Patents

Literature

10381results about "Working accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

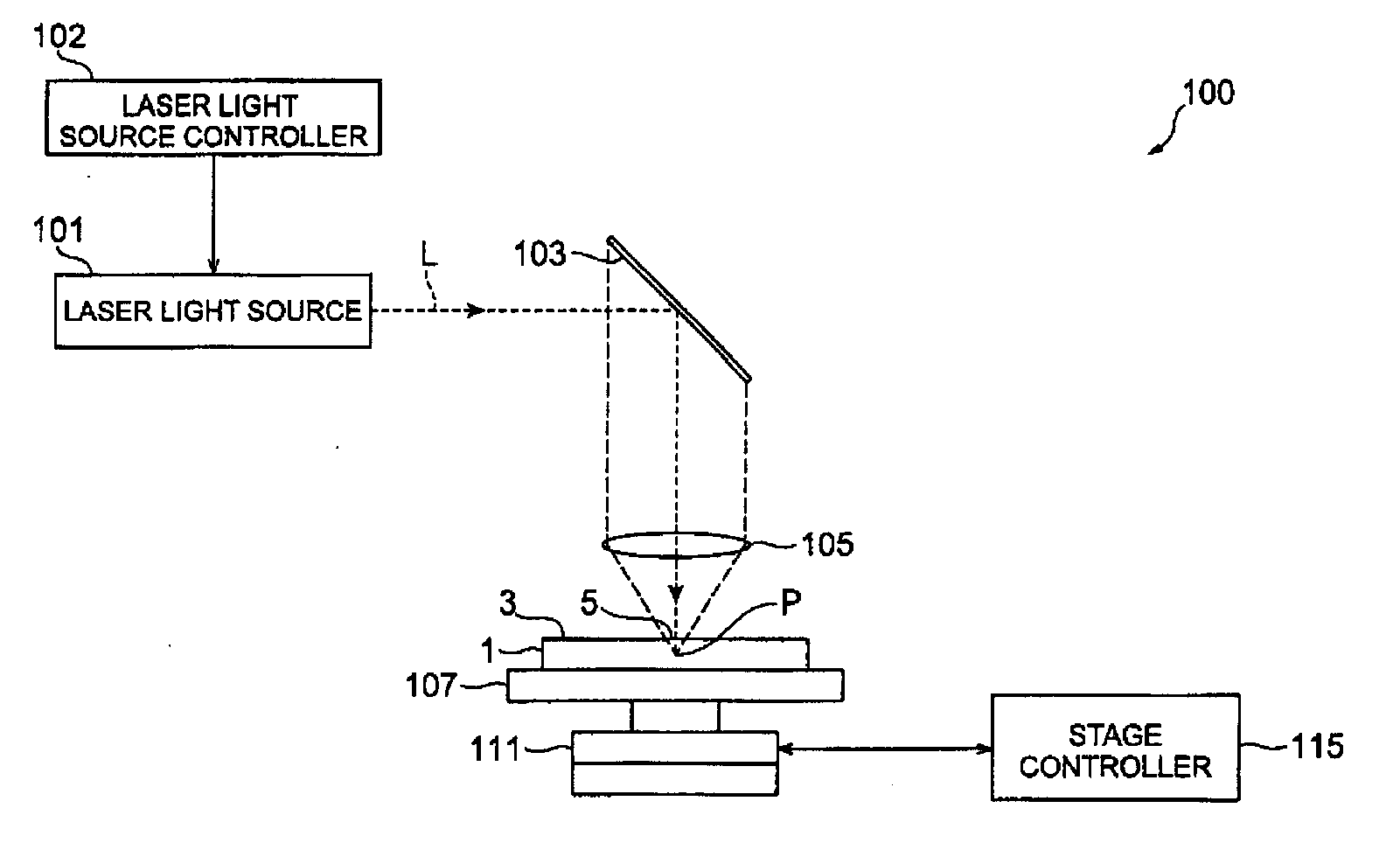

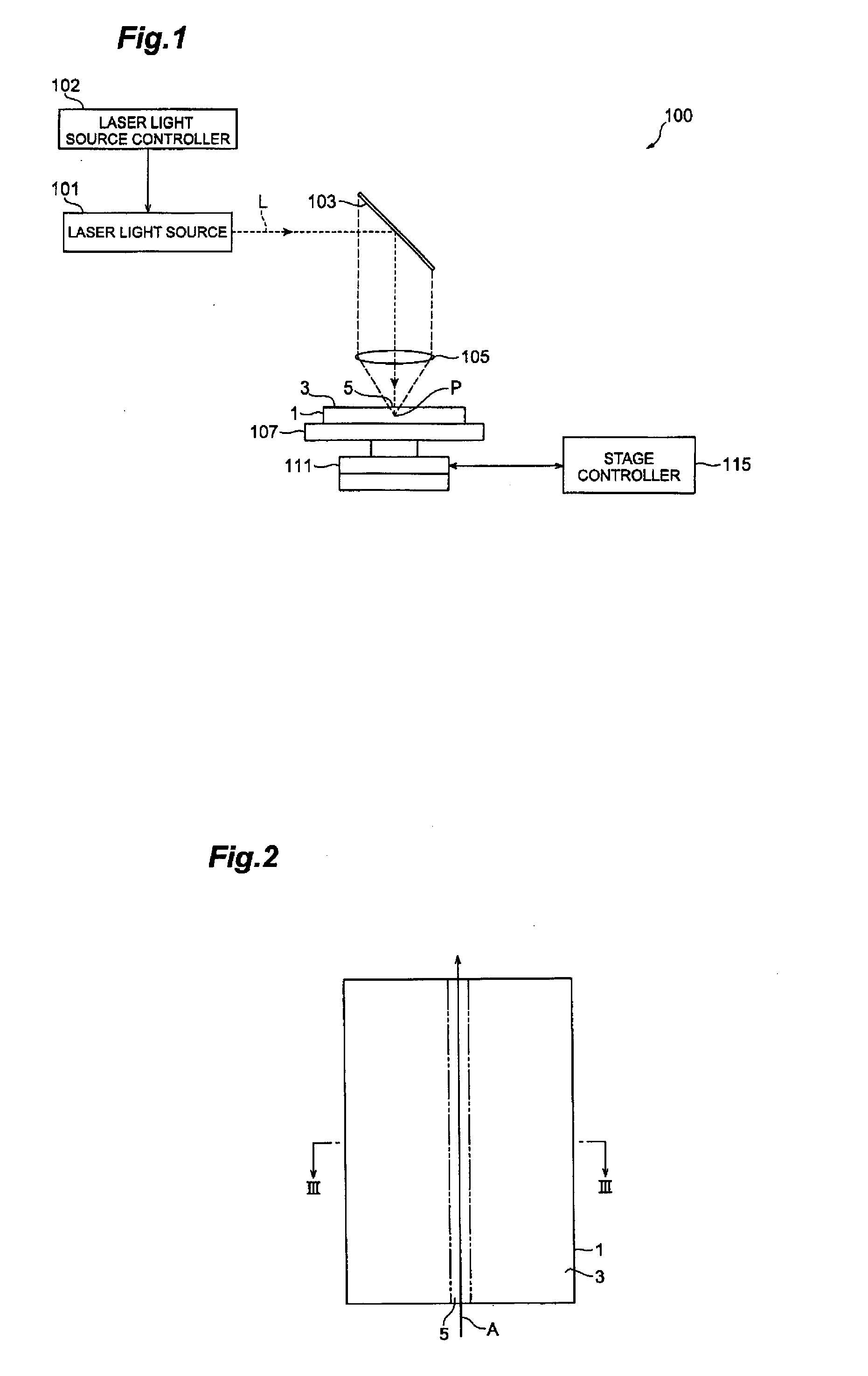

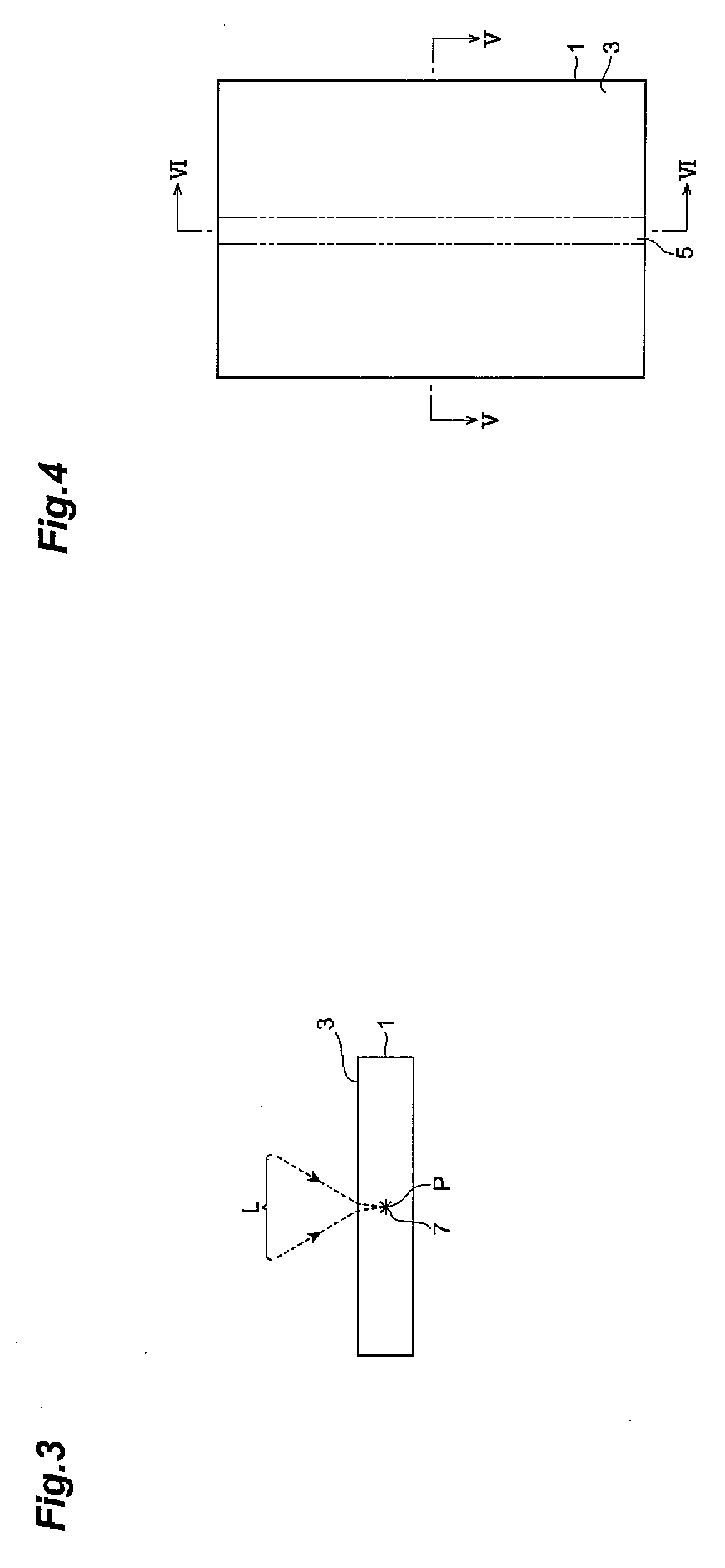

Object cutting method

ActiveUS20090098713A1Reliable preventionReliably preventedSemiconductor/solid-state device manufacturingWorking accessoriesProcess regionSemiconductor chip

An object cutting method which can reliably remove particles remaining on cut sections of chips is provided. An expandable tape 23 is electrically charged in a state where a plurality of semiconductor chips 25 obtained by cutting a planar object to be processed along a line to cut are separated from each other on the expandable tape 23. This electric action causes particles remaining on cut sections of the semiconductor chips 25 to eject therefrom even when a molten processed region is formed in the cut sections Therefore, particles remaining on the cut sections of the chips 25 can reliably be removed.

Owner:HAMAMATSU PHOTONICS KK

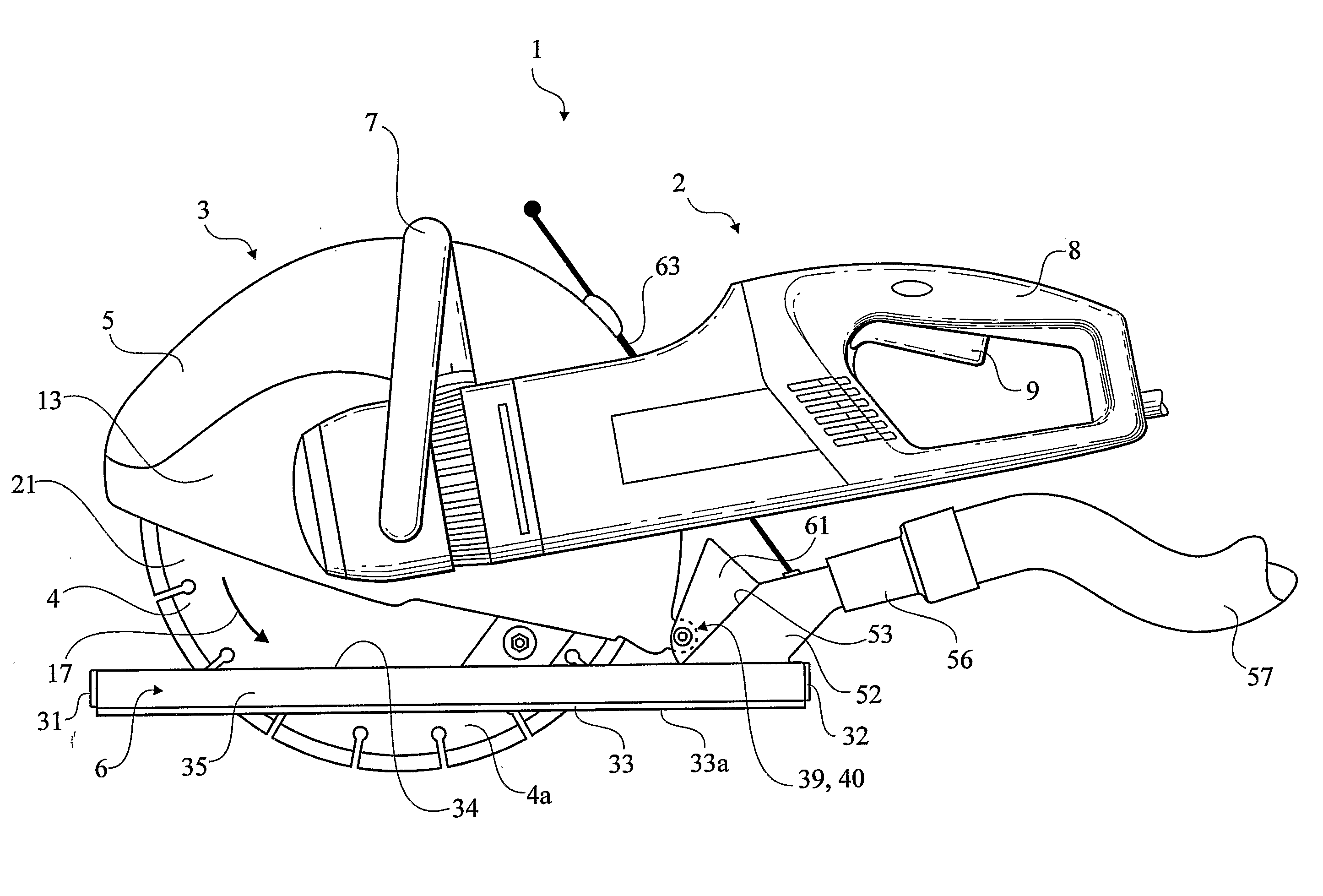

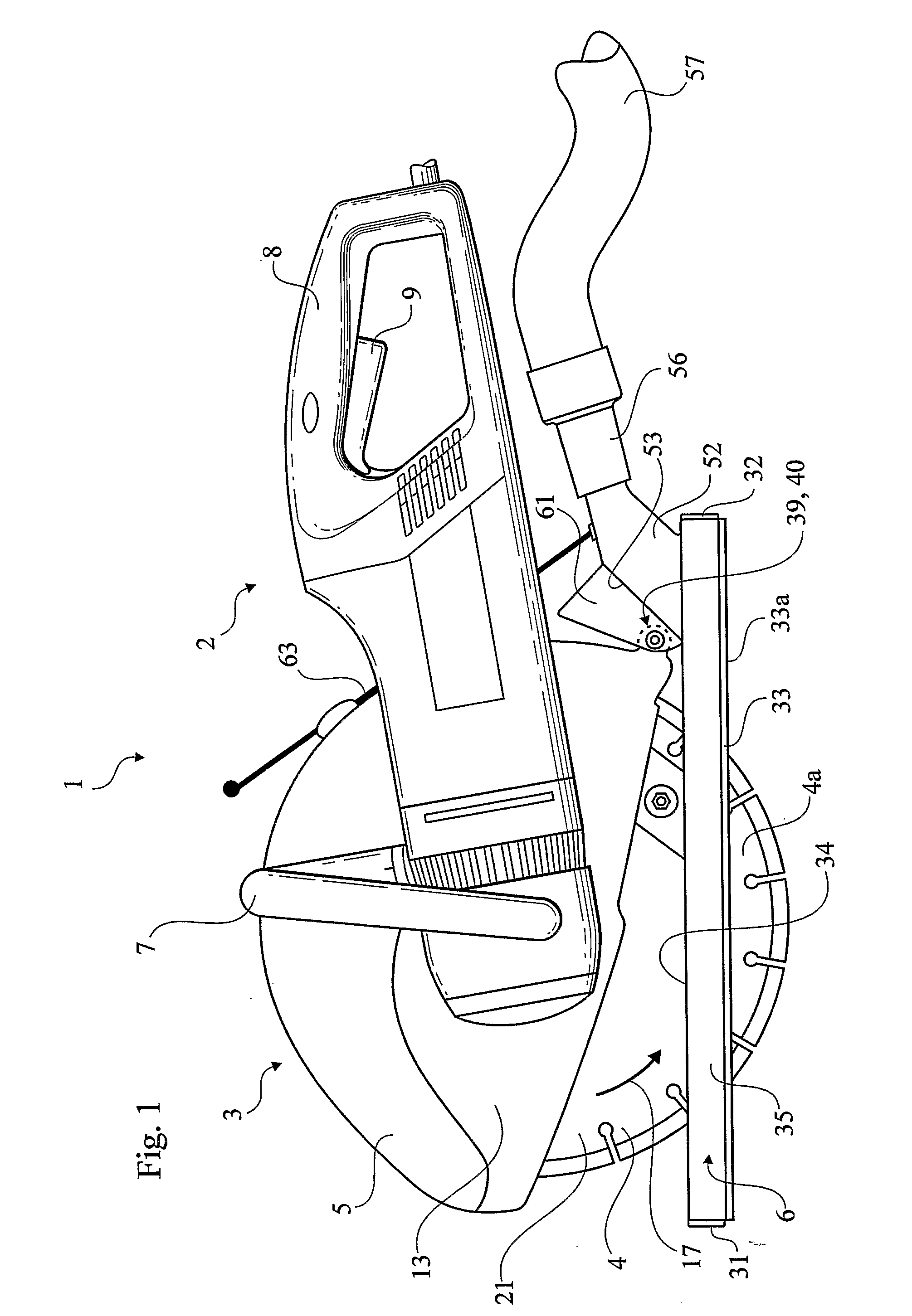

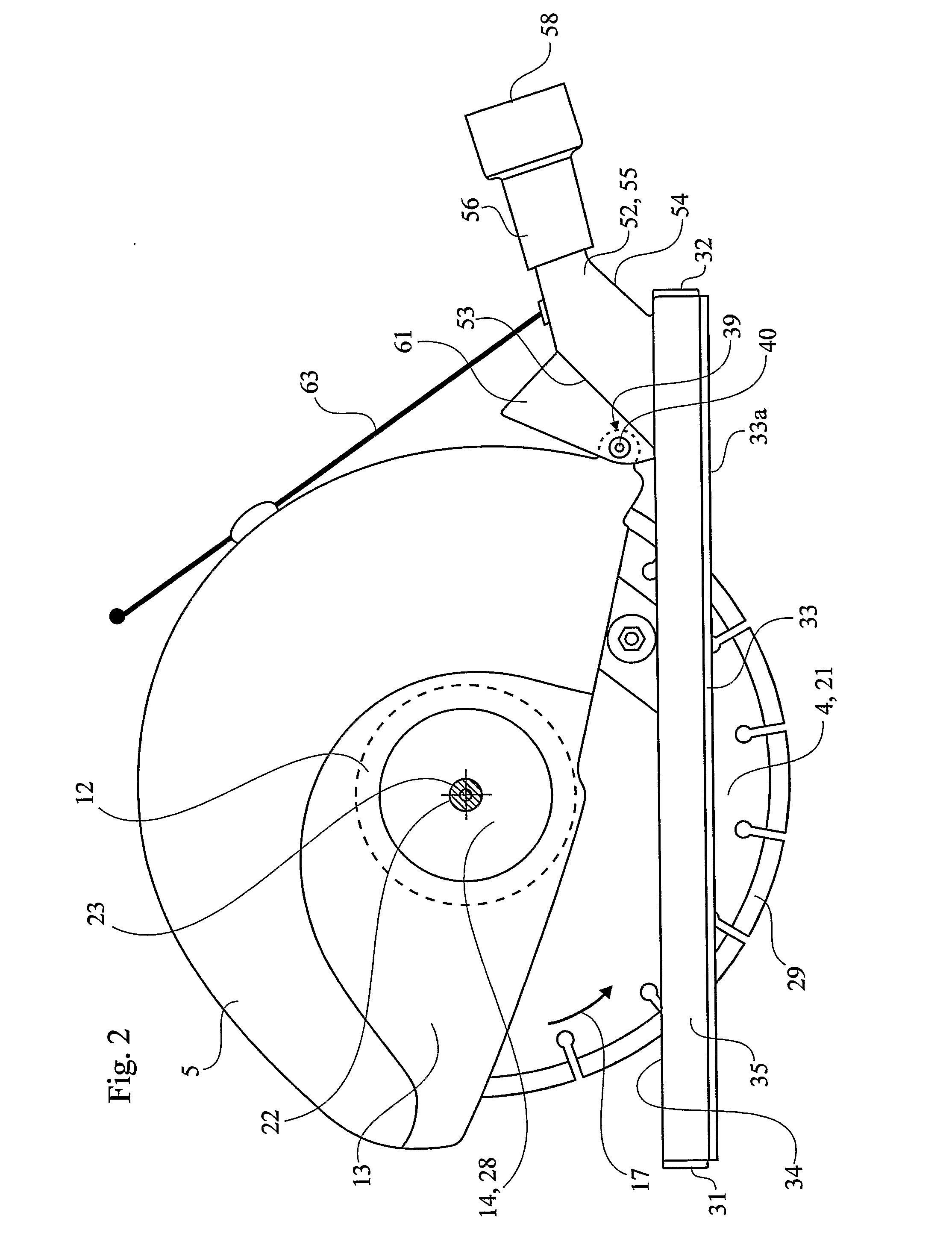

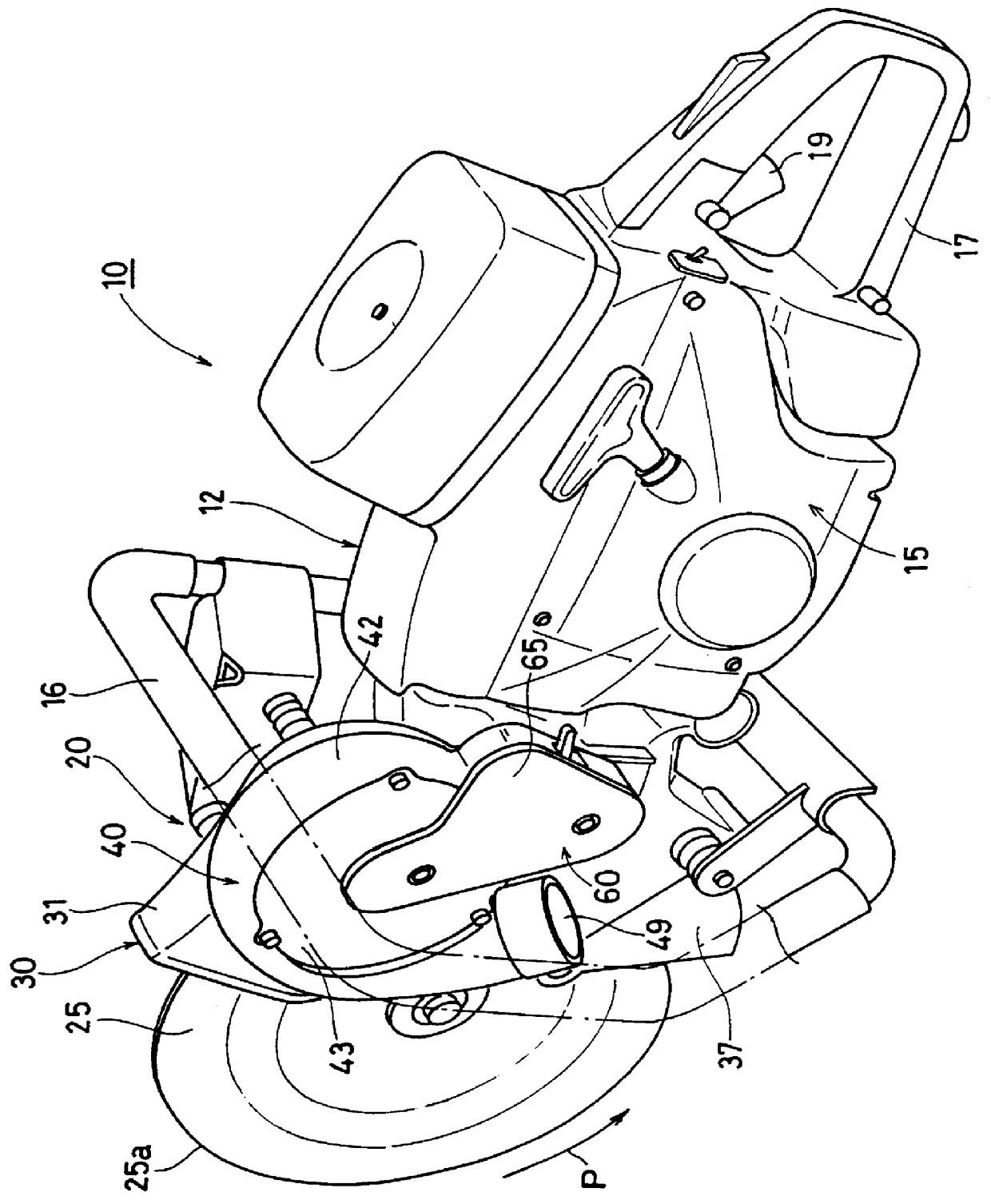

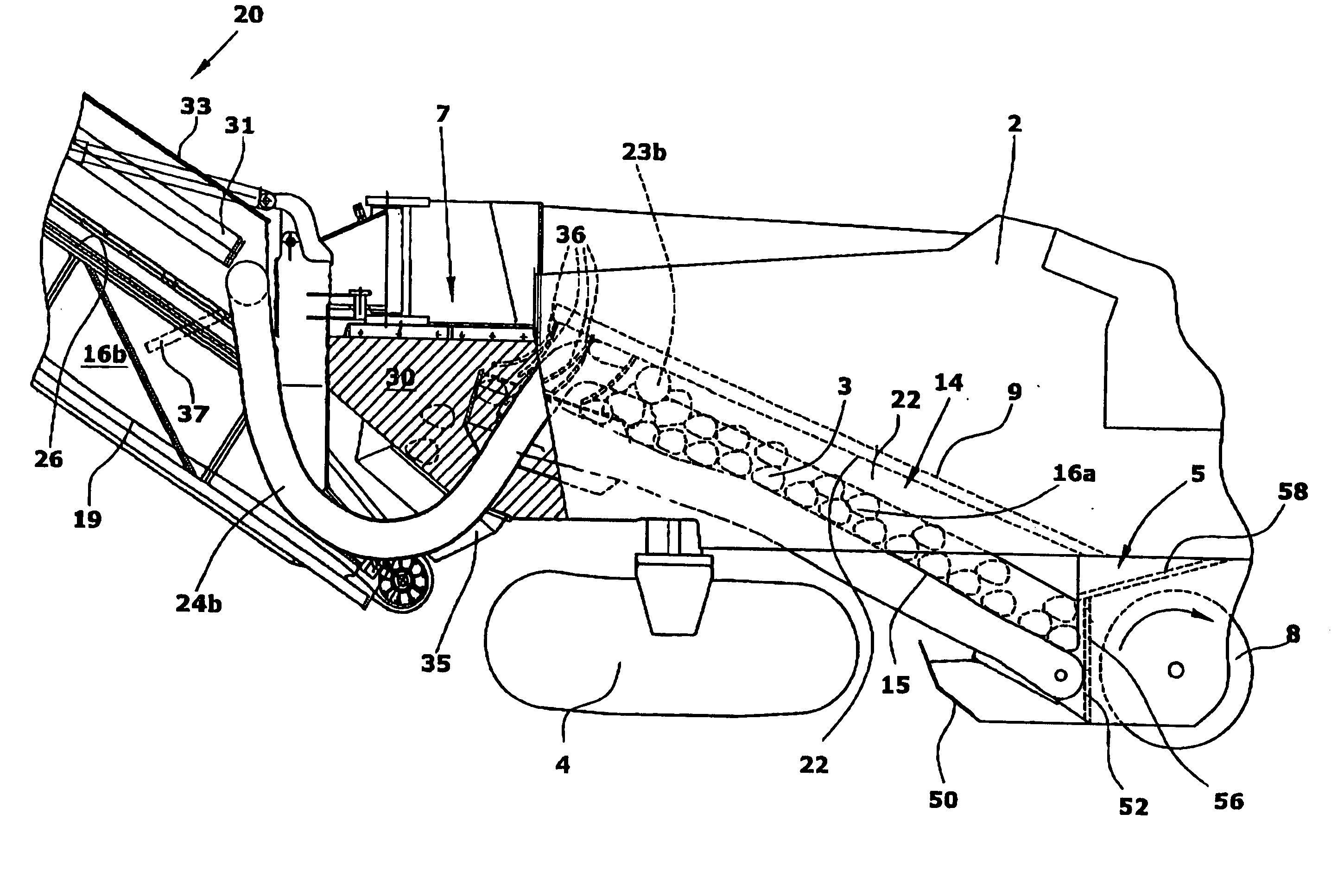

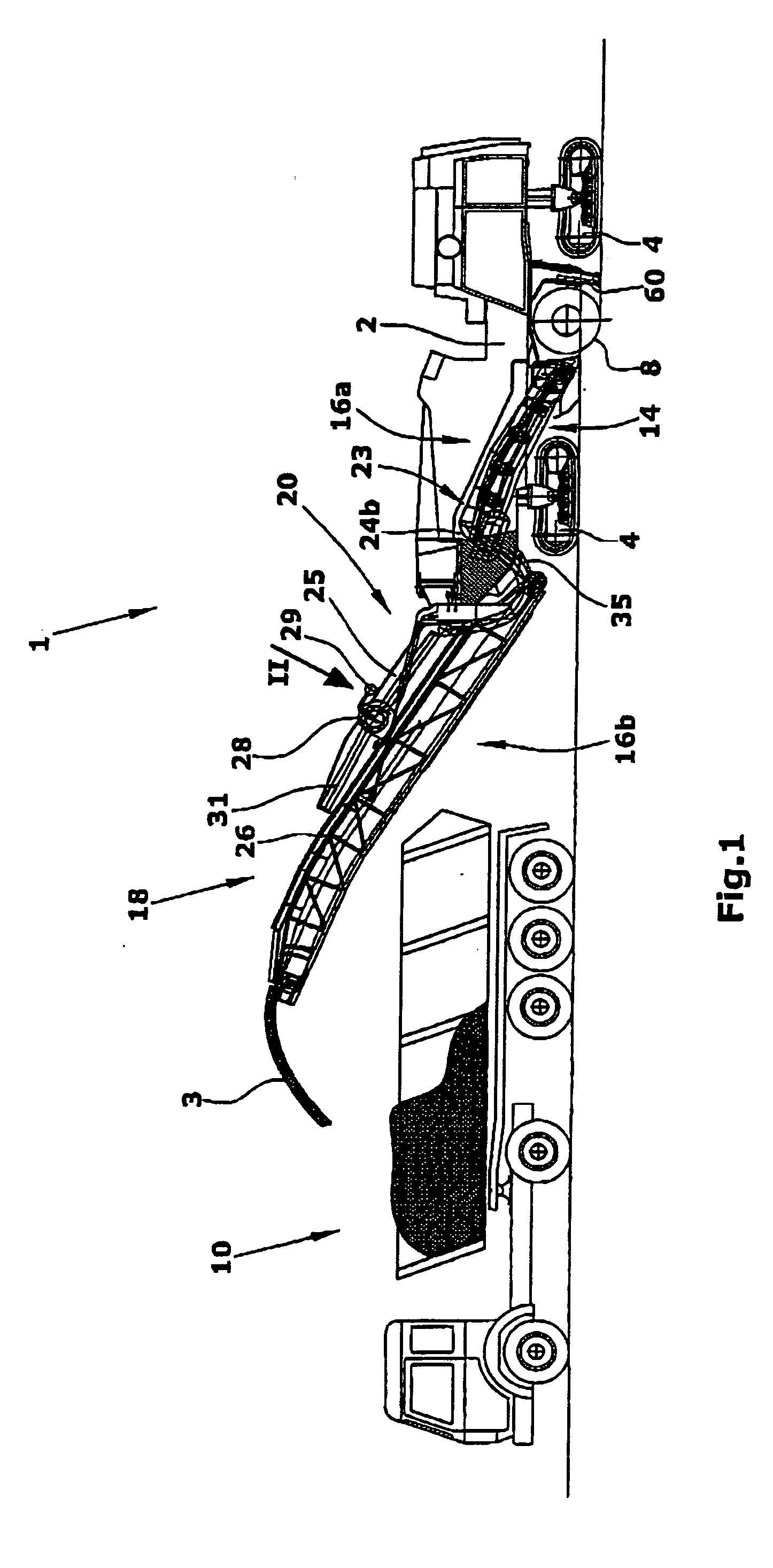

Cutting and Dust Collecting Assembly and Working Machine with Such Assembly

ActiveUS20080163492A1Avoid flyingEfficient collectionMetal sawing devicesMetal sawing accessoriesCircular sawDust control

A cutting and dust collecting assembly comprises a rotatable, circular saw blade (4) having a first side (20), a second side (21), and a cover device (6) with a terminal member (52). The bottom surface (36) of the cover device extends in a plane. A longitudinal passage (45, 46) for the saw blade extends through the cover device from its top surface to its bottom surface. The terminal member comprises a terminal chamber (60) having an inlet (45a), the mouth of which coincides with the plane of said bottom surface. An outlet (58) can be connected to a vacuum source. The direction of rotation of the operating blade is such that the rear part (4a) of the saw blade which has passed beyond the bottom surface of the cover device will move in a direction upwards-rearwards towards the bottom surface. The invention also concerns the cover device, a sealing body belonging to the cover device and a working machine which is provided with the cutting and dust collecting assembly.

