Patents

Literature

194 results about "Fibre treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

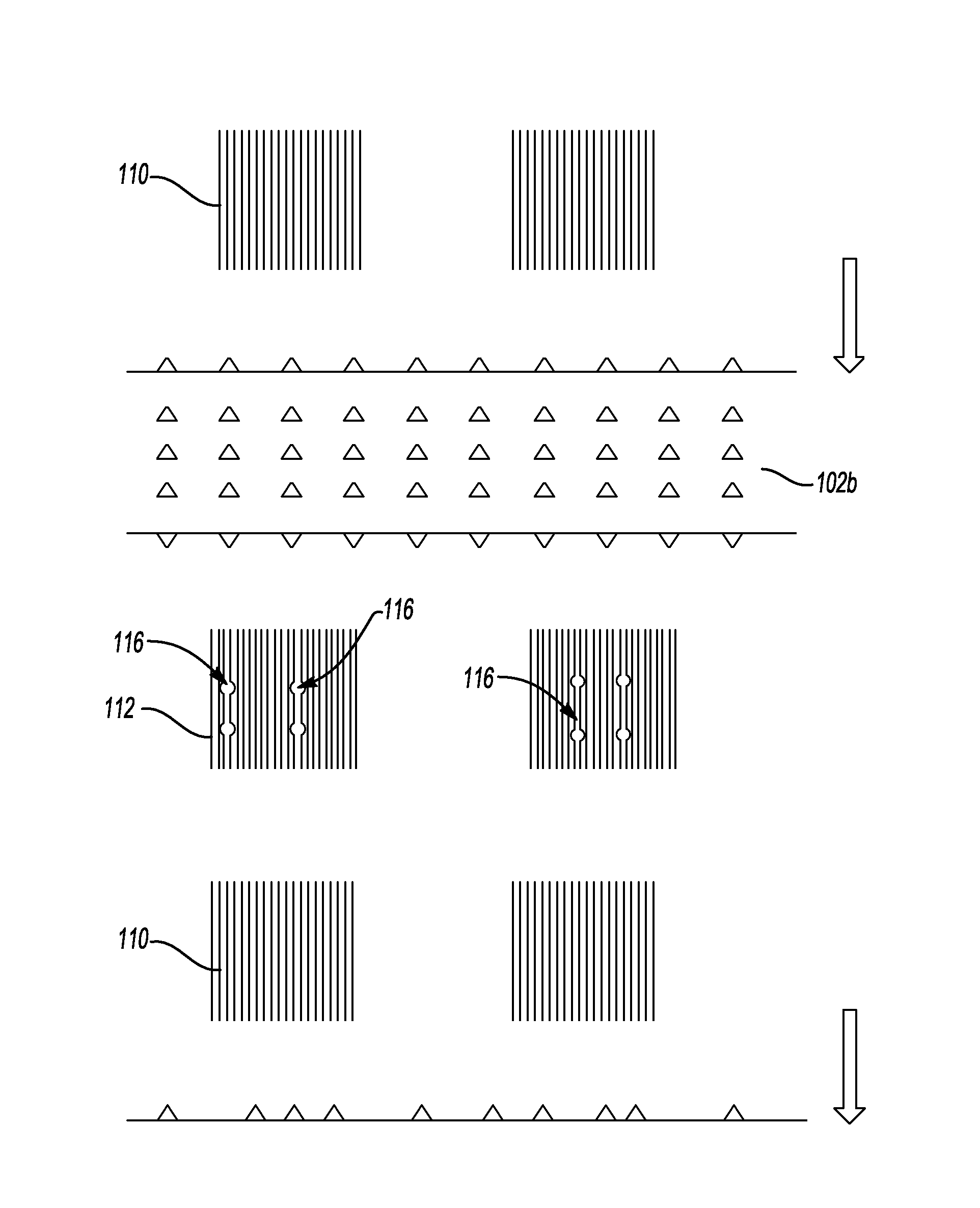

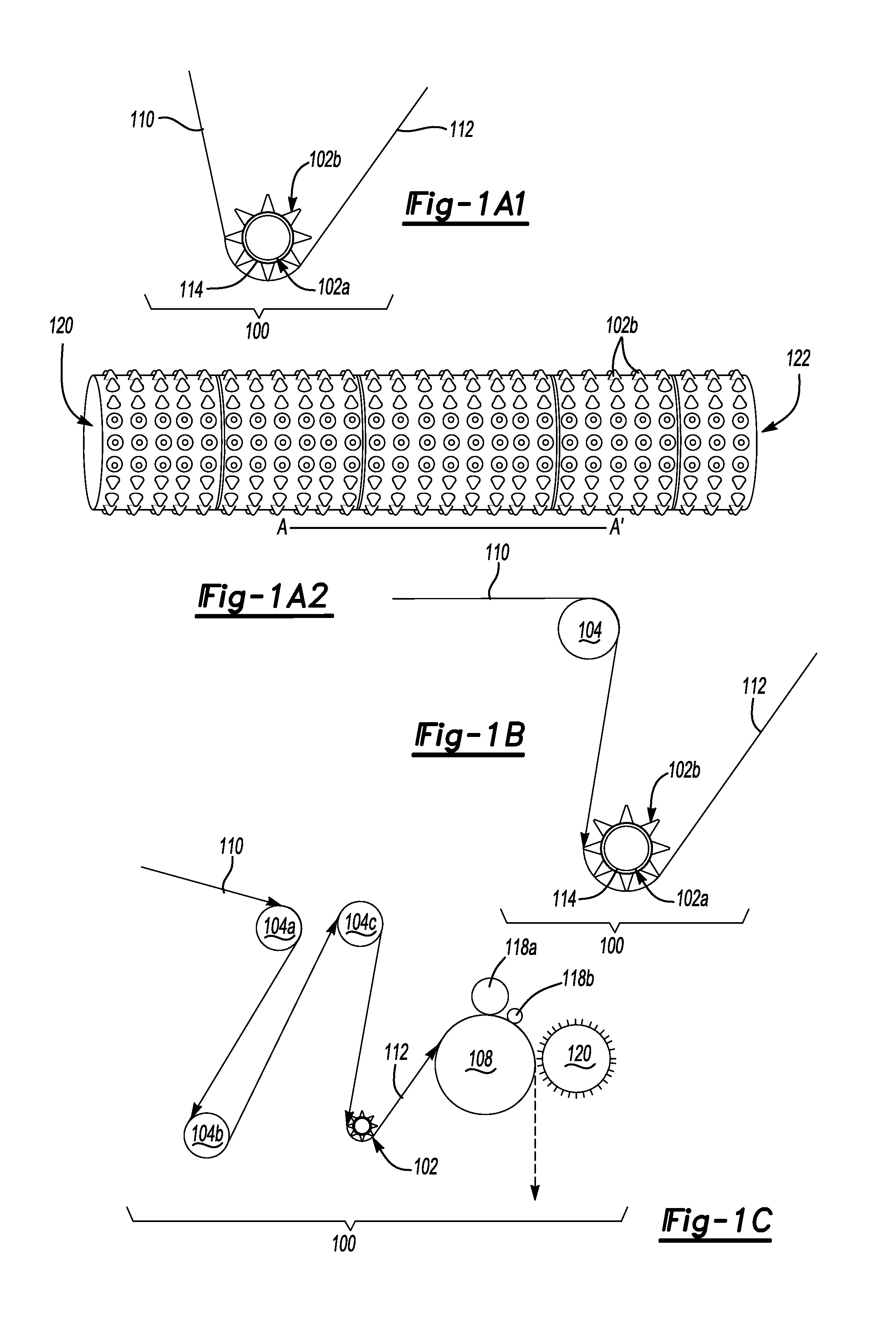

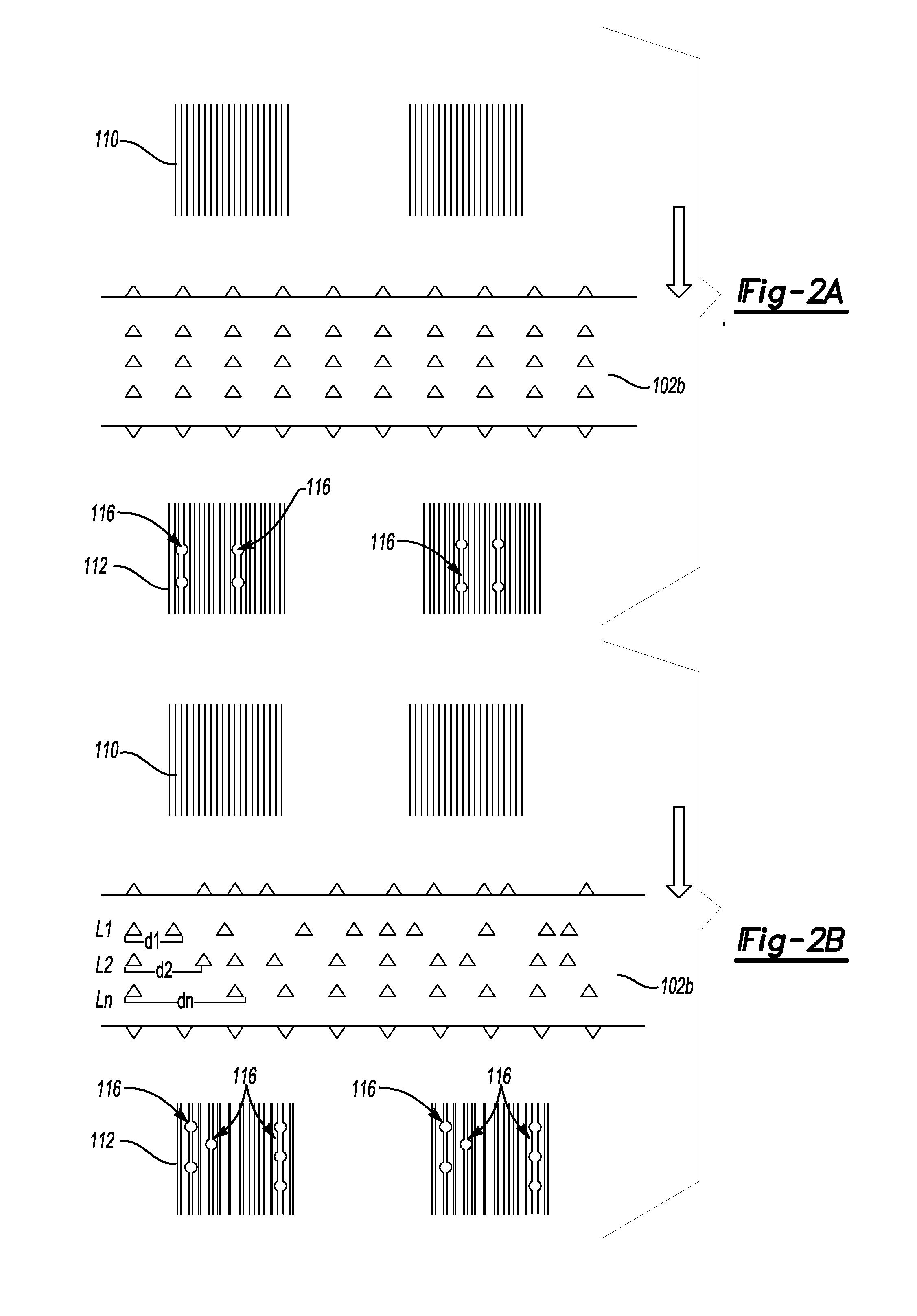

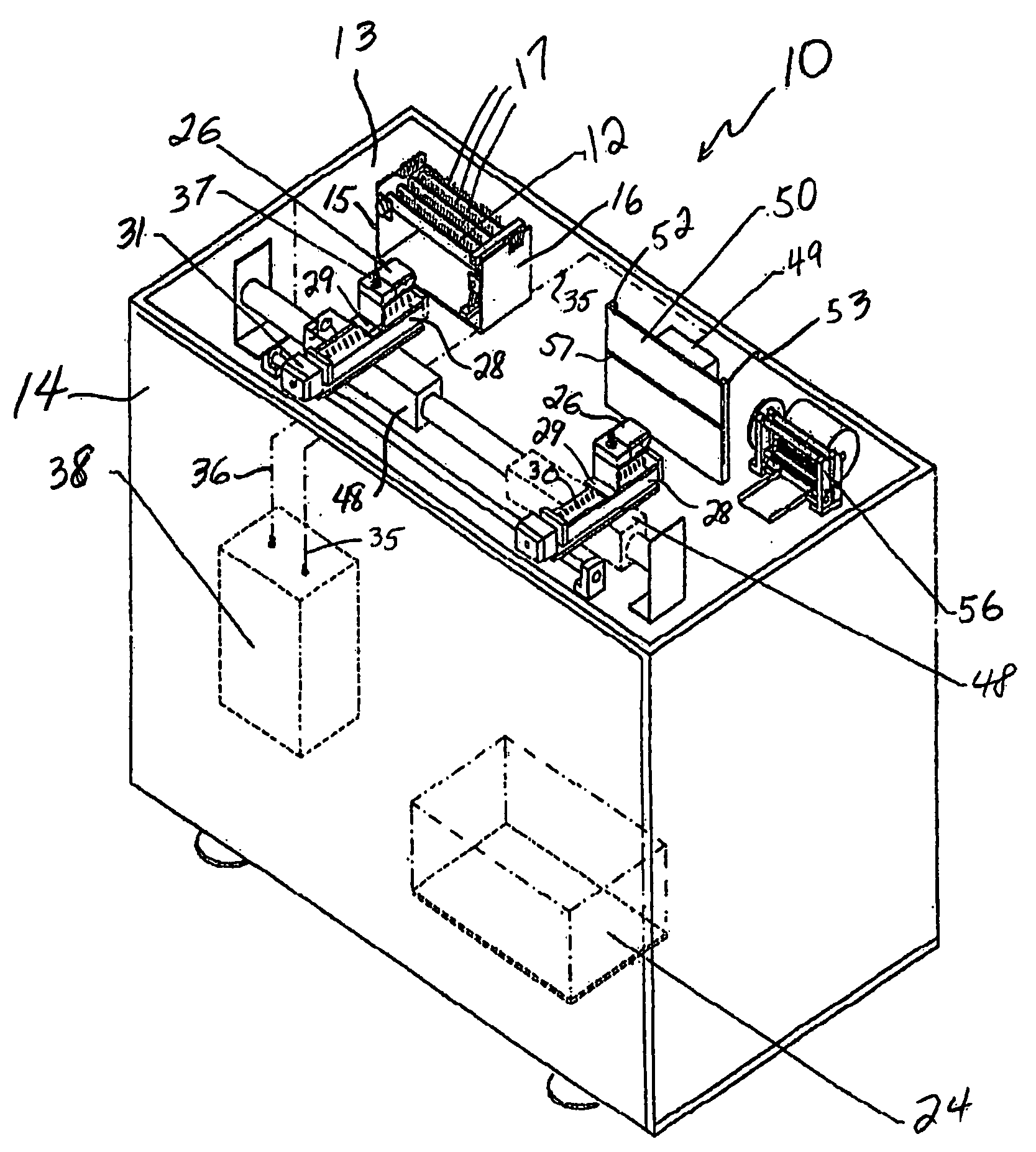

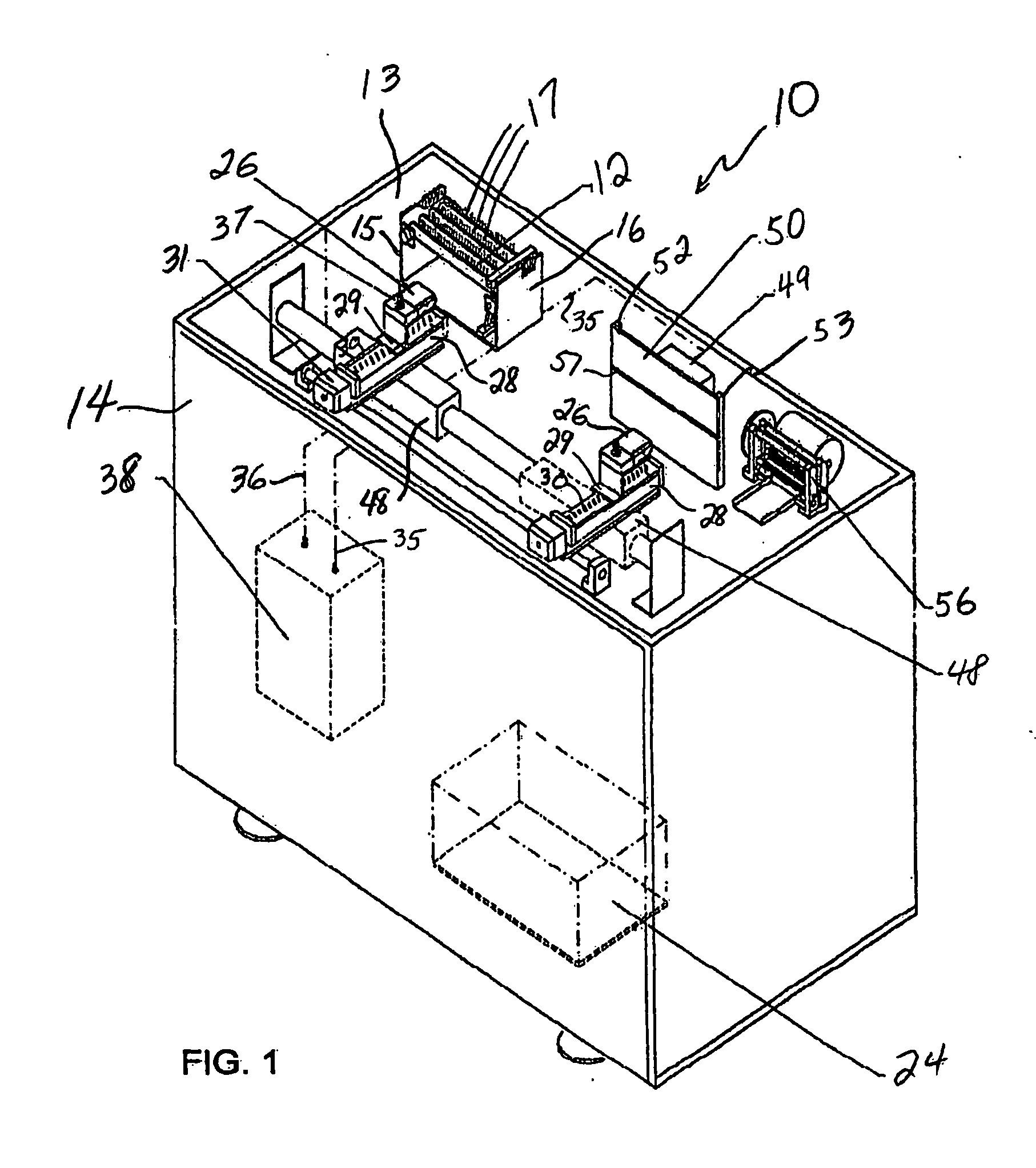

Fiber tow treatment apparatus and system

In one embodiment, a fiber treatment system includes a rotatable nubbed roller including an axis of rotation, a surface, and a number of spaced apart nubs projecting away from the surface, the number of spaced apart nubs imparting a number of spaced apart openings in a fiber tow. In another embodiment, the fiber treatment system further includes an optionally rotatable spreader roller for flattening the fiber tow. In yet another embodiment, the loosened, but still continuous fiber tow is chopped by a downstream chopper to form short fibers with reduced tow sizes.

