Patents

Literature

14506results about How to "Reduce intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

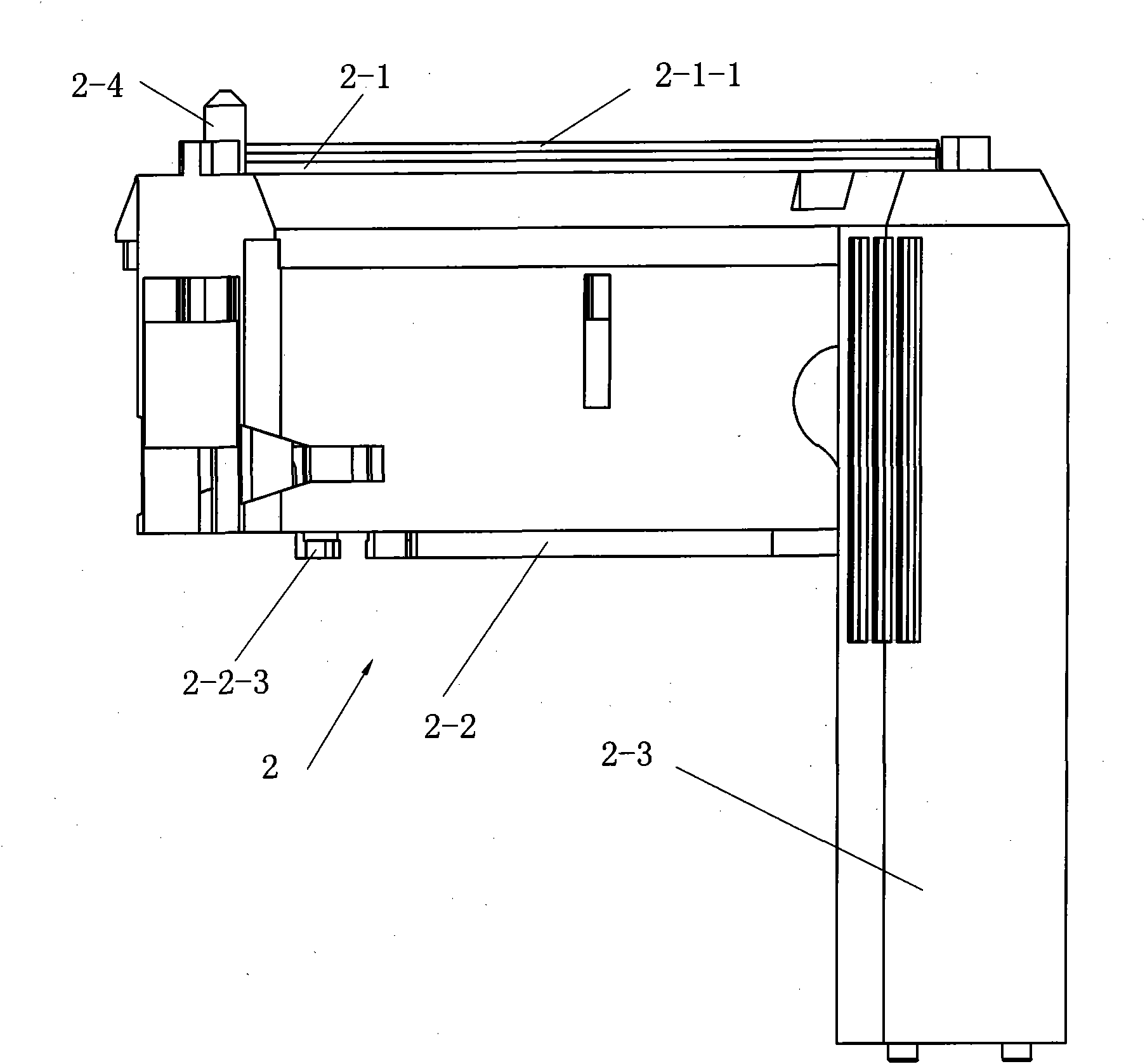

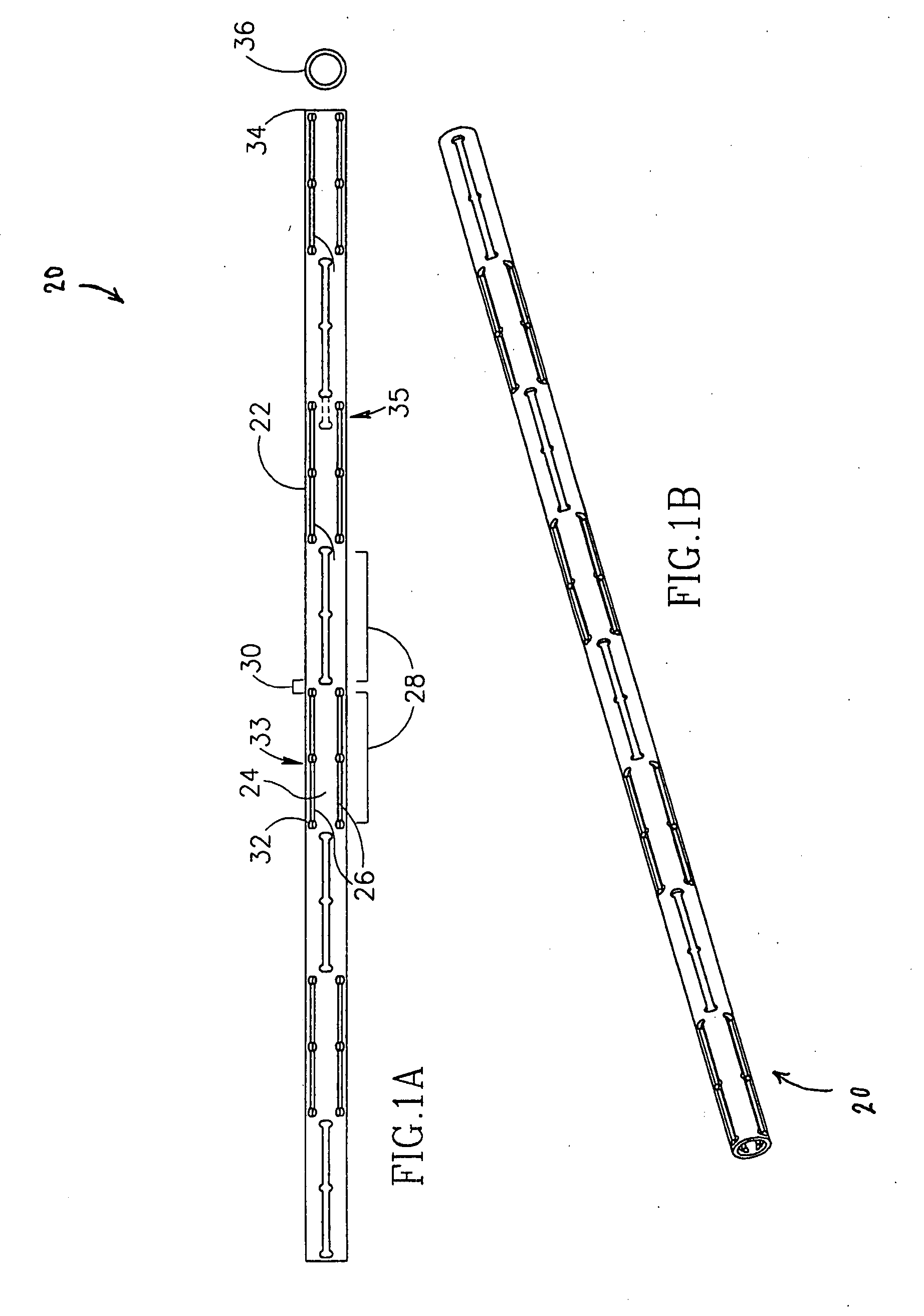

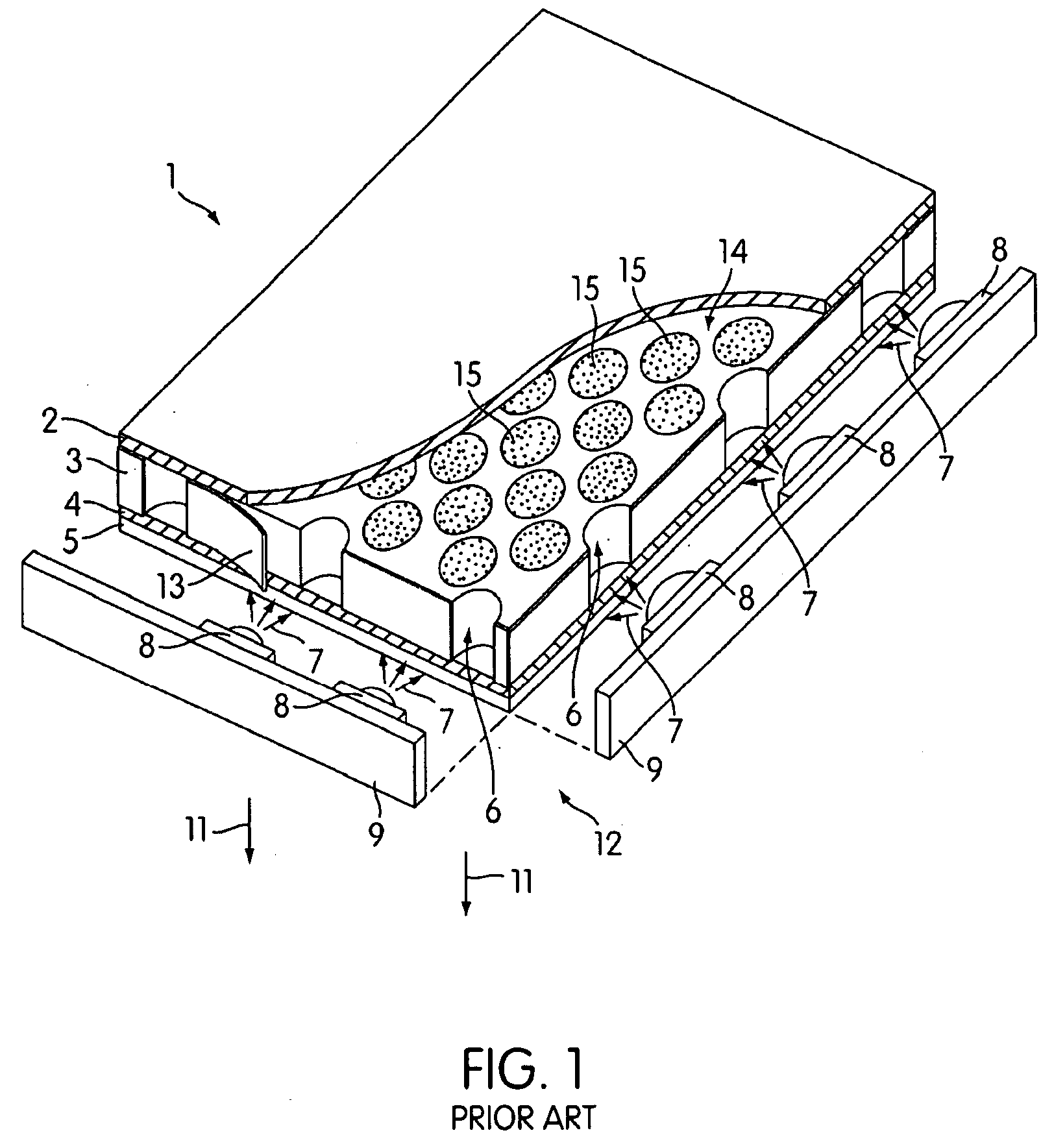

Rotatable stapling head of a surgical stapler

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

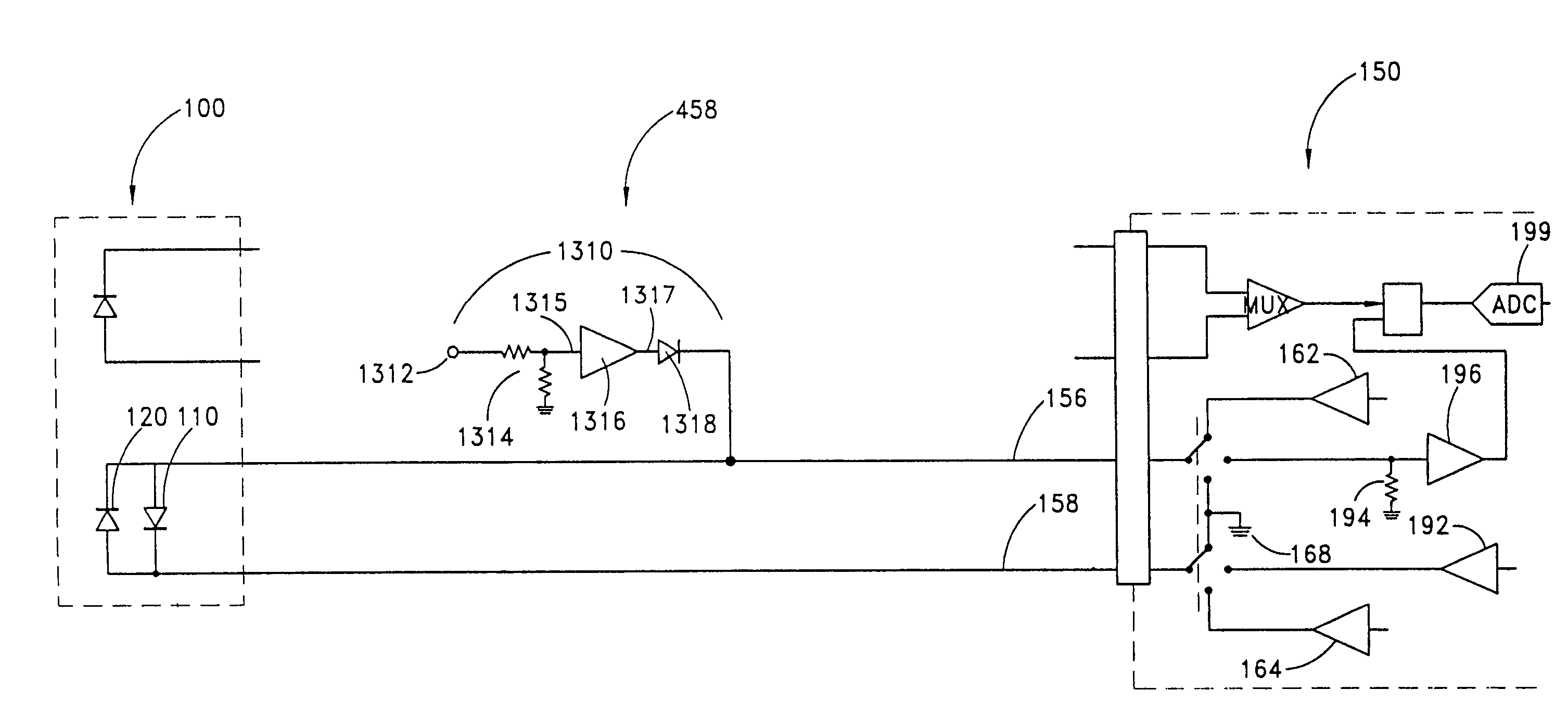

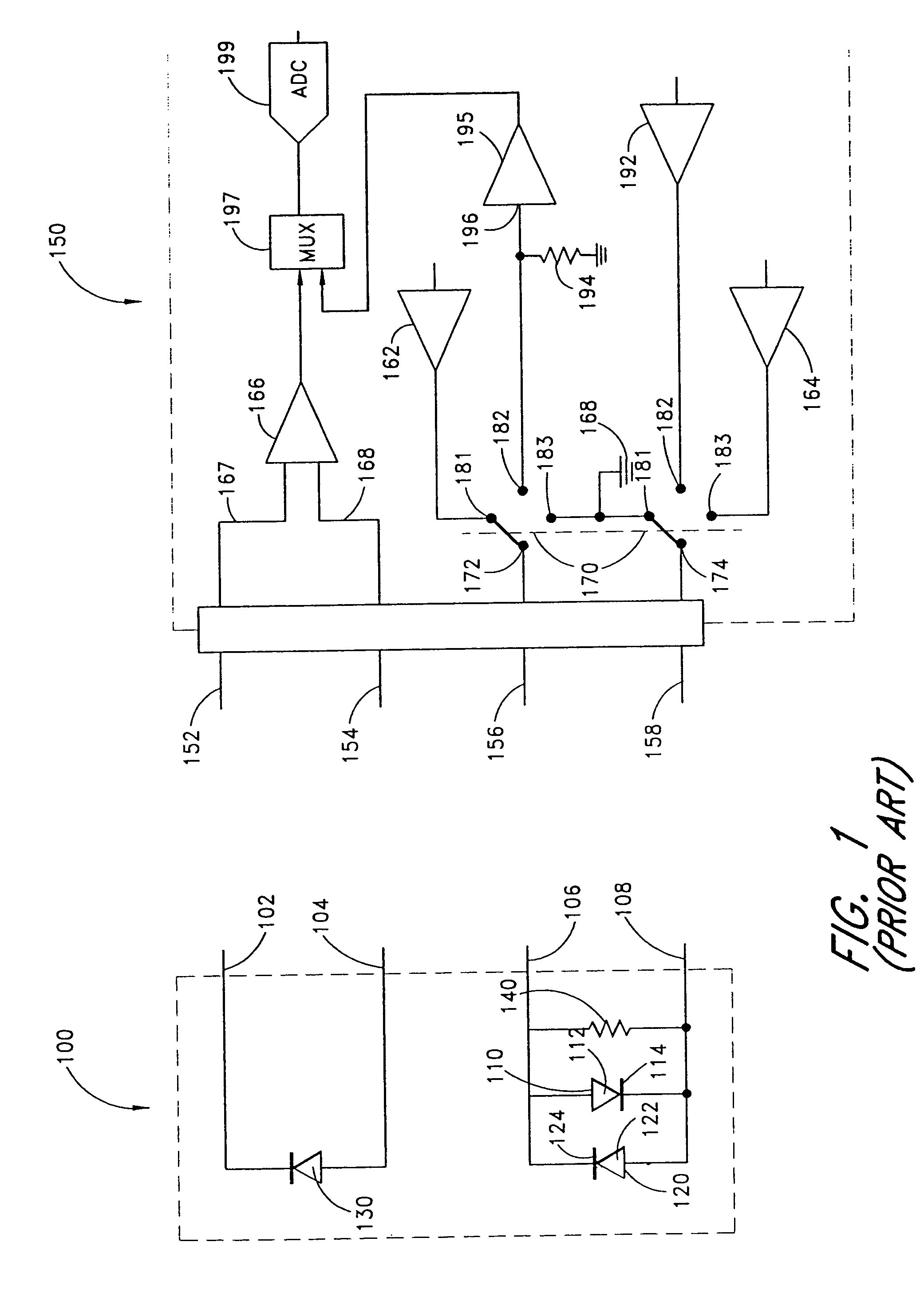

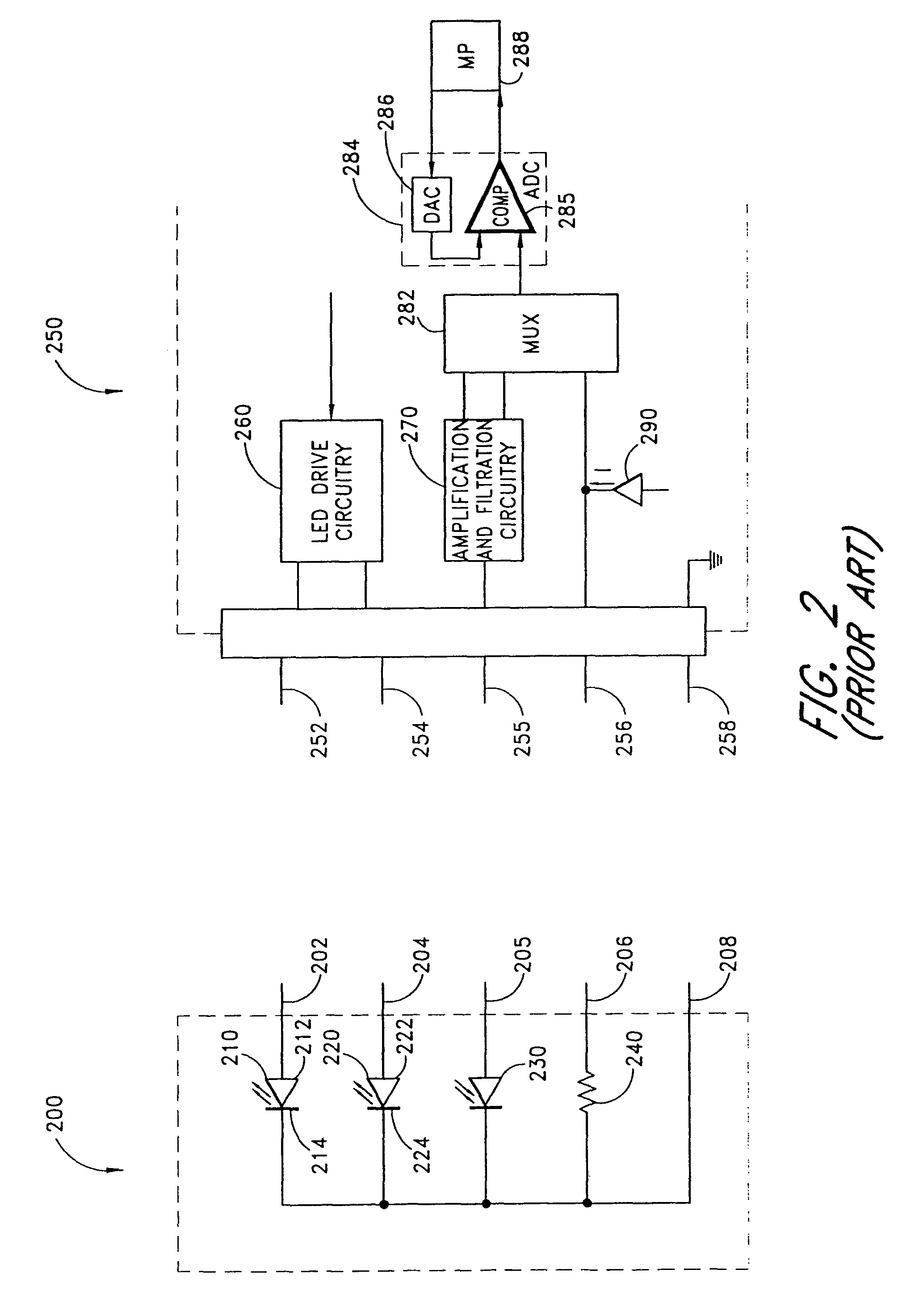

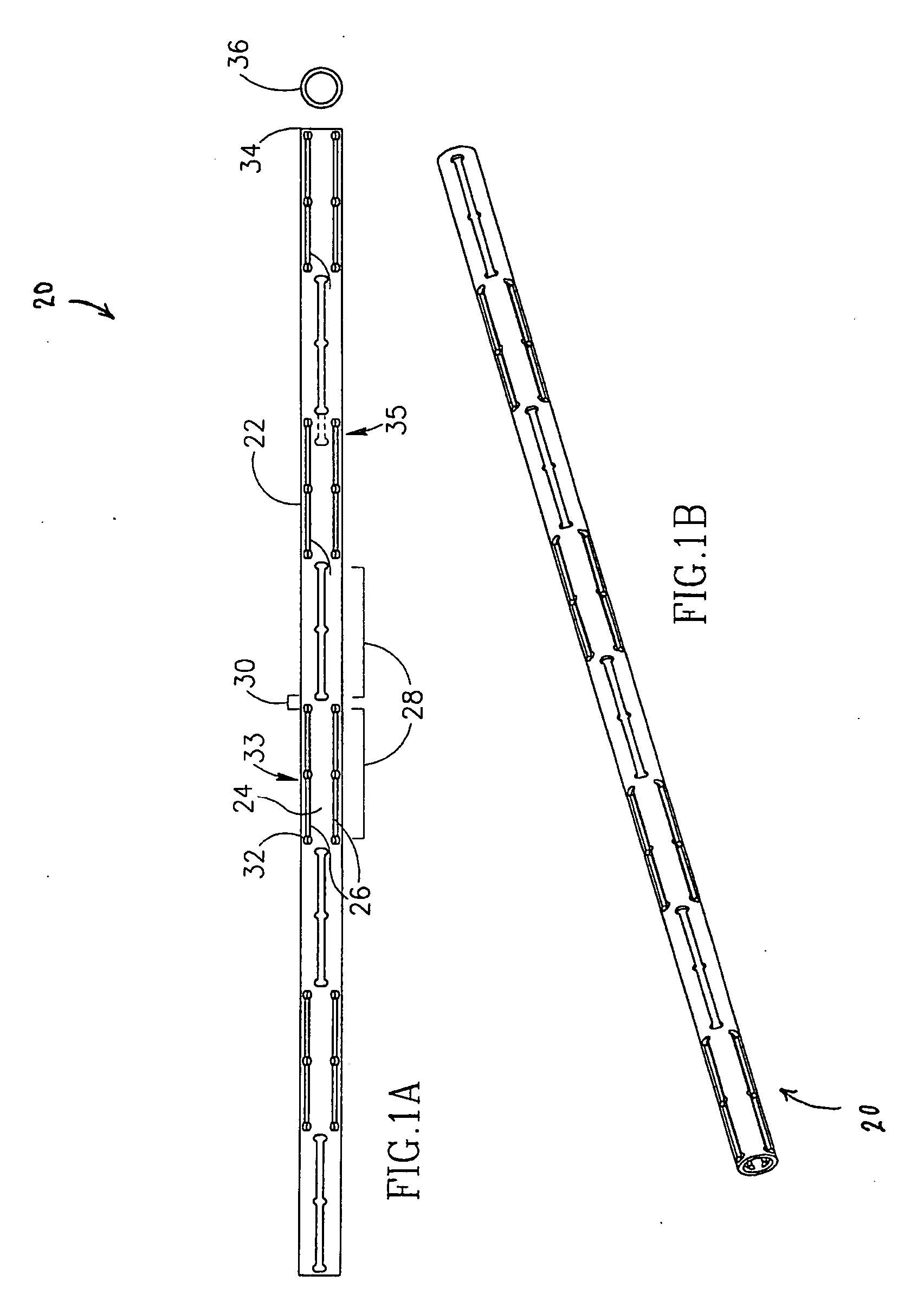

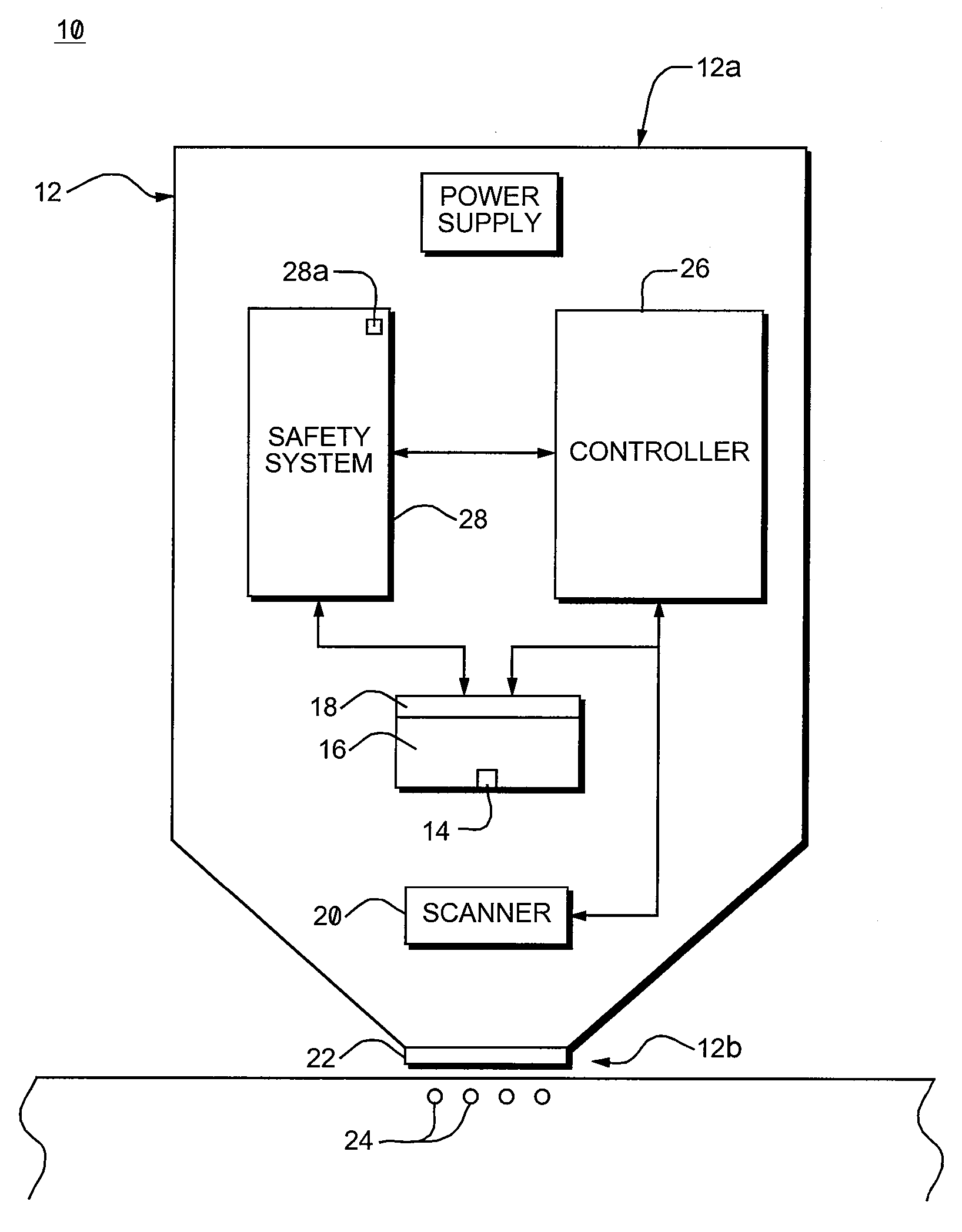

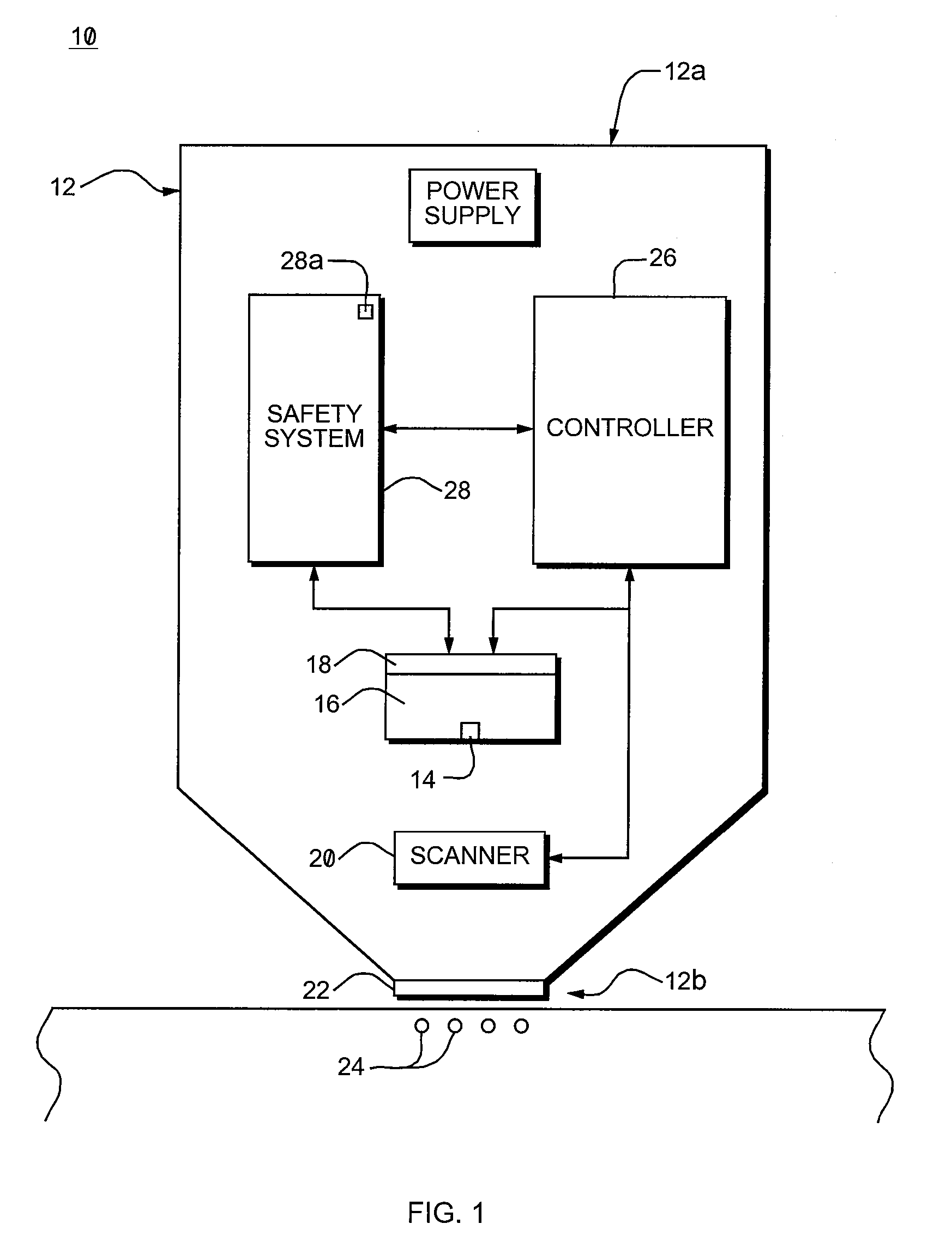

Pulse oximetry sensor adaptor

InactiveUS6993371B2Avoid complex processCost of very criticalDiagnostic recording/measuringSensorsAudio power amplifierPulse oximetry

An adapter allows the interconnection of a sensor originating from one manufacturer to be coupled with conventionally incompatible monitors originating from other manufacturers to form a properly functioning pulse oximetry system. The adapter matches a sensor driver in a monitor to the current requirements and light source configuration of a sensor. The adapter also matches a sensor's light detector signal level to the dynamic range requirements of a monitor preamplifier. Further, the adapter provides compatible sensor calibration, sensor type and security information to a monitor. The adapter may have a self-contained power source or it may derive power from the monitor, allowing both passive and active adapter components. The adapter is particular suited as an adapter cable, replacing a conventional patient cable or sensor cable as the interconnection between a sensor to a monitor in a pulse oximetry system.

