Patents

Literature

2730results about "Shaping cutters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

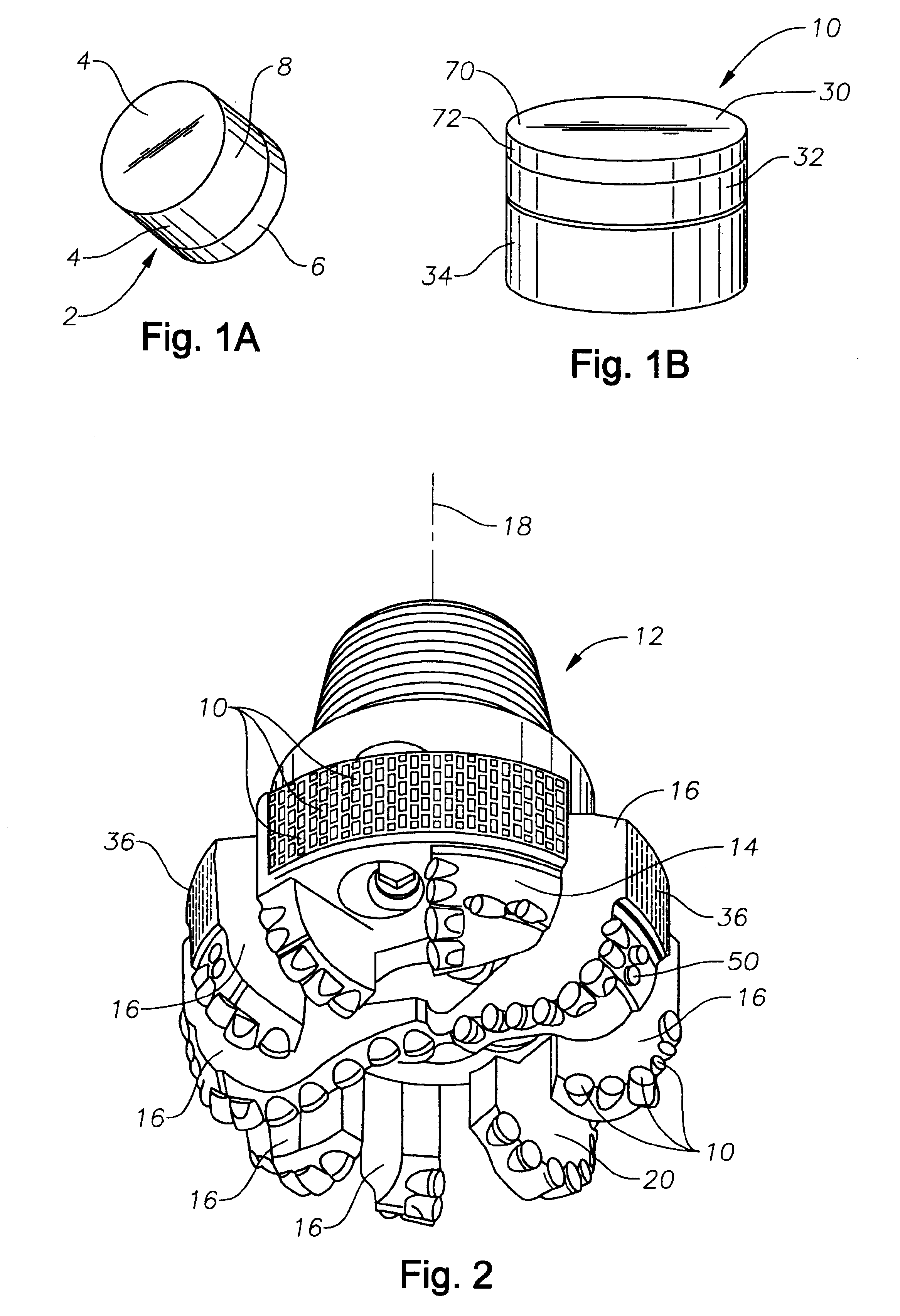

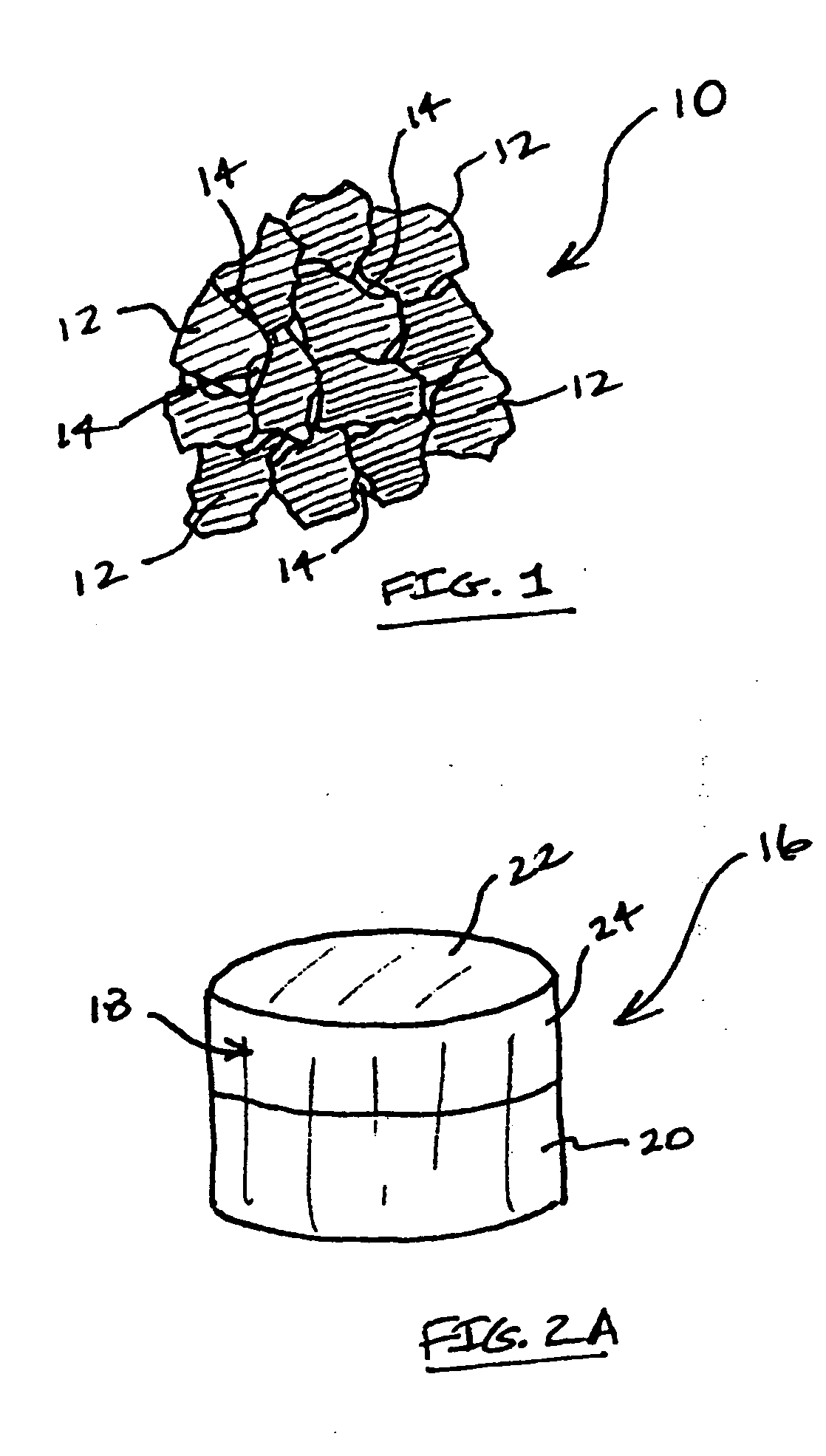

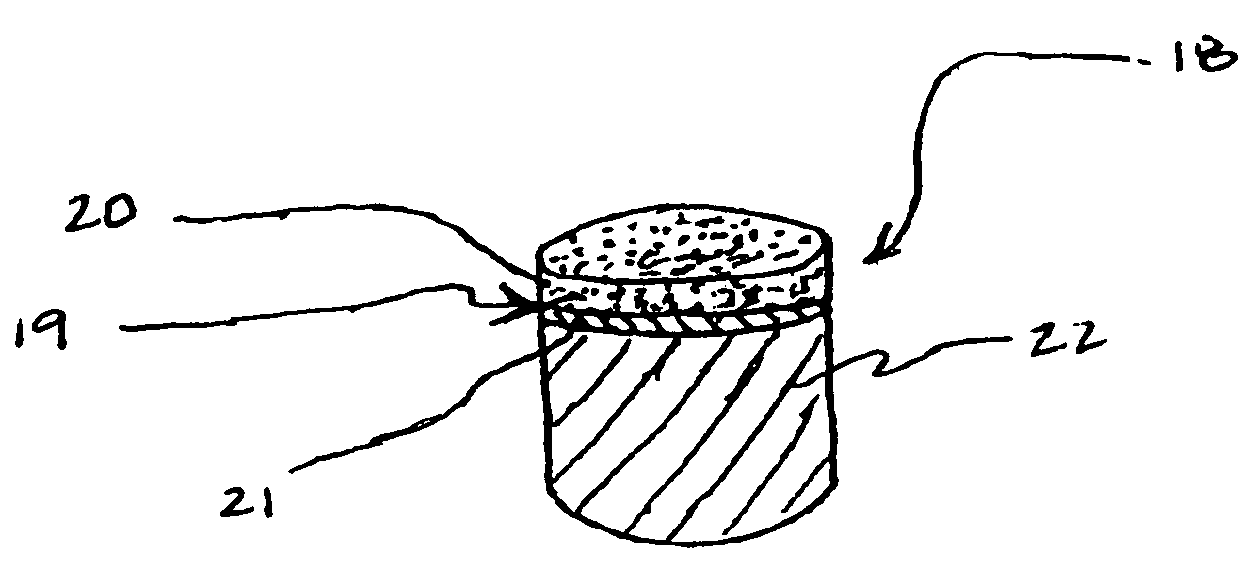

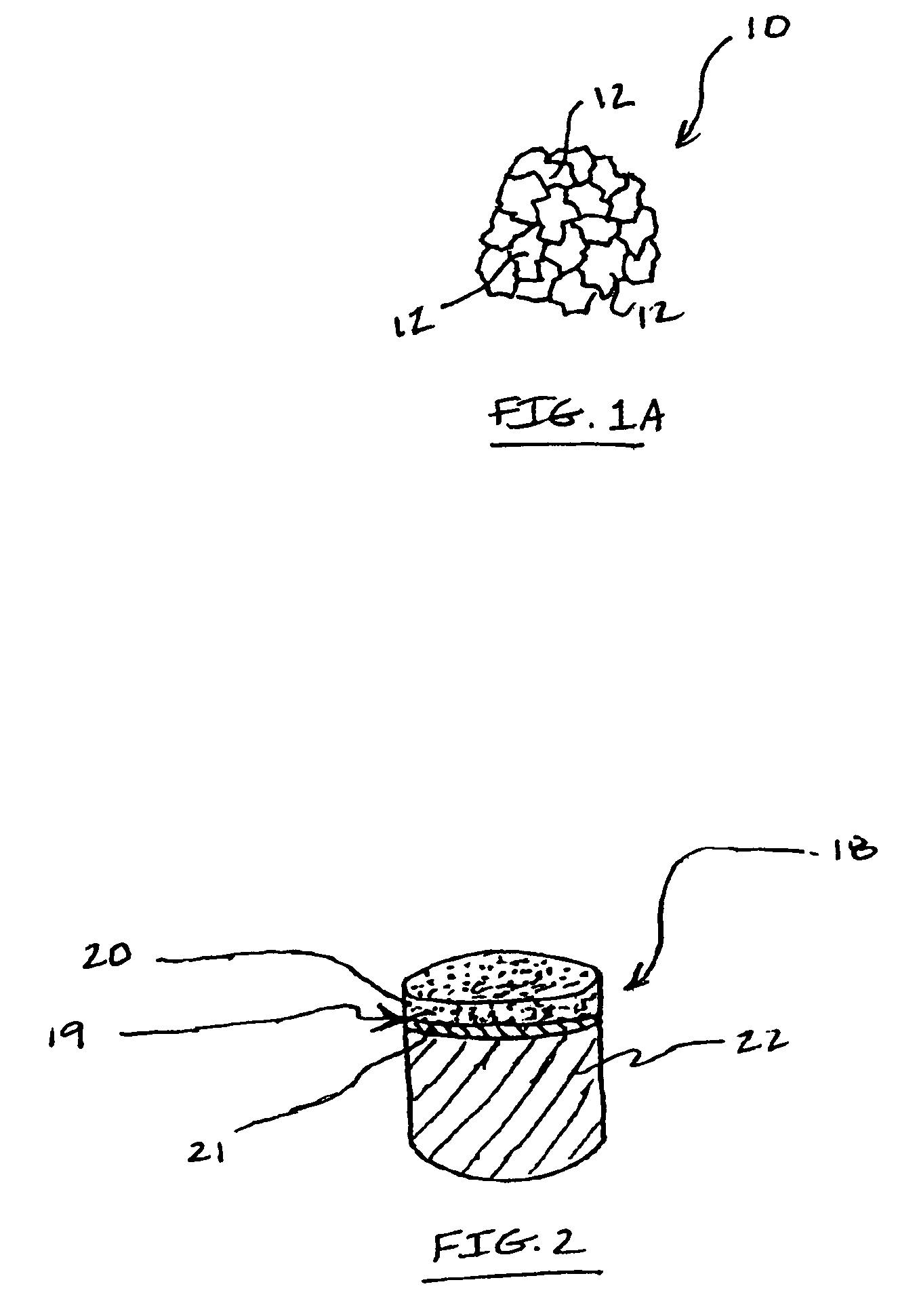

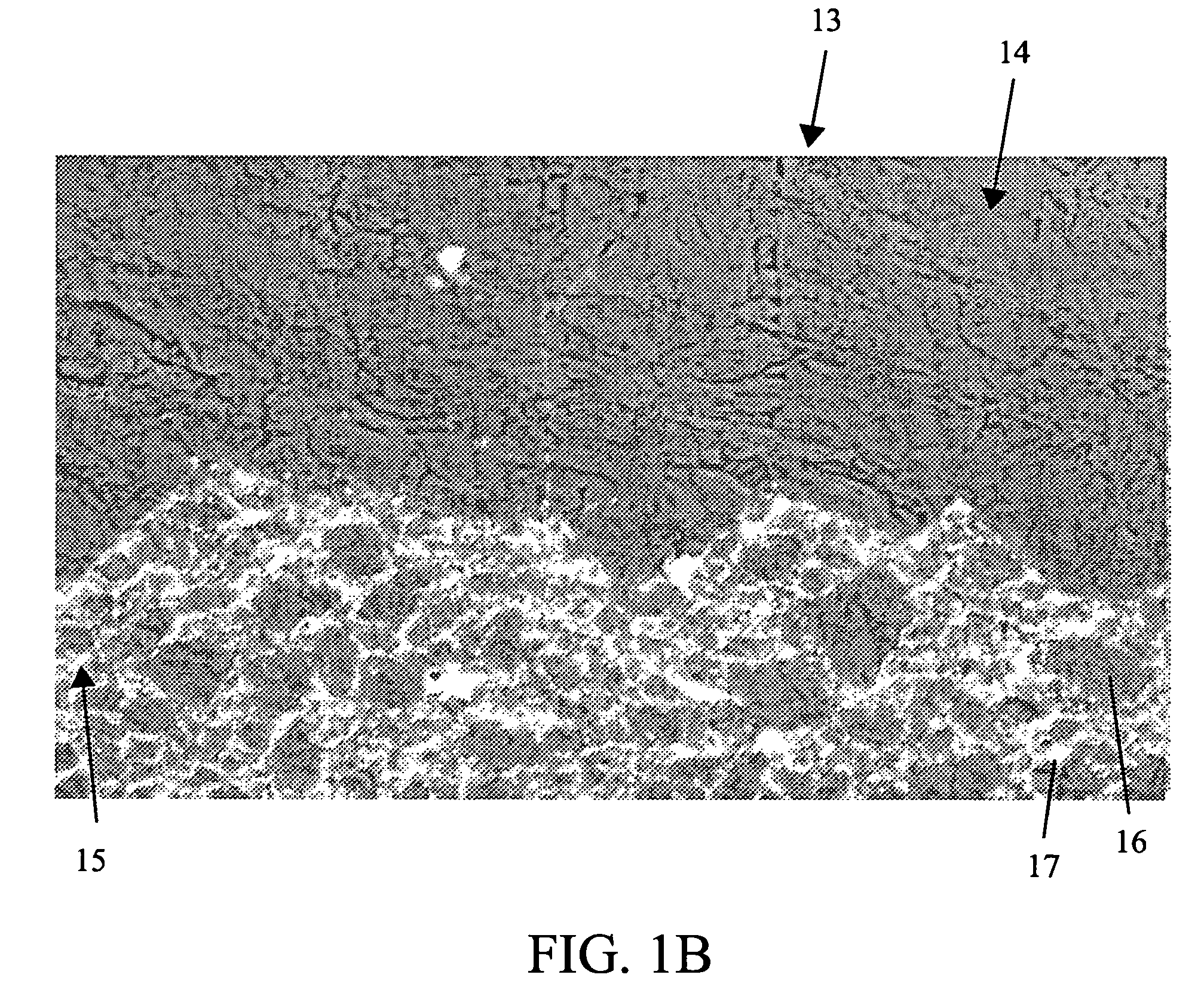

Polycrystalline diamond cutters with working surfaces having varied wear resistance while maintaining impact strength

InactiveUS6601662B2Improve wear resistanceMaintain strengthDrill bitsConstructionsDiamond crystalPolycrystalline diamond

