Patents

Literature

599 results about "Silazane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

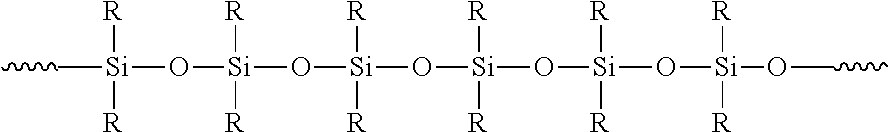

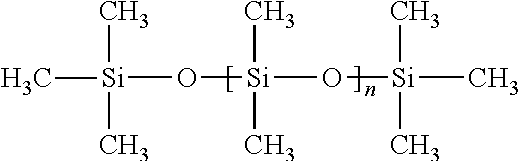

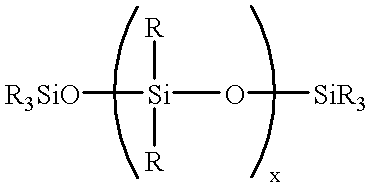

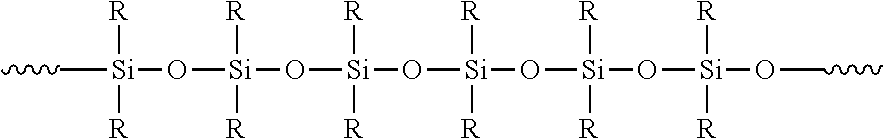

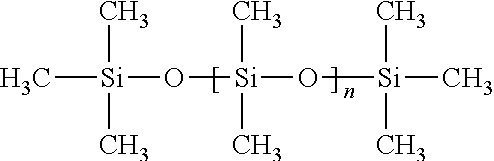

A silazane is any hydride of silicon and nitrogen having a straight or branched chain of silicon and nitrogen atoms joined by covalent bonds. By extension, the word is also used for any organic derivative of such compounds. They are analogous to siloxanes, with -NH- replacing -O-. Their individual name is dependent on the number of silicon atoms in the chemical structure. Hexamethyldisilazane contains two silicon atoms bonded to the nitrogen atom. The majority of silazanes are moisture sensitive.

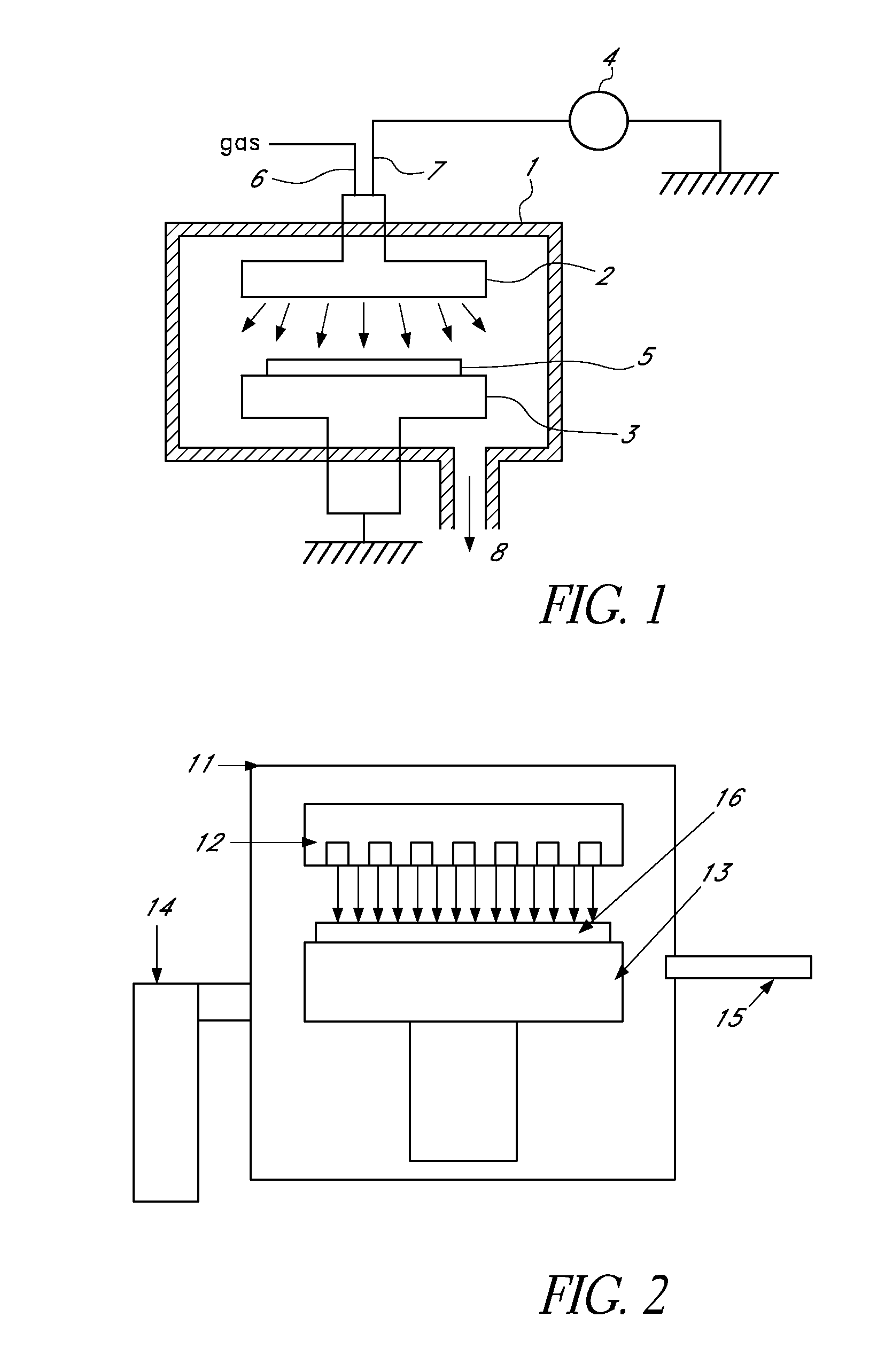

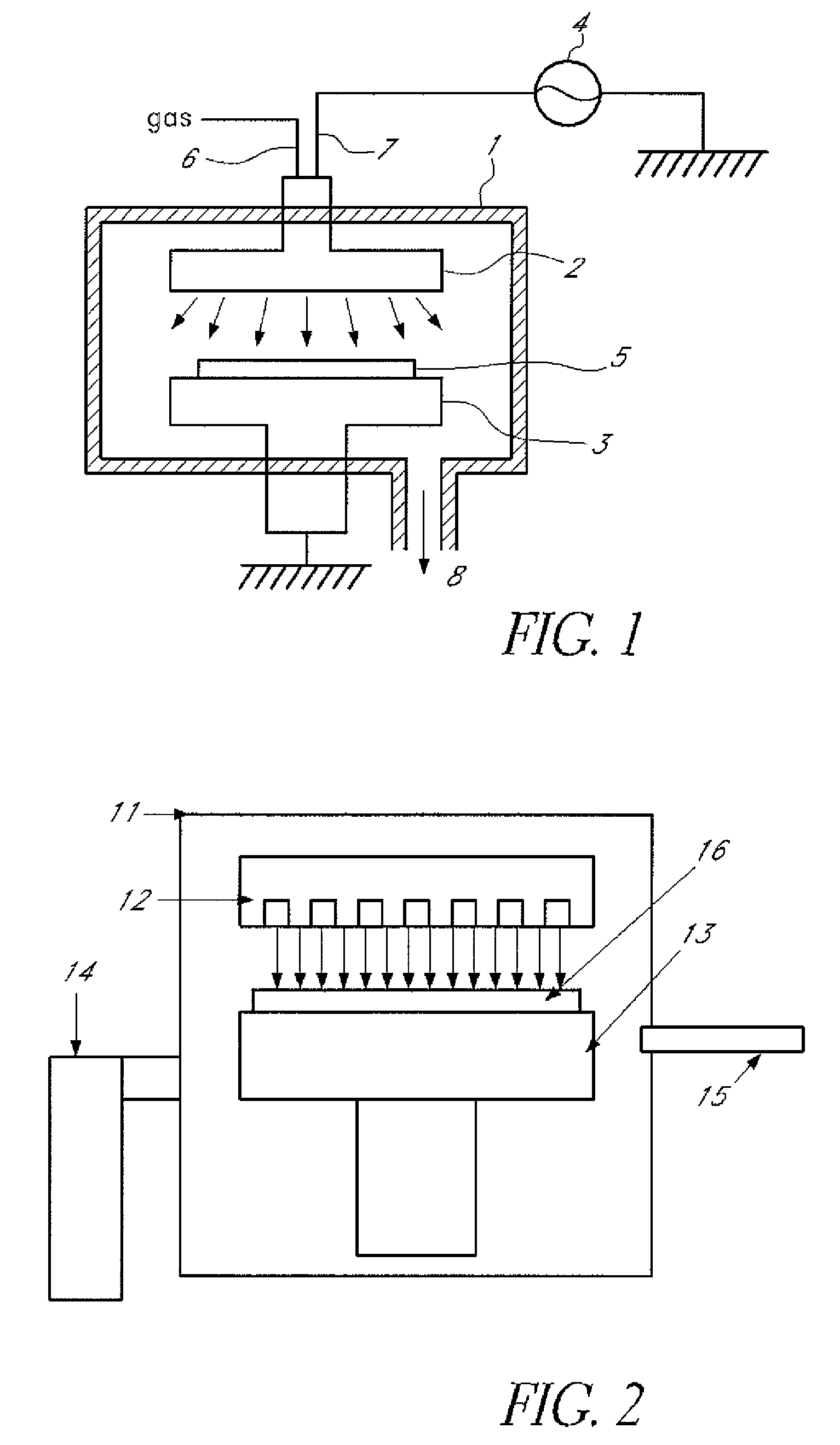

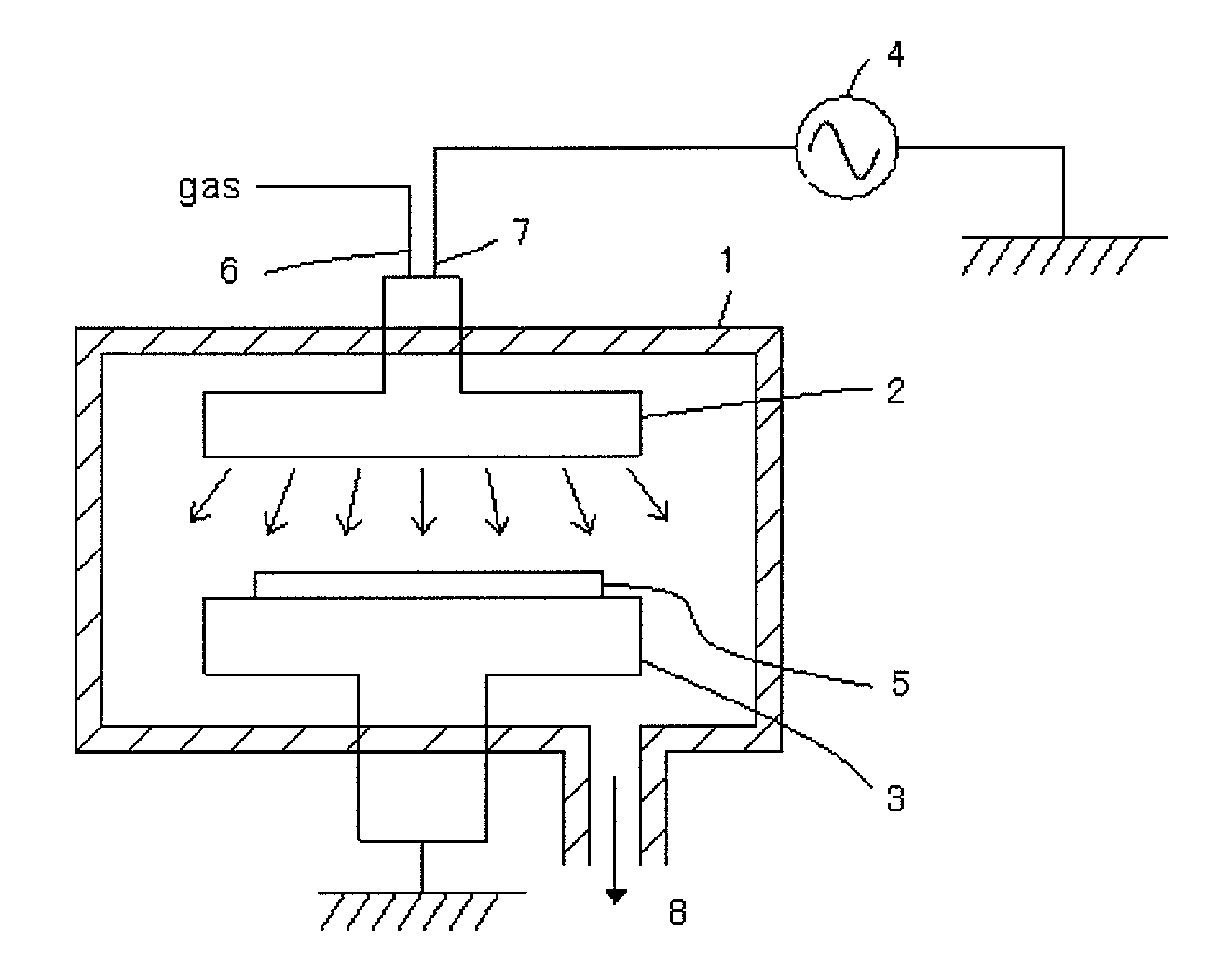

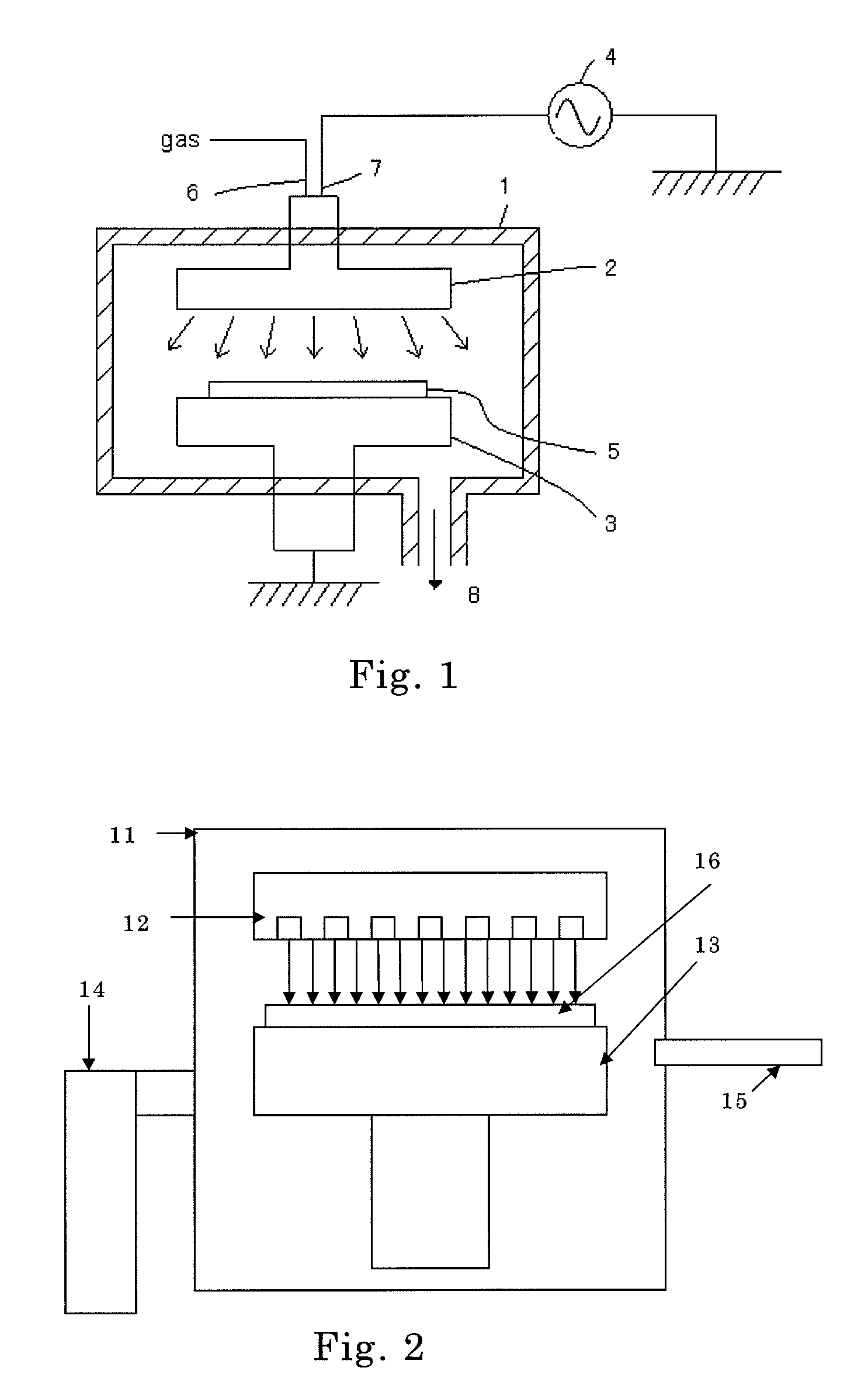

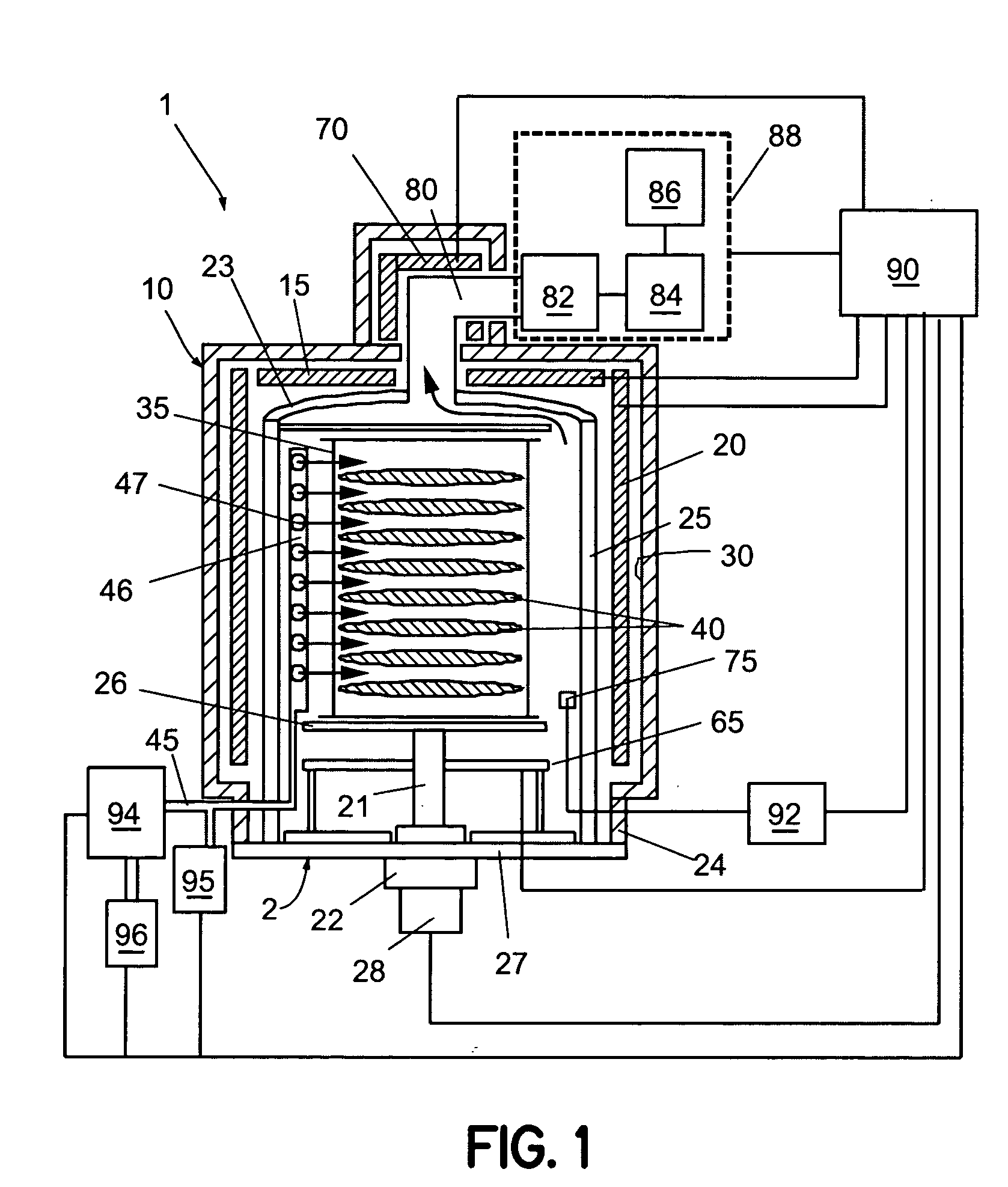

Method for forming silazane-based dielectric film

A method of forming a dielectric film includes: introducing a source gas essentially constituted by Si, N, H, and optionally C and having at least one bond selected from Si—N, Si—Si, and Si—H into a reaction chamber where a substrate is placed; depositing a silazane-based film essentially constituted by Si, N, H, and optionally C on the substrate by plasma reaction at −50° C. to 50° C., wherein the film is free of exposure of a solvent constituted essentially by C, H, and optionally O; and heat-treating the silazane-based film on the substrate in a heat-treating chamber while introducing an oxygen-supplying source into the heat-treating chamber to release C from the film and increase Si—O bonds in the film.

