Patents

Literature

66results about How to "Strong moisture absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chinese herbal medicine deodorization antibacterial health insole and manufacturing method thereof

InactiveCN102972922AFast absorptionRapid absorption and eliminationInsolesAntisepticsCardboardHoneycomb

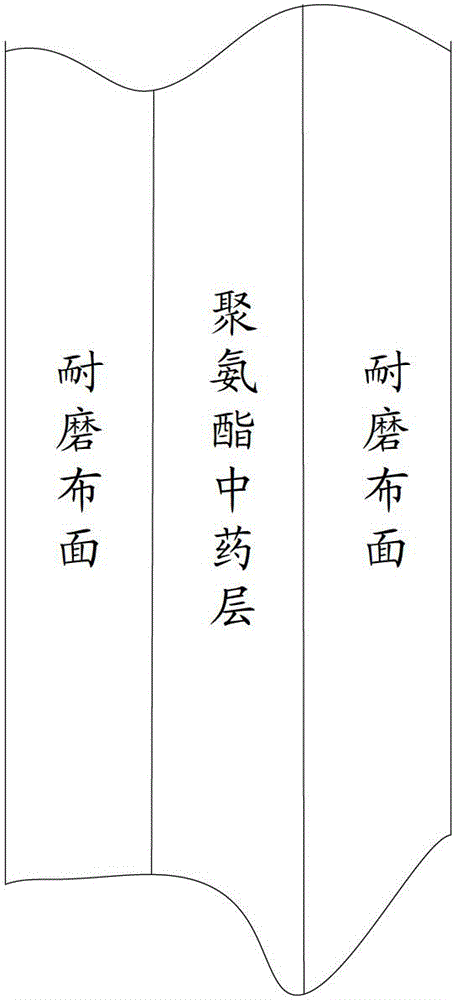

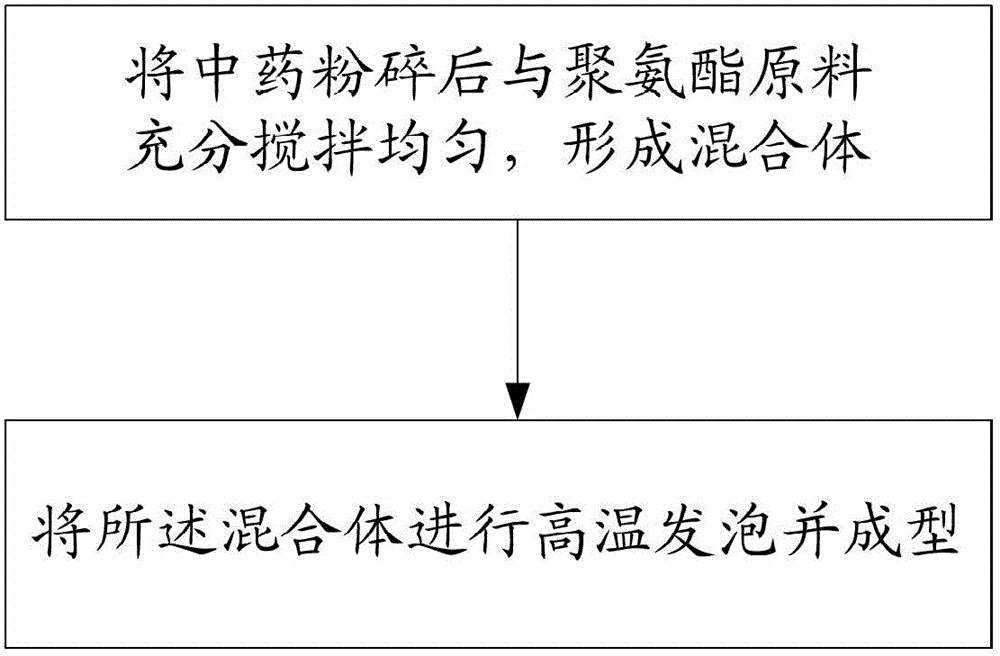

The invention discloses a Chinese herbal medicine deodorization antibacterial health insole which comprises a polyurethane traditional Chinese medicine layer; the polyurethane traditional Chinese medicine layer comprises polyurethane foam and traditional Chinese medicine which is scattered in the polyurethane foam, wherein all the components of the polyurethane foam are prepared by a polyurethane raw material high-temperature foaming technology; the polyurethane foam is of a bionic structure, has tens of thousands of ultrafine honeycomb pores which are open and communicated, is like natural breathable and permeable layers, has ultra-strong moisture absorption, permeation and general exhaust capability and can quickly absorb the sweat of feet which is perspired, so that the feet are kept dry and comfortable to the largest extent. Because of the moisture absorption and permeation capability, the functions of various Chinese herbal medicine can be fully played, and the foam can be permeated and integrated with various Chinese herbal medicine. Compared with the hardness of a Chinese herbal medicine cardboard pulp insole which is manufactured by paper pulp through a papermaking technology, the polyurethane foam is soft and lubricant, has good toughness and elasticity, and is more comfortable in wearing. The invention also discloses a manufacturing method of the Chinese herbal medicine deodorization antibacterial health insole.

Owner:林朝阳

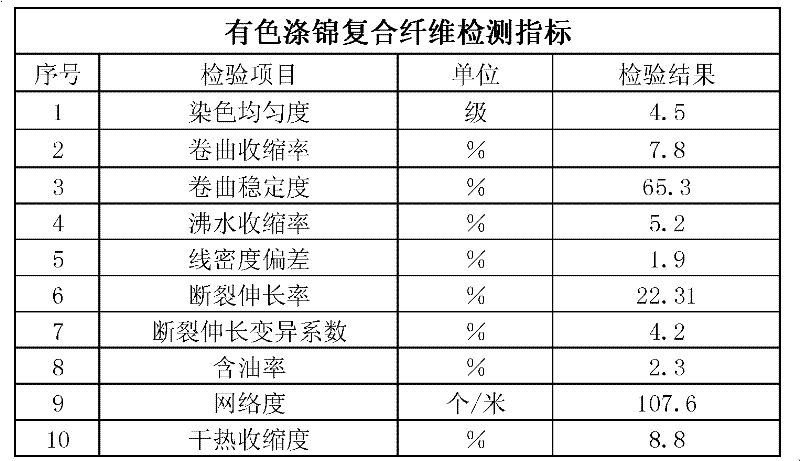

Jumping cloth for outdoor family leisure sports and preparation method thereof

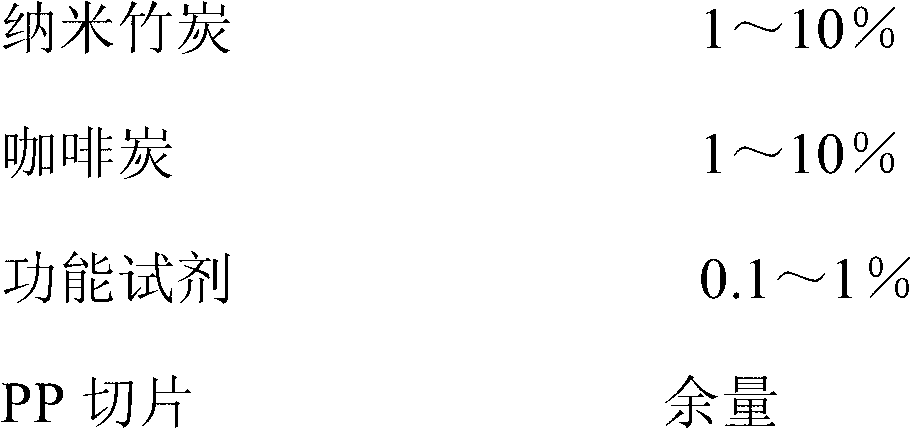

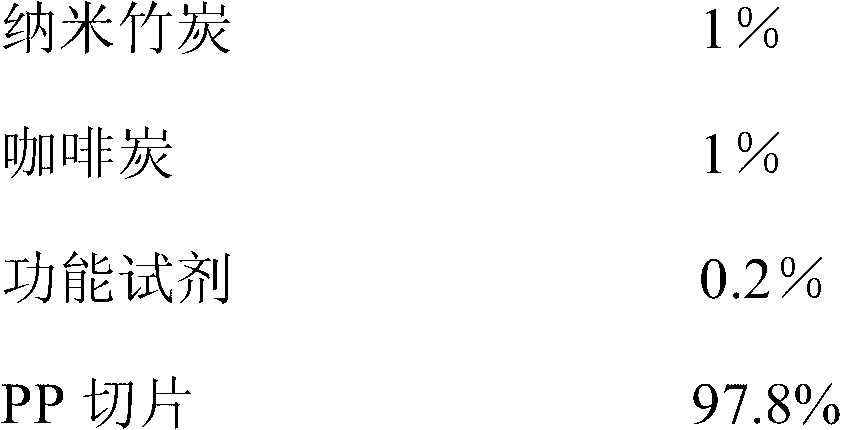

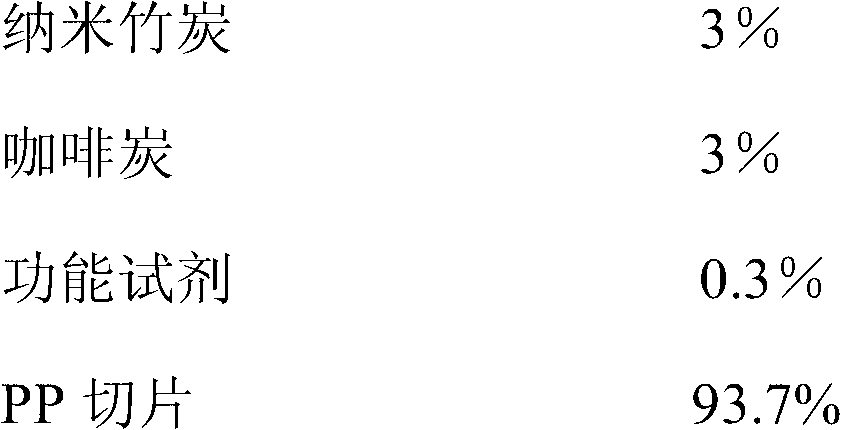

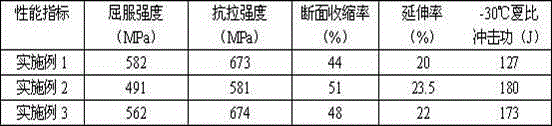

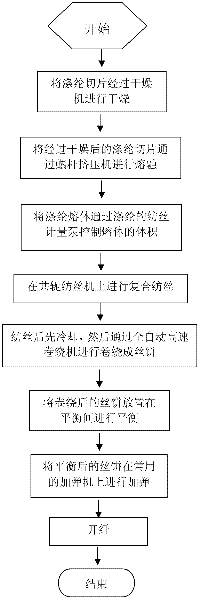

The invention relates to a jumping cloth for outdoor family leisure sports and a preparation method of the jumping cloth. The preparation method comprises the following steps: step (1) of preparing coffee carbon; step (2) of micronizing; step (3) of preparing nanoscale coffee carbon powder and nano bamboo charcoal powder containing function reagents; step (4) of preparing functional masterbatch; step (5) of blending and spinning, blending and spinning the functional masterbatch and polypropylene sections by a melting and spinning device to prepare anti-ultraviolet functional polypropylene silks, wherein the functional masterbatch accounts for 1-10% by mass of polypropylene fibers; and step (6) of weaving, weaving the anti-ultraviolet functional polypropylene silks to form yarns, thus weaving the jumping cloth by the yarns. The jumping cloth contains anti-ultraviolet agents and does not need additional anti-ultraviolet masterbatch so as to reduce the cost; products are environmental friendly and healthy and consistent with the social development trends.

