Patents

Literature

556 results about "Acrylic fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic Fiber. Acrylic fiber is a synthetic fiber that closely resembles wool in its character. According to the definition of the ISO (International Standards Organization) and BISFA (International Synthetic Fiber Standardization Office), fibers which contain a minimum of 85% acrylonitrile in their chemical structure are called "Acrylic Fibers".

Process for manufacturing antimicrobial conductive acrylic fibre fibre

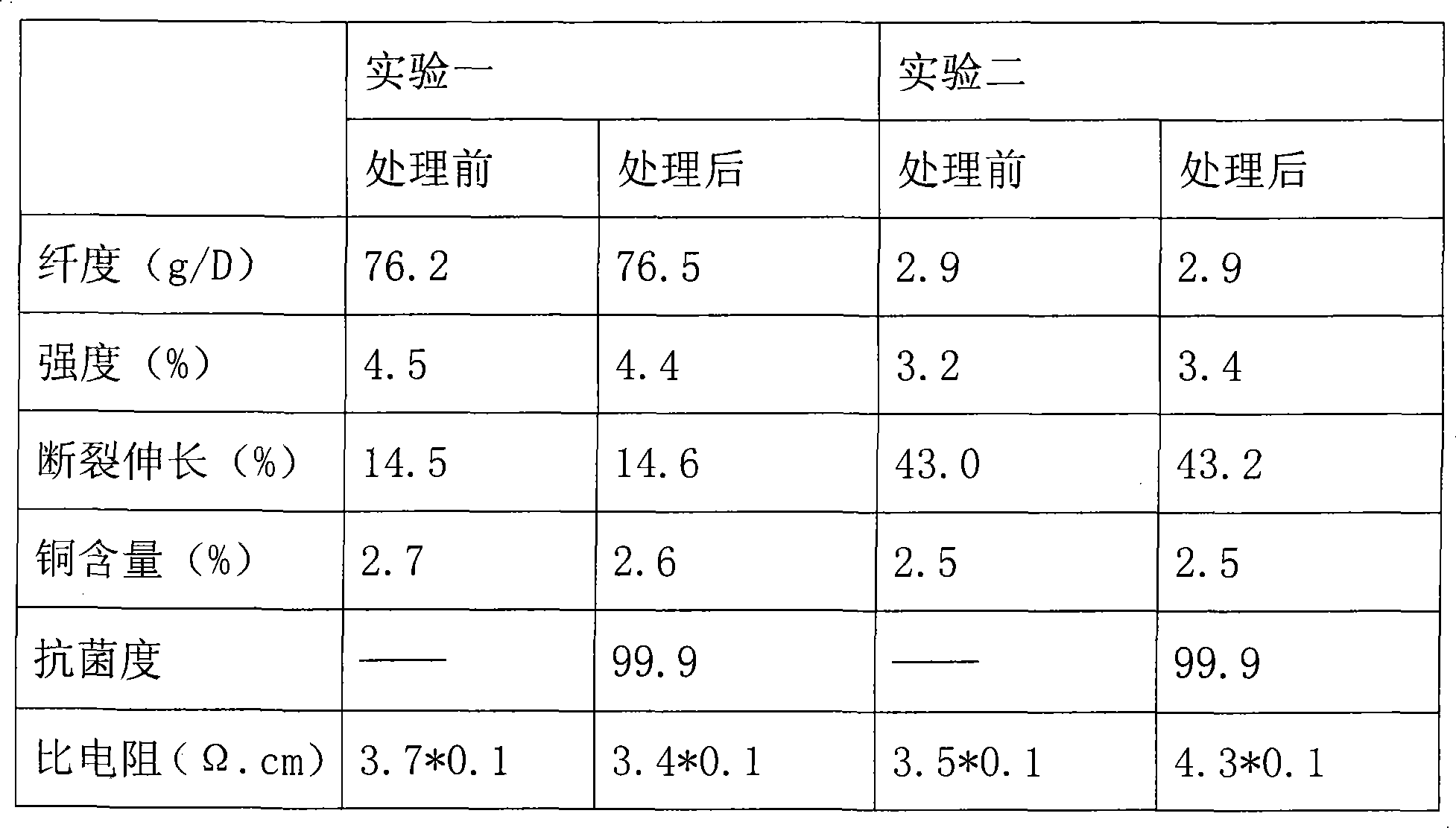

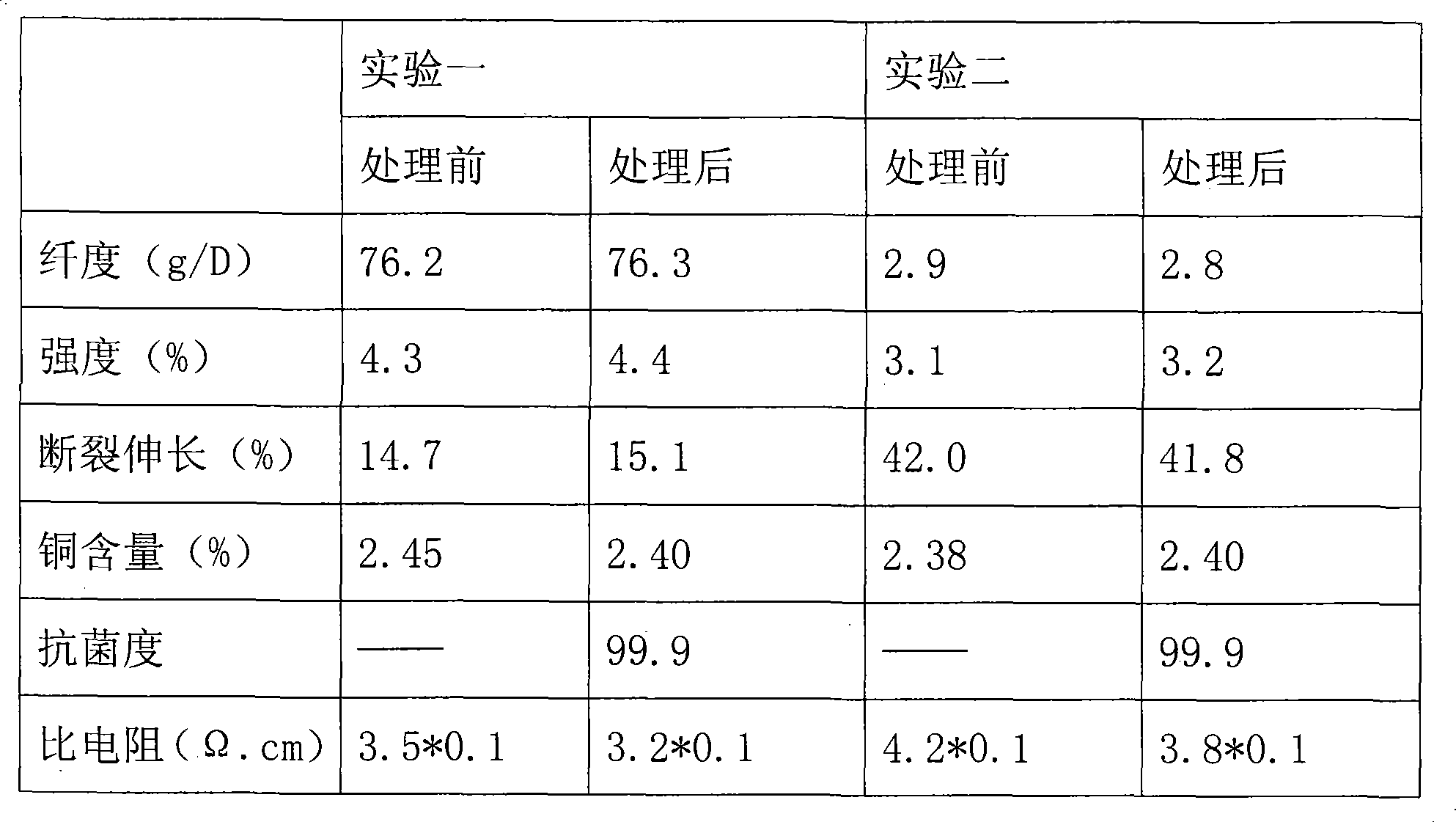

The invention belongs to a manufacture method of an antibacterial conductive acrylic fiber, which is characterized by being composed of the following steps: (1) arranging the acrylic fiber into a reaction vessel, then pouring a solvent into the reaction vessel, dissolving copper salt containing Cu<2+> into the solvent, adjusting the pH valve of the solution to be between 1.5 to 3.0, then adding a reducer and heating, maintaining the temperature of the solution to be between 90 to 100 DEG C, carrying out reduction on the Cu<2+> by utilizing the reducer to generate Cu<+> and lead the Cu<+> to be absorbed on the acrylic fiber; (2) adjusting the pH value of the solution to be between 1.5 to 3.0 and then maintaining the temperature of the solution to be between 40 to 120 DEG C, adding salt containing sulfur atoms and leading a great amount of Cu<+> to be oxidized to generate the Cu<2+> after the reaction time lasts 2 to 4 hours; thereby generating a sulfide of copper that is not easy to be dissolved in the solvent to lead the sulfide of copper to be sufficiently and uniformly dispersed on the surface of the whole fiber. The copper sulphide in the acrylic fiber manufactured by utilizing the method is dispersed on the surface of the whole fiber. The self physical and chemical characteristics of the copper sulphide lead the fiber to have excellent antibacterial property and conductibility; the copper sulphide on the fiber surface is not easy to fall off and has excellent anti-washing property.

