Patents

Literature

13867 results about "Reaction chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

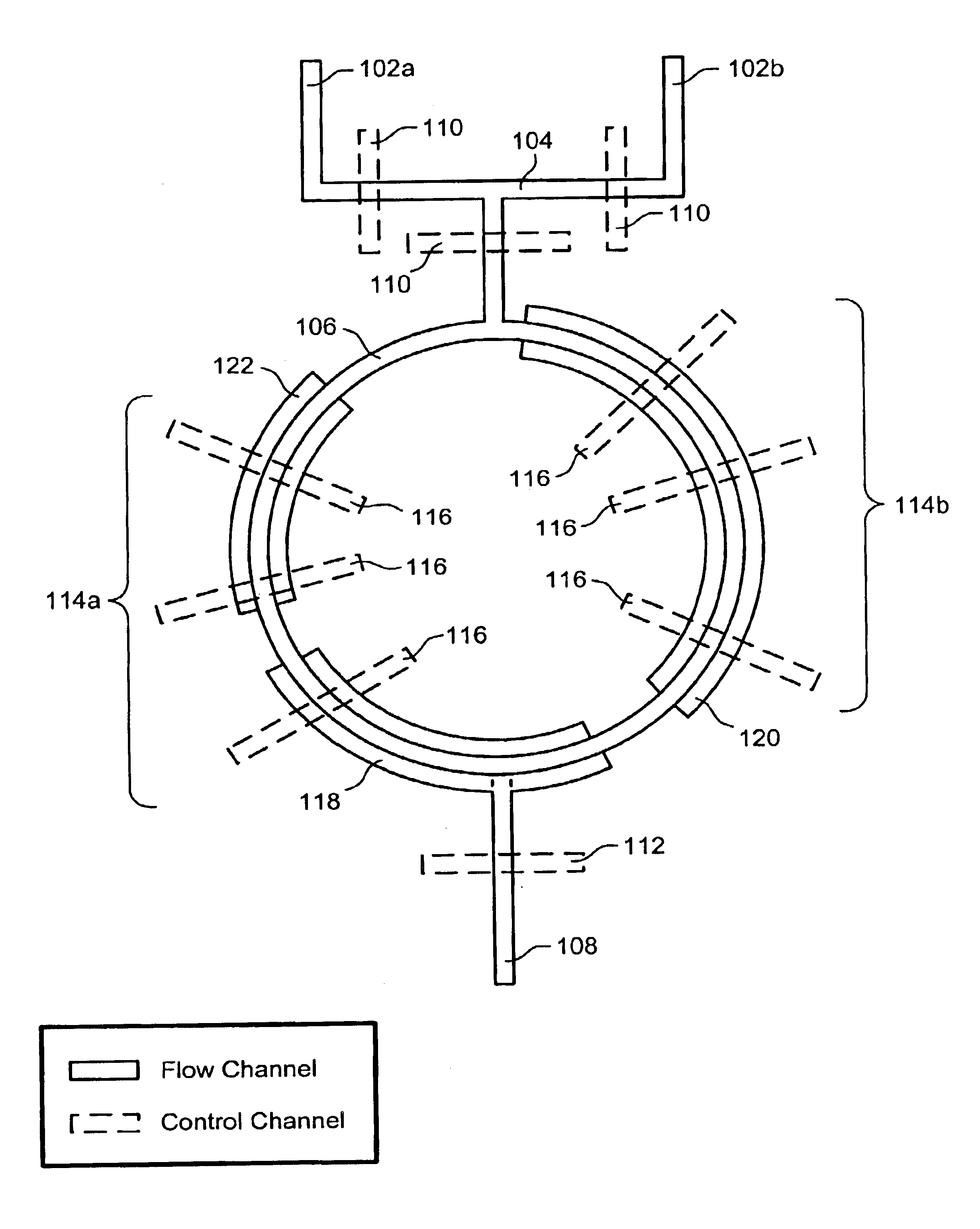

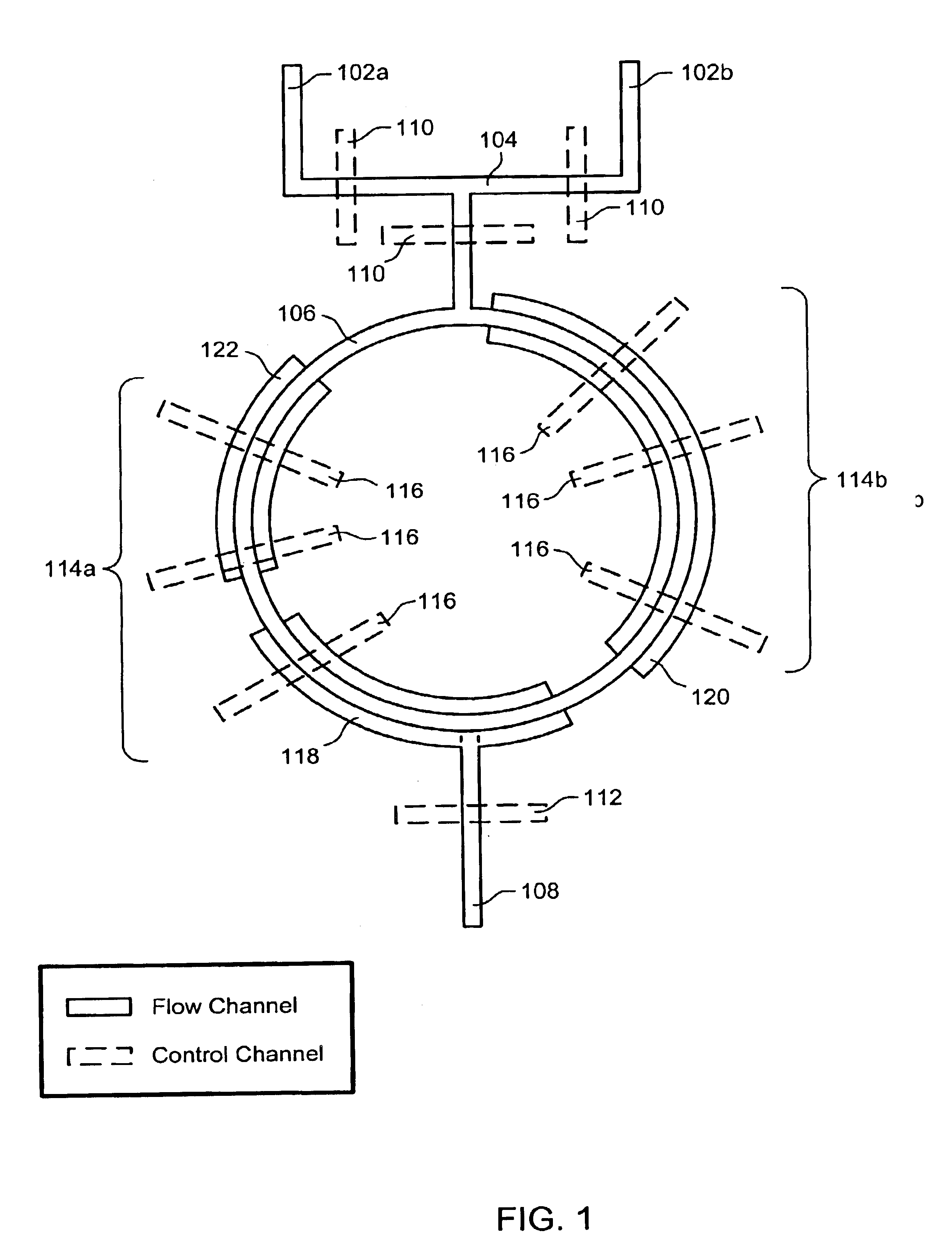

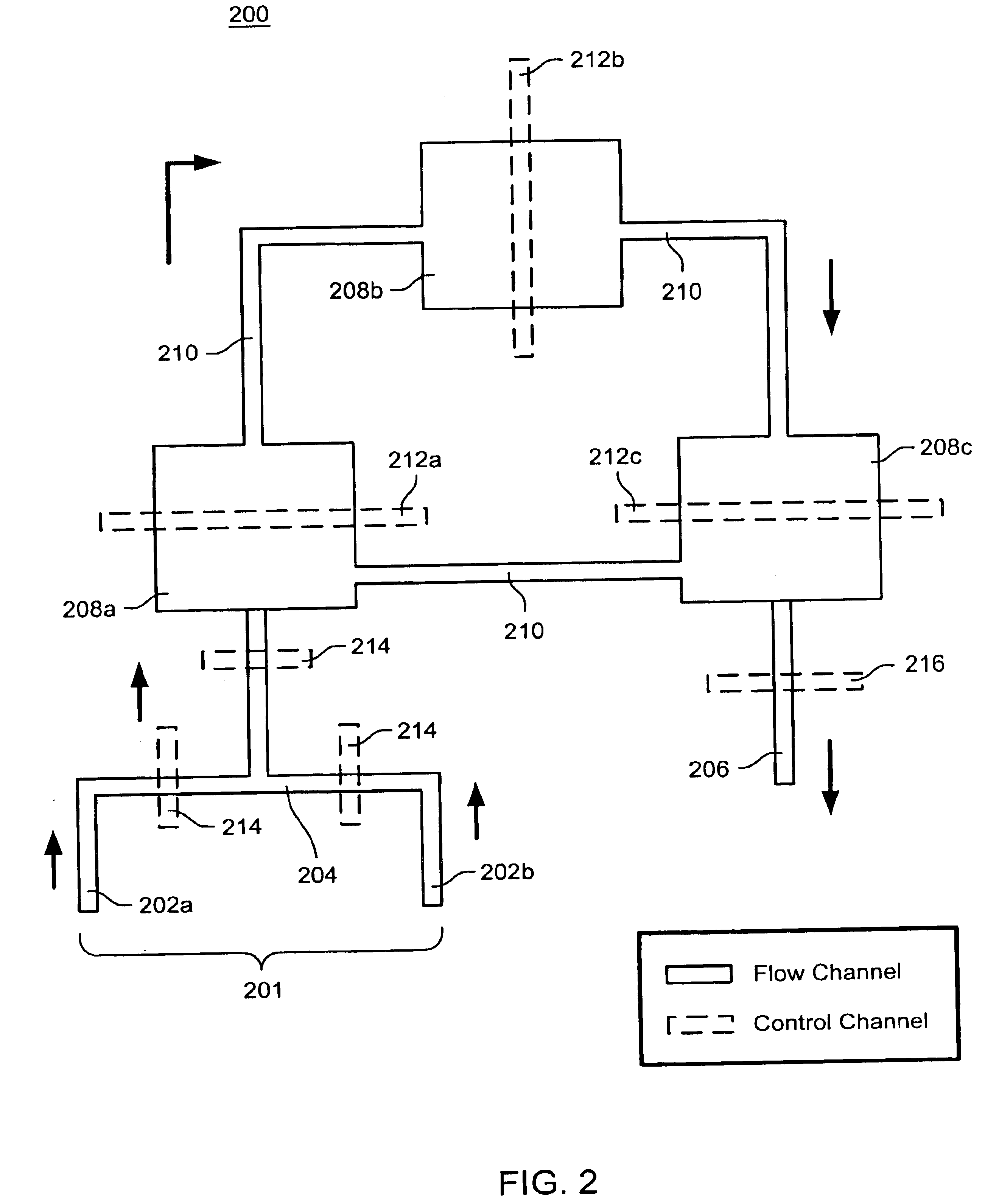

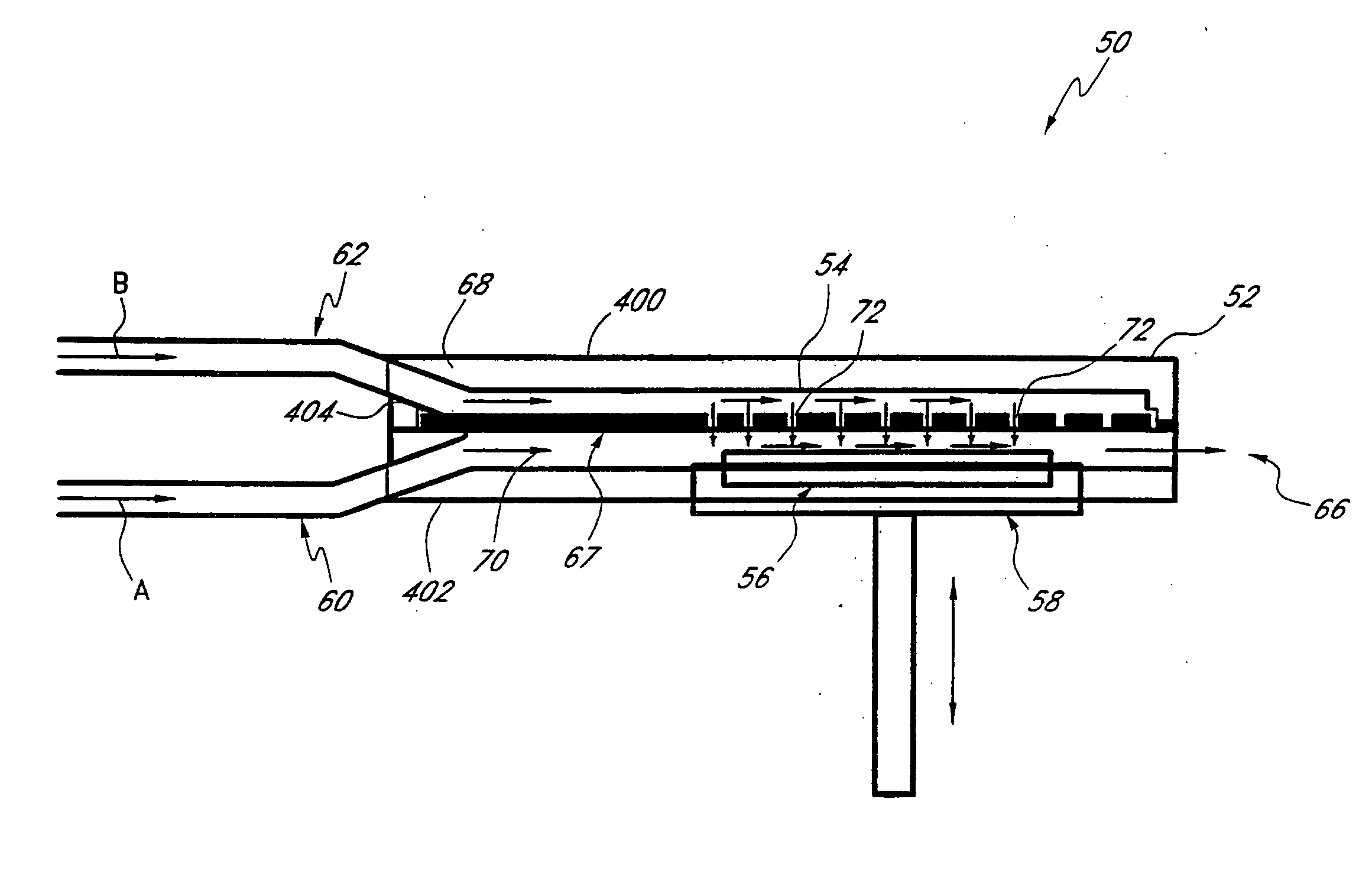

Nucleic acid amplification utilizing microfluidic devices

InactiveUS6960437B2Bioreactor/fermenter combinationsBiological substance pretreatmentsRegulation temperatureEngineering

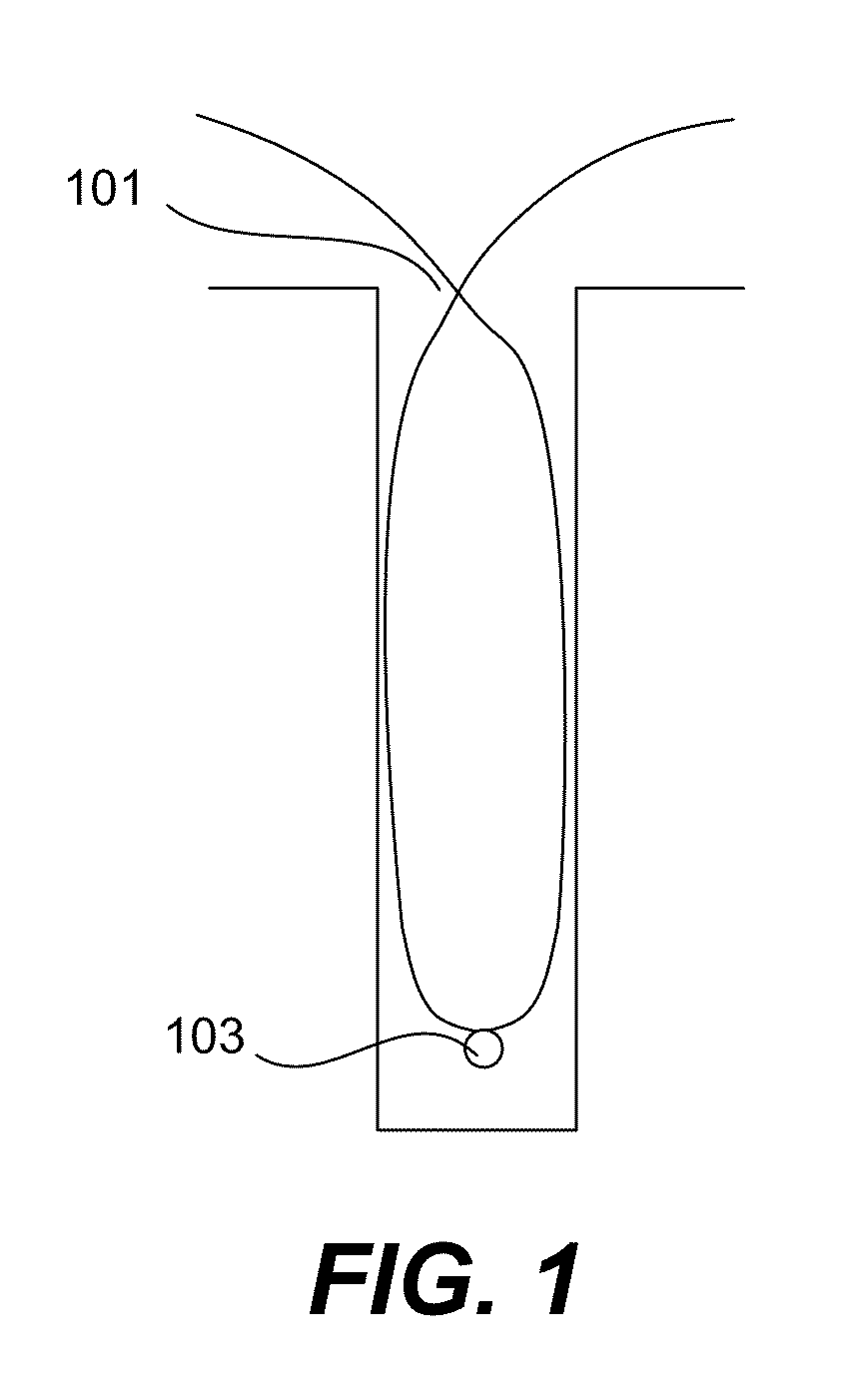

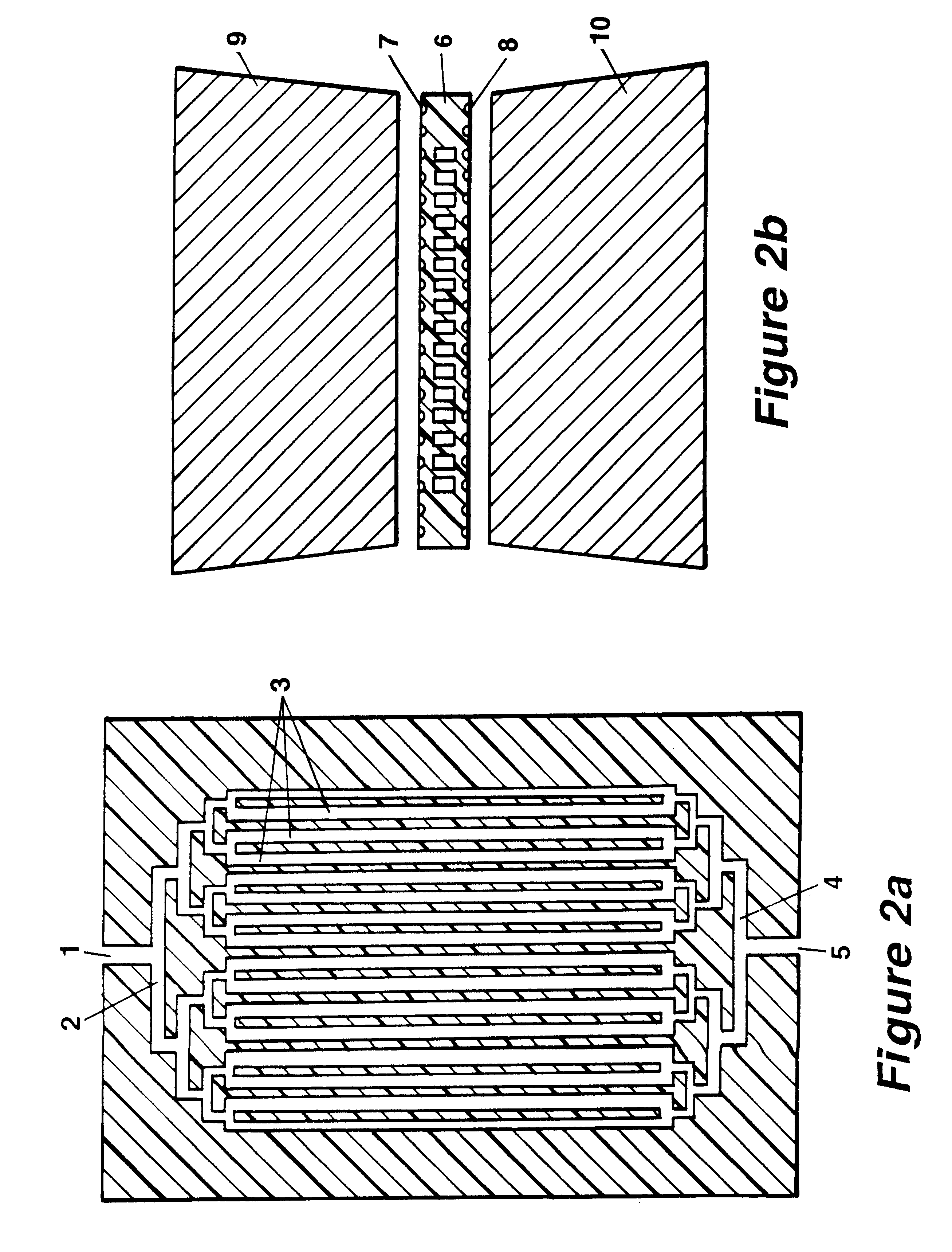

The present invention provides microfluidic devices and methods using the same in various types of thermal cycling reactions. Certaom devices include a rotary microfluidic channel and a plurality of temperature regions at different locations along the rotary microfluidic channel at which temperature is regulated. Solution can be repeatedly passed through the temperature regions such that the solution is exposed to different temperatures. Other microfluidic devices include an array of reaction chambers formed by intersecting vertical and horizontal flow channels, with the ability to regulate temperature at the reaction chambers. The microfluidic devices can be used to conduct a number of different analyses, including various primer extension reactions and nucleic acid amplification reactions.

