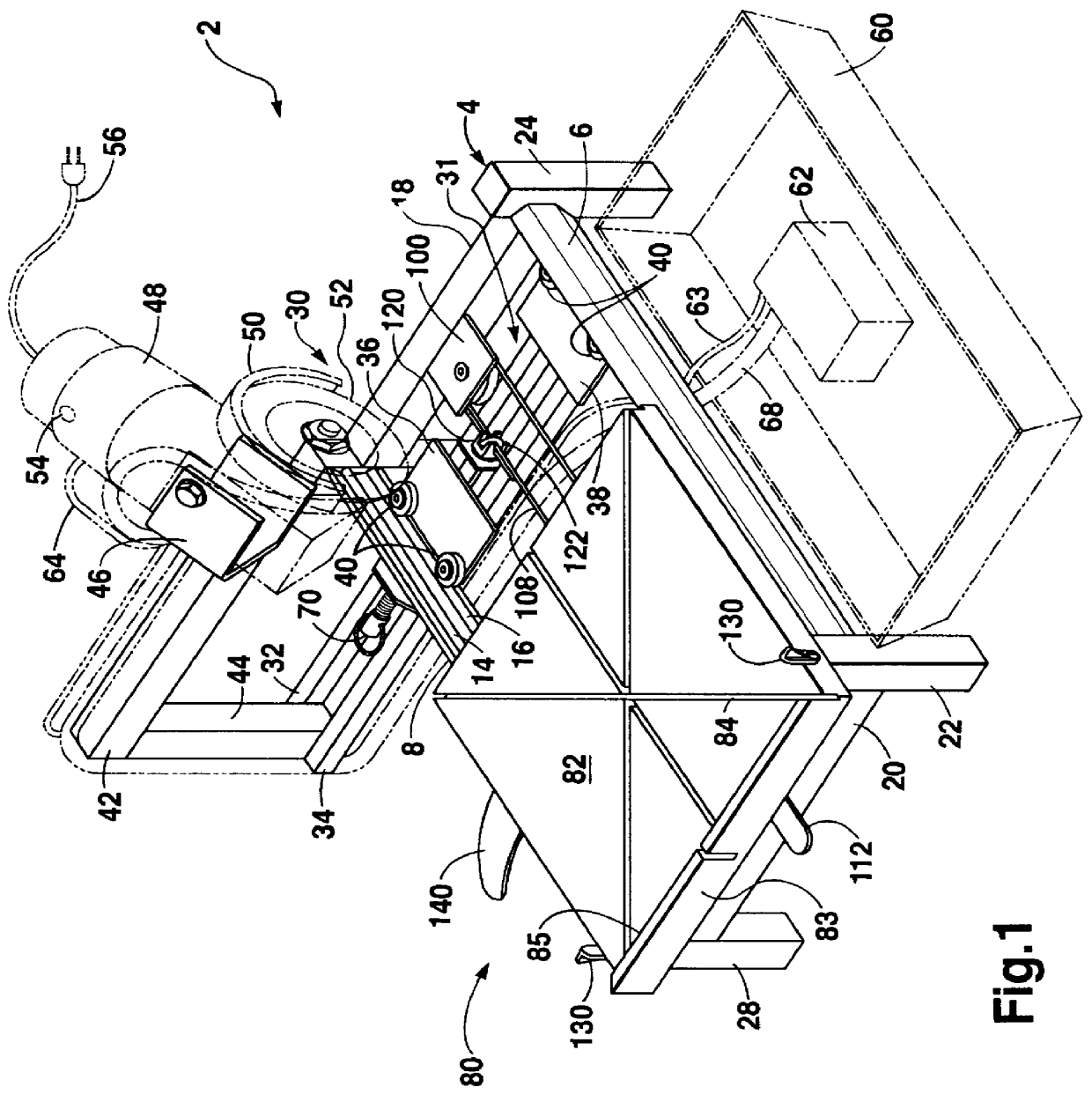

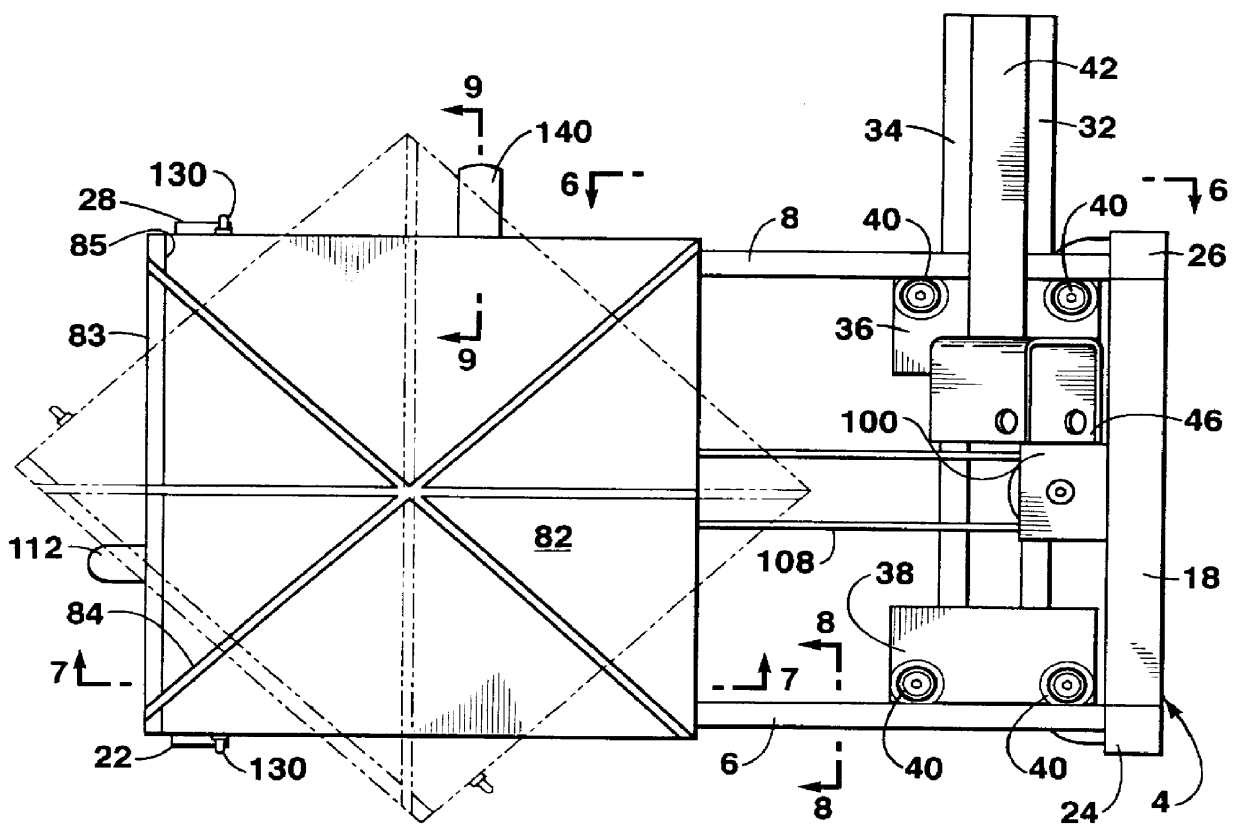

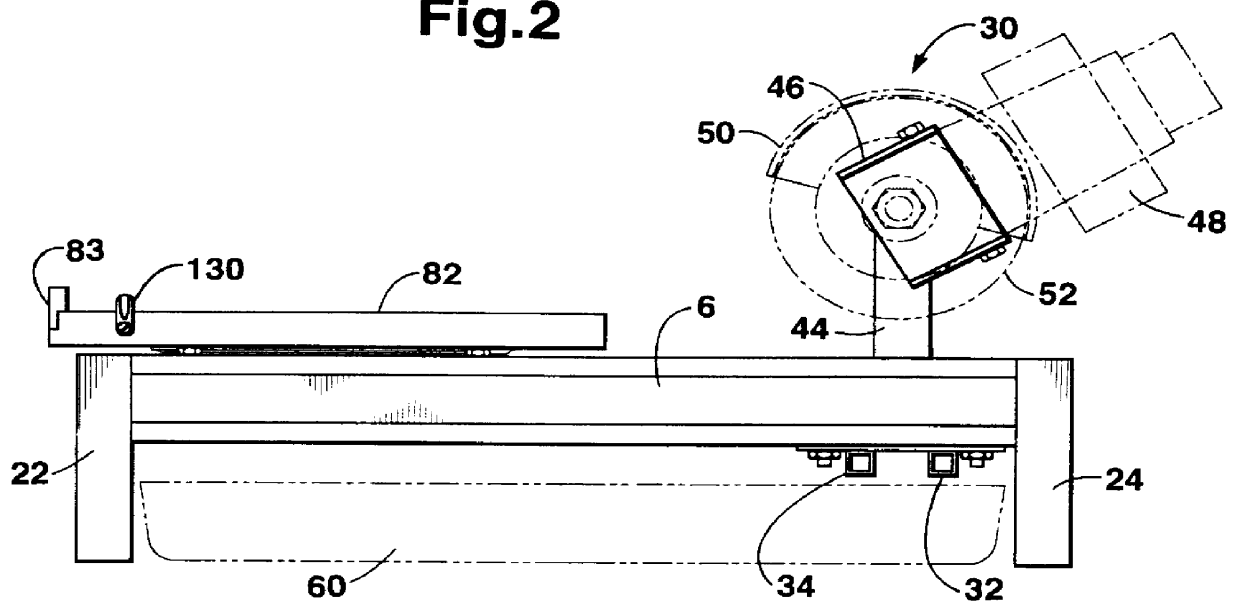

Saw having movable table and saw blade

InactiveUS6119676ANot up much spaceEasy to carryGrinding machine componentsWorking accessoriesWorkbenchEngineering

A compact tile saw which is especially adaptable for cutting of large-sized tiles wherein the table supporting the tile is movable towards the cutting saw, while at the same time the cutting saw is positionable in one of two positions of either being stationary or in moving in unison towards the table supporting the tile to be cut.

Owner:GREENLAND DARRELL

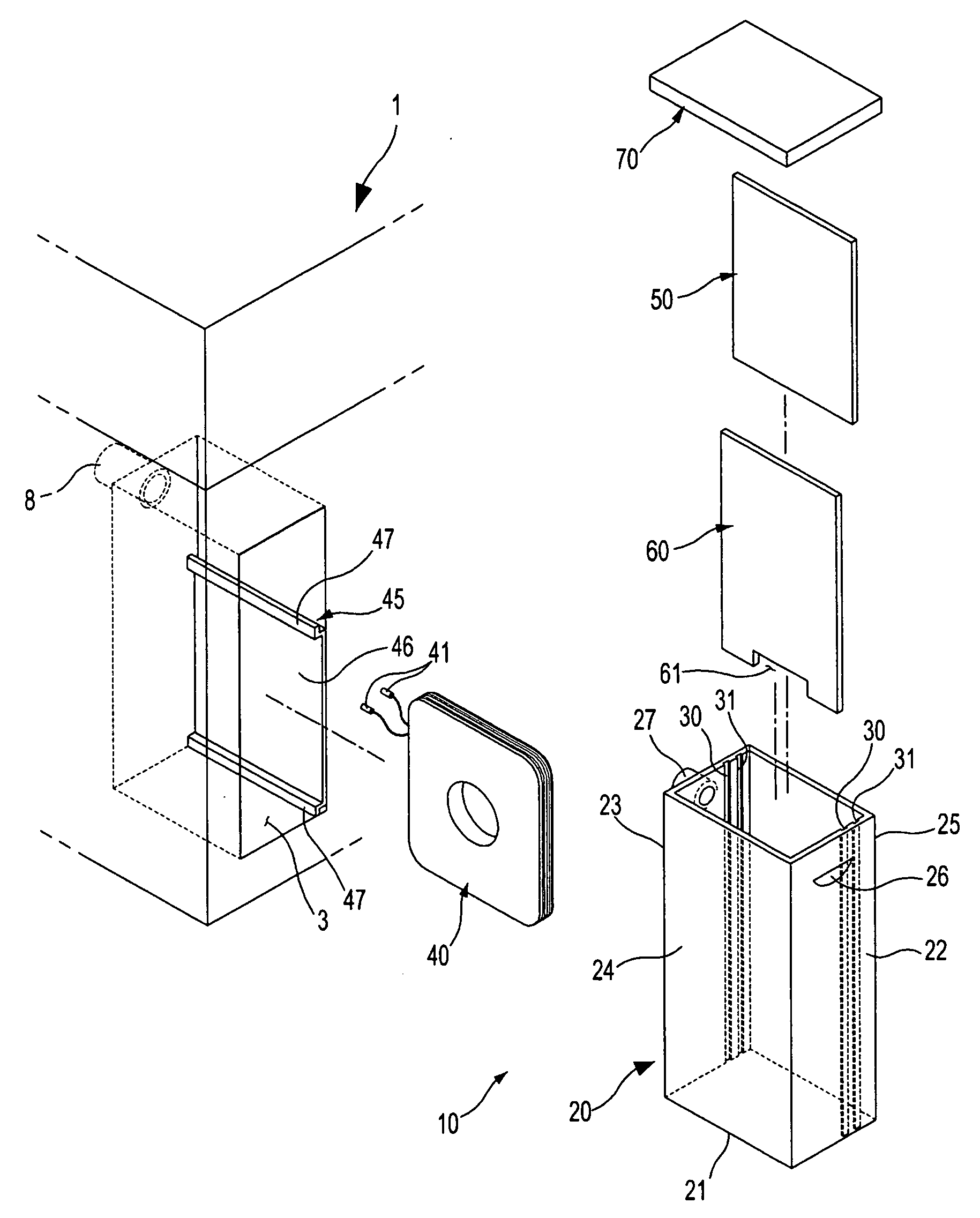

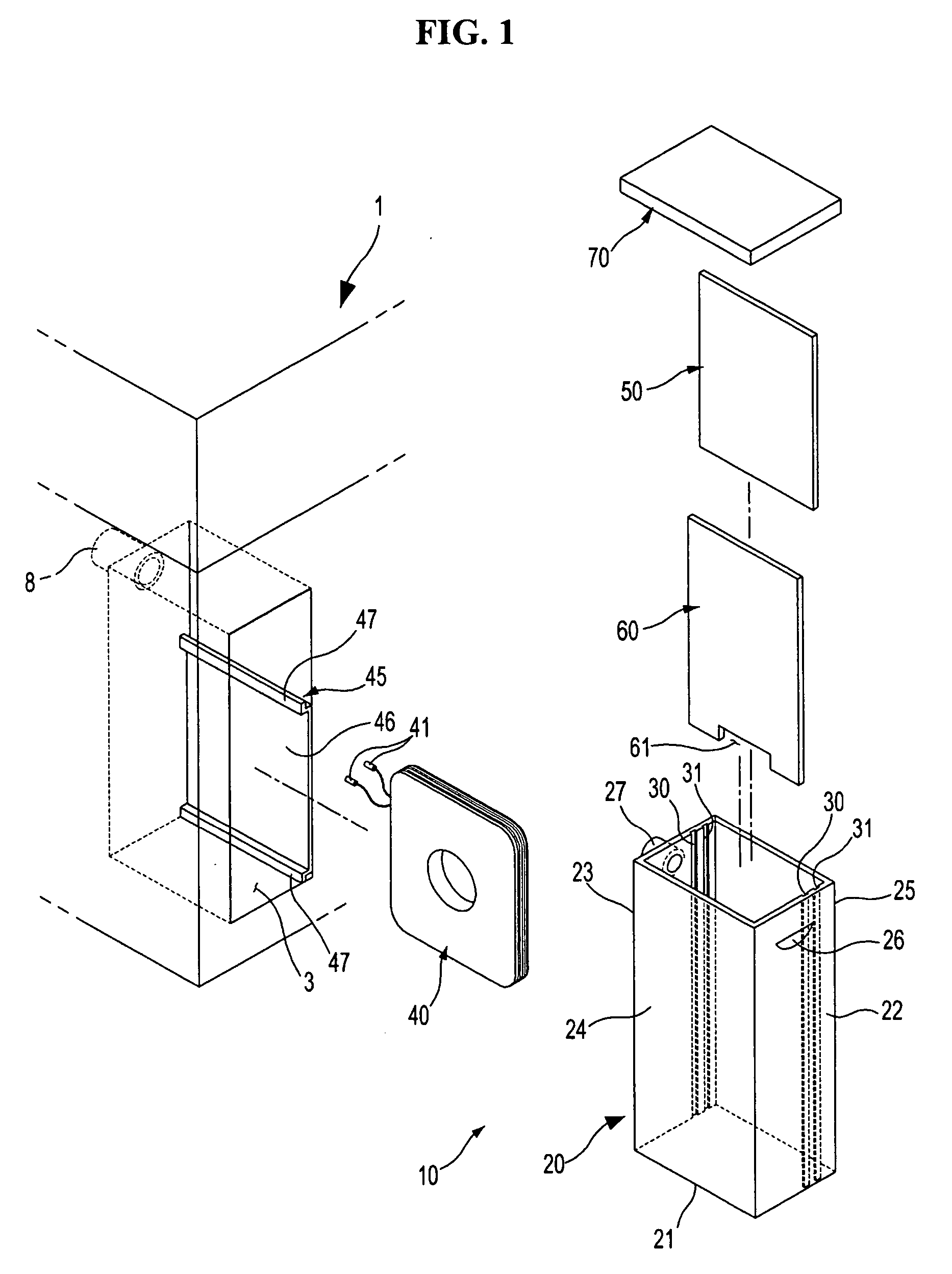

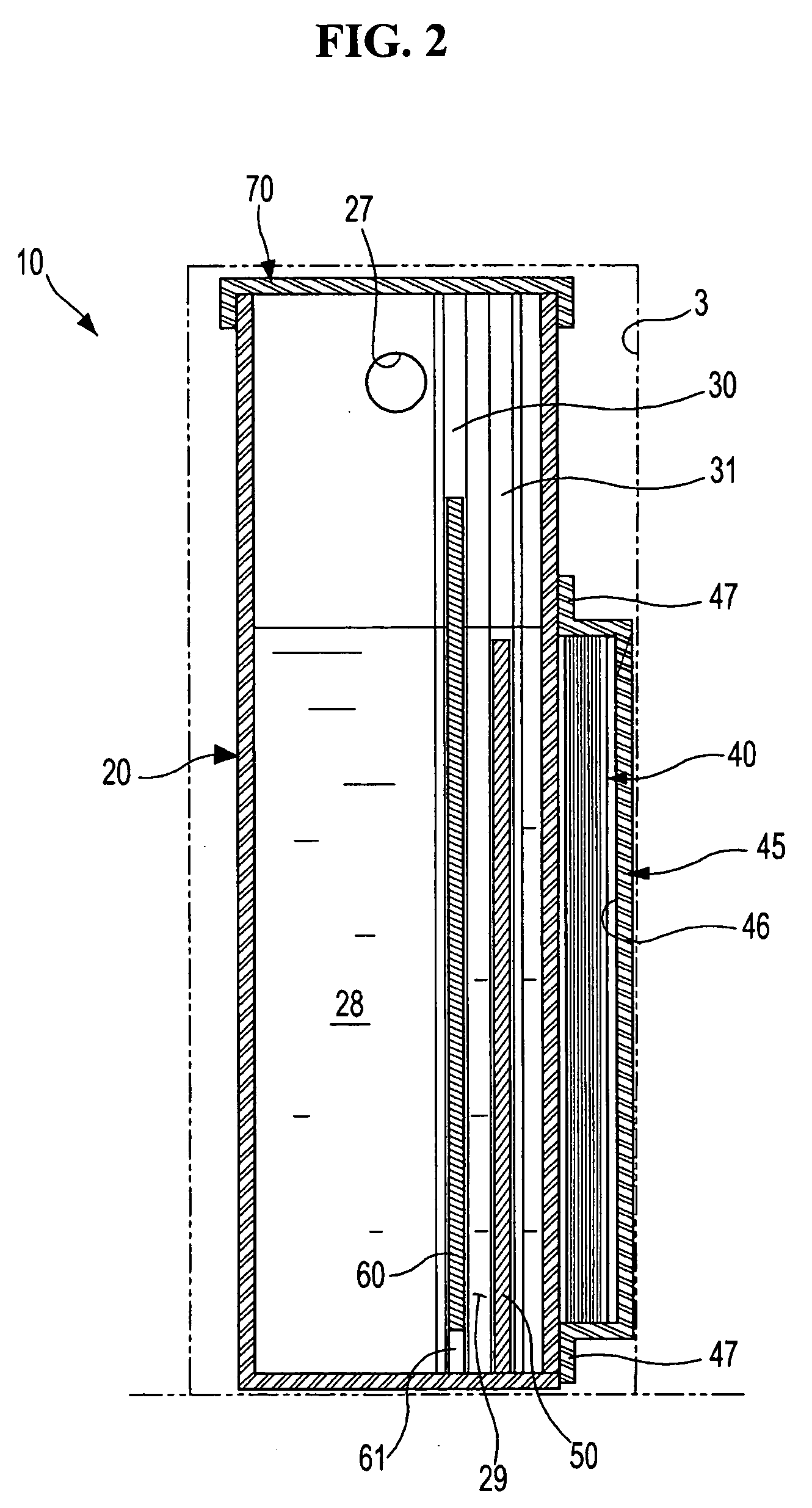

Steam generating apparatus and oven including the same

InactiveUS20060278630A1Easy to cleanRapidly generate steamGrinding machine componentsDomestic stoves or rangesEngineeringInduction coil

A steam generating apparatus, and an oven including the same. The apparatus includes a water tank adapted to enable convenient cleaning, and is adapted to heat water in the water tank via an induction heating method to generate steam rapidly. The water tank is provided with a steam discharging pipe. The apparatus further includes an induction coil assembly, an induction heating member fitted to the water tank such that it is located near the induction coil assembly, a barrier inserted into the water tank such that only a small amount of water is directly heated by the induction heating member which generates heat by the induction coil assembly, and a cover closing an upper portion of the water tank. The steam discharging pipe is connected with a steam supplying pipe which communicates a cavity with a cooking compartment to supply steam from the apparatus to the cooking compartment.

Owner:SAMSUNG ELECTRONICS CO LTD

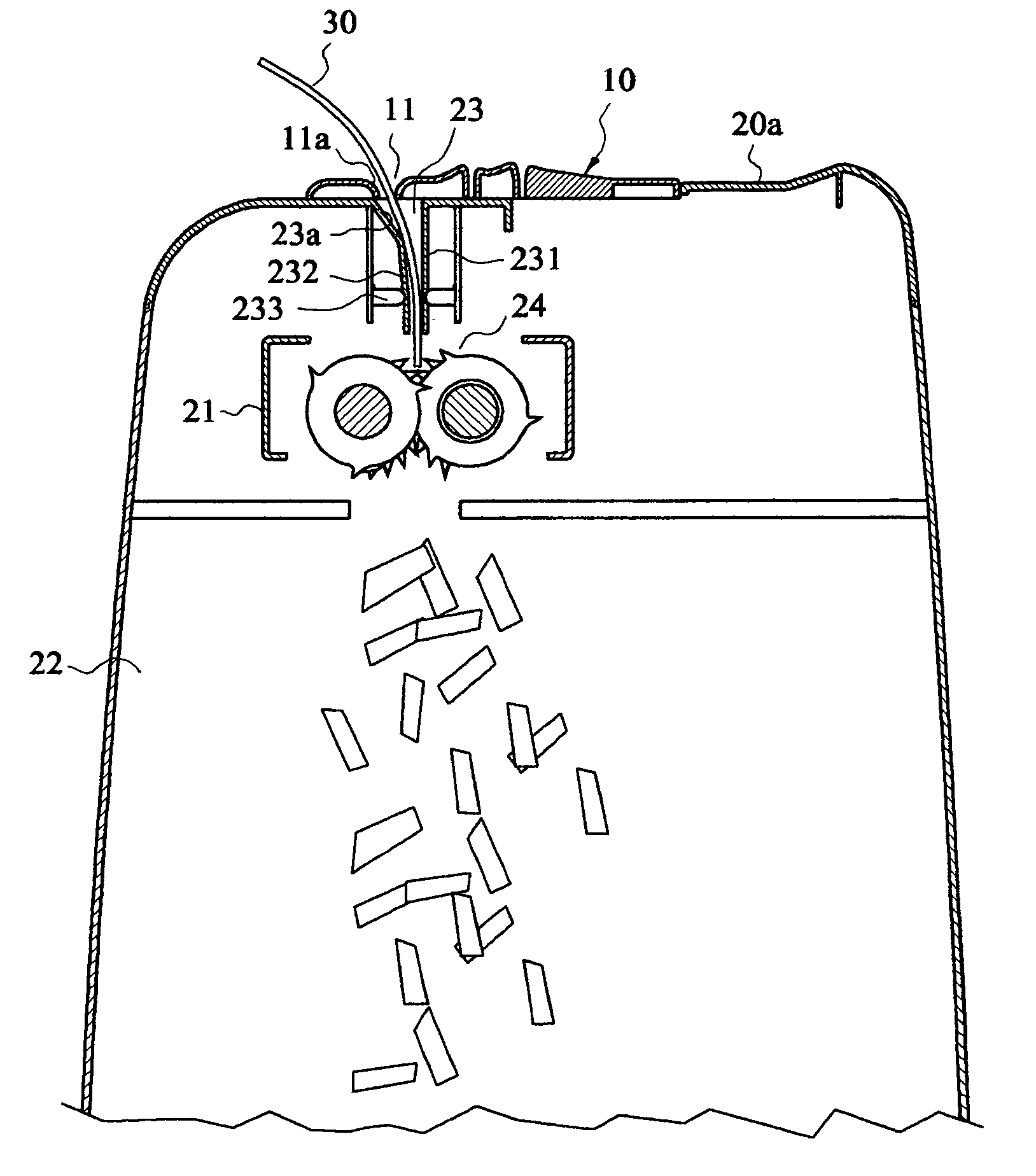

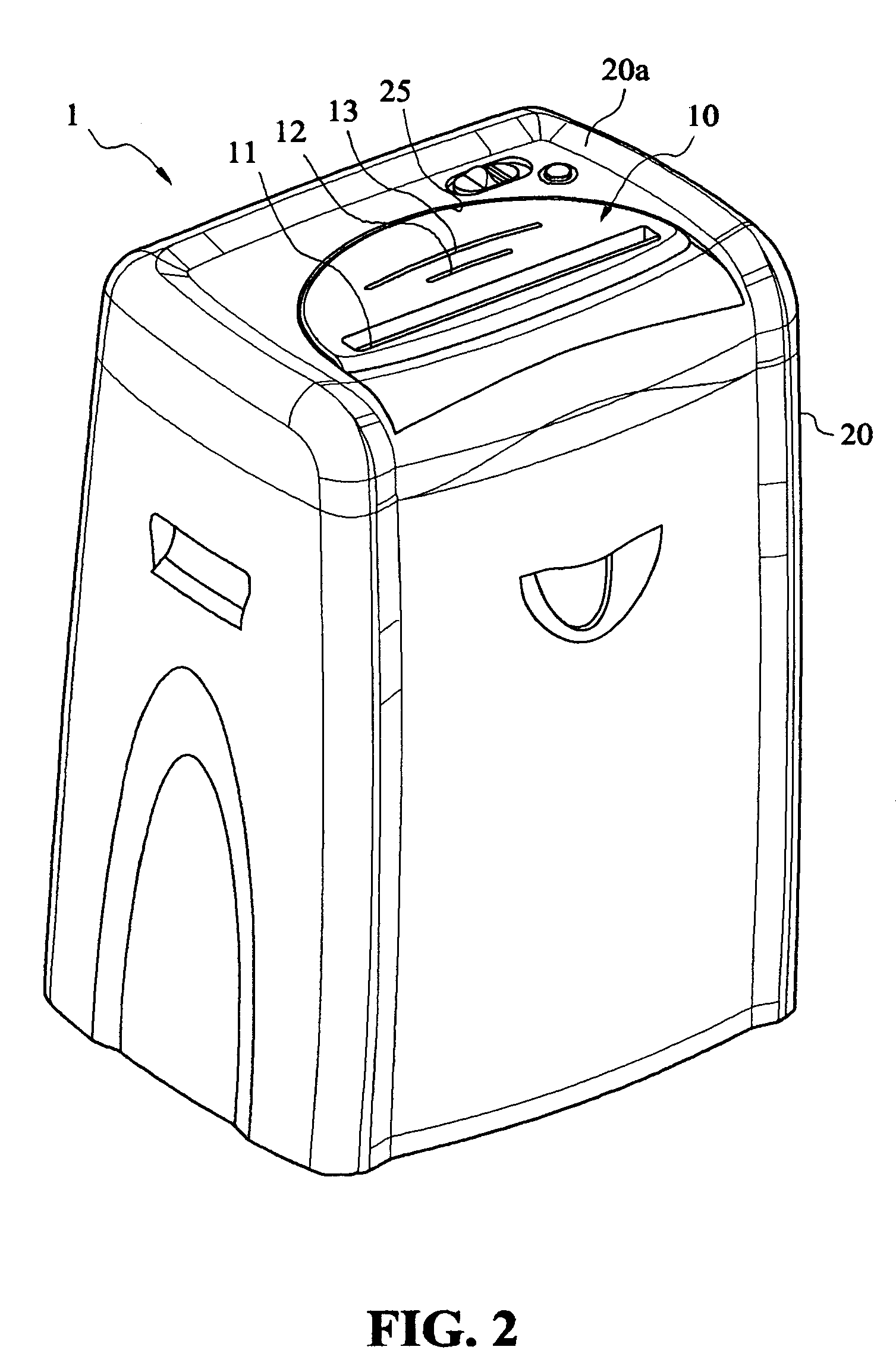

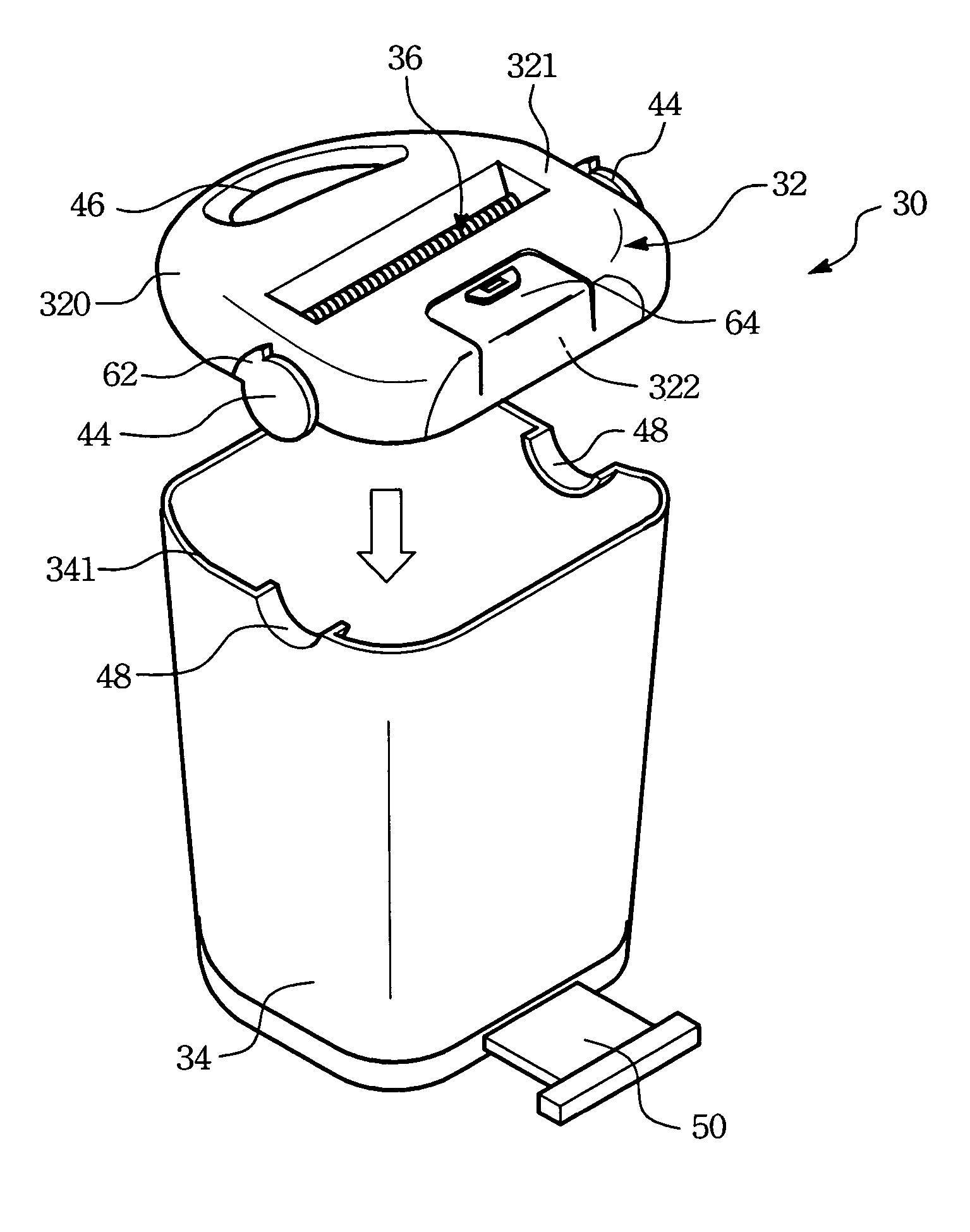

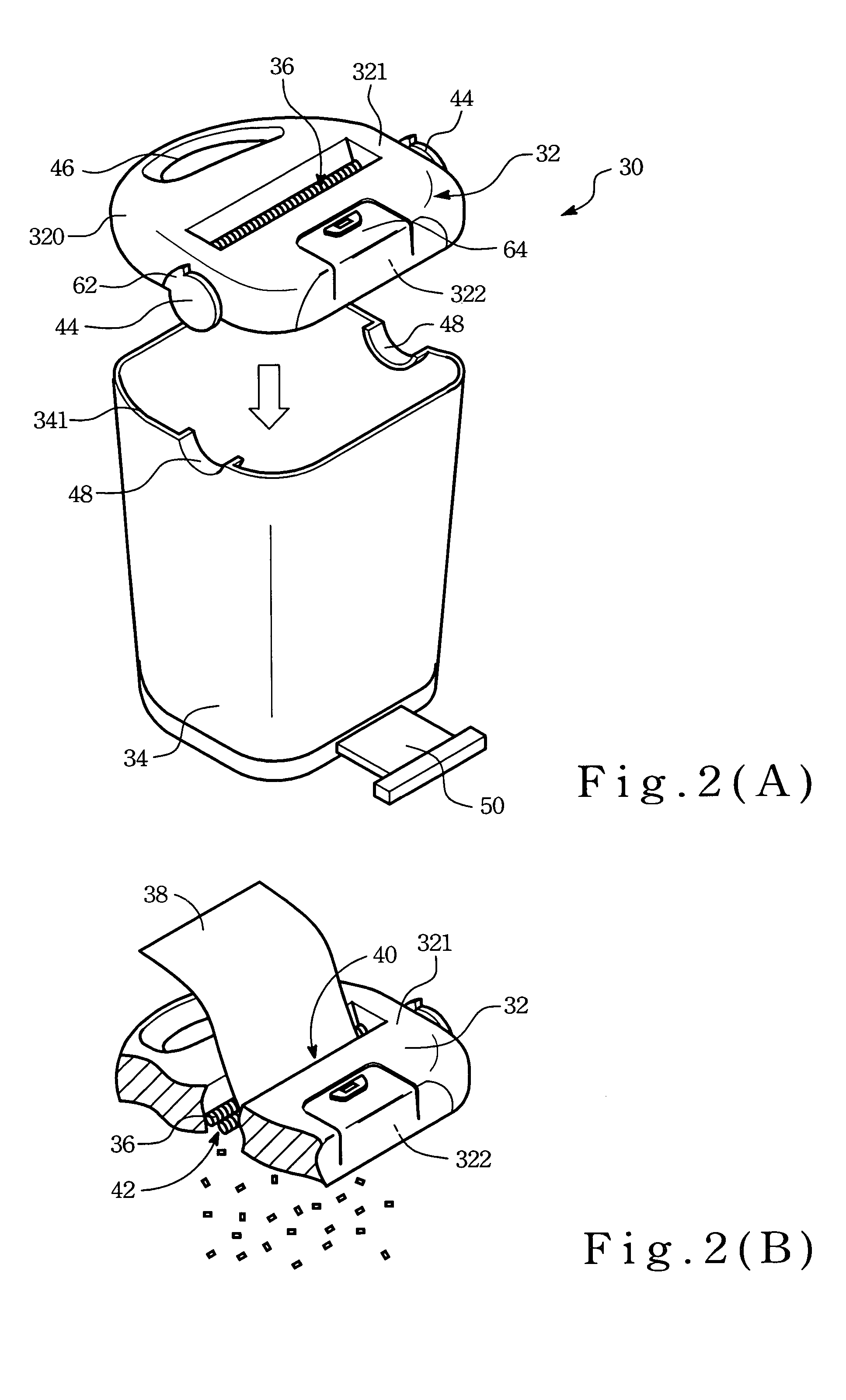

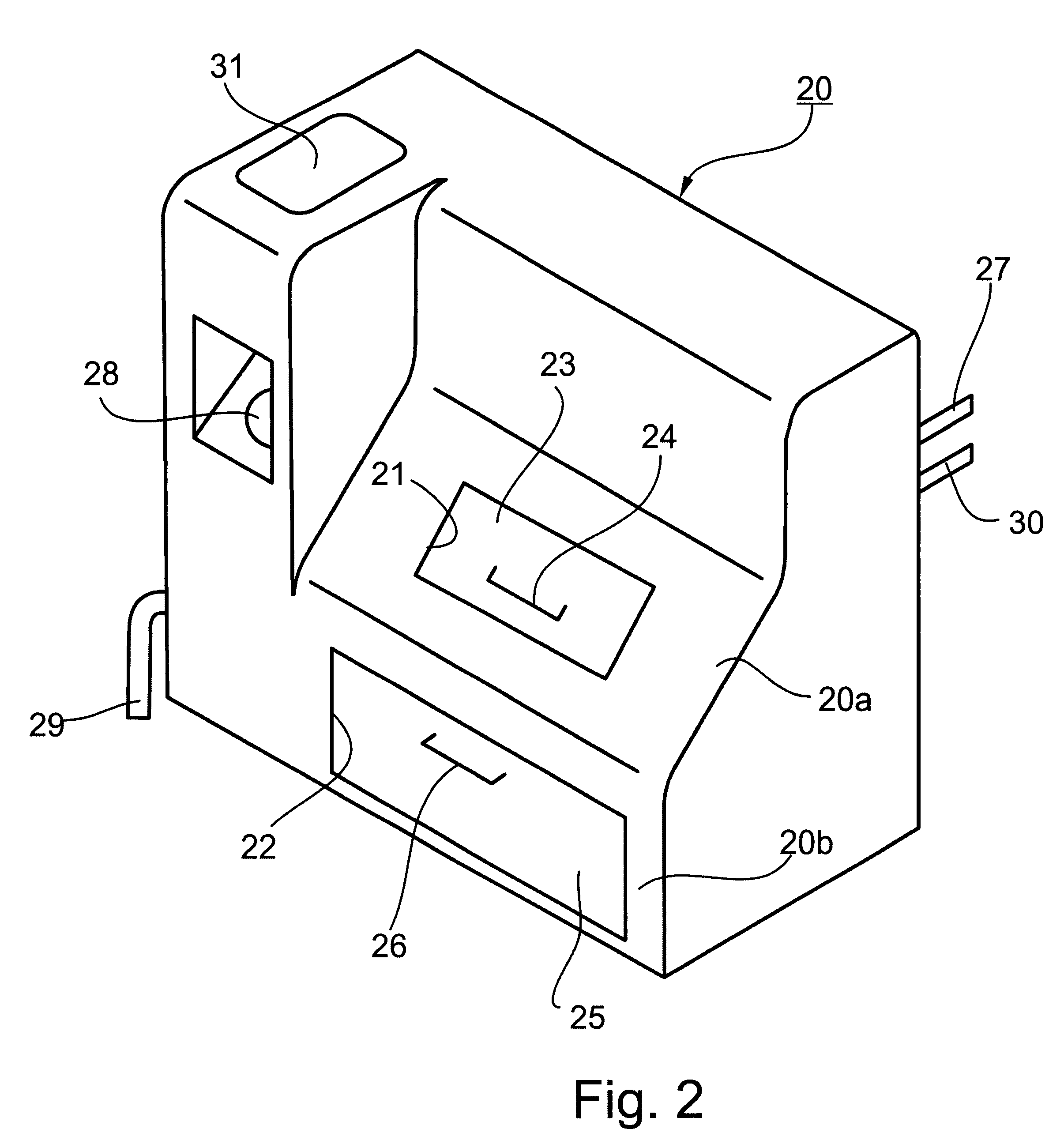

Multifunctional paper shredder

InactiveUS7213780B2Improve the problemLarge widthGrinding machine componentsCocoaInterior spaceImpeller

Disclosed is a sliding panel structure of a multifunctional paper shredder, the paper shredder includes a housing having an interior space, an installing section at the top, an accommodating space at the bottom, and a feeding slot under the installing section. A pair of rolling blade wheels are disposed under the feeding slot which has a pressing wall surface extended vertically downward and aligned with the middle of the rolling blade wheels. An accommodating section is defined at the top of the housing, and a positioning section having at least one sliding groove is disposed at an inner side of the accommodating section. A sliding panel, having a plurality of slots is slidably installed in the accommodating section, having a positioning pin disposed in the positioning section correspondingly, and at least one slide pin embedded into the sliding groove for guiding the movement of the sliding panel.