Owner:江苏金陵网业有限公司 +1

Methods for preparing phosphorus pentafluoride gas and preparing lithium hexafluorophosphate using the gas

ActiveCN101353161BEasily hydrolyzedStrong moisture absorptionPhosphorus halides/oxyhalidesLithiumPhysical chemistry

A preparation method of phosphorus pentafluoride gas comprises a step of causing phosphorus pentachloride to react with anhydrous hydrogen fluoride, wherein, the reaction occurs in the presence of a solvent. A preparation method of lithium hexaflourophosphate comprises a contact reaction between solid lithium fluoride and phosphorus pentafluoride gas, wherein the phosphorus pentafluoride gas is prepared by the method of the invention. Compared with the preparation method of the lithium hexaflourophosphate with the phosphorus pentafluoride gas as the raw material in the prior art, the phosphorus pentafluoride gas prepared by the preparation method of the invention has higher purity and lower cost. The yield of the lithium hexaflourophosphate prepared by the method of the invention is higher than 93%, and the purity thereof is up to 99.95%.

Owner:BYD CO LTD

Flux core powder for manufacturing seamless self-shielded welding wire

ActiveCN103949795AArc stabilizationArc blowing force is largeWelding/cutting media/materialsSoldering mediaCopper platingRare earth

The invention relates to flux core powder for manufacturing a seamless self-shielded welding wire. The skin of the seamless self-shielded welding wire adopts a mild steel strip, and the flux core powder is synchronously added to the mild steel strip on line. 100 parts of flux core powder comprises the ingredients: 35-50 parts of barium lithium fluoride, 3-5 parts of magnesium fluoride, 0-4 parts of sodium fluoride, 1-3 parts of calcium fluoride, 4-12 parts of iron oxide red, 1-3 parts of rare earth fluoride, 4-8 parts of metal manganese, 10-18 parts of aluminium magnesium alloy, 6-10 parts of metal nickel, 0.5-2 parts of metal zirconium, and the balance of iron powder. All the materials are mixed and stirred uniformly according to a customary method, so that the flux core powder is obtained; the mild steel strip is curled to form a linear seamed cylinder by roller molding, and the linear seamed cylinder wraps the flux core powder; the linear seamed cylinder is manufactured into a semi-finished product seamless self-shielded welding wire by using high-frequency induction or contact bond; the semi-finished product seamless self-shielded welding wire is subjected to annealing and reducing, and is subjected to copper plating, and then the seamless self-shielded welding wire is prepared. In order to prevent the flux core power from absorbing moisture, the skin can be subjected to copper plating, and thus, the rust resistance of the seamless self-shielded welding wire is improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

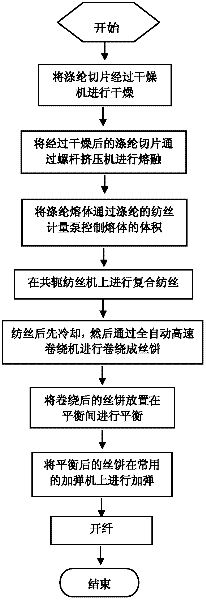

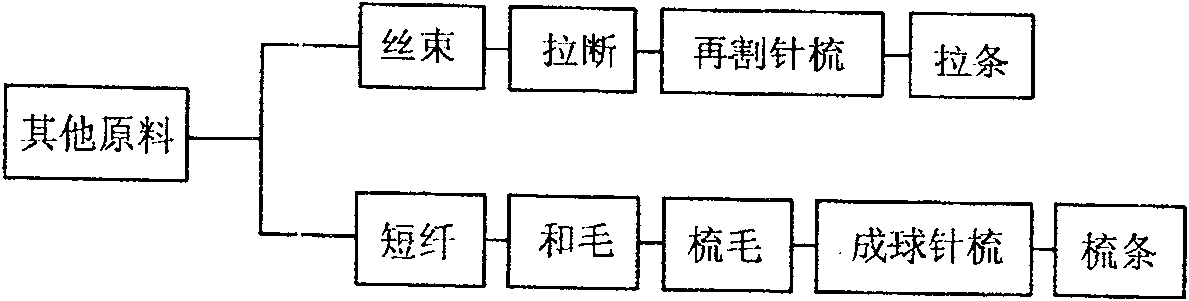

Method for manufacturing hollow micro-fine terylene denier fiber

ActiveCN102517719AHigh hollownessIncrease coverageHollow filament manufactureFilament/thread formingState of artFiber

The invention discloses a manufacturing process for a hollow micro-fine terylene denier fiber. The process is characterized by comprising the following steps of: a) preparing a raw material, i.e. sliced terylene; b) drying the sliced terylene through a cystallization dryer; c) injecting the dried sliced terylene into a screw extruder to be fused; d) controlling the volume of a melt through a spinning oil metering pump and a spinning metering pump; e) spinning on a spinning machine, and after spinning, coiling the silk into silk cakes through a fully-automatic high-speed coiler; f) balancing the silk cakes in a balance room to be balanced; and g) elasticizing the silk cakes on an elasticizer. Compared with the prior art, the process realizes the fiber of which the denier per filament is less than 0.5dpf.

Owner:NINGBO SANBANG MICROFIBER

Tussah spun silk textile as well as manufacturing method and application thereof

InactiveCN104695199AImprove insulation effectReduce weightBleaching apparatusAnimal fibresFiberPolymer science

The invention discloses a tussah spun silk textile as well as a tussah spun silk treatment technological method and application thereof. The method is characterized by comprising the steps of selecting tussah shell, refining by bleaching, refining, carrying out softening treatment, printing and dyeing, wetting by an auxiliary agent and spinning to obtain the tussah spun silk textile, wherein the tussah spun silk textile can be a cotton blend, hemp, wool or chemical fiber tussah spun silk textile. The tussah spun silk textile or tussah spun silk blended product manufactured by the method can be used for making clothes or ornaments; the produced clothes or ornaments have the advantages of being good in thermal insulation property, soft, smooth, light in weight, strong in moisture absorption performance, odor-resistant and sweat-resistant, and avoiding hair shedding; furthermore, tussah silk is formed by natural animal protein fiber and contains multiple amino acids needed by the human body, thus being capable of effectively improving the cell viability when being contacted with the skin, preventing skin aging, resisting bacteria and preventing diseases; therefore, the tussah silk is an ideal and natural health care product; furthermore, the treatment method of the tussah silk has the advantages of being advanced in technology, simple in operation and low in cost.

Owner:HAIMEN RUNSHENG TEXTILE

Producing and processing method for flue sheet material prepared by mixing straws

InactiveCN102674790AWith thermal insulationLubriciousSolid waste managementEcological environmentAdditional values

The invention provides a producing and processing method for flue sheet material prepared by mixing straws, and relates to flue sheet material for floor. The flue sheet material has the advantages of resisting fire and flaming, resisting moisture and mildew, and resisting insects and moth, and is good in waterproof property and high-temperature-resistant, is capable of being sawed and planed, is endurable, simple in production process, safe and convenient to operate, and high in production efficiency, thus being novel flue sheet material. Straws of rice and wheat are utilized as main raw material of the flue sheet, thus reducing pollution of burning the straws of rice and wheat to the environment, being low in cost, changing wastes into valuables, being high in additional value, lowering the manufacturing cost of the flue sheet, protecting the ecological environment, benefiting the country and people, and making contributions for creating economic and low-carbon society for China.

