Patents

Literature

958results about "Filament manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

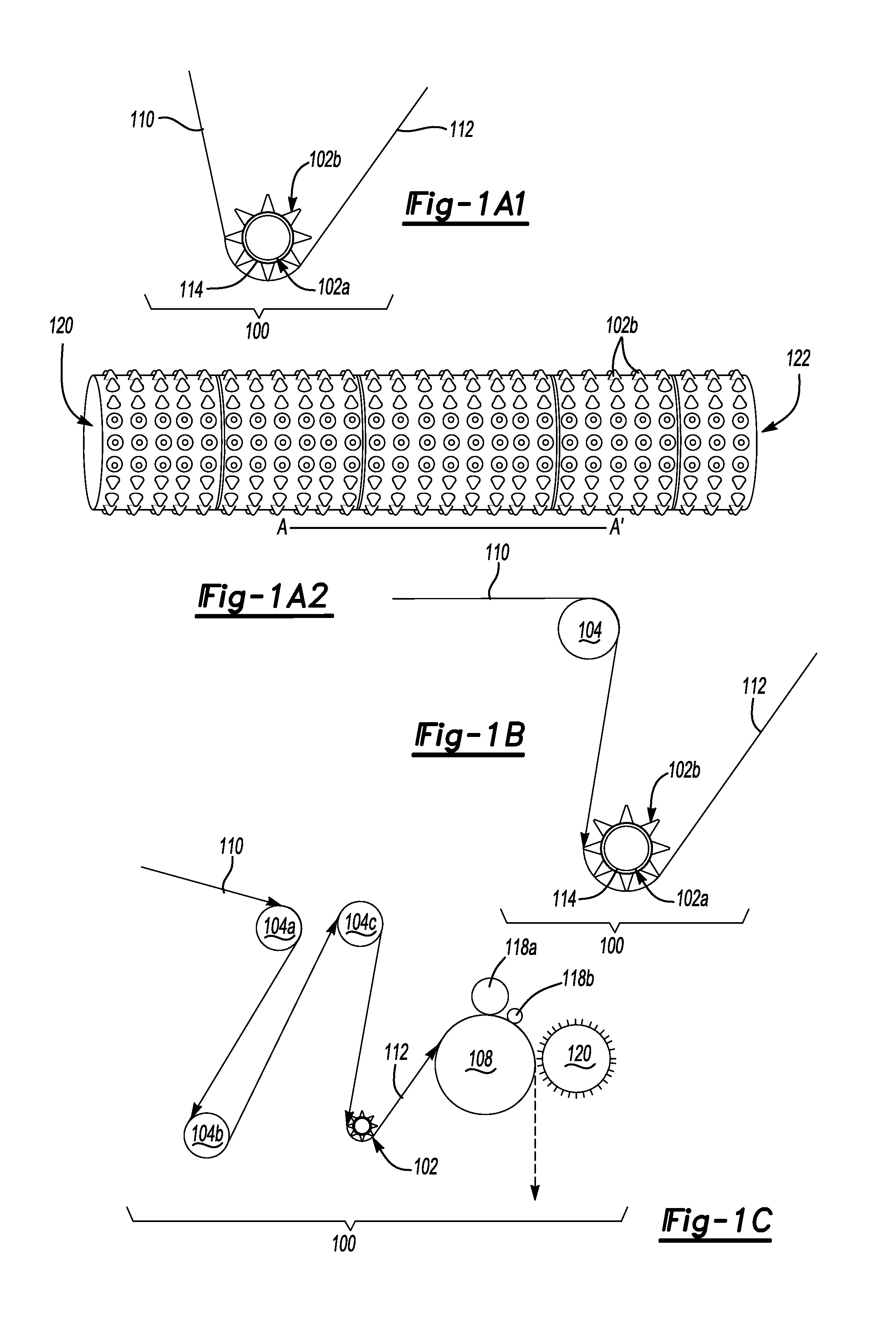

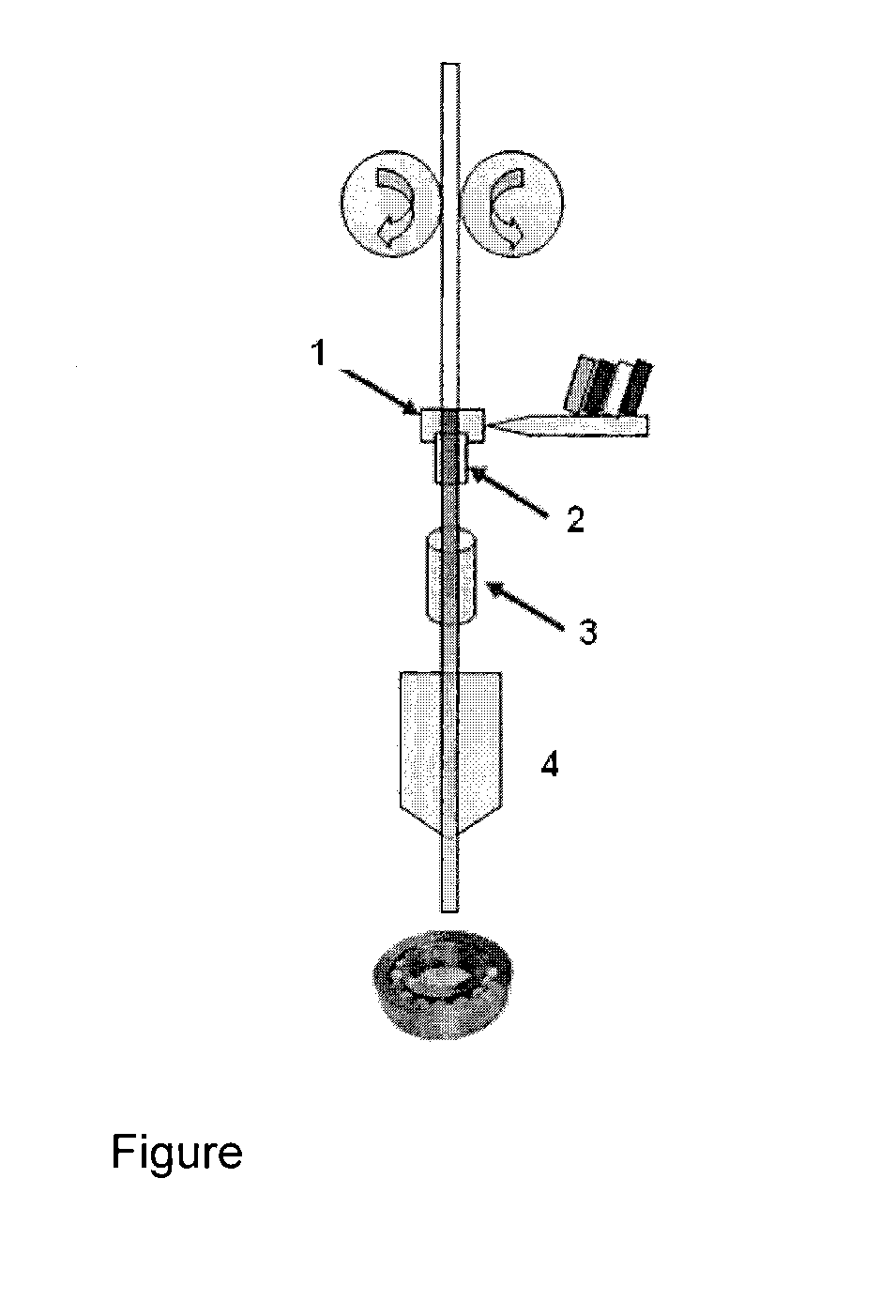

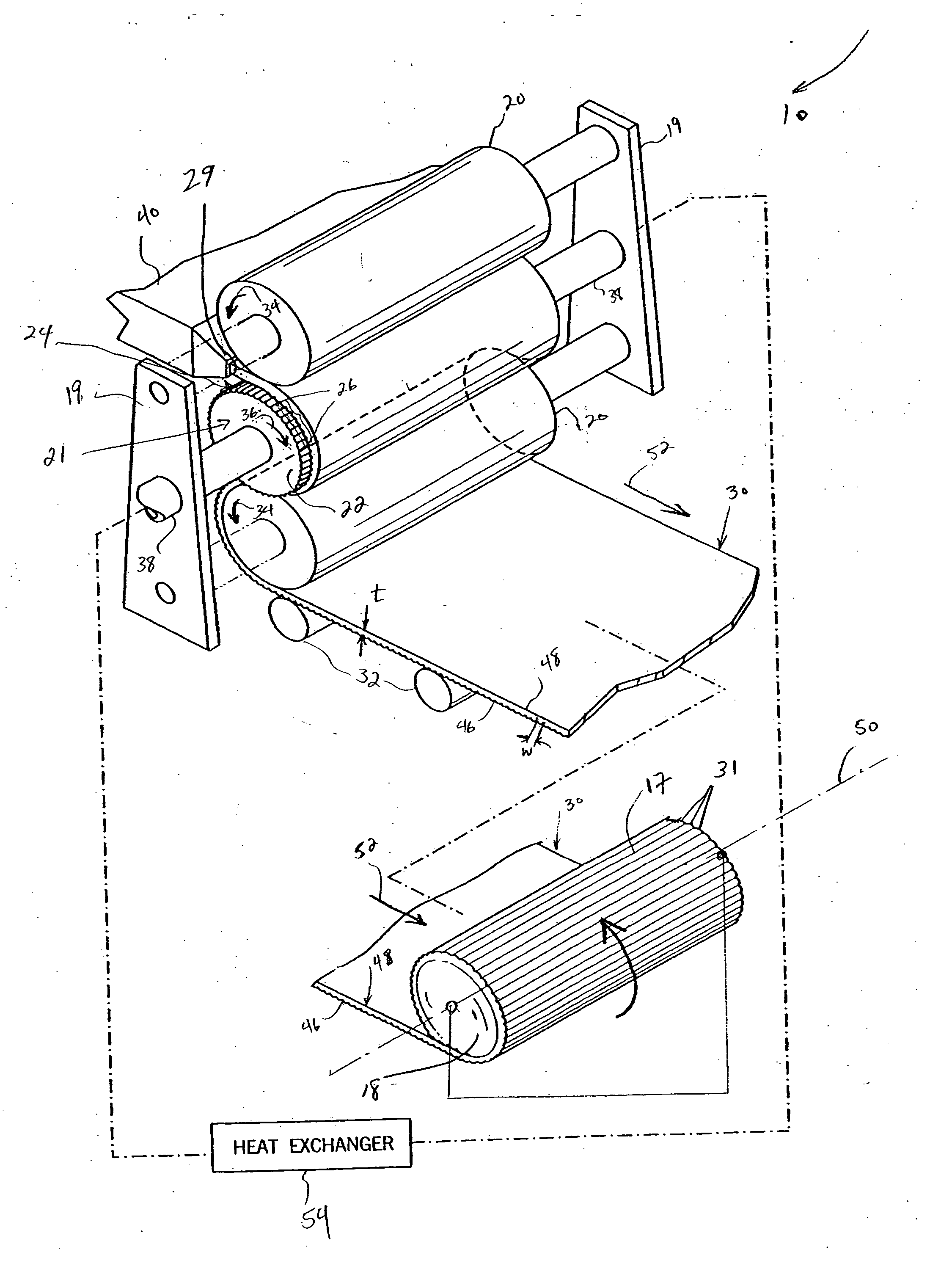

Fiber tow treatment apparatus and system

In one embodiment, a fiber treatment system includes a rotatable nubbed roller including an axis of rotation, a surface, and a number of spaced apart nubs projecting away from the surface, the number of spaced apart nubs imparting a number of spaced apart openings in a fiber tow. In another embodiment, the fiber treatment system further includes an optionally rotatable spreader roller for flattening the fiber tow. In yet another embodiment, the loosened, but still continuous fiber tow is chopped by a downstream chopper to form short fibers with reduced tow sizes.

Owner:US COUNCIL FOR AUTOMOTIVE RES

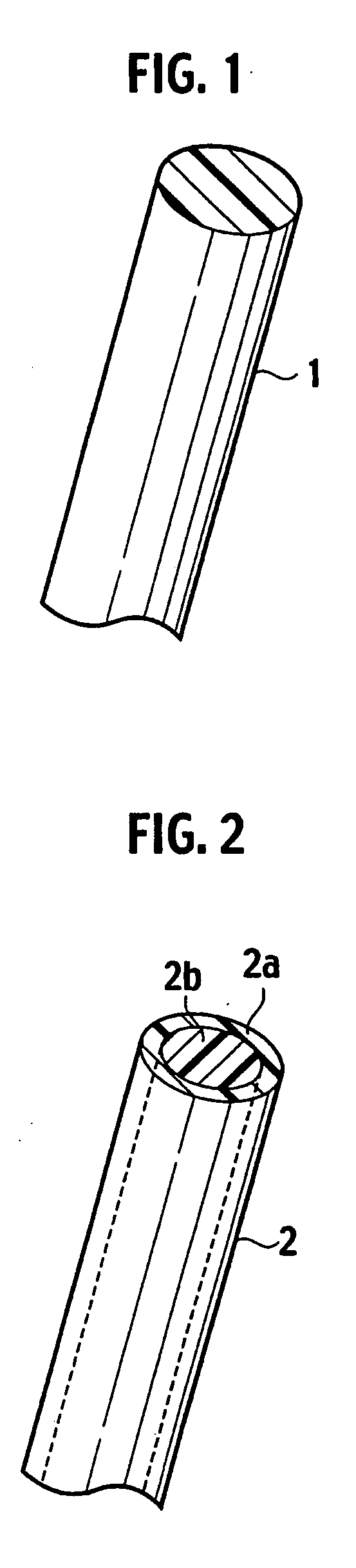

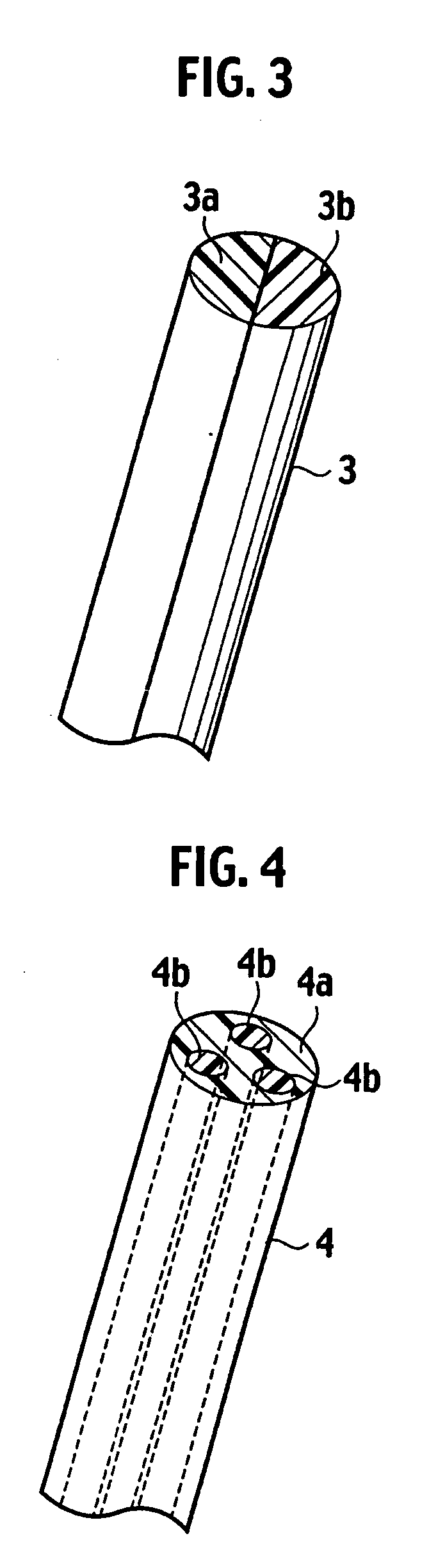

Multicolour extrusion-based 3D print process

A 3D extrusion print process for producing multicolored three-dimensional objects is provided. The process produces mechanically stable, multicolored 3D objects with good color definition. The process according to the invention is based on coating, upstream of the printing head, of the polymer strand used for producing the actual object, and on fixing of the coating upstream of entry of the polymer strand into the printing head. Downstream of the extrusion process in the printing head, the coating remains predominantly at the surface of the extruded strand.

Owner:EVONIK OPERATIONS GMBH

Use and production of coated filaments for extrusion-based 3D printing processes

ActiveUS20140134335A1Additive manufacturing apparatusFilament manufacturePolymer sciencePrinting press

Owner:EVONIK OPERATIONS GMBH

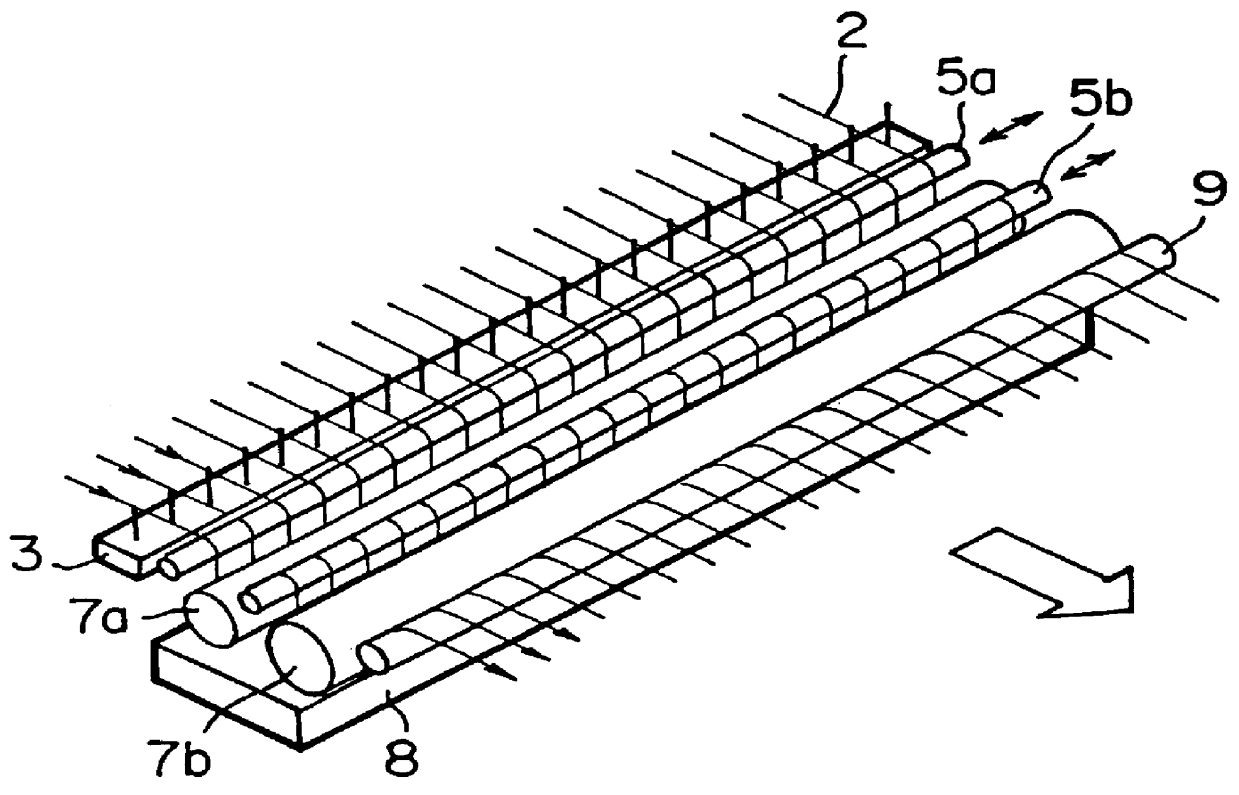

Method and apparatus for opening continuous filaments

InactiveUS7003856B2Simple conditionsUniform openingFilament manufactureFibre cleaning/openingEngineeringMechanical engineering

A method and an apparatus for opening continuous filaments provide stable quality of fibrous layer after opening crimped TOW. The TOW is transported by means of a plurality of rolls. While transported, the TOW is applied a resistance on one side of the TOW by slidingly contacting a sliding body onto the TOW at between rolls. As a result, continuous filaments stacked in a thickness direction of the TOW are caused to sift in a transporting direction of the TOW. Thus, the TOW is opened and the continuous filaments are spread in a width direction of the TOW.

Owner:UNI CHARM CORP

Medical chitosan fibre and preparation method thereof

ActiveCN101250759AHigh molecular weightEnough aminoFilament manufactureArtificial filament washing/dryingAcetic acidBrute force

The invention relates to medical chitosan fiber in the textile processing field and a preparing method thereof, the method for preparing spinning fluid comprises the following steps: arranging the chitosan powder in glacial acetic acid water solution and slowly dissolving by stirring under the condition of controlling temperature and time, wherein the dissolution temperature is 10-30DEG C, the dissolution time is 10-48h, and the stirring speed is 60-180r / min, wherein the chitosan powder occupies 3%-10%, dissolvent glacial acetic acid occupies 1%-5% and the other is water in the spinning raw materials, the chitosan content is more than 99.9% in chitosan fiber, and the chitosan fiber has higher molecular weight, sufficient amido, steady fiber structure, and good antibacterial property, brute force and hygiene security property.

Owner:HISMER BIO TECH

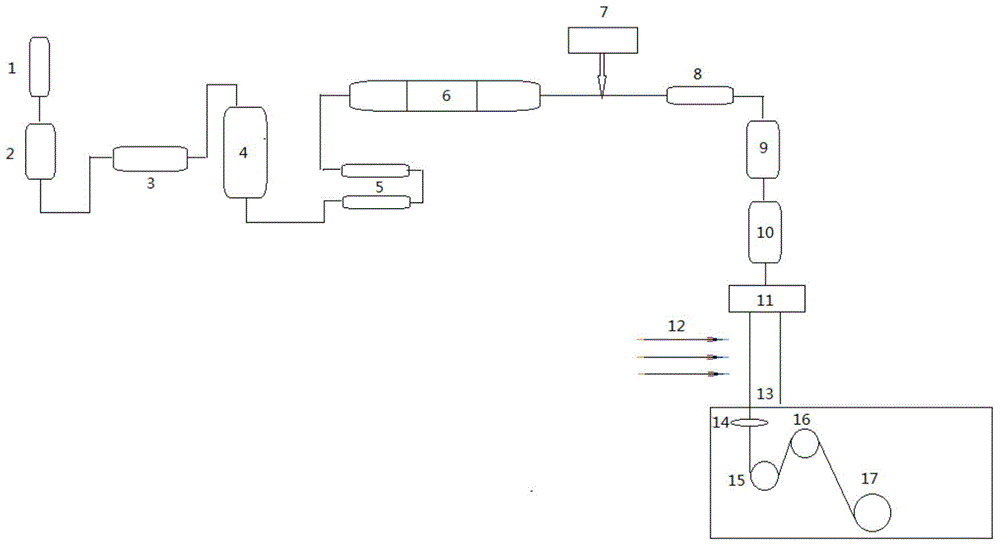

Nylon fibers and preparation method thereof

ActiveCN104562271AEmission reductionReduce pollutionFilament manufactureMonocomponent copolyamides artificial filamentYarnPolymer science

The invention discloses a preparation method of nylon fibers. The preparation method comprises the following steps: directly spinning after taking raw materials containing 1,5-pentamethylene diamine and adipic acid to react. The invention further provides the nylon fibers prepared by the method. The method adopts a manner of combining nylon polymerization and fusion direct spinning to prepare nylon 56 wires so that the production cost is reduced, the waste gas is reduced and the pollution to the environment is reduced. The high-performance nylon fibers prepared by the method can be further used for preparing textile materials including yarns, woven fabrics, knitted fabrics or non-woven fabrics, can be widely applied to the fields of clothing material industries, decoration carpets and the like, and has a wide industrial application prospect.

Owner:CATHAY R&D CENT CO LTD +1

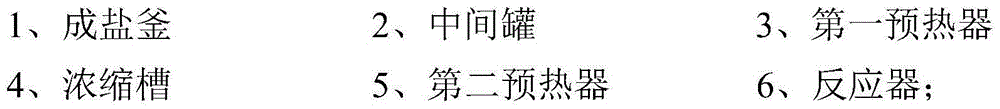

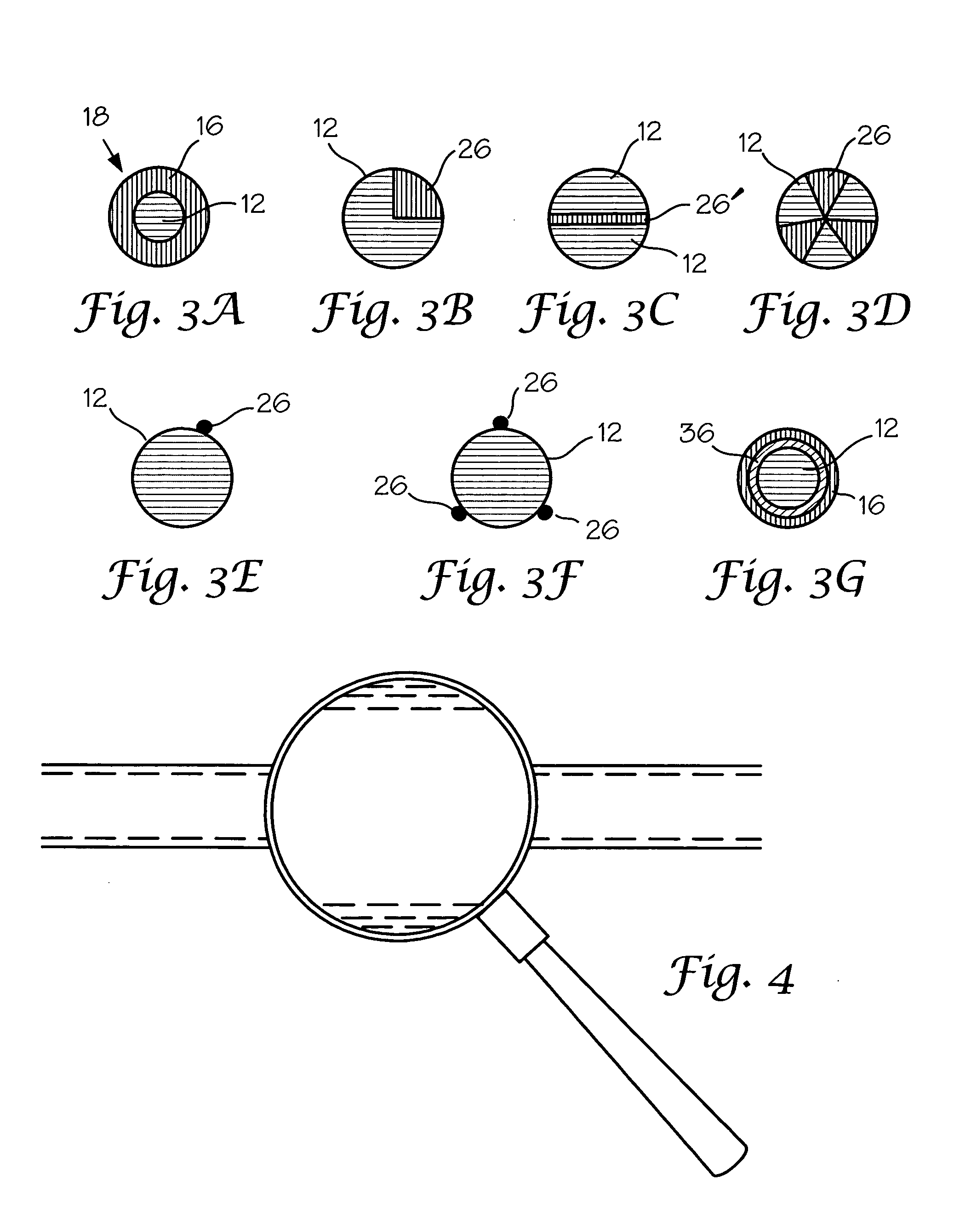

Conductive filament

InactiveUS20050170177A1Material nanotechnologyElectroconductive/antistatic filament manufactureYarnSecondary component

A multi-component conductive yarn which includes a primary component and a secondary component. The primary component consists of at least one elongated filament formed of polymeric material while the secondary component consists of a blend of polymeric material and carbon nanotubes. The secondary component is bonded with the primary component along its length. The carbon nanotubes comprise up to 20% of the secondary component. The conductive yarn comprises no more than 10% carbon nanotubes.

