Patents

Literature

2384 results about "Material transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

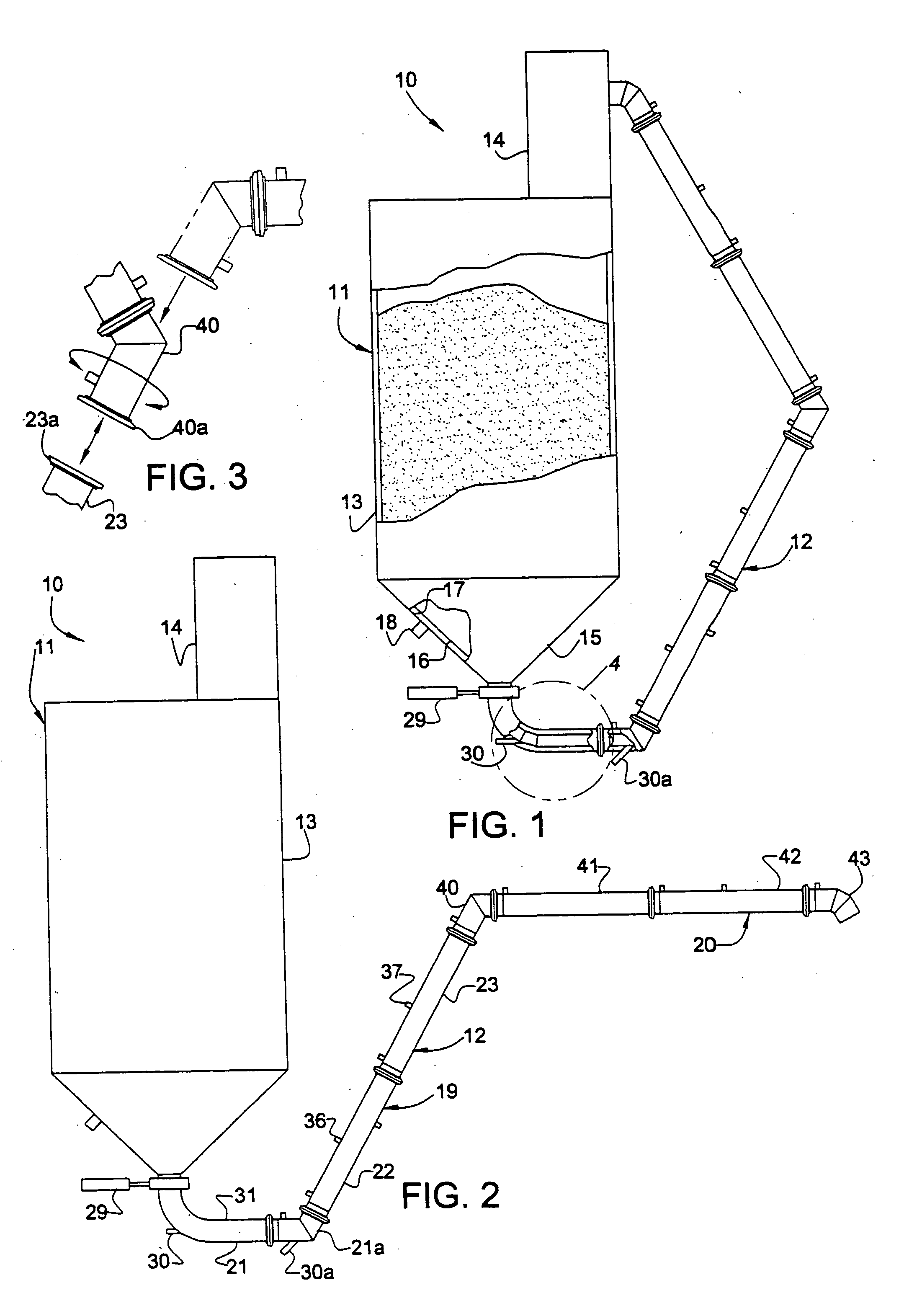

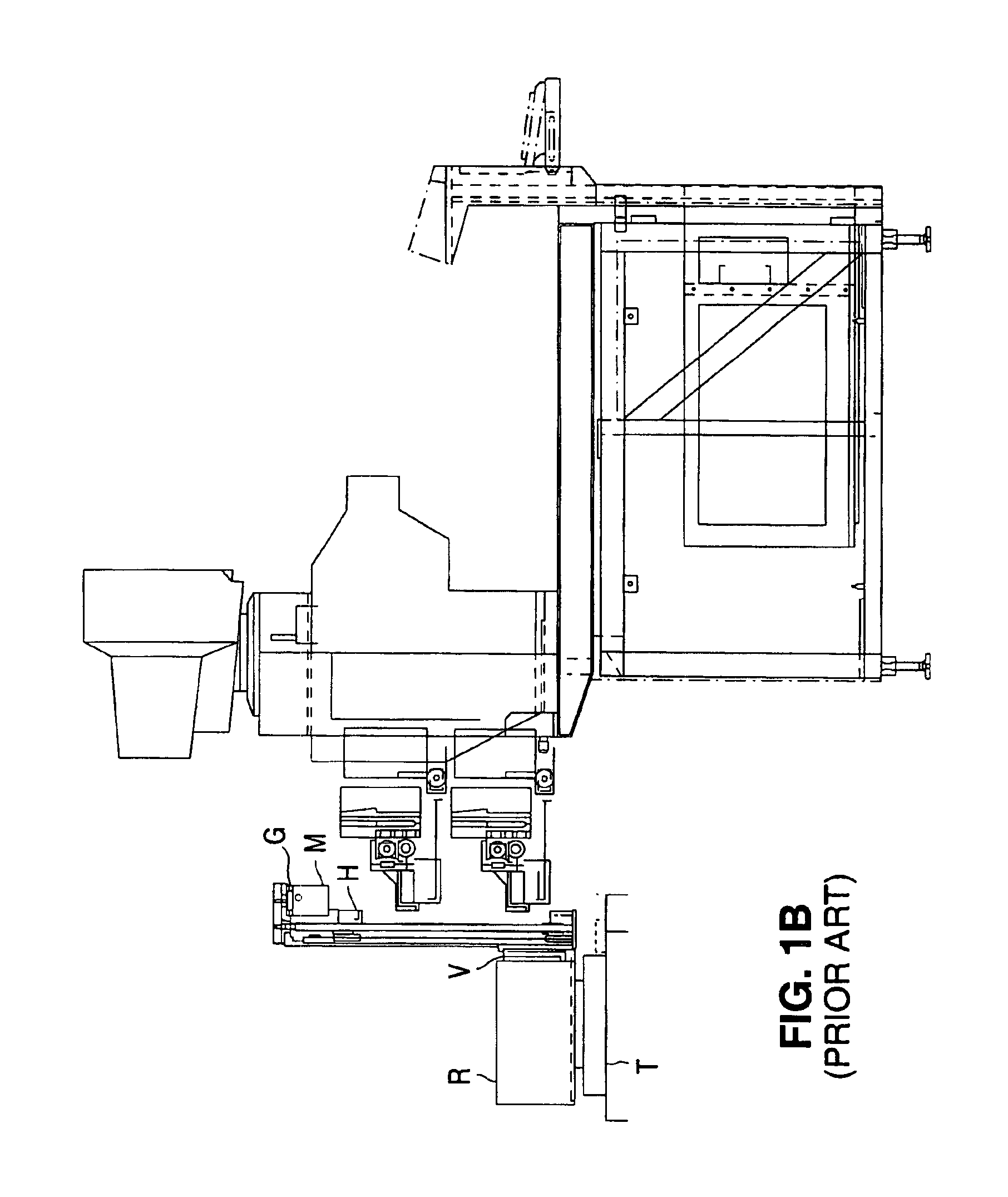

Method and apparatus for supplying bulk product to an end user

InactiveUS7214028B2Eliminate needEfficient transportTank vehiclesMixing operation control apparatusMarine engineeringEngineering

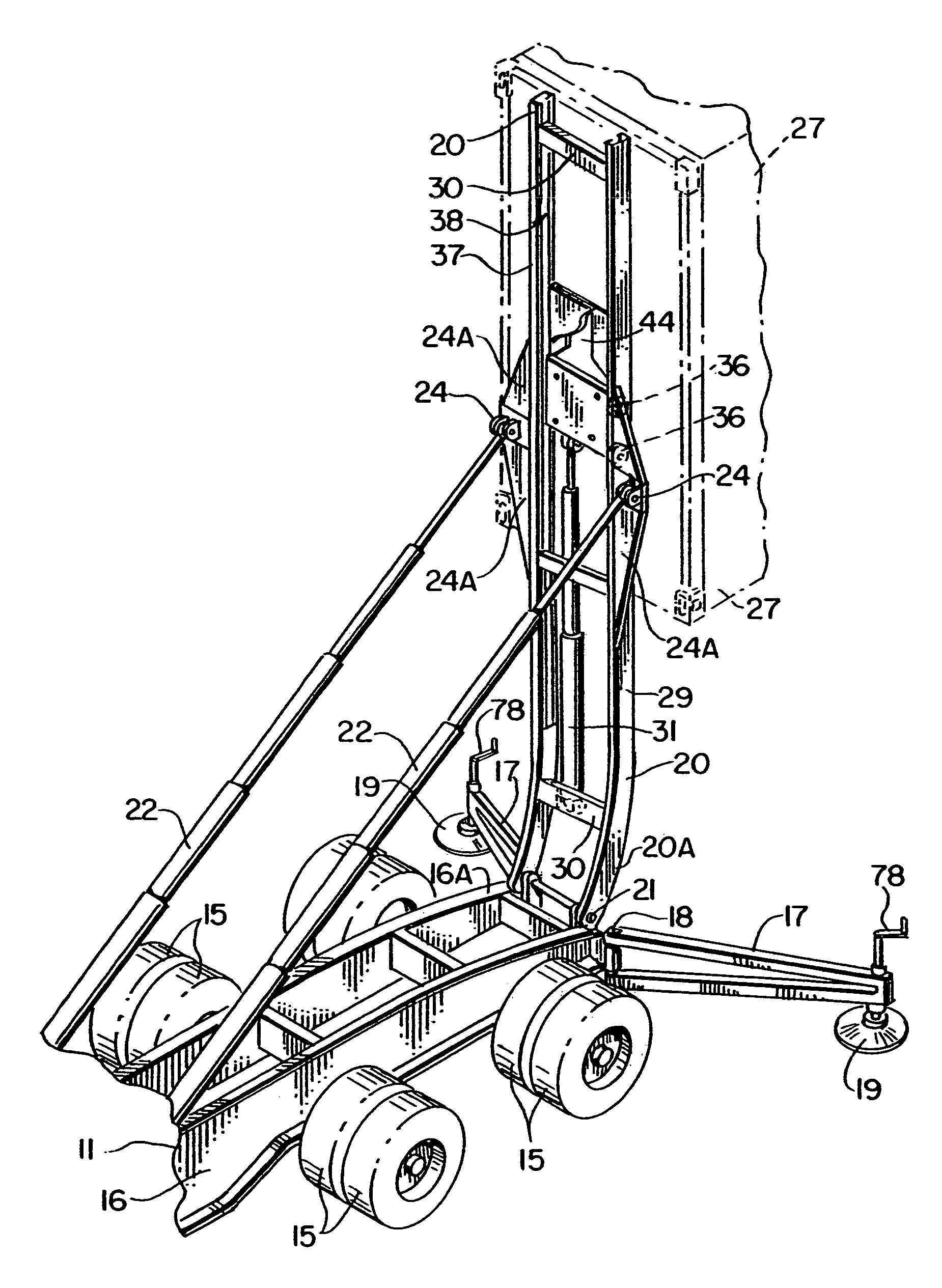

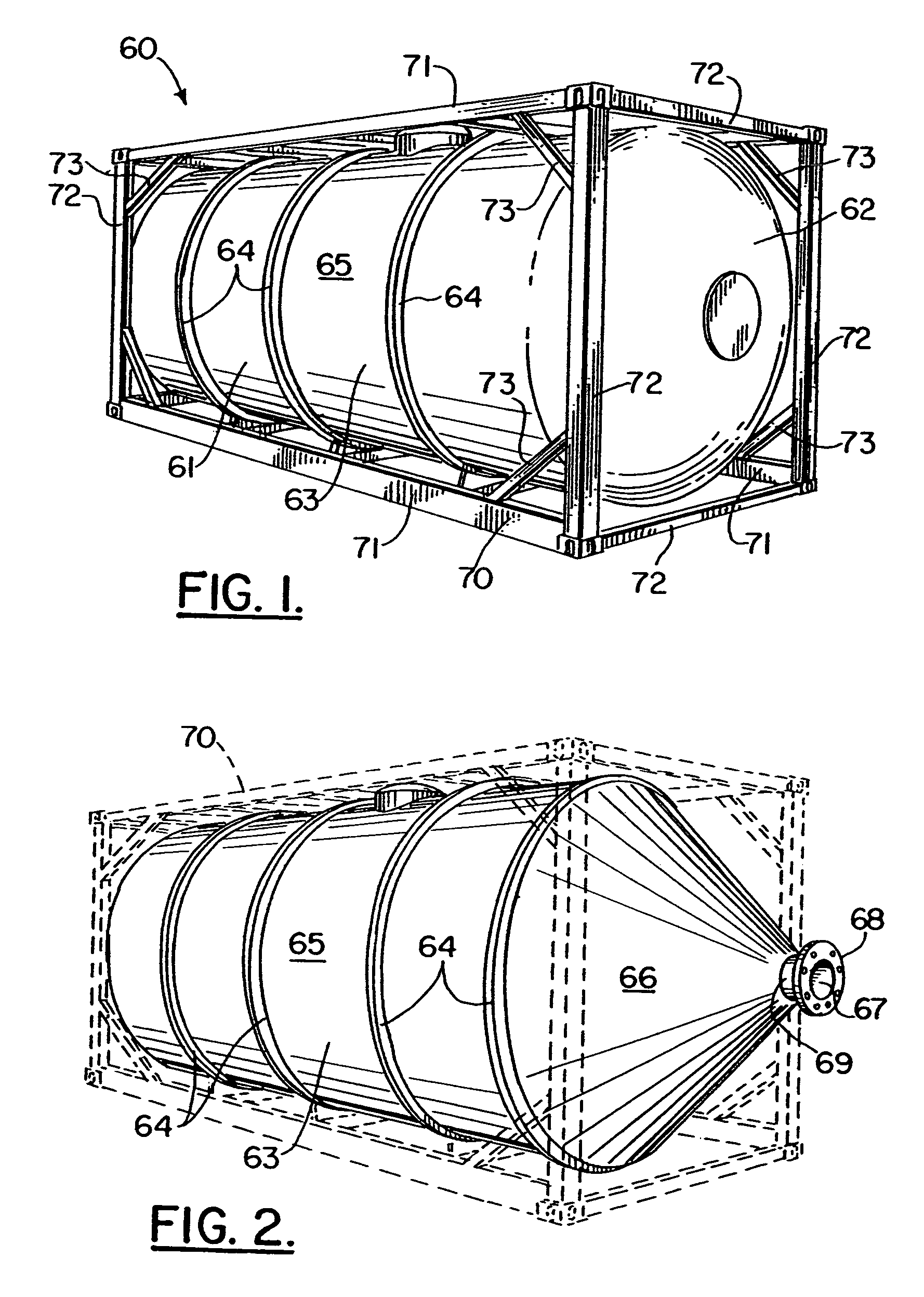

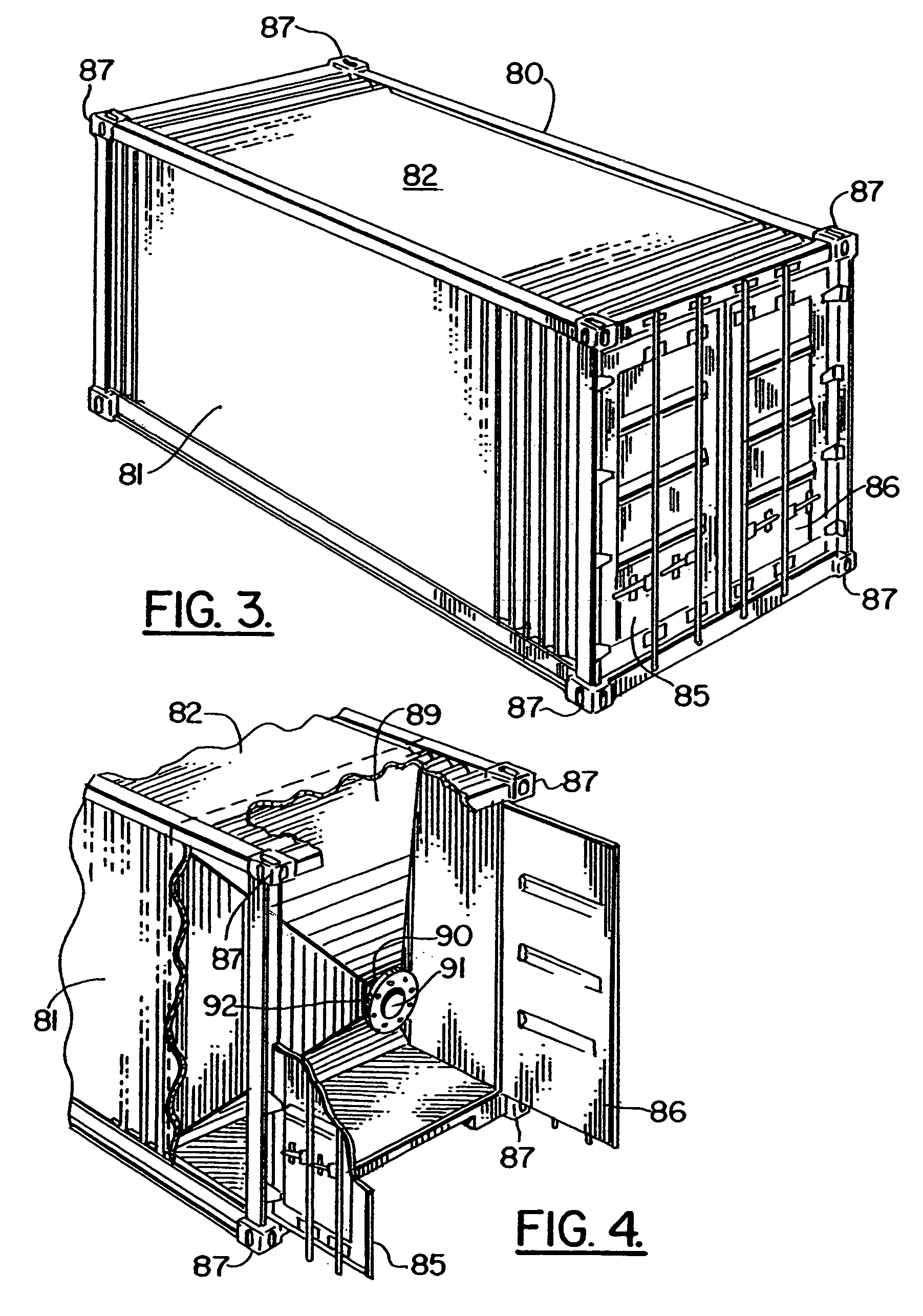

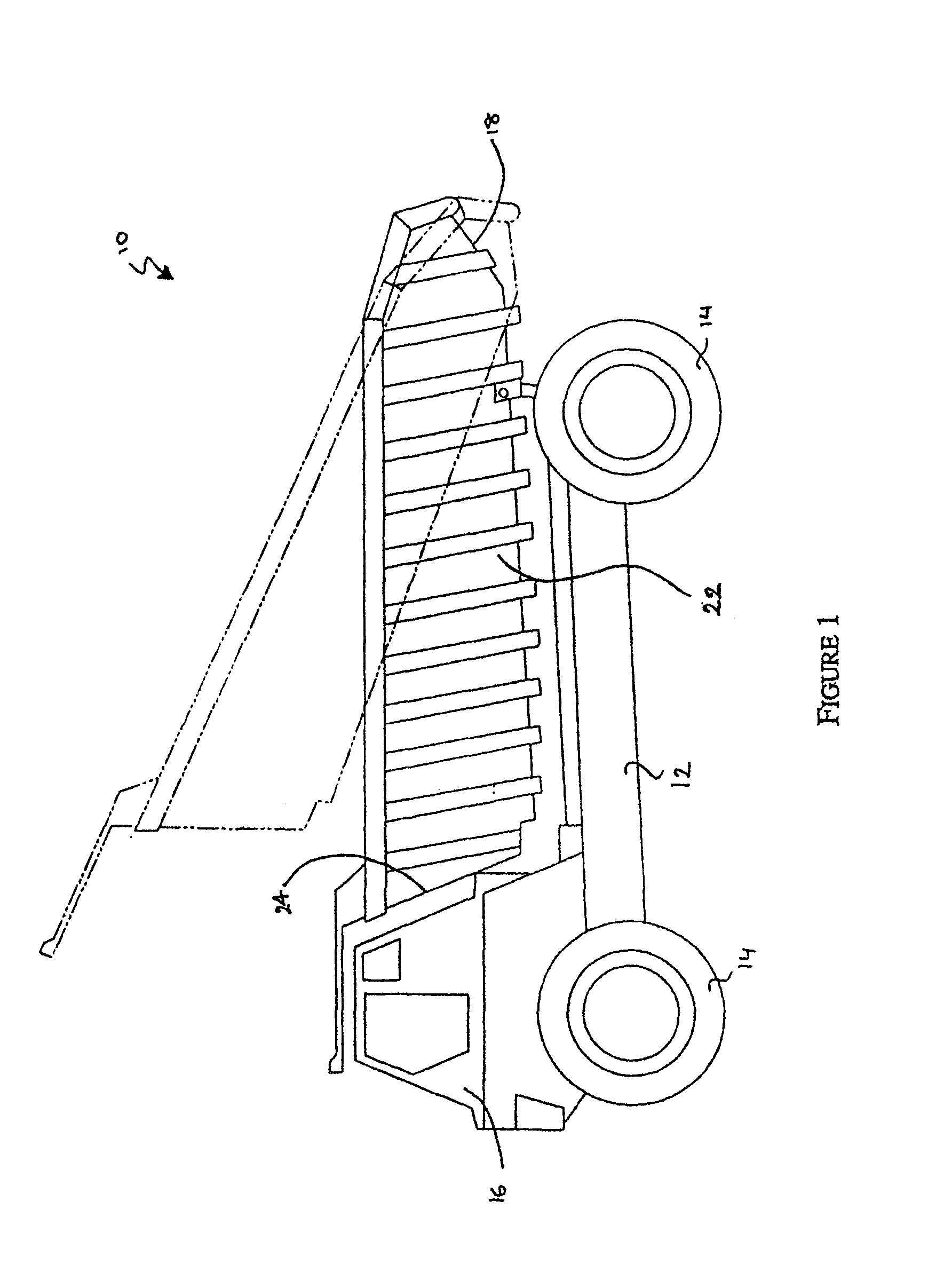

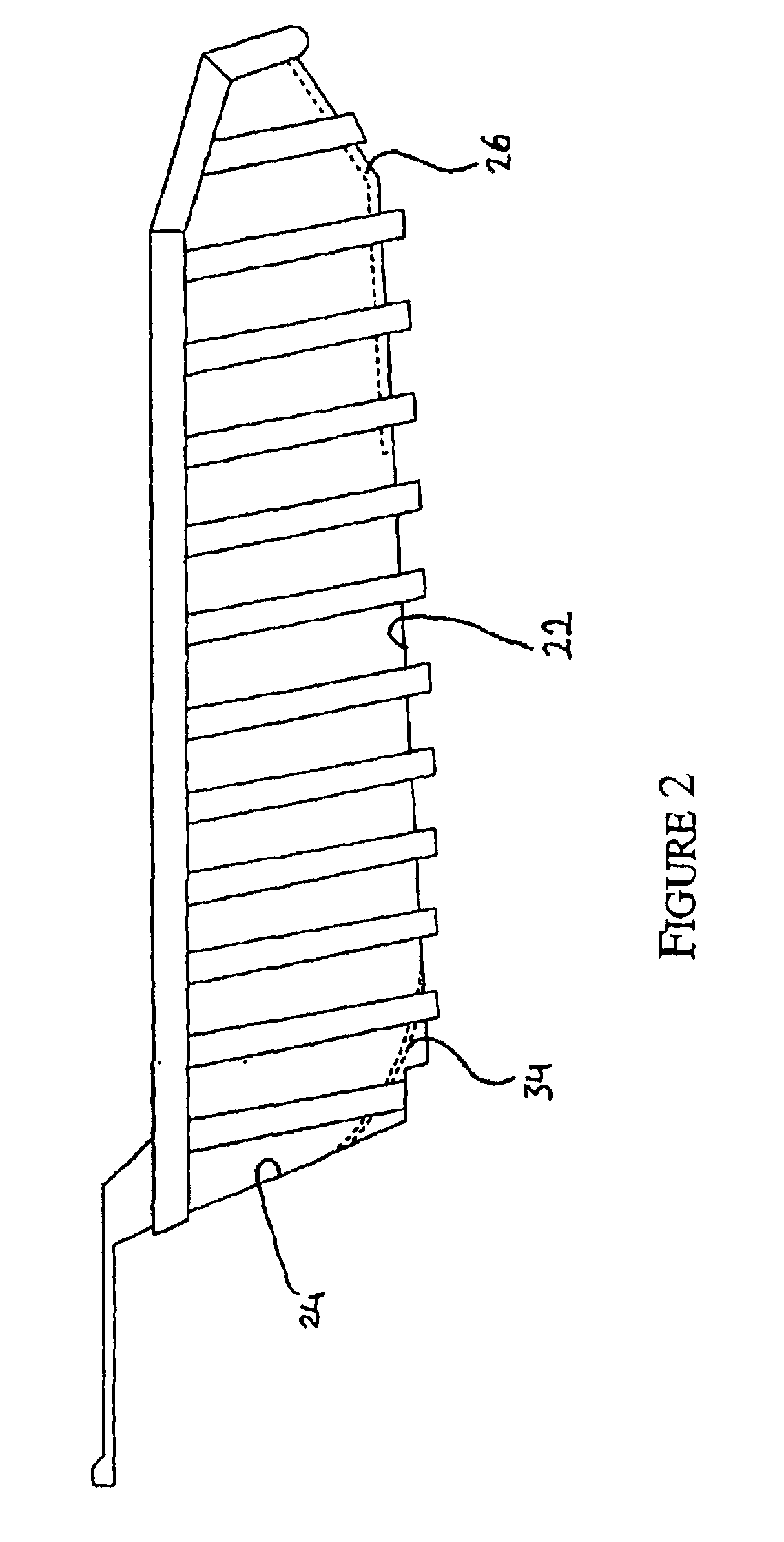

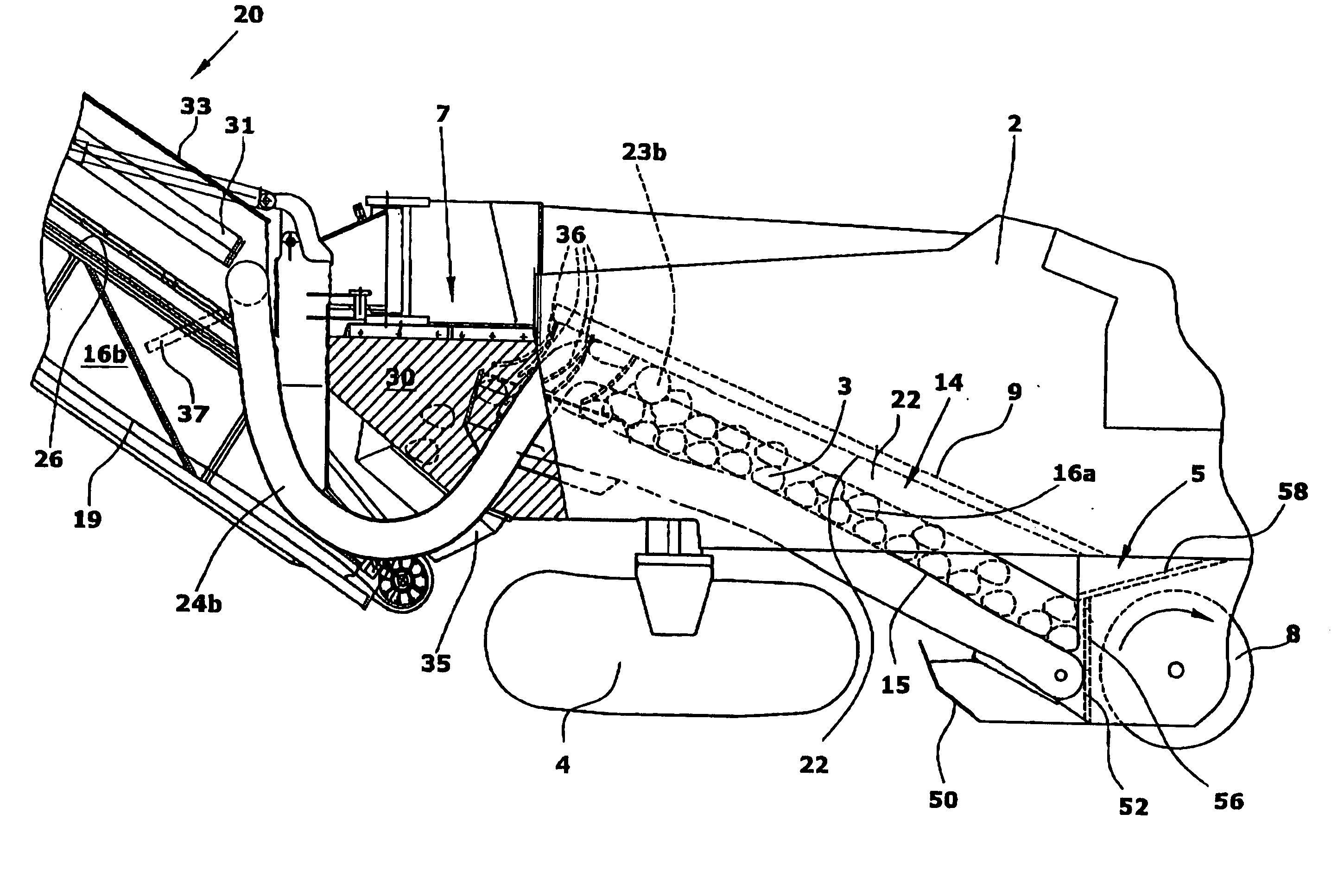

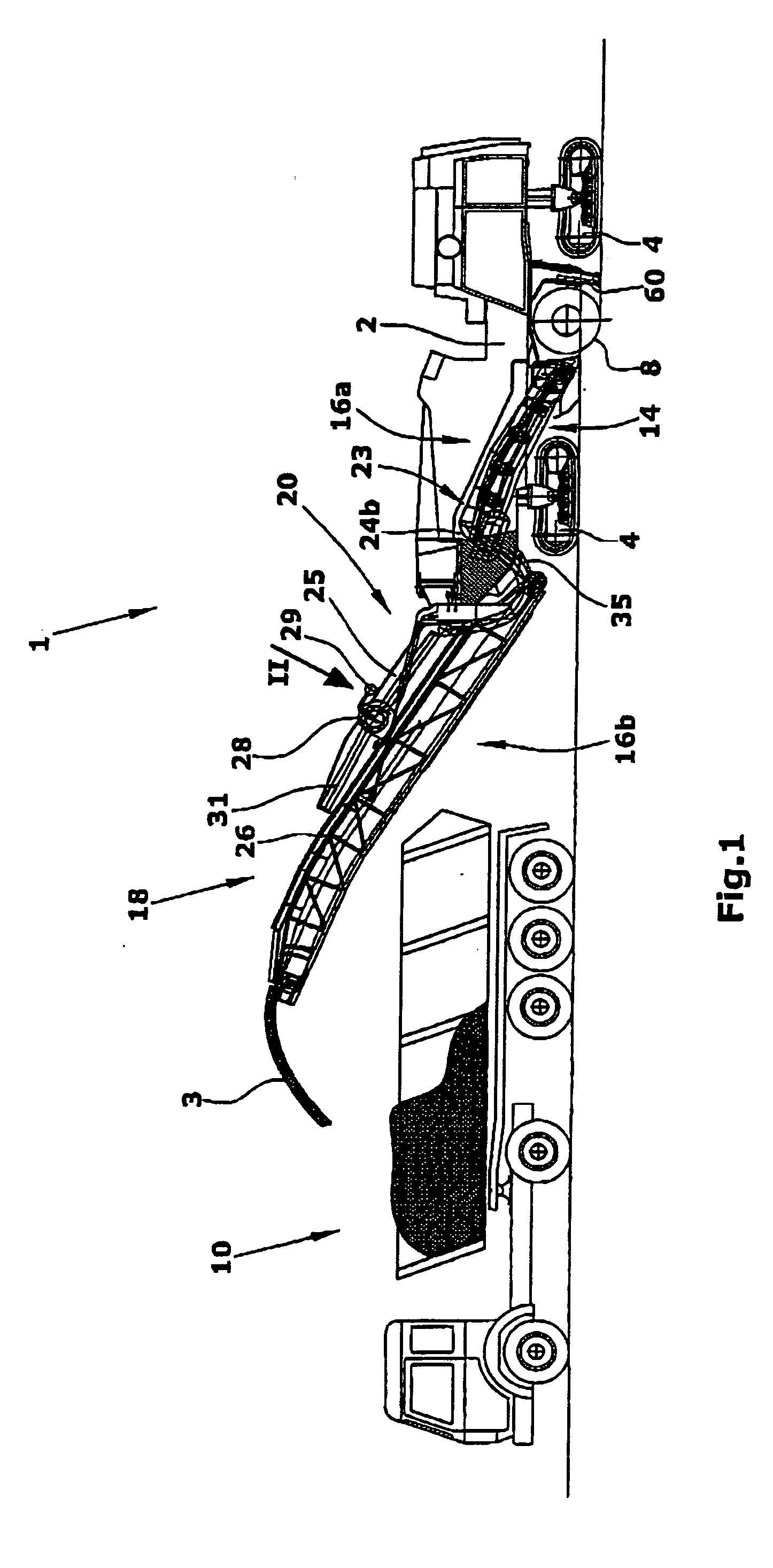

A method and apparatus for supplying bulk material to an end user includes the step of providing a bulk material source that is at a location distant from the end user and a specially configured vessel and trailer apparatus for transporting the bulk material to the end user. The vessel is filled with bulk material at the bulk material source and then transported with a specially configured trailer. Alternatively, at source or destination, the vessel can remain as a temporary storage device, free-standing from the trailer. During transport between the bulk material source and the end user, the vessel is filled or partially filled with a selected bulk material. During transport, the vessel is in a generally horizontal position, supported by the trailer and a specially configured elevator. The vessel is unloaded from the trailer by moving the vessel longitudinally along the trailer and by transferring the vessel from a generally horizontal position upon the trailer to an elevated upright position.

Owner:TILT TANK L L C

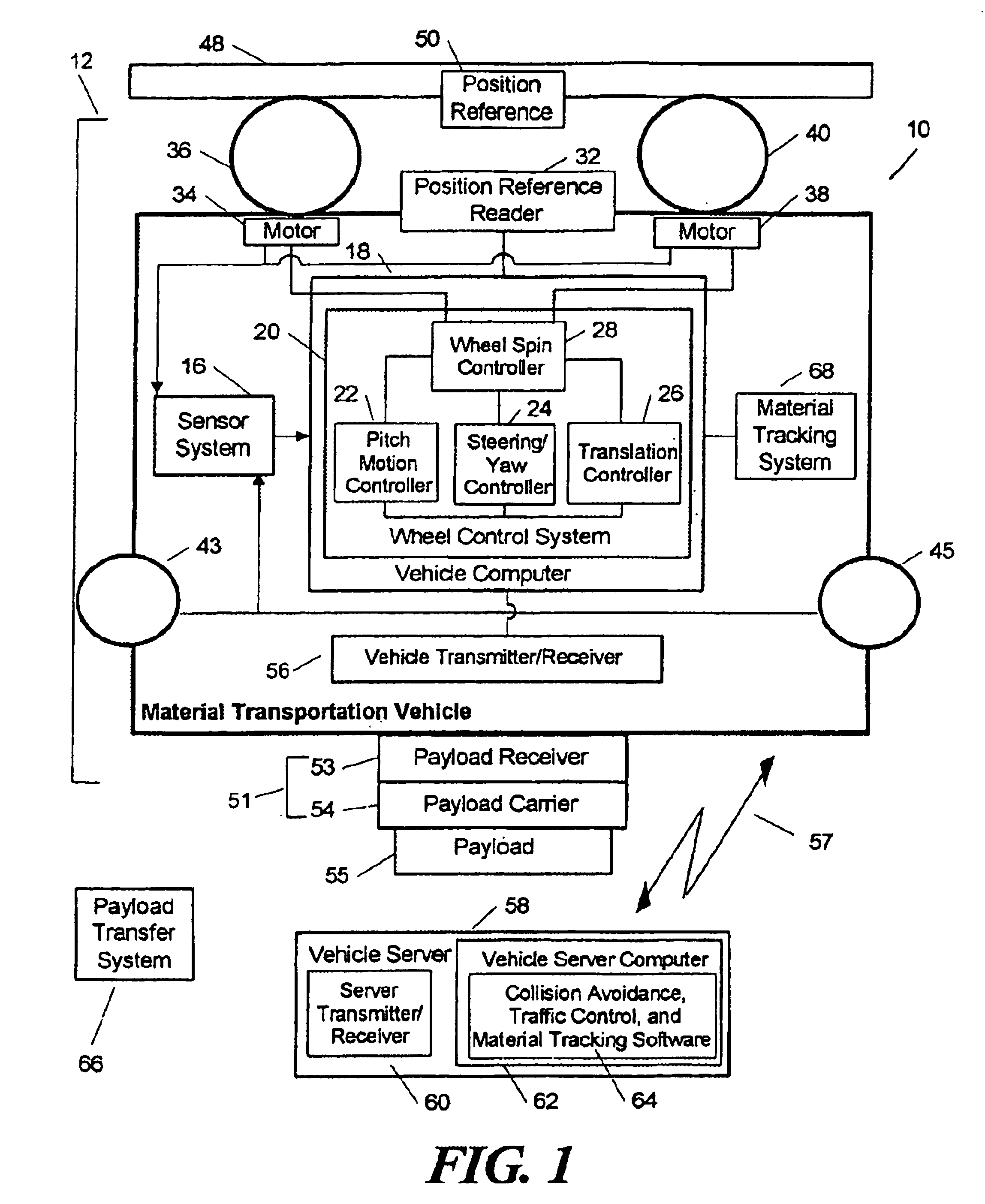

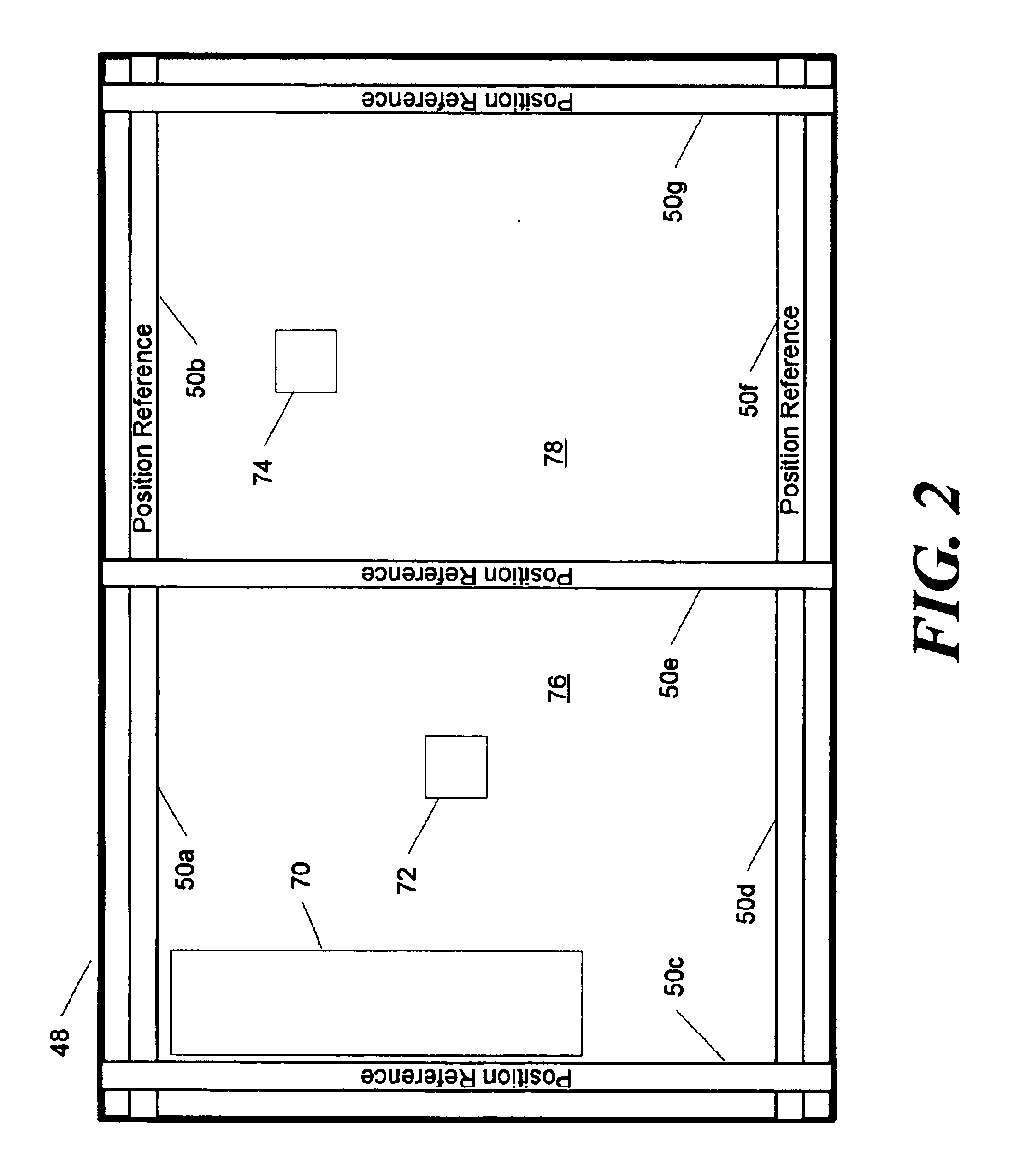

Material transportation system

InactiveUS6886651B1Avoid obstaclesEasy to adaptFrictional rollers based transmissionAutomatic initiationsControl systemMaterial transport

A material transportation system includes one or more material transportation vehicles, each having magnetic wheels coupled to a magnetically attractive surface that can include a ceiling, a wall, a floor, and / or a transition region. The material transportation vehicles are adapted to carry material from place to place. Each material transportation vehicle has sensors and motor controls that reduce swing motion of the material transportation vehicle and the material coupled thereto. A collision avoidance and traffic control system prevents collisions between the one or more material transportation vehicles.

