Patents

Literature

5996 results about "Tobacco leaf" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-Combustion Smoking Tool

InactiveUS20110290269A1Easy to useReduce the temperatureCigar manufactureTobacco pipesCombustionEnvironmental health

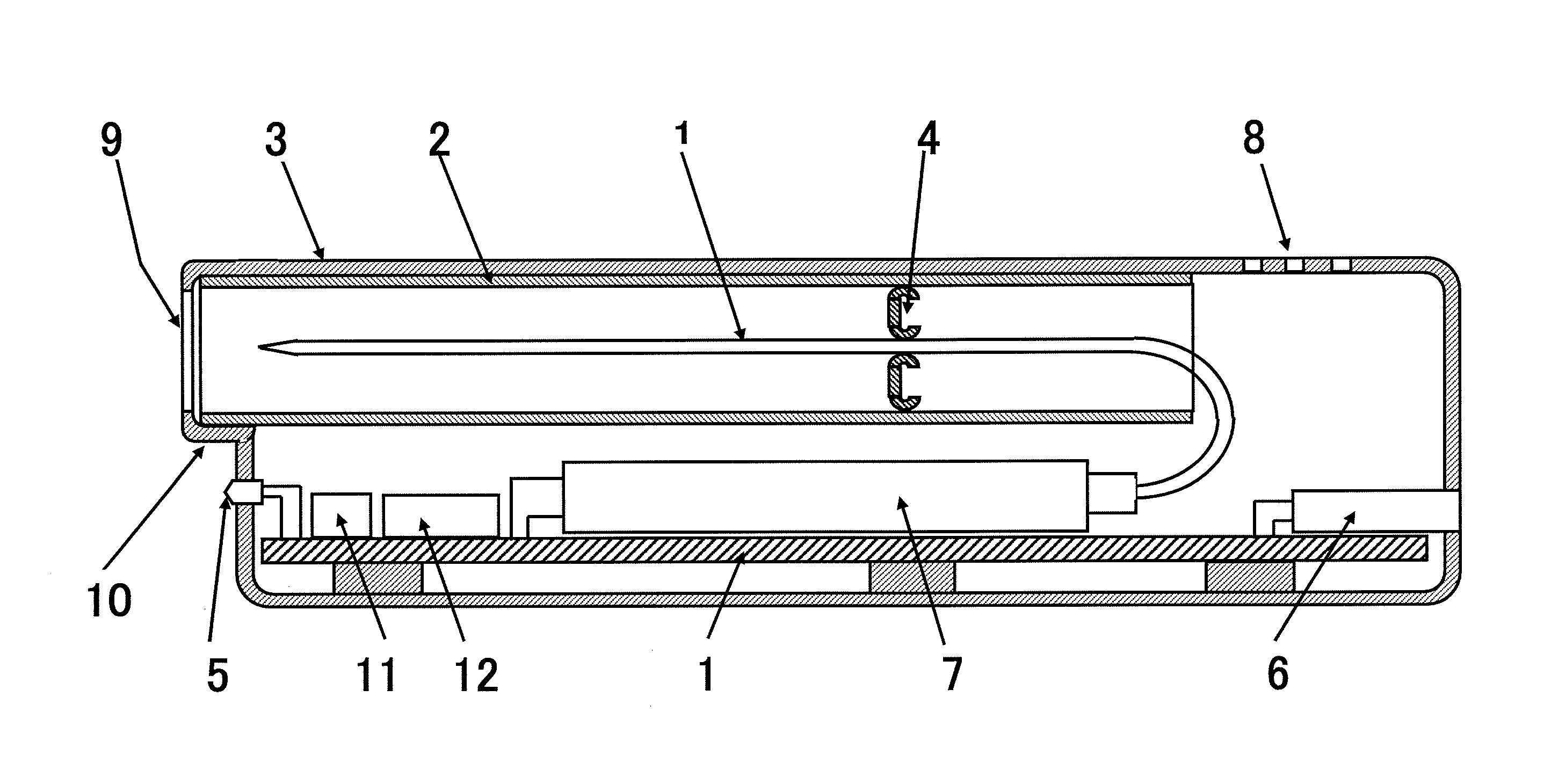

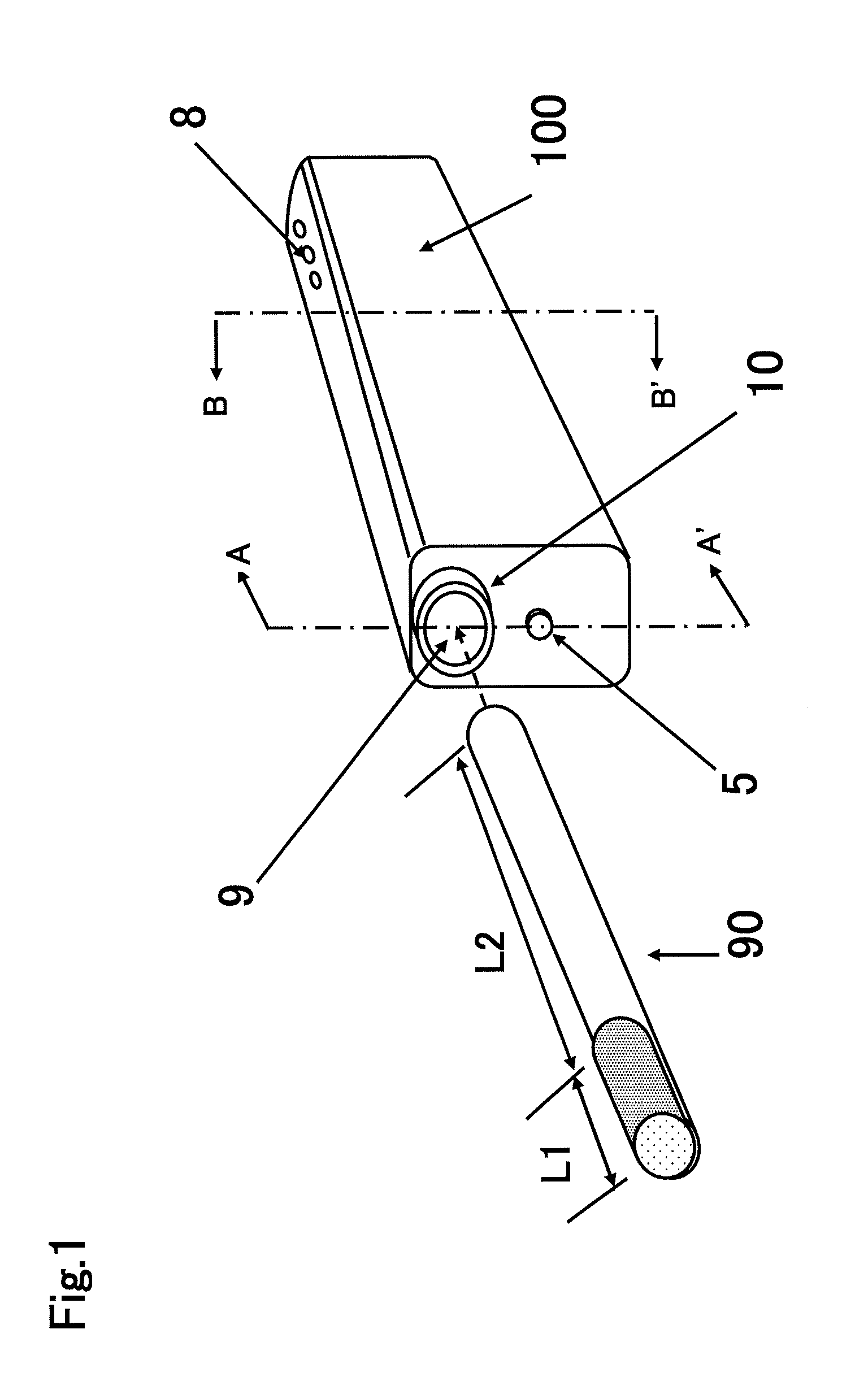

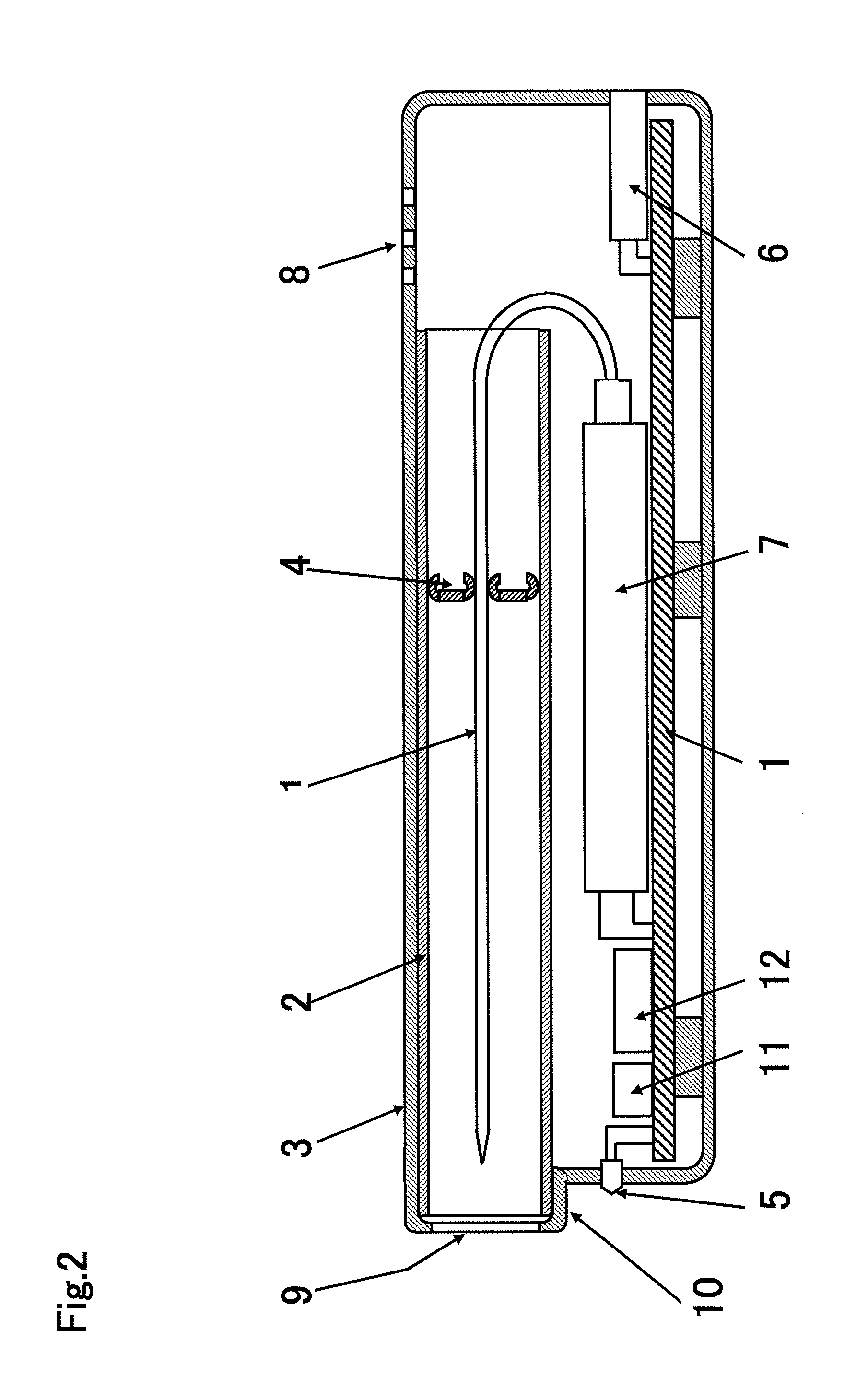

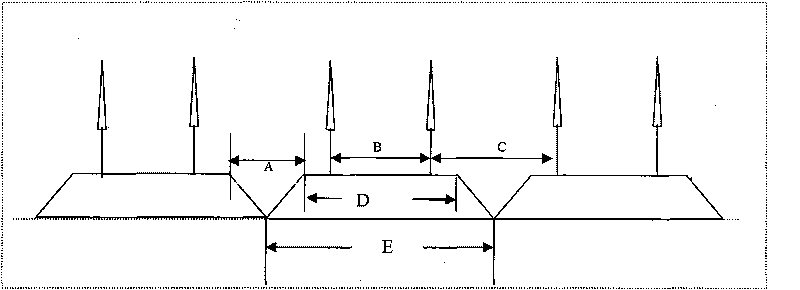

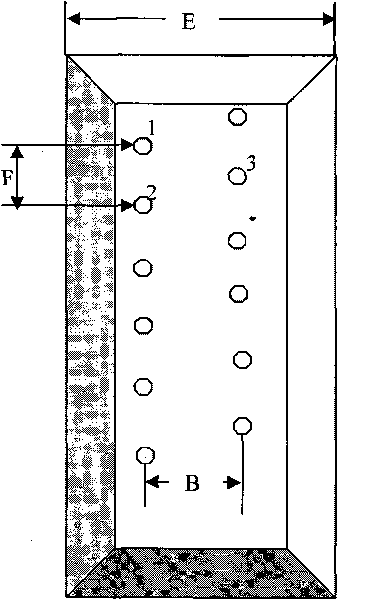

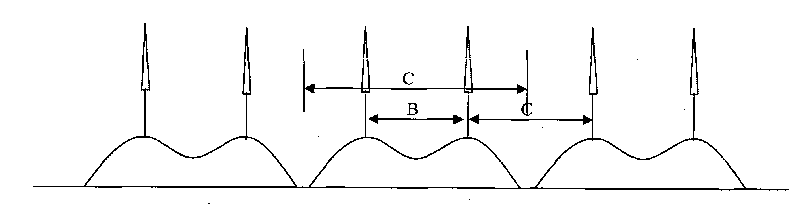

In order to use a commercially available cigarette or cigar as it is, vaporize nicotine from the tobacco leaves, and enable inhalation of the vaporized nicotine without burning the product, a non-combustion smoking tool comprises a slender heater 1 having a sharp end which is directly inserted into a commercially available cigarette or cigar 100 to directly heat the leaves of the cigarette or cigar by the heater so as to vaporize nicotine contained in the tobacco leaves and enable inhalation of the vaporized nicotine.

Owner:KAZUHIKO SHIMIZU

Ferment for tobacco fermentation and use thereof

ActiveCN101416778AIncrease aromaReduce mistTobacco preparationFungiNicotiana tabacumBacillus aryabhattai

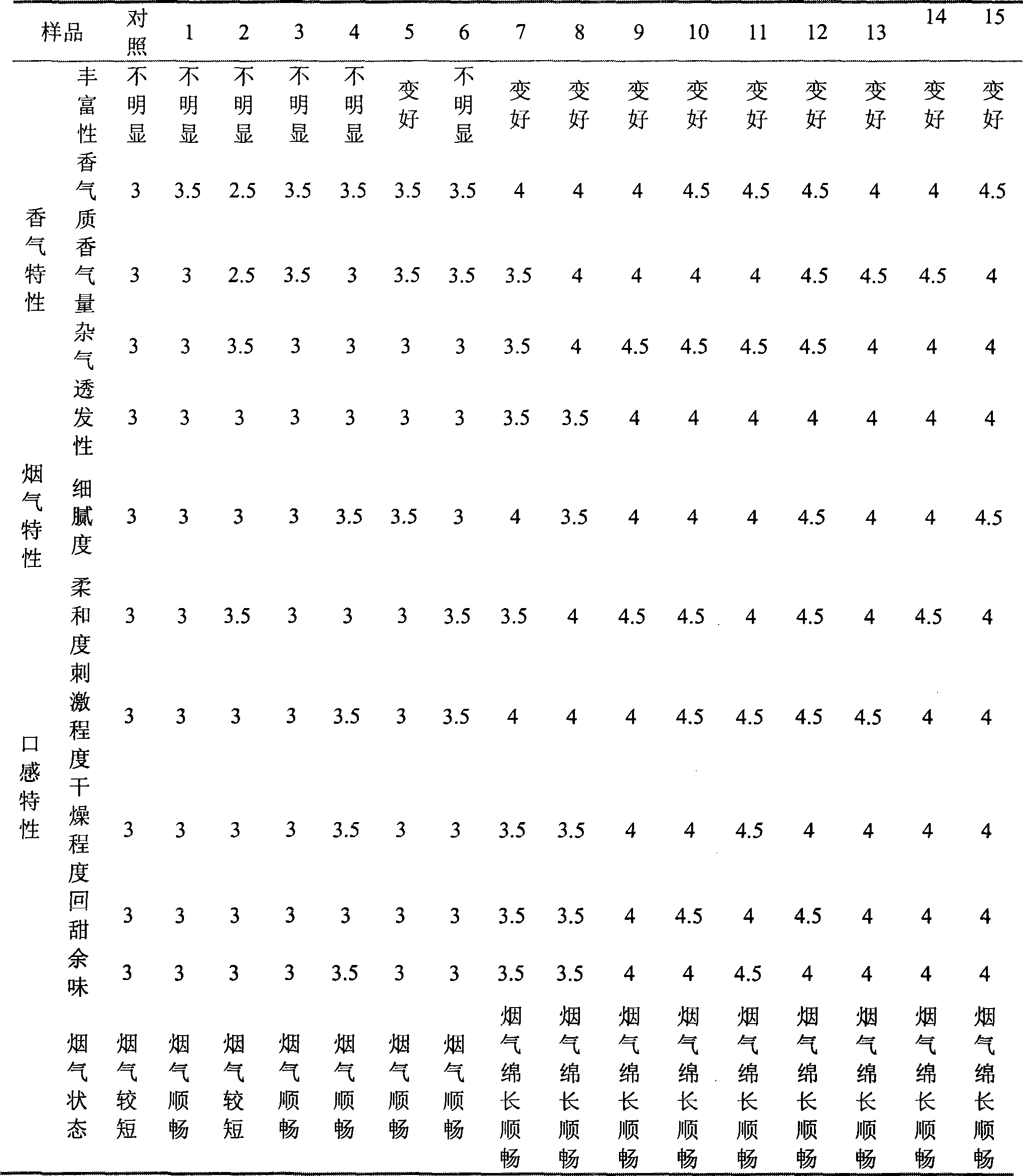

The invention discloses a hametz used for fermenting tobacco and applications thereof. The hametz is characterized by comprising three strains of Bacillus subtilis, lactobacillus and microzyme, the viable count ratio of which is 10 to 50: 2 to 30: 2 to 30. The hametz can ferment waste material of the tobacco or the flavor used for producing natural cigarettes by using the tobacco and can be used for tobacco fermentation. The flavor used for the natural cigarettes prepared by the hametz has a velvet fragrance and can remarkably increase the fragrance, reduce the unpurified gas and reduce the thrill as well when the flavor is used in the cigarettes, thus leading the smoke gas to be lingering and smooth. The hametz used for fermenting tobacco leaves can remarkably shorten the alcoholizing time and improve the quality of the tobacco leaves.

