Patents

Literature

458 results about "Oblique cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oblique cutting is another type of cutting in which the cutting edge of wedge shape cutting tool make a angle except right angle to the direction of tool motion.

Feature quantification from multidimensional image data

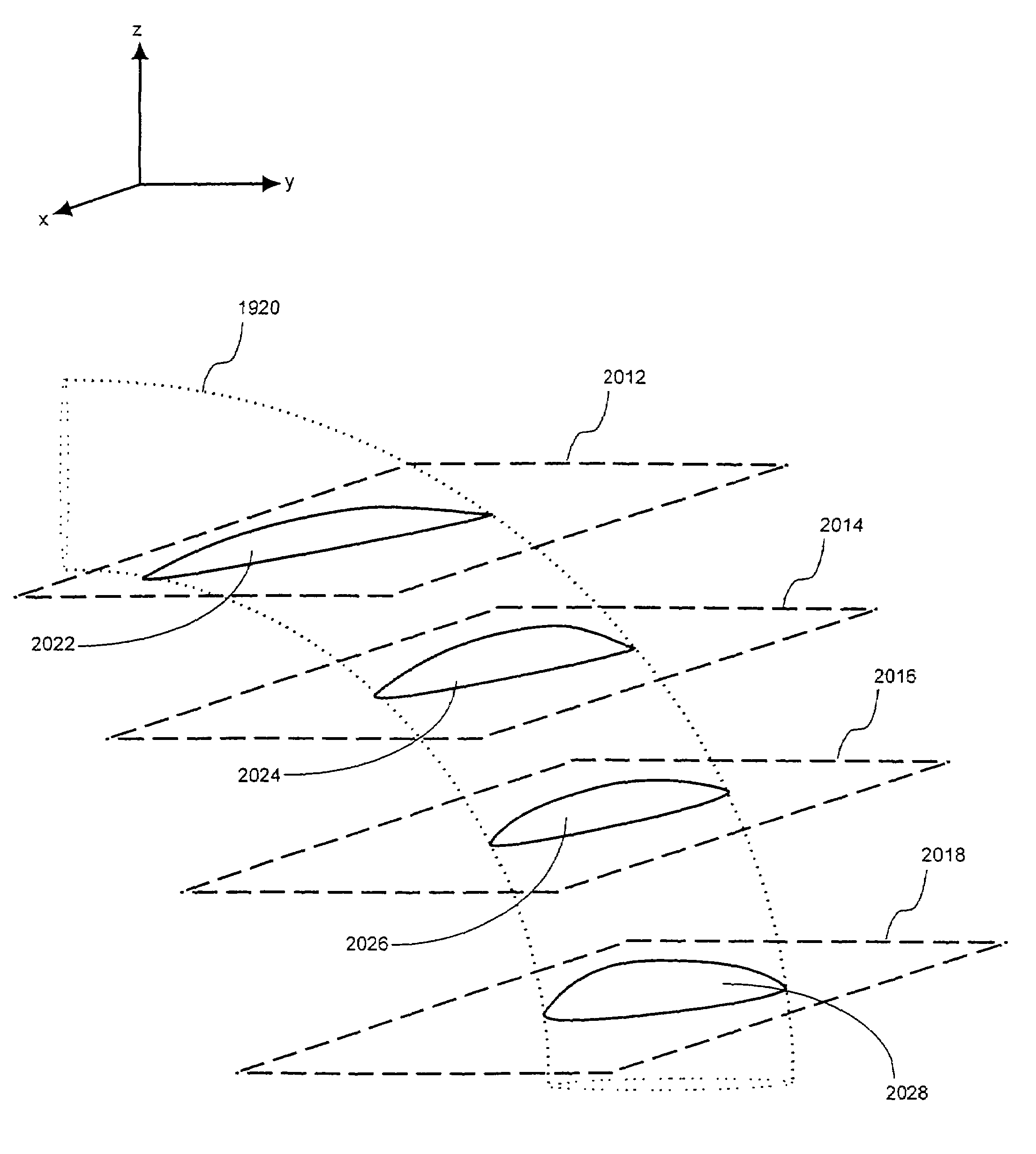

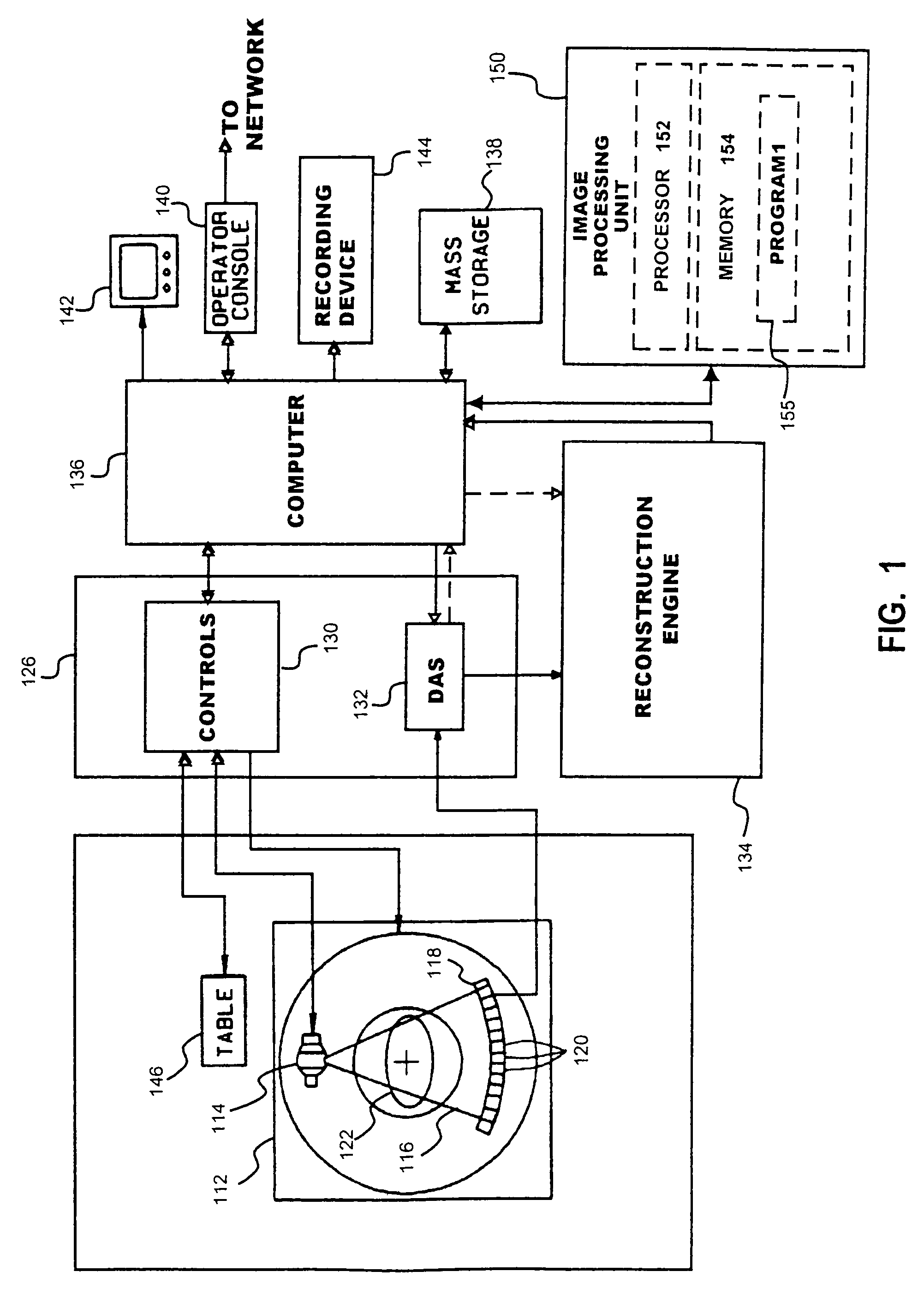

Techniques, hardware, and software are provided for quantification of extensional features of structures of an imaged subject from image data representing a two-dimensional or three-dimensional image. In one embodiment, stenosis in a blood vessel may be quantified from volumetric image data of the blood vessel. A profile from a selected family of profiles is fit to selected image data. An estimate of cross sectional area of the blood vessel is generated based on the fit profile. Area values may be generated along a longitudinal axis of the vessel, and a one-dimensional profile fit to the generated area values. An objective quantification of stenosis in the vessel may be obtained from the area profile. In some cases, volumetric image data representing the imaged structure may be reformatted to facilitate the quantification, when the structural feature varies along a curvilinear axis. A mask is generated for the structural feature to be quantified based on the volumetric image data. A curve representing the curvilinear axis is determined from the mask by center-finding computations, such as moment calculations, and curve fitting. Image data are generated for oblique cuts at corresponding selected orientations with respect to the curvilinear axis, based on the curve and the volumetric image data. The oblique cuts may be used for suitable further processing, such as image display or quantification.

Owner:GENERAL ELECTRIC CO

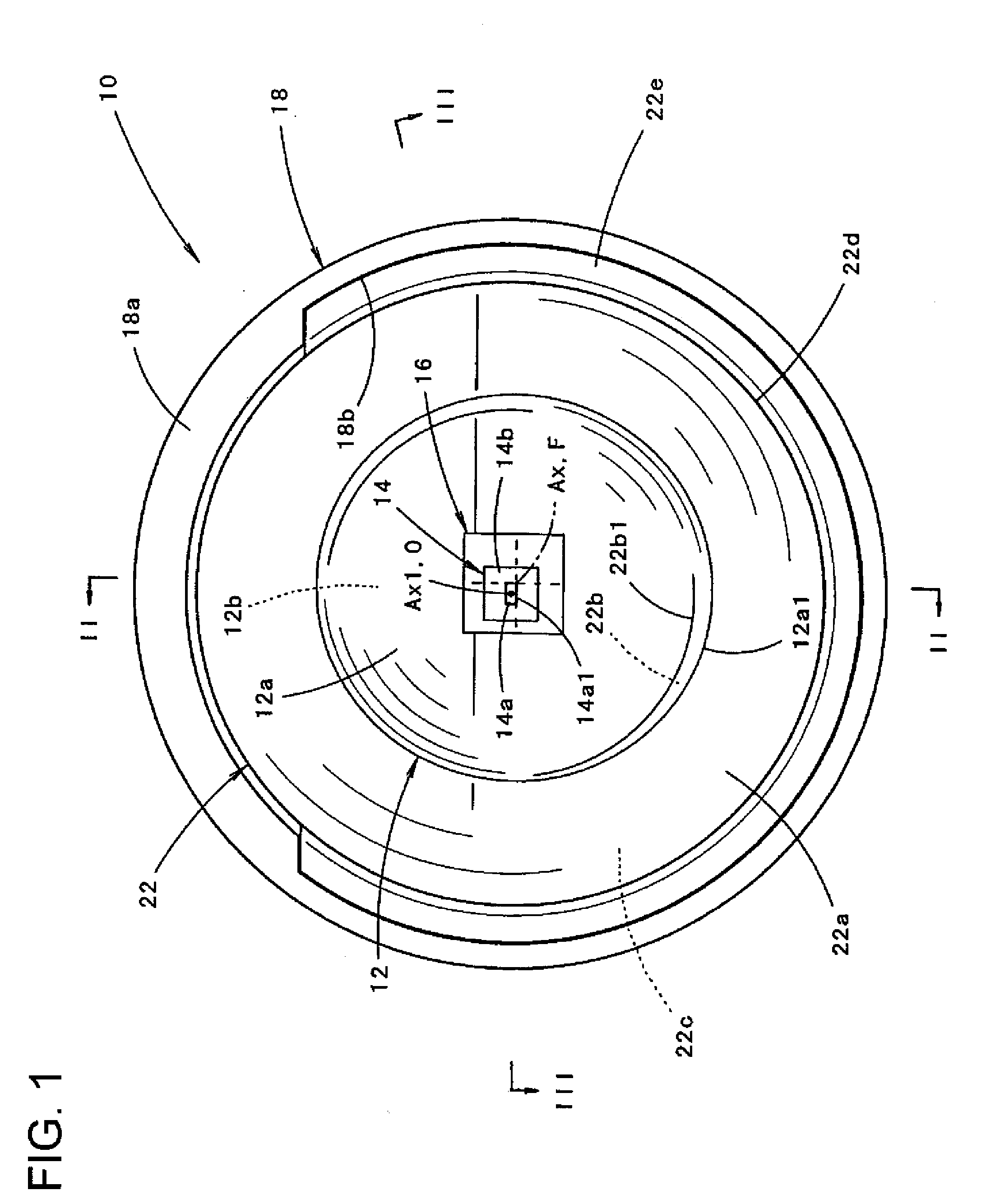

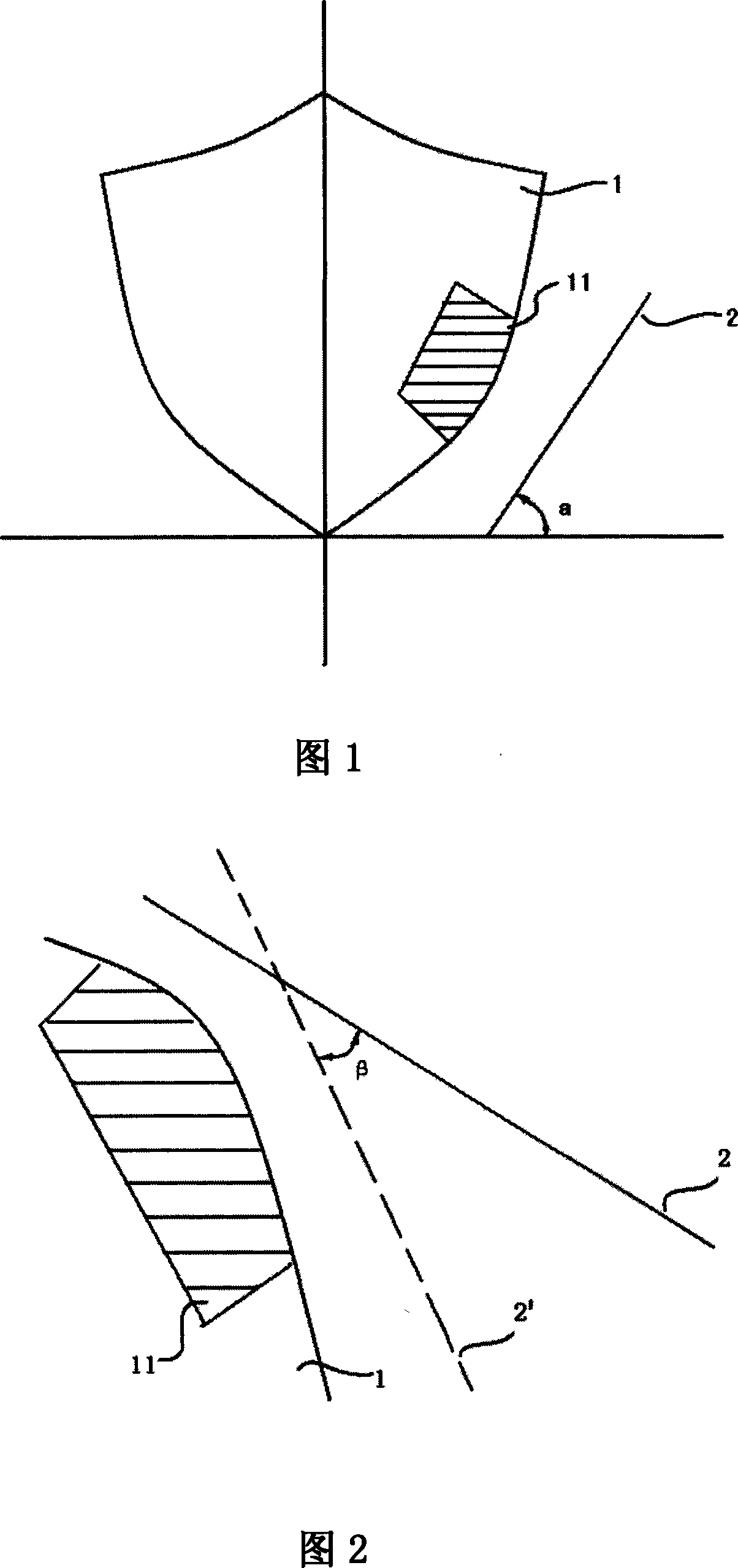

Lighting device and lighting fixture for a vehicle

ActiveUS20050052878A1Increase brightnessGood light distributionLighting support devicesPoint-like light sourceEffect lightDistribution pattern

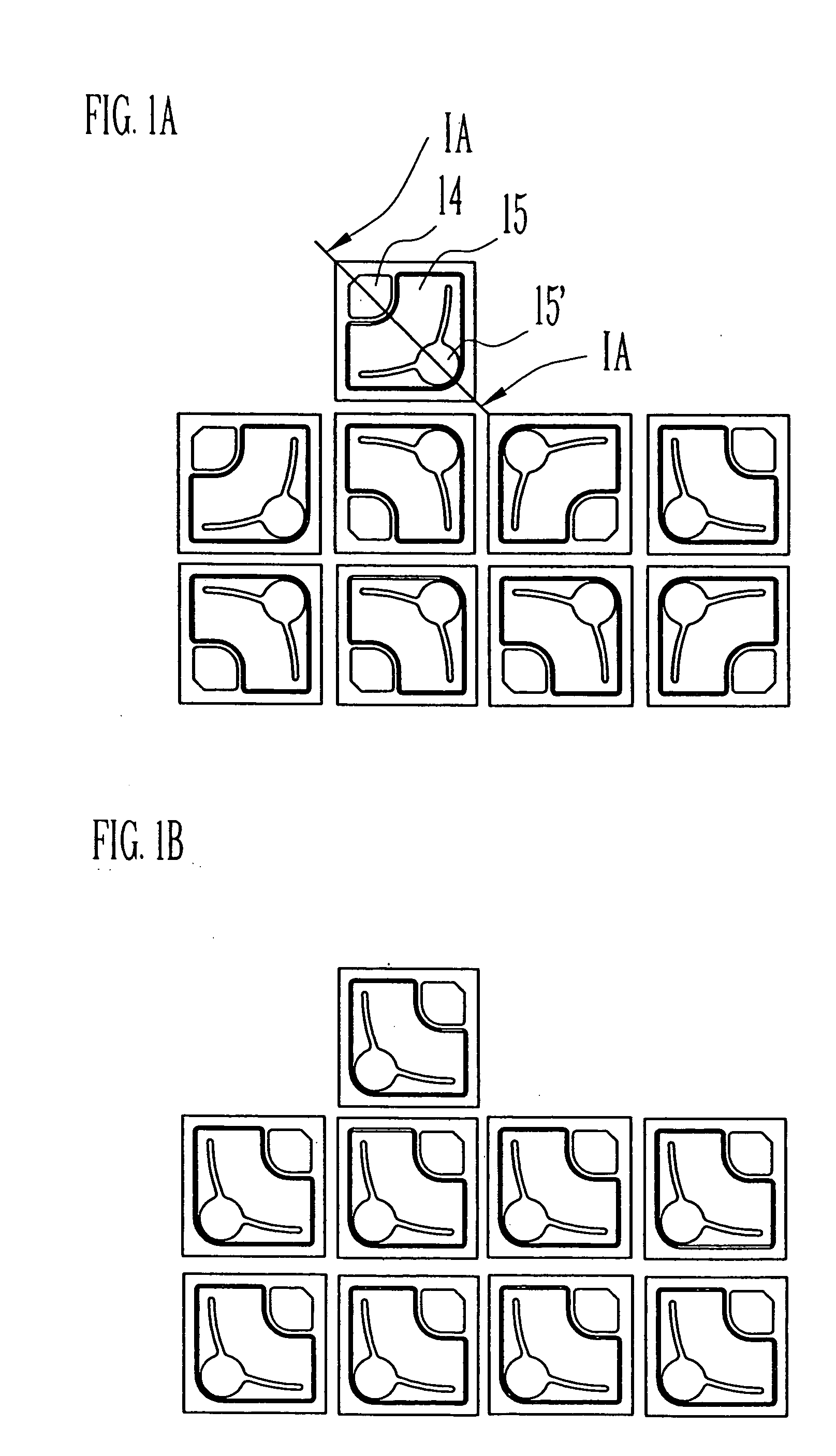

The light distribution pattern for a vehicle having a predetermined horizontal cut-off line section at the top portion on one side of the vertical central line and an oblique cut-off line section whose central line side is lowered in another side, and the light distribution pattern of the light source comprising a plurality of semiconductor light emitting devices are almost the same shape. Moreover, the light distribution pattern of the light source is formed by arranging a plurality of semiconductor light emitting devices with a configuration almost the same shape as the light distribution pattern for a vehicle. The semiconductor light emitting device has a luminance surface whose configuration is almost the same shape as the light distribution pattern for a vehicle. Further, the light source comprising the semiconductor light emitting device includes a fluorescent material whose excitation source is the emission from the nitride semiconductor device and a part of region of the fluorescent material emits light with higher luminance or higher color rendering properties compared with the other regions.

Owner:NICHIA CORP

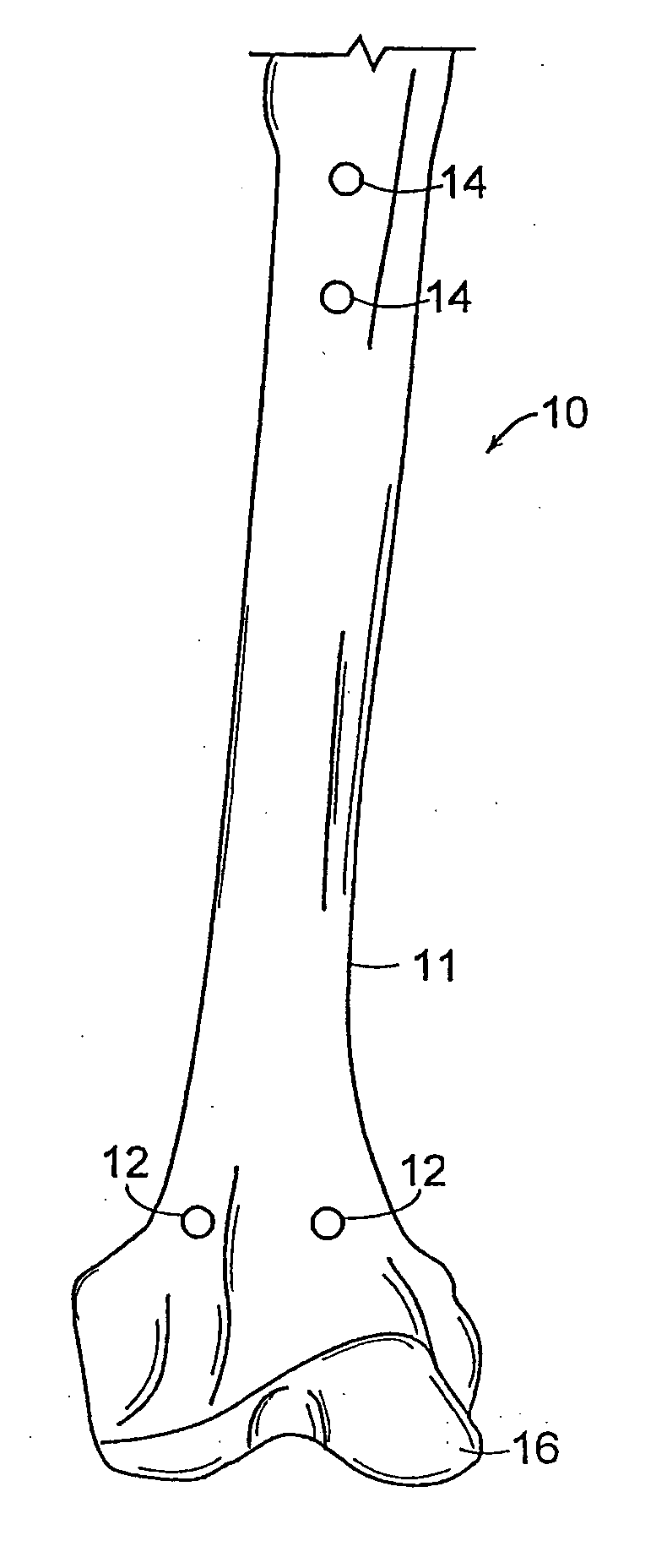

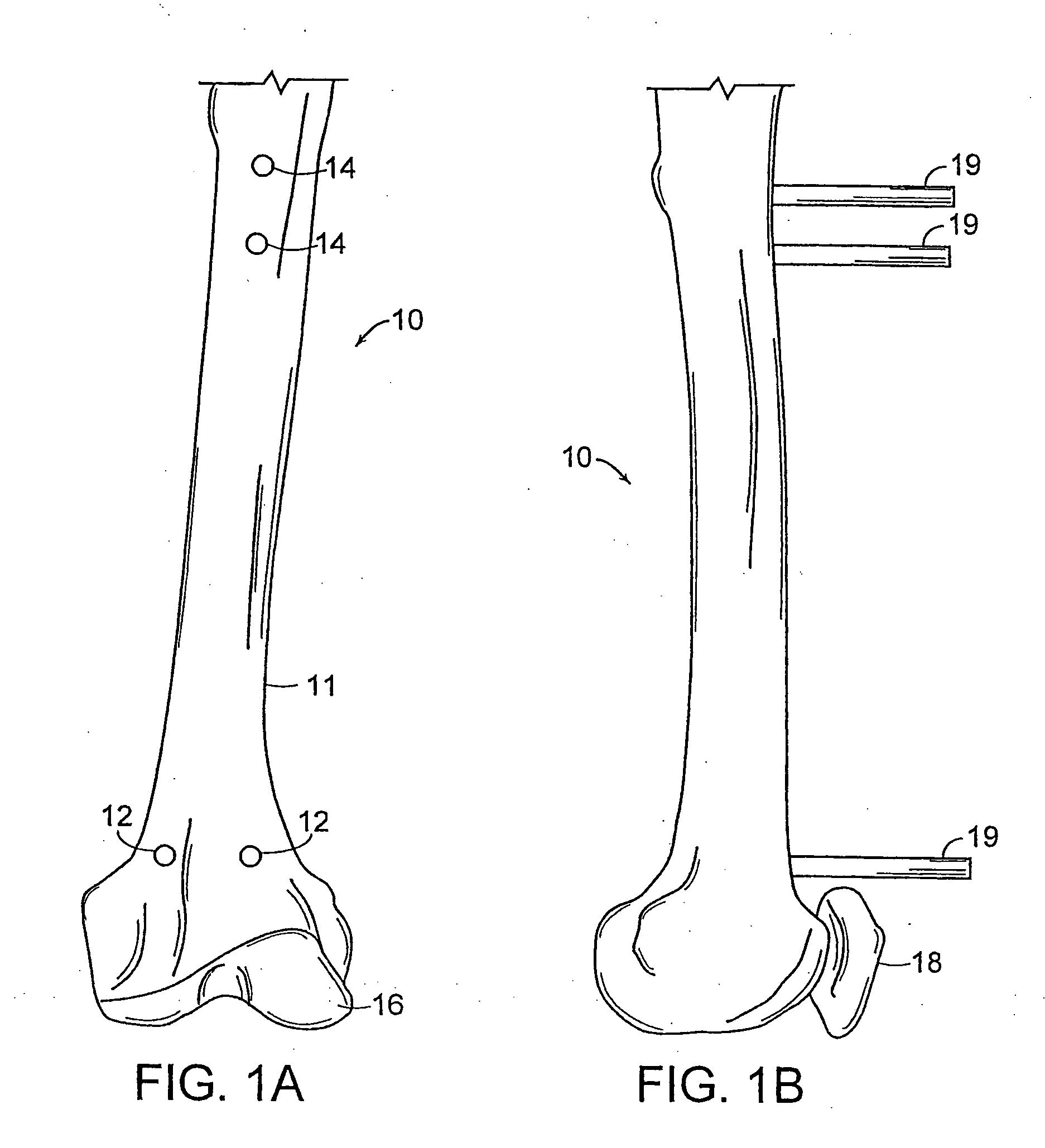

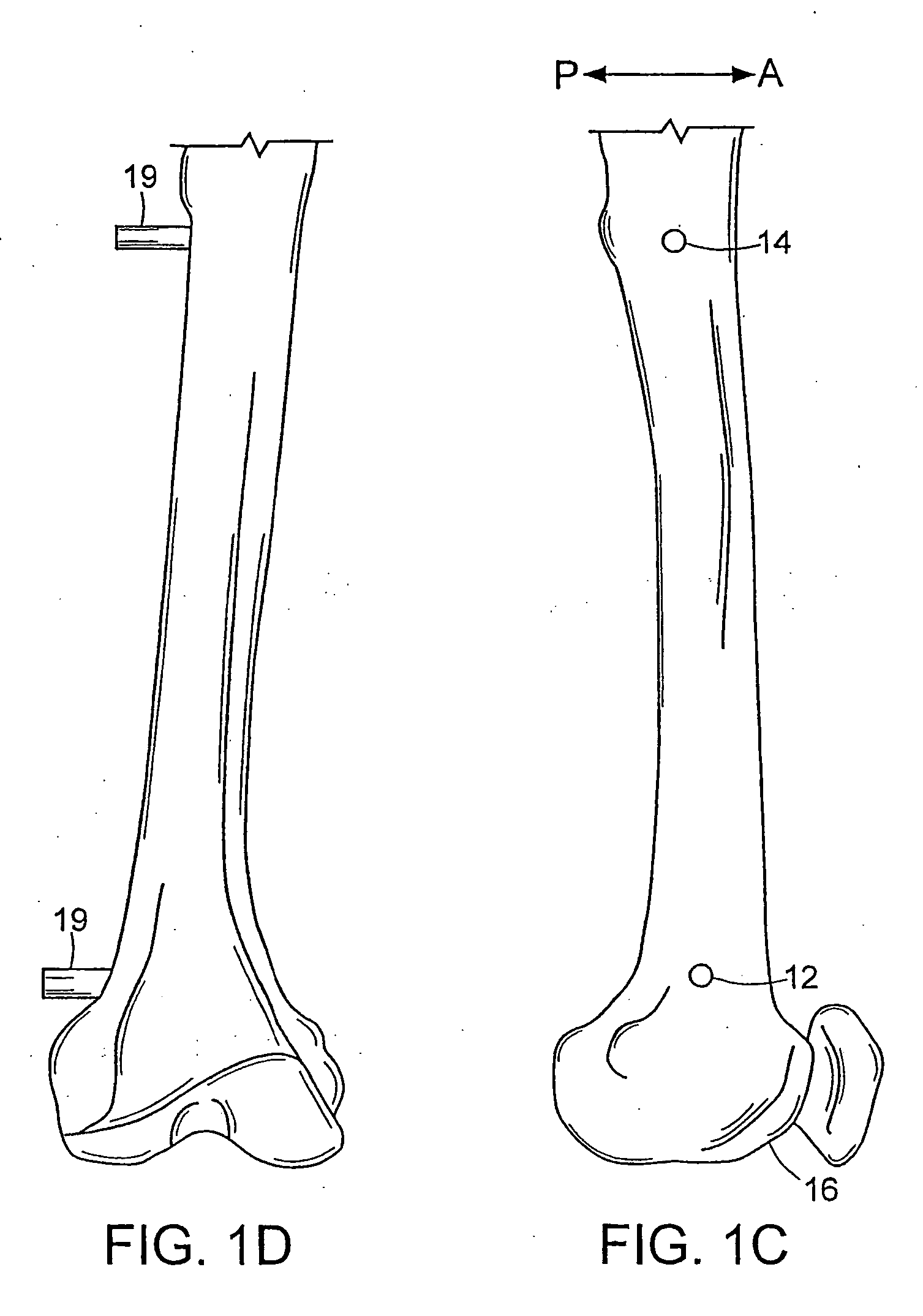

Systems and methods for producing osteotomies

Systems and methods for producing minimally invasive osteotomies to correct angular deformities of bones in and about the knee are disclosed. A method includes locating a plane in which the angle exhibited by the deformity is situated. An oblique cut is then made along a surface of the bone, such that the cut is transverse to the plane in which the angle is situated. Thereafter, the bone pieces are rotated about the cut relative to one another until a desired alignment between the bone pieces is achieved. To maintain the bone pieces in alignment, a device having an elongated body for extending into a tunnel between the bone pieces is provided. The system also includes a rigid member fixedly positioned at one end of the body. The rigid member is transverse to the body to engage one bone piece. The system further includes a locking mechanism at an opposite end of the body to engage the other bone piece. The system permits the bone pieces to be pulled against one another between the rigid member and the locking mechanism.