Owner:MASSACHUSETTS INST OF TECH

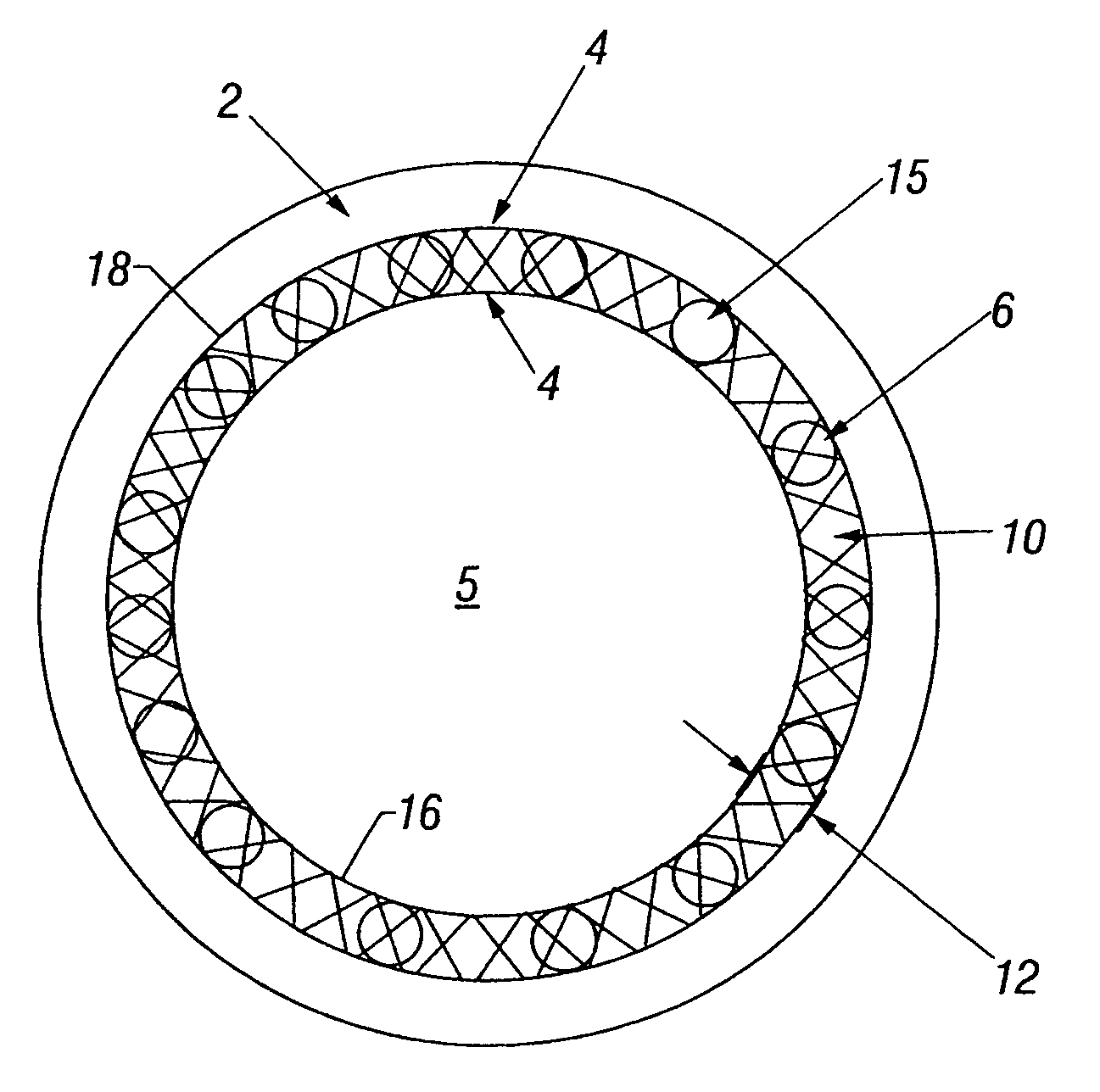

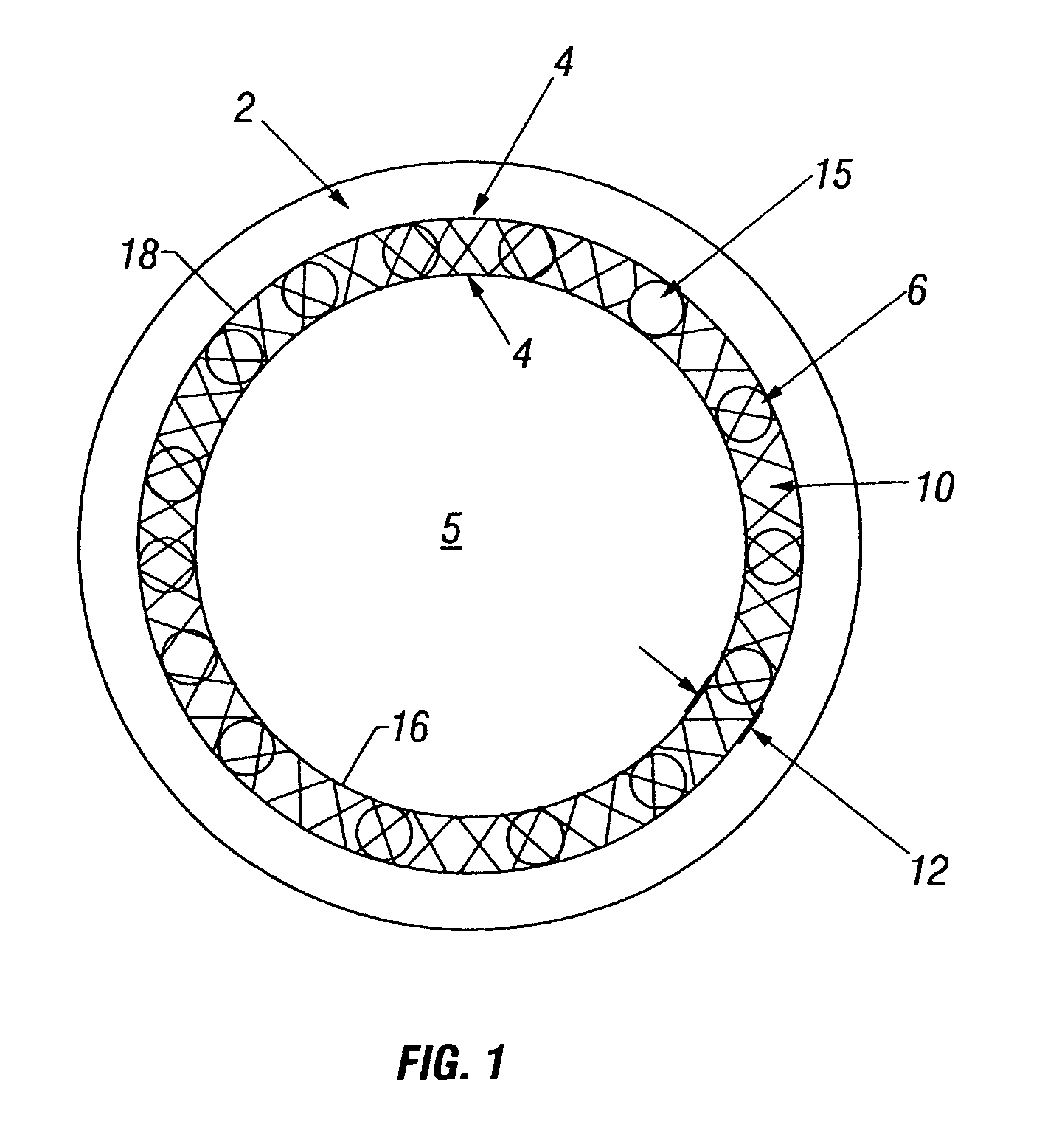

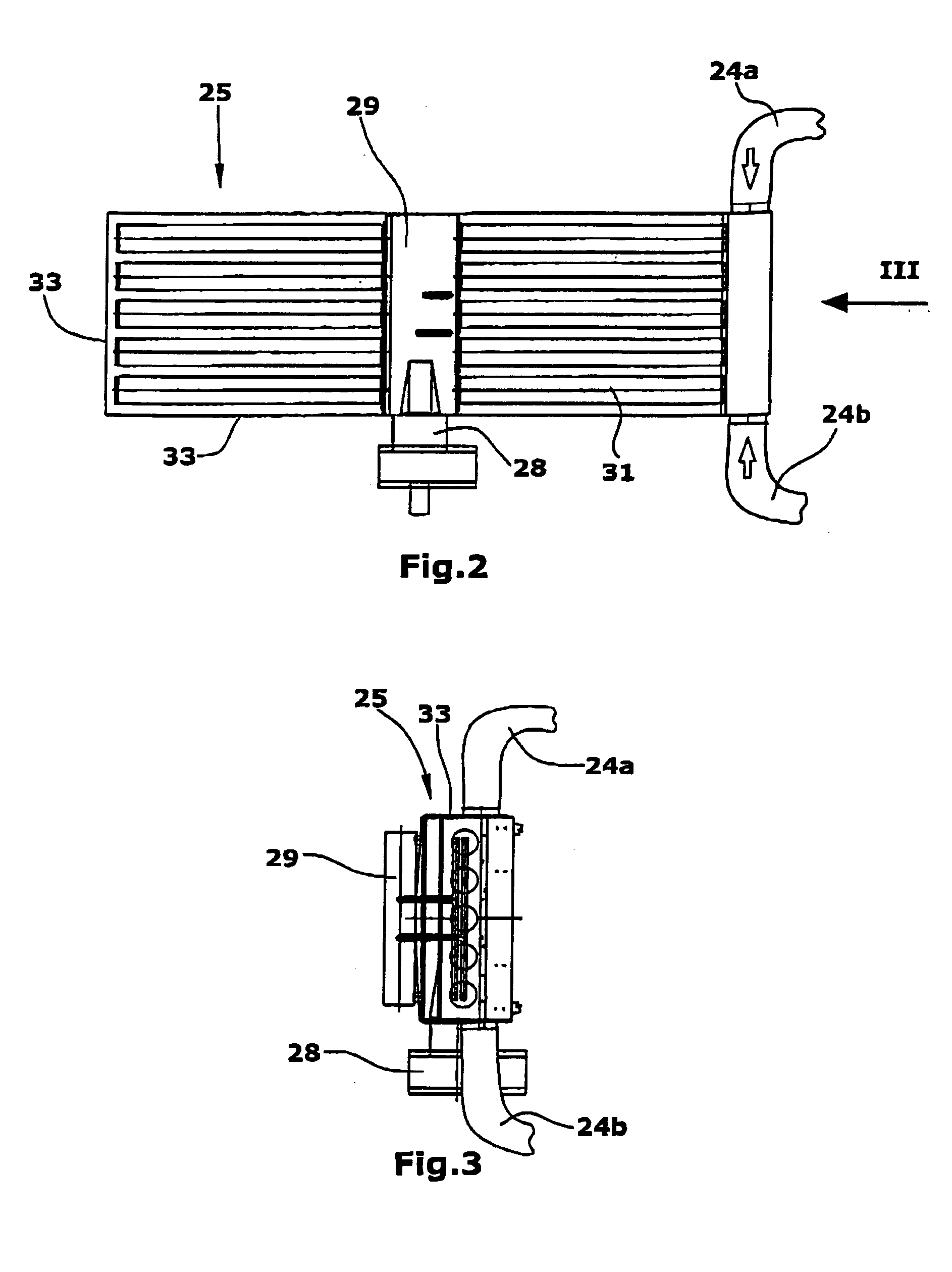

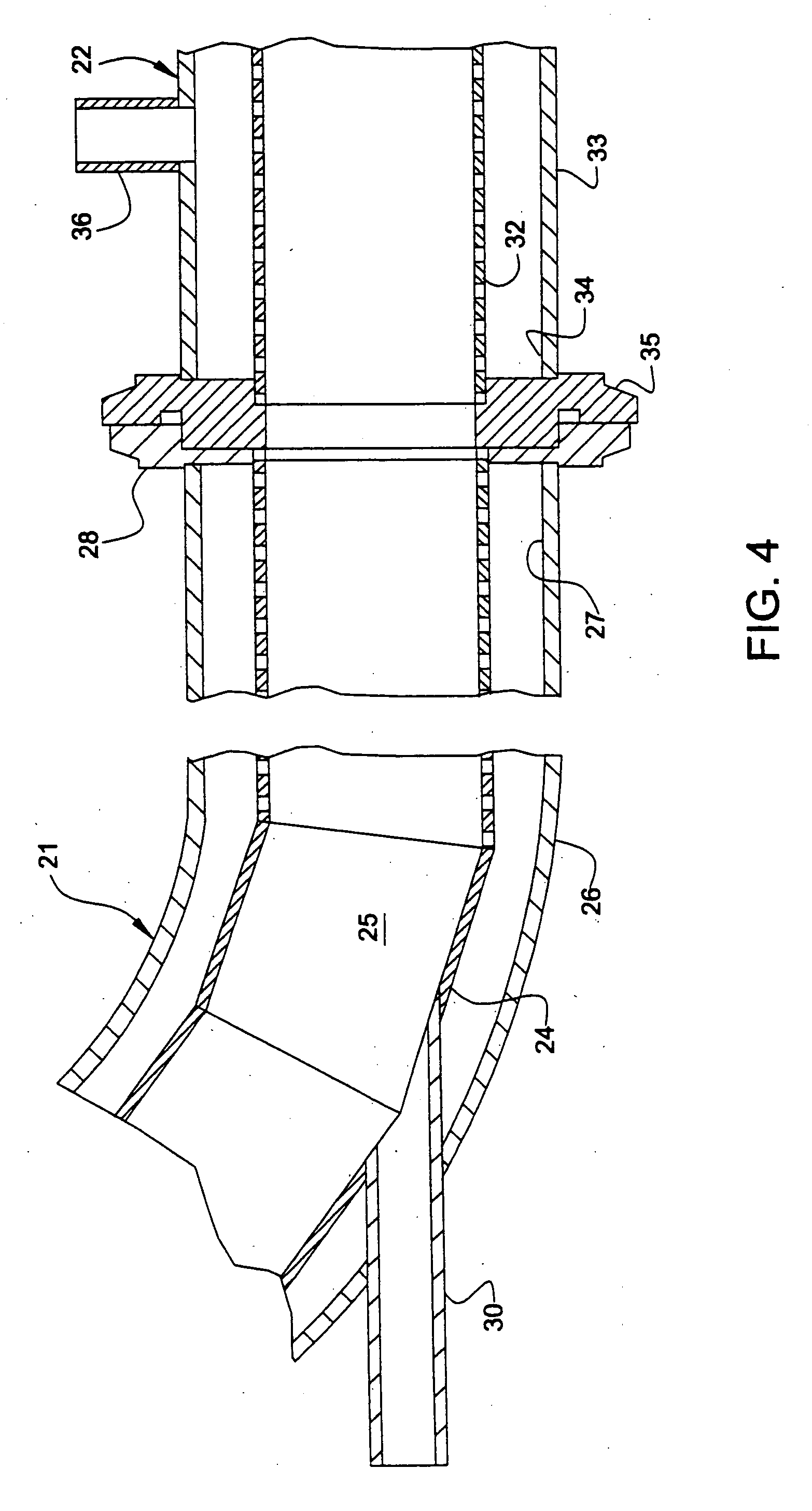

Method and apparatus for lining a conduit

Owner:HEAGY RICHARD T +3

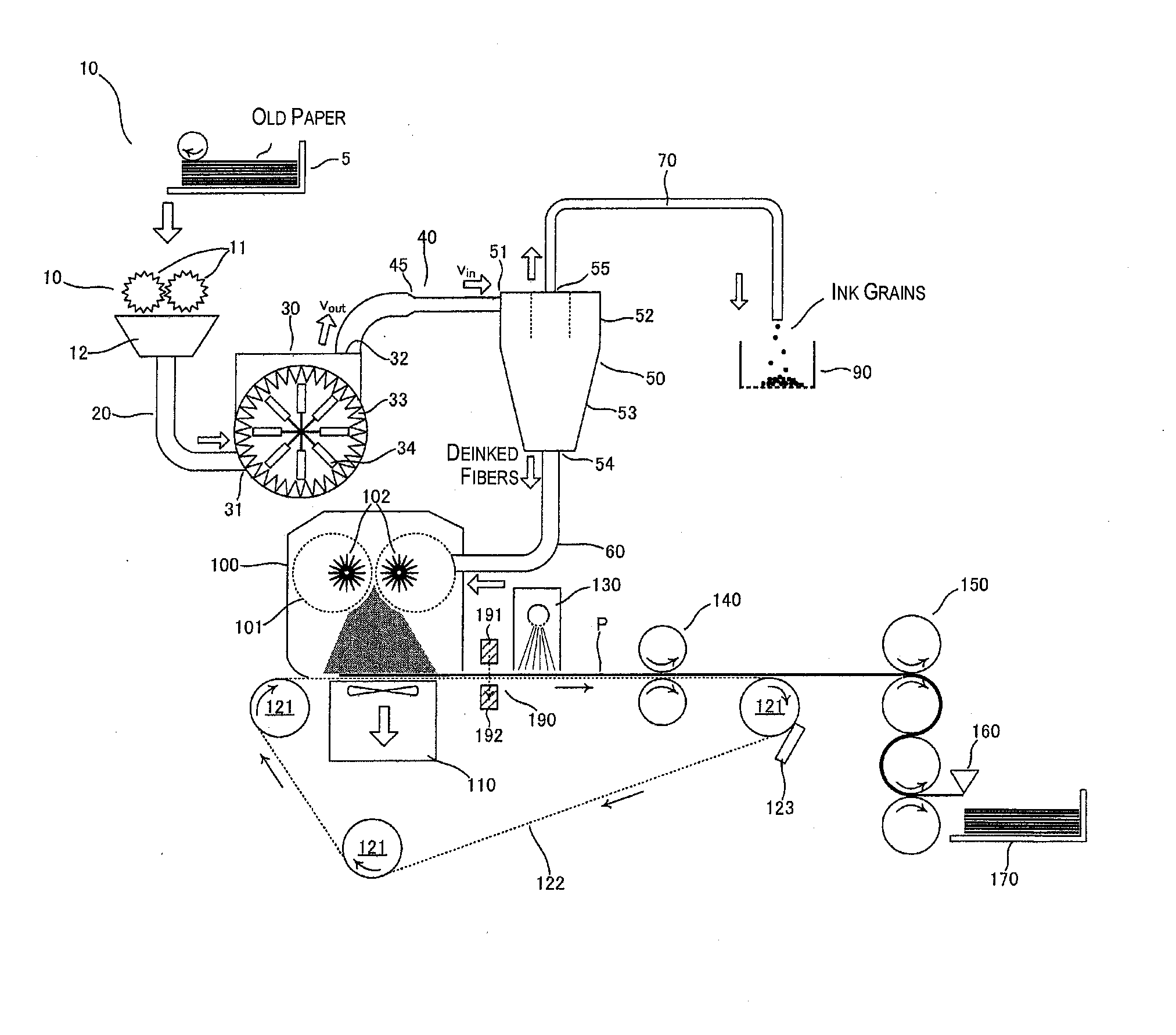

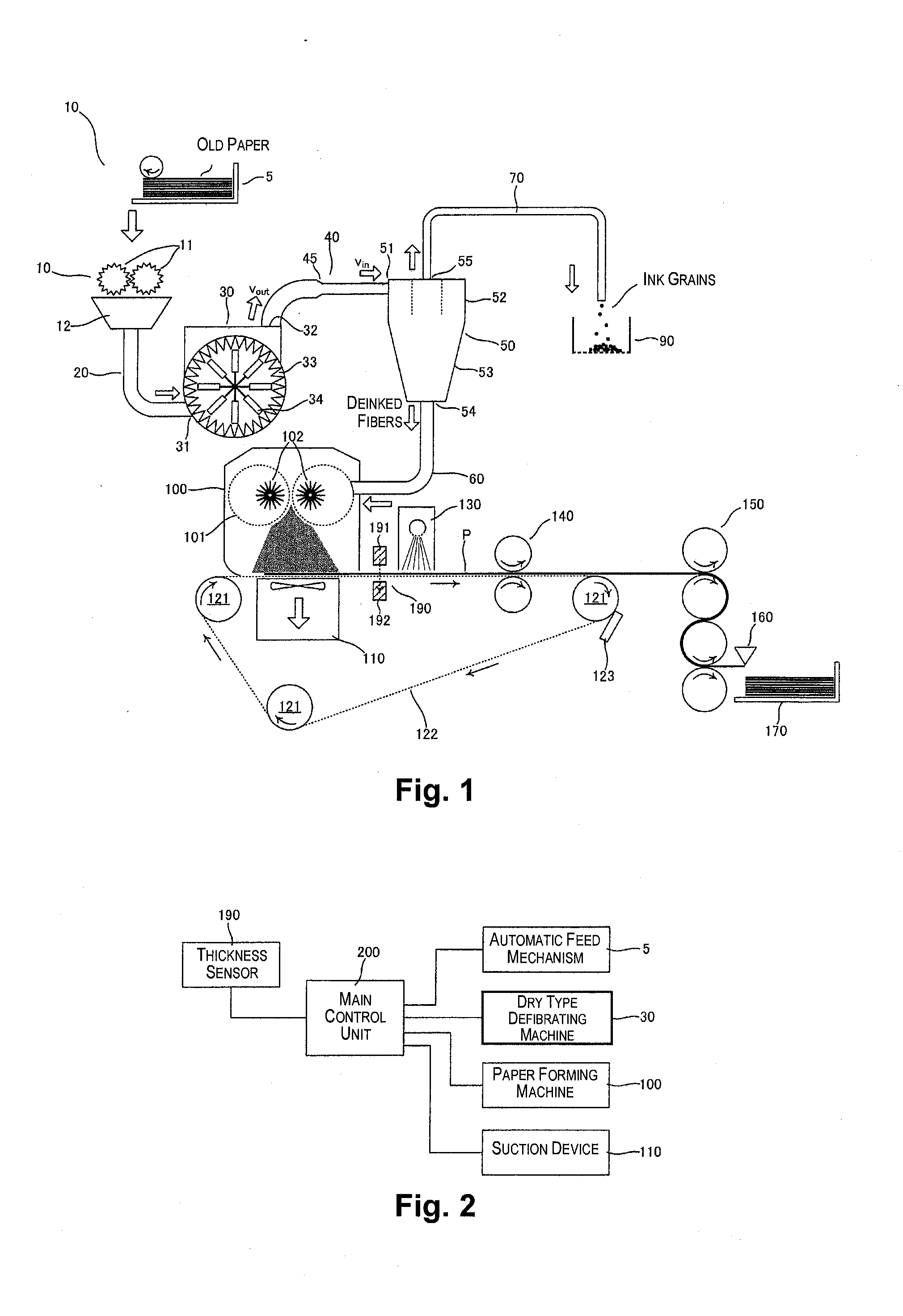

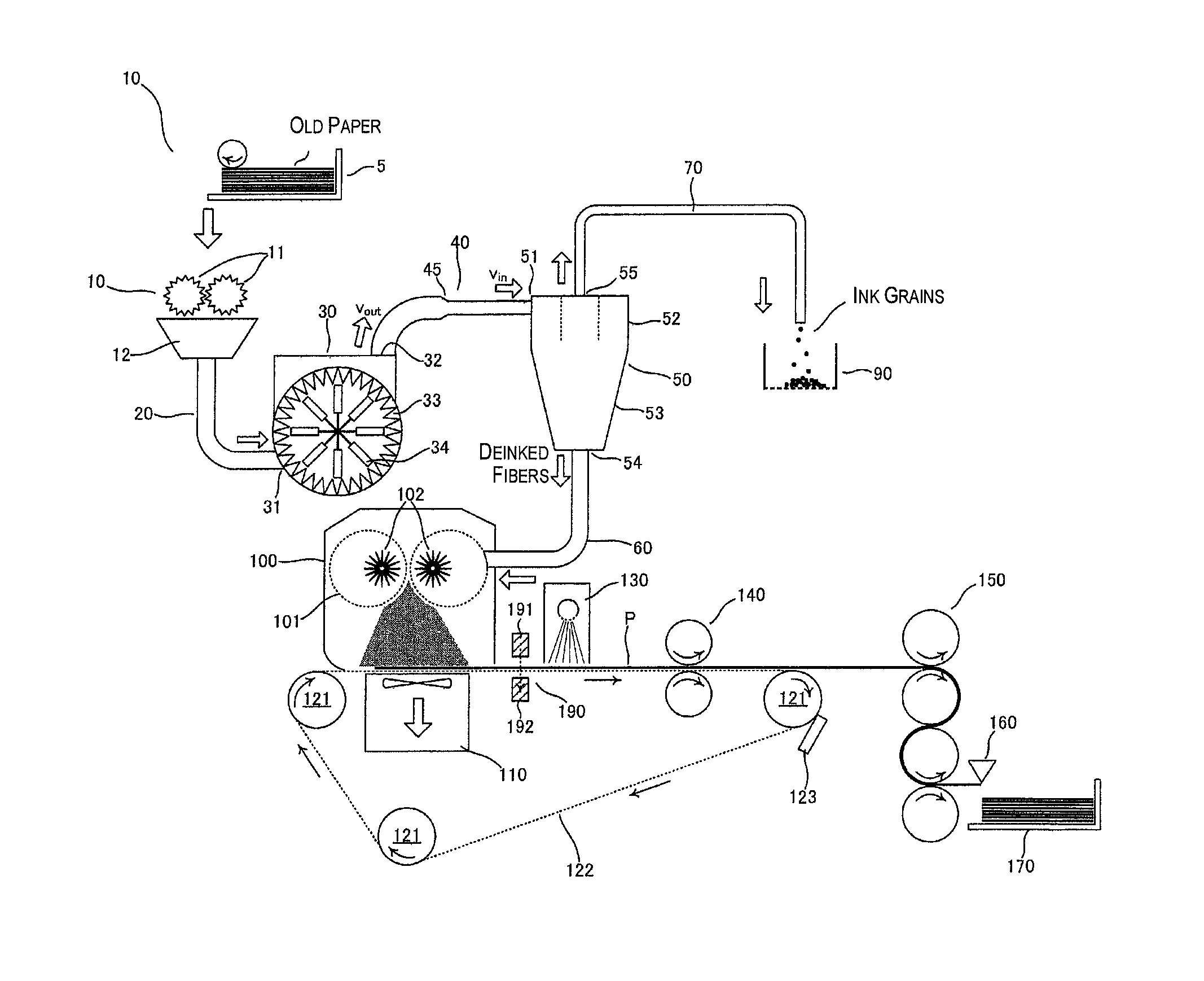

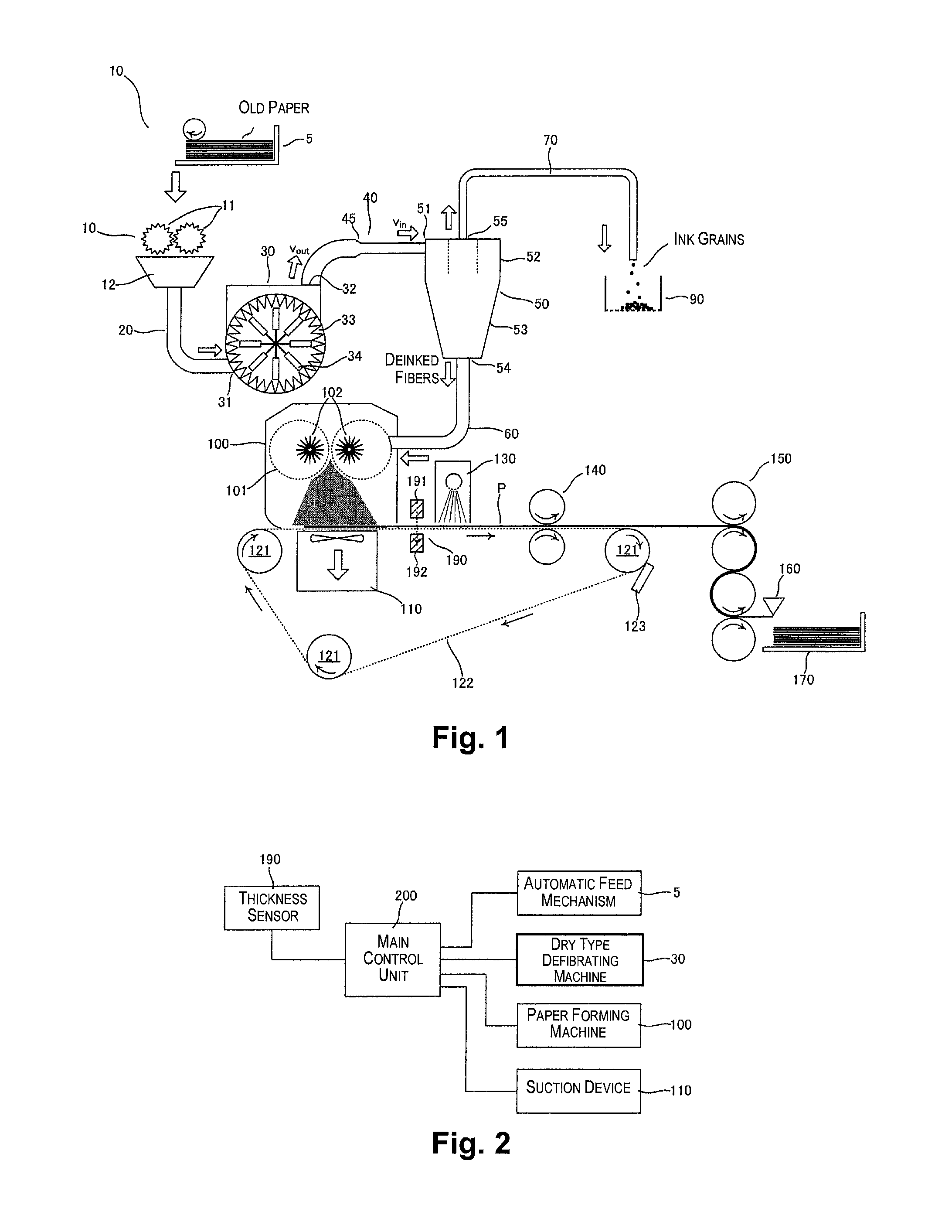

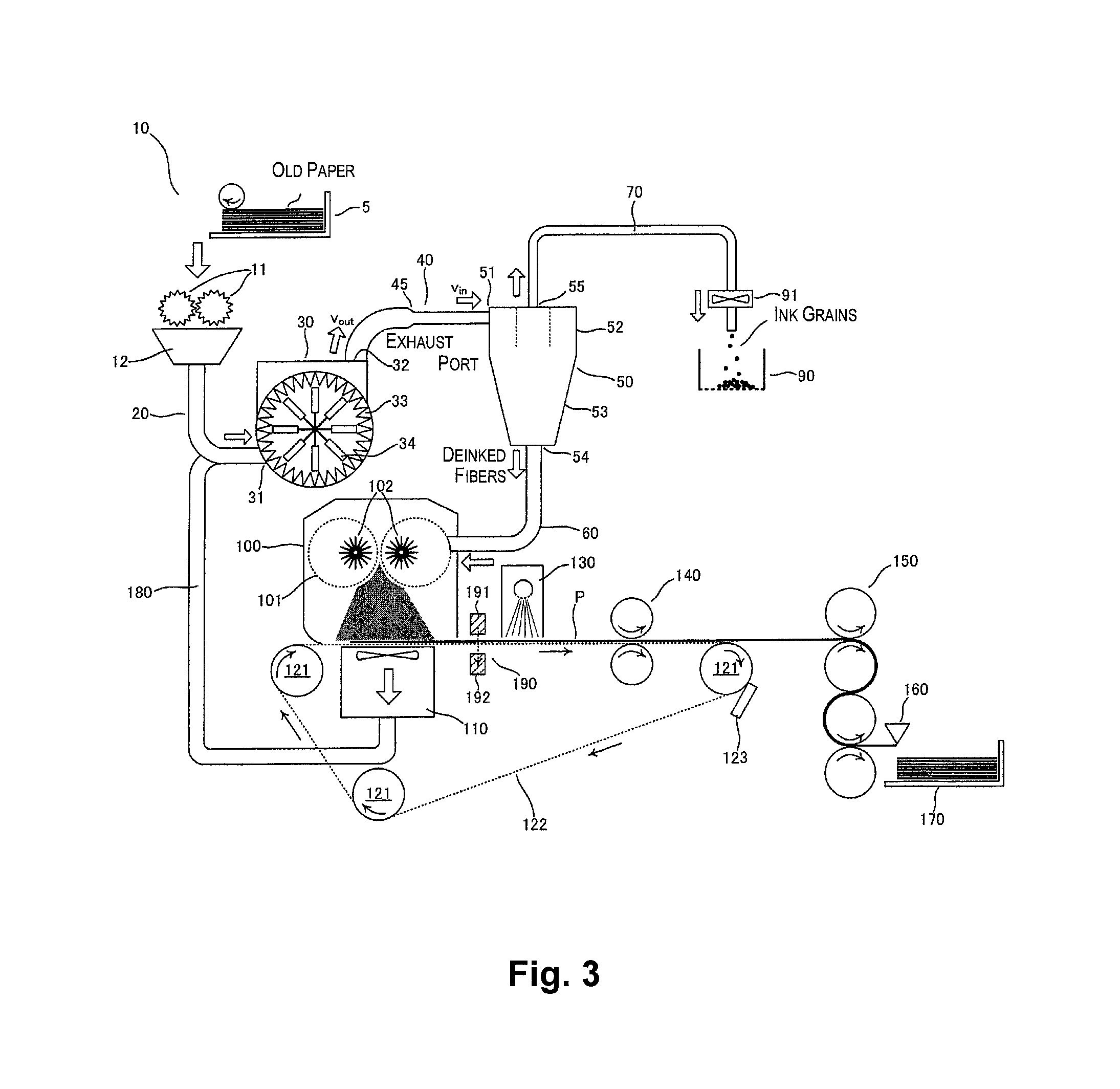

Paper recycling system and paper recycling method

InactiveUS20140027075A1Improve the level ofHigh whitenessPaper recyclingFlat articlesPaper recyclingPulp and paper industry

To provide a paper recycling device capable of recycling paper of increased whiteness level that can be widely used for applications other than paper for newspapers, the paper recycling device of the present invention has a dry type defibrator for crushing and defibrating paper, a first transport pipe for transporting defibrated material that was defibrated by the dry type defibrator, a cyclone for air classifying and deinking the defibrated material transported by the first transport pipe, a second transport pipe for transporting the defibrated material that was deinked by the cyclone, and a paper forming machine for forming paper with the defibrated material transported by the second transport pipe.

