Patents

Literature

921 results about "Lithium hexafluorophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium hexafluorophosphate is an inorganic compound with the formula LiPF₆. It is a white crystalline powder. It is used in commercial secondary batteries, an application that exploits its high solubility in non aqueous, polar solvents. Specifically, solutions of lithium hexafluorophosphate in carbonate blends of ethylene carbonate, dimethyl carbonate, diethyl carbonate and/or ethyl methyl carbonate, with a small amount of one or many additives like vinylene carbonate, serve as state-of-the-art electrolytes in lithium-ion batteries. This application also exploits the inertness of the hexafluorophosphate anion toward strong reducing agents, such as lithium metal.

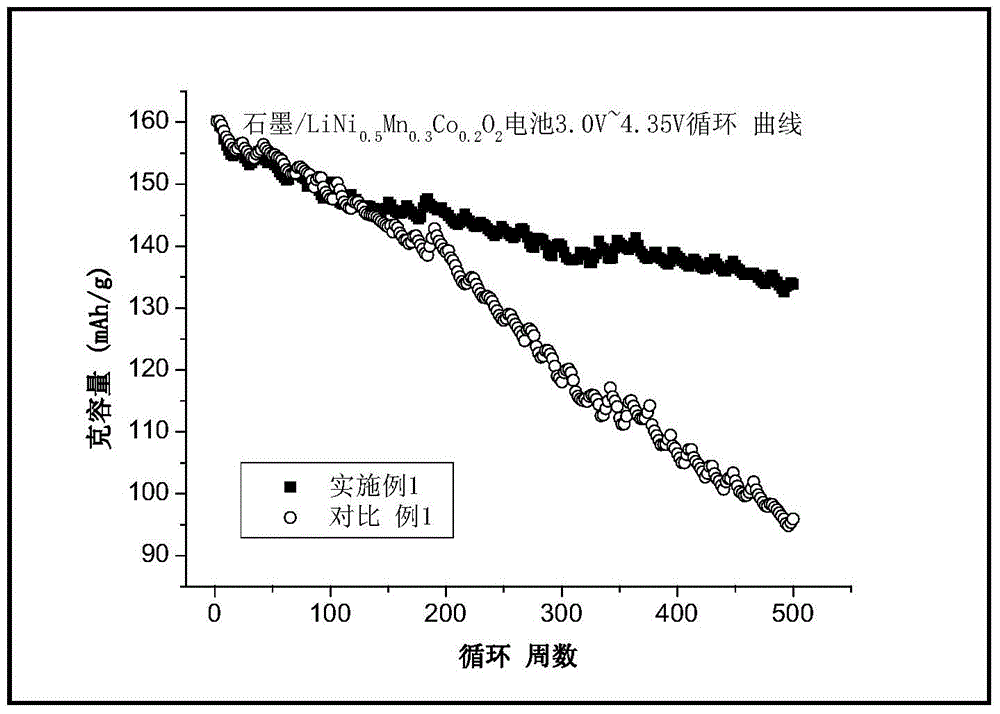

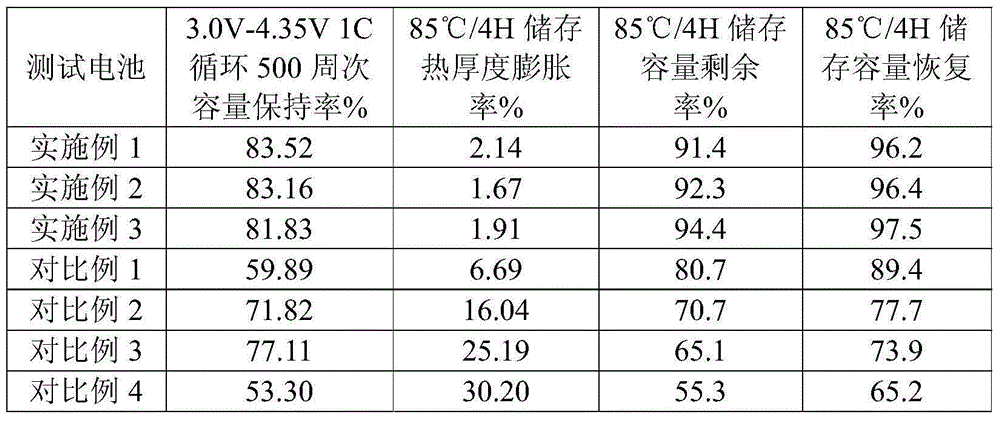

Electrolyte solution for high-capacity lithium-ion battery, preparation method and lithium-ion battery

InactiveCN104900916AAvoid direct contactInhibit cathode decompositionFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentElectrical battery

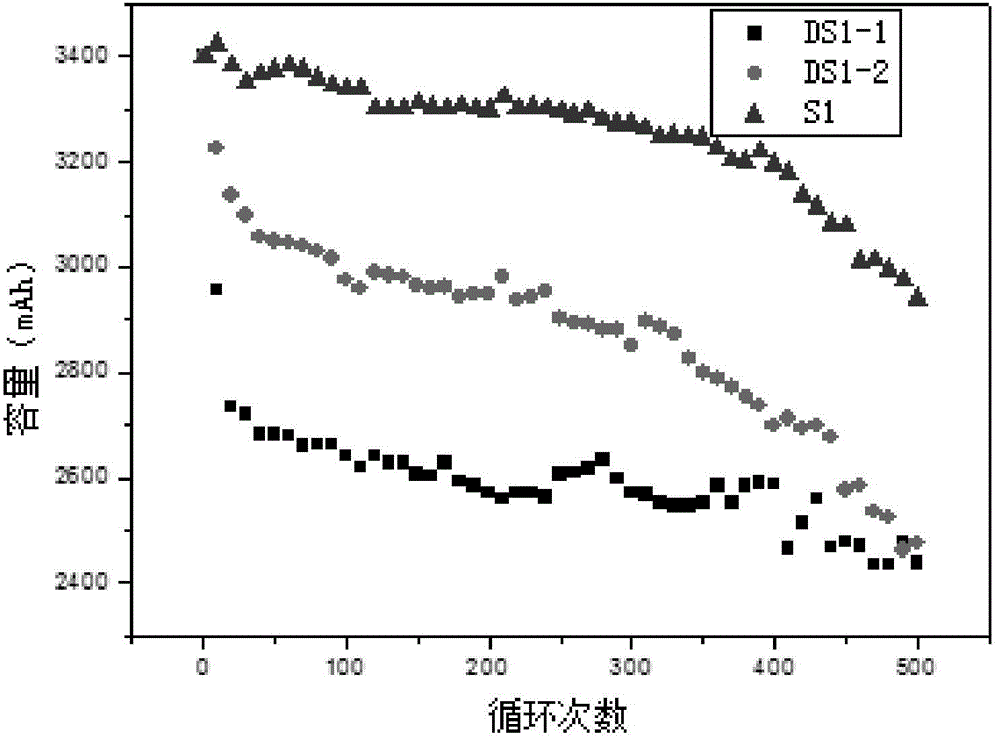

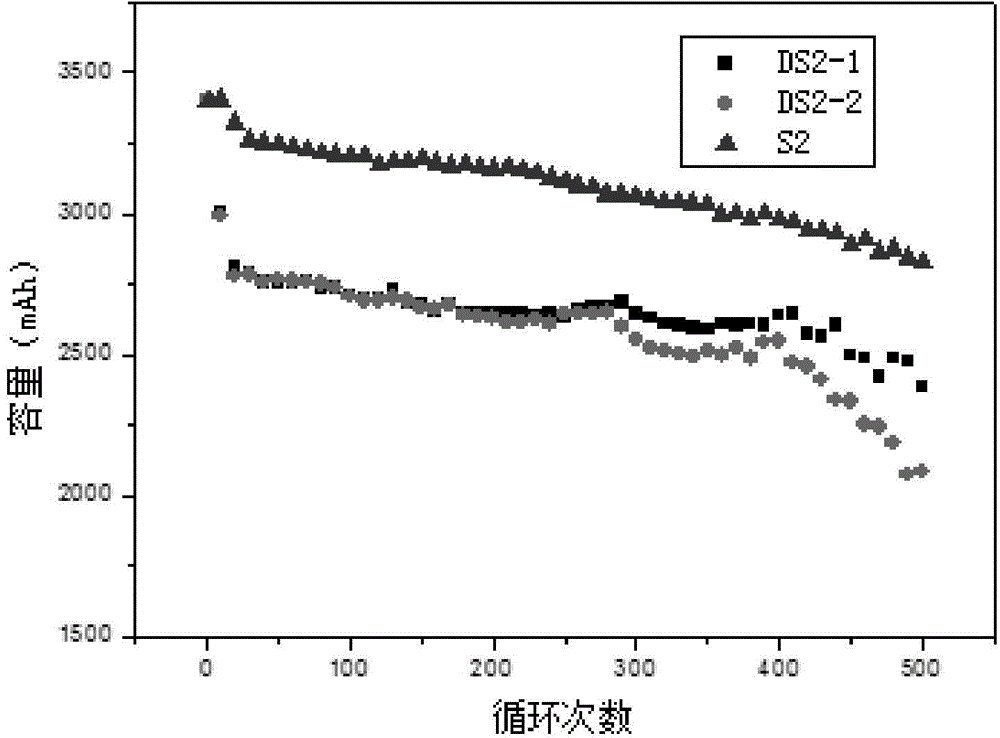

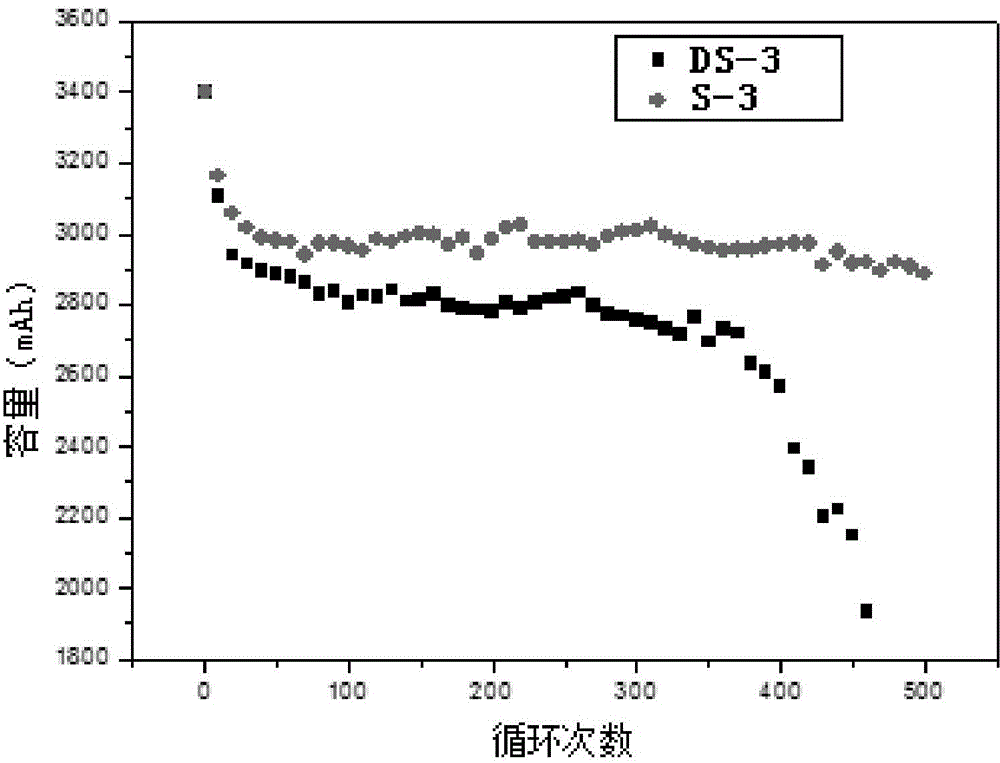

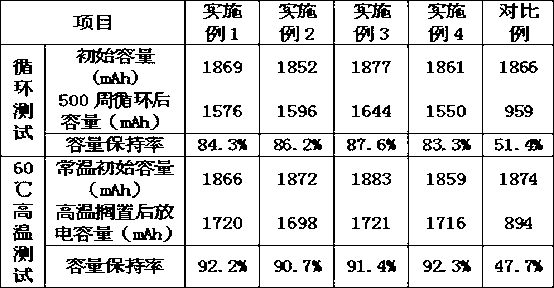

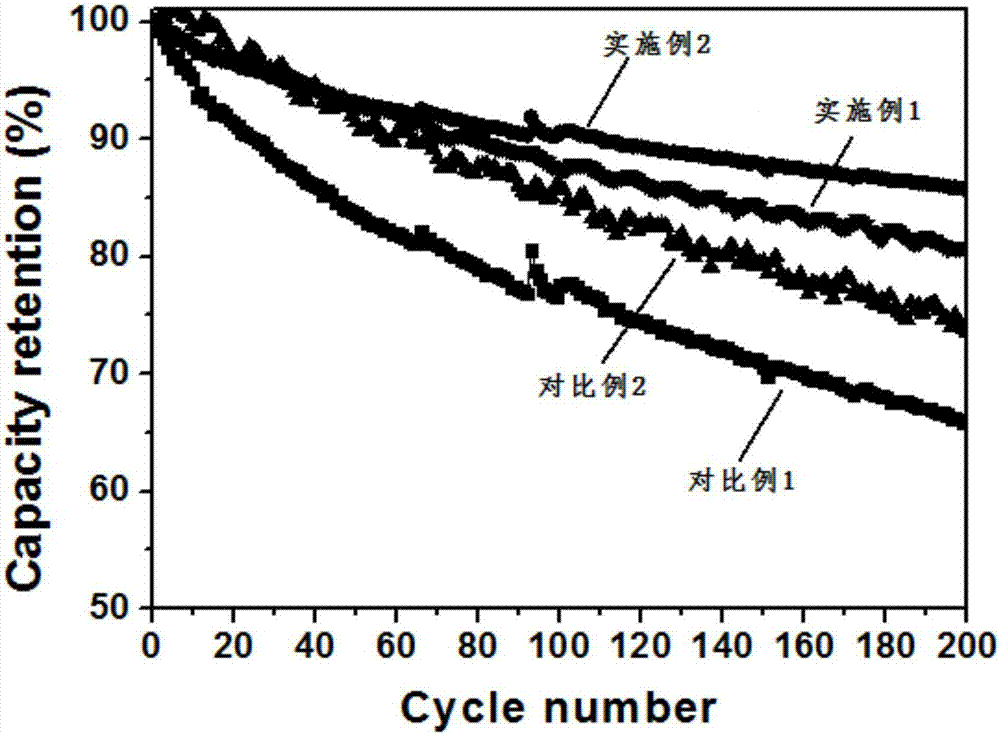

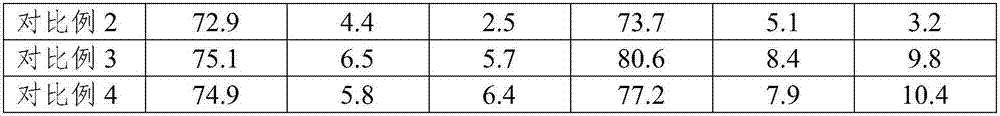

The invention discloses an electrolyte solution for a high-capacity lithium-ion battery. The electrolyte solution includes non-aqueous solvent, lithium hexafluorophosphate, negative electrode film forming additive, positive electrode surface activity inhibiting additive and transition metal ion complexant; the negative electrode film forming additive includes organic ester negative electrode film forming additive of 1 to 10wt% of the total electrolyte solution and inorganic lithium salt negative electrode film forming additive of 0.5 to 2wt% of the total electrolyte solution; the positive electrode surface activity inhibiting additive includes fluorinated ether additive of 1 to 5wt% of the total electrolyte solution and nitrile additive of 0.1 to 5wt% of the total electrolyte solution; the transition metal ion complexant is of 0.1 to 1.0wt% of the total electrolyte solution. The electrolyte solution is adaptive to the high-capacity lithium-ion battery and is capable of optimizing the circulating performance and high-temperature storage performance of the lithium-ion battery. The invention further provides a preparation method of the electrolyte solution and the high-capacity lithium-ion battery adopting the electrolyte solution.

Owner:GUANGZHOU TINCI MATERIALS TECH

Non-aqueous electrolyte for high-voltage lithium ion batteries

ActiveCN103268956ASimple compositionPromote circulationSecondary cellsHigh voltage batteryPropylene carbonate

The invention relates to a non-aqueous electrolyte for high-voltage lithium ion batteries, which is prepared from the following raw materials in percentage by weight: 70-85% of carbonate, 3-20% of functional additive and 11-17% of lithium hexafluorophosphate. The carbonate is one or mixture of more of ethylene carbonate, propylene carbonate, butylene carbonate, dimethyl carbonate, diethyl carbonate, dipropyl carbonate, methylethyl carbonate, methyl propyl carbonate and methyl butyl carbonate; and the functional additive is one or mixture of more of 0.5-10% of negative pole film-forming additive, 0.5-10% of high-temperature additive, 0.5-10% of positive pole film-forming additive, 0.5-10% of high-voltage additive and 0.001-2% of stability additive. The invention solves the problem of adaptation of the lithium ion battery electrolyte to the 4.35V high-voltage battery positive / negative pole, and provides an electrolyte for high-voltage batteries, which has the advantages of high cycle life, low inflation rate and favorable high-temperature properties.

Owner:广东金光高科股份有限公司

High-capacity lithium-ion battery electrolyte of considering high-and-low temperature performance, preparation method and lithium-ion battery

InactiveCN106252639AImprove bindingConsider high temperature performanceCell electrodesSecondary cellsCarbon compositesHigh temperature storage

The invention discloses a high-capacity lithium-ion battery electrolyte of considering high-and-low temperature performance. The electrolyte comprises a non-aqueous solvent, lithium hexafluorophate, a negative film-forming additive, an inflatable inhibition additive and a low-impedance additive, wherein the negative film-forming additive is prepared from fluoroethylene carbonate which accounts for 3%-15% of total mass of the electrolyte; the inflatable inhibition additive is prepared from one or two of 1,3-propene sultone or anhydride compounds which account for 0.3%-5% of total mass of the electrolyte; and the low-impedance additive is prepared from one or two of lithium difluorophosphate and difluoride phosphate lithium oxalate which account for 0.2%-3% of total mass of the electrolyte. The electrolyte is suitable for a high-nickel positive electrode and silicon-carbon composite negative electrode lithium-ion battery; the high-temperature storage performance and the low-temperature discharge performance of the lithium-ion battery are improved while the room-temperature cycle performance is considered; and meanwhile, the invention further provides a preparation method of the electrolyte and the high-capacity lithium-ion battery of using the electrolyte.

Owner:GUANGZHOU TINCI MATERIALS TECH

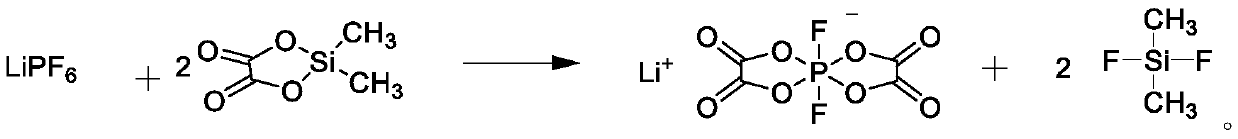

Method for Producing Difluorophosphate, Non-Aqueous Electrolyte for Secondary Cell and Non-Aqueous Electrolyte Secondary Cell

ActiveUS20080305402A1Poor battery performanceExcellent coating agentPhosphorus halides/oxyhalidesNon-aqueous electrolyte accumulatorsDifluorophosphatePhysical chemistry

A difluorophosphate effective as an additive for a nonaqueous electrolyte for secondary battery is produced by a simple method from inexpensive common materials.The difluorophosphate is produced by reacting lithium hexafluorophosphate with a carbonate in a nonaqueous solvent. The liquid reaction mixture resulting from this reaction is supplied for providing the difluorophosphate in a nonaqueous electrolyte comprising a nonaqueous solvent which contains at least a hexafluorophosphate as an electrolyte lithium salt and further contains a difluorophosphate. Also provided is a nonaqueous-electrolyte secondary battery employing this nonaqueous electrolyte.