Owner:HUSQVARNA AB

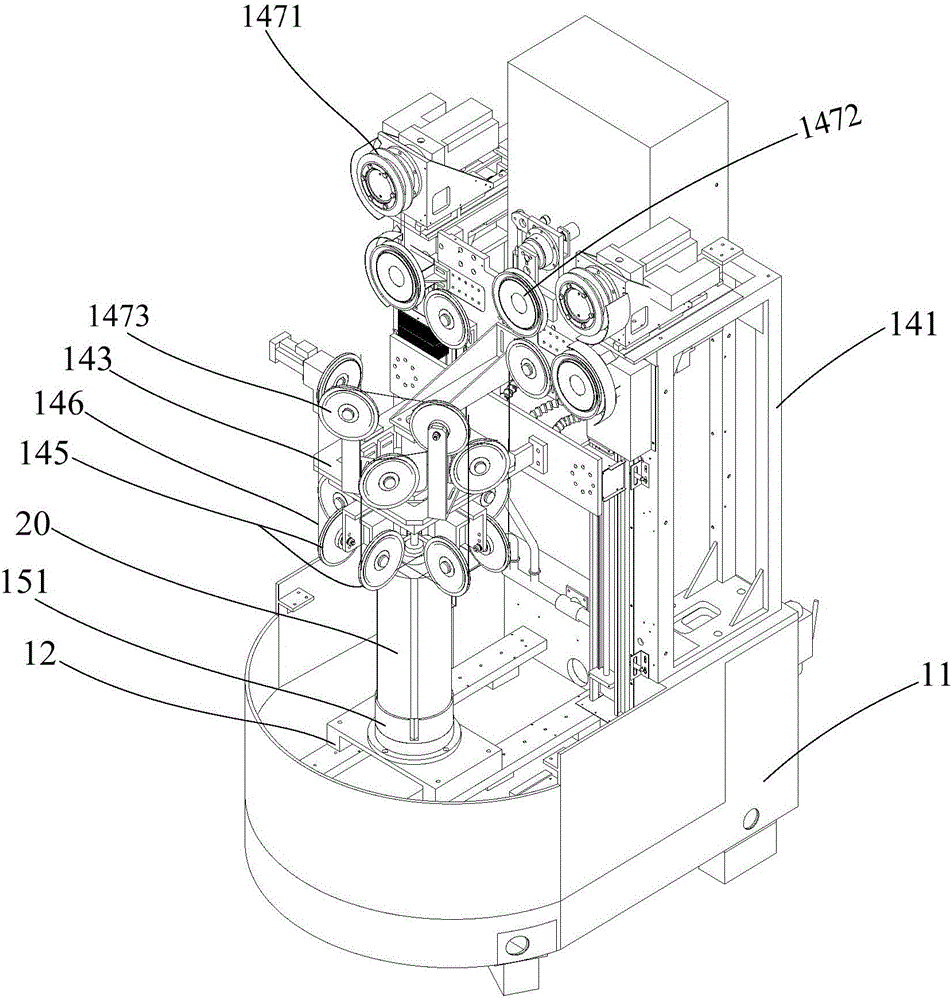

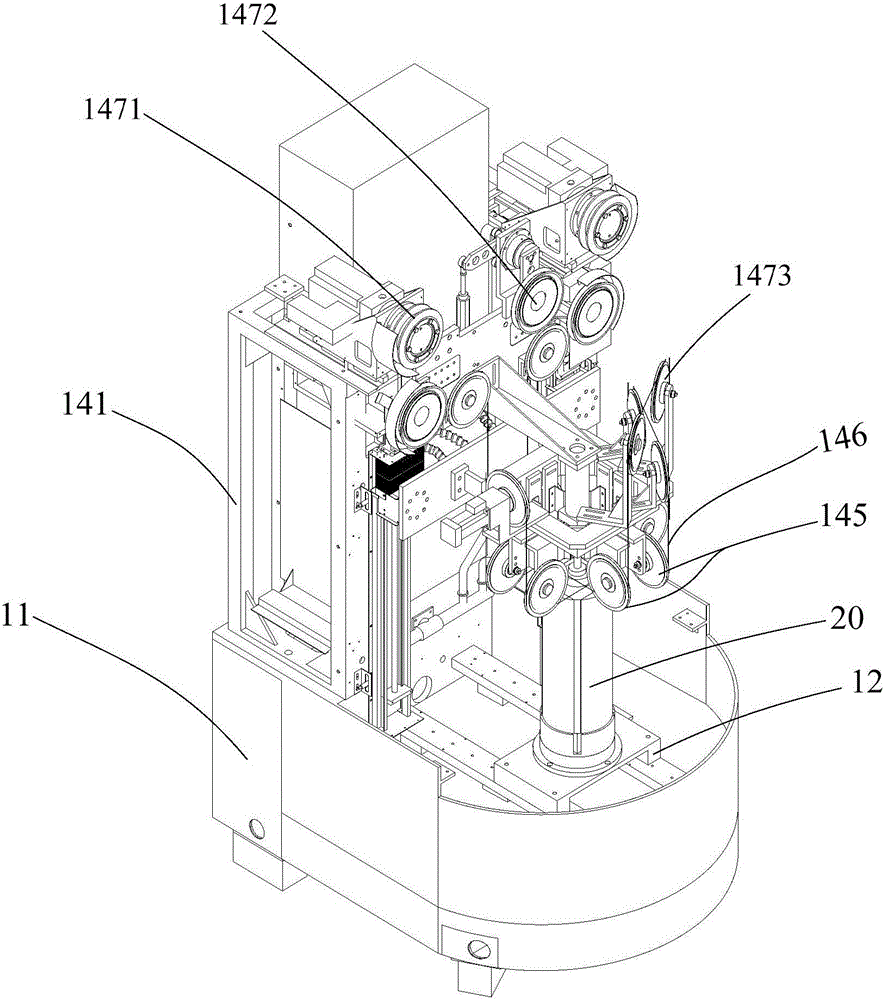

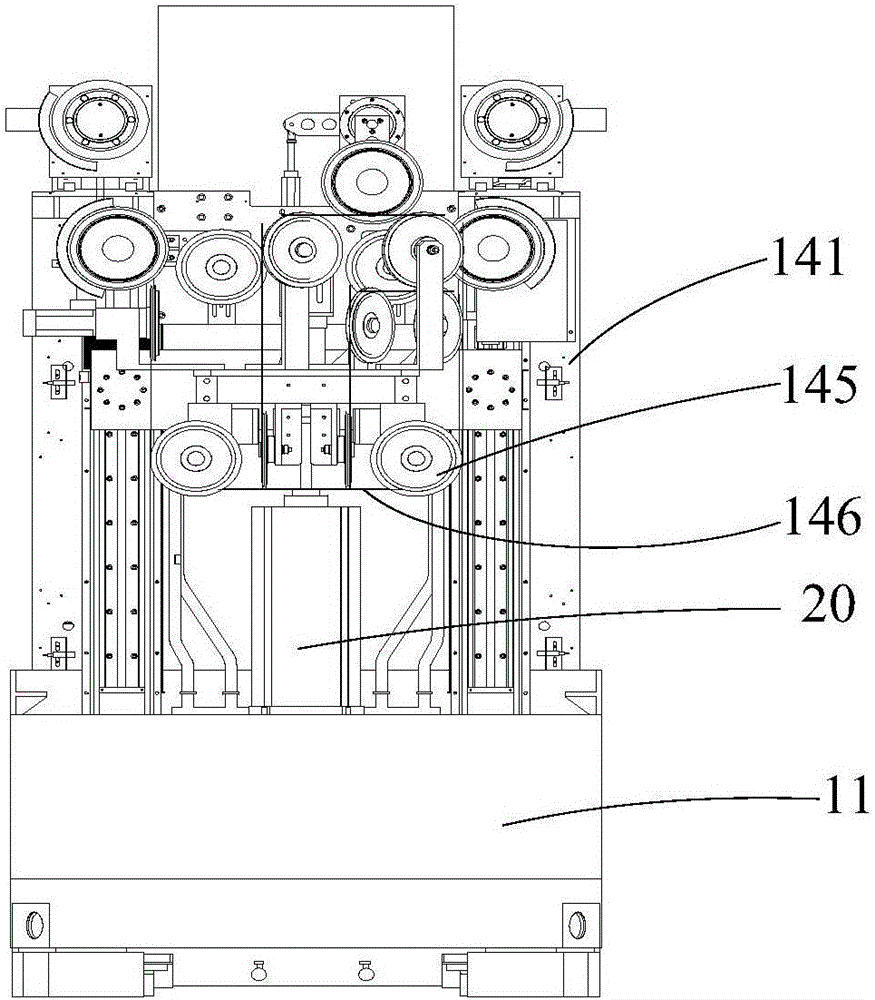

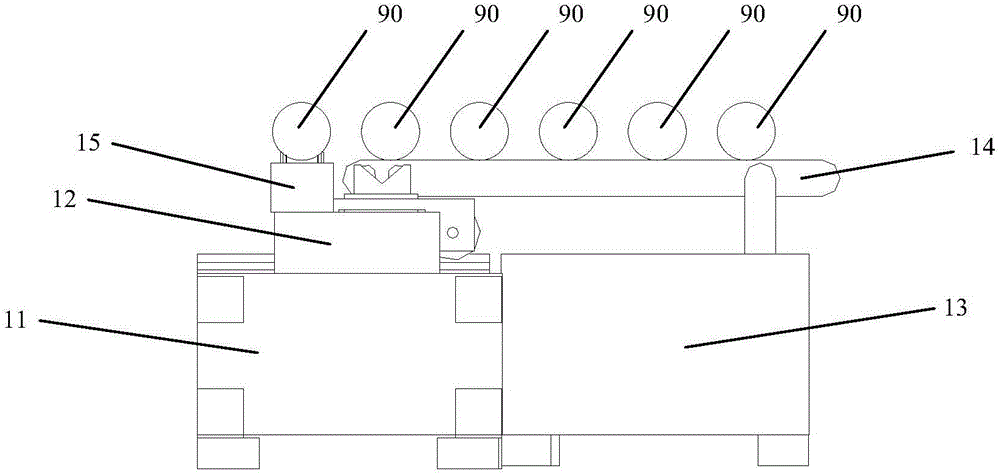

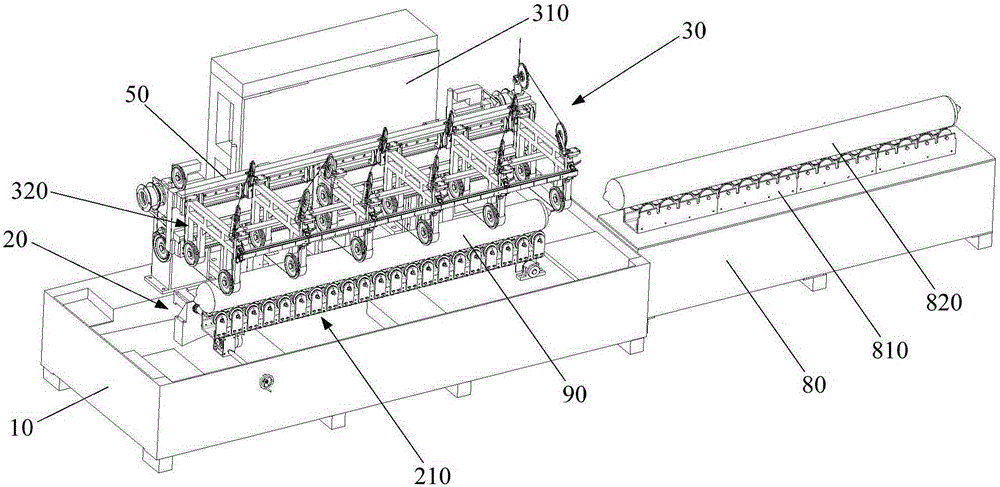

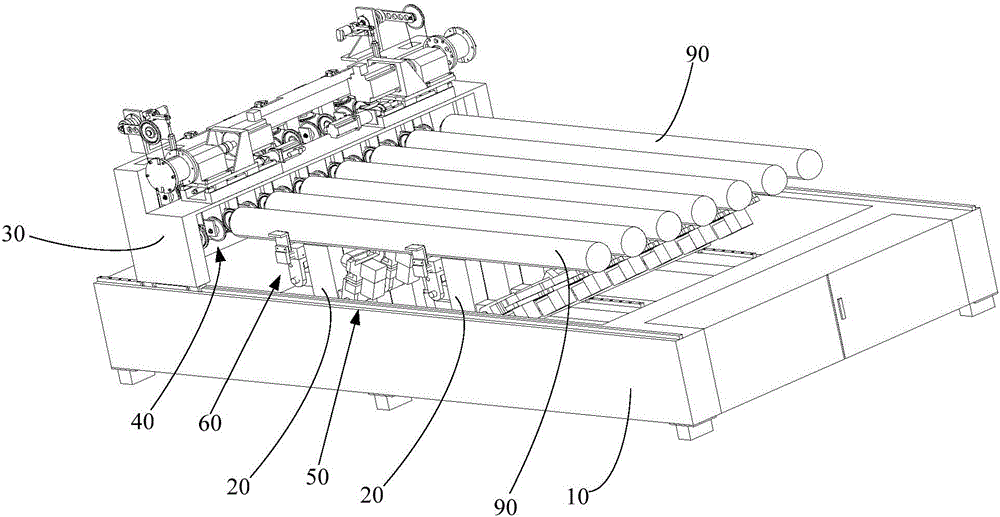

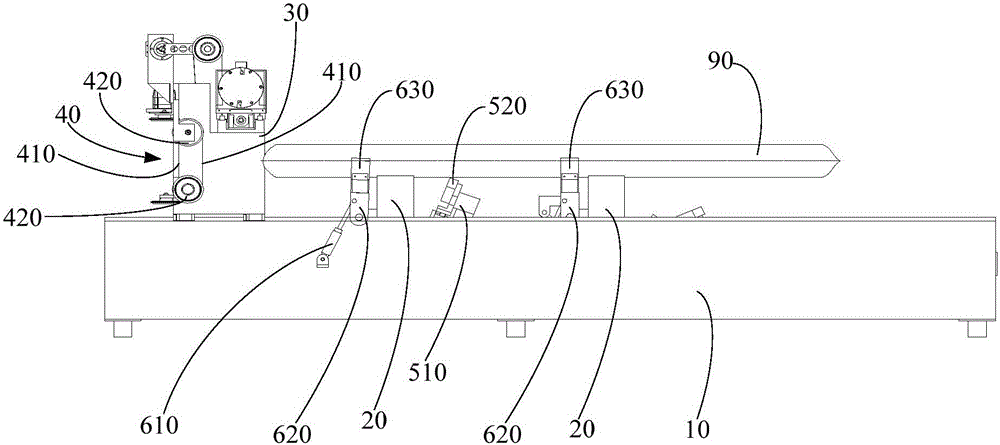

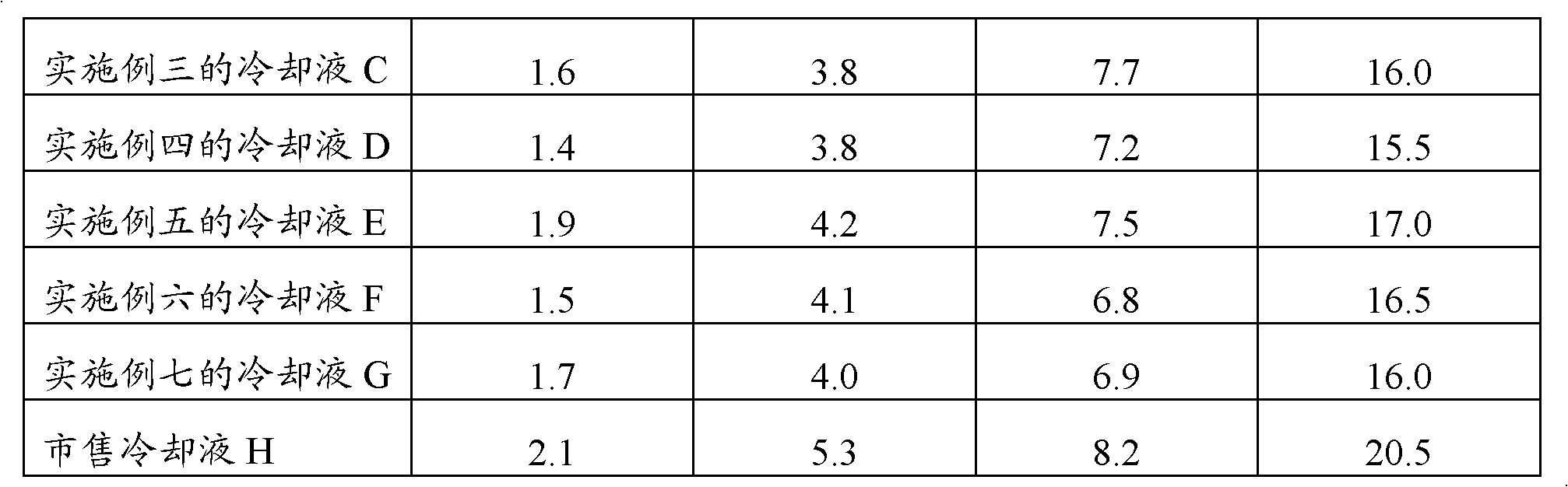

Silicon rod squarer

InactiveCN105818285AReduce labor costsIncrease productivityWorking accessoriesFine working devicesWire cuttingIngot

The invention provides a silicon rod squaring machine, comprising: a machine base with a square cutting area; a bearing platform arranged on the machine base and located in the square cutting area for carrying vertically placed silicon rods; The wire cutting equipment on the machine base includes: a cutting frame, which is arranged on the machine base and adjacent to the bearing table; The cut lines that form the cut line mesh. Compared with the prior art, the silicon ingot squaring machine of the present invention uses the supporting platform to carry the vertically placed silicon ingots, and cuts the silicon ingots below in a straight line through the wire cutting equipment, which can realize automatic cutting and complete the silicon ingot squaring operation. Save labor cost and improve production efficiency.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

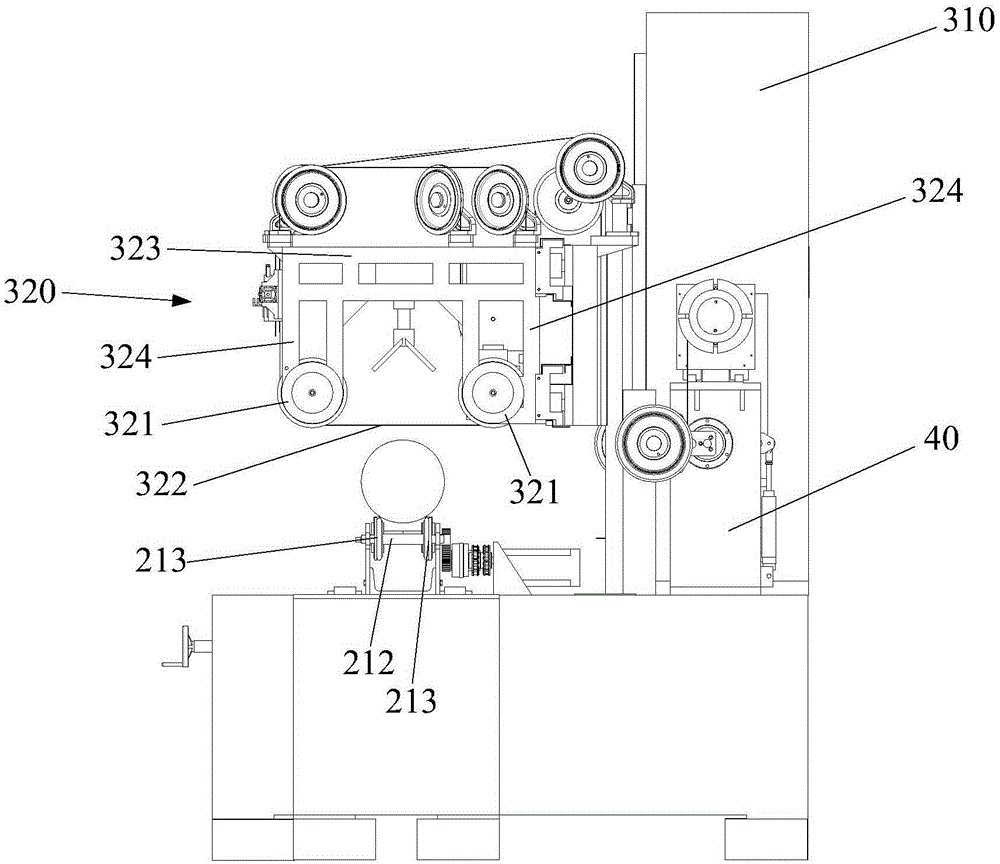

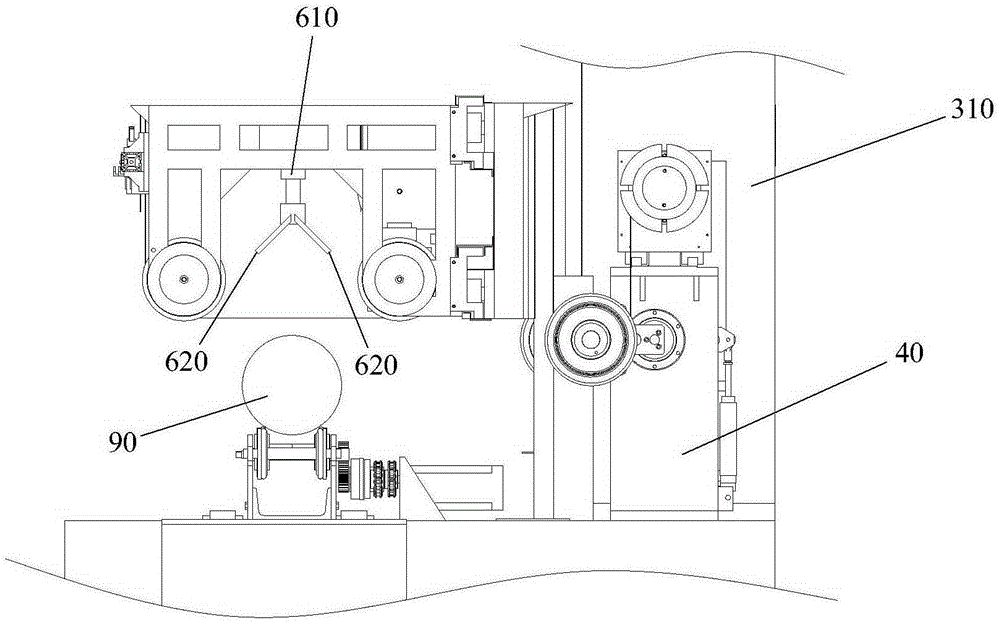

Silicon rod cutter and cutting method

The invention discloses a silicon rod cutter and a cutting method. The silicon rod cutter comprises a feeder device, a cutting device, a silicon rod conveyor table, an axis adjusting mechanism and a plurality of wire cutting units, wherein the feeder device is used for conveying a to-be-cut silicon rod to a to-be-loaded region; the cutting device is connected to the feeder device for performing a cutting operation on the to-be-cut silicon rod which is conveyed from the to-be-loaded region by the feeder device; the cutting device comprises a base; the silicon rod conveyor table is arranged on the base for carrying the to-be-cut silicon rod and driving the silicon rod to be conveyed along the axial direction of the silicon rod; the axis adjusting mechanism is arranged on the silicon rod conveyor table for adjusting the axis of the silicon rod to a horizontal state; and the plurality of wire cutting units are arranged on the base and are arranged above the silicon conveyor table in a liftable manner for cutting the to-be-cut silicon rod into a plurality of silicon rod sections. The to-be-cut silicon rod is conveyed to the to-be-loaded region through the feeder device, the plurality of wire cutting units can cut the to-be-cut silicon rod into the plurality of sections simultaneously, and the plurality of the silicon rod sections are removed from the silicon rod conveyor table to a material receiving table to be sequentially unloaded.

Owner:海宁市日进科技有限公司

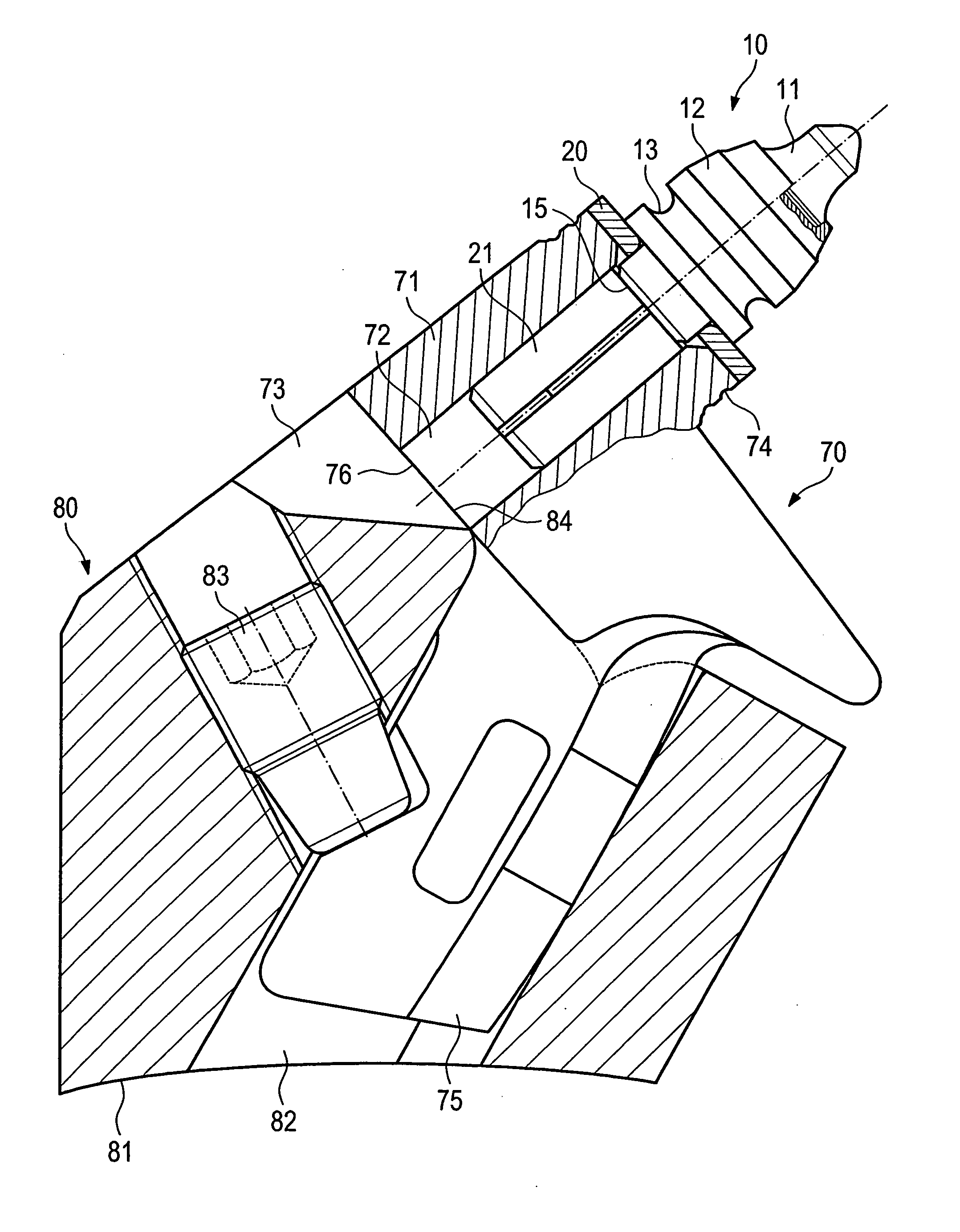

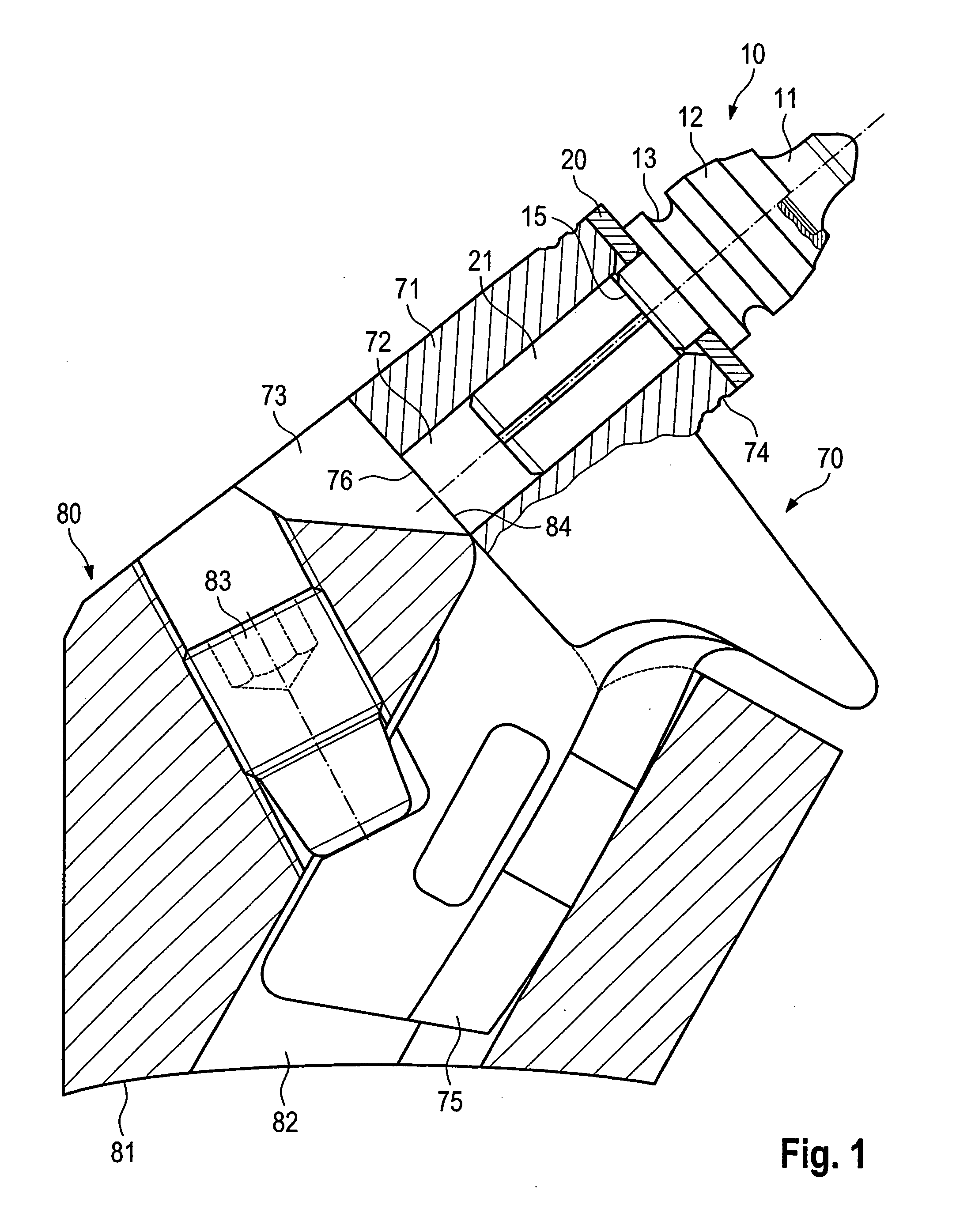

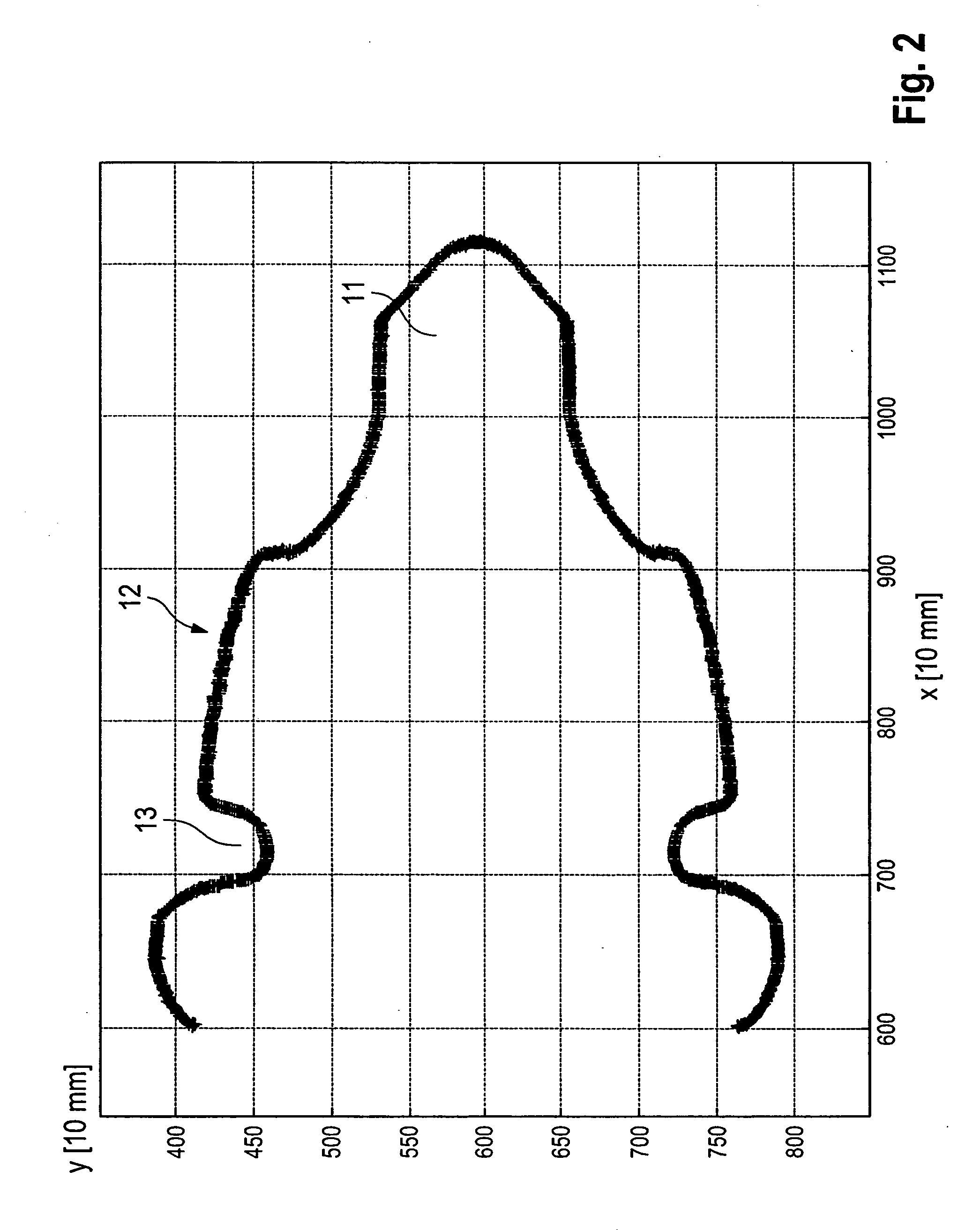

Method for determining the wear state

This invention relates to a method for determining a wear state of a chisel, a chisel holder, and / or a chisel holder replacement system equipped with a chisel and chisel holder. For this method to give the user qualitative and quantitative information about the wear, according to one embodiment of this invention, a position of at least one point of the chisel and / or the chisel holder is determined by a contactless measurement method and a corresponding measurement result is compared in a switching unit to a reference value stored in a memory device.

Owner:WIRTGEN GMBH

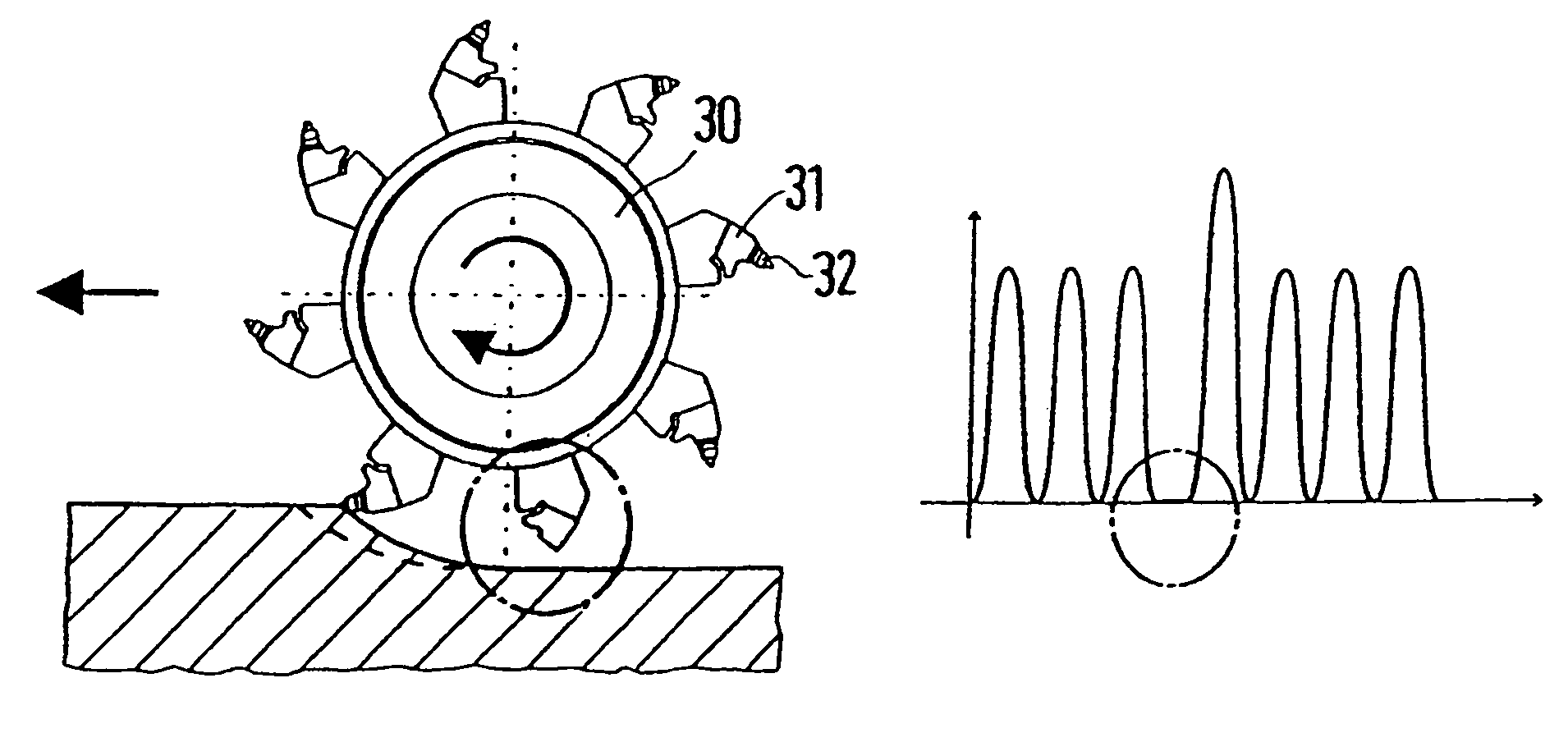

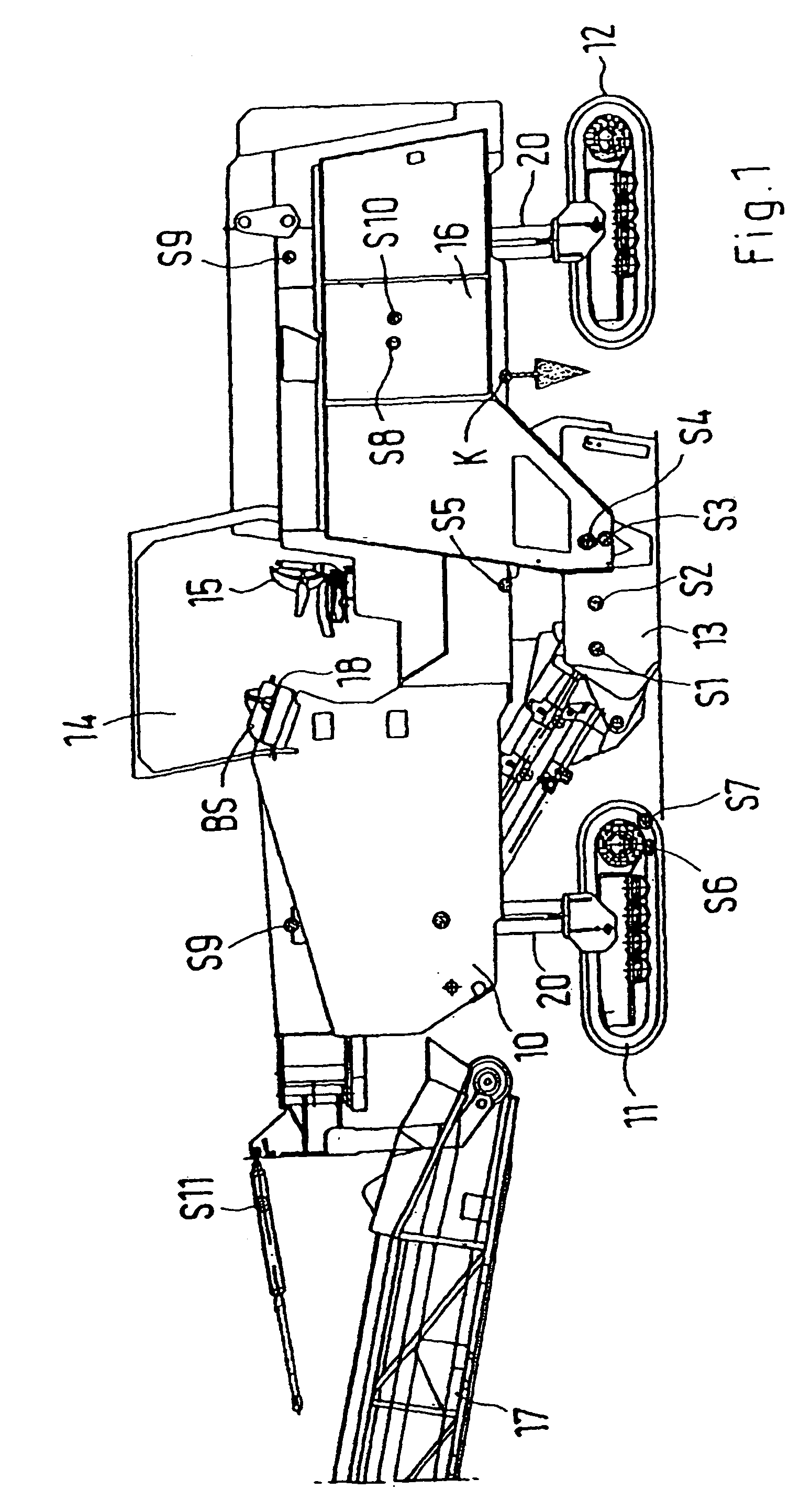

Road milling machine with optimized operation

InactiveUS7422391B2Reduce the burden onReduce cutting forceSlitting machinesWorking accessoriesChiselEngineering

A road milling machine having a milling roller with a plurality of chisels. A signal receiving unit is assigned to a machine component which is directly or indirectly involved in the milling process or to another machine component. The signal receiving unit detects an operating condition of the machine component and is connected to a signal emitting unit. An optical detecting device may be assigned to the road milling machine, whereby operations are made easier and the milling pattern is optimized.