Owner:SEIKO EPSON CORP

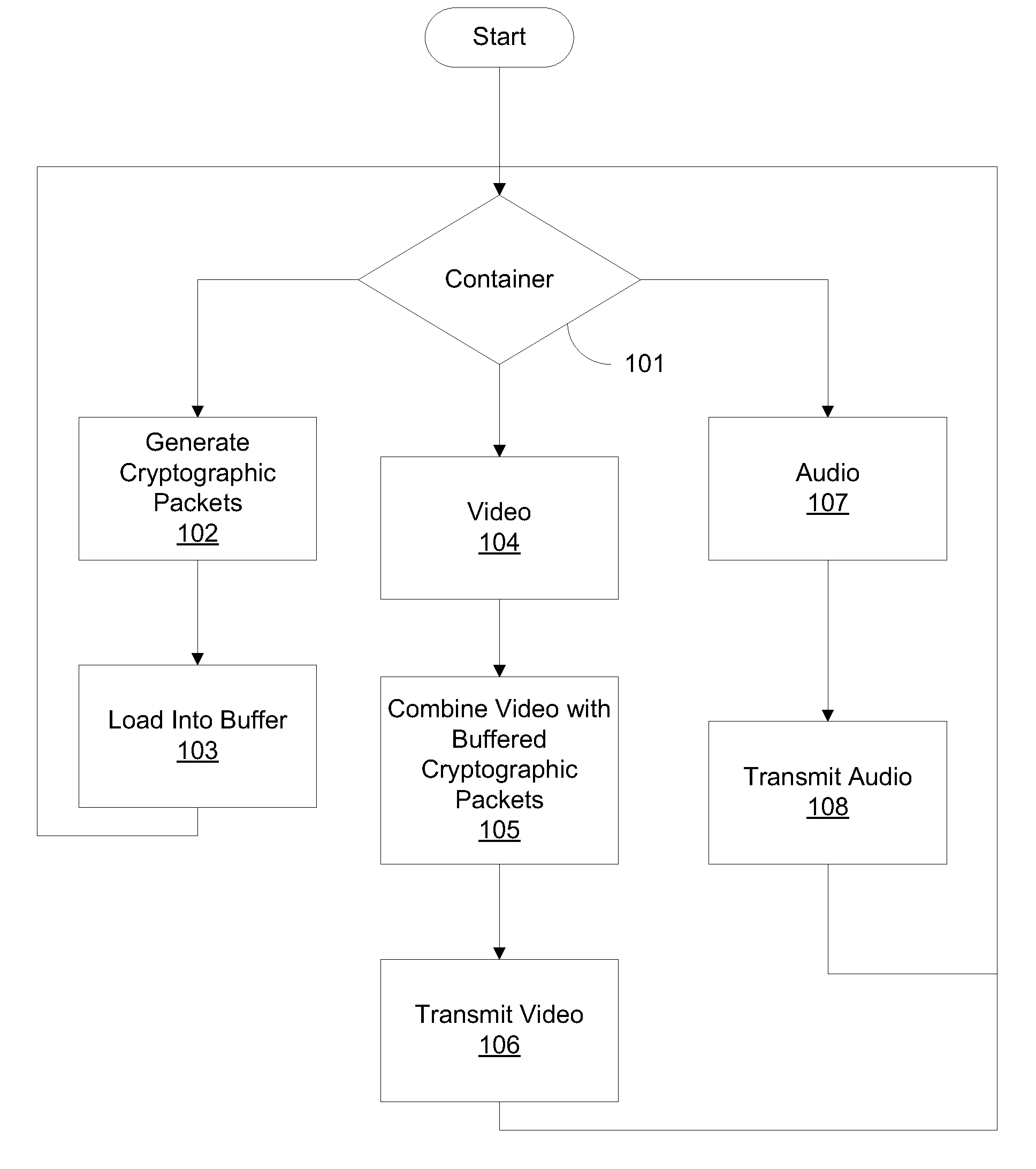

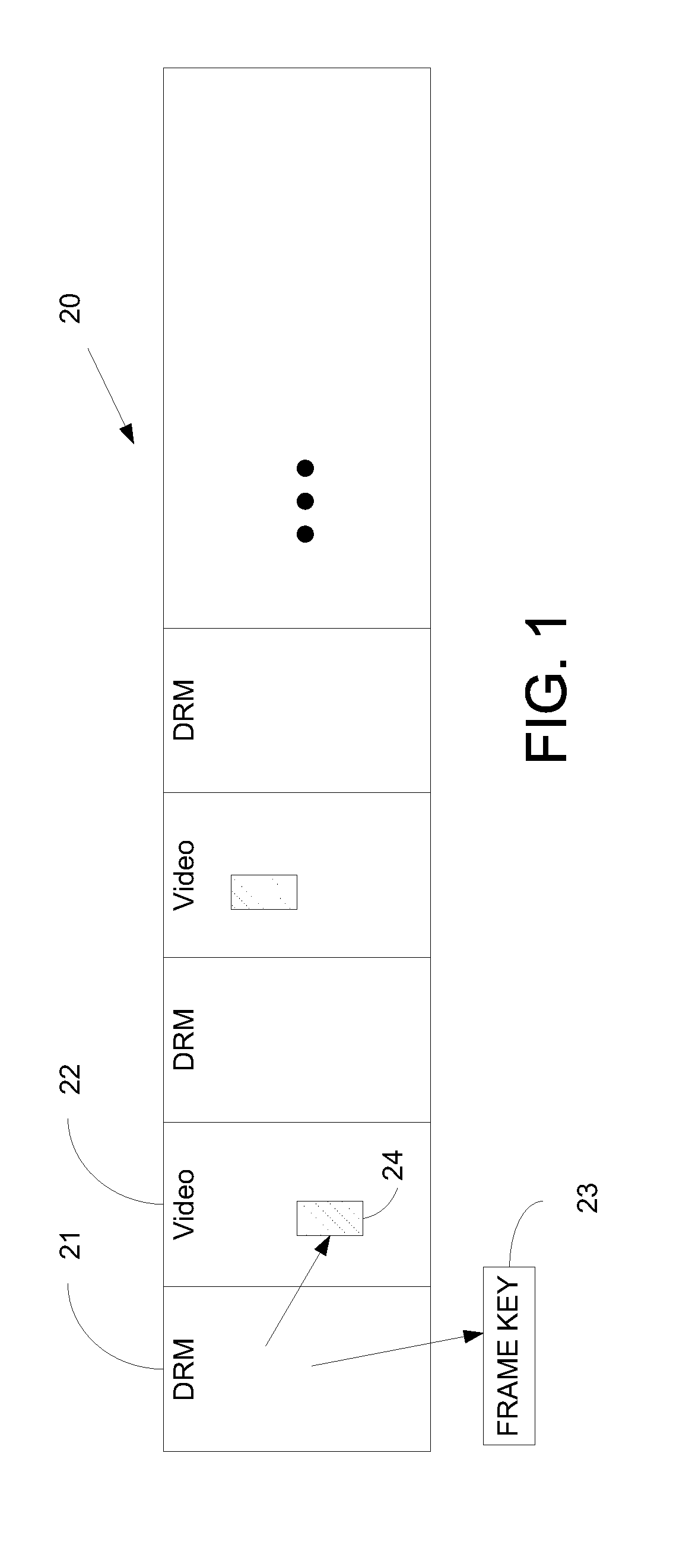

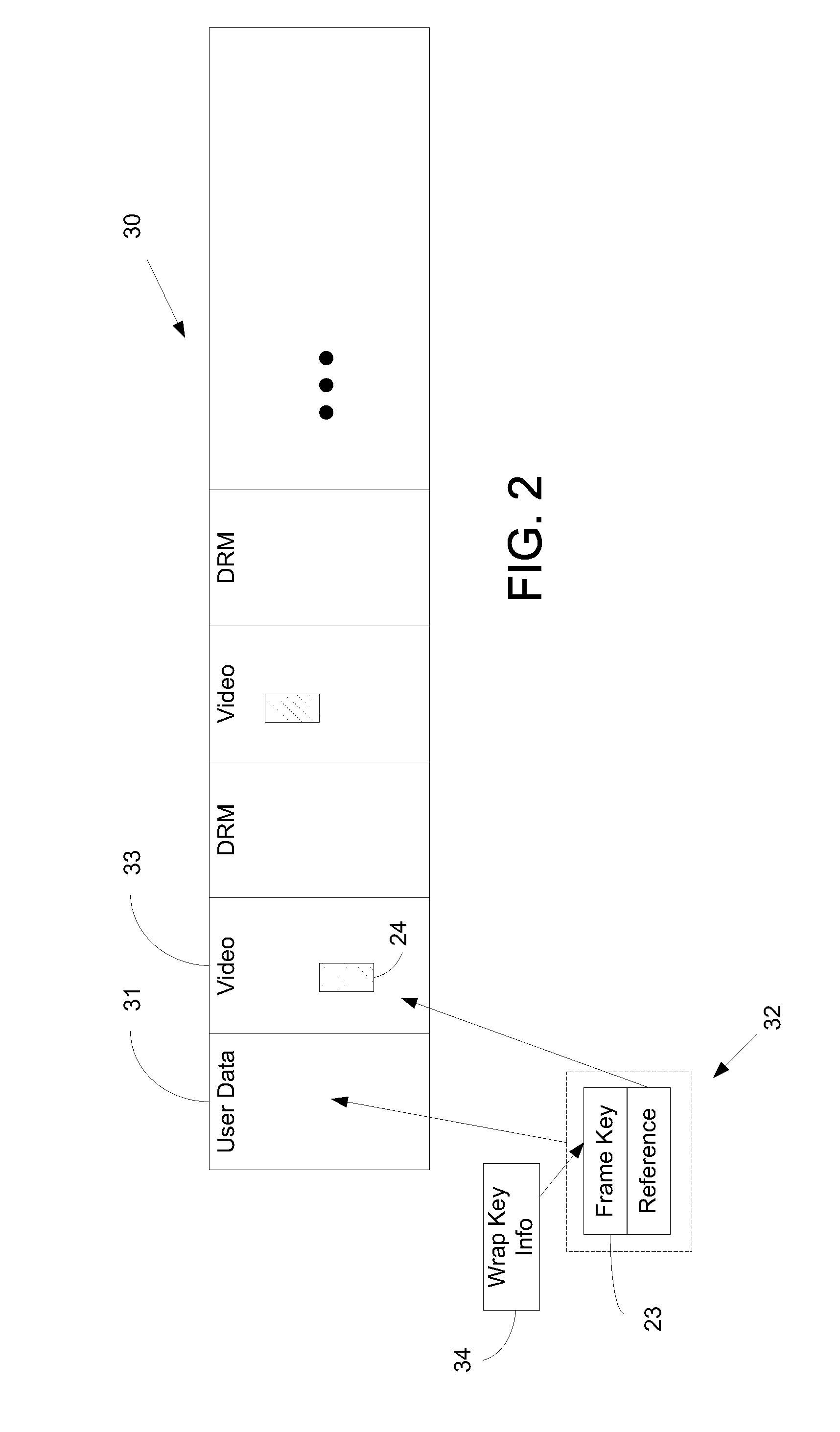

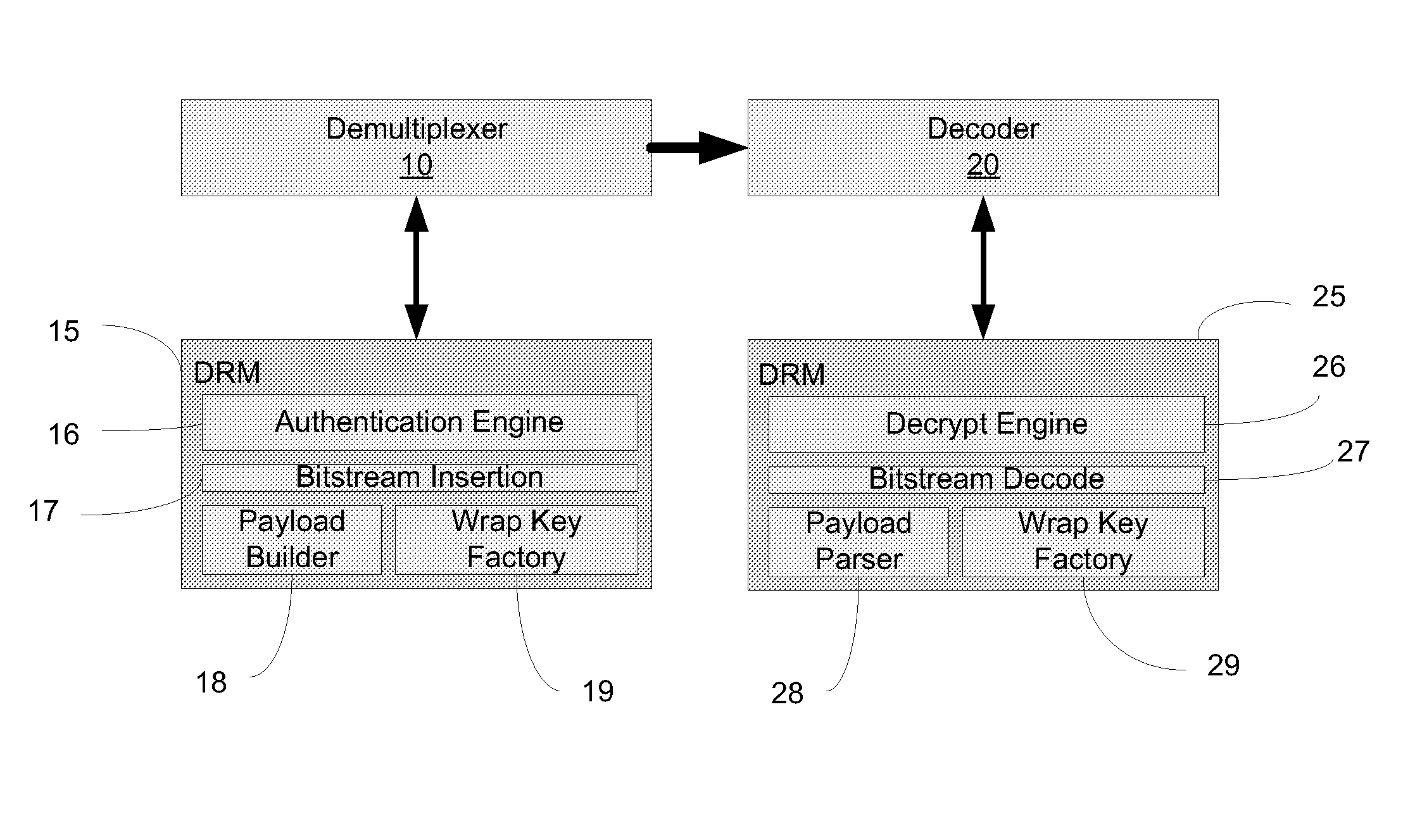

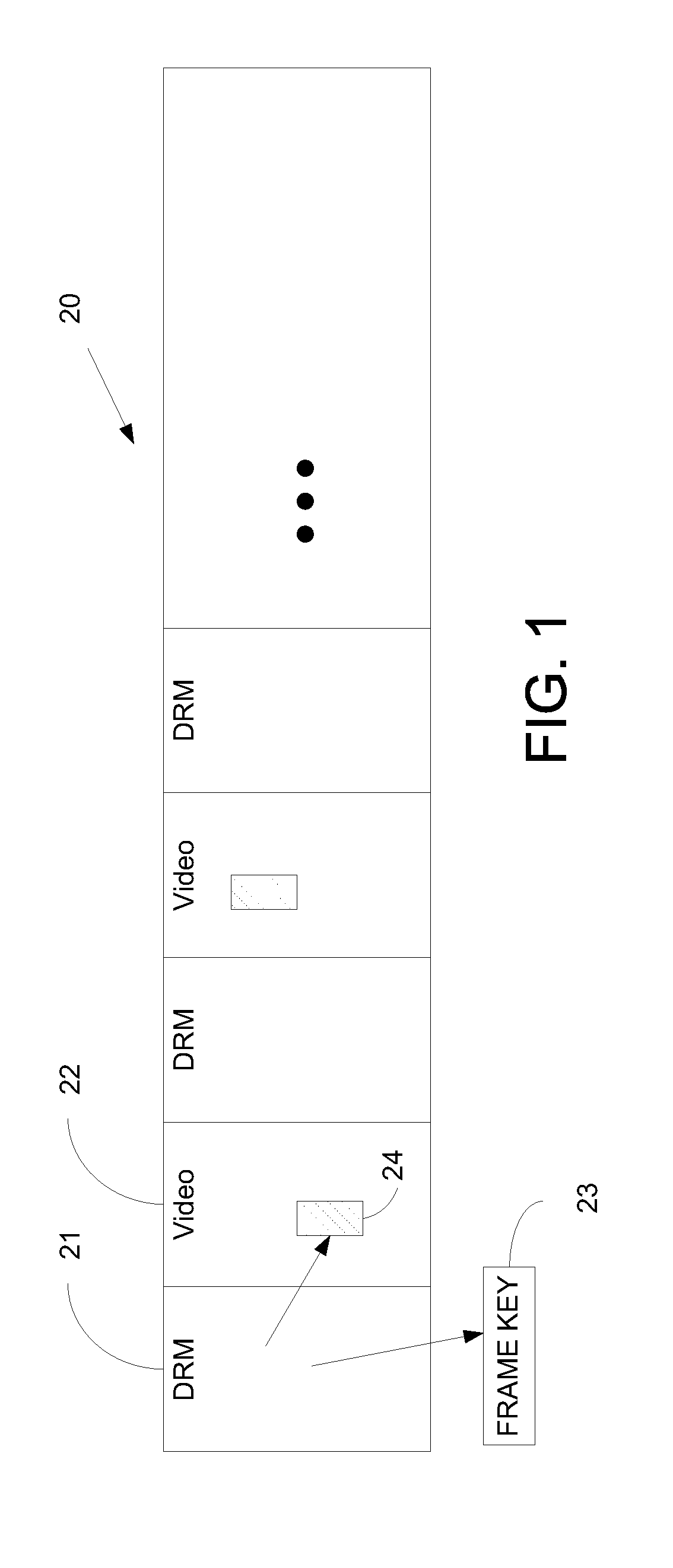

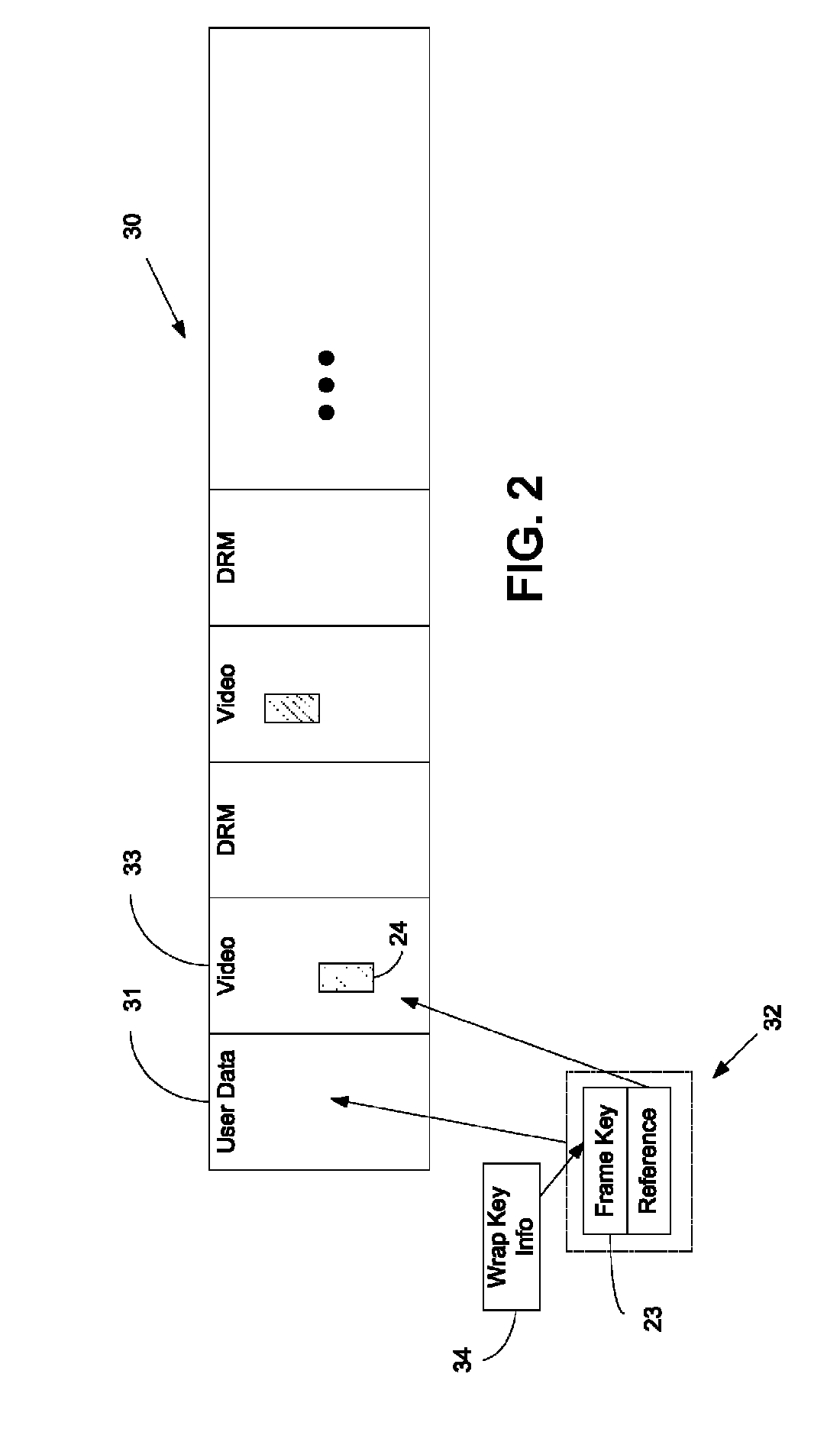

Elementary bitstream cryptographic material transport systems and methods

Systems and methods for providing multimedia content from one process or component to another process or component over an unsecured connection are provided. One embodiment includes obtaining the cryptographic information, extracting the at least partially encrypted video data from the container file to create an elementary bitstream, enciphering the cryptographic information, inserting the cryptographic information in the elementary bitstream, providing the elementary bitstream to a video decoder, extracting the cryptographic information from the elementary bitstream at the video decoder, deciphering the cryptographic information, decrypting the elementary bitstream with the cryptographic information and decoding the elementary bitstream for rendering on a display device using the video decoder.

Owner:DIVX INC

Nanostructured material transport devices and their fabrication by application of molecular coatings to nanoscale channels

InactiveUS20050023156A1Reduced cross-sectional dimensionReduce the cross-sectional areaMaterial nanotechnologyFixed microstructural devicesEngineeringNanostructured materials

Owner:RAMSEY J MICHAEL +3

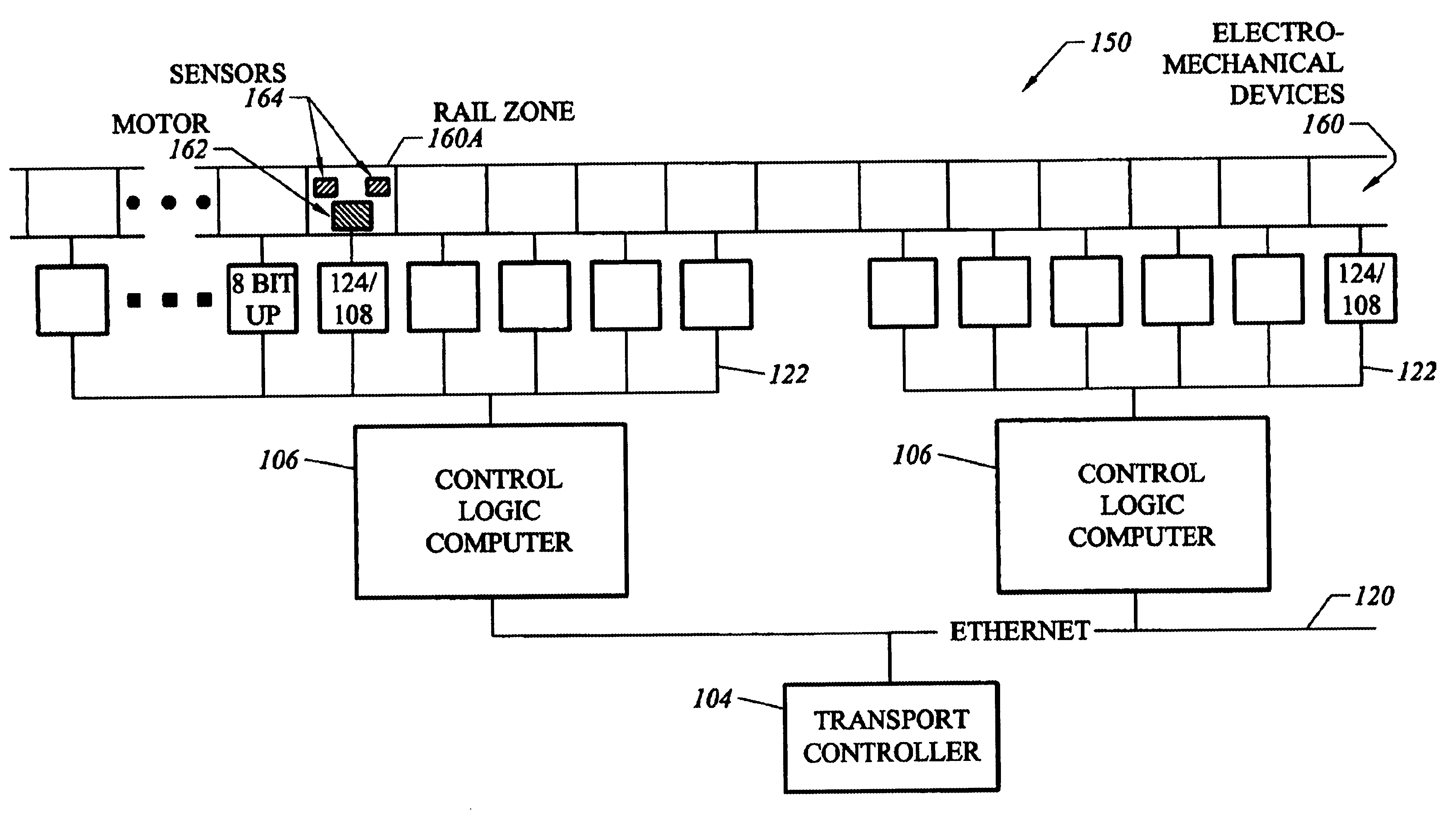

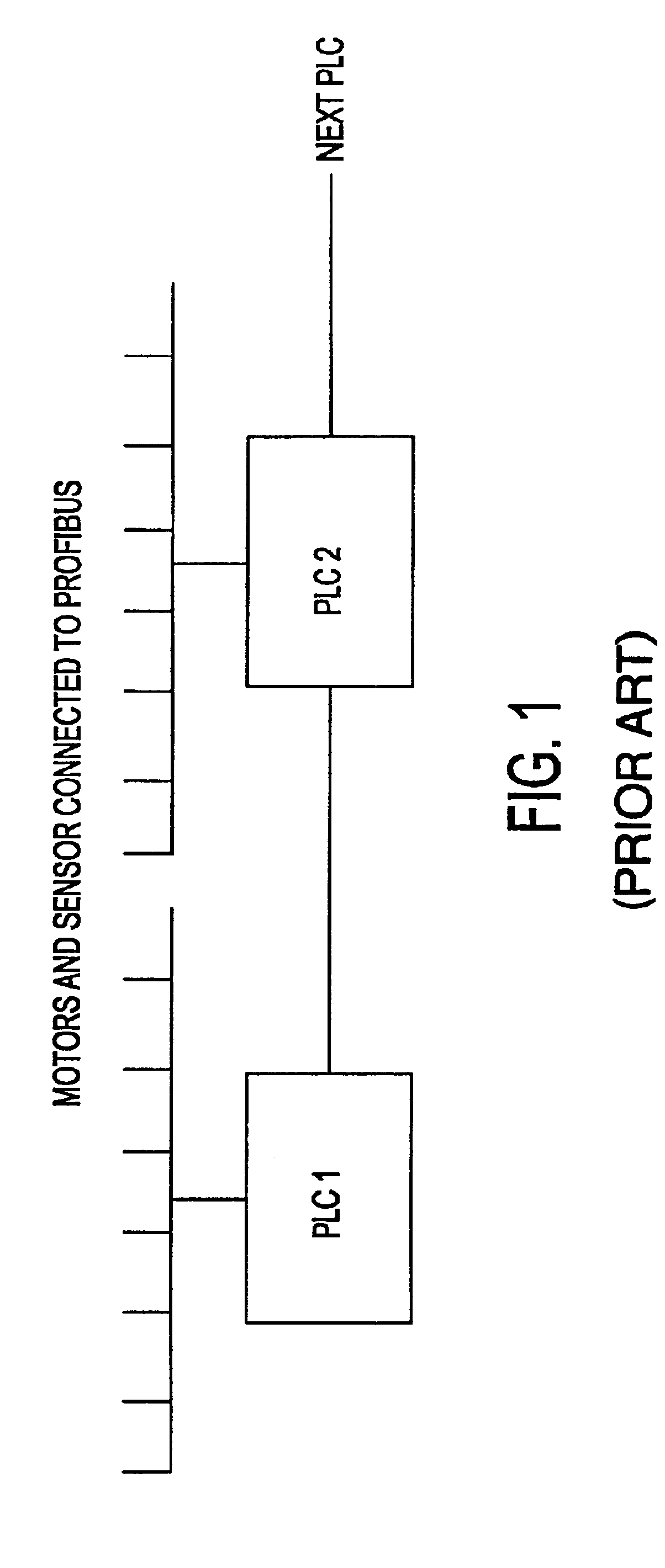

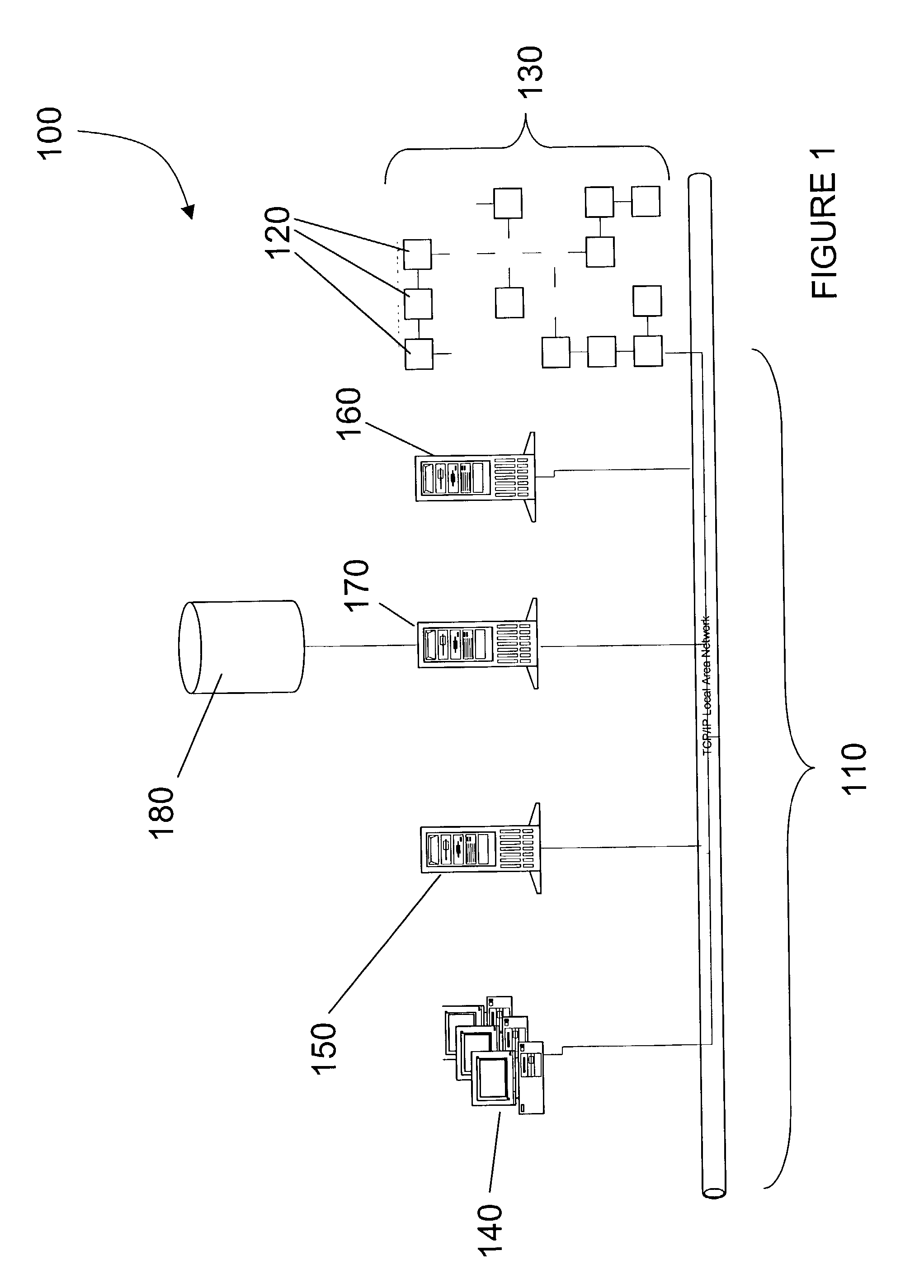

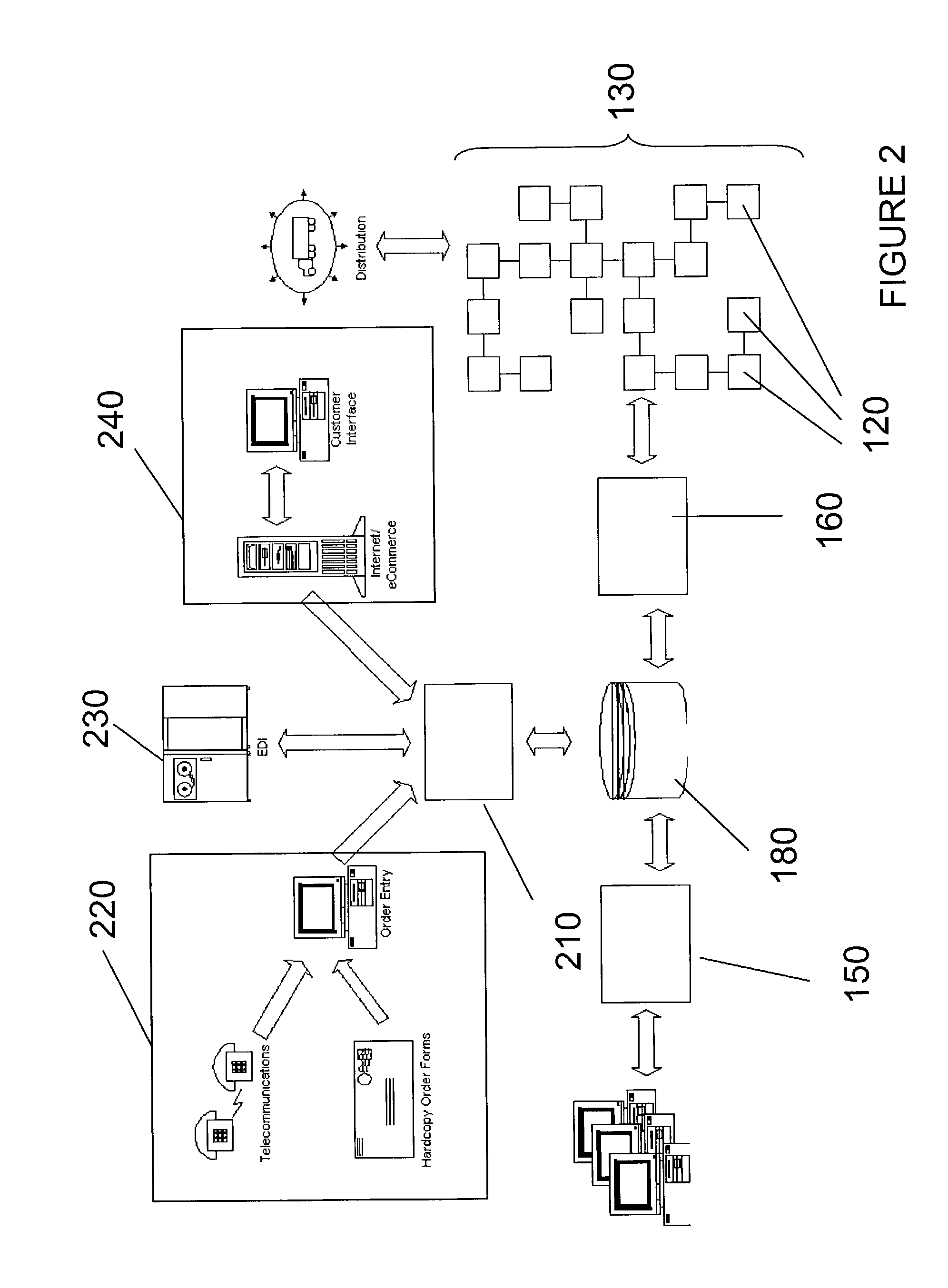

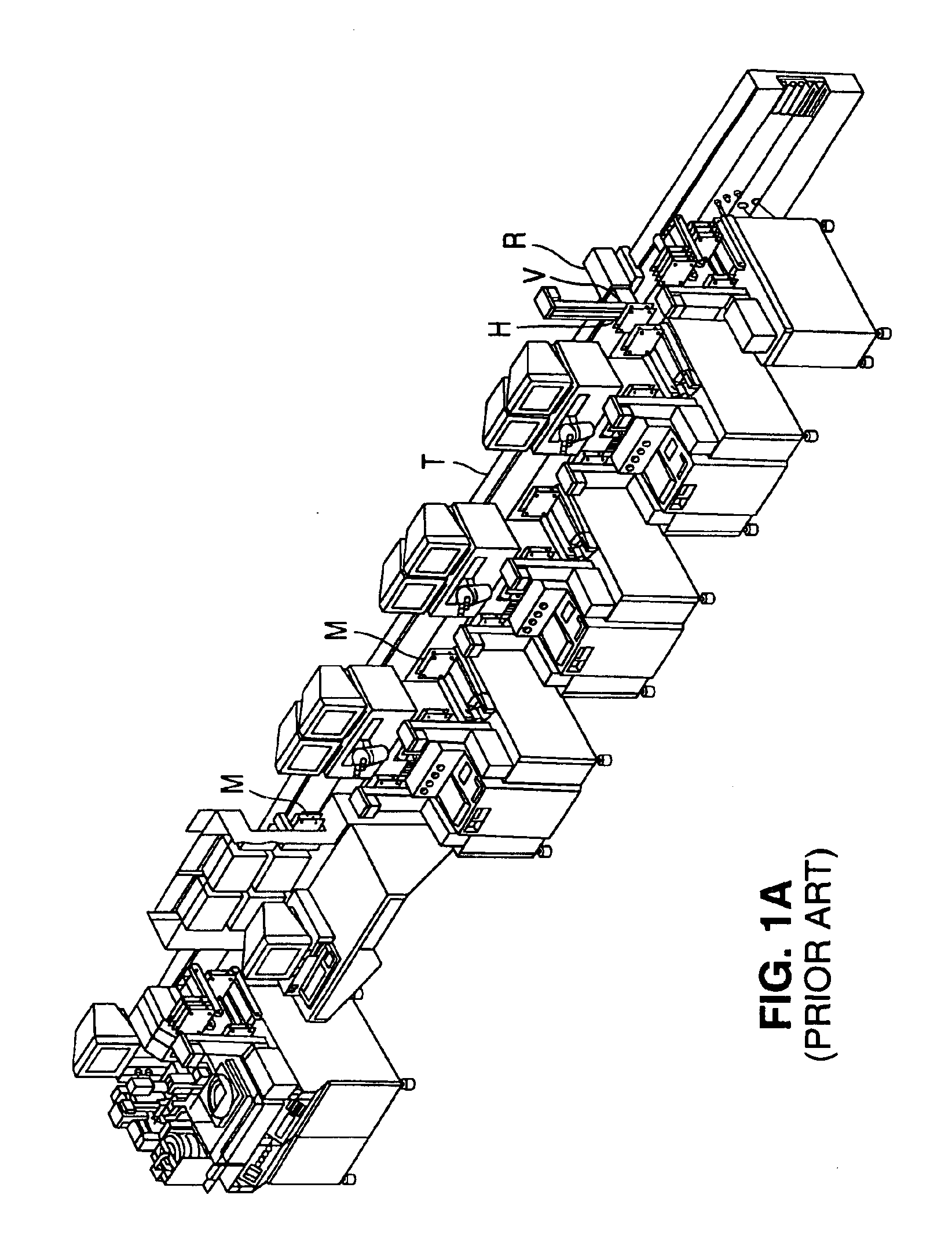

Distributed control system architecture and method for a material transport system

InactiveUS6853876B2Computer controlDigital data processing detailsTransport systemDistributed control system

An automated transport system for use in a material handling system. The automated transport system employs a distributed control system including a top level controller (transport controller), a plurality of second-level controllers (control logic computers) and a plurality of third-level controllers (intelligent drivers). The transport controller (TC) receives material commands from a conventional material control system (MCS). The TC breaks the command into sub-commands directing selected control logic computers (CLCs) to acquire, move to a destination or otherwise interact with a particular container designated by the MCS command. The transport controller selects the CLCs based on the transport system topology, the content of the MCS command and knowledge of which regions of the transport system are controlled by respective CLCs. Each CLC implements the sub-commands by issuing to the intelligent drivers low level control commands to accelerate, elevate, rotate, load or unload the container. Each intelligent driver directly controls one of the electromechanical devices that compose the transport system hardware in accordance with these low level commands. The electromechanical devices can include rail sections (zones), directors, elevators, load port transfer devices and tag readers.