Owner:金素娟

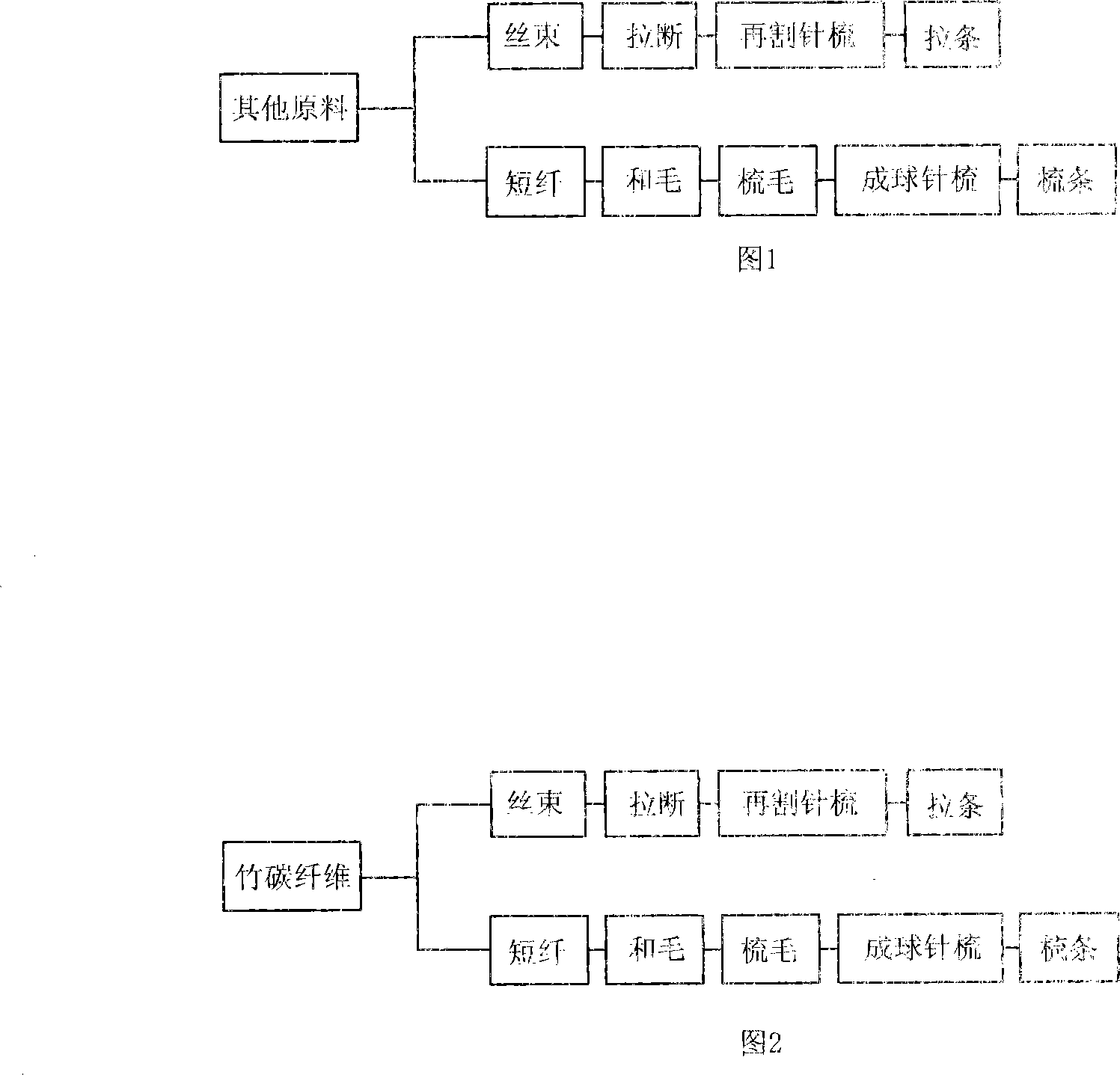

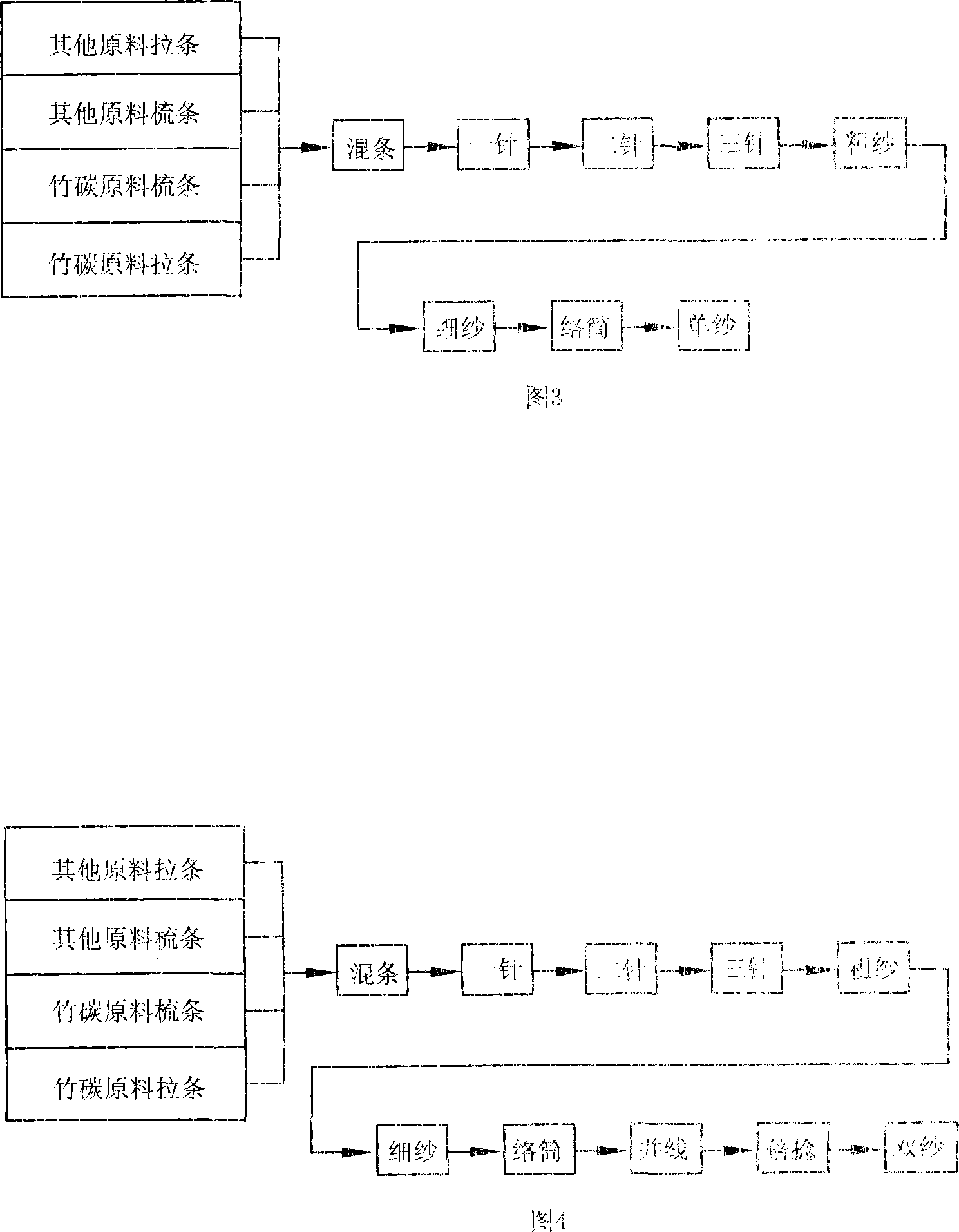

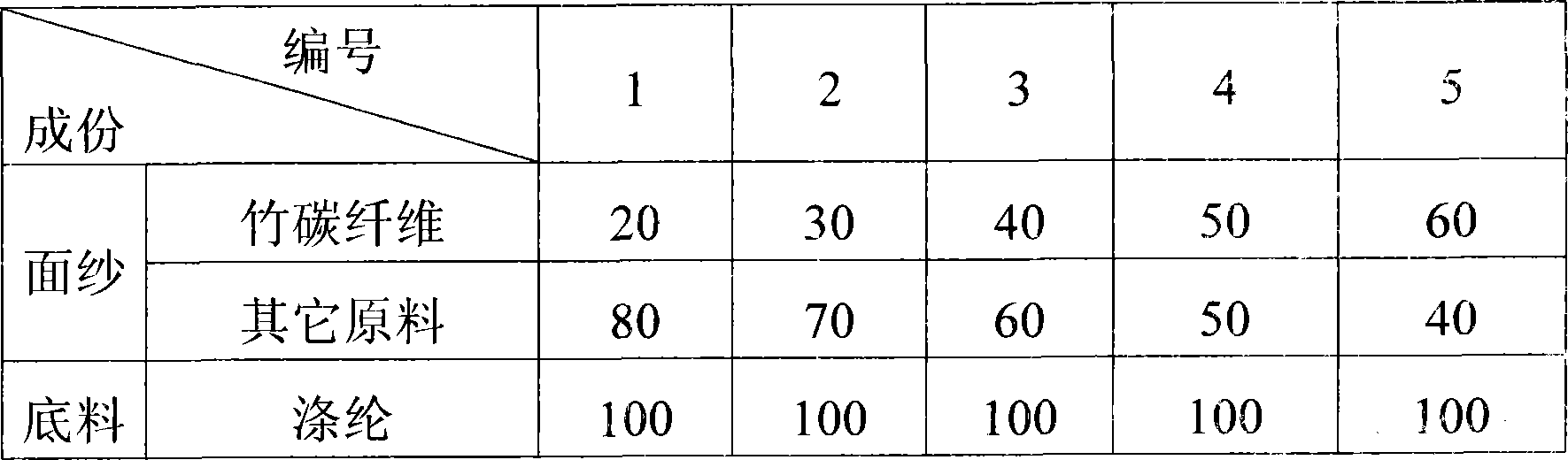

Bamboo carbon fiber blanket material and finished products thereof

The invention relates to woven bamboo charcoal fabric series woollen blankets using bamboo charcoal fabric and other components as raw materials. The material comprises following components by weight percentage: face yarns : bamboo charcoal fabric : 20%; other raw materials: 80%; bottom material: 100; wherein the other raw materials of the face yarn are one or several types selected from cotton, wool, real silk, chinlon, polypropylene, acrylic fibre, dacron and fabric; the bottom material is dacron; the material compatibility of the invented bamboo charcoal fabric woollen blanket is reasonable, and the invented bamboo charcoal fabric woollen blanket is provided with good weaving performance and moderate price, and accords with market demand; strong ultraviolet resistant ability and adsorption decomposition capacity of bamboo charcoal fibrous are utilized sufficiently; bamboo charcoal fabric raschel woollen blankets, acrylic bamboo charcoal fabric woollen blankets and coral fur bamboo charcoal fabric woollen blankets made by above materials are enriched of metallic elements such as potassium, magnesium, calcium, aluminum, zirconium, manganese and other carbides, have strong far-infrared ray emitting and negative ion emitting functions; and have strong moisture-guiding, moisture absorption, drying, deodor and bacteria inhibition functions.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Heating fiber underwear face fabric and processing technique thereof

InactiveCN101235573AGood flexibilityGood skin affinityWeft knittingDry-cleaning apparatus for textilesYarnCellulose fiber

The invention relates to a heating fiber underwear fabric, which is characterized in that the heating fiber underwear fabric is composed of raw materials with following weight percent: heating fiber 3-25%, anti-pilling acrylic fiber 30-52%, lenzing cellulose fiber 35-40%, polyamide fiber 4-6% and lycra elastic fiber 0.5-0.15%. A processing technique of the heating fiber underwear fabric comprises: firstly, spinning the heating fiber, the anti-pilling acrylic fiber and the lenzing cellulose fiber into sirospun union yarn, then, coating the lycra elastic fiber with the polyamide fiber, weaving and forming knitted underwear fabric, dying, soaping with nonionic soft finishing agent, vertically drying, shaping, and forming finished products of the heating fiber underwear fabric. The heating fiber underwear fabric of the invention has the advantages that the heating fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also has good warmth retention effect.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV +1

Flame-resistant, high visibility, anti-static fabric and apparel formed therefrom

InactiveUS6946412B2High tensile strengthImprove energy absorptionCombination devicesPressurized chemical processVisibilityFiber

A fabric for use in safety apparel comprising a first set of yarns comprising modacrylic fibers, and a second set of yarns comprising anti-static fibers. The fabric meets the Federal Test Method Standard 191A, Method 5931 for electrostatic decay, and the Electrostatic Discharge Association Advisory ADV11.2-1995 voltage potential.

Owner:GLEN RAVEN INC

Manufacture method of conductive fire-retardant acrylic fiber

InactiveCN104805684AMake up for the shortcomings of flammabilityPrevent static electricityFibre typesPolymer scienceFire retardant

The invention discloses a manufacture method of conductive fire-retardant acrylic fiber. The manufacture method comprises the following steps: (1) preparing a spinning solution; (2) performing spinning formation; (3) performing copper salt treatment; (4) adding acrylic fiber containing copper ions obtained in the step (3) into a mixed aqueous solution, and reacting in an airtight high-temperature reaction kettle at 120-140 DEG C for 4-5 hours to prepare the fire-retardant acrylic fiber; (5) taking out and cleaning the acrylic fiber obtained in the step (4), and putting the acrylic fiber at 70-90 DEG C for 2-3 hours in a constant-temperature manner. Through the manner and with the adoption of the manufacture method of conductive fire-retardant acrylic fiber, the acrylic fiber subjected to the antistatic treatment can prevent static electricity during application, ensures normal application of a user, has a fire-retardant function, and overcomes the flammable defect of cloth.

Owner:CHANGSHU XIANGYING SPECIAL FIBER

Limited-antimony-content and antimony-free modacrylic / aramid blends for improved flash fire and arc protection

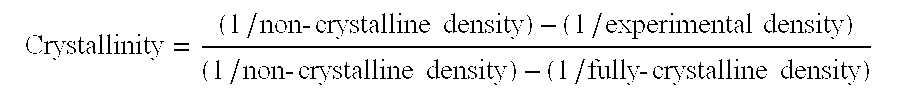

A yarn, fabric, and garment suitable for use in arc and flame protection comprising aramid fiber and modacrylic fiber wherein the modacrylic fiber has less than 1.5 percent antimony and is preferably antimony-free. In one embodiment, the yarn, fabric, and / or garments consist essentially of (a) 50 to 80 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%, (b) 10 to 40 weight percent modacrylic fiber that is antimony-free, (c) 5 to 20 weight percent para-aramid fiber, and (d) 1 to 3 weight percent antistatic fiber, based on the total weight of components (a), (b), (c) and (d). In some embodiments, garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

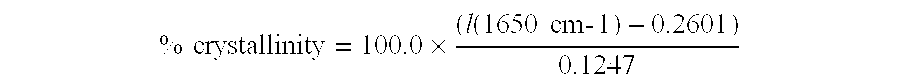

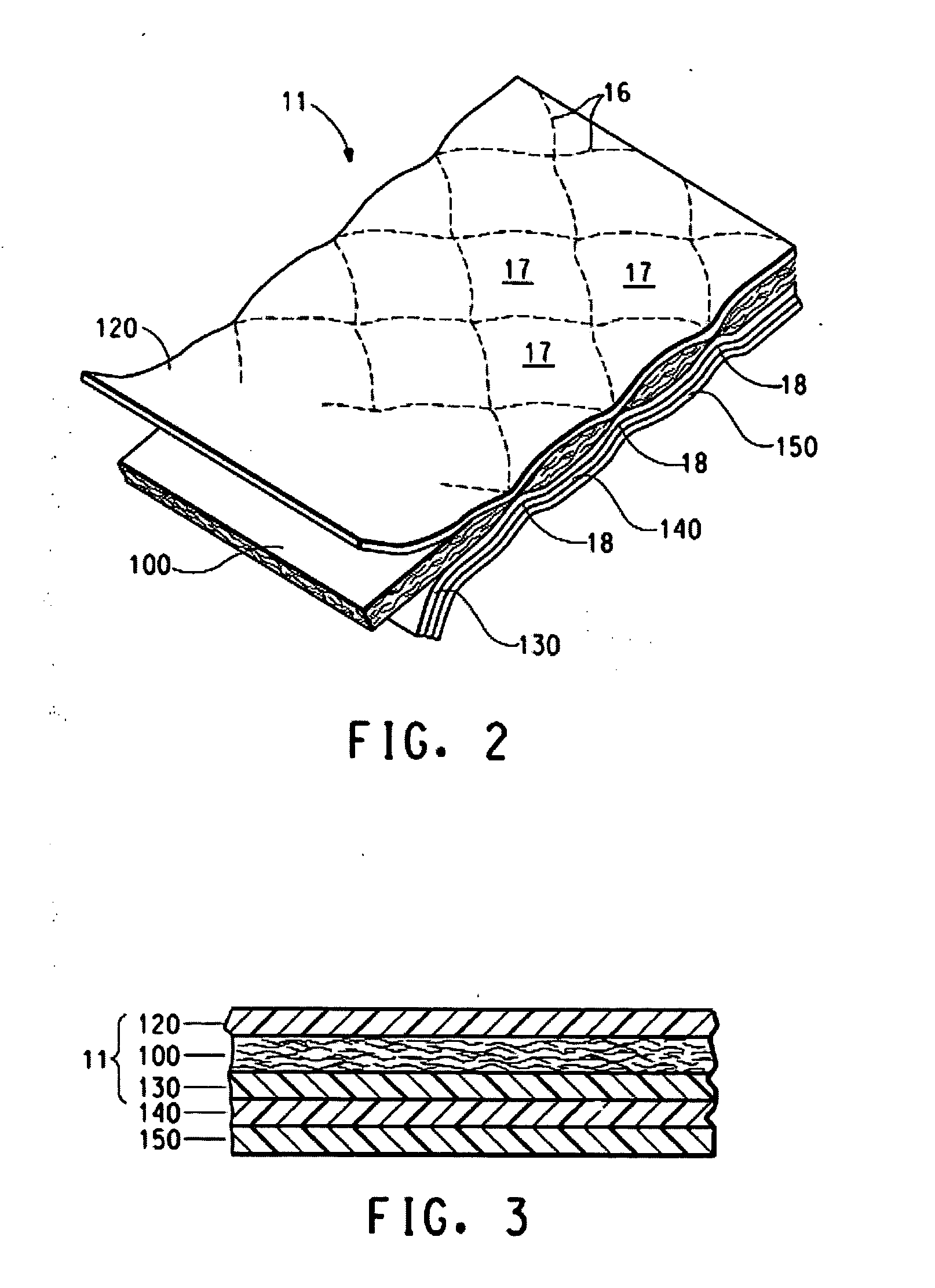

Fire blocker fiber composition, high loft web structures, and articles made therefrom