Owner:SOUTH CHINA UNIV OF TECH

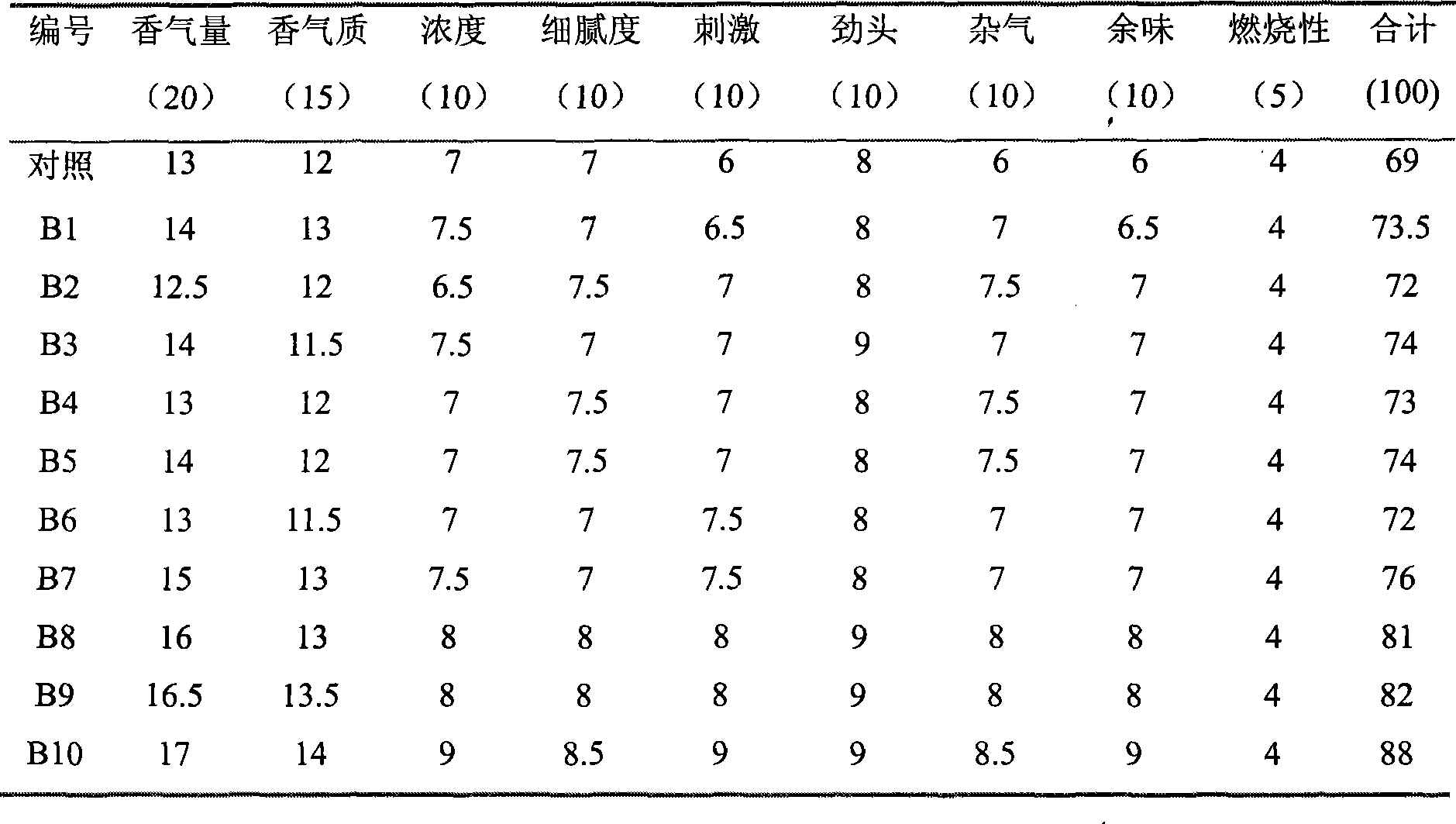

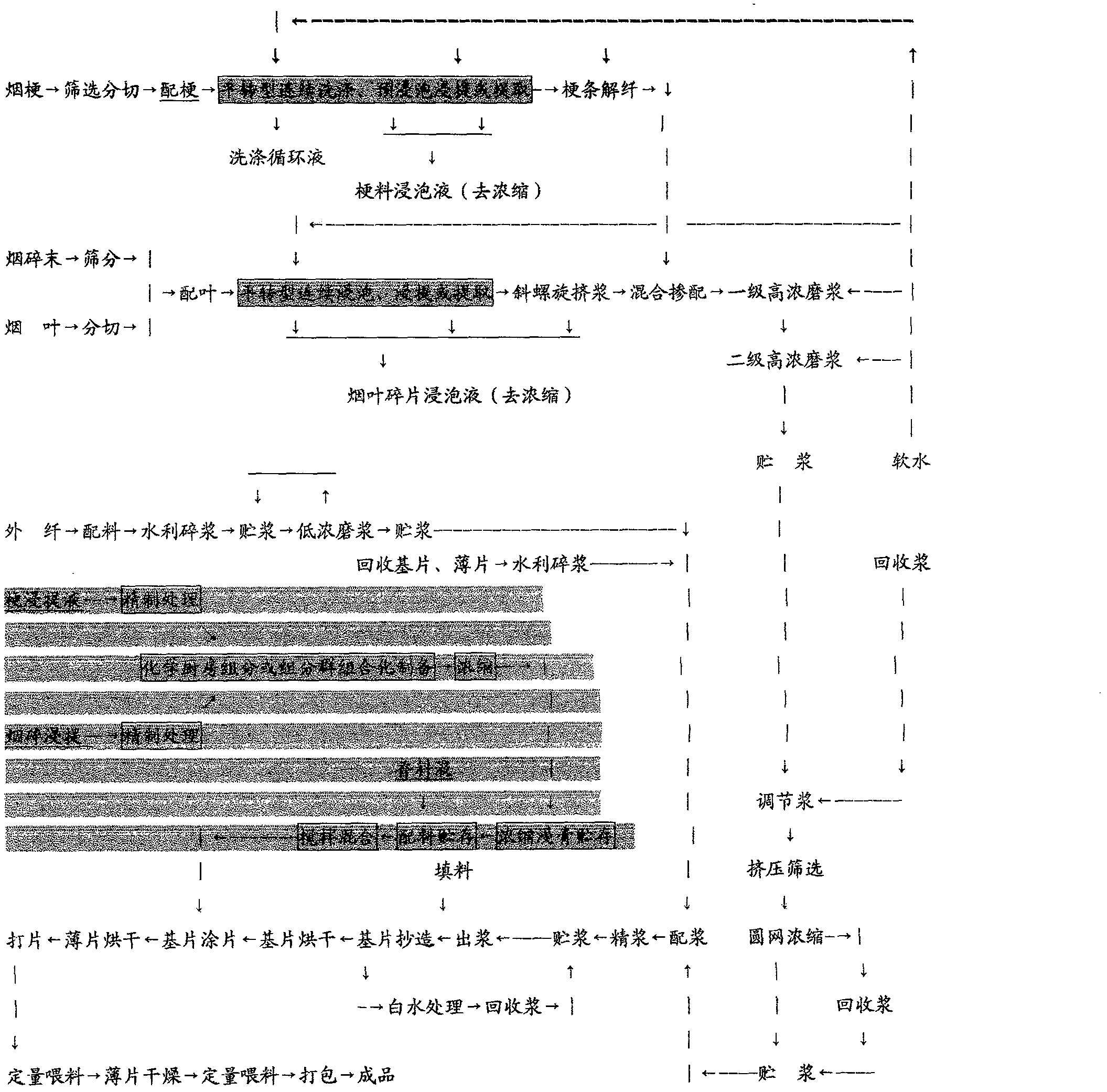

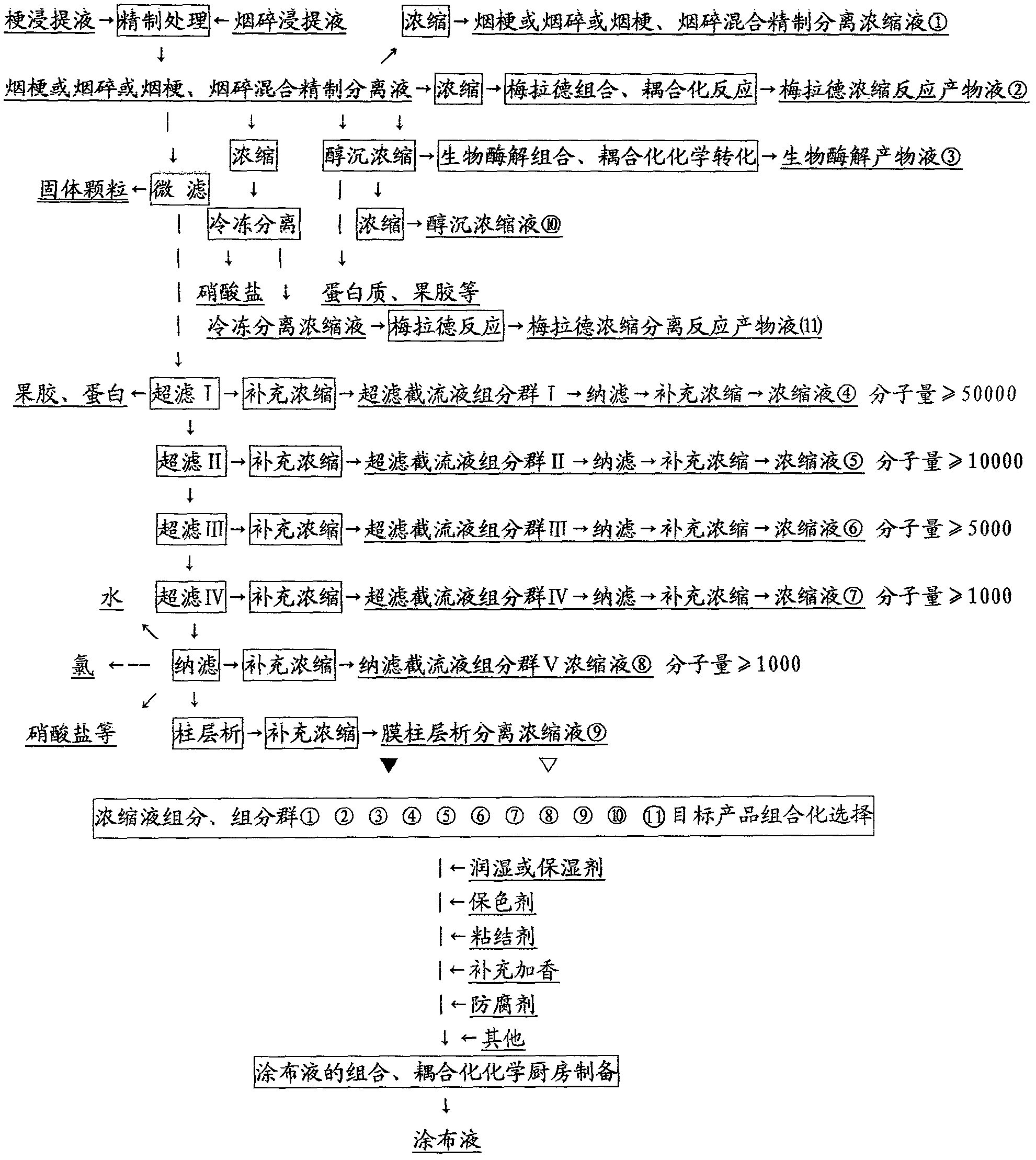

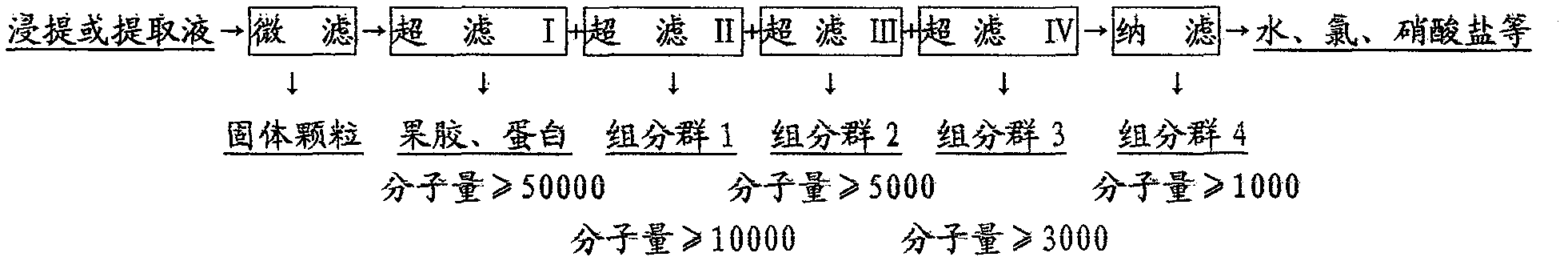

Reconstructed tobacco coating liquid component-component group chemical kitchen combination, coupling preparation, and coupling preparation process

The invention relates to a reconstructed tobacco coating liquid component-component group chemical kitchen combination, coupling preparation, and a coupling preparation process. Discarded waste tobacco leaves and stems are subjected to presoaking and enzymatic leaching or extraction to make tobacco leaf or stem enzymatically-leached / extracted solution, or tobacco leaf and stem mixed leached / extracted solution, certain components and component groups such as protein, pectin, chloride, nicotine, nitrosamines, nitrates and the like in the tobacco leaf and stem leached / extracted solution or tobacco leaf and stem leached / extracted mixture can be selectively converted, reduced or removed by combination of enzymolysis, Maillard reaction conversion, membrane separation / concentration or column separation, freeze separation, ethanol precipitation and the like, and the coupling preparation process for chemical components and component groups in the chemical kitchen, and accordingly, recombination or fitting, combination, regulation and coke reduction and harm reduction of the chemical components and component groups of the reconstructed tobacco coating liquid are achieved, quality of reconstructed tobacco is improved, and industrial technical integration and innovation on combination and coupling of the reconstructed tobacco coating liquid are realized.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Chewing tobacco substitute containing cotinine

The invention is a chewing tobacco substitute made from natural leaves and additives which simulate the taste and consistency of chewing tobacco to which a nicotine compound is added. The invention allows those addicted to chewing tobacco to chew and receive nicotine without incurring the other harmful side effects of tobacco. In one embodiment of the invention the product is provided with varying levels of nicotine.

Owner:WHALEN WILLIAM

Bacillus subtilis and use thereof in prevention and control of fungus disease

InactiveCN102154186AImprove qualityPromoting effect is goodBiocidePlant growth regulatorsVerticillium speciesNicotiana tabacum

The invention discloses Bacillus subtilis, which is named Bacillus subtilis. The Bacillus subtilis was collected in China General Microbiological Culture Collection Center on January 15th, 2009, with a collection number of CGMCC No.2843. The Bacillus subtilis strain disclosed by the invention is screened from tobacco leaf habitats. Experiments prove that the fermentation liquor of the strain has a strong inhibition effect on fungal pathogens such as Alternaria alternate and pepper anthracnose and demonstrates high prevention effect on Alternaria alternate, tobacco black shank, pepper anthracnose, tomato wilt, phytophthora melonis Katsura, verticillium dahlia and the like and has high growth promoting effects on tobacco, pepper, cucumber, tomato and eggplant. Therefore, the Bacillus subtilis disclosed by the invention can be used for preparing biological bactericides for preventing and controlling fungi in tobacco and vegetables and can be used for preparing growth promoting agents for promoting the growth of tobacco or vegetables.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +1

Chewing tobacco substitute containing nicotine

The invention is a chewing tobacco substitute made from natural leaves and additives which simulate the taste and consistency of chewing tobacco to which a nicotine compound is added. The invention allows those addicted to chewing tobacco to chew and receive nicotine without incurring the other harmful side effects of tobacco. In one embodiment of the invention the product is provided with varying levels of nicotine.

