Patents

Literature

1079 results about "Moisture regain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Independent tobacco cutting process and equipment based on paper making method regenerated tobacco leaf processing characteristics

ActiveCN102178337ASolve the strength problemAvoid pulling forceTobacco preparationPulp and paper industryMoisture regain

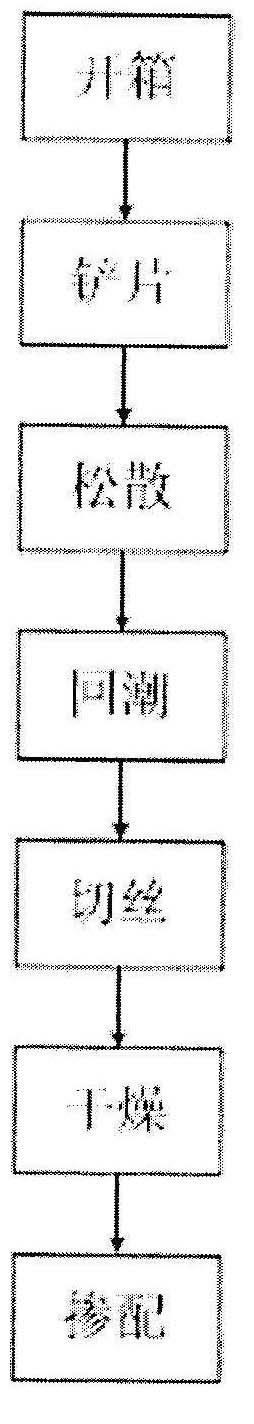

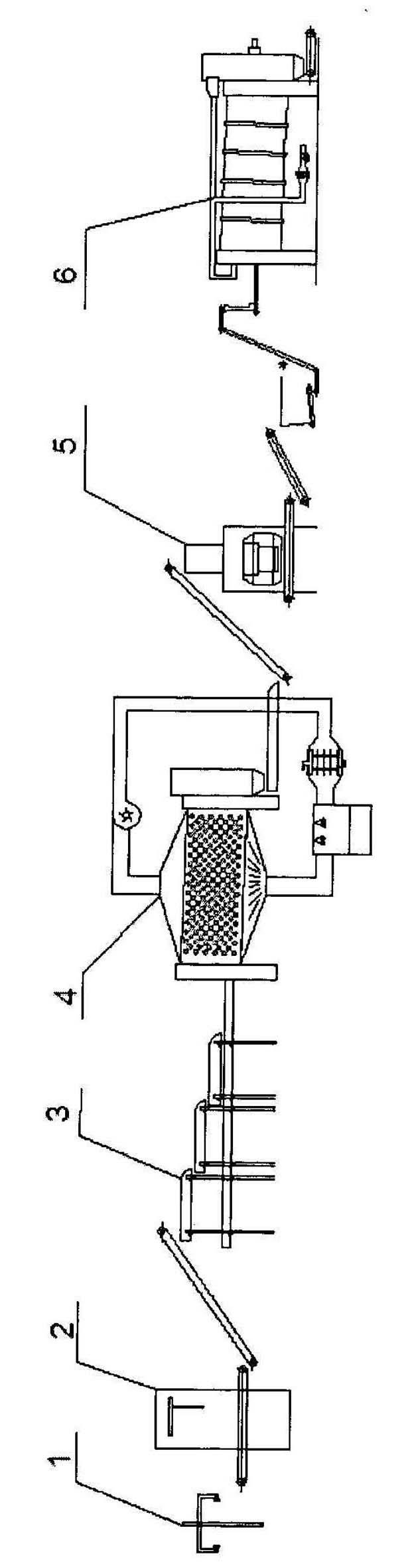

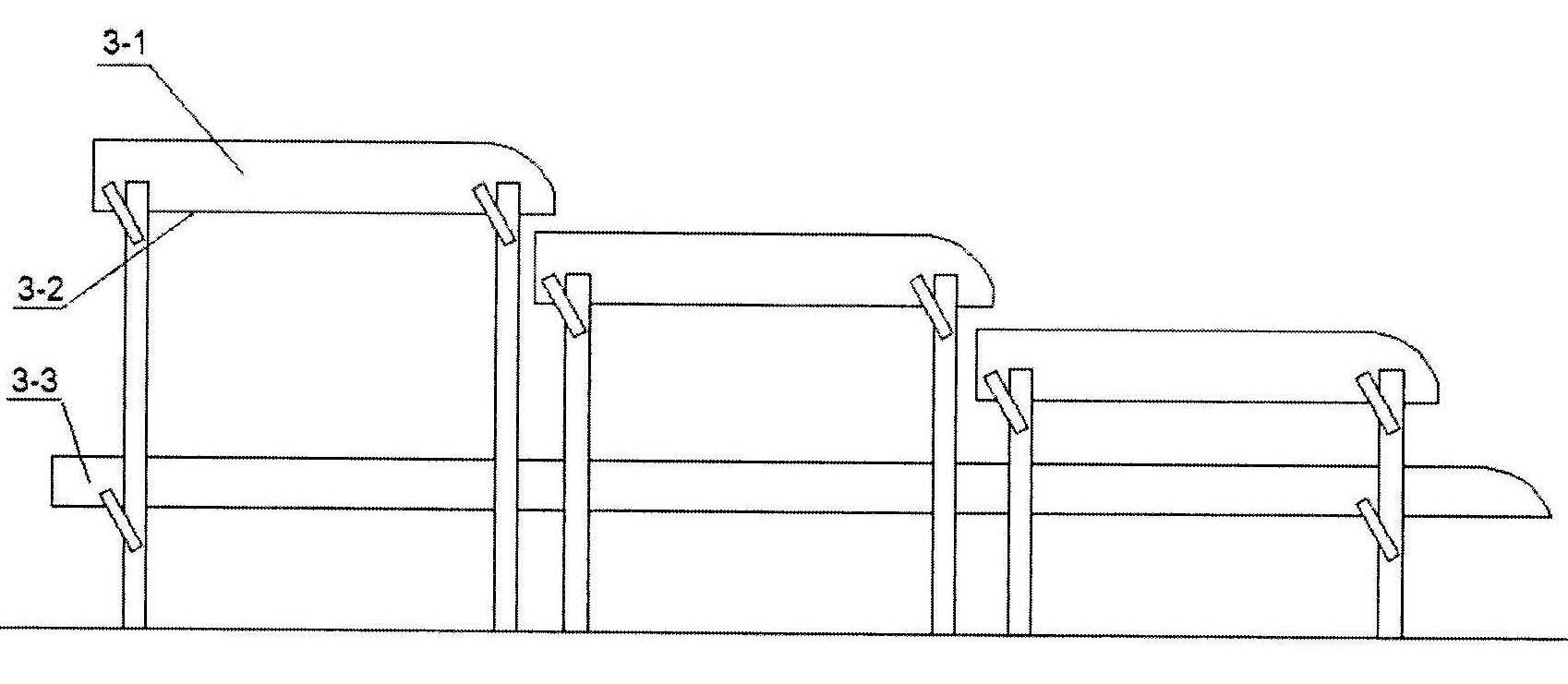

The invention discloses an independent tobacco cutting process and independent tobacco cutting equipment based on paper making method regenerated tobacco leaf processing characteristics. The process comprises the following process steps: opening a box, shoving tobacco leaves, loosening, regaining moisture, cutting, drying and mixing. The equipment comprises a box opening machine, a tobacco leaf shoving machine, a high-frequency-vibrating loosening machine, a moisture regaining machine, a cutting machine and a roller cut tobacco drying machine, wherein the mechanisms can be arranged and can operate alone or in combination through the connection by a material conveying and feeding mechanism. The process and the equipment can cut the boxed regenerated tobacco leaves independently according to the processing characteristics of the boxed regenerated tobacco leaves, thereby improving the effective utilization rate of the paper making method regenerated tobacco leaves, effectively retaining fragrance, improving visual quality, and making the prepared regenerated cut tobacco uniform in length and good in looseness so that the cut tobacco can be blended with other cut tobacco uniformly. The process and the equipment have high adaptability; meanwhile, according to the change in the form of supplied materials, 'three-step method' tobacco cutting adopted in the prior art is changed into one-step cutting with the same effect, the production efficiency is improved and the production cost is lowered.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

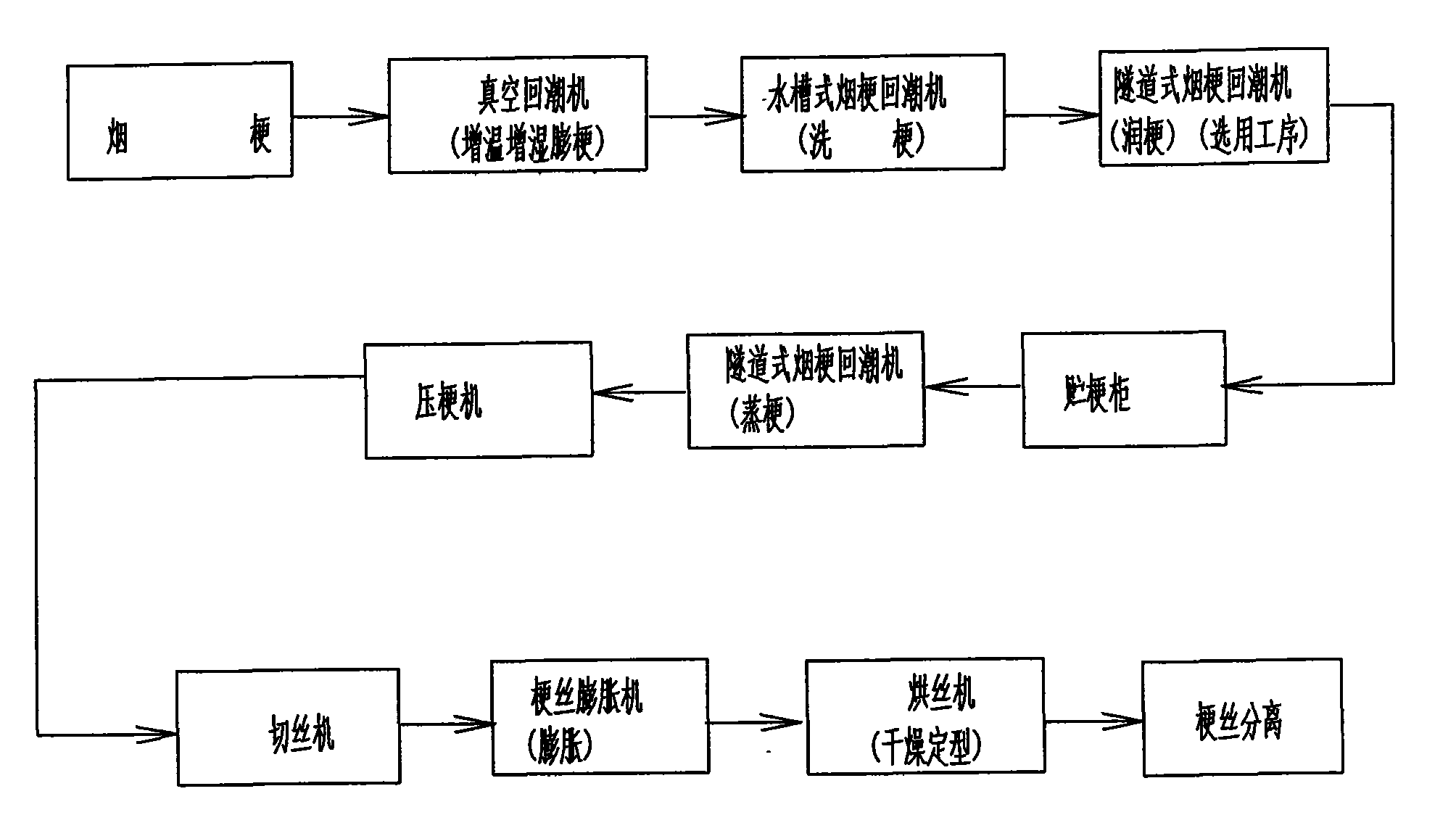

Method for improving quality of cut stems

ActiveCN103704867AImprove qualityIncrease vitalityTobacco preparationTobacco treatmentPulp and paper industryMoisture regain

The invention provides a method for improving the quality of cut stems. The method comprises the following steps that (1) tobacco stems are washed and degraded; (2) moisture regain is conducted on the tobacco stems and the tobacco stems are stored; (3) the tobacco stems are expanded and pressed; (4) stem pieces are degraded and stored; (5) material adding is conducted on the stem pieces; (6) the stem pieces are dried; (7) the dried stem pieces are stored; (8) moisture regain is conducted on the dried stem pieces and the dried stem pieces are expanded and pressed; (9) the stem pieces are cut into shreds and materials are added; (10) the cut stems are expanded and dried. Cigarettes with the cut stems prepared through the method are clear in fragrance characteristic, the fragrance quality is good, the smoke state is improved, the fine and smooth performance is improved, the harmony is better, miscellaneous gases are reduced, the dry sensation is reduced, and taste is more comfortable.

Owner:CHINA TOBACCO FUJIAN IND

Continuous production line based on processing of black tea, green tea, yellow tea and white tea, and method thereof

ActiveCN104814170AReduce equipmentImprove versatilityPre-extraction tea treatmentCooking & bakingProduction line

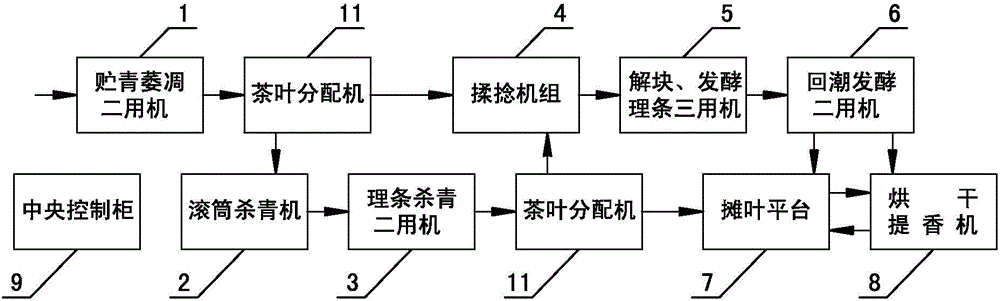

The present invention discloses a continuous production line based on the processing of black tea, green tea, yellow tea and white tea and a method thereof. The continuous production line includes tea leaf frying devices, tea leaf transporting devices connected between the tea leaf frying devices, a green leaf storage and withering double function machine connected with a rotary drum enzyme deactivating machine and a tea leaf rolling assembling unit through a tea leaf dispenser, a carding and enzyme deactivating double function machine connected with the rotary drum enzyme deactivating machine and connected with the tea leaf rolling assembling unit and a tea leaf spreading platform through the tea leaf dispenser, a deblocking, fermenting and carding triple function machine connected with the tea leaf rolling assembling unit, a moisture regaining and fermenting double function machine connected to the deblocking, fermenting and carding triple function machine, and connected with the tea leaf spreading platform and a baking and fragrance improving machine. The continuous production line effectively solves the problem that the current tea leaf production line and tea leaf processing technology can only process a single tea variety, but cannot meet the requirement of tea leaf processing of many varieties of tea leaves of tea farmers, has high device versatility and good product quality, and is of high practical value.

Owner:浙江丰凯机械股份有限公司

Method for producing hemp yarns through vortex spinning

ActiveCN102108574AImprove efficiencyImprove flexibilityContinuous wound-up machinesOpen-end spinning machinesYarnFibril

The invention provides a method for producing hemp yarns through vortex spinning. The method comprises the following steps: curing pretreatment of hemp fibers, a bale plucker, a bending and opening machine, an opening machine, a vibrating feed box, a lap machine, a carding machine, a pre-draw frame, a draw frame and lap machine combined, a combing machine, a draw frame and a vortex spinning machine, wherein in the step of curing pretreatment of hemp fibers, the addition of an oil feeding and conditioning soft penetrating agent is 6-8% of hemp fibrils by weight; the oil feeding and conditioning soft penetrating agent comprises 12-16% of emulsifying agent, 6-10% of softening agent and 75-79% of soft water; and the moisture regain is controlled between 12% and 15%. The method has the following advantages: the maximum count of the weaved hemp yarns can be 50; the noil rate is reduced; the flexibility, parallel straightness, spinnability and strength of the fibers are improved; the finished product rate is high; the hemp fibers are protected by adopting the methods of more opening and fewer beating and jogging; and the method lays the foundation for normal production through vortex spinning.