Owner:JPMORGAN CHASE BANK NA

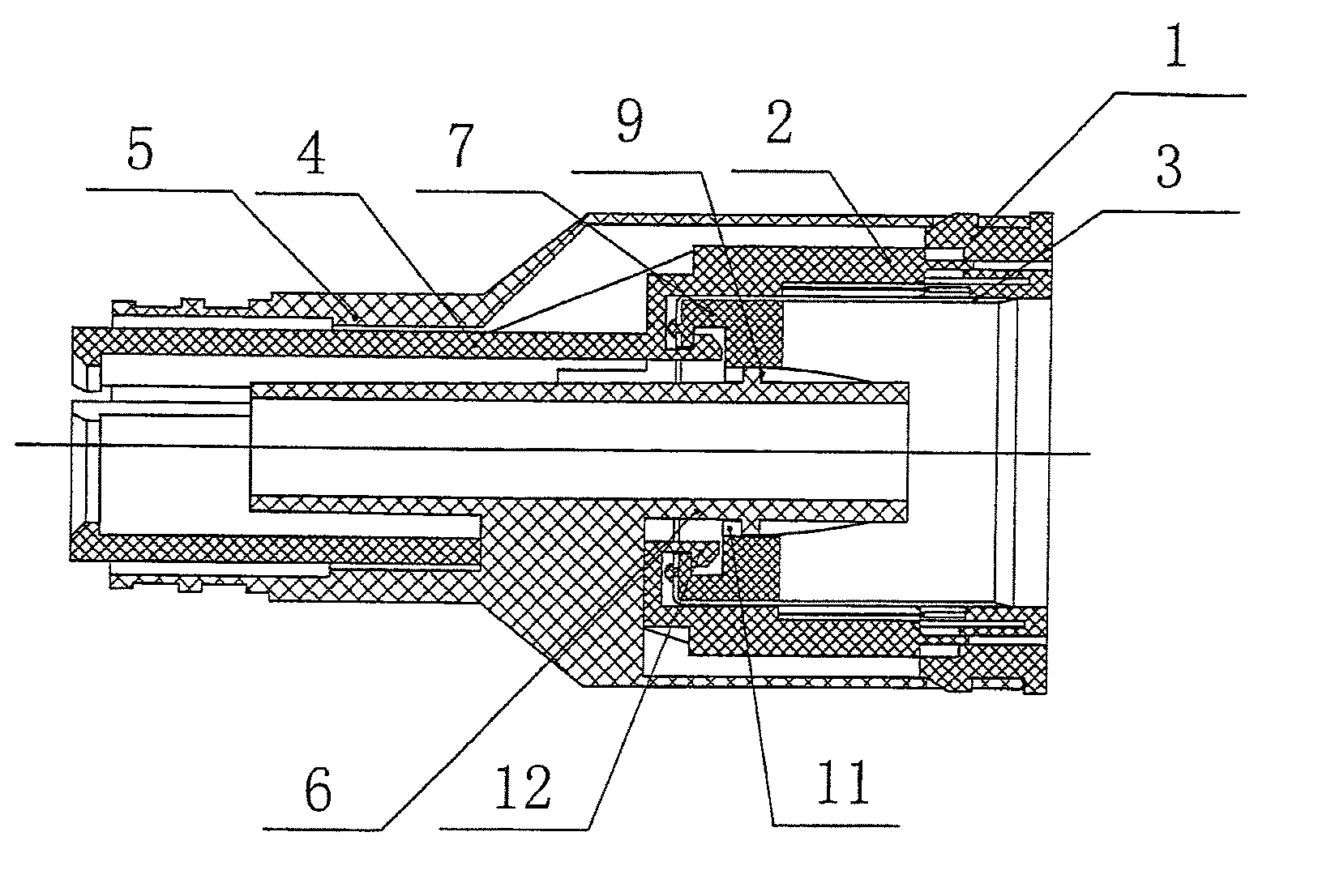

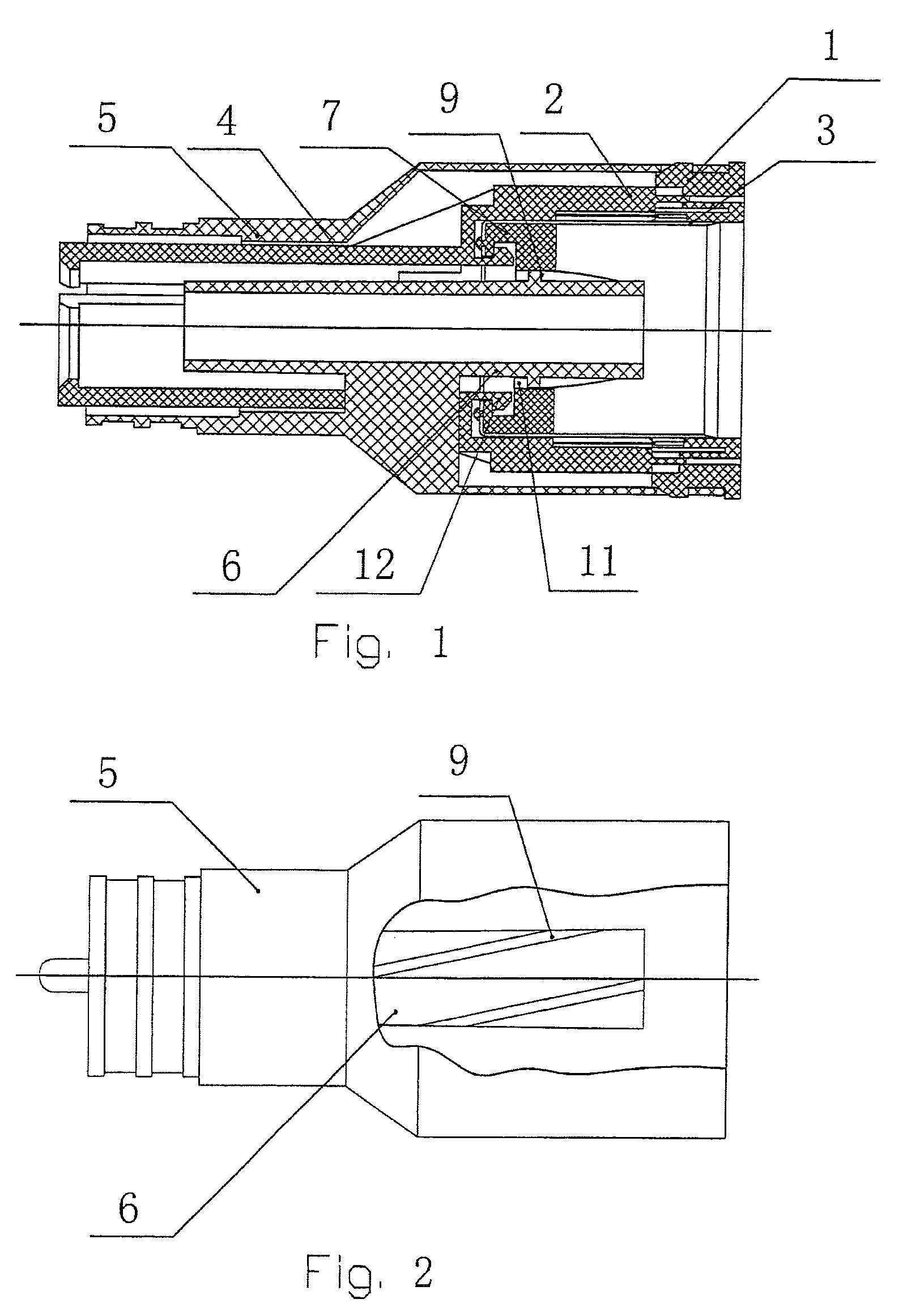

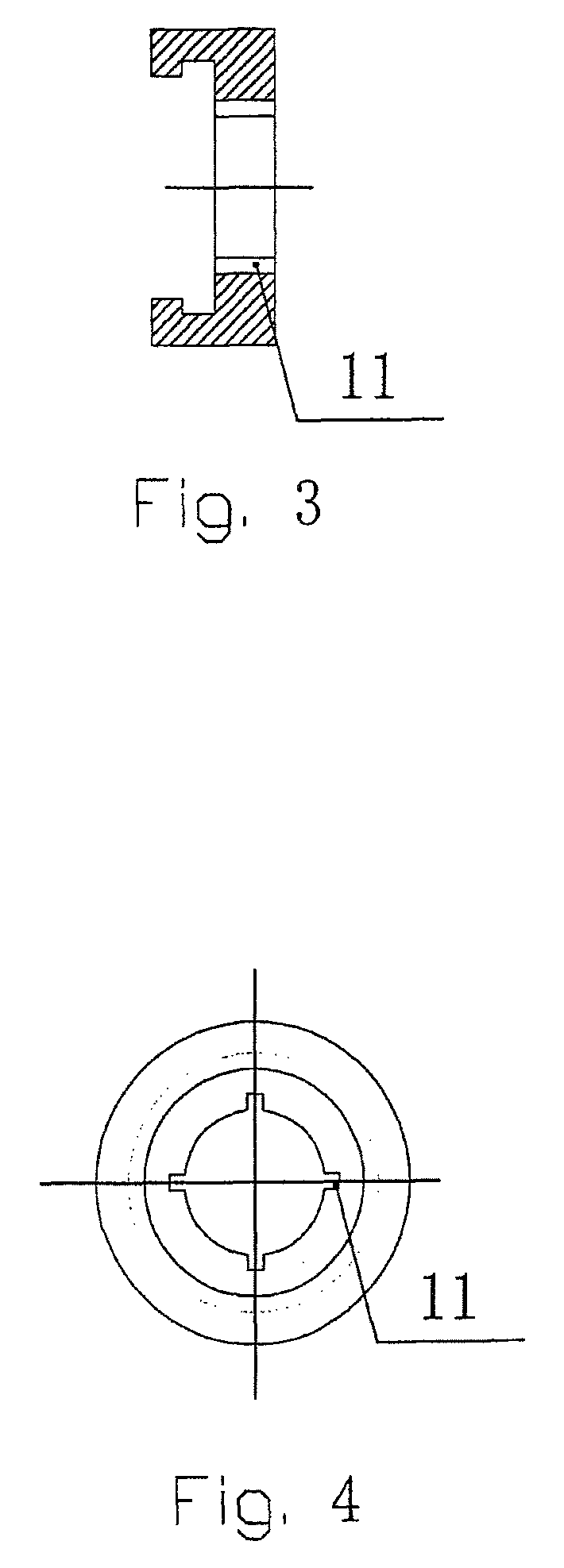

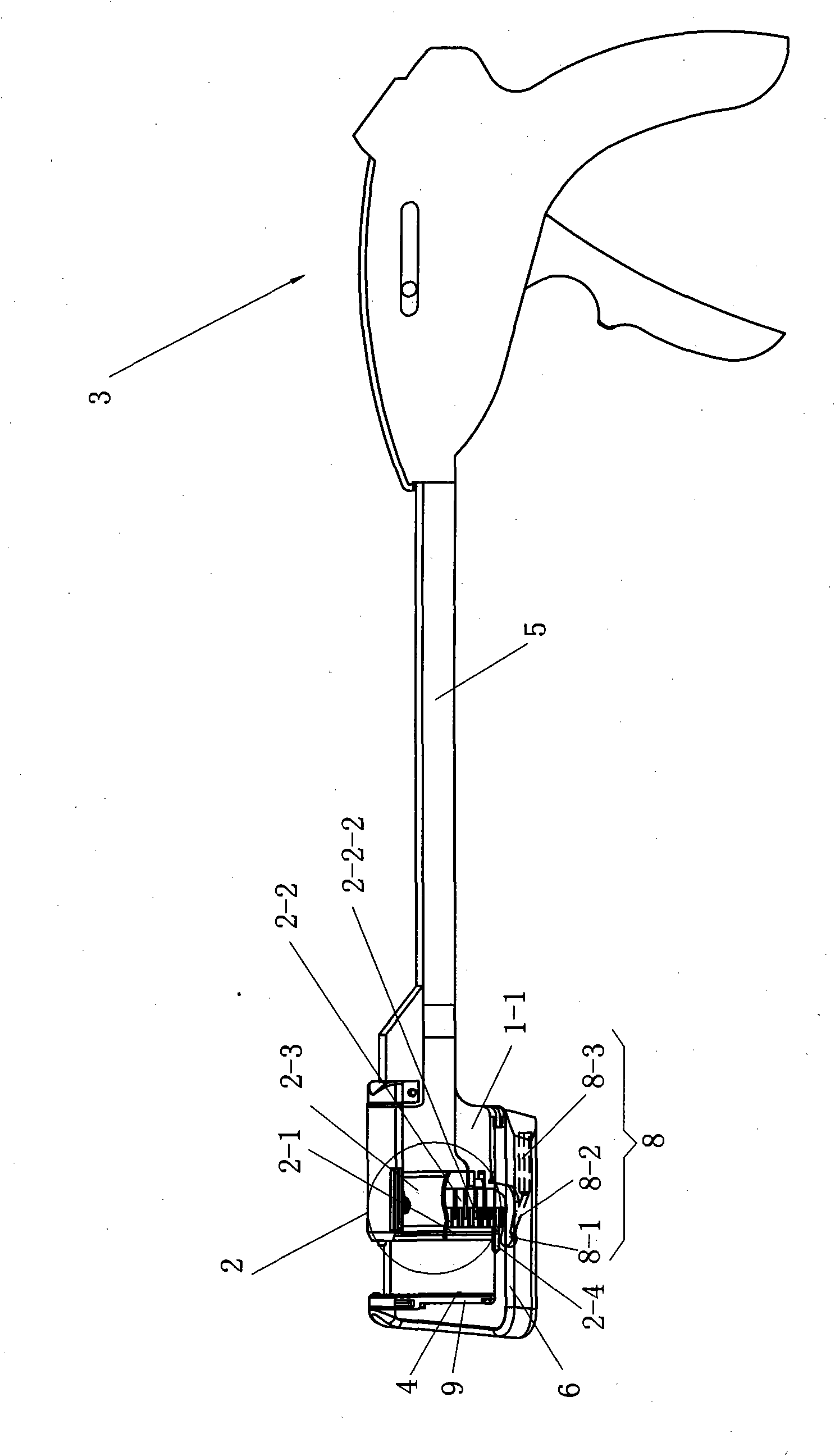

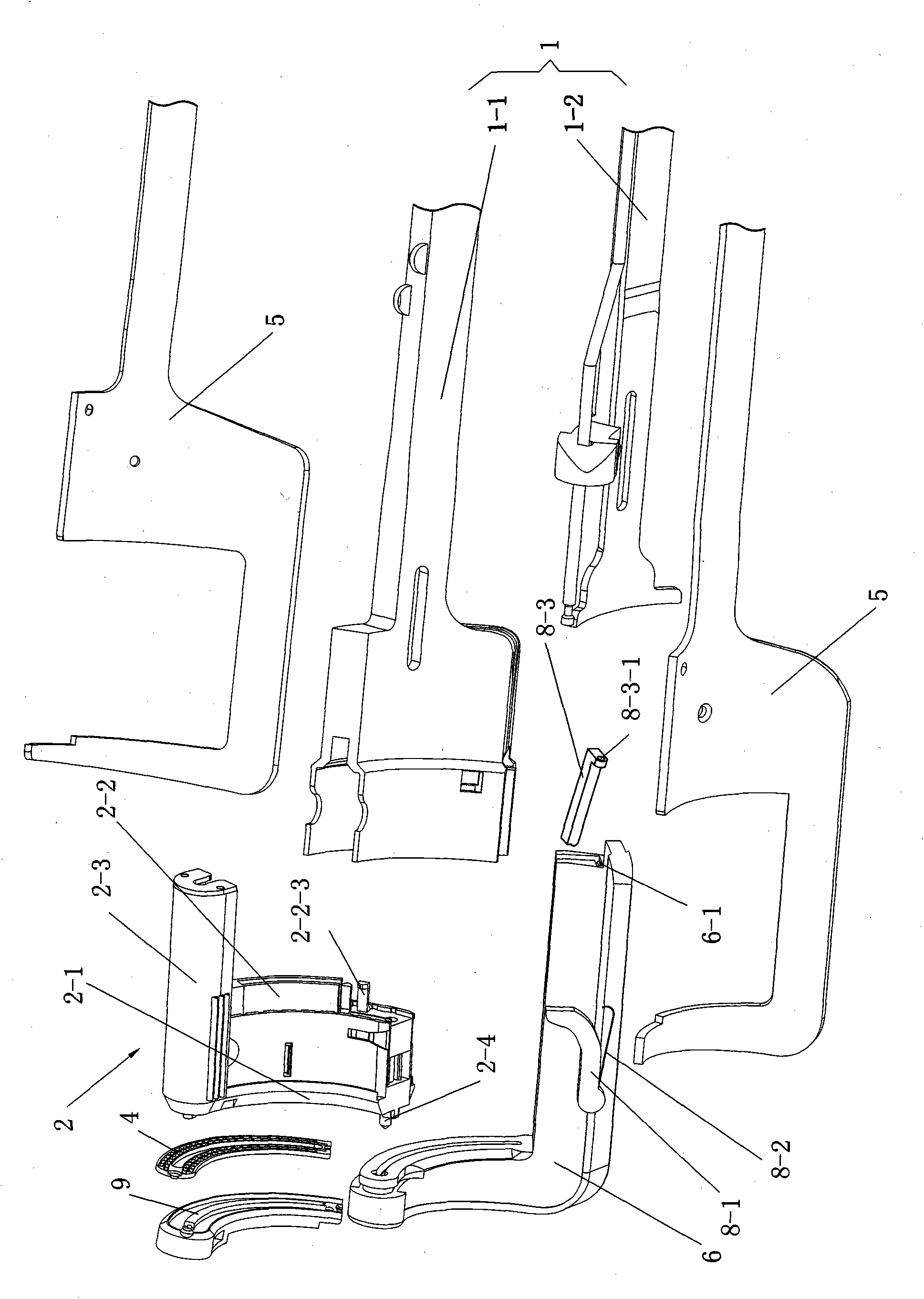

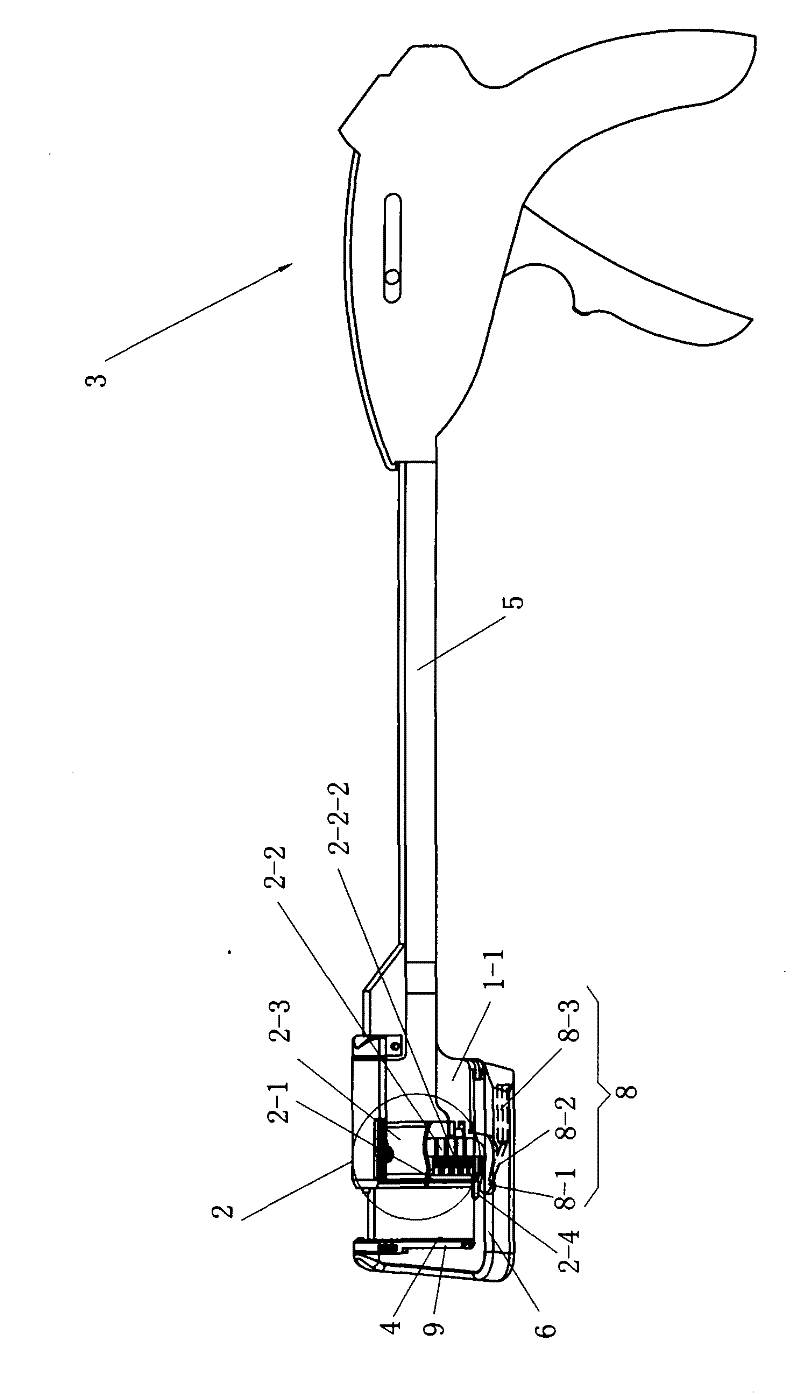

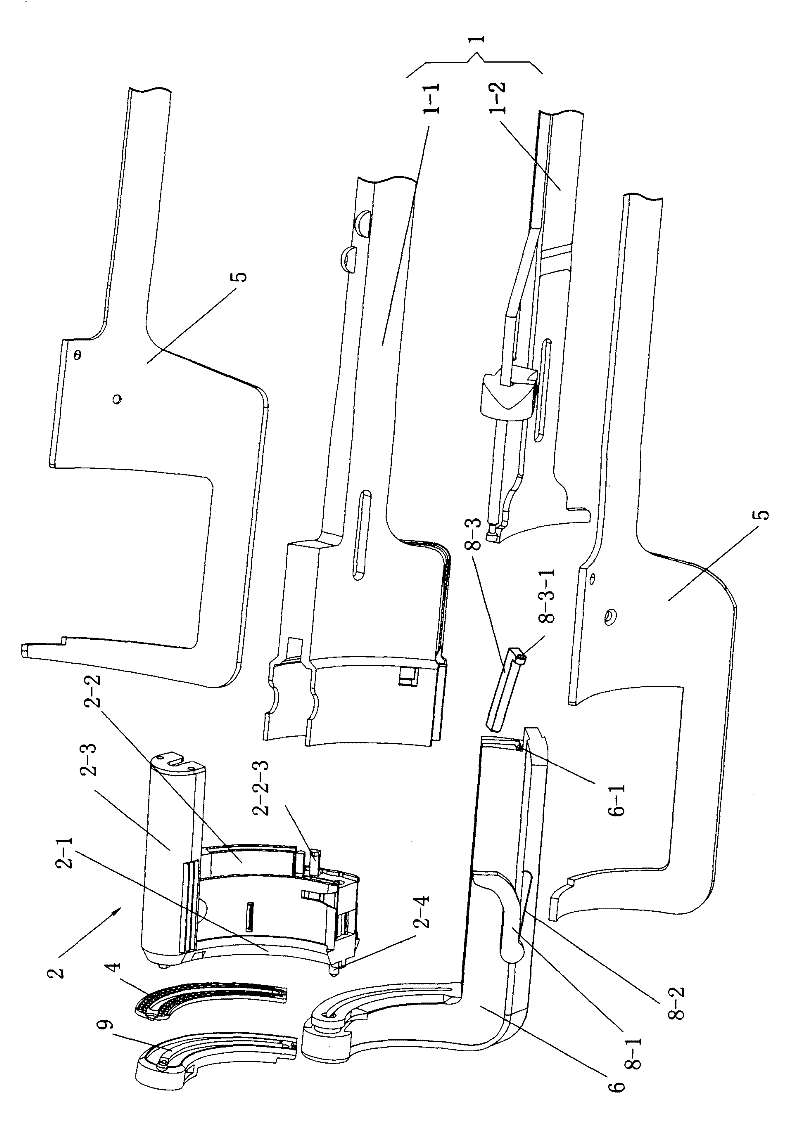

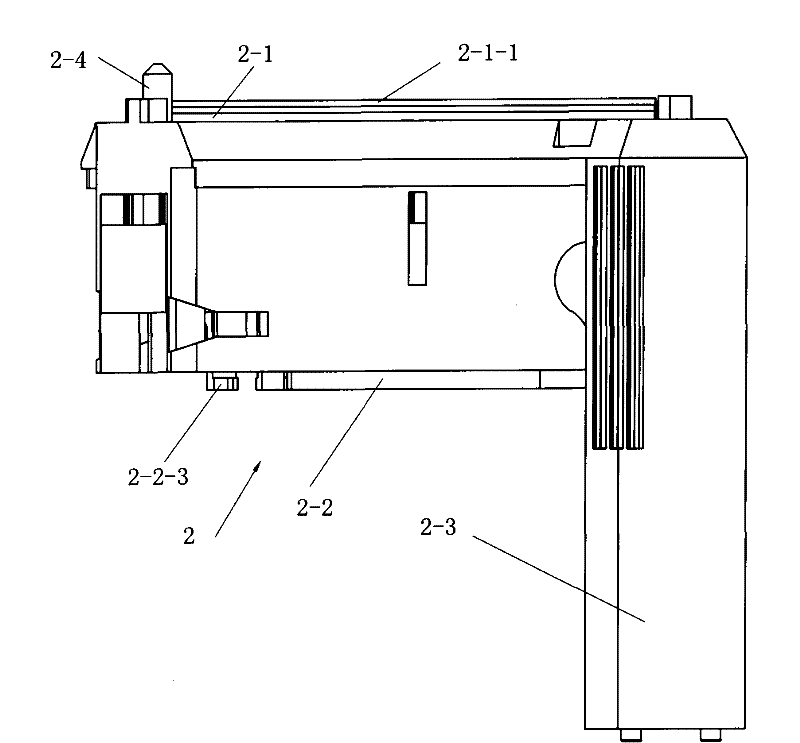

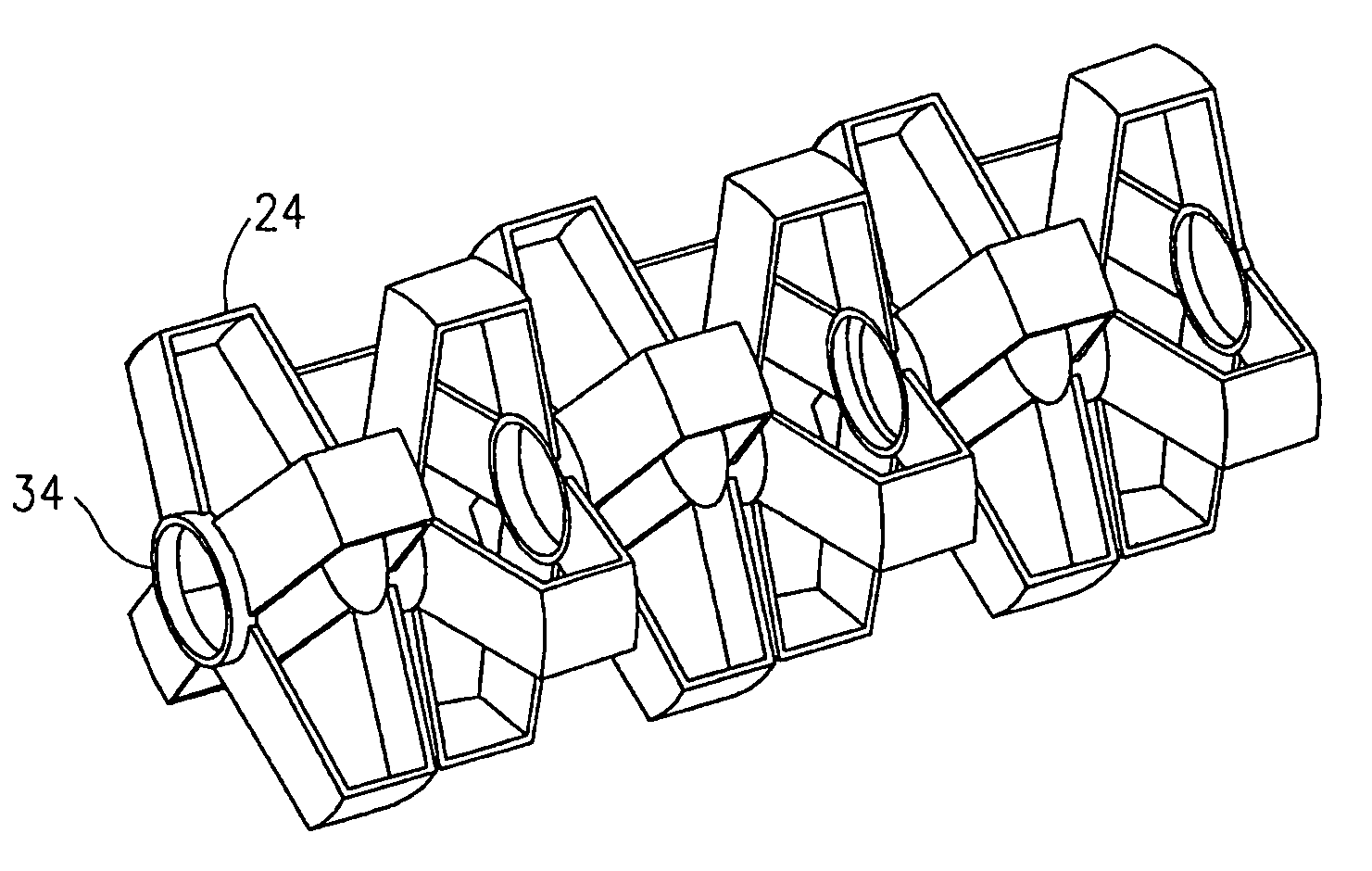

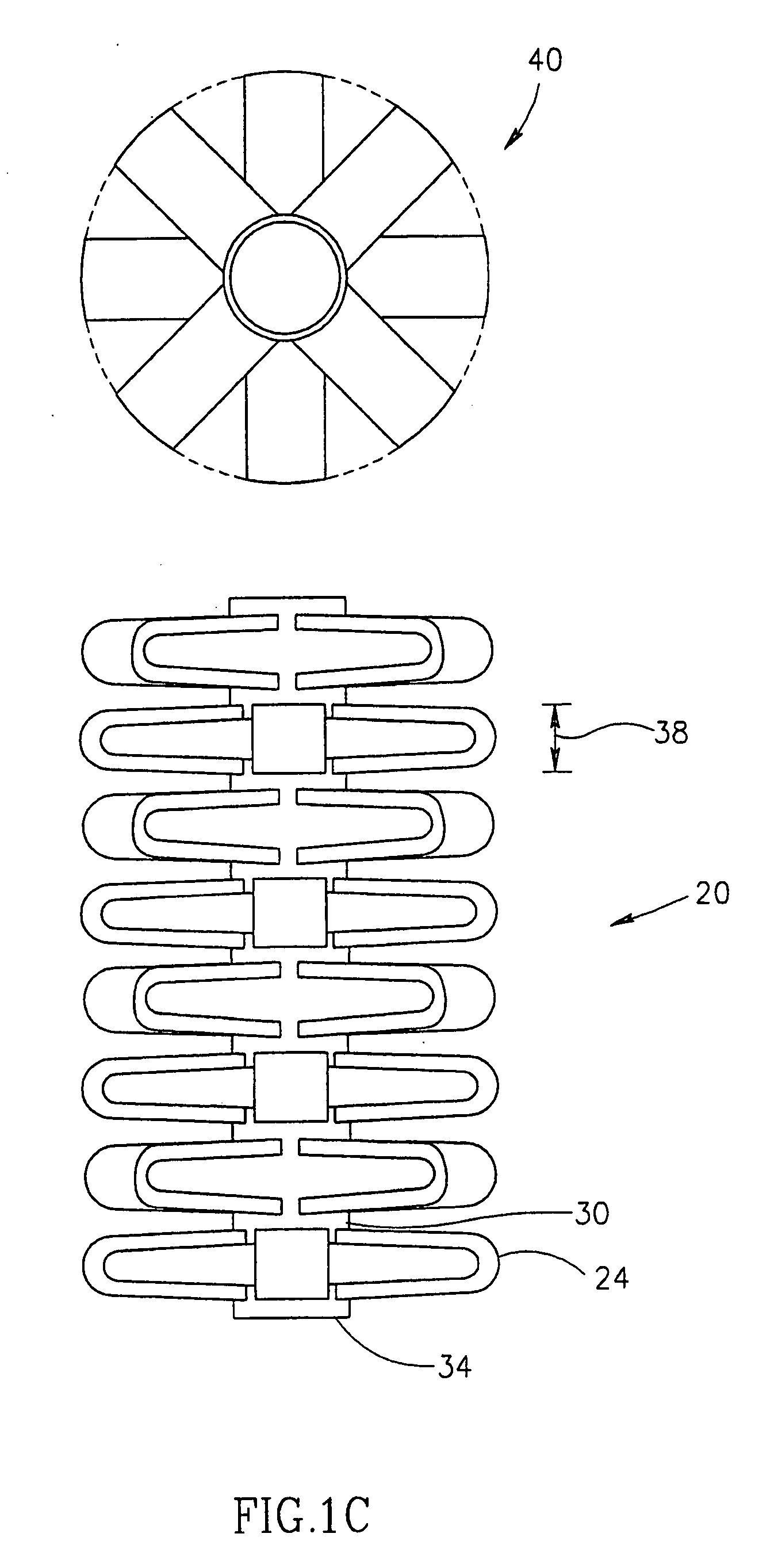

Arc-shaped cutting anastomat

ActiveCN101912284AGood assembly firmnessImprove reliabilitySurgical staplesDistal anastomosisEngineering

The invention relates to an arc-shaped cutting anastomat comprising an anastomosis nail shaping mechanism, a nail pushing assembly, a trigger handle, a nail supporting seat, a base of the nail supporting seat, a knife cushioning ring and two splints, wherein the nail pushing assembly comprises a cutting knife, a nail pushing sheet, a nail bin and a guide post; the end of the nail pushing sheet and both sides of the cutting knife are respectively provided with a plurality of inner nail pushing dental sheets which are near the cutting knife and a plurality of outer nail pushing dental sheets which are far away from the cutting knife; the cutting knife and the nail pushing sheet are injected and molded at a time to be fixed together; the outer side of the each outer nail pushing dental sheet on the nail pushing sheet is provided with a reinforcing rib; the inner side of each nail pushing dental sheet on the nail pushing sheet is provided with a reinforcing rib; both ends of the first guide surfaces of the nail pushing dental sheets are respectively connected with the first contact surfaces and the second contact surfaces of the nail pushing dental sheets through concave arc-shaped connecting surfaces, and both ends of the second guide surfaces thereof are respectively connected with the first contact surfaces and the second contact surfaces through the concave arc-shaped connecting surfaces; and the first contact surfaces and the second contact surfaces are respectively in contact with the inner walls of the nail pushing dental sheet holes of the nail bin. The invention has the advantages of good trigger anastomosis shaping effect and high safety.