Owner:MU IONIC SOLUTIONS CORP +1

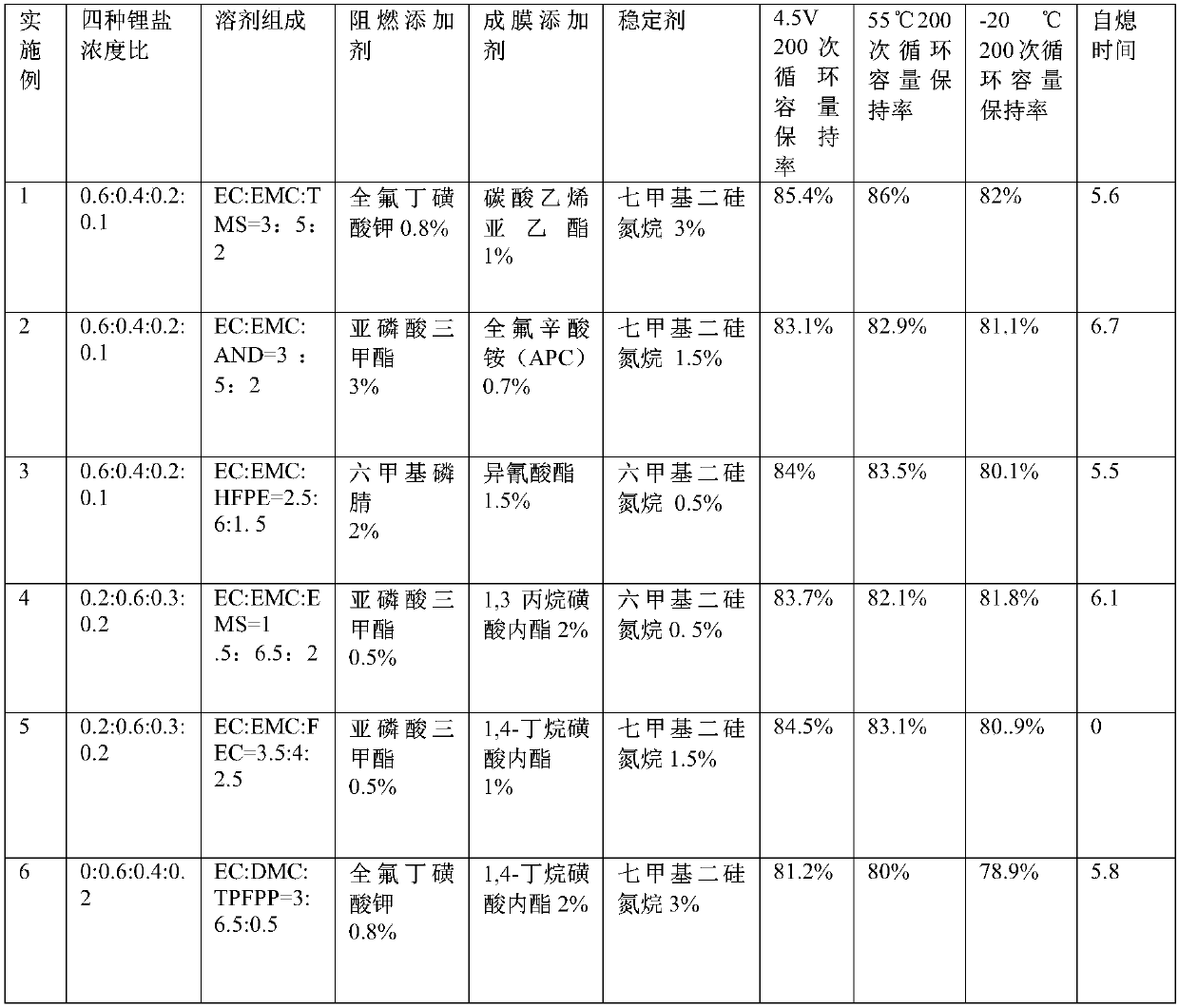

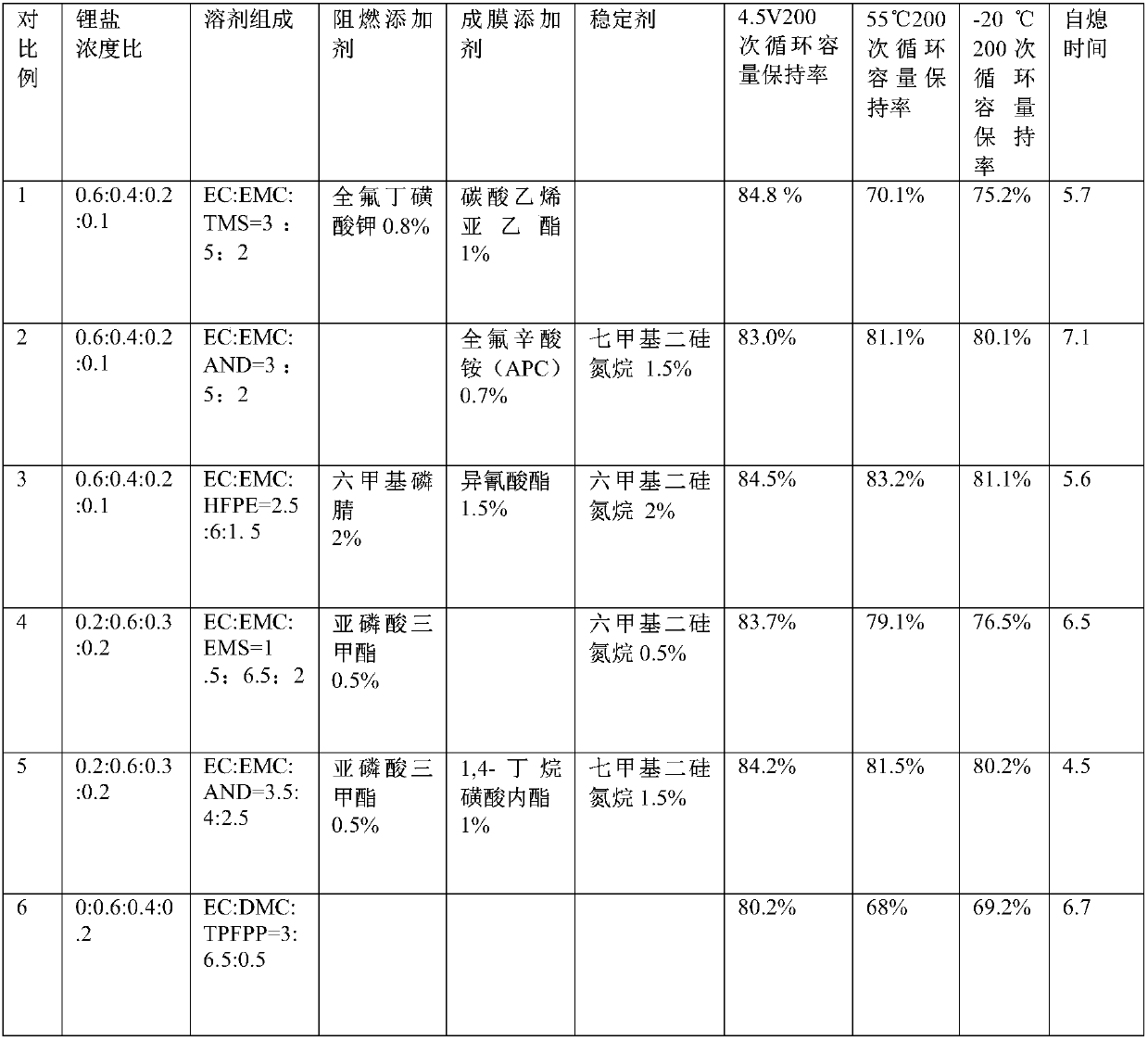

Lithium ion power battery electrolyte and lithium ion secondary battery

The invention discloses a lithium ion power battery electrolyte and a lithium ion secondary battery. The electrolyte comprises the following components in percentages by weight: 10% to 20% of a lithium salt mixture, 73% to 88.5% of a high voltage resistant organic solvent, 0.5% to 3% of a stabilizer and 1% to 4% of an auxiliary additive. The lithium salt of the electrolyte in the invention is composed of various lithium salts, and due to the synergistic effect of the various lithium salts, the stability of lithium hexafluorophate is improved; a nitriles solvent, a sulfones solvent and a fluorinated solvent with higher heat stability and higher oxidation potential are contained in the organic solvent, so that the electrolyte can work at relatively high temperature and voltage; the stabilizer is added into the electrolyte, water in the electrolyte can be absorbed, the generation of HF in the electrolyte is reduced, and an SEI film of the battery can be compacter and stabler through the introduction of a film-forming additive, so that the battery has preferable cycle performance.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

Method for recycling electrolyte of waste lithium ion battery

ActiveCN102496752AEasy to handleSimple processWaste accumulators reclaimingBattery recyclingSocial benefitsHydrogen fluoride

The invention discloses a method for recycling the electrolyte of a waste lithium ion battery. The method mainly comprises the following steps of: collecting and cleaning the lithium ion battery; after discharge, putting the lithium ion battery in a drying room or a glove box under protection of inert gas; opening the battery, carefully taking out the electrolyte and placing in a material tank; performing high-vacuum decompressed rectification and separation to obtain the organic solvent contained in the electrolyte; performing rectification and purification for recycling; putting a rough product of lithium hexafluorophate into a dissolution kettle, and adding a hydrogen fluoride solution for dissolving the recycled lithium hexafluorophate; filtering the solution and then putting into a crystallization kettle for crystallization and purification; and screening, drying, packaging and recycling to obtain the product lithium hexafluorophate. The method has simple technology, is practical, efficient, clean and environment-friendly and easy to control, and realizes close integration of economic benefits and environmental social benefits.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method of purifying lithium hexafluorosphate

InactiveUS6514474B1Phosphorus halides/oxyhalidesNon-aqueous electrolyte accumulatorsHydrogen fluoridePhosphor

A method of purifying lithium hexafluorosphate that allows to purify lithium hexafluorophosphate, useful as lithium secondary cell electrolyte, organic synthesis medium or the like, to an extremely high purity is provided. Lithium hexafluorophosphate containing harmful impurities such as oxyfluoride, lithium fluoride is purified by adding phosphoric chloride. The purification is performed in the presence of phosphoric chloride and hydrogen fluoride of the quantity equal or superior to the equivalent amount for reacting them, and then by converting lithium fluoride to lithium hexafluorophosphate with generated phosphor pentafluoride.

Owner:STELLA CHEMIFA CORP

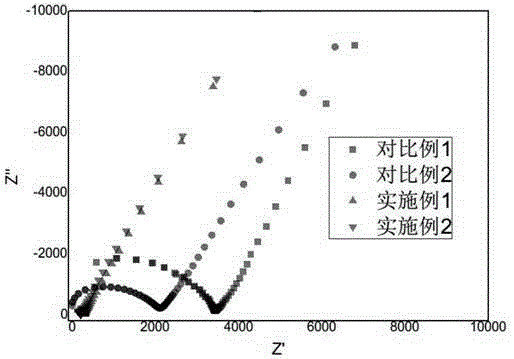

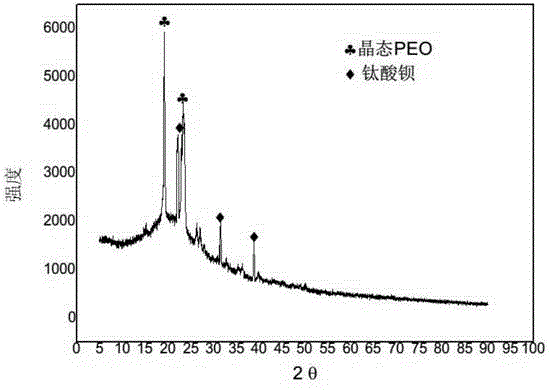

All-solid polymer electrolyte, and preparation method and application of all-solid polymer electrolyte

InactiveCN104538670AImprove conductivityHigh mechanical strengthSolid electrolytesFinal product manufacturePolyethylene oxideBarium titanate

The invention discloses an all-solid polymer electrolyte, and a preparation method and an application of the all-solid polymer electrolyte, and belongs to the field of lithium ion batteries. The all-solid polymer electrolyte comprises polyethylene oxide, lithium salt, inorganic nano particles and ion liquid, wherein a mass ratio of the lithium salt to polyethylene oxide is 0.1-0.5; the mass sum of the inorganic nano particles and the ion liquid is 10-30% of the mass of the all-solid polymer electrolyte; the lithium salt comprises one or several of bistrifluoromethane sulfonimide lithium salt, lithium tetrafluoroborate, lithium perchlorate, lithium hexafluorophosphate, lithium hexafluoroarsenate, lithium trifluoromethanesulfonate and lithium bis borate; and the inorganic nano particles comprise one or several of nano aluminum oxide, nano silicon oxide, nano zirconium oxide and nano barium titanate. The all-solid polymer electrolyte has better mechanical strength and higher ion conductivity. The method is simple in technology and low in cost; and raw materials are easy to obtain.

Owner:HUAZHONG UNIV OF SCI & TECH RES INST SHENZHEN

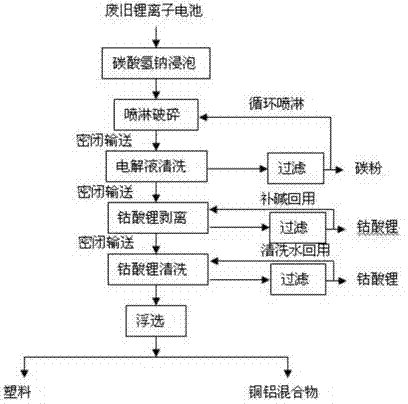

Method for comprehensively recycling waste lithium ion batteries

ActiveCN103943911AAccelerated corrosionAffect healthWaste accumulators reclaimingBattery recyclingSocial benefitsEconomic benefits

The invention discloses a method for comprehensively recycling waste lithium ion batteries, and belongs to the field of recycling of regeneration resource. The method comprises the following steps: a, performing discharging processing on waste lithium ion batteries; b, fragmenting waste lithium ion batteries into sheets with a diameter of 10-20 mm in a closed shearing-type crusher, and spraying during fragmentation to dissolve lithium hexafluorophosphate in the waste lithium ion batteries into a spraying solution; c, peeling carbon powder on the surface of aluminium foils through stirring, dissolving electrolyte into the spraying solution, and recovering carbon powder; d, sending the sheets into a sodium hydroxide solution, peeling lithium cobalt oxide powder on the surface of aluminium foils through stirring, and recovering lithium cobalt oxide powder; e, cleaning the sheets, and recovering lithium cobalt oxide powder; and f, separating and recovering plastic and a copper-aluminium mixture. The method realizes recovery of carbon powder, lithium cobalt oxide powder, the copper-aluminium mixture and plastic through a simple environment-friendly process, and has certain economic benefit and social benefit.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Lithium ion battery electrolyte with both high and low temperature performances

The invention relates to the technical field of lithium ion electrolytes, and in particular relates to a lithium-ion battery electrolyte with both high and low temperature performances. The electrolyte comprises lithium hexafluorophosphate, mixed organic solvents, filming additives, additives for improving the dielectric constant and the low temperature infiltration capability, and a lithium salt type additive, wherein the mixed organic solvents comprise a carbonic ester solvent and a linear carboxylic ester solvent; the linear carboxylic ester solvent in the mixed organic solvents is one or a mixture of more than two of ethyl propionate, propionic acid n-propyl ester, n-propyl acetate, acetic acid n-butyl ester and isobutyl acetate; and the additives for improving the dielectric constant and the low temperature infiltration capability are one or a mixture of more than two of fluoro ethylene carbonate, difluoro ethylene carbonate and 4-trifluoromethyl ethylene carbonate. A battery prepared from the lithium-ion battery electrolyte with both high and low temperature performances is long in service life, and both the good low temperature discharge performance of the battery is ensured, and the storage performance of the battery at the high temperature of 60 DEG C is effectively considered.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