Owner:ASM JAPAN

Method for forming silazane-based dielectric film

A method of forming a dielectric film includes: introducing a source gas essentially constituted by Si, N, H, and optionally C and having at least one bond selected from Si—N, Si—Si, and Si—H into a reaction chamber where a substrate is placed; depositing a silazane-based film essentially constituted by Si, N, H, and optionally C on the substrate by plasma reaction at −50° C. to 50° C., wherein the film is free of exposure of a solvent constituted essentially by C, H, and optionally O; and heat-treating the silazane-based film on the substrate in a heat-treating chamber while introducing an oxygen-supplying source into the heat-treating chamber to release C from the film and increase Si—O bonds in the film.

Owner:ASM JAPAN

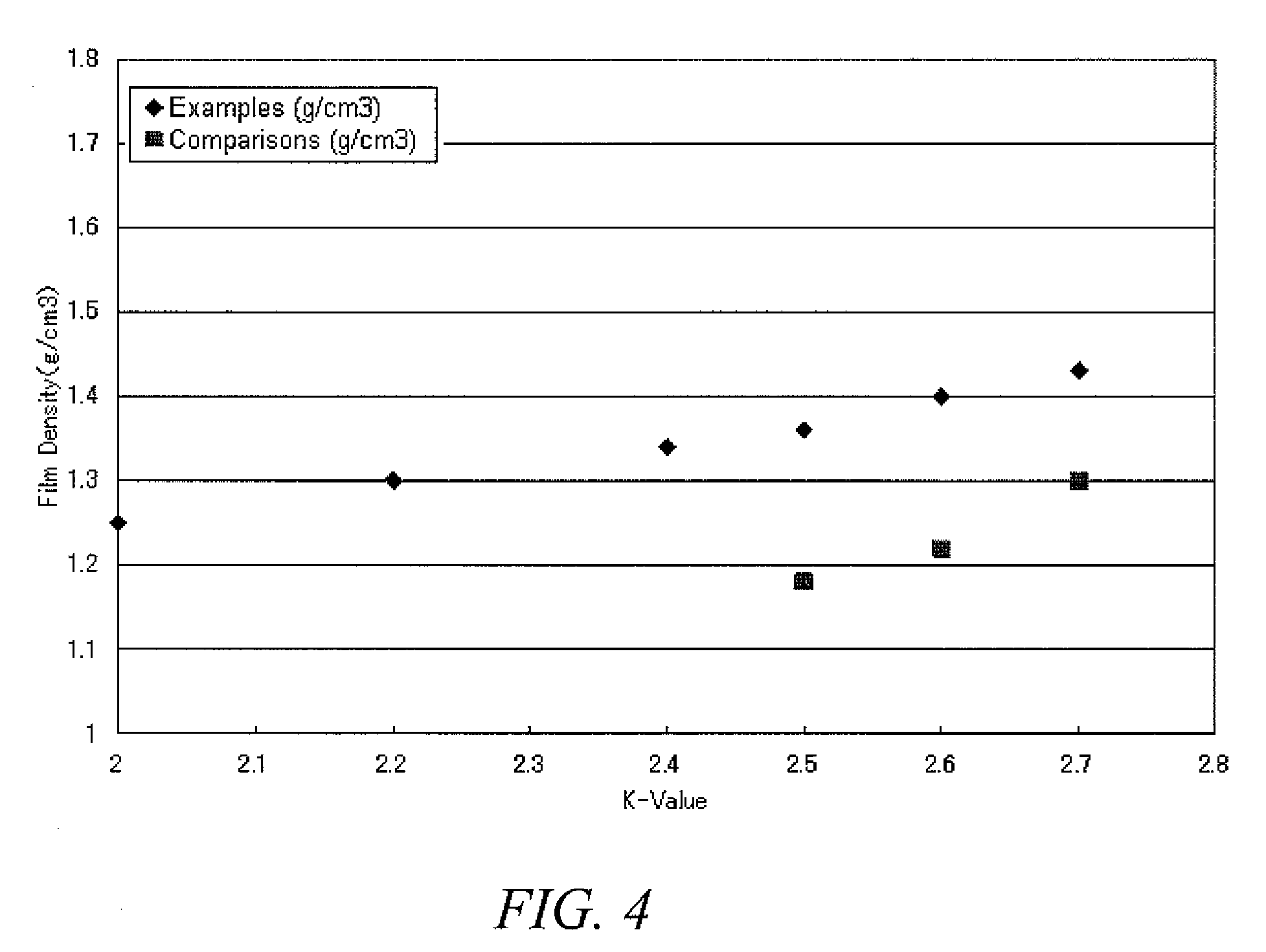

Method for forming dielectric film using siloxane-silazane mixture

ActiveUS8003174B2High densityHigh strengthPretreated surfacesSemiconductor/solid-state device manufacturingSilazaneMetallurgy

Owner:ASM JAPAN

Method for forming inorganic silazane-based dielectric film

ActiveUS7781352B2Reduction factorSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricSilazane

A method of forming an inorganic silazane-based dielectric film includes: introducing a gas constituted by Si and H and a gas constituted by N and optionally H into a reaction chamber where an object is placed; controlling a temperature of the object at −50° C. to 50° C.; and depositing by plasma reaction a film constituted by Si, N, and H containing inorganic silazane bonds.

Owner:ASM JAPAN

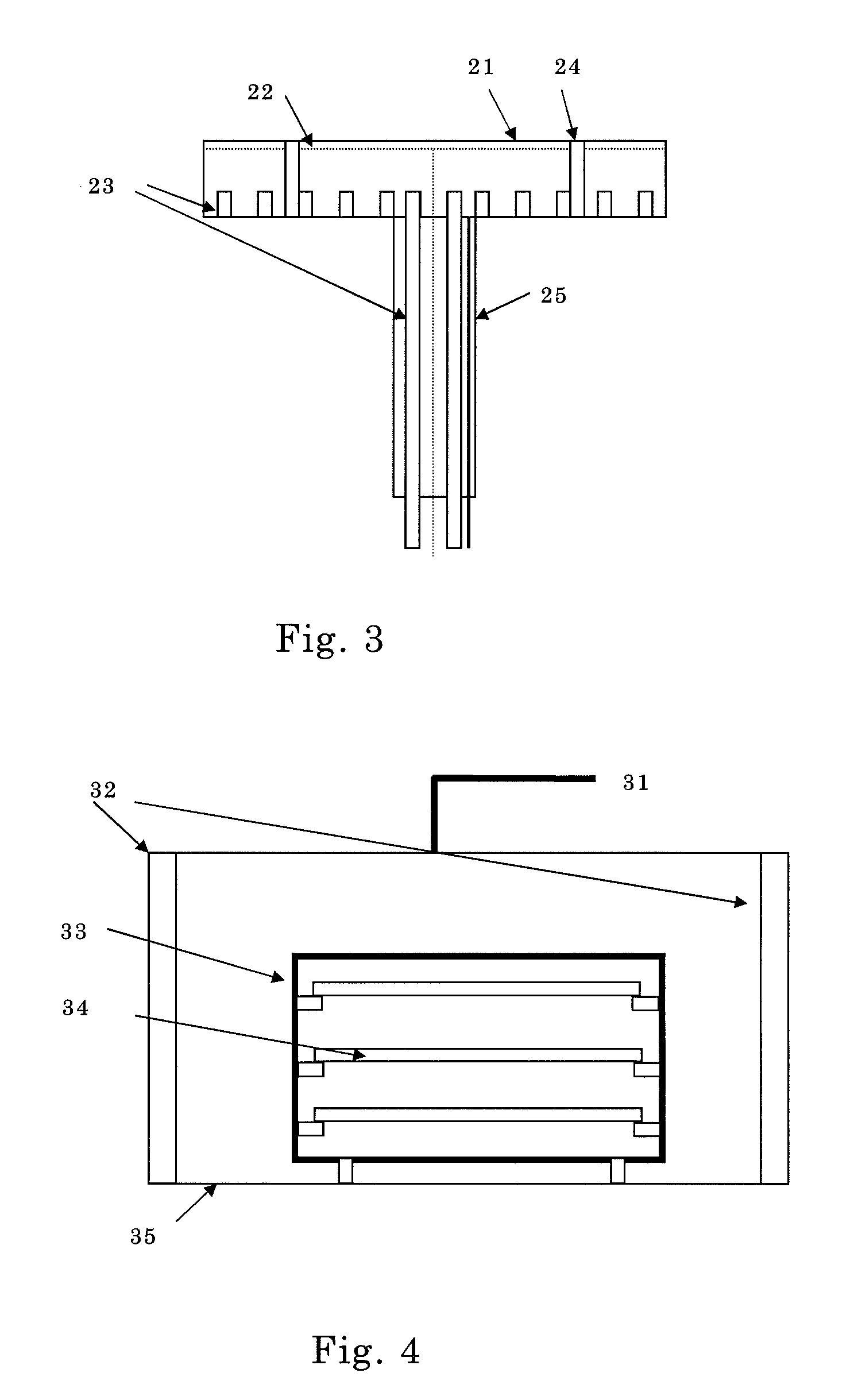

Method for forming dielectric film using siloxane-silazane mixture

ActiveUS20090156017A1High densityHigh strengthPretreated surfacesSemiconductor/solid-state device manufacturingSilazaneMetallurgy

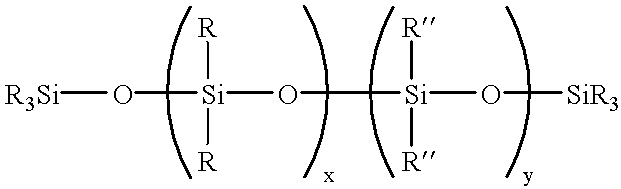

A method of forming a dielectric film, includes: introducing a siloxane gas essentially constituted by Si, O, C, and H and a silazane gas essentially constituted by Si, N, H, and optionally C into a reaction chamber where a substrate is placed; depositing a siloxane-based film including Si—N bonds on the substrate by plasma reaction; and annealing the siloxane-based film on the substrate in an annealing chamber to remove Si—N bonds from the film.