Owner:WIRTGEN GMBH

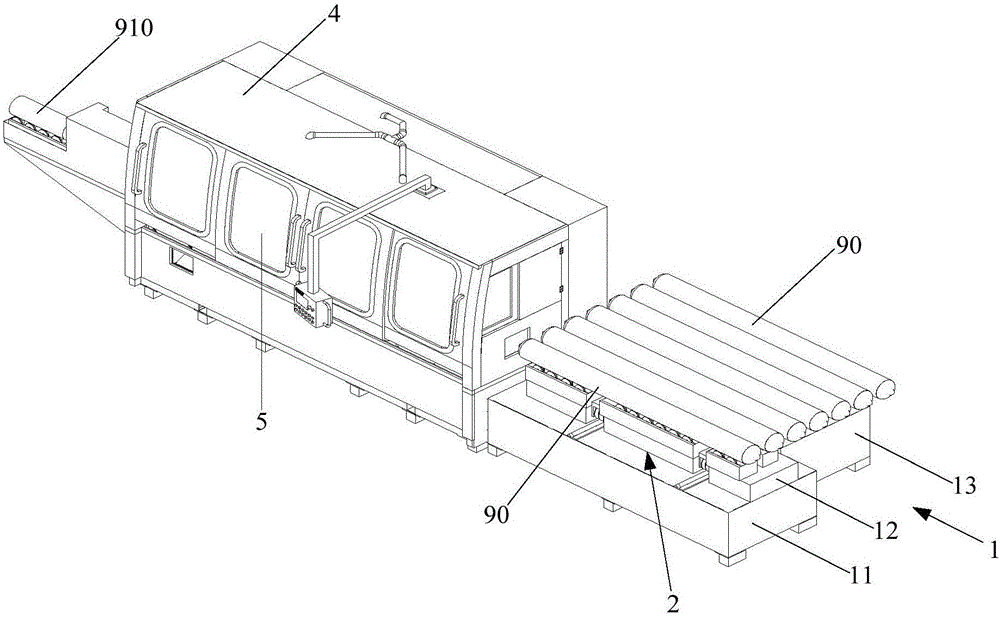

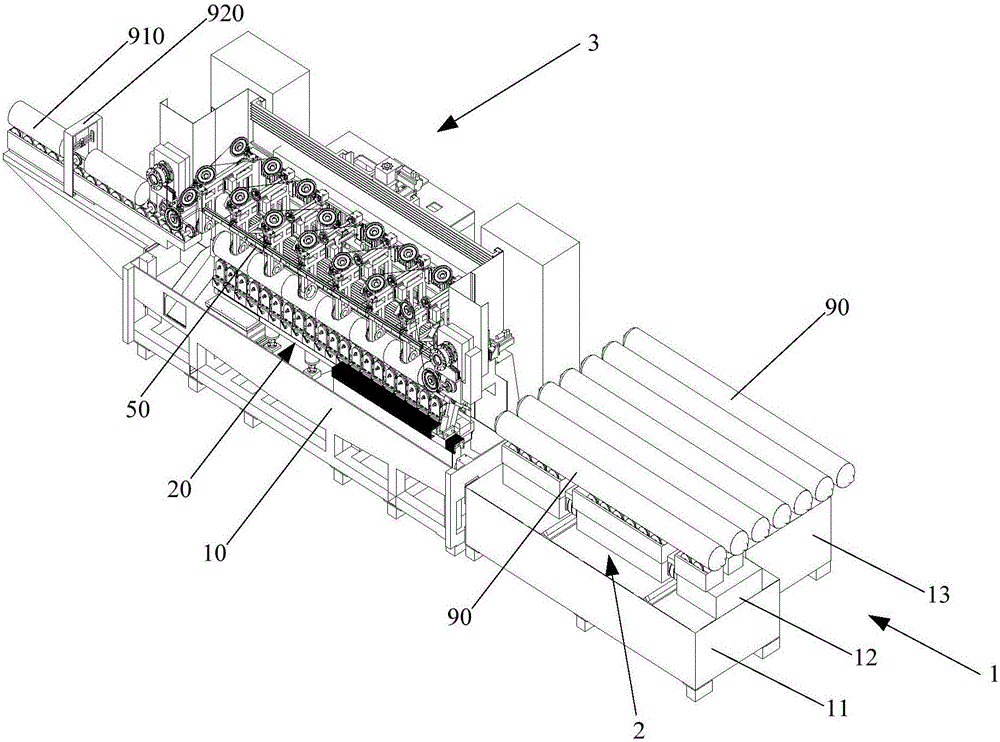

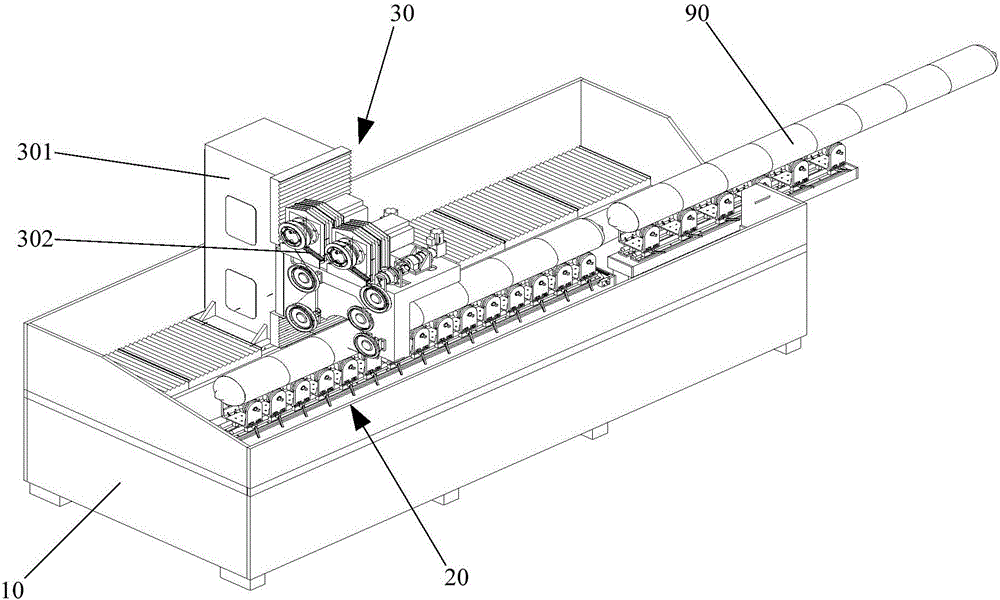

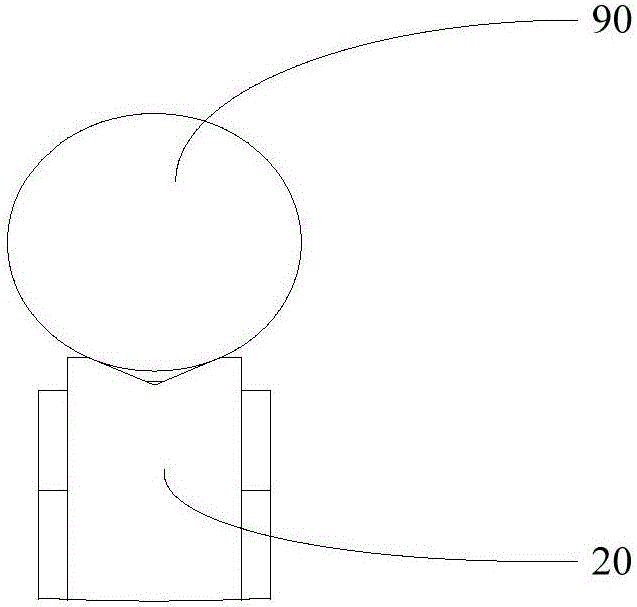

Single crystal silicon rod cutting-off machine and single crystal silicon rod cutting-off method

The invention discloses a single crystal silicon rod cutting-off machine and a single crystal silicon rod cutting-off method. The single crystal silicon rod cutting-off machine comprises a machine base, a material conveying table arranged on the machine base and used for bearing single crystal silicon rods to be cut and driving the single crystal silicon rods to be conveyed in the axial directions of the single crystal silicon rods, and a multi-wire cutting device comprises a machine frame arranged on the machine base and multiple wire cutting units arranged on the machine frame and arranged above the material conveying table through a lifting mechanism in a liftable mode. The multiple wire cutting units synchronously descend to the material conveying table under the control of the lifting mechanism and meanwhile cut the single crystal silicon rods into multiple single crystal silicon sections, and then the multiple single crystal silicon sections formed after cutting are sequentially discharged through the material conveying table. The single crystal silicon rod cutting-off machine can synchronously cut the single crystal silicon rods to be cut into the multiple single crystal silicon sections through the multi-wire cutting device, is high in cutting speed, moves the single crystal silicon sections formed through cutting from the material conveying table to a material receiving table in a sectioned mode for sequential discharge and ensures that the single crystal silicon sections do not bump.

Owner:海宁市日进科技有限公司

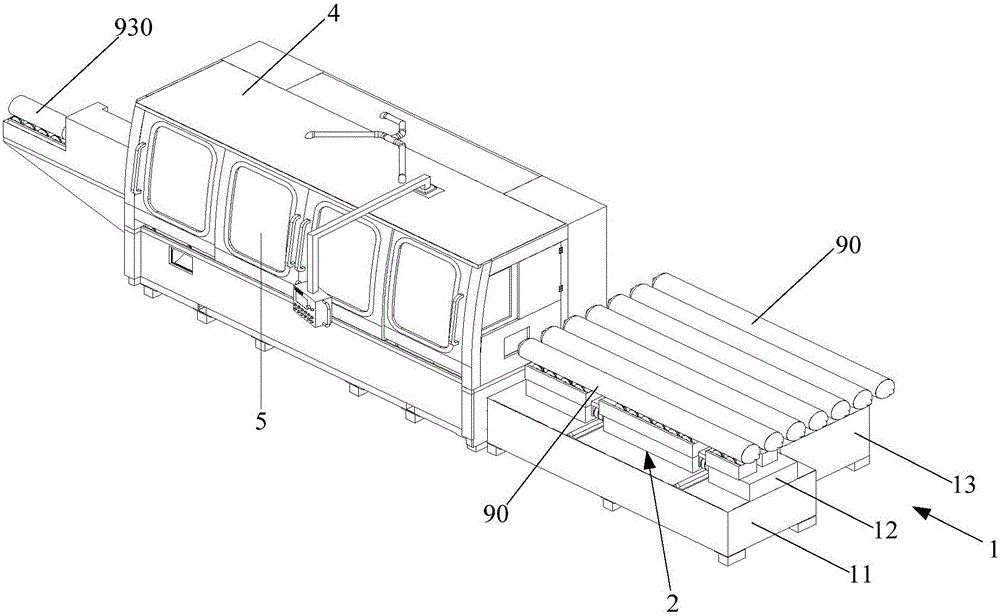

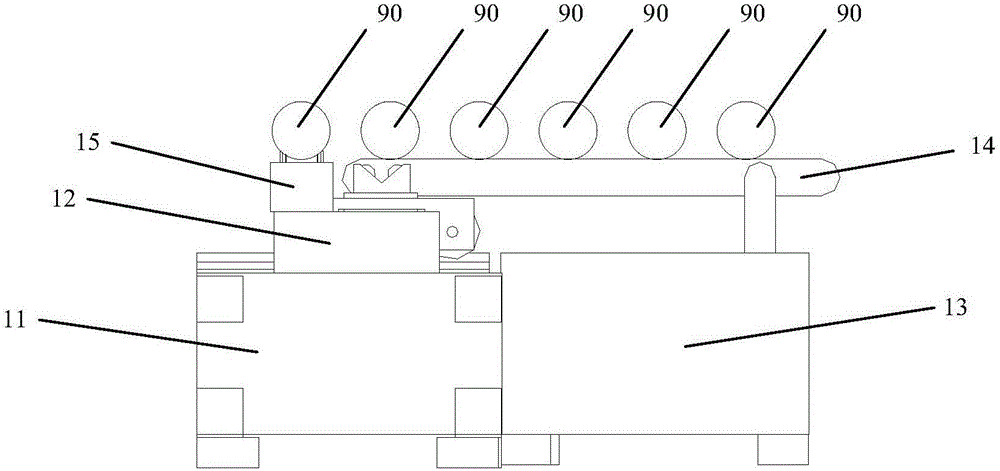

Single-section type silicon rod cutoff machine and cutoff method thereof

The invention discloses a single-section type silicon rod cutoff machine and a cutoff method of the single-section type silicon rod cutoff machine. The single-section type silicon rod cutoff machine comprises a machine base, a silicon rod conveying platform and single-section cutting equipment, wherein the silicon rod conveying platform is arranged in the cutting region of the machine base and used for bearing silicon rods to be cut and driving the silicon rods to be conveyed in the axial direction of the silicon rods; the single-section cutting equipment comprises a movable cutting frame slidably arranged on the machine base along the silicon rod conveying platform and a single-section linear cutting unit, wherein the single-section linear cutting unit is arranged on the movable cutting frame, arranged above the silicon rod conveying platform in a liftable manner and used for conducting single-section cutting in silicon rod cutting, and cut single-section silicon rod sections meeting the workpiece standard are obtained. According to the single-section type silicon rod cutoff machine and the cutoff method, the position of the movable cutting frame is adjusted according to the specified silicon rod size, and then single-section cutting is conducted in silicon rod cutting through the single-section linear cutting unit, so that the silicon rods to be cut accord with the specified cutting length, and the cut single-section silicon rod sections meeting the workpiece standard are obtained; and by adjusting the position of the movable cutting frame, the requirement of the cutting work of the silicon rods with any size can be met.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

Saw having movable table and saw blade

InactiveUS6119676ANot up much spaceEasy to carryGrinding machine componentsWorking accessoriesWorkbenchEngineering

A compact tile saw which is especially adaptable for cutting of large-sized tiles wherein the table supporting the tile is movable towards the cutting saw, while at the same time the cutting saw is positionable in one of two positions of either being stationary or in moving in unison towards the table supporting the tile to be cut.

Owner:GREENLAND DARRELL

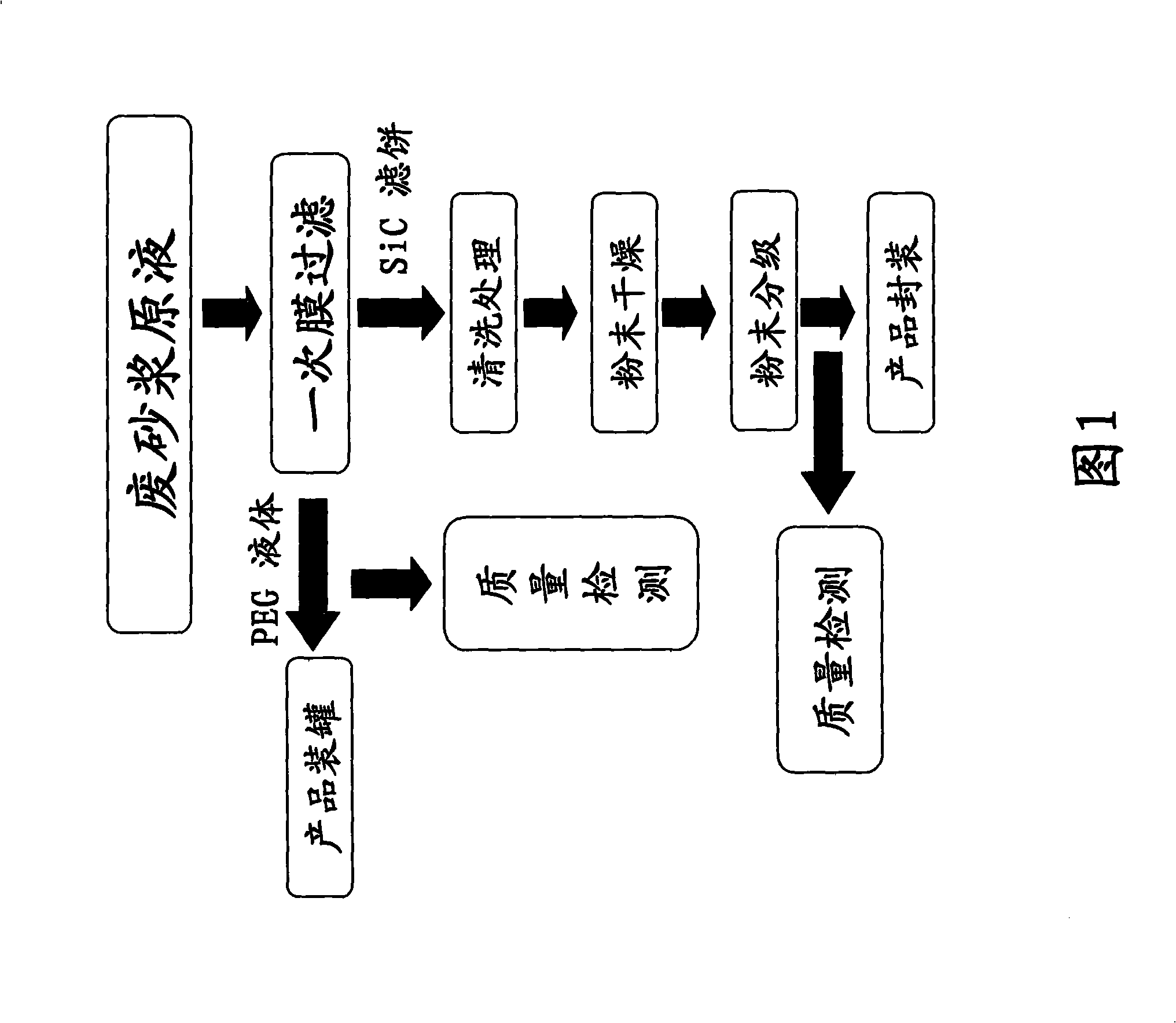

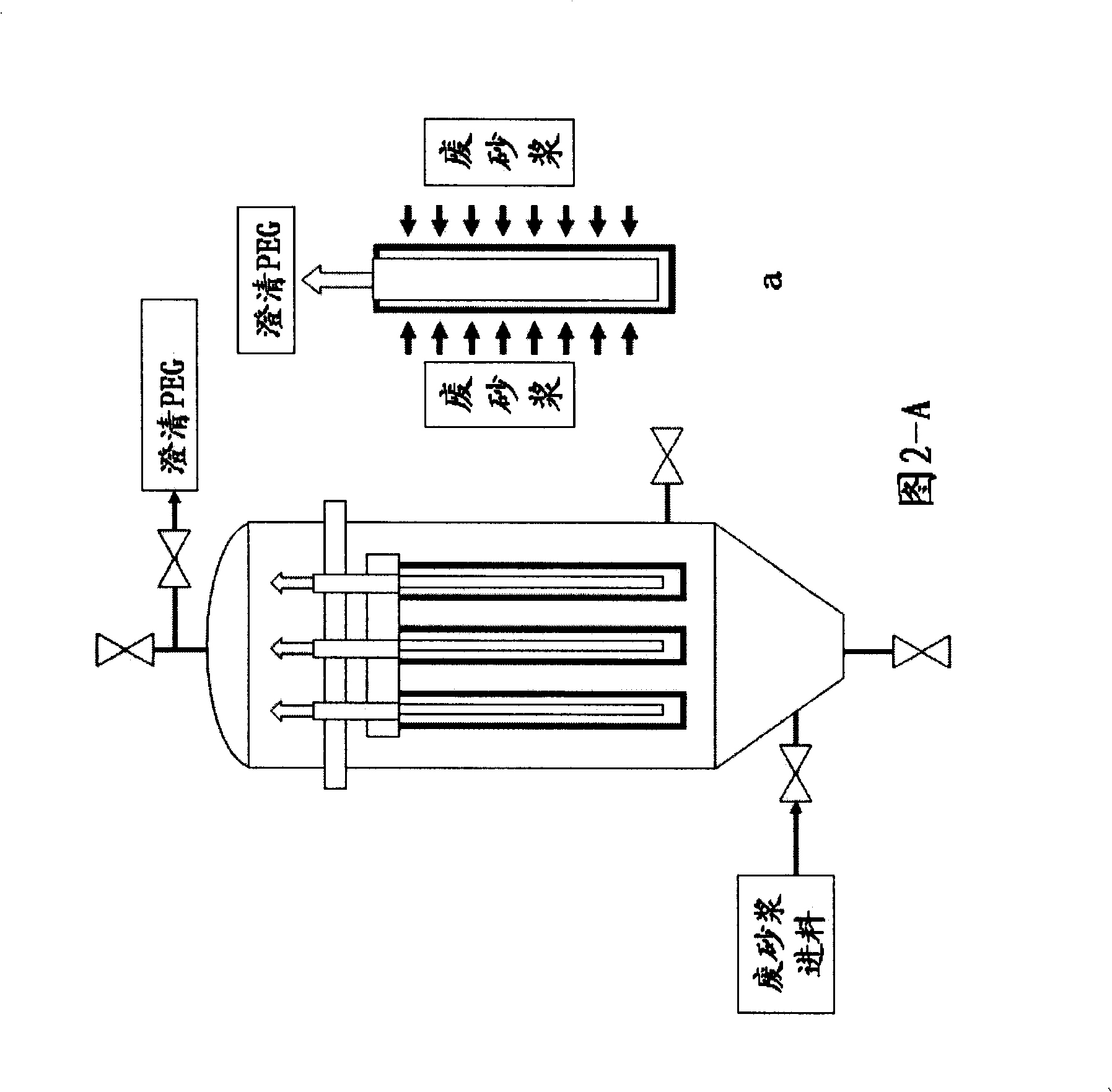

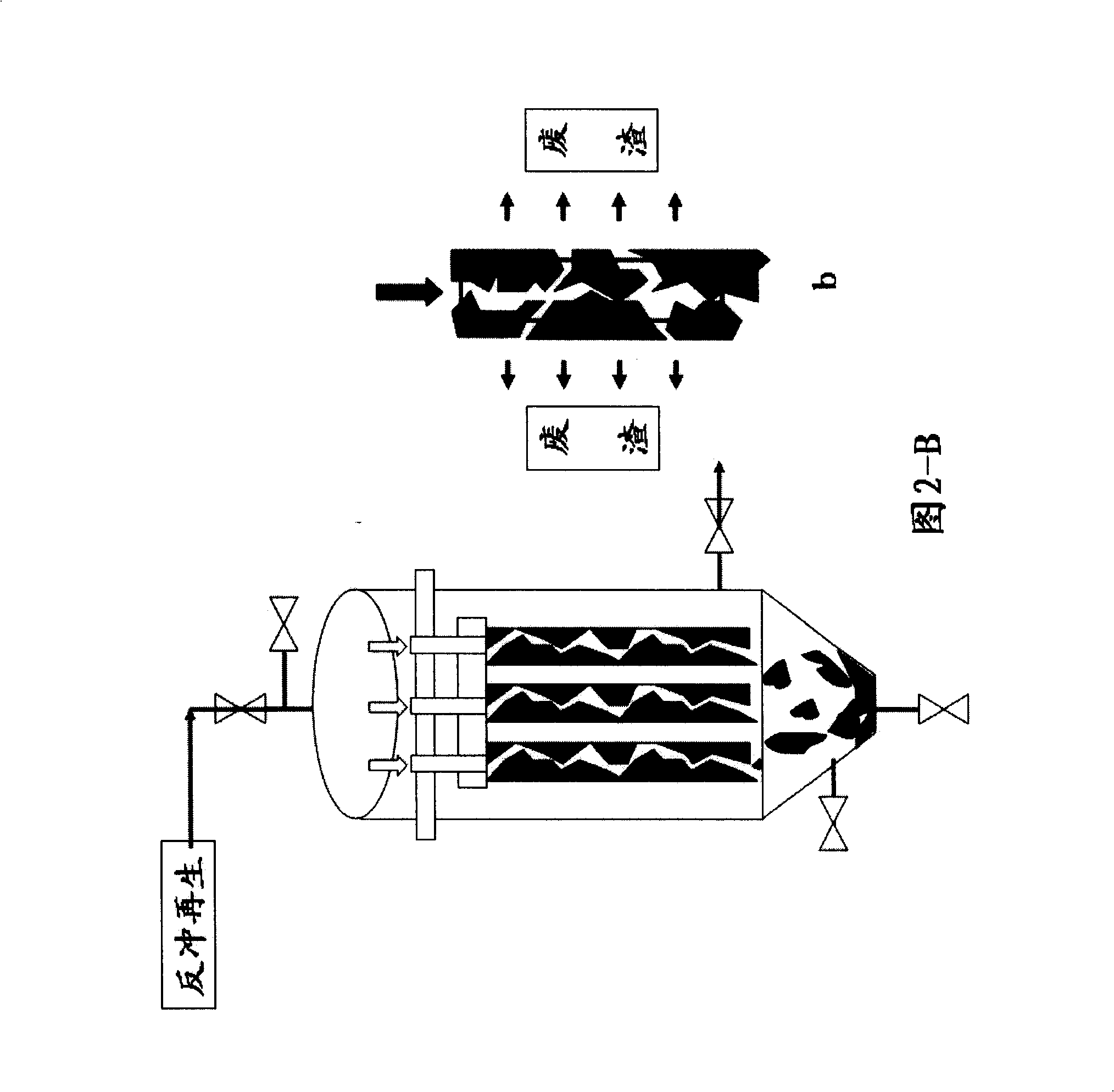

Mortar recovery technique for cutting single-crystal and polycrystalline silicon wire

InactiveCN101327622APhysical properties unchangedSlicing works wellWorking accessoriesFine working devicesFiltrationWire cutting

The present invention relates to a technique of recovering mortar used in the wire cutting of monocrystalline silicon or polycrystalline silicon. Silicon is an important material for solar batteries, semiconductors, liquid crystal displays, etc. A silicon rod is cut into silicon wafers by the wire cutting technique, and in the process, a wire-cutting machine needs to be added with cutting liquid mortar, which is mainly composed of liquid phase polyethylene glycol and solid phase silicon carbide powder. When the wire-cutting machine cuts the silicon rod, the solid particles in the mortar are changed into waste mortar as the silicon carbide grinds the silicon rod and a steel wire. If the waste mortar is discharged directly, environment is polluted, and the raw material is wasted. The present invention adopts the mortar-recovering technique to recover the waste mortar, so that the waste mortar can be reused and the discharging of the three wastes can be reduced, so while reducing production cost, the mortar-recovering technique can protect environment. The technique of recovering mortar used in the wire cutting includes the following flow: waste mortar dope, one-step membrane filtration and PEG liquid; waste mortar dope, one-step membrane filtration, cleaning, powder drying, powder classification and SiC powder.