Owner:CHANGZHOU JIANRUIBAO MEDICAL DEVICES

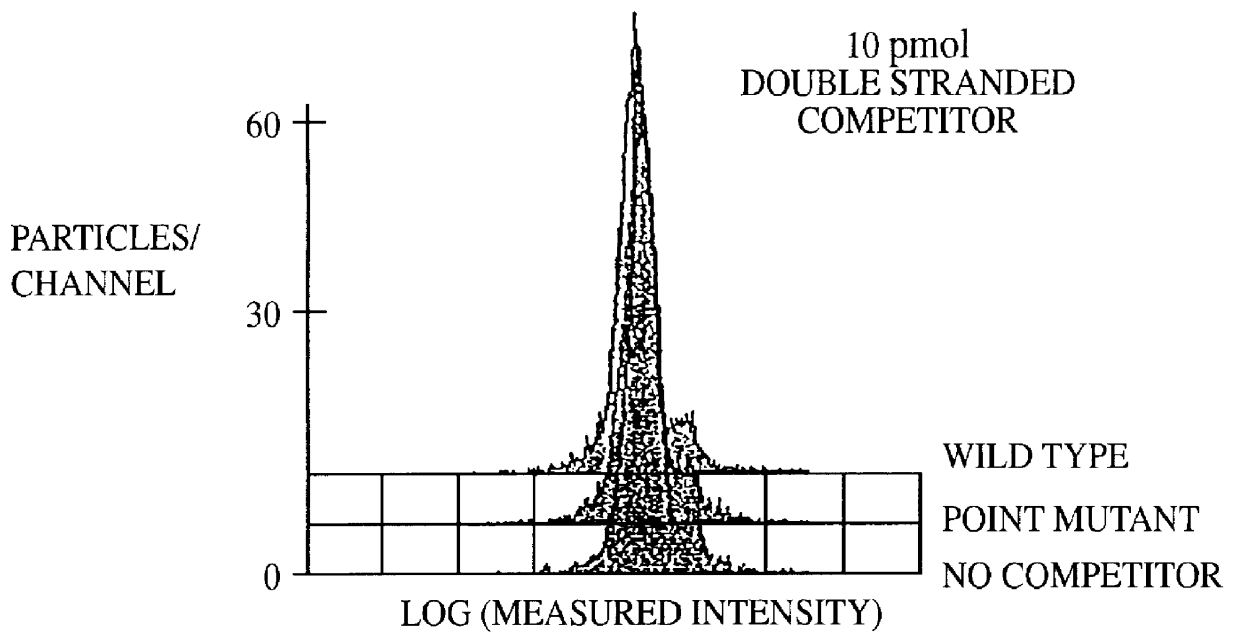

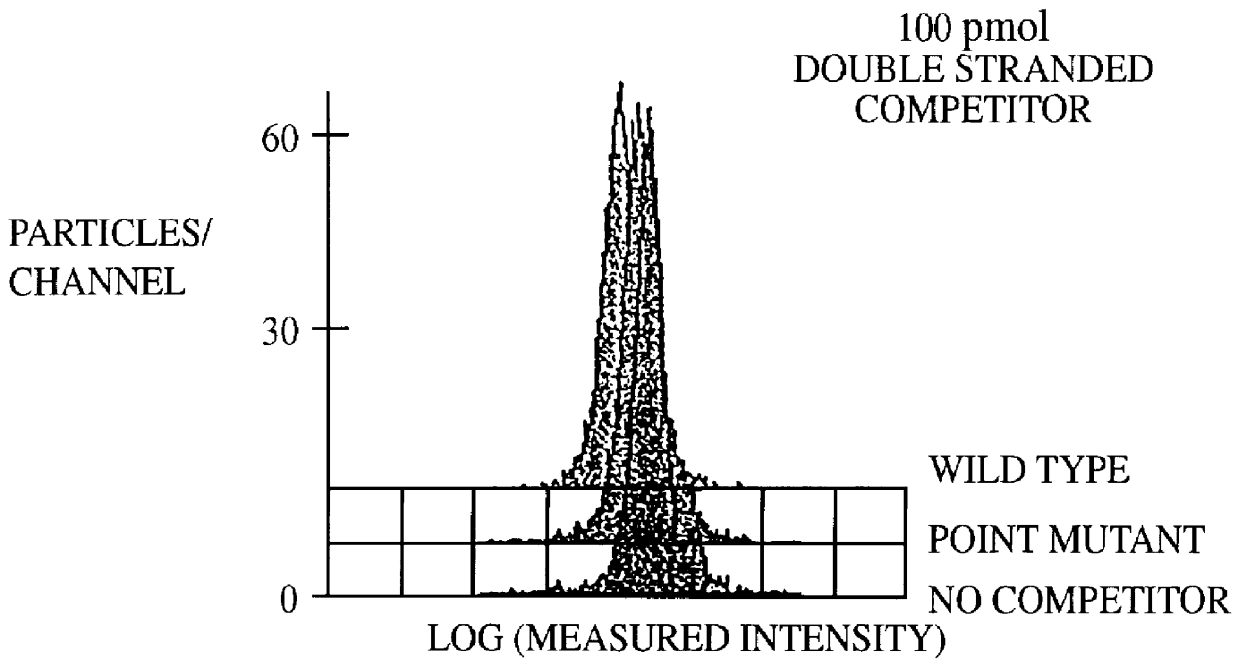

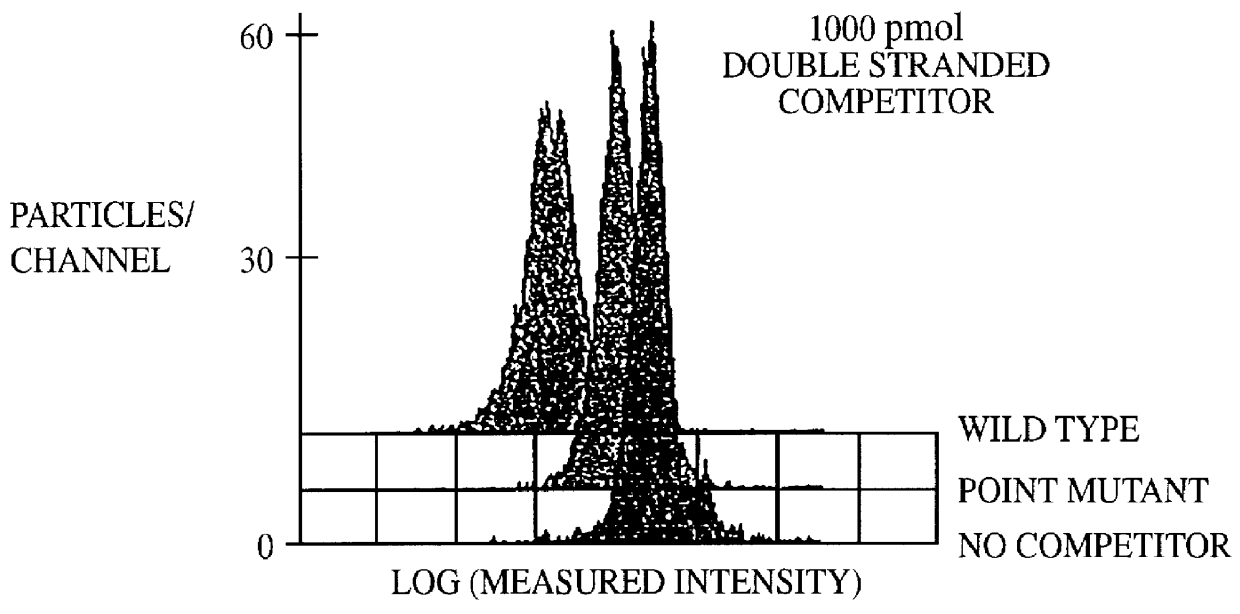

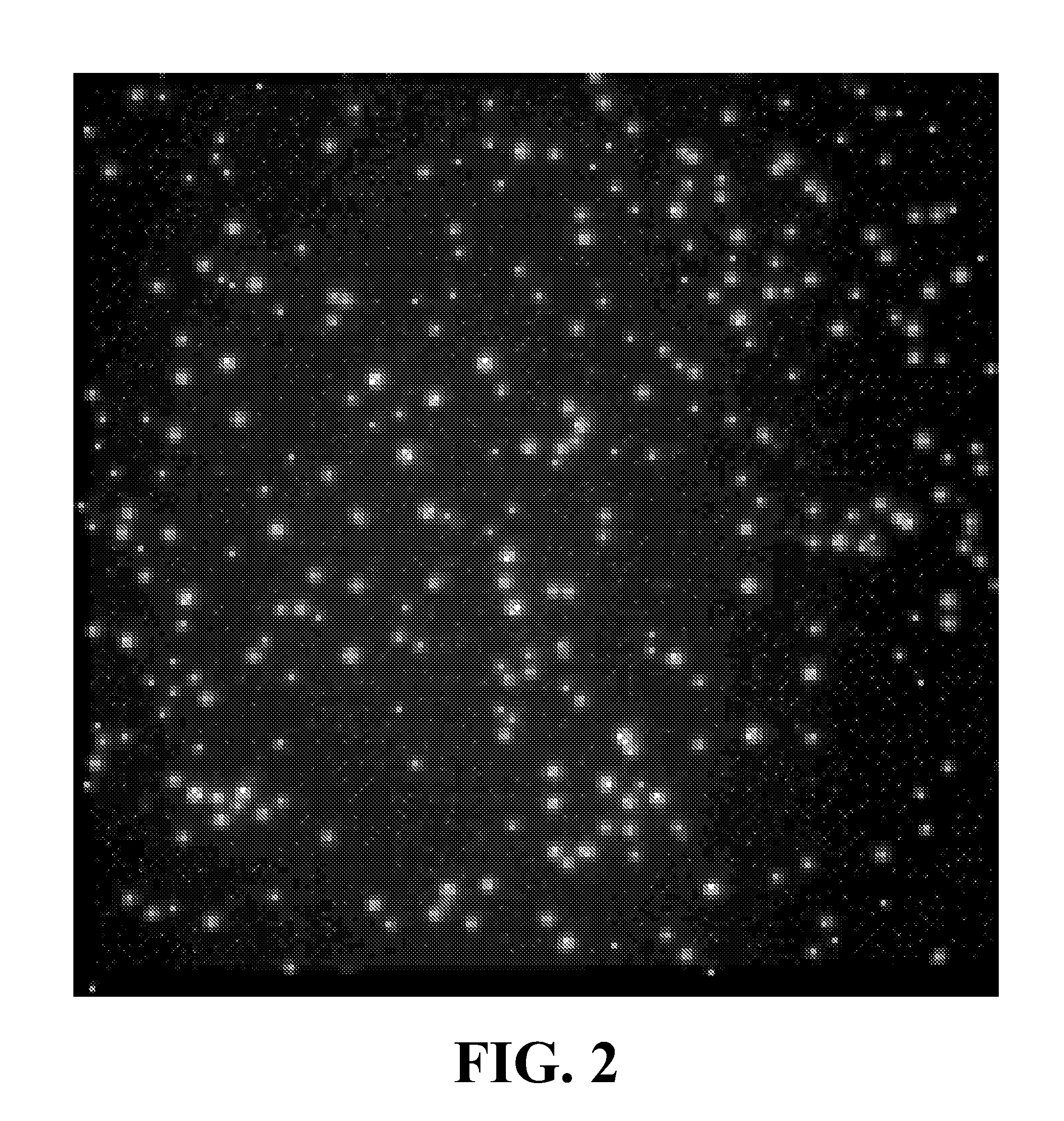

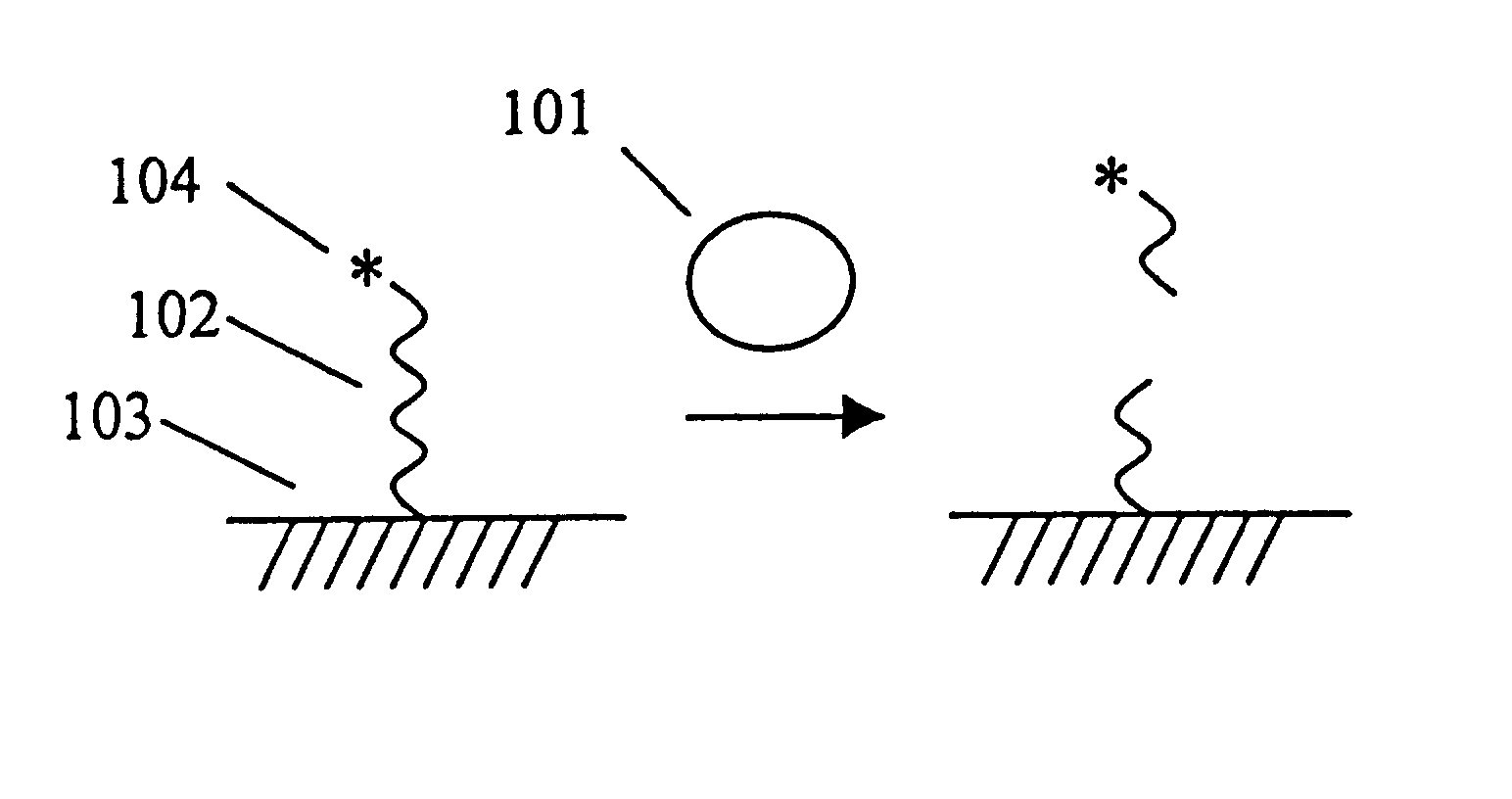

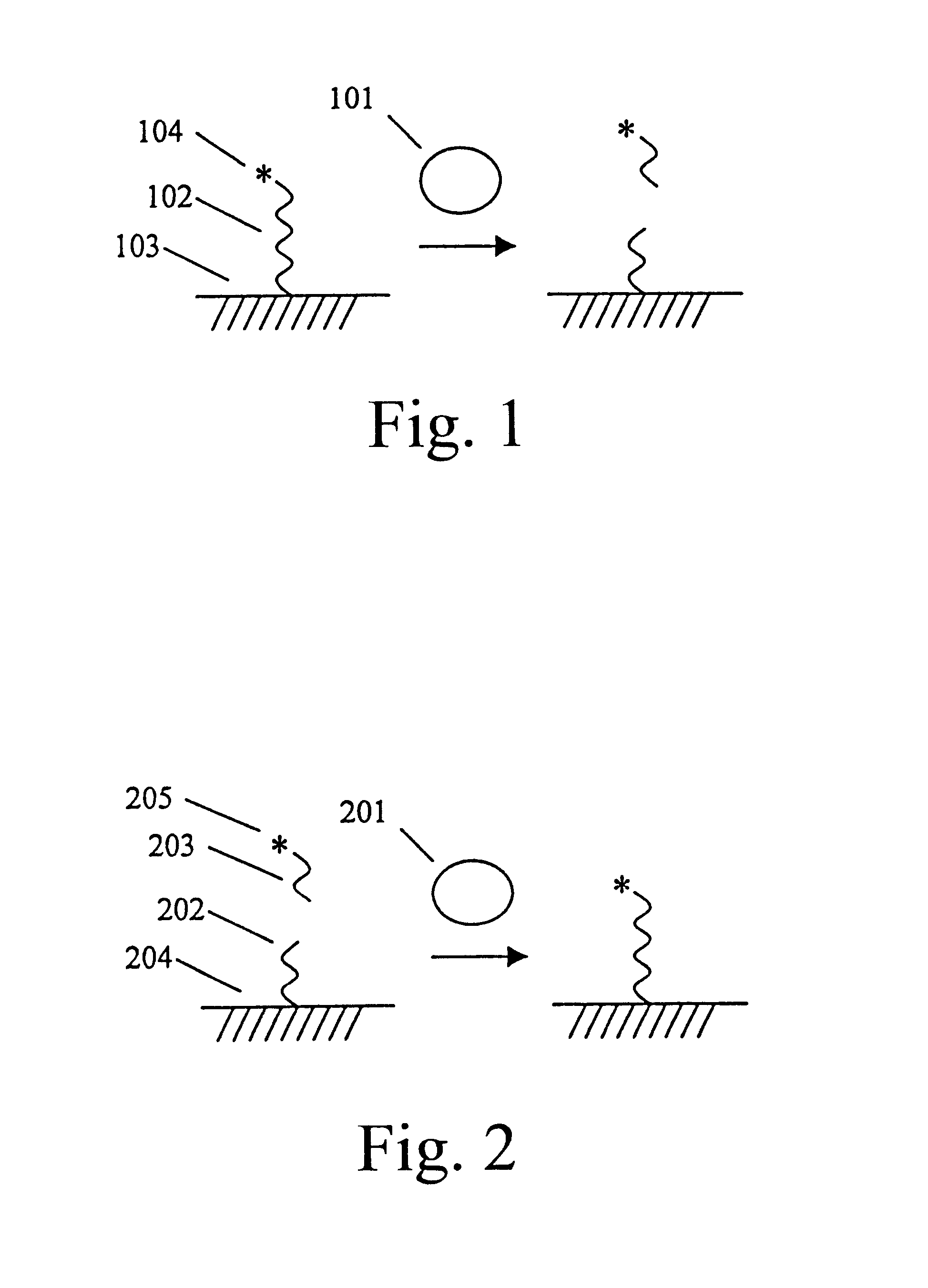

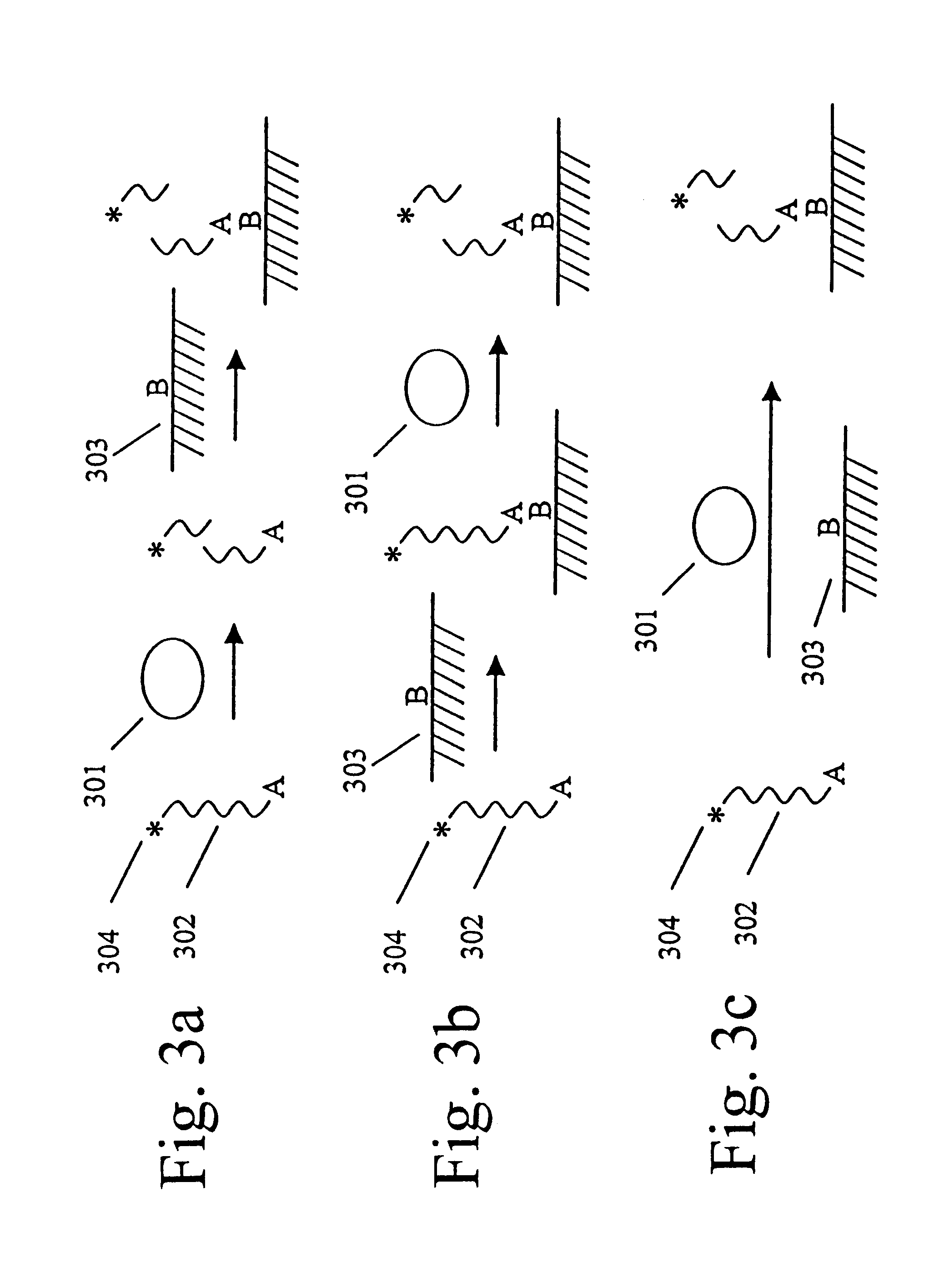

Methods and compositions for flow cytometric determination of DNA sequences

InactiveUS6057107AReduce fluorescenceReduce intensityMicrobiological testing/measurementIndividual particle analysisAnalysis dnaTest sample

A method for the analysis of DNA sequences and PCR products comprises the steps of constructing an oligonucleotide-labeled beadset, and labeled complementary probe, and exposing the beadset and probe to a DNA fragment or PCR product under hybridizing conditions and analyzing the combined sample / beadset by flow cytometry. Flow cytometric measurements are used to classify beads within an exposed beadset to determine the presence of identical or nonidentical sequences within the test sample. The inventive technology enables the rapid analysis of DNA sequences and detection of point mutations, deletions and / or inversions while also reducing the cost and time for performing genetic assays.

Owner:LUMINEX

Arc-shaped cutting anastomat

The invention relates to an arc-shaped cutting anastomat comprising an anastomosis nail shaping mechanism, a nail pushing assembly, a trigger handle, a nail supporting seat, a base of the nail supporting seat, a knife cushioning ring and two splints, wherein the nail pushing assembly comprises a cutting knife, a nail pushing sheet, a nail bin and a guide post; the end of the nail pushing sheet and both sides of the cutting knife are respectively provided with a plurality of inner nail pushing dental sheets which are near the cutting knife and a plurality of outer nail pushing dental sheets which are far away from the cutting knife; the cutting knife and the nail pushing sheet are injected and molded at a time to be fixed together; the outer side of the each outer nail pushing dental sheeton the nail pushing sheet is provided with a reinforcing rib; the inner side of each nail pushing dental sheet on the nail pushing sheet is provided with a reinforcing rib; both ends of the first guide surfaces of the nail pushing dental sheets are respectively connected with the first contact surfaces and the second contact surfaces of the nail pushing dental sheets through concave arc-shaped connecting surfaces, and both ends of the second guide surfaces thereof are respectively connected with the first contact surfaces and the second contact surfaces through the concave arc-shaped connecting surfaces; and the first contact surfaces and the second contact surfaces are respectively in contact with the inner walls of the nail pushing dental sheet holes of the nail bin. The invention has the advantages of good trigger anastomosis shaping effect and high safety.

Owner:CHANGZHOU JIANRUIBAO MEDICAL DEVICES

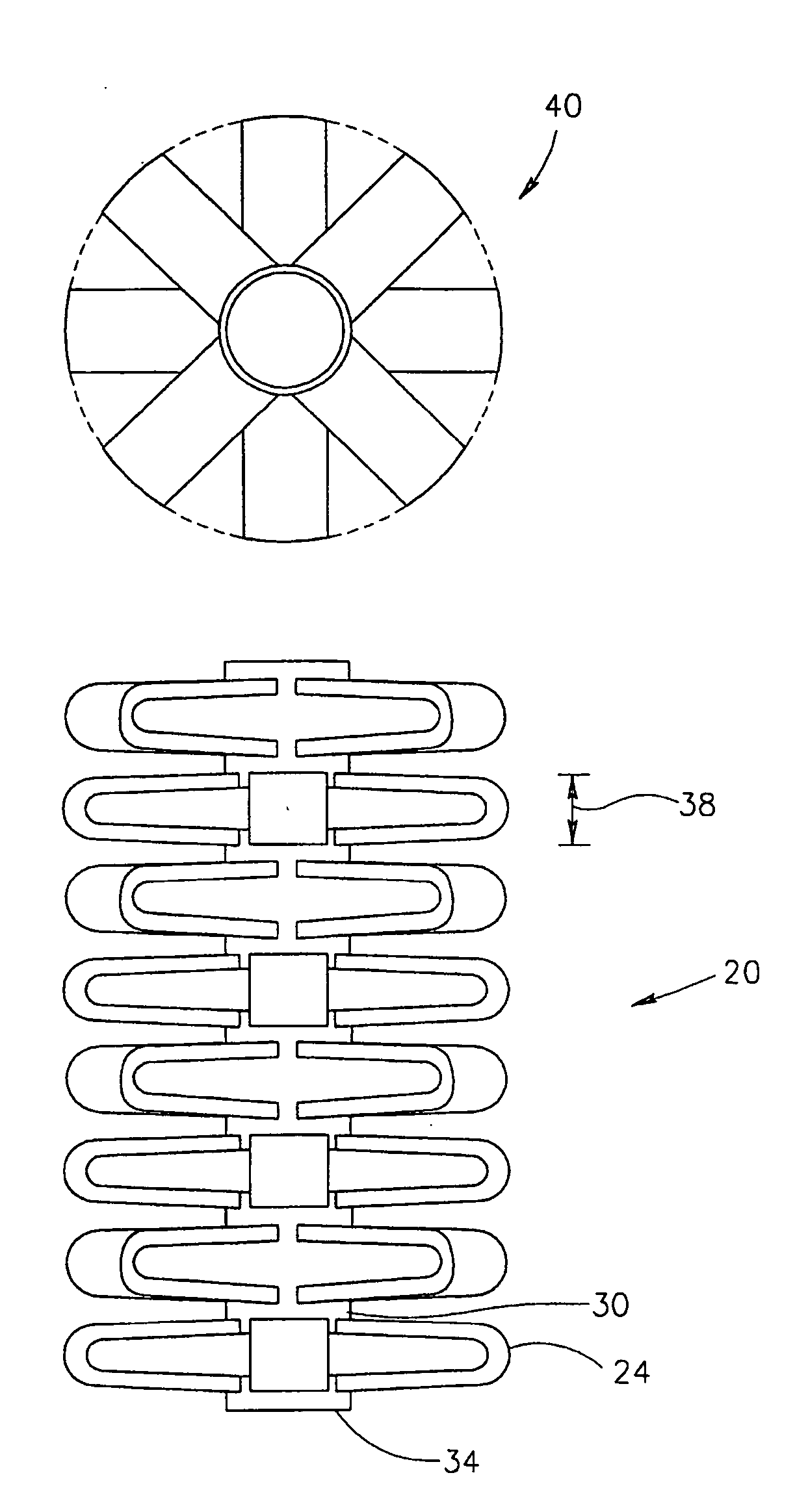

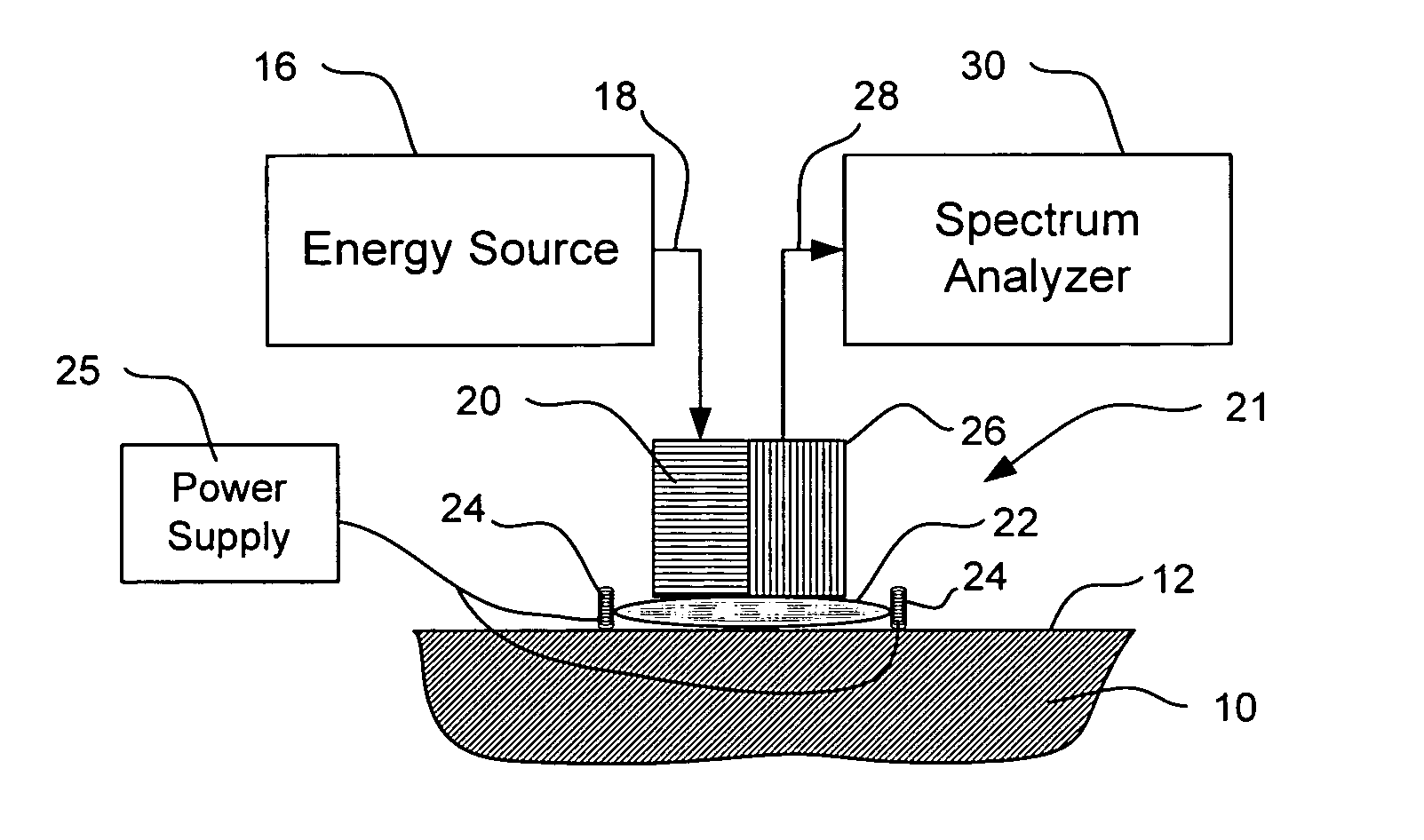

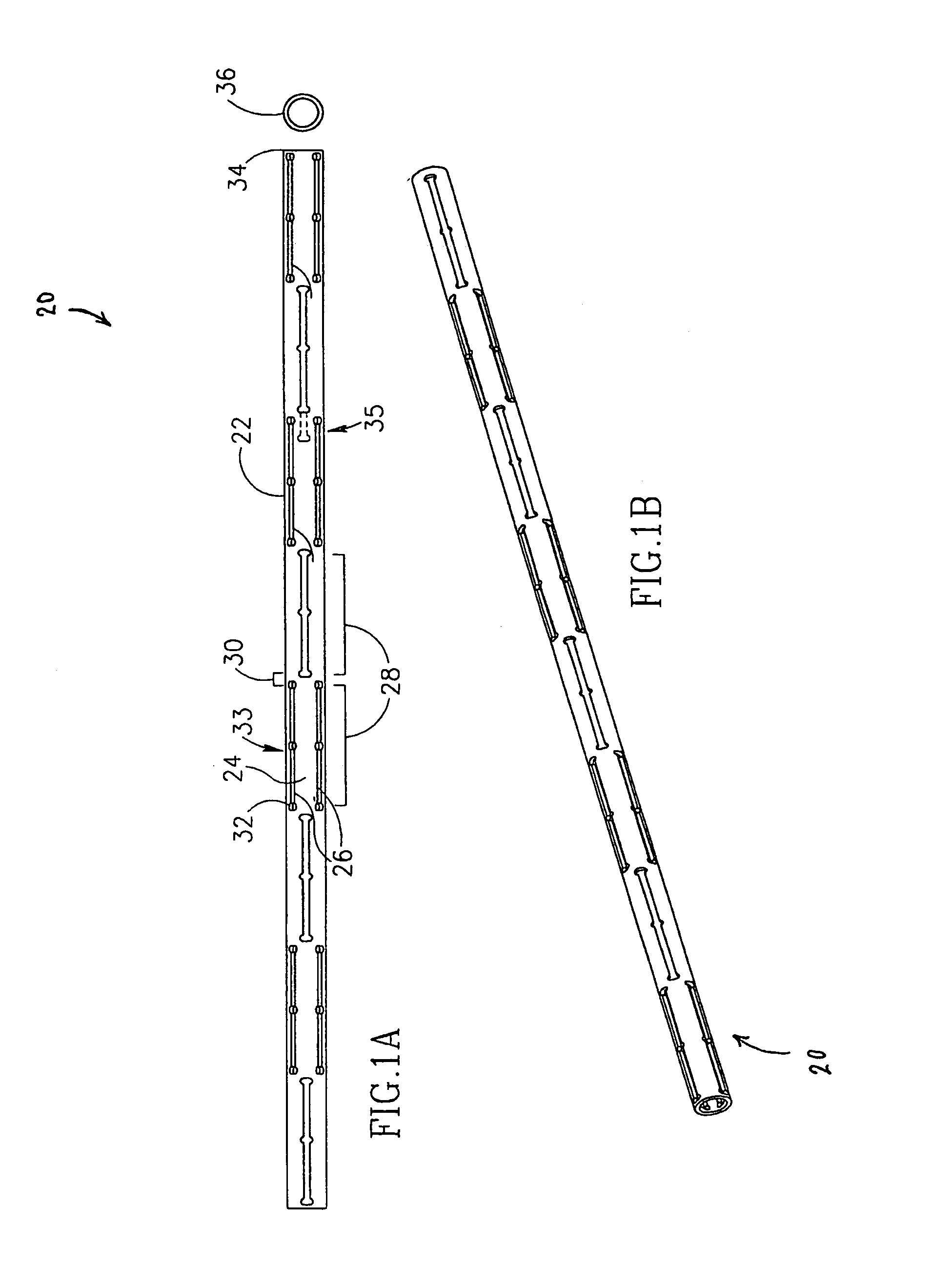

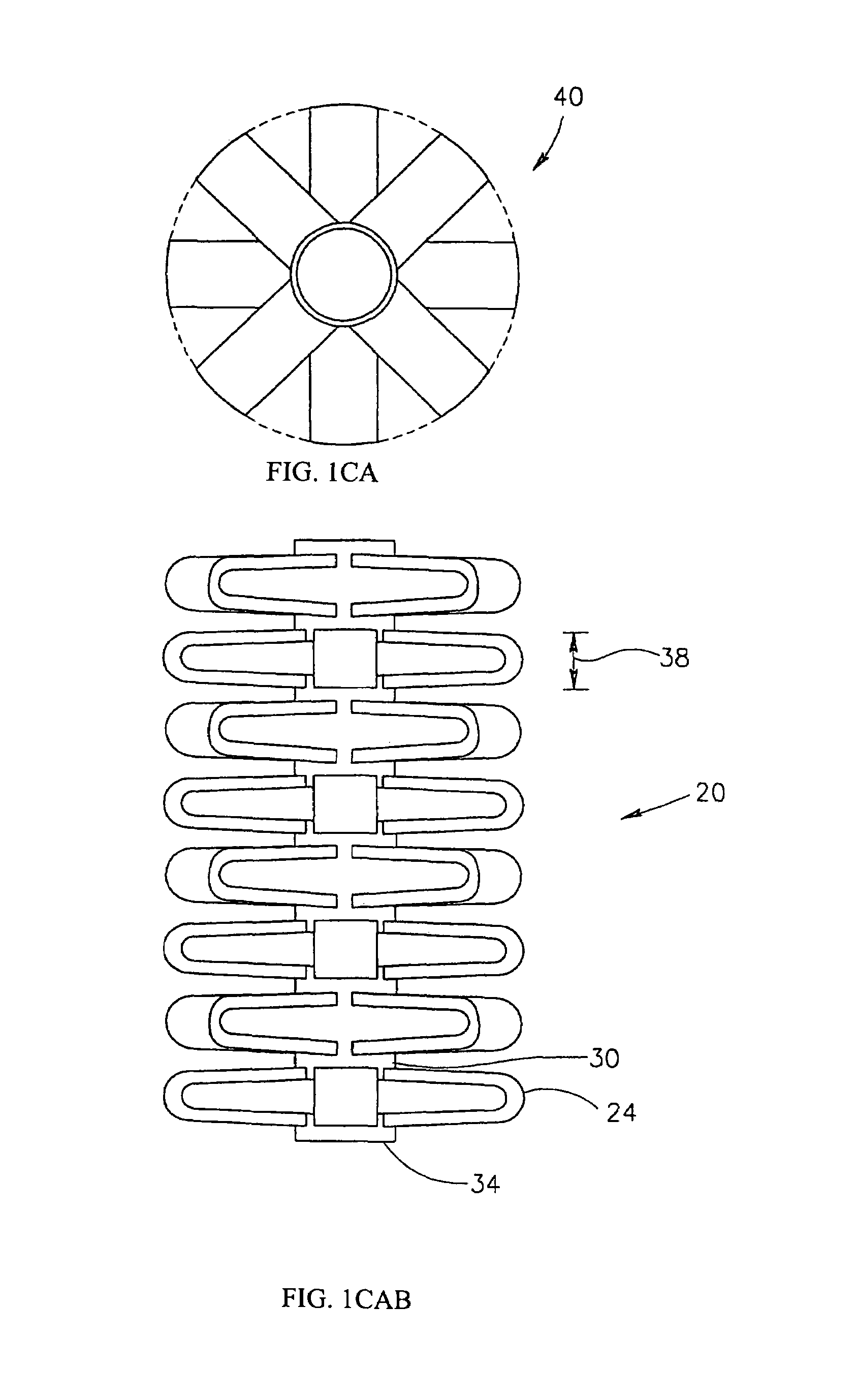

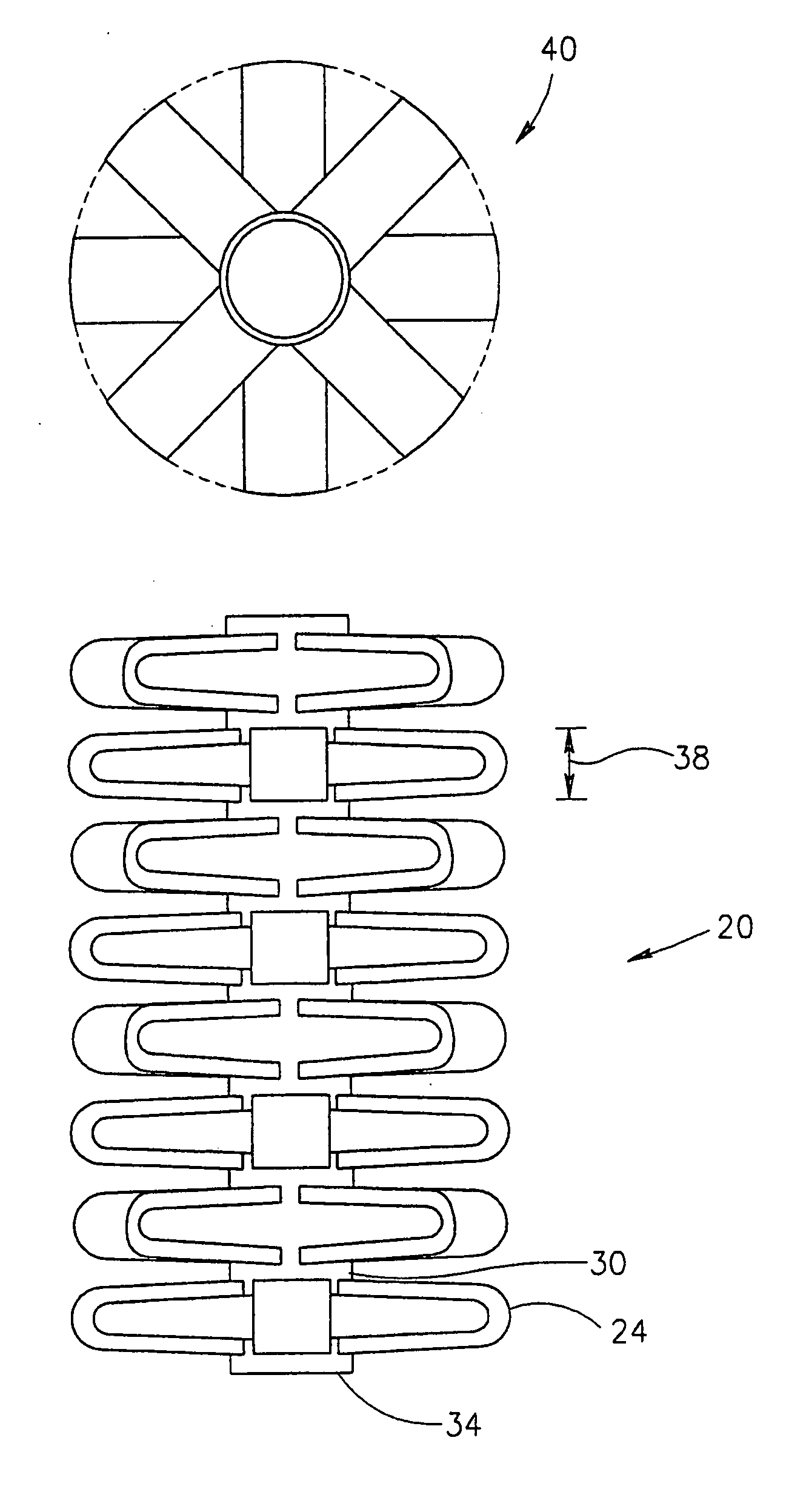

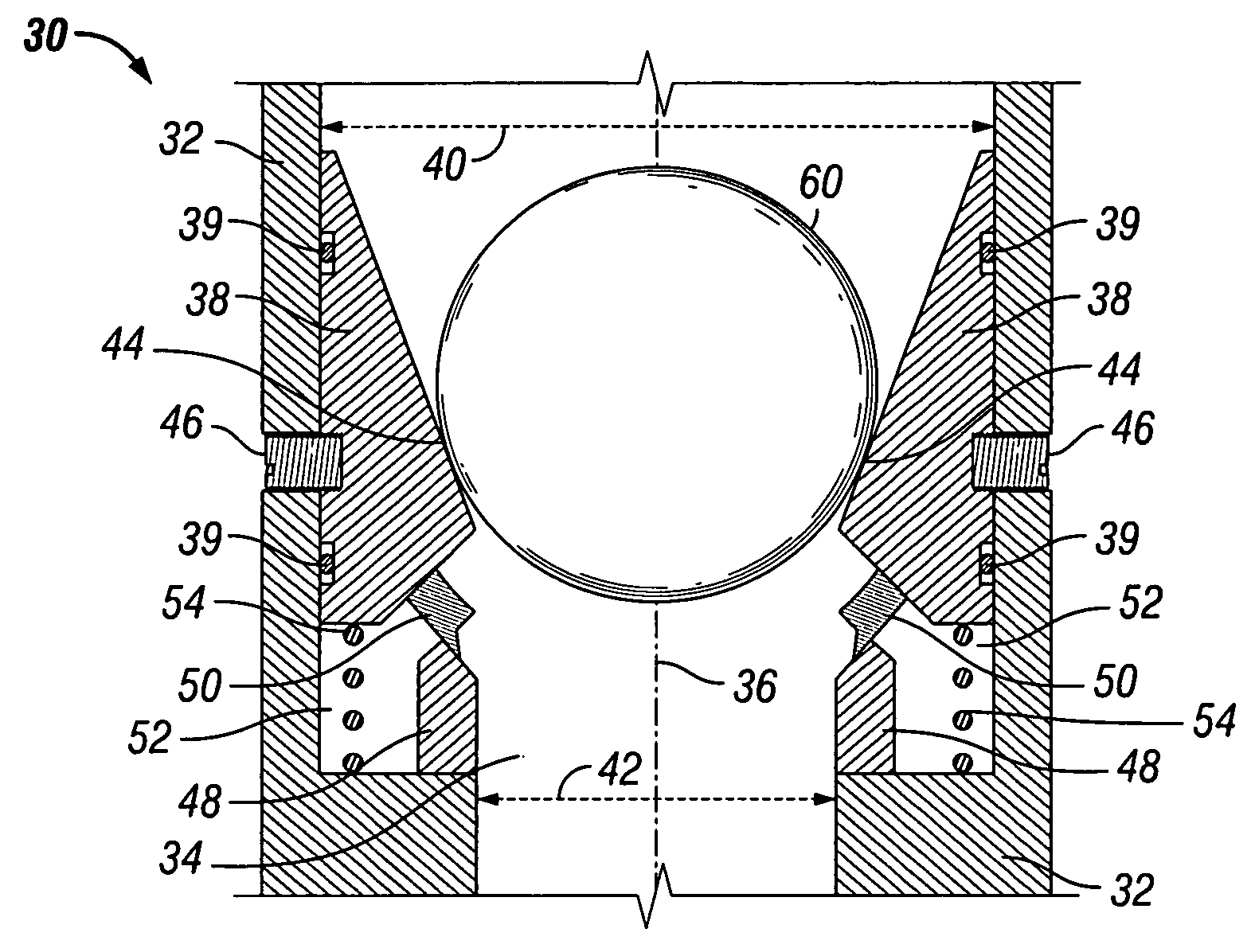

Expandable intervertebral spacer

ActiveUS20050143827A1Prevent crashIncrease contact surfaceDental implantsInternal osteosythesisBiomedical engineering

Owner:KYPHON

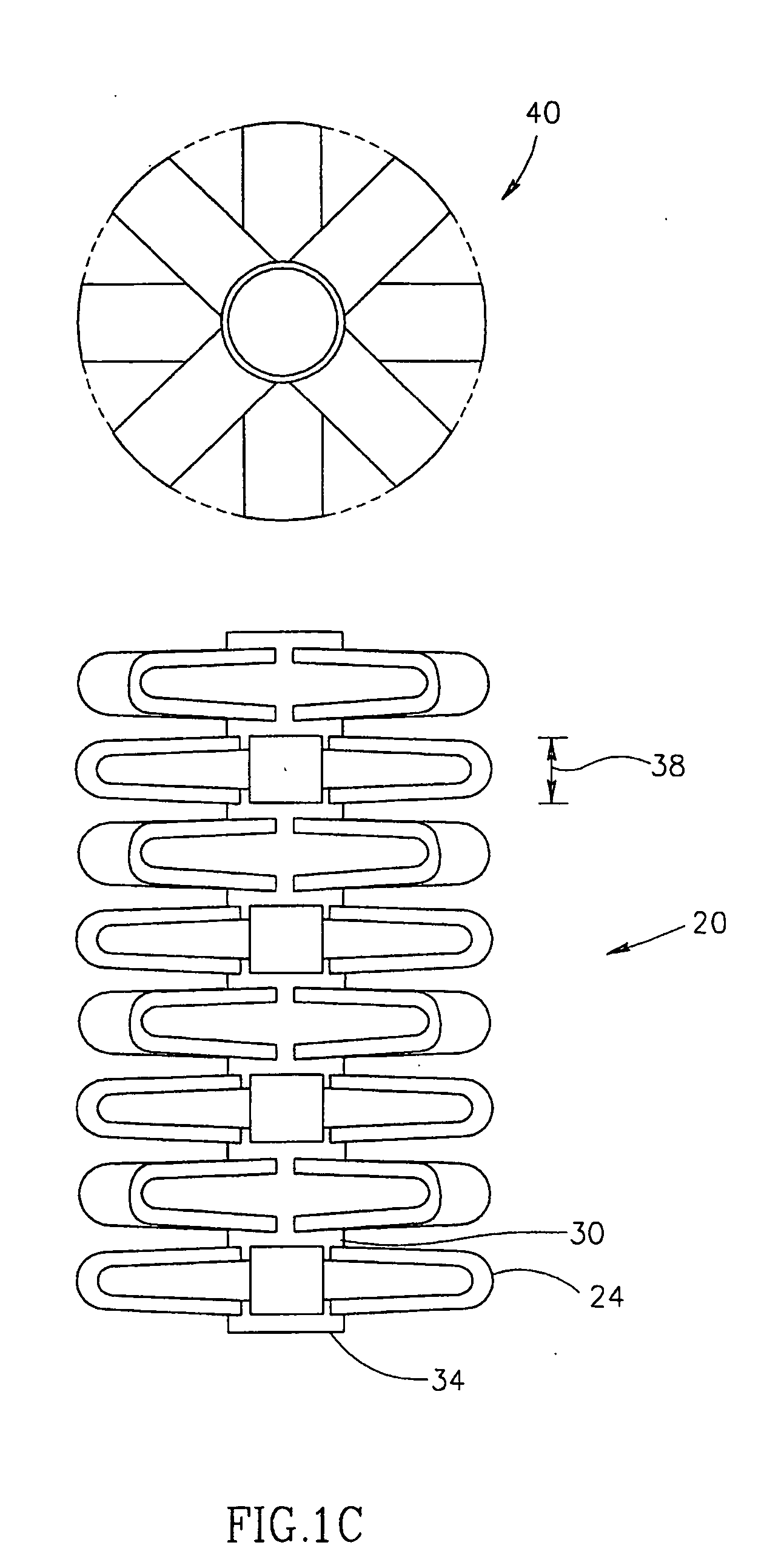

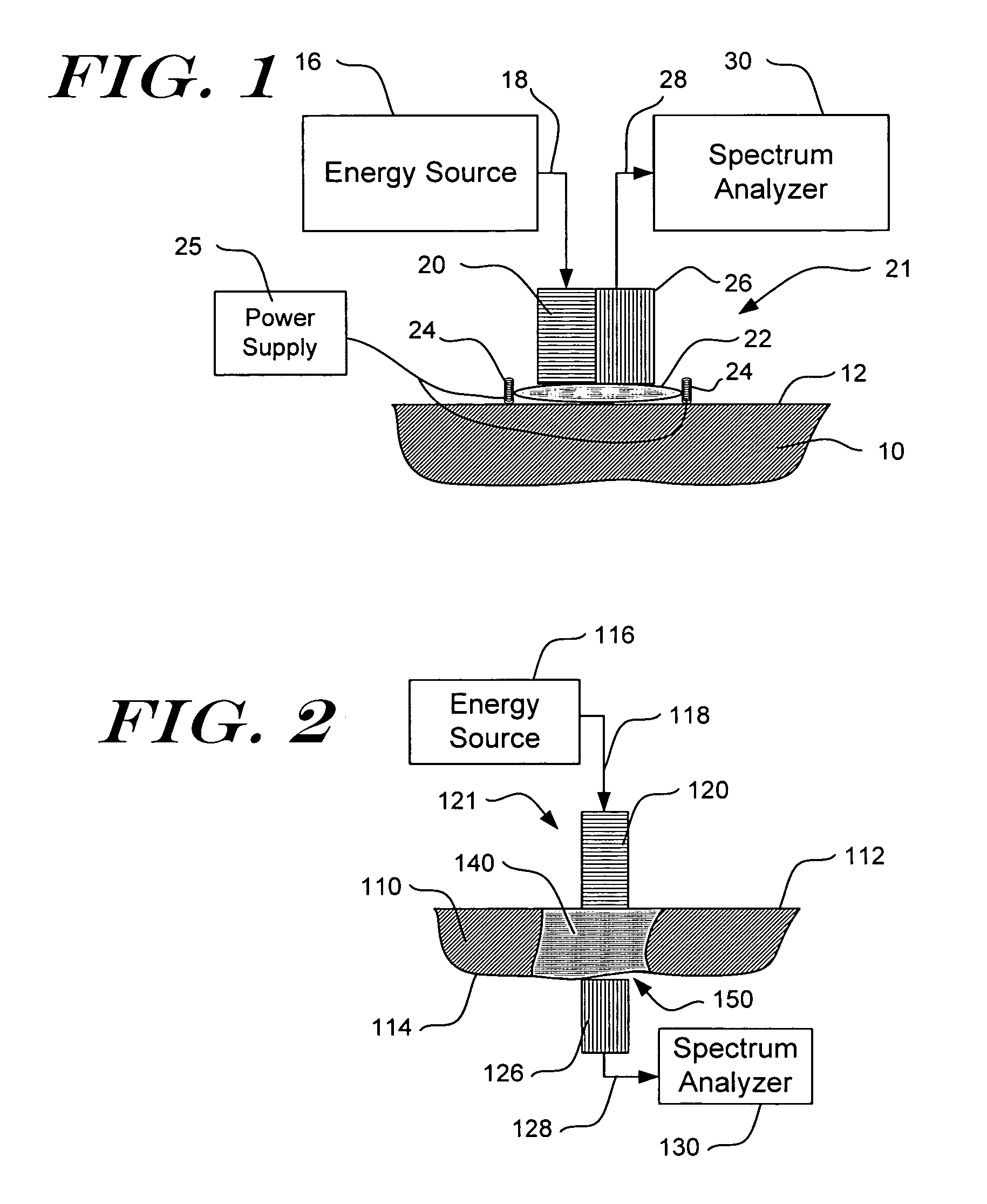

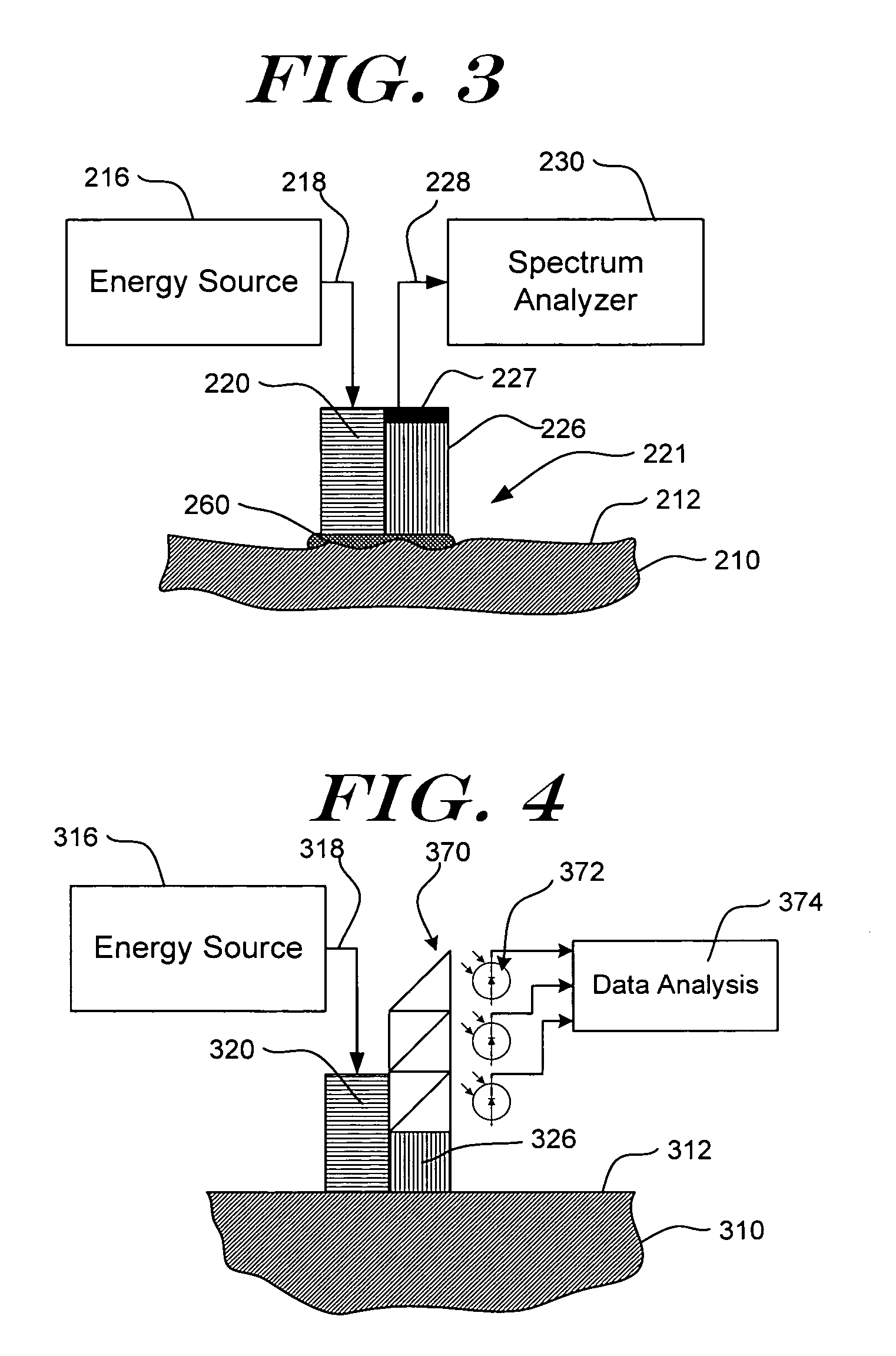

Non-invasive determination of direction and rate of change of an analyte

InactiveUS7016713B2Improve accuracyImprove stabilityDiagnostics using lightDiagnostics using spectroscopyAlcoholAnalyte

The present invention relates generally to a non-invasive method and apparatus for measuring a fluid analyte, particularly relating to glucose or alcohol contained in blood or tissue, utilizing spectroscopic methods. More particularly, the method and apparatus incorporate means for detecting and quantifying changes in the concentration of specific analytes in tissue fluid. Also, the method and apparatus can be used to predict future levels of analyte concentration either in the tissue fluid or in blood in an adjacent vascular system.