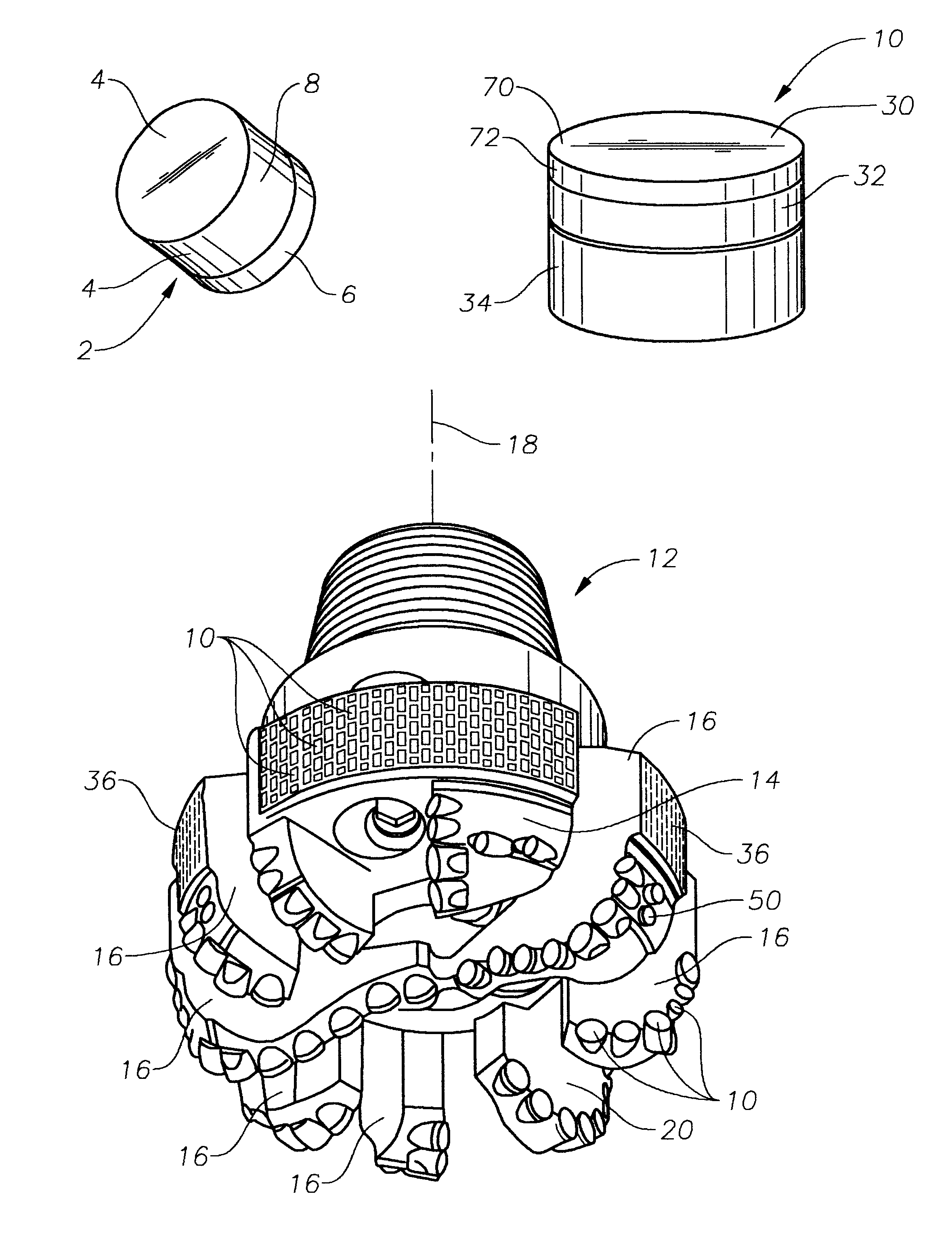

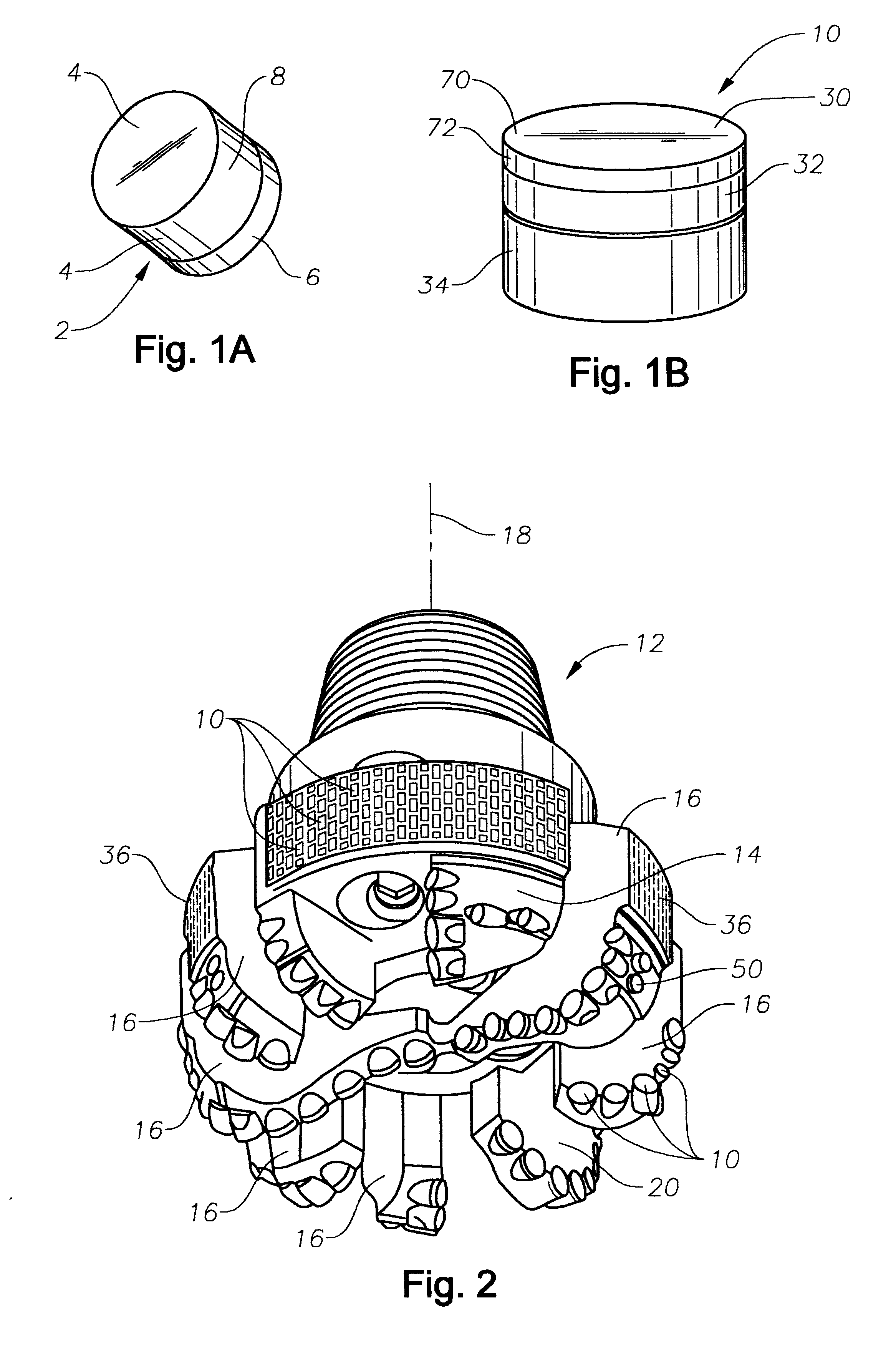

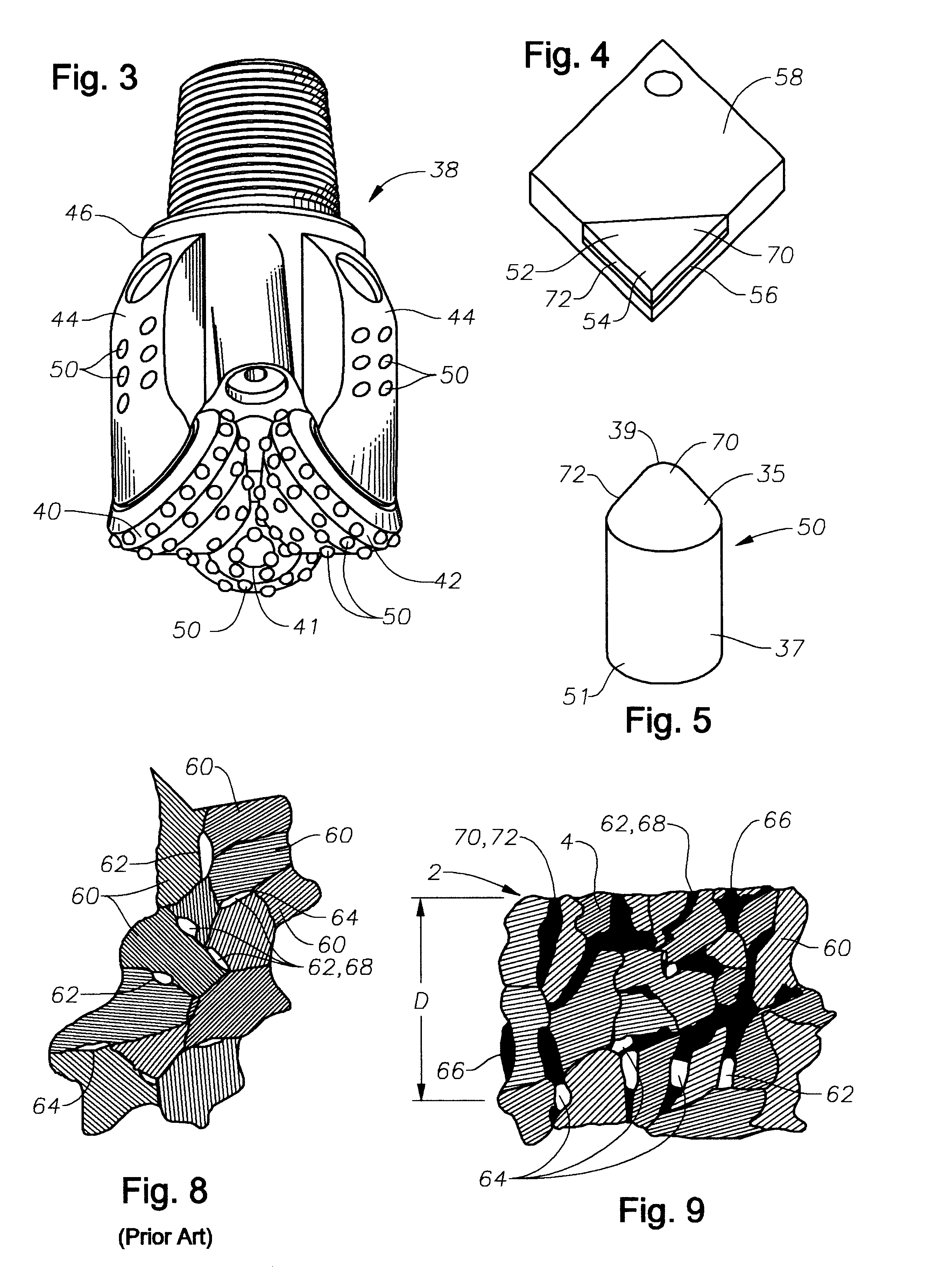

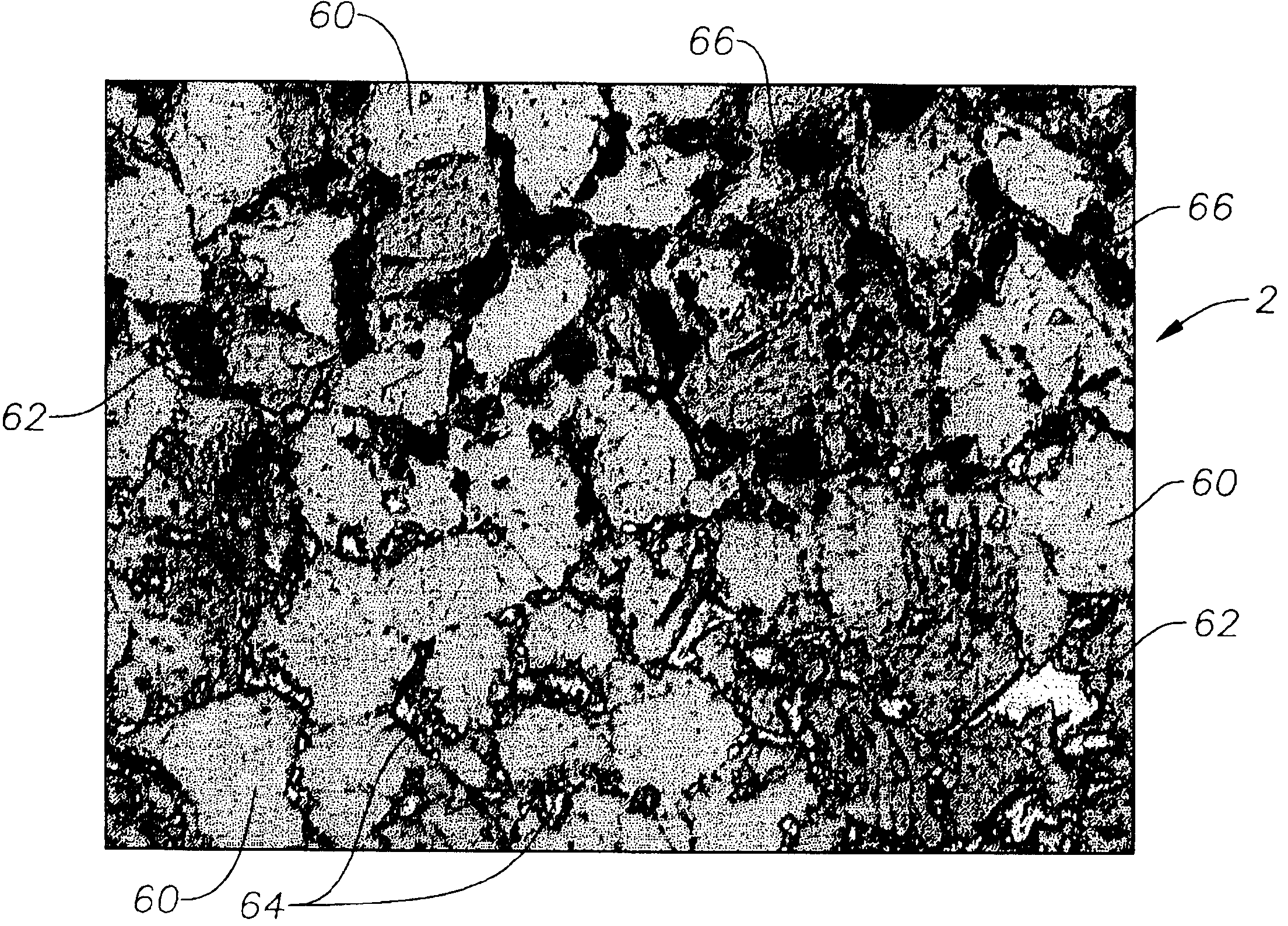

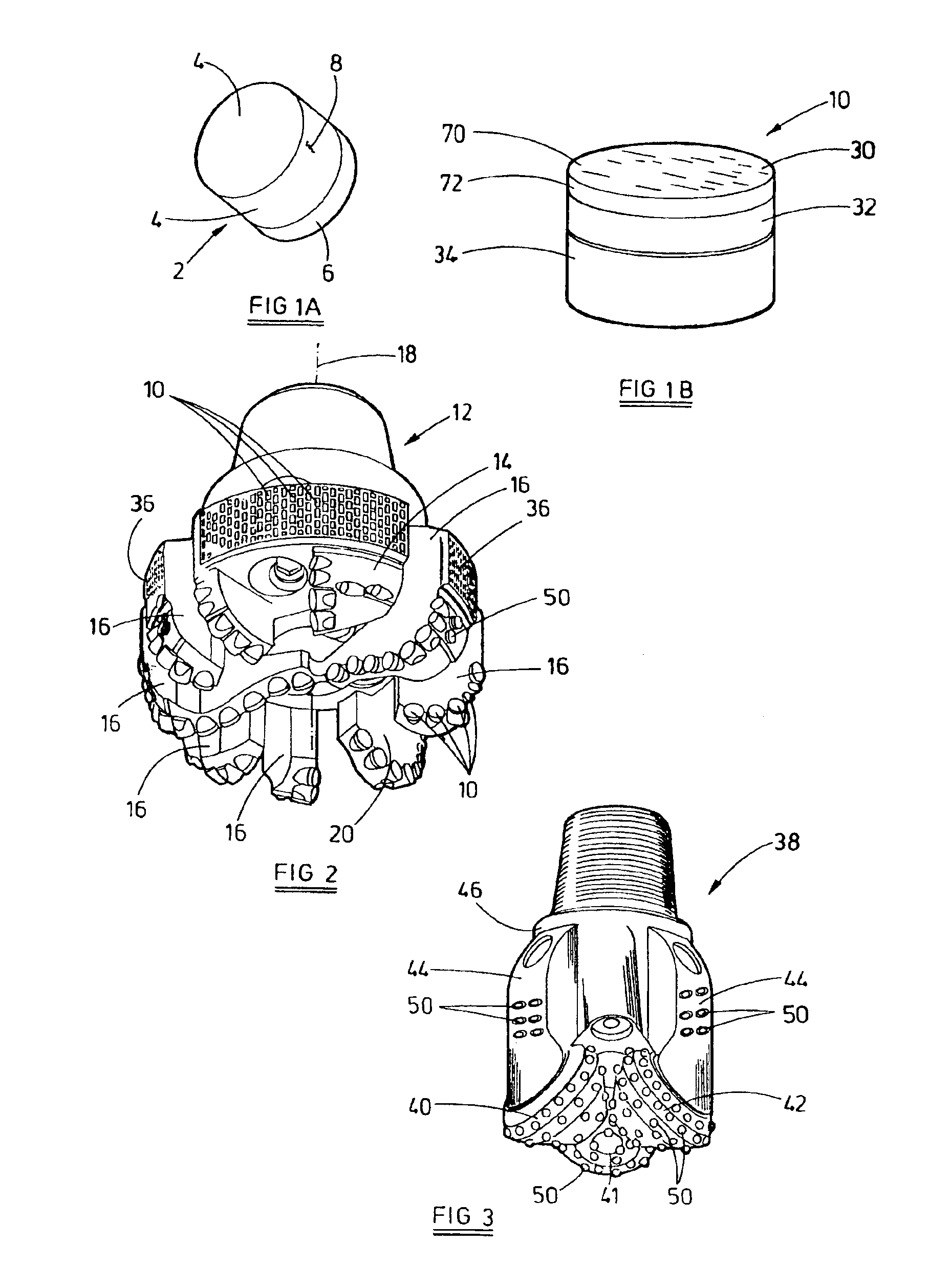

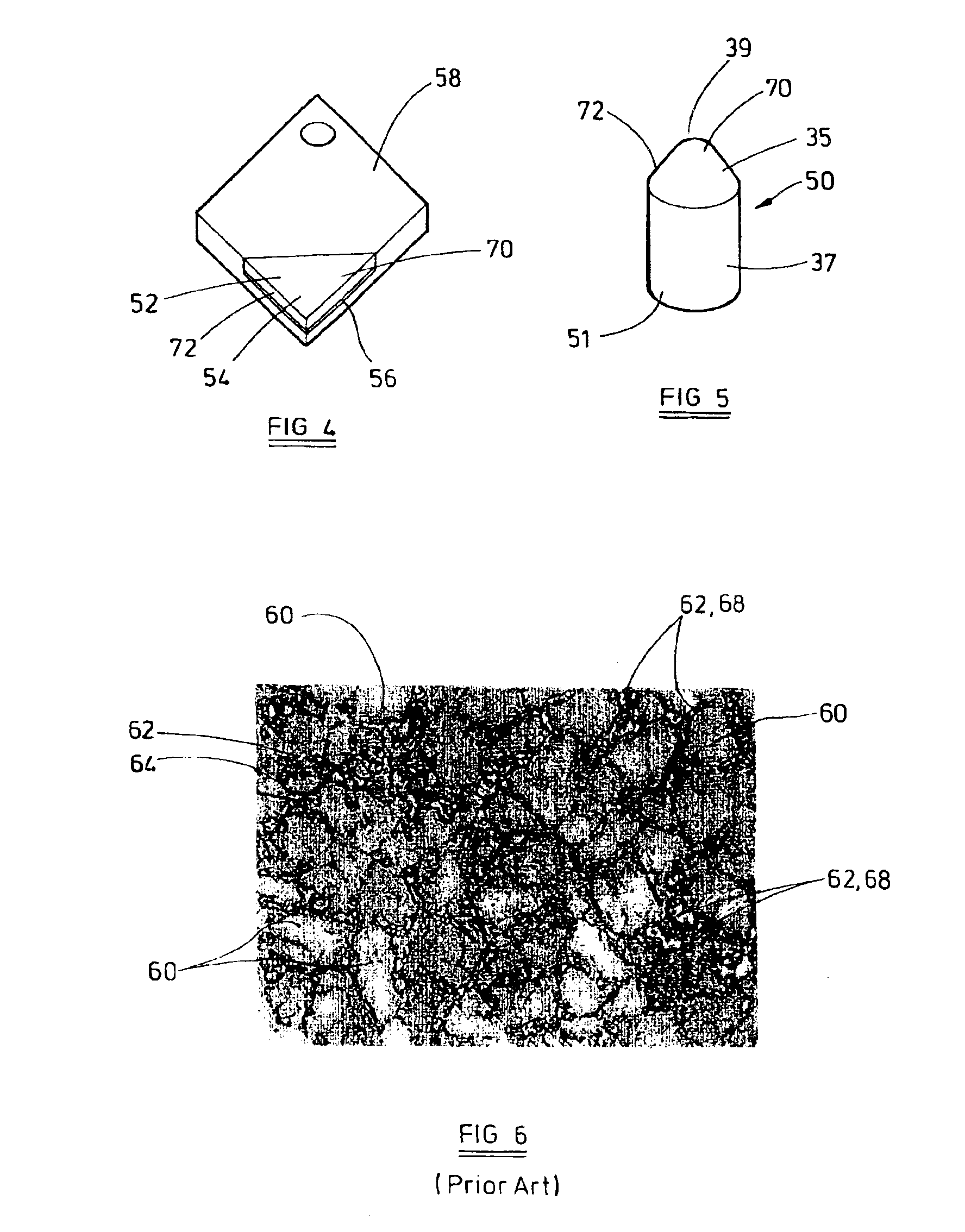

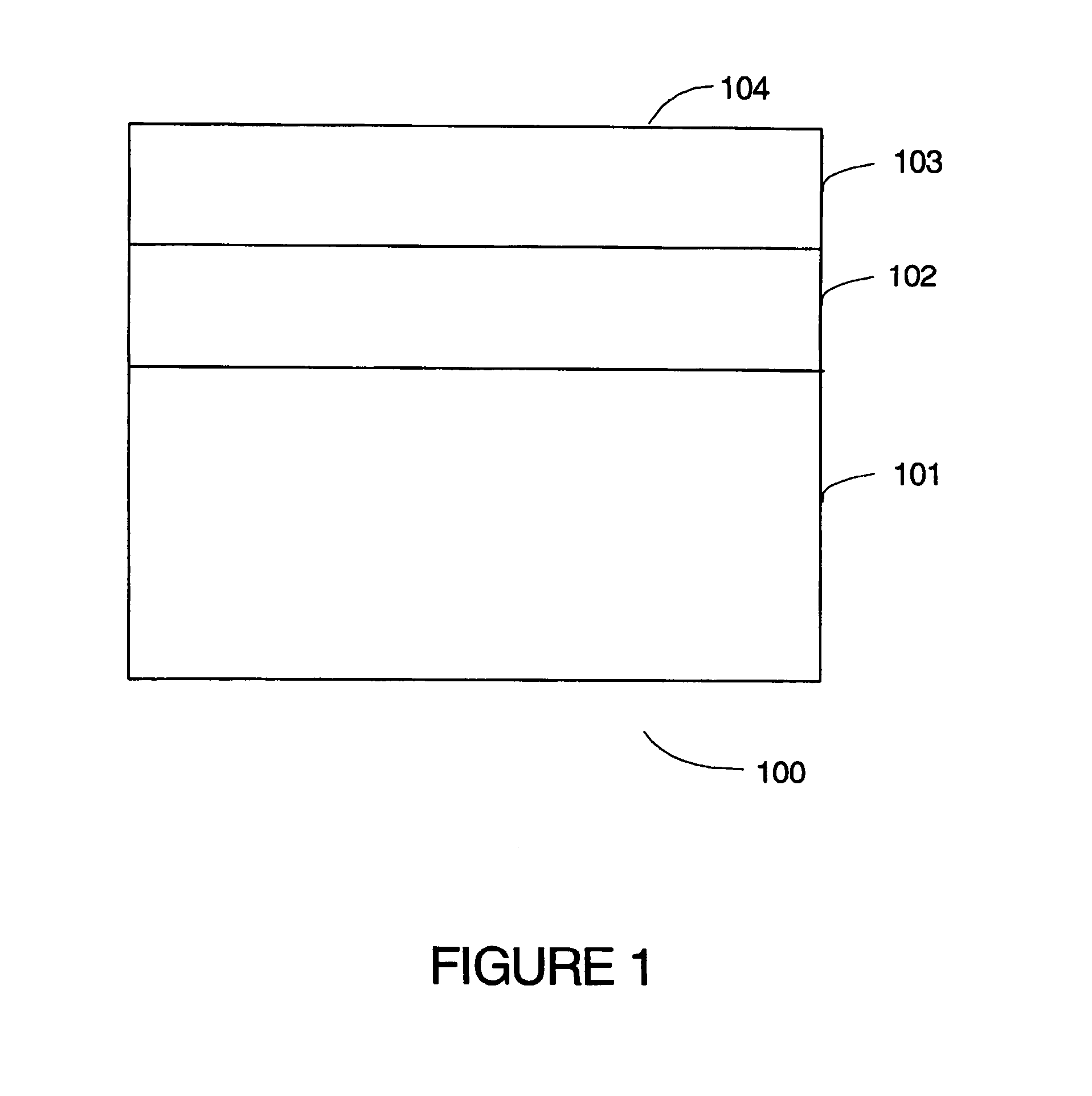

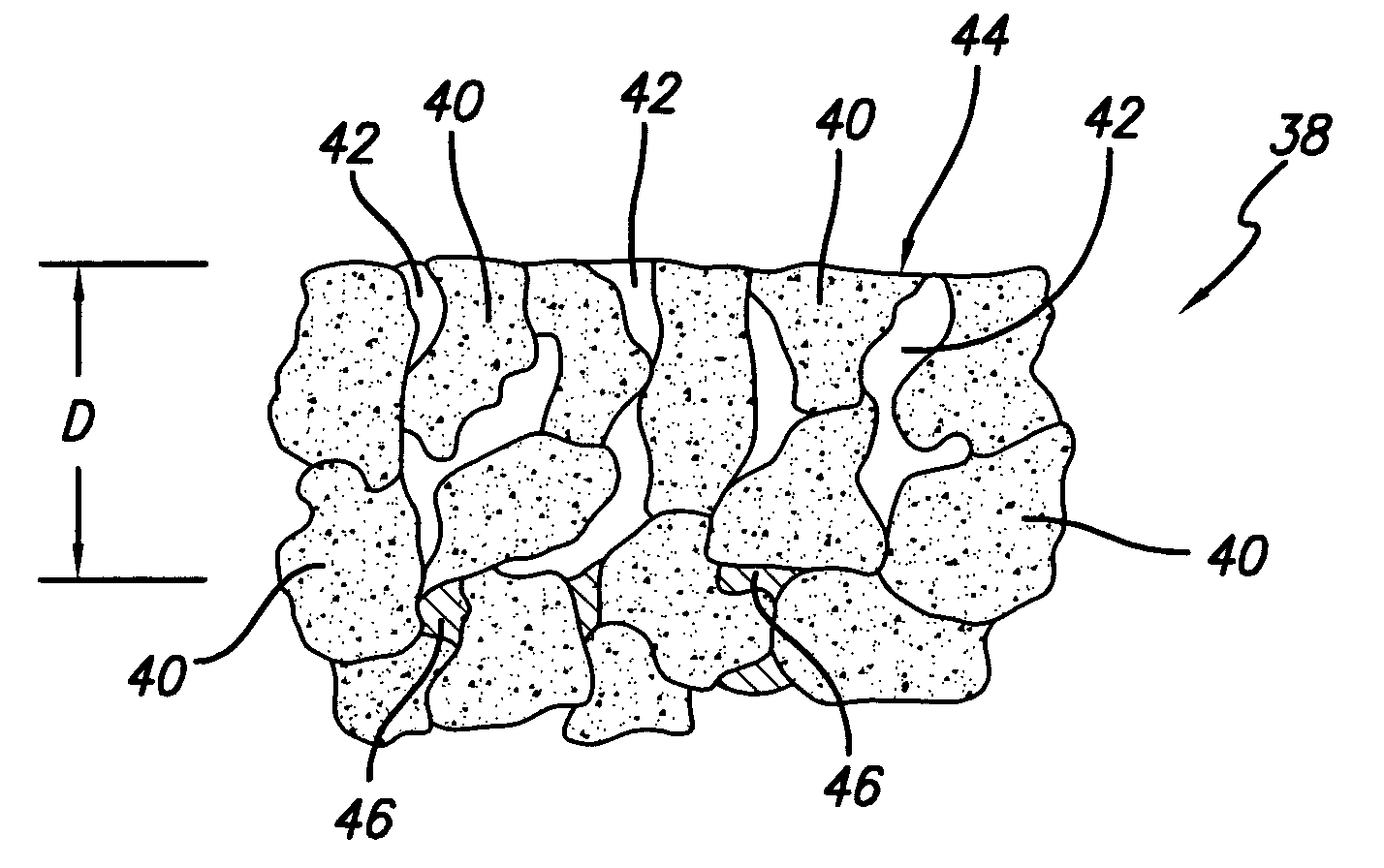

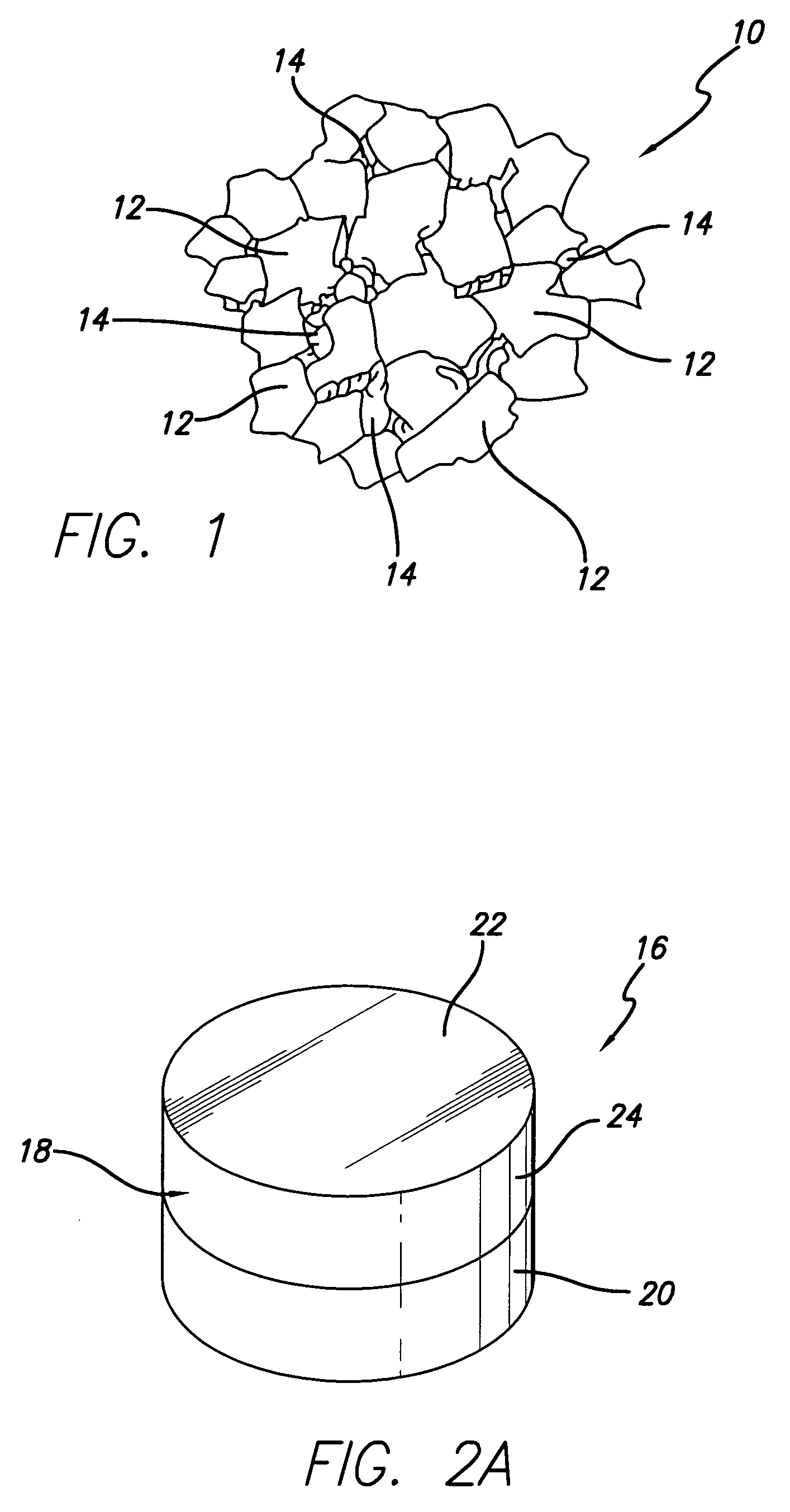

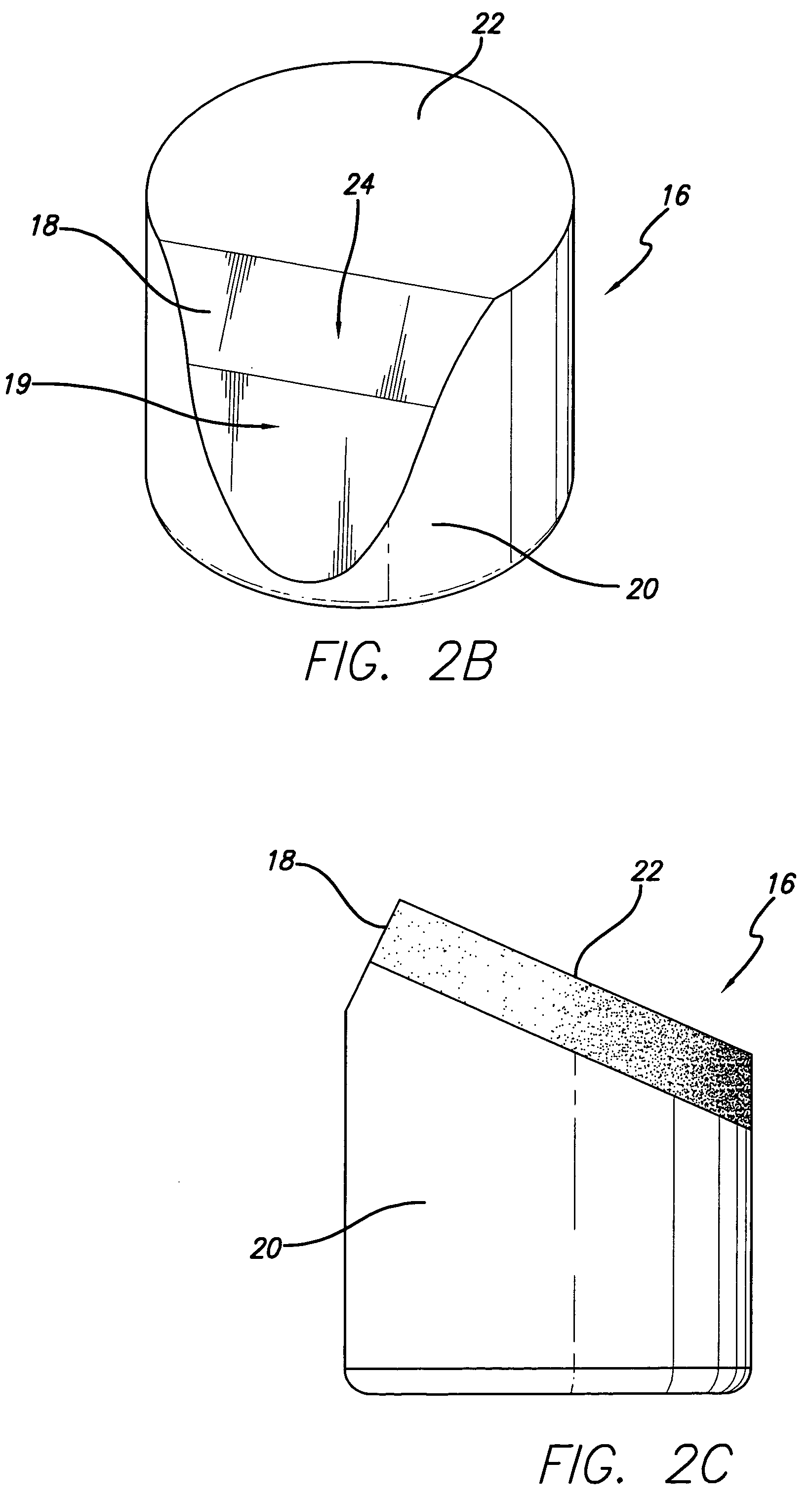

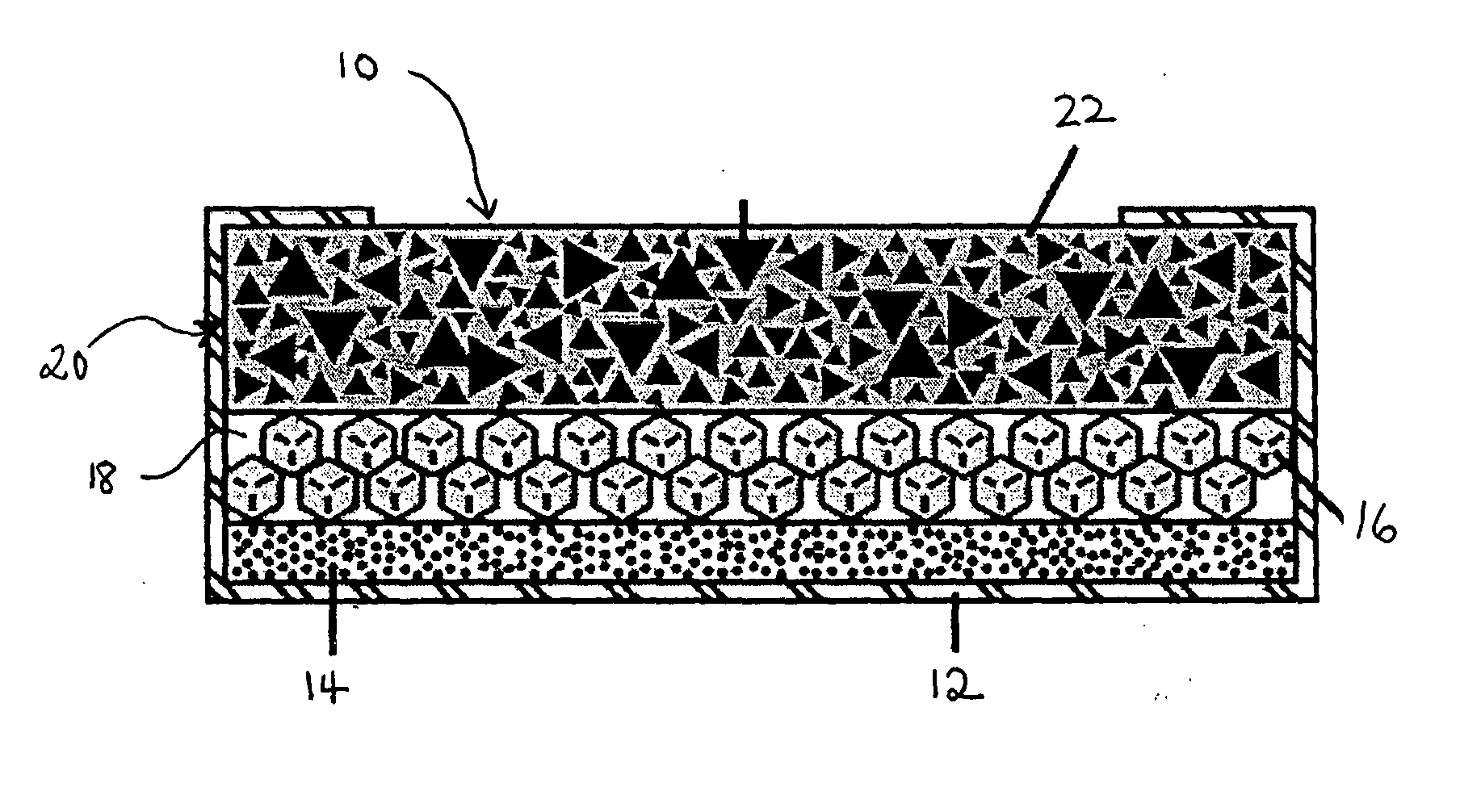

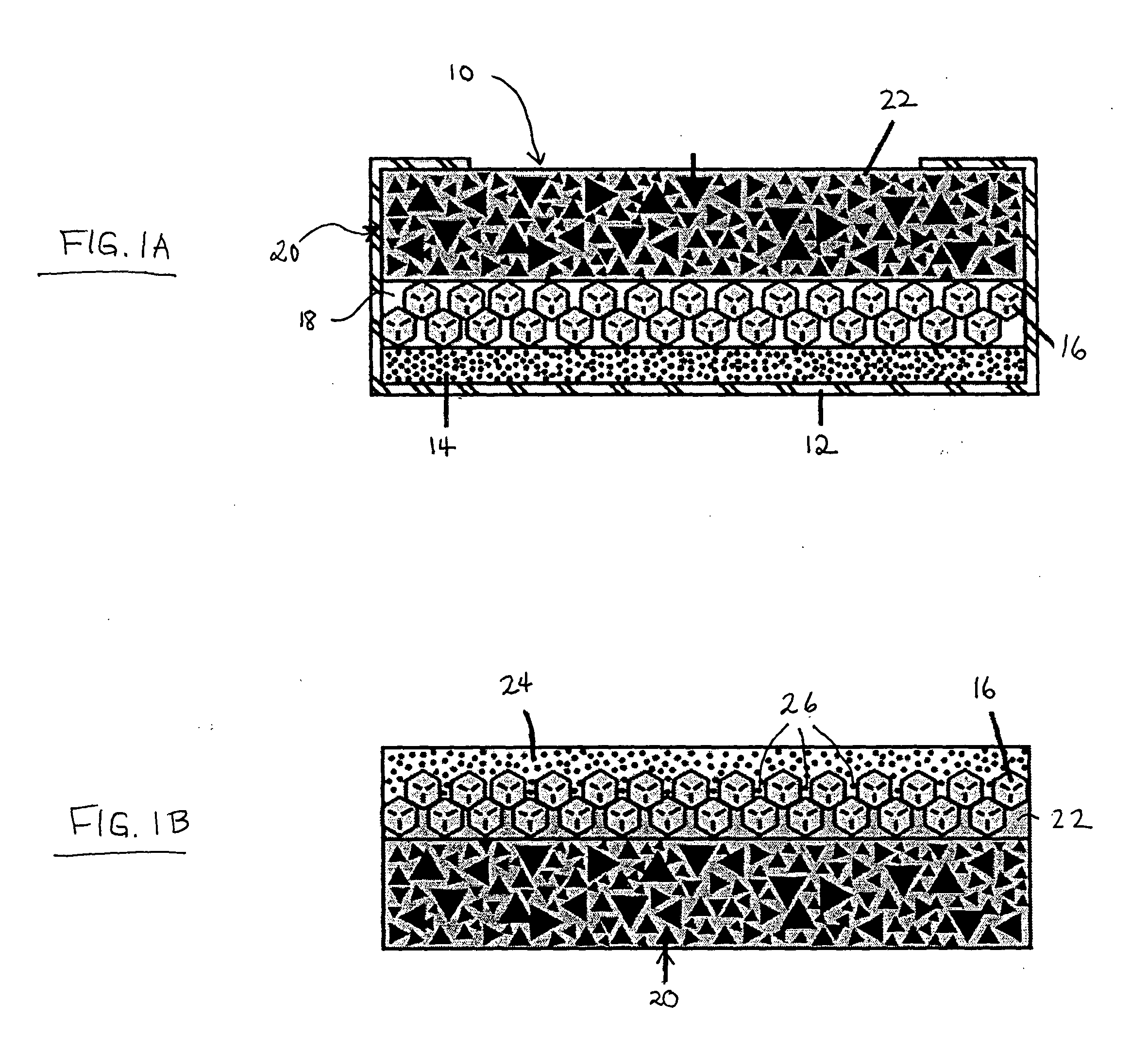

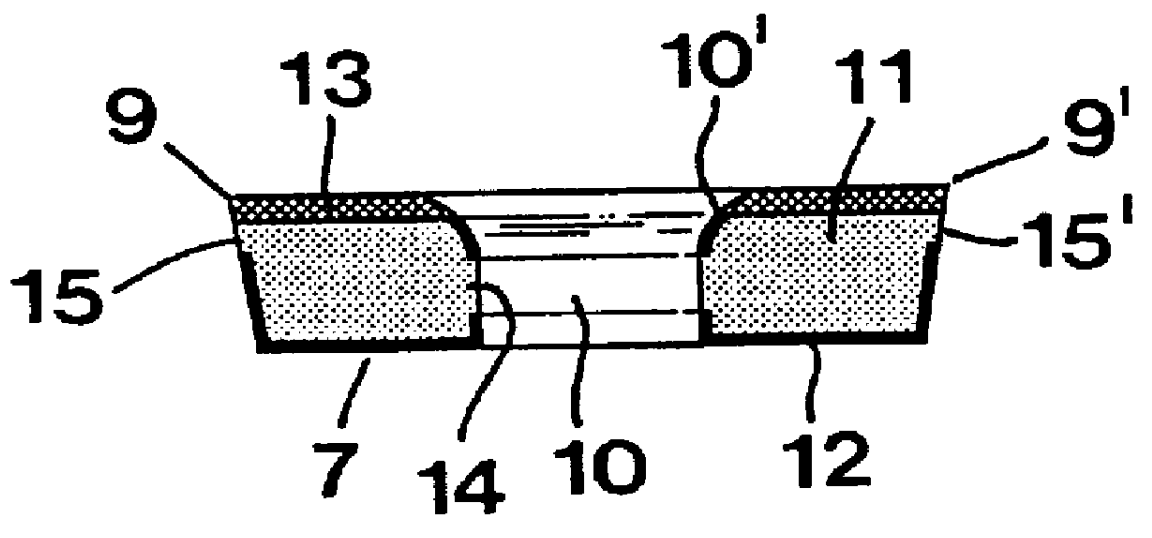

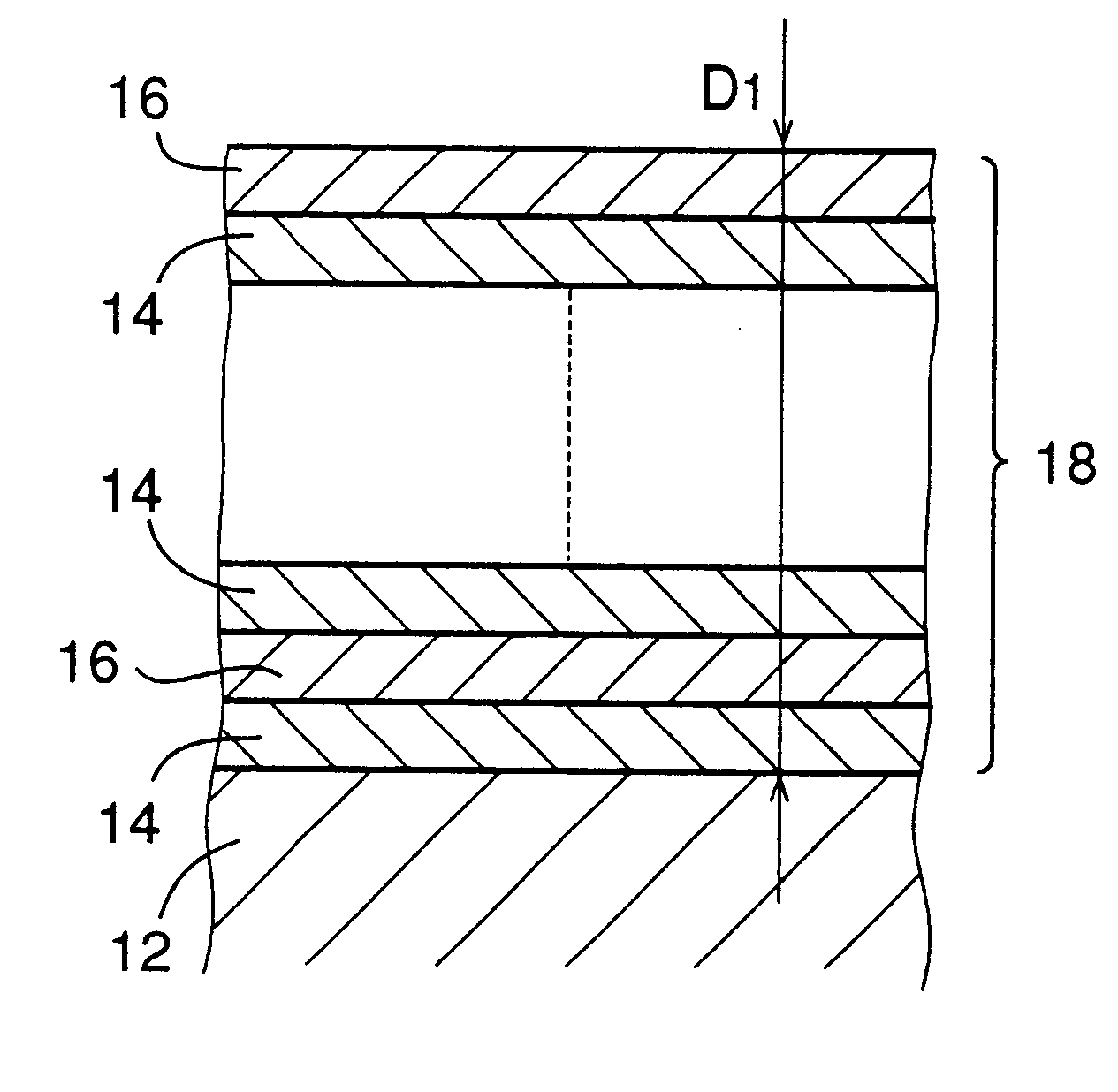

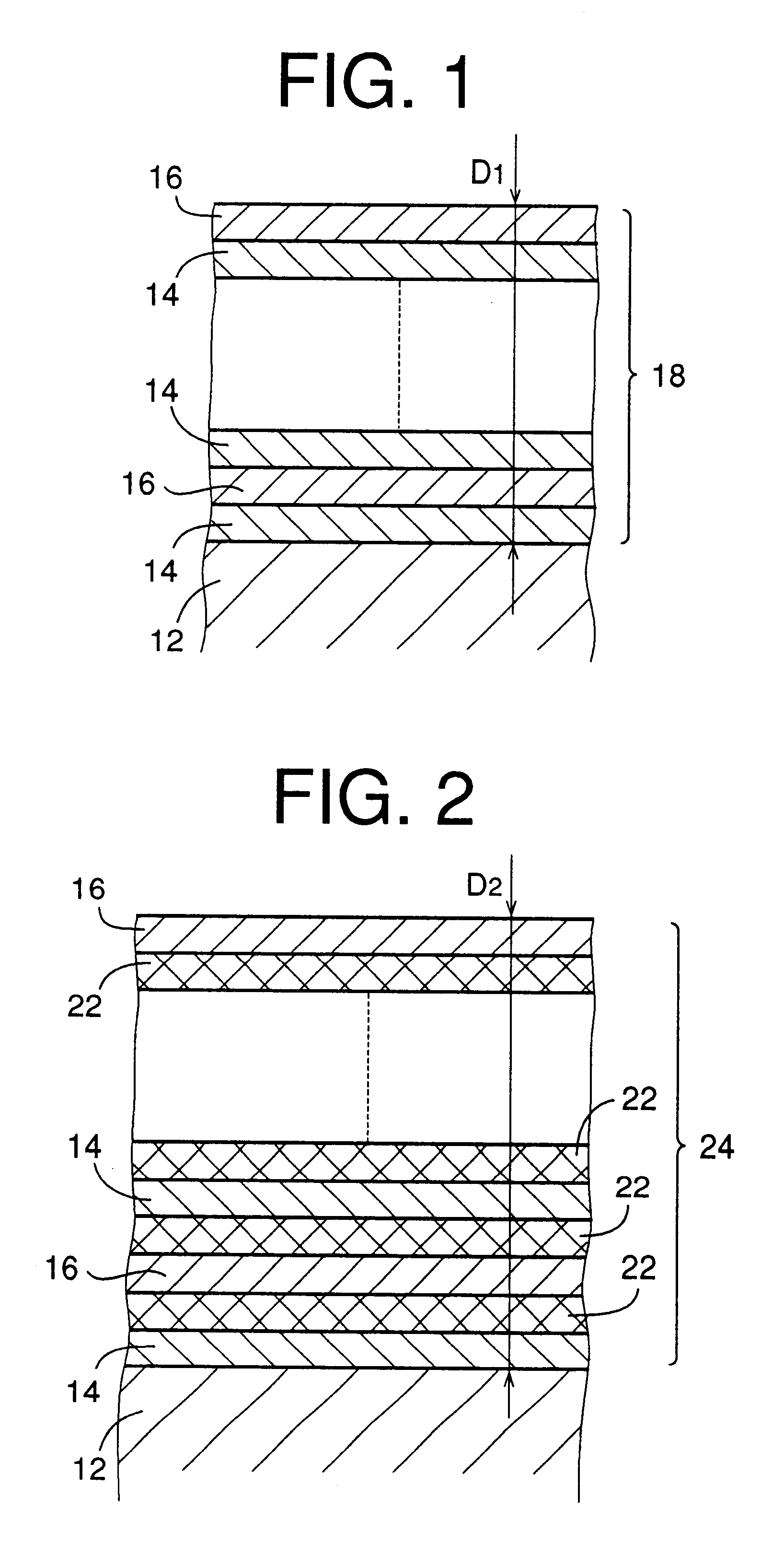

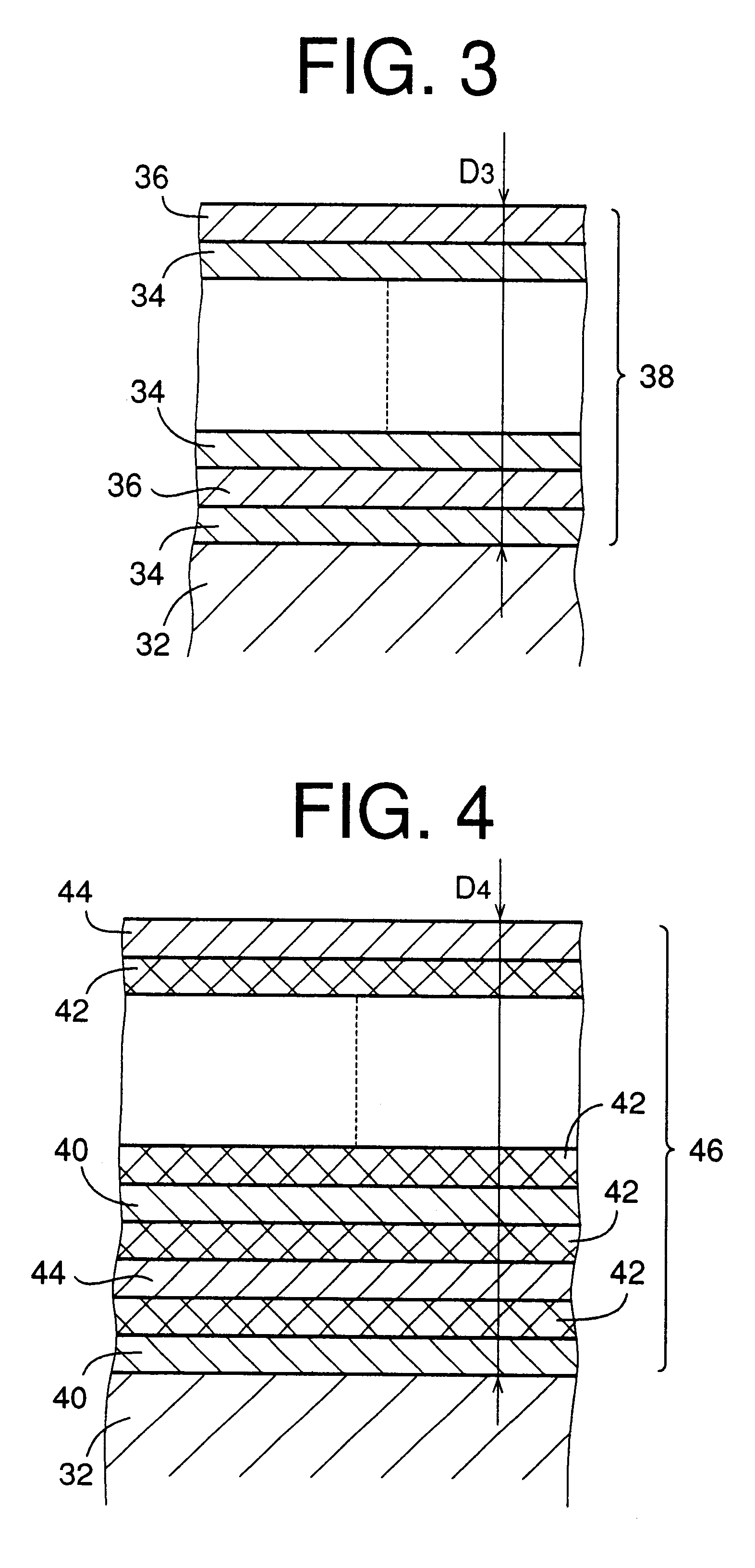

Disclosed is a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a first portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and a second portion of the interstitial matrix in the body adjacent to the working surface contains the catalyzing material. The first portion of the interstitial matrix and the second portion of the interstitial matrix have substantially the same impact strength.

Owner:REEDHYCALOG UK

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

Tool with a molybdenum sulfide containing coating and method for its production

InactiveUS6528171B1Improve wear resistanceRecord information storageMagnetic recordingMetallic materialsMonolayer

The invention relates to a tool, especially a cutting insert for cutting metallic materials, which consist of a hard metal, cermet ceramics or steel base, especially of a high speed steel base, and at least one layer deposited thereon. The single layer, or in the case of several layers the outer layer or the layer underneath the outer layer, contains molybdenum sulfide. The aim of the invention is to improve the resistance to wear of the friction-reducing, molybdenum sulfide containing layer even at high pressures. To this end, the molybdenum sulfide containing layer consists of an alternating sequence of two layer that are different from one another. The first layer contains 51 to 100% by weight of metallic molybdenum and the second layer contains 21 to 100% by weight of MoS2 which substantially consists of hexagonal crystals that are at least substantially oriented in a plane parallel to the tool surface.