Owner:AURORA GLOBAL INVESTMENT

Conical-shaped impact mill

ActiveUS7861958B2Maximize efficiencyReduce the temperatureGrinding machine componentsCocoaRotational axisEngineering

Owner:LEHIGH TECH INC

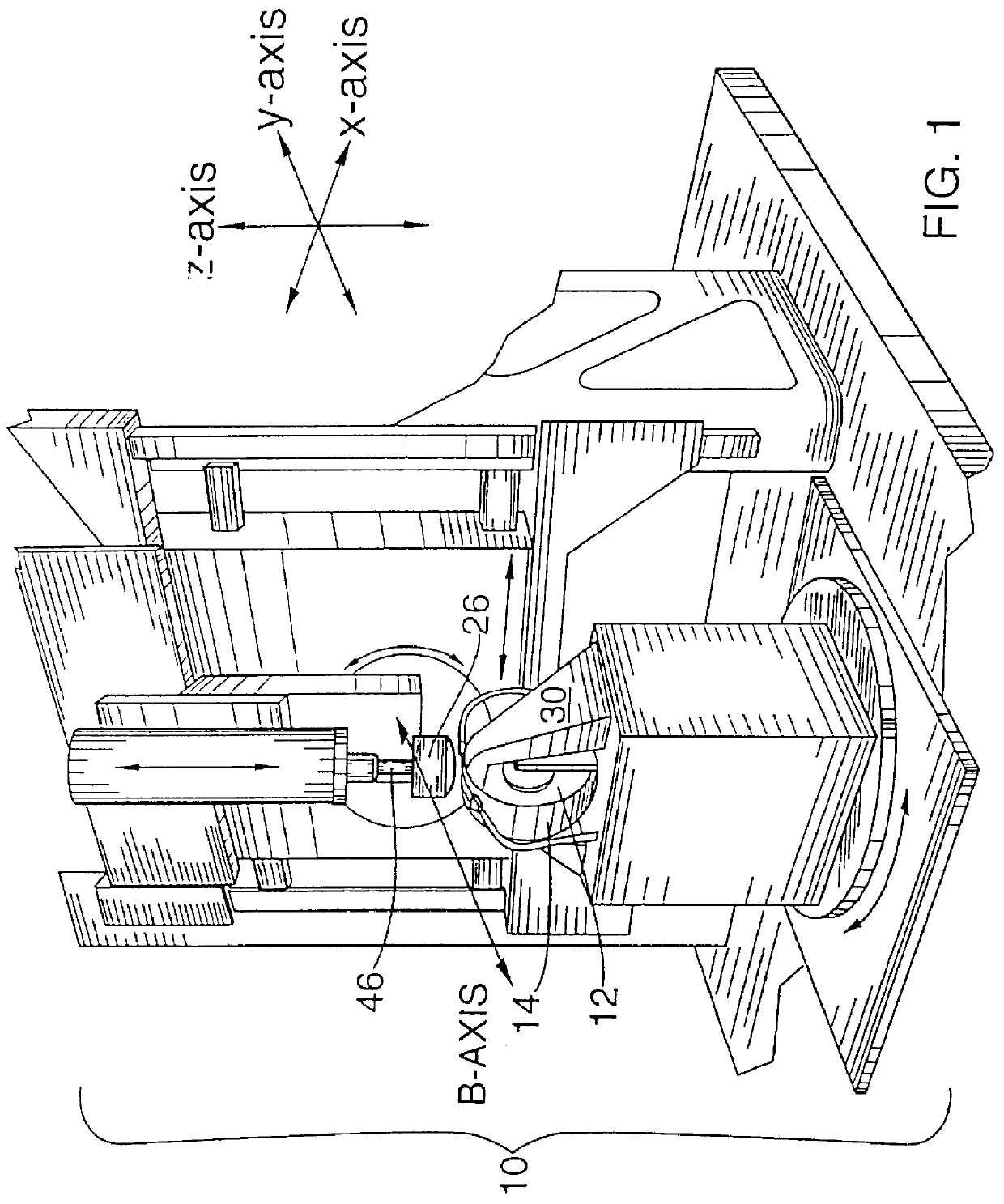

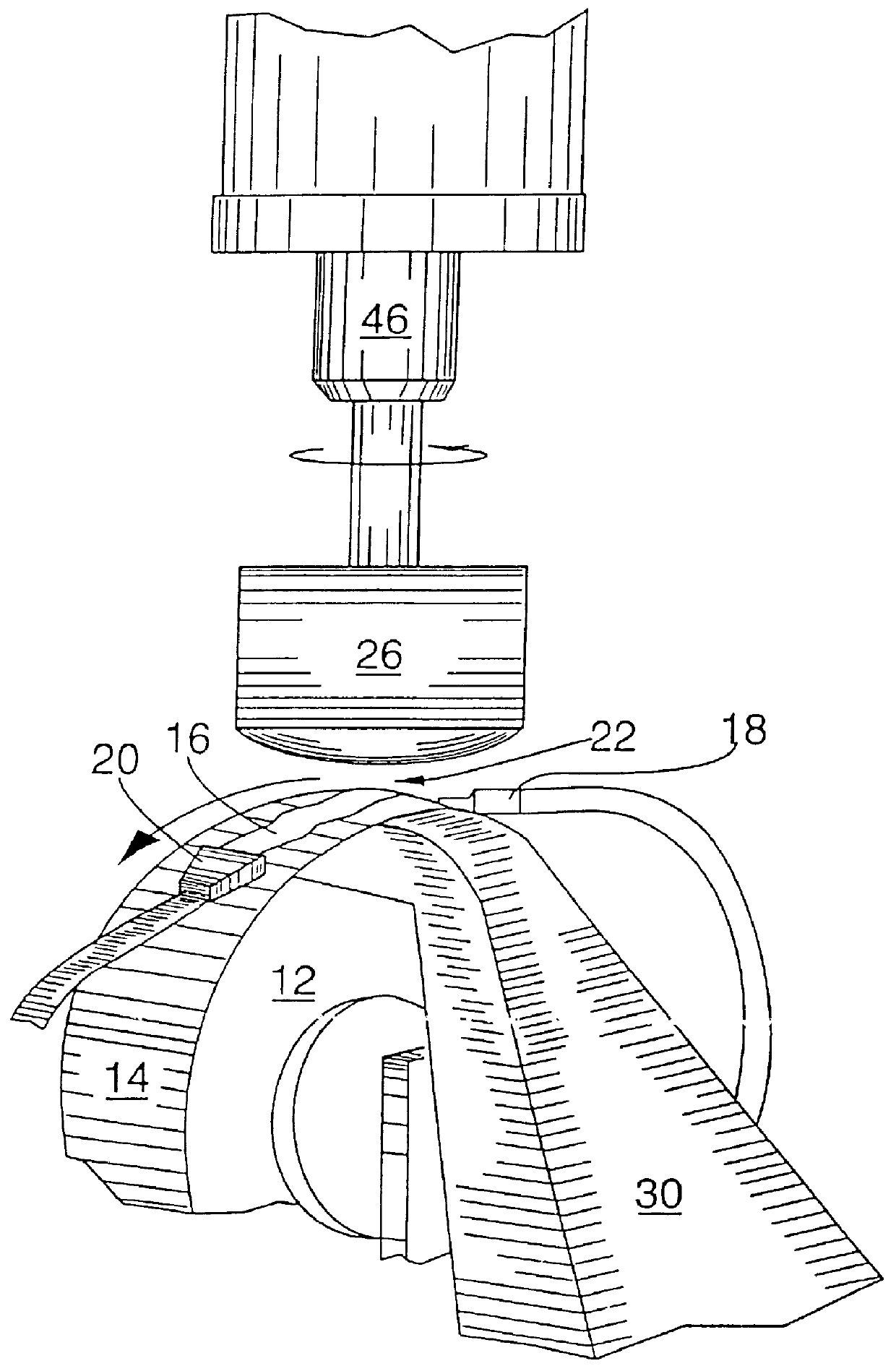

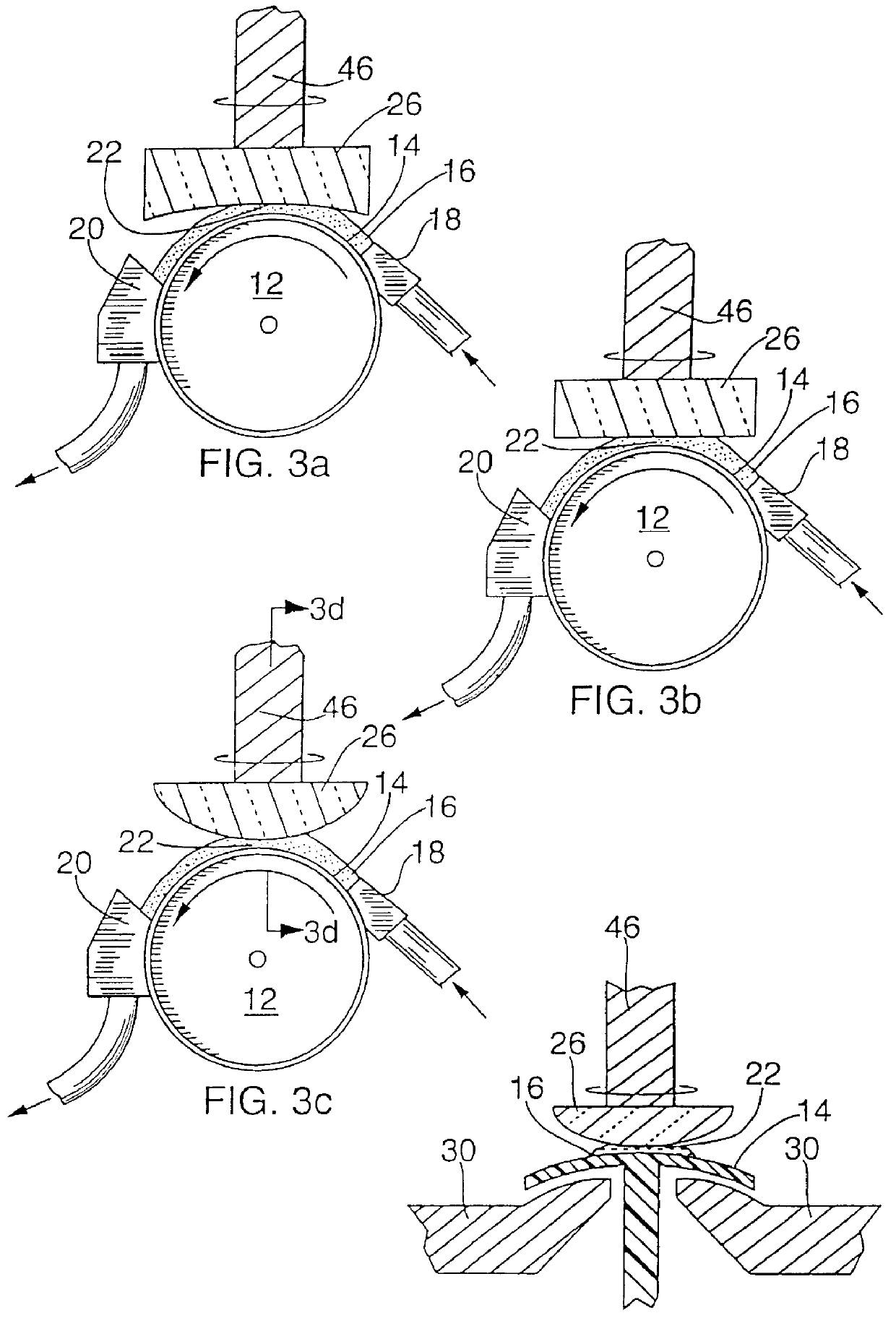

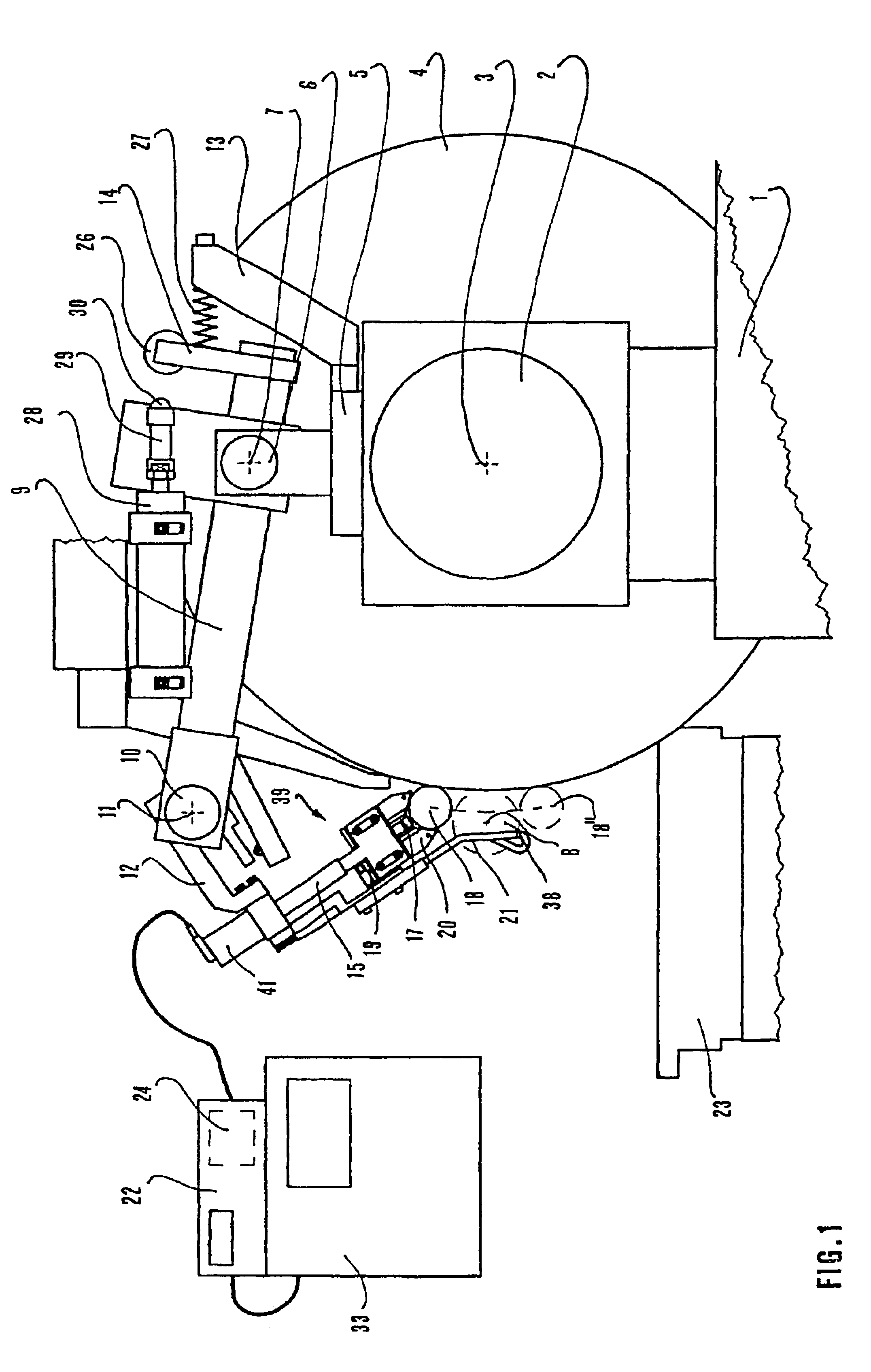

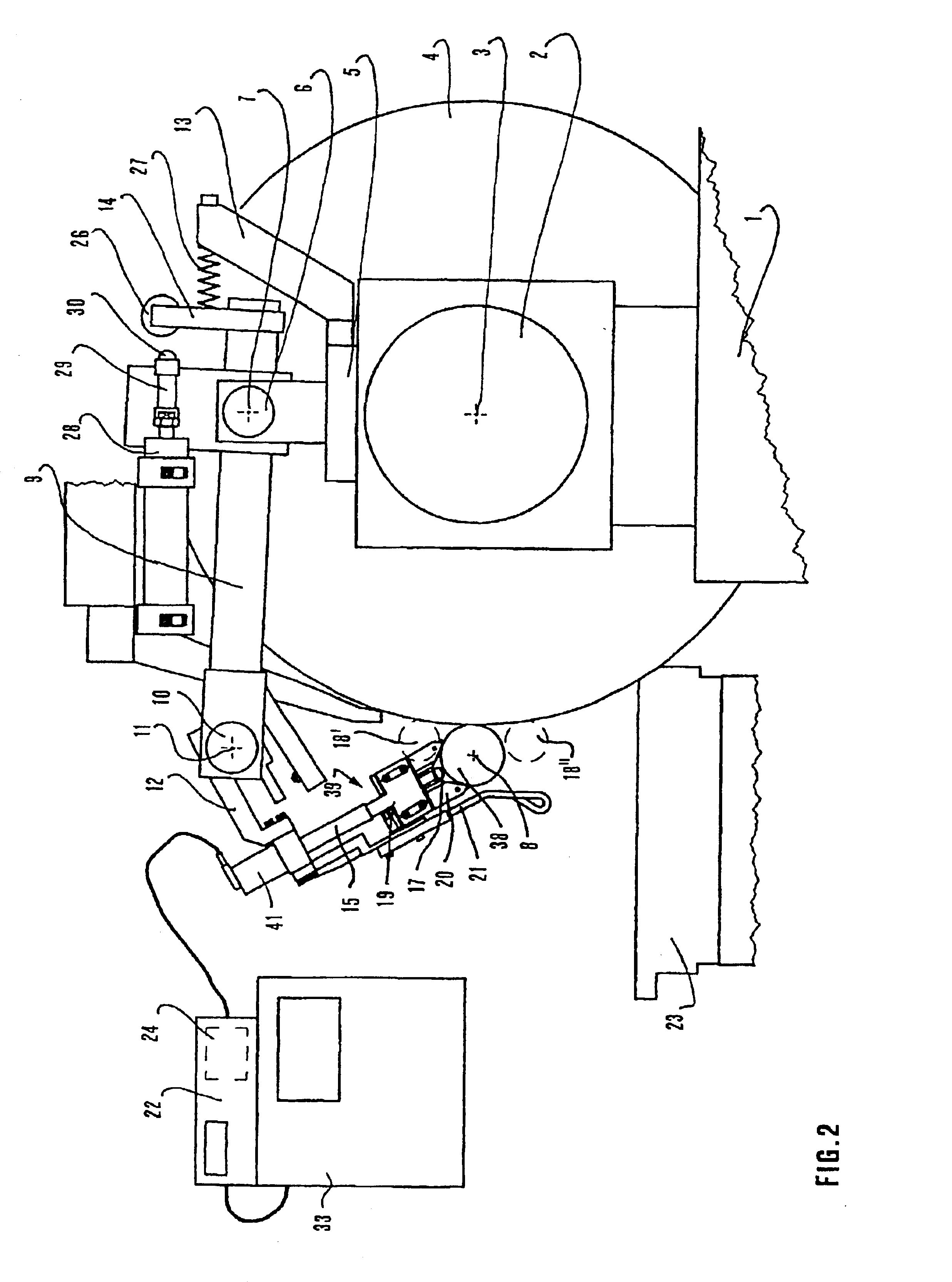

Deterministic magnetorheological finishing

InactiveUS6106380AConstantHigh viscosityEdge grinding machinesNanomagnetismMaterial removalMagnetorheological finishing

A method and apparatus for finishing a workpiece surface using MR fluid is provided wherein the workpiece is positioned near a carrier surface such that a converging gap is defined between a portion of the workpiece surface and the carrier surface; a magnetic field is applied substantially at said gap; a flow of stiffened MR fluid is introduced into said converging gap such that a work zone is created in the MR fluid to form a sub-aperture transient finishing tool for engaging and causing material removal at the portion of the workpiece surface; and the workpiece or the work zone is moved relative to the other to expose different portions of the workpiece surface to the work zone for predetermined time periods to selectively finish said portions of said workpiece surface to predetermined degrees.

Owner:QED TECH INT

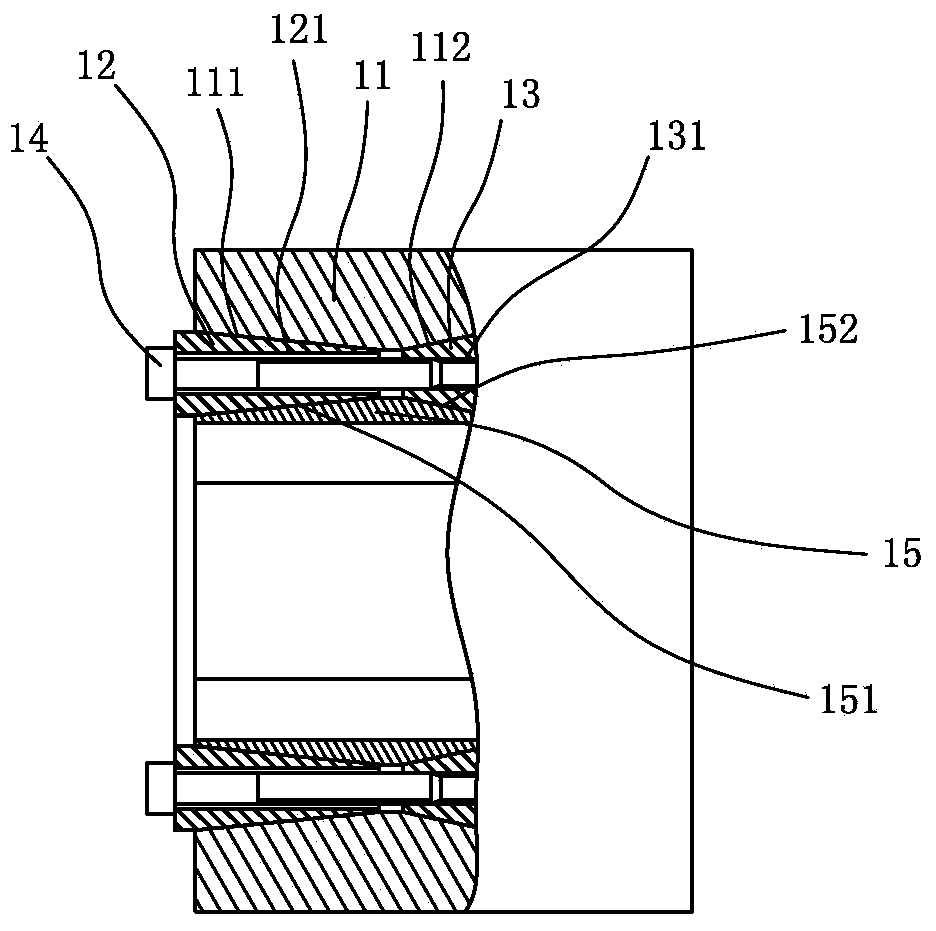

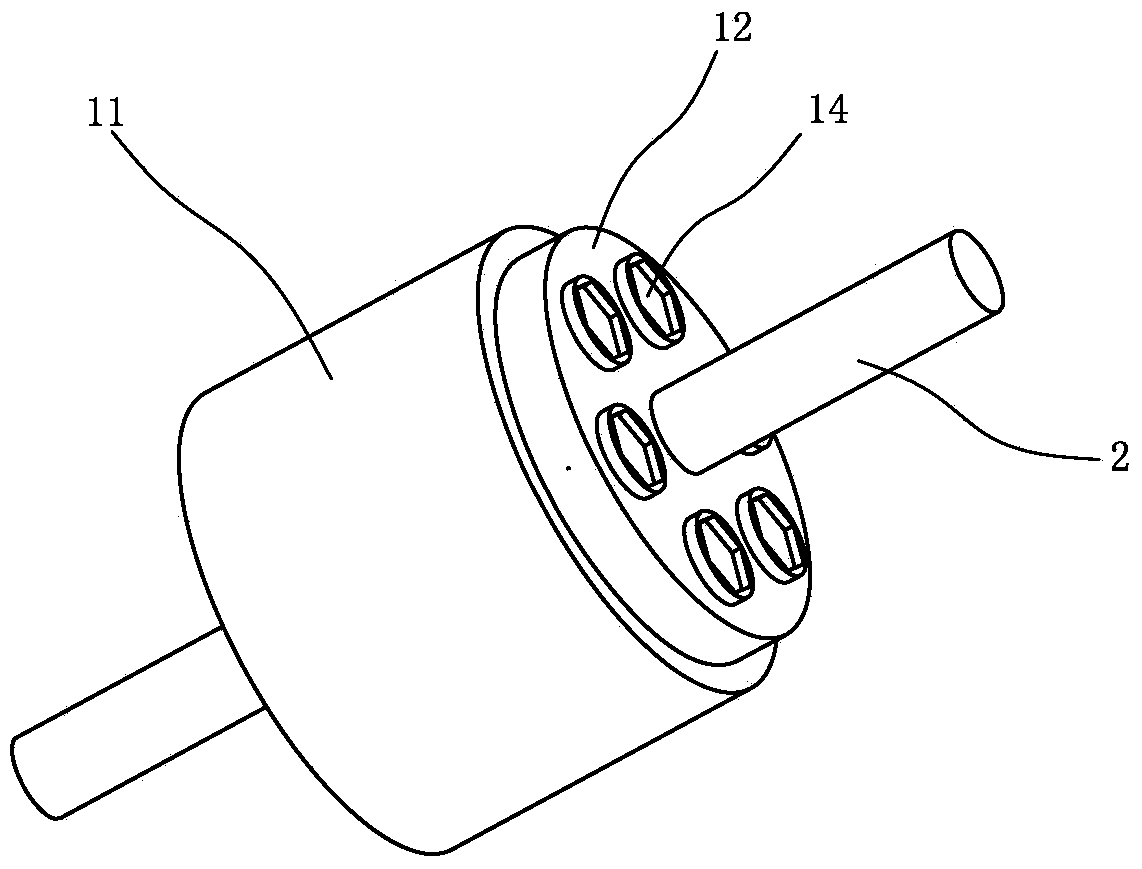

Axial shiftable type abrasive wheel and intelligent adjustment device thereof

ActiveCN103707182ARealize automatic tighteningAchieve releaseGrinding machine componentsEngineeringMechanical engineering

The invention provides an axial shiftable type abrasive wheel and an intelligent adjustment device of the axial shiftable type abrasive wheel. The abrasive wheel is adjustably arranged on a spindle and comprises a cylindrical abrasive wheel body, an elastic locking sleeve and a tightening mechanism, wherein the elastic locking sleeve is movably arranged on the spindle, and the tightening mechanism is arranged between the abrasive wheel body and the elastic locking sleeve. Two conical inner walls are formed on the abrasive wheel body, two conical outer walls opposite to the conical inner walls are formed on the elastic locking sleeve, and two wedge-shaped grooves are formed between the two conical inner walls and the two conical outer walls, wherein openings of the two wedge-shaped grooves are formed in the two ends of the abrasive wheel body. The tightening mechanism comprises two wedge-shaped lantern rings and a plurality of bolts, wherein the two wedge-shaped lantern rings are embedded into the two wedge-shaped grooves and can shrink and expand, the bolts are connected between the two wedge-shaped lantern rings, one wedge-shaped lantern ring is provided with through holes which are transversely through and allow the bolts to penetrate through, the other wedge-shaped lantern ring is provided with screw holes matched with the bolts, the two wedge-shaped lantern rings can be driven to move oppositely by screwing up the bolts, the wedge-shaped lantern rings expand under the effect of the wedge-shaped grooves to apply radial force to the elastic locking sleeve, and then the elastic locking sleeve clasps the spindle.