Owner:MURATA MASCH LTD

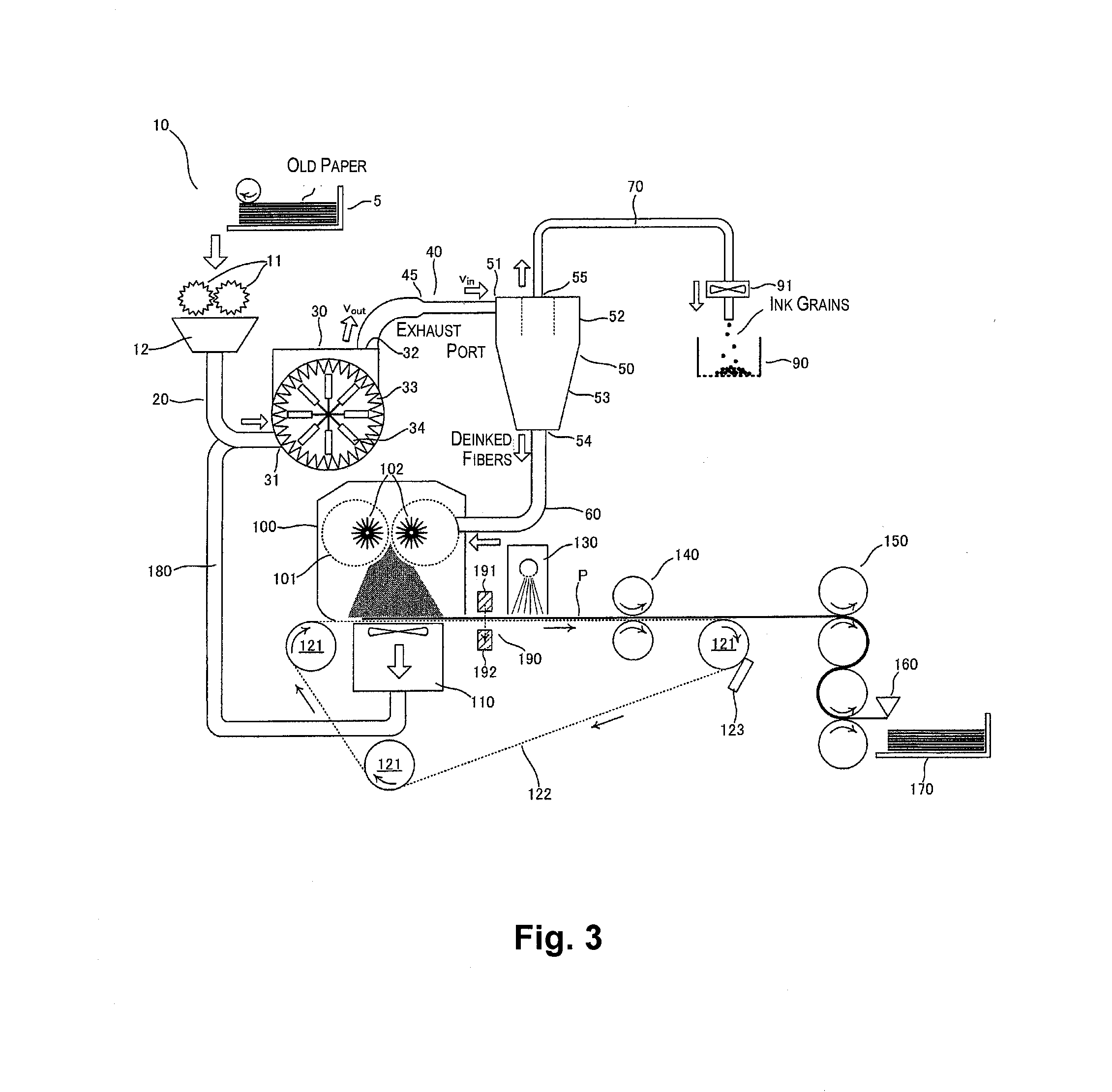

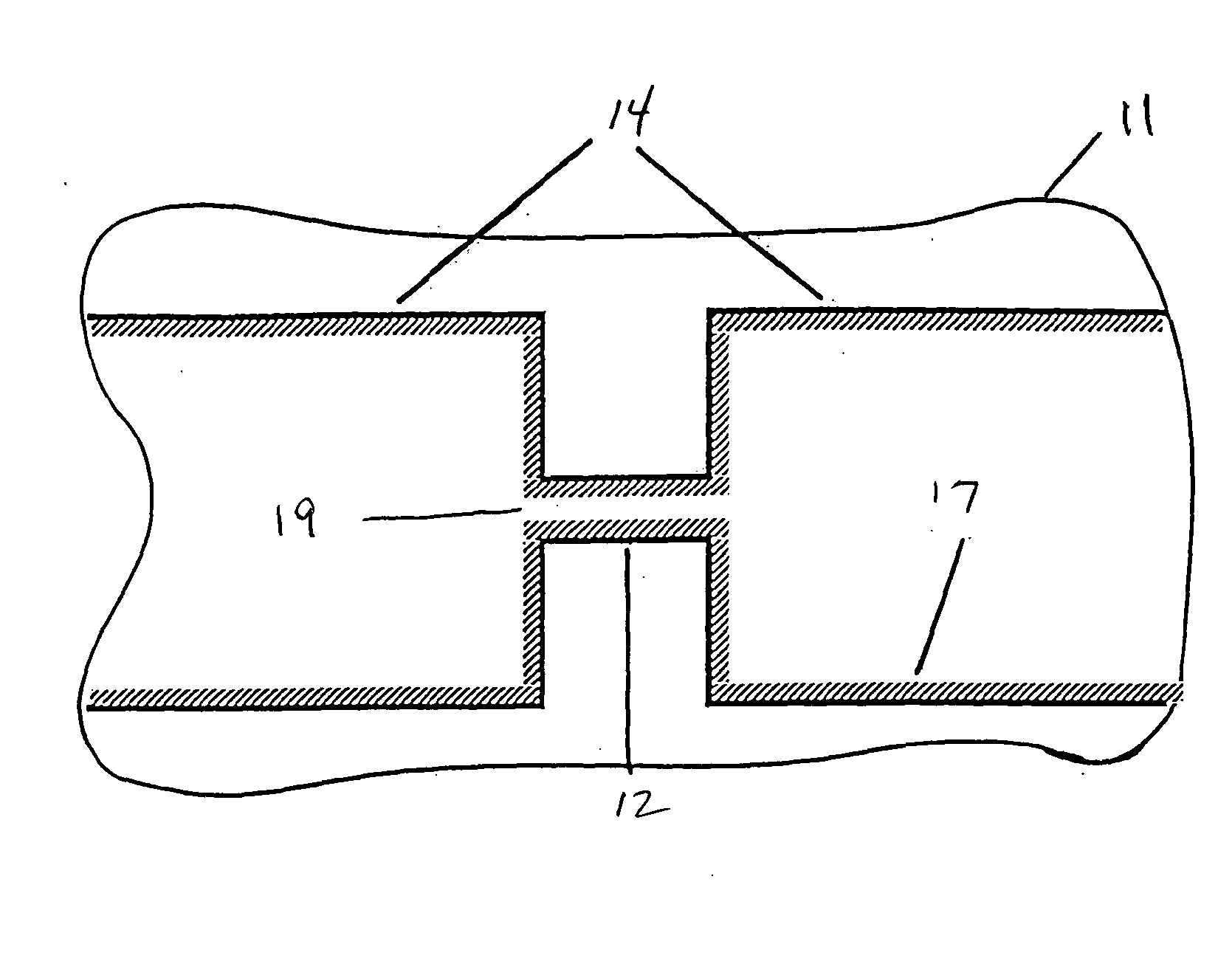

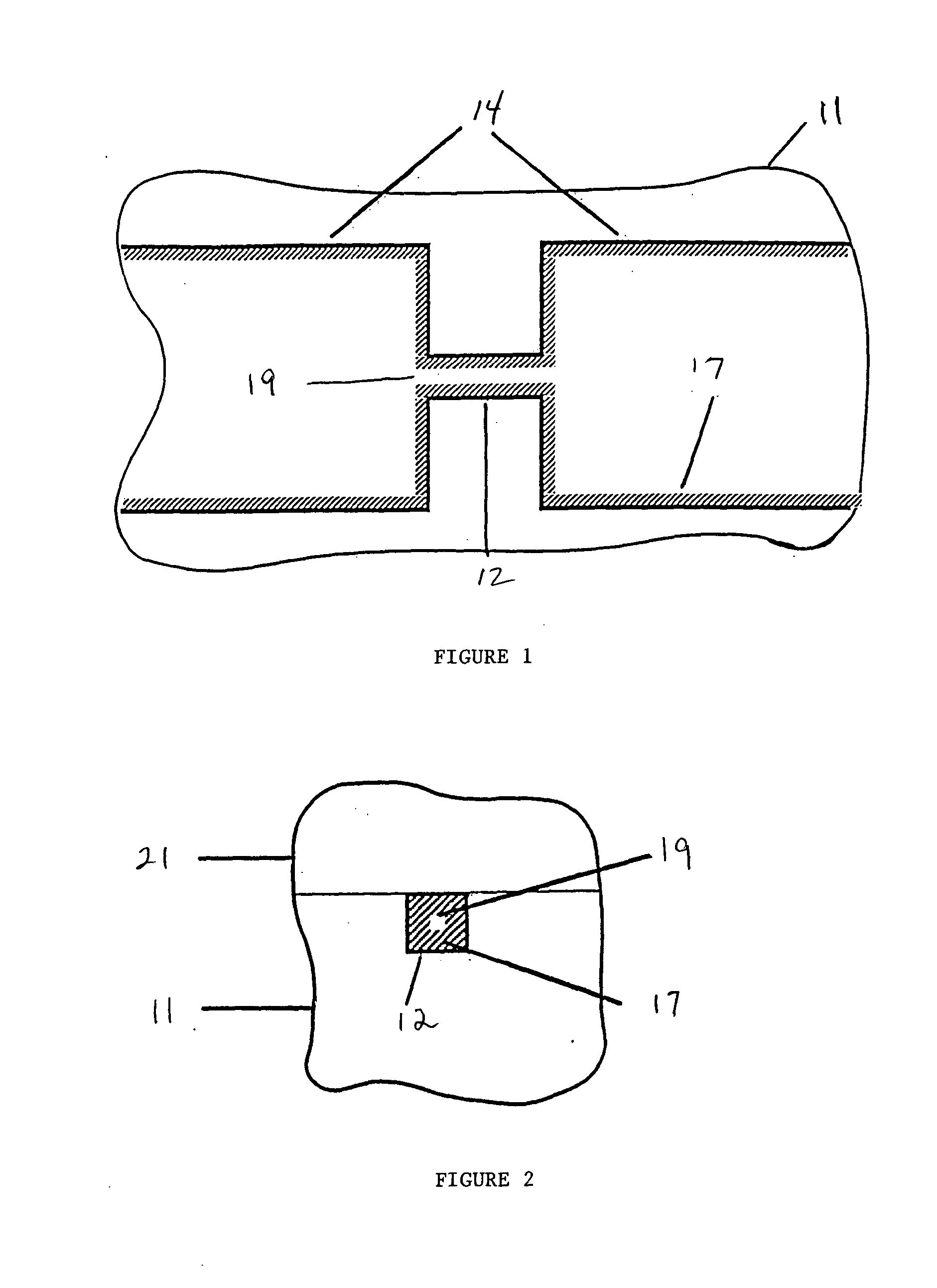

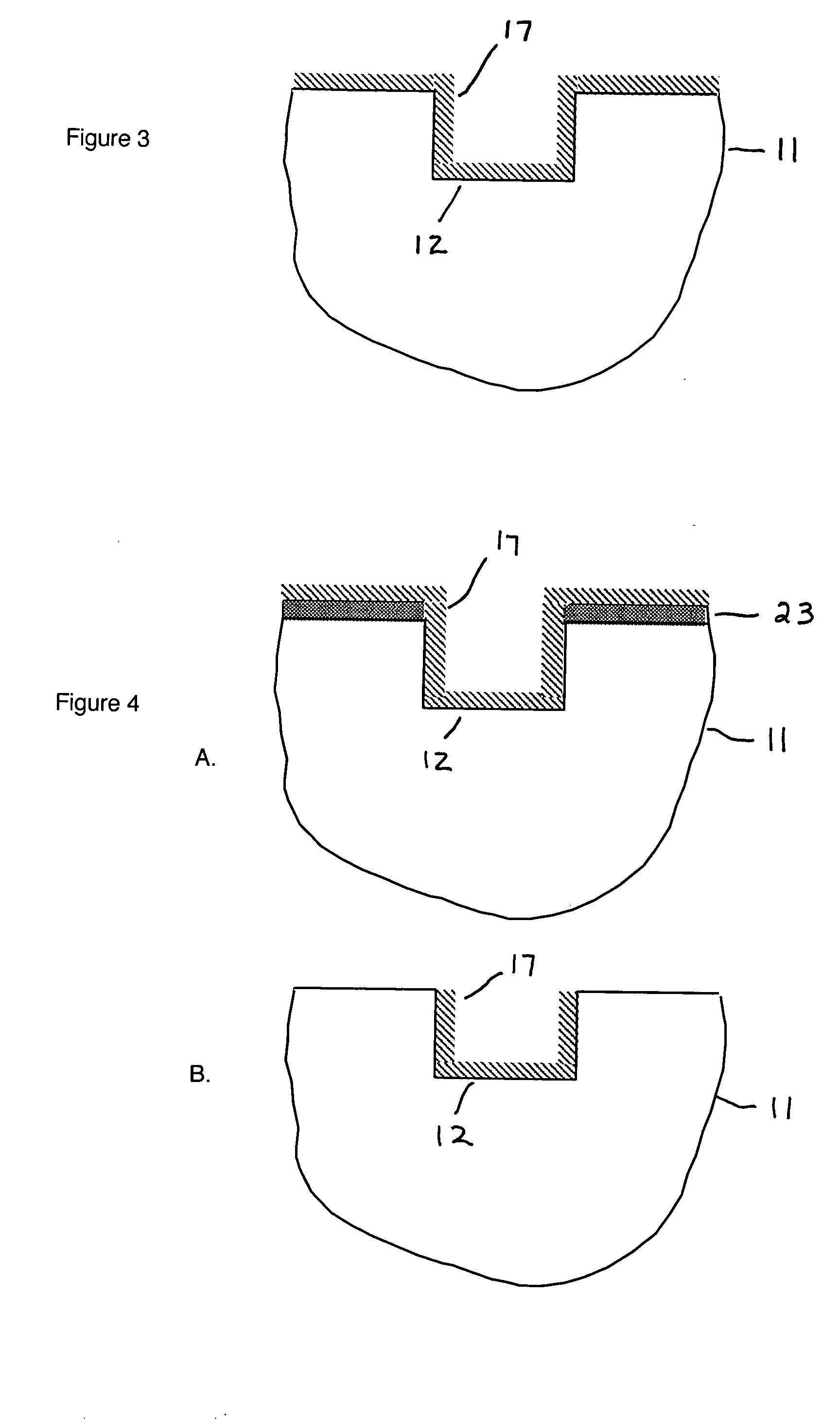

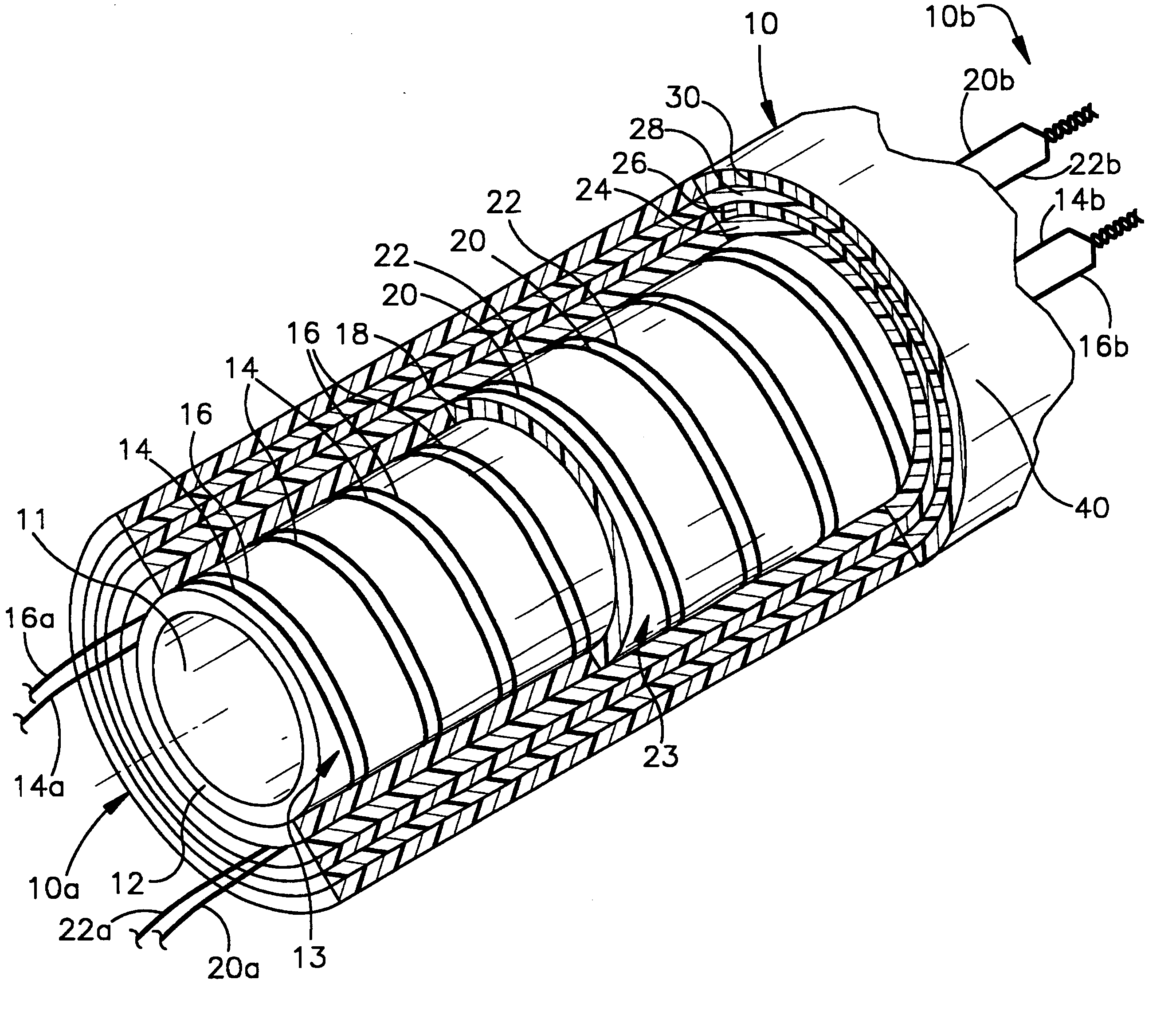

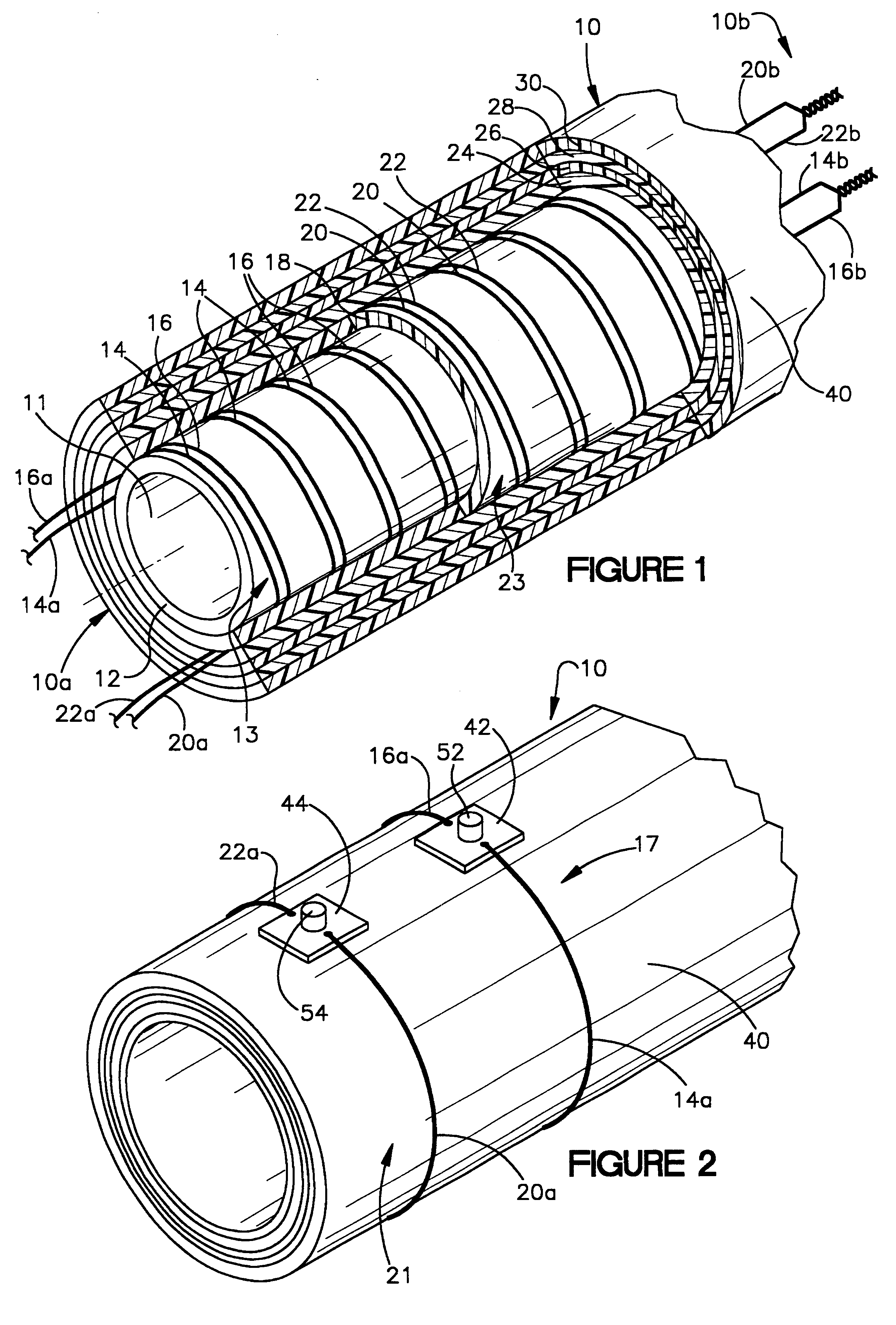

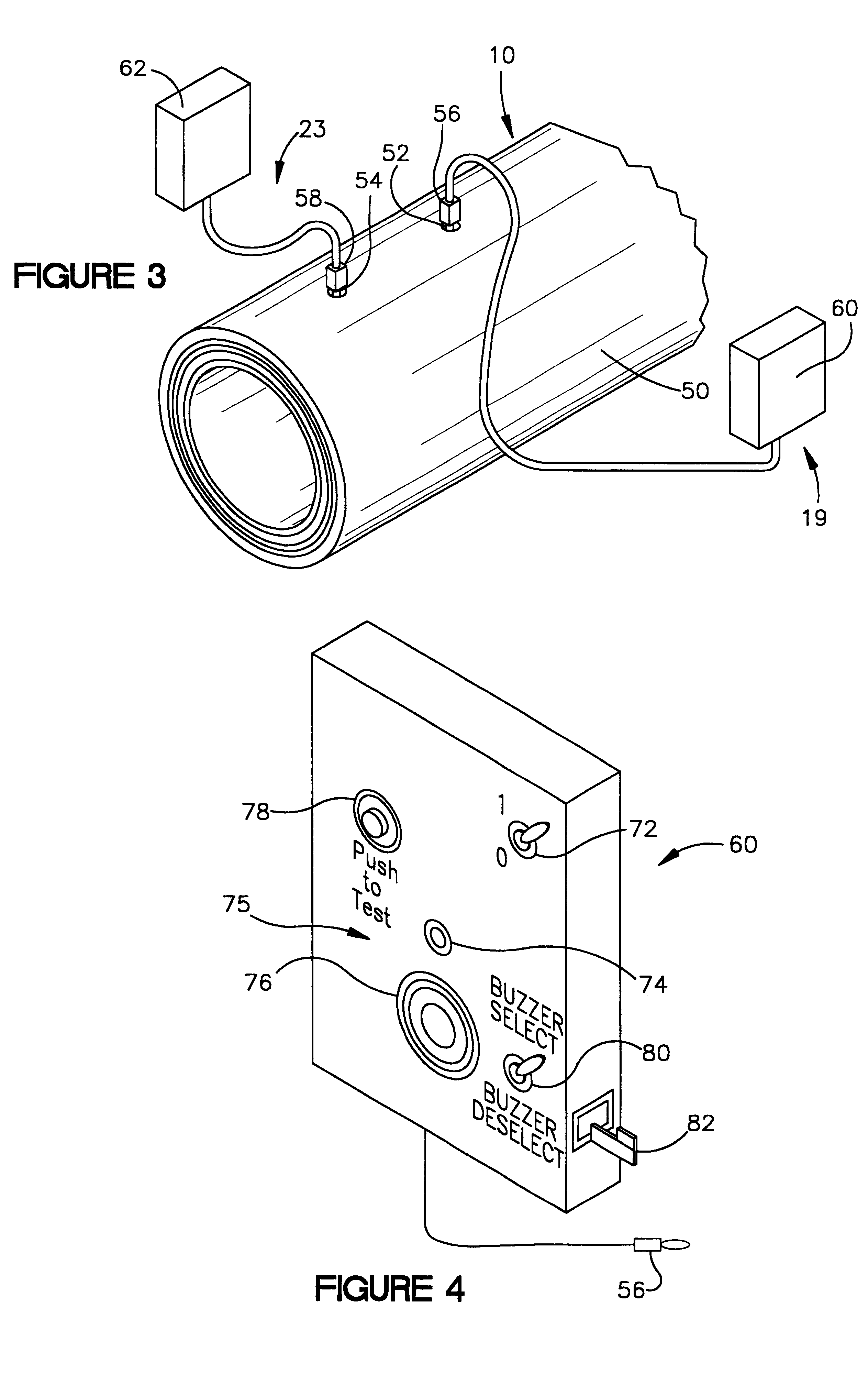

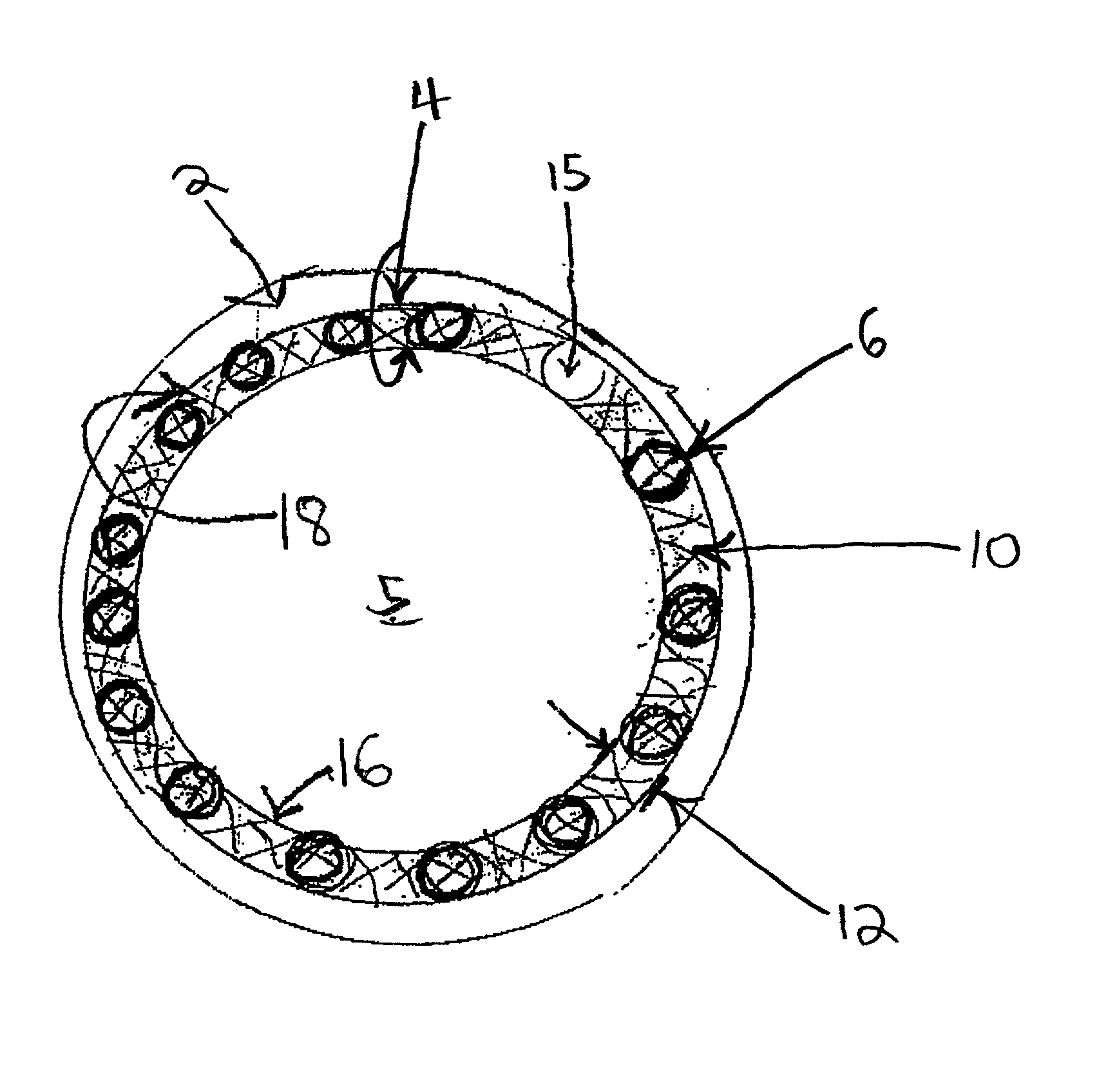

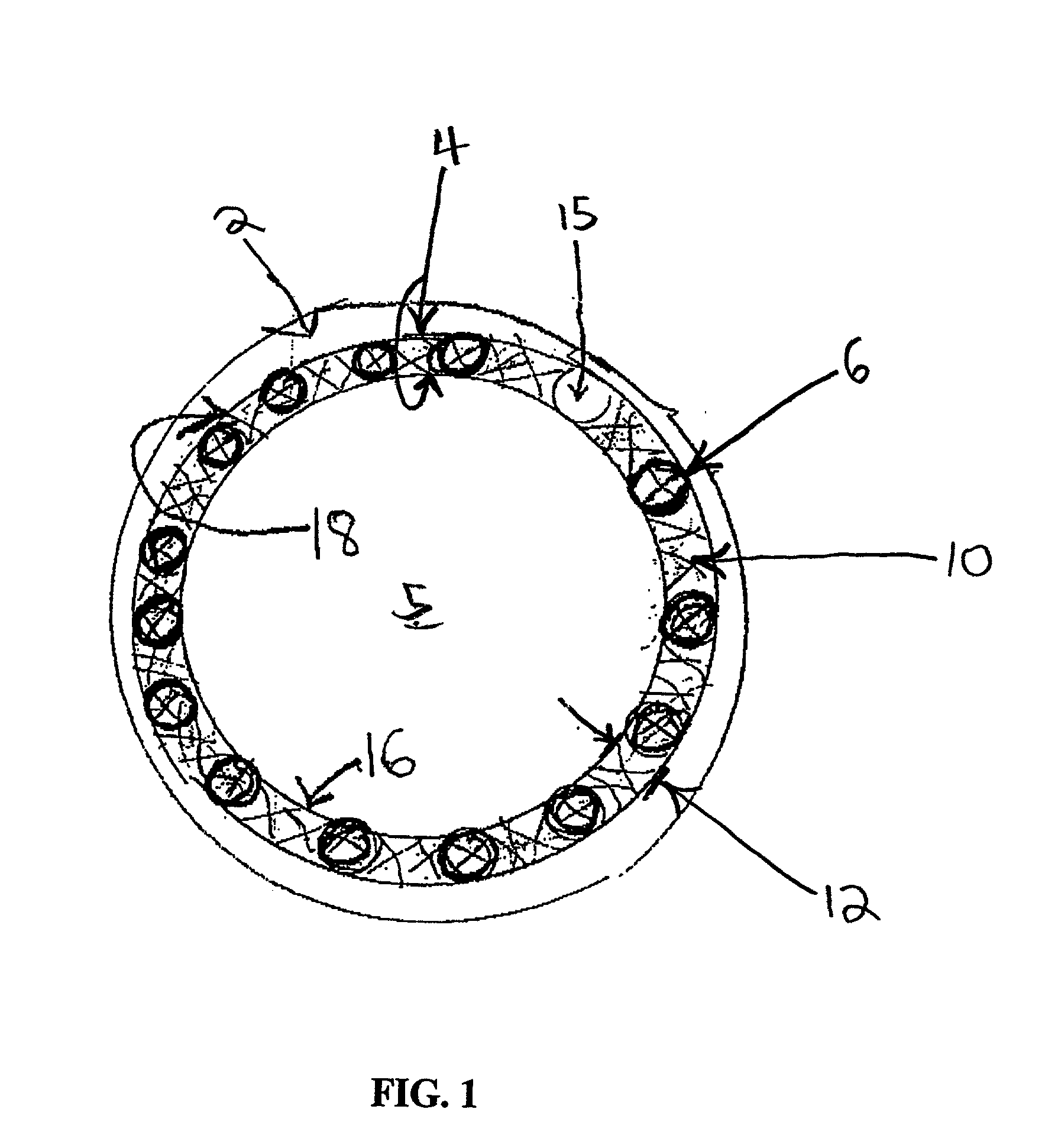

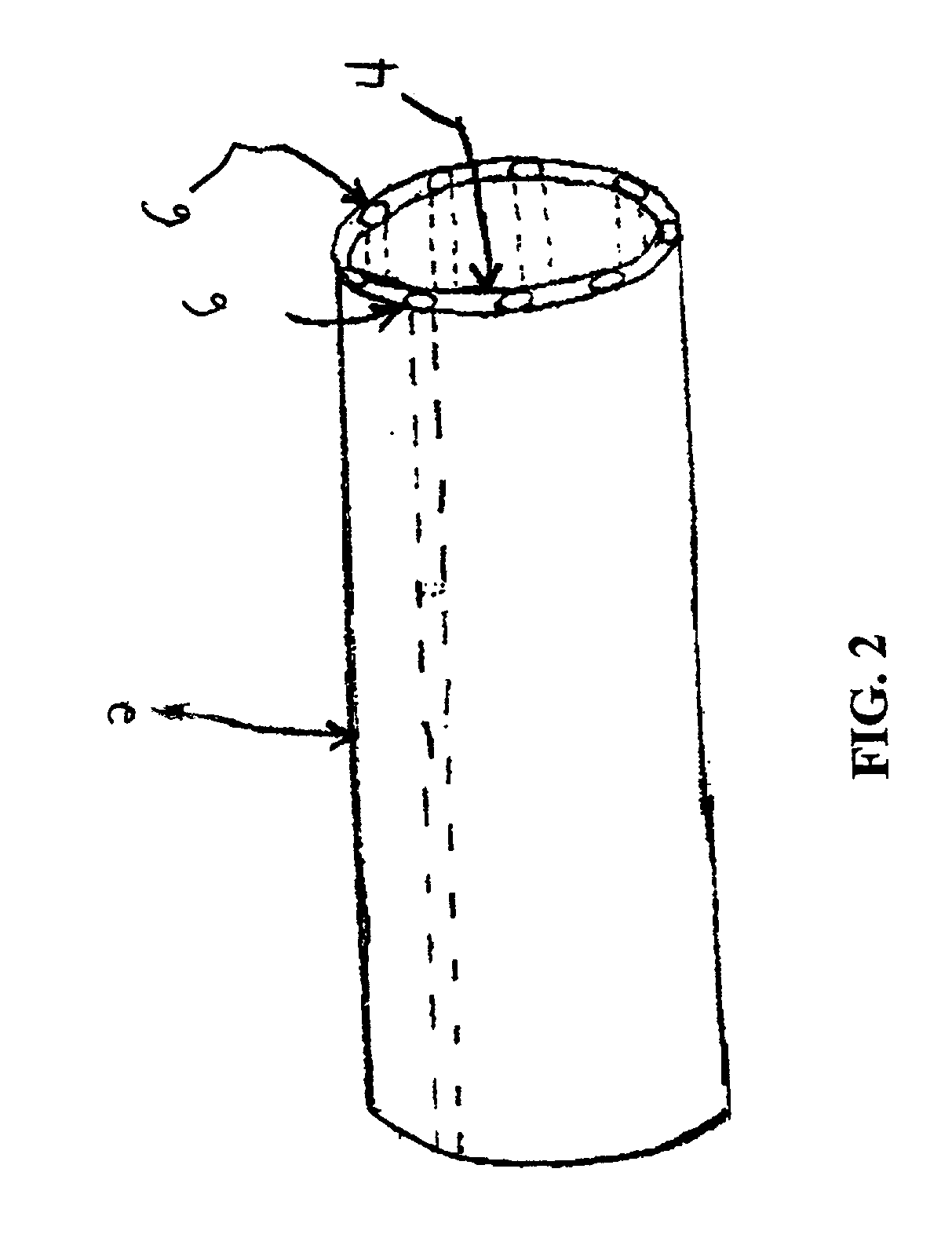

Abrasive material transport hose with wear detecting sensors

InactiveUS6386237B1Easy to replaceMaximum service lifePipe elementsFluid-tightness measurementEngineeringMaterial transport

The useful life of an abrasive material transport hose (10) can be maximized if the hose is repositioned at the first signs of internal wear. This is accomplished by disposing at least two wear sensing elements (17, 21), each at a specified distance from the inwardmost surface of the inner tube (12), and each monitoring a condition indicative of wear of the hose (10) at its specified distance from the inwardmost surface of the inner tube. When the innermost wear sensing element (17) implies wear, the hose can be repositioned to extend the useful life until the outermost wear sensing element (21) indicates wear requiring replacement of the hose.