Owner:WIDIA

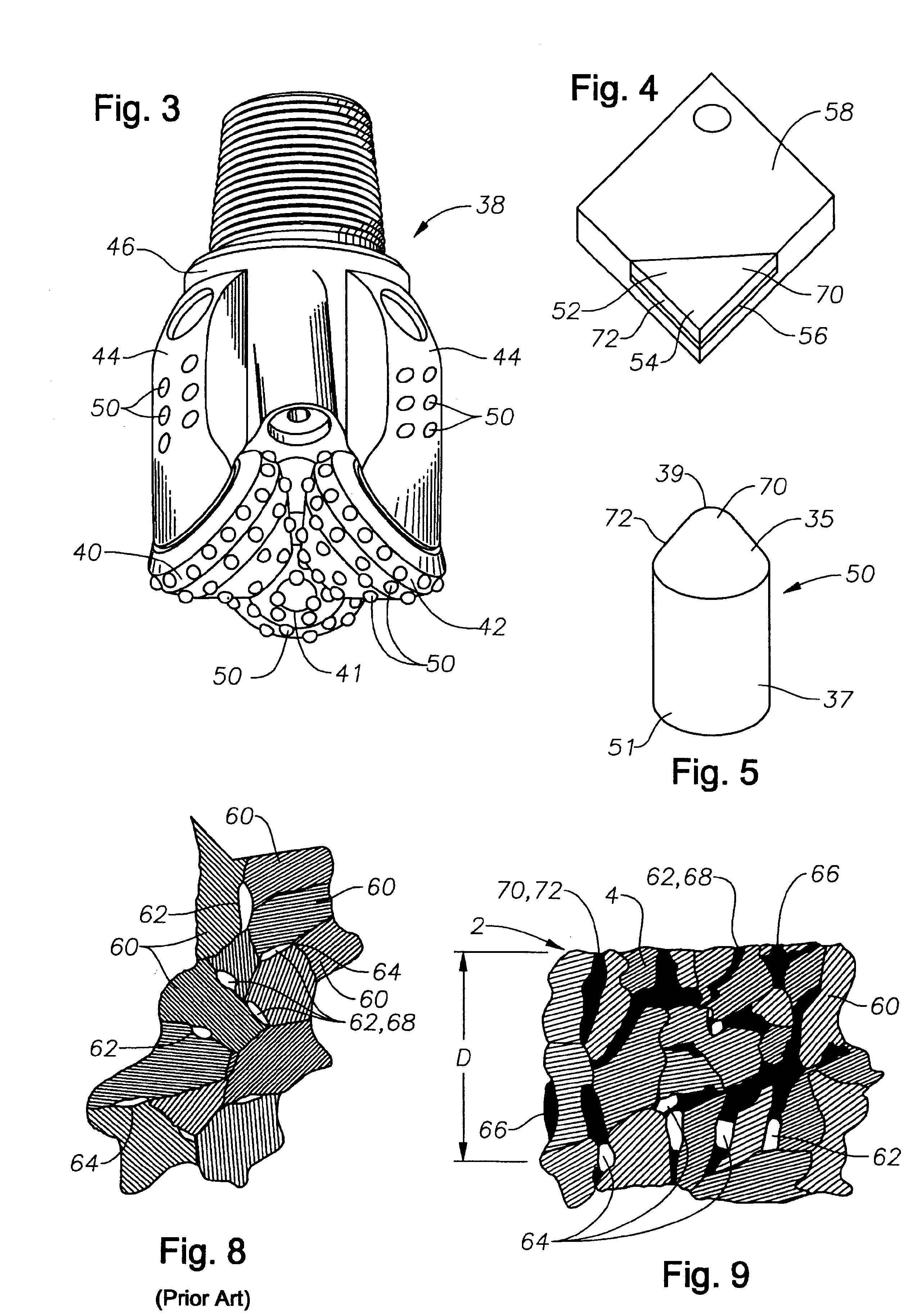

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060392A1Improve thermal stabilityGood adhesionDrill bitsConstructionsDiamond crystalPolycrystalline diamond

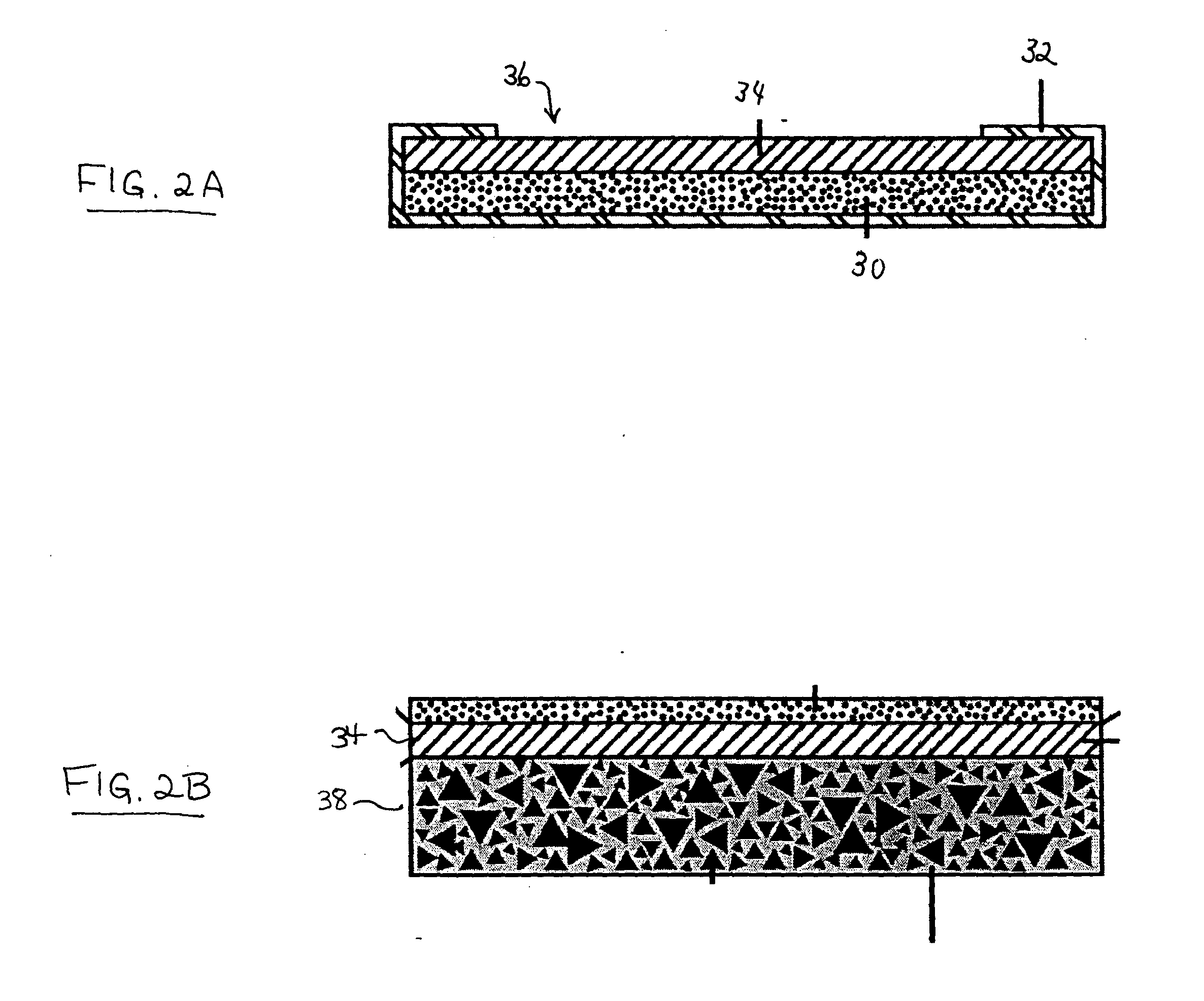

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals and interstitial regions disposed among the crystals. A metallic substrate is attached to the body. The body includes a first region substantially free of a catalyst material that extends a partial depth from a surface into the body, and a second region that includes the catalyst material. The body can include natural diamond grains and / or a blend of natural and synthetic diamond grains, and is treated to form the first region. Before treatment, a portion of the body to be treated is finished to an approximate final dimension so that the depth of the first region of the finished product is substantially the same as when treated. During treatment, catalyst materials as well as non-catalyst metallic materials are removed from the diamond body to provide a further enhanced degree of thermal stability.

