Patents

Literature

482results about "Dye addition to spinning solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

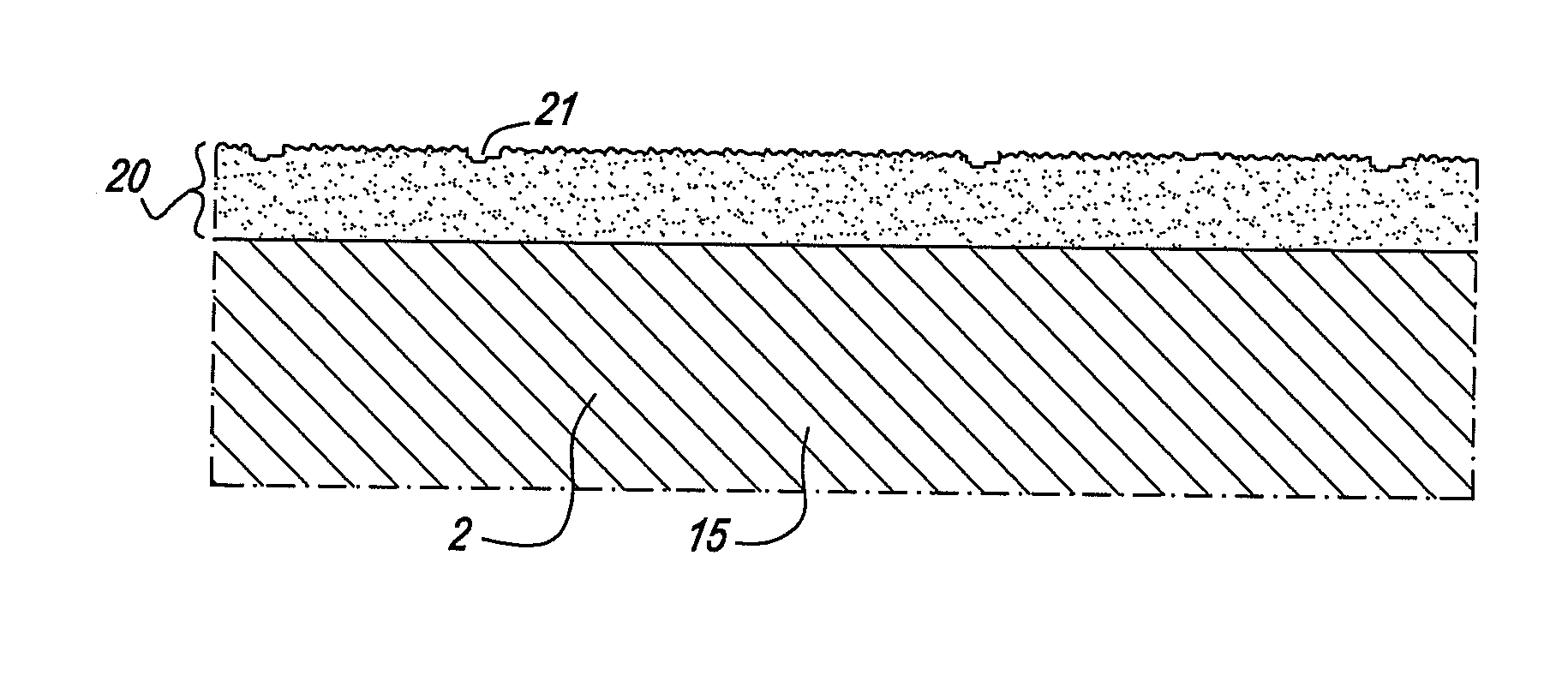

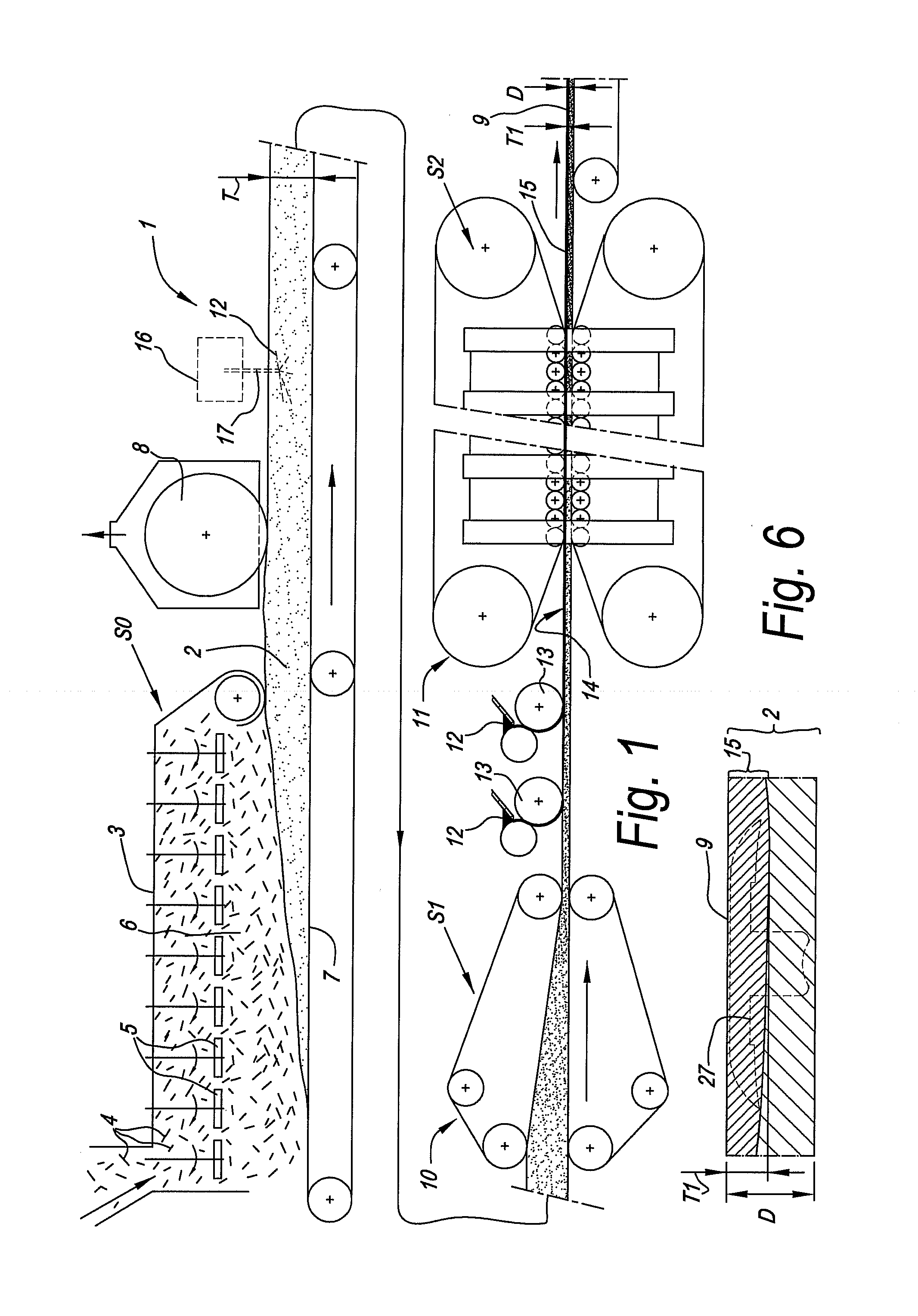

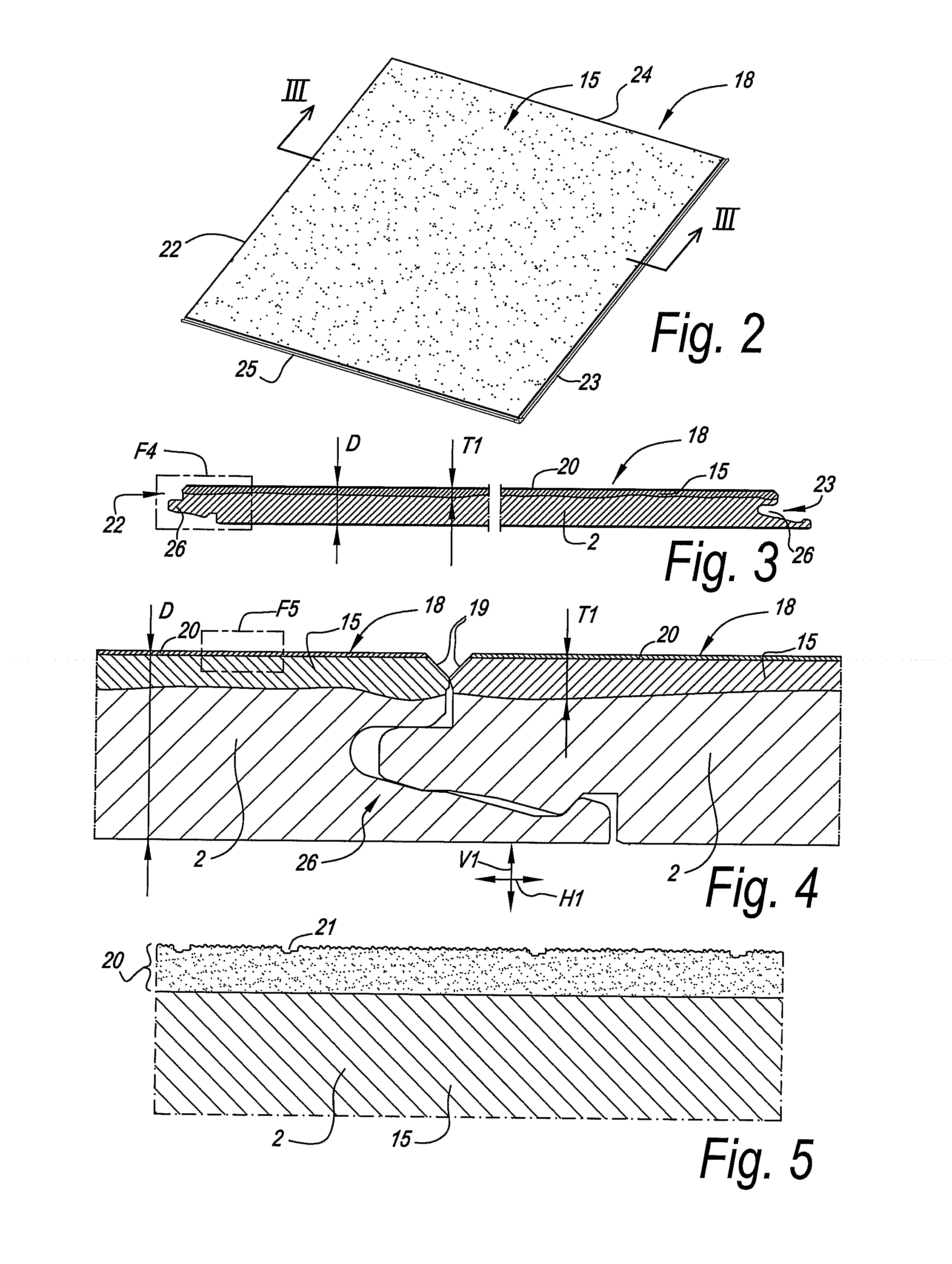

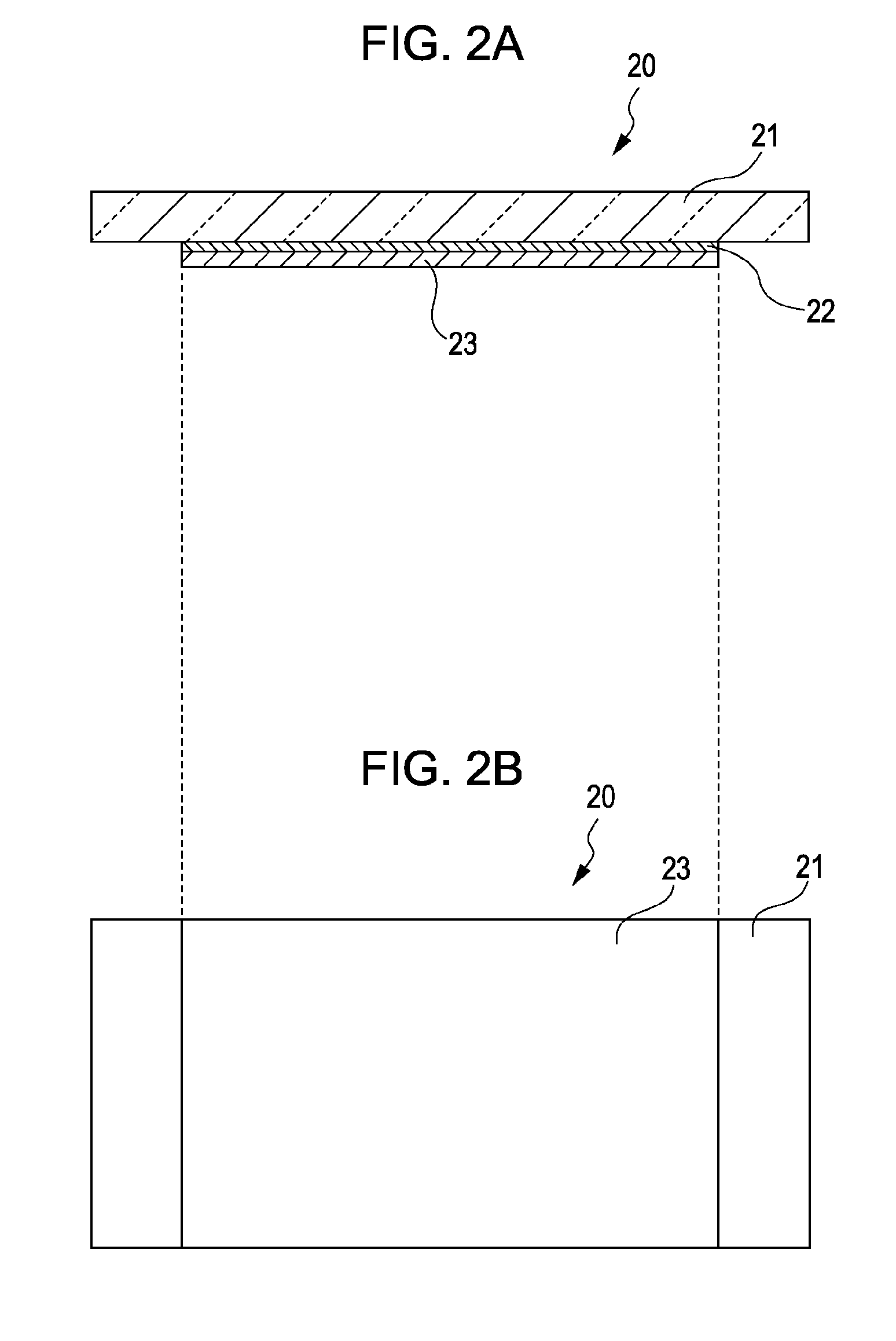

Method for manufacturing panels and panels obtained hereby

InactiveUS20110311806A1Simply formedFine surfaceLayered productsMonocomponent cellulose artificial filamentVolumetric Mass DensityEngineering

A method for manufacturing panels including a substrate on the basis of a pressed material mass, whereby it is started from a material mass to be densified, wherein the density of this material mass, in one or more densifying steps, is at least doubled. Prior to one or more of these densifying steps, a colorant is added to the material mass.