Owner:YANCHENG JINMA NEW ENVIRONMENT FRIENDLY BUILDING MATERIALS MFG

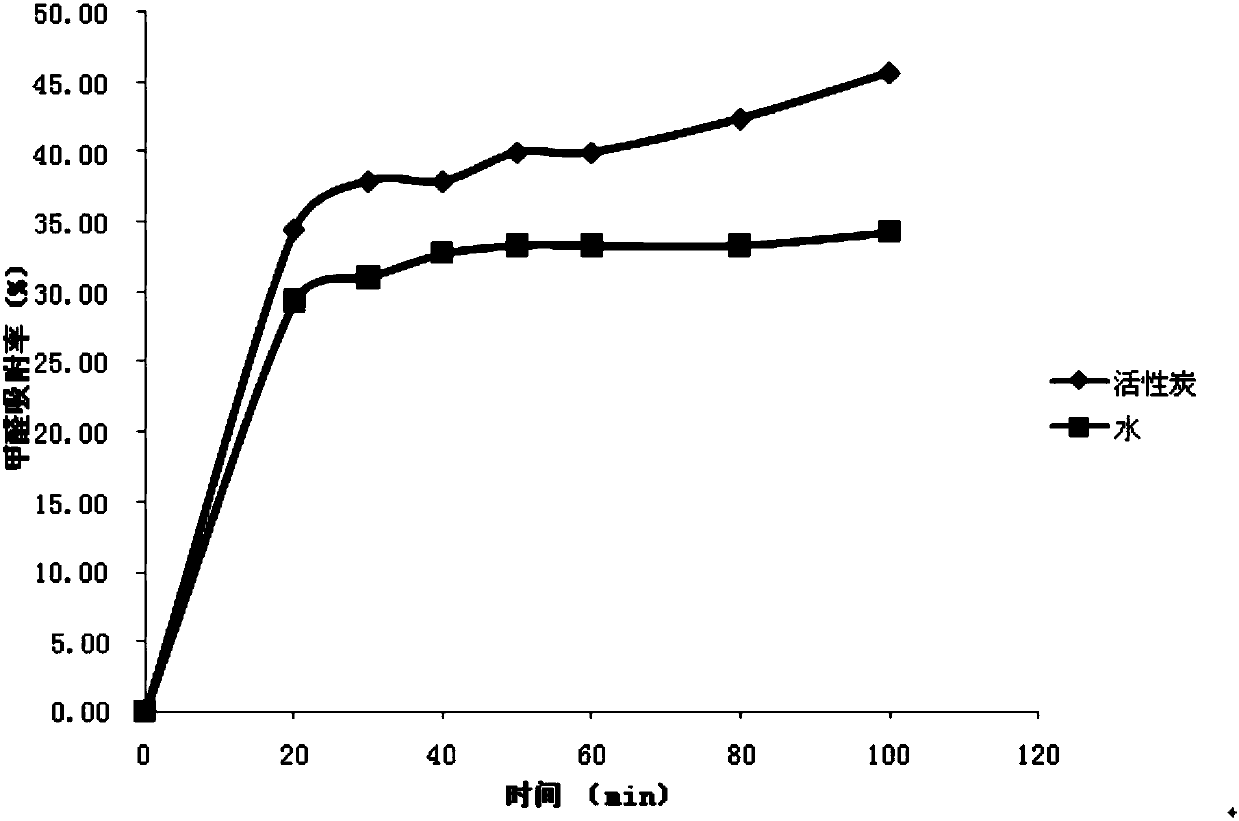

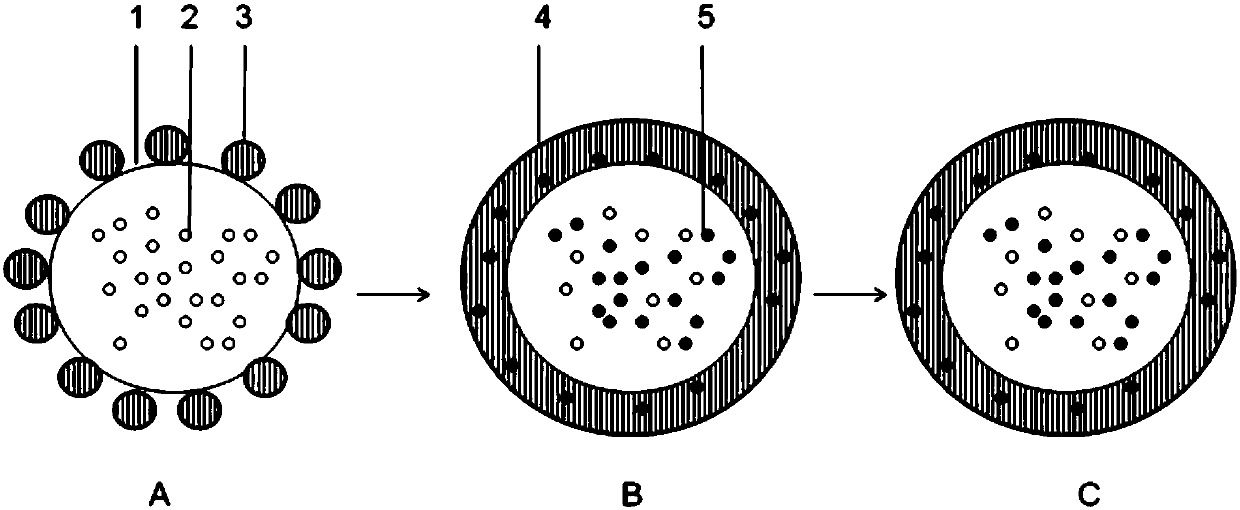

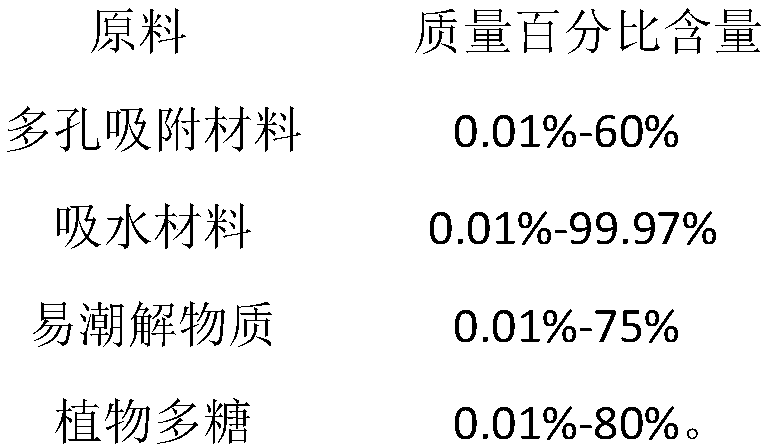

Moisture-absorbing smell-absorbing composite material, and preparation method thereof

ActiveCN107790111AStrong moisture absorptionWill not cause secondary pollutionGas treatmentOther chemical processesAdhesiveFluidized bed

The invention discloses a moisture-absorbing smell-absorbing composite material, and a preparation method thereof. The moisture-absorbing smell-absorbing composite material is prepared taking a porousadsorption material, a moisture-absorbing material, a deliquescent matter, and a plant polysaccharide as raw materials. The preparation method comprises following steps: the porous adsorption material, the moisture-absorbing material, the deliquescent matter, and the plant polysaccharide are uniformly mixed, are subjected to puffing under a certain pressure at a certain temperature, and then aresubjected to smashing, granulation, screening, and packaging; or an adhesive is added into the porous adsorption material for uniform stirring so as to obtain a wet porous adsorption material, in a fluidized bed, the moisture-absorbing material, the deliquescent matter, and the plant polysaccharide are sprayed onto the surface of the wet porous adsorption material, and then drying curing, smashing, screening, and packaging are carried out; or the porous adsorption material, the moisture-absorbing material, the deliquescent matter, and the plant polysaccharide are mixed, stirred to be uniform,and are subjected to smashing, screening, and packaging. The obtained moisture-absorbing smell-absorbing composite material is nontoxic, is excellent in moisture adsorption capacity, is capable of absorbing smell effectively; the preparation method is simple; operation is convenient; and production cost is low.

Owner:WUHAN LICHENG BIOTECH

Plant extracts for preventing eye from fatigue and their preparation and preparing method

InactiveCN1583011AQuality improvementEasy to makeSenses disorderPharmaceutical delivery mechanismBiotechnologyVitis vinifera

Owner:天津市壹杯红生物技术有限公司

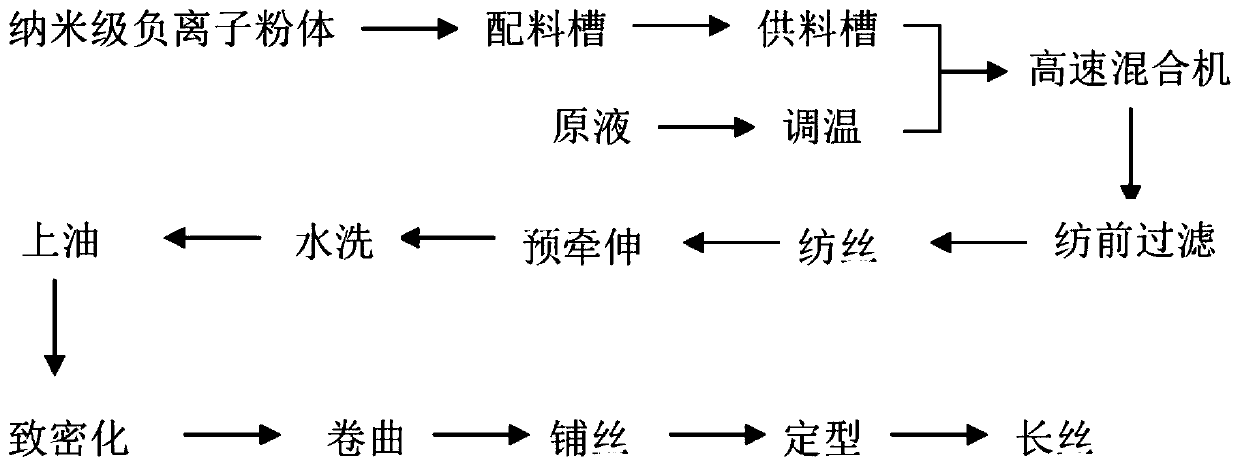

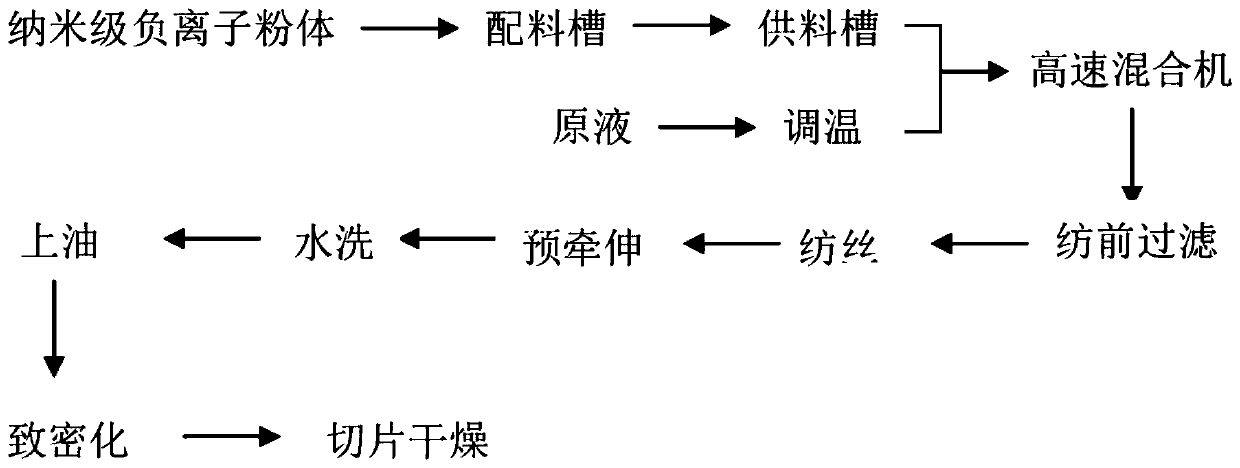

Weaving method and product of polyester and acrylic fiber anion fiber woven home textile fabric

InactiveCN110106621ACompatibility is reasonableLow costWarp knittingMonocomponent synthetic polymer artificial filamentPolyesterStock solution

The invention provides a weaving method and product of a polyester and acrylic fiber anion fiber woven home textile fabric. The method includes the steps of adding a acrylic fiber spinning stock solution to nanoscale anion powder with permanent spontaneous polarization to be evenly dispersed to prepare an anion acrylic fiber spinning stock solution, and weaving the acrylic fiber anion fiber home textile fabric from acrylic fiber anion fiber and polyester through spinning. The polyester is reasonable in ratio, high in spinnability and moderate in price and meets the market requirements; the advantages of being bright in color and luster, good in heat retention property and soft in handfeel of the acrylic fiber anion fiber can be given into full play; the fabric has the functions of emittingfar infrared rays and capable of realizing dehumidifying and drying; the fabric releases anions and is beneficial for body health; the fabric is high in mineral quality content and has a special healthcare function.