Owner:INLIGHT SOLUTIONS

Expandable intervertebral spacer

InactiveUS7621950B1Increase contact surfaceEasy to fillInternal osteosythesisBone implantBiomedical engineering

Owner:KYPHON

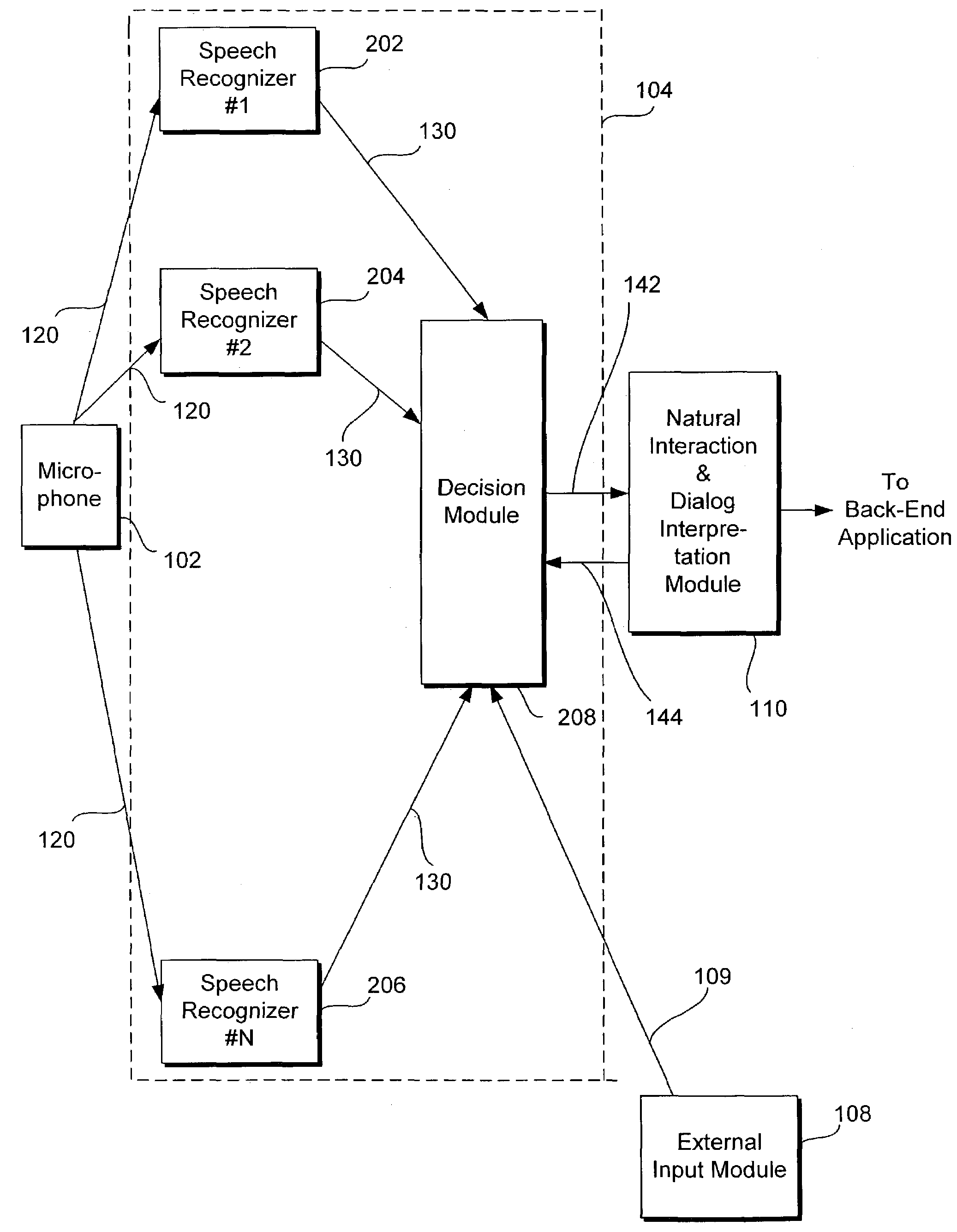

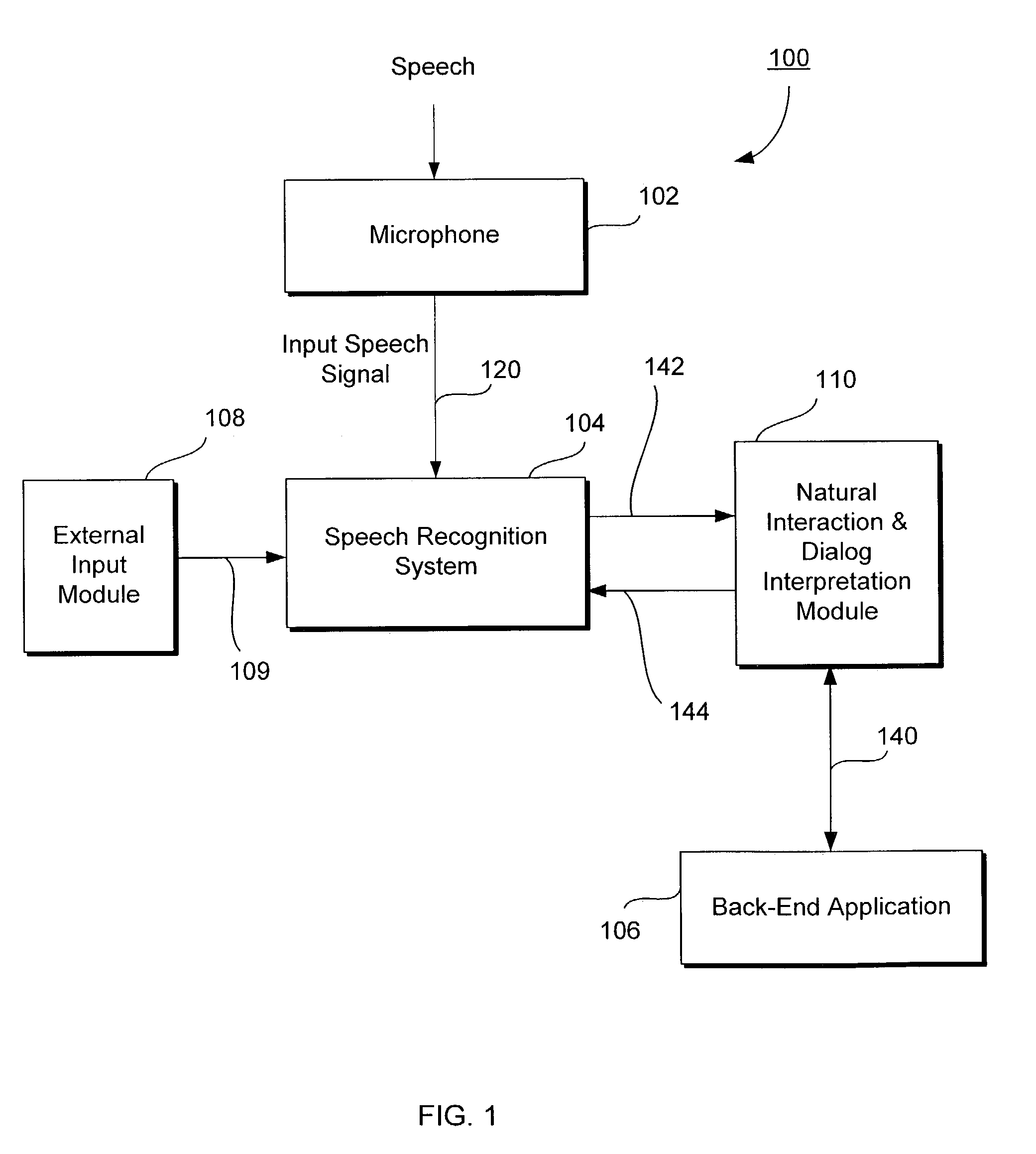

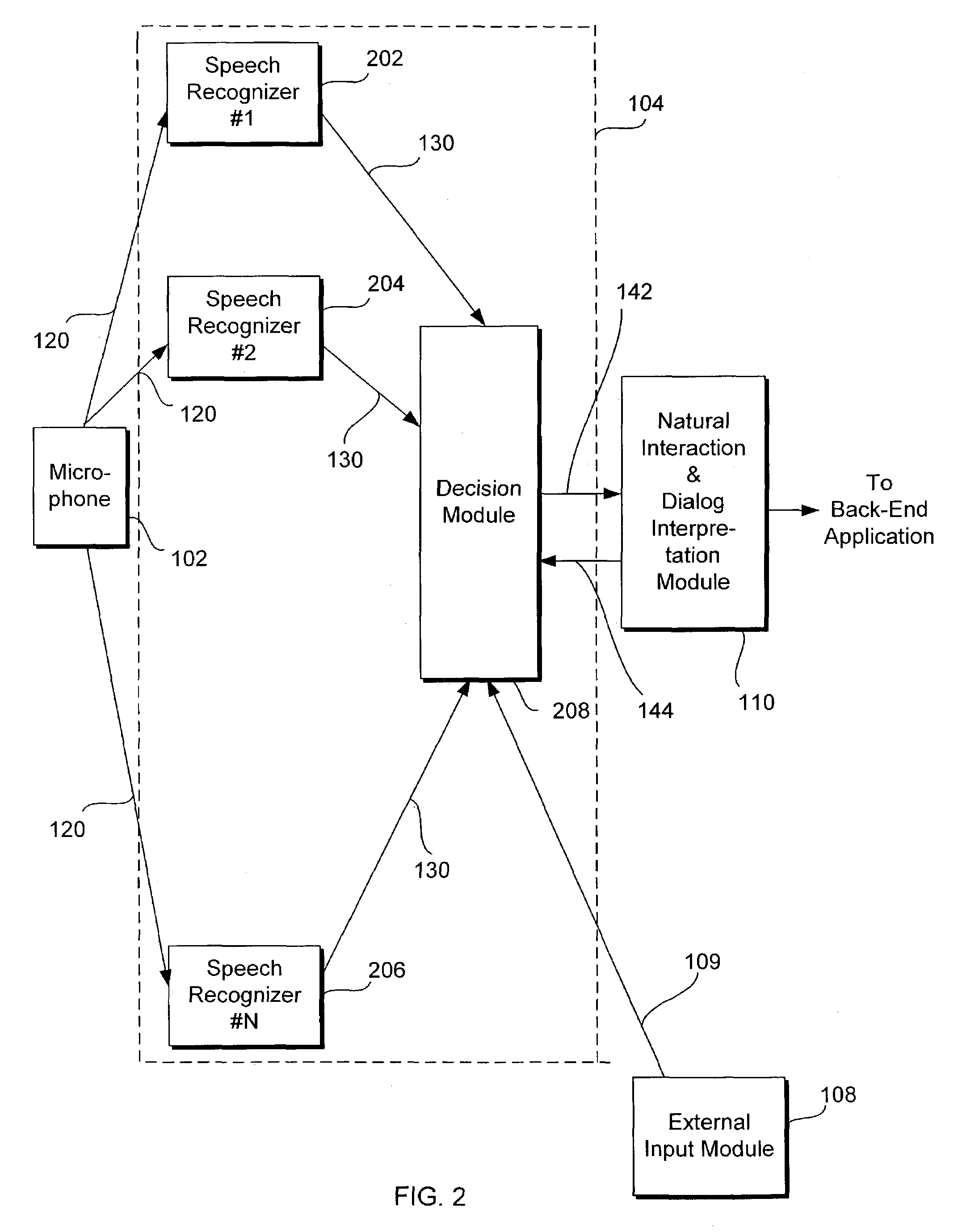

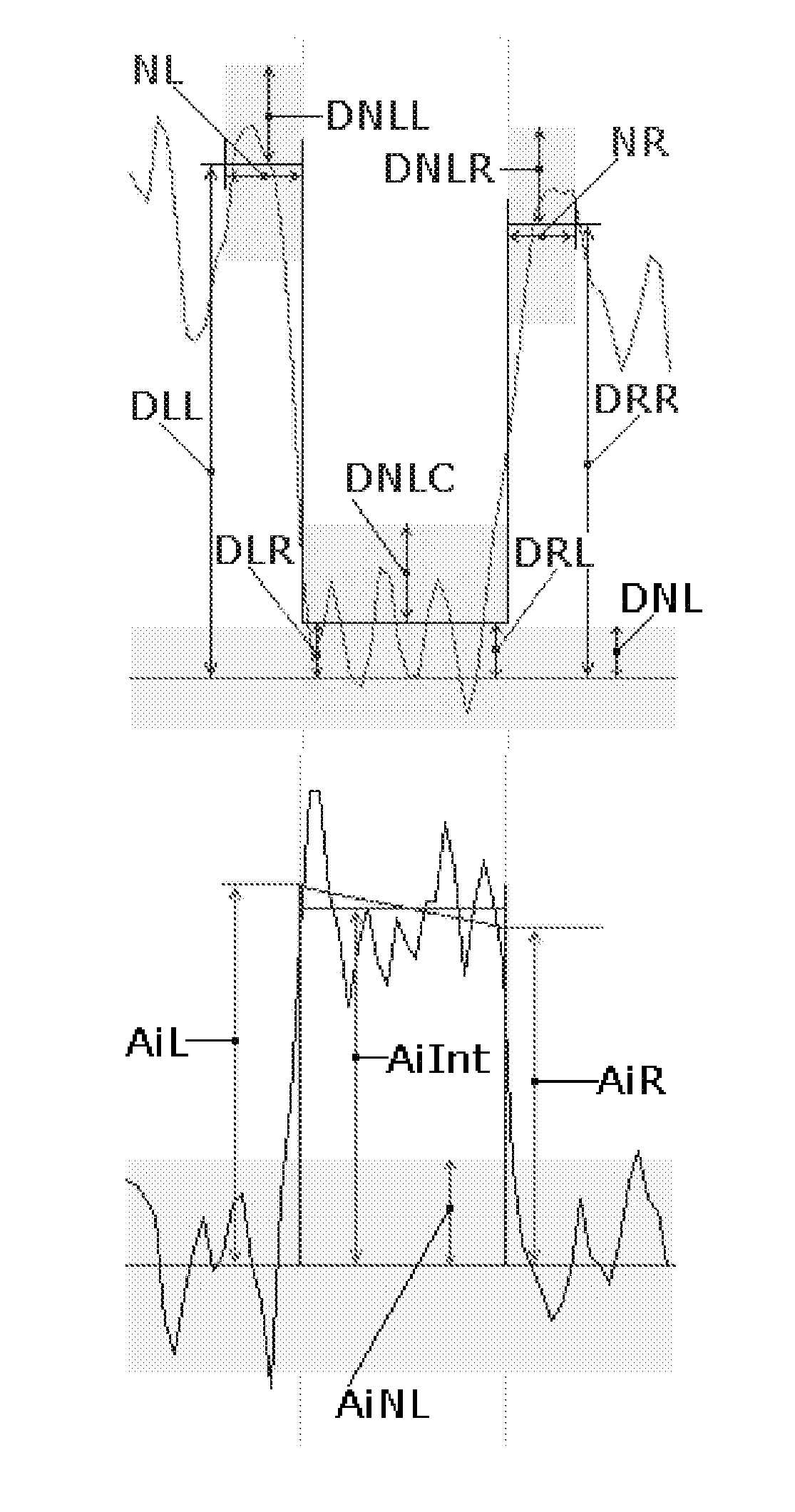

Speech recognition system having multiple speech recognizers

InactiveUS7228275B1Reduce intensityExcessive signalingSpeech recognitionSpeech identificationDecision taking

A speech recognition system recognizes an input speech signal by using a first speech recognizer and a second speech recognizer each coupled to a decision module. Each of the first and second speech recognizers outputs first and second recognized speech texts and first and second associated confidence scores, respectively, and the decision module selects either the first or the second speech text depending upon which of the first or second confidence score is higher. The decision module may also adjust the first and second confidence scores to generate first and second adjusted confidence scores, respectively, and select either the first or second speech text depending upon which of the first or second adjusted confidence scores is higher. The first and second confidence scores may be adjusted based upon the location of a speaker, the identity or accent of the speaker, the context of the speech, and the like.

Owner:TOYOTA INFOTECHNOLOGY CENT CO LTD +1

Expandable element

InactiveUS20070282443A1Prevent crashIncrease contact surfaceDental implantsInternal osteosythesisEngineeringBiomedical engineering

Owner:KYPHON

Handheld Photocosmetic Device

InactiveUS20080058783A1Maintain and improve benefitSimple designDiagnosticsControlling energy of instrumentHand heldDermatology

The present invention discloses handheld photocosmetic devices that can be utilized to apply EMR to the skin, e.g., to achieve fractional treatment of the skin. The invention discloses effective fractional photocosmetic devices for use in by a consumer in a non-medical and or non-professional setting. Thus, embodiments of such devices are disclosed herein that have one or more of the following attributes: capable of performing one or more cosmetic and / or dermatological treatments; efficacious for such treatments; durable; relatively inexpensive; relatively simple in design; smaller than existing professional devices (with some embodiments being completely self-contained and hand-held); safe for use by non-professionals; and / or not painful to use (or only mildly painful).

Owner:PALOMAR MEDICAL TECH

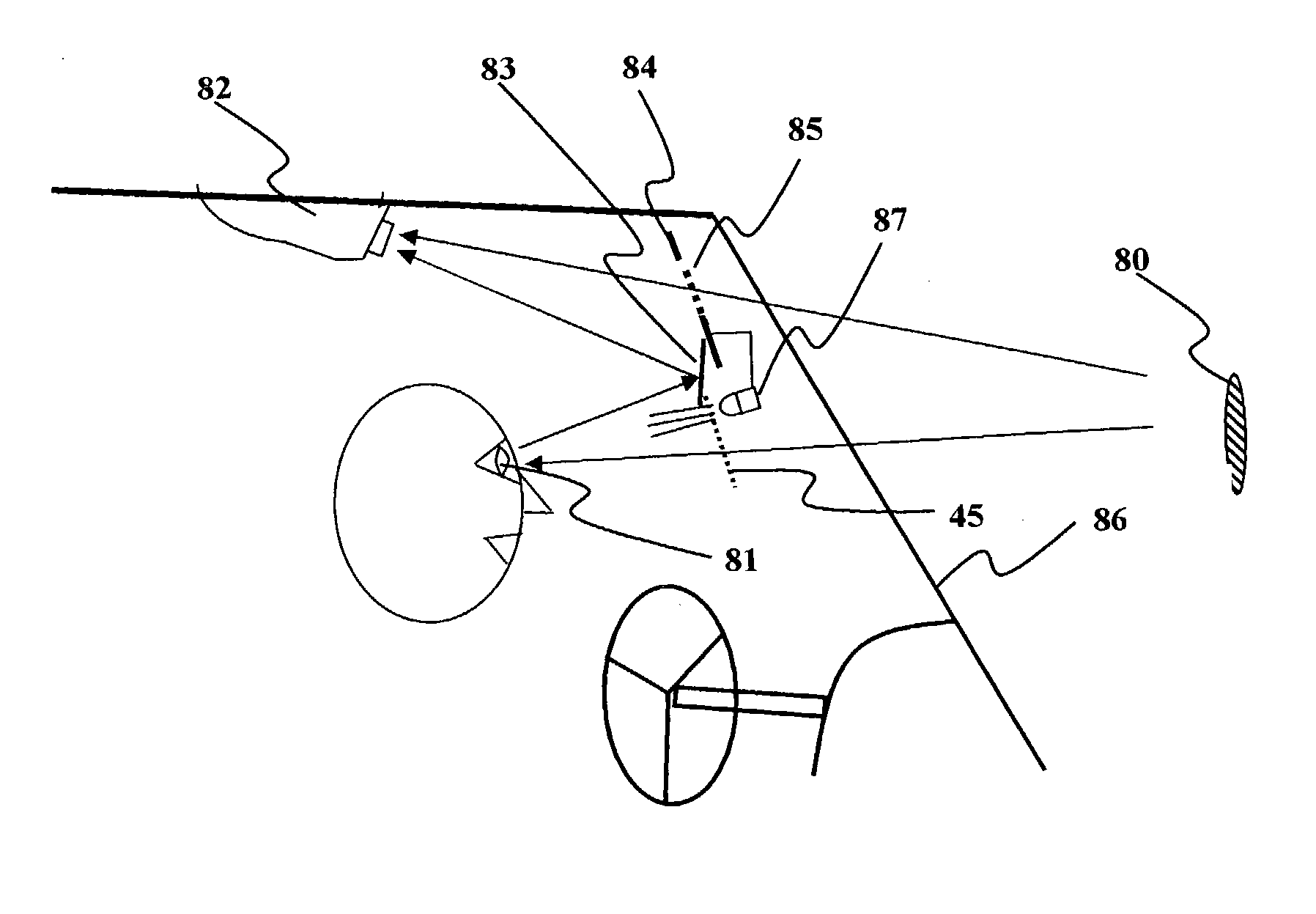

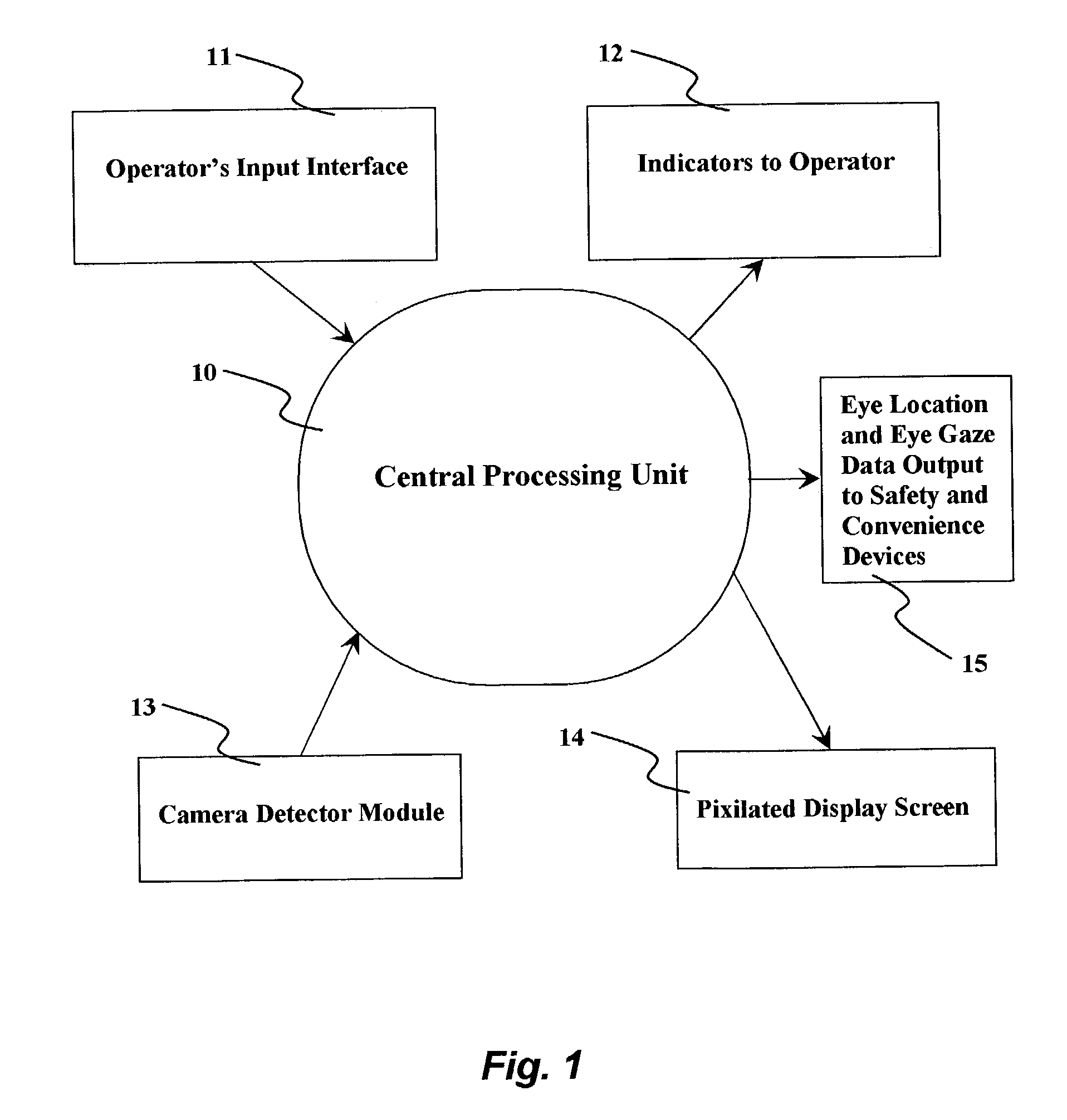

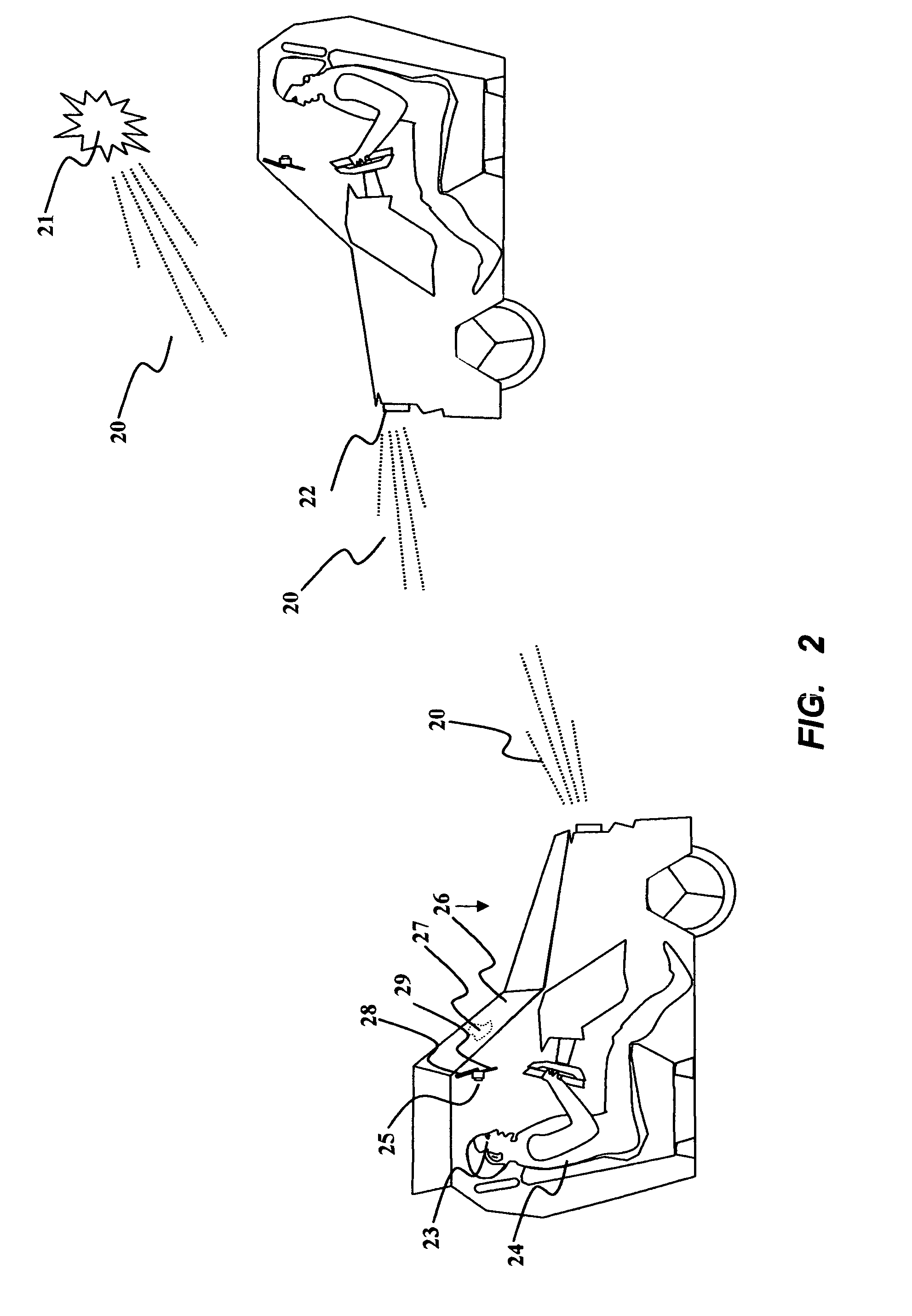

Enhanced vision for driving

InactiveUS7199767B2Reduce glareImprove viewing effectPhotometry using reference valueInstruments for comonautical navigationDriver/operatorLight source

A system for imposing a filter between a vehicle driver's eyes and a source of light including at least one detector facing inward into a compartment in the vehicle toward a likely position of the head of the vehicle driver and arranged to obtain images of the eyes of the driver and a processor coupled to the detector(s) and arranged to determine the location of the driver's eyes based on analysis of the images obtained by the detector(s) and to obtain information about objects exterior of the vehicle providing sources of light from the images obtained by the detector(s) based on reflections off of the driver's eyes, i.e., the position of such objects. A filter, such as a pixelated screen, is imposed between the sources of light and the driver's eyes based on the location of the driver's eyes and the information about the exterior objects providing the sources of light.

Owner:SPERO YECHEZKAL EVAN

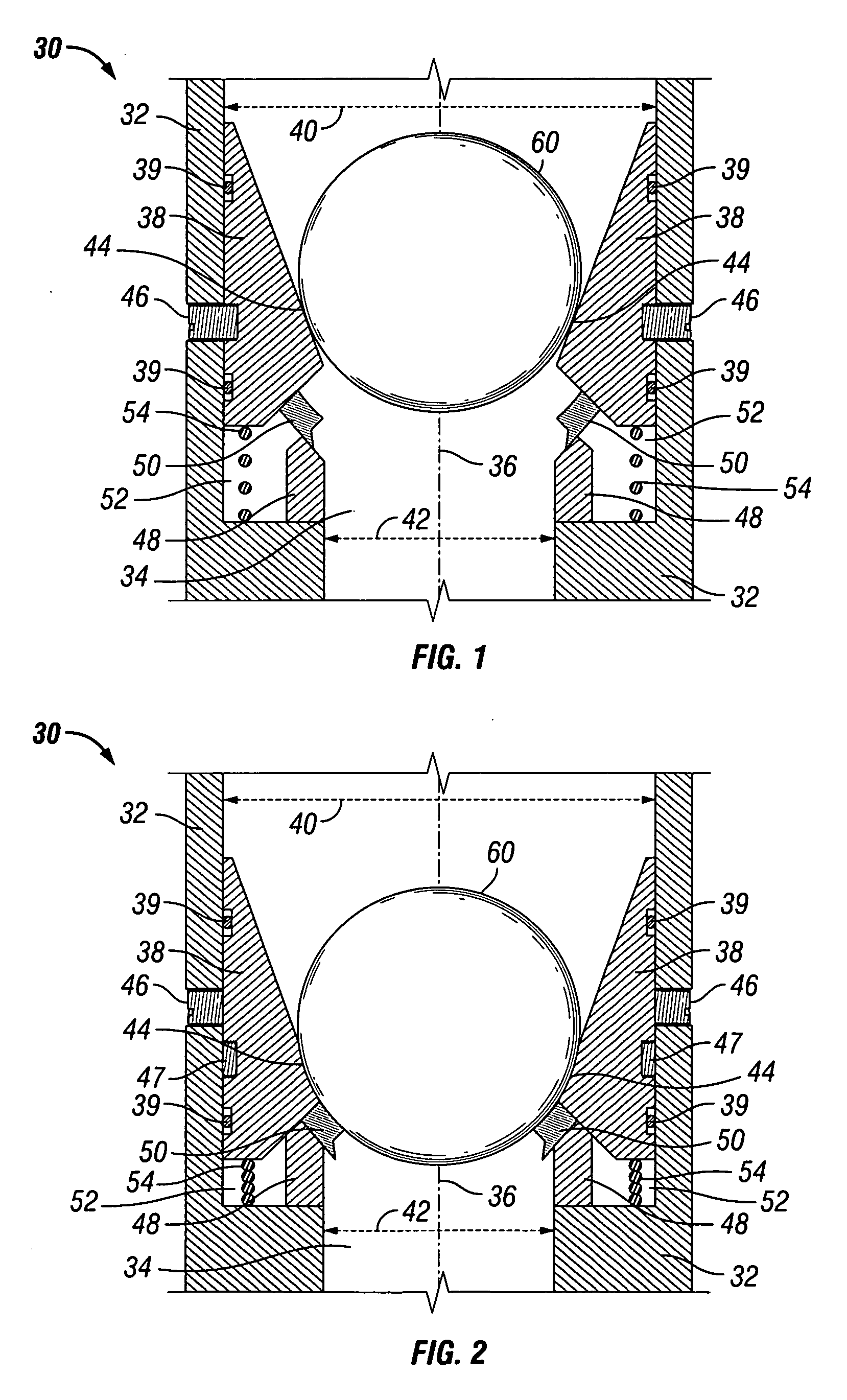

Ball seat having segmented arcuate ball support member

ActiveUS20090159289A1Increase pressureReduce the possibilityFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

