Aramid fiber surface grafting modification method

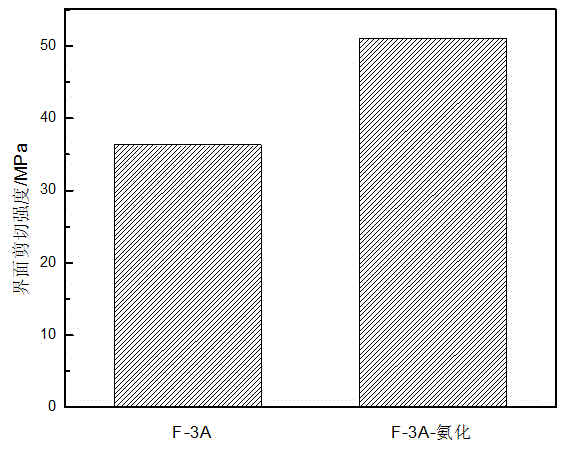

A surface graft modification, aramid fiber technology, applied in the field of chemical grafting on the surface of aramid fiber, can solve the problems of low surface activity of aramid fiber, poor adhesion of resin matrix, etc. Control and avoid the effect of reducing the strength of aramid fibers and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

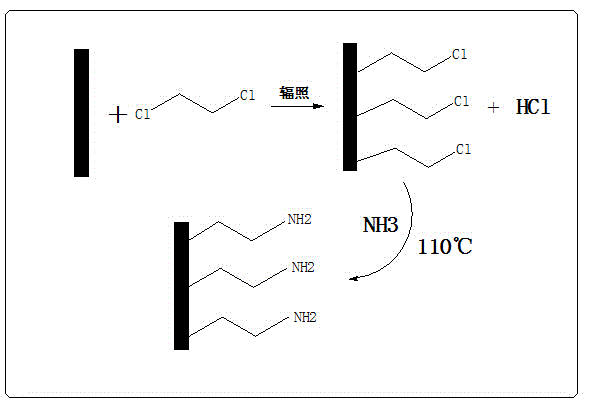

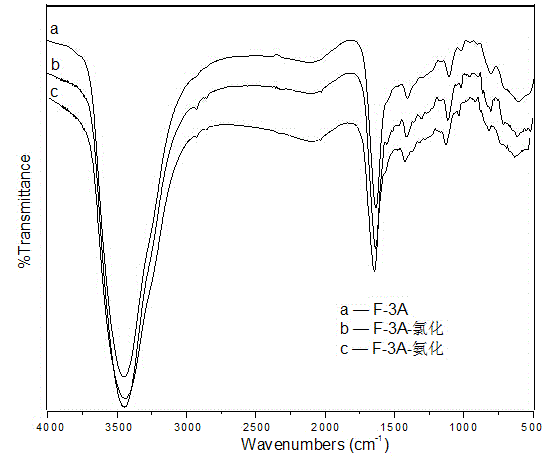

[0032] The invention provides a treatment method for ammonification modification of aramid fiber surface, which mainly includes three steps of fiber surface cleaning and drying, fiber surface chlorination reaction and fiber surface ammonification reaction, domestic aramid fiber F-3A is used as the For example, the specific content is as follows:

[0033] 1. Aramid fiber surface cleaning and drying, including:

[0034] (1) Put the F-3A aramid fiber bundle into a 15L high-pressure reactor, tighten the bolts to seal it, and after vacuuming with a vacuum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com