Owner:WHALEN WILLIAM F

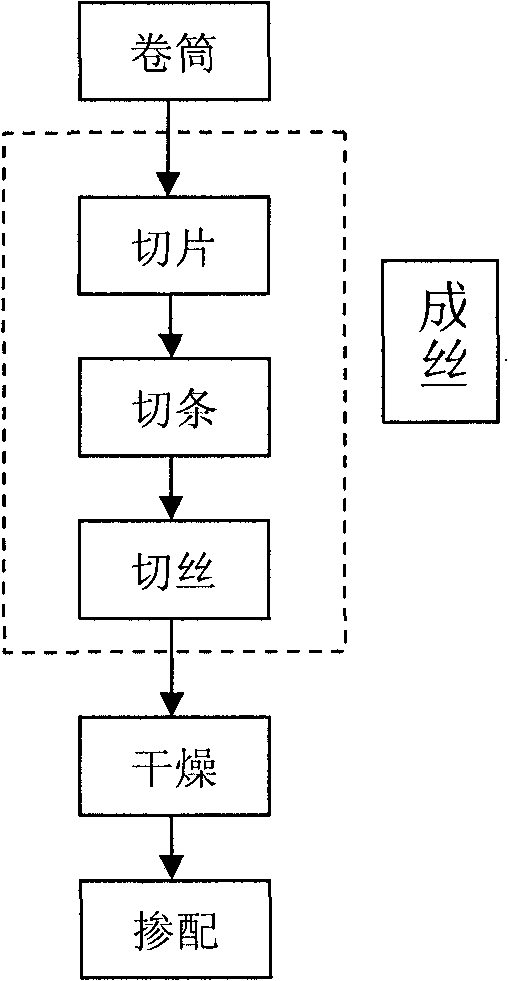

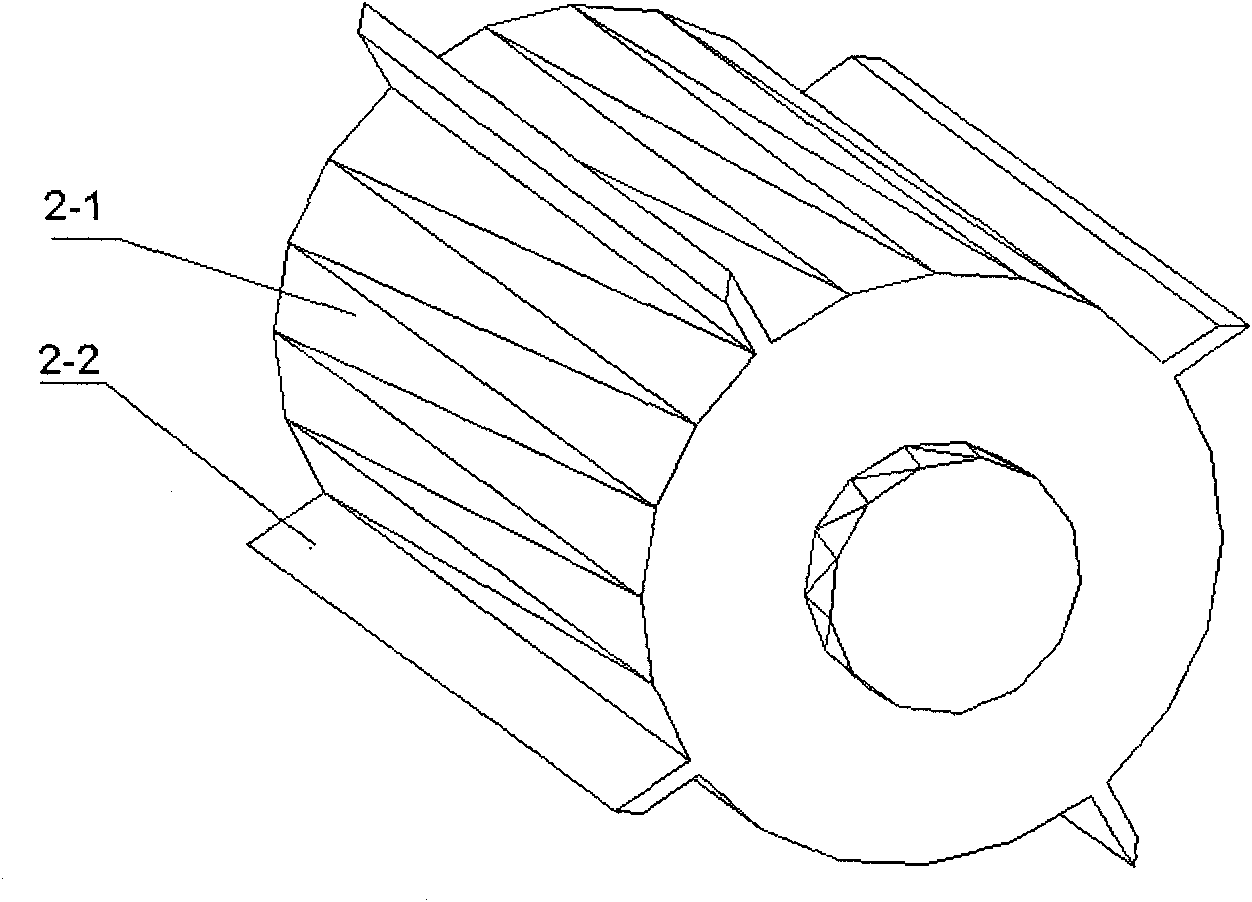

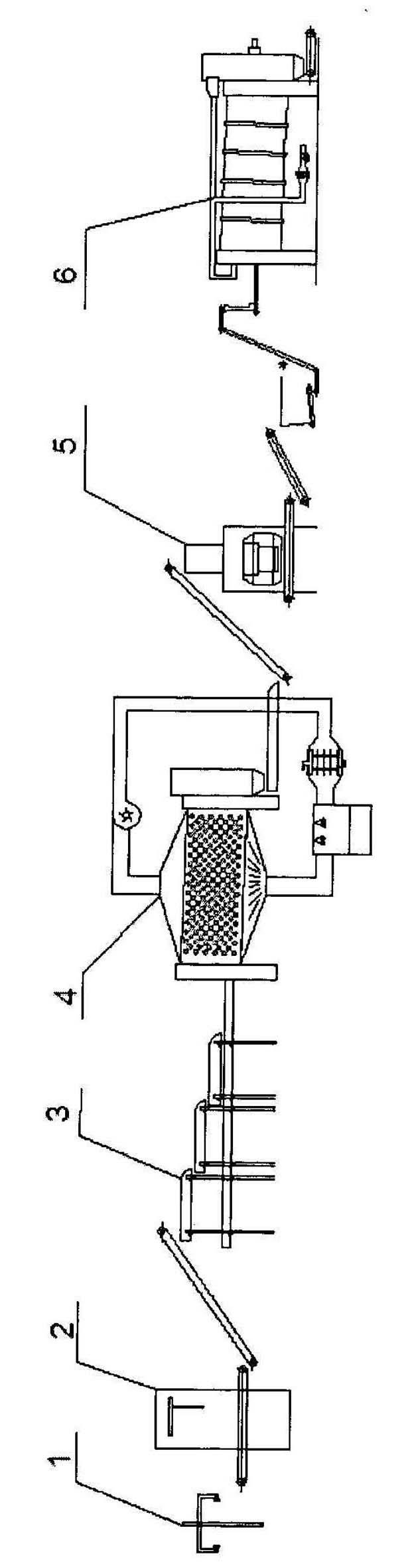

Filament forming process for paper making method-based reconstituted tobacco and device thereof

ActiveCN101828762ANot easy to runNo tearingTobacco preparationPulp and paper industryManufacturing line

The invention relates to a filament forming process for paper making method-based reconstituted tobacco and a device thereof. The invention is characterized in that the process comprises the following steps of: a. forming filaments by adopting a three-step slitting procedure, i.e. firstly slitting into slices, then slitting into strips, and finally slitting into filaments to carry out the filament forming step of the reconstituted tobacco; b. drying: feeding the reconstituted tobacco filaments having a water content of 16-20% to a drum type tobacco filament drier for drying by a constant feeder, wherein the water content of the dried reconstituted tobacco filaments is 11-13%; and c. blending: directly blending the dried reconstituted tobacco filaments in a tobacco filament production line according to the design proportion of a cigarette prescription. The process and the device can solve the problem that the paper making method-based reconstituted tobacco is difficult to make into filaments solely, raises the effective utilization rate of the paper making method-based reconstituted tobacco; and the made reconstituted tobacco filaments have uniform length, good bulking property, and effectively maintained fragrance, thereby improving the sensory quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

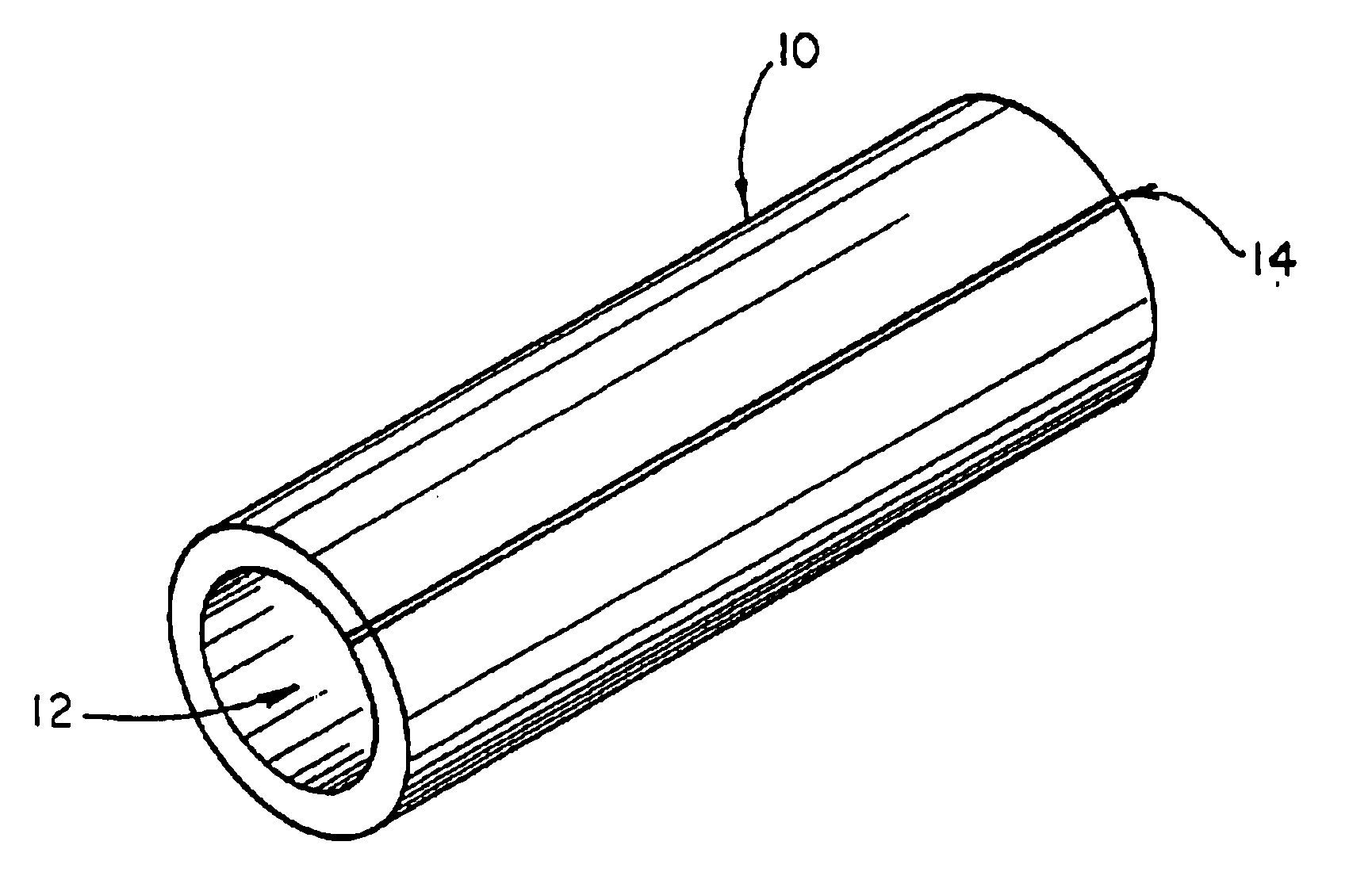

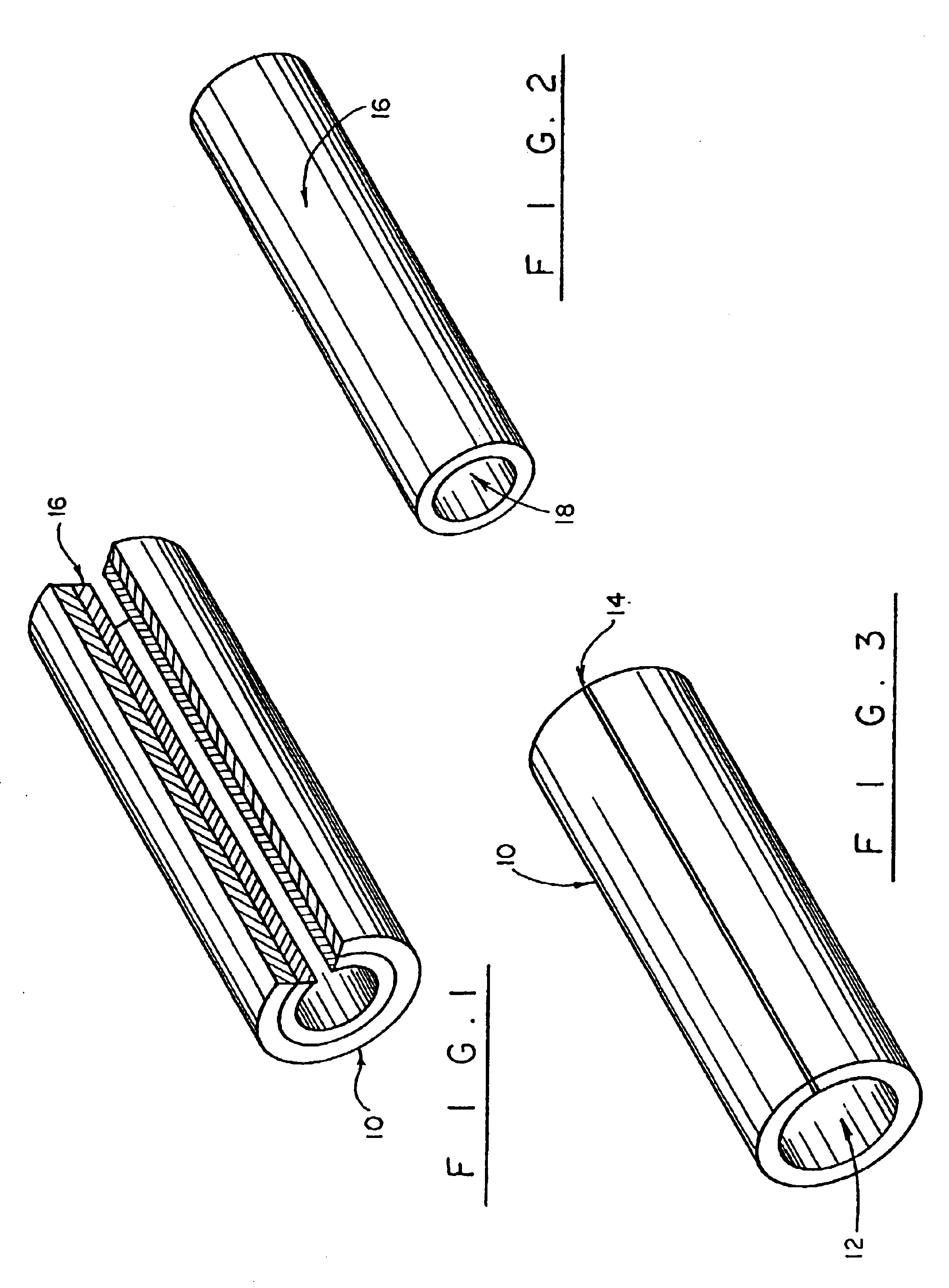

Tobacco product

InactiveUS6854471B1Exemption stepsTobacco preparationNon-fibrous pulp additionEngineeringTobacco product

A tobacco product is formed by rolling moistened tobacco leaves about a cylindrical form casing and allowing the leaves to dry to form a shell. After the form casing is removed a consumer can fill the shell with crushed tobacco leaves of a favorite blend, thereby eliminating some steps in the making of a “roll-your-own” tobacco product.

Owner:BLUNT WRAP US

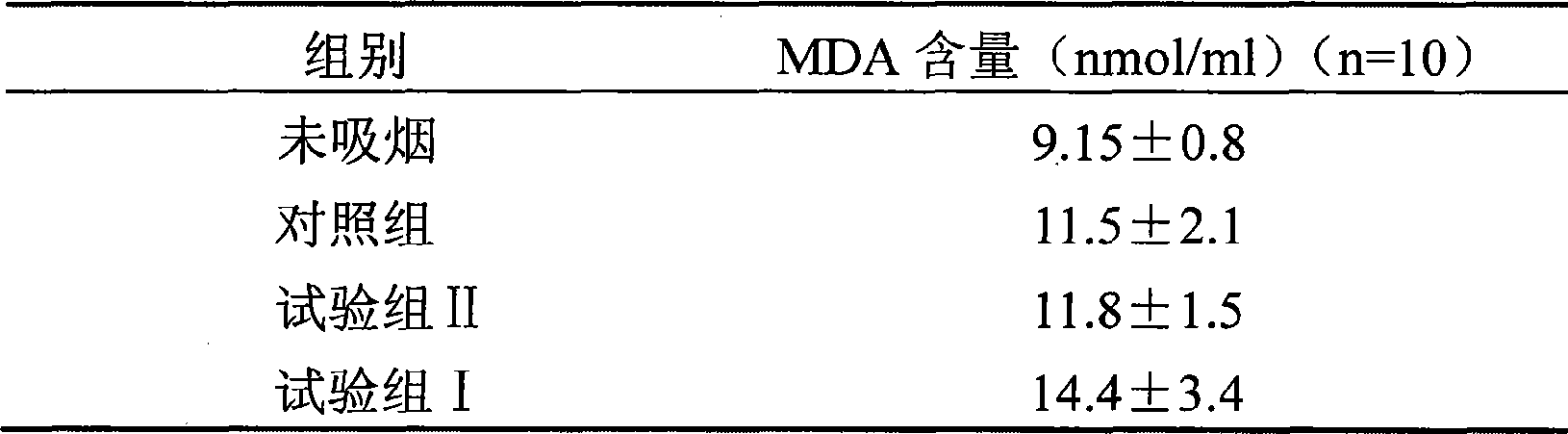

Modern snuff and its making method

InactiveCN1775117AHarm reductionReduce fatigueTobacco treatmentHydroxy compound active ingredientsAgricultural scienceTar

The present invention discloses a new-type snuff and its preparation method. It is made up by using dried tobacco leaf, dried natural vanilla and functional auxiliary material according to the mixing ratio of 1:0.8:0.2 through a certain preparation process. It can greatly reduce nicotine, tar and other harmful matter contents.