Owner:ASM JAPAN

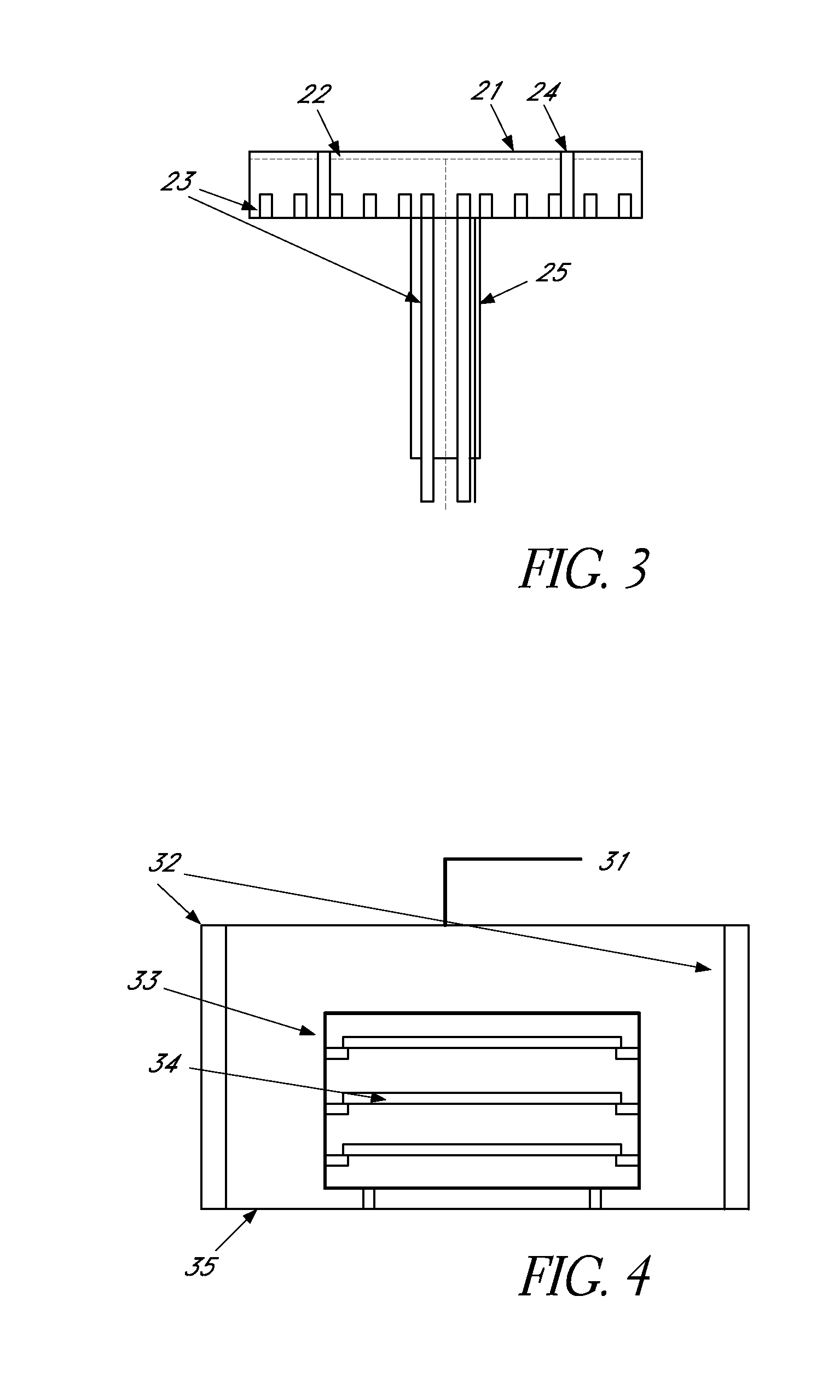

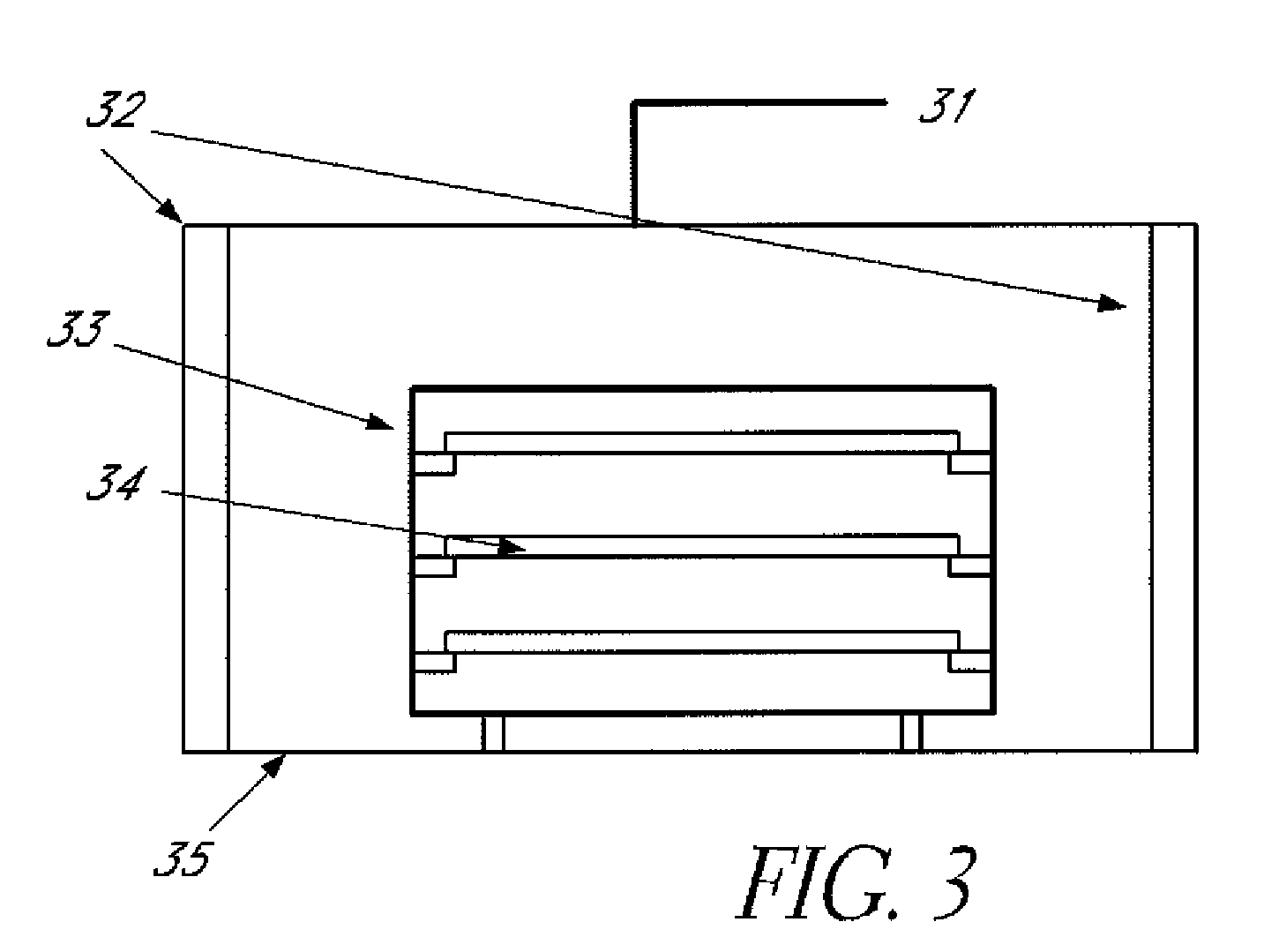

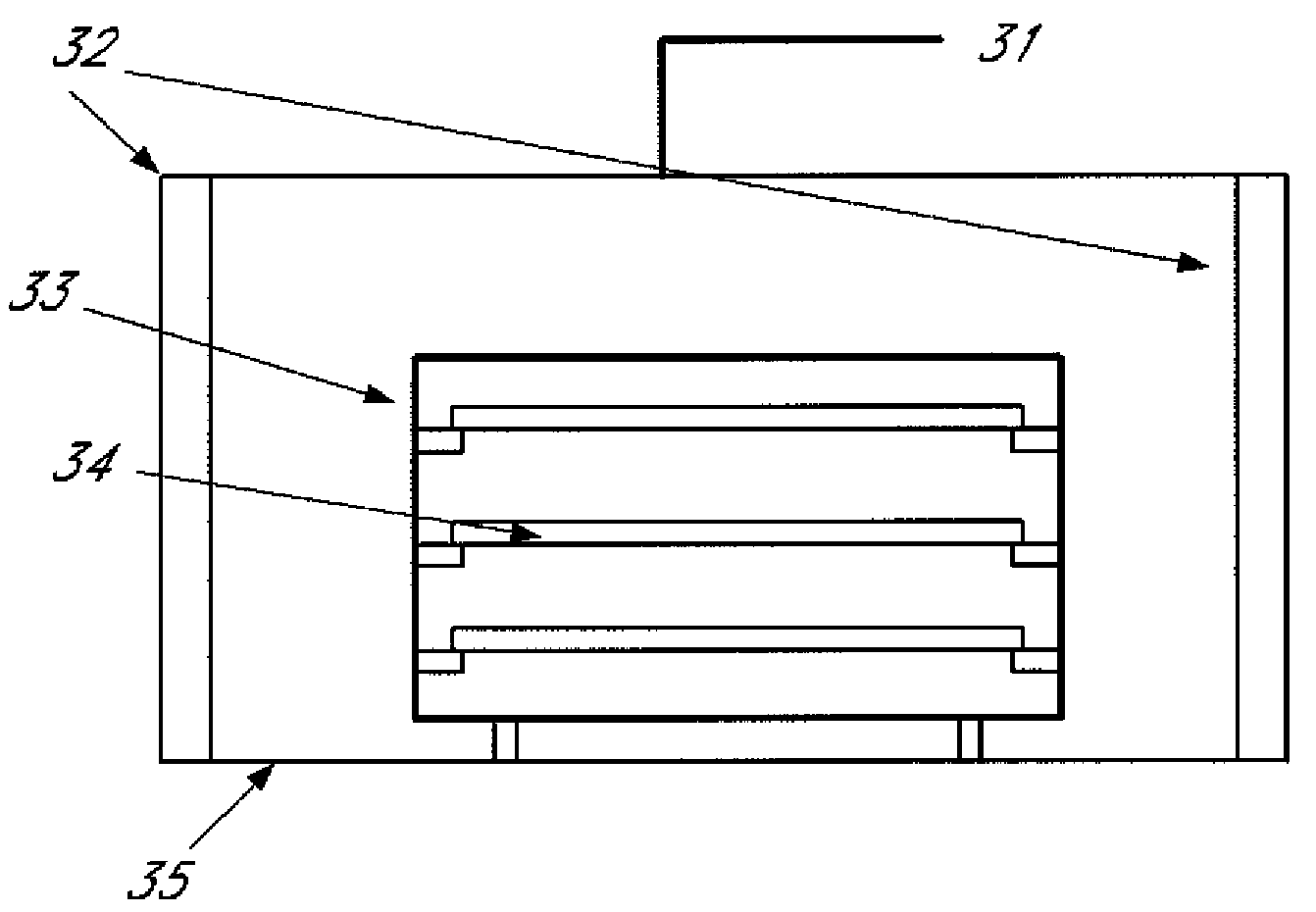

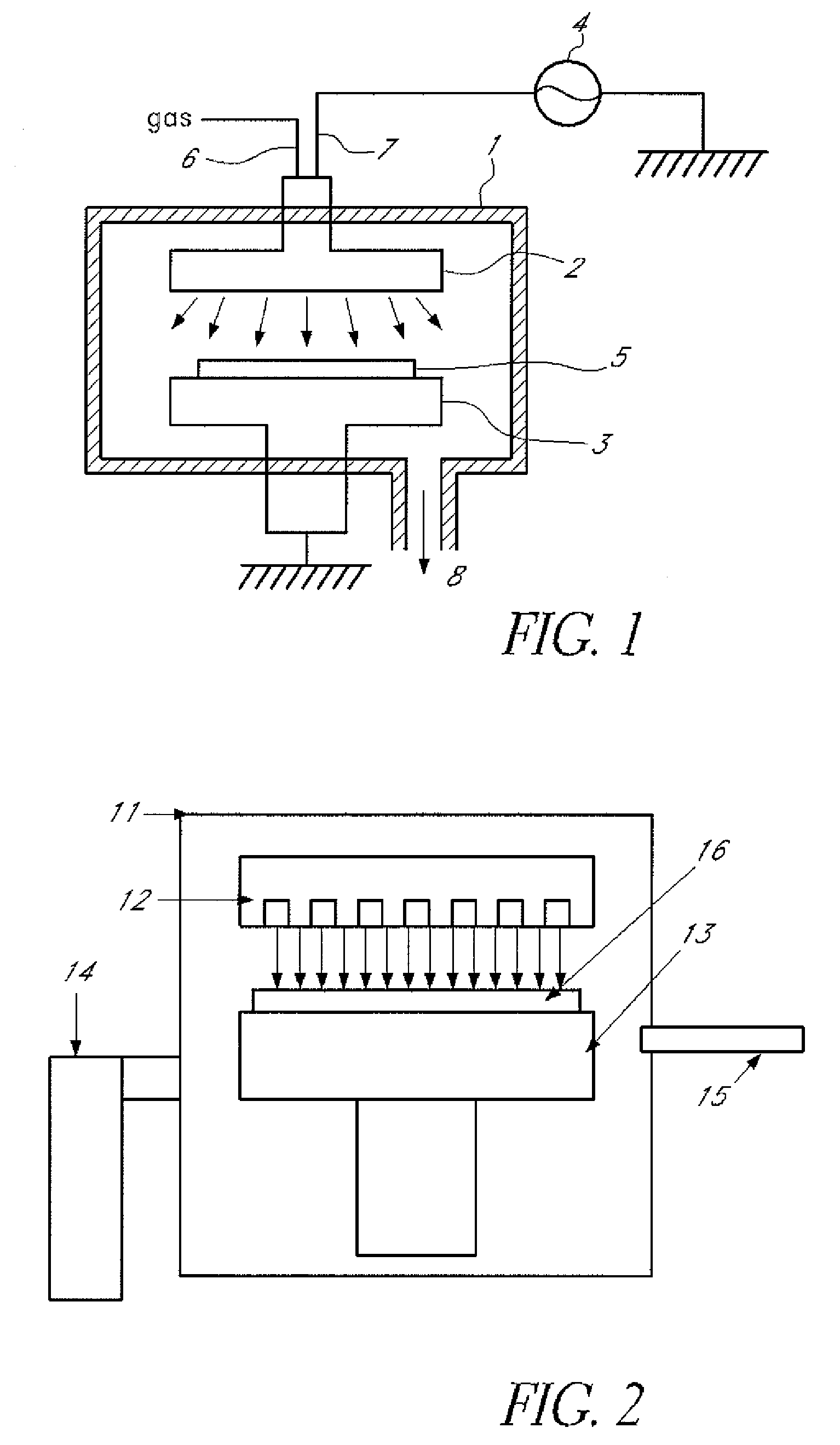

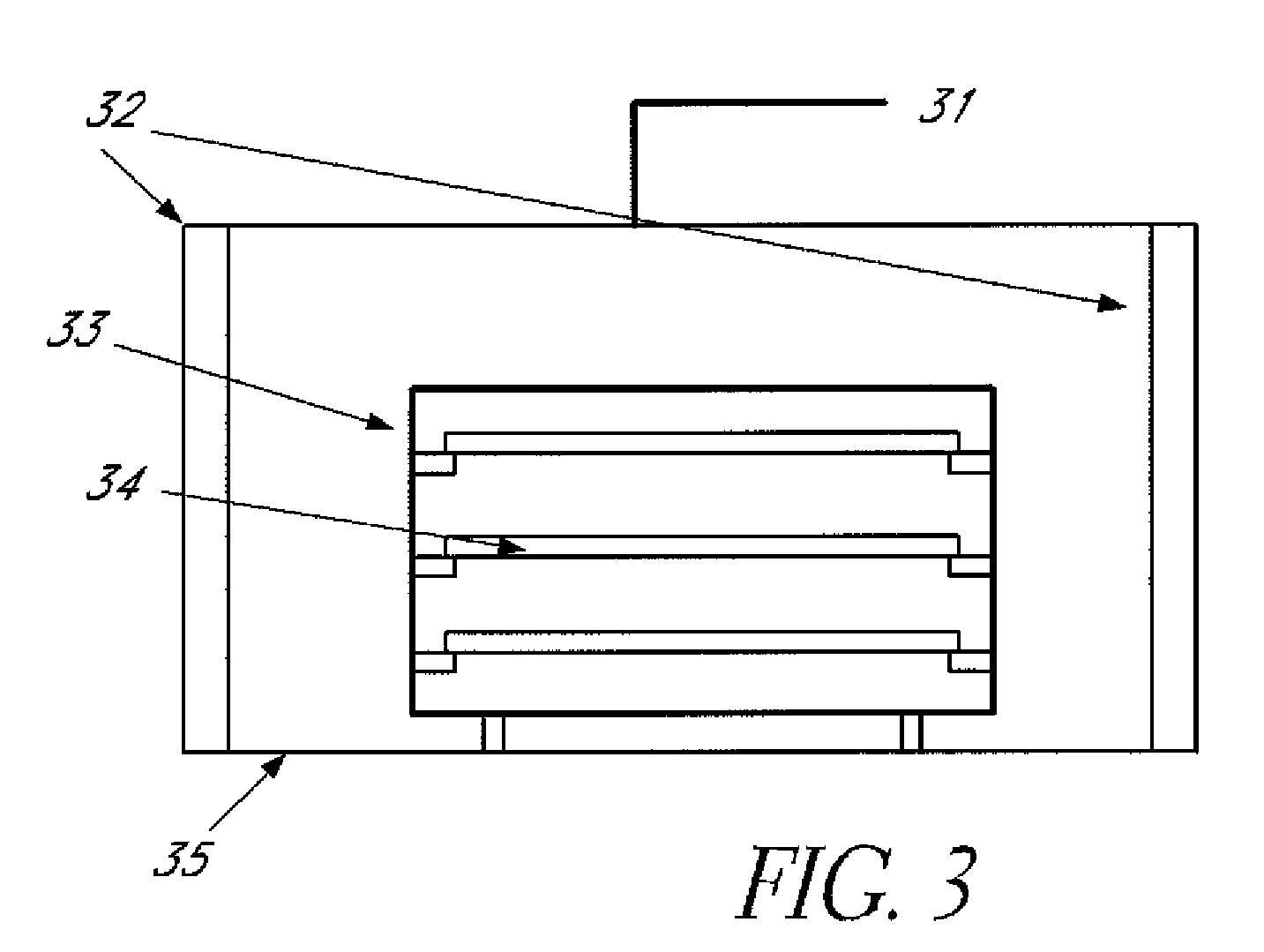

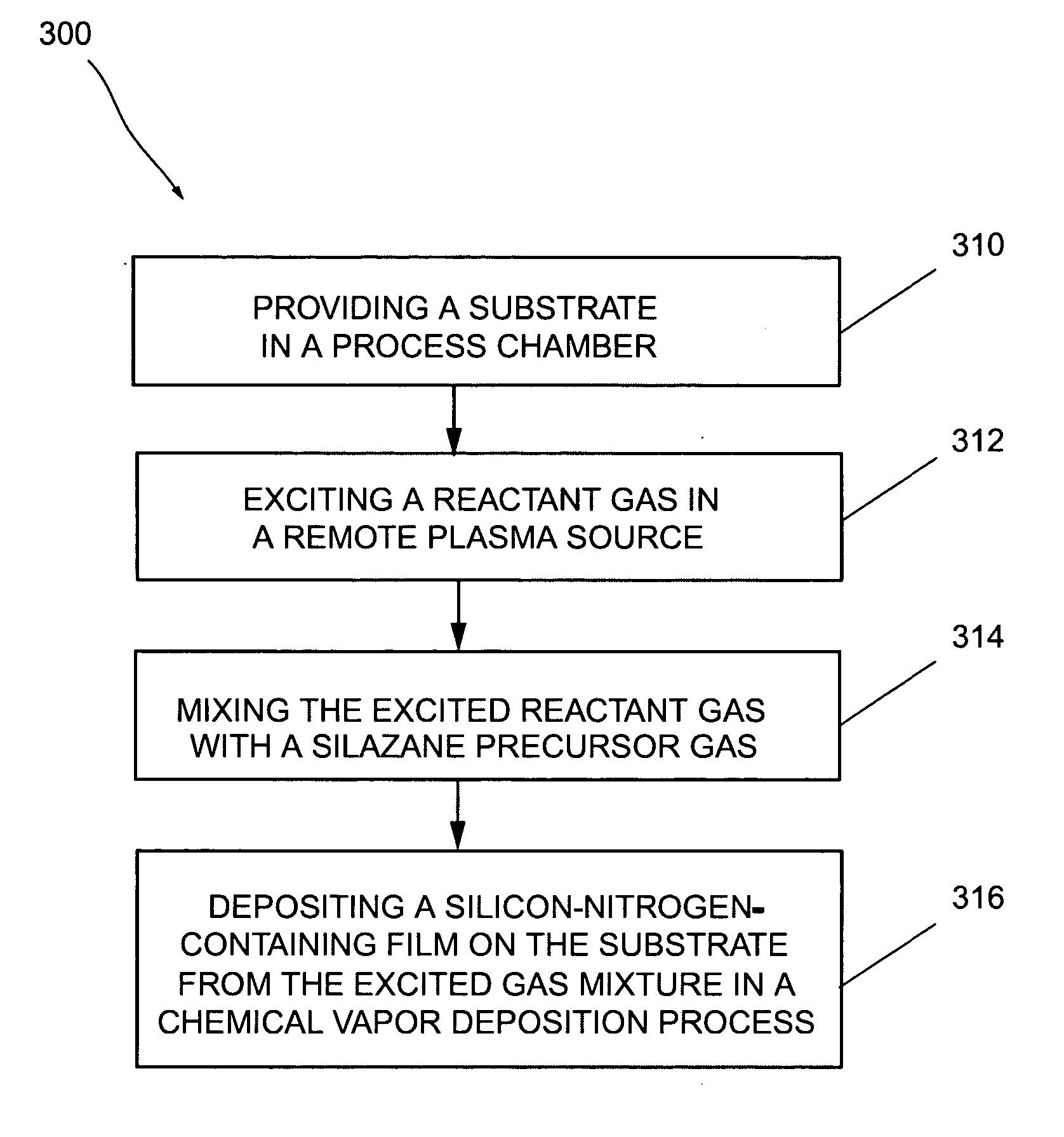

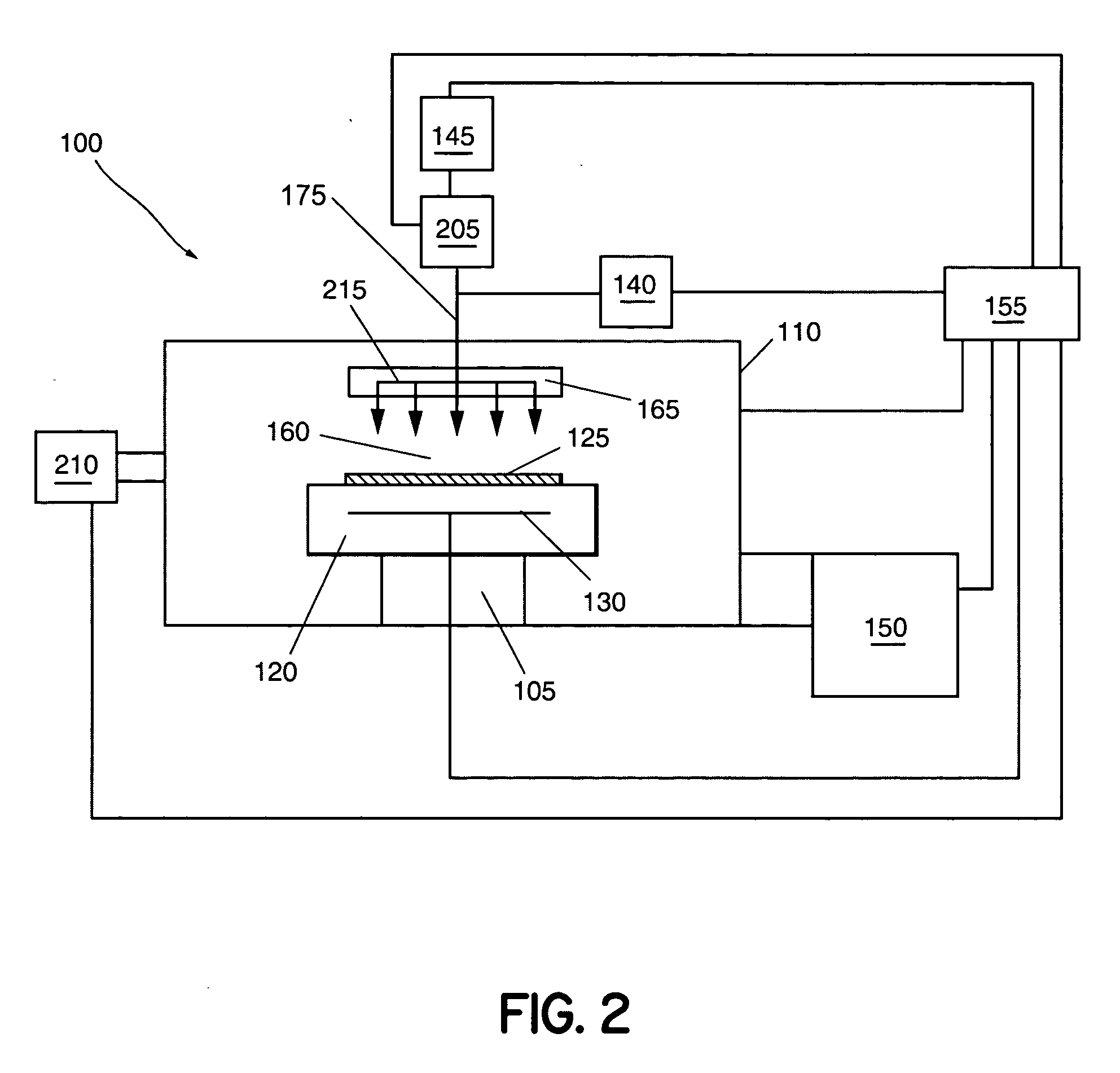

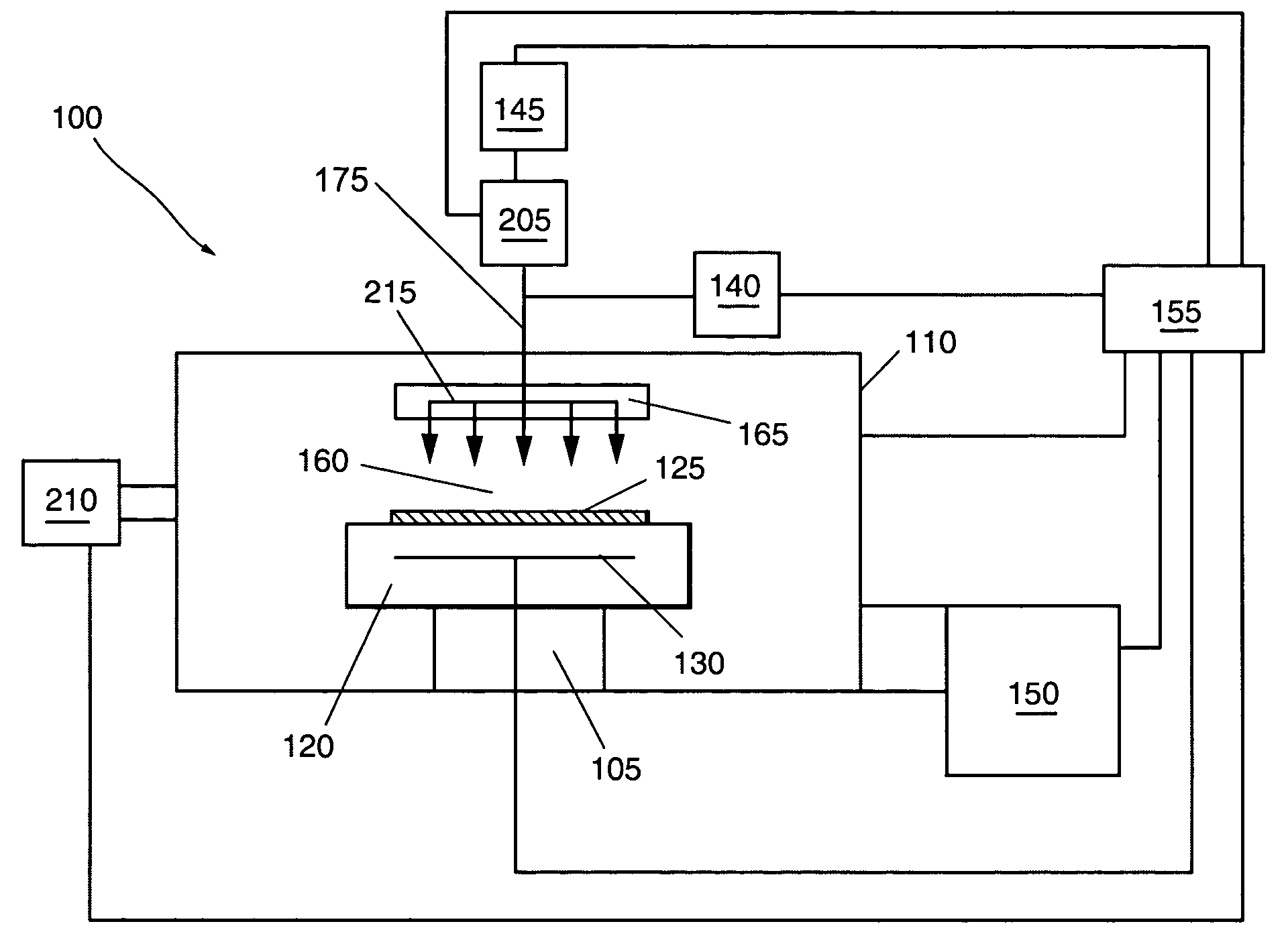

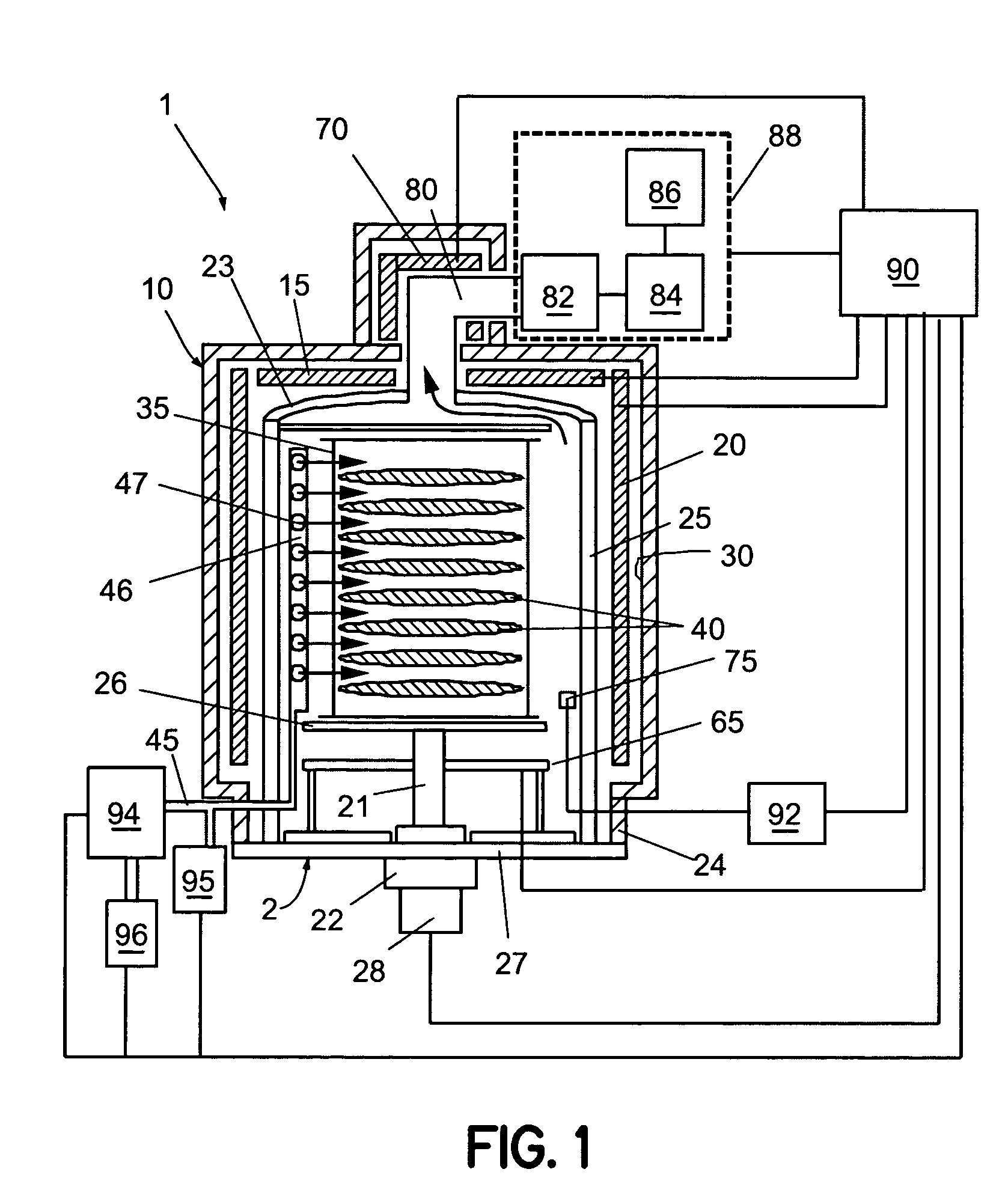

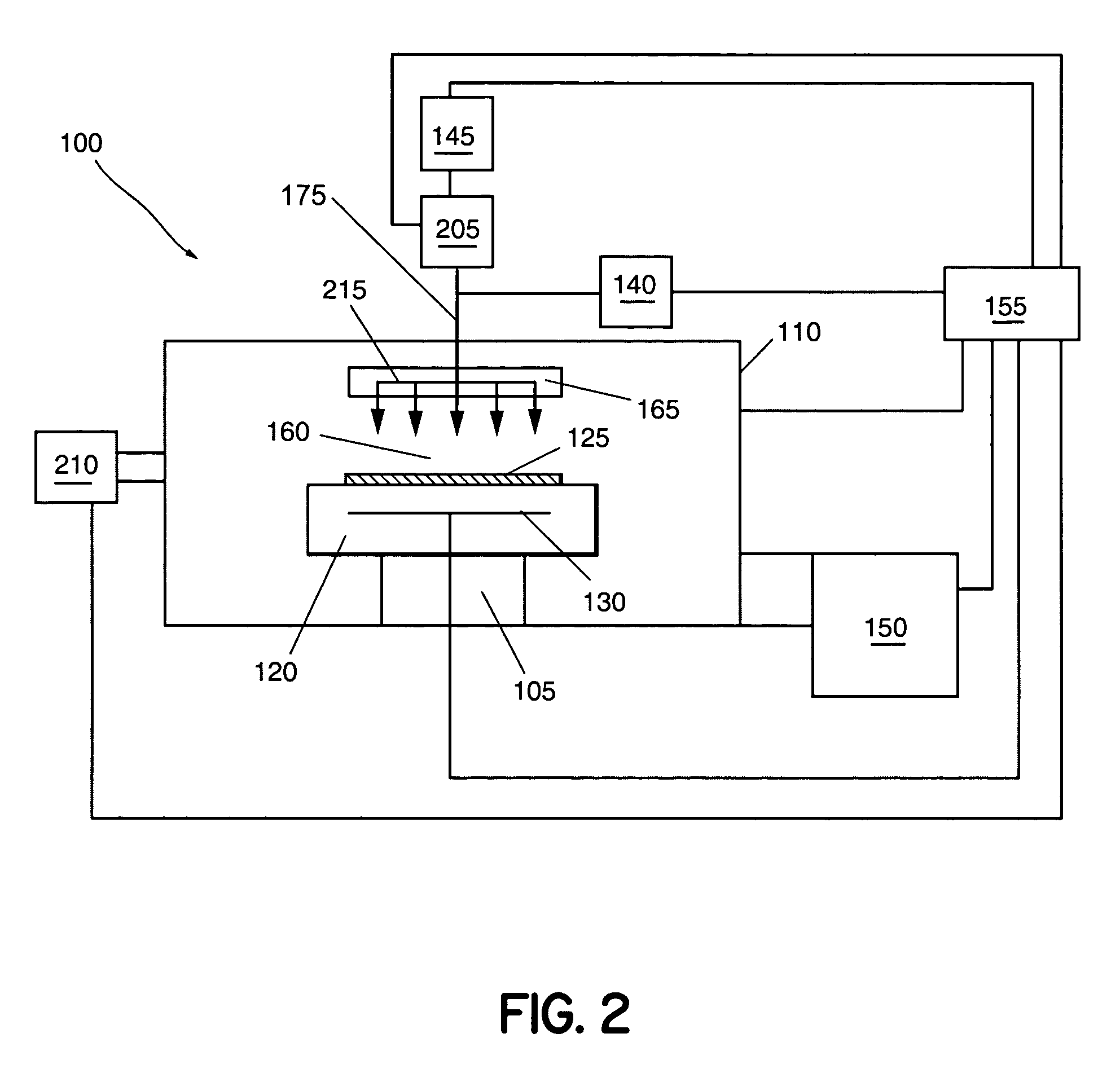

Low-temperature plasma-enhanced chemical vapor deposition of silicon-nitrogen-containing films

InactiveUS20060014399A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilazaneRemote plasma

A method for low-temperature plasma-enhanced chemical vapor deposition of a silicon-nitrogen-containing film on a substrate. The method includes providing a substrate in a process chamber, exciting a reactant gas in a remote plasma source, thereafter mixing the excited reactant gas with a silazane precursor gas, and depositing a silicon-nitrogen-containing film on the substrate from the excited gas mixture in a chemical vapor deposition process. In one embodiment of the invention, the reactant gas can contain a nitrogen-containing gas to deposit a SiCNH film. In another embodiment of the invention, the reactant gas can contain an oxygen-containing gas to deposit a SiCNOH film.

Owner:TOKYO ELECTRON LTD

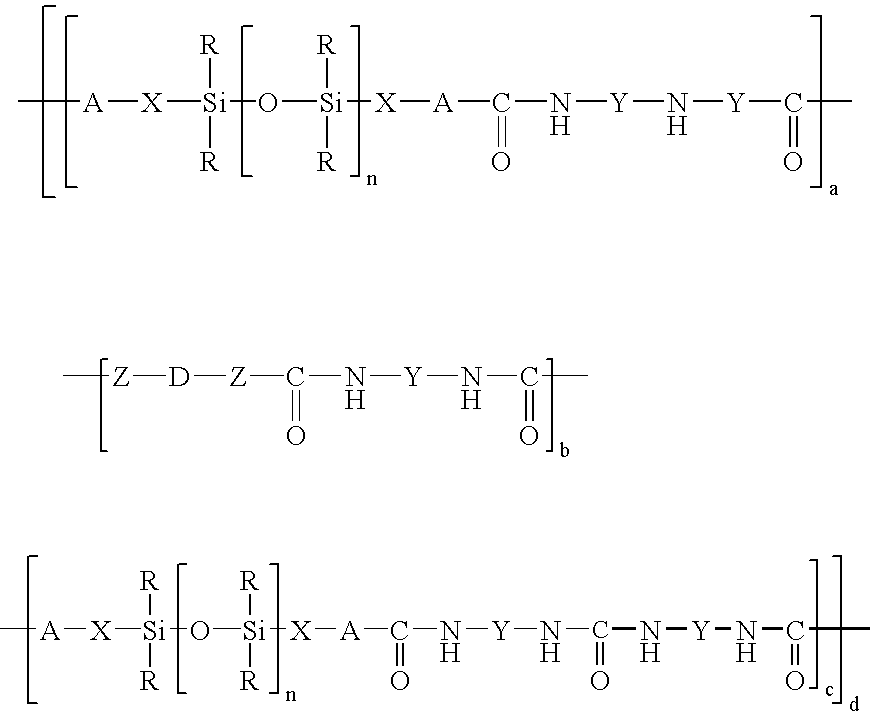

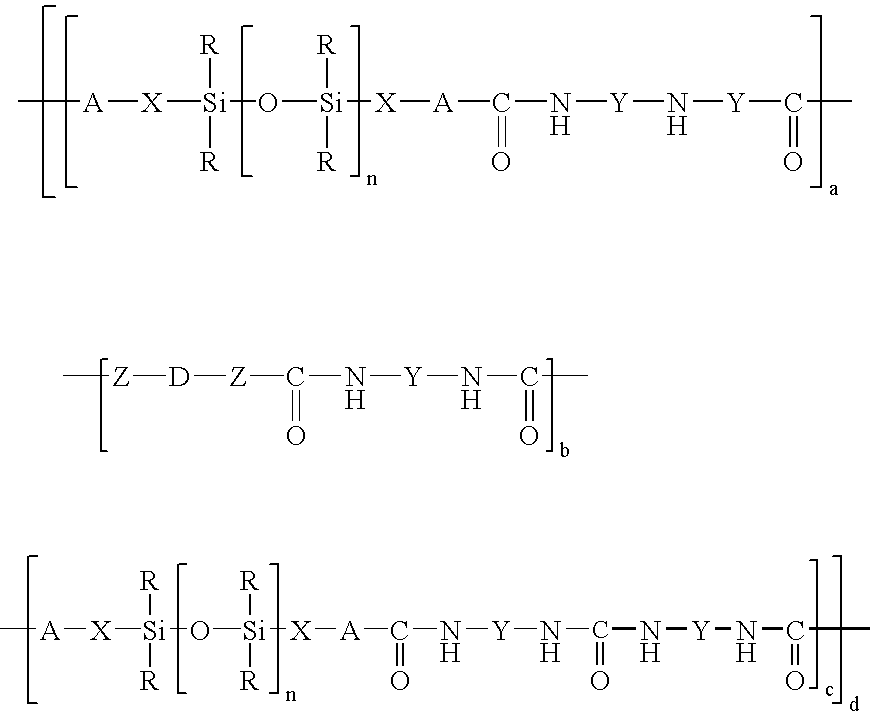

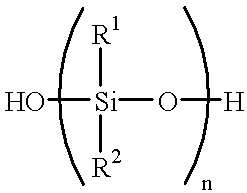

Organopolysiloxane/polyurea/polyurethane block copolymers

Organopolysiloxane / polyurea / polyurethane block copolymer elastomers exhibiting improved physical properties are prepared by reacting diisocyanates with aminoalkyl-functional organopolysiloxanes containing substantially no cyclic siloxanes, prepared by reacting a cyclic silazane with a bis(hydroxy)-organopolysiloxane. Traditional hydroxyl and amino-functional chain extenders may be reacted as well, to produce a wide range of block copolymer elastomers.

Owner:WACKER CHEM GMBH

