Bulk production line for reconstituted tobacco thin sheets by dry papermaking method

A technology for reconstituted tobacco leaves and dry-process papermaking, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems that have not been seen in the field of reconstituted tobacco leaf production, and achieves reduction of space occupation and manual participation, reduction of sewage discharge, and good social benefits. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

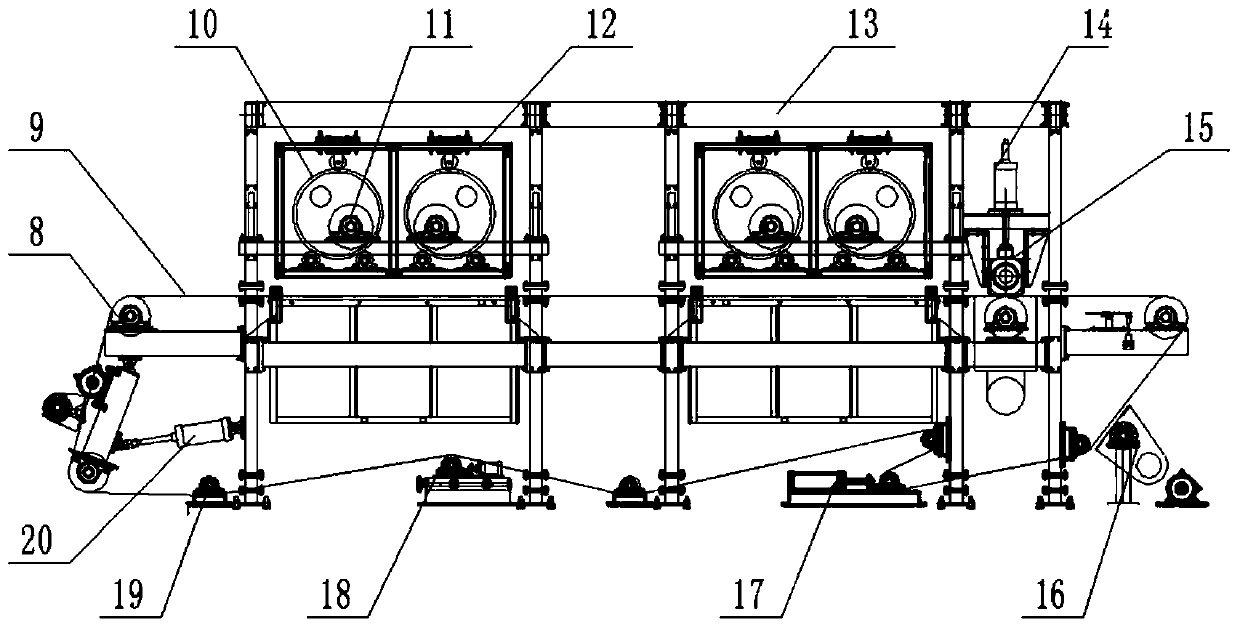

[0044] The invention provides a dry-process reconstituted tobacco sheet assembly production line, which includes a raw material processing section, a tobacco leaf forming section and a sheet forming section,