Owner:TEIJIN MONOFILAMENT U S +1

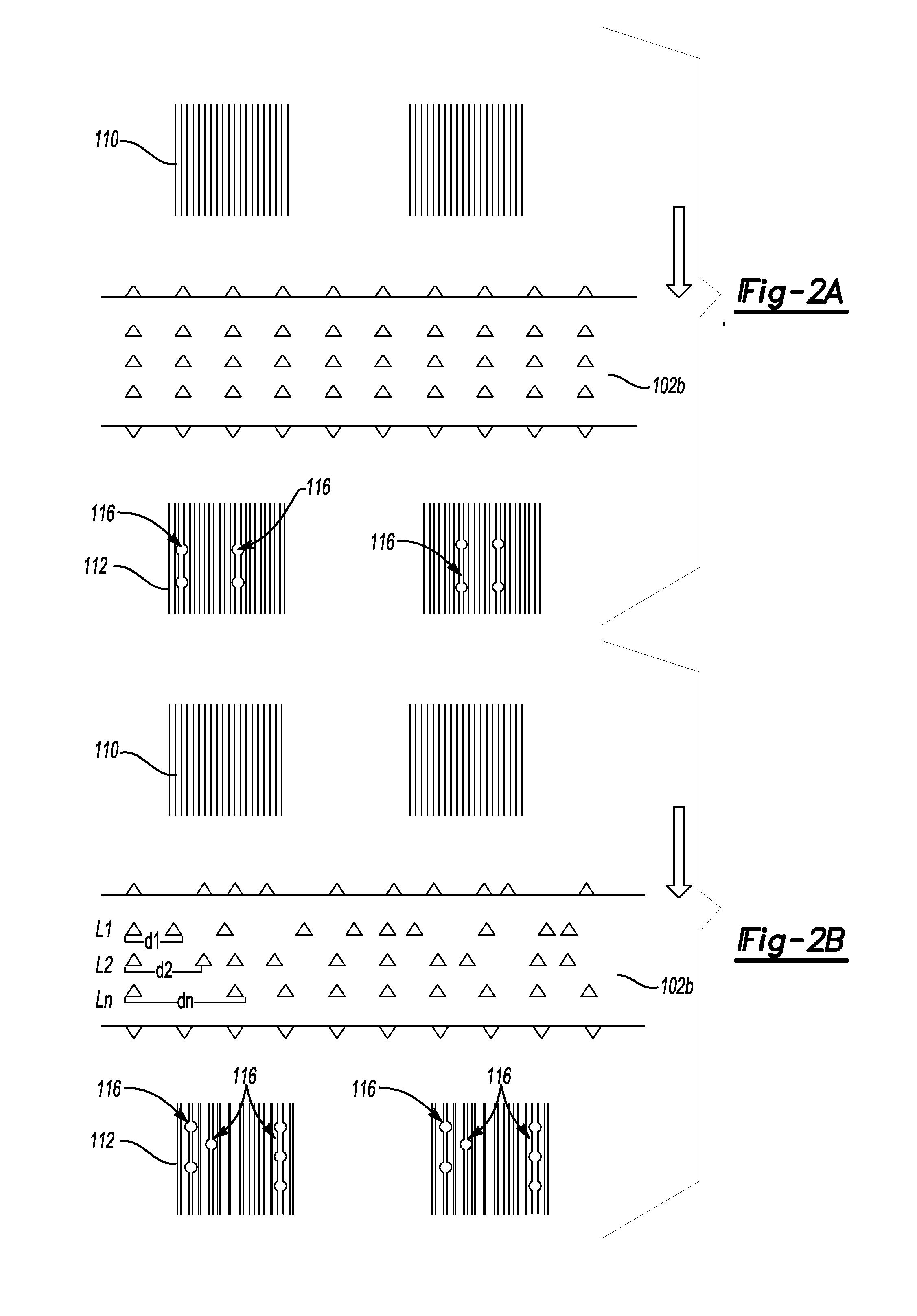

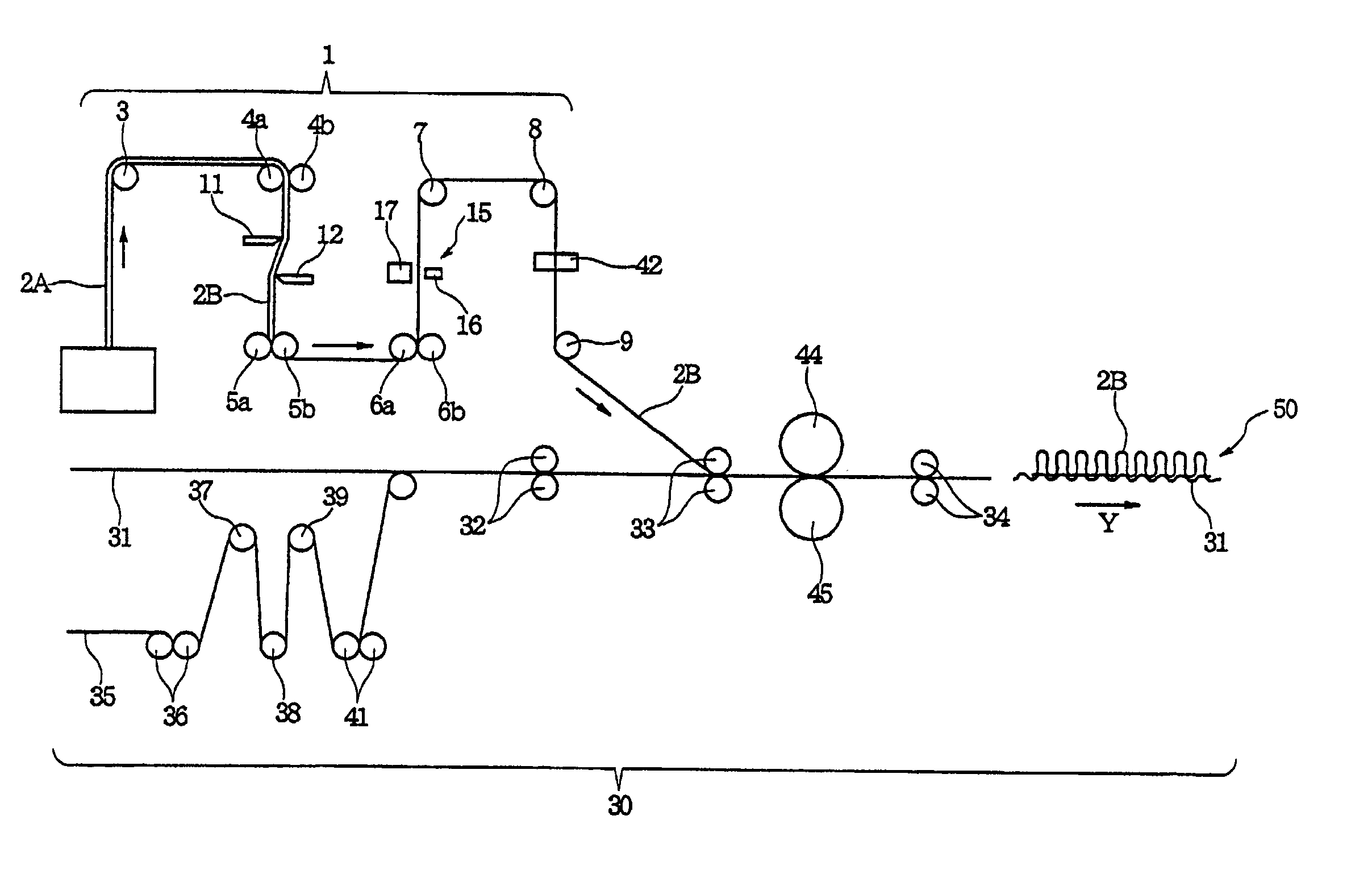

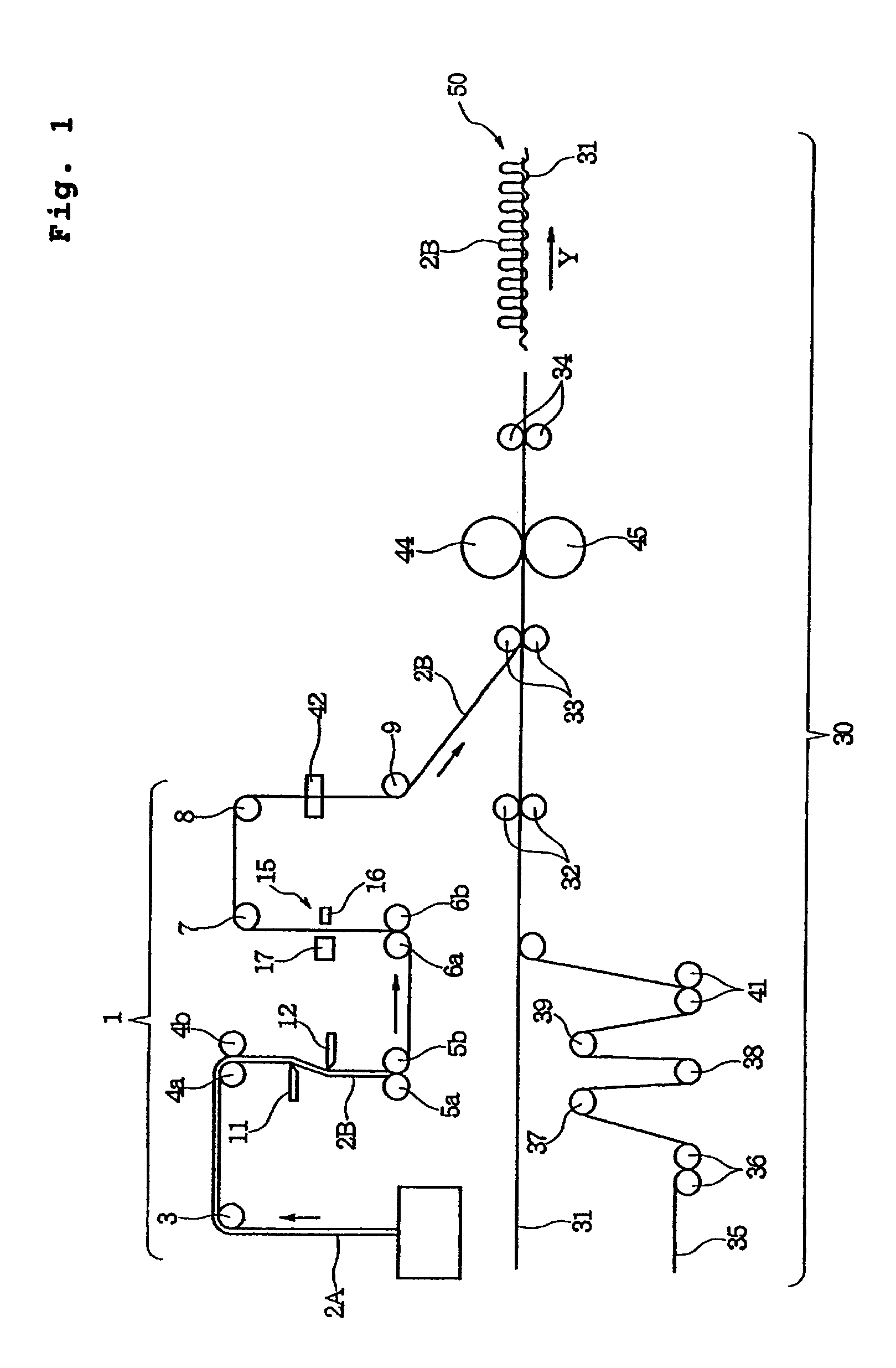

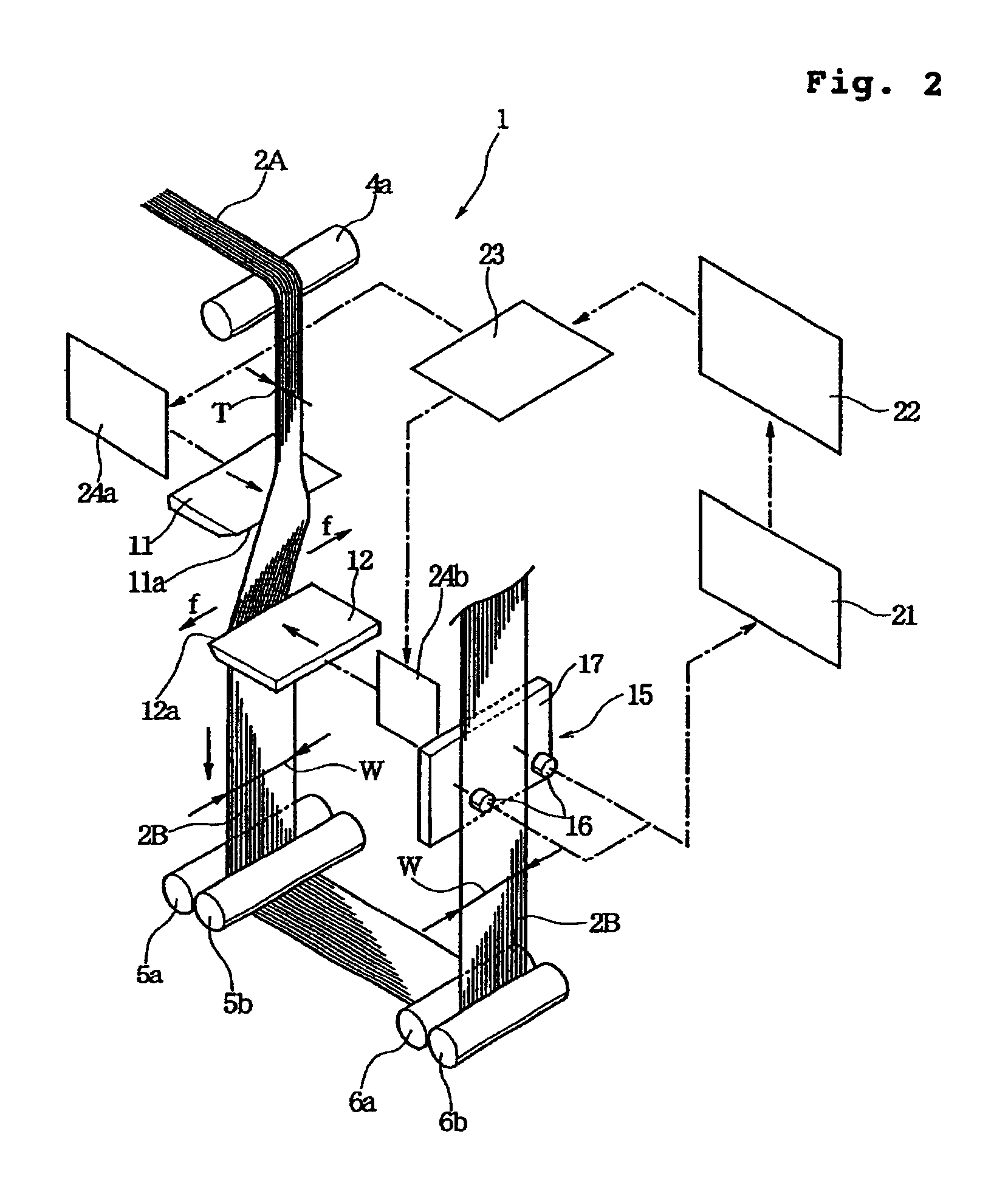

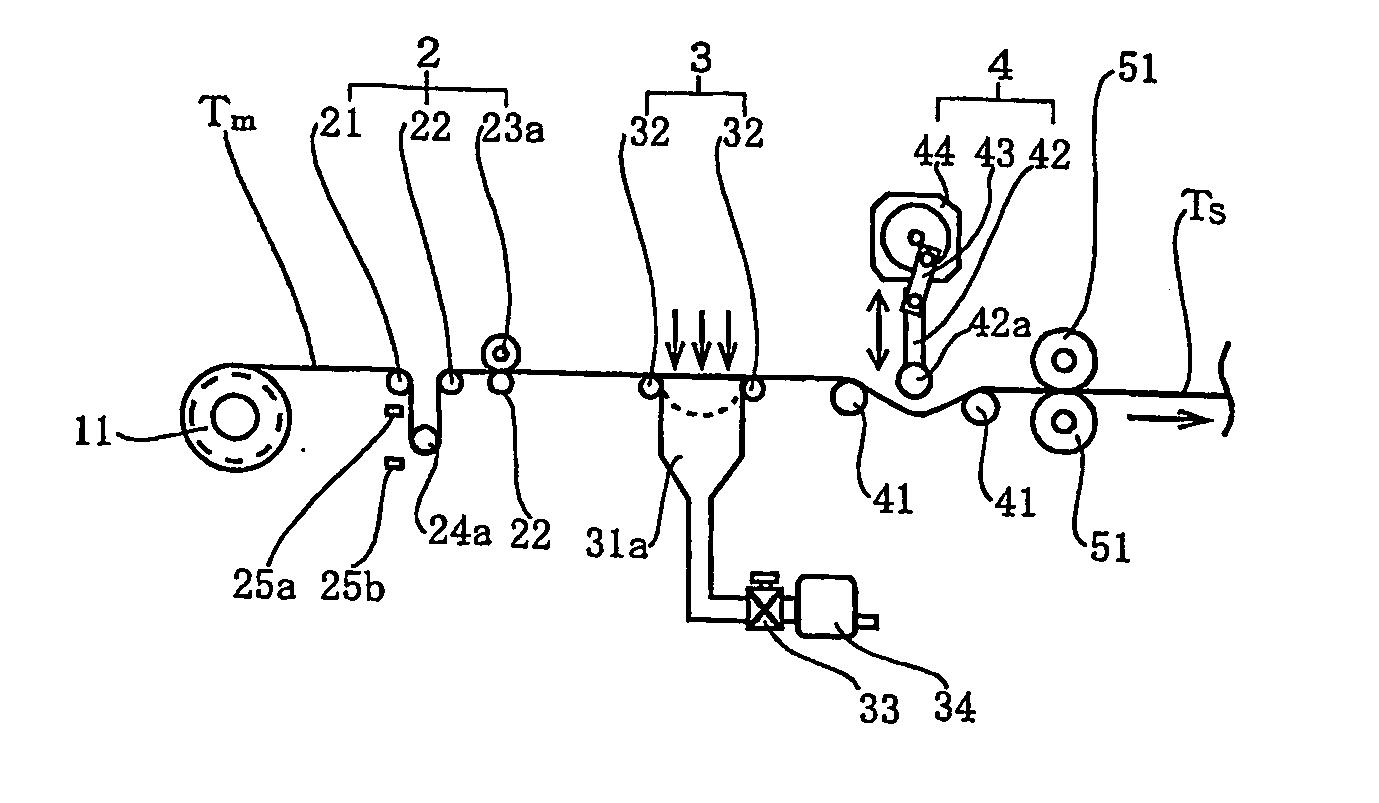

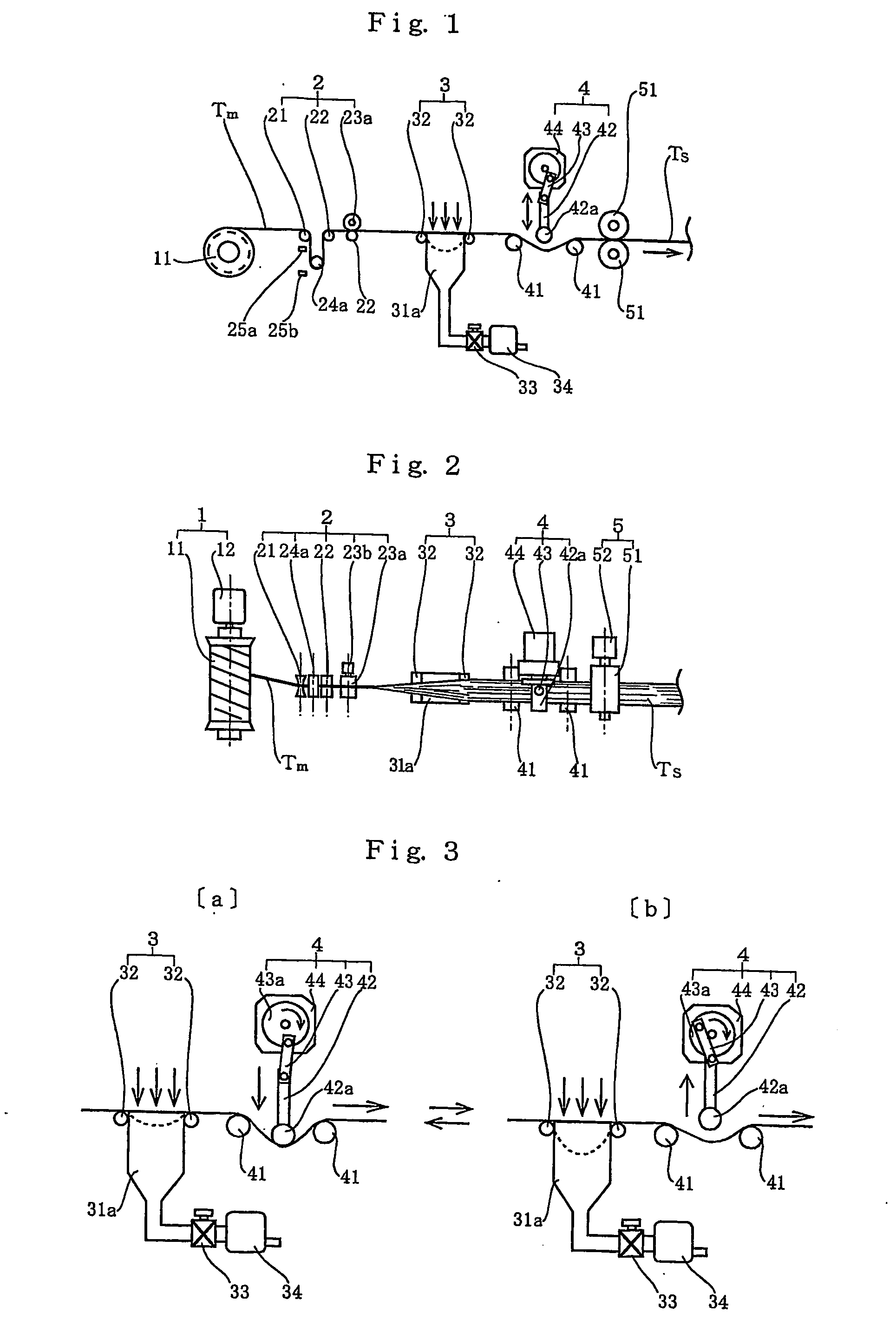

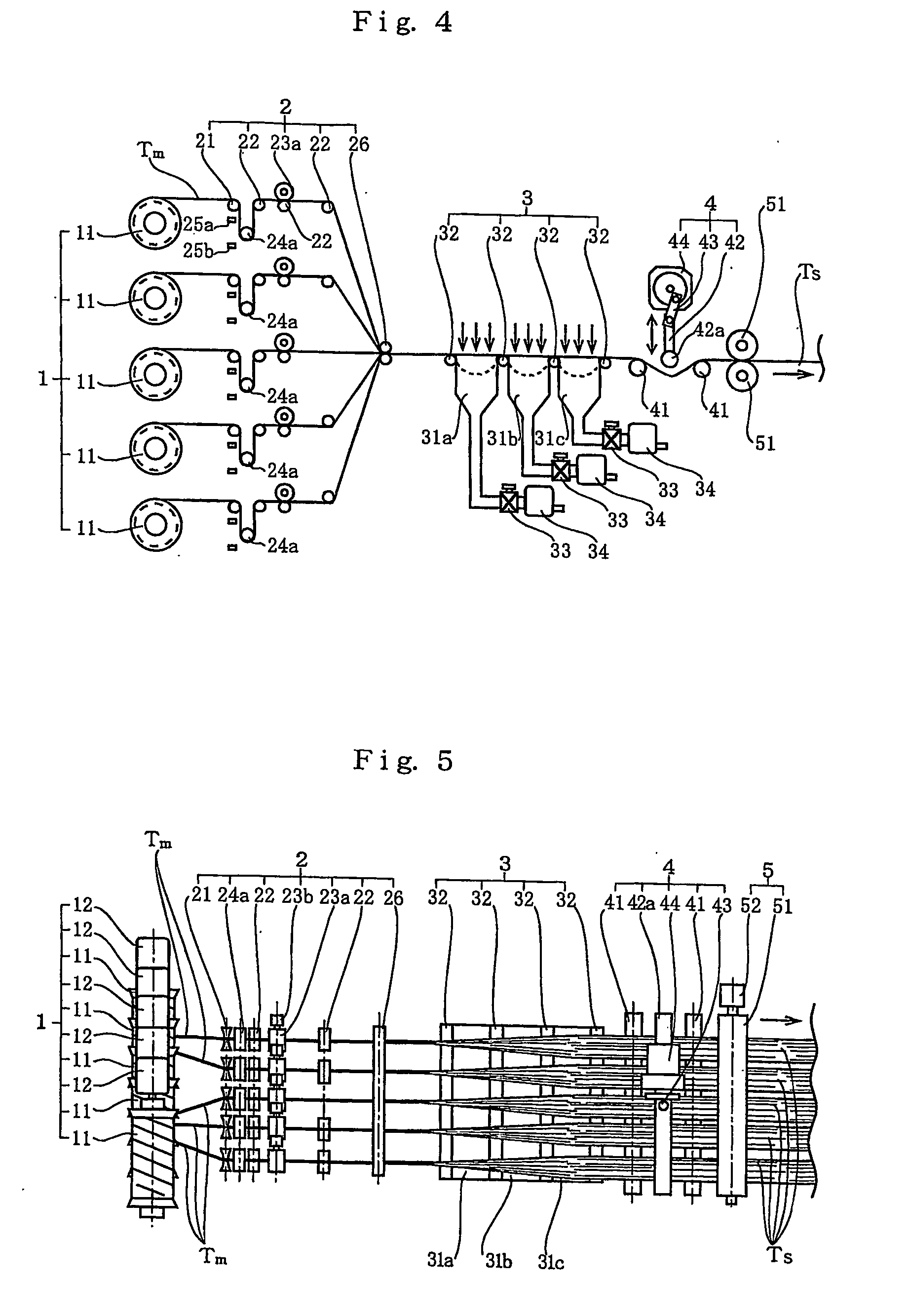

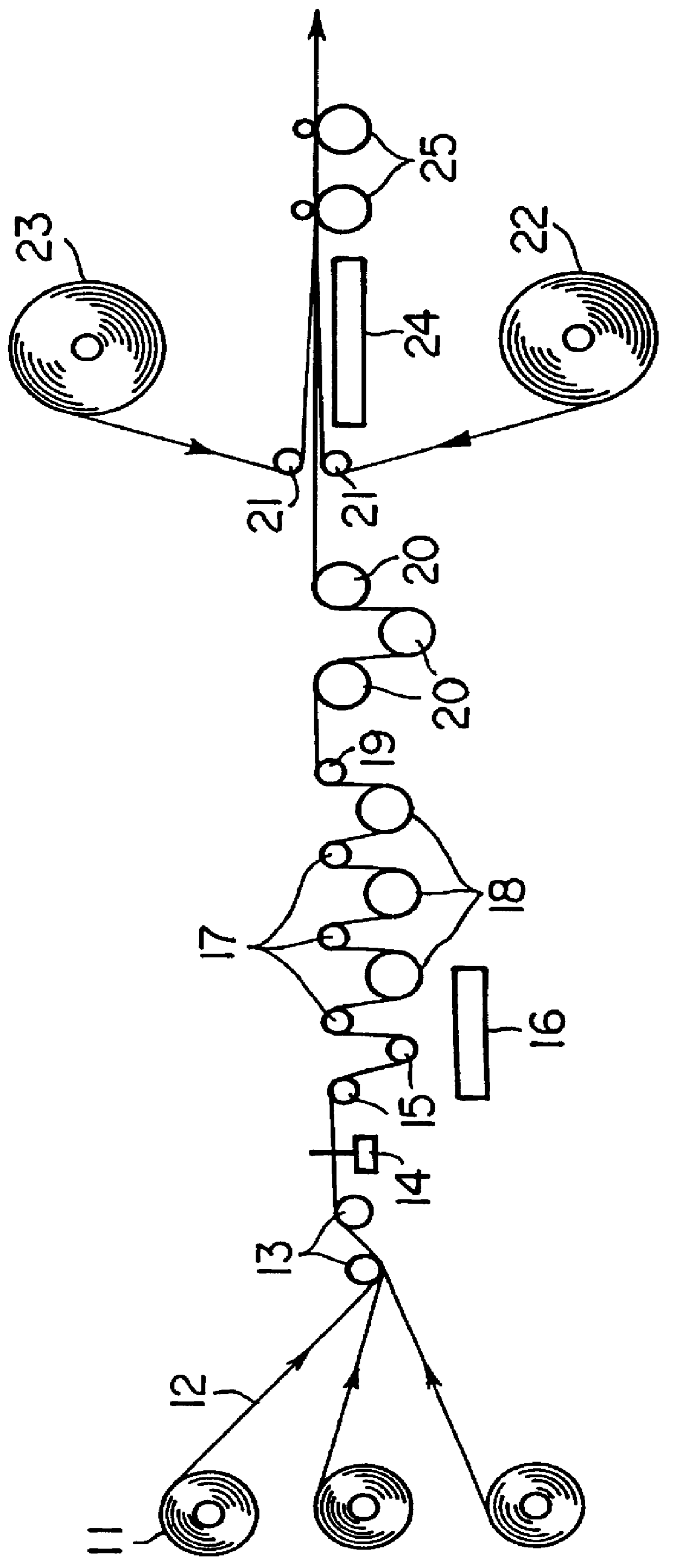

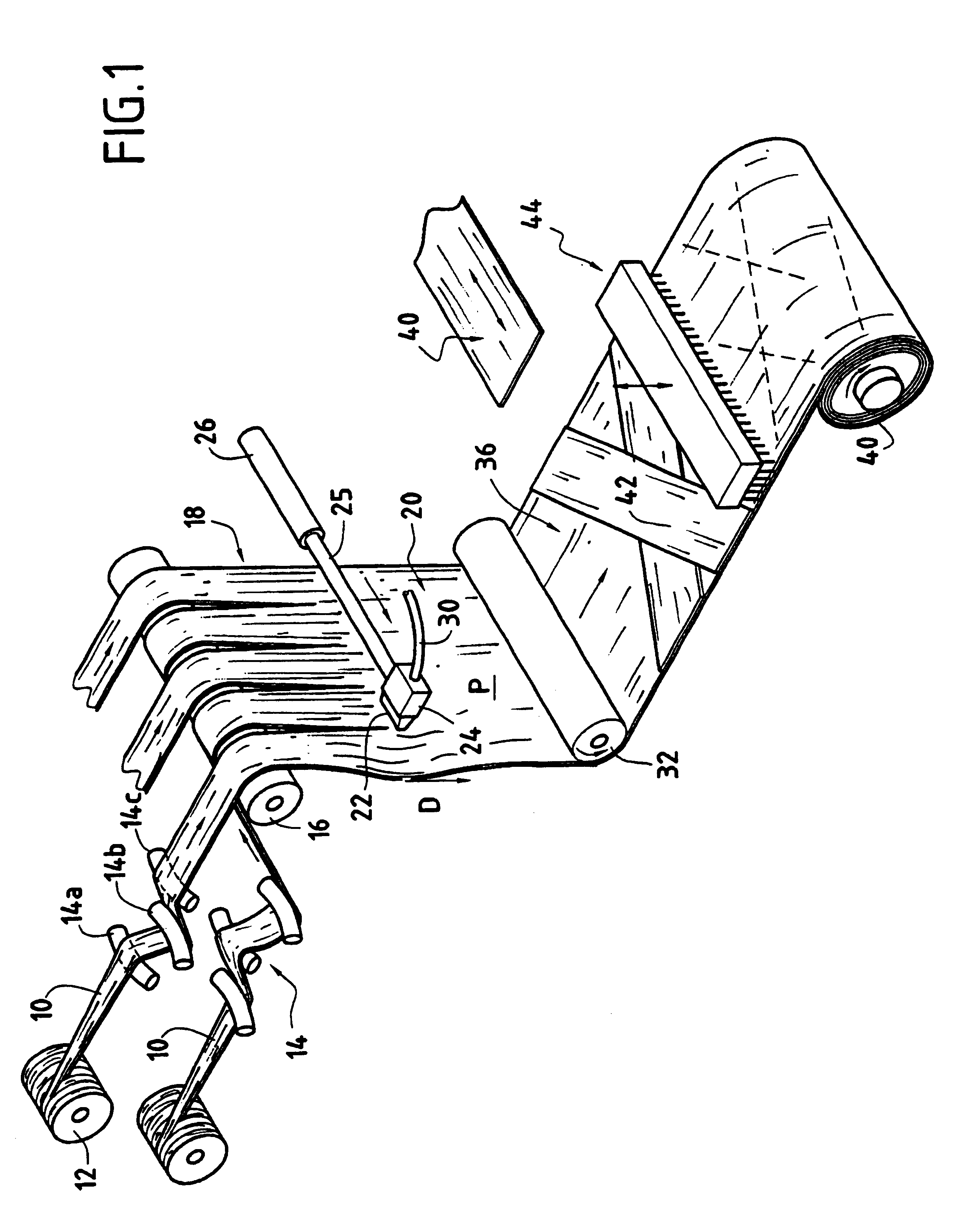

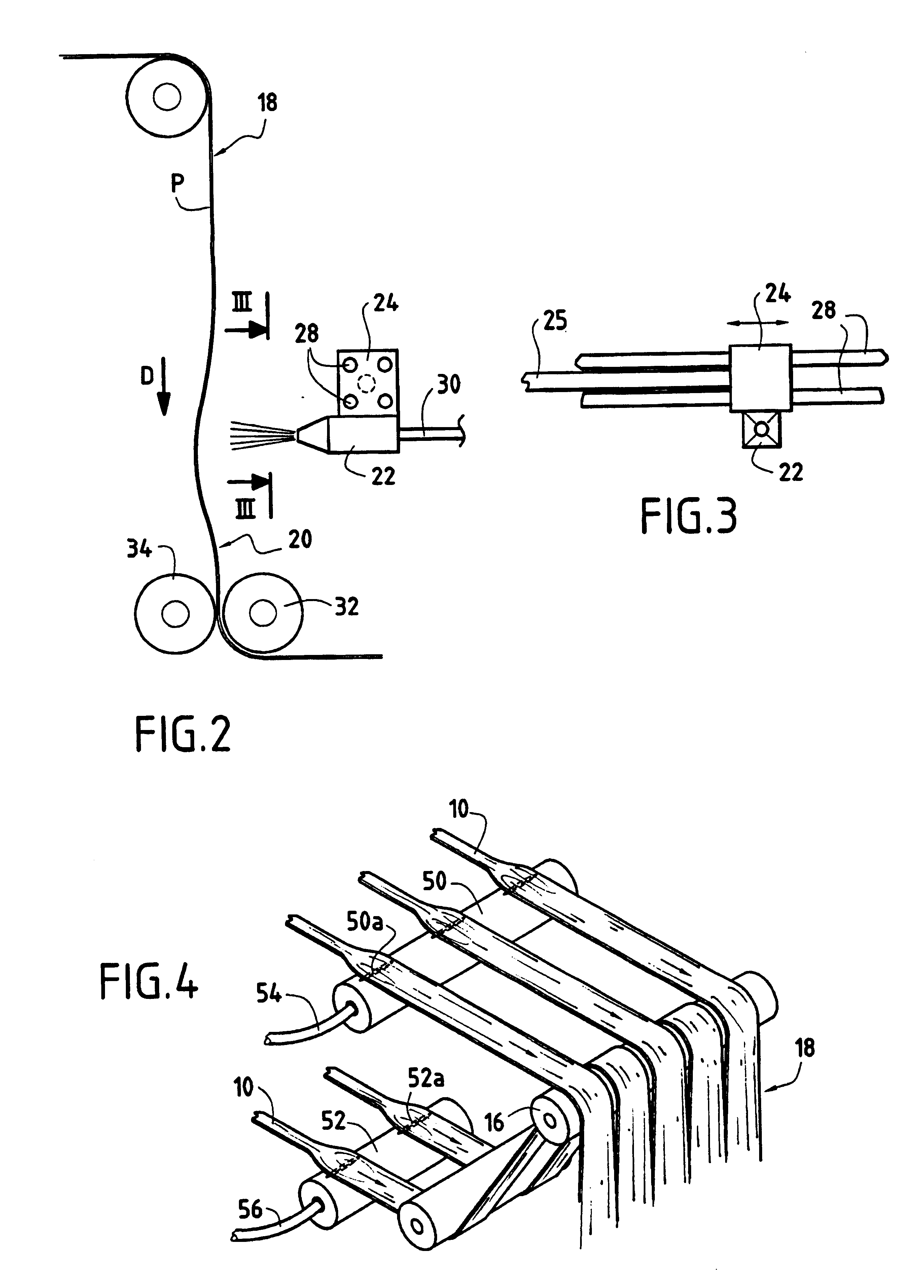

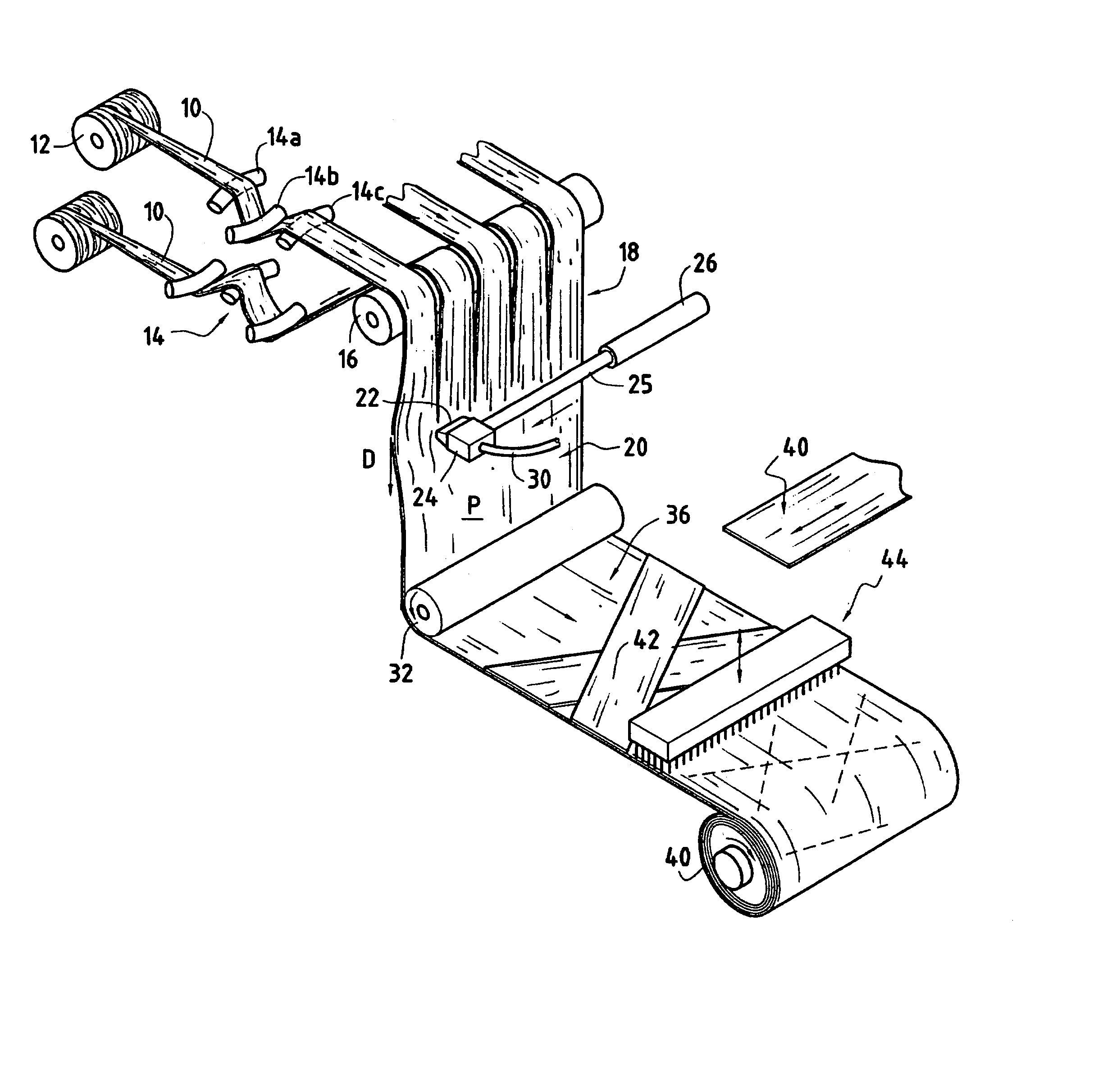

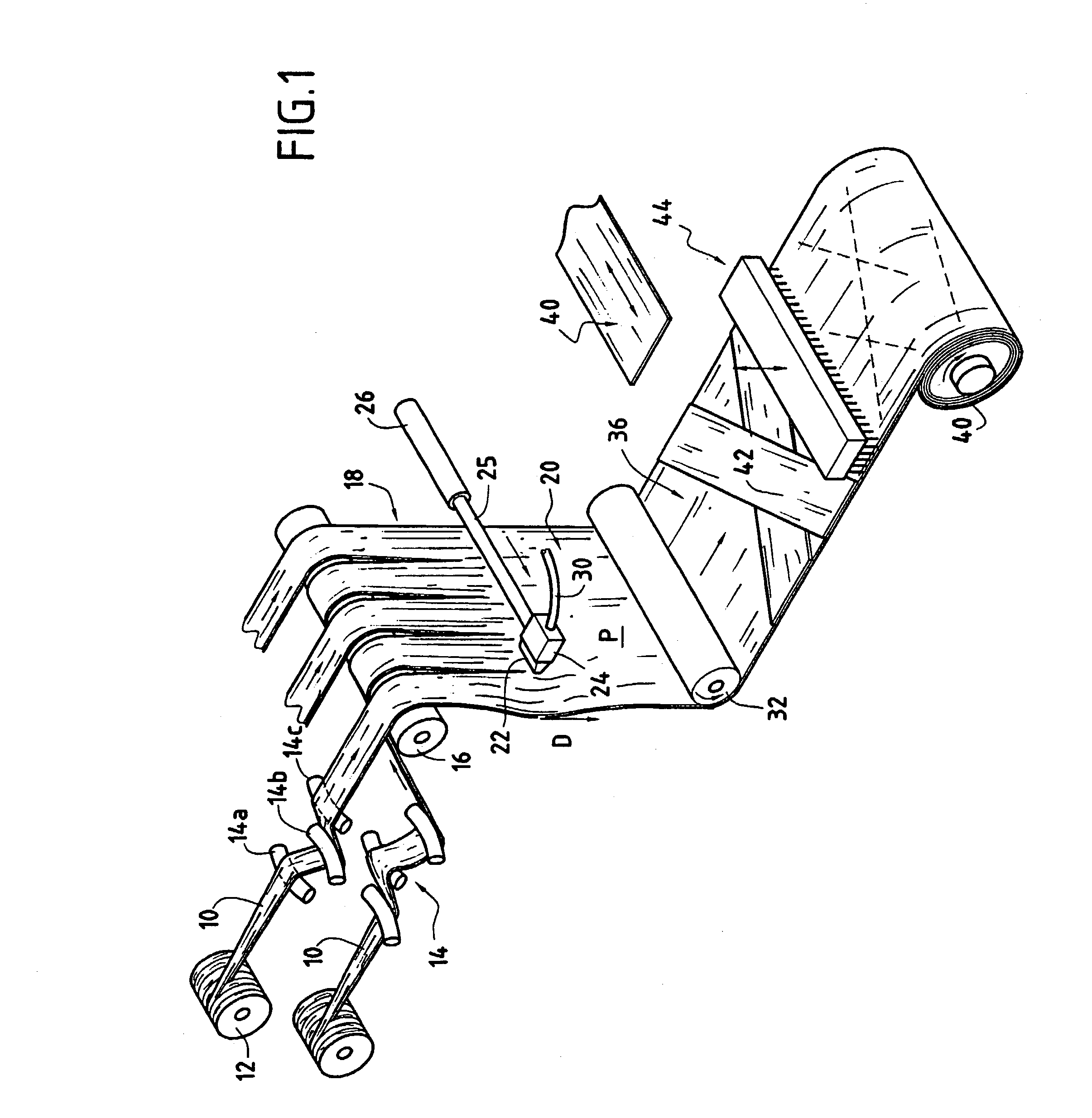

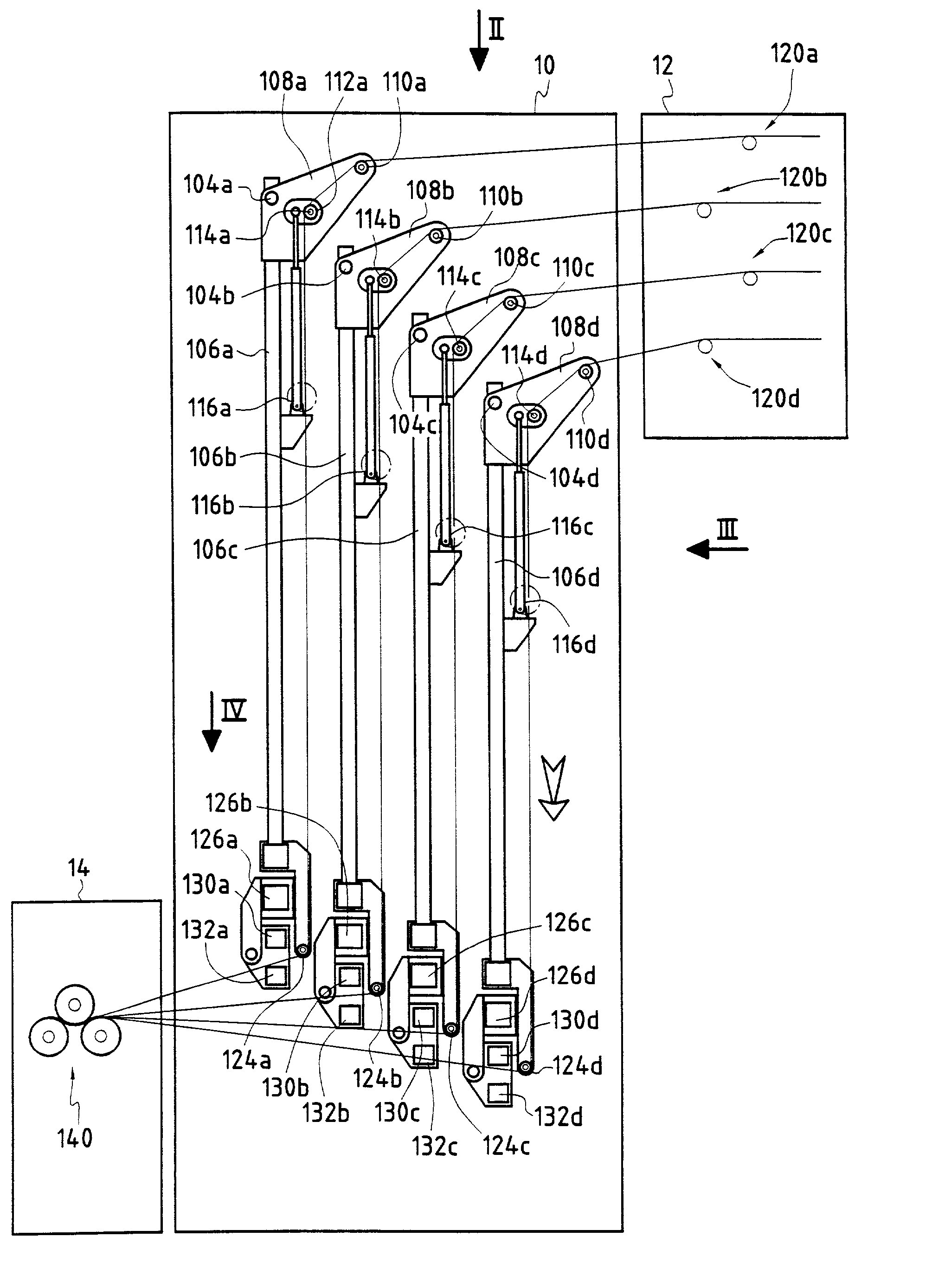

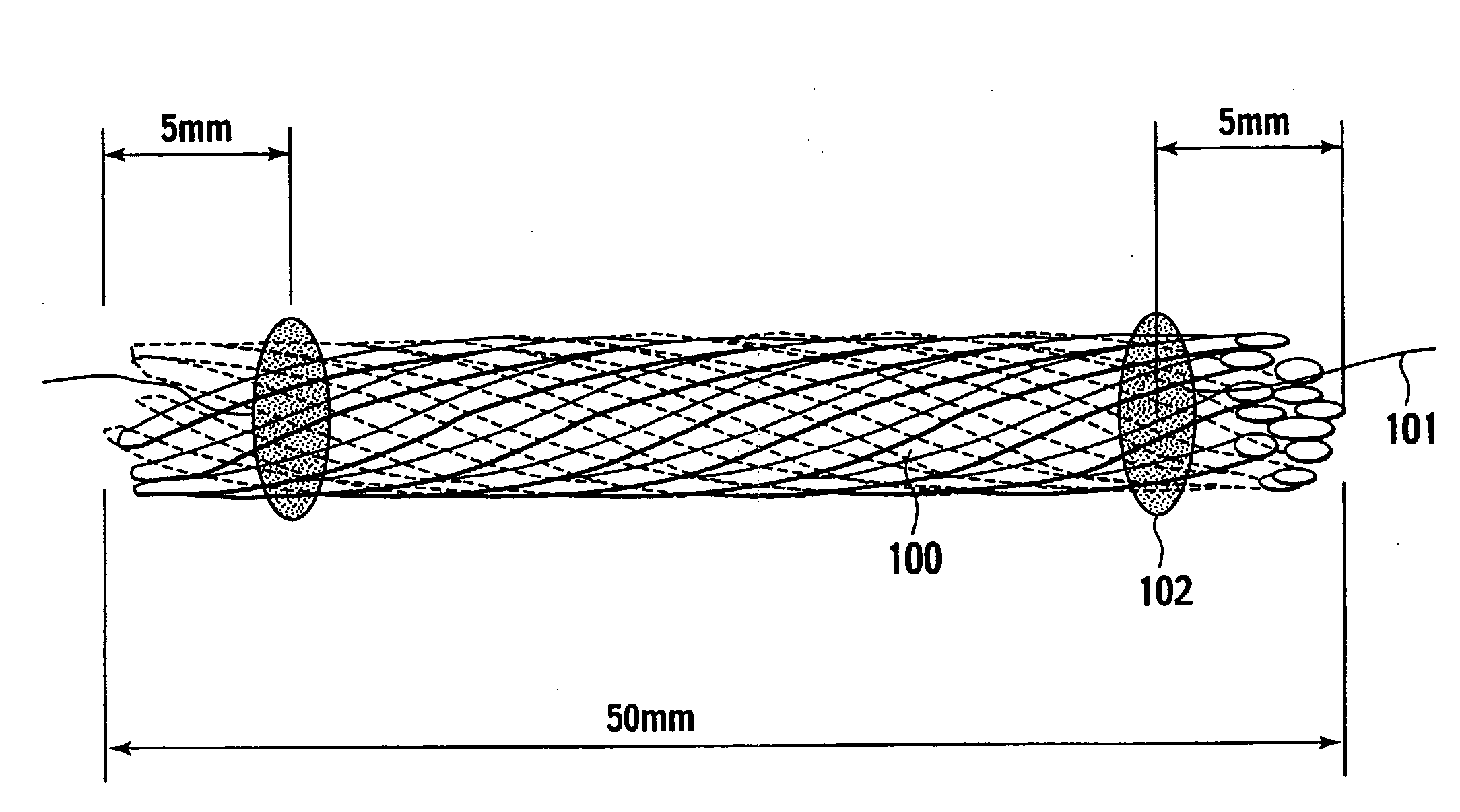

Method of producing a spread multi-filament bundle and an apparatus used in the same

ActiveUS20060137156A1Efficient mass productionImprove efficiencyButtonsRecord carriersEngineeringVolumetric Mass Density

A method of producing a spread multi-filament bundle and an apparatus is used in which an arbitrary number of multi-filament bundles of higher strength are simultaneously spread with high speed and a high-quality. A spread multi-filament bundle or sheet with the component monofilaments thereof aligned in parallel widthwise and uniformly distributed in density is produced. The respective multi-filament bundles fed from a yarn supplier