Owner:正申科技(北京)有限公司

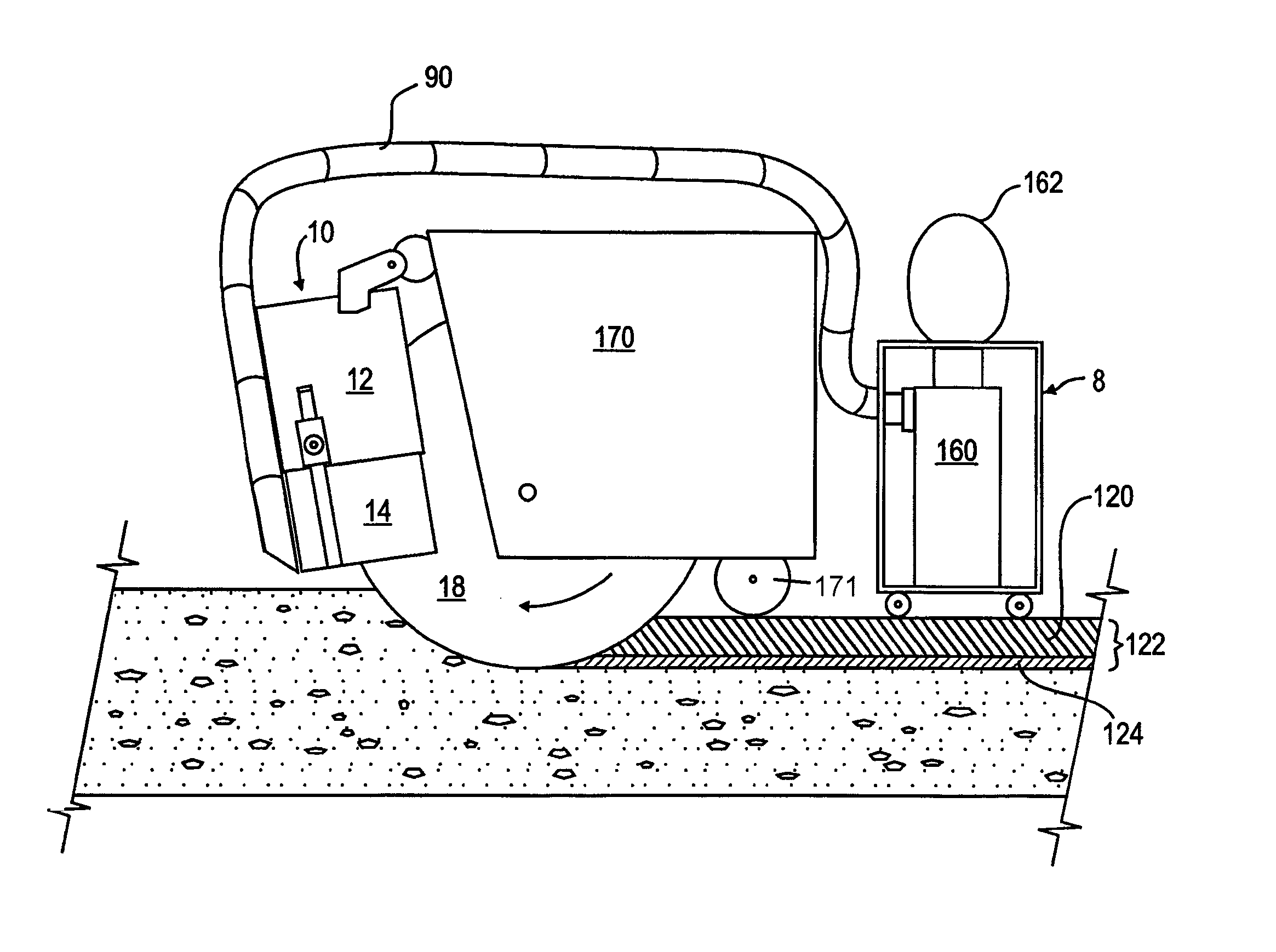

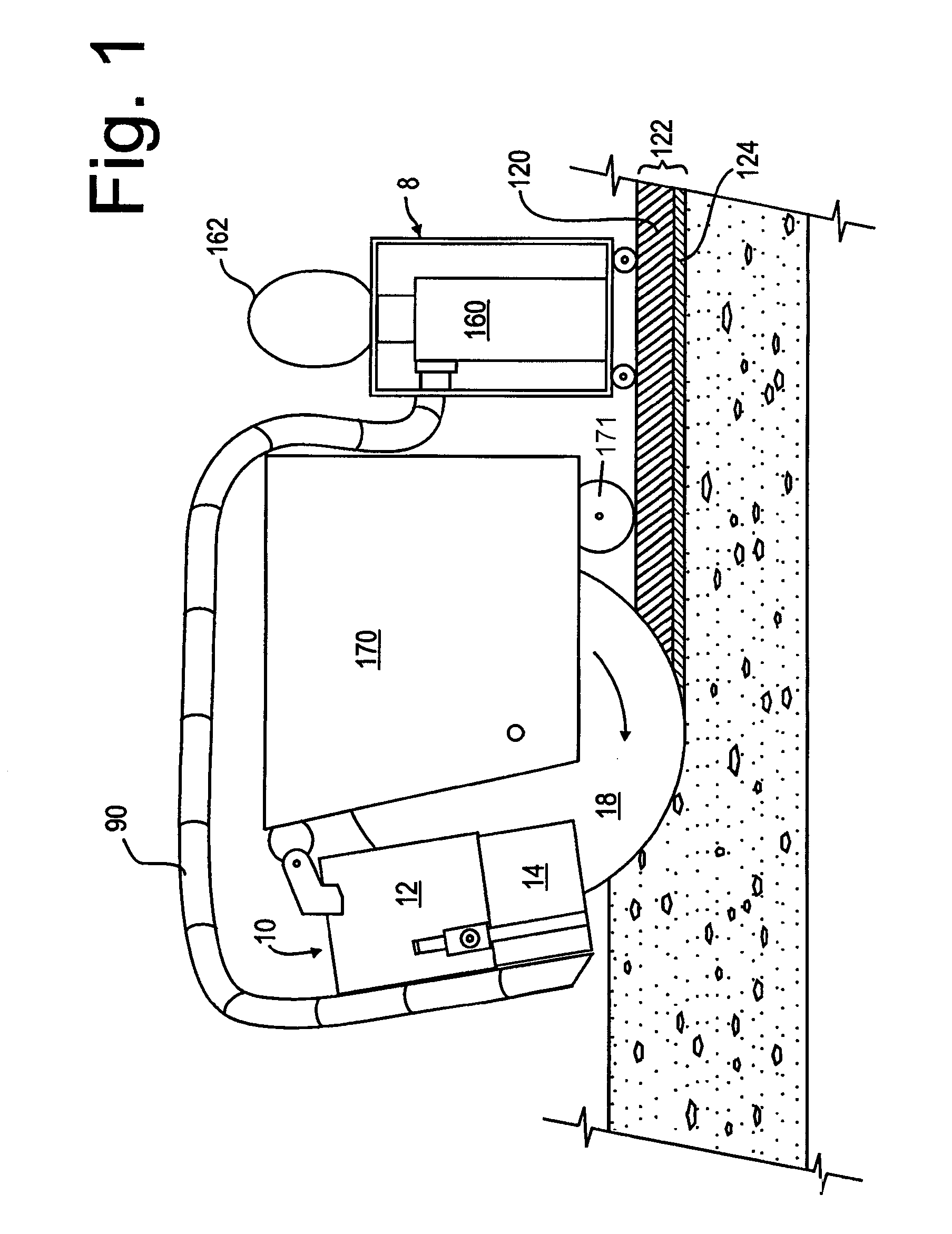

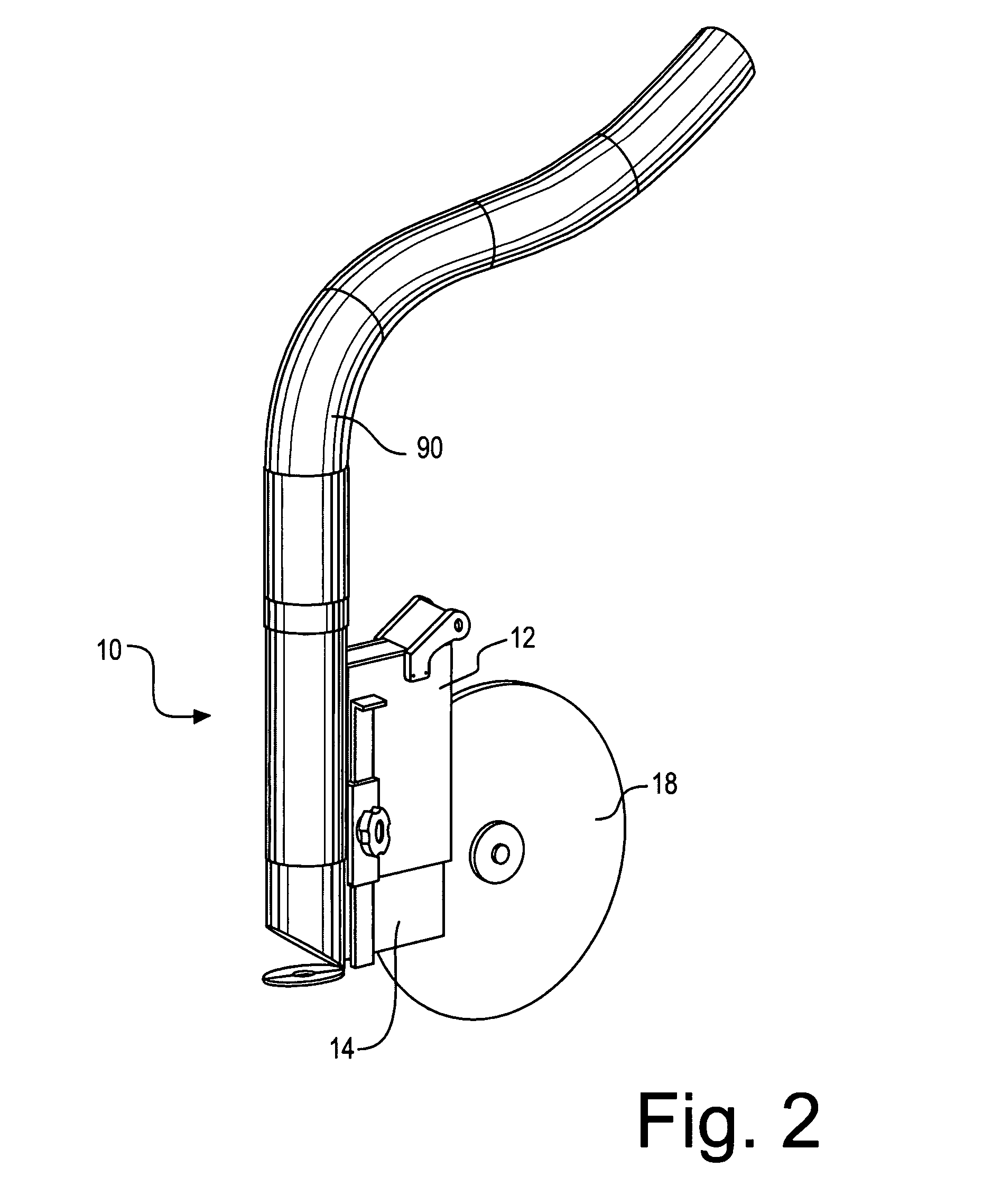

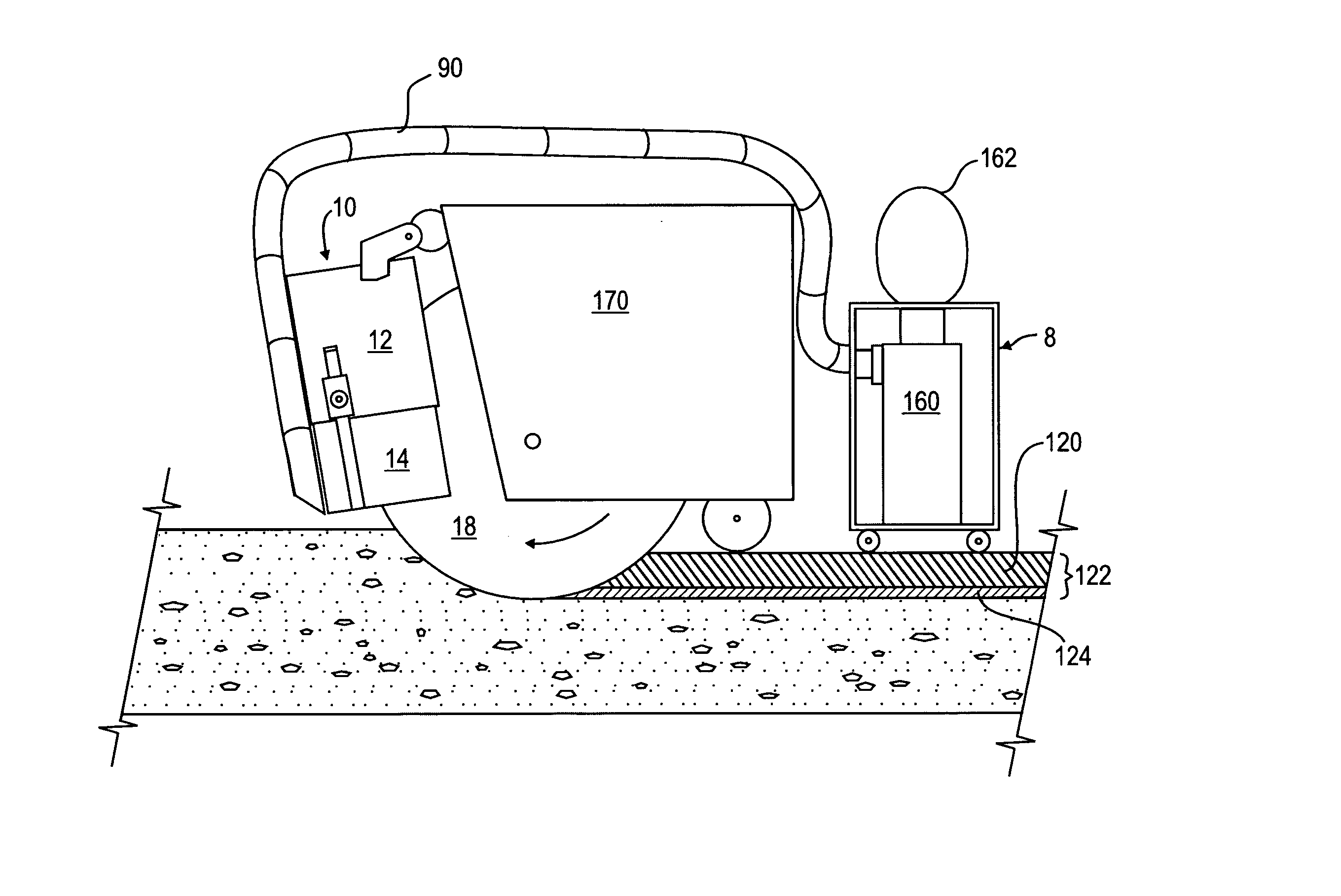

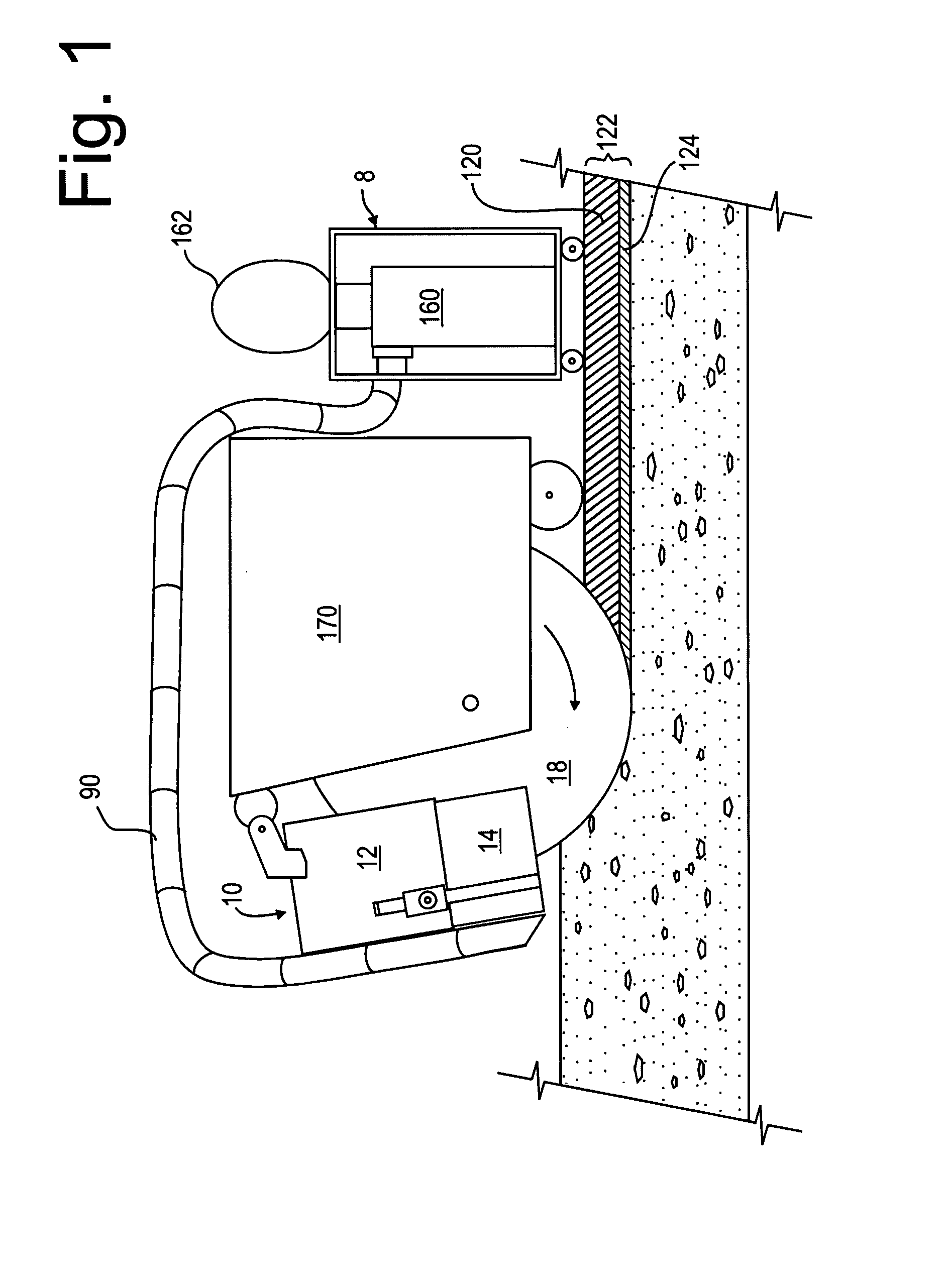

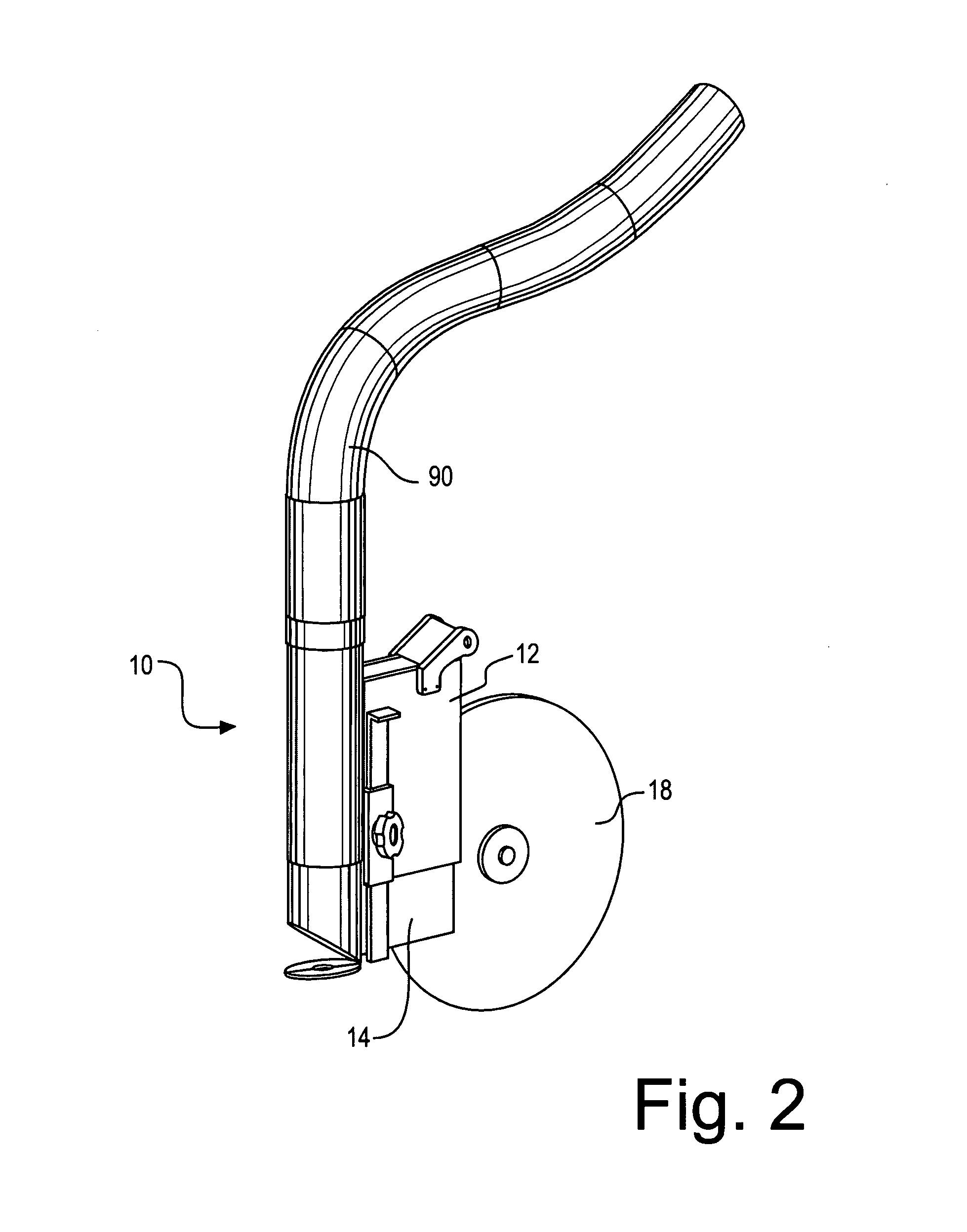

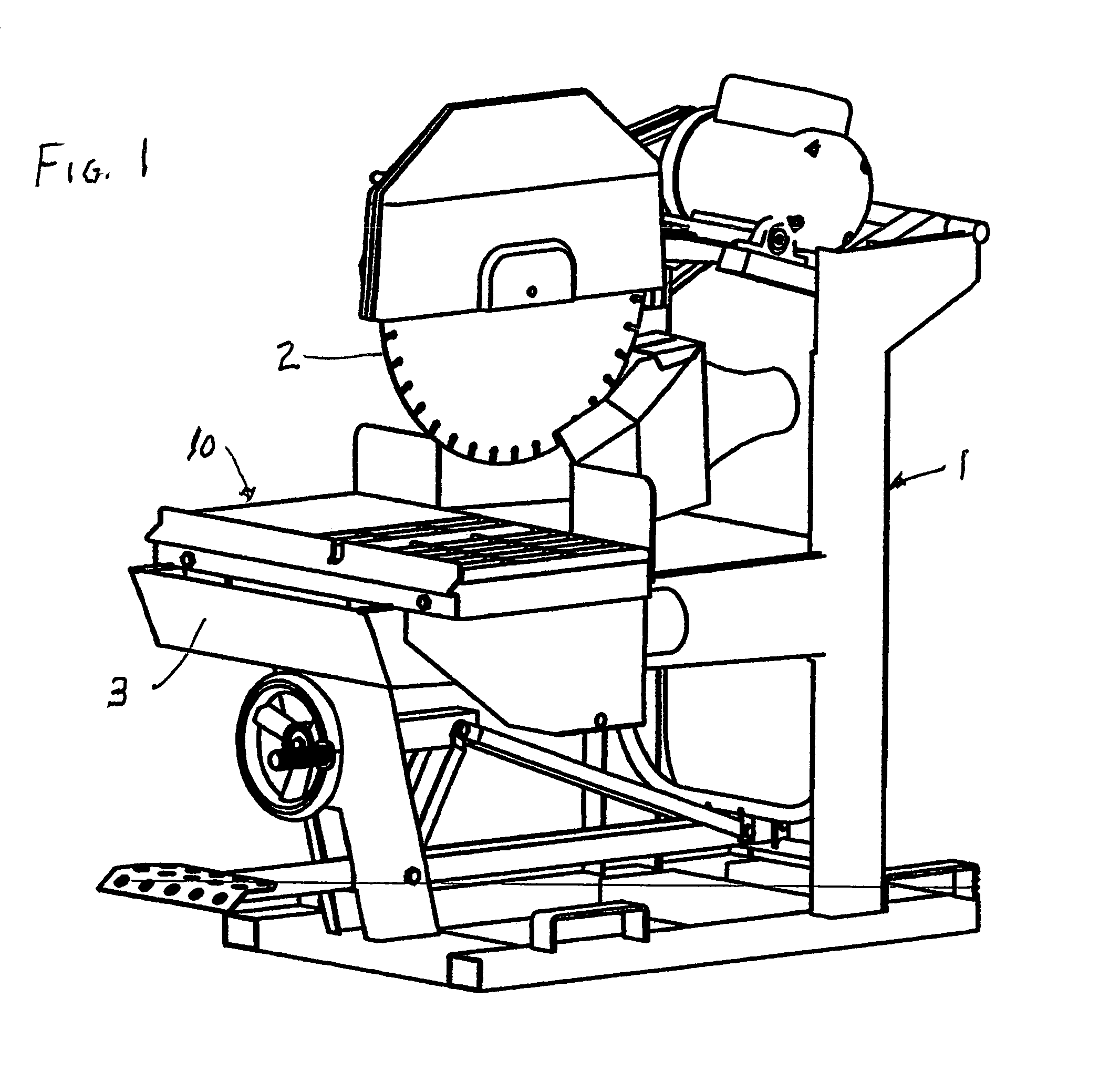

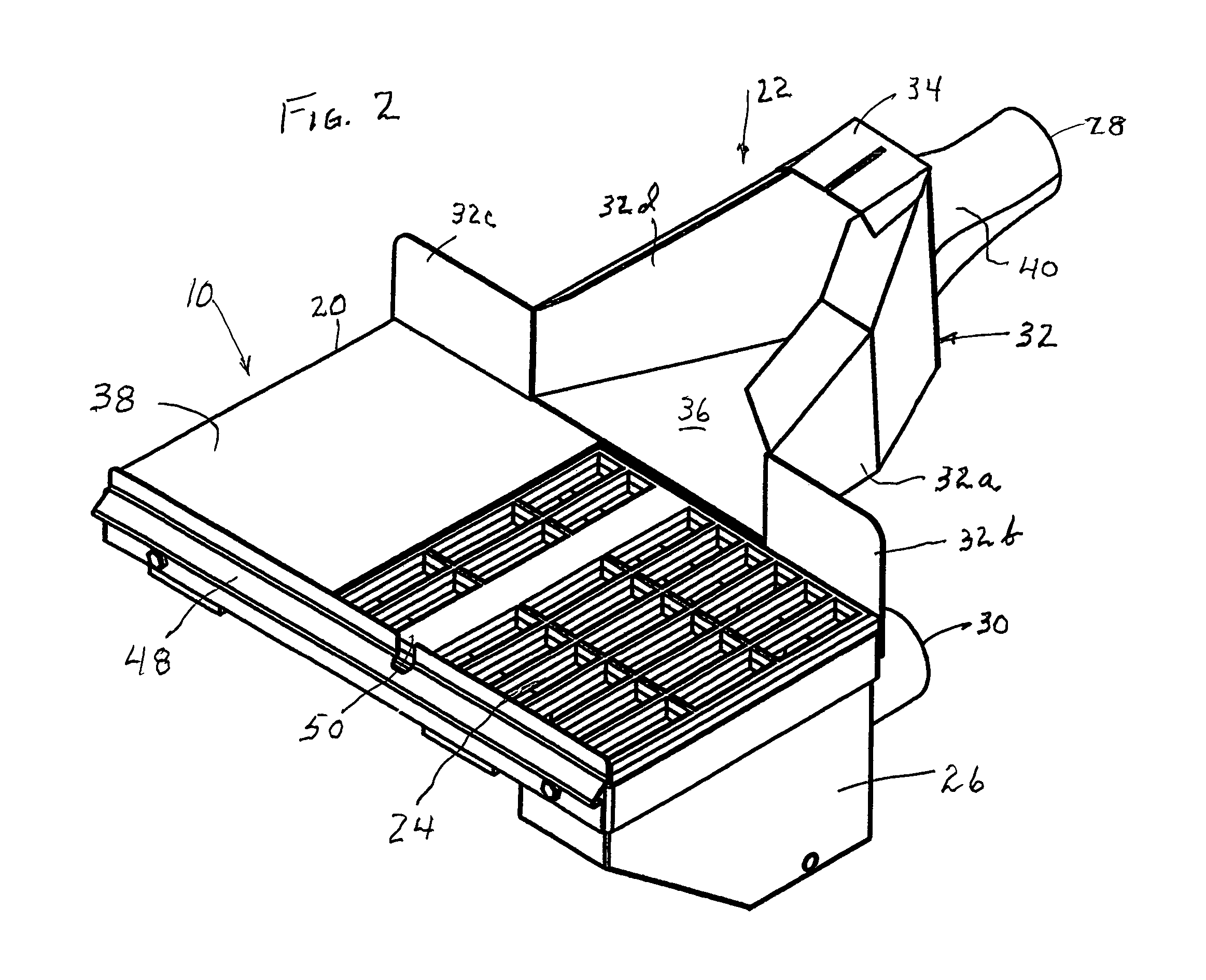

Slab saw with dust collector and method of dry-cutting pavement

A dust collector is provided for use with a SLAB saw, especially suited for dry-cutting a channel within pavement or similar exterior surface. The collector includes telescoping upper and lower housings, an open front and lower base to receive a portion of a circular saw into the interior of the housing, and an exhaust outlet, for attaching to a vacuum duct, so as to exhaust dust-laden air from the interior of the housing. The housing includes a pivot mount, pivotally mounting the unit to a slab saw. Also provided is a system, including the dust collector with a circular saw and optionally a vacuum source and dust filter unit or units. Also provided is a method for dry-cutting a trench or channel within pavement or similar hard outside surface, which is particularly suitable for laying of cable such as fiber optic cable. The method may include the step of cutting through the pavement into the underlying hard-packed substrate.

Owner:TERASPAN NETWORKS

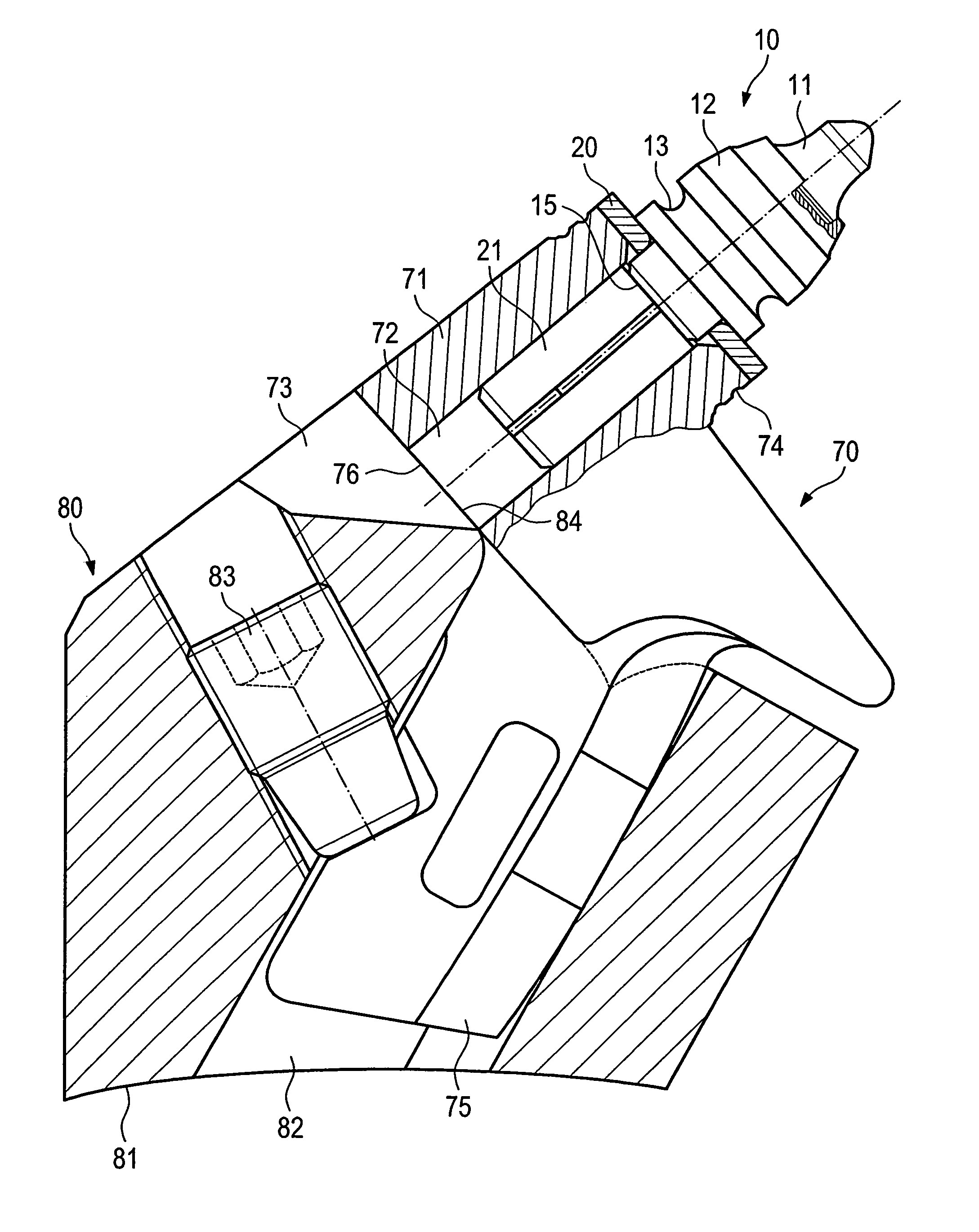

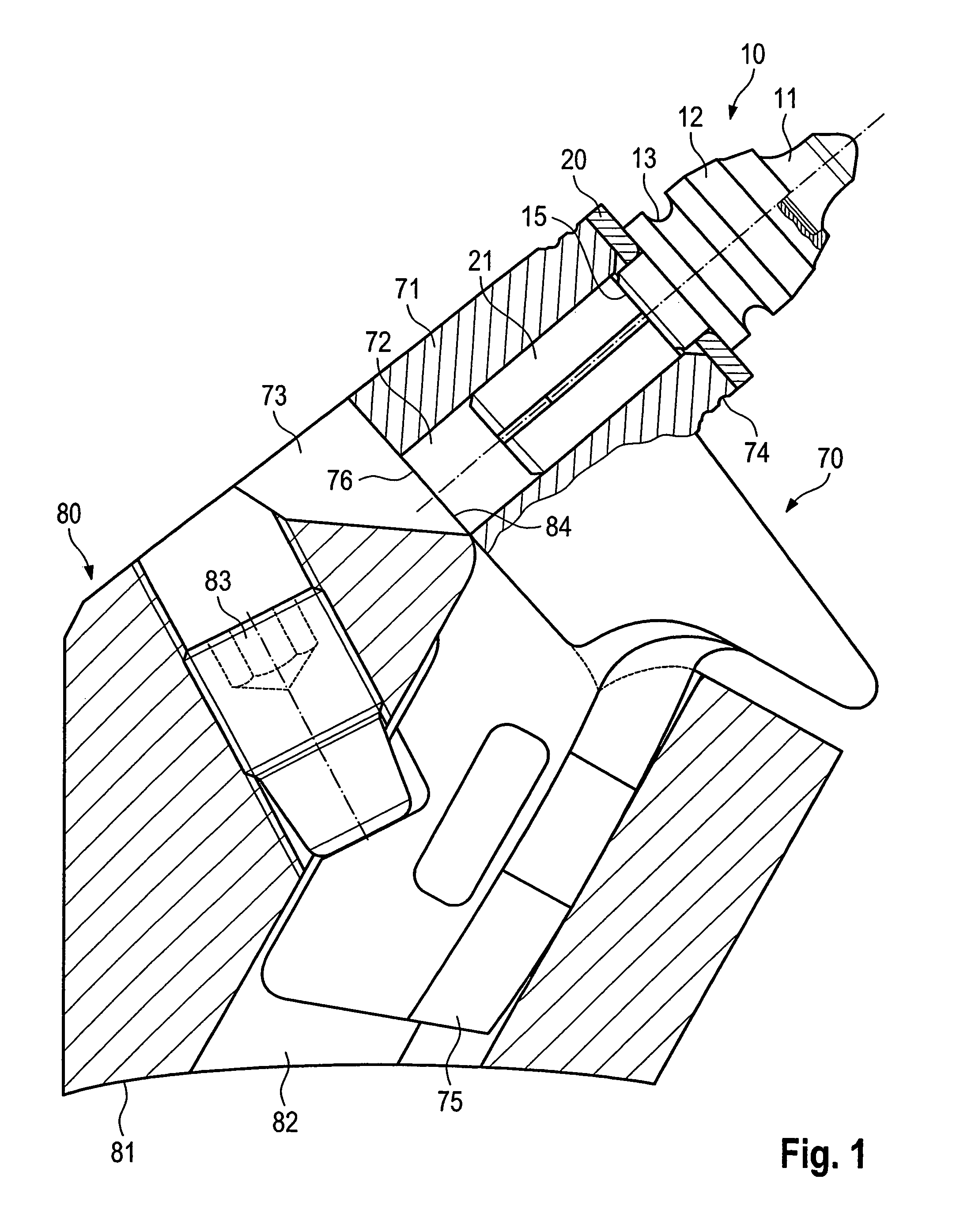

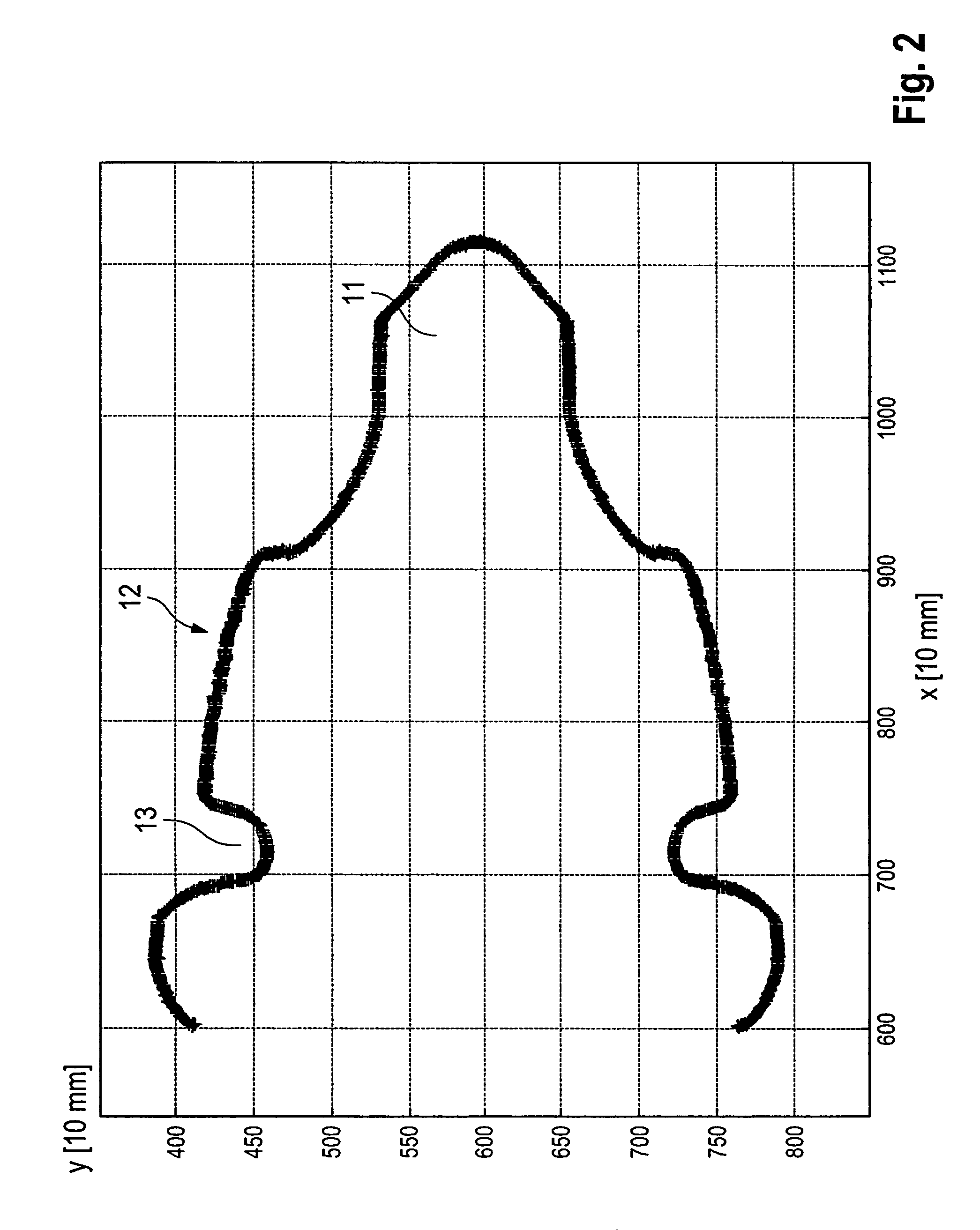

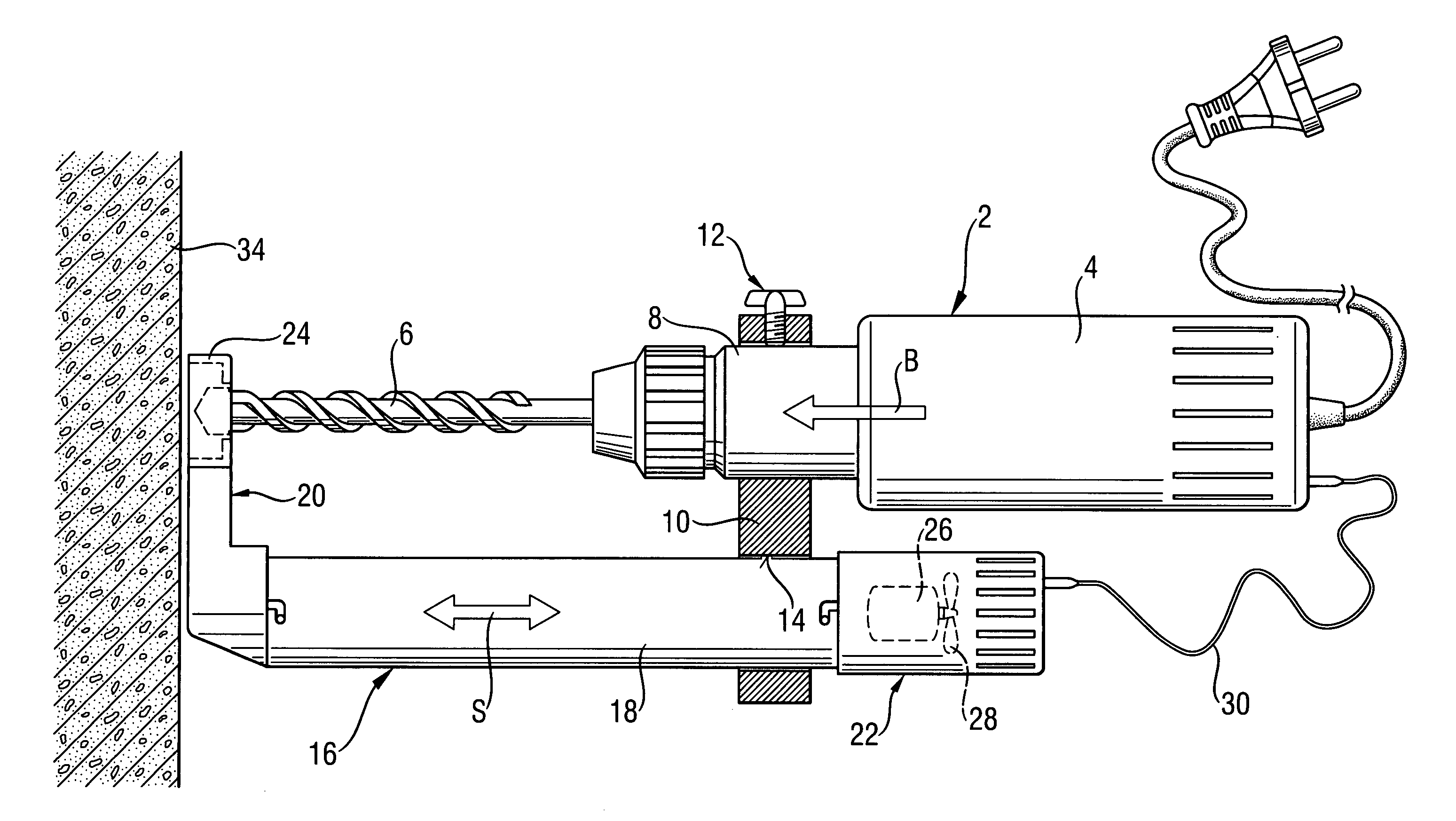

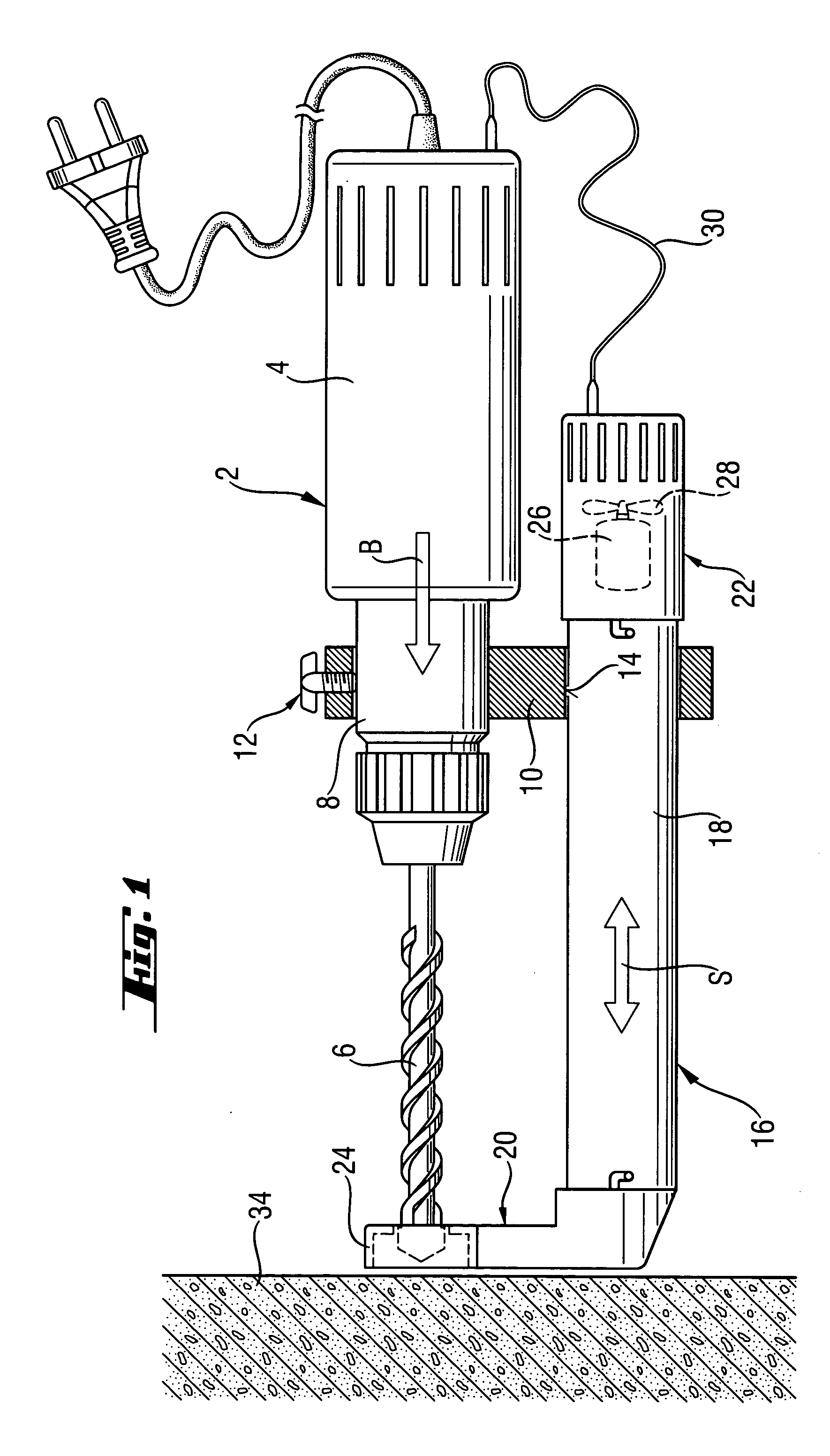

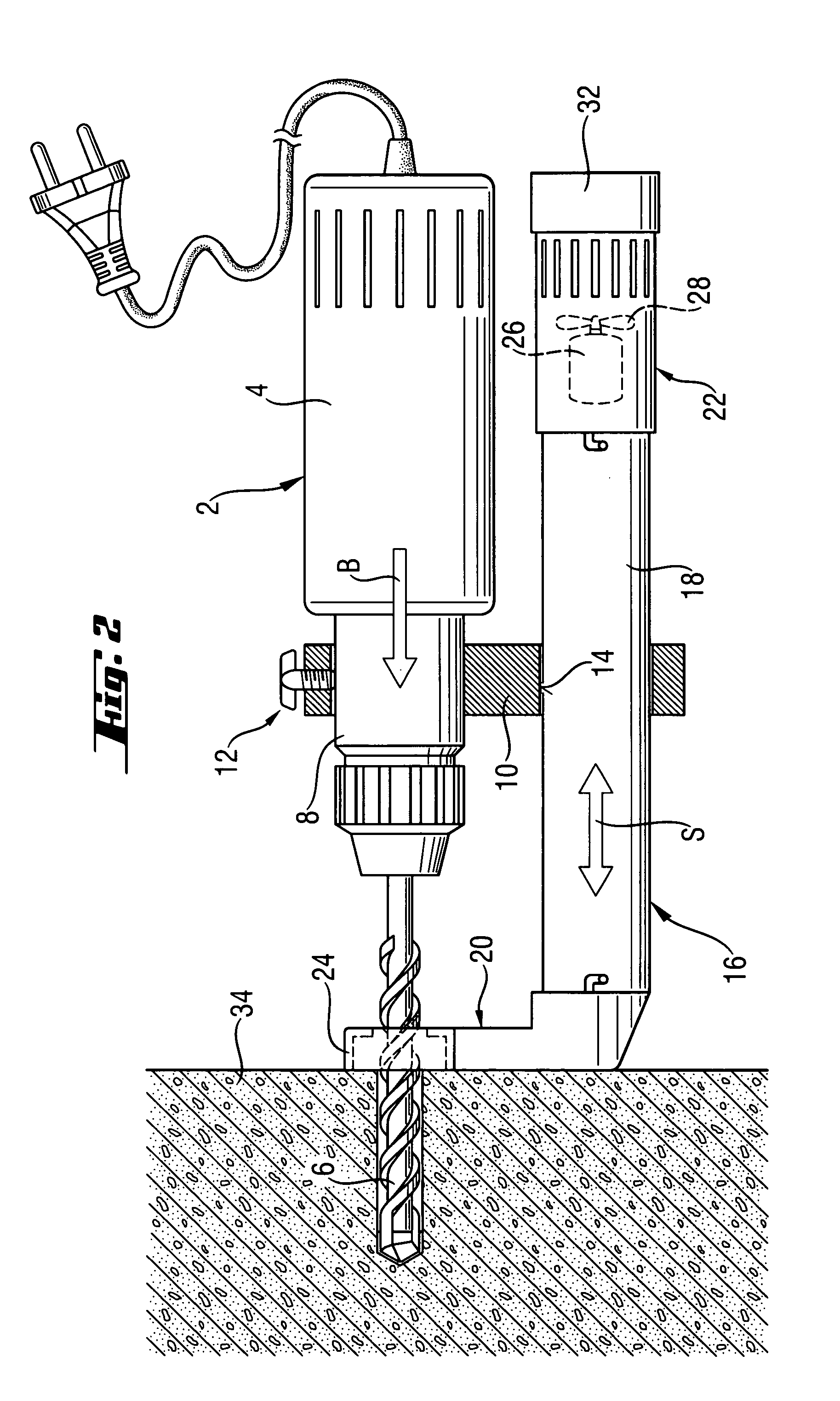

Suction device

InactiveUS7281886B2ConstantMaximal suction performanceDrilling/boring measurement devicesThread cutting feeding devicesEngineeringGuide tube

A suction device that is used with a power drilling tool for aspirating material removable during operation of the drilling tool, and which includes a suction head (20) displaceable relative to the drilling tool (2) in a direction opposite a drilling direction (B) of the drilling tool (2), and an aeration device (22) fixedly connected by a suction conduit with the suction head (20) for joint displacement therewith.