The present invention is directed to a fiber composition useful for fire blocking; a high loft web structure made from such fiber composition and a process for making such web structure; and a fire blocked article such as a mattress or furniture incorporating such high loft web structure and a method for fireblocking said articles; the fiber composition comprising (a) 1 to 20 parts by weight p-aramid fiber, (b) 5 to 30 parts by weight regenerated cellulose fiber containing silicic acid, and (c) 10 to 40 parts by weight modacrylic fiber, (d) 10 to 60 parts by weight polyester fiber, (e) up to 20 parts by weight binder material wherein the total of (a), (b), (c), (d) and (e) is on a basis of 100 parts by weight.

Owner:EI DU PONT DE NEMOURS & CO

Flame retardant blended yarn and production method thereof

InactiveCN104404671AImprove flame retardant performanceIncrease added valuePhysical treatmentYarnCotton fibreSingle fiber

The invention relates to a flame retardant blended yarn and a production method thereof. According to weight percentage, the flame retardant blended yarn is formed by the following components through blending: 25-30% of flame retardant polyester filament yarns, 20-25% of flame retardant acrylic fibers, 20-30% of hemp fibers and 20-30% of cotton fibers. The production method includes: making hemp fibers and cotton fibers into card slivers respectively and tearing the card slivers into loose fibers, and making the card slivers into hemp / cotton blended combed silvers through second blowing carding in a single fiber type mixing way; making the flame retardant acrylic fibers into flame retardant acrylic card silvers; producing blended rough yarns by use of the hemp / cotton blended combed silvers and the flame retardant acrylic card silvers; producing flame retardant blended yarns by use of spun yarns in a core spun mode; producing the needed flame retardant blended yarns after plasma preprocessing and yarn flame retardant finishing. According to the flame retardant blended yarn and the production method thereof, the hemp fibers, the cotton fibers and two flame retardant fibers are selected for blending, and accordingly the produced yarns have excellent flame retardant performance as well as good antibacterial, moisture absorptive and ventilate wearing performances; the spun yarns are in the core spun mode so the tare effect is eliminated and the flame retardance is improved.

Owner:青岛博徕施纺织有限公司

Method for preparing whisker material to make modification treatment of spinning chemical fibre

InactiveCN1483863ASimple processLow costWet spinning methodsArtifical filament manufactureState of artWhiskers

The present invention relates to a preparation method of spinning chemical fibre modified and treated by whisker material, and is characterized by that said preparation method includes the following steps: mixing whisker material and dispersing agent uniformly, adding deionized water, diluting and stirring by using high-speed shearing emulsifying machine to form whisker slurry material, in the wet spinning process of the chemical fibre adding the whisker slurry material so as to obtain the modified chemical fibres of acrylic fibre, viscose fibre and vinylon, etc. with the function of resisting static electricity, resisting bacteria and resisting UV ray, so that it has the extensive application.

Owner:DONGHUA UNIV +1

Acrylic fiber surface graft protein modified fiber and its producing method

InactiveCN1900413AImproved compatibility with human bodyGood hygroscopicityFibre treatmentProtein compositionSurface layer

The present invention relates to a orlon surface grafting protein modified fibre and manufacturing method. It consists of orlon and protein, featuring that: skin core layer structure surface layer being vegetable protein grafting cover layer, core being orlon fiber, protein cover layer occupying 1-20 per cent of fiber total mass, core orlon occupying 80-90 per cent. Said manufacturing method is firstly to make orlon fiber surface hydrolysis into fiber containing carboxylic acid base group, then reaction with thionyl chloride, grafting with protein, to obtain surface covering protein layered fiber. The present invention made modified fibre surface consists of protein molecule having preferable human body affinity, hygroscopicity and antistatic property.

Owner:SHANDONG UNIV OF TECH

High performance concrete reinforced by assorted fiber

The present invention relates to a high-performance mixed fibre reinforced concrete, its composition includes (by volume %) high elastic modulas fibre 1%-5%, low elastic modulus fibre 0.2%-3% and the rest general concrete, the described high elastic modulus fibre is one of steel fibre, carbon fibre and glass fibre, and the described low elastic modulus fibre is one of vinylon fibre, polypropylene fibre, acrylic fibre, nylon fibre and polyethylene fibre. Said invention can be used for making manhole cover which not only has higher strength, but also has higher impact resistance.

Owner:SHANGHAI JIAO TONG UNIV

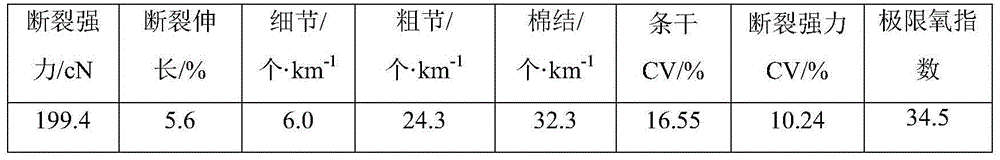

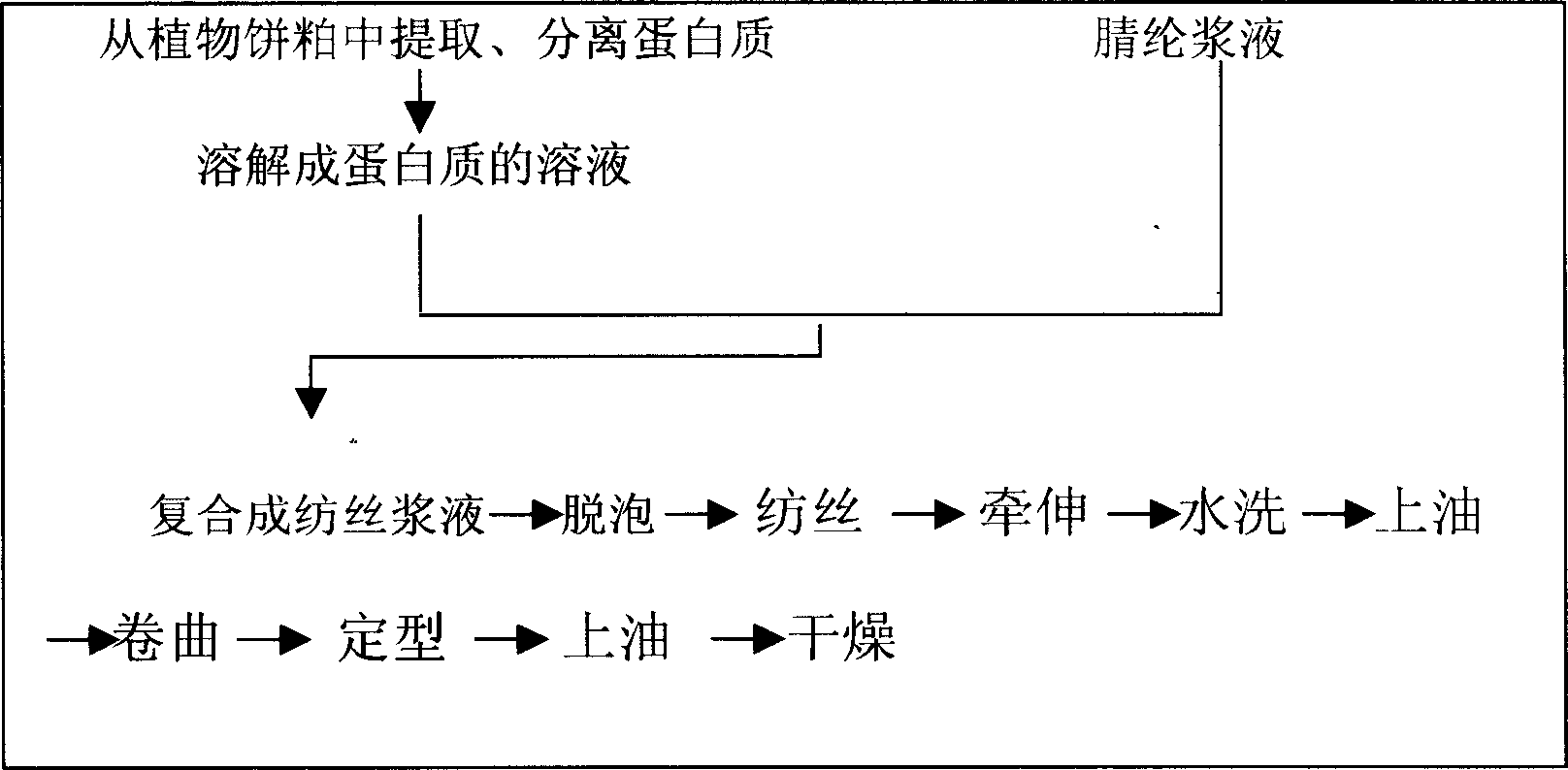

Composite fiber of plant protein and acrylon and its manufacturing method

InactiveCN1431343AReduce manufacturing costIncrease added valueConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsSlurryAcrylic fibre

A composite plant protein-acrylic fibre is prepared from natural high-molecular plant protein and polyacrylonitrile in Wt. ratio of (10-50):(50-90) through respectively preparing their solutions, proportional mixing, wet spinning, coagulating, drafting, hot stretching, curling, fixating shape, coating oil and drying. Its advantages are good thermal insulating, high dyeability and human affinity, and high antistatic performance.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD +1

Chelating function fiber and synthesis method

InactiveCN1478950AConvenient sourceReduce manufacturing costFibre treatmentSynthesis methodsWastewater

A fibre with chelating function for cleaning industrial sewage and removing the acidic gas (HCl, SO2 and H2S) is prepared from acrylic fibres through hydrolysis, chemically coating the polyvinylimine on the surface of acrylic fibre, and chemical cross-linking. Its advantages are high stability, adsorption capacity, selectivity and mechanical strength, no poison, and easy eluting.