Owner:MCGUIRE DAVID A

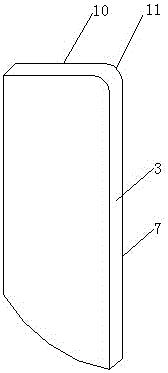

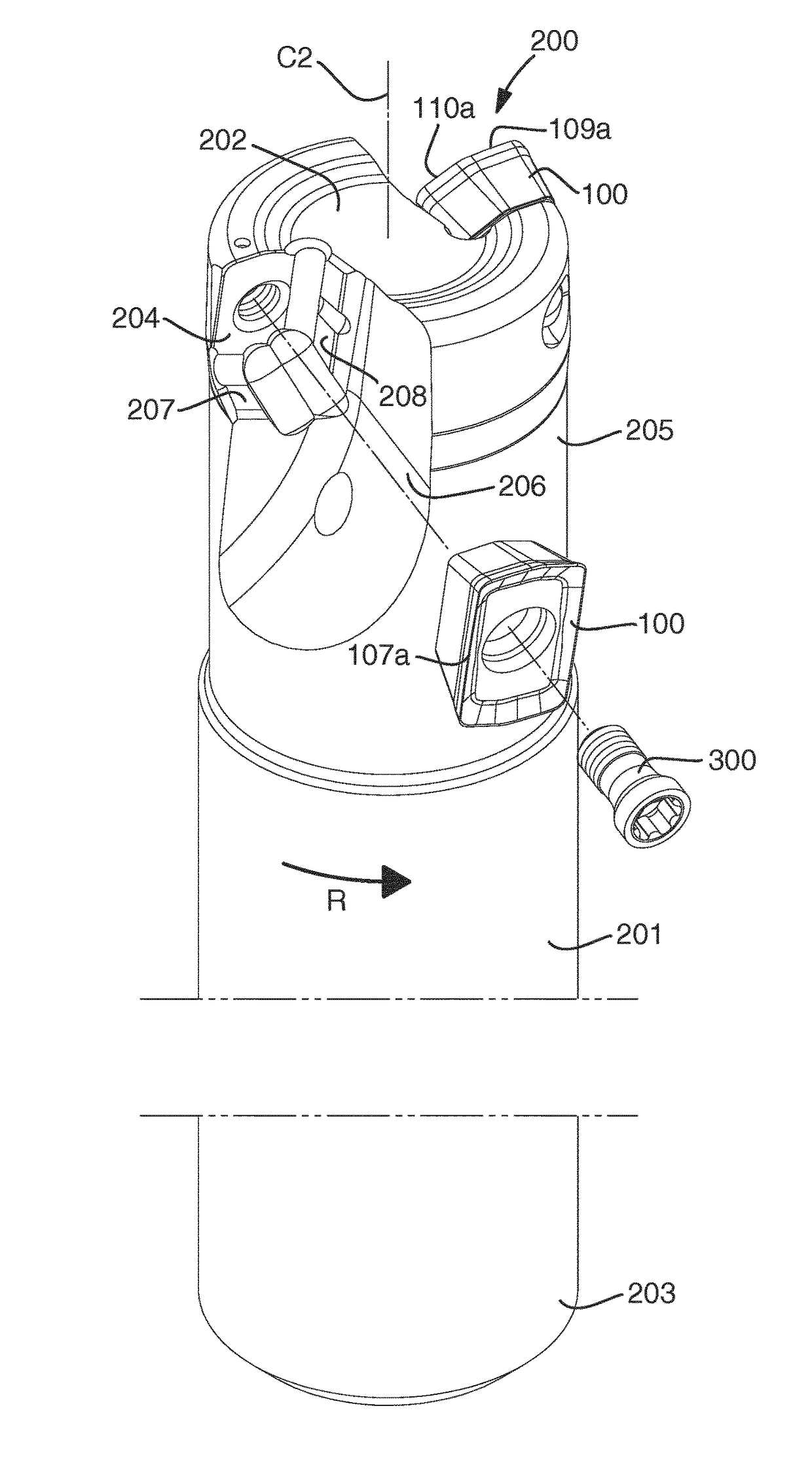

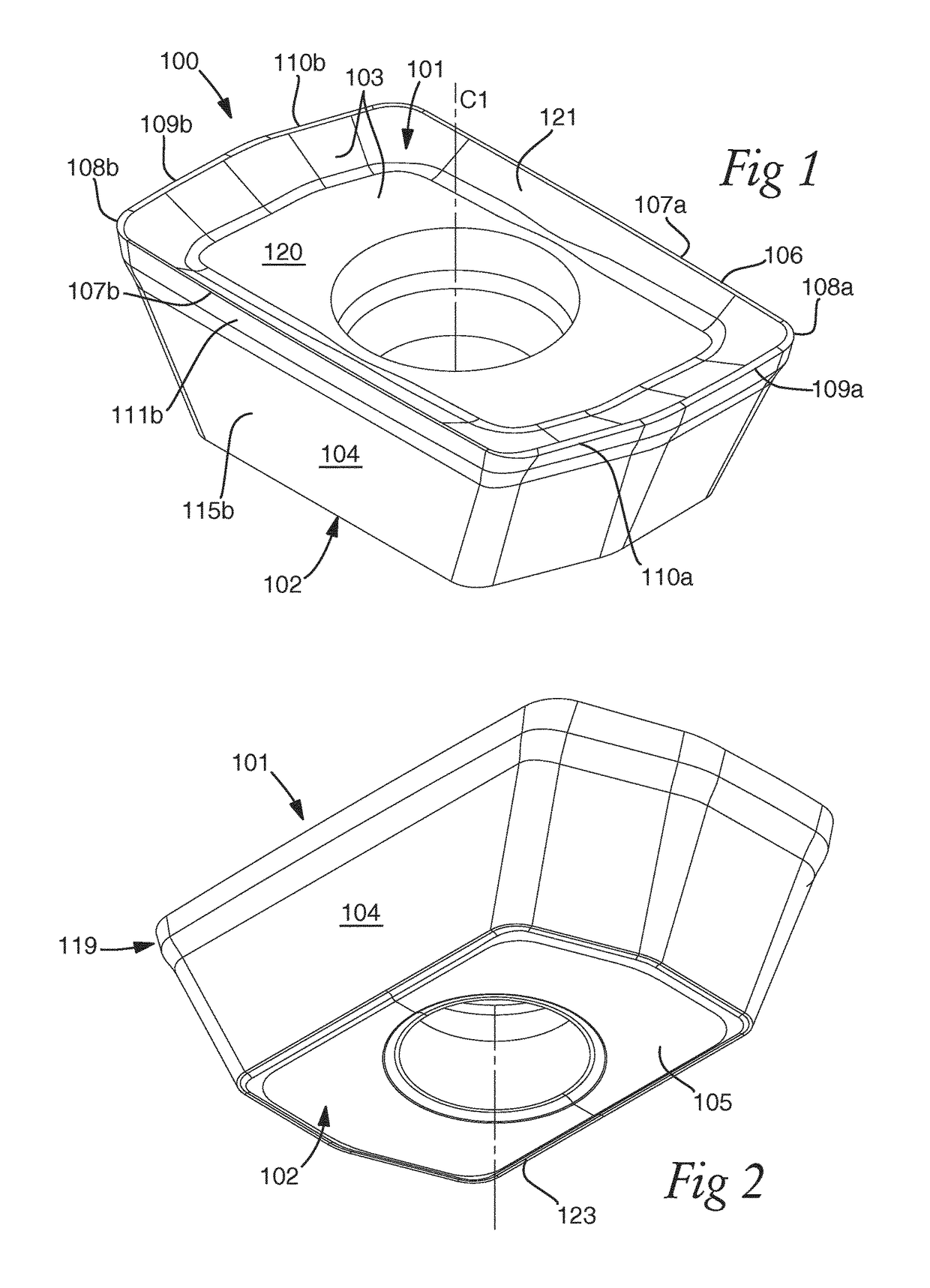

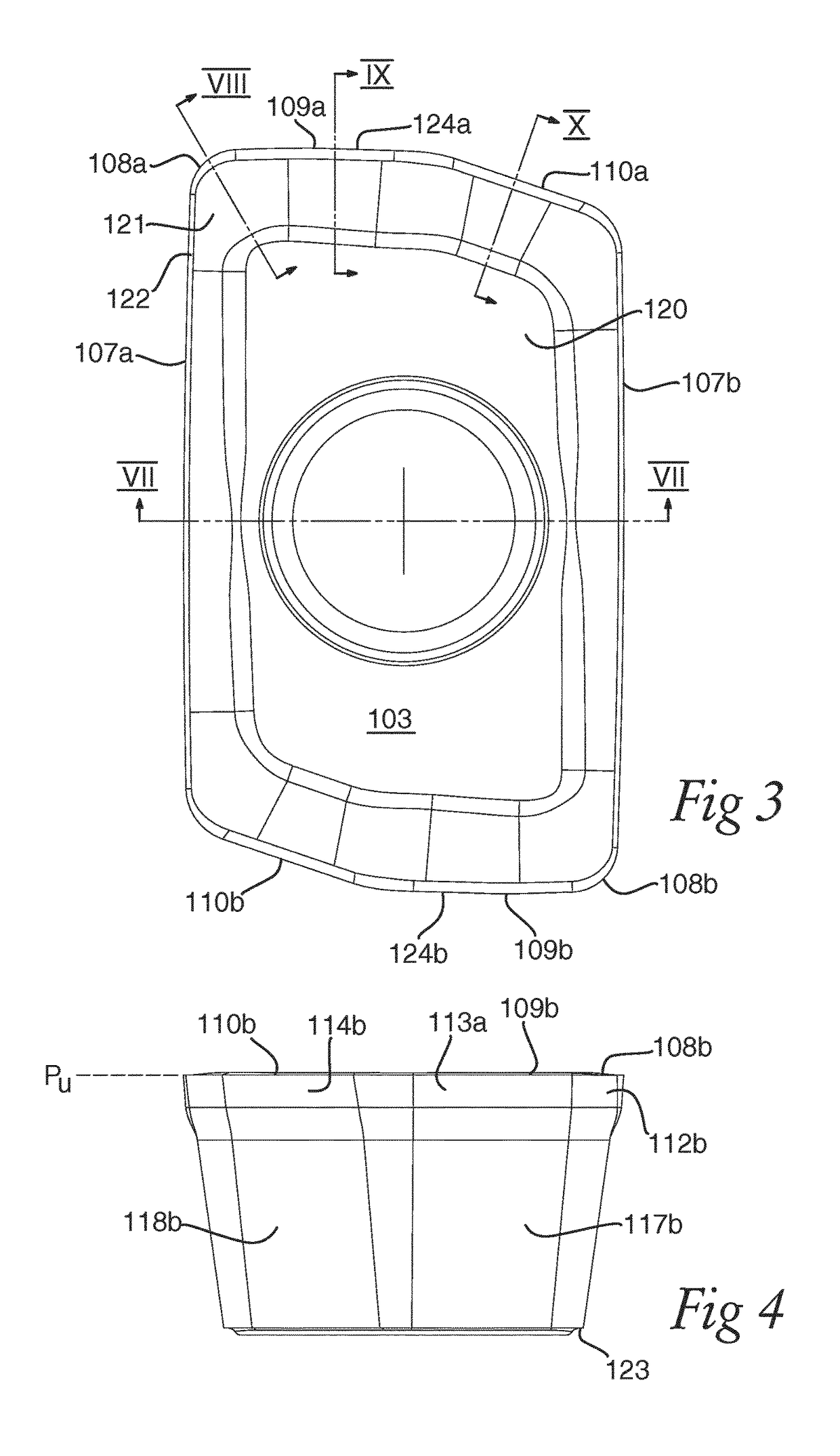

Cutting insert for high-speed milling cutter

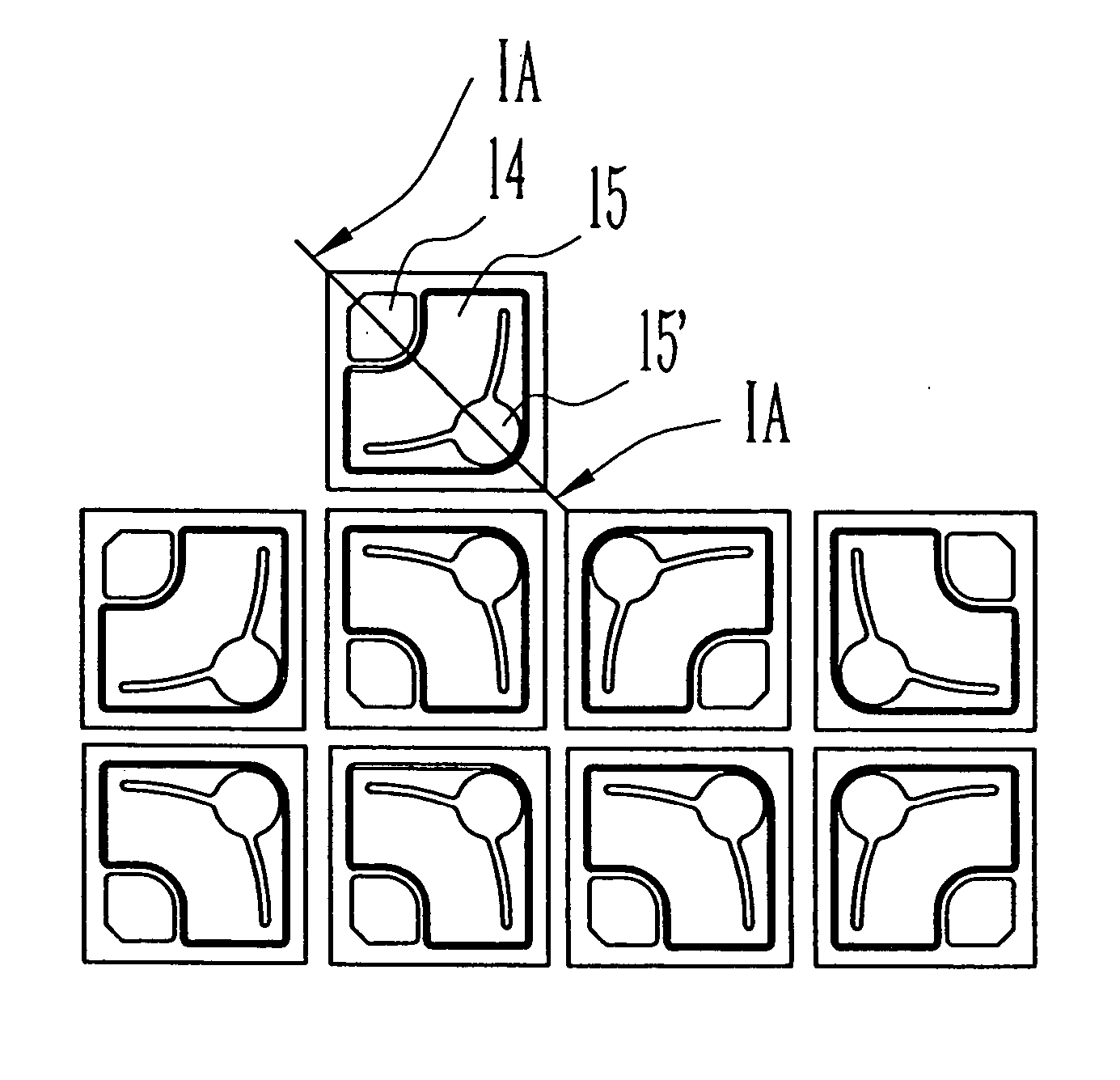

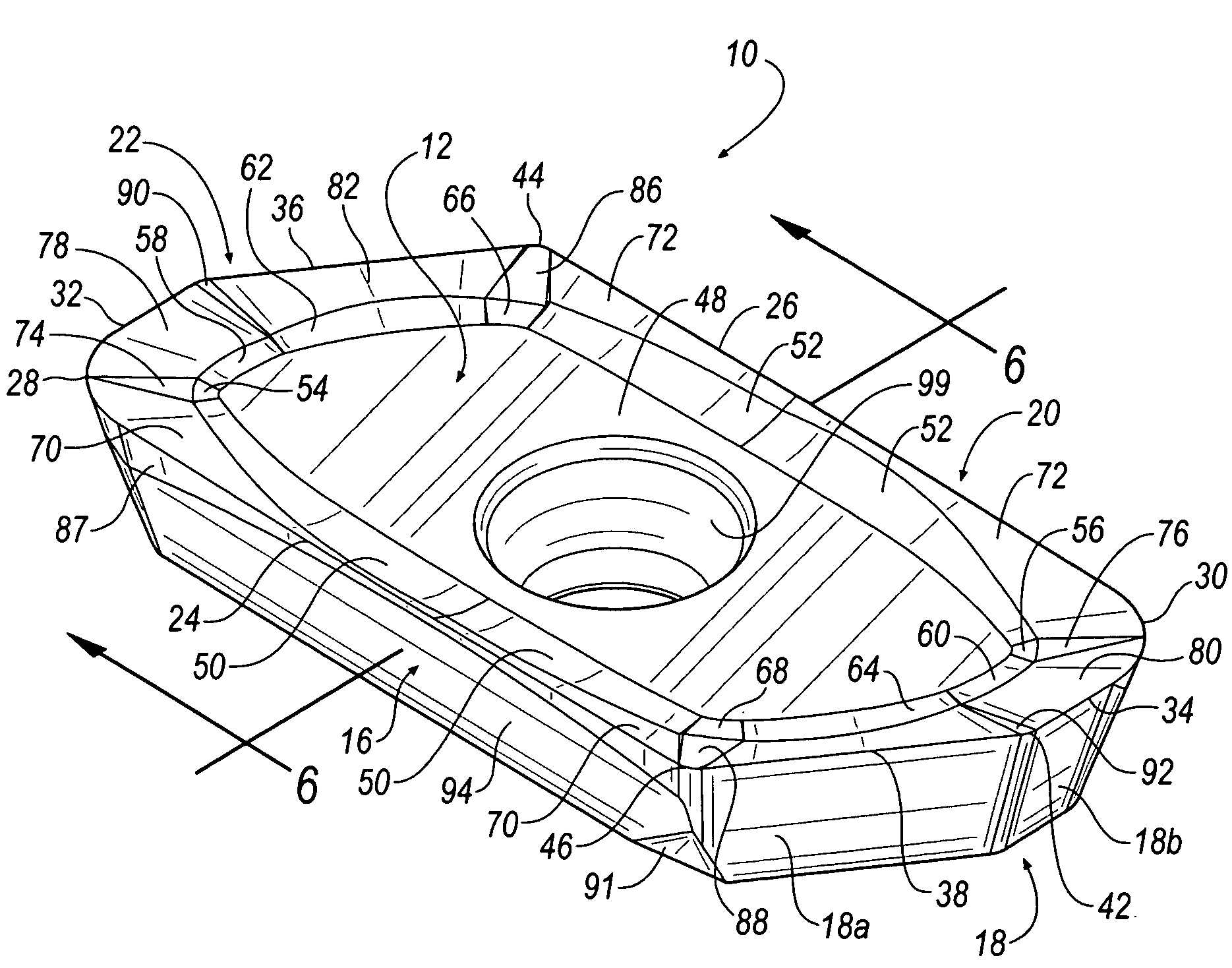

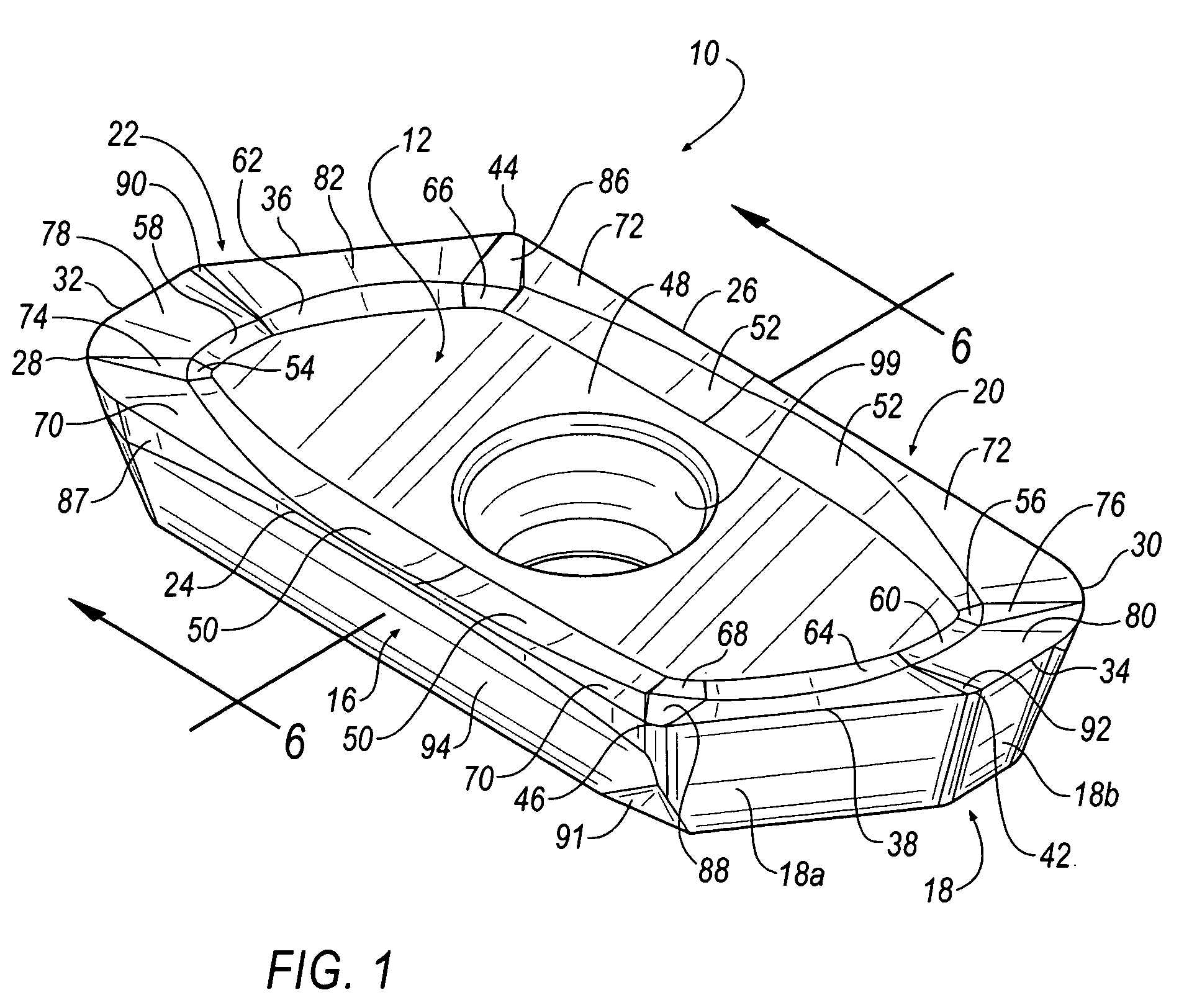

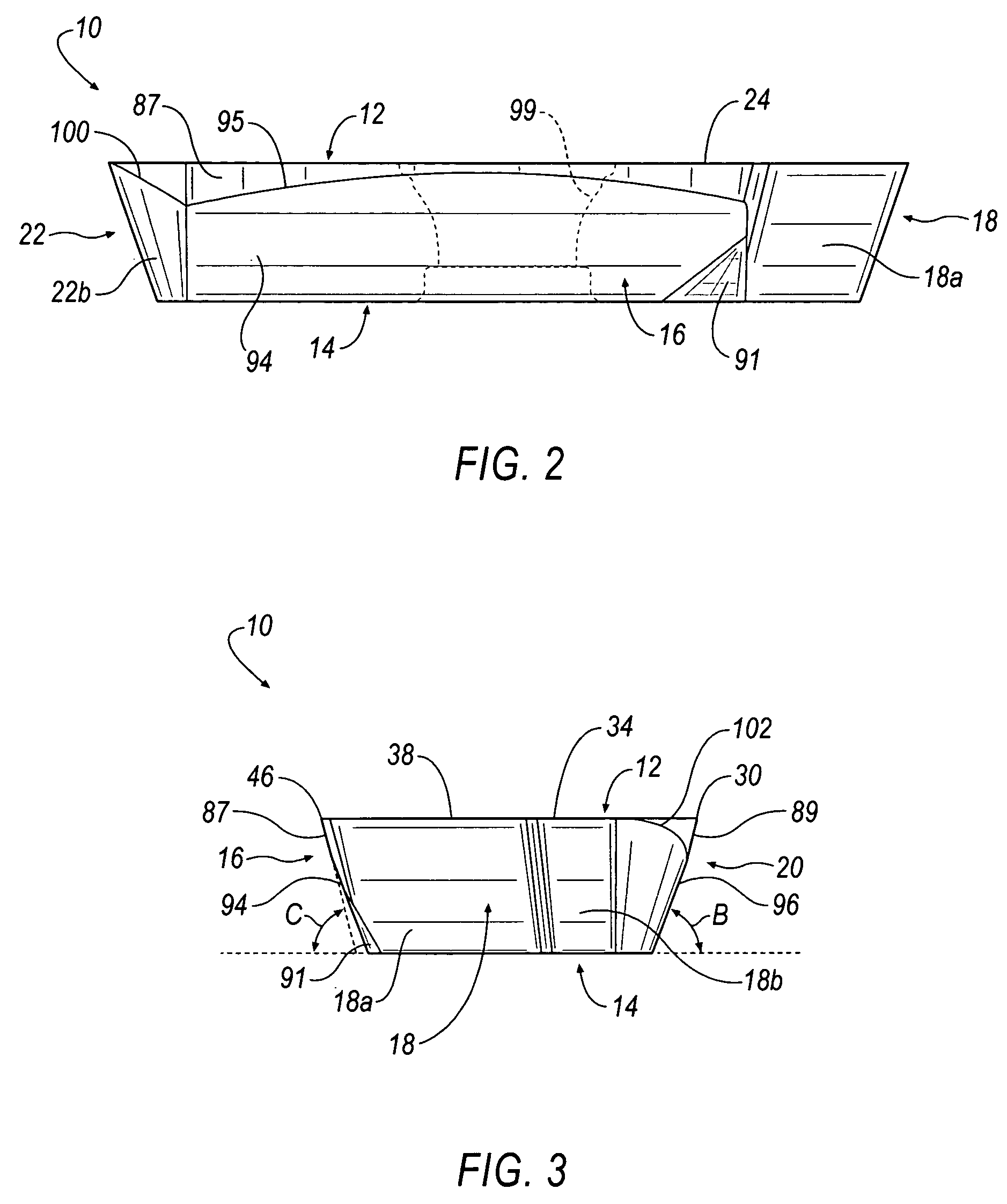

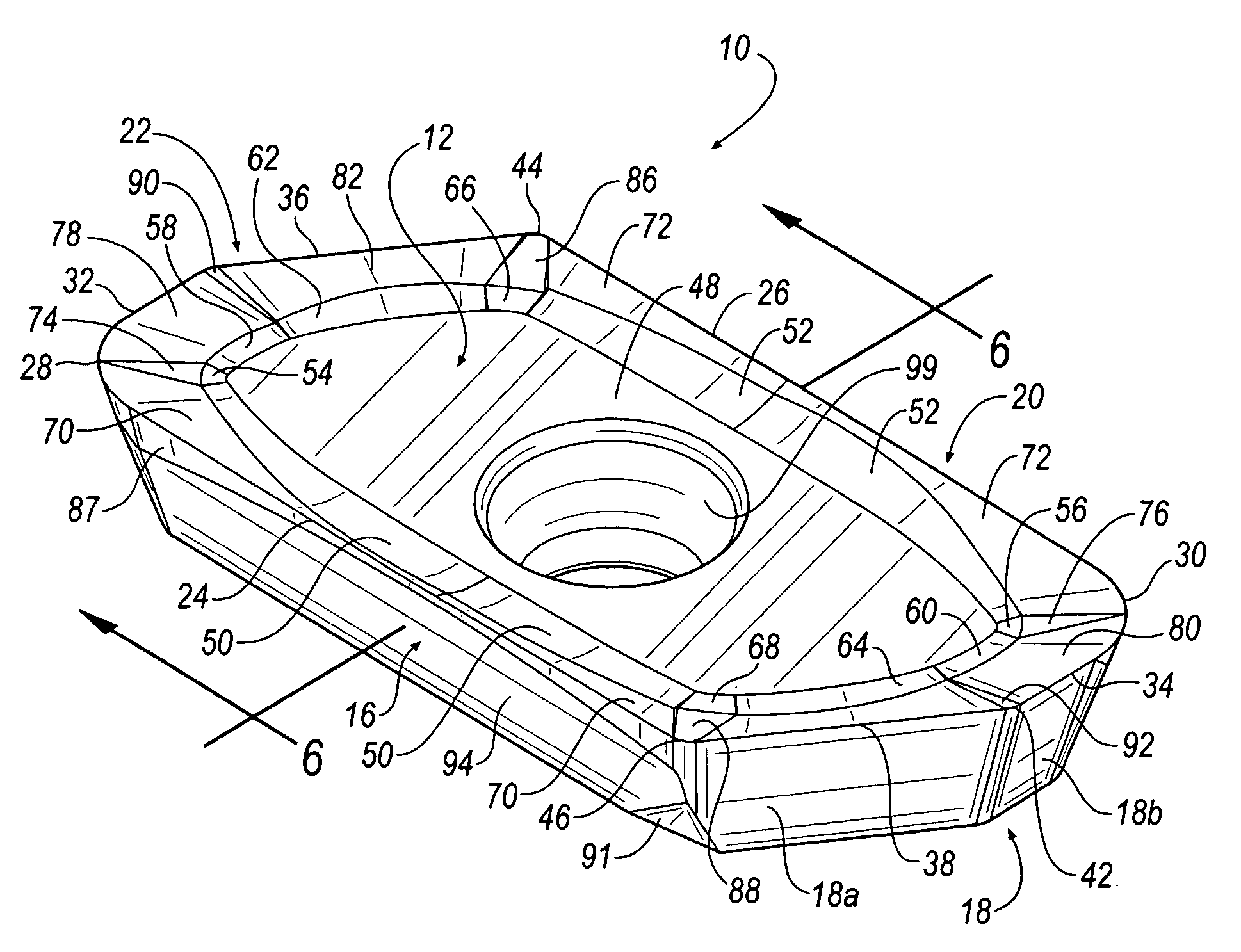

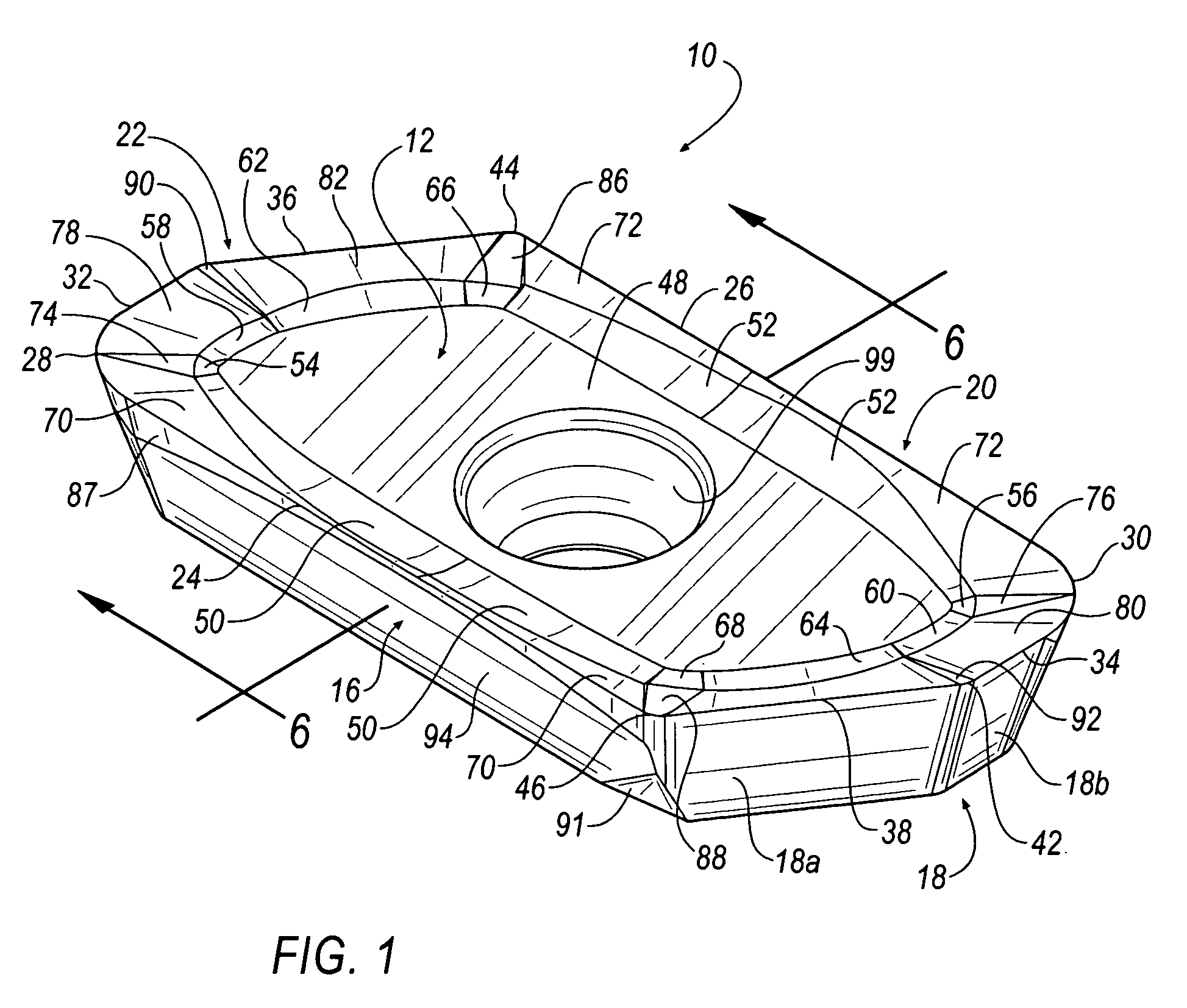

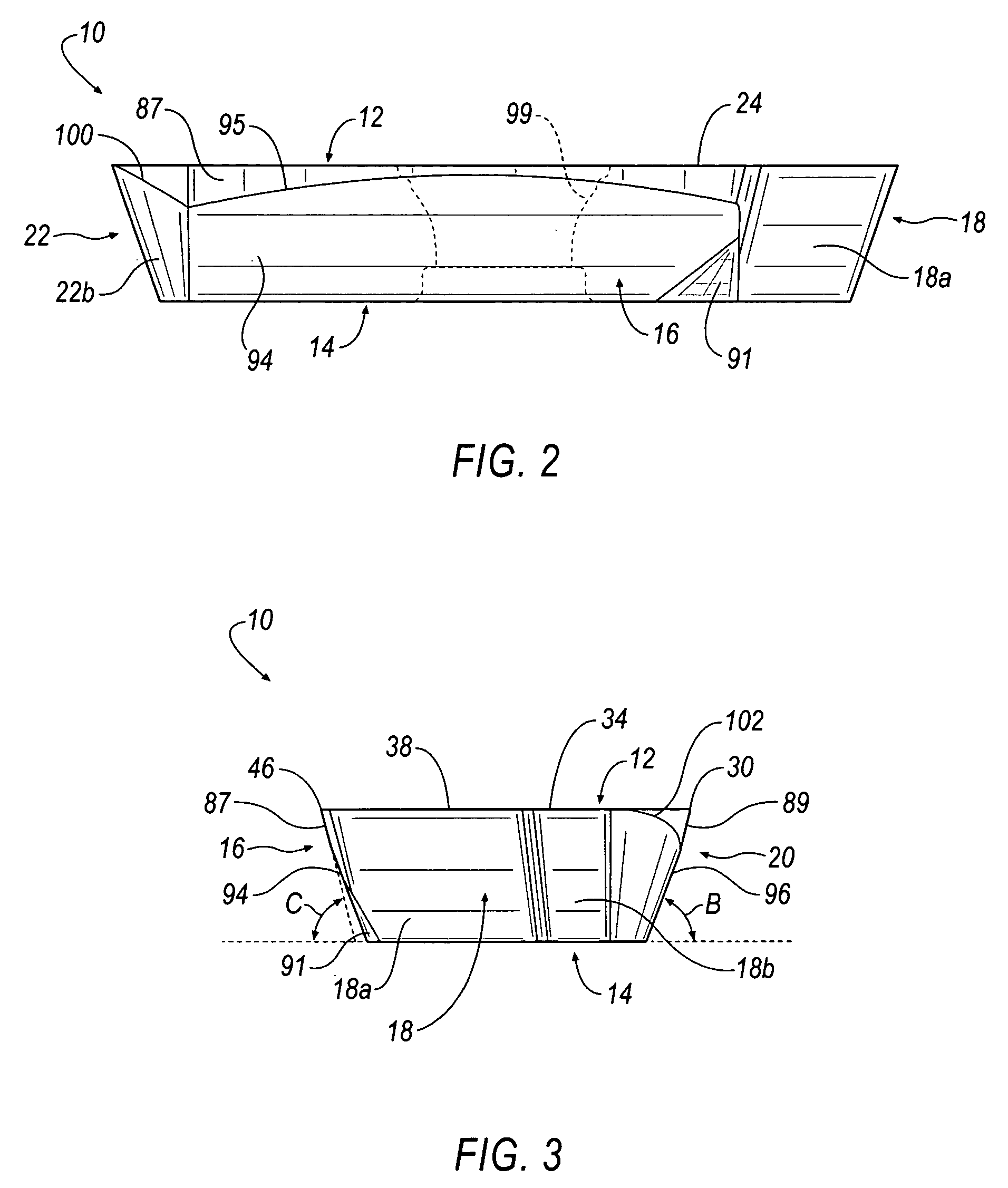

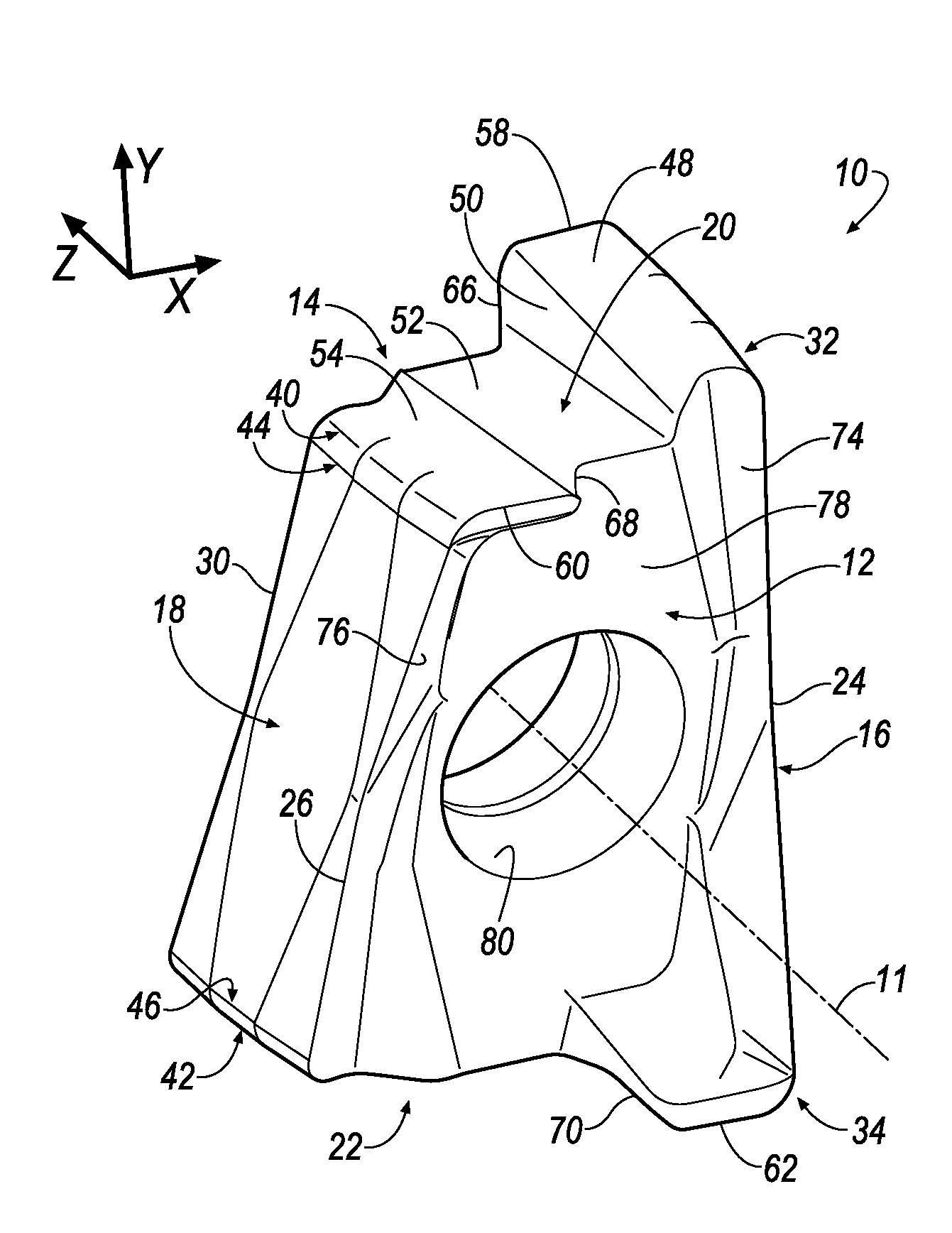

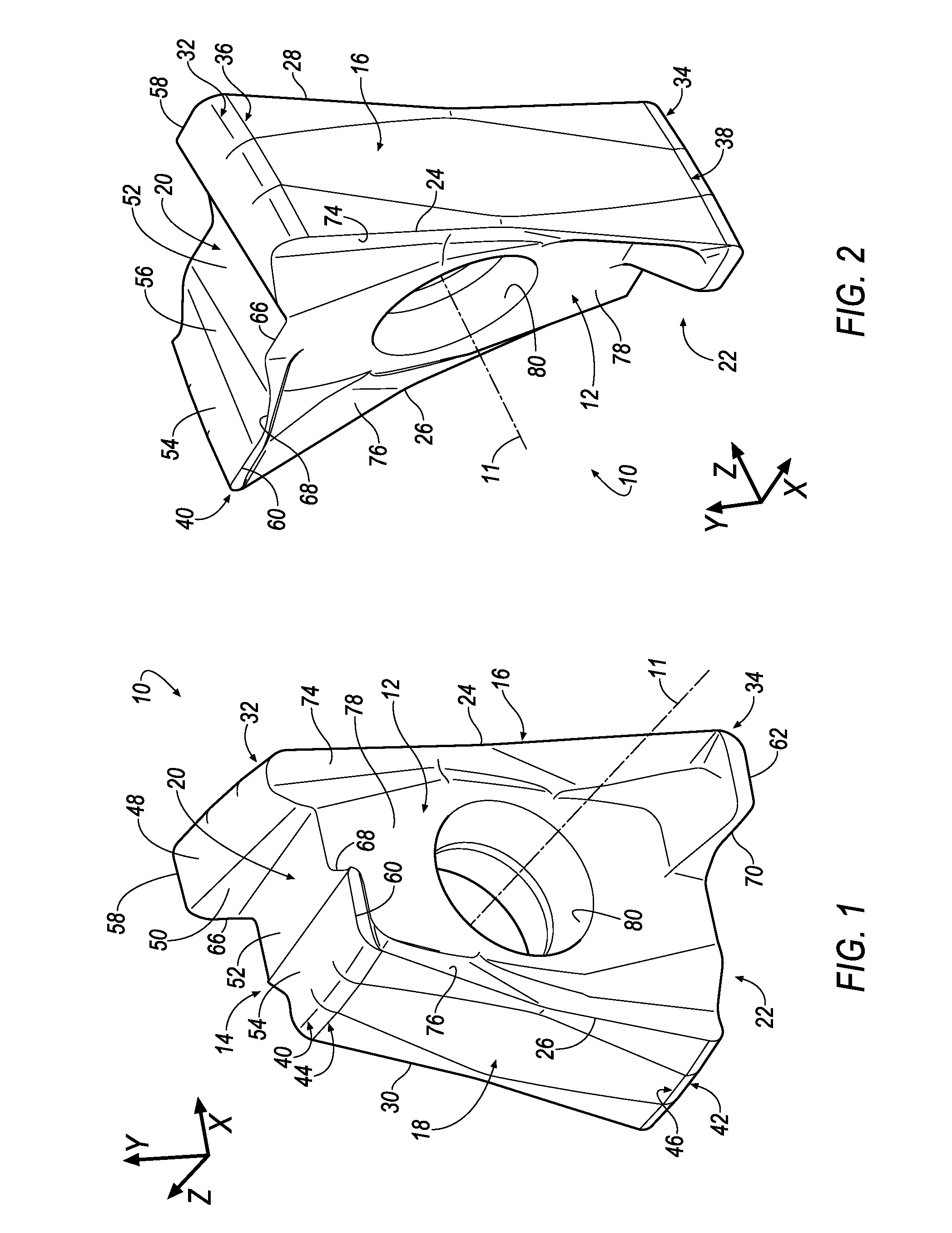

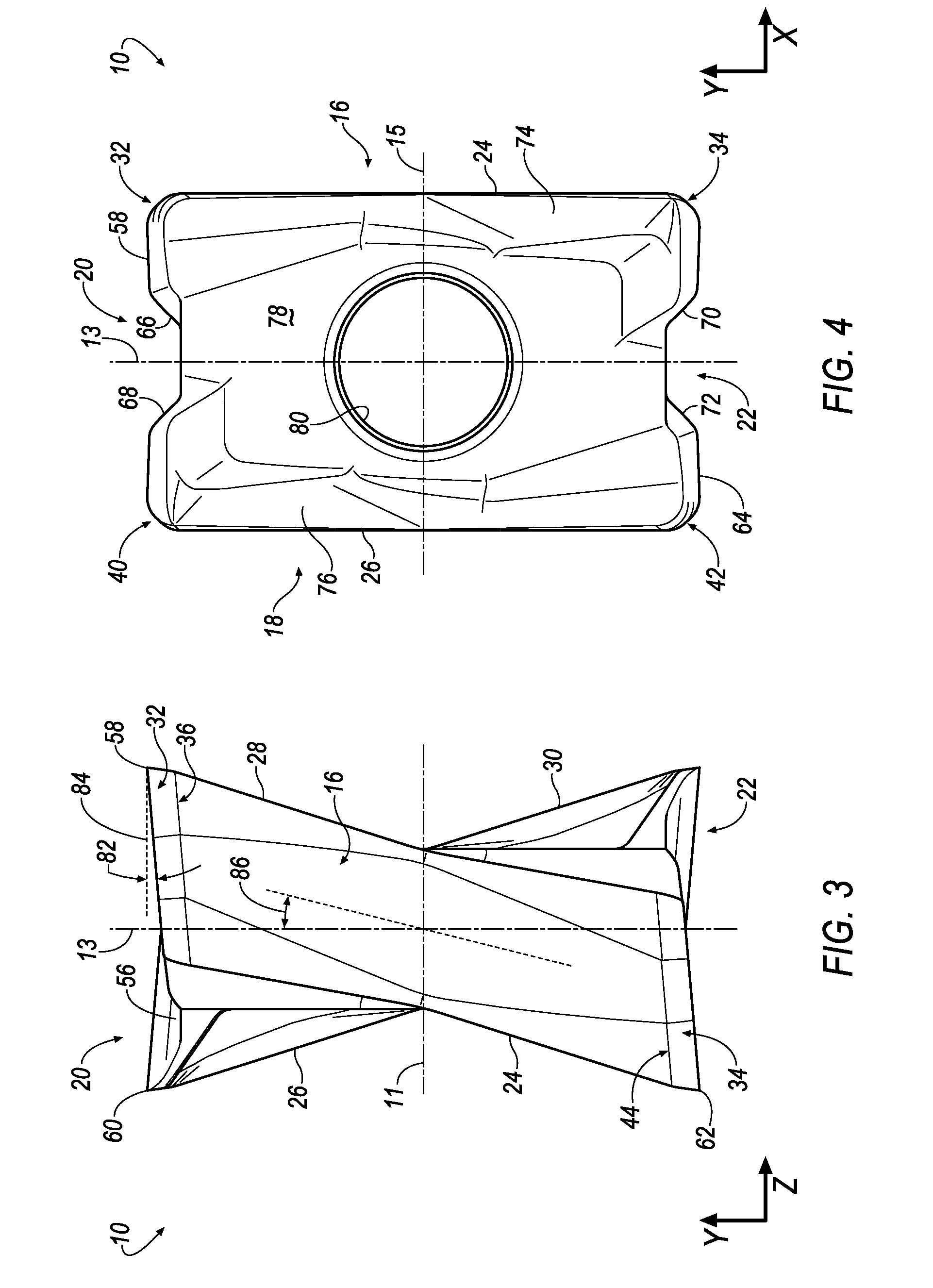

An indexable cutting insert (10) having a top surface (12) including a substantially planar central portion (48), a substantially planar bottom surface (14), and a plurality of side surfaces (16, 18, 20, 22). A long cutting edge (24, 26), a corner radius cutting edge (28, 30), a facet radius cutting edge (32, 34), and ramping cutting edge (36, 38) are defined at an intersection between the top surface (12) and one of the side surfaces (16, 18, 20, 22). A margin (87, 89) extends around a nose radius of the cutting insert (10) and blends into a flat surface (94, 96). A margin angle, C, formed by the margins (87, 89) is less than a seating angle, B, formed by the flat surfaces (94, 96). The top surface (12) includes a plurality of upward sloping radius blends (50, 52, 54, 56, 58, 60, 62, 64) extending between the substantially planar central portion (48) and a plurality of upward sloping rake faces (70, 72, 74, 76, 78, 80, 82, 84, 86, 88, 90, 92) extending between a respective radius blend and its respective cutting edge such that the rake face forms an angle, A, of between five and twenty-five degrees with respect to the central portion (48) of the top surface (12).

Owner:KENNAMETAL INC

Cutting insert for high-speed milling cutter

An indexable cutting insert (10) having a top surface (12) including a substantially planar central portion (48), a substantially planar bottom surface (14), and a plurality of side surfaces (16, 18, 20, 22). A long cutting edge (24, 26), a corner radius cutting edge (28, 30), a facet radius cutting edge (32, 34), and ramping cutting edge (36, 38) are defined at an intersection between the top surface (12) and one of the side surfaces (16, 18, 20, 22). A margin (87, 89) extends around a nose radius of the cutting insert (10) and blends into a flat surface (94, 96). A margin angle, C, formed by the margins (87, 89) is less than a seating angle, B, formed by the flat surfaces (94, 96). The top surface (12) includes a plurality of upward sloping radius blends (50, 52, 54, 56, 58, 60, 62, 64) extending between the substantially planar central portion (48) and a plurality of upward sloping rake faces (70, 72, 74, 76, 78, 80, 82, 84, 86, 88, 90, 92) extending between a respective radius blend and its respective cutting edge such that the rake face forms an angle, A, of between five and twenty-five degrees with respect to the central portion (48) of the top surface (12).

Owner:KENNAMETAL INC

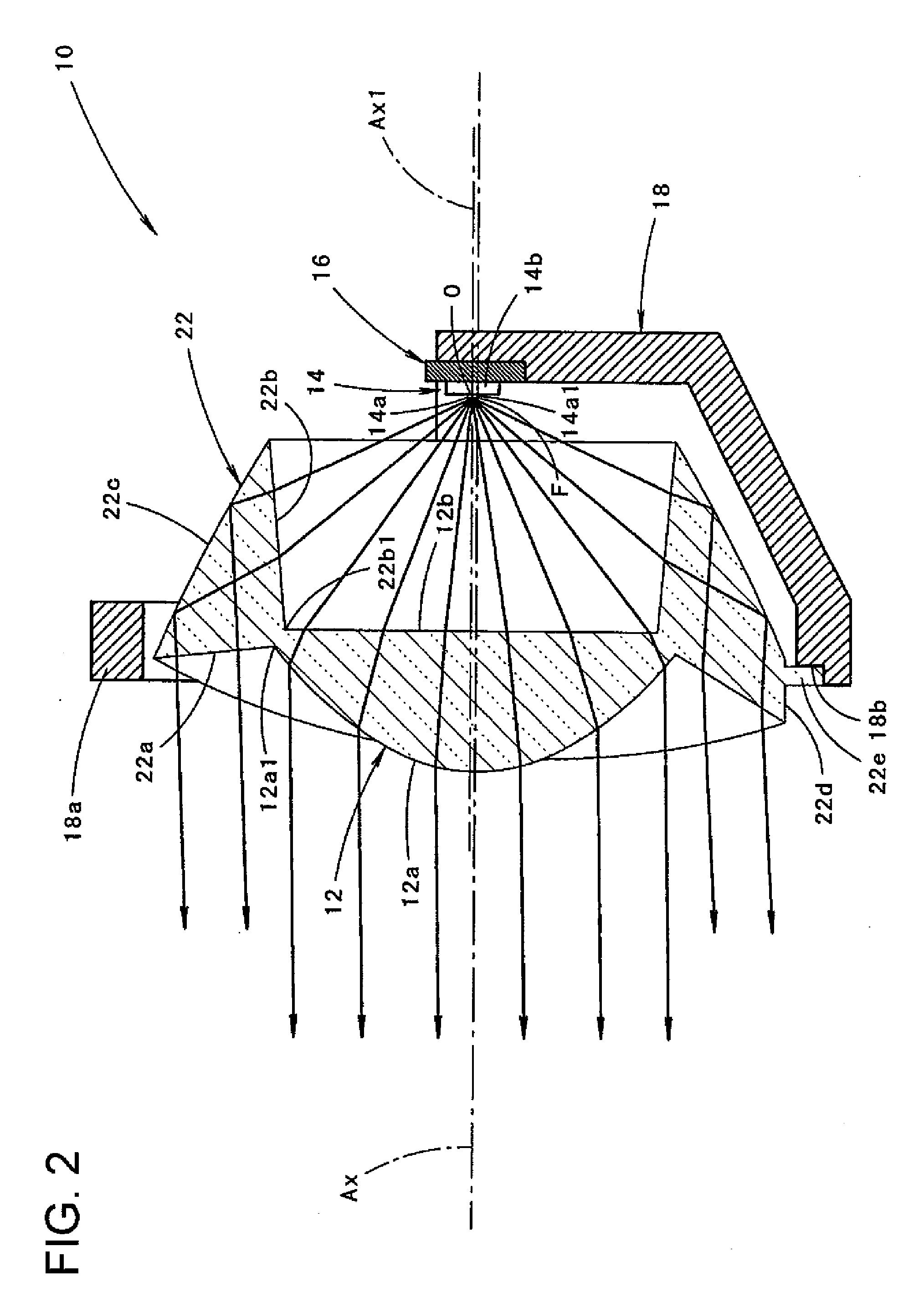

Vehicular illumination lamp

ActiveUS20090154185A1Appropriate shapeVehicle headlampsLighting support devicesOptical axisDistribution pattern

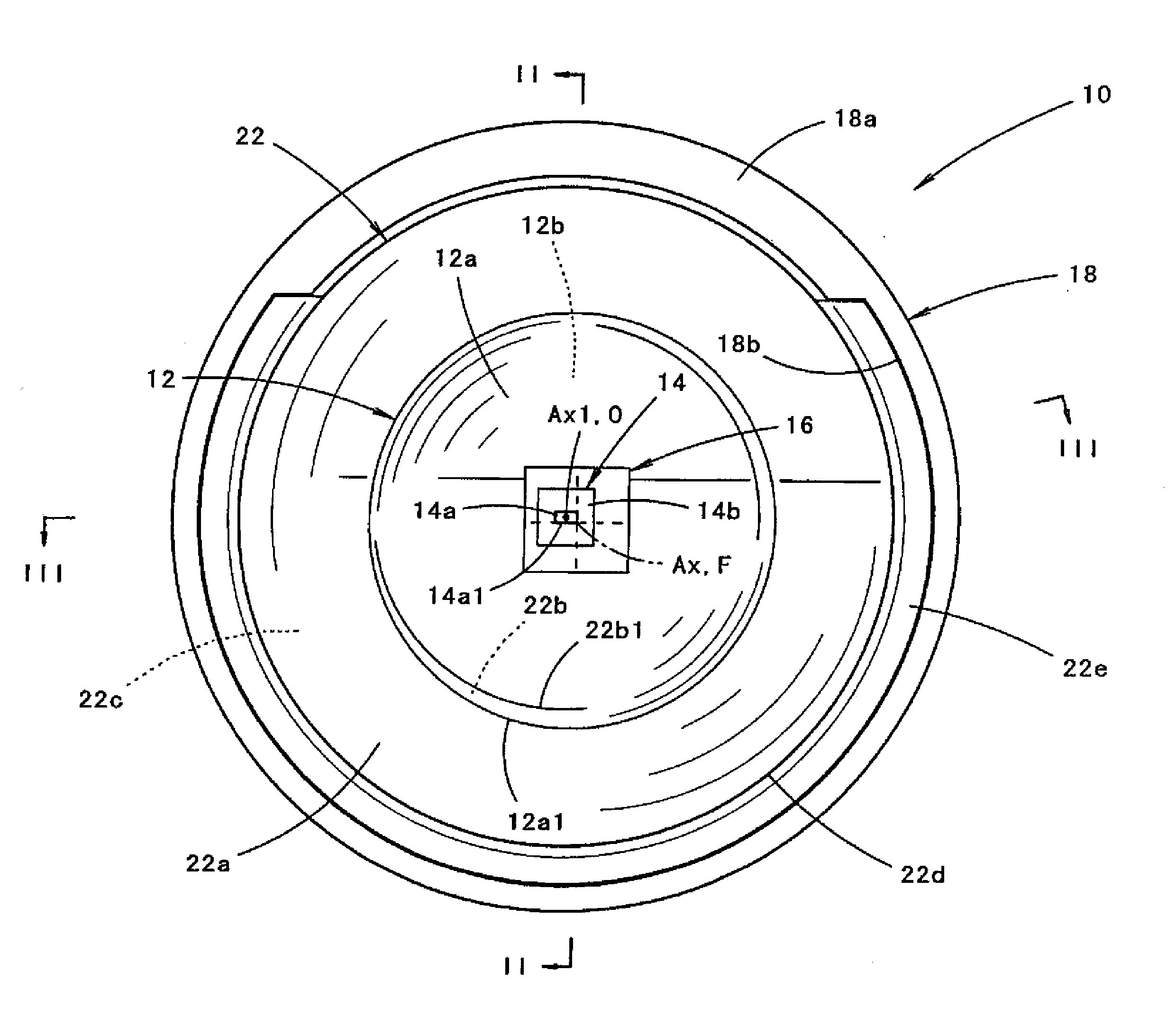