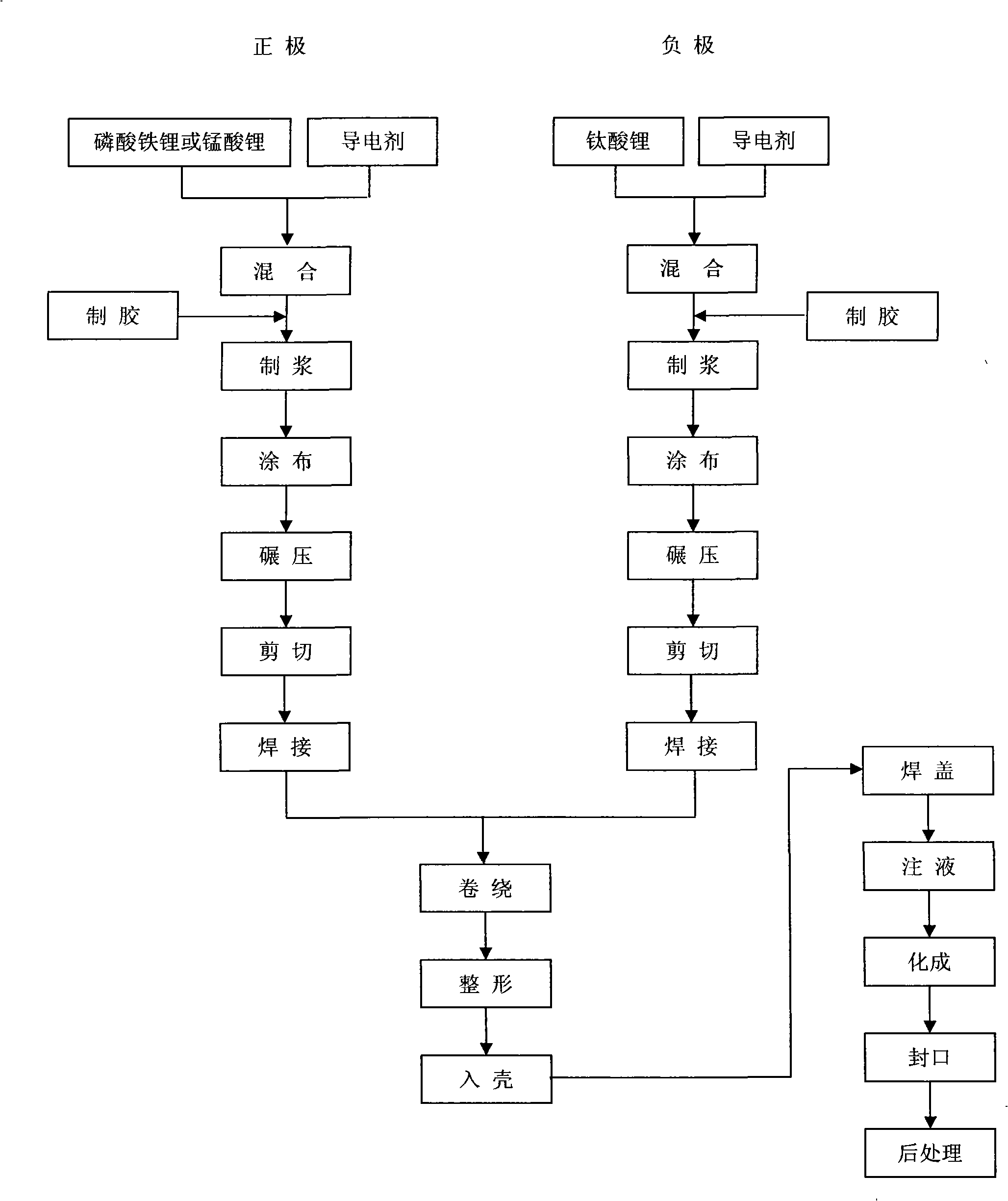

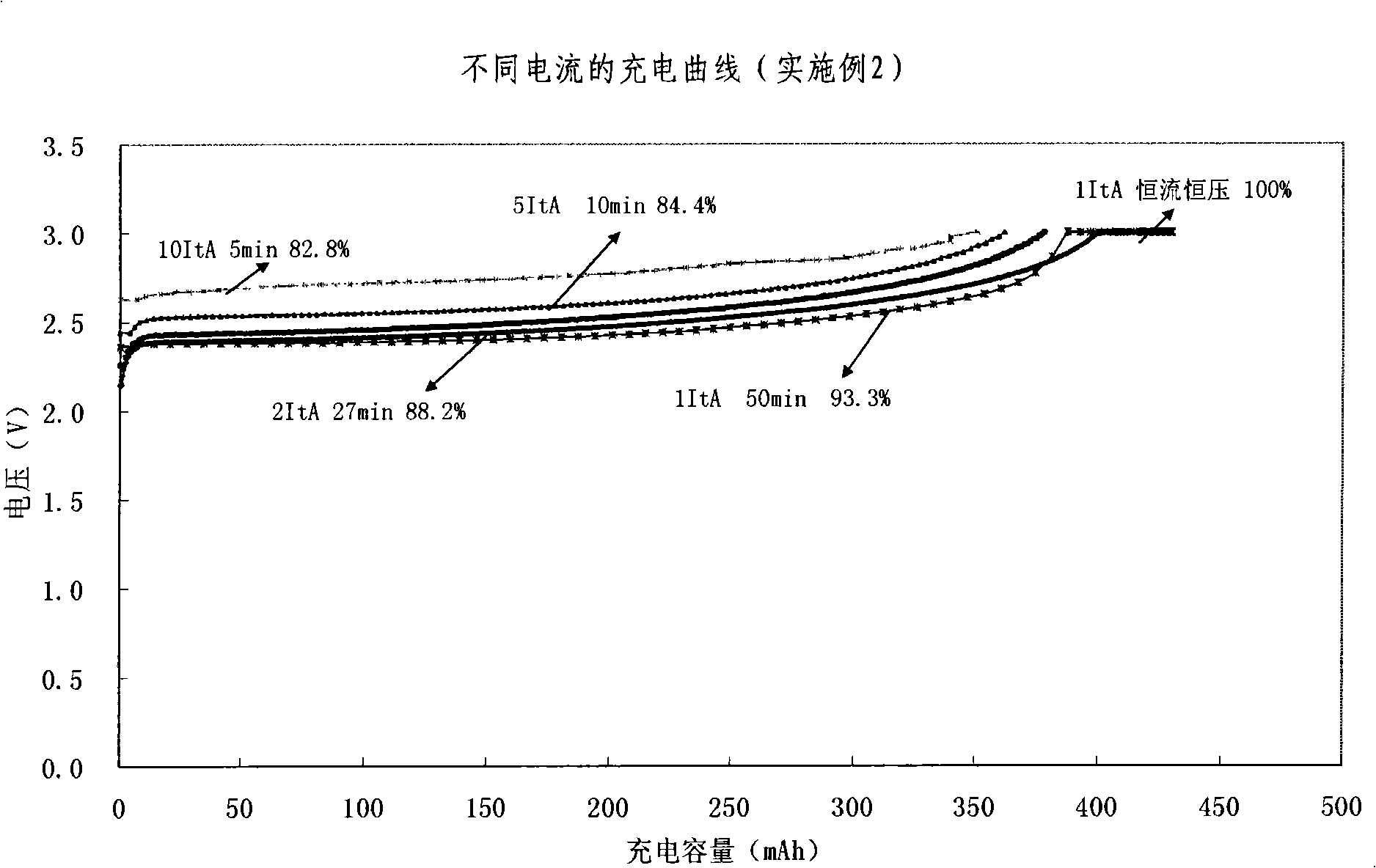

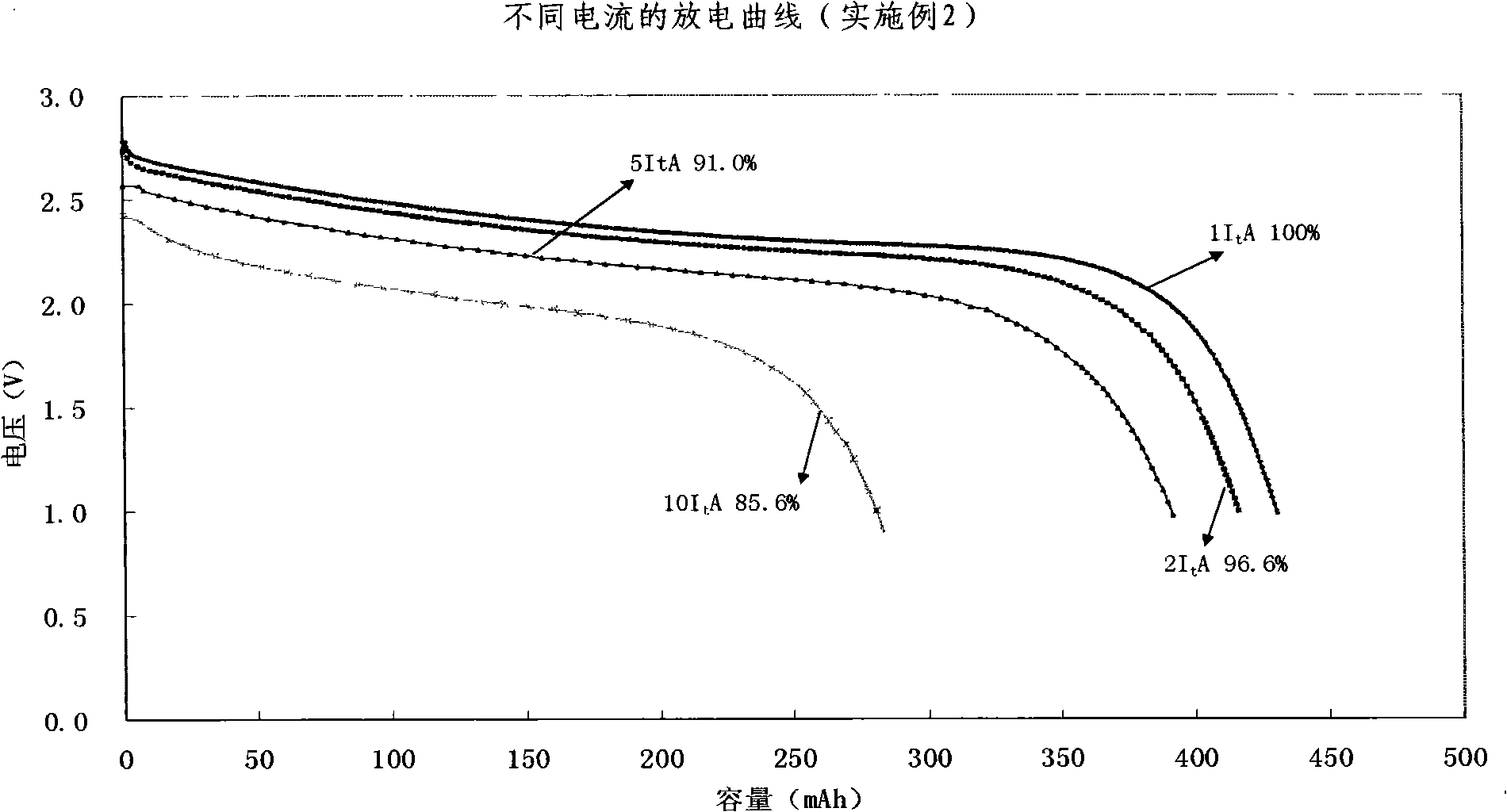

Quickly chargeable lithium ion battery and its making method

InactiveCN101262078AExcellent fast charge and discharge performanceCell electrodesFinal product manufactureMethyl carbonateManganate

The invention discloses a lithium-ion battery with fast charge property, which comprises an anode, a cathode, a diaphragm sandwiched between the anode and the cathode and an organic electrolyte, wherein, sub micrometer lithium titanate is used as the active substance of the cathode; one or several materials of lithium manganate (LiMn2O4), lithium iron phosphate (LiFePO4), lithium nickel cobalt oxide (LiNixCoyMzO2), ternary substance(LiNixMnxCo1-2xO2) are used as active materials of the anode, or a mixture of lithium cobalt (LiCoO2) and one of lithium manganate (LiMn2O4), lithium iron phosphate (LiFePO4), lithium nickel cobalt oxide (LiNixCoyMzO2), ternary substance(LiNixMnxCo1-2xO2) is adopted as the active materials of the anode; lithium hexafluorophosphate (LiPF6) is adopted as the electrolyte, and a multicomponent mixture of ethylene carbonate (EC), dimethylcarbonate(DMC), Ethyl Methyl Carbonate (EMC) is used as a solution. The invention also discloses a preparation method of the lithium-ion battery with fast charged property. The lithium-ion battery of the invention has excellent fast charging and discharging performance.

Owner:TIANJIN B&M SCI & TECH

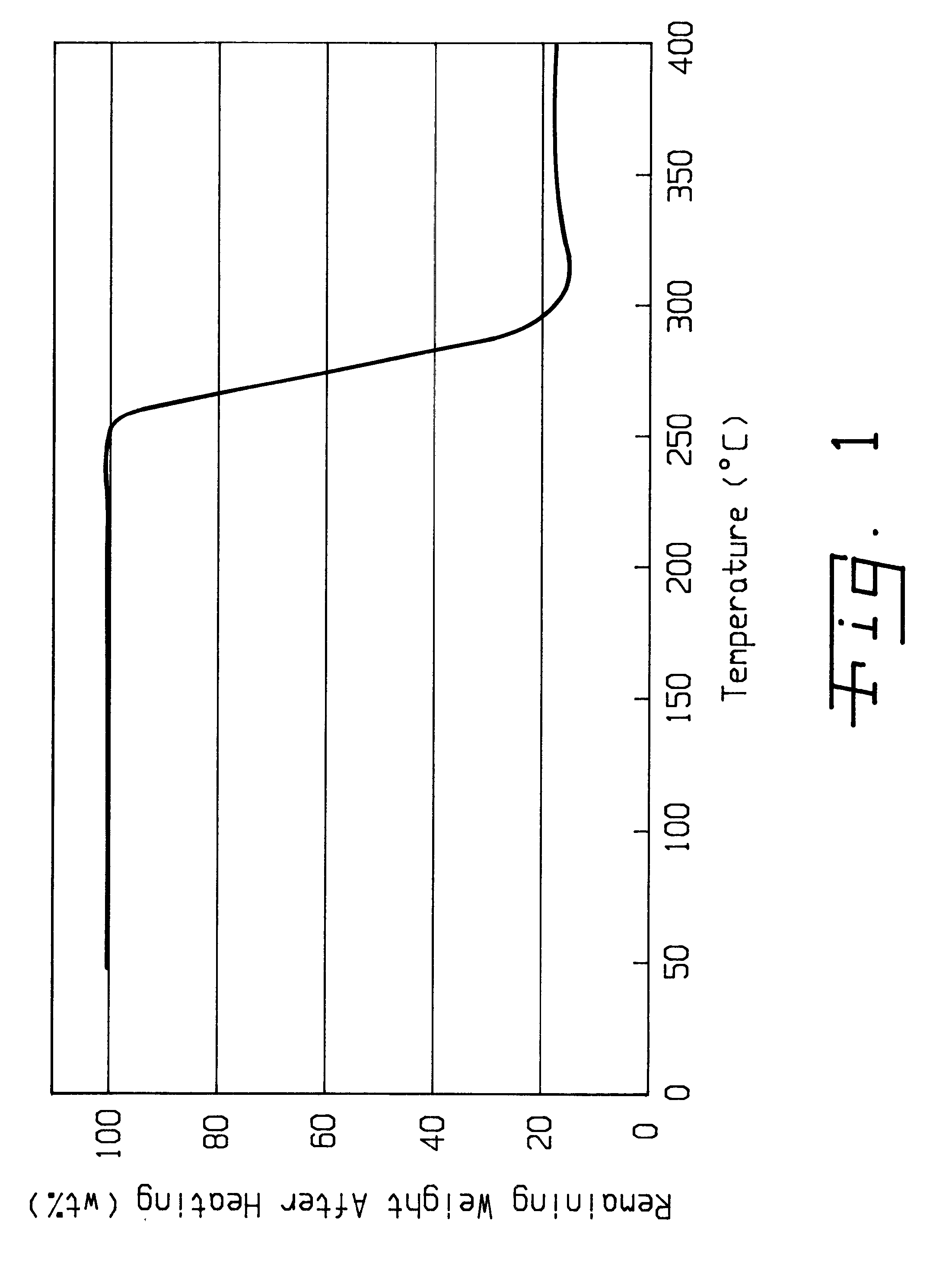

Preparation method of lithium hexafluorophosphate

ActiveCN102009972ARich sourcesReduce manufacturing costPhosphorus compoundsPhosphoric acidNitrogen gas

The invention relates to a preparation method of lithium hexafluorophosphate. The preparation method comprises the following steps of: (1) distilling to obtain hydrogen fluoride liquid of which the purity is over 99.99 weight percent; (2) reacting the high-purity hydrogen fluoride liquid with phosphorus pentachloride to obtain mixed gas of the phosphorus pentafluoride and hydrogen chloride; (3) introducing the mixed gas of the phosphorus pentachloride and the hydrogen chloride into hydrogen fluoride and lithium fluoride, reacting at a certain temperature and under certain pressure to obtain solution of lithium hexafluorophosphate, exhausting hydrogen chloride gas at regular time, and absorbing by using water to prepare byproduct hydrochloric acid; and (4) crystallizing and separating, namely filtering the solution of lithium hexafluorophosphate, delivering filtrate into a crystallizing slot, separating the lithium hexafluorophosphate out at the temperature of between -70 and 80 DEG C, filtering, and performing primary drying and secondary drying to obtain a lithium hexafluorophosphate product, wherein the residual hydrogen fluoride gas is displaced by nitrogen. The preparation method has readily available raw materials and is easy to operate, the purity of the obtained lithium hexafluorophosphate product is over 99.9 percent, the moisture is lower than 10ppm, and the production requirements of lithium ion electrolytic cells are met.