Owner:NO 718 INST NO 7 RES INST CHINA SHIPPING HEAVY IND GRP

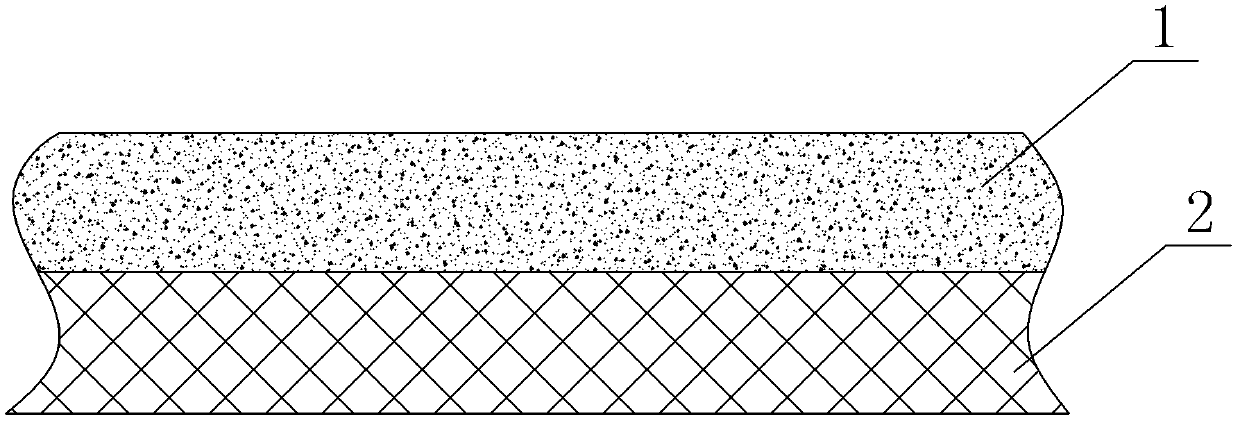

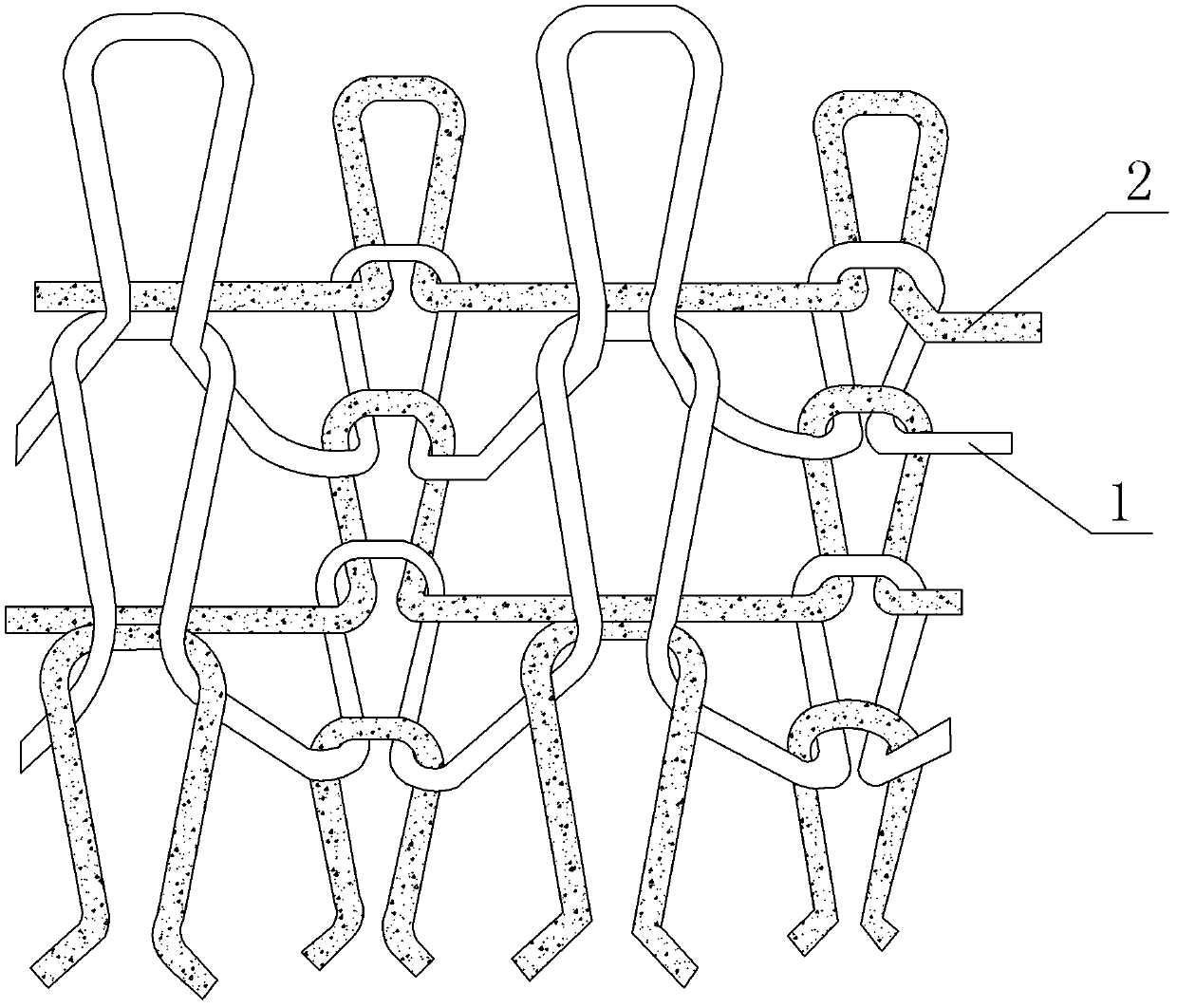

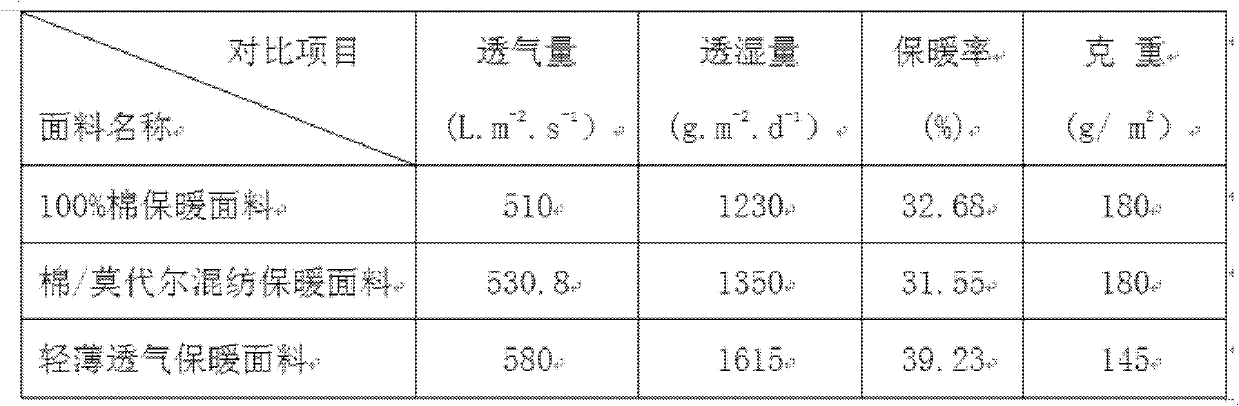

Thin breathable warm fabric and manufacture method thereof

InactiveCN102605523AHigh standardFullnessWeft knittingLiquid/gas/vapor treatment of propelled fabricsYarnMoisture absorption

The invention relates to a thin breathable warm fabric, comprising a surface fabric and an inner layer fabric, wherein the inner layer fabric is a moisture absorption and heating layer; the surface fabric is a warm breathable and moisture-leading layer; the moisture absorption and heating layer is formed by blending 30-60% of moisture absorption and heating EKS fibers and 40-70% of ordinary acrylic fibers; the warm breathable and moisture-leading layer is formed by blending 15-40% of bulk acrylic fibers, 20-60% of superfine acrylic fibers and 0-65% of modal fibers. The invention further relates to a manufacture method of thin breathable warm fabrics, comprising the steps of preparing yarns, weaving, sanding, dyeing, finishing softly and shaping; and the thin breathable warm fabric provided by the invention has the advantages of high wearing comfort, good thin and breathable performance as well as good anti-dropping, anti-static and warmth retention performances.

Owner:SHENZHEN HUIJIE GROUP

Moisturizing skin care warm-keeping knitted fabric and production technology thereof

ActiveCN104047102AHas skin care and moisturizing functionWith warm functionSucessive textile treatmentsWeft knittingTextile technologyPolymer science

The invention relates to the textile technical field, in particular to moisturizing skin care warm-keeping knitted fabric and a production technology thereof. The production technology comprises the following processing steps of a, spinning, b, weaving and c, dyeing and finishing. In the step of spinning, acrylic fibers including arginine and common viscose fibers are spun into siro spinning blended yarns, the proportion of the acrylic fibers in the blended yarns is 50%-80%, the proportion of the viscose is 50%-20%, the yarn count of the yarns is 40-80 S / 1, and the twist coefficient of the yarns is 330-370. In the step of weaving, the siro spinning blended yarns and spandex are interwoven, the linear density of the spandex is 15-40 D, a weft knitting circular weft knitting machine is used for weaving knitted gray cloth, and the tissue is plaiting tissue. In the step of dyeing and finishing, the following processes of pre-shaping, dyeing, soaping, cloth drying, cloth bottom sanding and shaping are included. The produced fabric has the skin care moisturizing function, the moisturizing skin care function cannot be weakened along with repeated washing, and the fabric has the warm-keeping function and is suitable for being worn in autumn and winter in which the air humidity is low.

Owner:GUANGDONG SMART TEAM TEXTILES TECH

Compact-Siro spinning white bamboo charcoal/acrylic fiber/viscose blended yarn and production method thereof

InactiveCN105908305AGood warmth retentionHas antibacterial and deodorizing propertiesYarnYarnCarding

The invention provides a compact-Siro spinning white bamboo charcoal / acrylic fiber / viscose blended yarn. The fabric is of the specification of white bamboo charcoal 30 / light-absorbing and heat-emitting acrylic fibers 28 / MeiYaBi superfine acrylic fibers 22 / viscose 20 40S, wherein the specification of white bamboo charcoal fibers is 1.2 D*38 mm, the specification of MeiYaBi superfine acrylic fibers is 0.9 D*38 mm, the specification of light-absorbing and heat-emitting acrylic fibers is 1.5 D*38 mm, and the specification of viscose is 1.2 D*38 mm. A production method of the blended yarn includes the steps that 1, light-absorbing and heat-emitting acrylic fibers and MeiYaBi superfine acrylic fibers are subjected to cotton cleaning with a cotton cleaner, cotton carding with a carding machine and pre-drawing; 2, white bamboo charcoal fibers are subjected to cotton cleaning, cotton carding and pre-drawing; 3, viscose is subjected to cotton cleaning, cotton carding and pre-drawing; 4, fibers obtained in the previous three steps are subjected to drawing including primary drawing, secondary drawing and final drawing, roving with a roving frame, spinning with a spinning frame, and spooling. The blended yarn obtains a good warmth retention property with light-absorbing and heat-emitting acrylic fibers and MeiYaBi superfine acrylic fibers, and also has certain anti-microbial and deodorant effects, a far infrared function and an anion release function due to added white bamboo charcoal fibers.