Owner:SMITH INT INC

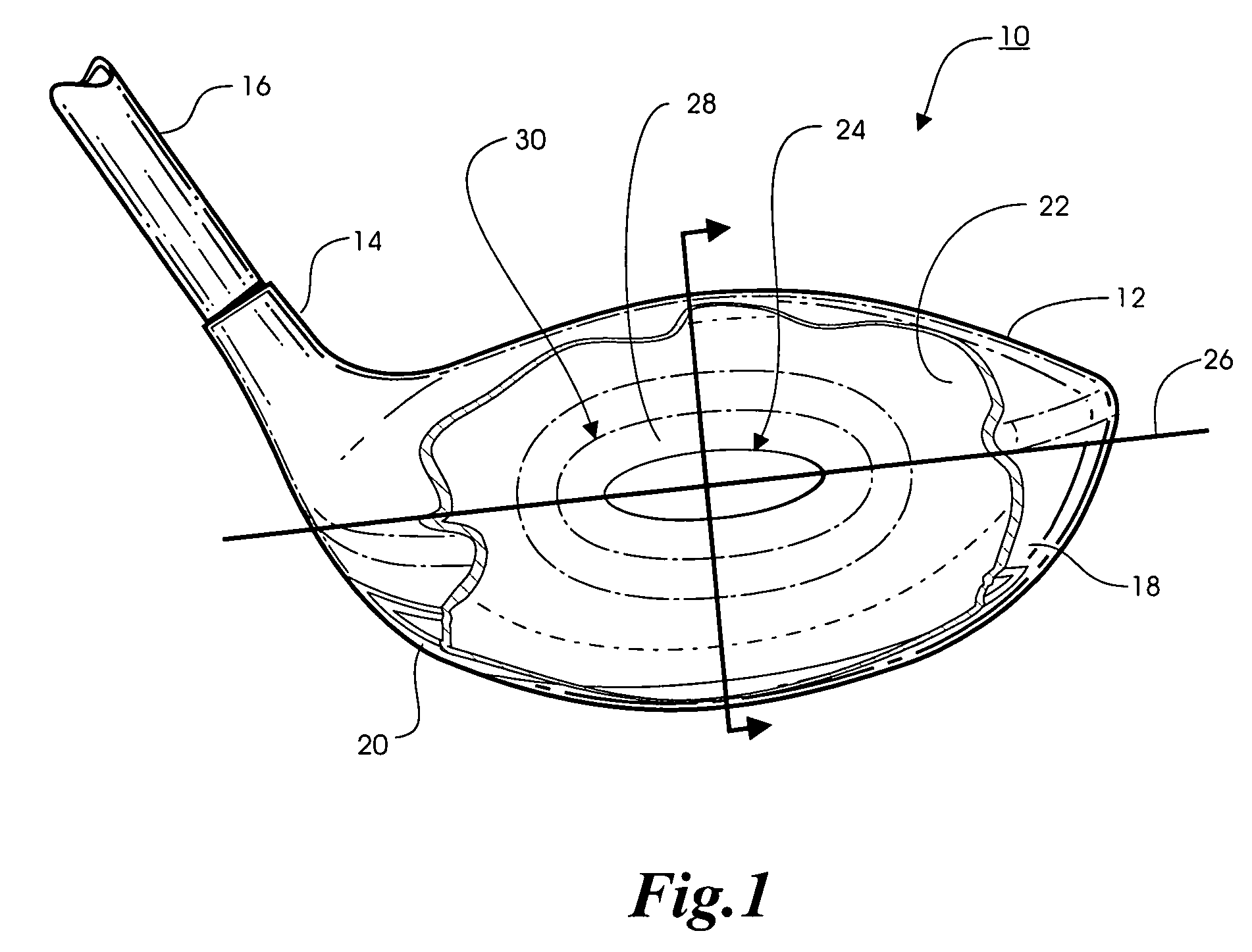

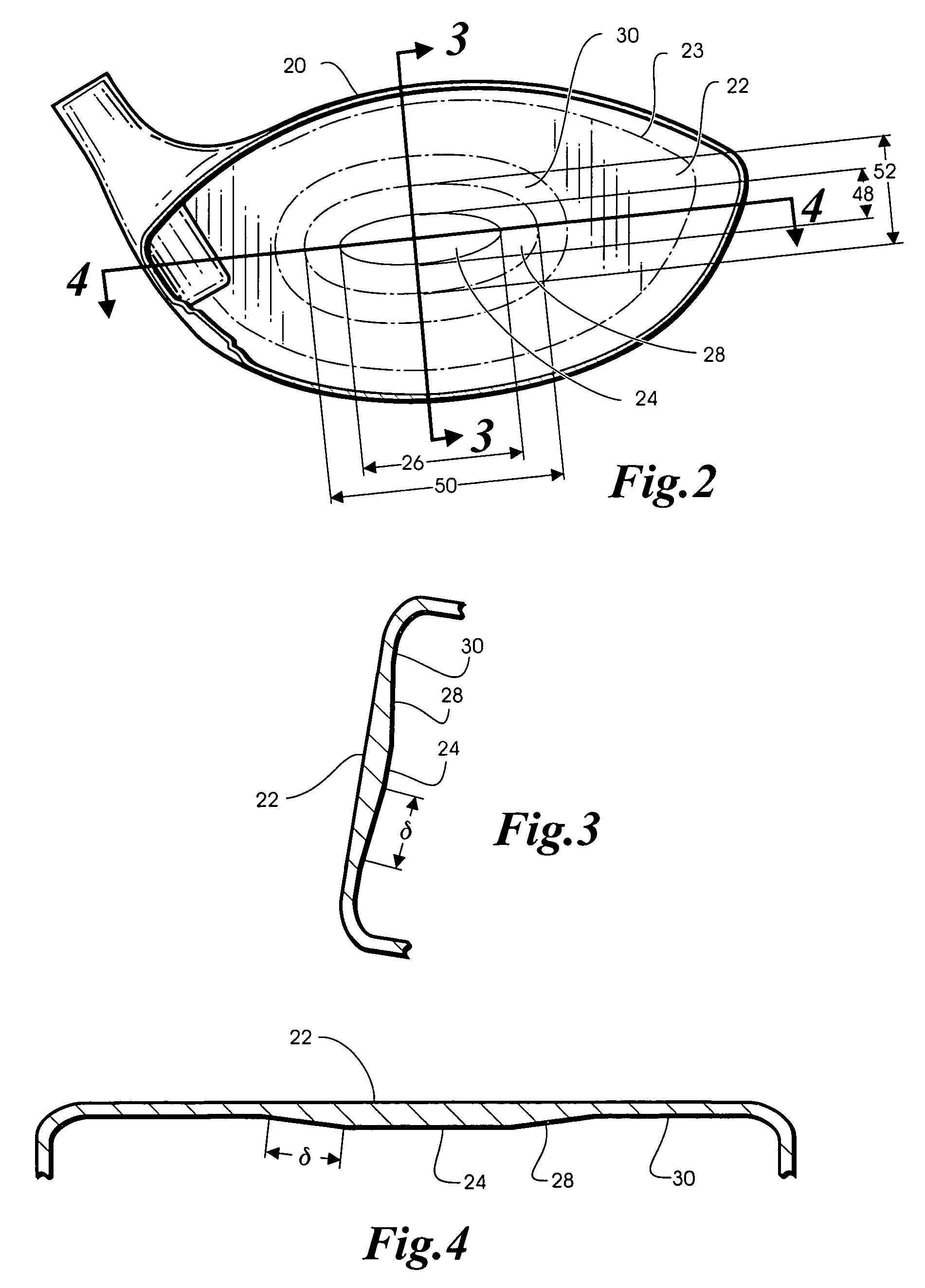

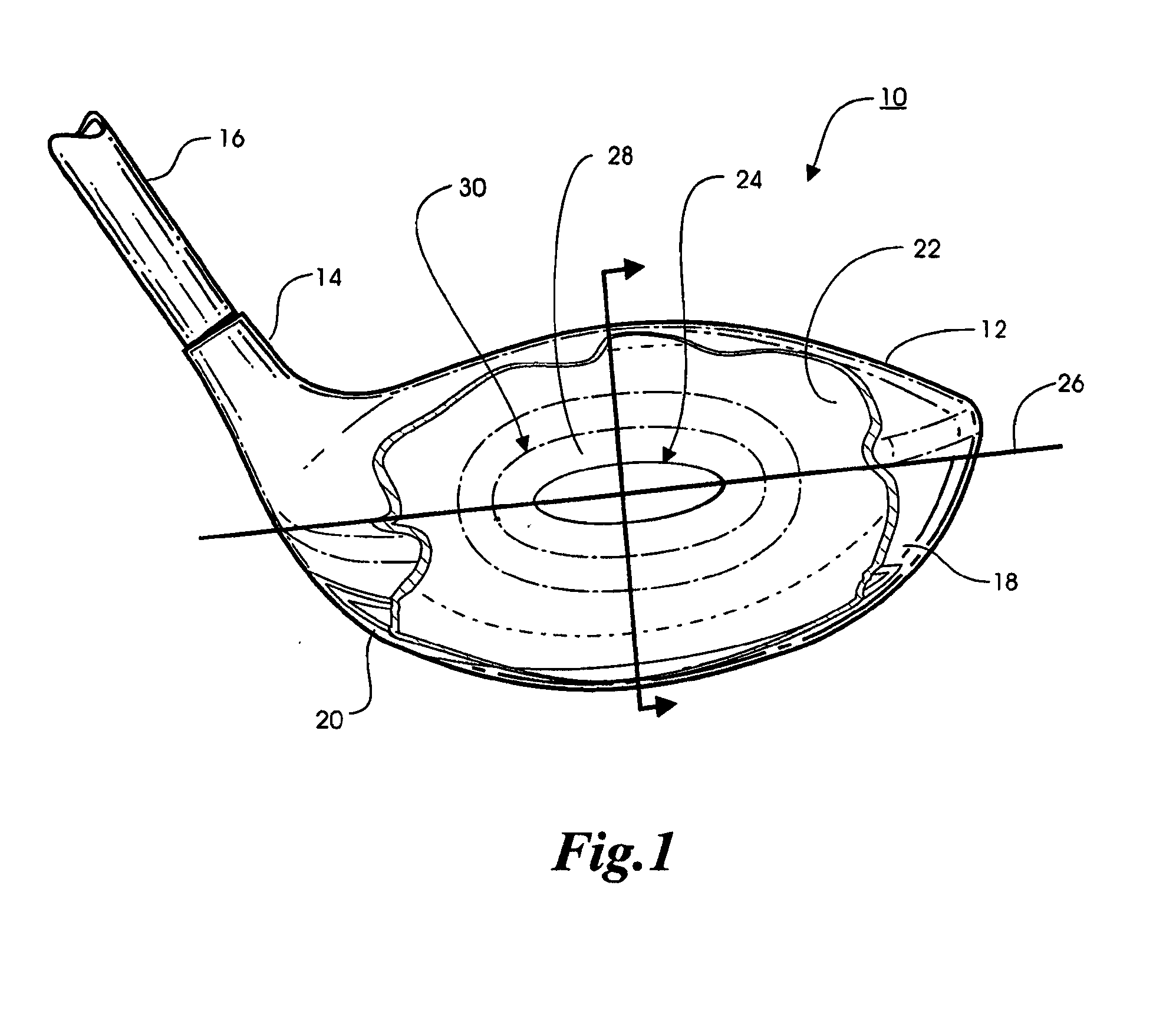

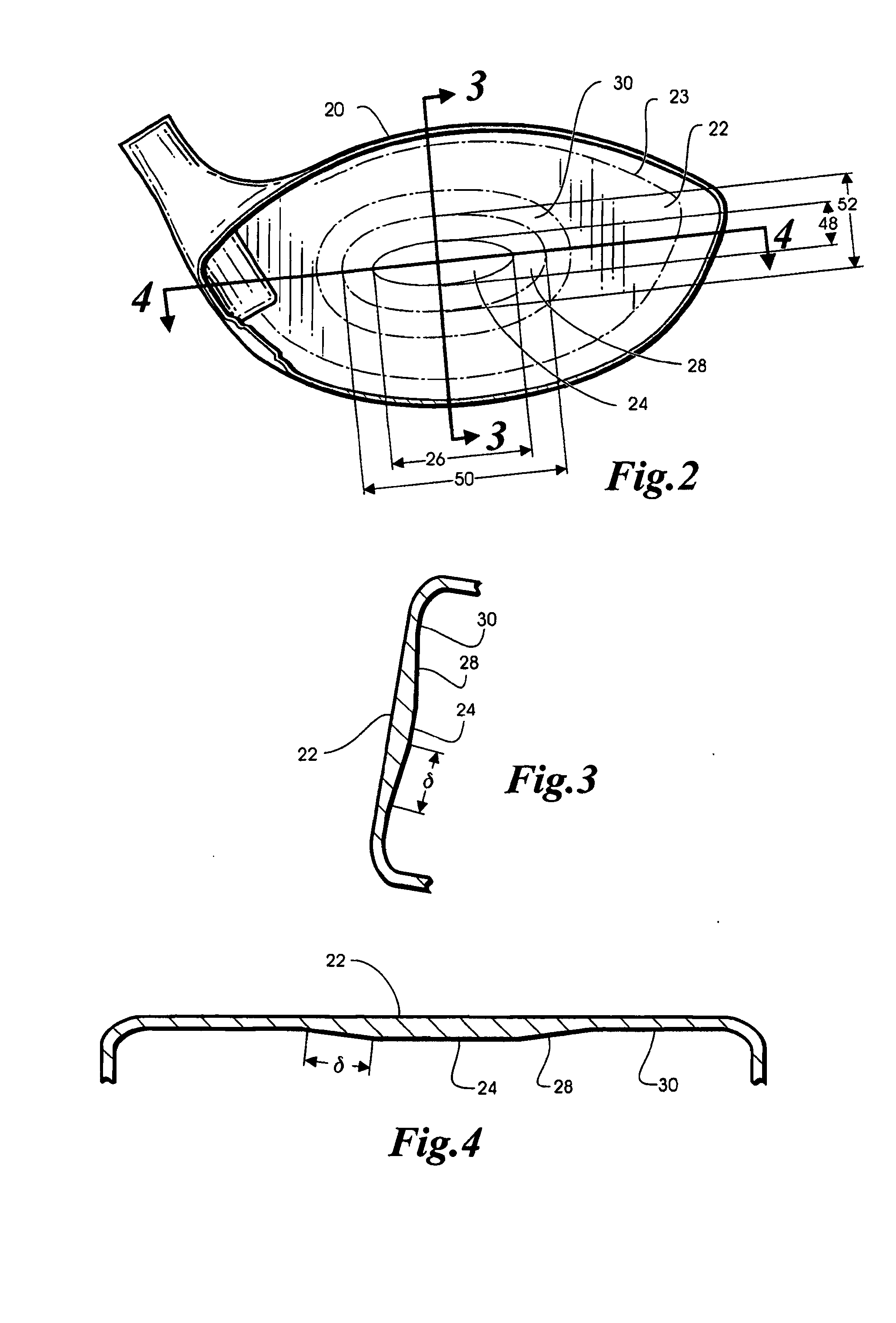

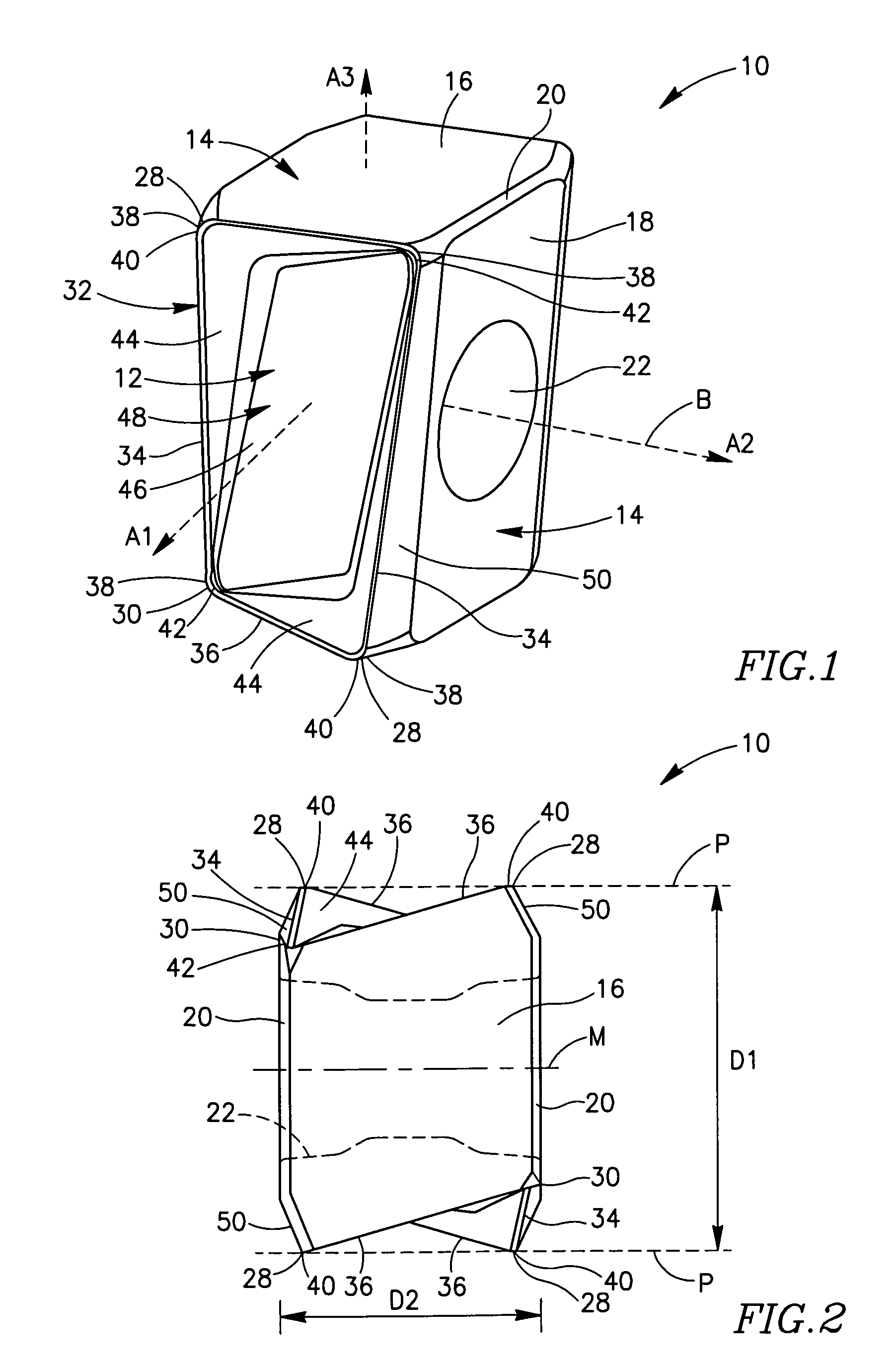

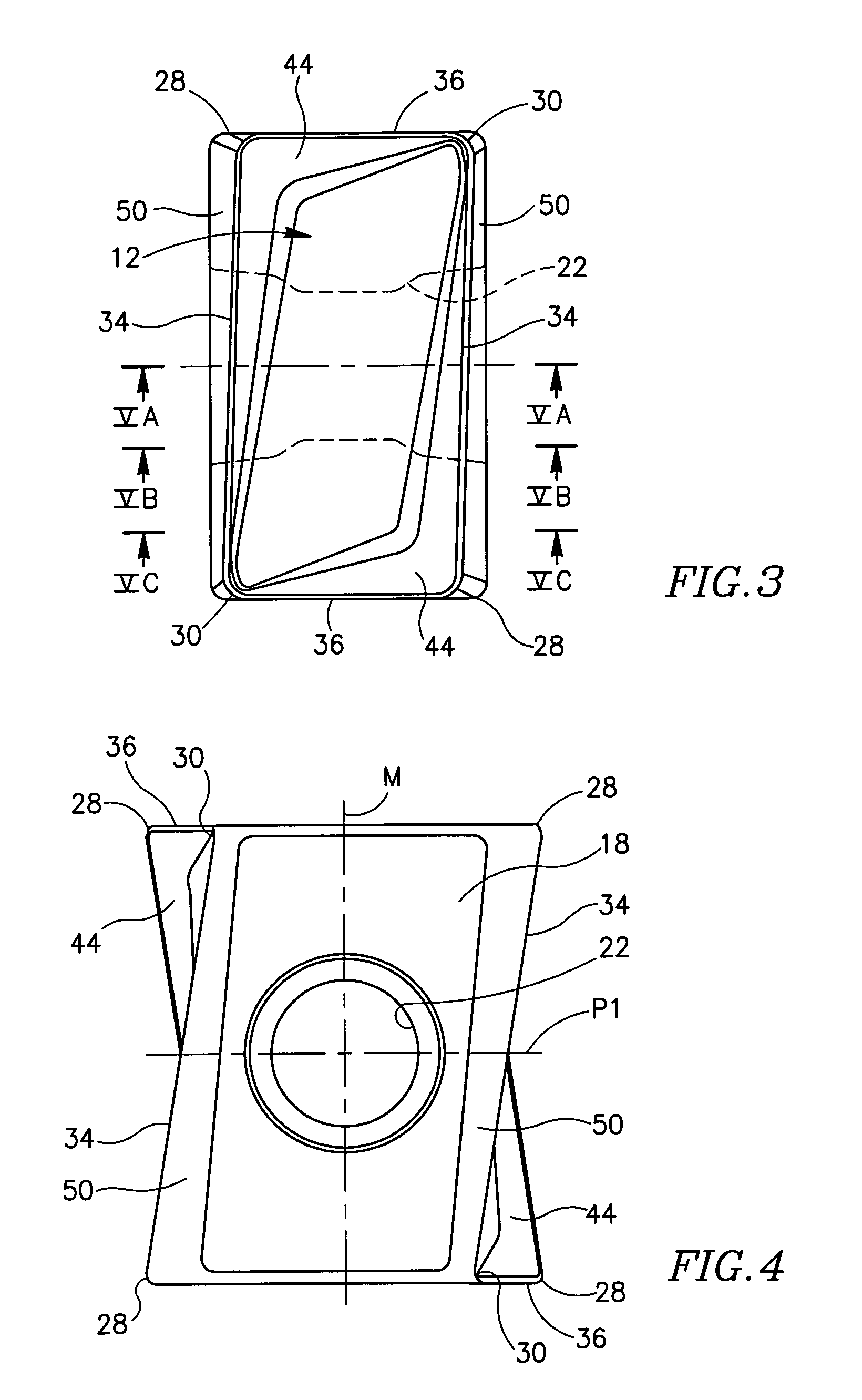

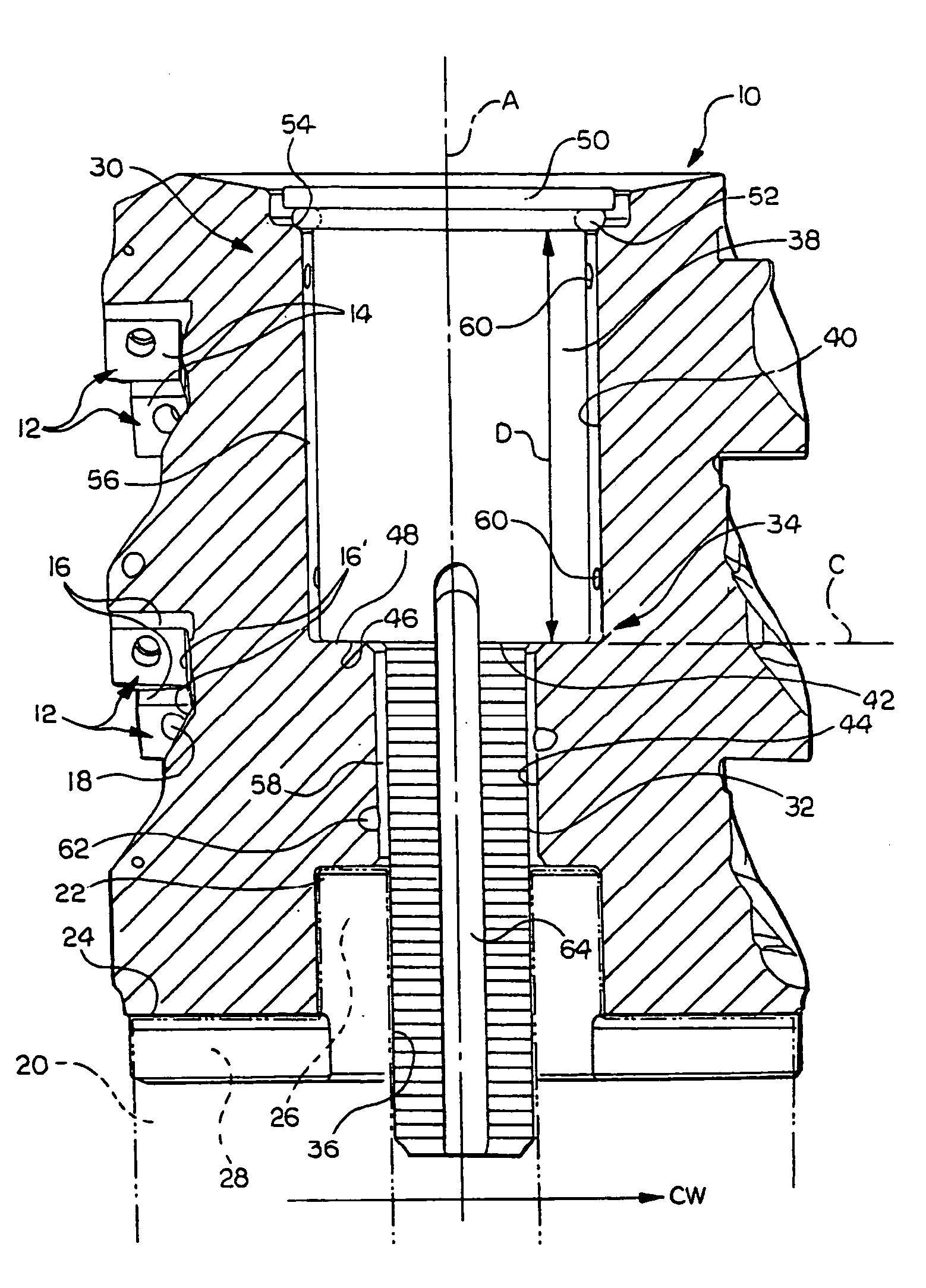

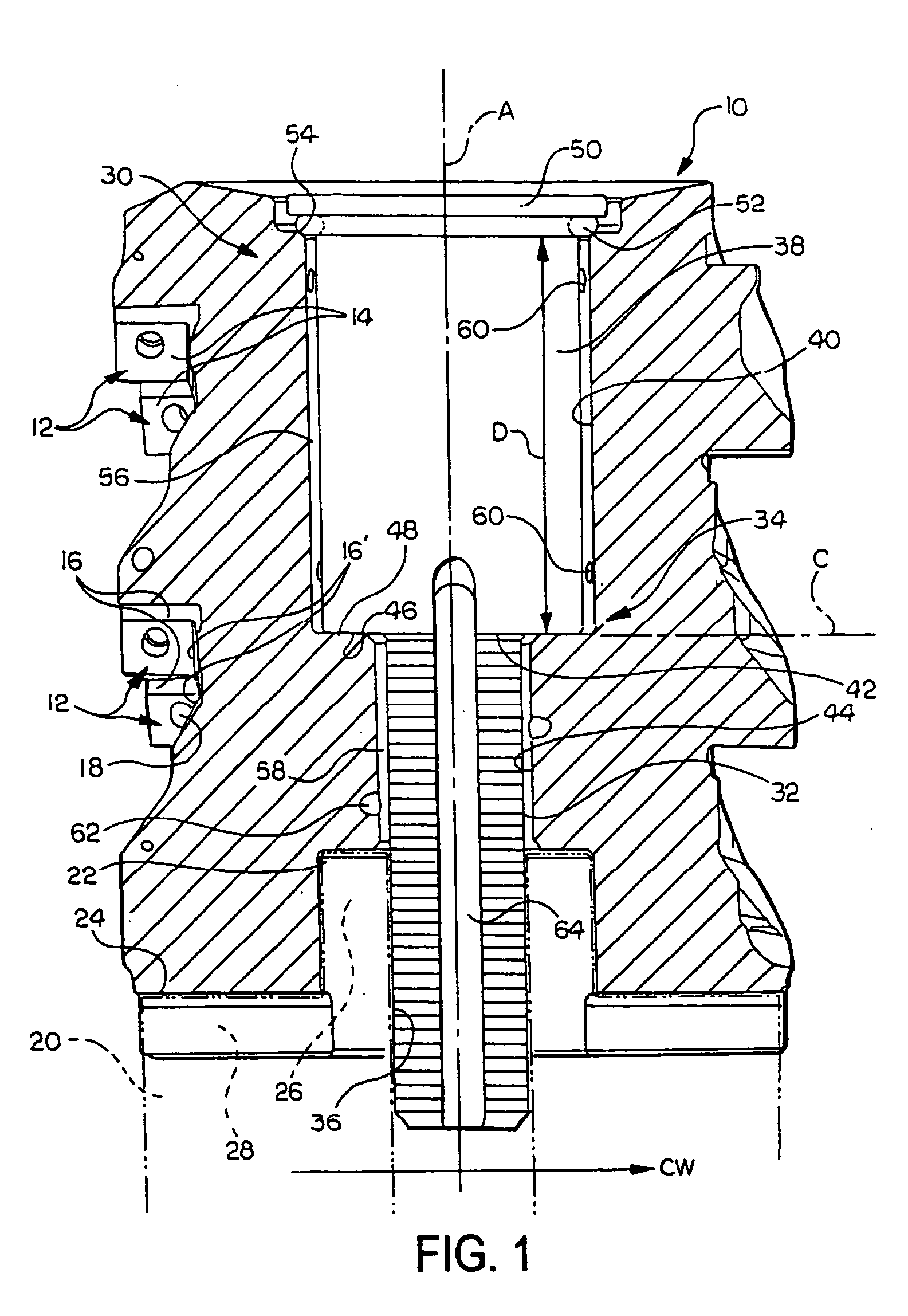

Method of manufacturing a face plate for a golf club head

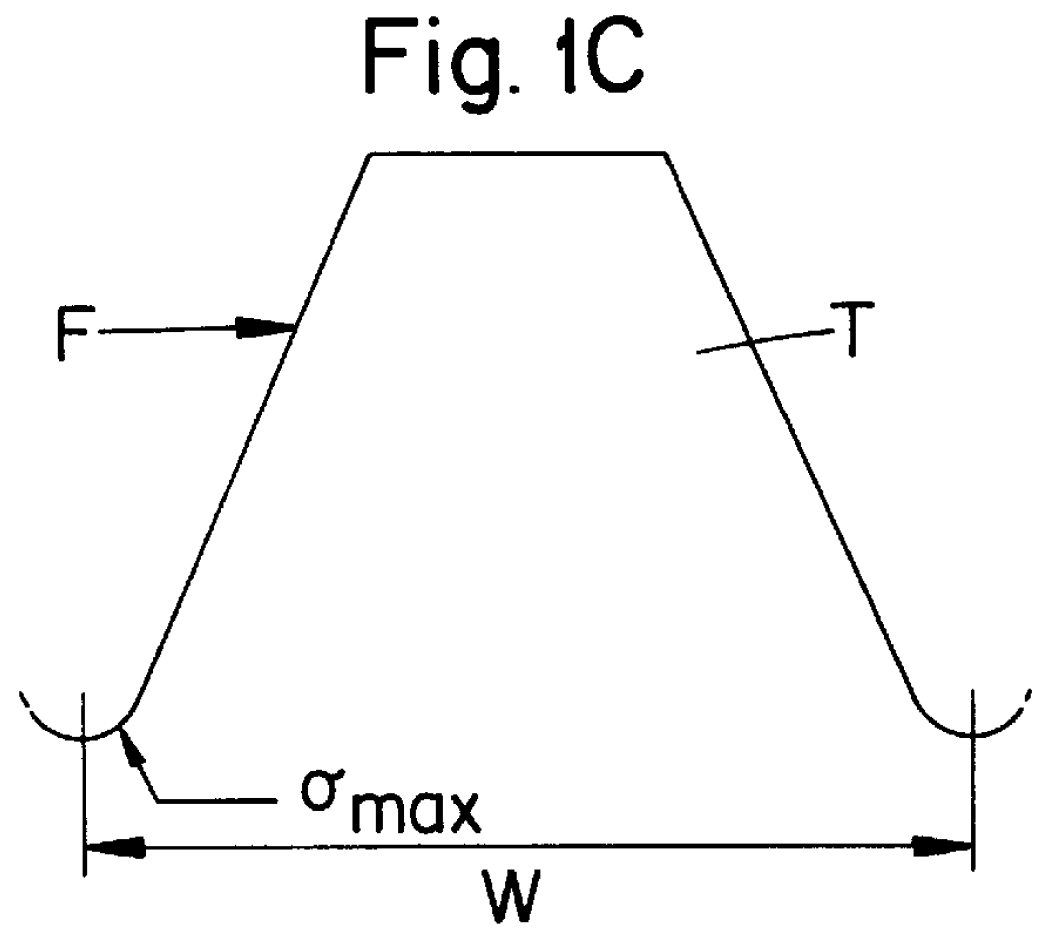

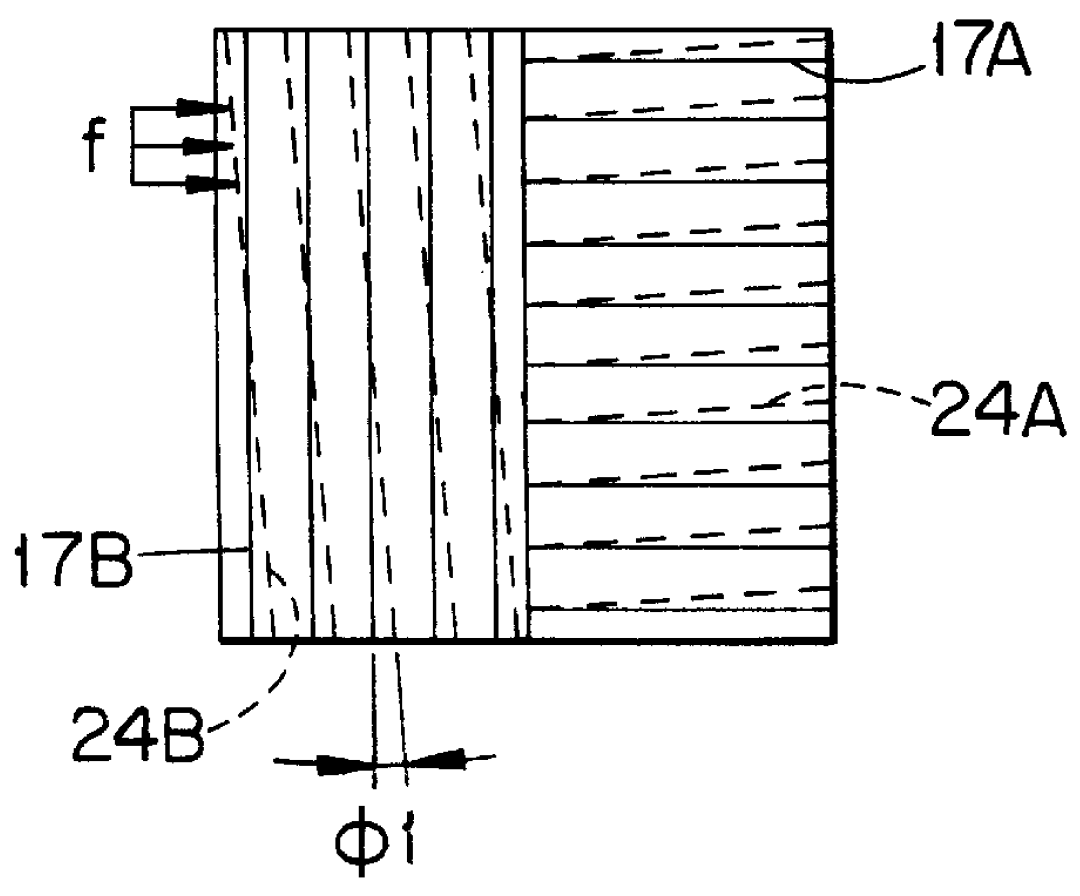

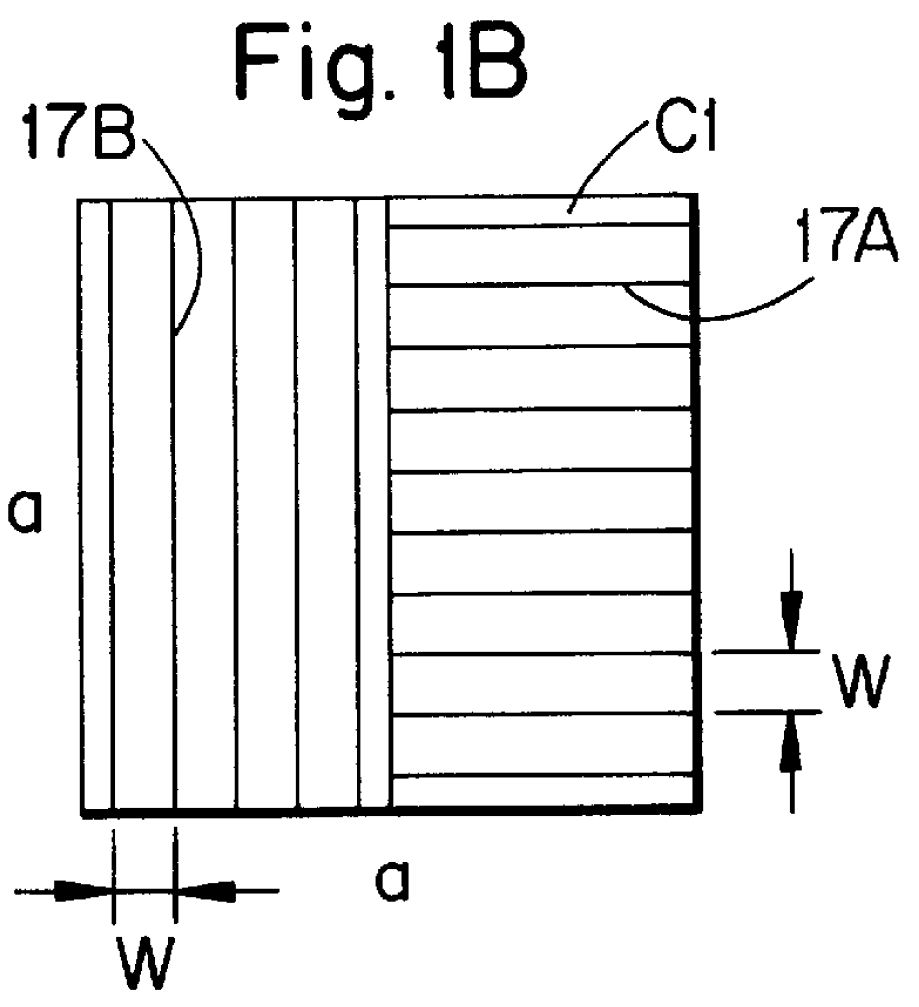

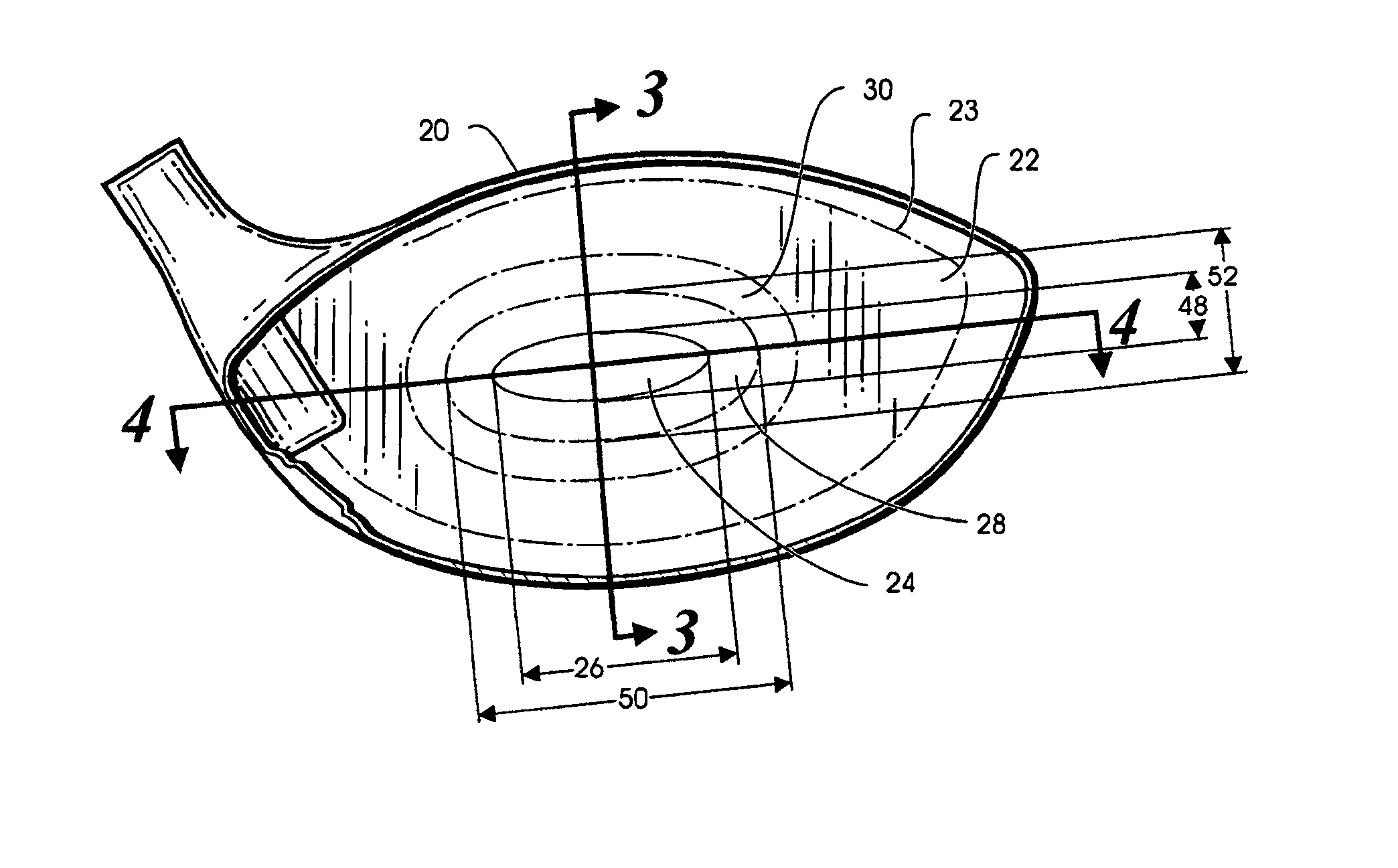

ActiveUS7347794B2Improve uniformitySignificant timeMilling equipment detailsShaping cuttersEngineeringGolf Ball

A golf club is manufactured by machining away a portion of the rear surface of a club face blank to form an elliptical central thickened region that tapers through a transition region to a thinner peripheral region. The elliptical central thickened region, transition region and the portion of the peripheral region surrounding the raised portion are formed in a single elliptical pass with a special cutting tool. The cutting tool, or “form cutter” has a conical lateral cutting surface, which forms the sloped transition region and the peripheral region surrounding it in a single operation.

Owner:KARSTEN MFG CORP

Polycrystalline diamond partially depleted of catalyzing material

Owner:REEDHYCALOG UK

Polycrystalline diamond compact (PDC) cutting element having multiple catalytic elements

InactiveUS7635035B1Improve thermal stabilityPigmenting treatmentDrill bitsPolycrystalline diamondThermal stability

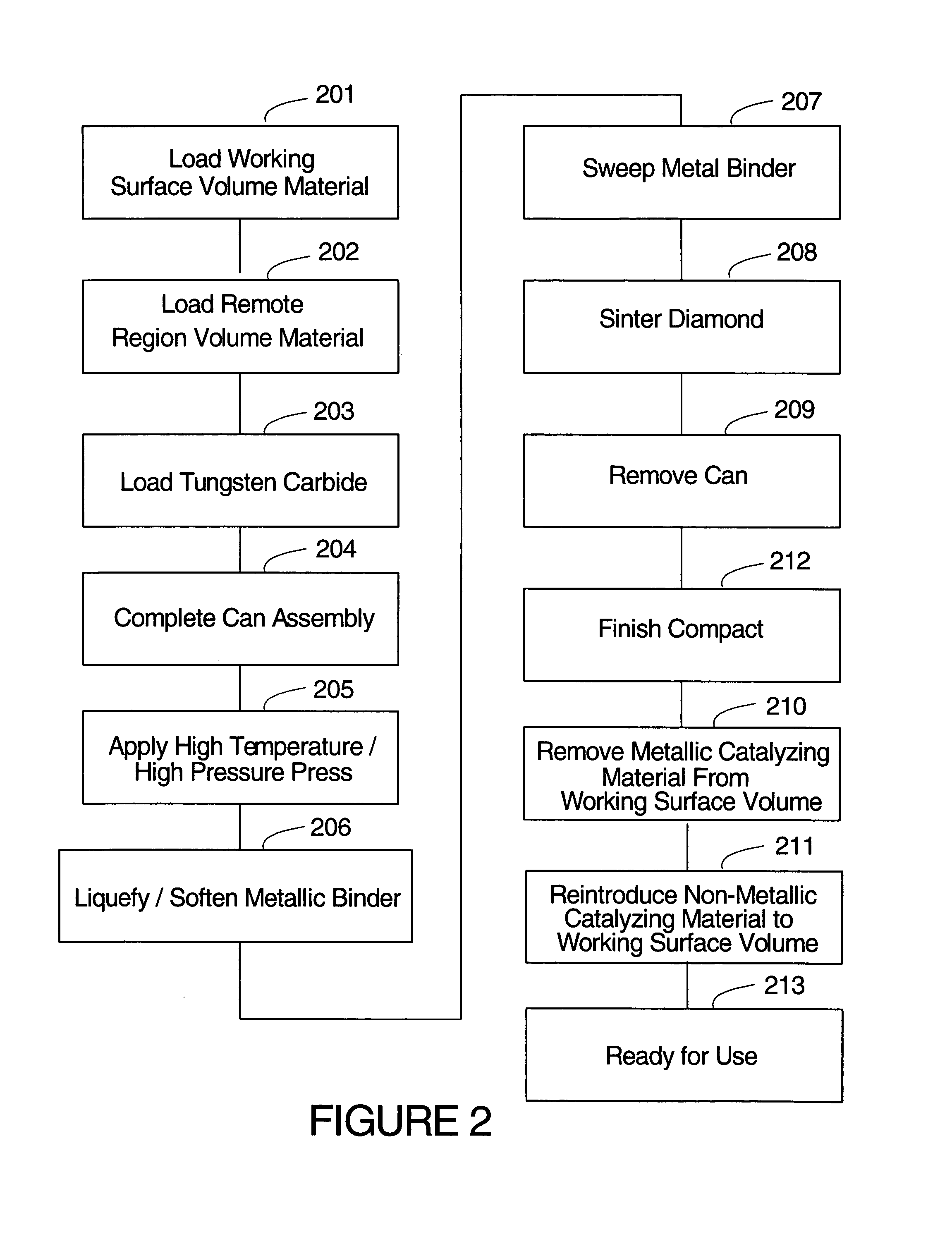

A polycrystalline diamond compact useful for wear, cutting, drilling, drawing and like applications is provided with a first diamond region remote from the working surface which has a metallic catalyzing material and a second diamond region adjacent to or including the working surface containing a non-metallic catalyst and the method of making such a compact is provided. This compact is particularly useful in high temperature operations, such as hard rock drilling because of the improved thermal stability at the working surface.

Owner:US SYNTHETIC CORP

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060390A1Improve thermal stabilityGood adhesionPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals, a plurality of interstitial regions disposed among the crystals, and a substrate attached to the body. The body includes a working surface and a side surface extending away from the working surface to the substrate. The body comprises a first region adjacent the side surface that is substantially free of a catalyst material and that extends a partial depth into the diamond body. The first region can further extend to at least a portion of the working surface and a partial depth therefrom into the diamond body. The diamond body can be formed from natural diamond grains and / or a mixture of natural and synthetic diamond grains. A surface of the diamond body is treated to provide the first region, and before treatment is finished to an approximate final dimension.

Owner:SMITH INT INC

Nanodiamond PCD and methods of forming

InactiveUS20050019114A1Improve high temperature performanceReduce manufacturing costMaterial nanotechnologyPigmenting treatmentDiamond crystalPolycrystalline diamond

A nanodiamond tool, including a mass of sintered nanodiamond particles can be produced having improved mechanical, thermal, and electrical properties. The sintered mass can contain greater than about 95% by volume nanodiamond and greater than about 98% by volume carbon. Such nanodiamond tools can be formed by assembling a mass of nanodiamond particles and sintering the mass of nanodiamond particles to form a sintered mass. Prior to sintering, the mass of nanodiamond particles can be substantially free of non-carbon materials such as metal binders, sintering aids or the like. Upon sintering, the nanodiamond particles sinter together at high pressures and lower temperatures than those typically required in producing polycrystalline diamond compacts with diamond crystals of a larger size. The absence of non-carbon materials improves the high temperature performance and reliability of the nanodiamond tools of the present invention.