Owner:BAKER HUGHES INC

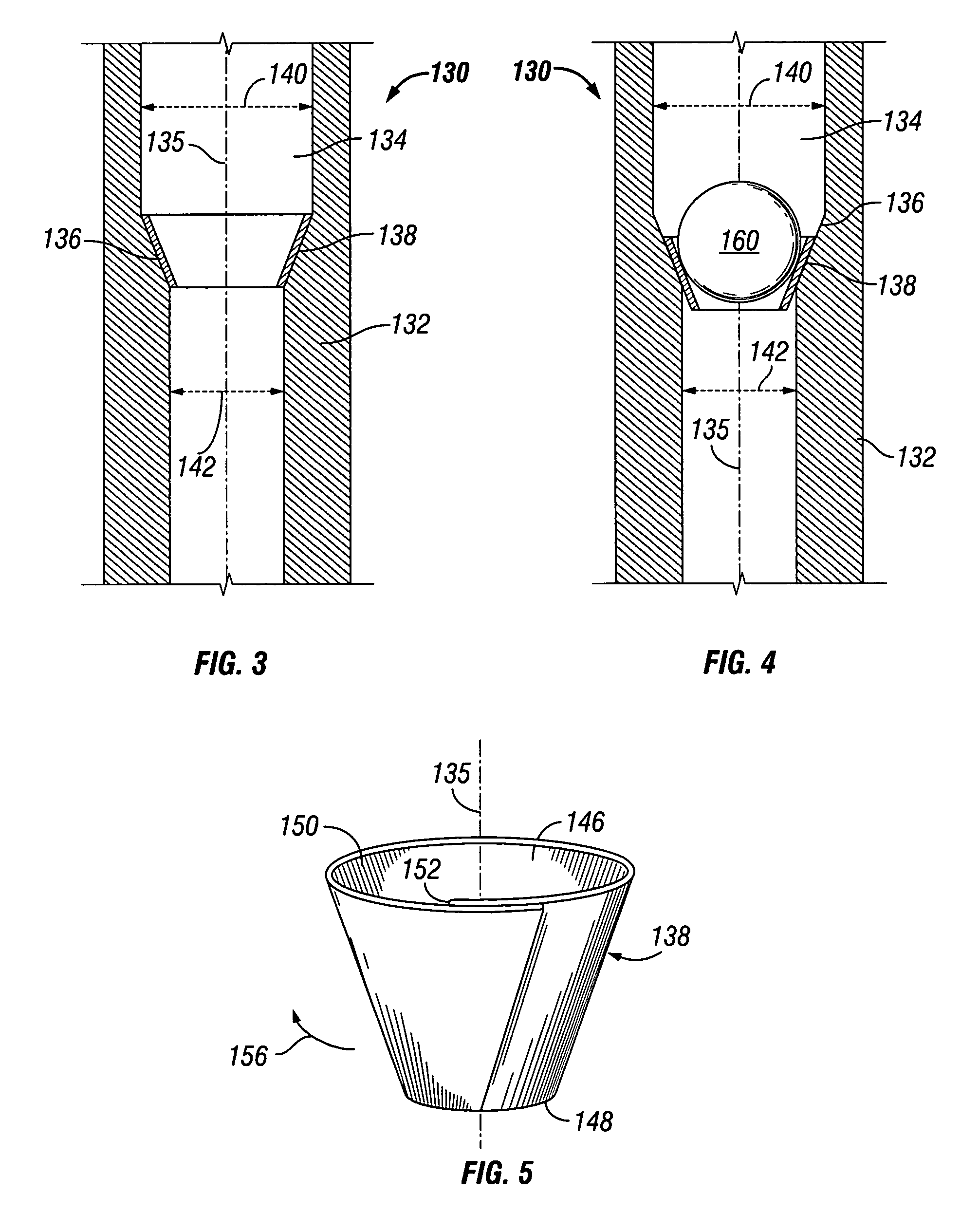

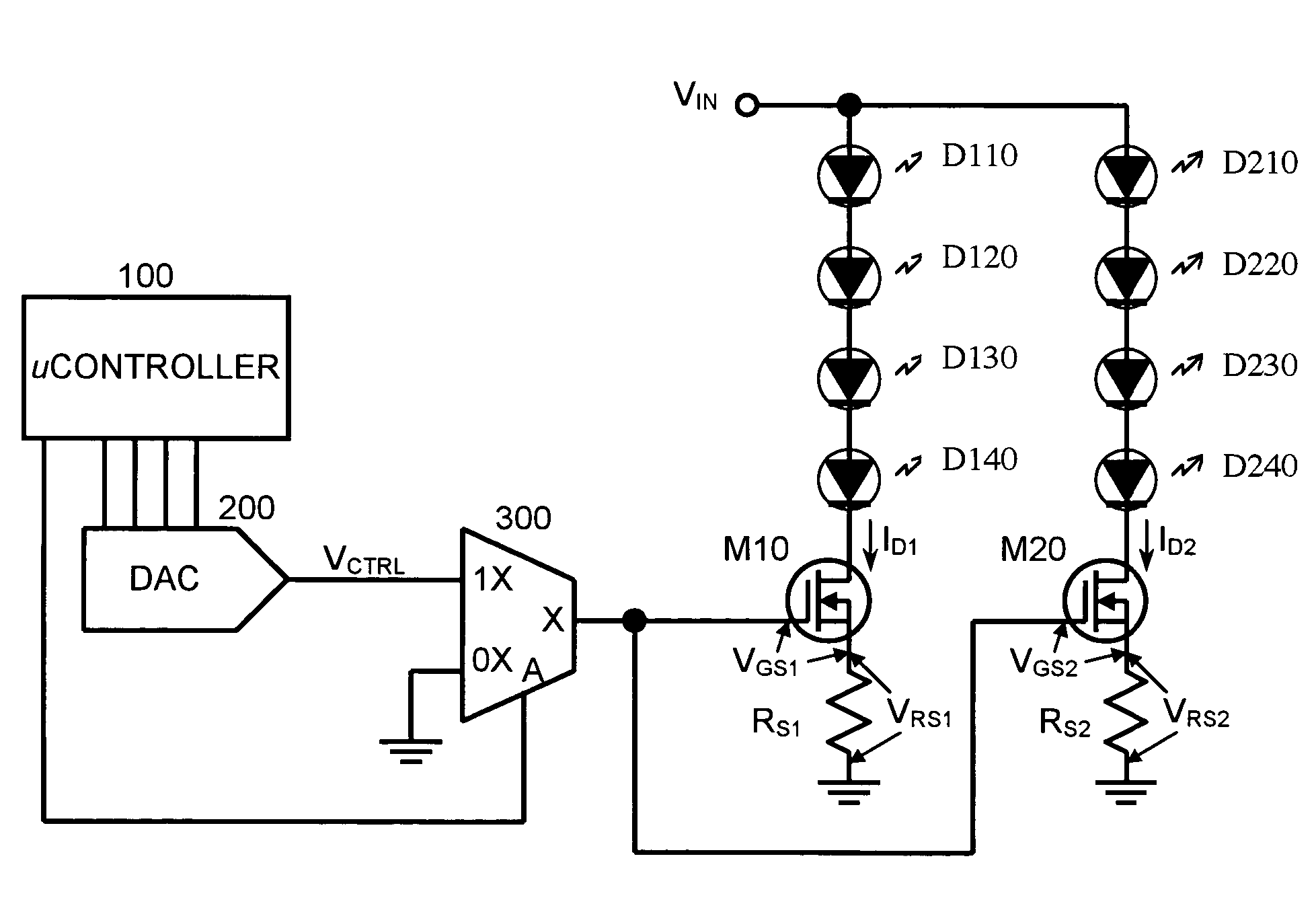

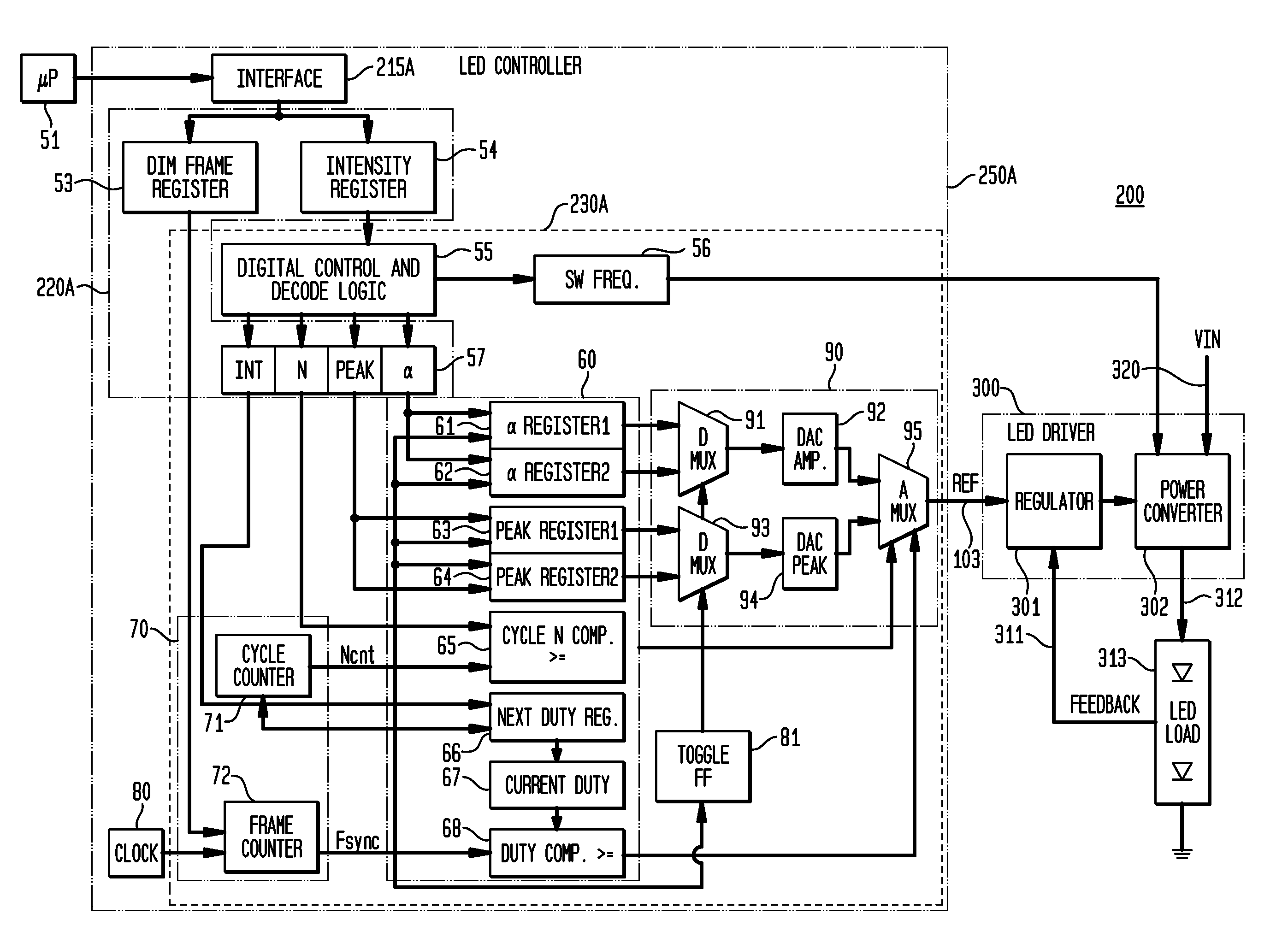

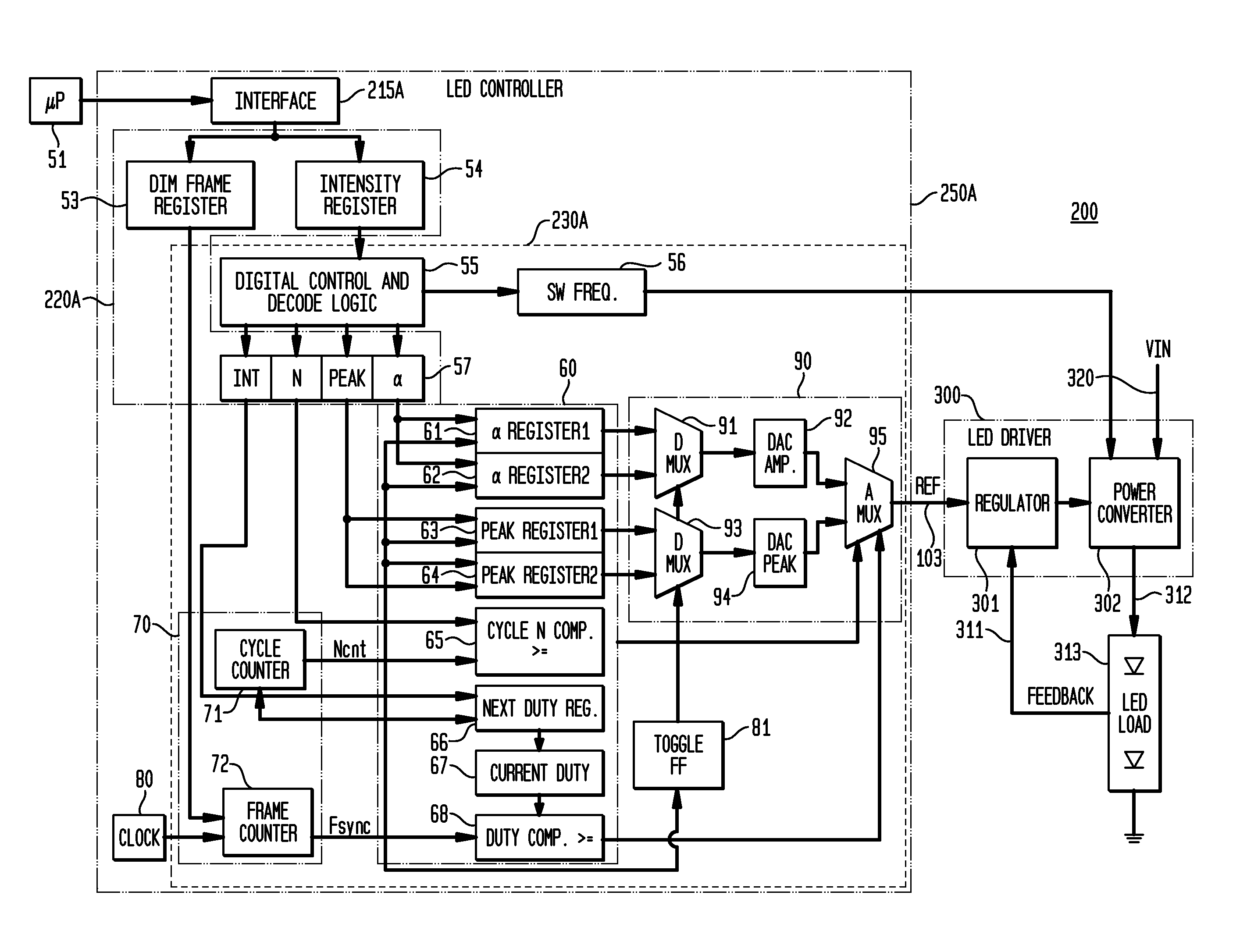

Modulated control circuit and method for current-limited dimming and color mixing of display and illumination systems

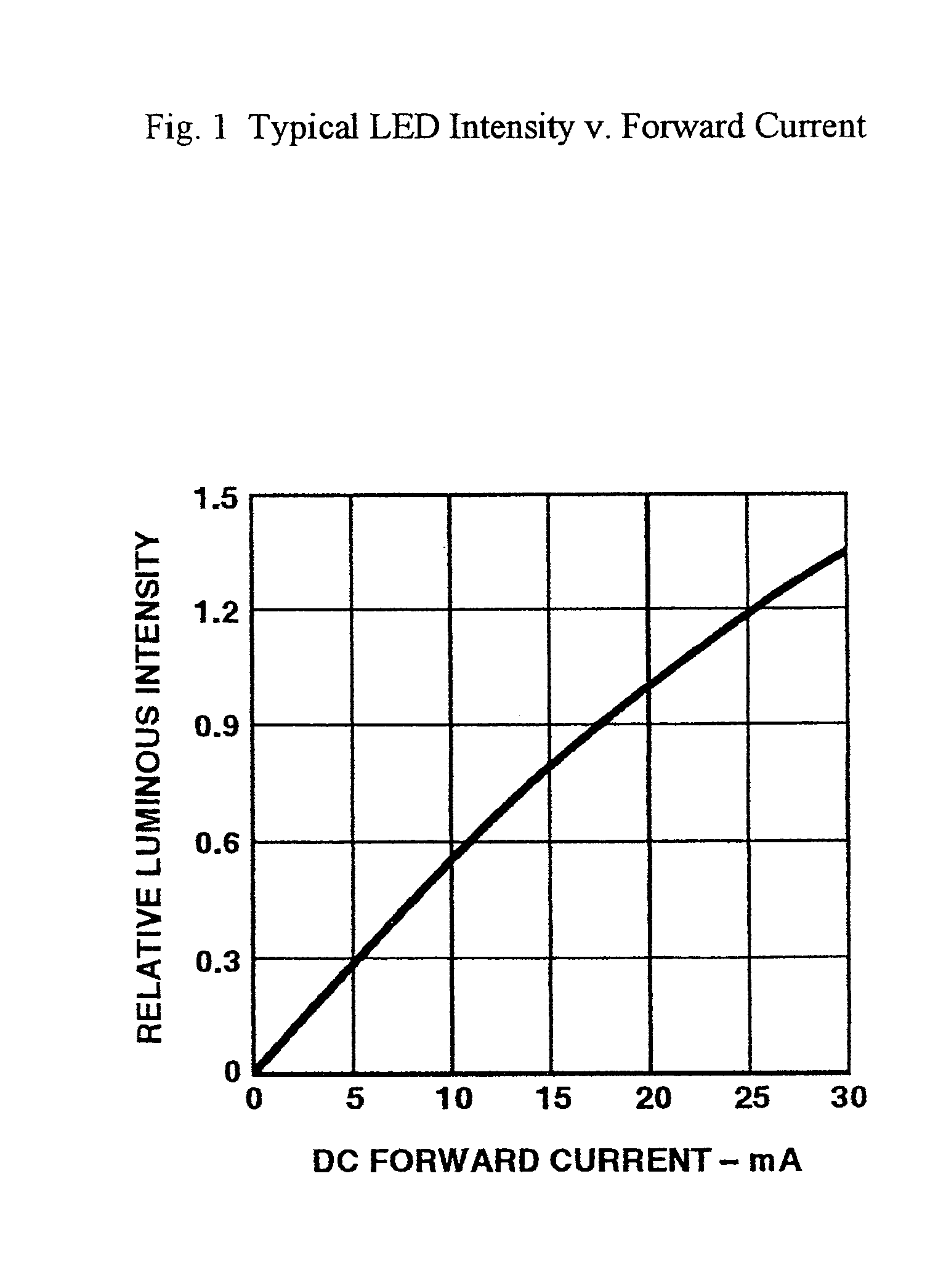

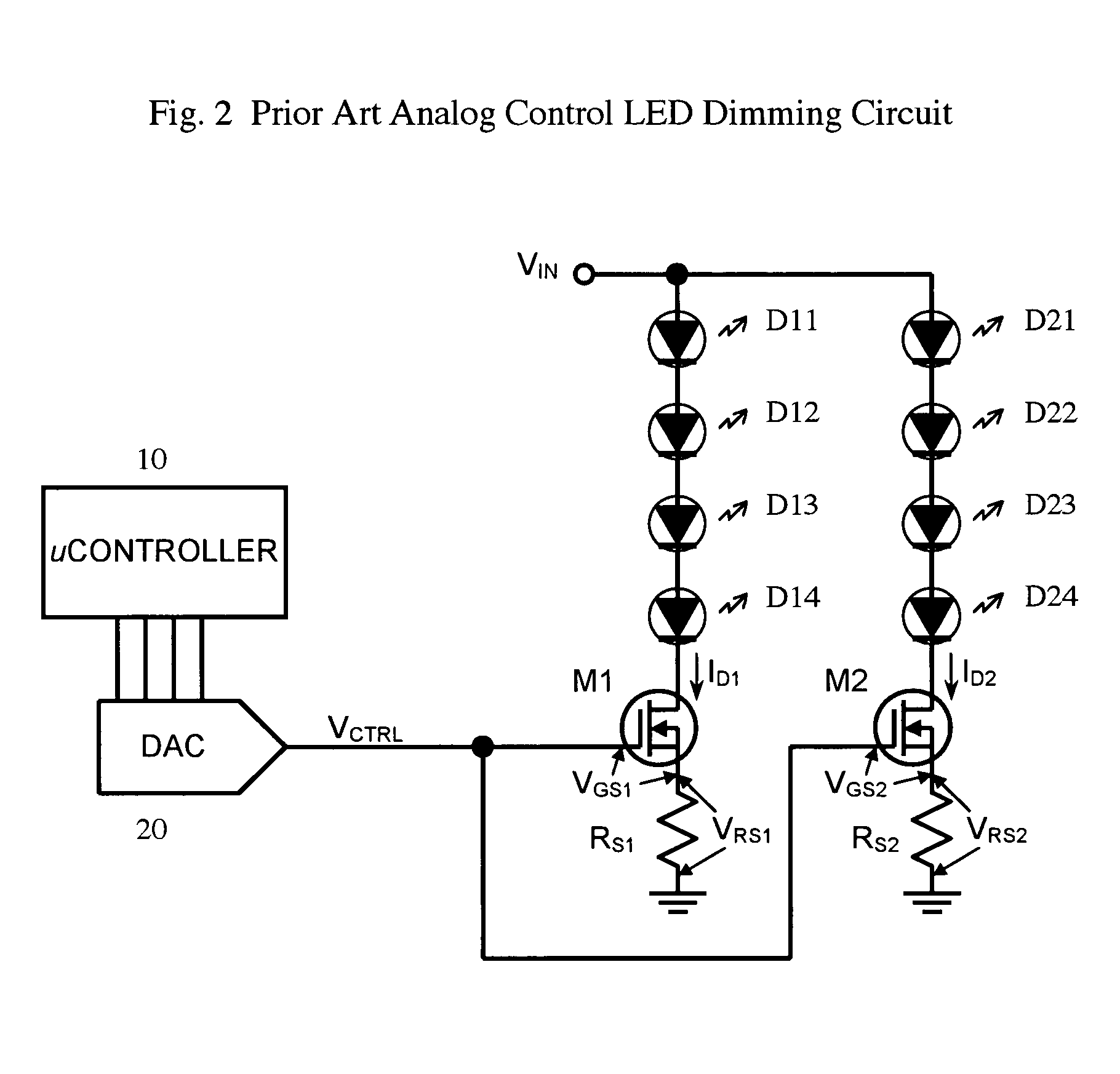

ActiveUS7088059B2Easy to controlReduce the differenceElectrical apparatusElectroluminescent light sourcesControl signalLighting system

A control circuit for a lighting system allows analog control over a first range of illumination intensities in which the intensity of the illumination source varies in proportion to the voltage level of the control signal. The circuit provides for improved dimming and color mixing capability by allowing pulse width or frequency modulation control in addition to analog control over a second range of illumination intensities.

Owner:BOCA FLASHER

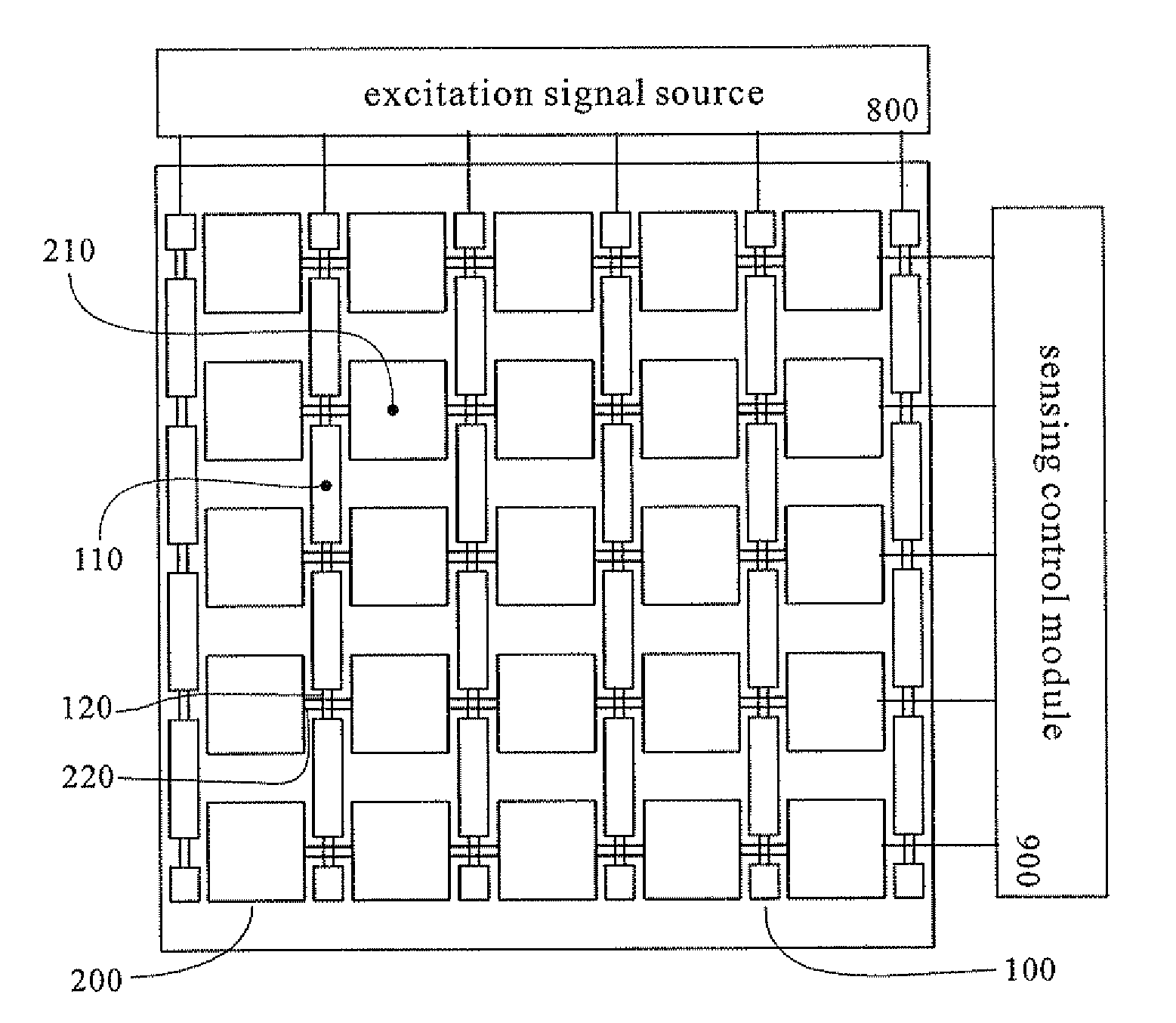

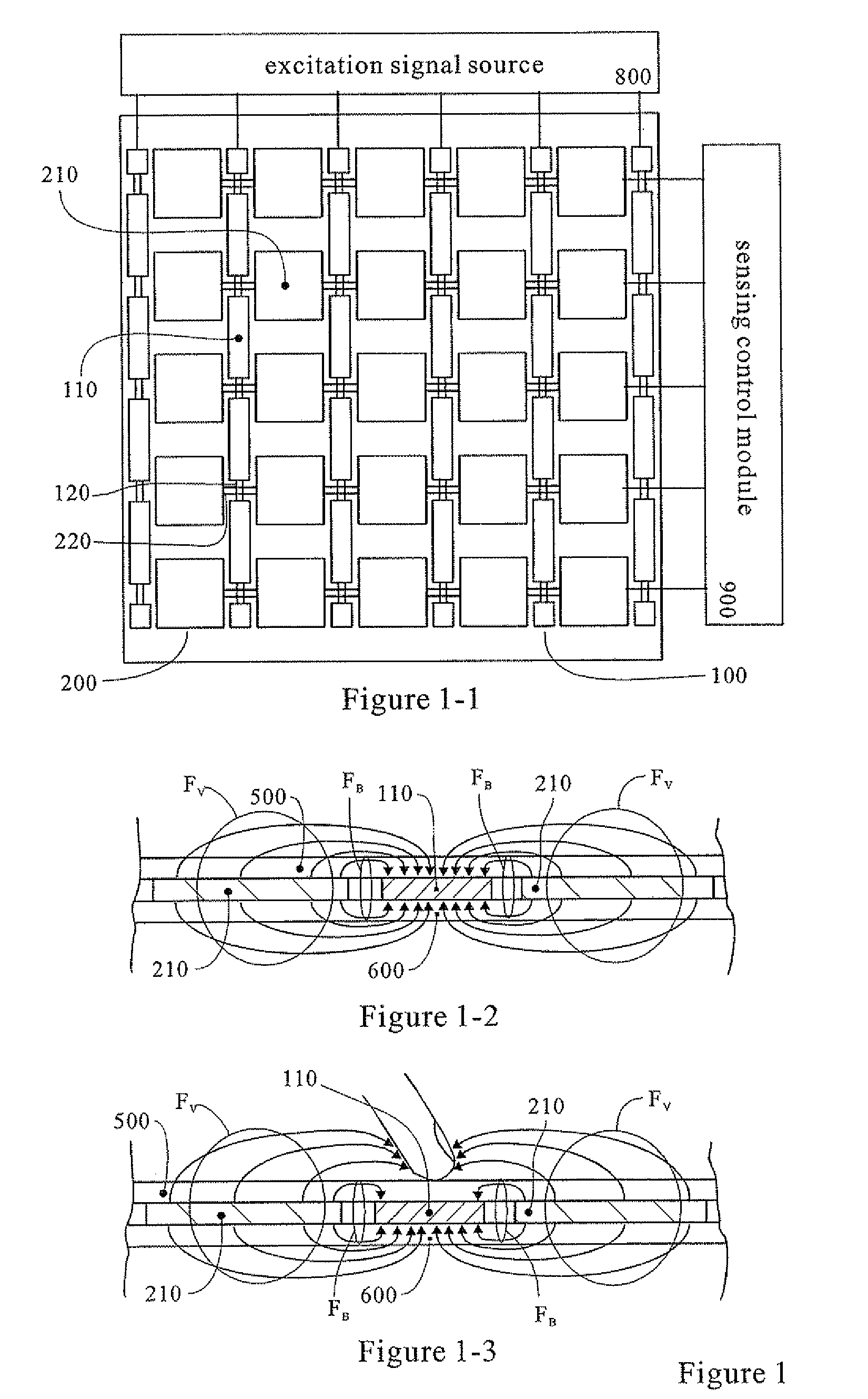

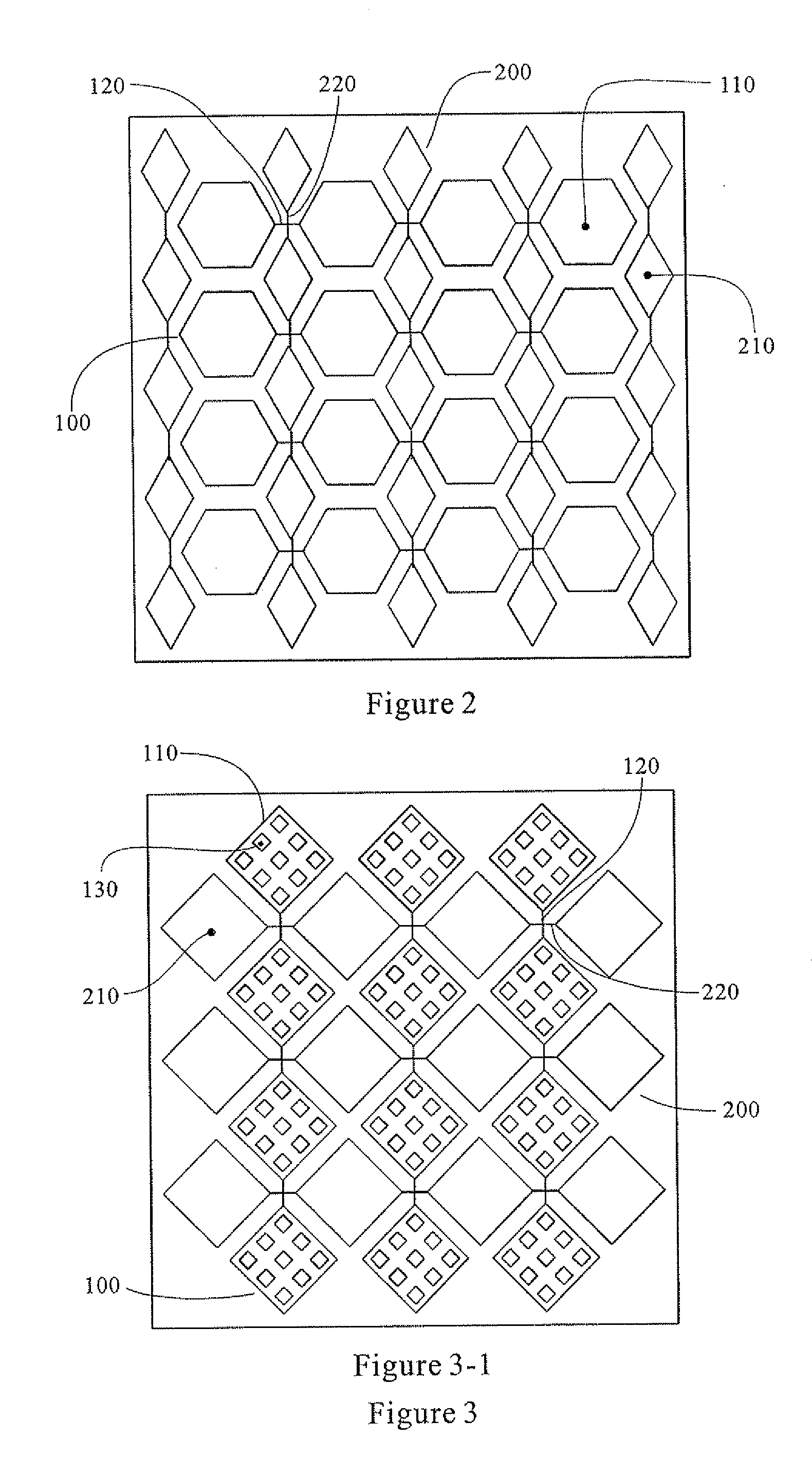

Ultrathin mutual capacitance touch screen and combined ultrathin touch screen

InactiveUS20110007030A1Increases the effective capacitivity of the monolayer touch screenHigh strengthInput/output processes for data processingConductive materialsTouchscreen

Ultrathin mutual capacitance touch screen and combined ultrathin touch screen composed by the said ultrathin mutual capacitance touch screen, the said ultrathin mutual capacitance touch screen comprises driving electrode clusters and sensing electrode clusters, wherein the driving electrode clusters are connected with an excitation signal source arranged outside the touch screen, and the sensing electrode clusters are connected with a sensing control module arranged outside the touch screen. The driving electrode clusters comprise tabulate driving electrodes which are made of transparent conductive materials and connected in series and / or in parallel, and the sensing electrode clusters comprise tabulate sensing electrodes which are made of transparent conductive materials and connected in series and / or in parallel. In particular, in a pair of adjacent driving electrode and sensing electrode of the touch screen, the plate area of at least one electrode producing the eigen mutual electric field is smaller than that of the same electrode producing the variable mutual electric field. The present invention make the thickness of the touch screen become thinner, and ensure a higher effective capacitivity.