or a creel are subjected to fluctuation of the tensile force applied thereto alternatively between tension and relaxation and the respective bundles as subjected to such fluctuation are passed in succession through a fluid flowing spreader.

Owner:FUKUI PREFECTURE

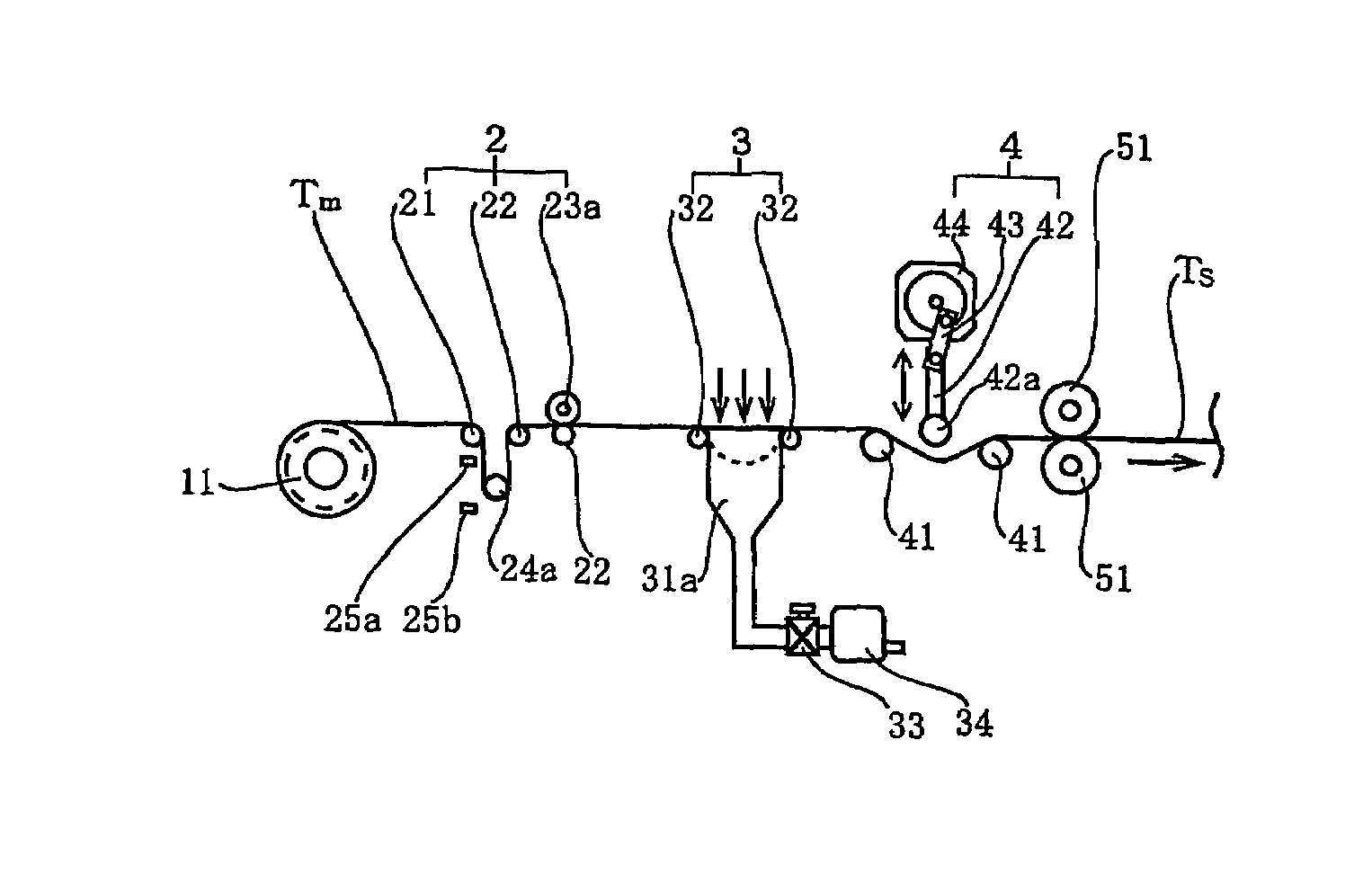

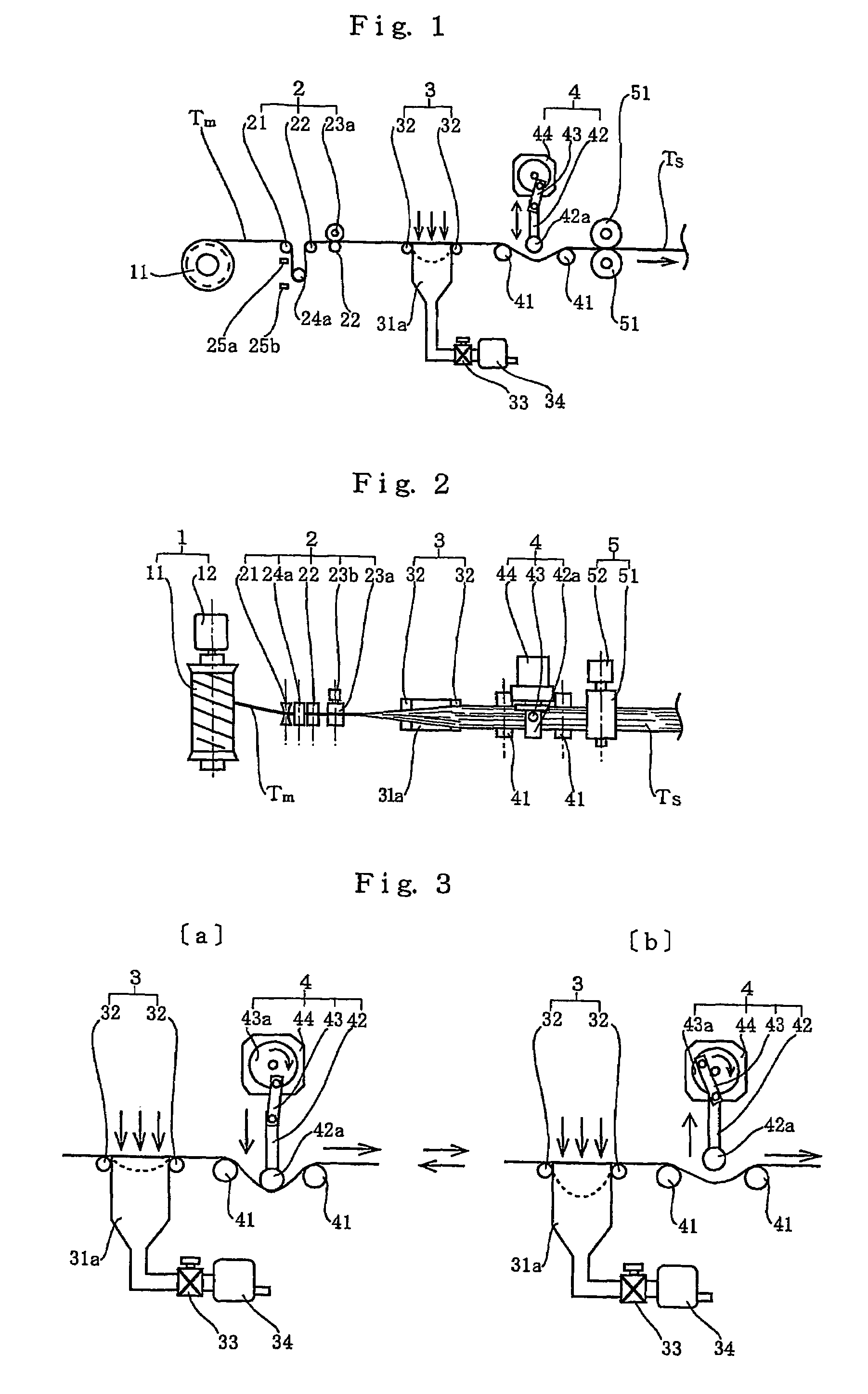

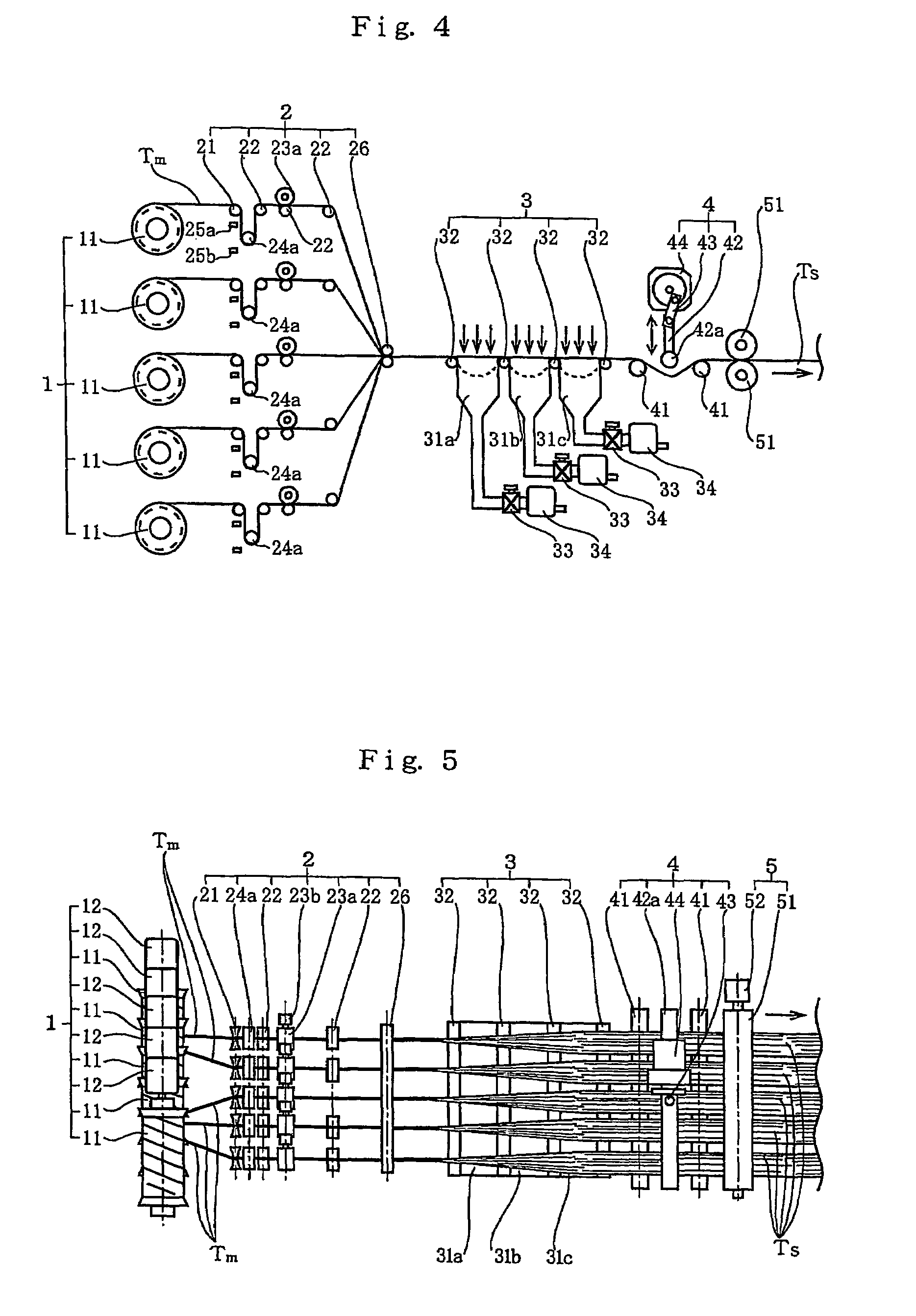

Method of producing a spread multi-filament bundle and an apparatus used in the same

ActiveUS7571524B2Efficient mass productionImprove efficiencyButtonsRecord carriersYarnVolumetric Mass Density

A method of producing a spread multi-filament bundle and an apparatus is used in which an arbitrary number of multi-filament bundles of higher strength are simultaneously spread with high speed and a high-quality. A spread multi-filament bundle or sheet with the component monofilaments thereof aligned in parallel widthwise and uniformly distributed in density is produced. The respective multi-filament bundles fed from a yarn supplier or a creel are subjected to fluctuation of the tensile force applied thereto alternatively between tension and relaxation and the respective bundles as subjected to such fluctuation are passed in succession through a fluid flowing spreader.