Owner:FLOORING IND LTD

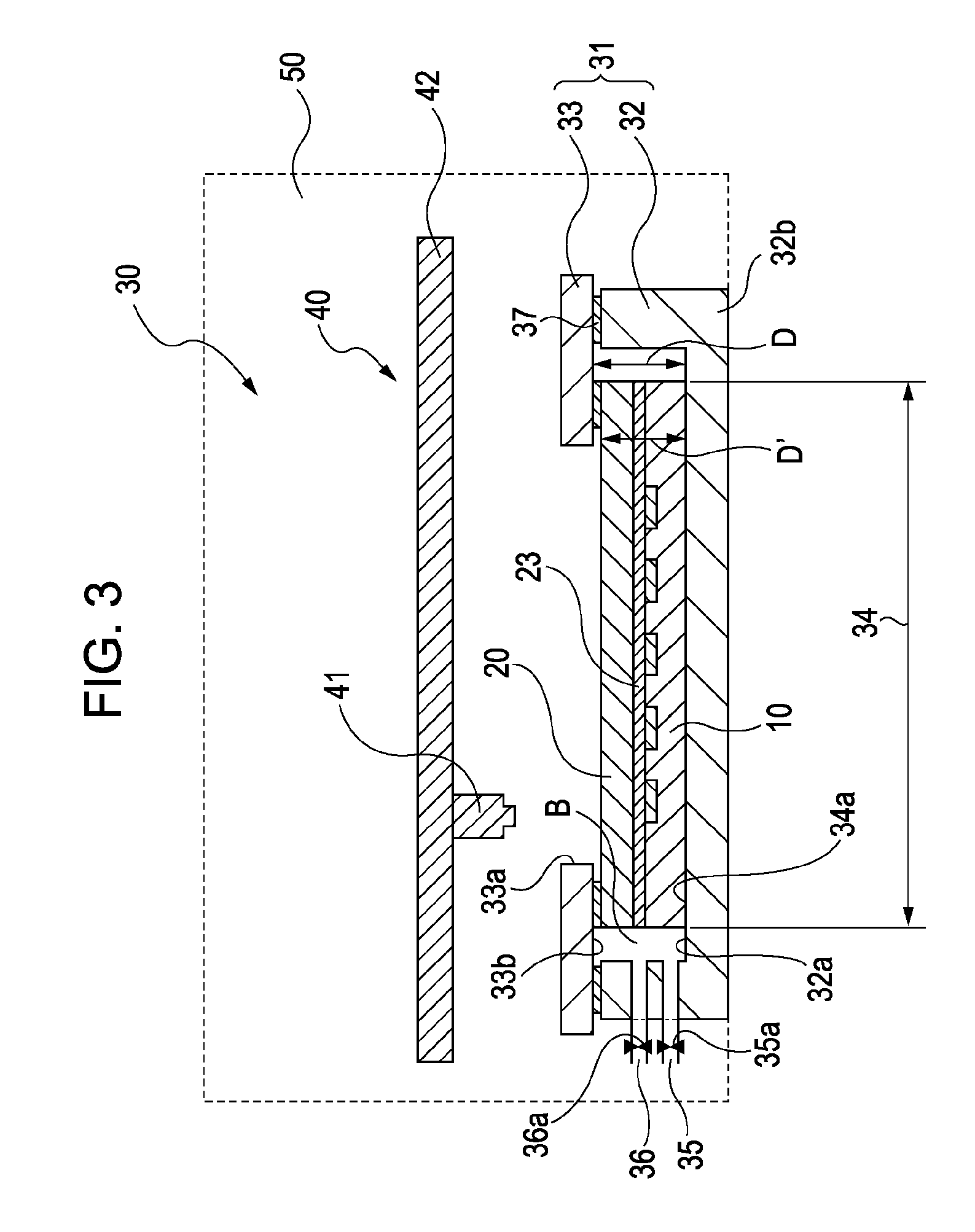

Transfer method and transfer apparatus

InactiveUS20060243377A1Simple structureReduce capacityElectrical apparatusDecorative surface effectsOptoelectronics

A transfer method includes the steps of placing a donor substrate including a support base and a transfer layer provided on the support base onto a receptor substrate such that the transfer layer faces the receptor substrate, evacuating a space between the receptor substrate and the donor substrate that are placed one on the other, and transferring the transfer layer onto the receptor substrate by applying a radiant ray onto the donor substrate in an evacuated atmosphere.