Owner:JIANGSU YDTEX GRP LTD

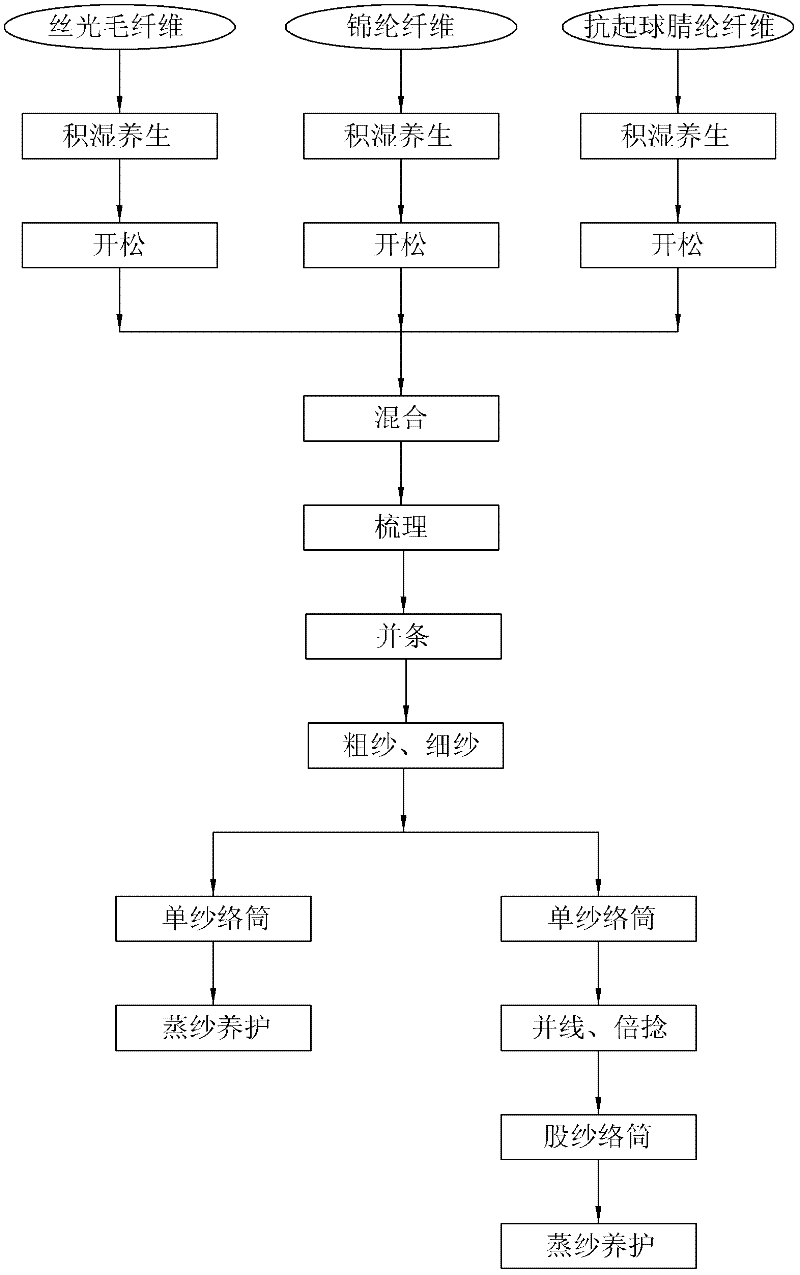

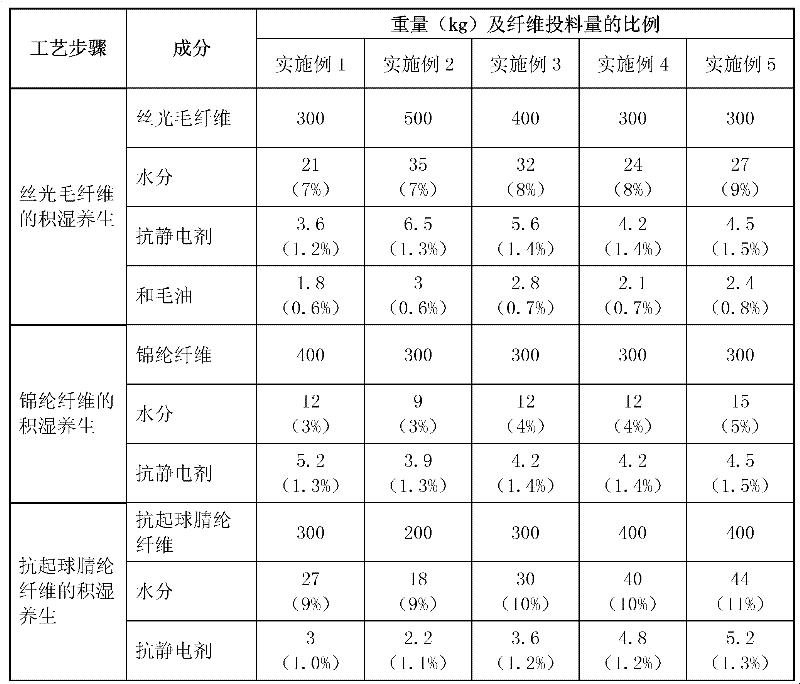

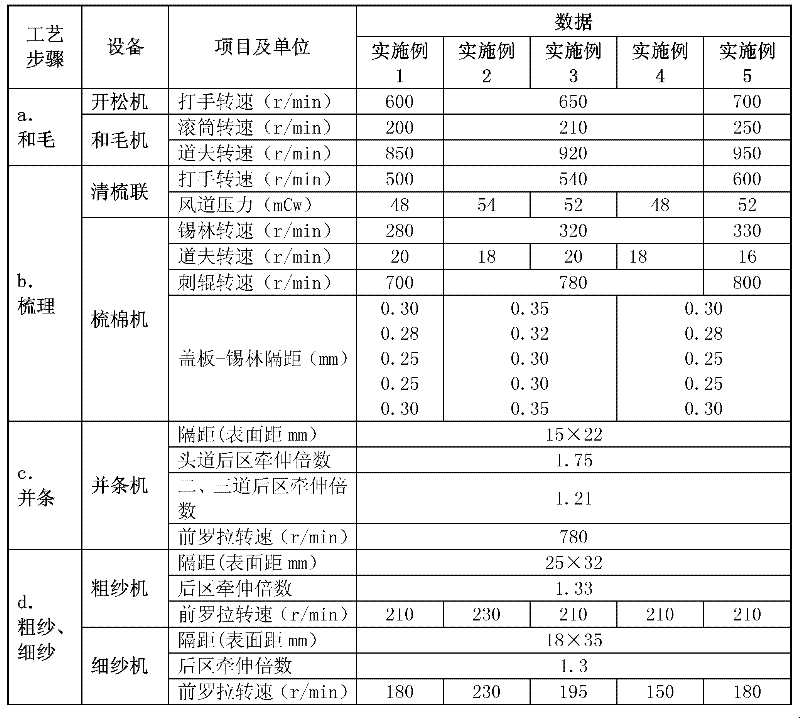

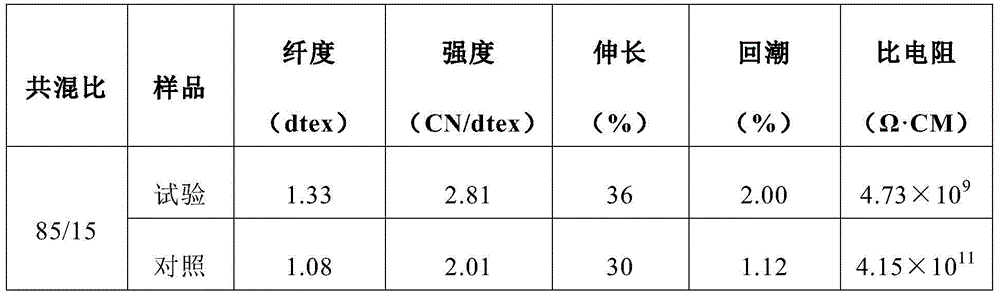

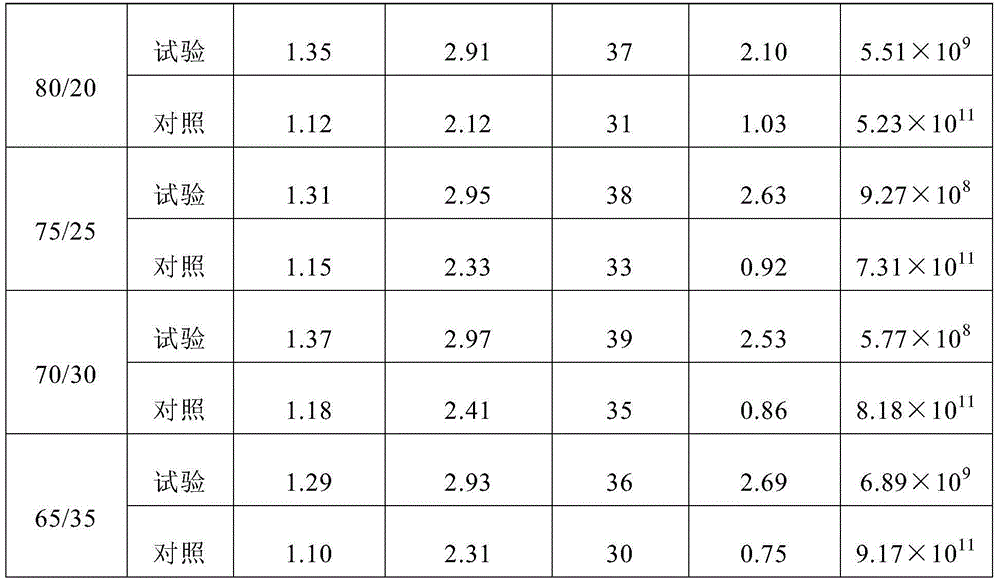

Blended yarns of mercerized wool, chinlon and anti-pilling acrylic fibers and preparation method thereof

The invention relates to yarns and a preparation method thereof, and discloses a preparation method of blended yarns of mercerized wool, chinlon and anti-pilling acrylic fibers. The blended yarns of mercerized wool, chinlon and anti-pilling acrylic fibers consist of 30-50 percent by weight of mercerized wool fibers, 30-40 percent by weight of chinlon fibers and 20-40 percent by weight of anti-pilling acrylic fibers. The preparation method of the yarns comprises wool blending, carding and drawing steps, wherein in the wool blending step, moisture of the mercerized wool fibers, chinlon fibers and anti-pilling acrylic fibers is accumulated respectively for curing, and loosening and mixing are performed. The yarns spun by using the method have the advantages of the mercerized wool fibers, chinlon fibers and anti-pilling acrylic fibers, and can be applied to knitting and weaving; and fabrics woven with the yarns have pure color, high air permeability, high hygroscopicity, high wrinkle resistance, high wearability, handfeel like cashmere and silk luster.

Owner:浙江桐基羊绒发展有限公司

Preparation method of spinning hairpiece by human hair and protein acrylic fibre

InactiveCN101037813AWith textureAppearanceWigsConjugated cellulose/protein artificial filamentsMean diameterAcrylic fibre

The invention relates to a preparation method for hairpiece formed by human hair and protein acrylon. The method comprises the following steps: human hairs being crushed into human hair powder at mean diameter of 1-10 micron, wherein the maximum size is not more than 30 micron; the human hair powder uniform distributing in polyacrylonitrile fibre, wherein the content of human hair powder is 1-30%(wt%) and the content of polyacrylonitrile is 70-99%(wt%); using wet-process acrylon spinning technique to finally obtain the protein acrylon hairpiece. The said human hair is crushed, no need of chemical extraction. The operation is simple, the souce of raw materianl is wide and the cost is low. The protein acrylon hairpiece has features of satia plump texture, good hand feeling, reality, similar burning property to human hair.

Owner:DONGHUA UNIV

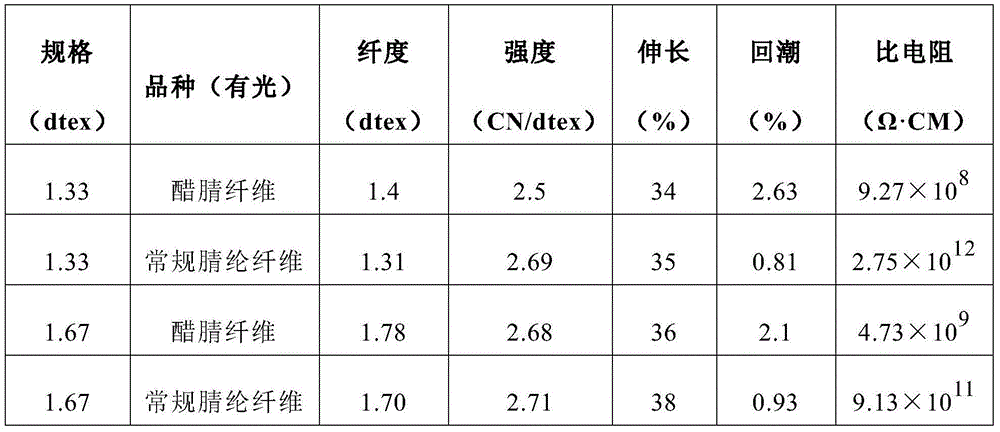

Acetate fiber and preparation method thereof

ActiveCN105002592AGood hygroscopicityHigh strengthConjugated cellulose/protein artificial filamentsMonocomponent synthetic polymer artificial filamentCellulose acetateAcrylic fibre

The invention relates to a fiber material, in particular to an acetate fiber and a preparation method thereof. The acetate fiber is composed of polyacrylonitrile and cellulose acetate. The mass ratio of the cellulose acetate to the polyacrylonitrile is an arbitrary ratio, preferentially, the ratio is 15-35 wt%:65-85 wt%, and more preferentially, the ratio is 15-30 wt%:70-85 wt%. The acetate fiber has the advantages that the defects that the acrylic fiber is bad in hygroscopicity, and static electricity is easily generated are overcome; the defects that the pure acetate fiber is low in strength and bad in serviceability are overcome; at the same time, the combination property of the acetate fiber is good.

Owner:河北艾科瑞纤维有限公司

Fire-retardant fiber blended yarn, preparation method of fire-retardant fiber blended yarn and fabrics of fire-retardant fiber blended yarn

ActiveCN103255521AImprove spinnabilityImprove flame retardant performanceFibre typesYarnYarnPolymer science

The invention relates to fire-retardant fiber blended yarn, a preparation method of the fire-retardant fiber blended yarn and fabrics of the fire-retardant fiber blended yarn. Double-layer fibers are used in the fire-retardant fiber blended yarn which comprises a surface layer and a core layer, the surface layer is composed of, by weight percentage, 20-30% of phenolic fibers, 20-25% of fire-retardant acrylic fibers, 30-40% of copolyamide fibers, 20-30% of antistatic synthetic fibers in a blending mode, the characteristics of the fibers can be sufficiently utilized, the problem existing in single fibers is solved, the spinnability of the fibers is improved, and a fire-retardant effect is improved. The core layer is composed of, by weight percentage, 10-20% of wool fibers, 30-40% of nylon fibers and 40-50% of polyester fibers, cost is lowered, and the air permeability of the fibers is improved. Fire retardant soaking treatment is conducted on the fibers of the core layer, and the core layer is made to have the fire-retardant capacity. The fire-retardant fiber blended yarn can be applied to clothing, home textiles, sports products, health care products, and fire-proof fabrics.

Owner:北京邦维普泰防护纺织有限公司

Preparation method of anti-pilling acrylic fiber

ActiveCN101818386AImprove dyeing effectSimple processFilament/thread formingMonocomponent synthetic polymer artificial filamentPolymer scienceAcrylonitrile

The invention discloses a preparation method of anti-pilling acrylic fiber, which comprises the steps: three monomers including 93.5-94.5wt% of acrylonitrile, 5.25-6.05wt% of vinyl acetate and 0.25-0.45% of sodium methylallyl sulfonate are mixed, the concentration of the mixture is regulated to 30-40wt%, water phase suspension polymerization reaction is continuously implemented; the polymer after reaction is terminated by means of chelation reaction and then steam-stripped to separate out unreacted monomer, the unreacted monomer is salt / moisture-removed by a washing filter, then subject to granulation molding and finally dried to result in powdery polymer, the powdery polymer is mixed with and dissolved in DMAC, the powdery polymer-dissolved DMAC is heated up, cooled and filtered to prepare spinning solution, and the spinning solution is subject to spinning, double diffused molding, water washing, oiling, drying and curling to include the draft multiple of 4-7, and the anti-pilling acrylic fiber with the level of anti-pilling performance larger than 4 and the strength of 0.6 + / - 0.2CN / dtex is obtained by shaping through shaping pressure of 120-200kPa.