Owner:QUANZHOU SHUANGYANG DIAMOND TOOL

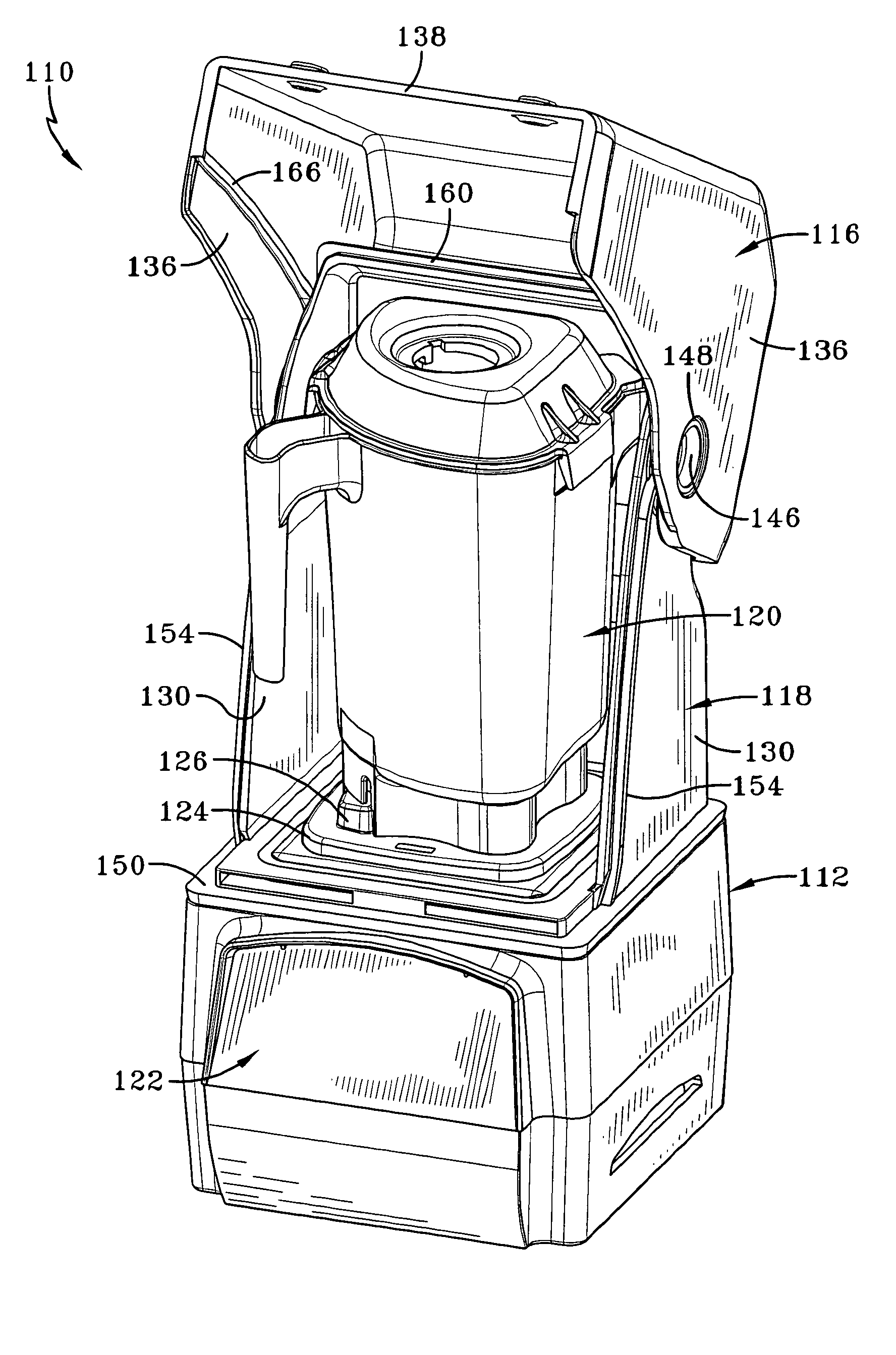

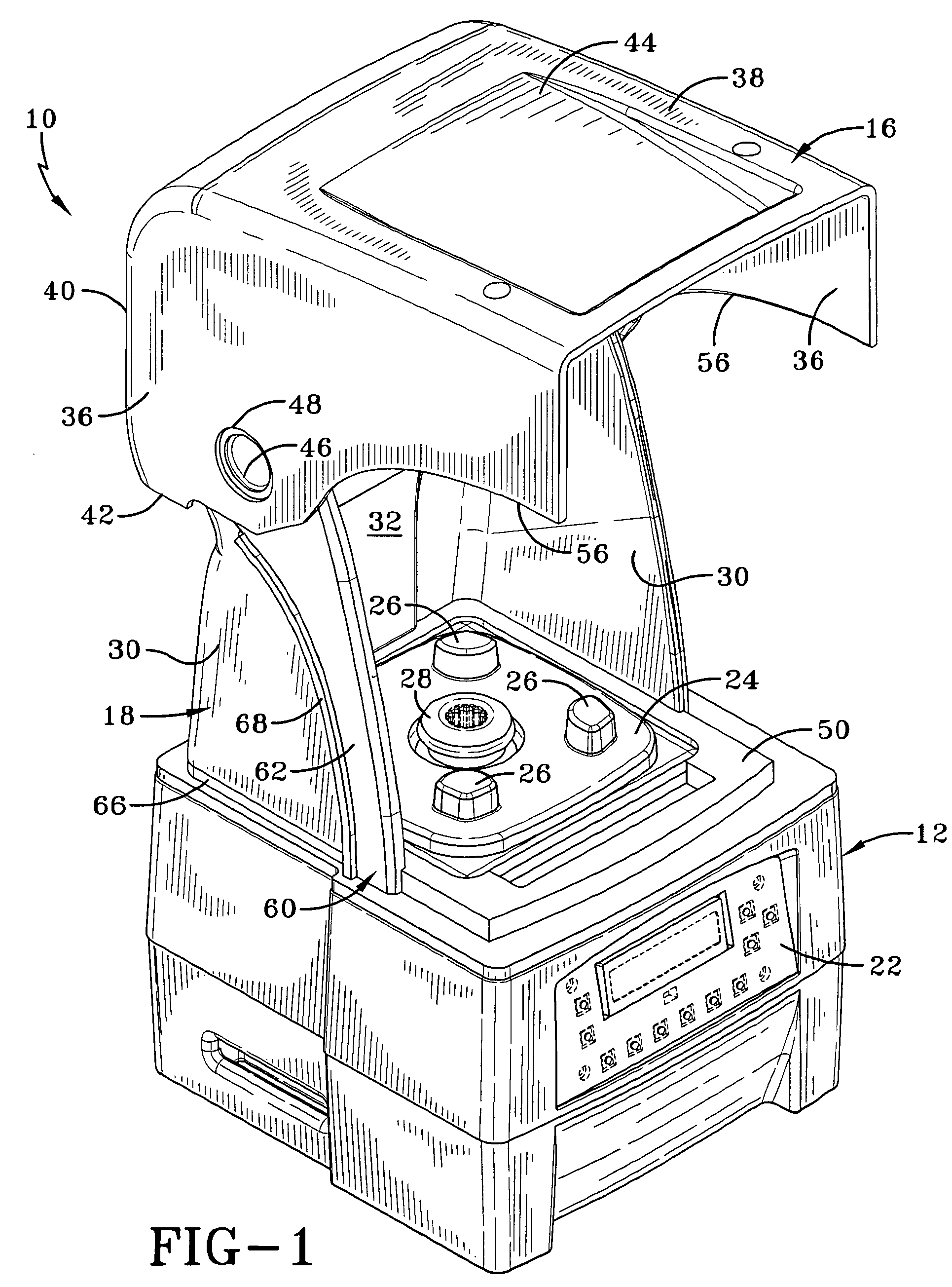

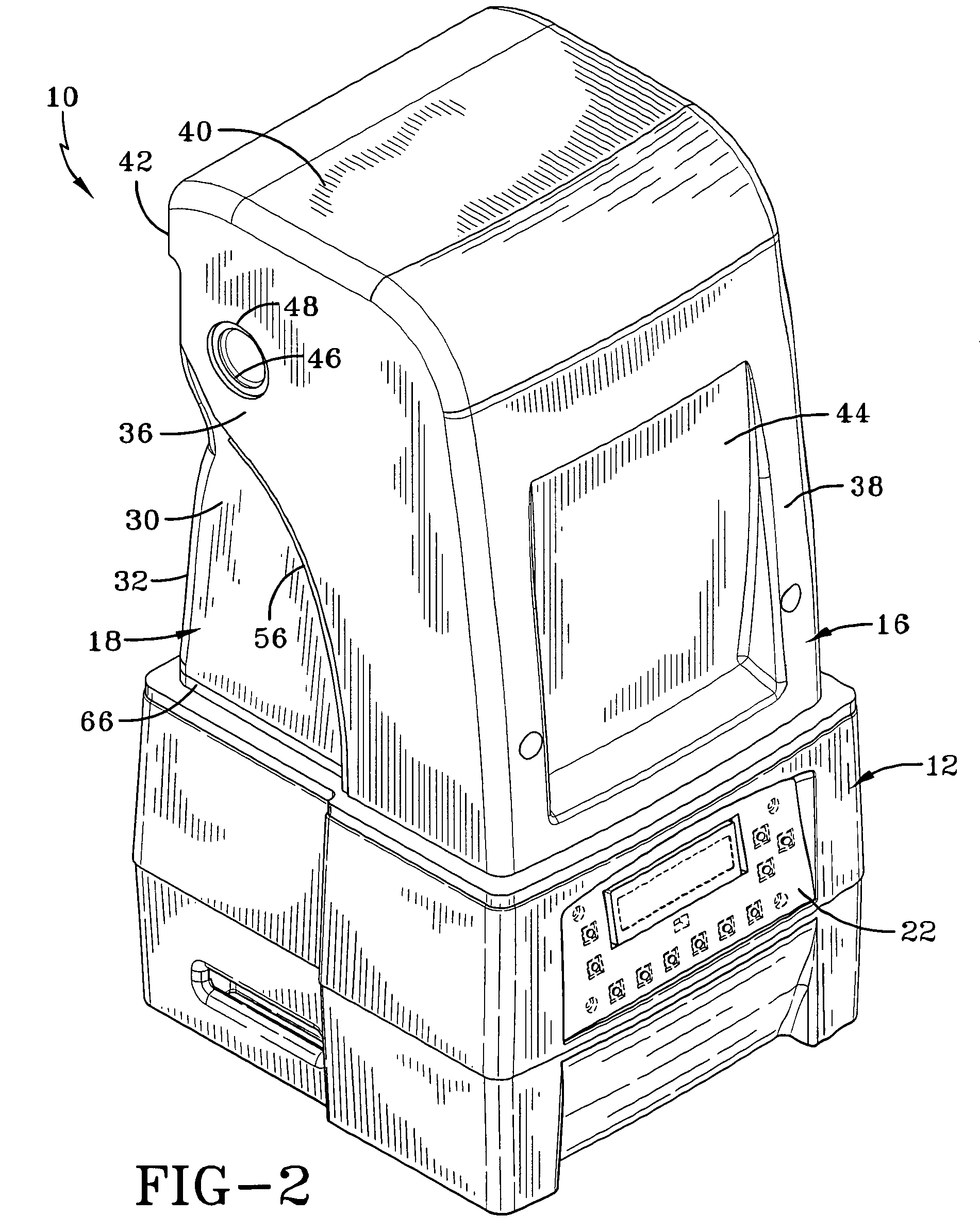

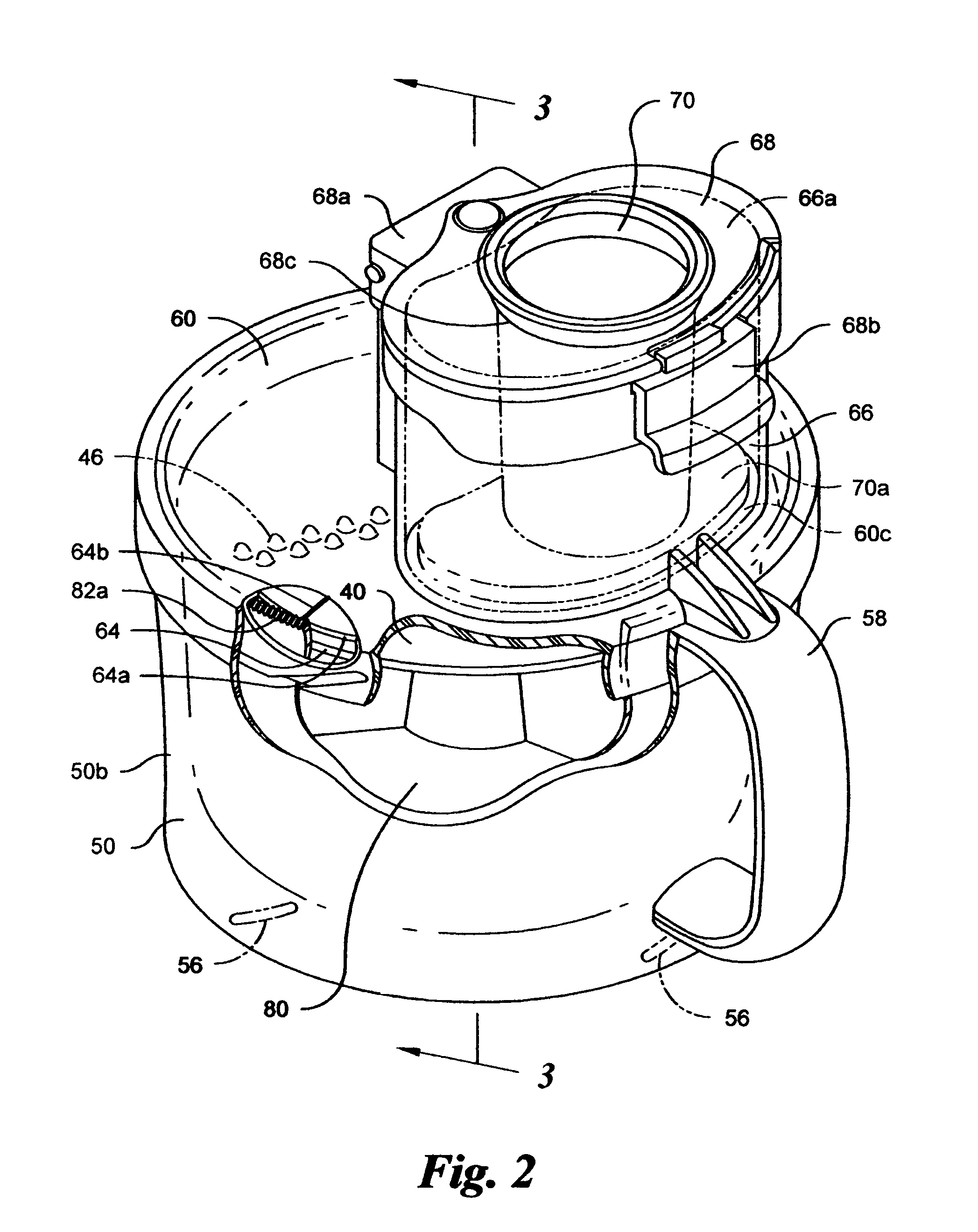

Sealing enclosure for a blender

ActiveUS8087603B2Reduce noise levelGrinding machine componentsTransportation and packagingEngineeringFlange

An enclosure for a blender including a body portion adapted to be secured to a base, and a cover pivotally attached to the body portion. The body portion includes sidewalls, a back wall, and an abbreviated top wall. The cover includes sidewalls, a front wall, a top wall, and an abbreviated back wall. A flange extends outwardly from the sidewalls and the top wall of the body portion and a gasket is provided thereon to create a seal between the cover and the body portion of the enclosure.

Owner:VITA MIX MANAGEMENT

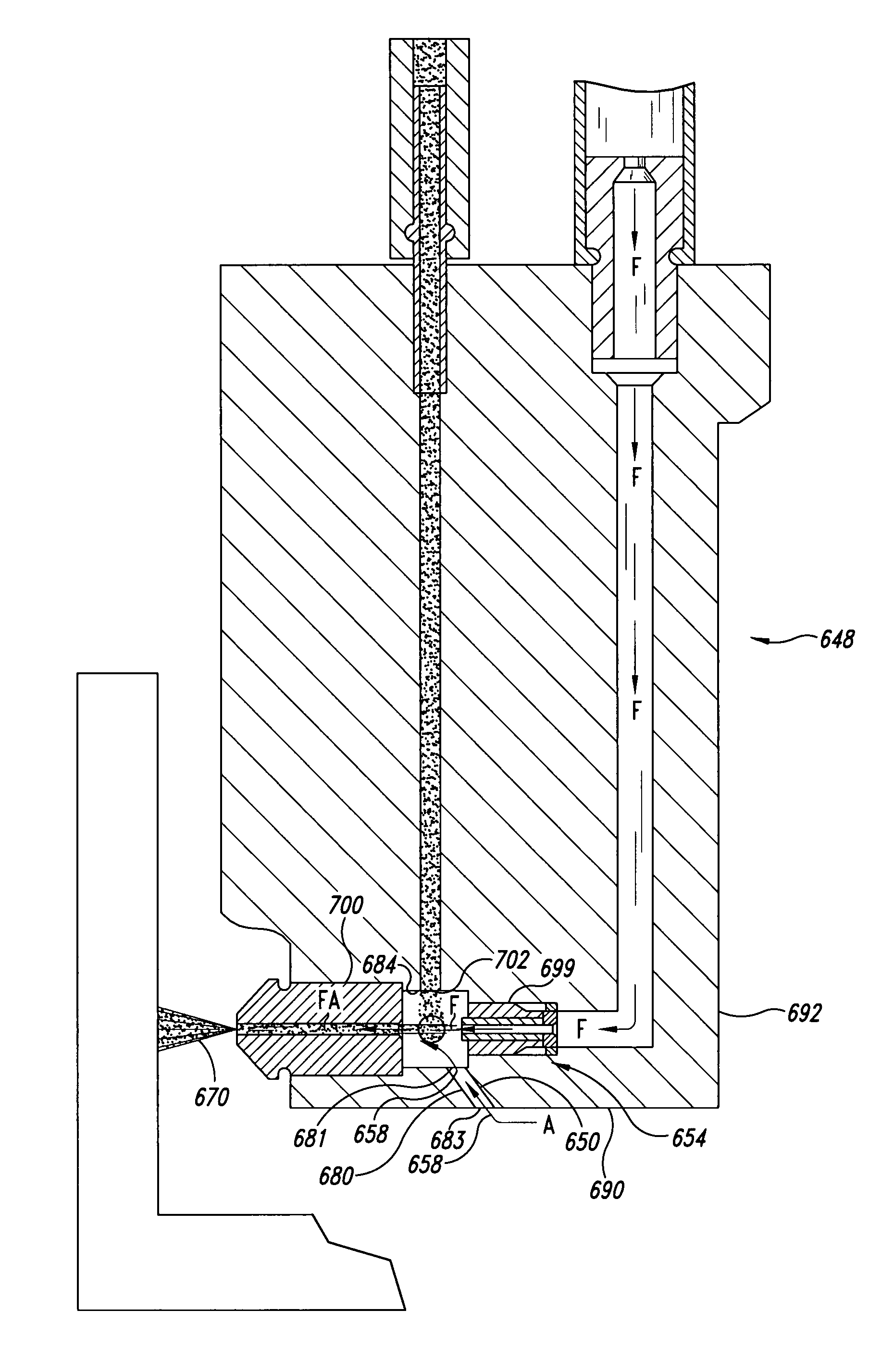

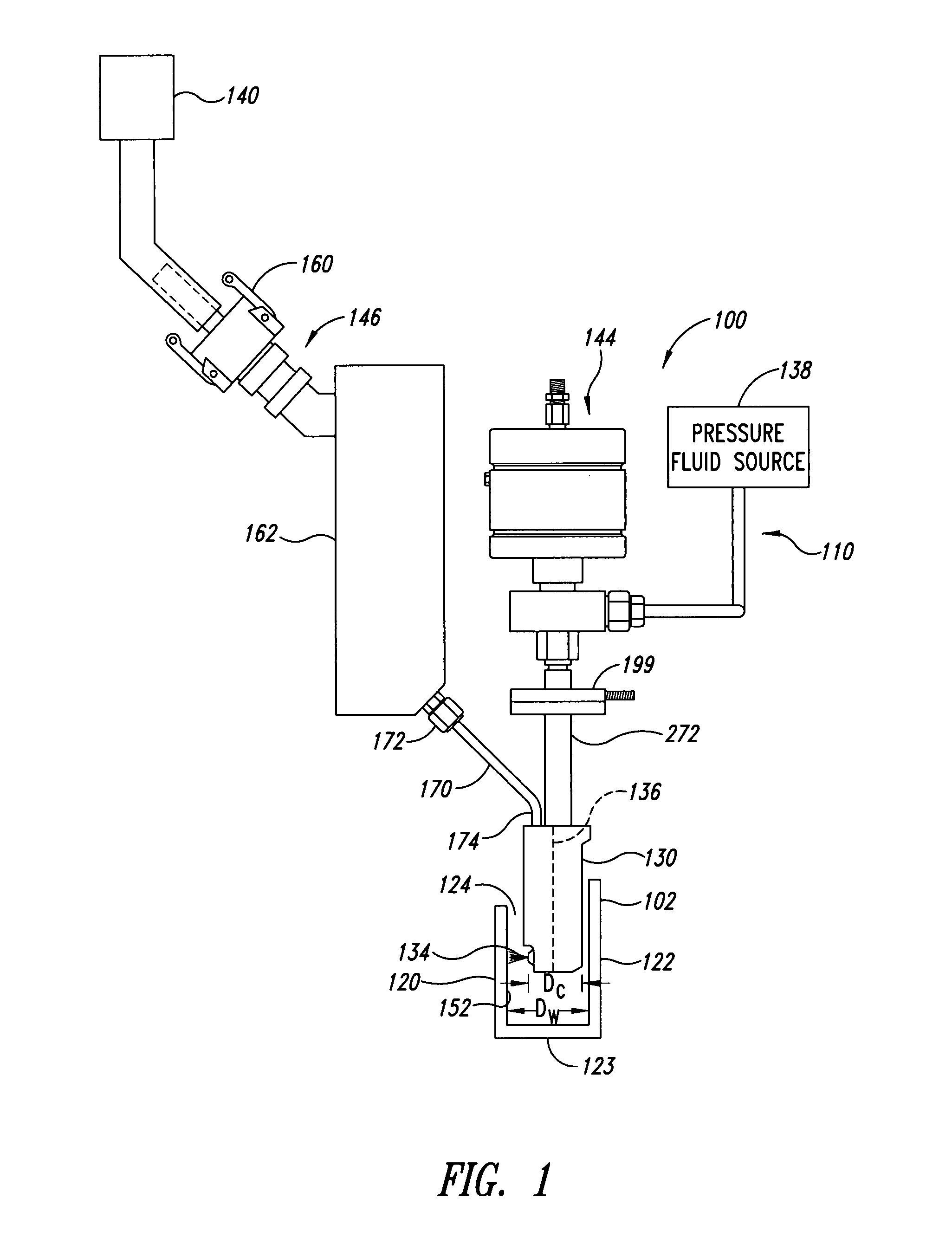

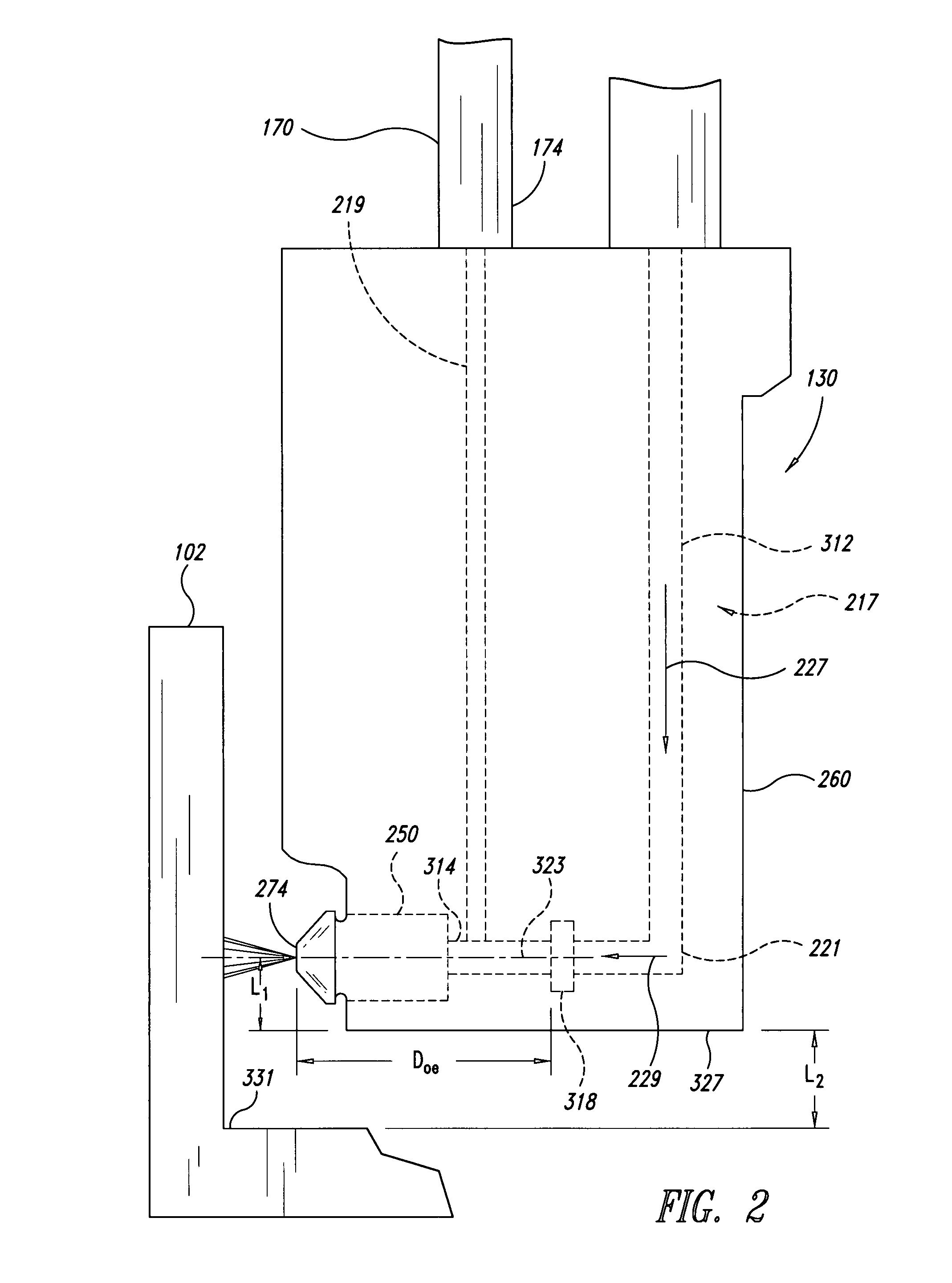

Apparatus and process for formation of laterally directed fluid jets

ActiveUS20090071303A1Liquid surface applicatorsGrinding machine componentsSpray nozzleMechanical engineering

A processing apparatus is provided to process a workpiece. The processing apparatus can have a low-profile nozzle system capable of navigating through spaces in order to process target regions with relatively small clearances. A fluid jet outputted from the nozzle system is used to cut, mill, or otherwise process the target region of the workpiece.

Owner:FLOW INT

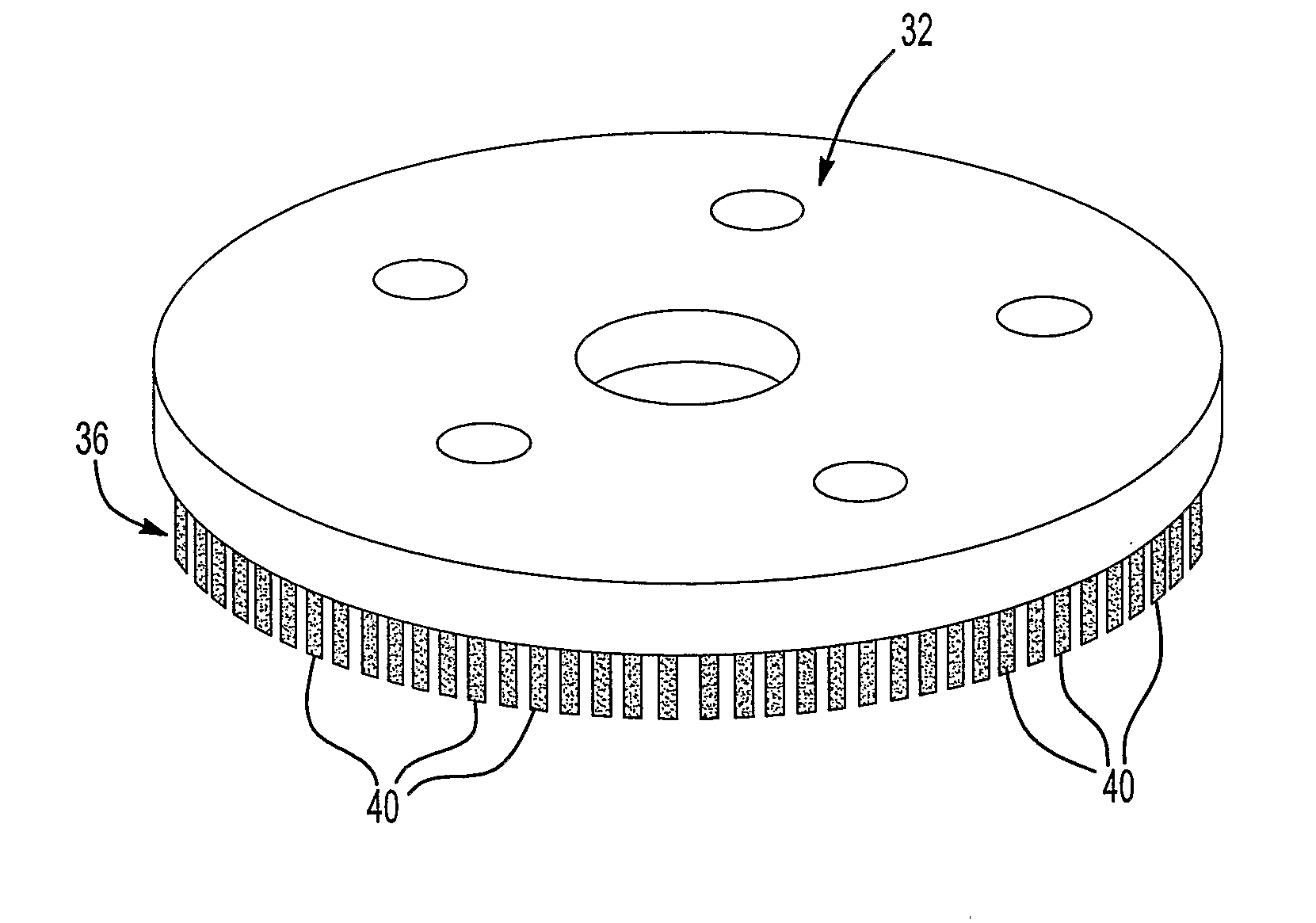

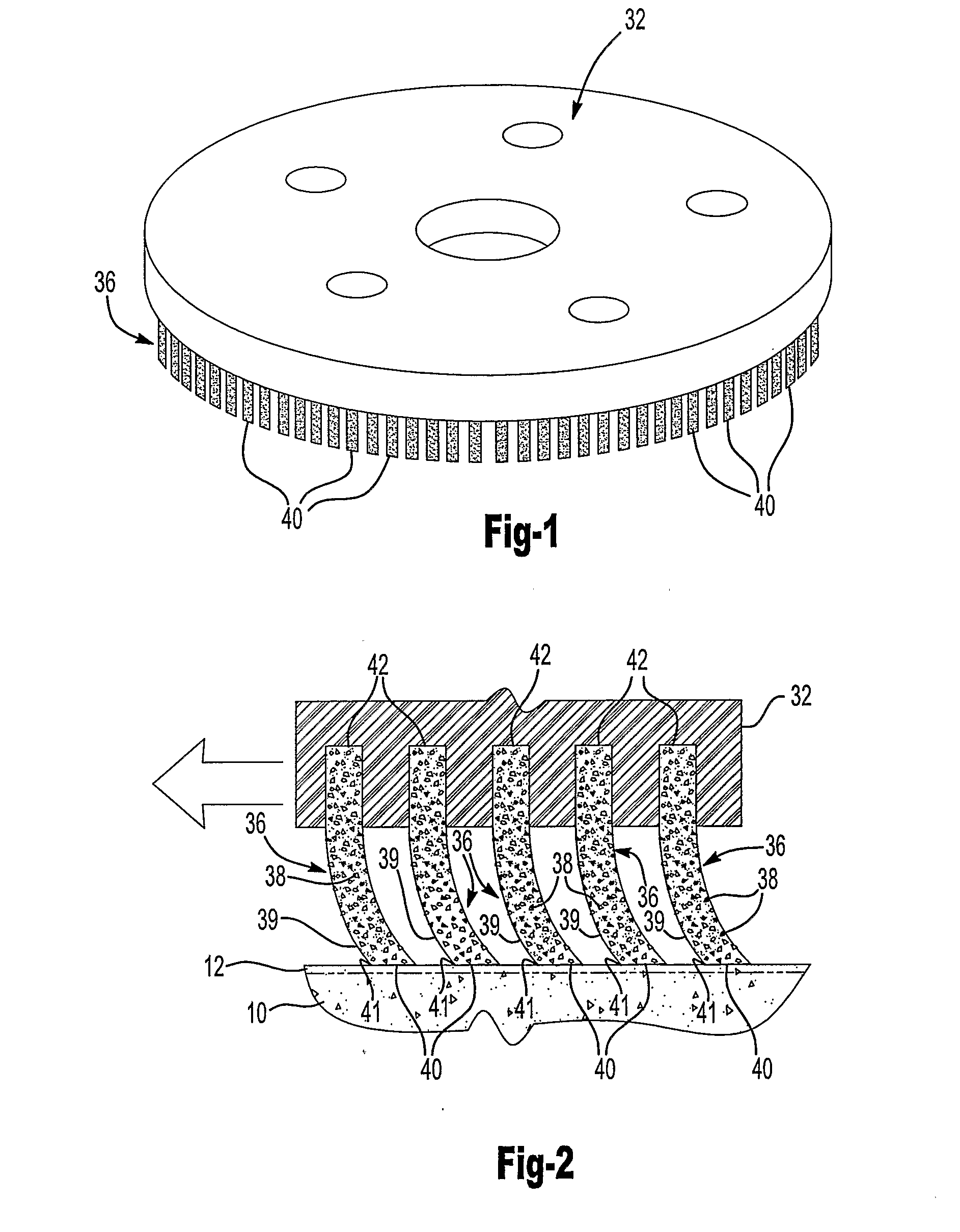

Abrasive Cleaning Device

ActiveUS20080160886A1Improve sanding effectStay flexibleGrinding machine componentsBrush bodiesSurface mountingEngineering

Owner:DIAMABRUSH

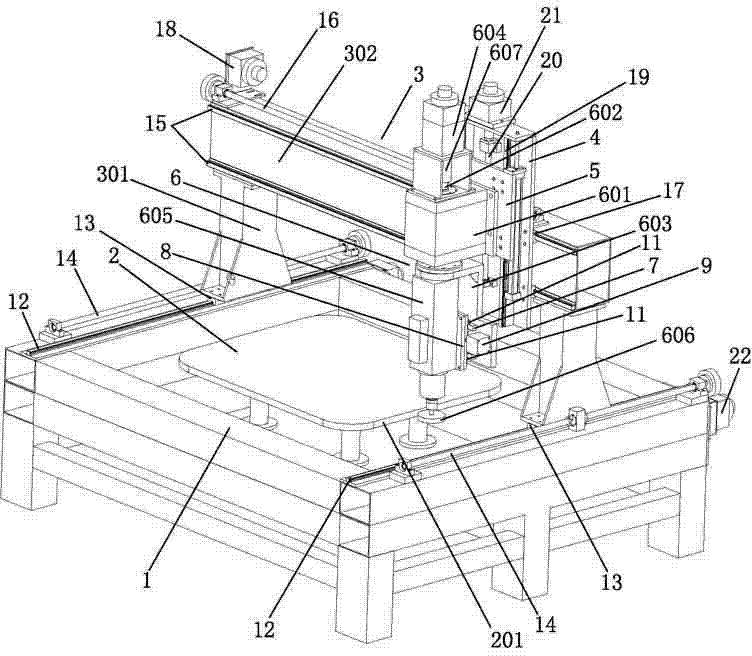

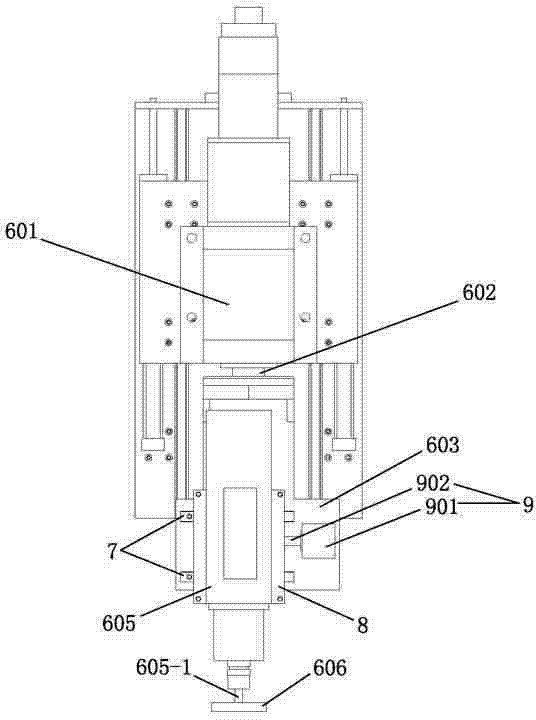

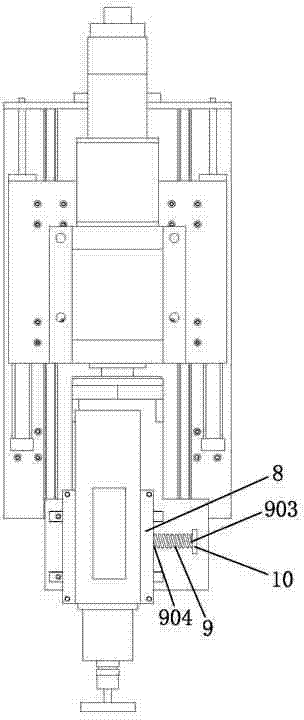

Novel numerically controlled special-shaped glass edge grinding machine

InactiveCN104759962AEnsure consistencyBest force contact areaEdge grinding machinesGrinding machine componentsEngineeringSlide plate

The invention provides a novel numerically controlled special-shaped glass edge grinding machine. A glass workpiece is adsorbed on a frame; a portal frame sliding along the Y axis is mounted on the frame; an X-axis sliding plate sliding along the X axis is mounted on the portal frame; a Z-axis sliding plate sliding up and down along the Z axis is mounted on the X-axis sliding plate; a main shaft mechanism is mounted on the Z-axis sliding plate; a tilt-angle main shaft sleeve is fixed on the Z-axis sliding plate; a tilt-angle main shaft is mounted in the tilt-angle main shaft sleeve; one end of the tilt-angle main shaft is in driving connection with a tilt-angle servo motor, while the other end of the tilt-angle main shaft is connected with a tilt-angle rotating stand; a transversely sliding assembly is arranged on the tilt-angle rotating stand; a grinding head motor is connected to the transversely sliding assembly by use of a transversely sliding plate; an elastic compensation assembly for driving the transversely sliding plate to slide front and back is connected to one side of the transversely sliding plate; a cutting tool is mounted on the output shaft of the grinding head motor; an automatic grinding wheel compensation function can be realized, so that the cutting tool is always held down in contact with the glass workpiece in the grinding process; as a result, a consistent grinding effect can be achieved, and the glass workpiece can be consistent in smoothness after being ground.