Owner:CALIFORNIA INST OF TECH

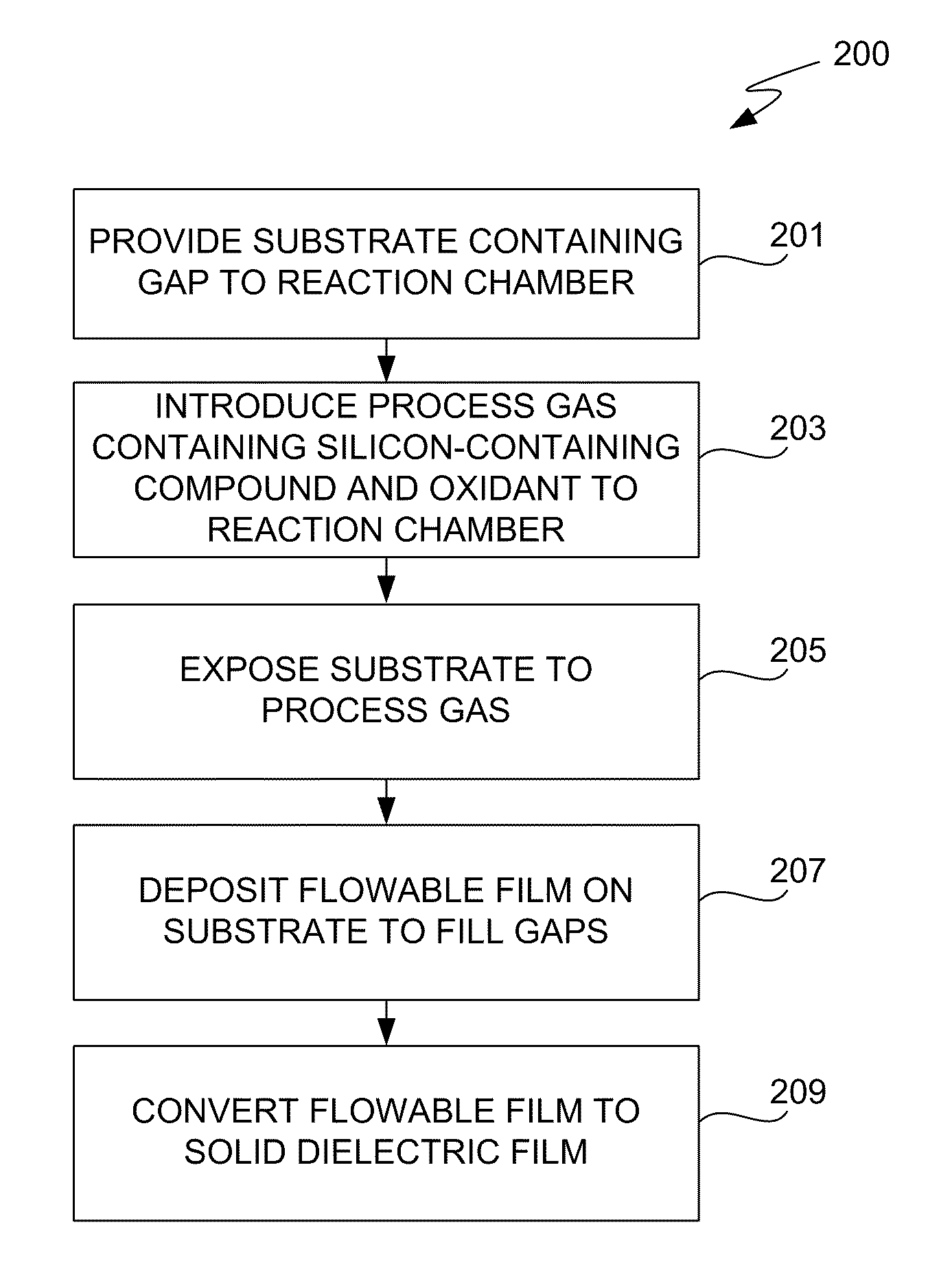

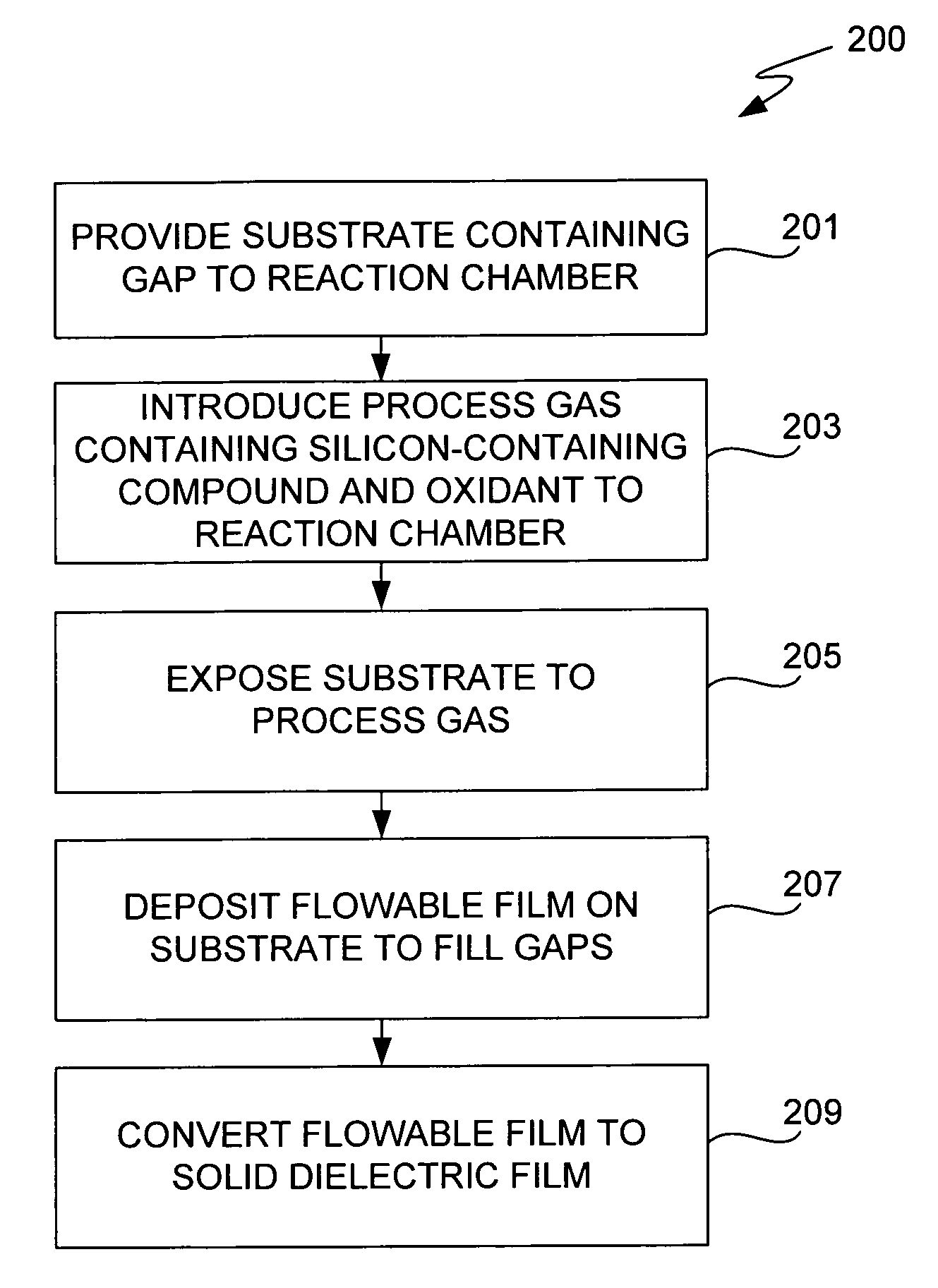

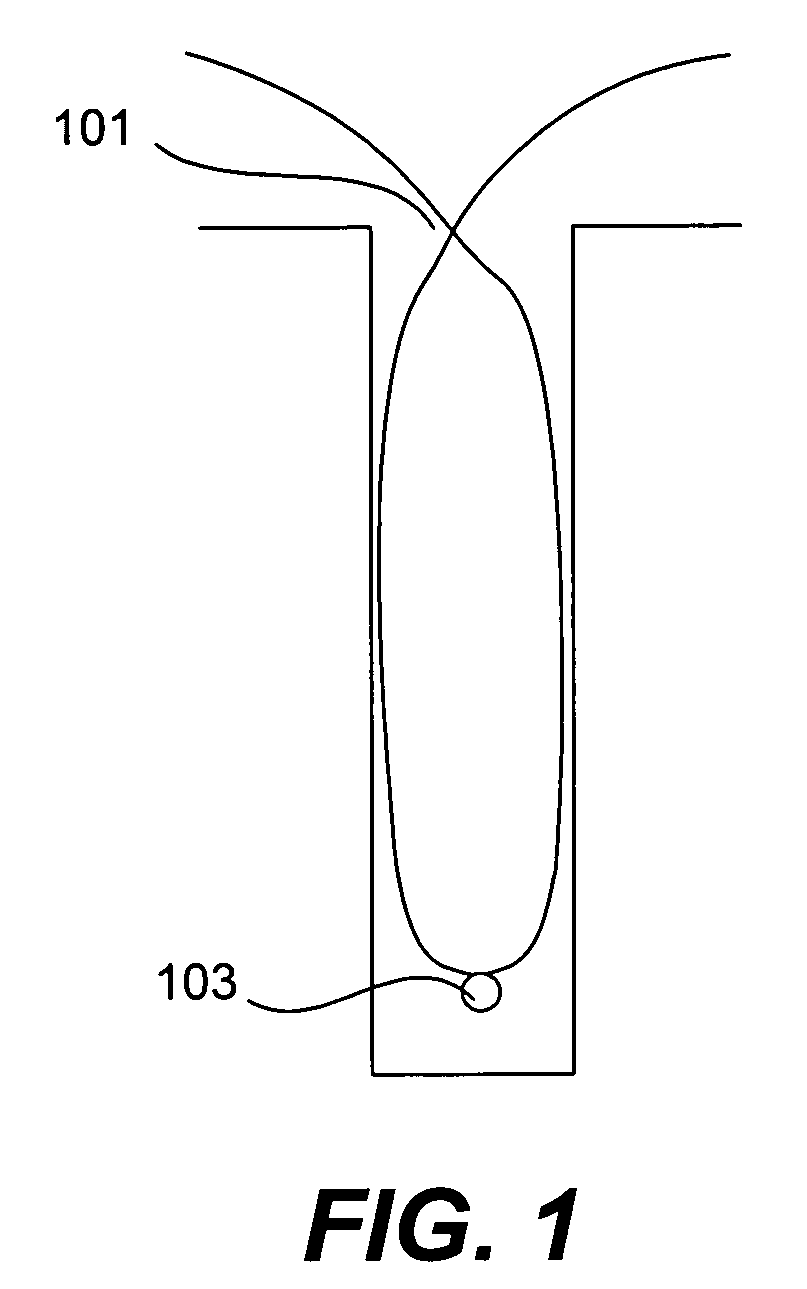

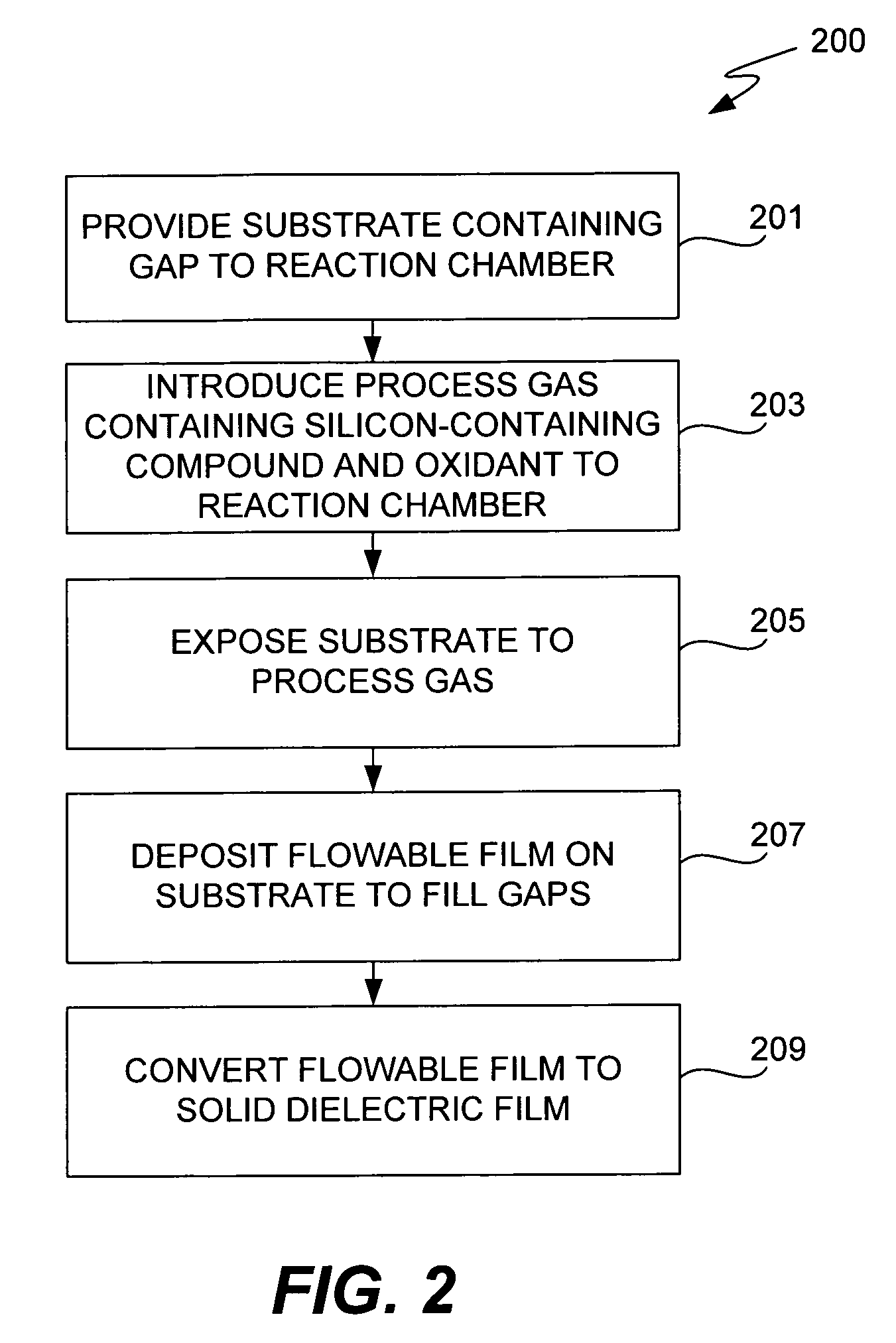

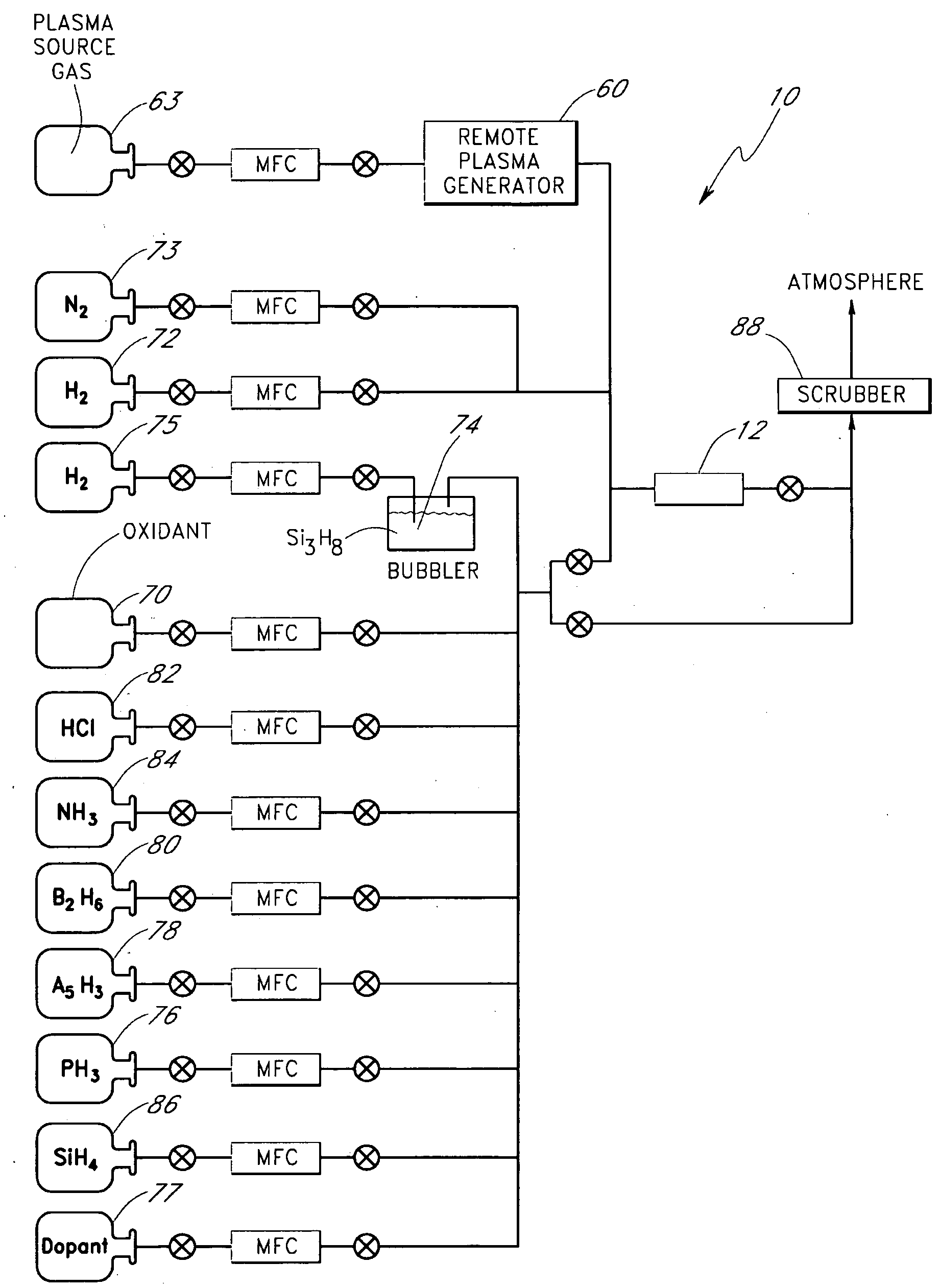

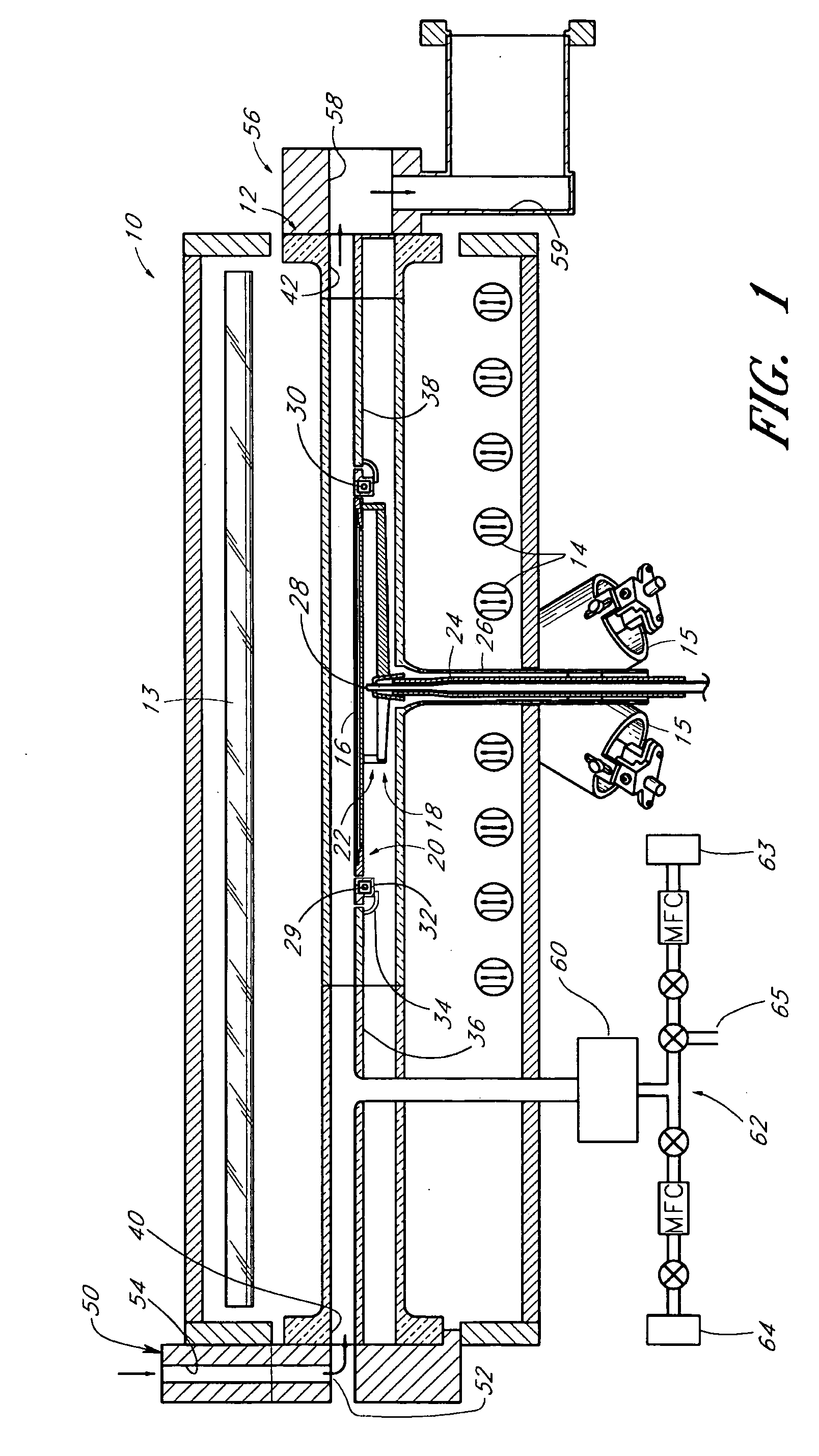

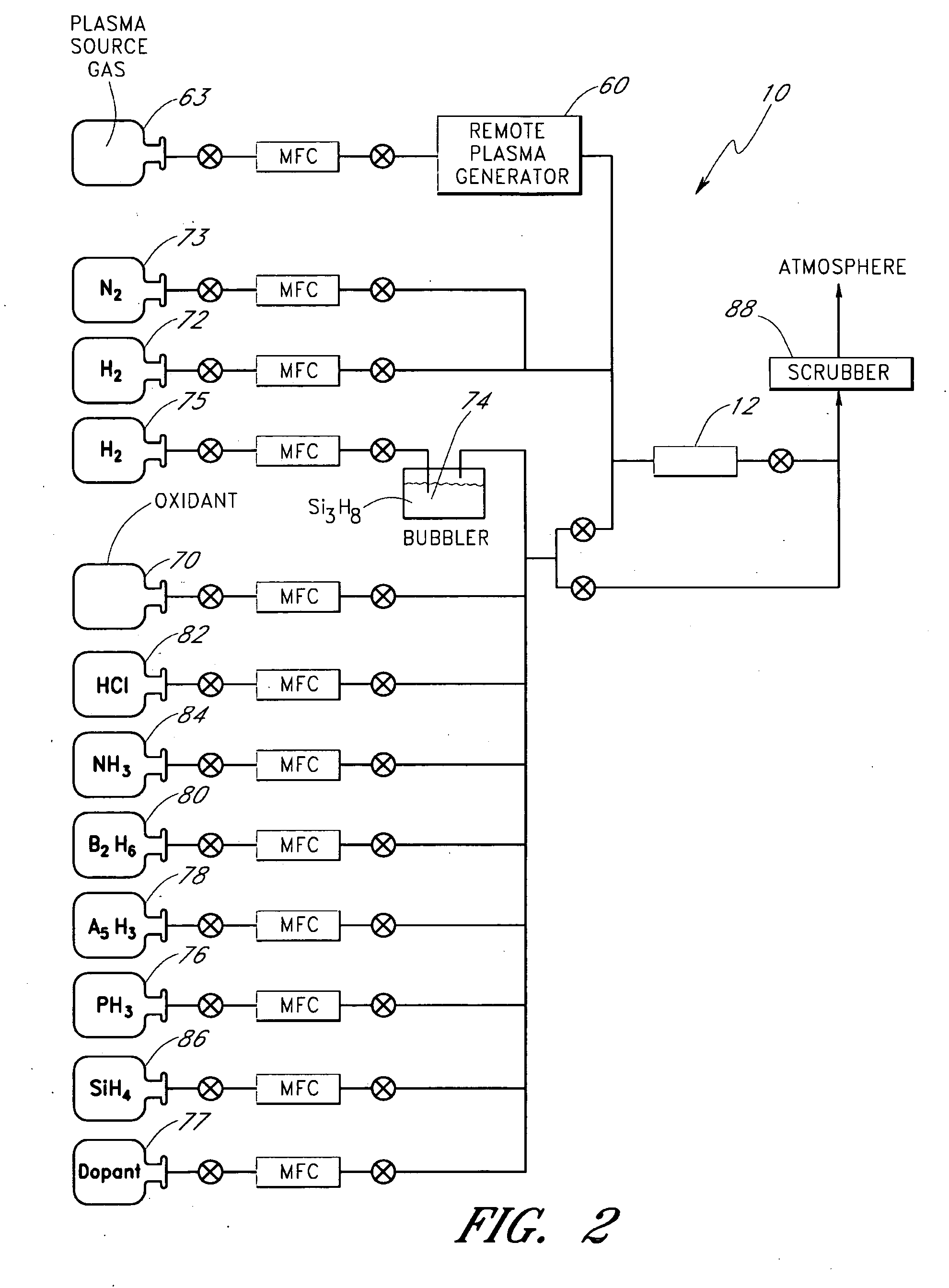

CVD flowable gap fill

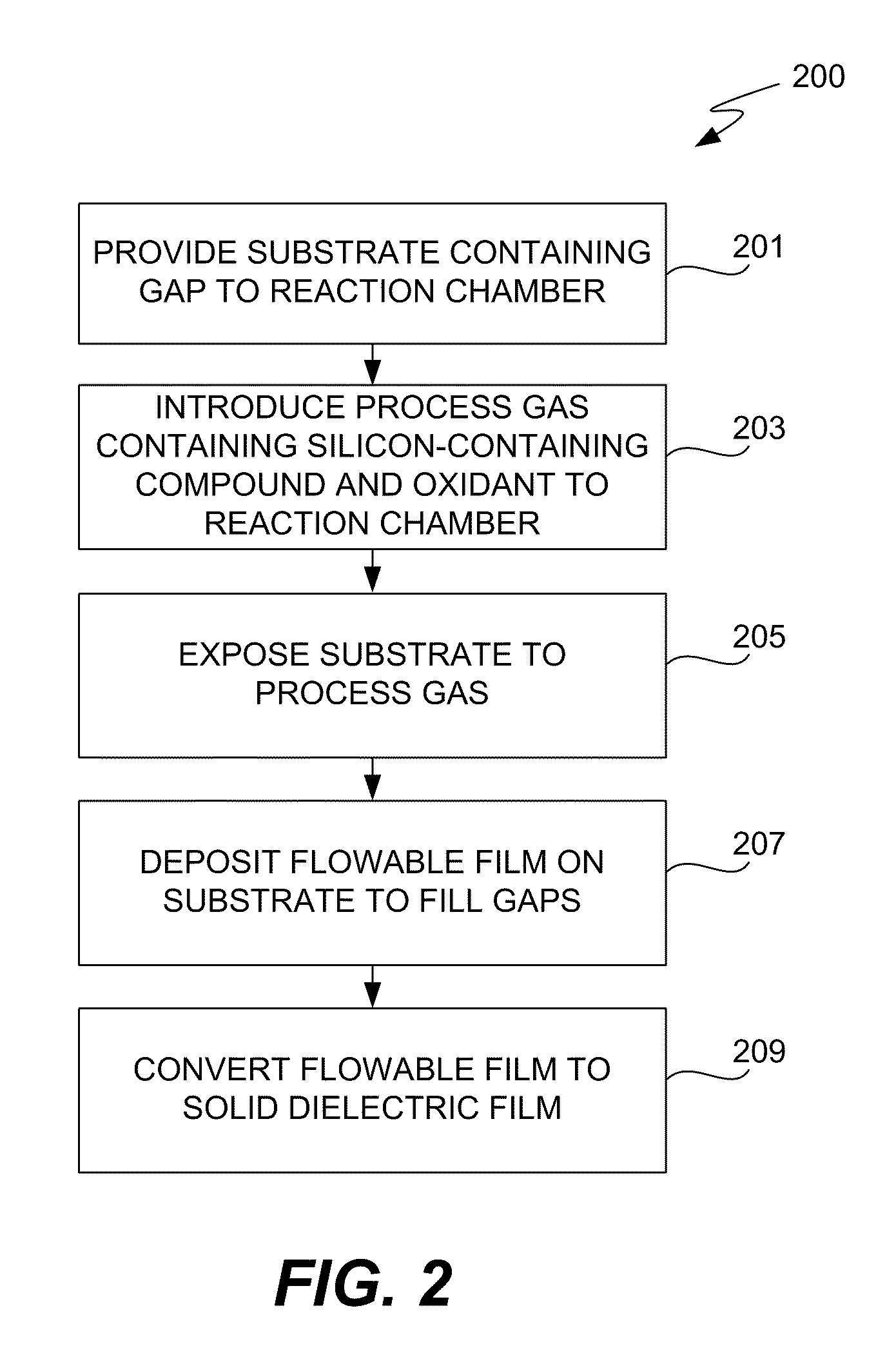

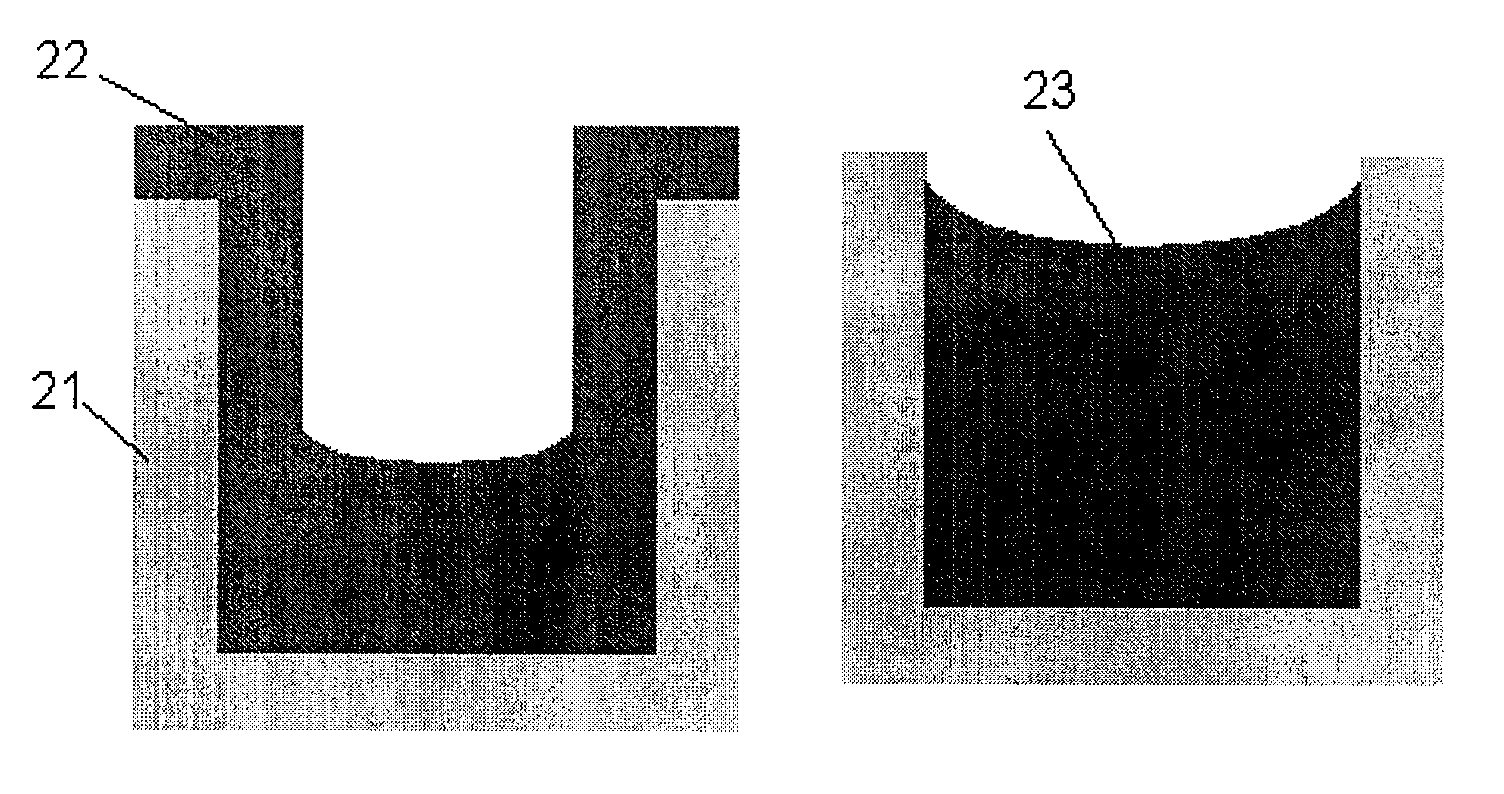

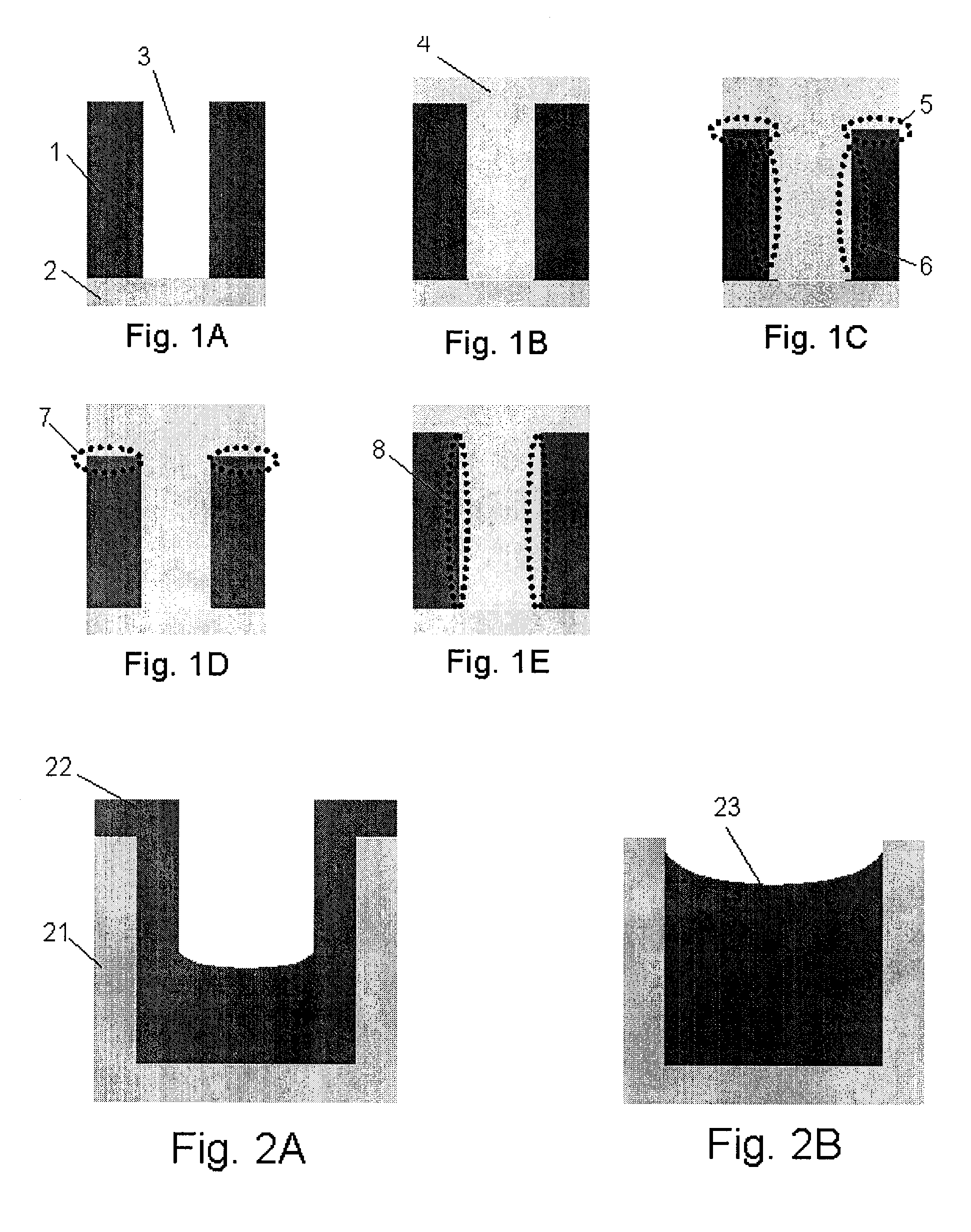

The present invention meets these needs by providing improved methods of filling gaps. In certain embodiments, the methods involve placing a substrate into a reaction chamber and introducing a vapor phase silicon-containing compound and oxidant into the chamber. Reactor conditions are controlled so that the silicon-containing compound and the oxidant are made to react and condense onto the substrate. The chemical reaction causes the formation of a flowable film, in some instances containing Si—OH, Si—H and Si—O bonds. The flowable film fills gaps on the substrates. The flowable film is then converted into a silicon oxide film, for example by plasma or thermal annealing. The methods of this invention may be used to fill high aspect ratio gaps, including gaps having aspect ratios ranging from 3:1 to 10:1.