A vehicular illumination lamp includes a convex lens positioned on an optical axis in a vehicular longitudinal direction and a light emitting element positioned in a proximity of a rear side focal point of the convex lens. The vehicle lamp is configured so as to form a light distribution pattern that has a horizontal cut-off line and an oblique cut-off line in an upper end portion thereof by exercising deflection control, with a use of the convex lens, over light directly emitted from the light emitting element. The light emitting element includes a light emitting chip that has a rectangular light emitting surface. The light emitting element is positioned facing forward in such a manner that a lower end edge of the light emitting chip is positioned on a plane that includes the optical axis, while one of end points of the lower end edge is positioned on the rear side focal point. An additional lens is provided around the convex lens. The additional lens is integrally formed with the convex lens in such a manner that the additional lens surrounds the convex lens in a manner of a band. The additional lens includes an incident plane that is formed generally in a shape of a circular cylindrical plane centered on an axial line passing through a position in a proximity of a light emission center of the light emitting element and being parallel to the optical axis and that causes light emitted from the light emitting element to become incident to the additional lens in such a manner that the light is refracted into a direction that draws apart from the axial line; a reflecting plane that causes the light that has become incident from the incident plane to be internally reflected to a front; and an emission plane that causes the light that has been internally reflected on the reflecting plane to be emitted to the front as diffused light.

Owner:KOITO MFG CO LTD

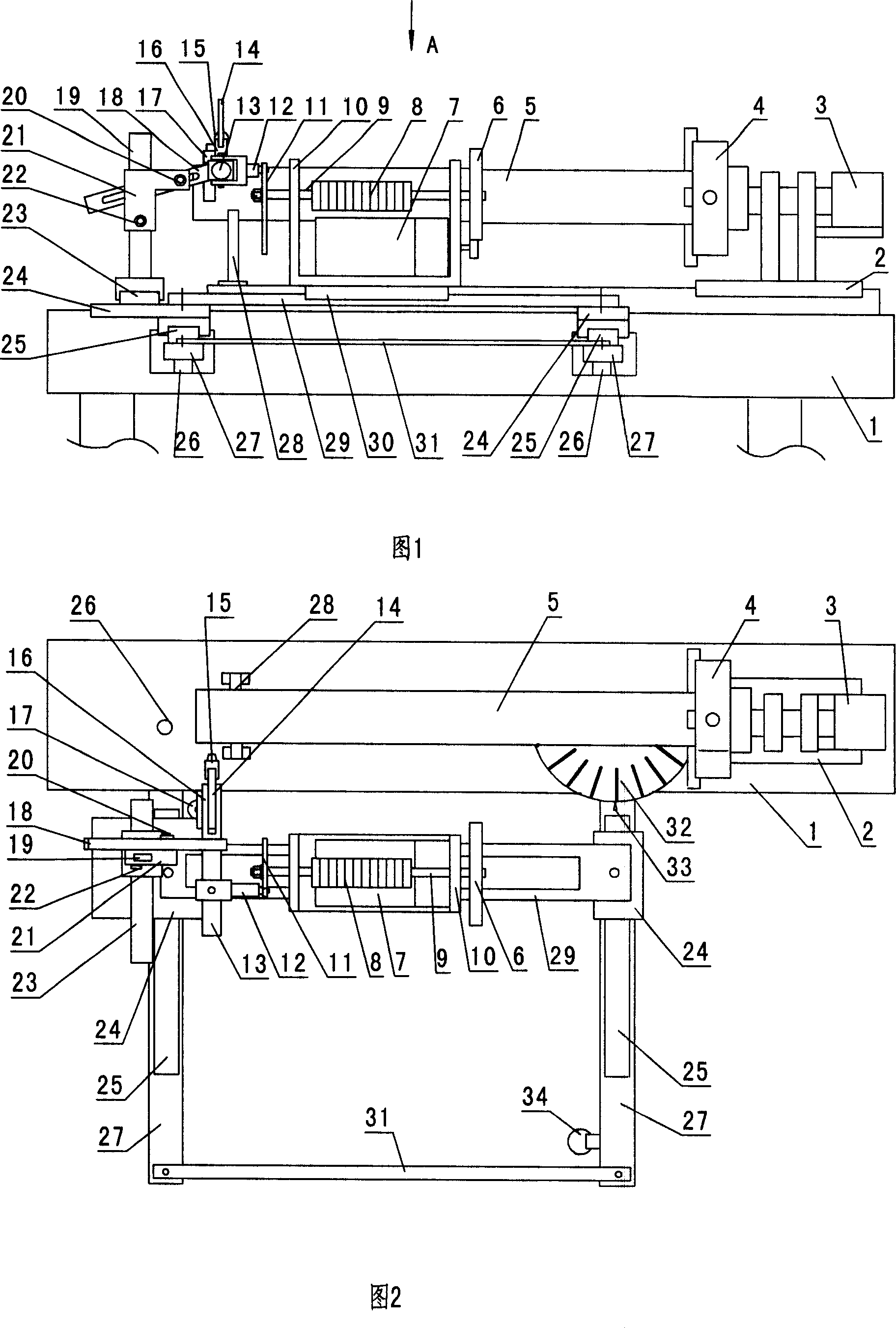

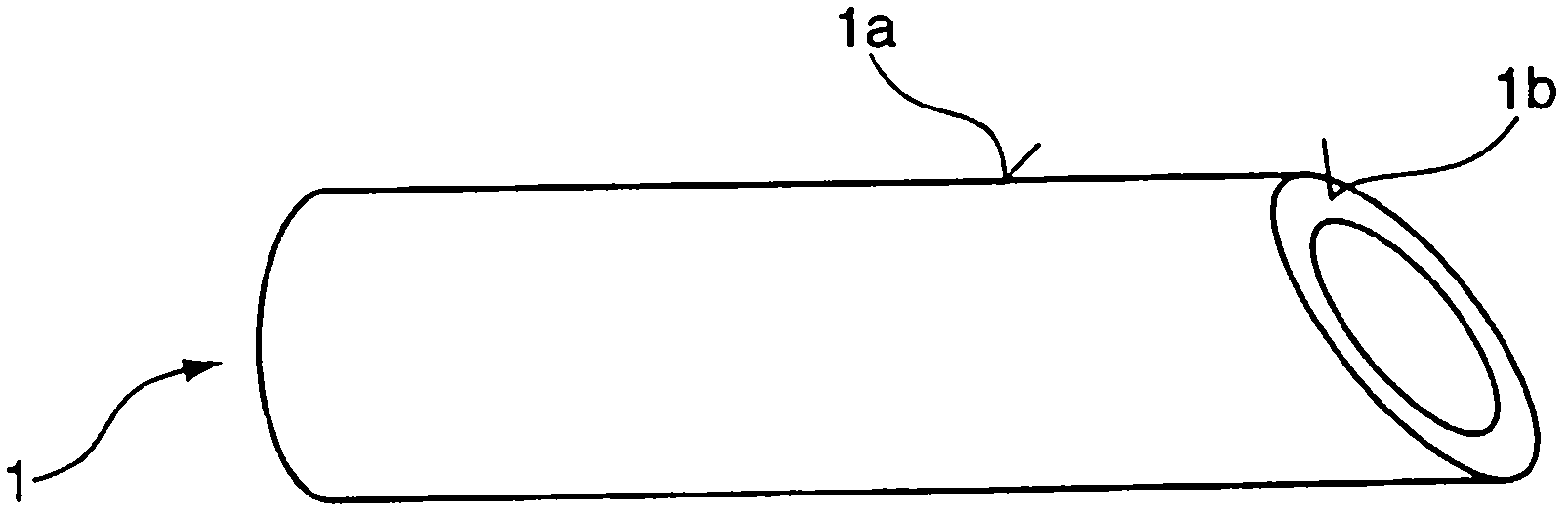

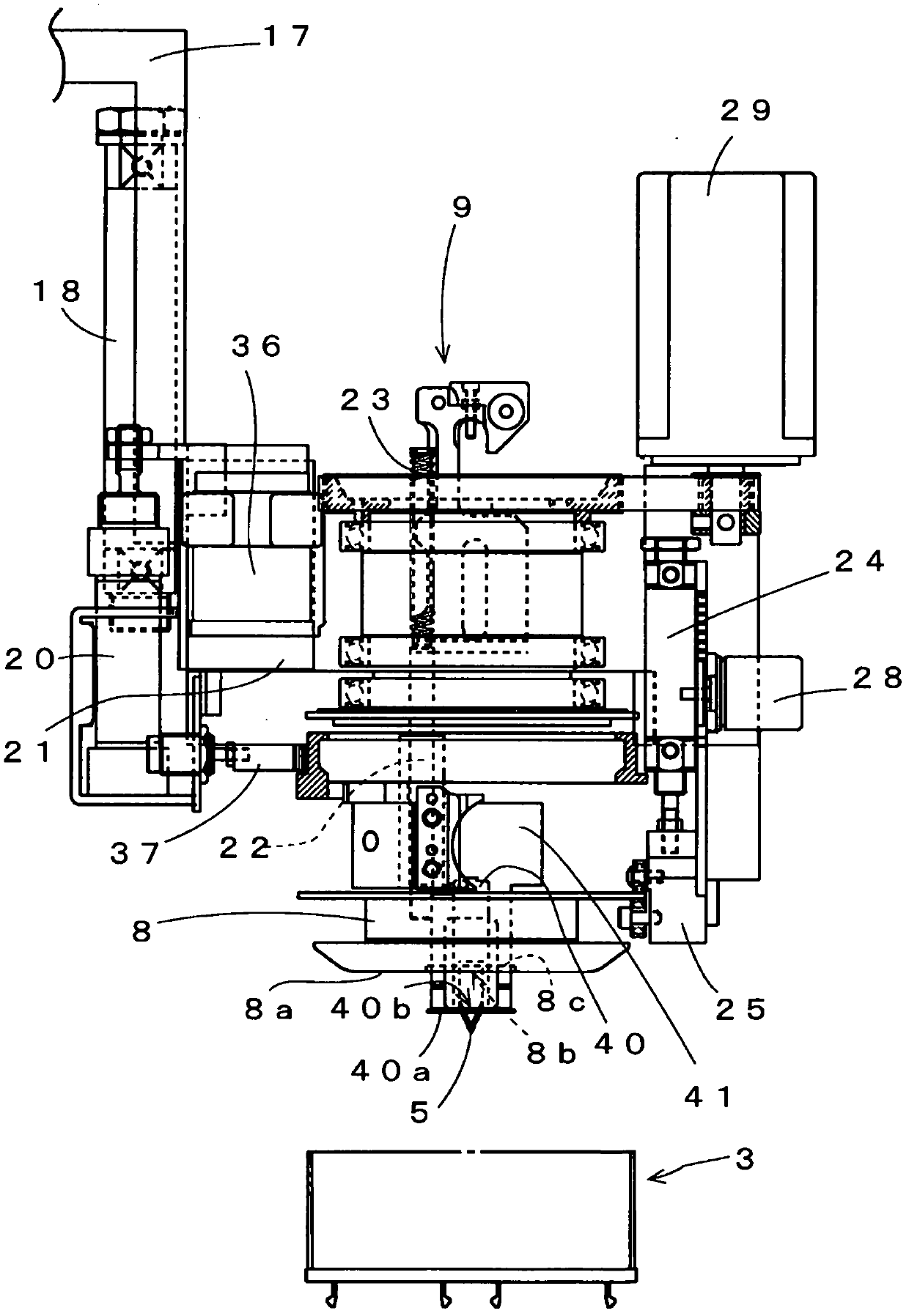

Cutting device for pipe intersecting lines

InactiveCN101011806ABest cutting angleEasy to useCopying process control systemsPlasma welding apparatusLow speedCross cut

A tube cutting device comprises the frame, tube fastening rack and cutting torch enabling the turn of 180 degree of the tube, a low speed rotating shaft parallel with the cut round tube axis reciprocating along the axial, the deflector rod cross bar of the drive hinged with the floating shaft, a high and low location continuously adjustable along the support axial direction, with one end of the support cup jointing with the thrust pole of the floating shaft whose front end having a centripetal cutting torch. It can realize the cross cut, oblique, cross cut eccentric, and oblique cutting, with convenient usage and adaptable diameter, easy for production and cheap in cost, especially suitable for the mass transversal line cutting.

Owner:宋宝安

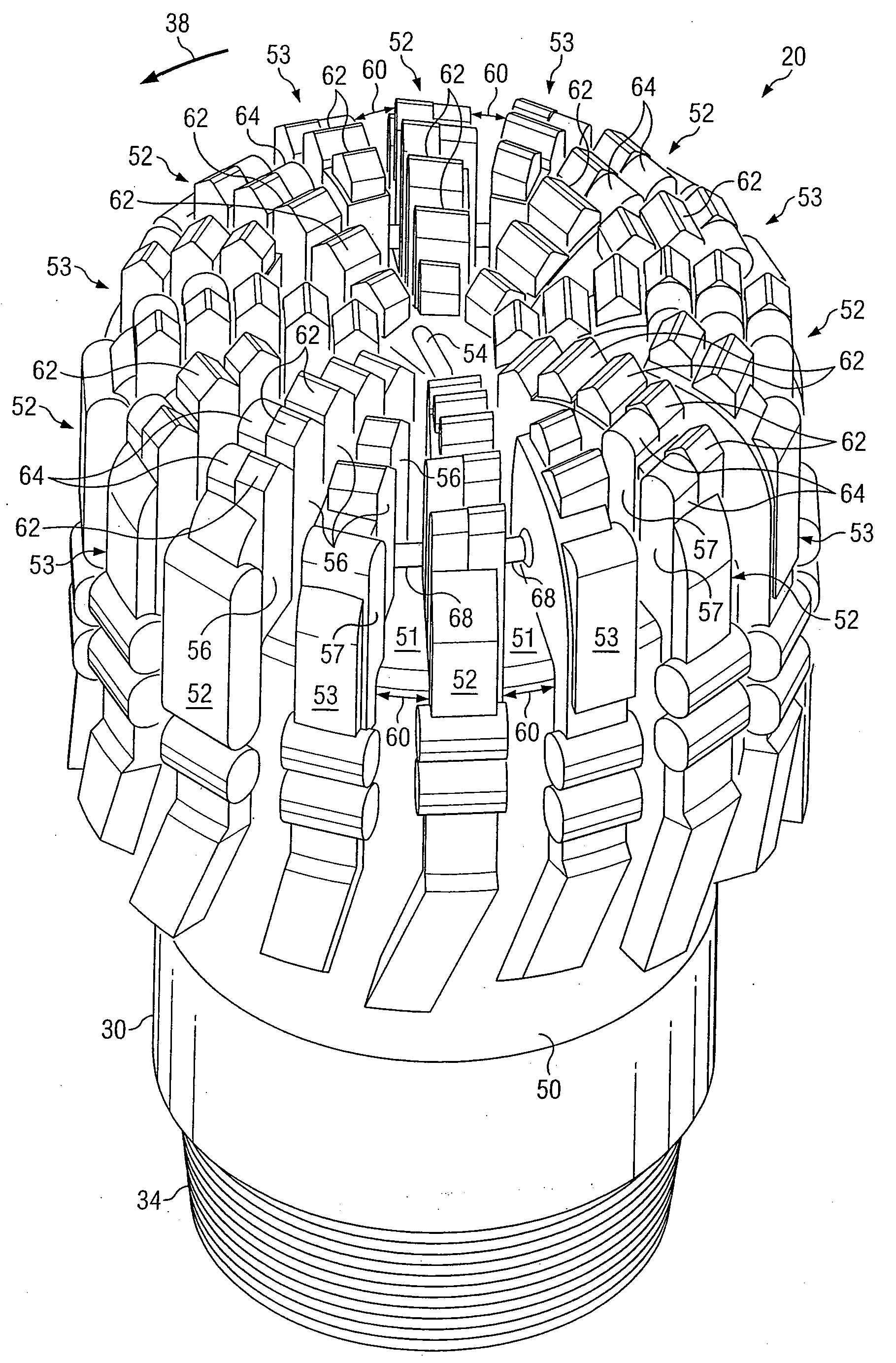

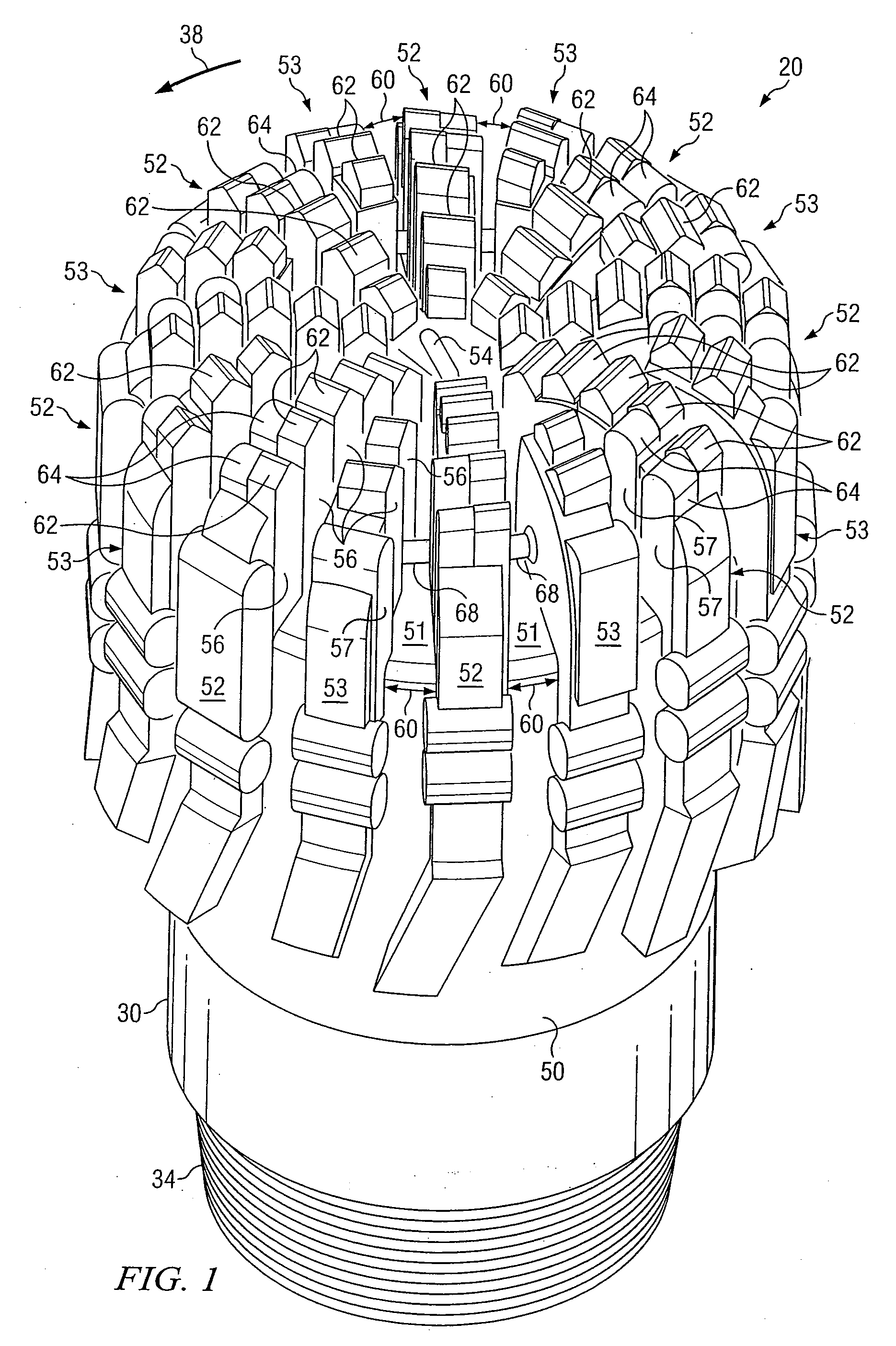

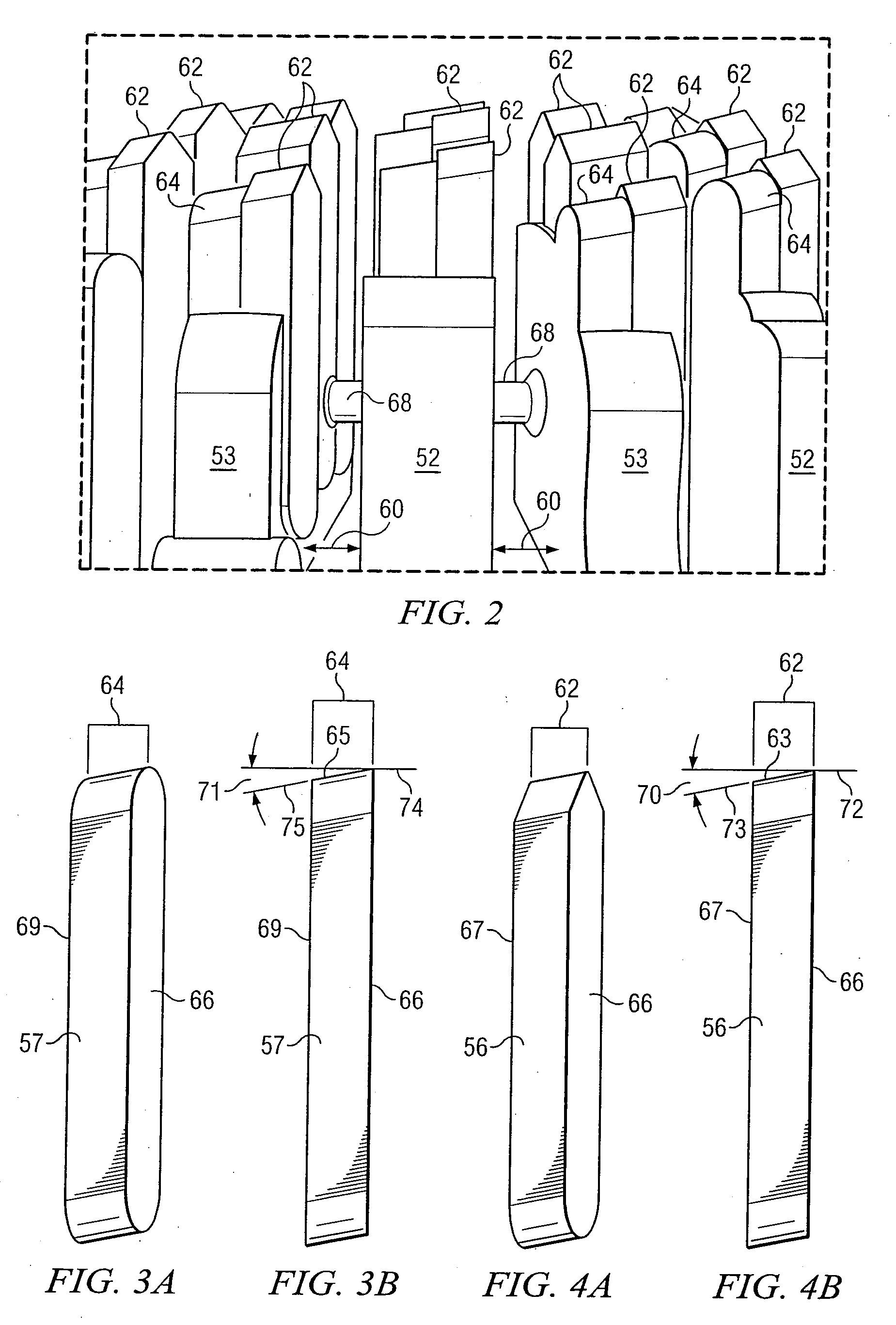

Matrix Drill Bits With Back Raked Cutting Elements

InactiveUS20070215389A1Eliminating and substantially reducing existing problemReduce problem encounteredDrill bitsCutting machinesWell drillingOblique cutting

A matrix drill bit and method of manufacturing a matrix bit having back raked cutting elements is disclosed. In one aspect, a matrix drill bit for well drilling includes a matrix bit body that has a front area in a direction of drilling and two or more diamond impregnated cutting blades protruding from the front area of the matrix bit body. The cutting blades each have a front external surface protruding from the front area of the matrix bit body and present a plurality of back raked downhole interface surfaces in the direction of drilling. The downhole interface surfaces span a leading face and a trailing face where the leading face extends to a first height and the trailing face extends to a second height and the first height is greater than the second height.