Owner:JIANGSU YUEDA HOME TEXTILE

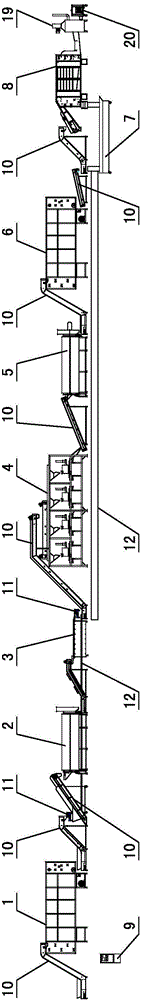

Tobacco stalk processing method

InactiveCN101611924AGood hygroscopicityIncrease moistureTobacco preparationTobacco treatmentPerformance indexEngineering

The invention discloses a tobacco stalk processing method, relating to a tobacco leaf processing method, in particular to a tobacco stalk processing method on a tobacco processing line. The invention comprises the steps of: vacuum moisture regaining, stalk washing in a water-tank tobacco stalk conditioning plant, stalk moistening in a channel tobacco stalk conditioning plant, stalk pressing, shredding, moisture regaining in a jetting stalk stem conditioning plant and stalk stem drying in a channel stalk stem drying machine. After being subjected to the tobacco stalk vacuum moisture regaining procedure, tobacco stalk absorbs atomizing water vapour, so that the tobacco stalk has certain temperature and moisture, which can greatly improve the performance index of the original procedure of washing stalks with water; after adding the tobacco stalk vacuum moisture regaining procedure, the moisture of the tobacco stalk can be ensured before the stalk stem is cut; impurities can be thoroughly discharged after the tobacco stalk is washed, the stalk stem cutting technology can be conveniently and safely finished, and the cut stalk stem is cleaner.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

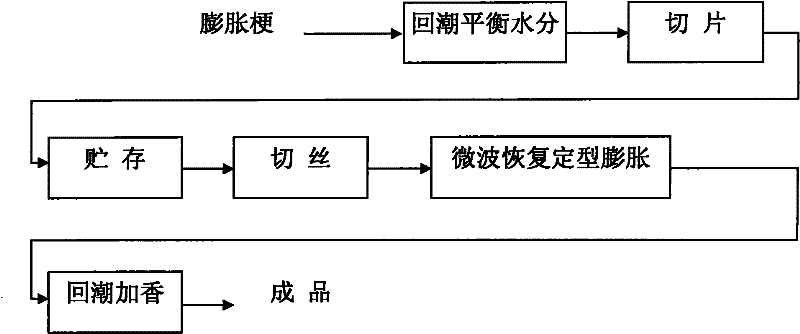

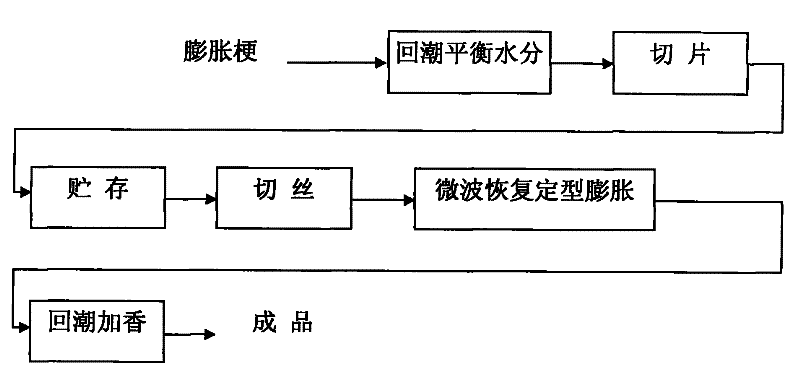

Process for preparing cigarette expanded stem shreds

ActiveCN102125293AWell mixedEvenly distributedTobacco preparationTobacco treatmentEngineeringMoisture regain

The invention discloses a process for preparing cigarette expanded stem shreds. The process comprises the following steps of: after performing moisture regain on expanded cigarette stems of which the expansion degree is over 150 percent in moisture-regain and moisture-balancing equipment until the water content is 30 percent and balancing the water content, cutting the expanded cigarette stems into expanded stem sheets of which the thickness is 0.2 to 1.8mm; storing the expanded stem sheets in a storage cabinet; cutting the expanded stem sheets into stem shreds of which the width is 0.2to 1.8mm and the length is 5 to 20mm; feeding the stem shreds into microwave heating equipment and drying until the water content is 3 to 4 percent; and feeding into moisture-regain and fragrance-adding equipment and performing moisture regain and fragrance adding to obtain the finished product of the expanded stem shreds of which the water content is 121 percent. The finished product of the expanded stem shreds, which is prepared by the process has high essences and fragrant material adsorption property, contains little wooden smell and other smell, and has obvious fragrance and high processing resistance. After being added in cigarettes, the expanded stem shreds are uniformly distributed and do not affect the smoking taste. The filling value of the expanded stem shreds can be up to 6 to 11cm<3> / g.

Owner:SHENZHEN HONGXIANG YISHENG TECH CO LTD

Processing method of handmade yellow tea

ActiveCN103444916ATo achieve aromaYellowish colorPre-extraction tea treatmentClimate change adaptationMoisture regainTea leaf

The invention belongs to field of tea leaf, and in particular relates to a processing method of handmade yellow tea. The processing method of handmade yellow tea comprises the following steps: picking fresh tea leaves, washing fresh tea leaves, sunning, performing primary roasting, shaping, spreading and cooling, performing primary drying, performing primary piling for yellowing, performing secondary drying, performing secondary piling for yellowing, extracting stalks, and refiring for extracting aroma. The processing method of the handmade yellow tea is a special processing method of Huoshan yellow tea, the fresh leaves are washed and dedusted to keep clean, the piling for yellowing is performed in a moisture regain machine after the primary drying is performed with the stacking thickness of about 10cm, piling for yellowing is performed after the primary drying is performed, secondary piling for yellowing is performed after the secondary drying is performed so as to further convert inclusions and achieve unique aroma taste of the yellow tea. By adopting the processing method, the processed Huoshan yellow tea has the characteristics of being similar in form of sparrow tongue, slight yellow of color and luster, lasting fragrance, mellow taste, sweet aftertaste, yellow bright, clean soup color, being durable for making tea, and being capable of being preserved for two years after being sealed at a normal temperature.

Owner:安徽抱儿钟秀茶业科技有限公司

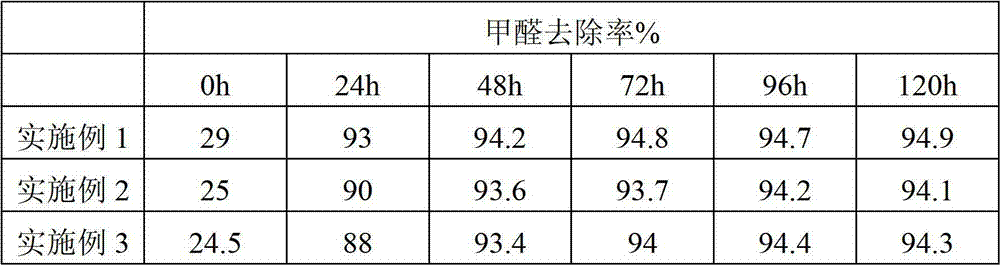

Compound-function wallpaper and preparation method thereof

ActiveCN102777004AImprove the shortcomings of single functionCompositeCovering/liningsManufacturing technologyComposite function

The invention discloses compound-function wallpaper and a preparation method thereof. The compound-function wallpaper is sequentially formed by a substrate layer, a glue sticking layer and a decoration layer from bottom to top, wherein the substrate layer is non-woven paper, non-woven cloth or plain weaving fabric which is processed by flame retardant finishing liquid; the glue sticking layer is formed by a binding agent, flame retardant powder, formaldehyde removing ultrafine powder and an additive; the formaldehyde removing ultrafine powder is formed by titanium dioxide ultrafine powder, zinc oxide ultrafine powder, tin oxide ultrafine powder, zinc sulfide ultrafine powder, ferric oxide ultrafine powder and diatomite ultrafine powder; and the decoration layer is a printing layer or an electrostatic flocking layer which is processed by the flame retardant finishing liquid. According to the compound-function wallpaper and the preparation method, disclosed by the invention, the flame retardant processing in each manufacturing technology stage of the compound-function wallpaper is realized, the all-directional fire flame retardant can be achieved, and the moisture regain is low; compound powder which can be used for catalyzing, resolving and removing formaldehyde in indoor environment is adopted for replacing common adsorptive material, thus the formaldehyde in the environment can be completely removed, and the repeatability does not exist; and selected anti-bacteria and mildew-proof anion far infrared products are both mature products in a market, and the multifunctional complex of the wallpaper is realized.