Owner:SUNG CHIEN MIN

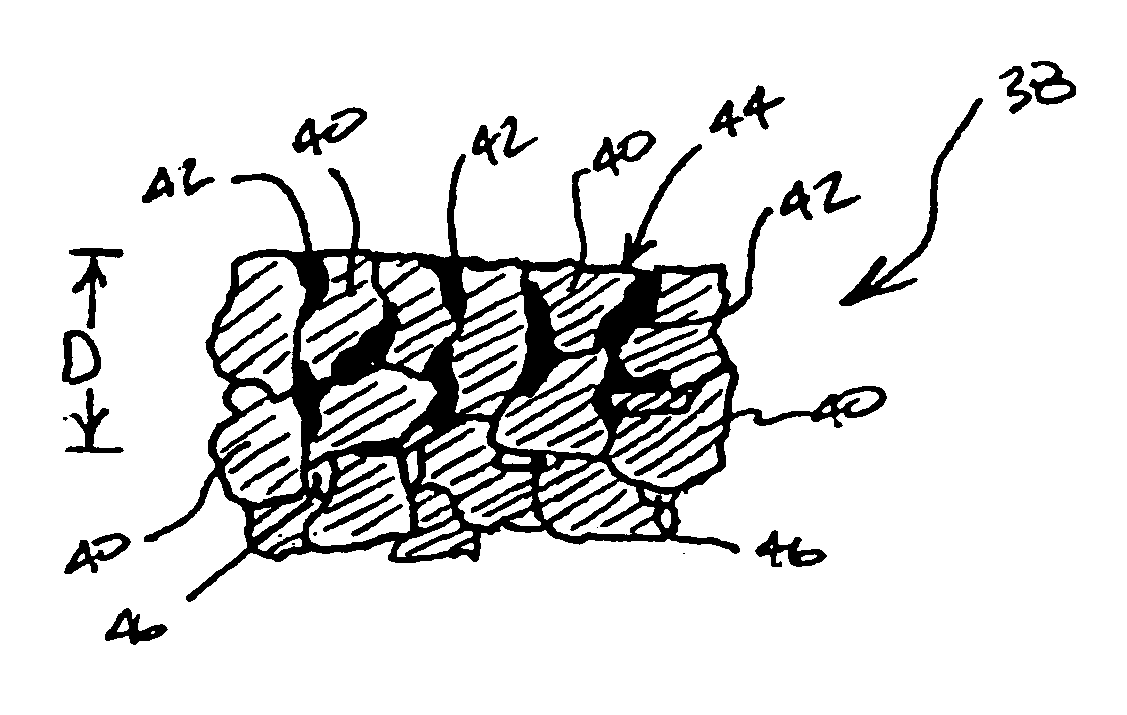

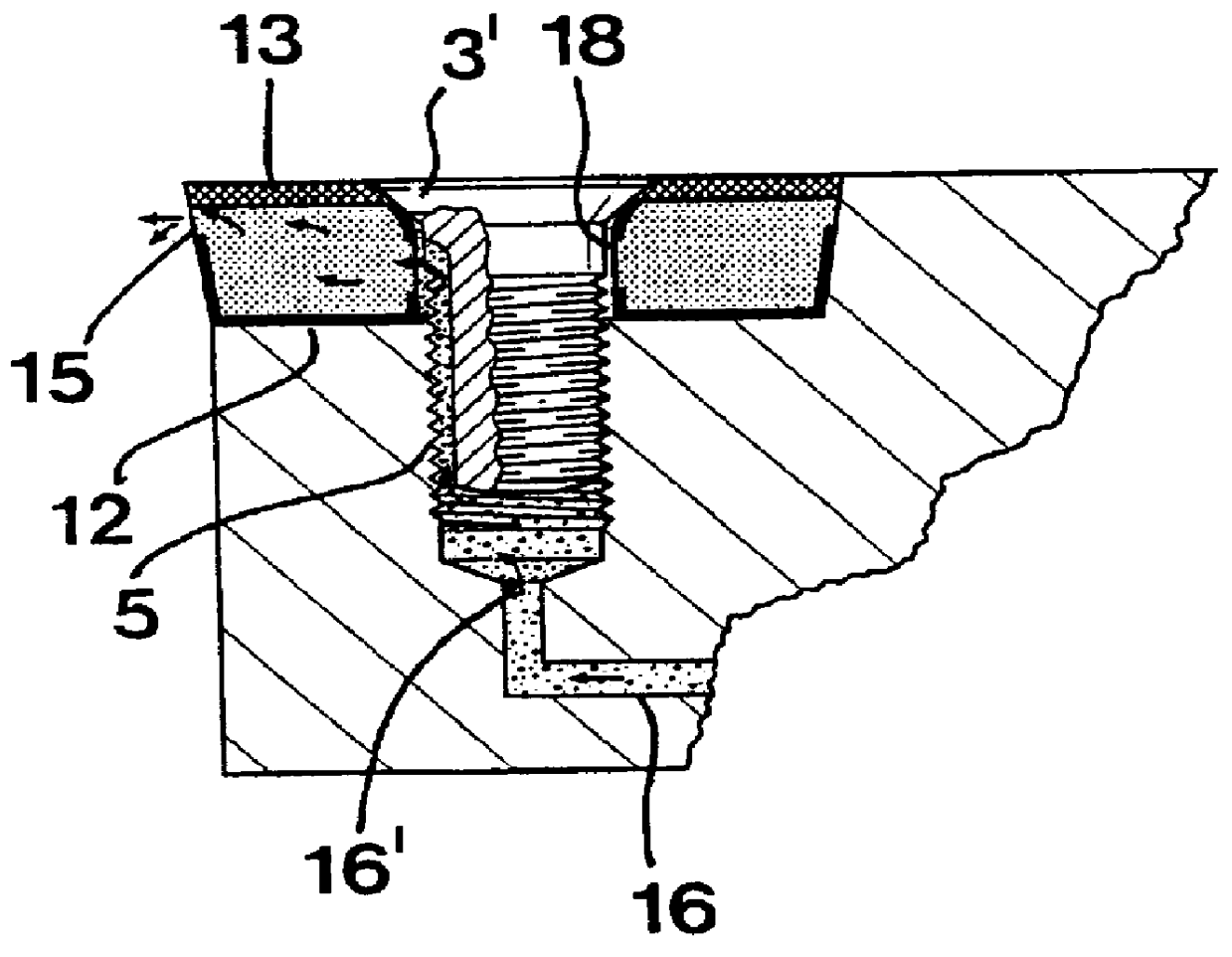

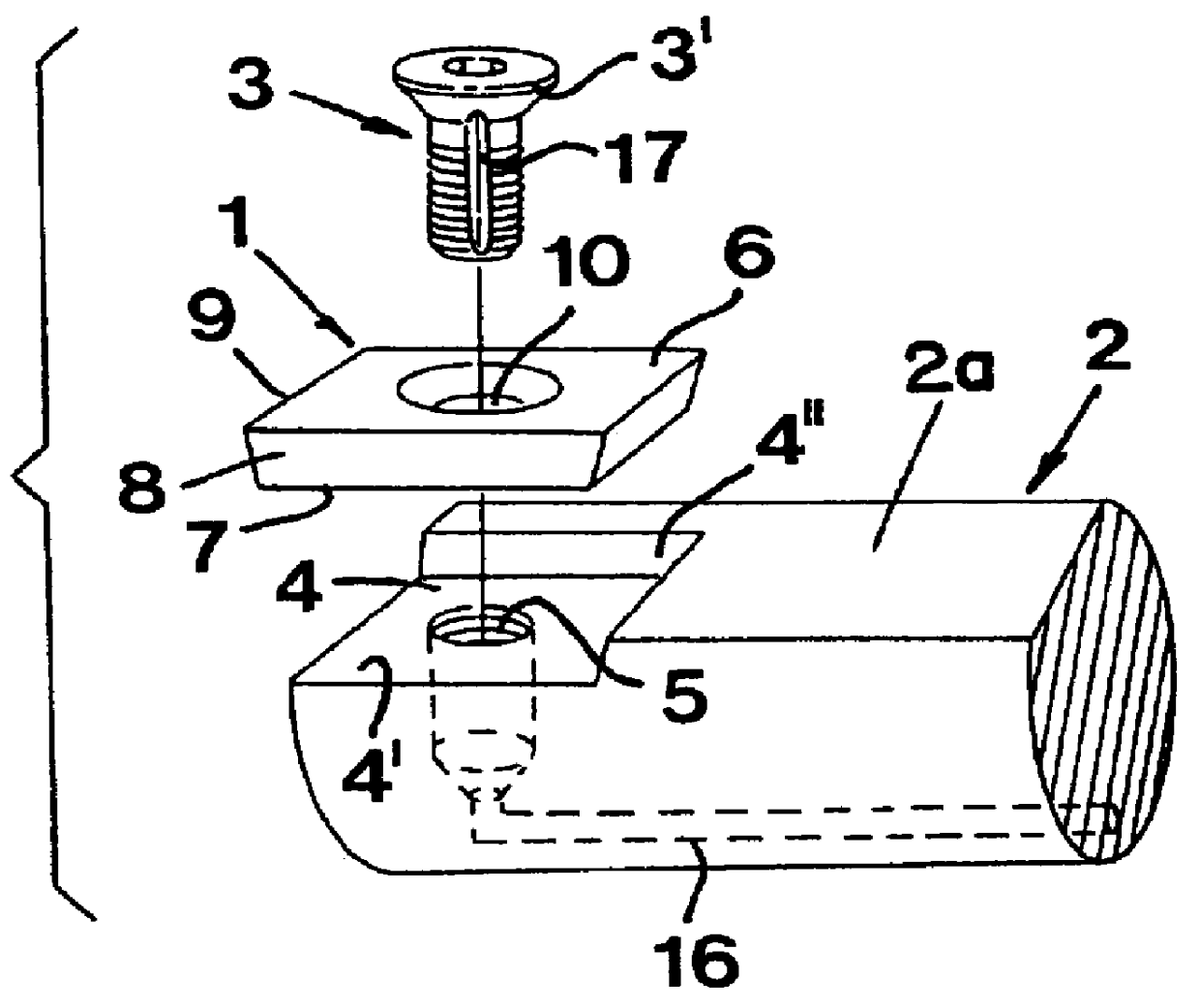

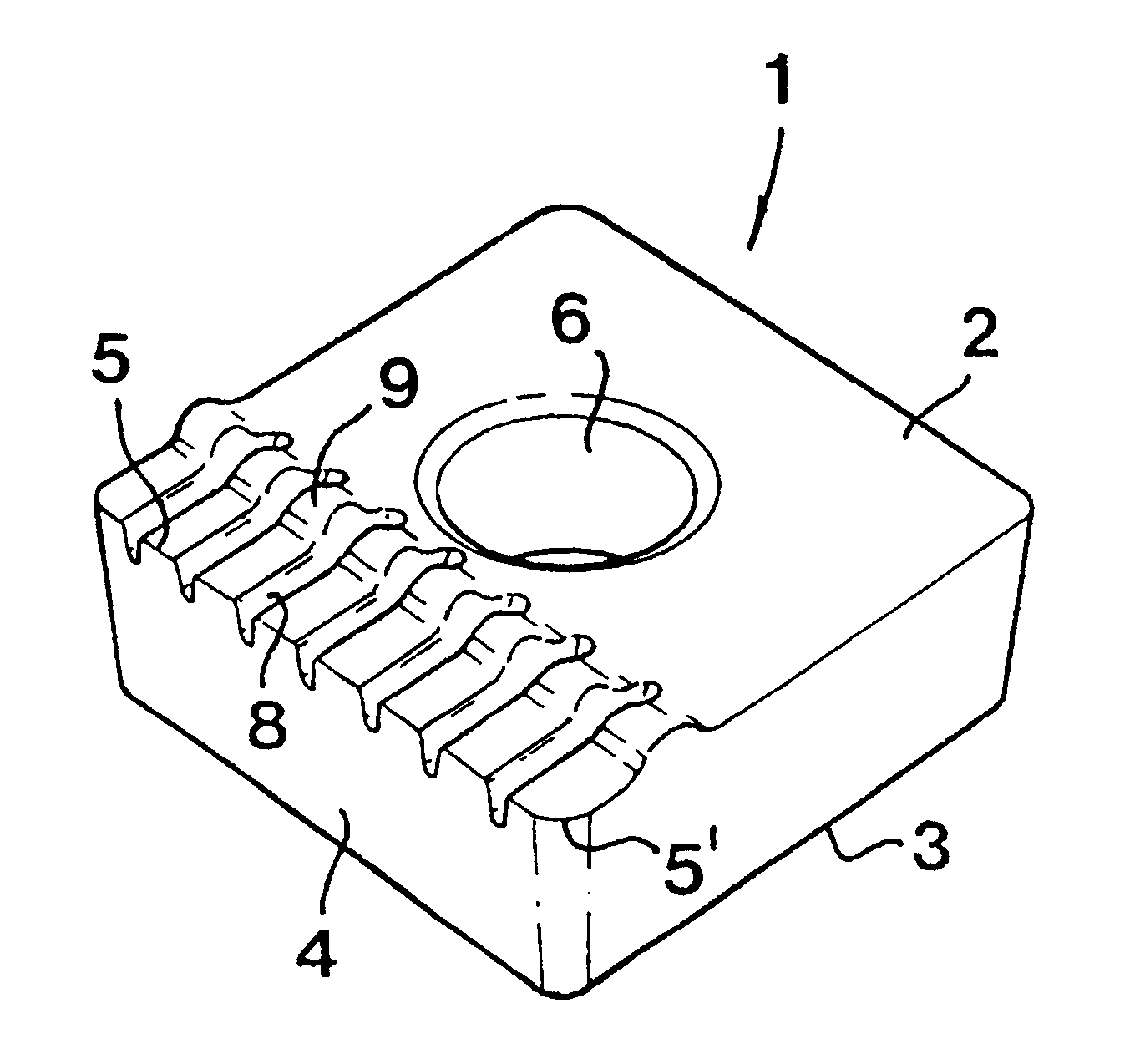

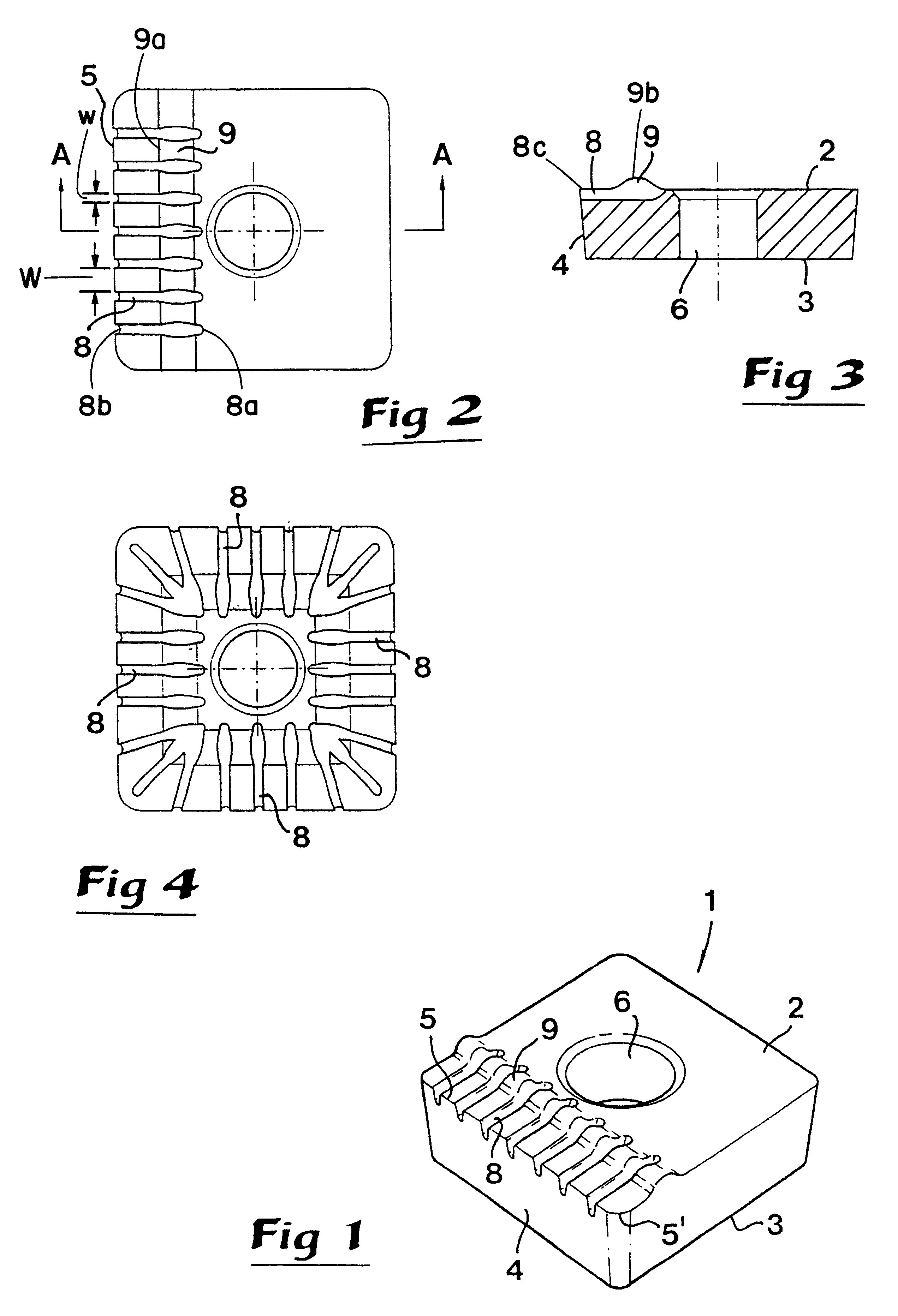

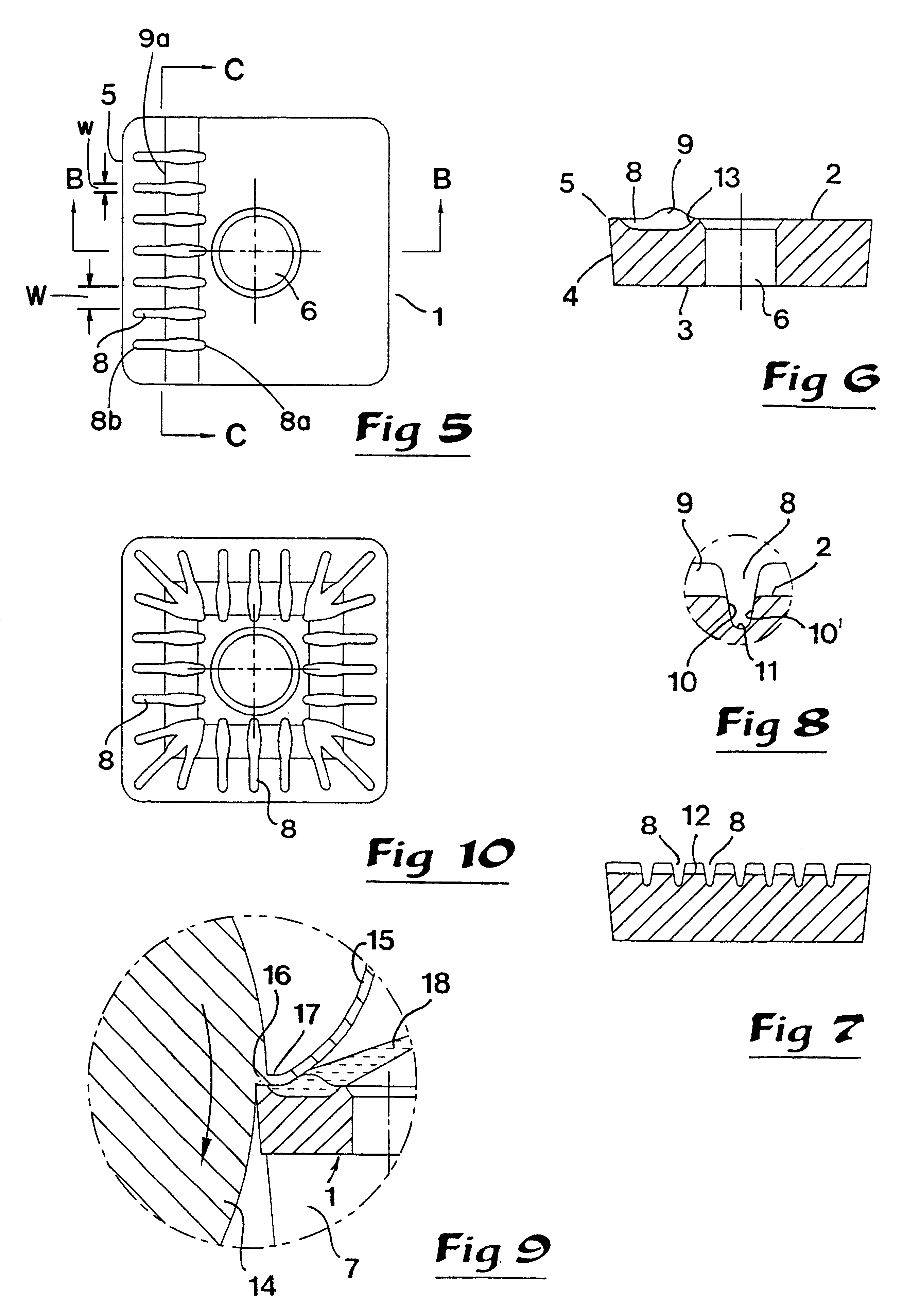

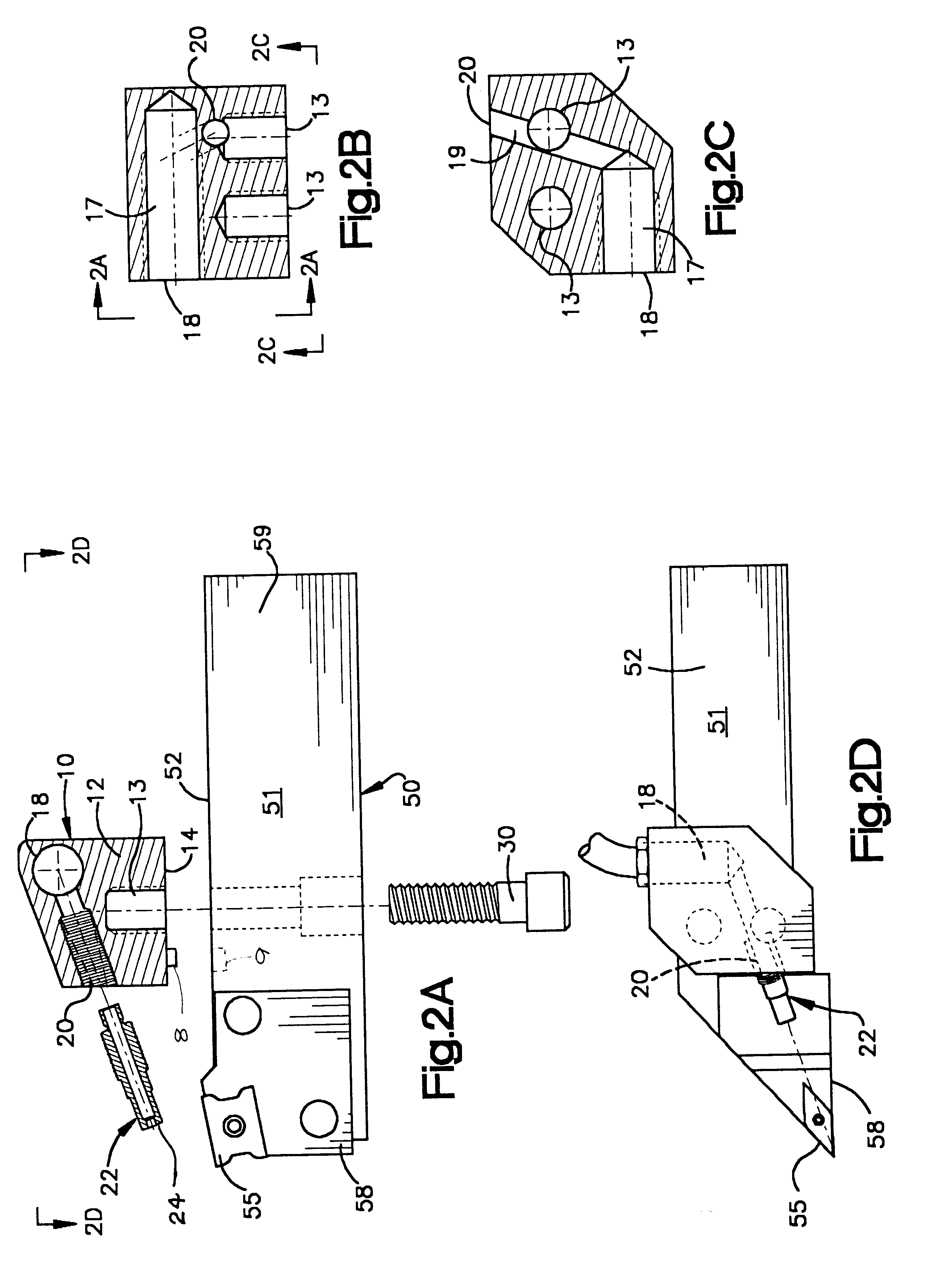

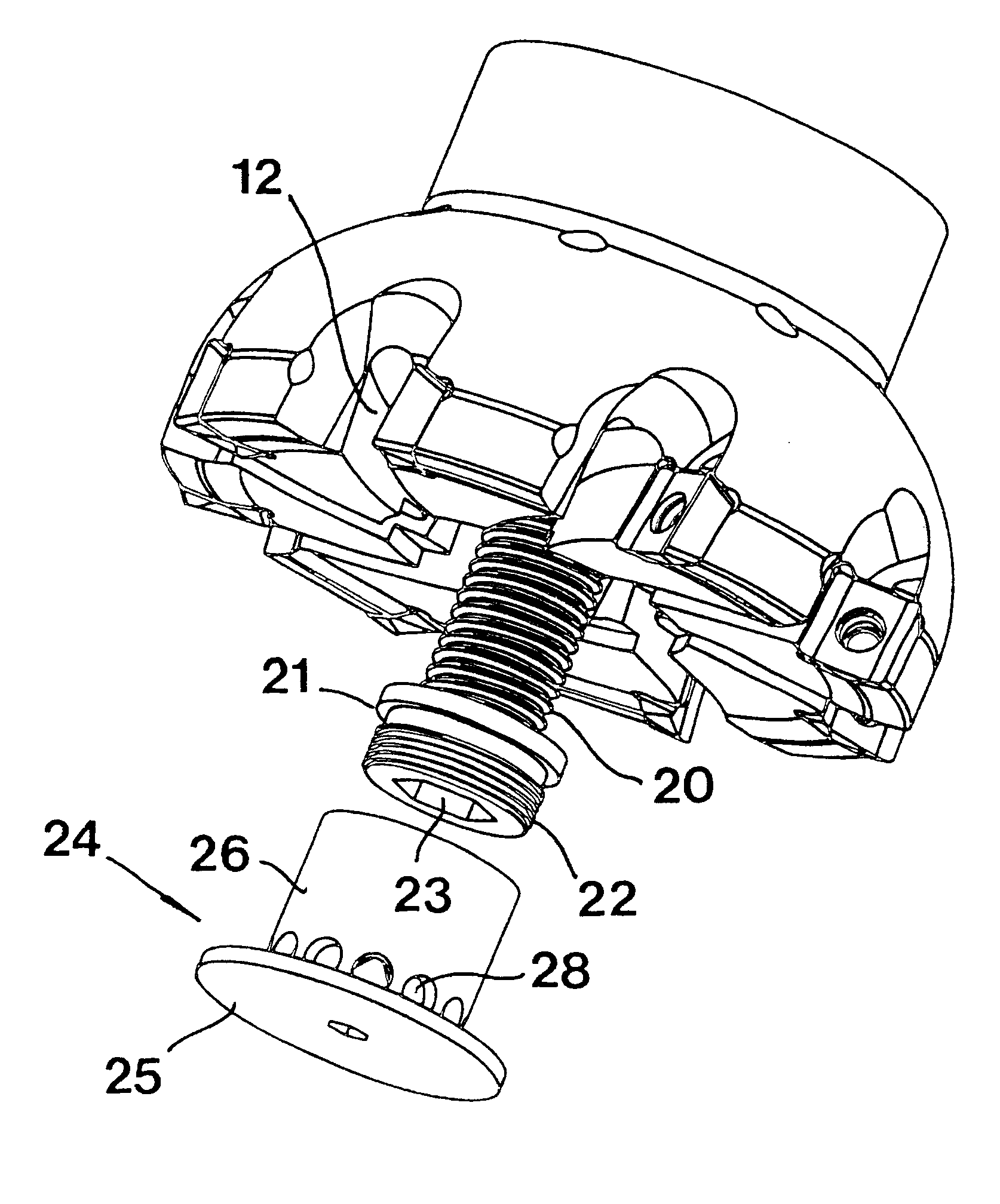

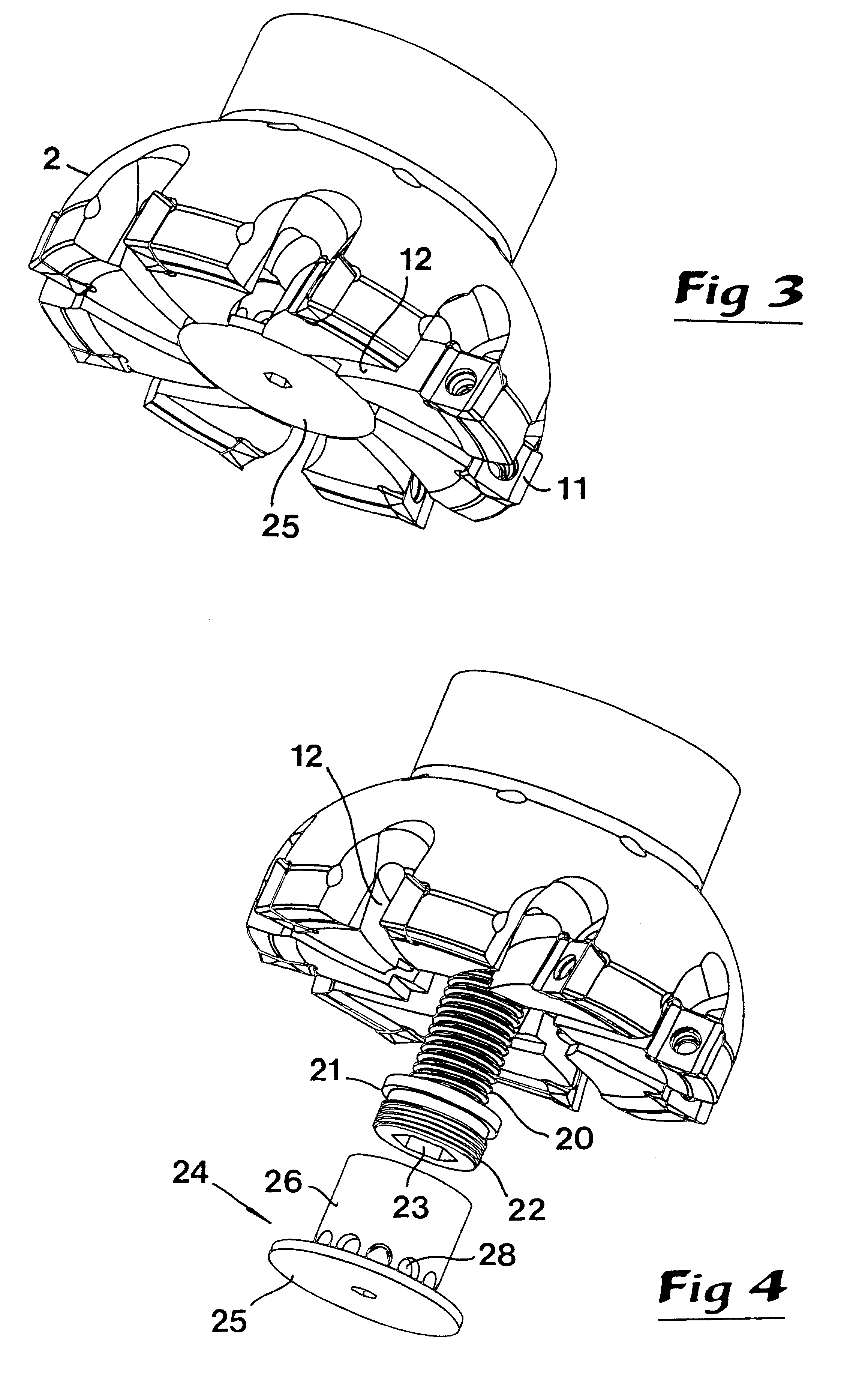

Tool coupling and method for coupling two tool parts

A tool includes a cutting head and a holder, wherein the cutting head and the holder form two cooperating surfaces that are pressed together. The surfaces possess rows of alternating parallel grooves and ridges for locking the surfaces to each other. Each of the surfaces has two rows of grooves, one row oriented 90 DEG relative to the other row. On one of the surfaces, some of the grooves of one row are in non-intersecting relationship with the grooves of the other row. On the other surface, the rows extend completely across one another, whereby the rows together form a waffle-like pattern. The cooperating surfaces allow at least four separate relative positions between the cutting head and holder.

Owner:SECO TOOLS AB

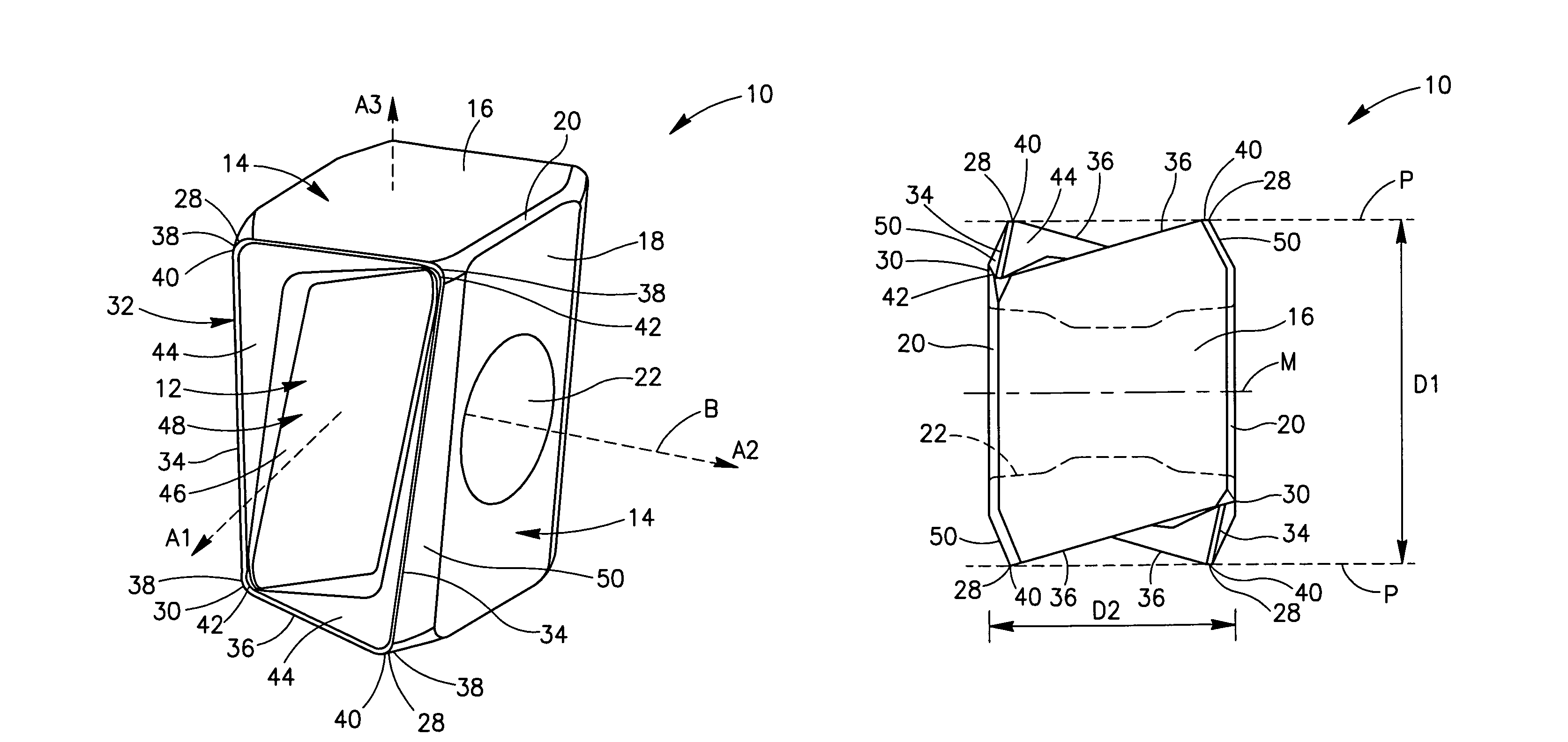

Method of manufacturing a golf club face

InactiveUS20080004133A1Improve uniformitySignificant timeMilling equipment detailsShaping cuttersEngineeringGolf Ball

Embodiments of methods of manufacturing a face plate for a golf cub are generally described herein. In one exemplary embodiment, a method for manufacturing a golf club face plate comprises: providing a face plate material, and milling the face plate material in an elliptical pattern to form a central region comprising, a first elliptical outer edge and a transition region extending from the first elliptical outer edge to a second elliptical outer edge. In this exemplary embodiment, each point along the second elliptical outer edge is displaced outward from the first elliptical outer edge by a predetermined distance. Other embodiments herein may be described and claimed.

Owner:KARSTEN MFG CORP

Chip forming cutting insert with internal cooling

InactiveUS6053669ADrawback can be obviatedEffective steeringCutting insertsTurning toolsEngineeringMachining

A cutting insert is cooled during chip removing machining of a workpiece by conducting cooling medium through a porous supporting body of the insert. The cooling medium enters the insert through an inlet formed therein at a location remote from a cutting edge of the insert and exits the insert through an outlet formed in the insert at a location proximate the cutting edge. The discharged cooling medium impinges on, and cools, the workpiece.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Hard multilayer coated tool having increased toughness

InactiveUS6309738B1Improve toughnessLower resistancePigmenting treatmentVacuum evaporation coatingTitaniumToughness

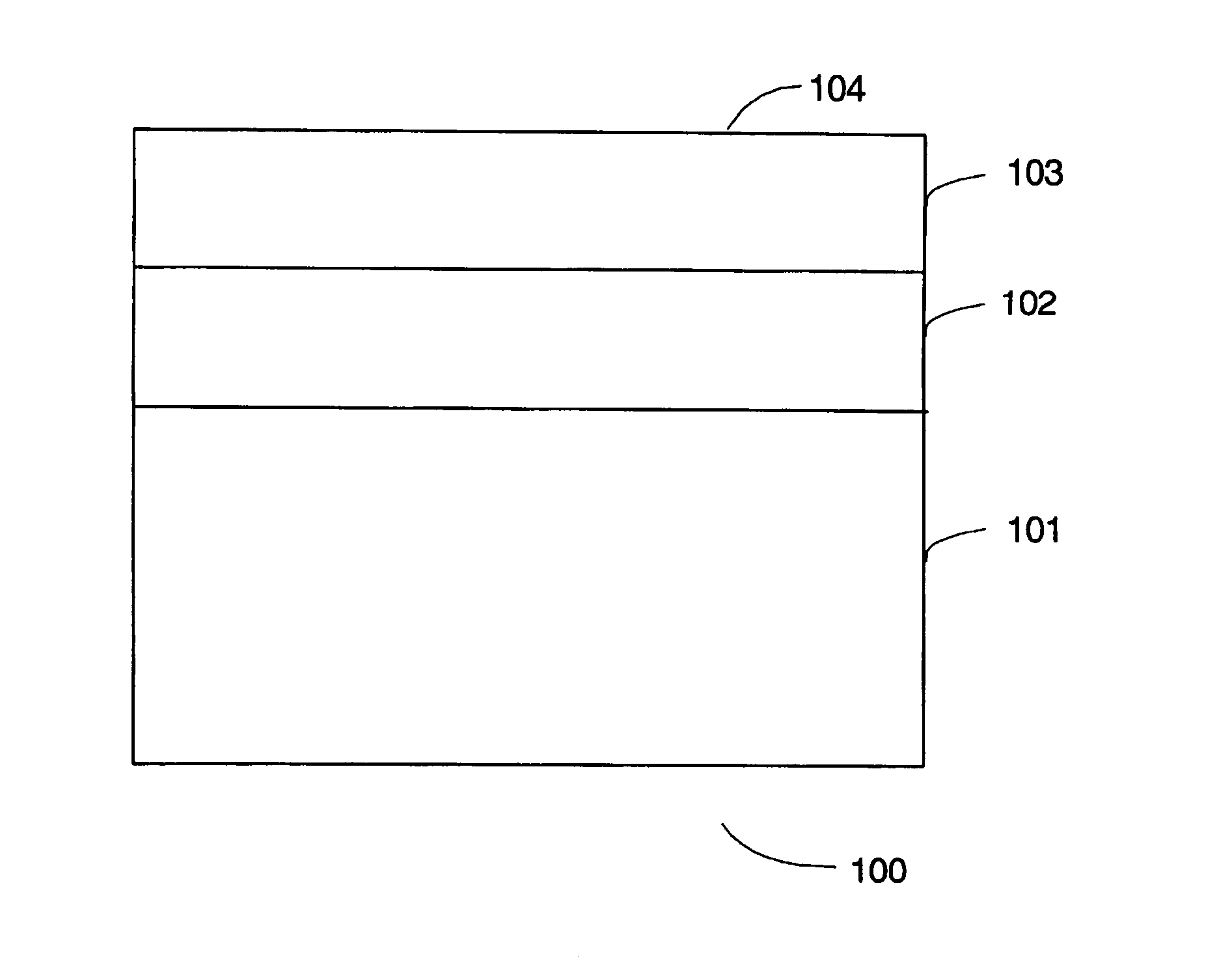

A hard multilayer coated tool including: (a) a substrate; and (b) a multilayer coating covering the substrate, the multilayer coating comprising first and second coating layers which are alternately laminated on the substrate, each of the first coating layers having and average thickness of 0.10-0.50 mum and containing titanium therein, each of the second coating layers having and average thickness of 0.10-0.50 mum and containing aluminum therein, the multilayer coating having and average thickness of 0.50-10.0 mum.

Owner:OSG

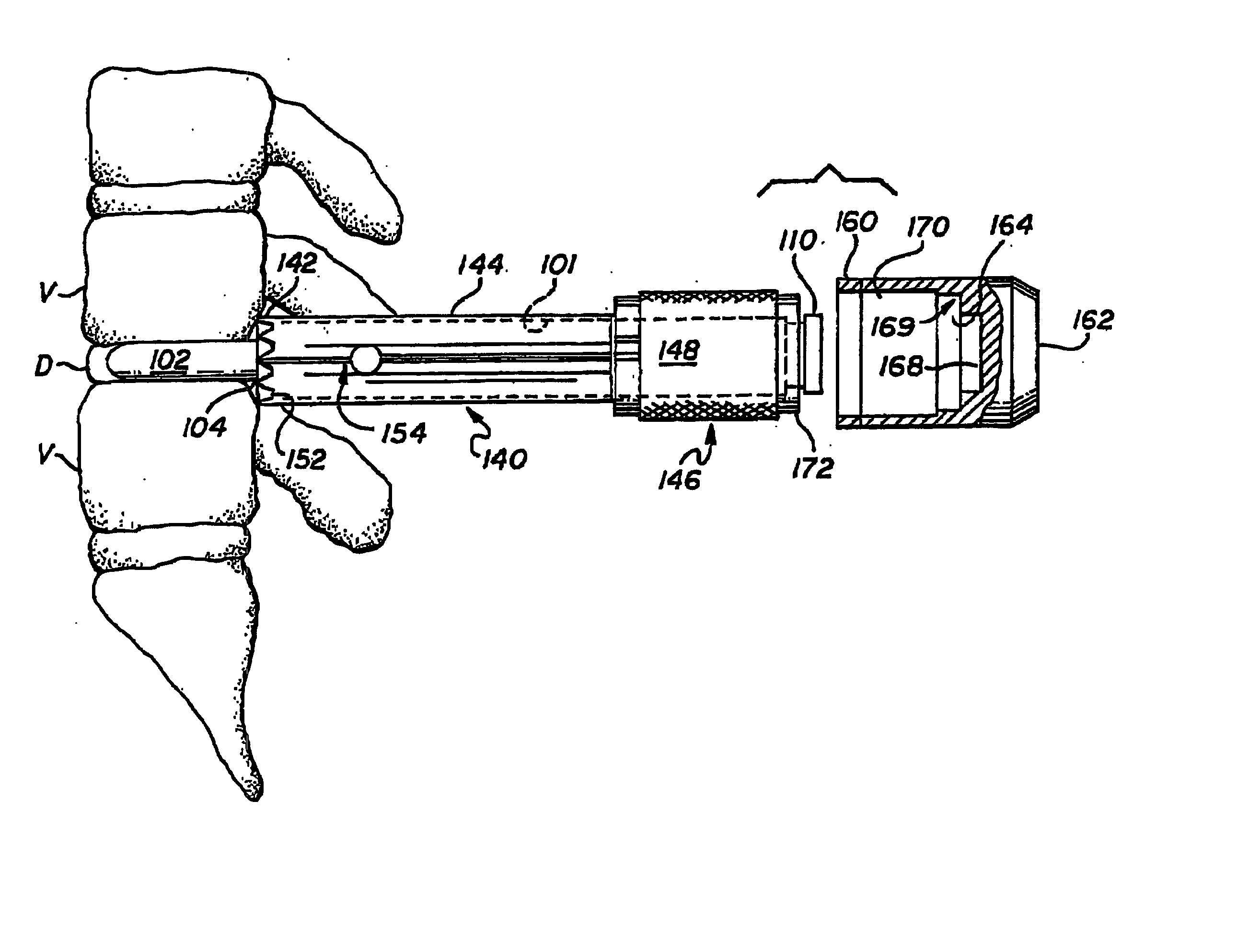

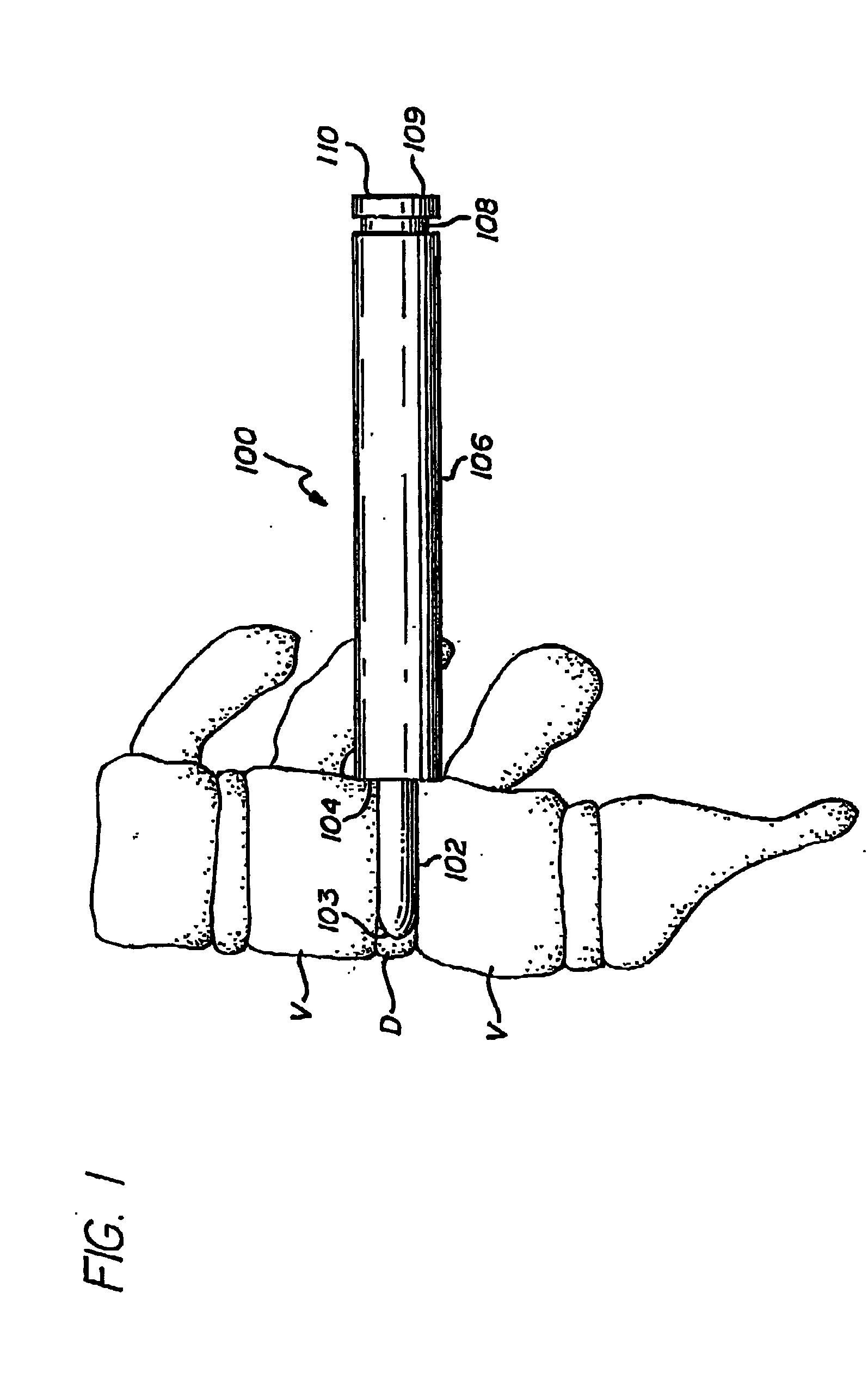

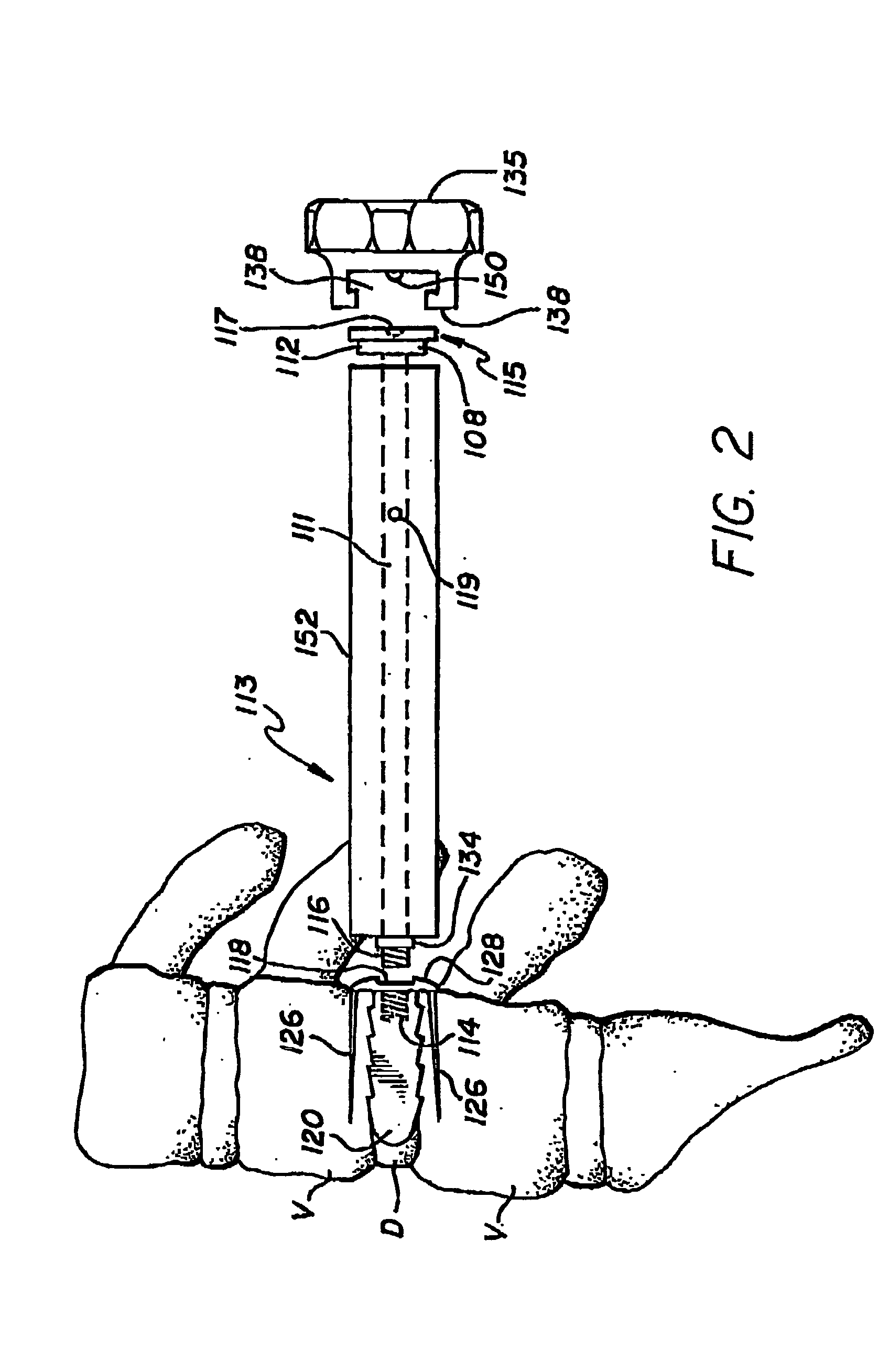

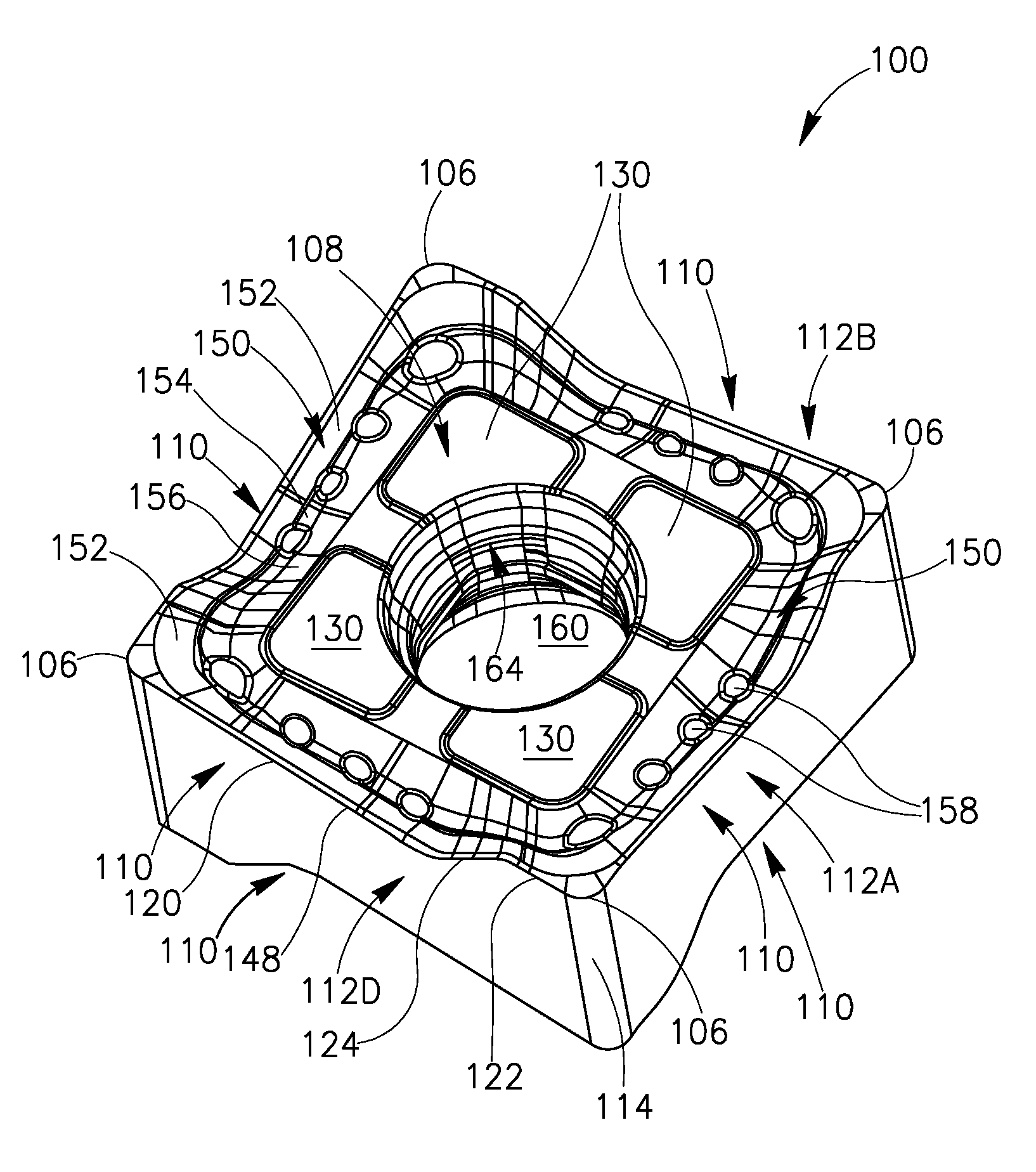

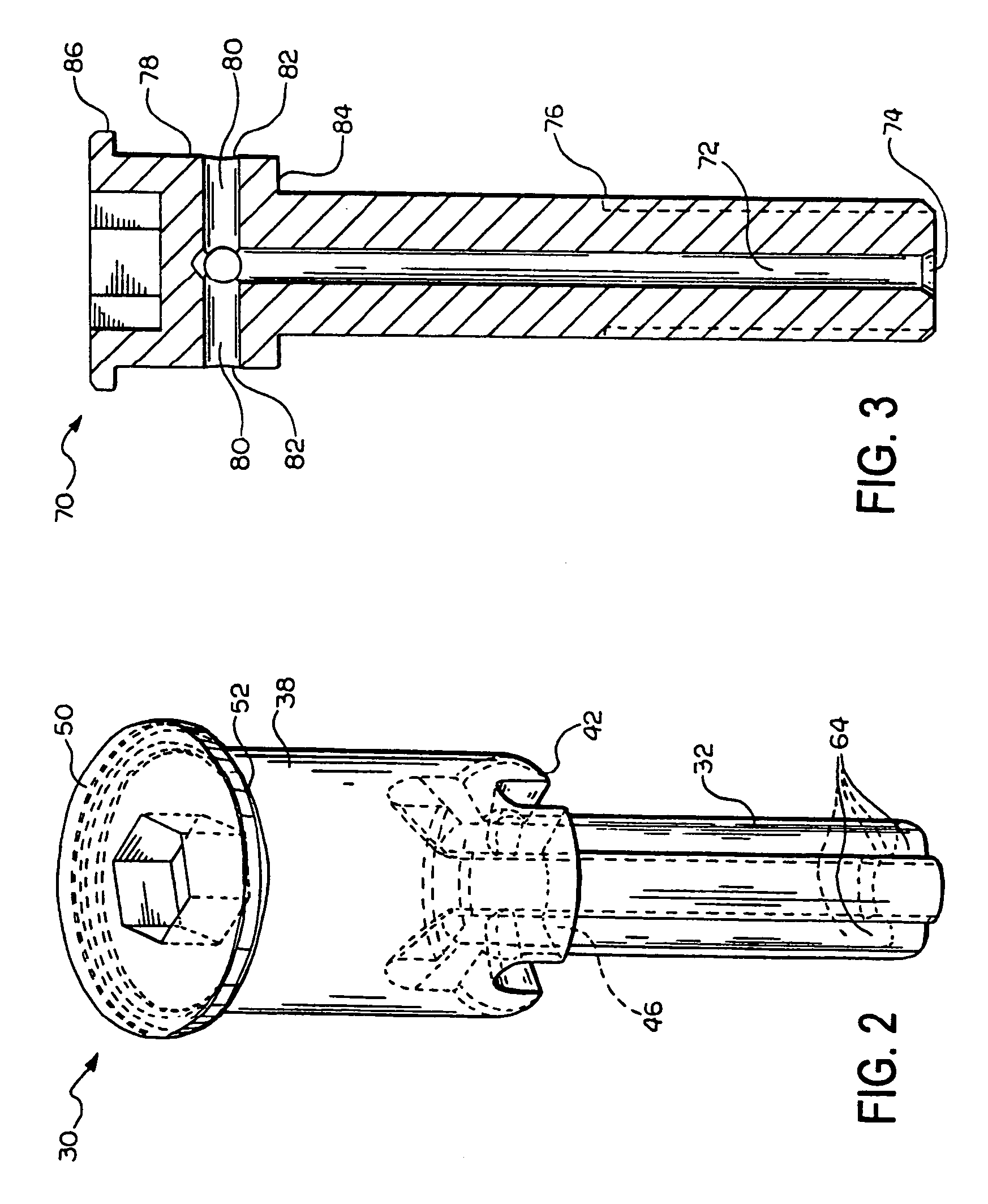

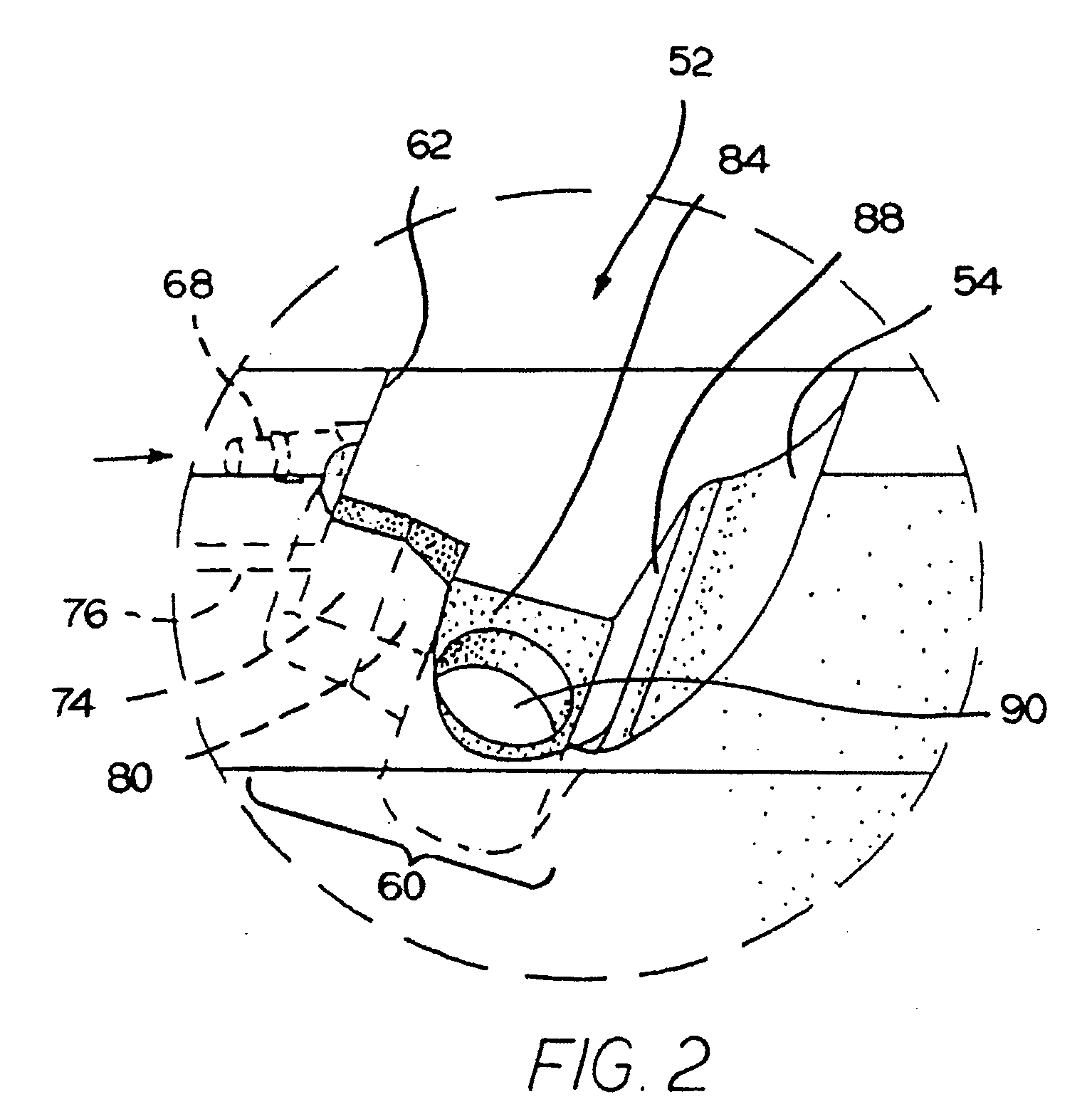

Apparatus and method of inserting spinal implants

InactiveUS20020198532A1Eliminate separationEfficient removalInternal osteosythesisSurgical needlesSpinal columnIntervertebral disc

Apparatus and a method of inserting spinal implants is disclosed in which an intervertebral space is first distracted, a hollow sleeve having teeth at one end is then driven into the vertebrae adjacent that disc space. A drill is then passed through the hollow sleeve removing disc and bone in preparation for receiving the spinal implant which is then inserted through the sleeve.