Owner:FOCALTECH SYST LTD

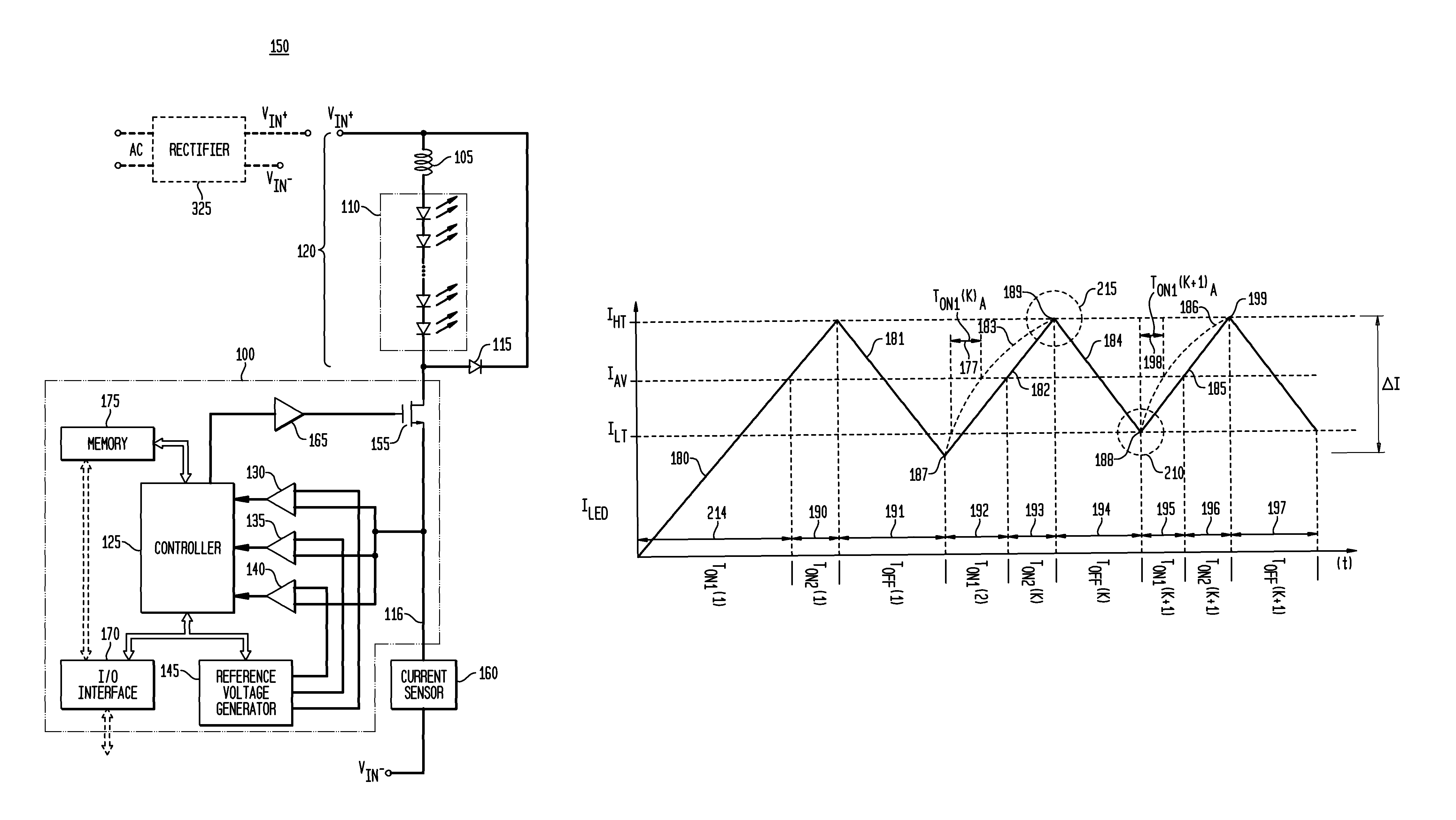

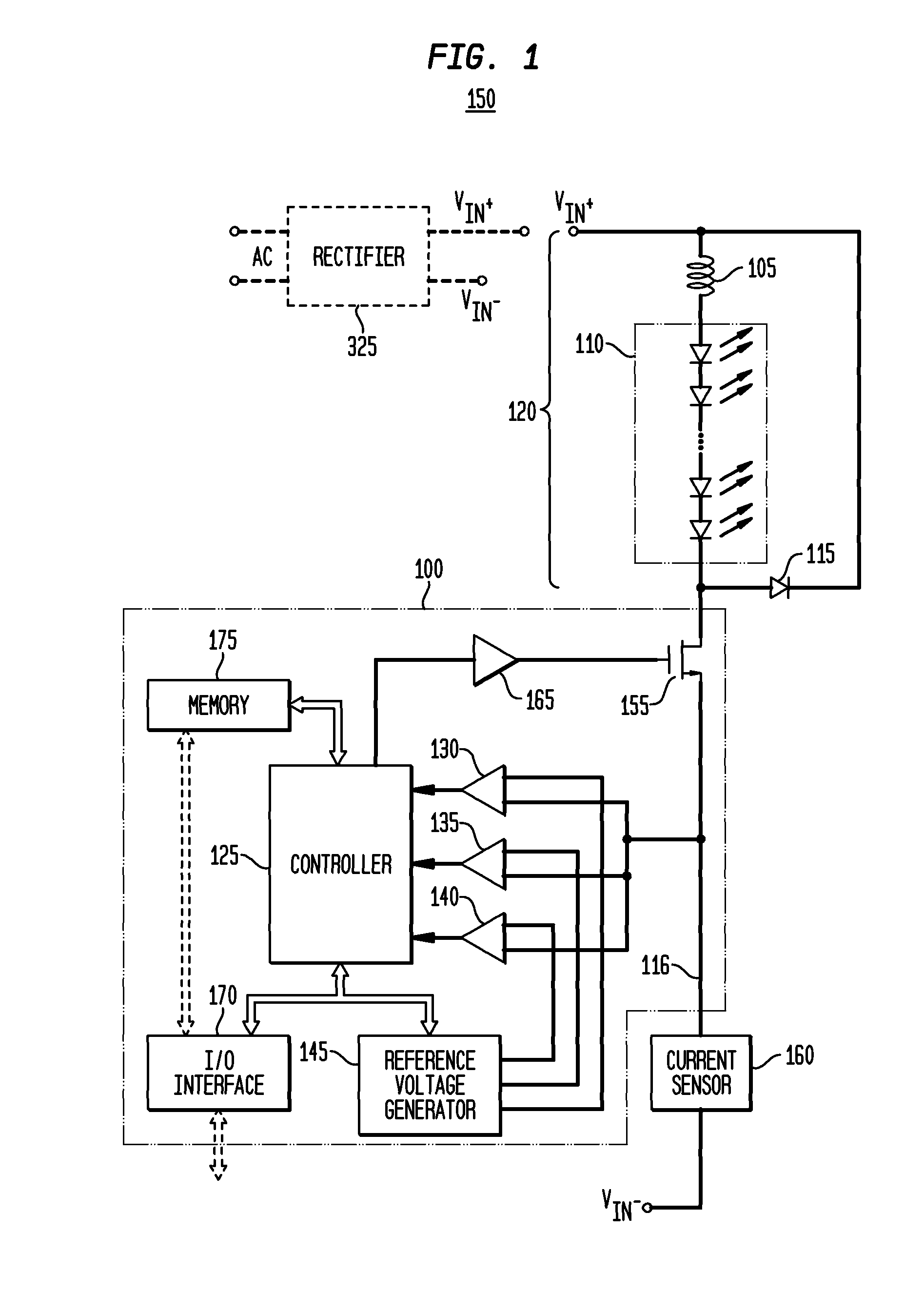

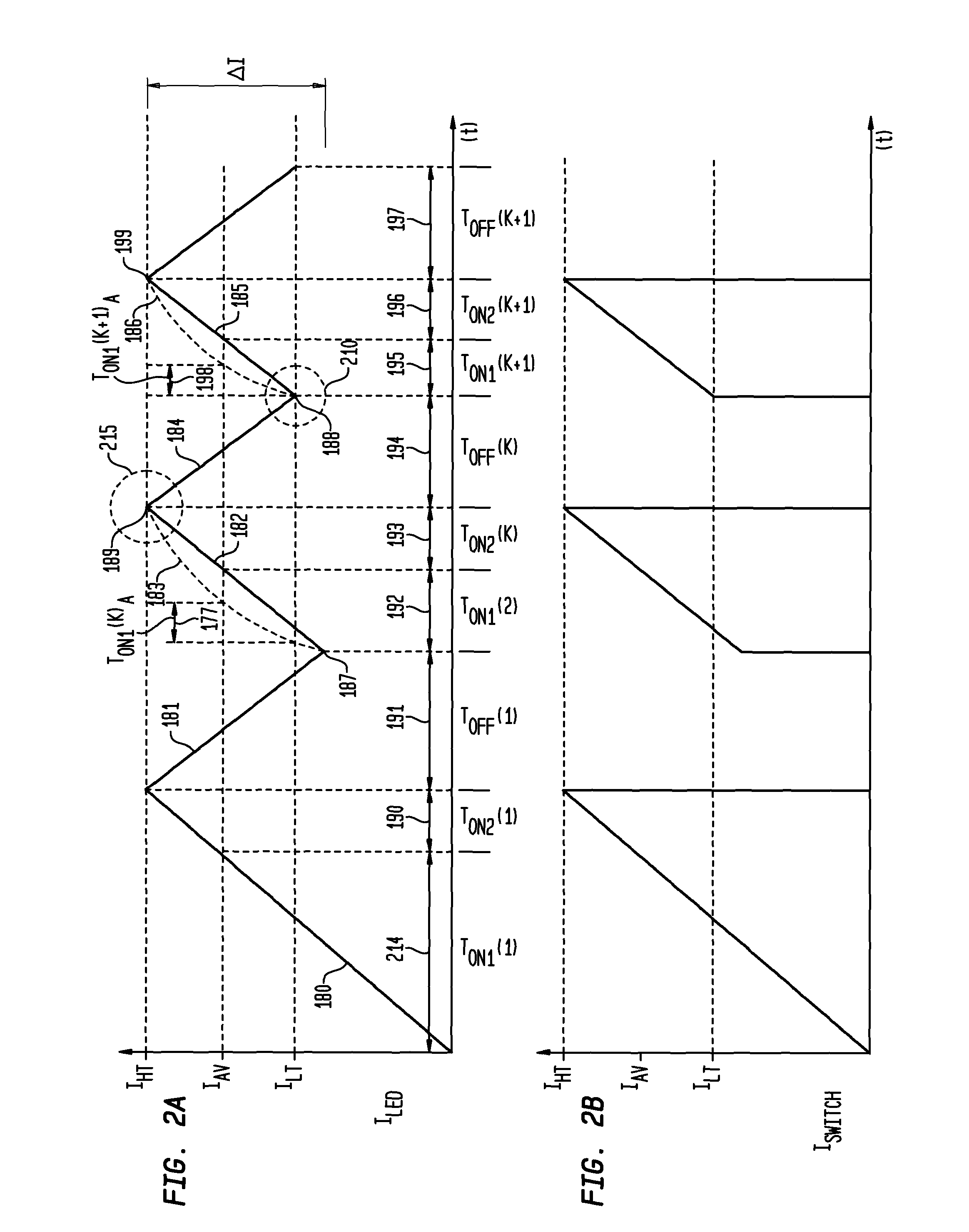

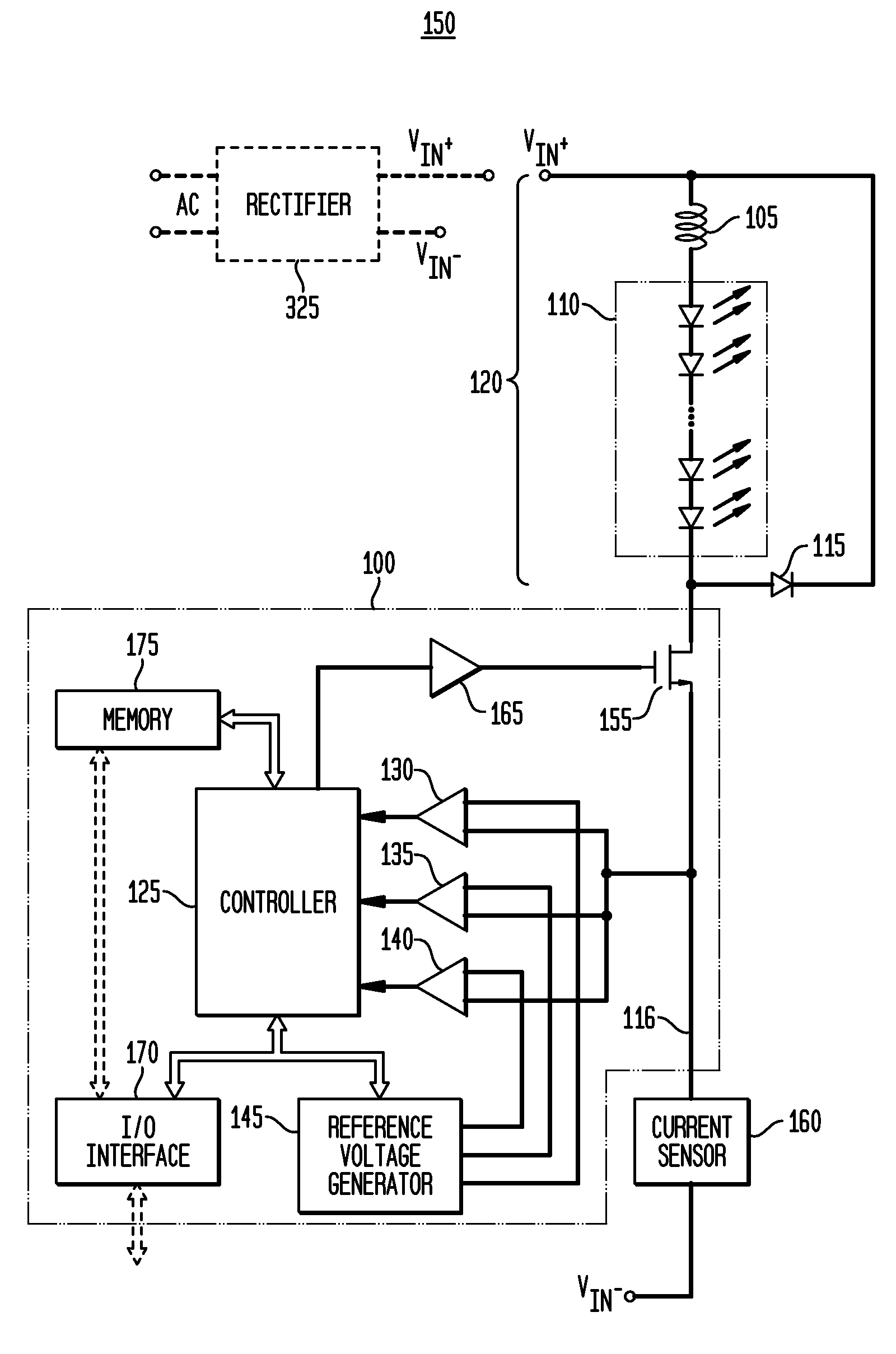

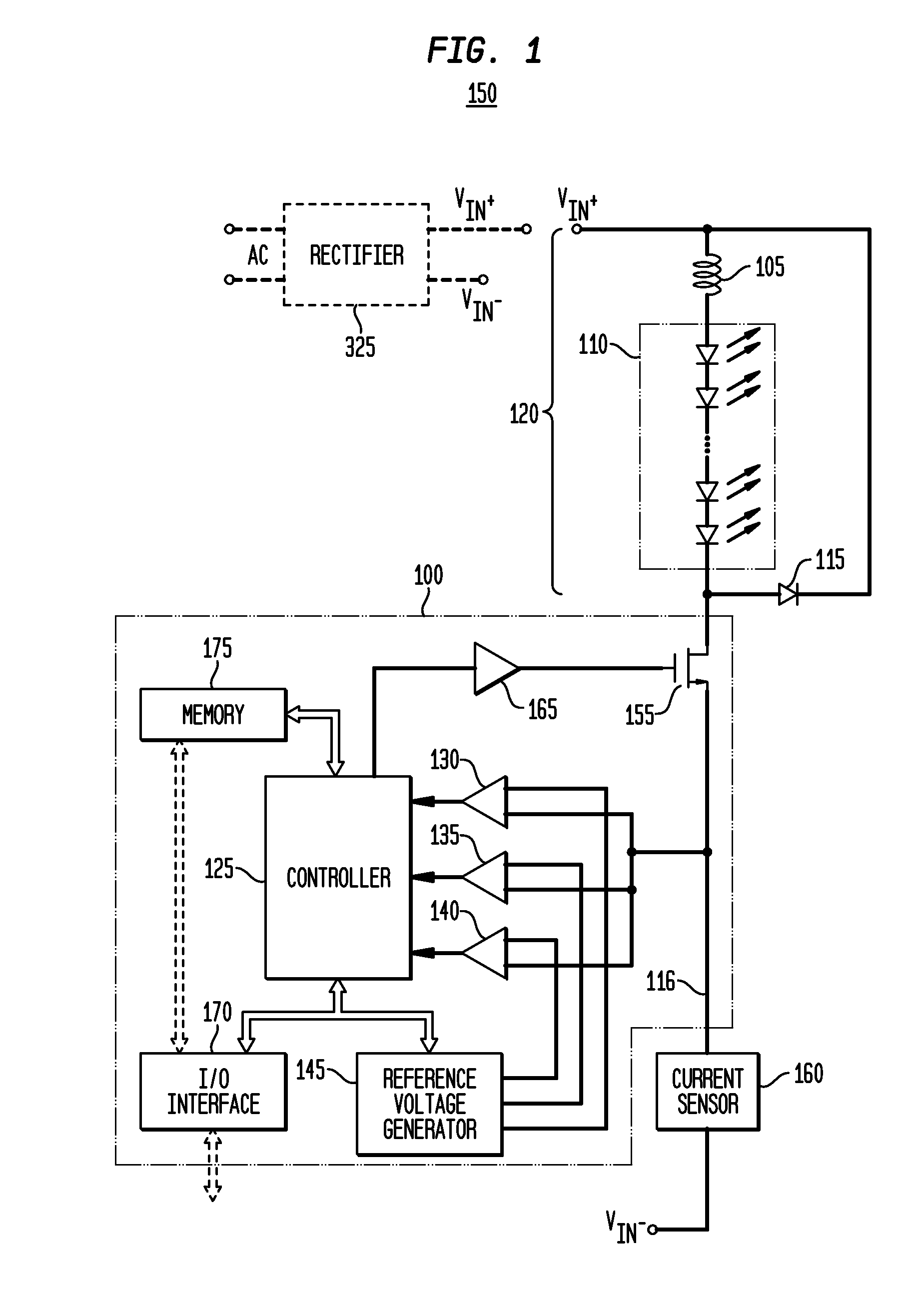

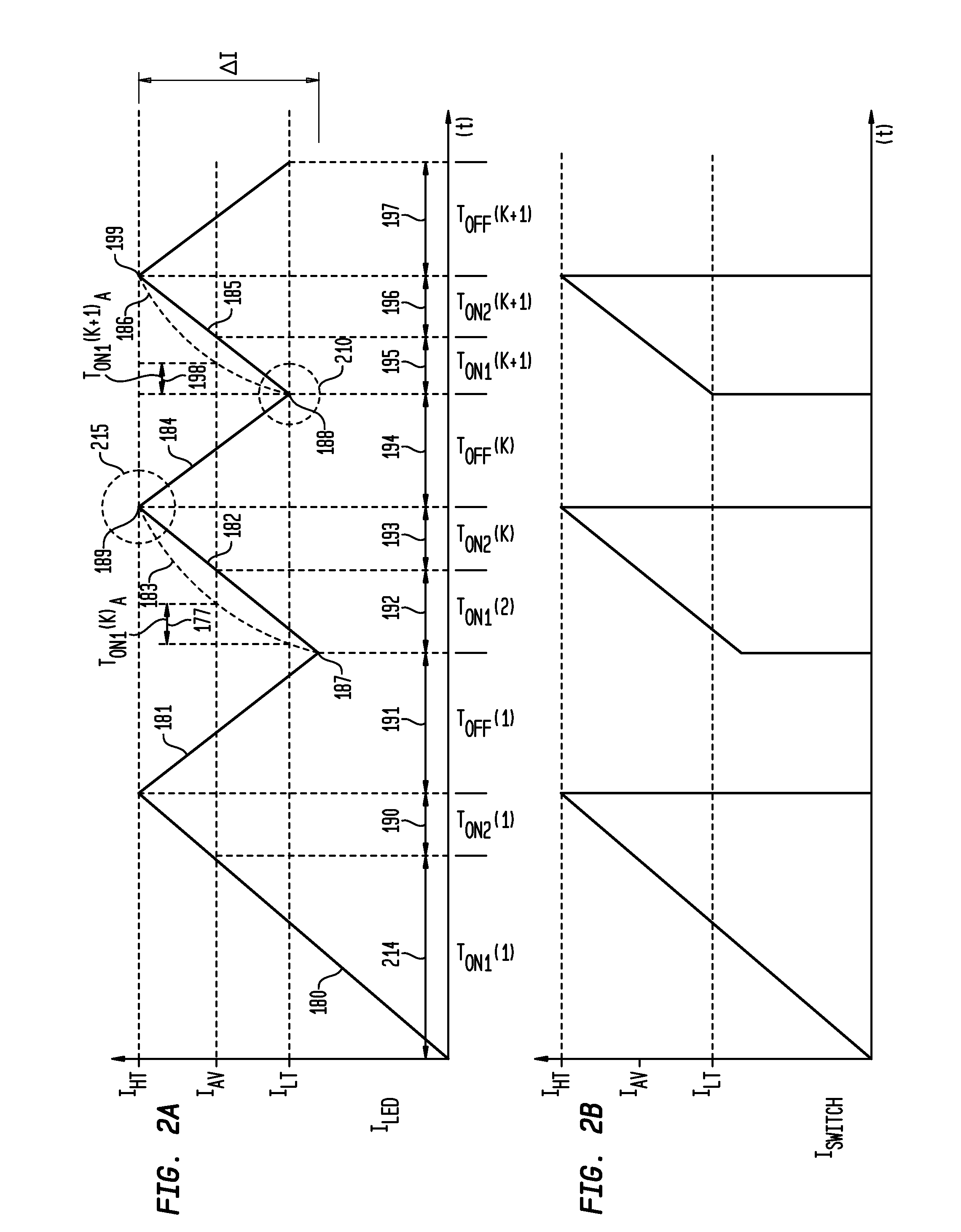

Digital driver apparatus, method and system for solid state lighting

ActiveUS7880400B2Low voltage implementationLow costElectrical apparatusElectroluminescent light sourcesAverage currentCurrent sensor

An apparatus, method and system are provided for controlling the solid state lighting, such as LEDs. An exemplary apparatus comprises: a switch for switching electrical current through the LEDs, a current sensor; a first comparator adapted to determine when a switch electrical current has reached a first predetermined threshold; a second comparator adapted to determine when the switch electrical current has reached a predetermined average current level; and a controller. The controller is adapted to turn the switch into an on state and an off state, to determine a first on time period as a duration between either a detection of a second predetermined current threshold or the turning the switch into the on state, and the detection of the predetermined average current level; to determine a second on time period as a duration between the detection of the predetermined average current level and the detection of the first predetermined current threshold; and to determine an on time period of the switch as substantially proportional to a sum of the first on time period and the second on time period. Additional exemplary embodiments utilize a difference between the first and second on time periods to generate an error signal to adjust the on time period of the switch.

Owner:CHEMTRON RES

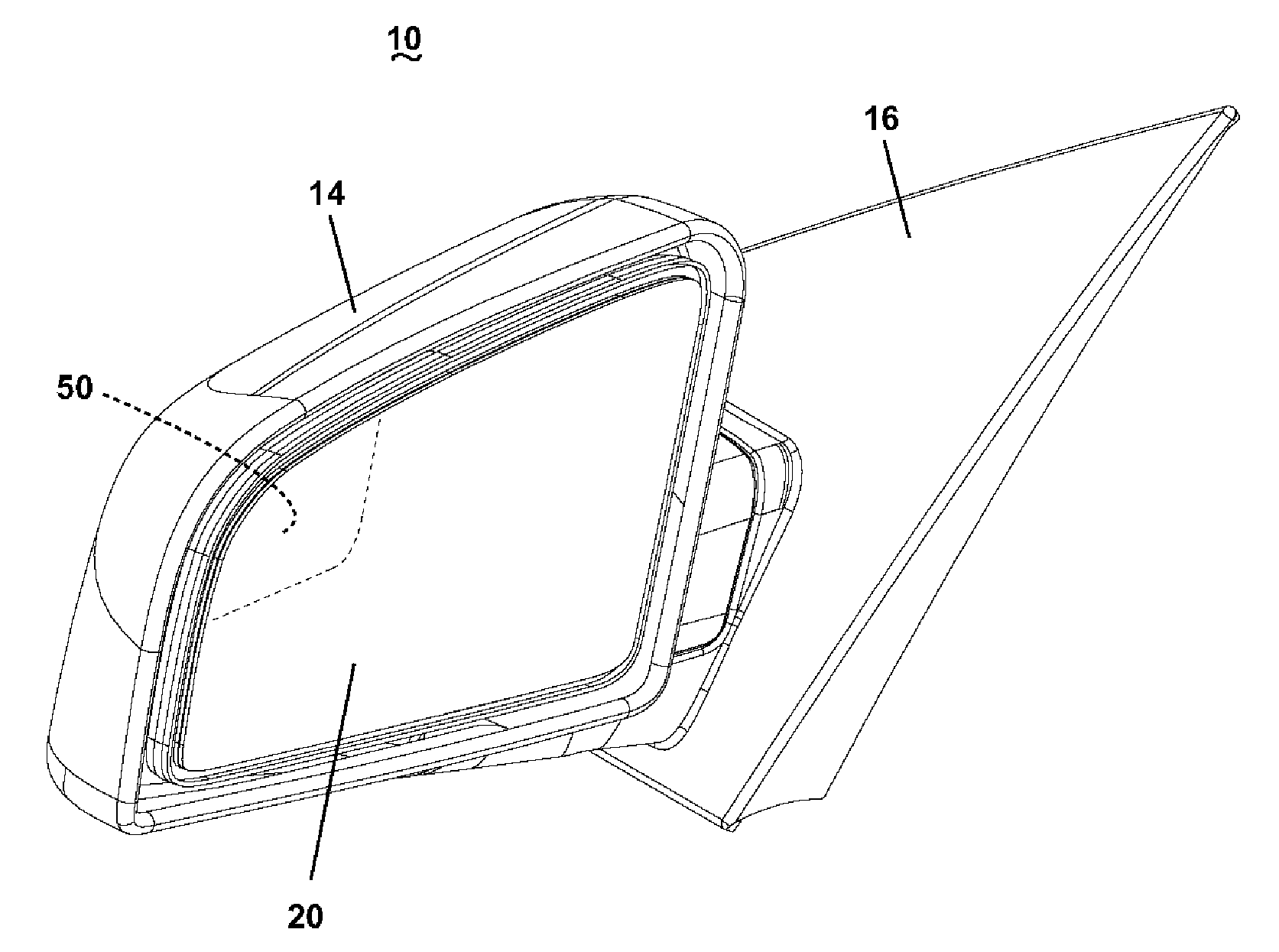

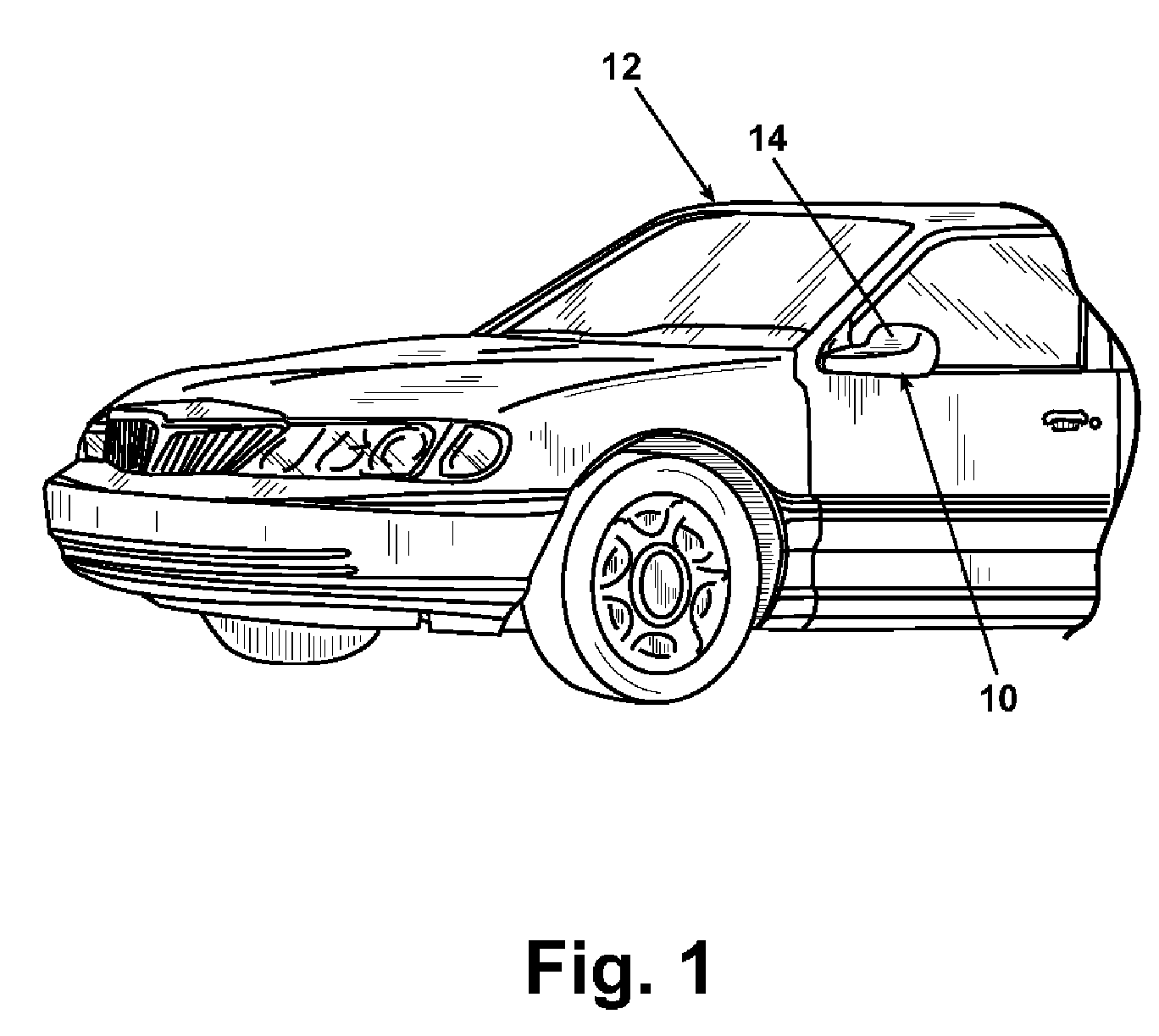

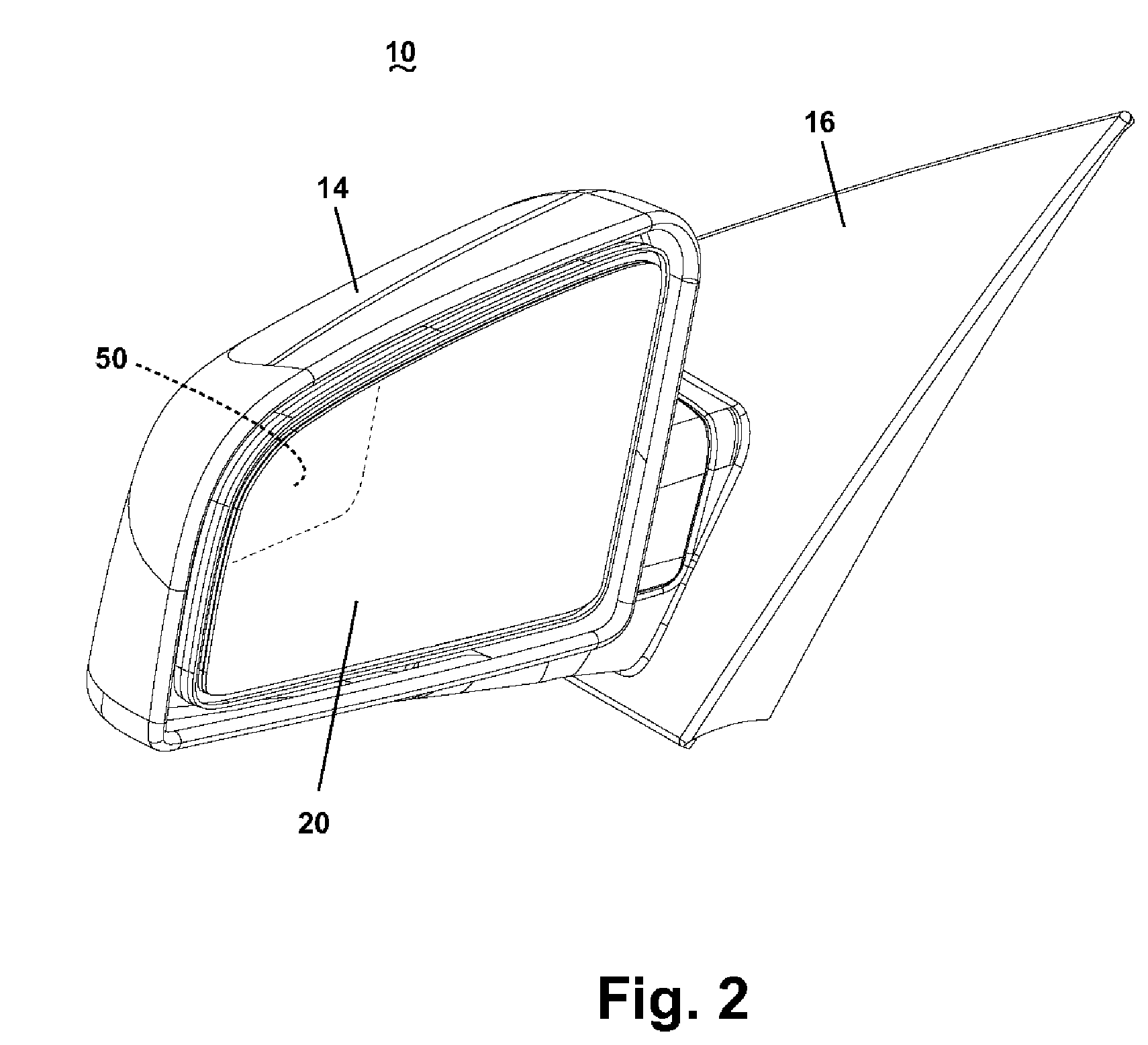

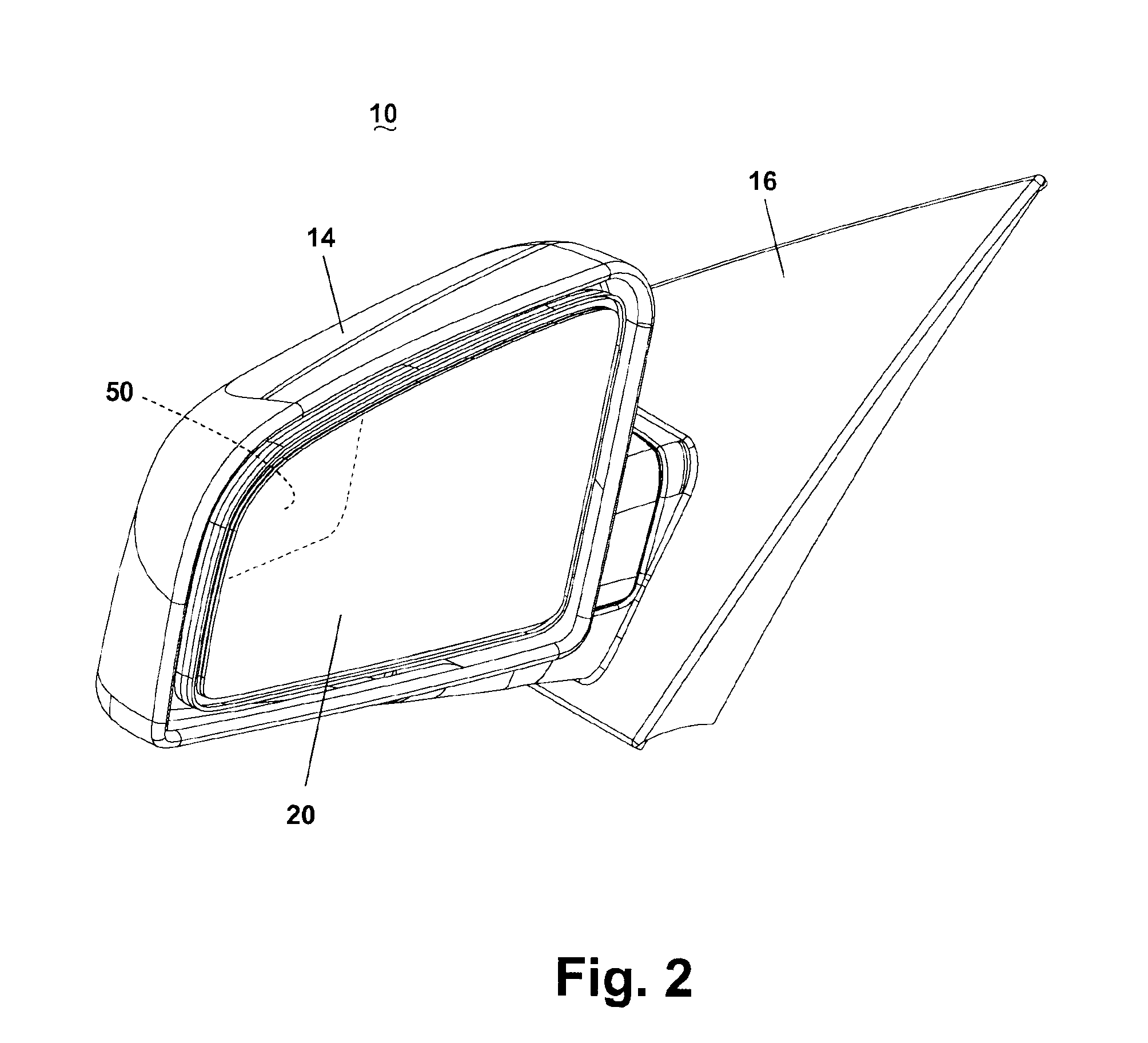

Dimming mirror with blind zone sub-mirror and indicator

InactiveUS7126456B2Efficient drawingReduce intensityAnti-collision systemsOptical signallingBlind zoneElectrochromism

A rearview mirror system comprises a spotter mirror for providing an image of an object in a vehicle's blind zone to the vehicle's operator. A recognition enhancement device is provided with the spotter mirror for drawing the attention of the driver to the spotter mirror when an overtaking vehicle enters the driver's blind zone. The signaling display is activated by a sensing system which senses the presence of the overtaking vehicle in the blind zone. An electrochromic element is incorporated into the spotter mirror to reduce the intensity of light transmitted from the object and reflected from the spotter mirror. Activation of the electrochromic element to darken the spotter mirror will induce the operator to observe the object in the spotter mirror.

Owner:MAGNA MIRRORS OF AMERICA INC

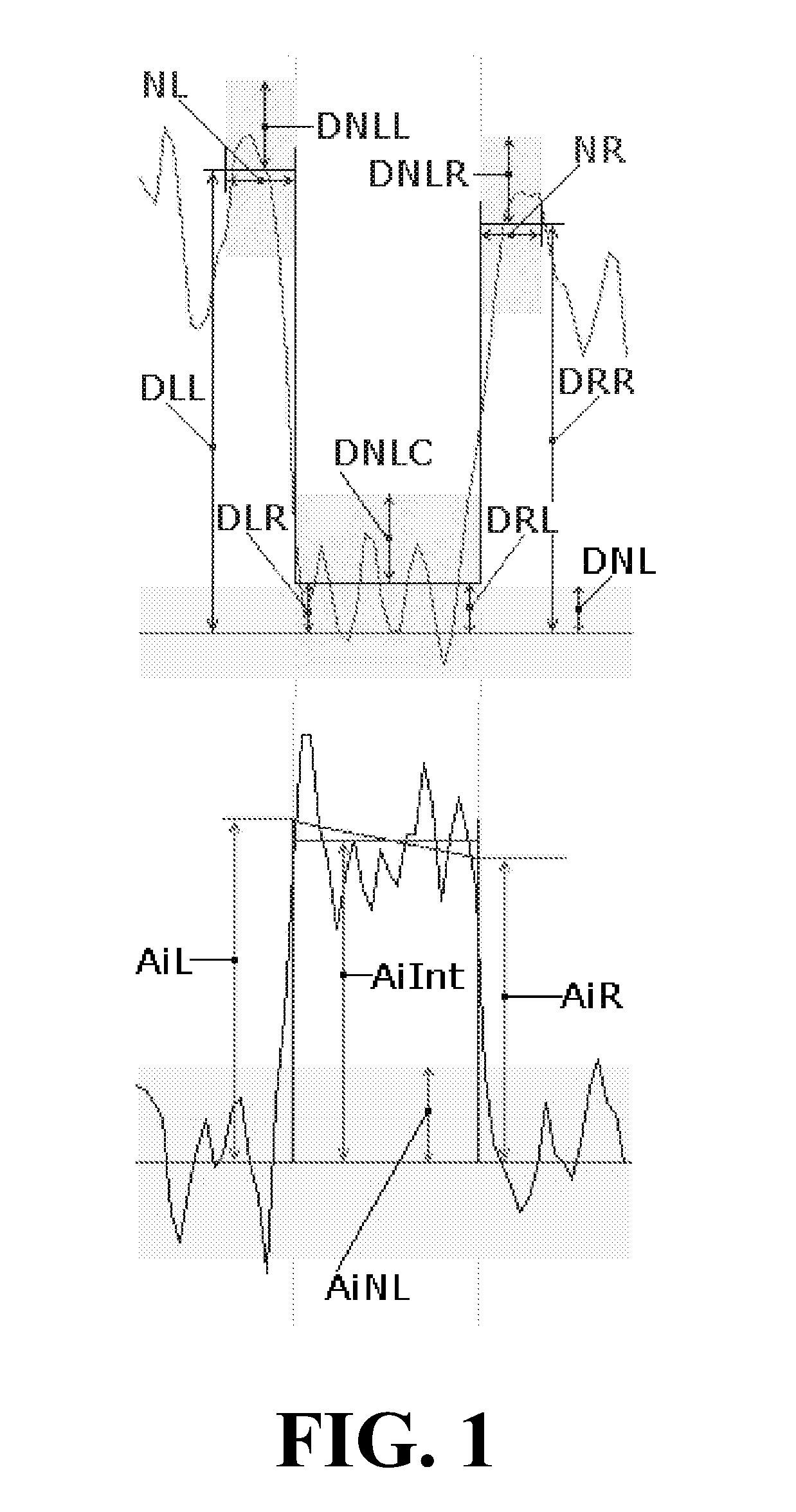

Method for analyzing dynamic detectable events at the single molecule level

InactiveUS20070250274A1Reduce intensityHigh strengthMicrobiological testing/measurementDigital computer detailsFluorescenceMolecular level

A method to be implemented on or in a computer is disclosed, where the method includes data collection, calibration, candidate selection, and analysis of data streams associated with each candidate to classify single molecule fluorescence resonance energy transfer events. Once classified, the classification can be related to the nature of the events, such as the identification of dNTP incorporation during primer extension to obtain a base read out of an unknown template.

Owner:LIFE TECH CORP

Topical Pharmaceutical Foam Composition

InactiveUS20070154402A1Reduced intensity of colorReduce odor intensityAntibacterial agentsBiocideAlcohol freeActive agent

A stable topical alcohol-free aerosol foam containing one or more keratolytic agents is provided. The foam-forming formulation is an emulsion which contains an HFA propellant and one or more keratolytic agents. The emulsion has an oil phase and an aqueous, i.e. water-containing, phase. The active agent(s) may be present in either phase of the emulsion or dispersed in the emulsion. The oil phase may consist at least in part of the HFA propellant. Either or both of the oil phase and the aqueous phase may contain one or more surfactants, emulsifiers, emulsion stabilizers, buffers, and / or other excipients. The foam is stable on the skin, for example, for at least 5 minutes at body temperature, preferably at least 20 minutes at body temperature, and disappears into the skin upon rubbing or after prolonged standing. In one embodiment, the formulation contains an HFA propellant which does not contain additional co-solvents or co-propellants. The formulations demonstrate reduced intensity of the odor and / or color associated with the keratolytic agent(s) as compared to conventional formulations containing keratolytic agents.

Owner:PRECISION DERMATOLOGY

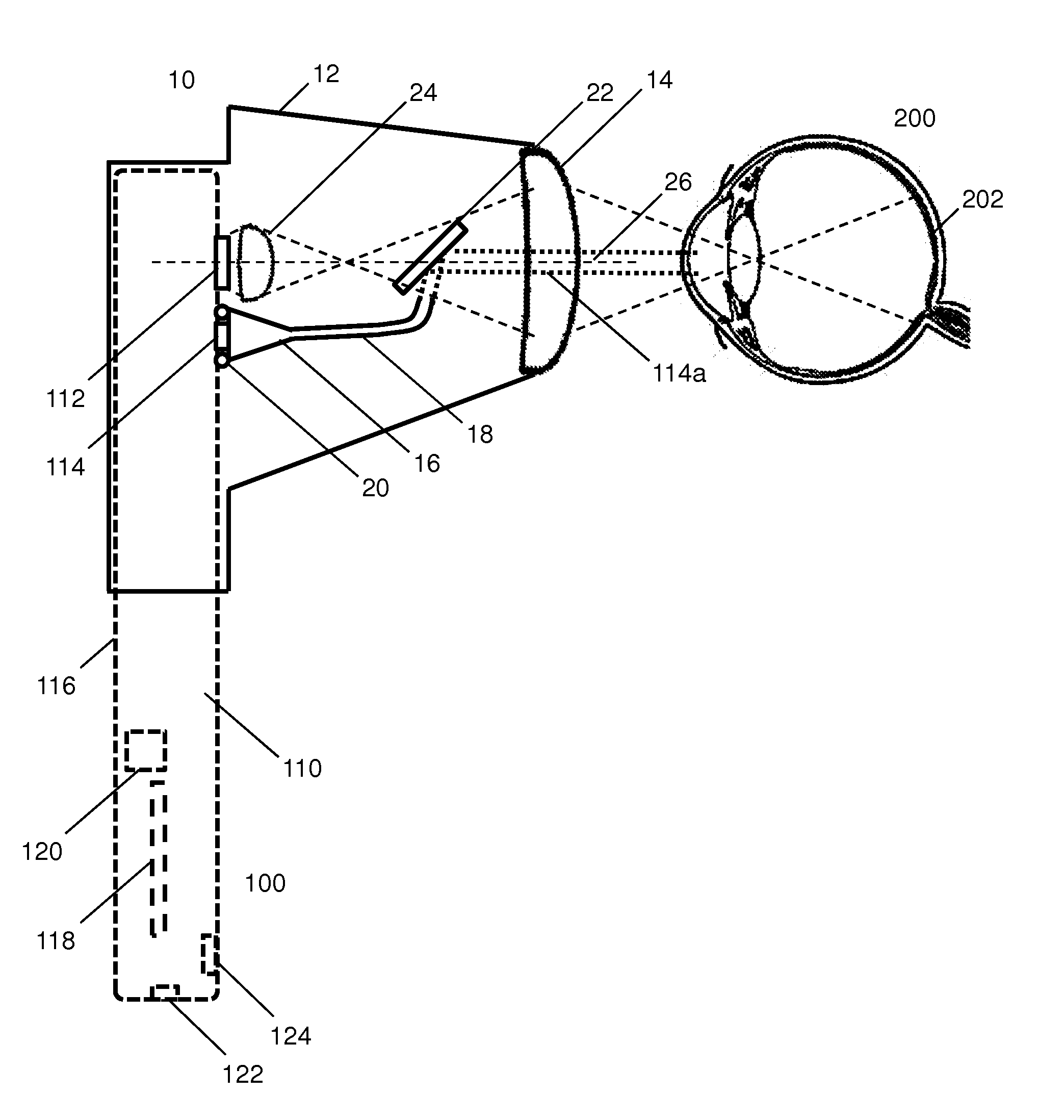

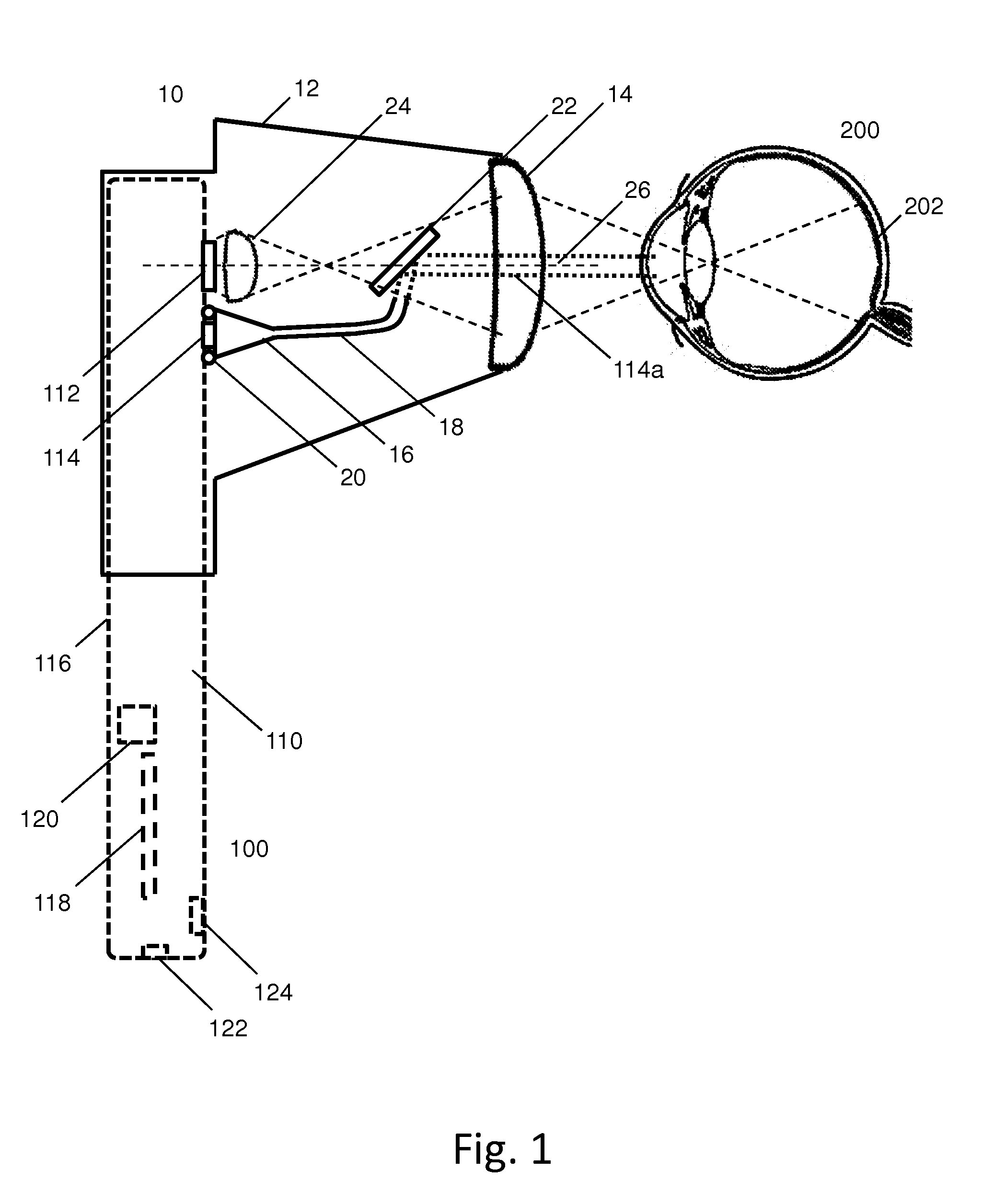

Optical adapter for ophthalmological imaging apparatus

InactiveUS20130083185A1Reduce intensityConvenient lightingColor television detailsClosed circuit television systemsCamera lensEngineering

An optical adapter system for a smart-phone has a lens and a light transmission guide within a housing. The adapter lens is located at the distal end of the housing in optical alignment with the smart-phone's camera lens, and the light transmission guide extends from one end that is adjacent to the smart-phone's light source toward the distal end of the housing and directs light outside of the housing to the subject being imaged. The optical adapter is preferably used in combination with the smart-phone as an ophthalmic examination tool and can be used with a computer program that runs on the smart-phone's processor. The computer program can be calibrated for use with the particular optical adapter and can be used to control the smart-phone's imaging system, such as varying the intensity of the light source, and can determine a refractive error in a patient's eye.