Owner:MORITA NEW ENERGY MATERIALS ZHANGJIAGANG CO LTD

Lithium battery and preparation method thereof

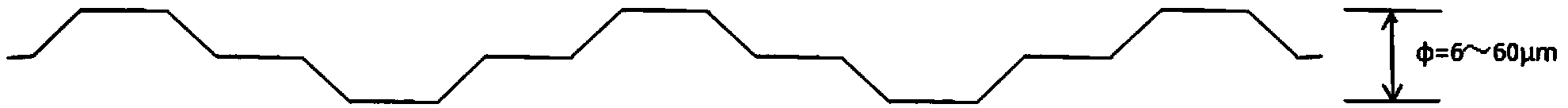

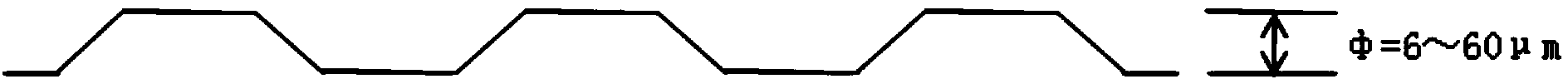

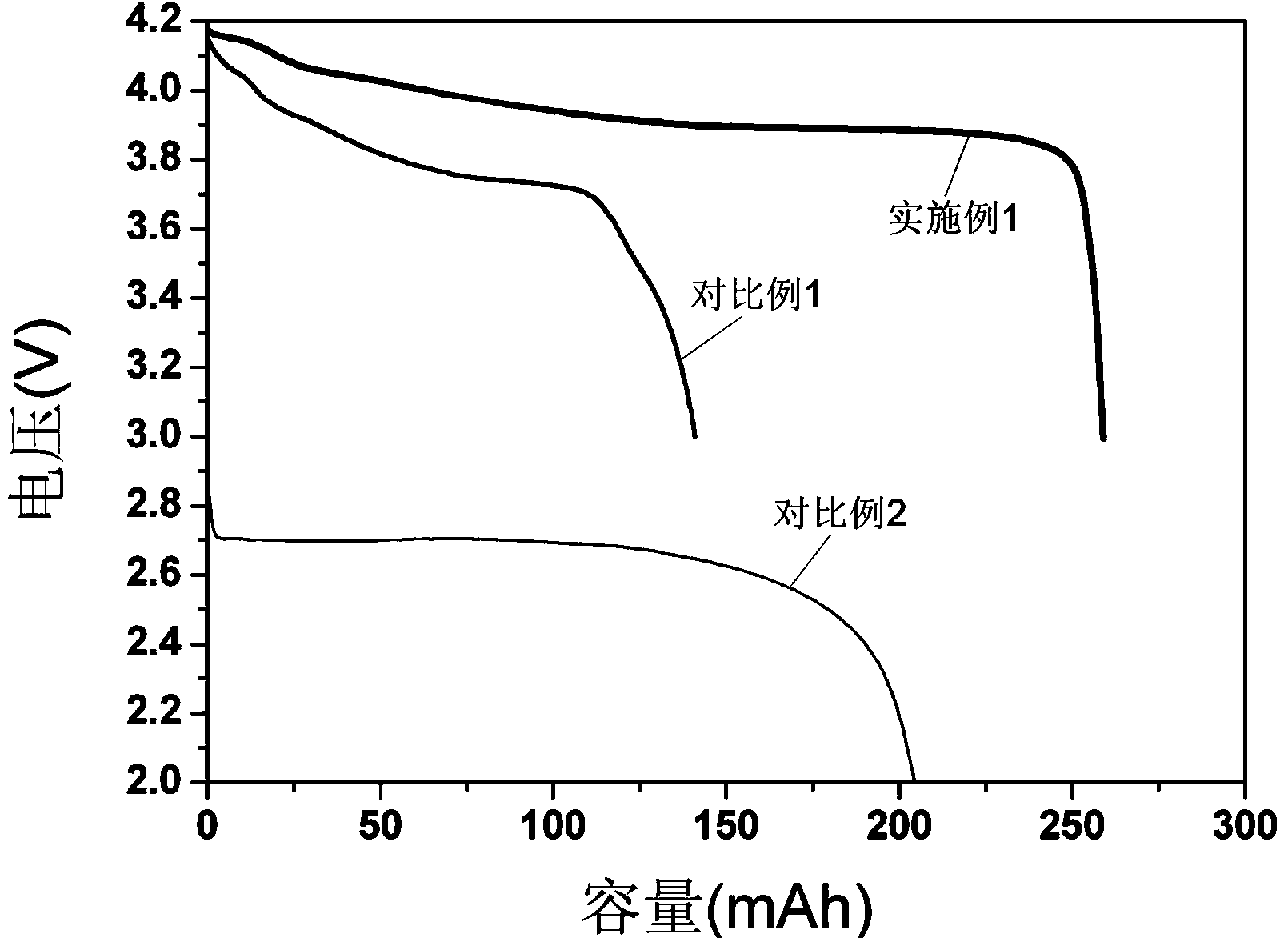

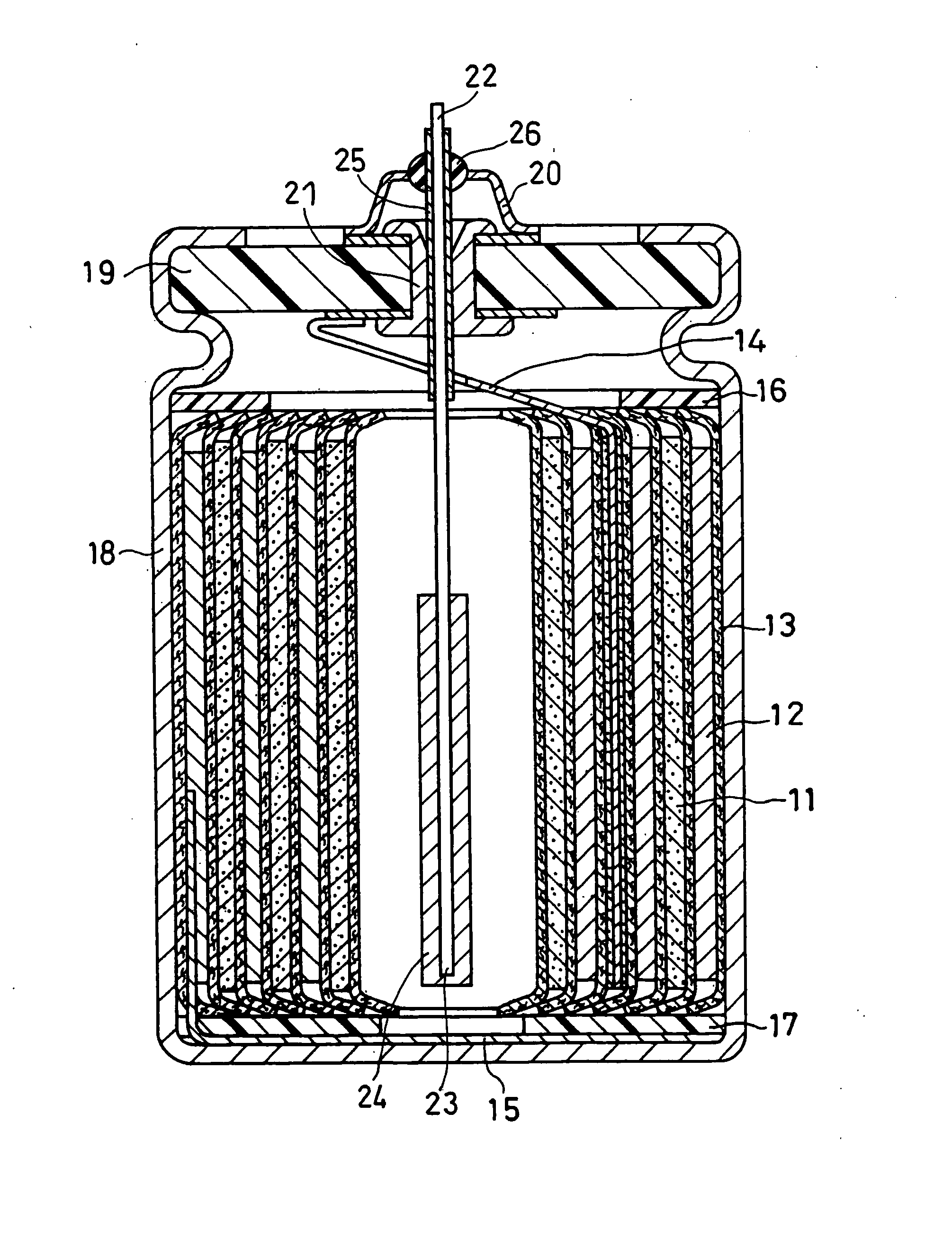

ActiveCN103730683AIncrease energy densitySave spaceFinal product manufactureElectrode carriers/collectorsConvex structureMetal foil

The invention discloses a lithium battery. The lithium battery comprises a positive plate, a negative current collecting substrate, an isolating membrane and an electrolyte, wherein the isolating membrane and the electrolyte are arranged between the positive plate and the negative current collecting substrate; the positive plate comprises a positive current collecting body, a positive diaphragm and a positive polar lug, the positive diaphragm is attached to the positive current collecting body and contains a positive active material, and the positive polar lug is welded on the positive current collecting body; the negative current collecting substrate is made of a metal foil or a metal mesh with a thickness of 6-25 mu m, is 6-60 mu m in thickness and has a plane or concave-convex structure; and the electrolyte contains a lithium salt and a solvent, the lithium salt is lithium hexafluorophosphate, and the concentration of the lithium salt in the electrolyte is 1.5-7mol / L. The lithium battery disclosed by the invention has the characteristics of high power, high energy and low self-discharge rate. Meanwhile, the invention also discloses a preparation method and applications of the lithium battery.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Non-aqueous electrolyte for lithium iron phosphate battery

The invention discloses a non-aqueous electrolyte for a lithium iron phosphate battery. The non-aqueous electrolyte comprises 70 to 85 weight percent of carbonic ester compound, 3 to 20 weight percent of various function additives and 11 to 17 weight percent of lithium hexafluorophosphate, wherein the carbonic ester compound is one of ethylene carbonate, propylene carbonate, butylene carbonate, dimethyl carbonate and diethyl carbonate or a mixture of more of the ethylene carbonate, the propylene carbonate, the butylene carbonate, the dimethyl carbonate and the diethyl carbonate; and the additives comprise one of 0.5 to 10 percent of film-forming additive, 0.5 to 10 percent of high-temperature additive, 0.5 to 10 percent of low-temperature additive, 0.5 to 10 percent of overcharge-preventing additive and 0.001 to 2 percent of stability additive, and a mixture of more of the additives. The non-aqueous electrolyte for the lithium iron phosphate battery has the advantages that the solubility and dissociation of the lithium hexafluorophosphate are improved, and electric conductivity is improved; the low temperature resistance of a solid electrolyte interphase (SEI) is reduced; the overall stability of the battery is improved, the overall service life of the battery is prolonged, the compatibility of an electrolyte and a cathode is improved, circulation of the battery is improved, and the service life is prolonged; and the non-aqueous electrolyte can have high performance at high temperature.

Owner:广东金光高科股份有限公司

Lithium-ion power battery electrolyte for high/low temperature environment

InactiveCN104810551AImprove high temperature performanceImprove discharge characteristicsSecondary cellsImidePower battery

The invention discloses a lithium-ion power battery electrolyte for a high / low temperature environment. The electrolyte comprises a lithium salt, an organic solvent and a negative electrode film forming additive. The lithium salt is a mixture of lithium hexafluorophosphate and lithium dis(trifluoromethanesulfonyl)imide or a mixture of lithium hexafluorophosphate and lithium difluoro(oxalato)borate. The organic solvent is a mixture of a carbonic ester solvent and a carboxylate solvent and a volume ratio of the carbonic ester solvent to the carboxylate solvent is 7-9: 1-3. Through modification of the lithium salt, the organic solvent and the film forming additive, charging-discharging, cycle and storage performances of the lithium-ion battery under condition of high / low temperature are obtained, and the problem that the existing lithium-ion power battery electrolyte has a low charging-discharging capacity, a short cycle life and poor storage performances in a high / low temperature environment is solved.

Owner:WANXIANG 123 CO LTD +2

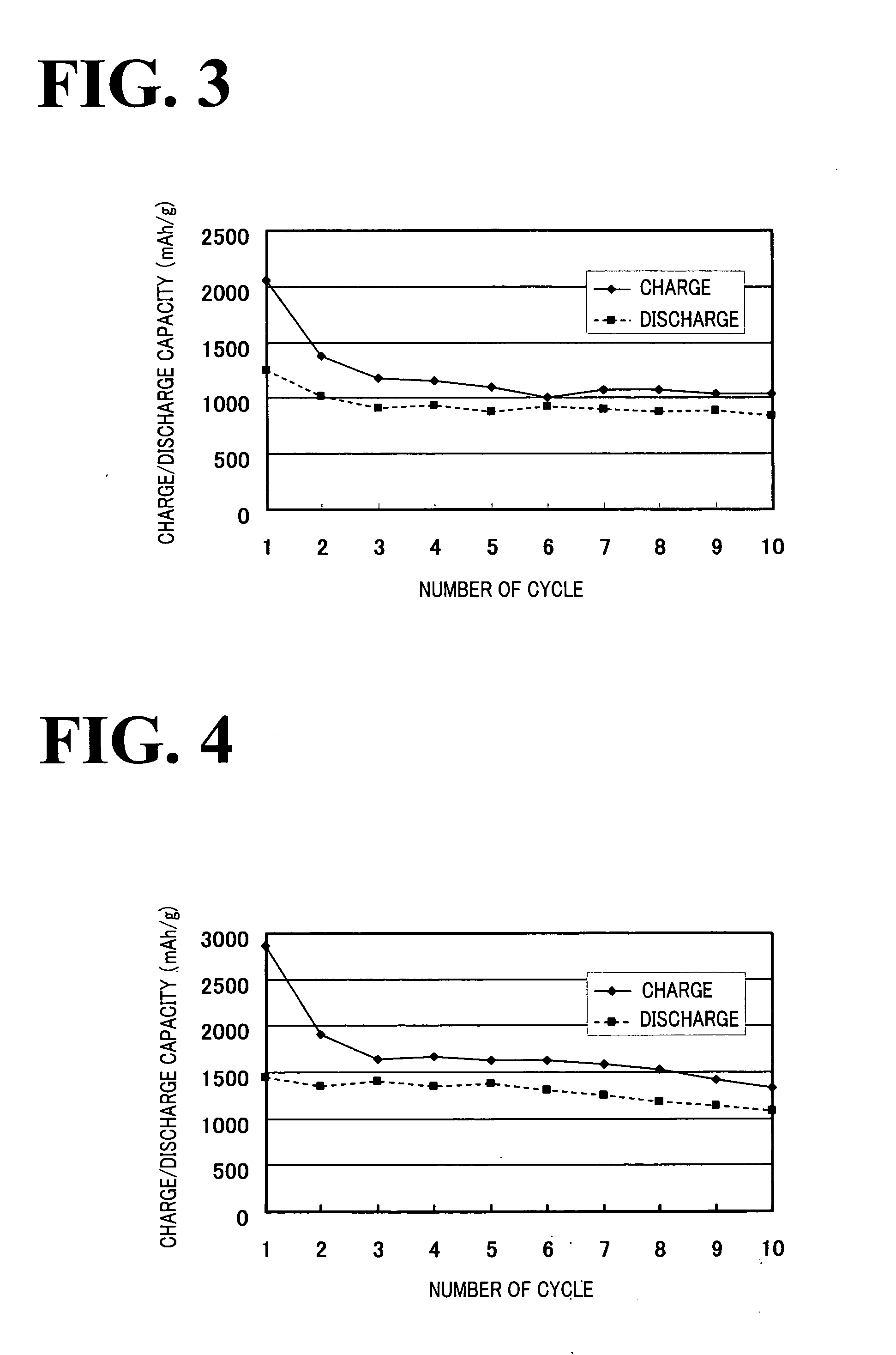

Lithium ion battery adopting graphene as cathode material

InactiveCN101572327AHigh specific capacityEasy to makeElectrode manufacturing processesSecondary cellsManganateCharge discharge

The invention provides a lithium ion battery adopting graphene as a cathode material. The lithium ion battery which is prepared by the low-temperature method and adopts the graphene material as the cathode material includes a metal casing, a plate electrode, electrolytic solution and a septum, wherein active substances used by the anode plate electrode are commonly used anode materials for the lithium ion battery and include lithium cobaltate, lithium iron phosphate, lithium manganate, lithium nickelate, a ternary lithium-nickelate-cobaltate-manganate material and the like; and the electrolytic solution is lithium hexaflourophosphate electrolytic solution used by the lithium ion battery. The cathode of the lithium ion battery adopting the graphene material as the cathode material is made of the graphene material. The first discharge capacity of the lithium ion battery adopting the graphene material as the cathode material can reach 400 to 800mAh / g, and the first charge discharge efficiency can reach 40 to 90 percent; and after 20 cycles, the discharge capacity of the lithium ion battery can still reach 380 to 450mAh / g. The lithium ion battery has the advantages of simple preparation process of the graphene material, easy operation and low cost; and the lithium ion battery adopting the graphene as the cathode material has high discharge capacity and favorable cycle performance.