Owner:HILTI AG

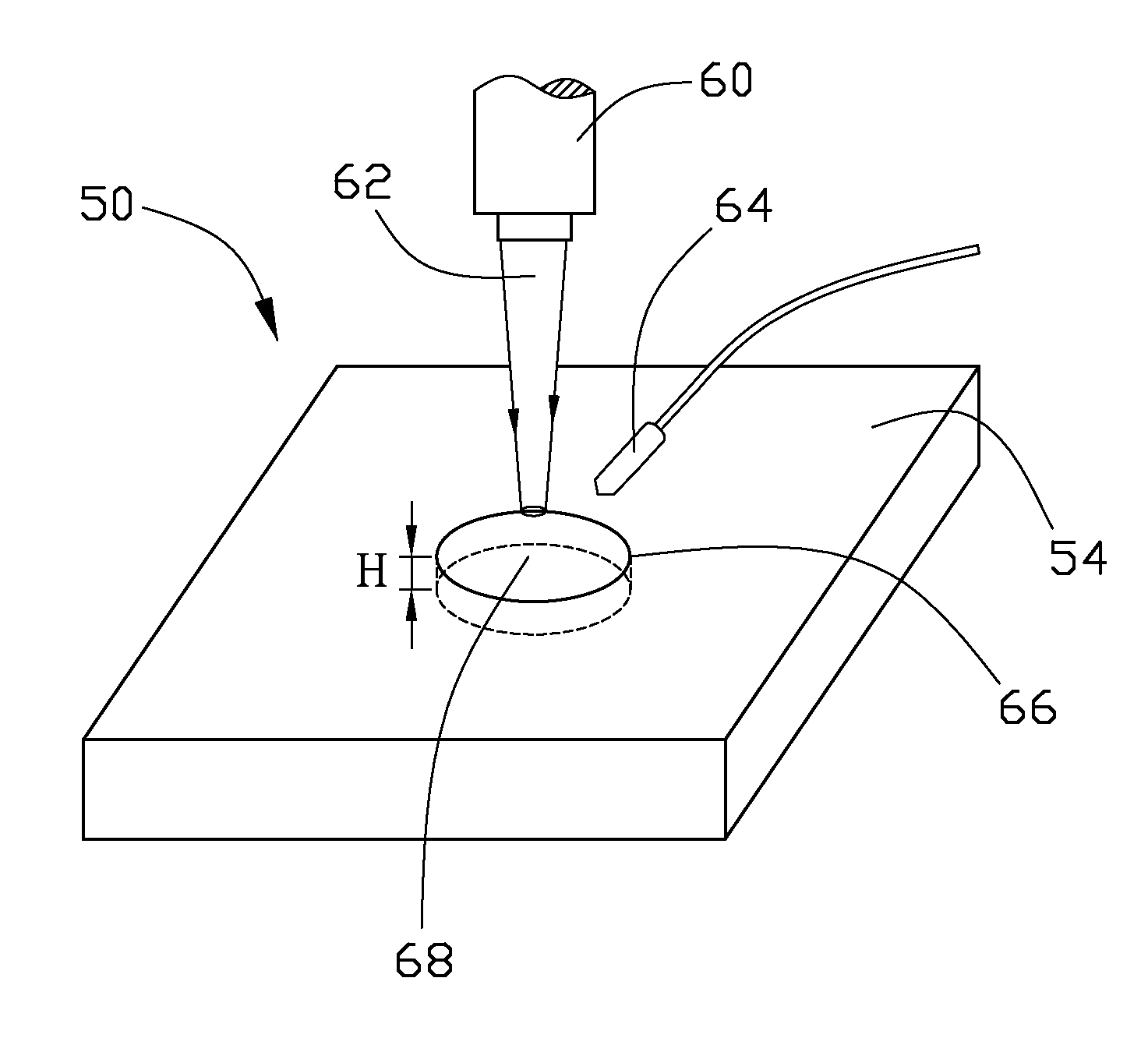

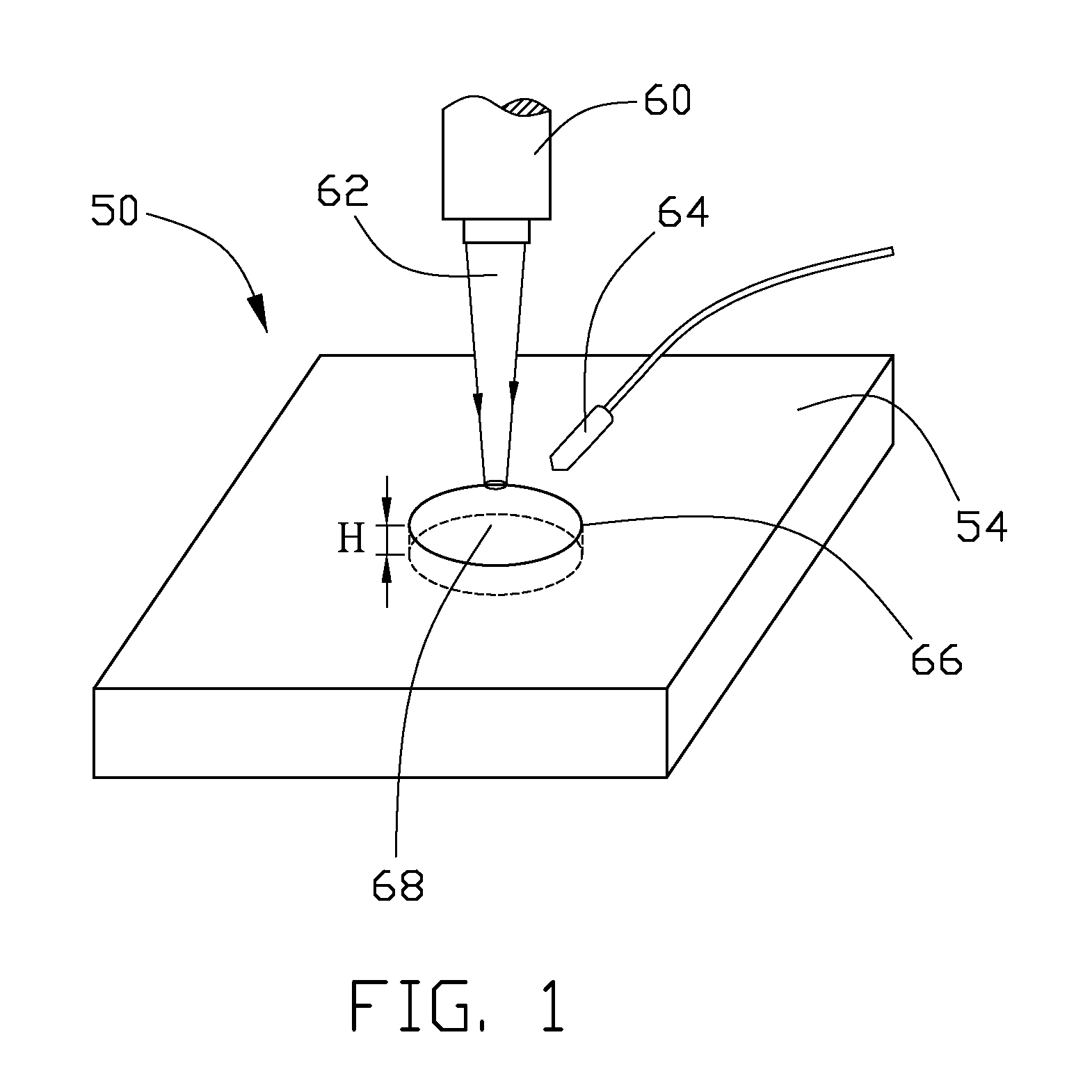

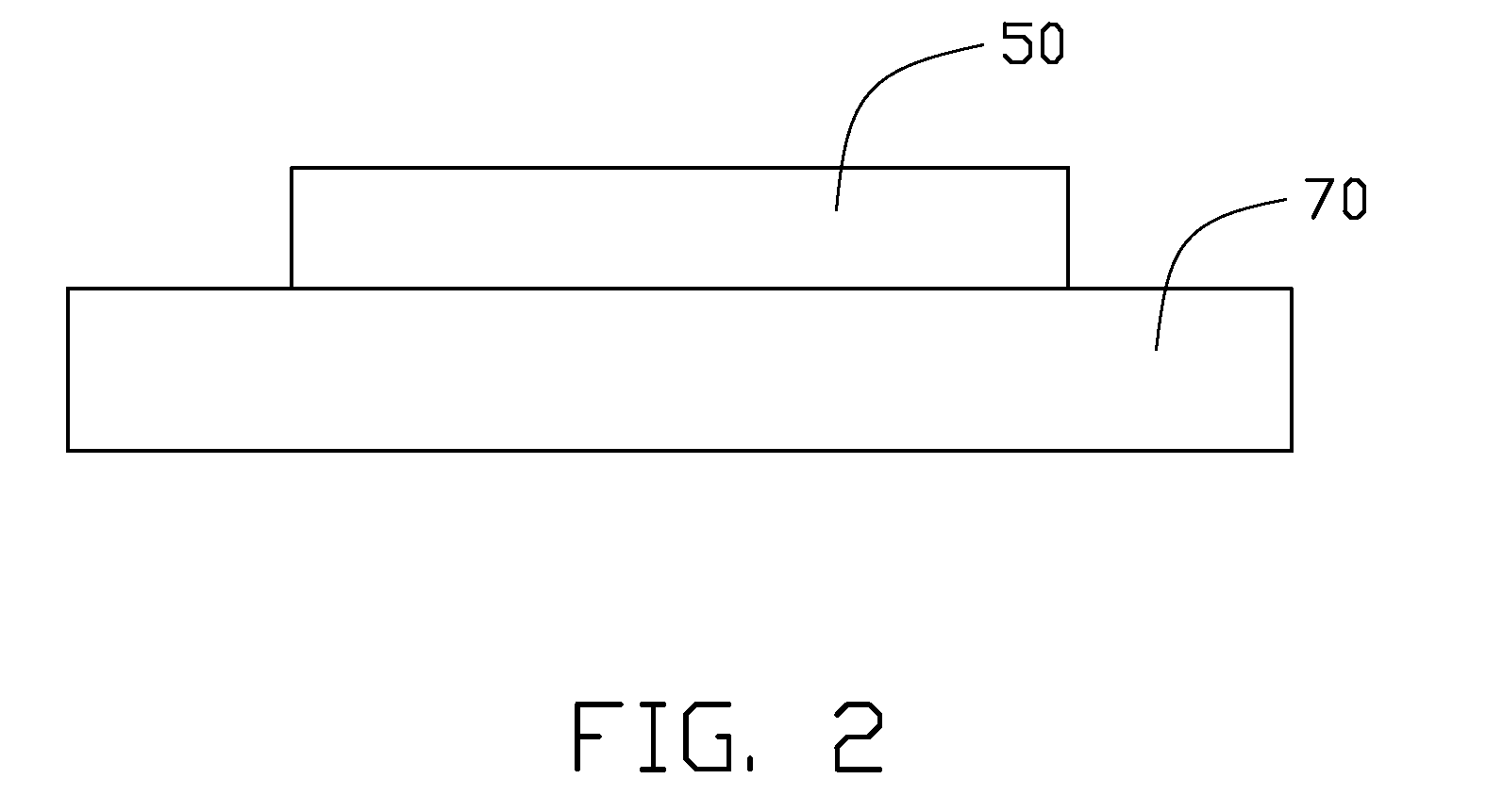

Brittle non-metallic workpiece with through hole and method for making same

An exemplary brittle non-metallic workpiece (80) defines a through hole (82). An inner surface (822) for forming the through hole has no microcracks and burrs. A method for making a through hole in a brittle non-metallic substrate (50) is also provided. The method includes as follows: forming an enclosing sketched etch (66) engraved into a brittle non-metallic substrate with a given depth (H) from a surface of the brittle non-metallic substrate; placing a cooling object (74) on an excess portion (68) inside the enclosing sketched etch (66); and extending the enclosing sketched etch through the brittle non-metallic substrate.

Owner:JIZHUN PRECISION IND HUIZHOU

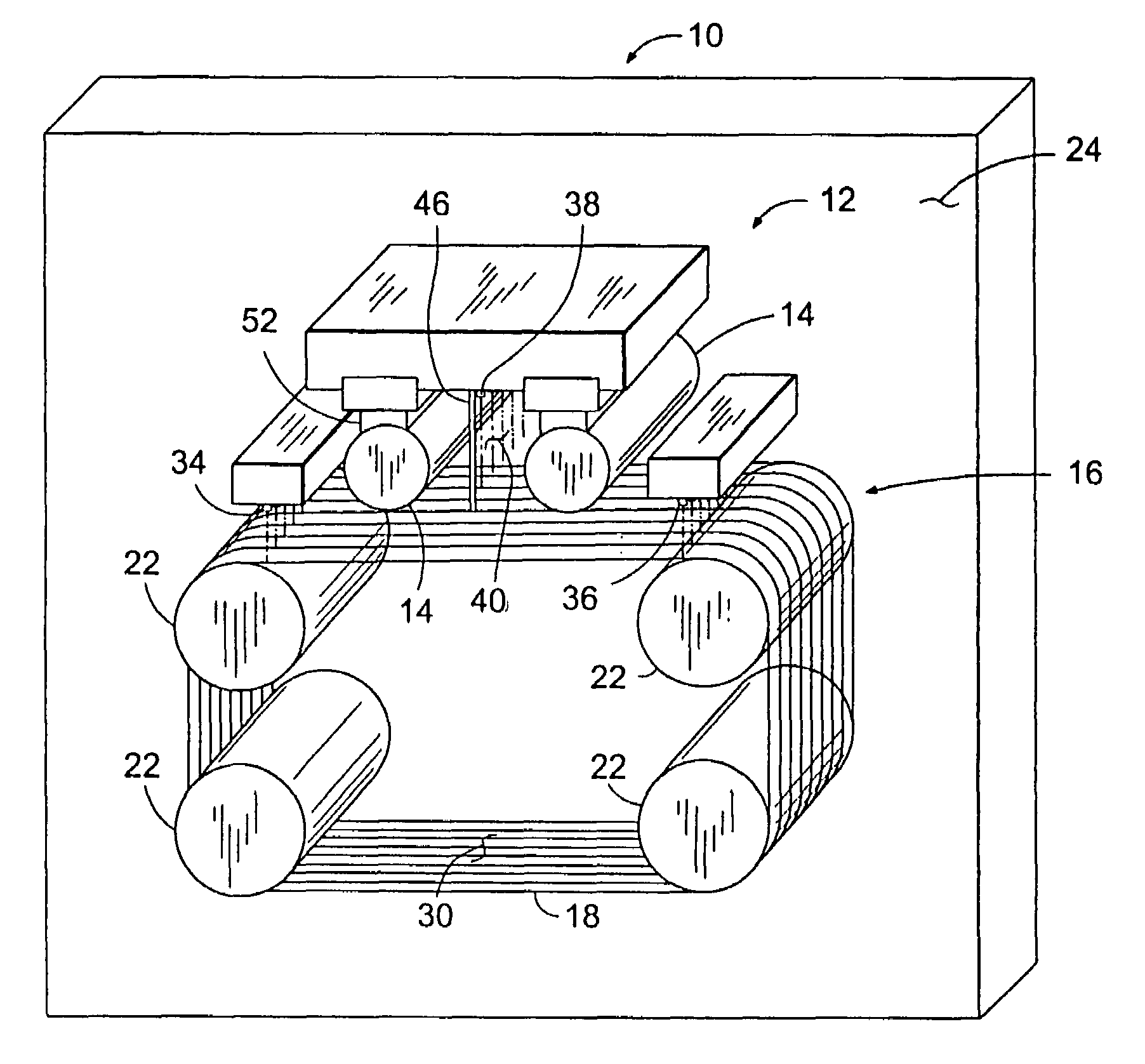

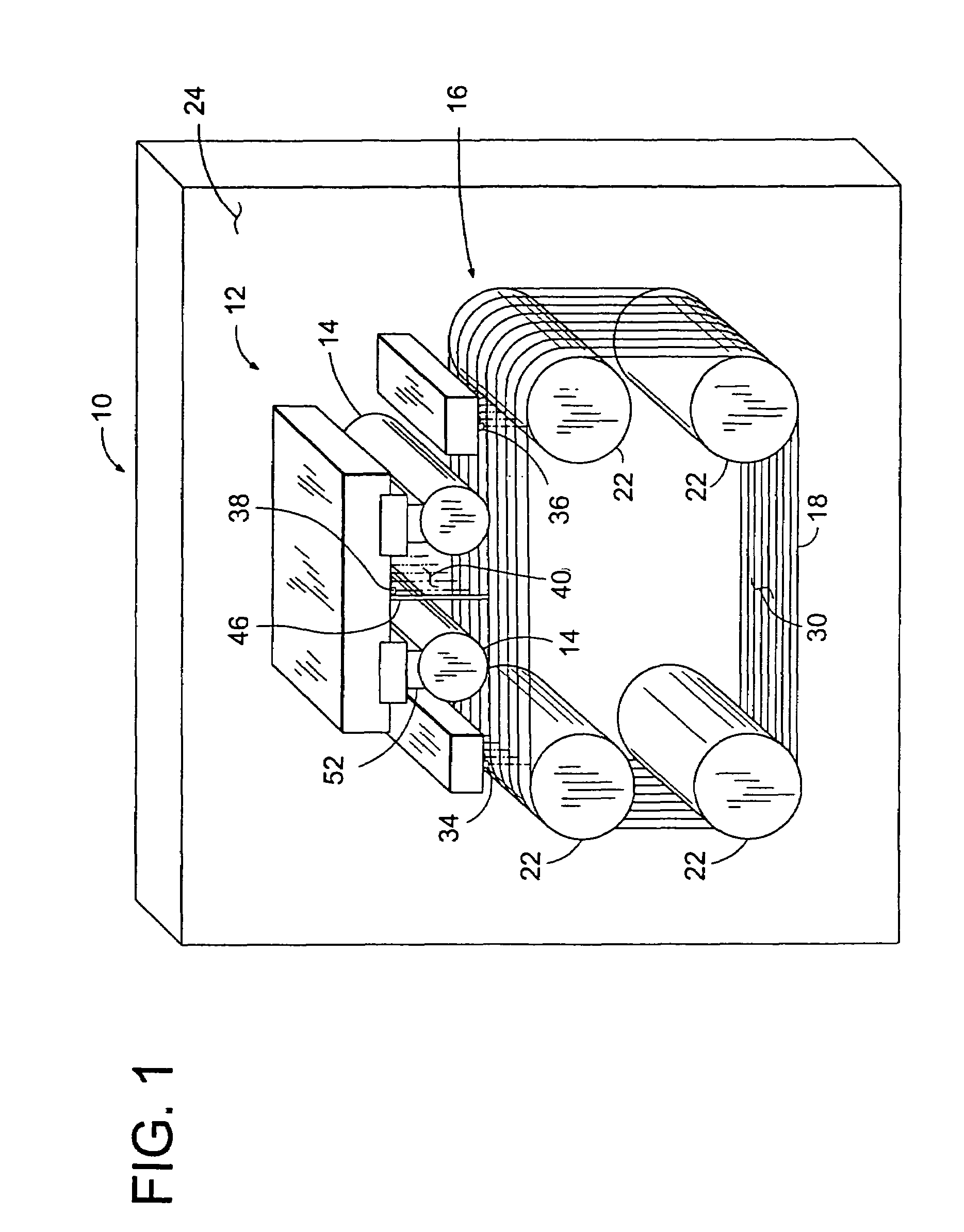

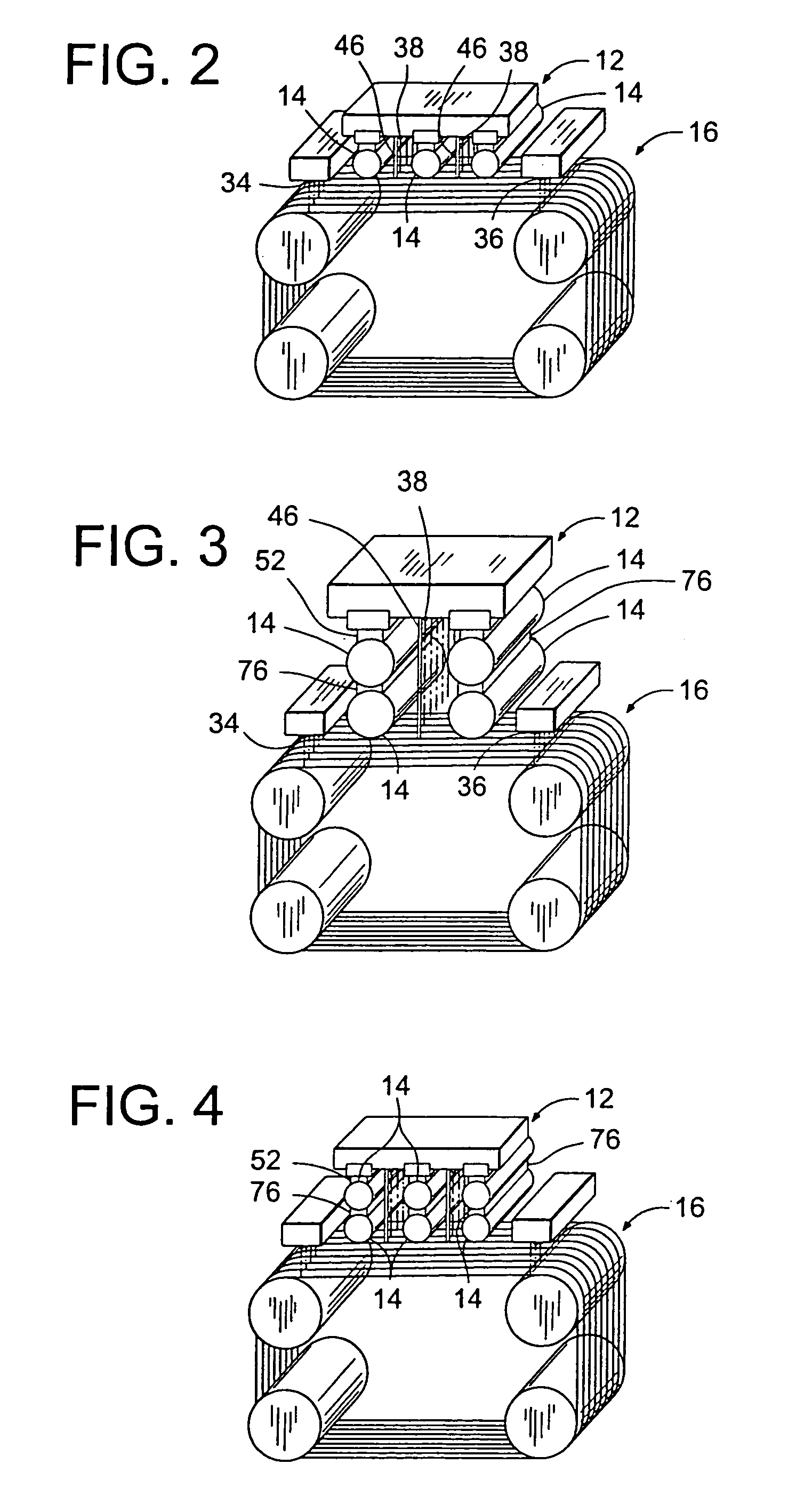

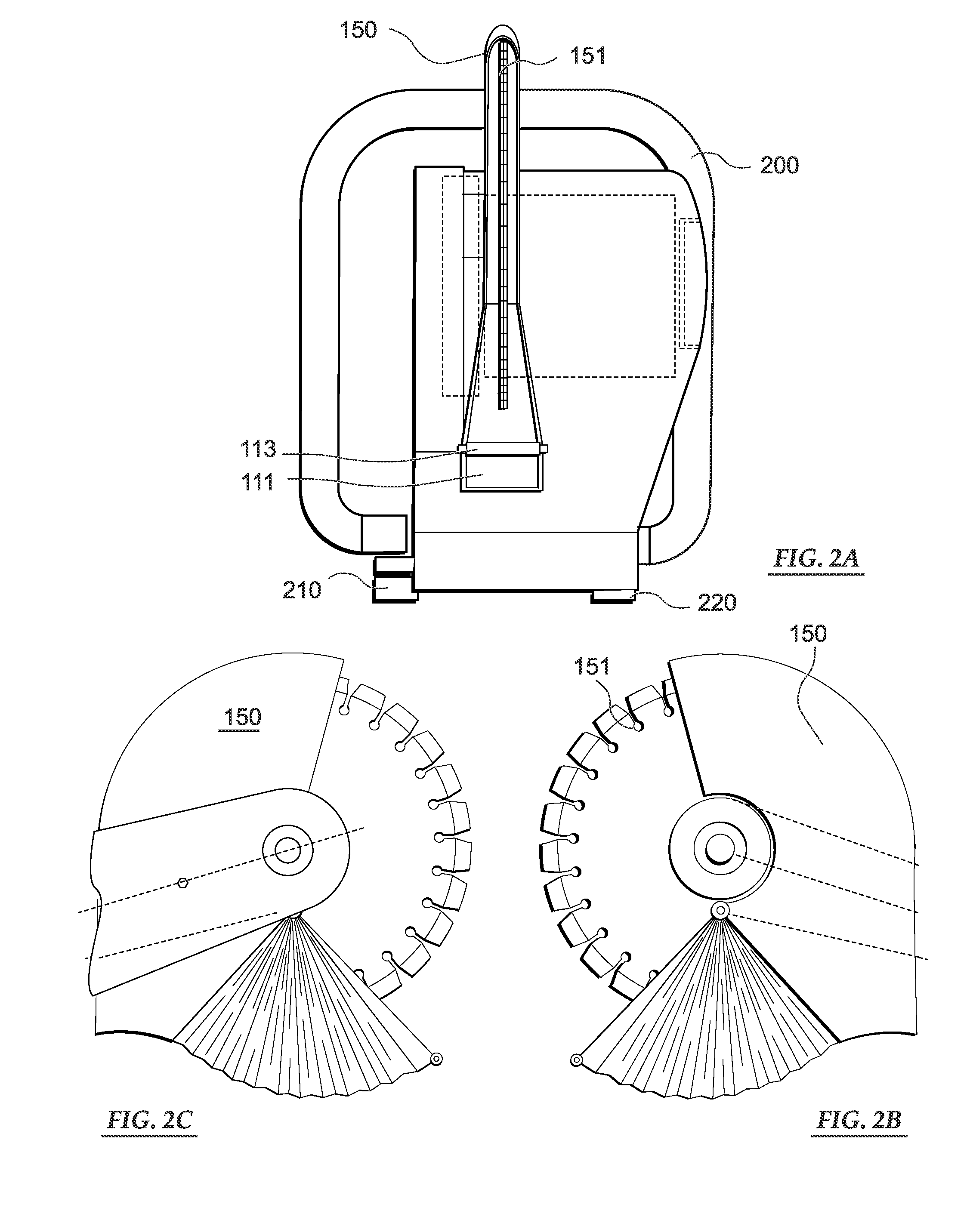

Wire saw and process for slicing multiple semiconductor ingots

InactiveUS6941940B1Improve throughputQuality improvementMetal sawing devicesSemiconductor/solid-state device manufacturingIngotSingle crystal

A wire saw (10) for simultaneously slicing multiple, generally cylindrical monocrystalline ingots (14) into wafers. The wire saw includes a cutting head (16), an ingot support (12), and multiple generally parallel lengths of cutting wire (18) defining a cutting web (30). A slurry delivery system includes nozzles (34, 36, and 38) positioned for dispensing slurry along the wire web generally at lateral sides of each ingot. A process for simultaneously slicing at least two generally cylindrical semiconductor ingots into wafers includes mounting at least two ingots to a common ingot support, moving the ingot support relative to the cutting web so that the two ingots simultaneously press against the cutting web at cutting regions, and dispensing a liquid slurry to at least three locations on the wire web including two outermost sides of the cutting regions and a location between each pair of ingots.