Owner:刘忠文 +1

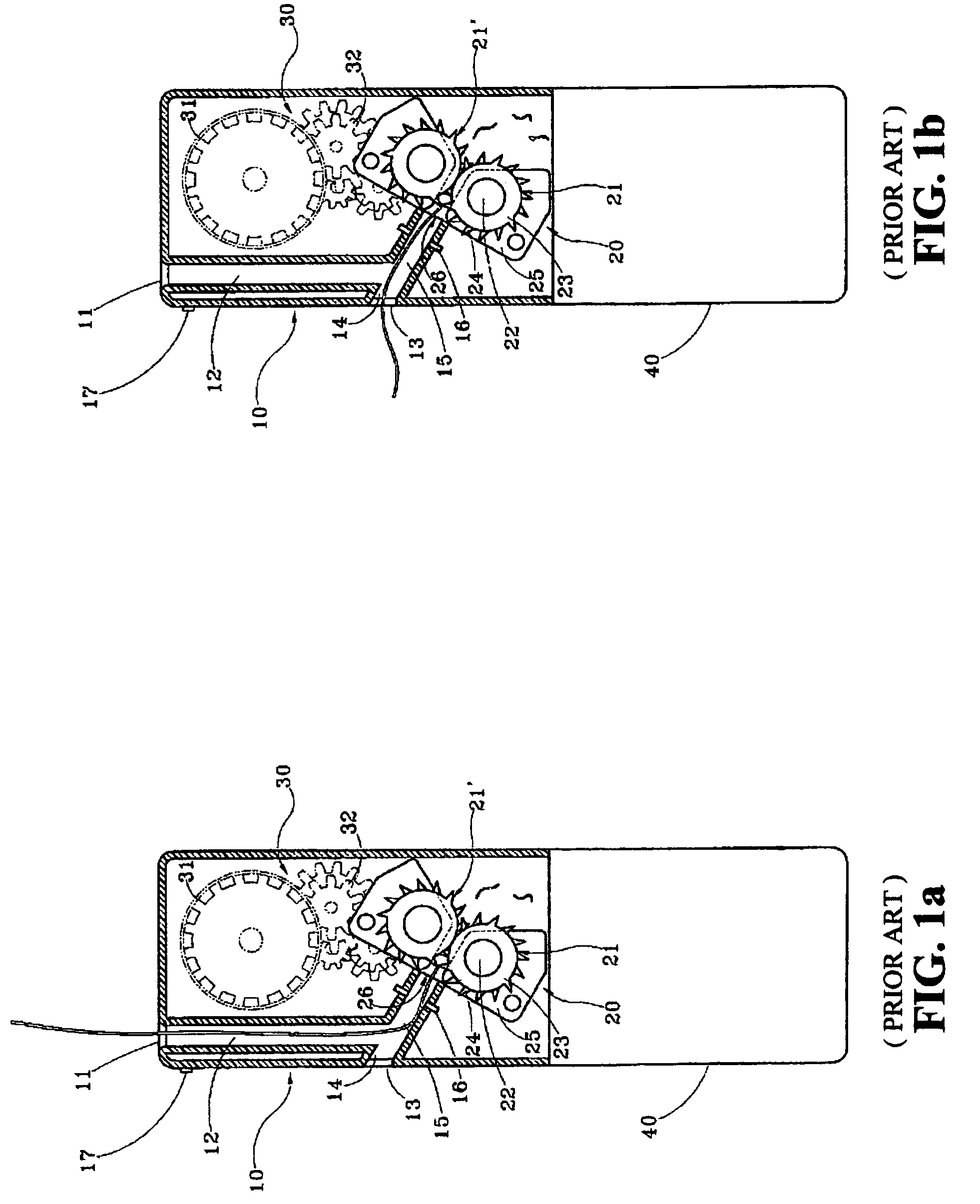

Paper shredder

InactiveUS7083131B2Eliminate disadvantagesGrinding machine componentsCocoaEngineeringMechanical engineering

Owner:INTELLECTUAL VENTURES I LLC

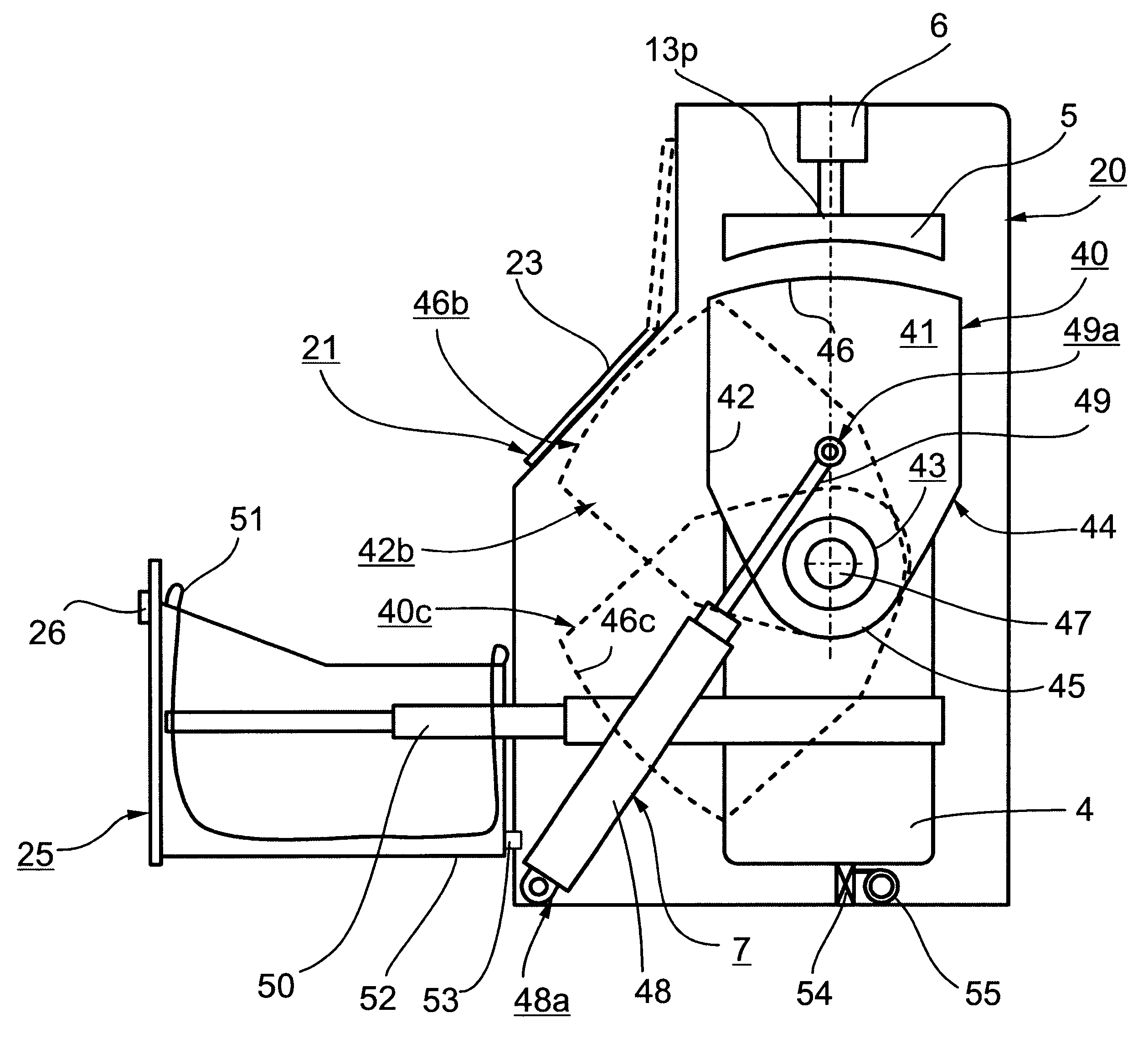

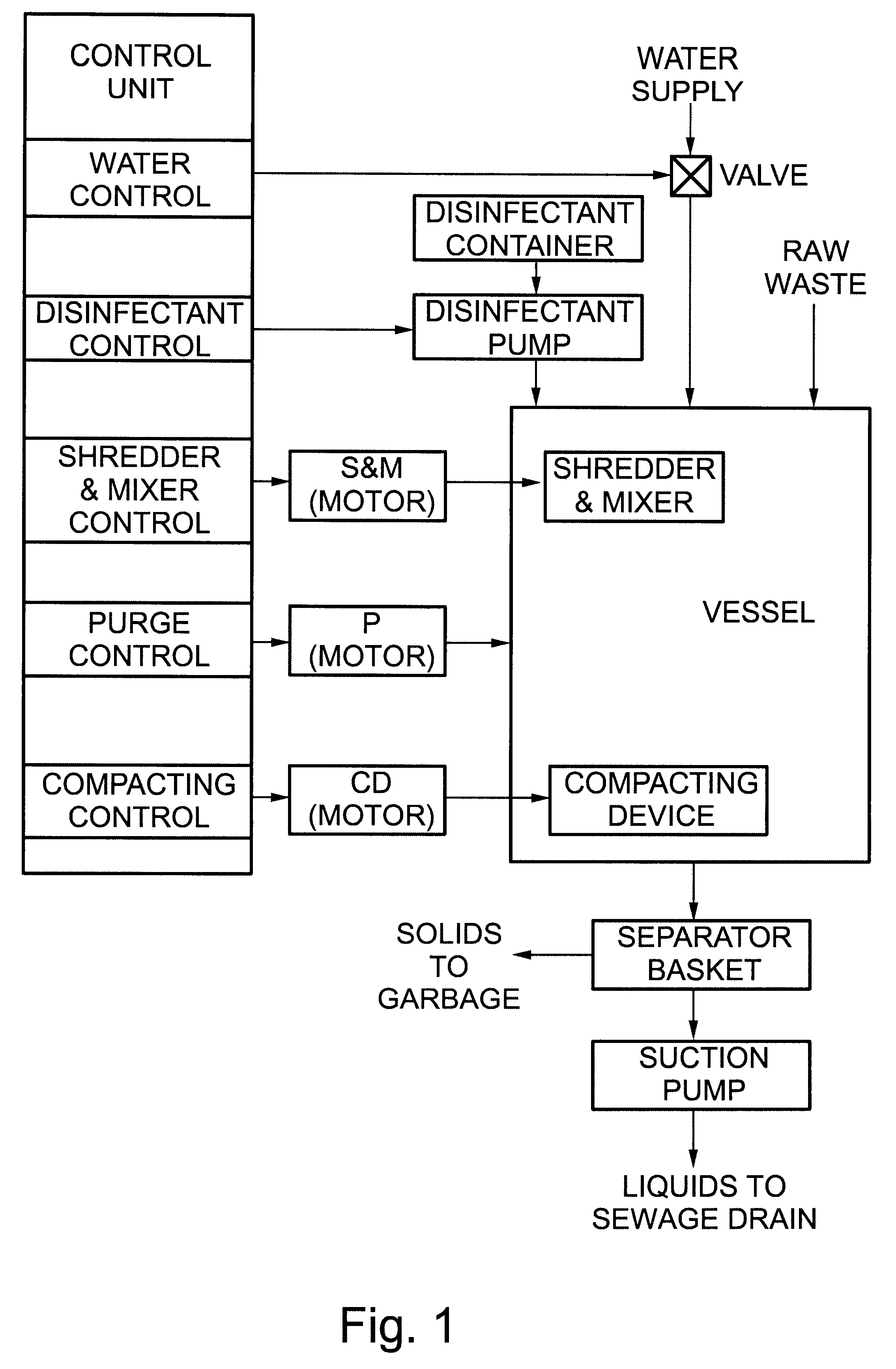

Apparatus for treating waste, particularly medical waste, to facilitate its disposition

InactiveUS6494391B2Simple and compactSuitable for useGrinding machine componentsGas current separationLine tubingDisinfectant

Apparatus for treating waste, particularly all types of medical waste, to facilitate its disposition includes a treatment vessel having an open top pivotal within a housing to a waste-loading position with its open top aligned with the housing inlet for receiving the waste, a waste-treating position for shredding the waste by a shredder unit disposed within the treatment vessel, and a waste-removing position with its open top aligned with the housing outlet for removing the shredded waste. The apparatus further include a compactor head for compacting the waste within the treatment vessel, a water feed line, and a disinfectant feed line, for feeding water and a disinfectant into the treatment vessel, for mixing with the waste while it is being compacted and shredded.

Owner:M C M ENVIRONMENTAL TECH INC

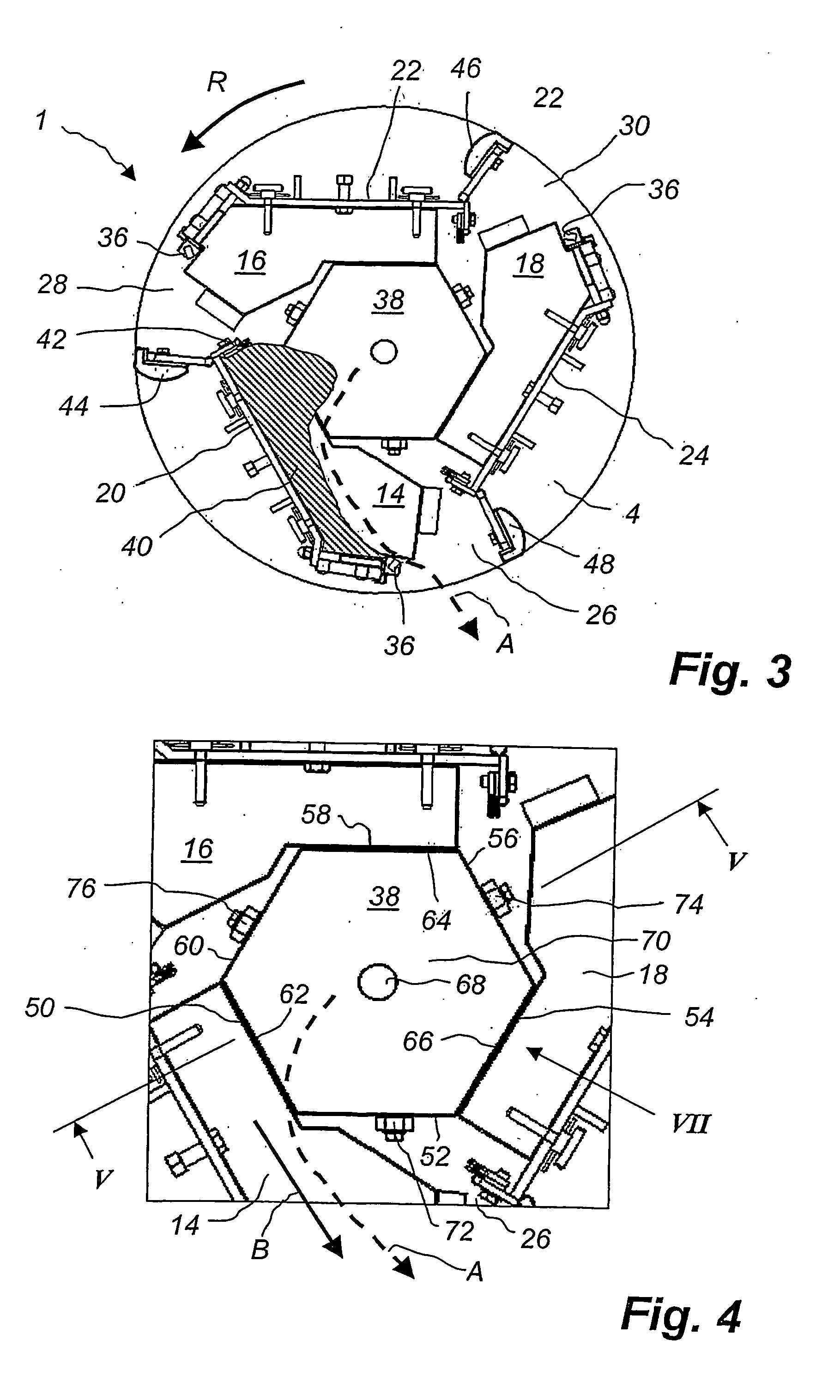

Wear part for a crusher

ActiveUS20060011762A1Solution to short lifeReduce downtimeGrinding machine componentsCocoaCrusherDistributor

A distributor plate adapted to be releasably mounted on a horizontal lower disc of a rotor of a vertical shaft impact crusher. The rotor has an opening for the intake of material to be crushed and at least one outflow opening for material leaving the rotor. The distributor plate is an equilateral polygon as seen from above.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

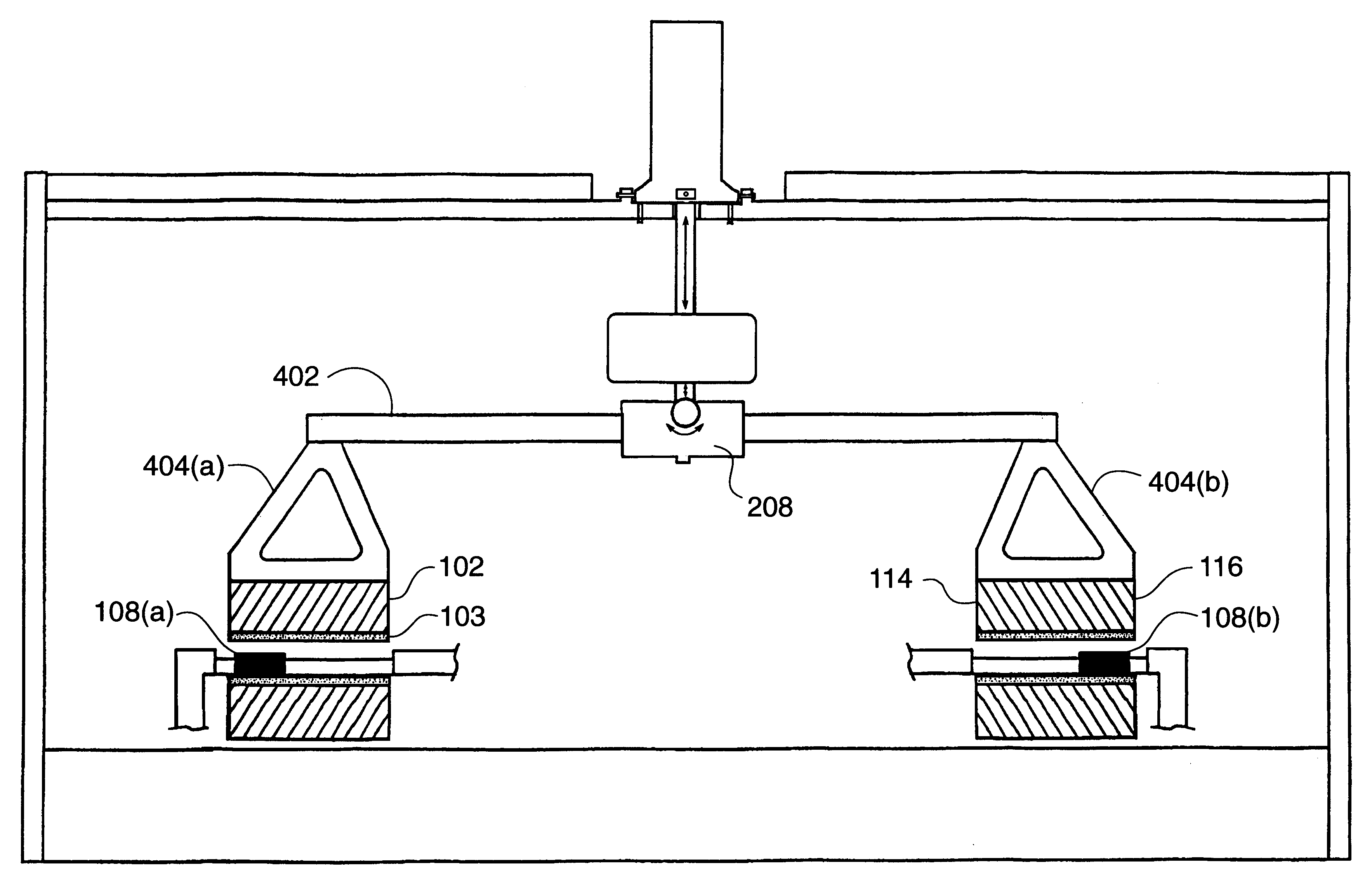

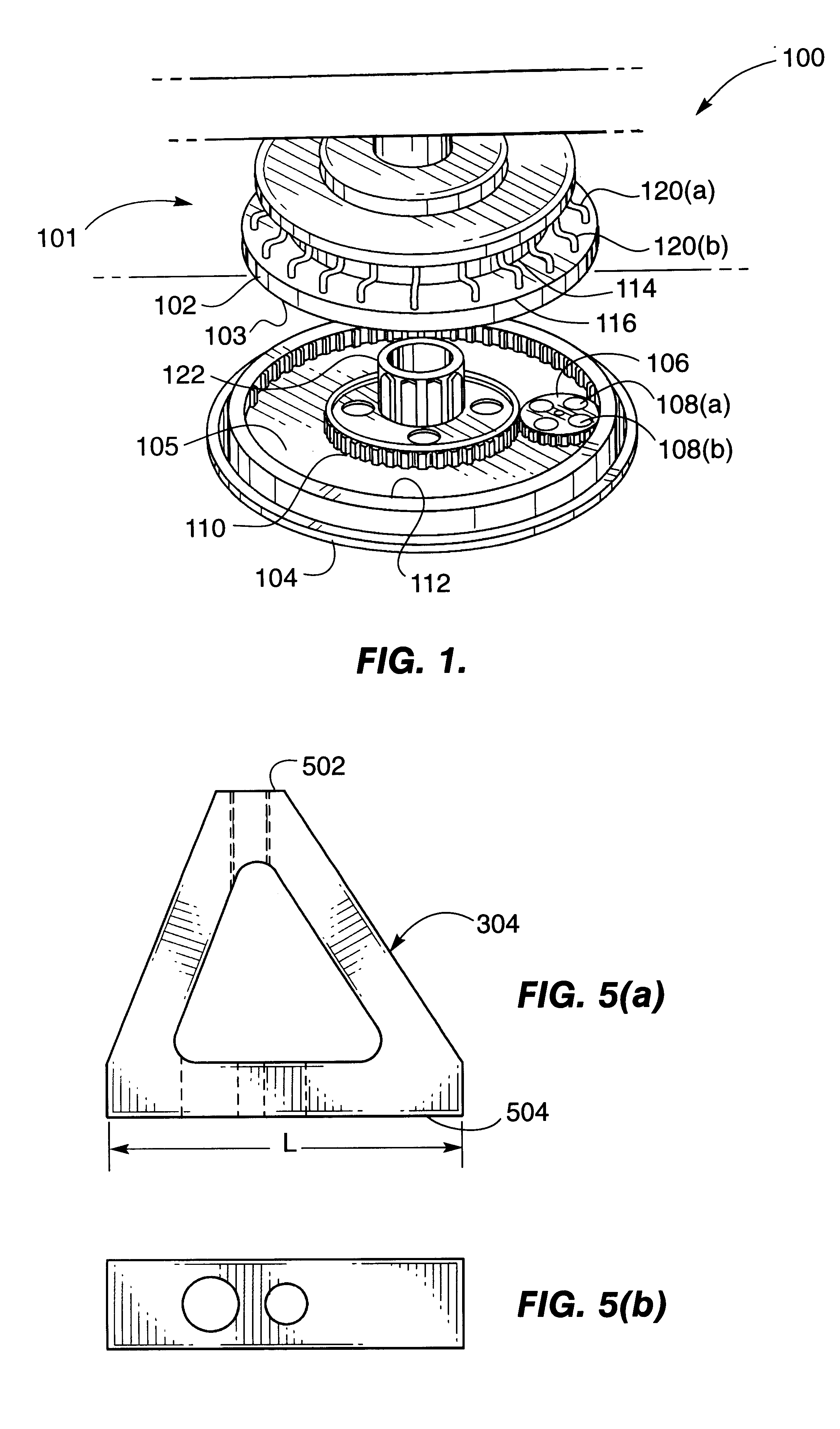

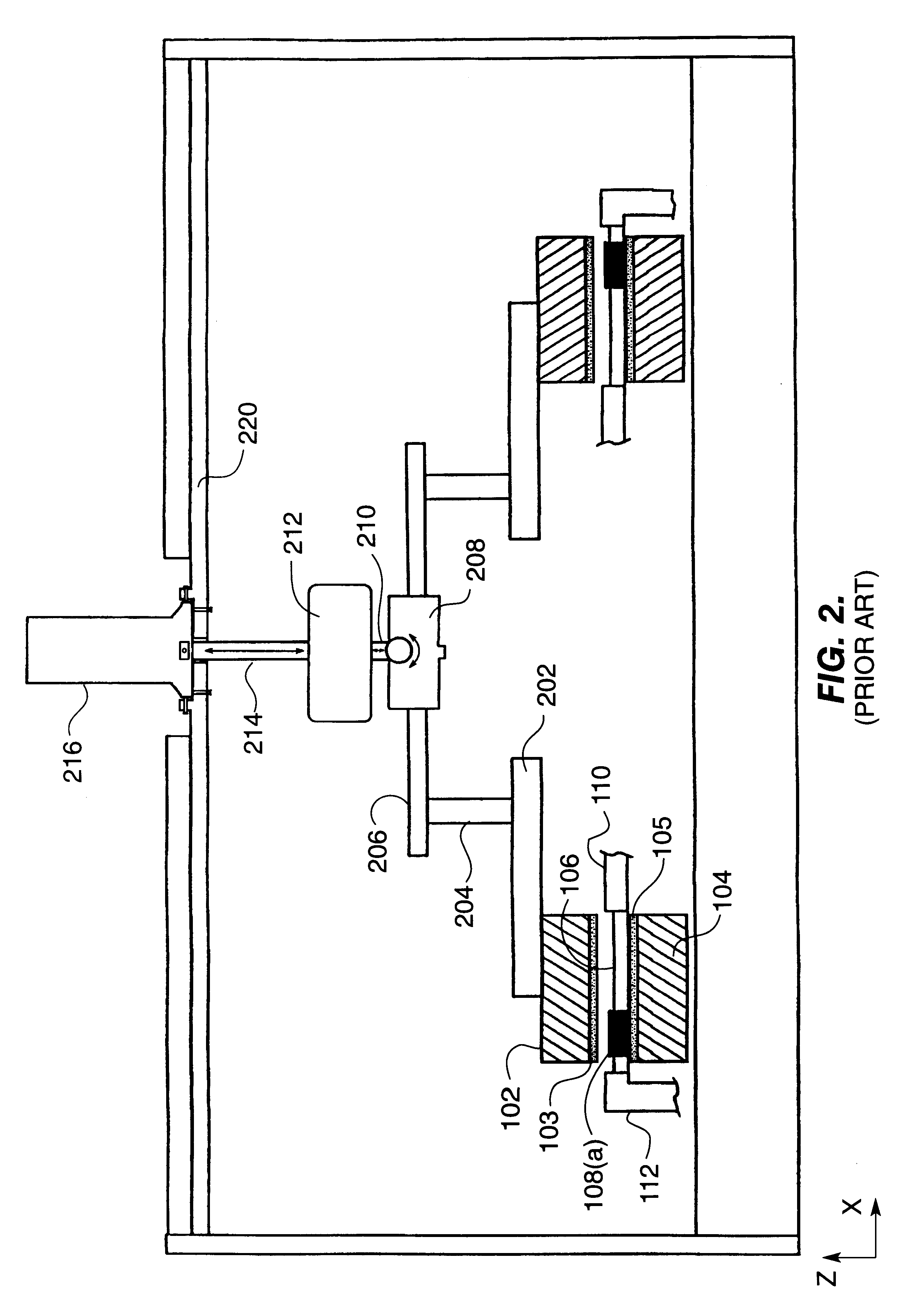

Apparatus for polishing using improved plate supports

InactiveUS6168506B1Reduce stress changesConstantEdge grinding machinesPolishing machinesRadial stressEngineering

A set of supports are advantageously disposed on a top plate having a polishing surface useful for polishing workpieces, thereby applying substantially uniform pressure to the top plate. In a preferred embodiment, the supports are non-isosceles triangular elements distributed evenly at 45 degree increments around a ring-shaped top plate. This structure effectively compensates for radial stress variations arising from non-optimum positioning of support points with respect to the inner and outer diameters of the polishing surface.

Owner:SPEEDFAM IPEC

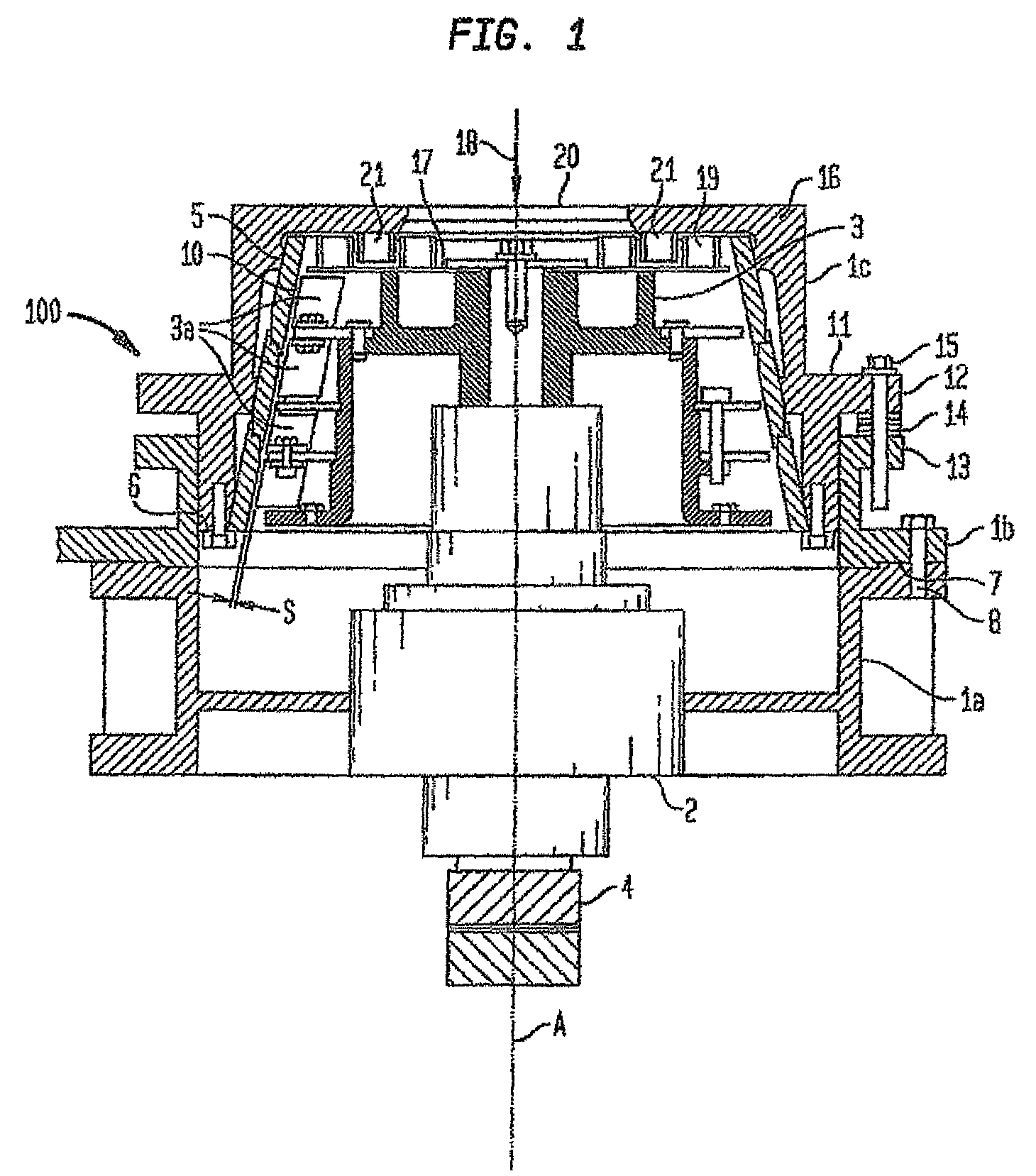

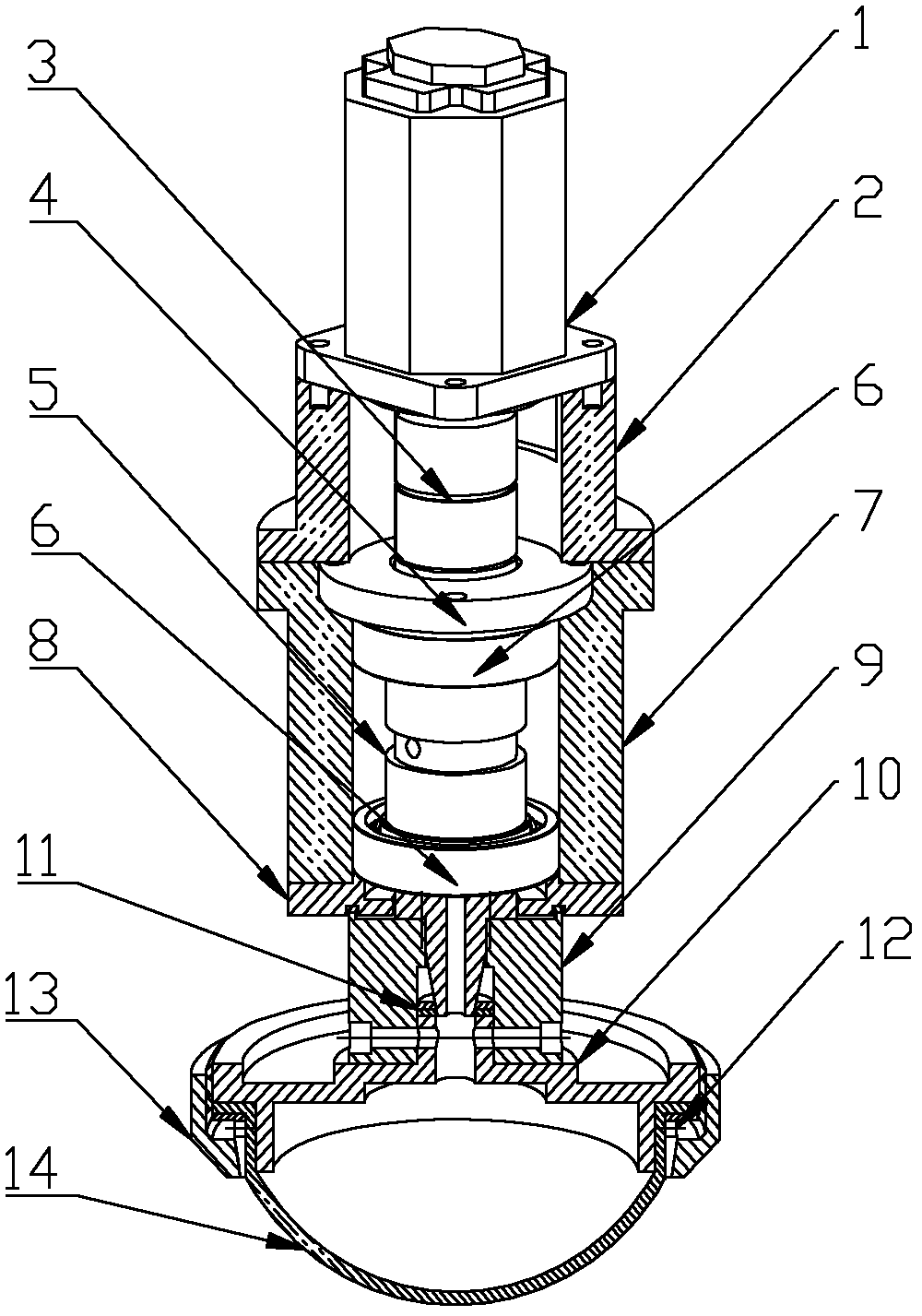

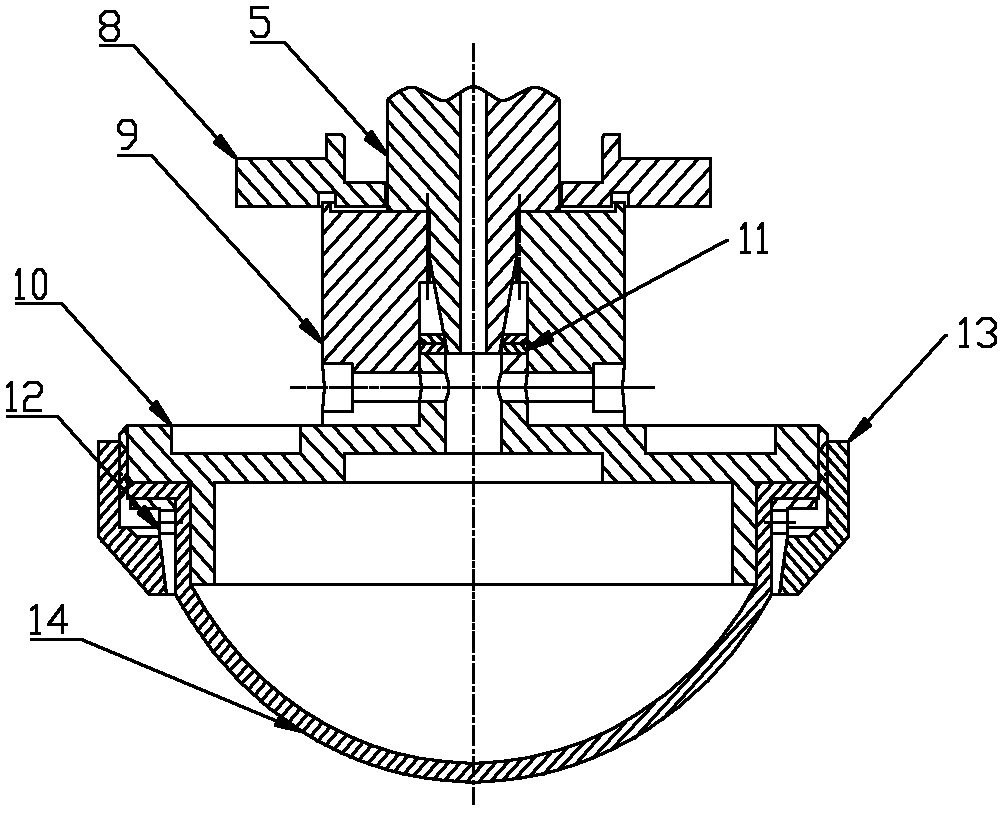

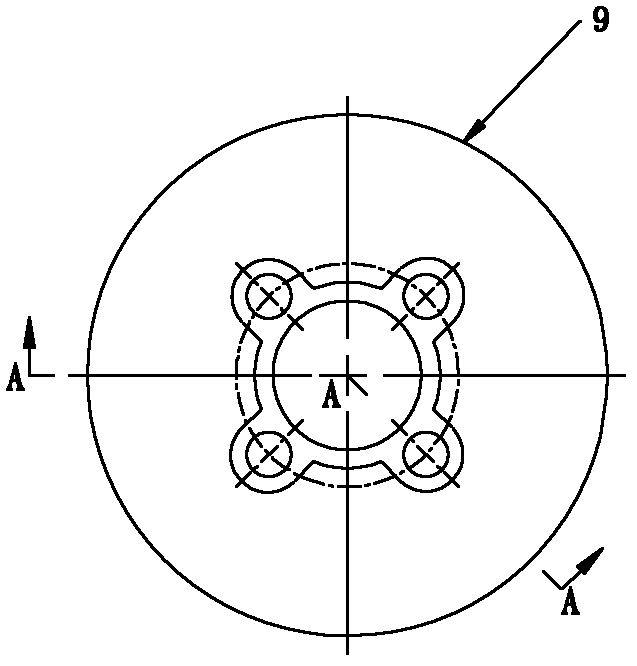

Dynamic load type flexible polishing head

ActiveCN102554749AEasy to assemble and disassembleFasten the connectionGrinding machine componentsPolishing machinesCouplingEngineering

The invention discloses a dynamic load type flexible polishing head and relates to a curve machining tool. The dynamic load type flexible polishing head is provided with a motor, a motor base, a coupling, an upper end cover, a rotating shaft, a bearing, a box body, a lower end cover, a front shaft sleeve, a shaft end connecting head, an elastic sleeve, a locking sleeve and an air bag, wherein the box body is connected below the motor base, the upper end cover is fixed on the box body, the lower end cover is fixed at the lower part of the box body, the front shaft sleeve is connected with the rotating shaft, the shaft end connecting head is connected with the front shaft sleeve, the air bag is fastened on the shaft end connecting head by the elastic sleeve, and the locking sleeve and the shaft end connecting head are joined with each other and clamp the elastic sleeve and the air bag between the locking sleeve and the shaft end connecting head.