Owner:吕世静

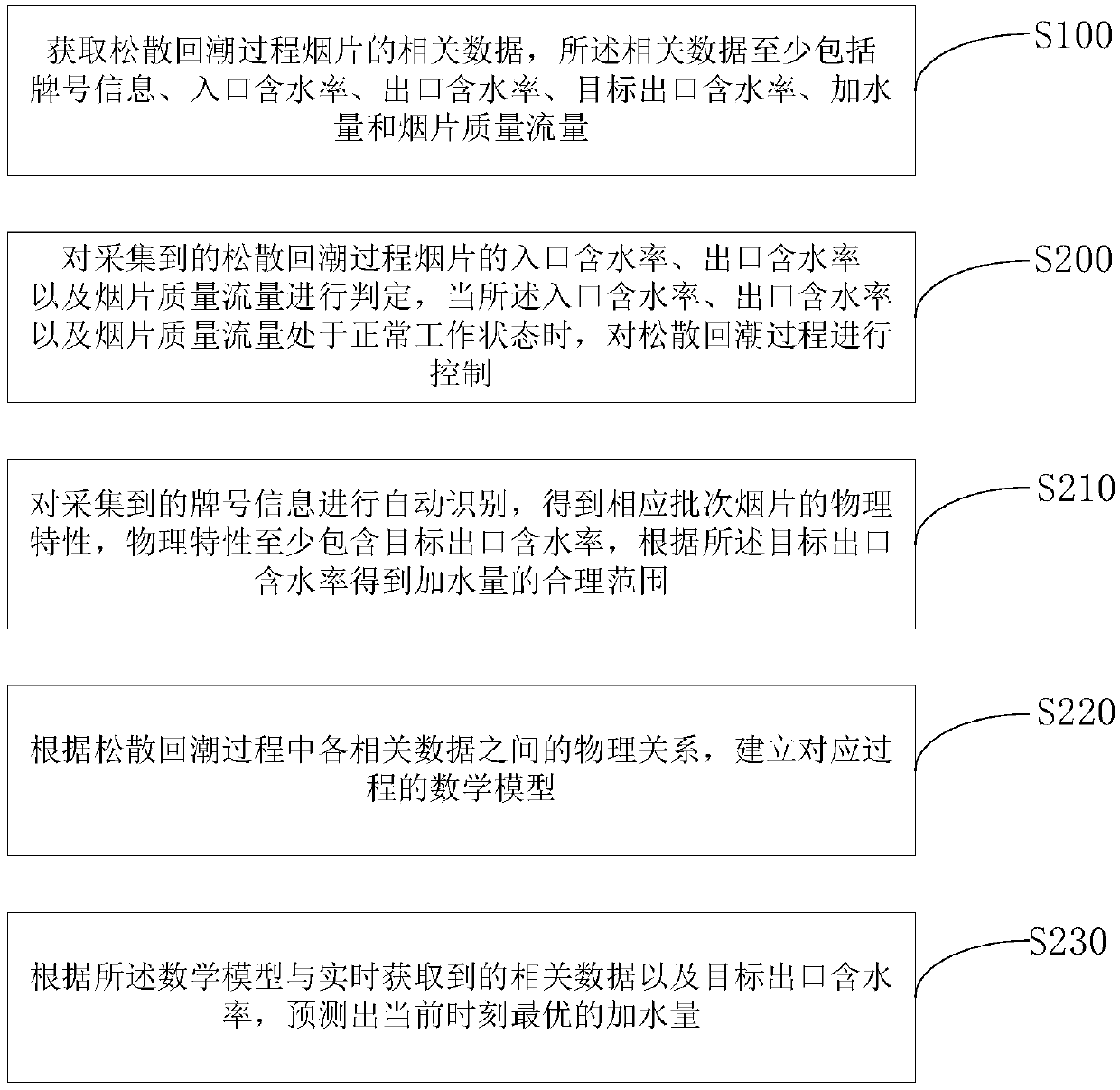

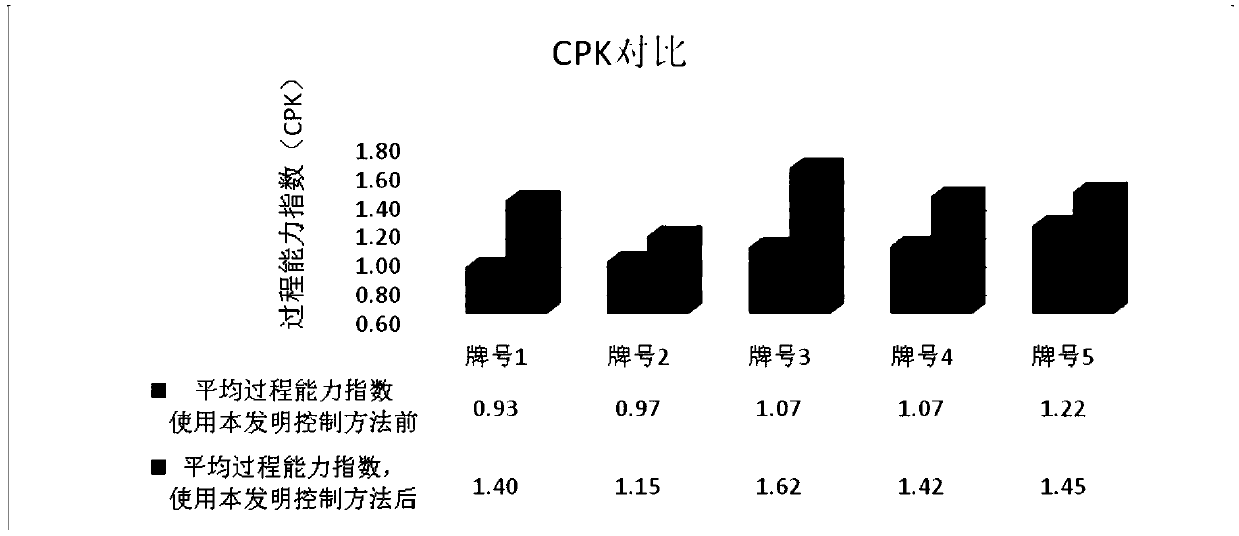

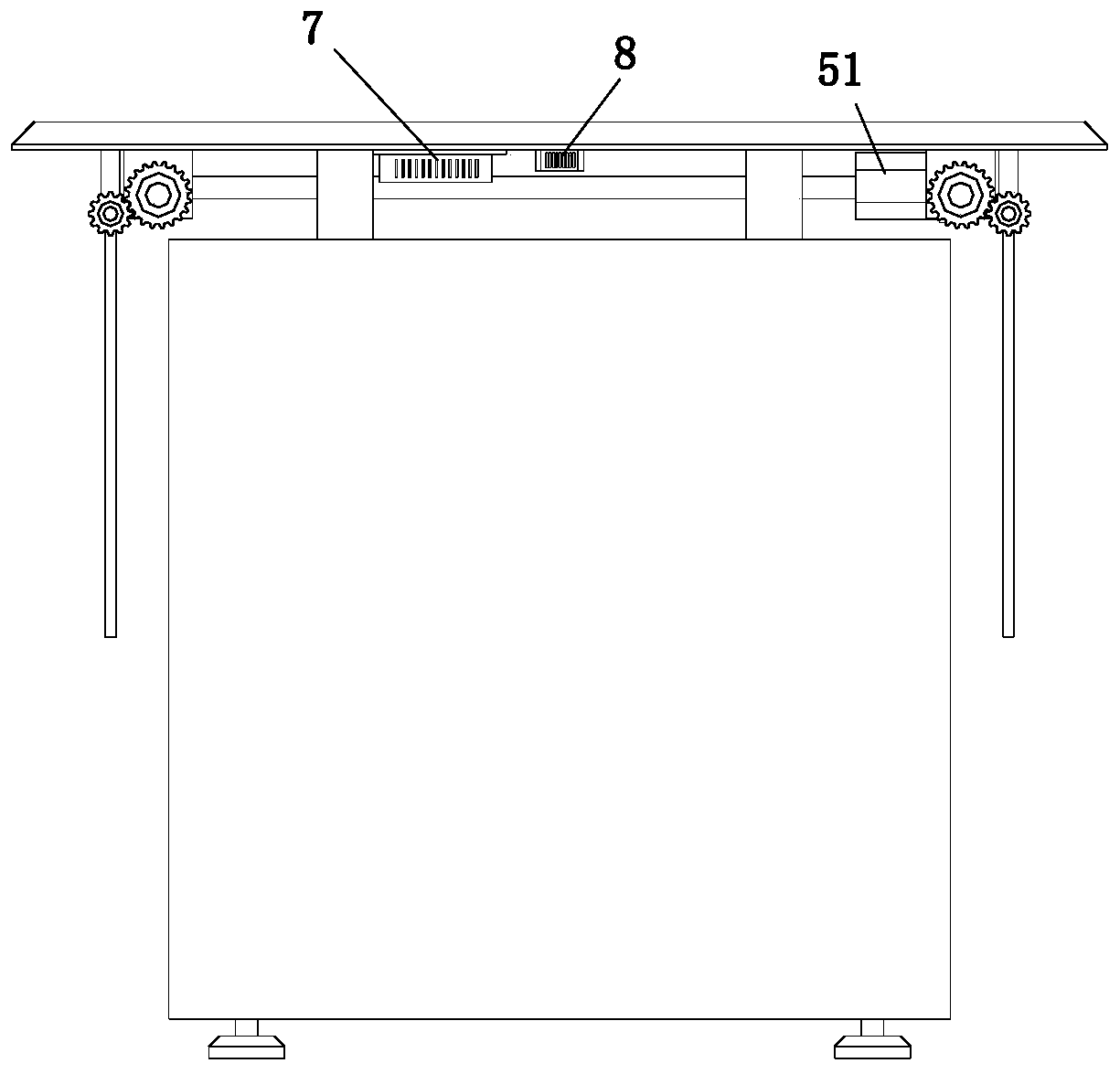

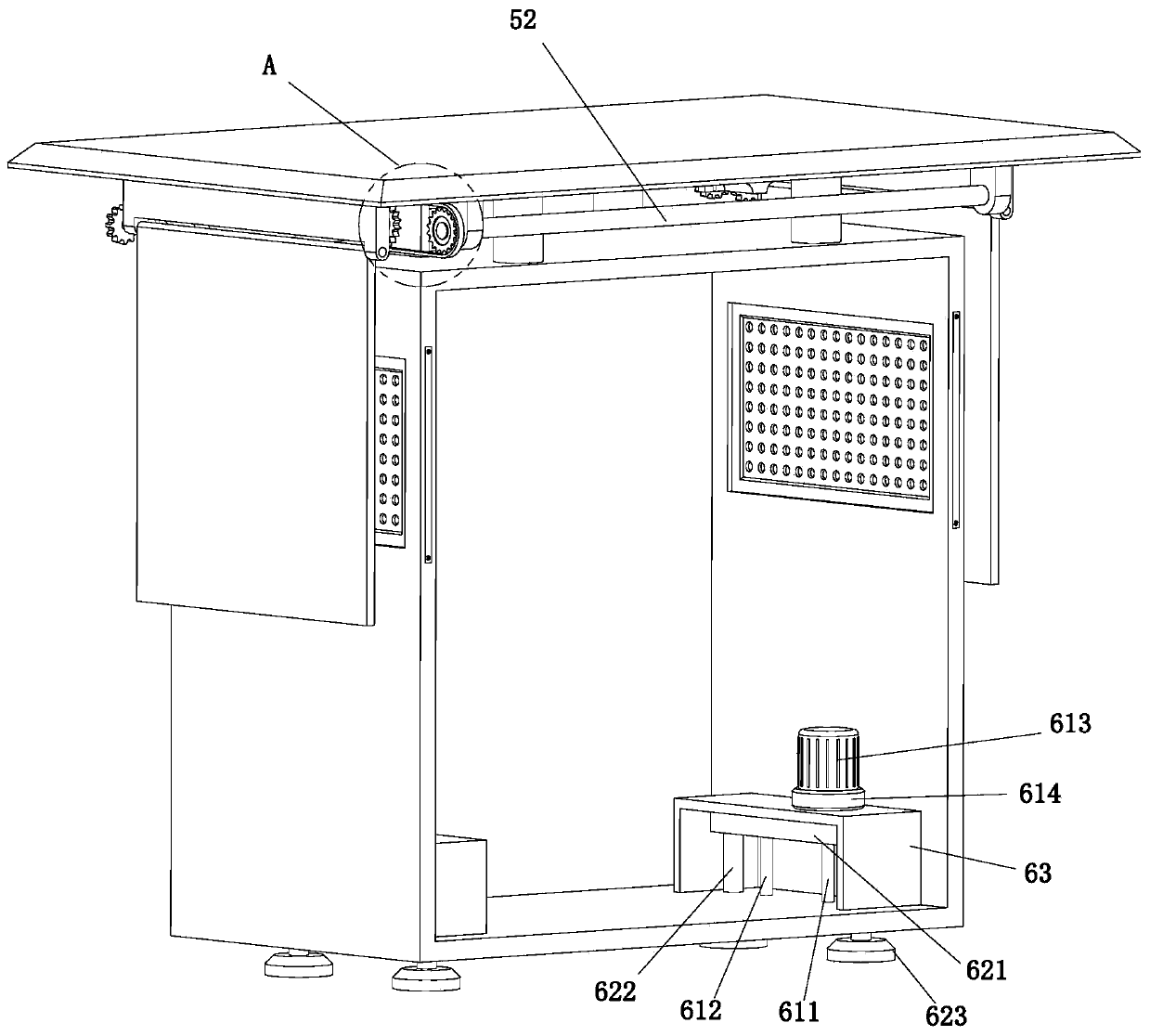

Digital physical model-based loose moisture regaining self-adaptive water control method and system

ActiveCN109602062AStable outlet moistureImprove pass rateTobacco preparationTobacco treatmentMathematical modelPhysical model

The invention discloses a digital physical model-based loose moisture regaining self-adaptive water control method. The method comprises the following steps: acquiring related data of a smoked sheet in a loose moisture regaining process, wherein the related data at least comprises plate number information, in-mouth water content, out-mouth water content, target out-mouth water content, water addition and smoked sheet quality flow. By judging the in-mouth water content, the out-mouth water content and the smoked sheet quality flow, when the in-mouth water content, the out-mouth water content and the smoked sheet quality flow are in a normal working state, the loose moisture regaining process is controlled and a detailed control process is disclosed. A mathematic model is constructed according to a physical relationship among variables in the loose moisture regaining process, and the data in the loose moisture regaining process is analyzed by using a polynomial regression method, so thattime-variable parameters in the model are identified in real time. The optimum water addition is solved according to the mathematic model and the out-mouth water content of the smoked sheet, and finally, the targets of stabilizing the out-mouth water content of the smoked sheet, improving the percent of pass of the smoked sheets and lowering the cigarette production cost are achieved finally.

Owner:HANGZHOU ANMAISHENG INTELLIGENT TECH CO LTD

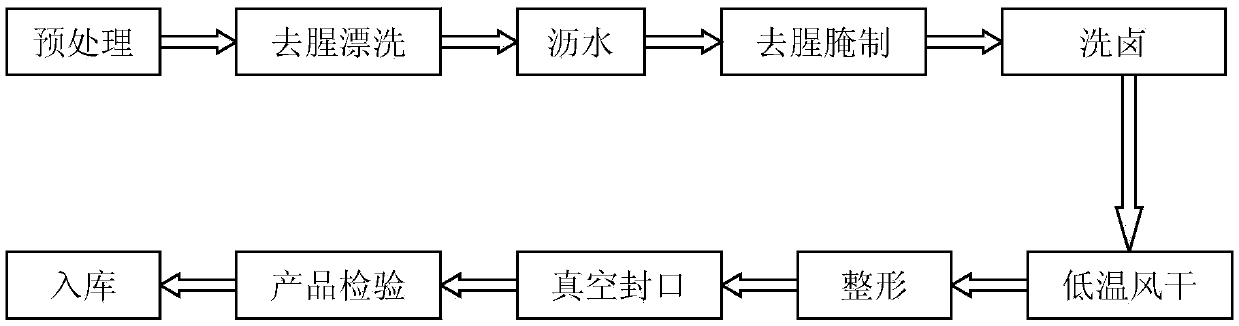

Method for producing de-fishy low-salt half-dry freshwater fish

InactiveCN105361001AReduce the degree of oxidationPreserve meat qualityFood dryingFood ingredient for microbe protectionProduct inspectionEvaporation

Owner:WUHAN RES INST OF FISHERIES SCI +1

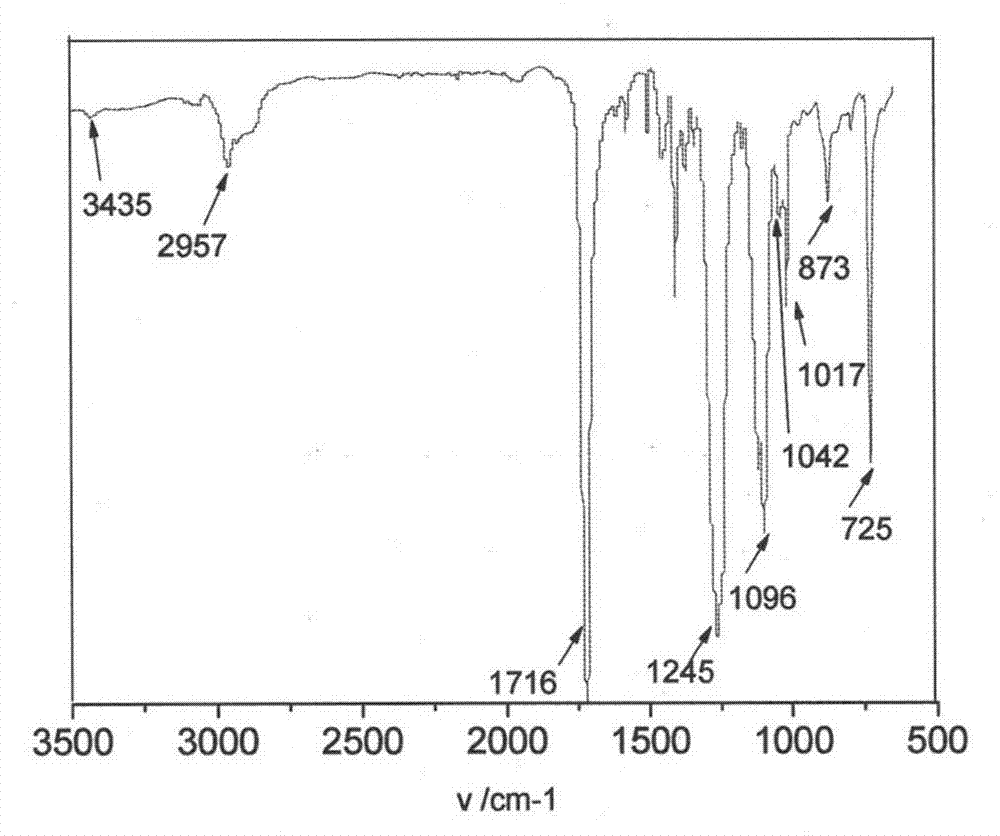

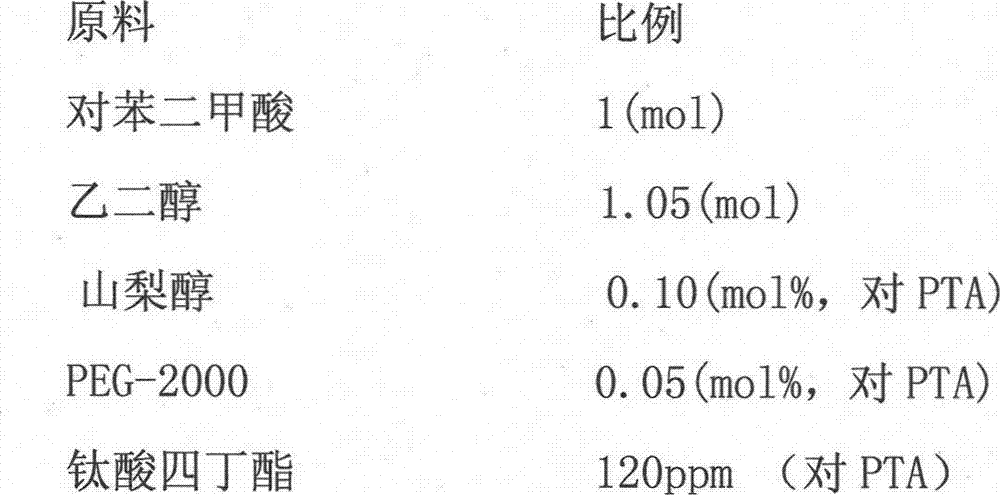

Hydrophilic polyester and preparation method thereof

ActiveCN102924701AImprove hydrophilicityLittle effect on spinnabilityMonocomponent copolyesters artificial filamentPolyesterCrystal structure

The invention provides a hydrophilic polyester and a preparation method of the hydrophilic polyester. The hydrophilic polyester is characterized in that the molecular chain comprises two chain segments like -COC6H4COOCH2CH2O- and -COC6H4COOCH2CH(OH)CH(OH)CH(OH)CH(OH)CH2O- with a quantitative proportion of 100:0.1-2.0; the intrinsic viscosity is 0.50-0.85g / dl and the melting temperature is 210-265 DEG C. The introduction of the hydrophilic groups into the polyester macromolecular chain and the change of the polyester crystal structure by increasing an amorphous zone are beneficial to the enterance of the water molecules, thereby increasing the hydrophilicity of the polyester, and the surface contact angle of the polyester chip is 40-65 degrees. The spun fiber has higher moisture regain rate and can be used for underwear, sporting suit, liner and the like. The method provided by the invention applys trace additive for the modification of the polyester, the additive has a few effects on the polymerization process, polyester quality and spinnability owing to the small addition amount. The obtained polyester has good modification effect and is especially suitable for melt direct spinning. The method provided by the invention reduces the development cost of the product and is easy to realize industrial production.

Owner:SHANGHAI YITAN NEW MATERIAL CO LTD +1

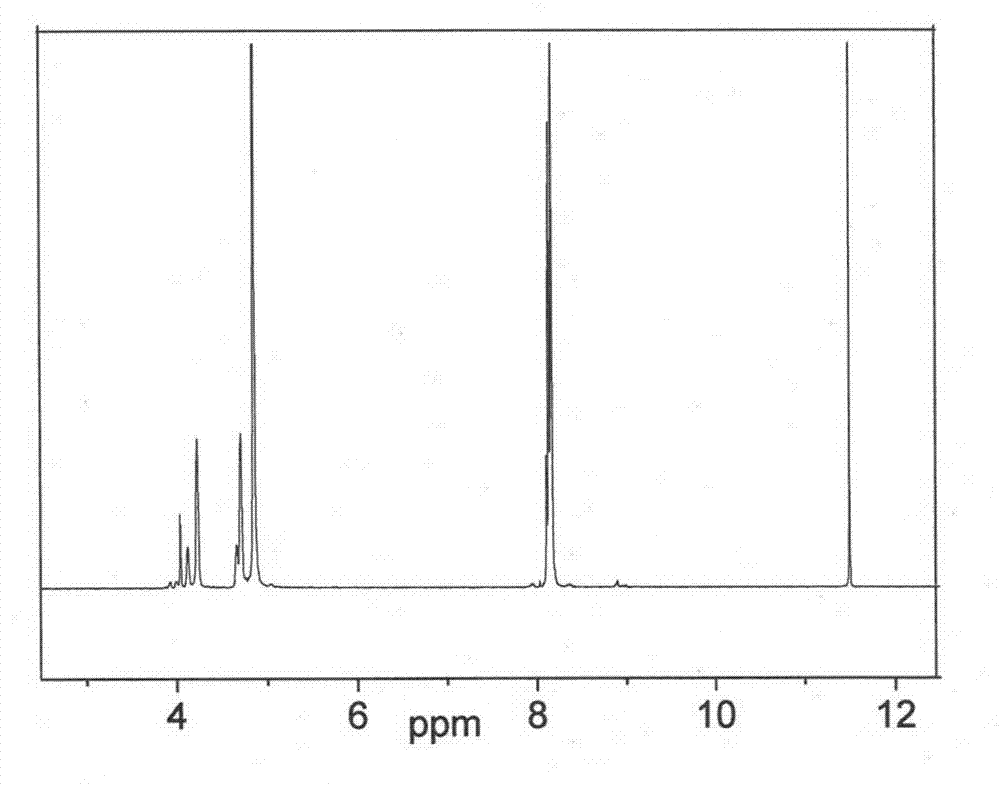

Semi-aromatic polyamides with low moisture regain

The present invention relates to a composition which includes the following components calculated with weight and the total weight is set to be 100: -60-99.5(preferably 70-93) at least one copolyamide with general formula X / Y, Ar, wherein: Y represents the residue of the aliphatic diamine with 8 to 20 carbon atoms, Ar represents the residue of aromatic dicarboxylic acid, X represents amino undecanoic acid NH2-(CH2)(10)-COOH, lactam-12 or the residual of corresponding amino acid, or X represents the unit Y, x, residue condensating with aliphatic dibasic acid (x) comprising 8 to 20 carbon atoms, or X represents Y, I and residue which come from diamin and condensates with the m-phthalic acid, -0.5-40(preferably 7-30) at least one product chosen from the following components: elasticizer, nano filling agent, polyolefin, crosslinked polyolefin and additive.