Owner:WARSAW ORTHOPEDIC INC

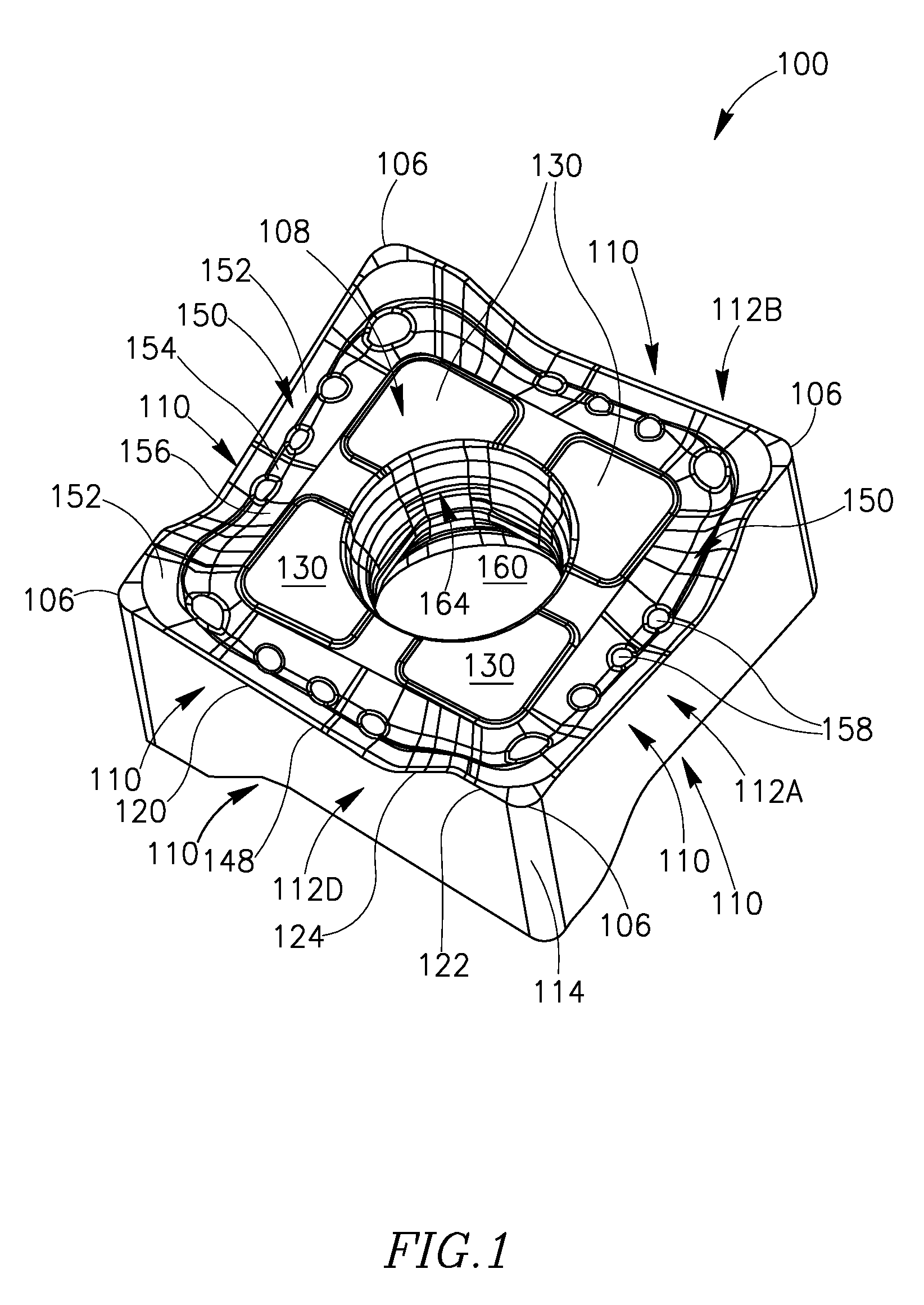

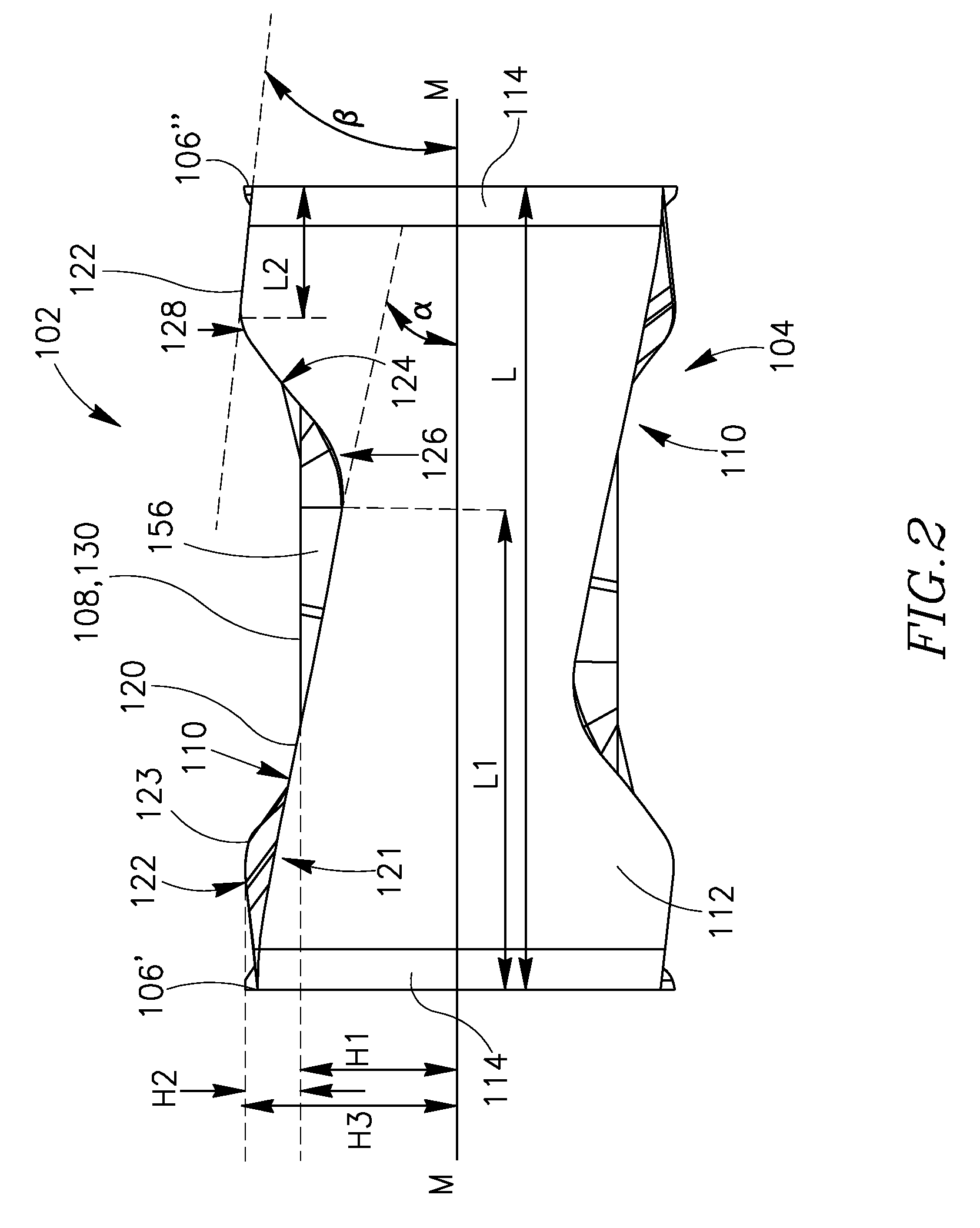

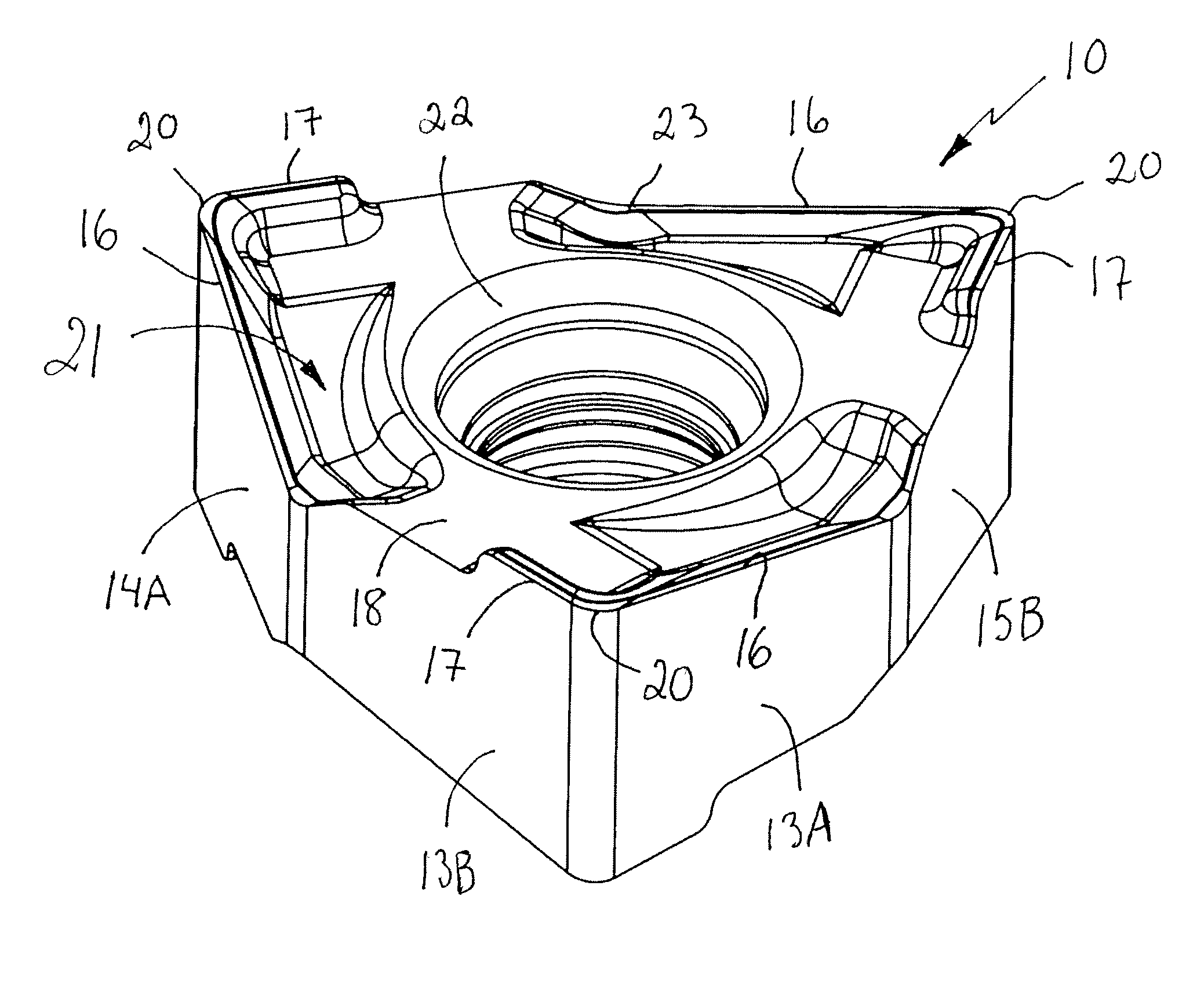

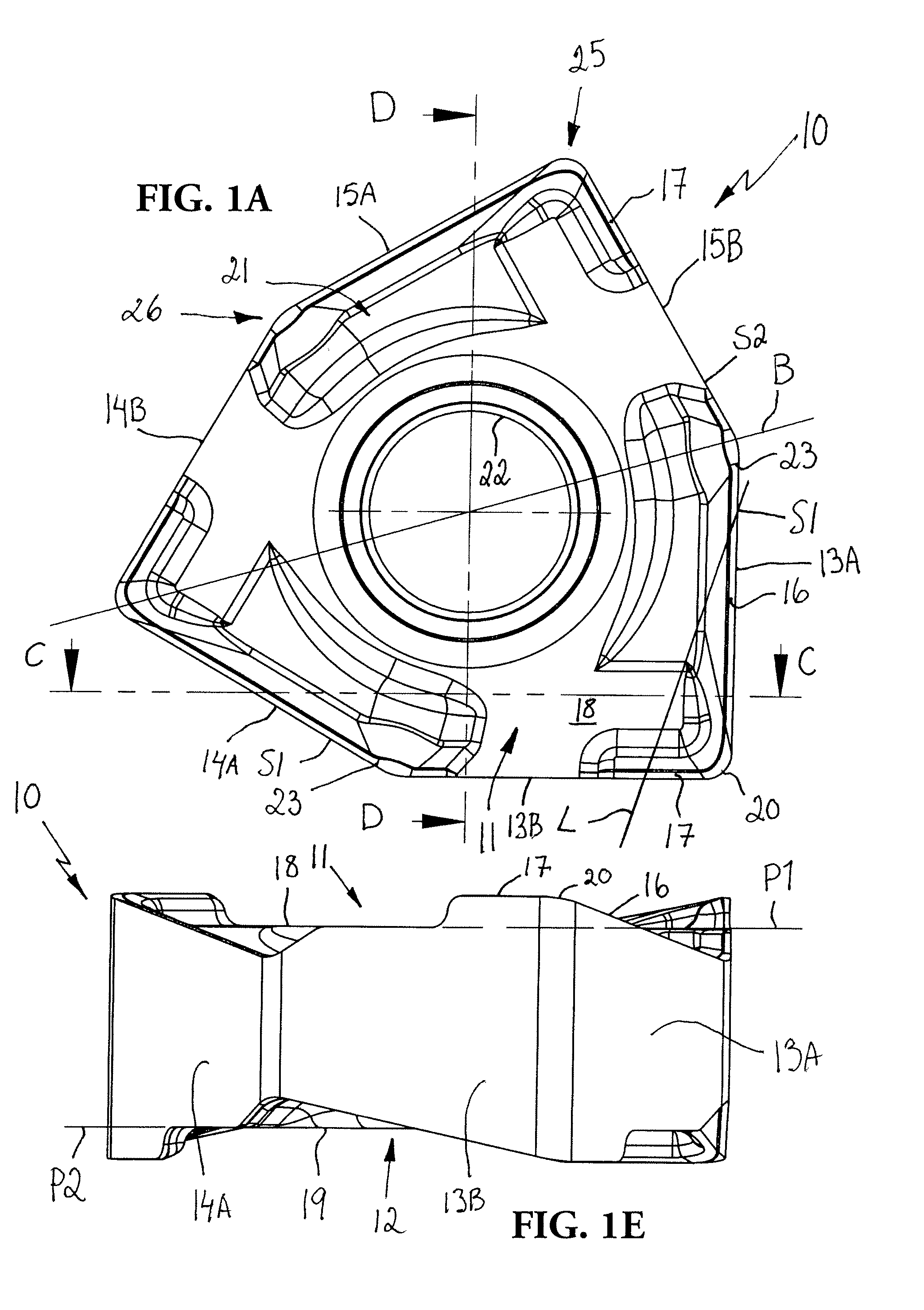

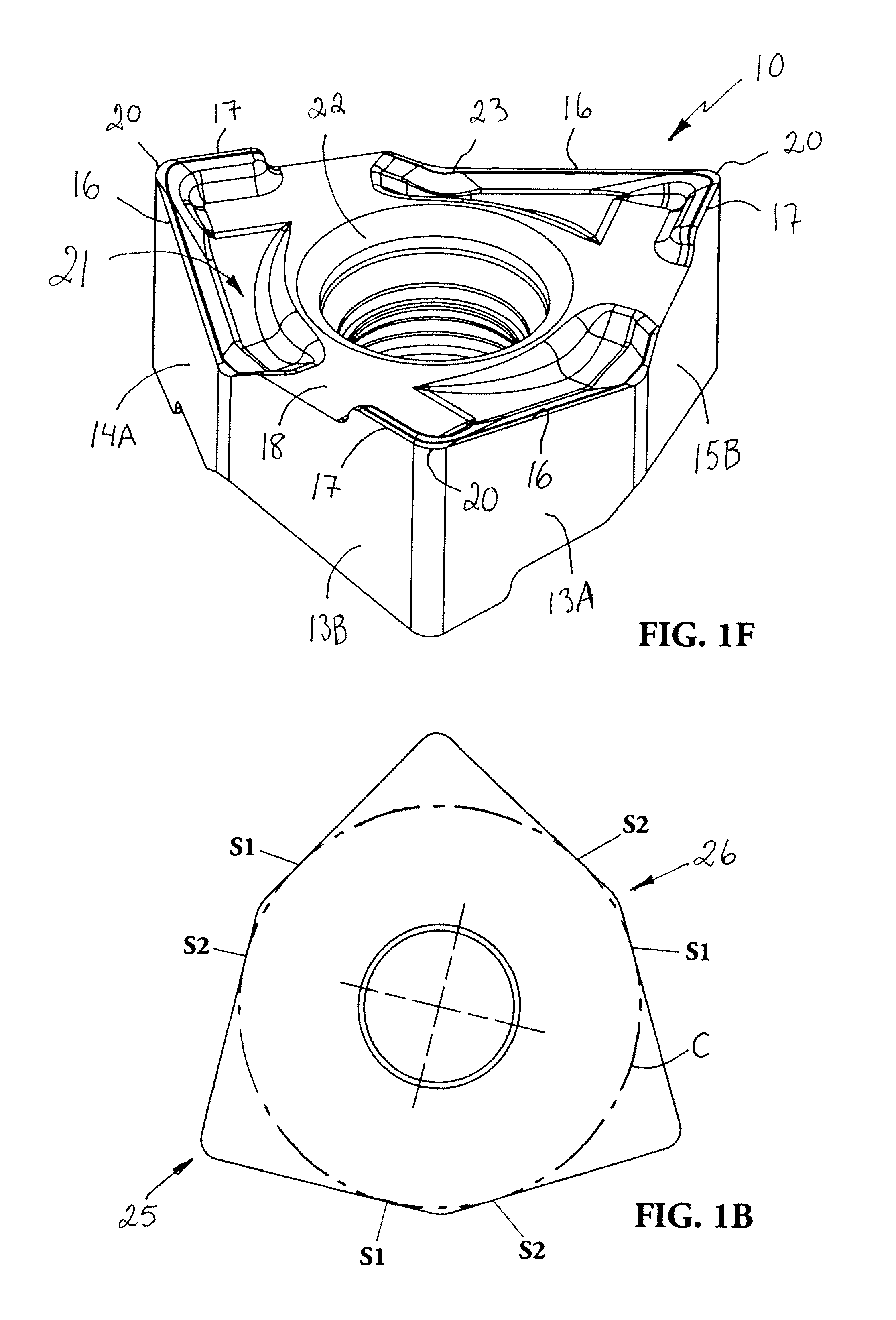

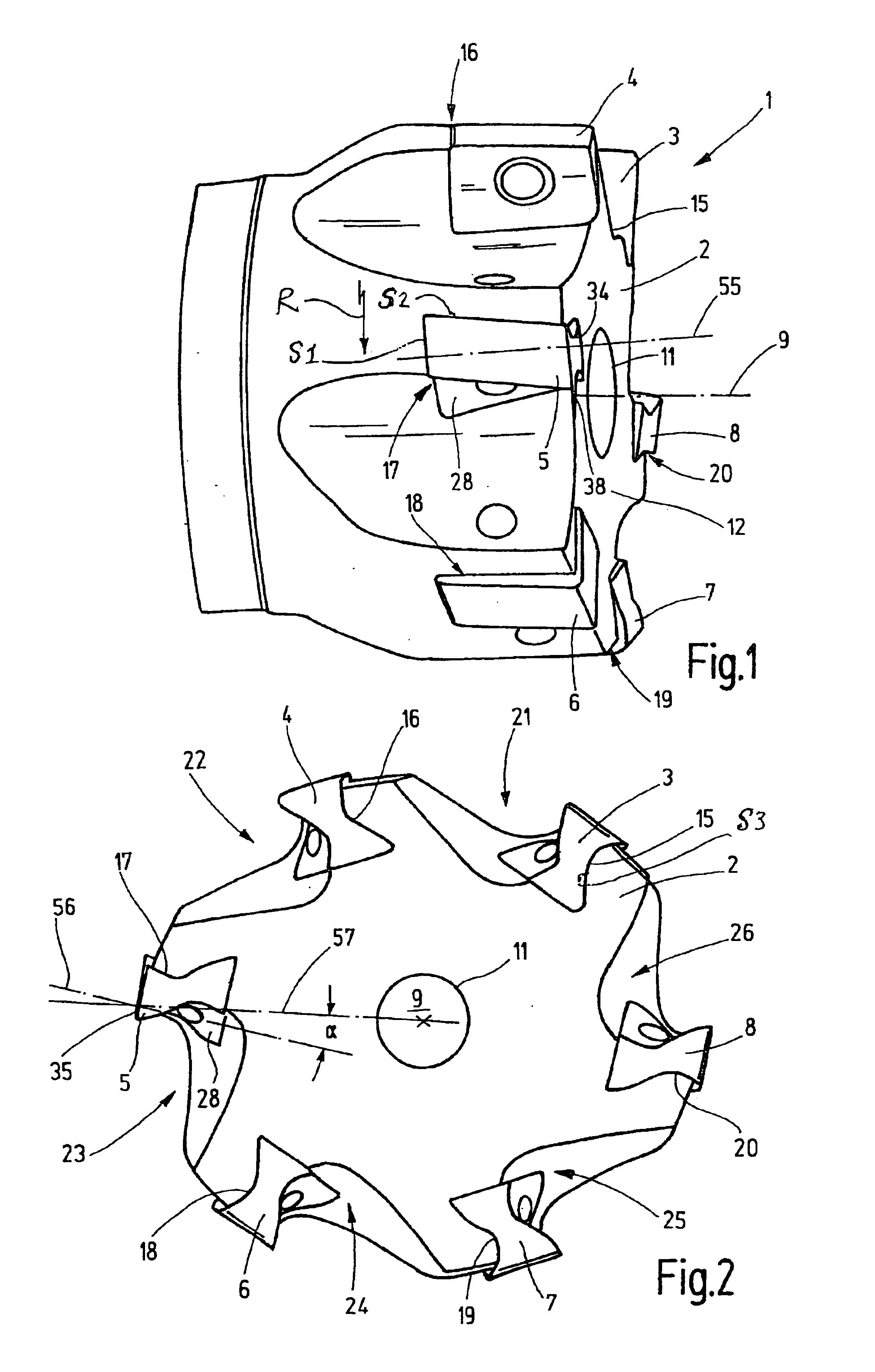

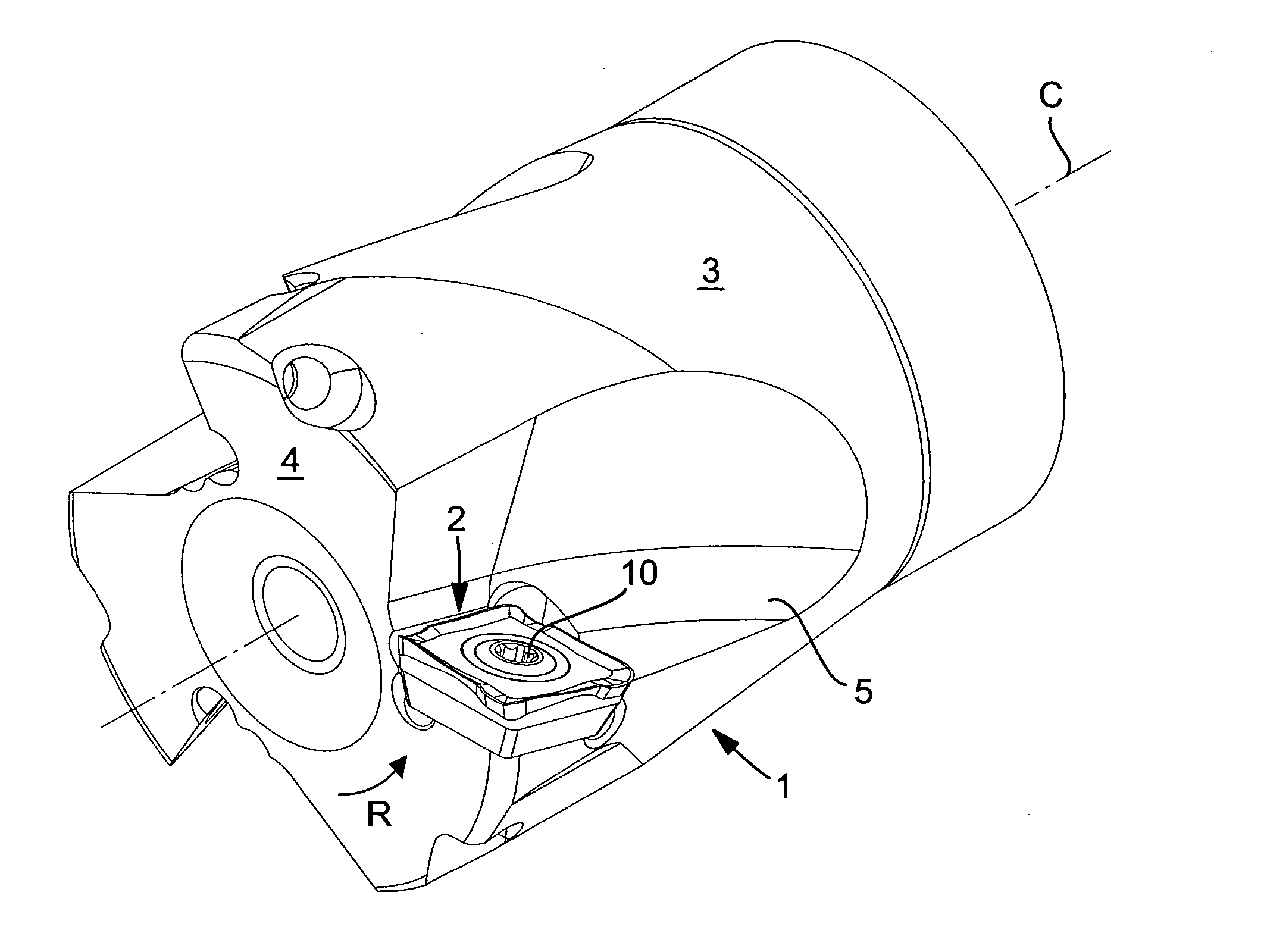

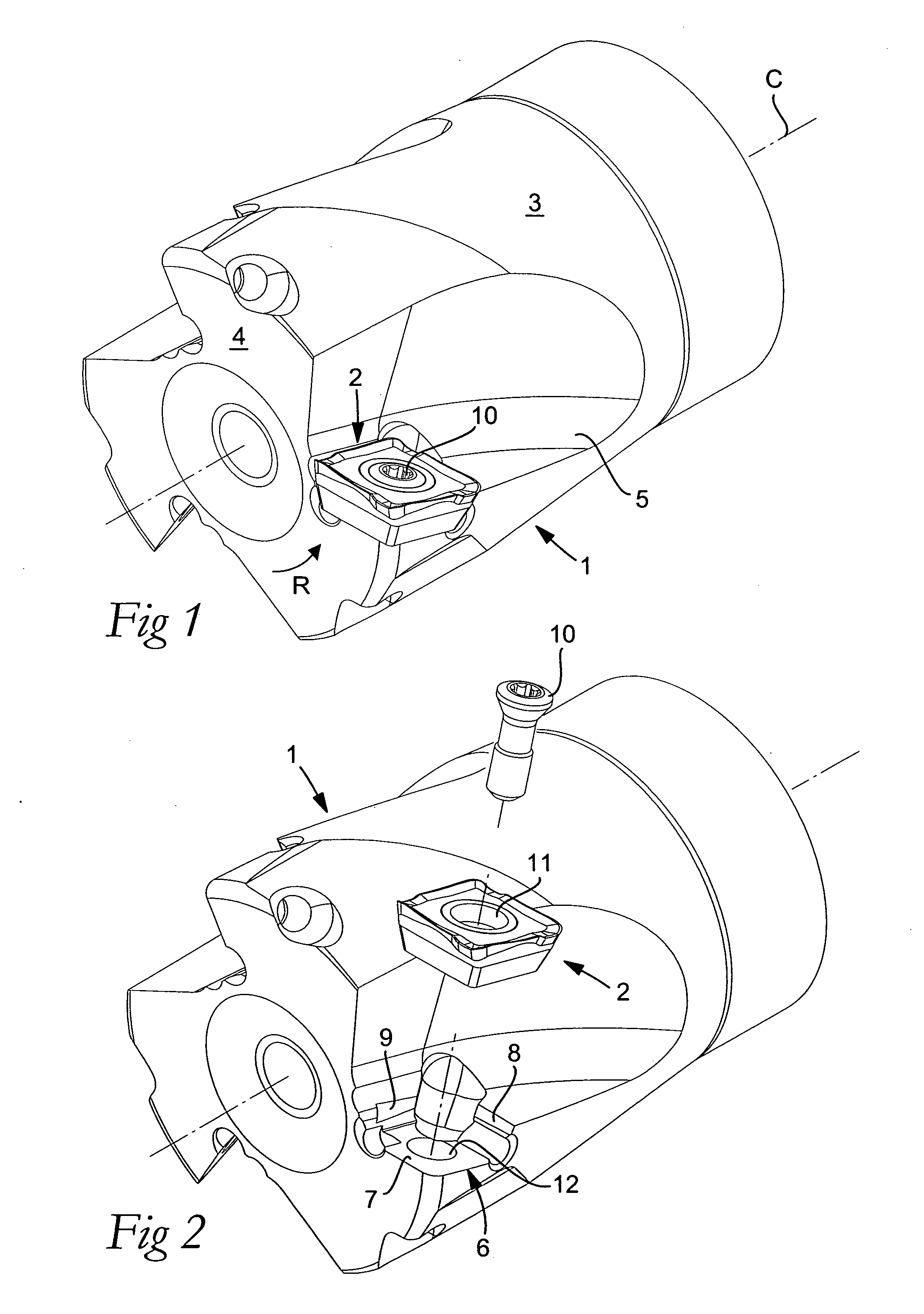

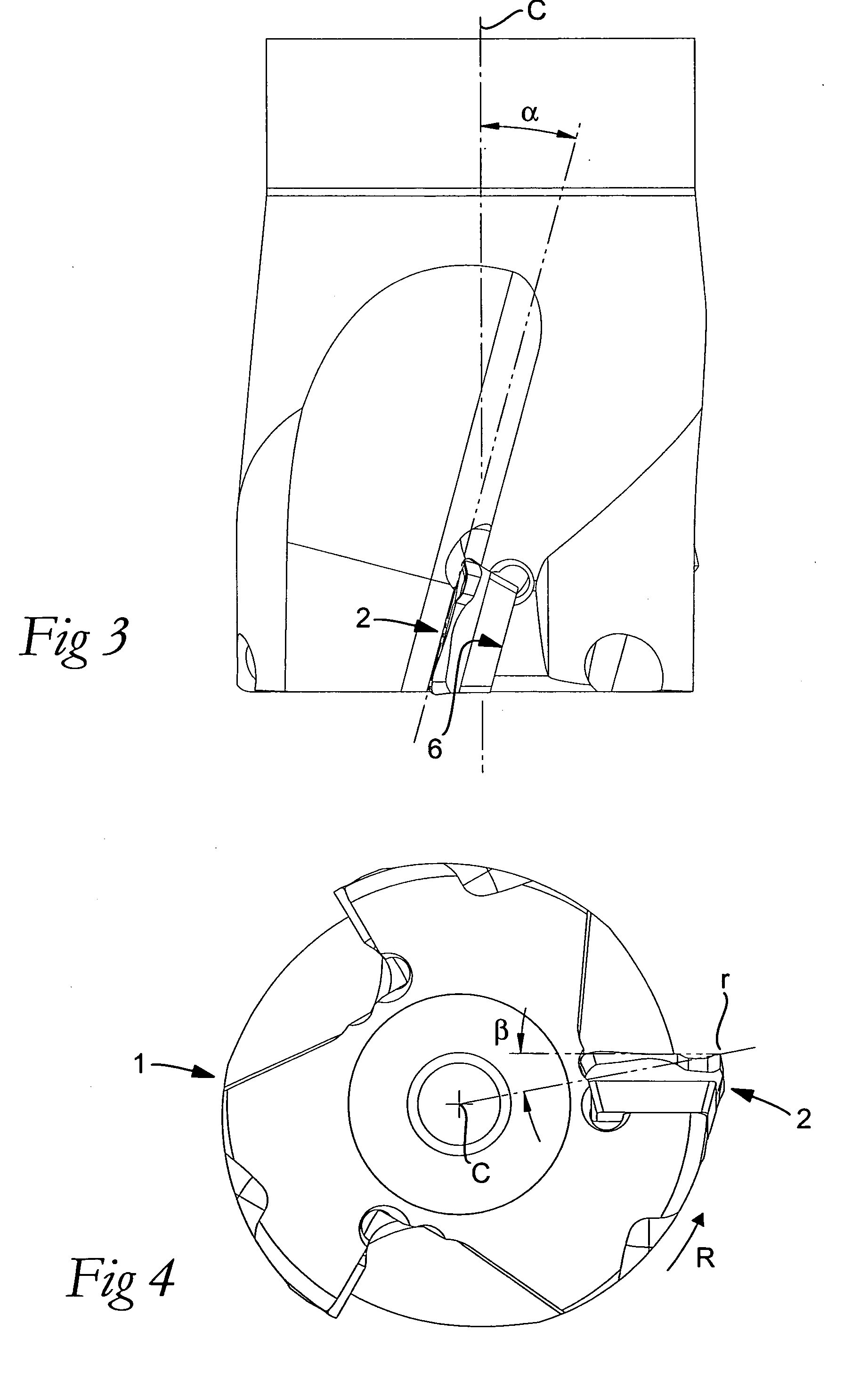

Cutting Insert for a Milling Cutter

ActiveUS20080232912A1Clearance can be providedMilling cuttersShaping cuttersMilling cutterEngineering