Owner:XIAMEN UNIV

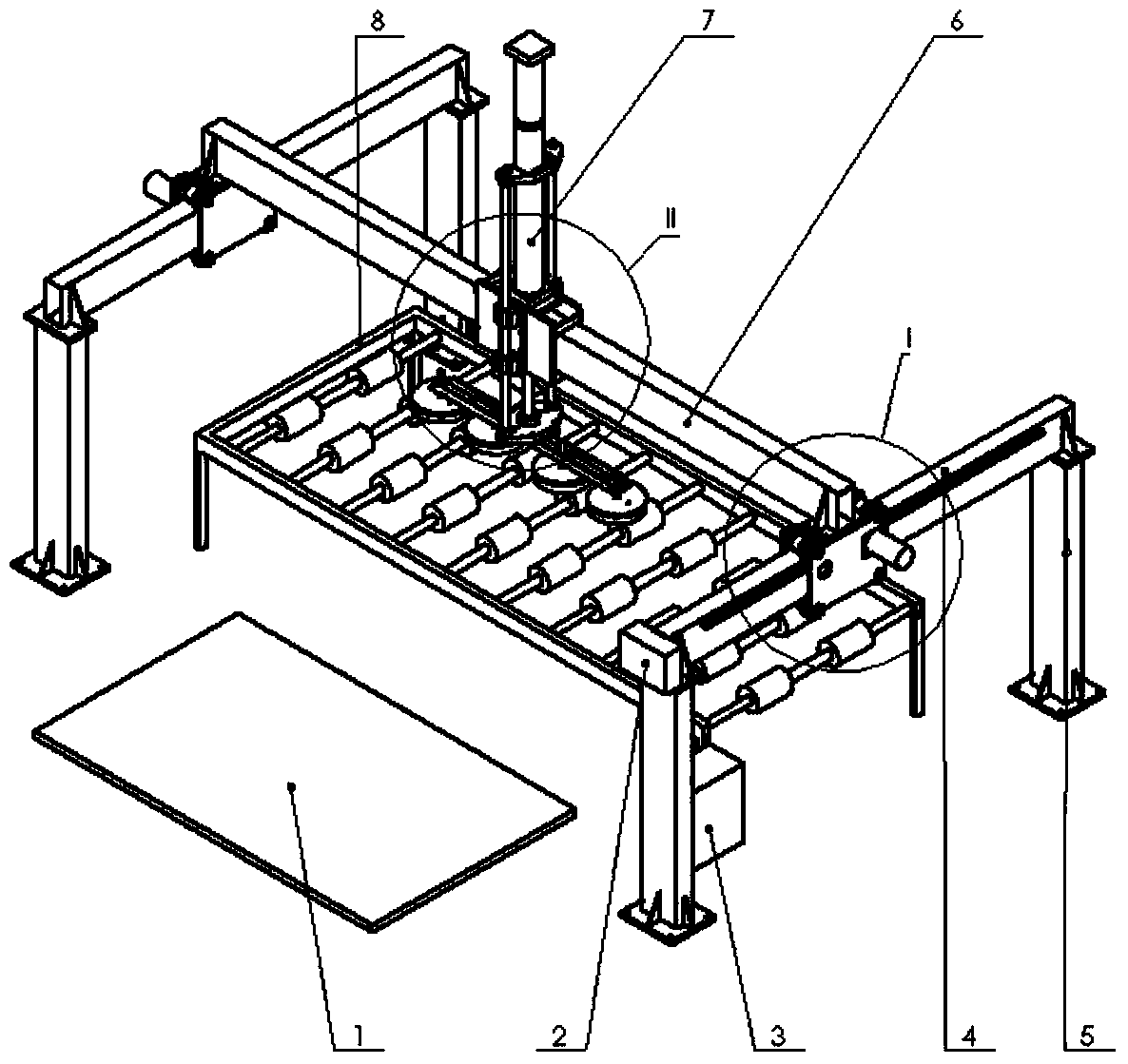

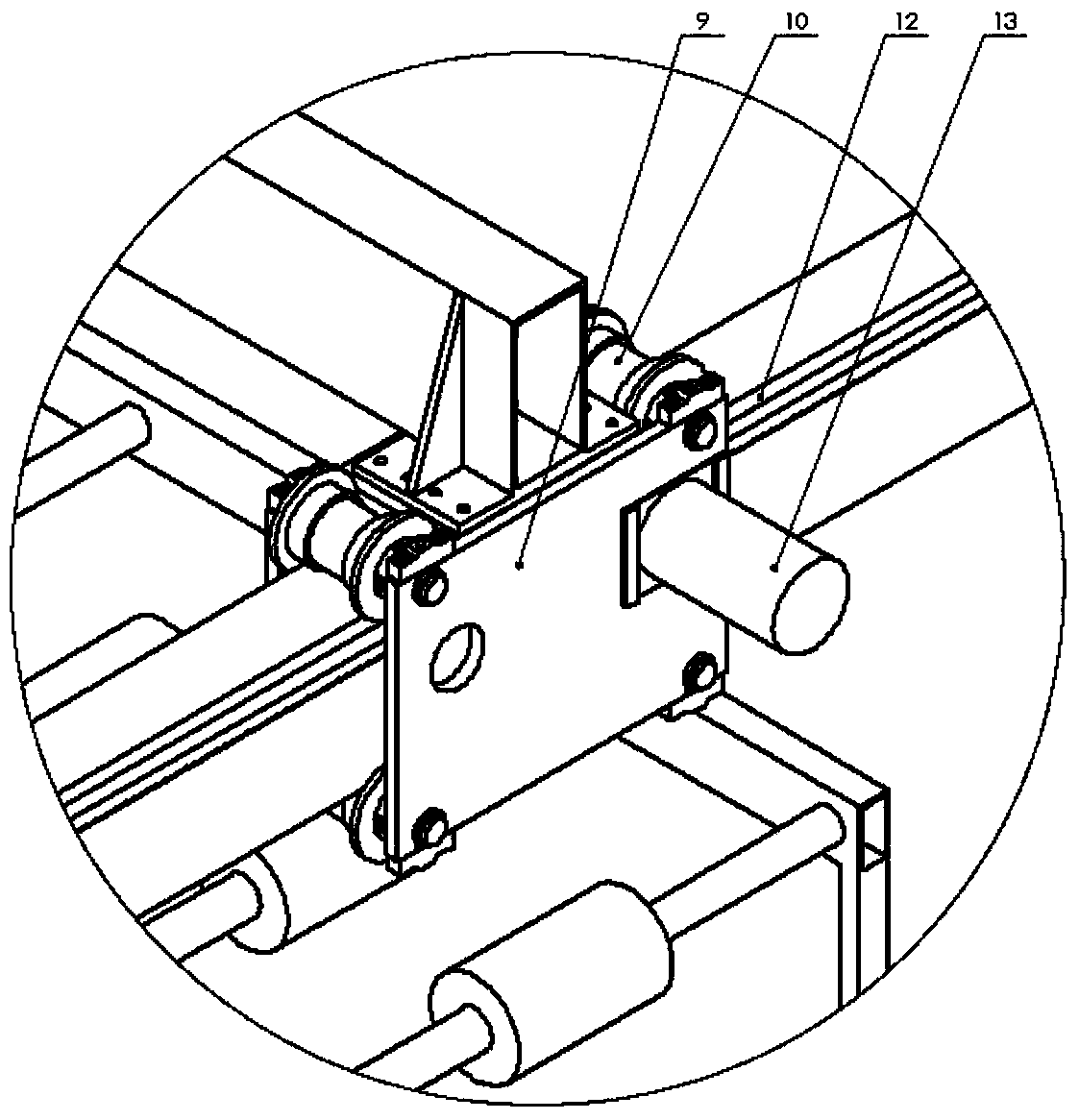

Device and method for automatic feeding and discharging of stone slabs

ActiveCN104176498ARealize automatic crawlingAchieve horizontal movementGrinding machine componentsConveyor partsMechanical engineeringTransverse beam

Owner:RIZHAO HEIN SAW

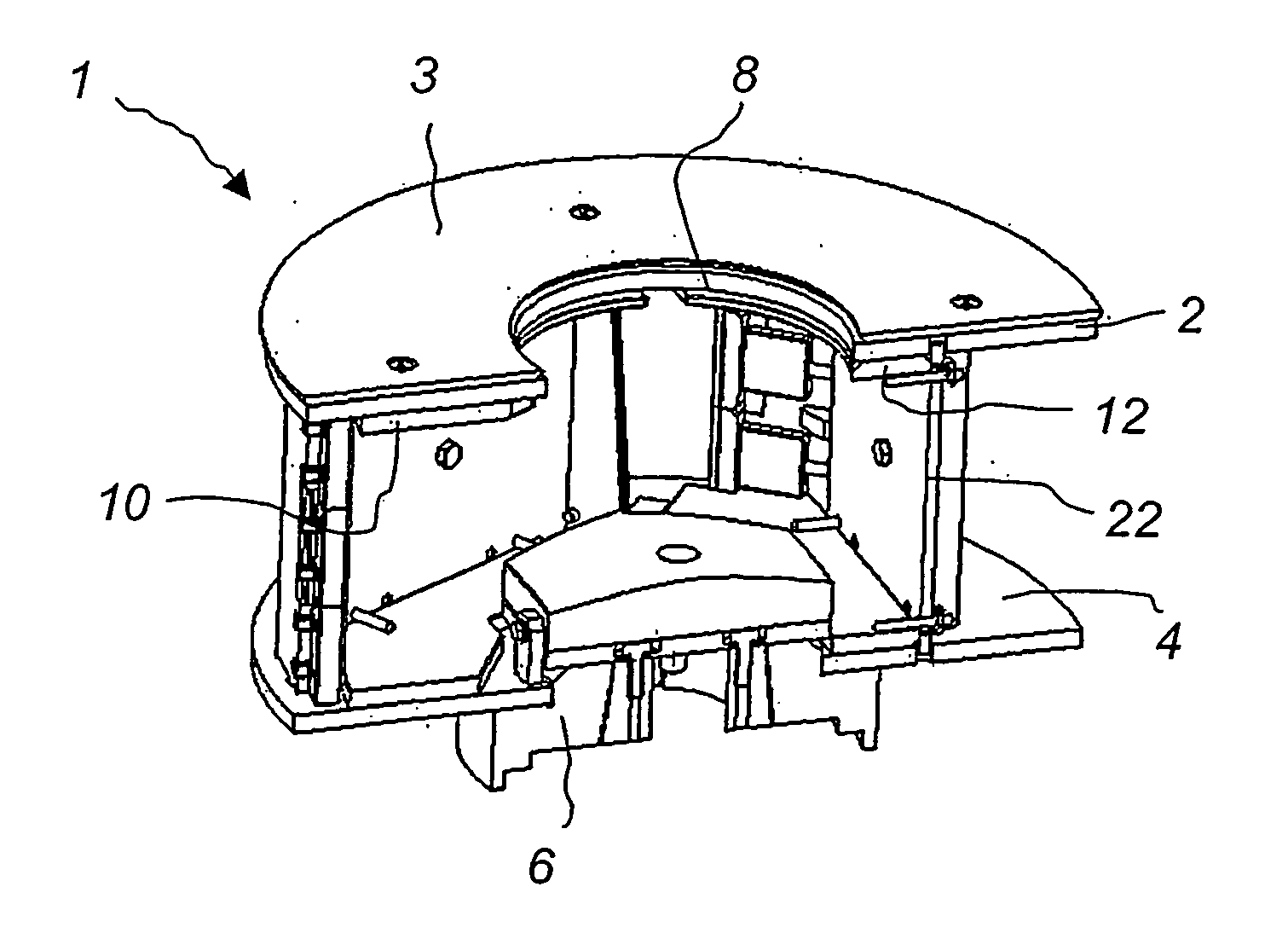

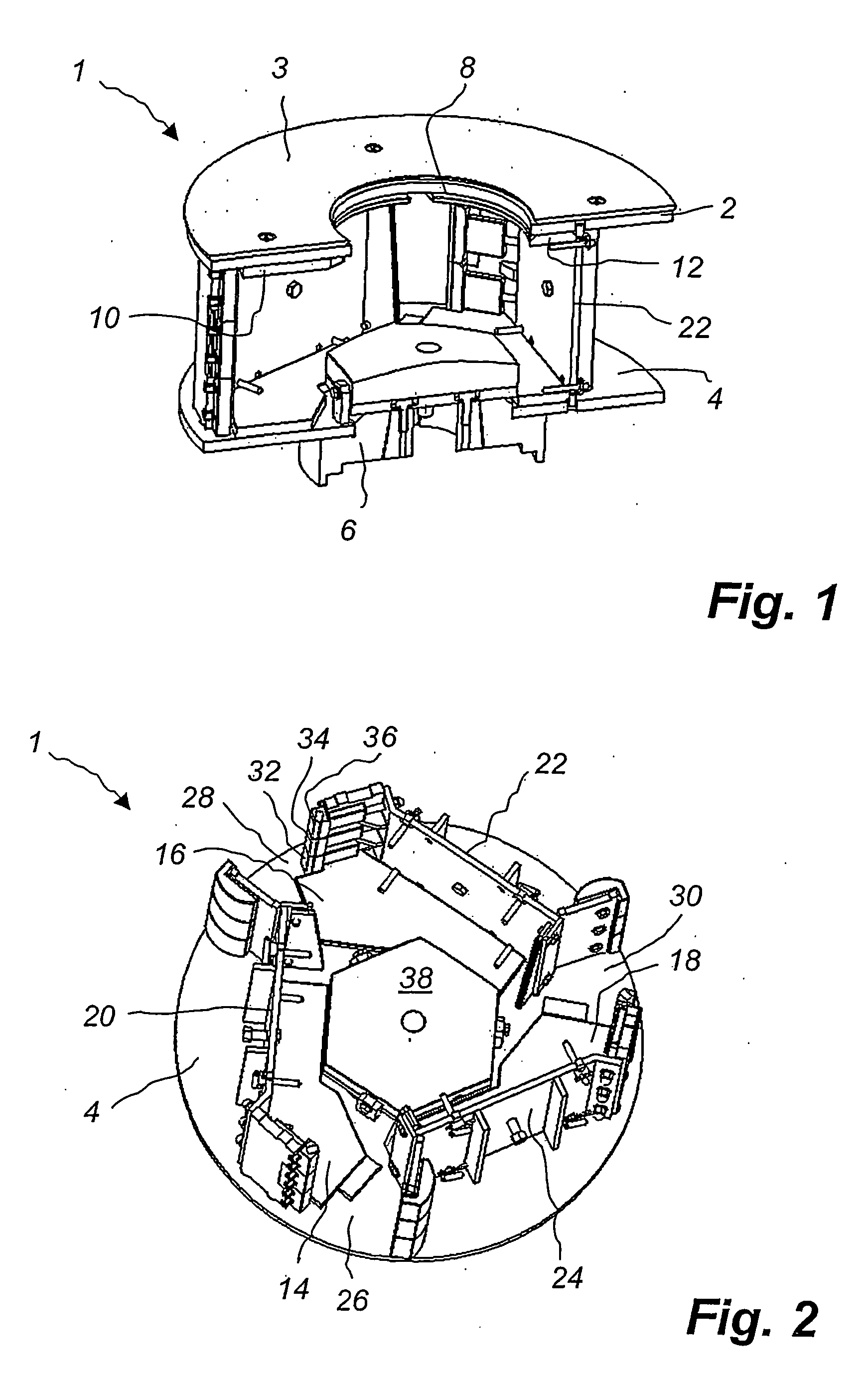

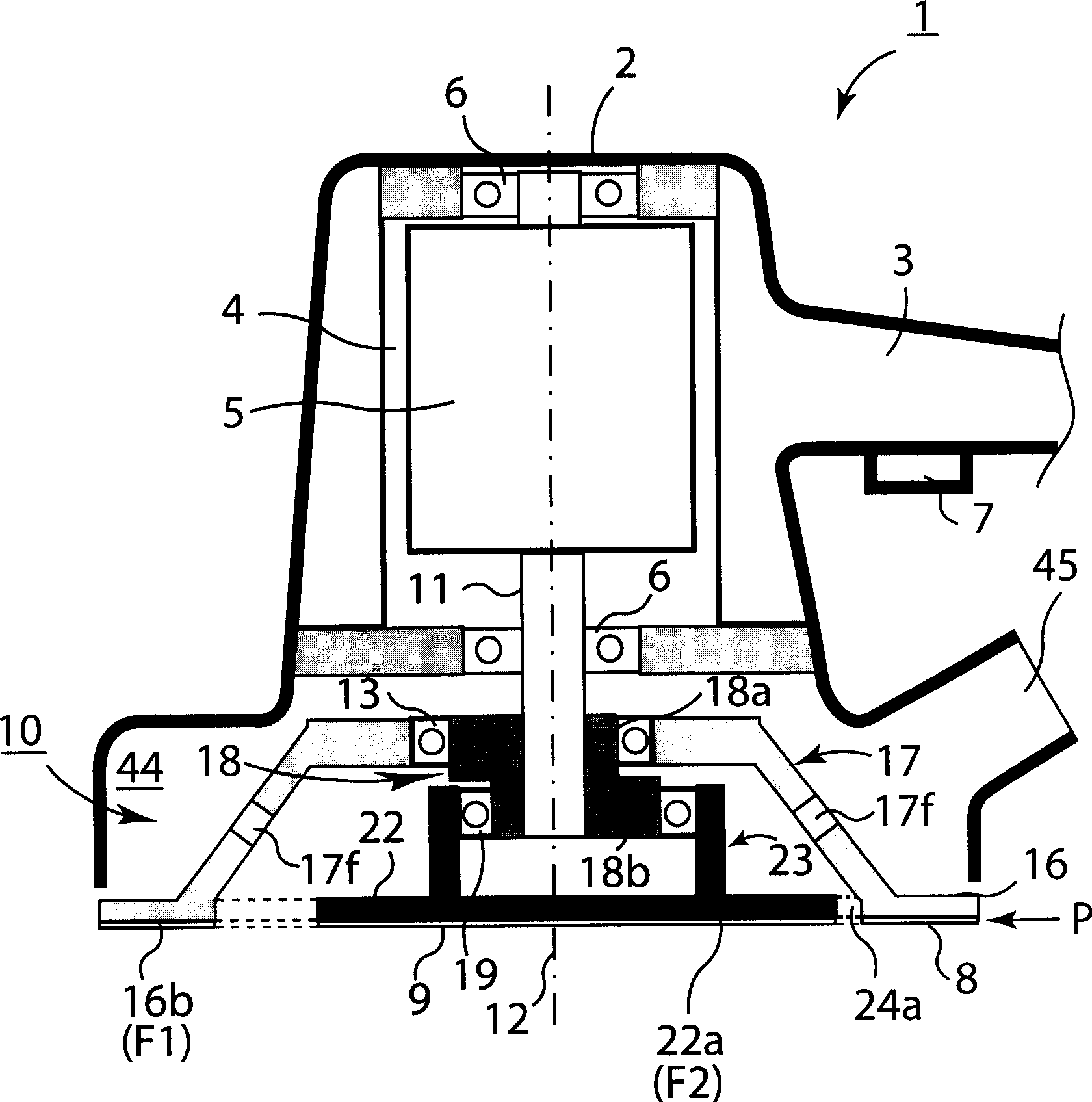

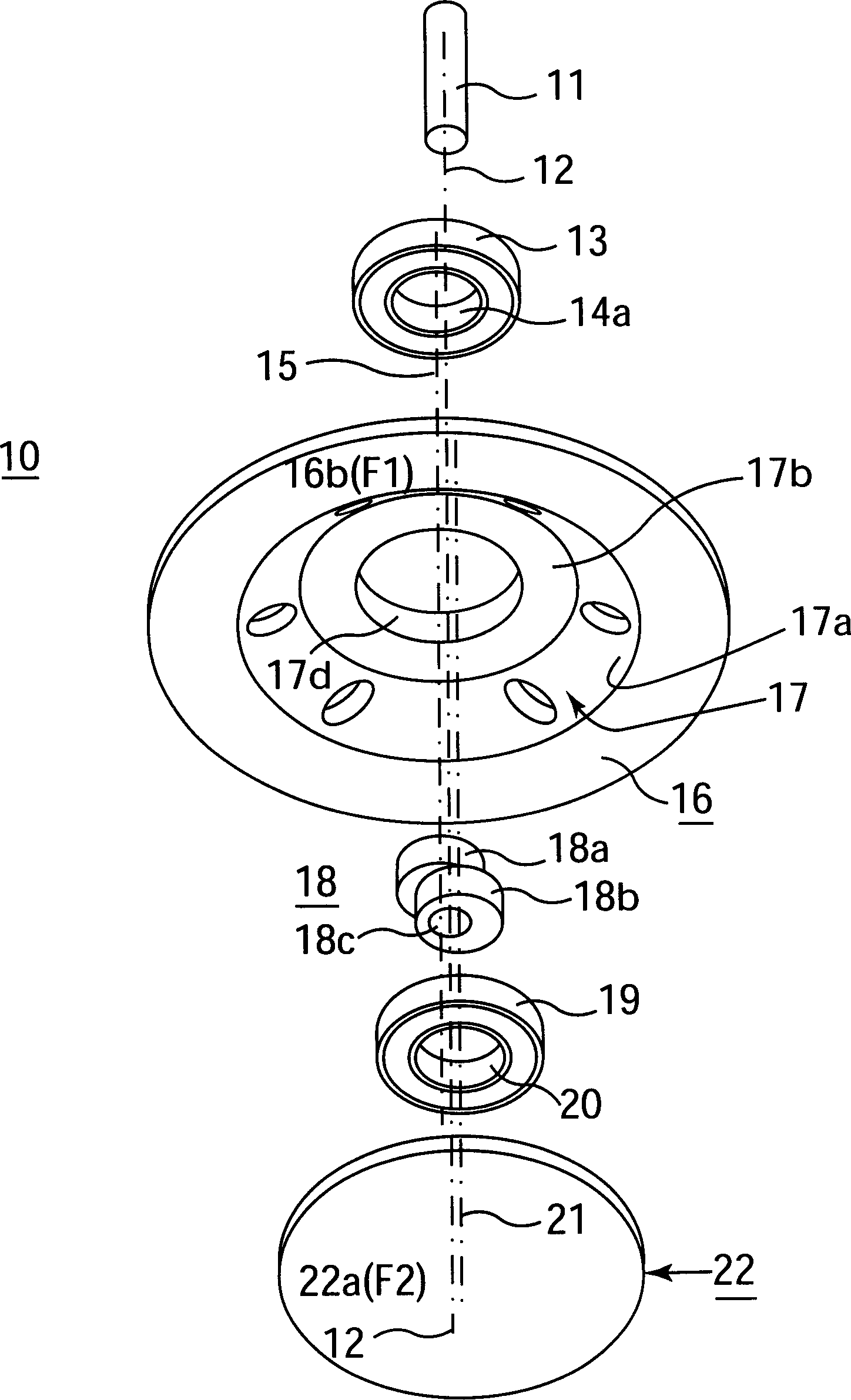

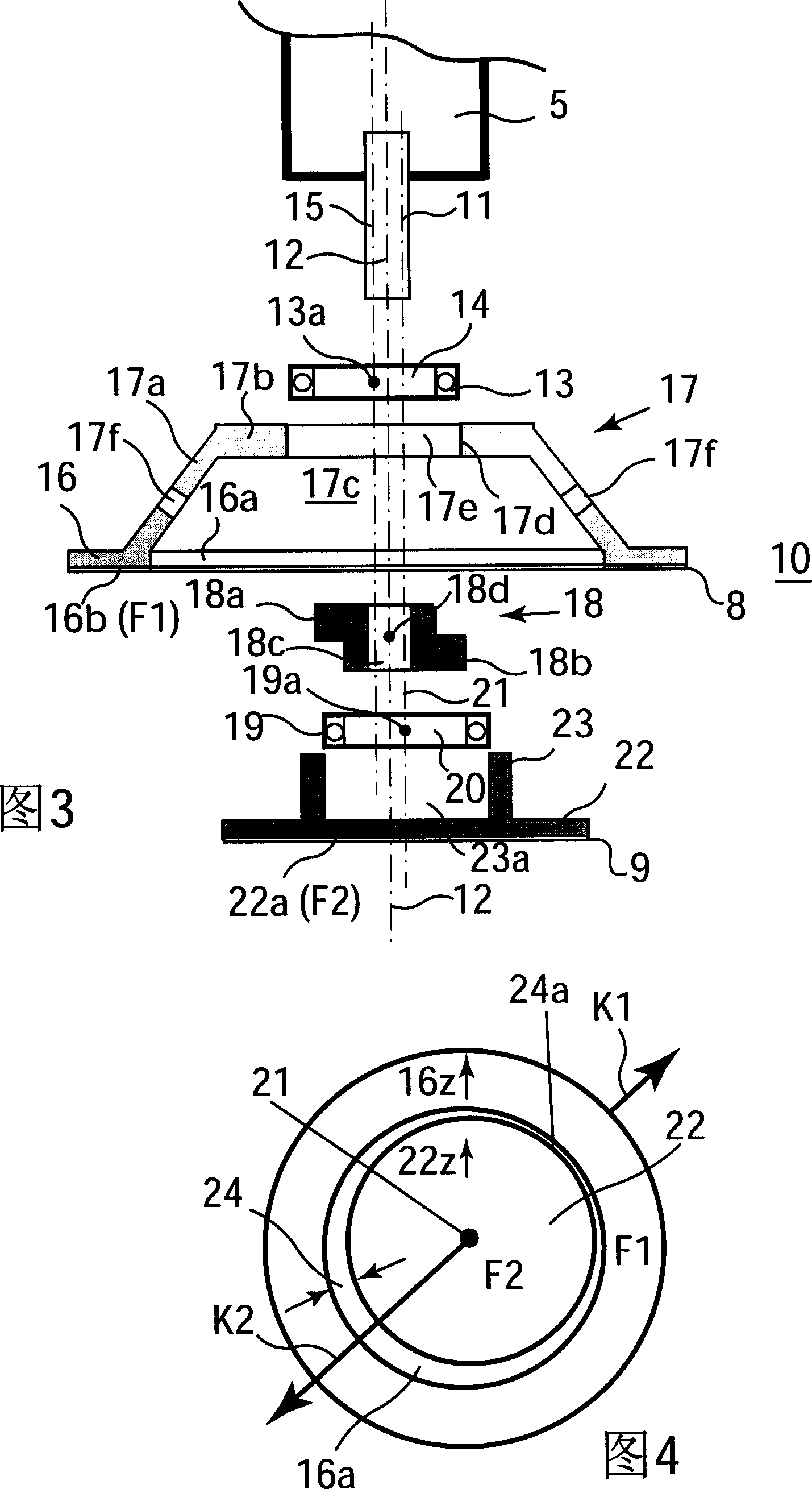

Anti-vibration arrangement, tool using said anti-vibration arrangement and its method for cleaning working surface

The invention relates to an eccentrically rotary swinging tool (1) which comprises a shell (2), an electric motor (4) arranged on the shell, a motor shaft (11), a first annular outer pad (16) connected with a first frosted piece (8) and a second round inner pad (22) connected with a second frosted piece (9); a vibration absorber (10) transmits the energy of the electric motor (4) to pads (6 and 22) through reverse movement, thereby inertia and friction are compensated by motion. At the same time, the vibration which is transmitted to the motor shaft (11) and then to an operator of the tool is greatly reduced. Even if the operator increases the force to the eccentrically rotary swinging tool (1) in order to increase the depth of grinding or to improve the speed of the grinding, the same effect also can be obtained. To achieve the aim, cams (18a and 18b) are fixed on the motor shaft (11) and drive center lines (5 and 21) of the pads (6 and 22) to rotate 180 degrees reversely around the center line (12) of the electric motor.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