Owner:杨利斌

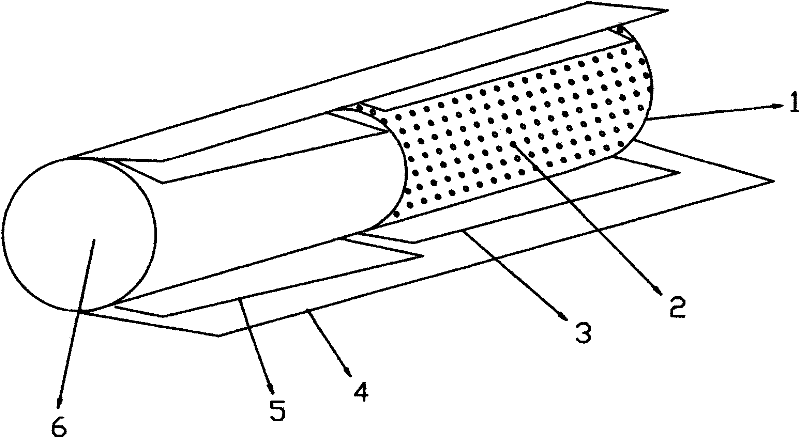

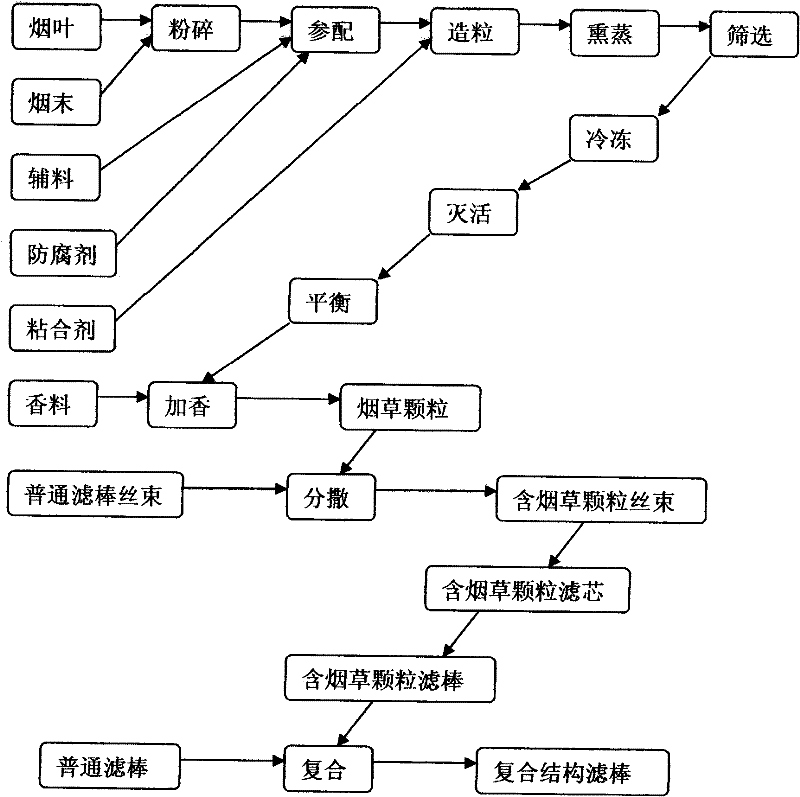

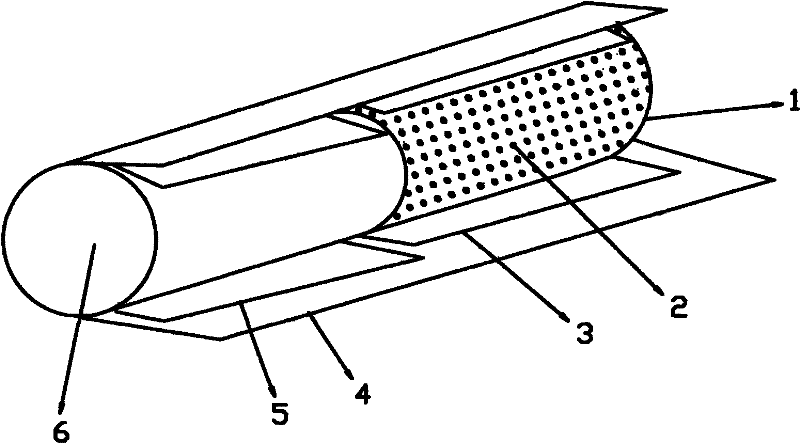

Filter stick containing tobacco particles and preparation method thereof

The invention provides a novel filter stick for cigarettes and a preparation method thereof. Tobacco particles are added in a filter core of the filter stick, tobacco leaves and tobacco smalls are adopted as main raw materials of the tobacco particles and are used as additives after the technical processing such as pulverizing, rotten prevention, granulating, fumigating, perfuming and the like tobe thrown into tows of the filter stick, and then the filter stick containing the tobacco particles or the filter stick with a composite structure can be prepared by adopting a filter stick forming machine. The filter stick can strengthen the adsorption function, can reduce the tar and alleviating the harm, and fragrance of the tobacco particles also can effectively compensate the decreased fragrance of the cigarette caused by the filtering of the filter stick. At the same time, the filter stick is easy to cut and is friendly to the environment.

Owner:NANTONG CIGARETTE FILTER

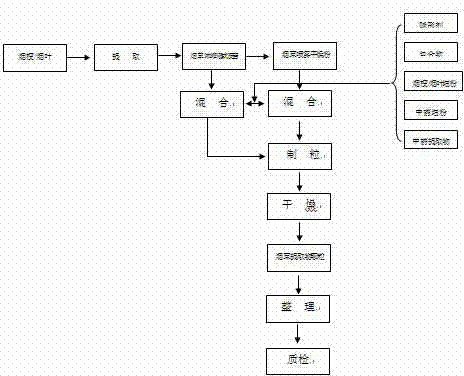

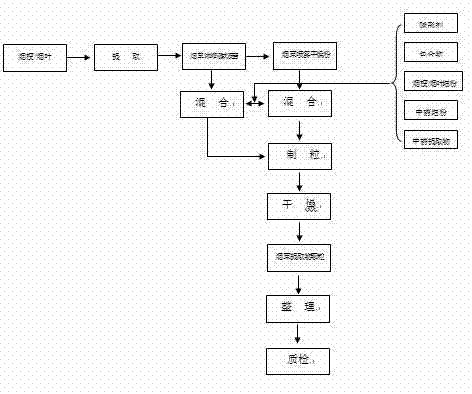

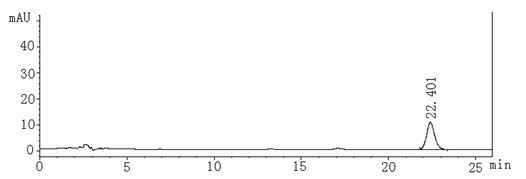

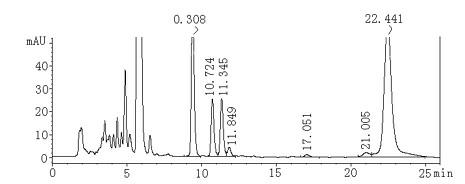

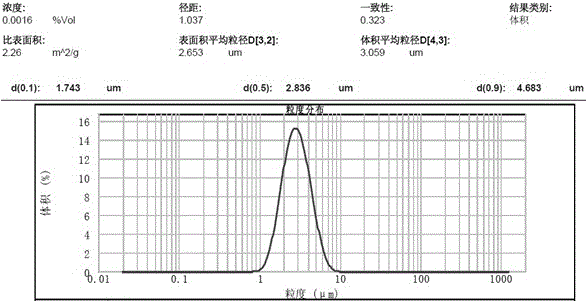

Preparation method of tobacco extract granules

The invention relates to a preparation method of tobacco extract granules, which comprises the following steps: firstly taking and cutting up tobacco leaves and / or tobacco stalks, taking water or ethanol or ethyl ether as a solvent for extraction, settling and filtering to obtain tobacco extract, then concentrating to the relative density of 1.00-1.30, and controlling the temperature to 20-40 DEGC to obtain tobacco extract concentrate or tobacco extractum; and including beta-cyclodextrin and flavouring essence for tobacco according to the mass ratio of 1-3:1 with the inclusion time of 1 / 5-3 hours to obtain a flavouring essence and beta-cyclodextrin inclusion compound, and then spray drying the flavouring essence for tobacco and beta-cyclodextrin inclusion compound and the tobacco extractconcentrate together to obtain tobacco spray dried powder; or directly spray drying the tobacco extractum to obtain the tobacco spray dried powder; and then adding excipient material to the tobacco spray dried powder for dry method or wet method granulation to obtain the tobacco extract granules. The tobacco extract granules obtained in the method disclosed by the invention are applied to cigarettes to improve the tar and harm reduction effect of the cigarettes, and can be used for aroma compensation, the utilization rate of waste tobacco leaf raw material is improved, and the cost of the cigarettes is reduced.

Owner:云南拓宝科技有限公司

Automatic grading system and method based on mass tobacco leaf data

ActiveCN103743486AIncrease speedReduce complexityColor measuring devicesMaterial analysis by optical meansImaging analysisData retrieval

The invention relates to an automatic grading system and an automatic grading method based on mass tobacco leaf data. The automatic grading system belongs to a system for carrying out analysis, storage, retrieval and automatic grading on tobacco leaf images by utilizing computer vision, image analysis, machine learning, big data retrieval and artificial intelligence technological algorithms. A mass data retrieval technology is introduced into an automobile tobacco leaf grading system, and corresponding databases and efficient retrieval engines are built, so grading results are more accurate, and the big data concept can become an irresistible trend along with the computer technology development. An artificial intelligence expert system algorithm is introduced, tobacco leaf knowledge in the specific fields is utilized for constructing an expert knowledge base, various complicated tobacco grading problems which can only be solved by human experts are simulated, and the computer intelligence with the same problem solving capability as the experts in the field is reached.

Owner:SHANGHAI UNIV

Method for preparing squalene based on tobacco as raw material

InactiveCN102161611AAbundant resourcesMeet the needs of industrializationTobacco treatmentAdsorption purification/separationOrganic solventBiochemical engineering

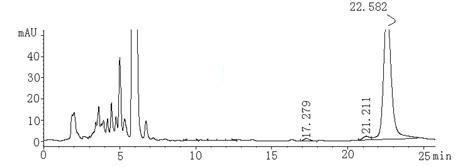

The invention provides a method for preparing squalene based on tobacco as a raw material. The method comprises the following steps: smashing dried tobacco leaves, leaching out fat-soluble substances with an organic solvent, and removing the organic solvent in the fat-soluble substances so as to obtain crude tobacco squalene; passing the crude tobacco squalene through a silica gel chromatograohiccolumn, eluting with the organic solvent, collecting eluent, and removing the organic solvent by using a decomposition distillation method so as to obtain the fine squalene. The content of the squalene in the crude squalene is more than 35%, the content of the squalene in the fine squalene is more than 95%. Tobacco resources are abundant and can meet industrial requirement; in the method, waste tobacco and cigarette fine waste in the cigarette production can be fully utilized to prepare the squalene; and according to the invention, a technical basis is provided for development and utilizationof the tobacco squalene, especially for the application of the tobacco squalene in the aspect of cigarette production. Thus, the social benefits and economic benefits are great.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL +1

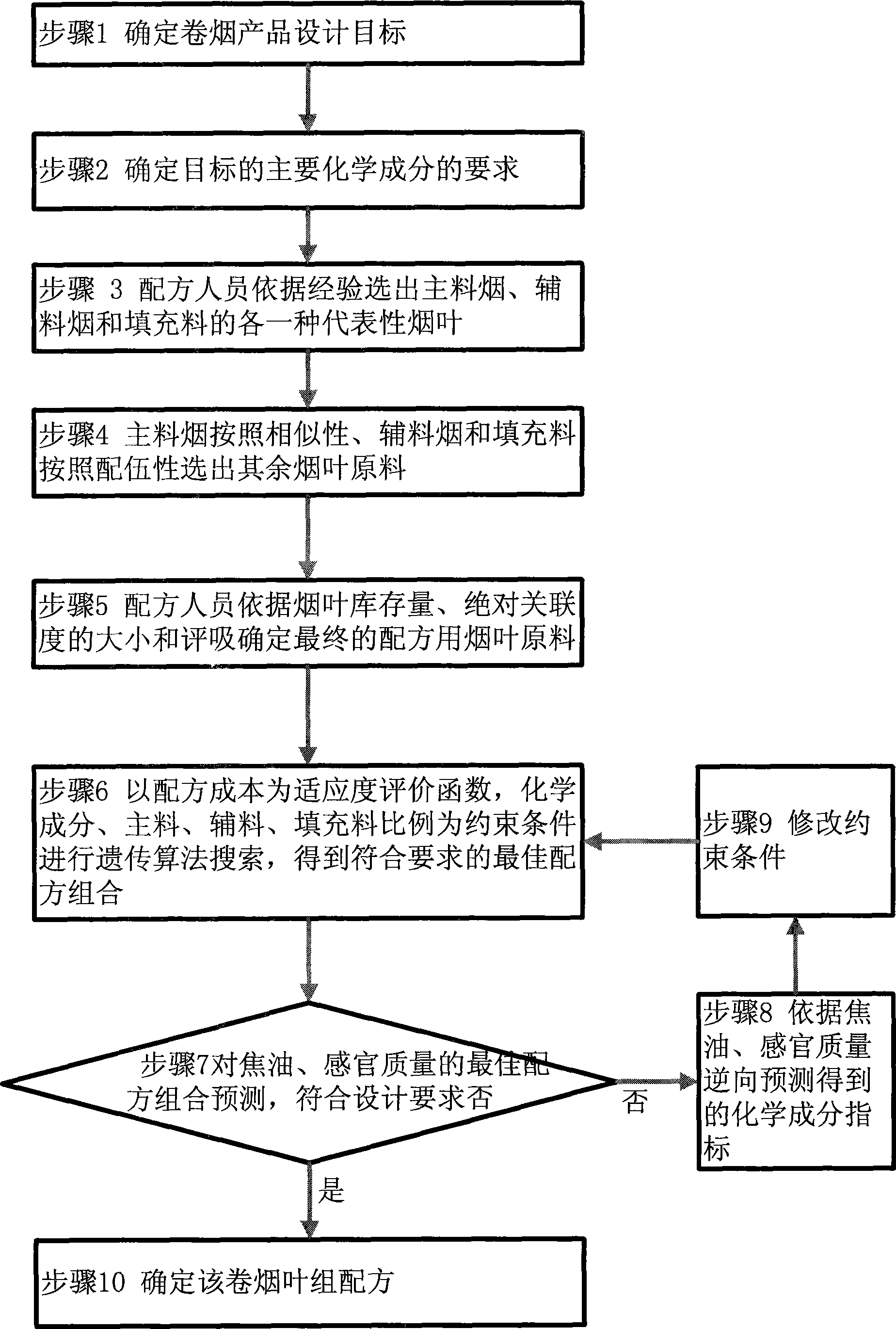

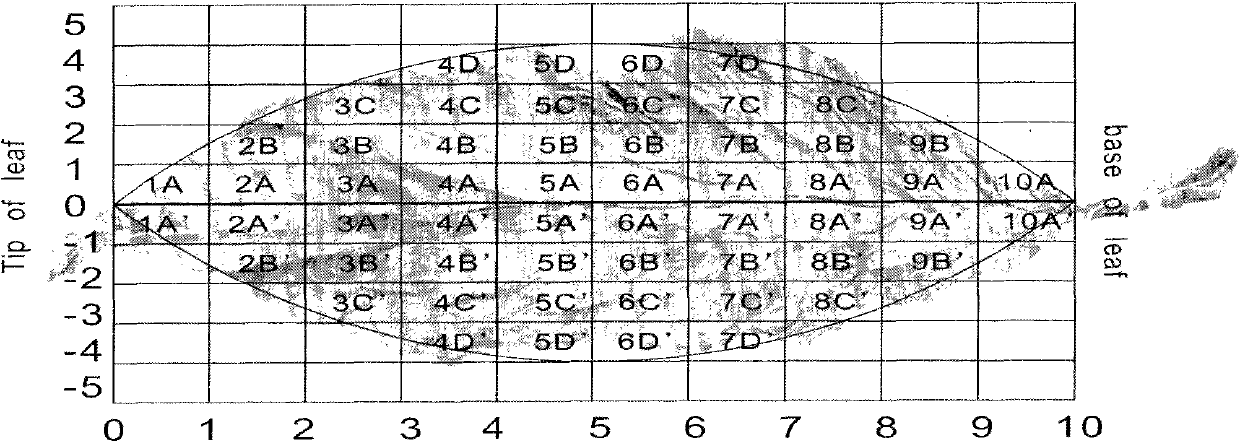

Cigarette tobacco leaf formulation design method

InactiveCN101385571ABroaden your optionsReduce workloadTobacco preparationTobacco treatmentChemical compositionFlue gas

The invention discloses a method for designing the formulation combination of tobacco leaf, which comprises the following steps: the design objective of cigarette products is determined; the requirement for the main chemical composition of the objective is determined; according to the experience, formulation personnel preliminarily select one representative tobacco leaves respectively from base cigarette, auxiliary material cigarette and filler; according to the similarity of the base cigarette and the compatibility of the auxiliary material cigarette and the filler, the rest tobacco leaf materials are selected; the final tobacco leaf materials used for the formulation are determined by the formulation personnel according to the storage rate of tobacco leaf, absolute degree of association and smoke panel test; the formulation cost is taken as evaluation function of fitness, and the proportion of the chemical composition, the main materials, the auxiliary materials and the filler are taken as constraint condition, the genetic algorithm is searched. The invention overcomes the deficiency that the prior art can not ensure the aesthetic quality, product style and flue gas index of the formulation of tobacco leaf to be in accordance with design requirements, and provides a method which supplies multiple formulation combinations that are in accordance with requirements, reduces the cost and lightens the workload of the formulation personnel, thus being widely applied to the field of cigarette production.