Owner:ATOFINA

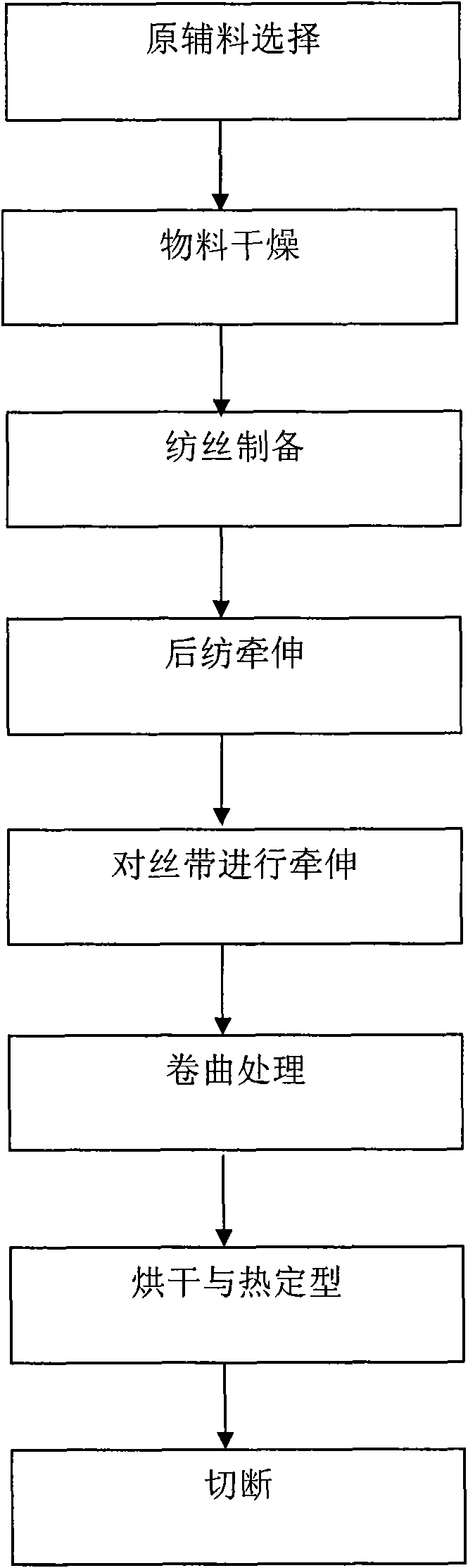

Preparation method of regenerative colored polyester fiber

InactiveCN101994163AIncrease elasticityImprove insulation performanceFilament manufactureHeating/cooling textile fabricsPolyesterHeat resistance

The invention discloses a preparation method of regenerative colored polyester fiber, comprising the following steps of: selecting supplementary materials; drying the materials; carrying out spinning preparation and post-spinning extension; evenly extending by two traction rollers under a heating state; rolling the extended raw tows; drying and thermally forming the raw tows; and finally, cutting the dried tows according to customer demands to obtain the regenerative colored polyester fiber with needed lengths. Because the produced regenerative colored fiber is directly spun in the natural color, the traditional color difference is greatly reduced. The obtained product has even color, is colorfast and has high strength, good thermal stability, good elasticity, good wear resistance, low water absorption moisture regain, good acid and base resistance, bio-incising resistance, and the like.

Owner:扬州天富龙集团股份有限公司

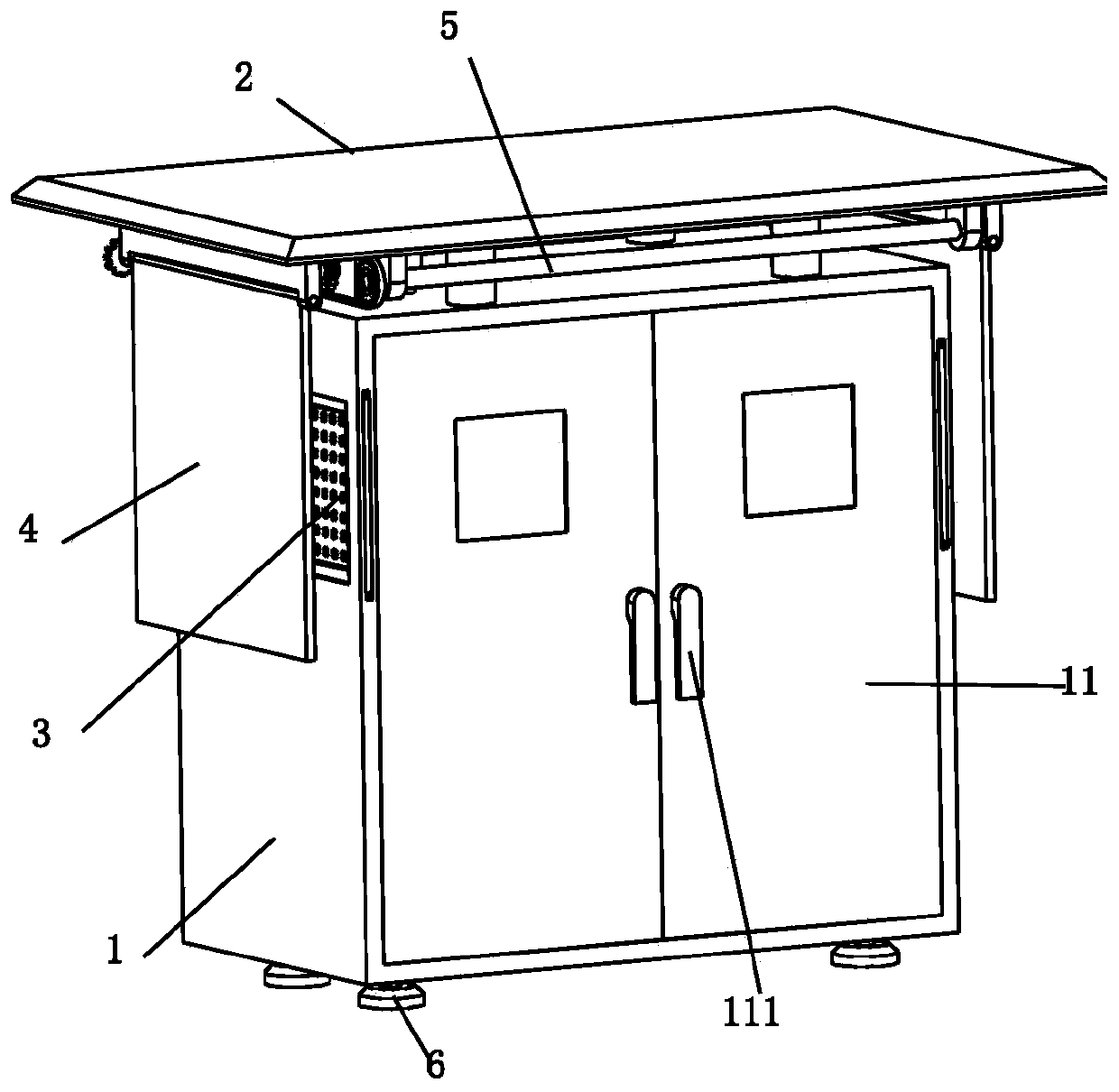

Portable waterproof distribution box

ActiveCN110620340AAvoid enteringImprove waterproof performanceSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringMoisture regain

The invention discloses a portable waterproof distribution box and belongs to the technical field of a distribution box. The distribution box comprises a distribution box body, wherein the top of thedistribution box body is provided with a rainproof baffle plate, ventilation mechanisms are arranged on side walls of two sides of the distribution box body, first rain blocking mechanisms are arranged on the left side and the right side of the rainproof baffle plate, a front side of the distribution box body is hinged with two closed door bodies, a handle is installed on each closed door body, asecond rain blocking mechanism is arranged on a front side of the rainproof baffle plate, two lifting mechanisms are arranged in the power distribution box body, a controller and a humidity sensor arefurther arranged at the bottom of the rainproof baffle, and the humidity sensor, the first rain blocking mechanism, the second rain blocking mechanism and the lifting mechanisms are all electricallyconnected with a controller. The distribution box is advantaged in that waterproofness of the distribution box body is improved through the second rain blocking mechanism and the two first rain blocking mechanisms, the rainwater is prevented from entering the box body, the whole distribution box body can be lifted through the lifting mechanisms, the moisture regaining phenomenon of the distribution box body close to the ground for a long time is avoided, and heat dissipation can be conducted through the ventilation mechanisms.

Owner:常德三欣电力电子科技有限公司

Novel production process for cut tobacco stems

InactiveCN102972856AIncrease softnessIncrease fill valueTobacco preparationTobacco treatmentAgricultural engineeringDrum drying

The invention discloses a novel production process for cut tobacco stems. The novel production process comprises the steps as follows: carrying out vacuum moisture regaining and evaporating the stems; storing the stems; heating and humidifying; straightening the stems; pressing the stems; arranging the stems; cutting the stems; feeding; expanding and drying; and perfuming. According to the novel production process, the vacuum moisture regaining and stem evaporating mode is adopted for moisture regaining of the tobacco stems, so that the impurity gases in the tobacco stems can be removed and the smoke softness is improved. The thinly pressing and cutting mode is adopted, so that the physical forms of the formed cut stems are threadlike and are closer to cut tobaccos. The flash evaporation, expansion and drum drying mode is adopted for drying of the cut stems, so that the cut stems are better in crimpiness and are closer to the form of the cut tobaccos and the filling capability of the cut stems can be improved. The cut steams produced by the production process has the advantages that the filling value is high, the impurity gases in the tobacco stems are reduced, the fragrance is increased, cigarettes can be endowed with a certain burned sweet fragrance, the physical forms of the cut stems are closer to the cut tobaccos, and the suitability is better in the cigarettes.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

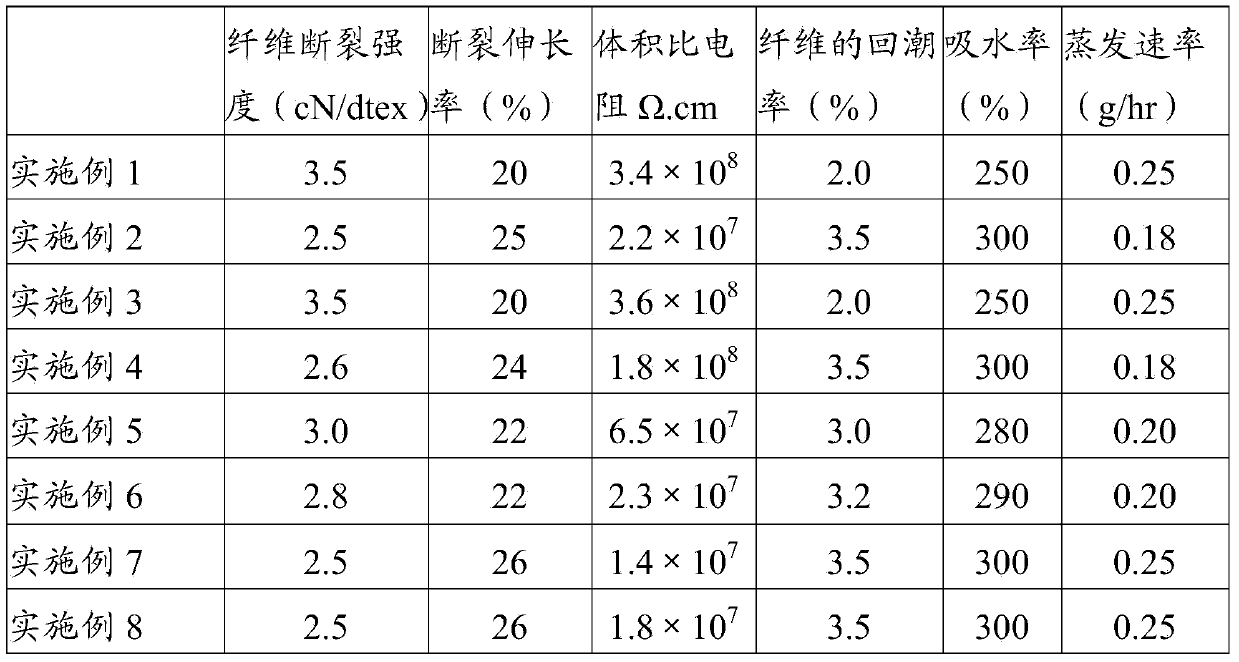

Hydrophilic polyester fiber and preparation method thereof

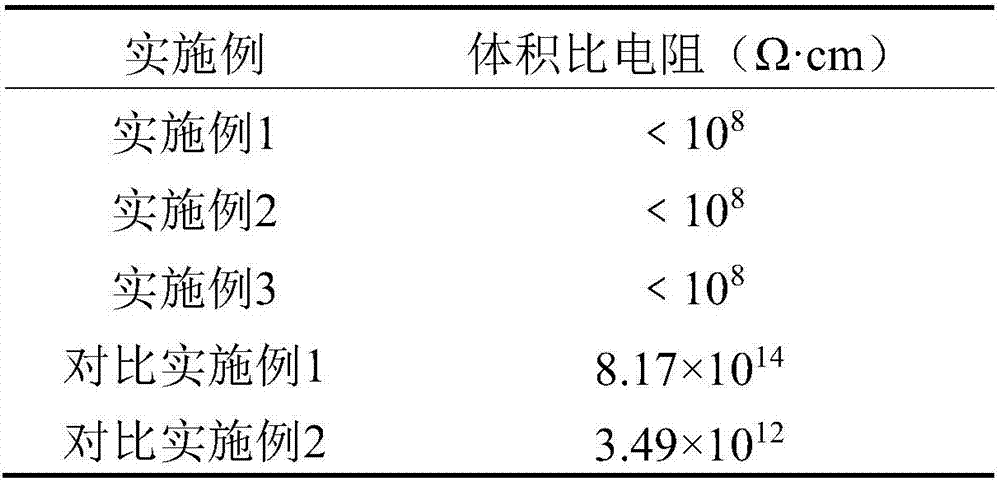

ActiveCN103741258AImprove thermal stabilityGood hygroscopicitySpinnerette packsMelt spinning methodsPolyesterMoisture absorption

The invention discloses a preparation method of a hydrophilic cotton-like polyester fiber. The preparation method is characterized by comprising the following steps: (1) dissolving chelate formed in a calcium chloride water solution by virtue of polyvinyl alcohol; (2) carrying out mixing granulation on polyester chips, a molecular weight modifier, an antioxidant and a lubricant so as to obtain cooled master batches; (3) carrying out blending and melt spinning on the obtained modified polyvinyl alcohol, the cooled master batches and polyester chips, and carrying out final processing to prepare the cotton-like polyester fiber. The invention further provides the hydrophilic cotton-like polyester fiber prepared by the preparation method. The fiber comprises 0.1wt%-5wt% of the modified polyvinyl alcohol, 0.005wt%-0.05wt% of the molecular weight modifier, 0.002wt%-0.02wt% of the antioxidant and 0.002wt%-0.02wt% of the lubricant; the fiber has the coefficients that the moisture regain is more than or equal to 2.0%, the water absorption rate is more than or equal to 250%, the evaporation rate is more than or equal to 0.18g / hr, the breaking strength is more than or equal to 2.5cN / dtex, the elongation at break is more than or equal to 20%, and the volume resistivity is less than or equal to 108 omega.cm. The cotton-like polyester fiber disclosed by the invention has the advantages that the moisture absorption performance is good, and the comfort level is greatly improved.

Owner:LI NING CHINA SPORTS GOODS

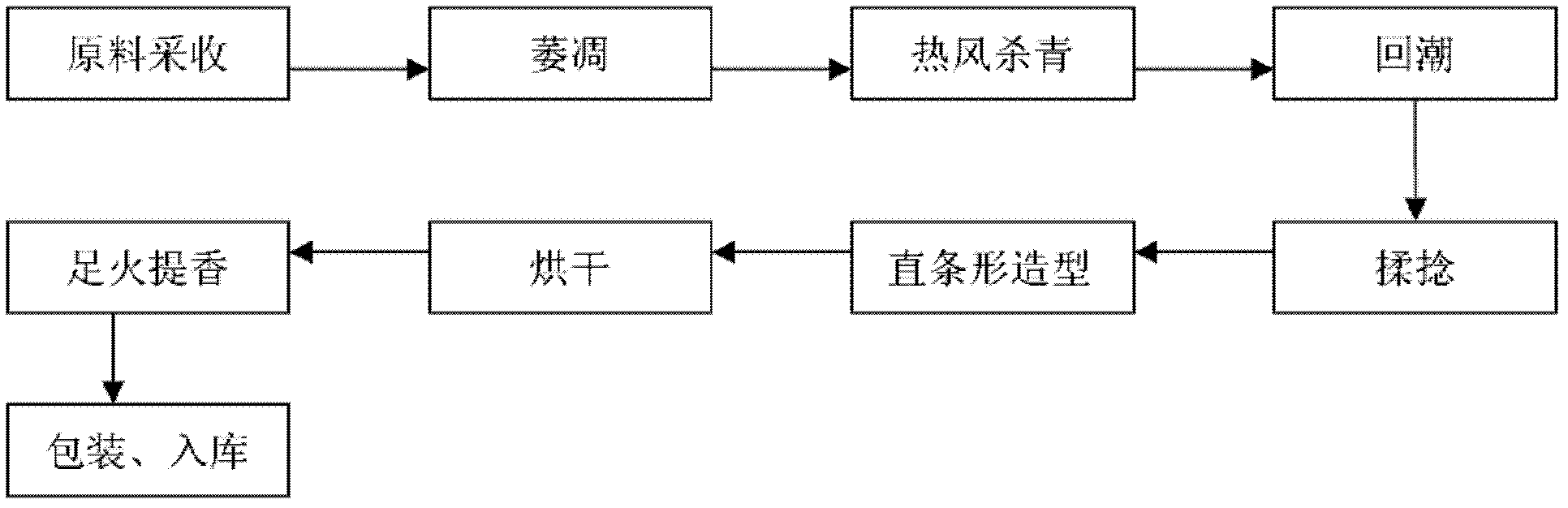

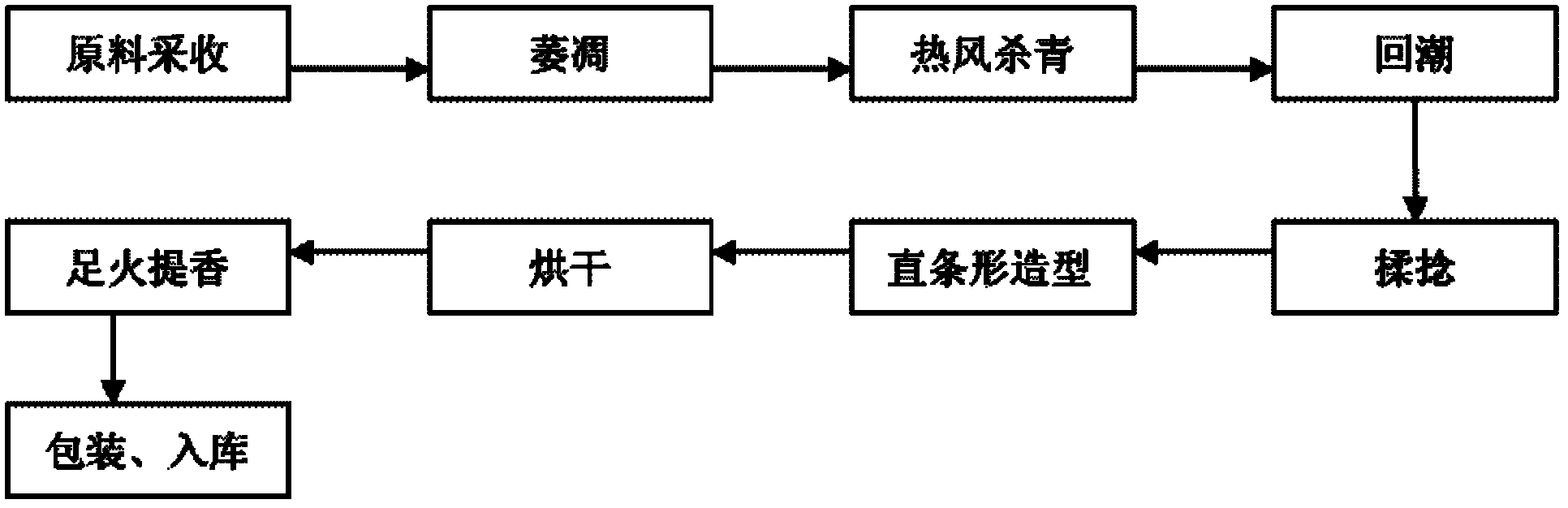

Processing technique for Guire No. 1 green tea

InactiveCN102613324APretty in appearanceEmerald green colorPre-extraction tea treatmentVertical barMoisture regain