Owner:JIANGYIN XIANGFEI APPAREL +1

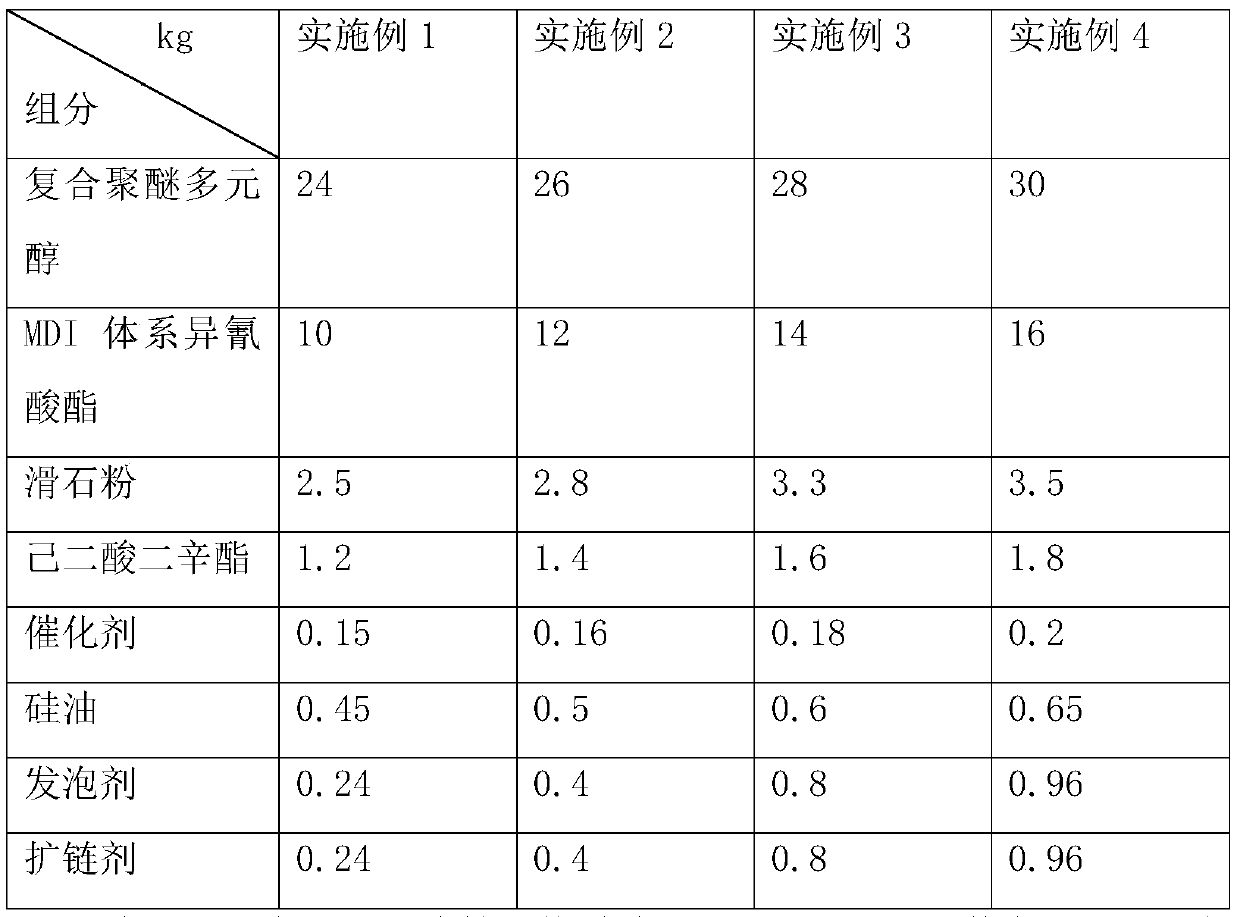

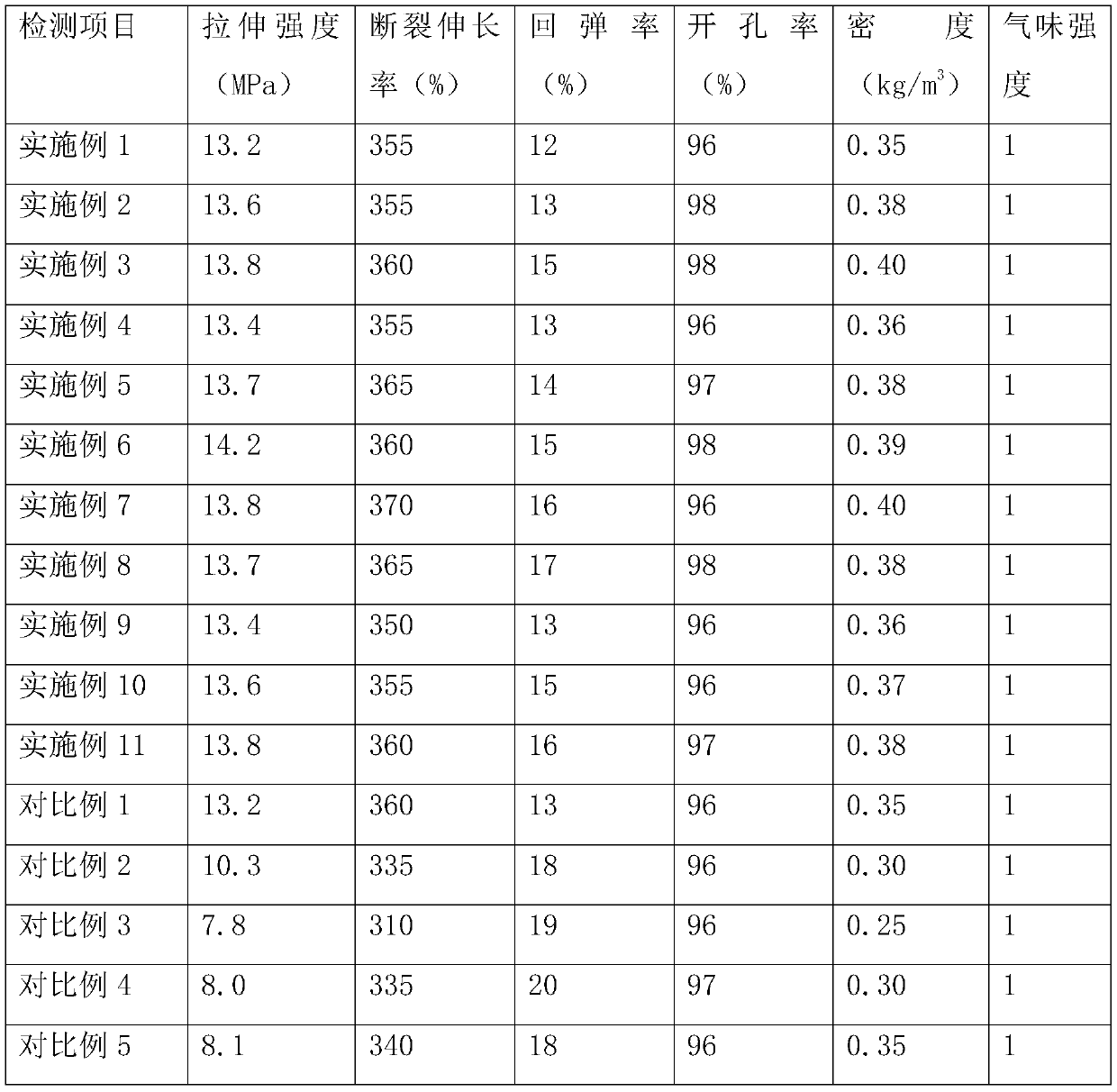

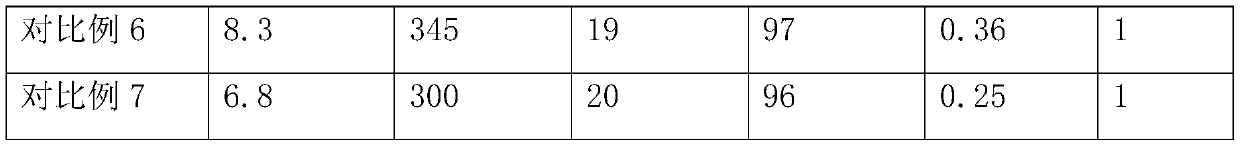

Slow-rebound polyurethane expanded foam and preparation method thereof

The invention discloses slow-rebound polyurethane expanded foam and a preparation method thereof. The slow-rebound polyurethane expanded foam comprises the following components: 24 to 30 parts of a composite polyether polyol, 10 to 16 parts of a MDI system isocyanate, 2.5 to 3.5 parts of talcum powder, 1.2 to 1.8 parts of dioctyl adipate, 0.15 to 0.20 part of a catalyst, 0.45 to 0.65 part of silicone oil, 0.24 to 0.96 part of a foaming agent and 0.24 to 0.96 part of a chain extender; wherein the composite polyether polyol is formed by mixing Polyol A, Polyol B and Polyol C, and the mass ratioof Polyol A to Polyol B to Polyol C is (6-8): (1-3): 1. The slow-rebound polyurethane expanded foam has the advantages of environmental protection, high air permeability, good heat dispersion performance, low temperature sensitivity and good slow-rebound effect at low temperature.

Owner:泉州玺堡家居科技有限公司

Foliar fertilizer for enhancing photosynthesis of flue-cured tobacco and preparation method for foliar fertilizer

InactiveCN107129381AIncrease contentPromote absorptionCalcareous fertilisersMagnesium fertilisersMinor elementPhotosynthetic enzymes

The invention discloses a foliar fertilizer for enhancing photosynthesis of flue-cured tobacco and a preparation method for the foliar fertilizer. The foliar fertilizer comprises nutritive substances and functional substances, wherein the nutritive substances comprise 31-50 parts by weight of potassium sulfate and 31-56 parts of potassium dihydrogen phosphate, and the functional substances comprise 5-10 parts by weight of organic acid, 5-10 parts of solid organosilicone surfactant, 2-3 parts of minor elements, 0.1-0.9 part of medium elements and 0.1-0.9 part of chelated rare earth. The foliar fertilizer for enhancing the photosynthesis of the flue-cured tobacco and the preparation method for the foliar fertilizer, provided by the invention, have the aims that the chlorophyll content, light energy absorption efficiency and photosynthetic enzyme activity are further improved, thus, the photosynthesis of the flue-cured tobacco is enhanced from a plant physiology aspect, the accumulation of carbon nitrogen metabolism and secondary metabolism products of tobacco plants is promoted, and the improvement on hierarchic structure and quality of tobacco leaves is facilitated.

Owner:云南五佳生物科技有限公司

Blended fabric of COOLMAX fiber, bamboo fiber and electroconductive fiber

InactiveCN102358978AMeet functional needsSolve the defects caused by the singleness of fibersWoven fabricsYarnFiberYarn

The invention discloses a blended fabric of COOLMAX fiber, bamboo fiber and electroconductive fiber. The blended fabric is formed by interweaving warp and weft, wherein both the warp and weft are selected from blended yarn of COOLMAX fiber, bamboo fiber and electroconductive fiber, and the warp and weft are in swansdown twill weaves. Because the selected blended yarn of COOLMAX fiber, bamboo fiber and electroconductive fiber has special ultra-strong and durable functions, the woven fabric has the functions and characteristics of ultra-strong moisture absorption, air permeation and sweat discharge properties (the drying rate of the fabric is 5 times of that of pure cotton), bacterial resistance, bacterial inhibition, odor prevention, ultraviolet resistance, wrinkle resistance, coolness, soft touch feeling, smoothness, static electricity resistance and the like, and is especially suitable for manufacturing military hats, police hats, travelling hats and working hats, or manufacturing sport underwear, knickers, shirts, bags and the like.