Owner:CHINA TOBACCO CHUANYU IND

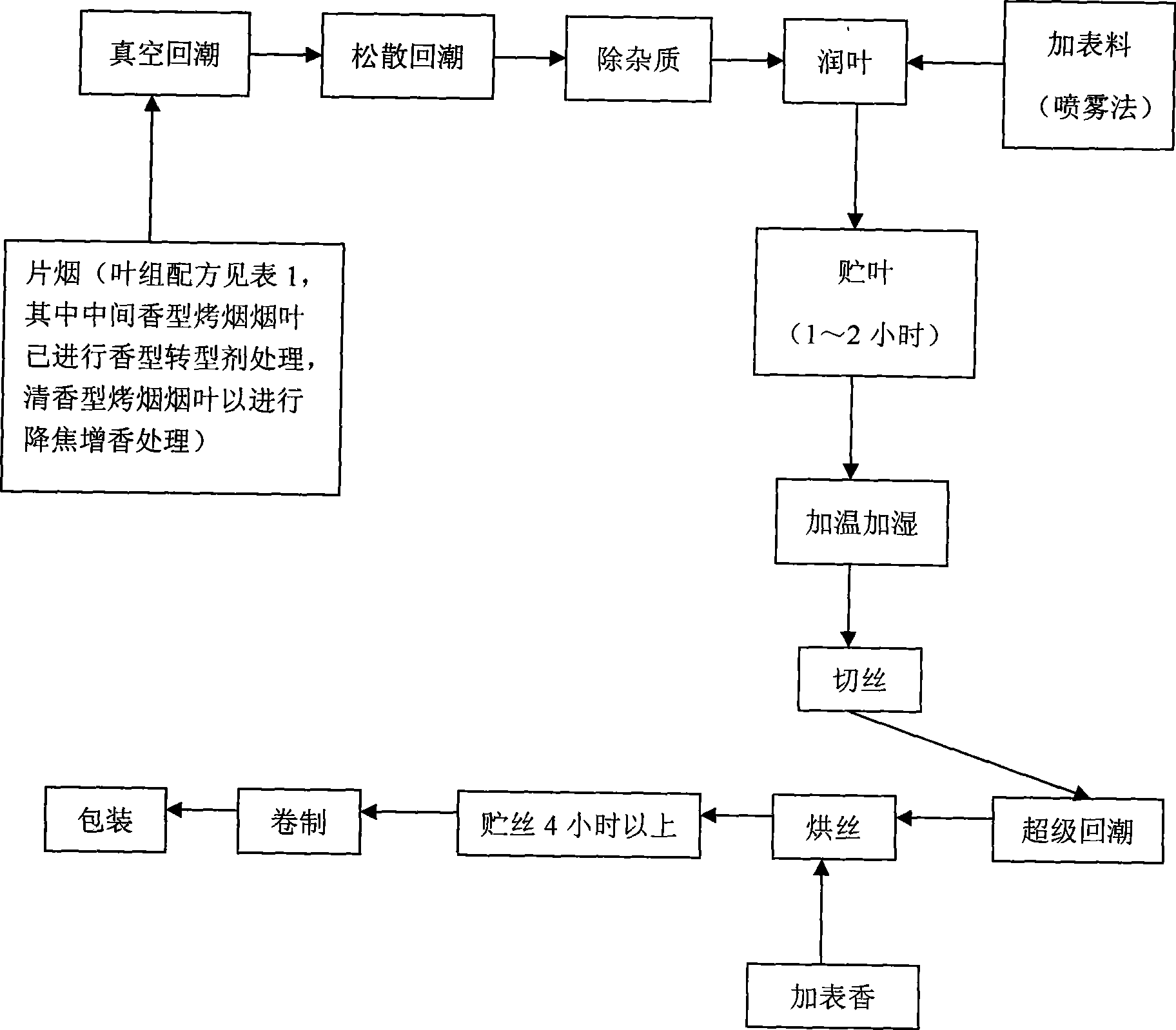

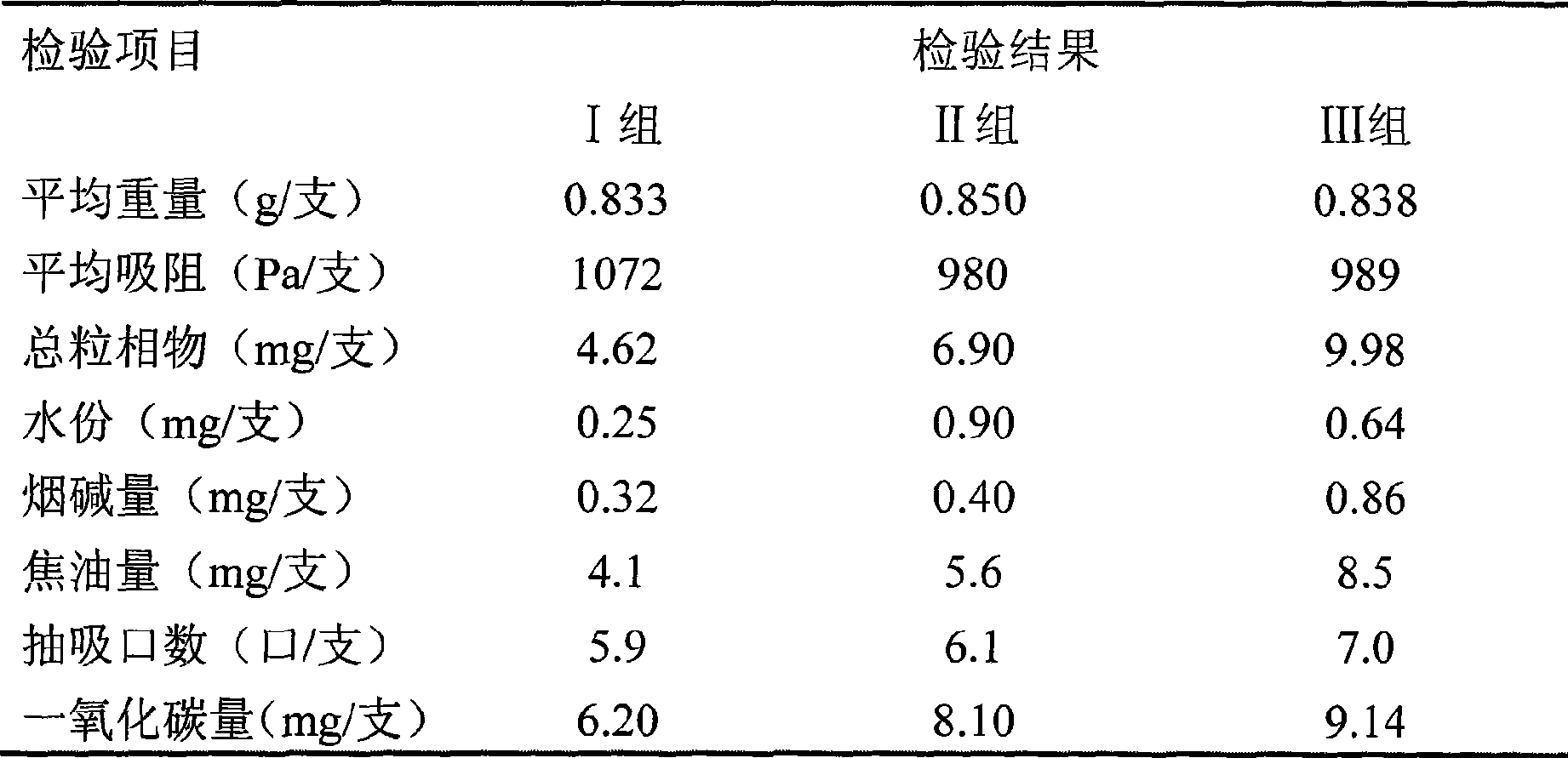

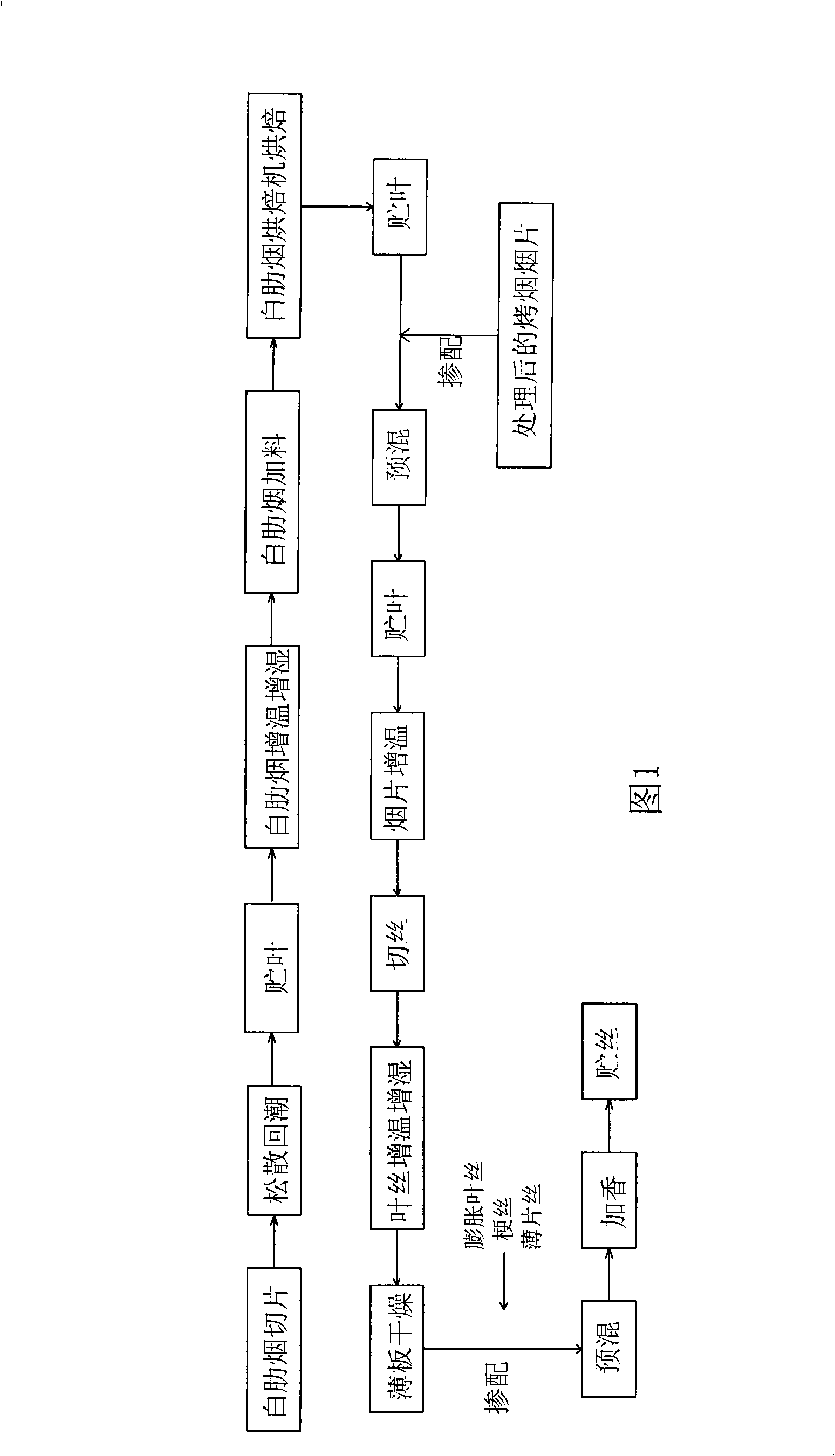

Fire-cured tobacco type low-coke tar cigarette and technique for preparing the same

The invention discloses a cured tobacco type low-tar cigarette prescription and preparation thereof. The cured tobacco type low-tar cigarette comprises cut tobacco, a filter rod, and cigarette paper. The cut tobacco is prepared by: 15-22 by weight parts of faint scent type tobacco leaf, 28-40 by weight parts of aroma type tobacco leaf, 25-35 by weight parts of middle scent type tobacco leaf, 8-15 by weight parts of air-cured tobacco, 10-20 by weight parts of papermaking flake, 10-20 by weight parts of stalk. The middle scent type tobacco leaf in the prescription is processed by tobacco leaf scent type modifier, so as to add fragrance to tobacco leaves, and modify scent type. The faint scent type tobacco leaf in the prescription is processed by cured tobacco leaf tar lowering fragrance adding agent, so as to make faint scent feature more outstanding and lower tar releasing quantity. An odor-absorbing modifying agent and a fluid producing agent are added combined with perfuming in cigarette making process, and a safe cured tobacco type low-tar cigarette with fragrant, gentle smell, and obvious individual characteristic. Tar content of the cured tobacco type low-tar cigarette is 3mg-8mg per one cigarette.

Owner:延吉烟悦科技有限公司 +1

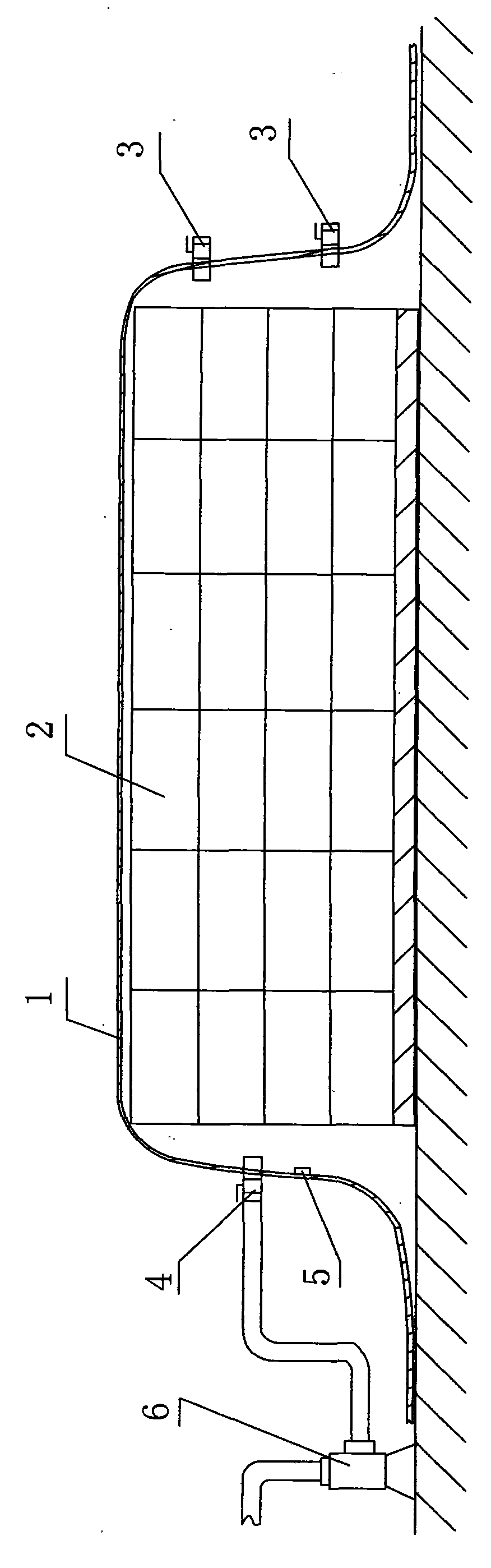

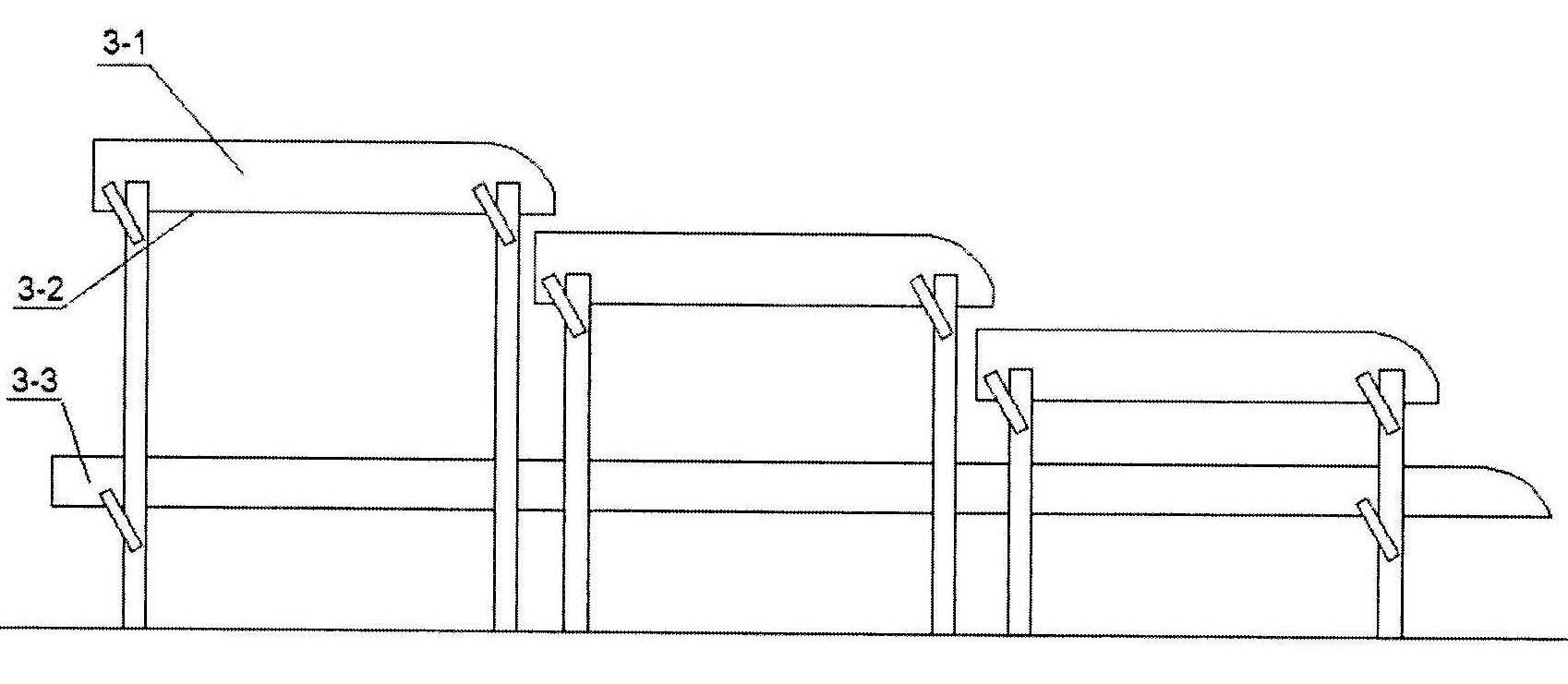

Multifunctional tobacco leaf stack sealing storage method capable of adjusting storage environment

ActiveCN101584280AImprove air tightnessImprove moisture resistanceAgriculture tools and machinesTobacco treatmentNatural ventilationInput control

The invention relates to a tobacco leaf stack sealing storage method capable of adjusting storage environment, comprising the following steps: 1) building a tobacco leaf stack sealing space capable of adjusting storage environment: covering the warehoused tobacco leaf stack using a plastic seal tent and enclosing the tobacco leaf stack in the sealed space; the sealed space enclosed by the plastic seal tent is perform air flow commutation with the outside when an air input control joint and an air output control joint are turned on and the sealed space enclosed by the plastic seal tent is at full sealed state when the air input control joint and the air output control joint are turned off; 2) gassing to disinfect; 3) filtering and purifying the steamed and disinfected noxious gas; 4) performing the daily tobacco-leaf mould proof conservation; 5) in winter, starting the plastic seal tent to perform the winder general investigation and natural ventilation and conservation of the tobacco leaf and restoring the plastic seal tent until the next early spring. The sealing storage method has low cost and environmental protection.