Owner:HALLIBURTON ENERGY SERVICES INC

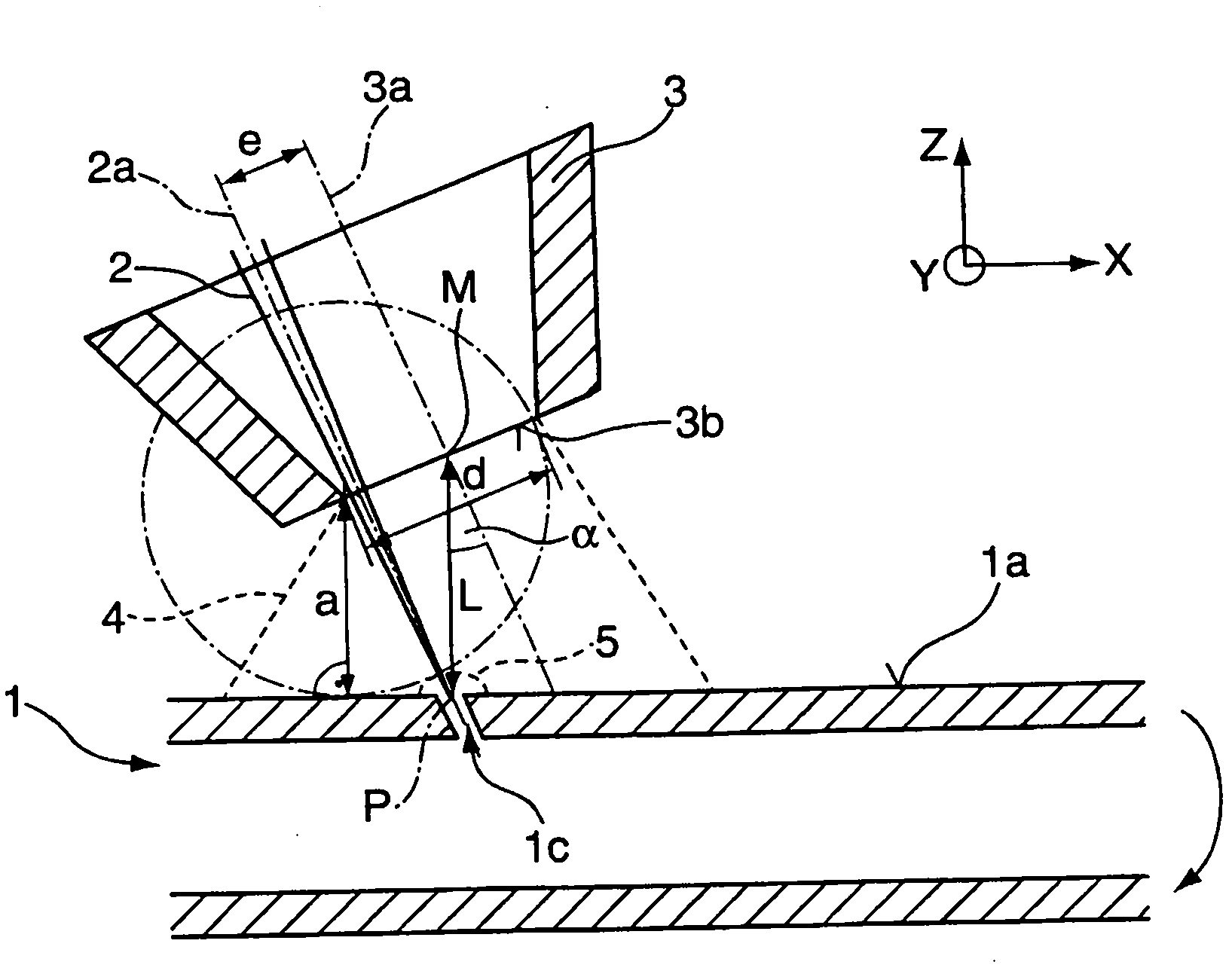

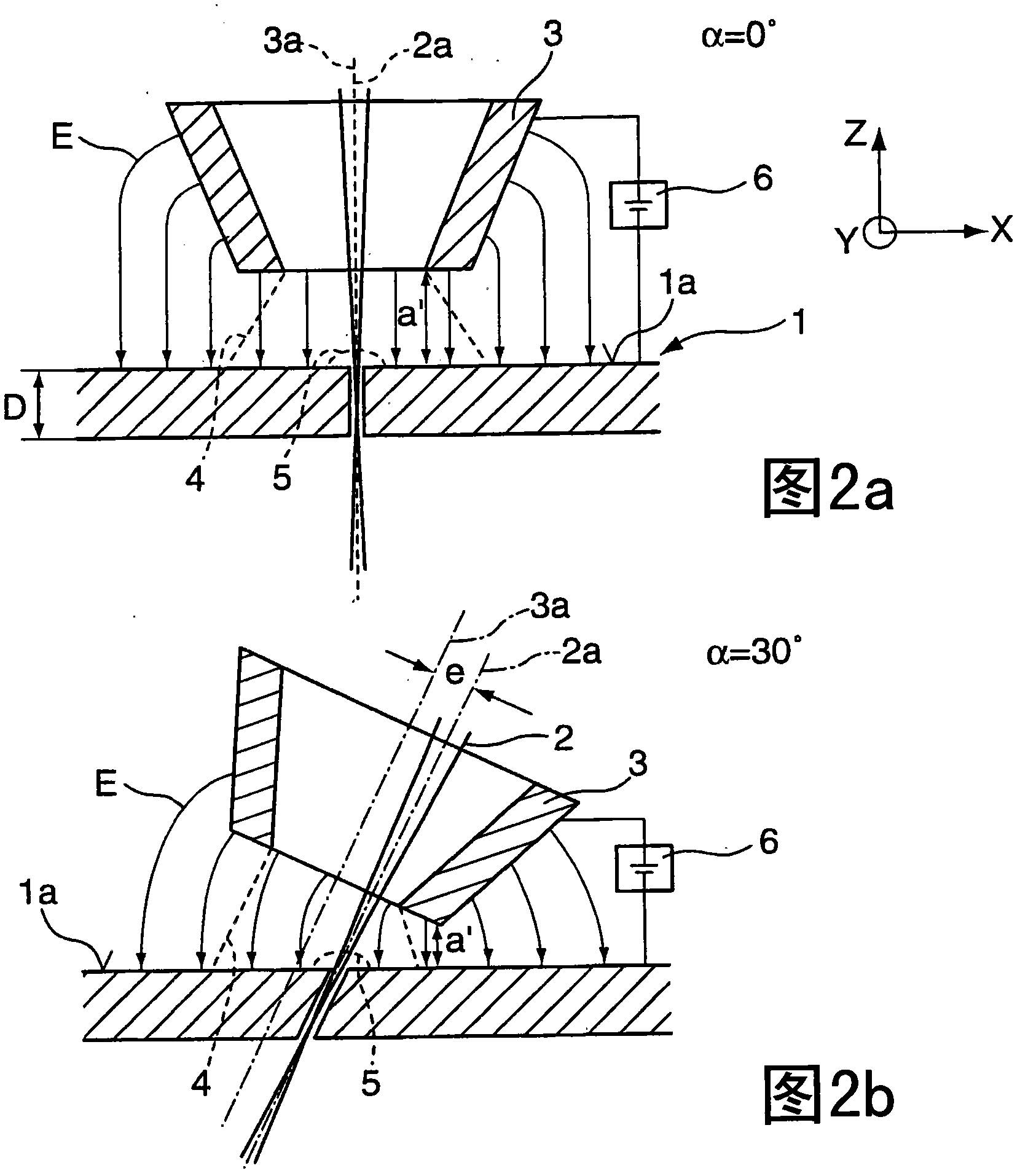

Method for eccentrically orienting a laser cutting beam in relation to a nozzle axis and for cutting at an angle, corresponding laser machining head and laser machining tool

ActiveCN102123818AAvoid dischargeIncreased static pressure levelLaser beam welding apparatusLaser processingHigh-pressure area

The invention relates to a method for the laser beam cutting at an angle of a workpiece (1). According to said method, a supersonic cutting gas stream (4) emerging from a cutting gas nozzle (3) is oriented at an oblique cutting angle (alpha) in relation to the workpiece surface (1a), the workpiece (1) and the laser cutting beam (2) being displaced in relation to each other during laser beam cutting at an angle. The oblique cutting angle (alpha) extends perpendicular to the direction of advance (Y). During the relative movement, the position (P) of the laser cutting beam (2) on the surface of the workpiece (1a) is adjusted such that the laser cutting beam (2) is incident on the surface of the workpiece (1a) in a high pressure area (5) formed within the supersonic cutting gas stream (4). The invention also relates to a laser machining tool for carrying out said method.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

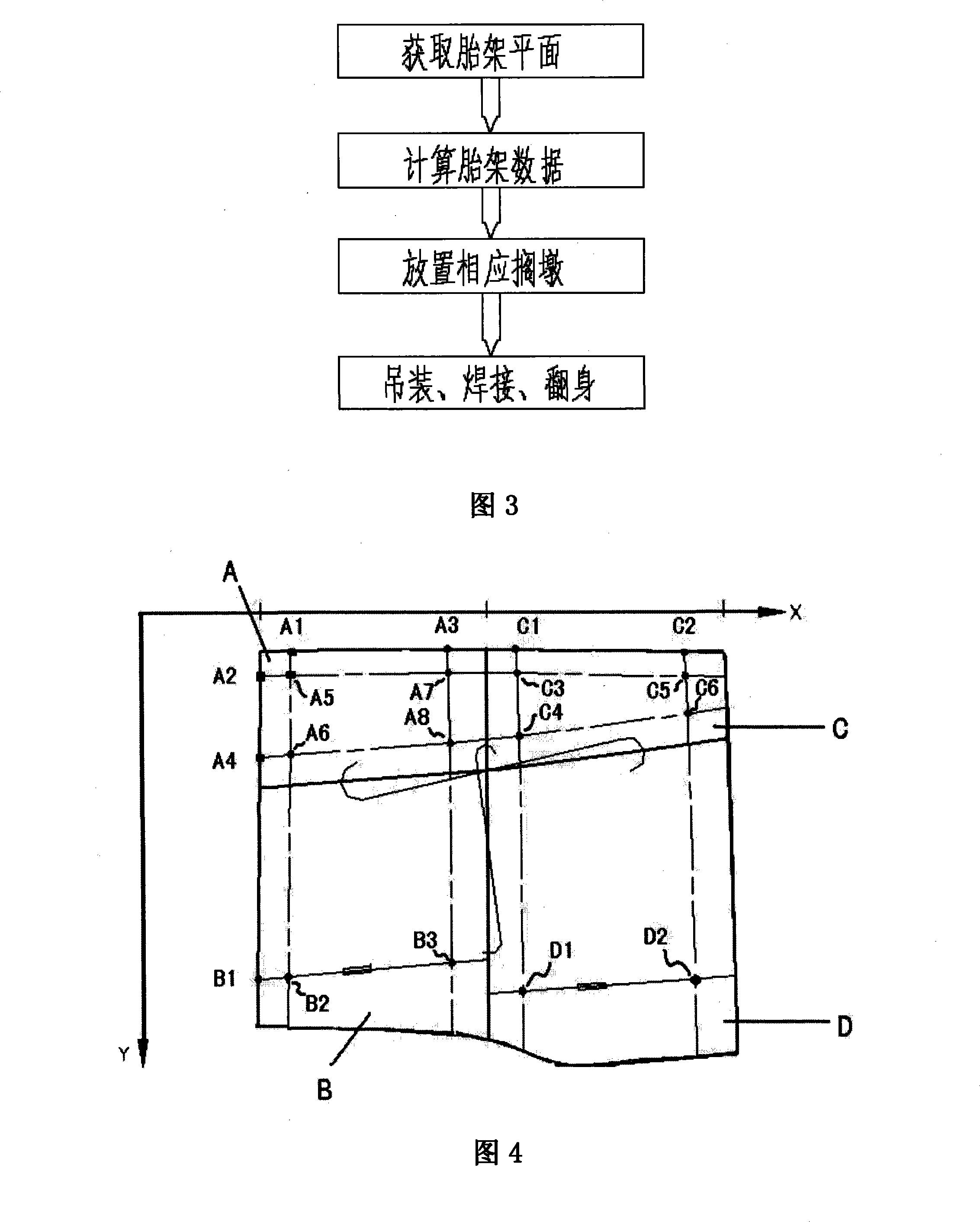

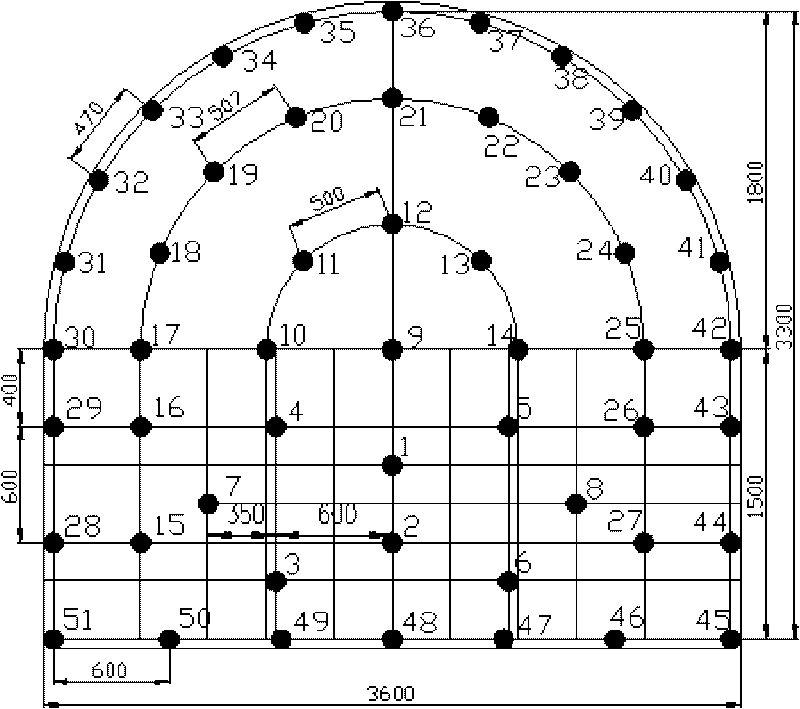

Sectionalized assembling method for ship bow luff part

The invention relates to a total assembly method for the section-dividing of shipping and shipboard parts, used for solving the problems of inconvenient operation and poor precision when the total assembly of a plurality of sections is carried out; the invention comprises the steps that (1) the plurality of sections are seen as an integrated section, and the assembly jig plane is obtained through longitudinal, transverse and oblique cutting on the integrated section; (2) a plurality of key points are obtained on the integrated section, the 3-d coordinates of all key points are found out and the vertical distance from each key point to the assembly jig plane; (3) the ground is taken as the assembly jig plane and supporting columns are correspondingly arranged on the lower part of all the key points; (4) a plurality of sections are respectively and correspondingly hung on the supporting columns for positioning, assembling and welding and overturning, thus implementing the total assembly of all sections. The method of the invention positions all unit sections to be totally assembled according to dimensions, thus reducing energy consumption and improving total assembly efficiency; the process solves the difficulty of large section for total assembly with large bidirectional linear change, thus saving a plurality of assembly jig materials and greatly improving the site turnaround efficiency of the total assembly, and improving the operation environment of the constructors.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

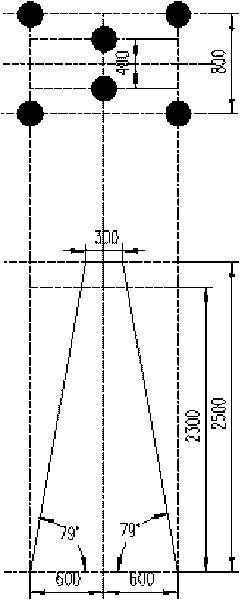

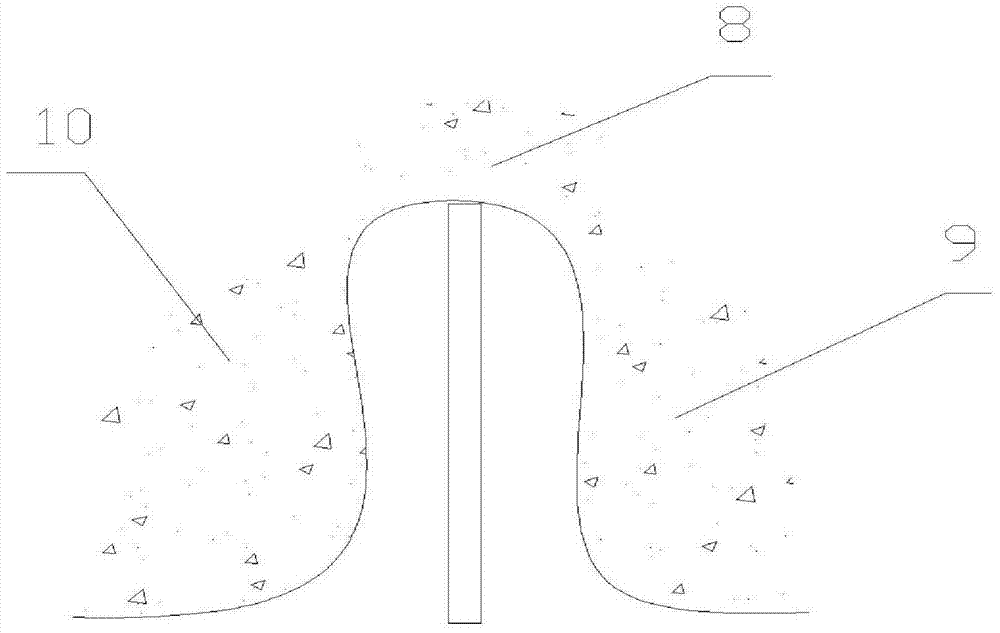

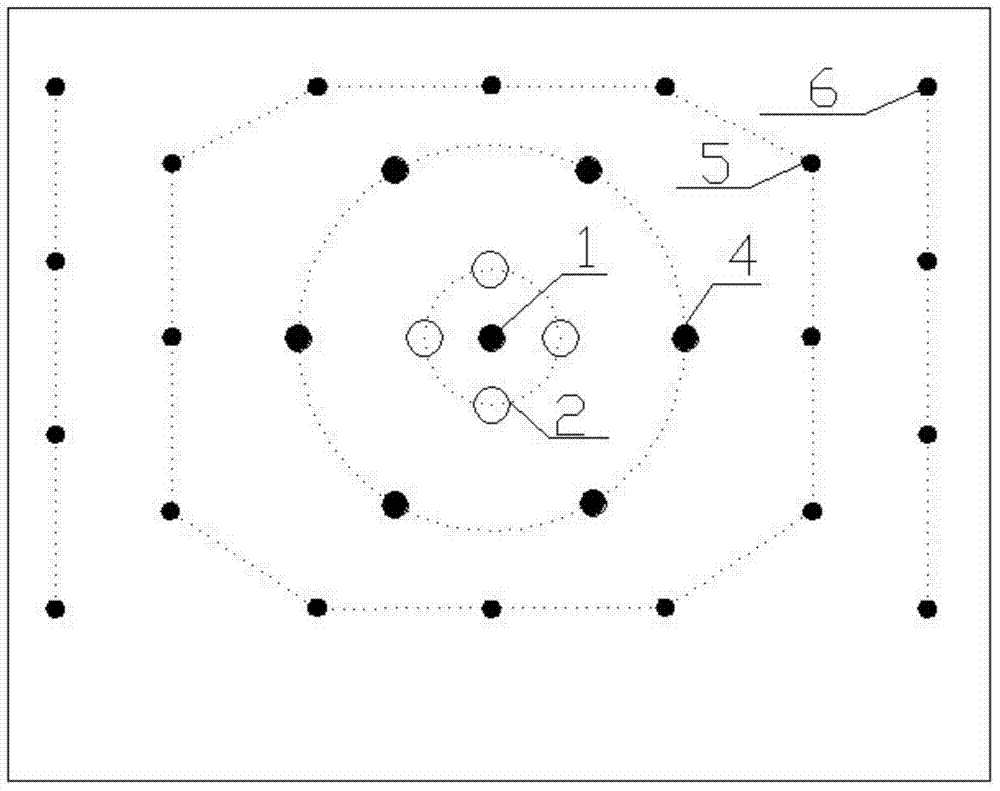

Tunnel medium-length hole smooth blasting method

InactiveCN101738148AImprove blasting effectEasy to operate downholeBlastingEngineeringOblique cutting

The invention provides a tunnel blasting method, in particular to a medium-length hole smooth blasting method. The method can not only realize good medium-length hole smooth blasting effect and facilitate the downhole operation of a coal mine, but also realize the more extensive applicability. The portable energy directional smooth blasting technology and the combined cutting blasting technology are adopted in the method. The tunnel blasting method mainly solves the two key technologies of the smooth blasting technology and the cutting blasting technology, and the full-section blasting process and the parameters are set on the basis of the two key technologies, thereby achieving the medium-length hole smooth blasting effect that the desired hole depth is not more than 3m. To this end, theportable energy directional smooth blasting technology is adopted, thereby realizing the good smooth blasting effect under the conditions of simple operation and low cost; and the combined cutting blasting technology with combined oblique cut and shatter cut is adopted, thereby achieving the good medium-length hole smooth blasting effect in middle explosive and difficult explosive rock bodies.

Owner:NANJING INST GENERAL INST OF COAL SCI +1

Double-sided, indexable cutting insert with ramping capability and cutting tool therefor

A double-sided, indexable cutting insert for a milling cutter includes a first surface, a second surface, and side surfaces. Major cutting edges are defined at an intersection between the first and second surfaces and side surfaces. Minor cutting edges and ramping cutting edges are defined at the intersection between the first and second surfaces and side surfaces. The cutting insert is mounted in a milling cutter having a bottom seating surface formed at an angle with respect to a central, rotational axis of the milling cutter, which provides superior performance for both milling and ramping cutting operations.

Owner:KENNAMETAL INC

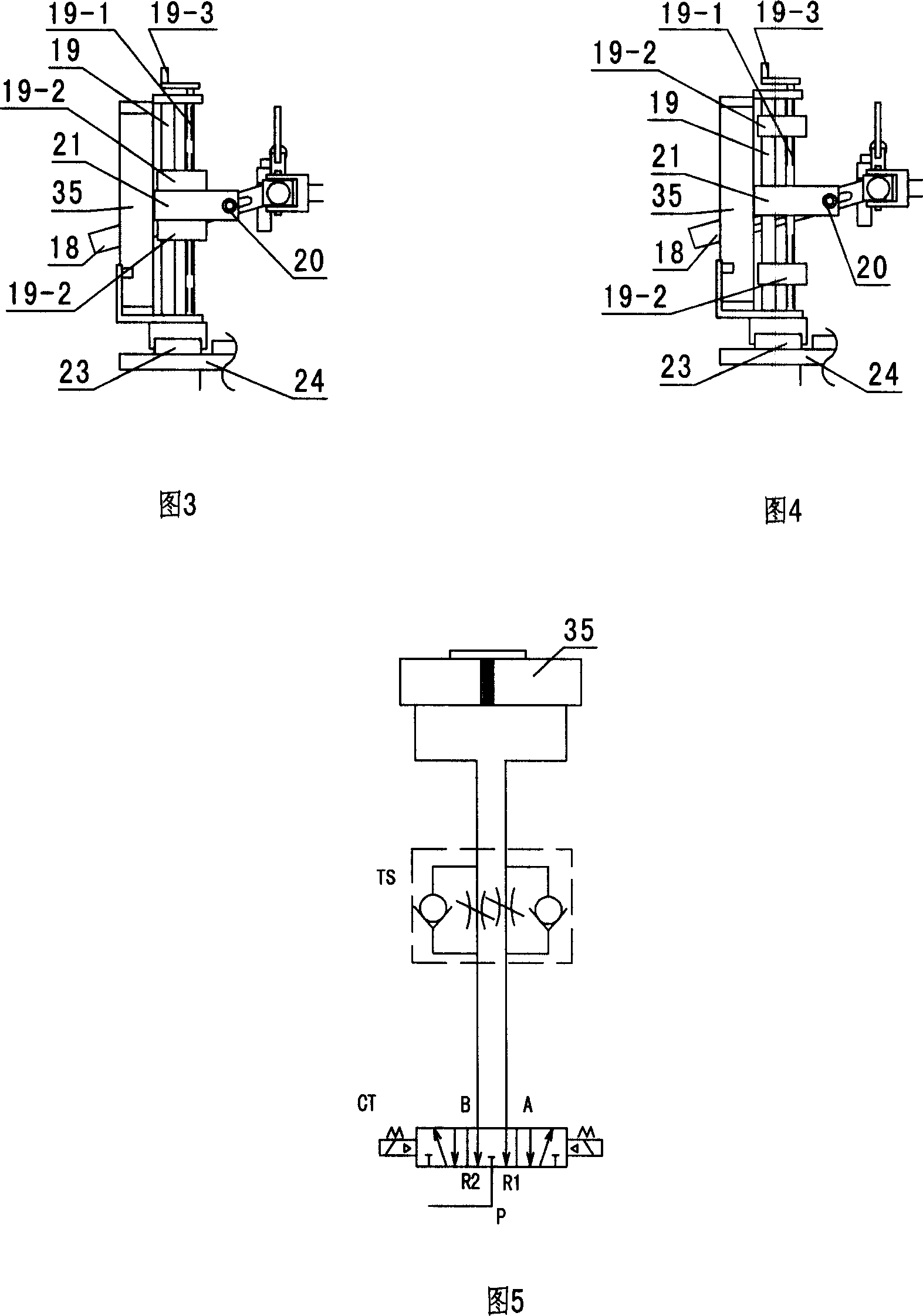

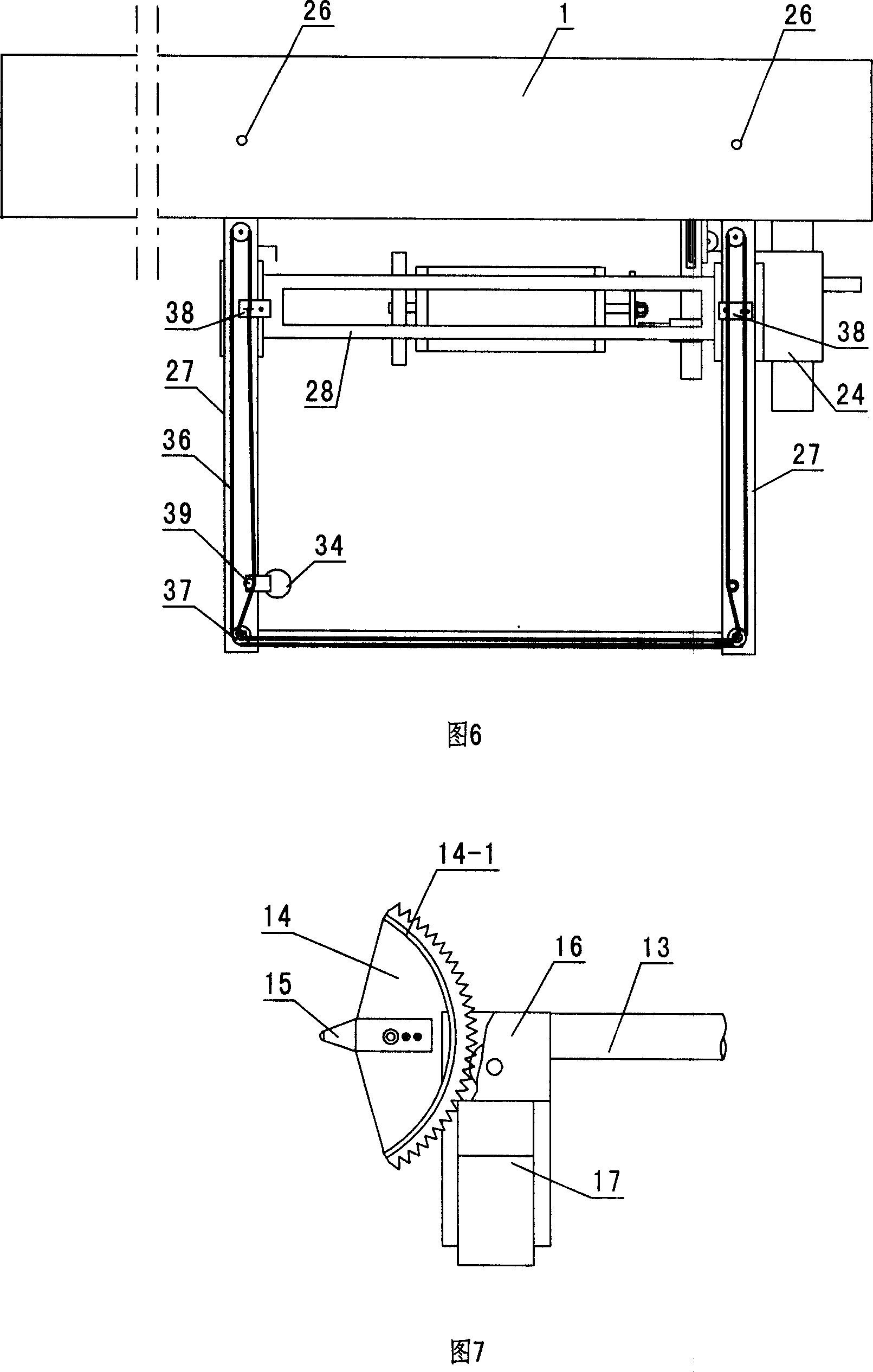

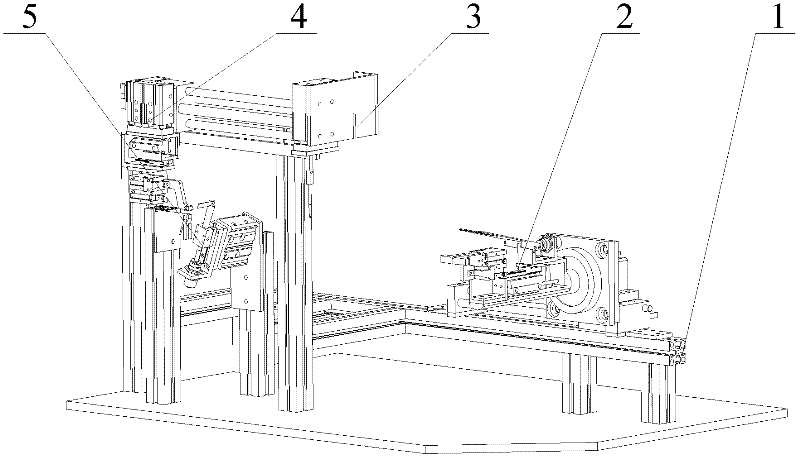

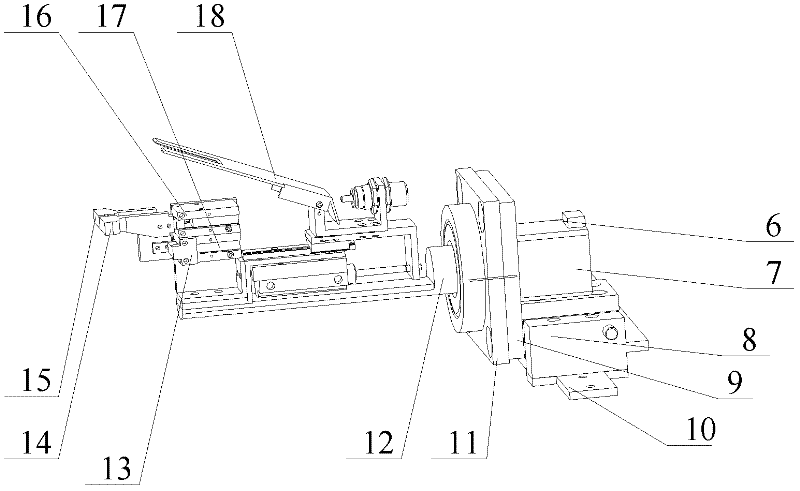

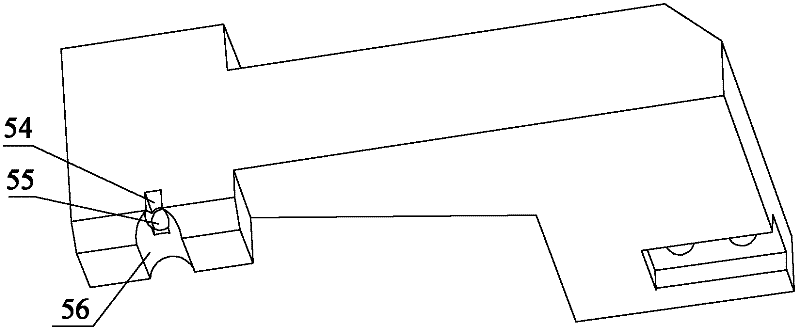

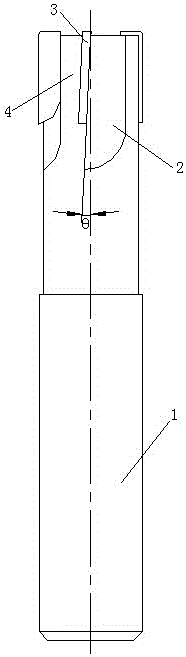

Adjustable rotary oblique-cutting automatic grafting device and method

The invention provides an adjustable rotary oblique-cutting automatic grafting device and a method. The device comprises a worktable, a rack, and a scion clamping and conveying mechanism, a scion cutting mechanism, a stock perforating mechanism and a stock clamping and conveying mechanism which are sequentially arranged from the left to the right. The scion clamping and conveying mechanism comprises a scion clamping drive mechanism, a pneumatic scion claw and a scion chuck which are sequentially connected from the top to the bottom, wherein the scion clamping drive mechanism is connected onto the worktable through the rack. The scion cutting mechanism comprises a scion cutting drive mechanism, a cutter mechanism and a scion cutting positioning block, wherein the scion cutting drive mechanism is connected with the cutter mechanism, the scion cutting positioning block is arranged at the front side of the cutter mechanism, and a cutter guide groove and a positioning groove are arranged on the side wall of the scion cutting positioning block. The scion cutting drive mechanism, the scion cutting positioning block and the stock clamping and conveying mechanism are respectively fixed on the worktable through the rack. The adjustable rotary oblique-cutting automatic grafting device has the advantages of convenience in operation, simple process and the like.

Owner:马稚昱 +1

Staggered PCD milling cutter used for processing reinforced fiber polymer and method

The invention discloses a staggered PCD milling cutter used for processing reinforced fiber polymer and a method, relates to the technical field of milling cutters and solves the problems that when a traditional milling cutter is adopted for processing CFRP, the cutter is rapid to wear, the processing surface is layered and torn, burrs are caused, and the processing efficiency is low. Four milling cutter blade grooves and four chipping grooves are arranged in the front end of the outer circumference of a hard alloy cutter body, wherein the four milling cutter blade grooves are obliquely arranged; a PCD milling cutter blade is welded in each milling cutter blade groove; the oblique directions of every two adjacent PCD milling cutter blades are opposite; the oblique cutting edges of every two PCD milling cutter blades with the same oblique directions are distributed in a staggered way; and the chipping grooves are arranged on one side of front cutter faces of the PCD milling cutter blades and closely adjoin the PCD milling cutter blades. The method comprises the steps of grinding the four chipping grooves and the four milling cutter grooves; welding the four milling cutter blades in the four milling cutter grooves; and grinding the end tooth cutting edges and the peripheral tooth cutting edges of the four PCD milling cutter blades. The staggered PCD milling cutter is used for milling the reinforced fiber polymer.