Owner:US COUNCIL FOR AUTOMOTIVE RES

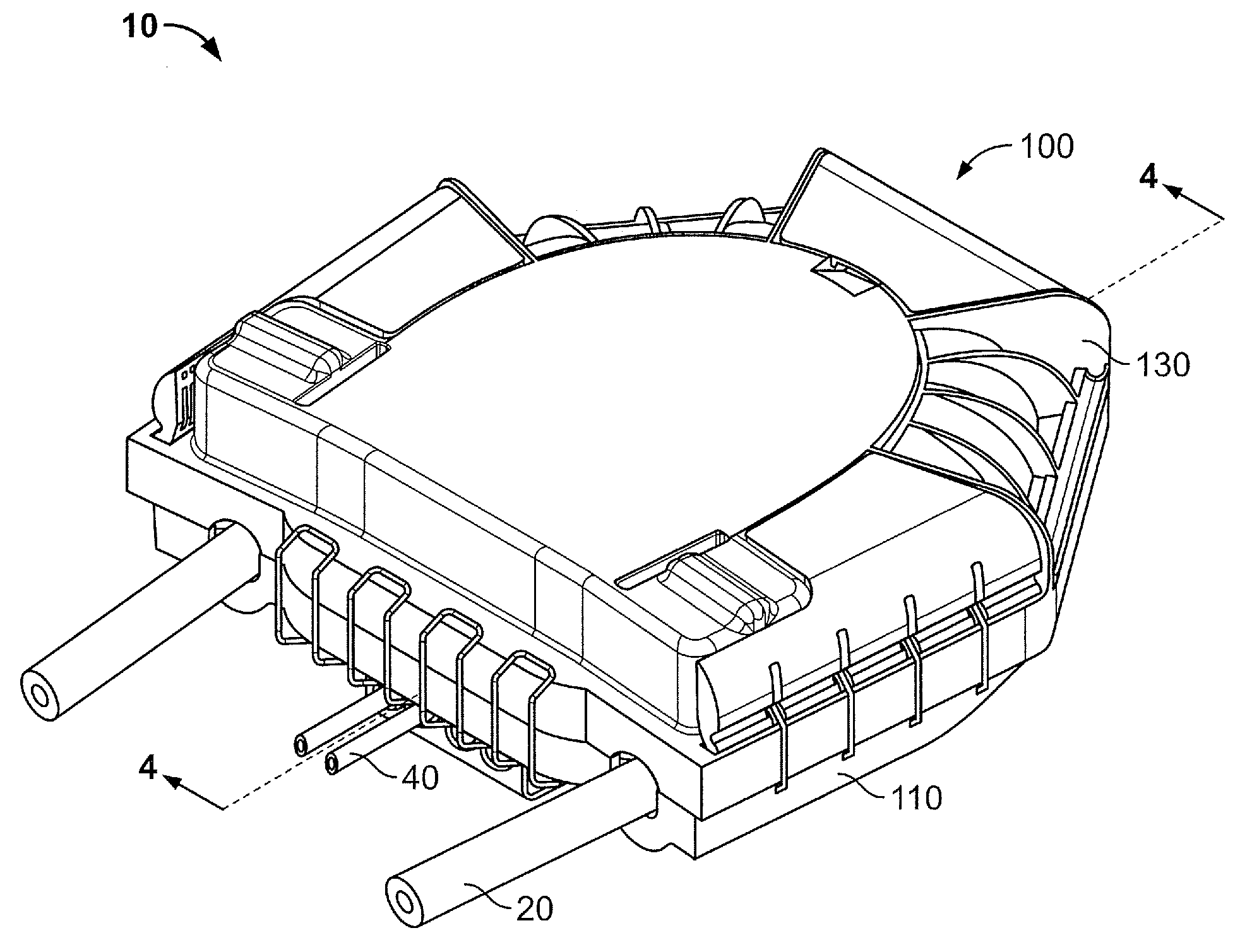

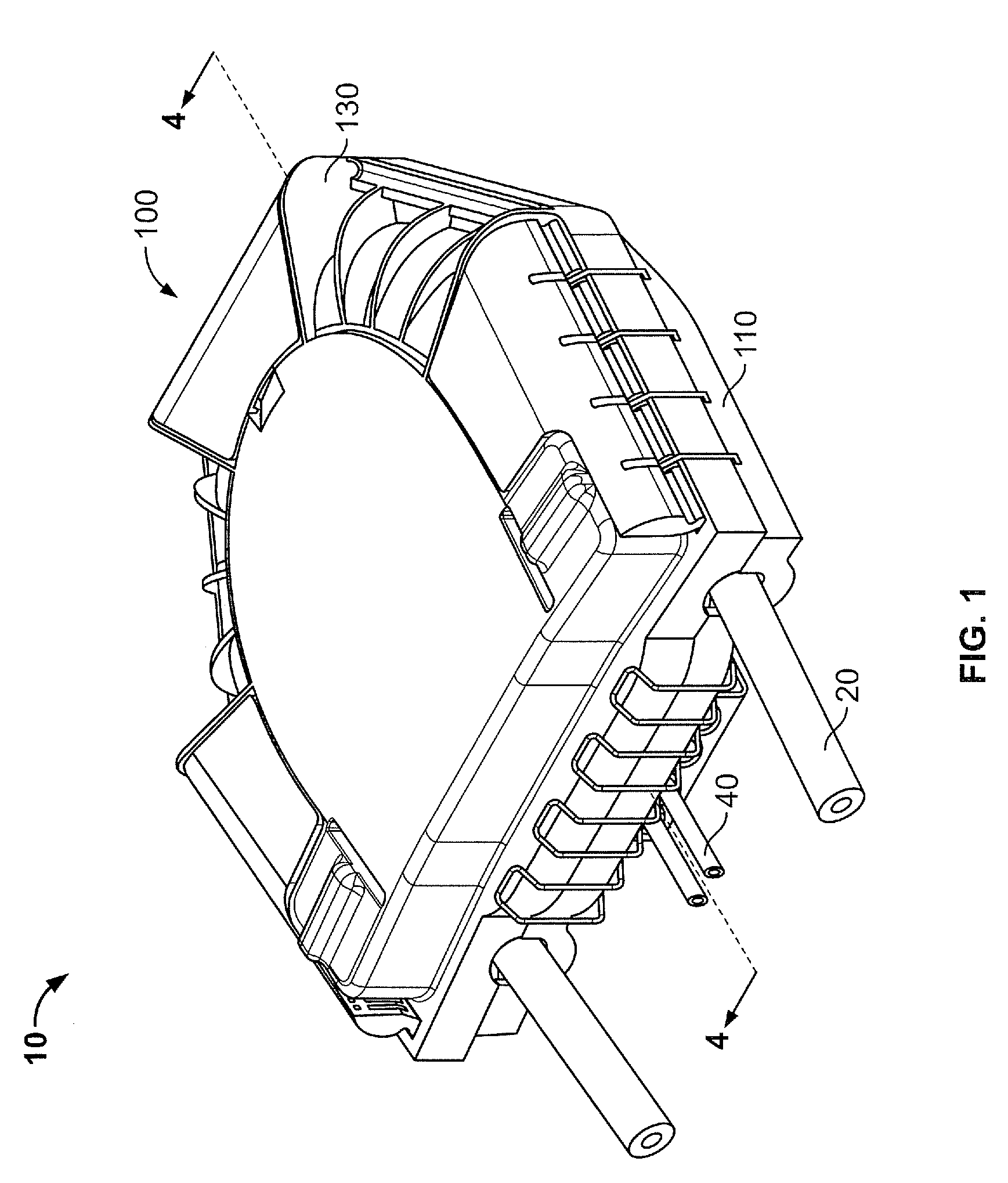

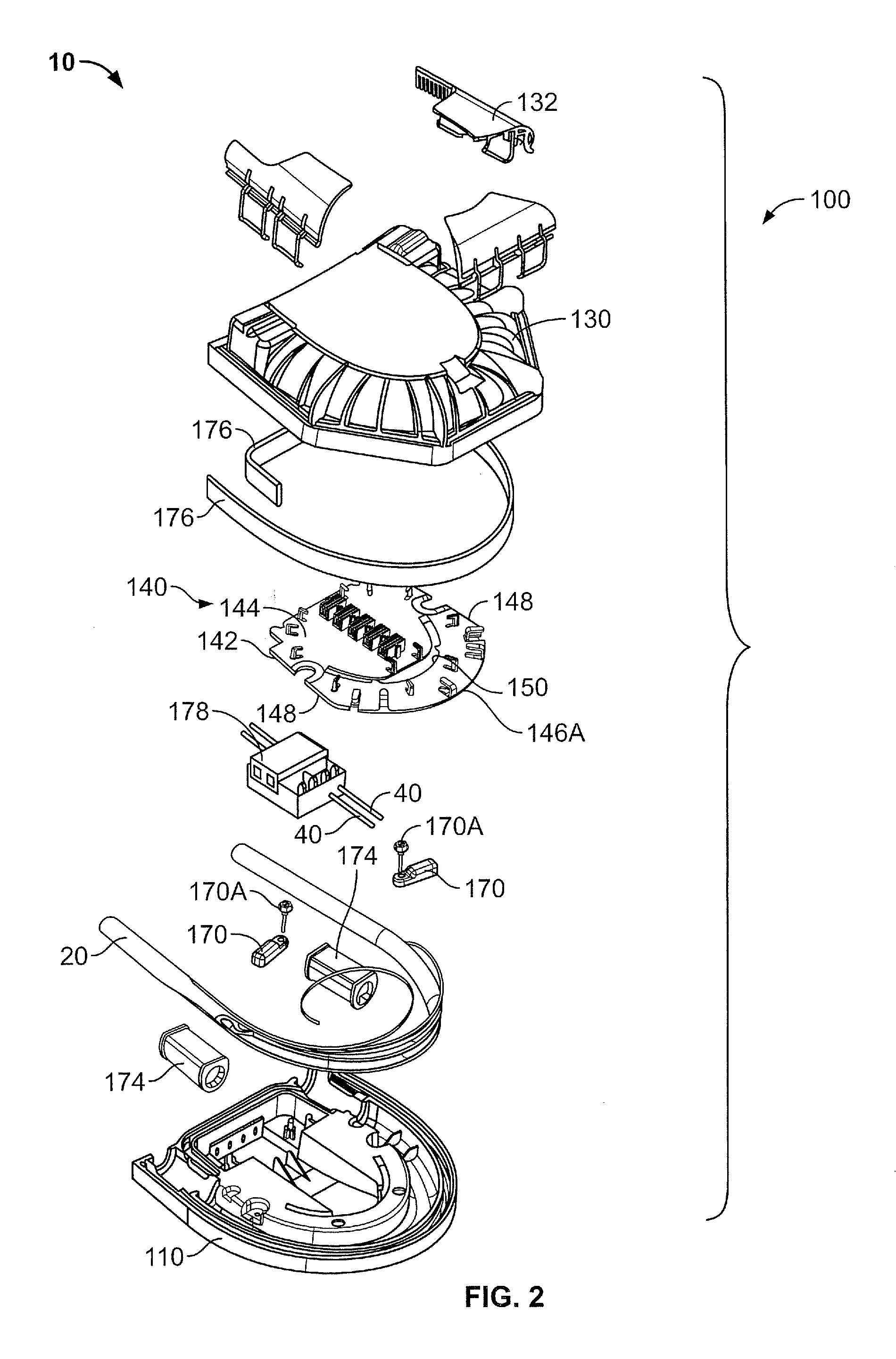

Tap-off closure systems and methods for using the same

A fiber optic cable connection assembly includes an enclosure housing and a fiber optic cable. The enclosure housing defines a chamber and a fiber handling region disposed in the chamber. The fiber optic cable has a lengthwise cable axis and including a plurality of cable optical fibers, a jacket surrounding the cable optical fibers and a strength member extending through the jacket. The cable includes an arcuately bent cable segment disposed in the chamber. The bent cable segment defines a cable plane and an interior region within the arc of the bent cable segment. At least one of the cable optical fibers extends fully through the enclosure housing uncut. The strength member extends fully through the enclosure housing uncut. The fiber handling region is disposed in the interior region. At least one of the cable optical fibers is removed from the bent cable segment and routed into the fiber handling region where at least a portion of the removed cable optical fiber is stored and / or spliced to another optical fiber.

Owner:COMMSCOPE TECH LLC

Softening lotion composition, use thereof in paper making, and resulting paper product

InactiveUS6207014B1Soft and slippery feelGreat pliancyCosmetic preparationsNatural cellulose pulp/paperFiberLotion

The invention concerns in particular a composition for a softening lotion used in fiber treatment. In the invention, the lotion composition is aqueous and liquid at a temperature of at least 5° C. and comprises, as active substances: (a) one or more saturated linear fatty alcohols having at least 16 carbon atoms, and (b) one or more waxy esters having a total of at least 24 carbon atoms. The application of the invention is to the manufacture of fibrous products such as disposable absorbent paper products.

Owner:COGNIS FRANCE SA +1

Polymer particles

The present invention provides polymer particles being capable of stably maintaining a hydrophobic protecting agent for skin and / or hair and a method of treating fibers by the polymer particles. It is polymer particles having a volume average particle diameter of 0.001 to 30 mum, which comprises an organic high-molecular polymer (a) as the wall membrane and a hydrophobic -protecting agent for skin and / or hair (b) as the core material, or chitosan and a polymer of an organic acid having reactive vinyl group and / or a salt thereof as the membrane wall and the protecting agent (b) as the core material; a fiber-treating agent comprising said polymer particles; fiber having said polymer particles present continuously or discontinuously on the surface thereof; or a fiber-treating method which comprises bringing said polymer particles or said fiber-treating agent into contact with fiber.