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

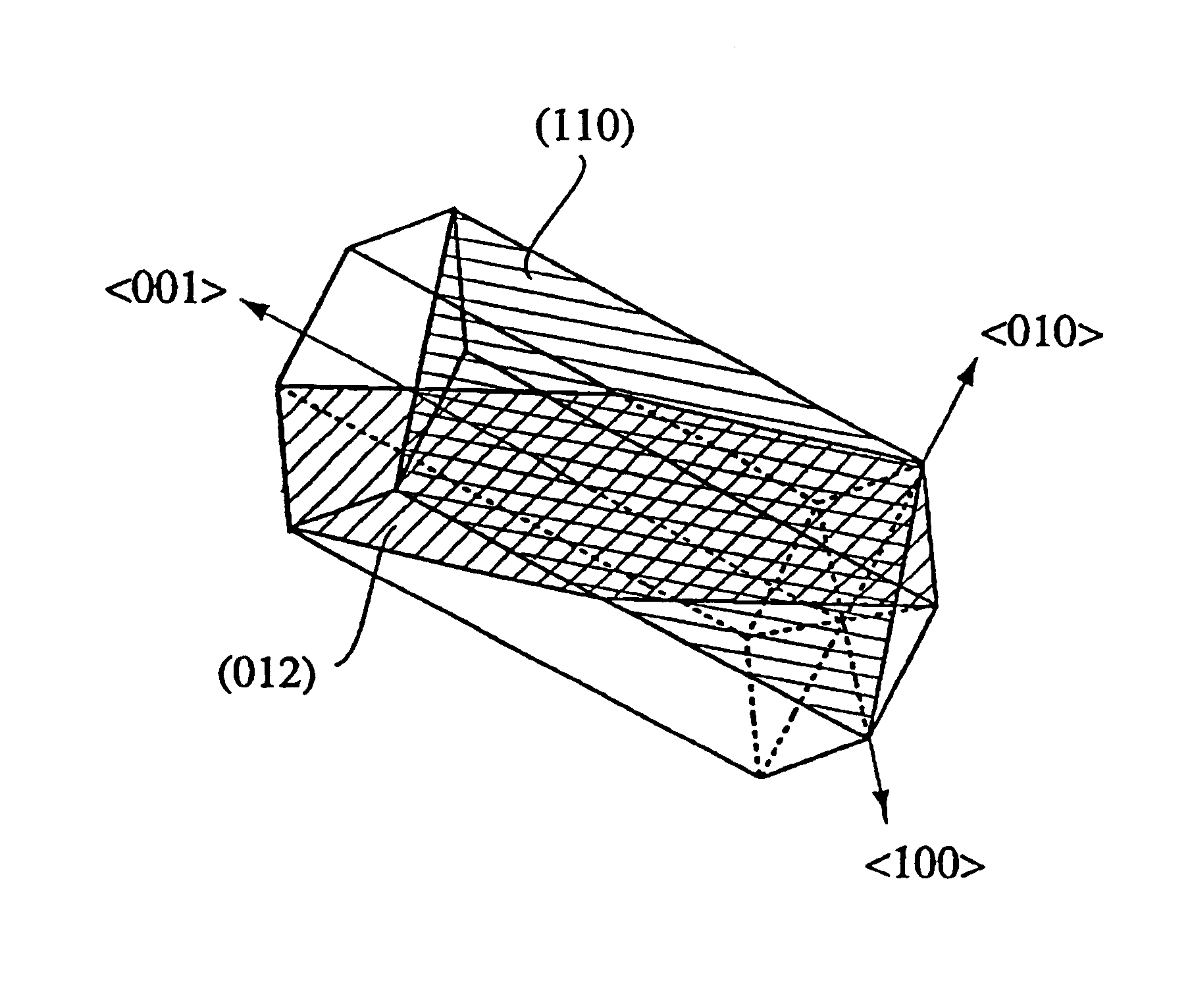

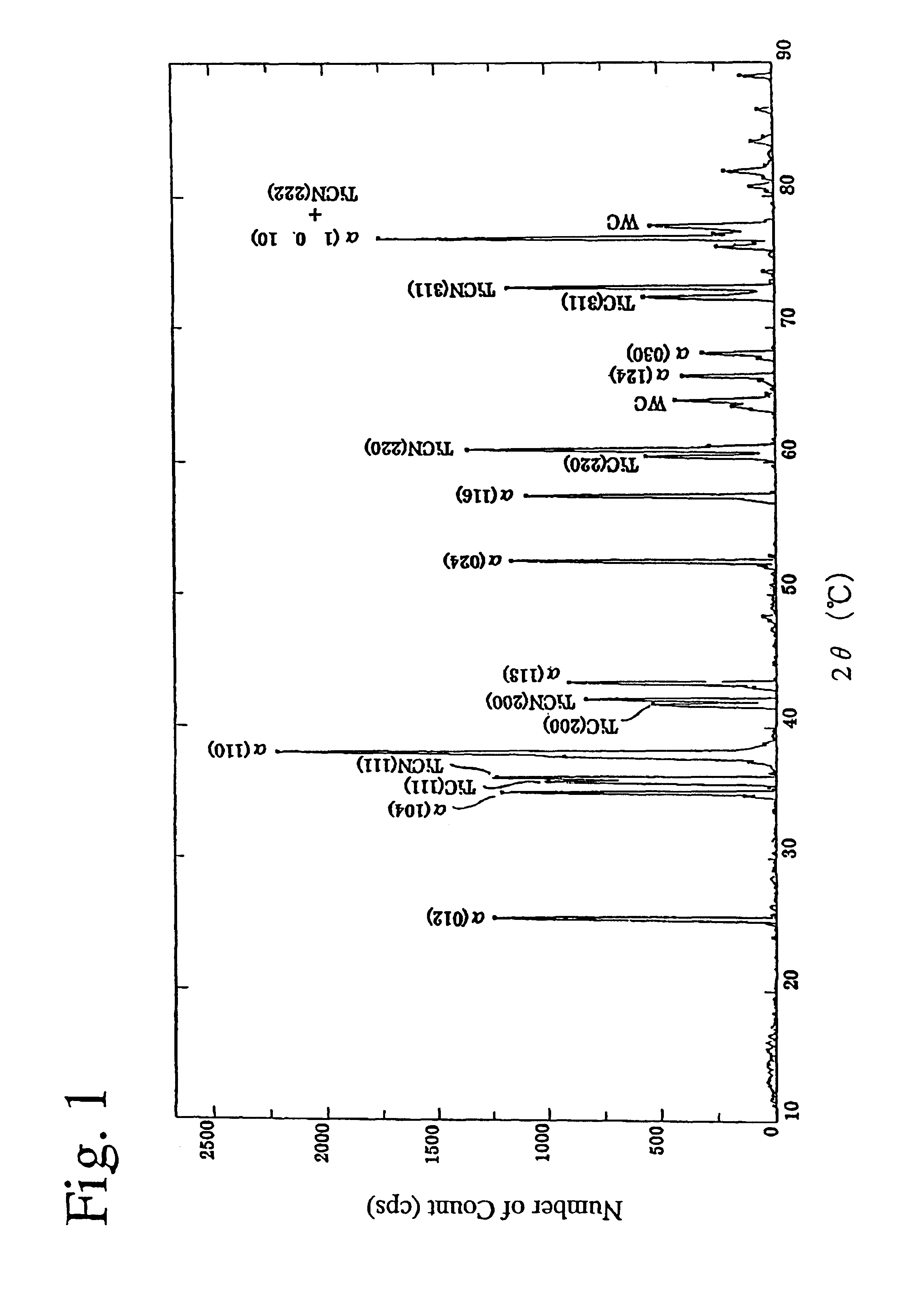

Aluminum oxide-coated article

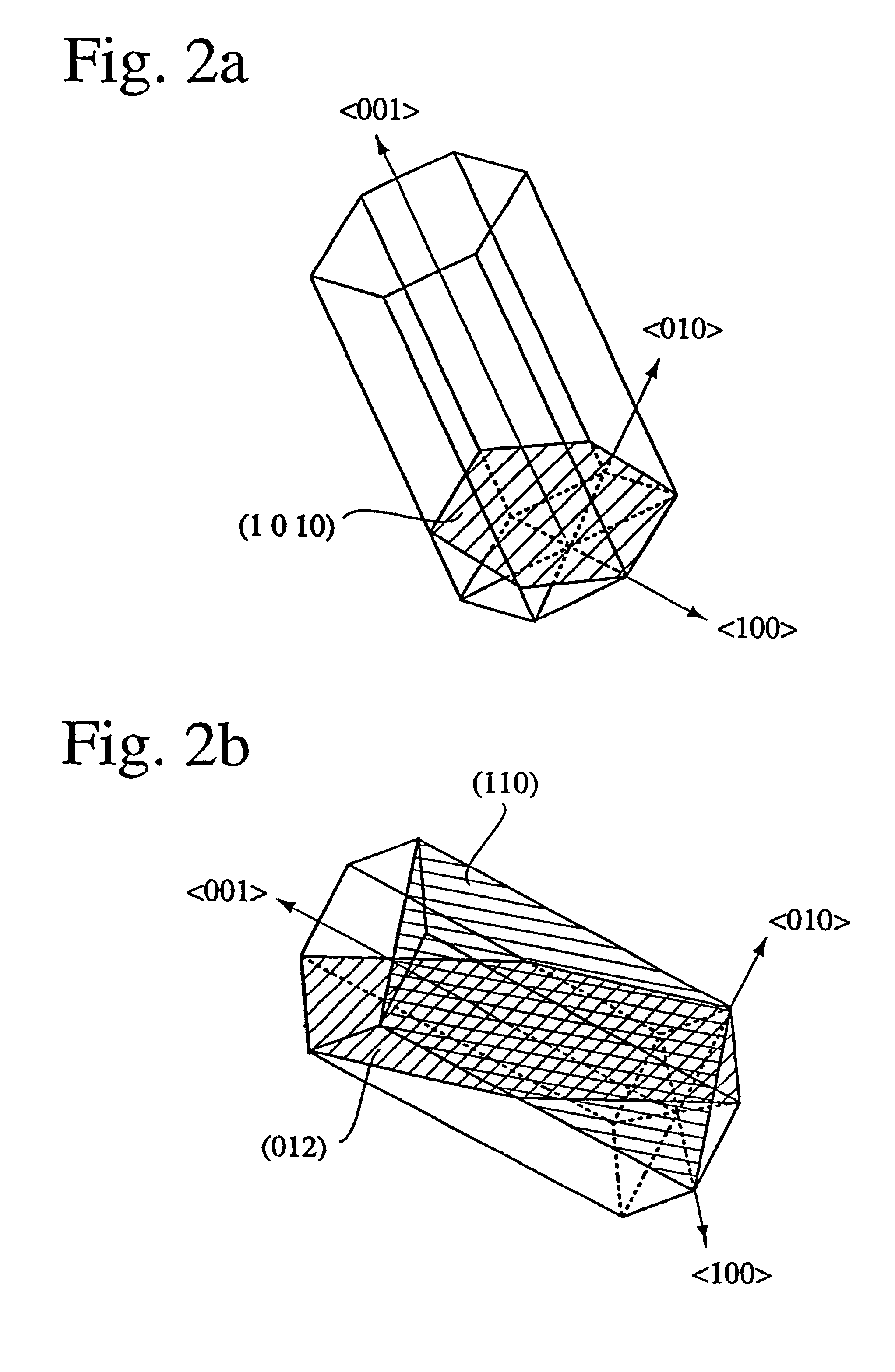

InactiveUS6333103B1Improve featuresReduced durabilityPigmenting treatmentRecord information storageX-rayCarbide

An aluminum oxde-coated article has a first coating layer and a second coating layer formed in this order on a substrate, the first coating layer having a single- or multi-layer structure and being made of at least one selected from the group consisting of carbides, nitrides, carbonitrides, oxides, oxycarbides, oxynitrides and oxycarbonitrides of metals in Groups IVa, Va and VIa of the Periodic Table, and the second coating layer being constituted by at least one alpha-aluminum oxide-based oxide layer, which has an equivalent X-ray diffraction peak ratio PR (1 0 10) of 1.3 or more in a (1 0 10) plane.

Owner:HITACHI TOOL ENG LTD

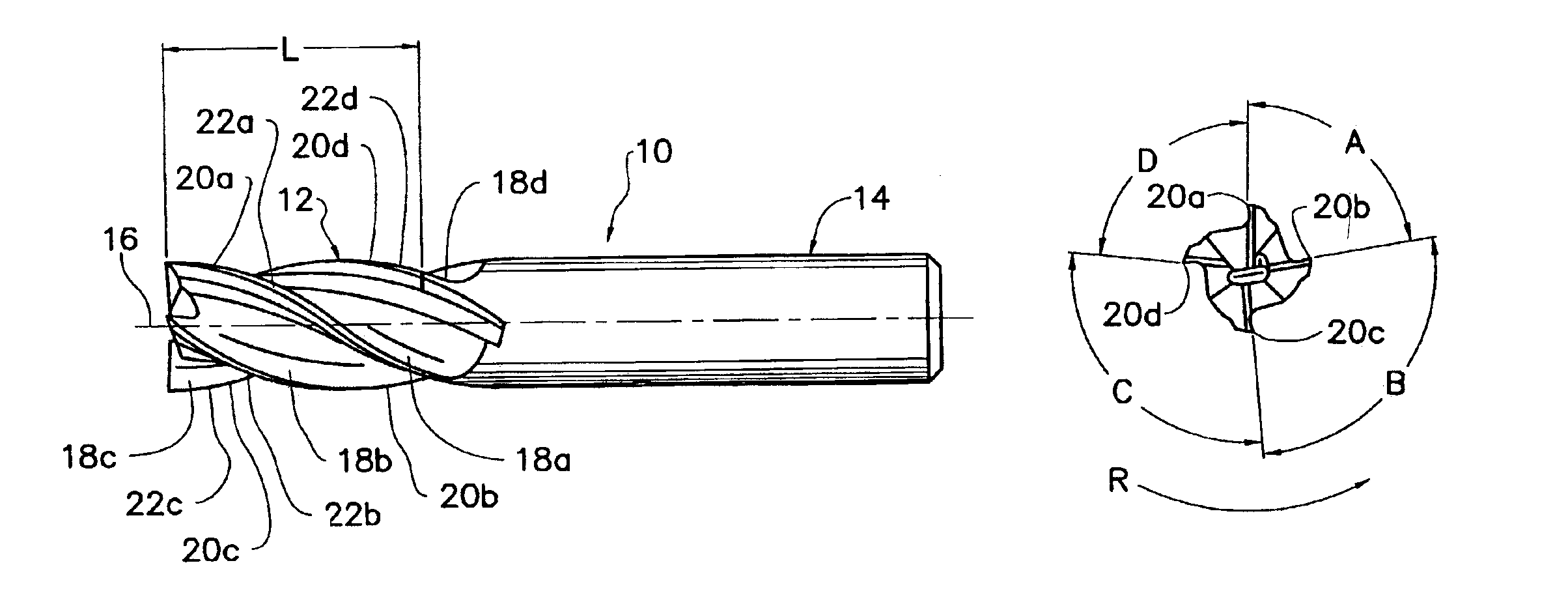

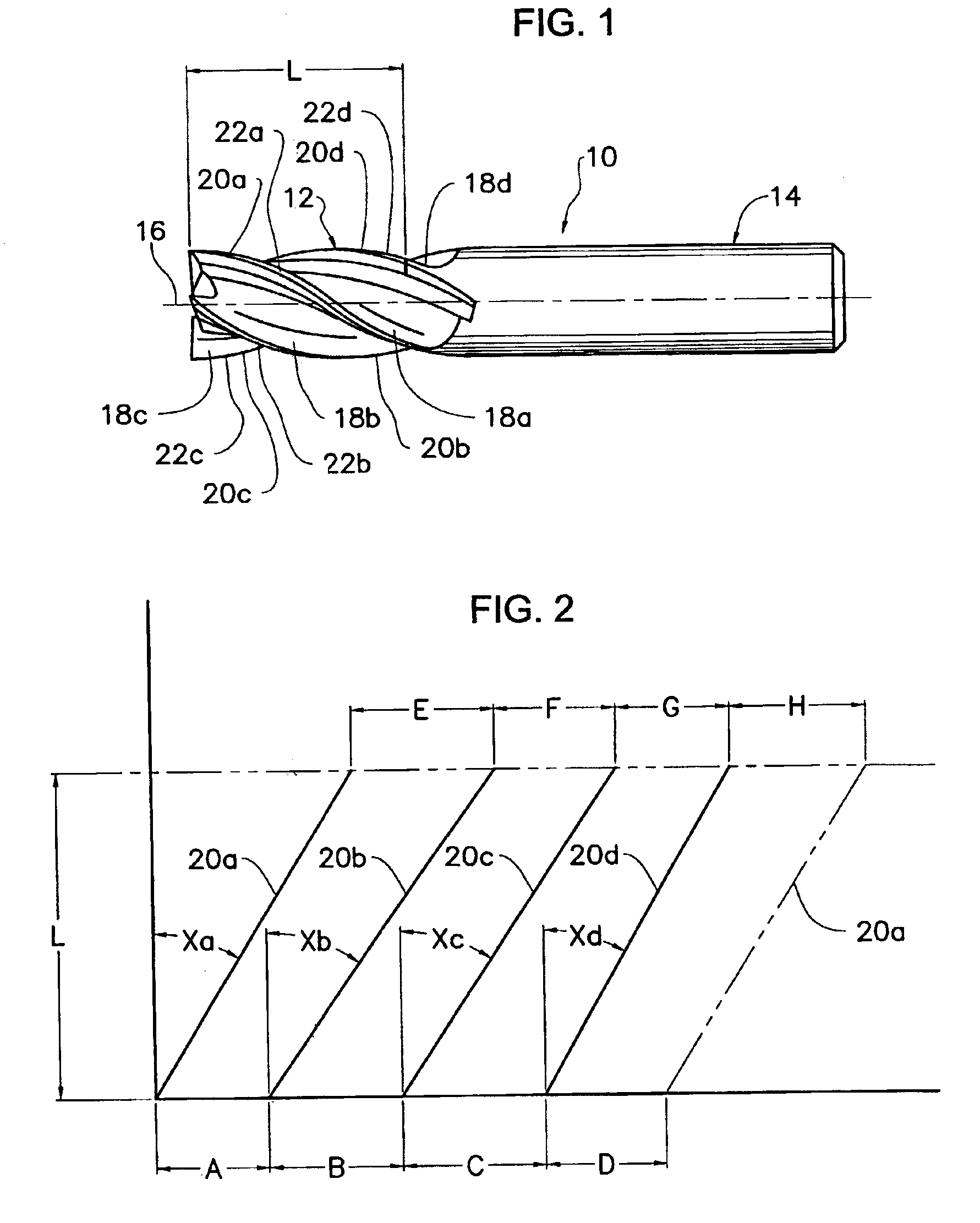

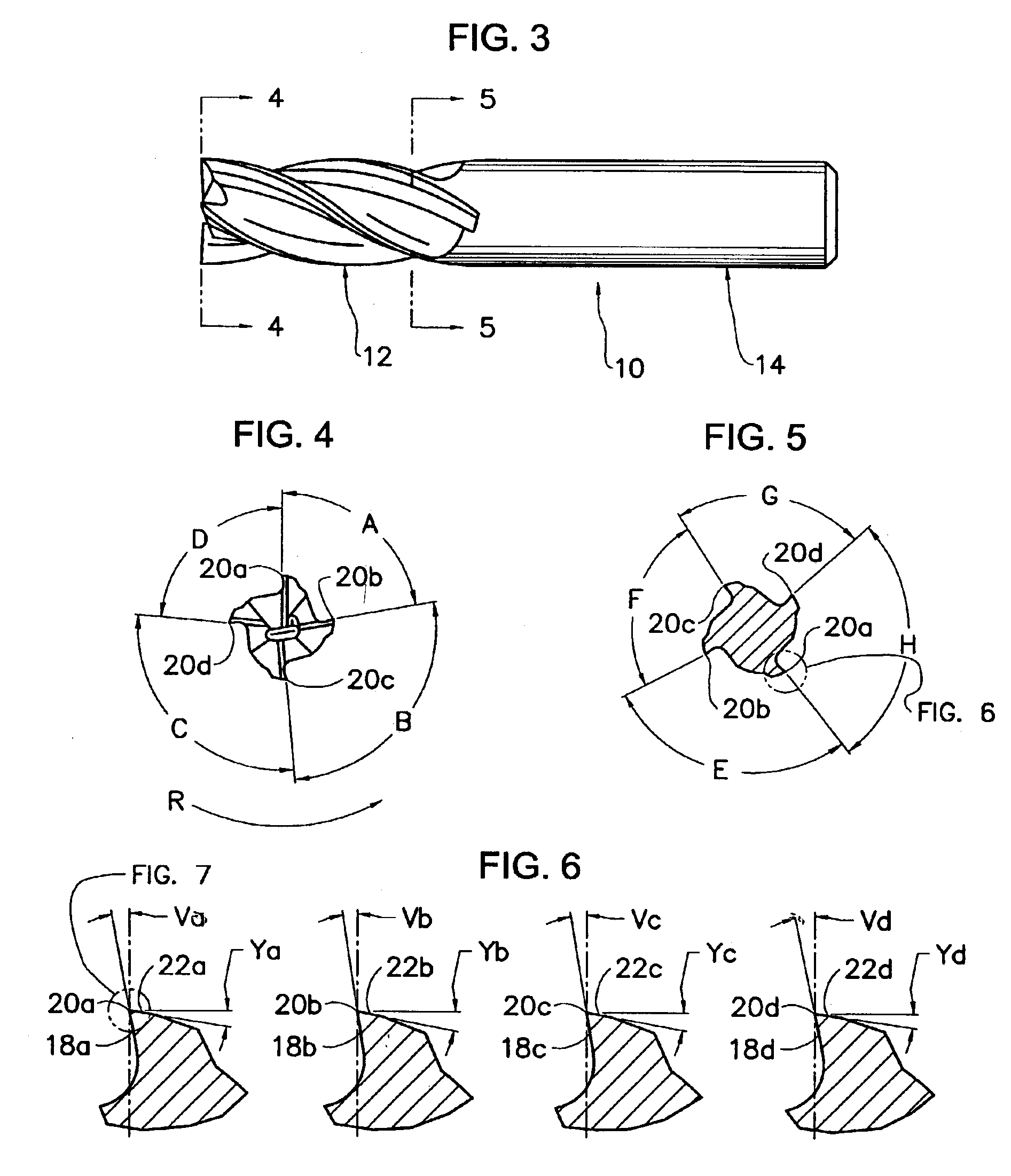

Rotary cutting tool

A rotary cutting tool that includes an elongated tool body, rotatable along a longitudinal axis of rotation is disclosed. It has a fluted cutting end on one end and a shank end on the opposite end of the tool body. The fluted cutting end includes a nose, a periphery and an end surface that extends from the nose to the periphery. A plurality of axial flutes extends from the end surface to the fluted cutting end and combines with a plurality of cutting edges. The cutting edges are unequally spaced along the circumference of the end surface lying in a plane perpendicular to the longitudinal axis of rotation. In addition, all cutting edges are of a different helix from one another and the cutting edge geometries vary from one another to create a different sound pattern. This reduces resonant harmonic vibrations.

Owner:NIAGARA CUTTER LLC

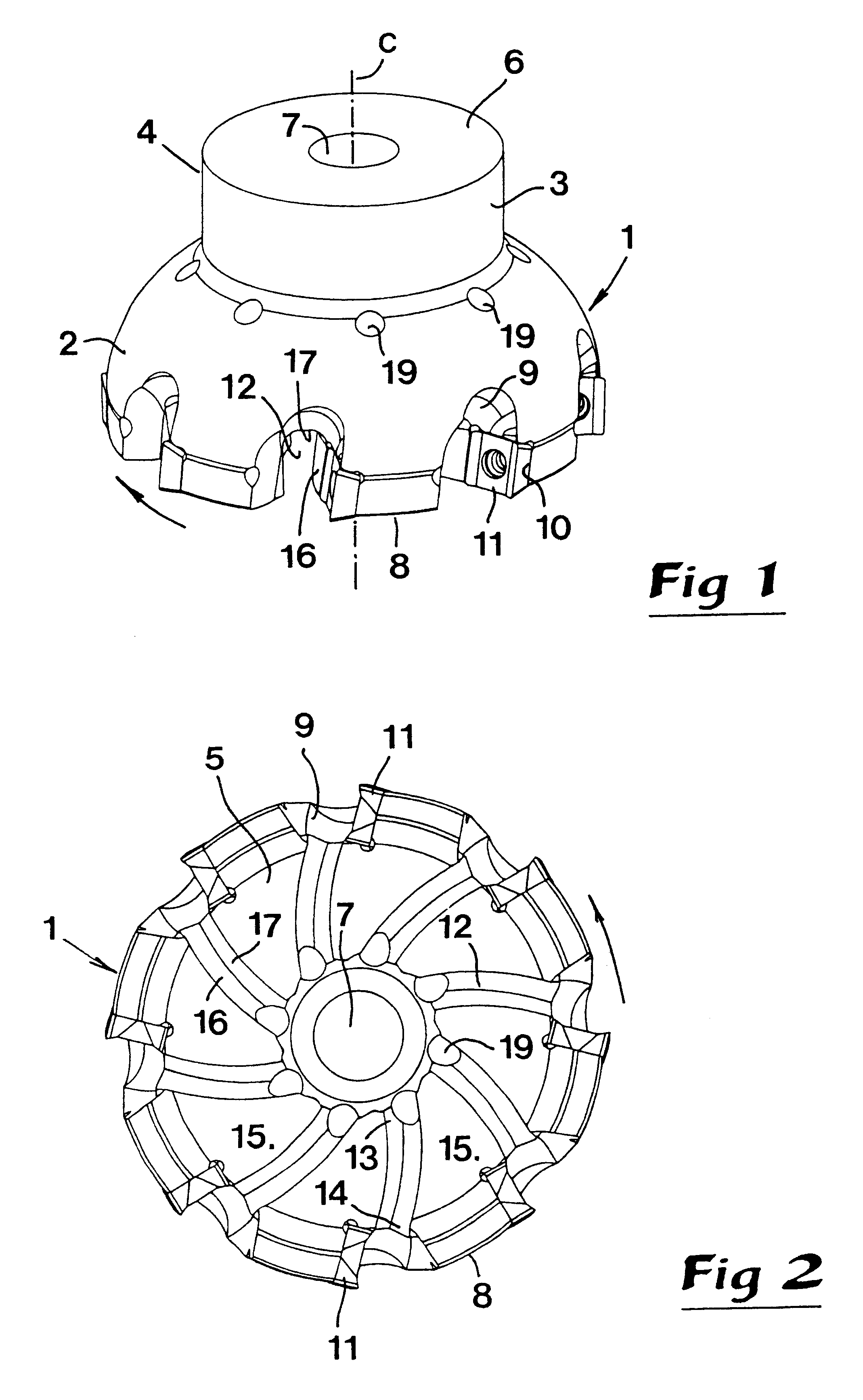

Milling insert and a milling tool

The present invention relates to an indexable milling insert and a milling tool for chip removing machining. The milling insert is intended to be able to mill substantially perpendicular corners in a work piece. The milling insert comprises an upper side, a lower side and edge surfaces extending therebetween. The upper side and the lower side are substantially identical. An imaginary circle inscribed in the milling insert touches the milling insert periphery in four to six points. Lines of intersection between the edge surfaces and the sides form relative to each other substantially perpendicular main cutting edges and minor cutting edges. Each of the sides includes a support surface, each of which being provided in a plane. Each minor cutting edge projects from the plane of the associated support surface. Each major cutting edge intersects the plane of the associated support surface.

Owner:SECO TOOLS AB

Cutting insert with cooling channel

A cutting insert for chipforming machine has a tip face with a cutting edge. Grooves are formed in the top face and extend toward the cutting edge. Chip-deflecting projections extend upwardly from the top face and are situated in spaces formed between adjacent grooves. A jet of cooling fluid is directed toward inner ends of the grooves and travels between the projections and within the grooves toward the cutting edge.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Double-sided cutting insert and milling cutter

A double-sided cutting insert, for use in a milling cutter, having two identical opposing end surfaces and two opposing identical major side surfaces with a through bore extending between, and opening out to, the major side surfaces. Major cutting edges are formed at the intersection of each major side surface with each end surface. Adjacent each major cutting edge, in each major side surface, is a primary relief surface. In each cross section of the cutting insert taken in a plane generally perpendicular to the major side surfaces, a line tangent to the primary relief surface at the major cutting edge is inclined to a median plane of the cutting insert at an acute interior angle.

Owner:ISCAR LTD

Polycrystalline diamond composite constructions comprising thermally stable diamond volume

ActiveUS7462003B2Improve thermal stabilityConstructionsRecord information storageComposite constructionDiamond crystal

PCD composite constructions comprise a diamond body bonded to a substrate. The diamond body comprises a thermally stable diamond bonded region that is made up of a single phase of diamond crystals bonded together. The diamond body includes a PCD region bonded to the thermally stable region and that comprises bonded together diamond crystals and interstitial regions interposed between the diamond crystals. The PCD composite is prepared by combining a first volume of PCD with a second volume of diamond crystal-containing material consisting essentially of a single phase of bonded together diamond crystals. A substrate is positioned adjacent to or joined to the first volume. The first and second volumes are subjected to high pressure / high temperature process conditions, during process the first and second volumes form a diamond bonded body that is attached to the substrate, and the second volume forms the thermally stable diamond bonded region.

