Silazane additive and lithium ion battery electrolyte prepared by using same and capable of preventing corrosion of steel shell

A lithium-ion battery, silazane technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of wasting manpower and material resources, not found to prevent corrosion of steel shells, etc., and achieve the effect of good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

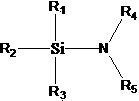

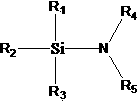

Method used

Image

Examples

Embodiment 1

[0030] In a glove box filled with argon (moisture <10ppm, nutrient <1ppm), take 85.0% of the total mass of lithium-ion battery electrolyte to prevent steel shell corrosion and organically mix dimethyl carbonate, ethyl methyl carbonate, and ethylene carbonate. solution, the mass ratio of dimethyl carbonate, ethyl methyl carbonate, and ethylene carbonate is 1:1:1, add 2.0% of the total mass of vinylene carbonate to the mixed solution, slowly add 12.0% of the total mass to the mixed solution % lithium hexafluorophosphate, stirred until the lithium hexafluorophosphate was completely dissolved, and finally added 1.0% of the total mass of hexamethyldisilazane to the mixed solution to obtain the lithium-ion battery electrolyte for preventing corrosion of steel shells in Example 1.

Embodiment 2

[0032] In a glove box filled with argon (moisture <10ppm, nutrient <1ppm), take an organic mixed solution of ethyl methyl carbonate and ethylene carbonate, which accounts for 85.0% of the total mass of the lithium-ion battery electrolyte to prevent steel shell corrosion, The mass ratio of ester to ethylene carbonate is 7:3, and a mixture of 2.0% of the total mass of ethylene vinylene carbonate and 1,3-propane sultone is added to the mixed solution, ethylene vinylene carbonate, 1,3 -The mass ratio of propane sultone is 1:1, slowly add 12.0% of the total mass of lithium tetrafluoroborate to the mixed solution, stir until the lithium tetrafluoroborate is completely dissolved, and finally add 1.0% of the total mass to the mixed solution % of heptamethyldisilazane, 1,3-butyl-1,1,3,3-tetramethyldisilazane, 1,1,3,3-tetramethyl-1,3-di Mixture of vinylsilazane, heptamethyldisilazane, 1,3-dibutyl-1,1,3,3-tetramethyldisilazane, 1,1,3,3-tetramethyl- The mass ratio of 1,3-divinylsilazane ...

Embodiment 3

[0034] In a glove box filled with argon (moisture <10ppm, nutrient <1ppm), take dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, Propylene carbonate, ethylene carbonate organic mixed solution, the mass ratio of dimethyl carbonate, diethyl carbonate, methyl ethyl carbonate, propylene carbonate, ethylene carbonate is 1:1:1:0.5:1.5, in the mixed solution Add 1,4-butane sultone accounting for 2.0% of the total mass into the mixed solution, and slowly add 12.0% of the total mass of lithium bisoxalate borate, lithium difluorooxalate borate, bis(trifluoromethylsulfonyl ) lithium imide, the mass ratio of lithium bisoxalate borate, lithium difluorooxalate borate, lithium bis(trifluoromethylsulfonyl)imide is 1:2:1, stir until lithium bisoxalate borate, difluorooxalate The mixture of lithium borate and lithium bis(trifluoromethylsulfonyl)imide is completely dissolved, and finally, 1.0% of the total mass of tetramethyldisilazane, hexamethyldisilazane, heptamethyldisilazane a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com