Owner:FUKUI PREFECTURE

Method and apparatus for opening reinforcing fiber bundle and method of manufacturing prepreg

PCT No. PCT / JP97 / 04541 Sec. 371 Date Dec. 18, 1998 Sec. 102(e) Date Dec. 18, 1998 PCT Filed Dec. 10, 1997 PCT Pub. No. WO98 / 45515 PCT Pub. Date Oct. 15, 1998The present invention provides a method and apparatus, in which a reinforcing fiber bundle consisting of a plurality of paralleled single fibers is or a plurality of mutually paralleled reinforcing fiber bundles respectively consisting of a plurality of paralleled single fibers are driven to run through a plurality of rolls while being bent to open the fiber, and in which the opened reinforcing fiber bundle is impregnated with resin to produce a prepreg, comprising vibrating at least one of the rolls in the axial direction of the roll, to open the reinforcing fiber bundle(s), pressing the reinforcing fiber bundle(s) to the peripheral surface of a roll located immediately downstream of the vibrating roll without vibrating the roll, and bringing the opened reinforcing fiber bundle(s) into contact with the peripheral surface of the non-vibrating roll with a contact length of not less than twice the contact length of the reinforcing fiber bundle(s) on the vibrating roll, for retaining the opened state of the reinforcing fiber bundle(s). The present invention allows the reinforcing fiber bundle(s) to be opened stably with little fuzzing caused, for producing a uniform and thin reinforcing fiber sheet, and from the uniform and thin reinforcing fiber sheet, a uniform and thin crack-less prepreg with a good grade can be obtained.

Owner:TORAY IND INC

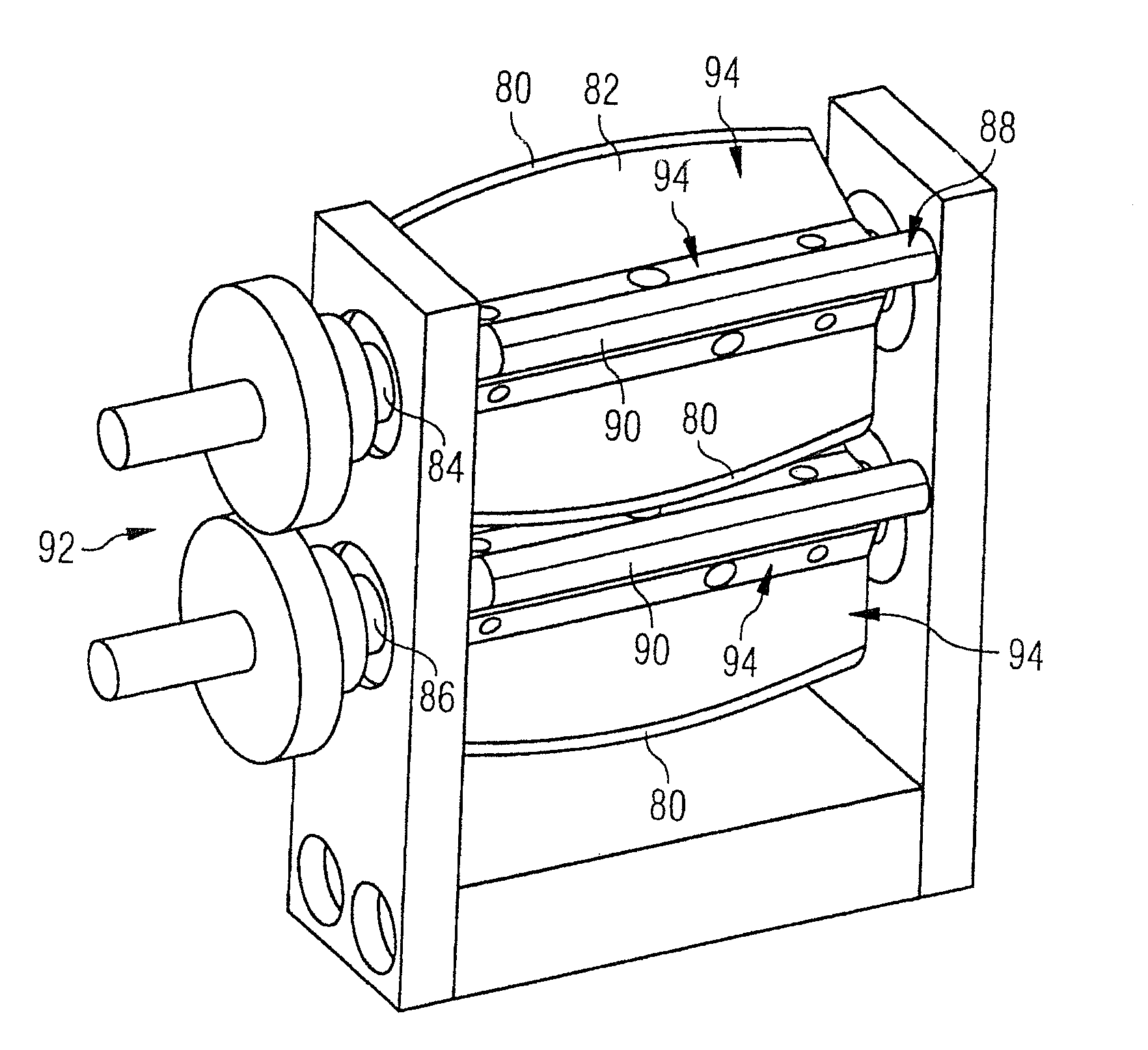

Spreading device for spreading out fiber filament bundles and spreading method carried out using the same

ActiveUS8191215B2Avoid concentrationEmbedded in matrixFilament manufactureFibre cleaning/openingFiberEngineering

A spreading device (20) for spreading a fiber filament bundle (32) to form a flat fiber band (14) has at least one convexly bent spreading edge (80) that is movable. The convexly bent spreading edge has at least one direction component perpendicular to a longitudinal extension of the fiber filament bundle (32) to be spread relative to the convexly bent spreading edge. The fiber filament bundle is configured to be placed under tension onto the convexly bent spreading edge (80) and thereafter is configured to be moved again with the at least one direction component perpendicular to the fiber filament bundle (32) away from the fiber filament bundle to release the fiber filament bundle from the convexly bent spreading edge (80).

Owner:EADS DEUT GMBH

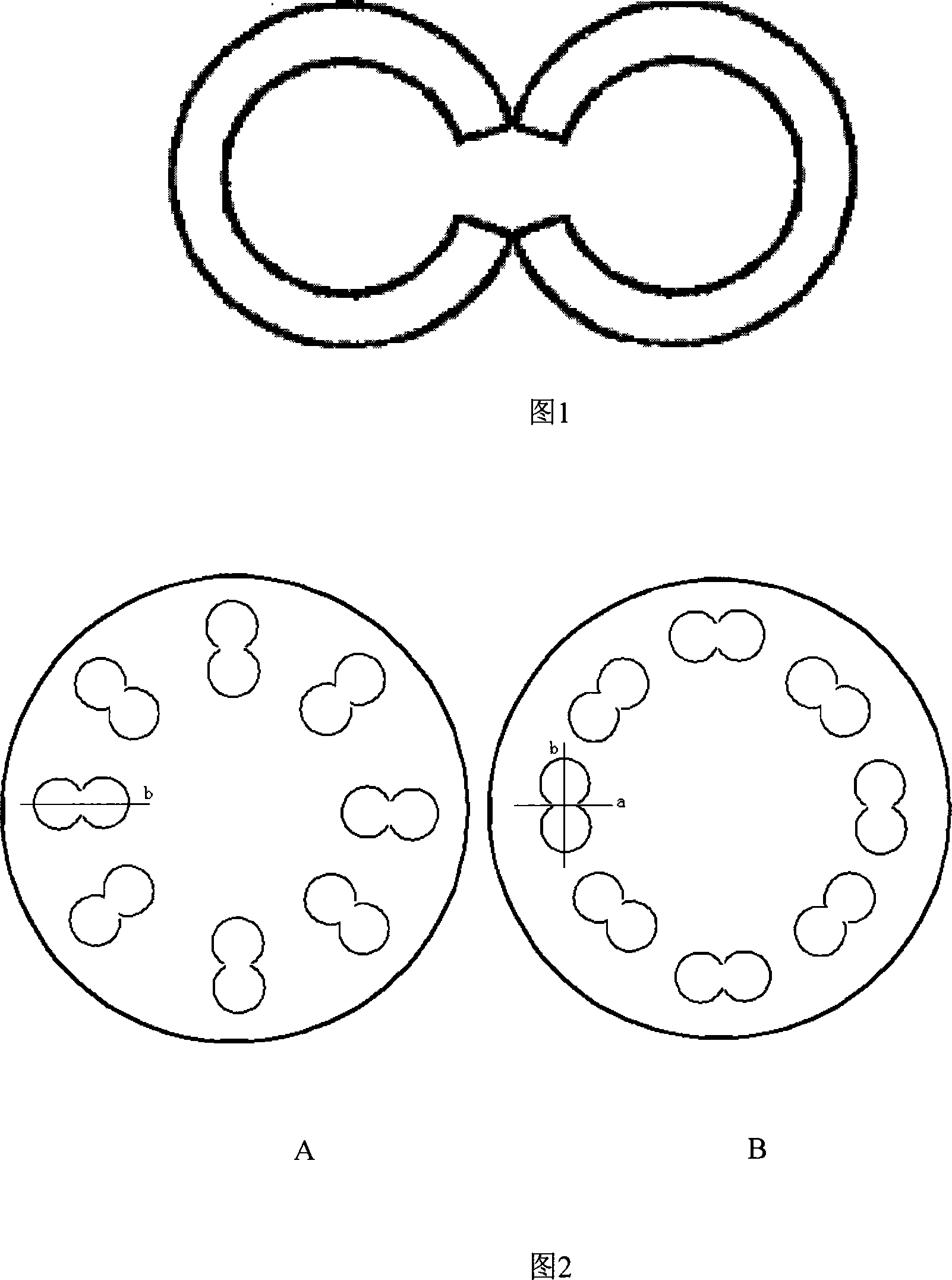

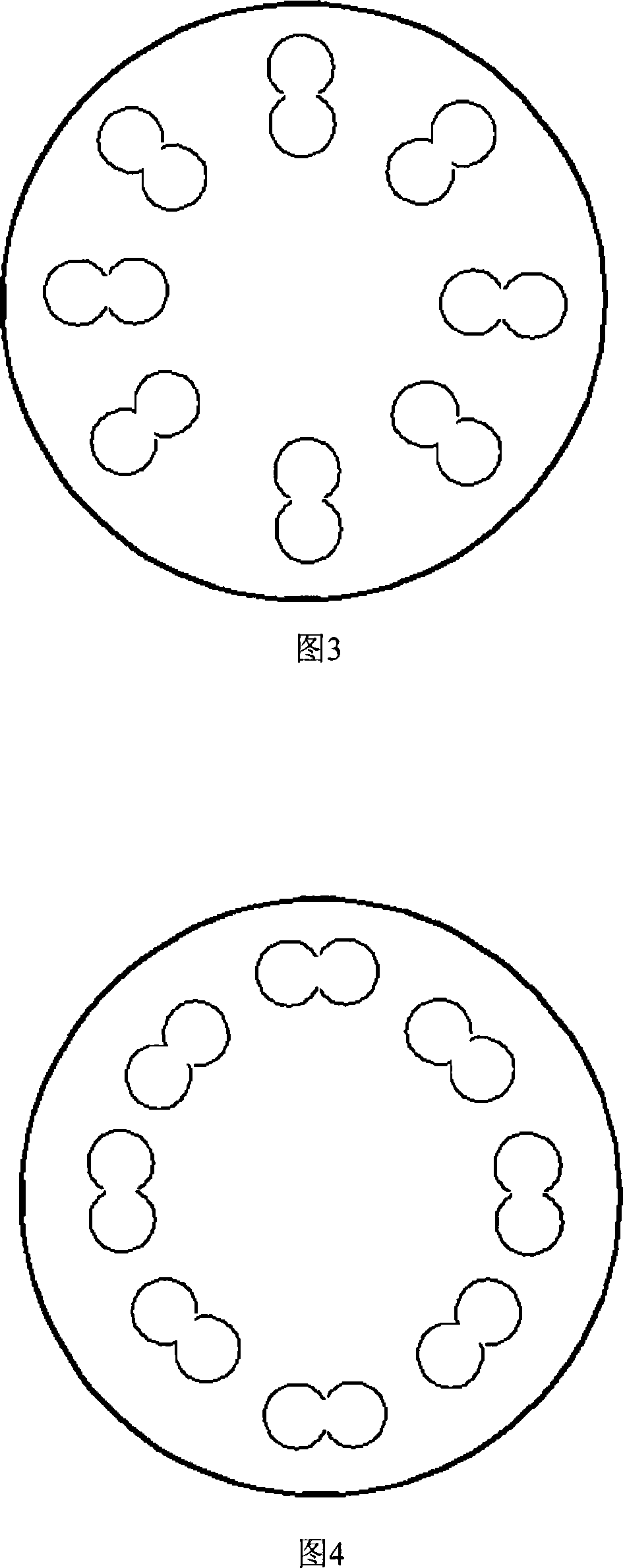

8-shaped pet/PTT hollow fibre and preparing method thereof

InactiveCN101215723ACurly giftMeet needsHollow filament manufactureFilament manufacturePolyesterPolymer science

The invention relates to '8'-shaped PET / PTT hollow fiber and a process for preparation. The fiber is prepared by composite spinning which is obtained through melting polyethylene glycol terephthalate PET and polyytrimethylene terephthalate PTT slice. The process for preparation comprises drying PET and PTT polyester slice, entering into a composite spinning assembly through a twin-screw extruder in parallel, carrying out melt spinning, cooling through cross air blow, oiling on an oil tanker, drafting by two channels, coiling, finally obtaining '8'-shaped PET / PTT hollow fiber. The fiber fully exerts the excellent property of PTT and PET fiber, which is thermal insulating, highly moisture absorbable and breathable, soft and touching, since PTT and PET fiber have different shrinkage ratio and have the potential function of coiling property, the product has greatly wide application prospect in the field of clothing face fabric and various filling material.

Owner:DONGHUA UNIV

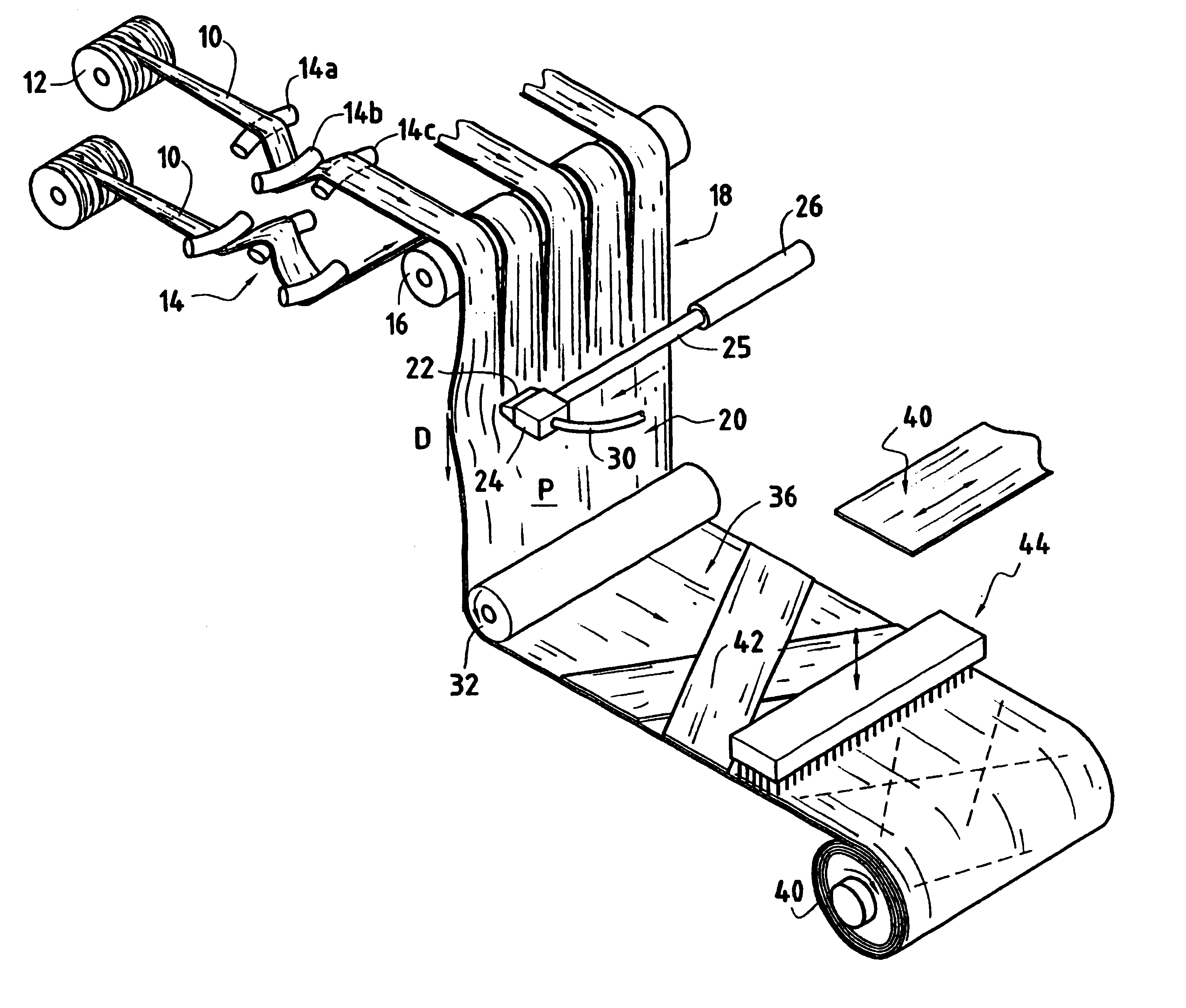

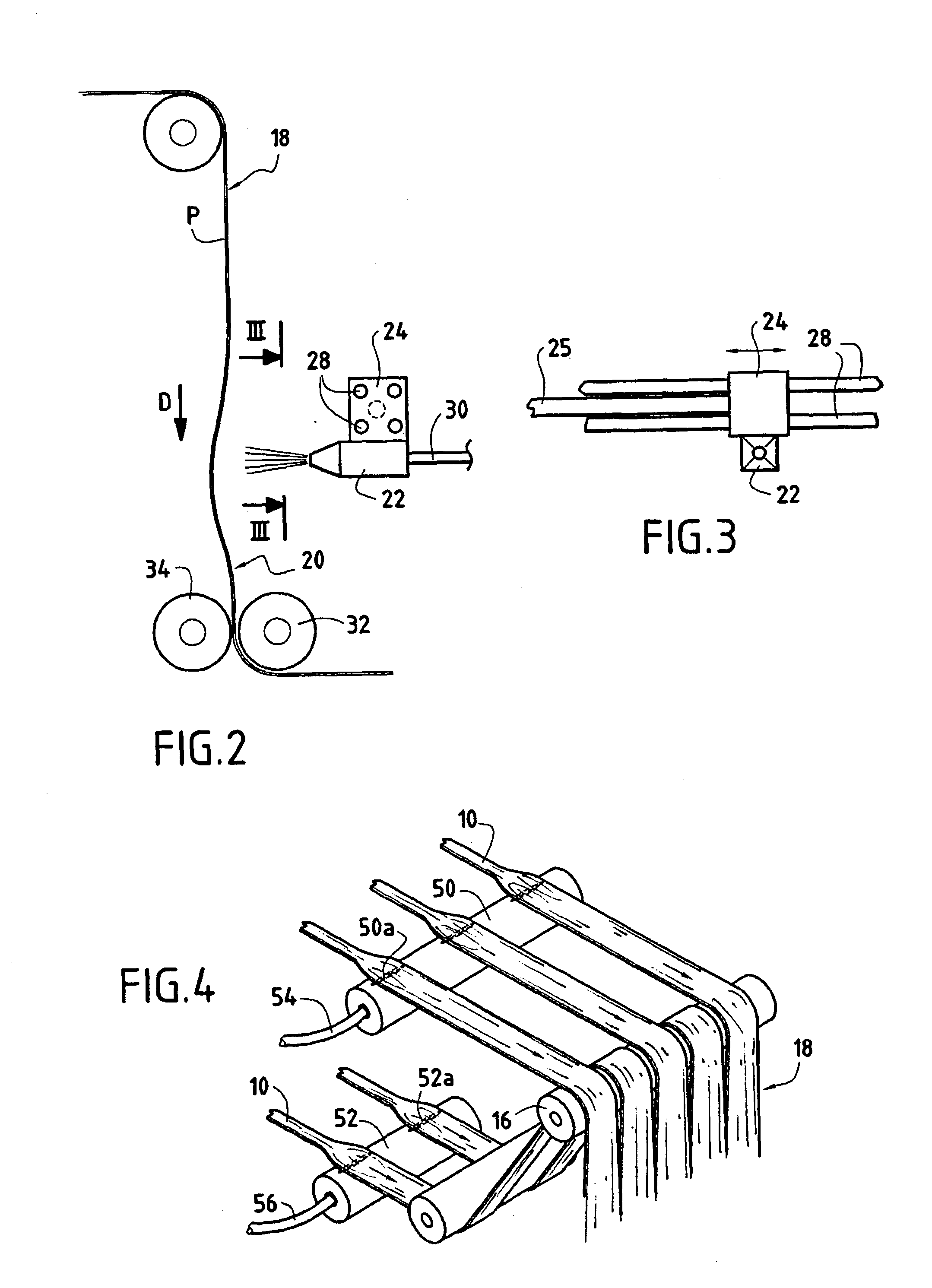

Method and apparatus for making a fiber sheet by spreading out tows.