Owner:NOVELLUS SYSTEMS

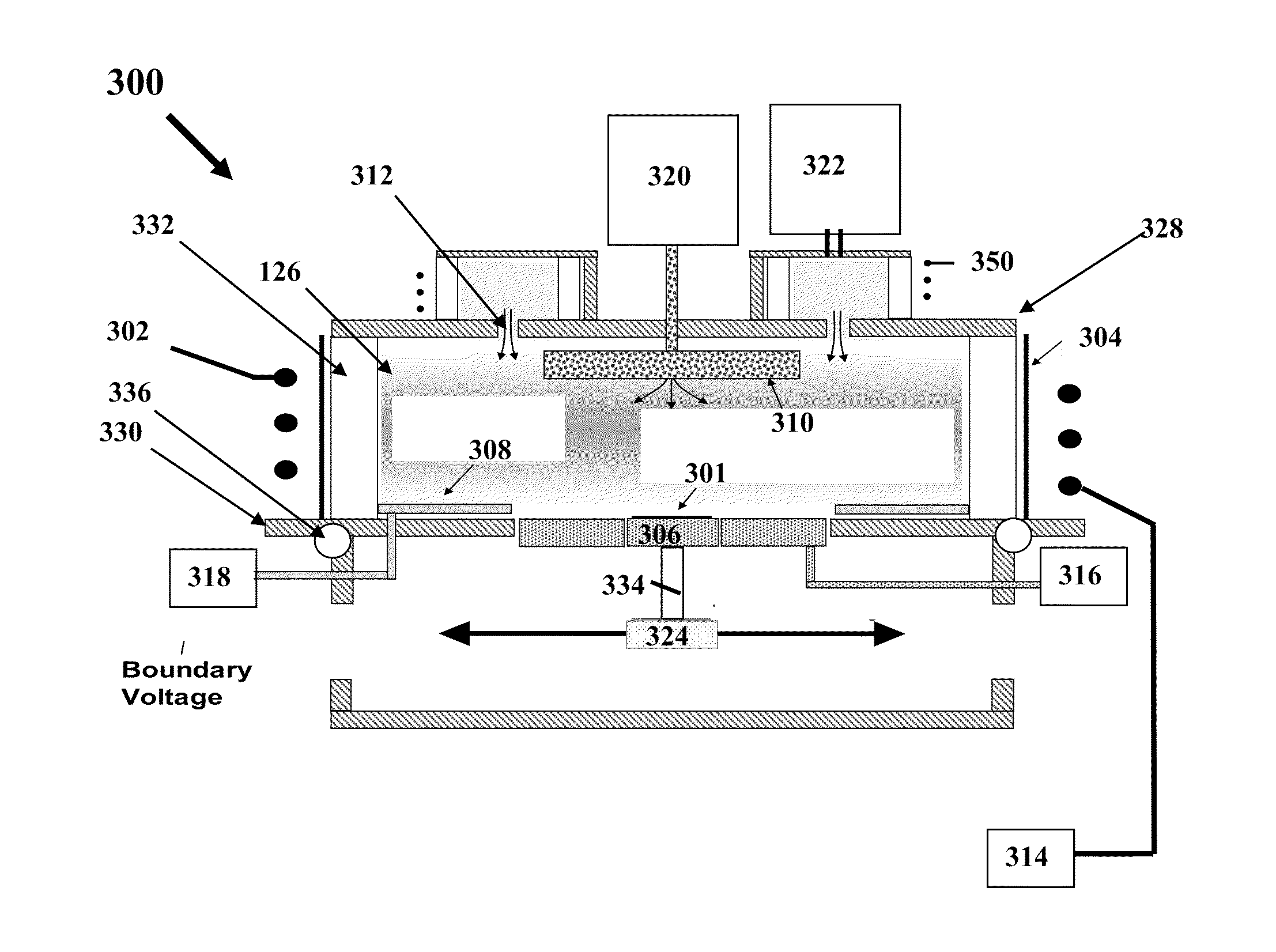

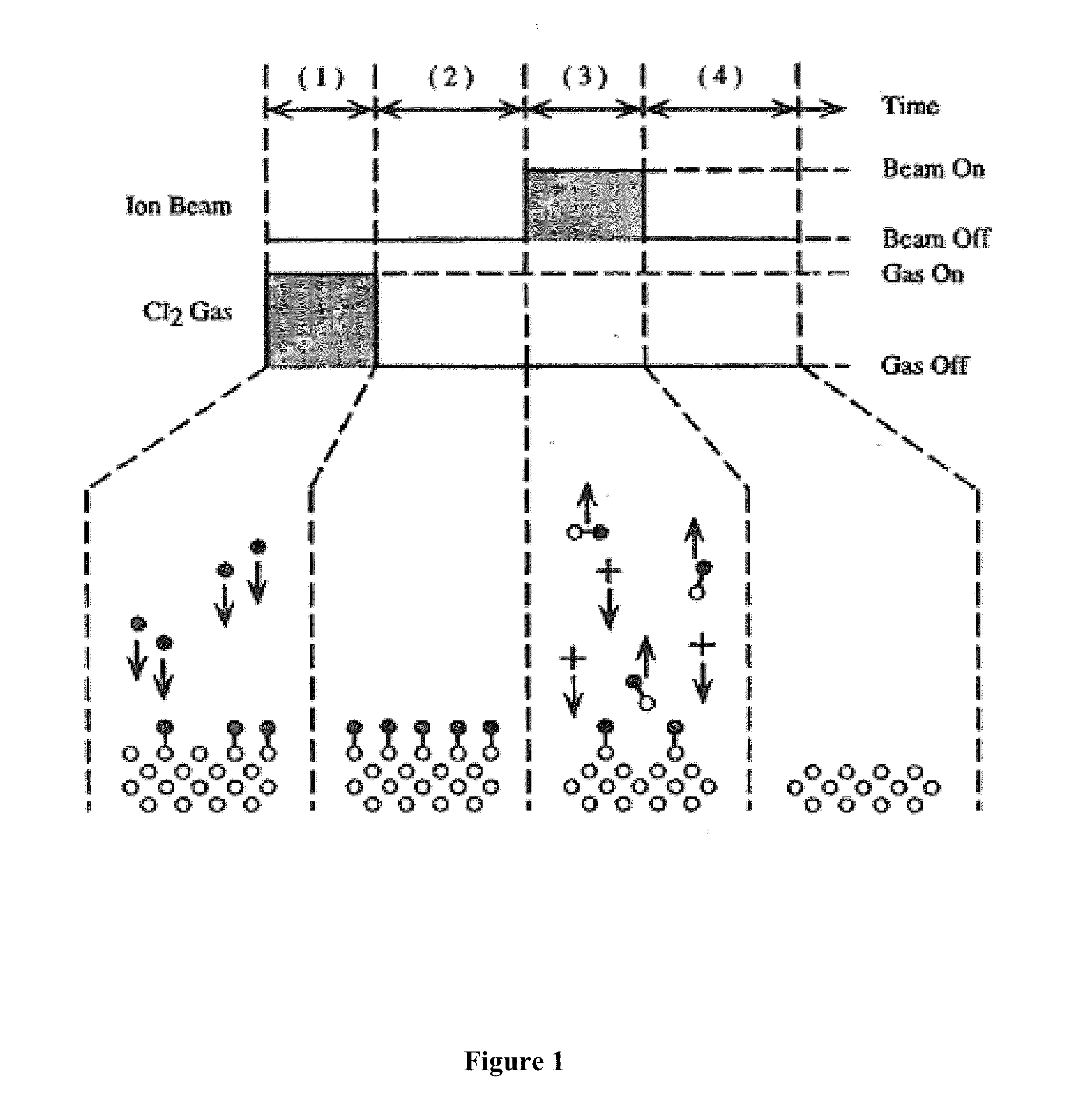

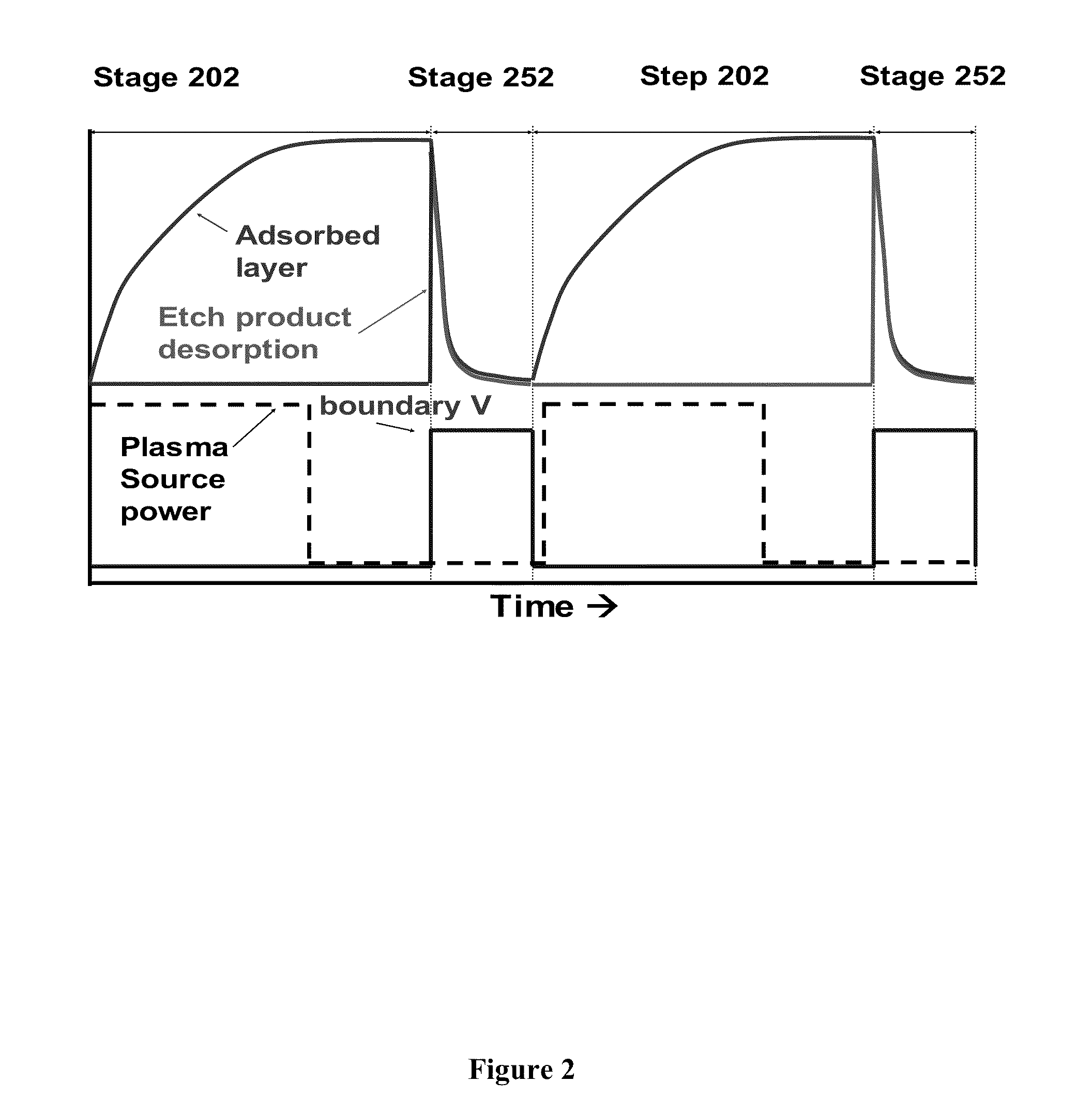

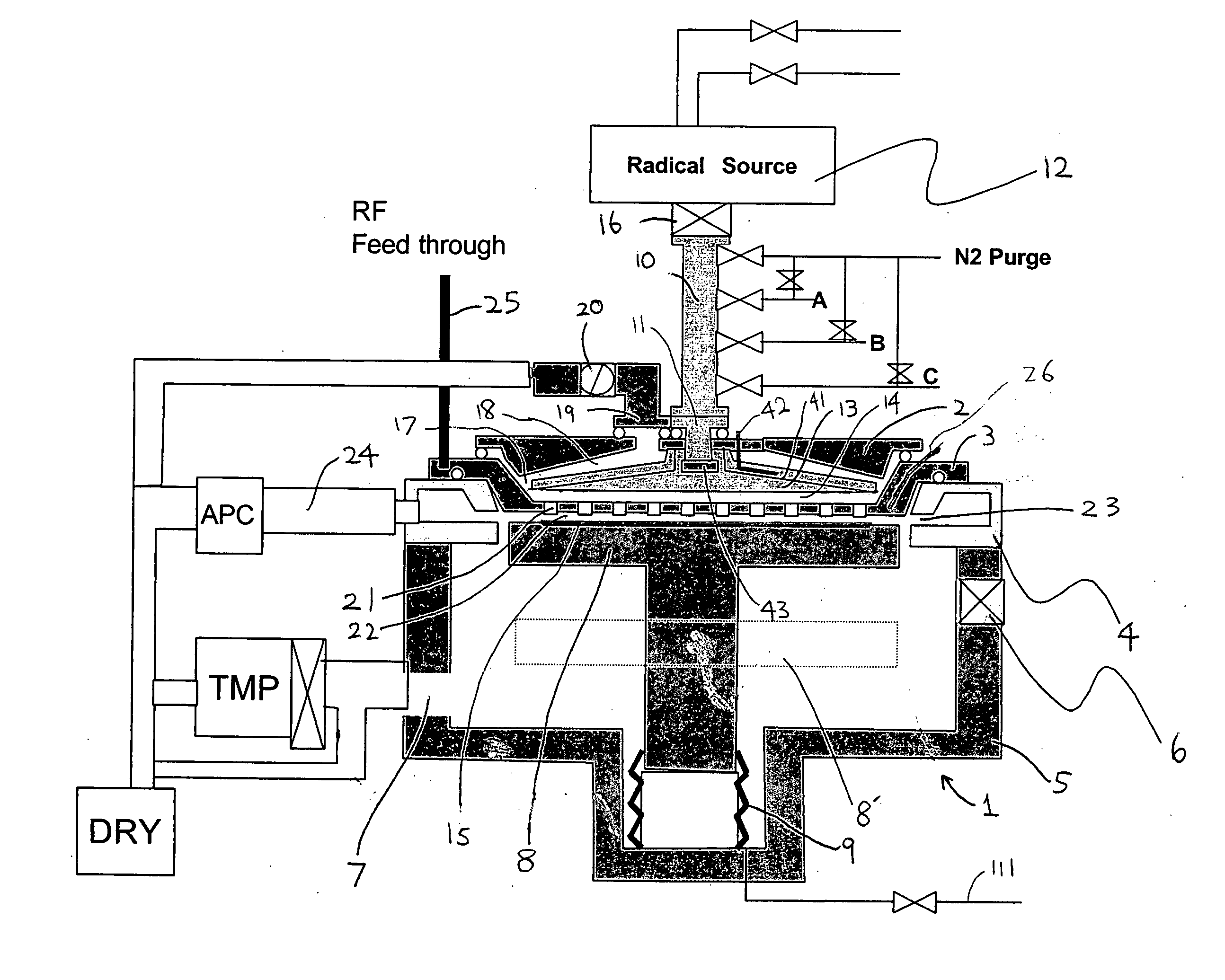

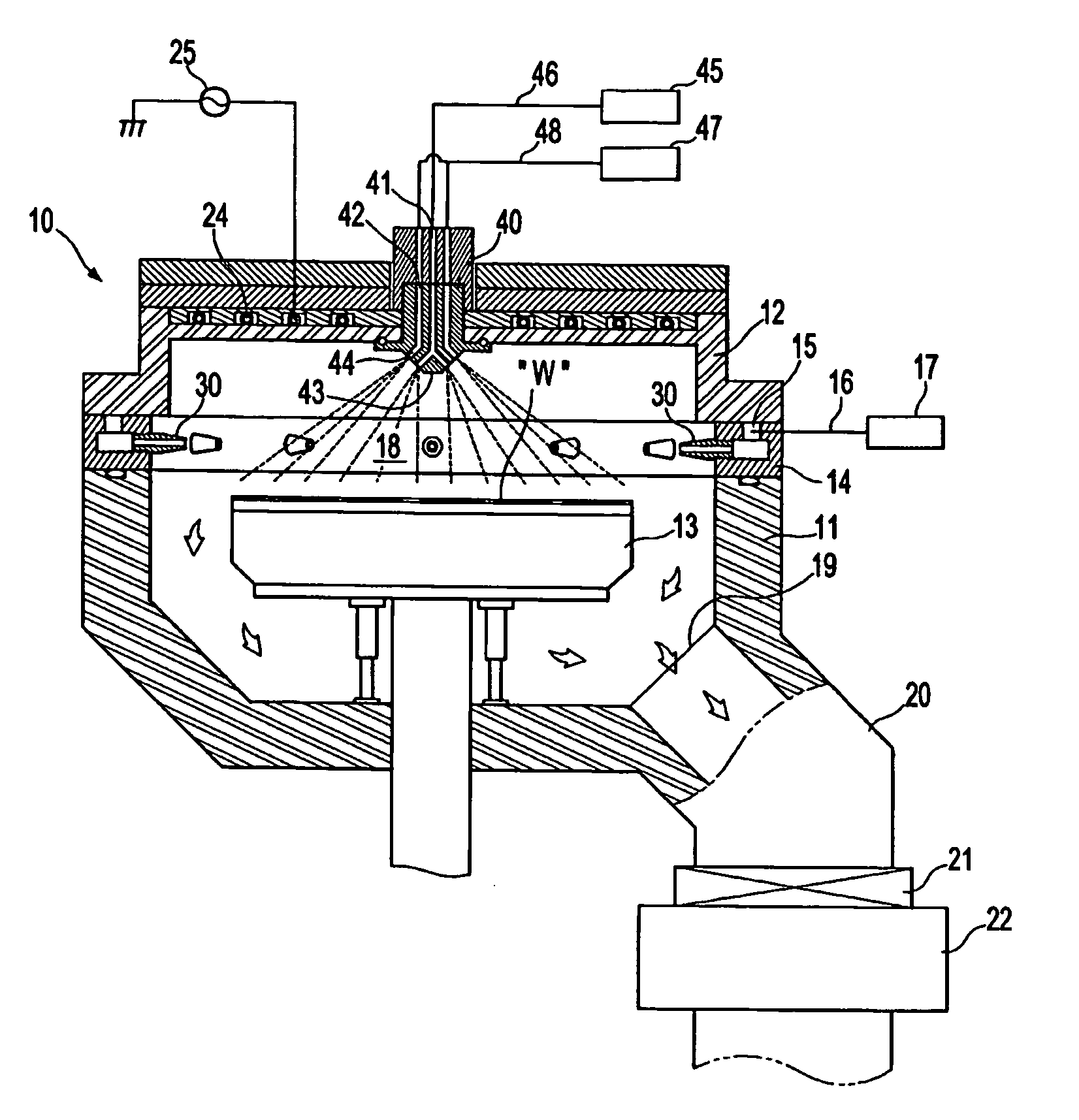

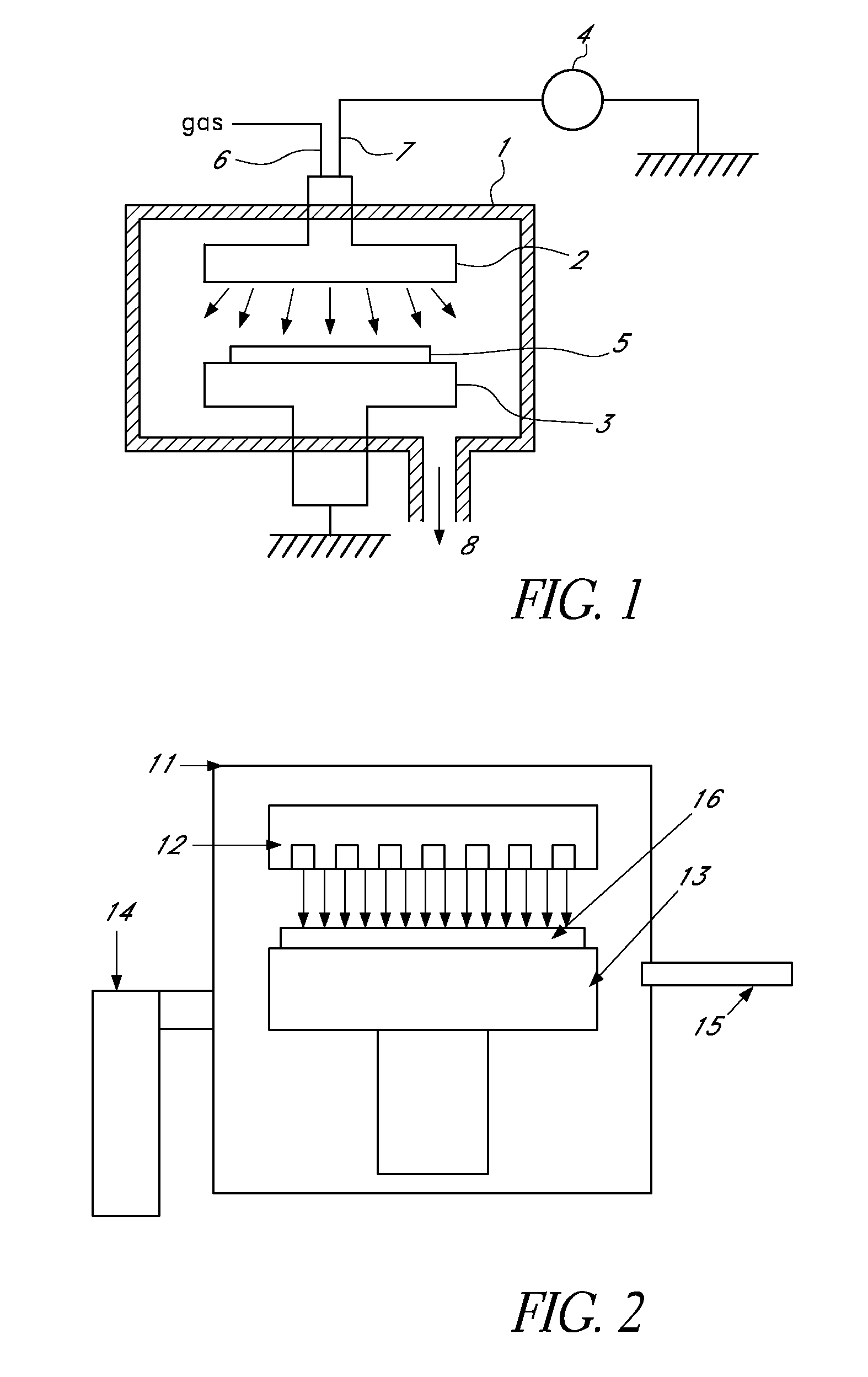

Atomic layer etching with pulsed plasmas

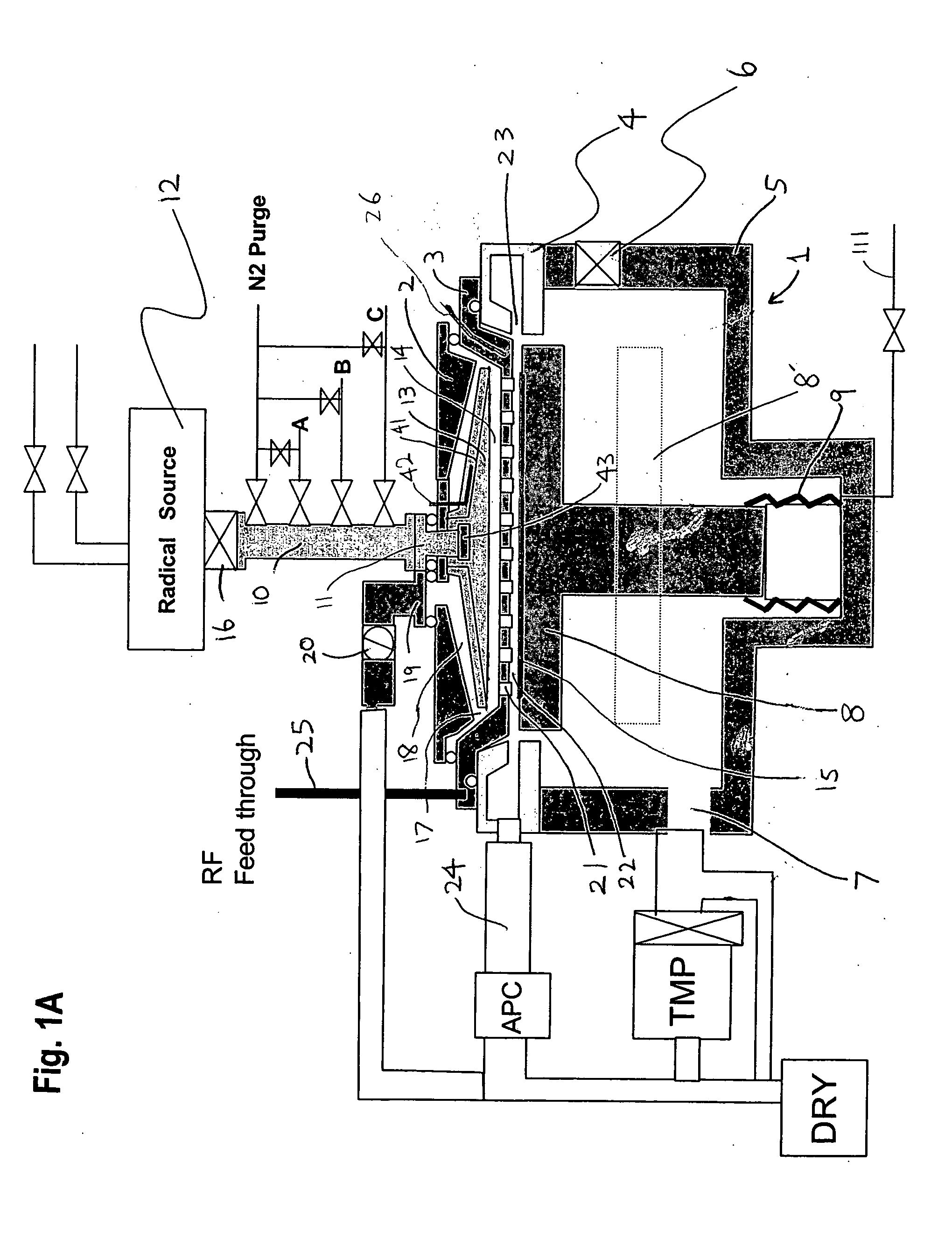

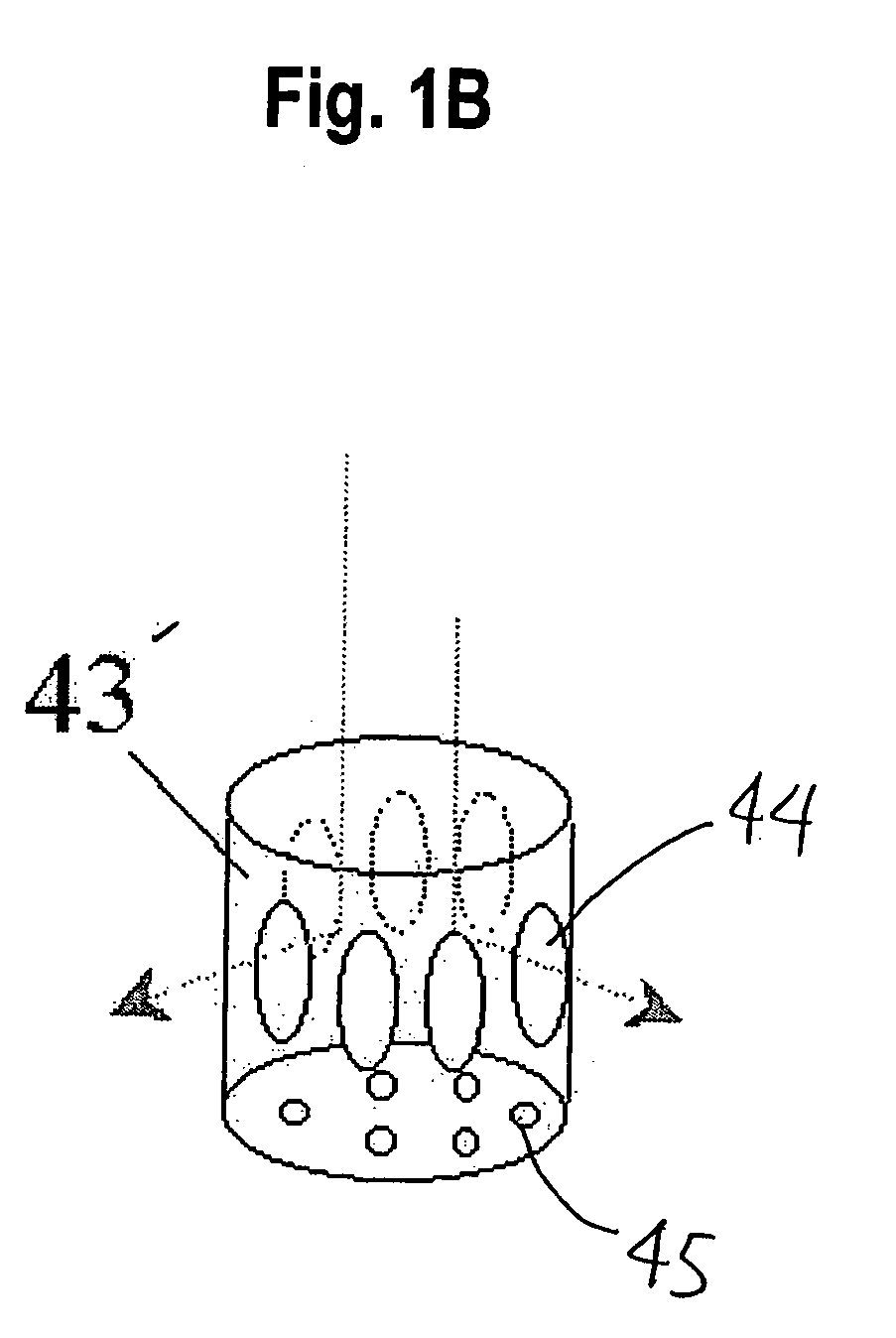

A system and method for rapid atomic layer etching (ALET) including a pulsed plasma source, with a spiral coil electrode, a cooled Faraday shield, a counter electrode disposed at the top of the tube, a gas inlet and a reaction chamber including a substrate support and a boundary electrode. The method includes positioning an etchable substrate in a plasma etching chamber, forming a product layer on the surface of the substrate, removing a portion of the product layer by pulsing a plasma source, then repeating the steps of forming a product layer and removing a portion of the product layer to form an etched substrate.

Owner:UNIV HOUSTON SYST

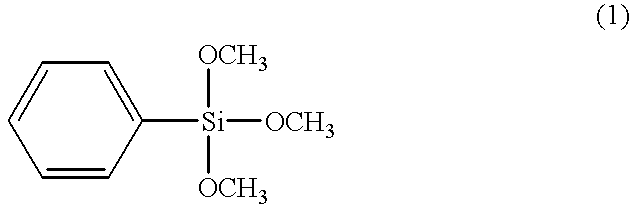

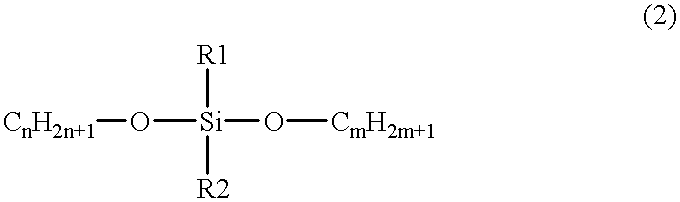

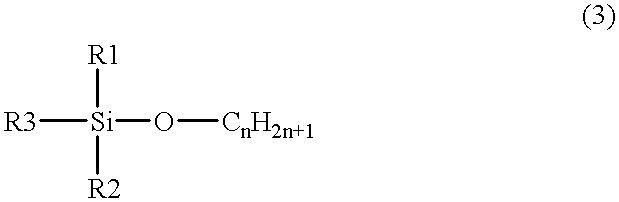

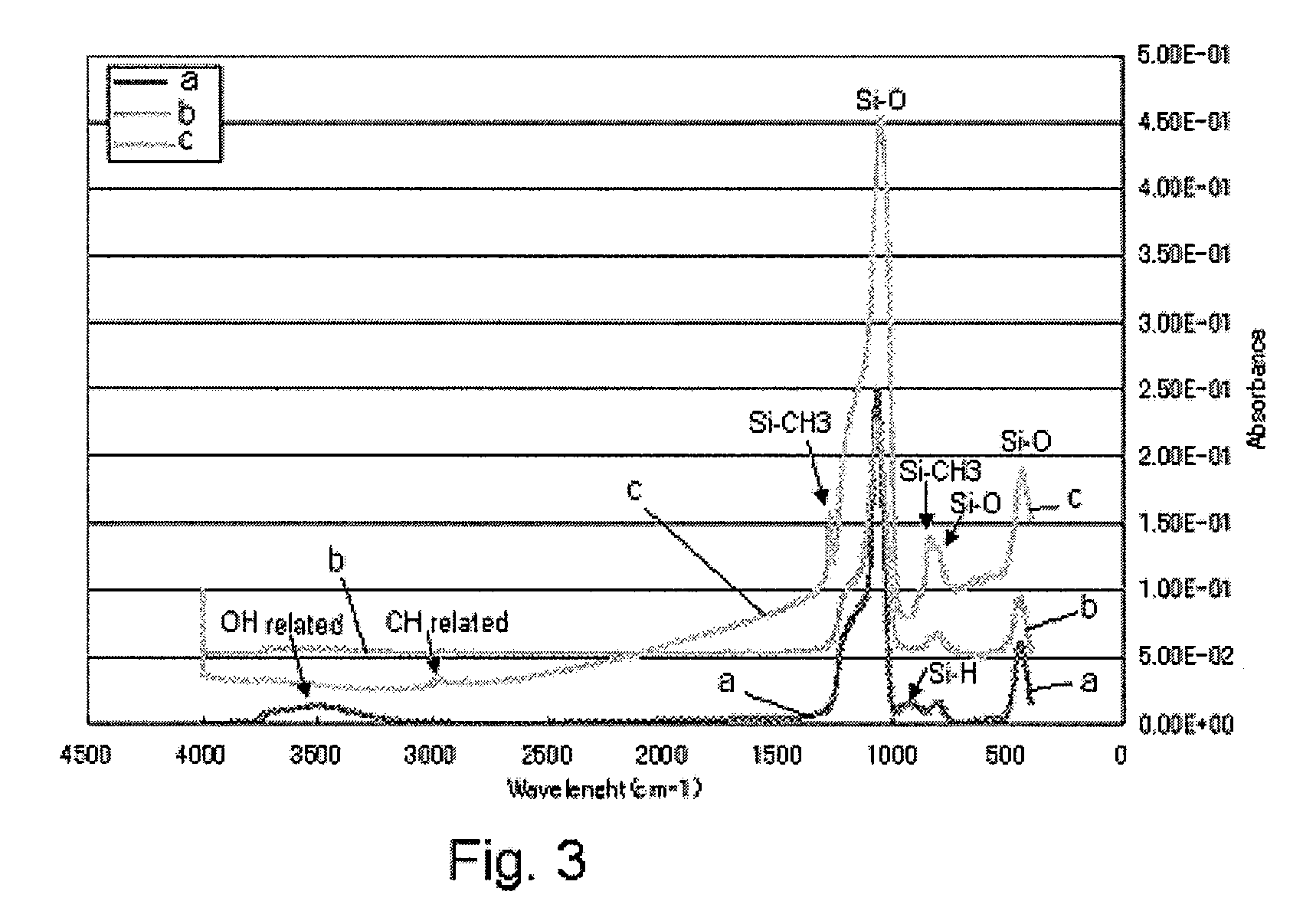

Silicone polymer insulation film on semiconductor substrate and method for forming the film

InactiveUS6352945B1Low dielectric constantImprove thermal stabilityLiquid surface applicatorsSemiconductor/solid-state device detailsPolymer scienceHigh humidity

A method for forming a silicone polymer insulation film having a low relative dielectric constant, high thermal stability and high humidity-resistance on a semiconductor substrate is applied to a plasma CVD apparatus. The first step is introducing a silicon-containing hydrocarbon compound expressed by the general formula SialphaObetaCxHy (alpha, beta, x, and y are integers) to the reaction chamber of the plasma CVD apparatus. The silicon-containing hydrocarbon compound has at most two O-CnH2n+1 bonds and at least two hydrocarbon radicals bonded to the silicon. The residence time of the material gas is lengthened by, for example, reducing the total flow of the reaction gas, in such a way as to form a silicone polymer film having a micropore porous structure with a low relative dielectric constant.

Owner:ASM JAPAN

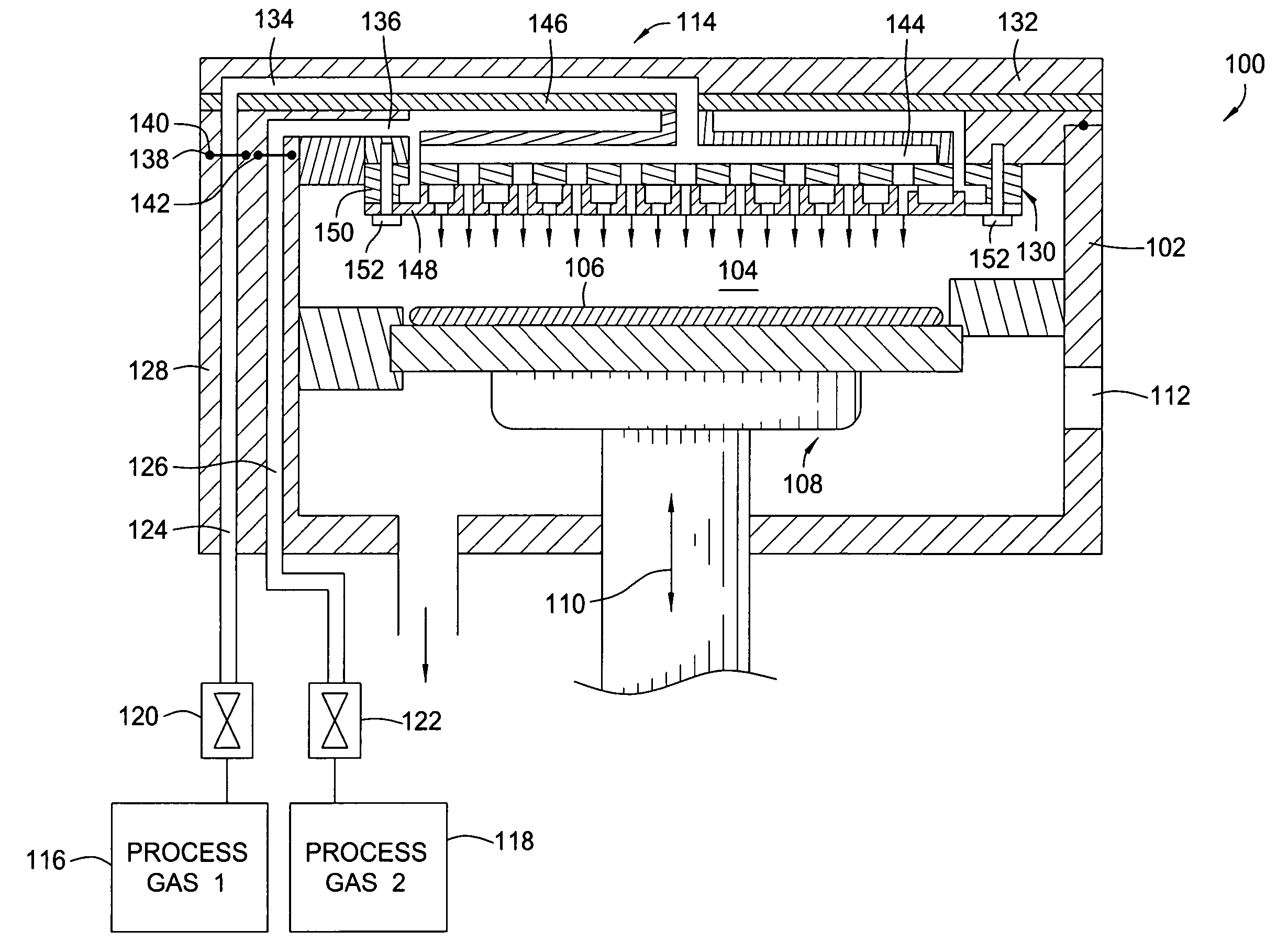

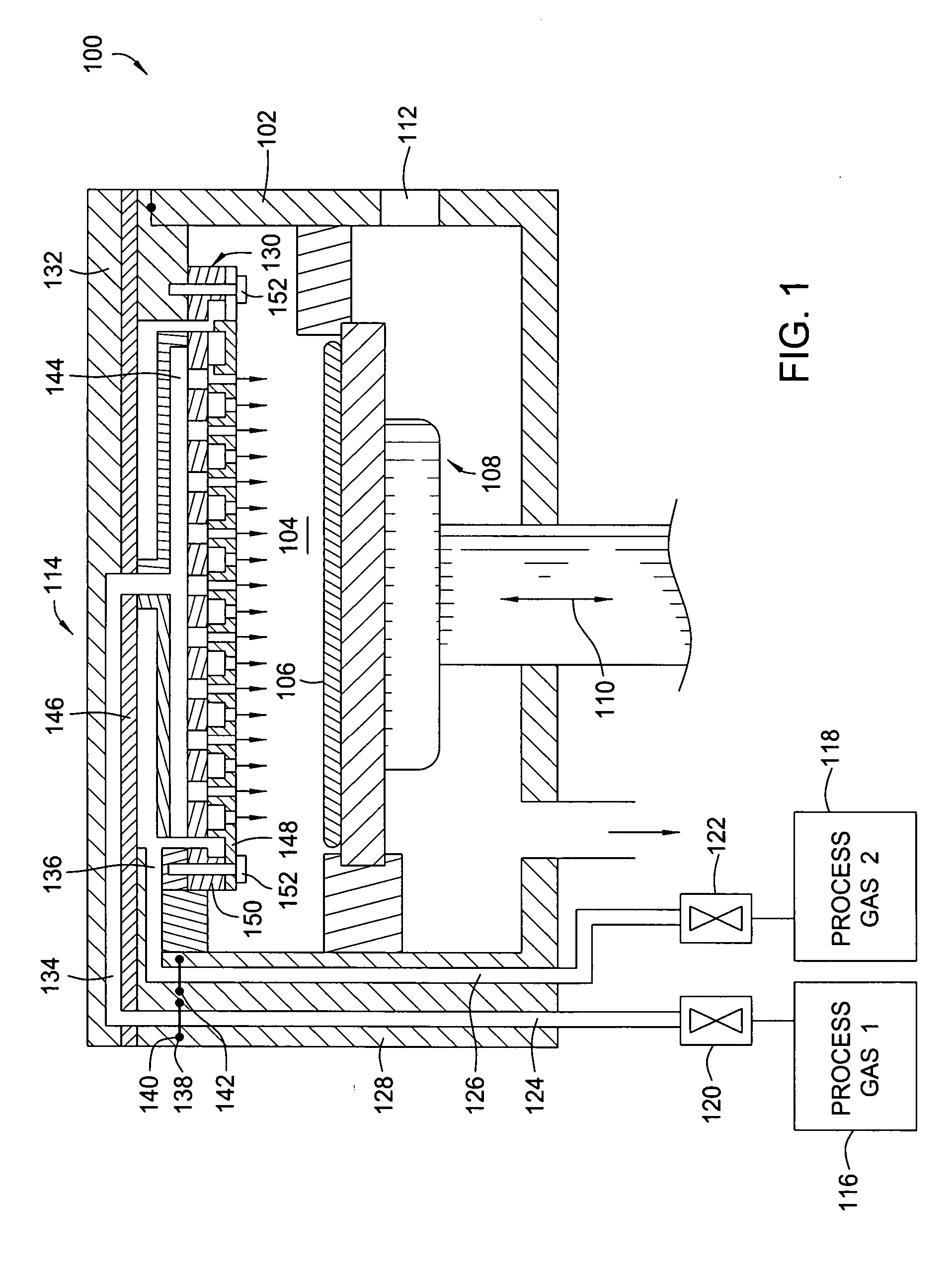

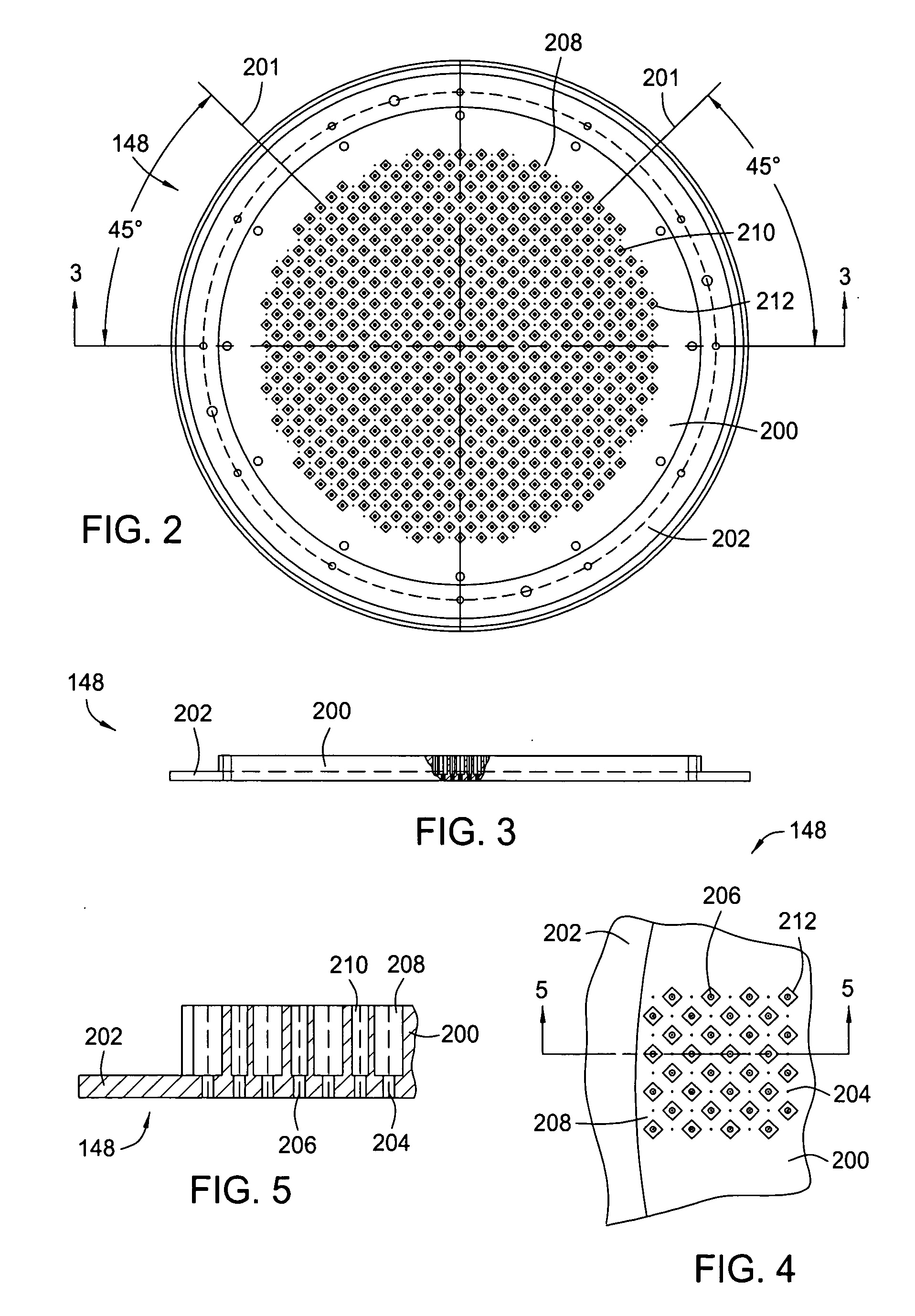

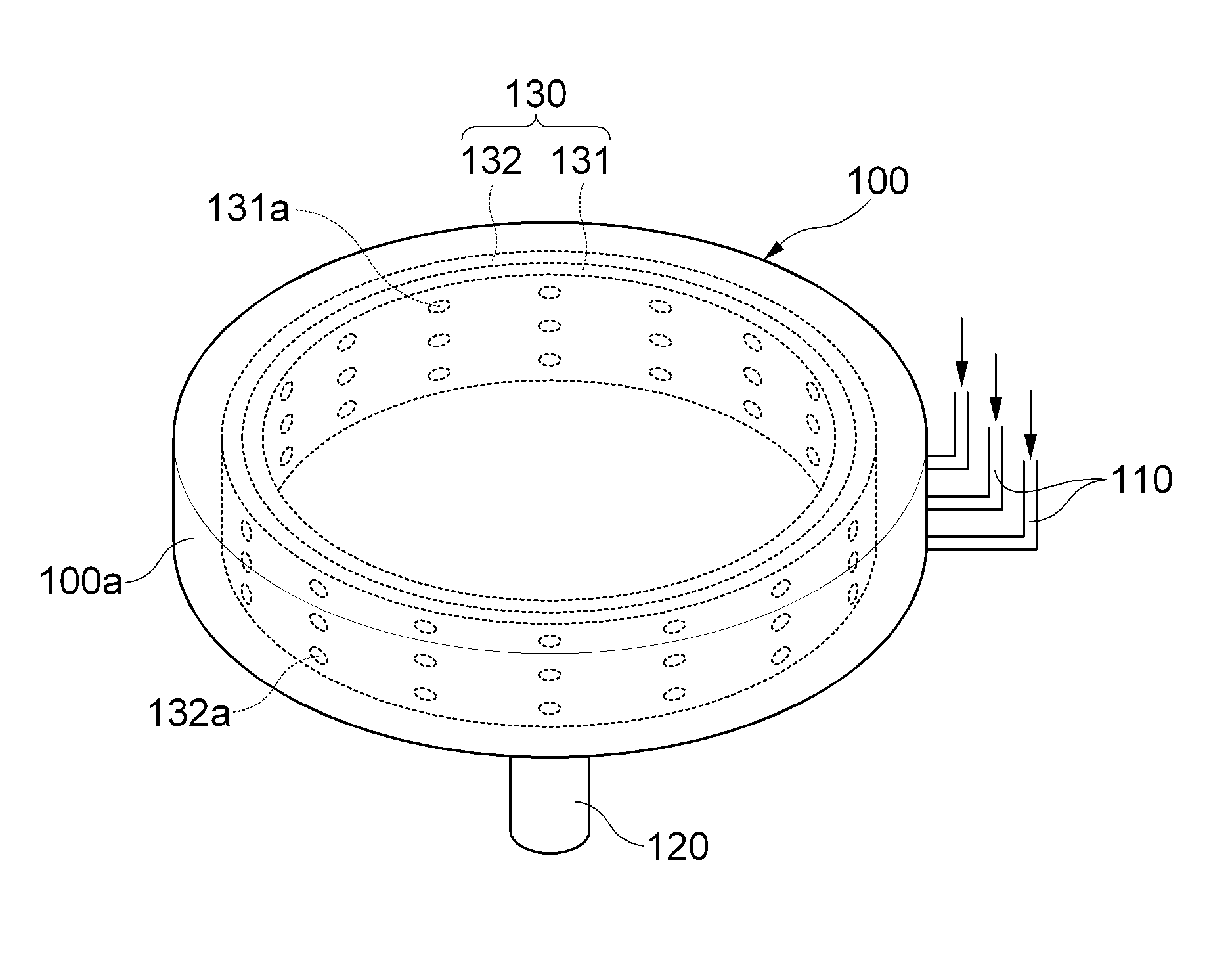

Dual gas faceplate for a showerhead in a semiconductor wafer processing system

InactiveUS20060021703A1Even gas distributionElectric discharge tubesSemiconductor/solid-state device manufacturingProcess regionProcess engineering

Owner:APPLIED MATERIALS INC

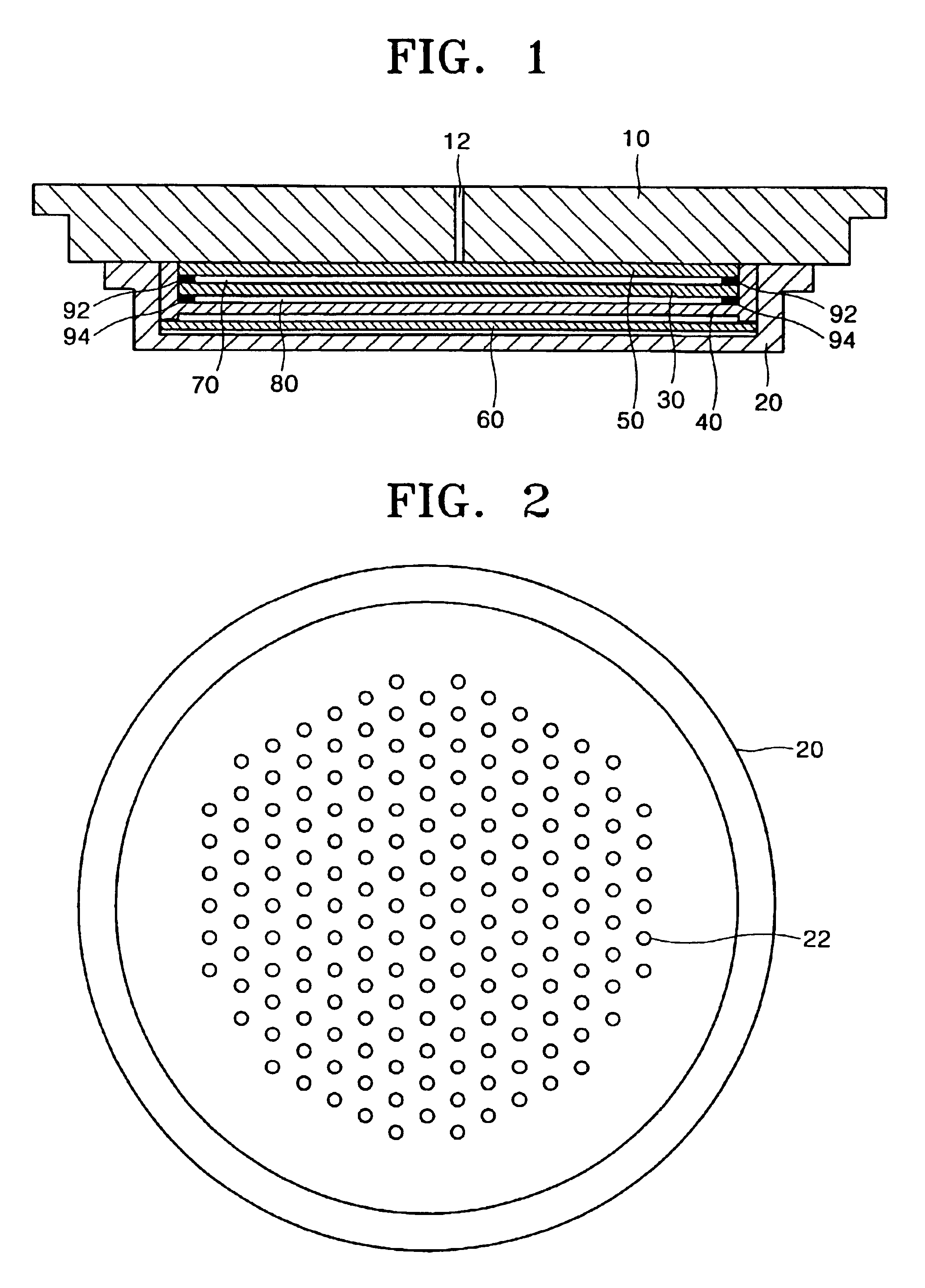

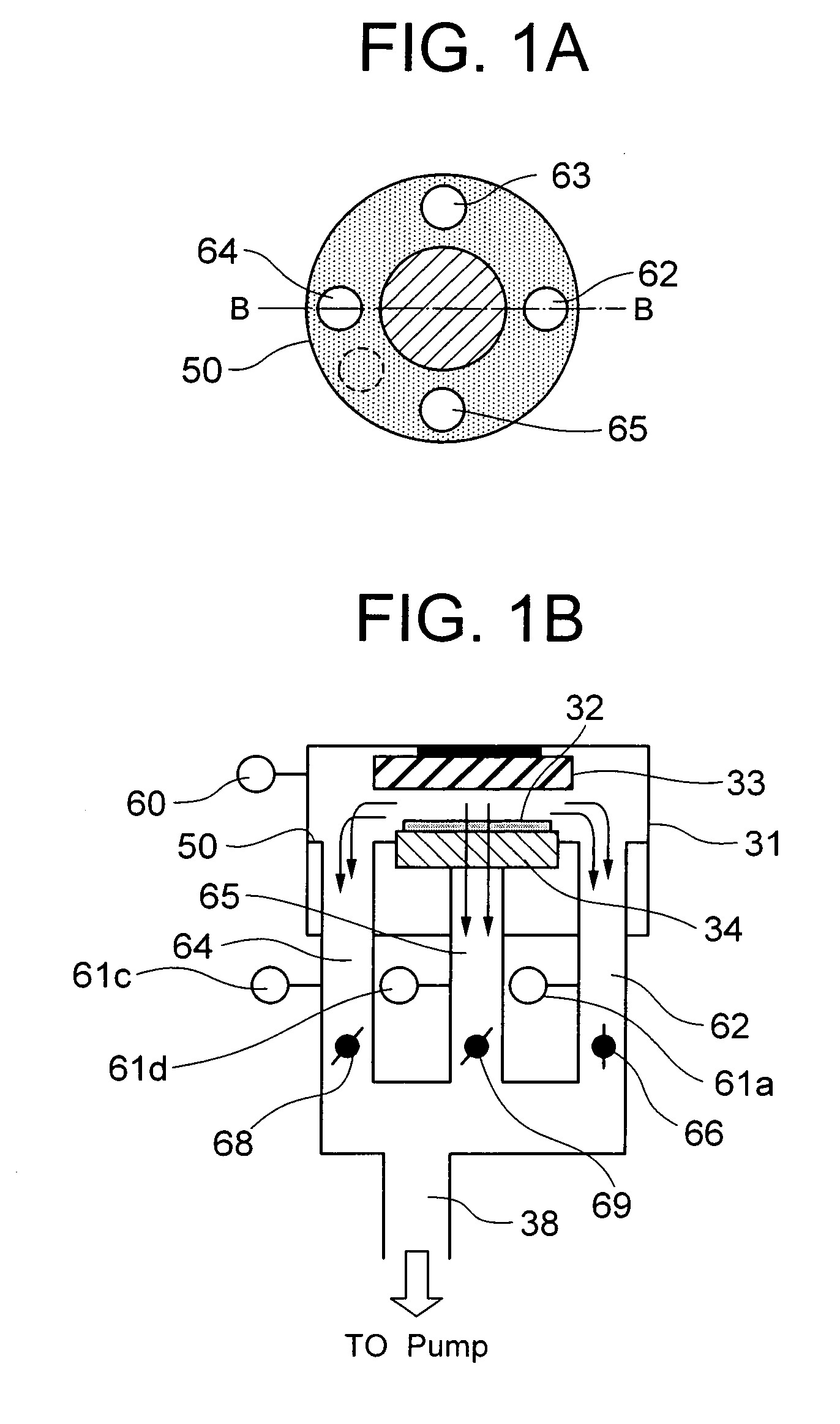

Apparatus and method for forming thin film using upstream and downstream exhaust mechanisms

ActiveUS20050208217A1Improve throughputUniform supplyElectric discharge tubesSemiconductor/solid-state device detailsGas supplySubstrate surface

A thin-film formation apparatus possesses a reaction chamber to be evacuated, a placing portion on which a substrate is placed inside the reaction chamber, a gas-dispersion guide installed over the placing portion for supplying a gas onto a substrate surface, a gas-supply port for introducing the gas into the gas-dispersion guide, a gas-dispersion plate disposed on the side of the substrate of the gas-dispersion guide and having multiple gas-discharge pores, a first exhaust port for exhausting, downstream of the gas-dispersion plate, the gas supplied onto the substrate surface from the gas-dispersion plate, and a second exhaust port for exhausting, upstream of the gas-dispersion plate, a gas inside the gas-dispersion guide via a space between the gas-dispersion guide and the gas-dispersion plate.