Owner:KAO CORP

Protective covers

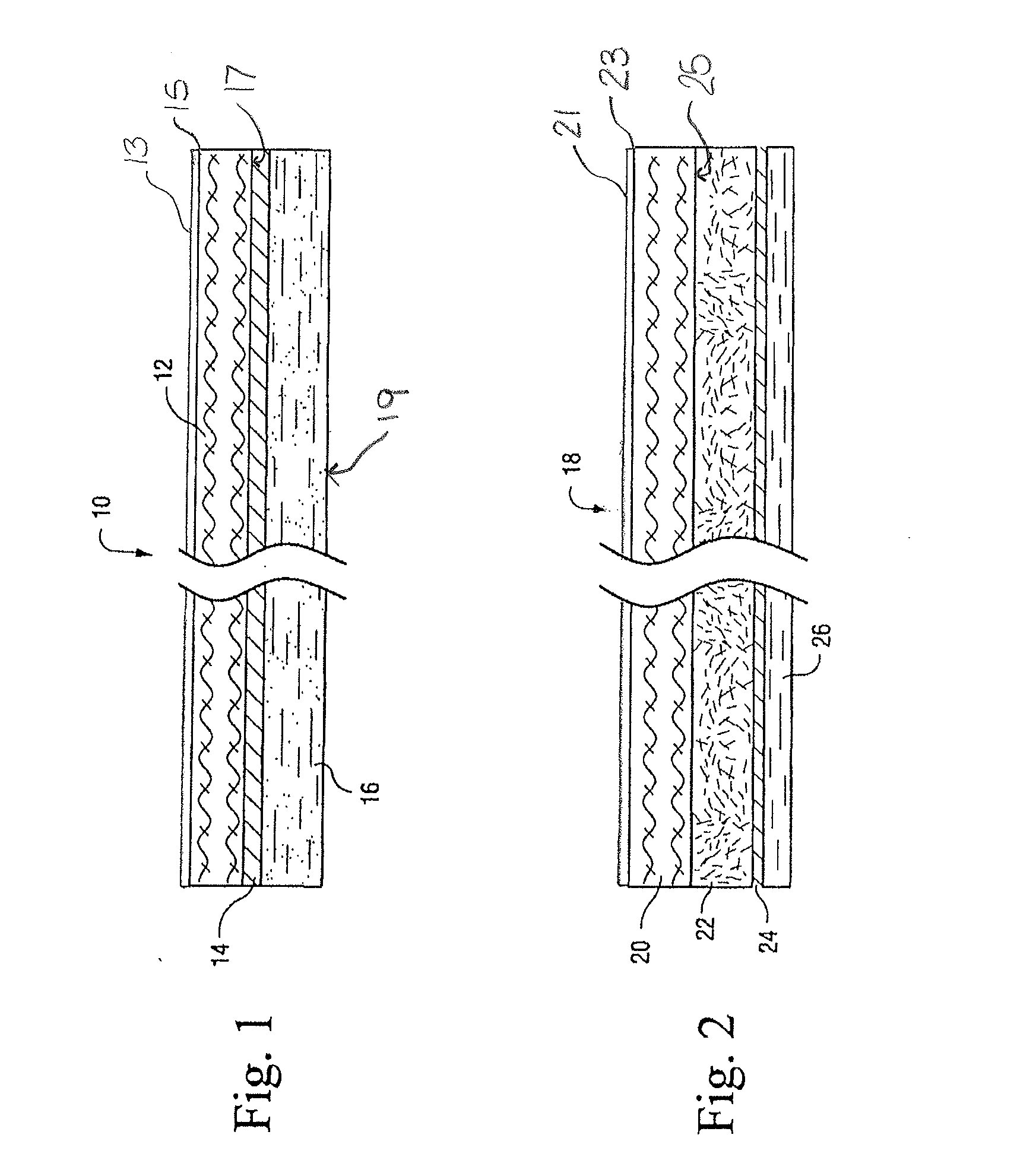

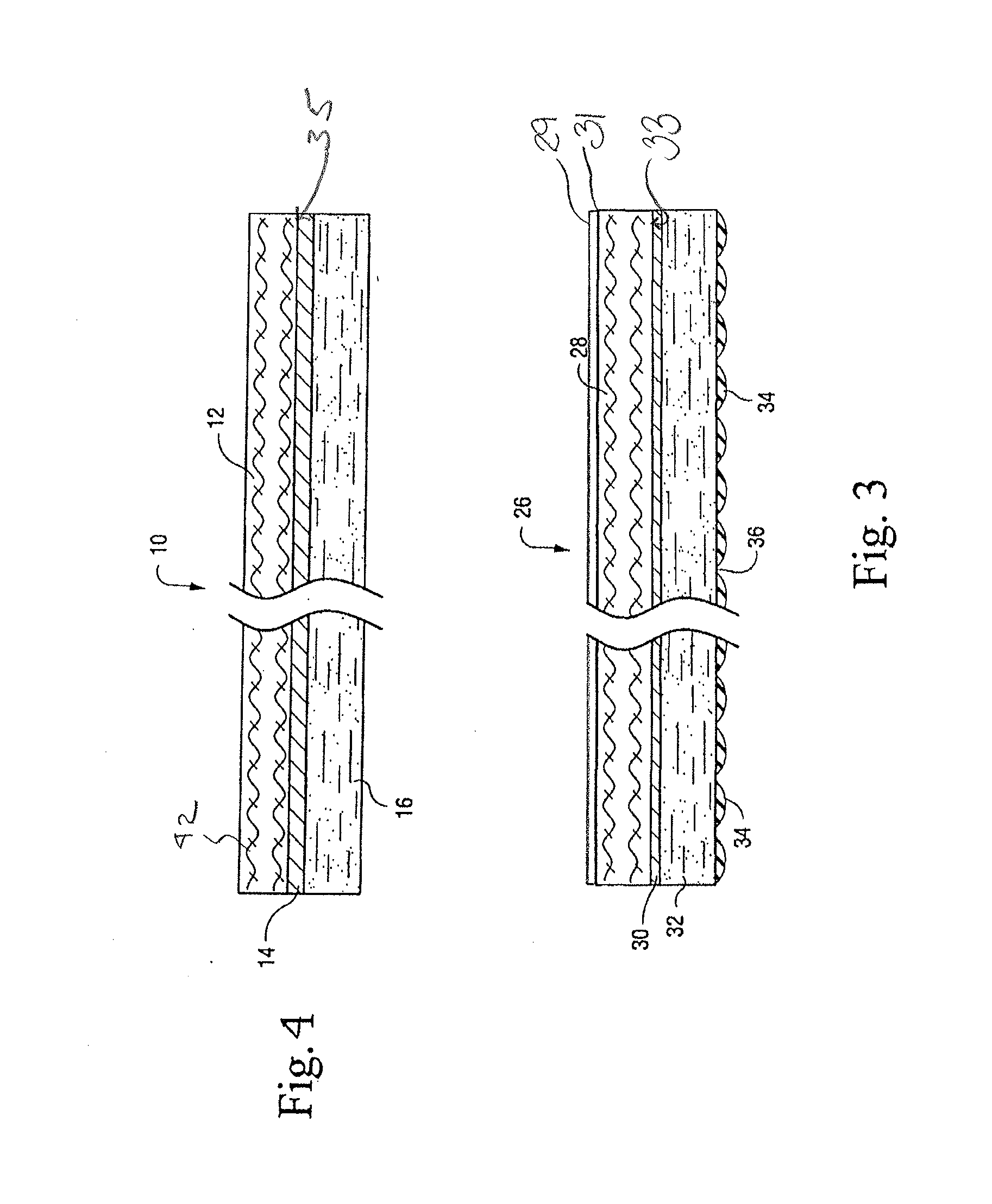

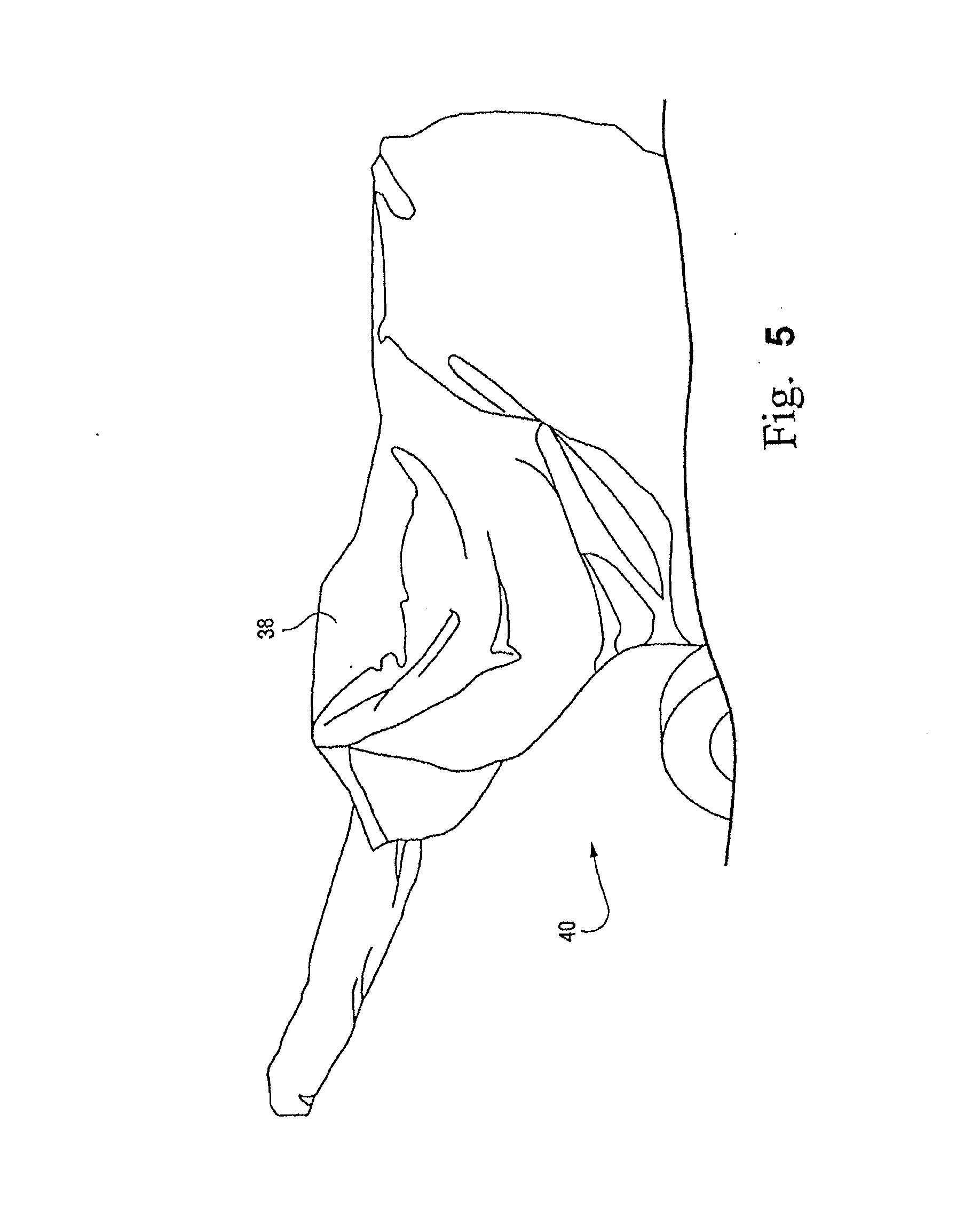

ActiveUS20130294002A1Stable pressureDesired water resistanceProtective equipmentSynthetic resin layered productsMaterial DesignFibre treatment

An enhanced protective cover includes a top and bottom textile layer and an air permeable, moisture-vapor-transmissive, expanded polytetrafluoroethylene membrane layer located between the two textile layers. The cover exhibits an MVTR rating of at least 4000 g / m2 / day. The protective cover also includes a top layer coating or fibre treatment of a nano-ceramic material designed to increase the durability of the cover and increase the resistance to abrasion and wear while also resisting environmental conditions including exposure to solar radiation, temperature and humidity. Alternatively, the upper layer of the protective cover may incorporate ceramic coated fibers or ceramic co-extruded fibers, or carbon nanotubes. The protective cover may also feature a fire resistant application. The top textile layer may also include a permanent, highly breathable and highly durable electro-static discharge feature added to the inside of the layer by laying down a carbon based printed pattern on the inside of the layer.

Owner:L&C PROTEC INC

Pulping equipment and pulping method for cow card paper

ActiveCN102493263AFix appearance problemsReduce manufacturing costPaper recyclingWaste paper working-upDeinkingFibre treatment

The invention relates to the technical field of cow card paper manufacture, in particular to pulping equipment and a pulping method for cow card paper. The pulping equipment comprises a pulper, rough sizing equipment, a grading sieve, long fiber treating equipment and short fiber treating equipment, wherein the long fiber treating equipment comprises fine sizing equipment, a heat dispersion deinking machine and a dise mill; and the short fiber treating equipment comprises a low-concentration desander, a light slag remover and another heat dispersion deinking machine. The pulping method comprises the following steps: a, pretreating wastepaper; b, sorting long fiber and short fiber; c, treating long fiber; and d, treating short fiber. Wherein, long fiber pulp stock is used for making the bottom layer of the cow card paper; 100 percent of the sandwich layer of the cow card paper and 30 to 50 percent of the surface layer of the cow card paper are short fiber pulp stock; and the surface layer contains 50 to 70 percent of wood pulp. The invention radically solves the appearance problems of paraffin points and black spots in the cow card paper, and reduces the production cost of the cow card paper.