Owner:GLOBALWAFERS CO LTD

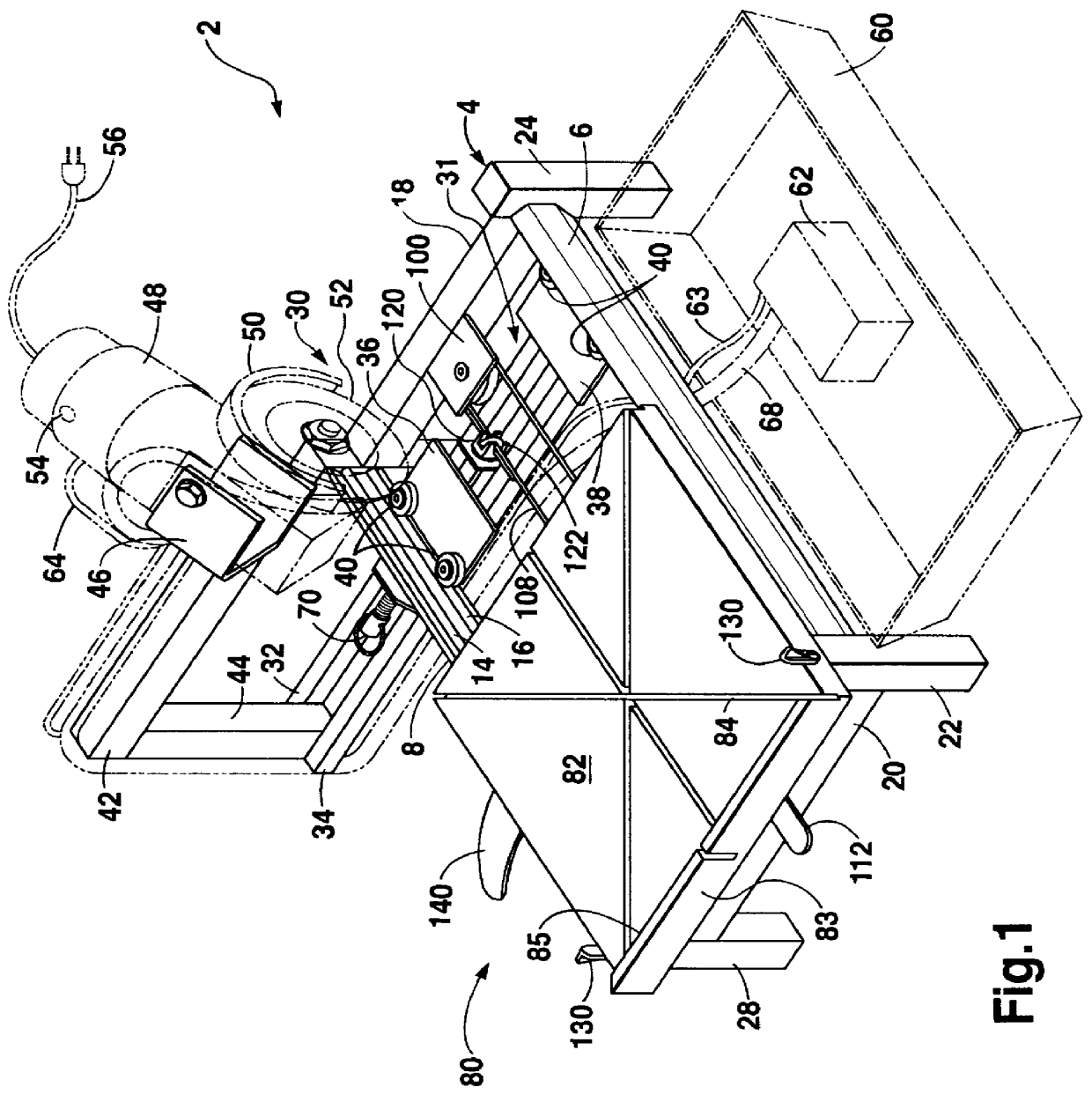

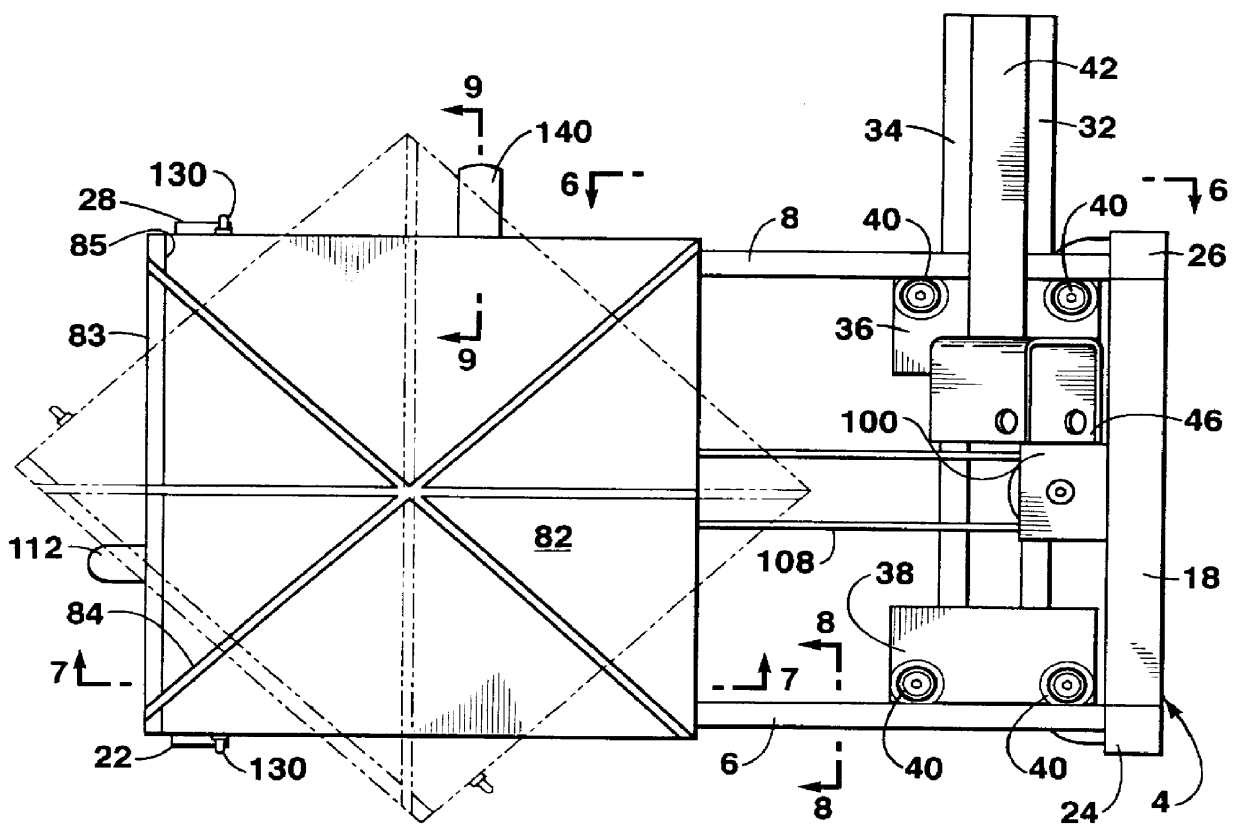

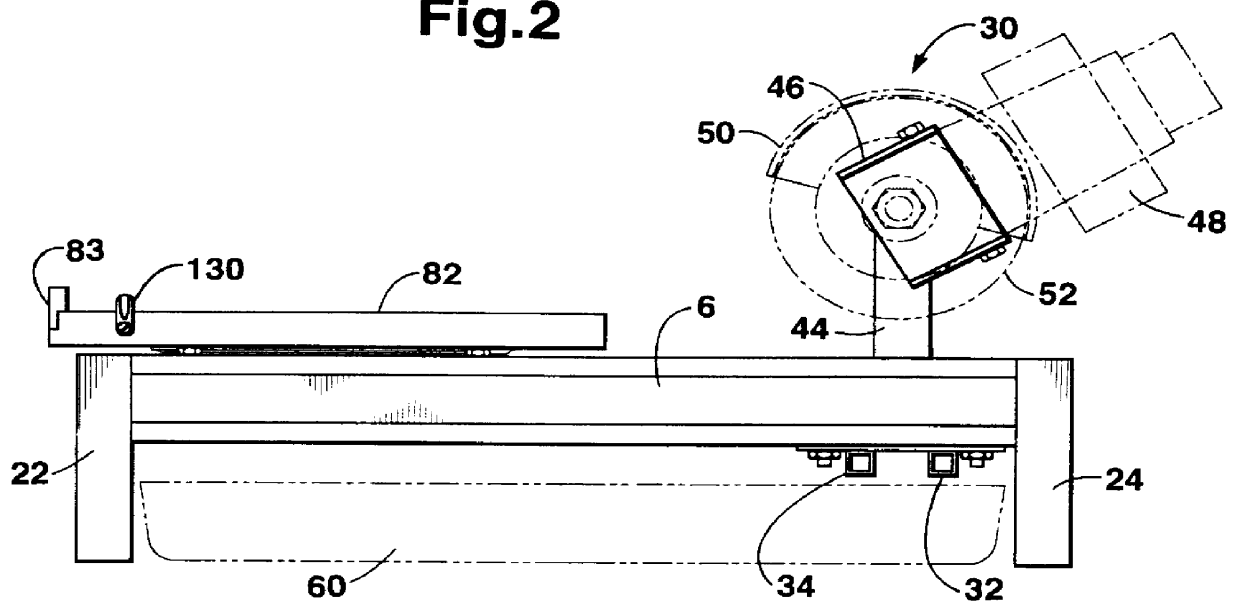

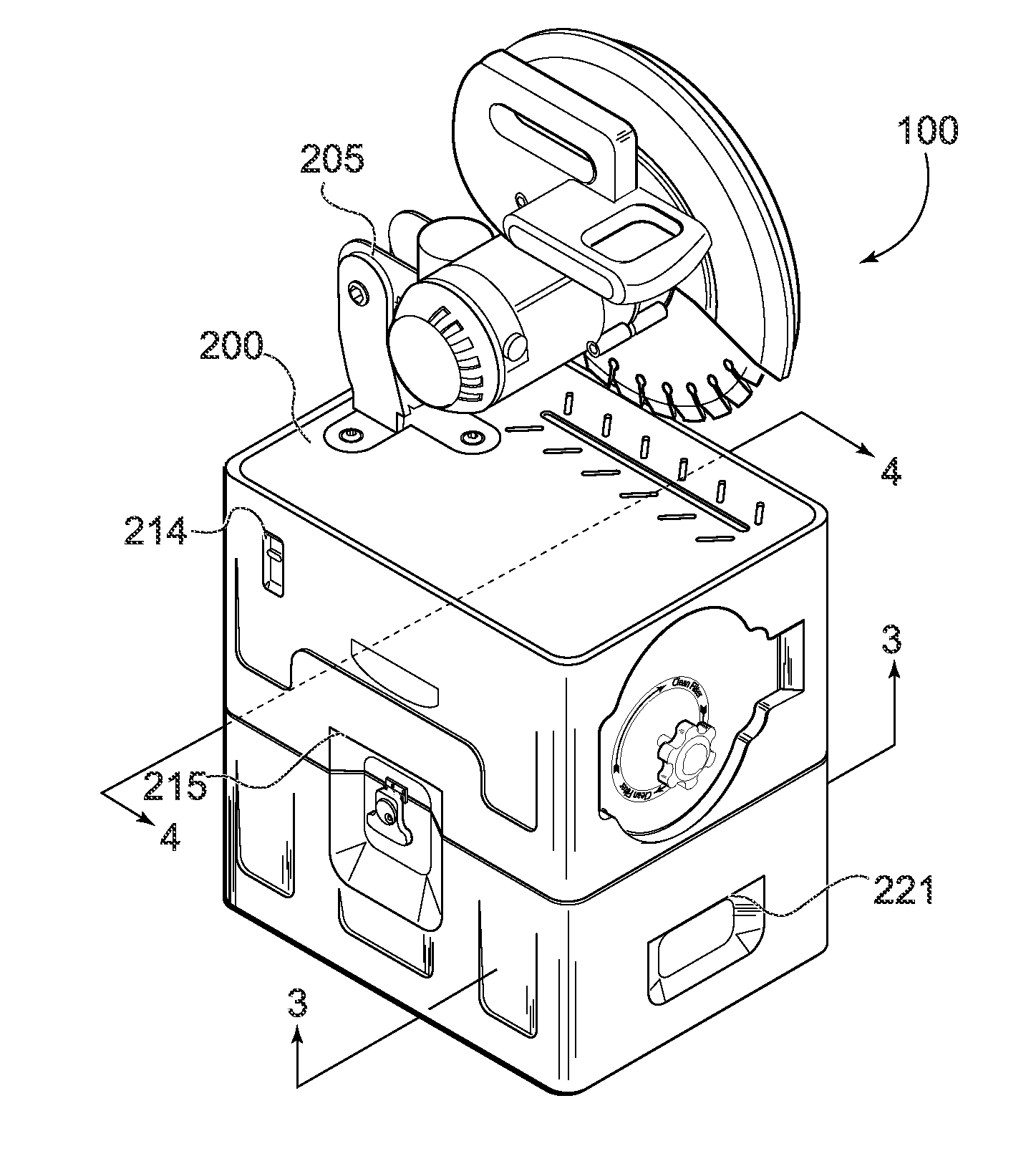

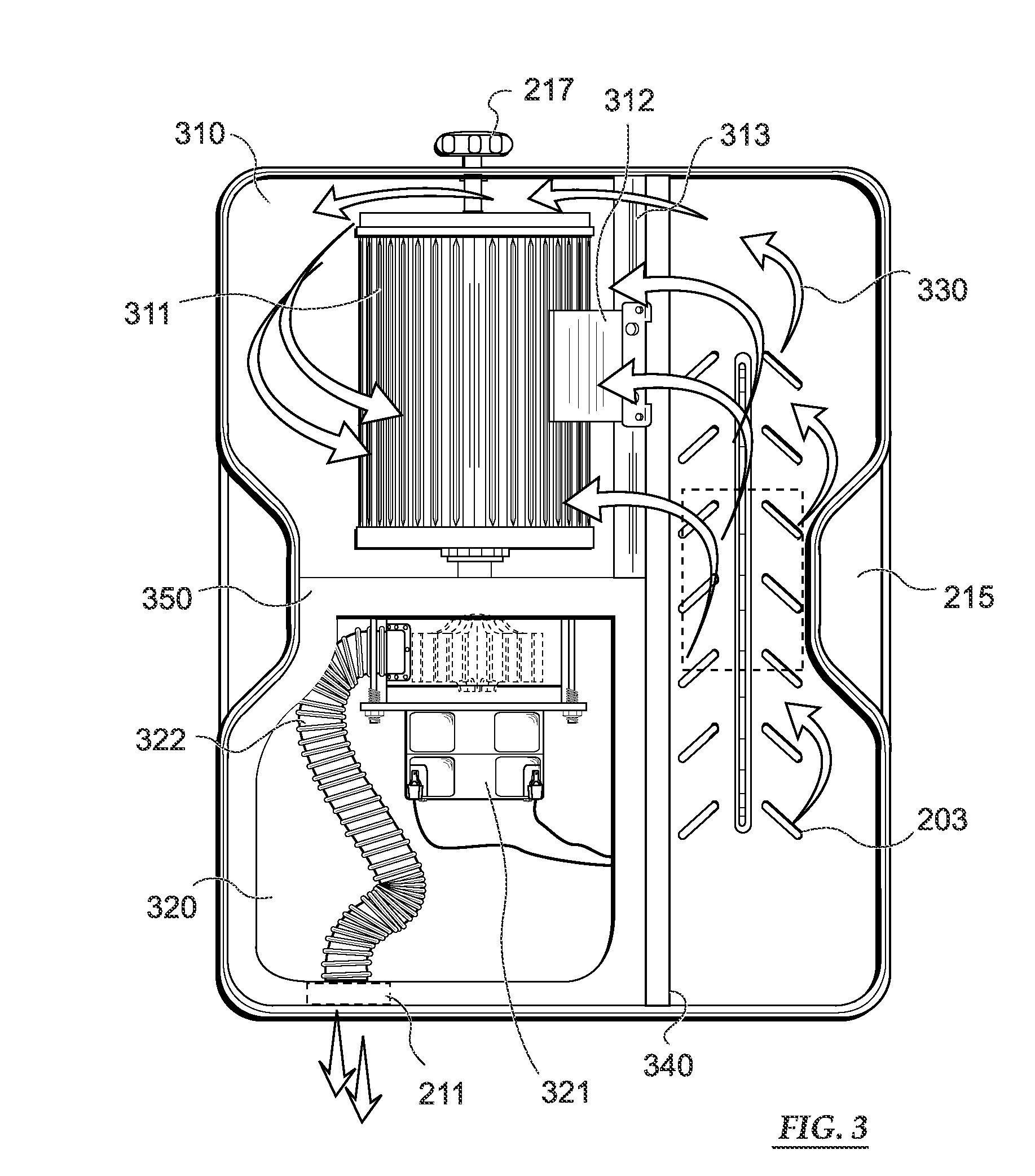

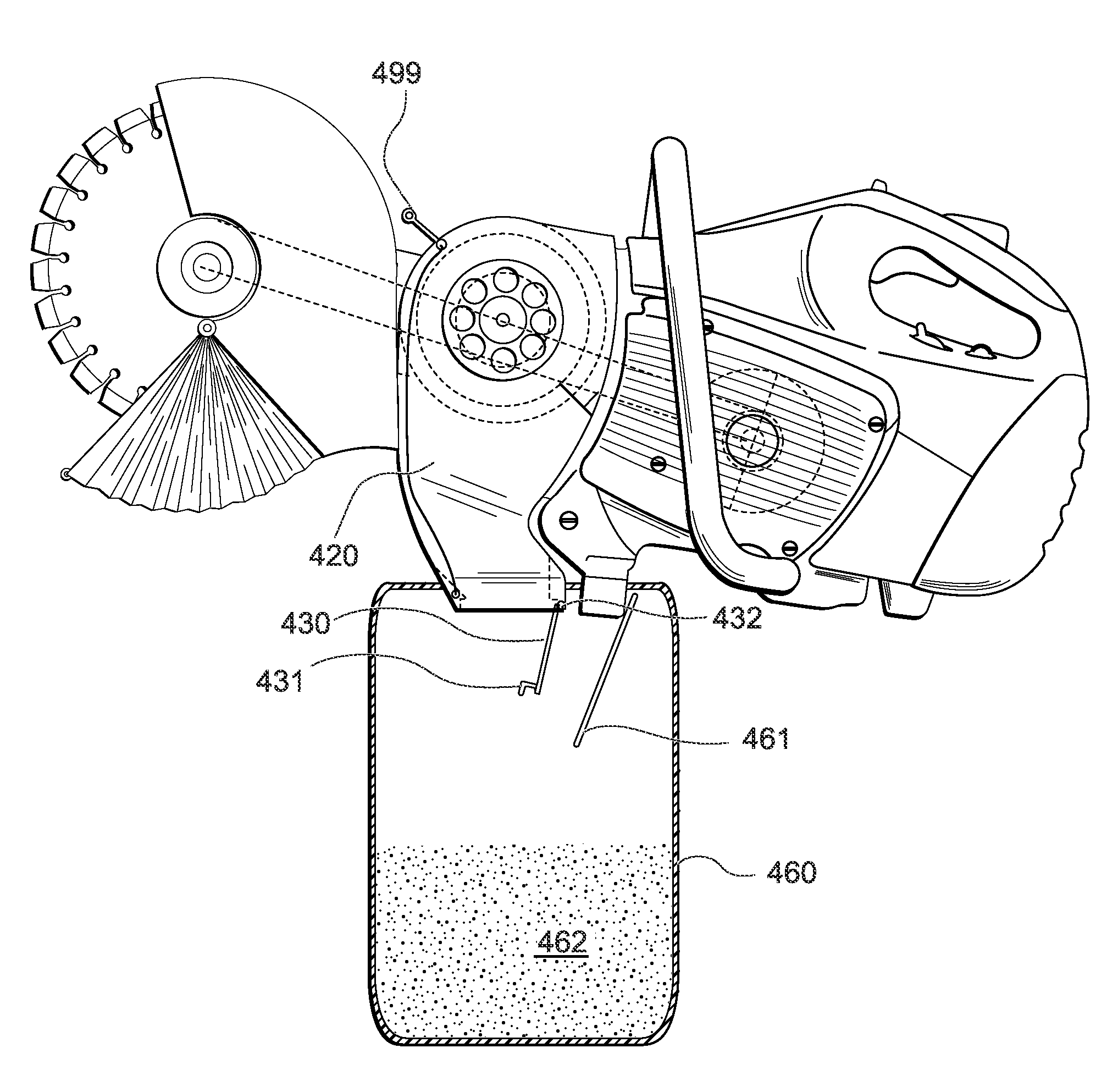

Chop Saw with Dust Collection System

ActiveUS20100116261A1Minimize undesirable current surgeIncrease usable surface areaMetal sawing devicesMetal sawing accessoriesParticulatesCircular saw

A chop saw, grinding wheel, or like apparatus is disclosed herein also incorporated to an easily portable dust collection system. In a preferred embodiment, a worktable is provided with a center slot for receiving a circular saw blade. A negative pressure and resulting air flow is provided at the center slot to capture particulate matter as a byproduct of cutting the workpiece. Side slots are also disclosed to assist in particulate collection. A unique filter chamber having a cylindrical filter is additionally provided to remove dust from air and discharge the filtered air at a lateral side of the apparatus. A filter cleaning knob is additionally disclosed to assist in cleaning the filter. Of the beneficial aspects of the chop saw with dust collection system is its portability being one integral unit and the dust filter being easily cleaned and maintained.

Owner:JPL GLOBAL

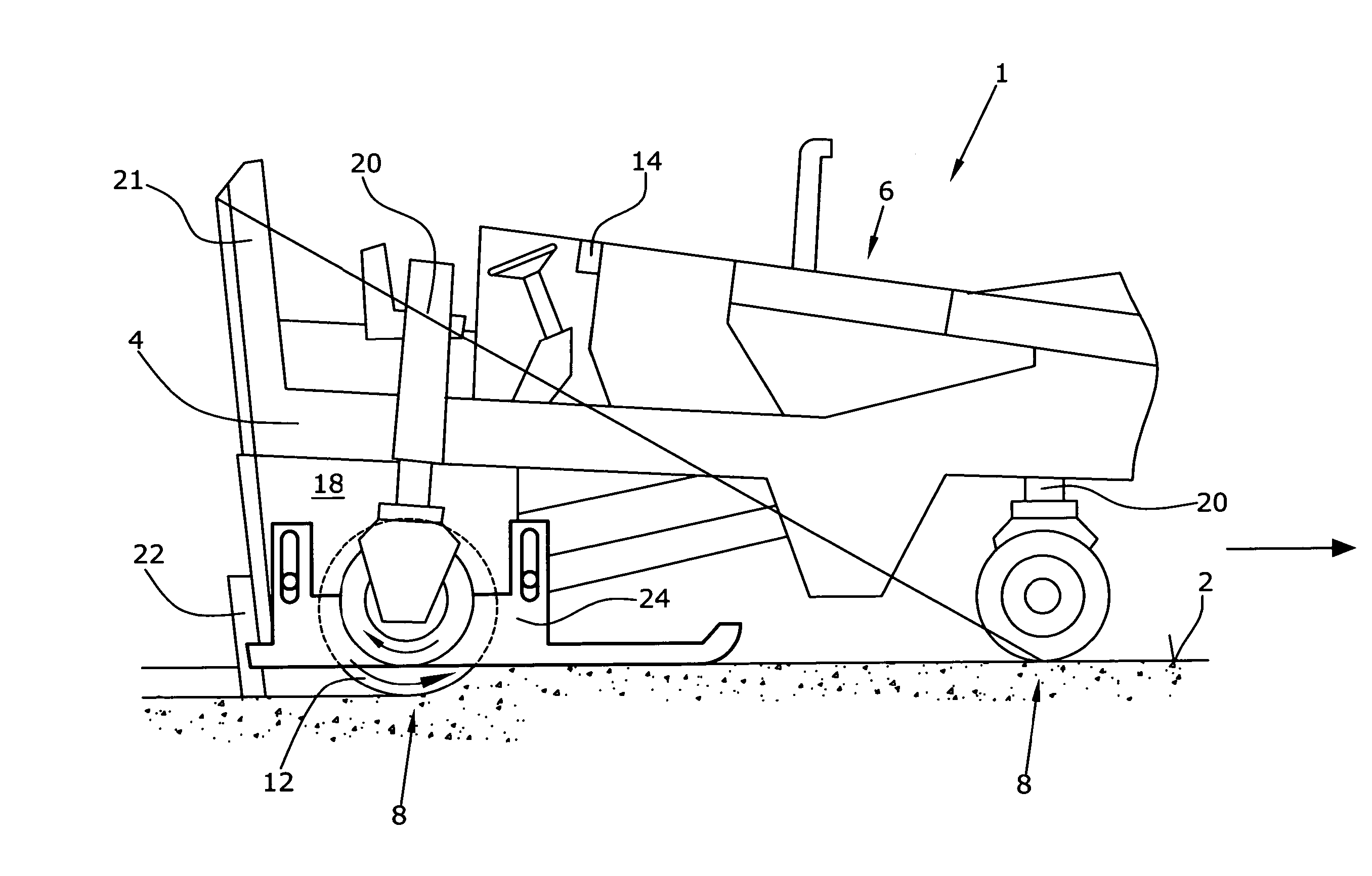

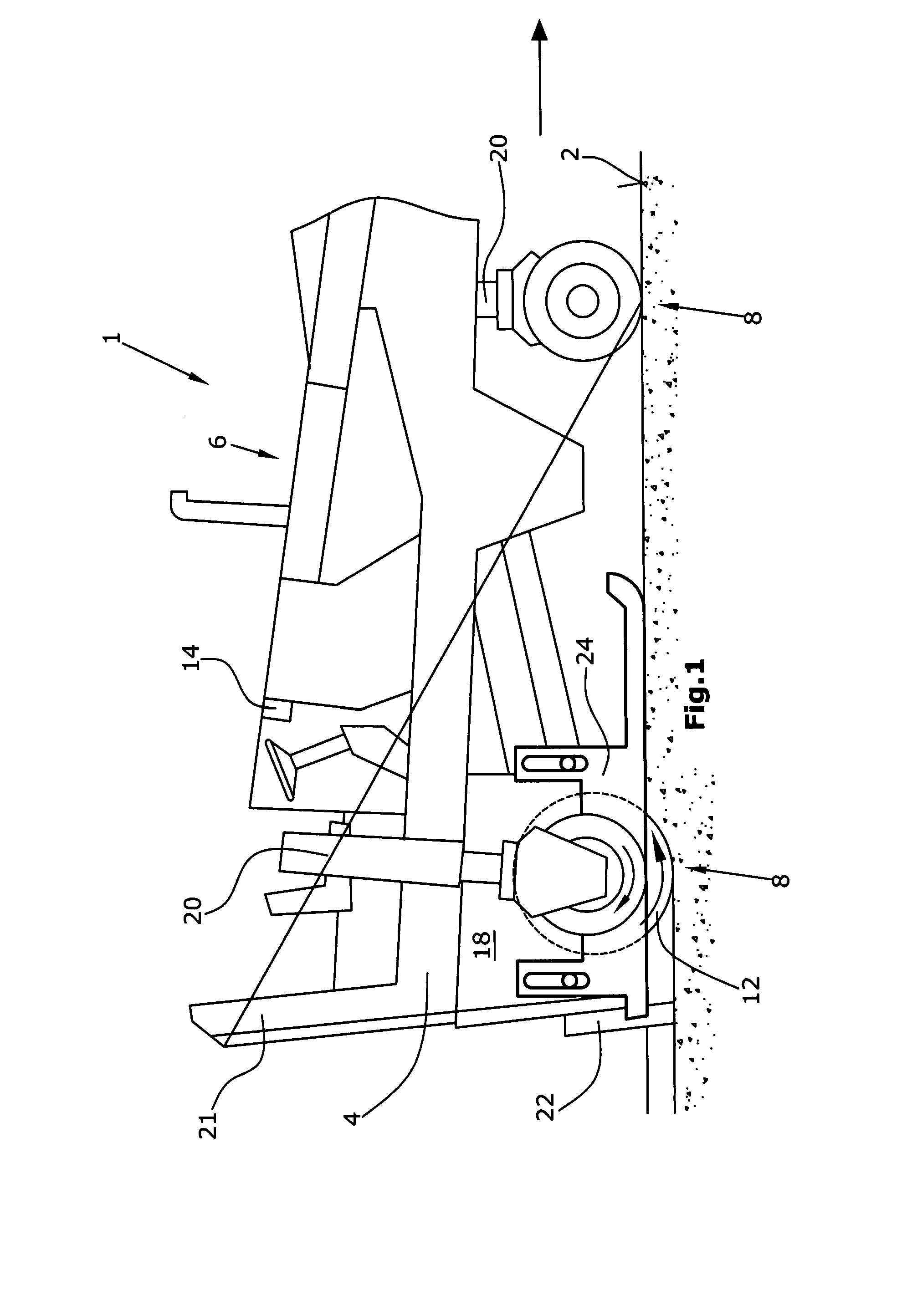

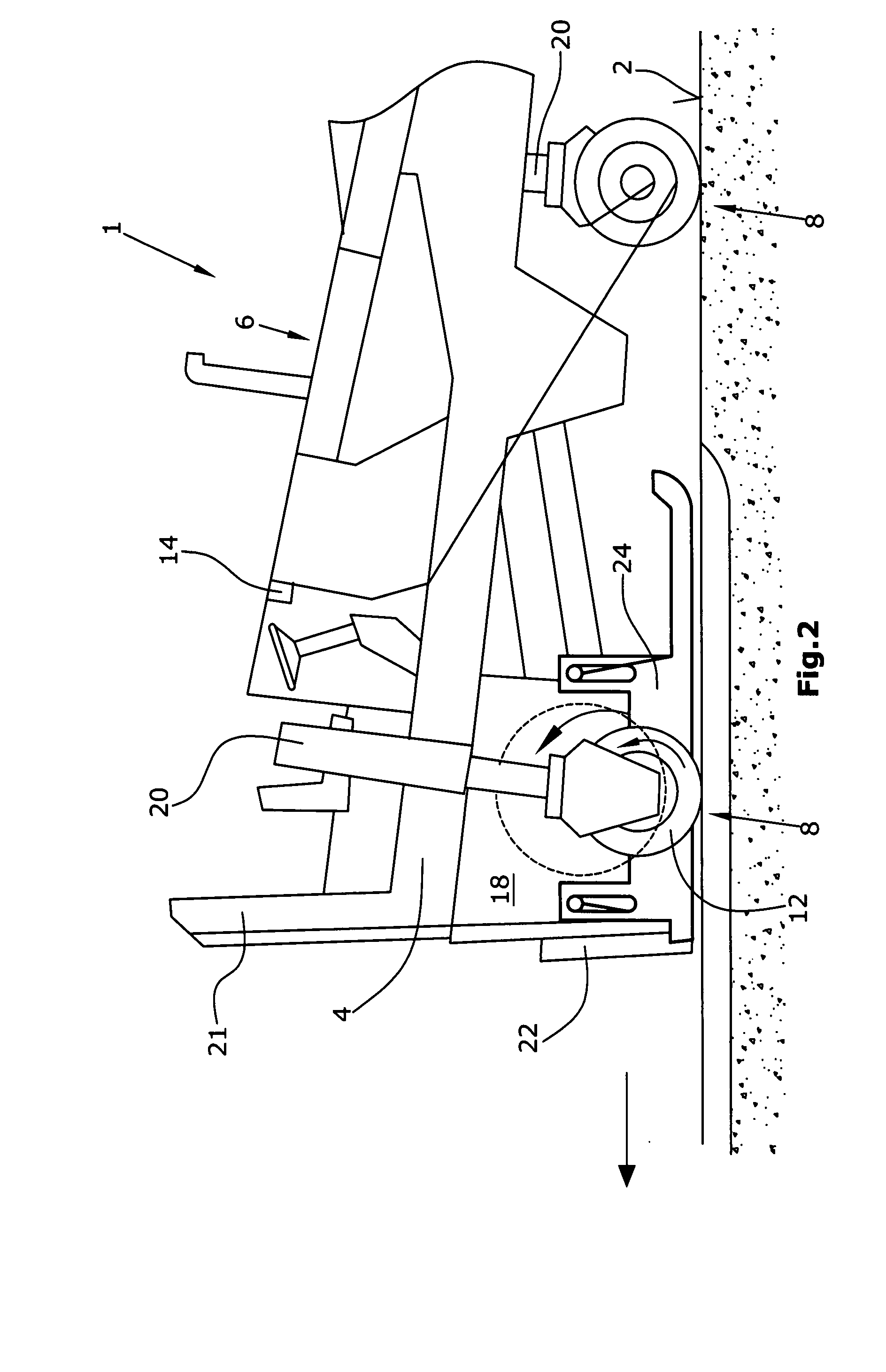

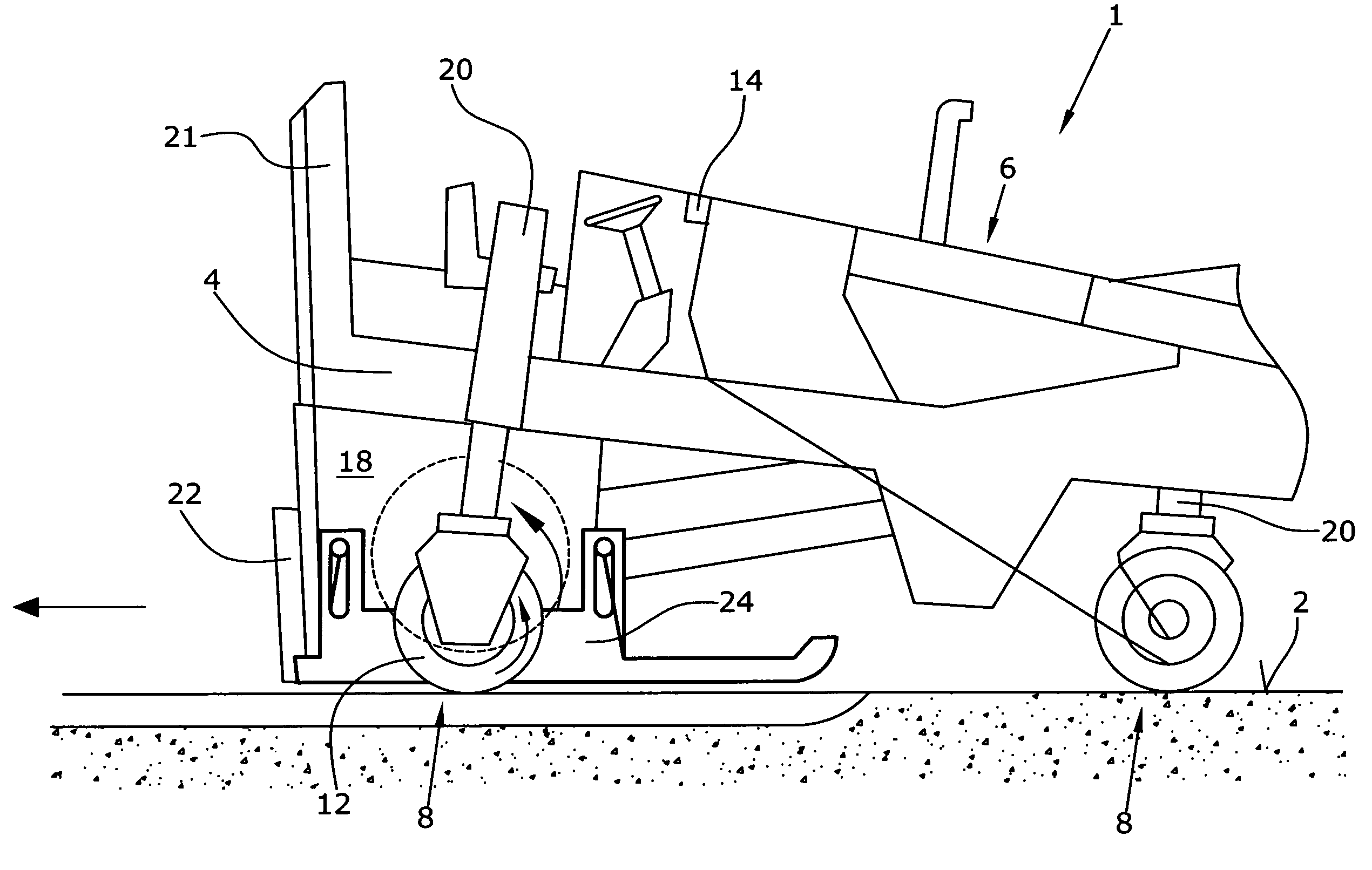

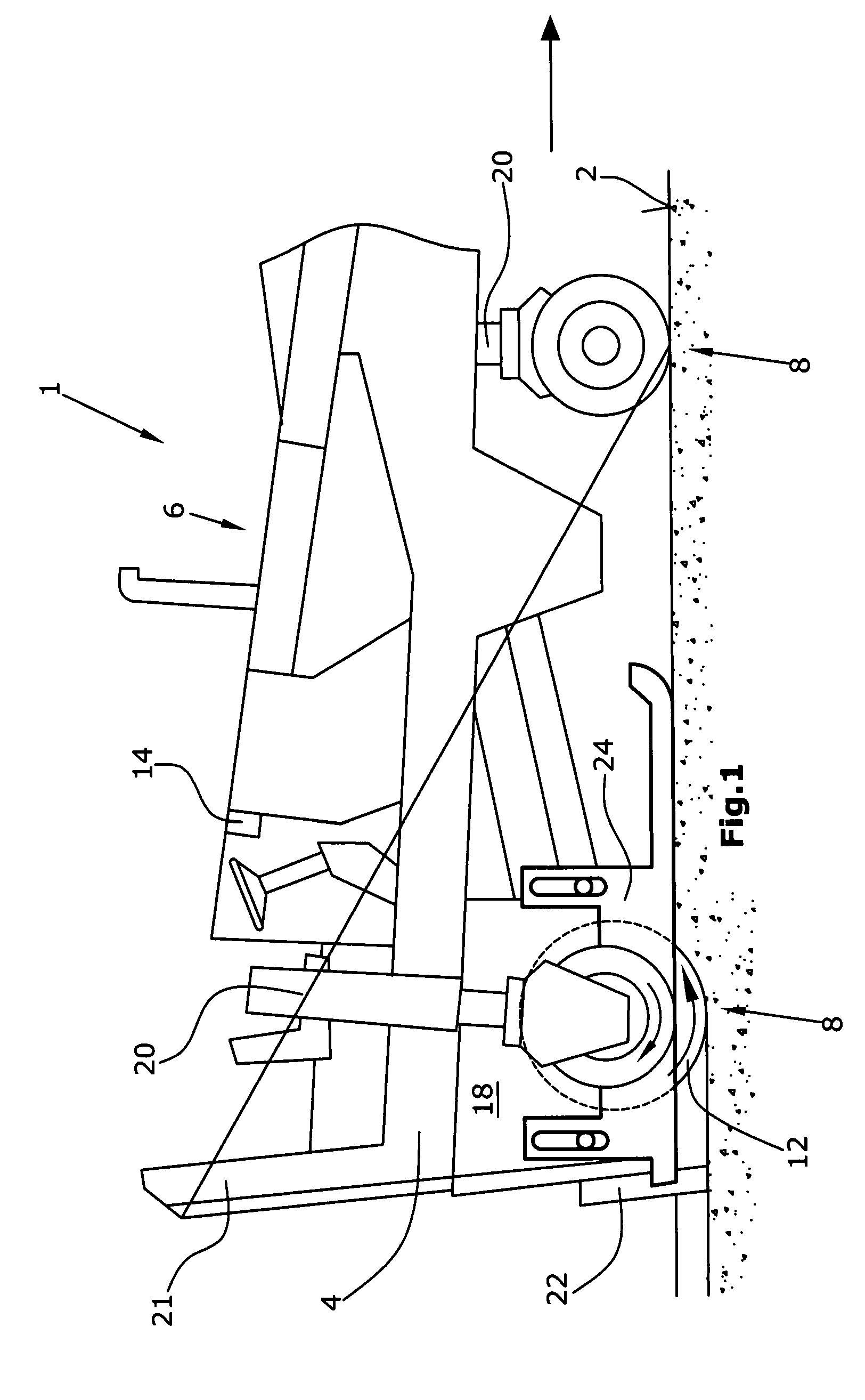

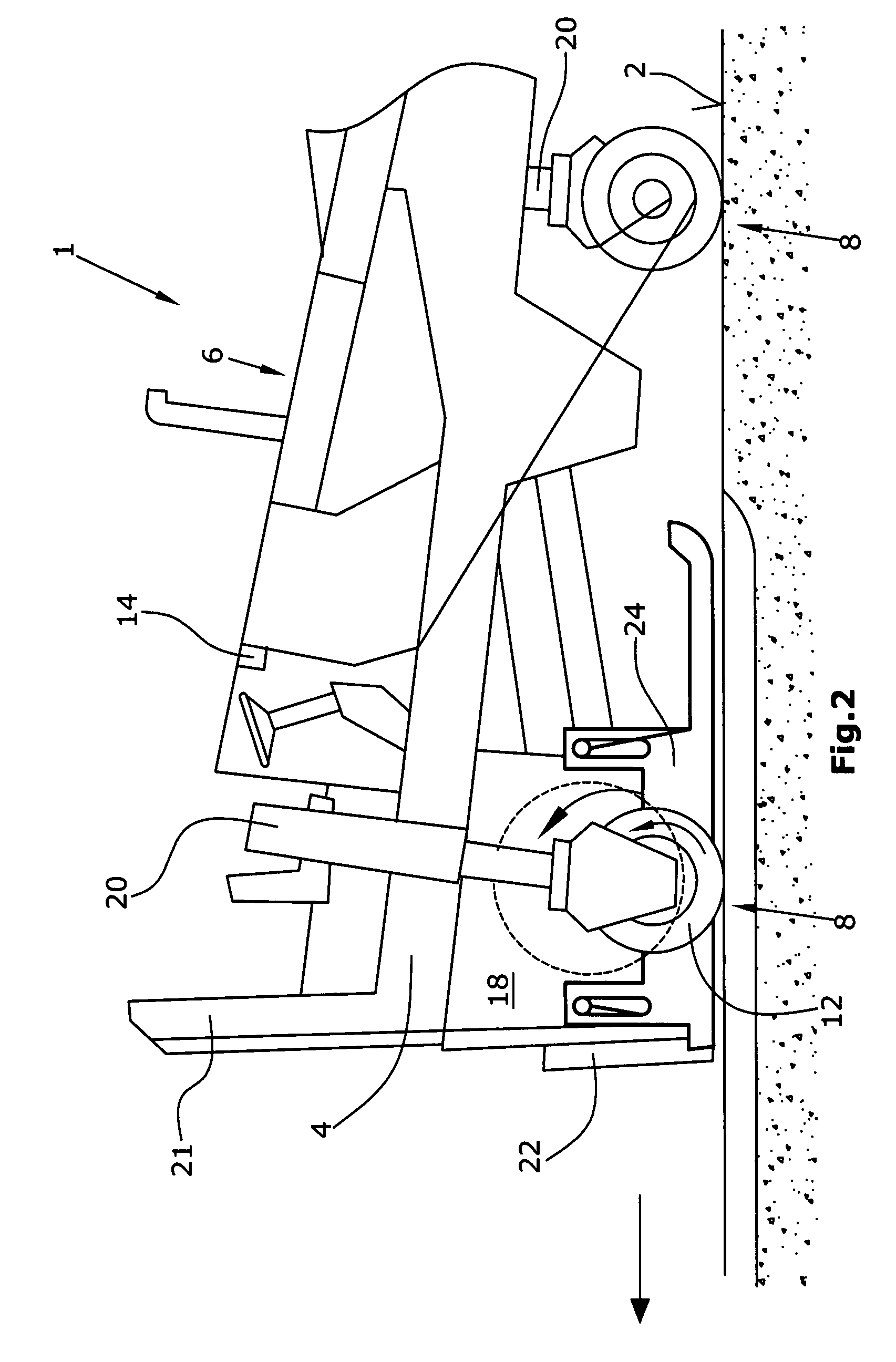

Automotive construction machine, as well as method for working ground surfaces

ActiveUS20070286678A1No time loss is incurredIncrease driving speedSlitting machinesSoil-shifting machines/dredgersDevice MonitorAlarm signal

An automotive construction machine for working ground surfaces, with a machine frame, a drive engine for driving traveling devices and for driving working devices, and a milling drum for milling the ground surfaces, which can be raised, driven by, and can be uncoupled from a drum drive, the milling drum can be moved into a raised position when not in milling mode, and when raised, the rotating direction of the milling drum corresponds to the rotating direction of the traveling devices and remains coupled with the drive engine, and a monitoring device monitors the distance between the milling drum and the ground surface and uncouples the raised milling drum from the drive engine or uncouples the traveling devices from the drive engine or raises the machine frame or generates an alarm signal when the monitoring device detects a deviation that falls below a pre-determined distance, or any of the latter.

Owner:WIRTGEN AMERICA

Slab saw with dust collector and method of dry-cutting pavement

A dust collector is provided for use with a SLAB saw, especially suited for dry-cutting a channel within pavement or similar exterior surface. The collector includes telescoping upper and lower housings, an open front and lower base to receive a portion of a circular saw into the interior of the housing, and an exhaust outlet, for attaching to a vacuum duct, so as to exhaust dust-laden air from the interior of the housing. The housing includes a pivot mount, pivotally mounting the unit to a slab saw. Also provided is a system, including the dust collector with a circular saw and optionally a vacuum source and dust filter unit or units. Also provided is a method for dry-cutting a trench or channel within pavement or similar hard outside surface, which is particularly suitable for laying of cable such as fiber optic cable. The method may include the step of cutting through the pavement into the underlying hard-packed substrate.

Owner:TERASPAN NETWORKS

All-silicon-rod squaring machine and squaring method

The invention discloses an all-silicon-rod squaring machine and squaring method. The all-silicon-rod squaring machine comprises a machine base, at least one bearing frame set, a cutting device and at least one lifting position adjusting device; each bearing frame set comprises a plurality of bearing frames arranged on the machine base in a front-and-back manner, and the bearing frames are used for transversely bearing an all-silicon rod; the cutting device comprises a slippage support which slips along the machine base and at least one linear cutting unit; each linear cutting unit is arranged on the slippage support and corresponds to the corresponding bearing frame set, and each linear cutting unit internally comprises two opposite cutting lines; each lifting position adjusting device is arranged on the machine base, corresponds to the corresponding bearing frame set and is used for jacking the all-silicon rod and driving the all-silicon rod to rotate by a cutting angle to adjust the cutting position; and according to the all-silicon-rod squaring machine, the number of the bearing frame sets, the number of the linear cutting units and the number of the lifting position adjusting devices each can be multiple, and the aim of squaring the multiple all-silicon rods at the same time can be achieved.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

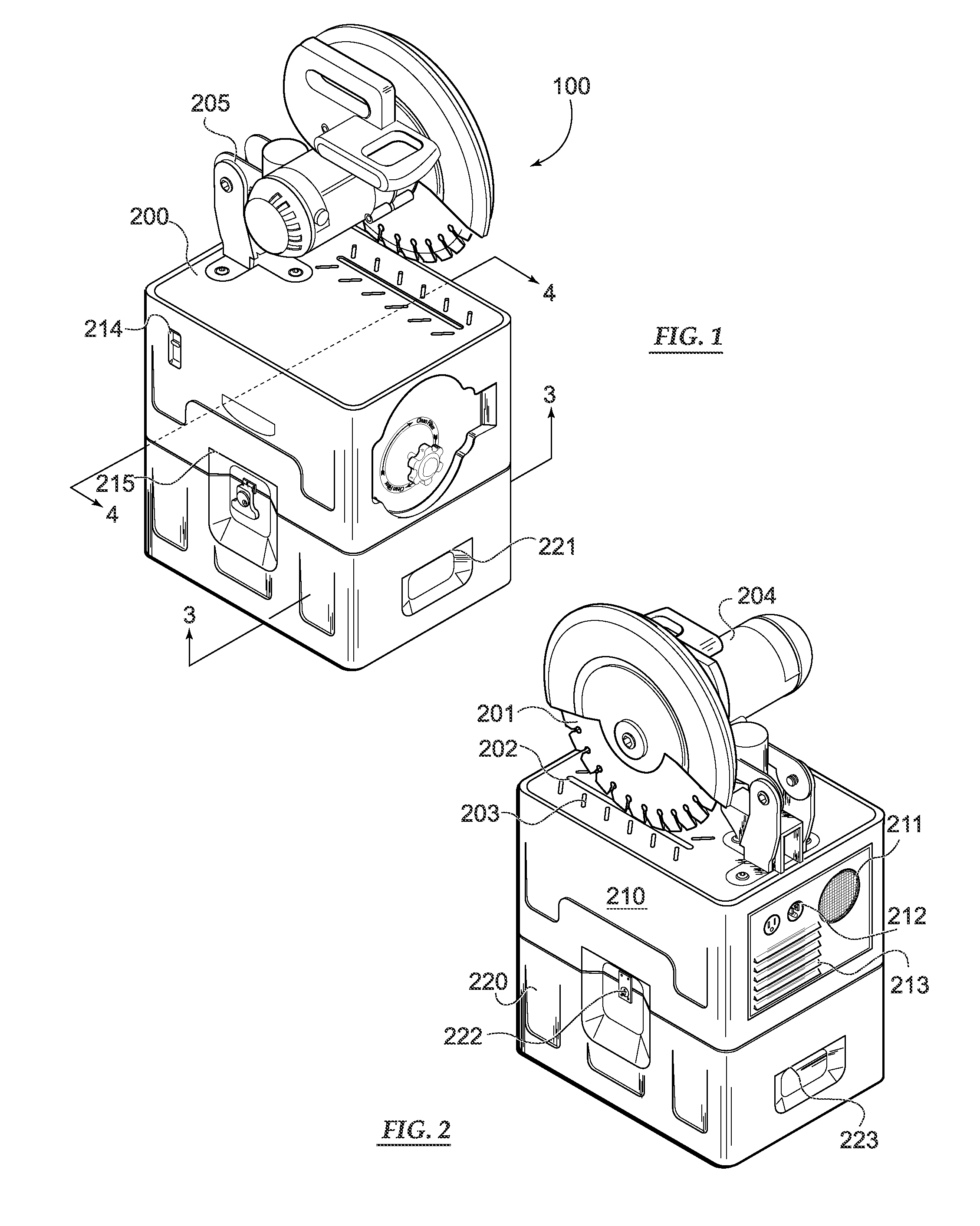

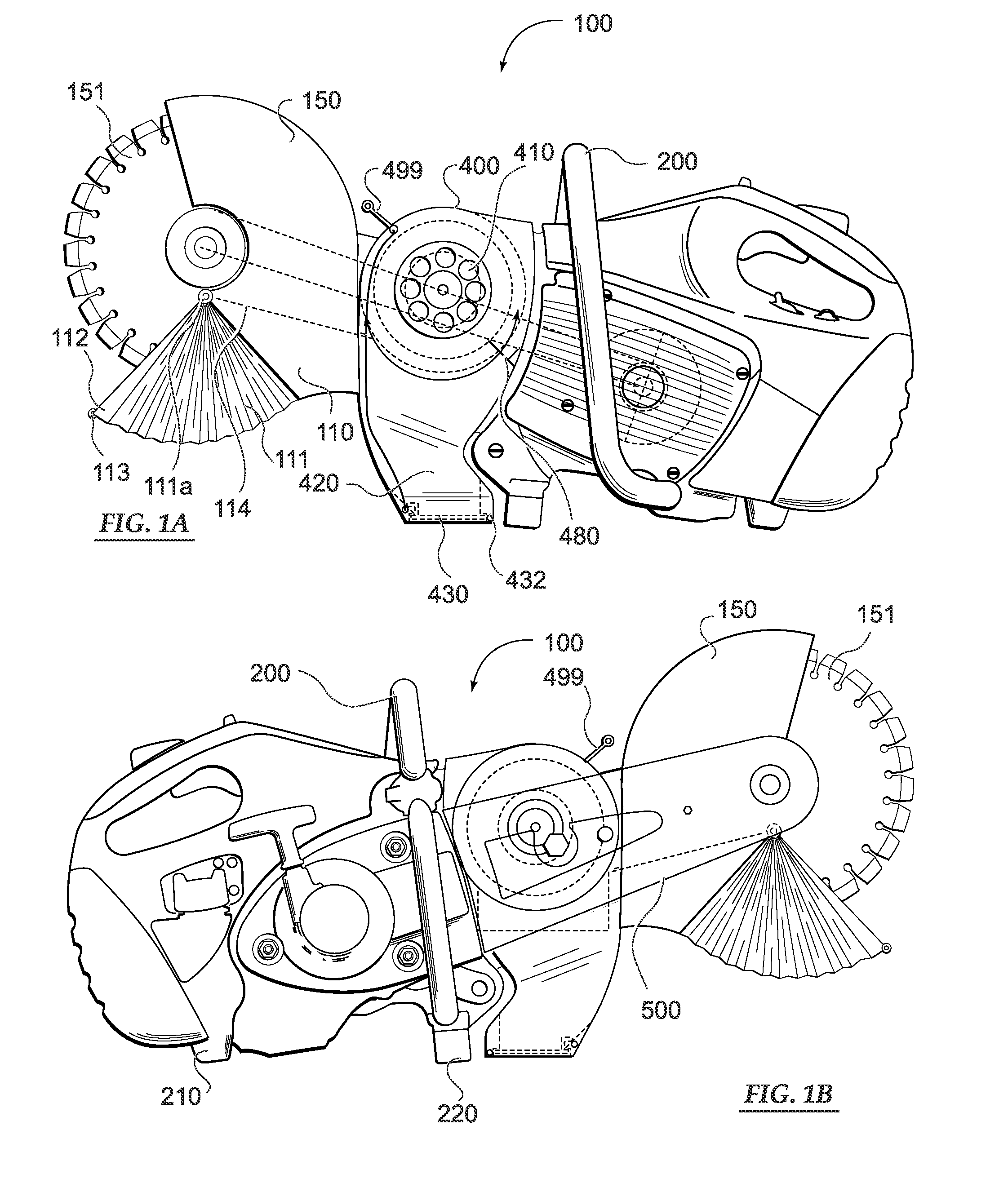

Power saw apparatus with integrated dust collector

ActiveUS20110079207A1Reduce frictionUseful surface areaMetal sawing devicesMetal sawing accessoriesParticulatesSpins

A power saw having a circular saw blade or, grinding wheel incorporated to a dust collection system that is easily portable is disclosed herein. In a preferred embodiment, negative pressure and resulting air flow is provided at a lower blade guard to capture particulate matter as a byproduct of cutting a work piece. A unique dust collection housing is additionally provided having a filter to remove dust from air and exhaust the filtered air at a lateral side of the saw. A spin handle is additionally disclosed to increase the usable surface of the filter and to work in conjunction with a filter cleaning flap. A drive belt according to a preferred embodiment, drives the circular saw and a vacuum fan. Among the beneficial aspects of the power saw is its portability by obviating a need for a dust collection bag and / or a separate vacuum unit.