The invention discloses a processing technique for Guire No. 1 green tea, which comprises the steps of raw material harvesting, wilting, deactivation of enzymes by hot wind, moisture regain, rolling, vertical-bar shaping, drying, perfuming by complete fire, wherein the three critical steps that guarantee the unique quality of the Guire No. 1 green tea are as follows: fresh leaves are purchased strictly in accordance with the standard of one bud one leaf, the temperature for the deactivation of the enzymes by the hot wind is 280-320 DEG C, the sorting temperature is strictly controlled to be 40-50 DEG C, and the sorting time is controlled to be 8-10 minutes. With the application of the technique, the standardized and scale production of the Guire No. 1 green tea is realized, the processed Guire No. 1 green tea is good in appearance, bright green in color, blooming, yellow green and bright in liquor color, and mellow and sweet in taste, the castanea mollissima fragrance is persistent, leaf bases are light green and even, and the requirements of tea lovers on high-quality tea can be met.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

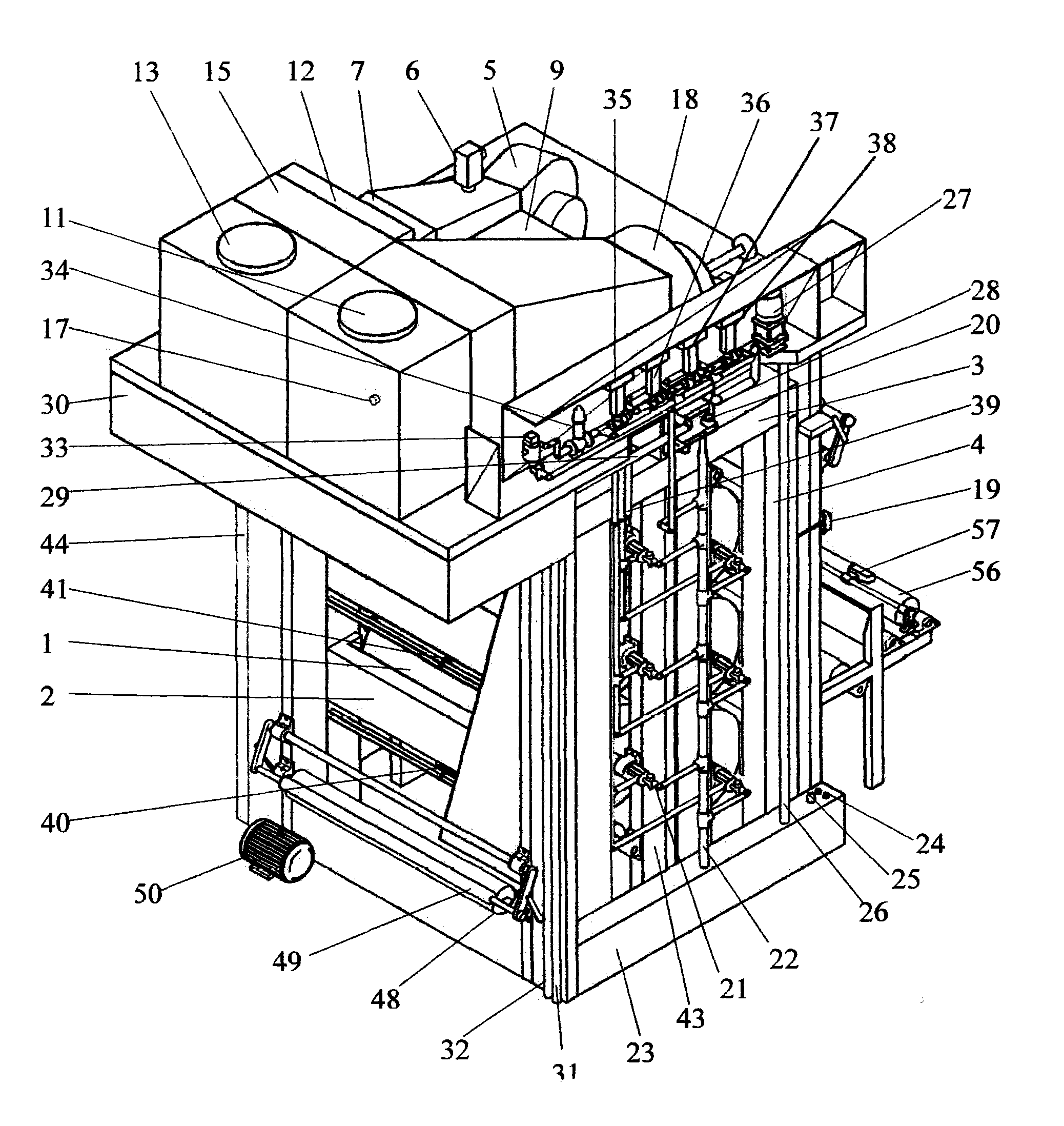

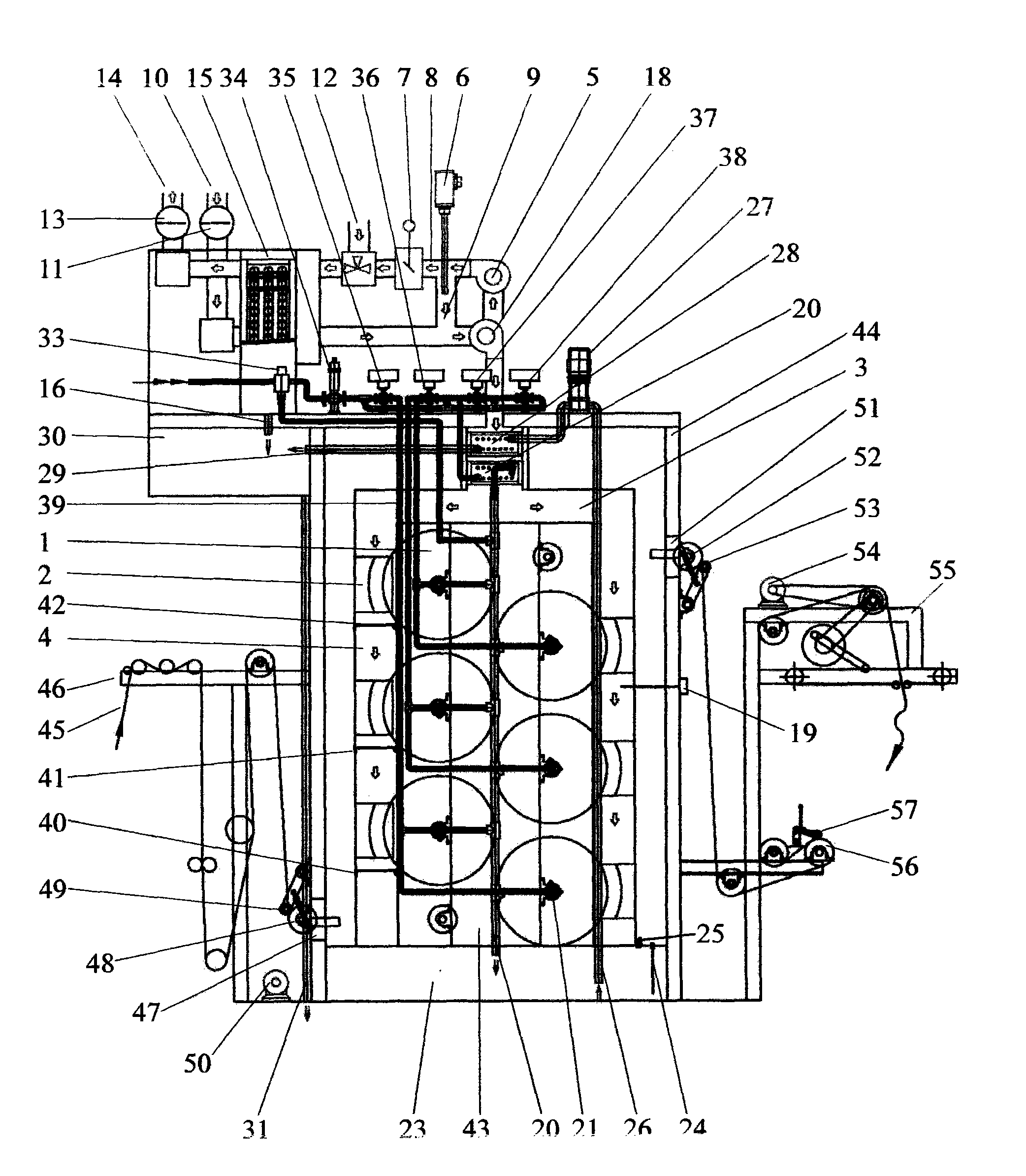

Electronic jet drying cylinder dryer

InactiveCN102183128AMeet production needsSatisfy productivityDrying gas arrangementsLiquid/gas/vapor removalTextile printerWaste heat recovery unit

The invention discloses a textile printing and dyeing electronic jet drying cylinder dryer and a jet drying cylinder, waste gas heat recovery and condensate water recovery thereof and a method for setting a moisture regain reference roller. The electronic jet drying cylinder dryer consists of a heat insulating and preserving drying room, the jet drying cylinder, a heat recovery and jet system and an electronic information system, wherein exhaust air is divided into exhausted air and circulating air according to humidity of the exhaust air; heat of the exhausted air is recovered by fresh air; the fresh air is mixed with the circulating air; the heat of condensate water is then recovered and the condensate water is sprayed to a textile; heating is performed and drying conditions are improved; complete on-line detection and control are performed on temperature, tension and moisture regain of the textile and humidity, temperature and speed of an air flow; therefore, heat application efficiency and drying efficiency are increased, production cost is reduced and production requirement of high-grade textiles is met in a scientific, strict, careful and reliable drying mode. The electronic jet drying cylinder dryer can be used for substituting a drying cylinder dryer or is made by modifying the drying cylinder dryer; a waste gas heat recovery system and a condensate water recovery system are suitable for various heating production occasions; and by the method for setting the moisture regain reference roller, reliability and validity of moisture regain control are solved.

Owner:段新顺 +1

Extraction method of bamboo shoot case fibre for spinning

InactiveCN101117731ASimple processLow costVegetable materialBacteriological rettingChemical treatmentPre treatment

The present invention relates to a method for extracting spinning fiber from bamboo shoot shells. The extracting method of spinning fiber from bamboo shoot shells is characterized in that the present invention comprises the following steps: firstly, pretreatment: cutting the bamboo shoot shells into pieces 20-100mm long; storing the pieces in a sealed environment and adjusting the humidity to control the moisture regain rate at 6 percent -10 percent; secondly, degumming treatment: using one or combination of any two or three of steam explosion treating method, microbial treating method and chemical treating method for degummed bamboo shoot shell fiber; thirdly, post-treatment: a, oil feeding: adding wool oil to the degummed bamboo shoot shell fiber, the wool oil being 1-2 percent of the degummed bamboo shoot shell fiber in weight; b, drying: controlling the temperature of the drying oven at 60-80 DEG C; c, fiber dispersing: obtaining spinning bamboo shoot shell fiber. The present invention has the advantages of simple process and low cost and, applied to textile processing, can take full use of bamboo shoot shell resources and protect the environment.