Owner:ASM JAPAN

CVD flowable gap fill

The present invention meets these needs by providing improved methods of filling gaps. In certain embodiments, the methods involve placing a substrate into a reaction chamber and introducing a vapor phase silicon-containing compound and oxidant into the chamber. Reactor conditions are controlled so that the silicon-containing compound and the oxidant are made to react and condense onto the substrate. The chemical reaction causes the formation of a flowable film, in some instances containing Si—OH, Si—H and Si—O bonds. The flowable film fills gaps on the substrates. The flowable film is then converted into a silicon oxide film, for example by plasma or thermal annealing. The methods of this invention may be used to fill high aspect ratio gaps, including gaps having aspect ratios ranging from 3:1 to 10:1.

Owner:NOVELLUS SYSTEMS

High stress nitride film and method for formation thereof

ActiveUS20060199357A1Increase the tensile stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantNitrogen

A silicon nitride film is formed on a substrate in a reaction chamber by introducing trisilane and a reactive nitrogen species into the chamber in separate pulses. A carbon precursor gas is also flowed into the chamber during introduction of the trisilane and / or during introduction of the reactive nitrogen species, or in pulses separate from the trisilane and reactive nitrogen species pulses. The carbon is used as a dopant in the silicon nitride film and advantageously allows a high stress silicon nitride film to be formed.

Owner:ASM INTERNATIONAL

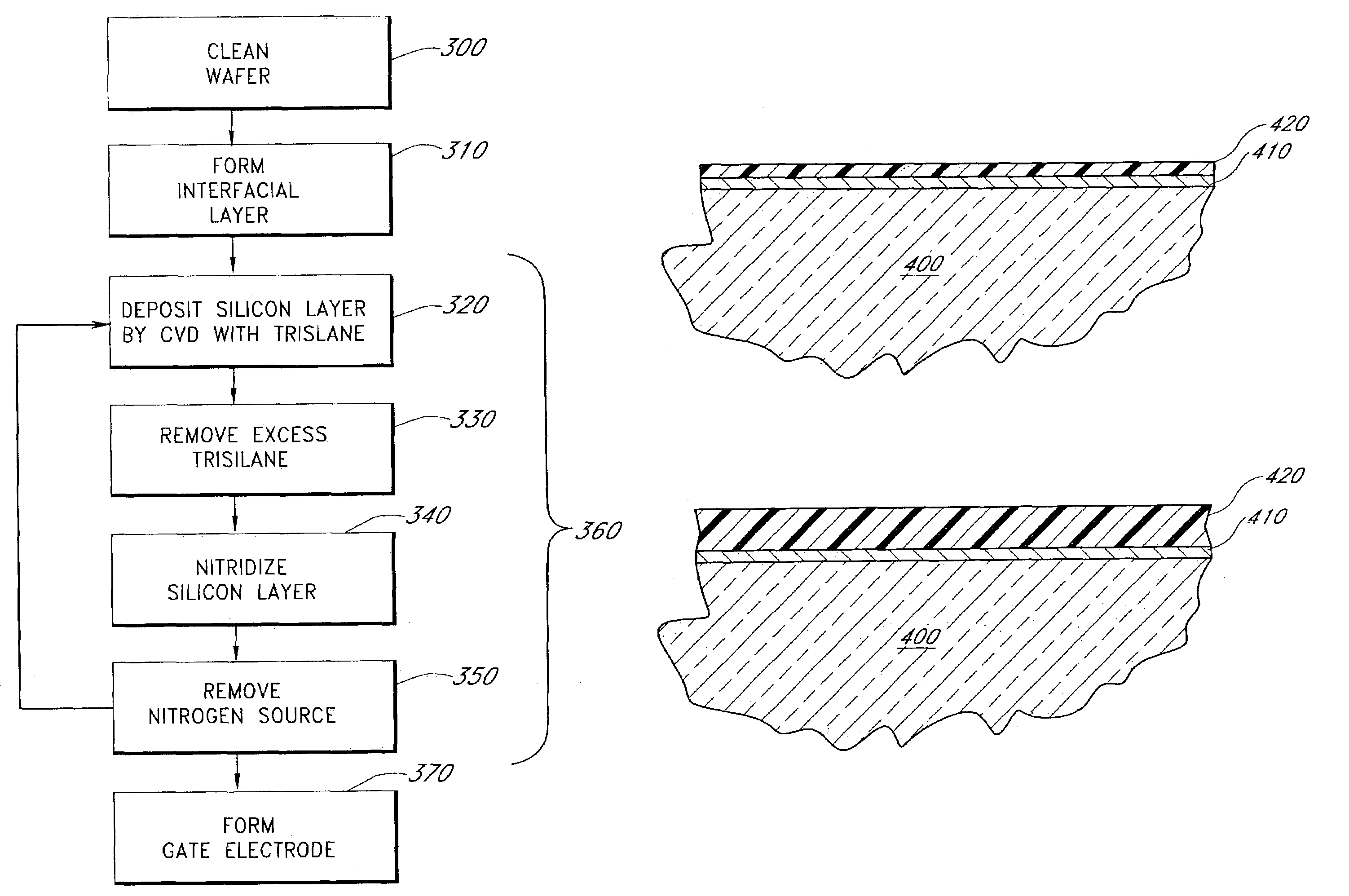

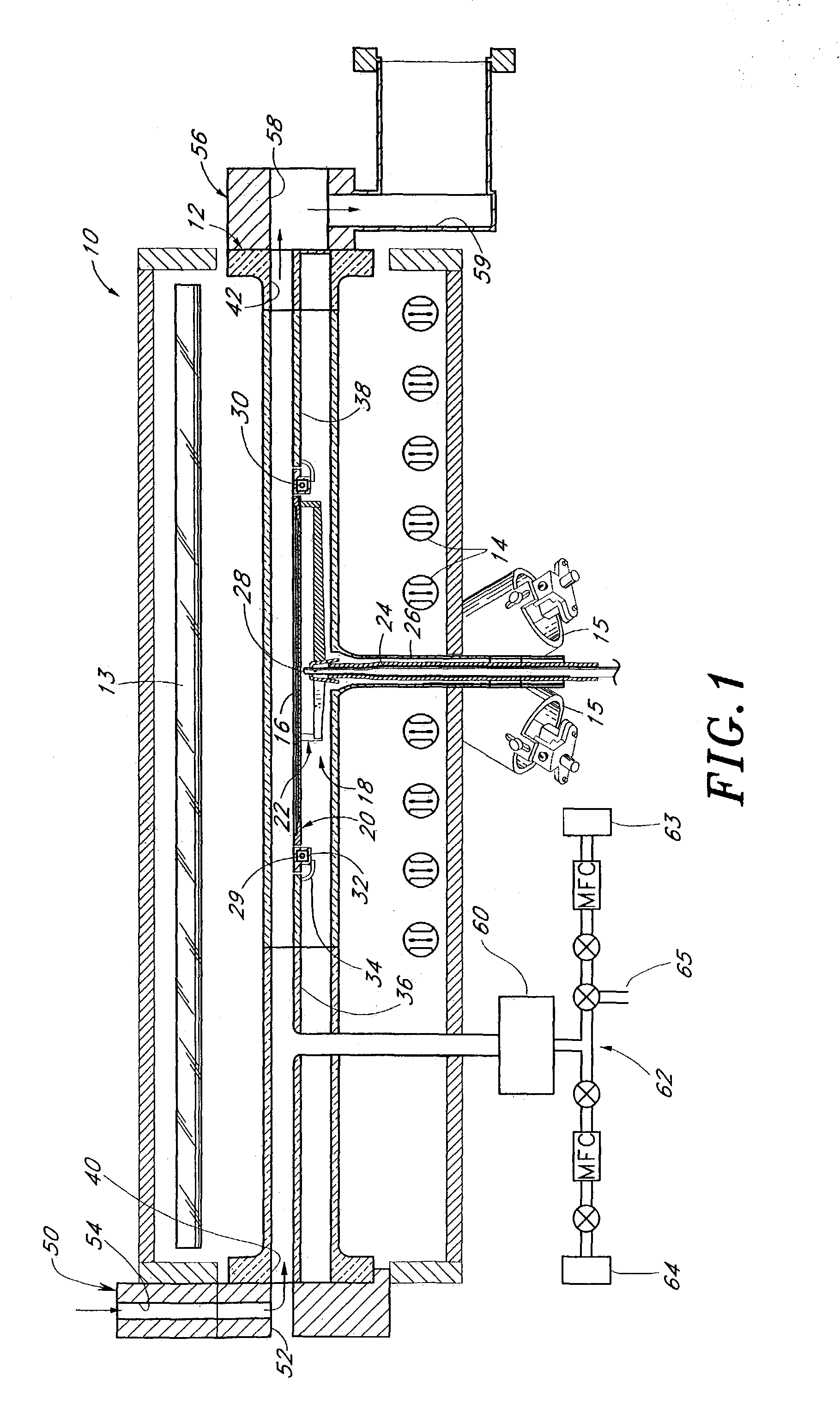

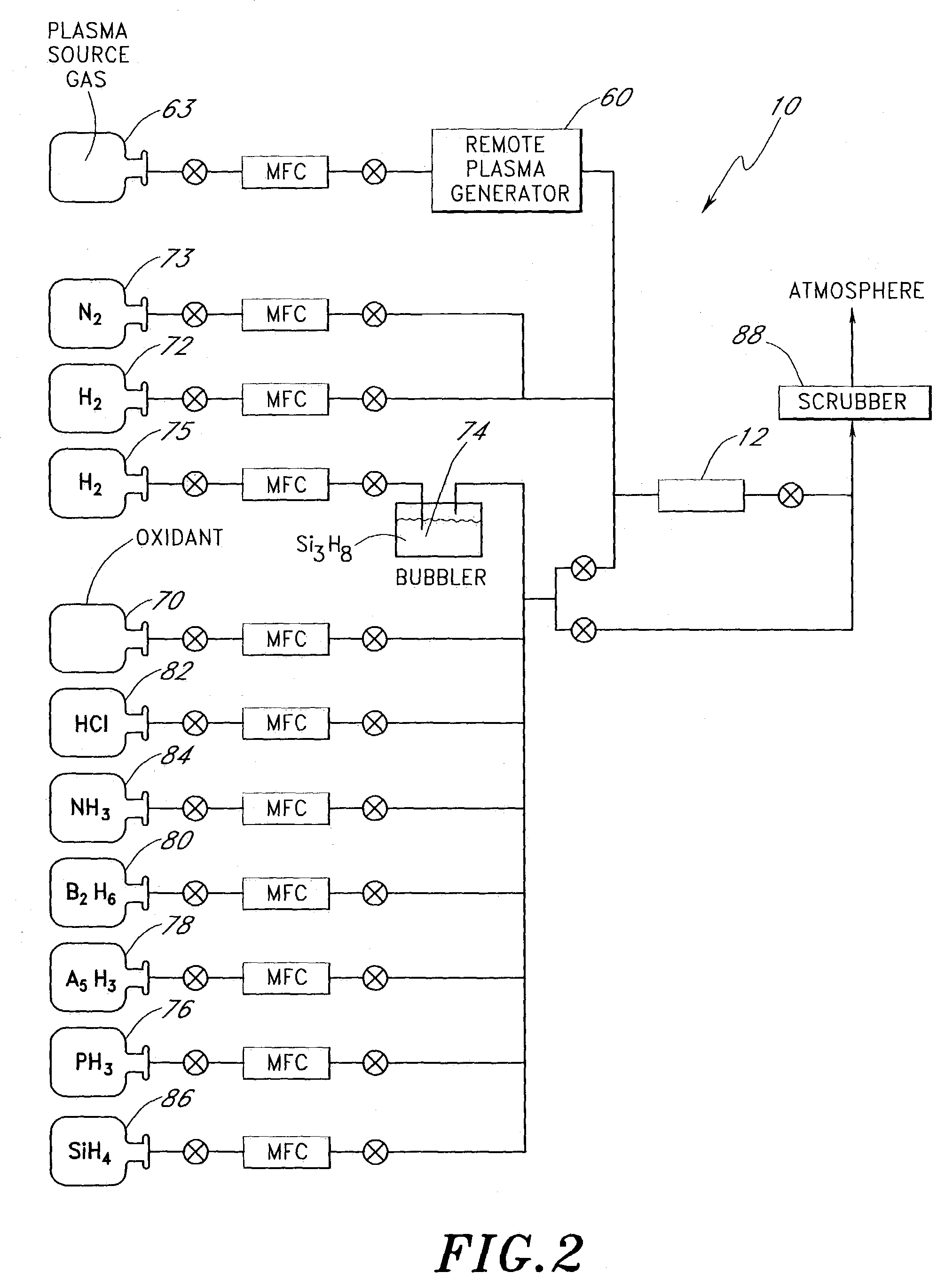

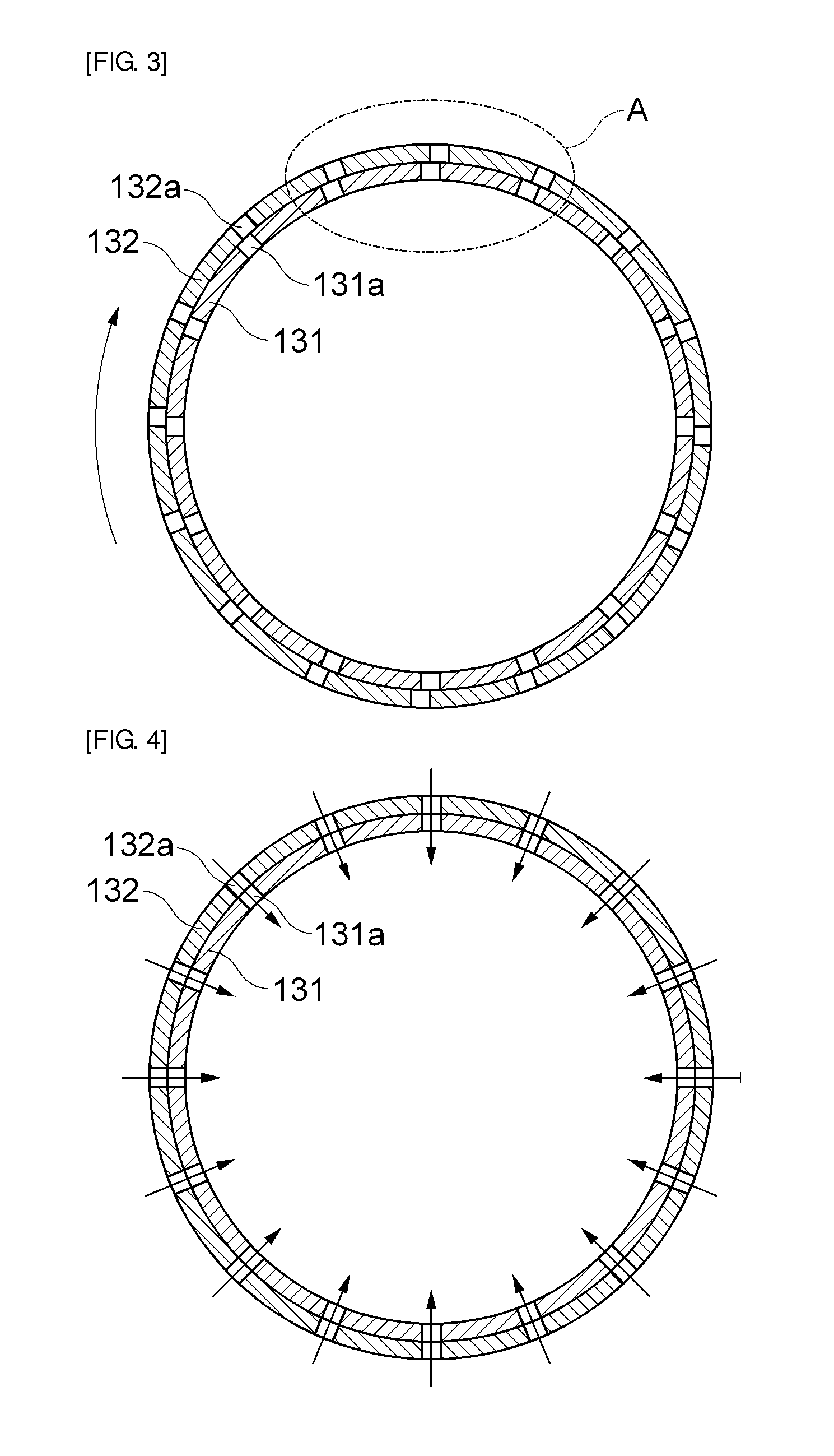

Method to form ultra high quality silicon-containing compound layers

InactiveUS7297641B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTrisilaneReaction chamber

Multiple sequential processes are conducted in a reaction chamber to form ultra high quality silicon-containing compound layers, including silicon nitride layers. In a preferred embodiment, a silicon layer is deposited on a substrate using trisilane as the silicon precursor. A silicon nitride layer is then formed by nitriding the silicon layer. By repeating these steps, a silicon nitride layer of a desired thickness is formed.

Owner:ASM IP HLDG BV

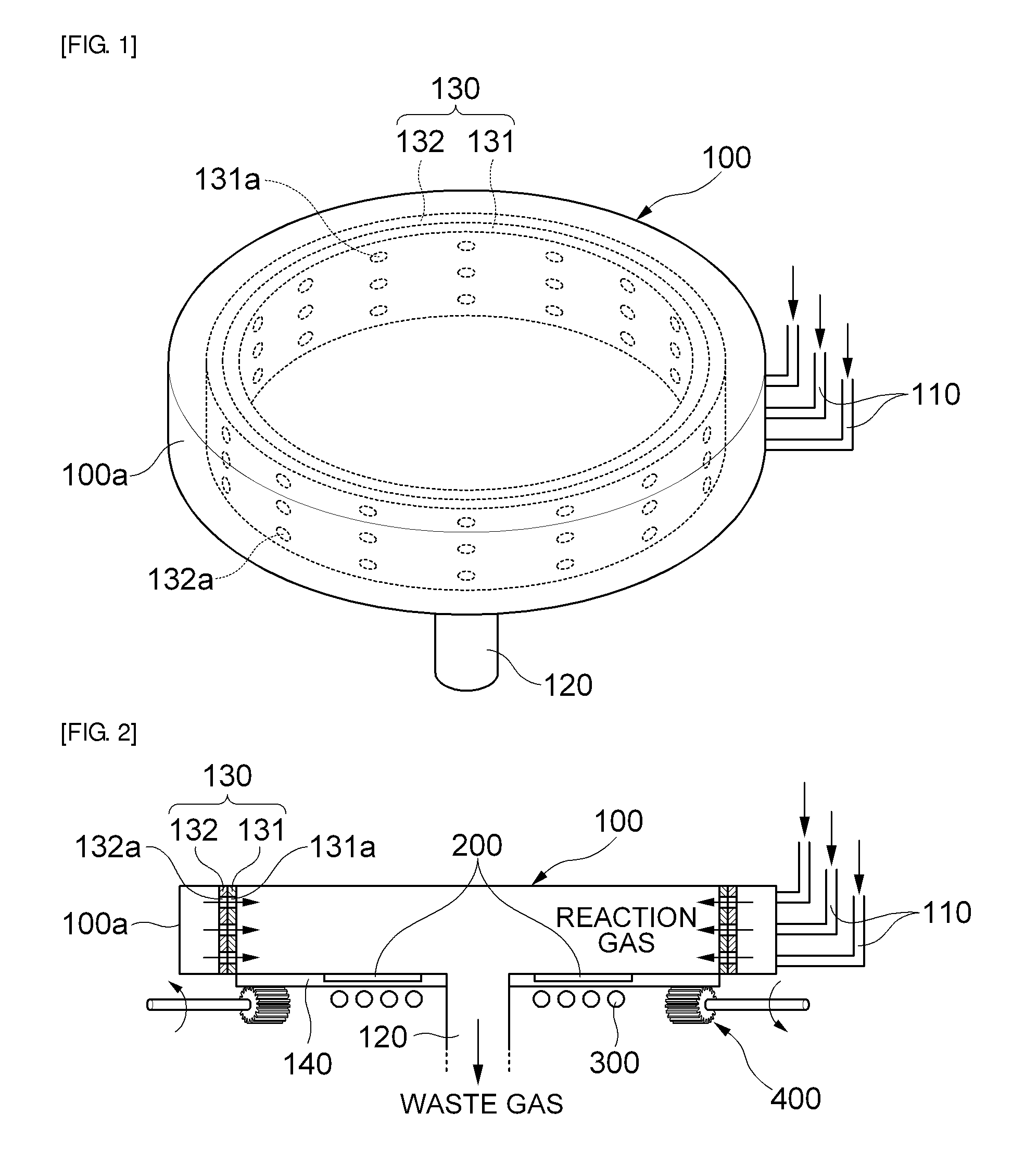

Chemical vapor deposition apparatus

InactiveUS7749326B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorChemical vapor deposition

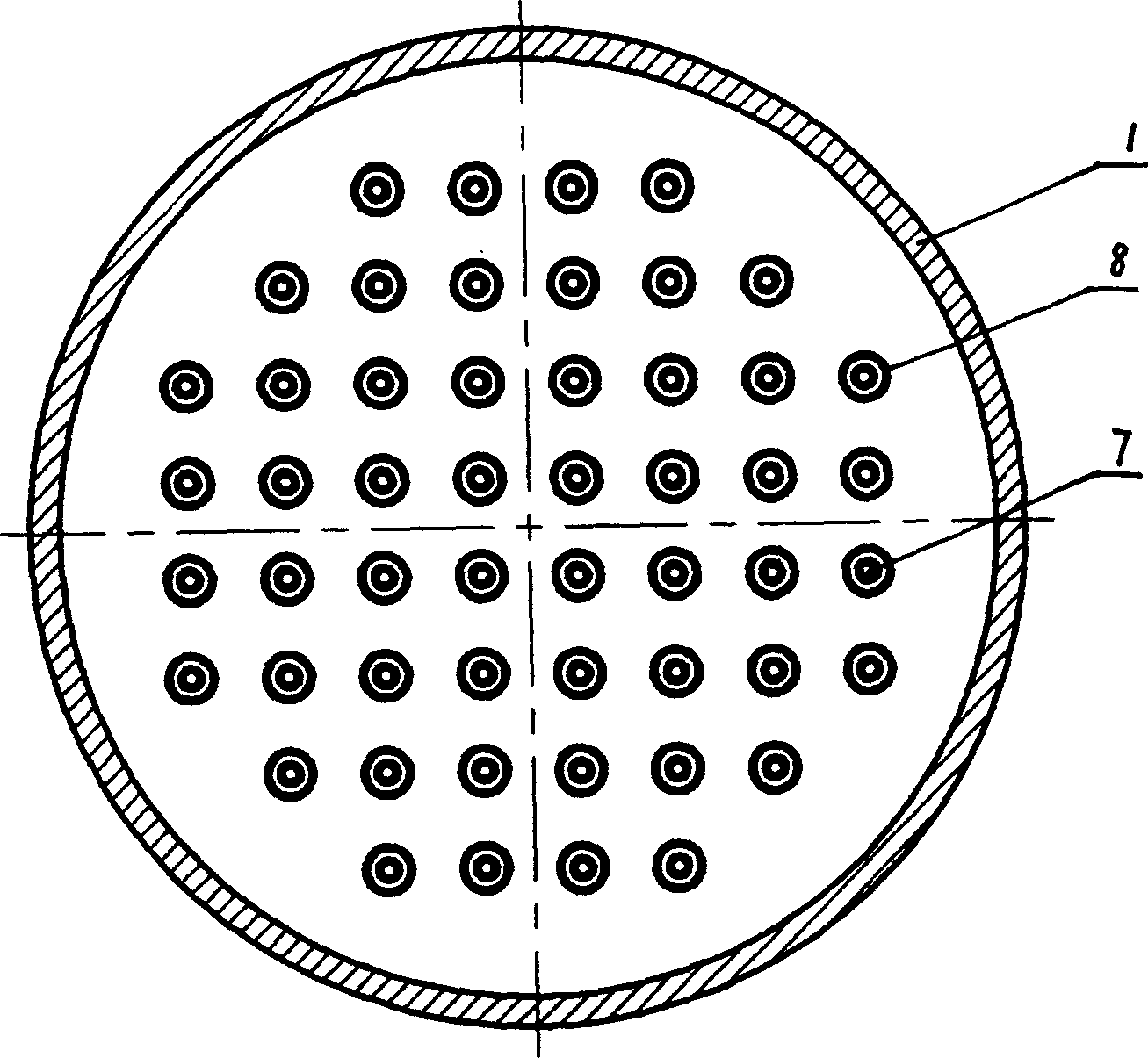

Provided is a chemical vapor deposition apparatus including a reaction chamber; a susceptor that is provided in the reaction chamber and has a plurality of wafers mounted thereon; a rotation driving unit that rotates the susceptor; a gas inlet that is provided in the reaction chamber and introduces reaction gas into the reaction chamber from the outside of the reaction chamber; a gas outlet that is provided in the reaction chamber and discharges the reaction gas, of which the reaction is finished, from the inside of the reaction chamber along the rotation-axis direction of the susceptor; and a variable gas-flow adjusting unit that is provided between the gas inlet and the gas outlet and is formed by superimposing a plurality of gas jetting plates having a plurality of holes.

Owner:SAMSUNG ELECTRONICS CO LTD

Method to form ultra high quality silicon-containing compound layers

InactiveUS20050118837A1Semiconductor/solid-state device detailsSolid-state devicesMaterials scienceReaction chamber

Multiple sequential processes are conducted in a reaction chamber to form ultra high quality silicon-containing compound layers, including silicon nitride layers. In a preferred embodiment, a silicon layer is deposited on a substrate using trisilane as the silicon precursor. A silicon nitride layer is then formed by nitriding the silicon layer. By repeating these steps, a silicon nitride layer of a desired thickness is formed.

Owner:ASM IP HLDG BV

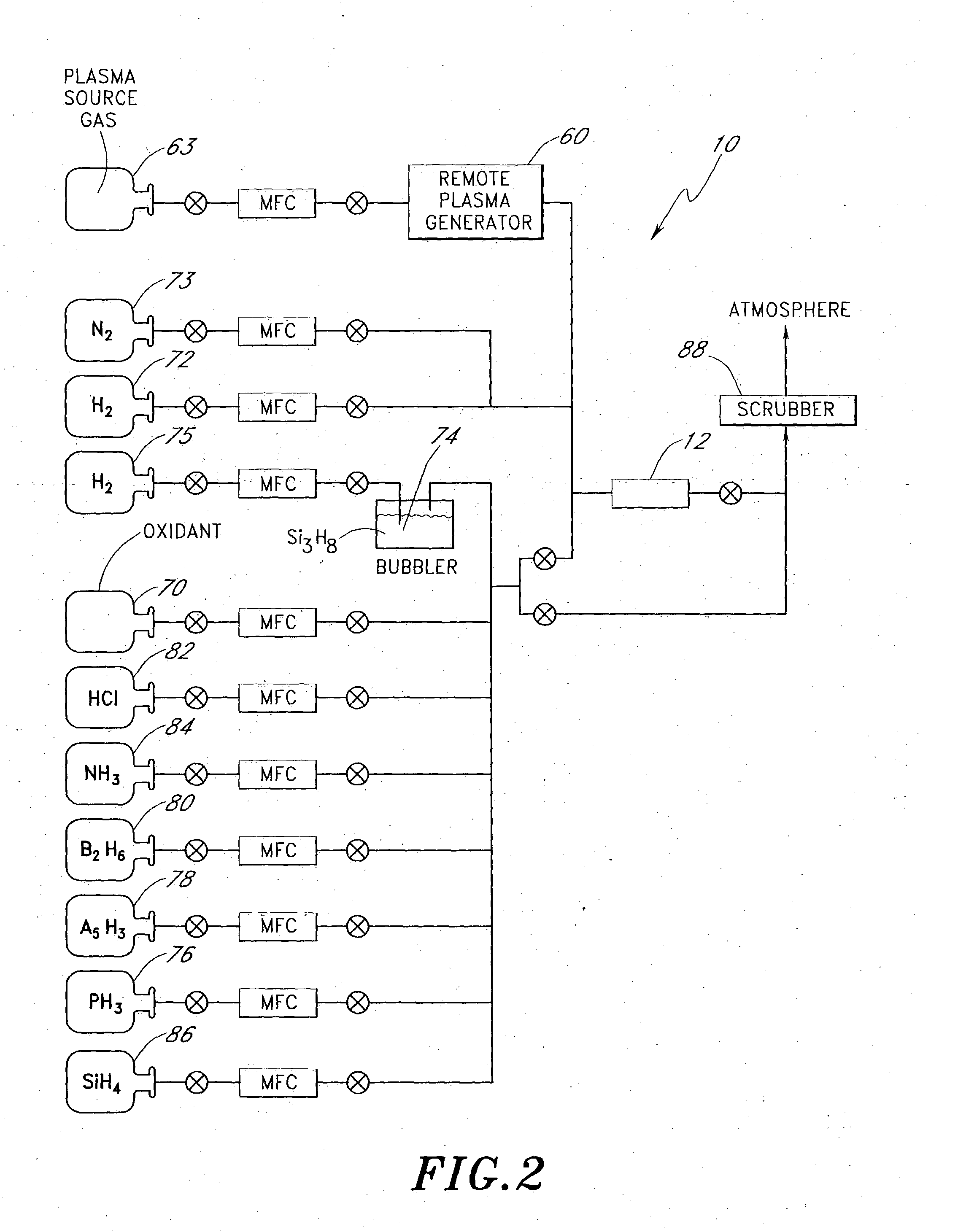

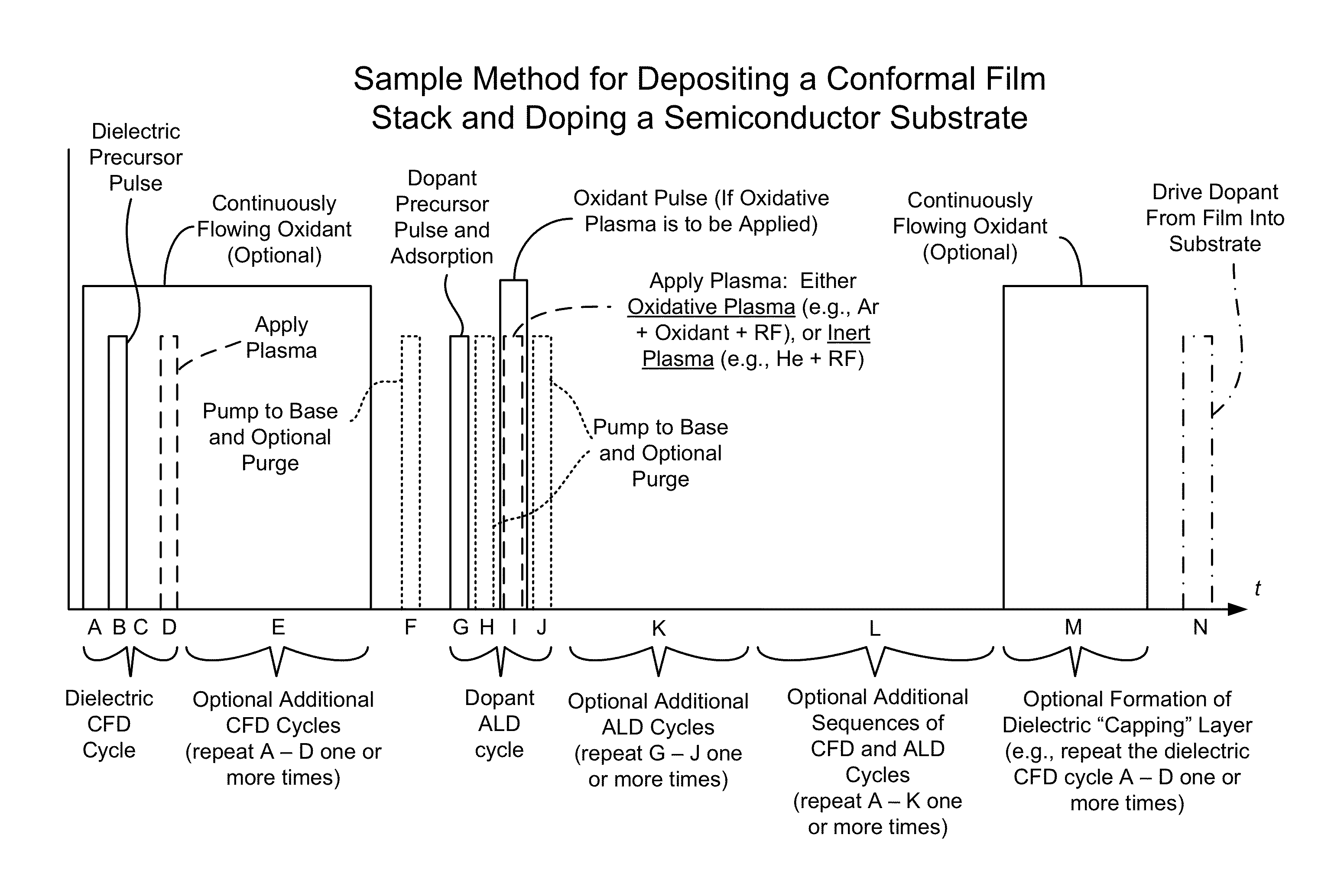

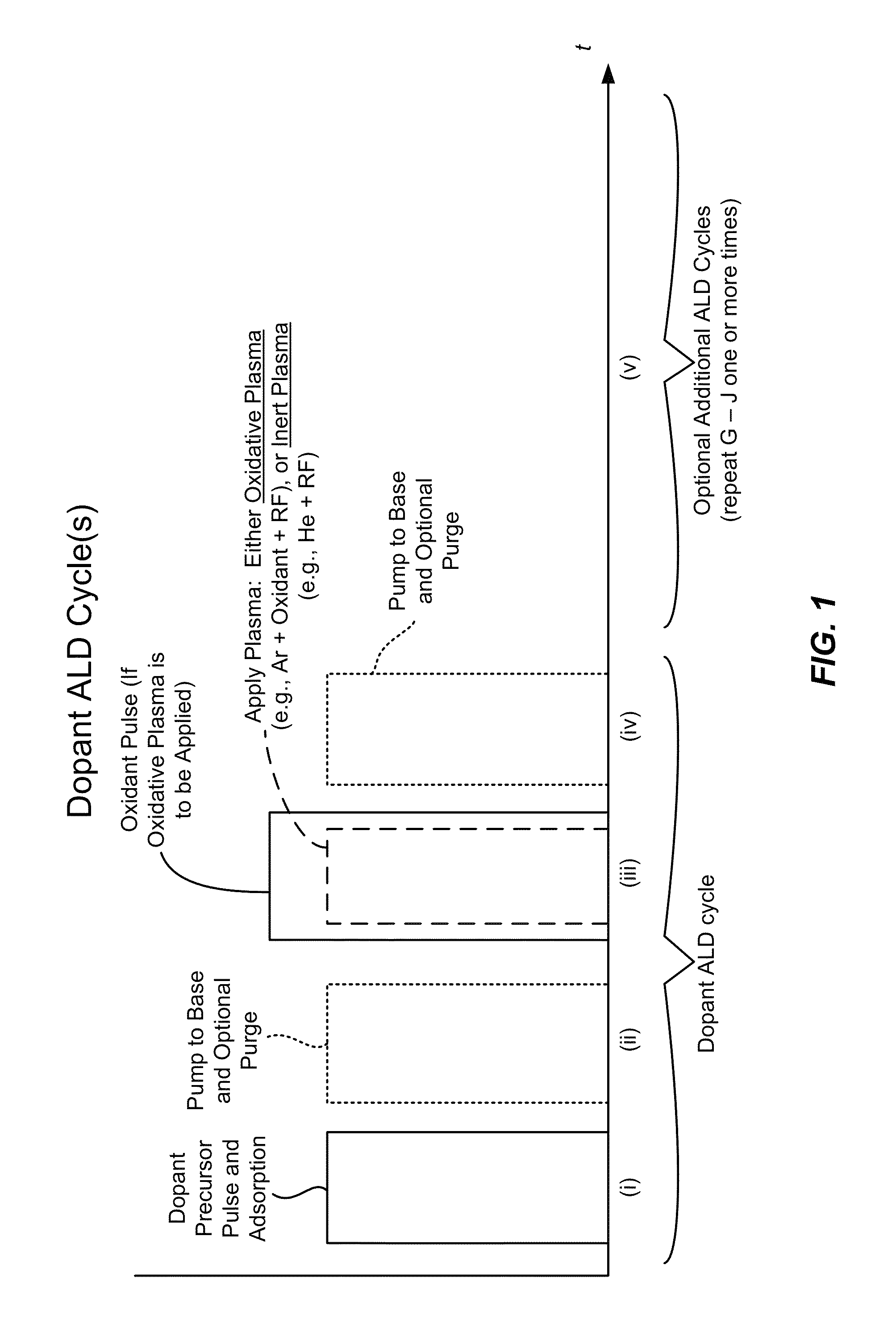

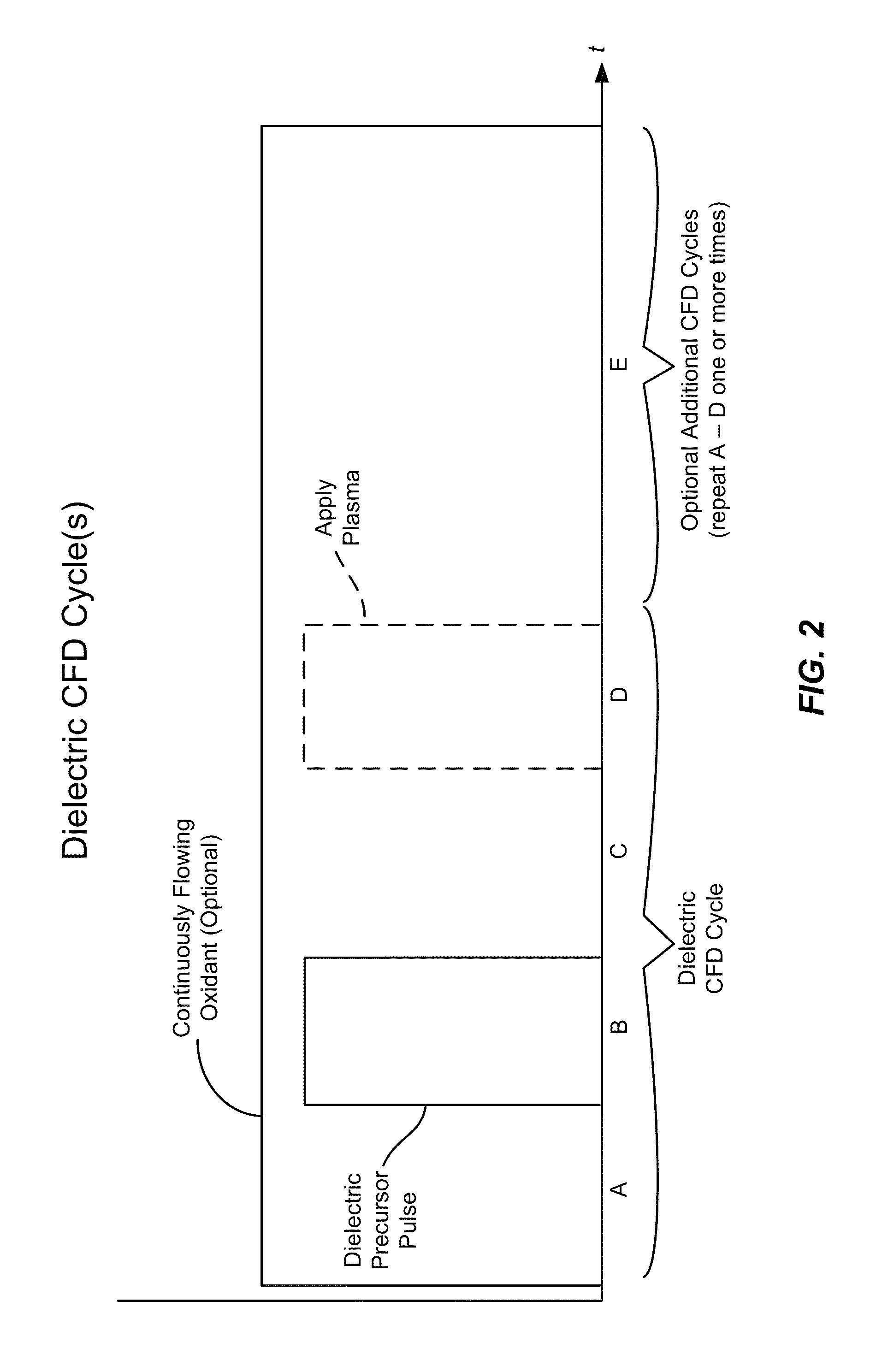

Conformal doping via plasma activated atomic layer deposition and conformal film deposition

ActiveUS8956983B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingDopantPatterned substrate

Disclosed herein are methods of doping a patterned substrate in a reaction chamber. The methods may include forming a first conformal film layer which has a dopant source including a dopant, and driving some of the dopant into the substrate to form a conformal doping profile. In some embodiments, forming the first film layer may include introducing a dopant precursor into the reaction chamber, adsorbing the dopant precursor under conditions whereby it forms an adsorption-limited layer, and reacting the adsorbed dopant precursor to form the dopant source. Also disclosed herein are apparatuses for doping a substrate which may include a reaction chamber, a gas inlet, and a controller having machine readable code including instructions for operating the gas inlet to introduce dopant precursor into the reaction chamber so that it is adsorbed, and instructions for reacting the adsorbed dopant precursor to form a film layer containing a dopant source.