Owner:WUHAN DONGCHANG STORAGE TECH

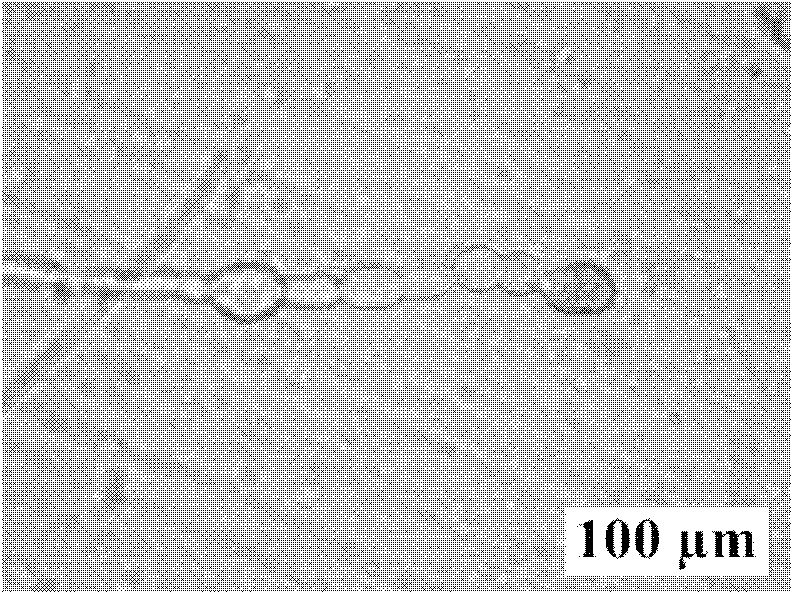

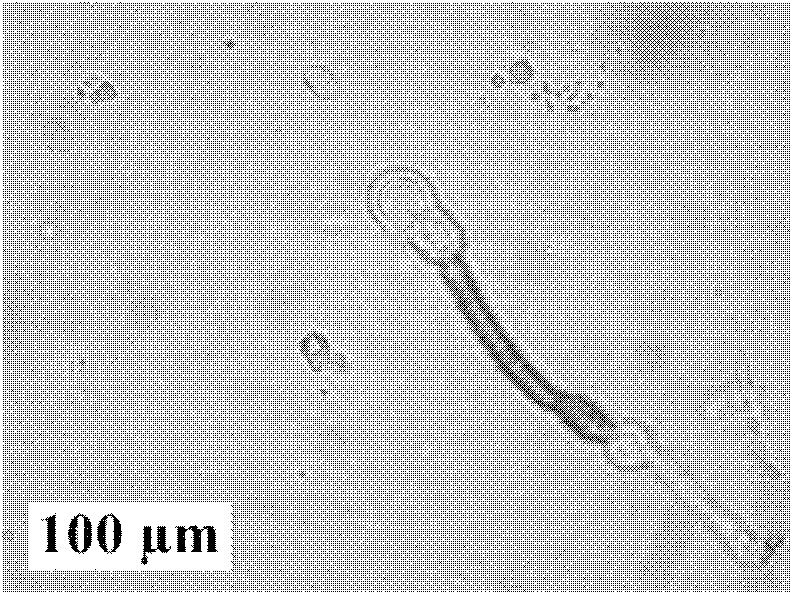

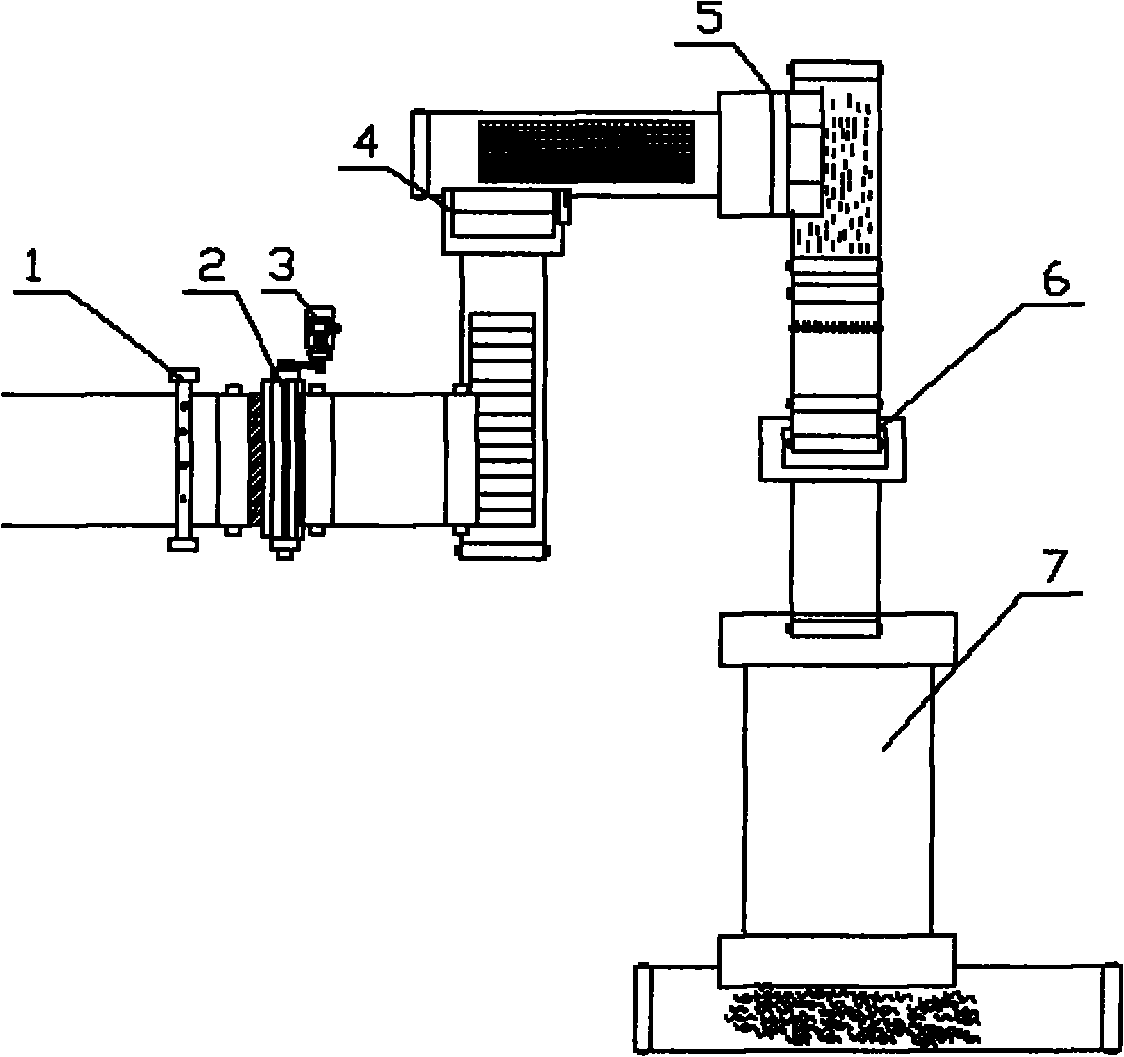

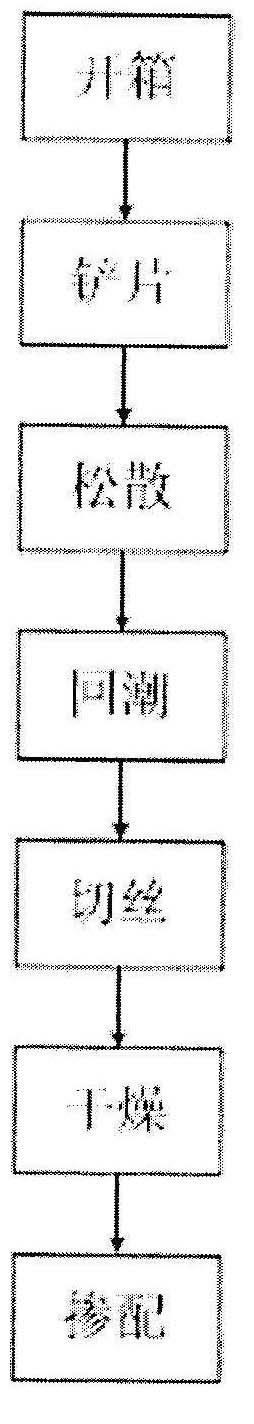

Independent tobacco cutting process and equipment based on paper making method regenerated tobacco leaf processing characteristics

ActiveCN102178337ASolve the strength problemAvoid pulling forceTobacco preparationPulp and paper industryMoisture regain

The invention discloses an independent tobacco cutting process and independent tobacco cutting equipment based on paper making method regenerated tobacco leaf processing characteristics. The process comprises the following process steps: opening a box, shoving tobacco leaves, loosening, regaining moisture, cutting, drying and mixing. The equipment comprises a box opening machine, a tobacco leaf shoving machine, a high-frequency-vibrating loosening machine, a moisture regaining machine, a cutting machine and a roller cut tobacco drying machine, wherein the mechanisms can be arranged and can operate alone or in combination through the connection by a material conveying and feeding mechanism. The process and the equipment can cut the boxed regenerated tobacco leaves independently according to the processing characteristics of the boxed regenerated tobacco leaves, thereby improving the effective utilization rate of the paper making method regenerated tobacco leaves, effectively retaining fragrance, improving visual quality, and making the prepared regenerated cut tobacco uniform in length and good in looseness so that the cut tobacco can be blended with other cut tobacco uniformly. The process and the equipment have high adaptability; meanwhile, according to the change in the form of supplied materials, 'three-step method' tobacco cutting adopted in the prior art is changed into one-step cutting with the same effect, the production efficiency is improved and the production cost is lowered.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

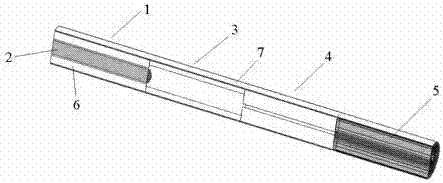

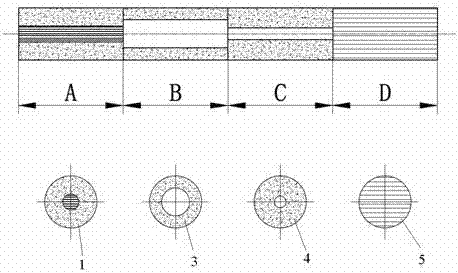

Quaternary composite electric heating incombustible cigarette

The invention discloses quaternary composite electric heating incombustible cigarette, and belongs to the technical field of heating incombustible cigarette. The quaternary composite electric heating incombustible cigarette consists of a heating segment, a guide segment, a cooling segment and a filtering segment, wherein the heating segment is a layered smoking stick made of regenerated tobacco, bamboo fiber paper or coating molding paper; the guide segment comprises a first hollow filter stick and is connected with the heating segment; the cooling segment comprises a second hollow filter stick and is connected with the guide segment; the airflow retention area of the second hollow filter stick is larger than that of the first hollow filter stick; the filtering segment is connected with the cooling segment. The quaternary composite electric heating incombustible cigarette is applicable to heating devices of different heating modes of central heating, peripheral heating and the like, and is also applicable to heating incombustible cigarette devices of different device specifications; on the premise that the smoke quantity of cigarette is ensured, the temperature of fume entering mouths is lowered, and certain harmful substances are adsorbed; mental and physiological needs of customers can be relatively well met.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

Method for improving reconstituted tobacco paper-base quality through adding calcium carbonate and reconstituted tobacco paper-base

ActiveCN102715642APlay the role of reducing focus and harmImprove surface propertiesTobacco preparationTobacco treatmentPaper basedGuar gum

The invention discloses a method for improving the reconstituted tobacco paper-base quality through adding calcium carbonate and a reconstituted tobacco paper-base, belonging to the technical field of cigarette production. The method for improving the reconstituted tobacco paper-base quality through adding calcium carbonate comprises the steps of soaking and extracting tobacco stems and tobacco powder, grinding, pulping, sheet making, squeezing and drying, wherein in the sheet making step, the calcium carbonate and guar gum which respectively occupies 10-70% and 0.05-0.5% of the mass percent of the tobacco raw pulp are added into the tobacco raw pulp. Researches show that after the calcium carbonate and the guar gum are added according to an appropriate proportion, the tensile index, tear index and air permeability of the produced reconstituted tobacco paper-base are obviously improved, the whole water-absorption performance of the reconstituted tobacco paper-base is also improved, the tar yield, CO content and total particle matter content of the sheet paper-base are obviously decreased, so that the tar and harm reduction function of the reconstituted tobacco is better played, the combination property of the tobacco sheet is effectively improved, and the operation performance and effectiveness of a reconstituted tobacco production line are improved.

Owner:CHINA TOBACCO GUANGDONG IND +1

Technology for processing tobacco stalk into shreds

ActiveCN102631016AUniform expansionSimilar expansion rateTobacco preparationTobacco treatmentMicrowaveTar

The invention provides a technology for processing tobacco stalk into shreds, and belongs to the technical field of tobacco processing. The technology disclosed by the invention has the following steps of: pretreating tobacco stalk, expanding the tobacco stalk with microwave, washing the tobacco with water, storing the tobacco stalk, straightening out the tobacco stalk, slicing the tobacco stalk, charging and storing stalk slices, shredding the stalk slices, drying and shaping the stalk shreds, and perfuming the stalk shreds and storing the stalk shreds. Equipment used in the technology is purchased from the market, wherein the equipment which is purchased from the market, adopts a low-frequency (915MHz) high-power (more than 10kW) microwave magnetron, and transports the tobacco stalk by a belt is improved into equipment which adopts an ultrahigh-frequency (2450MHz) single-pipe low-power (1.5kW) microwave magnetron, performs group control on the microwave magnetron and transports tobacco stalk by a drum. The technology has the characteristics that the tobacco stalk shreds are good in quality consistency and more similar to tobacco leaf shreds in the physical property, and have high sensory quality and filling value; and uniformity, stability and mixing proportion of the tobacco stalk shreds are improved when the tobacco stalk shreds are mixed with the tobacco leaf shreds, the quality of cigarette is improved, the application range and use ratio of the tobacco stalk shreds in the cigarette are improved, and the aims of tar reducing, harm reducing, cost reducing and efficacy enhancing are achieved.