Owner:TIANJIN UNIV

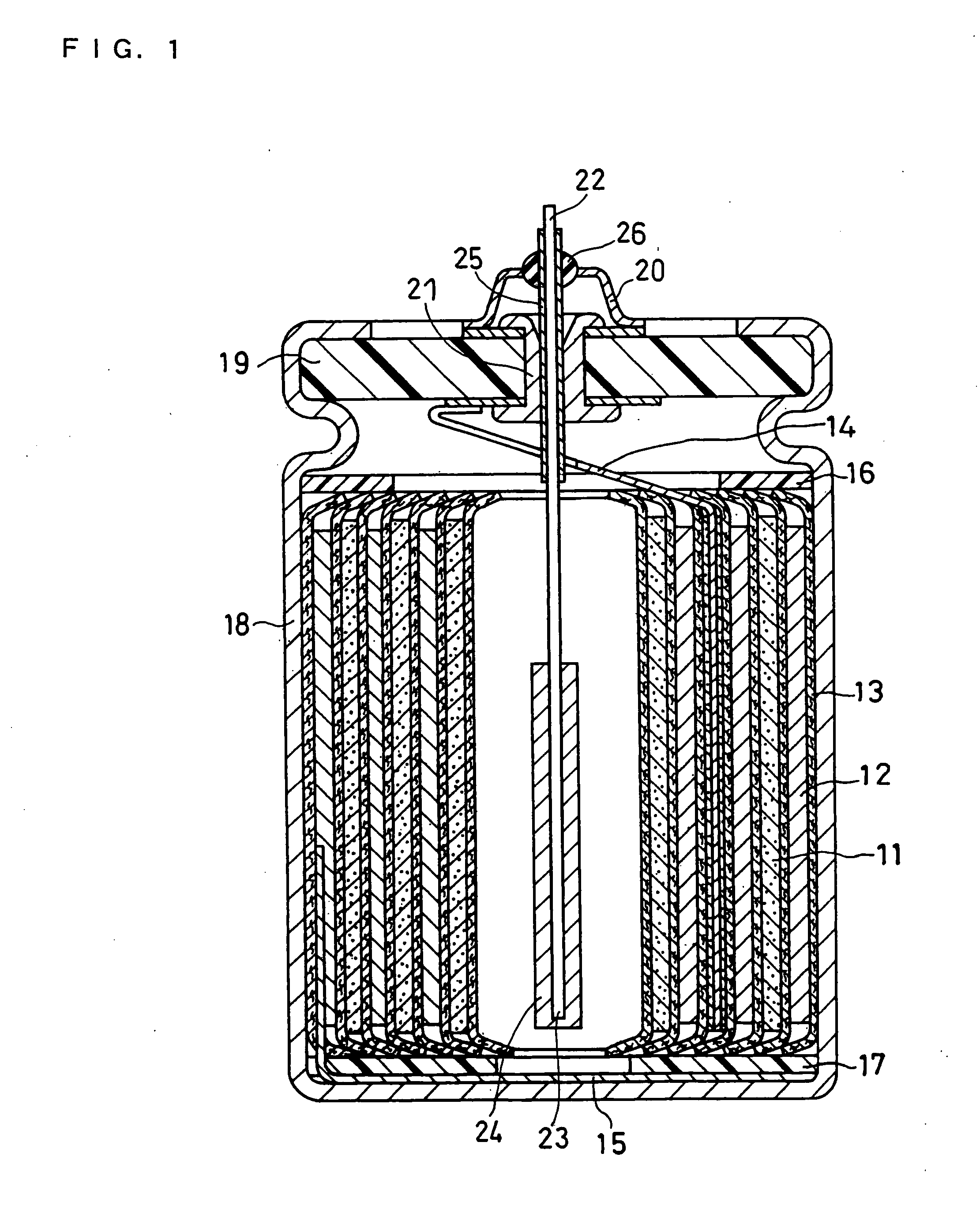

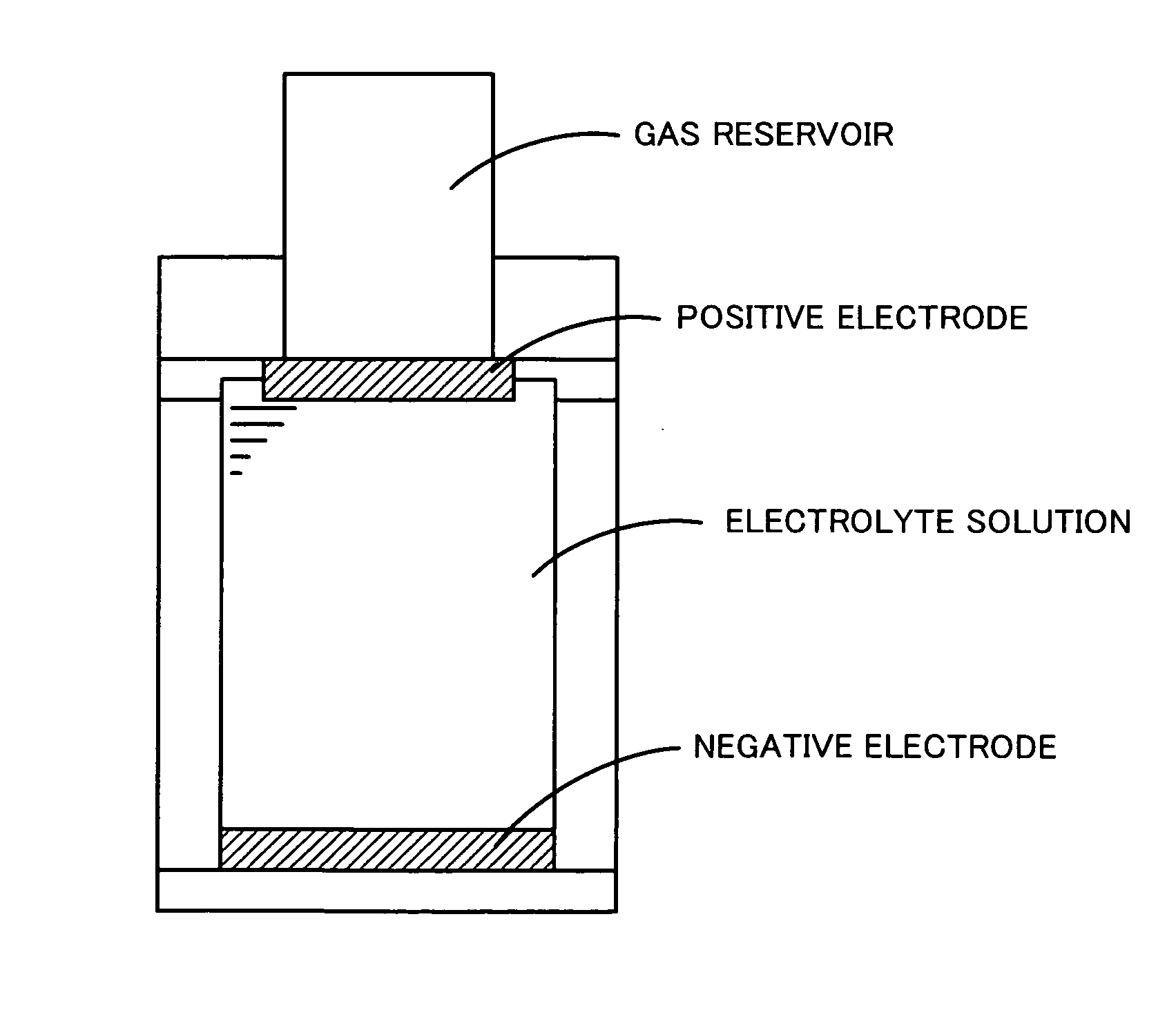

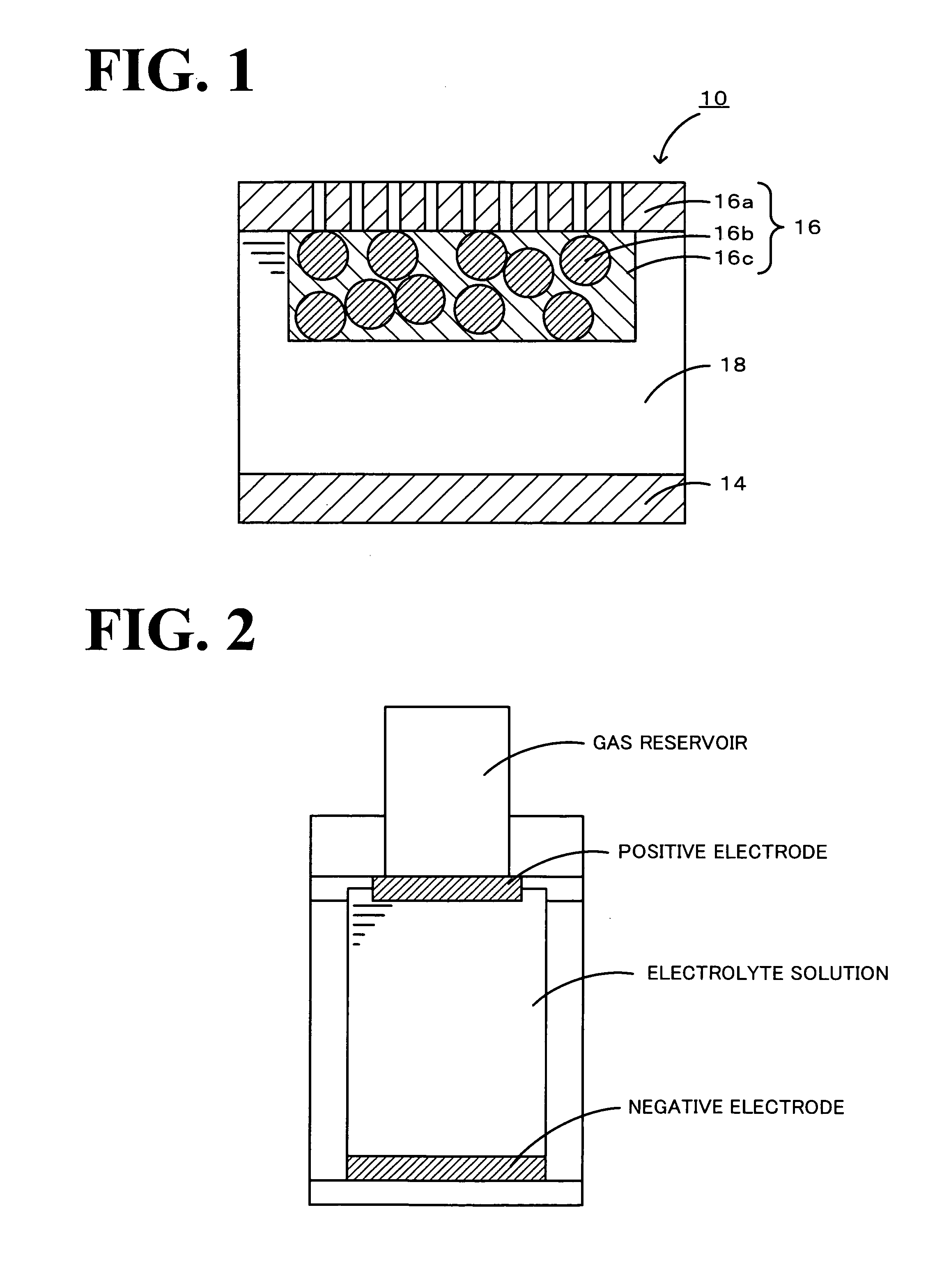

Non-aqueous electrolyte secondary battery

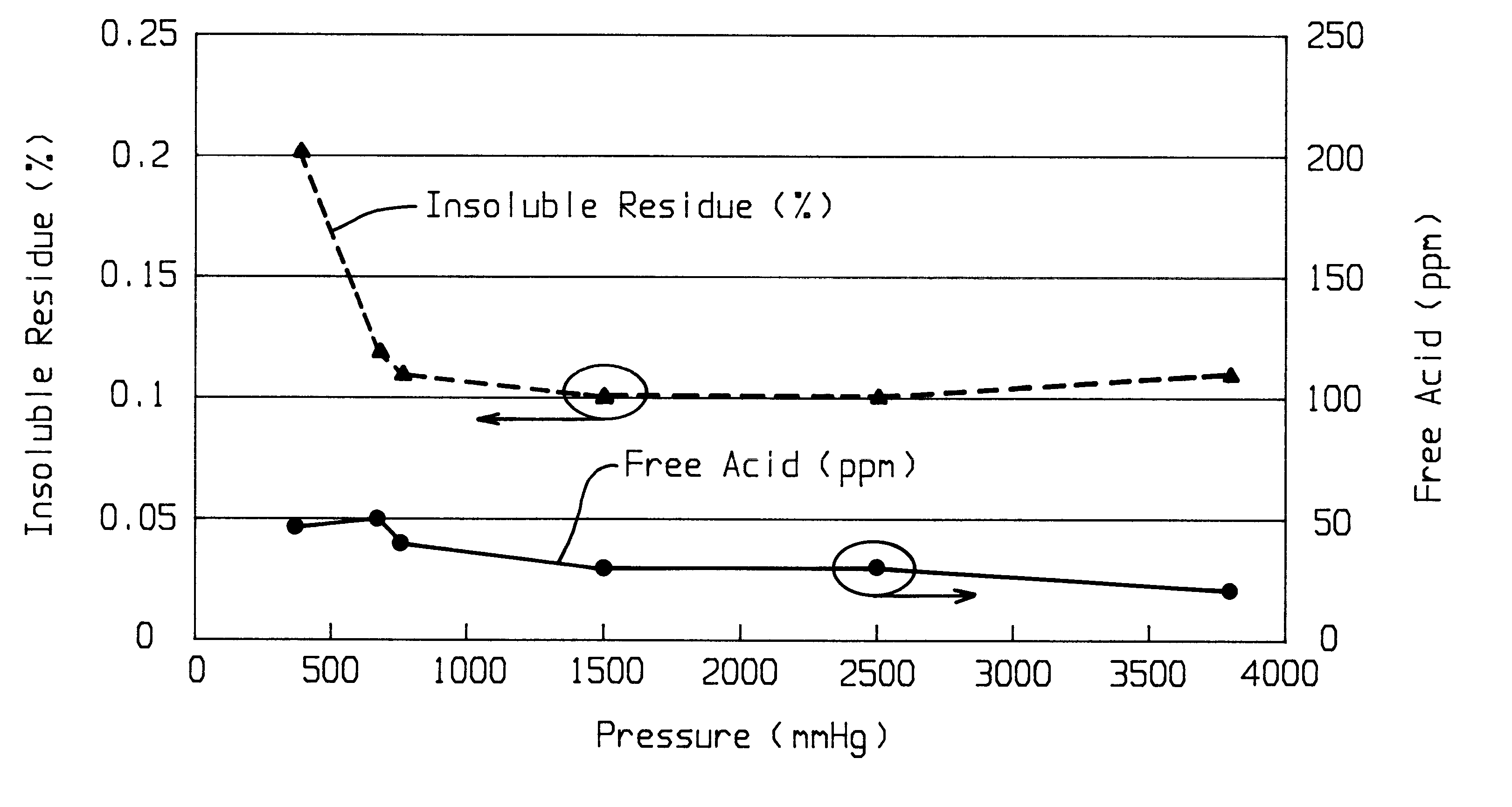

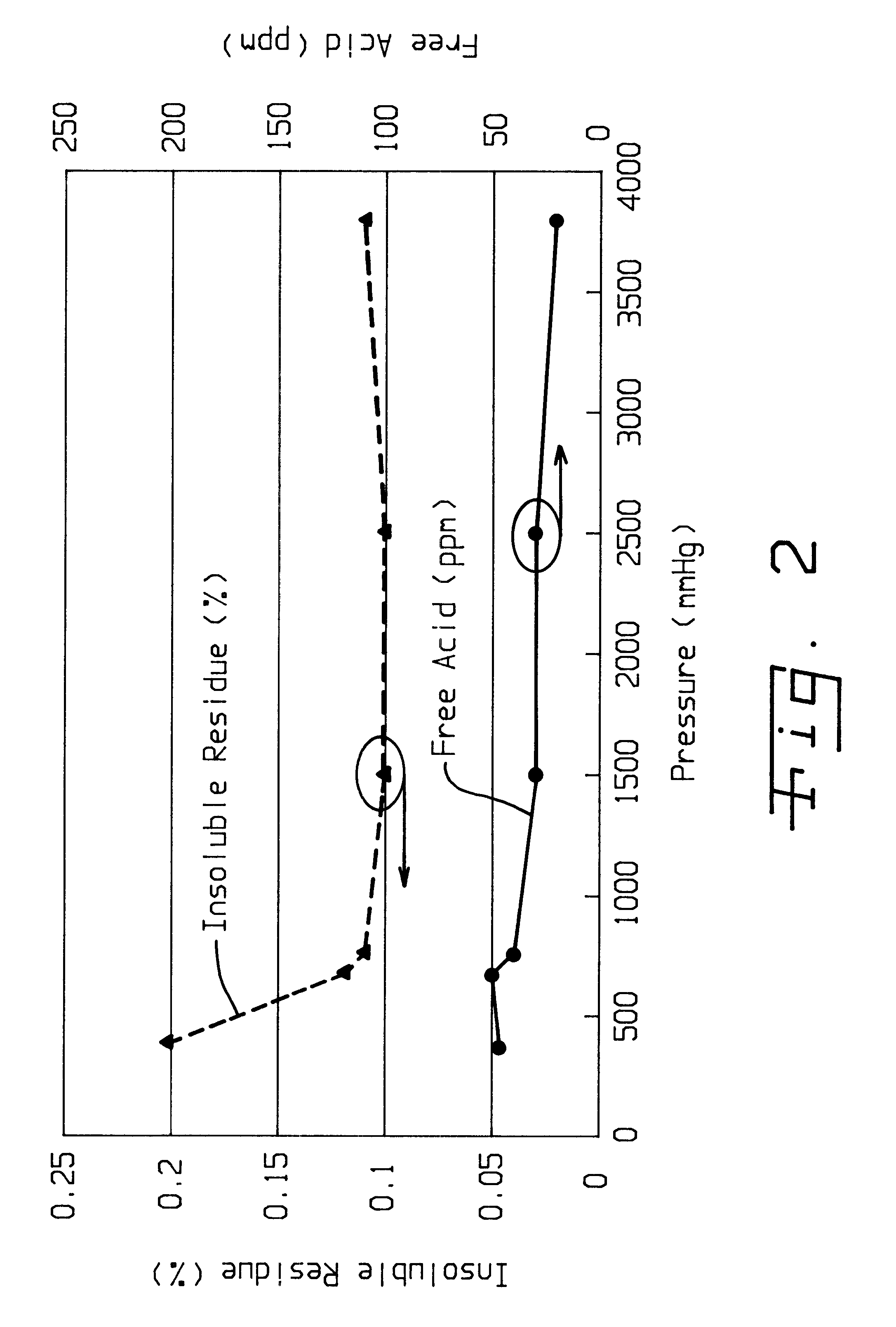

ActiveUS20060286458A1Large capacityImprove featuresNegative electrodesElectrolytesSupporting electrolyteDissolution reaction

A non-aqueous electrolyte secondary battery including: a positive electrode; a negative electrode, and a non-aqueous electrolyte. The negative electrode includes a negative electrode active material that includes at least Si. The non-aqueous electrolyte includes lithium hexafluorophosphate as a main supporting electrolyte and has an acid content of not less than 50 ppm and not more than 200 ppm. The negative electrode has a potential of not less than 0.6 V and not more than 1.5 V relative to a Li electrode at an end-of-discharge voltage of the battery. The battery is prevented from suffering degradation of storage characteristics caused by the dissolution reaction of Si from the negative electrode during charging and the precipitation reaction of the dissolved Si.

Owner:PANASONIC CORP

Methods for preparing phosphorus pentafluoride gas and preparing lithium hexafluorophosphate using the gas

ActiveCN101353161AEasily hydrolyzedStrong moisture absorptionPhosphorus halides/oxyhalidesLithiumPhysical chemistry

A preparation method of phosphorus pentafluoride gas comprises a step of causing phosphorus pentachloride to react with anhydrous hydrogen fluoride, wherein, the reaction occurs in the presence of a solvent. A preparation method of lithium hexaflourophosphate comprises a contact reaction between solid lithium fluoride and phosphorus pentafluoride gas, wherein the phosphorus pentafluoride gas is prepared by the method of the invention. Compared with the preparation method of the lithium hexaflourophosphate with the phosphorus pentafluoride gas as the raw material in the prior art, the phosphorus pentafluoride gas prepared by the preparation method of the invention has higher purity and lower cost. The yield of the lithium hexaflourophosphate prepared by the method of the invention is higher than 93%, and the purity thereof is up to 99.95%.

Owner:BYD CO LTD

Ternary positive electrode material lithium ion battery electrolyte

The invention provides a ternary positive electrode material lithium ion battery electrolyte, and relates to the technical field of a lithium ion battery. The ternary positive electrode material lithium ion battery electrolyte comprises a carbonate ester organic solvent, a lithium salt and an additive, wherein the lithium salt is lithium hexafluorophate, the lithium hexafluorophate accounts for 12-18% of the total mass of the lithium salt and the carbonate ester organic solvent, and the additive accounts for 5-15% of the total mass of the lithium salt and the carbonate ester organic solvent. The carbonate ester organic solvent is used, so that the solvent is high in solubility of the lithium salt and low in viscosity; and meanwhile, fluoroethylene carbonate is used as a low-temperature additive, the electrolyte is compatible with the electrochemical performance such as capacity and internal resistance, the ternary positive electrode material battery also has excellent cycle property, and the cycle time of the battery under a low-temperature condition is prolonged.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

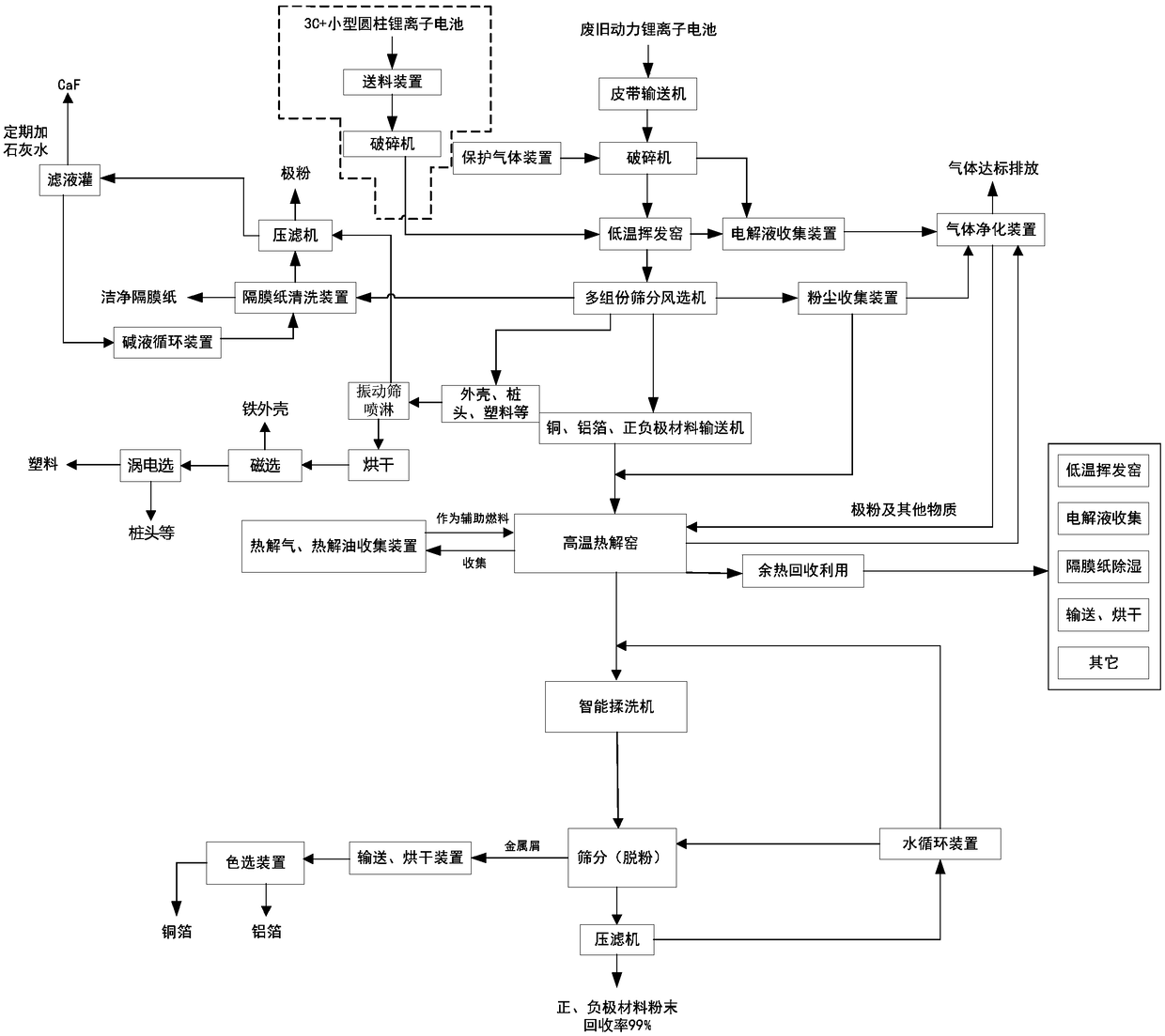

A method for separating and recovering valuable components of waste power lithium batteries

ActiveCN109193064ARealize charged crushingSteps to simplify discharge handlingWaste accumulators reclaimingBattery recyclingOrganic solventWastewater

The invention discloses a method for separating and recovering valuable components of waste power lithium batteries. The method is that the waste power lithium batteries are electrified and crushed, the organic solvent is volatilized and recovered, the lithium hexafluorophosphate is innocuously treated, and the light material, the heavy material and the intermediate weight material are sorted by amulti-component screening wind separator. Recovering diaphragm from light material, pyrolyzing intermediate weight material and powder, recovering pyrolysis oil and pyrolysis gas generated from pyrolysis as auxiliary fuel, separating aluminum foil and copper foil by color separation after pyrolysis residue is separated by intelligent kneading and washing machine, and separating shell, pile head and plastic from heavy material. The waste water and waste gas in the whole process of the method are treated centrally, no pollutants are discharged, and the whole component in the waste power lithiumbattery can be recovered efficiently. At the same time, the method fully realizes waste rebenefit, reduces energy consumption, reduces environmental pollution, and the process is simple and applicable to a wide range of batteries.