Owner:NOVELLUS SYSTEMS

Method for depositing thin films by mixed pulsed CVD and ald

ActiveUS20080317972A1Easy to customizeImprove responseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical vapor depositionAtomic layer deposition

Films are deposited on a substrate by a process in which atomic layer deposition (ALD) is used to deposit one layer of the film and pulsed chemical vapor deposition (CVD) is used to deposit another layer of the film. During the ALD part of the process, a layer is formed by flowing sequential and alternating pulses of mutually reactive reactants that deposit self-limitingly on a substrate. During the pulsed CVD part of the process, another layer is deposited by flowing two CVD reactants into a reaction chamber, with at least a first of the CVD reactants flowed into the reaction chamber in pulses, with those pulses overlapping at least partially with the flow of a second of the CVD reactants. The ALD and CVD parts of the process ca be used to deposit layers with different compositions, thereby forming, e.g., nanolaminate films. Preferably, high quality layers are formed by flowing the second CVD reactant into the reaction chamber for a longer total duration than the first CVD reactant. In some embodiments, the pulses of the third reactant at separated by a duration at least about 1.75 times the length of the pulse. Preferably, less than about 8 monolayers of material are deposited per pulse of the first CVD reactant.

Owner:ASM INTERNATIONAL

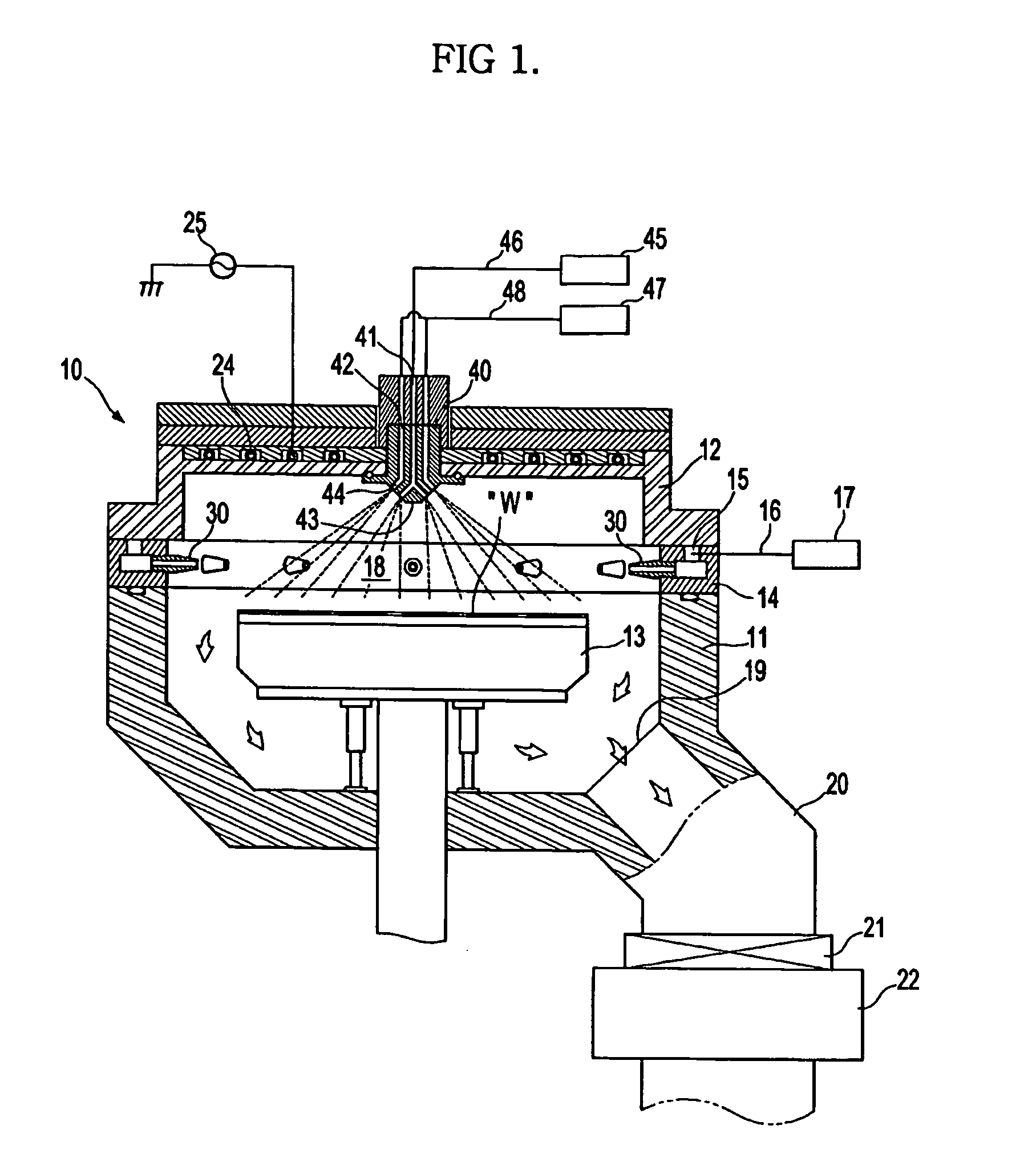

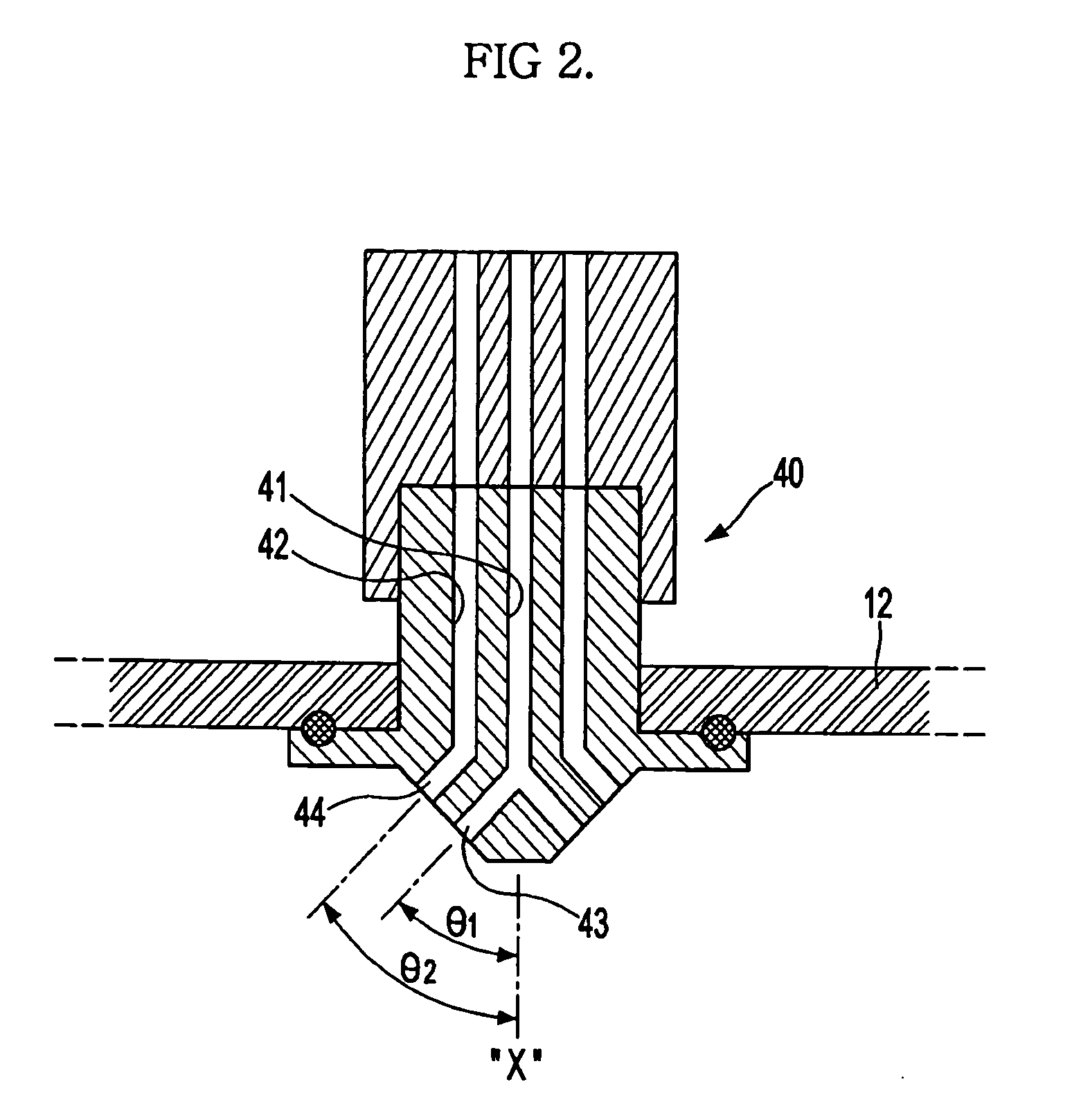

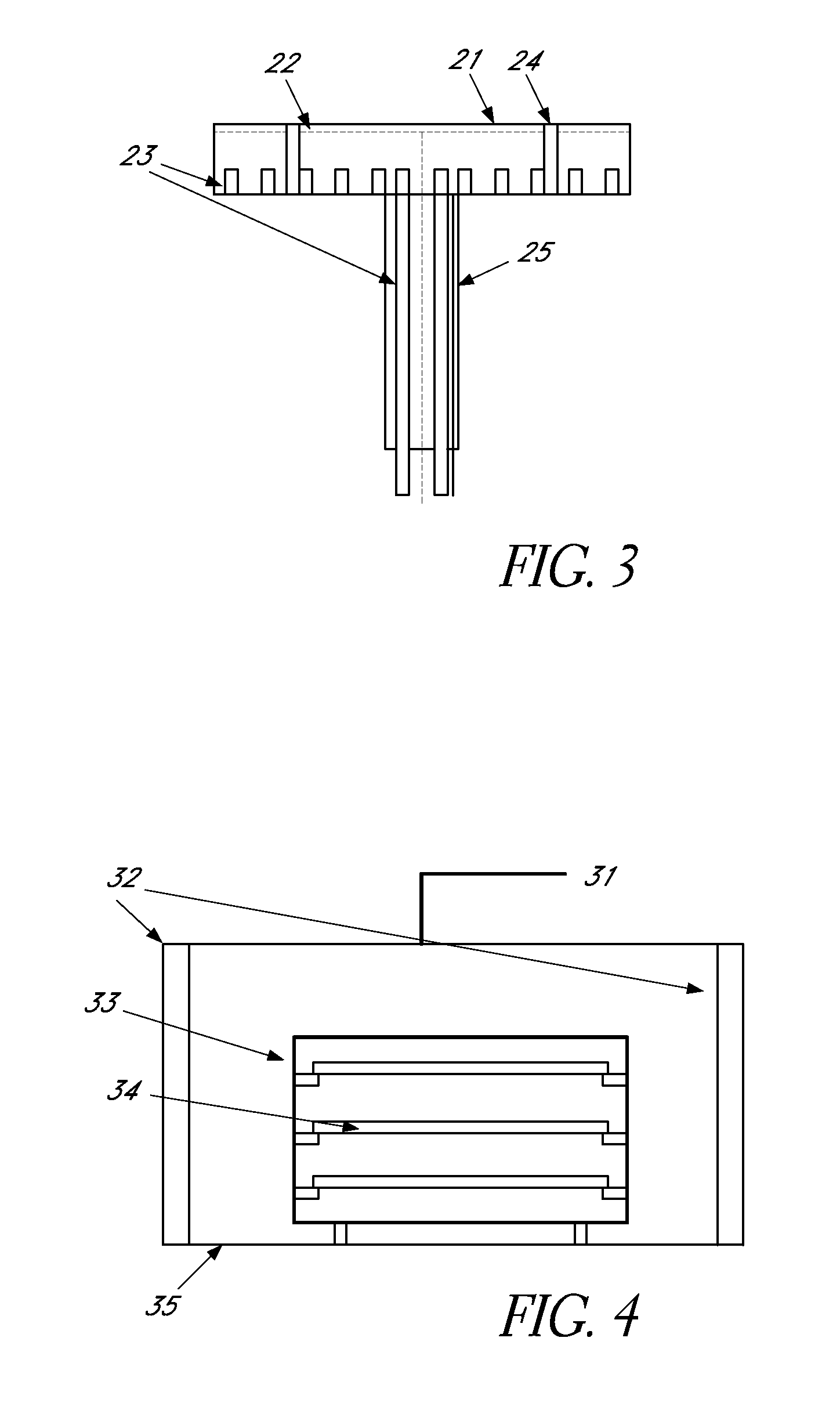

Apparatus to manufacture semiconductor

InactiveUS20060096540A1Expand the scope of diffusionUniformlySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringGas supply

An apparatus to manufacture a semiconductor, in which distribution of process gases supplied to a reaction region in a reaction chamber is uniform, includes a gas supply nozzle to supply process gases to a semiconductor substrate in the reaction chamber, wherein the gas supply nozzle includes a first supply channel formed in a longitudinal direction, and first outlet channels formed at an outlet of the first supply channel such that the first outlet channels are inclined with respect to the direction of the first supply channel at a designated angle to diffuse the process gas supplied through the first supply channel.

Owner:SAMSUNG ELECTRONICS CO LTD

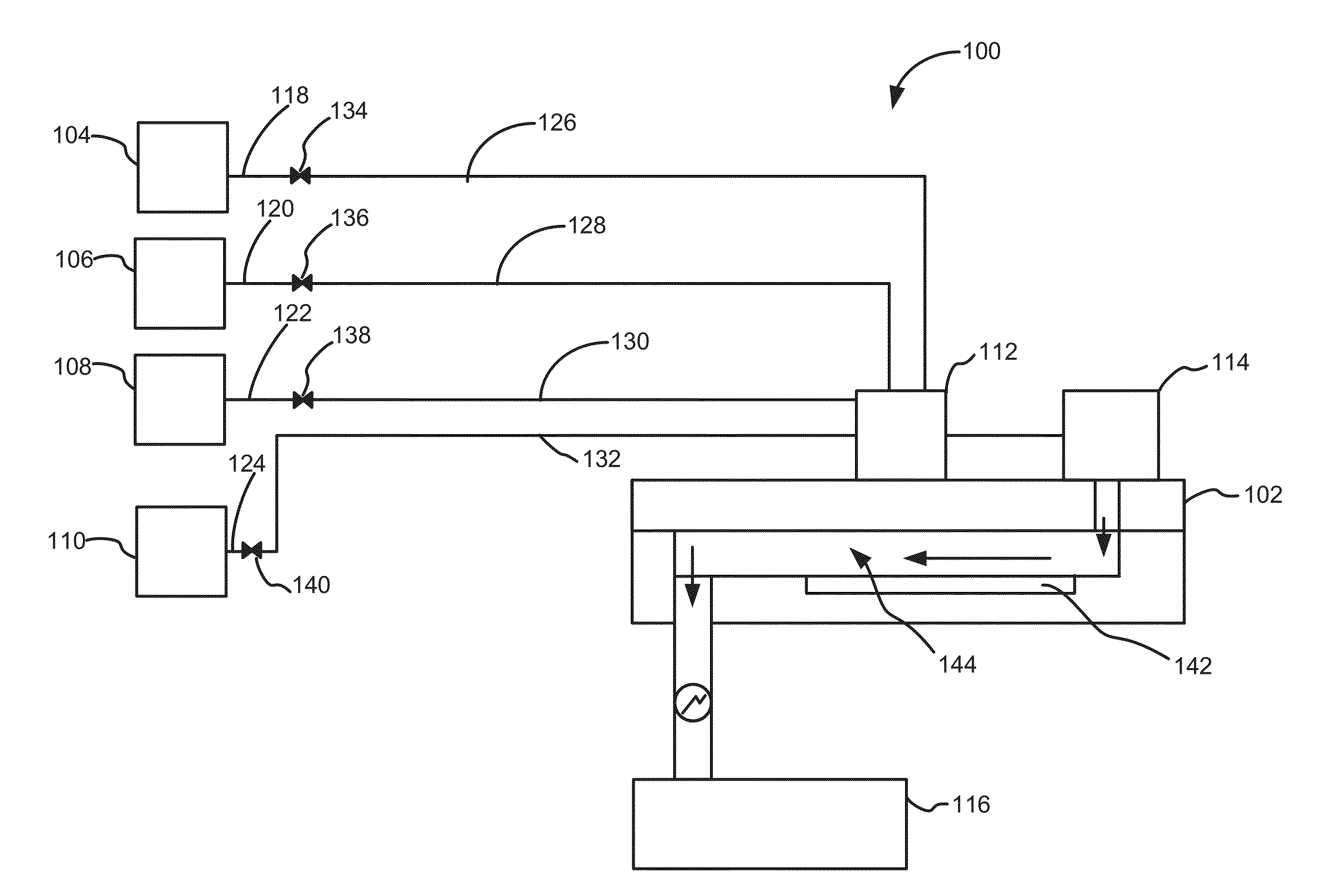

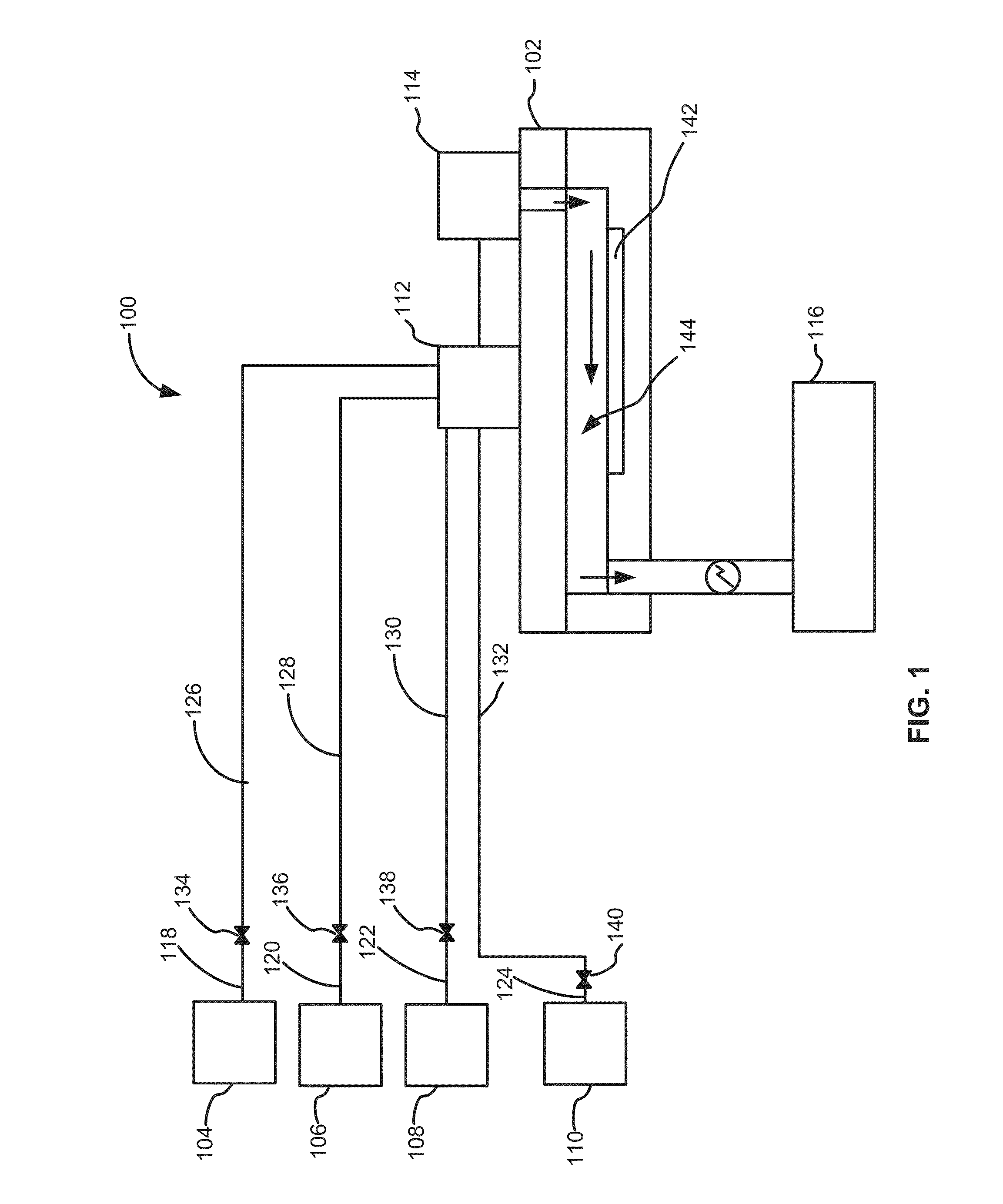

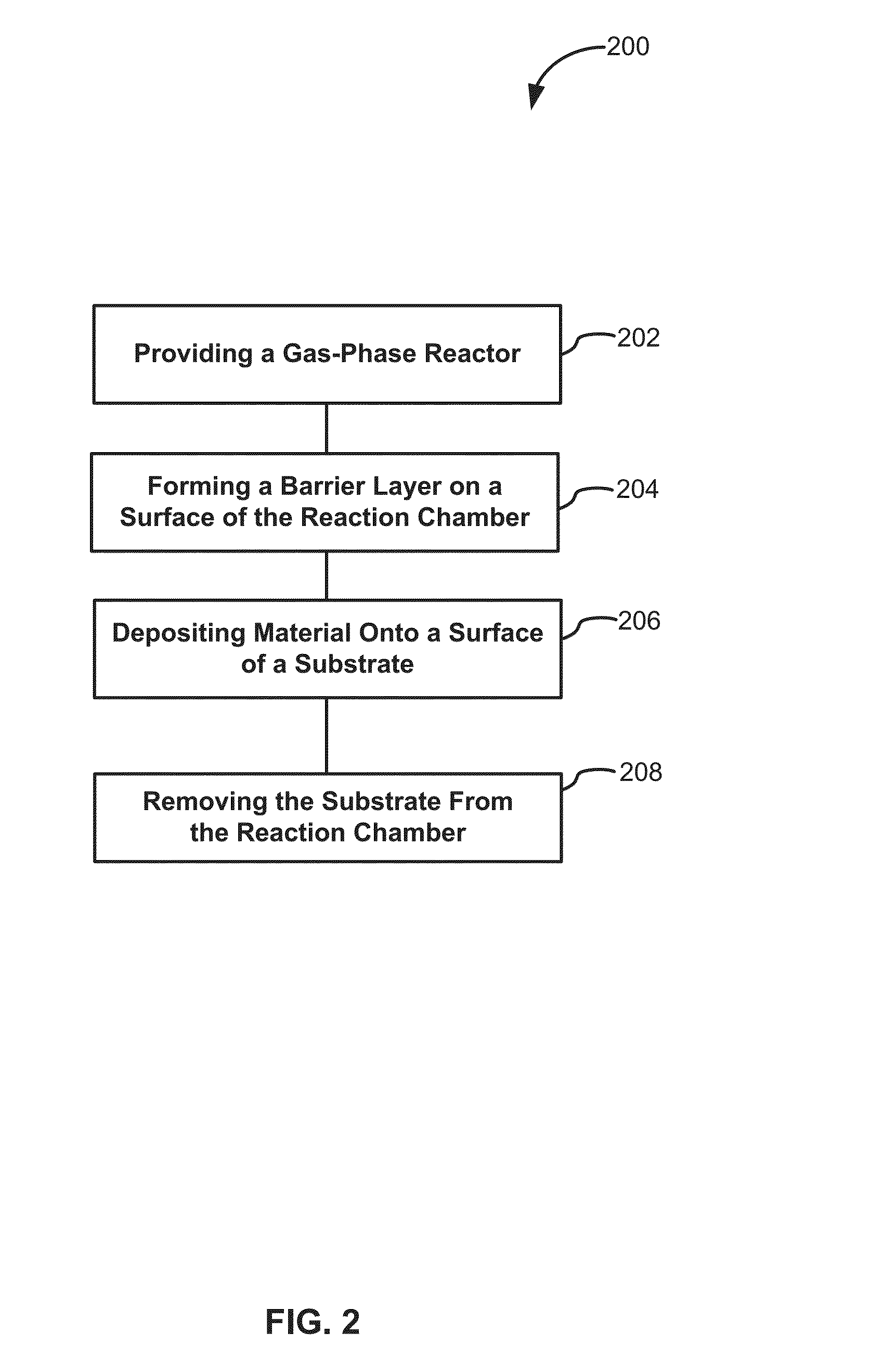

Method and system to reduce outgassing in a reaction chamber

ActiveUS20150140210A1Reduce outgassingImprove thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingOutgassingGas phase

Systems and methods of reducing outgassing of a substance within a reaction chamber of a reactor are disclosed. Exemplary methods include depositing a barrier layer within the reaction chamber and using a scavenging precursor to react with species on a surface of the reaction chamber. Exemplary systems include gas-phase deposition systems, such as atomic layer deposition systems, which include a barrier layer source and / or a scavenging precursor source fluidly coupled to a reaction chamber of the system.

Owner:ASM IP HLDG BV

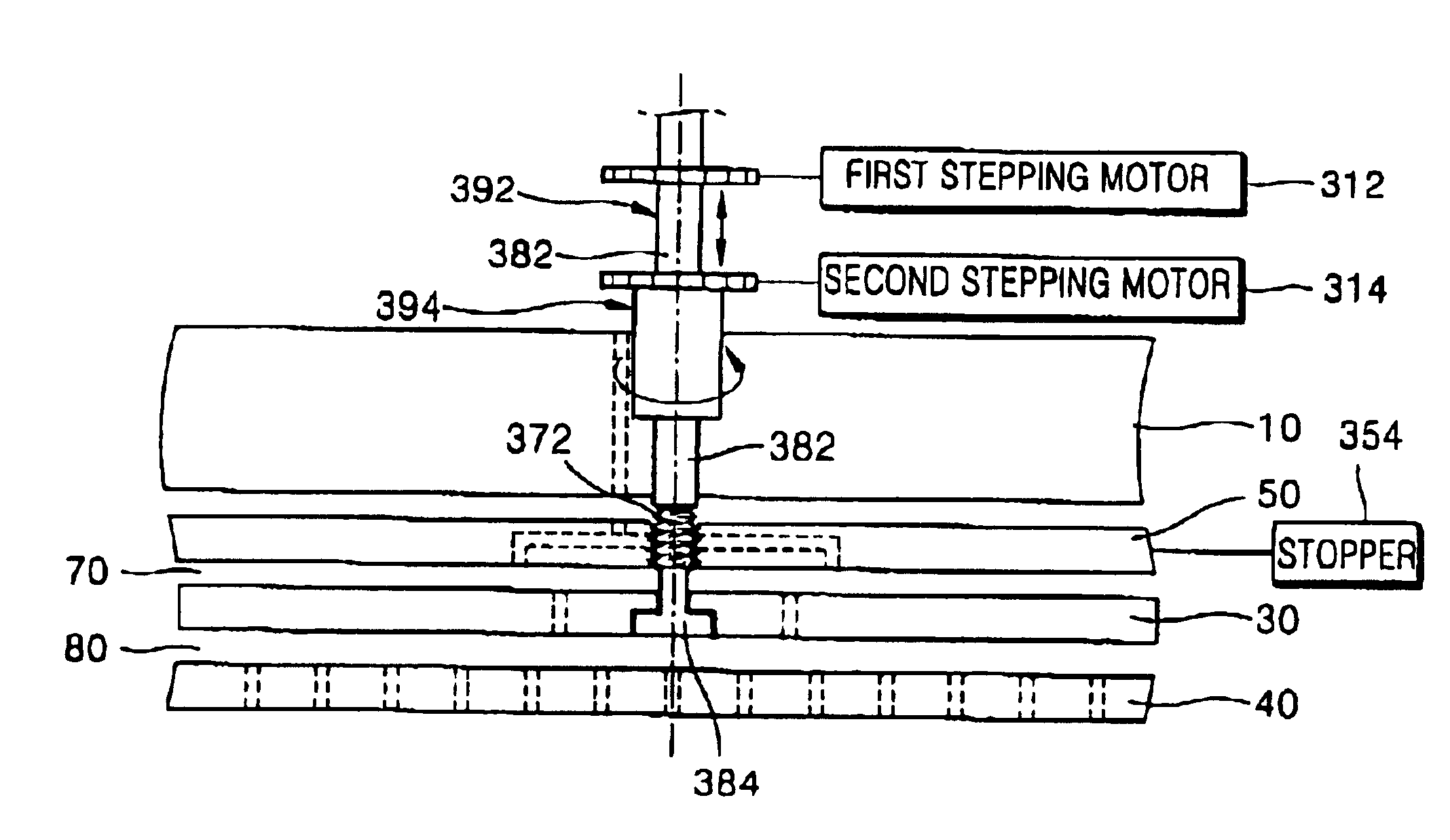

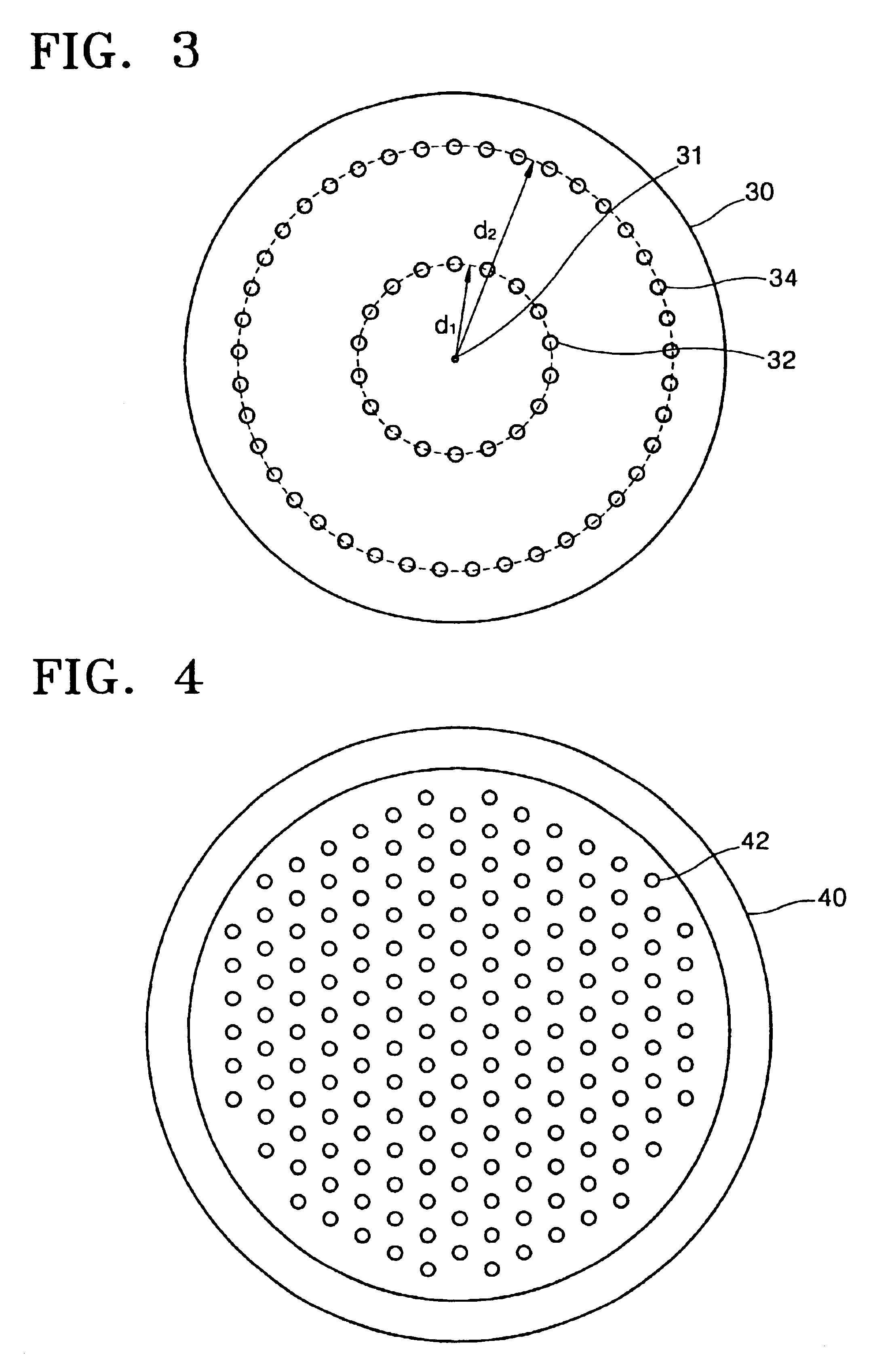

Shower head of a wafer treatment apparatus having a gap controller

InactiveUS6872258B2Improve uniformityEtch rate be optimizedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess regionSemiconductor

A shower head for adjusting distribution of a reactant gas in a process region of a semiconductor manufacturing reaction chamber, wherein a top plate has a gas port for introducing the reactant gas into the reaction chamber; a face plate, having through holes, disposed opposite the process region; a first baffle plate, having through holes, disposed between the top plate and the face plate and capable of moving up or down, wherein the first baffle plate has a top surface that defines a first gap for forming a first lateral flow passage; a second baffle plate, having through holes, disposed between the first baffle plate and the face plate and capable of moving up or down, wherein the second baffle plate has a top surface that defines a second gap for forming a second lateral flow passage; and a gap controller for determining widths of the first and second gaps.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for forming silazane-based dielectric film

A method of forming a dielectric film includes: introducing a source gas essentially constituted by Si, N, H, and optionally C and having at least one bond selected from Si—N, Si—Si, and Si—H into a reaction chamber where a substrate is placed; depositing a silazane-based film essentially constituted by Si, N, H, and optionally C on the substrate by plasma reaction at −50° C. to 50° C., wherein the film is free of exposure of a solvent constituted essentially by C, H, and optionally O; and heat-treating the silazane-based film on the substrate in a heat-treating chamber while introducing an oxygen-supplying source into the heat-treating chamber to release C from the film and increase Si—O bonds in the film.