Owner:JPL GLOBAL

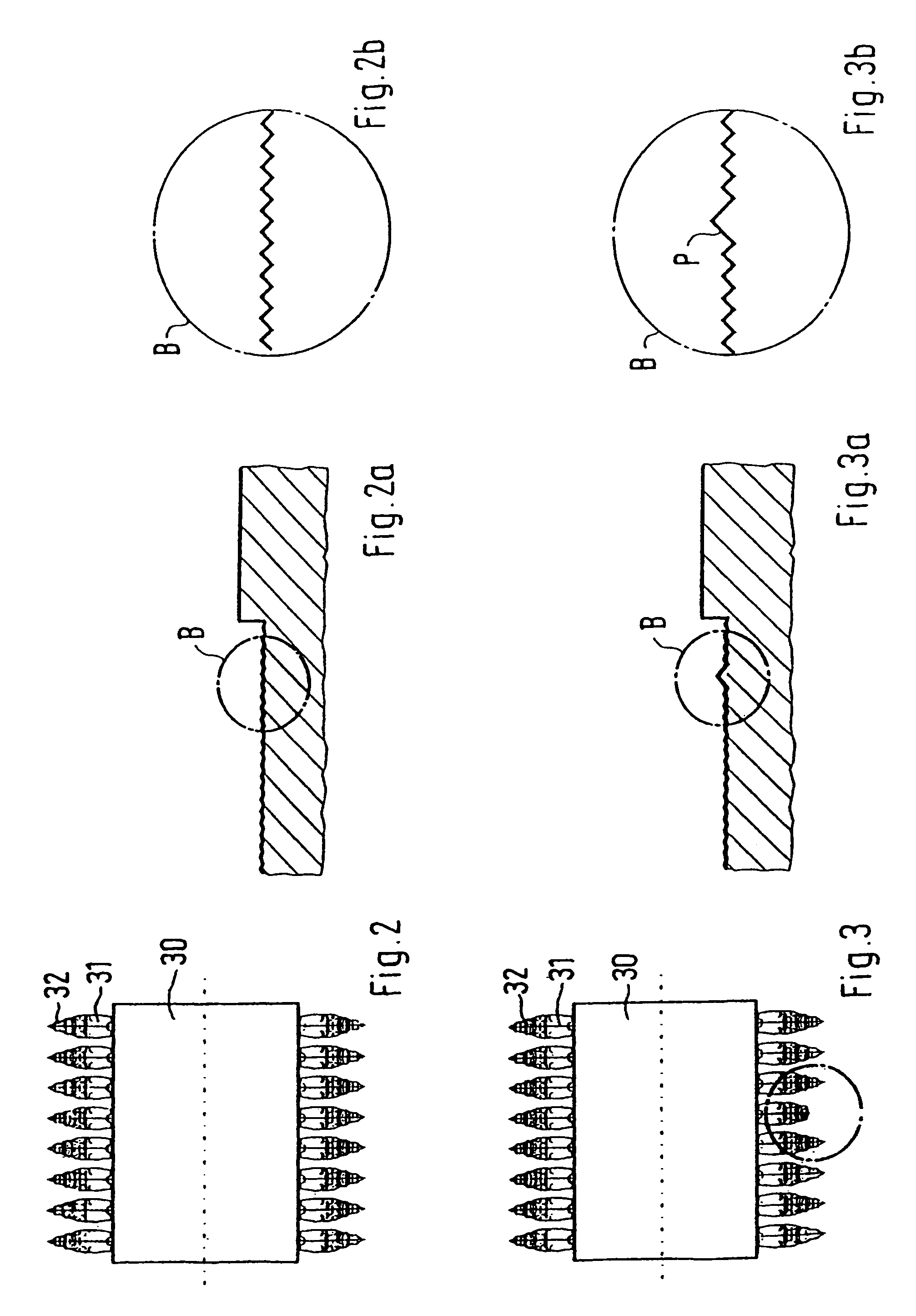

Concrete stone texturing machine, method and product

InactiveUS6668816B1Overcome disadvantagesMeet needsGrinding drivesWorking accessoriesRough surfaceKnife blades

A concrete stone texturing machine, method and a stone having an irregular rough surface resembling a real stone face is described. The machine conveys concrete stones having opposed flat surfaces to a pitching station having at least one pair of opposed pitching blade assembles aligned in a common plane on a respective side of the pitching station. The pitching blade assemblies are displaced towards and away from one another a predetermined distance. Each assembly has a plurality of pitching blades secured in side-by-side aligned relationship. Each of the pitching blades has a forward projecting cutting edge and a securing body portion. A first group of the pitching blades has their cutting edges aligned along a first straight cutting axis which is offset from the cutting edges of the second group of pitching blades aligned along a second straight cutting axis. The cutting axes are parallel to one another. With the offset cutting edges a unique appearance of the pitched blocks surface is obtained when the pitching blades are forced to penetrate a predetermined distance in an associated one of the surrounding transverse faces of the block adjacent a surface to be pitched.

Owner:CICCARELLO CHARLES

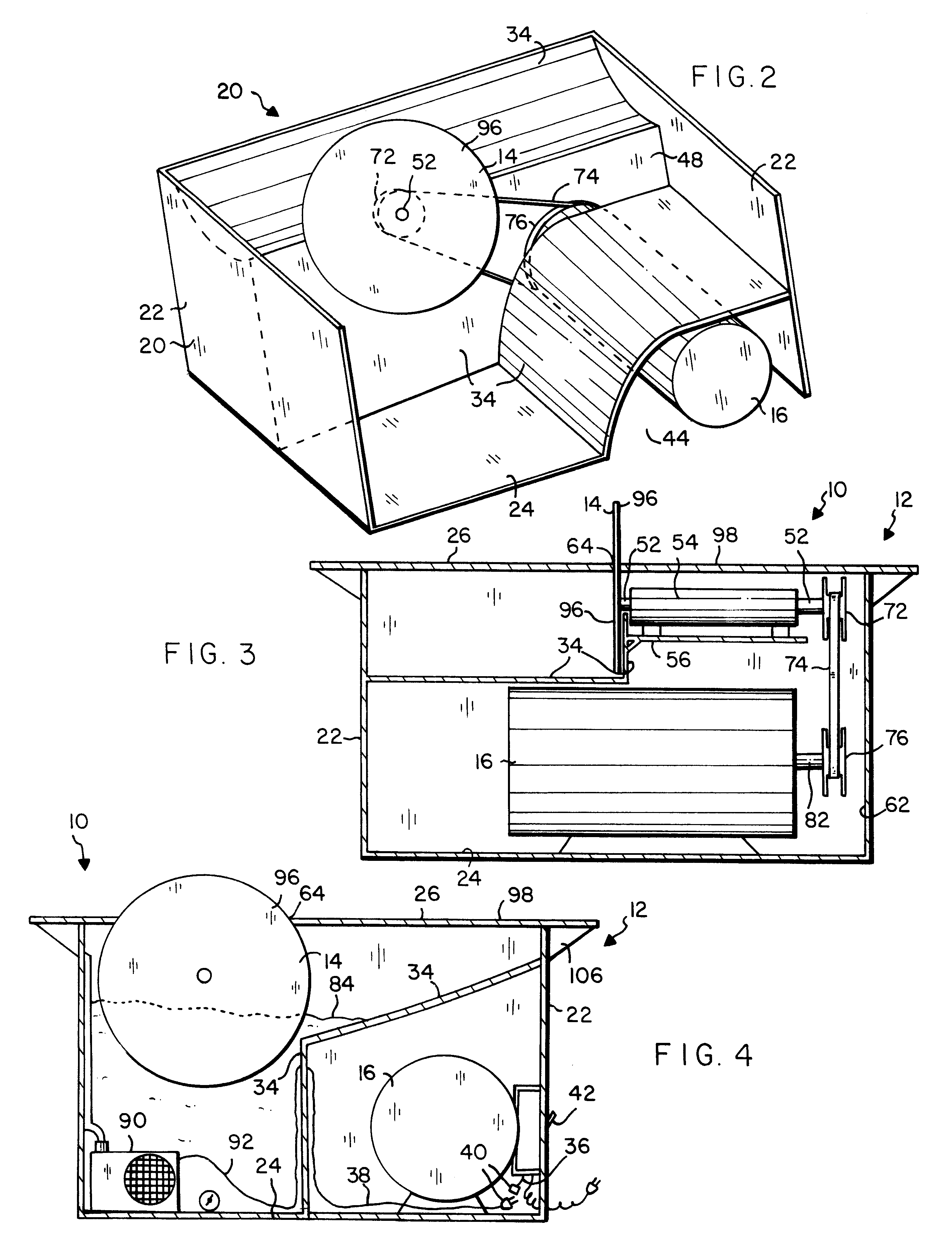

Stone and tile table saw apparatus

InactiveUS6253757B1Maximizes workProlong lifeMetal sawing devicesMetal sawing accessoriesCircular sawEngineering

A saw apparatus for cutting a work piece includes a circular saw blade, a saw blade drive mechanism including a motor drivably connected to the saw blade and having a motor pulley, and including a blade mounting structure, a saw table including a housing with a housing side wall, and a housing top wall having a blade passing opening and being hingedly secured to and resting on the housing side wall, a housing partition defining a drive mechanism chamber and a blade mounting chamber within the housing having a drive mechanism chamber bottom wall sealingly joined to the housing side wall, and a cooling liquid contained within the blade mounting chamber, so that the blade mounting mechanism includes a blade axle extending through the housing partition between the blade mounting chamber and the drive mechanism chamber, and the blade protrudes up through the blade passing opening and down into the cooling liquid, and a blade axle pulley is secured to the blade axle, passes through the housing partition, and a belt extends from the blade axle pulley to the motor pulley.

Owner:BENSON WALTER J

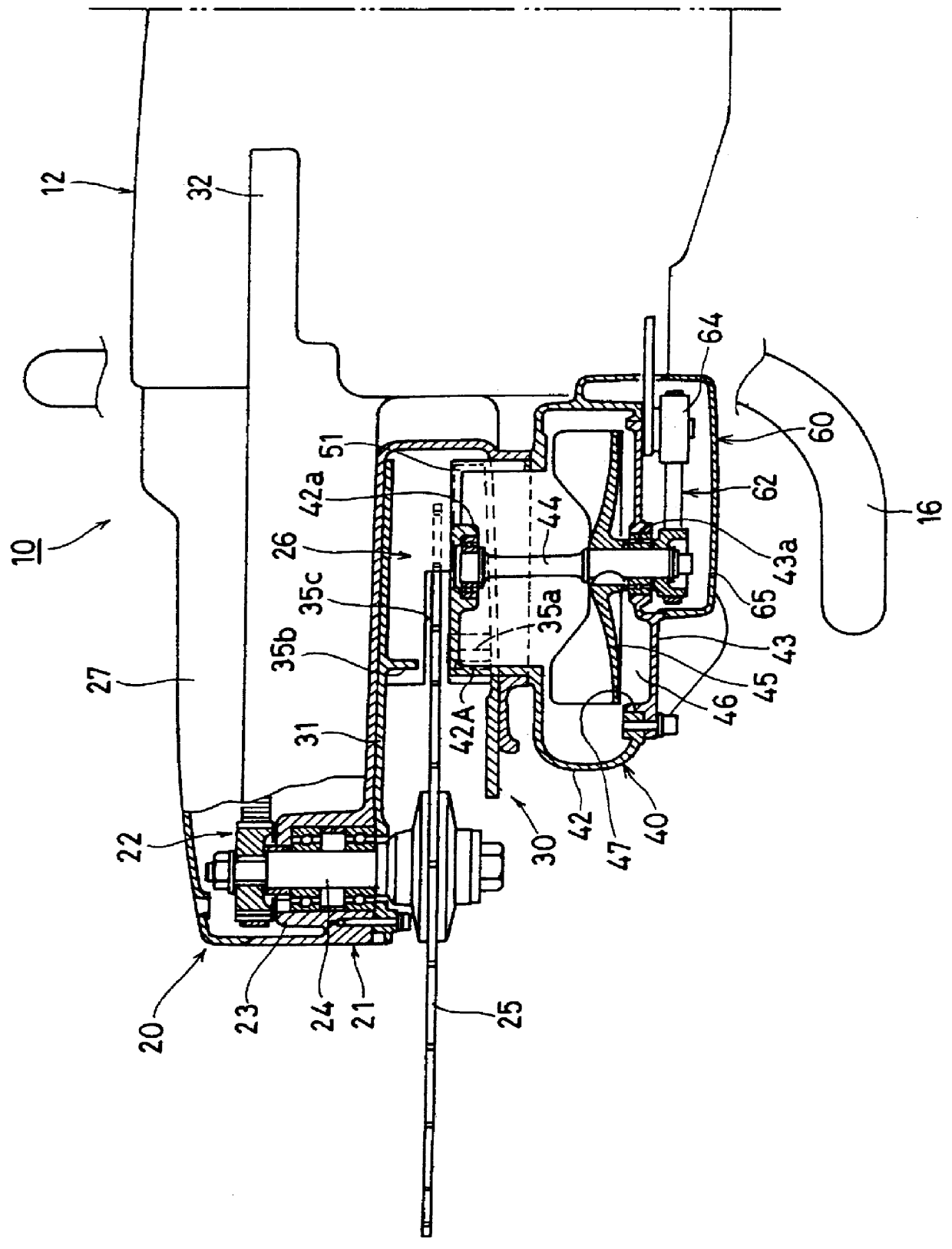

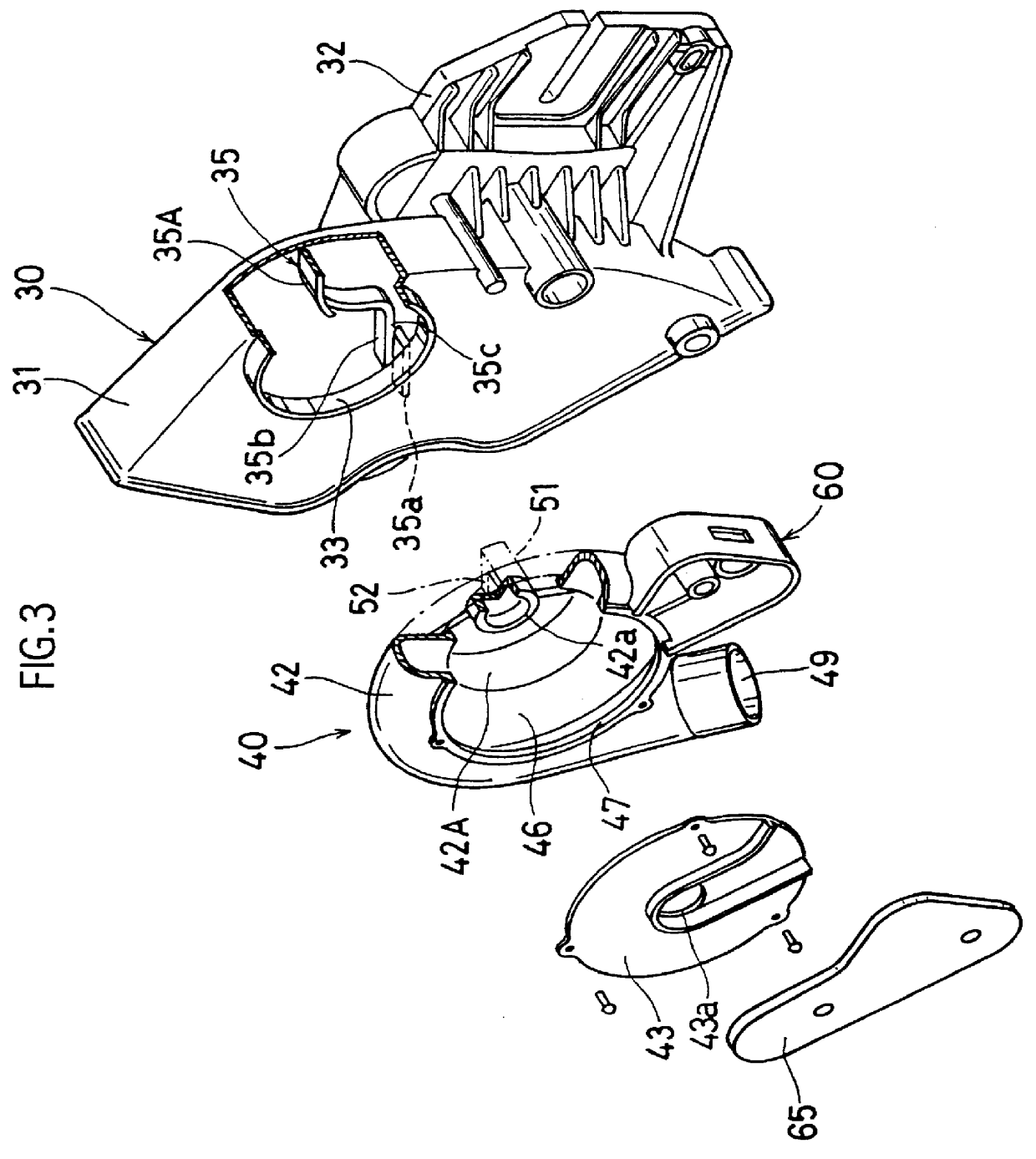

Power cutter

InactiveUS6155246AQuantity minimizationMetal sawing accessoriesDirt cleaningEngineeringElectric motor

A power cutter which comprises a main body provided with a motor, a work-cutting portion including a circular cutting blade to be rotated by the motor and a safety cover covering both sides of an edge portion of the cutting blade so as to form a dust-discharging passageway, a fan attached to the safety cover for sucking and removing dust generated during cutting operations through the dust-discharging passage, a barrier wall attached to the safety cover so as to intercept the dust-discharging passageway, and a main dust-sucking port and a supplementary dust-sucking port disposed respectively in front of and behind the barrier wall as viewed in the rotational direction of the cutting blade.

Owner:KIORITZ

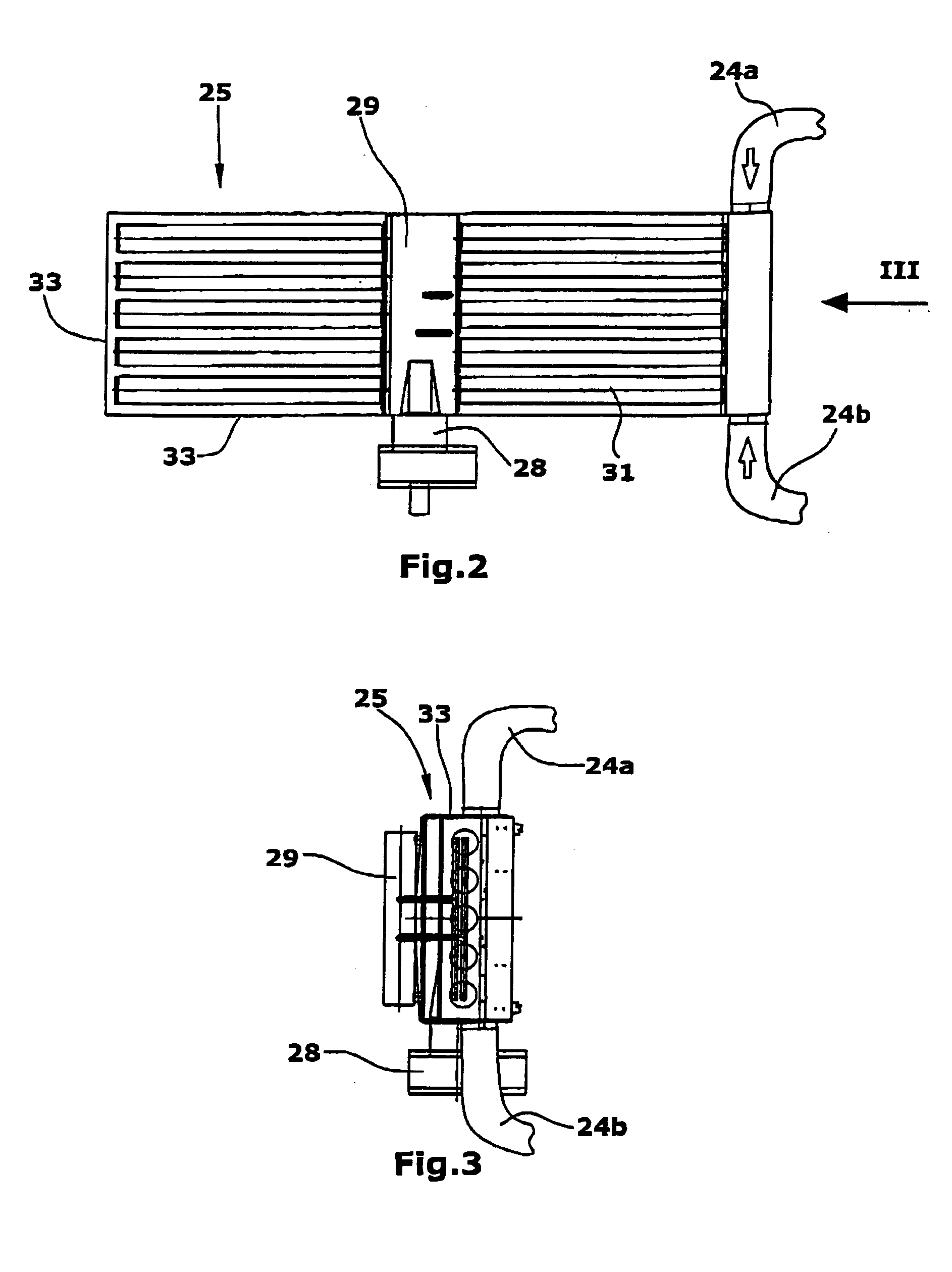

Milling machine as well as method for working ground surfaces

ActiveUS20050179309A1Inhibit currentEasy to useCombination devicesSlitting machinesEngineeringContaminated air

At a milling machine to work ground surfaces, with a machine frame, a milling drum supported at the machine frame, at least one transport device arranged at the machine frame which accepts the milled material from the milling drum, as well as with a suction device for the air polluted with dusts and vapors, whereby the milled material on the at least one transport device is enclosed by a channel, the suction device is connected to a rear channel section of the channel in the direction of the material transport and sucks off the air polluted during milling at the milling drum and in the rear channel section essentially in the direction of the material transport, it is provided that the suction device consists of a suction ventilator, a separator device for solids and a suction channel which is connected to the rear channel section, that the suction ventilator is arranged downstream of the separator device, and that the suction device disposes of the separated solids onto the transport device in a forward channel section in the direction of the material transport or into a collecting device, and the suction ventilator blows off the cleaned air into the environment.

Owner:WIRTGEN GMBH

Automotive construction machine, as well as method for working ground surfaces

ActiveUS7530641B2No time loss is incurredIncrease driving speedSlitting machinesSoil-shifting machines/dredgersDevice MonitorMachine

An automotive construction machine for working ground surfaces, with a machine frame, a drive engine for driving traveling devices and for driving working devices, and a milling drum for milling the ground surfaces, which can be raised, driven by, and can be uncoupled from a drum drive, the milling drum can be moved into a raised position when not in milling mode, and when raised, the rotating direction of the milling drum corresponds to the rotating direction of the traveling devices and remains coupled with the drive engine, and a monitoring device monitors the distance between the milling drum and the ground surface and uncouples the raised milling drum from the drive engine or uncouples the traveling devices from the drive engine or raises the machine frame or generates an alarm signal when the monitoring device detects a deviation that falls below a pre-determined distance, or any of the latter.

Owner:WIRTGEN AMERICA

Method for determining the wear state

This invention relates to a method for determining a wear state of a chisel, a chisel holder, and / or a chisel holder replacement system equipped with a chisel and chisel holder. For this method to give the user qualitative and quantitative information about the wear, according to one embodiment of this invention, a position of at least one point of the chisel and / or the chisel holder is determined by a contactless measurement method and a corresponding measurement result is compared in a switching unit to a reference value stored in a memory device.

Owner:WIRTGEN GMBH

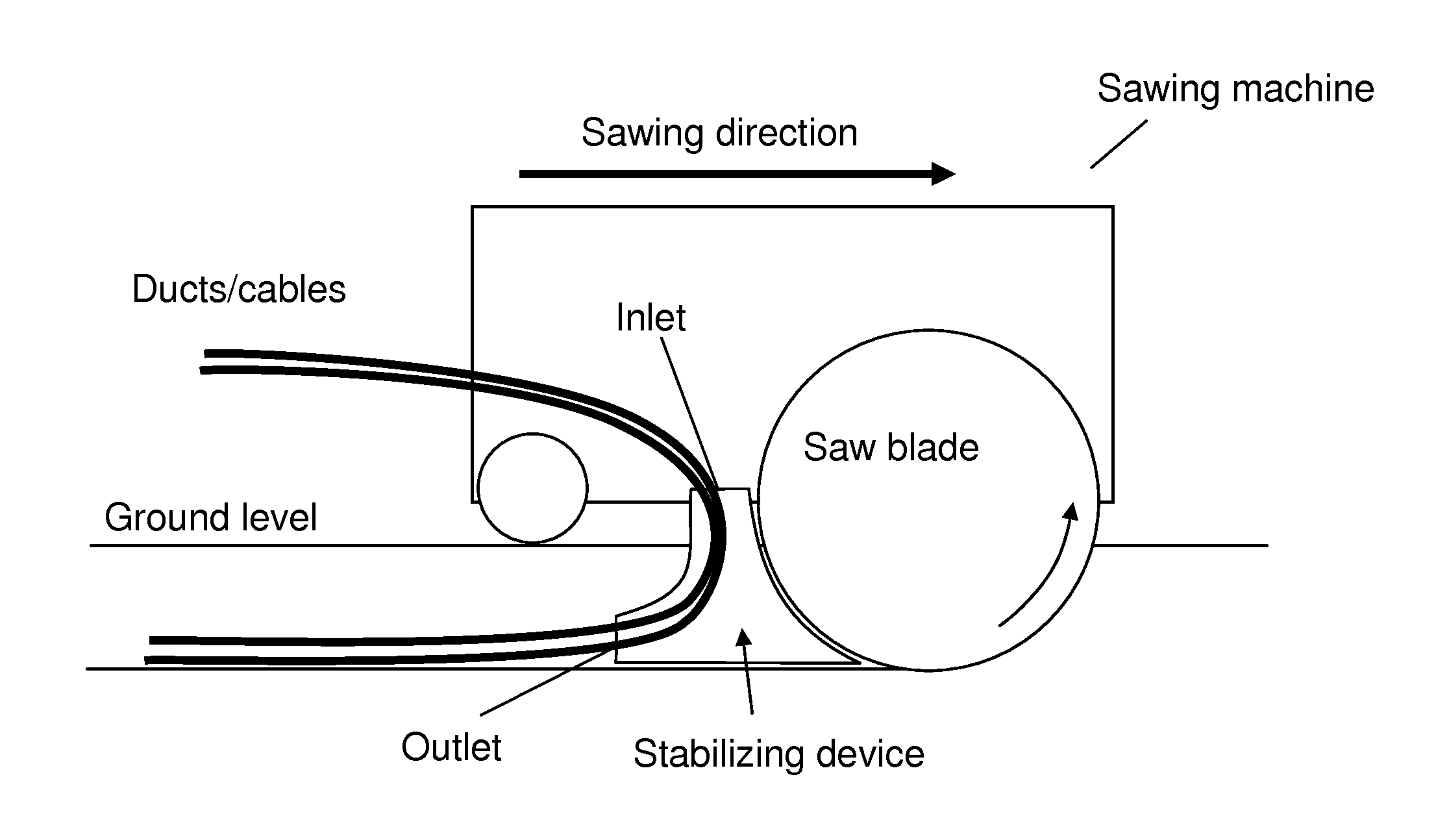

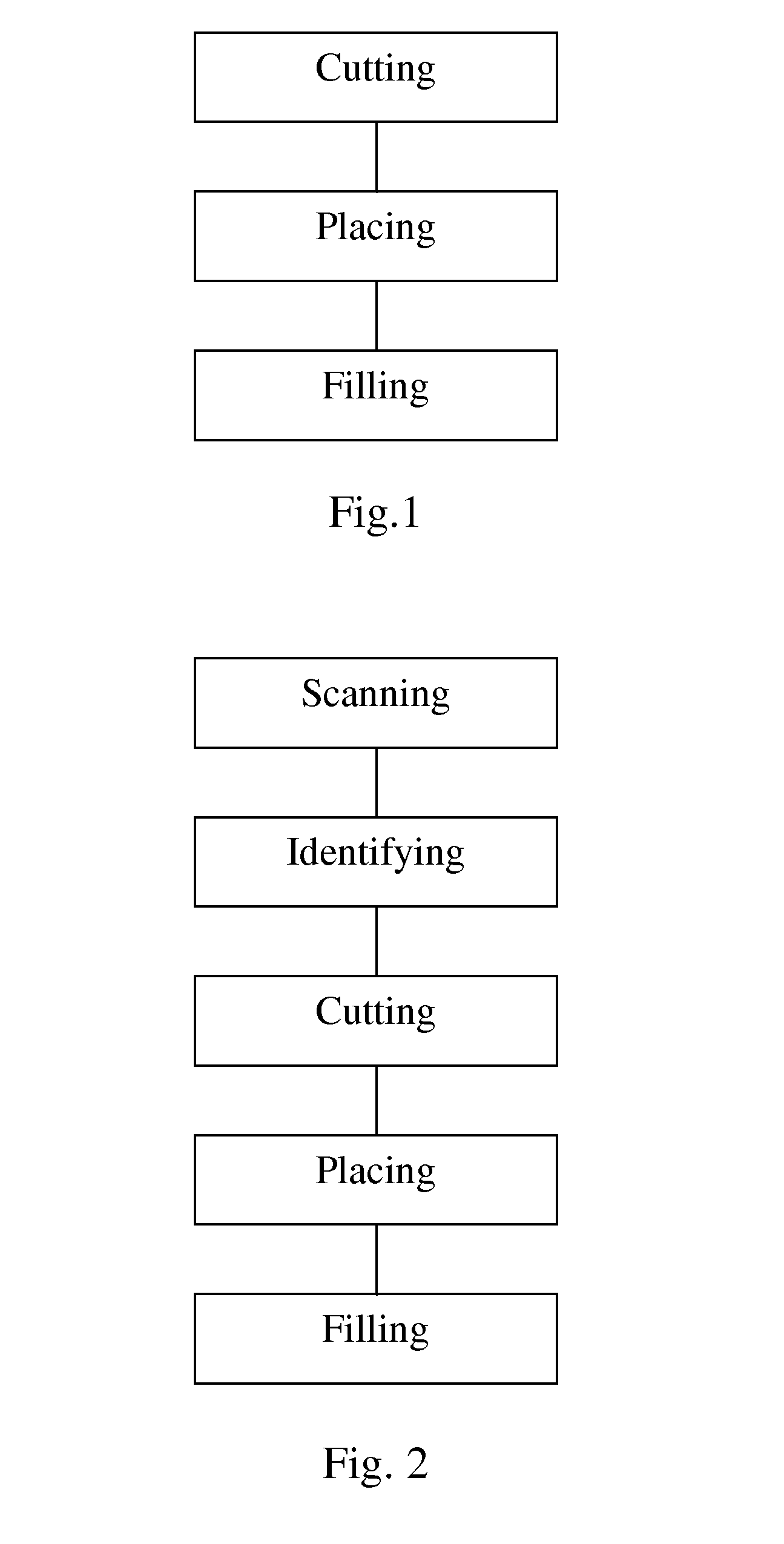

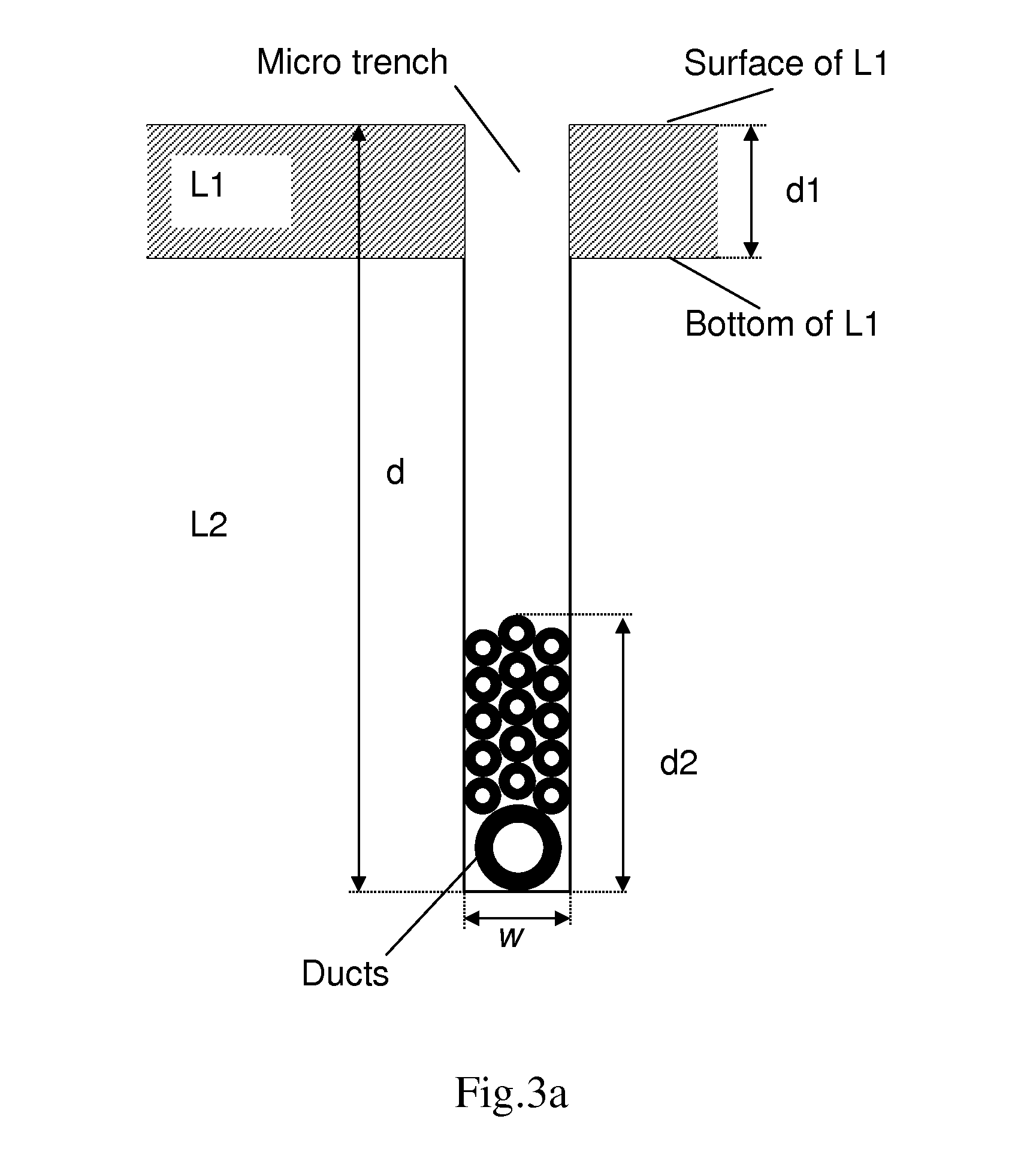

Method for placing at least one duct/communication cable below a road surface in an area

ActiveUS20130294839A1Low costNetwork securitySoil-shifting machines/dredgersFoundation engineeringEngineeringRoad surface