Owner:SAFRAN CERAMICS SA

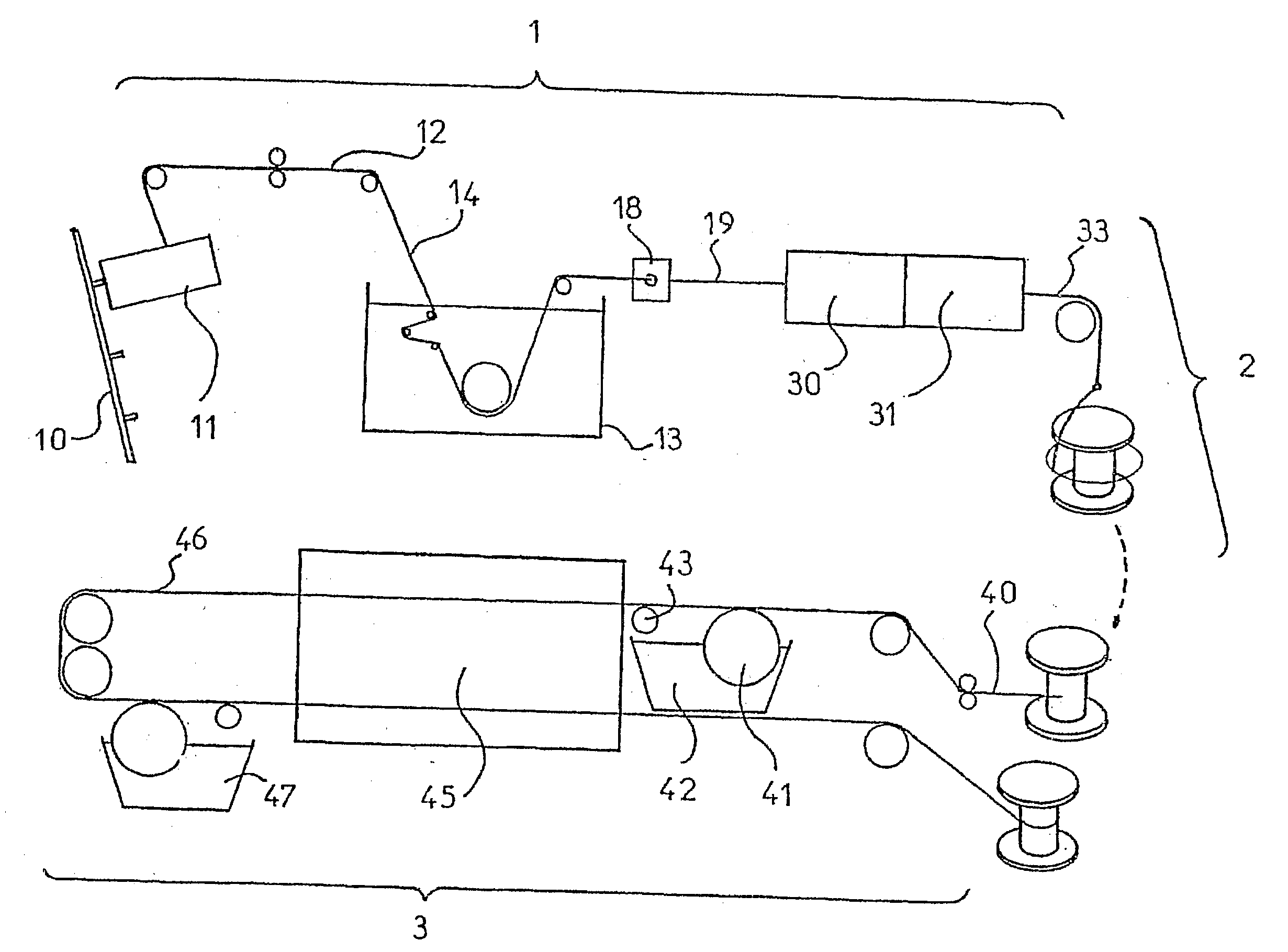

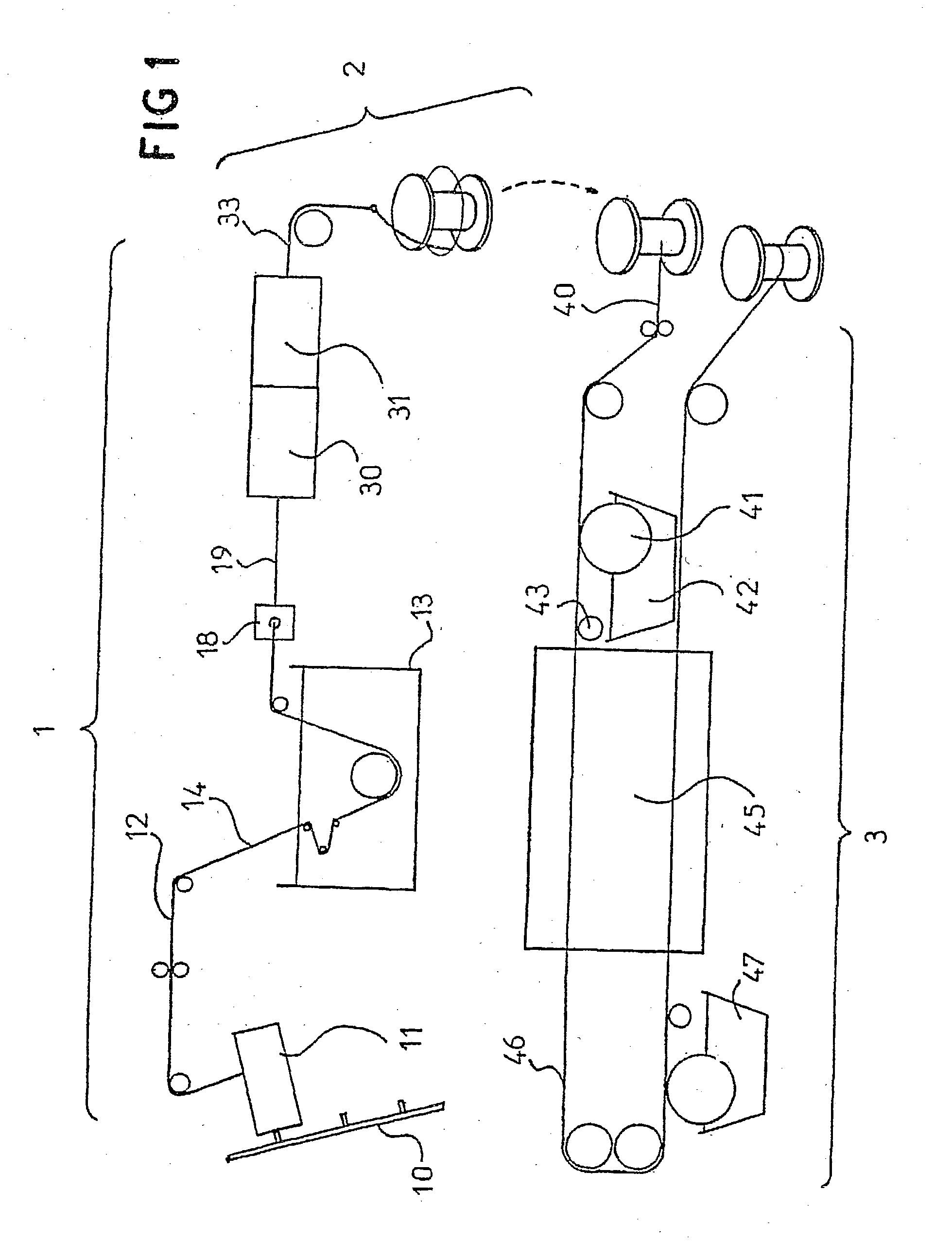

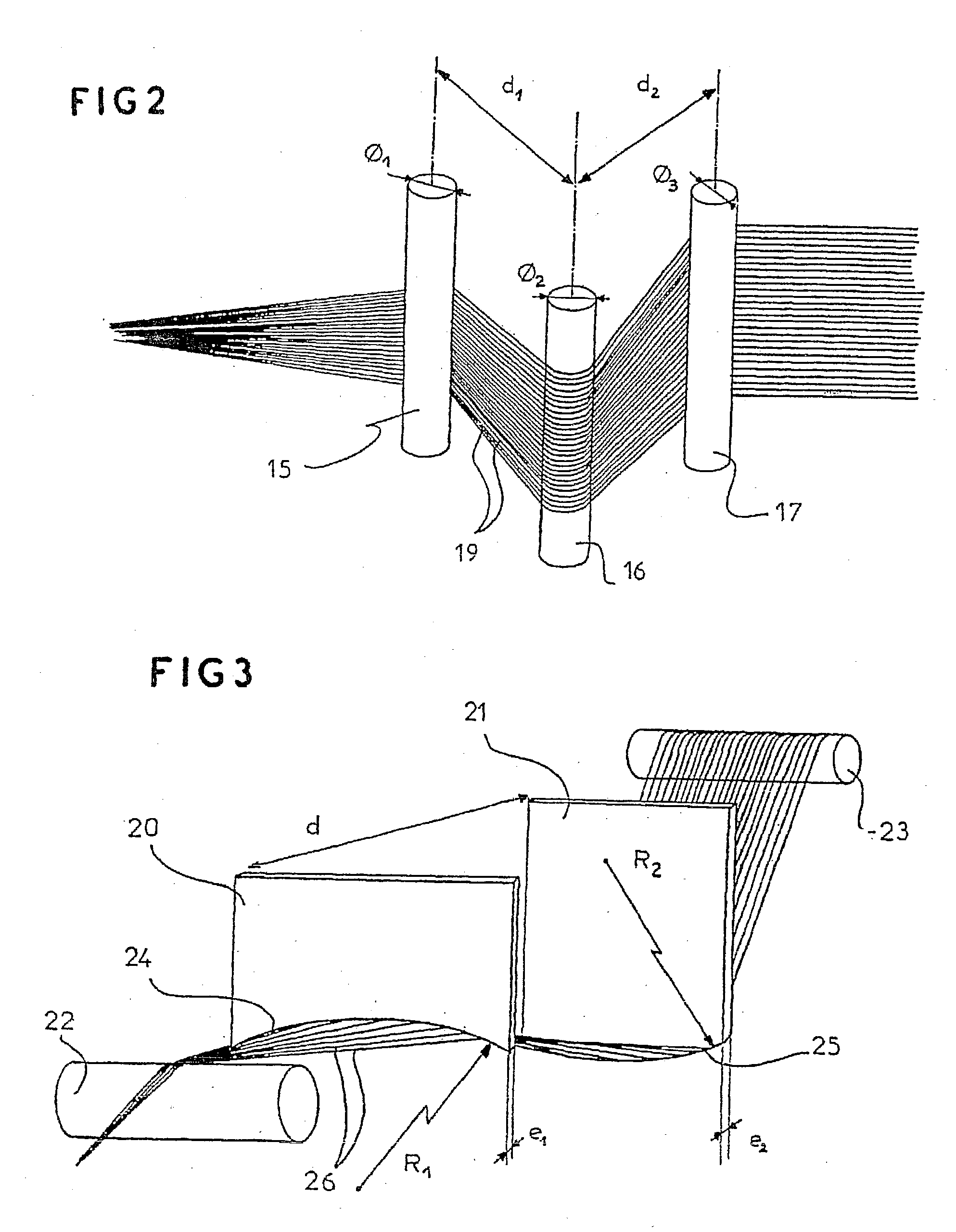

Method and device for producing a textile web by spreading tows

Owner:SAFRAN CERAMICS SA

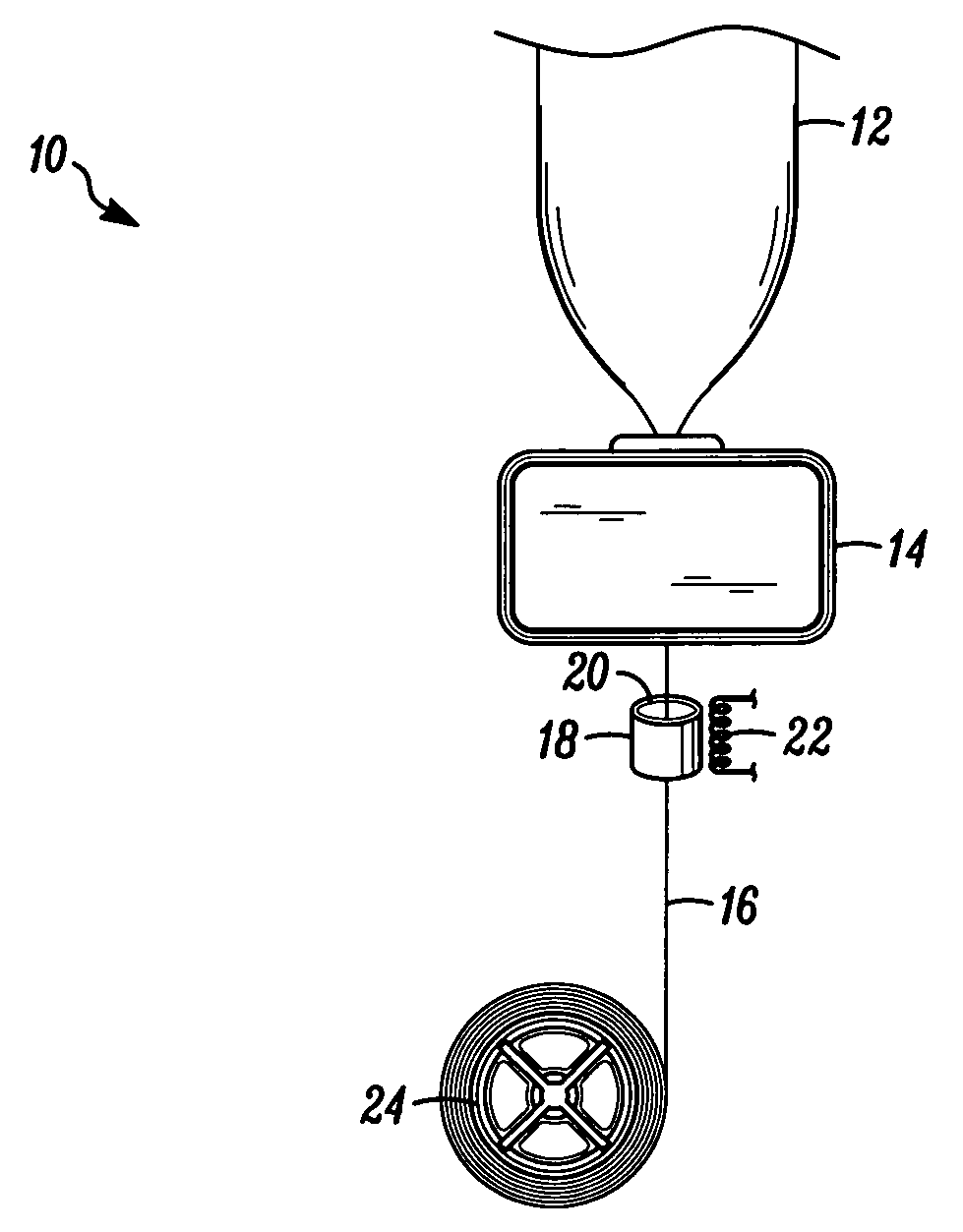

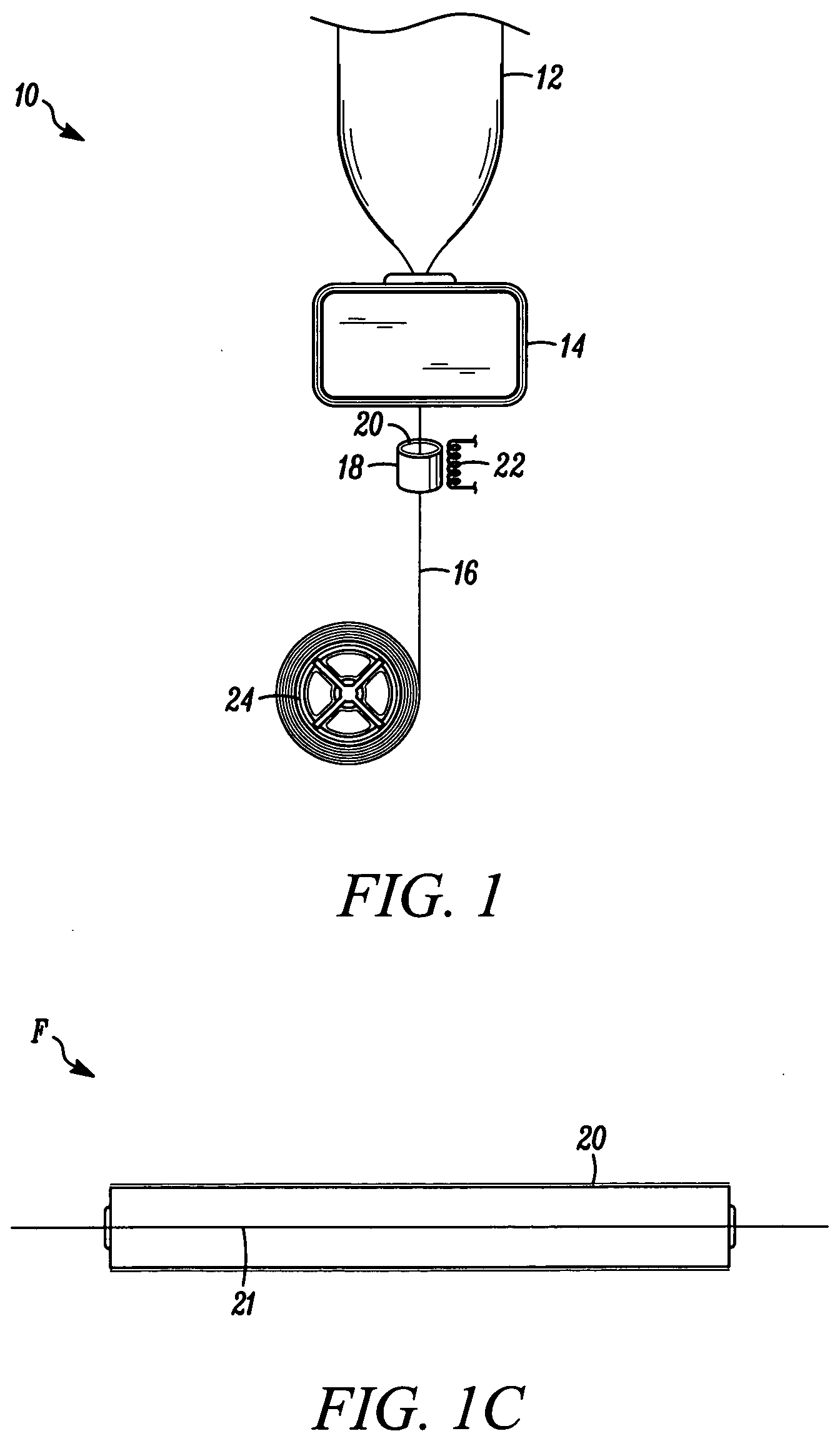

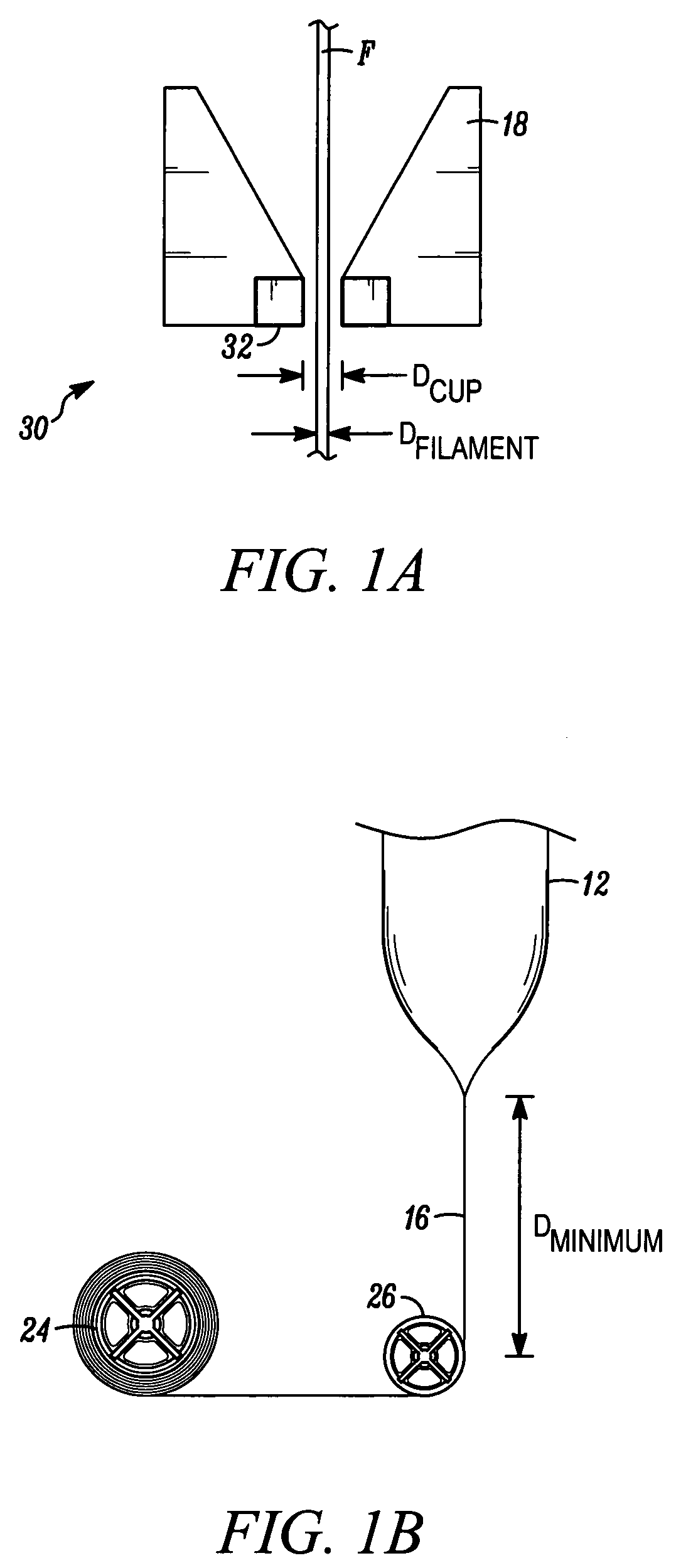

Filament with easily removed protective coating and methods for stripping the same

InactiveUS20060134324A1Easy to disassembleImprove solubilityCladded optical fibreFilament manufactureWaxWater soluble

The present invention provides a filament with an easily removable protective coating as well as a method and apparatus for applying the protective coating to the filament during a draw process that can be easily removed with a reasonably benign solvent such as water, or if necessary, acetone or ethanol. The protective coating is water-soluble and can be easily dissolved in-line with a spooling process. The coating material may include a water-soluble “wax-like” material called Aquabond 65, distributed by Aquabond Technologies, as well as other grades of Aquabond such Aquabond 55 and Aquabond 85, which behave essentially the same but are dissolved at different temperatures.

Owner:ILLUMINA INC

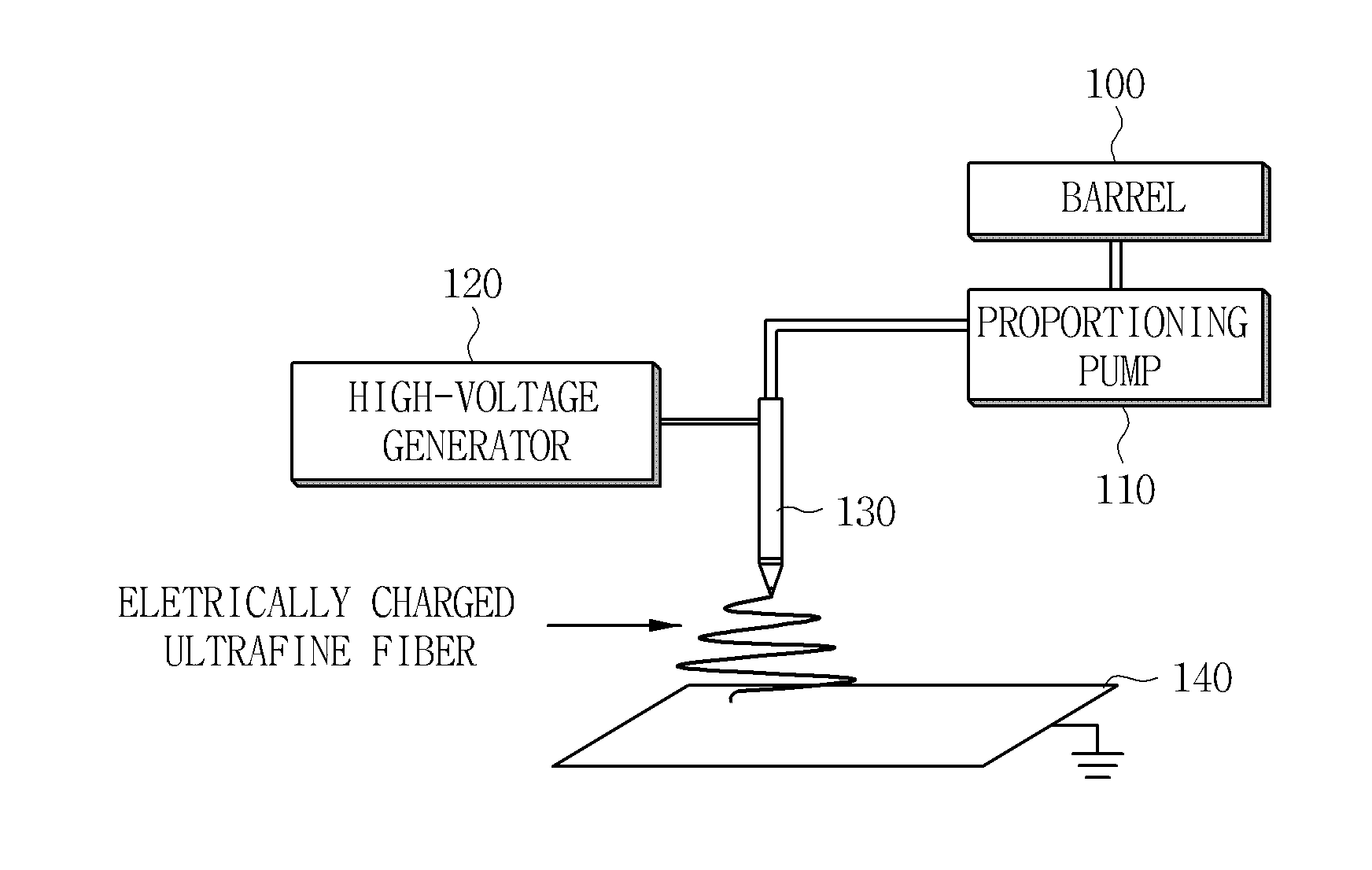

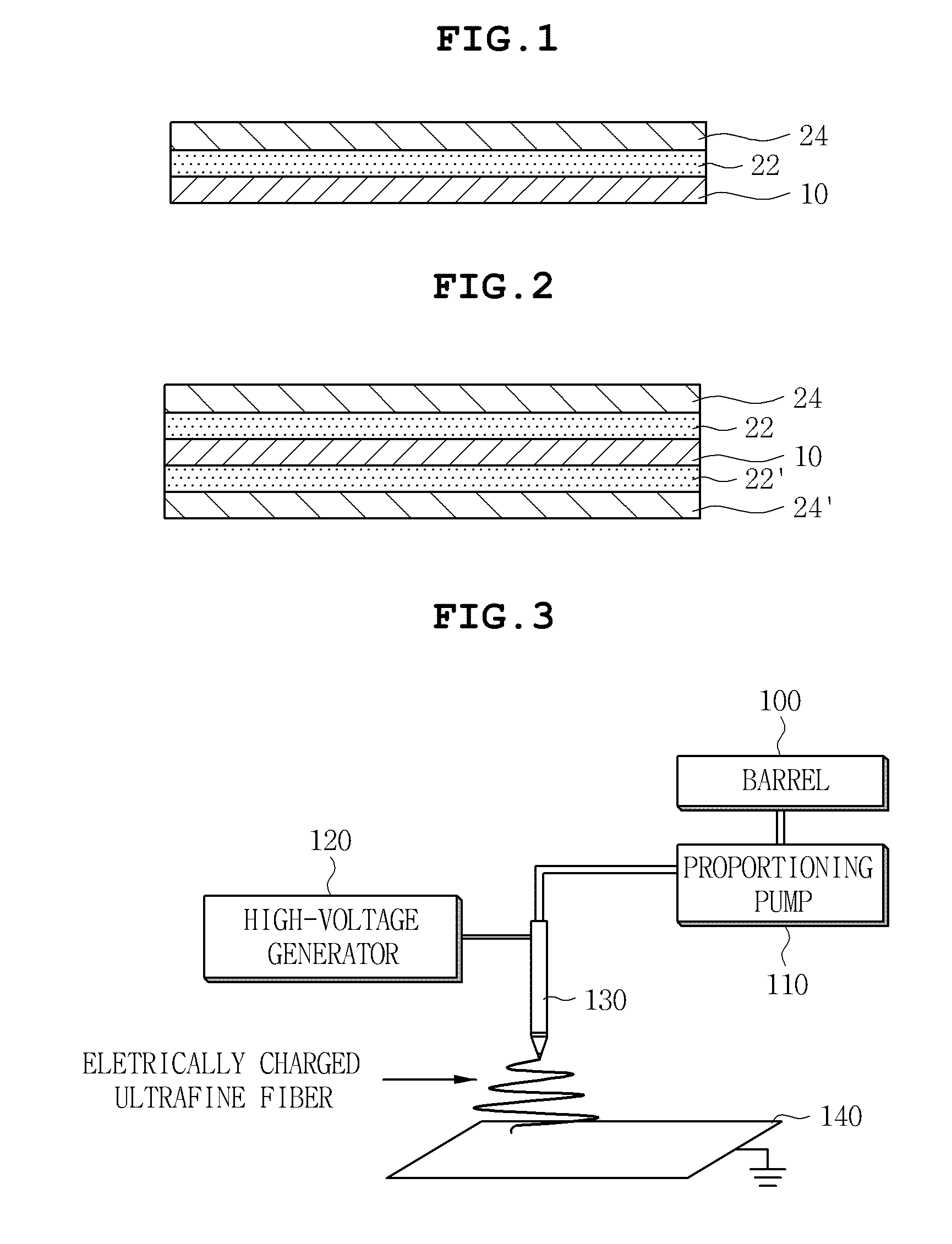

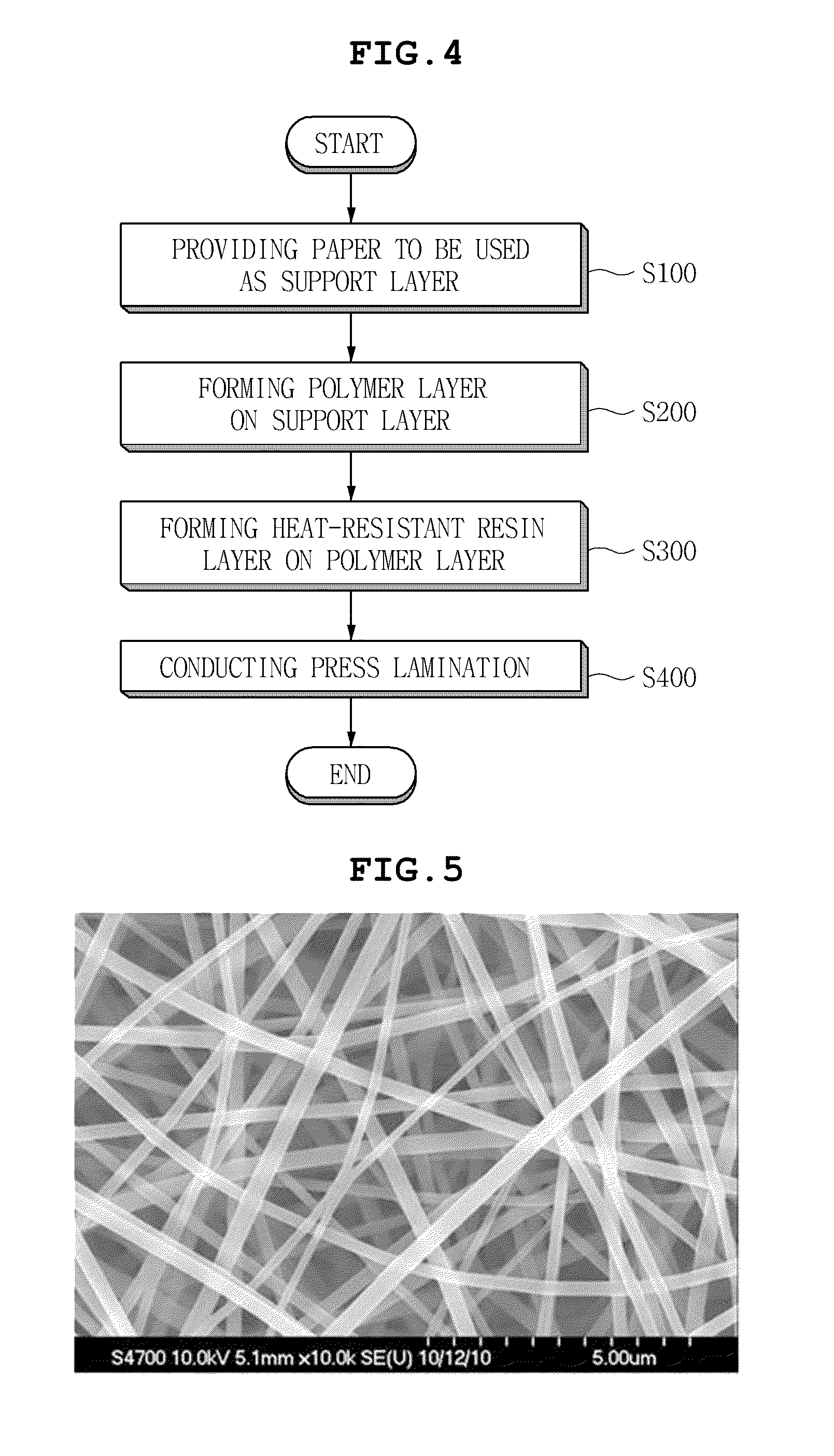

Fibrous separation membrane for secondary battery and manufacturing method thereof

InactiveUS20110236744A1Broaden your optionsHigh strengthElectric discharge heatingFilament manufactureCellulose fiberChemistry

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Cotton-simulated terylene short fiber and preparation method thereof

ActiveCN101831727AGuaranteed spinnabilitySimple processHollow filament manufactureFilament manufacturePolyesterState of art

The invention provides a cotton-simulated terylene short fiber. Concave pits are formed on the surface of the cotton-simulated terylene short fiber; and the cotton-simulated terylene short fiber comprises 0-1 percent by weight of calcium sulphate, 1-10 percent by weight of PEG (Polyethylene Glycol) and 1-10 percent by weight of ECDP (Easy Cationic Dyeable Polyester). The invention also provides a preparation method of the cotton-simulated terylene short fiber, comprising the following steps of: slicing the PET; drying a mixture of the calcium sulphate, the ECDP and the PEG and fusing and spinning the mixture into a terylene raw filament at 270-280DEG C by using a profile spinneret; carrying out winding, doffing, balanced bundle collection, wire guiding, pre-stretching and oiling; after primary or secondary stretching, dissolving out partial calcium sulphate in the soaking process by alkali treatment to form mocropores on the surfaces of fibers; and finally carrying out tense heat setting, curling, loosed heat setting, cutting and packaging to obtain the cotton-simulated terylene short fiber. The invention solves the problems that a compound spinning process in the prior art is not only complicated, but also has low yield and makes up the defects that the terylene has poor hydrophilicity and the textile is humid and muggy to wear.