Owner:HARBIN UNIV OF SCI & TECH

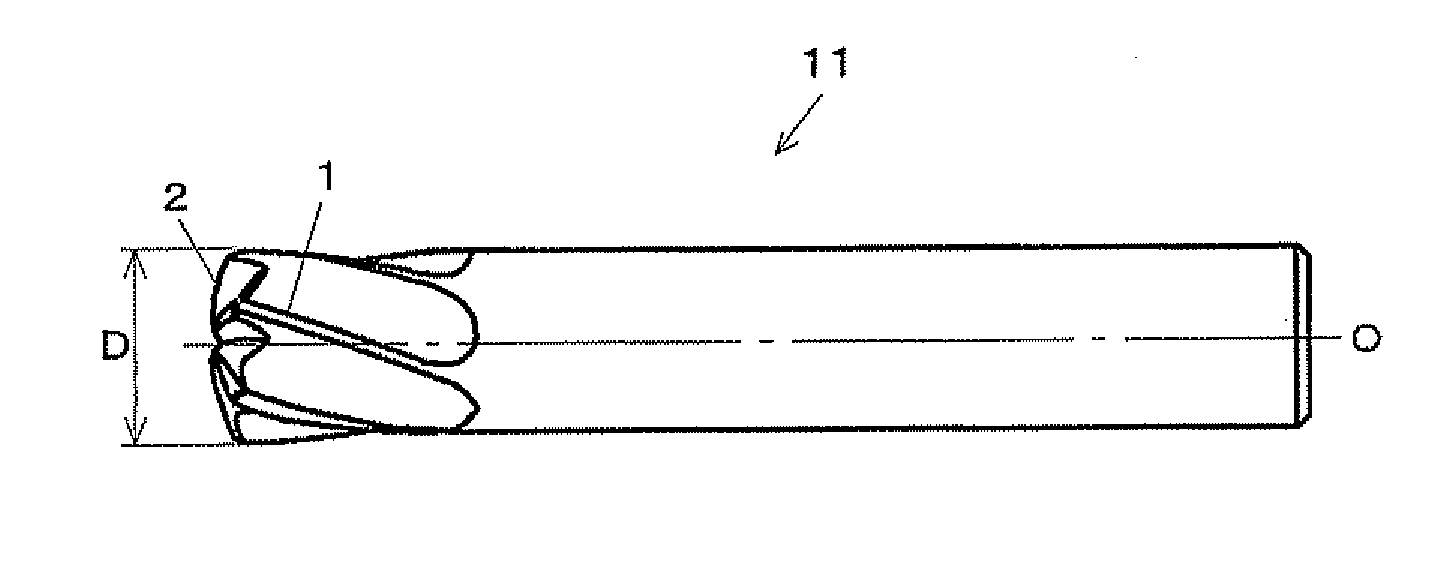

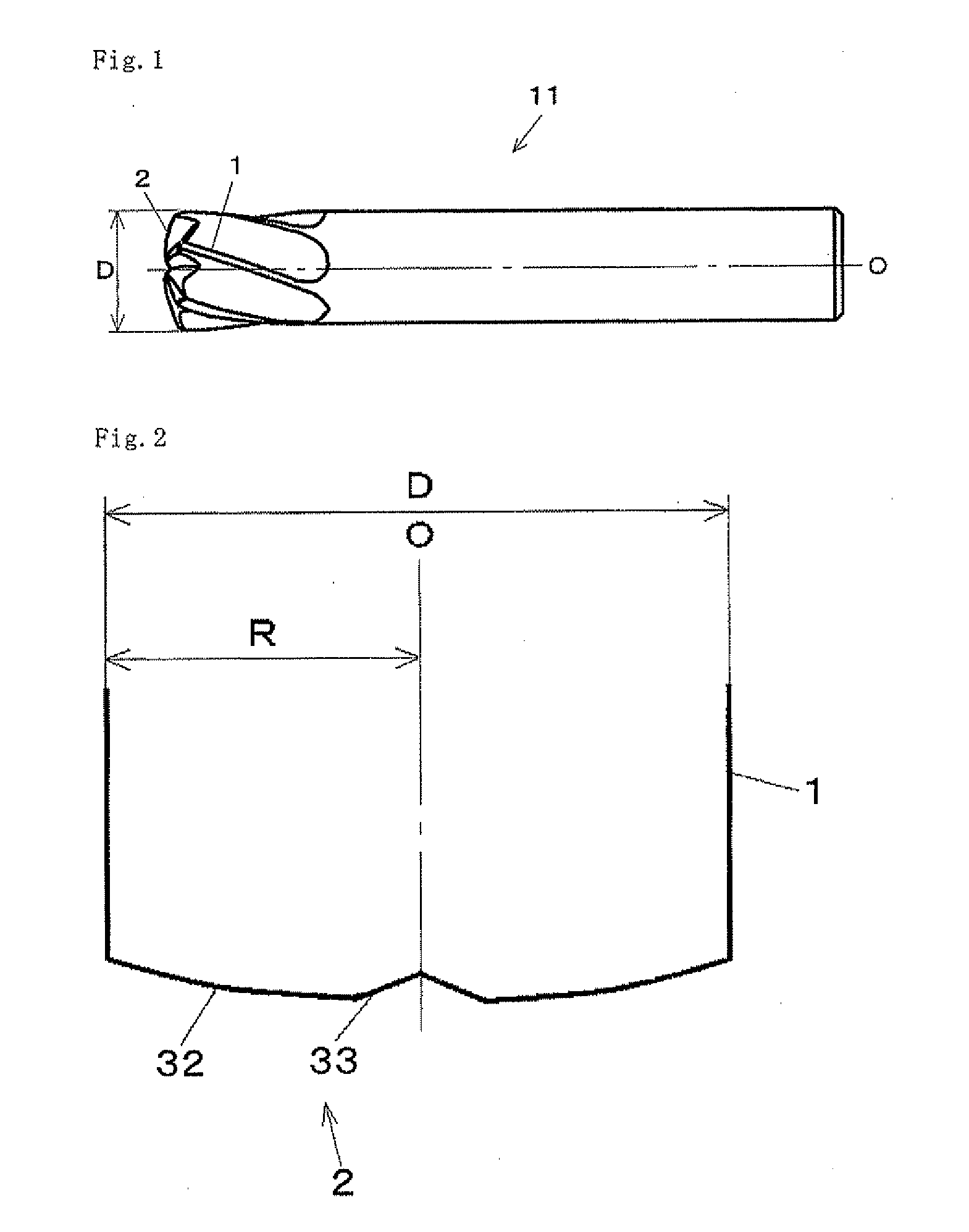

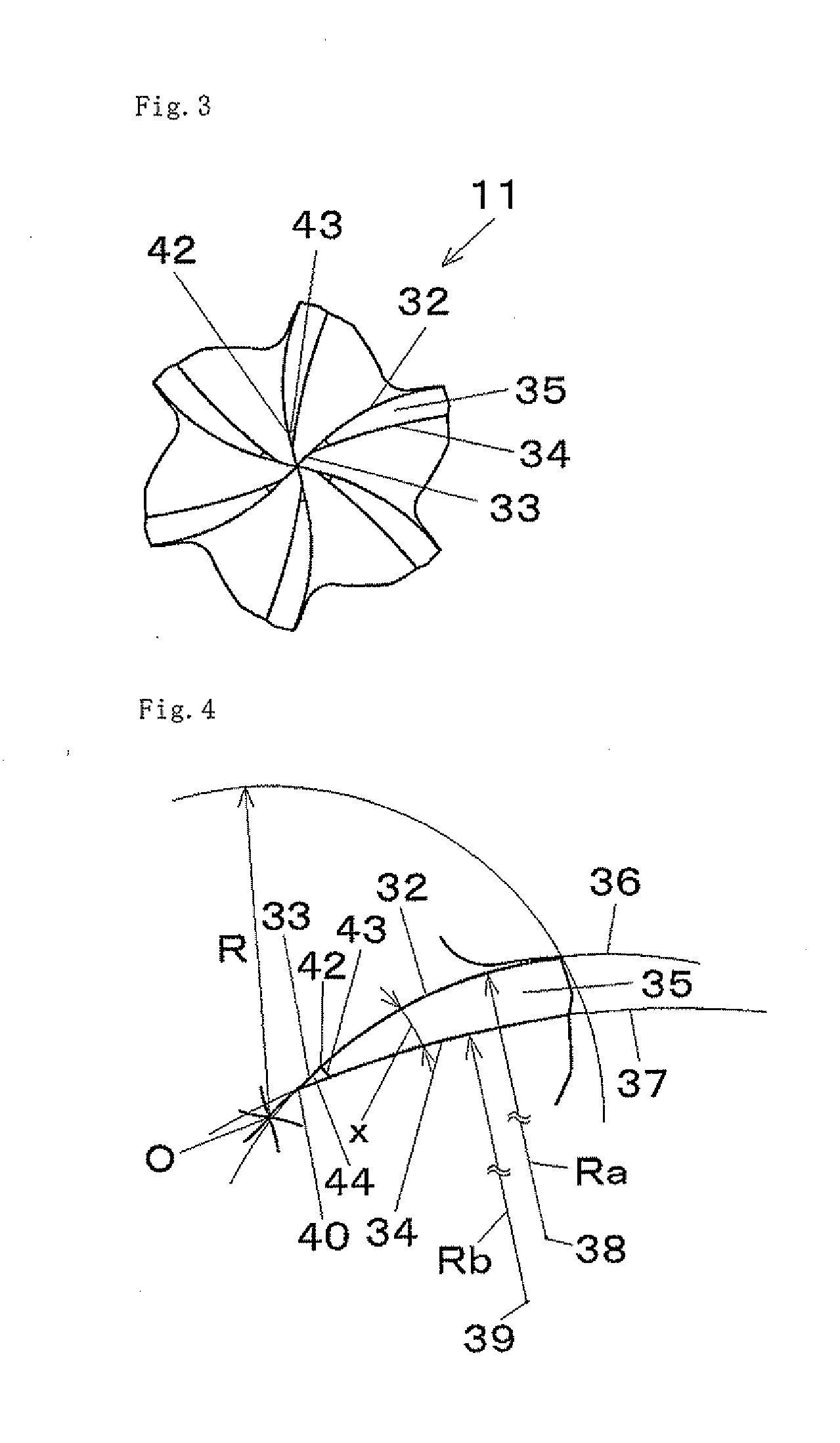

End mill for cutting of high-hardness materials

ActiveUS20140003873A1High cutting rateImprove cutting efficiencyMilling cuttersShaping cuttersMilling cutterOblique cutting

The present invention relates to an end mill, which comprises a bottom edge, which is composed of an arc-shaped cutting edge that is curved when seen from a direction perpendicular to the tool axis and a linear or curved medium-to-low inclination cutting edge, and a peripheral edge, wherein, when seen from a direction parallel to the tool axis, the arc-shaped cutting edge and a rim at the rearward side of the rotation at a flank of the arc-shaped cutting edge are curved with radii of curvatures, and the radius of curvature of the arc-shaped cutting edge is smaller than the radius of curvature of the rim at the rearward side of the rotation at the flank of the arc-shaped cutting edge.

Owner:HITACHI TOOL ENG LTD

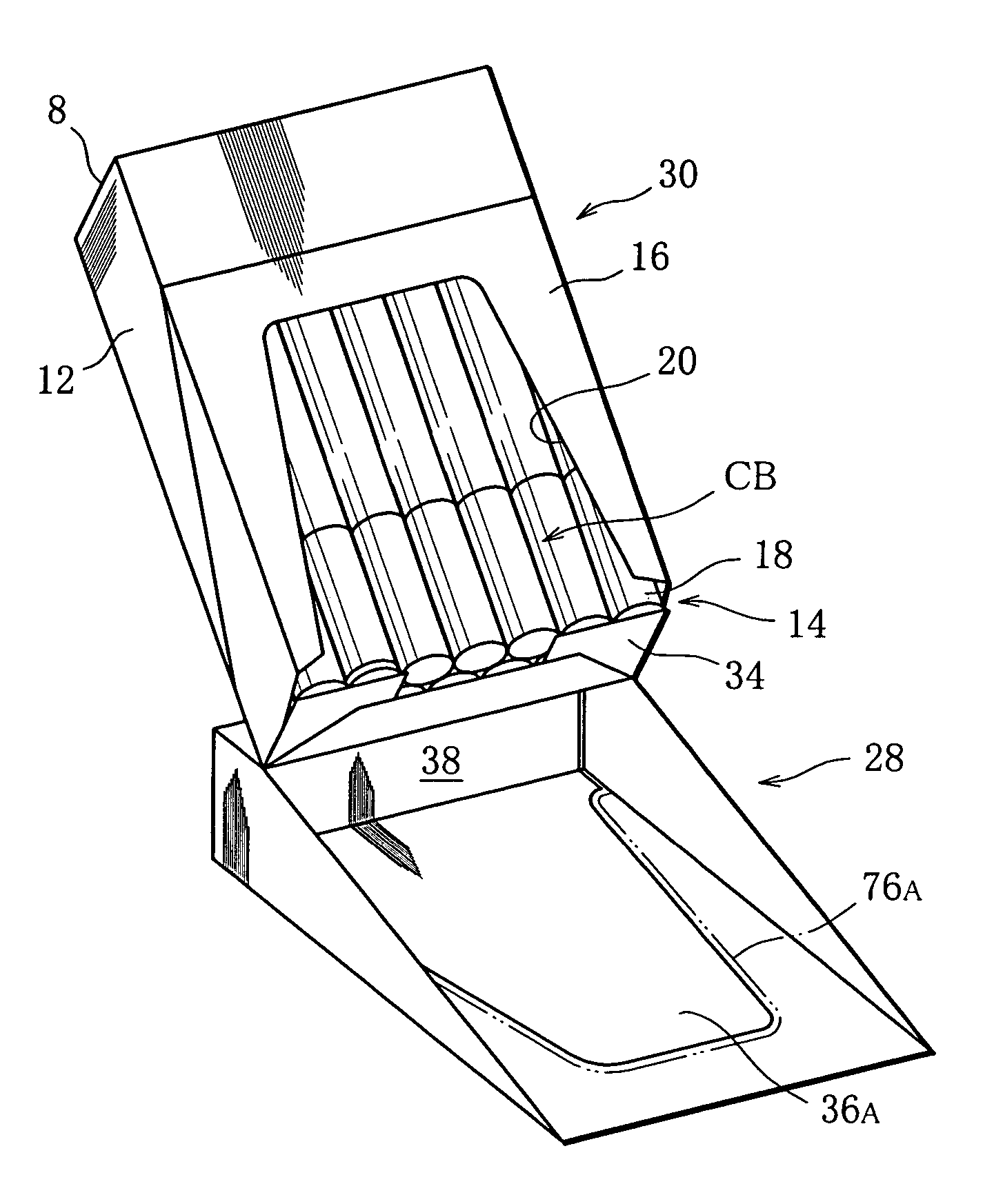

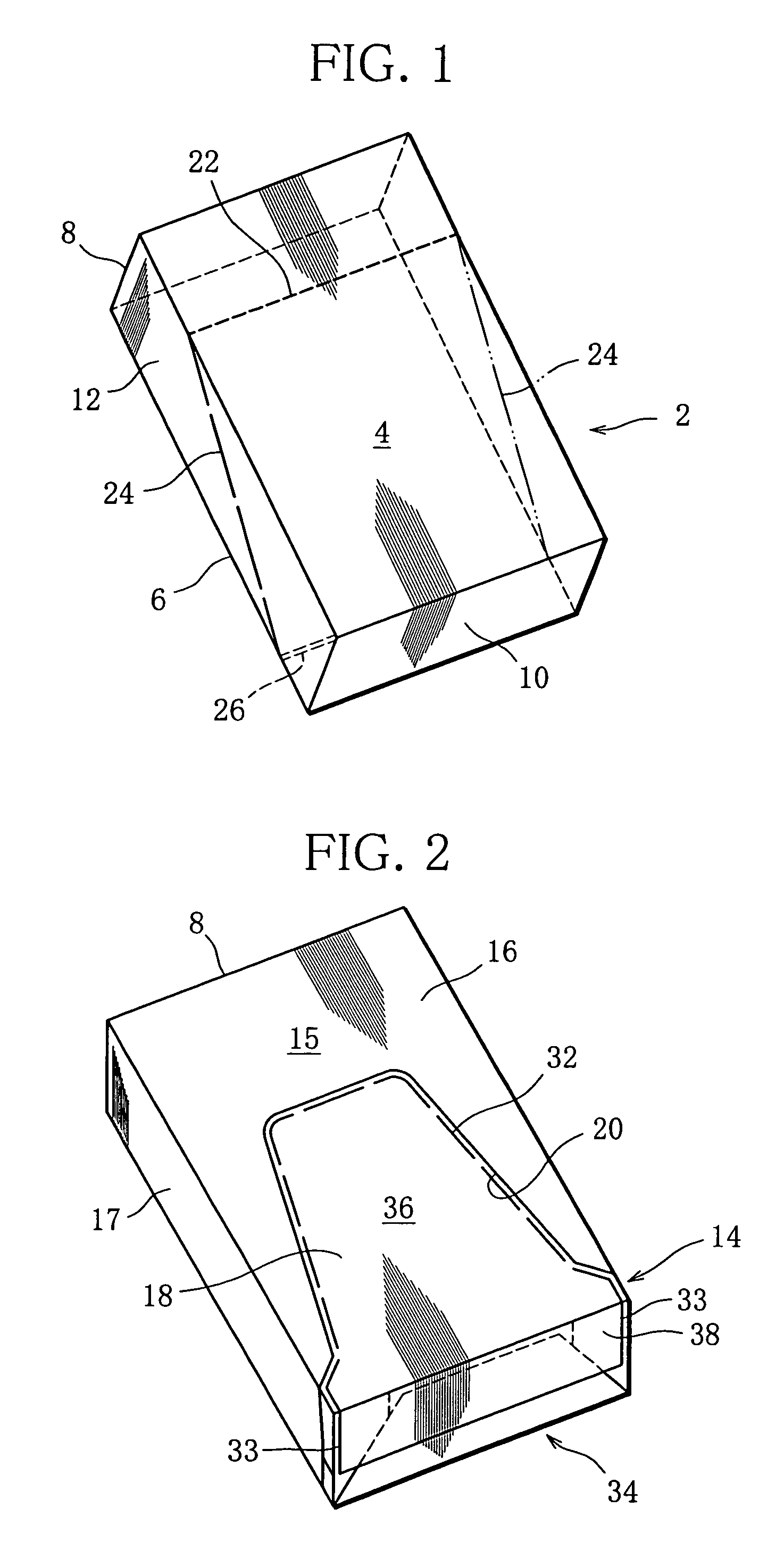

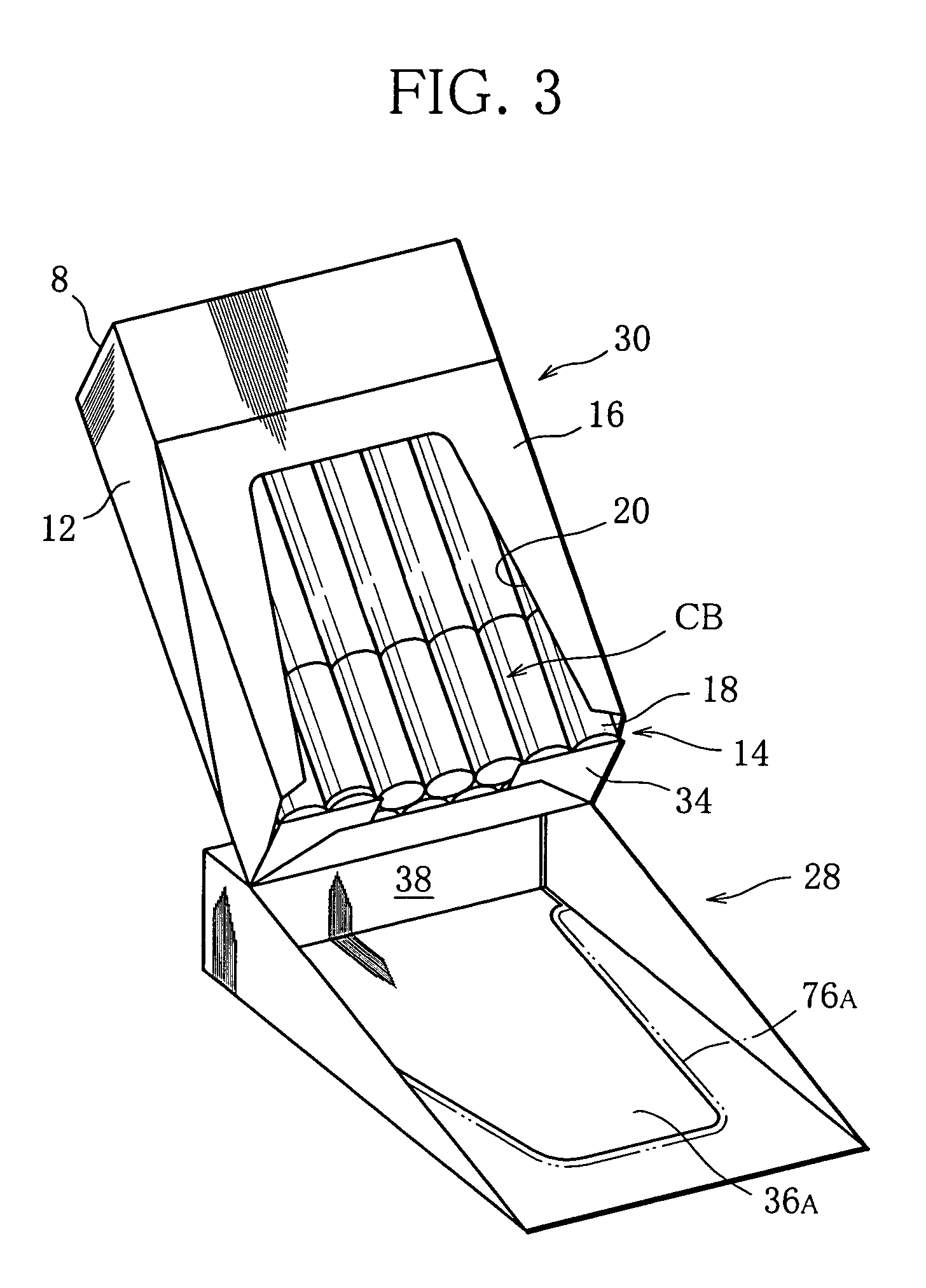

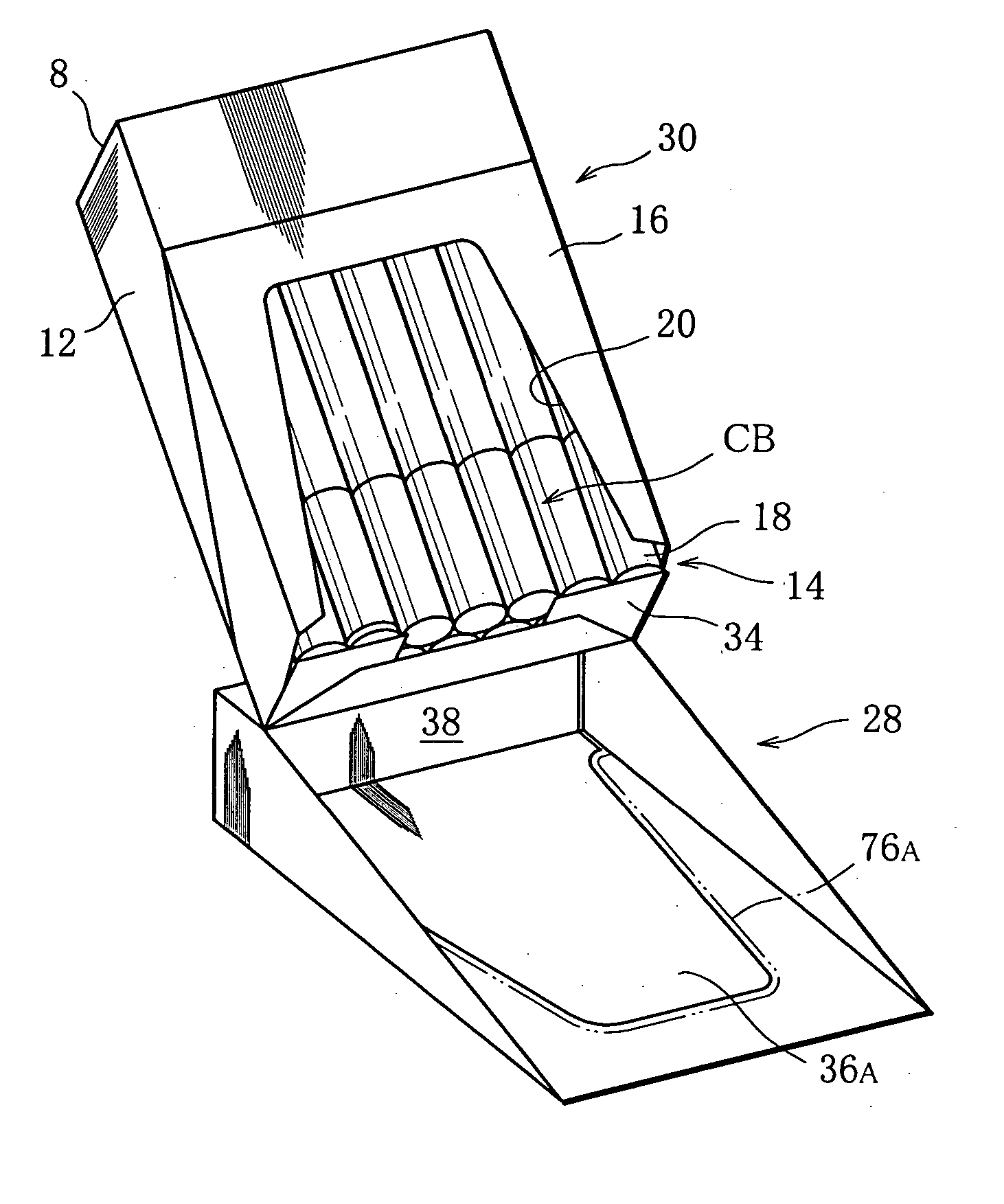

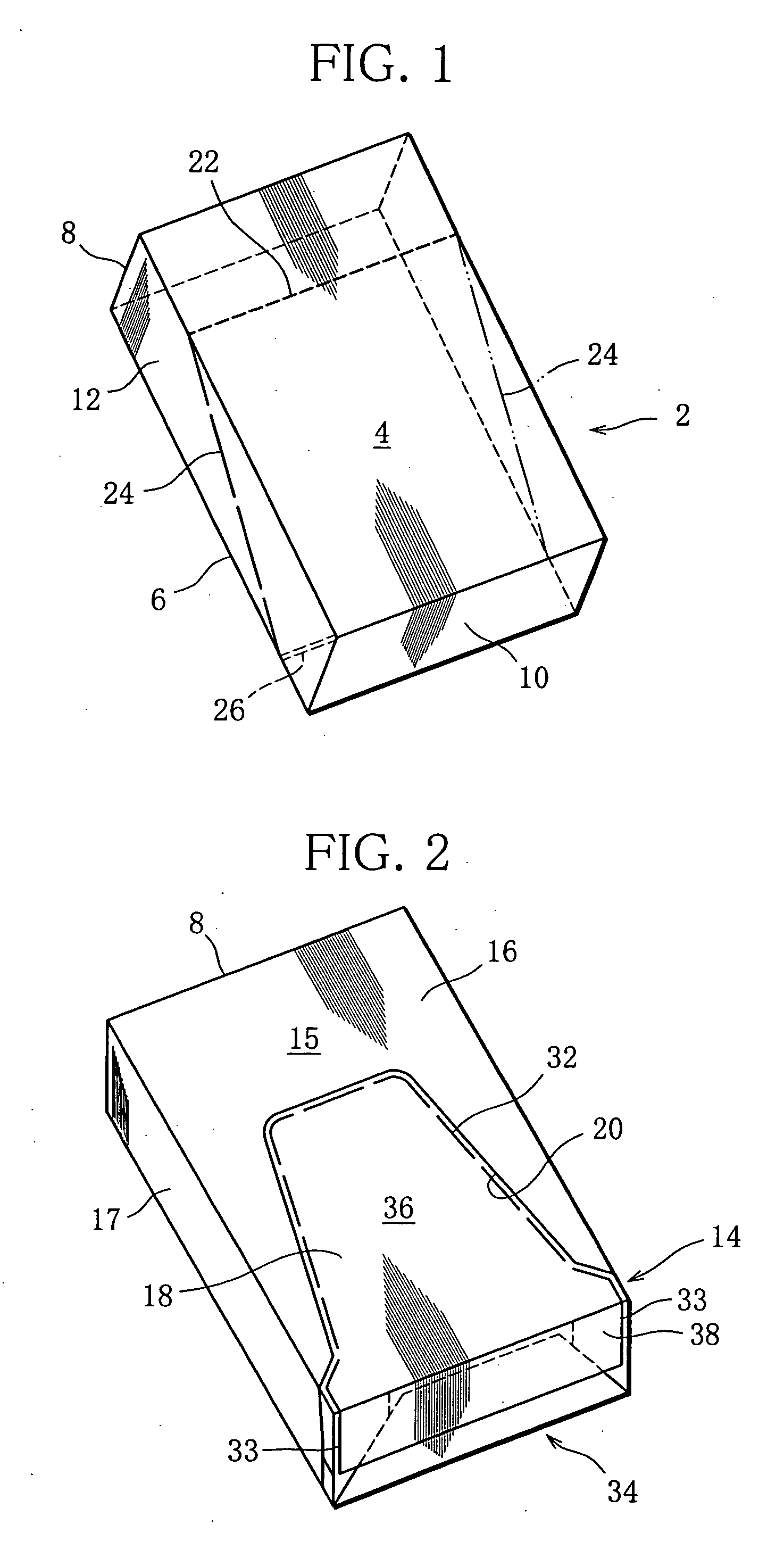

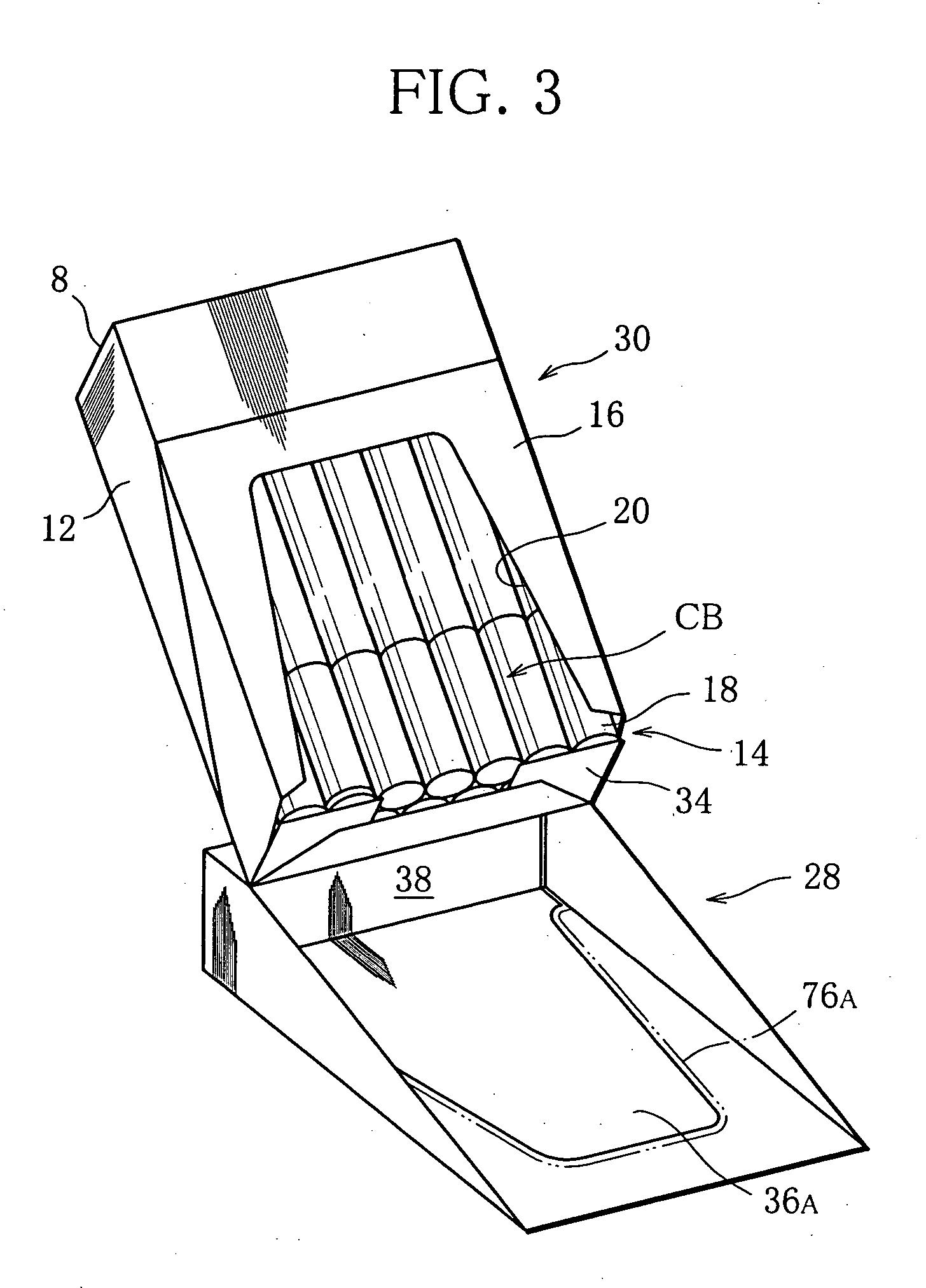

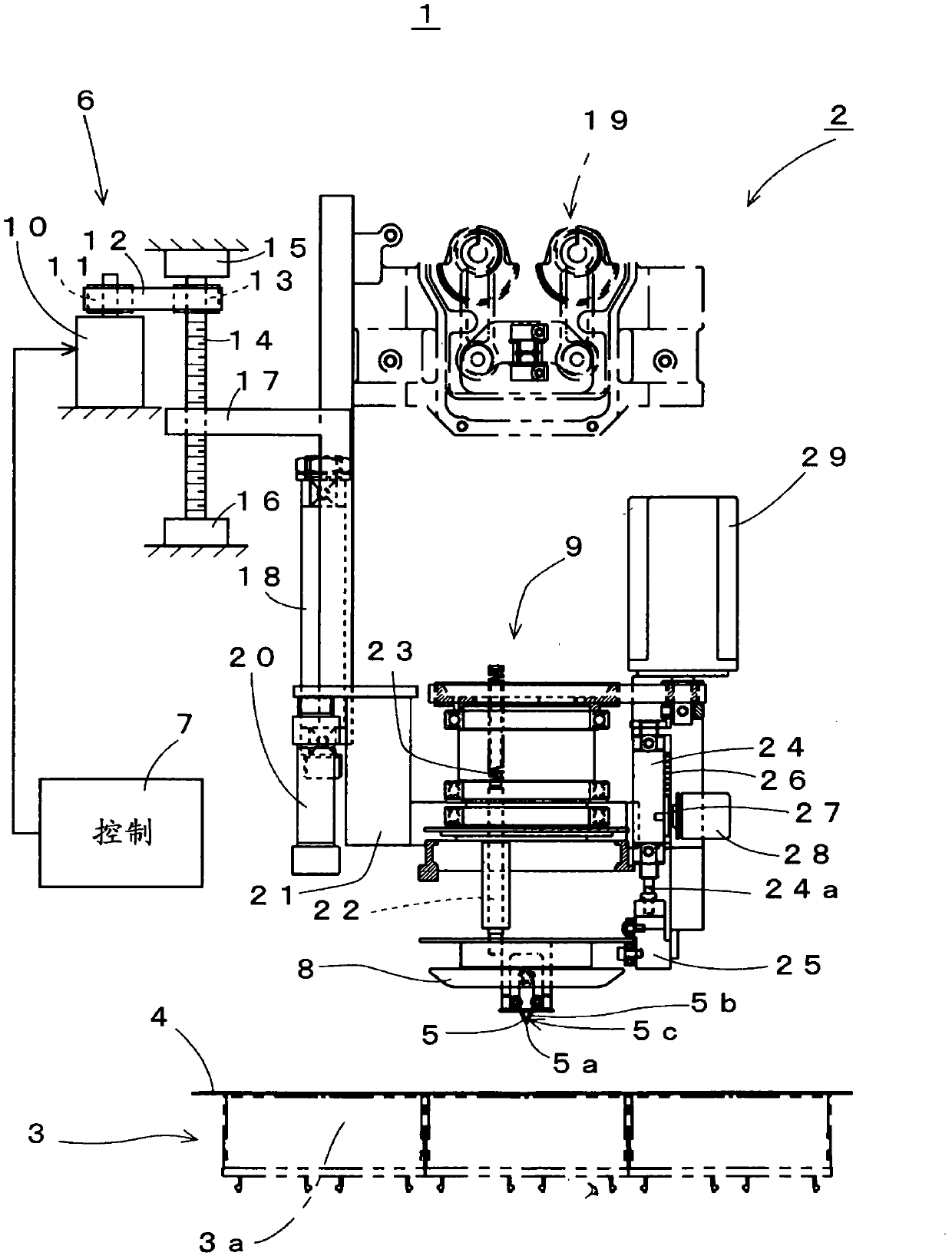

Hinged-lid pack for rodlike smoking articles and blank for the pack

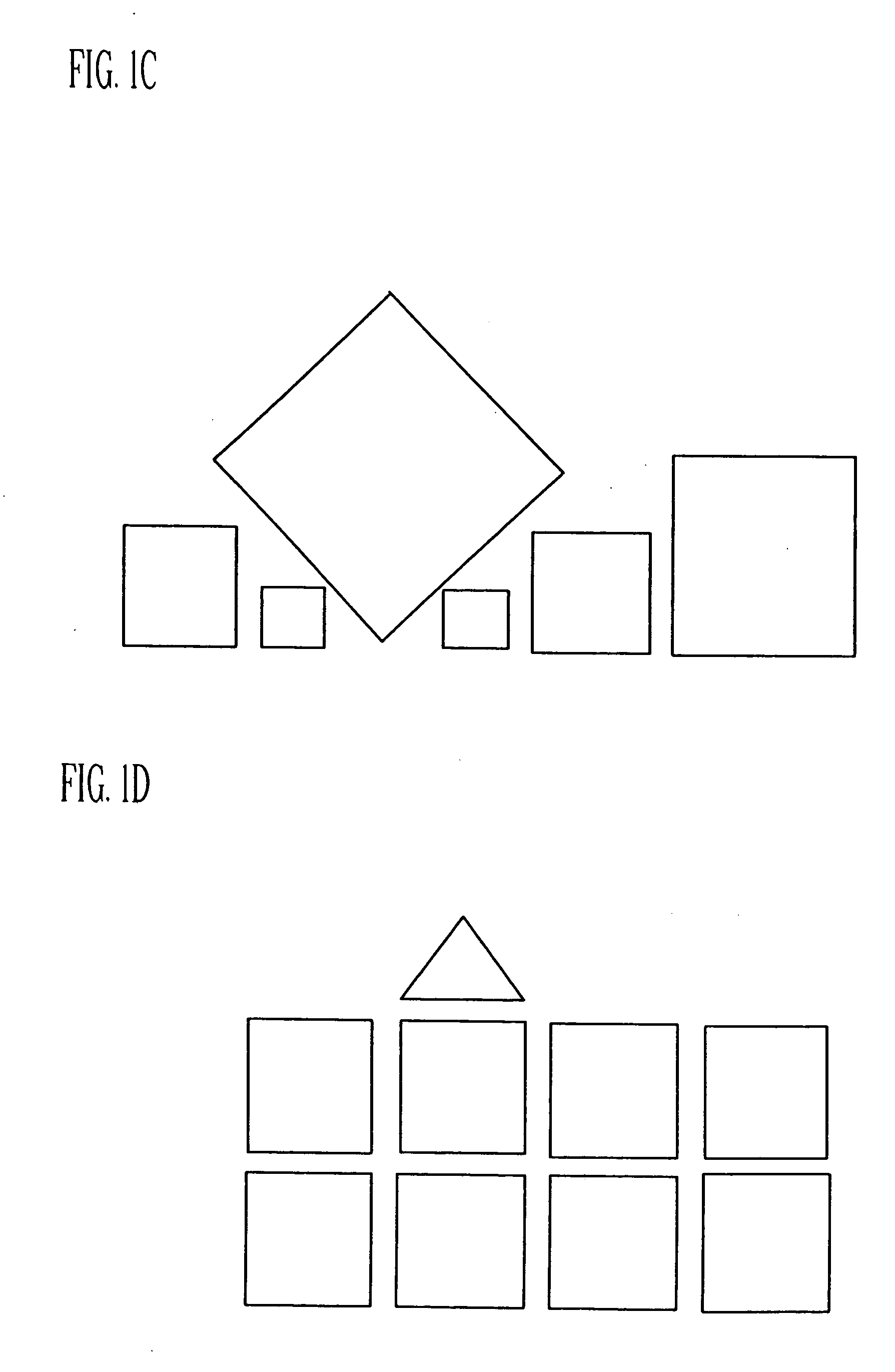

ActiveUS7175022B2Strong impressionEffective preventionContainers for flexible articlesPackaging cigaretteOblique cuttingBiomedical engineering

A hinged-lid pack includes a case (2), and contents (14) contained in the case (2) and fit with an inner frame (16). The case (2) has a transverse cutting line (22) formed in a front wall (4) thereof, oblique cutting lines (24) respectively formed in right and left side walls (12) thereof, and a self-hinge (26) formed at a rear wall (6) thereof. When the case (2) is split apart along the transverse cutting line (22) and the oblique cutting lines (24), the case (2) is divided into a box (30) and a recloseable lid (28).