Owner:YUNNAN RES INST OF TOBACCO SCI

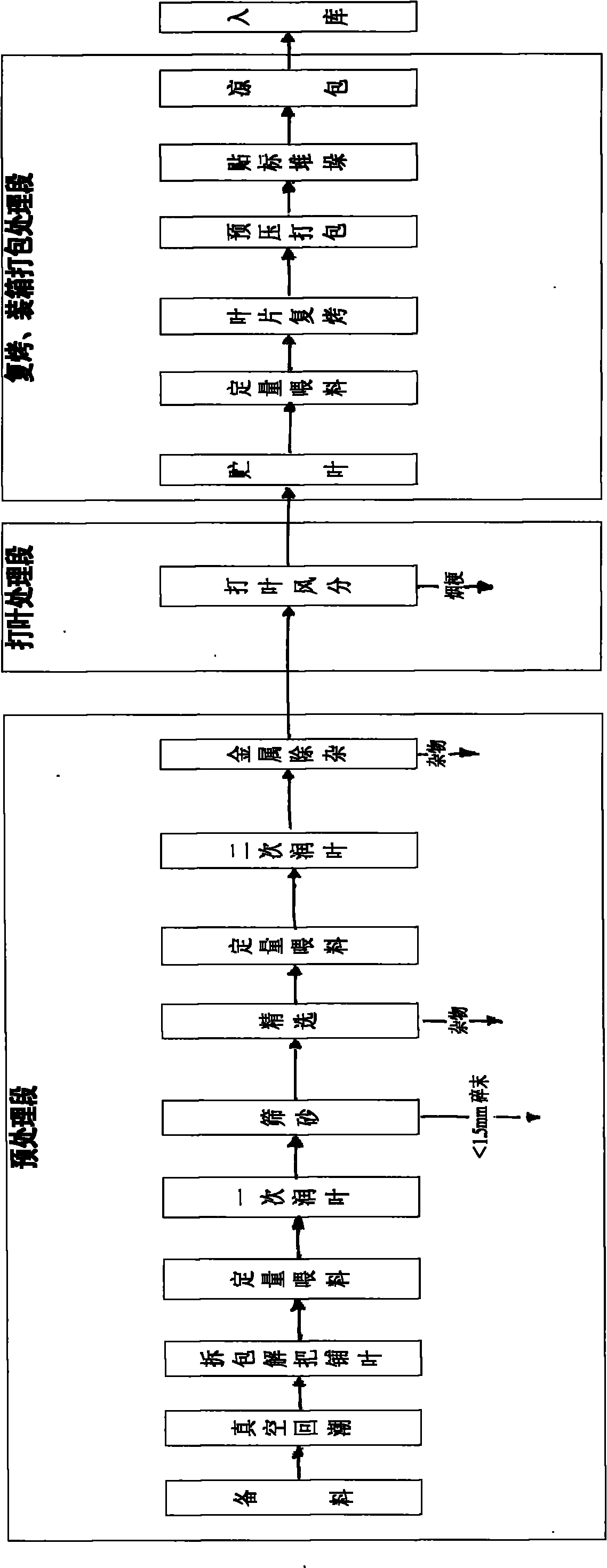

Tobacco hitting and redrying homogenizing processing technology

InactiveCN103653227AImprove the level of homogenization production and processingQuality improvementTobacco preparationTobacco treatmentChemical compositionEngineering

The invention relates to a tobacco hitting and redrying homogenizing processing technology. The tobacco hitting and redrying homogenizing processing technology includes the following steps that raw tobaccos are laid according to a single variety, a single grade and a single product or different varieties, different grades and different production places; the laid tobaccos are arranged in boxes and stored respectively; according to the requirements of a production formula list, the corresponding tobaccos are selected from the stored tobaccos and orderly delivered according to the grades, the varieties and the production places, box overturning and feeding are performed according to the material dispensing ratio of the production formula list, and the tobaccos of all grades are pre-mixed after box overturning and feeding are performed; the tobaccos which are pre-mixed sequentially receive the processing of one-time tobacco moistening, sand sieving, winnowing, impurity removing, manual selecting and secondary tobacco moistening. The tobaccos receive the processing of tobacco hitting and wind dividing; the tobaccos are mixed after receiving the processing of tobacco hitting and wind dividing, and after the on-line chemical component detection shows that the tobaccos are qualified, the redrying processing is performed. The tobaccos which are redried are packaged after the on-line chemical component detection shows that the tobaccos are qualified. The tobacco hitting and redrying homogenizing processing technology solves the problem that formula homogenization is difficult to control in the producing and processing processes of the tobaccos of original tobacco hitting and redrying enterprises.

Owner:FUJIAN WUYI TOBACCO

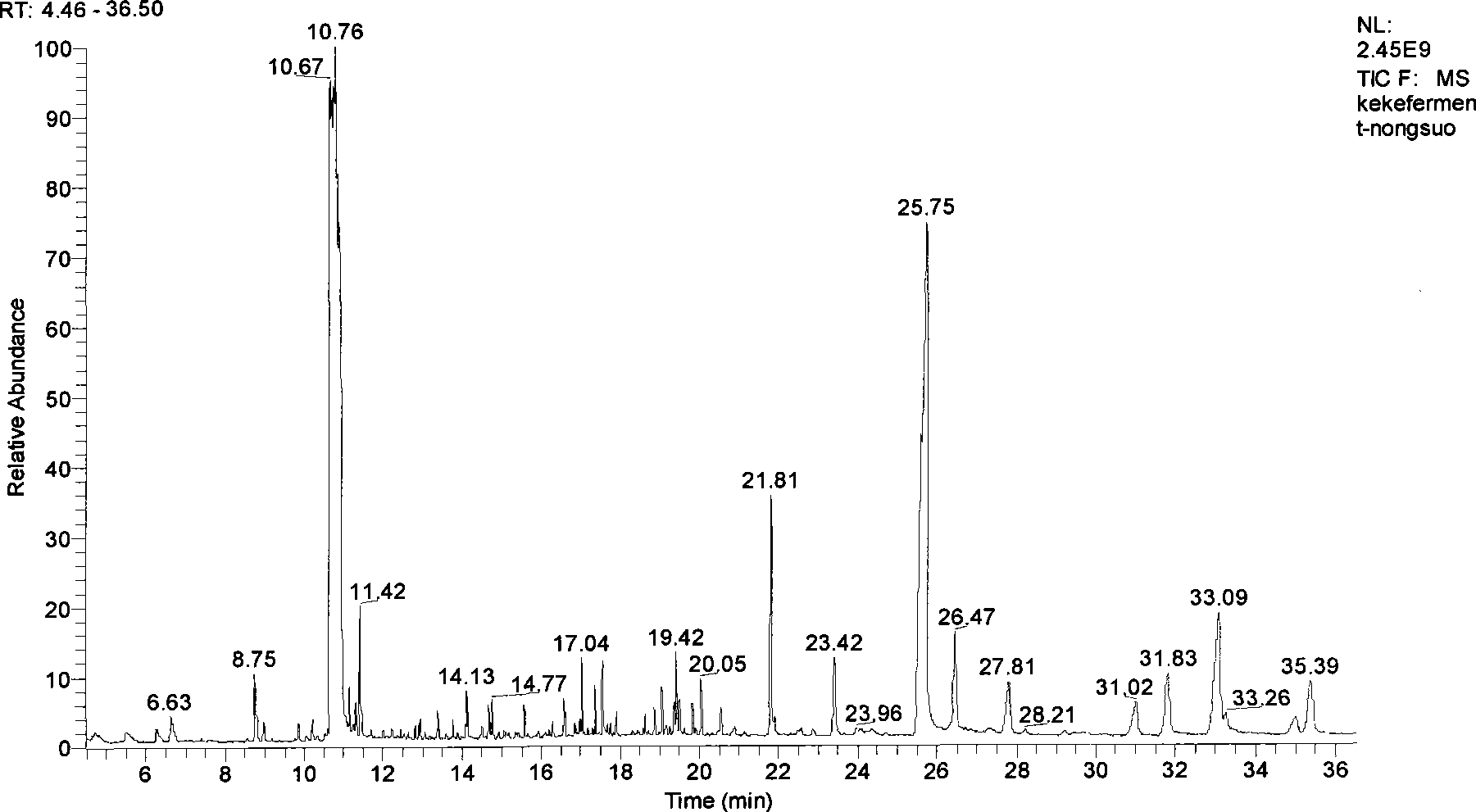

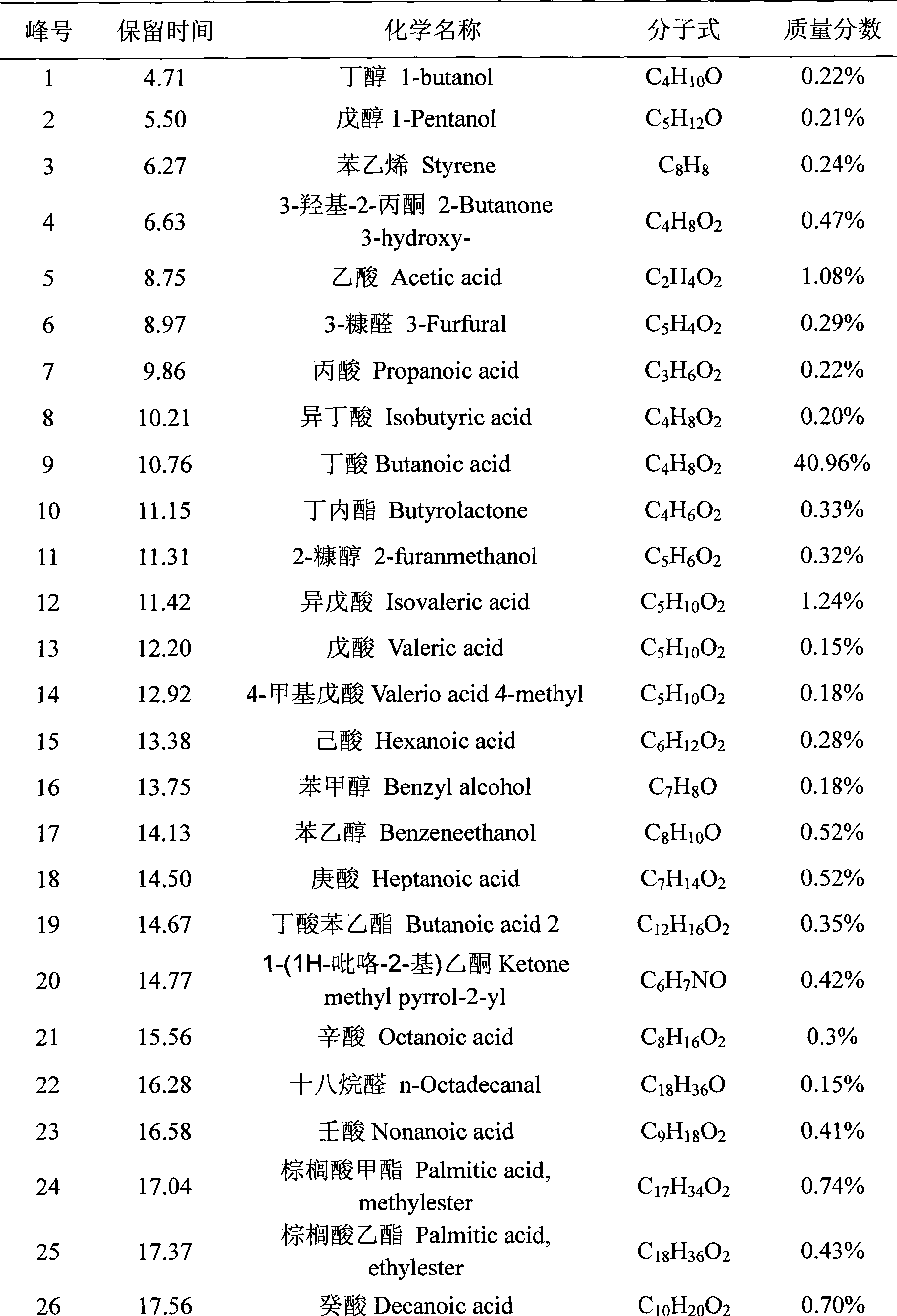

Method for preparing cigarette flavor by microbial fermentation of coffee

ActiveCN101497844ASimple processLow costTobacco treatmentEssential-oils/perfumesMicroorganismBiotechnology

The invention discloses a method for preparing tobacco perfume by adopting organism fermented coffee, and relates to a preparation method of tobacco perfume, which belongs to the technical field of tobacco. The method comprises the following steps: (1) preparing tobacco leaf synthetic medium; (2) selecting the organism producing perfume; (3) performing liquid fermentation or solid fermentation to coffee by using selected burley tobacco leaf surface dominant bacteria and obtaining the fermented coffee tobacco perfume. The method has simple process and low cost, and the obtained coffee tobacco perfume can be directly used as the perfume of cigarettes. The coffee tobacco perfume has special fragrant characteristic of acid fragrance, thereby lowering the stimulation, richening the smoke gas hiding the mixed gas, leading the smoke gas to be soft and improving the mouthfeel when being added into the cigarettes.

Owner:HUBEI CHINA TOBACCO IND

Method for threshing ad redrying tobacco by using microwave technology

InactiveCN1659985AImproves moisture uniformityEasy to processTobacco preparationEngineeringMicrowave technology

Owner:JIANGJUN TOBACCO GROUP CO LTD

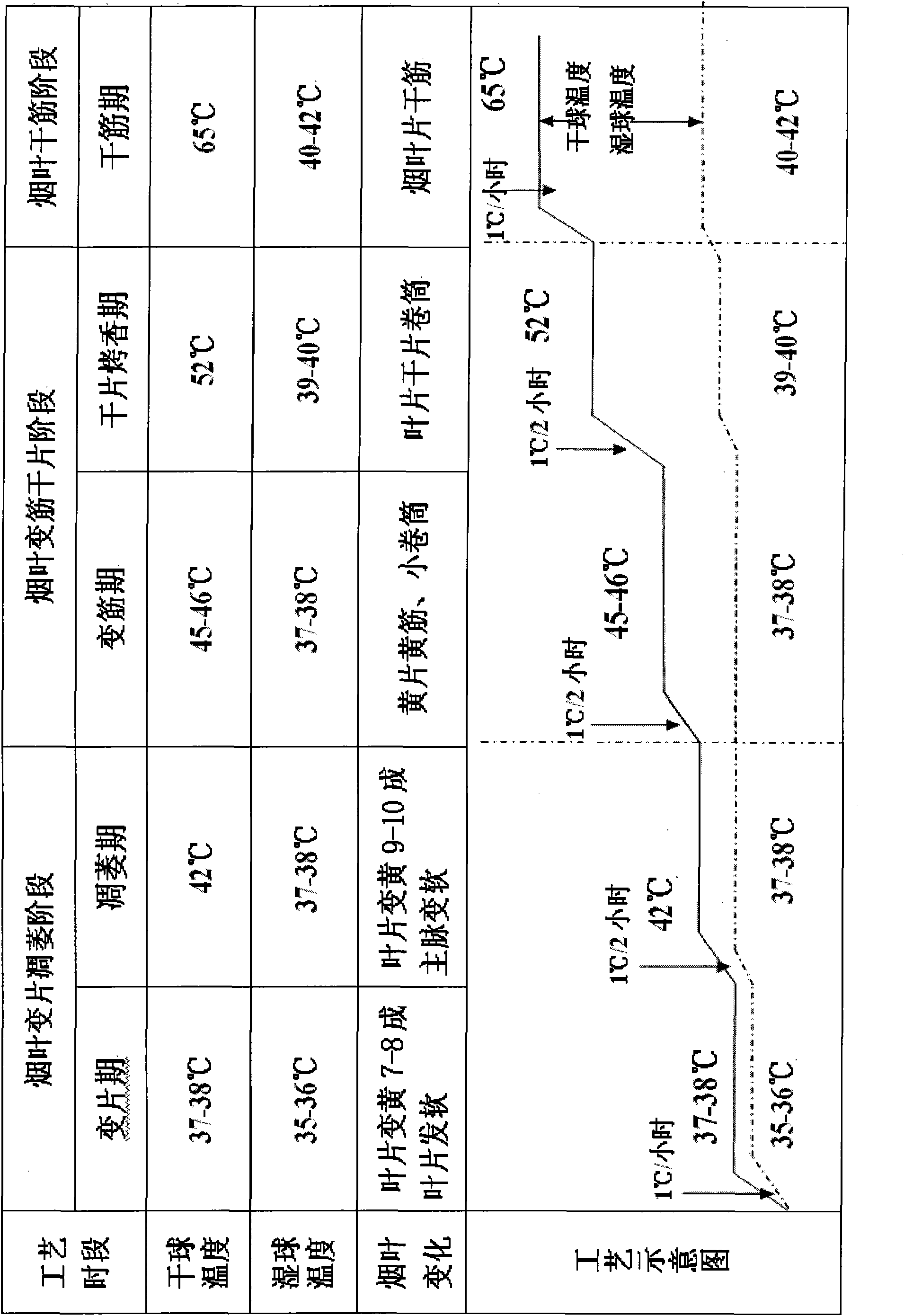

New technology for curing red flower gold dollar tobacco leaf to be yellow and fragrant

ActiveCN101843357AReduced bake-onImprove aroma qualityTobacco preparationNicotiana tabacumGreen leaf

The invention discloses a new technology for curing the red flower gold dollar tobacco leaf to be yellow and fragrant, belonging to the technical field of tobacco preparation. The technology comprises the following steps of: a first stage: (1) a leaf changing period: drying a ball at 37-38 DEG C and wetting the ball at 35-36 DEG C till that the leaf is turned to be yellow at 7-8 level and the leaf is softened and withered, and (2) a withering period: drying the ball at 42 DEG C and wetting the ball at 37-38 DEG C till that the leaf is turned to be yellow at 9-10 level and a main vein is soften; a second stage: (1) a vein changing period: drying the ball at 45-46 DEG C and wetting the ball at 37-38 DEG C till that the yellow leaf and the yellow vein are changed to be the status of a small winding drum, and (2) a period for curing the dried leaf to be fragrant: drying the ball at 52 DEG C and wetting the ball at 39-40 DEG C for 12+ / -0.5h till that the dried leaf is changed to be a winding drum; and a third stage: drying the ball at 65 DEG C and wetting the ball at 40-42 DEG C till that the vein of the full baked tobacco leaf is dried. The new curing technology can obviously reduce the green smoke rate and the curing phenomena of the green vein, the green leaf, the floating green and the like, and can improve the fragrant quality and the appearance quality of the tobacco leaf.