Owner:ASM JAPAN

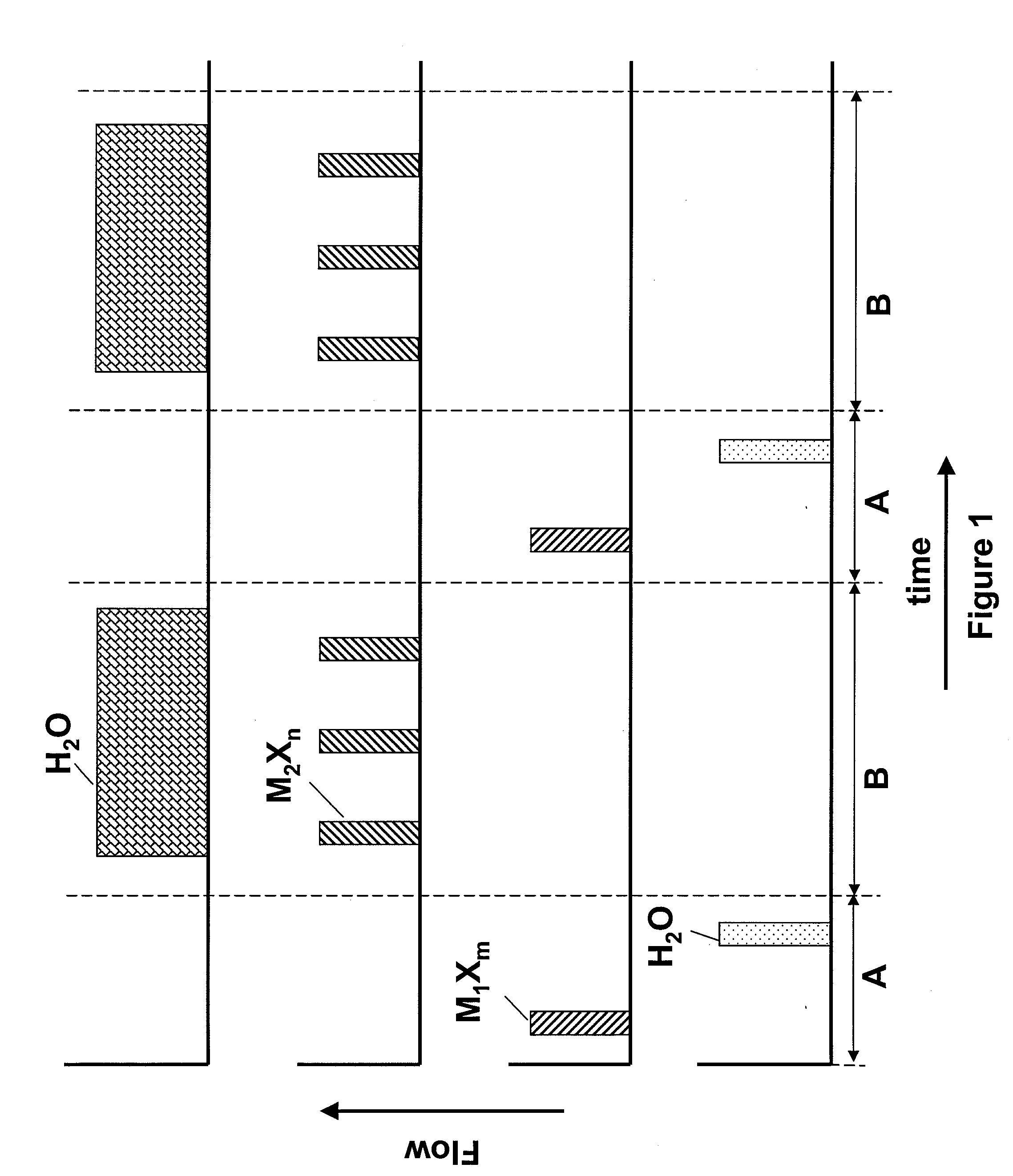

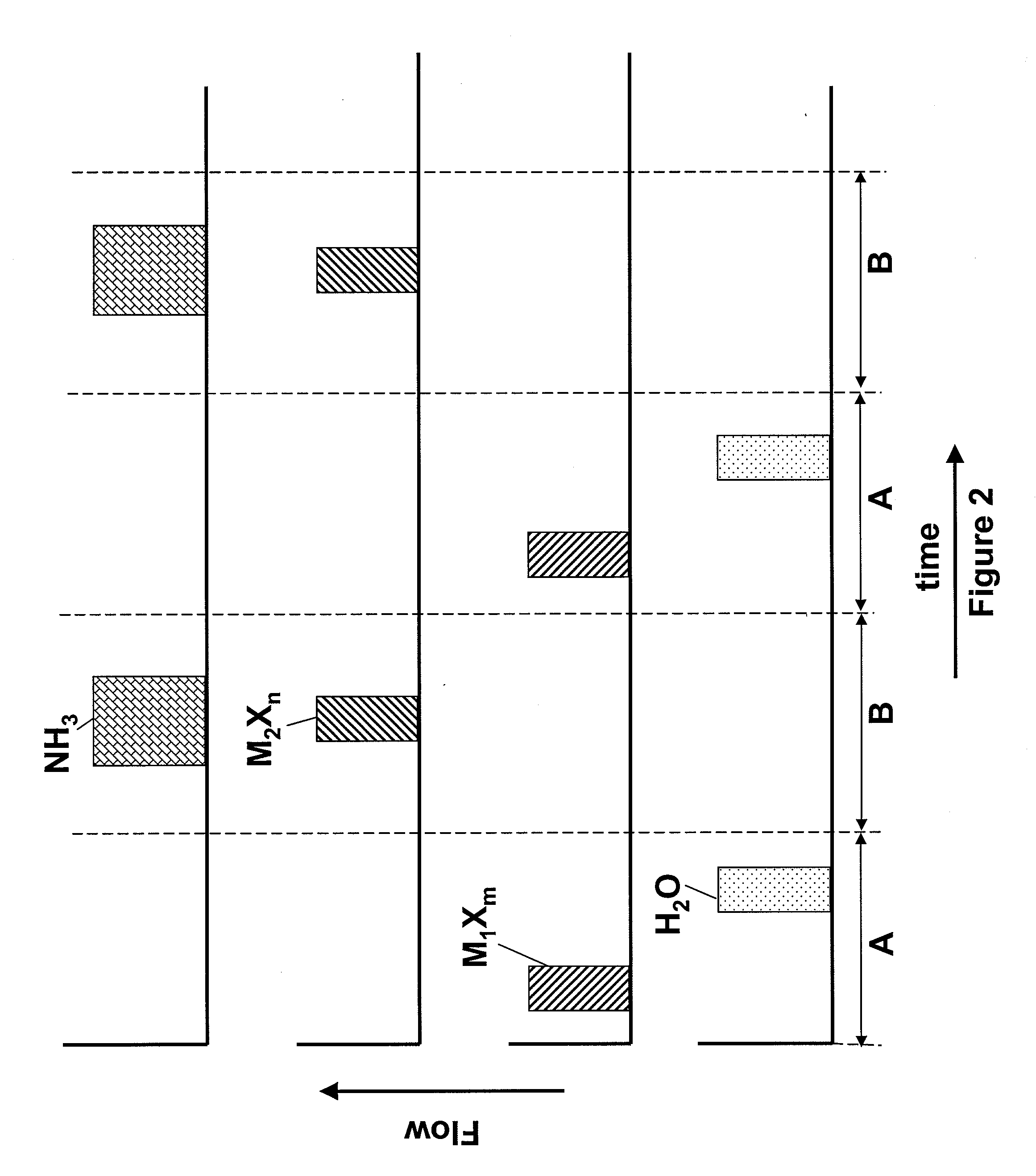

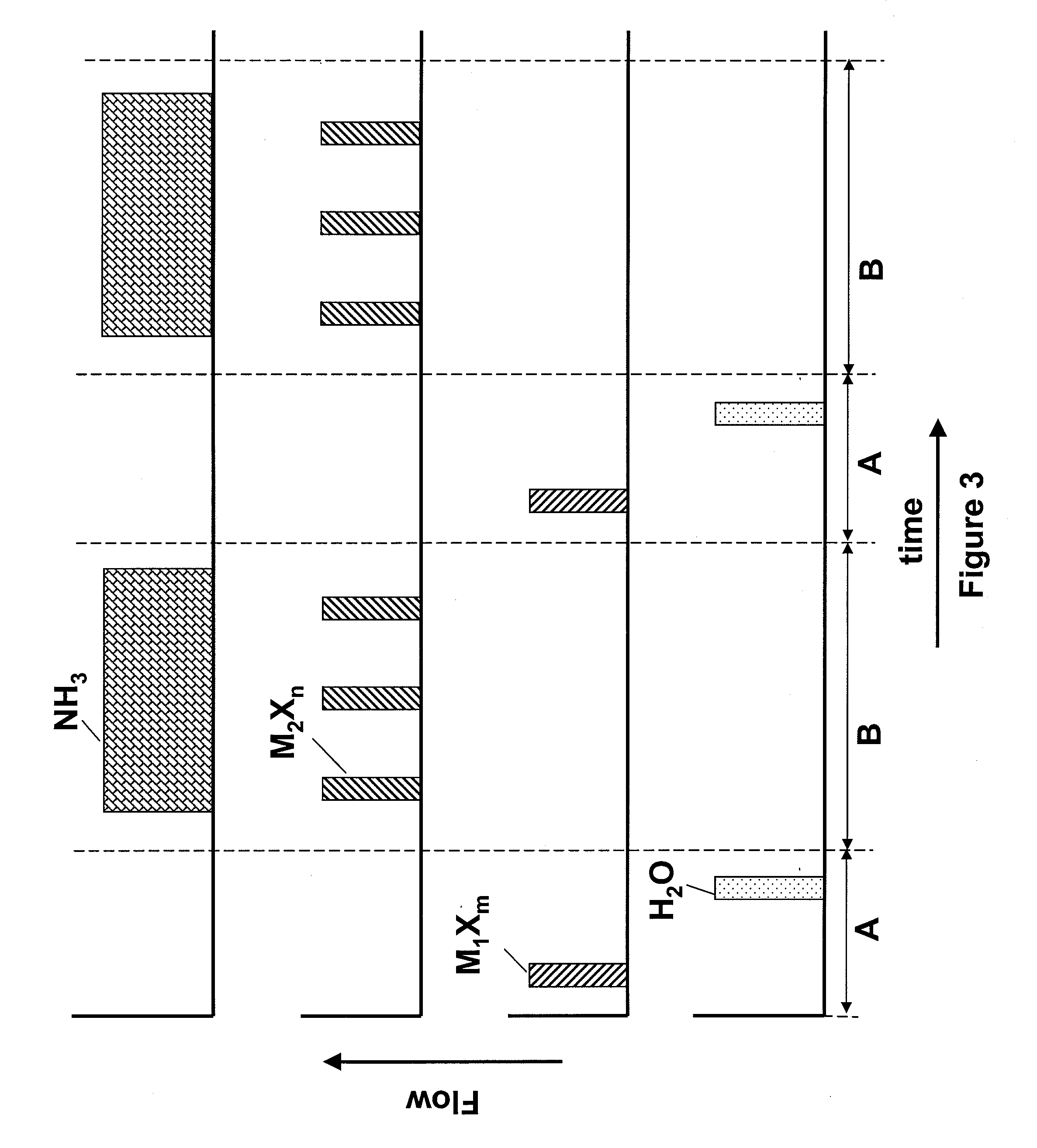

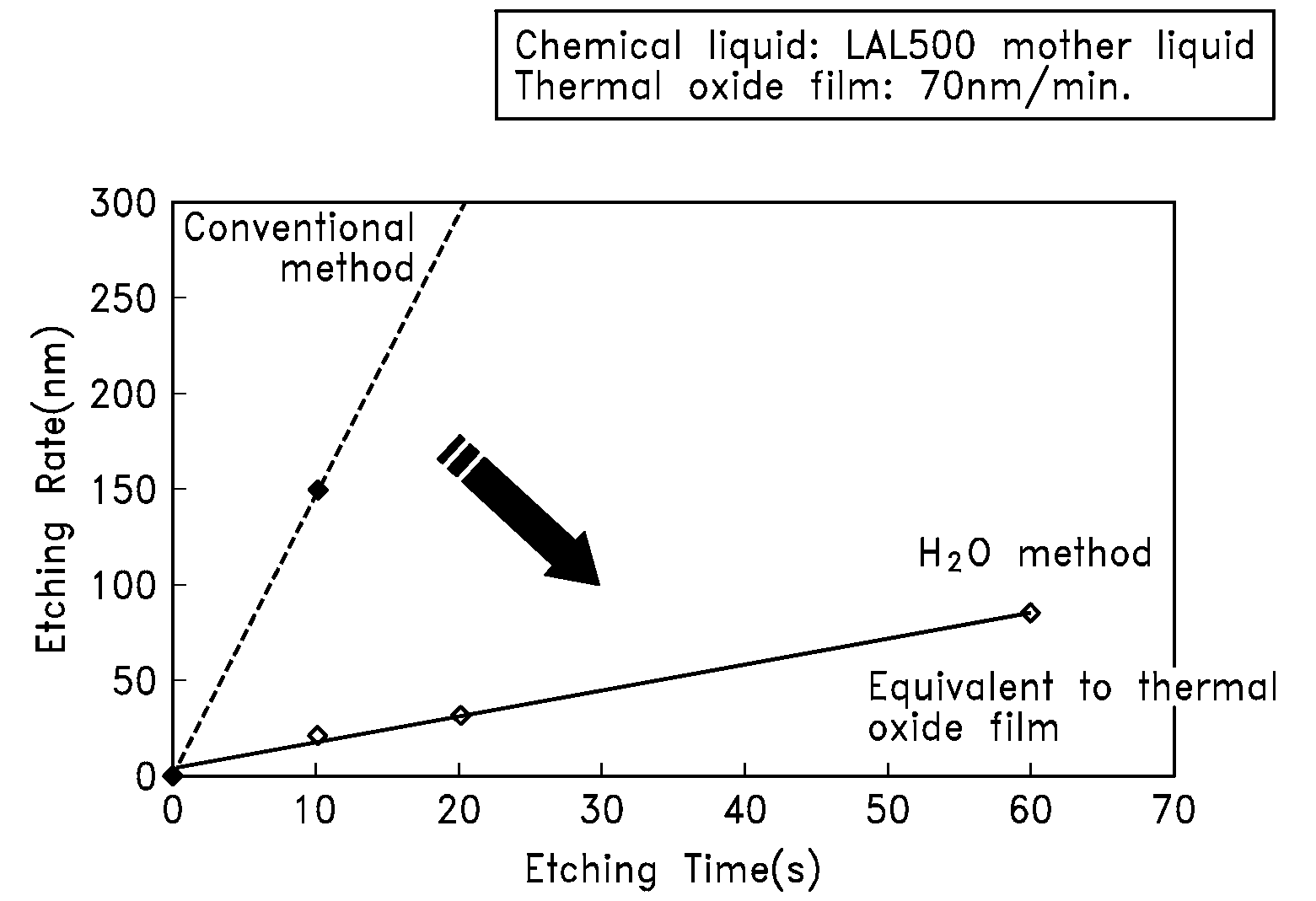

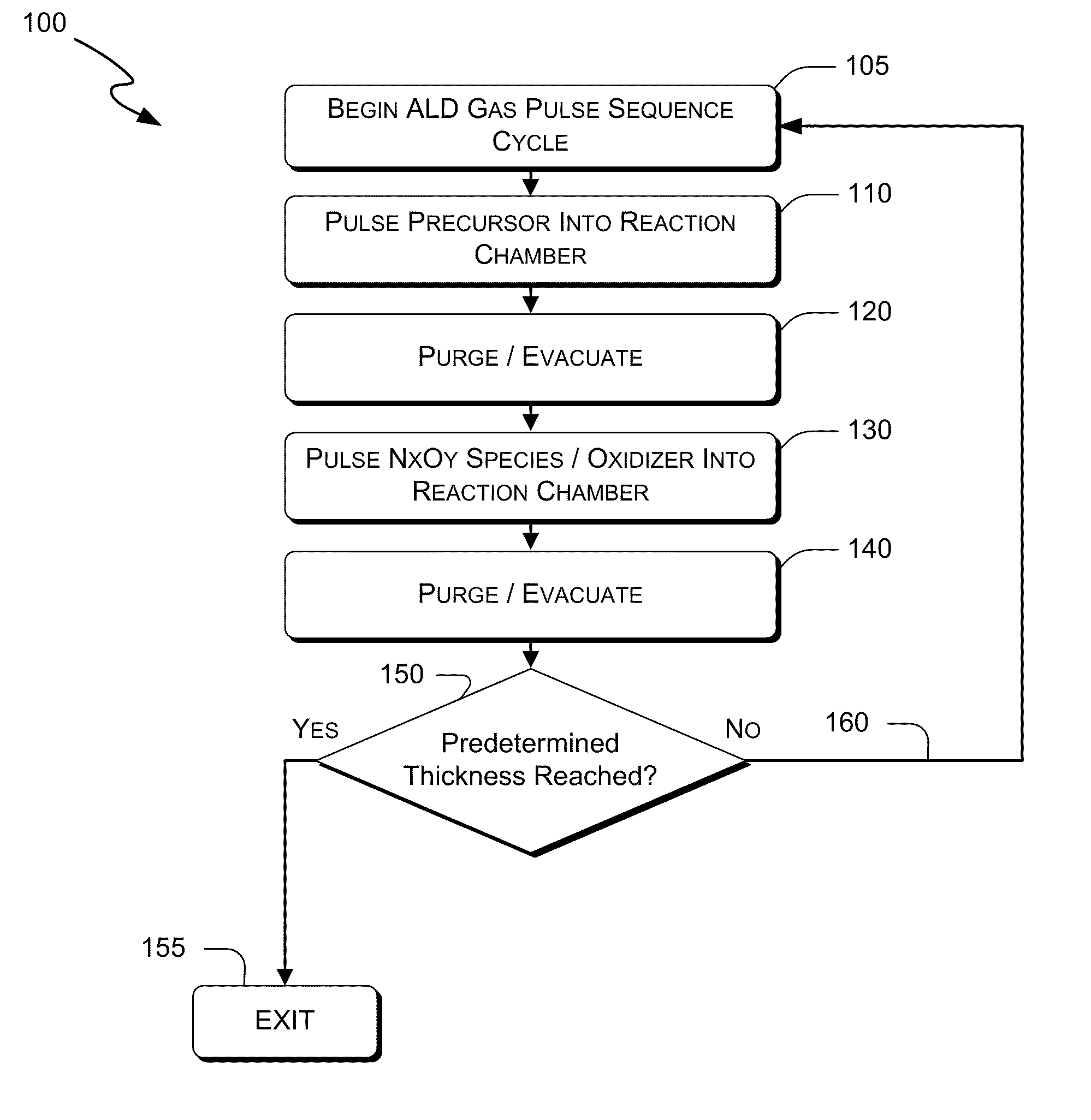

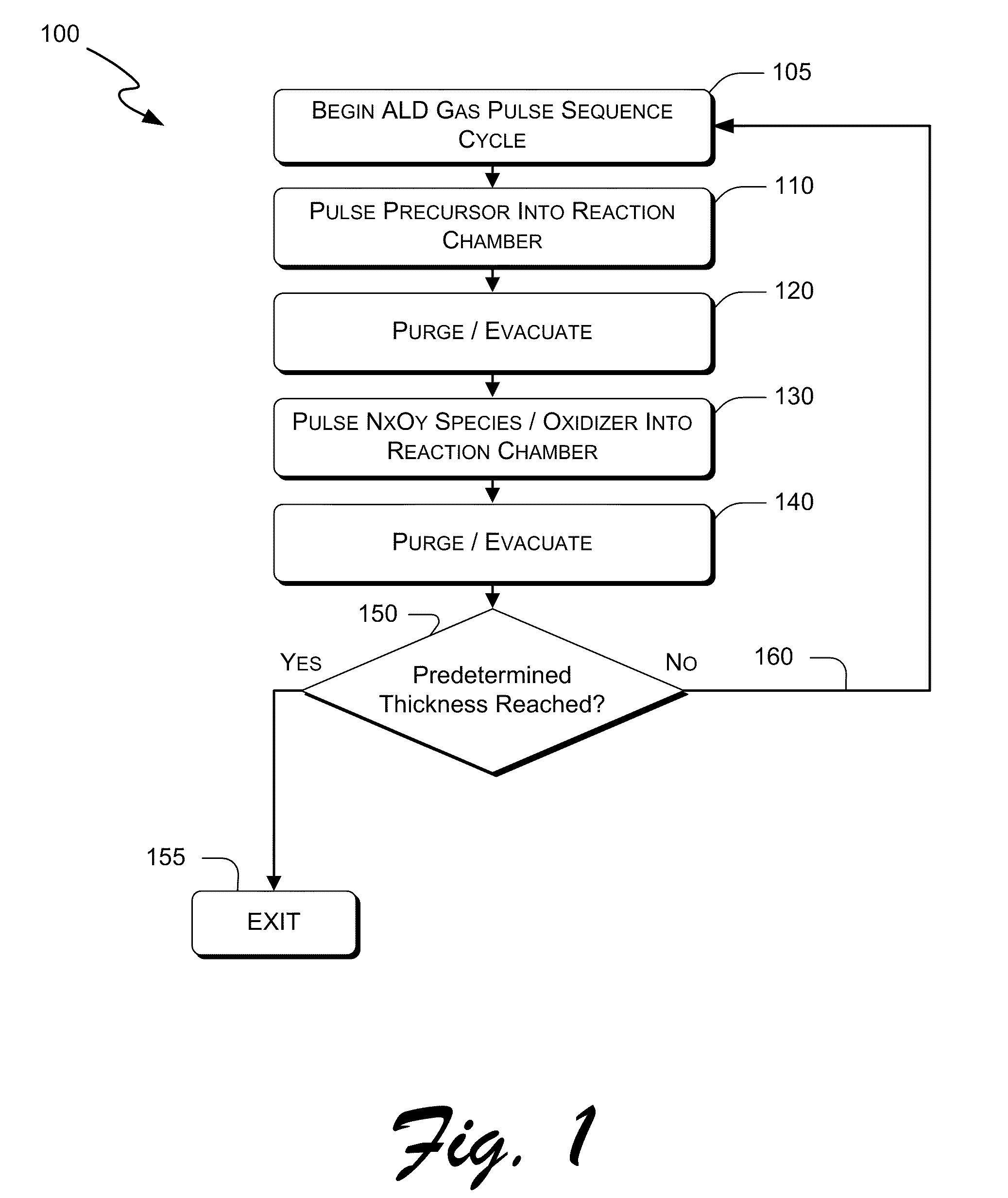

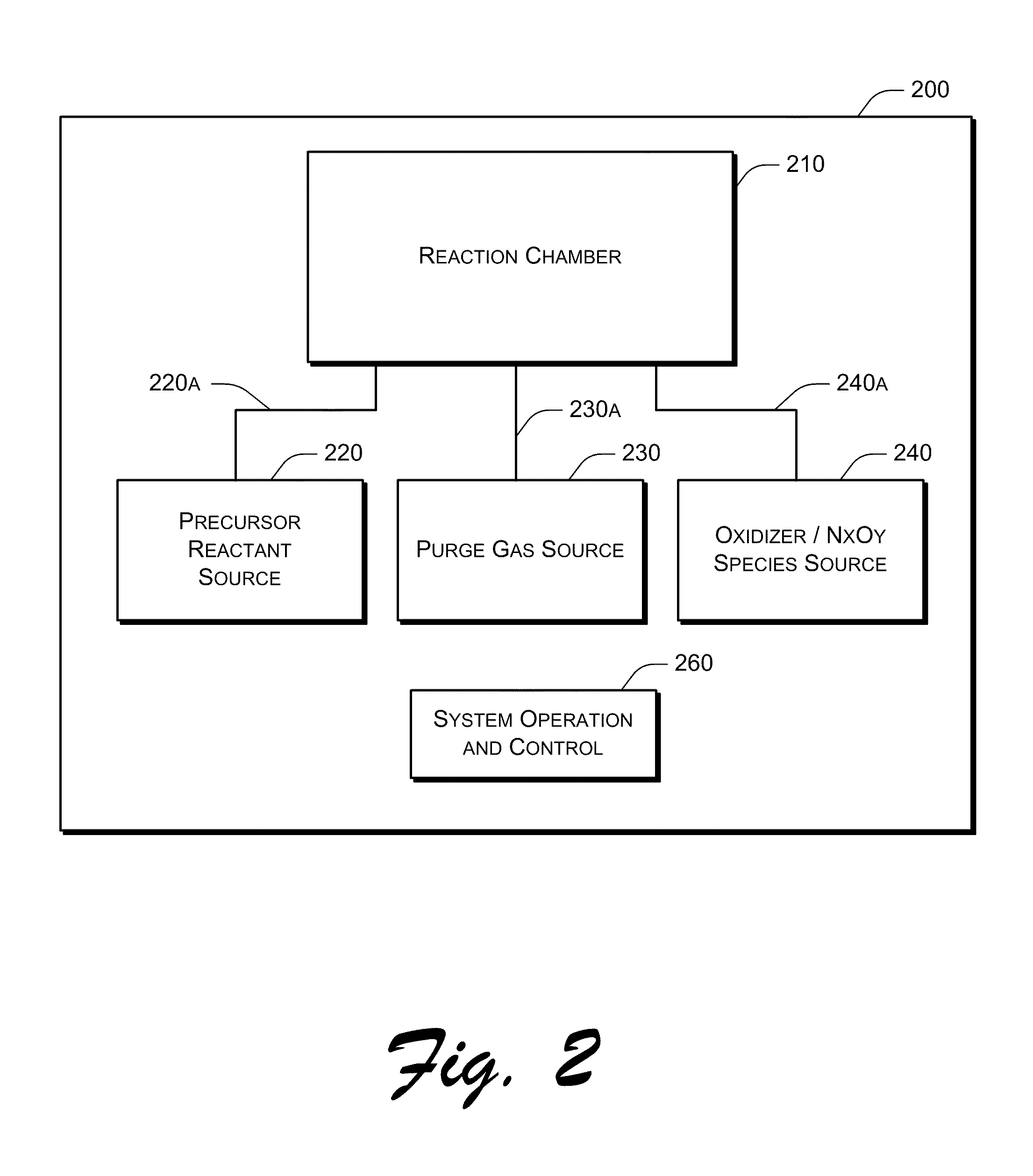

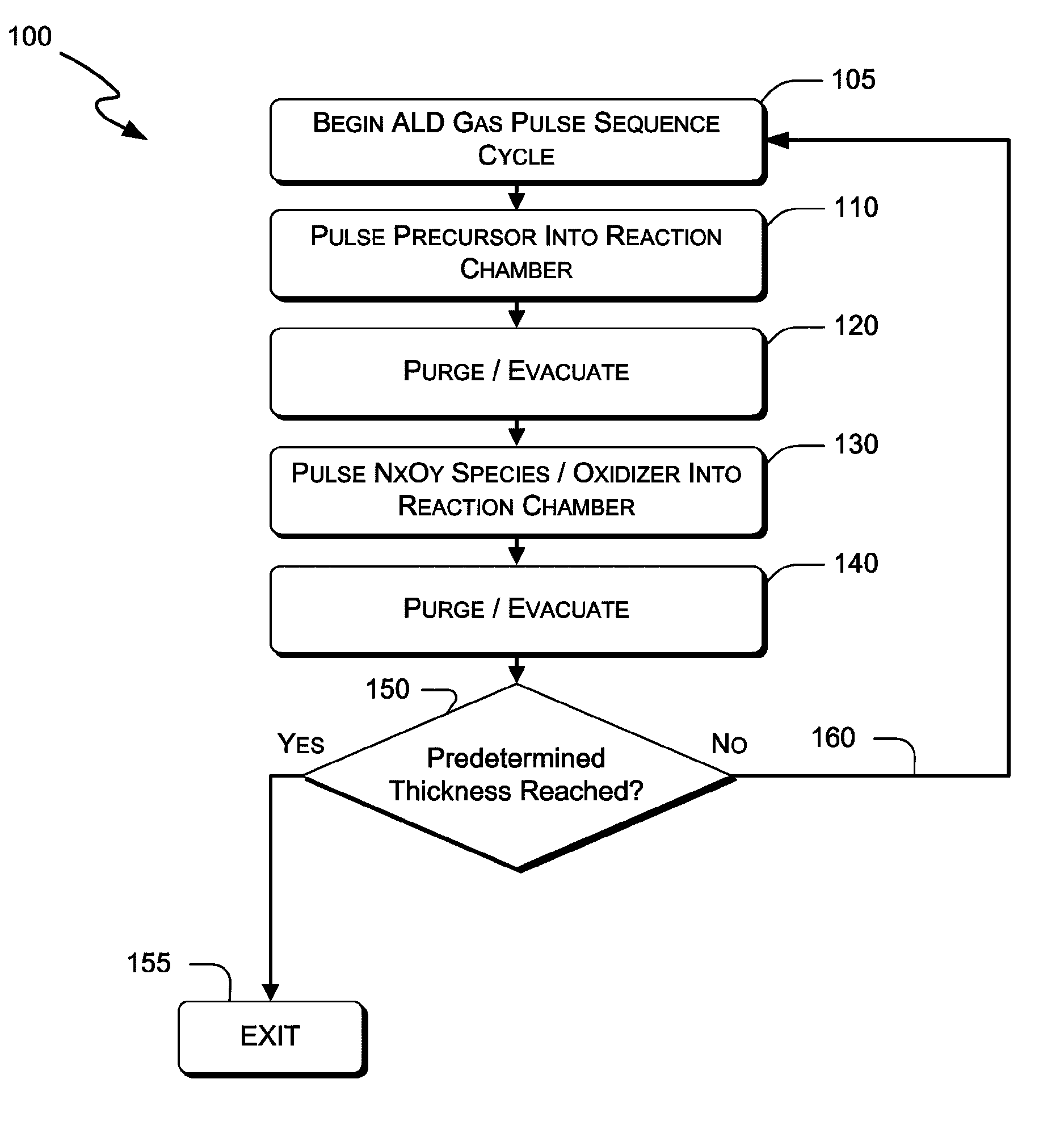

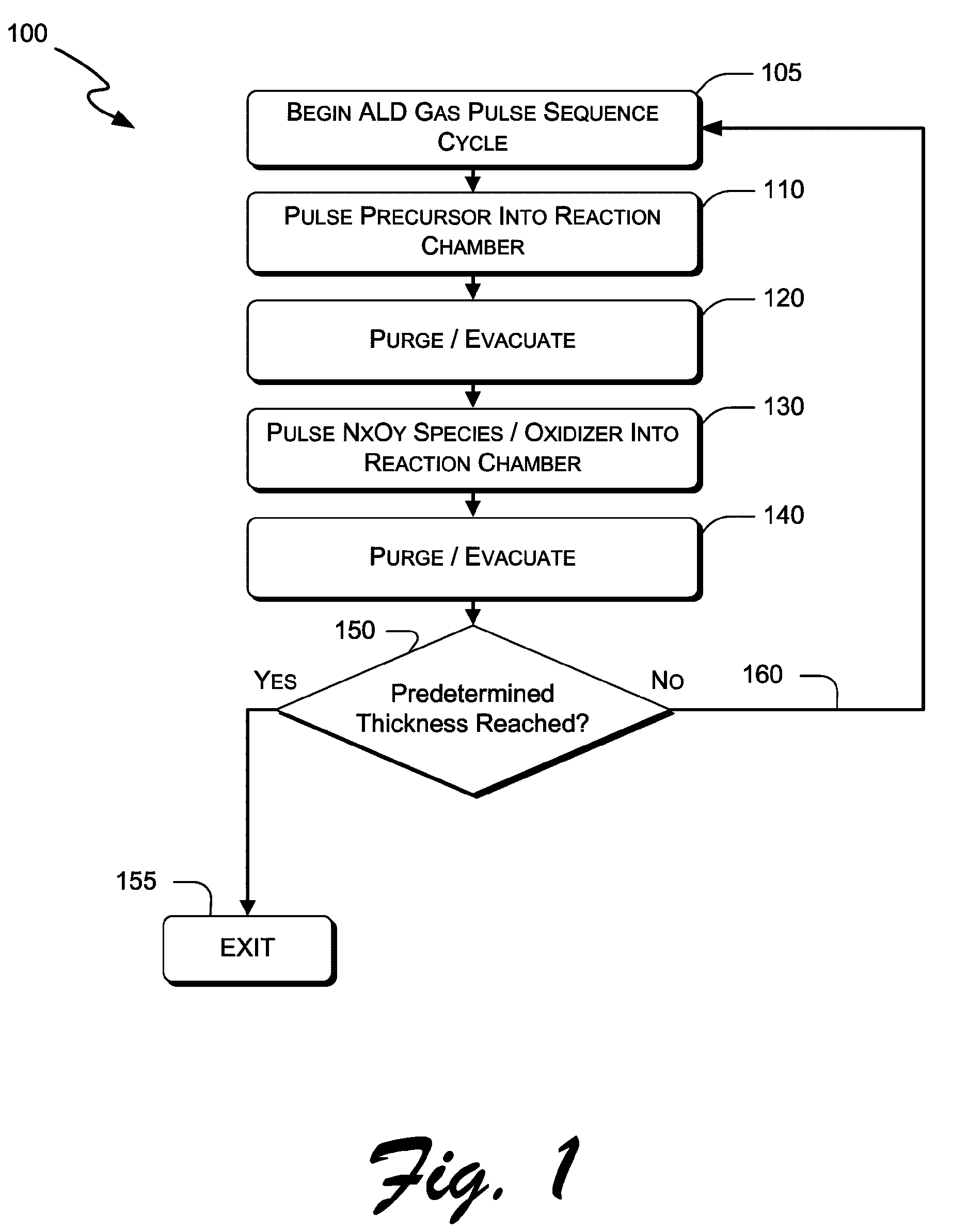

Systems and methods for thin-film deposition of metal oxides using excited nitrogen-oxygen species

ActiveUS20110070380A1Improve deposition efficiencyImprove uniformitySemiconductor/solid-state device manufacturingElectrical discharge ozone preparationNitrogenOxygen

Systems and methods are delineated which, among other things, are for depositing a film on a substrate that is within a reaction chamber. In an exemplary method, the method may comprise applying an atomic layer deposition cycle to the substrate, wherein the cycle may comprise exposing the substrate to a precursor gas for a precursor pulse interval and then removing the precursor gas thereafter, and exposing the substrate to an oxidizer comprising an oxidant gas and a nitrogen-containing species gas for an oxidation pulse interval and then removing the oxidizer thereafter. Aspects of the present invention utilize molecular and excited nitrogen-oxygen radical / ionic species in possible further combination with oxidizers such as ozone. Embodiments of the present invention also include electronic components and systems that include devices fabricated with methods consistent with the present invention.

Owner:ASM IP HLDG BV

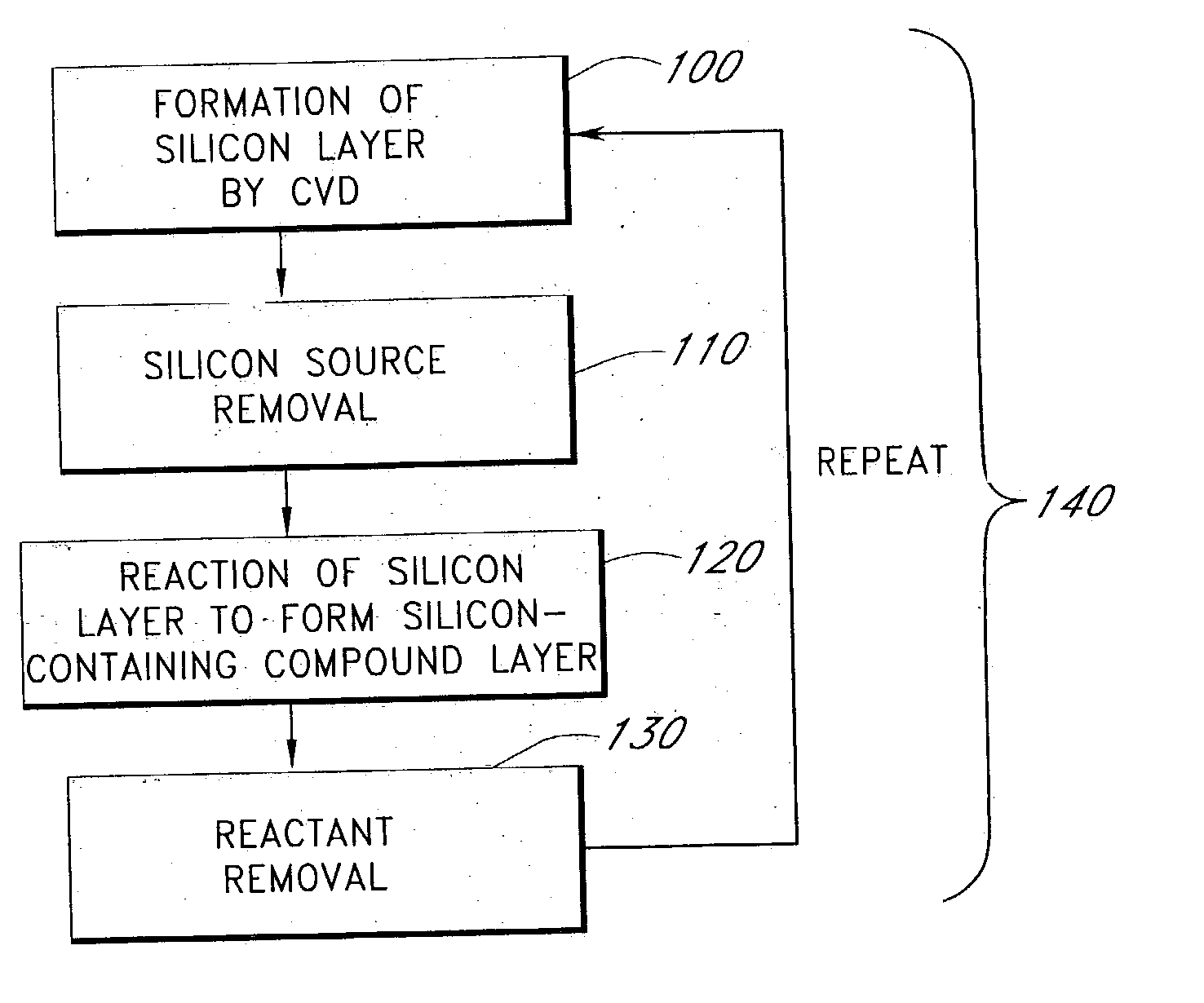

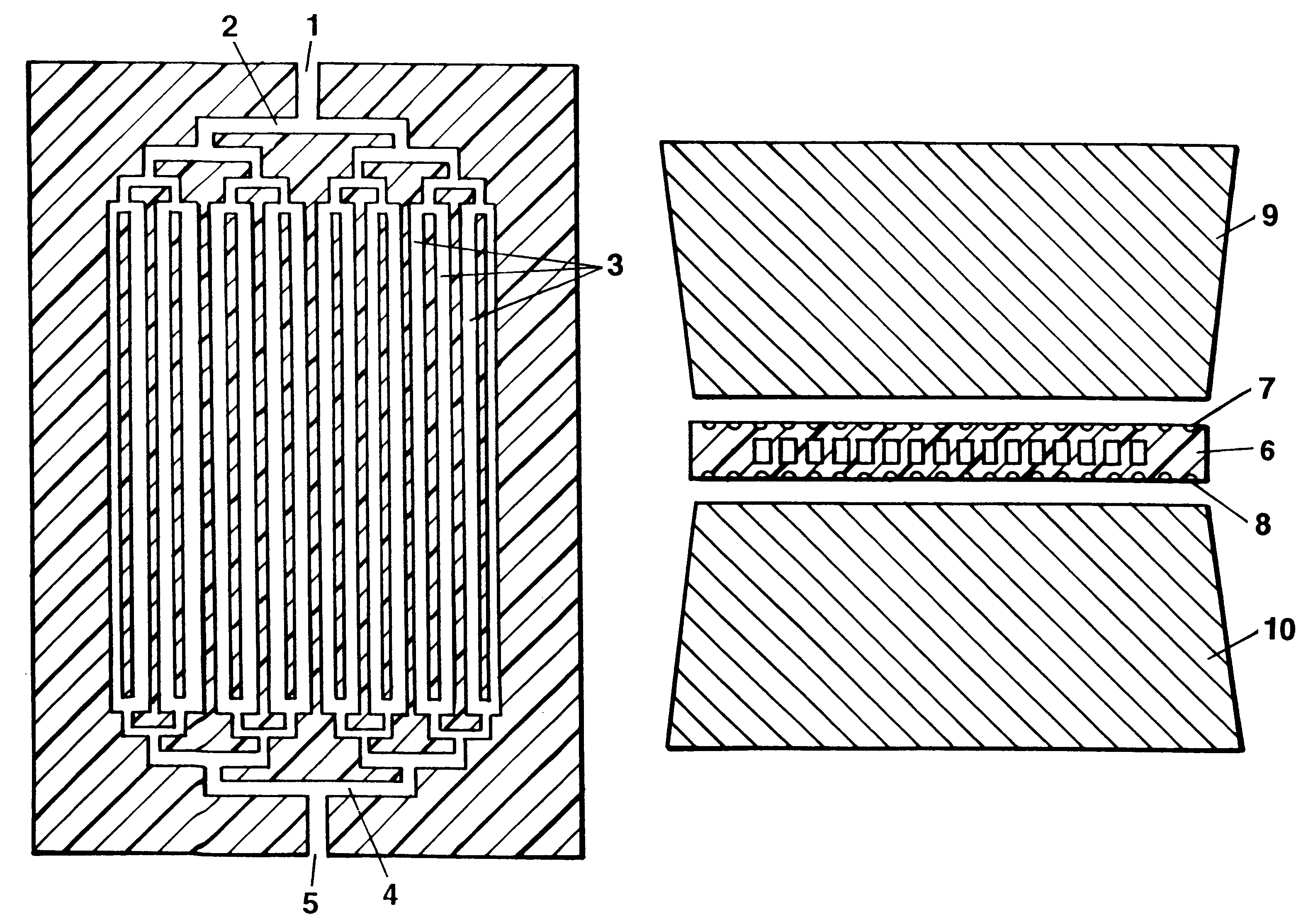

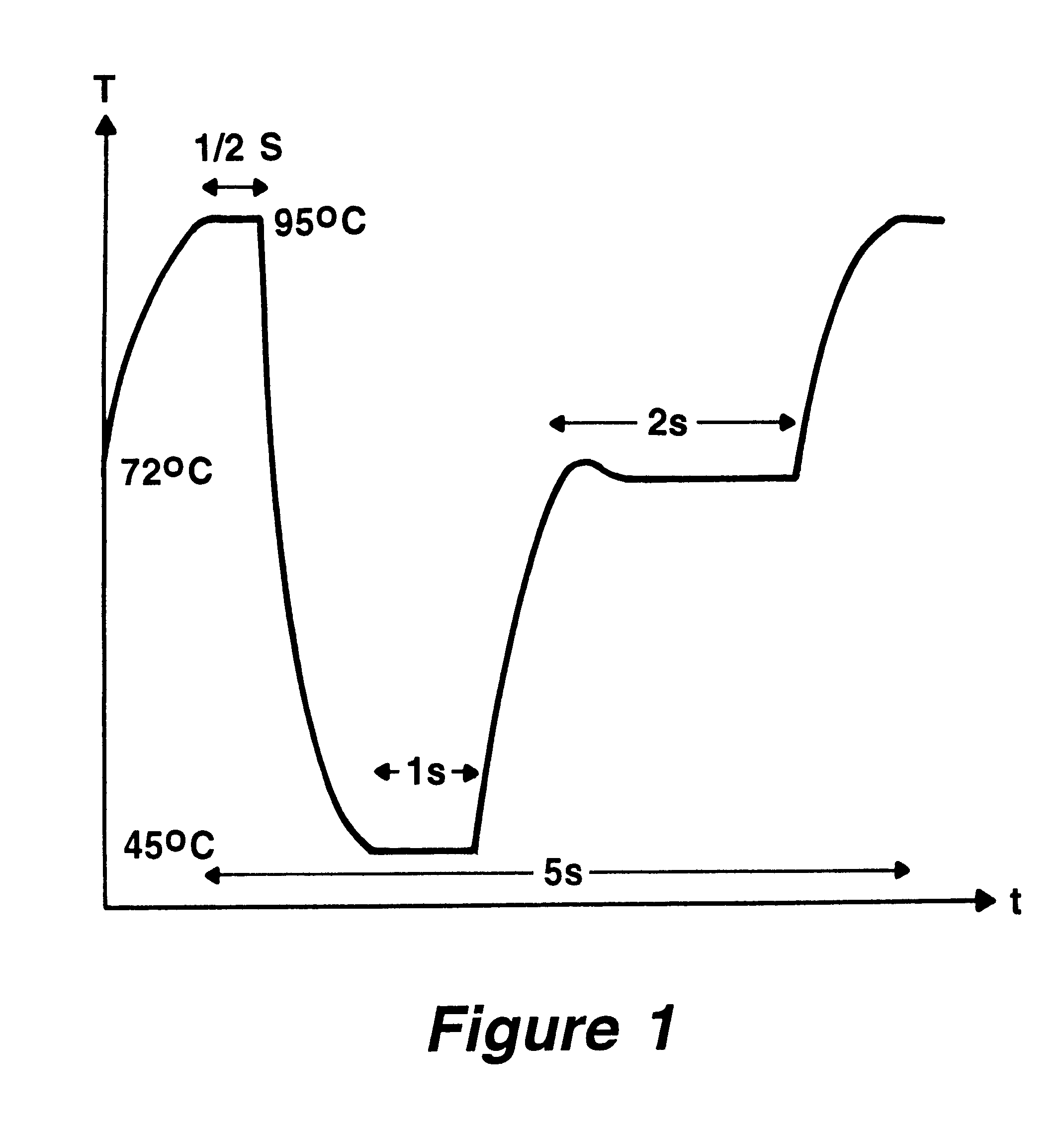

Method and devices for extremely fast DNA replication by polymerase chain reactions (PCR)

InactiveUS6180372B1Shorten cycle timeHigh sensitivityBioreactor/fermenter combinationsNanotechPolymerase LBiological materials

The invention concerns methods and instruments for fast, selective replication of deoxyribonucleic acid (DNA) from biomaterial through the known polymerase chain reaction (PCR), working in individual duplication thermocycles. The invention consists of extremely brief cycle times of only a few seconds for the PCR reactions, generated, on the one hand, by reaction chambers for the reception of the reaction solution constructed of a pattern of fine capillaries in close proximity to heating and cooling elements in order to optimally accelerate the temperature setting in the reaction solution for the three temperature phases of the PCR duplication cycles and, on the other hand, by keeping the flow rates in the capillaries to a minimum during the amplification phase so that the polymerase reaction is not disturbed. The capillary pattern can be simply produced by means of microsystern technology.

