Fiber tow treatment apparatus and system

a technology of tow treatment and fiber, which is applied in the direction of severing to form staple fibres, thin material processing, textiles and paper, etc., can solve the problem of non-uniform positioning of spacing apart nubs along the rotation axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0048]FIG. 4 illustrates fiber composite tensile strength as a function of fiber tow size (number of fiber filaments in a fiber tow). As depicted in FIG. 4, the tensile strength of fiber composites increases from 85 MPa to 270 MPa as the fiber tow size decreases from 12 K to 0.5 K. An improvement in strength reinforcement may be attributed to better wet-out and dispersion of the smaller tow fibers in the resin matrix. This example demonstrates that fibers at certain tow size such as a tow size larger than 12K provides very little reinforcement in tensile strength of the resin composites.

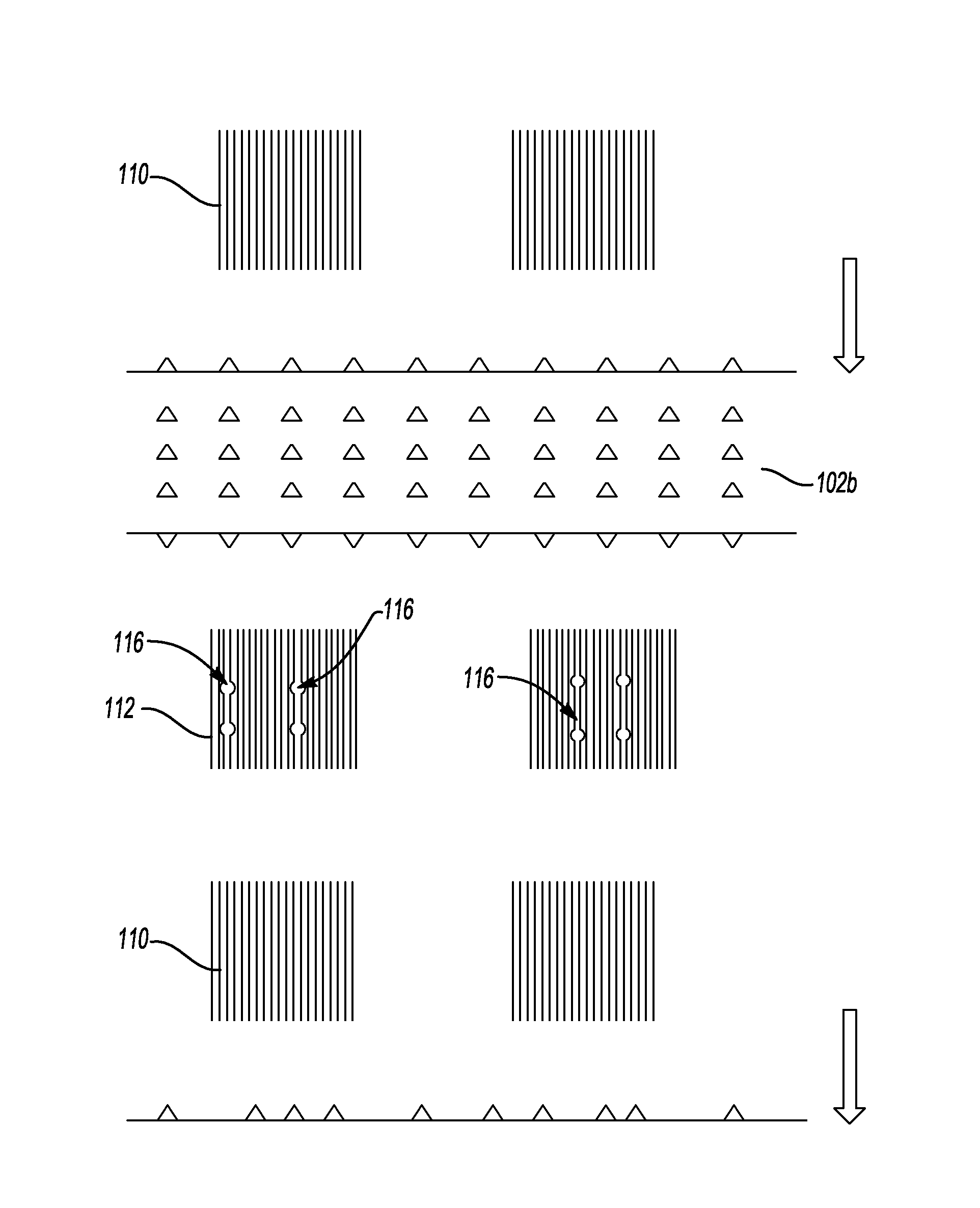

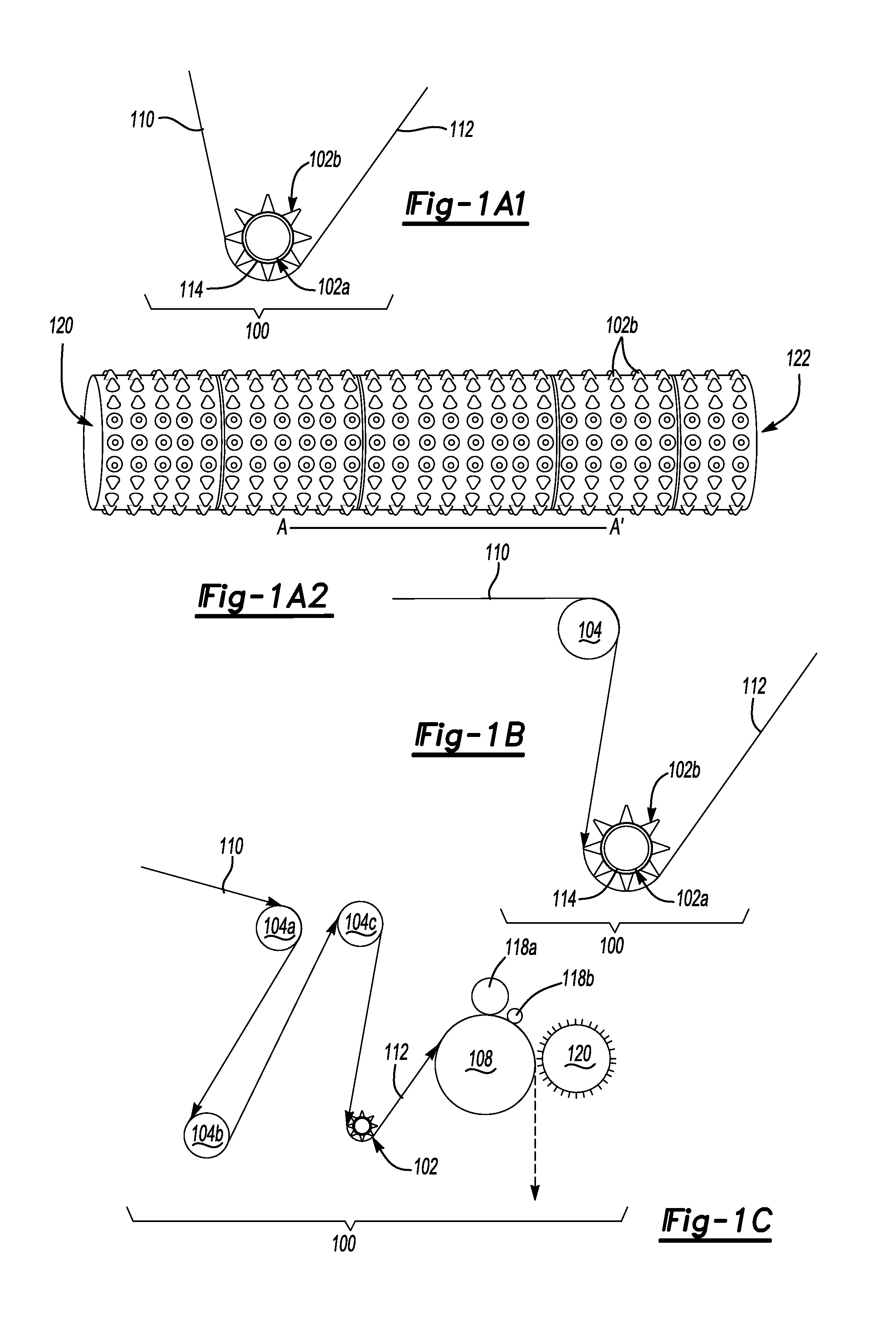