Modified silicon dioxide aerogel microsphere thermal-insulation coating

ActiveCN104231798AGood dispersionGood heat insulationEpoxy resin coatingsPigment treatment with organosilicon compoundsPolymer scienceSilanes

The invention discloses a thermal-insulation coating by taking hydrophobic silicon dioxide aerogel microspheres as thermal-insulation packing. The coating is prepared by the following main steps: preparing the hydrophobic silicon dioxide aerogel microspheres; and mixing the prepared hydrophobic silicon dioxide aerogel microspheres and a polymer emulsion to prepare the thermal-insulation coating. Hydrophobic modification of the silicon dioxide aerogel microspheres includes the following two modes: in one mode, silicon dioxide wet-gel microspheres are modified by adopting halogenated hydrocarbon and in the other mode, alkoxy silane, silazane or siloxane is added into a mixed solution in a sol preparing stage. When the coating is prepared, a surfactant is added, so that the compatibility between the hydrophobic silicon dioxide aerogel microspheres and the polymer emulsion can be improved, the dispersibility of the microspheres in the coating can be improved, the coating quality can be improved, and the thermal-insulation performance of the coating can be improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

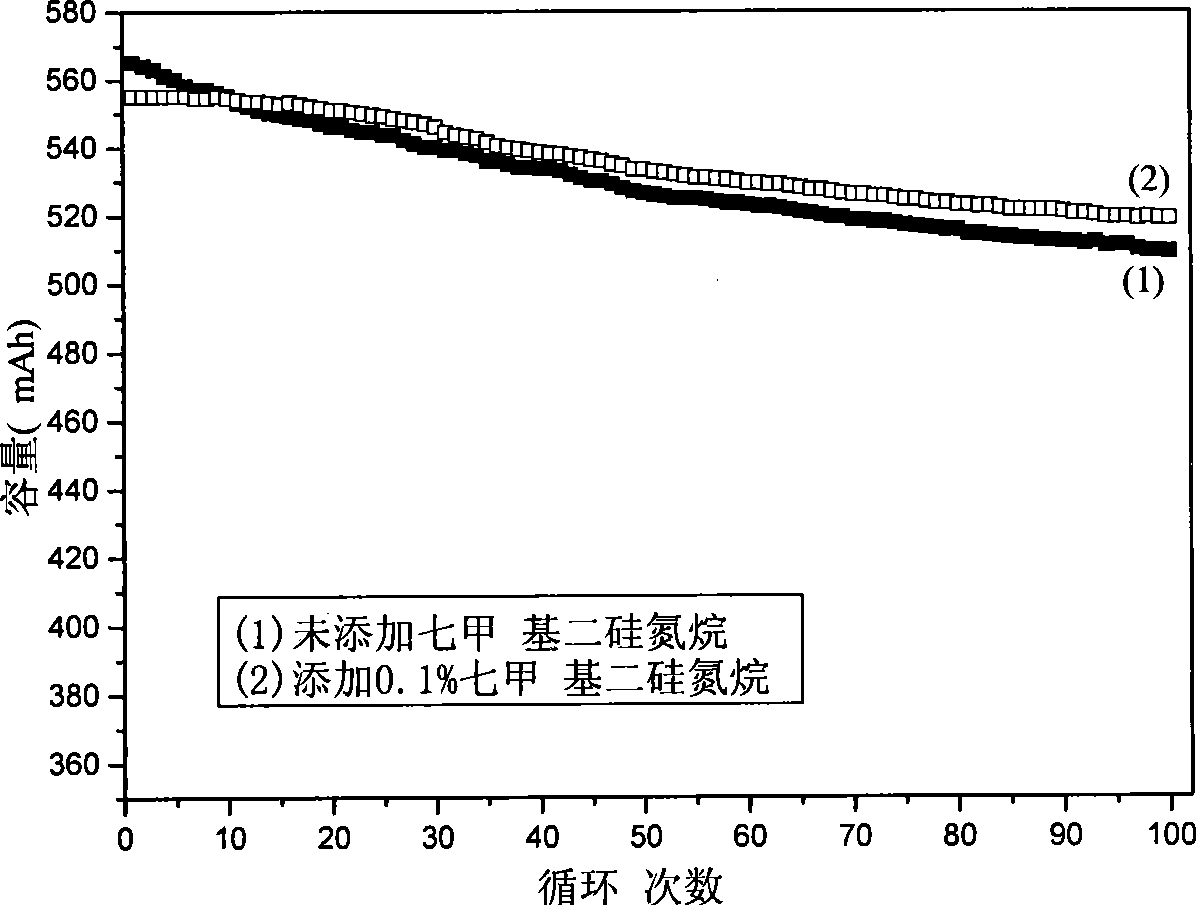

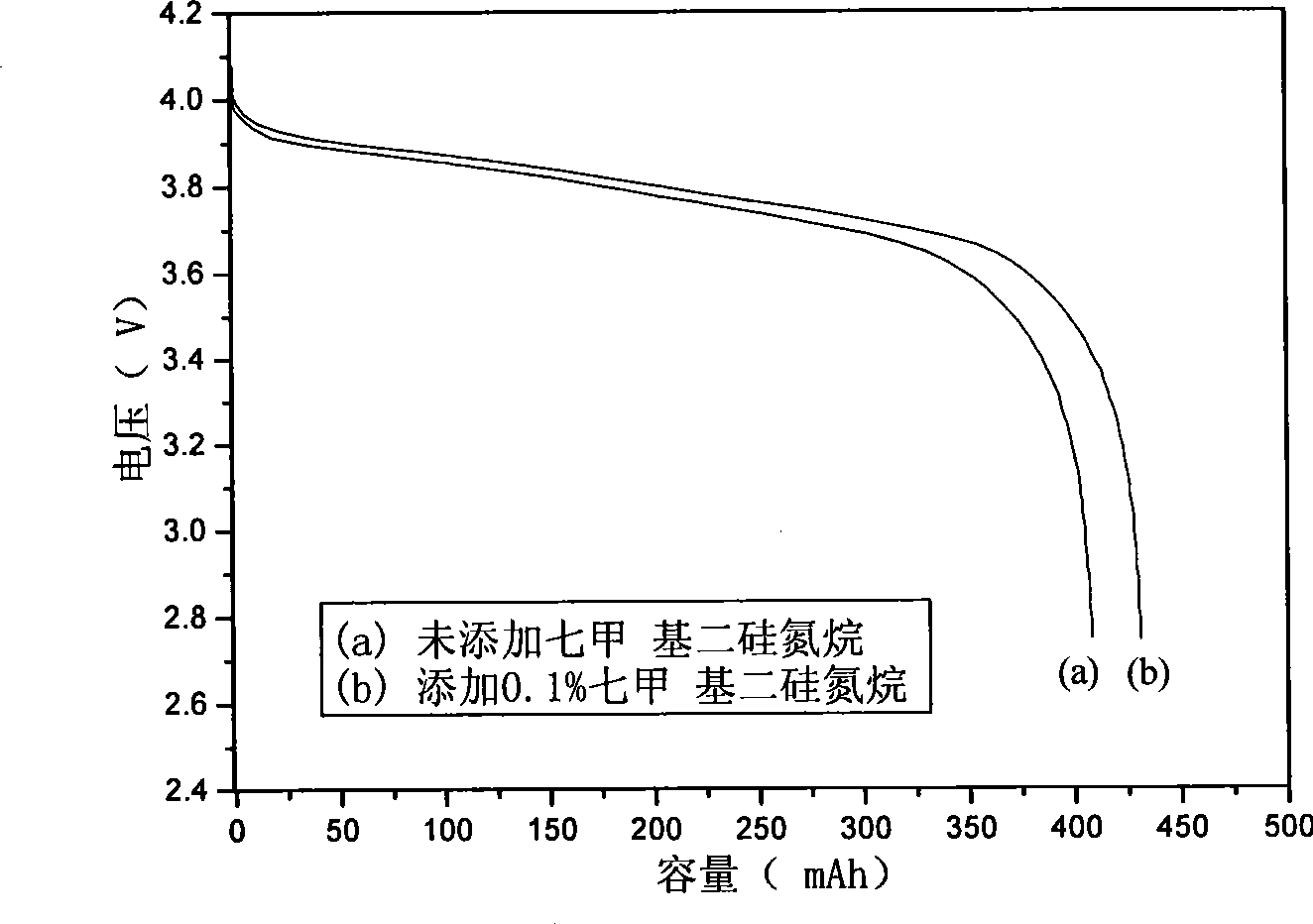

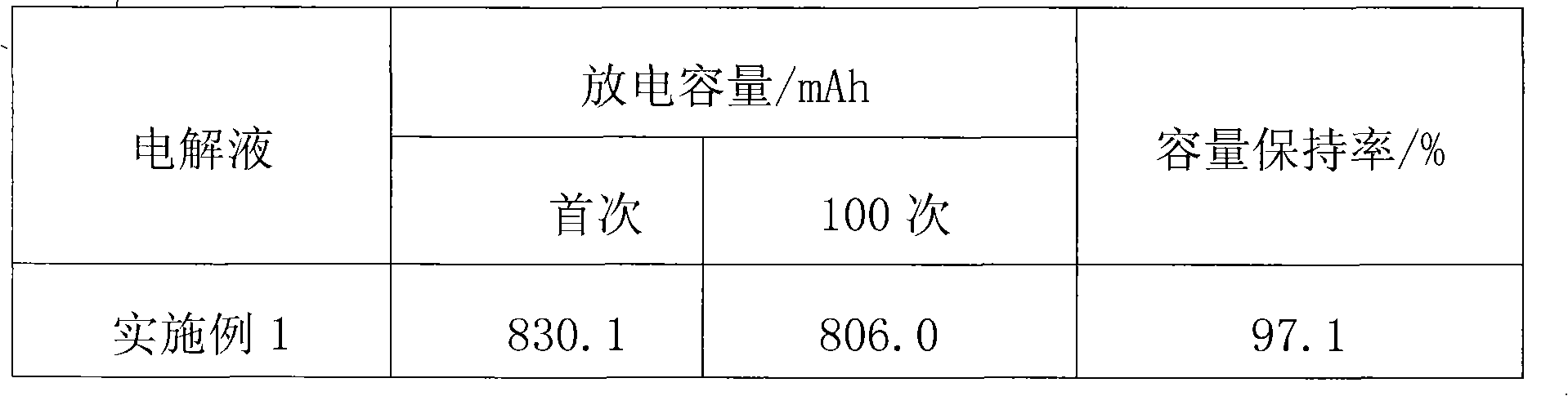

Electrolysis liquid for lithium manganate battery

The invention discloses electrolyte solution of a manganic acid lithium battery. The electrolyte solution comprises lithium salt, non-aqueous organic solvent, film-forming additive and stabilizing additive, namely seven-methyl two-silazane. Because the stabilizing additive, seven-methyl two-silazane is added into the electrolyte solution, the acidity of the electrolyte solution can be controlled. The cycle life and the high temperature storage performance of a lithium ion battery can be improved by using the electrolyte solution to prepare a battery.