Owner:BRUKER FRANZEN ANALYTIK

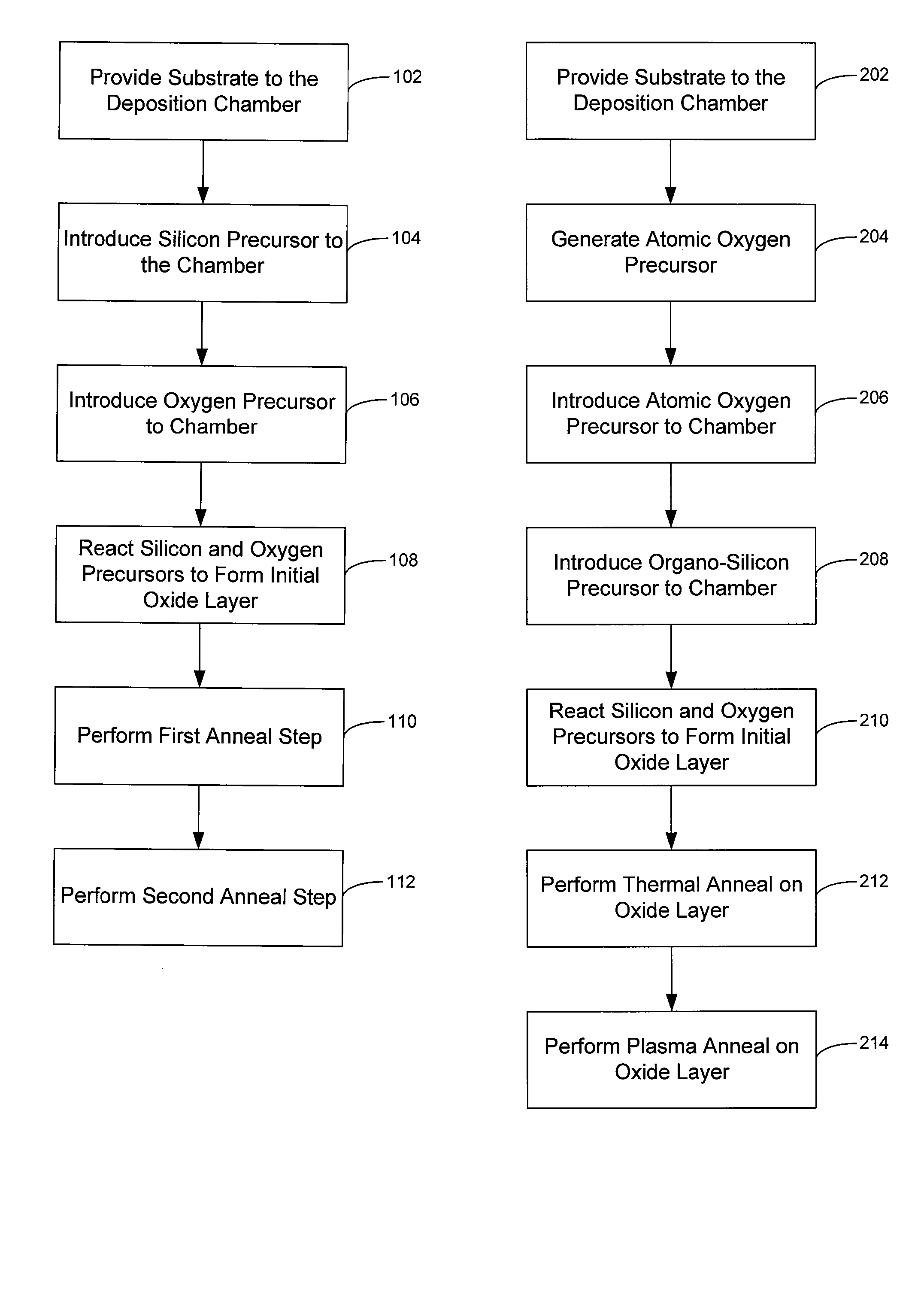

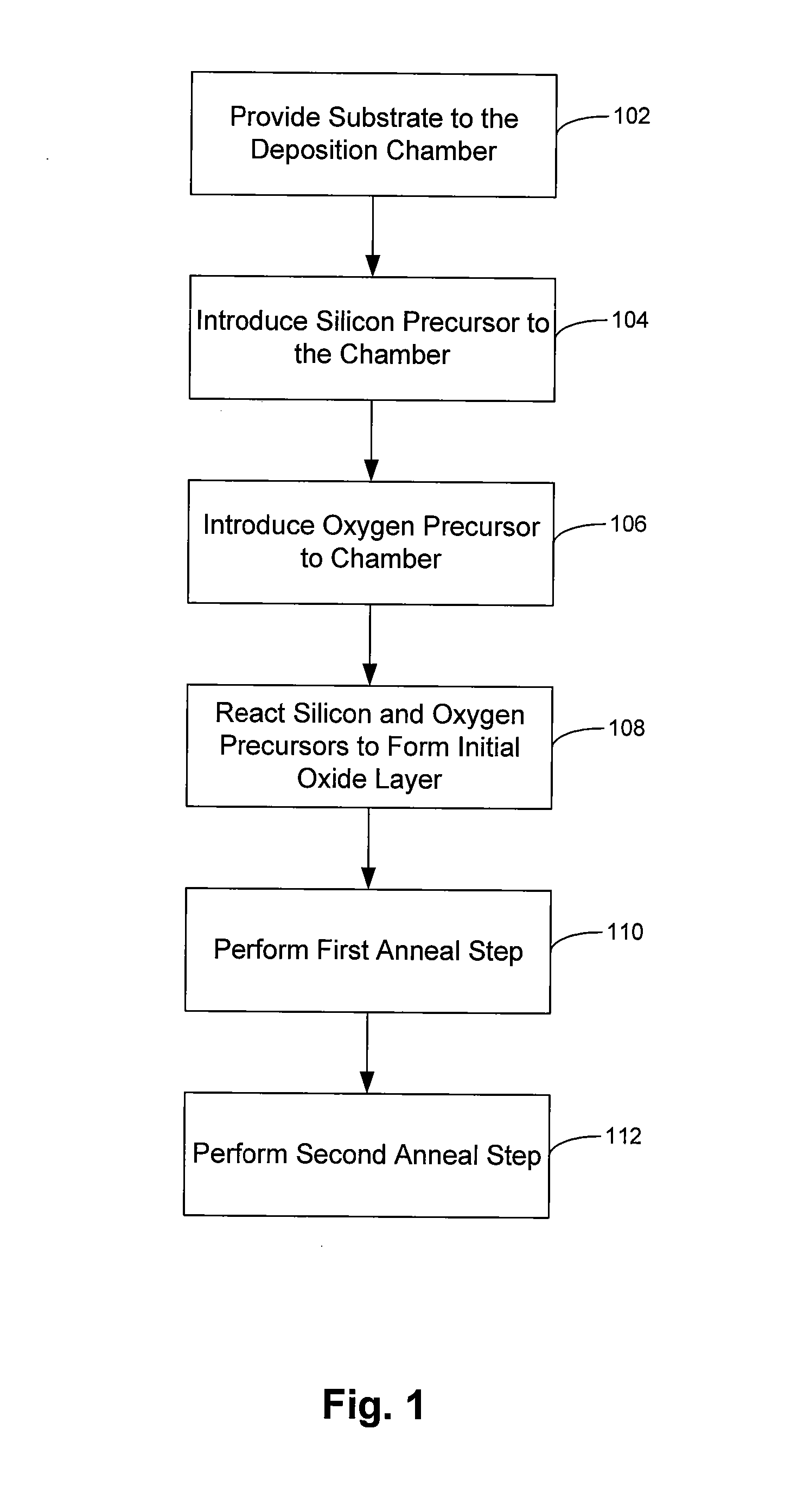

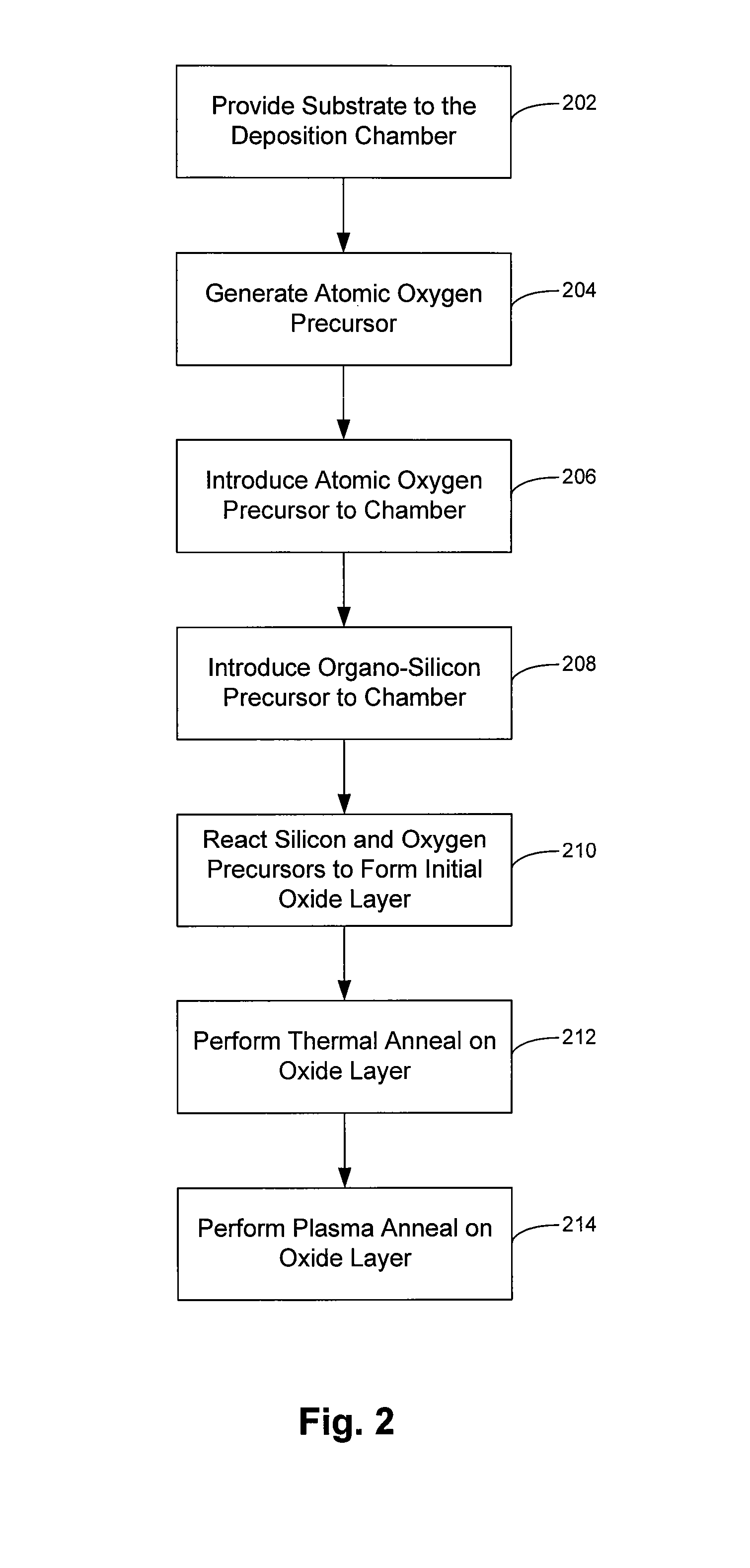

Method for depositing and curing low-k films for gapfill and conformal film applications

ActiveUS20080026597A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideAtomic oxygen

Methods of making a silicon oxide layer on a substrate are described. The methods may include forming the silicon oxide layer on the substrate in a reaction chamber by reacting an atomic oxygen precursor and a silicon precursor and depositing reaction products on the substrate. The atomic oxygen precursor is generated outside the reaction chamber. The methods also include heating the silicon oxide layer at a temperature of about 600° C. or less, and exposing the silicon oxide layer to an induced coupled plasma. Additional methods are described where the deposited silicon oxide layer is cured by exposing the layer to ultra-violet light, and also exposing the layer to an induced coupled plasma.

Owner:APPLIED MATERIALS INC

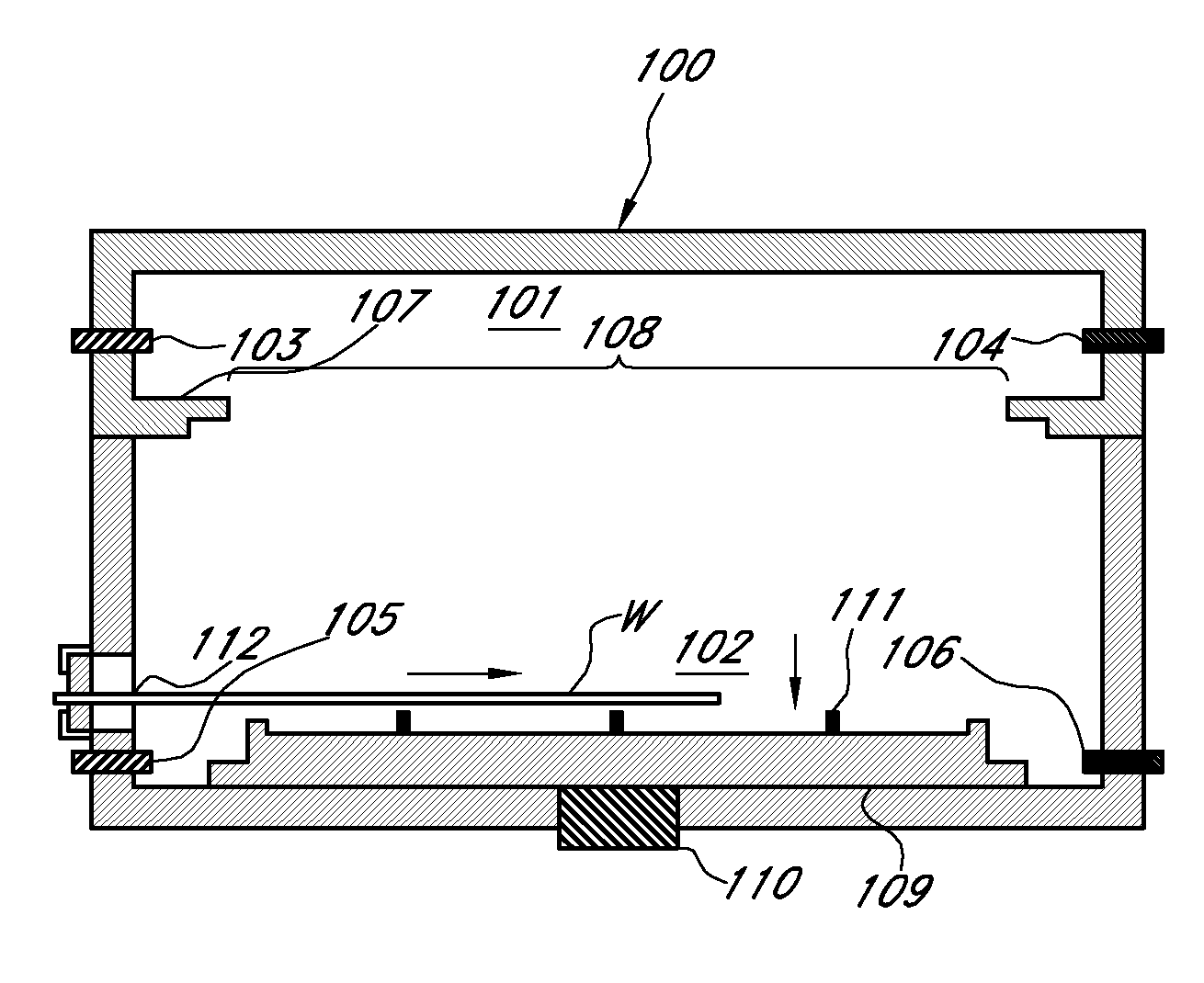

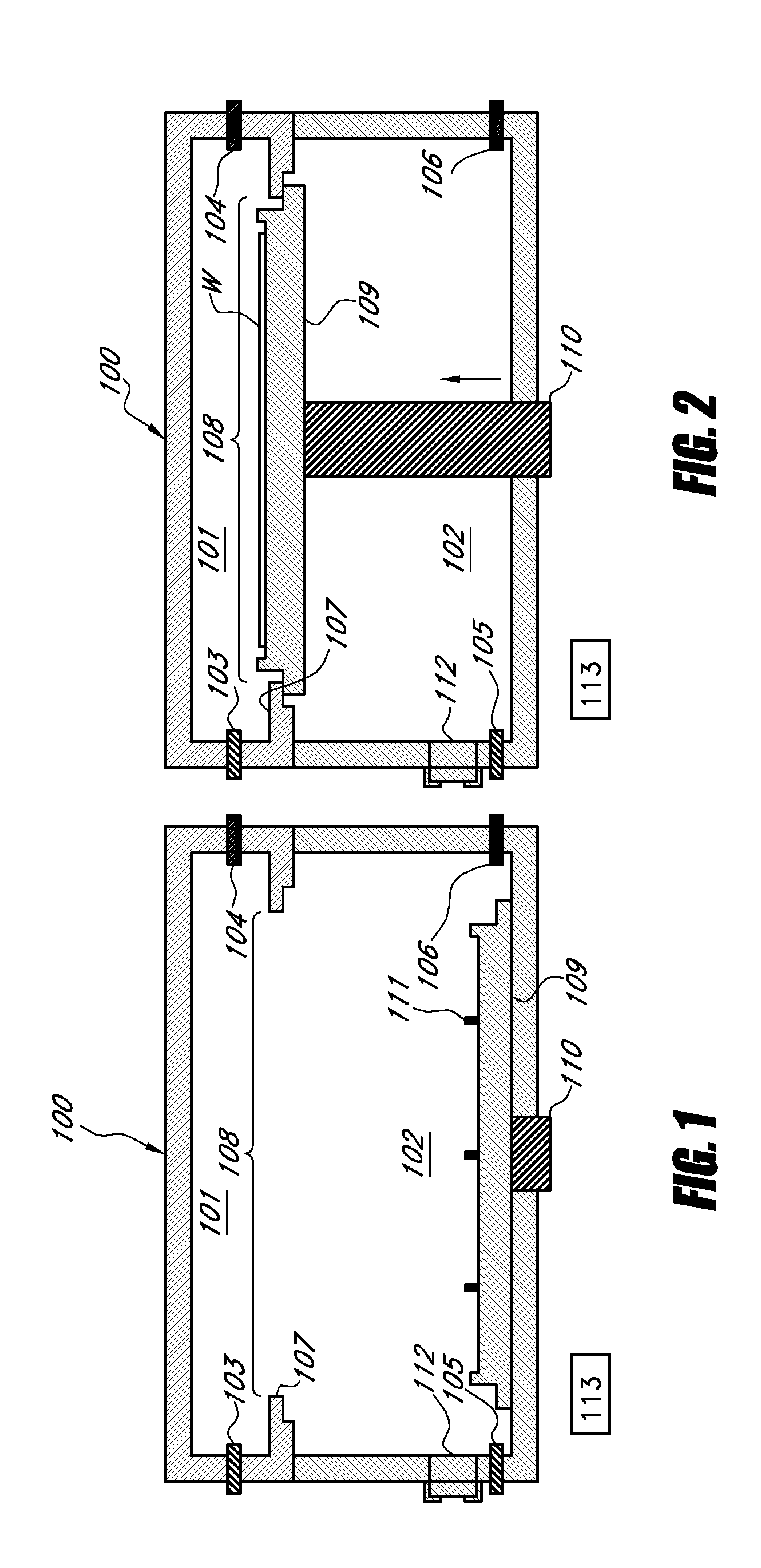

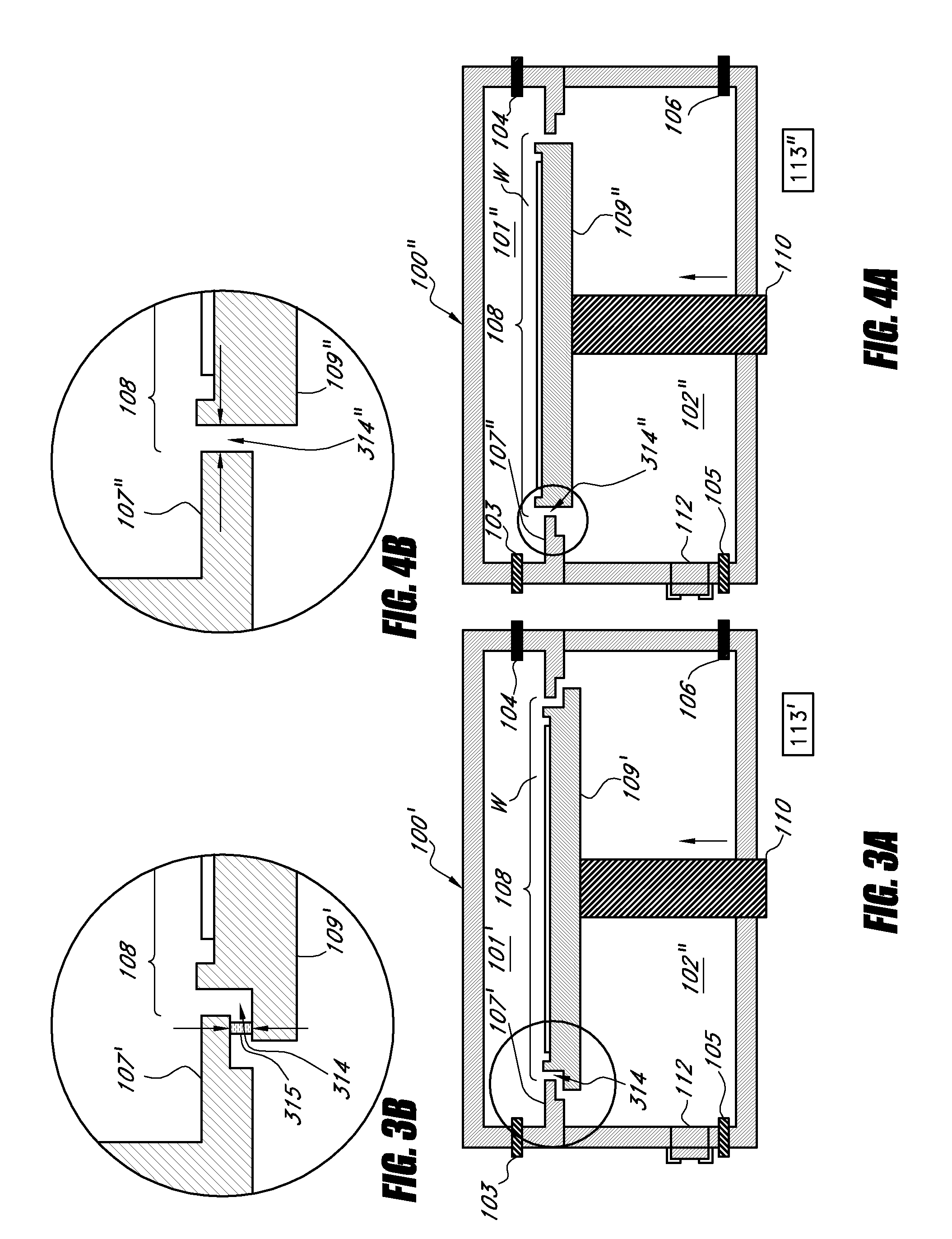

Method and apparatus for minimizing contamination in semiconductor processing chamber

ActiveUS8287648B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingPositive pressureControl system

A semiconductor processing apparatus includes a reaction chamber, a loading chamber, a movable support, a drive mechanism, and a control system. The reaction chamber includes a baseplate. The baseplate includes an opening. The movable support is configured to hold a workpiece. The drive mechanism is configured to move a workpiece held on the support towards the opening of the baseplate into a processing position. The control system is configured to create a positive pressure gradient between the reaction chamber and the loading chamber while the workpiece support is in motion. Purge gases flow from the reaction chamber into the loading chamber while the workpiece support is in motion. The control system is configured to create a negative pressure gradient between the reaction chamber and the loading chamber while the workpiece is being processed. Purge gases can flow from the loading chamber into the reaction chamber while the workpiece support is in the processing position, unless the reaction chamber is sealed from the loading chamber in the processing position.

Owner:ASM IP HLDG BV

Atomic layer deposition reactor

Various reactors for growing thin films on a substrate by subjecting the substrate to alternately repeated surface reactions of vapor-phase reactants are disclosed. In one embodiment, the reactor comprises a reaction chamber. A showerhead plate divides the reaction chamber into upper and lower parts. A first precursor is directed towards the lower half of the reaction chamber and a second precursor is directed towards the upper half of the reaction chamber. The substrate is disposed within the lower half of the reaction chamber. The showerhead plate includes plurality passages such that the upper half is in communication with the lower half of the reaction chamber. In another arrangement, the upper half of the reaction chamber defines a plasma cavity in which in-situ radicals are formed. In yet another arrangement, the reaction chamber includes a shutter plate, which is configured to selectively open and close the passages in the showerhead plate. In other arrangements, the showerhead plate is arranged to modify the local flow patterns of the gases flowing through the reaction chamber.

Owner:KILPELA OLLI +6

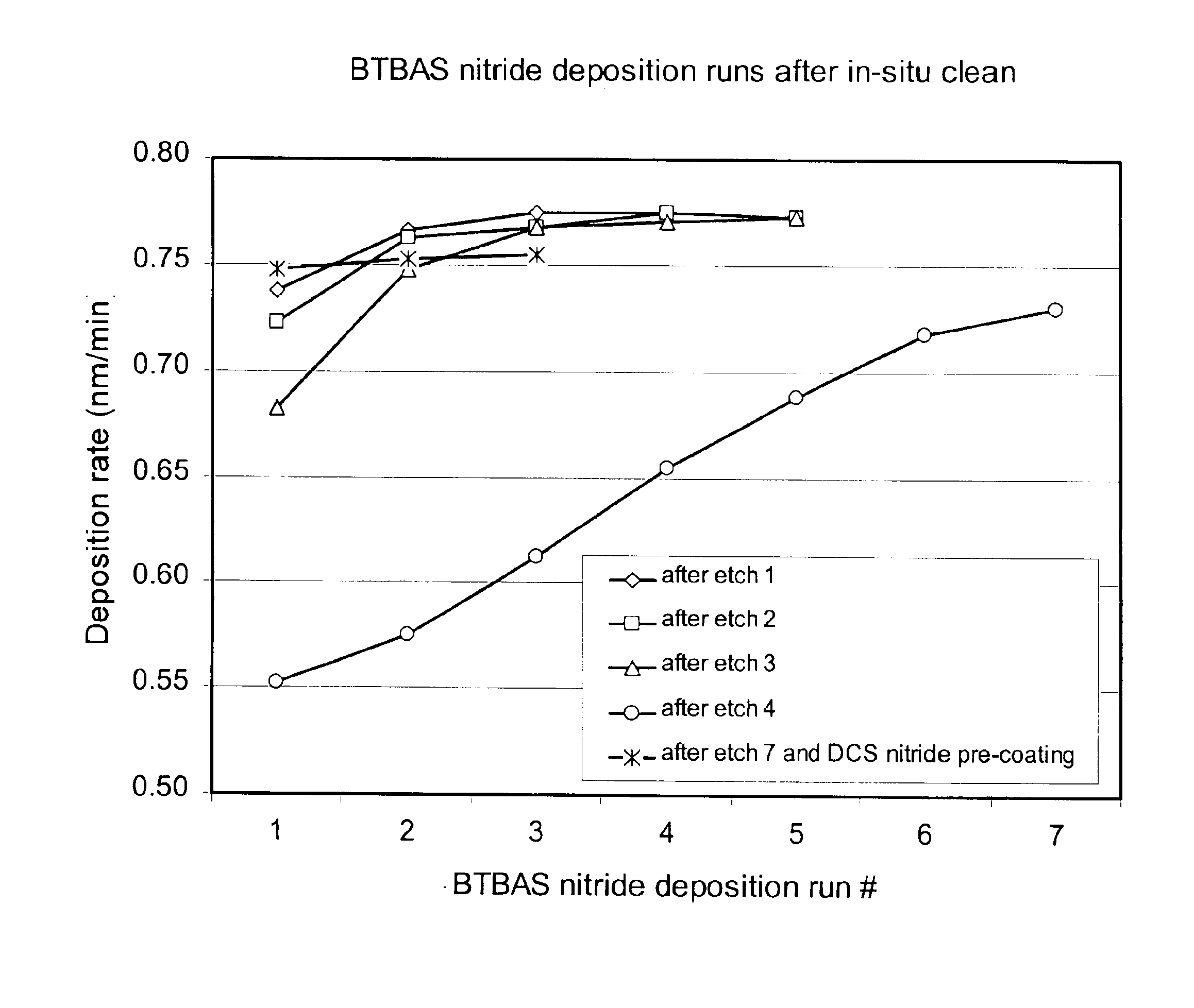

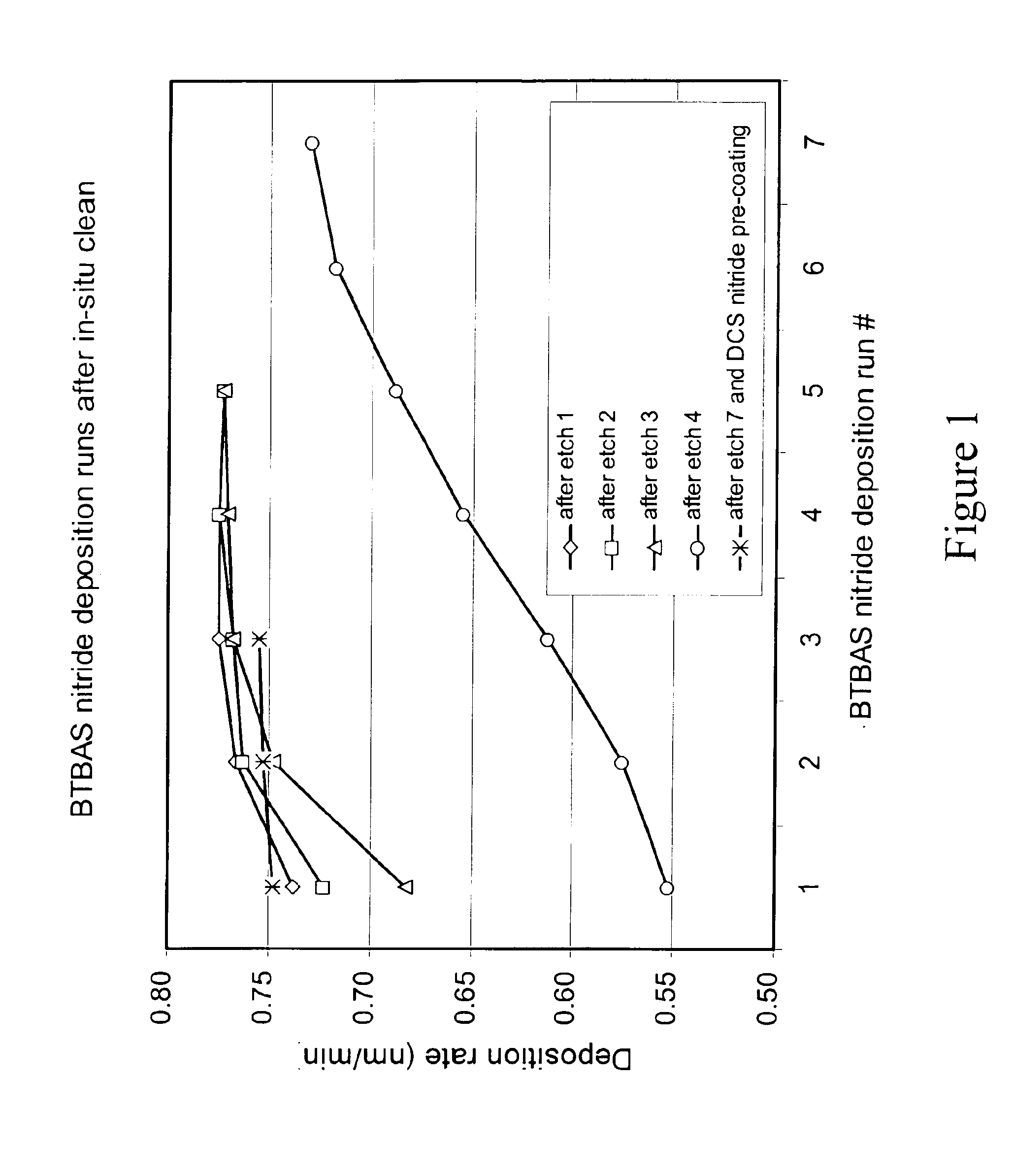

Reactor precoating for reduced stress and uniform CVD

InactiveUS6974781B2Reduce the probability of depositionIncreasing and maintaining deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingInorganic compositionOrganic layer

Owner:ASM INTERNATIONAL

Systems and methods for thin-film deposition of metal oxides using excited nitrogen—oxygen species

ActiveUS8883270B2Improve deposition efficiencyEnhance growth rate and uniformitySemiconductor/solid-state device manufacturingElectrical discharge ozone preparationOxygenAtomic layer deposition

Systems and methods are delineated which, among other things, are for depositing a film on a substrate that is within a reaction chamber. In an exemplary method, the method may comprise applying an atomic layer deposition cycle to the substrate, wherein the cycle may comprise exposing the substrate to a precursor gas for a precursor pulse interval and then removing the precursor gas thereafter, and exposing the substrate to an oxidizer comprising an oxidant gas and a nitrogen-containing species gas for an oxidation pulse interval and then removing the oxidizer thereafter. Aspects of the present invention utilize molecular and excited nitrogen-oxygen radical / ionic species in possible further combination with oxidizers such as ozone. Embodiments of the present invention also include electronic components and systems that include devices fabricated with methods consistent with the present invention.

Owner:ASM IP HLDG BV

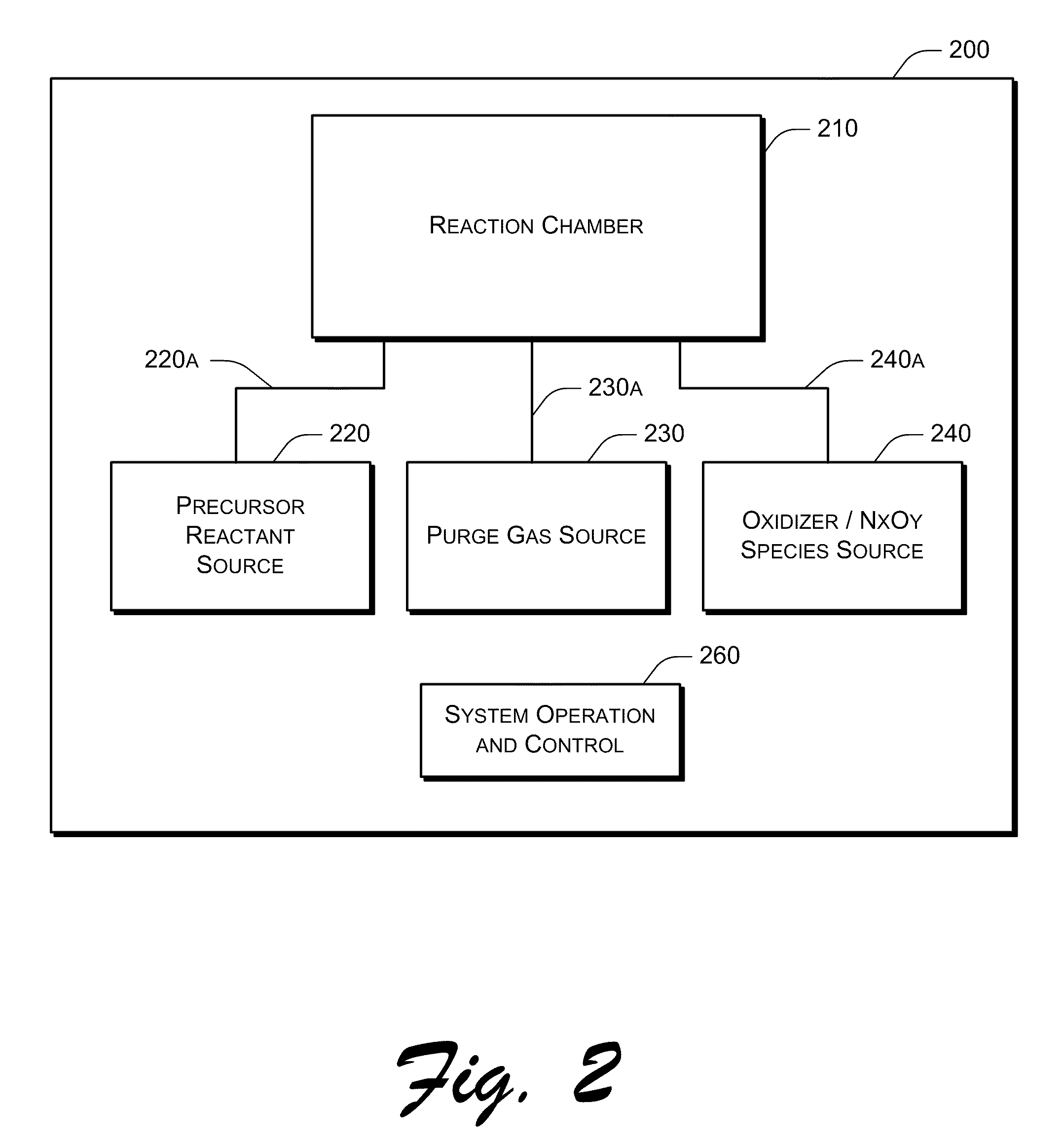

Bilayer inlet gas spray nozzle in use for metal-organic chemical vapor deposition device

This invention discloses a two-layer gas inlet blow head of a metal organic chemical gas phase deposit device including a closed shell having an upper gas inlet cavity and a lower gas inlet cavity, an upper escape pipe communicating with the upper gas cavity and reaction chamber is set between the upper-middle and the base plate and a lower escape pipe communicating with a lower gas inlet cavity and the reaction chamber is set between the lower plate and base plate characterizing that diameter of the lower escape pipe is layer than the upper and the upper is put in the lower. A cooling cavity is designed, the first reaction gas enters into the reaction chamber at the substrate surface from the upper and lower escape pipes separately.