Owner:WUHAN TEXTILE UNIV

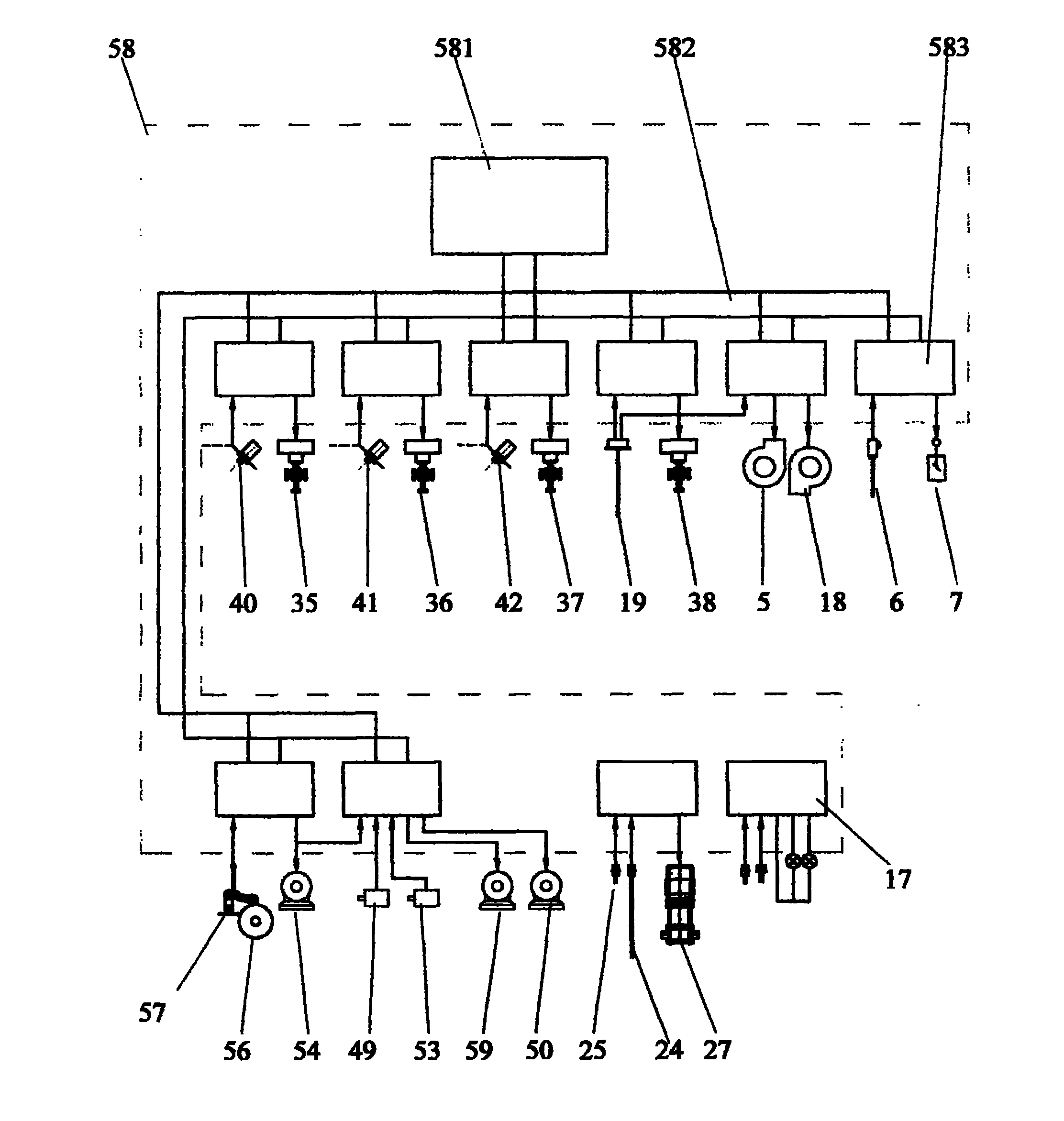

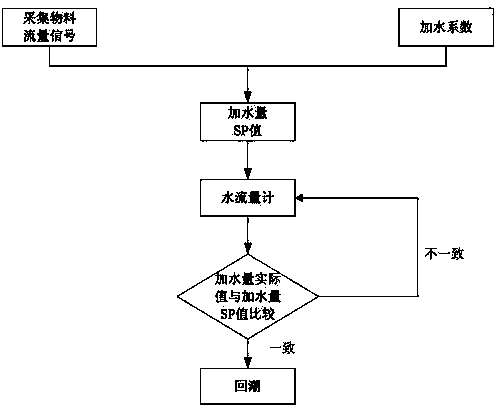

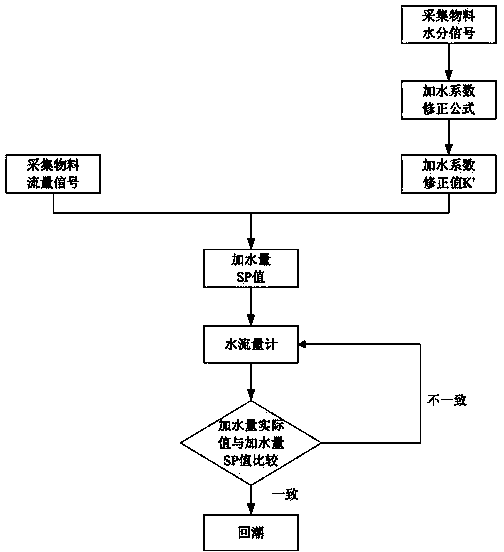

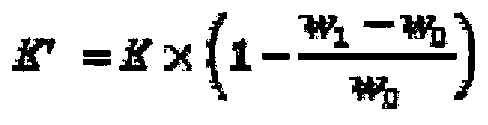

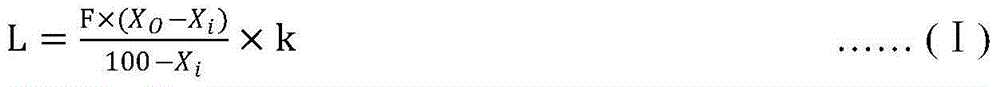

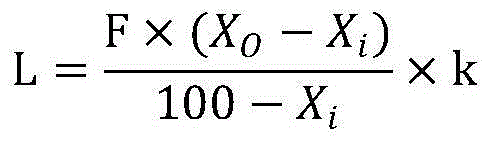

Moisture regaining feed-forward control method based on supplied material water content differences

InactiveCN103383541AImprove the calming effectShort delayRatio controlAdaptive controlLoop controlClosed loop

The invention discloses a moisture regaining feed-forward control method based on supplied material water content differences. Due to comparison of the differences of smoke block supplied material water content and a preset value, a water supplying coefficient of a loose moisture regaining cylinder is modified, and therefore actual water supply amount is adjusted. The method includes the steps of collecting material water signal w1, comparing the differences between the w1 and a material water content preset value w0, obtaining a water supply coefficient modified value K' through calculation, collecting material flow signal P, obtaining a water supply amount value SP after calculation, and modifying an actual water supply amount value in real time according to the water supply amount value SP through a water flow meter after data stack delay so that the actual water supply amount value is consistent with the water supply amount value SP. Front-period turbulence is taken as a main reason, on the basis of the water content differences between smoke blocks at an inlet, a water supply coefficient K is modified, and the preventing effect of turbulence of the water content at a smoke sheet outlet is good. Data stack delay is short, and the response speed of water supply amount closed-loop control of a loose moisture regaining device is greatly improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Moisture-absorbing anti-static and anti-bacterial polyester fiber, moisture-absorbing anti-static and anti-bacterial fabric and preparation and application

InactiveCN107475801AImprove water absorptionGood hygroscopicityElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterPolyethylene terephthalate glycol

The invention belongs to the field of clothes textiles, and particularly relates to a moisture-absorbing anti-static and anti-bacterial polyester fiber, a moisture-absorbing anti-static and anti-bacterial fabric and preparation and application. A preparation method of the moisture-absorbing anti-static and anti-bacterial polyester fiber comprises the following steps of mixing and spinning polyethylene terephthalate, polyvinyl alcohol, nanosilver and polyethylene glycol, so as to obtain mixed fiber; respectively treating the mixed fiber by a lipase water solution and a quaternary ammonium salt chitosan / glyoxal solution, and washing by water; stretching the mixed fiber after water washing, coiling, and thermally shaping, so as to obtain the moisture-absorbing anti-static and anti-bacterial polyester fiber. The moisture-absorbing anti-static and anti-bacterial fabric comprises the moisture-absorbing anti-static and anti-bacterial polyester fiber. The prepared moisture-absorbing anti-static and anti-bacterial polyester fiber has the advantages that the defects of poor moisture absorbing property, low moisture regain rate, easiness in electrostatic charge forming and the like in the unmodified polyester fiber are overcome; the water absorbing property, moisture absorbing property, anti-static property and antibacterial property are good.

Owner:广州弘雅服装科技有限公司

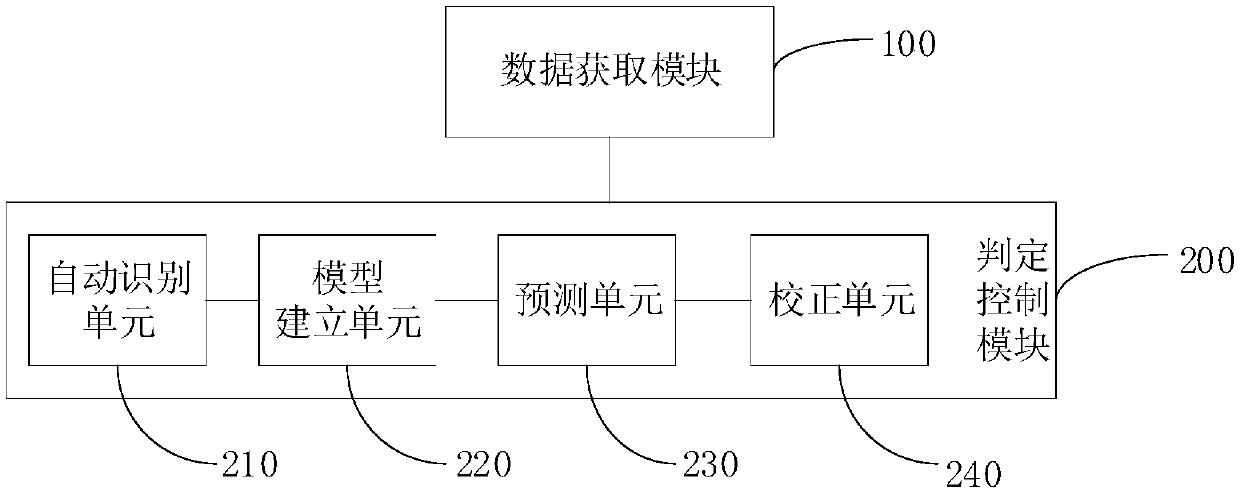

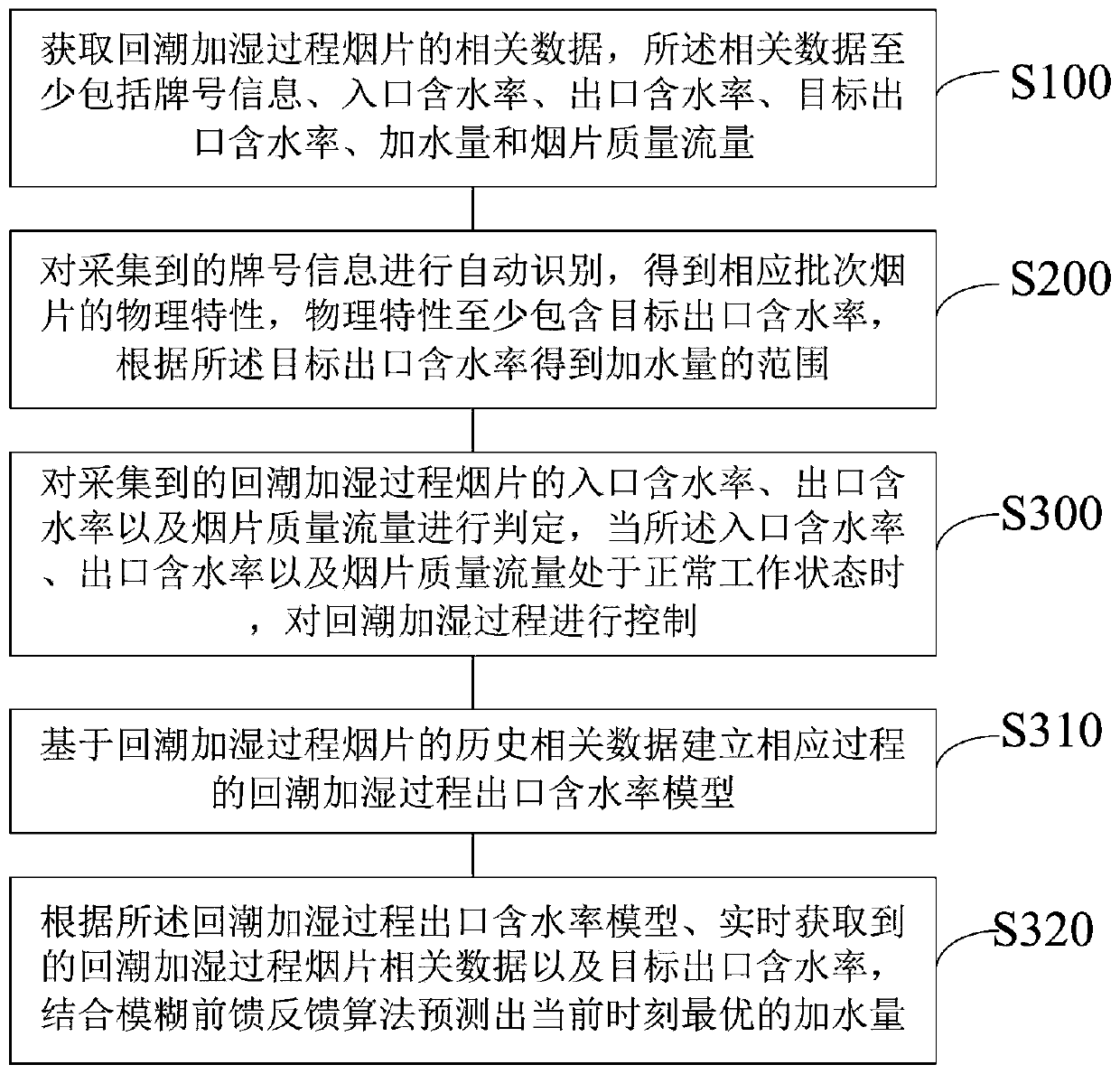

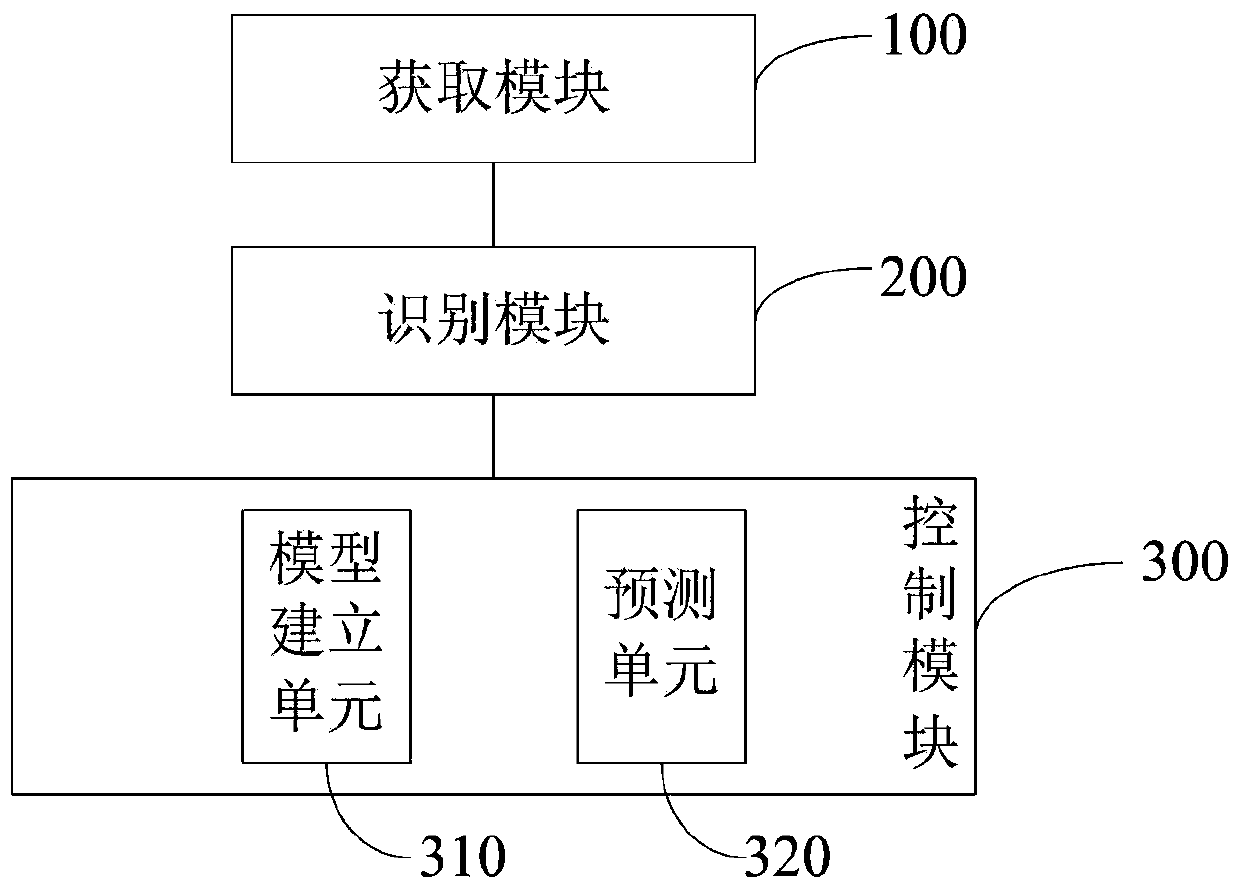

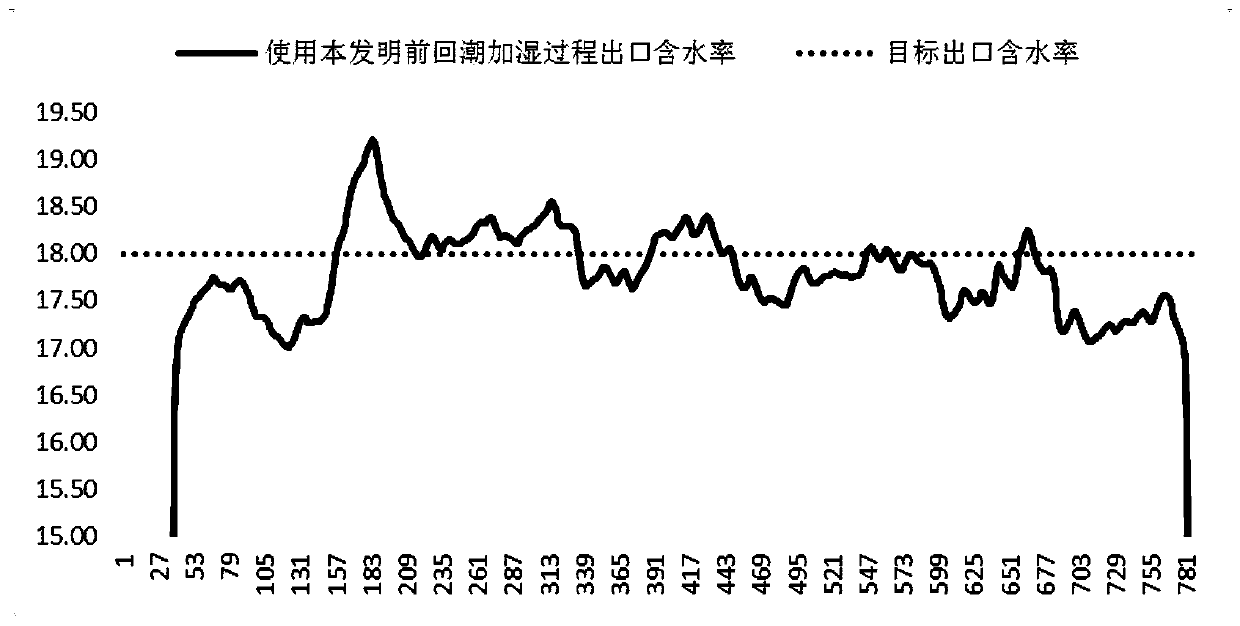

Moisture control method and system in moisture regaining and moistening process based on fuzzy feedforward feedback algorithm

ActiveCN110101106AGood technical effectStable outlet moistureTobacco preparationTobacco treatmentPass rateMoisture regain

The invention discloses a moisture control method and system in the moisture regaining and moistening process based on a fuzzy feedforward feedback algorithm. The method comprises the following stepsthat related data of tobacco sheets in the moisture regaining and moistening process is acquired; collected mark number information is automatically recognized, physical characteristics of the tobaccosheets of the corresponding batch are obtained and at least comprise target output moisture content, and according to the target output moisture content, a range of the water addition amount is obtained; the collected input moisture content, output moisture content and tobacco sheet quality flow of the tobacco sheets in the moisture regaining and moistening process are judged, and when the inputmoisture content, the output moisture content and the tobacco sheet quality flow are in the normal work state, the moisture regaining and moistening process is controlled. The moisture control methodand system finally achieves the purposes that moisture control over the moisture regaining and moistening process is conducted, the output moisture of the tobacco sheets can be stabilized, the qualification rate of the tobacco sheets is increased, and the production cost of cigarettes is reduced. Through the moisture control method and system, the robustness and control precision of the system areimproved, and the deviation caused by disturbance can be quickly eliminated.