Owner:GUANGZHOU TINCI MATERIALS TECH

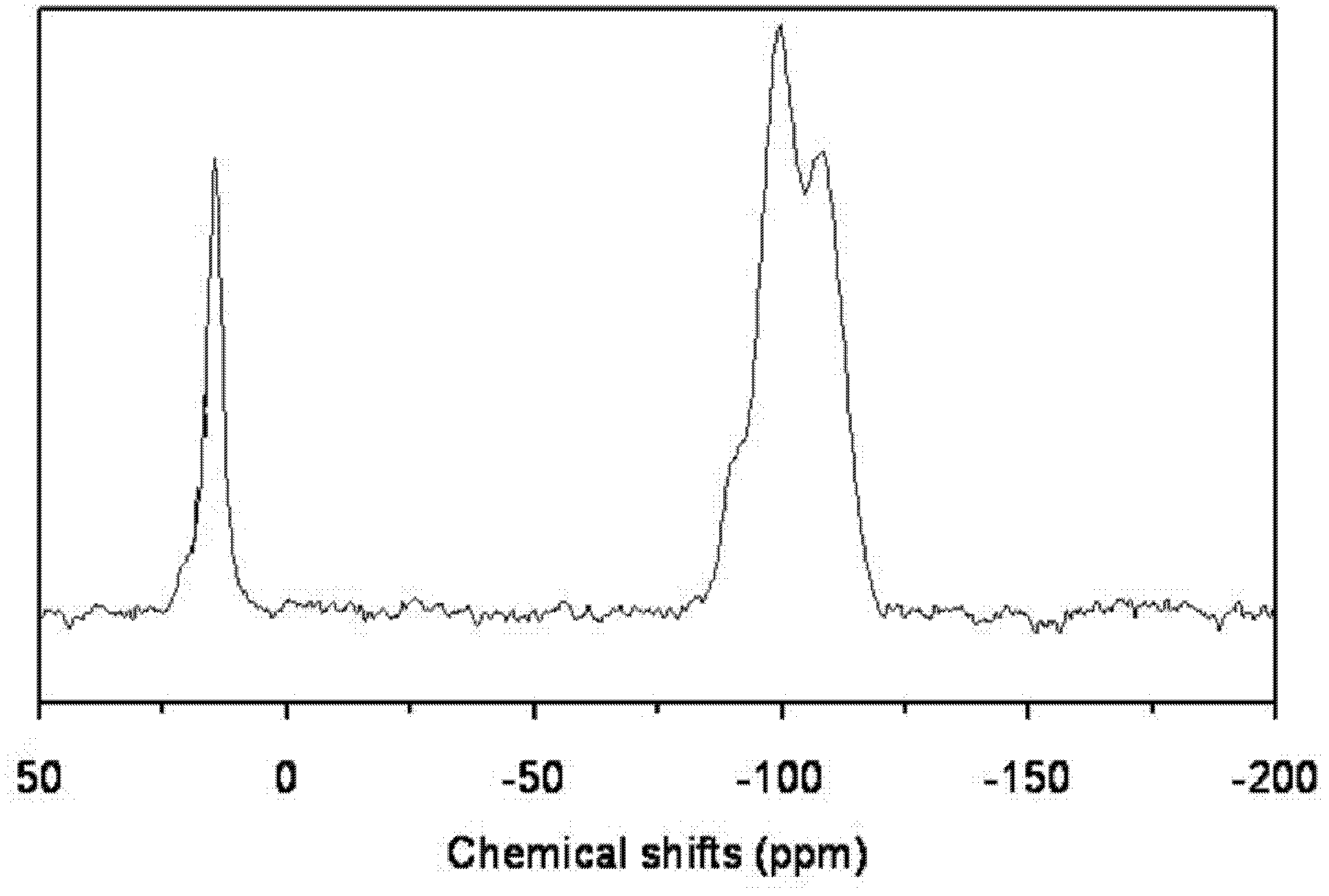

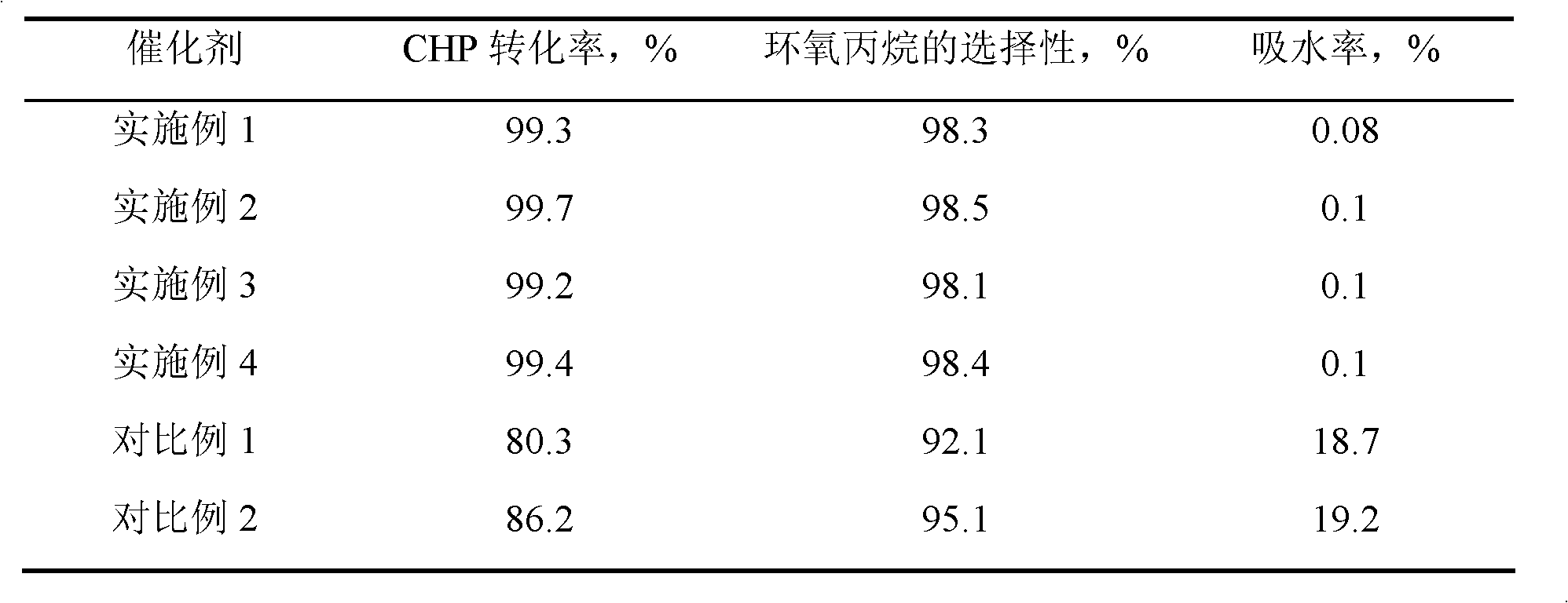

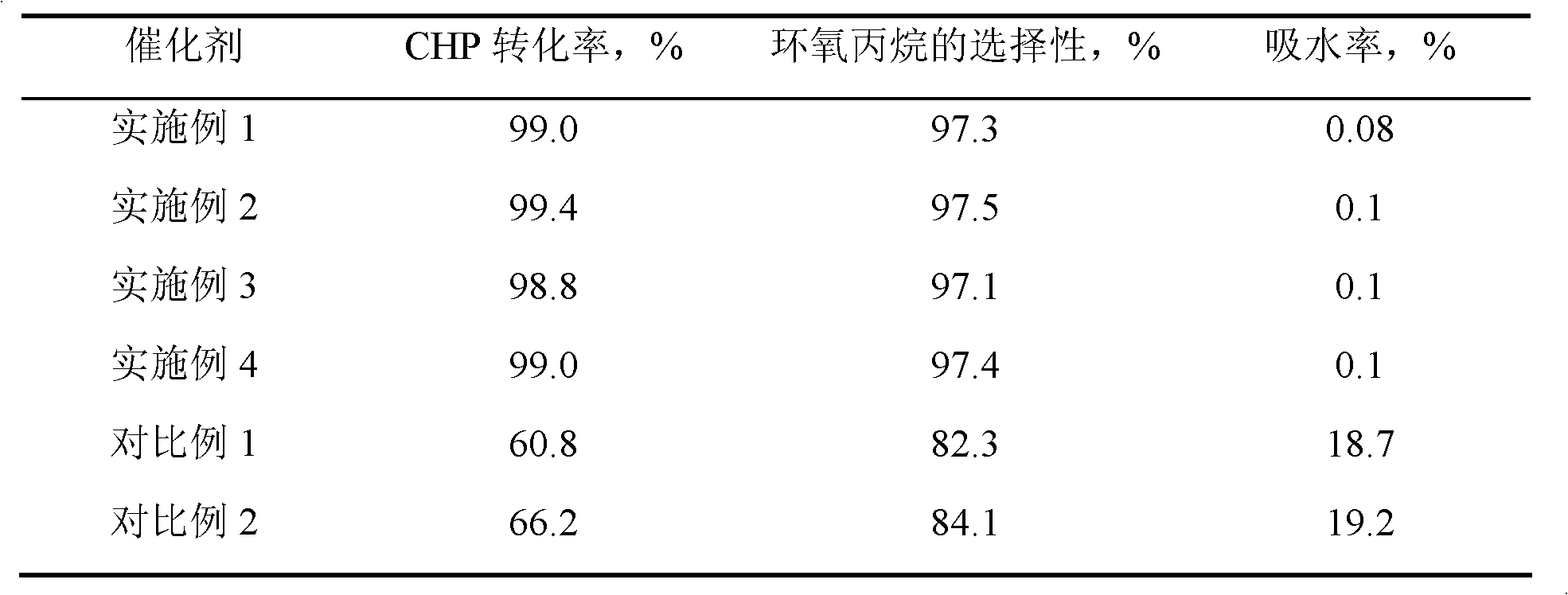

Method for modifying TS-1 titanium-silicon molecular sieve catalyst

InactiveCN101602013AImprove catalytic performanceImprove hydrophobicityOrganic chemistryMolecular sieve catalystsMolecular sieveSilazane

The invention relates to a method for modifying a TS-1 titanium-silicon molecular sieve catalyst, which mainly solves the problems that a silanization reagent is easy to hydrolyze to cover the active center of the catalyst and has large consumption, difficult recovery and environmental pollution when being used for processing the TS-1 molecular sieve catalyst in a dipping mode in the prior art. The method better solves the problem by adopting the technical scheme that a TS-1 titanium-silicon molecular sieve catalyst matrix reacts for 0.5-10 hours by leading into the silanization reagent at 50-300 DEG C in a nitrogen atmosphere, and then a modified TS-1 titanium-silicon molecular sieve catalyst is obtained, wherein the silanization reagent is selected from organosilane, organic silylamine, organic silicyl amide or organic silazane, and the dosage of the silanization reagent is 2-20 percent of the weight of the catalyst matrix. The method can be applied to the industrial production of epoxy chloropropane.

Owner:CHINA PETROLEUM & CHEM CORP +1

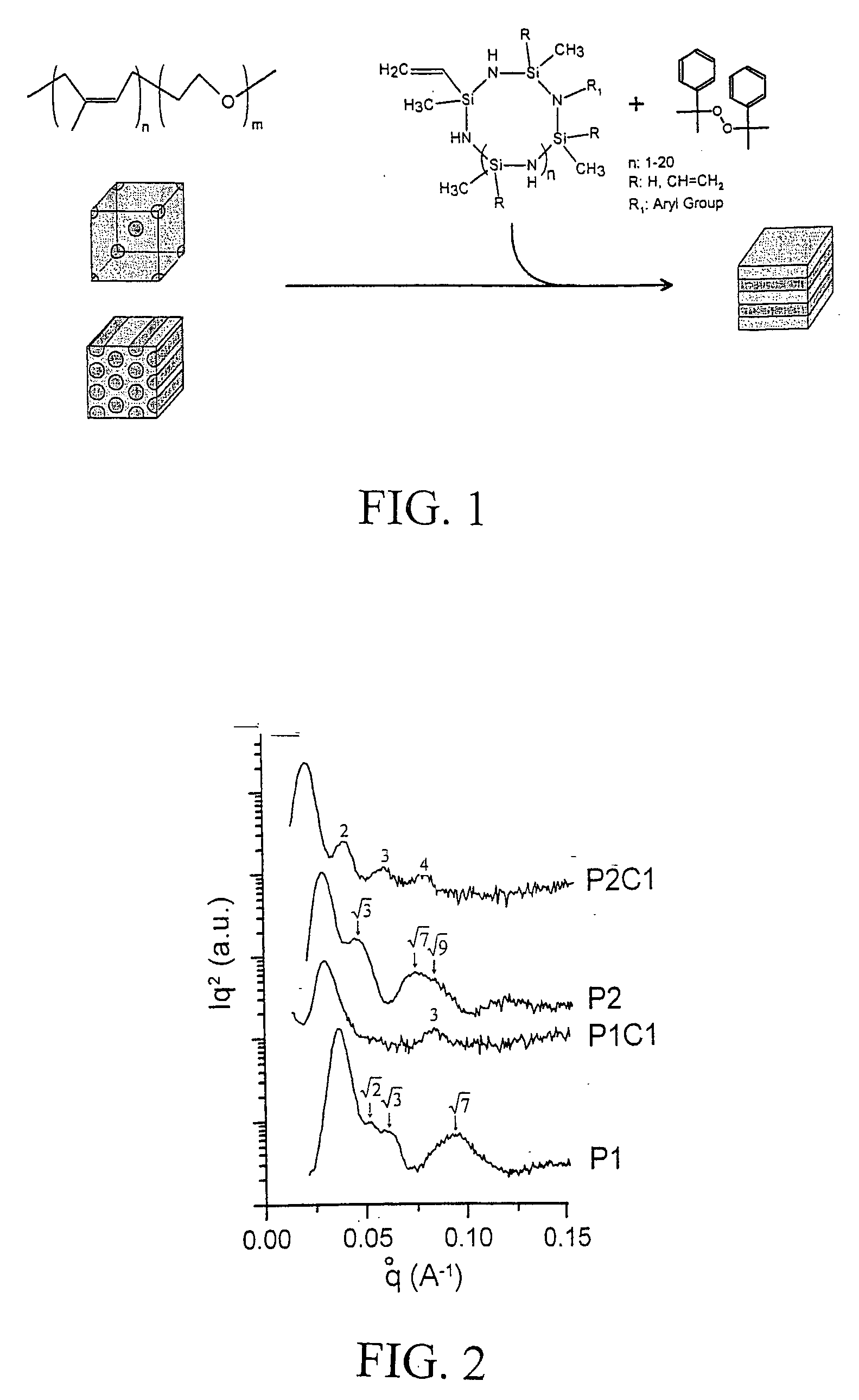

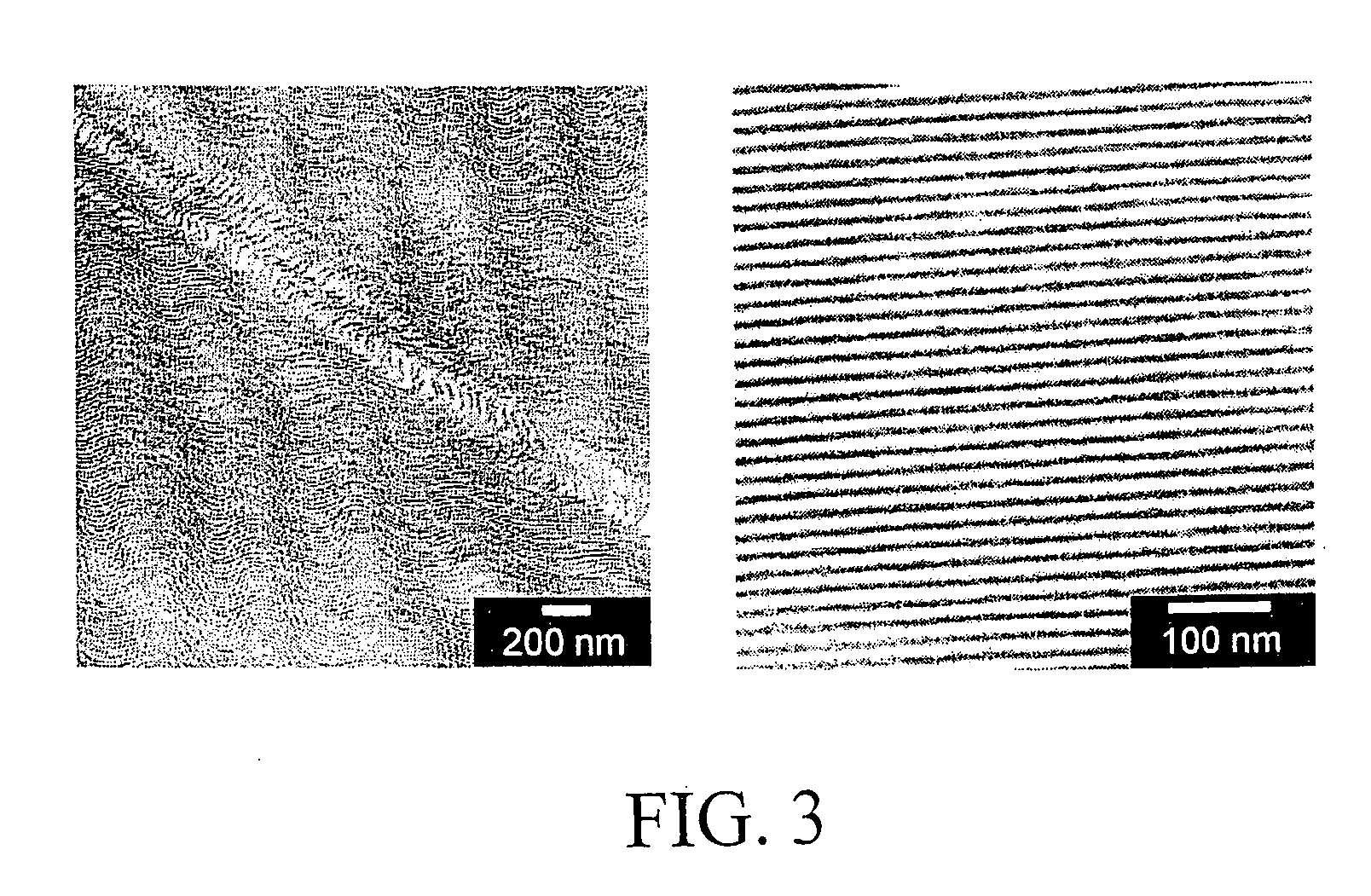

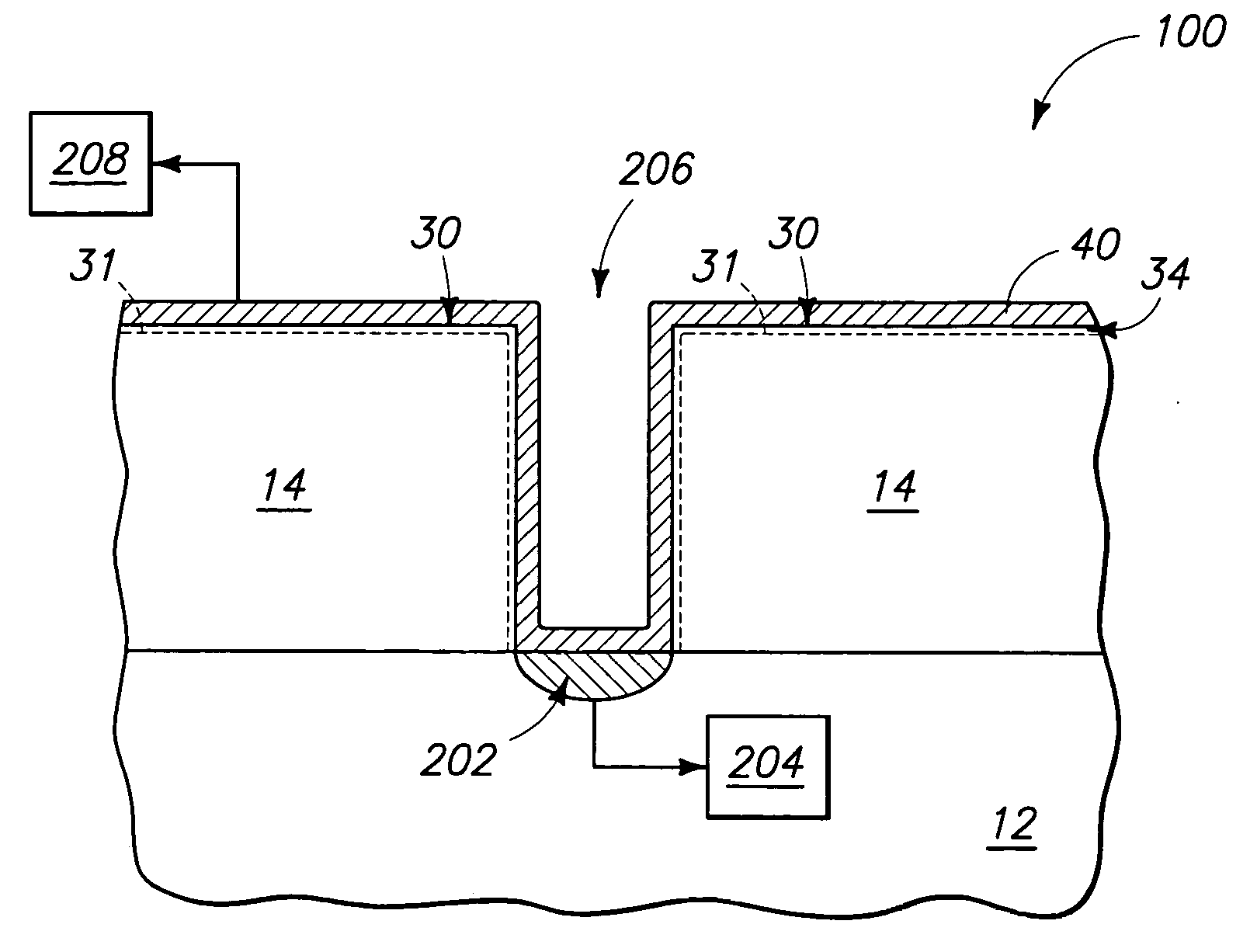

High temperature SiCN and SiC-type nanostructured ceramic material from block copolymer mesophases

InactiveUS20050036931A1Simple and easily controlled pathwayCarbon compoundsNitrogen and non-metal compoundsNon oxide ceramicsPolymer science

A block copolymer, preferably a block copolymer such as poly(isoprene-block-ethylene oxide), PI-b-PEO, is used as a structure directing agent for a polymer derived ceramic (PDC) precursor, preferably a silazane, most preferably a silazane commercially known as Ceraset. The PDC precursor is preferably polymerized after mixing with the block copolymer to form a nanostructured composite material. Through further heating steps, the nanostructured composite material can be transformed into a nanostructured non-oxide ceramic material, preferably a high temperature SiCN or SiC material.

