Preparation method of regenerative colored polyester fiber

A colored polyester and fiber technology is applied in the field of the preparation of recycled colored polyester fibers, which can solve the problems of poor fiber physical index and unstable color, and achieve the effects of low water absorption and moisture regain, full hand feeling and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

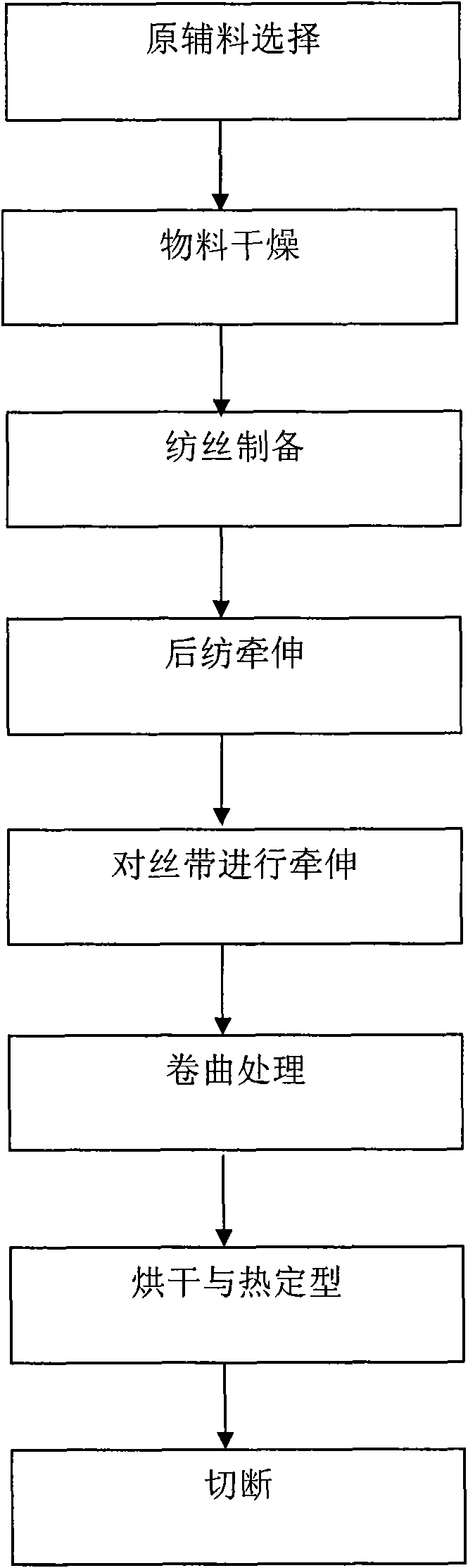

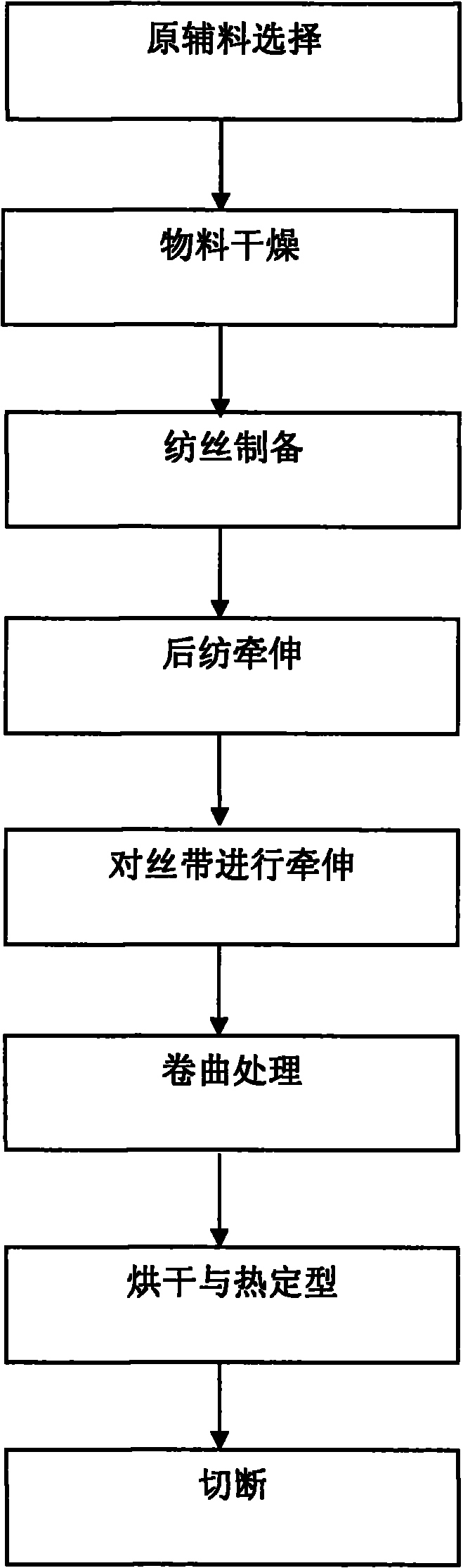

[0016] In conjunction with accompanying drawing, a kind of preparation method of regenerated colored polyester fiber of the present invention comprises the following steps:

[0017] Step 1: Selection of raw and auxiliary materials, specifically: select raw materials with an intrinsic viscosity of 0.55-0.7dl / g containing less than 2 / 10,000 impurities, and the raw materials are waste polyester bottle flakes, waste polyester cloth corner foam or polyester waste silk A mixture of foam material and color masterbatch (commercially available); the mass ratio of the above raw materials is: 35-40% of waste polyester bottle flakes, 55-60% of waste polyester cloth corner foam material or polyester waste silk foam material, and 4% of color masterbatch ~5%;

[0018] Step 2: Dry the material, specifically: put the raw material into the drum and heat it with steam, the temperature of the steam heating is 158-162°C; then use a vacuum pump to remove the water, so that the water content of the ...

Embodiment 1

[0026] Embodiment 1: Select the raw material with an intrinsic viscosity of 0.55dl / g with an impurity content lower than 2 / 10,000, and the raw material is waste polyester bottle flakes, waste polyester cloth corner foam material or polyester waste silk foam material, color