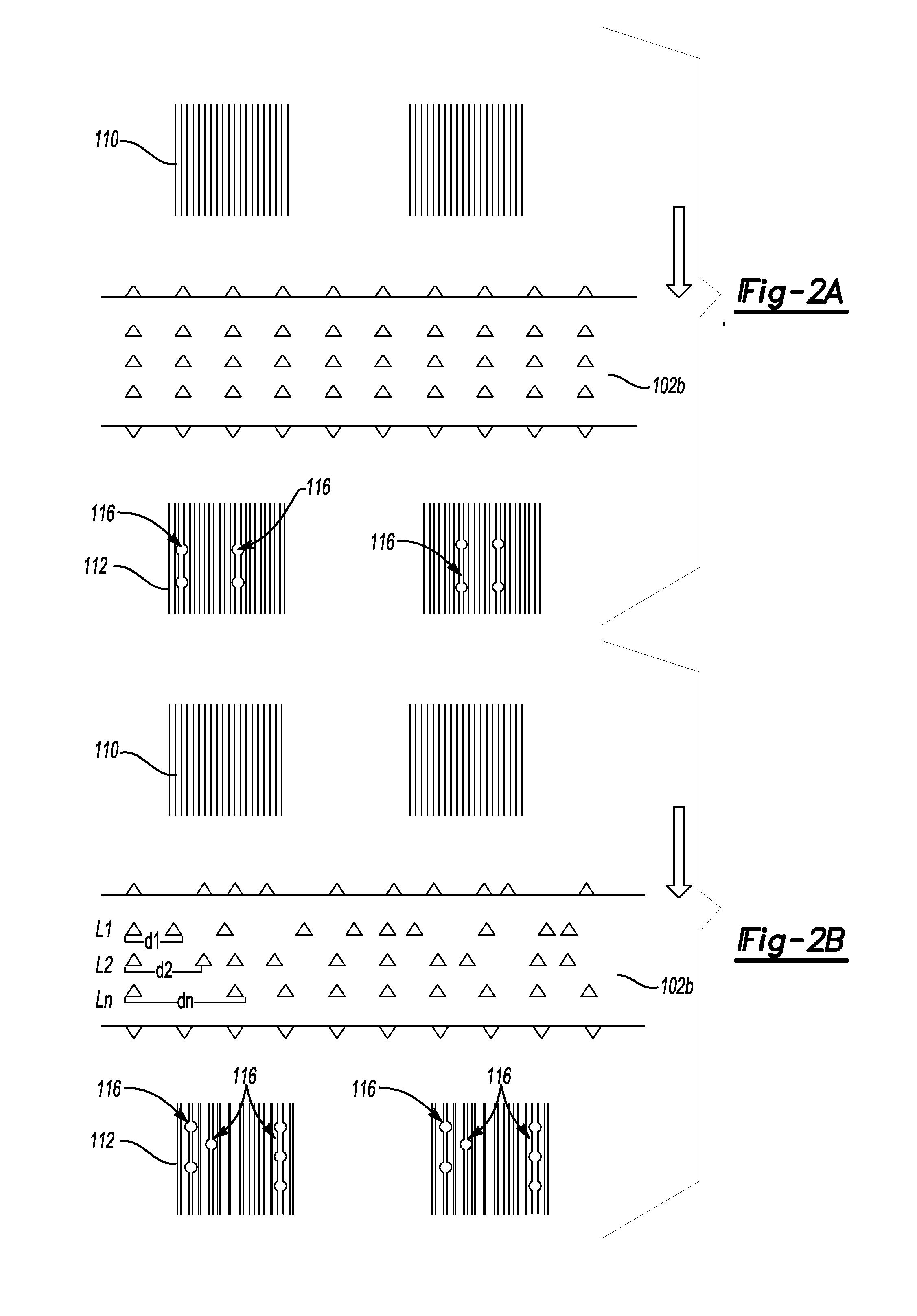

[0049]FIGS. 5A and 5B depict two comparative fiber treatment systems. According to the system of FIG. 5A, a fiber tow 510 is pulled via a pulling roller 508 and is cut via a chopper (not shown) to form 1-inch chopped fibers. The system of FIG. 5A does not involve the use of any spreader roller such as the spreader roller 104 of FIG. 1B or any nubbed roller such as the nubbed roller 102 of FIG. 1A. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com