Owner:JILIN QIFENG CHEM FIBER

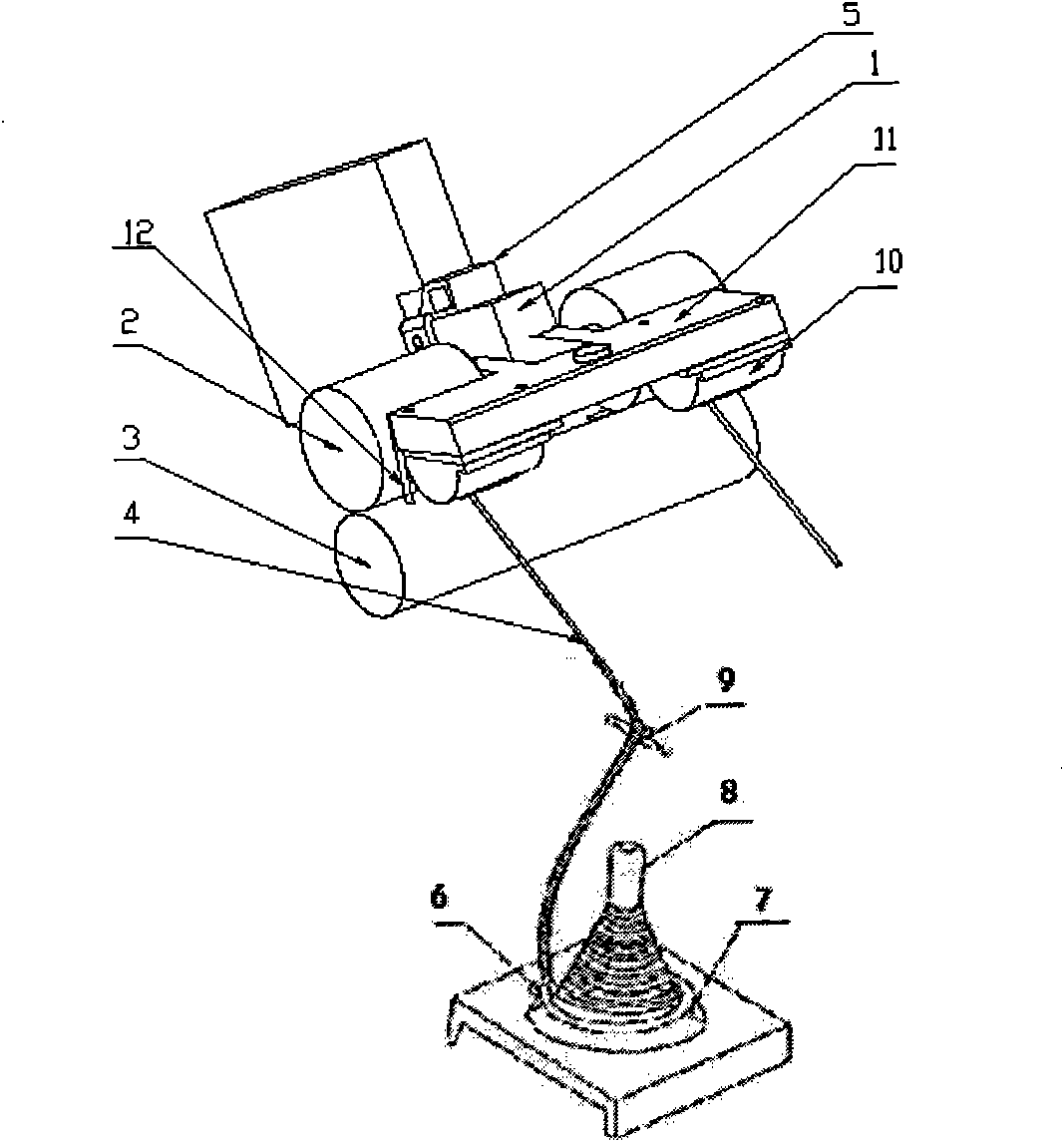

Spinning method for performing damp heat ironing treatment to fiber strands

The invention relates to a spinning method for performing damp heat ironing treatment to fiber strands, and belongs to the technical field of textile processing. A damp heat ironing treatment device is additionally installed in a twist trigonal zone in front of a front leather roller and a front roller of a ring spinning frame and used for performing damp heat ironing treatment to fibers in the fiber strands; the damp heat ironing treatment device comprises a base, a humidifying component and an ironing treatment component; the damp heat ironing treatment device can perform humidifying to the fibers in the fiber strands in the twist trigonal zone and then perform high-temperature ironing treatment, so that the rigidity of the fibers is instantaneously reduced, and the flexibility of the fibers is enhanced; and meanwhile, the movement of the fibers in the fiber strands in the twist trigonal zone is controlled. The spinning method can remarkably reduce the fibrous yarn of resultant yarn, enhance the strength of yarn formation and reduce the phenomenon of kinking due to twisting. The damp heat ironing treatment device is convenient for a knitter to operate, has little influence on the operation of the knitter, and is suitable for cotton fibers, wool fibers, fibrilia, polyester fibers, polyamide fibers and acrylic fibers.

Owner:WUHAN TEXTILE UNIV

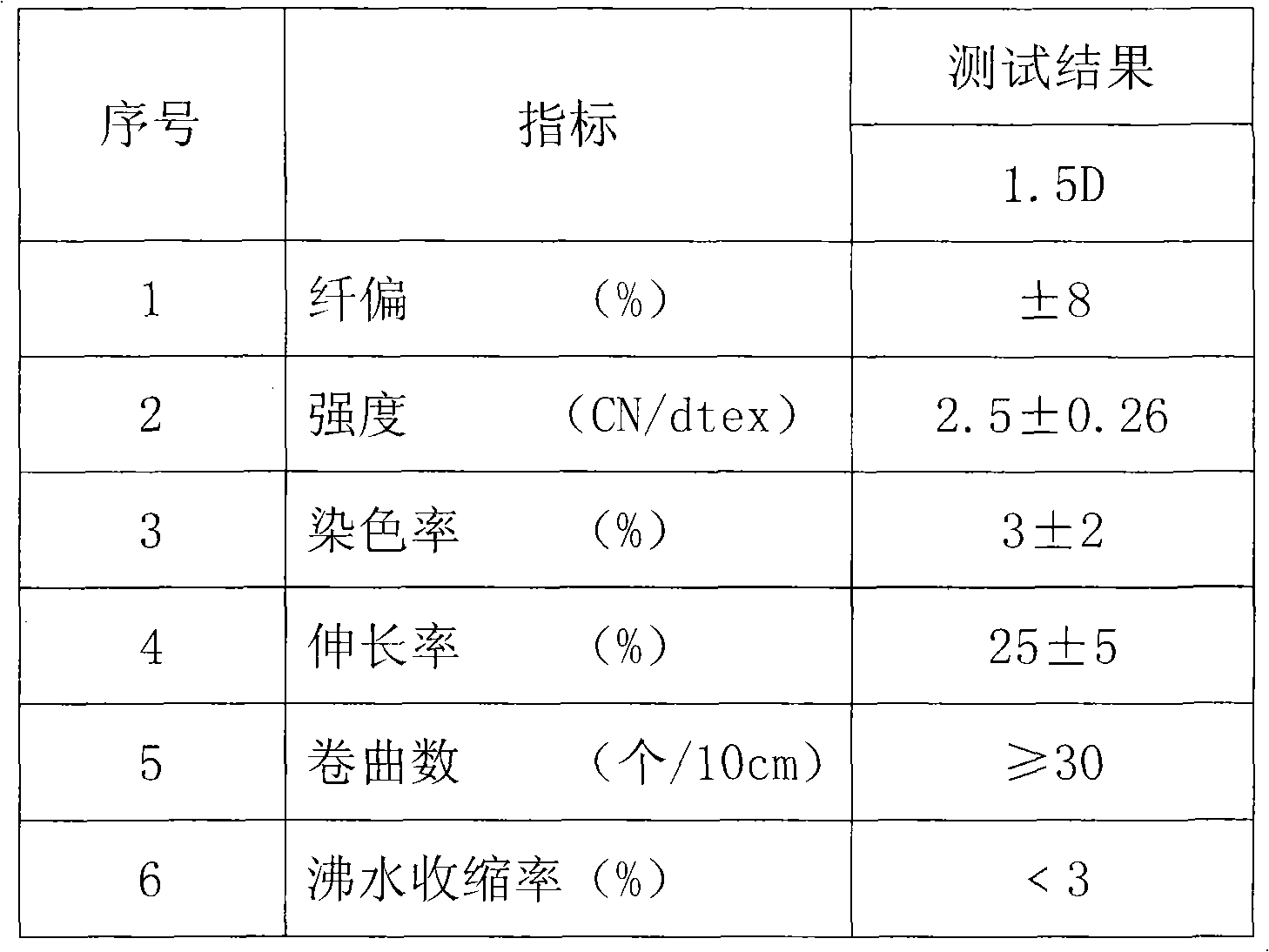

Method for preparing acrylic fibre with wet-process

InactiveCN101270501AGood molding effectIncrease the amount of participationSpinnerette packsFilament manufactureState of artEngineering

A preparation method for wet acrylic fiber is characterized by including the following steps in turn: a, spinning and shaping; b, washing and drafting; c, oiling; d, drying; e, winding; f, shaping. Furthermore, compared with the prior art, the invention makes improvement on the shaping technique and post treatment technique through the specific design of a silk spray plate and selects proper spinning, shaping and post treatment condition technique parameters through a plurality of tests to improve the coagulation bath circulation amount, improve the adding amount and the drafting times of an oil agent and improve the winding door pressure. The acrylic fiber manufactured by the invention improves the shaping effect of the fiber.

Owner:浙江杭州湾腈纶有限公司

Method for preparing colorant used in producing color acrylic fibre by mass coloration method

The present invention relates to a preparation method of coloring material for producing colored acrylic fiber by adopting mass coloration process. Said method includes the following steps: mixing pigment, dispersing agent and NaSCN aqueous solution and grinding in ball-grinding machine, in the coloring material the pigment content is 5-25 wt%, the weight ratio of pigment and dispersing agent is 100:3-30, and the ginding time is 0.5-5.0, then the coloring material product can be obtained. The above-mentioned dispersing agent is one compound selected from naphthalenesulfonate formaldehyde condensate, methyl naphthalene sulfonate formaldehyde condensate or benzyl naphthalene sulfonate formaldehyde condensate or mixture of them, and the pigment is carbon black, phthalocyanine blue, iron oxide or ultrasmarine.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Heating blended yarn and spinning process thereof

The invention discloses a heating blended yarn and a spinning process thereof. The heating blended yarn comprises the following components in percentage by weight: 5% to 15% of heating fiber, 25% to 30% of anti-pilling acrylic fiber, 20% to 25% of modal fiber, 20% to 25% of tencel fiber and 20% to 25% of viscose fiber. The fibers are spun to yarn through a semi-comb spinning process. The spinning process sequentially comprises a dyeing process, a cotton carding process, a drawing process, a roving process, a spinning process and a spooling process. The heating blended yarn is formed by blending various types of fibers, highlights the characteristics of each fiber by reasonably arranging the weight ratio of each fiber, integrates the advantages of various types of the fibers into a whole, maintains the basic performance of the yarn, and has the heating and warming functions. The yarn is more fluffy and softer than spun yarn and is more uniform and glossy than the coarse yarn. The adaptability of the semi-comb spinning process route to raw materials is wider, the spinning quantity can be high or low, the technology is popularized, equipment investment is low, and occupied plant area is small.