Owner:INTUITIVE MEDICAL TECH

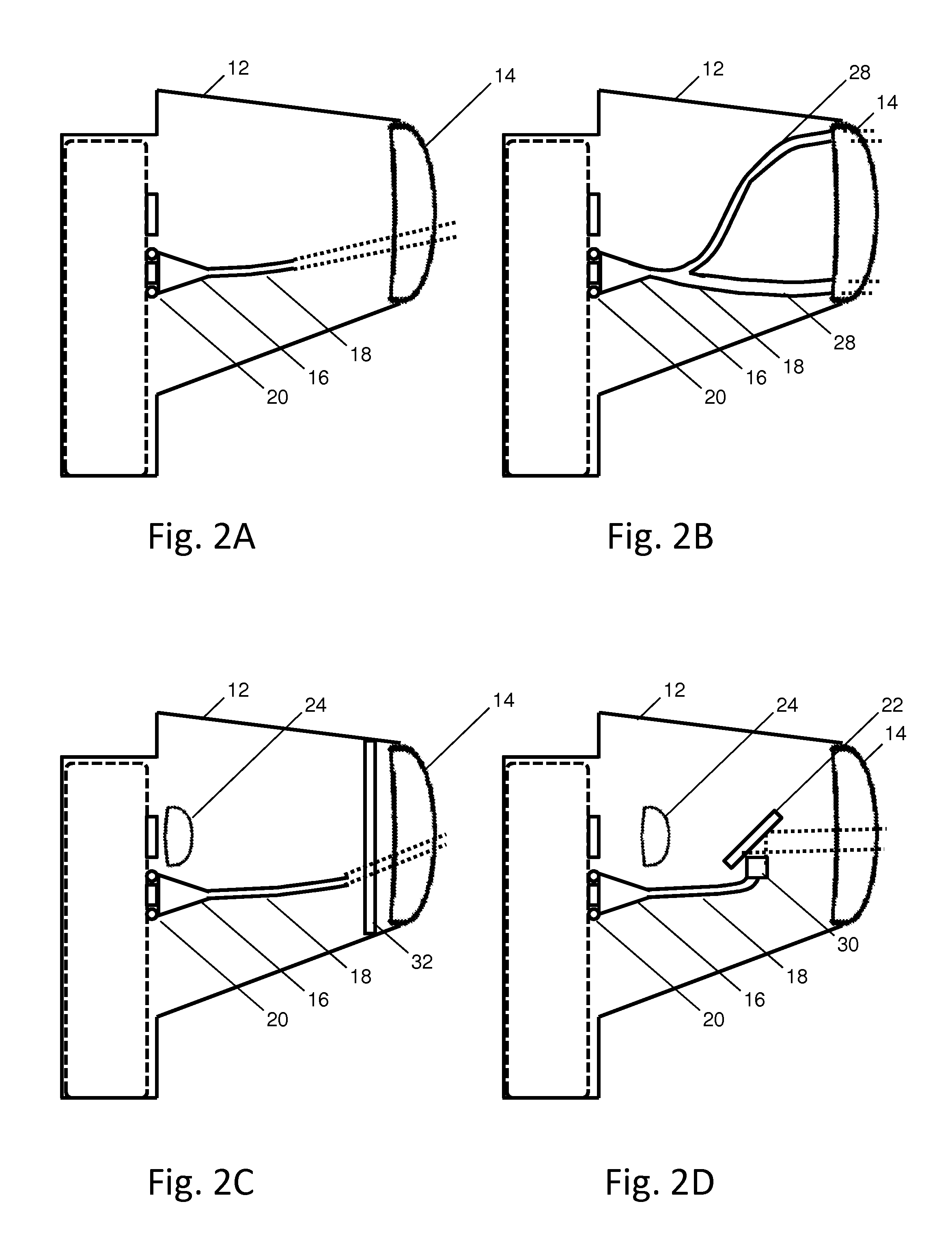

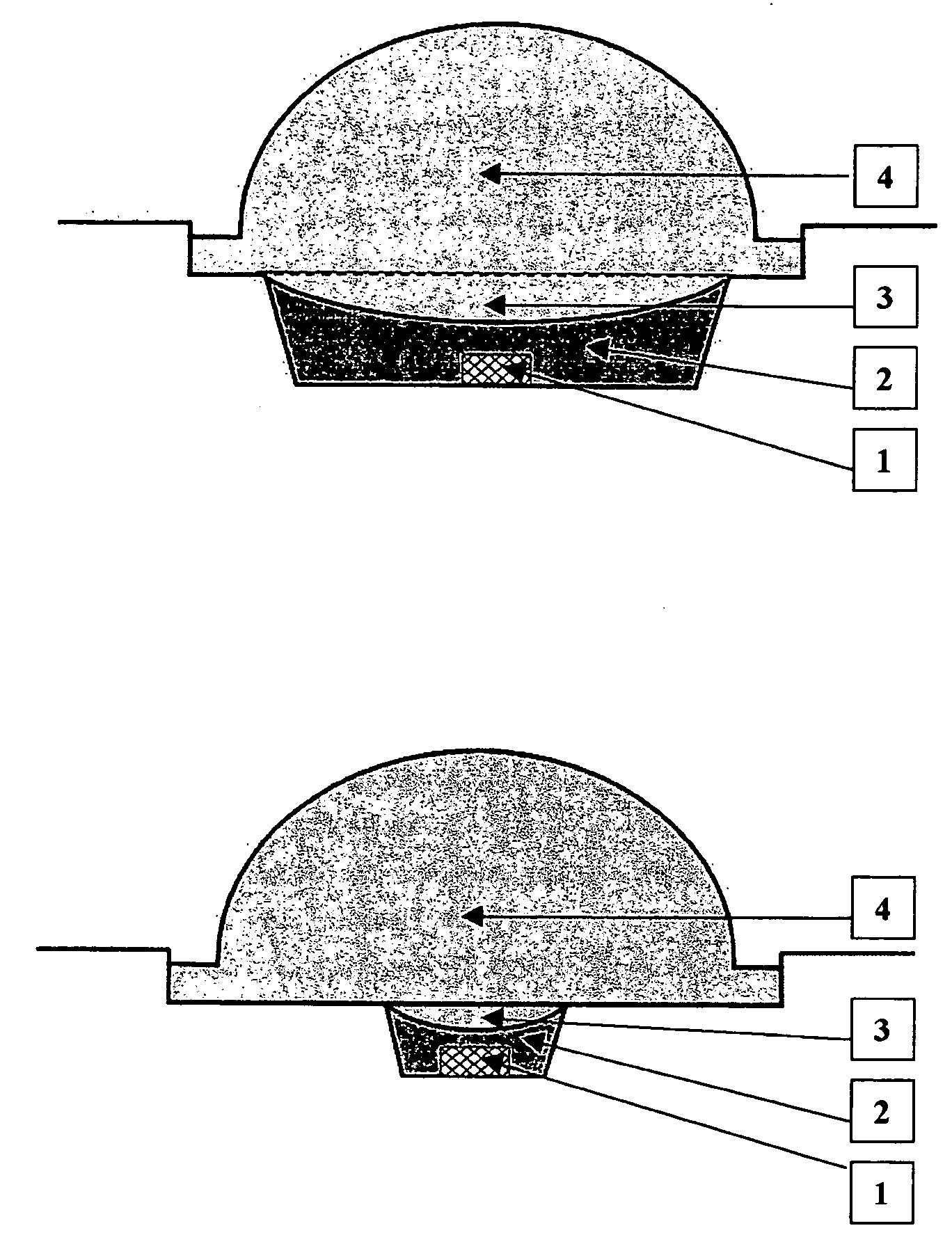

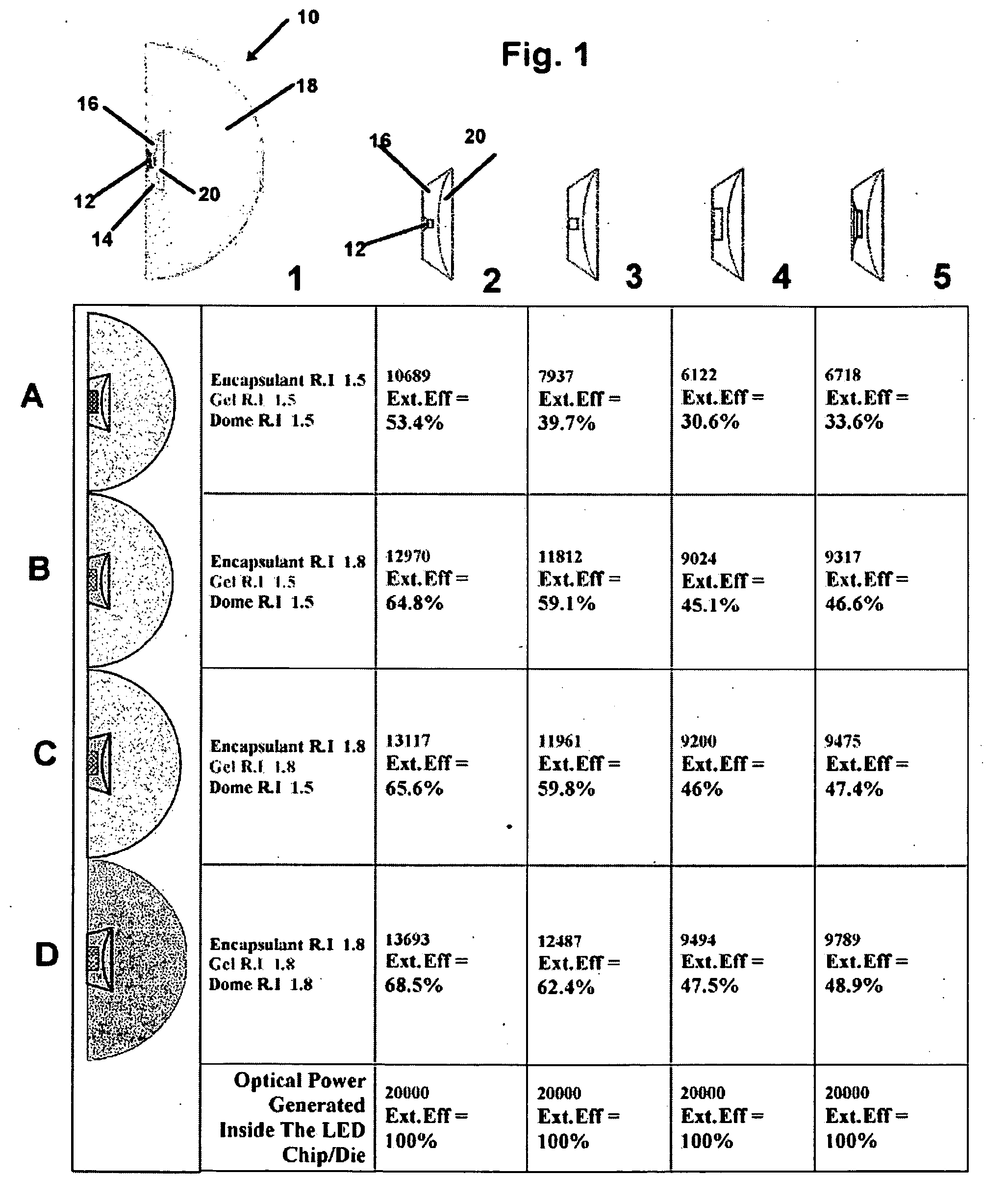

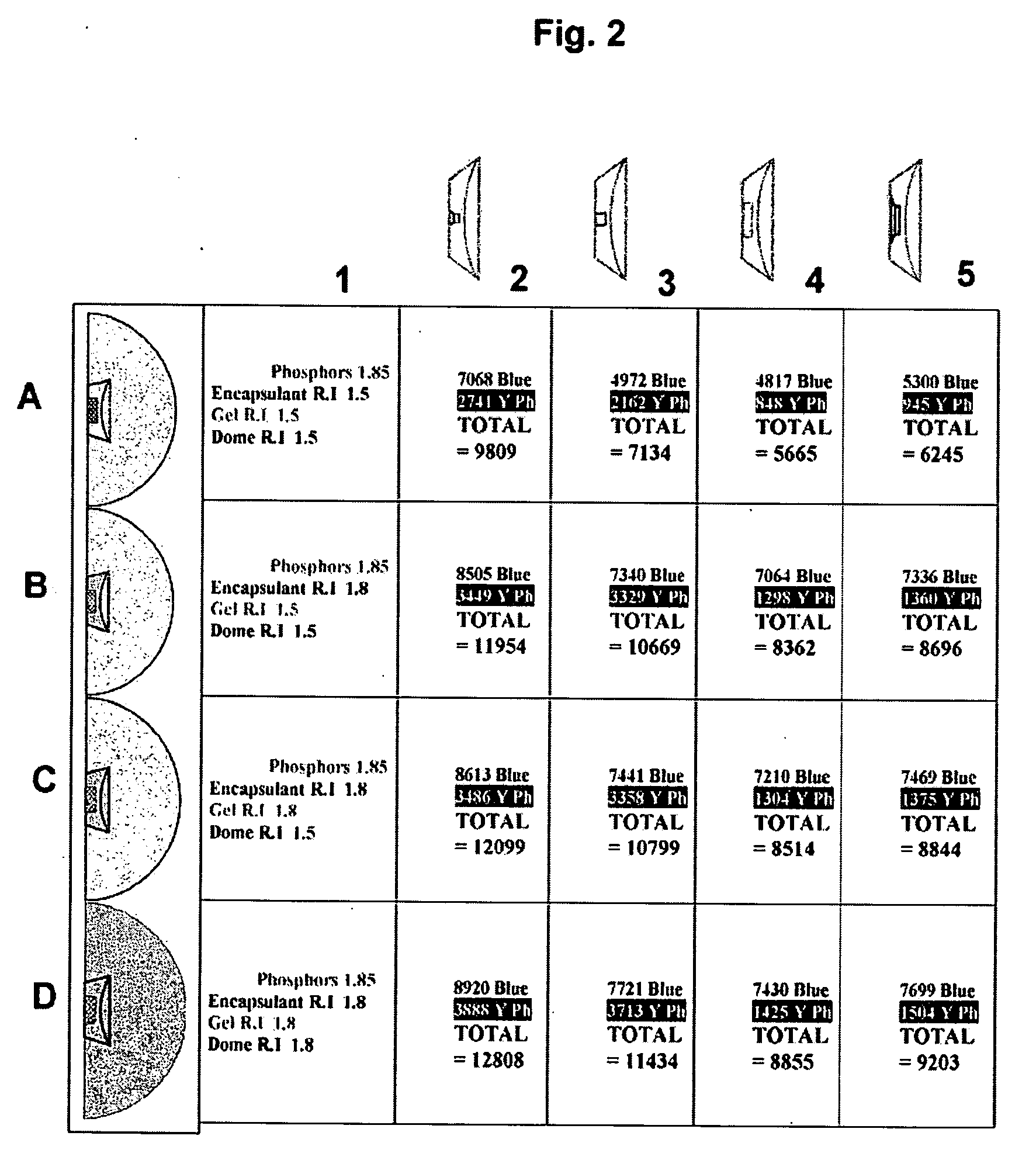

Light efficient packaging configurations for LED lamps using high refractive index encapsulants

InactiveUS20060255353A1High refractive indexImprove optical efficiencyMechanical apparatusPoint-like light sourceSurface mountingRefractive index

Light efficient packaging configurations for LED lamps using high refractive index encapsulants. The packaging configurations including dome (bullet) shaped LED's, SMD (surface mount device) LED's and a hybrid LED type, including a dome mounted within a SMD package. In another embodiment used with SMD LED devices a relatively small semi-hemispherical “blob” of HRI encapsulant surrounds the LED chip with the remainder of the SMD cavity filled with conventional encapsulant. The packaging configurations increase the LED's light emission efficiency at a reasonable cost and in a commercially viable manner, by maximizing the light efficiency while minimizing the amount of high refractive index encapsulant used.

Owner:TASKAR NIKHIL R +3

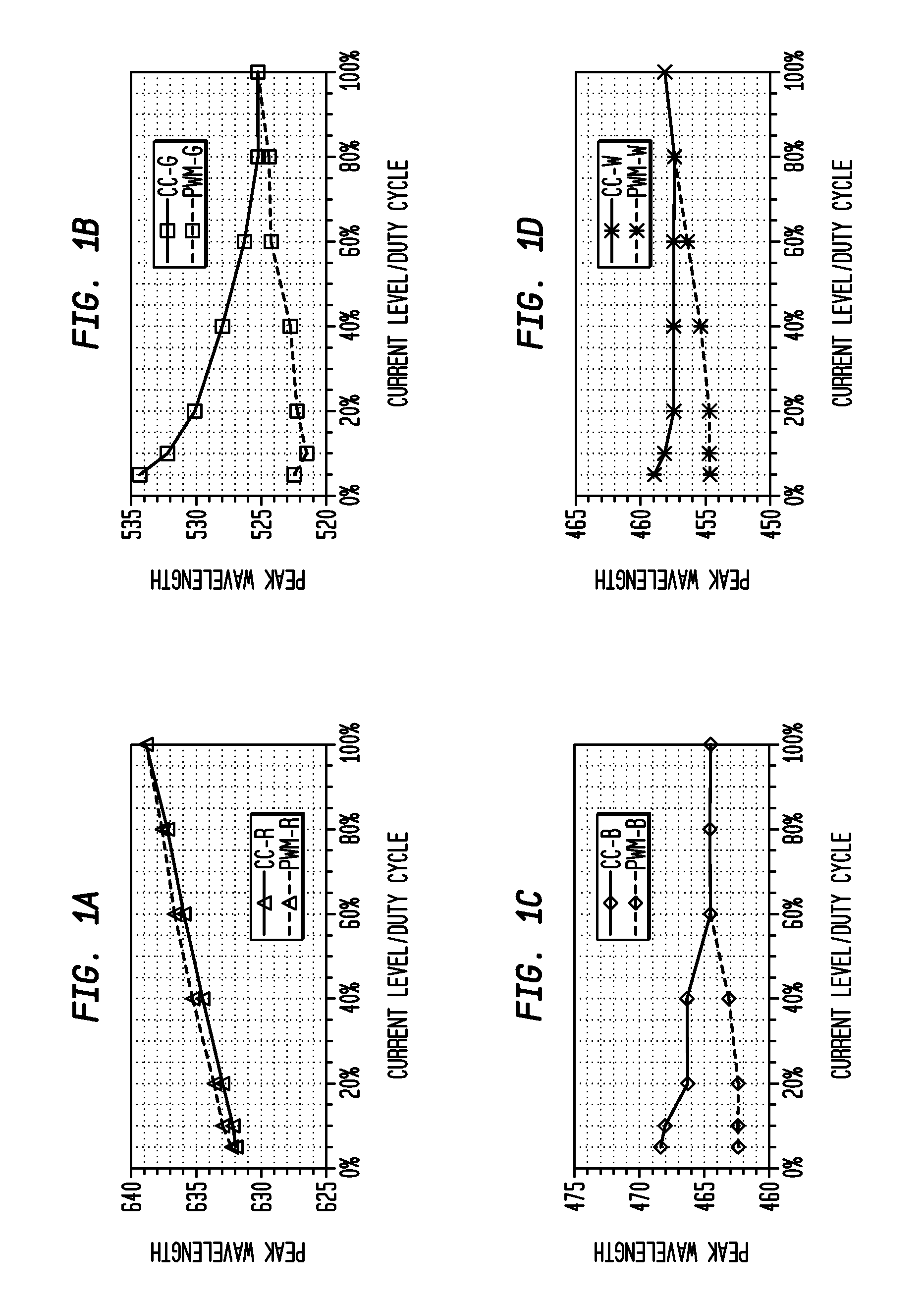

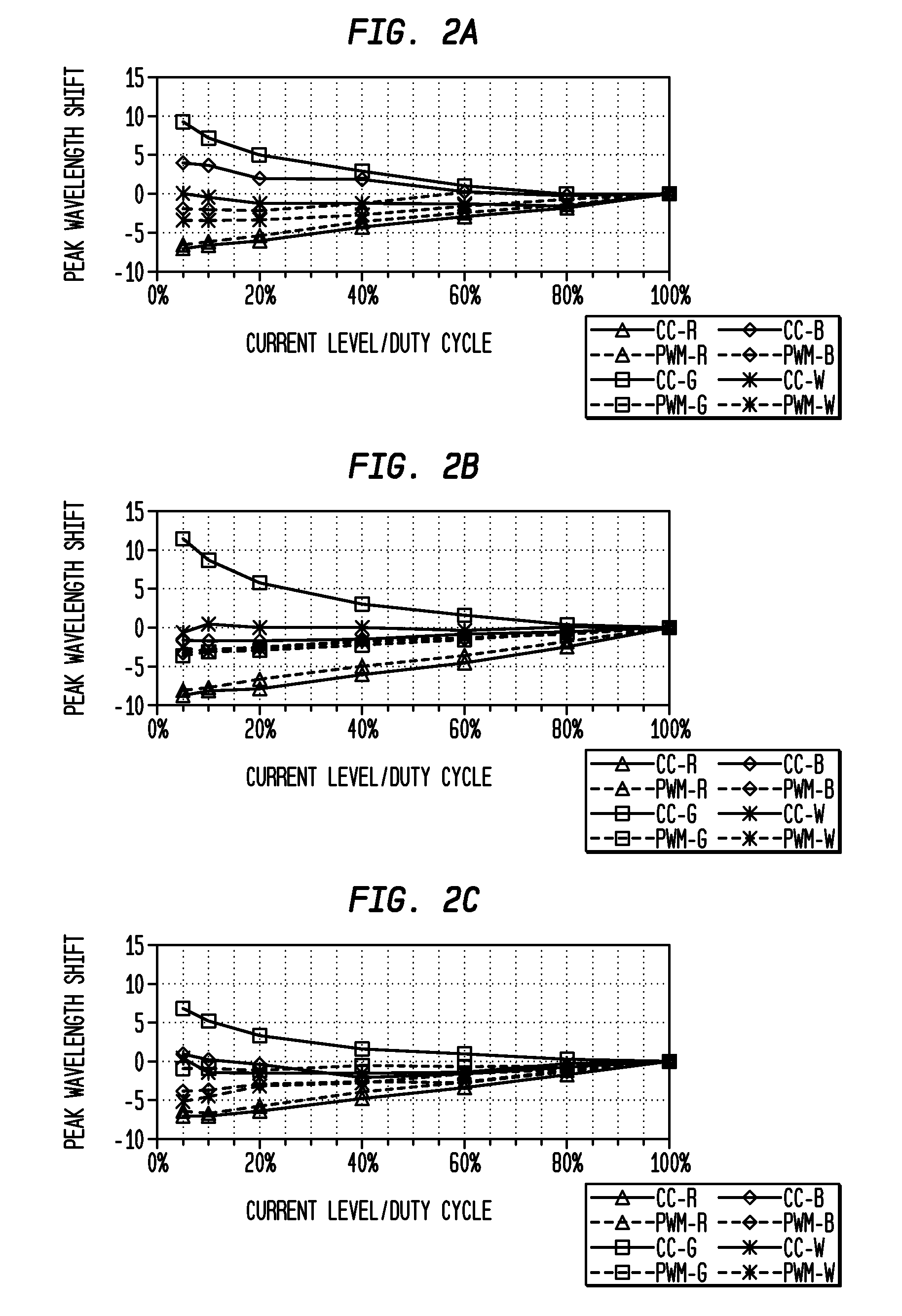

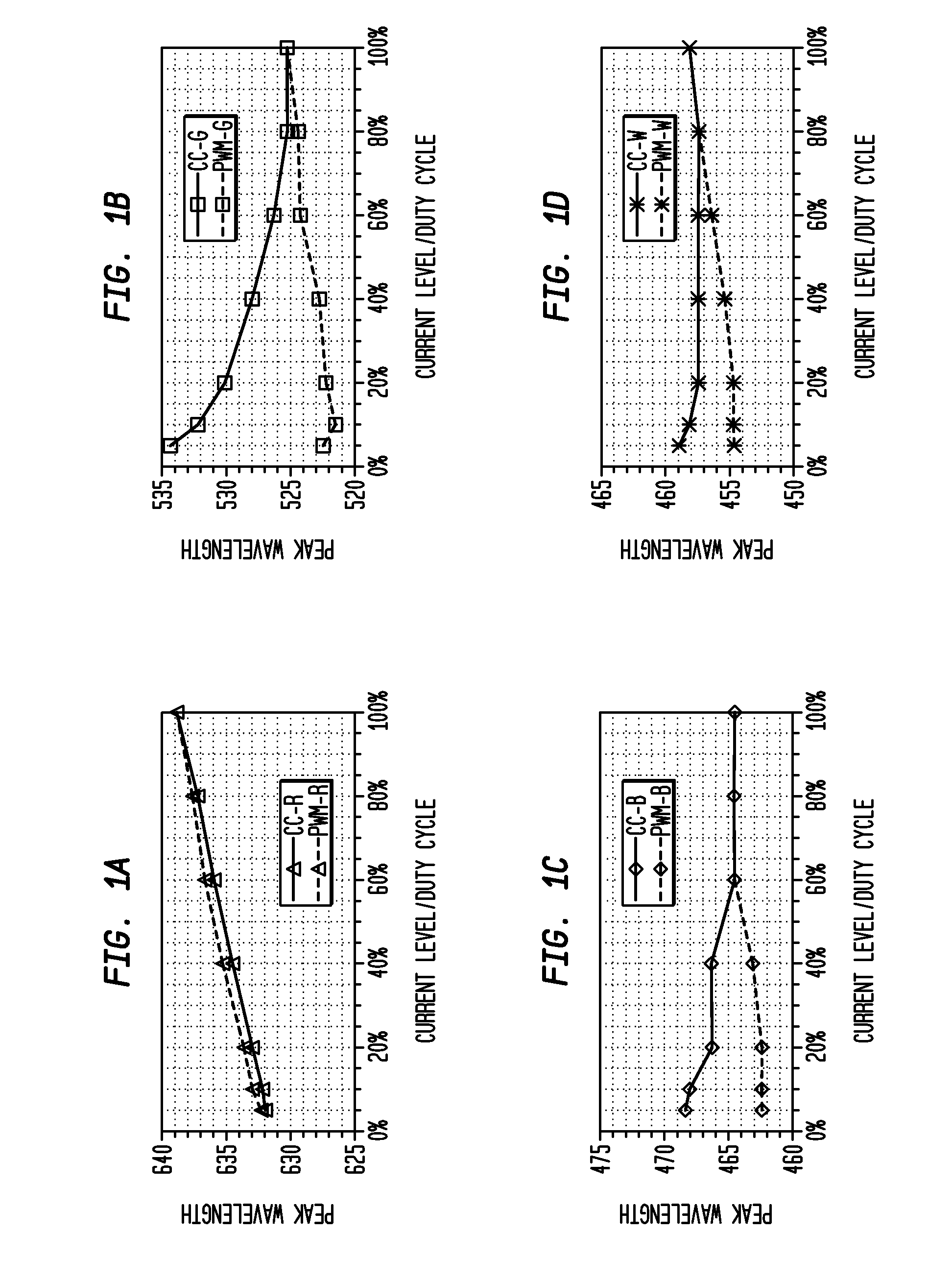

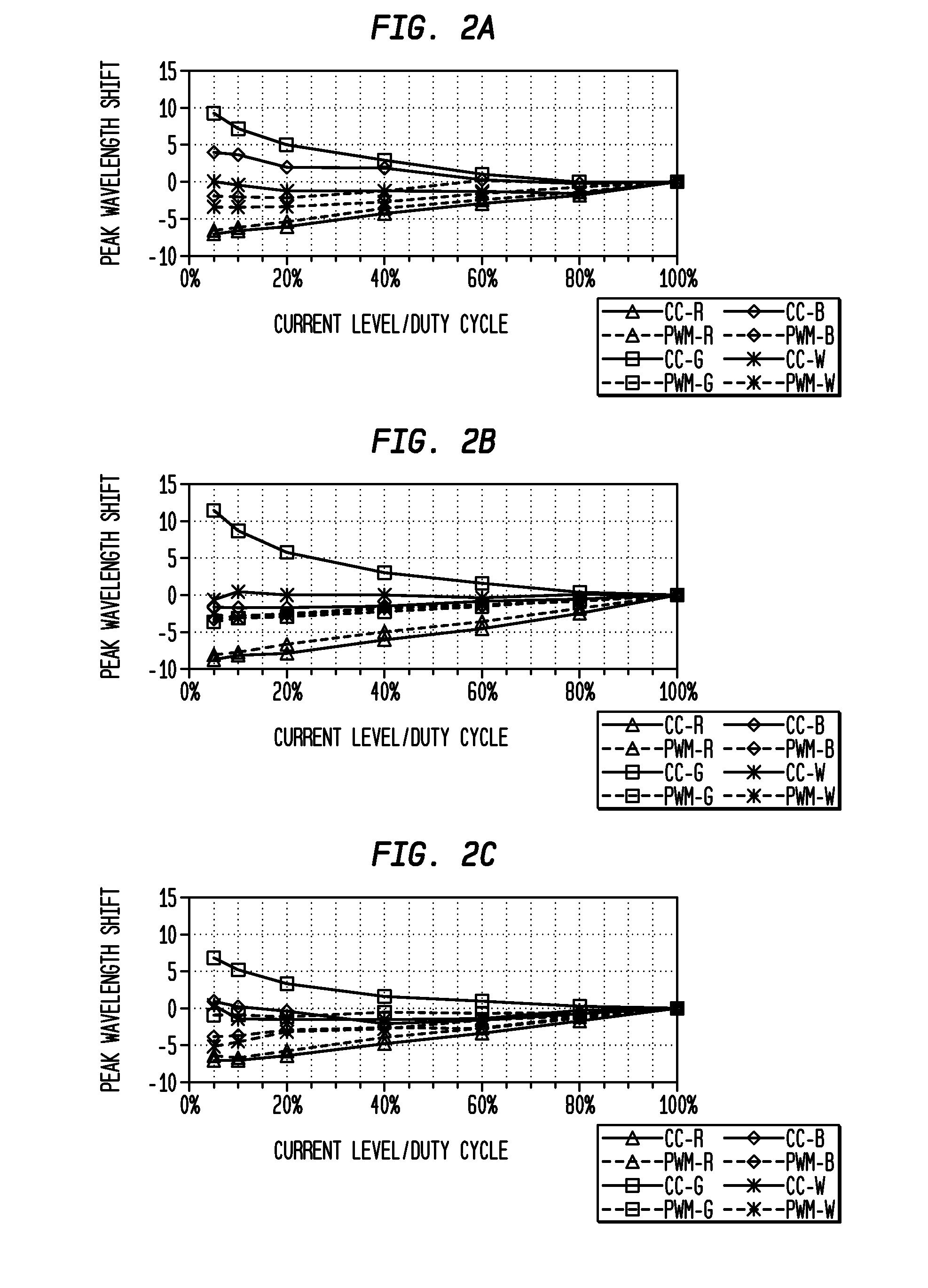

Regulation of Wavelength Shift and Perceived Color of Solid State Lighting with Intensity Variation

ActiveUS20090079357A1Improve efficiencyReduce size and costElectrical apparatusElectroluminescent light sourcesSolid-stateIntensity change

Exemplary embodiments of the invention provide a system, apparatus, and method of controlling an intensity and spectrum of light emitted from a solid state lighting system. The solid state lighting has a first emitted spectrum at full intensity and at a selected temperature, with a first electrical biasing for the solid state lighting producing a first wavelength shift, and a second electrical biasing for the solid state lighting producing a second, opposing wavelength shift. Exemplary embodiments provide for receiving information designating a selected intensity level or a selected temperature; and providing a combined first electrical biasing and second electrical biasing to the solid state lighting to generate emitted light having the selected intensity level and having a second emitted spectrum within a predetermined variance of the first emitted spectrum over a predetermined range of temperatures.

Owner:CHEMTRON RES

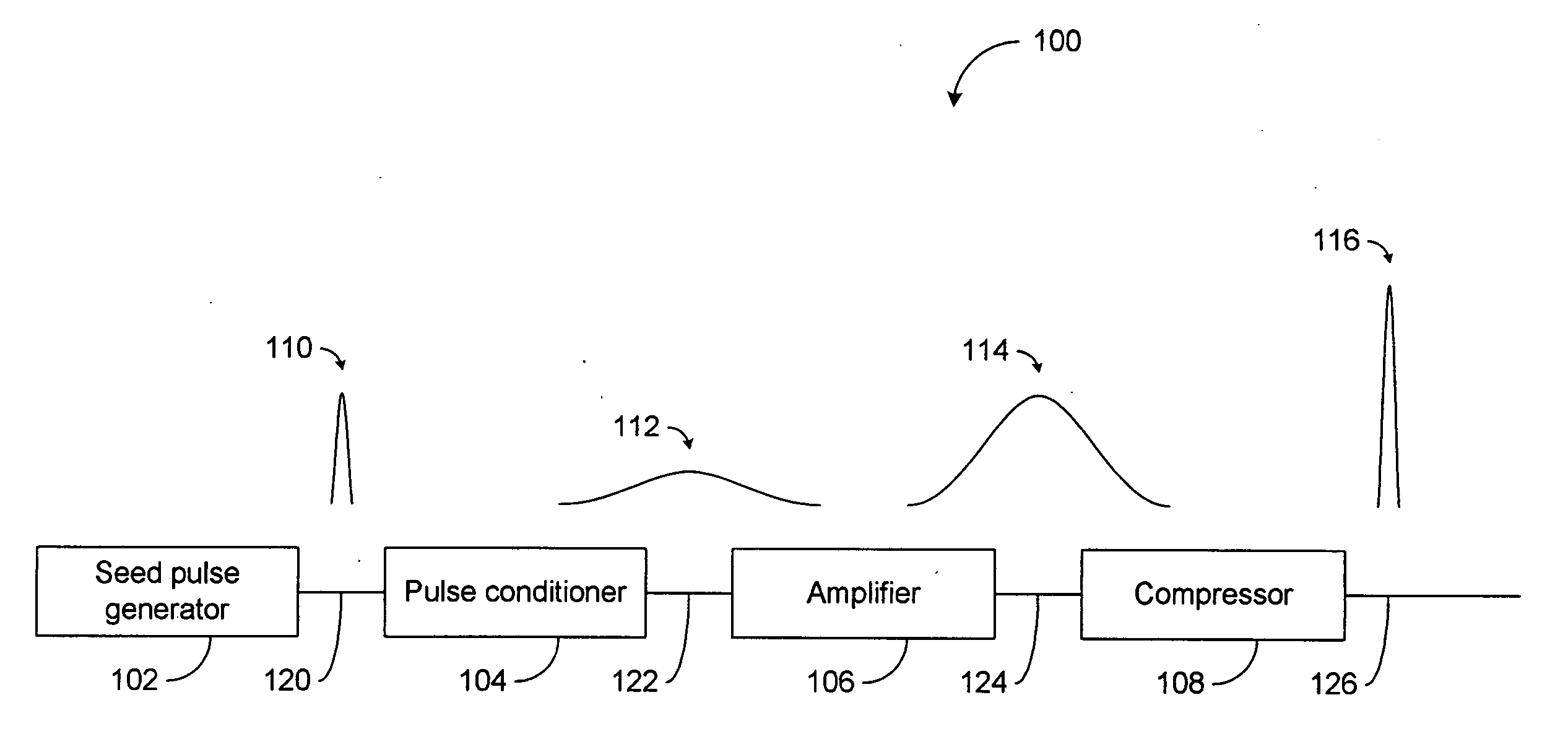

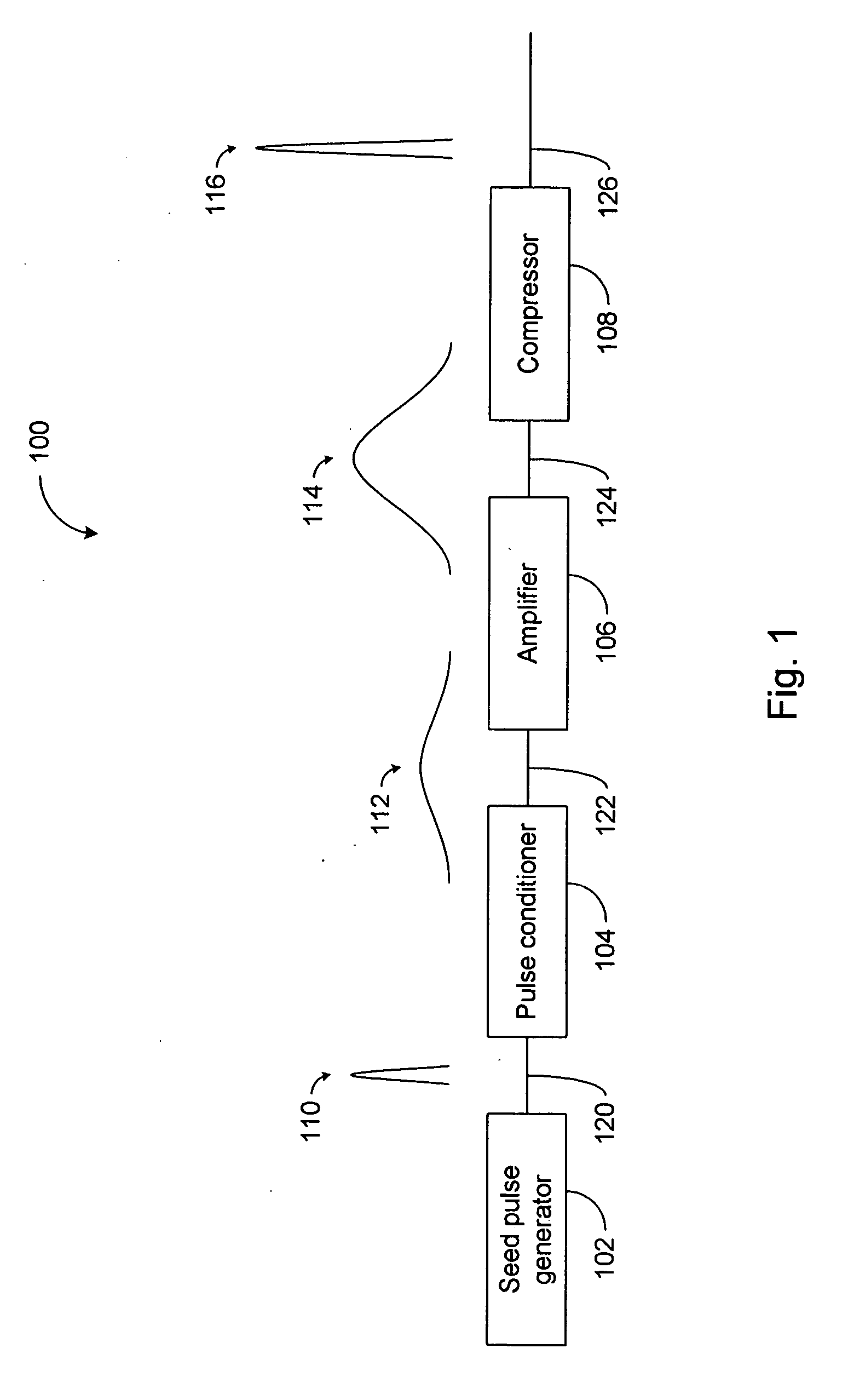

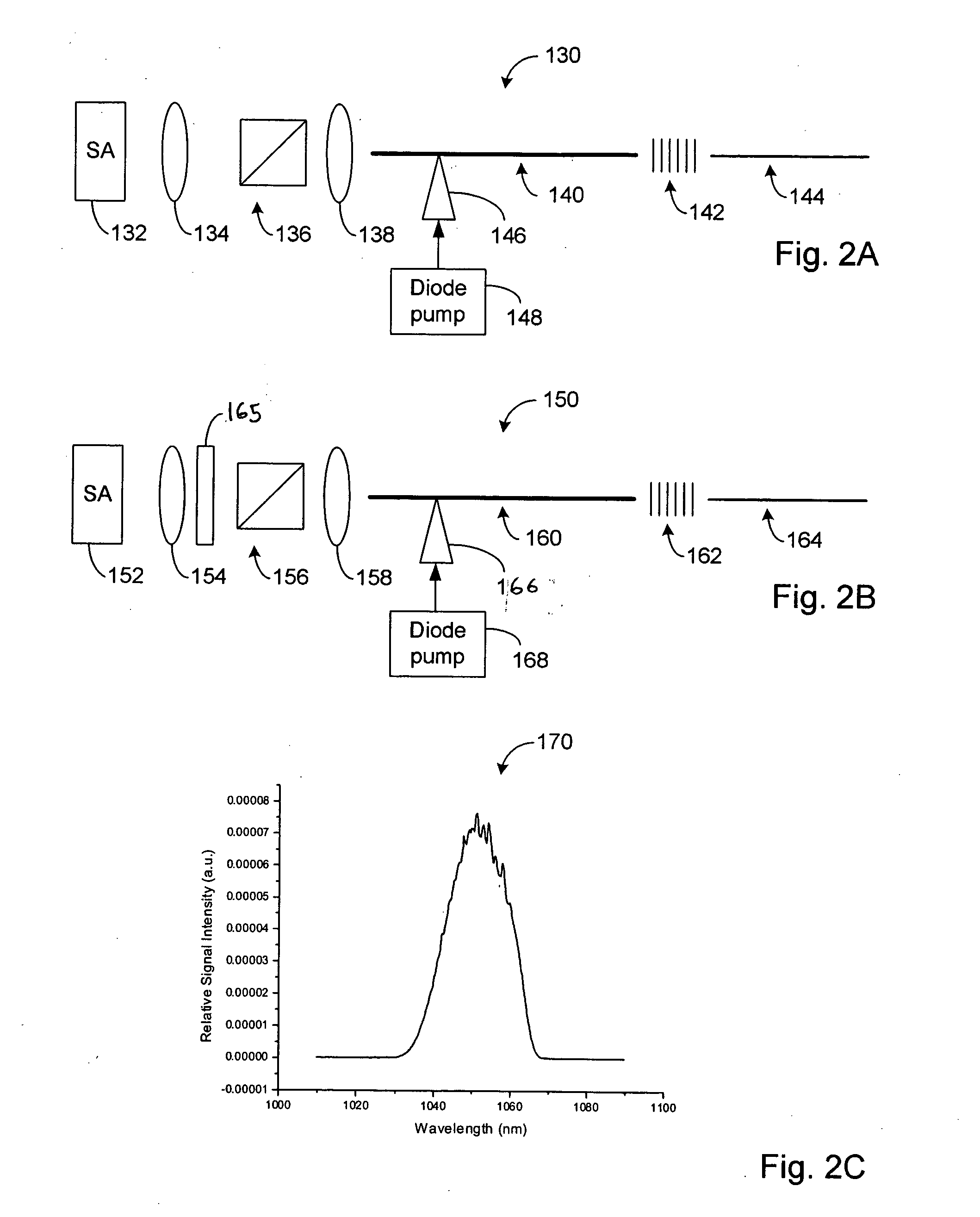

High power short pulse fiber laser

InactiveUS20050226278A1Reduce widthWeaken energyLaser using scattering effectsLaser arrangementsAudio power amplifierPigtail

A pulsed laser comprises an oscillator and amplifier. An attenuator and / or pre-compressor may be disposed between the oscillator and amplifier to improve performance and possibly the quality of pulses output from the laser. Such pre-compression may be implemented with spectral filters and / or dispersive elements between the oscillator and amplifier. The pulsed laser may have a modular design comprising modular devices that may have Telcordia-graded quality and reliability. Fiber pigtails extending from the device modules can be spliced together to form laser system. In one embodiment, a laser system operating at approximately 1050 nm comprises an oscillator having a spectral bandwidth of approximately 19 nm. This oscillator signal can be manipulated to generate a pulse having a width below approximately 90 fs.