Owner:CONTITECH USA INC

Paper recycling system and paper recycling method

Owner:SEIKO EPSON CORP

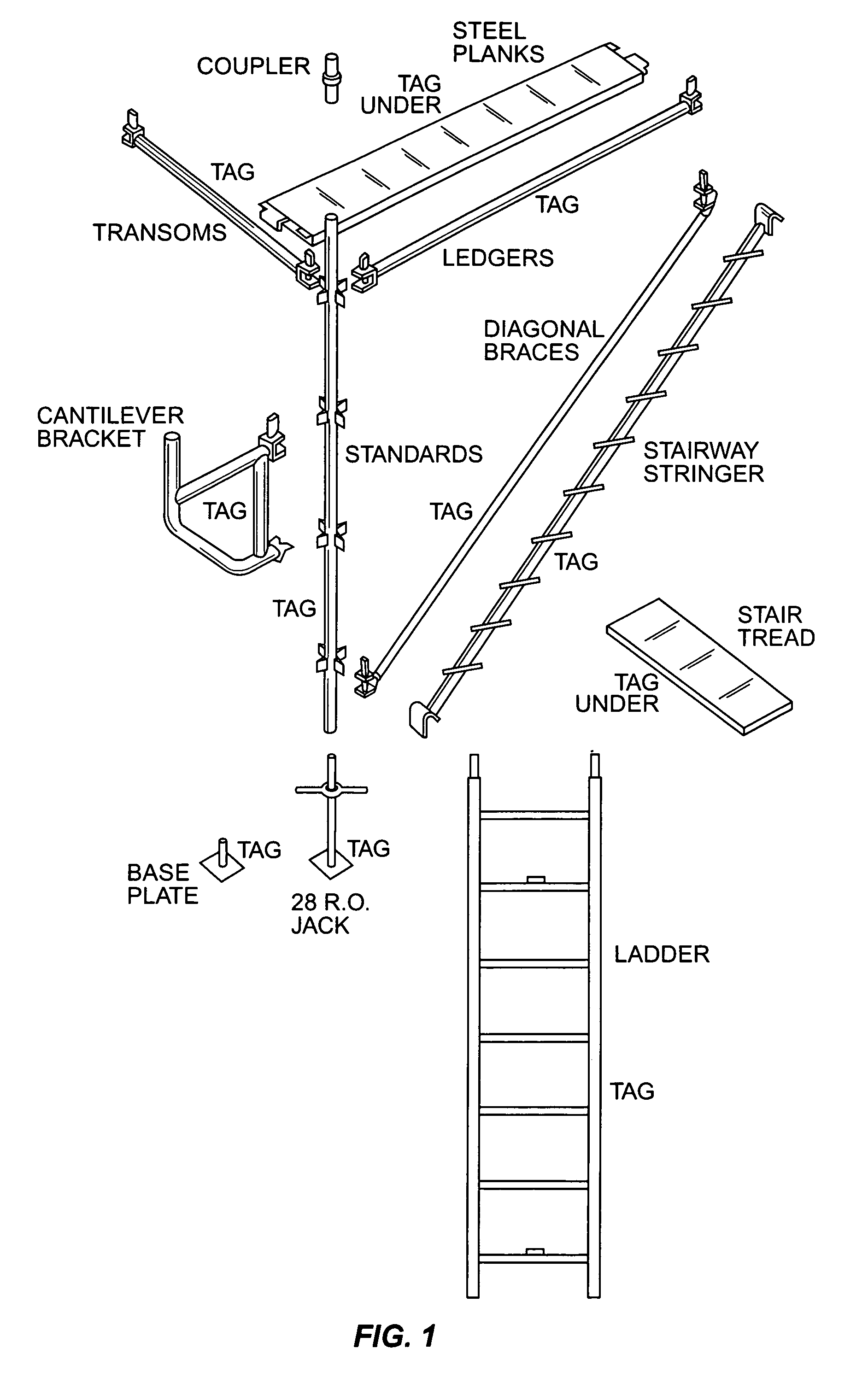

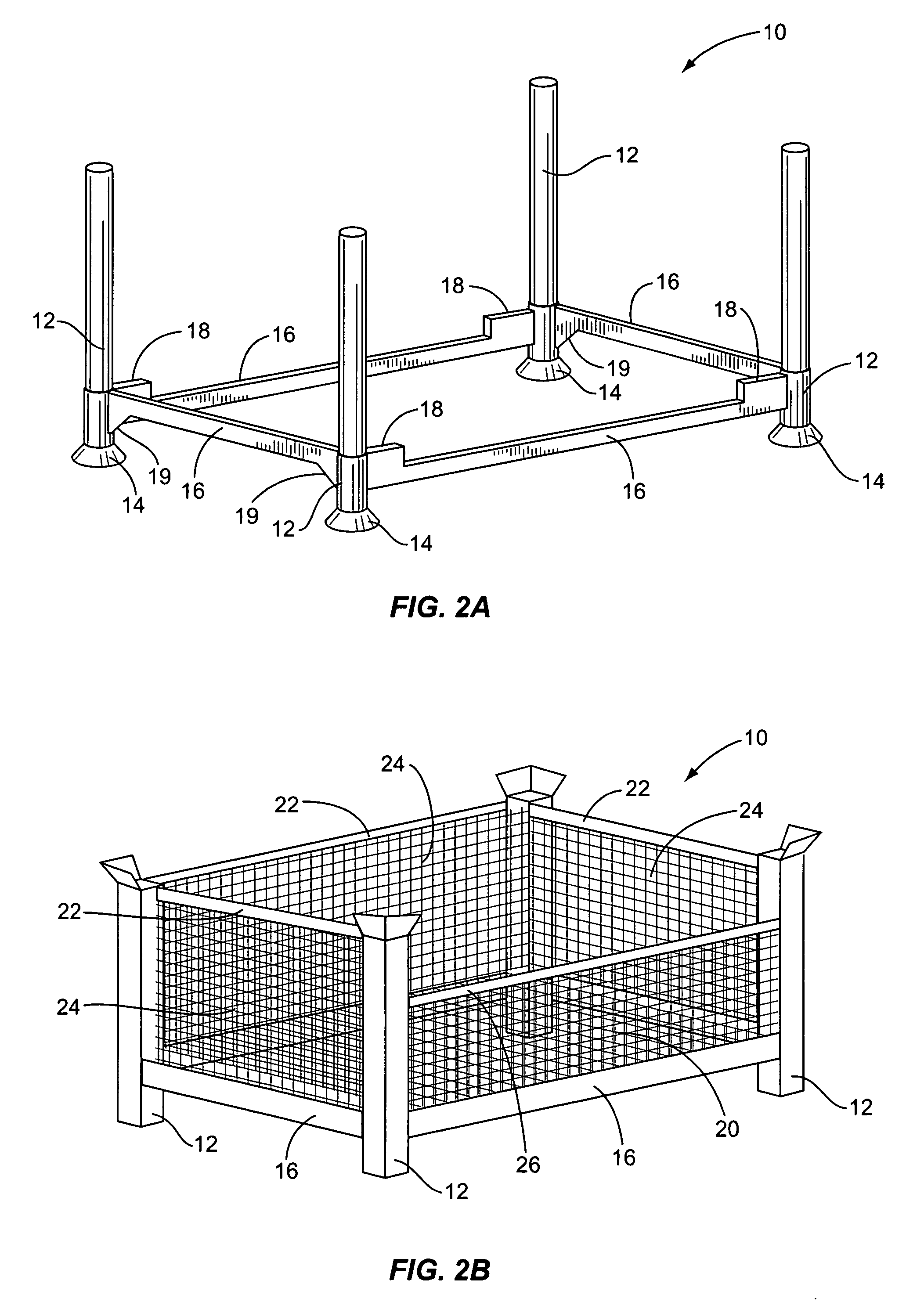

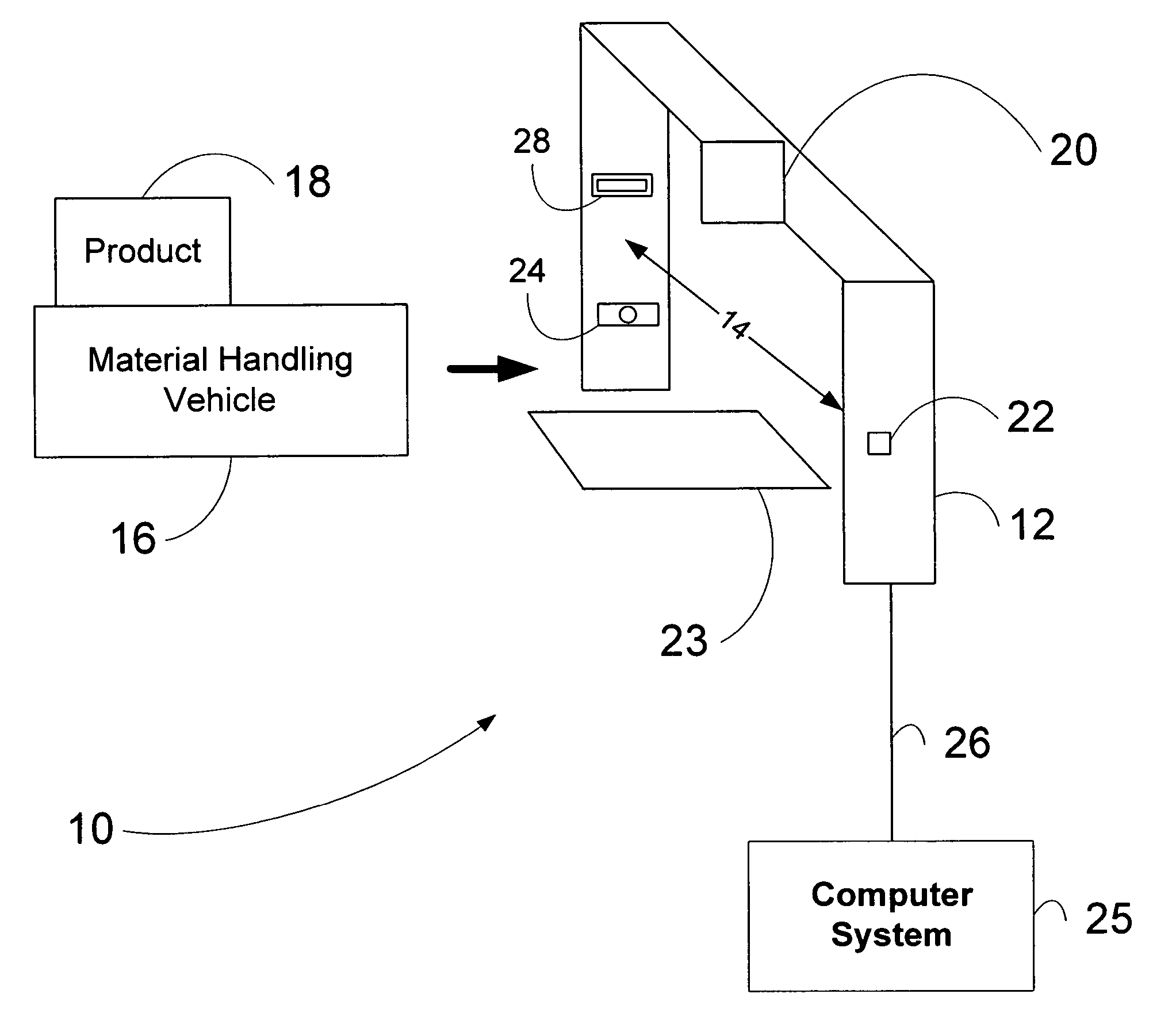

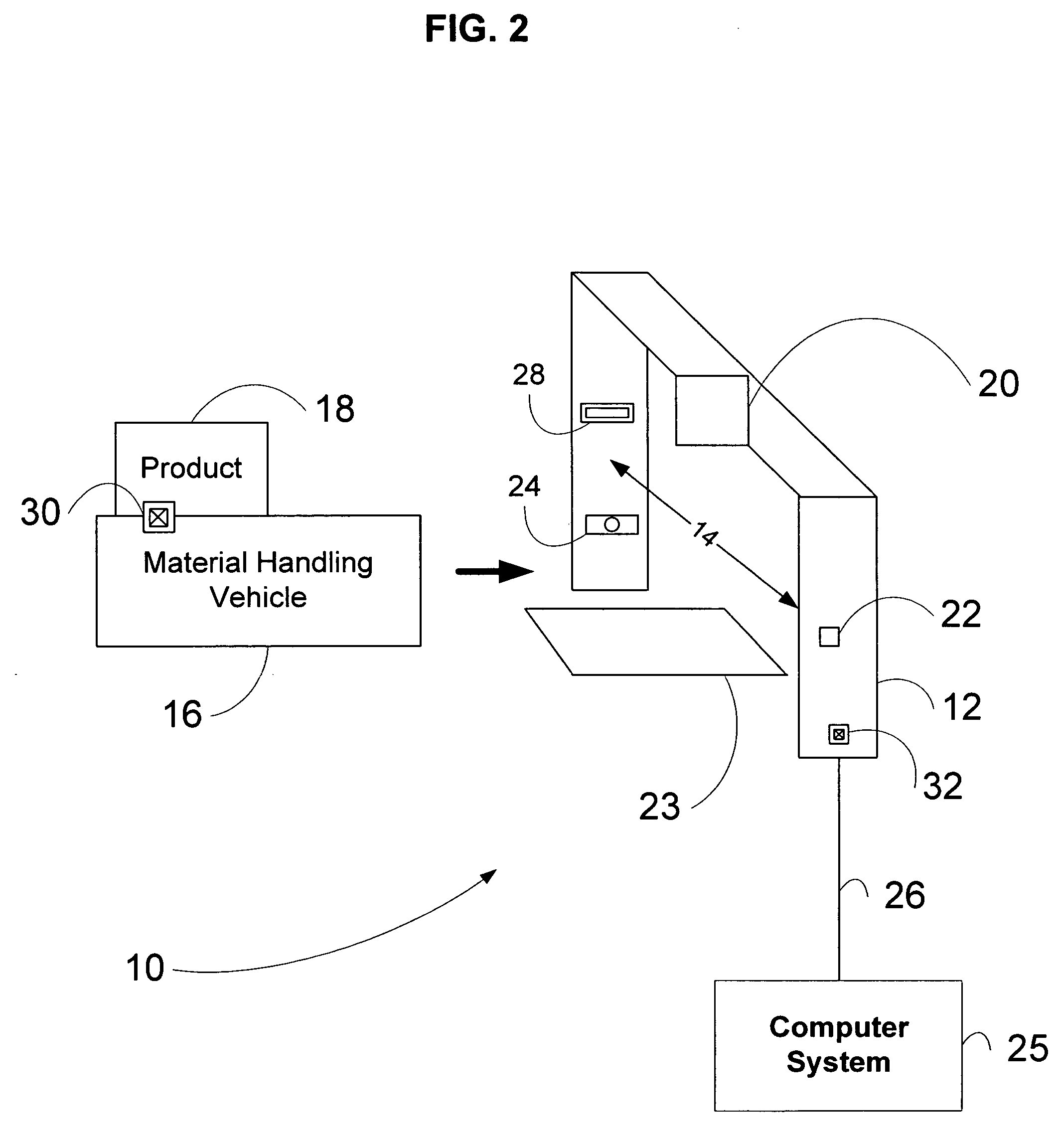

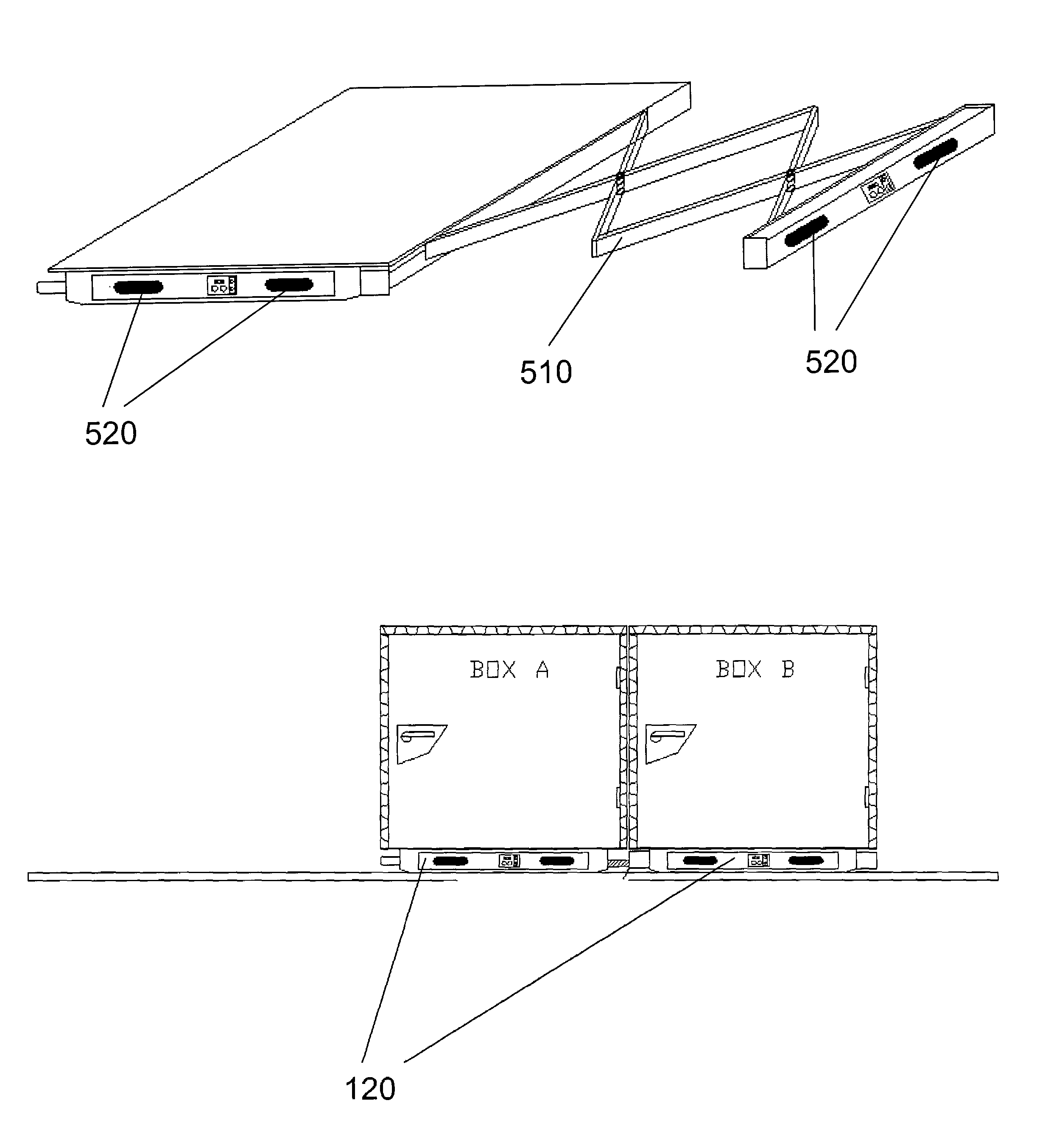

Intelligent reader system and method for identifying and tracking goods and materials transported in pallets, including but not limited to scaffolding materials

InactiveUS20060232412A1Automatically determineEliminate requirementsCo-operative working arrangementsSensing record carriersEngineeringIdentification device

An intelligent tracking system designed to accurately detect and track goods and / or materials present within a pallet. An identification reader is coupled to the pallet and used to detect identification devices, such as RFIDs, that are attached to the goods or materials contained therein. The pallet is constructed in a manner to allow and limit the identification reader to detect the identification devices that are contained only within the attached pallet. Thus, identification devices are automatically detected by the identification reader and information relating to the identification devices is stored in a database in order to track the contents of a specified pallet. In this manner, goods and / or materials can be continuously and accurately tracked for shipping or storing purposes in order to provide real-time tracking capabilities.

Owner:JORGE TABACMAN & ASSOCS PL

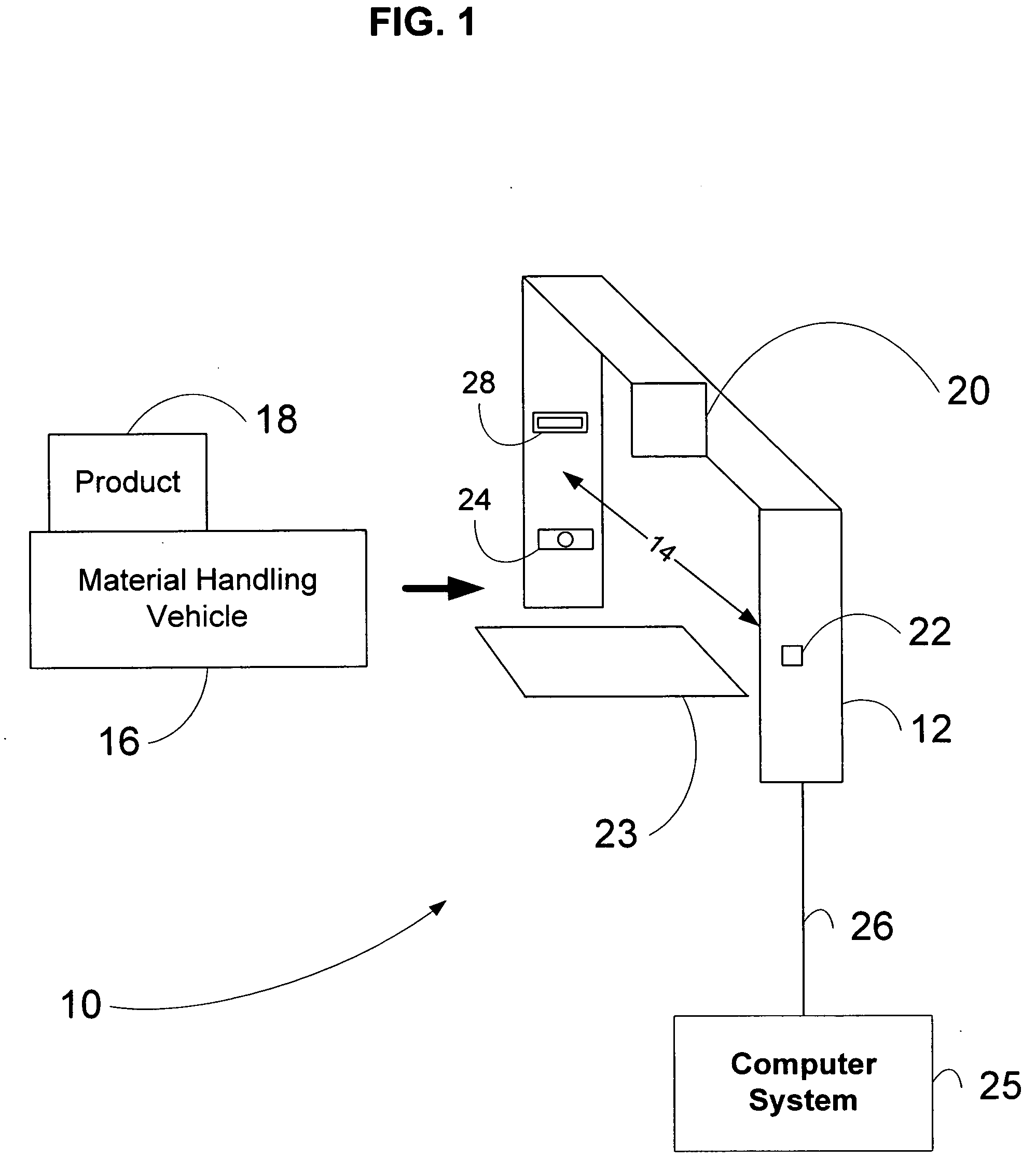

Material transport in-motion product dimensioning system and method

Methods, systems, and devices to obtain dimensions of an article or product in association with material handling vehicles are disclosed. A dimension detection device is installed in an enclosure and is used to acquire geometrical dimensions of the object in association with the vehicle. A predetermined dimension of the vehicle is subtracted from the overall detected dimension to determine the dimensions, including weight, of the product alone. One or more dimension detection devices may also be positioned on a mast or other portion of the material handling vehicle allowing the material handling vehicle to act as a mobile product dimensioning system.

Owner:RICE LAKE WEIGHING SYST

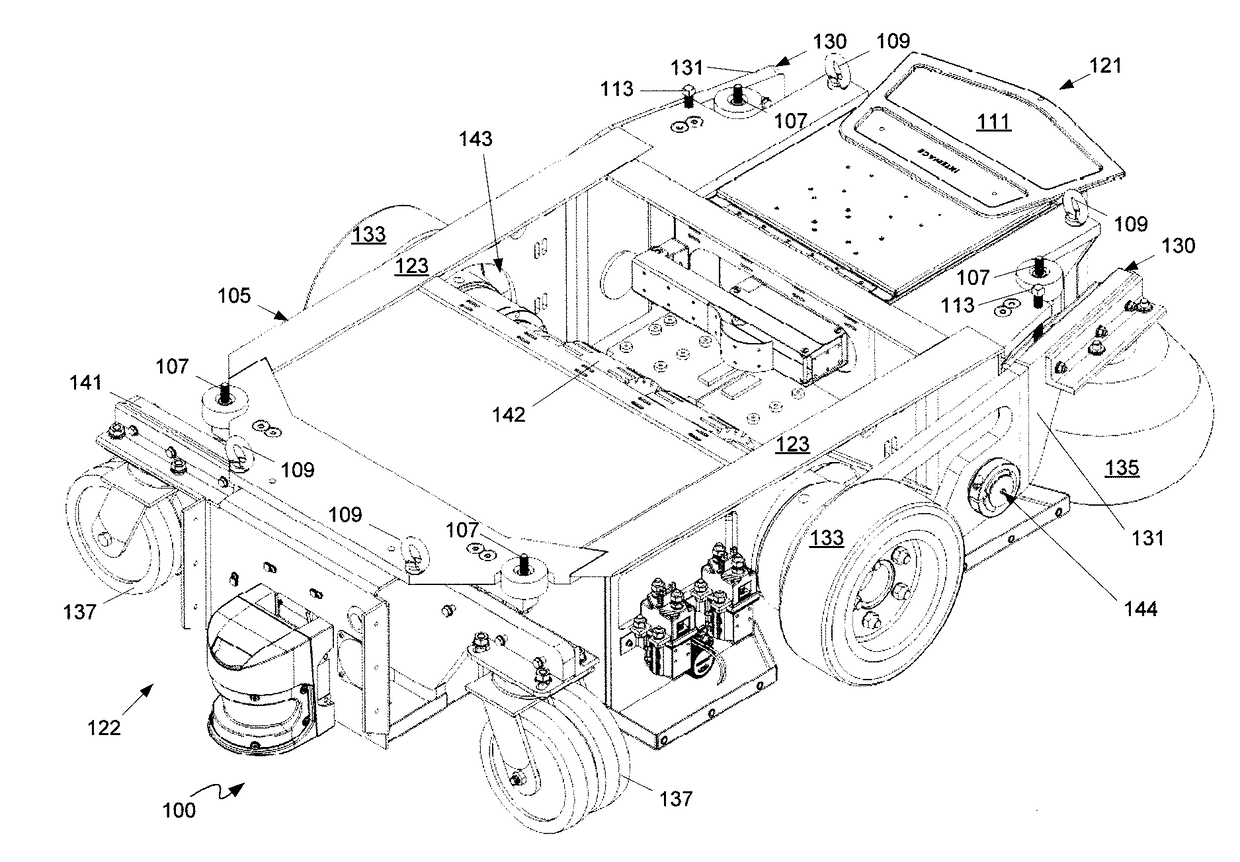

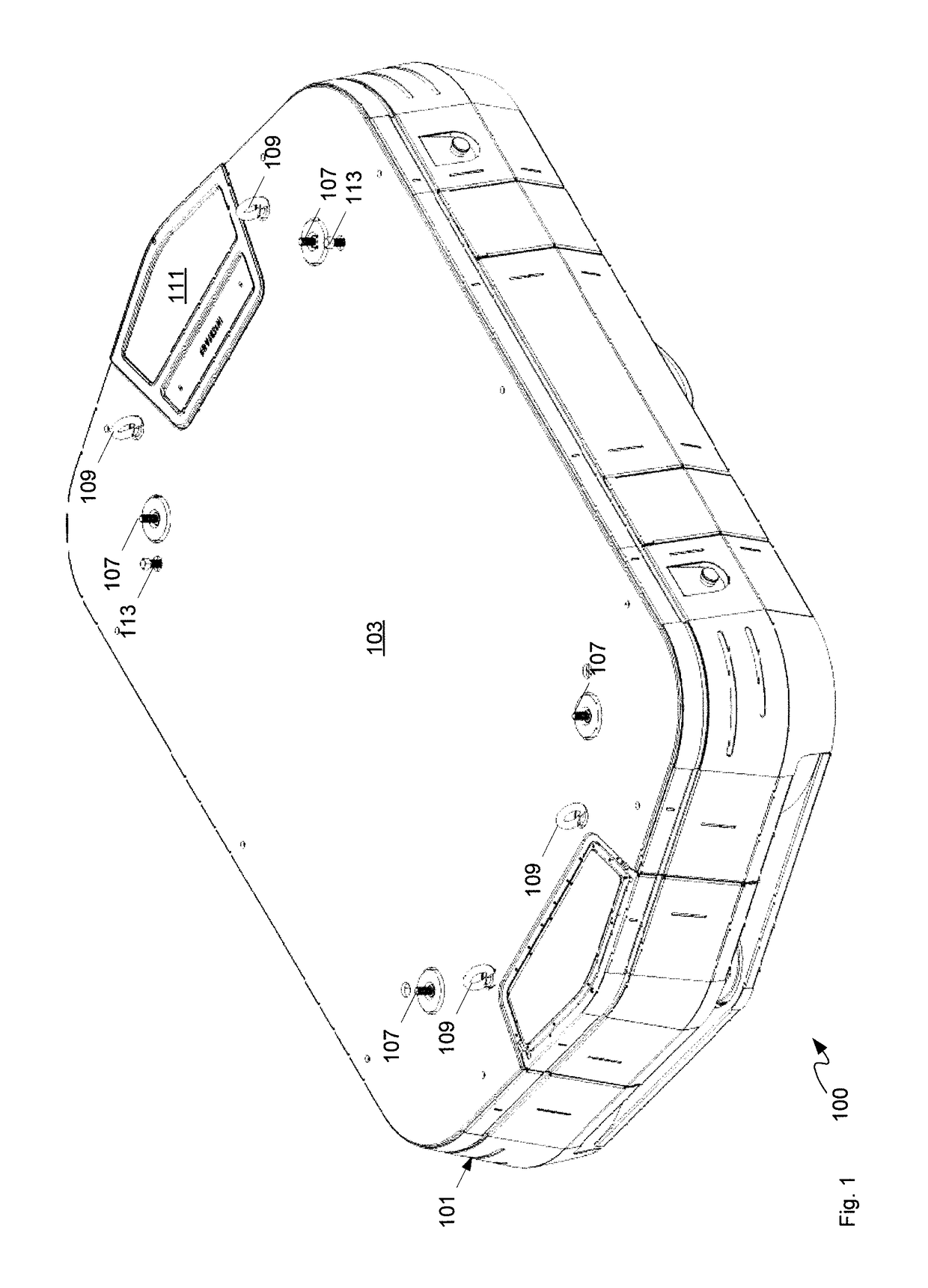

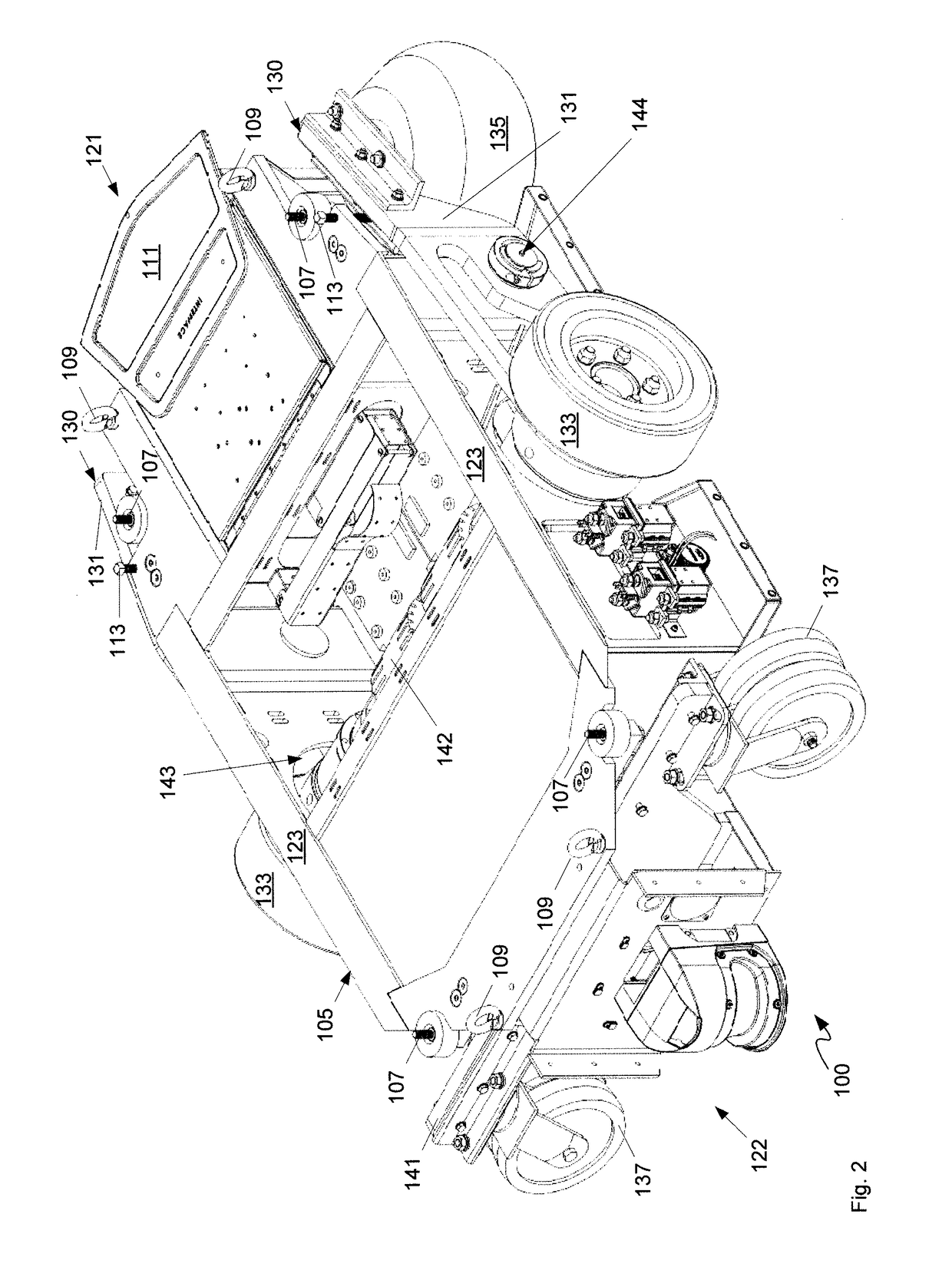

Mobile platform for materials transport

A mobile platform for materials transport is provided. The platform includes a pair of suspension devices that in turn include a pair of rocker beams which can be rotated between two positions: a first position where central wheels attached thereto can be used to drive the platform; and a second position where the central wheels are retracted and the platform can be rolled on end wheels without the friction of the central wheels, and an associated drive system, impeding movement of the platform. Furthermore, data from sensors and / or load cells can be used to control movement of the platform; specifically, shifts in load distribution and / or sensed forces at the suspension devices can indicate that a load (and / or materials) has shifted and / or is shifting and movement of the platform is adjusted accordingly, for example to prevent the platform and / or the load (and / or materials) from tipping.

Owner:CLEARPATH ROBOTICS

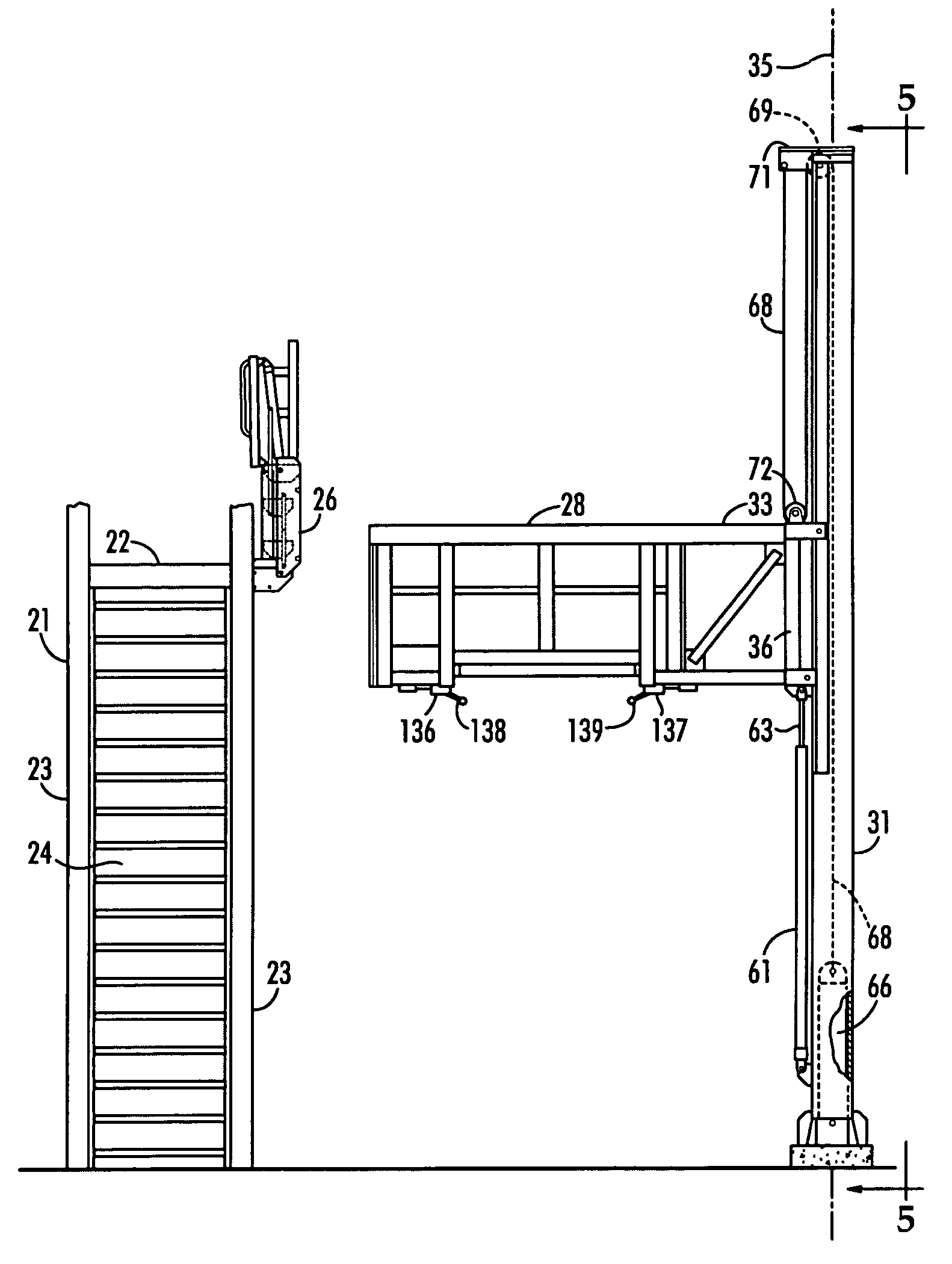

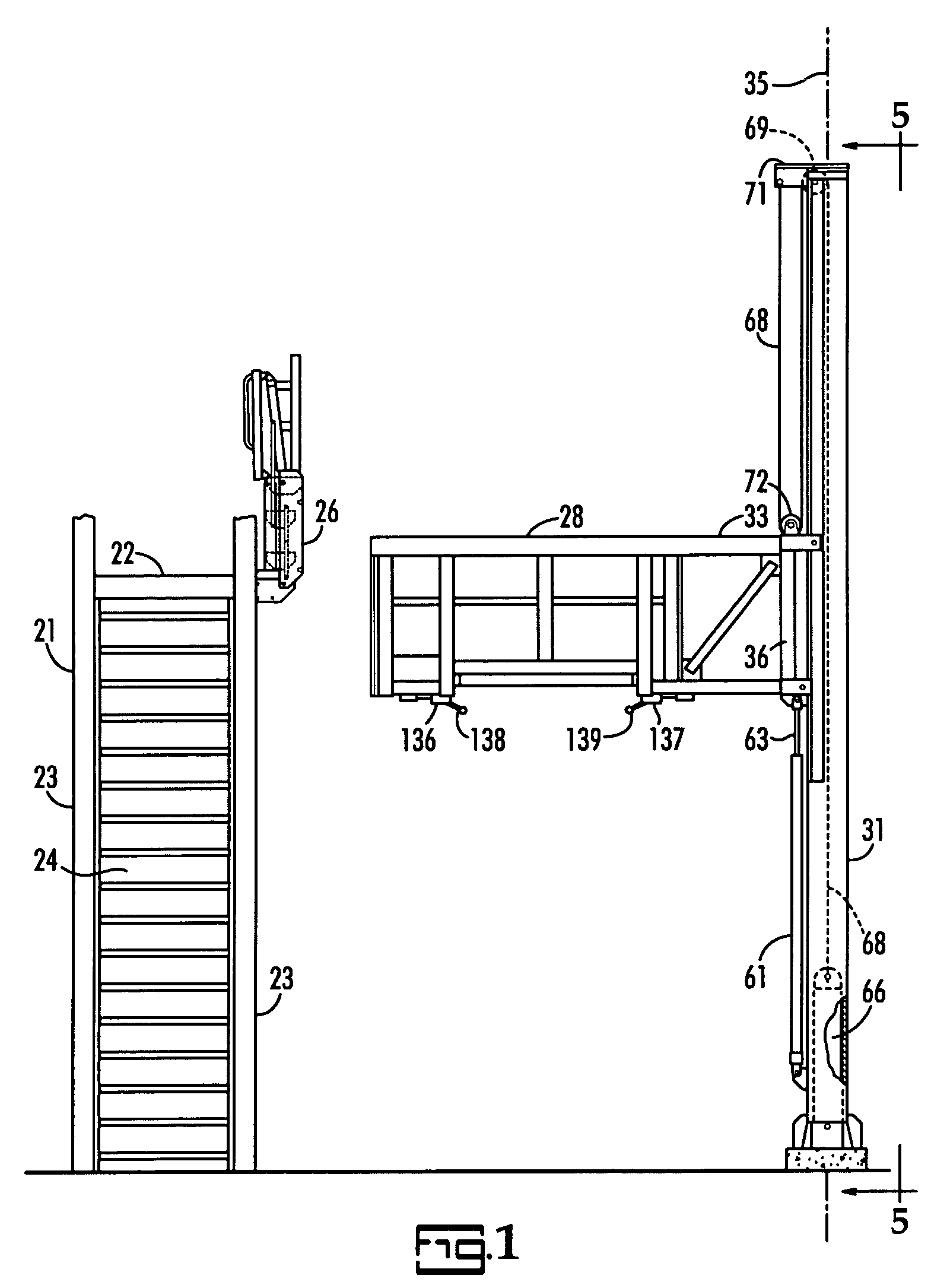

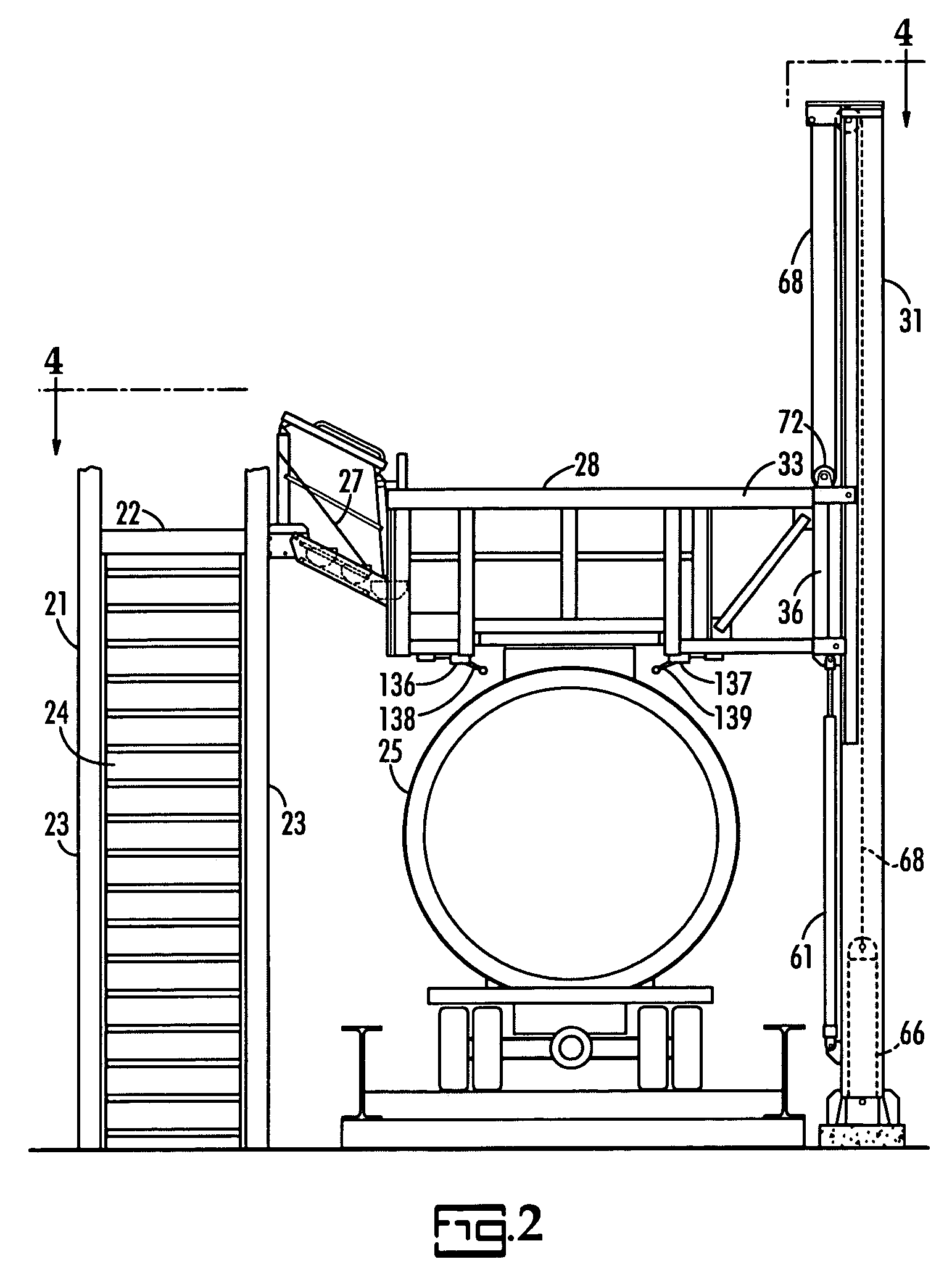

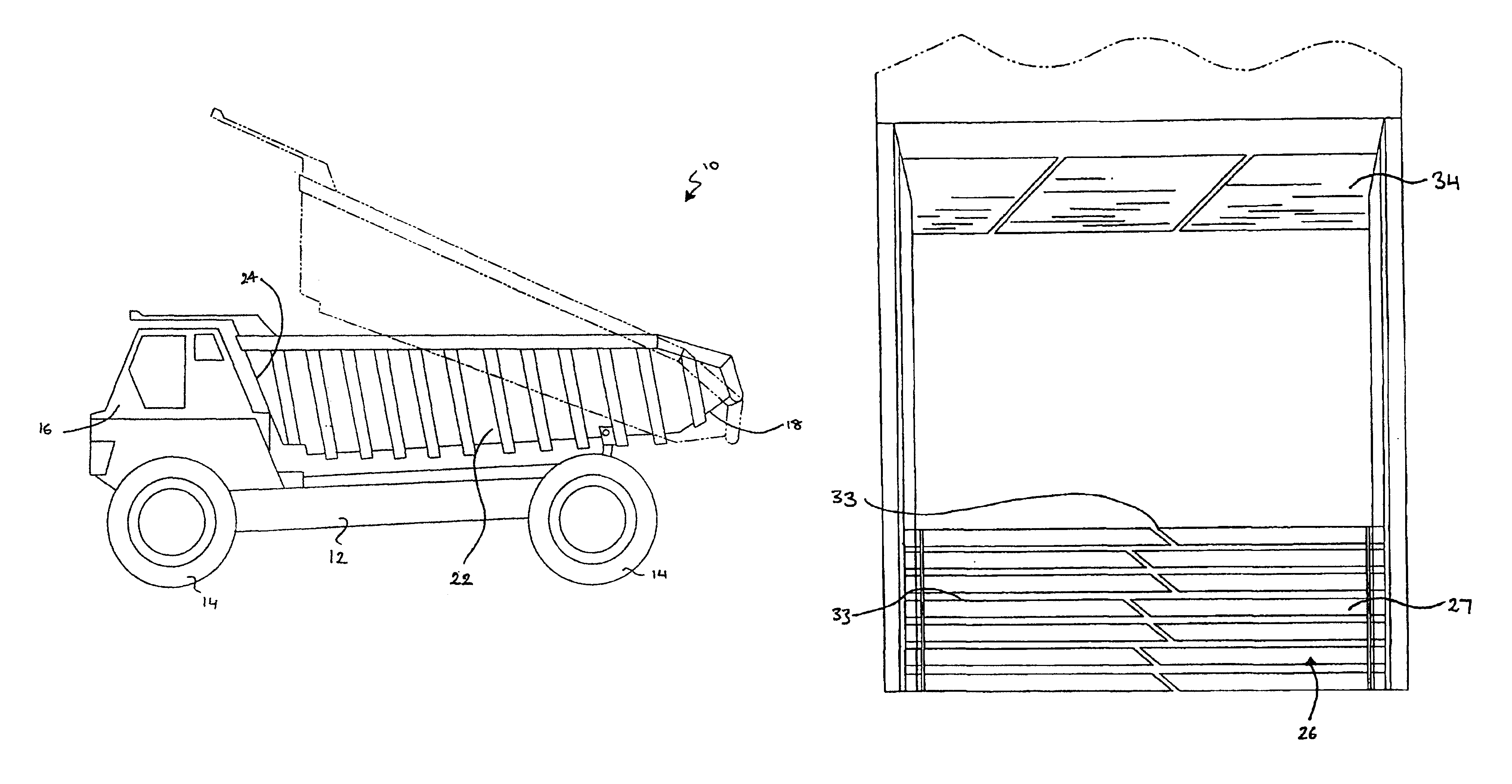

Bulk material transport vehicle access structure

ActiveUS7140467B2Inhibit bindingReduce stepsSteps arrangementBuilding support scaffoldsElectricityAccess structure

A bulk material transport vehicle access structure includes an elongated service platform for workers which is pivotally supported at its opposite ends to cantilever arms on parallel horizontal axes to avoid binding between the roller carriages of the cantilever arms and a pair of support pillars. The floor of the platform includes a walkway and a doorway covered by a plurality of side by side doors which may be selectively opened. Electric controls are provided to automatically stop operation of the power means used to control the elevation of the cantilever arms should the service platform become tilted a predetermined extent. Electric controls are also provided to stop lowering of the service platform when it reaches the top of a bulk material transport vehicle.