Owner:JAPAN TOBACCO INC

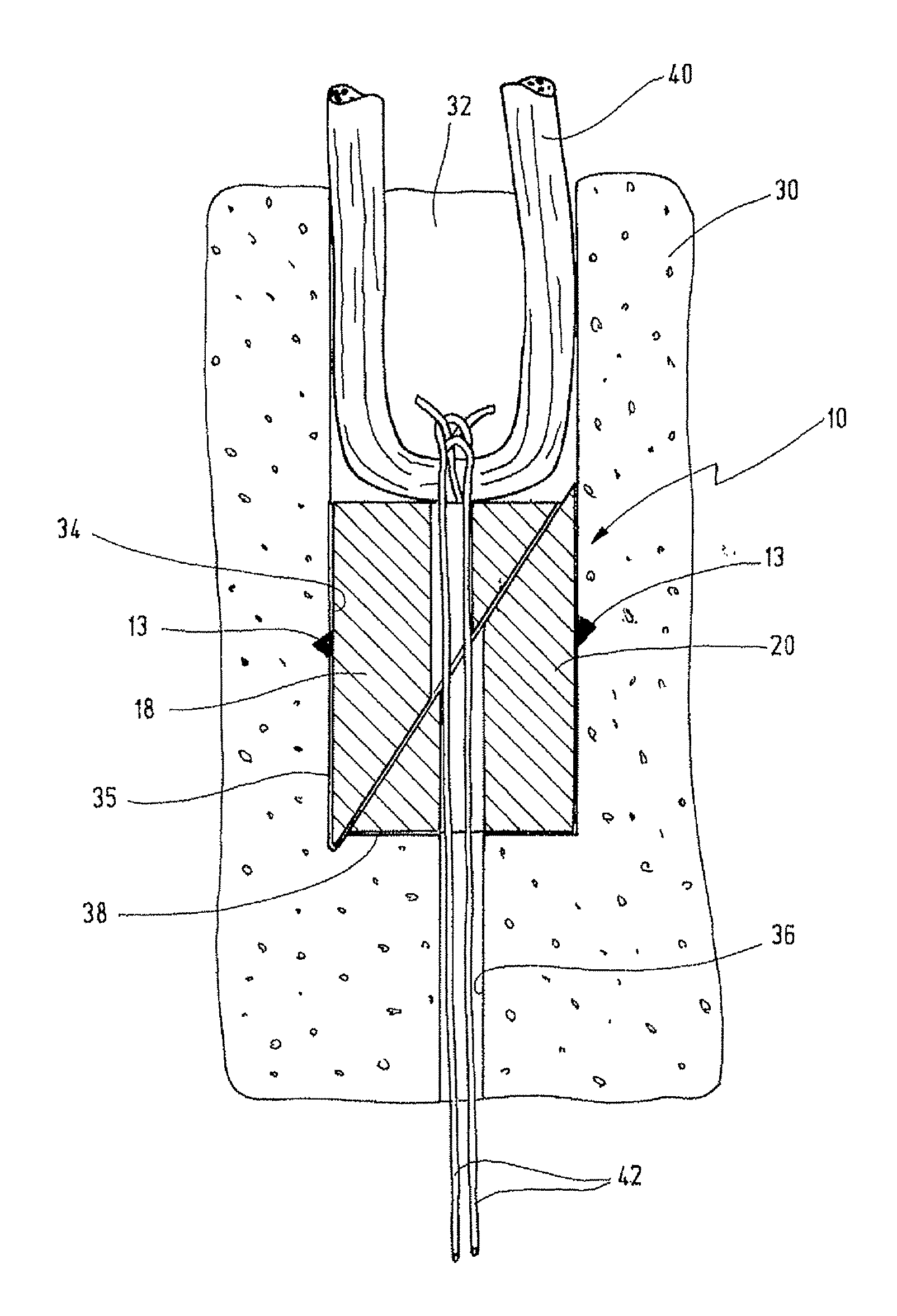

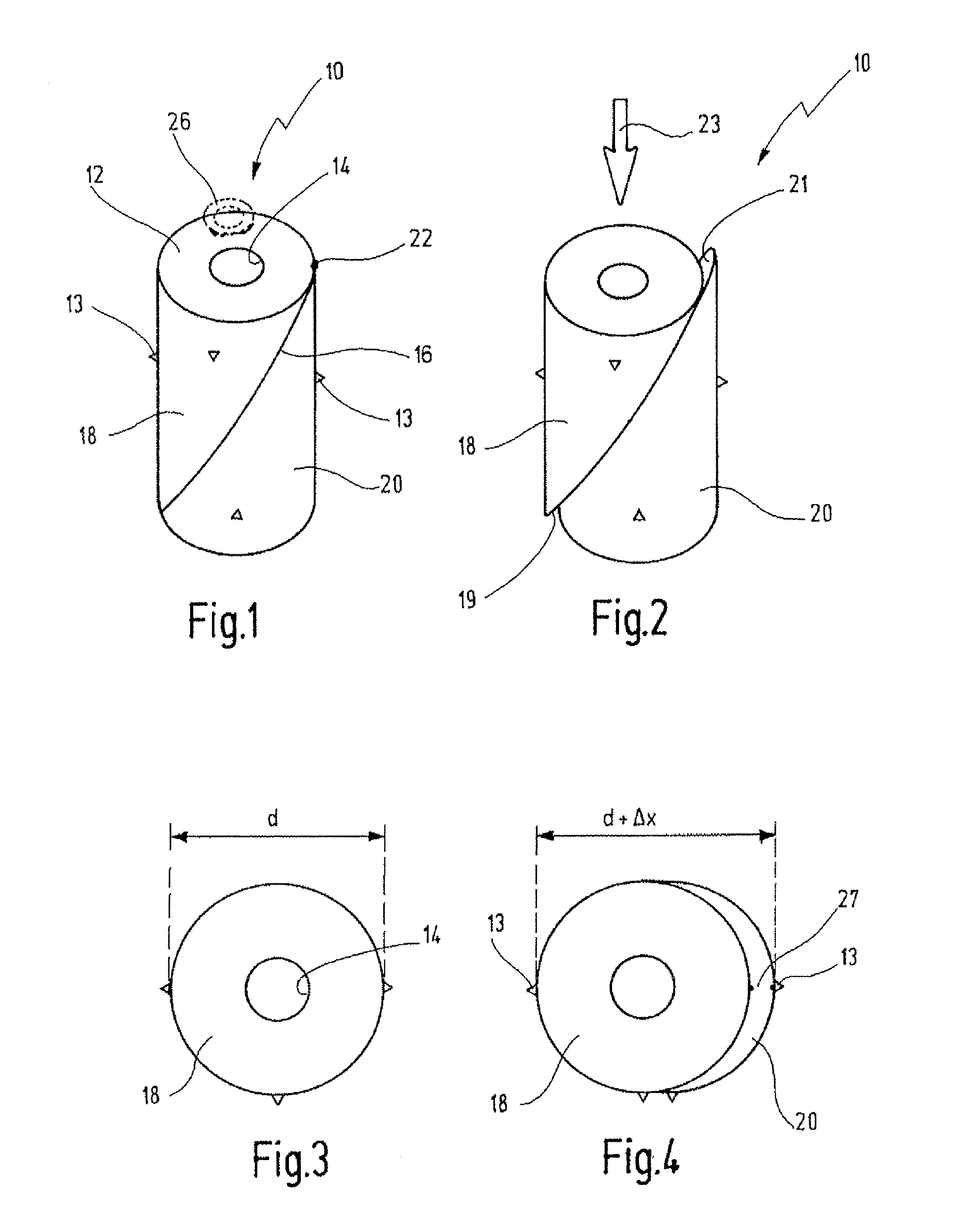

Device For Blocking A Tendon Graft

InactiveUS20080097604A1Effective and irreversible blockingSuture equipmentsLigamentsOblique cuttingSurgery

A device serves for blocking a tendon graft in a drilled hole. An element is connected to said tendon graft which can be expanded radially. The element has a cylindrical body which is divided by an oblique cut into two wedge-shaped bodies initially connected to one another via a predetermined break point.

Owner:KARL STORZ GMBH & CO KG

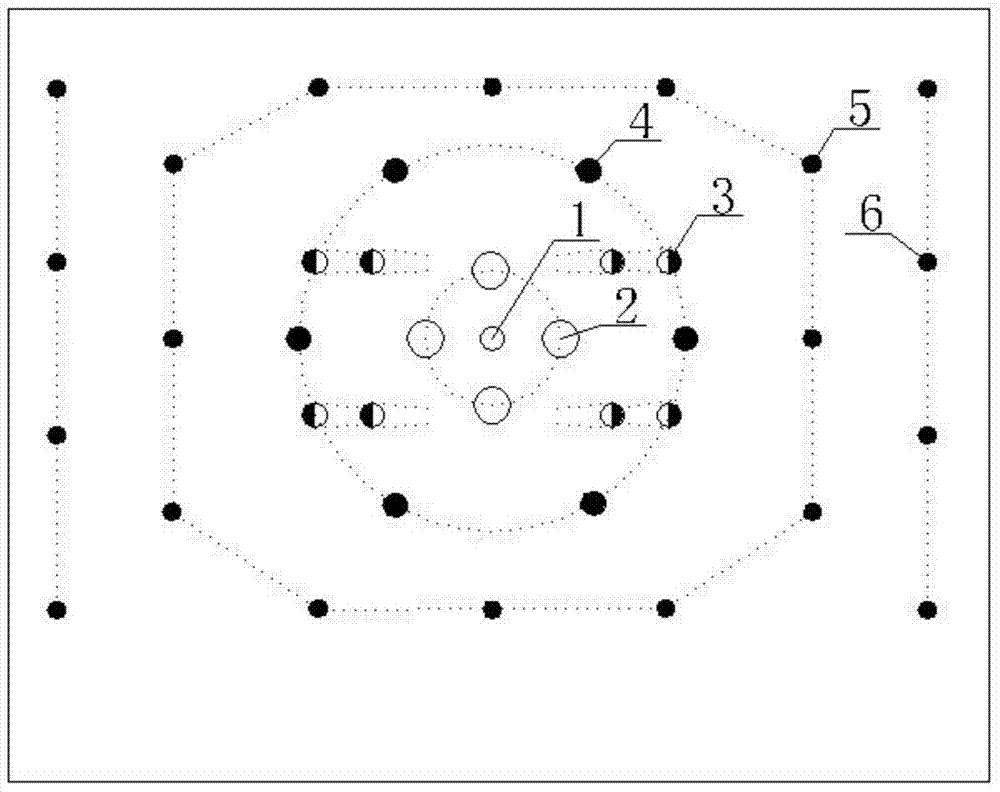

Novel roadway blasting construction method

InactiveCN103575172AContour surface forming is regularGood free surfaceBlastingOblique cuttingEngineering

The invention discloses a novel roadway blasting construction method, belongs to the technical field of shaft building construction, and provides a novel cutting blasting shaft-forming construction method. Four kinds of blast holes are formed in a whole cross section of a roadway, wherein V-shaped ejection holes, cutting holes, auxiliary holes, interval cutting holes and peripheral holes are formed sequentially from inside to outside; and the cutting holes are formed on two sides of each auxiliary hole. Compared with other methods, free surfaces of the auxiliary holes is added, and the number of the free surfaces is increased from two to three; a blank hole is drilled at the interval of every two blast holes among the interval cutting holes and isn't filled with explosive; the oblique cutting angle of each ejection hole is 80-85 degrees, and a small amount of the explosive is filled in the ejection holes; and the reserved holes are taken as compensation space of the free surfaces and crushed rock mass during cutting hole blasting, and a throwing effect on rock mass after cutting hole blasting is realized. With the adoption of the novel interval cutting hole method, influences of blasting vibration on surrounding rock are reduced, the free surfaces are added, the cutting depth and the cutting size are increased, the blasting effect is improved, and the blasting efficiency is improved.

Owner:ANHUI UNIV OF SCI & TECH

Milling insert and a milling tool

ActiveUS20180015554A1Improve attributesEasy to analyzeTool workpiece connectionTransportation and packagingMilling cutterOblique cutting

A milling insert for shoulder milling having s a positive basic shape and includes an upper side having a rake surface, a lower side including a planar bottom surface, a side surface extending around the periphery of the milling insert, and a cutting edge formed between the side surface and the rake surface. The cutting edge has at least a major cutting edge portion, a corner radius cutting edge portion, a ramping cutting edge portion, and a surface wiping cutting edge portion. The side surface includes an upper set of primary clearance surfaces and a lower set of secondary clearance surfaces having a plurality of planar secondary clearance surfaces, wherein the upper set of primary clearance surfaces forms an overhang protruding with respect to the secondary clearance surfaces and extending around the entire upper periphery of the milling insert.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

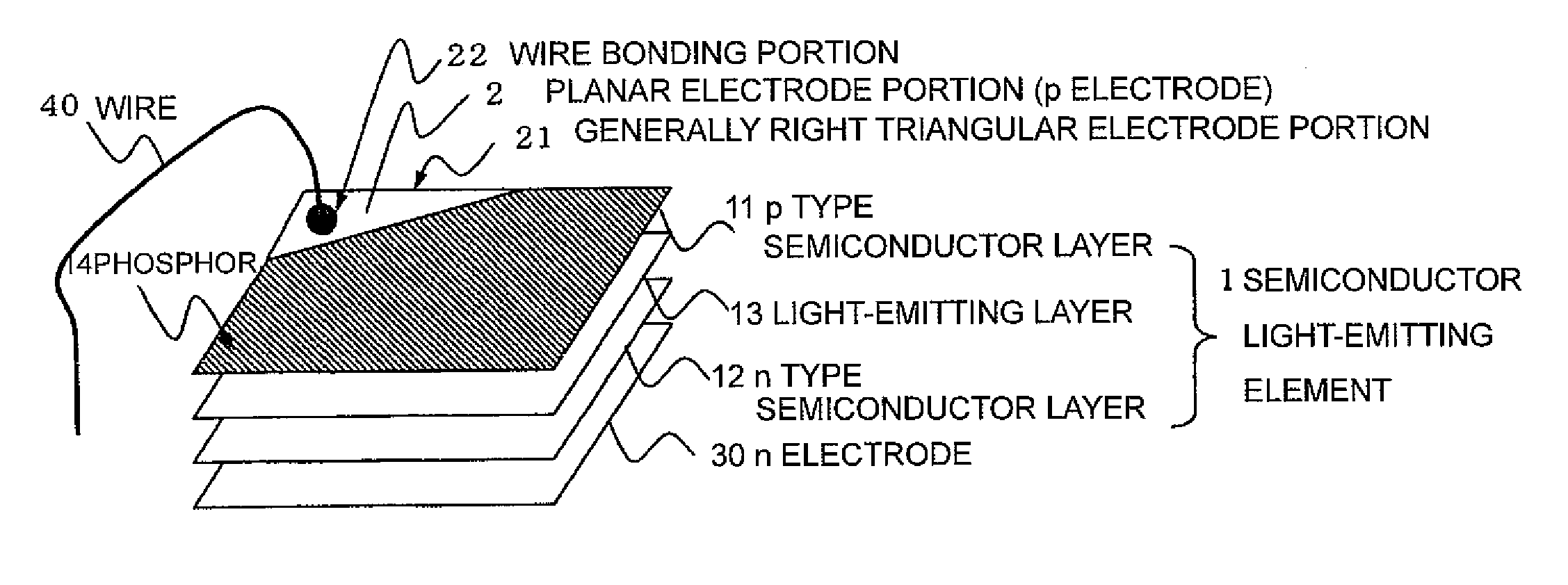

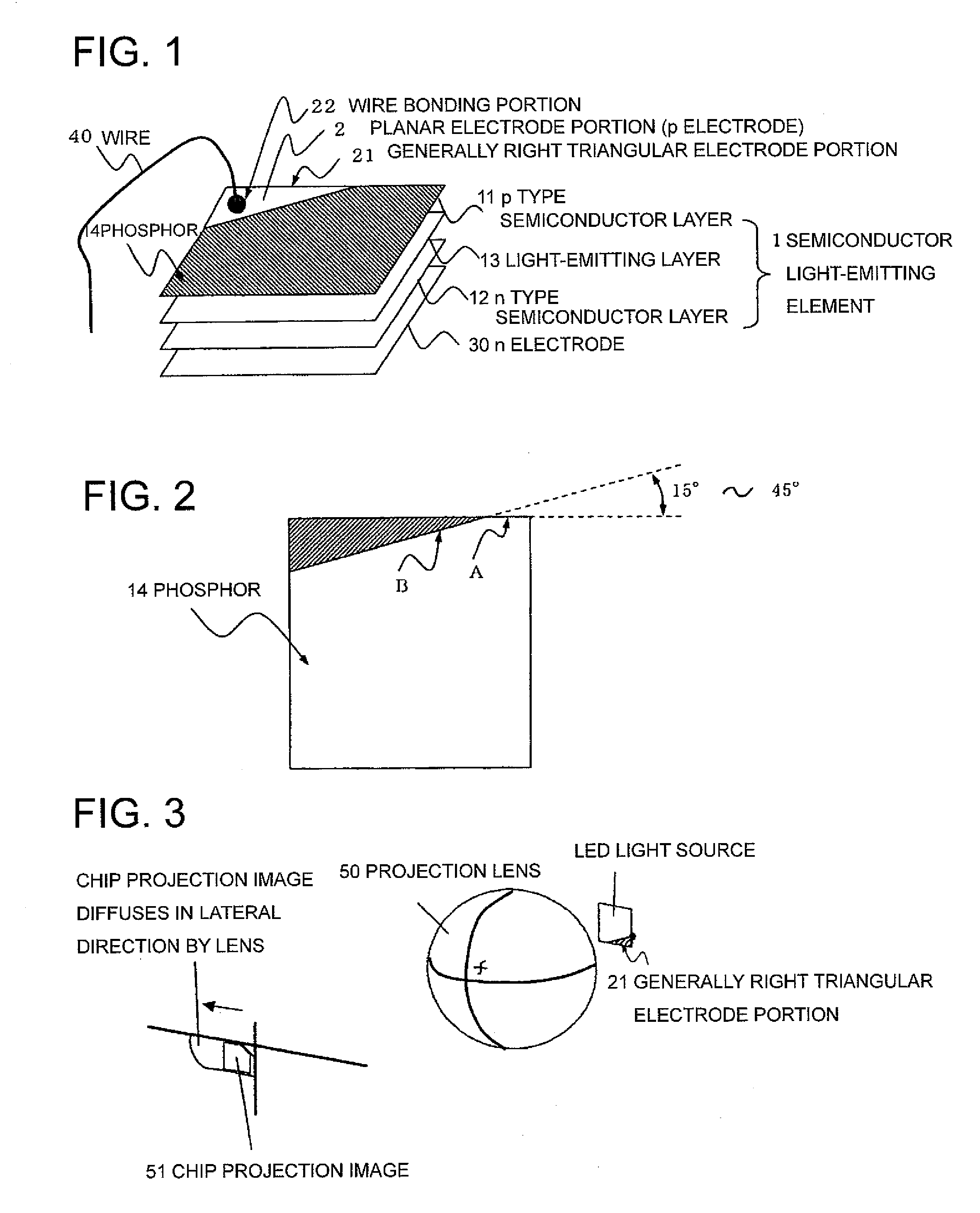

Light-emitting module of vehicular lamp

InactiveUS20080111143A1Reduce unevennessUneven light distributionPlanar light sourcesVehicle headlampsPlanar electrodeOblique cutting

A light-emitting module includes a semiconductor light-emitting element with a generally oblong shape, and a planar electrode formed on a surface of the semiconductor light-emitting element. The planar electrode has a generally right triangular electrode portion that is defined by an oblique cut-off line on any one of four corners of the semiconductor light-emitting element. The planar electrode is formed with a wire bonding portion that establishes a current-carrying connection with the generally right triangular electrode portion.

Owner:KOITO MFG CO LTD

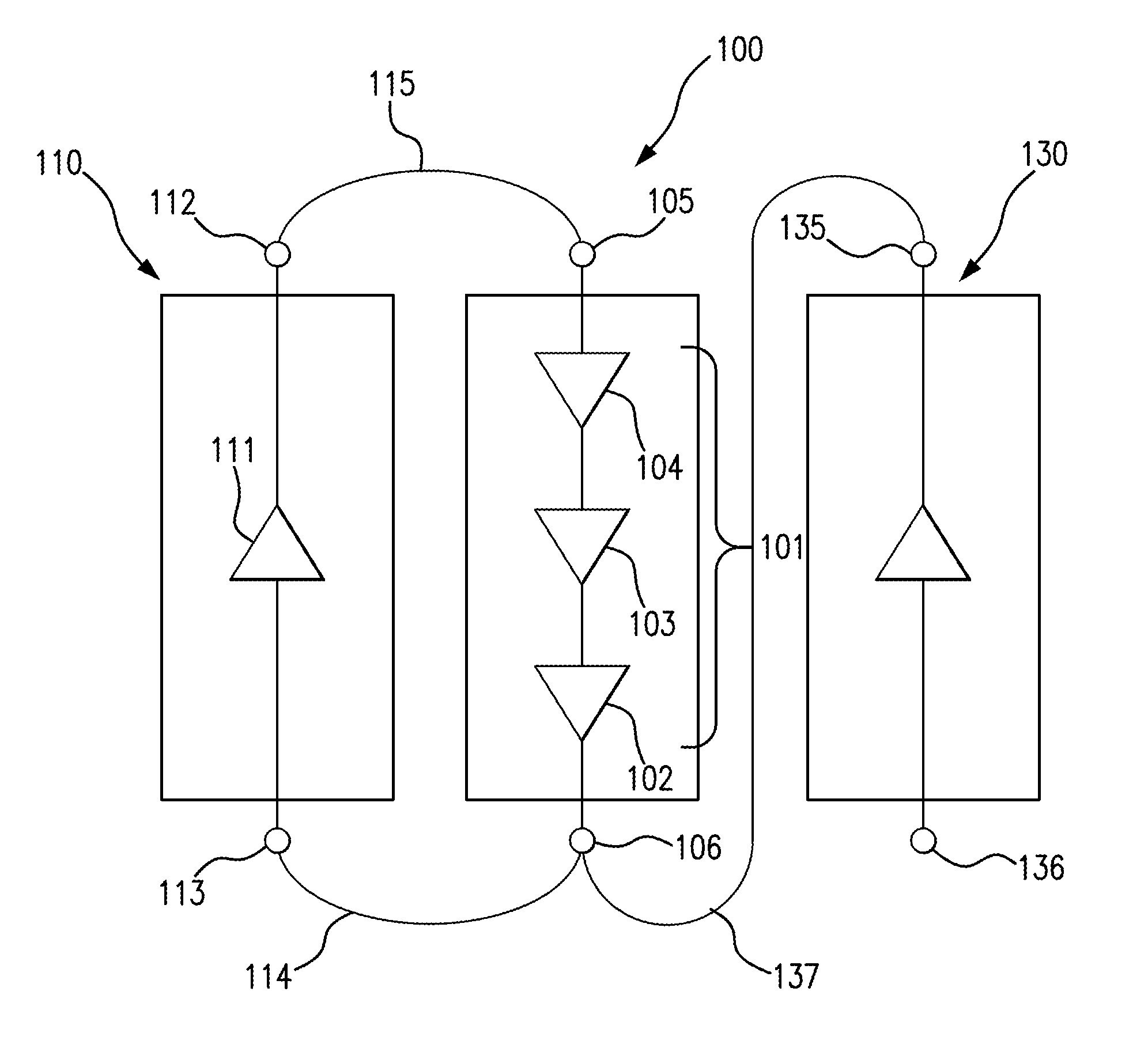

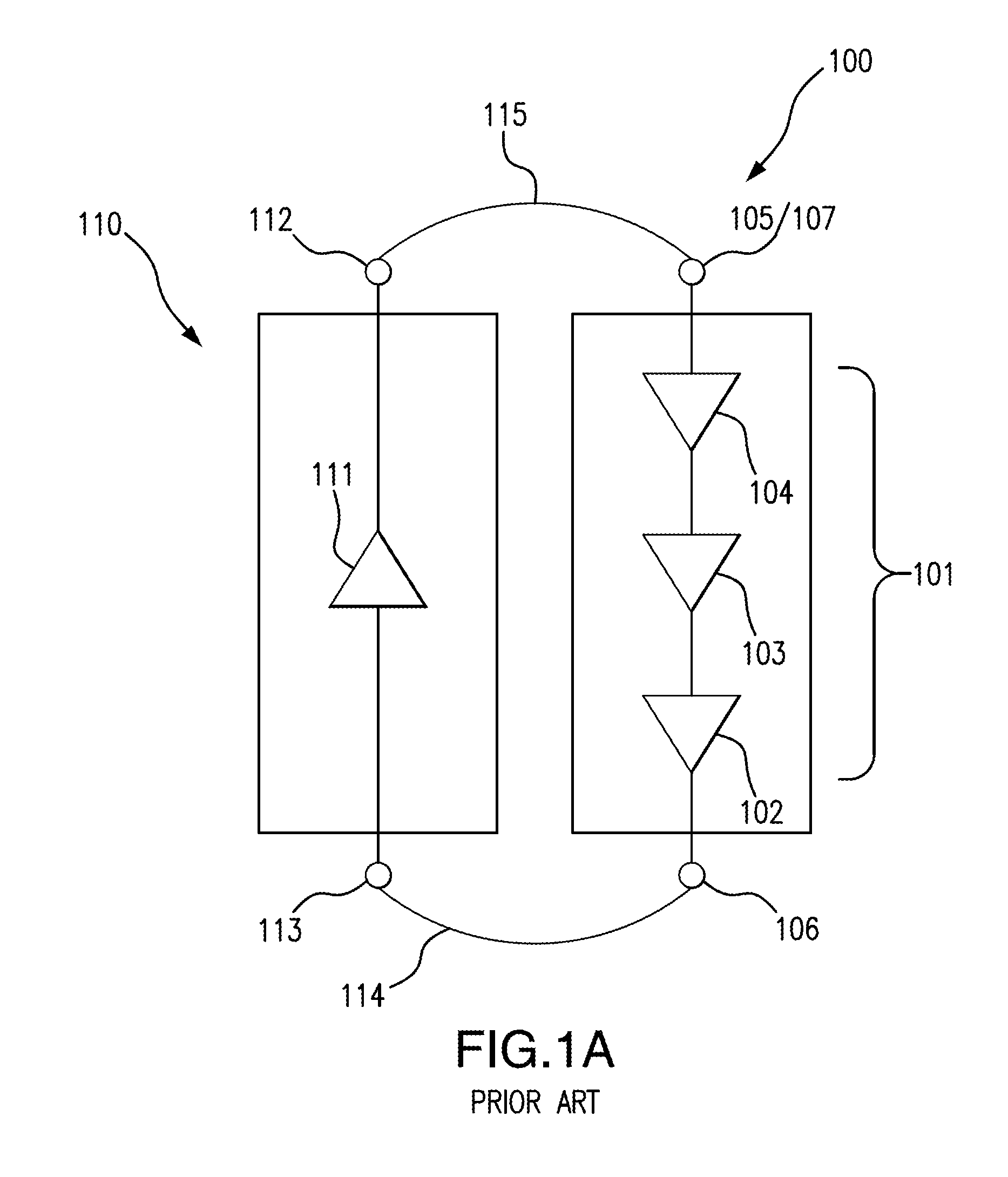

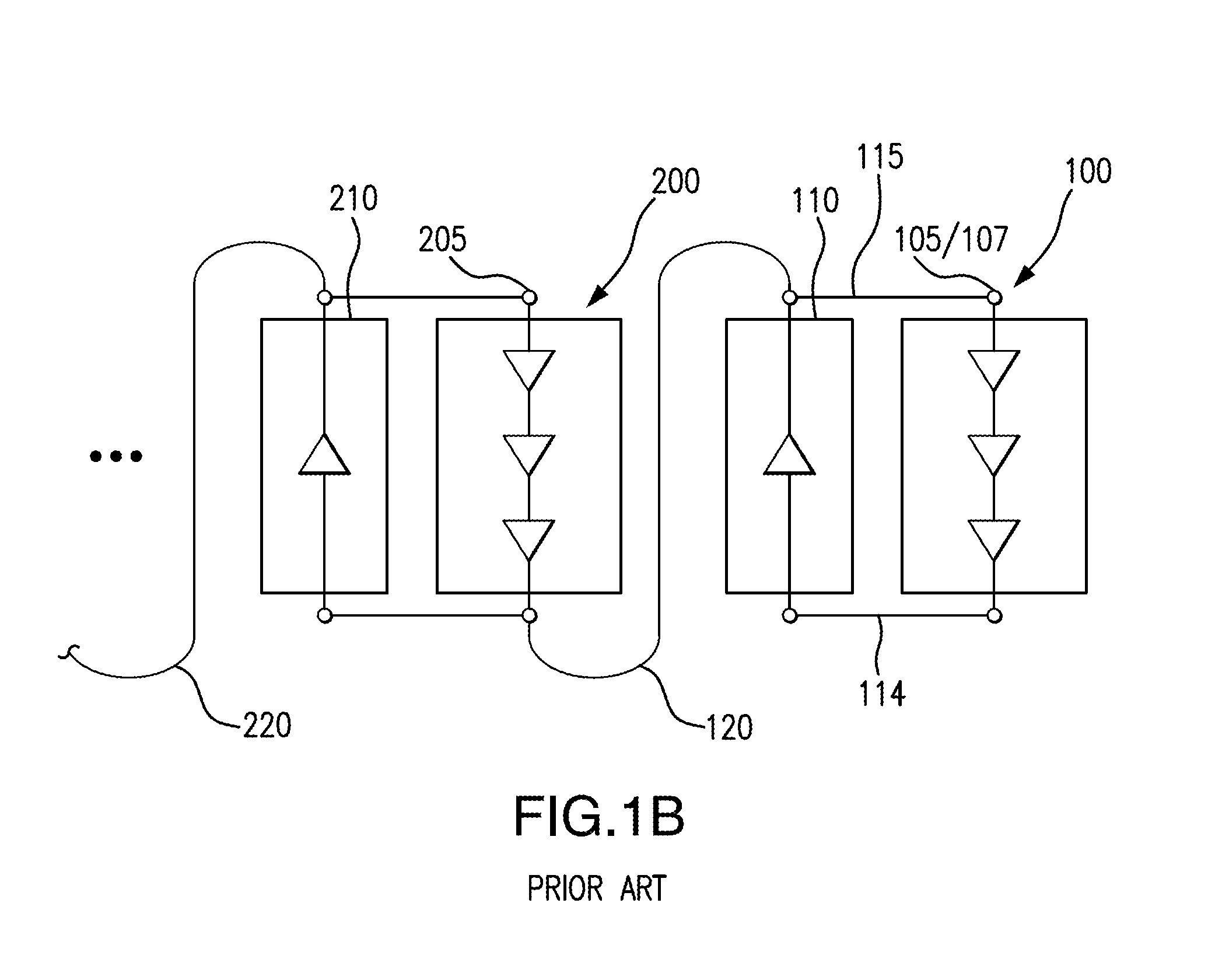

Space solar cell panel with blocking diodes

InactiveUS20160218665A1Improve space utilizationEasy to usePhotovoltaicsPhotovoltaic energy generationOblique cuttingEngineering

A solar cell assembly or sub-array that comprises a string of series connected solar cells, one of the solar cells being a final solar cell of the string of solar cells. The final solar cell has at least one oblique cut corner. The solar cell assembly further comprises a contact member connected to the final solar cell through a blocking diode, positioned in correspondence with the space provided by the space provided by the oblique cut corner.

Owner:SOLAERO TECH CORP

Cutting raise cutting method used in underground mining

InactiveCN103696770AImprove securityImprove production efficiencyUnderground miningBlastingOblique cuttingEngineering

The invention discloses a new cutting raise cutting technology used in underground mining. The technology is characterized by combining step cutting with parallel and oblique composite cutting, charging by steps and delaying primary blasting, wherein a parallel cut hole runs through the whole cutting raise length and is charged by two steps and an oblique cut hole inclines relative to a blasting plane and extends towards a center hole. The technology has the beneficial effects that the cutting raise once cutting length can be greatly increased, the cutting times can be reduced, the mine stoping process can be optimized and hazardous operation of workers under the condition that roofs are quite unstable during repeated cutting can be simultaneously avoided, thus reducing consumption of human and financial resources in the underground mine stope stoping process and improving the mine safety and production benefits.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