Owner:HUBEI CHINA TOBACCO IND

Electronic cigarette tobacco juice prepared from faint scent tobacco leaves

The invention discloses electronic cigarette tobacco juice prepared from faint scent tobacco leaves. The electronic cigarette tobacco juice is prepared by uniformly mixing 10 to 30 percent of faint scent flue-cured tobacco leave extract, 5 to 10 percent of tobacco flavor, 1 to 5 percent of tobacco perfume, 5 to 10 percent of deionized water, 10 to 20 percent of glycerol and the balance of propylene glycol. The faint scent flue-cured tobacco leave extract is one of a Yunnan faint scent flue-cured tobacco leave extract and a Fujian faint scent flue-cured tobacco leave extract, or a mixture of the Yunnan faint scent flue-cured tobacco leave extract and the Fujian faint scent flue-cured tobacco leave extract. The electronic cigarette tobacco juice takes a faint scent tobacco leave extract as a main component, so that the aroma and mouthfeel of an electronic cigarette are close to those of the traditional faint scent cigarette. The electronic cigarette tobacco juice is used for atomizing the electronic cigarette and does not generate tar and CO, the harm to consumers is greatly reduced and the product cannot generate the harm of passive smoking.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Method for baking tobacco leaf of intelligentized miniature compact tobacco flue-curing house

InactiveCN101342006ASolve insufficient capacityImprove roast qualityTobacco preparationPulp and paper industryIntelligent control

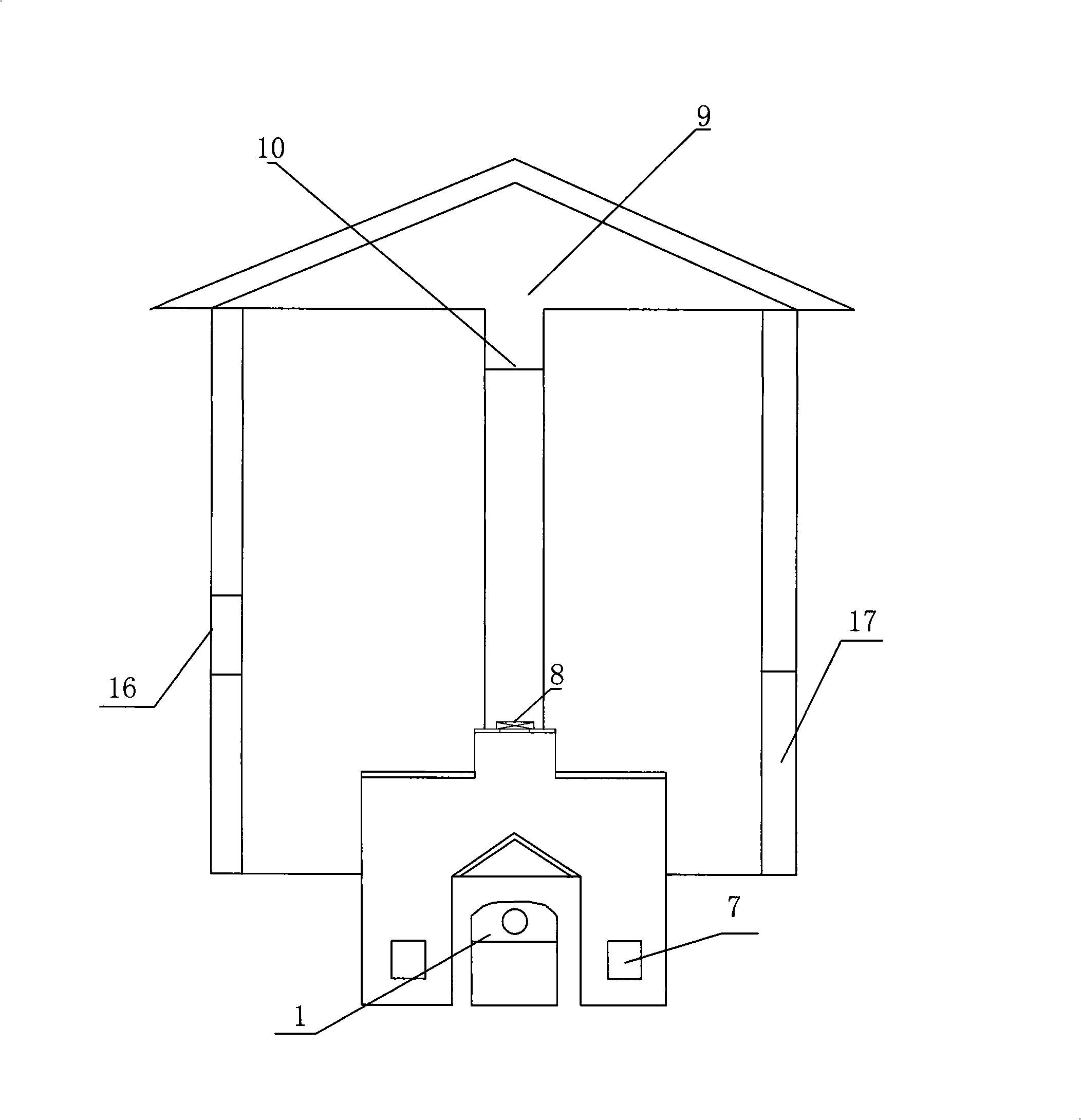

The invention relates to a method for curing tobacco leaves in a small intelligent concentrated tobacco curing barn; an air inlet is arranged in the curing barn; the top part is provided with a clearstory and a return intake; a hearth, a main fire tube, branch fire tubes, a chimney, a hot air course and an air outlet are arranged on a horizon; the main fire tube is connected with the hearth; a plurality of branch fire tubes are arranged in a circuitous way; the distribution of the hot air course below the fire tube is consistent to the fire tube; a clapboard is arranged above a hot air chamber; a fan is arranged above the opening of a branch hot air course and is connected with the return intake and the air inlet to form a hot air circulating system; intelligent control is formed by a temperature controller, a humidity controller, a temperature sensor, a humidity sensor, the fan, a blower and an air door in a connection way; the technique of the curing barn is divided into a yellowingstage,a leaf drying stage and a stem drying stage; the temperature of the stem drying stage is controlled to be 32 to 36 DEG C for 10 to 15 hours; then the temperature is raised to 39 to 42 DEG C for 10 hours; the temperature of the leaf drying stage is 45 to 48 DEG C for 12 hours; then the temperature is raised to 50 to 52 DEG C for 12 hours; then the temperature is raised to 54 to 55 DEGC for 12hours; the temperature of the stem drying stage is raised to 60 to 68 DEG C; the stems of tobacco is cured to be completely dry; then the fire is stopped; then dampening and removing from a kang are carried out.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP

Method for slitting, striking and redrying tobacco

The invention relates to a method for slitting, striking and redrying tobacco, which is technically characterized by comprising the following step of: cutting tobacco lead bases with minimum tensile strength, poorest physical processing resistance and poorer perception smoke panel test quality and appearance quality in the tobacco for singly cutting, striking and redrying. The method has the mainadvantages that remained non leaf base tobacco leaves are crushed to be smaller when leaves and stems are separated singly after the tobacco leaf bases are cut for being singly processed, the leaf structures are more uniform after the leaves are separated from the stems, the green and impurity content in the tobacco is reduced, thus the large-medium leaf ratio after the striking is improved, the crushing generated when the leaves are separated from the stems is reduced, the leaf yield is improved, and the purity of the tobacco is increased. After the tobacco is processed by using a slitting, striking and redrying method of the invention, the leaf base smoking quality is better, the fragrance quantity is improved, the smoke explosive force is increased, the smoking comfort is enhanced, andthe impurity gases are reduced, thus the use value of the tobacco can be improved.

Owner:HONGTA TOBACCO GRP

Culturing method of one-ridge double-row flue-cured tobacco dislocation

InactiveCN101699954AGuaranteed housekeepingGuaranteed incomeHorticultureSoil-working methodsOrganic fertilizerDislocation

The invention discloses a culturing method of one-ridge double-row flue-cured tobacco dislocation, comprising the following steps: (1) selecting tobacco field and preparing soil; (2) ridging; (3) applying base fertilizer; (4) transplanting; and (5) uncovering film, ridging and loading. The method has the following advantages that: (1) on the premise that the use amount of fertilizer for soil in unit area is not changed, the fertilizer use amount of single plant in flue-cured tobacco field is reduced, and the use amount of field organic fertilizer, especially oil cake fertilizer is increased to lead the field tobacco plant to present the growth of middle-plant tobacco, thus obviously improving the tobacco leaf quality; (2) compared with the conventional single ridge, the one-ridge double-row tobacco reduces the labor capability of ridging by about one third, the ridging height is obvious lower than the conventional height, thus reducing ridging labor intensity of tobacco growers; and (3) the one-ridge double-row flue-cured tobacco increases flue-cured tobacco planting density, and meanwhile, a dislocated equal plant distance planting method improves utilization rate of tobacco field to the utmost, ensures the housework operation of tobacco growers, and the row space of the ridge just satisfies growth space of tobacco plants in the field, thus ensuring the income of the tobacco growers.

Owner:GUIZHOU TOBACCO SCI INST

Method for extracting Chinese-style flue-cured tobacco fragrance cigarette juice for electronic cigarette

ActiveCN104041935ASuitable for needsCigarette tobacco smell strongTobacco treatmentTobacco devicesFlavorLiquid smoke

The invention discloses a method for extracting Chinese-style flue-cured tobacco fragrance cigarette juice for an electronic cigarette. The method comprises the following steps: 1, blending flue-cured tobacco type tobacco leaves, tobacco shreds or tobacco powder; 2, applying cigarette feed liquid or materials with high sugar content on the tobacco leaves, tobacco shreds or tobacco powder; 3, performing destructive distillation on the tobacco leaves, tobacco shreds or tobacco powder by different temperature sections; 4, collecting fractions. The fractions collected by the method can directly serve as electronic cigarette juice, and cigarette essence perfume having characteristic flavor, or edible essence perfume also can be added to enrich the styles of the electronic cigarette tobacco juice; the electronic cigarette juice collected by the method has the style characteristic and flavor similar to those of a Chinese-style cigarette, the satisfaction is good, the fragrance is harmonious, and the taste is pure and mild.

Owner:CHINA TOBACCO SHANDONG IND

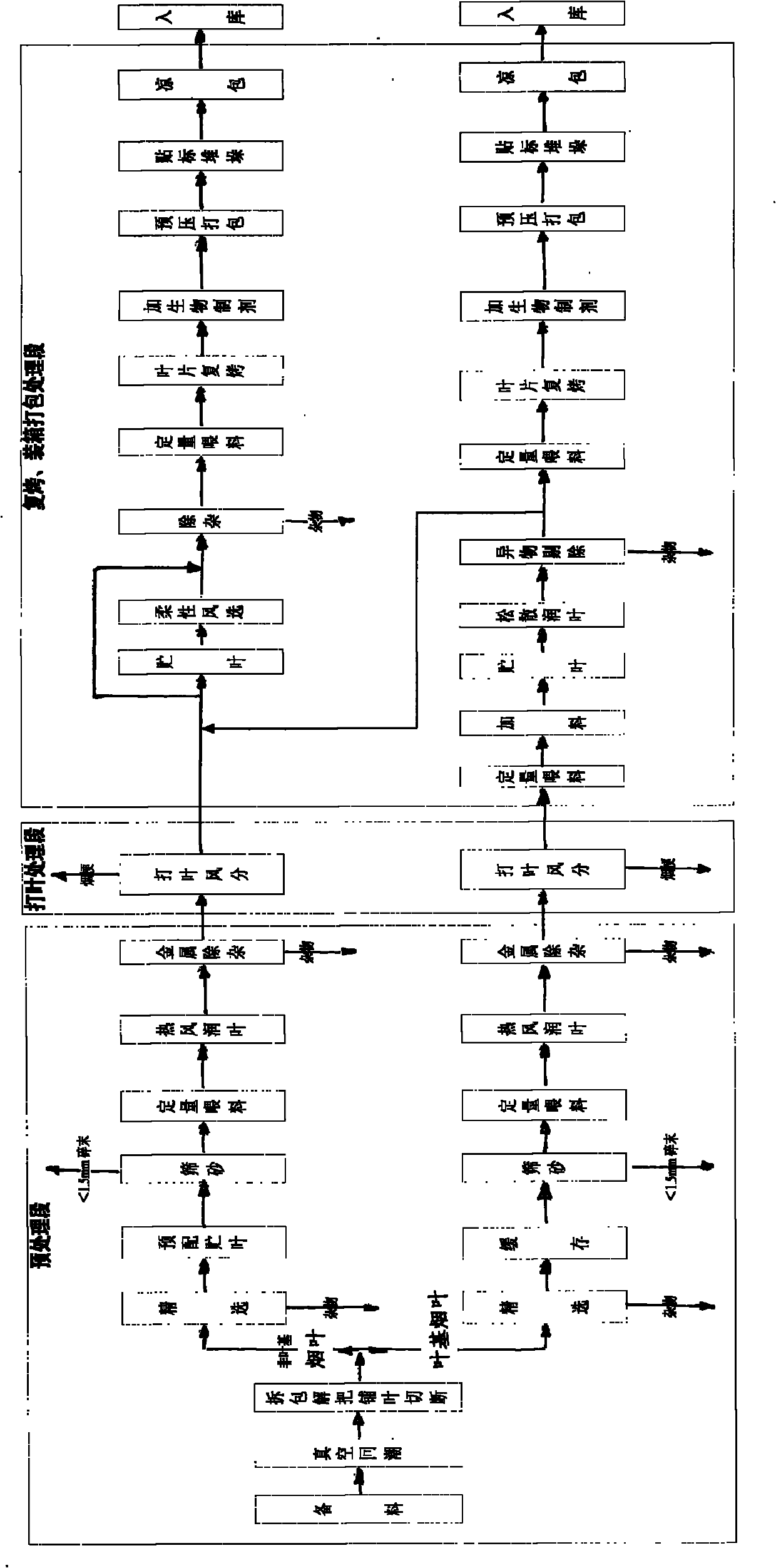

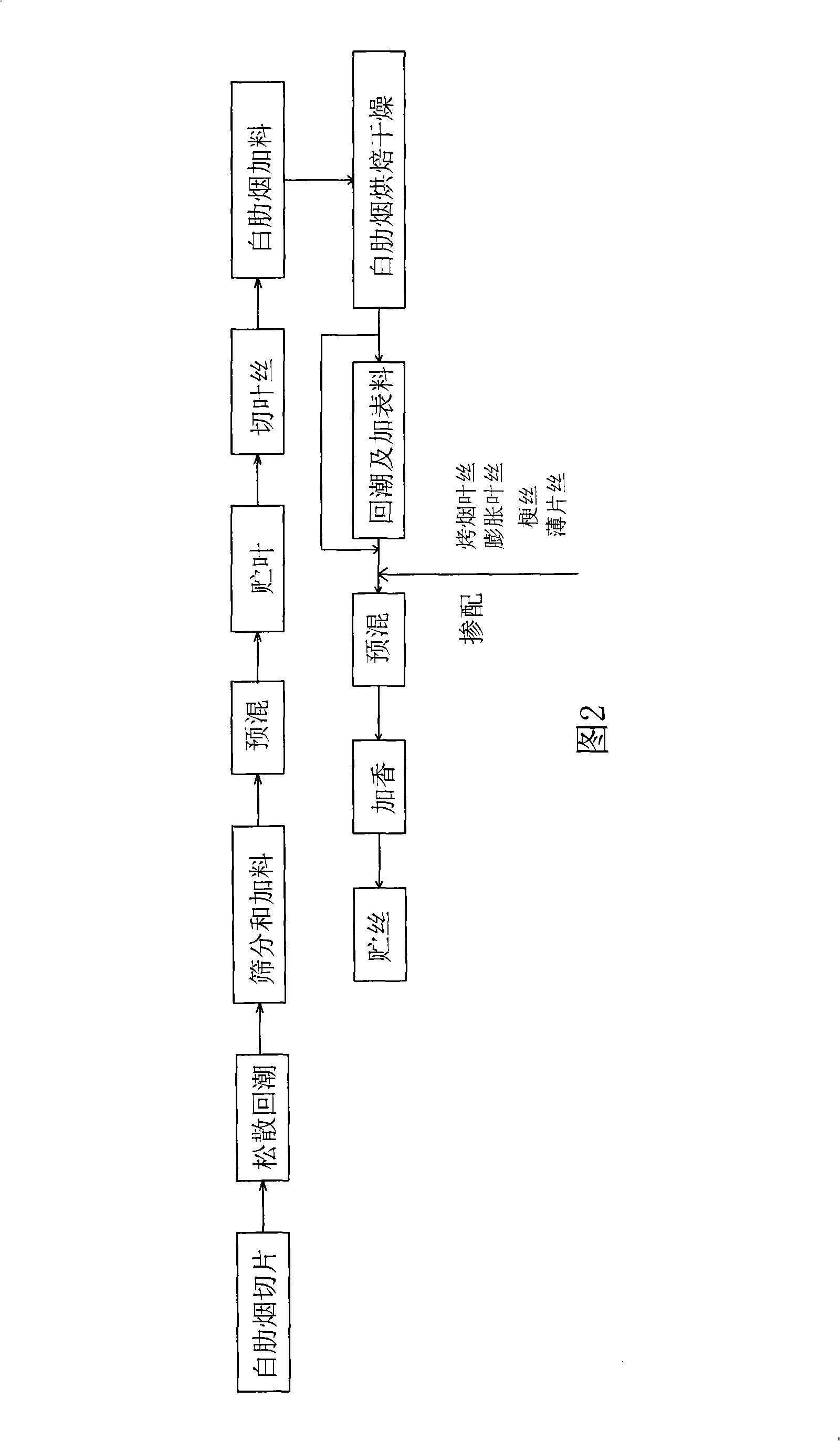

Process technique for burley tobacco in blend type cigarette

The invention discloses a burley tobacco processing and treating technic in a blended type cigarette. The technic performs a burley tobacco leaf blade making workshop section, a burley tobacco making leaf shred workshop section, and a leaf shred mixing workshop section. The burley tobacco processing and treating technic is used for processing and treating a burley tobacco which is used as an individual formula module in the blended type cigarette, and is impenetrated in the whole process from leaf blade making to leaf shred marking; aiming at the treatment of the material of the burley tobacco, for example, the feed liquid of the burley tobacco is applied by steps and proportion; the baking and the drying of the burley tobacco are performed after cutting shred; the existing burley tobacco baking mode is substituted, a burley tobacco leaf shred baking and drying process mode is adopted, the water ratio and the temperature of the exported leaf shred is fed back and controlled; the processing route of the existing burley tobacco processing technic is changed, a processing technic for shred mixing is adopted. The burley tobacco processing and treating technic can adopt different processing parameters and routes according to the needs of products and different qualities and characters of different burley tobacco raw materials, thus the aesthetic quality of the blended type cigarette is improved, the process flow is simpler, and the processing method is more flexible.

Owner:XIAMEN TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com