Owner:SHAOXING SHULILE TEXTILE PROD

Composite deodurizing shoe-pad

The present invention provides a composite type odor destroying shoe-pad. It includes lower layer of shoe-pad, upper layer of shoe-pad and bamboo charcoal granules layer between said lower layer of shoe-pad and upper layer of shoe-pad. Said shoe-pad has the functions of inhibiting fungal propagation, absorbing moisture, deodorizing and stopping itching, etc.

Owner:田华

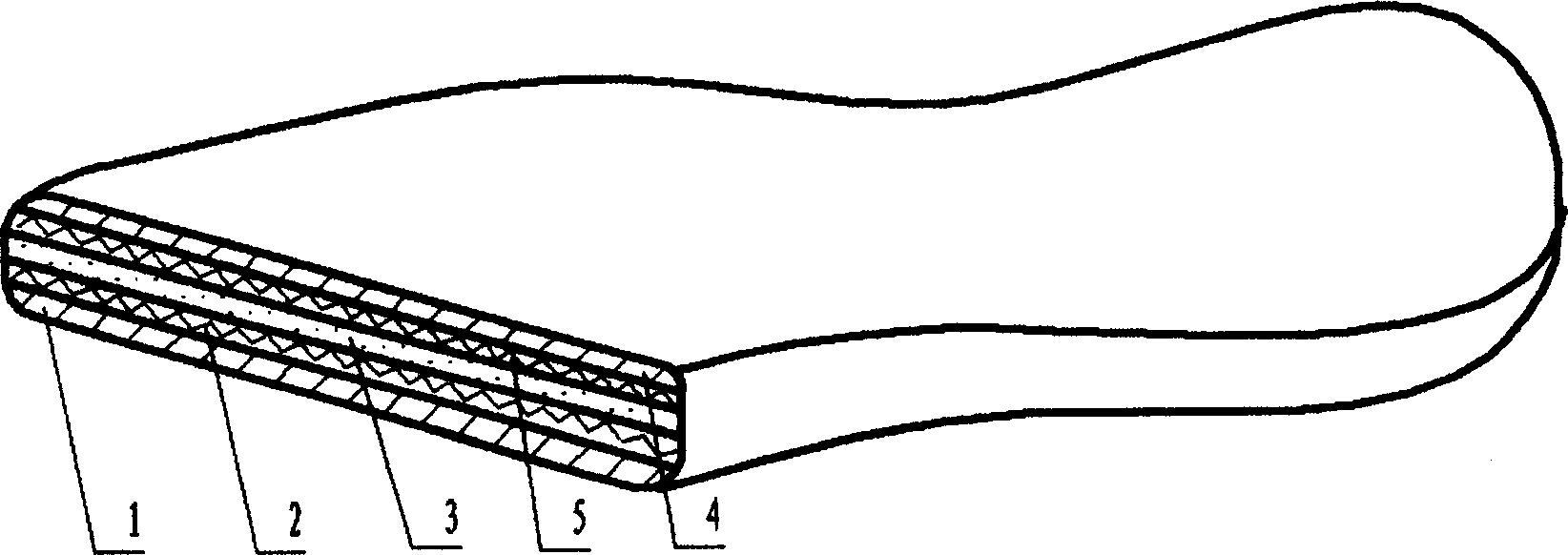

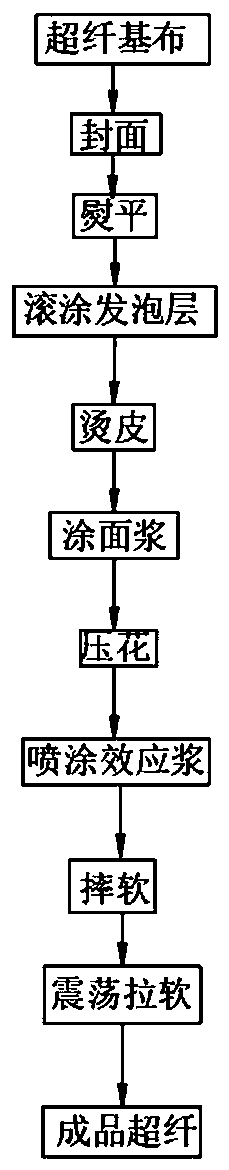

Water-based directly-coated microfiber sofa leather

InactiveCN110592956AOvercome body shape differencesOvercoming poor thickness uniformityTextiles and paperWater basedSpray coating

The invention belongs to the technical field of leather, and particularly discloses water-based directly-coated microfiber sofa leather, and a water-based directly-coated microfiber sofa leather production process. The water-based directly-coated microfiber sofa leather is prepared by preparing a microfiber base fabric and a cover, conducting ironing, roll-coating a foaming layer, conducting scalding, coating surface slurry, conducting embossing, spray-coating effect slurry, and conducting milling and oscillation staking to obtain the finished product (microfiber sofa leather). By means of microfiber gray cloth, the sofa leather has a microstructure similar to that of natural leather, overcomes the poor body form part and poor thickness uniformity of genuine leather, has super moisture absorption performance, and has the structure closer to that of genuine leather; in cooperation with the finishing of the genuine leather, the microfiber leather is more environmentally friendly, even has the texture of the genuine leather and has the unique moisture absorption performance and breathability, is higher in firmness and more durable in use, and even has performance on some aspects better than that of the genuine leather; in addition, the finishing process is close to the processing method of the genuine leather, and therefore the water-based directly-coated microfiber sofa leather has the appearance and the internal structure both close to those of the natural leather.