Owner:CORNELL RES FOUNDATION INC

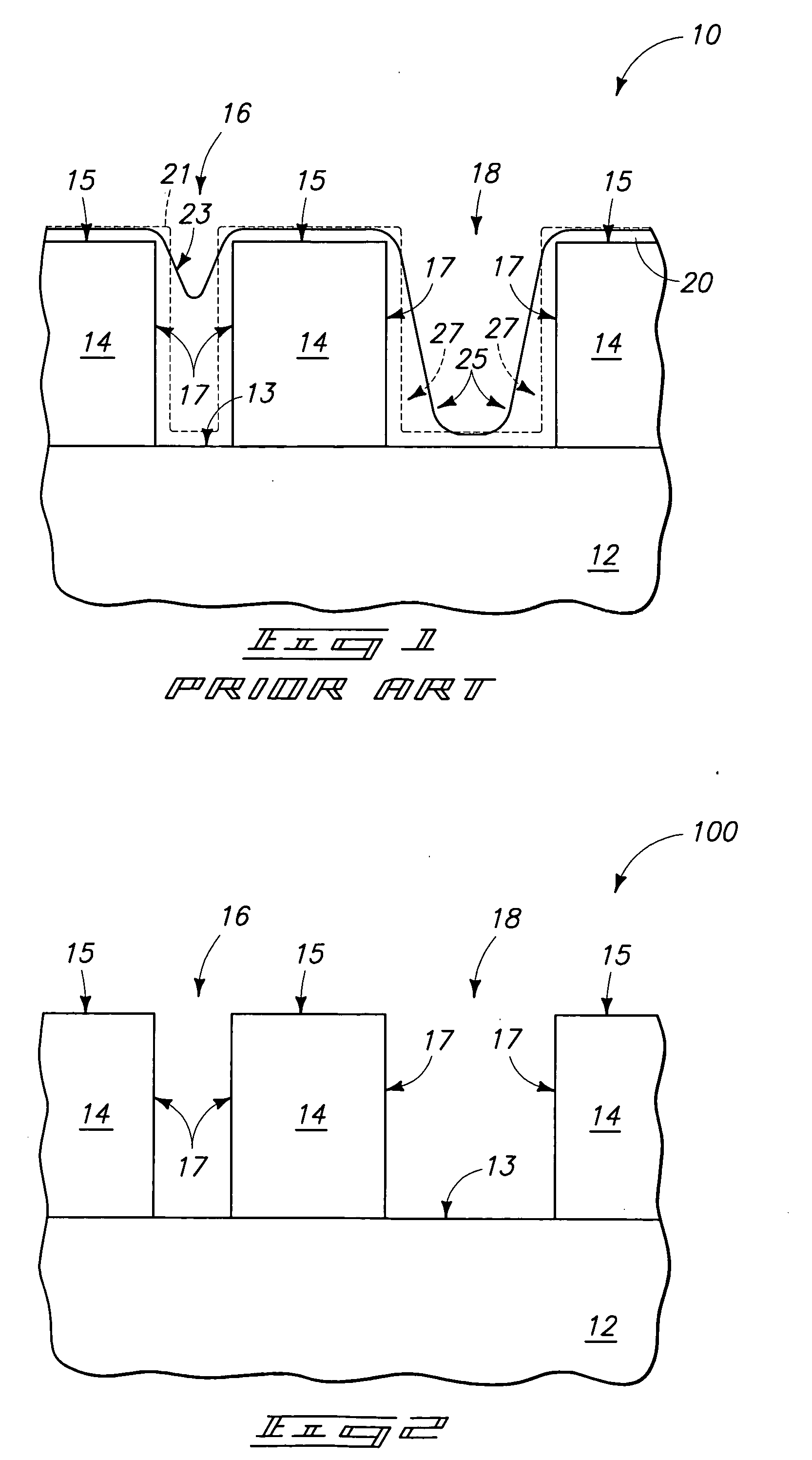

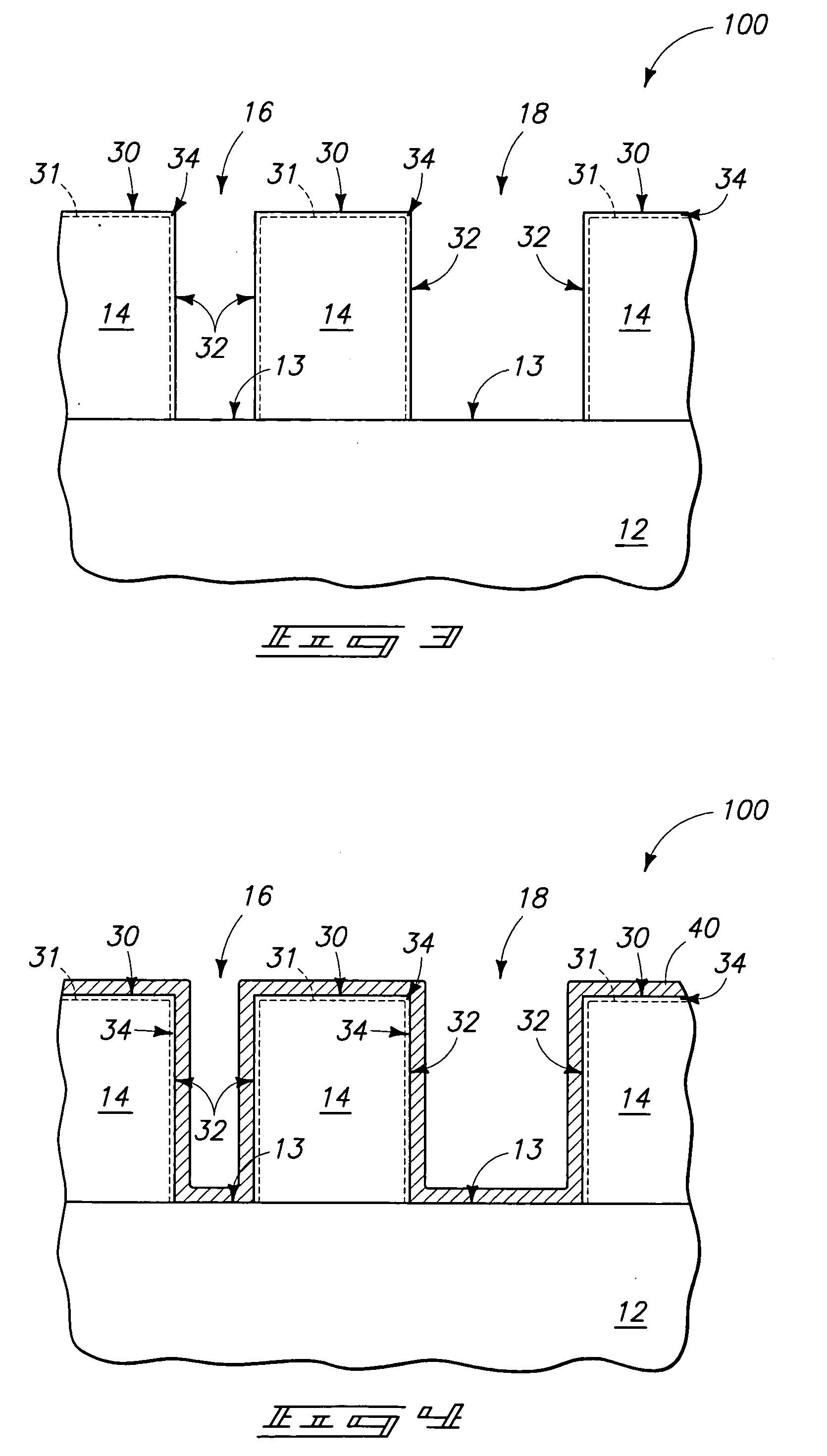

Semiconductor constructions and methods of forming layers

ActiveUS20070049003A1Semiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingSilazaneSilanes

The invention includes methods of forming layers conformally over undulating surface topographies associated with semiconductor substrates. The undulating surface topographies can first be exposed to one or more of titanium oxide, neodymium oxide, yttrium oxide, zirconium oxide and vanadium oxide to treat the surfaces, and can be subsequently exposed to a material that forms a layer conformally along the treated surfaces. The material can, for example, comprise one or both of aluminum silane and aluminum silazane. The invention also includes semiconductor constructions having conformal layers formed over liners containing one or more of titanium oxide, yttrium oxide, zirconium oxide and vanadium oxide.

Owner:MICRON TECH INC

Process for producing hydrophobic silica powder

InactiveUS20060112860A1Good dispersionSimple equipmentMaterial nanotechnologyPigmenting treatmentColloidal silicaAzane

A process for producing a hydrophobic silica powder, comprises the steps for hydrophobic treatment of: adding to an aqueous silica sol containing hydrophilic colloidal silica having a specific surface area of 5.5 to 550 m2 / g, a disilazane compound represented by formula (1) (R13Si)2NH (1) wherein each R1 is C1-6alkyl group or phenyl group that is selected independently of one another, in an amount of 0.1 to 10 mmol per surface area 100 m2 of the hydrophilic colloidal silica, to obtain a first mixture of the aqueous silica sol and the disilazane compound; and heating the mixture at a temperature of 50 to 100° C. for aging it to obtain a slurry as dispersion of hydrophobic treated colloidal silica. The process provides a hydrophobic silica powder through a simple hydrophobic treatment step.

Owner:NISSAN CHEM IND LTD

Low-temperature plasma-enhanced chemical vapor deposition of silicon-nitrogen-containing films

InactiveUS7129187B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaSilazane

A method for low-temperature plasma-enhanced chemical vapor deposition of a silicon-nitrogen-containing film on a substrate. The method includes providing a substrate in a process chamber, exciting a reactant gas in a remote plasma source, thereafter mixing the excited reactant gas with a silazane precursor gas, and depositing a silicon-nitrogen-containing film on the substrate from the excited gas mixture in a chemical vapor deposition process. In one embodiment of the invention, the reactant gas can contain a nitrogen-containing gas to deposit a SiCNH film. In another embodiment of the invention, the reactant gas can contain an oxygen-containing gas to deposit a SiCNOH film.

Owner:TOKYO ELECTRON LTD

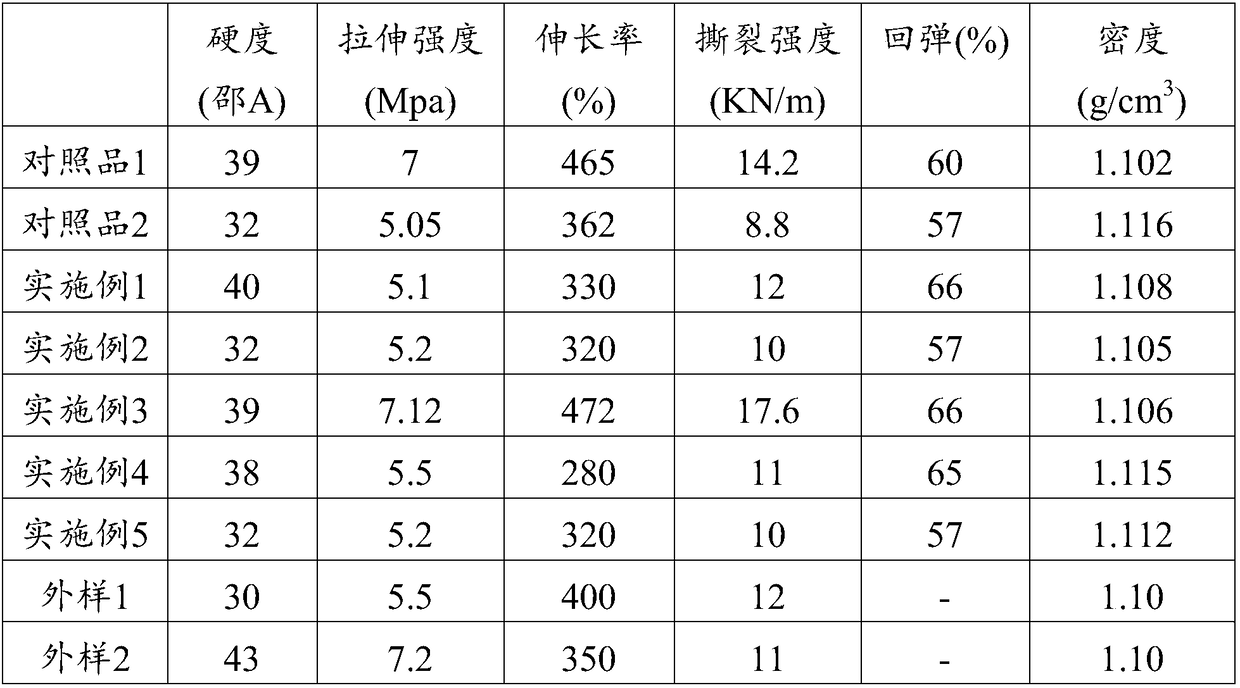

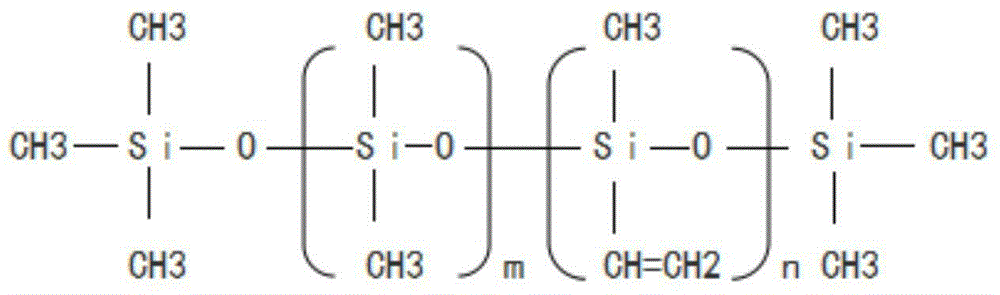

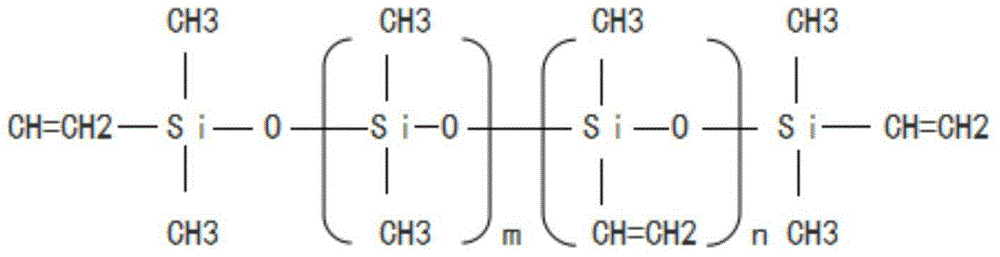

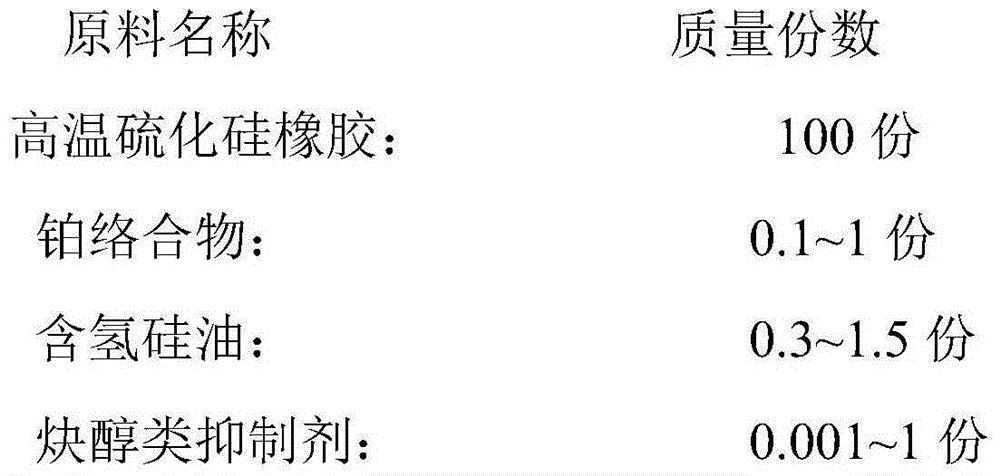

Double-component addition-type liquid silicone rubber as well as preparation method of same

The invention belongs to the technical field of silicone rubber and particularly relates to double-component addition-type liquid silicone rubber as well as a preparation method of same. The liquid silicone rubber is prepared by mixing, curing and shaping a component A and a component B, wherein the component A includes 100 parts of basic rubber, 8-18 parts of vinyl-terminated silicone oil, 1-2 parts of a tackifier, and 0.5 parts of a platinum catalyst; the component B includes: 20-70 parts of vinyl-terminated silicone oil, 30-80 parts of hydrogen-containing silicone oil, and 0.3-0.5 parts ofan inhibitor; the basic rubber includes 100 parts of vinyl-terminated silicone oil, 5-10 parts of vinyl-terminated silicone oil having side-chain vinyl group, 40 parts of fumed silica, 10-15 parts ofa silazane processing agent, and 0-5 parts of a siloxane processing agent. In the liquid silicone rubber, the components are cooperated and are matched in reasonable ratio, so that firmness of the liquid silicone rubber on surfaces of fabrics is improved, and tensile strength and tearing strength of the silicone rubber are increased; the silicone rubber is high in vulcanization speed and high in production efficiency. The invention also provides a preparation method of the double-component addition-type liquid silicone rubber. The method is optimized in process and has simple operations.