Owner:东莞理文造纸厂有限公司

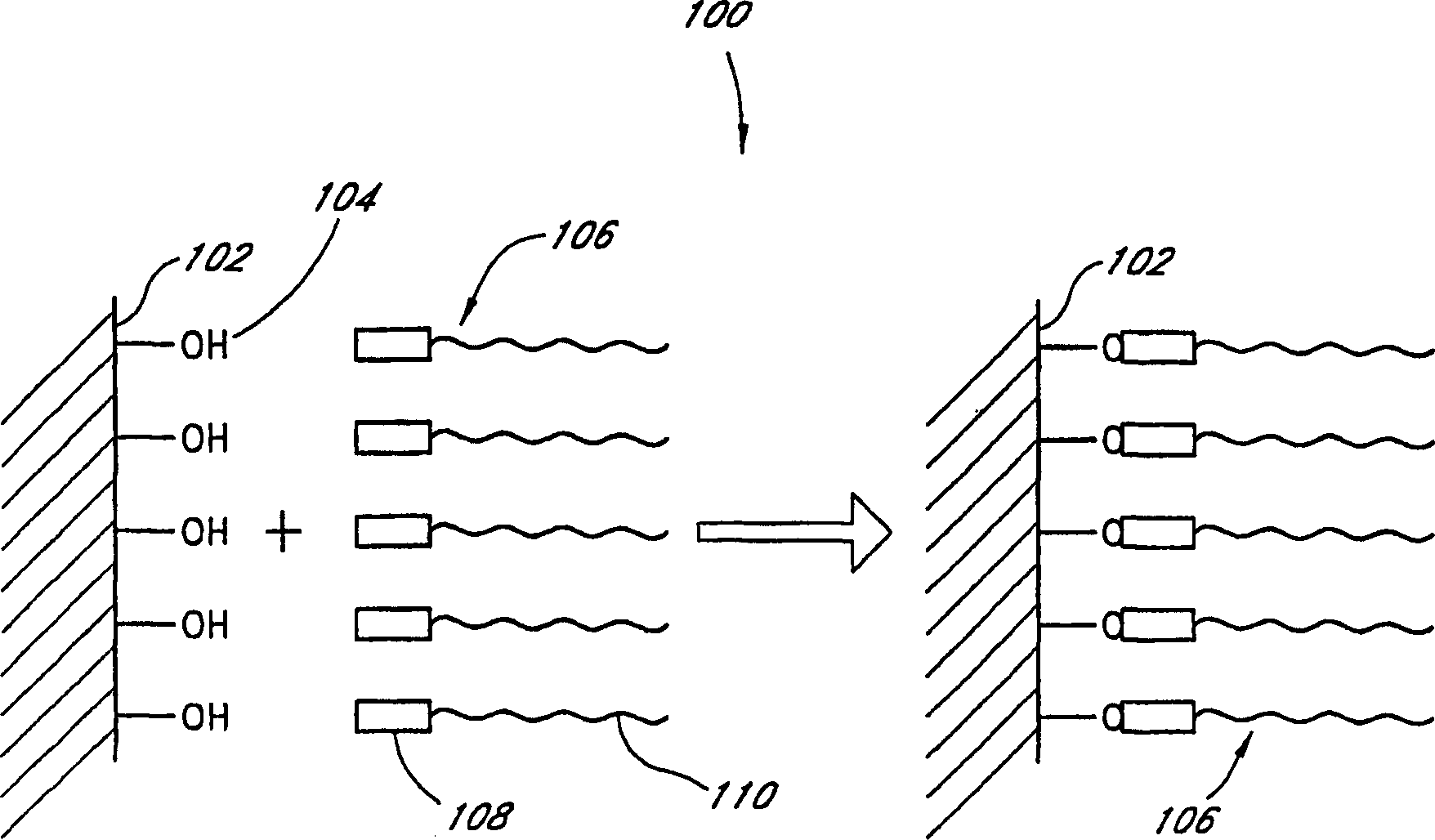

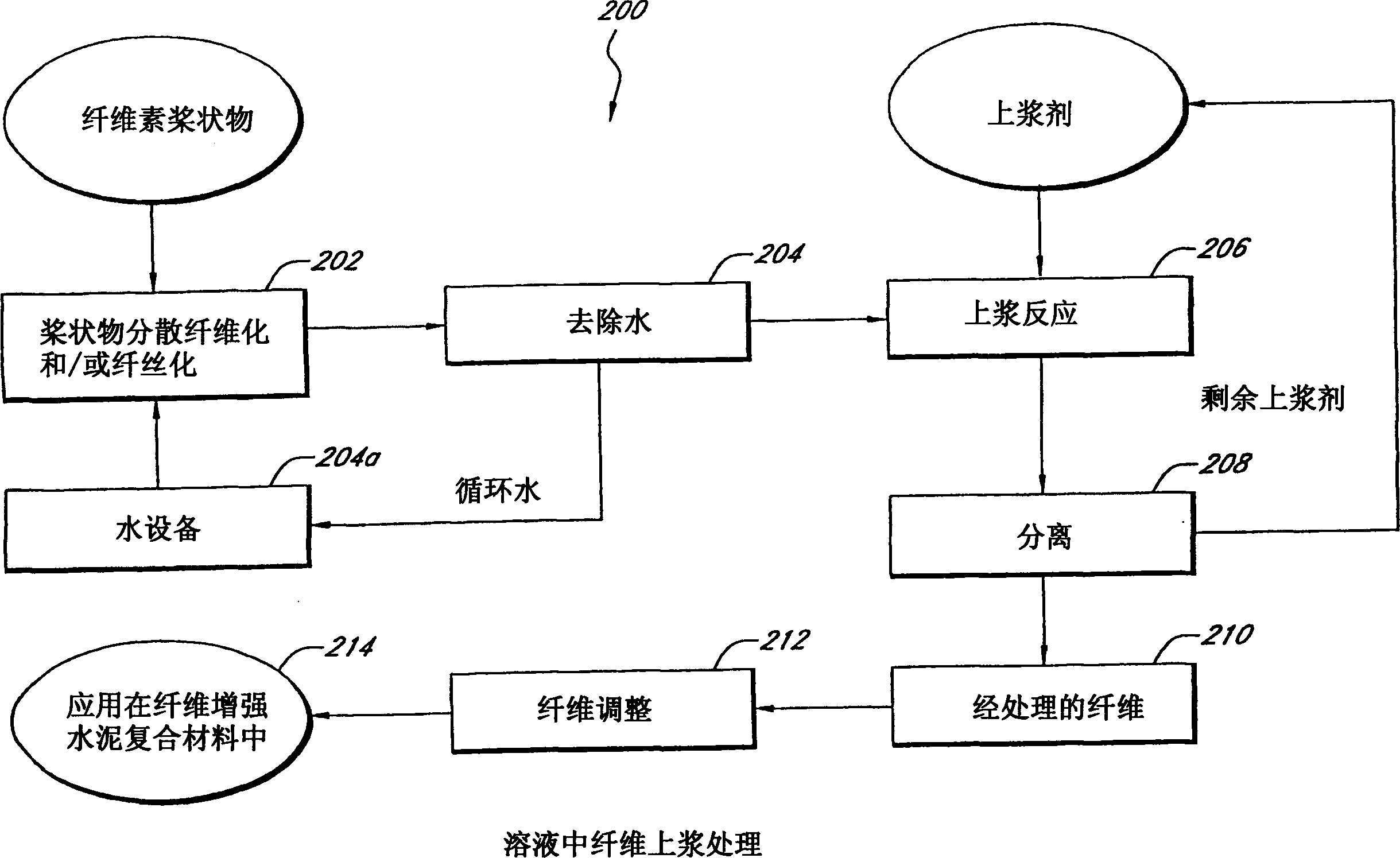

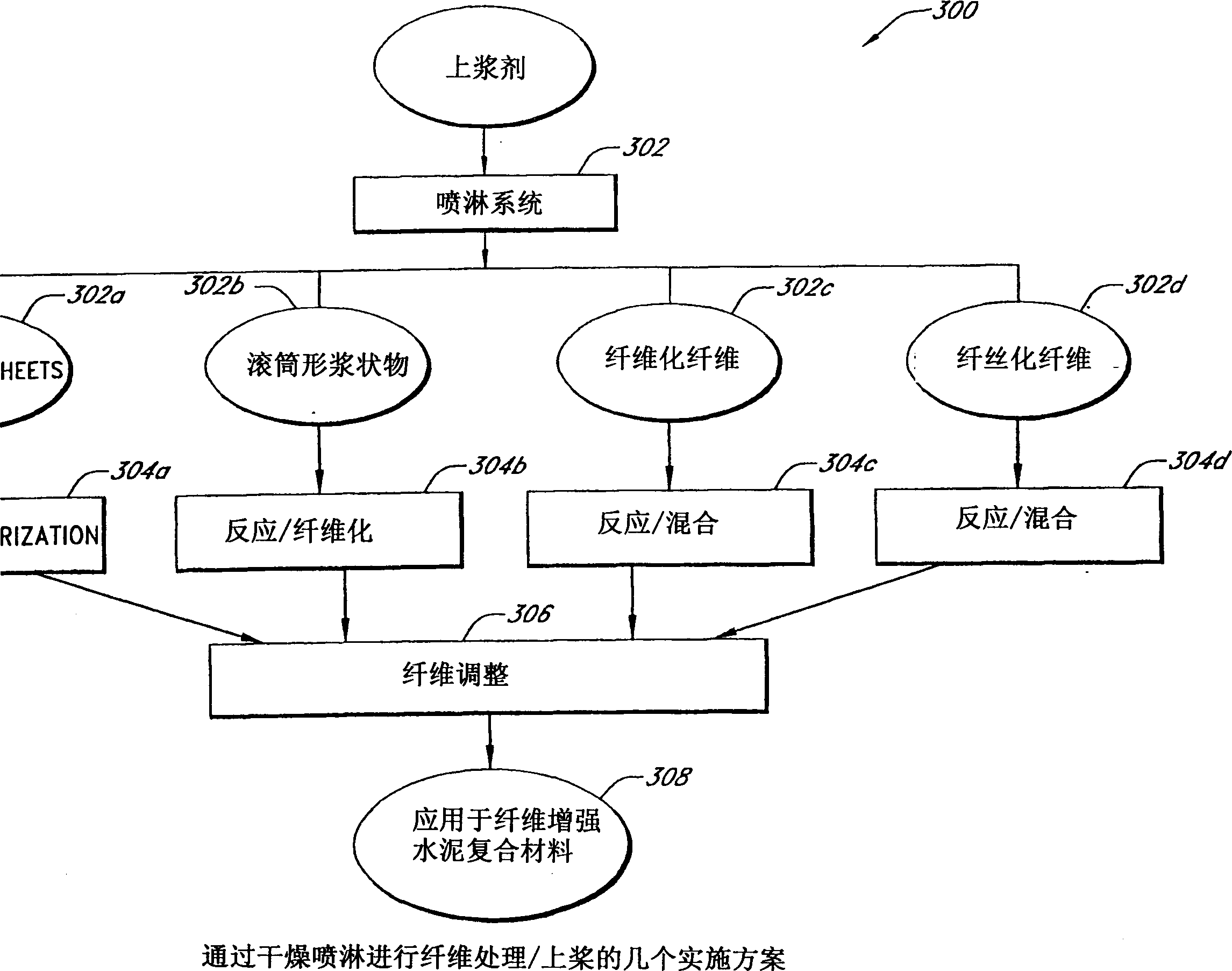

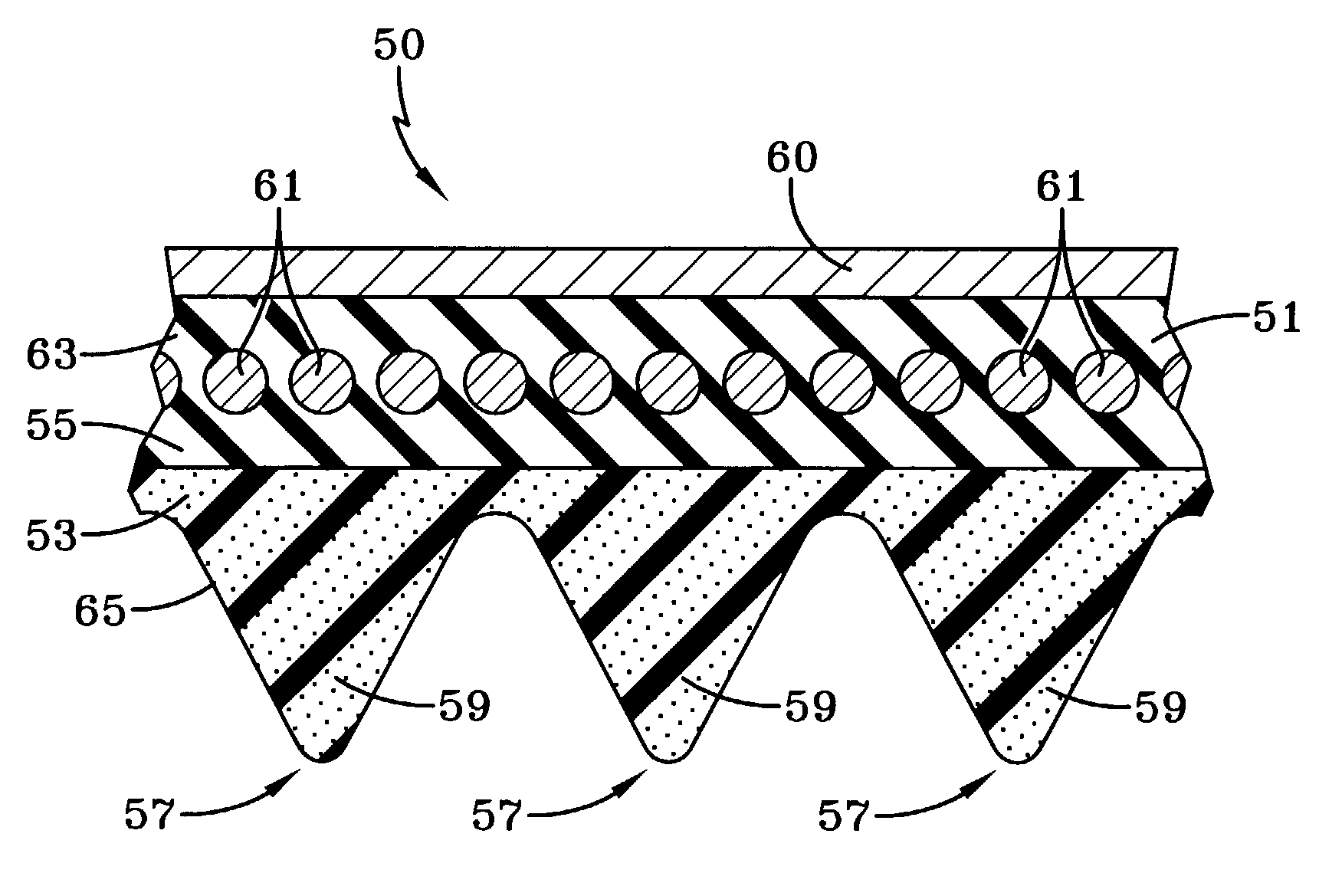

Fiber cement composition materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveCN1473138AImprove mechanical propertiesEasy to useConstruction materialSolid waste managementChemical treatmentCement composites

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using cellulose fibers that are treated with inorganic and / or organic resins to make the fibers more hydrophobic, as well as other chemical treatments. This invention discloses four aspects of the technology: fiber treatment, formulations, methods and the final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, and improved rot and UV resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness. In some cases the physical and mechanical properties are improved. This invention also discloses the method of treating cellulose fibers with various chemicals to impart the fiber hydrophobicity for applications in the fiber reinforced cement composite materials.

Owner:JAMES HARDIE INT FINANCE BV

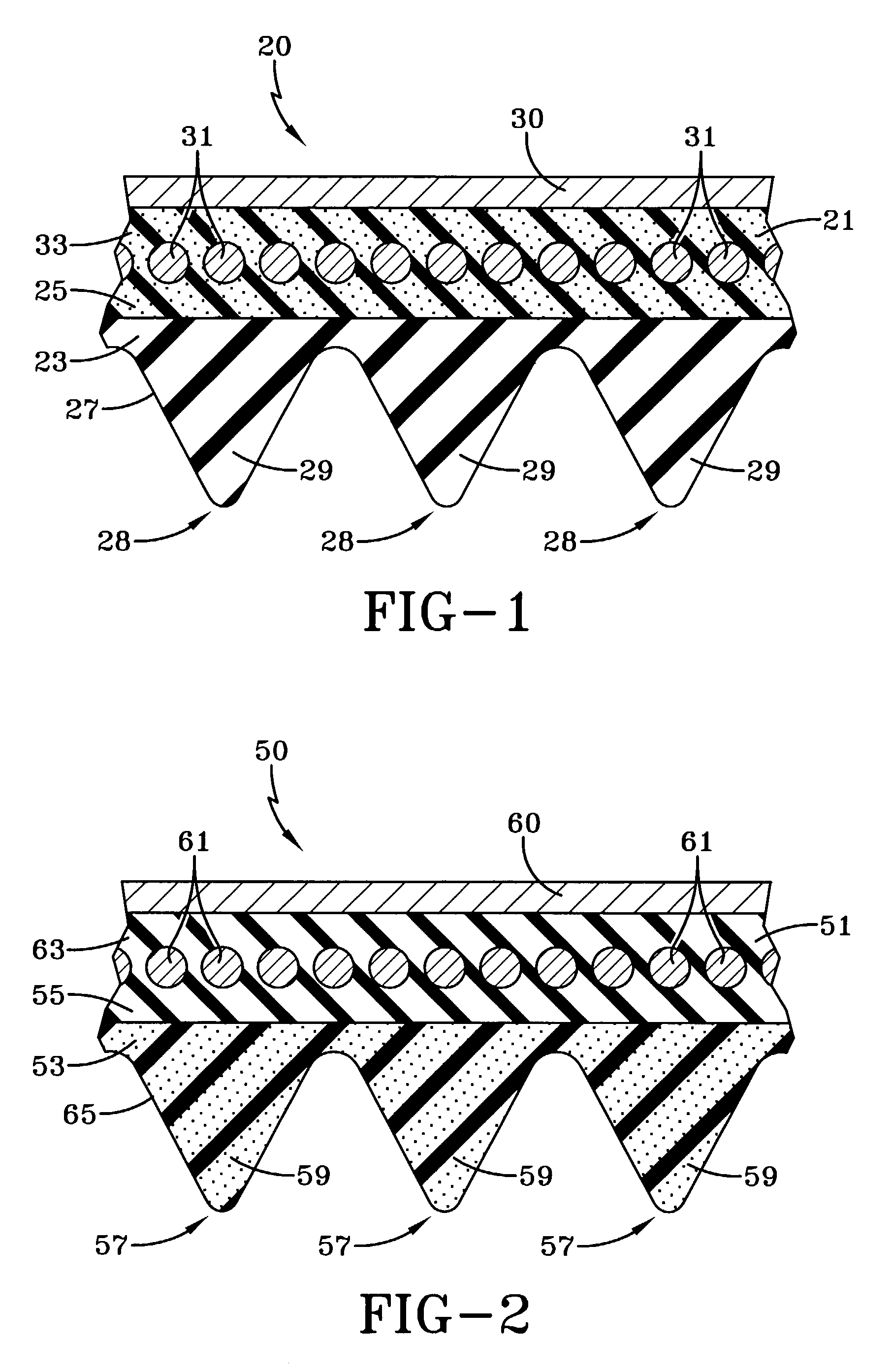

Reinforced Composite Material

ActiveUS20080286572A1Reduce the impactEquivalent propertySynthetic resin layered productsPretreated surfacesGlass fiberPolymer science

The present invention relates to a reinforced composite material and a method for its production. The composite material comprises at least one cured resin having a reinforcing material. Preferably the reinforcing material is a plurality of glass fibres which are treated such that the properties of the interphase substantially surrounding each fibre are substantially equivalent to those of the bulk cured resin. The fibre treatment may be selected from the group consisting of a polymeric coating, a hydrophilic surface coating, a surface coating of a free radical inhibitor, or a reduction in the total surface area of the fibres. The reinforced composite material of the invention provides improved long-term mechanical properties compared to traditional glass fibre reinforced materials.

Owner:SPOKE HLDG LLC

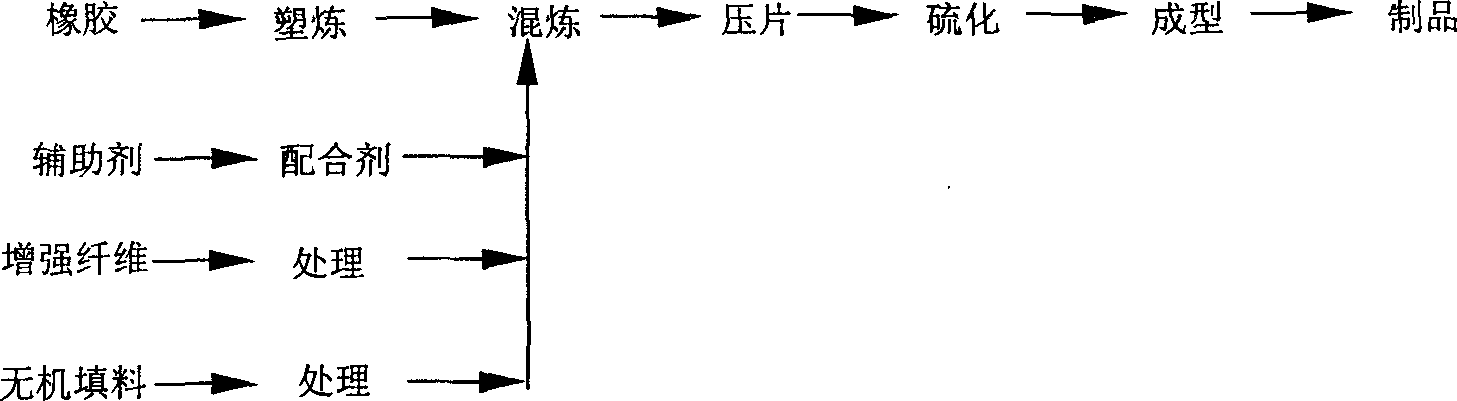

Nonasbestos mixed fiber enhanced rubber base sealing composite materials and method for making same

InactiveCN1631954AHigh mechanical strengthHigh compression resilienceOther chemical processesPolymer scienceMass ratio

The invention relates to a pre- preoxidated string, aramid fiber or mixed fiber strengthened rubber sealing compound material and its producing technique. The components comprises of : 1, strengthened fiber, 2. enlarged-volume fiber, 3. flexible sticker, 4. filling material, 5. assistant; the mass ratios of each component are: strengthened fiber 10%-36%, enlarged-volume fiber 40-65%, flexible sticker 10-23%, filling material 9.6-21%, assistant 1.6-4.7%. The strengthened fiber is the mixture of pre- preoxidated fiber and aramid fiber or, assistant is accelerant, activator, vulcanizing agent and antioxidant, the technique of the compound material is : plasticate the flexible sticker, mixing the strengthened fiber, inorganic filling material having been prepared, the enlarged-volums fiber and assistant, press into slices, sulfurate to acquire the product. The material has solved the problems such as the unsatisfying range of temperature of the present material NAFC, high productive cost, bad antitensile stress and aging, it is a new NAFC resistant to high temperature, with low cost.

Owner:NANJING UNIV OF TECH

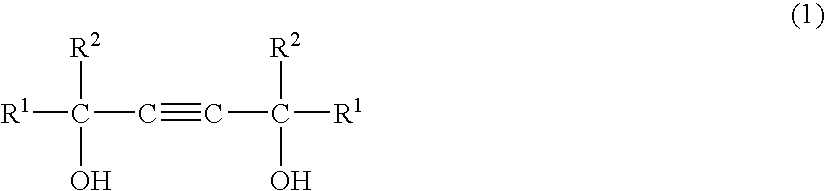

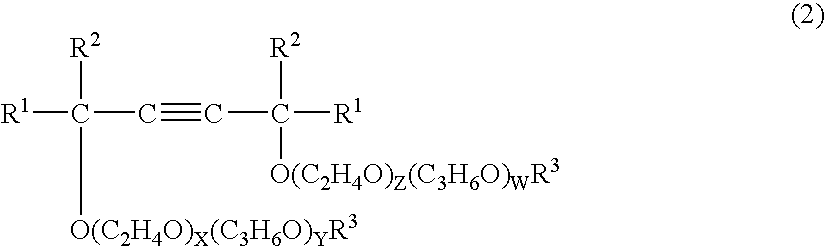

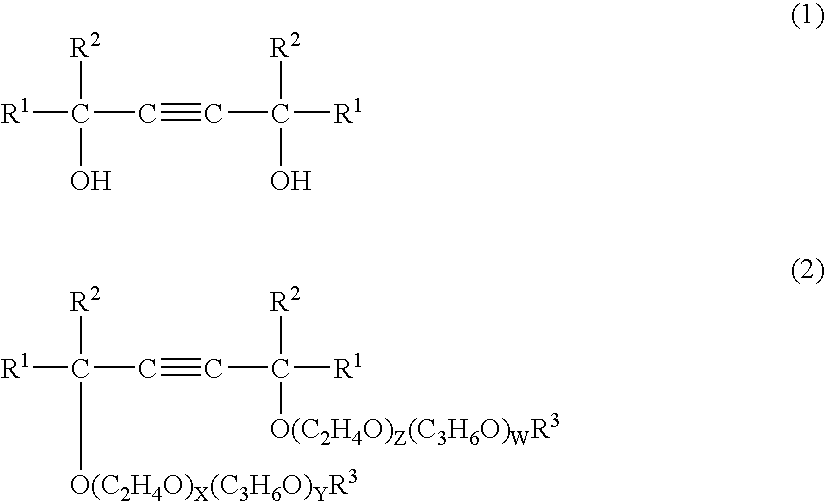

Glass fiber-treating agent and glass fiber-treating composition

InactiveUS20070031671A1Reduce contact angleReduce dynamic surface tensionFibre treatmentYarnGlass fiberFibre treatment

A glass fiber-treating agent comprising (A) 5-95% by weight of an acetylene glycol or an ethylene oxide and / or propylene oxide adduct of acetylene glycol and (B) 5-95% by weight of a silicone surfactant. The agent functions to reduce dynamic and static surface tension and contact angle and offers excellent wetting, penetrating and antifoaming properties when glass fibers are treated therewith.

Owner:NISSHIN CHEM IND CO LTD +1

Method for manufacturing medium-density fiberboard in inorganic gluing

InactiveCN102922587AFireproofWaterproofWood working apparatusFlat articlesGreen environmentFibre treatment

The invention discloses a method for manufacturing a medium-density fiberboard in inorganic gluing. The method comprises the following steps of: A, performing fiber treatment; B, preparing cement size; C, mixing, D, performing pressure penetration; E, laminating; and F, hot-pressing and demolding. The fiberboard has the characteristics of fire resistance, water resistance, ageing resistance, mildew prevention and no formaldehyde and belongs to a green environment-friendly product.

Owner:HUBEI ZHONGBAI TECH

Reinforced composite material

The present invention relates to a reinforced composite material and a method for its production. The composite material comprises at least one cured resin having a reinforcing material. Preferably the reinforcing material is a plurality of glass fibres which are treated such that the properties of the interphase substantially surrounding each fibre are substantially equivalent to those of the bulk cured resin. The fibre treatment may be selected from the group consisting of a polymeric coating, a hydrophilic surface coating, a surface coating of a free radical inhibitor, or a reduction in the total surface area of the fibres. The reinforced composite material of the invention provides improved long-term mechanical properties compared to traditional glass fibre reinforced materials.

Owner:ADVANCED COMPOSITES INT

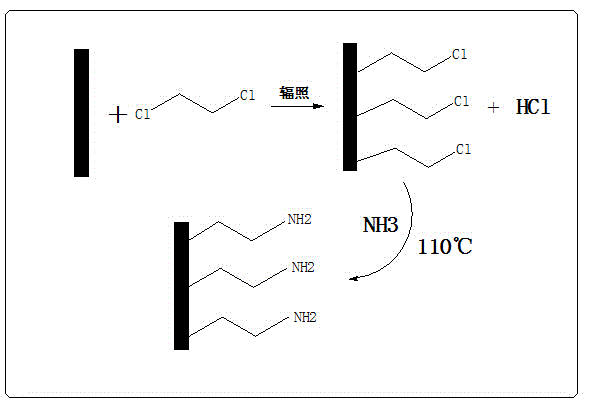

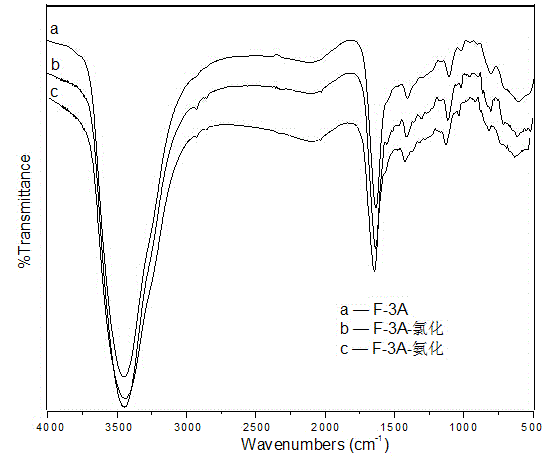

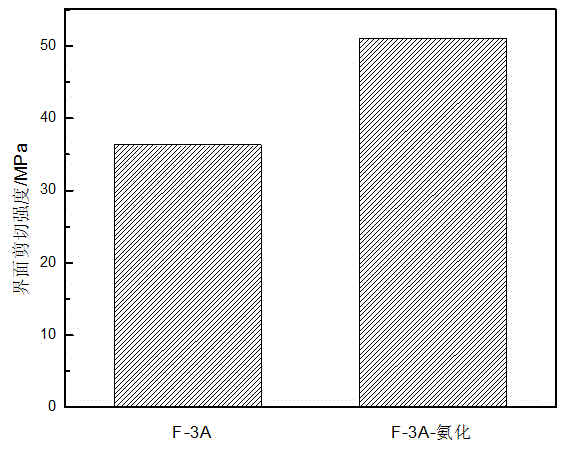

Aramid fiber surface grafting modification method

ActiveCN104372603AAvoid damageImproved "skin-core" structurePhysical treatmentPolymer scienceFibre treatment

The invention relates to an aramid fiber surface grafting modification method, belonging to the field of aramid fiber modification field and aiming at solving the problems of low aramid fiber surface activity and poor bonding property with a resin matrix. The aramid fiber surface grafting modification method comprises the steps of carrying out fiber surface cleaning and drying, fiber surface chlorination and fiber surface ammonolysis reaction. High-energy gamma rays with strong penetrability are utilized to excite the activities of fiber surface functional groups and a grafting agent, namely 1,4-dichlorobutane, the grafting reaction is initiated on the fiber surface, and the damage to the fiber surface structure, caused by the other surface treatment methods, can be alleviated; and meanwhile, a sheath core structure of the aramid fiber can be improved by irradiation of the gamma rays, and the phenomenon of reduction of the strength of the aramid fiber after modification treatment is effectively avoided; the process is simple, the efficiency is high, the fiber handling capacity is controllable, and the method is suitable for large-scale industrial production.