Owner:江苏优贝斯新材料科技有限公司

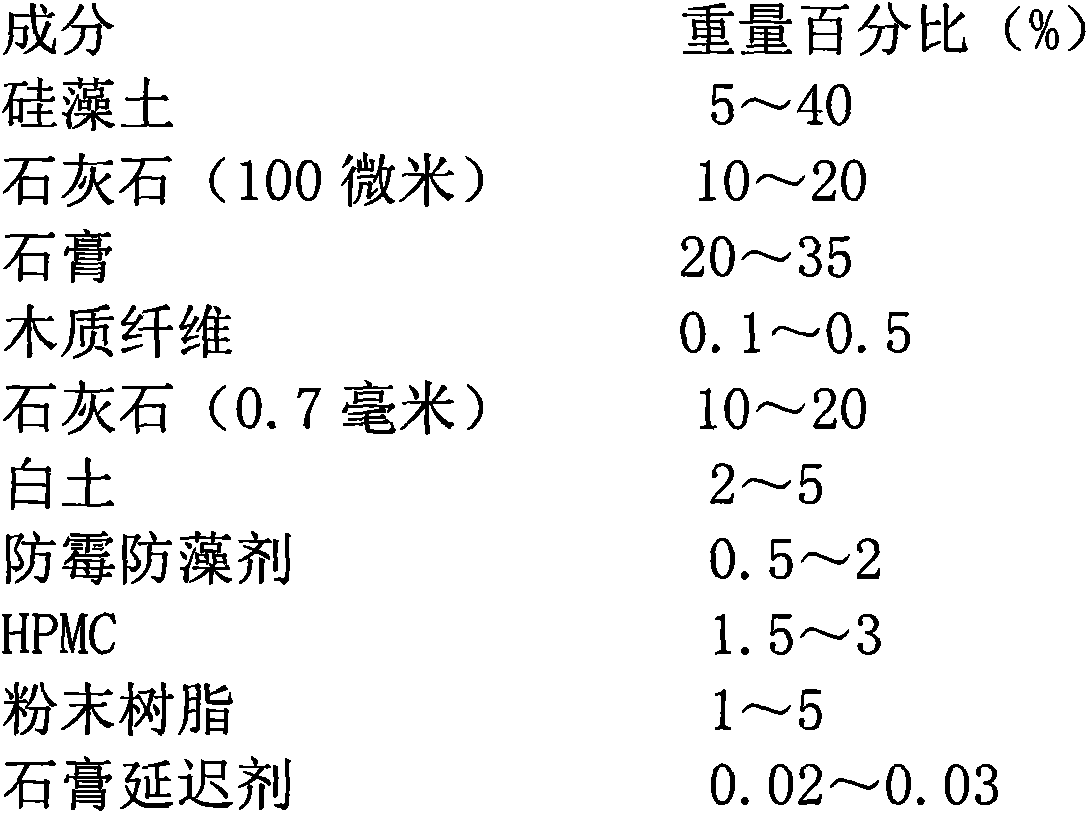

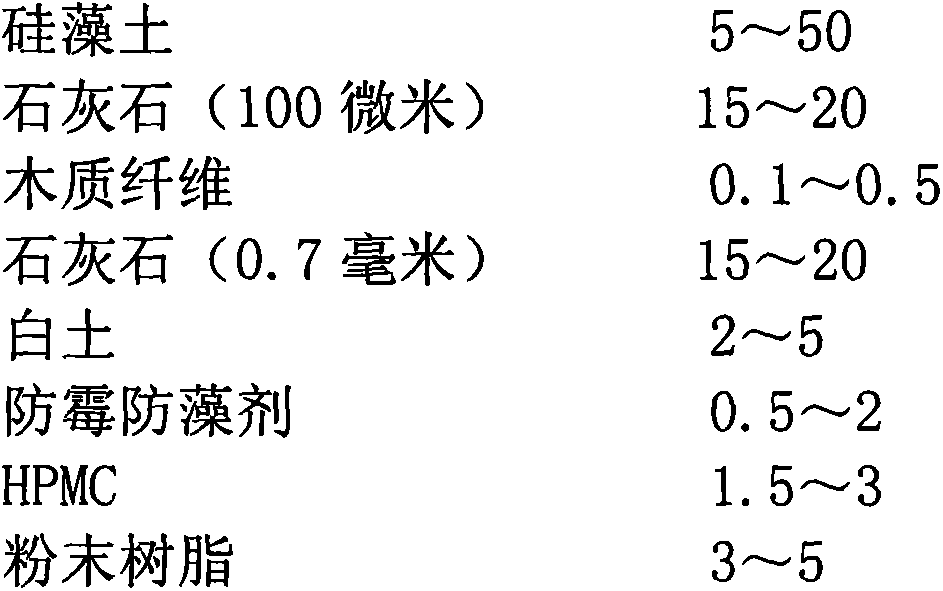

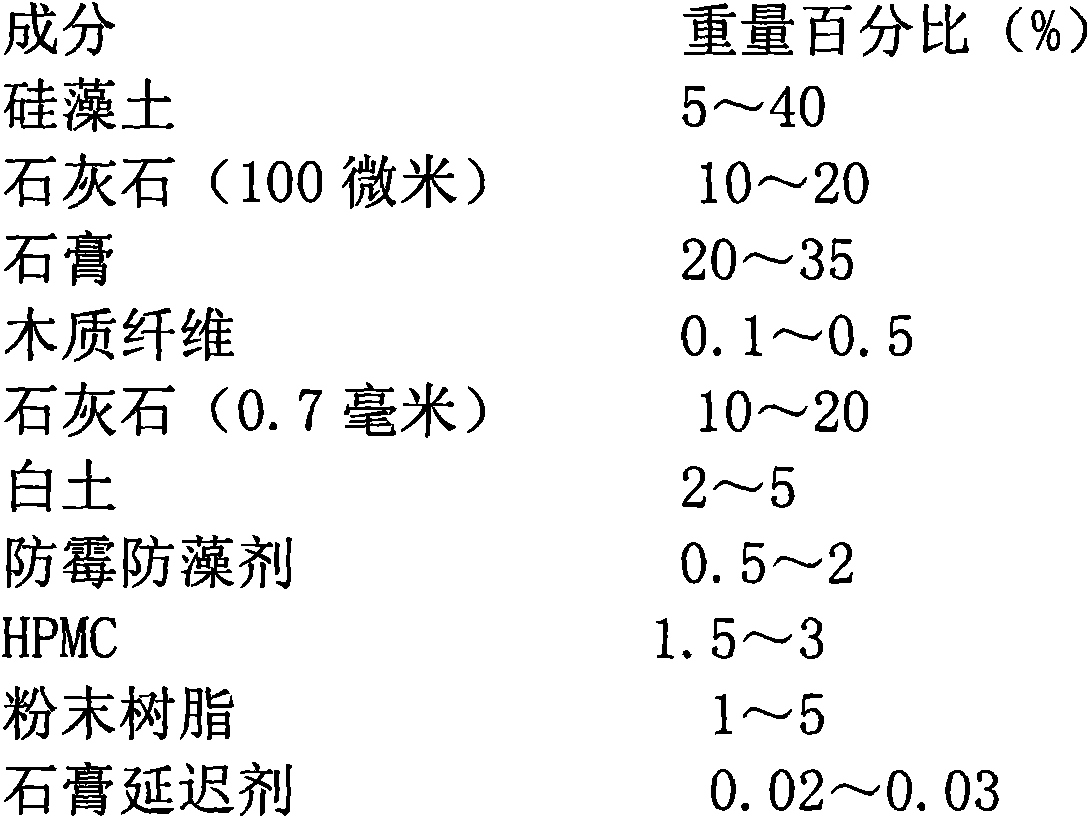

Substrate material capable of adjusting moisture and manufacturing method of substrate material

The invention discloses a substrate material capable of adjusting moisture and a manufacturing method thereof, and discloses a substrate material for painting indoor walls of buildings. The substrate material contains sintered and non-sintered diatomite ingredients and auxiliary materials, such as gypsum, limestone, wood fiber, carclazyte, anti-mildew algicide, hydroxypropyl methylcellulose and powdered resin, and the like. The method is simple and easy to implement. Since having reasonable material proportion, the substrate material has strong crack resistance, adhesion, abrasion resistance, moisture absorption and moisture releasability; the root cause is as follows: the diatomite is used as the main raw material; since the diatomite is porous and has big specific surface area, the diatomite can store moisture and has excellent moisture retention; the moisture can be released in dry condition. Since having wood fiber and powdered resin, and the like, the crack resistance and abrasion resistance are strengthened; the fastness of the substrate material to a wall surface is improved. Moist and mildew can be effectively avoided by adding the anti-mildew algicide, and thus indoor environment is more environment friendly. The substrate material capable of adjusting moisture is ideal, and solves the problems of the existing substrate material.

Owner:营口盼盼硅藻材料集团有限公司

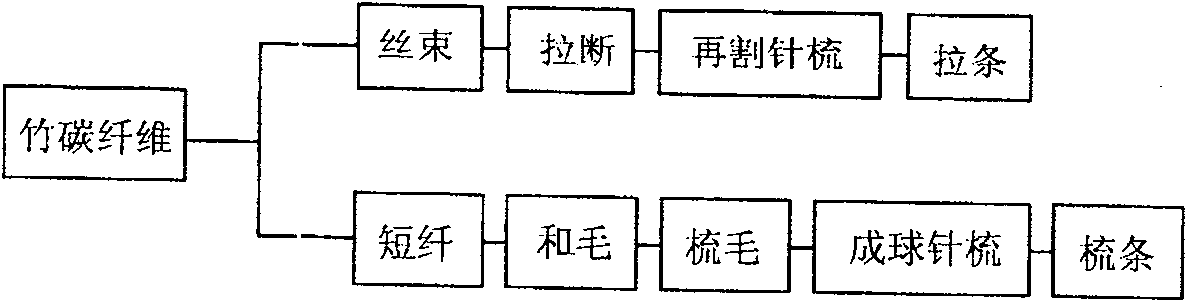

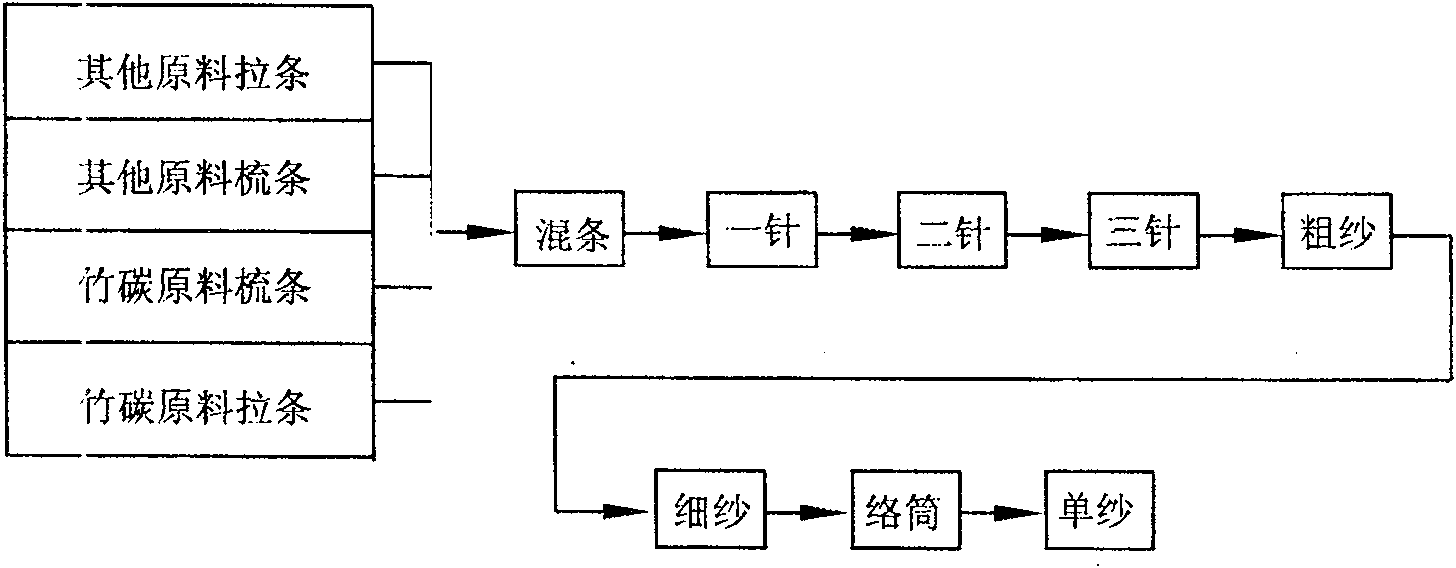

Bamboo carbon fiber blanket material and finished products thereof

InactiveCN100582341CStrong UV resistanceImprove adsorption capacityWeft knittingWarp knittingYarnCarbon fibers

The invention relates to woven bamboo charcoal fabric series woollen blankets using bamboo charcoal fabric and other components as raw materials. The material comprises following components by weight percentage: face yarns : bamboo charcoal fabric : 20%; other raw materials: 80%; bottom material: 100; wherein the other raw materials of the face yarn are one or several types selected from cotton, wool, real silk, chinlon, polypropylene, acrylic fibre, dacron and fabric; the bottom material is dacron; the material compatibility of the invented bamboo charcoal fabric woollen blanket is reasonable, and the invented bamboo charcoal fabric woollen blanket is provided with good weaving performance and moderate price, and accords with market demand; strong ultraviolet resistant ability and adsorption decomposition capacity of bamboo charcoal fibrous are utilized sufficiently; bamboo charcoal fabric raschel woollen blankets, acrylic bamboo charcoal fabric woollen blankets and coral fur bamboo charcoal fabric woollen blankets made by above materials are enriched of metallic elements such as potassium, magnesium, calcium, aluminum, zirconium, manganese and other carbides, have strong far-infrared ray emitting and negative ion emitting functions; and have strong moisture-guiding, moisture absorption, drying, deodor and bacteria inhibition functions.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Method for refining valid target of bitter gourd for dropping blood sugar

InactiveCN101181336AQuality improvementRaise the preparation levelMetabolism disorderPharmaceutical delivery mechanismOrganic solventBitter gourd

The invention belongs to the technical field of medicine and discloses a refining method of an effective part of bitter gourd for reducing blood sugar, comprising the steps that: (1) the bitter gourd medicine liquid is prepared before decoloring and refining: the decoction sheet of the bitter gourd is dried, crushed, extracted in an recycling manner by ethanol and concentrated to gain the extract; the extract is diluted, absorbed through big-pore absorbing resin column, washed, eluted with the ethanol solution to obtain the bitter gourd medicine liquid before decoloring and refining; (2) a refining process is carried out: the ethanol eluting solution of the resin column is collected and a discoloring agent is added , the mixing solution is heated and recycled, filtered, concentrated after reducing the pressure, dried in vacuum to obtain the steroidal glucoside of the bitter gourd. The steroidal glucoside of the bitter gourd extracted by the method of the invention can be directly made into various preparations, such as troche, capsule, grain, oral liquid, tablet, suspension, pill, cataplasma and paste, etc. Compared with the traditional technique, the invention is characterized by small volume, strong resistance against moisture and high content of the effective component. Compared with a solvent extracting method, the invention does not use organic toxic solvent which volatilizes easily in the technological flow, thus, the invention has safe and reliable operation, low production cost and no pollution to the environment.