Owner:XUZHOU SILK FIBER TECH

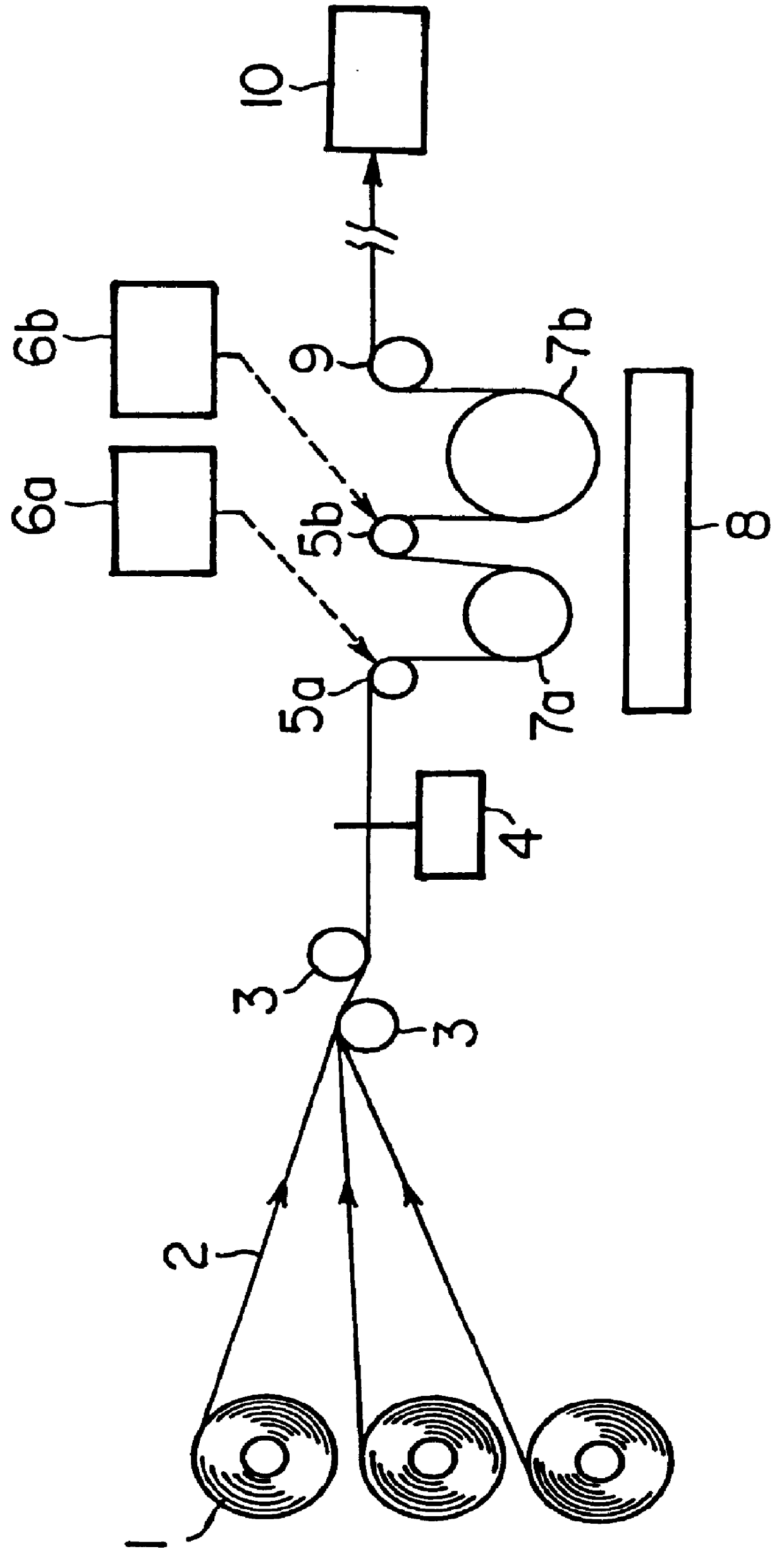

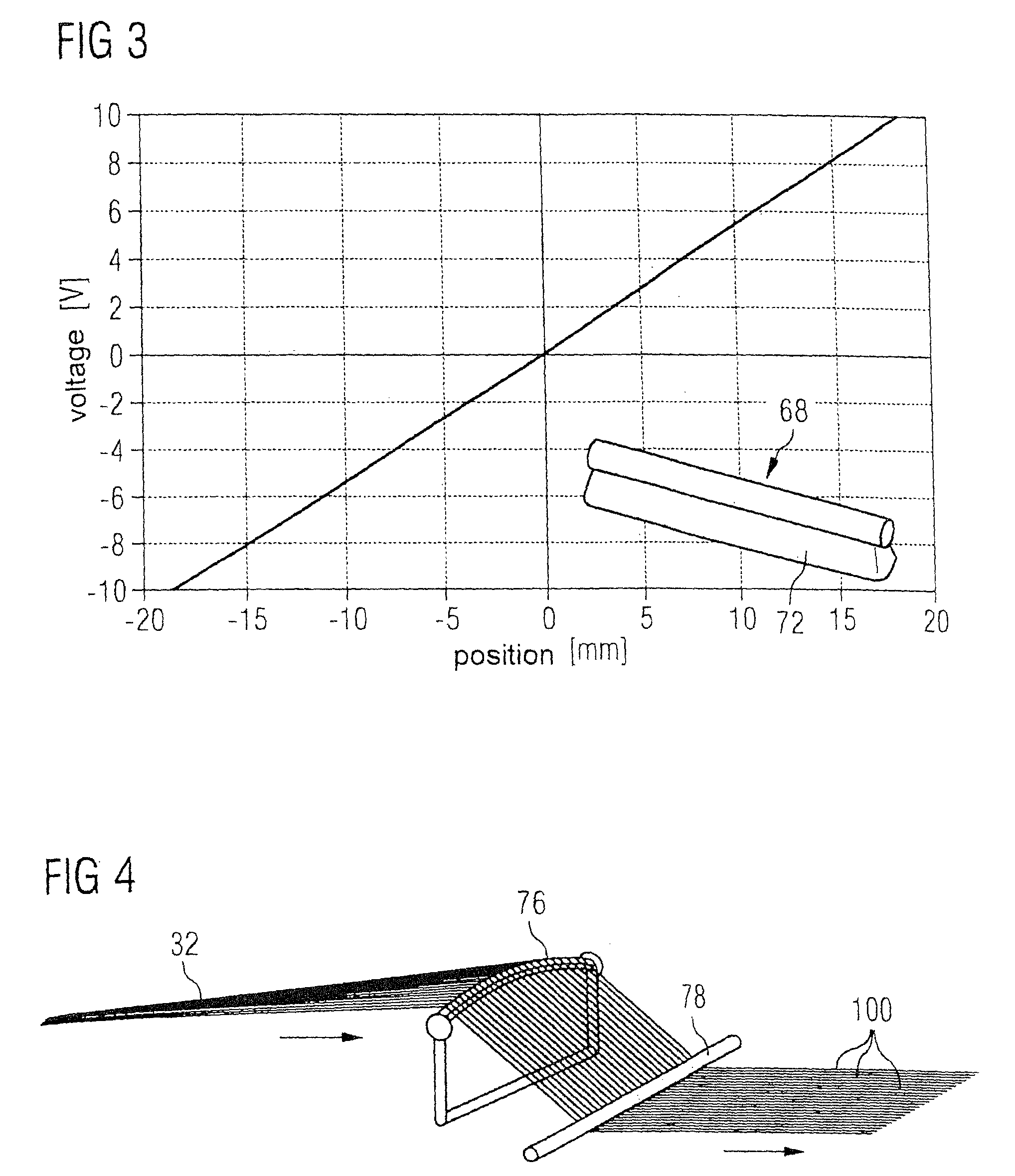

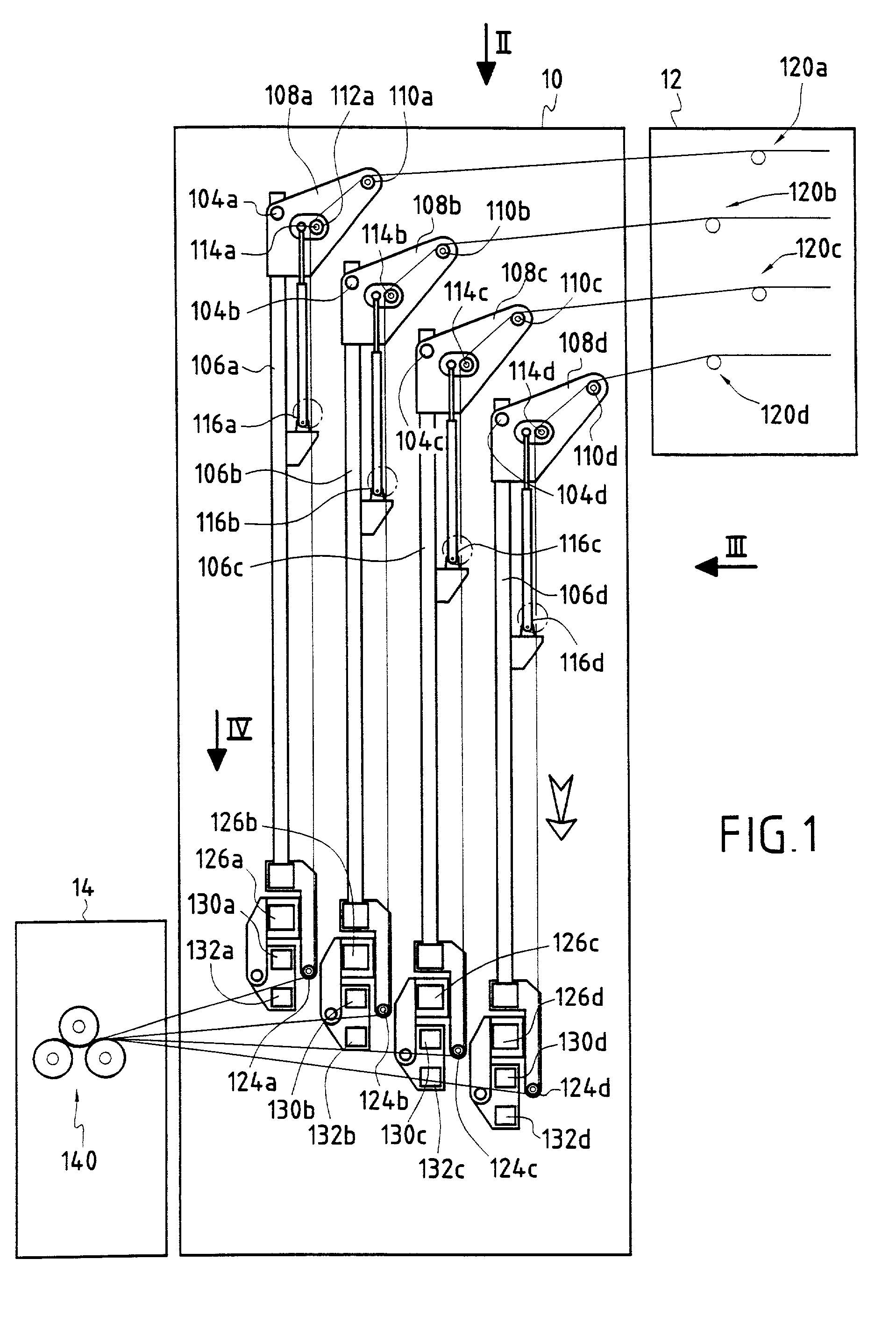

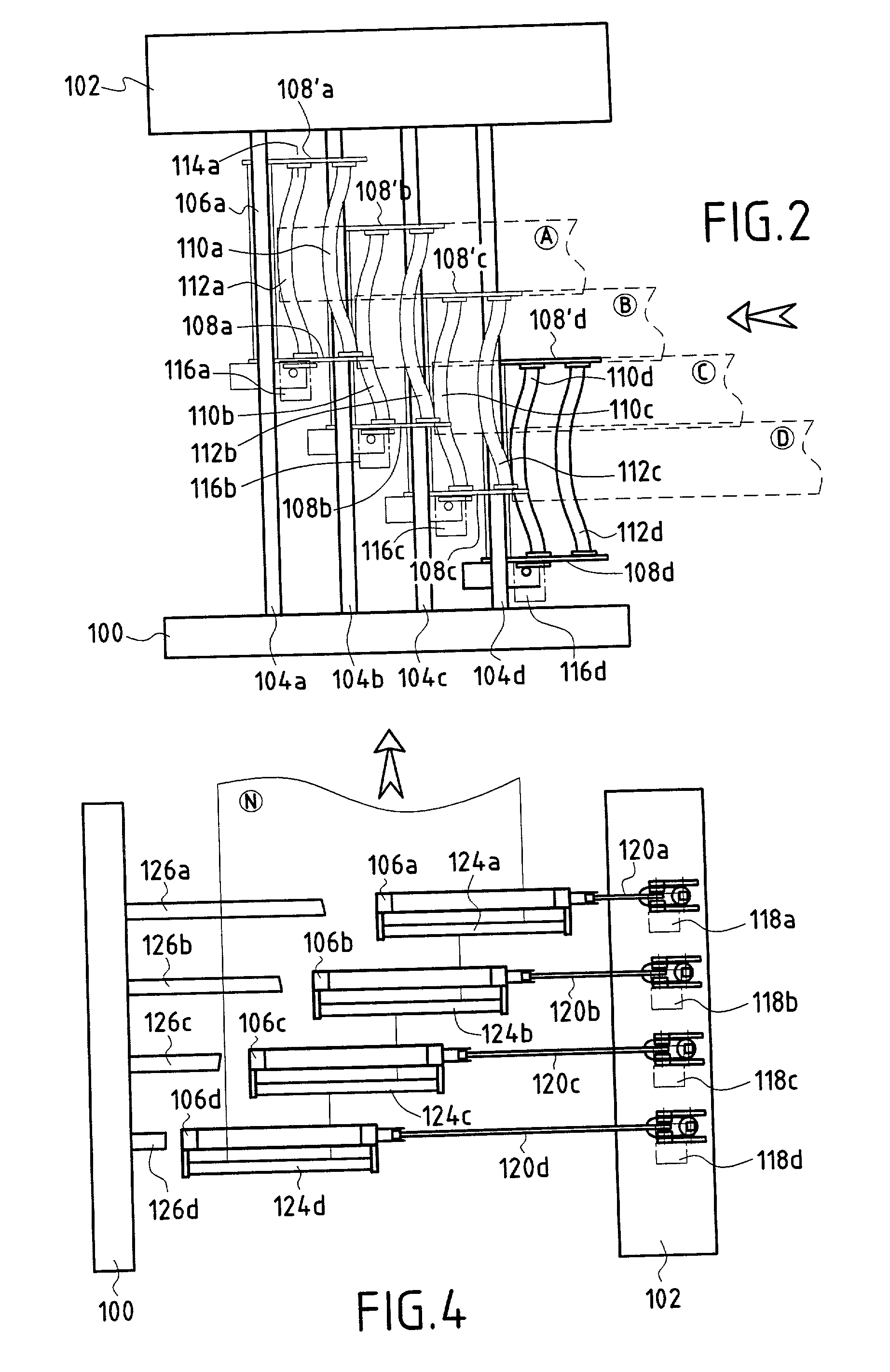

System For Automatically Controlling The Spreading Of A Textile Sheet

InactiveUS20020123819A1Mitigate such drawbackFilament manufactureNeedling machinesAutomatic controlComputer module

Apparatus for automatically controlling the spreading of a textile sheet made up of a plurality of tows coming from a tow feed module and serving to feed a drive module, the apparatus comprises means for measuring the positions of the longitudinal edges of each tow, means for individually adjusting the width of each tow, means for individually adjusting the position of each tow in a direction perpendicular to a tow advance direction, and digital processor means responsive to said position measuring means to control the adjustment means in such a manner that the textile sheet presents determined width and position.

Owner:SAFRAN LANDING SYSTEMS

Method for preparing high-performance polyacrylonitrile-based carbon fiber protofilament through dry spraying and wet spinning

InactiveCN101760791AIncrease spinning speedIncrease productivityArtificial filament washing/dryingFilament manufactureCarbon fibersSolvent

The invention relates to a method for preparing high-performance polyacrylonitrile-based carbon fiber protofilament through dry spraying and wet spinning, which comprises the following steps: preparing a polyacrylonitrile spinning stock solution; filtering and metering the polyacrylonitrile spinning stock solution after the demonomerization and deaeration; squeezing obtained materials through a spinning jet for forming fine spinning streams for entering a coagulating bath for coagulating forming through an air section; and carrying out drafting, water washing, drying densification, steam drafting and drying hot forming to obtain the high-performance polyacrylonitrile-based carbon fiber. The fiber firstly passes through a section of air layer, and then enters the coagulating bath for spinning forming by a wet method. The fine streams of the spinning solution is in a cylindrical shape after leaving spinneret orifices under the action of the gas-liquid interface tension, a primary cuticular layer is formed, and the cuticular structure is smooth. The method has the advantages of simple process, easy control and relatively low cost. In addition, the method also has the advantages that the spinning speed is high, the production efficiency can be improved, in addition, the surface of the obtained protofilament is smooth, the residual quantity of the solvents is greatly reduced, the quality homogenization degree of the protofilament is improved, and the mechanical property is excellent.

Owner:ZHONGFU SHENYING CARBON FIBER

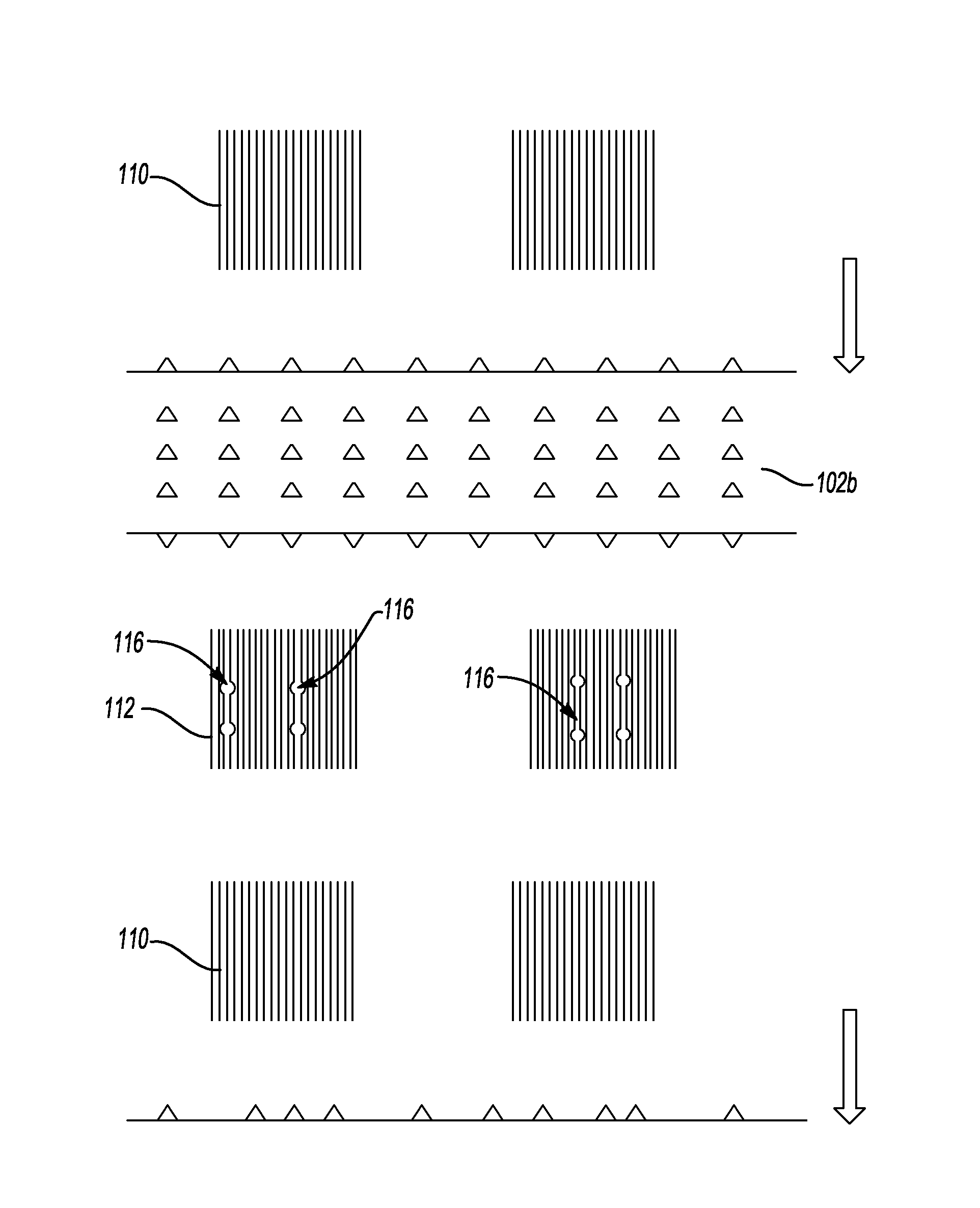

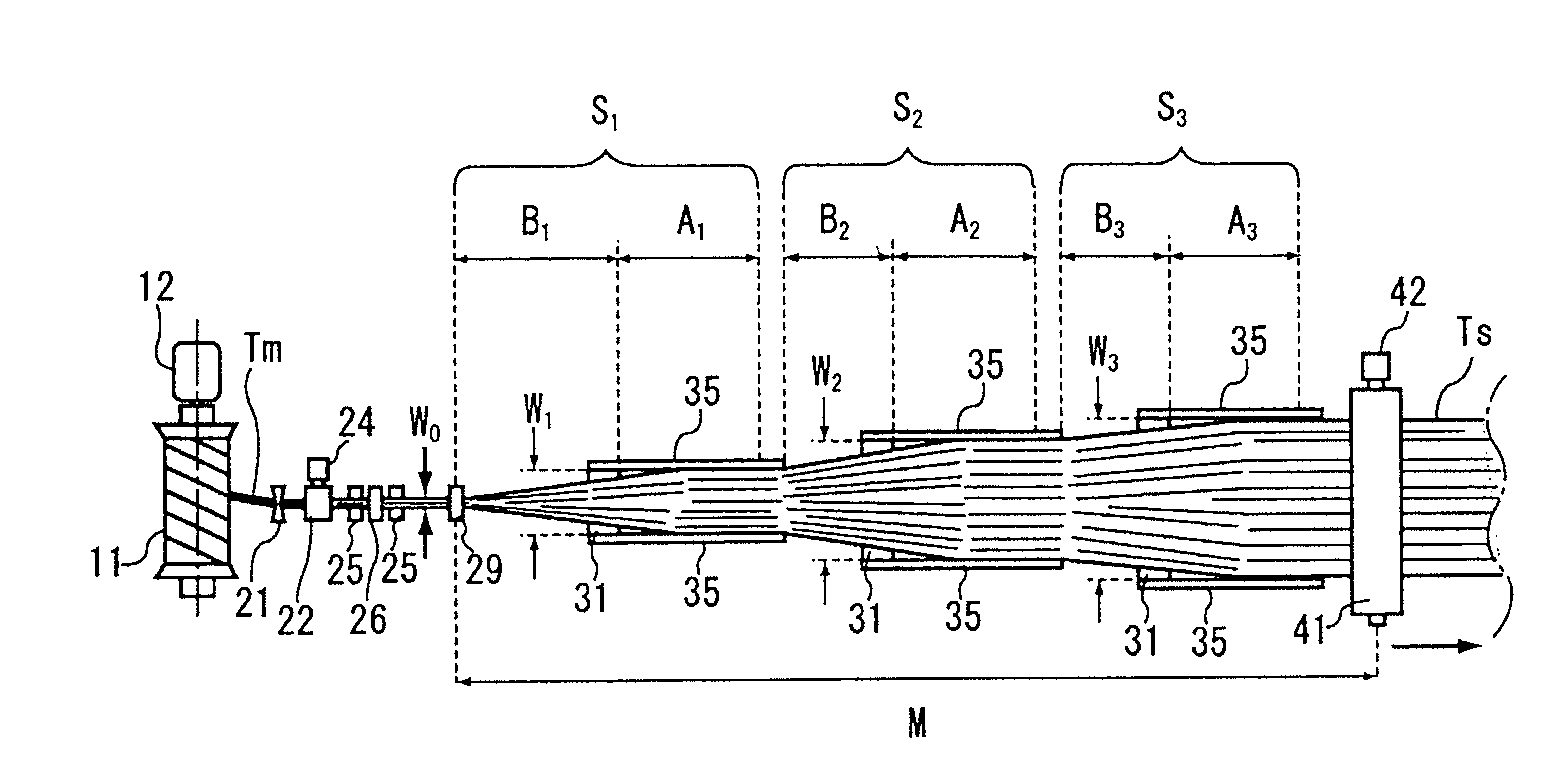

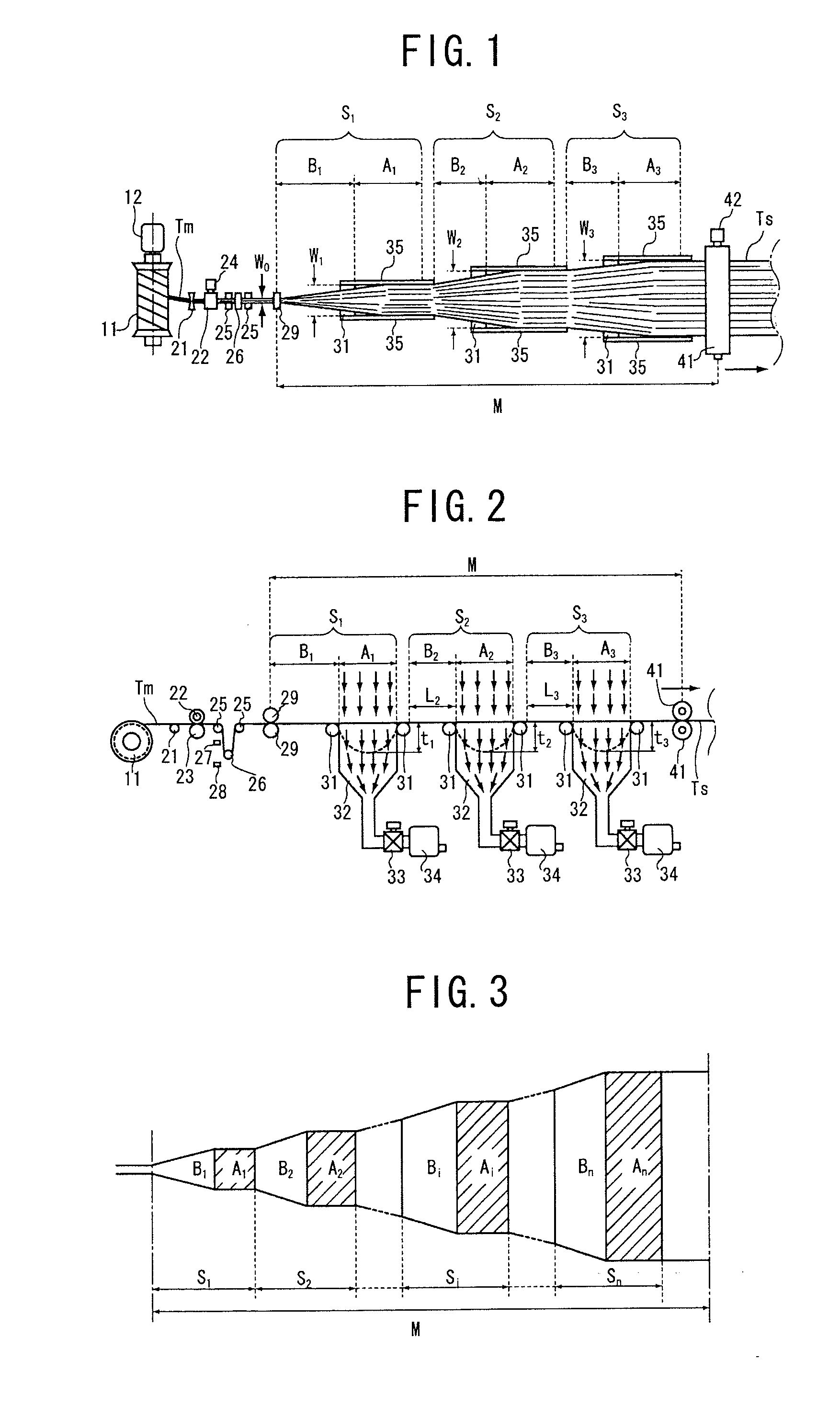

Method for spreading fiber bundles, spread fiber sheet, and method for manufacturing a fiber-reinforced sheet

ActiveUS20120135227A1Avoid even distributionImprove straightnessLayered productsFilament manufactureFiber bundleMaterials science

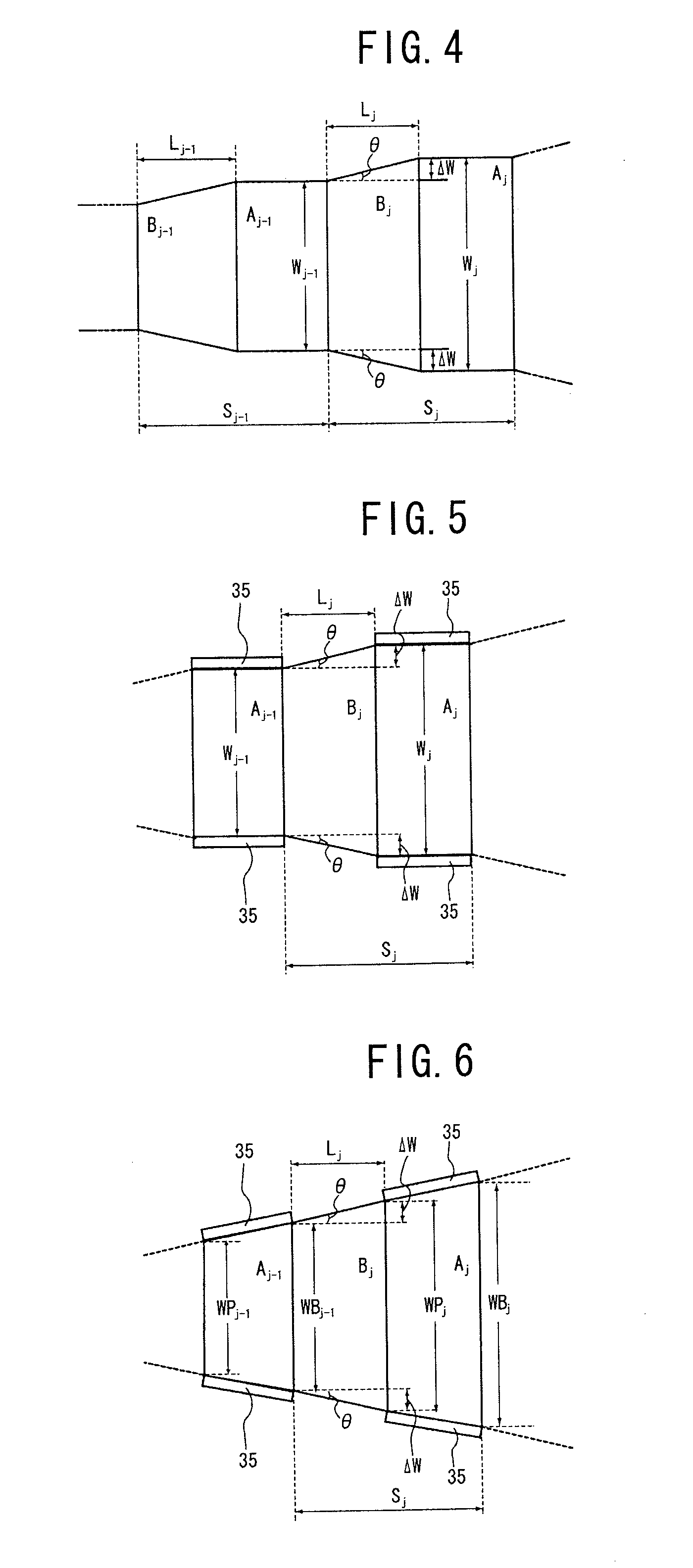

The present invention has an object to provide a fiber-spreading method which can form a thin spread fiber sheet having a large and uniform spread width by uniformly distributing fibers of a fiber bundle having an increased number of fibers. Since a set of regions Si each including a pair of a fiber-spreading region Ai and an expansion region Bi are arranged in a movable region M set so that the fibers of the fiber bundle can move in the width direction, the fiber-spreading region Ai moving the fibers in the width direction while bending the fibers by letting a fluid pass through the fiber bundle, thereby spreading the fiber bundle to a spread width Wi (i=1, . . . , n), and the expansion region Bi which is set on the upstream side in the feeding direction corresponding to the fiber-spreading region Ai and in which the width of the fiber bundle expands toward the end with movement of the fibers in the width direction in the fiber-spreading region Ai, by performing pre-spreading in which a movement phenomenon in the width direction caused by distribution of the fibers of the fiber bundle occurring in the fiber-spreading region Ai is made to act on the expansion region Bi on the upstream side, the fibers can be uniformly distributed in the fiber-spreading region Ai and the spread width can be expanded to a predetermined width so as to make the thickness uniform.