Owner:HANGZHOU ANMAISHENG INTELLIGENT TECH CO LTD

Lightweight and environment-friendly type fibrilia composite plate and preparation method thereof

ActiveCN102602067APlay a skeleton roleHigh strengthSynthetic resin layered productsLaminationComposite plateMoisture regain

The invention relates to a lightweight and environment-friendly type fibrilia composite plate and a preparation method thereof, belonging to the technical field of interior ornaments for automobile decoration. The composite plate comprises PE (polyethylene) film layers (1) and a fibrilia mat layer (2), wherein the fibrilia mat layer (2) is an intermediate layer, and the PE film layers (1) are compounded on the upper surface and lower surface of the fibrilia mat layer (2); and the fibrilia mat layer (2) is a needle-punched fibrilia mat, comprises 55-65% by weight of fibrilia and 35-45% by weight of PP (polypropylene) fiber, and is formed by mixing, forming a net and performing needle-punching. The method comprises the following steps of: (1) fibrilia processing: soaking the harvested fibrilia raw material in a hydrogen peroxide solution for 20-25 days, then washing with water, and further sequentially performing peeling, airing, opening, coiling and cutting off so as to produce a fibrilia crude product; and (2) performing rinsing, drying and fine opening on the fibrilia crude product for later use. The prepared composite plate has the advantages of low density, high strength, good stretch-proof effect, low probability of moisture regain and mildew, no toxicity and environmental protection.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

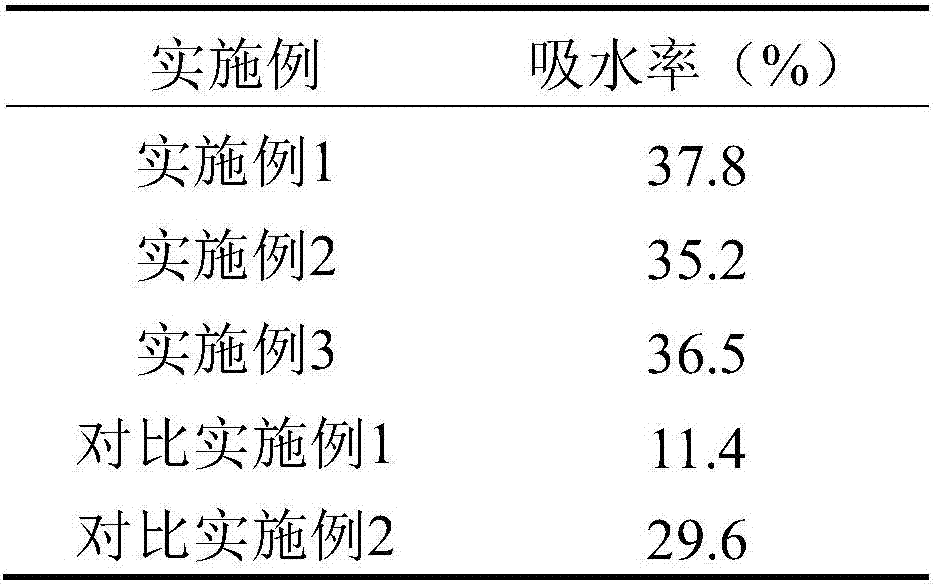

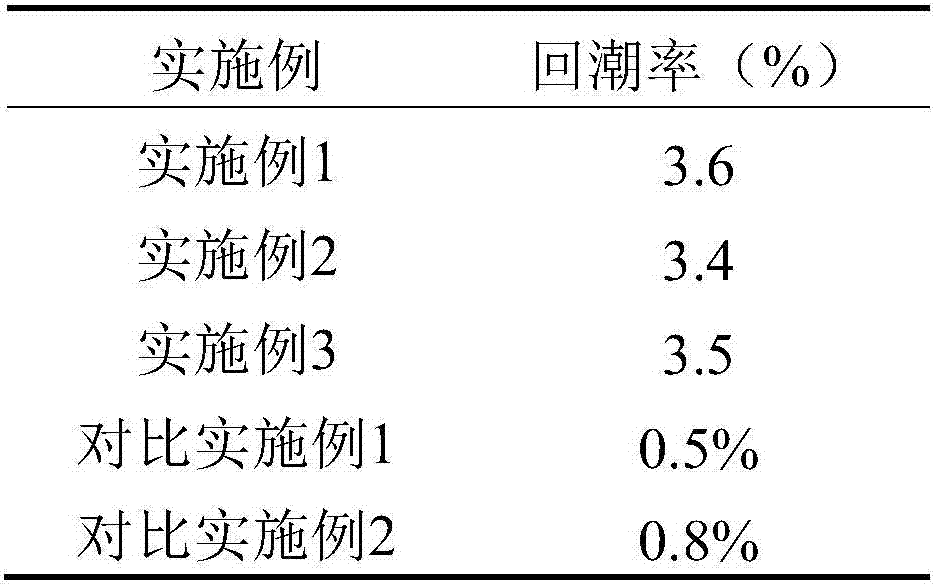

Method for controlling loosening and conditioning of tobacco leaves

The invention provides a method for controlling loosening and conditioning of tobacco leaves. The method comprises the following steps of dividing the same leaf group formula into a plurality of processing modules according to the difference of the water absorption rate of each batch of flue-cured tobacco laminas to be processed; arranging corresponding channels, and setting water adding coefficients and the temperatures of moisture regaining water; utilizing an electronic belt scale to weigh the flue-cured tobacco laminas; setting the water adding coefficients, the temperatures of the moisture regaining water and moisture instrument channel numbers of the processing modules; calculating the water adding amount to carry out loosening and conditioning on the flue-cured tobacco laminas. According to the method for controlling loosening and conditioning of tobacco leaves, raw materials of the flue-cured tobacco laminas with similar processing performance in the leaf group formula are integrated into a single module, each batch of leaf group of each mark is formed by the multiple modules, and the corresponding processing parameters can be set according to the processing characteristics of the modules during production, so that the stability in the processing process is improved. The moisture instrument is calibrated in the loosening and conditioning procedure according to different processing characteristics of the modules during production, the corresponding channels are arranged, the measurement accuracy of the moisture instrument is improved, and the stability of the loosening and conditioning procedure in the processing process is improved.

Owner:CHINA TOBACCO SHANDONG IND

Blended cut tobacco and preparation method thereof

InactiveCN101744356AFully embodies different flavor characteristicsUnique tasteTobacco preparationTobacco treatmentFlavorEngineering

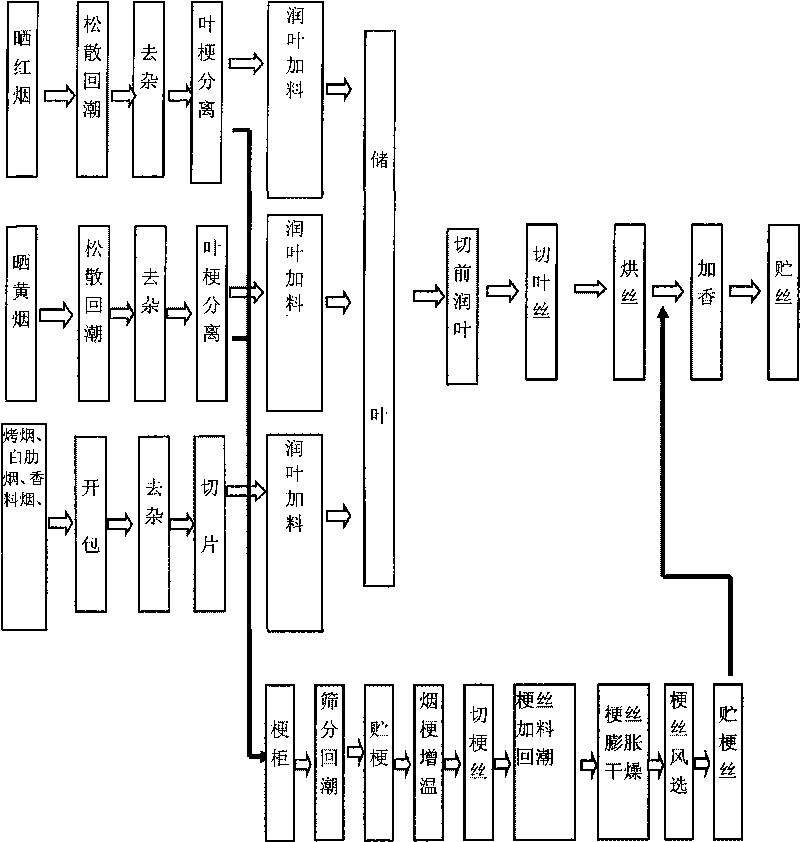

The invention relates to a blended cut tobacco, which is prepared by blending sun-cured red tobacco and sun-cured yellow tobacco with flue-cured tobacco or white burley tobacco or aromatic tobacco in any proportion. The preparation method comprises: carrying out loosening and moisture regaining to sun-cured red tobacco and sun-cured yellow tobacco, removing impurities, separating leaves and stems, and processing moist leaves with more materials to obtain sun-cured red tobacco leaves, sun-cured yellow tobacco leaves, sun-cured red tobacco stems and sun-cured yellow tobacco stems; unpacking flue-cured tobacco or white burley tobacco or aromatic tobacco, removing impurities, slicing, and processing moist leaves with more materials to obtain flue-cured tobacco leaves or white burley tobacco leaves or aromatic tobacco leaves; blending sun-cured red tobacco stems and sun-cured yellow tobacco stems, and cutting to obtain blended cut tobacco stems; blending all the tobacco leaves and cutting to obtain blended cut tobacco leaves; blending the blended cut tobacco stems and cut tobacco leaves, flavoring and storing to obtain the blended cut tobacco. The invention fully shows different flavor and quality characteristics of various types of tobacco, and the obtained cut tobacco has unique smoking taste.

Owner:CHINA TOBACCO ANHUI IND CO LTD

White tea processing method

InactiveCN101658212AUniform whole rateImprove qualityPre-extraction tea treatmentMoisture regainTea leaf

The invention discloses a white tea processing method. The method comprises the following steps: fresh tea leaves spreading to cool; water removal; moisture regain; light kneading: light kneading on fresh tea leaves in a kneading machine for 20-30 min after moisture regain; pressurization for 4-6min in mid-process; strip arrangement; shaping and drying. The light-kneading procedure is added to theprocedures of the original fresh tea leaves spreading, water removal, moisture regain, strip arrangement, shaping and drying, so the quality of the white tea is obviously improved, i.e. wrinkled andcompact strips are luster, green and bright in water, good and lasting in aroma, cool and heavy in taste, and the like. The tea manufacture process is convenient to operate. The tea leaf block is reduced after being lightly kneaded, so the strip management, shaping and drying procedures are favorable, the fine package and the storage and transportation are convenient, and the appearance is improved. The light kneading procedure is added into the original manufacture procedures, the crushing rate of the white tea is uniform, the tea water is golden, and the quality of the white tea is more perfect. The invention takes the tea leaves contacting the cover plate of the kneading machine as reference to guarantee the moderate kneading pressure, therefore guaranteeing the kneading effect.

Owner:JIANGSU YIYUAN TEA

Coffee viscose fiber and preparation method thereof

ActiveCN102191579ABacteriostaticDeodorizingArtificial filaments from viscoseWet spinning methodsCellulosePerspiration

The invention relates to coffee viscose fiber, which is prepared by crude materials including cotton pulp and coffee residue, wherein the content of the coffee residue accounts for 10 to 30 wt% of cellulose. A preparation method of the coffee viscose fiber comprises the following steps: taking pulp as a crude material for staple fiber production; performing processes including dipping, squeezing, crushing, aging, yellowing, dissolving, defoaming, and filtering so as to obtain a viscose solution; grinding coffee residue into powder and dispersing the powder into an aqueous solution to obtain a slurry; adding the slurry into the viscose solution to obtain a spinning viscose stock solution, wherein the addition amount of the coffee residue accounts for 10 to 30% by weight of the cellulose of the viscose solution; and carrying out spinning and molding on the prepared spinning viscose stock solution in a coagulating bath, and performing processes of drafting, refining, and drying to obtain a finished product of the coffee viscose fiber. According to the invention, the coffee residue, which is distributed evenly in the fiber, is not easy to be lost, so that the antibiotic and odor resistant functions of the coffee residue are lasting. The coffee viscose fiber not only has functions of bacteriostasis, deodorization, and moisture absorption and perspiration, but also has characteristics of moisture absorption and air permeability as well as comfortable wearing property of the viscose fiber. Textiles made from the coffee viscose fibers have a good moisture adsorption performance and a good moisture regain rate as well as have characteristics of comfortable hand feeling and softness and dryness.

Owner:潍坊欣龙生物材料有限公司

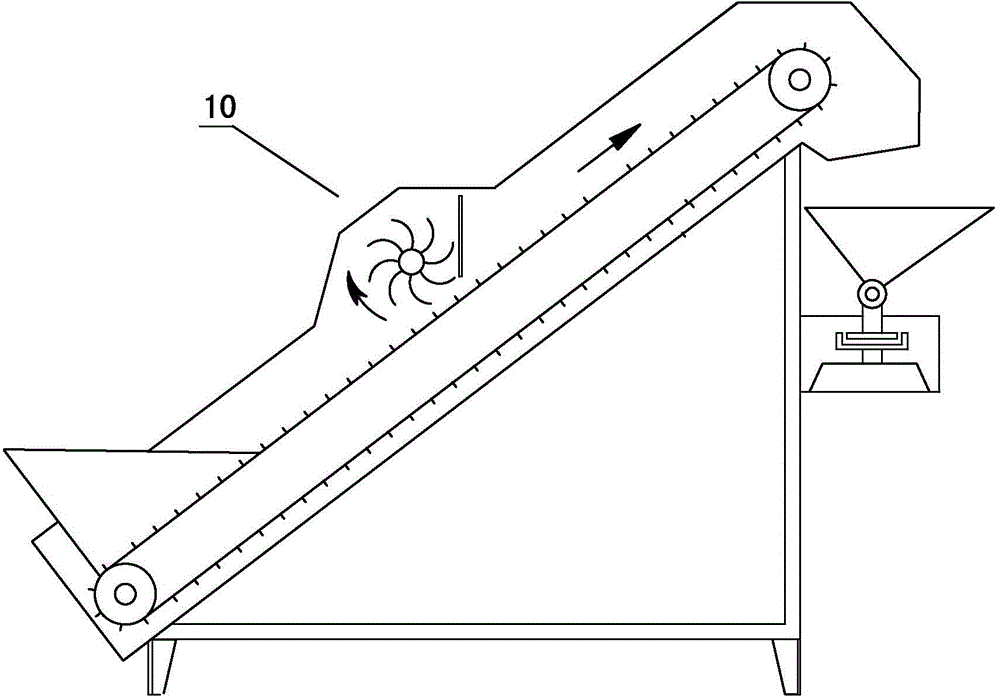

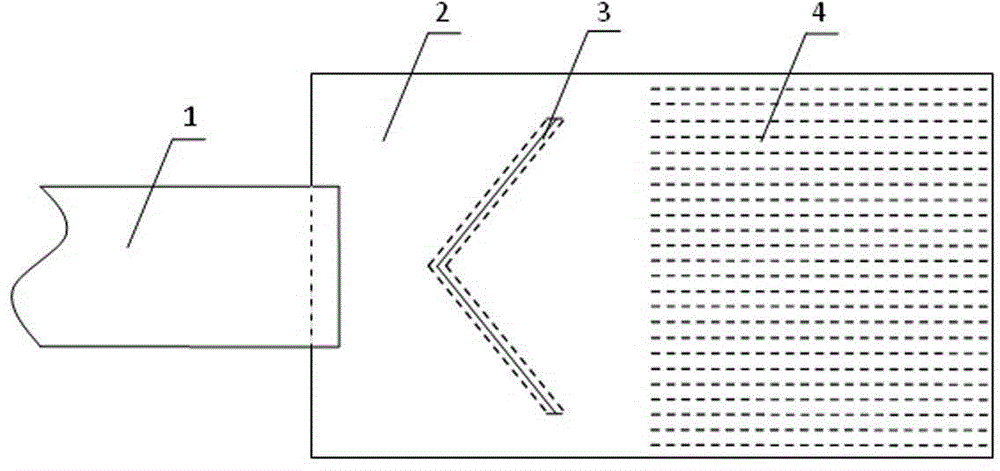

Cigarette processing and shredded tobacco making method and apparatus for loosening shredded tobacco