Owner:SAM CARBIS ASSET MANAGEMENT

System and apparatus for materials transport and storage

InactiveUS7123988B2Little strengthLow friction movementDigital data processing detailsCharge manipulationEngineeringMaterial transport

Owner:RUSSELL PAUL ROBERT +1

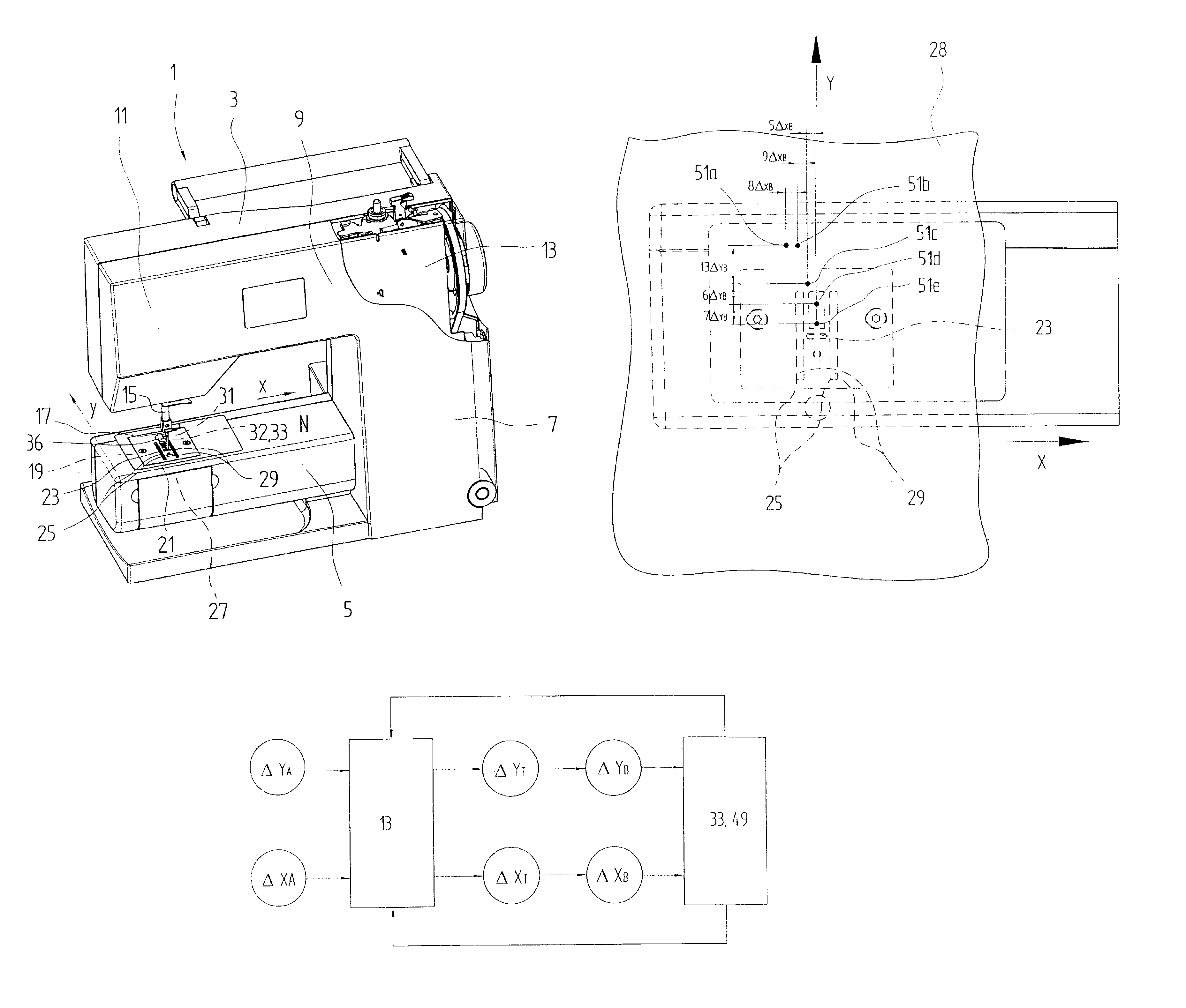

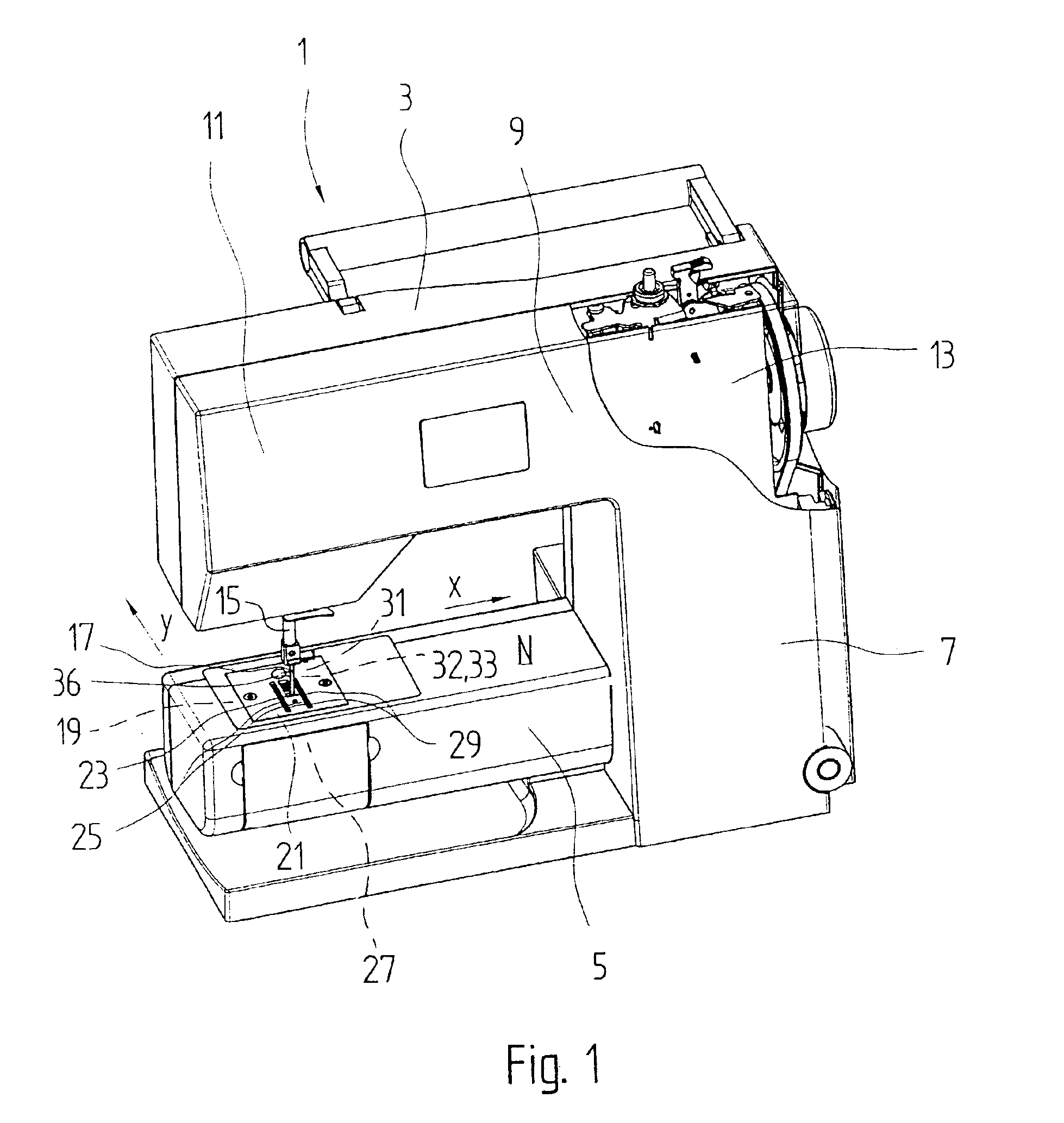

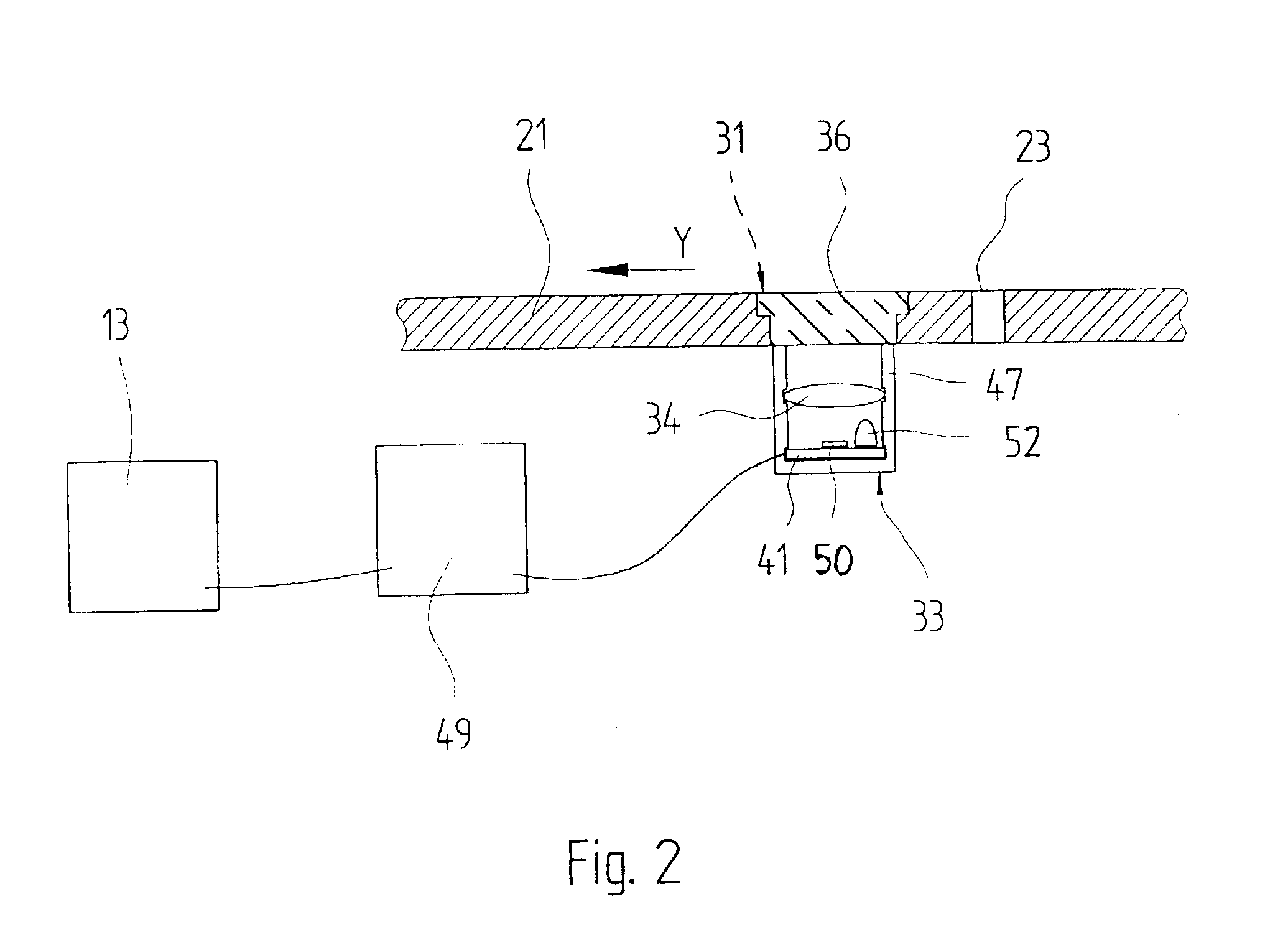

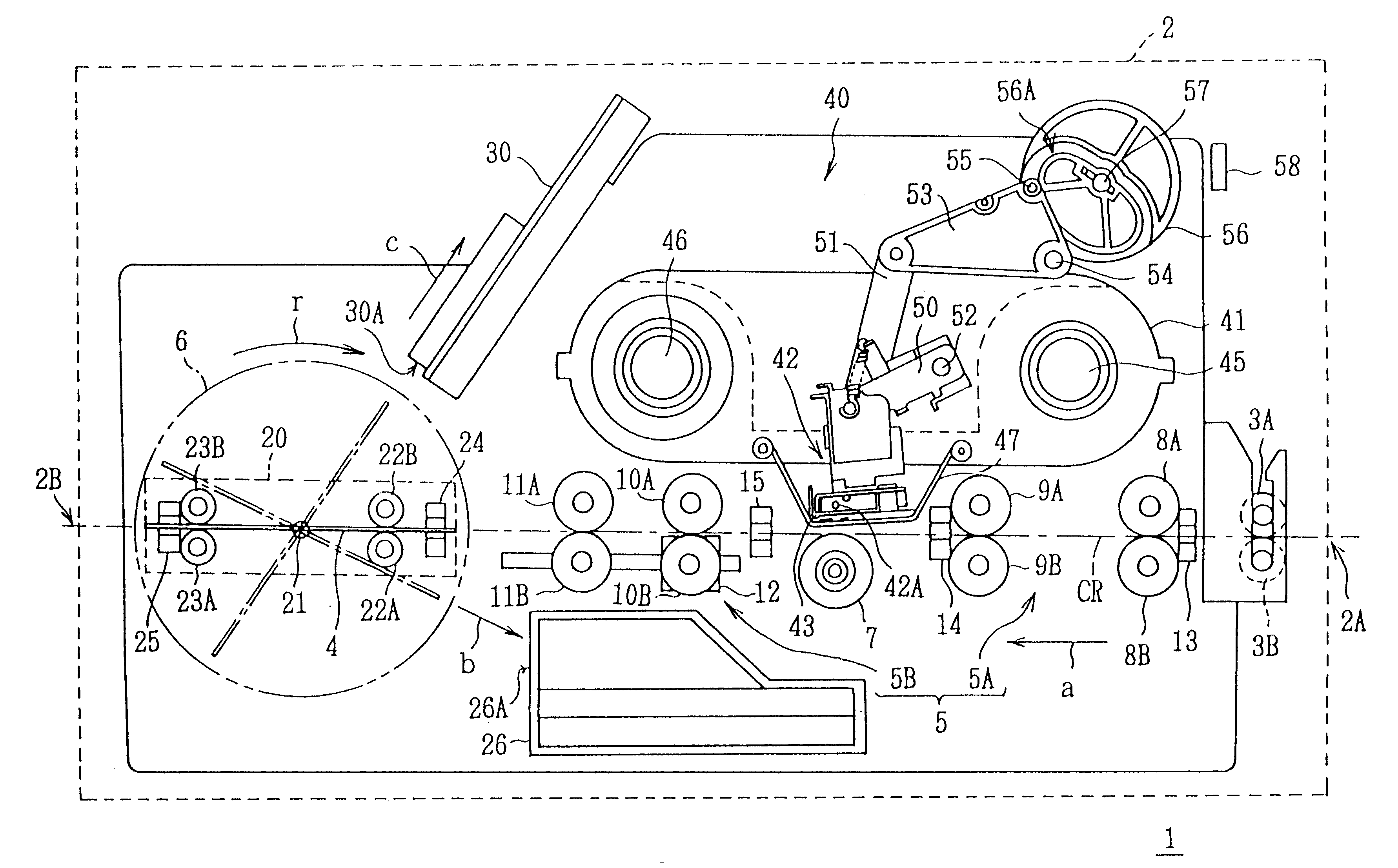

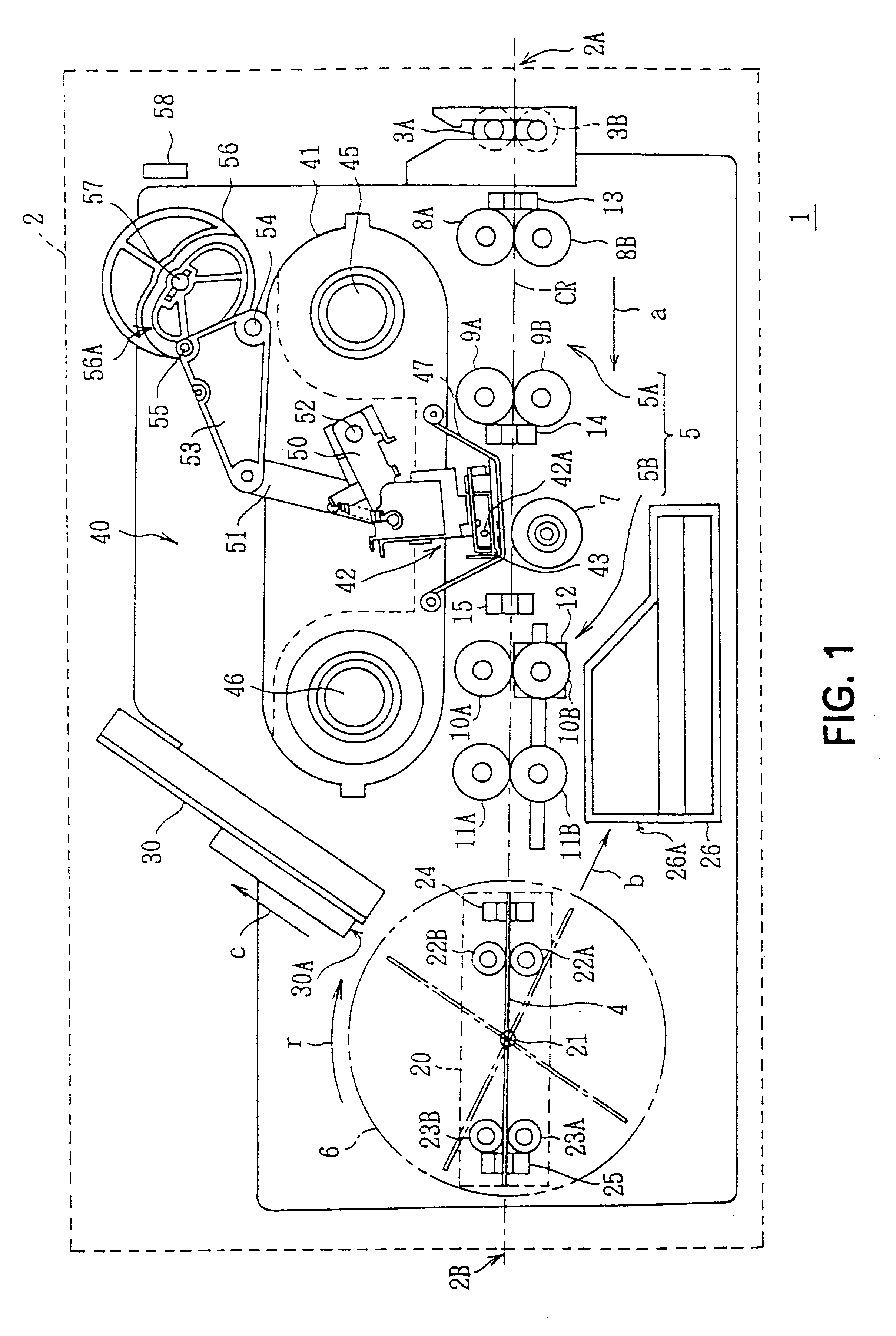

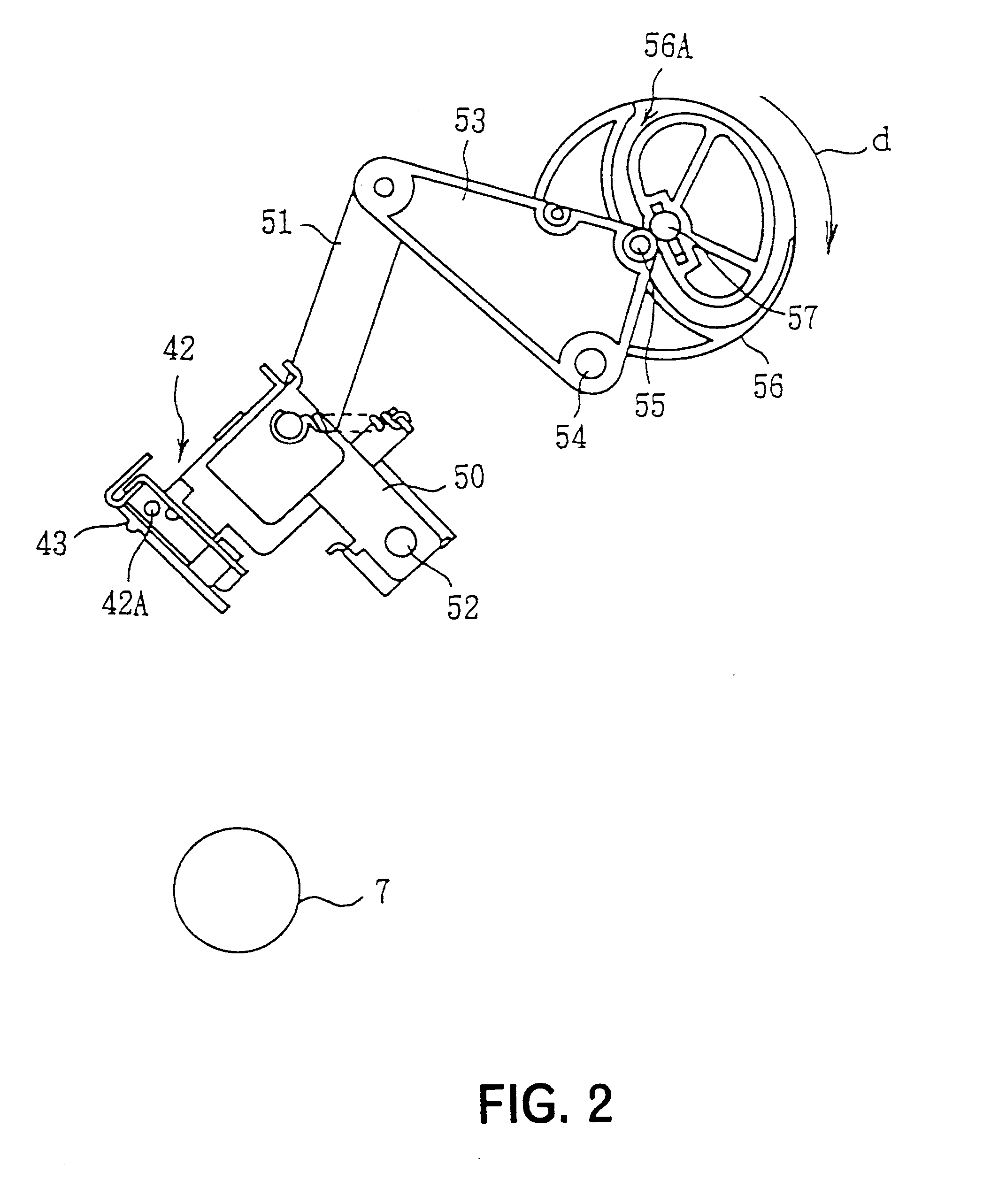

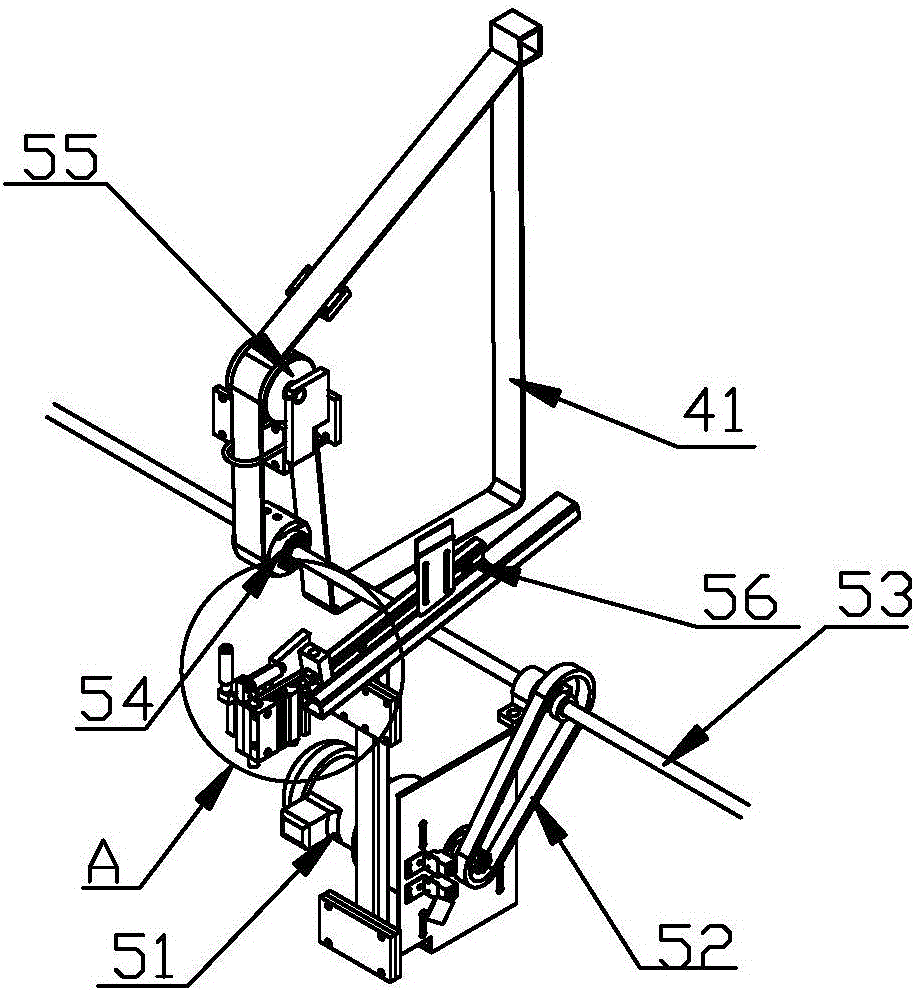

Method and device for regulating material transport in a sewing or embroidery machine

InactiveUS6871606B2Quickly and accurately calculated and compensatedImprove scanning rateProgramme-controlled sewing machinesWork-feeding meansMaterial transportMotion sensors

A method and device for regulating the transport of material in a sewing or embroidery machine (1) that uses information from a position or movement sensor (33) located underneath the throat plate (21). The controls for the sewing machine (1) calculate deviations of the actual feeding increments of the article to be sewn from the corresponding target values from the periodically read sensor signals. With this information, the feeding increments are regulated in such a way that the deviations are cancelled out by averaging.

Owner:FRITZ GEGAUF AKTIENGES BERNINA NAHMASCHFAB

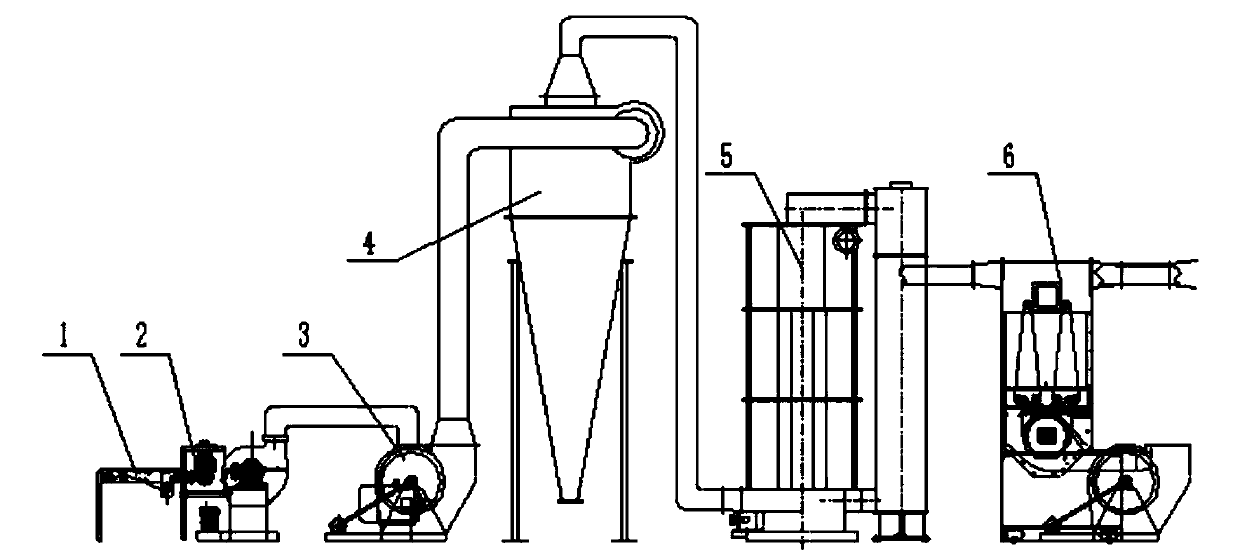

Bulk production line for reconstituted tobacco thin sheets by dry papermaking method

ActiveCN103431514AIncrease profitHigh degree of integration and automationTobacco preparationFiberProduction line

The invention discloses a bulk production line for reconstituted tobacco thin sheets by a dry papermaking method. The whole production line mainly comprises a raw material treatment part, a tobacco forming part and a thin sheet forming part, wherein material transportation is mainly executed through a carrying roller and a mesh belt, and is assisted through air flow of a fan; a conveying component of the whole production line is provided with a cleaning device, a tensioning device and a deviation correction device. According to the production line, wood pulp or tobaccos are smashed into fibers, then reconstituted tobaccos are produced through dry forming; finished products, namely the tobacco thin sheets, are produced through reconstituted tobacco treatment; the production requirements on the reconstituted tobacco thin sheet low sewage emission, low energy consumption and high quality are met.

Owner:SHANXI LIGONG MECHANICAL & ELECTRICAL TECH

Sublimating card printing apparatus and method

InactiveUS6236420B1Minimized in sizeEasy constructionRecording apparatusInking apparatusSignal onEngineering

A sublimating card printing apparatus, the size of which is reduced with a simple construction while providing multiple functions. A sublimating card printing apparatus for recording predetermined information in a magnetic recording medium and / or semiconductor memory provided on a card material and printing an image based on a supplied printing signal on the card material. The apparatus comprises a rotary transporting device for switching a transporting direction of the card material, provided along a linear transport path of the card material, a card tray for containing the card material transported by the rotary transporting device where errors occur in recording onto the magnetic recording medium or memory recording medium, and both a memory recording / reproducing device and a magnetic recording / reproducing device provided on the rotary transport path through the rotary transporting device, the length of the transport path thereby being reduced and the card tray being contained in the apparatus, the whole apparatus thereby being minimized in size and complexity while retaining multiple functions.

Owner:SONY CORP

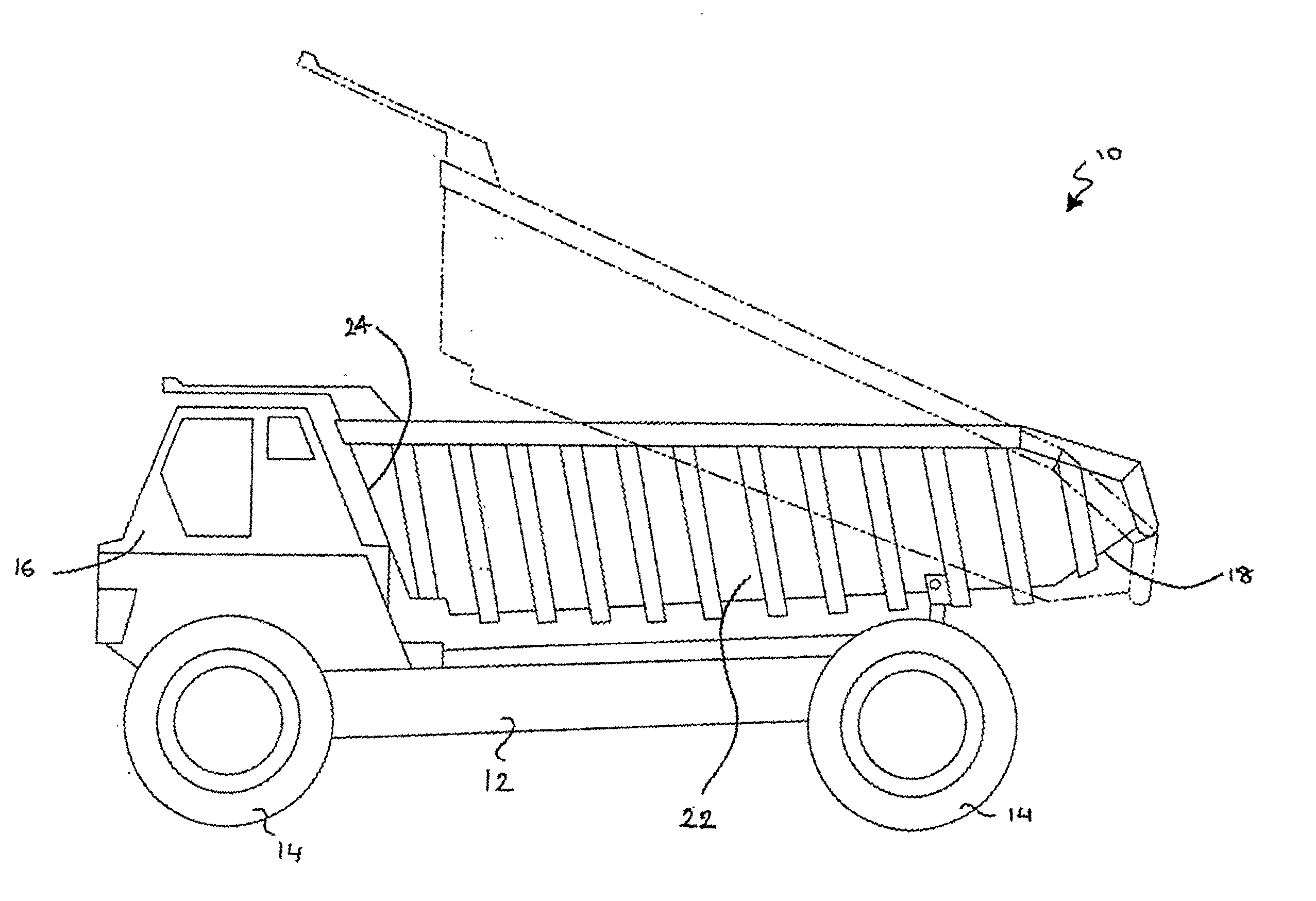

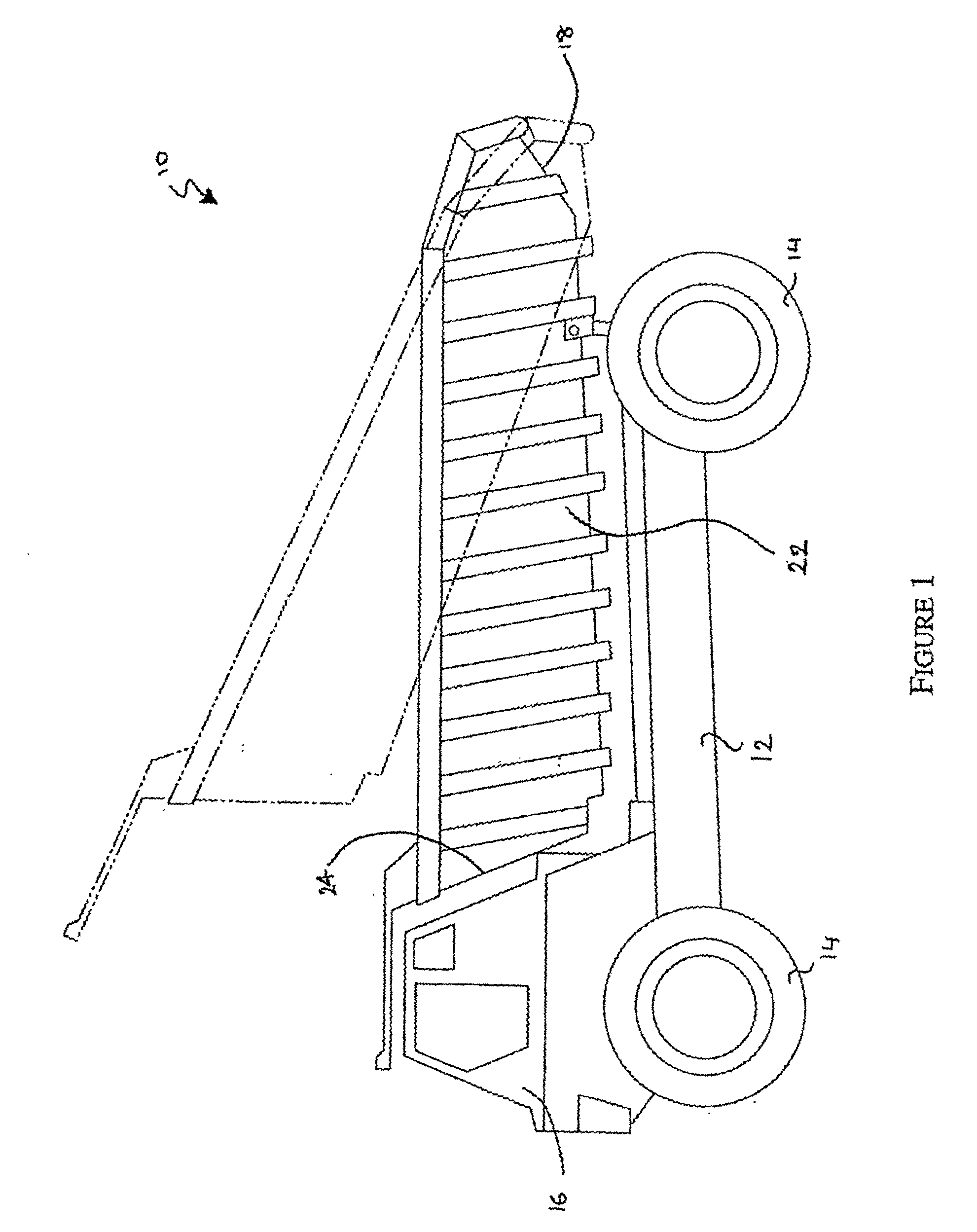

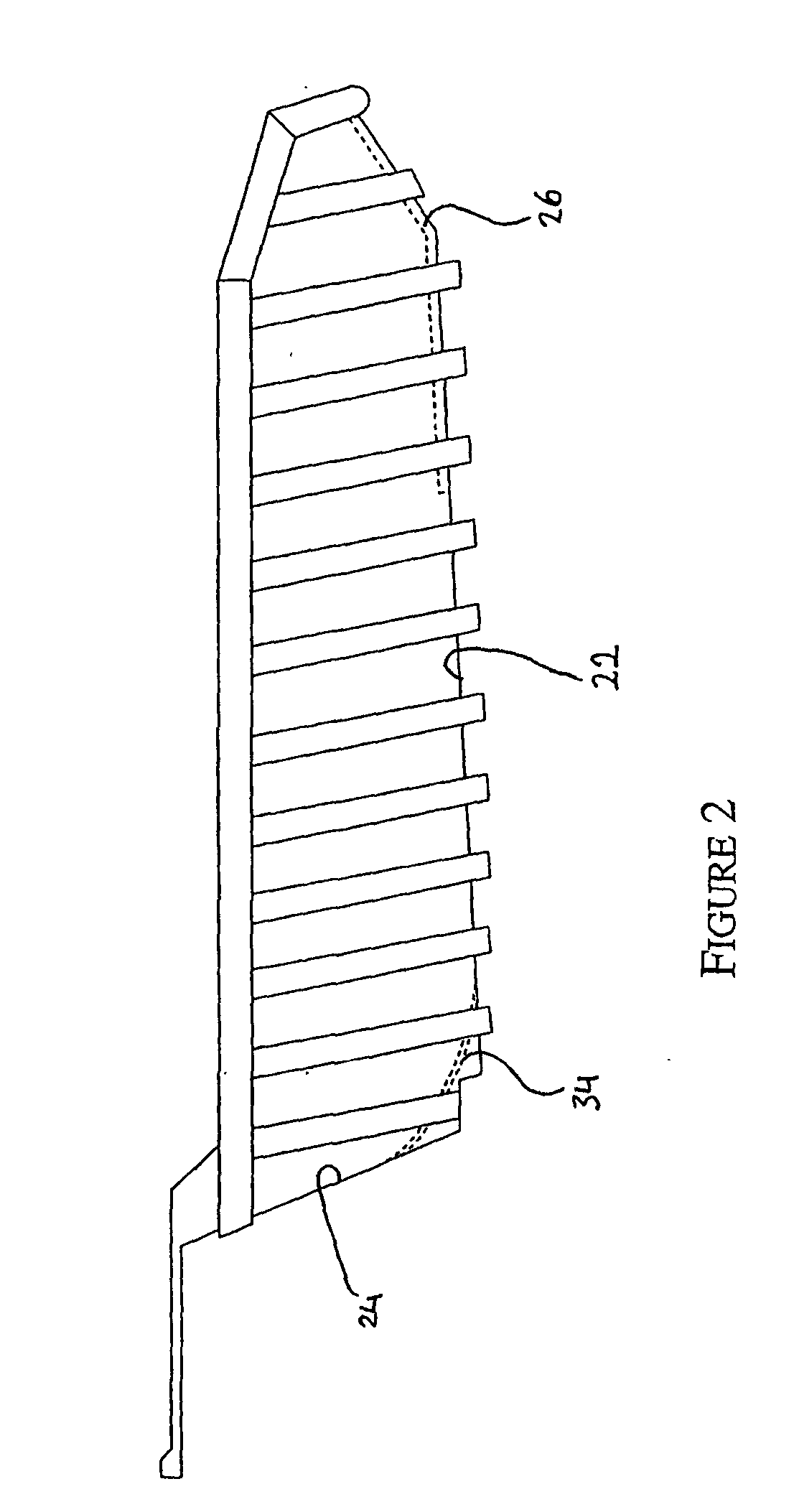

Materials transport container

InactiveUS6854808B2Easy to slideSoil-shifting machines/dredgersMonocoque constructionsEngineeringMaterial transport

Owner:KOSTECKI GENE

Milling machine as well as method for working ground surfaces

ActiveUS20050179309A1Inhibit currentEasy to useCombination devicesSlitting machinesEngineeringContaminated air

At a milling machine to work ground surfaces, with a machine frame, a milling drum supported at the machine frame, at least one transport device arranged at the machine frame which accepts the milled material from the milling drum, as well as with a suction device for the air polluted with dusts and vapors, whereby the milled material on the at least one transport device is enclosed by a channel, the suction device is connected to a rear channel section of the channel in the direction of the material transport and sucks off the air polluted during milling at the milling drum and in the rear channel section essentially in the direction of the material transport, it is provided that the suction device consists of a suction ventilator, a separator device for solids and a suction channel which is connected to the rear channel section, that the suction ventilator is arranged downstream of the separator device, and that the suction device disposes of the separated solids onto the transport device in a forward channel section in the direction of the material transport or into a collecting device, and the suction ventilator blows off the cleaned air into the environment.