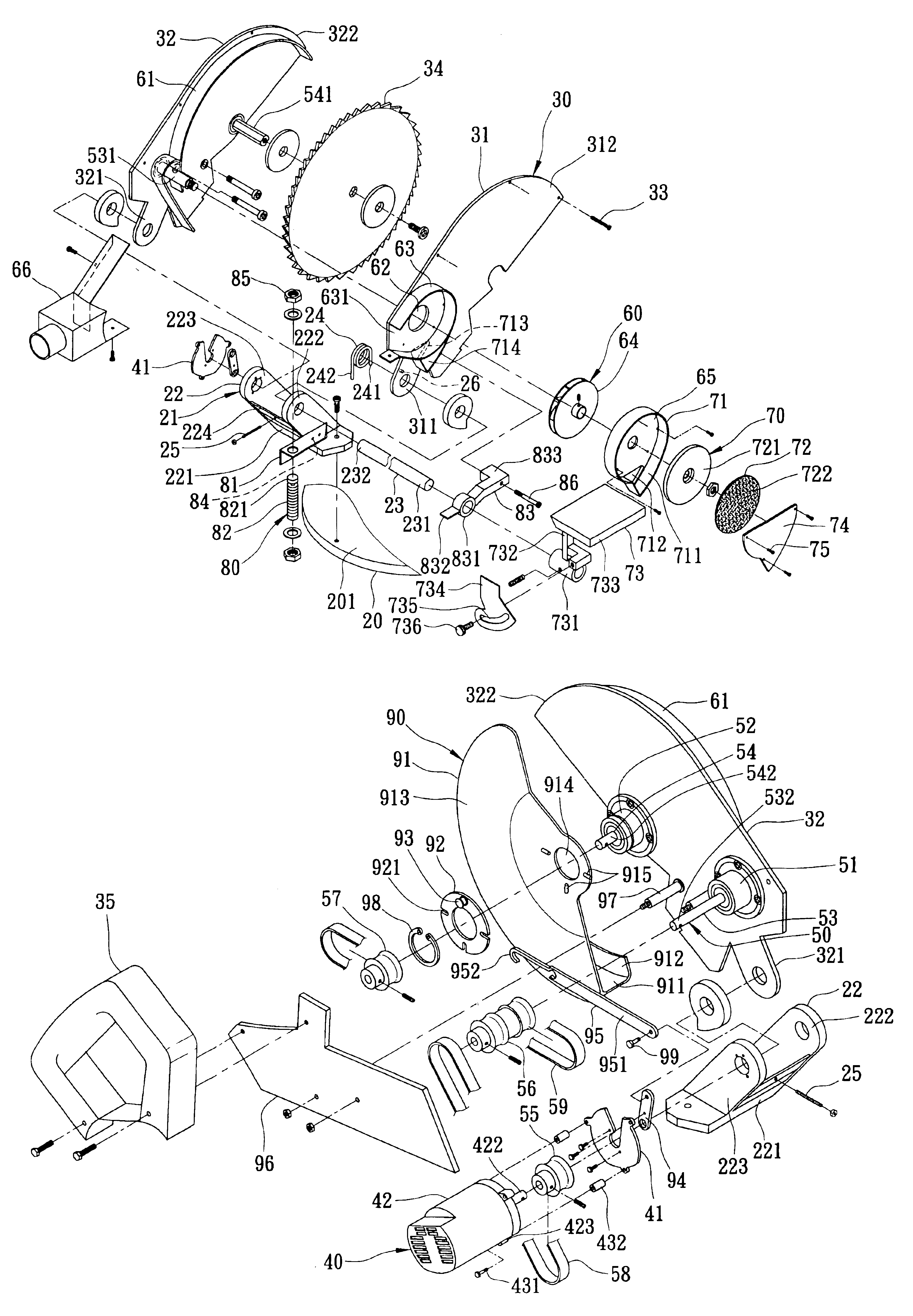

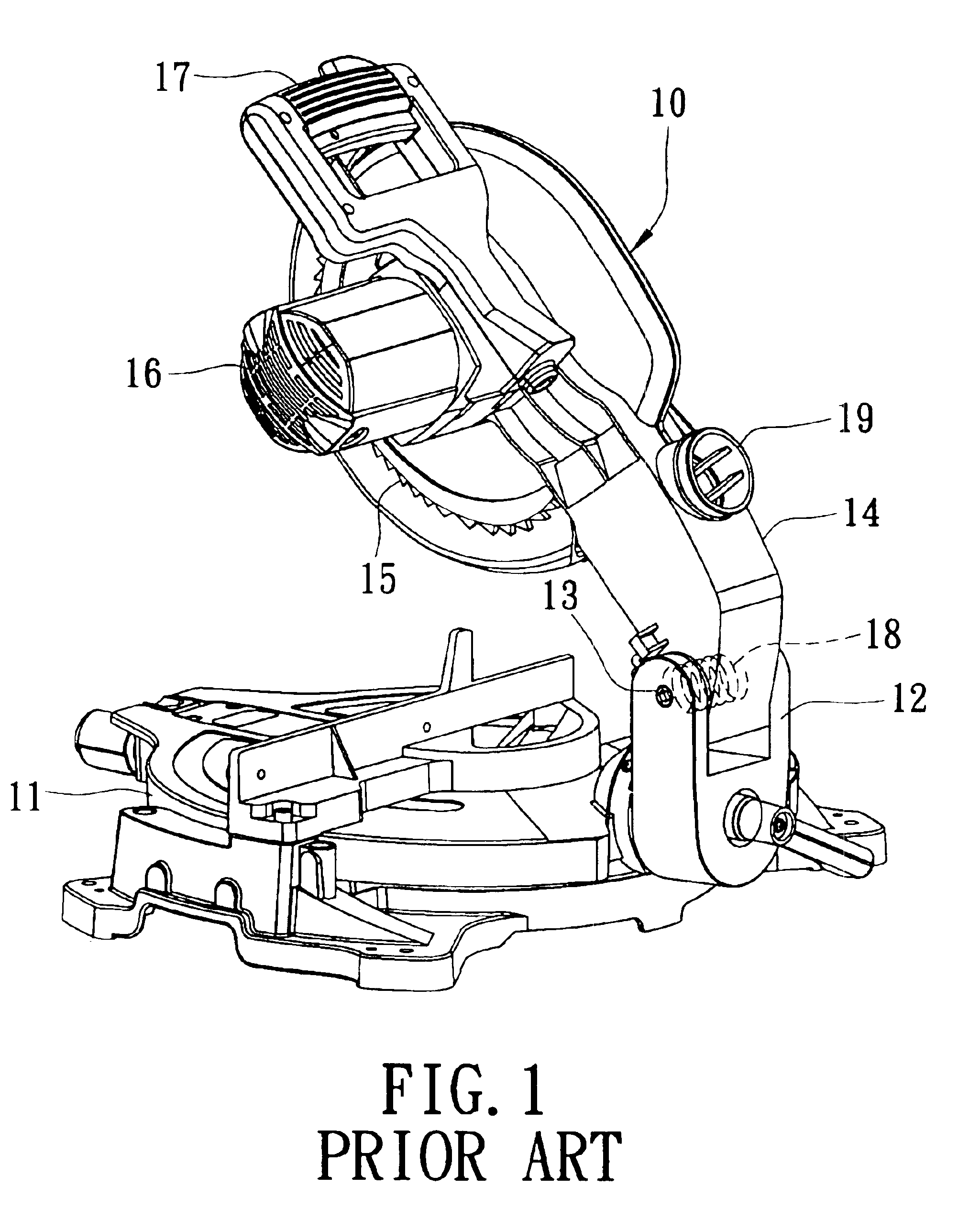

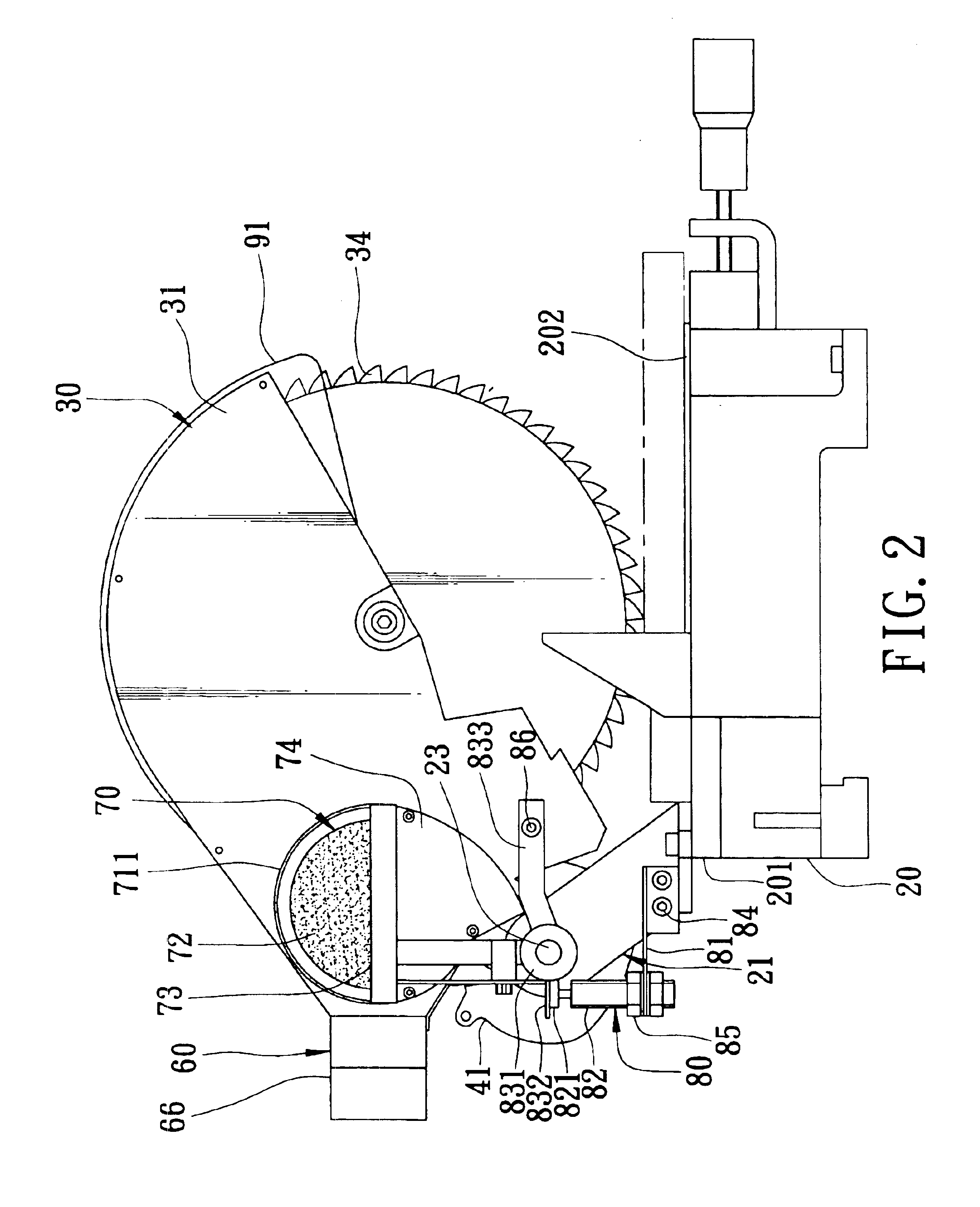

Circular saw

InactiveUS6866568B1Save effortAvoid damageMetal sawing devicesEdge grinding machinesCircular sawKnife blades

A circular saw includes a worktable, a mounting seat extending upwardly from the worktable for mounting a motor thereon, a blade supporting unit pivotally mounted on the mounting seat at a pivot end so that an opposite free end is turnable to be close to and away from the worktable, and a saw blade shaft mounted rotatably on the blade supporting unit about a blade axis parallel to an output shaft axis of an output shaft of the motor and having a saw blade mounted thereon. The saw blade shaft is coupled to the output shaft by a drive transmitting unit which transmits driving force of the output shaft to the saw blade shaft so as to rotate the saw blade.

Owner:LIAO HUI CHUAN

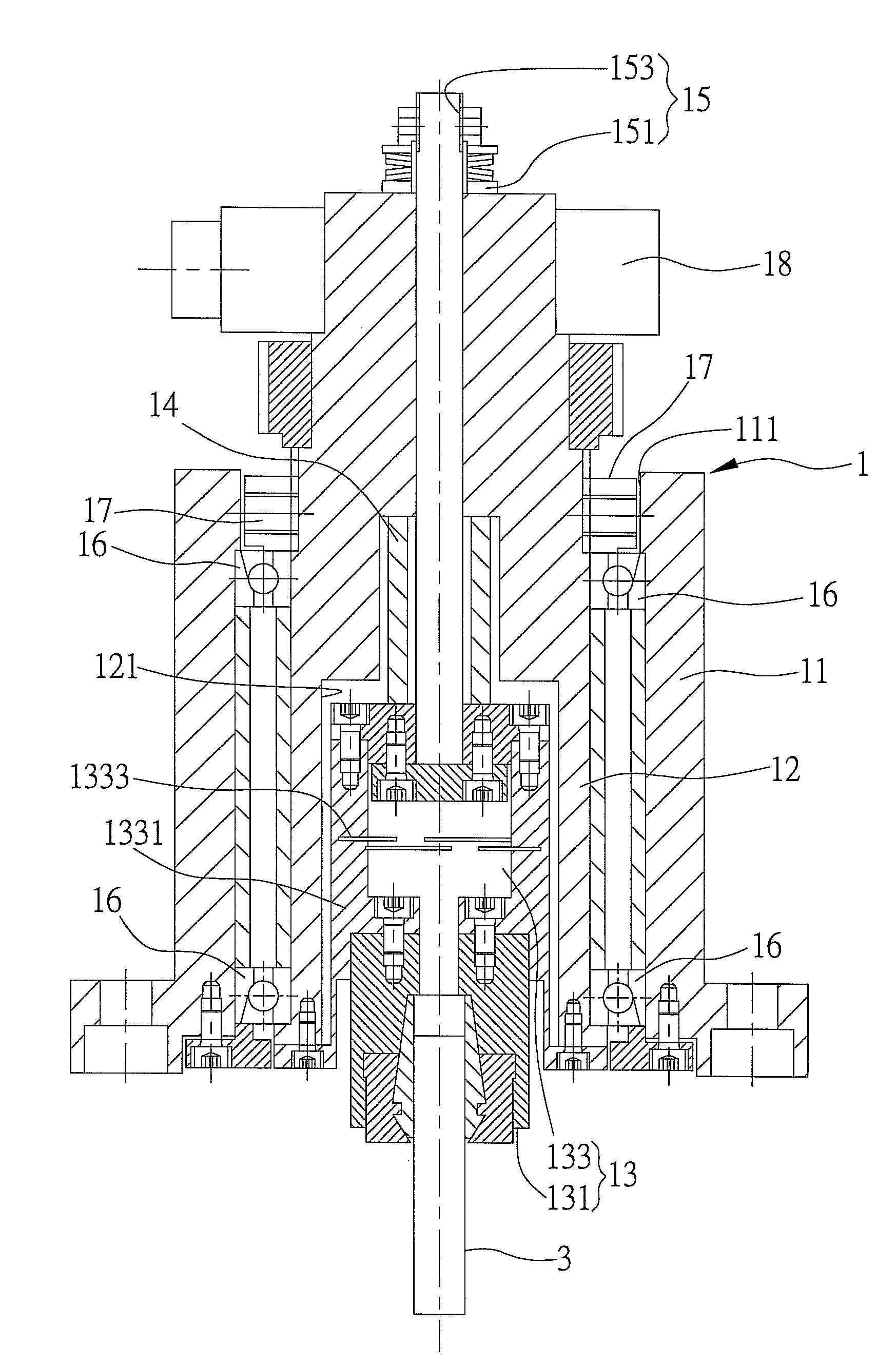

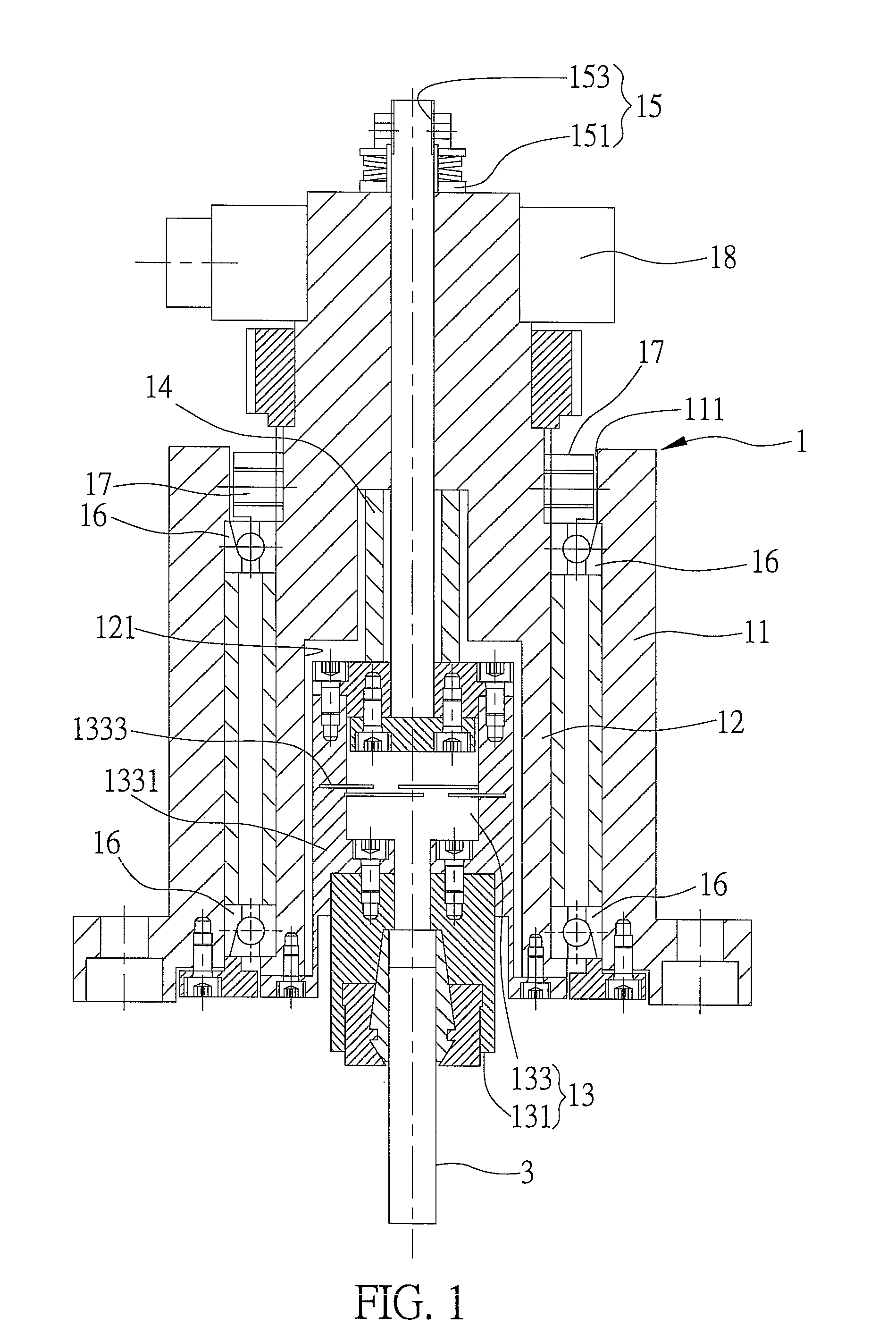

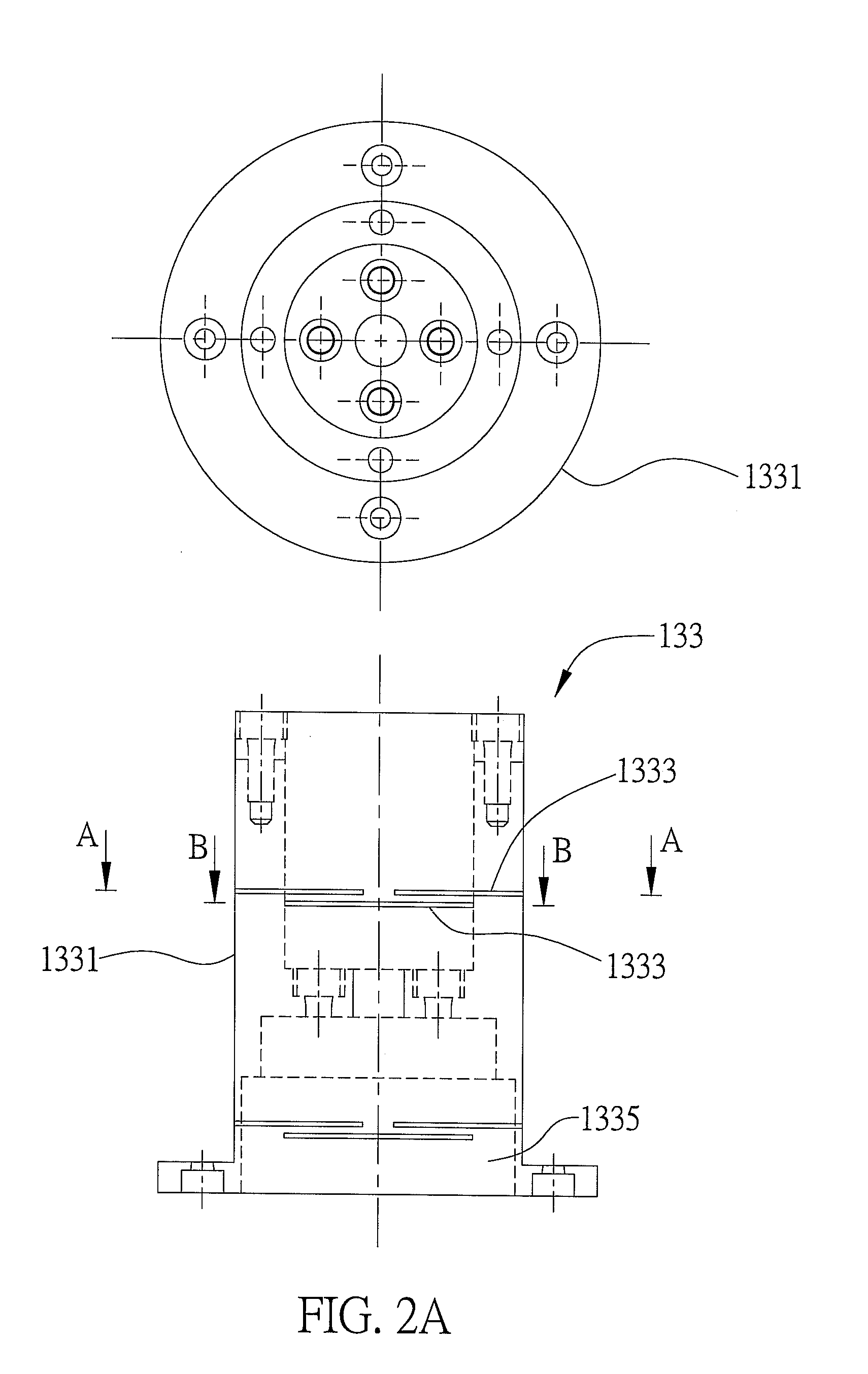

Spindle and flexible hinge used in ultrasonic machine

ActiveUS20090146530A1Eliminates design restriction on lengthImprove design flexibilityGrinding machine componentsPiezoelectric/electrostriction/magnetostriction machinesEngineeringPressure units

A spindle used in an ultrasonic machine for transmitting vibration to a working tool of the ultrasonic machine is disclosed. The spindle includes a main body, a rotor disposed in the main body, an elastic clamping unit disposed in the rotor, a vibrating unit having one end thereof connected to the inner wall of the rotor while the other end connected to the elastic clamping unit, and a pre-pressure unit penetrating the rotor and one end thereof connected to the elastic clamping unit to provide the elastic clamping unit with rigidity against the rotor, thereby making the elastic clamping unit provide pre-pressure to the vibrating unit which further provides the elastic clamping unit with vibration against the rotor. The present invention further provides a flexible hinge for the spindle.

Owner:IND TECH RES INST

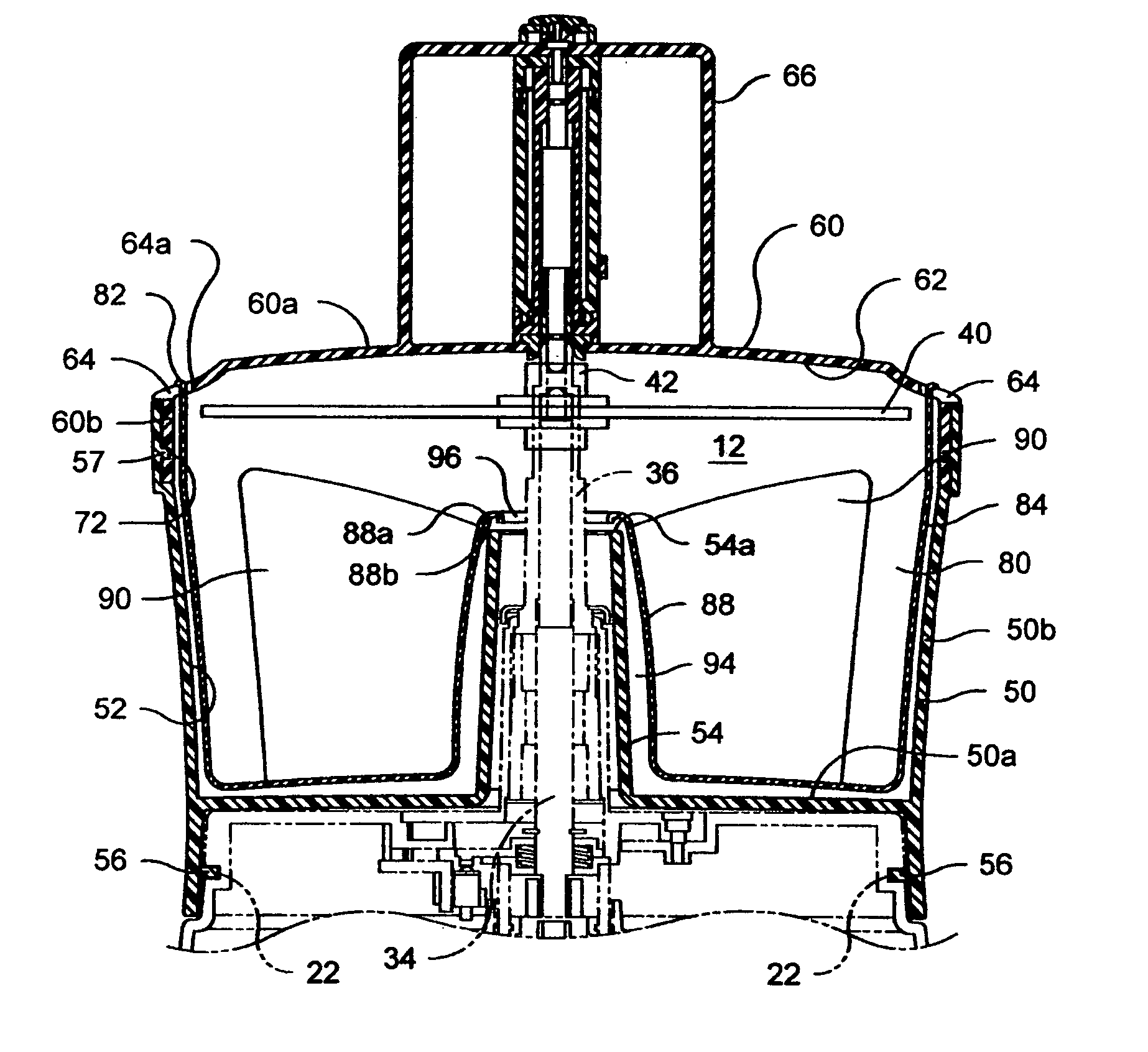

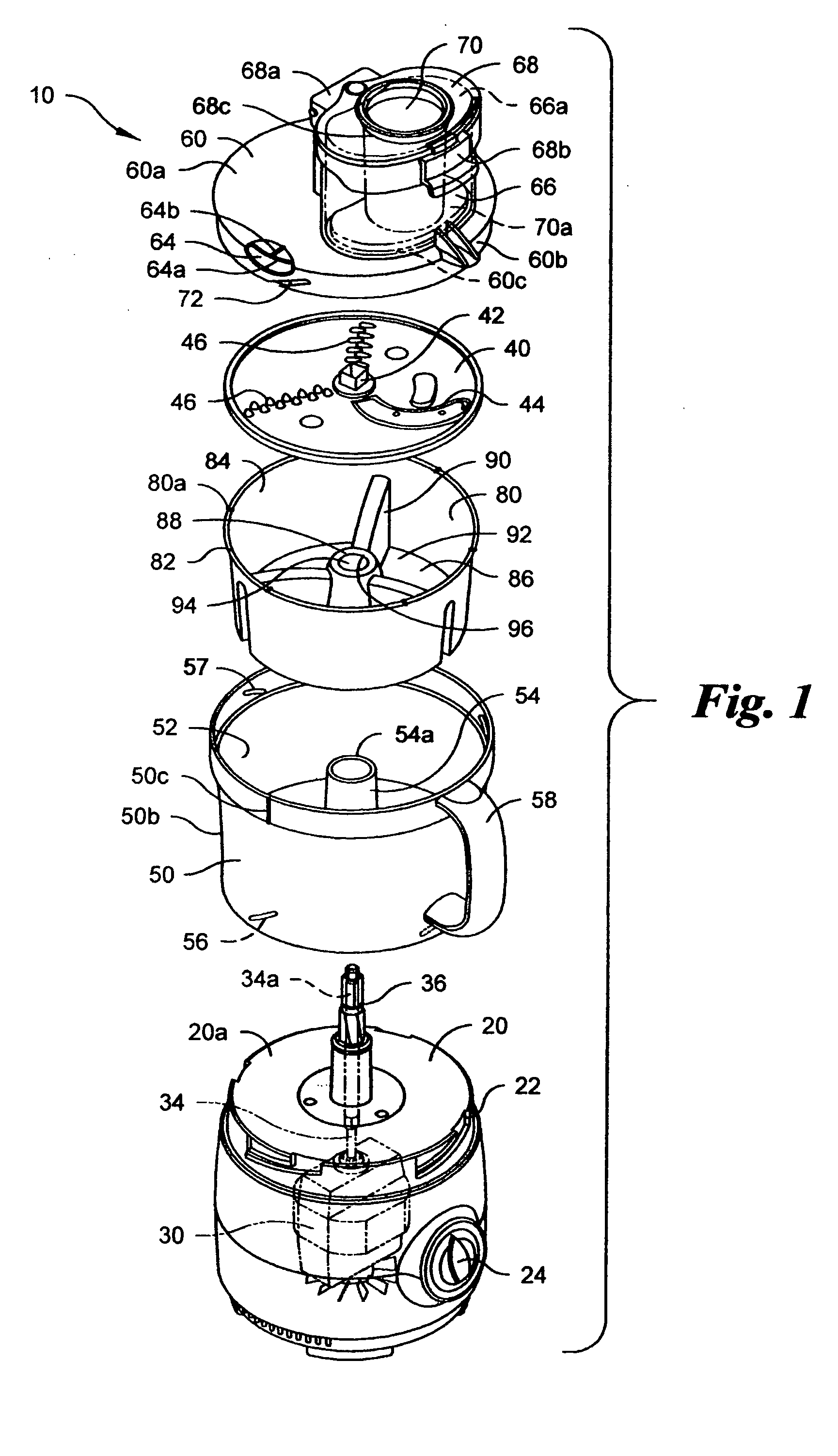

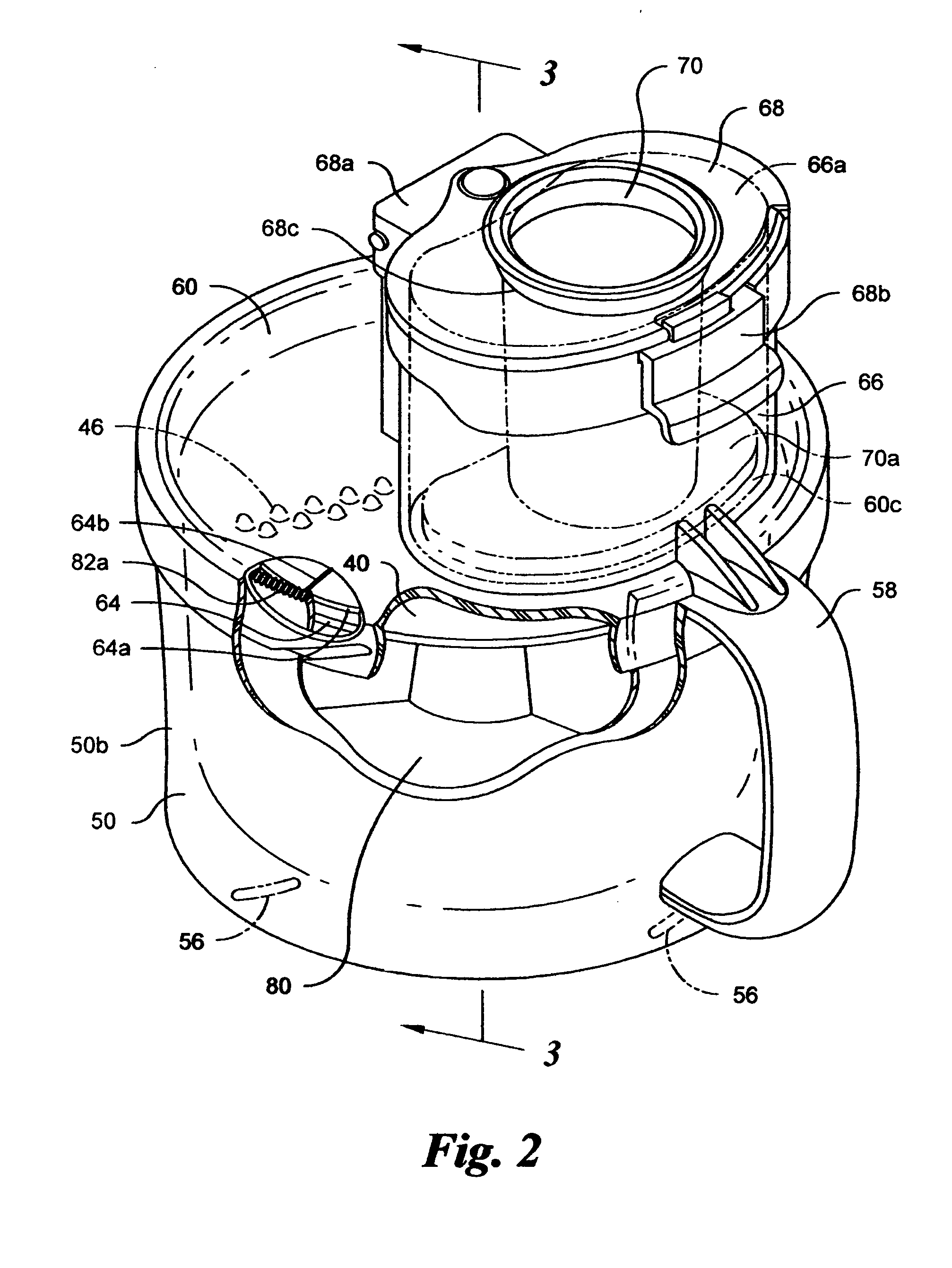

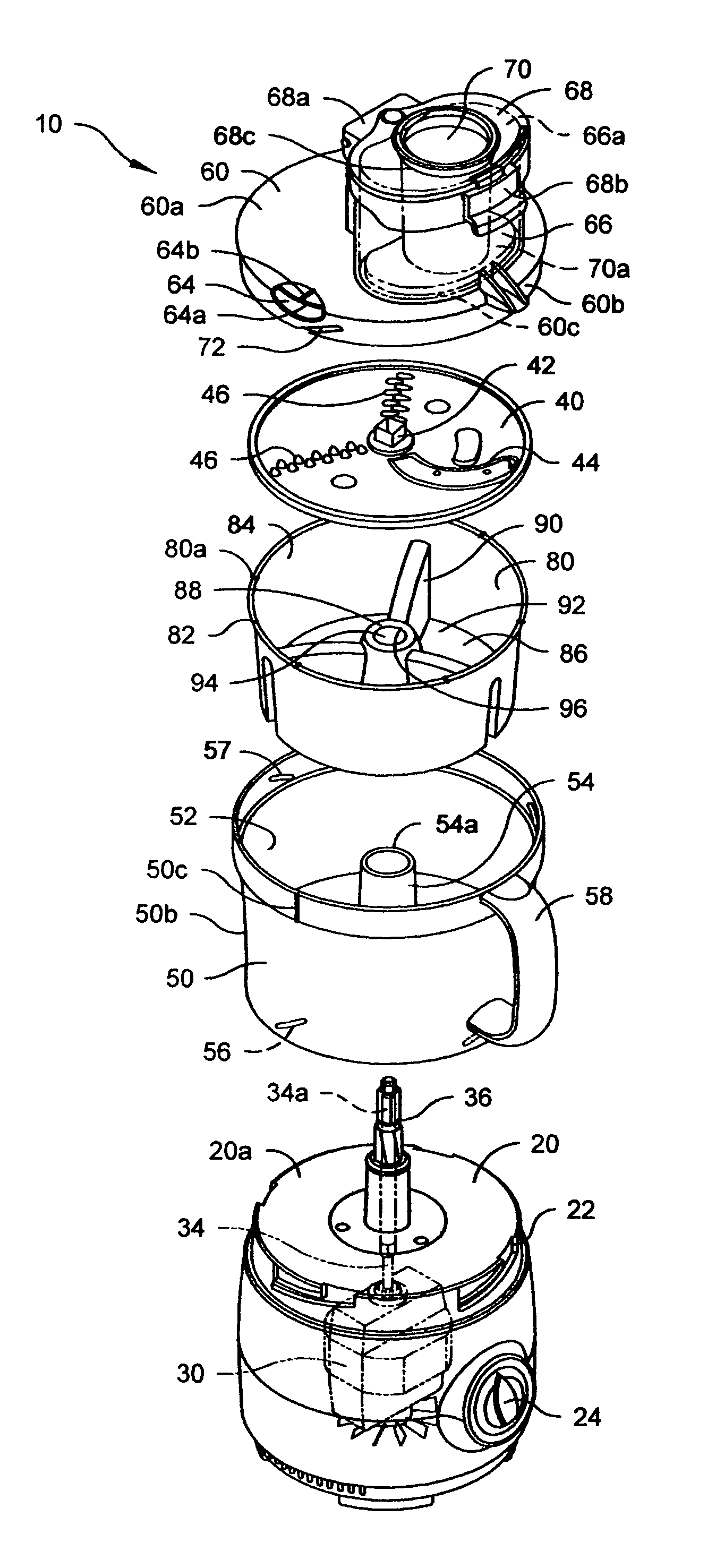

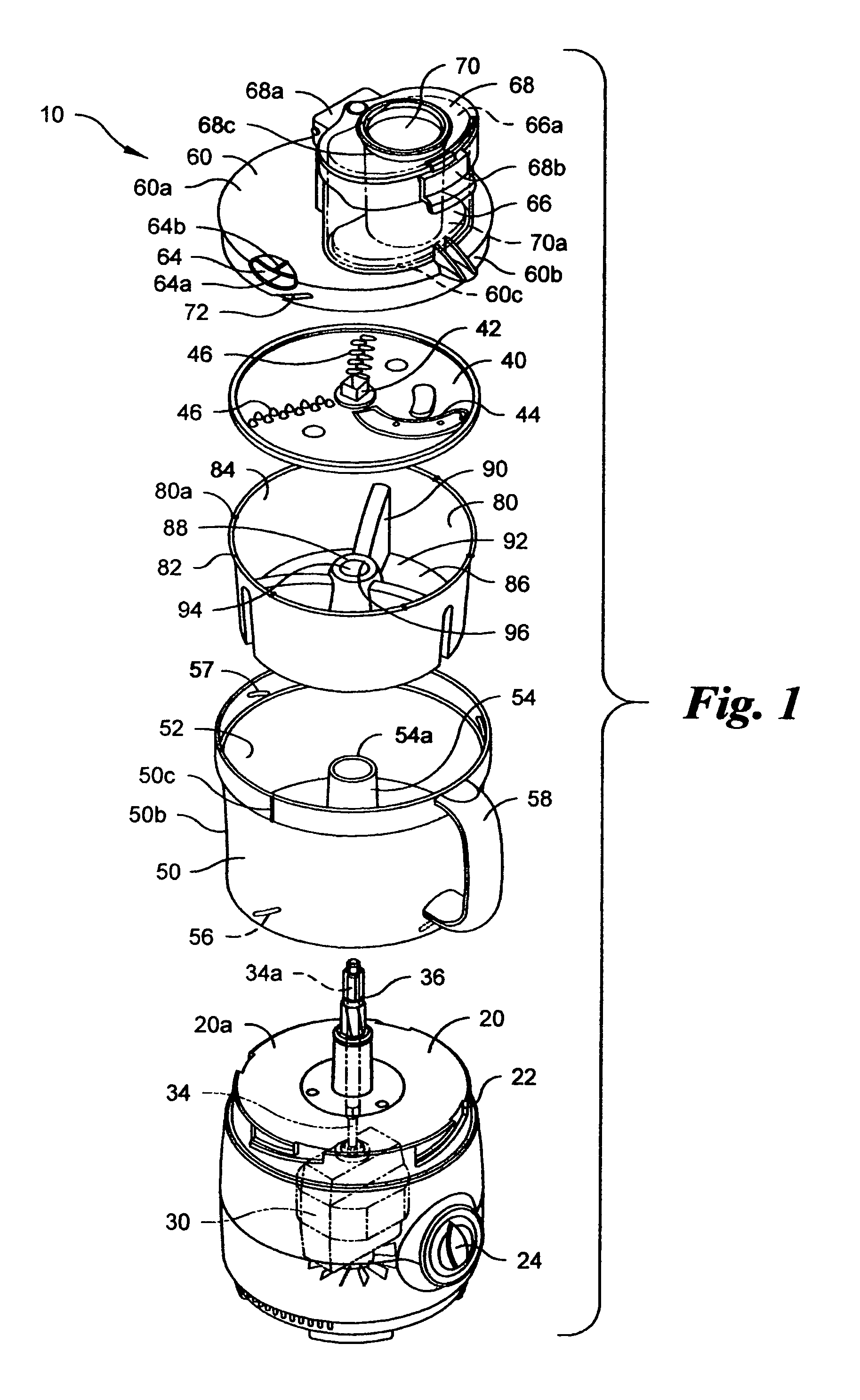

Rotatable tray for food processor

A food processor for processing foodstuffs comprises a base housing, a motor, a drive shaft, a tool, a bowl, a lid and a tray. The tool is rotatably securable to the drive shaft and rotatable by the motor. The bowl is removably securable to the base housing and includes an inner surface area. The lid has an inner surface area. The lid is removably securable to the bowl to create a processing chamber between the inner surface areas of the bowl and lid in an assembled position. The tray is removably securable within the processing chamber and is manually rotatable relative to the bowl and lid, independently of the drive shaft and tool, in the assembled position.