Owner:湖南江冶新能源科技股份有限公司

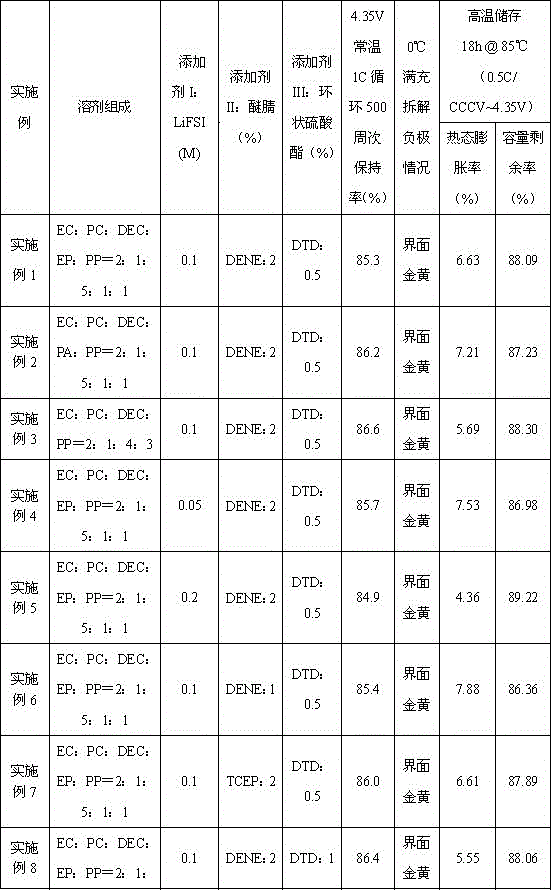

High voltage electrolyte considering high and low temperature performance and lithium ion battery using the electrolyte

InactiveCN105576283AImprove wettabilityImprove cycle performanceSecondary cellsElectrolytesElectrolytic agentCarboxylic acid

The invention discloses high voltage electrolyte considering high and low temperature performance and a lithium ion battery using the electrolyte. The high voltage electrolyte comprises a non-aqueous organic solvent, an electrolyte lithium salt, an ether nitrile compound and a low impedance additive, wherein the non-aqueous organic solvent comprises a carbonate solvent and a linear carboxylic acid ester solvent with a wide liquid range; the electrolyte lithium salt is a combination of lithium hexafluorophate and lithium triflurosulfimide according to a molar ratio of 0.01-0.5; and the low impedance additive is a cyclic sulfate compound. The linear carboxylic acid ester solvent for perfecting the electrode / electrolyte interface is contained in the high voltage electrolyte, by means of the optimized combination of the ether nitrile compound, the lithium triflurosulfimide and the cyclic sulfate compound and other additives, a high voltage battery can be guaranteed to have excellent circulation performance, and meanwhile, the excellent high and low temperature performance of the high voltage battery of storage for 18 h in a full charge state at 85 DEG C and no lithium separation in the full charge state at 0 DEG C is considered.

Owner:GUANGZHOU TINCI MATERIALS TECH

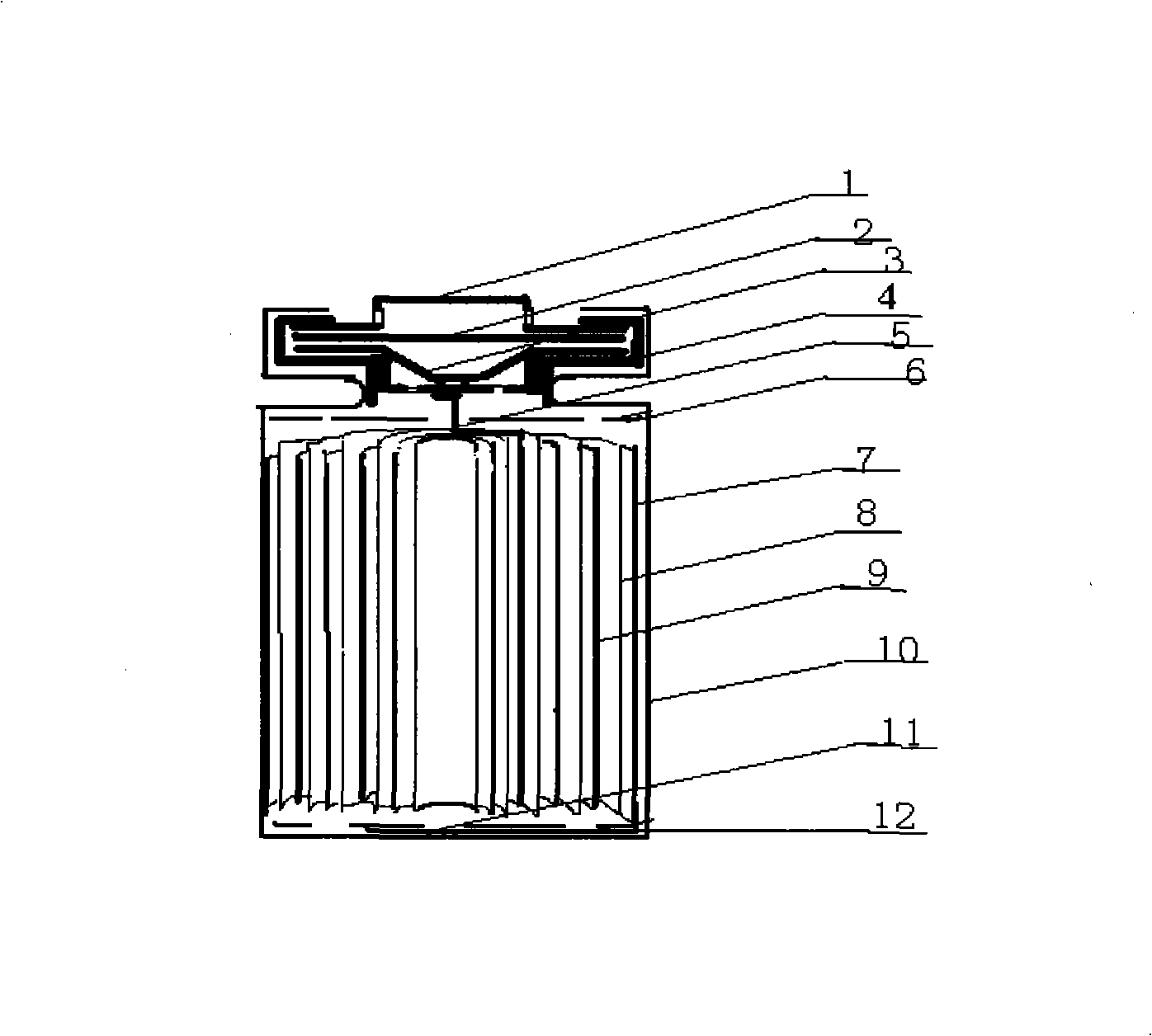

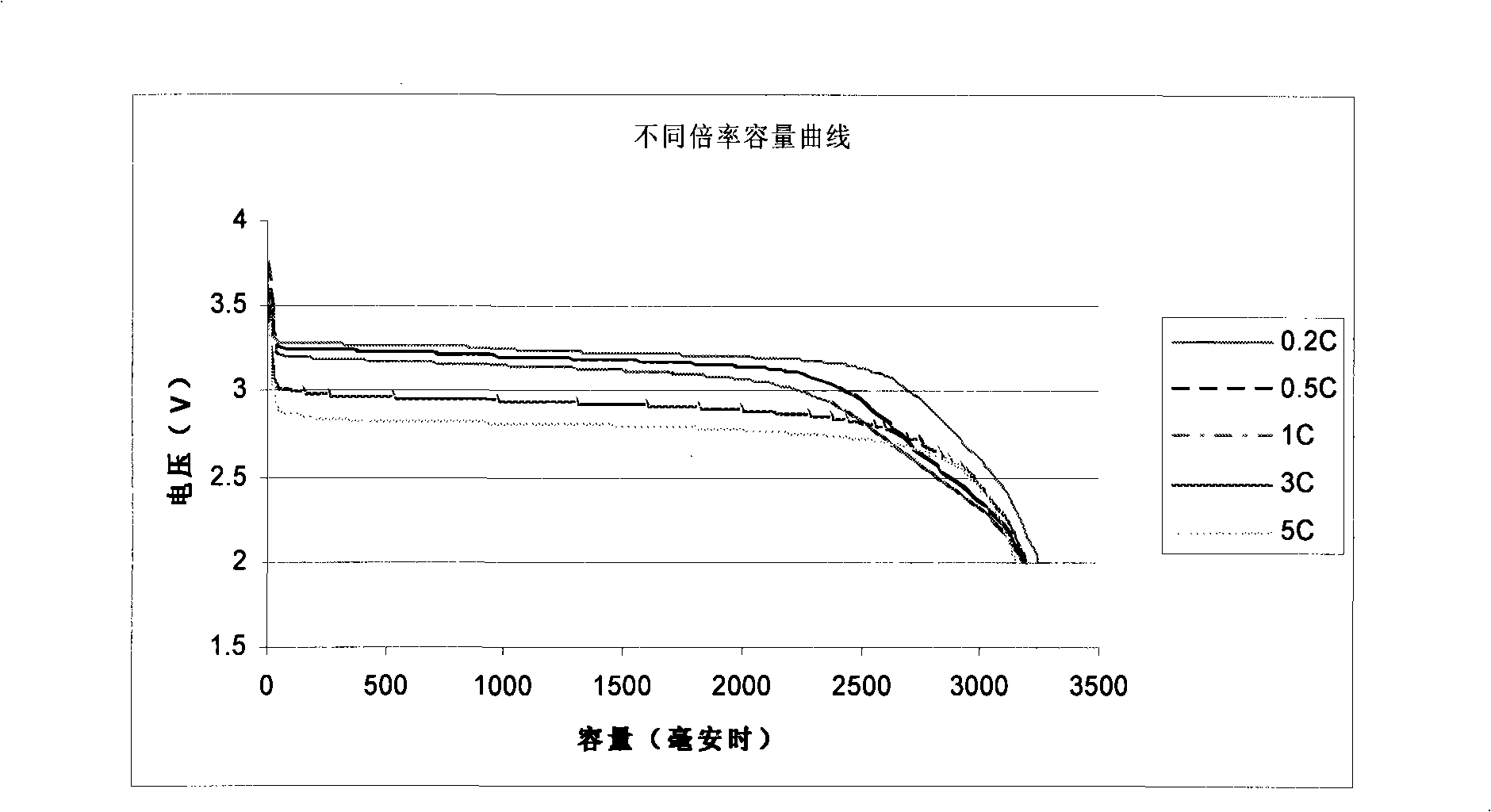

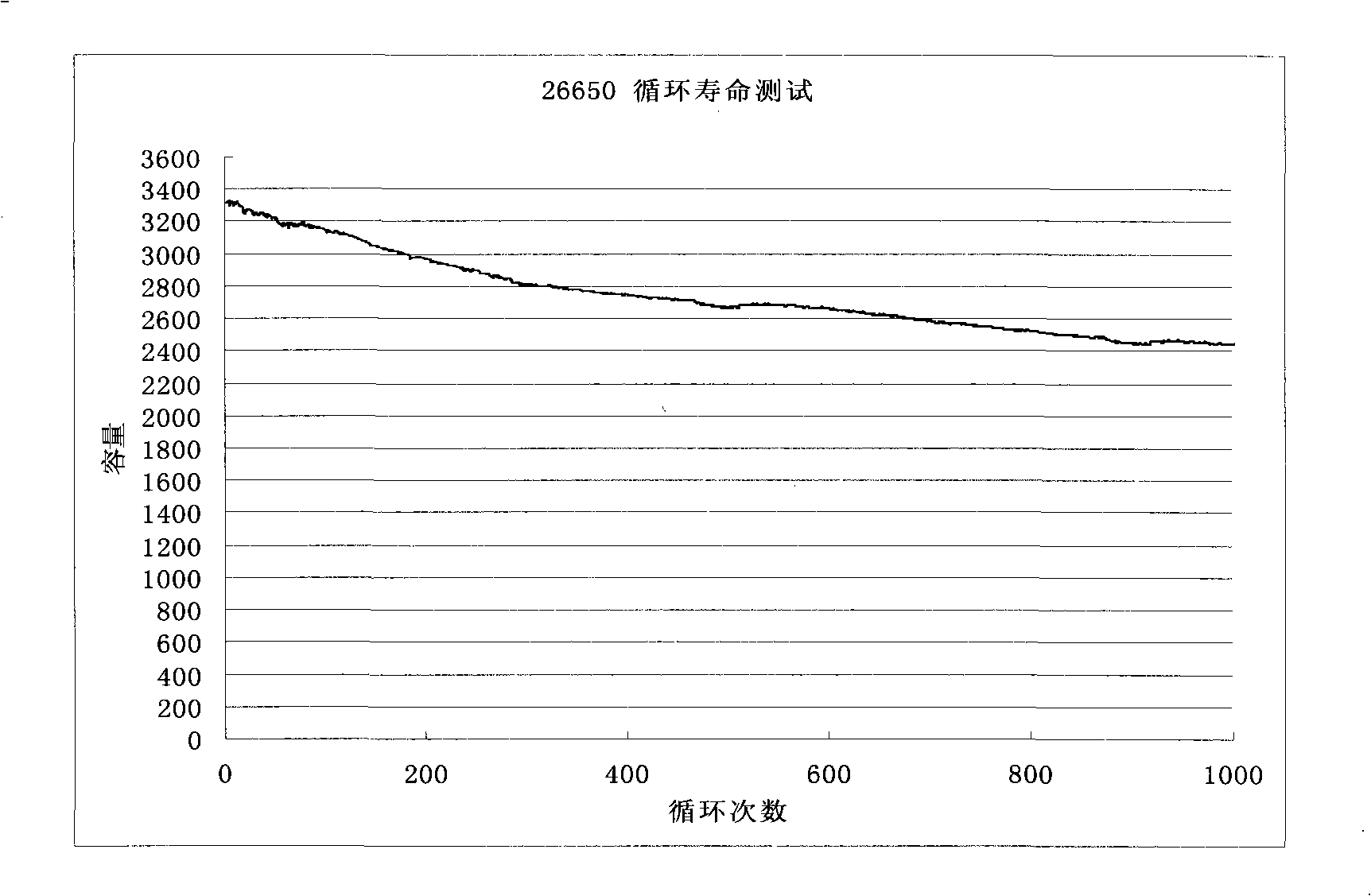

A high-capacity secure 26650 lithium ion battery and its making method

InactiveCN101262077AHigh feasibilityFinal product manufactureCell electrodesMethyl carbonatePhosphate

The invention relates to the technical field of a secondary power (a chargeable battery) which can be reused, in particular to a 26650 type lithium ion battery which is safe and has high capacity and a preparation method thereof. Lithium ferrous phosphate is used as cathode material; graphite materials are adopted as anode materials; mixture of EC (ethylene carbonate), DMC (Di Methyl Carbonate), EMC (methyl ethyl carbonate) (based on volume ratio of 1: 1: 1) is used as electrolyte solution, and LiPF6 (lithium hexafluorophosphate ) with molar ration 1.0 to 1.4 mol / L is adopted as electrolyte; multi-porous PP (polypropylene) and PE (polyethylene) are used as separating membrane, and a metal tank is used as a shell, thus the 26650 type battery is made with the diameter of 26mm and the height of 65mm; the capacity of the battery can reach 3200mAh, the internal resistance is within 30mOmega, and the cycle life thereof is more than 1000 times. The 26650 type lithium ion battery mainly solves the limitation problem of the existing lithium ion battery in the respect of safe and large size, and develops towards large size, has longer service life and higher safety and belongs to an environment protection chemical power with wider application.