masterbatch Mixture: 39% of waste polyester bottle flakes, 56% of waste polyester corner foam or polyester waste silk foam, and 4.5% of color masterbatch. Put the raw material into the drum and heat it with steam, the temperature of the steam heating is 159°C; then use a vacuum pump for 7 hours to remove the water; the dried raw material is prepared through a screw extruder, a filter, and a spinning nozzle Raw filaments are formed; the model of the screw extruder is φ5, and the temperature in each area of the screw extruder is 268-285°C during the working process; the temperature of the filter is 278-282°C, and the front pressure of the filter is 10 MPa. The back pressure is 5.5 MPa. Divide the above-ment...

Embodiment 2

[0027] Embodiment 2: Select the raw material with an intrinsic viscosity of 0.6dl / g with an impurity content lower than 2 / 10,000. The raw material is waste polyester bottle flakes, waste polyester cloth corner foam material or polyester waste silk foam material, and color masterbatch. Mixture: 37% of waste polyester bottle flakes, 58% of waste polyester corner foam or polyester waste silk foam, and 4% of masterbatch. Put the raw material into the drum and heat it with steam, the temperature of the steam heating is 160°C; then use a vacuum pump for 8 hours to remove the water; the dried raw material is prepared through a screw extruder, a filter, and a spinning nozzle Raw filaments are formed; the model of the screw extruder is φ5, and the temperature in each area of the screw extruder is 268-285°C during the working process; the temperature of the filter is 278-282°C, and the front pressure of the filter is 11 MPa, The back pressure is 5 MPa. Divide the above-mentioned raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com