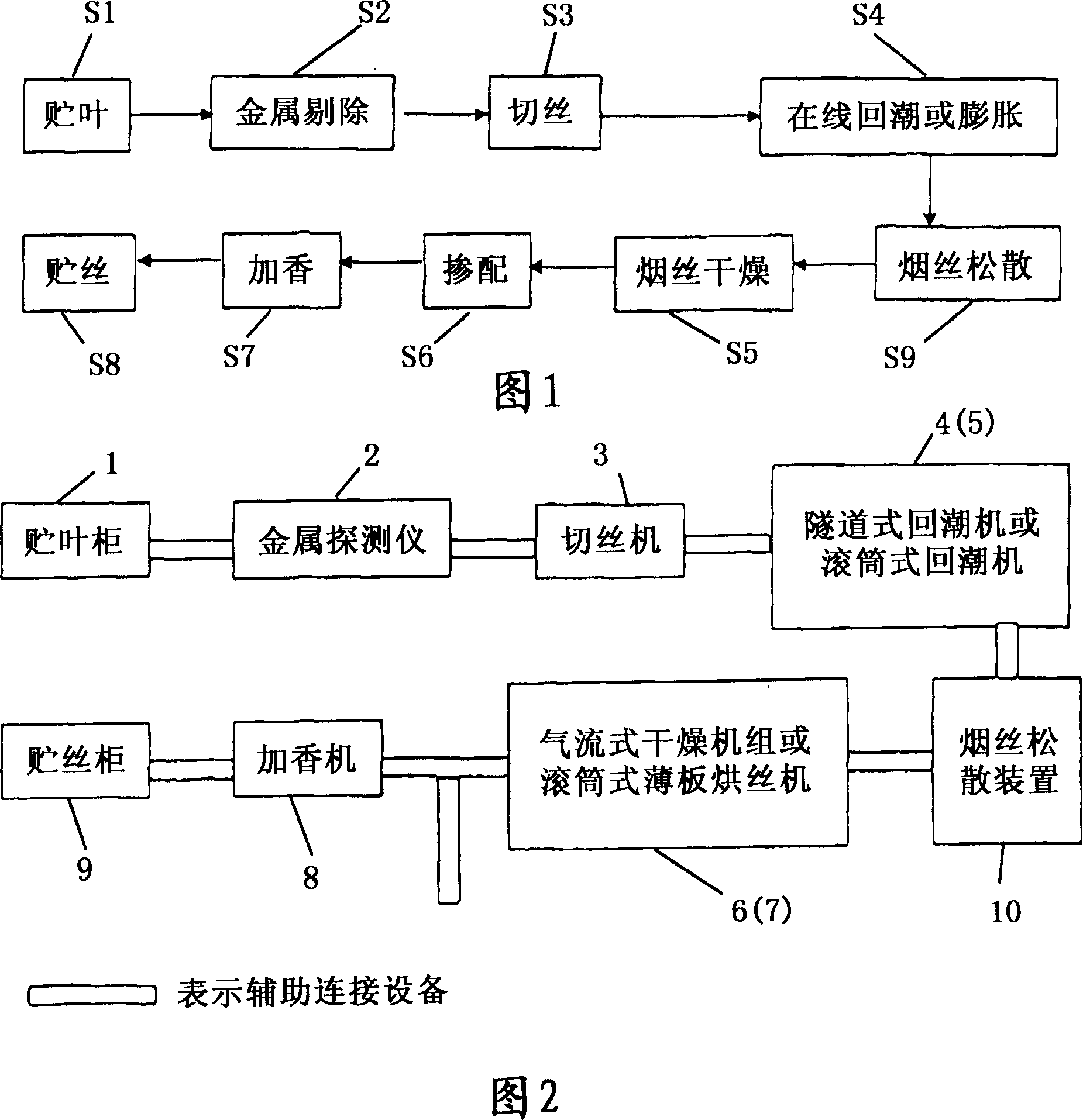

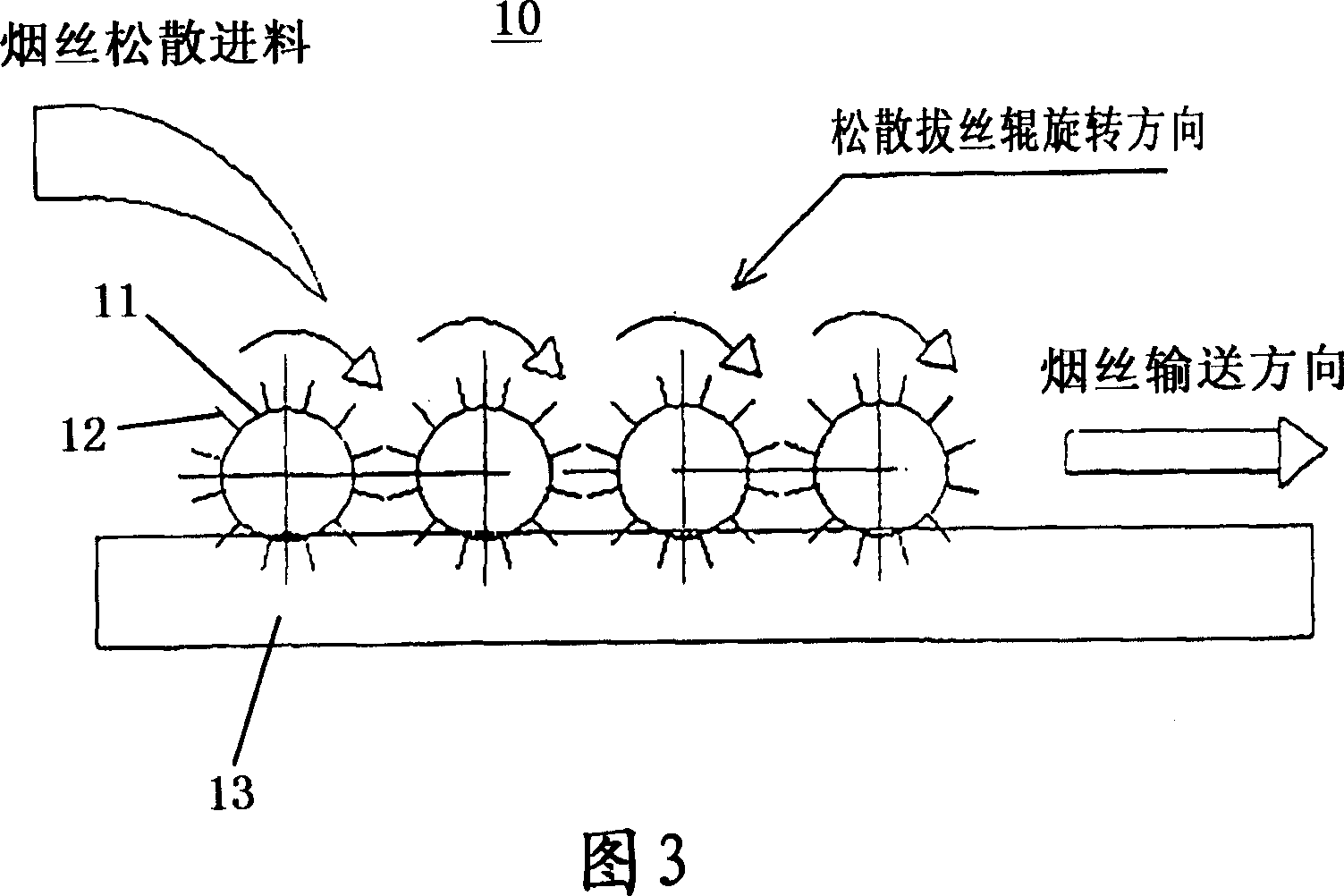

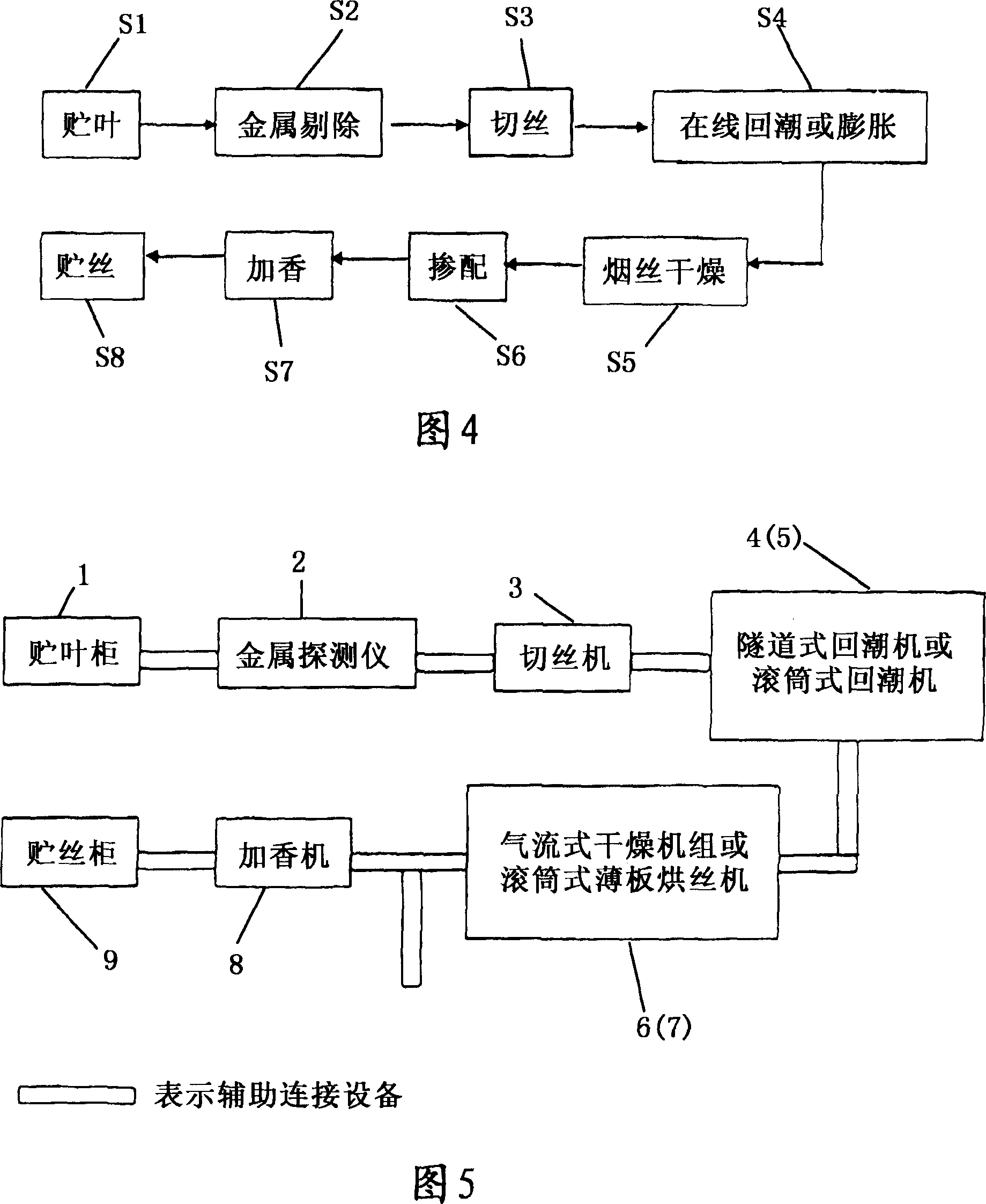

The invention discloses a making method of loosening device of cut tobacco, which is characterized by the following: loosening cut tobacco through tunnel-typed moisture regain machine or cylinder-typed moisture regain machine; modifying the uniformity of flow of tobacco in the drying procedure. The loosening device of cut tobacco contains multiple paralleling drawing rolls along transmitting direction of cut tobacco, dispersant pins on the roll, wherein the drawing roll rotates with the same direction with transmitting direction of cut tobacco.

Owner:LONGYAN CIGARETTE FACTORY

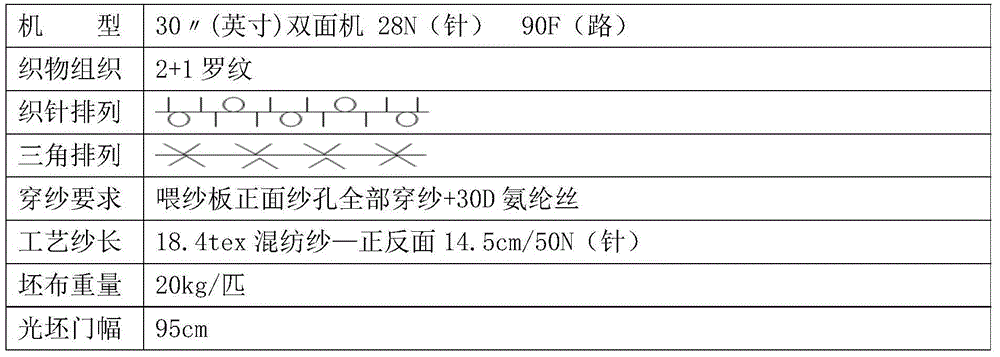

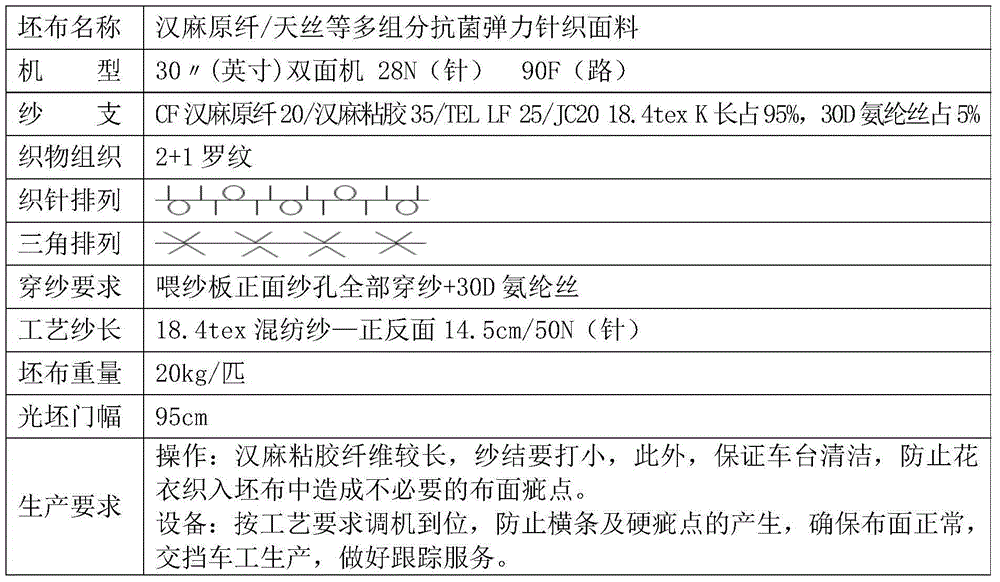

Anti-bacterium elastic knitted fabric containing china-hemp virgin fiber/silk and multiple components and weaving method thereof

The invention discloses an anti-bacterium elastic knitted fabric containing china-hemp virgin fiber / silk and multiple components and a weaving method of the anti-bacterium elastic knitted fabric. The anti-bacterium elastic knitted fabric is prepared by the following raw materials according to the mass portion: 20% of china-hemp virgin fiber, 35% of china-hemp mucilage glue, 25% of silk (LF) fiber, and 20% of long staple; besides a 30D polyurethane filament is added; the china-hemp virgin fiber is 55mm in length, the china-hemp short fiber is about 2500Nm in fineness, the over-length fiber rate is 9.13%, the hard fiber rod rate is 10.5%, the china-hemp particle is 35 particles / g, and the moisture regain is 9.02%; the fine denier fiber with the size of 1.6dtex*38mm is selected as the china-hemp viscose; the silk (LF) fiber with the size of 1.4dtex*38mm is adopted; 137 long-staple cotton fiber is selected as the long staple, and the yarn with the size of 18.4tex (32S) is adopted; the 30D polyurethane filament is adopted; the content of the china-hemp virgin fiber accounts for 20%. Through the special weaving method, the product detection standard meets the standard first-class product requirements of GB18401-2010 Basic Safety Technology Criterion of National Textile Product B type and GB / T22848-2009 Yarn-dyed Pattern Fabric.

Owner:JIANGSU YDTEX GRP LTD

Hazardous substance removing material, method for removing hazardous substances, and nonwoven fabric

ActiveUS7927885B2Efficiently capturing and quickly inactivating hazardous substanceMinimize impactMembrane filtersWater/sewage treatment by substance additionHazardous substanceNonwoven fabric

An objective to be solved by the present invention is to provide a hazardous substance removing material capable of efficiently capturing and quickly inactivating hazardous substances of microbe origin such as viruses and bacteria, so as to minimize influences on the human body. The present invention provides a hazardous substance removing material which comprises a support having antibodies supported thereon, wherein the support is made of a fiber, and the moisture regain of the core fiber of the support is different from the moisture regain of the sheath fiber of the support.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com