Owner:上海德朗能电池有限公司

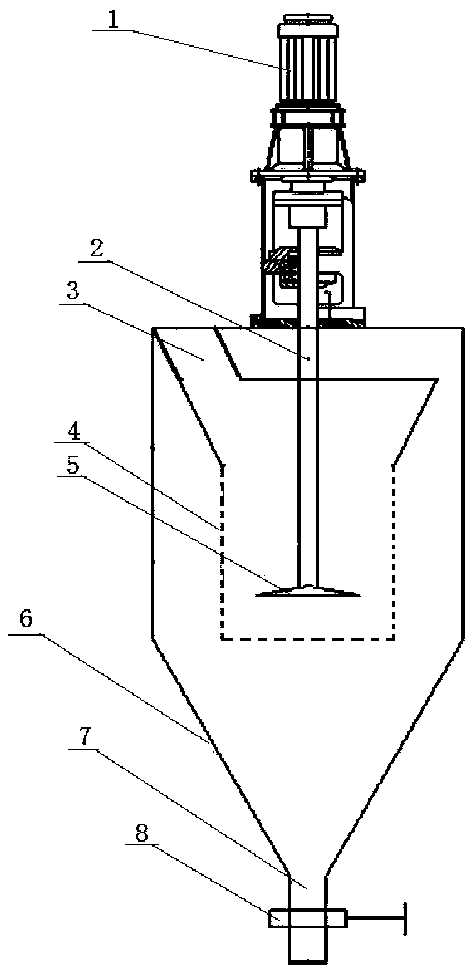

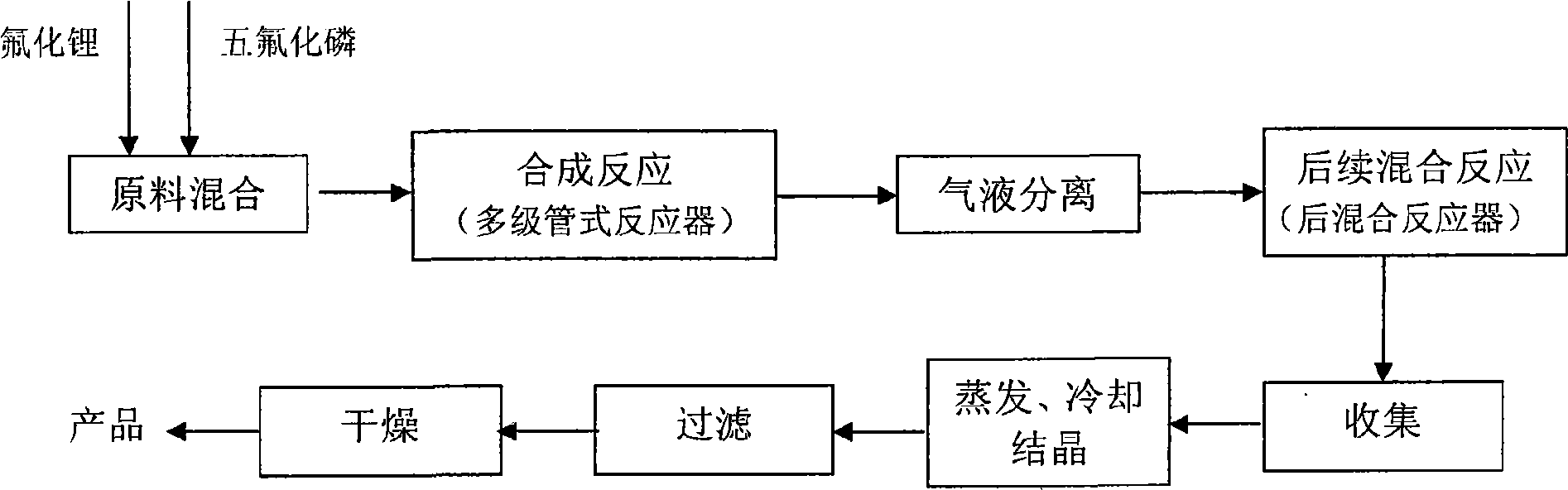

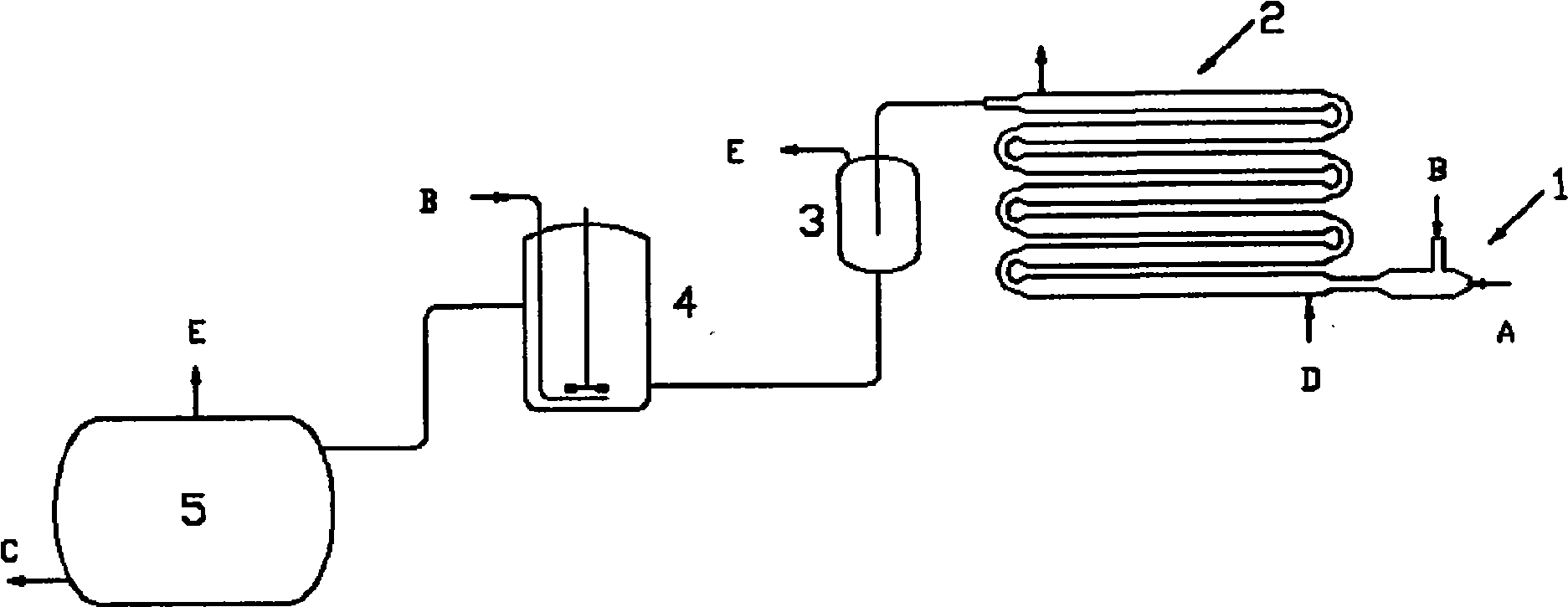

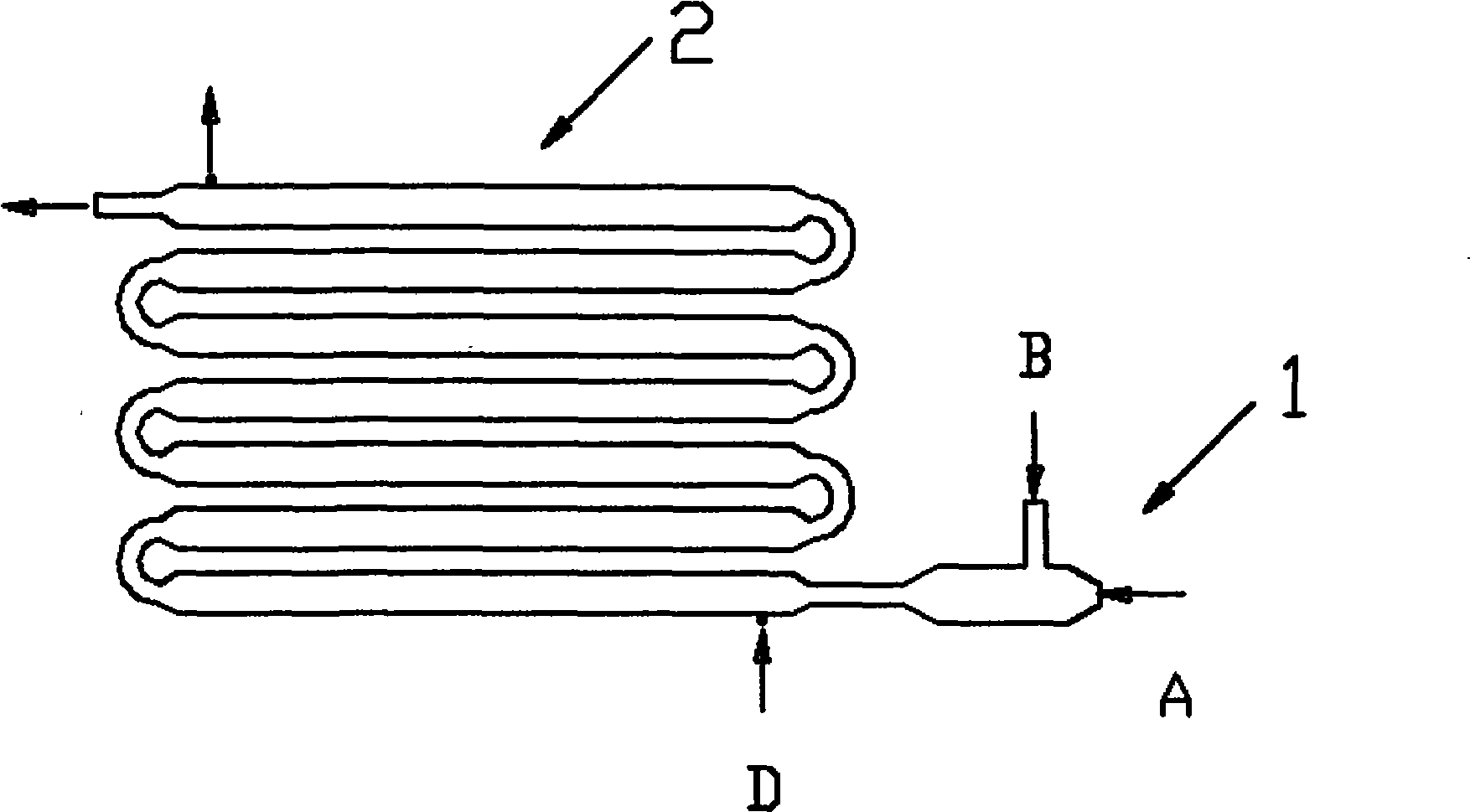

Process and device for continuous preparation of lithium hexafluorophosphate

ActiveCN101544361AAchieve conversionAchieve serializationSecondary cellsPhosphorus compoundsLiquid productFiltration

The invention discloses a process for the continuous preparation of lithium hexafluorophosphate and a device thereof. The process comprises the following steps that: a fluorine hydride solution A of lithium fluoride and phosphorus pentafluoride or a mixed gas of the phosphorus pentafluoride and other gases are subjected to raw material mixing; the raw material mixture undergoes a multistage synthetic reaction; the product of the multistage synthetic reaction enters a gas-liquid separator to remove unreacted gases; the liquid product of the multistage reaction undergoes a consequent hybrid reaction and the product of the consequent hybrid reaction is reacted with the additionally introduced phosphorus pentafluoride gas B to remove a micro amount of possibly unreacted lithium fluoride in the solution; the product of the reaction is then subjected to evaporation, cooling, crystallization, filtration and drying to form lithium hexafluorophosphate crystal with a purity of 99.9 percent; and a parent solution obtained after separation and crystallization is added with the lithium fluoride to form the raw material solution A for cycle use. The invention adopts a multistage tubular reactor which has excellent mass and heat transfer performance and can realize full gas-liquid contact, continuous material feeding and discharging and the like and consequently realize the continuous operation of a production process.

Owner:산산어드밴스드머테리얼스(취저우)컴퍼니리미티드

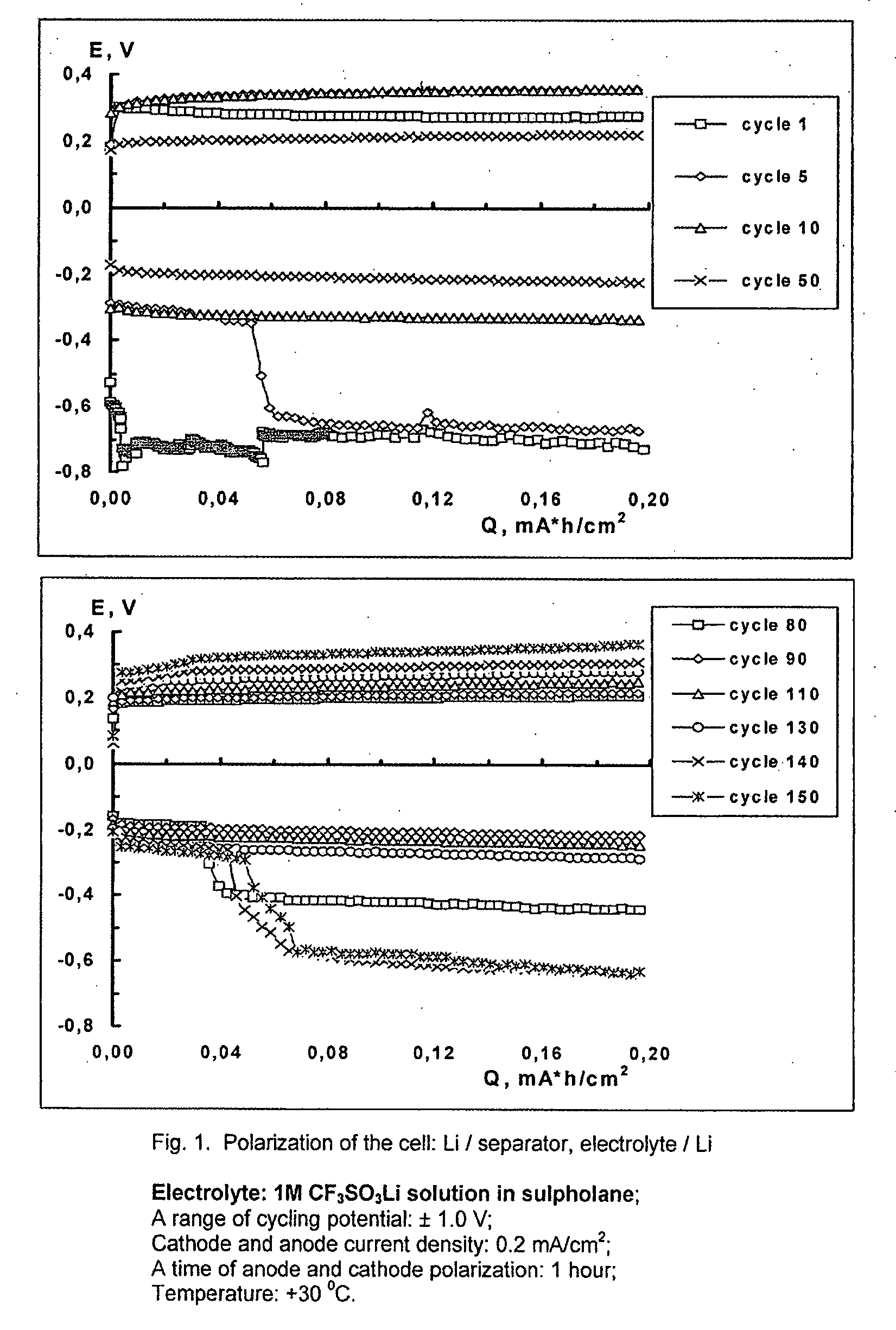

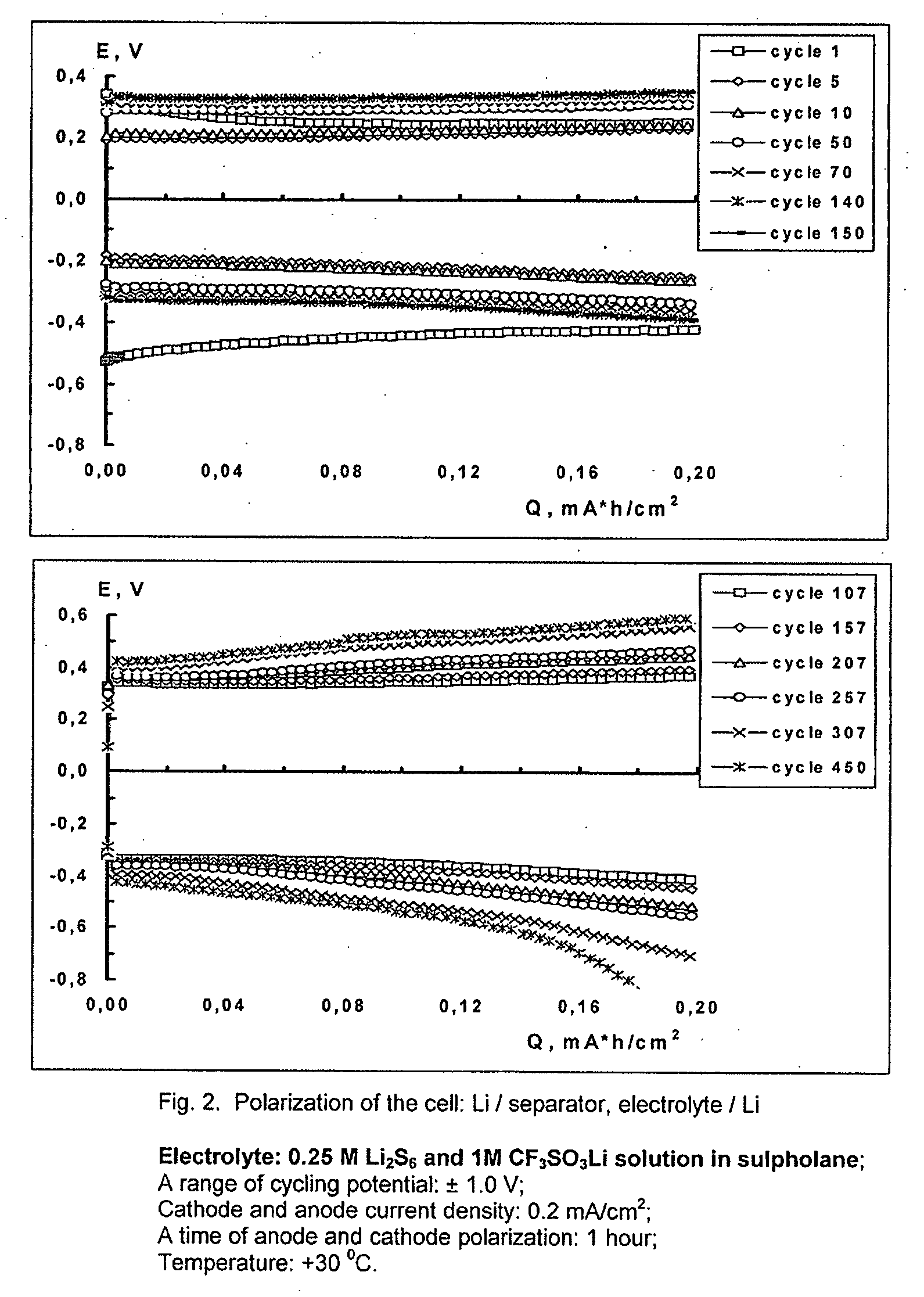

Cell or battery with a metal lithium electrode and electrolytes therefor

InactiveUS20080038645A1Improve cycle lifeOrganic electrolyte cellsLi-accumulatorsSulfolaneMetallic lithium

An electrolyte for rechargeable batteries with a negative electrode of lithium or lithium containing alloys comprising: one or several non-aqueous organic solvents, one or several lithium salts and one or several additives increasing the cycle life of the lithium electrode. The electrolyte solution may comprise one or several solvents selected from the group comprising: tetrahydrofurane, 2-methyltetrahydrofurane, dimethylcarbonate, diethylcarbonate, ethylmethylcarbonate, methylpropylcarbonate, methylpropylpropyonate, ethylpropylpropyonate, methylacetate, ethylacetate, propylacetate, dimetoxyethane, 1,3-dioxalane, diglyme (2-methoxyethil ether), tetraglyme, ethylenecarbonate, propylencarbonate, γ-butyrolactone, and sulfolane. The electrolyte solution may further comprise at least one salt or several salts selected from the group consisting of lithium hexafluorophosphate (LiPF6), lithium hexafluoroarsenate (LiAsF6), lithium perchlorate (LiClO4), lithium sulfonylimid trifluoromethane (LiN(CF3SO2)2)) and lithium trifluorosulfonate (CF3SO3Li) or other lithium salts or salts of another alkali metal or a mixture thereof. Also disclosed is an electrochemical cell or battery with an anode of metallic lithium or a lithium-containing alloy, and such an electrolyte.

Owner:OXIS ENERGY

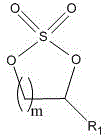

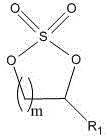

Lithium-ion battery electrolyte for high-voltage ternary positive electrode material system

ActiveCN105140564AImprove cycle performanceImprove high temperature performanceSecondary cellsOrganic electrolytesSolventStructural formula

The invention provides a lithium-ion battery electrolyte for a high-voltage ternary positive electrode material system. The lithium-ion battery electrolyte comprises a non-aqueous solvent, lithium hexafluorophate and a functional additive; the functional additive comprises a cyclic anhydride compound, a lithium salt type additive and methylene methanedisulfonate; the general structural formula of the cyclic anhydride compound is as shown in the description, wherein R1, R2, R3 and R4 are independently selected from any one of hydrogen atom, fluorine atom, or straight chain or branched chain alkyl with the number of carbon atoms of 1-4. The cyclic anhydride compound used in the lithium-ion battery electrolyte is higher in reduction potential (the reduction potential of succinic anhydride is 1.50 V vs Li+ / Li) on the negative electrode surface, so that other components in the electrolyte can be preferably reduced into films in the first charging process of the battery, the formed SEI film is high in stability. The cyclic anhydride compound used in the lithium-ion battery electrolyte is capable of effectively improving the cycle performance and high-temperature performance of the battery; and compared with fluoroethylene carbonate, the cyclic anhydride compound has excellent high-temperature performance as well as capability of improving the cycle performance.

