Arc-shaped cutting anastomat

A stapler and arc-shaped technology, applied in the field of arc-shaped cutting staplers, can solve the problems of inconvenient firing, difficult assembly, large contact area, etc., and achieves avoiding the phenomenon of bevel, good assembly firmness, and high operation safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

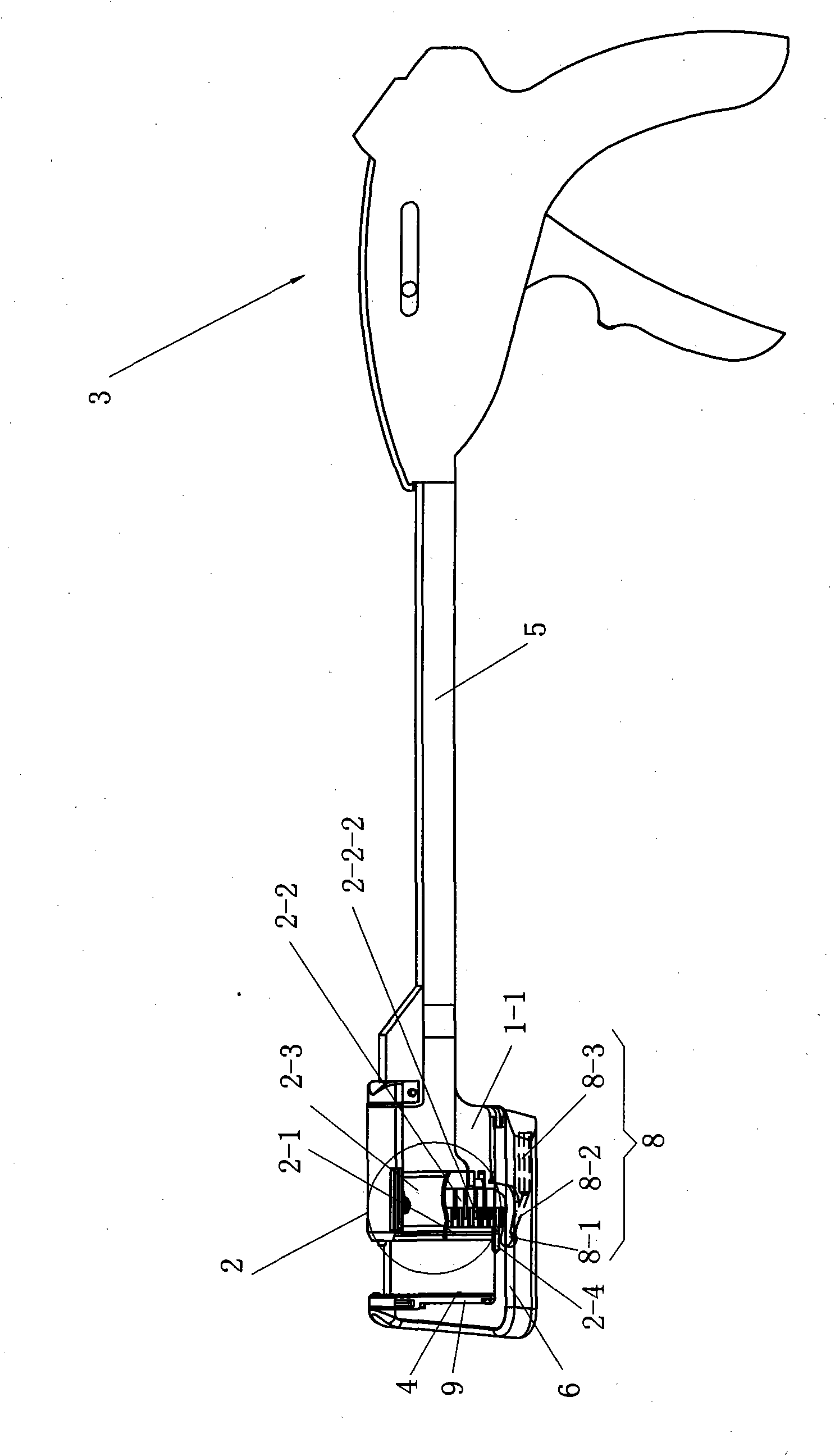

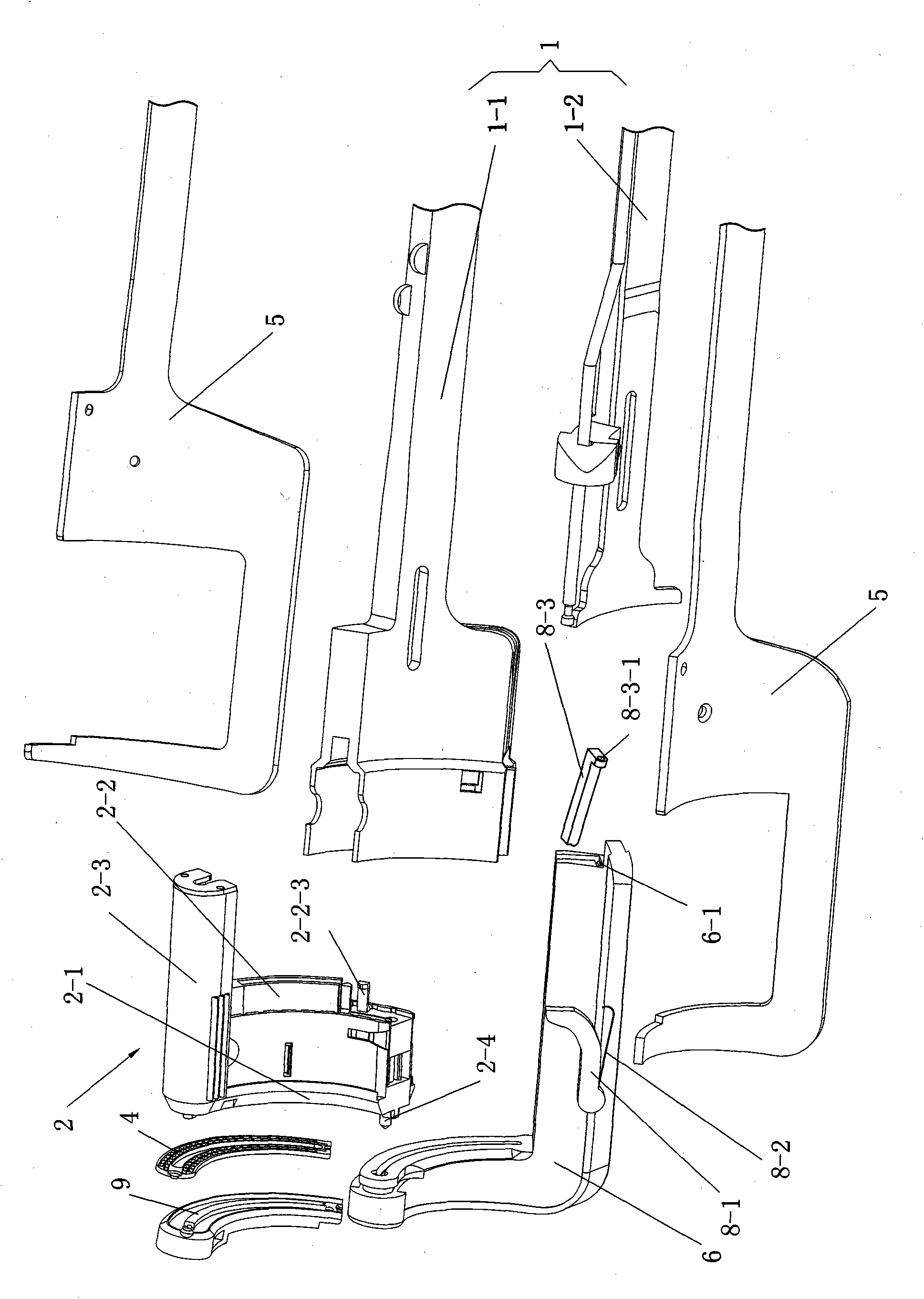