Owner:WIRTGEN GMBH

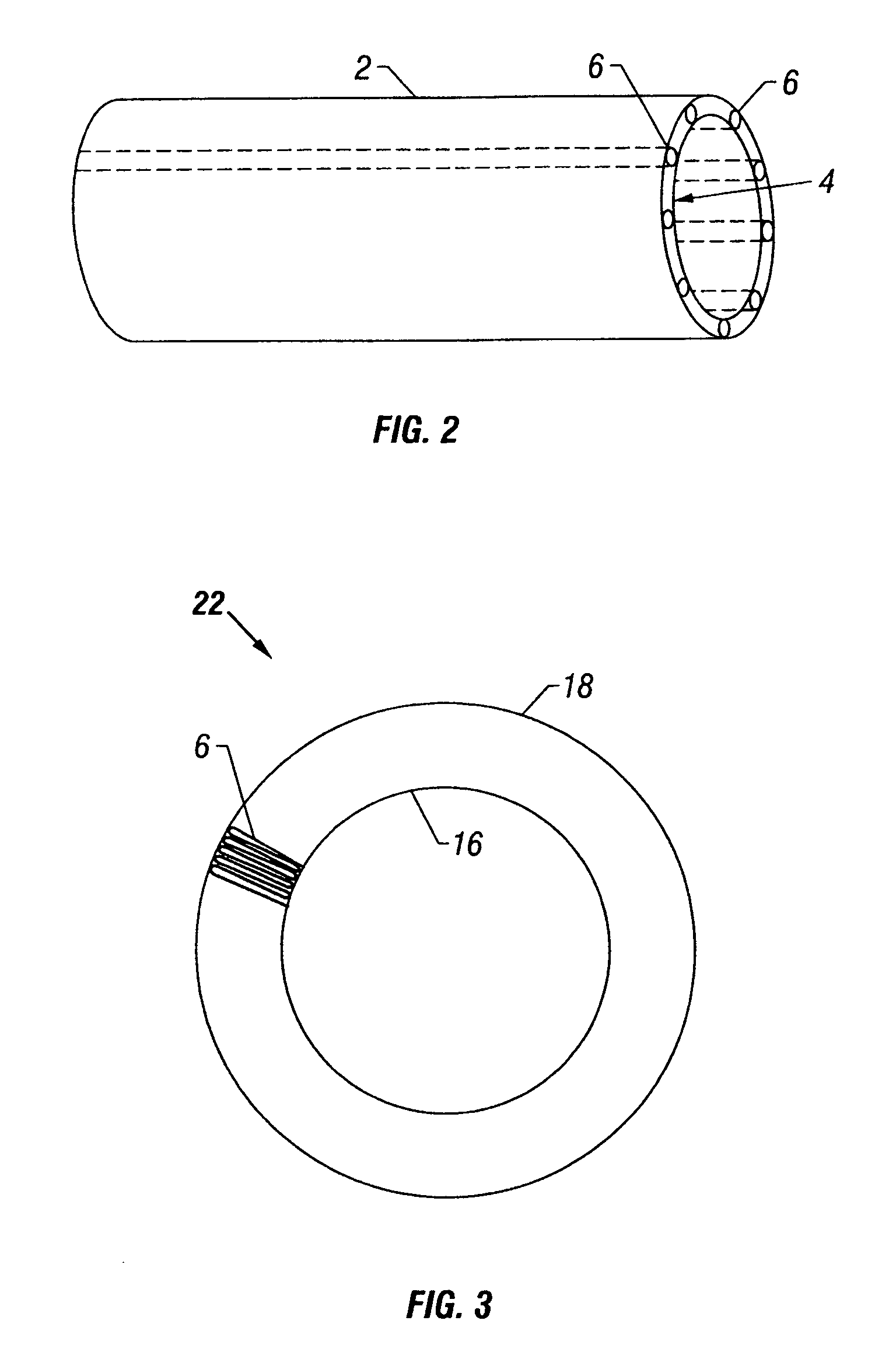

Method and apparatus for lining a conduit

InactiveUS20020033554A1Facilitates inspection and installation and servicingReduce or eliminate "slLaminationTyresFiberSlurry

Method and apparatus for installing a liner material into a host conduit such as, e.g., a sewer pipe, hydrocarbon pipeline, gas line, water line, industrial chemical pipe, or a saltwater line. The liner material may include a compression liner and / or a preliner that is attached to the inner wall of the host conduit to repair or reinforce the host conduit or separate the host conduit from materials transported within the new liner formed from the liner material. Curable resin, slurry, or cement can be placed between the liner material and the host conduit to affix the liner material into place. Before and during curing, a fluid such as air or water can be used to inflate the compression liner outwardly toward the host conduit. Spacers positioned between at least a portion of the liner material and the host conduit may be used to (i) calibrate the thickness of the liner material and curable material that is cured to form the new liner, and (ii) form communication channels adapted to house devices such as wire, cable, fiber optic cable, telephone lines, power lines, etc. The spacers and channels can be selectively inflatable to various sizes to allow calibration of the liner thickness and to form communication channels having a selected width or height. Additionally, the liner material may be formed into a one-piece, tubular lining member having an inflatable enclosure defined between an inner and an outer layer of the lining member. The enclosure can be selectively inflated to (i) calibrate the resulting thickness of the cured liner material, and (ii) form communication channels running along the length of the host conduit.

Owner:HEAGY RICHARD T +3

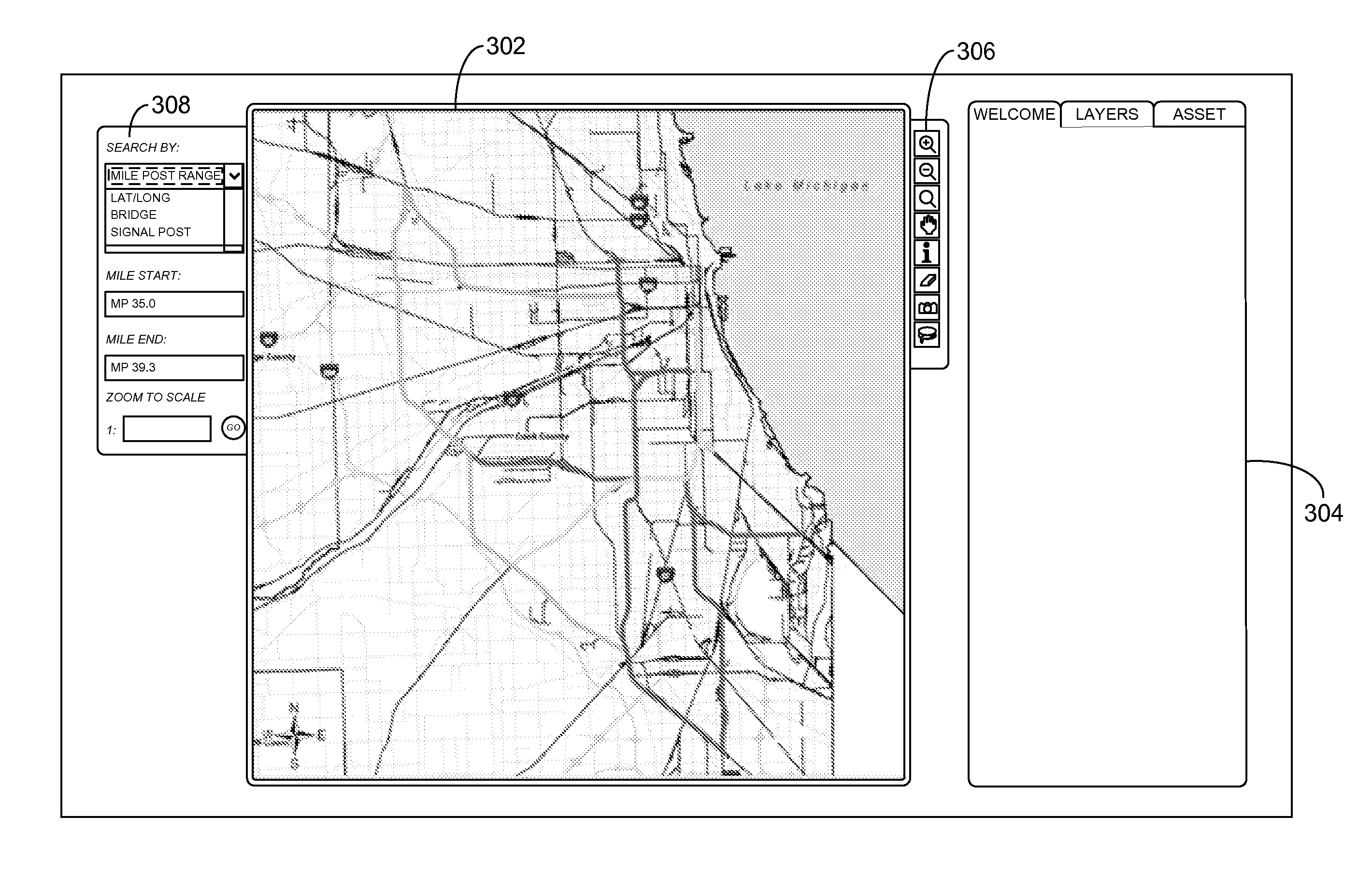

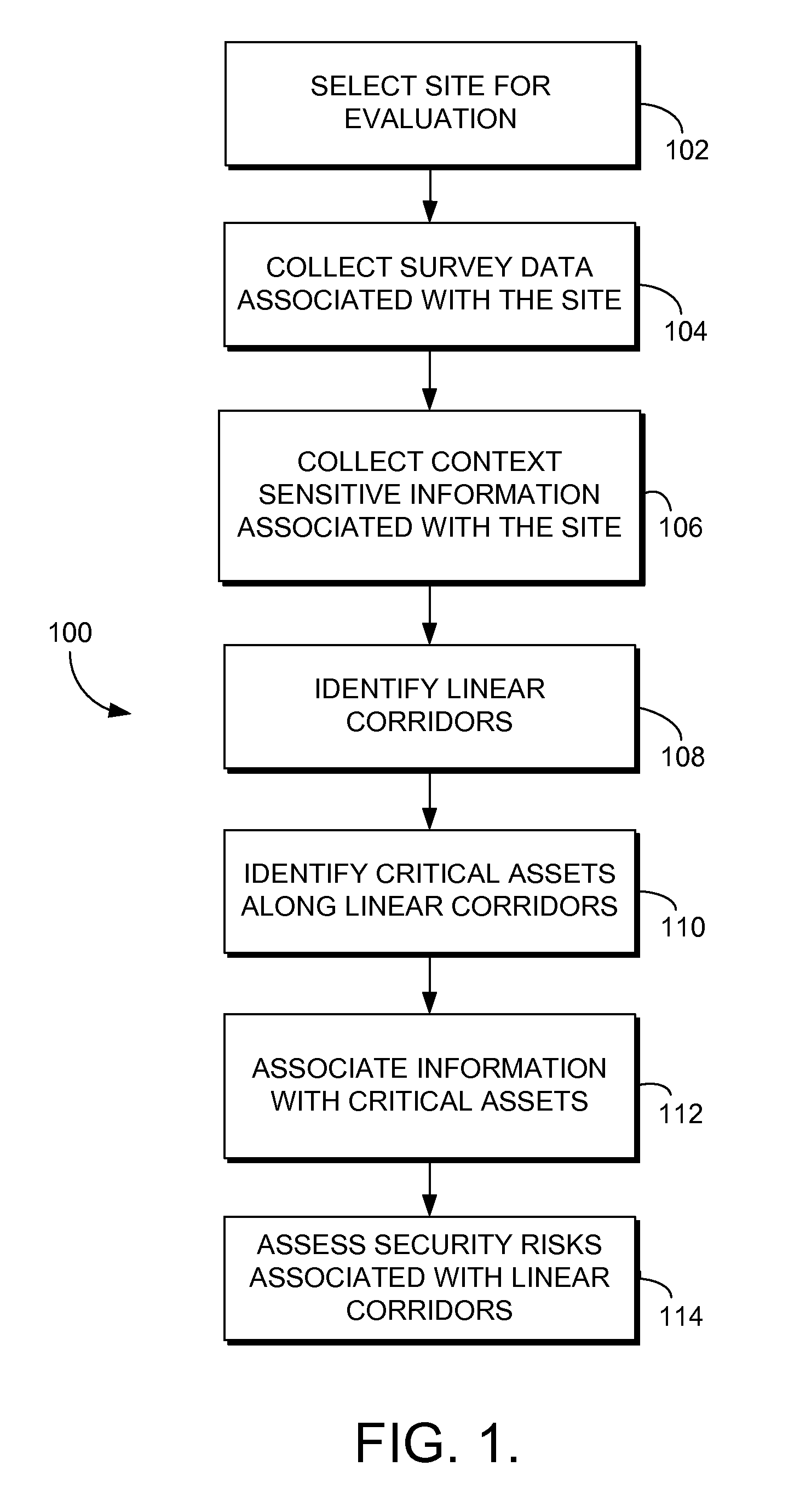

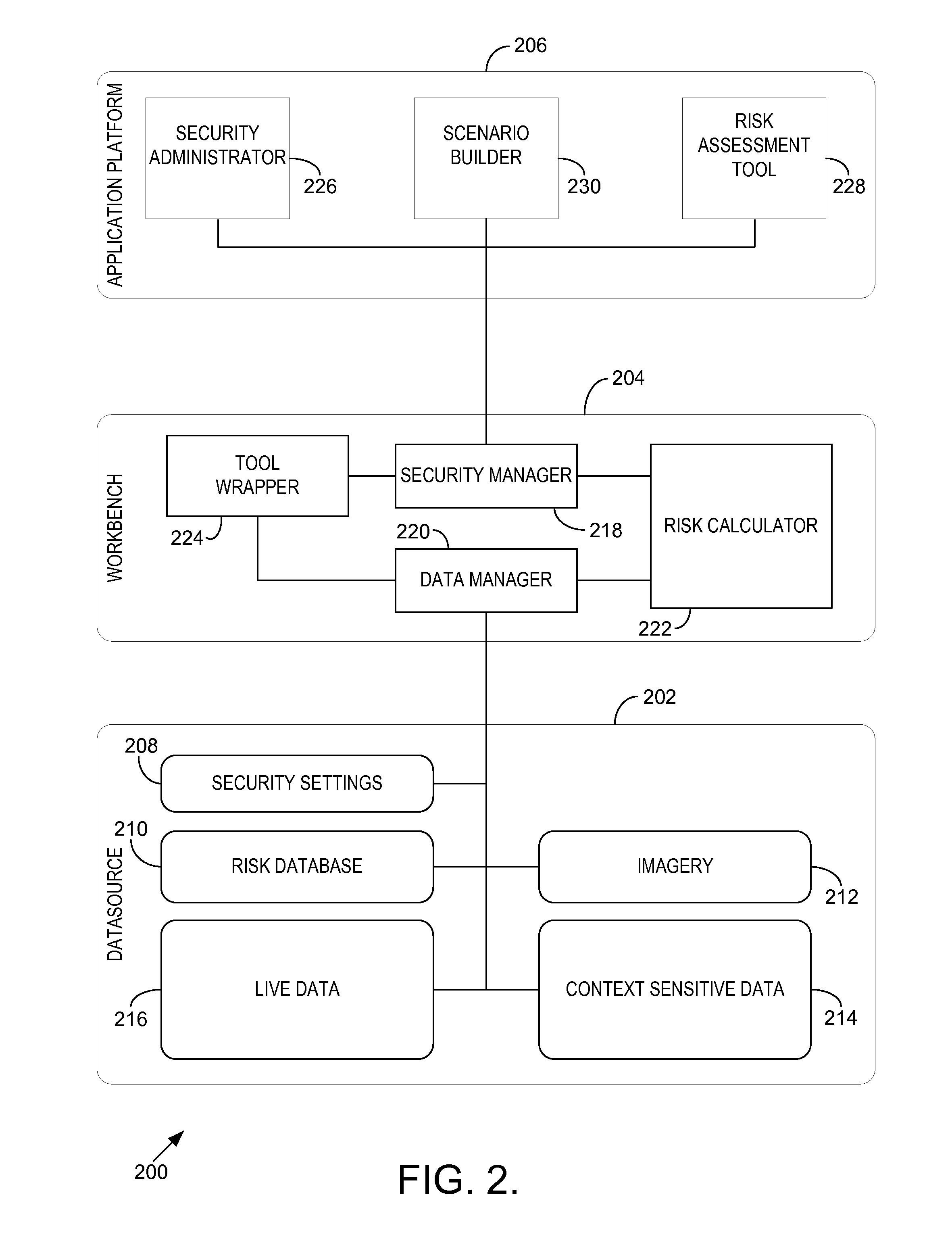

Methods and systems for identifying safe havens for hazardous transports

The identification of safe havens for hazardous material transports is provided. Safe havens include locations at which a hazardous material transport is less susceptible to an event that may result in a hazardous material release and / or a location at which the impact of a hazardous material release is reduced. When an event occurs indicating that hazardous material transports should be moved to safe havens, the locations of hazardous material transports are determined. Safe havens may then be determined for each hazardous material transport. In some cases, safe havens may be selected from a group of predetermined locations designated as safe havens. In some cases, locations may be dynamically designated as safe havens for hazardous material transports after the occurrence of an event. The hazardous material transports are then moved to the selected safe havens, thereby reducing their susceptibility to events and / or minimizing the impact of an event that involves a hazardous material transport.

Owner:HNTB HLDG

Elementary bitstream cryptographic material transport systems and methods

Systems and methods for providing multimedia content from one process or component to another process or component over an unsecured connection are provided. One embodiment includes obtaining the cryptographic information, extracting the at least partially encrypted video data from the container file to create an elementary bitstream, enciphering the cryptographic information, inserting the cryptographic information in the elementary bitstream, providing the elementary bitstream to a video decoder, extracting the cryptographic information from the elementary bitstream at the video decoder, deciphering the cryptographic information, decrypting the elementary bitstream with the cryptographic information and decoding the elementary bitstream for rendering on a display device using the video decoder.

Owner:DIVX INC

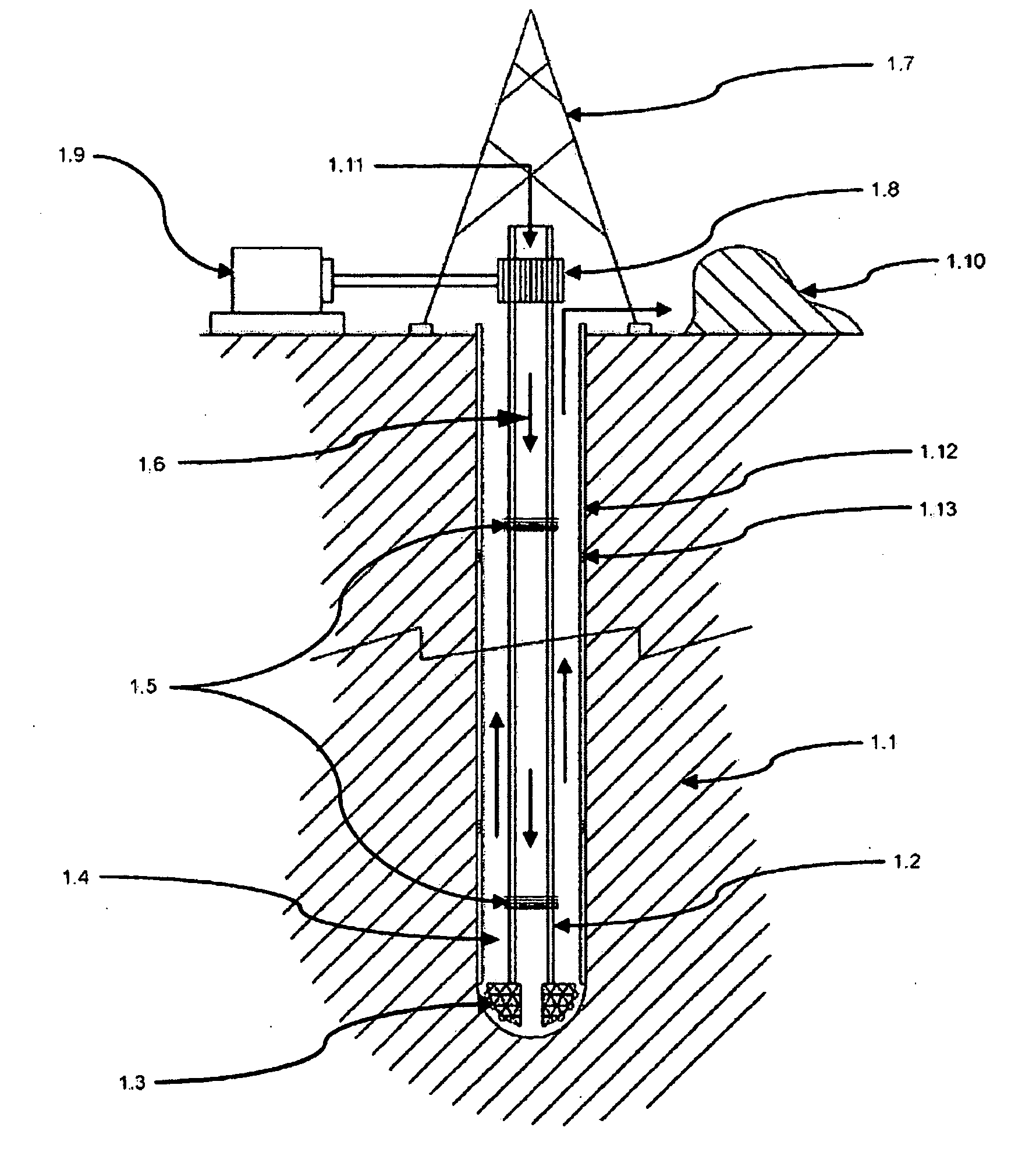

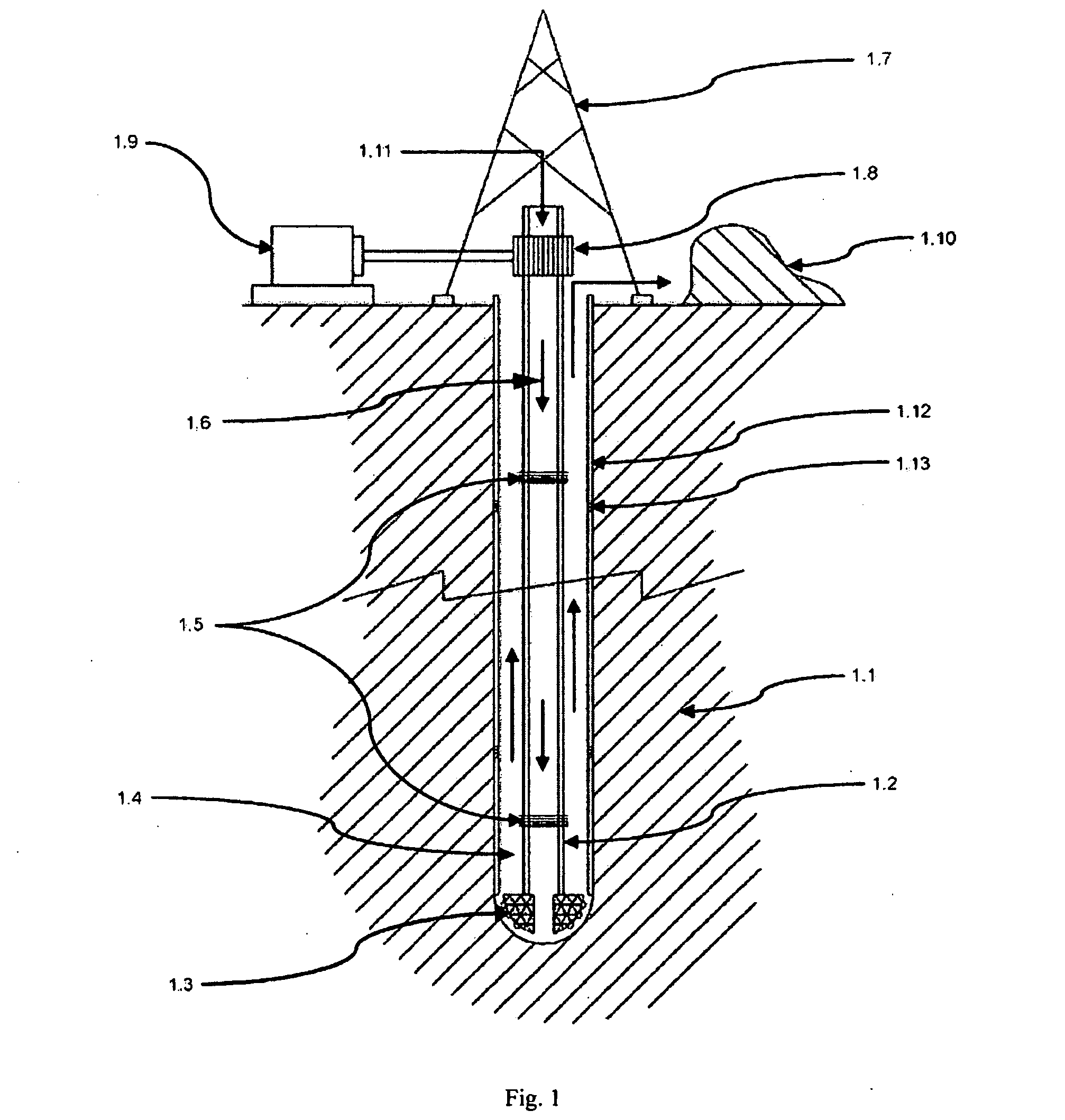

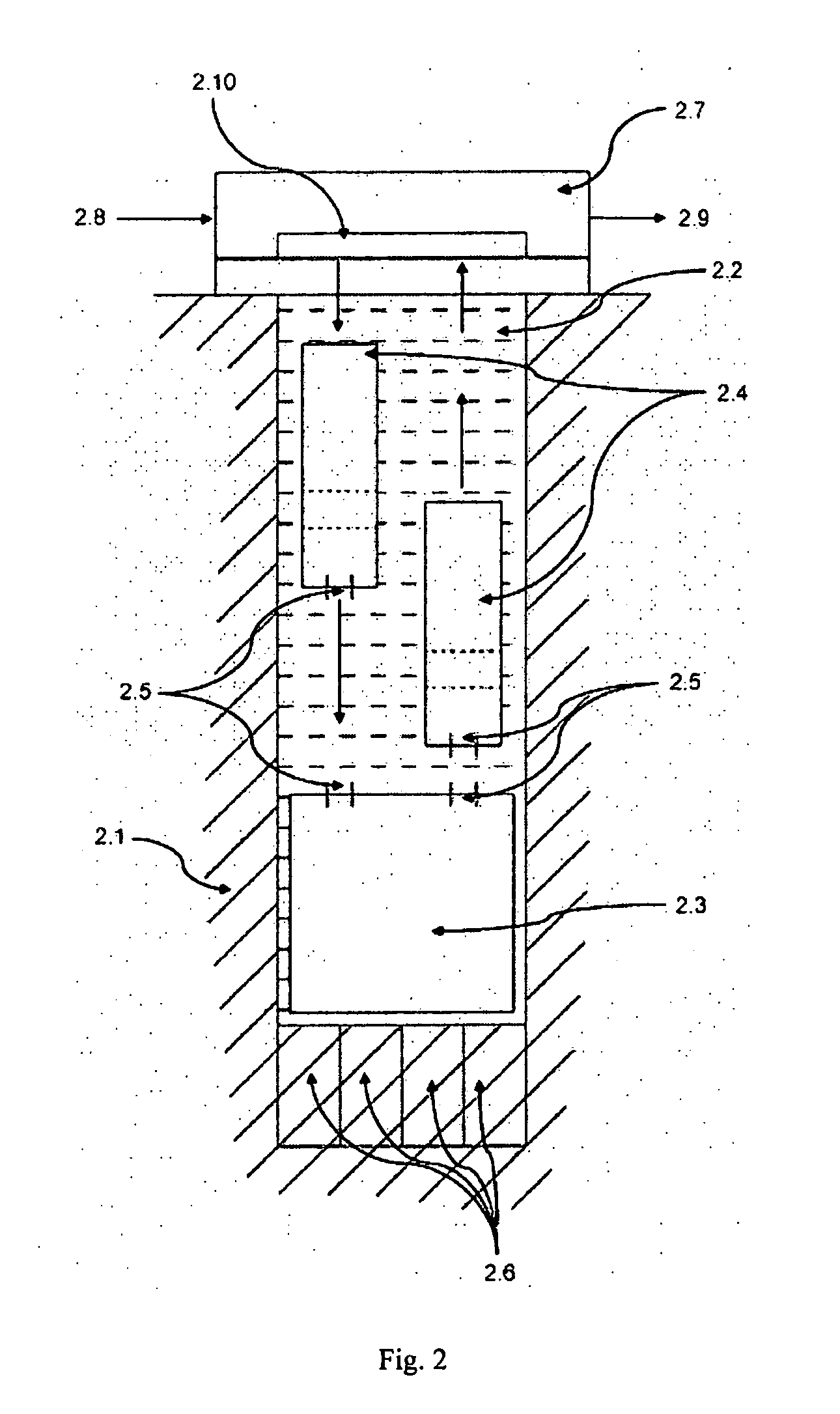

Equipment for excavation of deep boreholes in geological formation and the manner of energy and material transport in the boreholes

InactiveUS20100224408A1Considerable energy savingLarge boreholeDisloding machinesThermal drillingEngineeringEnergy depletion

Utilisation of geothermal energy in depths above 5 km could contribute considerably to resolving the global problems related to a lack of energy and to glasshouse gases from fossil fuels. The invention describes innovative equipment which makes deep holes in geological formations (rock) by disintegrating the soil into blocks carried to the land surface through the excavated hole filled with liquid, using transport modules yielded up by gas buoyancy interaction in the transport module utilising supercavitation. In an opposite direction—by help of negative buoyancy—the necessary energy carriers, materials and components, or entire devices required for rock excavation, are carried to the bottom. The opportunity to transport rock in entire blocks reduces energy consumption considerably, because the rock is disintegrated in the section volumes only. Some of the extracted rock and material carried from the surface is used to make a casing of the hole using a part of the equipment. The equipment also allows the generation of the necessary high pressure of liquid at the bottom of the hole, to increase permeability of adjacent rock. The equipment as a whole allows by its function that there is almost linear dependence between the price and depth (length) of the produced hole (borehole).

Owner:GA DRILLING AS

Materials transport container

InactiveUS20040026959A1Easy to slideSoil-shifting machines/dredgersMonocoque constructionsEngineeringMaterial transport

Owner:KOSTECKI GENE

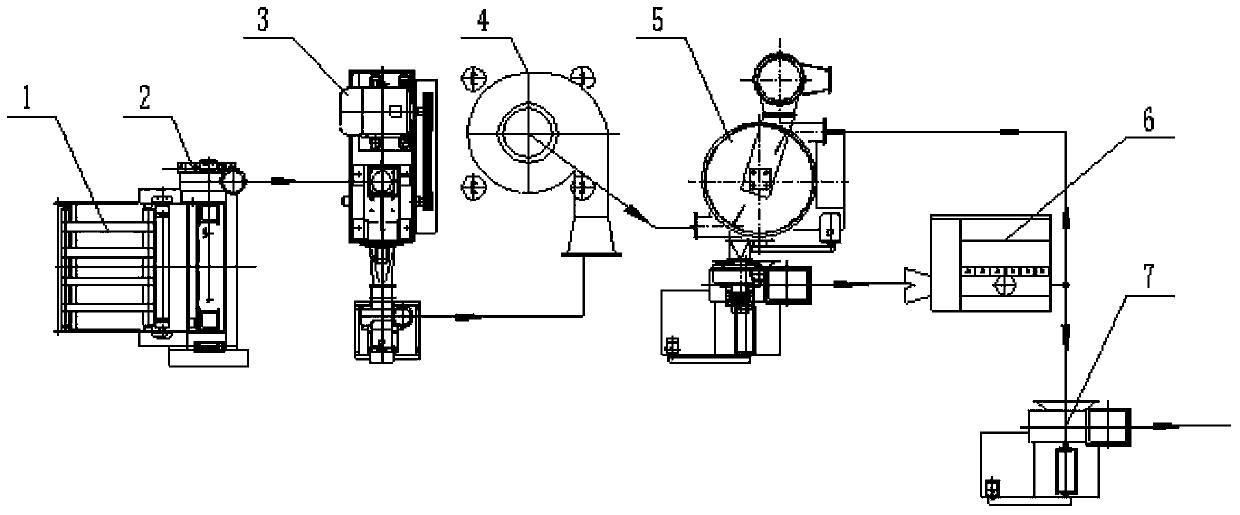

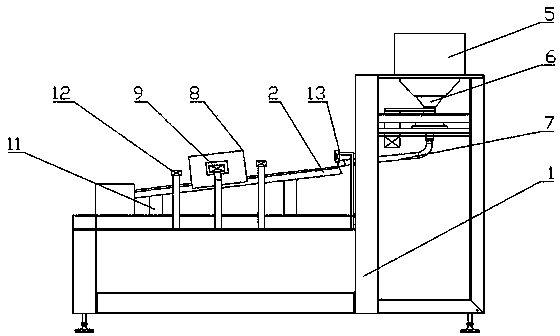

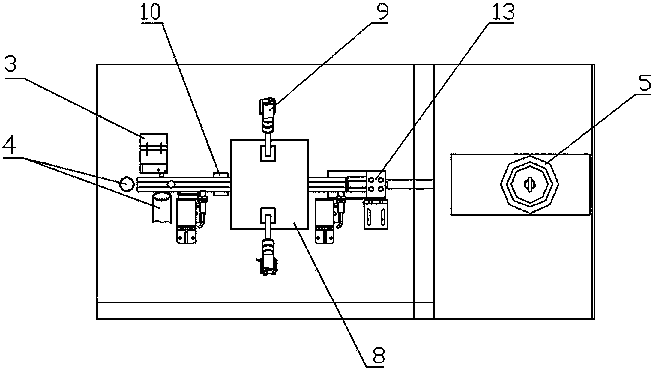

Detection sorting device for steel balls

ActiveCN104043596ARealize automatic feeding processEasy to detectOptically investigating flaws/contaminationSortingEngineeringStructural engineering

The invention relates to a detection sorting device for steel balls The detection sorting device comprises a rack, a feed mechanism, an unfolding mechanism, a stock stop, a detecting mechanism, a sorting mechanism and a material collecting mechanism, wherein the feed mechanism comprises a material storing box, a material discharging hopper and a material discharging pipe; the unfolding mechanism comprises a material transporting guide rail, the material transporting guide rail is a V-shaped linear guide rail, the material discharging hopper is connected with an initiating end of the material transporting guide rail through the material discharging pipe, and the detecting mechanism comprises a light source assembly and a camera assembly; the light source assembly is arranged on the material transporting guide rail in a sleeved mode, the sorting mechanism and the material collecting mechanism are arranged on the tail end of the material transporting guide rail, and the separate collection of defect steel balls and qualified steel balls are realized through the sorting mechanism and the material collecting mechanism. The detection sorting device provided by the invention has the advantages that the automatic feed, detection and sorting of the steel balls are realized, a detection process is that two-dimensional motion of a traditional unfolding disc is changed into single one-dimensional rolling of one-sided steel balls, the detection efficiency is high, a false drop ratio and an omission ratio are low, and the steel balls are not magnetized or the surfaces of the steel balls are not damaged in a detection process.

Owner:LUOYANG FANGZHI MEASUREMENT & CONTROL

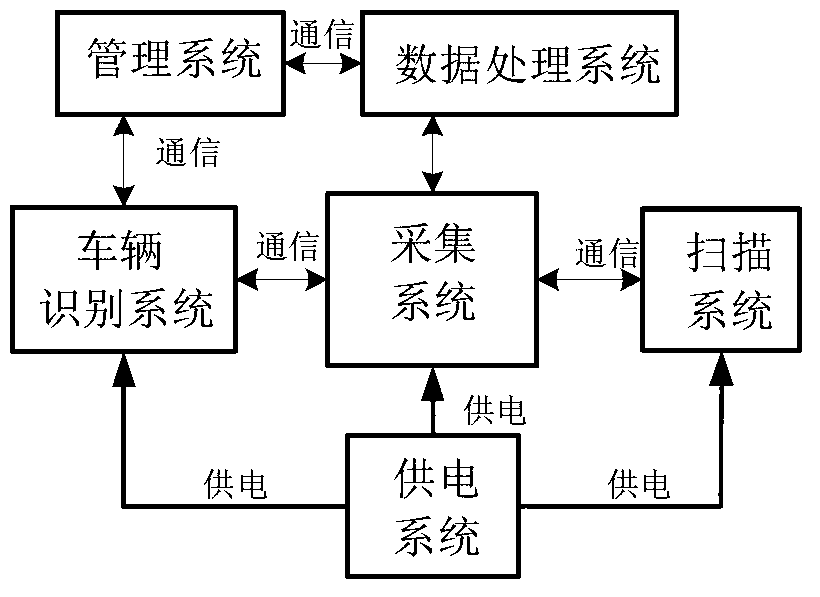

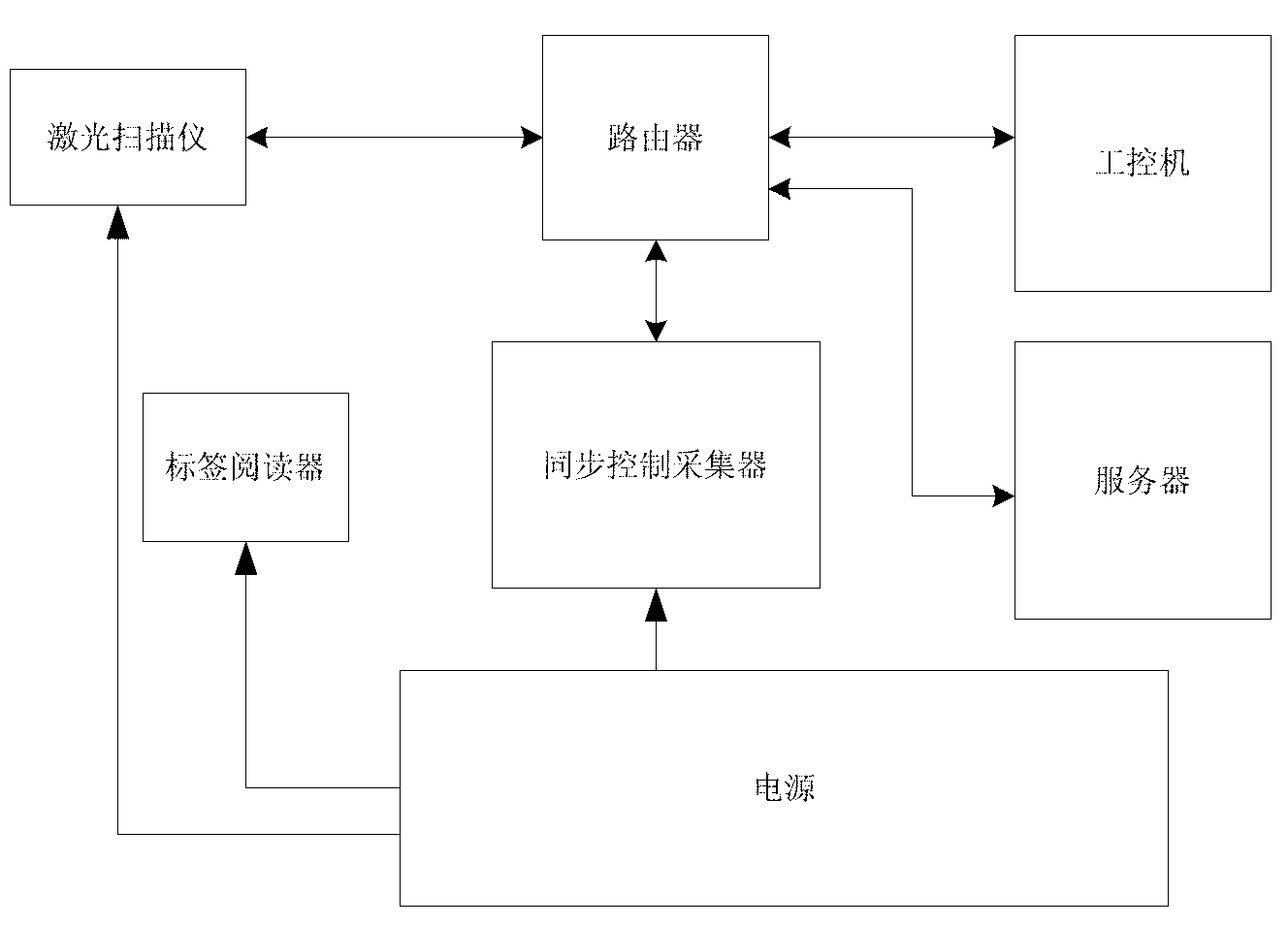

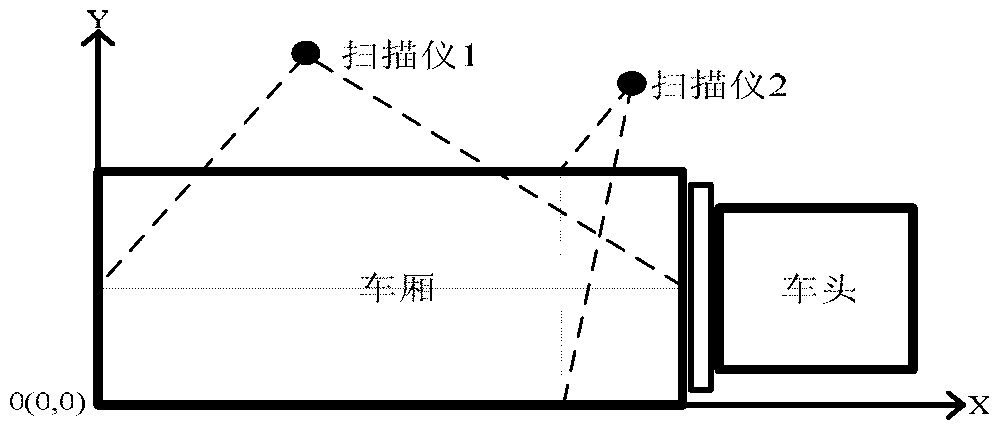

Fixed type automatic volume measurement system and measuring method thereof

InactiveCN102980512AQuick measurementAccurate measurementUsing optical meansMultiple sensorMaterial transport

The invention relates to a fixed type automatic volume measurement system and a measuring method of the fixed type automatic volume measurement system. The fixed type automatic volume measurement system is an automated measurement and calculation system based on multi-sensor integration. According to the system, multiple sensors are mainly used for synchronous control of a collector, a control tag reader and a high-speed laser scanner, and are in synchronous communication with an industrial personal computer to achieve data collection. Collected data are processed primarily by a controller to filter invalid data and transmitted to the industrial personal computer rapidly after being marked in a real-time mode with timing marks. A three-dimensional coordinate is computed through calculation processing software running in the industrial personal computer and by aid of the three-dimensional coordinate computational algorithm, vehicle-mounted material stack body modeling is carried out by combining the three-dimensional modeling algorithm, and then the volume of vehicle-mounted materials to be measured is calculated. Therefore, the fixed type automatic volume measurement system and the measuring method of the fixed type automatic volume measurement system have the advantages that a traditional method that a material transport vehicle is guarded all day long and recorded manually is replaced by a method that the material transport vehicle can be identified quickly and automatically, the volume of the vehicle-mounted materials can be measured quickly and accurately, and the material transport vehicle and the materials can be managed effectively.