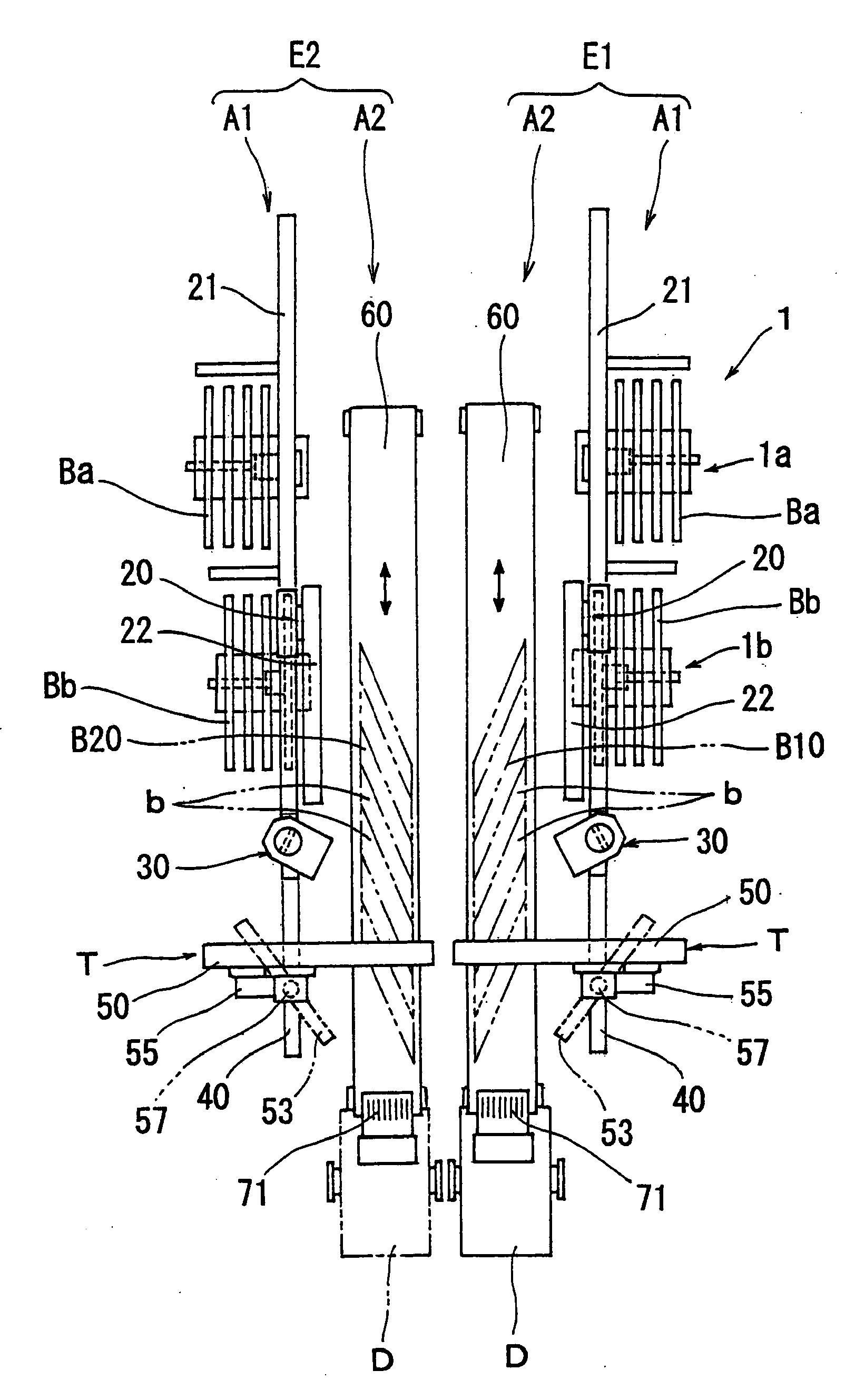

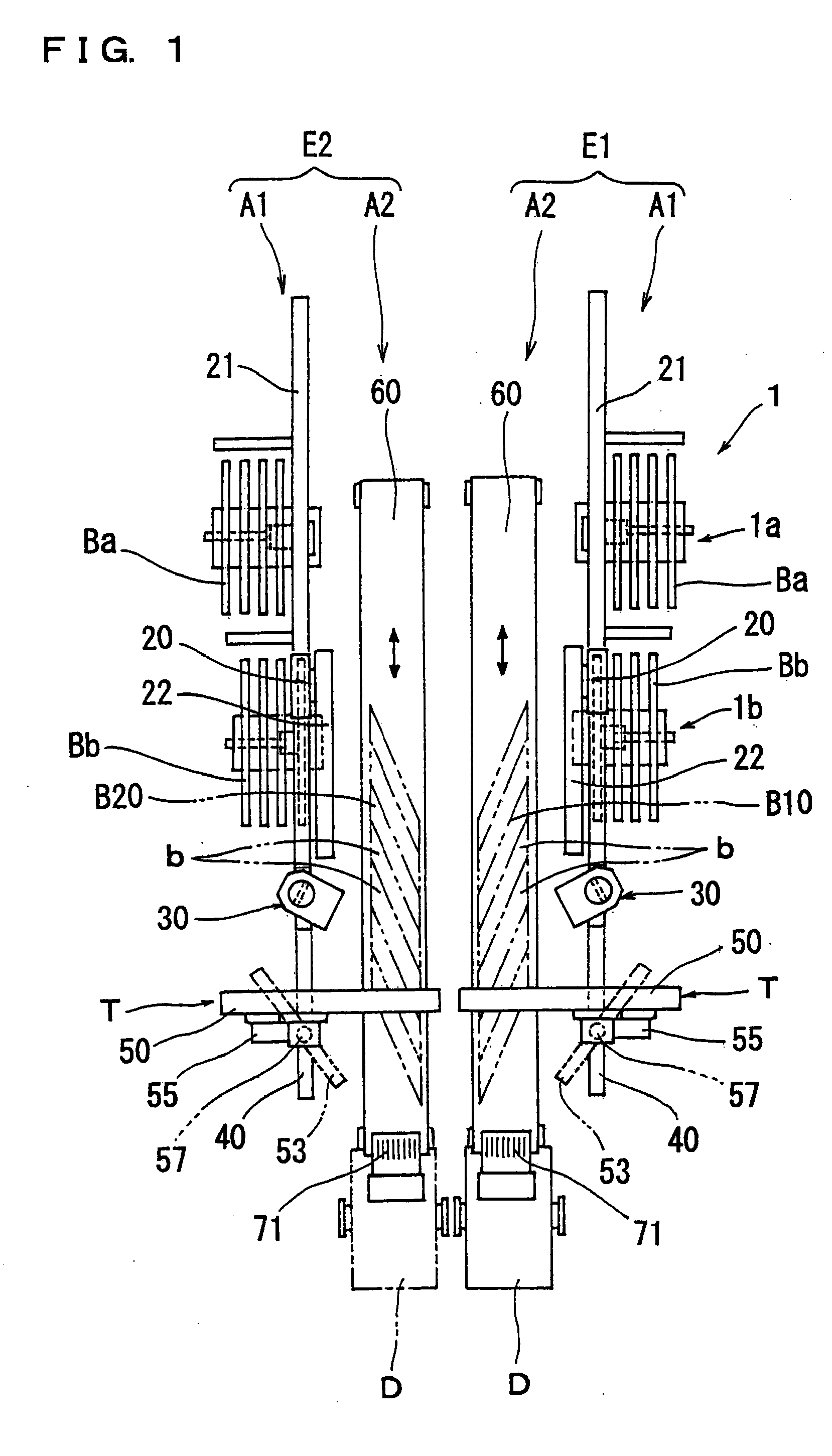

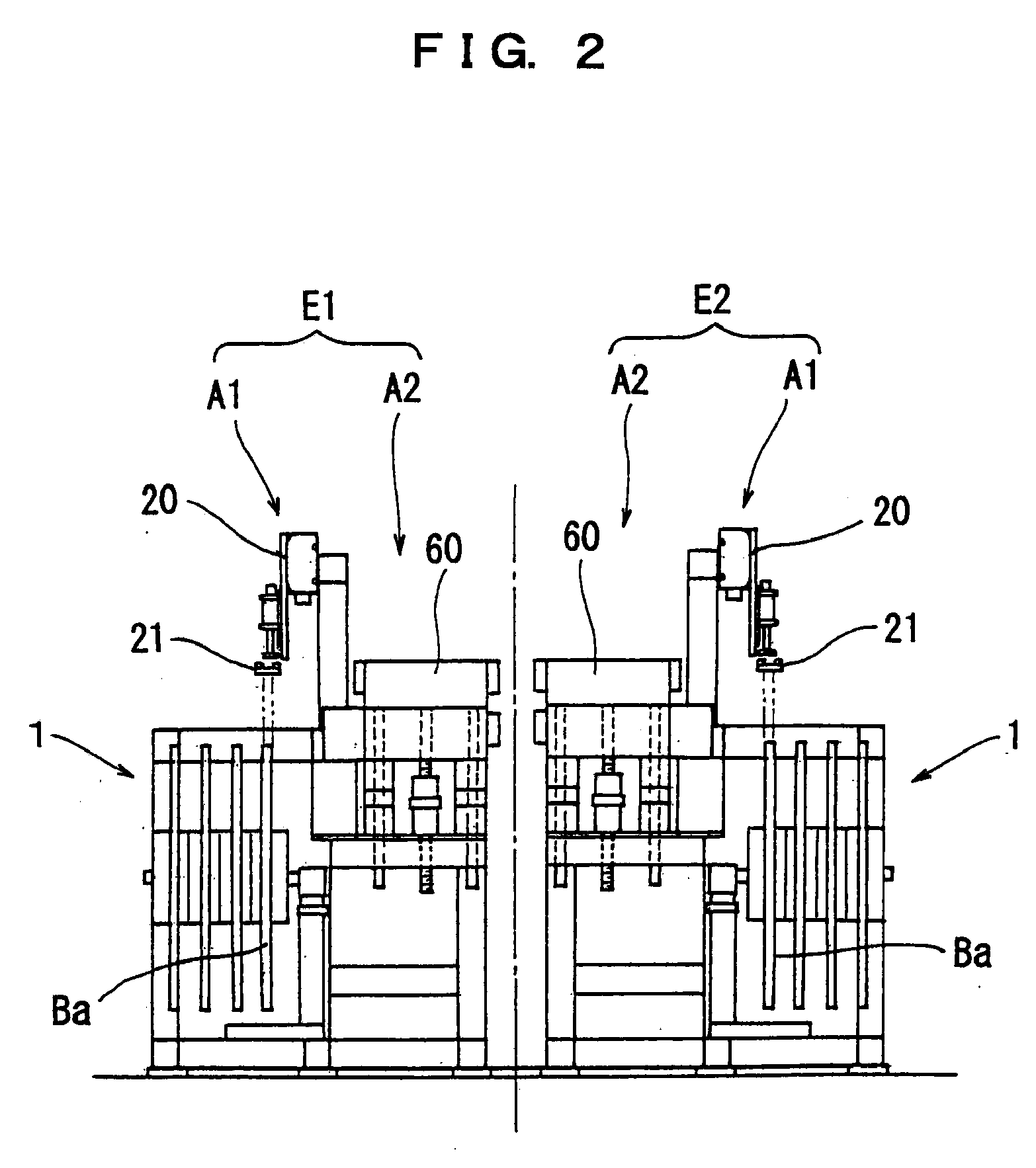

Tire Belt Manufacturing Method And Apparatus

InactiveUS20090032181A1Reduced space required for installationIncrease the use of spaceLamination ancillary operationsControlling laminationBand shapeOblique cutting

In obliquely cutting a belt band-shaped material (B) to a predetermined length and joining belt material pieces (b) as cut to fabricate a belt member (B10) for a tire, according to the invention, a space, in which an apparatus is mounted, is decreased, a belt member of good quality and high accuracy of joining is manufactured, a cut processing section (A1) for a band-shaped material and an alignment processing section (A2) for belt material pieces as cut are arranged in parallel, in the cut processing section, whenever the band-shaped material (B) is intermittently forwarded, a leading end portion of the band-shaped material is held on a holding table 40 and obliquely cut by a cutter unit (30), the belt material pieces (b) as cut are attracted and held on an underside of a holding member (53) of a transfer unit (T) to be transferred onto and placed on an alignment conveyor (60) with oblique cut ends trued up, and in the alignment processing section, whenever a belt material piece (b) is transferred, the alignment conveyor (60) is intermittently forwarded and the respective belt material pieces are sequentially aligned and joined to form a belt member with reinforcement cords inclined.

Owner:TOYO TIRE & RUBBER CO LTD

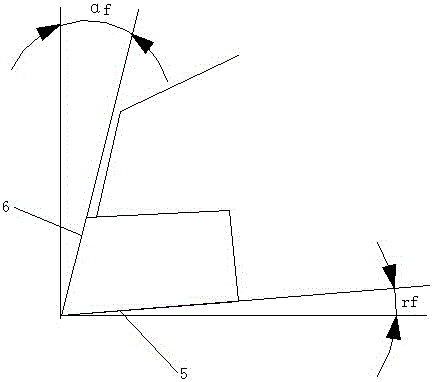

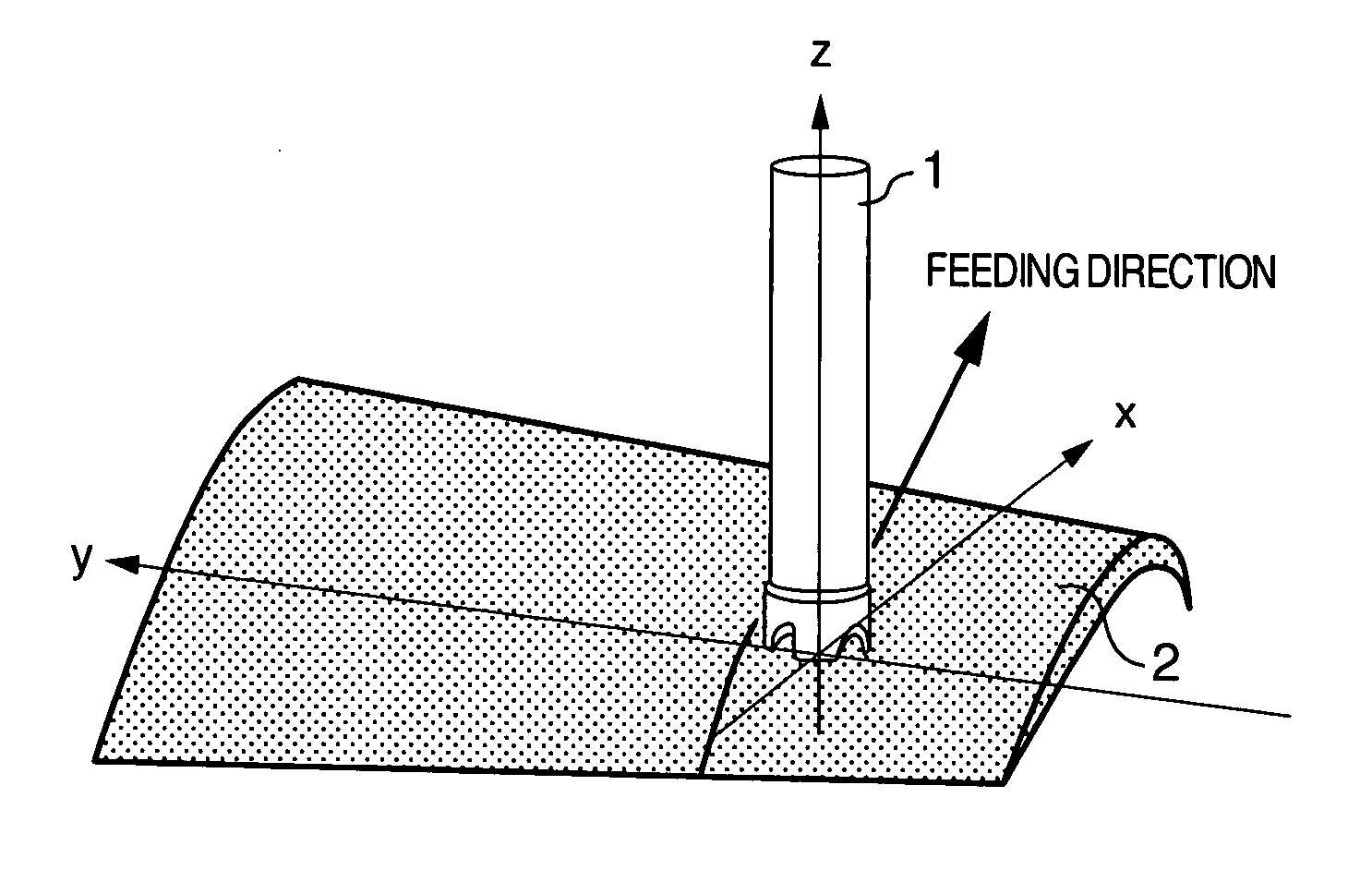

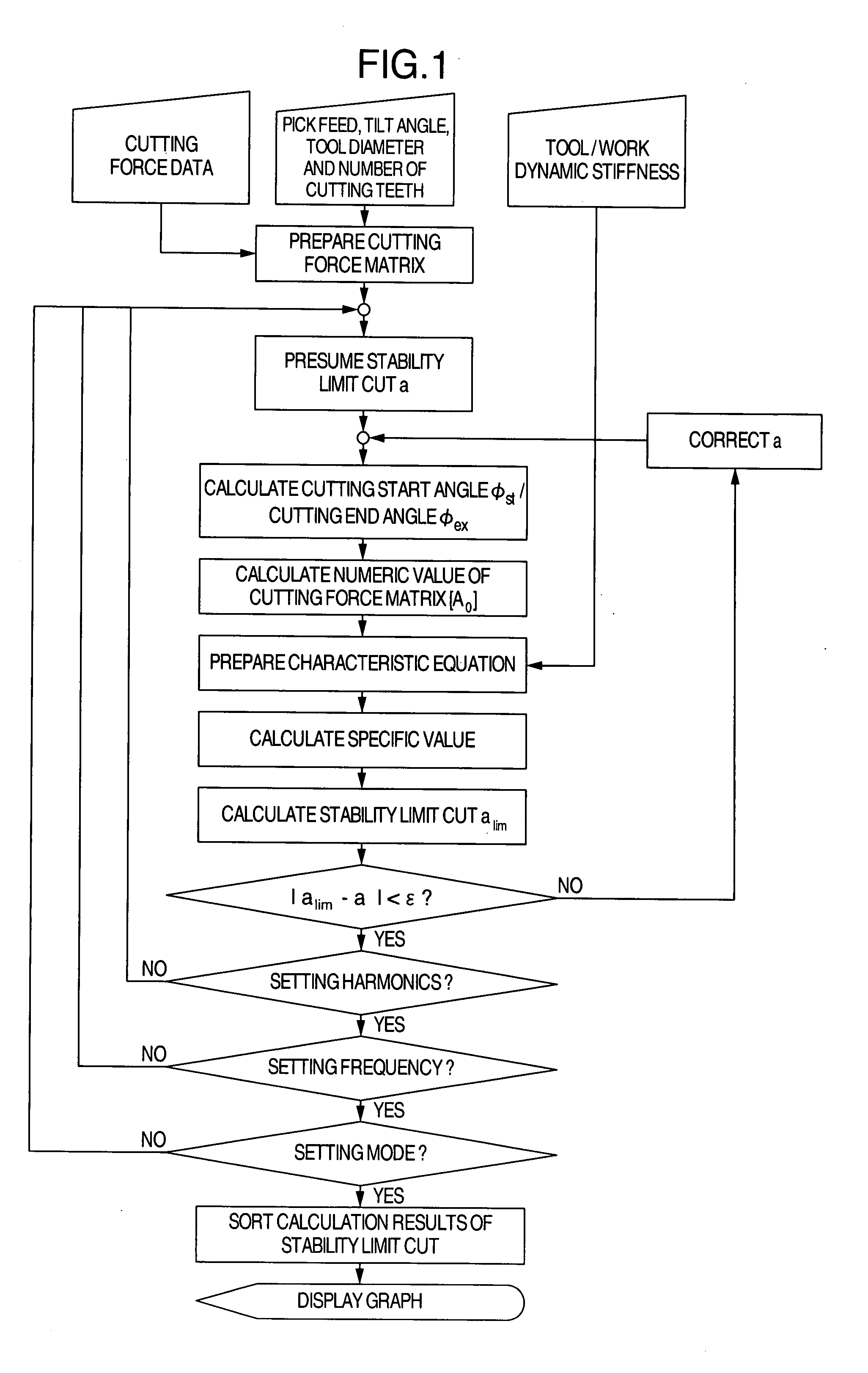

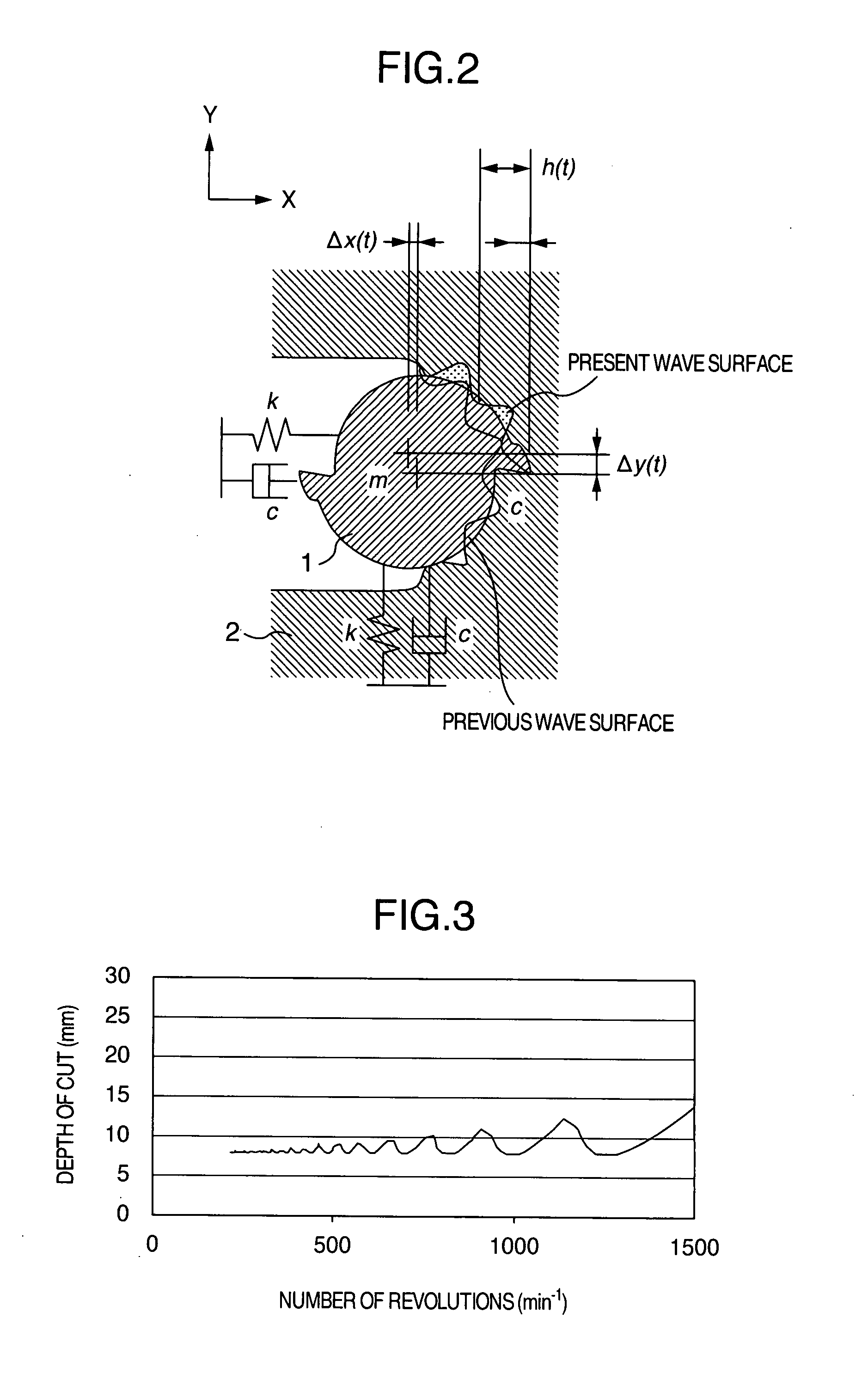

Method for estimating self-vibration of milling tool in the operating process

InactiveUS20070201956A1Reduce in quantityTurning machine accessoriesMilling machinesDynamic stiffnessConstant error

In a cutting method of an oblique surface by a rotary tool, for analyzing in advance a stability limit depth of cut with respect to a self-excited cutting vibration in consideration of a pick feed amount and a work oblique angle and reducing the number of steps necessary for preparation and correction of NC data, a tool diameter, the number of cutting teeth and dynamic stiffness of the rotary tool, a cutting force coefficient determined by a combination of the tool and work materials, dynamic stiffness of the work, the pick feed amount, oblique angles between the tool and the work and the like are used as input values, an initial value of the stability limit depth of cut is determined based on the input values, and calculation is performed based on the initial value. In this case, the initial value is compared with the calculated value, the initial value is corrected by a certain rule, and the calculation is repeated until both the initial value and the calculated value fall in a constant error range to thereby calculate the stability limit depth of cut during the oblique cutting.

Owner:HITACHI LTD

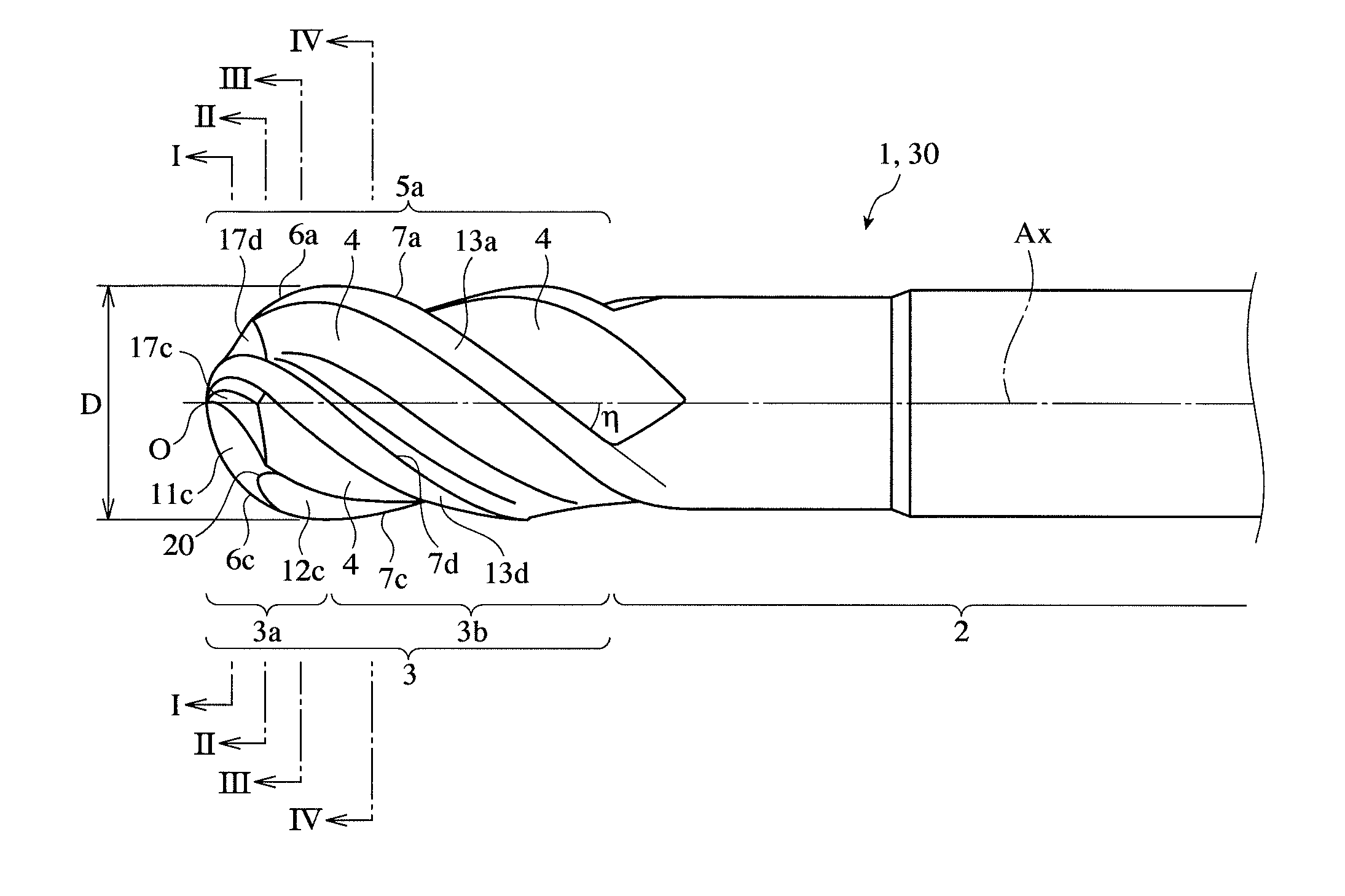

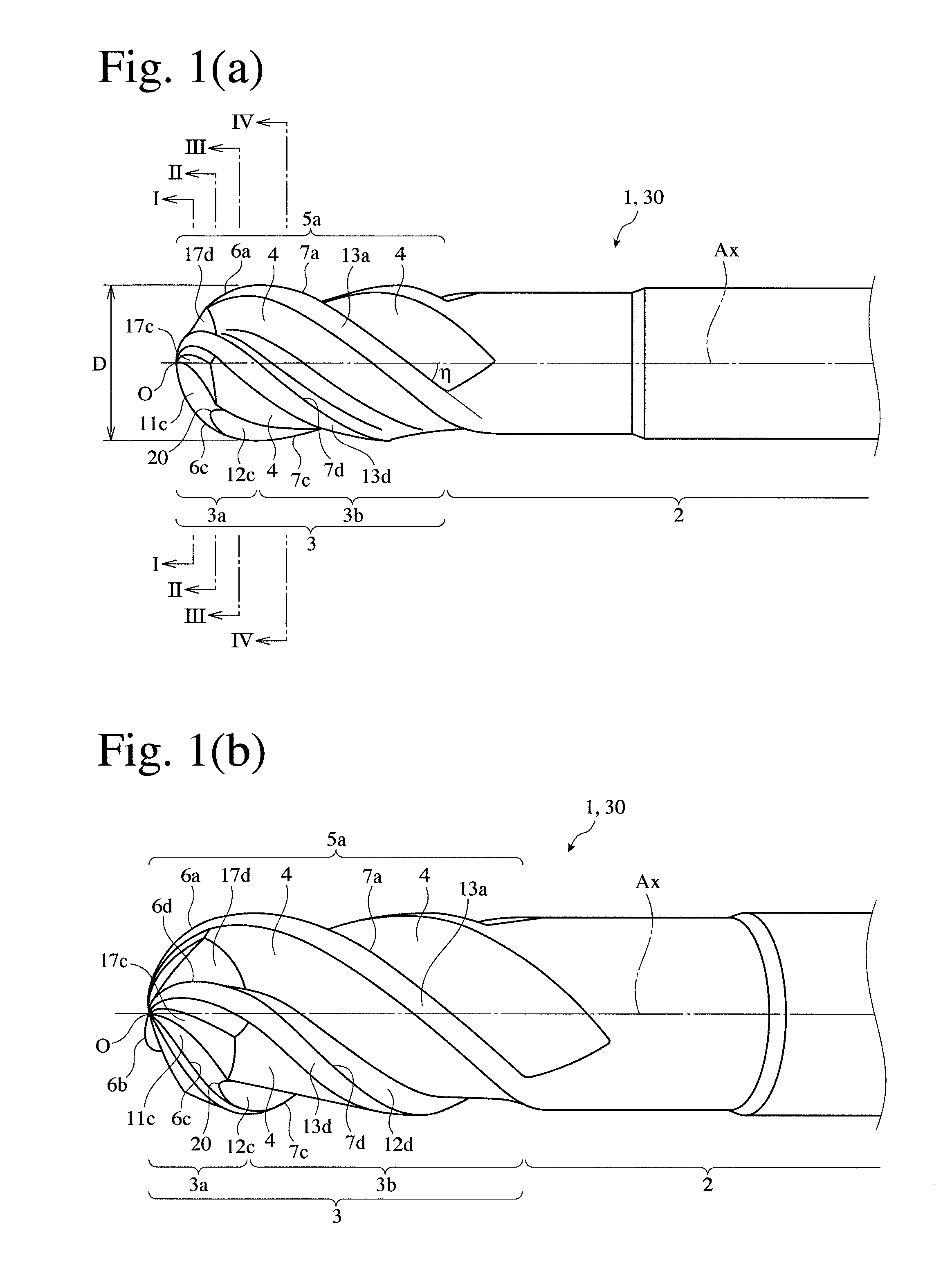

Multi-flute ball end mill

A multi-flute ball end mill comprising a shank portion, a cutting edge portion having a ball-shaped tip portion, and 3 or more cutting edges formed in the cutting edge portion; each cutting edge being constituted by a peripheral cutting edge having a twist angle η of 35-45°, and a ball-end cutting edge having a twist angle μ at the outermost peripheral point, the twist angle η and the twist angle μ meeting the relation of η−μ≦7°, such that the ball-end cutting edge is smoothly connected to the peripheral cutting edge; the ball-end cutting edge having a radial rake angle of −37° to −11°; the peripheral cutting edge having a radial rake angle of 2-8°; and a center-lowered, inclined cutting edge integrally extending from a tip end of each ball-end cutting edge to a rotation center point, in a tip end portion of the ball portion near the rotation center point.

Owner:HITACHI TOOL ENG LTD

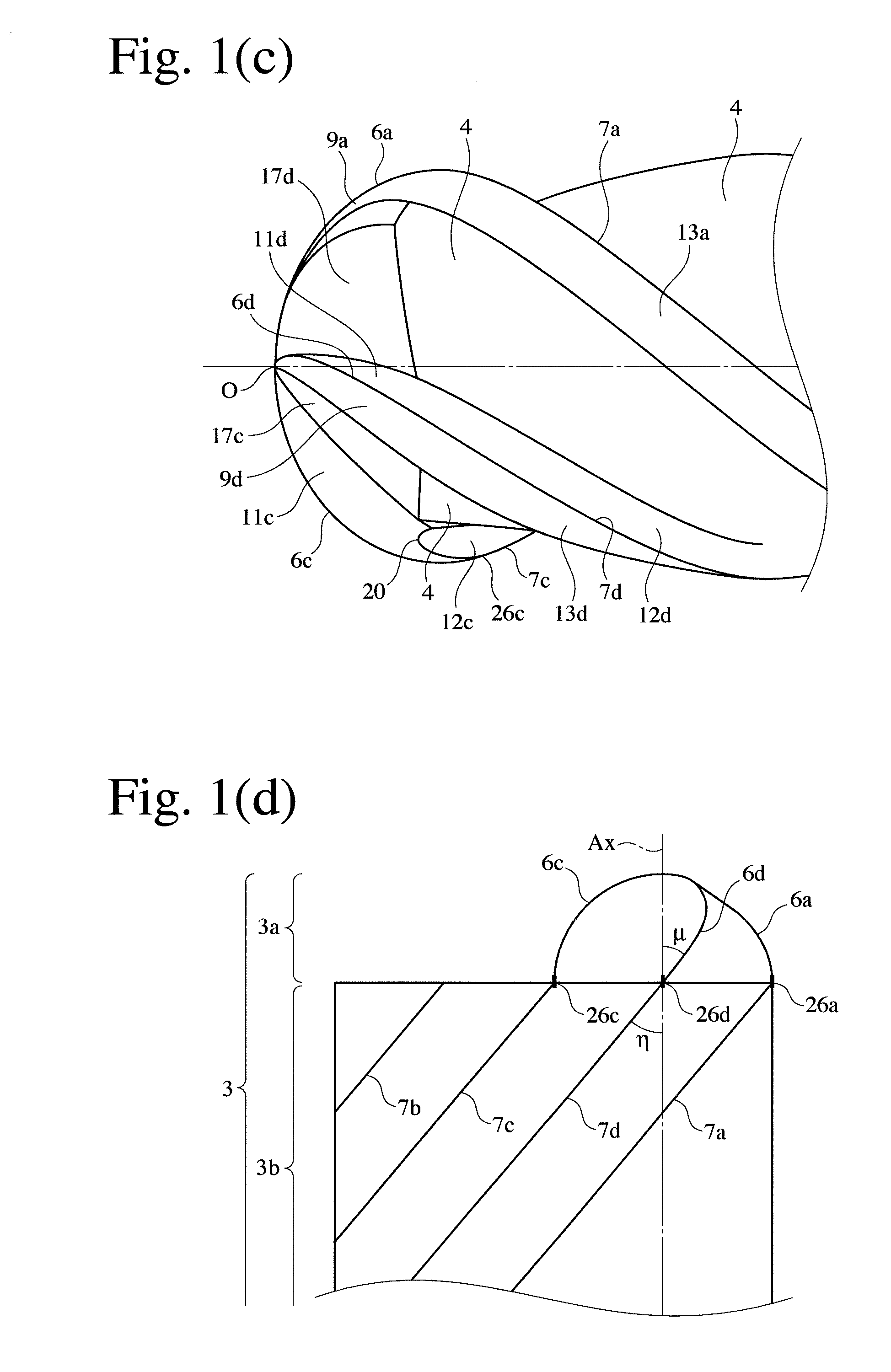

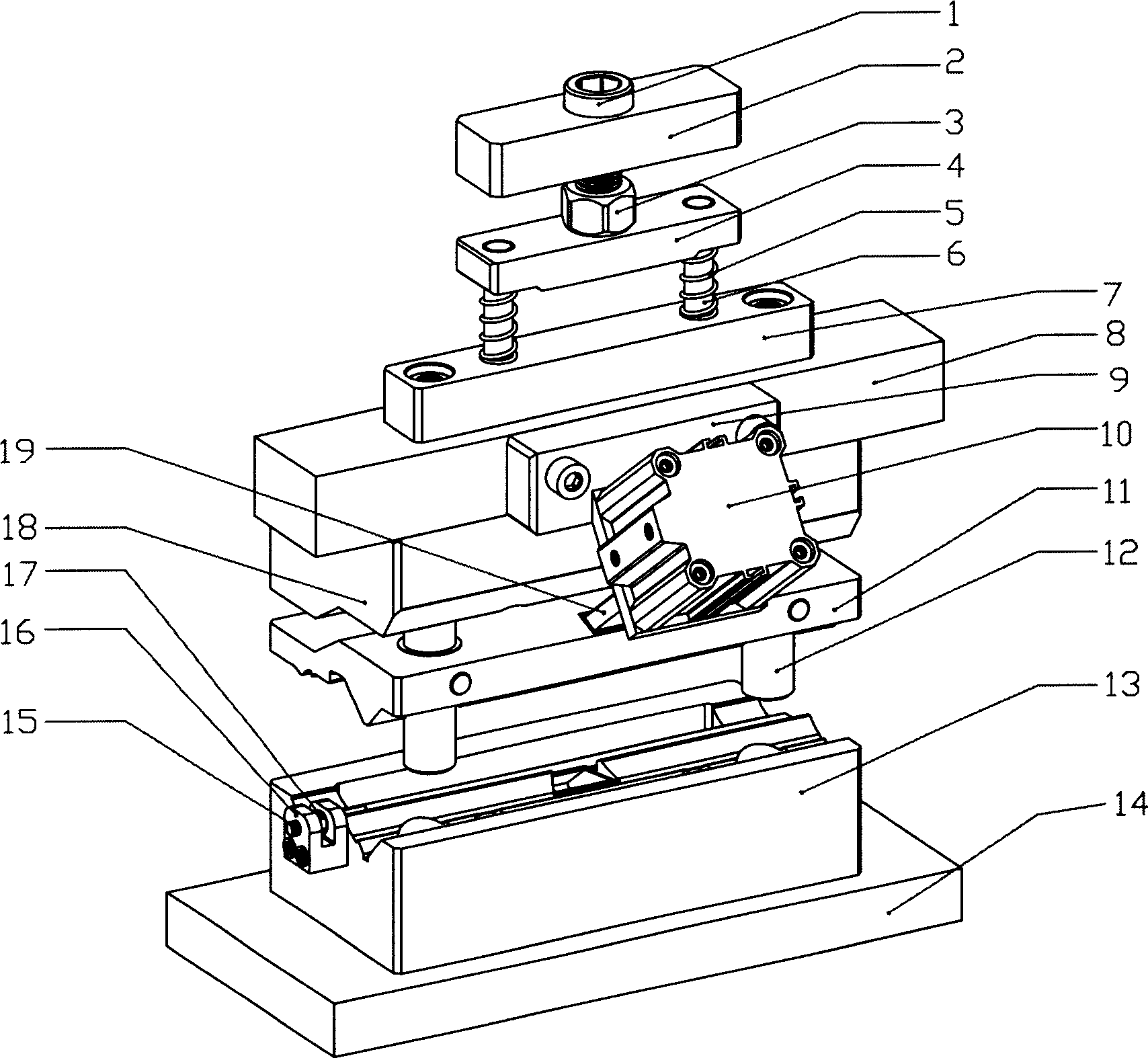

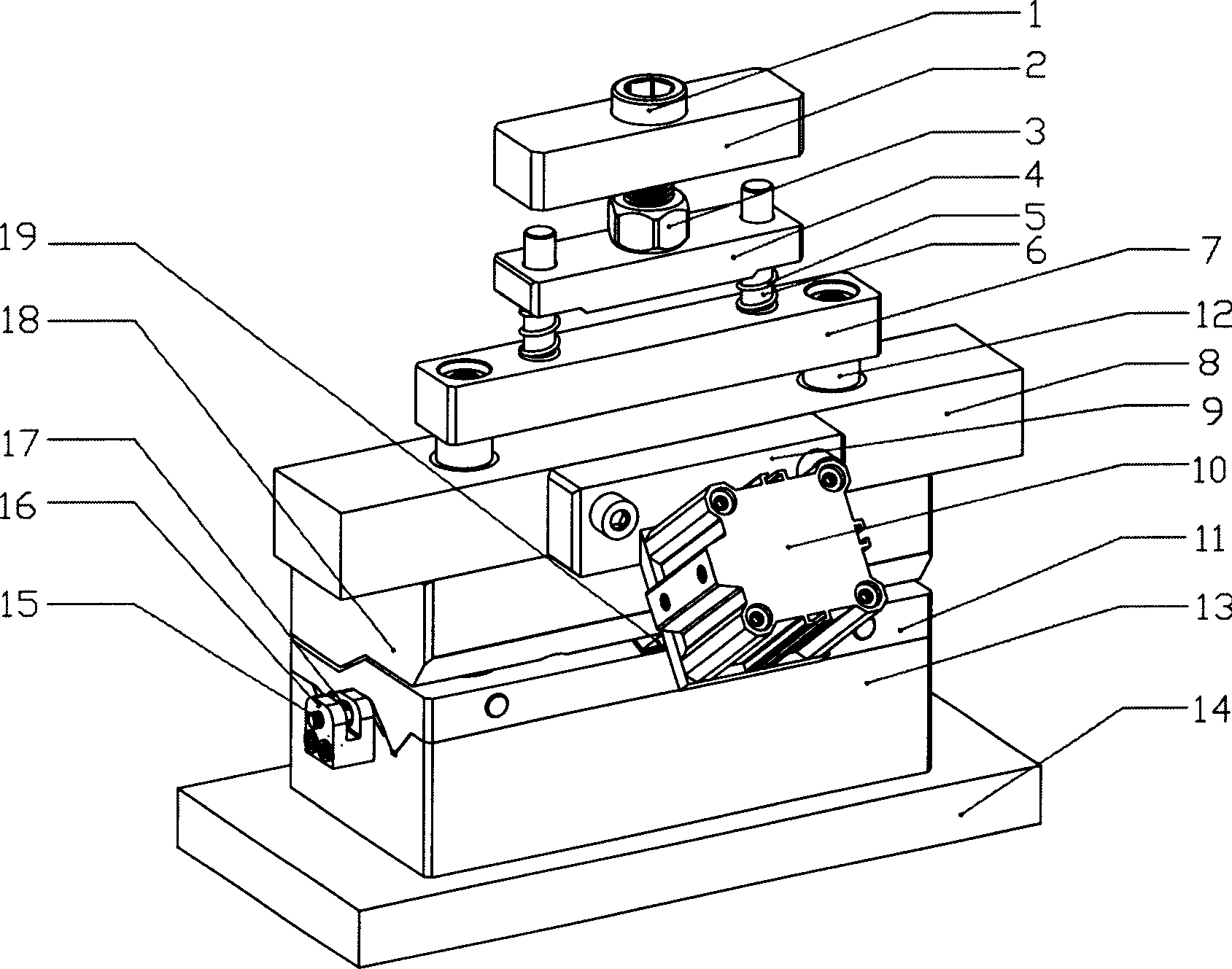

Apparatus for blanking and processing profile notches of rubber sealing strip

InactiveCN1669751AMeet mass production requirementsEasy to locateMetal working apparatusPunchingOblique cutting

This invention discloses a device for blanking and processing rubber sealed strip-type slot; essentially composed by counter die part, upper die part and oblique cutting part. It is characterized in adopting work piece outline of the counter die's surface and its end face's lateral positioning machine to actualize rapid and accurate position for work piece's feeding; the outline of pressing plate and counter die's surface individually furring with upper and lower surfaces of sealing strip to prevent its surface from destroying; pressing device of upper die mainly comprising adjusting screw rod, packing force adjusting nut, spring block, spring guide and connecting block, and being able to adjusting packing force of work piece; using inclined punching guiding block of the oblique cutting part to avoid interference of upper die to oblique punching tool. The invention has the advantages of simple structure, high processing quality and efficiency.