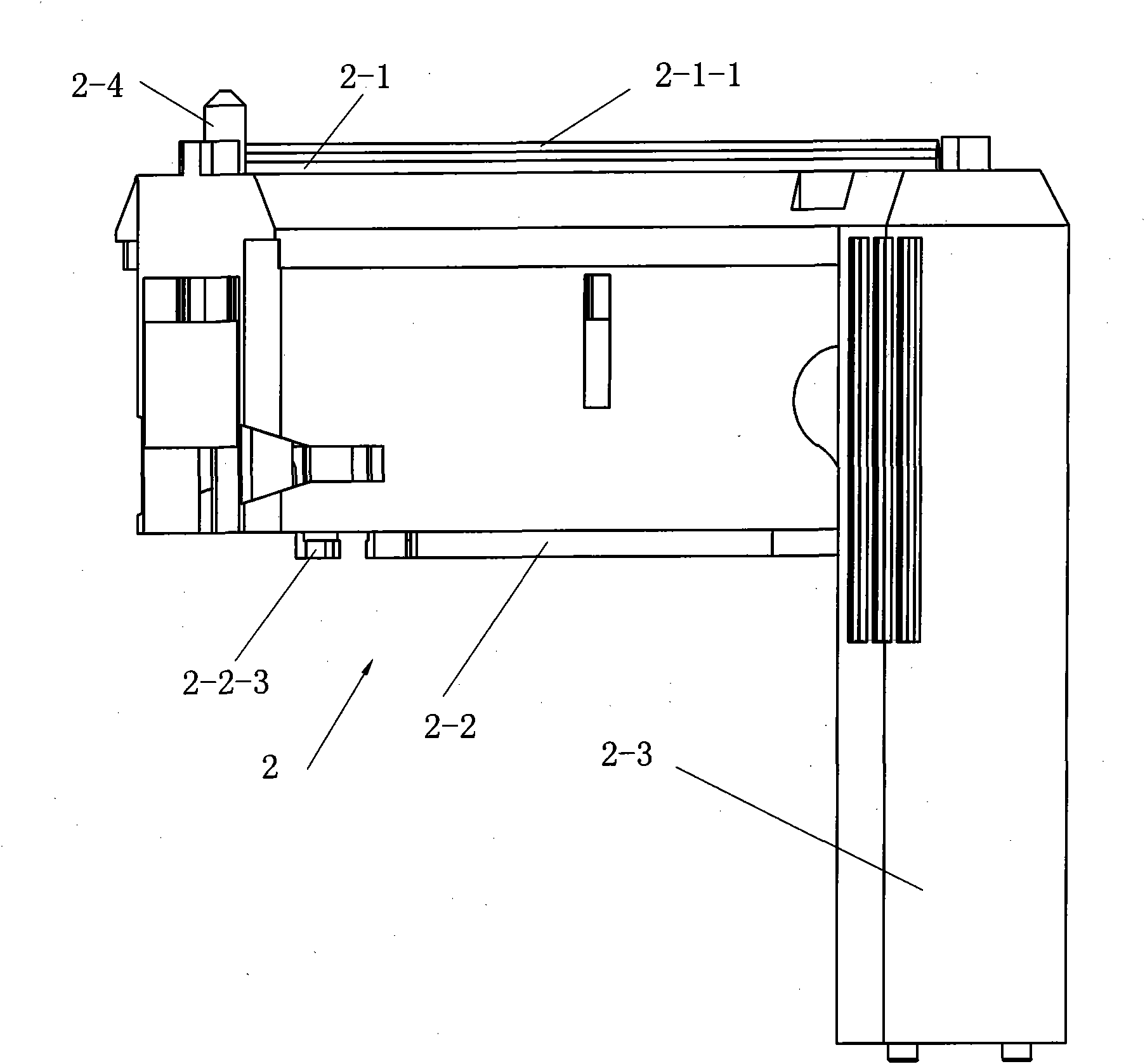

[0033] Such as Figure 1-19As shown, an arc-shaped cutting stapler includes a staple forming mechanism 1, a staple pusher assembly 2, a firing handle 3, an abutment seat 4, a base 6 of the abutment seat, a spacer ring 9 and two splints 5. The staple forming mechanism 1 includes a component bracket 1-1 and a pusher plate 1-2, the pusher plate 1-2 is inserted in the component bracket 1-1 and is slidably matched with the component bracket 1-1, and the firing handle 2 Drive connection with the component bracket 1-1 and nail pusher plate 1-2, and fixed connection with two splints 5, the nail anvil 4 is fixed on the spacer ring 9, and the spacer 9 is fixed on the base 6 of the nail anvil , the base 6 of the nail anvil is fixedly connected to the two splints 5, the nail pusher assembly 2 is mounted on the assembly bracket 1-1 and is opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com