Owner:IMRA AMERICA

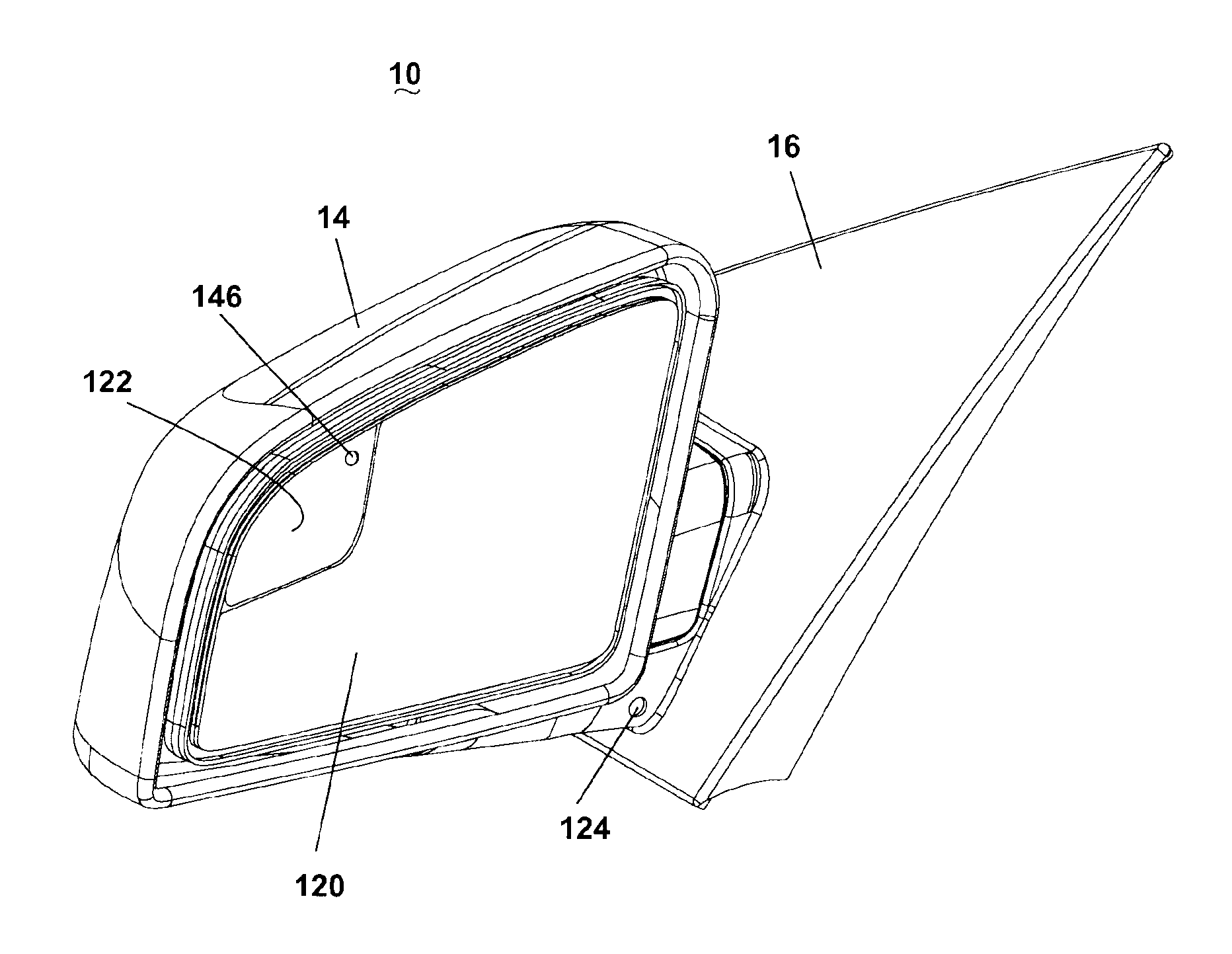

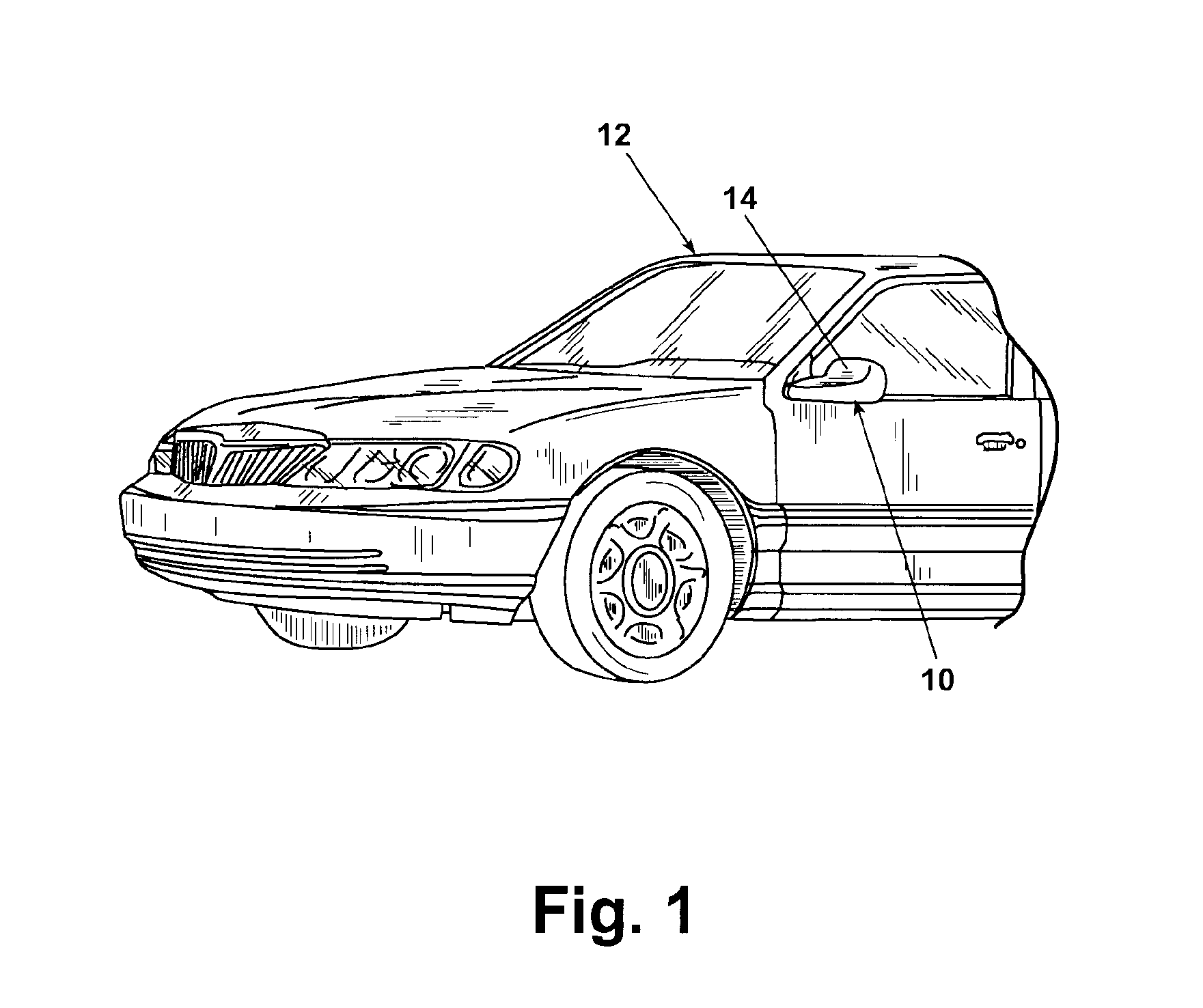

Dimming mirror with blind zone sub-mirror and indicator

ActiveUS6919796B2Reduce light intensityReduce intensityMirrorsAnti-collision systemsComputer visionWing mirror

A rearview mirror system comprises a spotter mirror for providing an image of an object in a vehicle's blind zone to the vehicle's operator. A recognition enhancement device is provided with the spotter mirror for drawing the attention of the driver to the spotter mirror when an overtaking vehicle enters the driver's blind zone. The signaling display is activated by a sensing system which senses the presence of the overtaking vehicle in the blind zone. An electrochromic element is incorporated into the spotter mirror to reduce the intensity of light transmitted from the object and reflected from the spotter mirror. Activation of the electrochromic element to darken the spotter mirror will induce the operator to observe the object in the spotter mirror.

Owner:MAGNA MIRRORS OF AMERICA

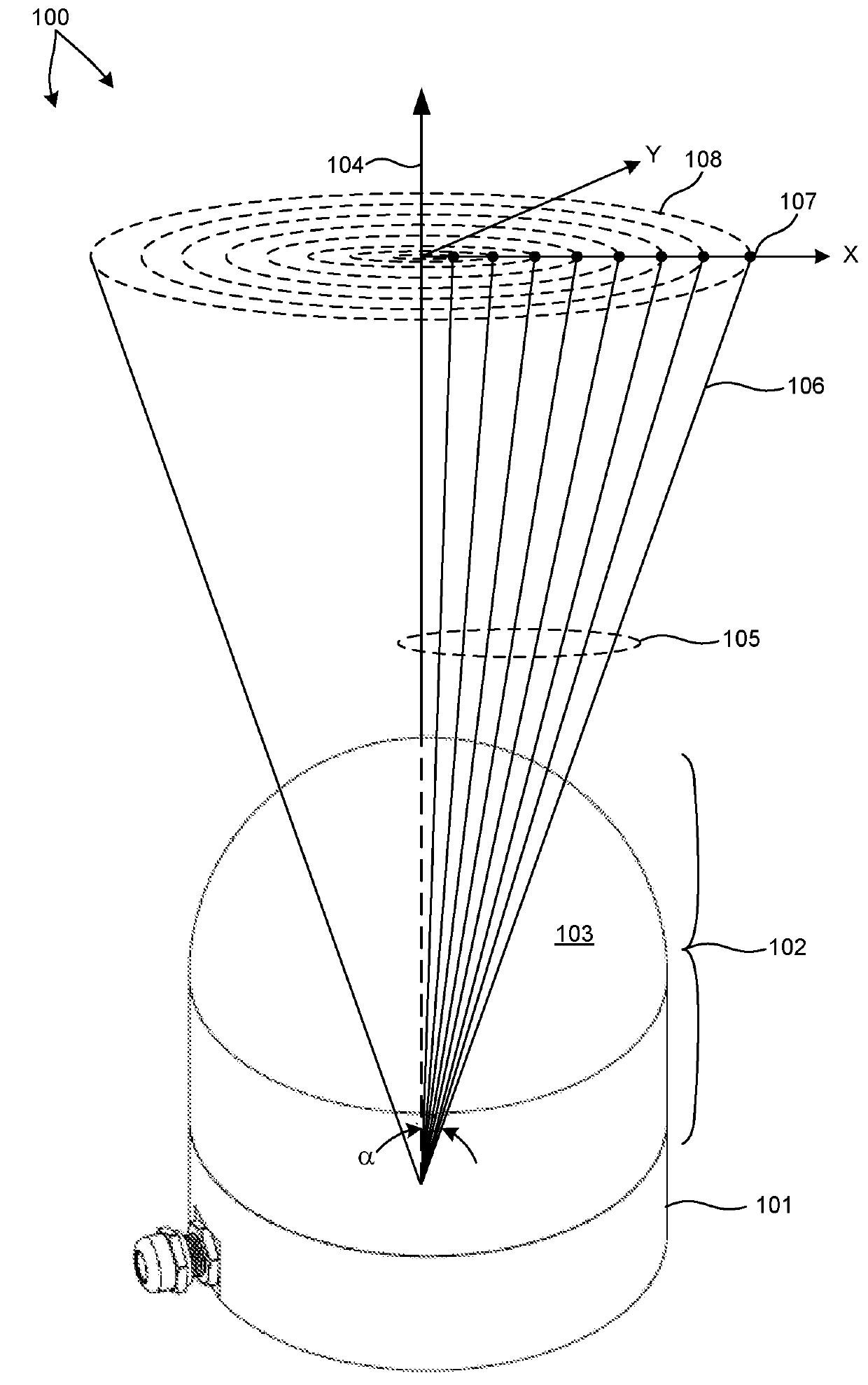

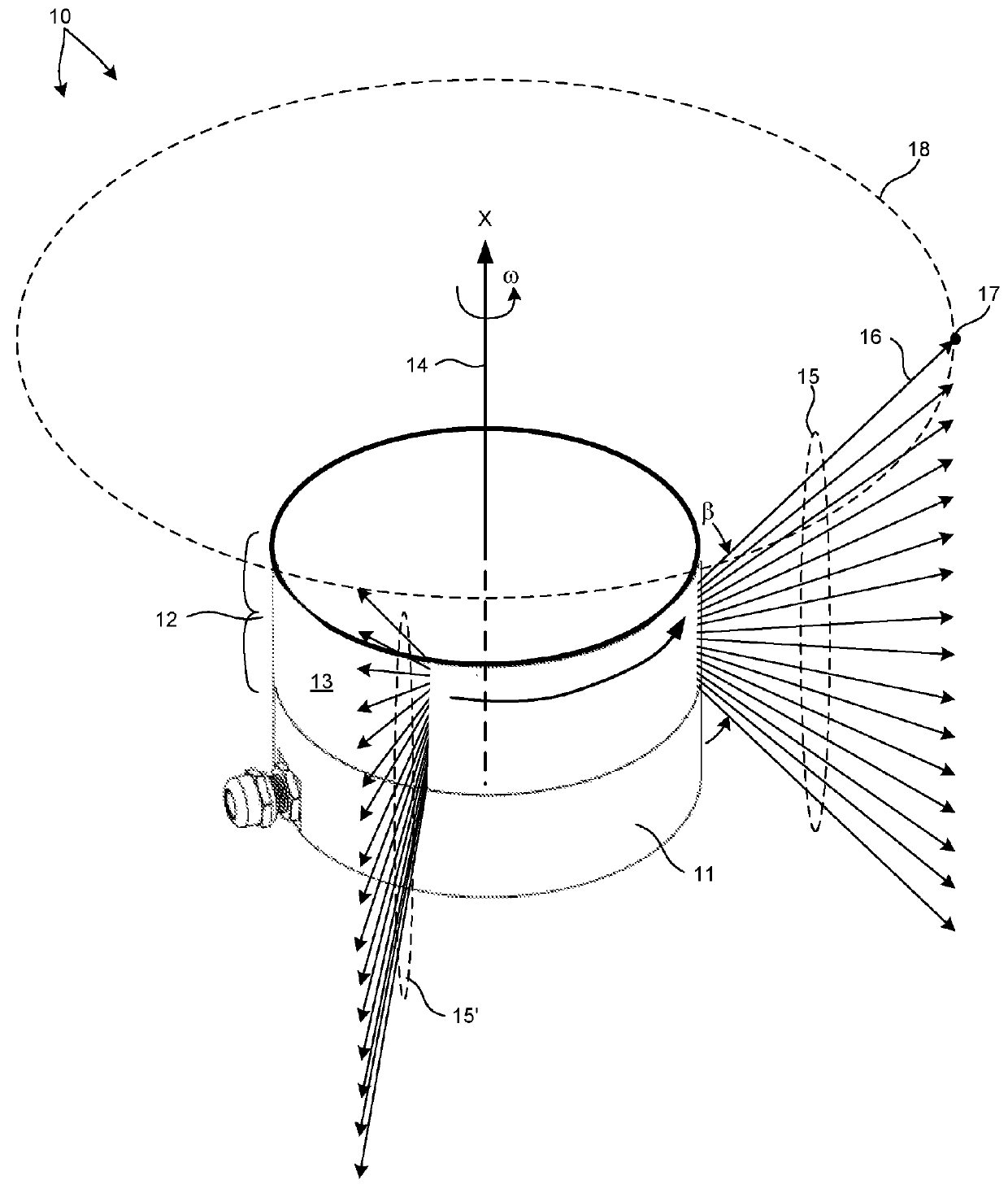

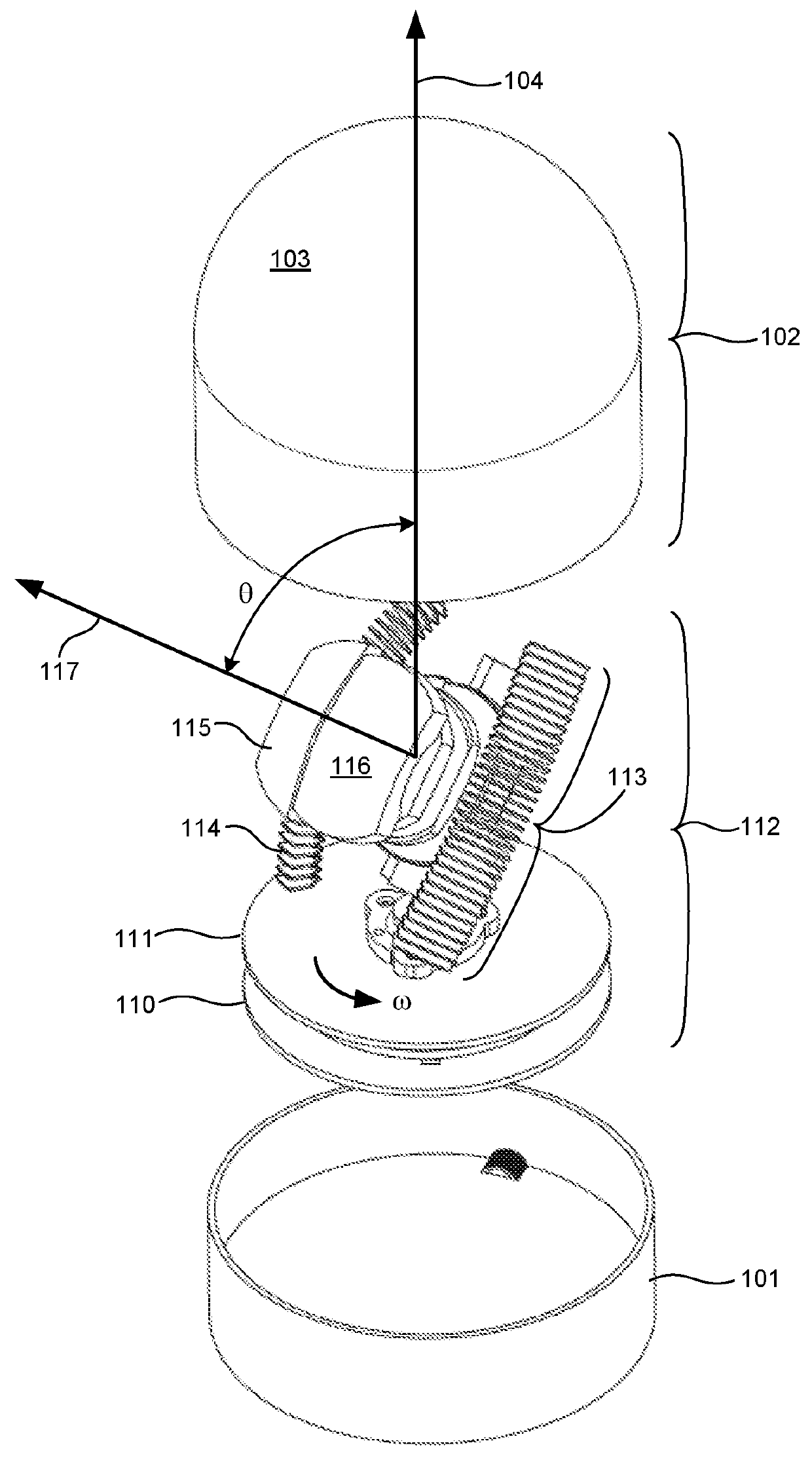

LIDAR Based 3-D Imaging With Varying Illumination Intensity

ActiveUS20170269197A1Reduce energy consumptionReduce consumptionElectromagnetic wave reradiationRadarPulse sequence

Methods and systems for performing three dimensional LIDAR measurements with different illumination intensity patterns are described herein. Repetitive sequences of measurement pulses each having different illumination intensity patterns are emitted from a LIDAR system. One or more pulses of each repetitive sequence have a different illumination intensity than another pulse within the sequence. The illumination intensity patterns are varied to reduce total energy consumption and heat generated by the LIDAR system. In some examples, the illumination intensity pattern is varied based on the orientation of the LIDAR device. In some examples, the illumination intensity pattern is varied based on the distance between a detected object and the LIDAR device. In some examples, the illumination intensity pattern is varied based on the presence of an object detected by the LIDAR device or another imaging system.

Owner:VELODYNE LIDAR USA INC

Digital Driver Apparatus, Method and System for Solid State Lighting

ActiveUS20090079355A1Low costLow voltage implementationElectrical apparatusElectroluminescent light sourcesTime segmentAverage current

An apparatus, method and system are provided for controlling the solid state lighting, such as LEDs. An exemplary apparatus comprises: a switch for switching electrical current through the LEDs, a current sensor; a first comparator adapted to determine when a switch electrical current has reached a first predetermined threshold; a second comparator adapted to determine when the switch electrical current has reached a predetermined average current level; and a controller. The controller is adapted to turn the switch into an on state and an off state, to determine a first on time period as a duration between either a detection of a second predetermined current threshold or the turning the switch into the on state, and the detection of the predetermined average current level; to determine a second on time period as a duration between the detection of the predetermined average current level and the detection of the first predetermined current threshold; and to determine an on time period of the switch as substantially proportional to a sum of the first on time period and the second on time period. Additional exemplary embodiments utilize a difference between the first and second on time periods to generate an error signal to adjust the on time period of the switch.

Owner:CHEMTRON RES

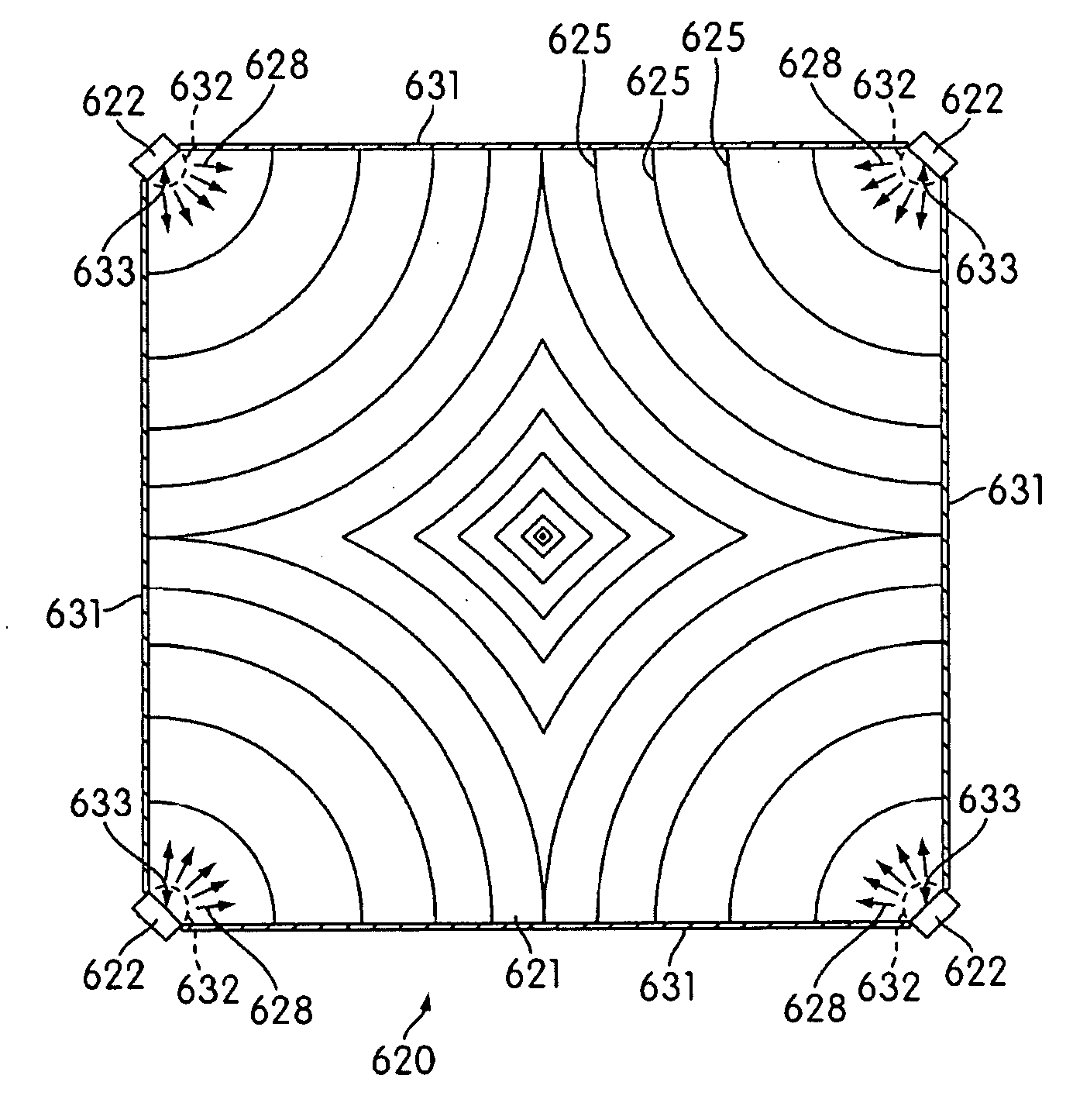

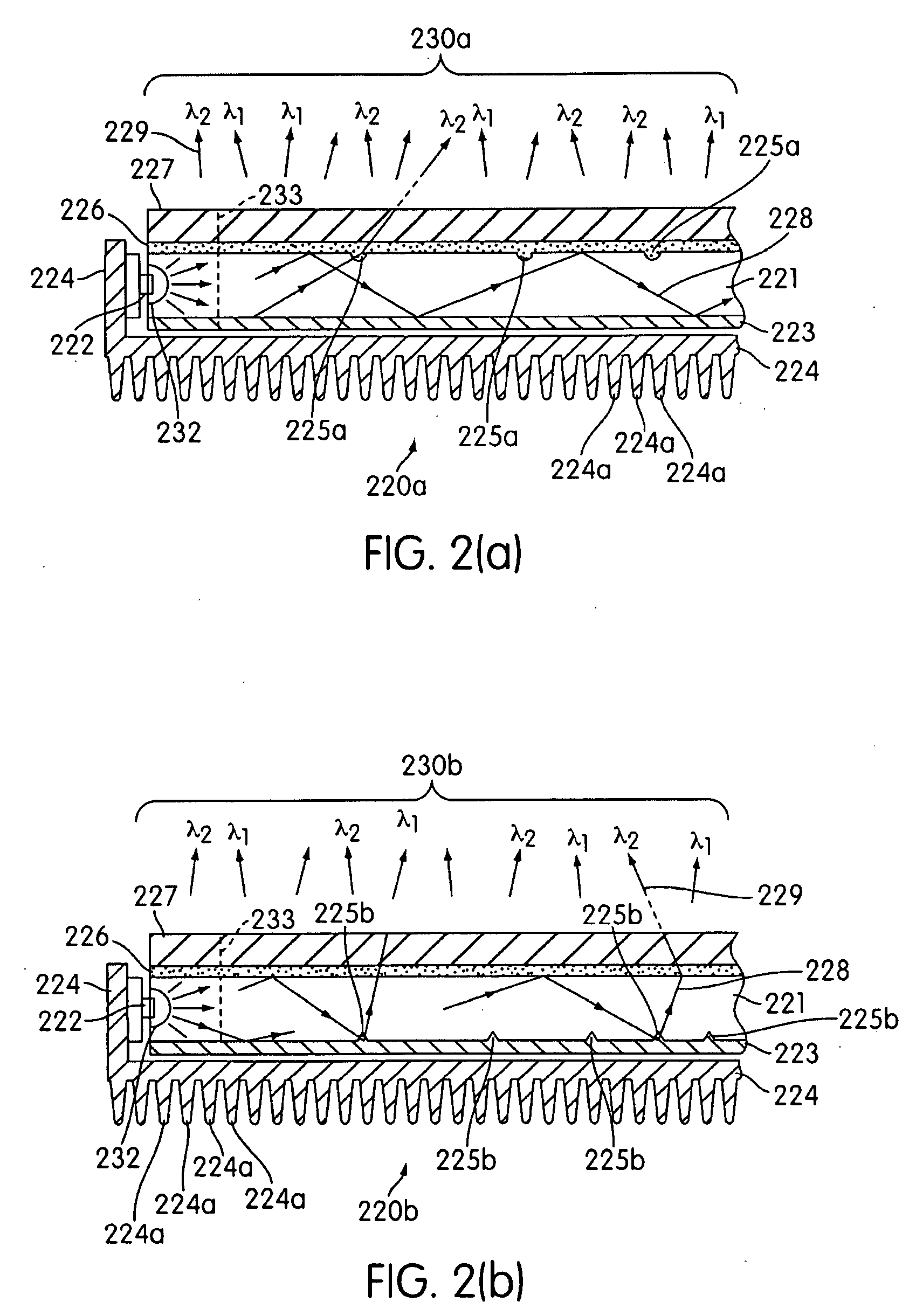

Light Emitting Panel

InactiveUS20100027293A1Increase distanceReduce spacingMechanical apparatusPlanar/plate-like light guidesLight guideLight-emitting diode

A light emitting panel comprises a light guiding medium having at least one light emitting face and a plurality of light sources (LEDs) configured to couple light into an edge of the light guiding medium at four or fewer locations around the edge. A pattern of optical features (discontinuities) is provided on at least one face of the light guiding medium for promoting emission of light from the light emitting face. The pattern of features is configured such as to reduce a variation in emitted light intensity over substantially the entire surface of the light emitting face such that the variation is less than or equal to about 25%. The pattern of features is configured in part in dependence on a light intensity distribution within the light guiding medium and the spacing, size, shape and / or number of features per unit area can depend on distance from each light source.

Owner:INTEMATIX

Regulation of Wavelength Shift and Perceived Color of Solid State Lighting with Intensity and Temperature Variation

ActiveUS20090079362A1Improve efficiencyLow costDischarge tube luminescnet screensCathode ray tubes/electron beam tubesEngineeringWavelength

Exemplary embodiments of the invention provide a system, apparatus, and method of controlling an intensity and spectrum of light emitted from a solid state lighting system. The solid state lighting has a first emitted spectrum at full intensity and at a selected temperature, with a first electrical biasing for the solid state lighting producing a first wavelength shift, and a second electrical biasing for the solid state lighting producing a second, opposing wavelength shift. Exemplary embodiments provide for receiving information designating a selected intensity level or a selected temperature; and providing a combined first electrical biasing and second electrical biasing to the solid state lighting to generate emitted light having the selected intensity level and having a second emitted spectrum within a predetermined variance of the first emitted spectrum over a predetermined range of temperatures.

Owner:CHEMTRON RES

Assays for measuring nucleic acid damaging activities

InactiveUS6214552B1Simple and accurate and reliable assayEfficient transferSugar derivativesMicrobiological testing/measurementElectrochemiluminescenceDouble strand

A method for assaying a sample for a nucleic acid damaging activity using at least one singular double-stranded nucleic acid with at least one electrochemiluminescent label, and a method for measuring an inhibitor of a nucleic acid damaging activity with at least one singular double-stranded nucleic acid using at least one electrochemiluminescent label, are disclosed.

Owner:BIOVERIS CORP

Integrated electronic device and method of making the same

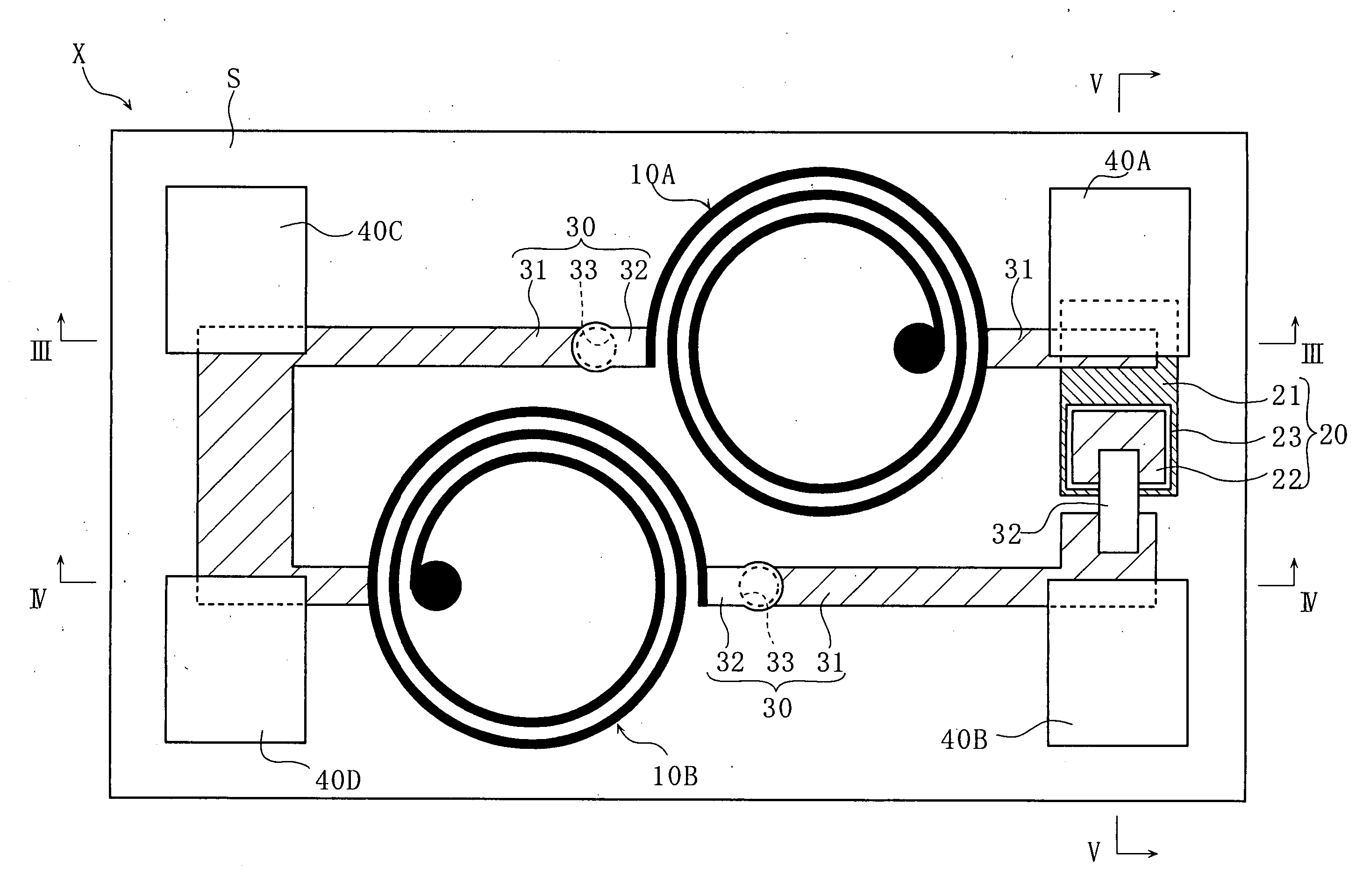

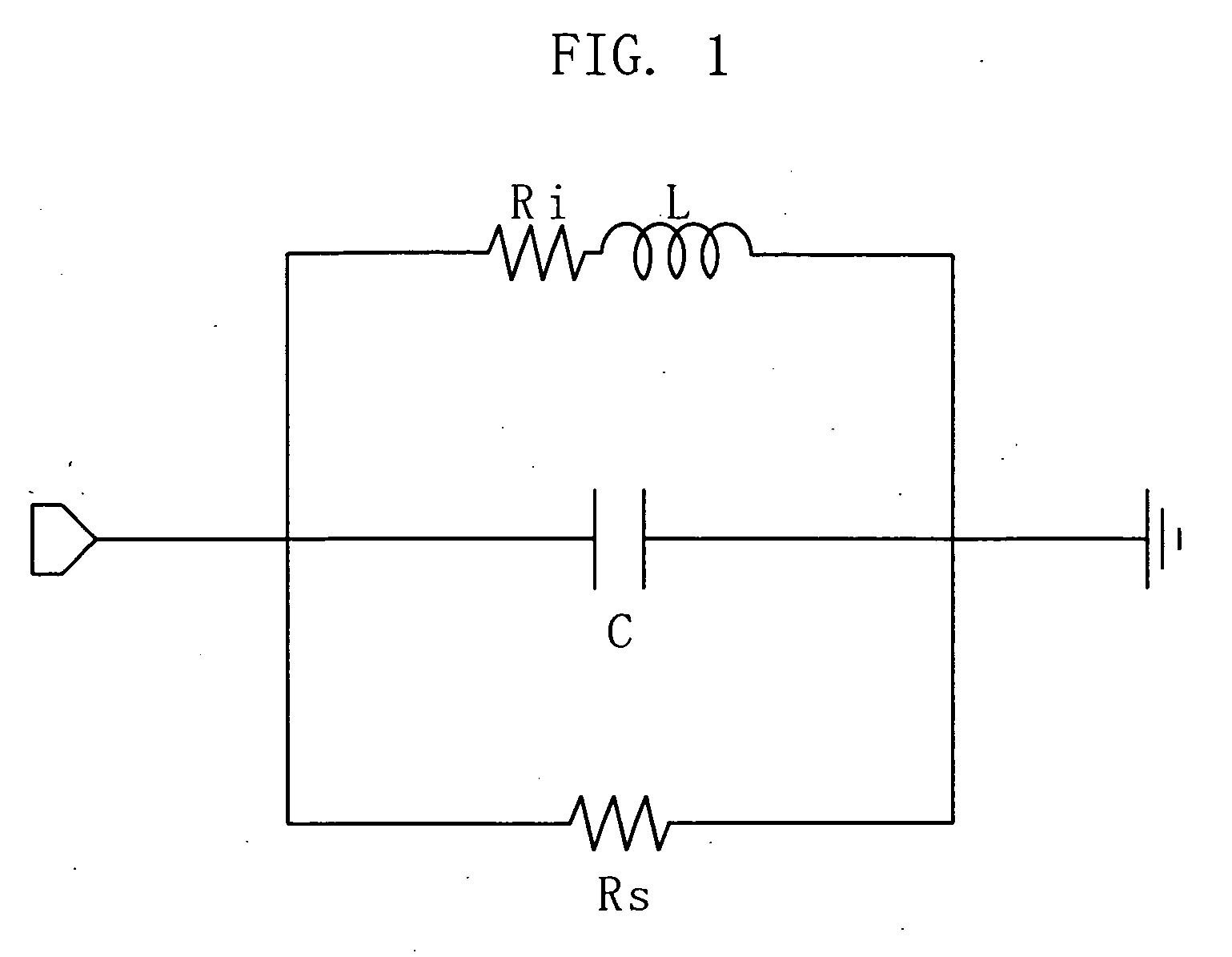

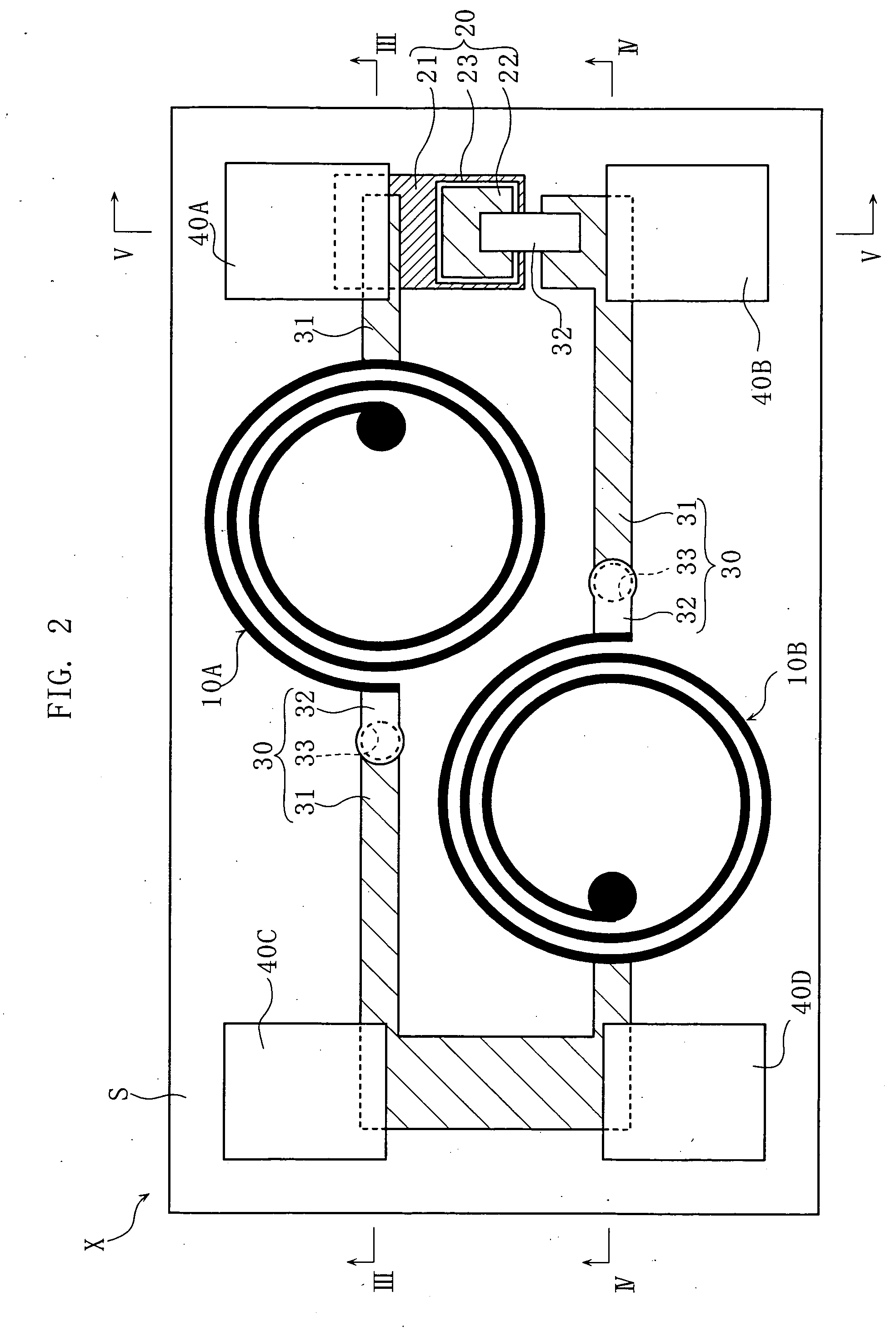

ActiveUS20070045773A1Small sizeReduce skin effectMultiple-port networksSemiconductor/solid-state device detailsInductorInductance

An integrated electronic device includes a substrate, passive components, pads for external connection, and three-dimensional wiring. The passive components includes a multi-stage coil inductor provided on the substrate. The multi-stage coil inductor has a plurality of coils disposed in several layers. Mutually adjacent coil wires are spaced-apart from each other. The three-dimensional wiring includes a first wiring portion which extends on the substrate, a second wiring portion which extends off the substrate but along the substrate, and a third wiring portion connecting with the first wiring portion and the second wiring portion.

Owner:TAIYO YUDEN KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com