Method of manufacturing a golf club face

a manufacturing method and golf club technology, applied in the field of golf clubs, can solve the problems and achieve the effect of saving substantial time and money and great uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

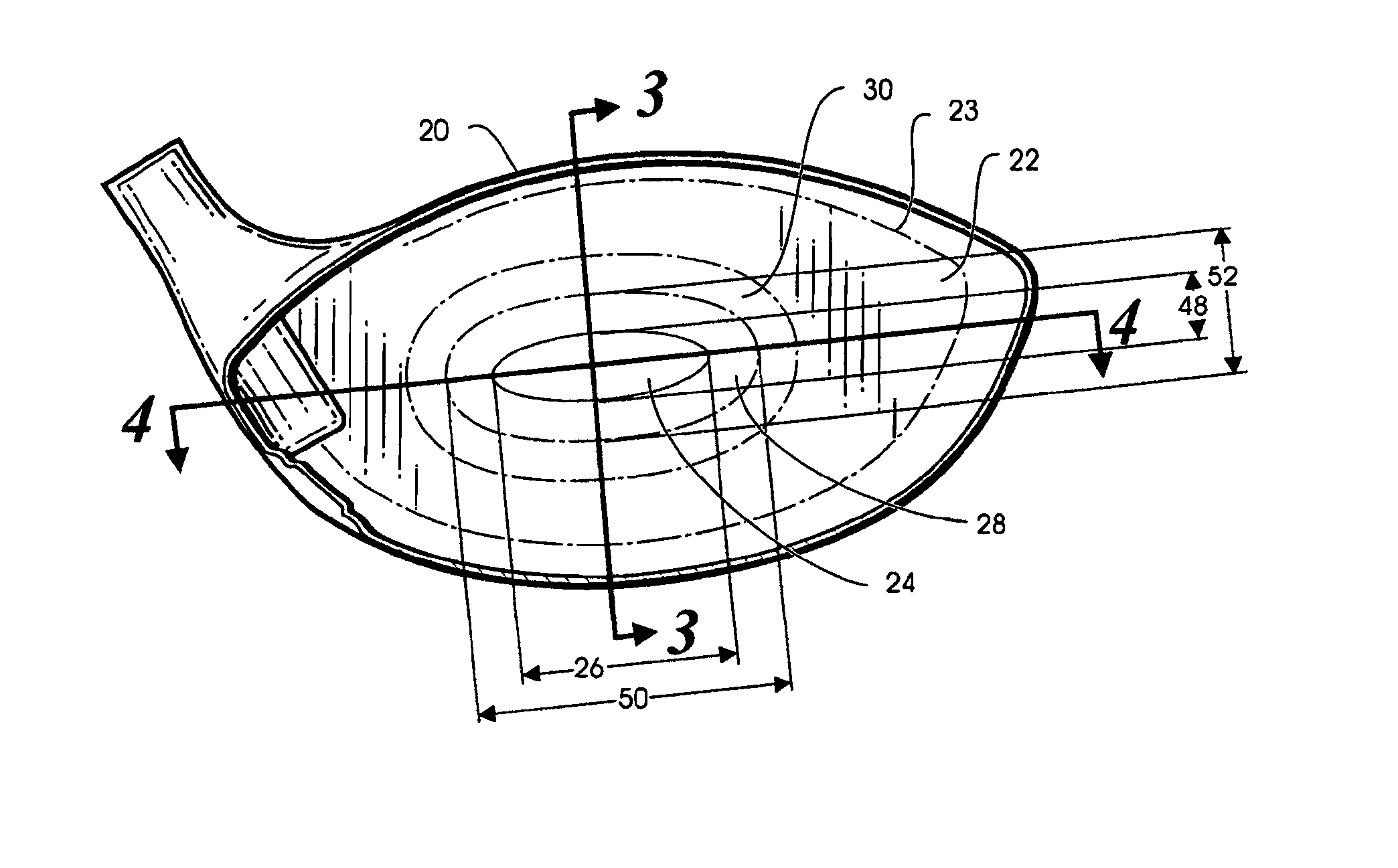

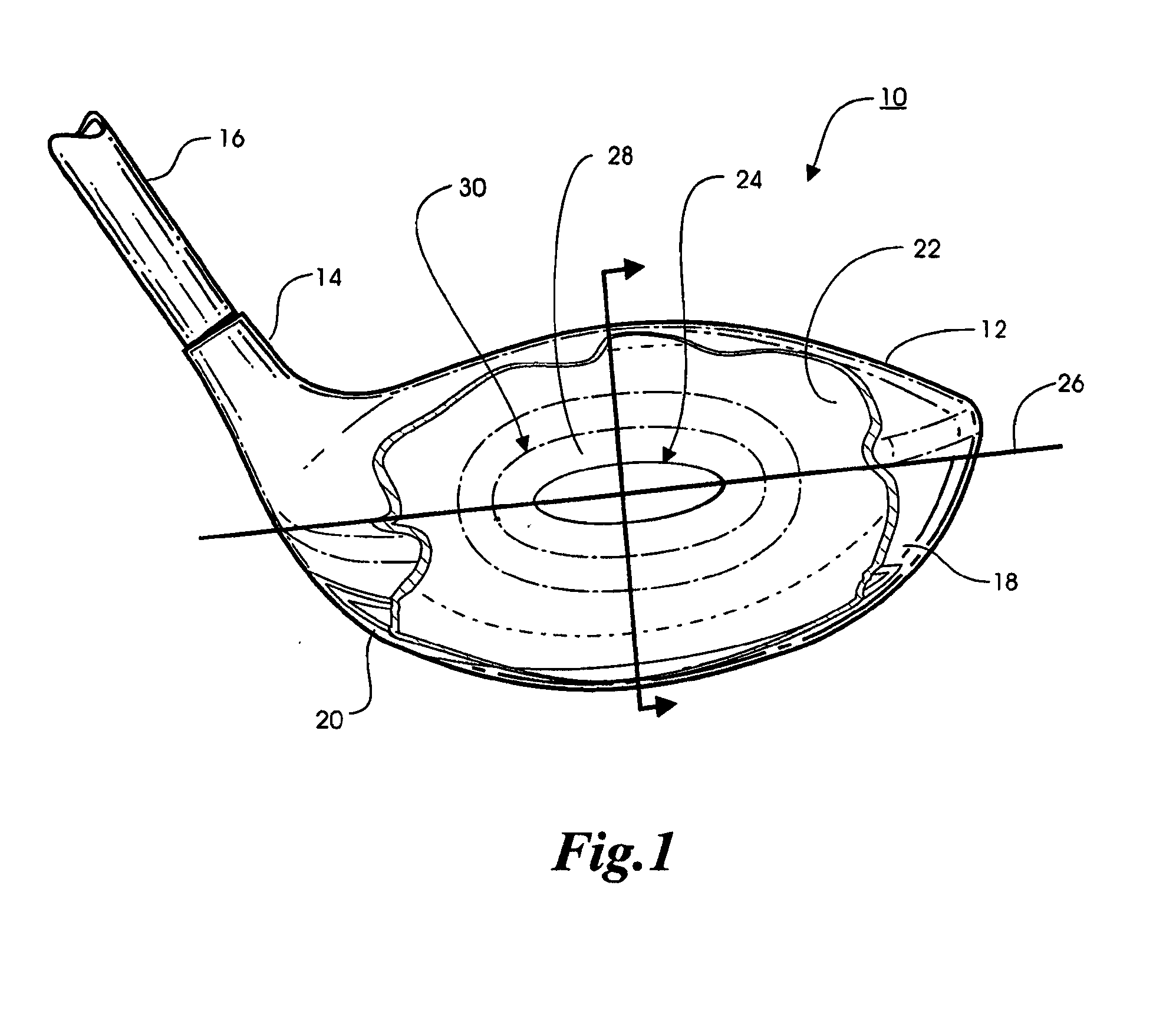

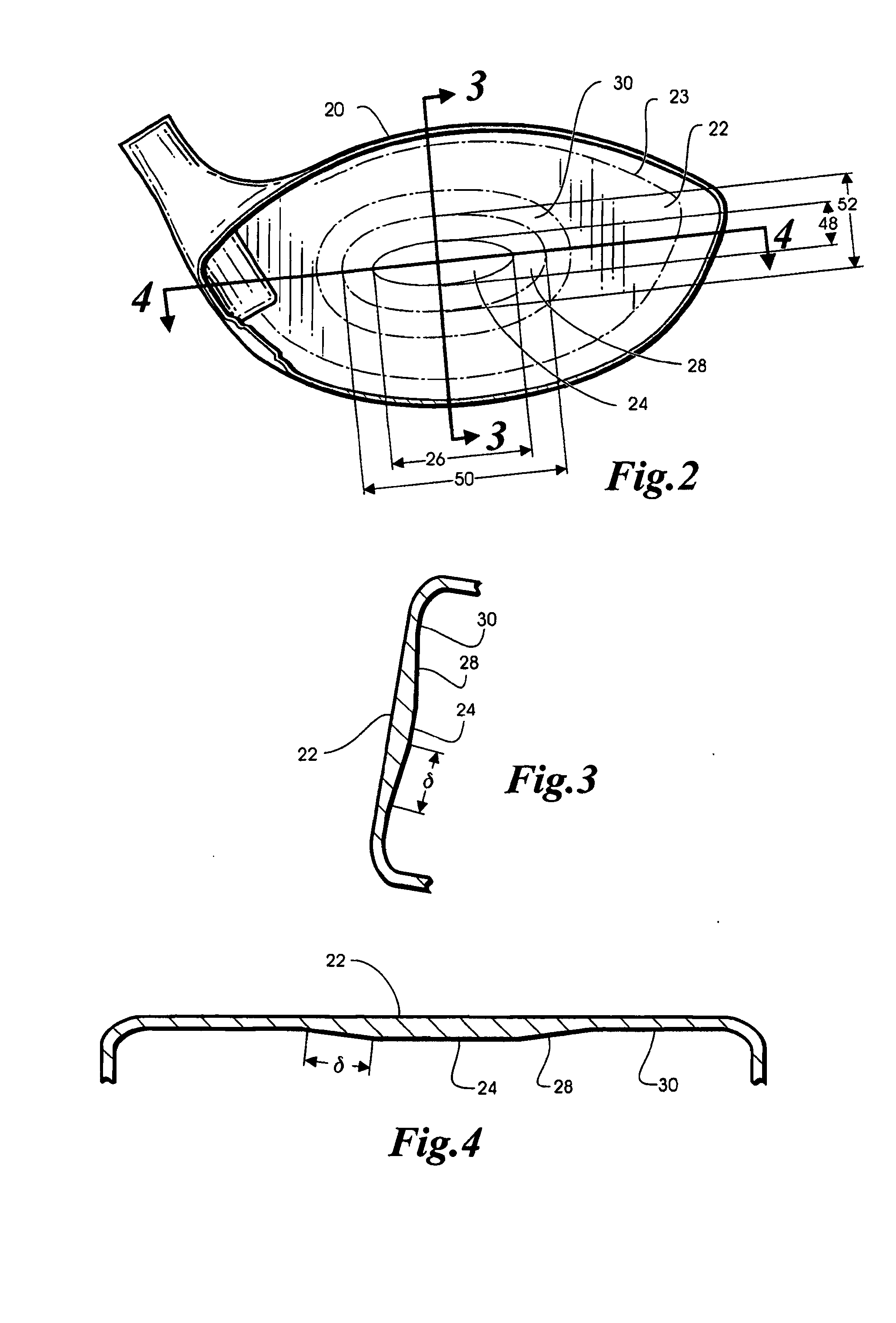

[0014] The drawing figures are intended to illustrate the general manner of construction and are not necessarily to scale. In the description and the in the drawing figures, specific illustrative examples are shown and herein described in detail. It should be understood, however, that the drawing figures and detailed description are not intended to limit the invention to the particular form disclosed but are merely illustrative and intended to teach one of ordinary skill how to make and / or use the invention claimed herein and for setting forth the best mode for carrying out the invention.

[0015] Referring to FIG. 1, a golf club 10 includes a head 12, a hosel 14 and a shaft 16. Head 12 includes a hollow body 18 made of a metal material such as titanium. Hollow body 18 is formed as a shell 20, which may be assembled from a series of forged pieces but, in the illustrative embodiment, comprises a titanium investment casting. A face plate 22 is attached by conventional means such as plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com