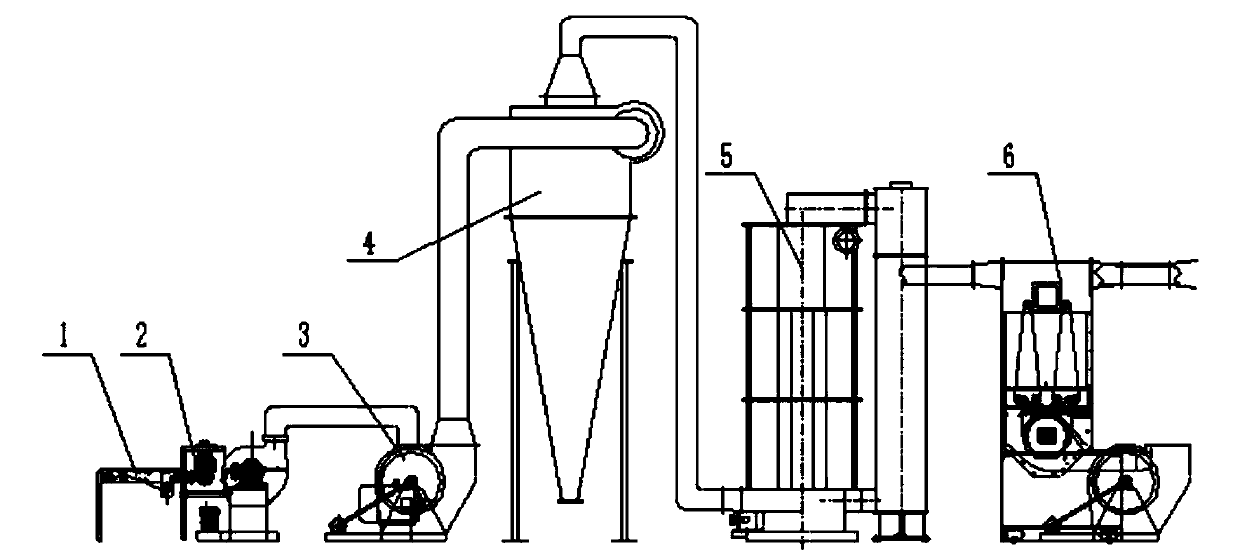

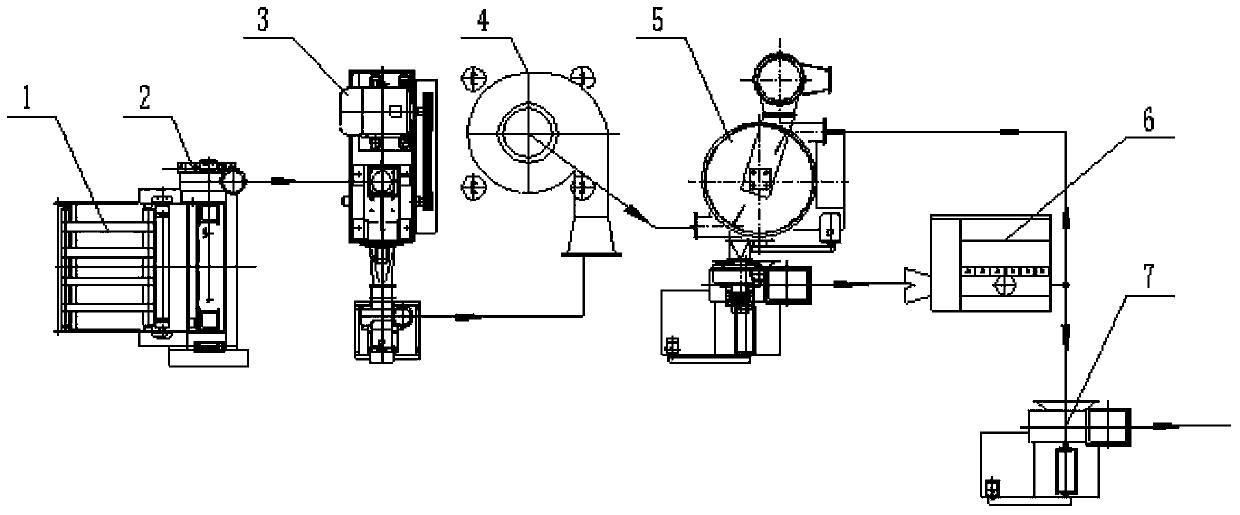

[0045] Such as figure 1 and figure 2The raw material processing section shown includes a raw material conveyor 1, which is connected with a coarse crusher 2 through a conveyor belt, and the coarse crusher 2 is sequentially connected with a fine crusher 3, a cyclone dust collector 4, a storage tank 5, and a fiber counting machine 6 and feeding blower fan 7 are connected through air ducts,

[0046] The raw material processing part of the present invention sends the wood pulp or tobacco fiber to the storage tank 5 after being processed by the raw material conveyor 1 through the coarse crusher 2, the fine crusher 3 and the cyclone dust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com