Owner:佛山市天宝利硅工程科技有限公司

Silazane additive and lithium ion battery electrolyte prepared by using same and capable of preventing corrosion of steel shell

ActiveCN103401019AImprove corrosion resistanceSimple preparation processSecondary cellsElectrolytic agentSilazane

The invention specifically relates to a silazane additive and a lithium ion battery electrolyte prepared by using the same and capable of preventing corrosion of a steel shell, belonging to the technical field of additives for lithium ion battery electrolytes. The silazane additive provided by the invention is used as a steel shell corrosion inhibitor in the lithium ion battery electrolyte and can continuously react with moderately strong corrosive substances in the lithium ion battery electrolyte, thereby enabling the steel shell to maintain shining even after long time storage in the lithium ion battery electrolyte. The lithium ion battery electrolyte prepared by using the silazane additive and capable of preventing corrosion of the steel shell is directed at respective physicochemical characteristics of a solvent, a lithium salt and the additive and allows the solvent, the lithium salt and the silazane additive to perform respective advantages and mutually inhibit respective disadvantages after appropriate proportioning of the solvent, the lithium salt and the silazane additive; through the synergistic effect of the solvent, the lithium salt and the silazane additive, the anticorrosion effect of the lithium ion battery electrolyte provided by the invention is far better than that of conventional lithium ion battery electrolytes, and a preparation process for the lithium ion battery electrolyte is simple and easily practicable and has good market prospects.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

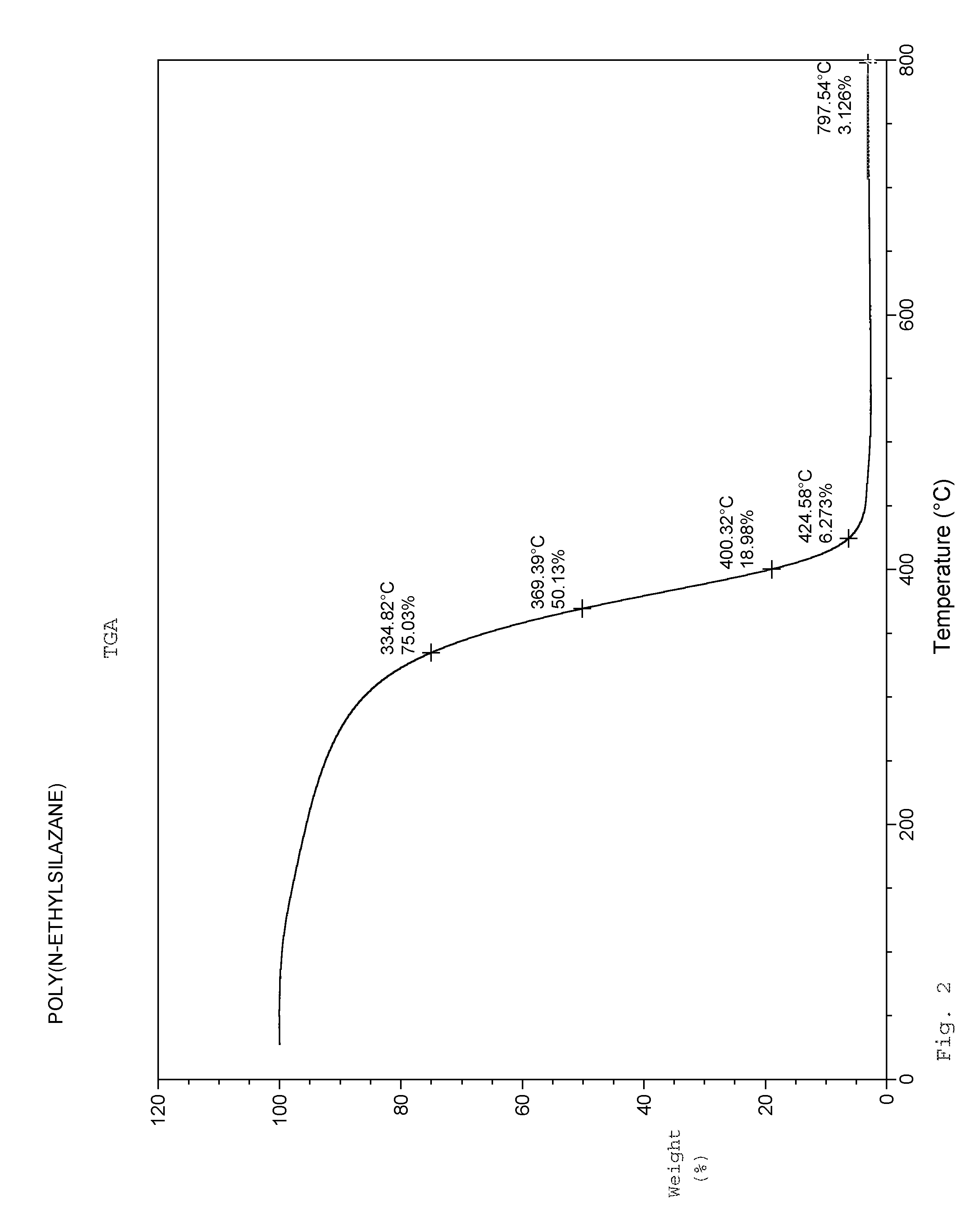

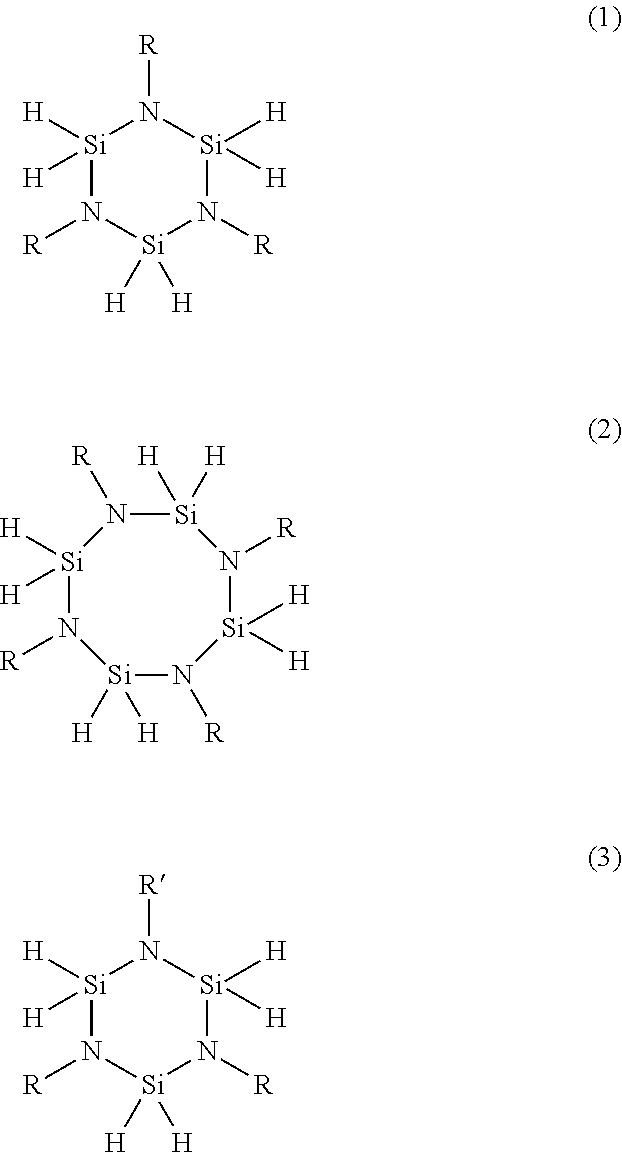

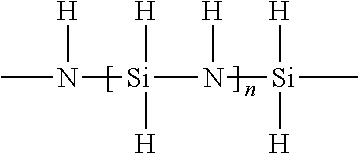

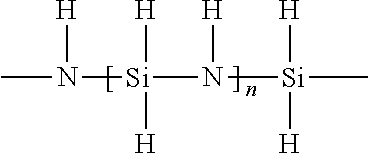

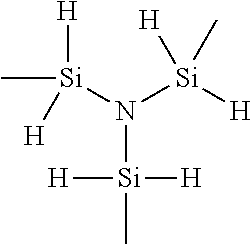

N-alkyl substituted cyclic and oligomeric perhydridosilazanes, methods of preparation thereof, and silicon nitride films formed therefrom

Novel N-alkyl substituted perhydridocyclic silazanes, oligomeric N-alkyl perhydridosilazane compounds, and N-alkylaminodihydridohalosilanes, and a method for their synthesis are provided. The novel compounds may be used to form high silicon nitride content films by thermal or plasma induced decomposition.

Owner:GELEST

Storage phosphor panel, radiation image sensor and methods of making the same

InactiveUS20040164251A1Improve moisture resistancePrevent peelingX-ray/infra-red processesElectrical apparatusSilazanePhysics

A stimulable phosphor adapted to convert incident radiation into visible light is formed on one surface of a substrate in a storage phosphor panel, wherein surfaces of phosphor and, optionally, the said substrate, are covered with a poly-paraxylylene film, whereas a film-forming silazane or siloxazane type polymeric compound covers the outermost surface of the poly-paraxylylene film on the phosphor side.

Owner:T2PHARMA GMBH

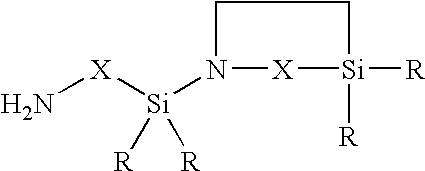

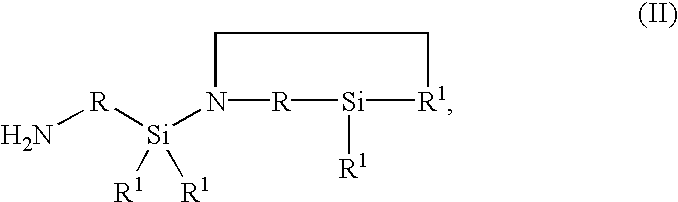

Solids surface-modified with amino groups

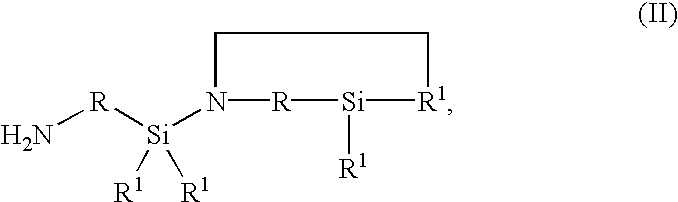

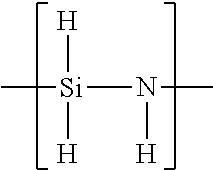

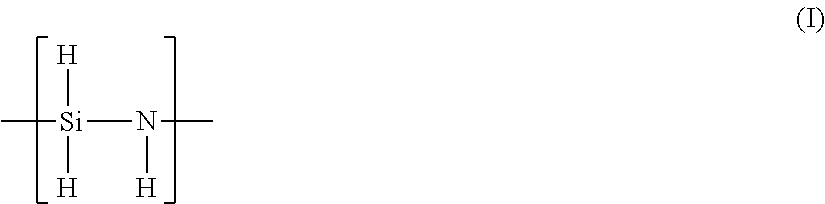

Surface-modified solids bearing groups of the formula ISiR12—R—NH2 (I),are prepared by reacting a solid having OH groups on a surface thereof with a cyclic silazane of the general formula II whereR is a divalent optionally substituted hydrocarbon radical optionally containing heteroatom containing groups, andR1 is a hydrogen atom, or a monovalent optionally substituted hydrocarbon or hydrocarbonoxy group optionally containing heteroatom-containing groups. The surface-modified solids are preferably metal oxide particles. Such surface-modified particles are useful in numerous products.

Owner:WACKER CHEM GMBH

High performance silicon based thermal coating compositions

ActiveUS20130302526A1Reduce odorLow costFireproof paintsPretreated surfacesOrganic solventMaterials science

A silicon based coating composition for a wide range of surfaces, which composition is formed from a mixture of constituents comprising appropriate portions of silazane, siloxane, and silane, and optionally organic solvent and additives, and the composition results in a coating having a thickness between 0.4 mil and 1.5 mil, a hardness of 4-9H and an endurance to continuous temperature above 1600° F.

Owner:BURNING BUSH GRP

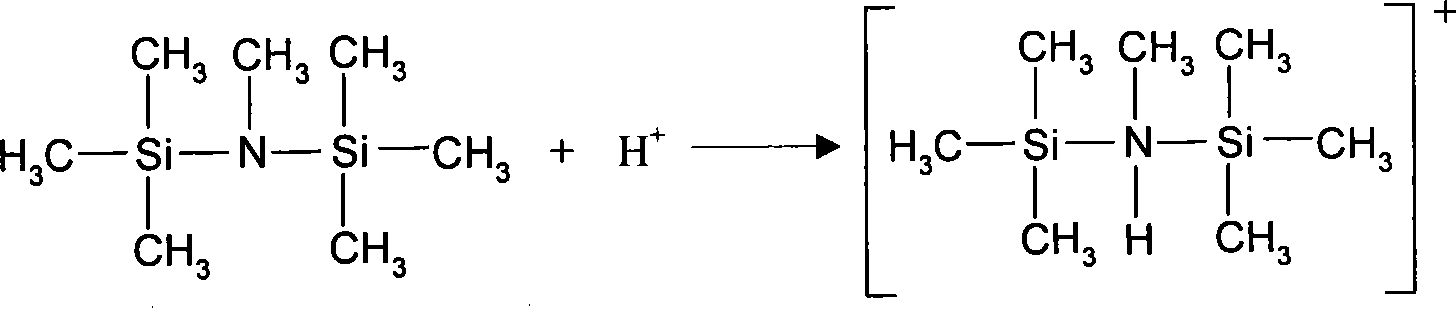

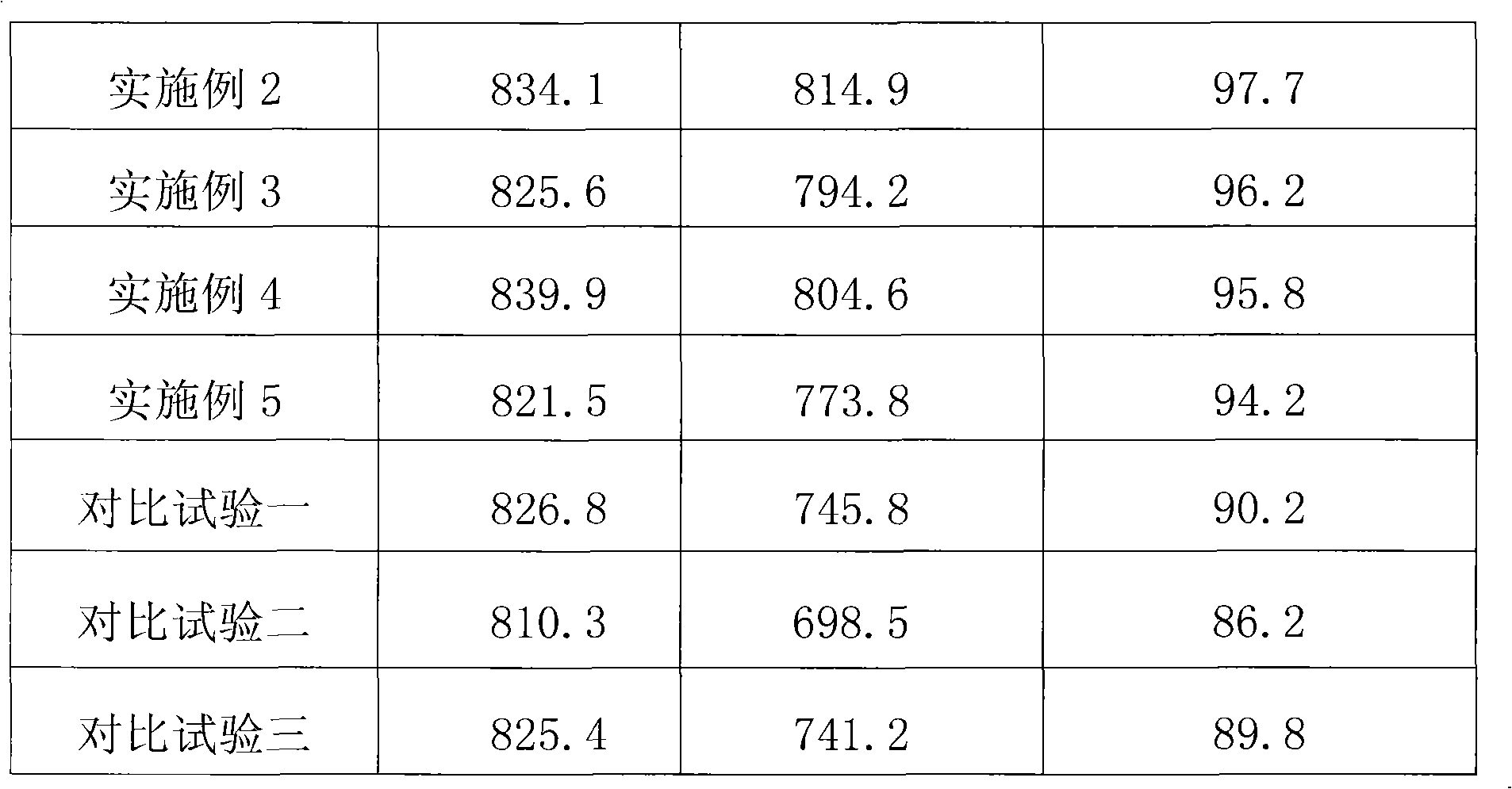

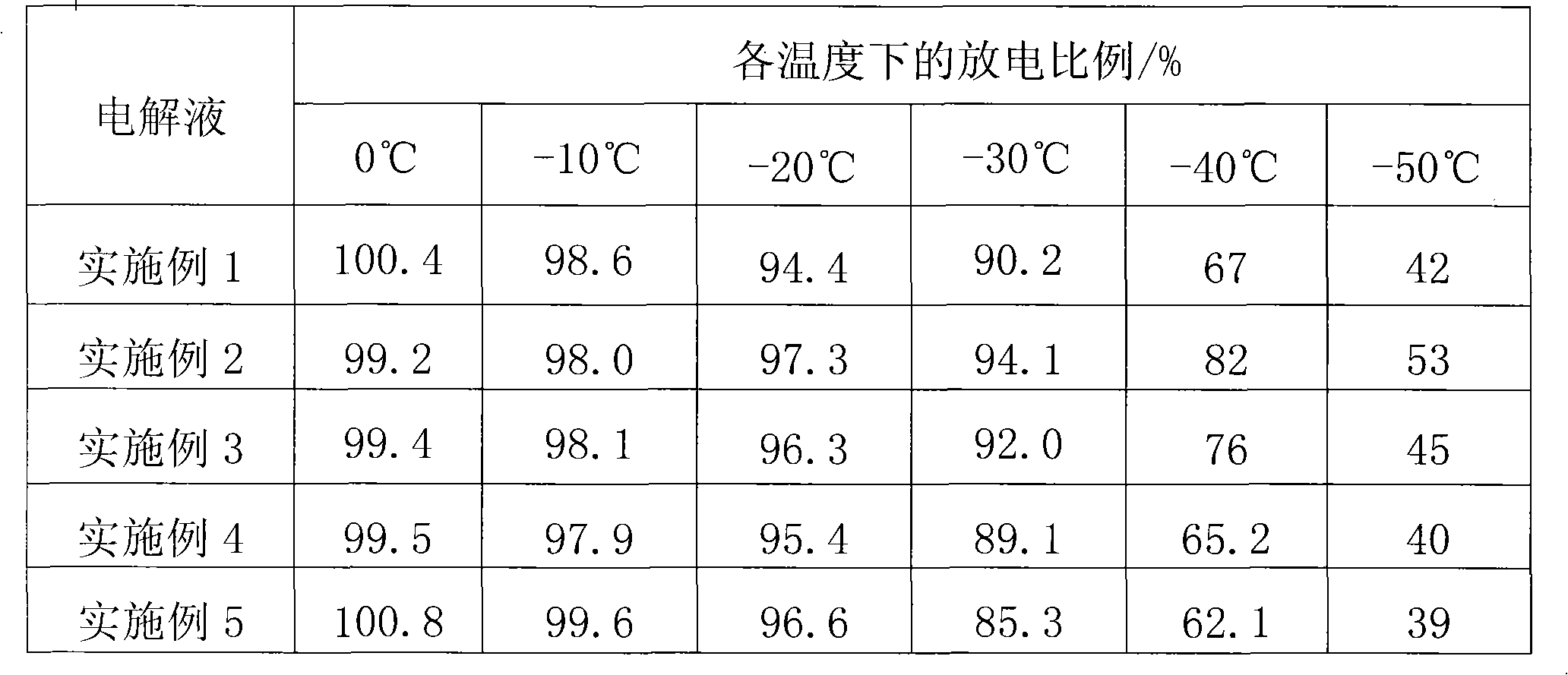

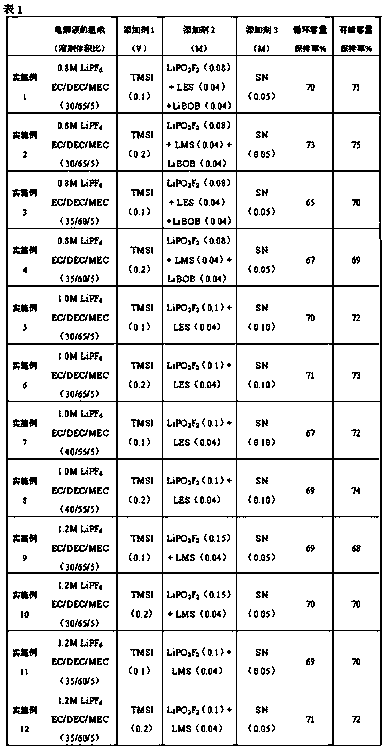

Low temperature type lithium ion battery electrolyte with high temperature property and lithium ion battery

InactiveCN101867064AEasy to manufactureEasy to operateSecondary cellsCell component detailsOxalateOrganic solvent

The invention discloses a low temperature type lithium ion battery electrolyte with high temperature property and lithium ion battery. The electrolyte is made by uniformly mixing and confecting electrolytic salt, non-water organic solvent, alkali additive and film-forming additive, the electrolytic salt is mixed lithium salt made by uniformly mixing lithium tetrafluoroborate and lithium bis(oxalate)borate, and the mol ratio of the two is 96-73: 4-27, the concentration of the mixed lithium salt solution formed by the electrolytic salt and the non-water organic solvent is 0.8-1.2mol / L; the alkali additive is heptamethyldisilazane and the mass ratio of the hepatmethyldisilazane and the non-water organic solvent is 0.1-8%; the mass ratio of the film-forming additive and the non-water organic solvent is 0.1-5%; and the lithium ion battery comprises an anode, a cathode, a diaphragm and low temperature type lithium ion battery electrolyte with high temperature property. The invention has reasonable design, simple preparation method steps and convenient implementation, and the prepared electrolyte and lithium ion battery have favourable comprehensive performances.

Owner:XIAN SAFTY ENERGY TECH

Filler/silicone oil masterbatch with treating agent for RTV polysiloxanes

A method for preparing the first component of a two-component room temperature-vulcanizable (RTV) silicone composition comprises (a) preparing a filler / oil masterbatch by (i) adding an unreactive silicone oil and untreated, aggregated filler particles to a mixer; (ii) adding a filler treating agent such as an organosilane, a polyorganosilane or a silazane to the unreactive silicone oil / filler mixture; and (iii) mixing the unreactive silicone oil / filler mixture and treating agent under conditions sufficient to breakdown the aggregated filler particles to an average size of less than about 300 nm for a time of less than about 24 hours to form the filler / oil masterbatch; and (b) adding said filler / oil masterbatch to a reactive silicone oil.

Owner:GENERAL ELECTRIC CO

Lithium ion battery electrolyte and lithium ion battery prepared therefrom

InactiveCN108306048AImprove thermal stabilityImprove permeabilitySecondary cellsHigh temperature storageAluminium-ion battery

The invention discloses a lithium ion battery electrolyte and a lithium ion battery prepared therefrom, and belongs to the technical field of lithium ion batteries. The invention aims to solve the problems that due to the accumulation of decomposed substances, the output performance degrades after high temperature storage, and the circulation performance of batteries degrades therefore. The electrolyte is characterized by comprising lithium salts, a non-aqueous organic solvent and an additive. A functional additive is dissolved in the non-aqueous organic solvent. The additive also comprises afunctional additive. The functional additive is composed of an organic substance based on trimethyl silazane and at least one lithium salt of lithium salts with an oxalic acid skeleton, lithium saltswith a phosphoric acid skeleton, and lithium salts with S=O groups. The circulation performance of a lithium ion battery is improved, after high temperature storage, the discharge capacity is well maintained, and the lithium ion battery can be applied to commercial application.