Owner:HARBIN INST OF TECH

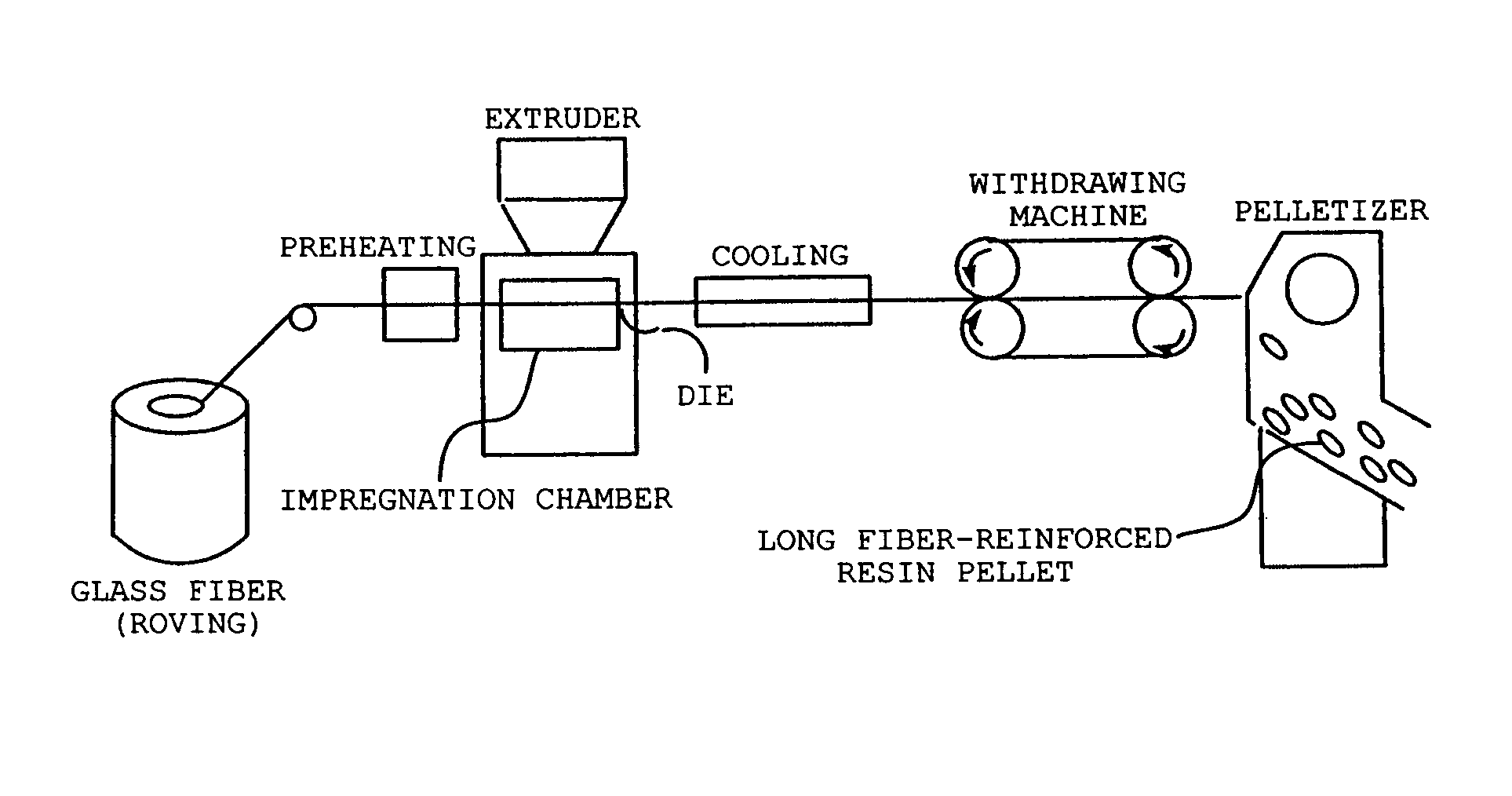

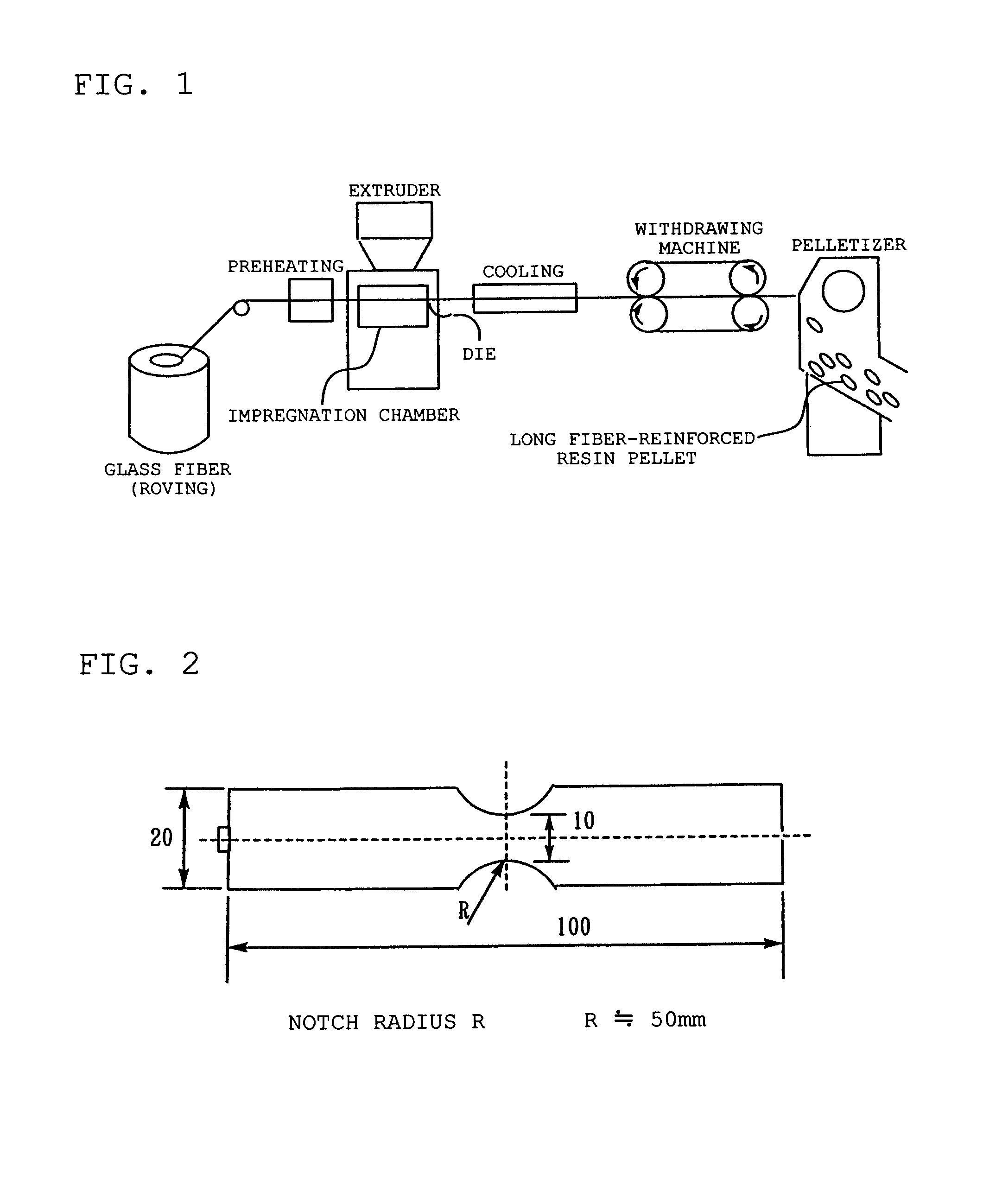

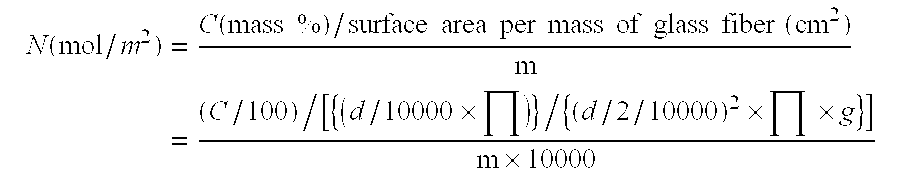

Modified polyolefin resin for glass fiber treatment, surface-treated glass fiber, and fiber-reinforced polyolefin resin

ActiveUS8709586B2Easy to carryEnsure firm bondSynthetic resin layered productsCellulosic plastic layered productsGlass fiberPolymer science

An acid-modified polyolefin-based resin for glass fiber treatment having: (1) an amount of components extractable with boiling methyl ethyl ketone of 8 mass % or less; (2) a number average molecular weight (Mn), measured by gel permeation chromatography (GPC), of 6,000 to 48,000; and (3) an amount of an acid which has been added, measured by Fourier transform infrared spectroscopy, of 0.1 to 12 mass %.

Owner:PRIME POLYMER CO LTD

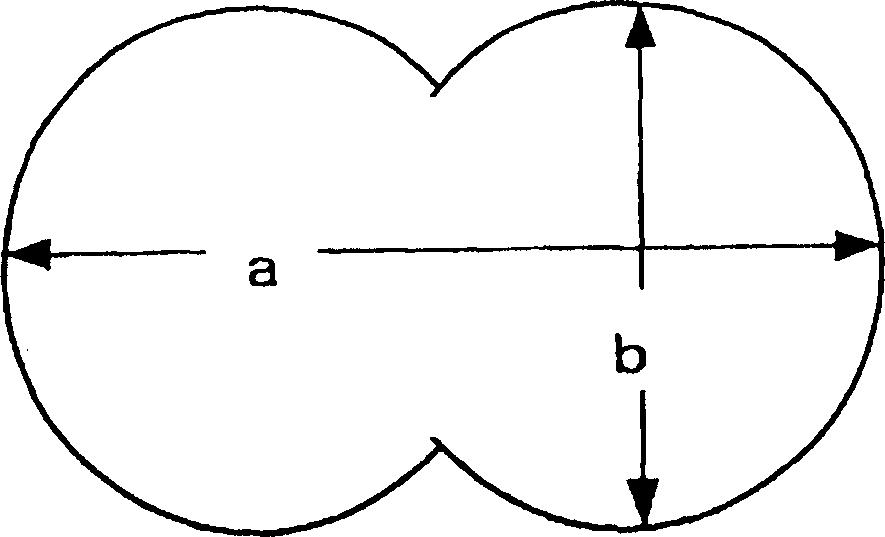

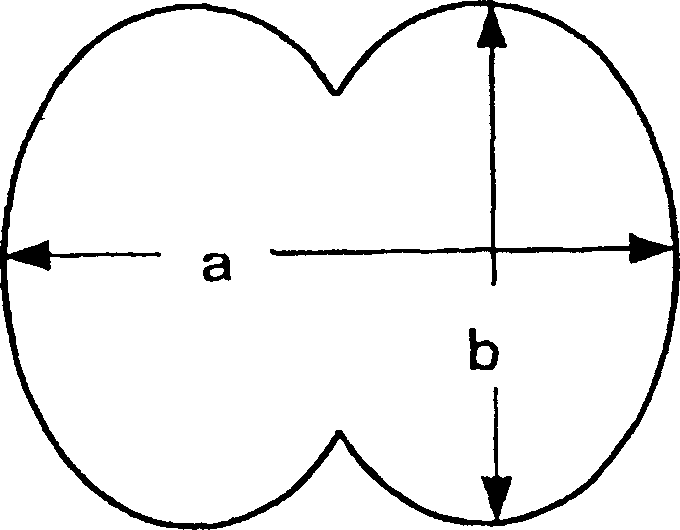

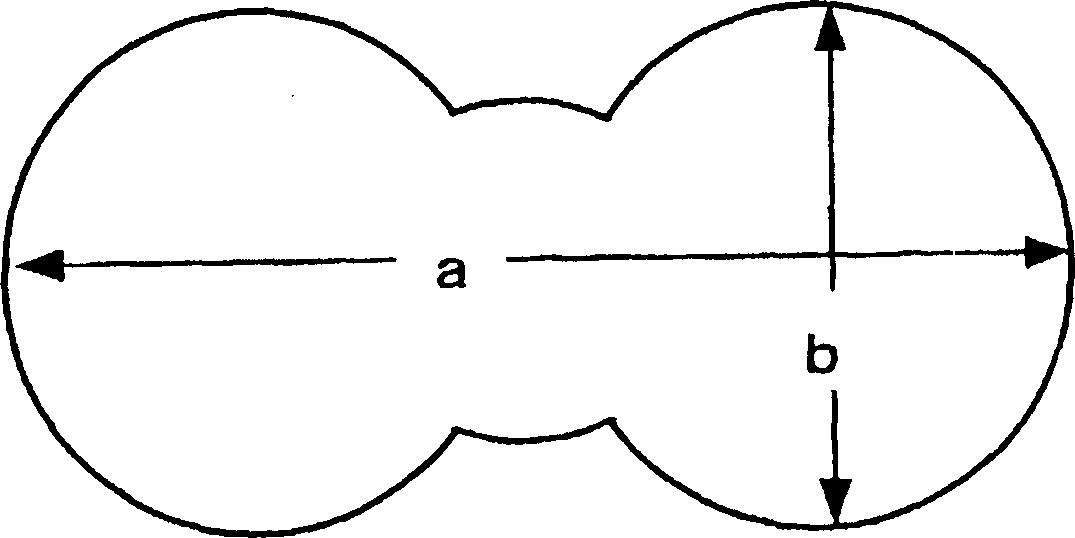

Flame-retardant polyester fibers for artificial hair

The invention relates to a flame-retardant polyester fiber for artificial hair which is produced by melt-spinning a composition comprising 100 parts by weight of at least one polyester (A) selected from among polyalkylene terephthalates and copolyesters comprising polyalkylene terephthalates as the main component and 5 to 30 parts by weight of a brominated epoxy flame retardant (b). Further, the invention relates to a flame-retardant polyester fiber for artificial hair as described above which has at least one modified cross section; a flame-retardant polyester fiber for artificial hair as described above which is a mixed fiber having a mixing ratio of circular cross section to modified cross section of 8 : 2 to 1 : 9; and a flame-retardant polyester fiber for artificial hair which is produced by making a hydrophilic fiber treatment adhere to the above polyester fiber and is excellent in smoothness to the touch, combing properties, and flame retardance.

Owner:KANEKA CORP

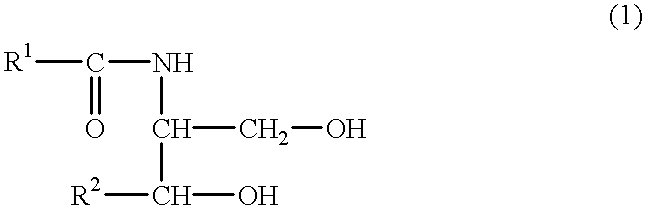

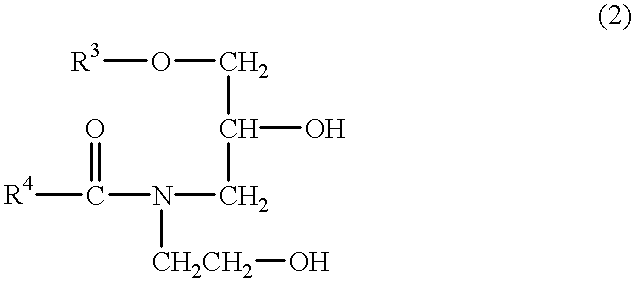

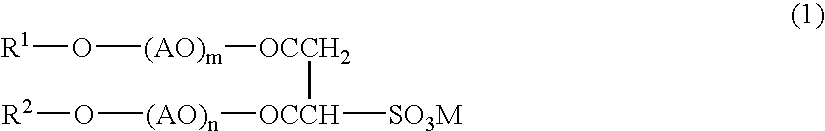

Fiber processing agent

The ivention provided a fiber sizing agent highly stable in its emulsion form and excellent in uniform pickup tendency on a filament undergoing high-speed sizing operation. The fiber sizing agent comprises (A) a base oil, (B) a polyhydric alcohol fatty acid ester alkylene oxide adduct and (C) a monohydric alcohol alkylene oxide adduct, wherein the component C essentially includes a compound(c1) of the general formula(1):R-O-(PO)m-(EO)nH(wherein, R is a 4-15C alkyl; PO is an oxypropylene group; EO is an oxyethylene group; m is an integer of 10-40; and n is an integer of 5-15).

Owner:SANYO CHEM IND LTD

Color-spun yarns and processing method thereof

InactiveCN103451800ADoes not affect coloringInfection preventionDyeing processYarnYarnPolymer science

The invention discloses color-spun yarns, which are obtained by mixing and dyeing dye-resistant fibers and fibers to be dyed into yarns. The color-spun yarns are prepared by the following steps of a, treating dye-resistant fibers: treating the fibers with microcapsules and a bonding agent and drying to obtain the dye-resistant fibers, wherein dye-retarding agents or dye-resistant agents are coated in the microcapsules; b, spinning: mixing fibers to be dyed with the dye-resistant fibers obtained in the step a and spinning to obtain yarns; c, dyeing: dyeing the yarns obtained in the step b with a dye; d, washing the yarns dyed in the step C with water and drying to obtain color-spun yarns. The colors of the color-spun yarns can be dyed in a customized mode, the delivery period is less than one week, and the problems of reduction in the spinning efficiency, increase in unattached fibers, rise of direct cost, great reduction in the strength of finished yarns, incapability of spinning high-count yarns and the like caused by the increase of chopped fiber rate due to dyeing pretreatment of the conventional color-spun yarns are solved.