Owner:SHENYANG PHARMA UNIVERSITY

Flux for heat resistant magnesium alloy

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

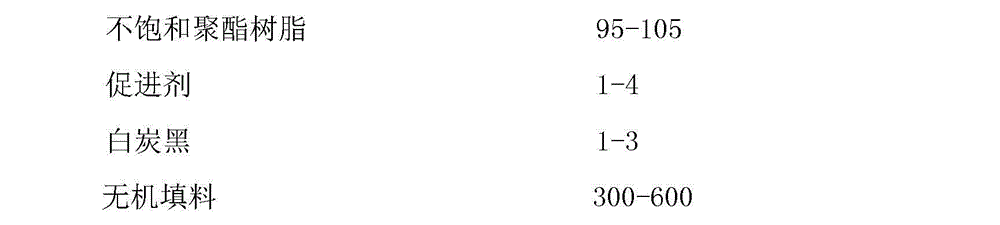

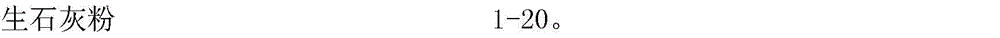

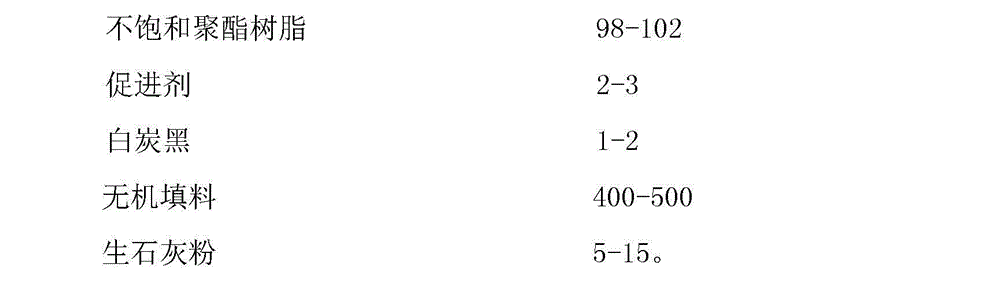

Resin anchoring agent

The invention discloses a resin anchoring agent which comprises raw materials by weight parts: 95 to 105 parts of unsaturated polyester resin, 1 to 4 parts of a promoter, 1 to 3 parts of white carbon black, 300 to 600 parts of inorganic filling materials and 1 to 20 parts of quicklime powder. The resin anchoring agent is added with the quicklime which is strong in moisture absorption capacity, and can absorb excess resin in clay and effectively prevent the resin from flowing out of two ends of the anchoring agent. The resin anchoring agent prepared by the formula can effectively prevent occurrence of glue flowing phenomena, and does not influence performance indicators of anchoring agent industry standards of MT146.1-2011.

Owner:美亚高新材料股份有限公司

Comprehensive high and low frequency radiation protective clothing fabric and preparation process thereof

ActiveCN109291567AGood radiation protectionGood absorption and shielding effectProtective equipmentSynthetic resin layered productsPolyesterCellulose acetate

The invention provides a comprehensive high and low frequency radiation protective clothing fabric and a preparation process thereof. Protective clothing comprises a lining, a double-radiation protection layer and an anti-bacterial surface layer arranged from inside to outside in turn. The double-radiation protection layer is composed of an inner nonmetal composite fiber layer and an outer metal composite fiber layer which are hot-pressed and fixedly connected by a hot melt adhesive film, the inner nonmetal composite fiber layer is a modified cotton fiber / polyester fiber / cellulose acetate composite fabric, and the outer metal composite fiber layer is a doped modified polyester fiber-metal fiber composite fabric. The prepared protective clothing has excellent radiation protection performance, good absorption and shielding effects for low-frequency and high-frequency radiation, strong protection, excellent mechanical properties, good antibacterial property and high wearing comfort through rational arrangement of multi-layer functional fabric raw materials and setting of textile parameters.

Owner:山东双鹰医疗器械有限公司

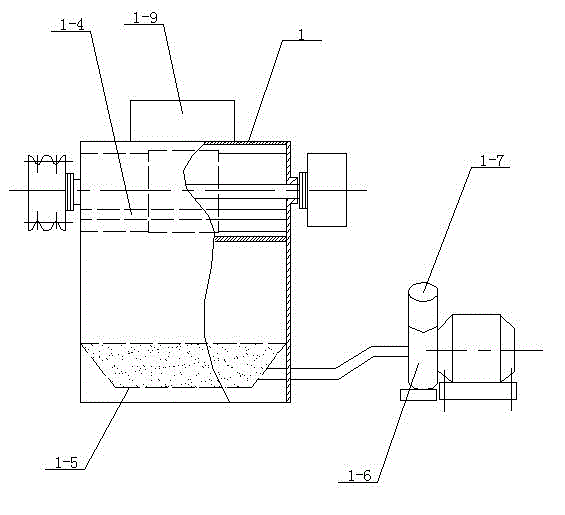

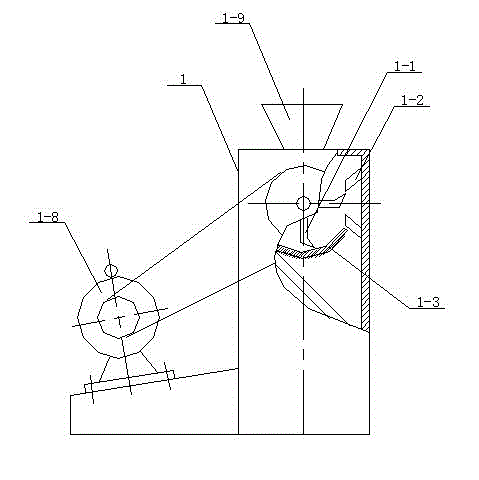

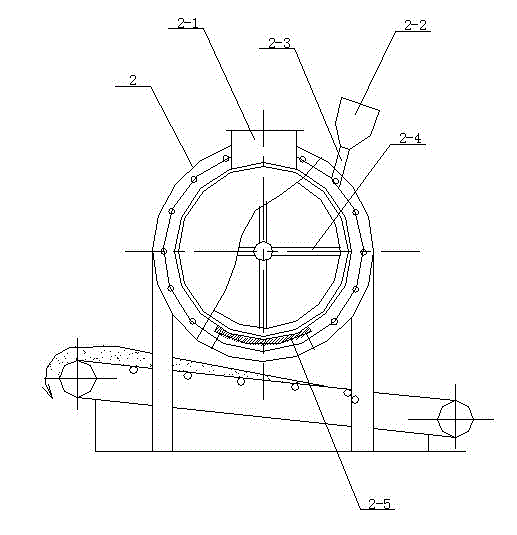

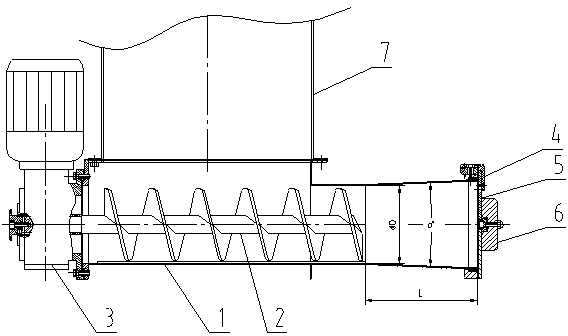

Vertical regenerated cotton device and production technology

InactiveCN102912462ASimple structureEasy to operateArtificial thread manufacturing machinesFilament/thread formingRaw materialPolyurethane

The invention discloses a vertical regenerated cotton device and a production technology, and relates to the field of regenerated cotton production methods. The technology comprises the following steps: (e), discharging mixed and foamed waste polyurethane mixture into a reaction die machine, and compressing in the reaction die machine (3) in a mechanical manner; (f), passing the compressed waste polyurethane mixture through steam so as to molding immediately; (g), stripping molded finished product from a die; and (h), cutting the stripped finished product by a circle cutting machine to obtain a product. The device is simple in structure and convenient to operate, consumes less raw material, lowers the cost, and can realize rapid molding and cutting by using special polyurethane and performing steam heating; and moreover, the produced product has higher ventilation property, higher antibacterial property, higher moisture absorption property and high elasticity.

Owner:曾维民

Formaldehyde-absorbing and dehumidifying granules

InactiveCN106310917AStrong moisture absorptionAlso has bactericidal effectGas treatmentDispersed particle separationHazardous substanceCarbide

The invention discloses formaldehyde-absorbing and dehumidifying granules. The granules are prepared from the following components in parts by weight: 45-50 parts of bamboo charcoal powder, 25-35 parts of nano titanium dioxide, 15-20 parts of soybean straw carbide powder, 15-23 parts of traditional Chinese medicine powder particles, 10-18 parts of diatom powder and 19-28 parts of calcium oxide. The granules have very strong effects of absorbing moisture and absorbing harmful substances such as formaldehyde, benzene series and sulfur dioxide. Furthermore, the Chinese herbal medicine is capable of neutralizing the formaldehyde and peculiar smell so as to remove same, thus achieving the effect of removing the formaldehyde and the peculiar smell; furthermore, the formaldehyde-absorbing and dehumidifying granules also have a sterilizing effect.

Owner:宁贻伟

Attapulgite clay drying agent dedicated to automobile-used braking gas circuit

InactiveCN105289467AImprove performanceLow costOther chemical processesDispersed particle separationEngineeringCalcination

An attapulgite clay drying agent dedicated to an automobile-used braking gas circuit is prepared according to the following steps: first, ore dressing, drying and grinding; next, compounding according to a proportion; then, pelletizing; finally, carrying out calcination and activization to obtain a finished product, and packaging.

Owner:蒋寿悟

Resin adsorption technology for extracting oligopyrrolidine carboxylic acid from ficus carica

InactiveCN109806295AQuality improvementRaise the preparation levelOrganic active ingredientsSenses disorderCatechinic acidFicus erecta

The invention provides a resin adsorption technology for extracting oligopyrrolidine carboxylic acid from ficus carica. A key point of a primary technology thereof is that content of an effective partof ficus carica seeds prepared by a ficus carica waste residue (ficus carica seeds, ficus carica peels and ficus carica stems or a mixture thereof) reaches 50% or more, wherein content of monomer effective component catechinic acid is within a range of 0.5-20% and the monomer effective component catechinic acid is used as a raw material for preparing a preparation. The technology is capable of preparing the preparation by using the effective part of the ficus carica seeds obtained by using the ficus carica waste residue as the raw material, wherein cost is low, and the technology is simple and rational, keeping an original structure and activity of the effective part, wherein an extract of the ficus carica seeds can be prepared as any medical and health-care product drug forms for preventing and treating eyestrain, and the technology is applied to the medical treatment and health-care fields of preventing and treating the eyestrain.

Owner:雷萌

Deodorization toilet lid and production method thereof

The invention discloses a deodorization toilet lid and a production method thereof. The deodorization toilet lid is characterized by containing the following components in parts by weight: 40-60 parts of urea resin, 6-14 parts of a curing agent, 1.2-3.5 parts of a coupling agent, 3-4.3 parts of a water absorbent, 2-3.6 parts of an accelerant, 1-2.3 parts of a reinforcing agent and 2.4-4.4 parts of white charcoal. The deodorization toilet lid has the beneficial effects that the automatic deodorization can be realized, and the air quality in a toilet is improved.

Owner:ZHEJIANG HENGYUAN SANITARY WARE

High elastic thermal fabric and processing technology thereof

InactiveCN108754769AIncrease elasticityImprove wear resistanceWoven fabricsYarnPolyesterCuprammonium rayon

The invention discloses high elastic thermal fabric interwoven together by warp and weft. The high elastic thermal fabric is characterized in that the warp is made of cuprammonium rayon, polyacrylonitrile fiber and polyester fiber which conduct blended weaving; the weft is made of polyacrylonitrile fiber and cuprammonium rayon which conduct blended weaving; the blending ratio of the cuprammonium rayon, polyacrylonitrile fiber and polyester fiber in the warp is 2: 3: 1; the blending ratio of the polyacrylonitrile fiber and cuprammonium rayon in the weft is 2: 1. The disclosed high elastic thermal fabric has the advantages of having soft touch, high elasticity, silk feeling, strong moisture absorption and dehumidification, high wear resistance, refreshing anti-static property and high warmthretention.