Owner:JIANGNAN UNIV +1

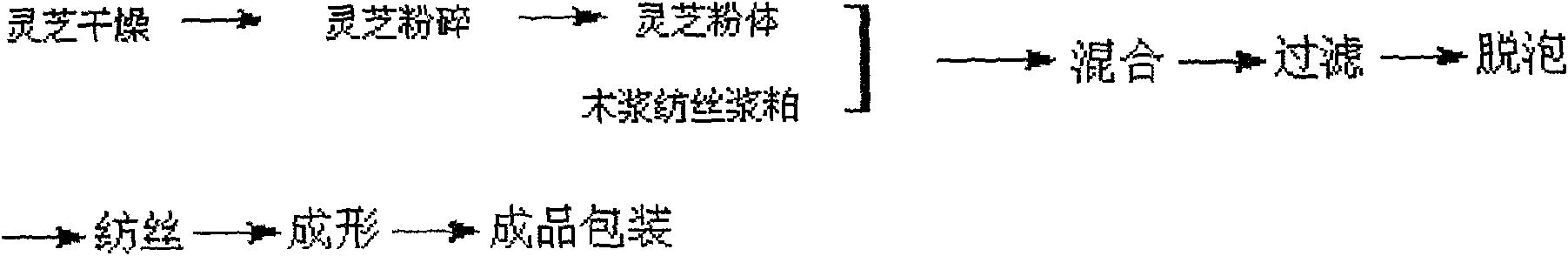

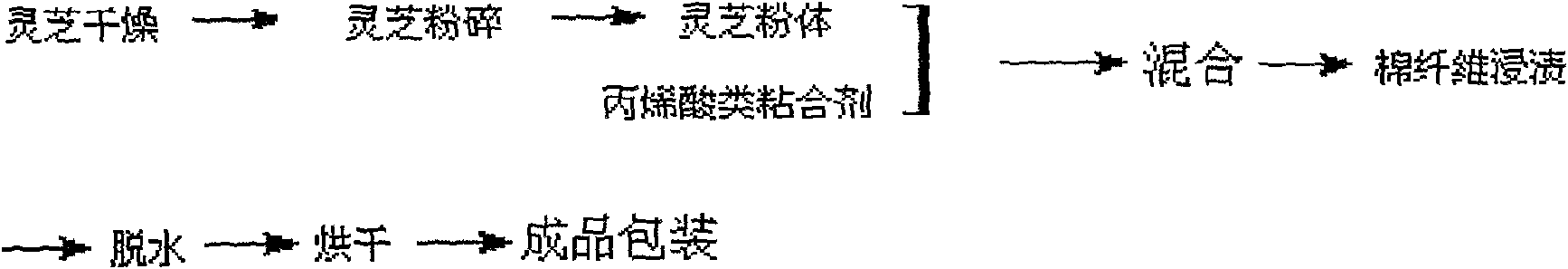

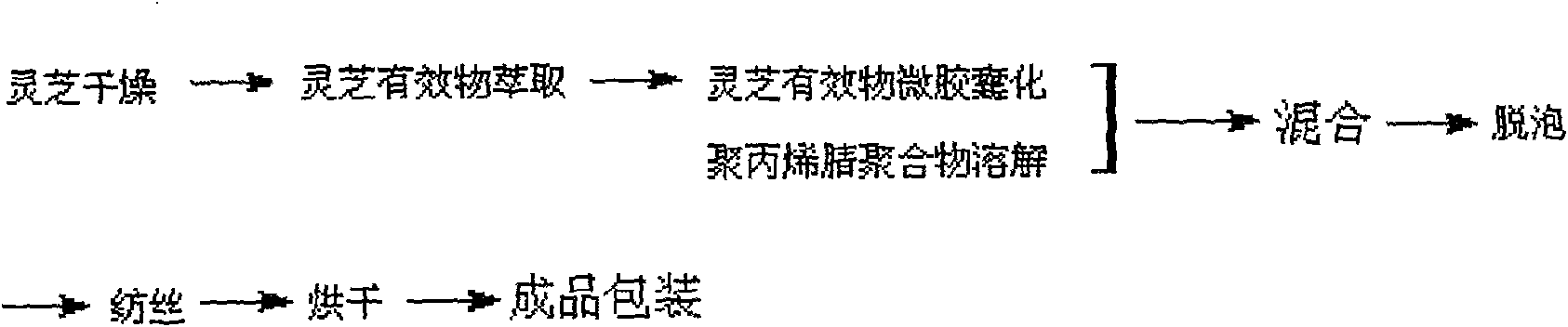

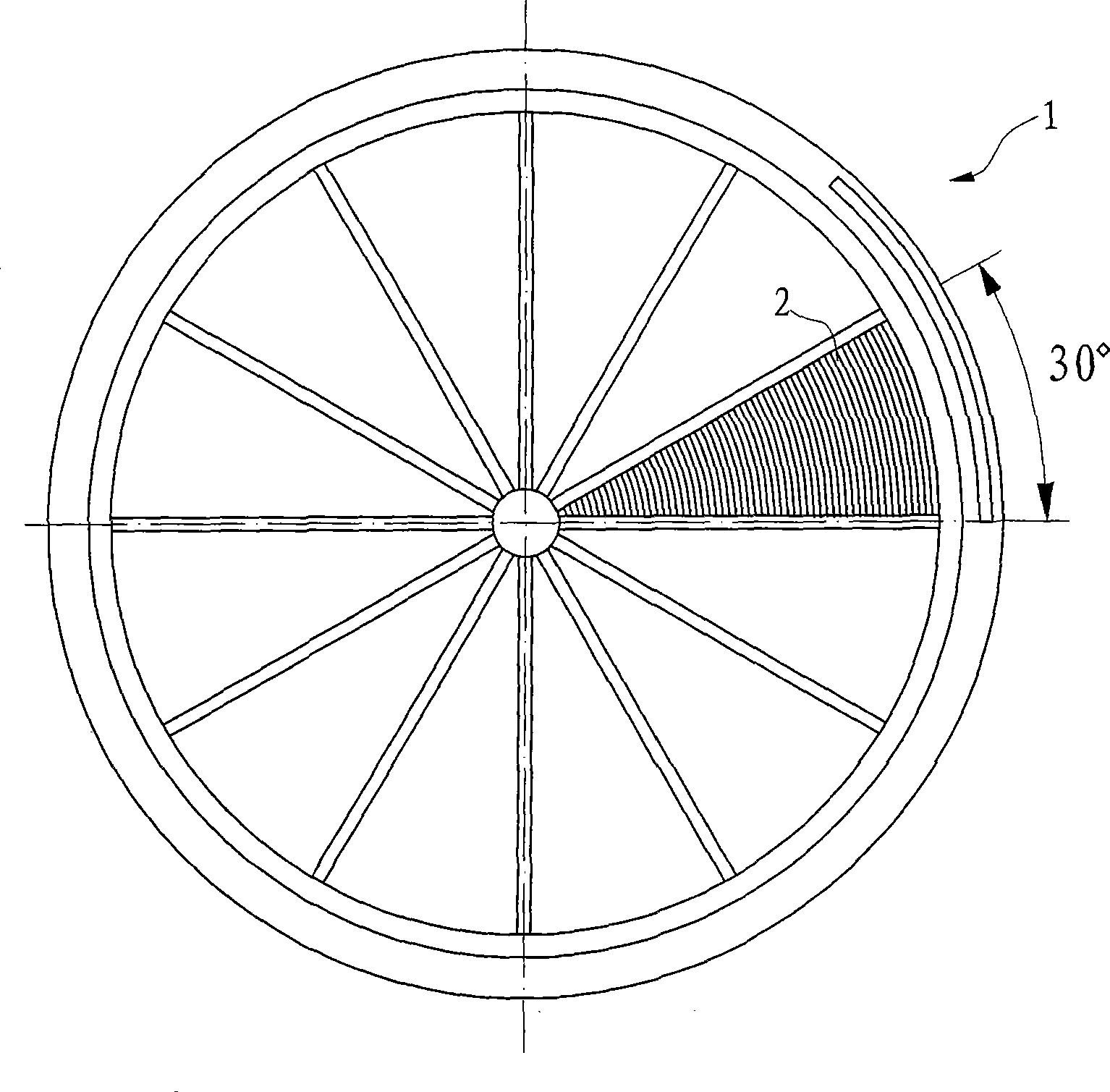

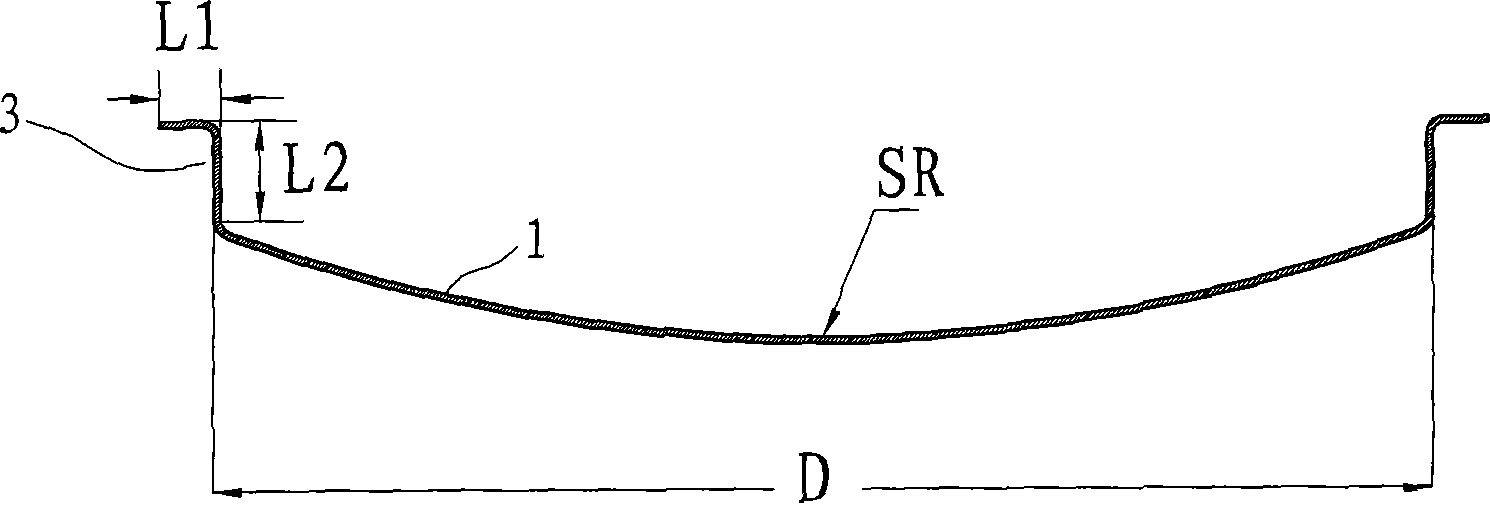

Ganoderma lucidum fibre with function of health care and preparation method thereof

InactiveCN101634055AImprove the immunityImprove immunityMonocomponent protein artificial filamentSynthetic fibresDiseaseNylon 66

The invention relates to ganoderma lucidum fibre with the function of health care and a preparation method thereof. The fibre contains traditional Chinese medicine ganoderma lucidum components; the preparation method comprises the following steps: adding the ganoderma lucidum components into regenerated cellulose fibre spinning liquid, regenerated protein fiber spinning liquid, terylene fibre spinning liquid, orlon fibre spinning liquid and nylon 6 or nylon 66 fibre spinning liquid and adopting conventional spinning to obtain the ganoderma lucidum fibre. The fibre can reinforce the resistance and immunity of an organism, eliminates in-vivo free radicals, resists radiation and has the effects of preventing and treating diseases, building the body, strengthening the body and prolonging the life; the invention has simple preparation method and is suitable for industrialized production.

Owner:陈对范 +1

Preparation method of flat acrylic fiber

InactiveCN101445967ASoft touchImprove rigidityFilament manufactureArtificial filament washing/dryingSolventAcrylic fibre

A preparation method of flat acrylic fiber is characterized by sequentially comprising the following steps: a. spinning forming to prepare as-spun fiber: taking dry polyacrylonitrile powder as a raw material and taking dimethyl acetamide as a solvent to make polymer stock solution with the concentration of 23-26%, heating by a heater followed by extruding monofilament from odd shaped spinneret orifices on a spinneret, and controlling the temperature of the heater at 120-130 DEG C, gelatin supply rate at 50-60r / min, the coagulation bath temperature at 35-45 DEG C, and the concentration of the dimethyl acetamide at 51-54% by weight percentage in the coagulation bath; b. washing and drafting; c. applying oil; d. drying; e. winding; and f. shaping. Compared with the prior art, the preparation method has the advantages that the flat acrylic fiber satisfying the production requirements is prepared by regulating and improving the polymer components, the gelatin supply rate, the temperature of the stock solution, the coagulation bath temperature and the like, and the product has soft hand feeling, high rigidity and good spinnability.