Owner:WUXI NATURAL GREEN FIBER TECH

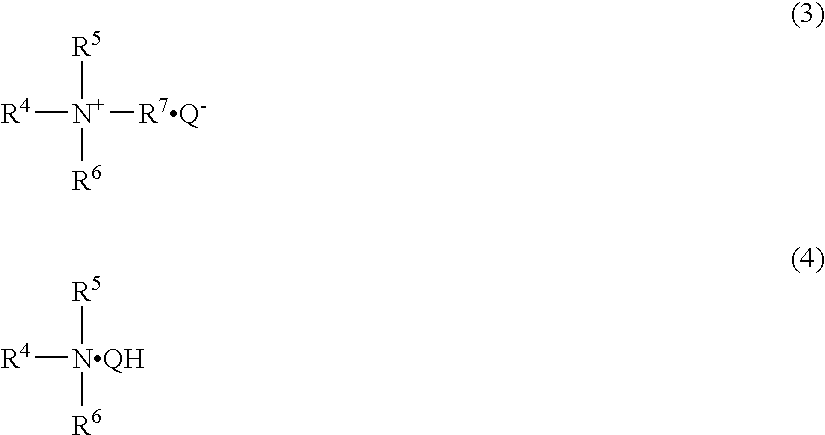

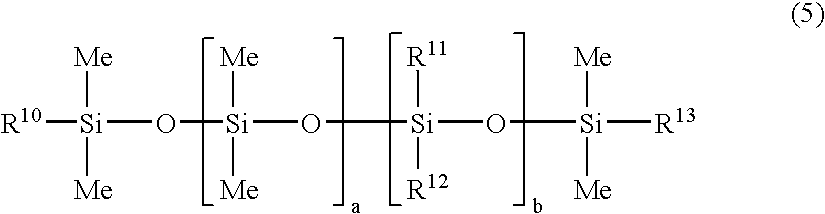

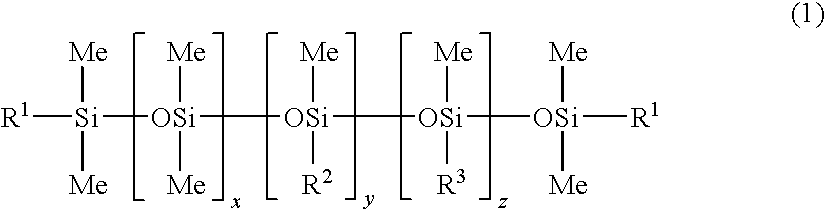

Oiling Agent for Fiber Treatment

InactiveUS20080200358A1Good anti-adhesionStable rewindabilitySilicon organic compoundsPulp properties modificationPolymer scienceFibre treatment

The present invention has its object to provide a lubricant for fibers which shows, in particular, good anti-tackiness property against fiber-to-fiber tackiness in the manufacture of elastic fibers, and good time-dependent stability for a long period of time as a lubricant for treating fibers.The present invention provides a lubricant for treating fibers to be used for fibers made of a polymer material (a) wherein the angle of contact with water at 25° C. of the surface of a sheet made of the material (a) is not greater than 60° and the angle of contact with water at 25° C. of the surface of the sheet made of the material (a) applied with the lubricant for treating fibers is 70° to 180°.

Owner:SANYO CHEM IND LTD

Quantitative analysis method for yarns

The invention provides a quantitative analysis method for yarns. The quantitative analysis method comprises the following steps of: processing fibers in a yarn to be a fiber test sample with a size less than 0.5mm; selecting a proper dispersed medium; placing the fiber test sample into a measuring pot for stirring according to the difference of densities of fiber raw materials which is used for preparing the yarn, so that the fiber test sample is layered; and separating the fiber test sample, and washing, drying and weighing the fiber test sample, so that the yarn is quantitatively analyzed, and a blending ratio of the yarn is obtained. The quantitative analysis method provided by the invention has the beneficial effects of being simple, quick in operation, and accurate and reliable in test result, can be used for the conventional fibers, and has a universal type. Meanwhile, the body damage and the environment pollution on operators can be avoided as a harmful chemical reagent is not used.

Owner:YANCHENG FANGTIAN NON WOVEN PORDUCTS CO LTD

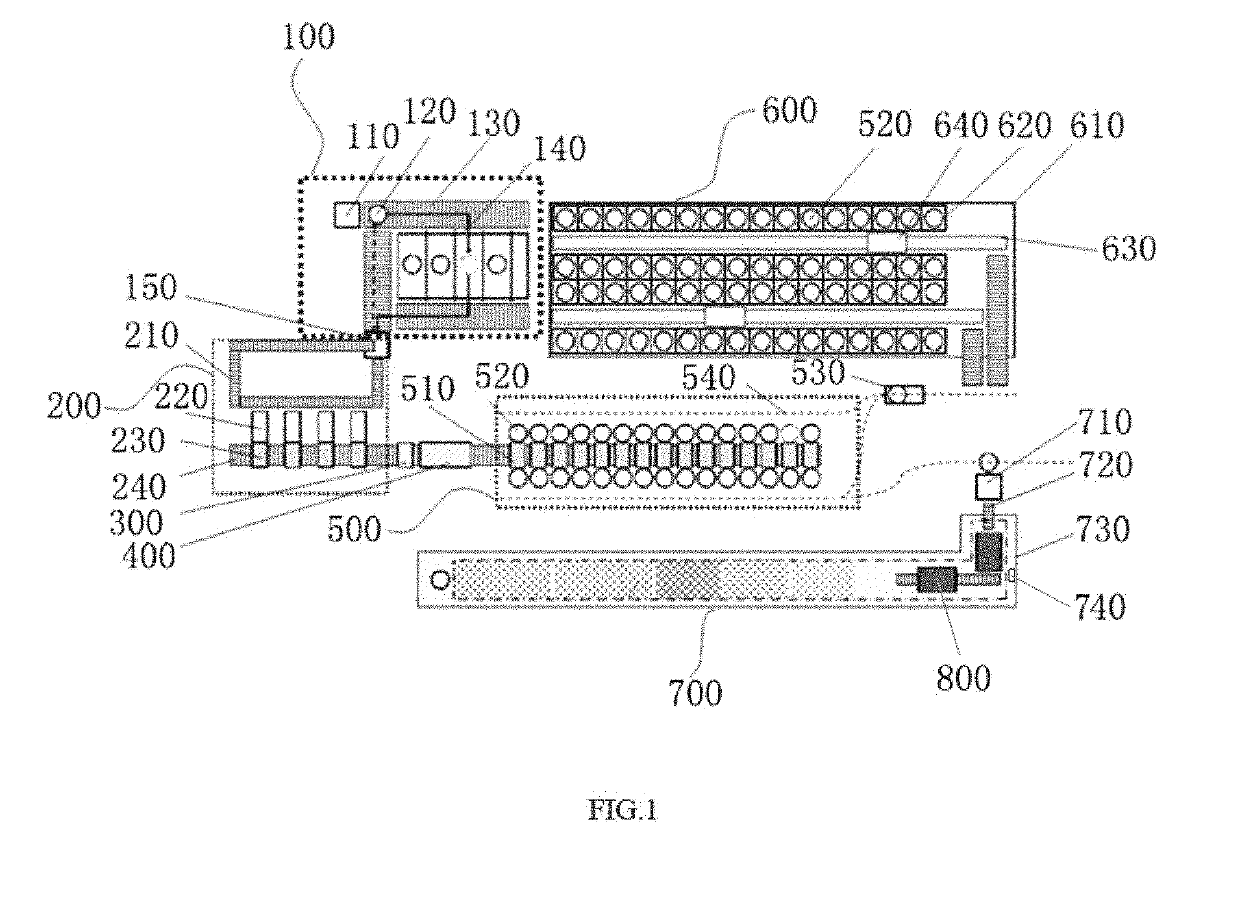

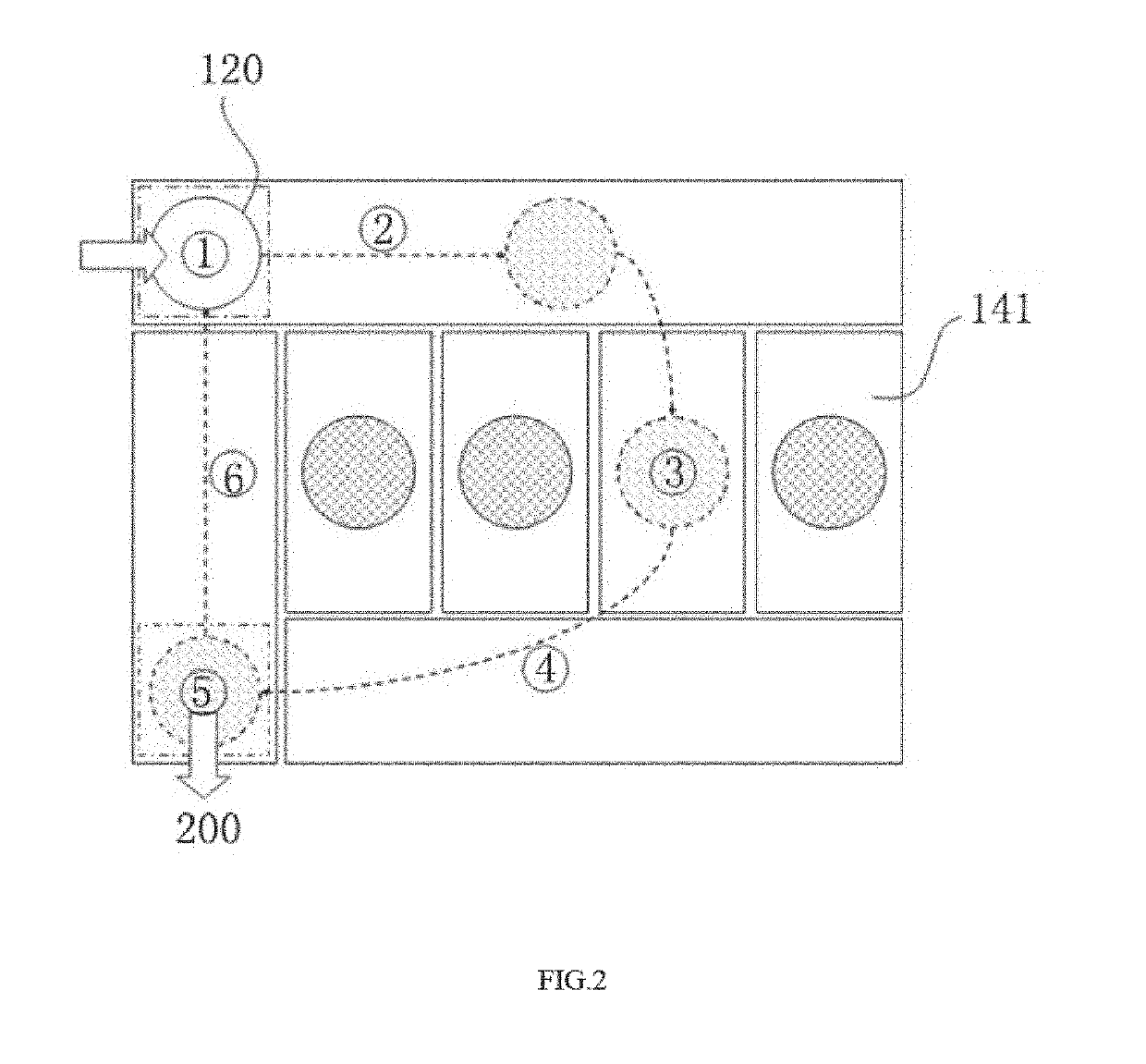

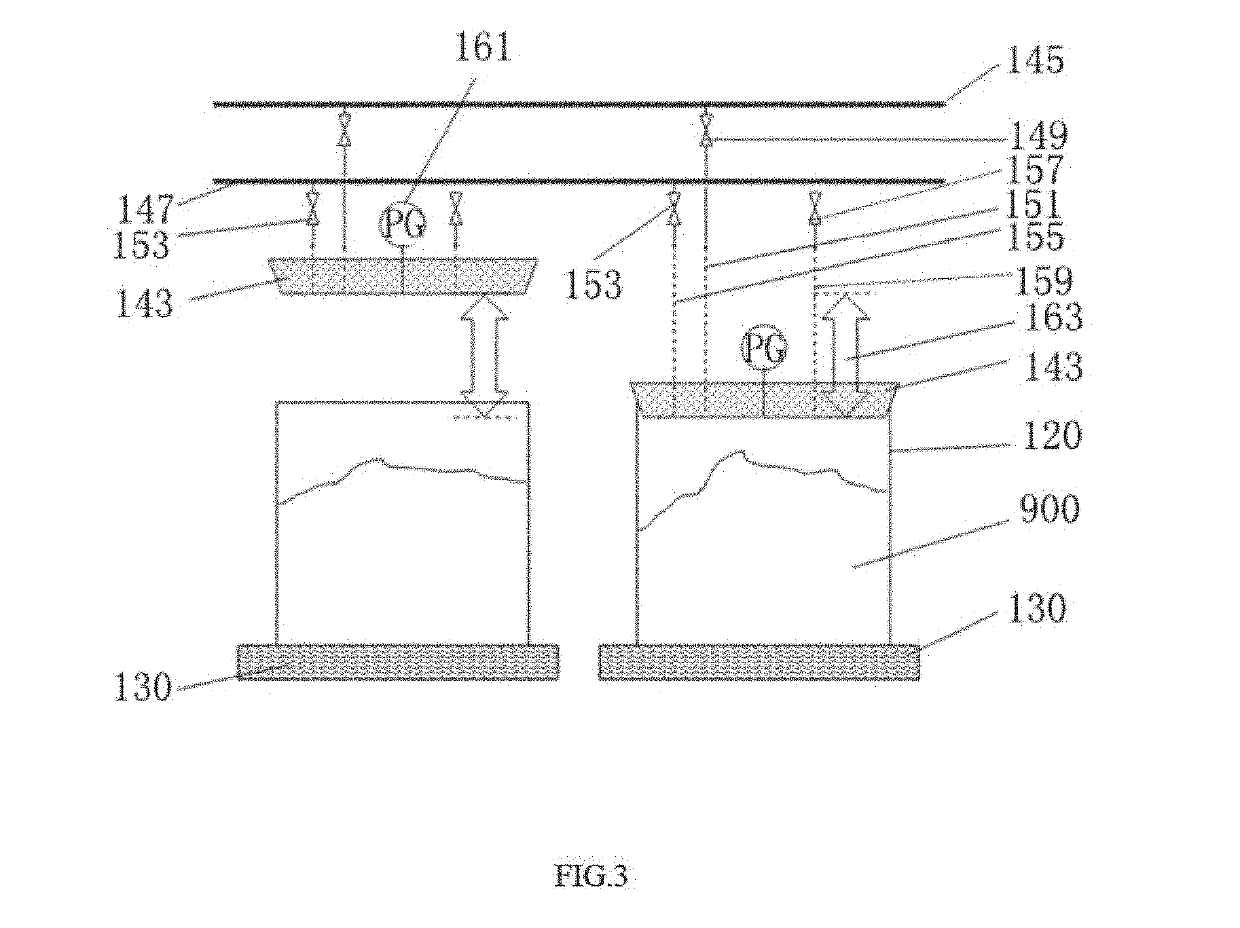

Automatic fiber processing system including method and apparatus for producing end-aligned fiber samples

InactiveUS20060179932A1Reliable estimateImprove accuracyCombing machinesMaterial strength using tensile/compressive forcesFibre treatmentEngineering

The apparatus for the preparation of an end-aligned fiber sample comprises an array of fiber combs, a first drive unit, a fiber collection device connected to the first drive unit, a suction device, a detection device and a control unit to control each of the foregoing components. The method for preparing an end-aligned fiber sample uses the control unit to operate each of the foregoing components to prepare an end-aligned fiber sample. The apparatus can be combined with testing units for testing the end-aligned fiber samples. One of the testing units can test for short fiber content. The testing for short fiber content also can employ the detection device of the apparatus.

Owner:PREMIER EVOLVICS PVT LTD

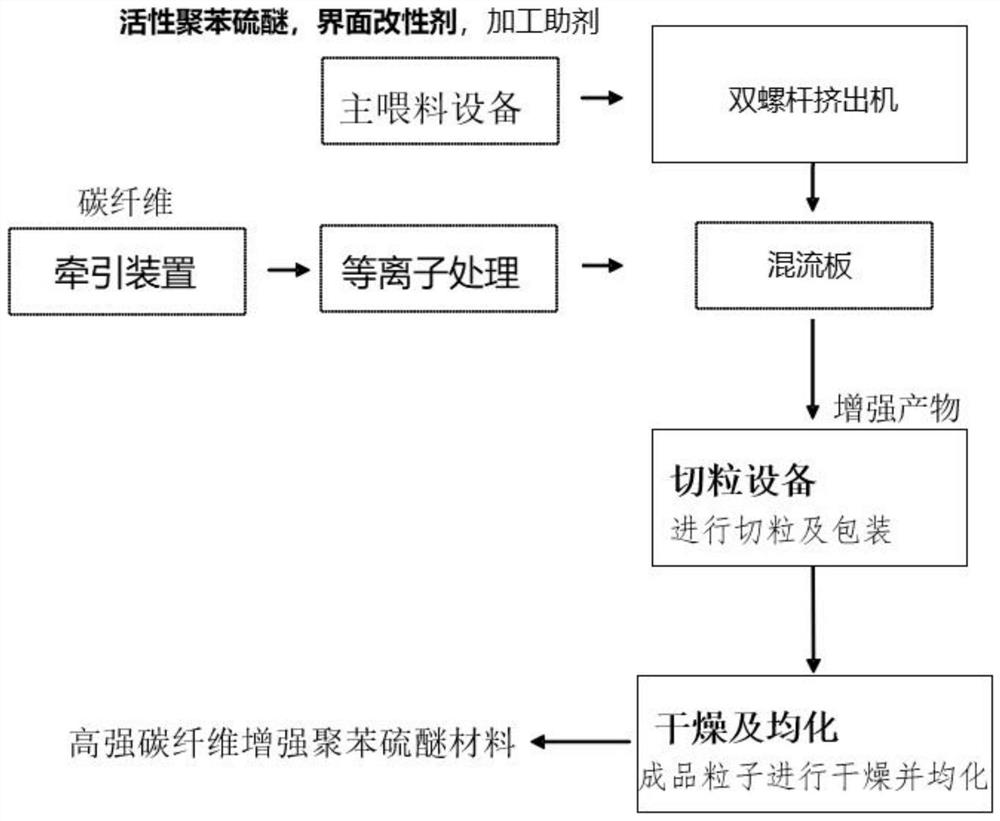

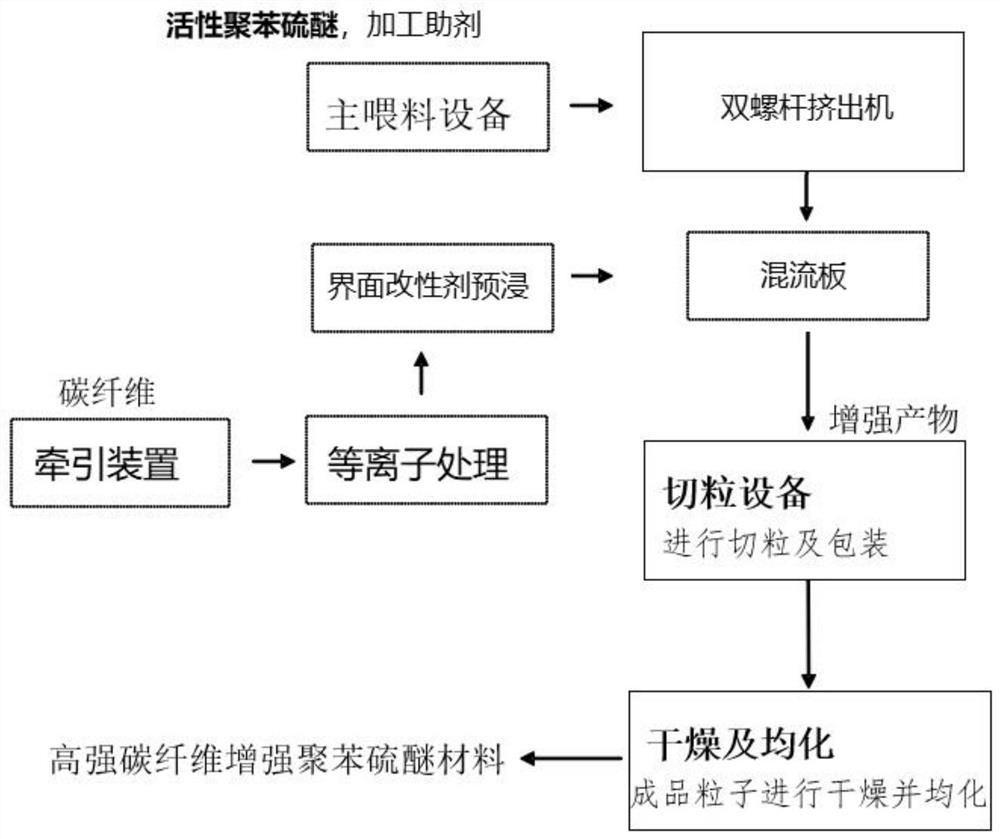

Continuous carbon fiber reinforced polyphenylene sulfide composite material

A continuous carbon fiber reinforced polyphenylene sulfide composite material comprises the following substances in parts by weight: 5-65 parts of continuous carbon fibers, 30-95 parts of polyphenylene sulfide resin, 0.3-10 parts of an interface modifier and 0.3-1 part of a processing modifier. According to the prepared composite material, the interface bonding performance between the continuous carbon fibers and the polyphenylene sulfide resin is effectively improved through the carbon fiber treatment process and the interface modifier, the high-strength and heat-resistant continuous carbon fiber / polyphenylene sulfide composite material is prepared, and the application prospects in the industries of spaceflight, military industry, traffic vehicles and sports goods are good.