Owner:WUHAN WUDA ZOYON SCI & TECH

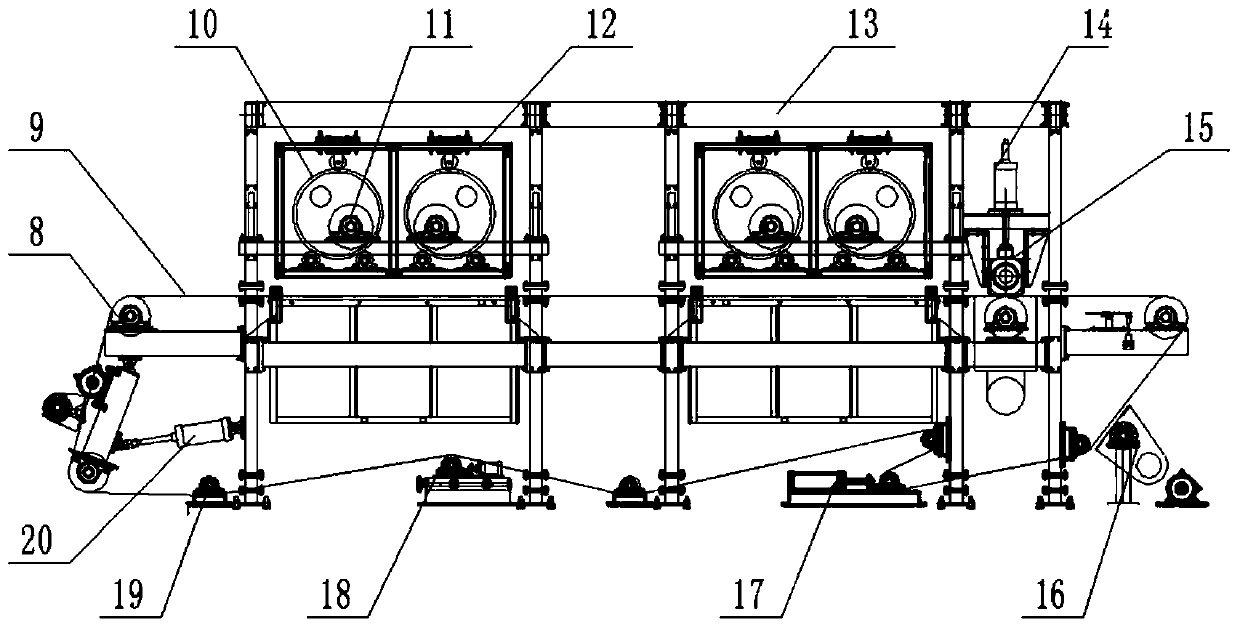

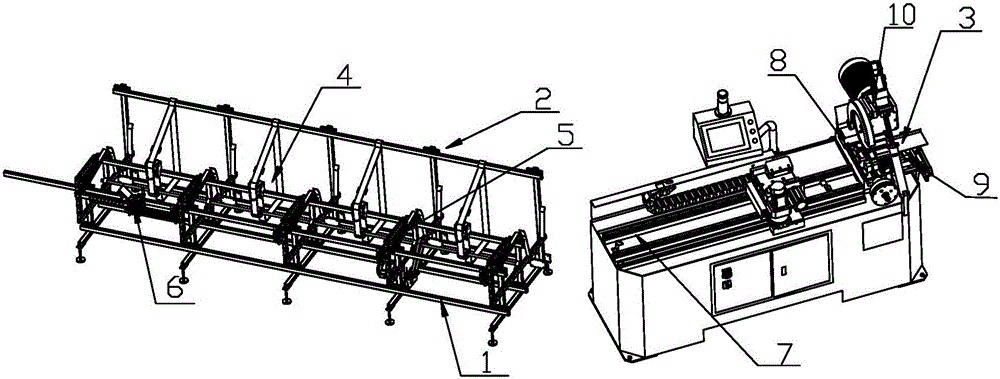

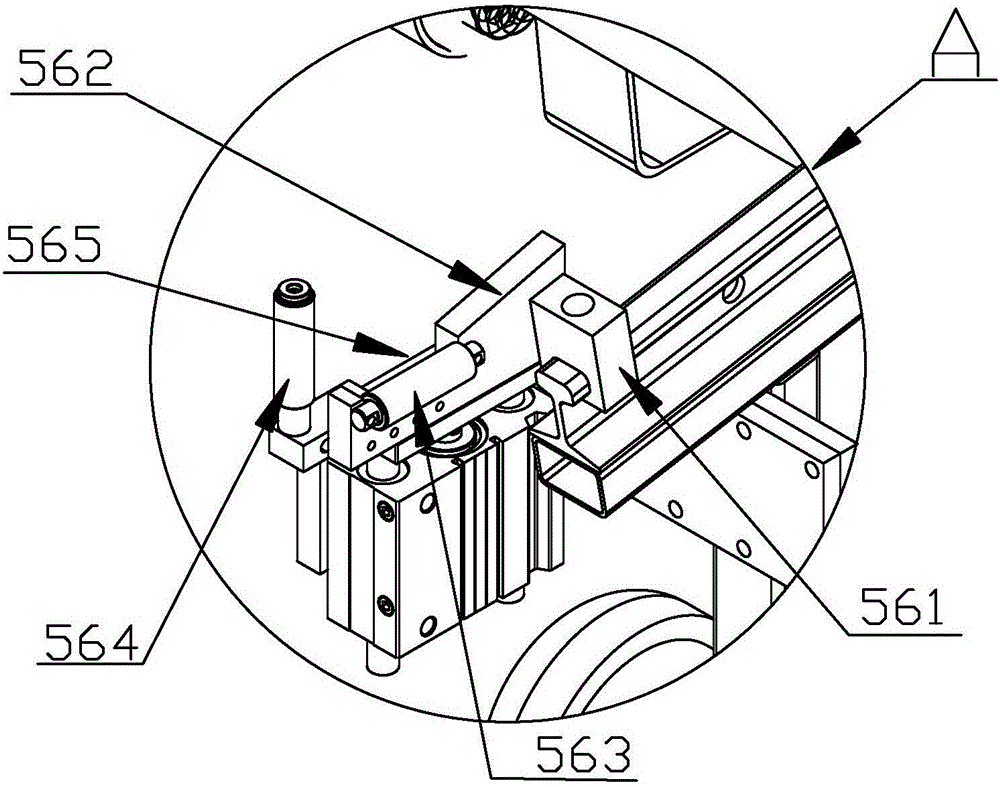

Fully automatic pipe material saw cutting machine

ActiveCN105772851AImprove efficiencyHigh degree of automationMetal sawing devicesLeveling mechanismEngineering

The invention provides a fully automatic pipe material saw cutting machine. The fully automatic pipe material saw cutting machine comprises automatic feeding devices, a cutting device and a discharging device, wherein each of the automatic feeding devices comprises material storing mechanisms, pre-feeding mechanisms, a pipe material tail leveling mechanism, a movable pincers assembly and a sliding mechanism; the cutting device comprises a main pincers seat assembly, tailing pincers seat movable assemblies and a saw cutting mechanism, the main pincers seat assembly is fixedly mounted on a machine frame, and the tailing pincers seat movable assemblies are arranged behind the main pincers seat assembly in parallel and can move back and forth along the pipe material transporting direction relative to the main pincers seat assembly. According to the fully automatic pipe material saw cutting machine disclosed by the invention, the automatic feeding devices are arranged, the tail leveling mechanism is used for performing tail alignment, the movable pincers assembly is used for performing clamping, and then pipe materials are transported through the sliding mechanism, so that the efficiency is high; besides, the tailing pincers seat movable assemblies are arranged in the cutting device, if cut pipe material tailings can also be cut into a finished product, the tailing pincers seat movable assemblies are used for clamping the tails of the pipe material tailings to move forwards, then the saw cutting mechanism is used for cutting, and waste is reduced to the maximum extent.

Owner:ZHEJIANG SEOKHO ROBOT TECH CO LTD

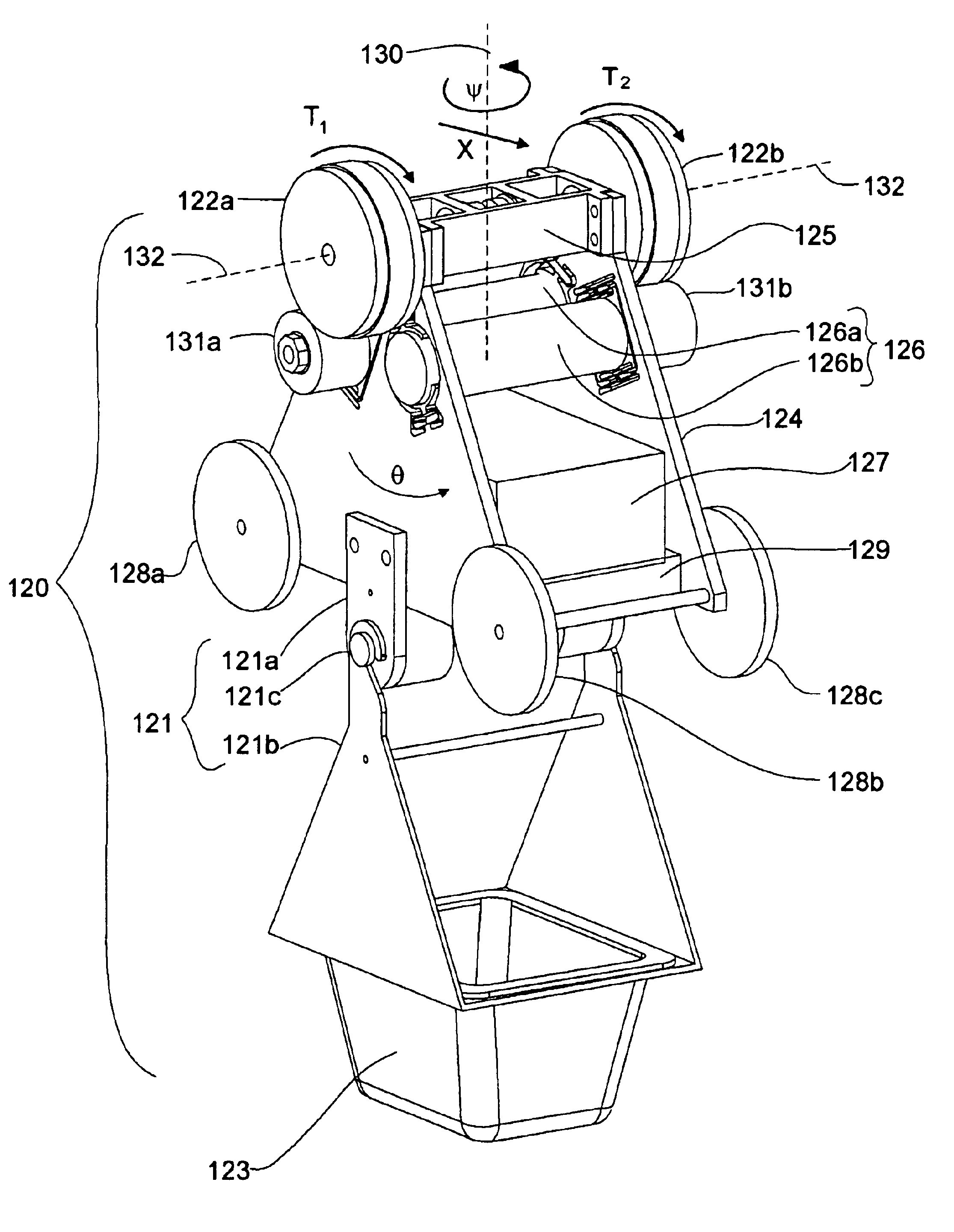

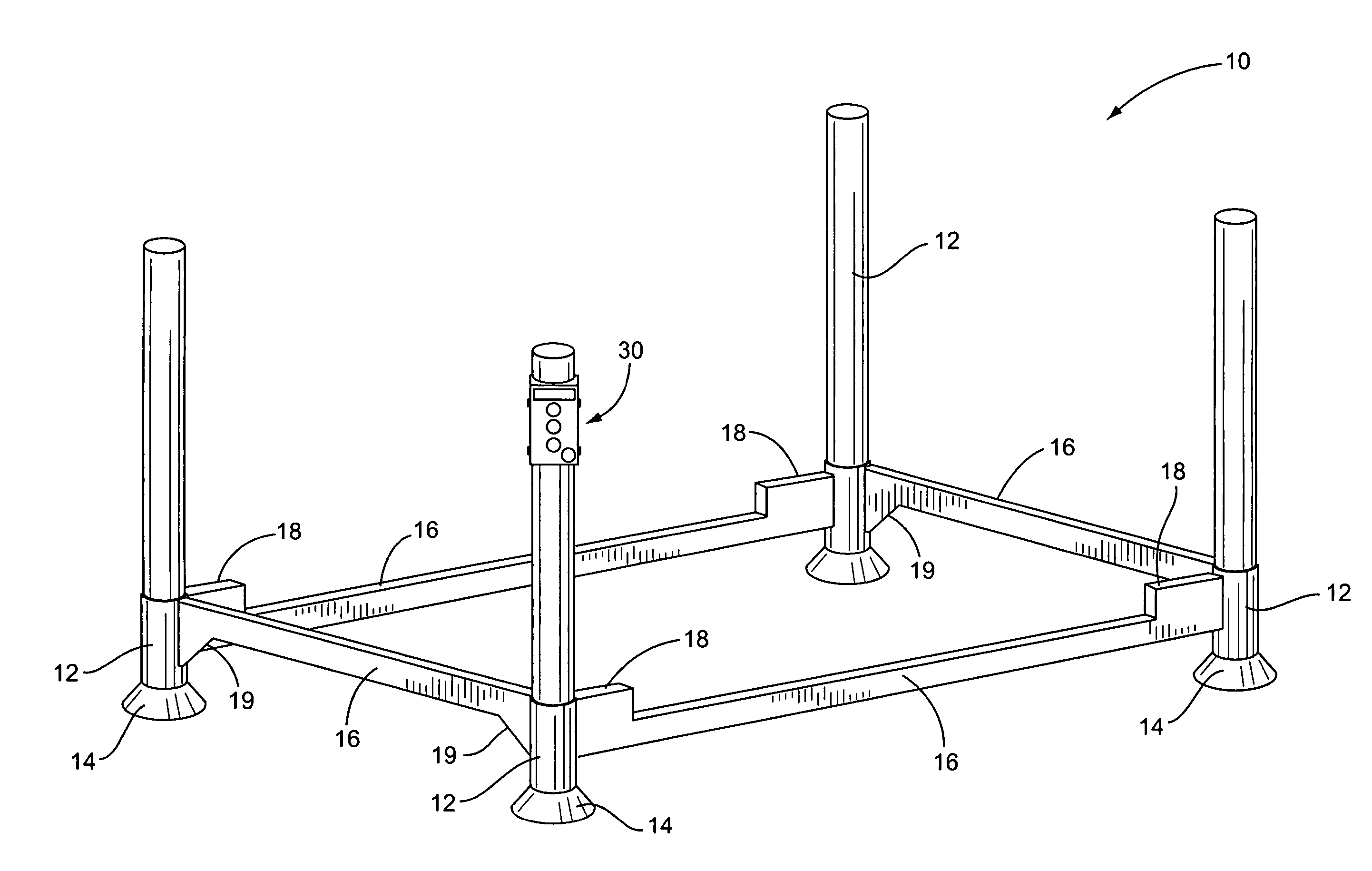

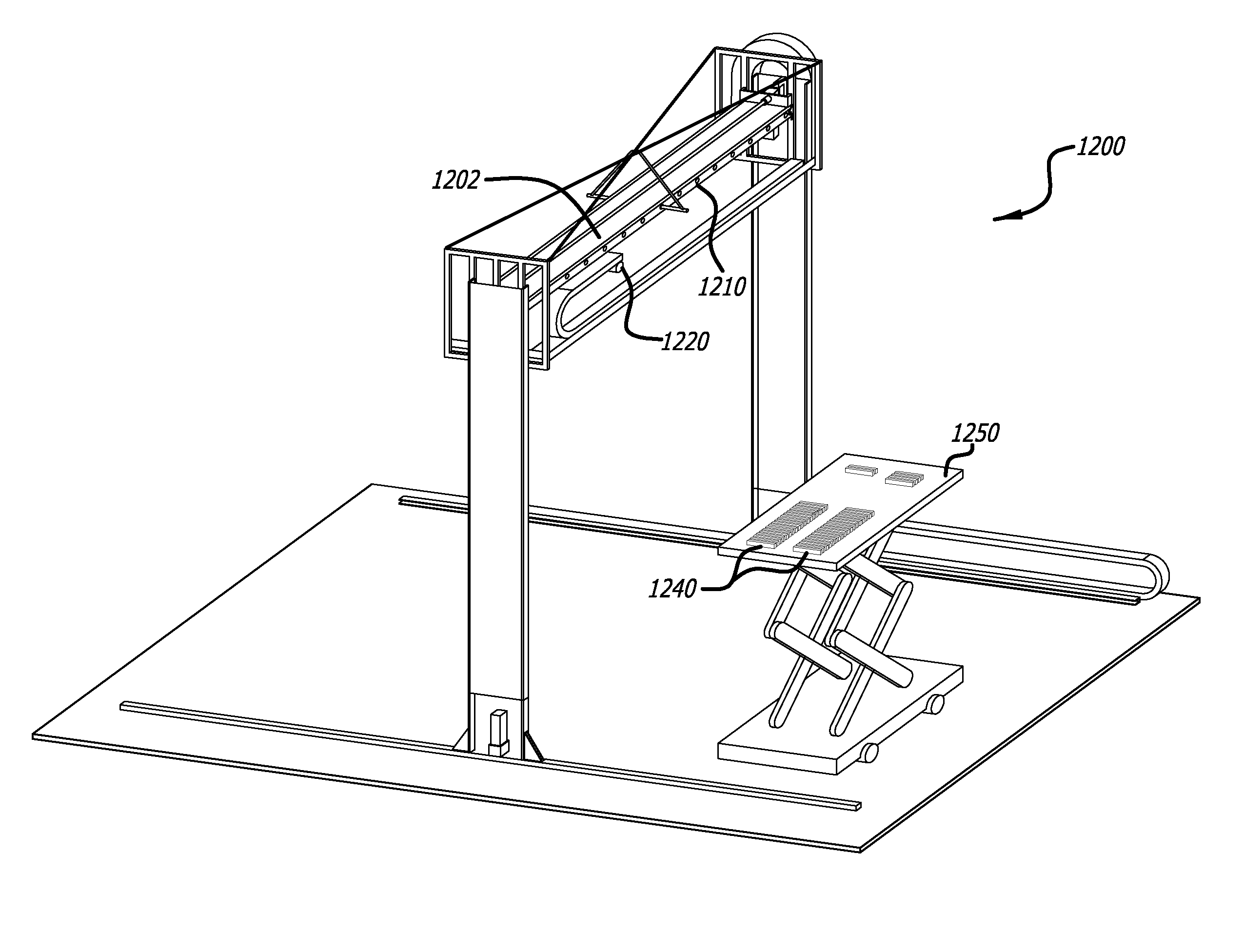

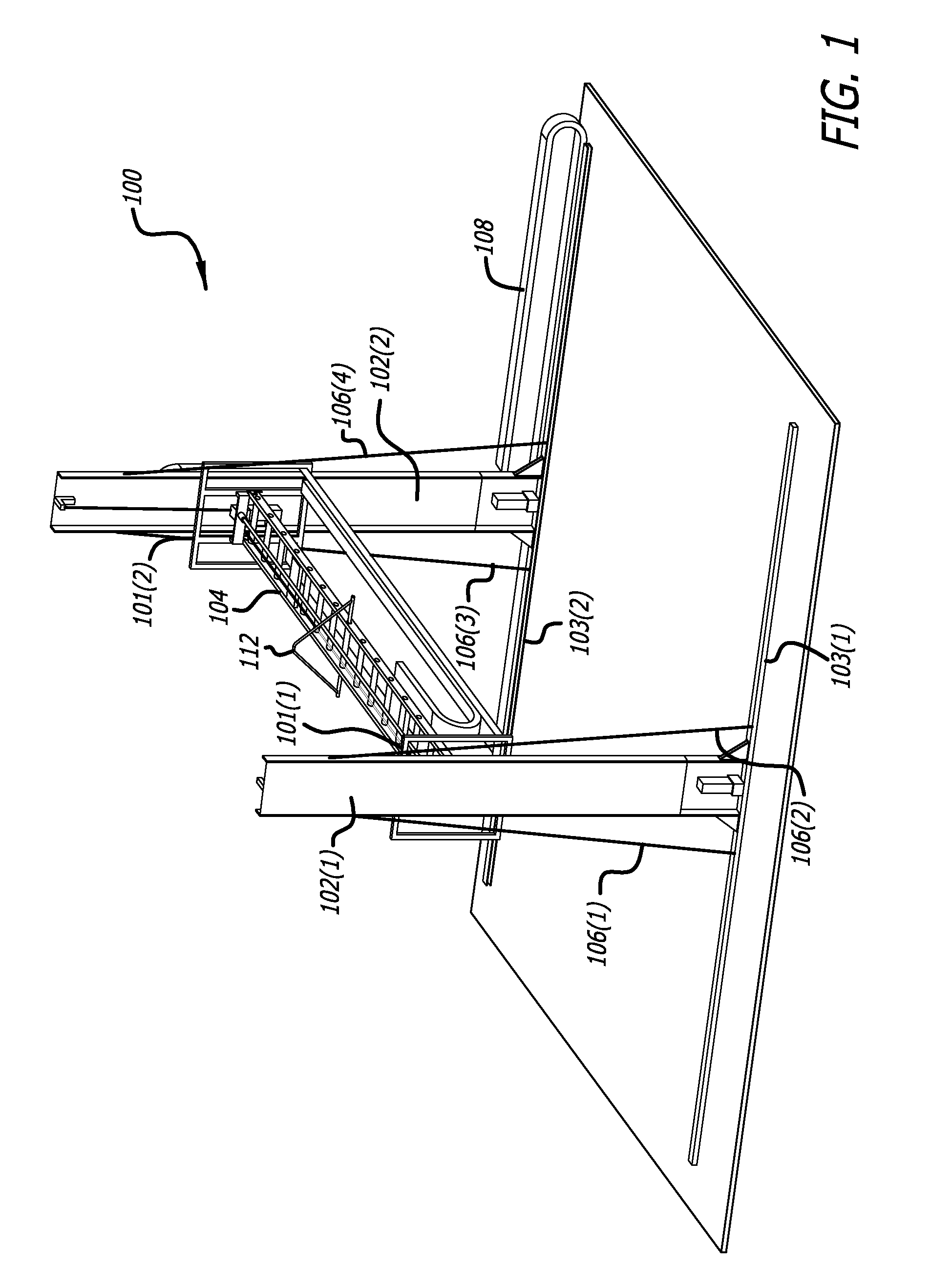

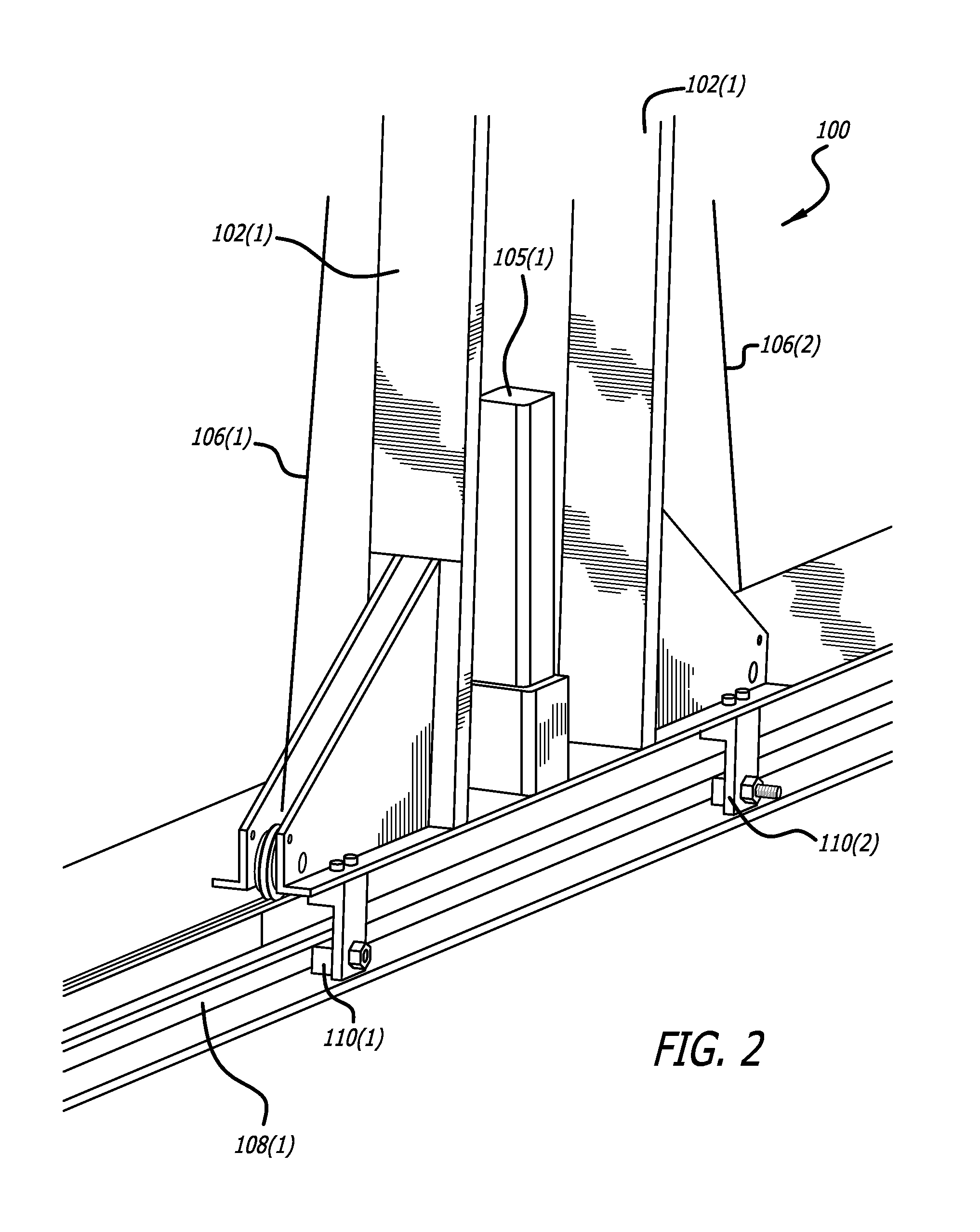

Gantry robotics system and related material transport for contour crafting

Apparatus and methods are disclosed that are useful for robotic gantry systems that are lightweight while at the same time offering rigidity or stiffness for implementation in Contour Crafting construction and material delivery techniques. The present disclosure is directed to robotic gantry system and material transport apparatus that use of very light structural members that have sufficient compressive strength, but which may otherwise be weak in the presence of bending forces, in conjunction with cables that provide stiffness against bending. Use of such cables provides needed tension while at the same time allowing the robotic gantry system to be very light compared to solid structures, e.g., those with I-beams, etc. Material delivery systems including passive articulated arms are also disclosed.

Owner:UNIV OF SOUTHERN CALIFORNIA

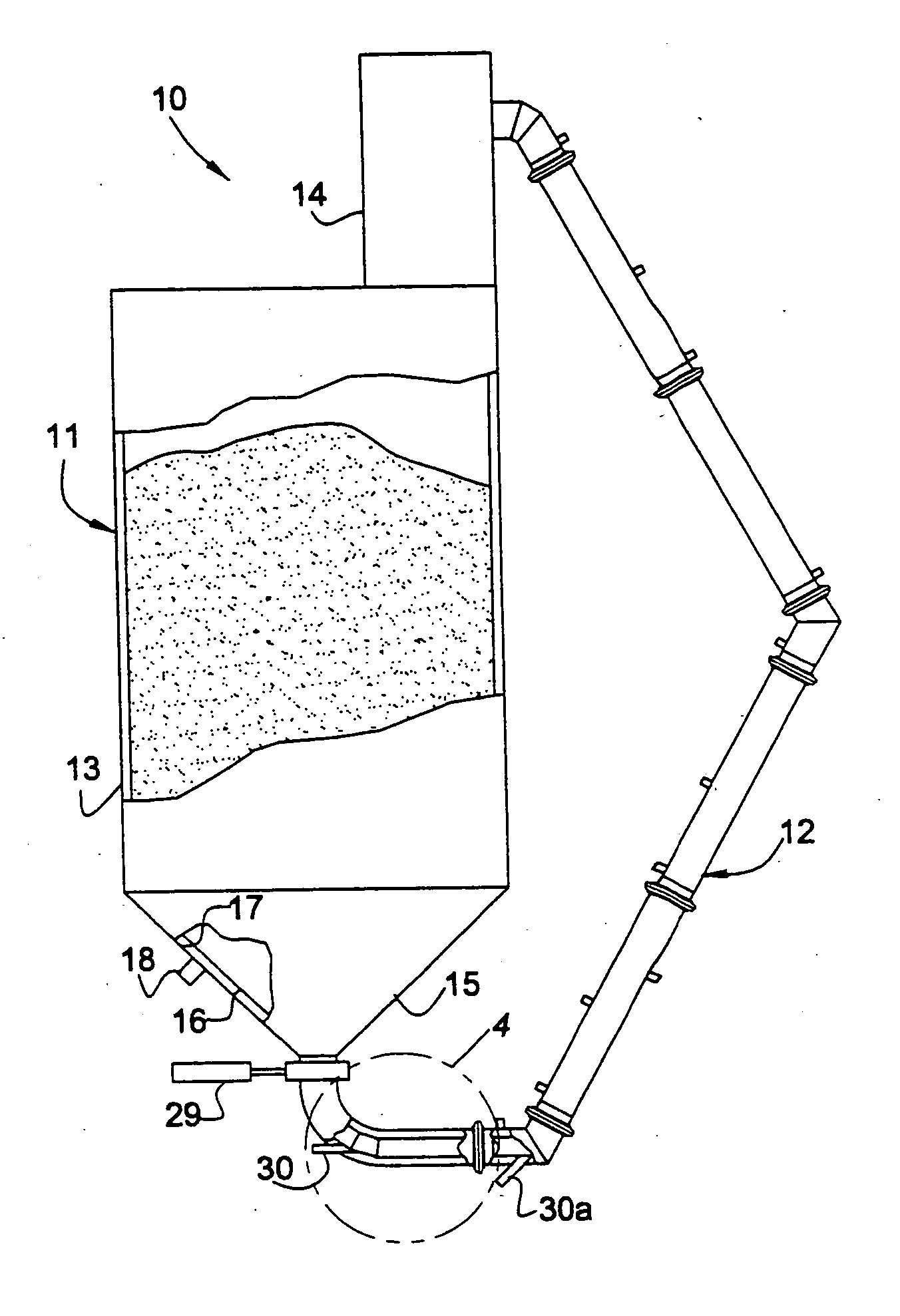

System for pneumatically conveying bulk particulate materials

A system for pneumatically conveying a bulk particulate material generally consisting of means for holding such material, having an inlet and an outlet; a first material transport line segment including a first conduit formed of a gas permeable material having an inlet communicating with the outlet of the holding means and an outlet, defining a material flow passageway, and a second conduit formed of a gas impermeable material spaced from and encompassing the first conduit, defining a plenum; a second material transport line segment including a first conduit formed of a gas permeable material having an inlet communicating with the outlet of the first conduit of the first segment, defining a continuation of the material flow passageway, and an outlet, and a second conduit section formed of a gas impermeable material spaced from and encompassing the first conduit thereof, defining a plenum; the second segment being displaceable relative to the first segment between a first position communicating the outlet of the first conduit of the second segment with a receptacle into which the material is to be conveyed, and a second position communicating the outlet of the first conduit of the second segment with the inlet of the material holding means; means for supplying gas under pressure to the plenums, causing such gas to penetrate the first conduits to fluidize material flowing in the passageways and means for inducing the flow of material in the passageways, causing material induced therein from the holding means to be impelled therethrough.

Owner:YOUNG INDS

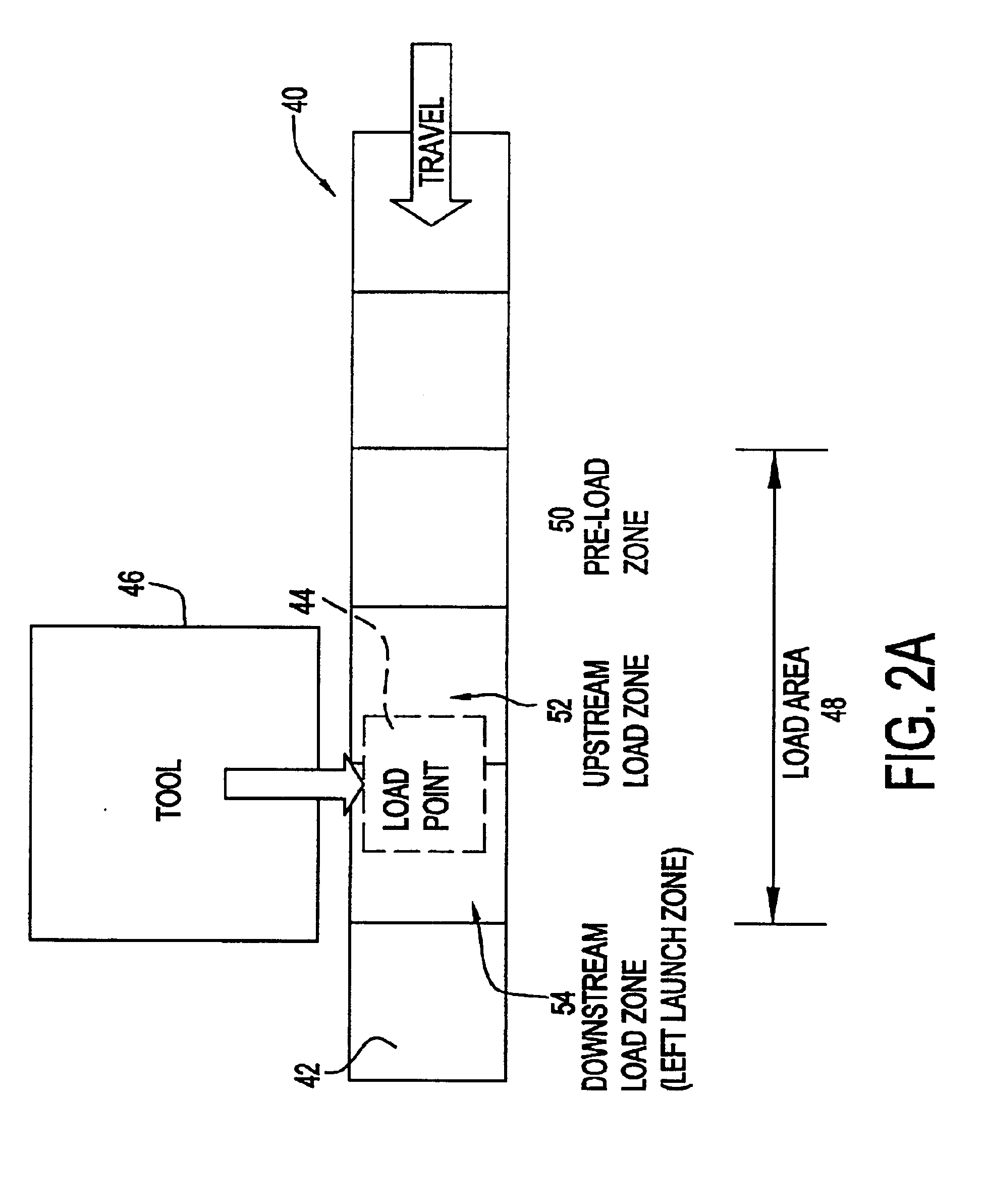

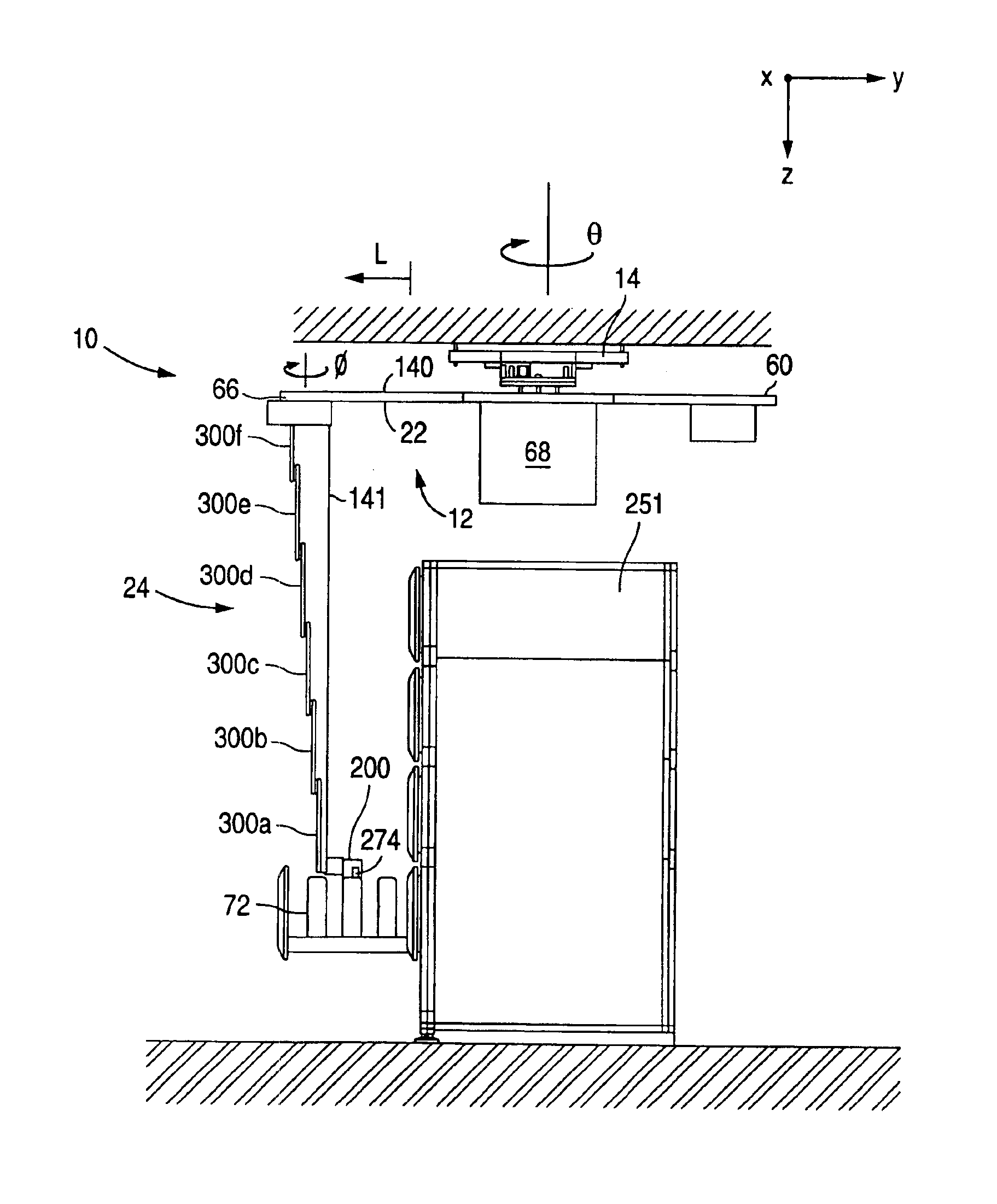

Material transport method

InactiveUS6889813B1Easy loadingImprove space utilizationSemiconductor/solid-state device manufacturingControl devices for conveyorsRange of motionMagnetic tape

A controlled material transport method for carrying materials to and from workstations, test equipment, and processing and assembly tools in a common facility. The present invention includes a rigid “robot vehicle” mountable to a passive track system, which can be routed to service all processing tools on the factory floor. The robot vehicle includes a hoist assembly and gripper assembly, which together perform such functions as picking up magazines, placing magazines, and loading magazines into the processing tools. The hoist assembly is capable of functioning in an operational envelope, which includes any target location within a 3-axis Cartesian coordinate system, to the extent of the range of motion of the hoist assembly. The hoist assembly also provides rigid and controlled z-axis travel, while being compact when retracted. The gripper assembly facilitates loading of the magazines, especially chute style magazines, which are commonly found on many existing processing tools.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com