Owner:HAMILTON BEACH BRANDS

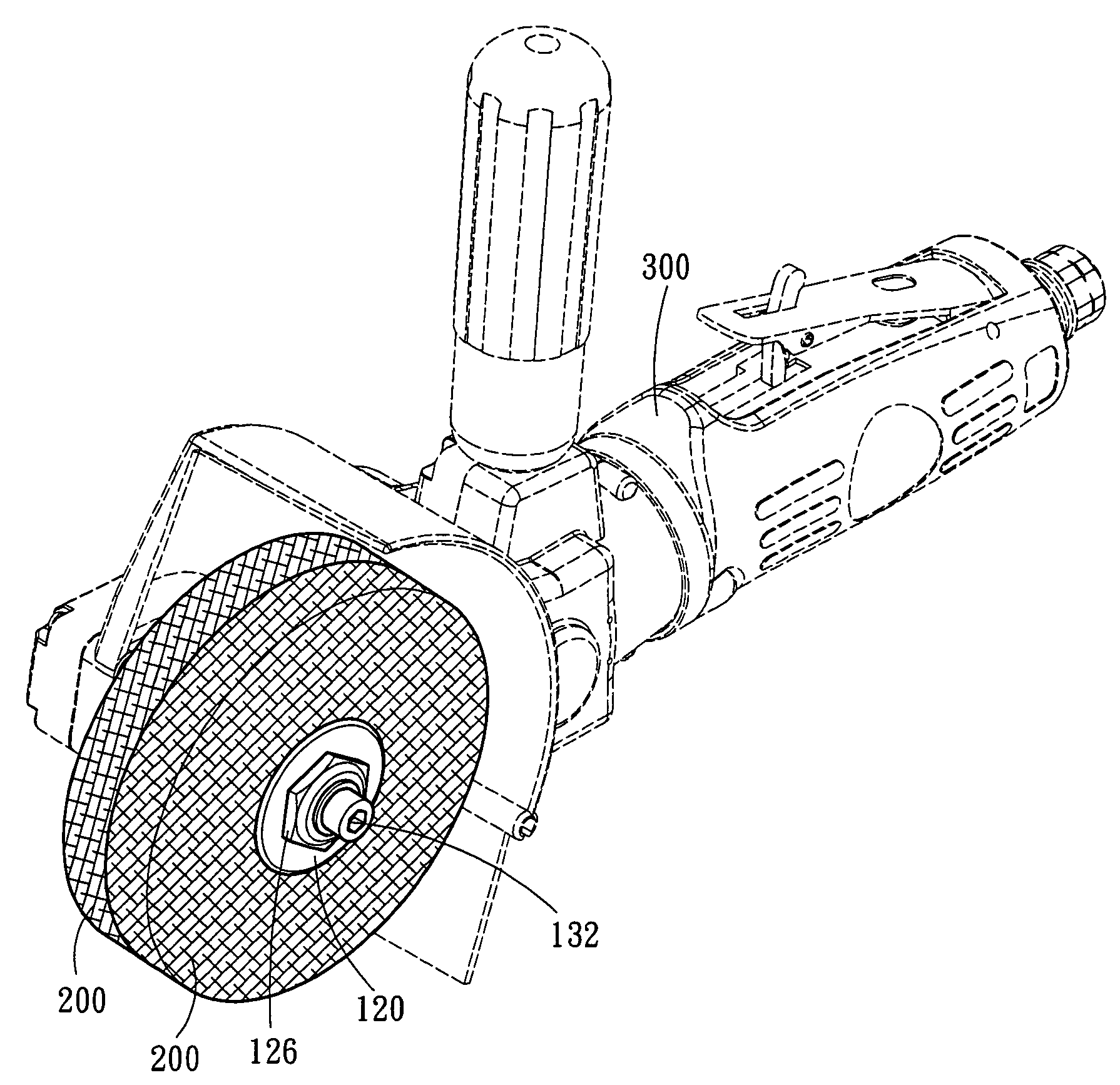

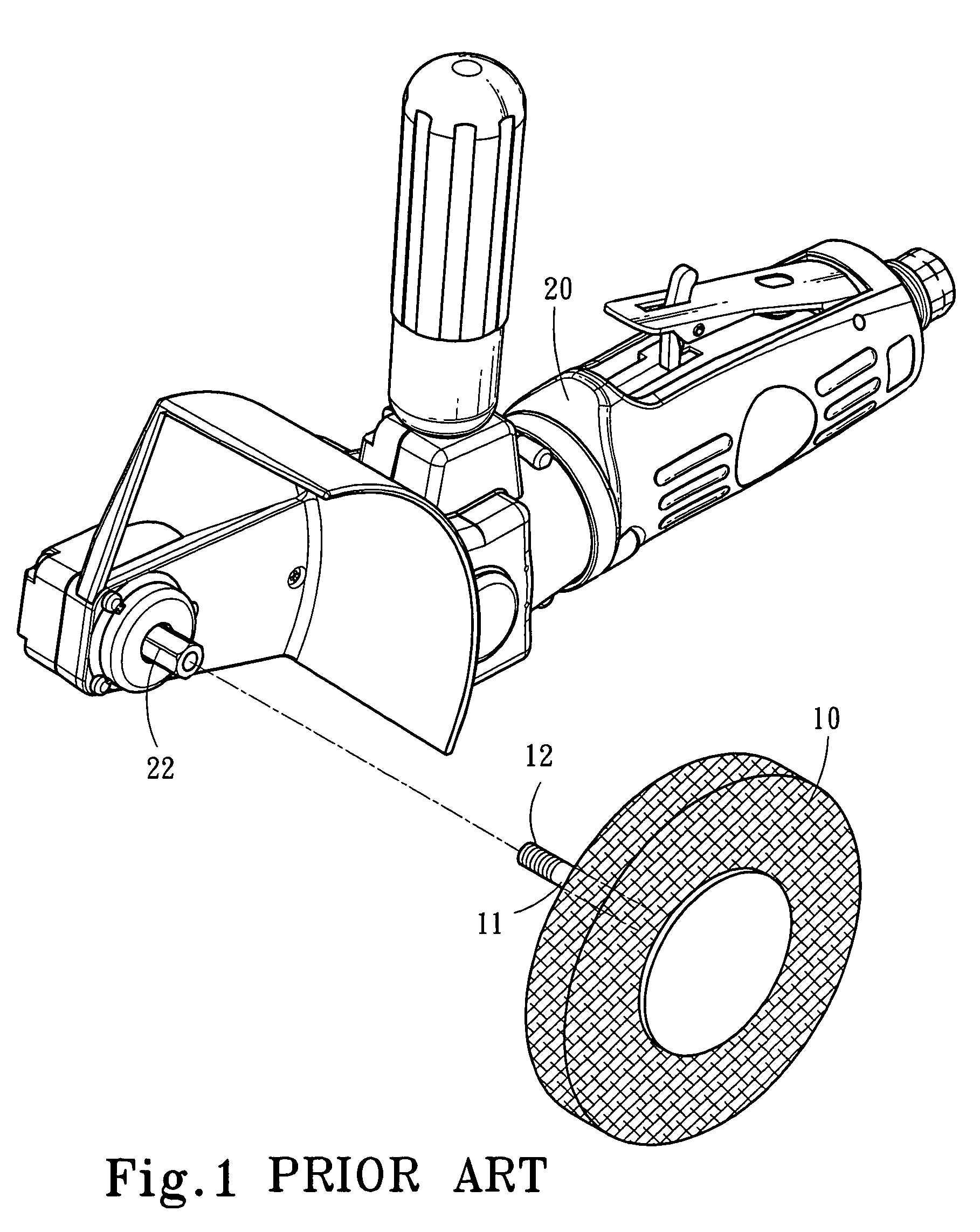

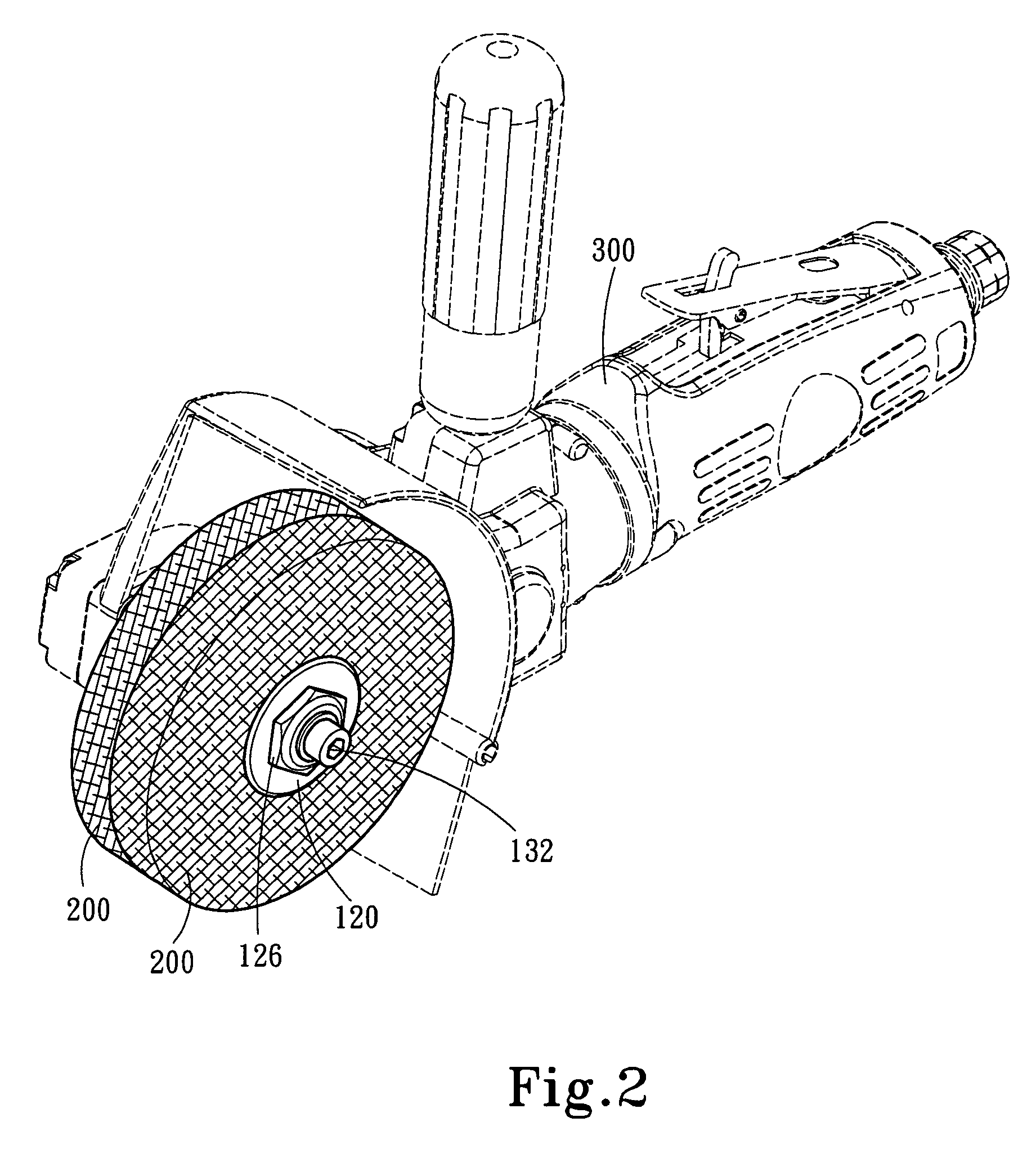

Coupling structure for grinding members

InactiveUS7115028B1Simple structureLow costGrinding machine componentsRevolution surface grinding machinesCouplingEngineering

Owner:SUNMATCH INDAL

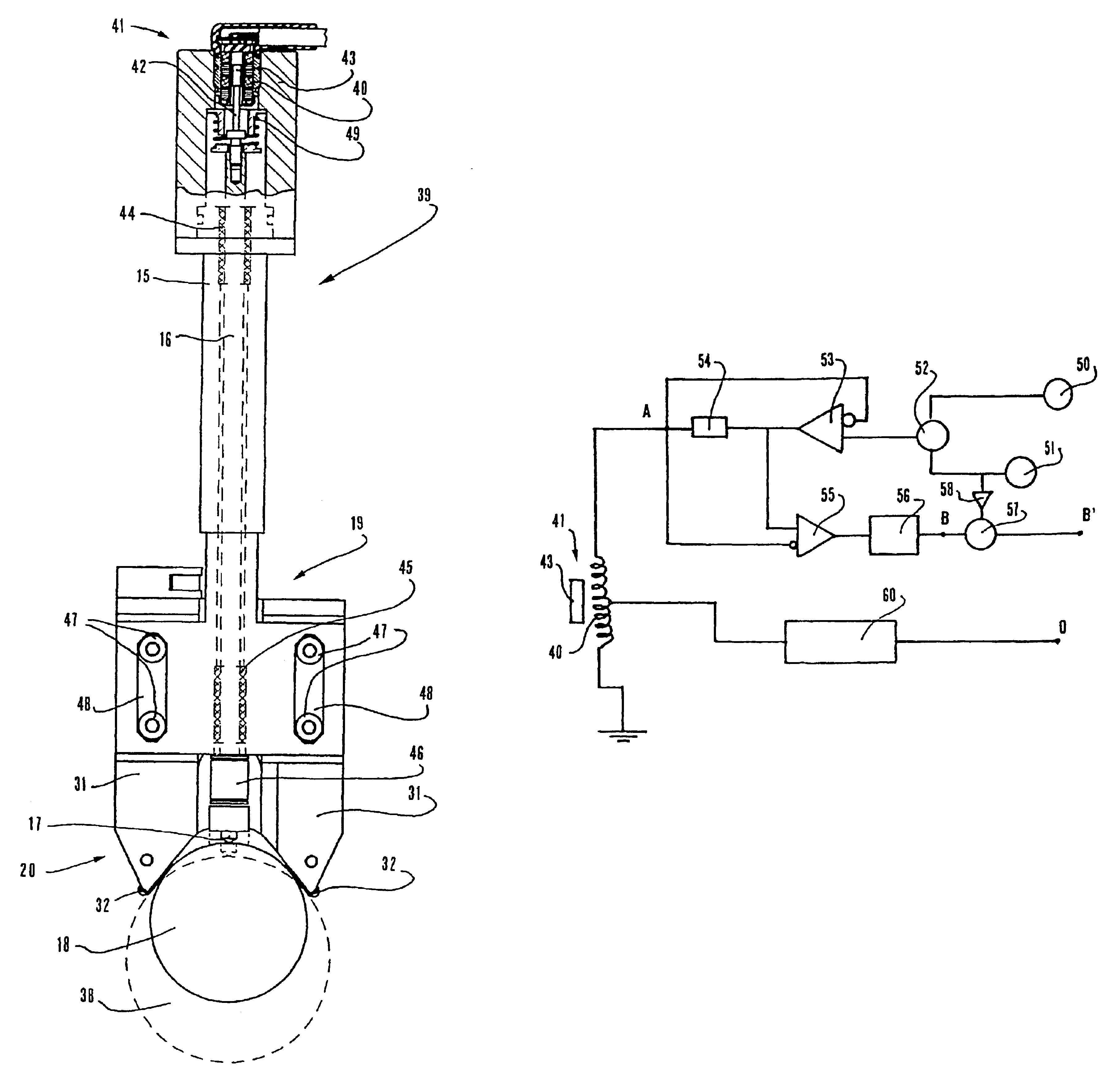

Apparatus and methods for measuring the pin diameter of a crankshaft at the place of grinding

InactiveUS6931749B2The process is simple and fastWide measurement rangeGrinding machine componentsFeeding apparatusNumerical controlDisplay device

An apparatus for checking diametral dimensions of crankpins and main journals in the course of grinding is provided. The apparatus includes a head with a Vee-shaped reference device and an axially movable feeler that contacts the surface of the pin to be checked, and an articulated support device, coupled to the grinding wheel slide that carries the head and enables it to keep contact with the surface of the pin during possible orbital rotations. A transducer in the head cooperates with the feeler for detecting its displacements and transmits signals to a processing and display device in turn connected with the computer numerical control of the grinding machine. The processing and display device processes the transducer signals with compensation values or coefficients stored in a memory unit for obtaining measuring signals output by the head that vary in a linear way in a wide range and for compensating errors due to temperature variations.

Owner:MARPOSS SPA

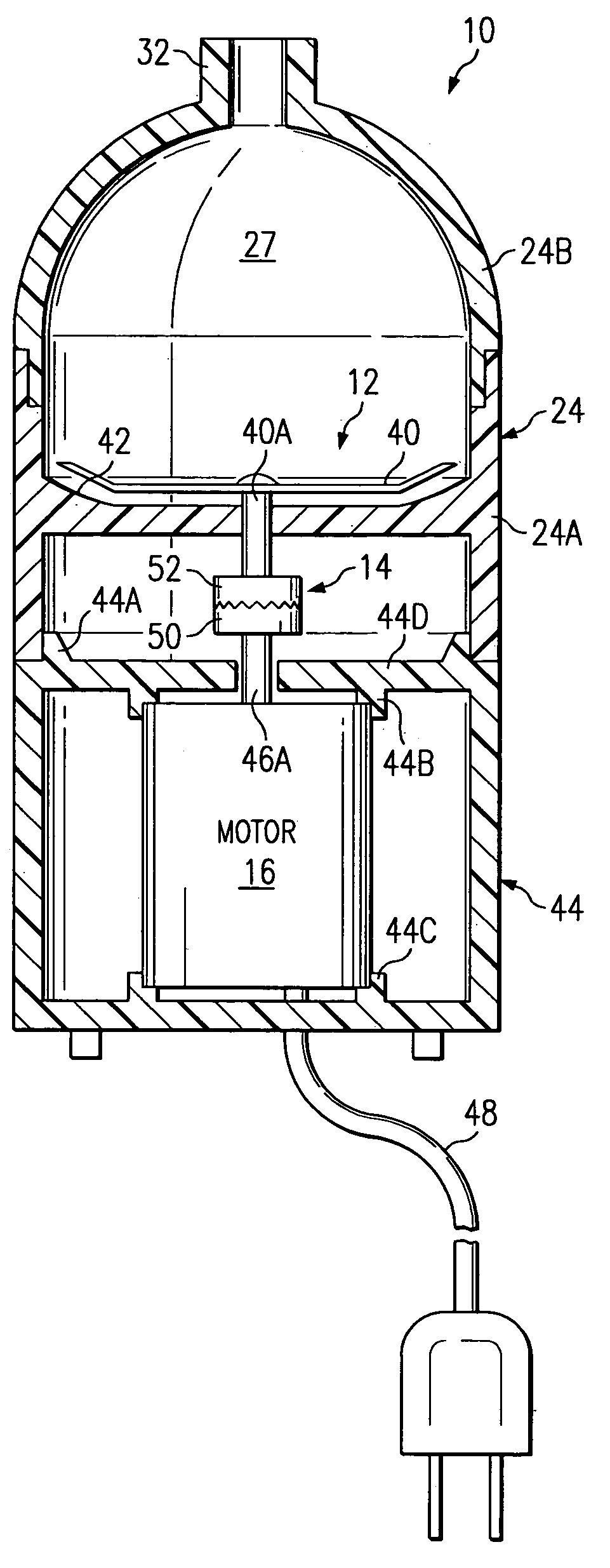

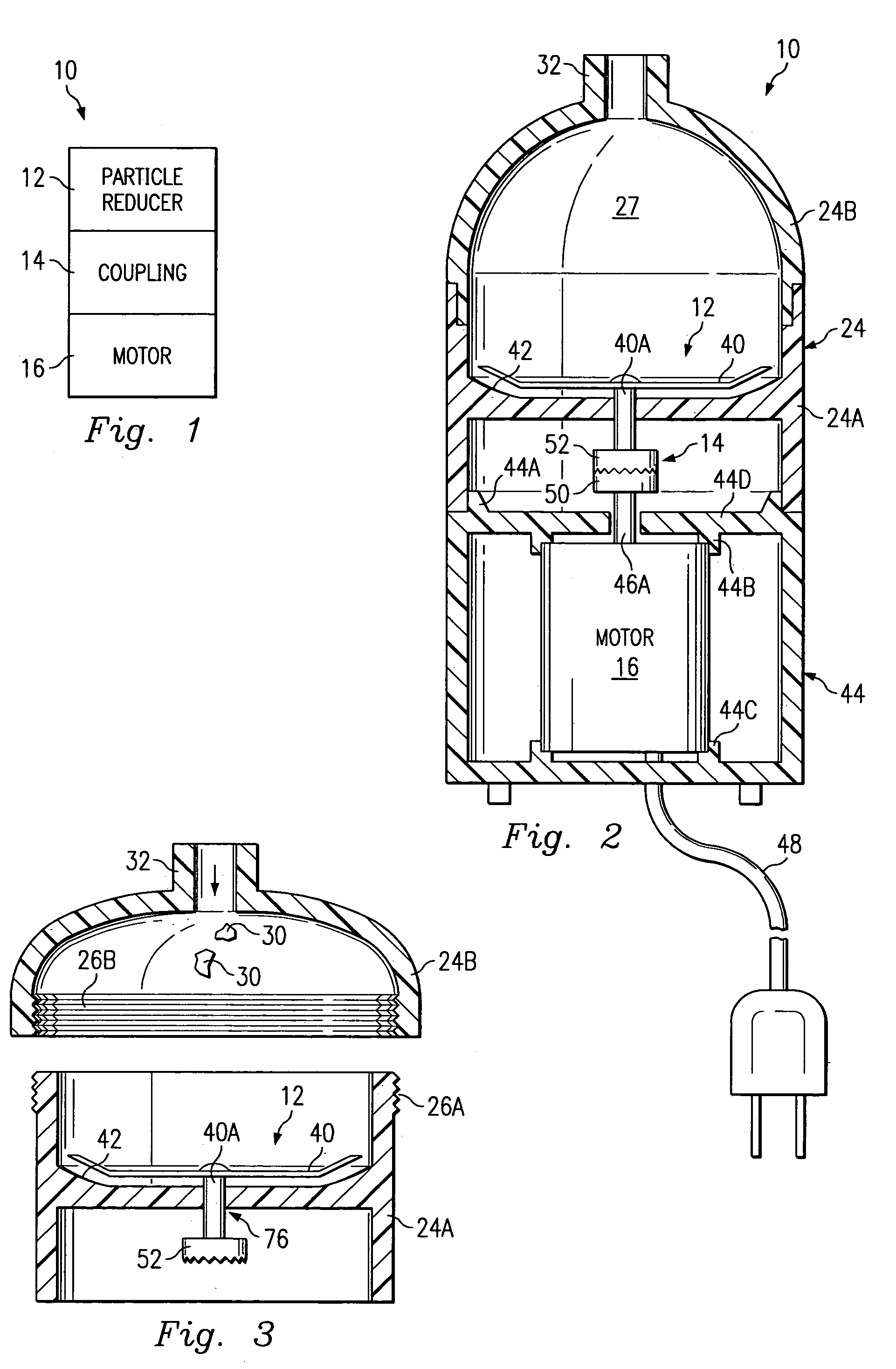

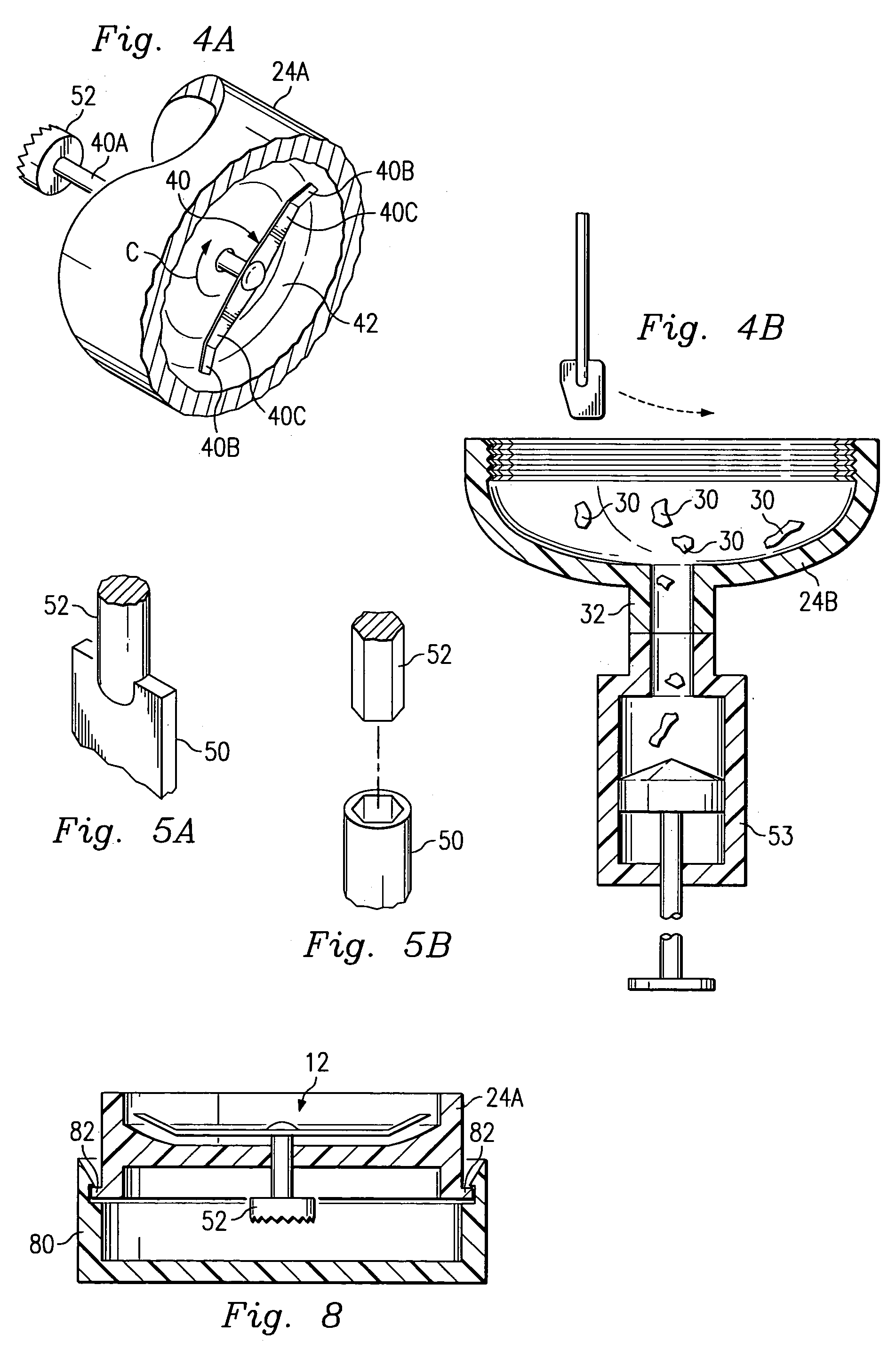

Automatic bone mill

A bone mill for use in a surgical or otherwise sterile environment includes a particle reducer such as a pulverizing blade, a motor such as an electrical motor, and a coupling such as a rotary shaft for connecting the particle reducer to the motor.

Owner:MEDTRONIC PS MEDICAL

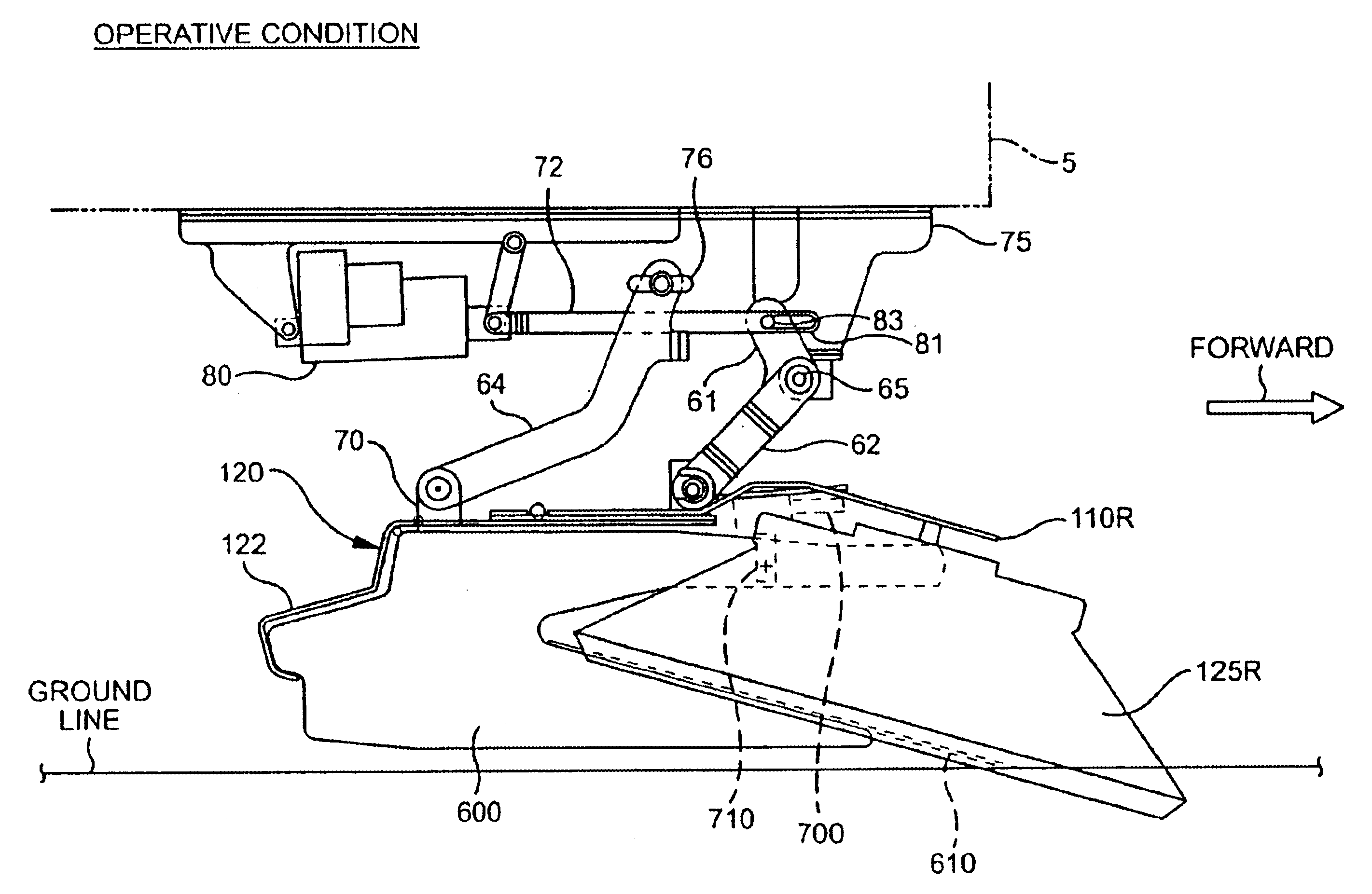

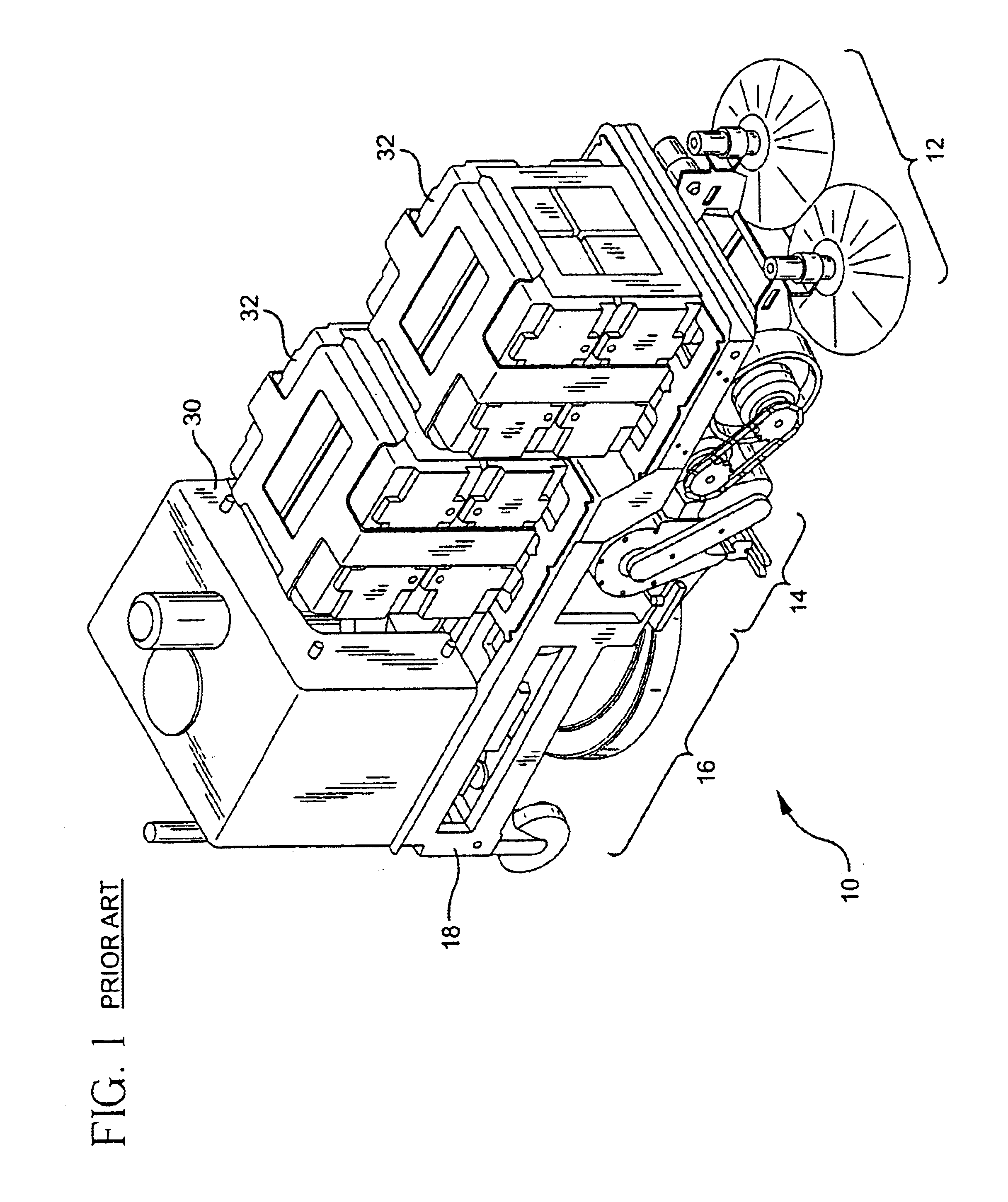

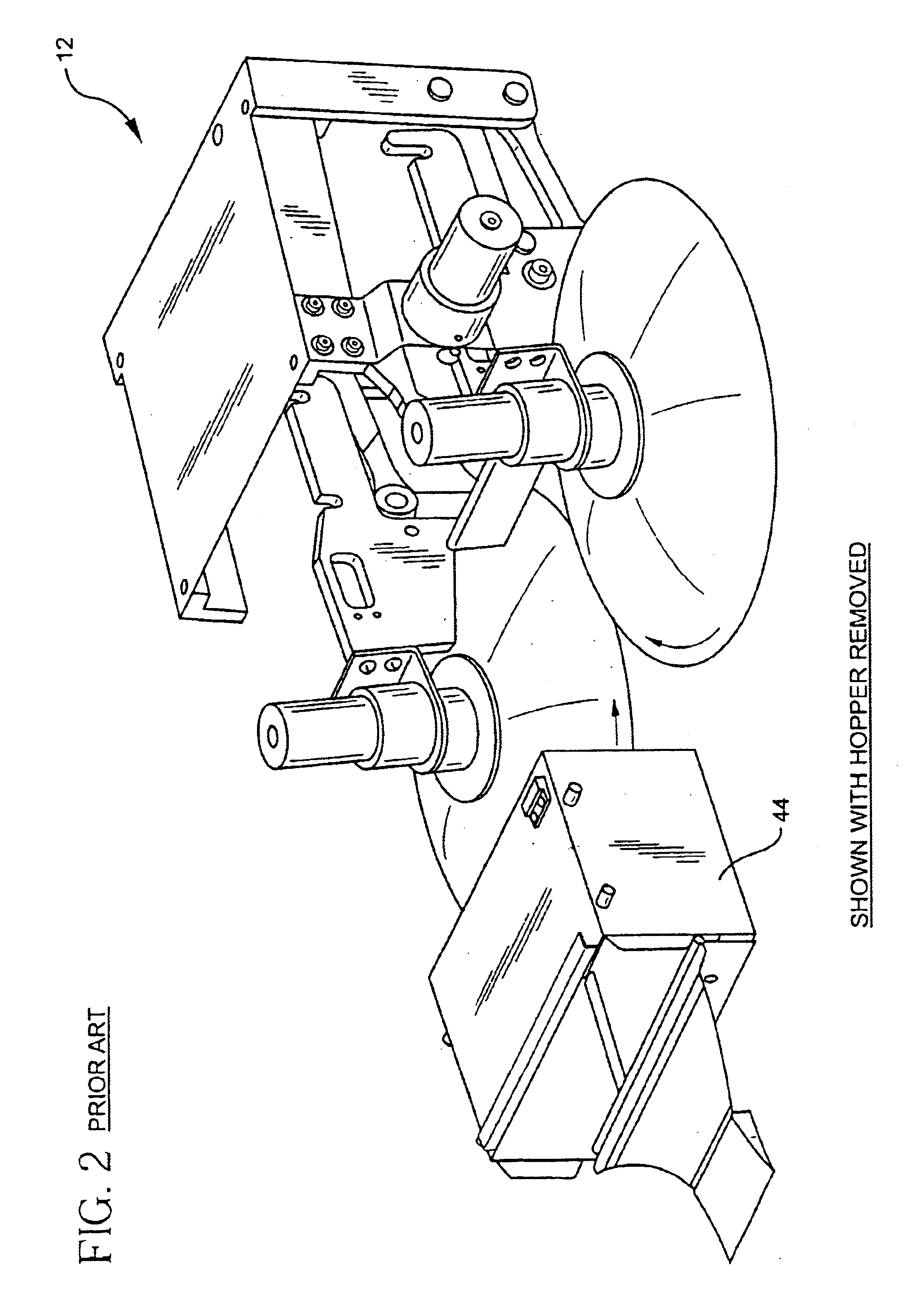

Suspension device for floor maintenance appliance

InactiveUS6836919B2Avoid damageEasy maintenanceGrinding machine componentsCarpet cleanersActuatorReliability engineering

A suspension device for coupling a surface maintenance appliance to a surface maintenance machine is disclosed. The suspension device includes a carriage member movably supported upon the maintenance machine through a plurality of linkages coupled to the carriage member. Together the plurality of linkages permit the carriage and surface maintenance appliance to follow undulations in the floor surface during operation of the surface maintenance machine. An actuator engages a lost motion device to lift the carriage member away from the ground surface. A variety of different floor surface maintenance appliances may be coupled to surface maintenance vehicles according to aspects of the present invention.