Owner:GUSTAVSSON CONNY MR +2

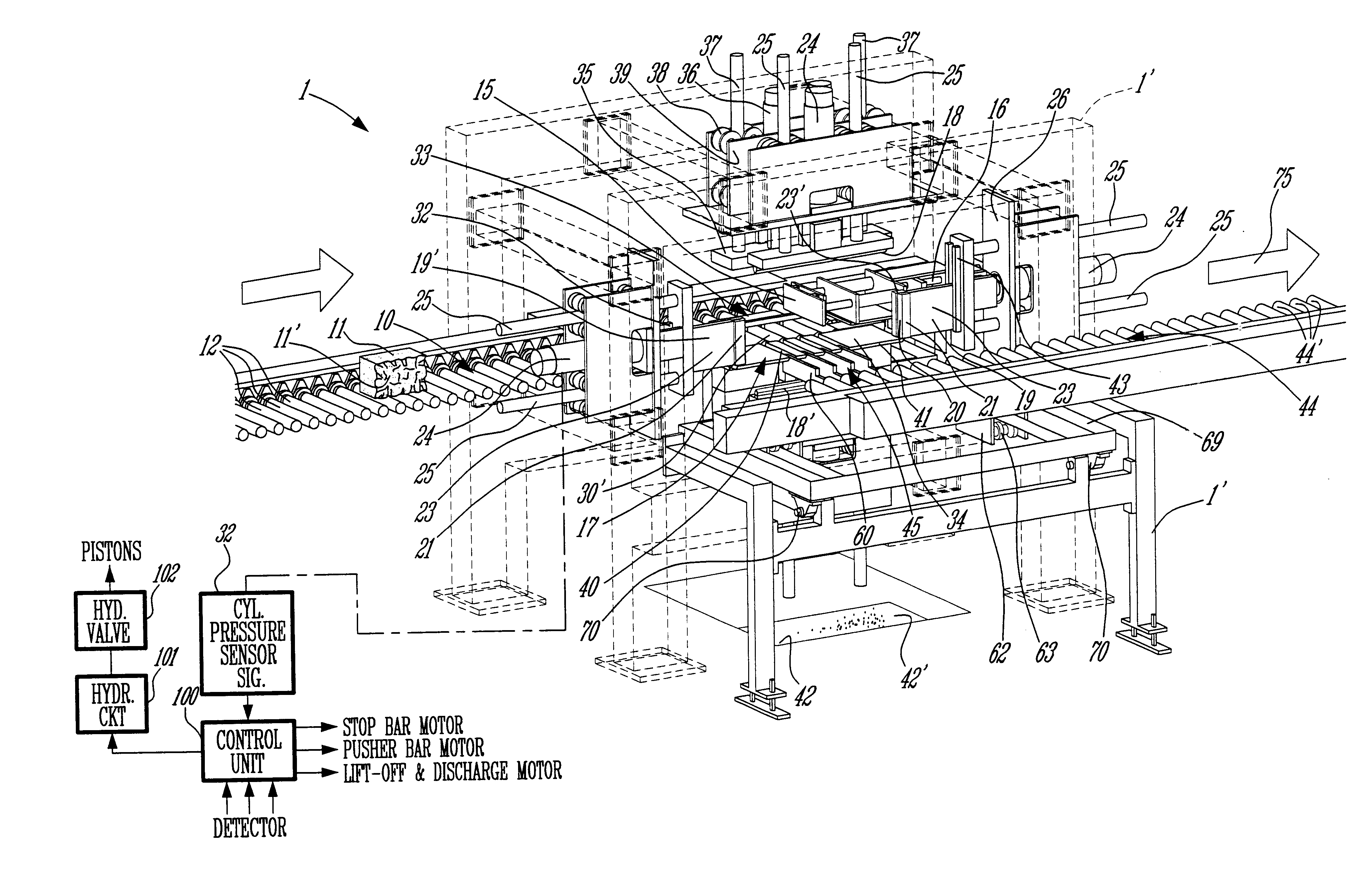

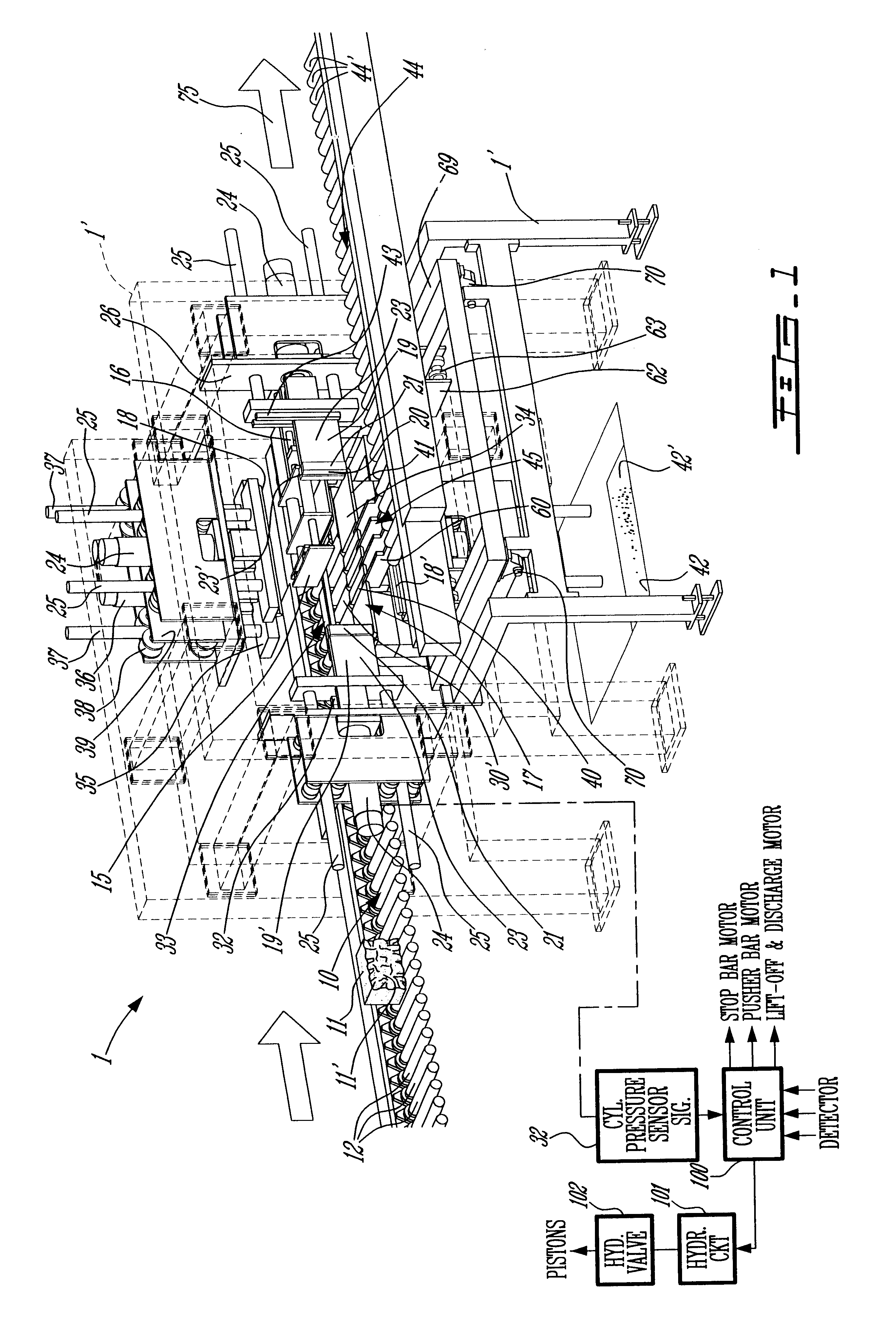

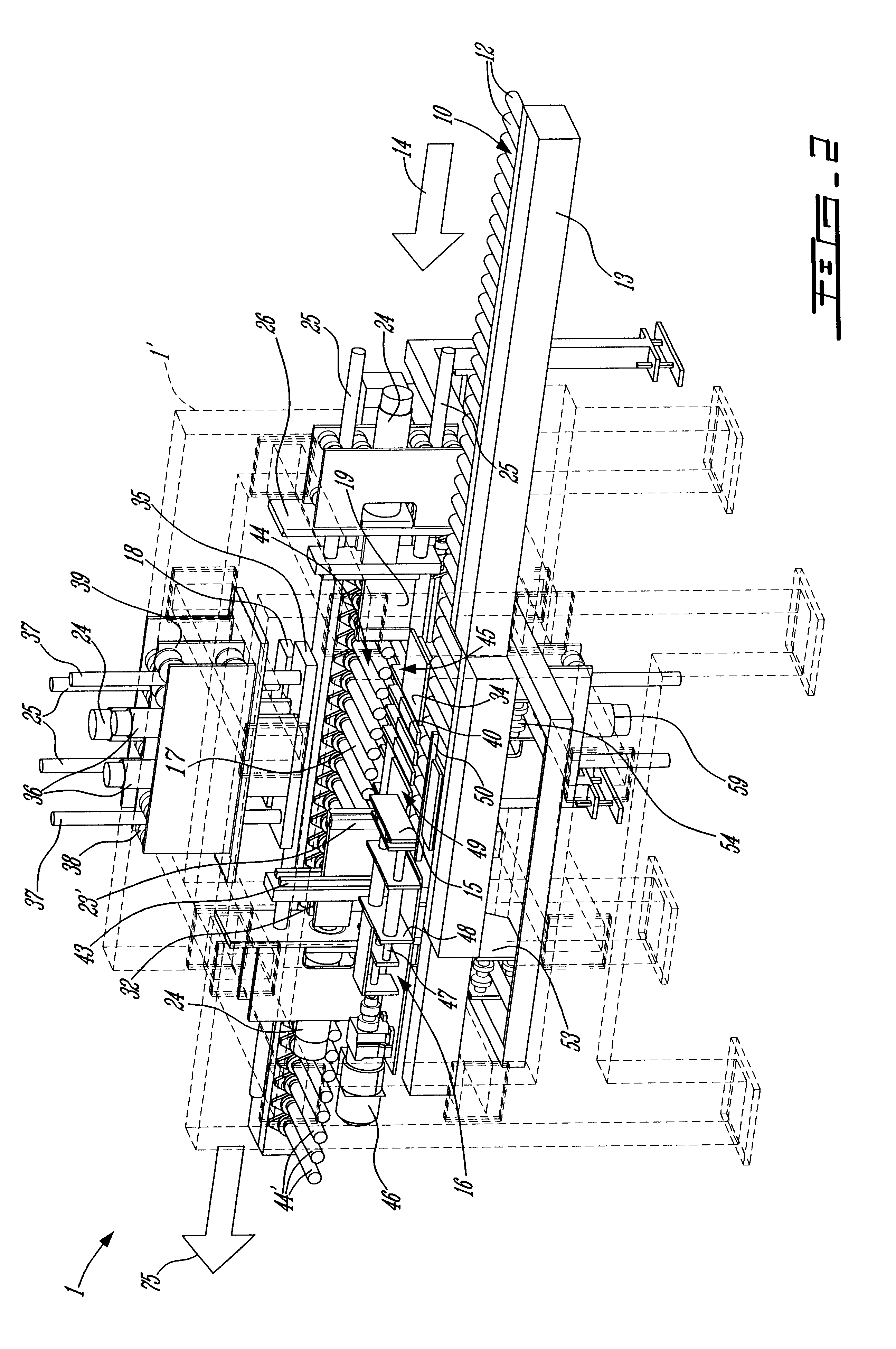

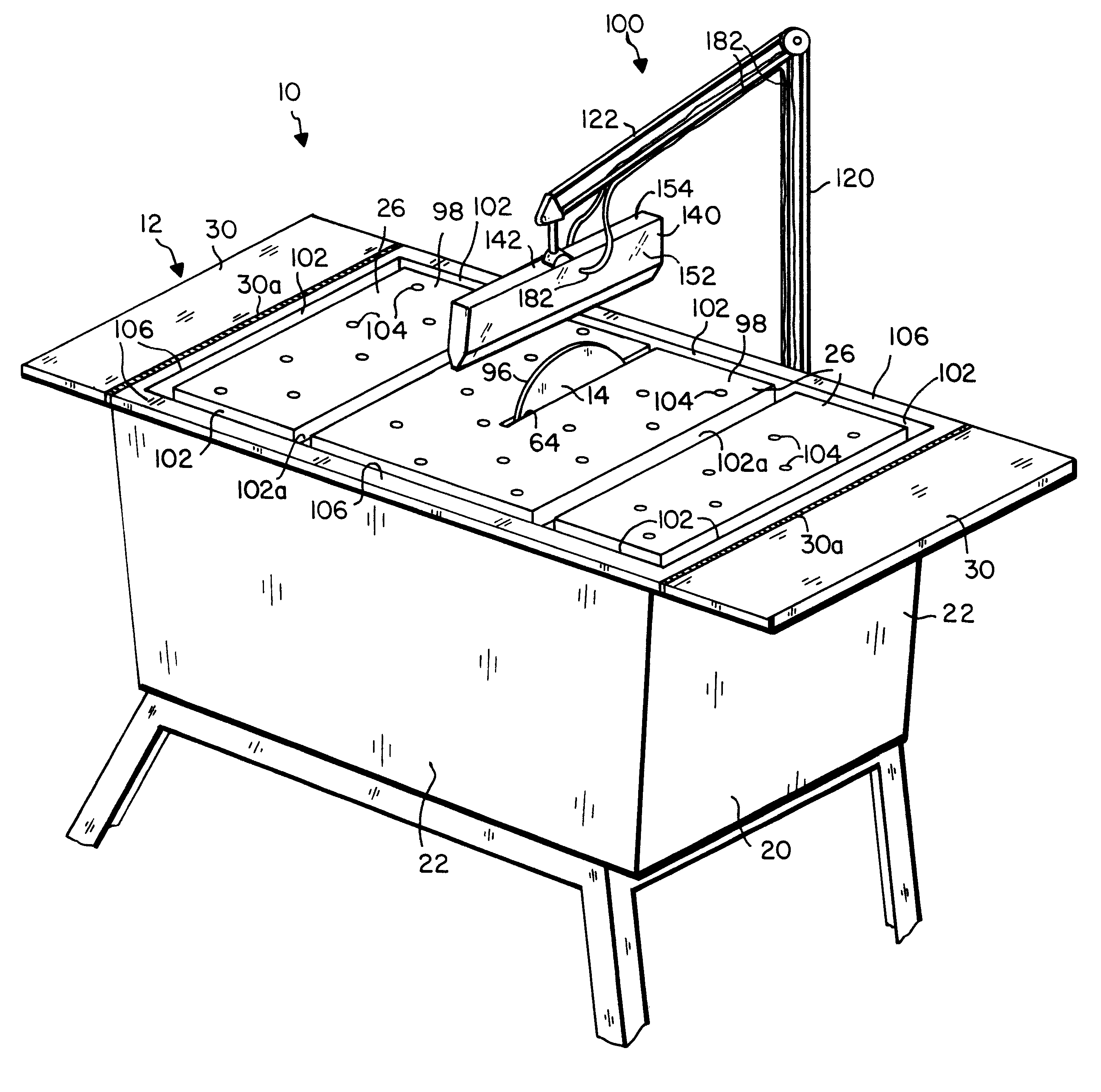

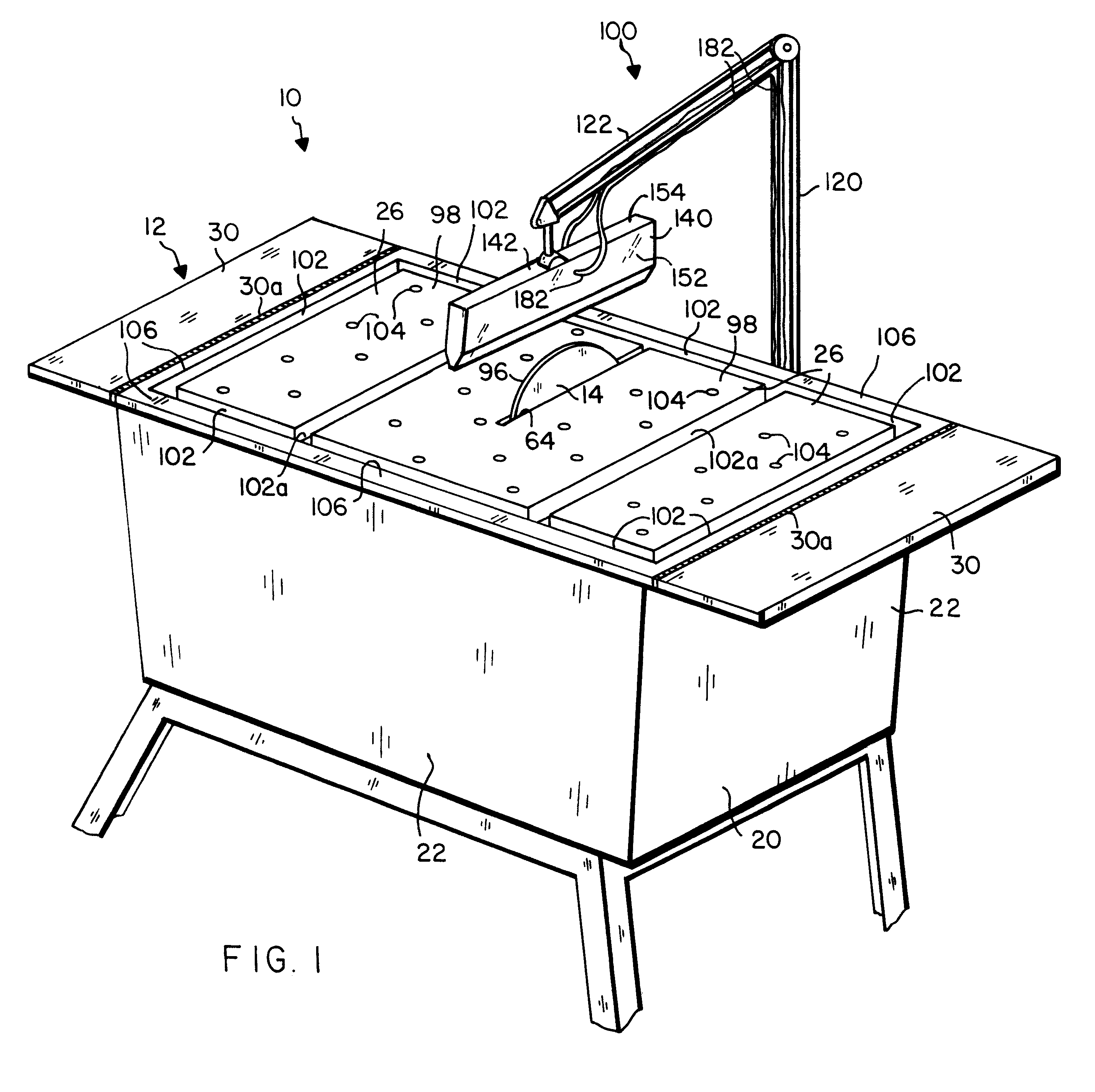

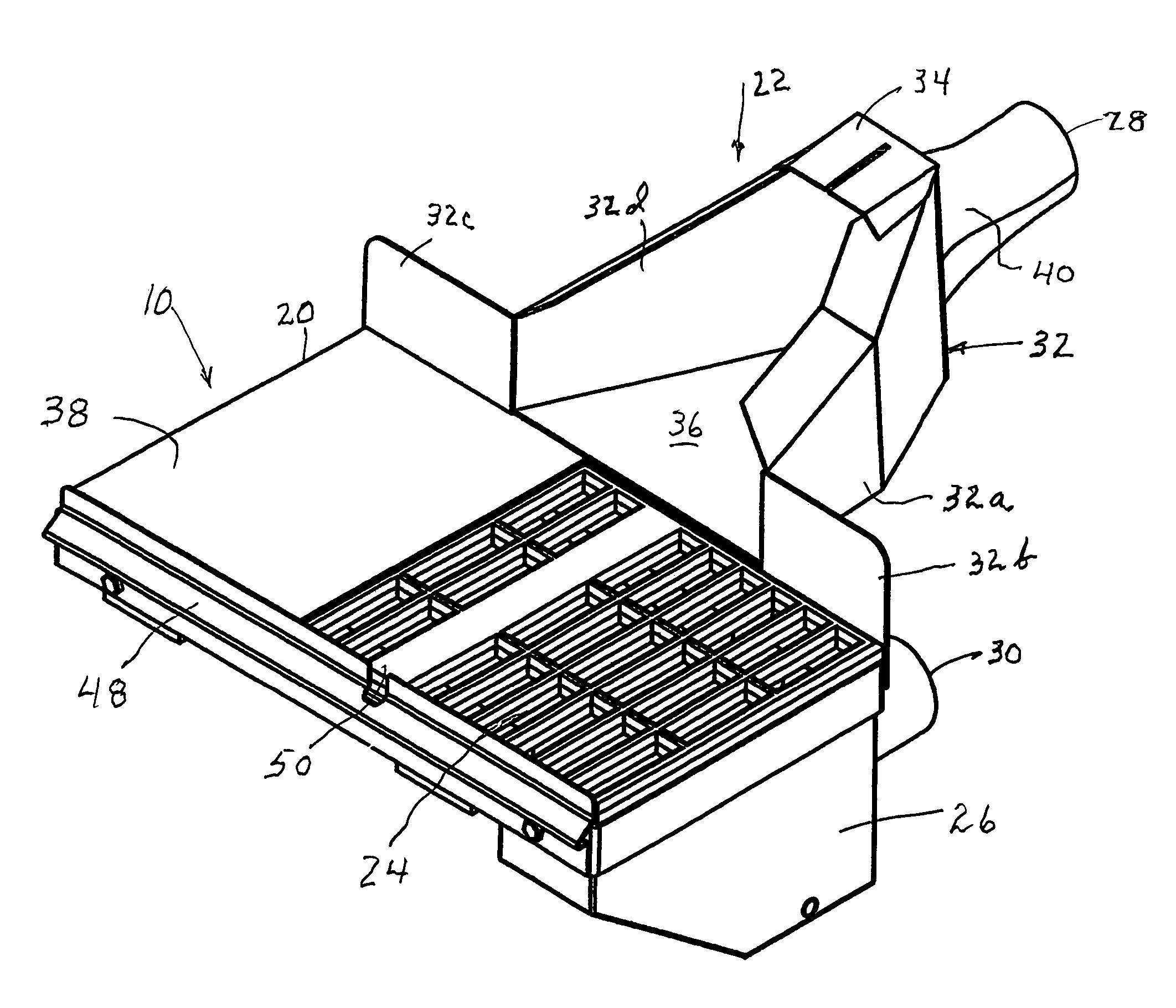

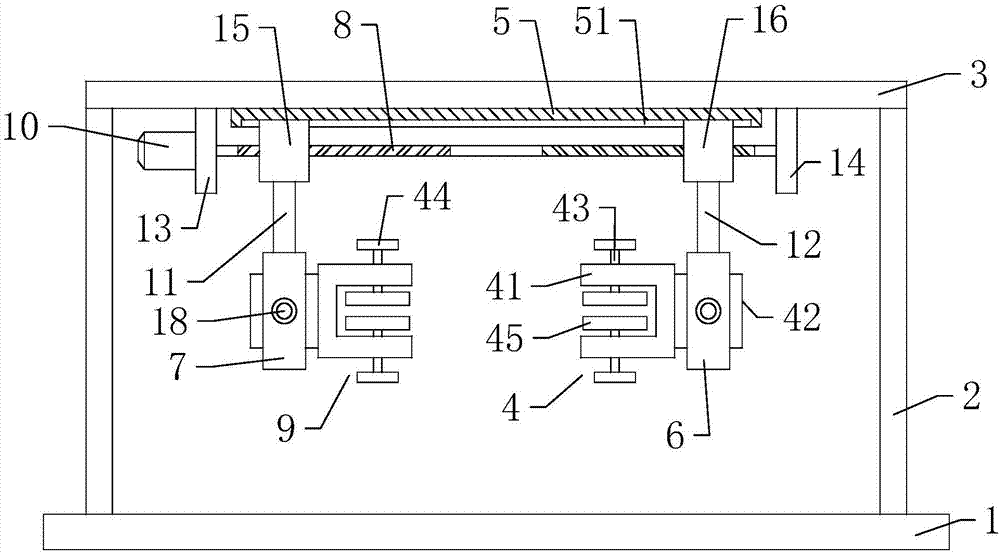

Dust collection system for a masonry saw

ActiveUS7013884B2Quantity minimizationIncrease the areaWorking accessoriesGrinding work supportsBrickCollection system

Dust and debris resulting from the sawing or cutting of concrete masonry units, blocks, bricks, tiles and other masonry products is collected via a three point dust and debris collection system. A movable work supporting table for cooperation with a masonry saw has a grated surface, a vacuum chamber below the grated surface acting as one collection point or area, a heavy debris collection chamber below and in communication with the table vacuum chamber acting as another collection point or area, and a shroud or hood assembly extending rearwardly from the table adapted to extend about the sides and rear of the saw blade and including a vacuum chamber acting as a primary collection point or area. The system is highly effective in achieving dust capture.

Owner:JPL GLOBAL

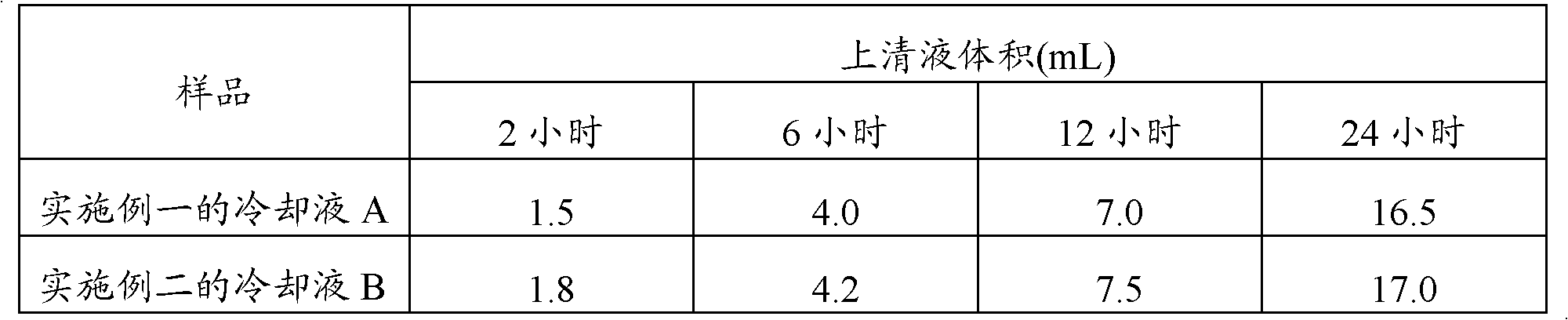

Cooling liquid for diamond wire cutting technology

ActiveCN103184094AImprove the lubrication effectImprove cooling effectWorking accessoriesLubricant compositionSurface finishPreservative

The invention relates to cooling liquid for diamond wire cutting technology, which mainly comprises a lubricant, an emulsifier, an antirust agent, a dispersant, a preservative, and deionized water, wherein the mass percents of the components are 5-50% of the lubricant, 0.05-10% of the emulsifier, 0.1-5% of the antirust agent, 0-10% of the dispersant, 0-5% of the preservative, and the balance being deionized water. The cooling liquid has excellent lubricity and dispersibility, is easy to clean, suitable for cutting of hard and brittle materials such as crystal silicon, sapphire, and the like, can not only meet requirements for diamond wire high-speed cutting, but also realize good surface finish of cut pieces, and can significantly increase product qualified rates.

Owner:LIAONING OXIRANCHEM INC

Interval-adjustable type glass clamping device

InactiveCN107443248ASmooth motionAchieve mutual clampingWorking accessoriesGrinding work supportsIndustrial engineeringEngineering

The invention discloses a glass clamping device with adjustable spacing, comprising a base, a first clamping mechanism, a lead screw, a second clamping mechanism, a left sliding block and a right sliding block. The left sliding block is threaded and sleeved on the wire. The left outer ring of the rod, the right sliding block is sleeved on the right outer ring of the lead screw through a threaded connection, the bottom end of the left sliding block is fixedly welded with a second support rod, and the bottom end of the second support rod is fixedly installed with a second support rod. No. 1 connecting sleeve, the second clamping mechanism is arranged on the No. 2 connecting sleeve, the bottom end of the right slider is fixedly welded with a No. 1 support rod, and the bottom end of the No. 1 support rod is fixedly installed with a No. 1 connecting sleeve, the first The clamping mechanism is arranged on the No. 1 connecting sleeve. The invention is simple in structure, convenient in use, convenient in disassembly and maintenance, is suitable for glass workpieces of different sizes, has a wide application range, is convenient for multi-angle processing operations on glass workpieces, and is suitable for popularization and use.

Owner:吴步晨

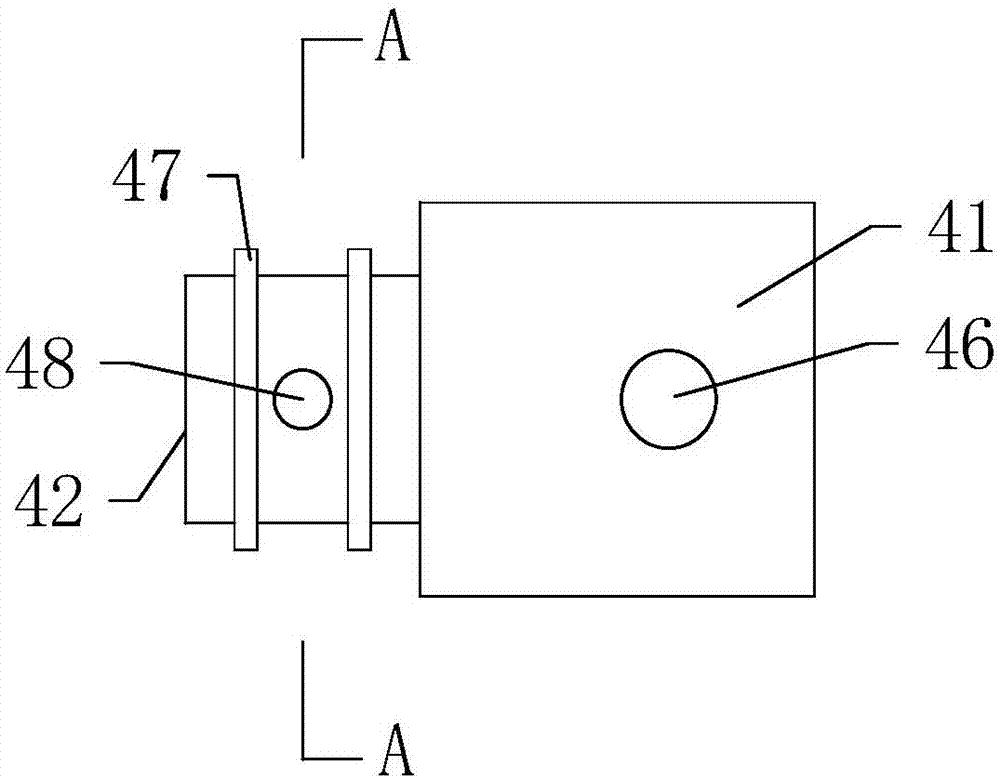

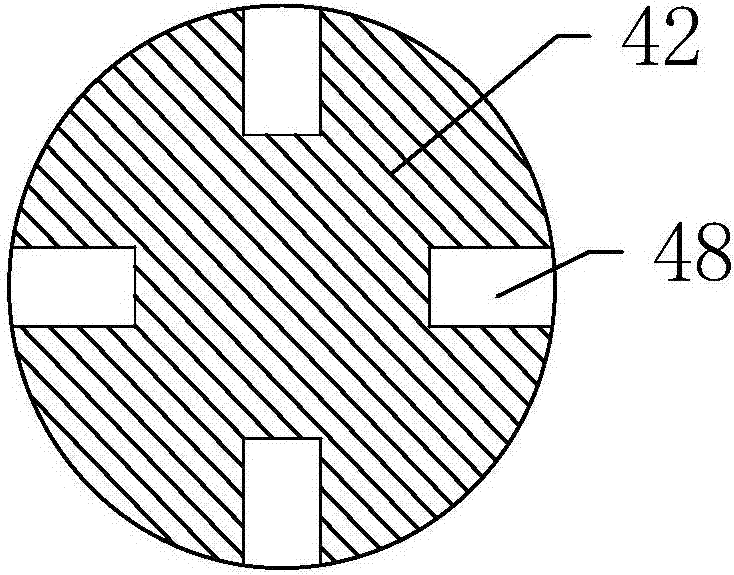

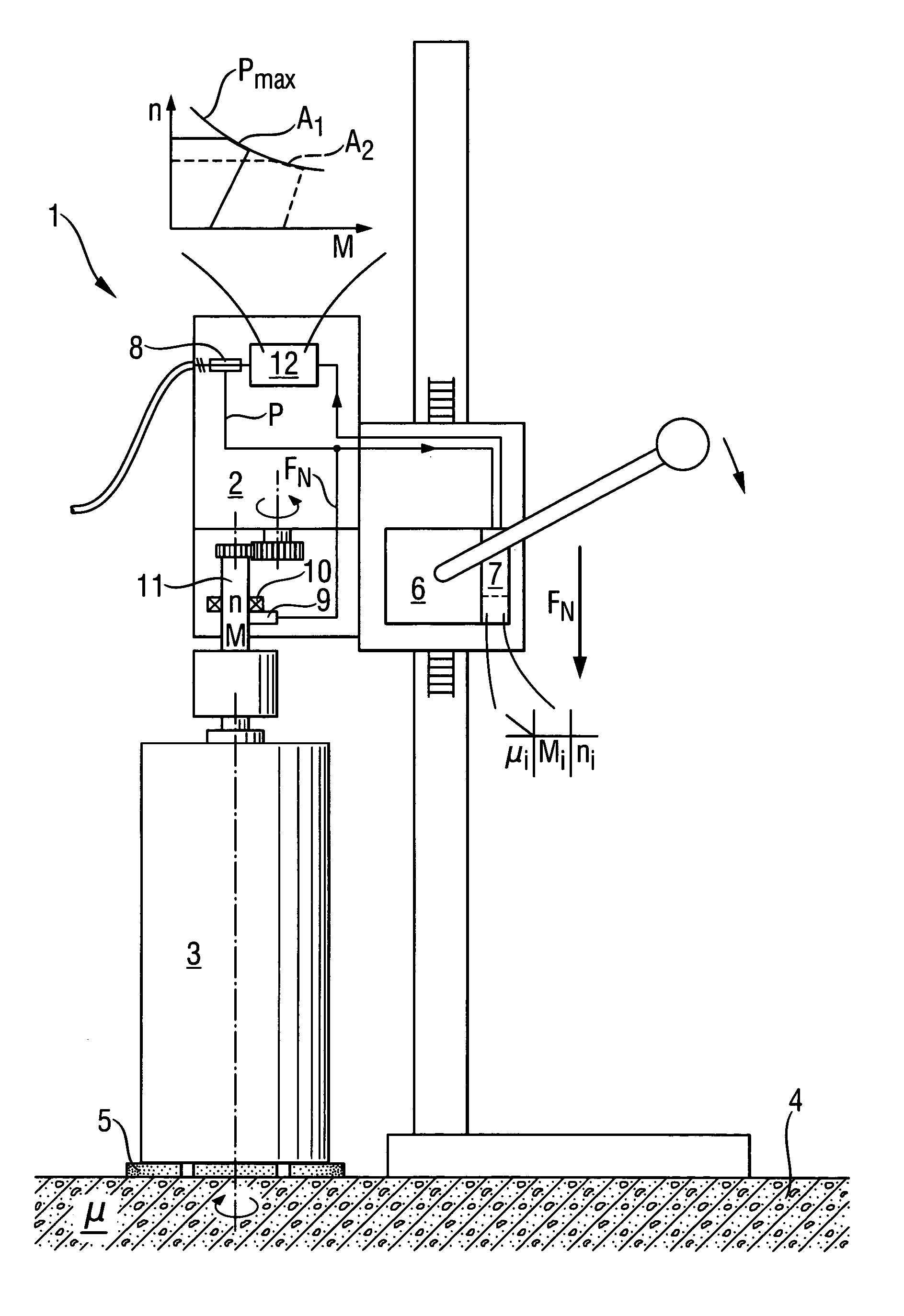

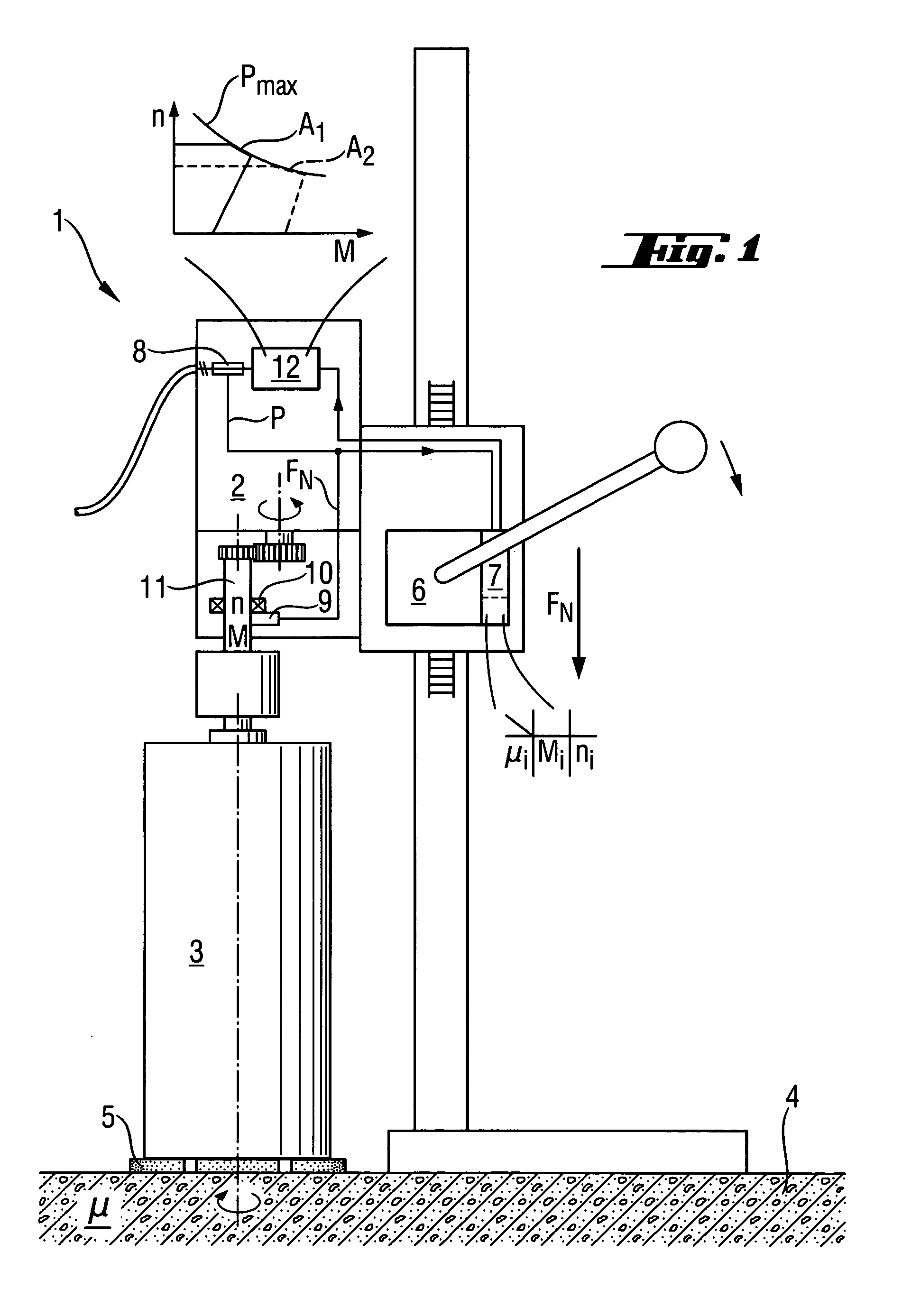

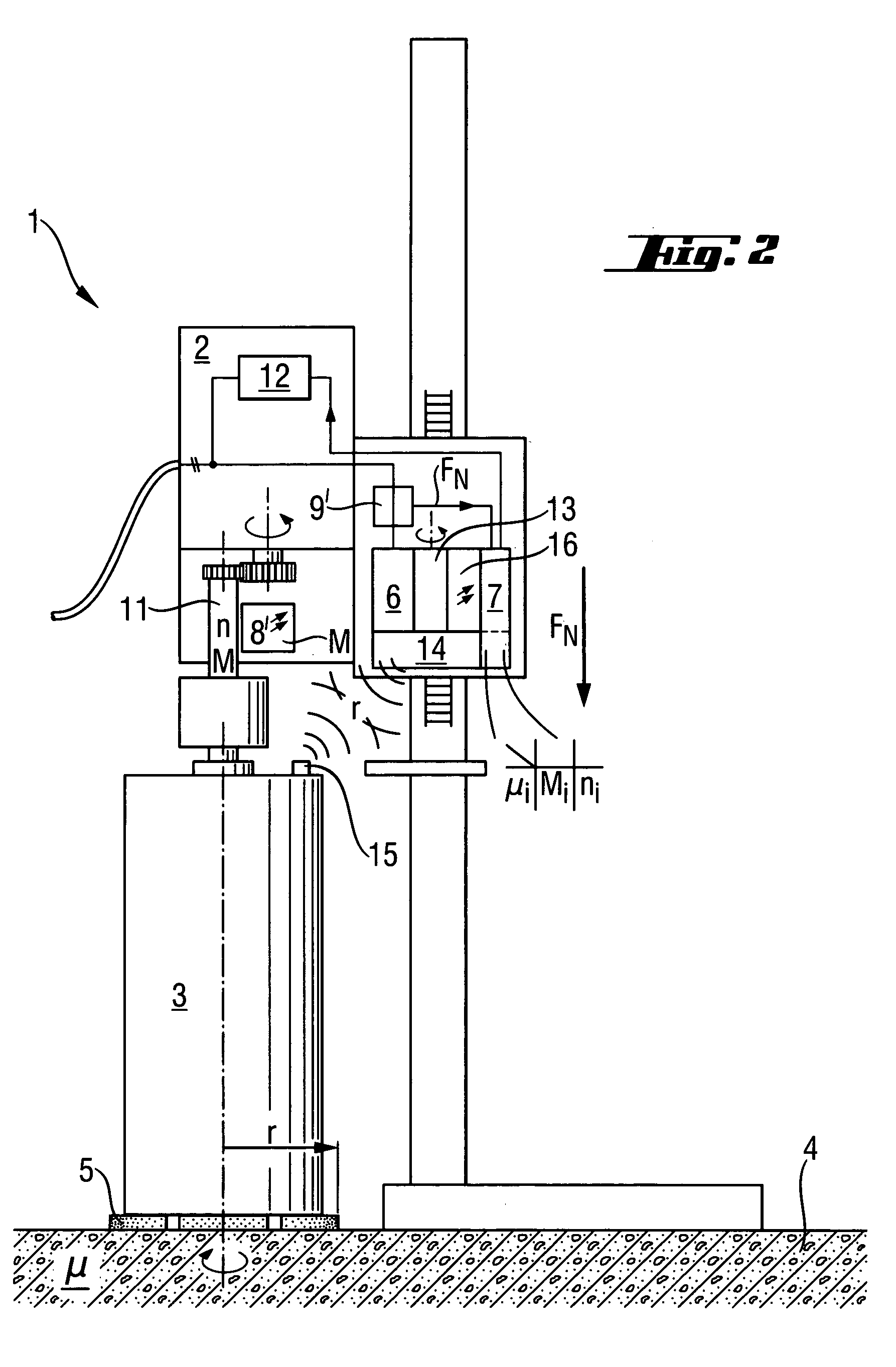

Feed adaptation core drill

A process for controlling and a core drilling machine (1) having an electrical motor (2) for rotational drive of a core drill bit (3) having cutting edges (5) oriented axial to a work piece (4), a feeding means (6) for generating the feed of the core drill bit (3) against the work piece (4) and having a controller (7) for controlling, relative to a first one-to-one control parameter, detected by a sensor (8, 8′) for electrical power consumption (P) or torque (M). A force sensor (9, 9′) is connected to the controller (7) for detecting the contact pressing force (FN) of the core drill bit (3) as the second control parameter.

Owner:HILTI AG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com