Owner:FUKUI PREFECTURE

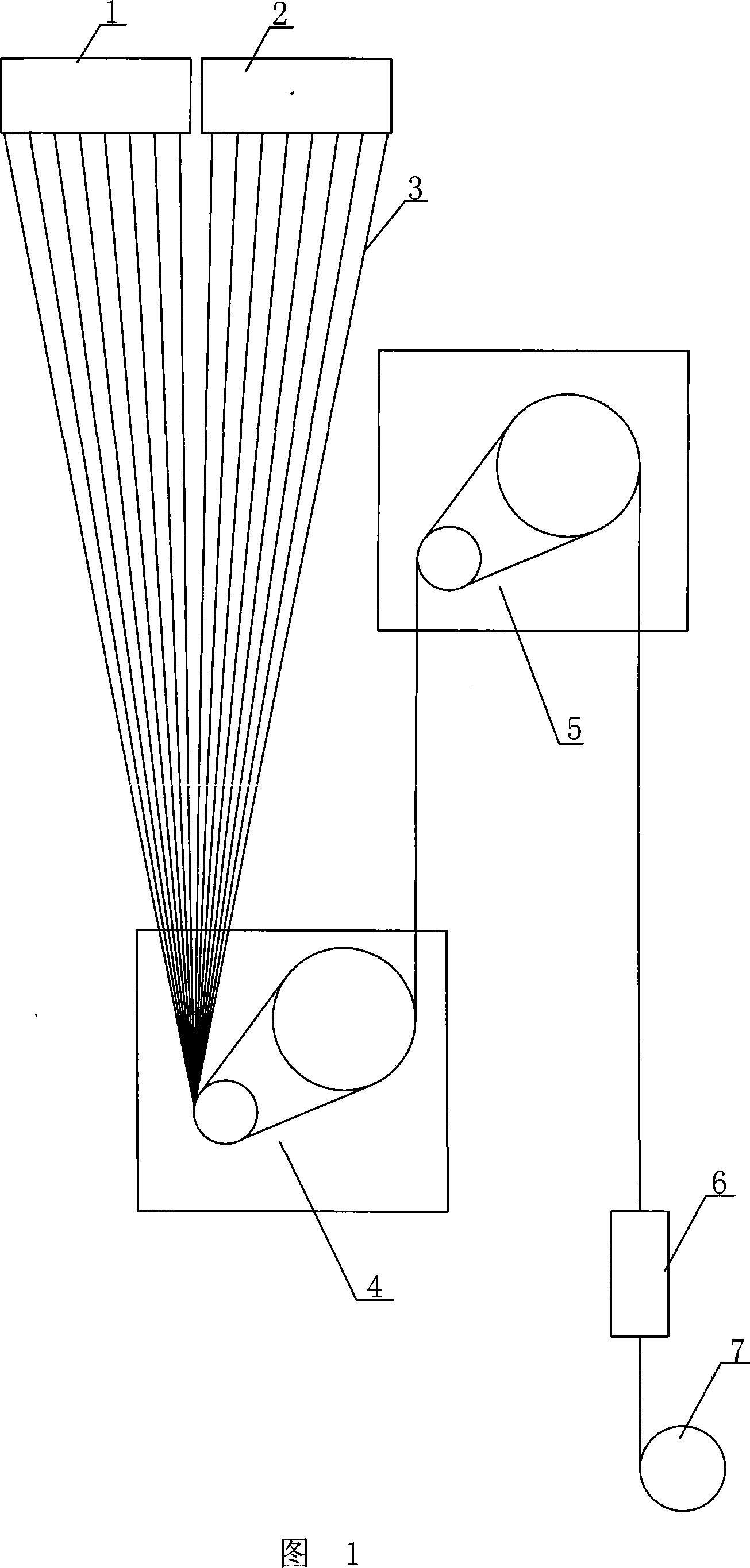

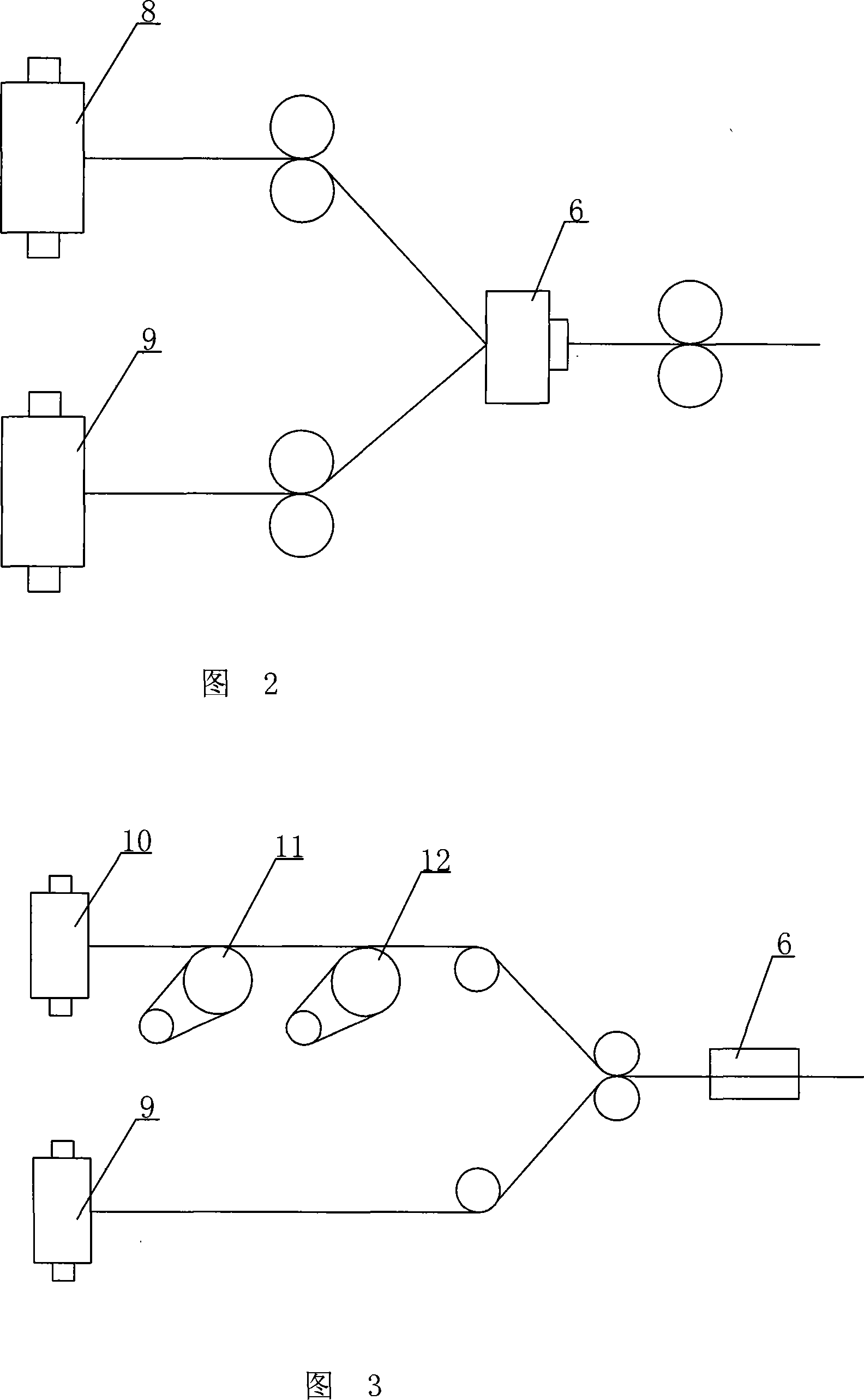

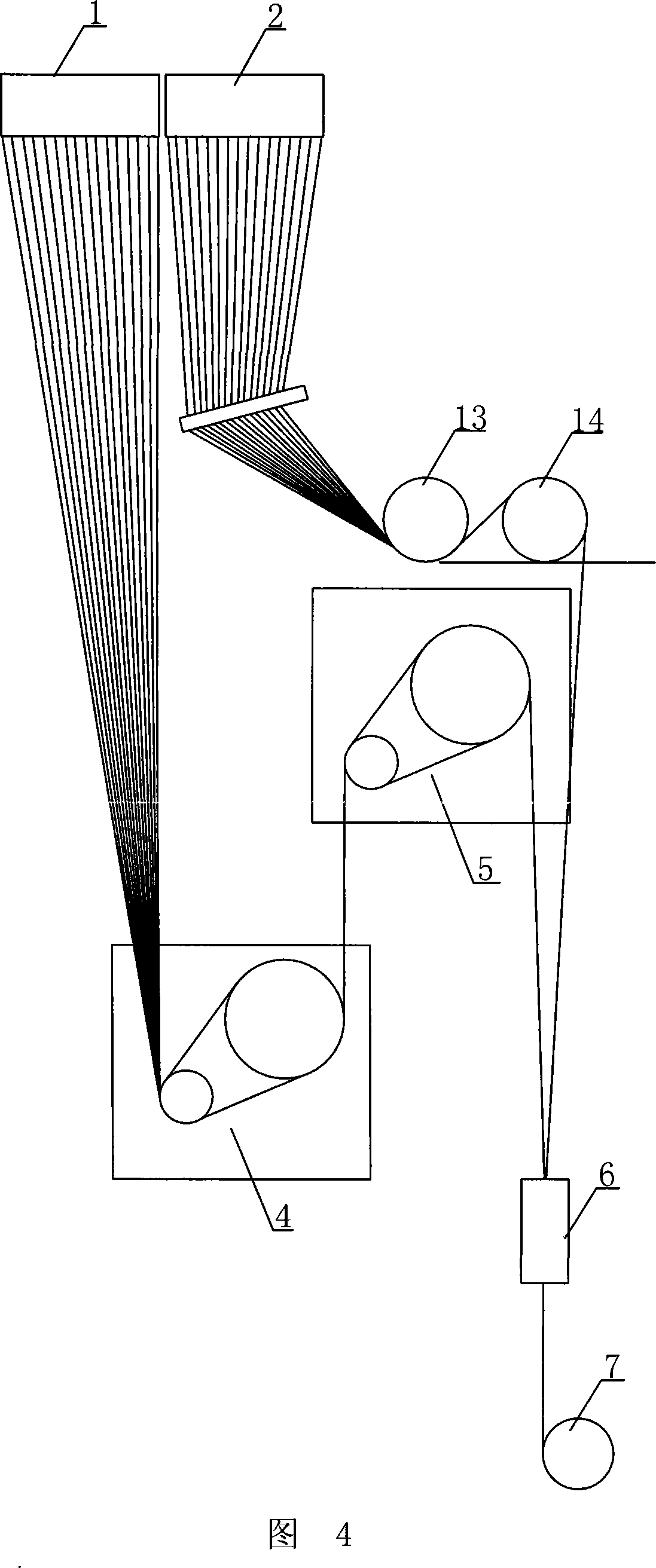

Method and device for manufacturing fully drawn yarn/pre-oriented yarn stranding composite yarn by one-step process

ActiveCN101200826AReduce consumptionSolve technical problemsSpinnerette packsFilament manufactureEngineeringRaw material

The invention discloses a one-step preparation method of stranding composite yarn of fully drawn yarn / pre-oriented yarn and a device thereof. The method includes that an FDY filament device is adopted to haul part tow on the back of a spinning box to two clod godet rollers to obtain POY yarn. The left tow is hauled to two hot godet rollers to obtain FDY yarn. The two tows are winded with a speed of 2800-3200m / min after being networked through a network device to obtain multi-strands of stranding composite yarn of fully drawn yarn / pre-oriented yarn. The device is to add two cold godet rollers on the filament device. The network device and a winding device are arranged to the back of the cold godet rollers and two hot godet rollers. The invention shortens the production process, reduces theequipment occupying space, lowers the consumption of the production cost, raw materials and energies and effectively solves the technical problem of finishing the spinning and the stranding in one step. The whole process is stable. The product quality is reliable. The quality defect that monofilament in yarn is easy to appear in a composite yarn product can be completely eliminated. The yield is three times of that of the prior art. And the production efficiency can be improved greatly.

Owner:WUJIANG FUDONG TEXTILE GROUP

Method for the production of a carbon fiber-based reinforcing element for tires

InactiveUS20040043213A1Reduce riskImprove the lubrication effectCarbon fibresFilament handlingFiberCarbon fibers

A method for the production of a multifilament carbon fibre-based longitudinal reinforcing element, designed to be incorporated in a rubber-based item. Said method comprises the following steps, whereby untwisted carbon fibres are plunged into an impregnating bath contained a solution of resorcinol-formaldehyde resin and rubber latex, the impregnated fibres are then dried and the dried fibres are subsequently twisted. The inventive method is characterised by the fact that it also comprises a step, during the impregnation step, consisting in opening out the carbon fibres by spreading out the constituent filaments thereof in such a way that each fibre has an increased surface area on which the impregnation can be performed.

Owner:SOVOUTRI SOC VOULTAINE DE TRANSFORMES INDS

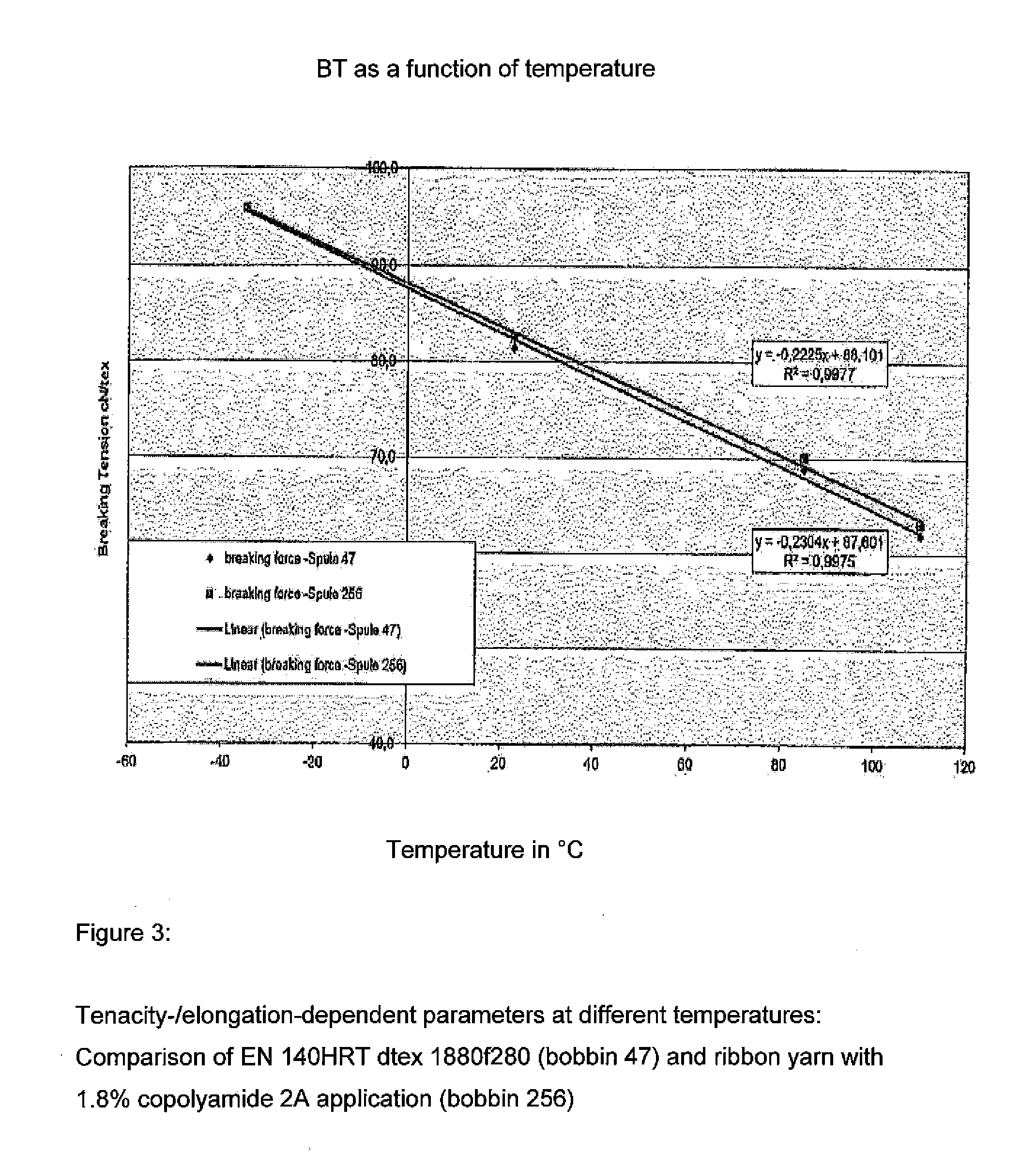

Ribbon yarn

ActiveUS20150167207A1Broaden applicationExcellent combustion resistanceMechanical impurity removalFilament handlingBand shapeEngineering

A method is disclosed for fabricating a ribbon yarn, the method including: spreading the yarn such that not more than five filaments are lying over one another, fixing the yarn by forming a matrix of one or more fixatives, winding the fixed yarn, wherein the fixative or fixatives are selected from a group consisting of copolyamides, copolyesters and silicones and also mixtures or blends thereof. Also described is the ribbon yarn and the application of the ribbon yarns for airbag fabrics, as a tire reinforcement and in textile construction.

Owner:PHP FIBERS GMBH

Method for producing regenerated cellulose fiber by dual-bath coagulation

InactiveCN101429682ASlow down the curing speedFully curedArtificial filaments from cellulose solutionsFilament manufactureThioureaCellulose fiber

The invention belongs to the material field, and provides a method for preparing a regenerated cellulose fiber by double solidification bath. The method comprises the following steps: precooling cellulose to a temperature of between 8 DEG C below zero and 12 DEG C below zero in a mixed solution which contains the following compositions in weight percentage: 7 to 10 percent of sodium hydroxide, 4.5 to 7 percent of thiourea, 1 to 10 percent of urea, and 73 to 87.5 percent of water to prepare a cellulose solution with concentration of between 2 and 12 percent through filtering and defoaming; spinning the cellulose solution through a spinning machine, and presolidifying and predrafting the cellulose solution in a first solidifying bath; sufficiently solidifying, regenerating, drafting and orientating the cellulose in a second solidifying bath; washing and drying cellulose; and finally, oiling the fiber through a prepared composite oil solution, and winding the fiber to obtain the regenerated cellulose fiber with excellent mechanical performance.