Owner:南昌硅基半导体科技有限公司

Method for depositing flowable material using alkoxysilane or aminosilane precursor

ActiveUS7825040B1Reducing film shrinkageReduce carbon contentSolid-state devicesSemiconductor/solid-state device manufacturingSilanesPlasma reaction

A method of filling a recess with an insulation film includes: introducing an alkoxysilane or aminosilane precursor containing neither a Si—C bond nor a C—C bond into a reaction chamber where a substrate having an irregular surface including a recess is placed; and depositing a flowable Si-containing insulation film on the irregular surface of the substrate to fill the recess therewith by plasma reaction at −50° C. to 100° C.

Owner:ASM JAPAN

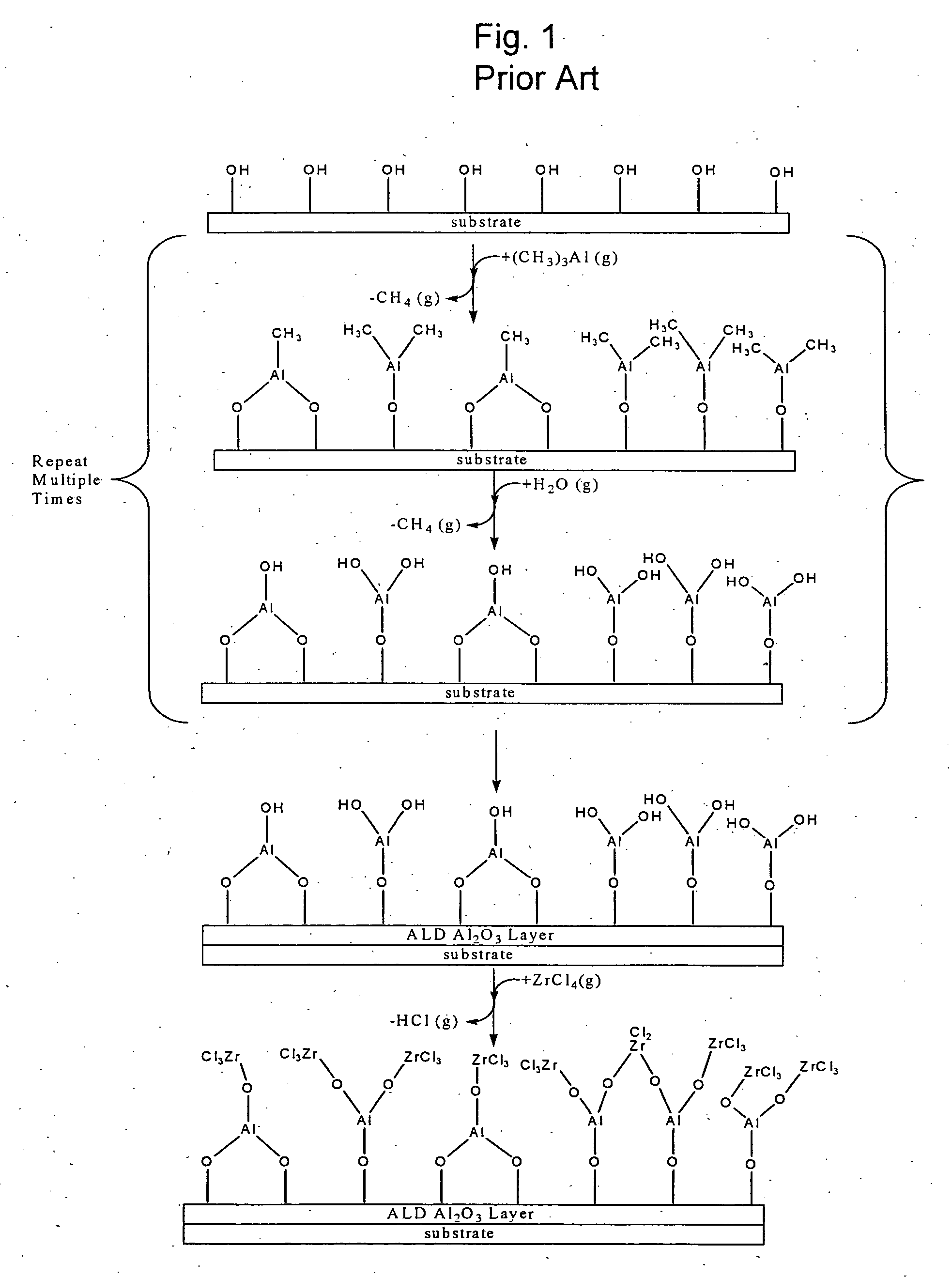

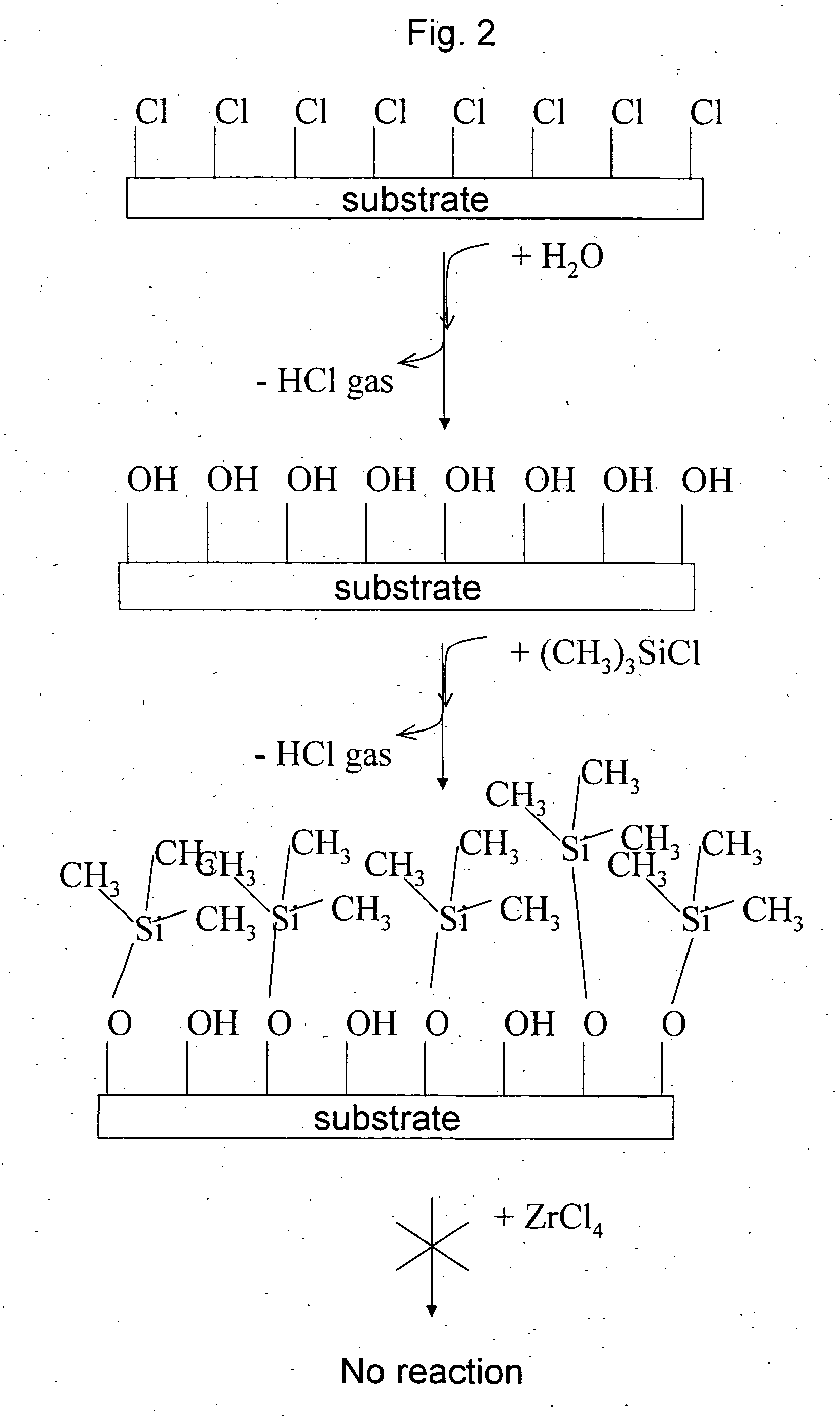

Passivating ALD reactor chamber internal surfaces to prevent residue buildup

InactiveUS20060040054A1Minimizing undesired chemisorptionReduce accumulationChemical vapor deposition coatingImproved methodDeposition process

This invention is directed to an improved method for preventing deposition residue buildup on the internal surfaces of an ALD reactor chamber. In an ALD deposition process, the surfaces of a substrate are treated with an initiating precursor generating a labile atom reactive with a deposition precursor. Excess initiating precursor is removed from the reactor and the substrate surface then is exposed to a deposition precursor reactive with the labile atom under conditions for generating a fugitive reaction product containing the labile atom and leaving a deposition product. The process is repeated generating alternate layers of initiation and deposition precursor reaction products. The improvement in the ALD process resides in passivating the internal surfaces of the reactor by removing labile atoms reactable with either the initiating or deposition precursors prior to effecting ALD deposition.

Owner:VERSUM MATERIALS US LLC

Atomic layer deposition system including a plurality of exhaust tubes

InactiveUS20080176412A1Uniform film qualityHigh aspect ratioLiquid surface applicatorsSemiconductor/solid-state device manufacturingControl valvesVapor phase

An atomic layer deposition system includes a reaction chamber, a plurality of exhaust tubes communicated to the reaction chamber, a plurality of first vacuum gauges for monitoring the degree of vacuum of the respective exhaust tubes, a second vacuum gauge for monitoring the degree of vacuum of the reaction chamber, and control valves for adjusting the exhaust volume of the exhaust tubes independently of one another. The control valves are controlled based on the pressures measured by the first and second control valves for achieving a uniform flow of the vapor phase reactant.

Owner:PS4 LUXCO SARL

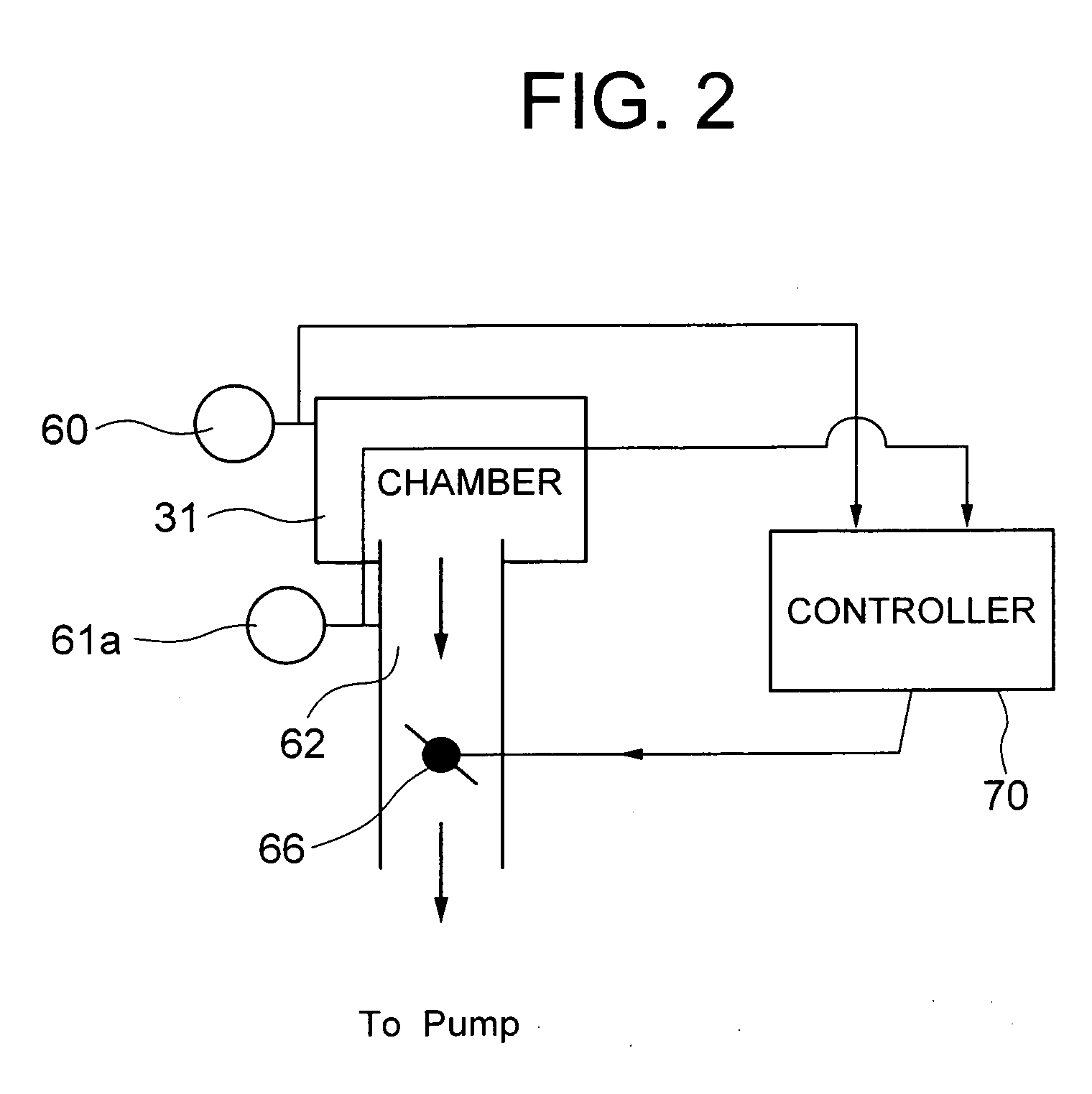

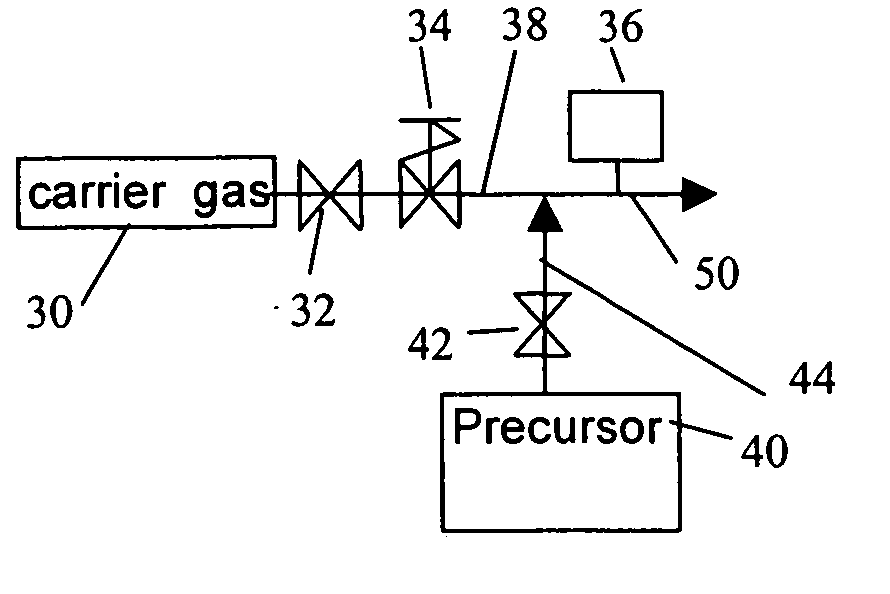

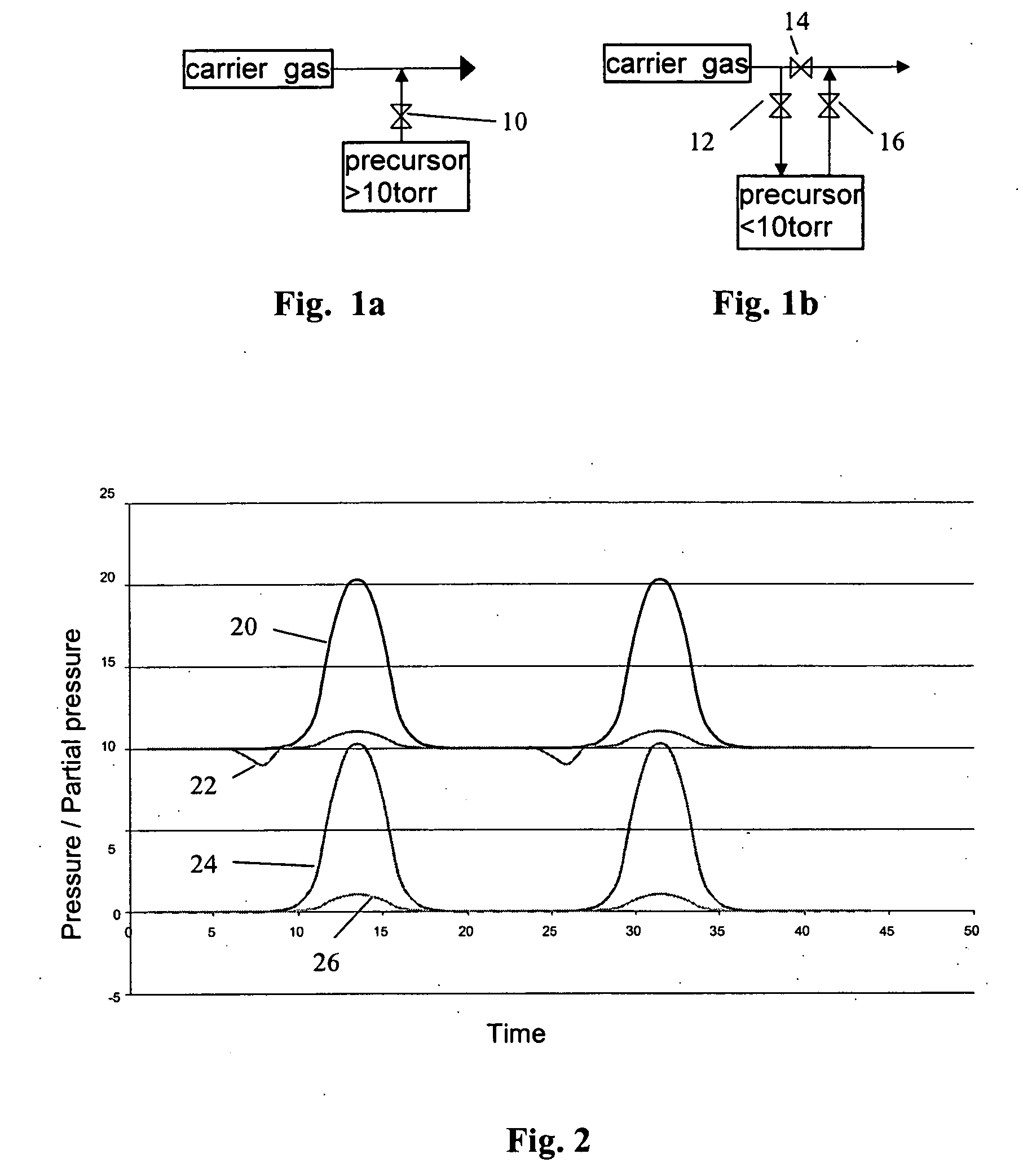

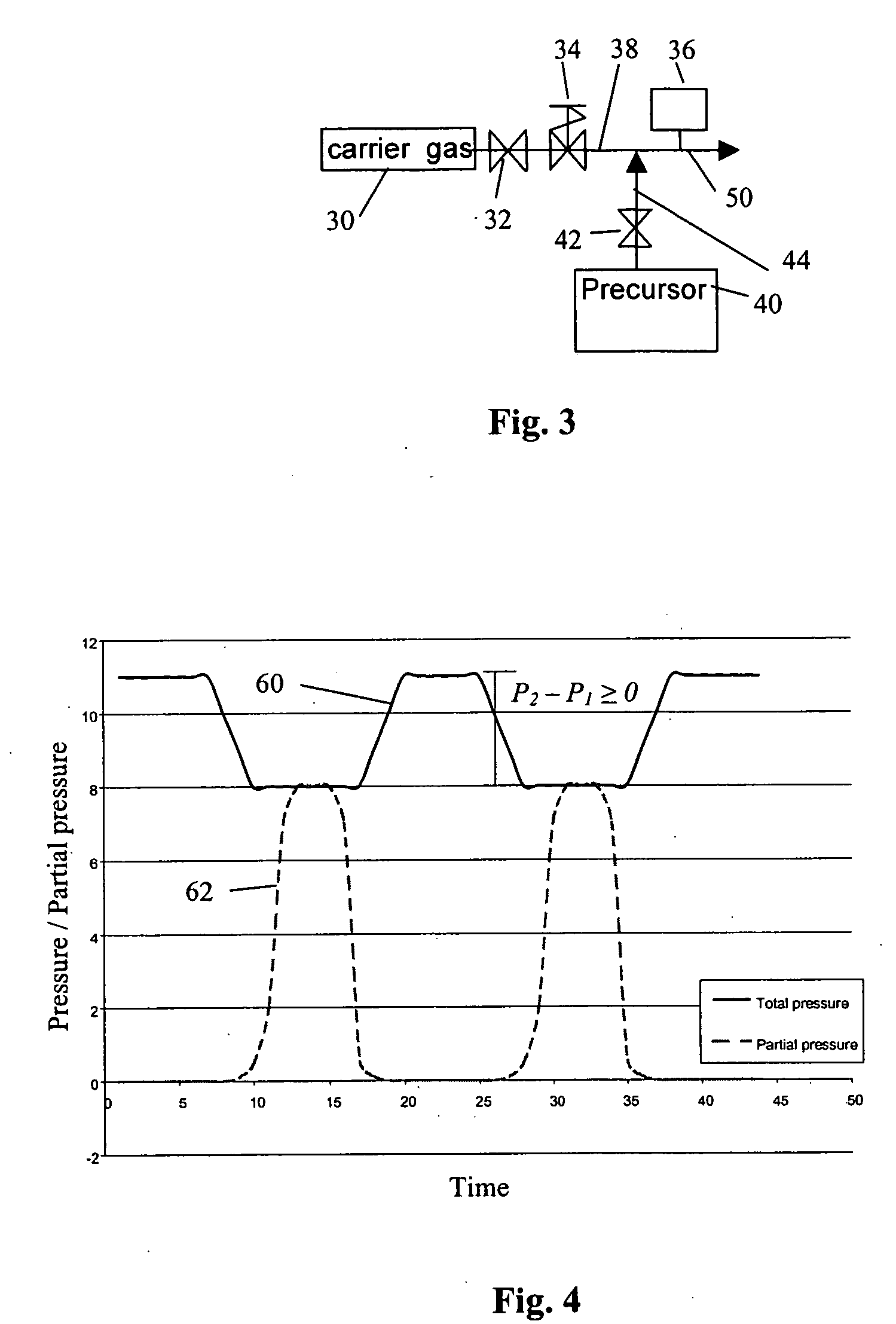

Method of pulsing vapor precursors in an ALD reactor

ActiveUS20060147626A1Faster film growthImproved pulse separationPolycrystalline material growthFrom chemically reactive gasesSource materialGas phase

A method of growing a thin film on a substrate by pulsing vapor-phase precursors material into a reaction chamber according to the ALD method. The method comprises vaporizing at least one precursor from a source material container maintained at a vaporising temperature, repeatedly feeding pulses of the vaporized precursor via a feed line into the reaction chamber at a first pressure, and subsequently purging the reaction chamber with pulses of inactive gas fed via the feed line at a second pressure. The second pressure is maintained at the same as or a higher level than the first pressure for separating successive pulses of said vaporized precursor from each other.

Owner:ASM IP HLDG BV

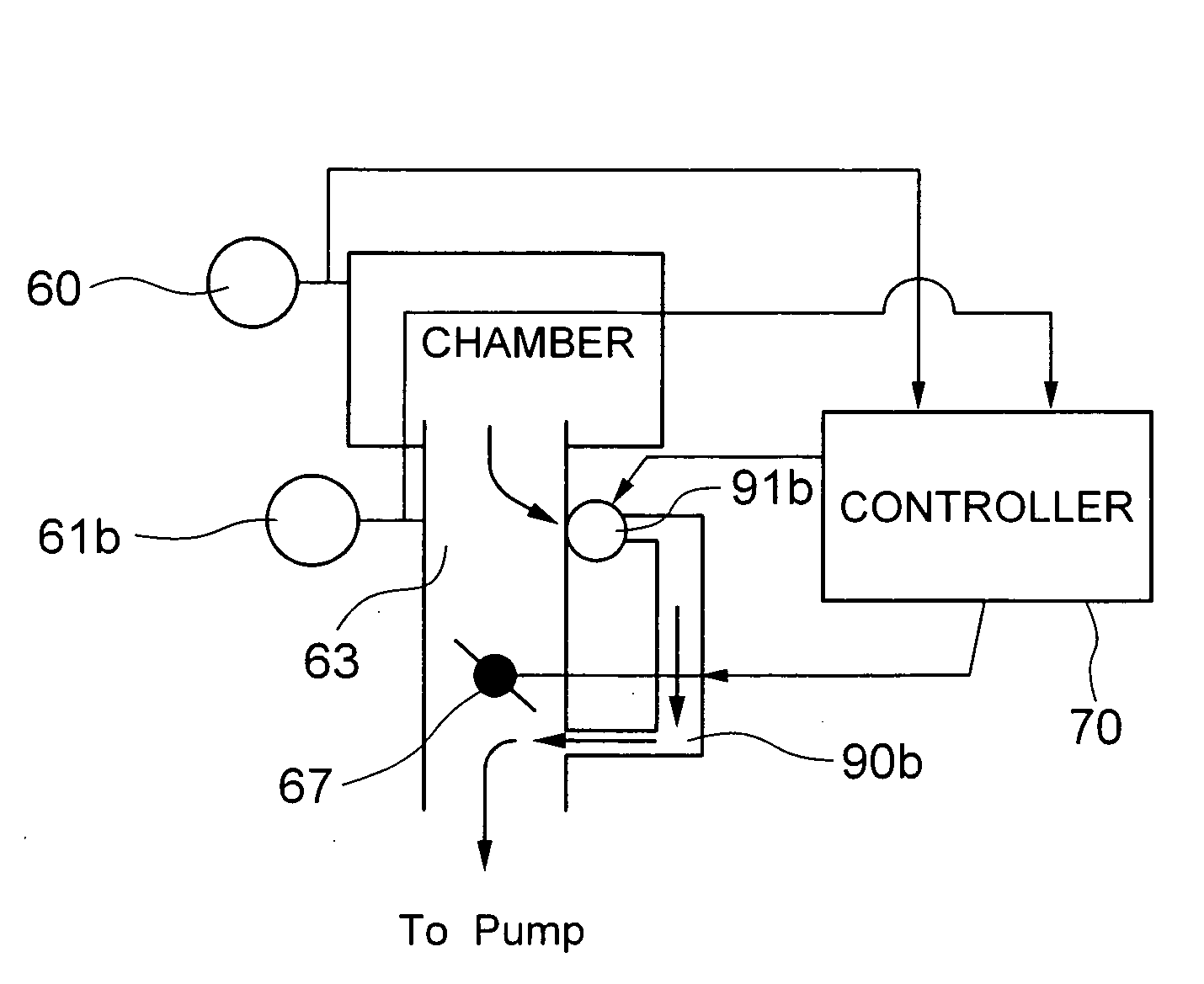

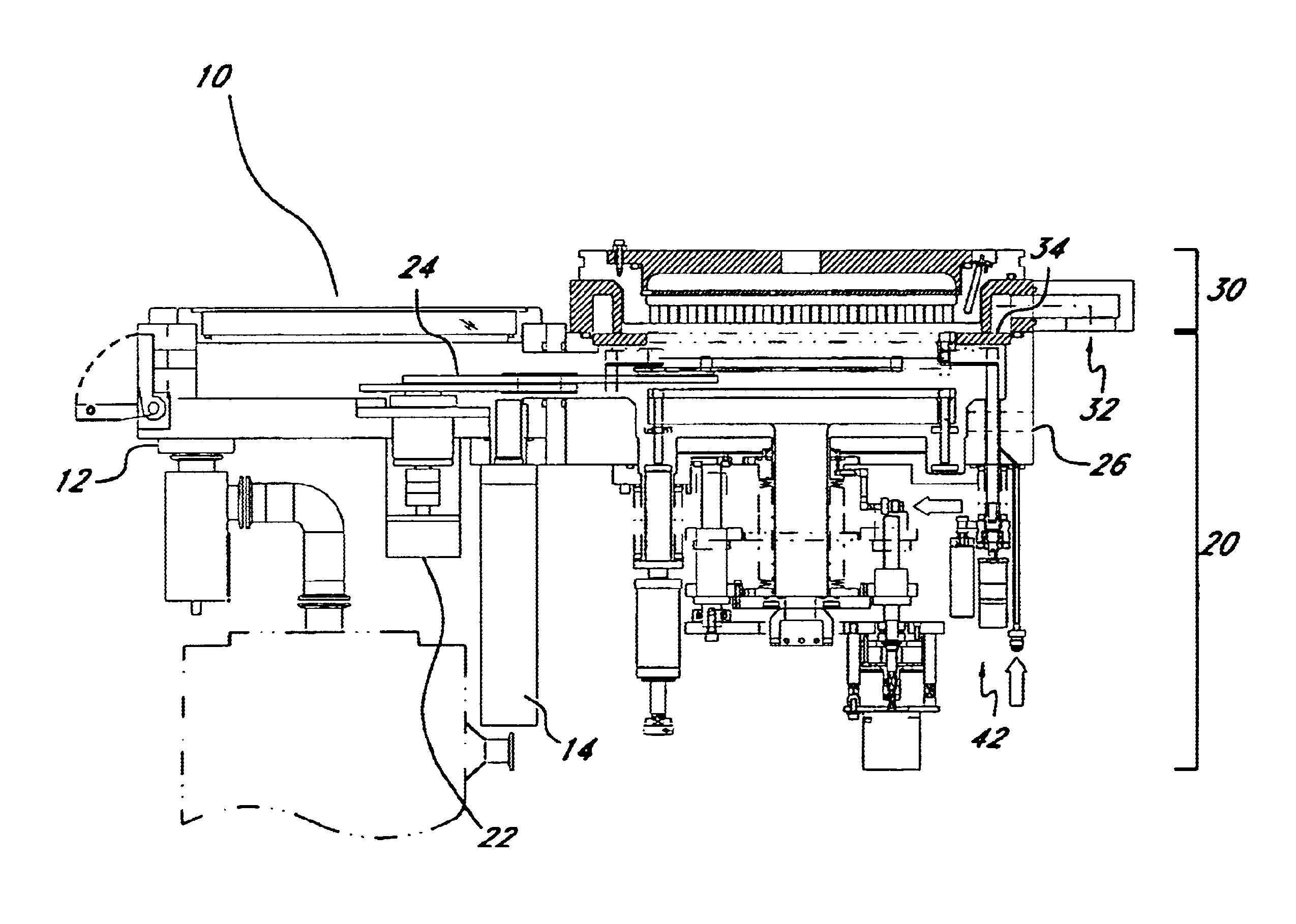

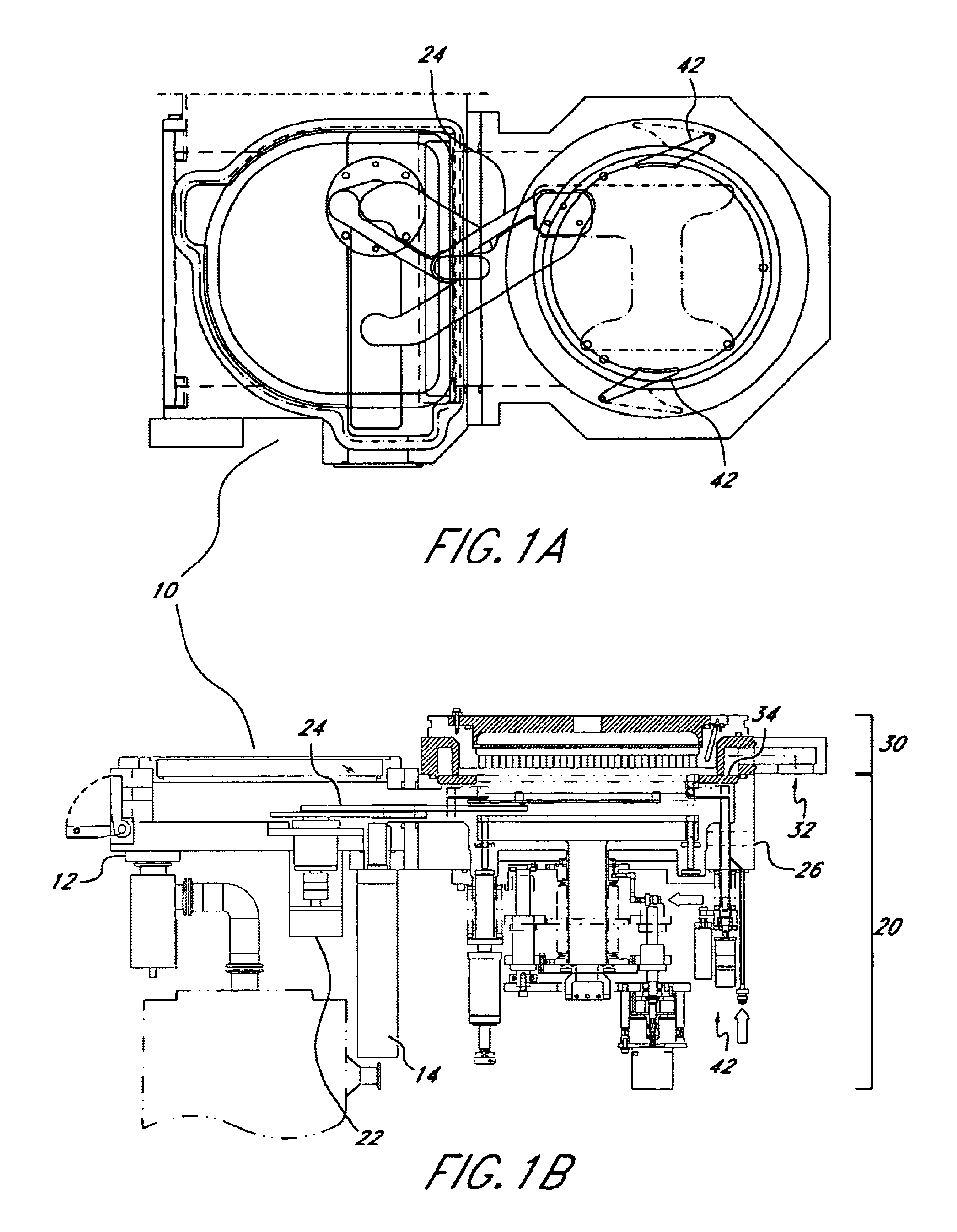

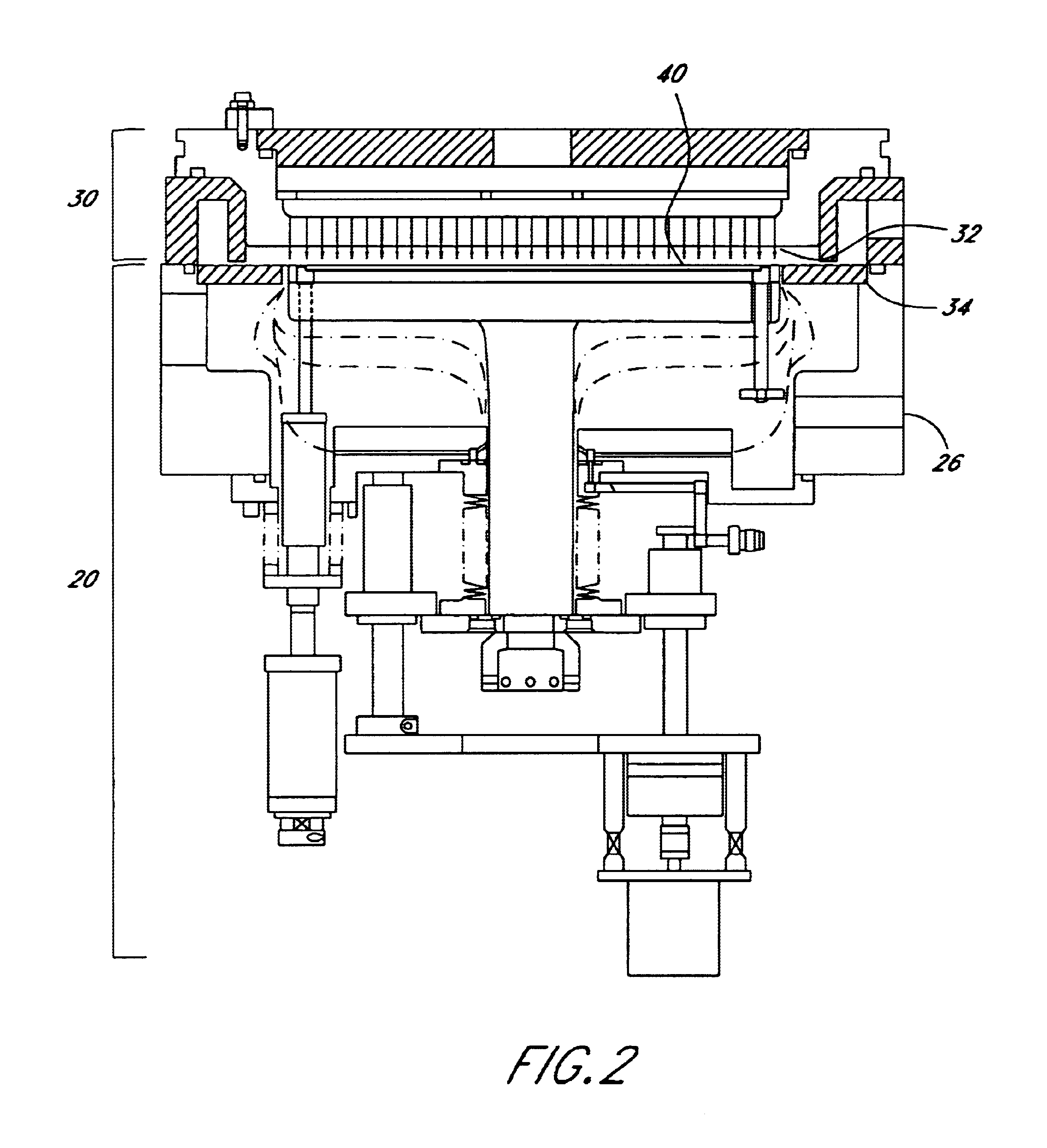

Semiconductor processing apparatus comprising chamber partitioned into reaction and transfer sections

InactiveUS6899507B2Reduce adhesionImprove efficiencySemiconductor/solid-state device manufacturingCharge manipulationEngineeringSemiconductor

Semiconductor processing equipment that has increased efficiency, throughput, and stability, as well as reduced operating cost, footprint, and faceprint is provided. Other than during deposition, the atmosphere of both the reaction chamber and the transfer chamber are evacuated using the transfer chamber exhaust port, which is located below the surface of the semiconductor wafer. This configuration prevents particles generated during wafer transfer or during deposition from adhering to the surface of the semiconductor wafer. Additionally, by introducing a purge gas into the transfer chamber during deposition, and by using an insulation separating plate 34, the atmospheres of the transfer and reaction chambers can be effectively isolated from each other, thereby preventing deposition on the walls and components of the transfer chamber. Finally, the configuration described herein permits a wafer buffer mechanism to be used with the semiconductor processing equipment, thereby further increasing throughput and efficiency.

Owner:ASM JAPAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com