Owner:SHANDONG DAWN POLYMER CO LTD

Treatment method for impacting properties of absorbing and releasing moisture to fiber

InactiveUS7004978B2Monocomponent protein artificial filamentFibre typesHydrophilic monomerPolymer science

The present invention provides a fiber-treating process wherein fiber is treated, in the presence of a polymerization initiator, with a fiber-treating composition containing (A) reactive protein synthesized by chemically bonding protein with a compound having polymerizable unsaturated group(s) or (A′) grafted protein which has been produced by graft-copolymerizing (C) hydrophilic monomer having vinyl group(s) onto (A) reactive protein synthesized by chemically bonding protein with a compound having polymerizable unsaturated group(s), and (B) hydrophilic monomer having vinyl group(s).The process provides fiber imparted with moisture absorbability and releasability durable against washing, antistaticity, water absorbability, and dry hand.

Owner:MATSUMOTO YUSHI SEIYAKU

System and method for recycling fibers from textiles waste

ActiveUS20190226125A1Fibre cleaning and opening machine combinationsSolid waste disposalFibre treatmentPre treatment

The present disclosure related to a system and method for recycling fibers from textiles waste. The system includes a first sanitization device; a pre-processing device; a fabric sorting device; a storage device; a fiber processing device; and a second sanitization device mounted in the fiber processing device. The first sanitization device, the pre-processing device, the fabric sorting device, the storage device and the fiber processing device are arranged along a transmission path of the textiles waste.

Owner:NOVETEX TEXTILES LTD

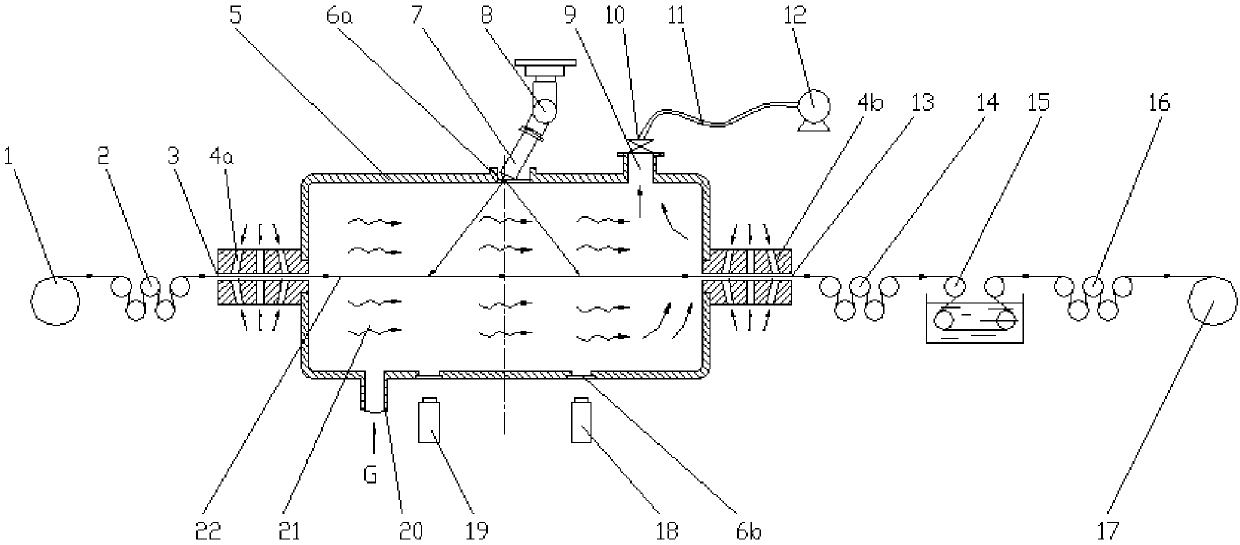

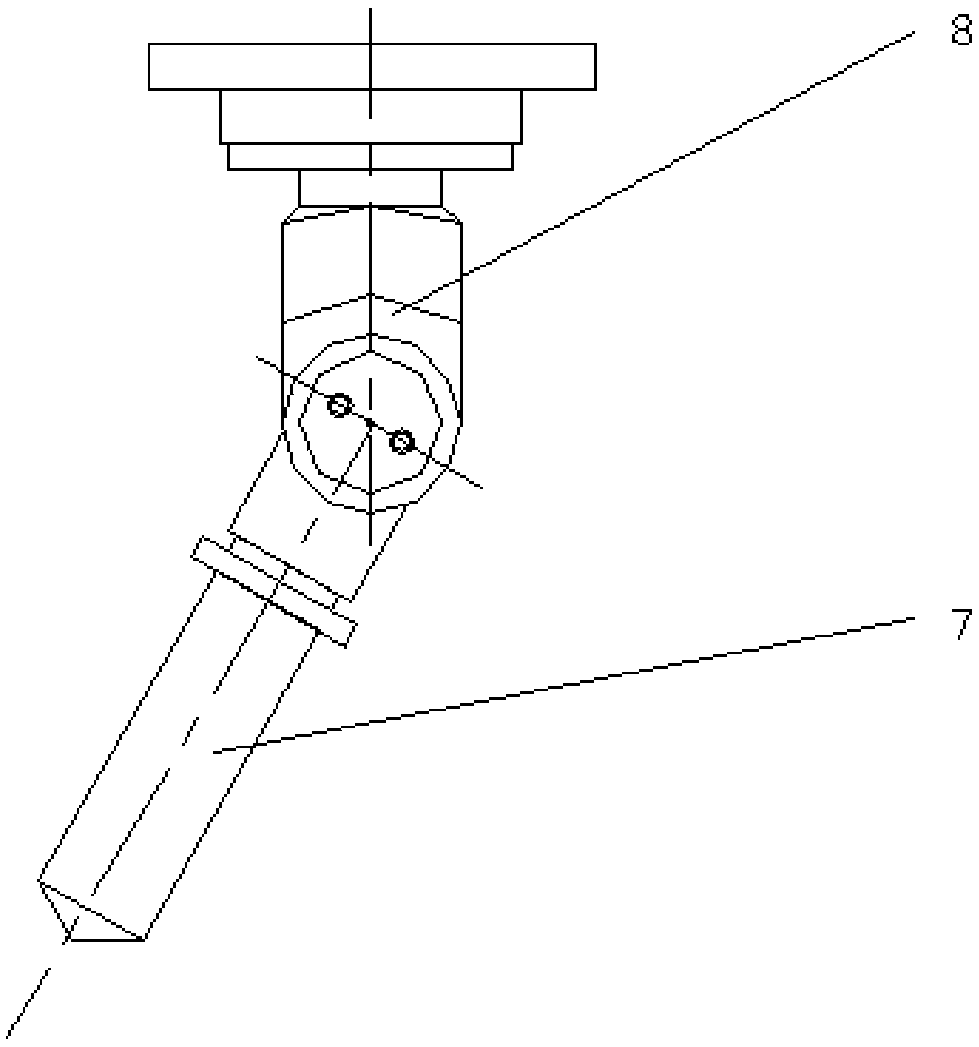

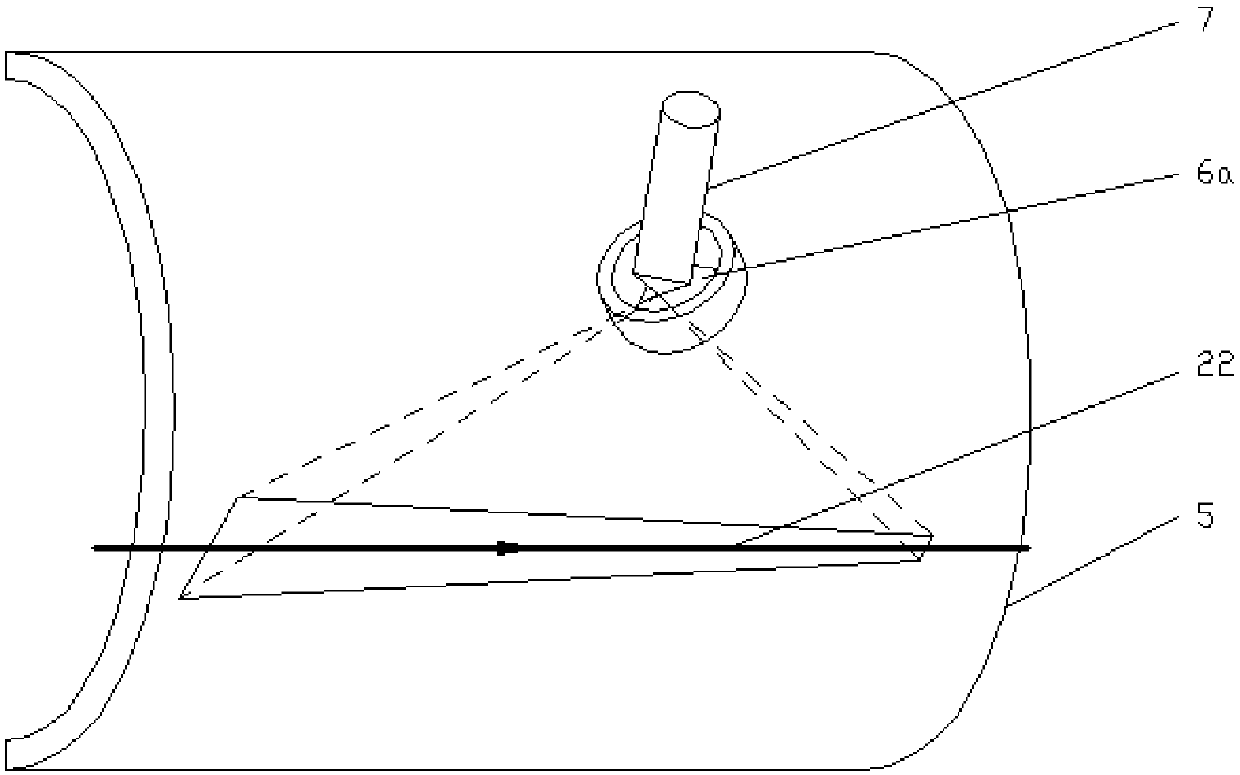

Device and method for efficiently preparing gradually varied laser carbonization furnace

PendingCN107761193AImprove carbonization efficiencyLow furnace efficiencyFibre chemical featuresChemical industryPolymer scienceCarbon fibers

The invention provides a device and a method for efficiently preparing a gradually varied laser carbonization furnace, relates to a fiber carbonization efficient preparation device and a fiber carbonization efficient preparation method, and belongs to the field of carbon fiber preparation. The device mainly comprises a silk releasing device, a front drafting device, a gradually varied laser carbonization furnace, a back drafting device, a sizing device, a drying device and a silk receiving device which are arranged sequentially; the silk releasing device is arranged at front end; the silk releasing device releases pre-oxidation raw silk, one set of drafting devices is arranged in the front and at the back of the gradually varied laser carbonization furnace to apply a drafting force to thecarbon fiber; a motor controls the rotating speed of a drafting roller to control the silk inlet speed of the carbon fiber; surface treatment is conducted in the sizing device and the drying device; and the treated carbon fiber is rolled by the silk receiving device. The device and the method have the following advantages: the heatable temperature range is high, the device occupies small space, and the processing cost is low.

Owner:BEIJING UNIV OF CHEM TECH

Method for treating reinforcing fibre and method for producing a reinforced composite article from the treated fibre

ActiveUS8153200B2Increase resistanceHigh strengthPretreated surfacesCeramic shaping apparatusGlass fiberPolymer science

The present invention relates to a reinforced composite material and a method for its production. The composite material comprises at least one cured resin having a reinforcing material. Preferably the reinforcing material is a plurality of glass fibres which are treated such that the properties of the interphase substantially surrounding each fibre are substantially equivalent to those of the bulk cured resin. The fibre treatment may be selected from the group consisting of a polymeric coating, a hydrophilic surface coating, a surface coating of a free radical inhibitor, or a reduction in the total surface area of the fibres. The reinforced composite material of the invention provides improved long-term mechanical properties compared to traditional glass fibre reinforced materials.

Owner:SPOKE HLDG LLC

Treatment method for imparting properties of absorbing and realeasing moisture to fiber

InactiveUS20040117917A1Monocomponent protein artificial filamentPhysical treatmentHydrophilic monomerPolymer science

The present invention provides a fiber-treating process wherein fiber is treated, in the presence of a polymerization initiator, with a fiber-treating composition containing (A) reactive protein synthesized by chemically bonding protein with a compound having polymerizable unsaturated group(s) or (A') grafted protein which has been produced by graft-copolymerizing (C) hydrophilic monomer having vinyl group(s) onto (A) reactive protein synthesized by chemically bonding protein with a compound having polymerizable unsaturated group(s), and (B) hydrophilic monomer having vinyl group(s). The process provides fiber imparted with moisture absorbability and releasability durable against washing, antistaticity, water absorbability, and dry hand.

Owner:MATSUMOTO YUSHI SEIYAKU

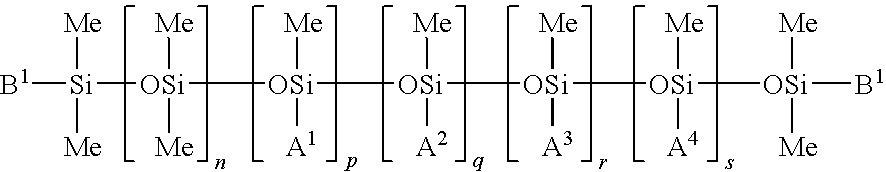

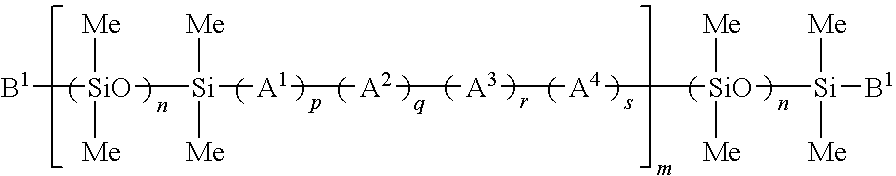

Durable Fiber Treatment Composition

InactiveUS20090068135A1Increased durabilityDurableCosmetic preparationsHair cosmeticsChemical treatmentFibre treatment

A fiber treatment composition is presented comprising organomodified silicones having defined physico-chemical properties and a additive which allows the organomodified silicone to be retained on the hair over longer periods of time than traditionally has been the case. The present composition finds particular application on hair that has been damaged through chemical treatments, such as occurs during permanent dyeing, bleaching and permanent waving.