Owner:NANTONG ZHONGRUN TEXTILE PRINTING & DYEING CO LTD

Tea biomass composite material and preparation method and application thereof

The invention discloses a tea biomass composite material and a preparation method and application thereof. The tea biomass composite material is prepared from the following raw materials in parts by weight: 60 to 70 parts of tea biomass, 20 to 50 parts of wood meal, 12 to 30 parts of straw powder, 2 to 5 parts of compatilizer, 0.2 to 1.5 parts of lubricant, 2 to 3 parts of coloring agent, 0.1 to 3 parts of antioxidant and 0.1 to 3 parts of stabilizer. The preparation method comprises the following steps of weighing the raw materials according to requirements; soaking the tea biomass for 20 to 48h at the temperature of 60 to 80 DEG C, cleaning, airing, and crushing to 10 to 20 meshes for further use; mixing the tea biomass treated in step 2 and the wood meal, the straw powder, the compatilizer, the lubricant, the coloring agent, the antioxidant and the stabilizer, uniformly stirring, and feeding into a granulating machine for granulating at the temperature of 60 to 118 DEG C, so as to obtain a master batch; feeding the master batch into an extruding machine, and extruding, so as to obtain the tea biomass composite material. The tea biomass composite material has the advantages that the mechanical property is good, the sterilizing and bacteria-inhibiting ability is strong, the moisture absorbing ability is realized, and the tea biomass composite material is suitable for serving as an outdoor floor and furniture material.

Owner:ZUNYI MEDICAL UNIVERSITY

Blocking-prevention dust compactor

InactiveCN103316552AGuaranteed tightnessNot easy to flyDispersed particle filtrationEngineeringSpeed reduction

Owner:JIANGSU JINGYA ENVIRONMENT TECH

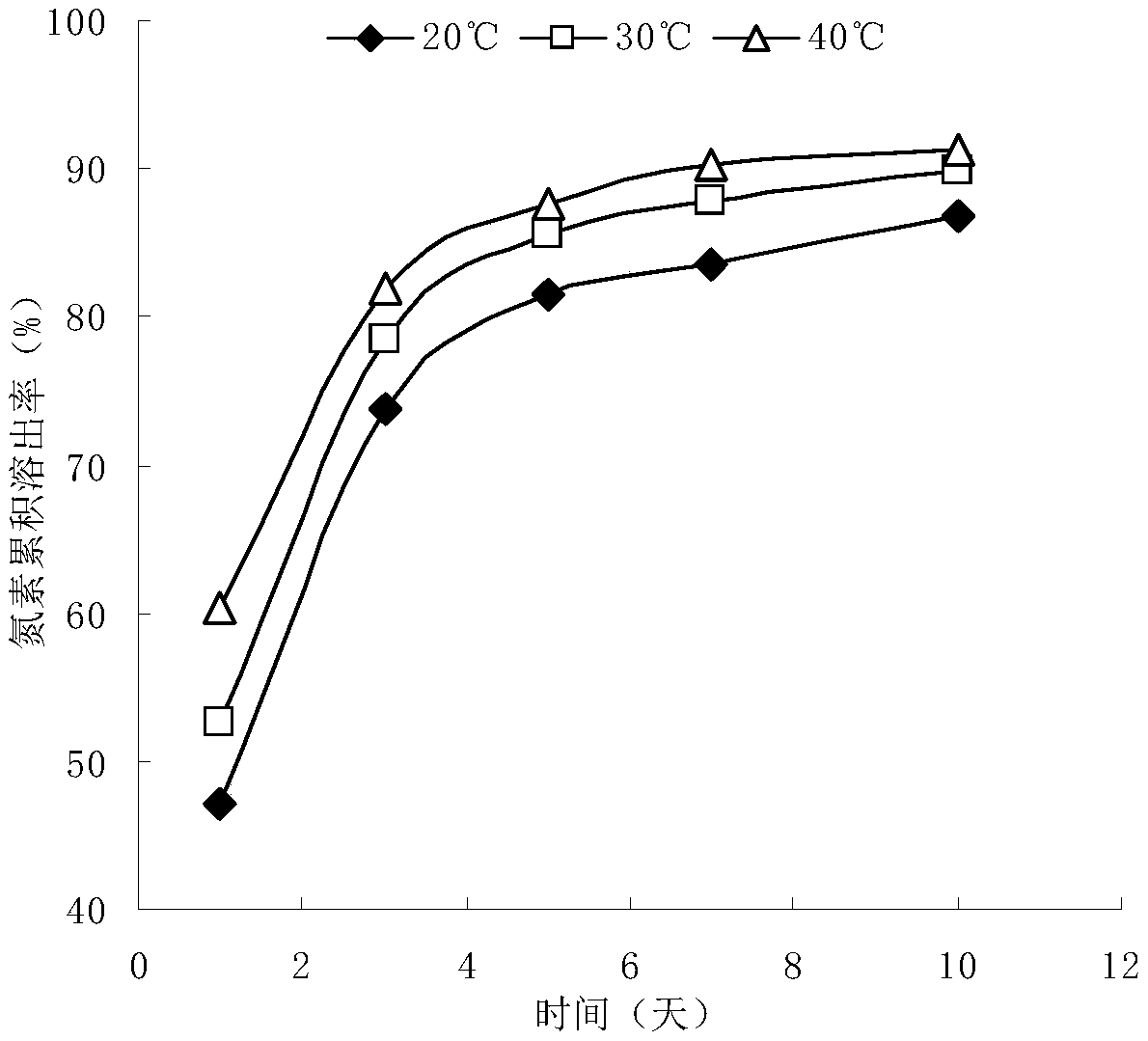

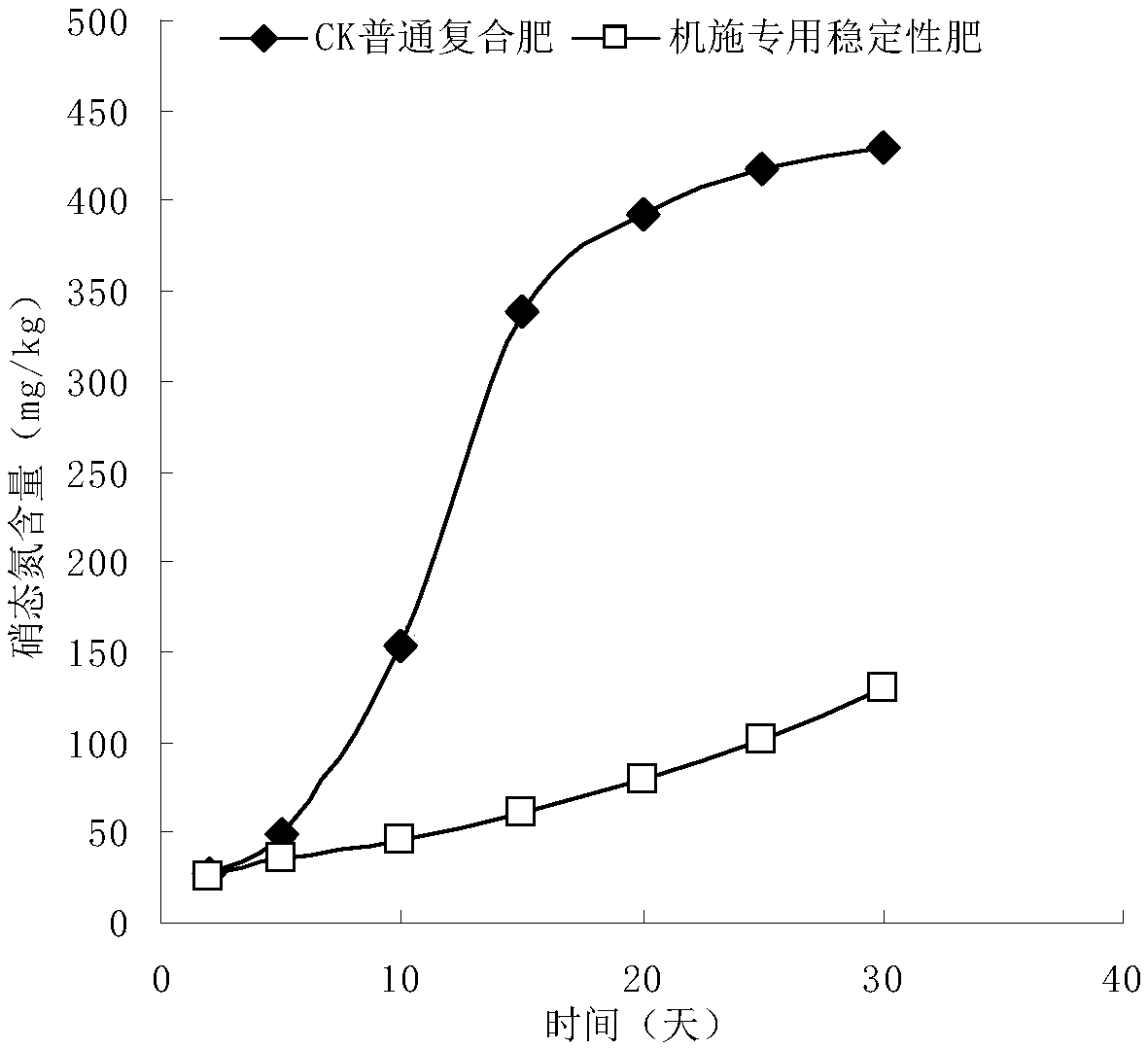

Stabilized fertilizer and preparation method thereof

InactiveCN109456121AThe composition formula is reasonableAchieve long-lasting sustained-release effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphatePotassium

The invention provides a stabilized fertilizer and a preparation method thereof. The stabilized fertilizer disclosed by the invention comprises fertilizer inner core particles and external coating film materials coating the outer surfaces of the fertilizer inner core particles; a material of the fertilizer inner core particles comprises the following raw materials in parts by weight: 35 to 50 parts of urea, 30 to 40 parts of potassium chloride, 10 to 25 parts of monoammonium phosphate, 1.0 to 2.0 parts of cyanoguanidine, 2.0 to 4.0 parts of humic acid powder and 2.5 to 8.0 parts of attapulgite; the external coating film materials comprise kaolin layers attached to the outer surfaces of the fertilizer inner core particles, paraffin layers attached to the outer surfaces of the kaolin layersand talcum powder layers attached to the outer surfaces of the paraffin layers. The stabilized fertilizer provided by the invention is applicable to implement synchronous carryout of rice transplanting and fertilization in a synchronous rice transplanting and fertilizing machine, and has the advantages of a high nutrient utilization rate, low cost, smooth surfaces of the fertilizer particles, difficulty in breakage, difficulty in moisture absorption, no caking and the like.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com