Owner:SMITH INT INC

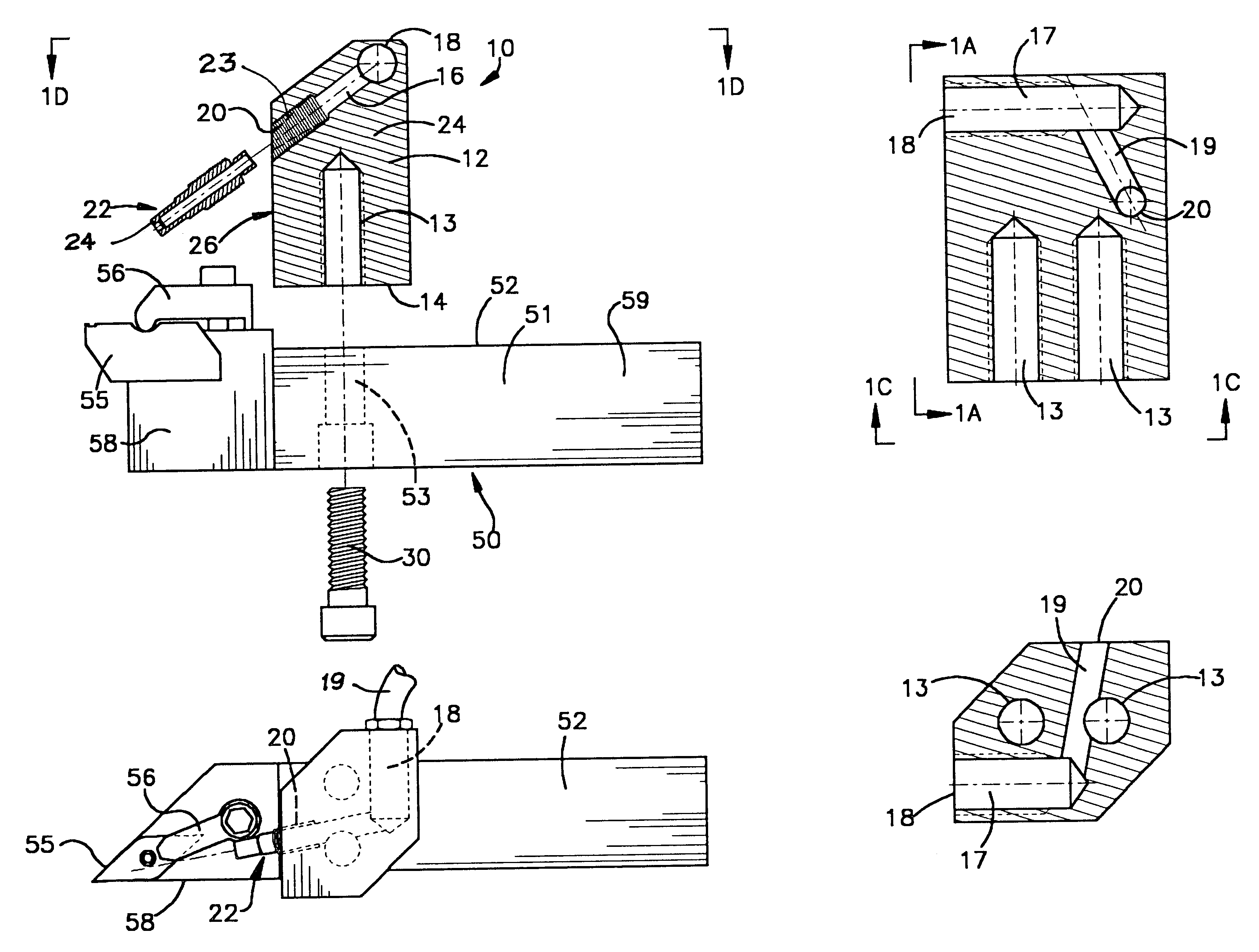

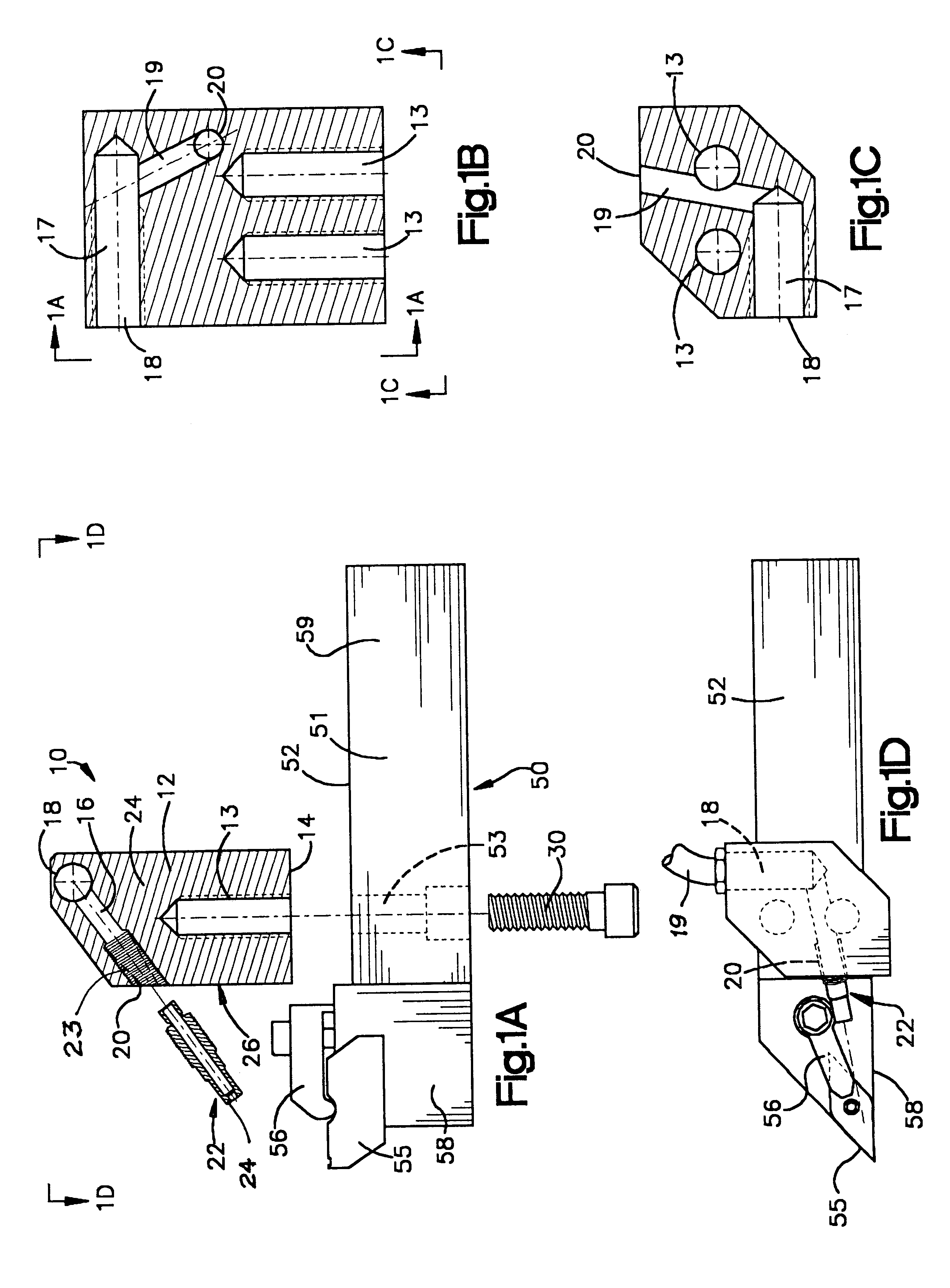

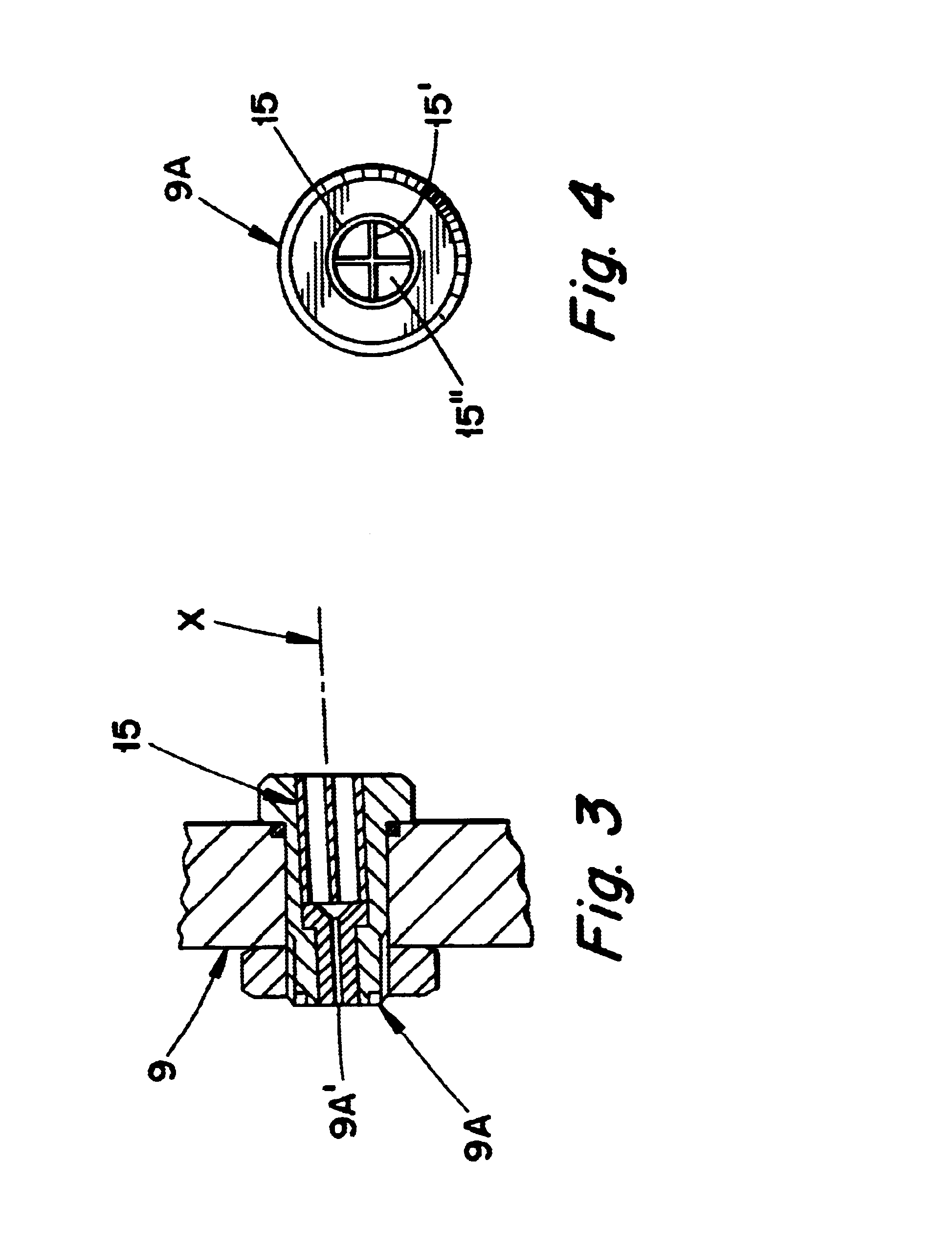

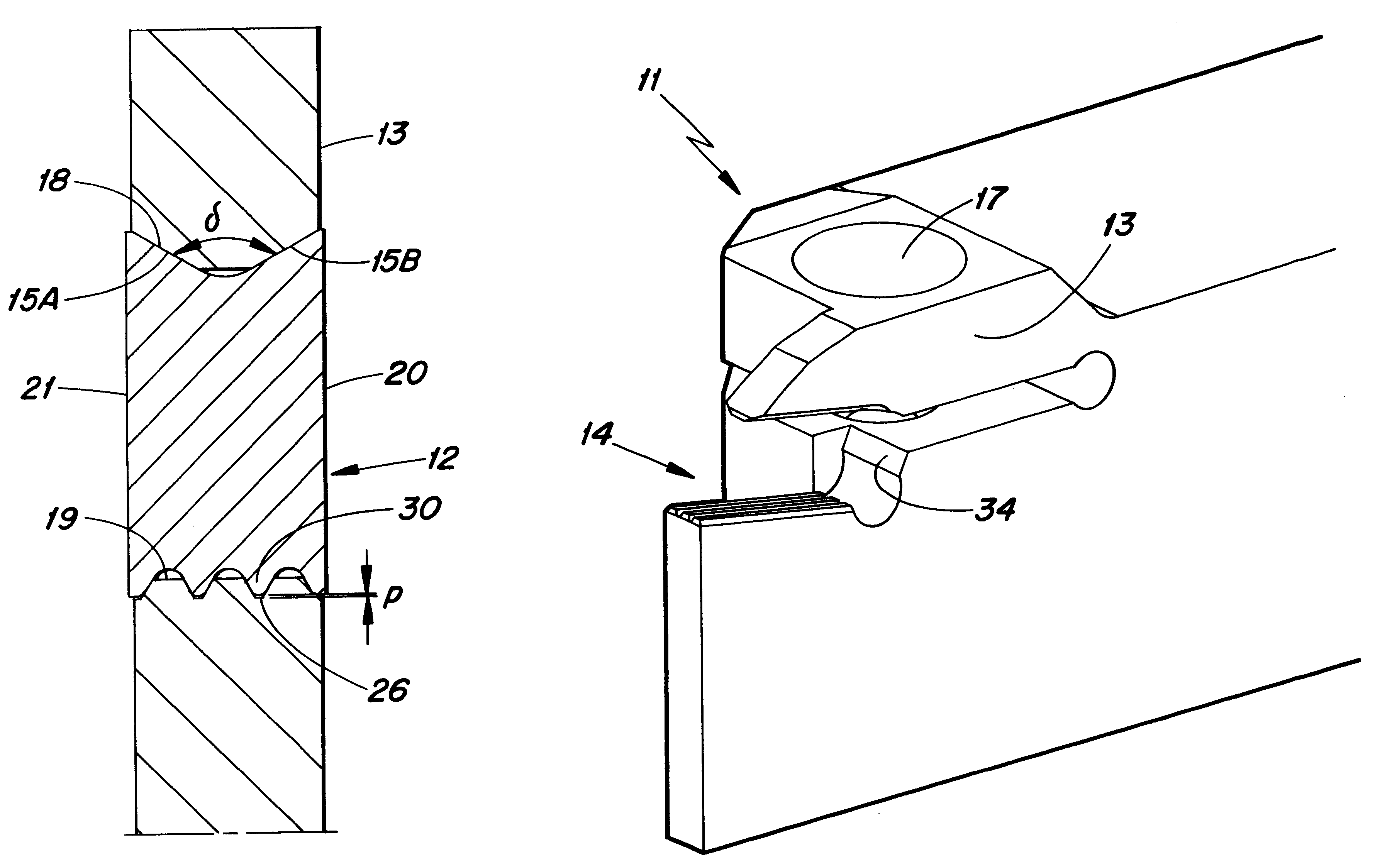

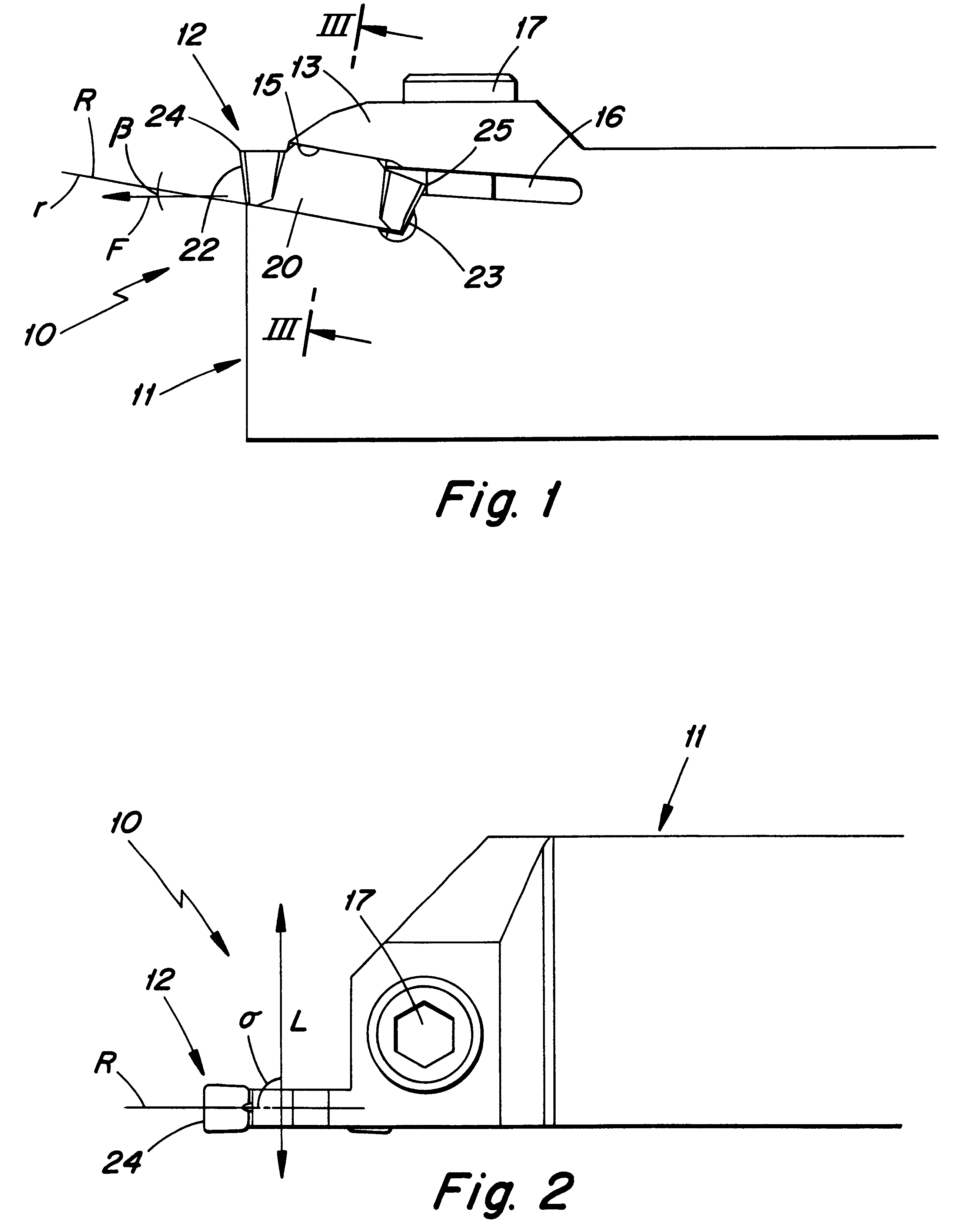

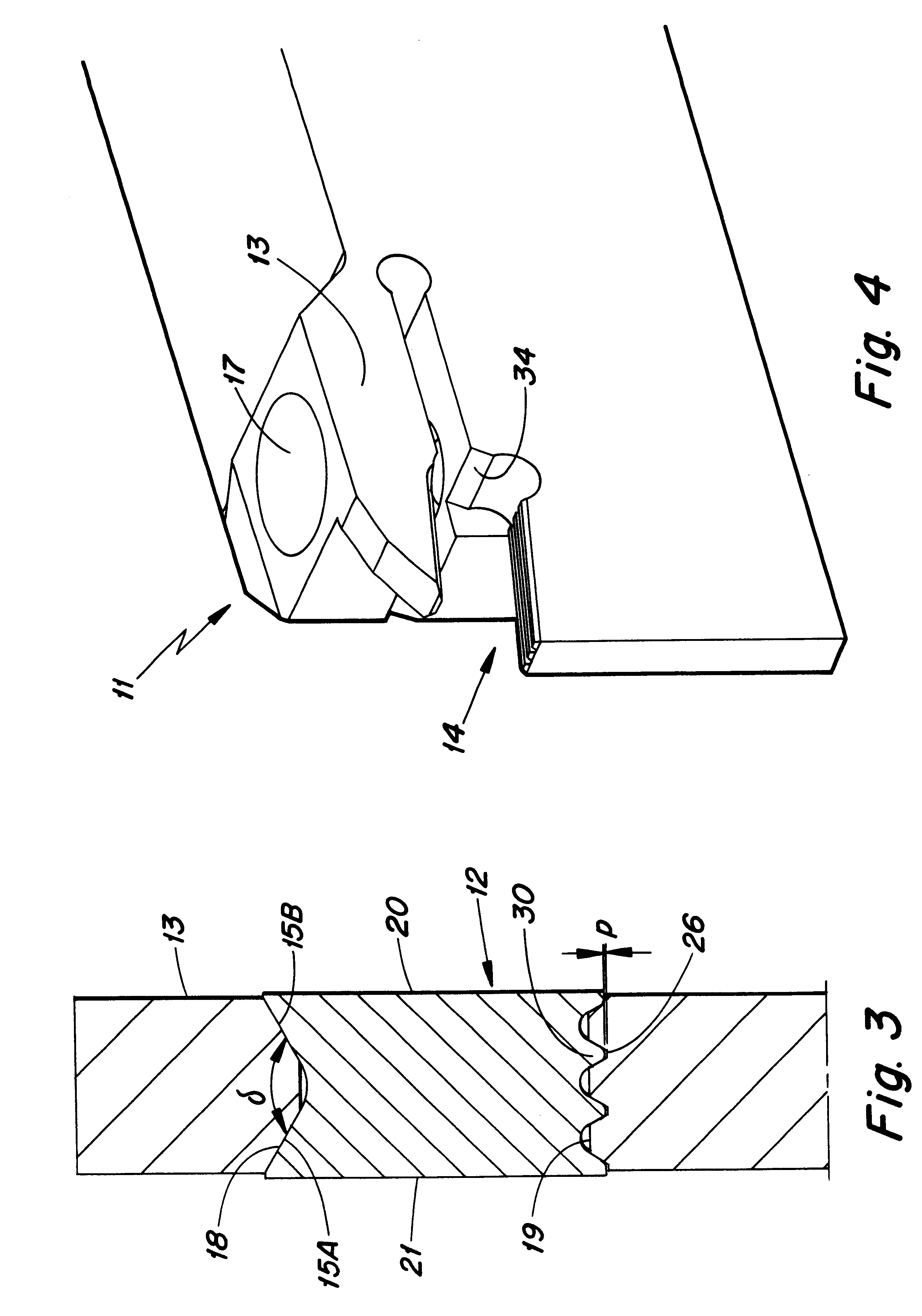

Universal tool holder coolant delivery adapters

InactiveUS6299388B1Increase COOOptimized coolant deliveryTurning toolsShaping cuttersLine tubingSpray nozzle

Universal tool holder coolant delivery adapters have adapter bodies which are removably attachable to a tool holder by at least one fastening device, the adapter located between an attachment end of the tool holder and a distal end of the tool holder, the distal end of the tool holder having a cutting tool attached thereto, the adapter bodies having an internal coolant passageway including an intake port and an exit port, the intake port adapted for attachment to a pressurized coolant supply line and the outlet port adapted for attachment to or configured in the form of a coolant spray nozzle, the coolant spray nozzle being closely positioned and substantially aligned with the cutting interface of the cutting tool and a workpiece.

Owner:SLABE MACHINE PROD

Tool for chip removing machining and having fluid-conducting branch ducts

InactiveUS6595727B2The effect is outstandingManufactured in simple and inexpensiveMilling cuttersTurning toolsEngineeringBranch Duct

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Chip removing machining of a workpiece while applying high pressure cooling liquid

The chip removing machining of a workpiece is performed by a cutting tool which includes a cutting insert. In order to cool the cutting insert, one or more over-cooling nozzles is arranged for directing a jet of cooling liquid downwardly toward a contact area between the workpiece and a chip surface of the cutting insert. A sub-cooling nozzle is arranged for directing a jet of cooling liquid upwardly toward a contact area between the workpiece and a flank surface of the cutting insert. A jet of cooling liquid can be emitted from only the over-cooling nozzle, or from only the sub-cooling nozzle, or from both of those nozzles simultaneously.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

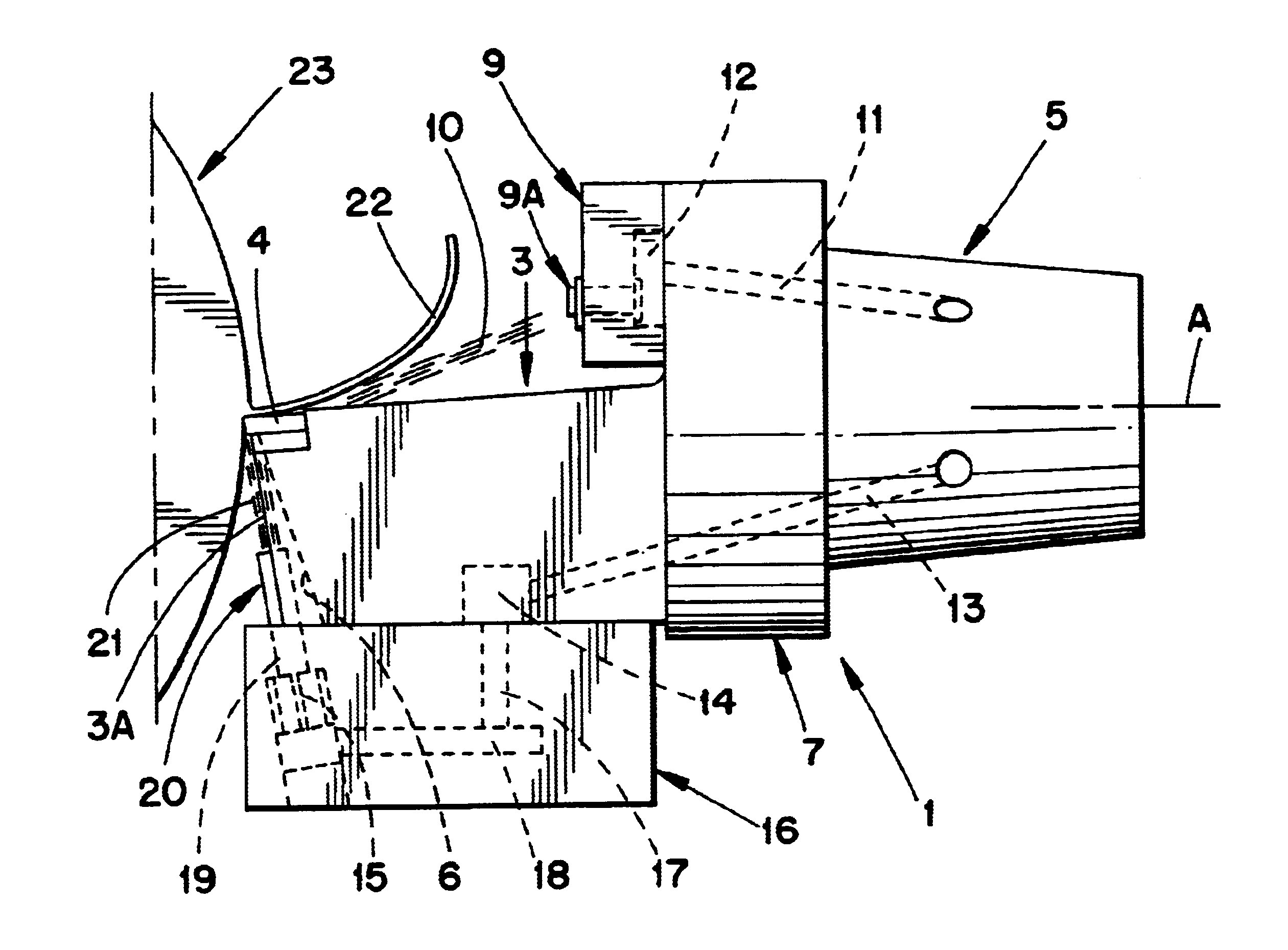

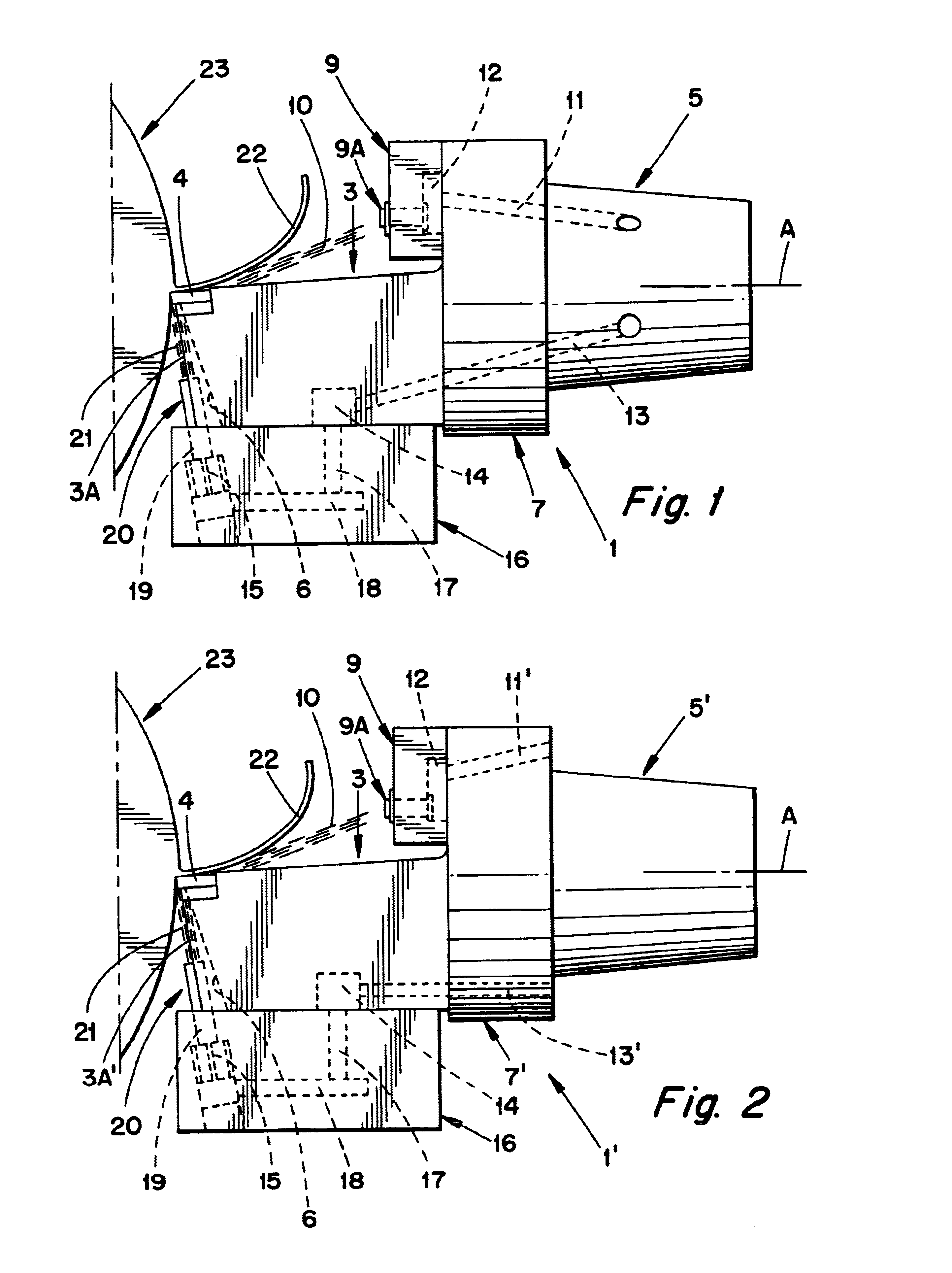

Tool and insert for chip removal machining

A tool for chip removing machining includes a holder and a cutting insert clamped within a pocket of the holder. The pocket has upper and lower sides, and the cutting insert comprises an upper surface and a lower surface. The upper side of the pocket and the upper surface of the cutting insert comprise first cooperating contact surfaces defining a first flank angle. The lower side of the pocket and the lower surface of the cutting insert comprise second cooperating contact surfaces which define a second flank angle. The first flank angle is larger than the second flank angle. The lower surface of the cutting insert and the lower side of the pocket form intermeshing projections and recesses which define the second contact surfaces.

Owner:SECO TOOLS AB

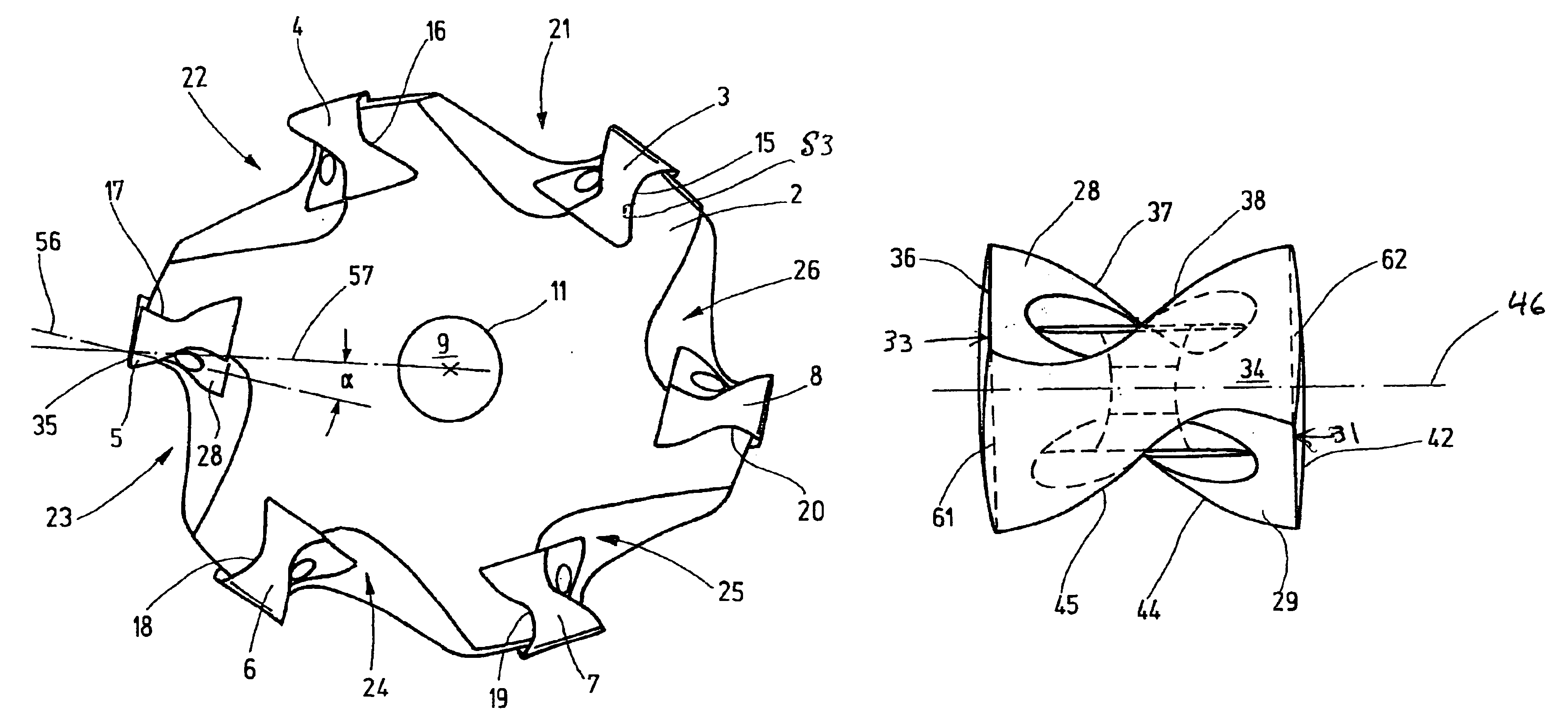

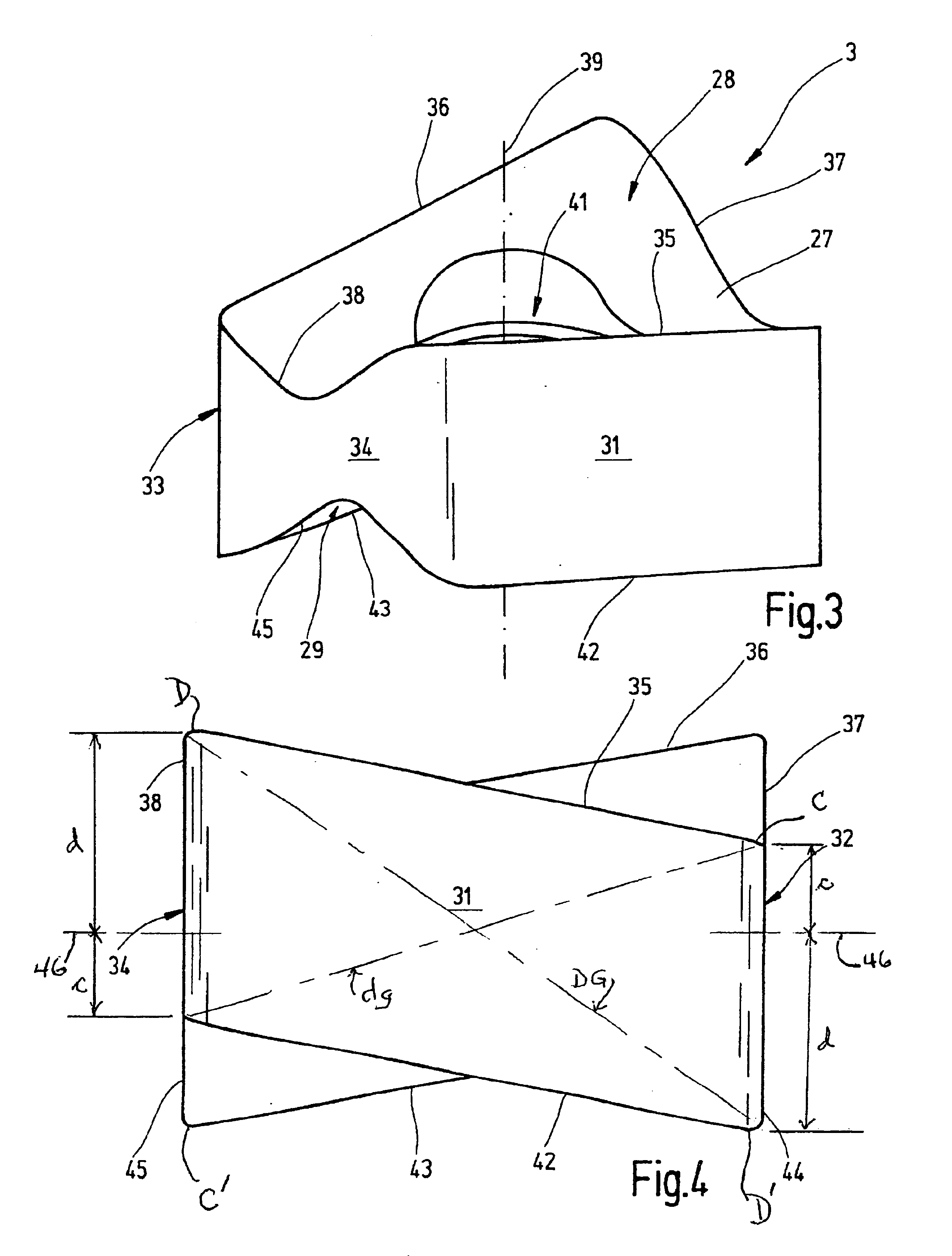

Cutter insert and milling tool

ActiveUS6921233B2Easy to useEasy to manufactureMilling cuttersTurning toolsEngineeringMechanical engineering

A cutter insert for milling tools includes a base body having a base surface, a top surface, and four side surfaces. The four side surfaces, together with each of the base surface and the top surface, define respective cutting edges. The base body is twisted about each of two perpendicular, coplanar axes of the base body. Each side surface has two opposite corner edges that are offset from one another in a direction parallel to a center axis of the base body.

Owner:WALTER AG

Coated cutting insert and method of making it

PCT No. PCT / SE96 / 01579 Sec. 371 Date Sep. 1, 1998 Sec. 102(e) Date Sep. 1, 1998 PCT Filed Nov. 29, 1996 PCT Pub. No. WO97 / 20083 PCT Pub. Date Jun. 5, 1997A coated turning insert particularly useful for dry and wet machining in low and medium alloyed steels, stainless steels, with or without raw surface zones under severe conditions such as vibrations, long overhang and recutting of chips. The insert is characterized by a WC-Co cemented carbide with a low content of cubic carbides and a rather low W-alloyed binder phase and a coating including an innermost layer of TiCxNyOz with columnar grains and a top layer of TiN and an intermediate layer of kappa -Al2O3. The layers are deposited by using CVD-methods.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

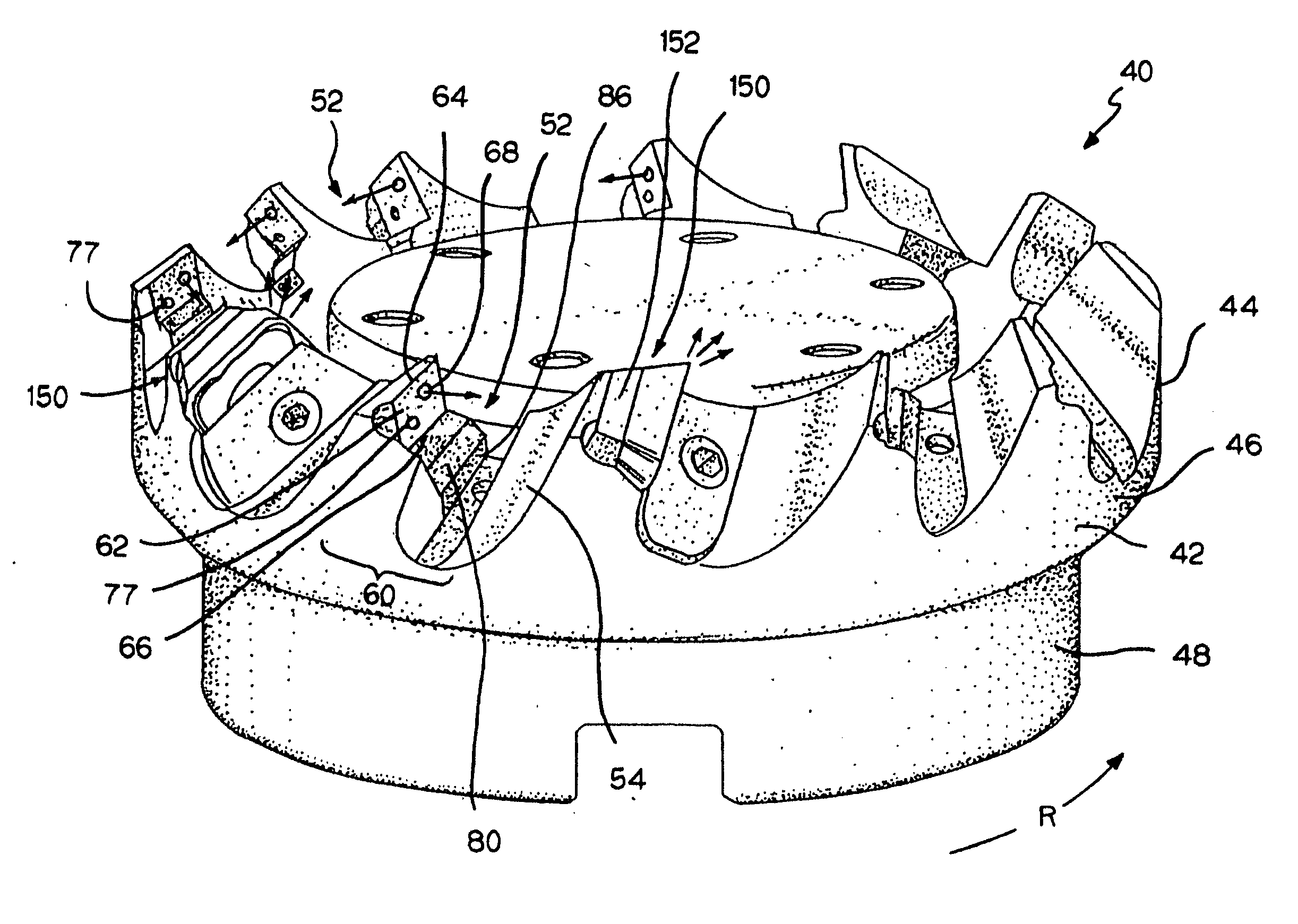

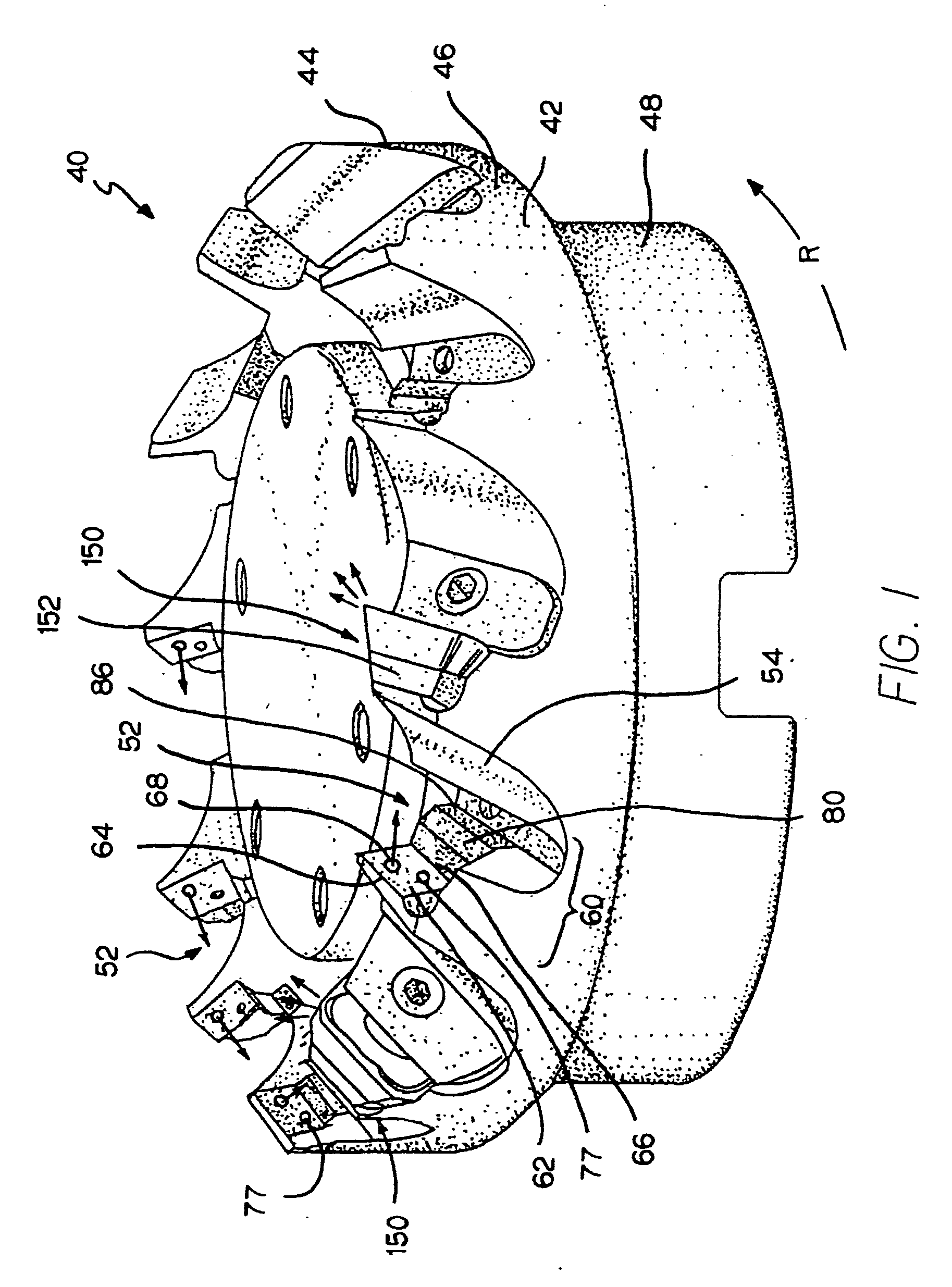

Milling cutter and milling insert with coolant delivery

A cutting insert for use in chipforming and material removal from a workpiece wherein coolant is supplied to the cutting insert from a coolant source. The cutting insert includes at least one discrete cutting location and at least one distinct internal channel that corresponds to the cutting location. The internal channel has an inlet to receive coolant and an outlet to exit coolant. The outlet is proximate to the cutting location, and the inlet is radial inward of the outlet.

Owner:KENNAMETAL INC

Indexable end-milling insert

ActiveUS20080304924A1Good chip formationWorn evenly and slowlyTransportation and packagingMilling cuttersEngineeringKnife blades

An indexable end-milling insert including an underside, an upperside and a plurality of cutting edges that are formed between the upperside and a number of clearance sides and that include a chip-removing main edge as well as a surface-wiping wiper edge. The cutting insert has a square basic shape and includes four main edges and four wiper edges that are countersunk to a lower level than the main edges. The wiper edge is included in a lip projecting in relation to a secondary clearance surface and has a tertiary clearance surface, which laterally transforms into a primary clearance surface. The primary clearance surface has a width that decreases from the two opposite ends thereof toward a section having a smallest width therebetween.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com