Owner:浙江杭州湾腈纶有限公司

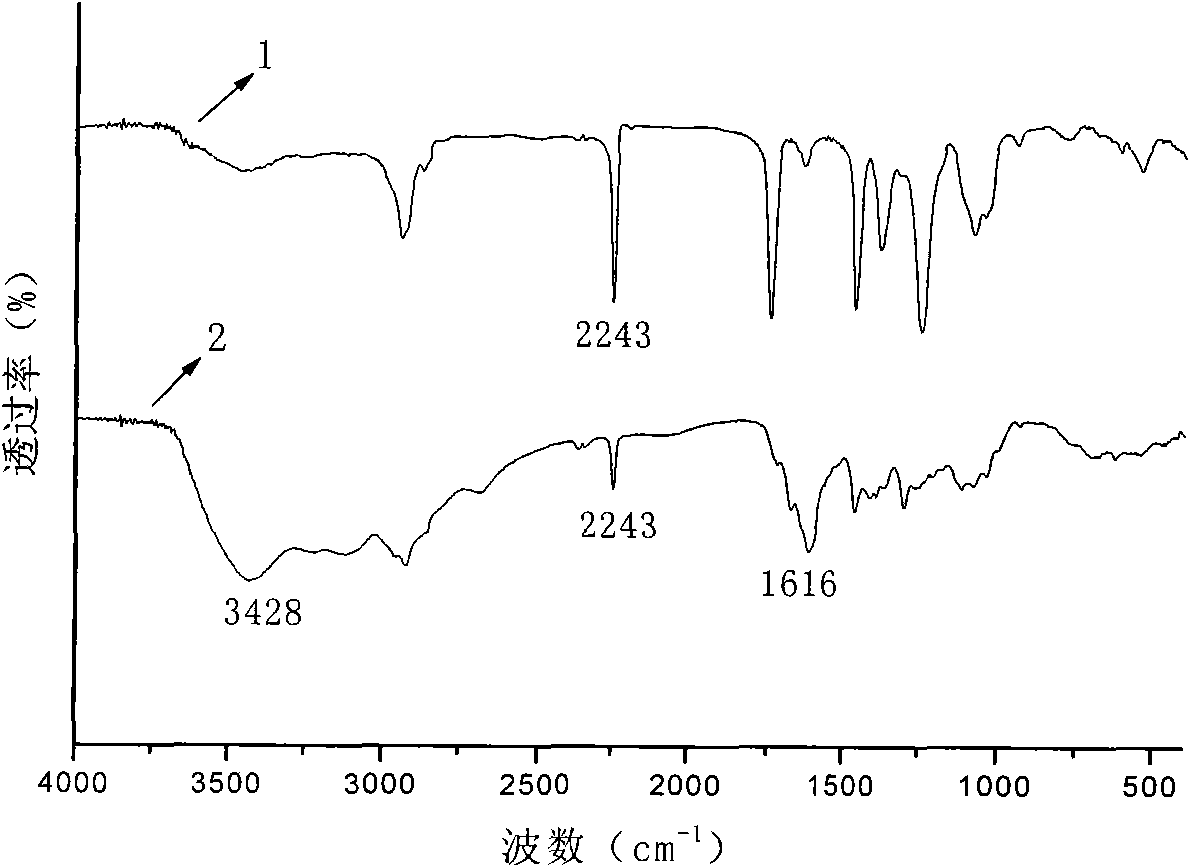

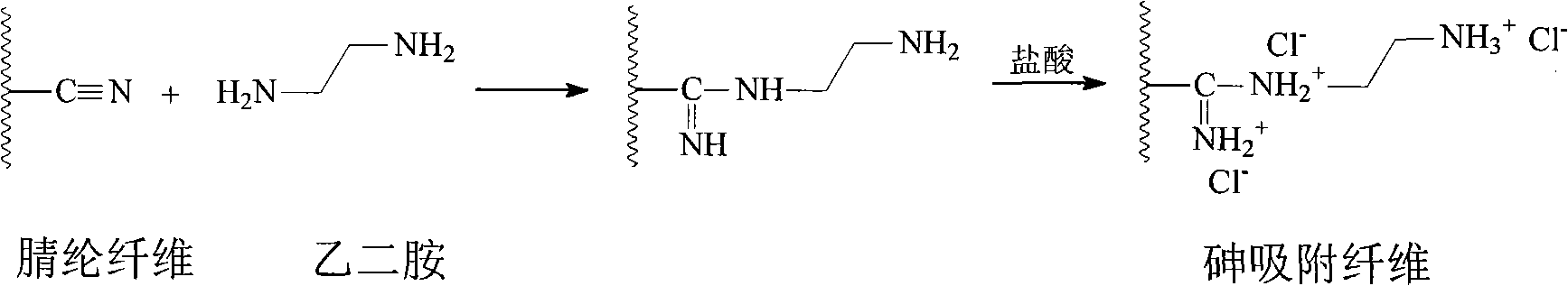

Arsenic adsorbing fiber and synthesizing method thereof

ActiveCN101569854ALarge specific surface areaSmall circulation resistanceOther chemical processesAlkali metal oxides/hydroxidesIon exchangeCarbon dioxide

The invention discloses an arsenic adsorbing fiber using acrylic fiber as a fundamental frame and a synthesizing method thereof, belonging to the technical field of polymer materials. In the structure of the fiber material, amido existing in a mode of hydrochloride is contained, and the amido can effectively adsorb arsenic radical in the water through an ion exchange reaction. The method for synthesizing the fiber is to lead the acrylic fiber to firstly perform a grafting reaction with a multi-amido compound to introduce amido, and the acrylic fiber reacts with the hydrochloric acid to transform the amido into the hydrochloride, and has simple reacting process and mild condition. The neutral fiber is stable in the air, cannot absorb carbon dioxide and other acid gases, and cannot affect the pH value of the water body when the arsenic adsorbing fiber is used in the water as an adsorbent.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

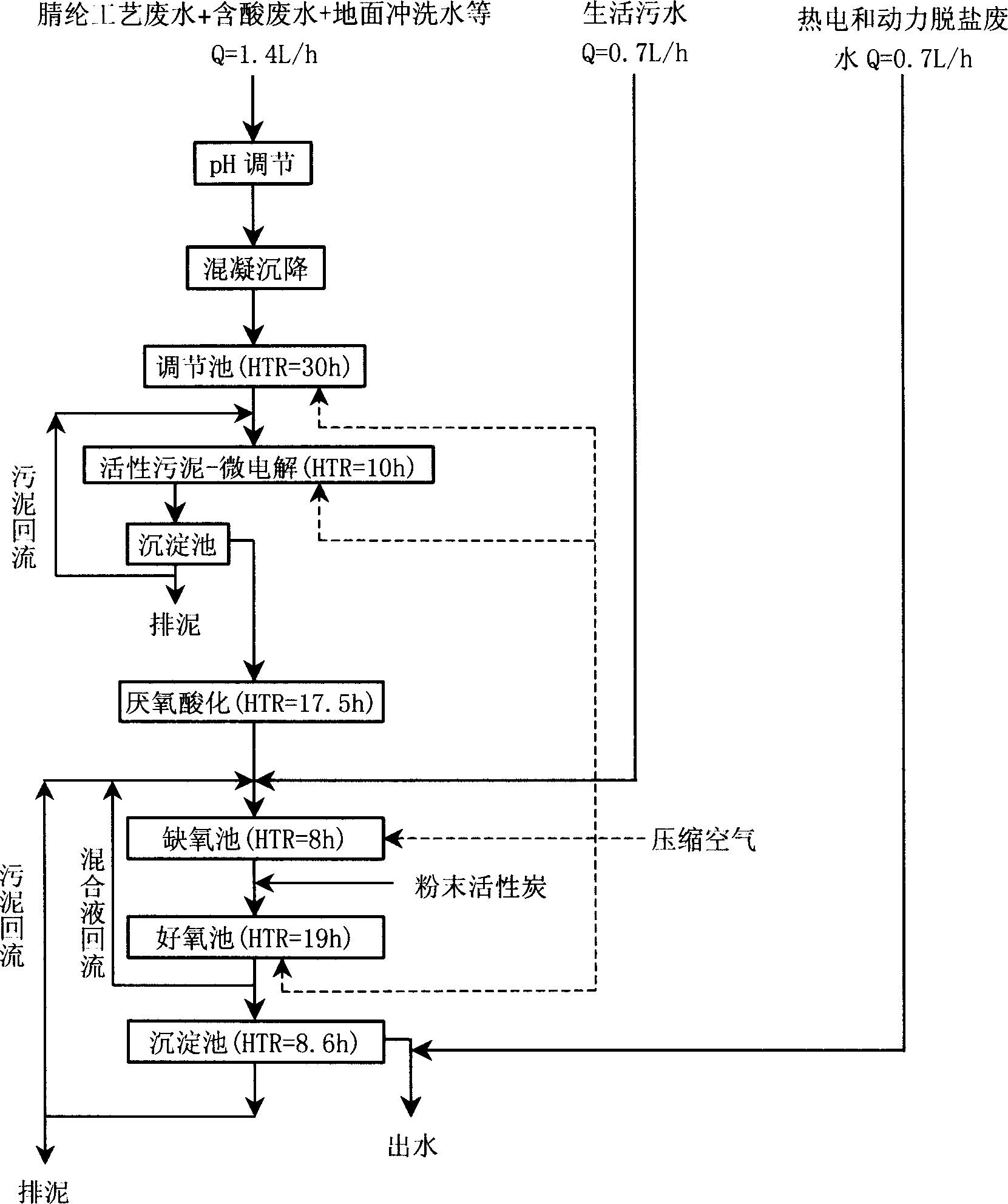

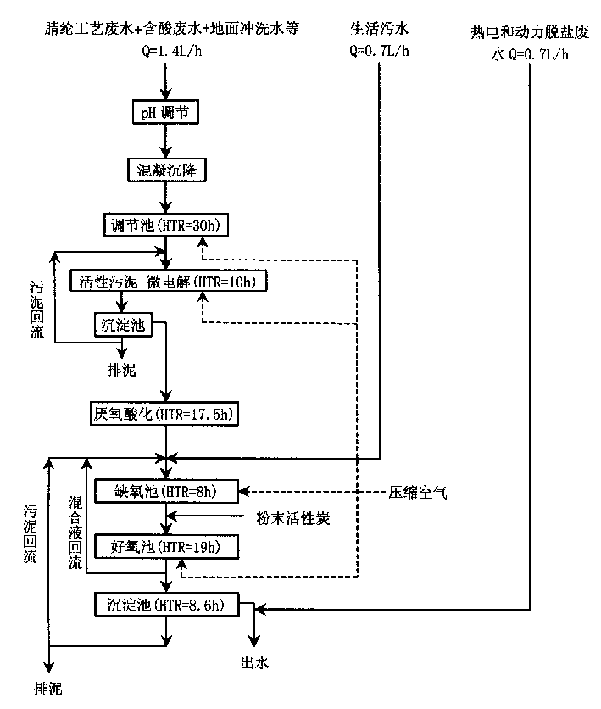

Method for treating wastewater from industry of spinning acrylics thrugh two steps wet processes by using sodium thiocyanate as solvent

InactiveCN1539766AGood effectEasy to handleMultistage water/sewage treatmentSustainable biological treatmentIndustrial effluentOligomer

A two-step process using sodium thiocyanate as solvent for treating the sewage generated by west spinning of acrylic fibres includes microelectrolyzing to degrade oligomer, adding flocculant, coagulating while depositing, separation, mixing the polymerized sewage with cyanogen contained sewage, homogenizing, hydrolyzing, acidifying, carbonifying, nitrating, denitrating, post-aerating, and separating the deposit mud from supernatant. Its advantage is high treating effect.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

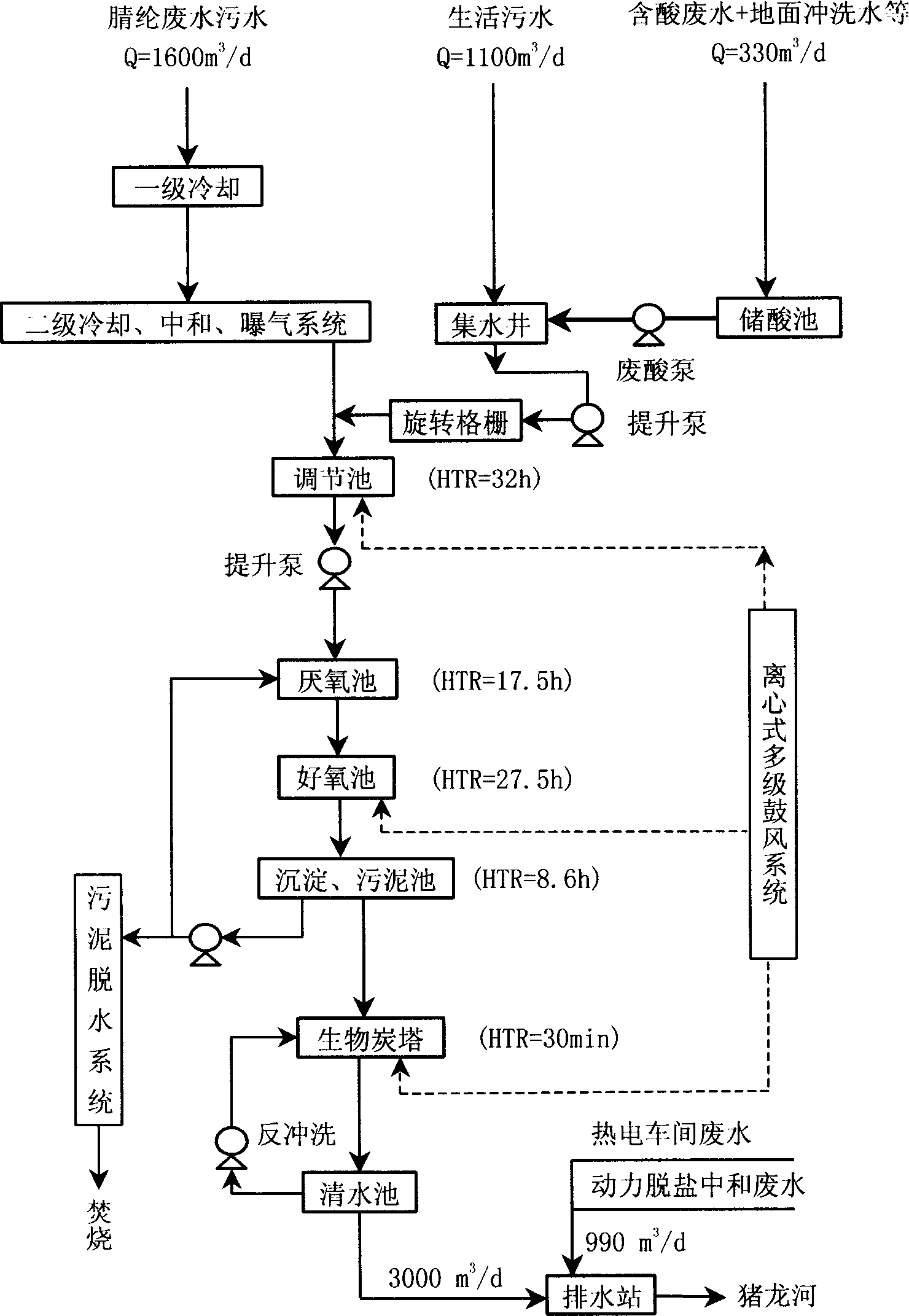

Treatment technology for acrylic fibers waste water by dry process

InactiveCN1413928AReasonable processEasy to handleMultistage water/sewage treatmentAnaerobic aerobicIndustrial waste water

A process for treating the sewage generated by preparing acrylic fibre by dry method includes such steps as regulating pH value, coagulation-deposition to remove suspended substance and colloid, cooling supernatant, flowing in conditioning pool, active mud-microeletrolyzing stemp while providing oxygen to the active mud, anaerobic acidifying while introducing life sewage for removing EDTA and Na salt, and anaerobic-aerobic step for biologic denitrifying. Its advantages are high effect and easy operation.

Owner:QILU PETRO CHEM - SINOPEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com