Owner:TENNANT COMPANY

Rotatable tray for food processor

A food processor for processing foodstuffs having a base housing, a motor, a drive shaft, a tool, a bowl, a lid and a tray. The tool is rotatably securable to the drive shaft and rotatable by the motor. The bowl is removably securable to the base housing and includes an inner surface area. The lid has an inner surface area. The lid is removably securable to the bowl to create a processing chamber between the inner surface areas of the bowl and lid in an assembled position. The tray is removably securable within the processing chamber and is manually rotatable relative to the bowl and lid, independently of the drive shaft and tool, in the assembled position.

Owner:HAMILTON BEACH BRANDS

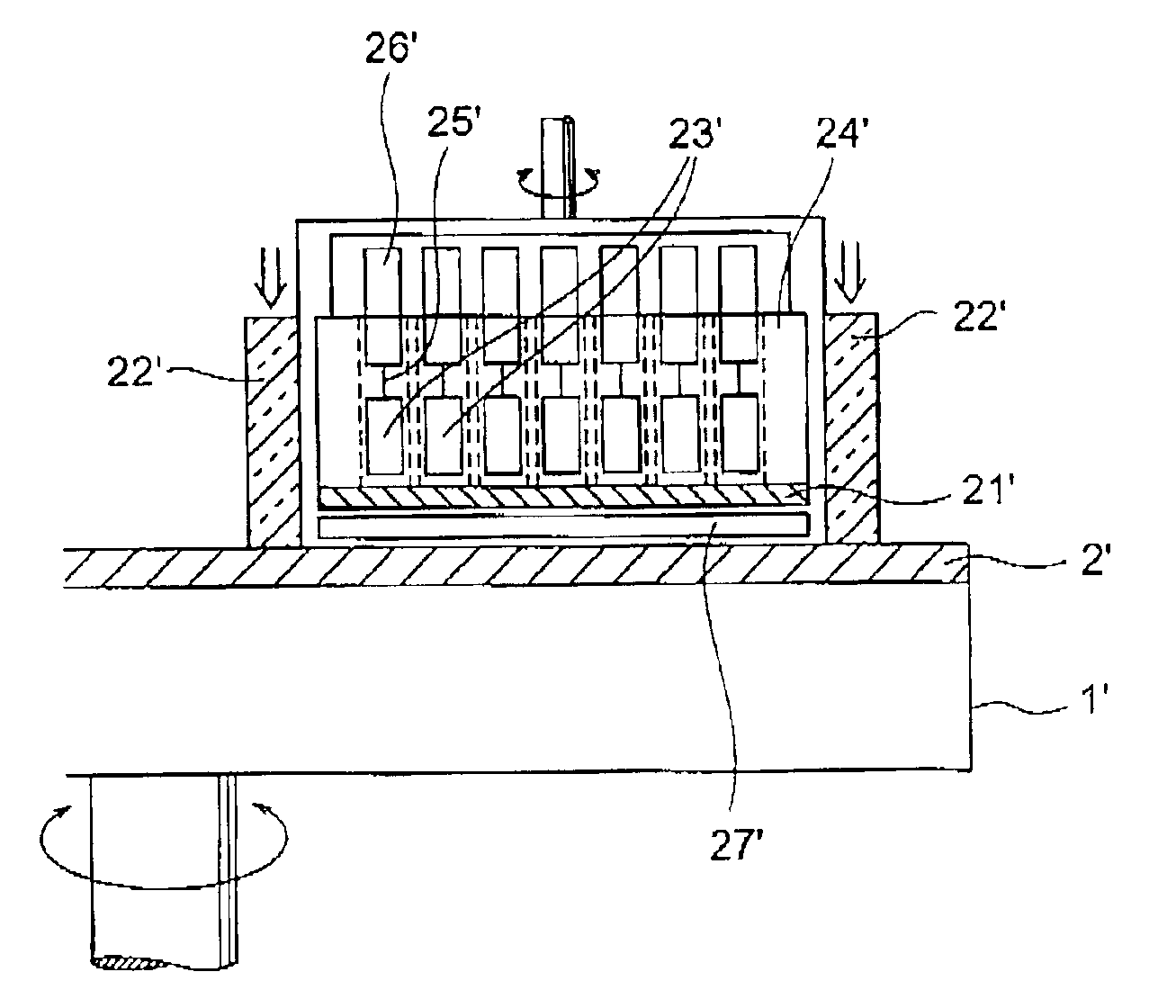

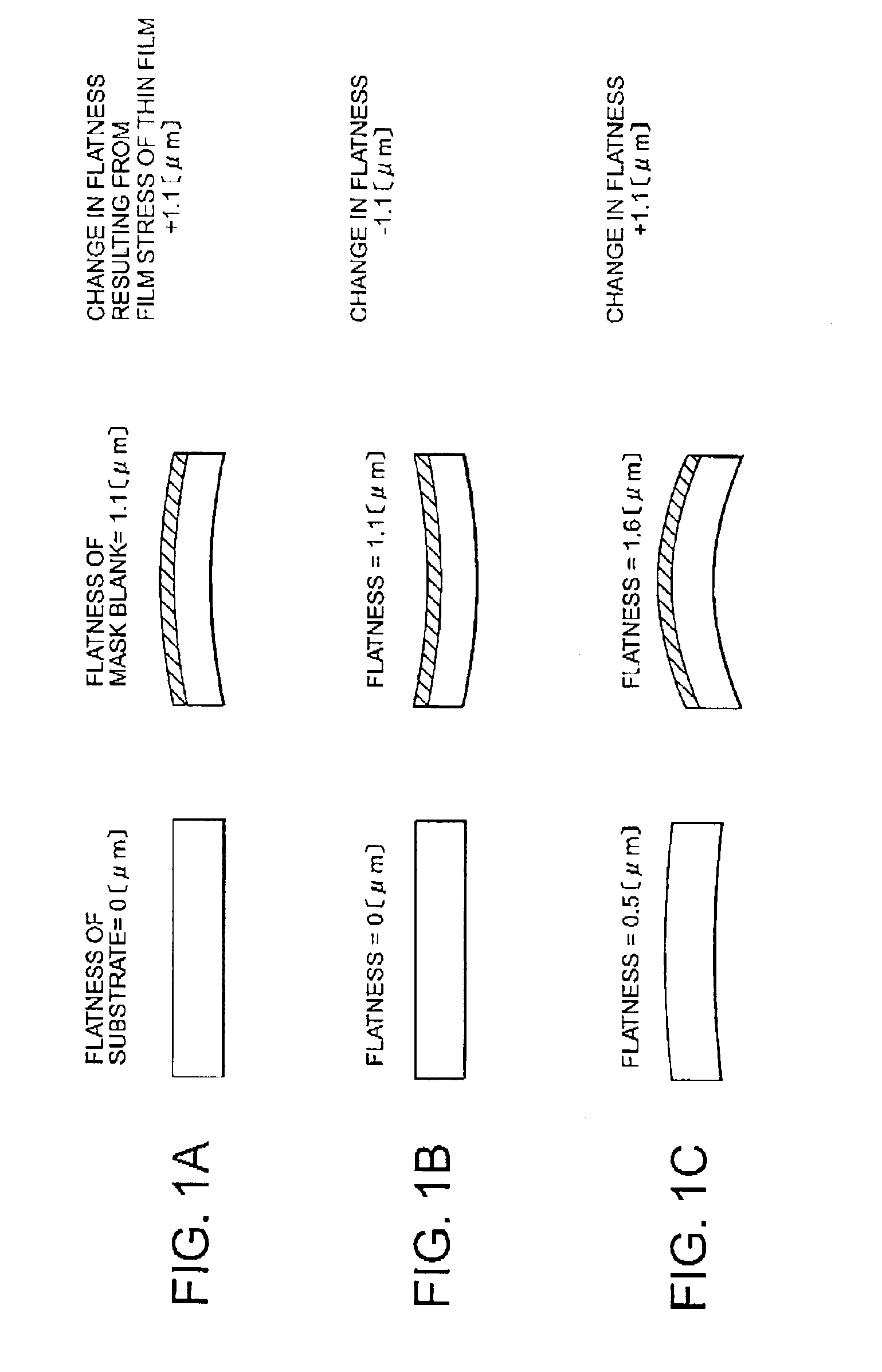

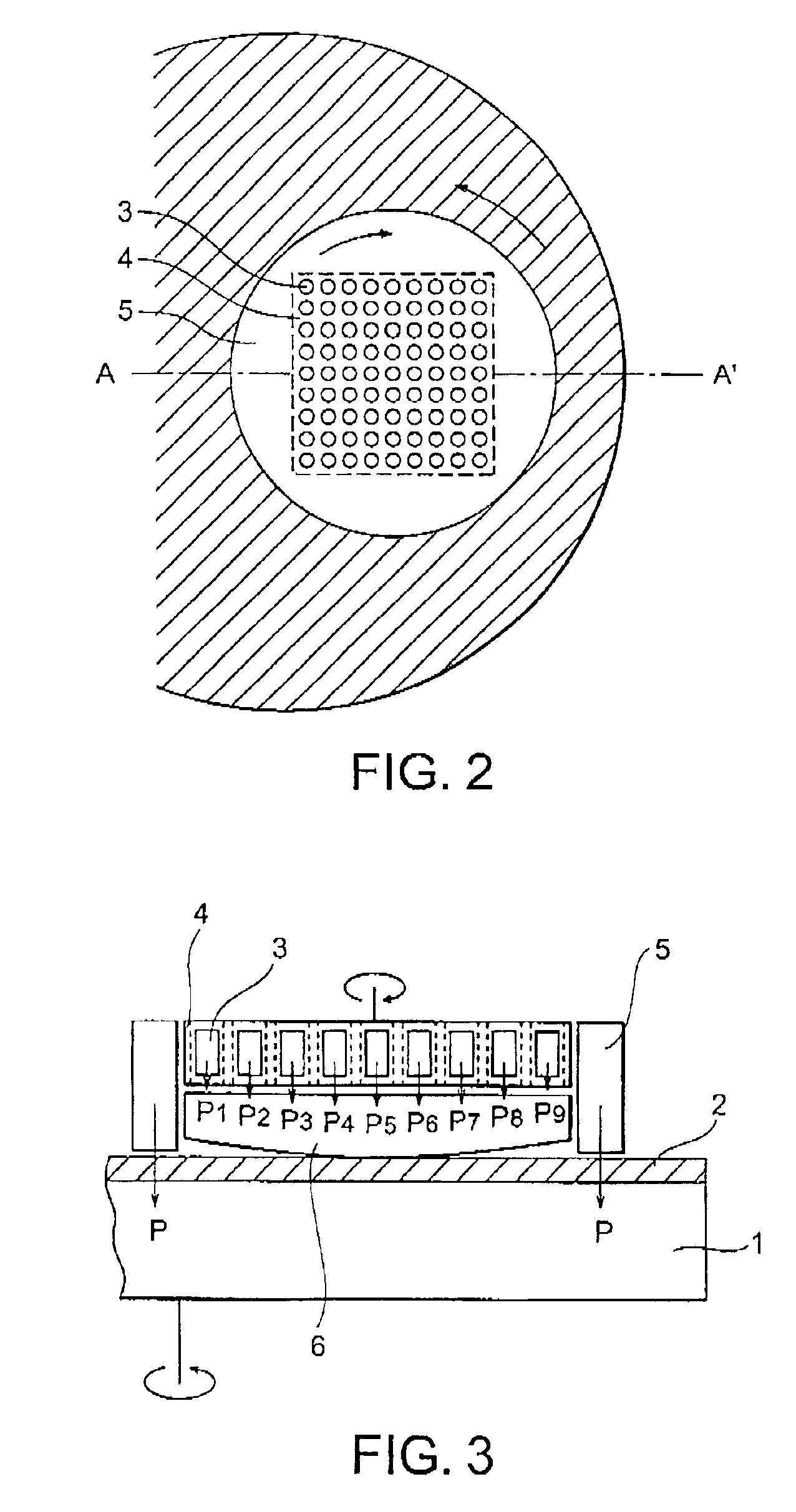

Method of determining a flatness of an electronic device substrate, method of producing the substrate, method of producing a mask blank, method of producing a transfer mask, polishing method, electronic device substrate, mask blank, transfer mask, and polishing apparatus

InactiveUS6951502B2Avoiding deterioration in pattern position accuracyDesired flatness of the mask blankGrinding machine componentsVacuum evaporation coatingSubstrate surfaceElectron

A flatness of a substrate is determined to achieve a desired flatness of a mask blank by predicting the variation in flatness resulting from a film stress of a thin film formed on the substrate. The flatness is adjusted by measuring the flatness of the substrate as a measured flatness, selecting a load type with reference to the measured flatness, and polishing the substrate under pressure distribution specified by the load type. A principal surface of the substrate has a flatness greater than 0 μm and not greater than 0.25 μm. A polishing apparatus includes a rotatable surface table, a polishing pad formed thereon, abrasive supplying means for supplying an abrasive to the polishing pad, substrate holding means, and substrate pressing means for pressing the substrate. The substrate pressing means has a plurality of pressing members for individually and desirably pressing a plurality of divided regions of the substrate surface.

Owner:HOYA CORP

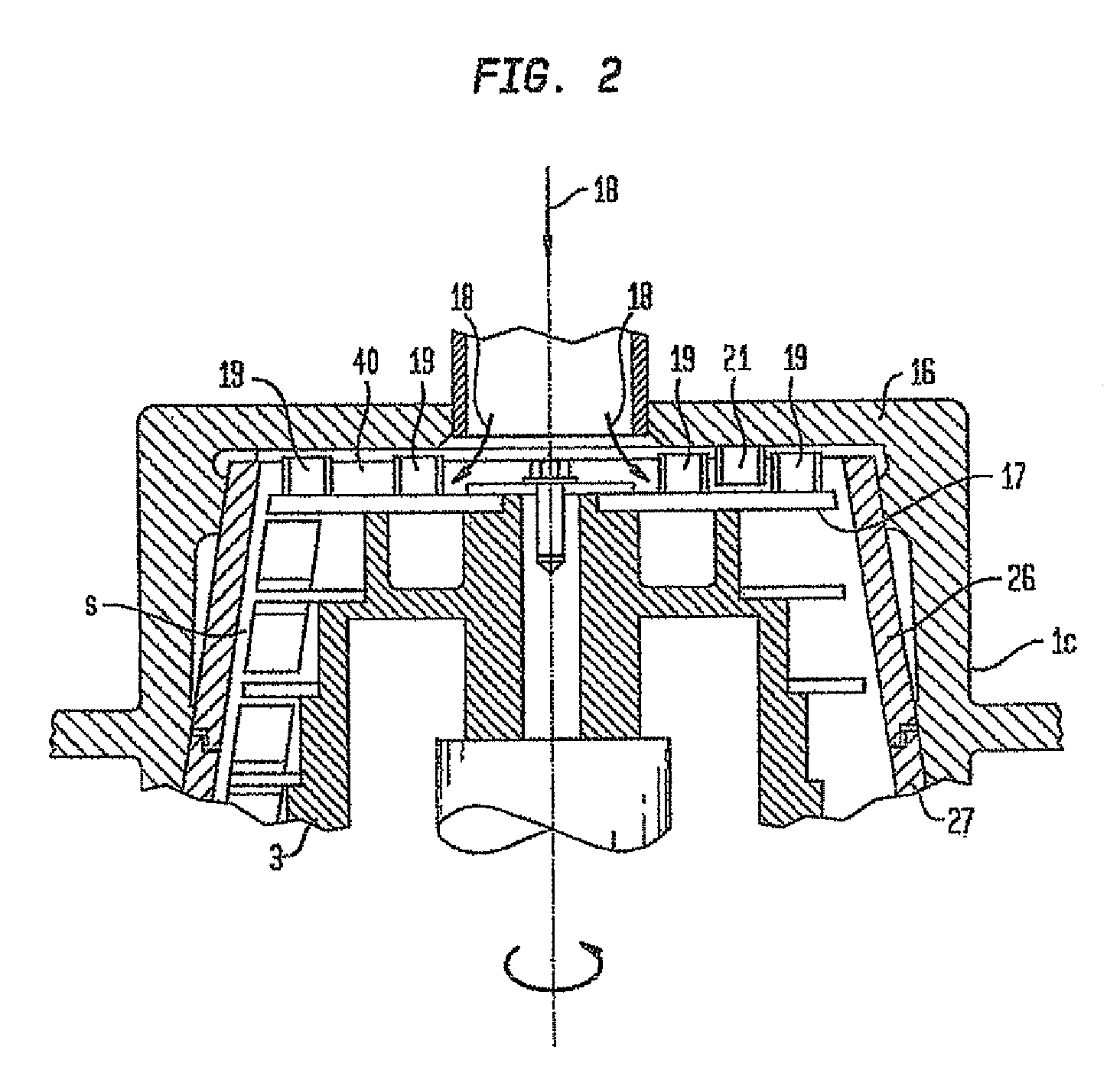

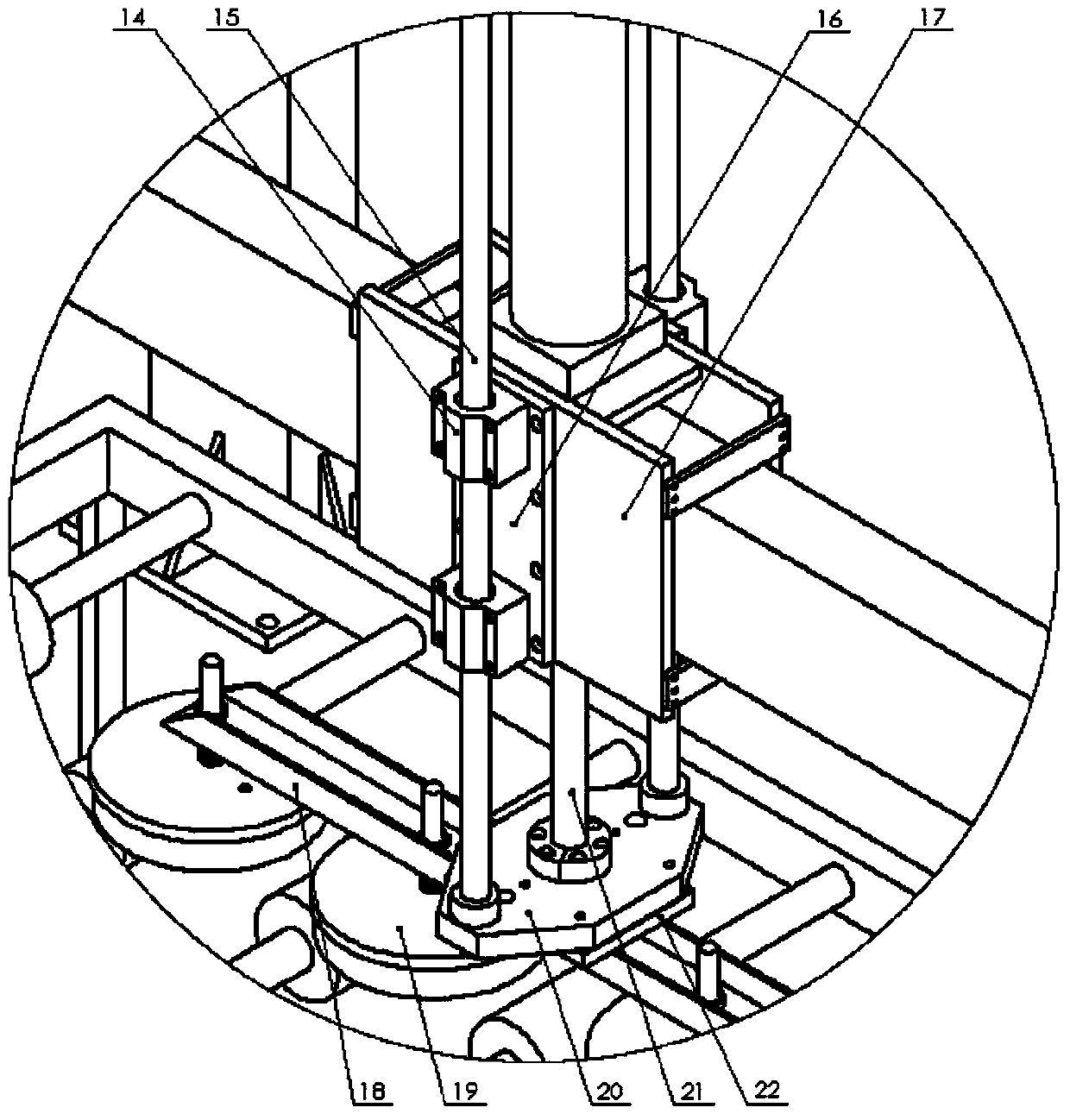

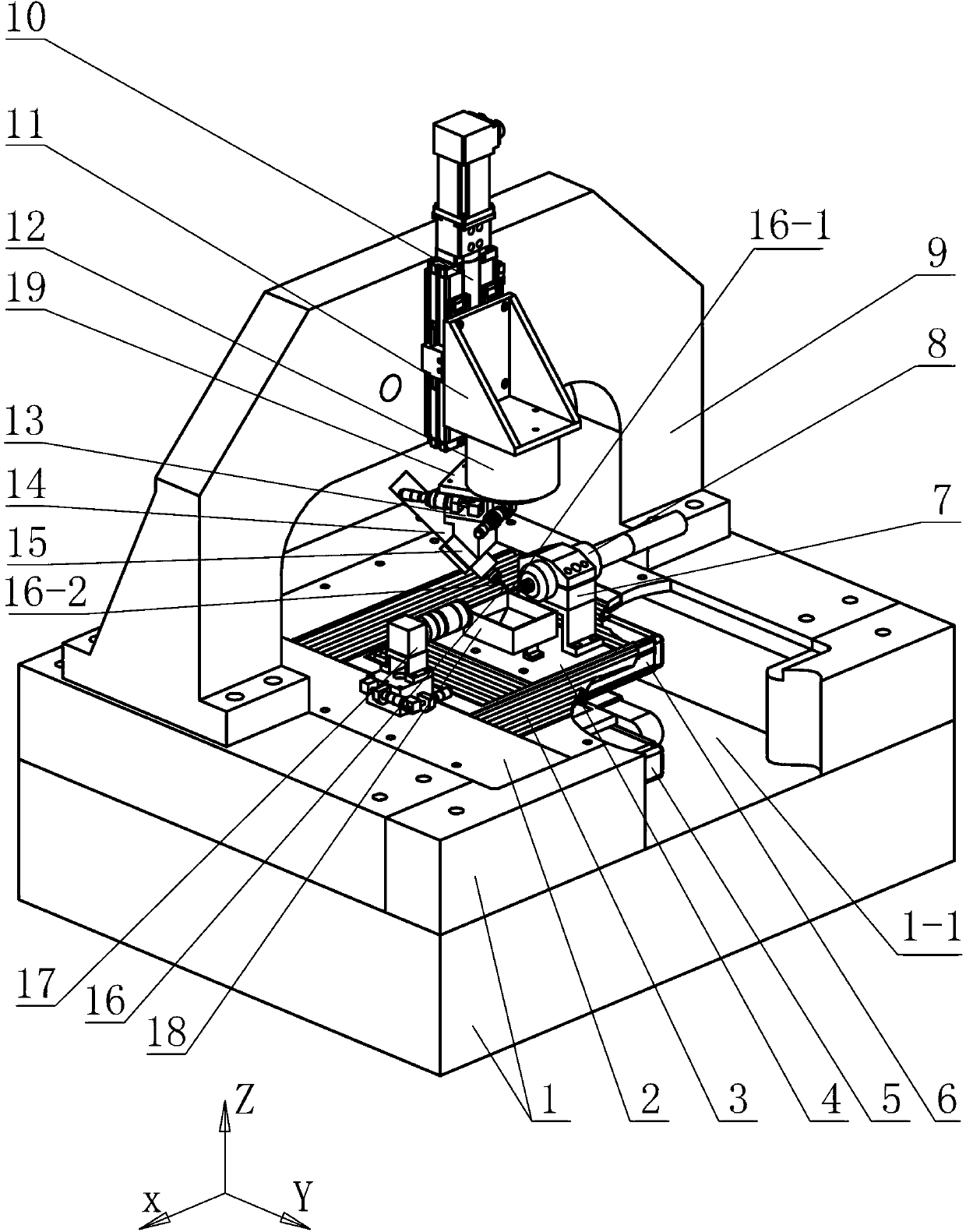

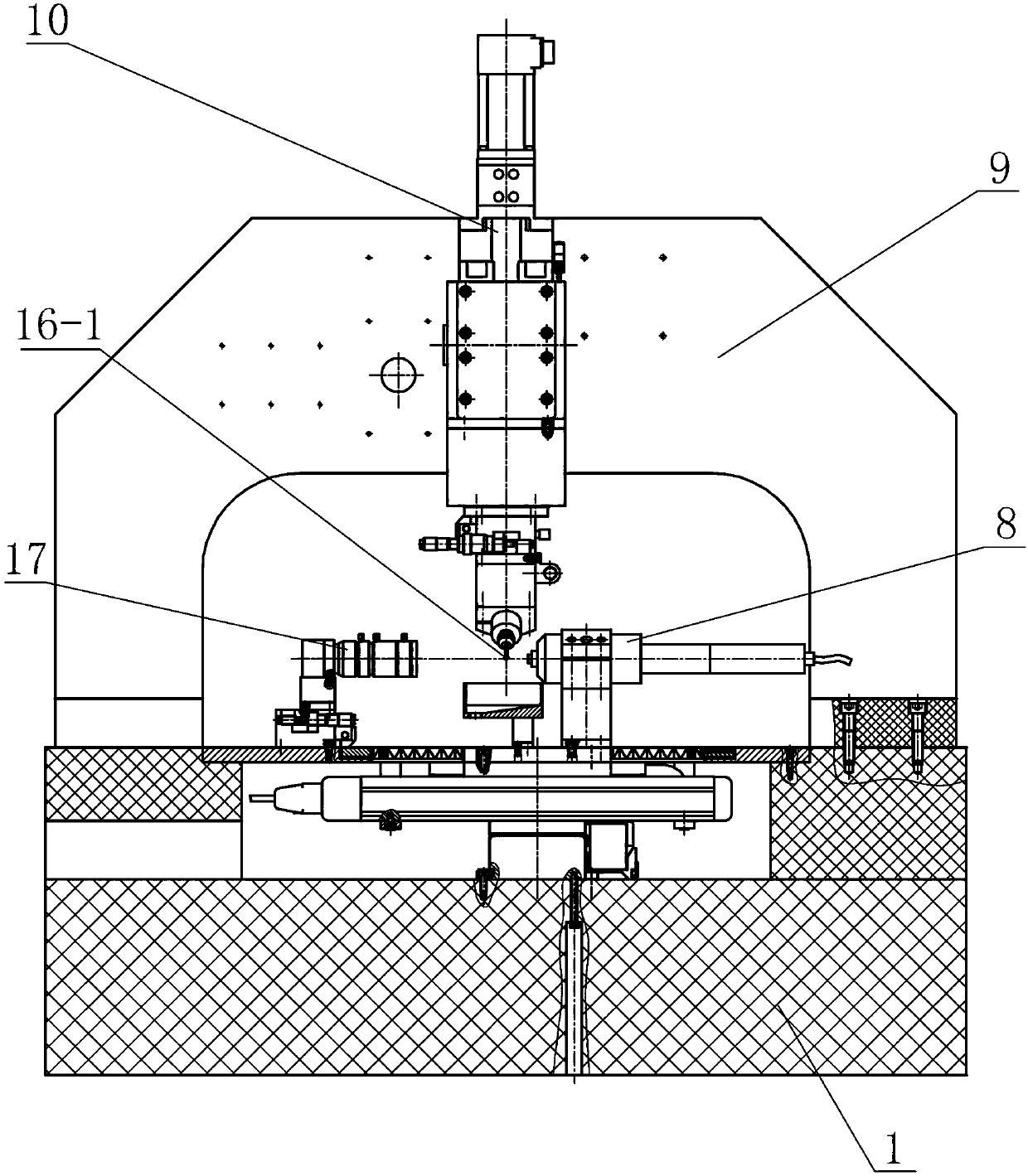

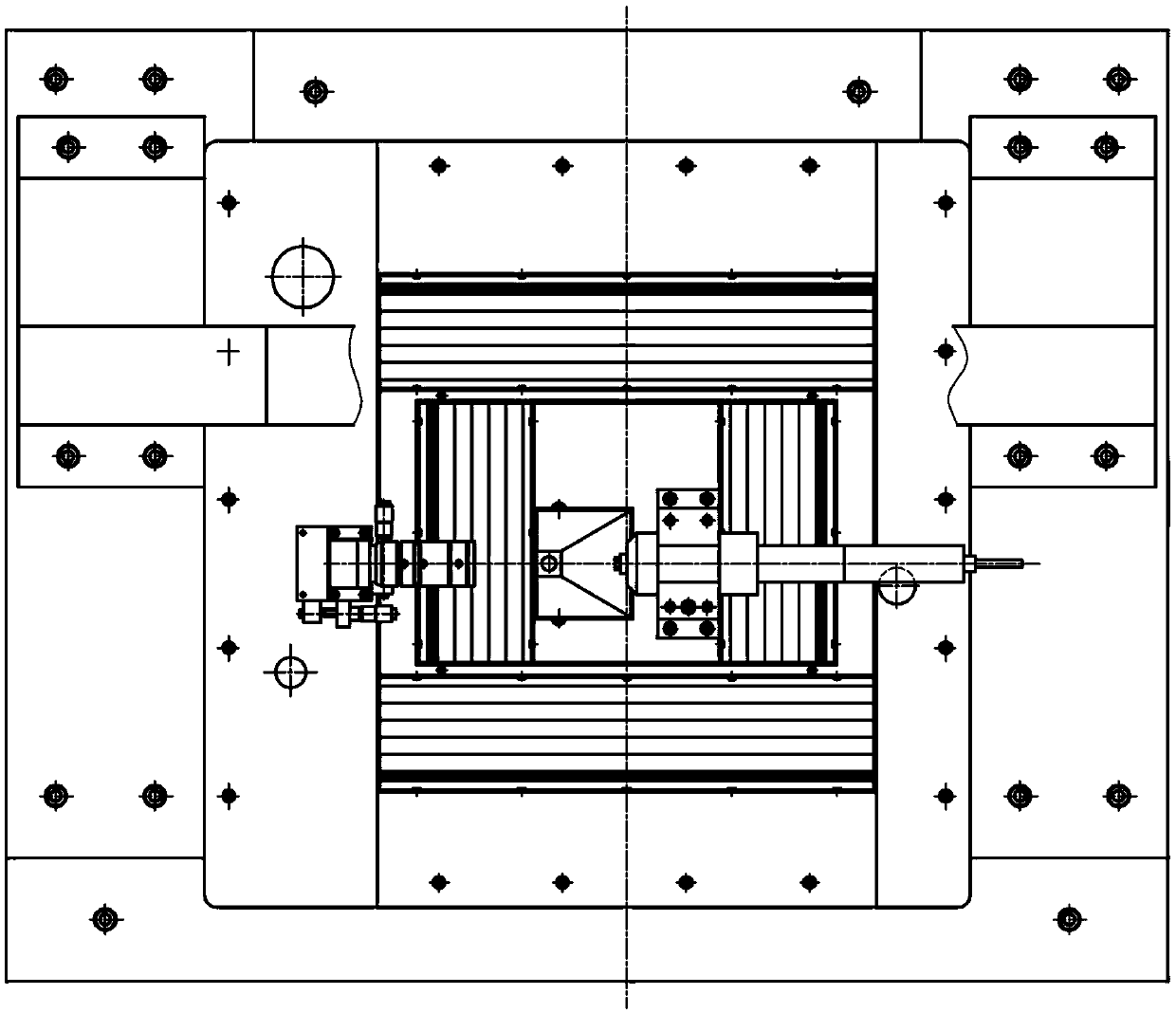

Small-caliber non-spherical permanent magnet magnetorheological polishing processing machine tool

ActiveCN103072047AIncrease contactAvoid interferenceGrinding machine componentsMachine toolComputer science

The invention discloses a small-caliber non-spherical permanent magnet magnetorheological polishing processing machine tool, which belongs to the technical field of grinding-polishing processing, and is used for solving the problem that the shape and size accuracy requirements of a processed part cannot be met since each position of a small-caliber non-spherical curved surface to be processed cannot be contacted during processing of workpieces with the conventional polishing processing equipment. A workbench is arranged on an X axis linear unit of an XY precision movable platform; an organ protection cover is arranged between the edge of the workbench and a cover plate; a workpiece main shaft is arranged on the workbench through a workpiece main shaft bracket; a Z axis linear unit is arranged on a portal frame; a revolving table is arranged on the Z axis linear unit through a right-angle connecting frame; the shaft end of a rotating shaft in the revolving table is connected with a polishing head main shaft bracket through a two-dimensional precision fine adjustment displacement table; and the polishing head main shaft bracket has a certain inclination angle, so that an included angle between a polishing head main shaft on the polishing head main shaft bracket and a horizontal plane is 40-45 degrees. The machine tool is suitable for ultra-precision polishing processing of high-accuracy small-caliber non-spherical parts.

Owner:HARBIN INST OF TECH

Abrasive article

Abrasive article including a backing plate. Backing plate has a first major surface and a second opposite major surface. A central aperture extends through backing plate. An abrasive layer is secured to the first major surface of backing plate. A fastener is press fit to backing plate so as to define the central aperture.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com