Owner:SONY CORP

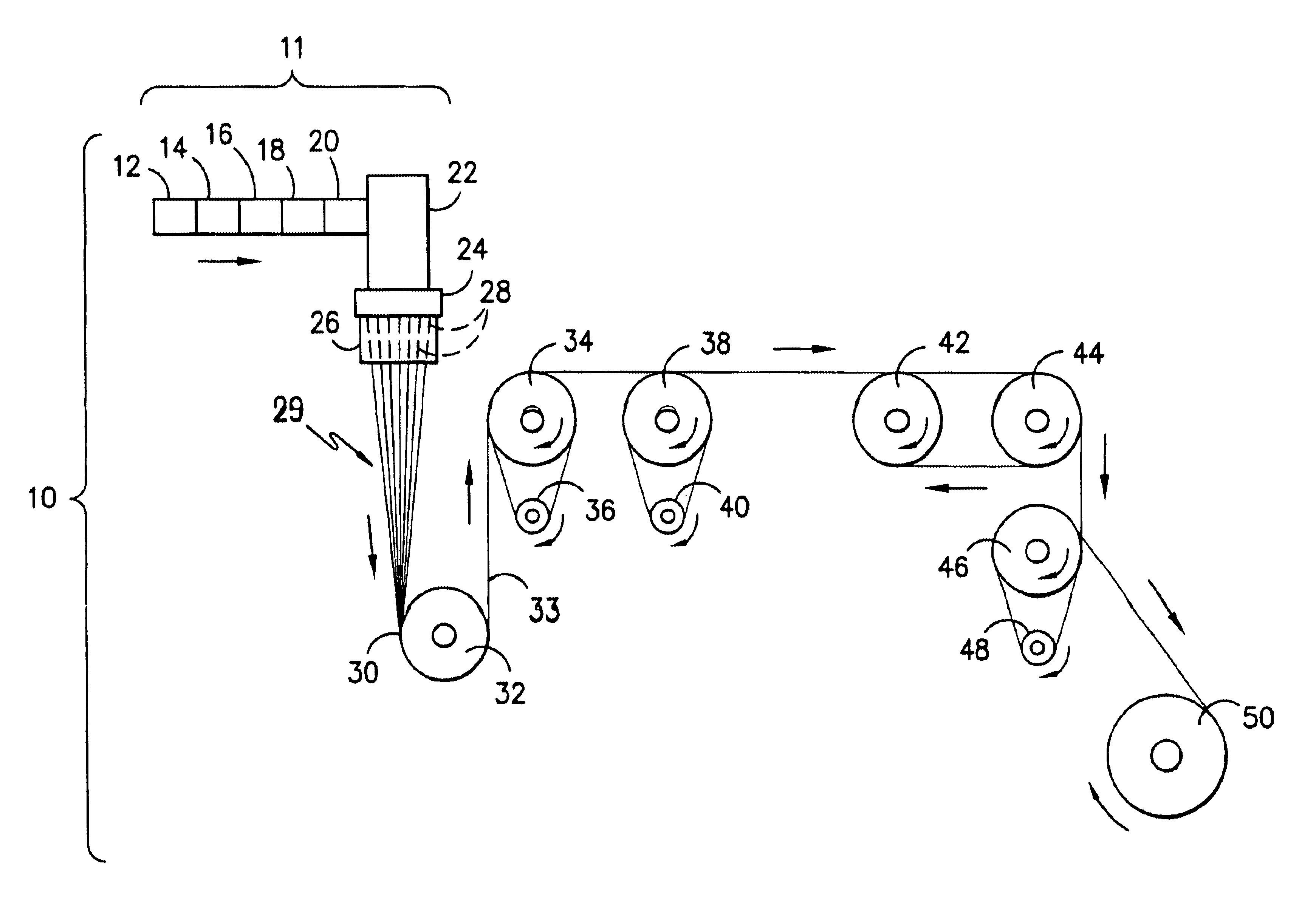

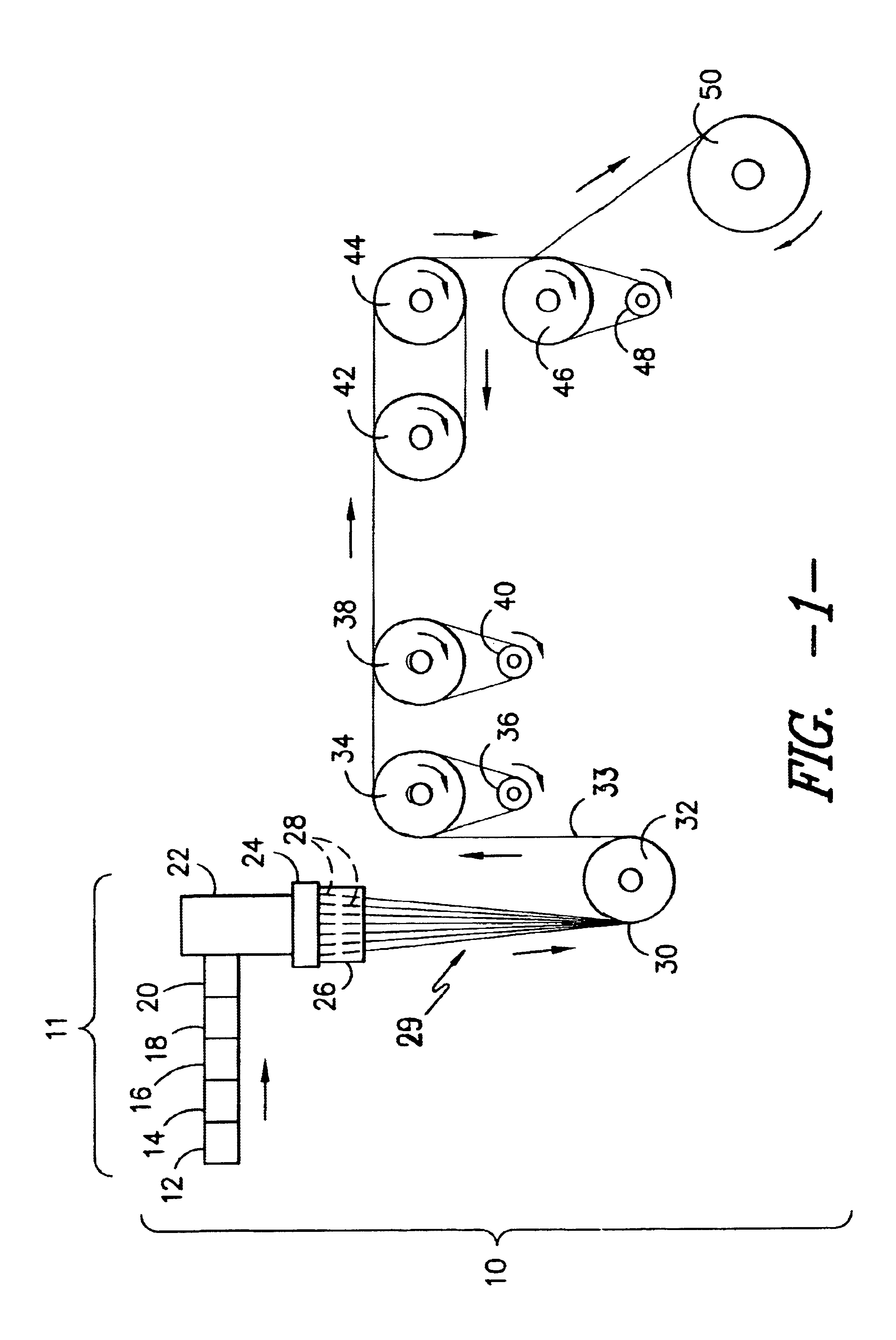

Thermoplastic fibers exhibiting durable high color strength characteristics

InactiveUS6849330B1Reduce extractionQuick and efficient changeoverFireproof paintsSynthetic resin layered productsYarnPolymer science