Owner:THE PROCTER & GAMBLE COMPANY

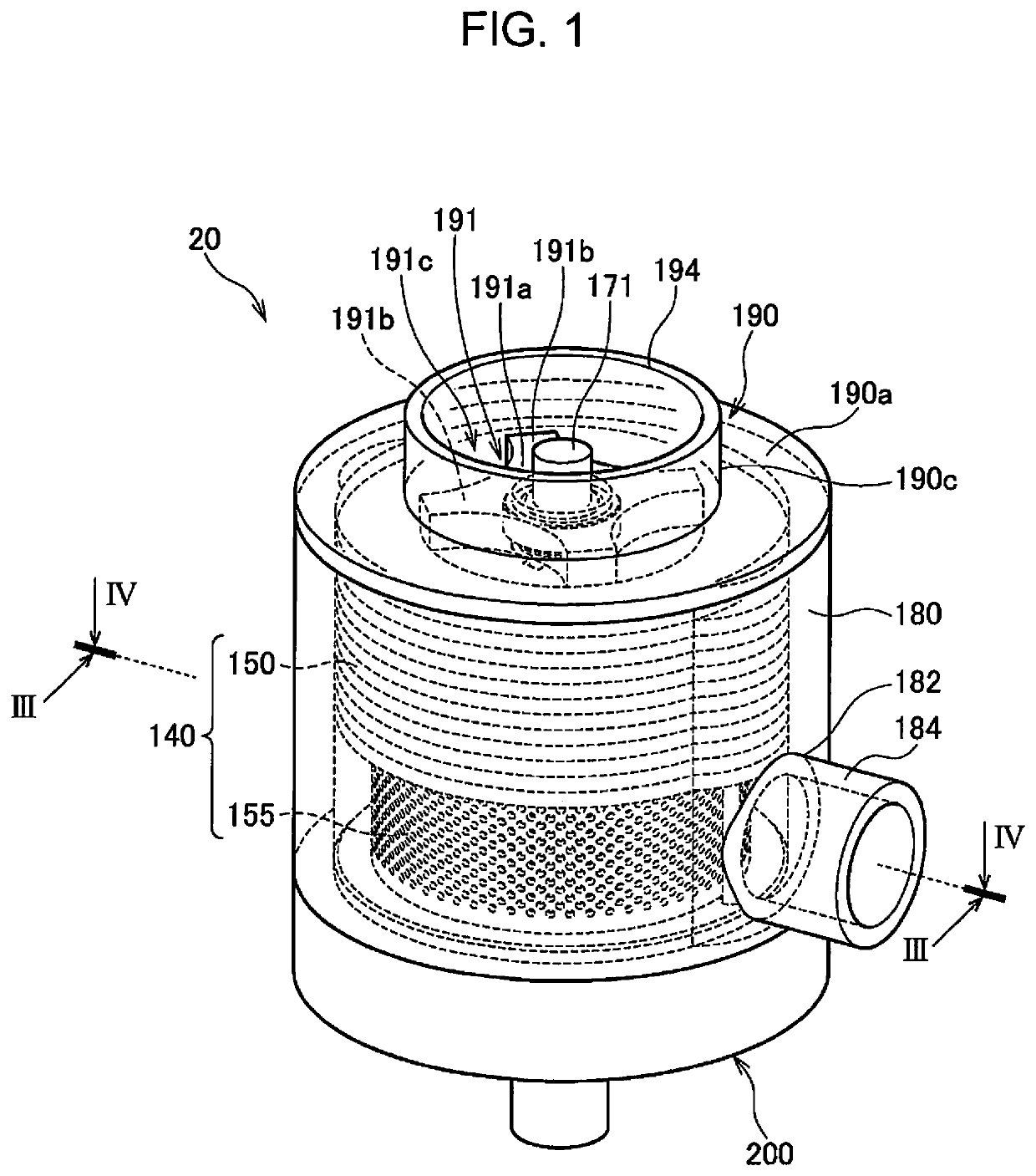

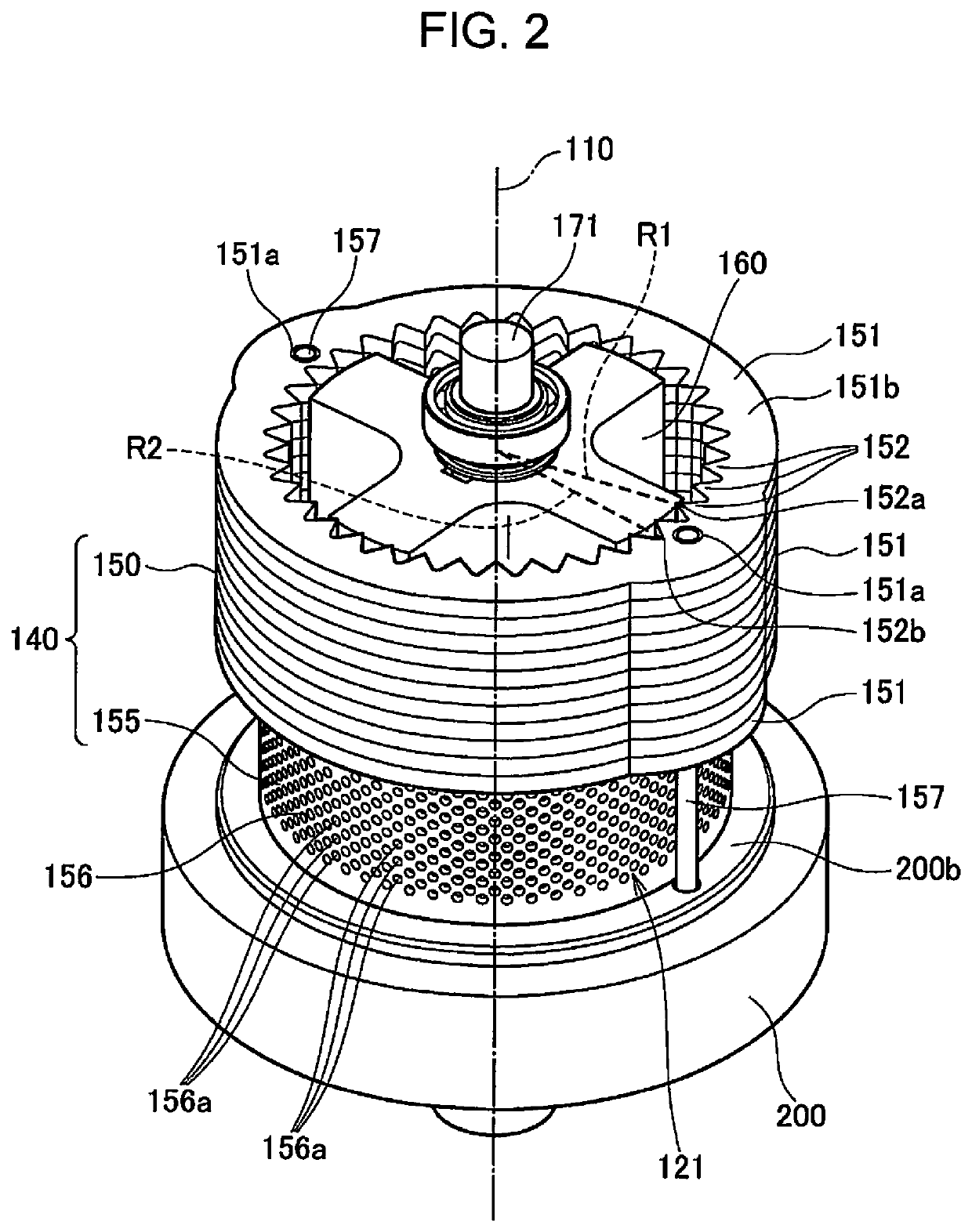

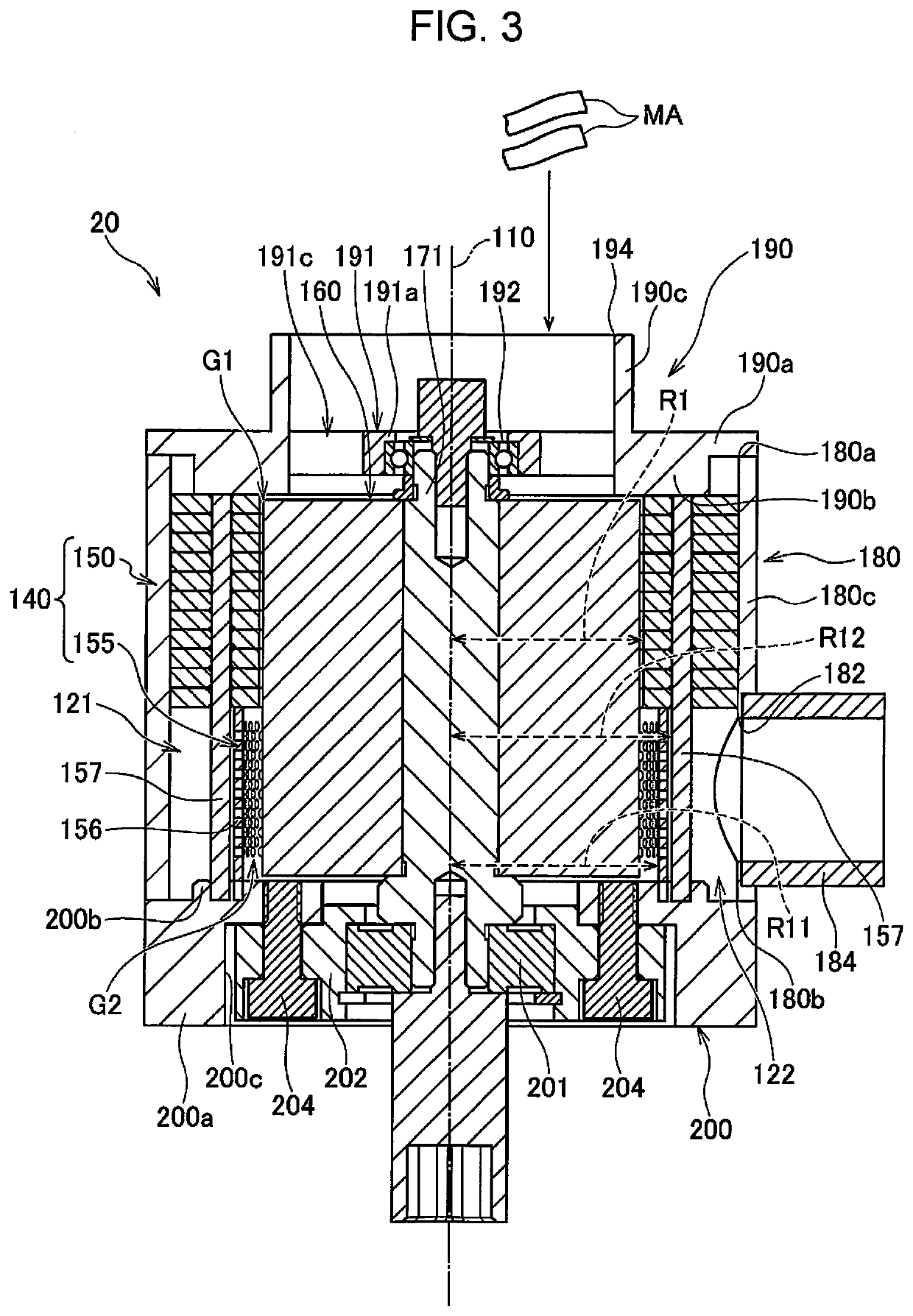

Defibration processing apparatus and fiber processing apparatus

A defibration processing apparatus includes: an input port into which a raw material is input; a rotating body that rotates about a rotary shaft; a stationary member that covers at least part of the rotating body; and a discharge port through which a defibrated object obtained by the rotating body and the stationary member defibrating the raw material is discharged, in which the rotating body has a plurality of rotating blades protruding in a direction away from the rotation center shaft, and the stationary member has a configuration in which a screen having a plurality of openings is disposed in at least part of the stationary member in a direction of the rotation center shaft and surrounds the rotating body in a rotation direction.

Owner:SEIKO EPSON CORP

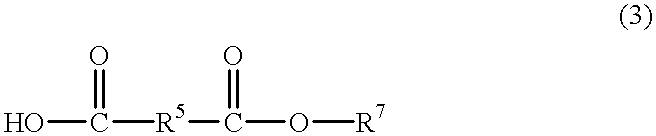

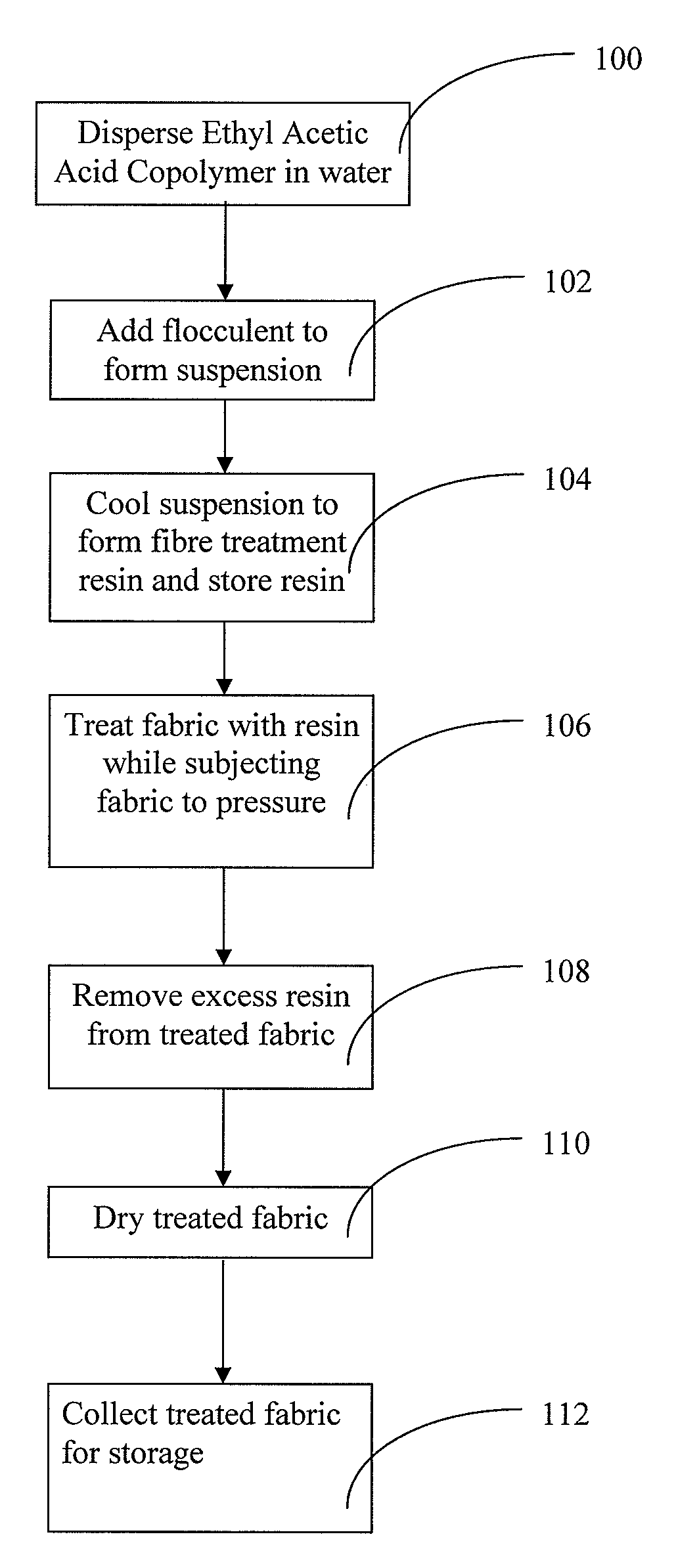

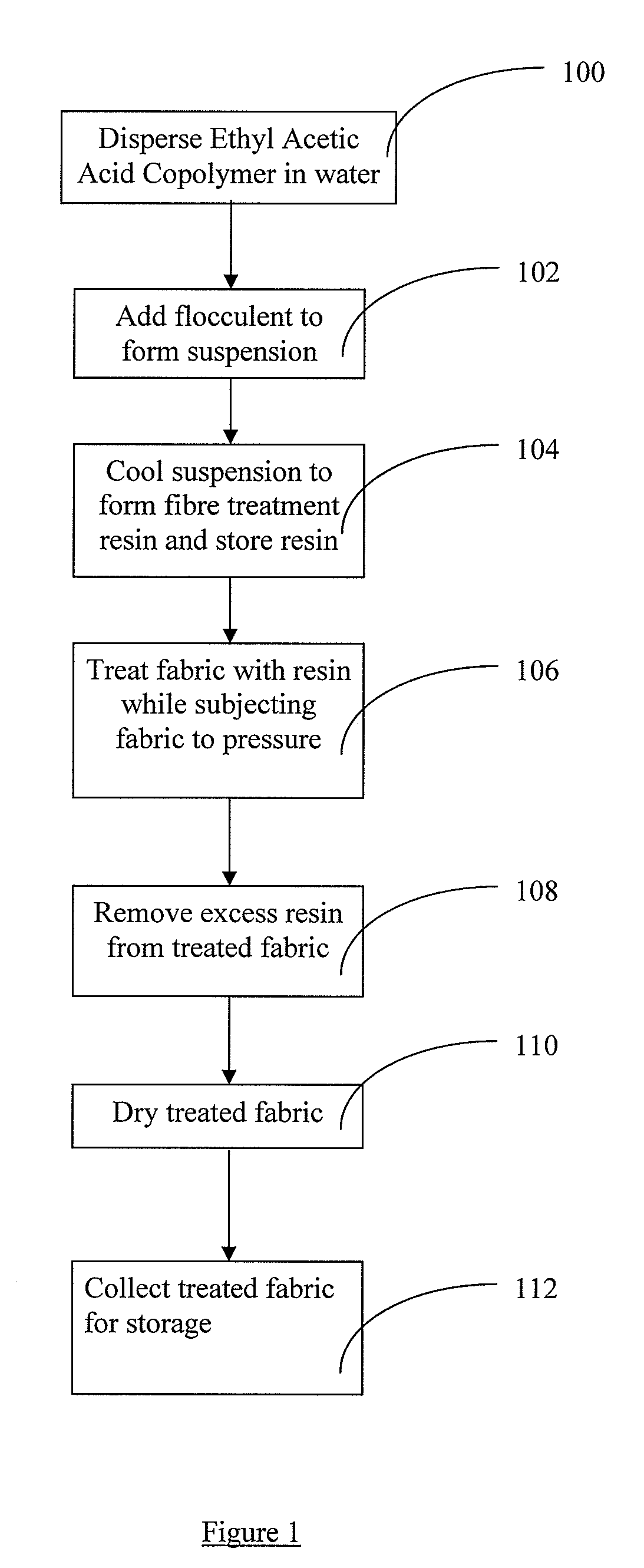

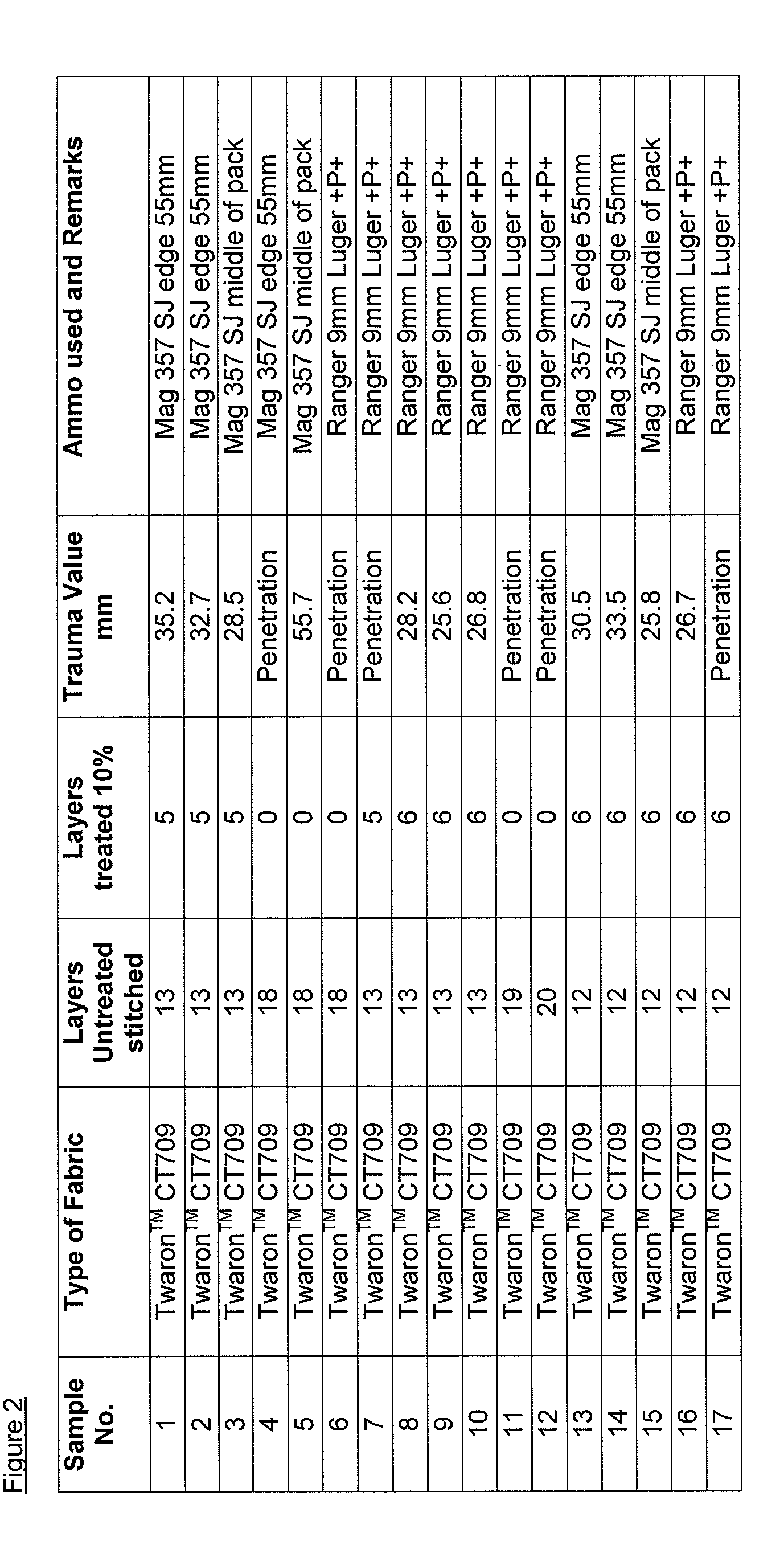

Fibre treatment resin and method of preparing such resin

InactiveUS20090094719A1Improve ballistic performanceExcellent phase change propertiesArmourFibre treatmentAcetic acidFibre treatment

A method of preparing fibre treatment resin is disclosed herein. In a preferred embodiment, at step 100, the method comprises dispersing ethyl acetic acid copolymers in water to form a mixture at predetermined temperature and at step 102, ammonia is introduced as a flocculent into the mixture to form a suspension; and at step 104, the suspension is cooled to form the fibre treatment resin. Fibres treated with the fibre treatment resin exhibits improved tenacity and enable the fibres to be stretched and absorb the energy of incidental pressure such as those from a projectile.

Owner:FRAL PRIVATE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com