Owner:CAMEL GRP WUHAN OPTICS VALLEY R&D CENT CO LTD

High performance silicon based coating compositions

ActiveUS20130287959A1Low costSimplify mixing stepSilicon organic compoundsPretreated surfacesOrganic solventSilazane

A silicon based coating composition for a wide range of surfaces, which composition is formed from a mixture of constituents comprising appropriate portions of silazane, siloxane, and silane, and optionally organic solvent and additives, and the composition results in a coating having a thickness between 0.1 and 1.5 mil, a hardness of 2-9H and a standard coefficient of friction between about 0.03 to about 0.04.

Owner:BURNING BUSH GRP

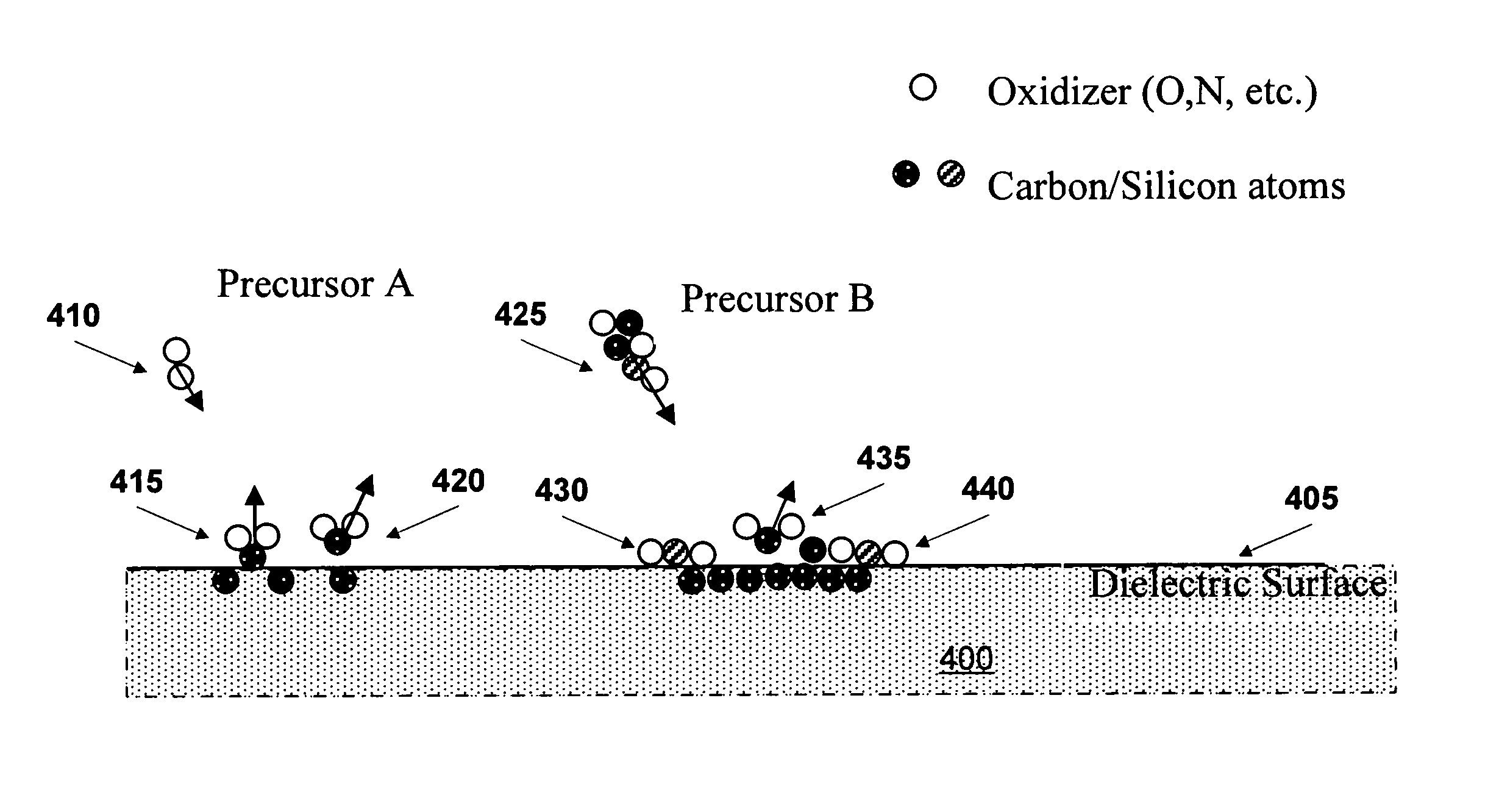

FIB milling of copper over organic dielectrics

ActiveUS7060196B2Electric discharge tubesDecorative surface effectsCharged particle beamNitropropane

Apparatus and processes are disclosed for milling copper adjacent to organic low-k dielectric on a substrate by directing a charged-particle beam at a portion of the copper and exposing the copper to a precursor sufficient to enhance removal of the copper relative to removal of the dielectric, wherein the precursor contains an oxidizing agent, has a high sticking coefficient and a long residence time on the copper, contains atoms of at least one of carbon and silicon in amount sufficient to stop oxidation of the dielectric, and contains no atoms of chlorine, bromine or iodine. In one embodiment, the precursor comprises at least one of the group consisting of NitroEthanol, NitroEthane, NitroPropane, NitroMethane, compounds based on silazane such as HexaMethylCycloTriSilazane, and compounds based on siloxane such as Octa-Methyl-Cyclo-Tetra-Siloxane. Products of the processes are also disclosed.

Owner:DCG SYST

Method for producing epoxypropane through reaction between cumyl hydroperoxide and propylene

ActiveCN103030612AImprove catalytic performanceReduce in quantityOrganic chemistryMolecular sieve catalystsSilanesReaction temperature

The invention relates to a method for producing epoxypropane through reaction between cumyl hydroperoxide and propylene, mainly aiming at solving the problems of low catalyst activity, low epoxypropane selectivity and poor reaction stability existing in the prior art. Reaction raw materials are in contact with catalyst to produce the epoxypropane by using the cumyl hydroperoxide and the propylene as the raw materials under the conditions that the molar ratio of the cumyl hydroperoxide to the propylene is 1:1 to 1:10, the reaction temperature is 50-100DEG C, the reaction pressure is 1-5MPa and the mass space velocity of the cumyl hydroperoxide is 1-30h<-1>. The catalyst is prepared by adopting a method which comprises the following steps of: a) evenly mixing organic silicon sources, inorganic silicon sources, titanium sources and organic templates with water, and filtering, water-washing, drying and roasting the product to obtain precursors I, wherein the inorganic silicon sources are selected from at least one of silica sol, silicate ester and solid silicon oxide, and the organic silicon sources are methyltrimethoxysilane; and b) by taking inert gas as carriers, feeding silanization agent into the precursors I for reaction to obtain the catalyst, wherein the silanization agent is selected from at least one of organic silane, organic silicylamine, organic silicylamide and organic silazane. By adopting the technical scheme, the problems are better solved and the method can be used for the industrial production of the epoxypropane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inorganic polysilazane resin

InactiveUS20150004421A1Small shrinkageSmall residual stressSilicon halogen compoundsLayered productsOligomerSilazane

An inorganic polysilazane resin of the present invention has a Si / N ratio (i.e. a ratio of contained silicon atoms to contained nitrogen atoms) of 1.30 or more. The inorganic polysilazane resin having such a high Si content can be produced by, for example, a method in which an inorganic polysilazane compound containing both Si—NH and Si—Cl is heated to react NH with Cl, a method in which a silazane oligomer (polymer) that leaves no Si—Cl bond is synthesized and a dihalosilane is added to the synthesized silazane oligomer (polymer) to perform a thermal reaction, and the like. A siliceous film can be formed by, for example, applying a coating composition containing the inorganic polysilazane resin onto a base plate and then dried and the dried product is then oxidized by bringing the dried product into contact with water vapor or hydrogen peroxide vapor and water vapor under heated conditions.

Owner:AZ ELECTRONICS MATERIALS LUXEMBOURG R L

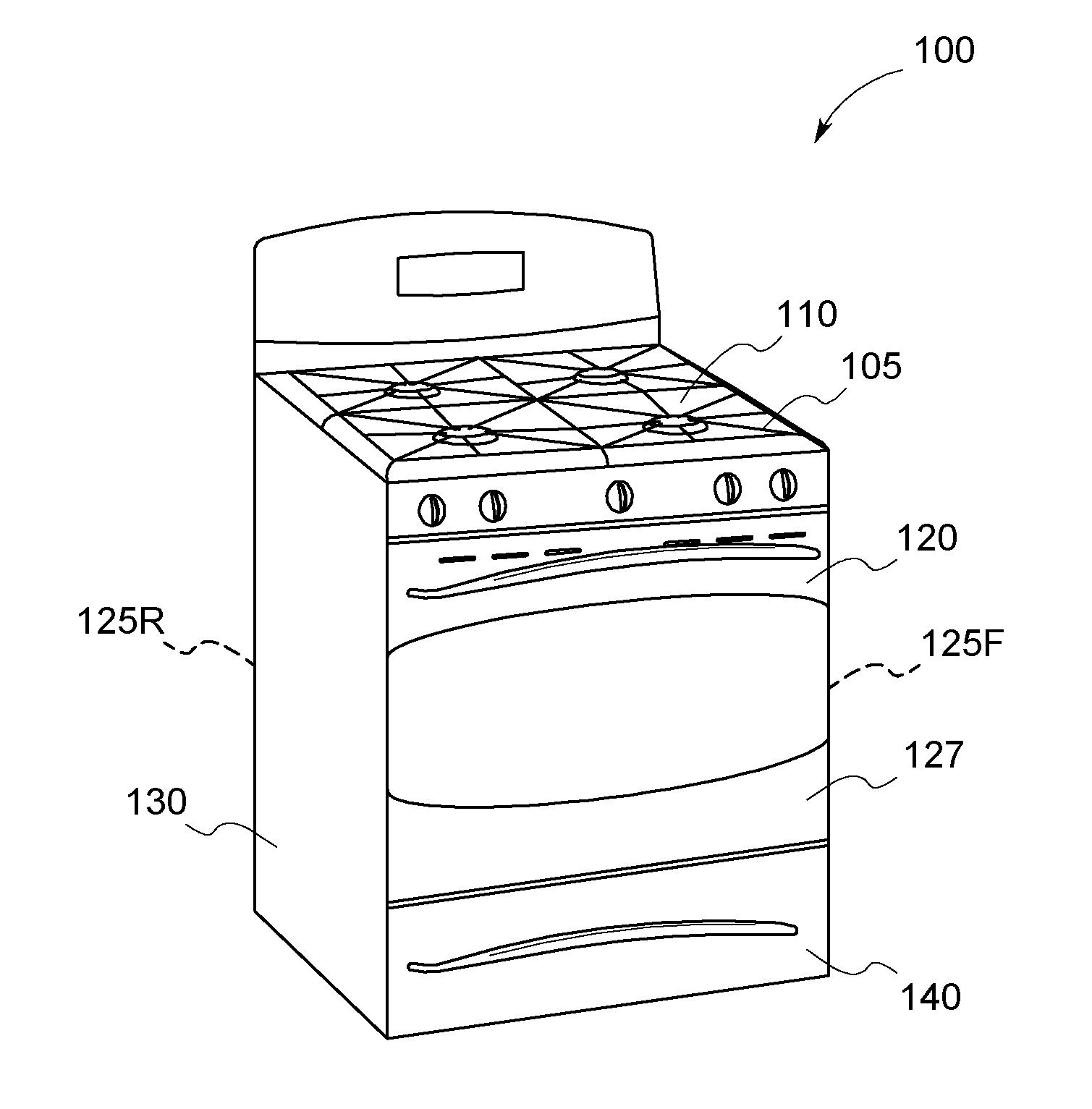

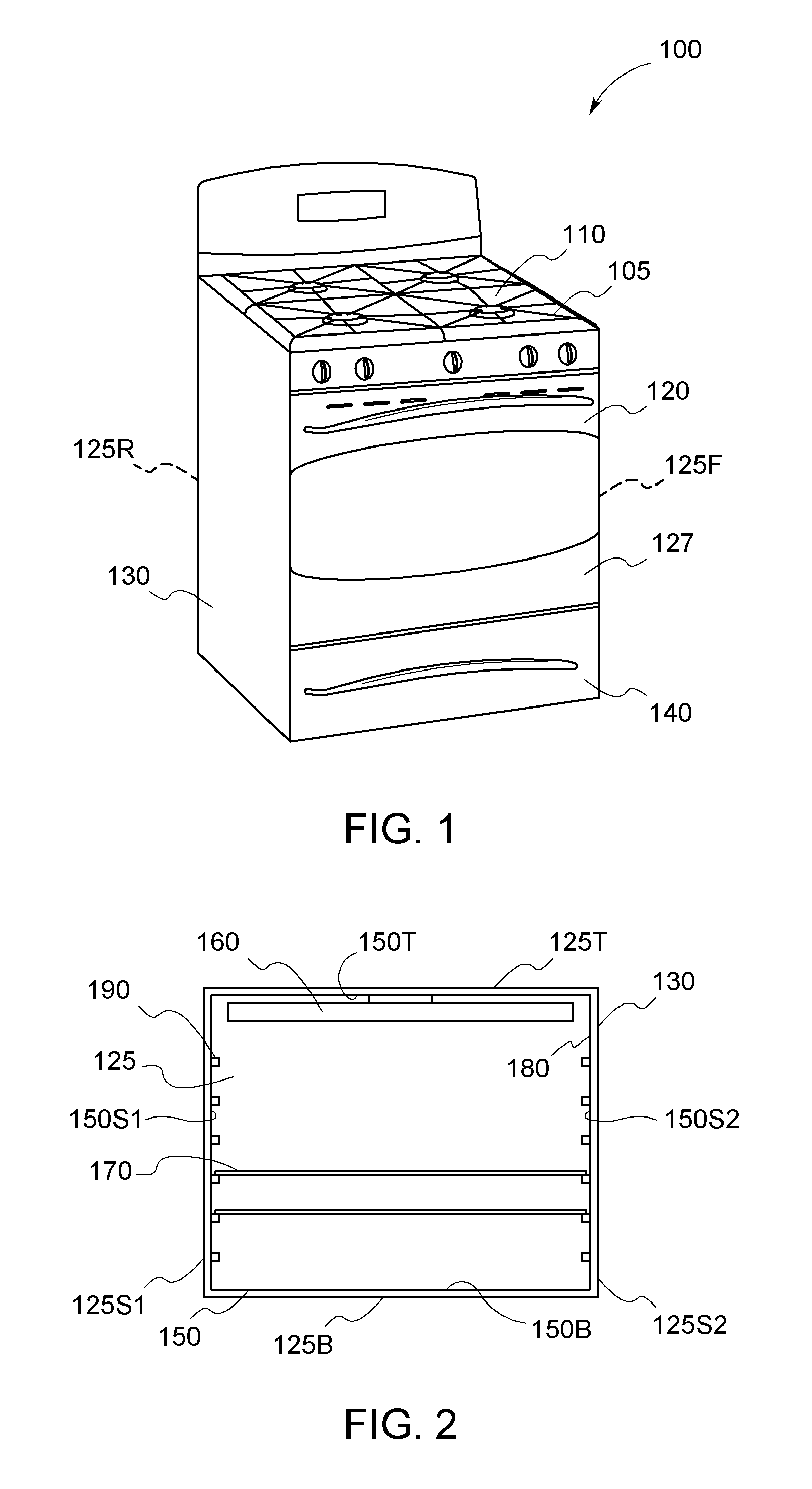

Cleanability of ovens and cooktops

An oven cavity for an oven or range appliance includes a heat-stable base substrate, and a hard ceramic coating disposed on the base substrate. The hard ceramic coating is a poly-condensated silicone, polymeric silazane or poly-ceramic coating composition. A method of forming a surface for an oven or range appliance is also disclosed.

Owner:GENERAL ELECTRIC CO

High-temperature vulcanized silicone rubber for cold-contracted sleeve and process for high-temperature vulcanized silicone rubber

The invention discloses high-temperature vulcanized silicone rubber for a cold-contracted sleeve and a process for the high-temperature vulcanized silicone rubber. The silicone rubber is prepared from the following raw materials in parts by mass: 12 to 20 parts of first silicone raw rubber, 15 to 23 parts of second silicone raw rubber, 47 to 66 parts of third silicone raw rubber, 8 to 20 parts of fourth silicone raw rubber, 1 to 8 parts of fifth silicone raw rubber, 0 to 3 parts of vinyl silicone oil, 0 to 5 parts of dimethylsilicone oil, 28 to 40 parts of white carbon black, 2 to 8 parts of silazane, 1 to 4 parts of de-ionized water, 1.2 to 5 parts of a silane coupling agent and 0.08 to 0.3 part of an internal releasing agent, wherein the first silicone raw rubber and the second silicone raw rubber are methyl-terminated methylvinyl silicone raw rubber with different vinyl molar contents; the third silicone raw rubber, the fourth silicone raw rubber and the fifth silicone raw rubber are vinyl-terminated methylvinyl silicone raw rubber with different vinyl molar contents. The cold-contracted sleeve made from the silicone rubber is strong in tear strength and stretching tensile strength, high in breakage elongation and low in stretching permanent deformation rate.

Owner:SHENZHEN COTRAN NEW MATERIAL CO LTD

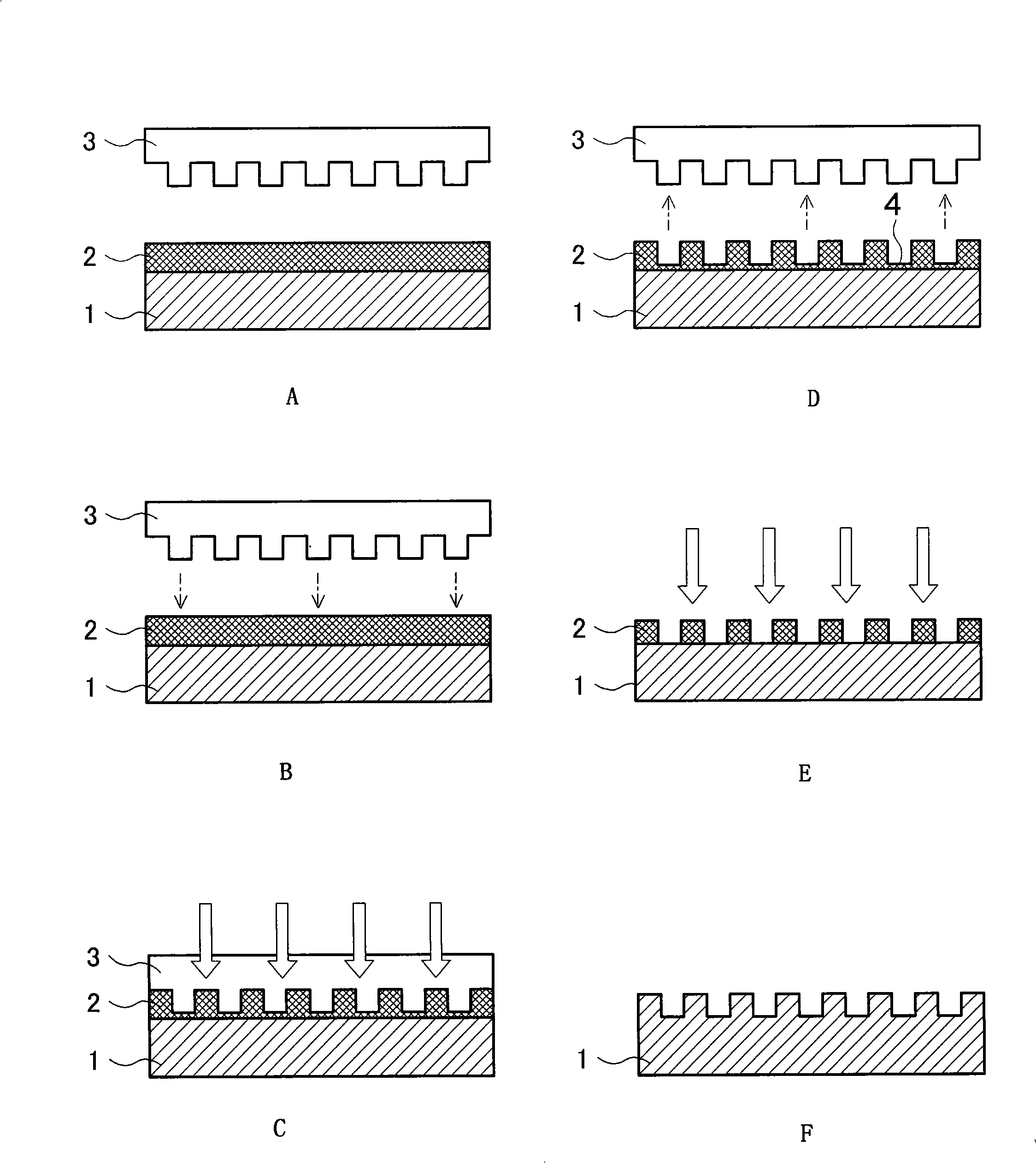

Film forming composition for nanoimprinting and method for pattern formation

ActiveCN101258018AIncreased etch resistancePrevent peelingIndividual molecule manipulationNanoinformaticsResistSilazane

Owner:TOKYO OHKA KOGYO CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com