Owner:GUANGZHOU TINCI MATERIALS TECH

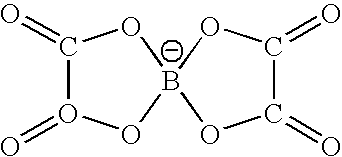

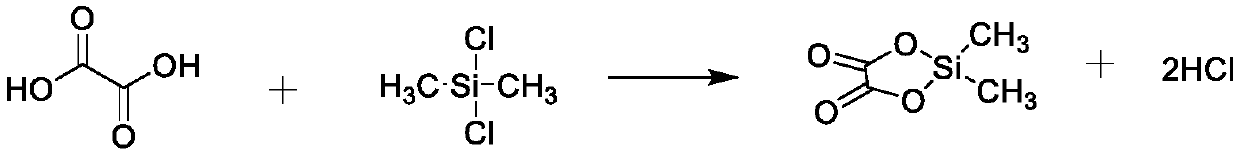

Preparation method of lithium difluorobisoxalate phosphate solution

The invention provides a preparation method of a lithium difluorobisoxalate phosphate solution. The preparation method of the lithium difluorobisoxalate phosphate solution comprises the following steps that (1) dichlorodimethylsilane and oxalic acid are reacted in the presence of a non-aqueous solvent to generate dimethyl silicon-based oxalate; and (2) lithium hexafluorophosphate is added into thereaction solution in the step (1), and reacting is carried out to obtain the lithium difluorobisoxalate phosphate solution. The preparation method is simple and practical, and industrial production can be achieved; the prepared lithium difluorobisoxalate phosphate solution can be directly used as an additive of a non-aqueous electrolyte battery; and the prepared lithium difluorobisoxalate phosphate solution has few chlorine compounds and free acids, wherein the chlorine compounds in terms of chlorine concentration are less than 5 mass ppm, and the free acids in terms of acid concentration converted from hydrofluoric acid are less than 200 mass ppm.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

Method for preparing potassium hexafluoro phosphate

The invention relates to Li ion battery technique, a lithium hexafluoro- phosphate preparing method, characterized in comprising the process steps of: using easy sublimation property of phosphorus pentachloride, heating and sublimating it to remove nonvolatile components, refining industrial anhydrous hydrogen fluoride to remove water and heavy metal impurities; reacting them with each other to prepare mixed gas of phosphorus pentachloride and hydrogen chloride; leading the mixed gas into anhydrous hydrogen fluoride of lithium fluoride, reacting, crystallizing and separating and drying to obtain pure lithium hexafluoro-phosphate.

Owner:TIANJIN CHEM RES & DESIGN INST

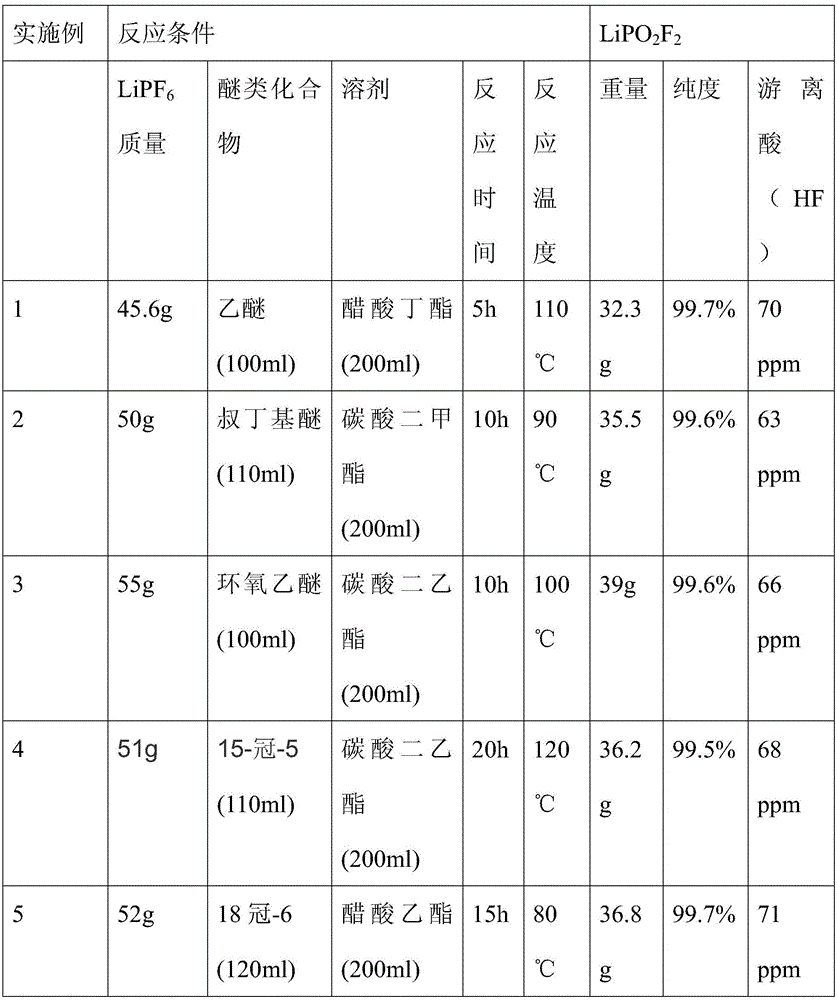

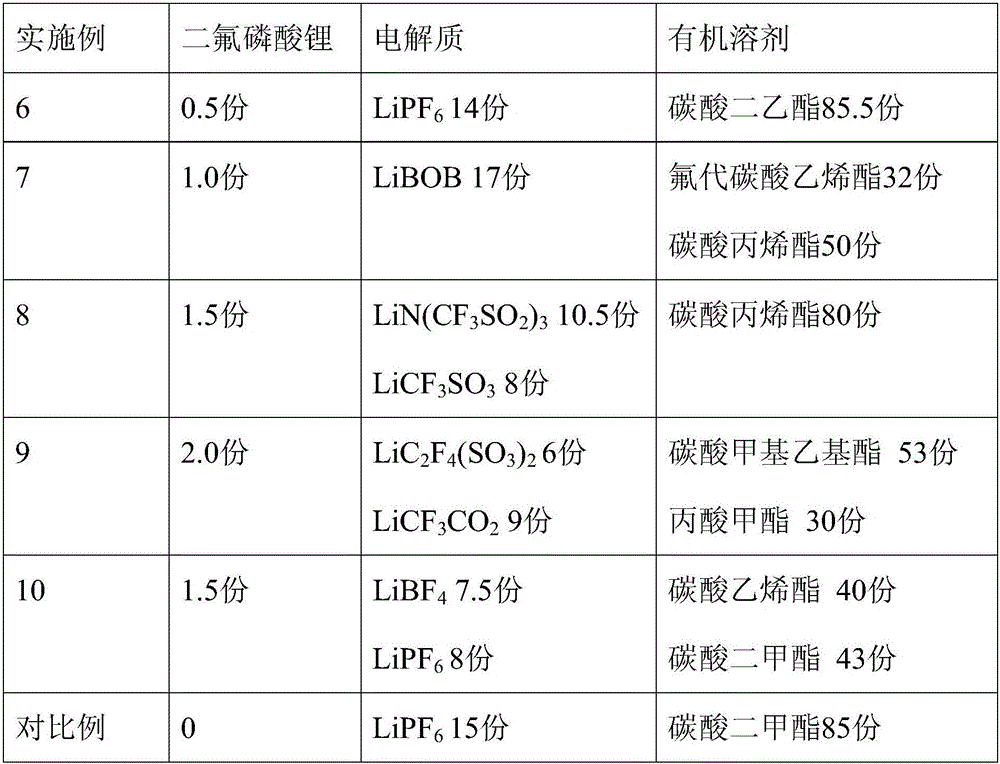

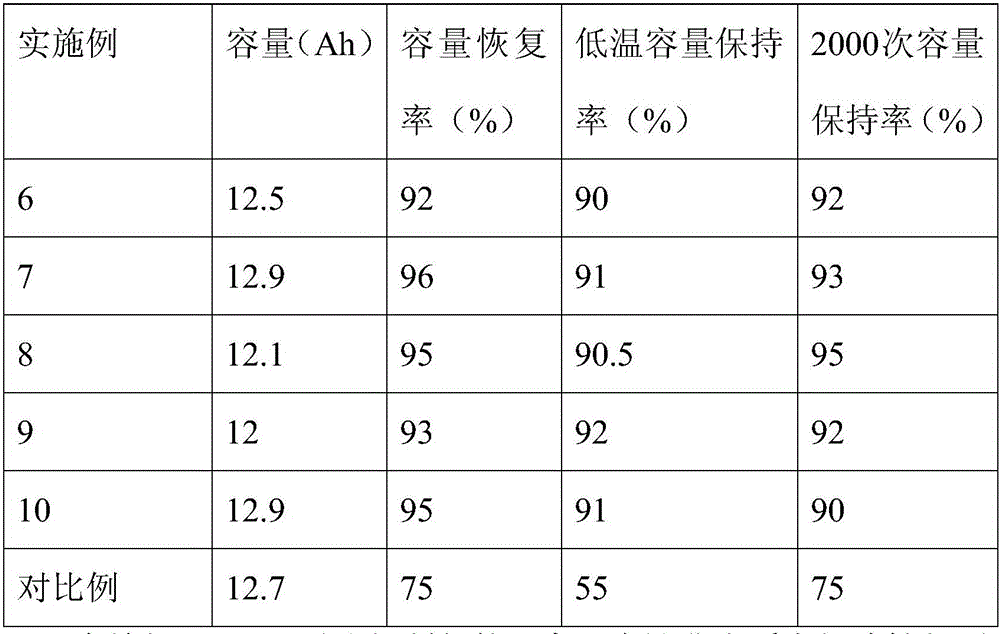

Method for preparing difluoro-lithium phosphate and lithium-ion battery non-aqueous electrolyte

ActiveCN105800582AEasy to separate and purifyHigh puritySecondary cellsPhosphorus compoundsOrganic solventEther

The invention discloses a method for preparing difluoro-lithium phosphate and a lithium-ion battery non-aqueous electrolyte.The method includes the steps that under protection of inert gas, an organic solvent serves as a reaction medium, lithium hexafluorophosphate and an ether compound are reacted in a reaction vessel with an inner layer containing a PFA protective layer or a PTFE protective layer, wherein the reacting temperature is 50 DEG C-150 DEG C, and the reacting time is 5 h-20 h; after reaction is finished, a product is filtered and dried to obtain the difluoro-lithium phosphate product.The invention further relates to the lithium-ion battery non-aqueous electrolyte of the difluoro-lithium phosphate prepared with the method.The lithium-ion battery non-aqueous electrolyte comprises 0.5%-2.0% of difluoro-lithium phosphate, 15%-20% of electrolyte salt and 80%-85% of organic solvent.The method for preparing the difluoro-lithium phosphate is easy to operate, mild in condition and convenient to purify, and the high-purity difluoro-lithium phosphate can be obtained.

Owner:QUZHOU FLUORIDE & SILICON RES INST +1

Nonaqueous electrolyte battery

InactiveUS20090061315A1Large capacityIncrease productionActive material electrodesSecondary cellsMetallic lithiumLithium hexafluorophosphate

A nonaqueous electrolyte battery includes a negative electrode composed of a metallic lithium foil and a positive electrode, the negative electrode and the positive electrode being arranged so as to face each other with an ion-conducting medium therebetween. The positive electrode is formed by a method in which a conductive agent and a binder are mixed, and then the mixture is press-formed onto a current collector. The ion-conducting medium contains, in addition to a lithium salt such as lithium hexafluorophosphate, a halogen such as iodine, and a halogen compound (e.g., lithium iodide). Furthermore, the positive electrode may contain a lithium halide.

Owner:TOYOTA CENT RES & DEV LAB INC

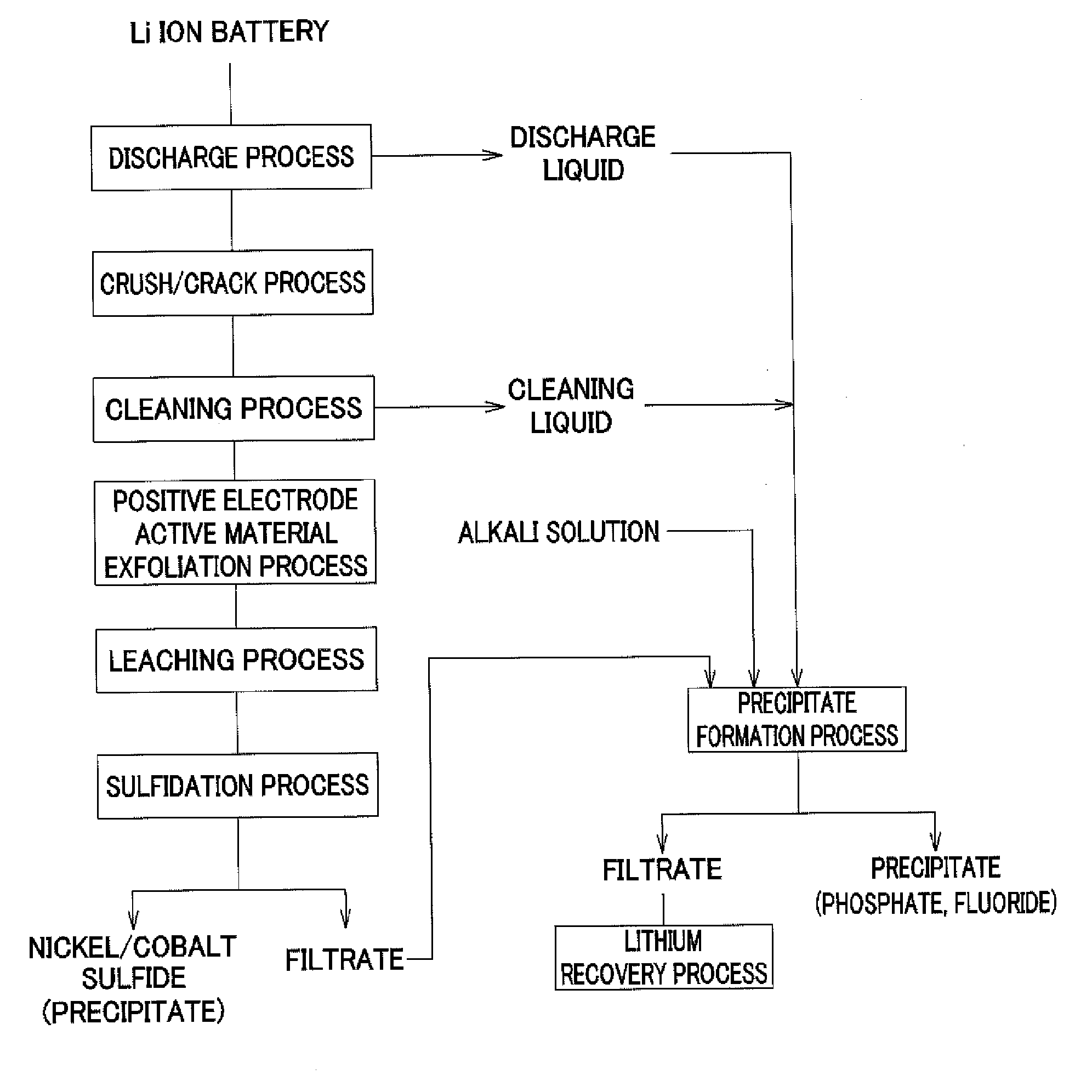

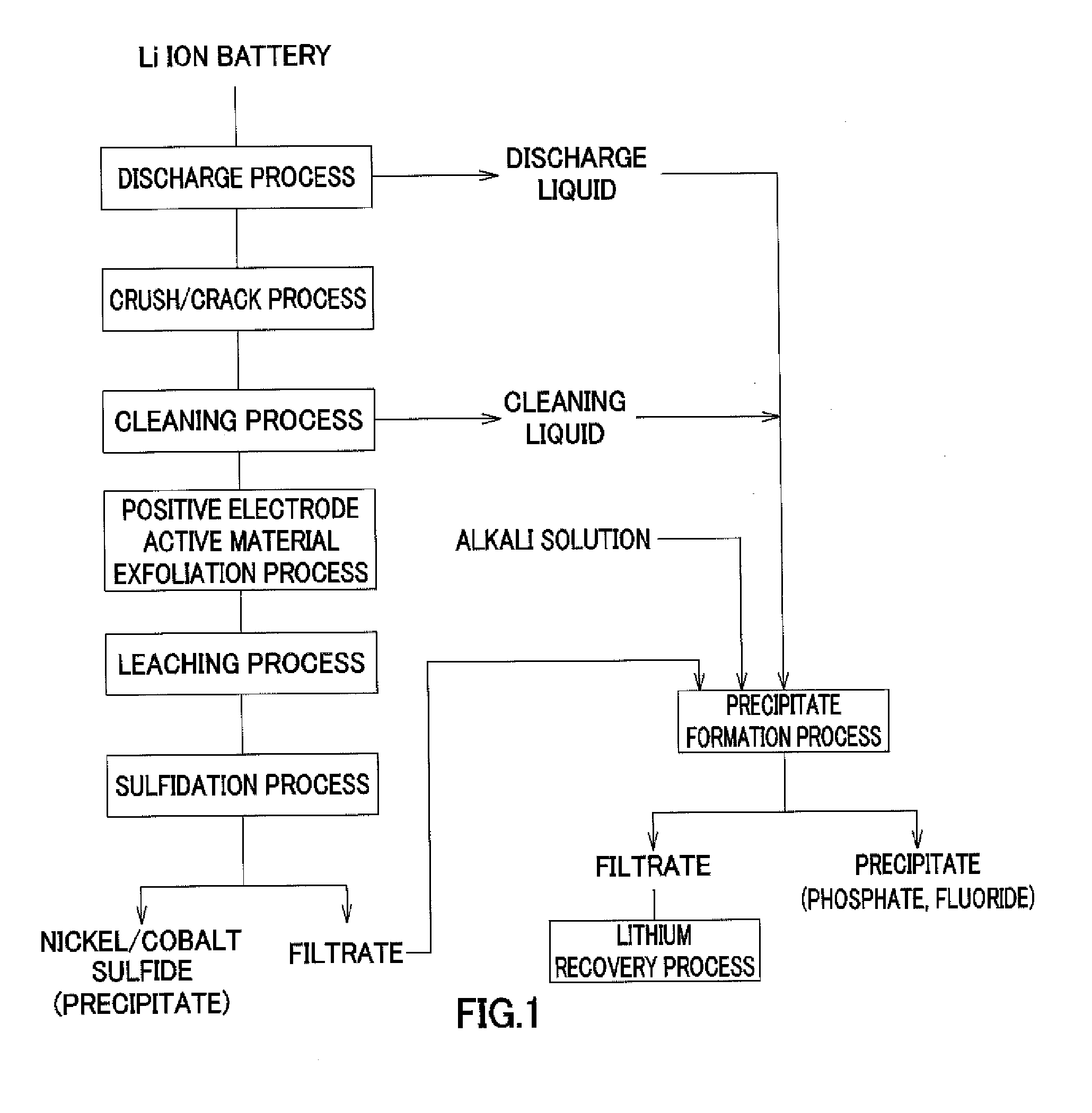

Method for recovering lithium

ActiveUS20150013499A1Efficient removalWaste accumulators reclaimingLi-accumulatorsPhosphatePhysical chemistry

To provide a method for recovering lithium, that is capable of efficiently recovering lithium without containing impurities, such as phosphorus and fluorine, from a lithium-containing solution containing lithium hexafluorophosphate and separated from a lithium ion battery. In the present invention, alkali hydroxide is added to the lithium-containing solution and the solution is made to have pH 9 or more, a precipitate of a phosphate and a fluoride salt is formed, the formed precipitate is separated and removed, and then lithium is recovered from filtrate.

Owner:SUMITOMO METAL MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com