Owner:SHANGHAI JIAO TONG UNIV

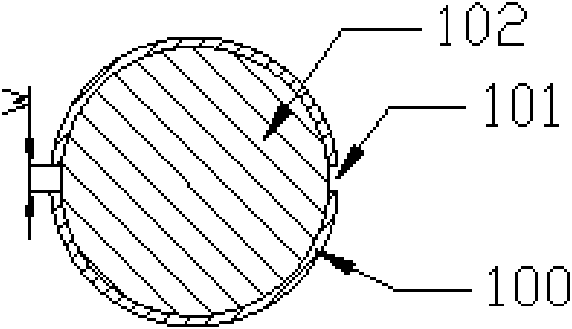

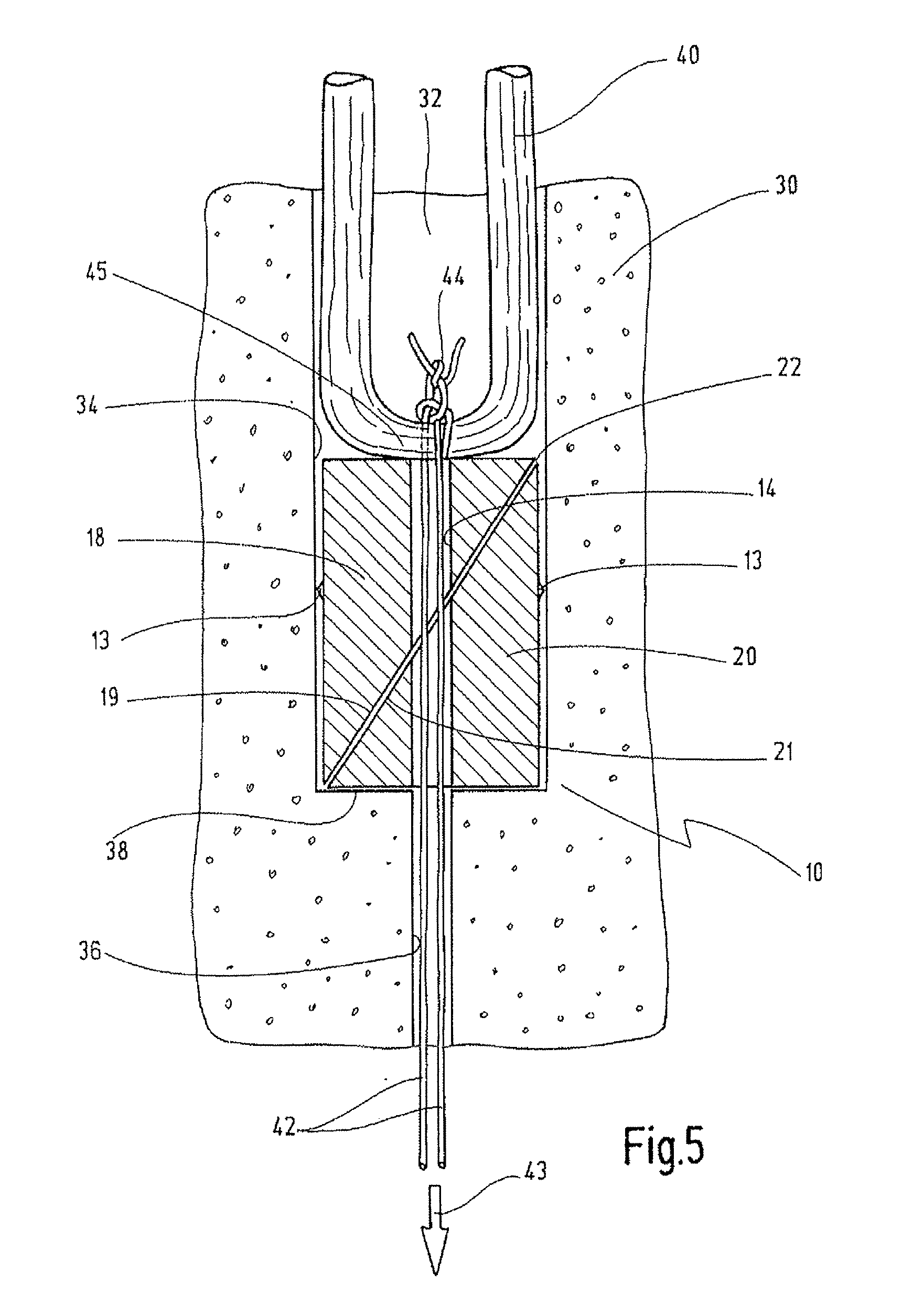

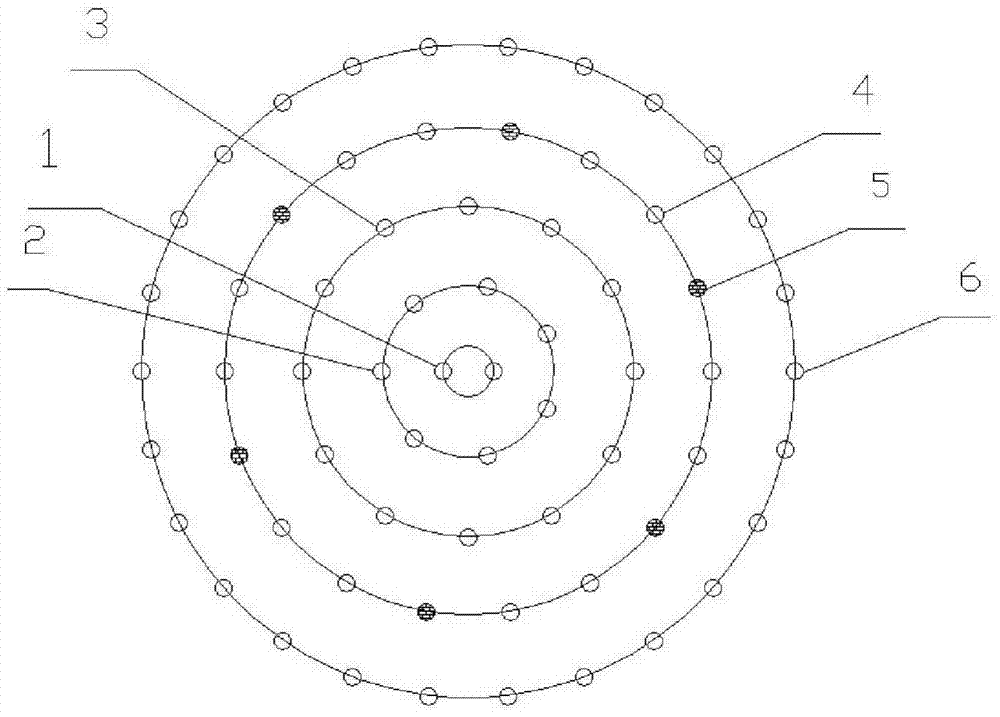

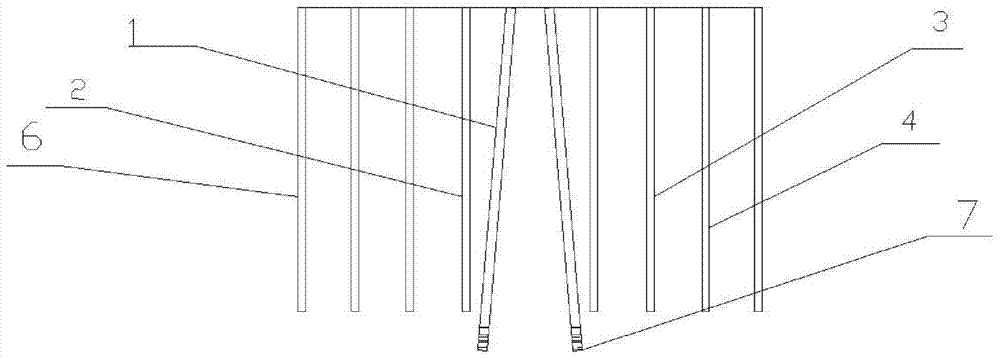

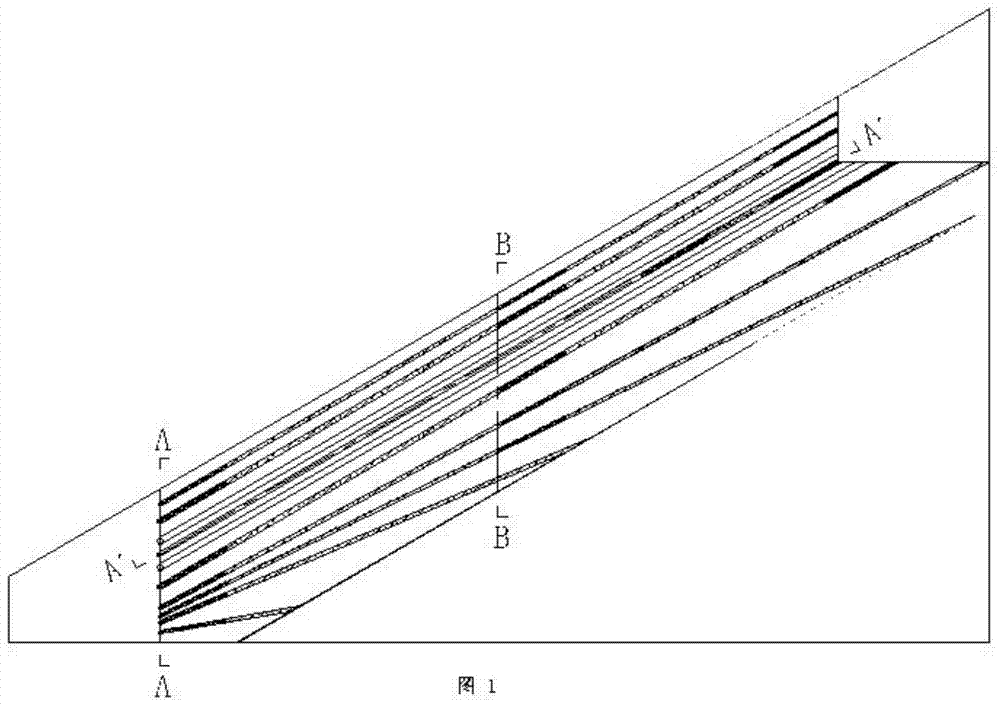

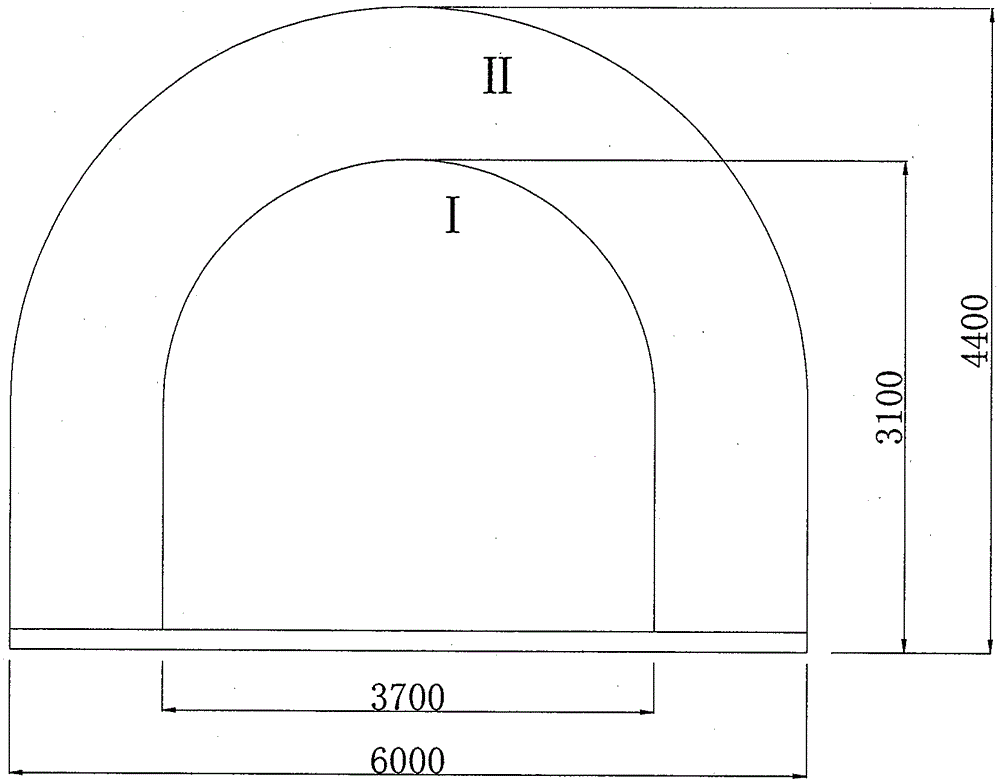

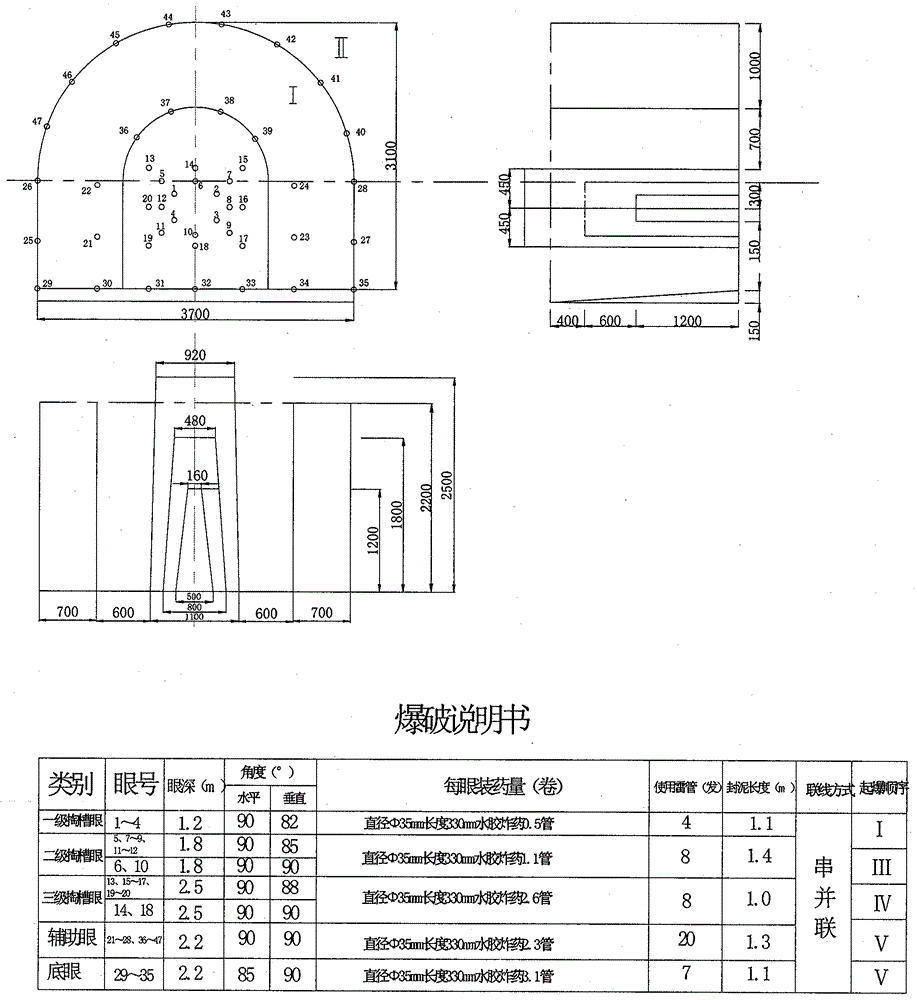

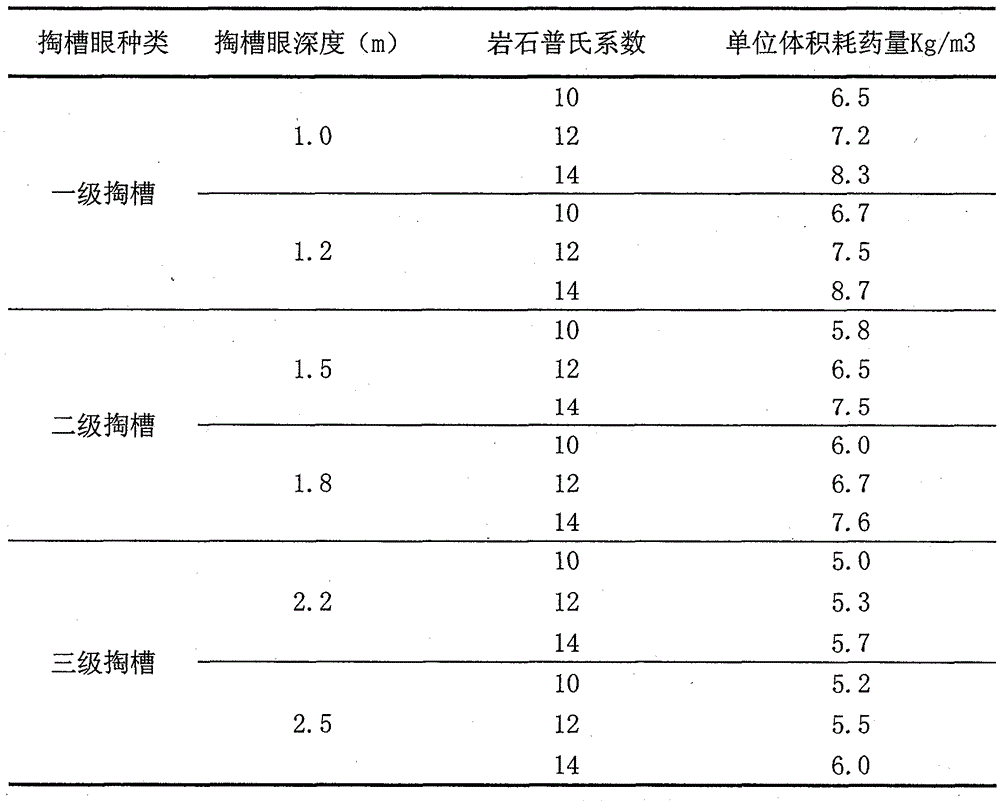

Fast and highly-efficient tunneling method for large section of hard-rock tunnel in coal mine by combination of fully-mechanized tunneling and blasting driving

The invention relates to a fast and highly-efficient tunneling method for a large section of a hard-rock tunnel in a coal mine by combination of fully-mechanized tunneling and blasting driving. As shown in the figure 1, a cut hole with the borehole diameter of Phi 40.0 mm and a reliever hole with the charge diameter of Phi 35.0 mm are arranged in the section of the hard-rock tunnel with the protodyakonov coefficient f larger than 10.0 for digging out a groove cavity with s approximately equal to 14.0 m<2>. As shown in the figure 2, the cut hole adopts a three-stage oblique cut with stages deepening and angles of inclination increasing stage by stage. The consumption of charge in unit volume is determined based on the hard-rock protodyakonov coefficient and shot hole depth according to quantification of the figure 3. Three stages of oblique cuts respectively select I, III, IV-section millisecond delay detonators. A V-section millisecond delay detonator is selected by the reliever hole. The oblique cuts and the whole section of the reliever hole are detonated once with the total delay time no more than 130.0ms. After the groove cavity is formed in a blasting method. The reasonable tooth parameters are selected to rapidly expand the groove cavity to the design section and contour is finished under effect of a free surface of a fully-mechanized coal winning machine. Due to millisecond delay detonation of the oblique cut in three stages and larger borehole diameter, stemming is blocked to increase so that rocks do not affect the fully-mechanized coal winning machine after the working surface during the throwing process. The safe and efficient effect can be achieved.

Owner:湖南省煤业集团红卫矿业有限公司

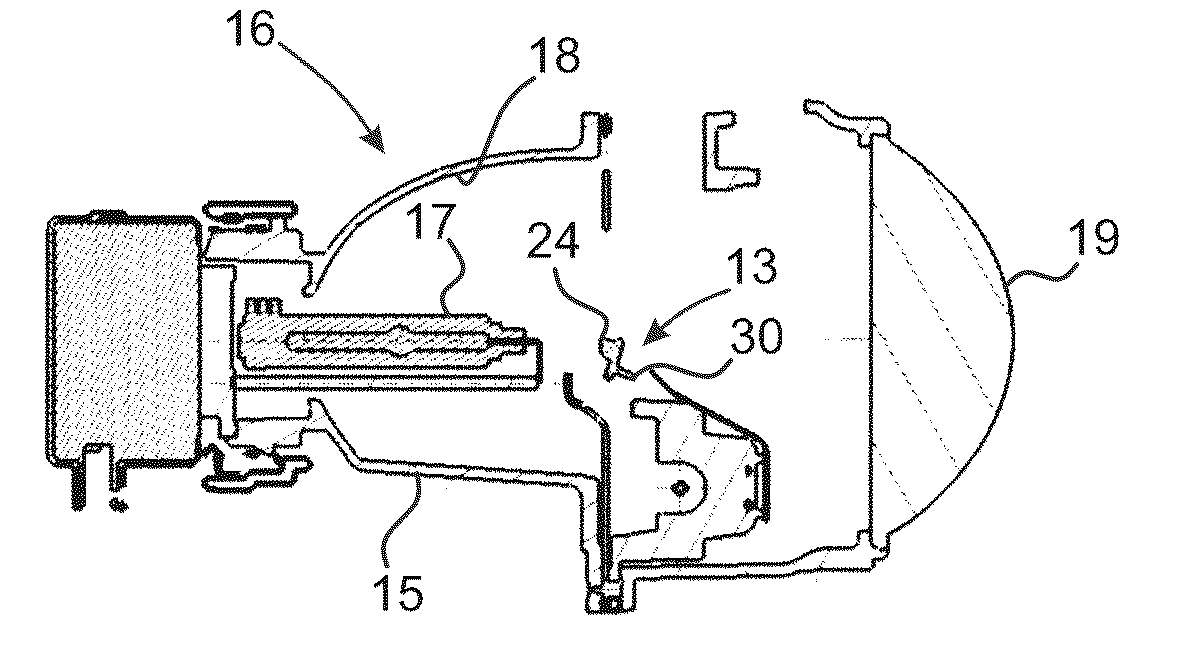

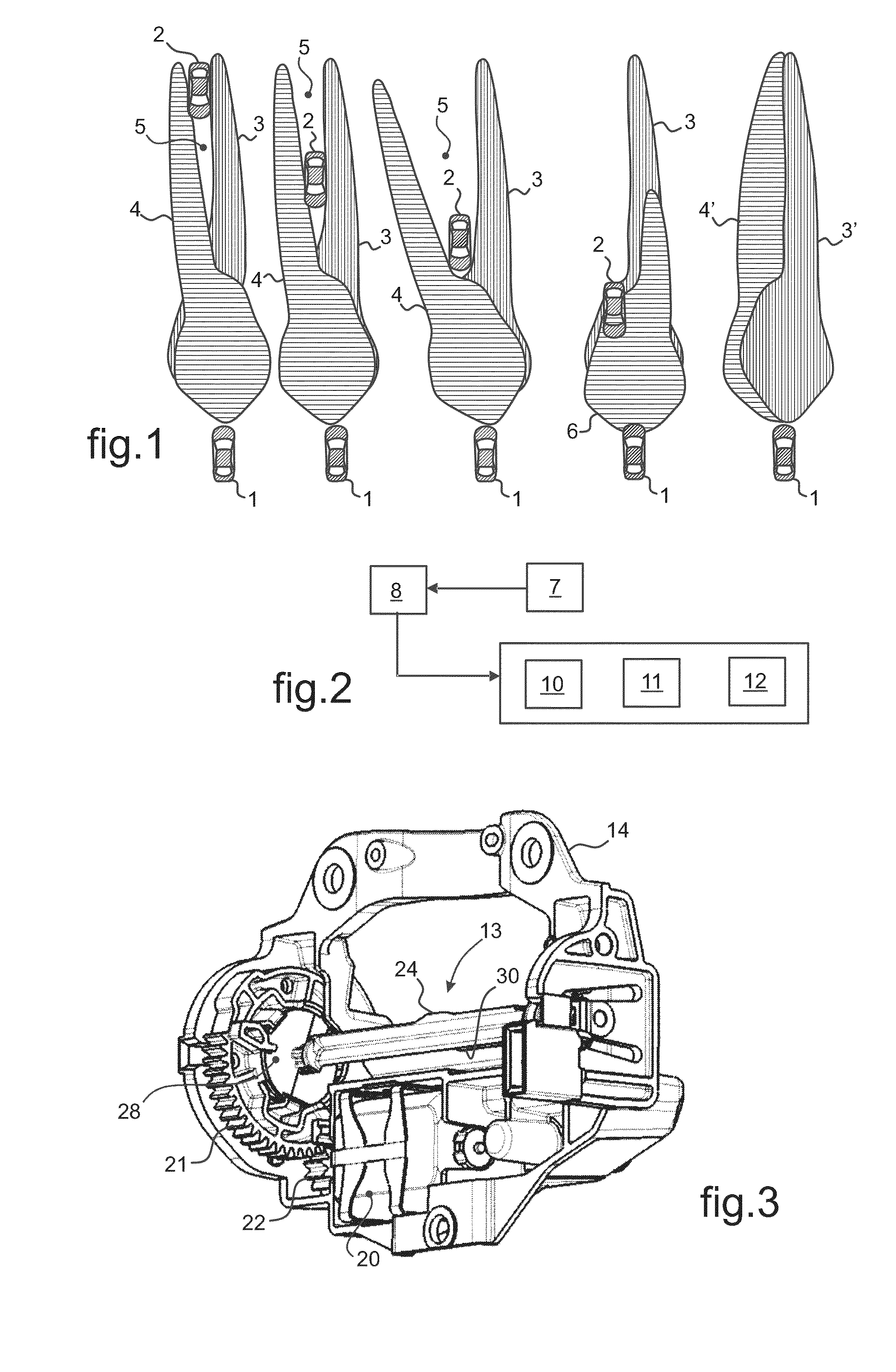

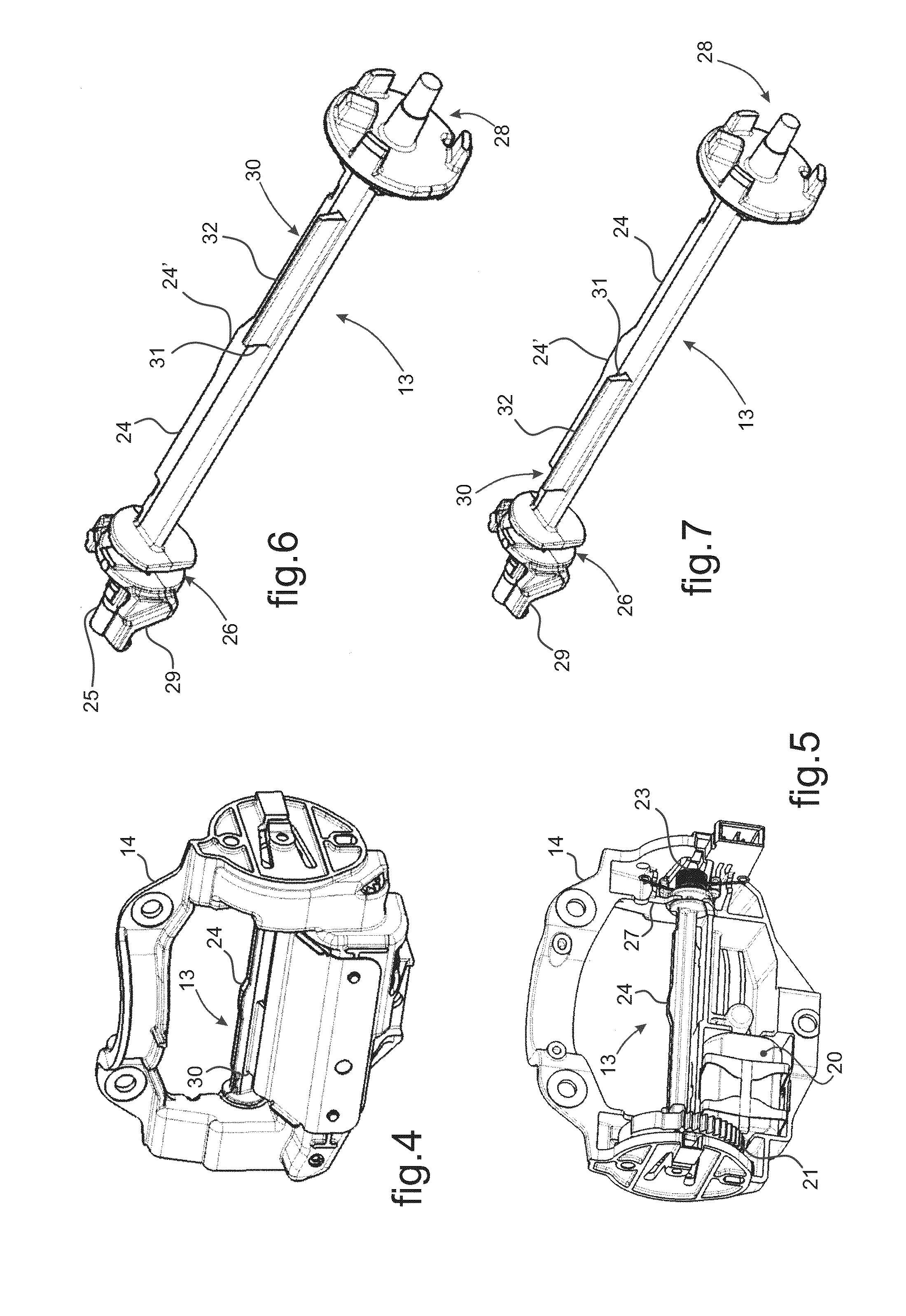

Optical module for a motor vehicle capable of selectively lighting a zone

InactiveUS20100091514A1Convenient lightingSimple structureVehicle headlampsPoint-like light sourceMobile vehicleOptical Module

A headlamp for a motor vehicle, this headlamp comprising at least one optical module capable of emitting a plurality of light beams, including a low beam and at least one additional light beam. The optical module is equipped with a cover plate which can be moved between at least two positions, this movable cover plate being configured along a shaft mounted so as to rotate in the optical module and driven in rotation at least by a motor. The shaft comprises at least one first cut-off member configured as a double-edged cover plate providing an oblique cut-off for emission of the low beam, and at least one second cut-off member configured as a wall of substantially constant height, angularly offset relative to the first cut-off member and providing at least one substantially vertical cut-off line for emission of a high beam.

Owner:VALEO VISION SA

Hinged-lid pack for rodlike smoking articles and blank for the pack

ActiveUS20050236283A1Strong impressionEffective preventionContainers for flexible articlesPackaging cigaretteOblique cuttingEngineering

A hinged-lid pack includes a case (2), and contents (14) contained in the case (2) and fit with an inner frame (16). The case (2) has a transverse cutting line (22) formed in a front wall (4) thereof, oblique cutting lines (24) respectively formed in right and left side walls (12) thereof, and a self-hinge (26) formed at a rear wall (6) thereof. When the case (2) is split apart along the transverse cutting line (22) and the oblique cutting lines (24), the case (2) is divided into a box (30) and a recloseable lid (28).

Owner:JAPAN TOBACCO INC

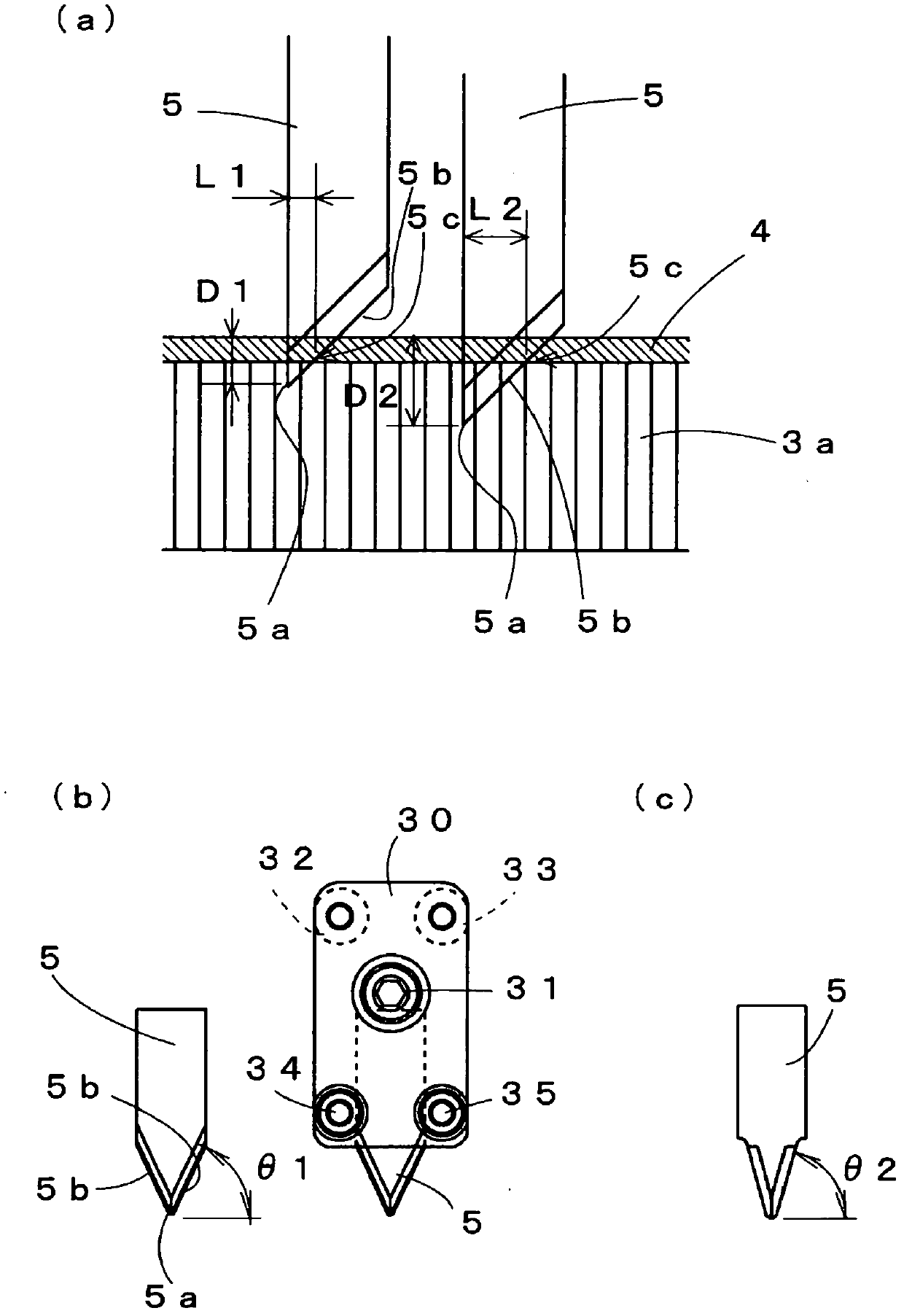

Cutting machine

ActiveCN103085102ASeek long lifeReduce replacement workMetal working apparatusEngineeringOblique cutting

The invention provides a cutting machine which may prolongs service life of a cutting knife in a simple structure and can reduce replacing work of the cutting knife. Cutting a sheet-like article is performed in an action position (5c) that becomes a part of a knife edge (5b) in a state of stabbing an oblique cutting knife (5) to the sheet-like article from above. A cutting knife elevation mechanism (6) is provided for elevating and moving the oblique cutting knife. Even if service life of the action position (5c) reaches the service life of the knife edge (5b), the action position can be switched to other action positions (5c) for continuous cutting. Since the knife edge (5b) is oblique, a distance between a reference position of a cutting head (2) and the action position (5c) varies according to the height of the action position (5c) relative to a knife tip (5a). Concerning the variation, control of the cutting head (2) is performed by modifying cutting data by the control portion (7), and thus cutting with no error can be performed.

Owner:SHIMA SEIKI MFG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com