Owner:DONGHUA UNIV

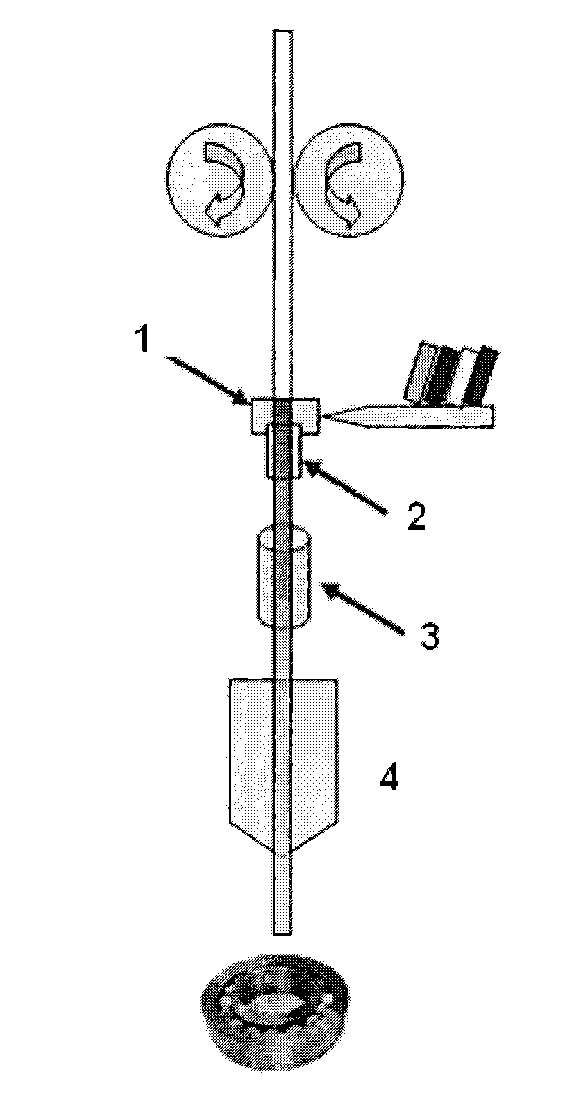

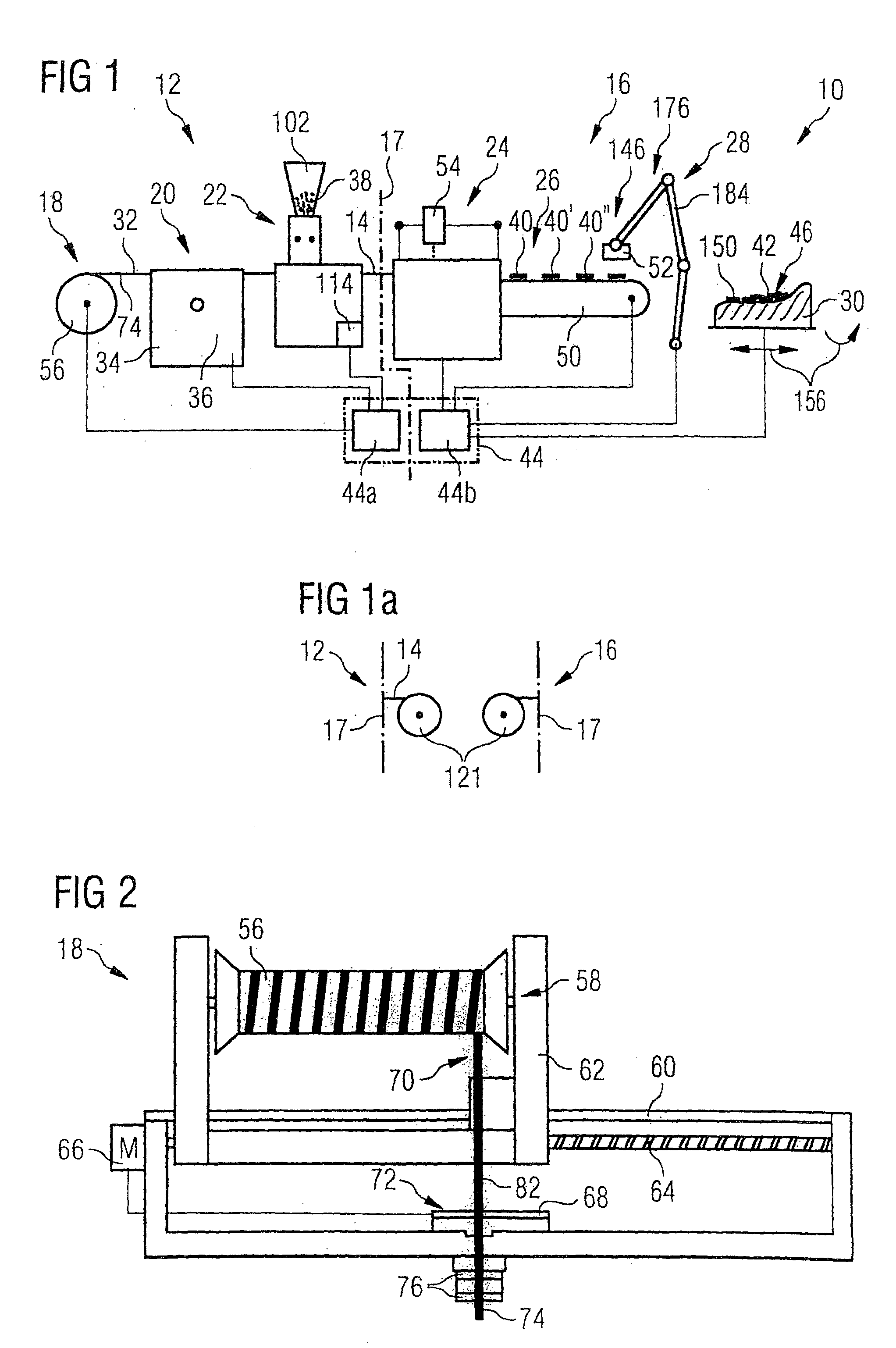

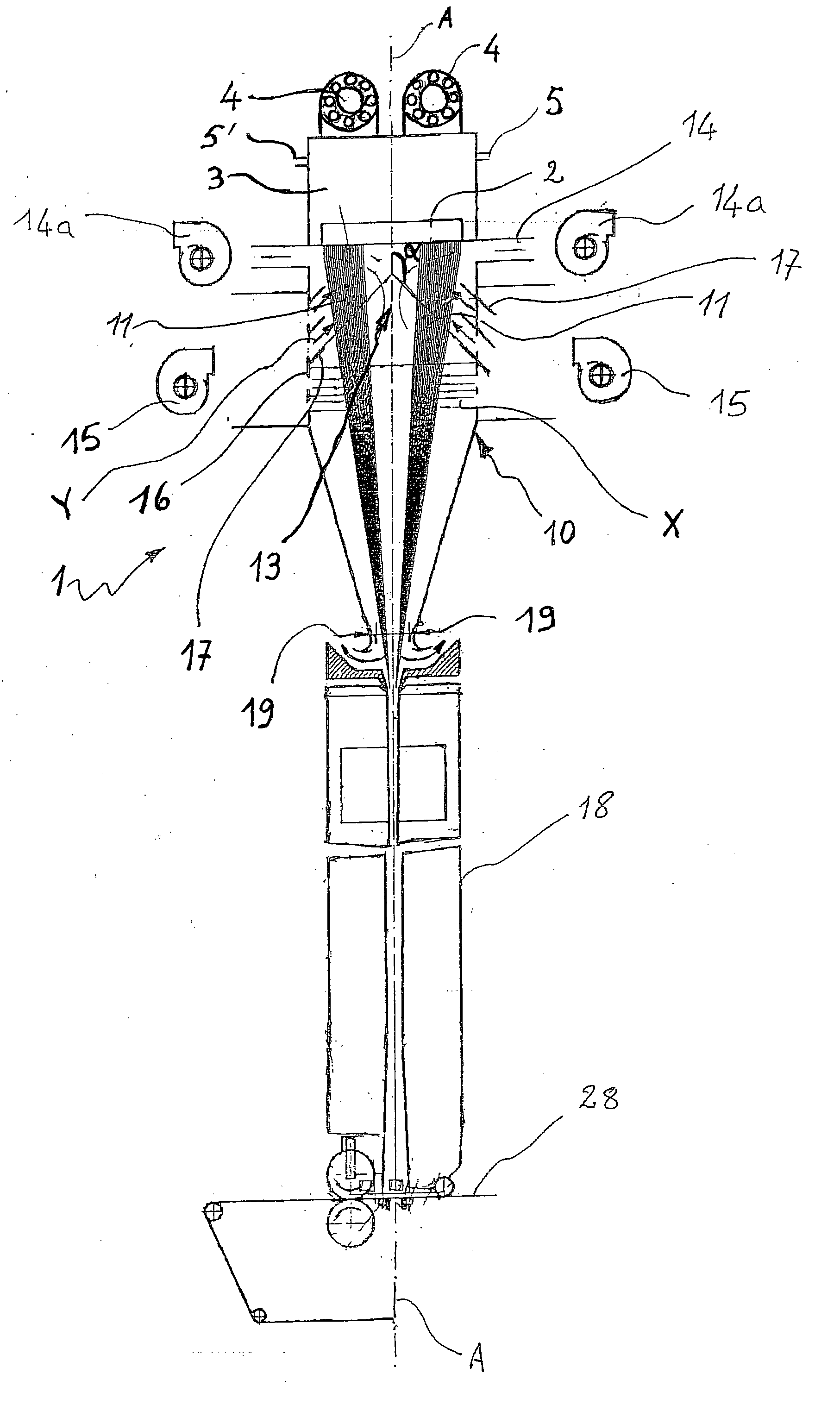

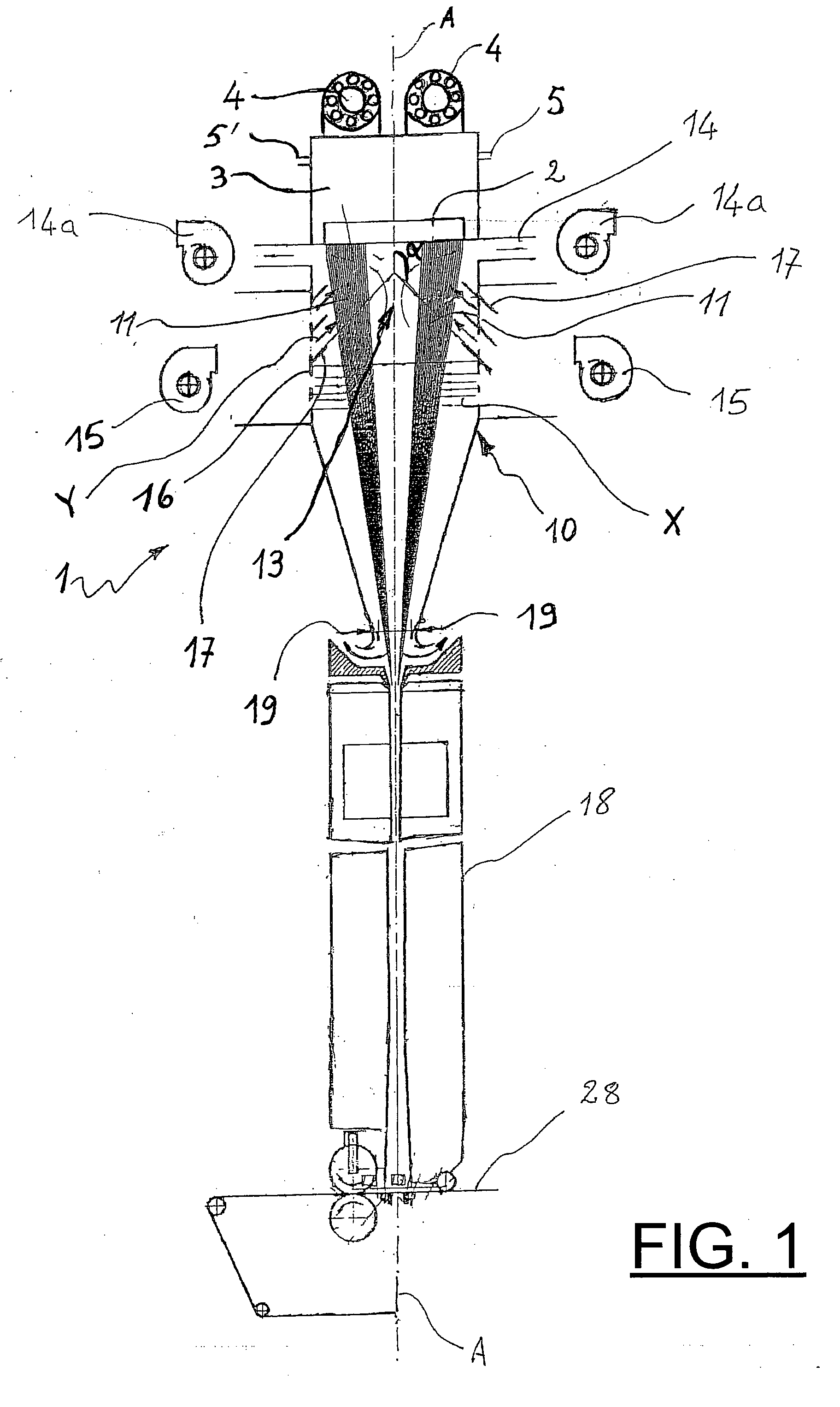

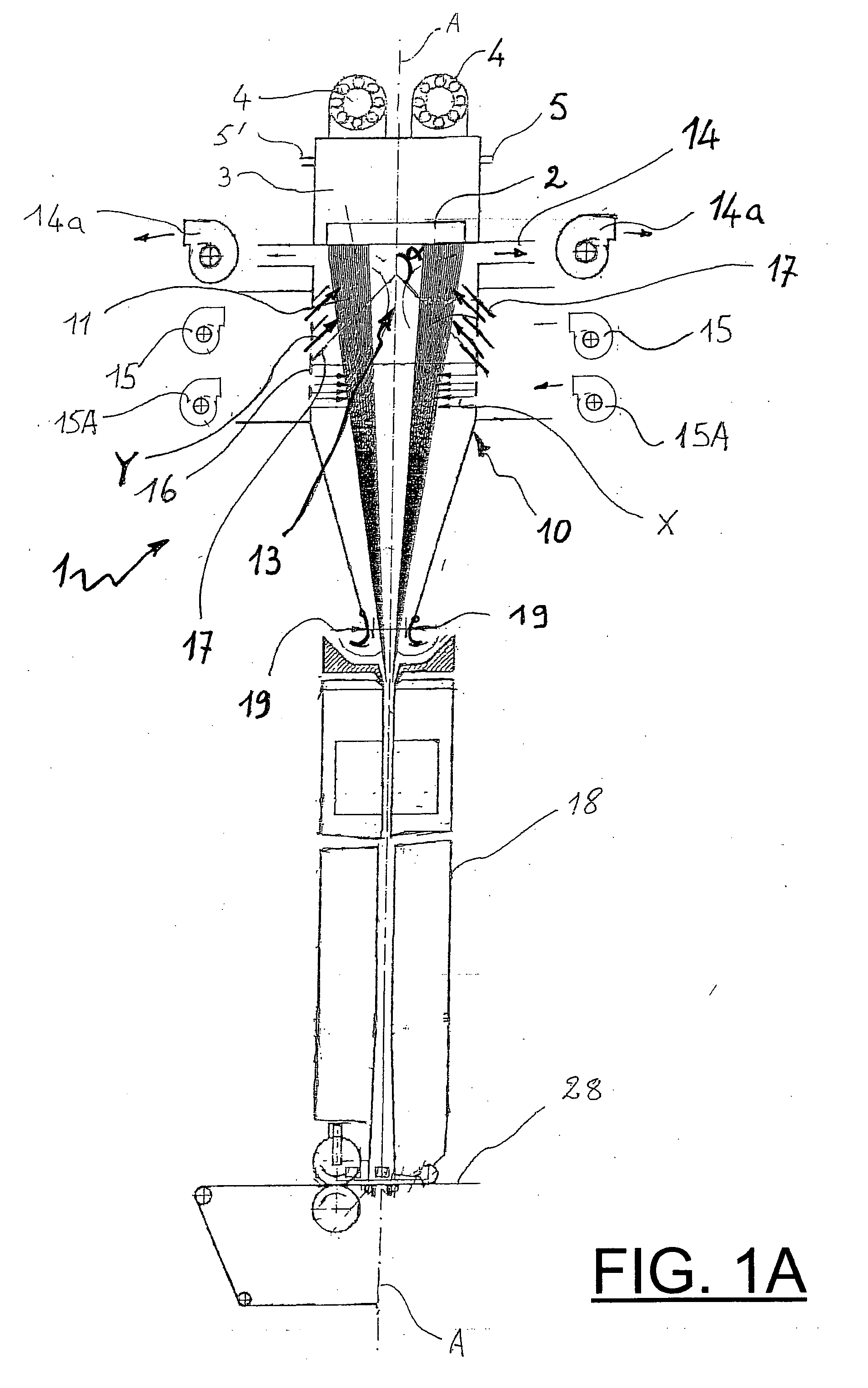

Process and apparatus for the production of nonwoven fabrics from extruded filaments

ActiveUS20100099321A1Gradual uniform coolingEasy to stretchEngine sealsFilament/thread formingCooling chamberEngineering

In an apparatus for the production of a non-woven fabric, a plurality of filaments (11) are extruded by a spinneret (2) into at least two groups spaced from each other to define an area of the cooling chamber without filaments and structures; the filaments are cooled by an air flow (Y) conveyed into the cooling chamber directed towards an intermediate area between said two groups of filaments, said area being located below an area of the spinneret without extrusion holes.

Owner:FARE

Variable-airflow cloth, sound absorbing material, and vehicular part

ActiveUS20090029620A1Reduce weightSave spaceGarment special featuresProtective fabricsFiberPolymer science

Cloth, in which air permeability is variable by energization, includes: a fibrous object composed of composite fibers, each of the composite fibers including: an electrical-conductive polymeric material; and a material different from the electrical-conductive polymeric material, the different material being directly stacked on the electrical-conductive polymeric material; and electrodes which are attached to the fibrous object, and energize the electrical-conductive polymeric material. Each of the composite fibers has a structure in which the material different from the electrical-conductive polymeric material is stacked on at least a part of a surface of the electrical-conductive polymeric material, or a structure in which either one of the electrical-conductive polymeric material and the material different from the electrical-conductive polymeric material penetrates the other material in a longitudinal direction. The cloth is capable of controlling the air permeability by a control factor enabling weight reduction and space saving.

Owner:NISSAN MOTOR CO LTD

Preparation method of fishery polyamide wear-resistant monofilament

ActiveCN103147157AImprove wear resistanceImprove bending strengthFilament forming substance formingArtificial thread manufacturing machinesWinding machinePolymer science

The invention discloses a preparation method of a fishery polyamide wear-resistant monofilament. The fishery polyamide wear-resistant monofilament comprises polyamide resin, ultra-high molecular weight polyethylene powder, active nano silicon dioxide and PE (polyethylene) grafting maleic anhydride. The preparation method is characterized by comprising the following steps of: mixing polyamide resin, ultra-high molecular weight polyethylene powder, active nano silicon dioxide and PE grafting maleic anhydride; stirring by a stirrer after mixing, heating by a twin screw and granulating into particles by a granulator, mixing and melting the mixed particles through a plastic extruding machine with a mixing head, extruding through a high pressure metering pump, cooling molten and extruded monofilament to put in a drawing machine for drawing with the drawing temperature of 90-95 DEG C and the drawing time of 5-6.5 times, putting the drawn monofilament in a setting machine for setting, carrying out surface coating treatment on the monofilament through an antistatic oil, and winding the set monofilament on a winding machine, wherein the winding tension of 0.06-6mm monofilament is 50-800cN, and the winding speed is 10-200m / min.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

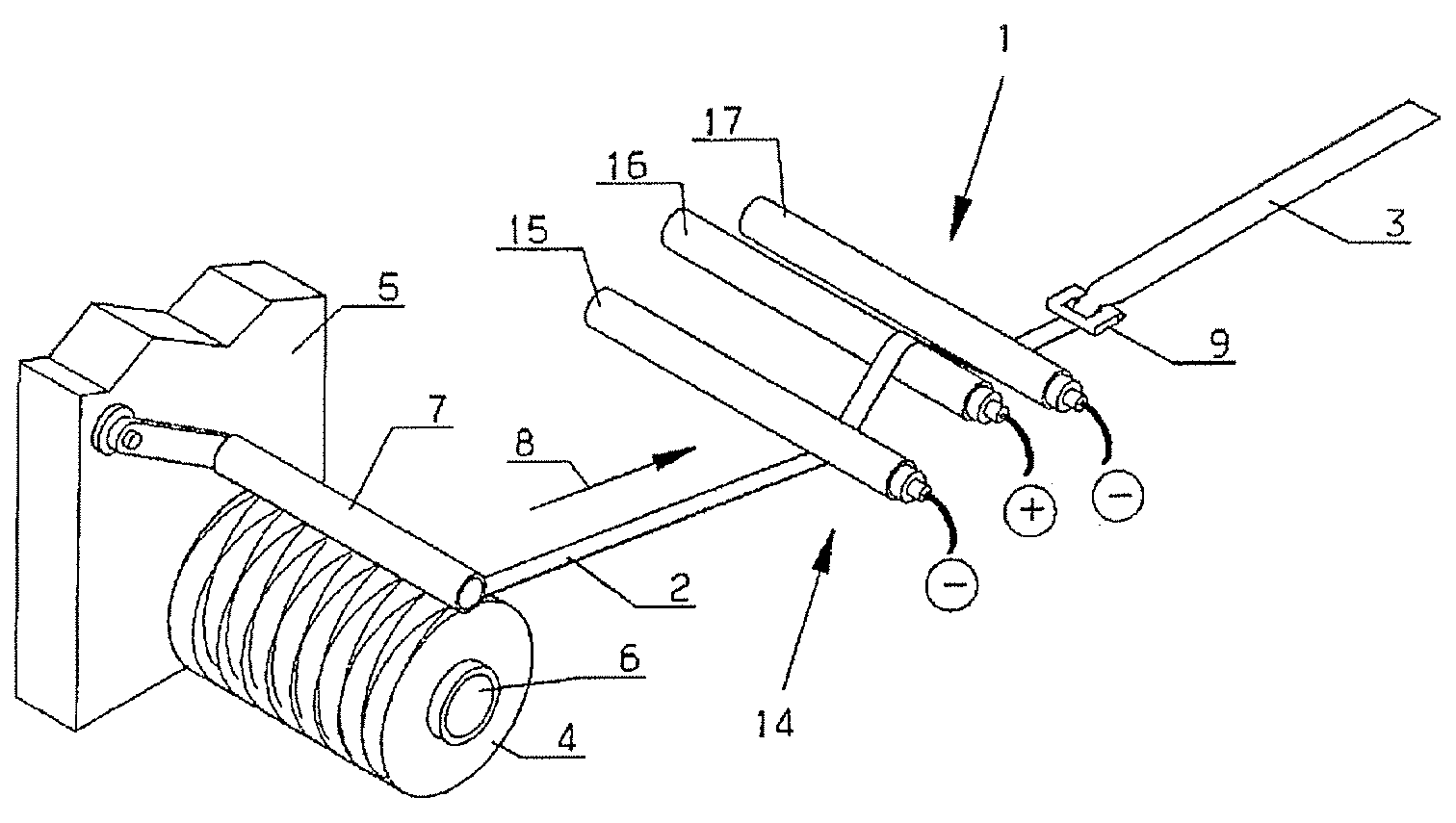

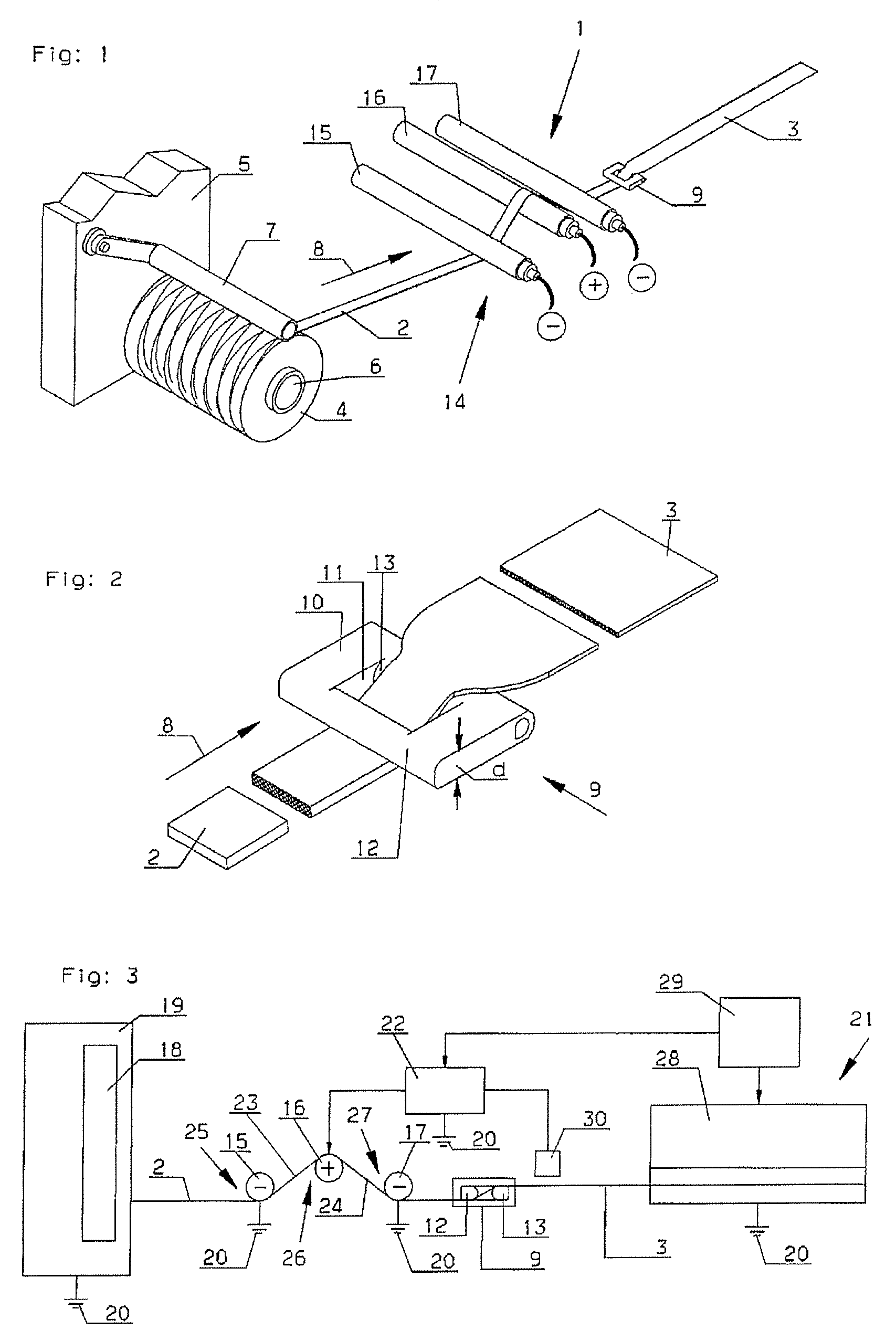

Device and method for spreading a carbon fiber hank

InactiveUS7536761B2Spread carbon fiber hanksSimple wayFilament manufactureArtificial filament supportFiberCarbon fibers

Device and method for spreading a carbon fiber hank into a carbon fiber band. The device includes a heating device having at least two electrodes that are spaced apart from each other and coupled to a power supply, and a spreading device arranged after the heating device in the traveling direction of the carbon fiber hank.

Owner:KARL MAYER MALIMO TEXTILMASCHFAB

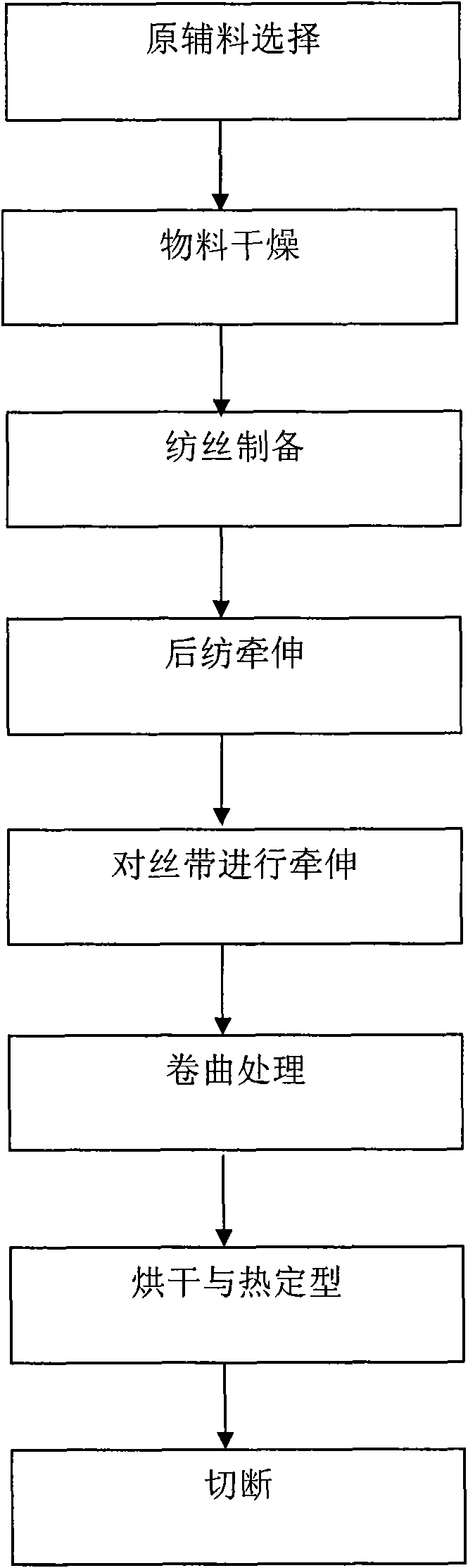

Preparation method of regenerative colored polyester fiber

InactiveCN101994163AIncrease elasticityImprove insulation performanceFilament manufactureHeating/cooling textile fabricsPolyesterHeat resistance

The invention discloses a preparation method of regenerative colored polyester fiber, comprising the following steps of: selecting supplementary materials; drying the materials; carrying out spinning preparation and post-spinning extension; evenly extending by two traction rollers under a heating state; rolling the extended raw tows; drying and thermally forming the raw tows; and finally, cutting the dried tows according to customer demands to obtain the regenerative colored polyester fiber with needed lengths. Because the produced regenerative colored fiber is directly spun in the natural color, the traditional color difference is greatly reduced. The obtained product has even color, is colorfast and has high strength, good thermal stability, good elasticity, good wear resistance, low water absorption moisture regain, good acid and base resistance, bio-incising resistance, and the like.

Owner:扬州天富龙集团股份有限公司

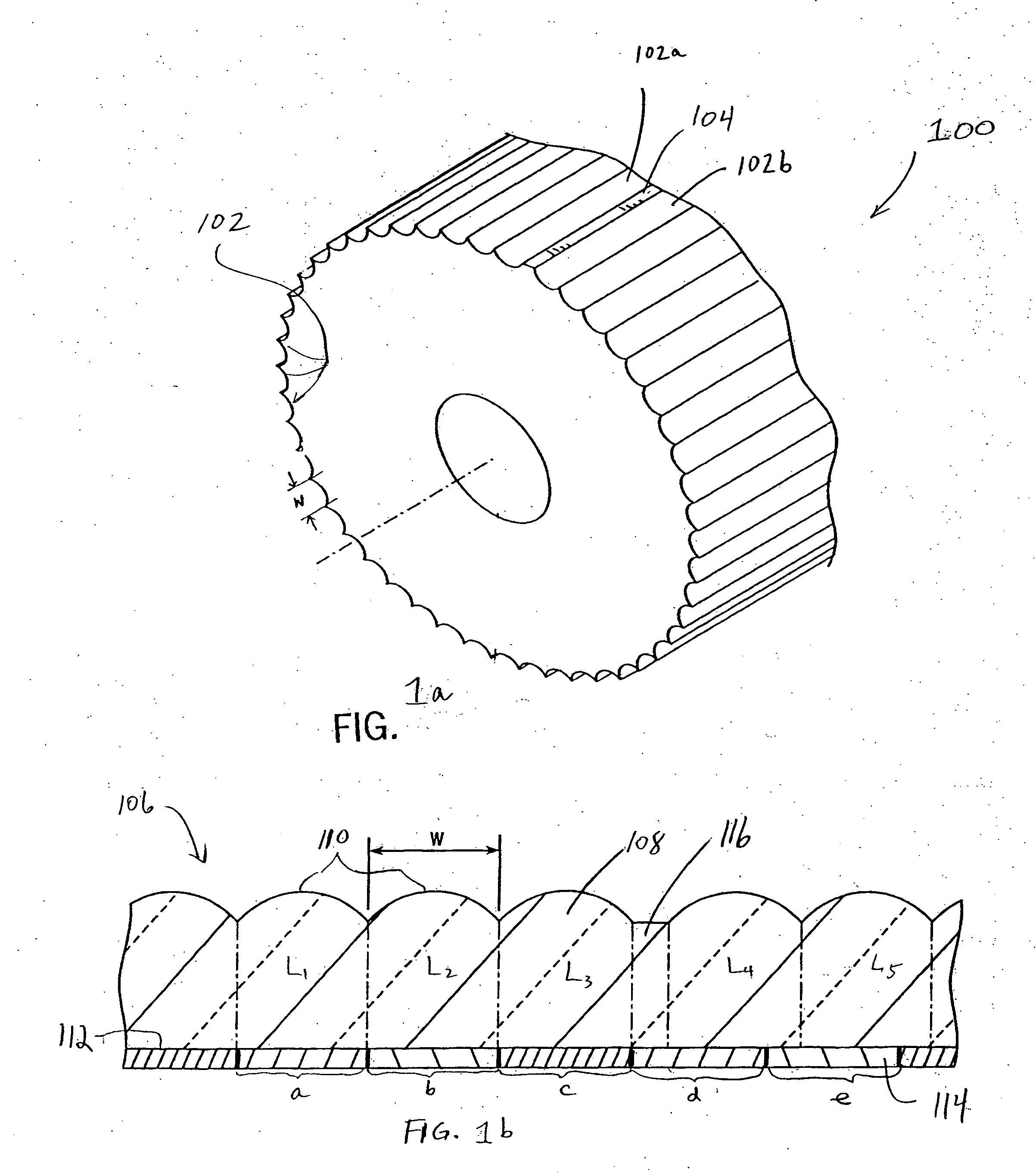

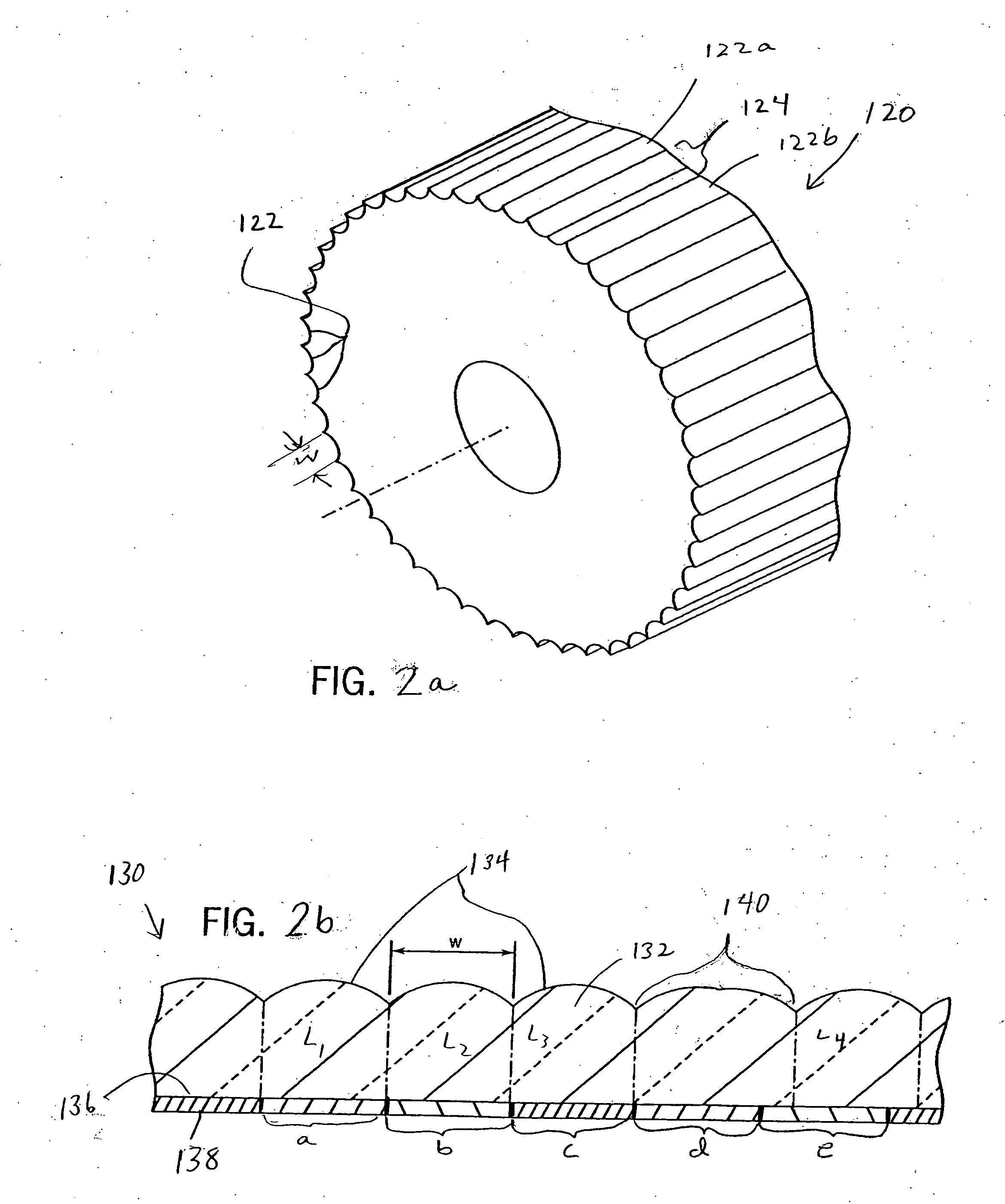

Lenticular lens pattern-forming device for producing a web roll of lenticular lens

InactiveUS20050286134A1Dough-sheeters/rolling-machines/rolling-pinsConfectioneryGroove widthEngineering

Owner:GOGGINS TIMOTHY P

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com