Improvements in permitting brighter colorations within polypropylene fibers and / or yarns while simultaneously providing more efficient production methods of manufacturing of such colored fibers as well are provided. Generally, such fibers and / or yarns have been colored with pigments, which exhibit dulled results, or dyes, which exhibit high degrees of extraction and low levels of lightfastness. Such dull appearances, high extraction levels, and less than stellar lightfastness properties negatively impact the provision of such desirable colored polypropylene fibers and / or yarns which, in turn, prevents the widespread utilization of such fibers and yarns in various end-use applications. Thus, it has surprisingly been determined that brighter colorations, excellent extraction, and more-than-acceptable lightfastness characteristics can be provided, preferably, through manufacture with certain polymeric colorants that include poly(oxyalkylene) groups thereon. Fabric articles comprising such novel fibers and / or yarns are also encompassed within this invention.

Owner:MILLIKEN & CO

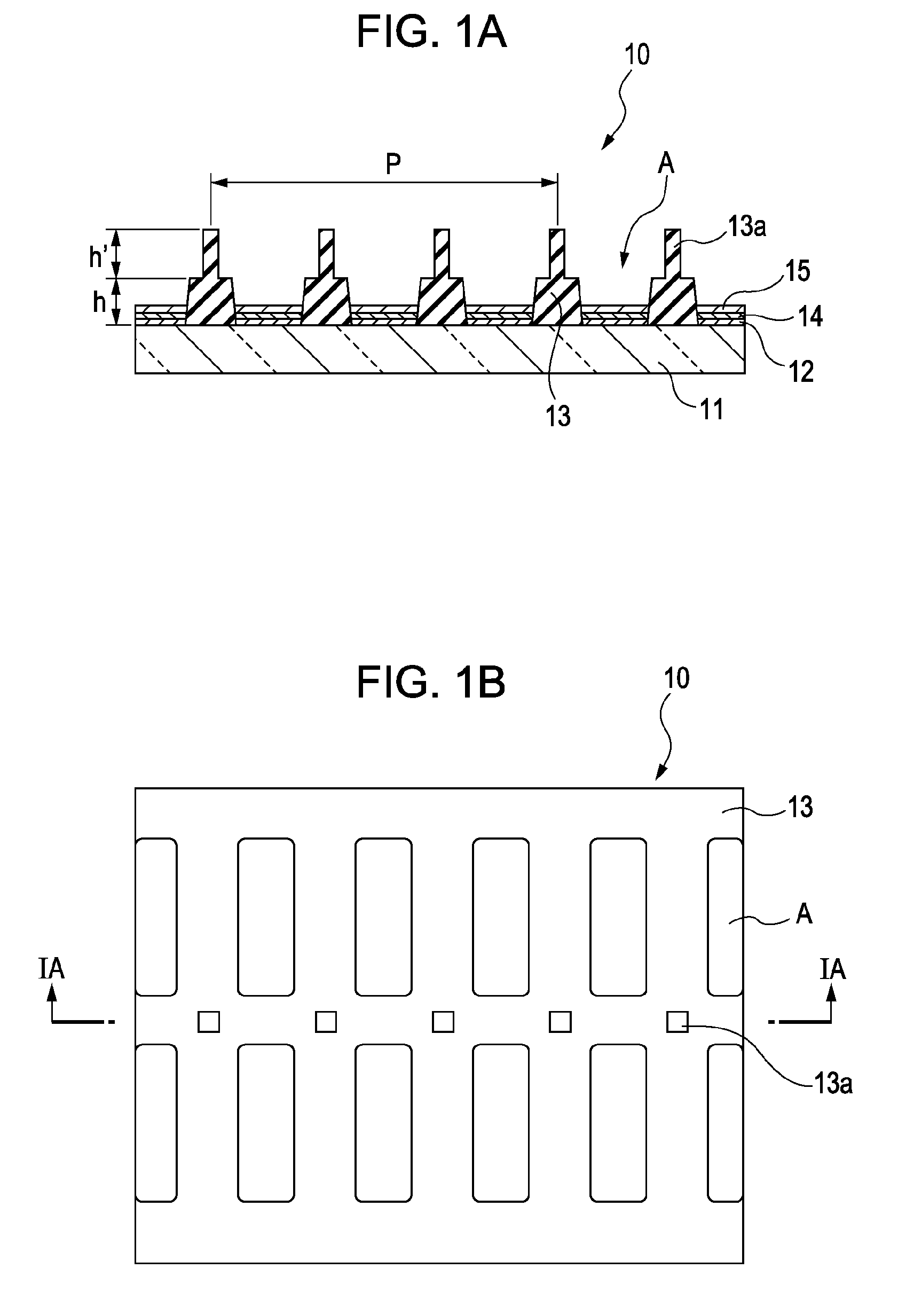

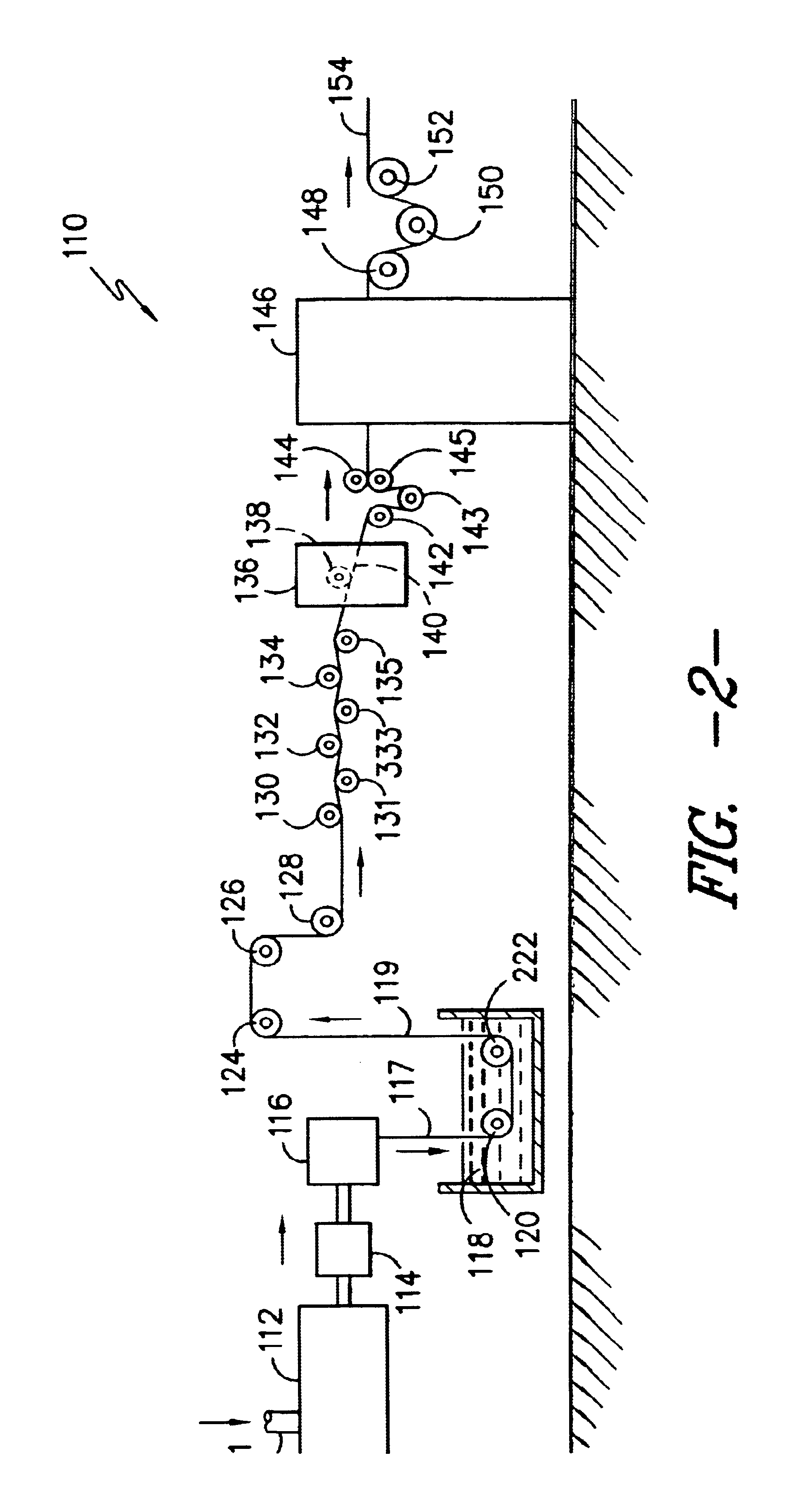

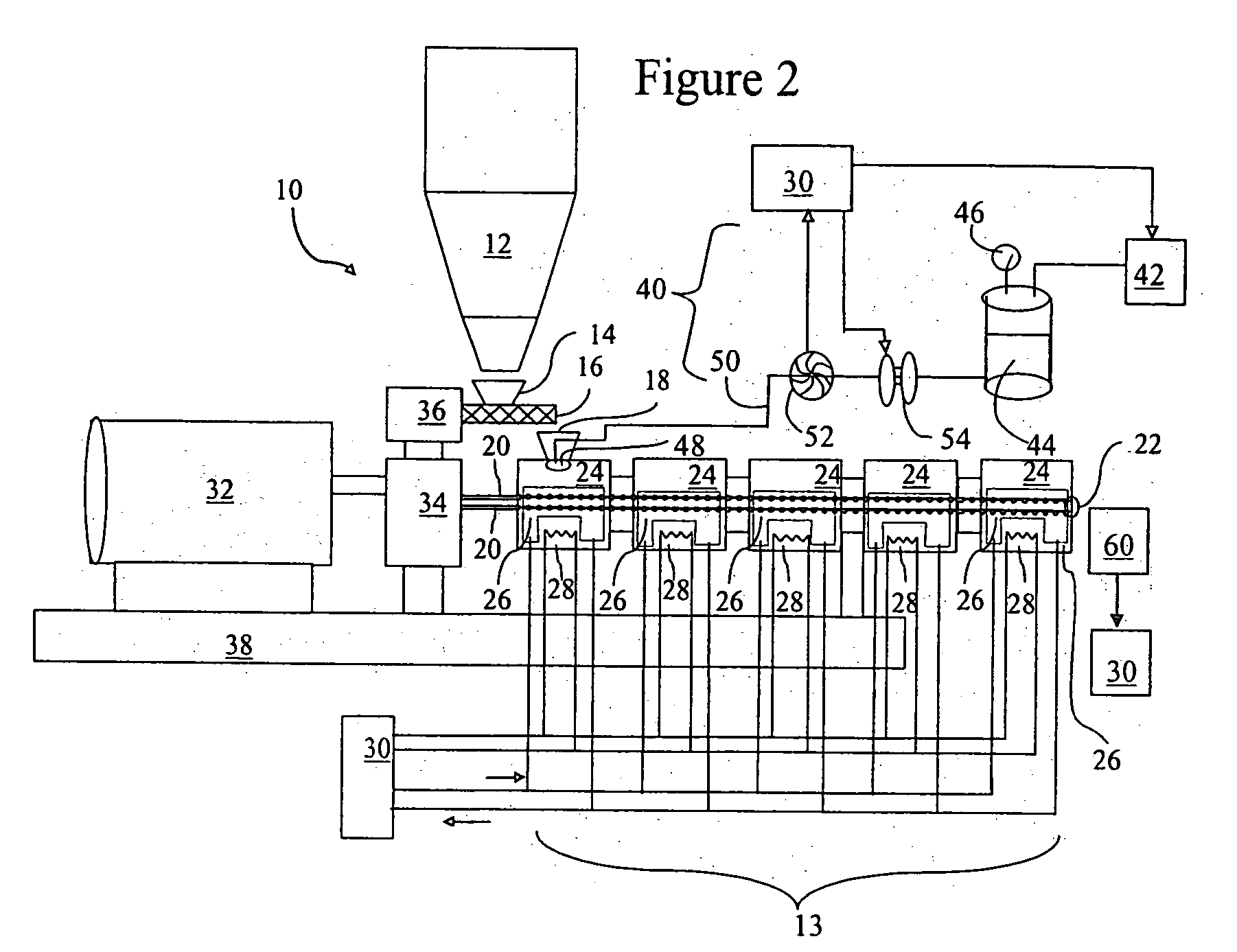

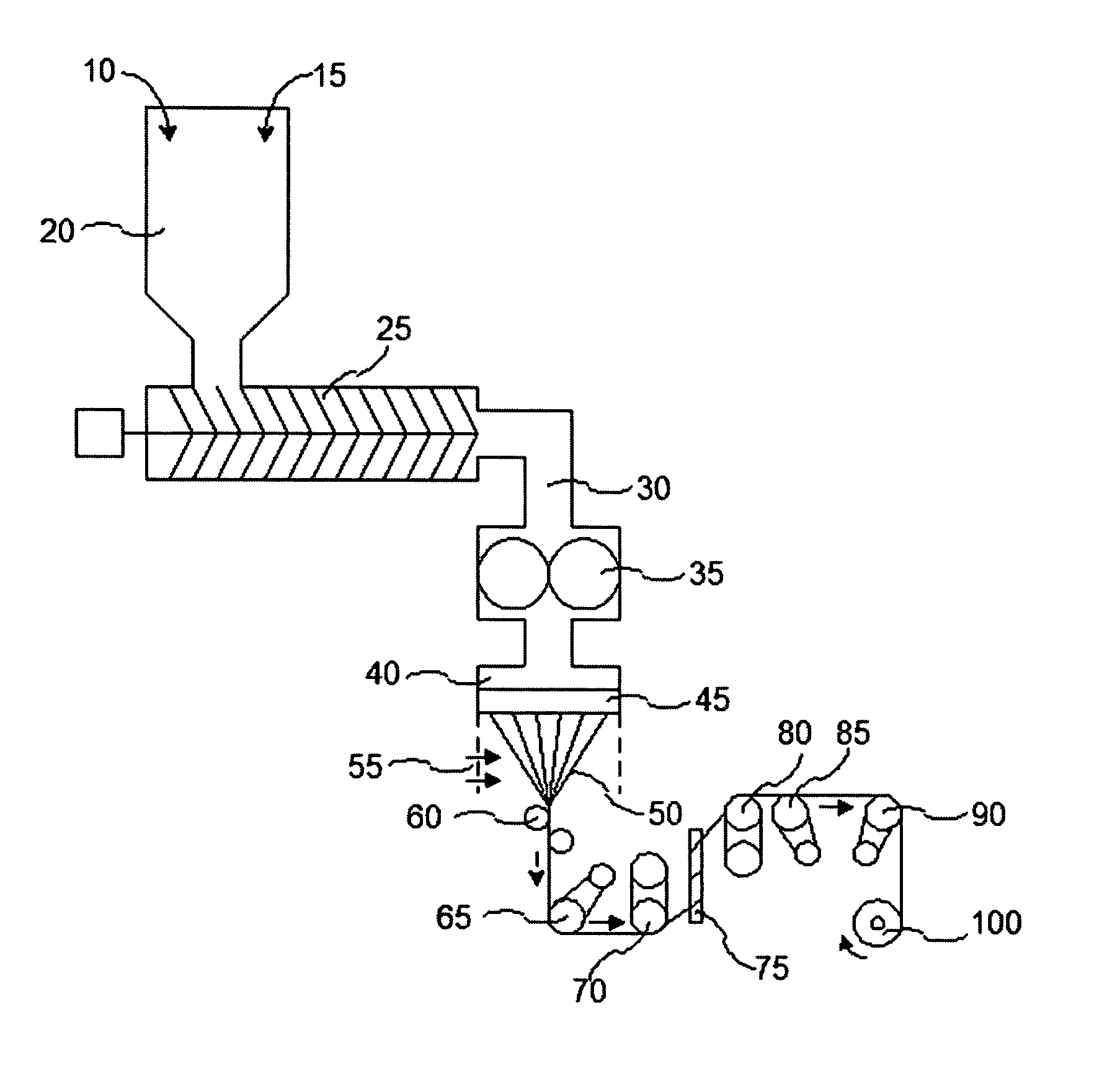

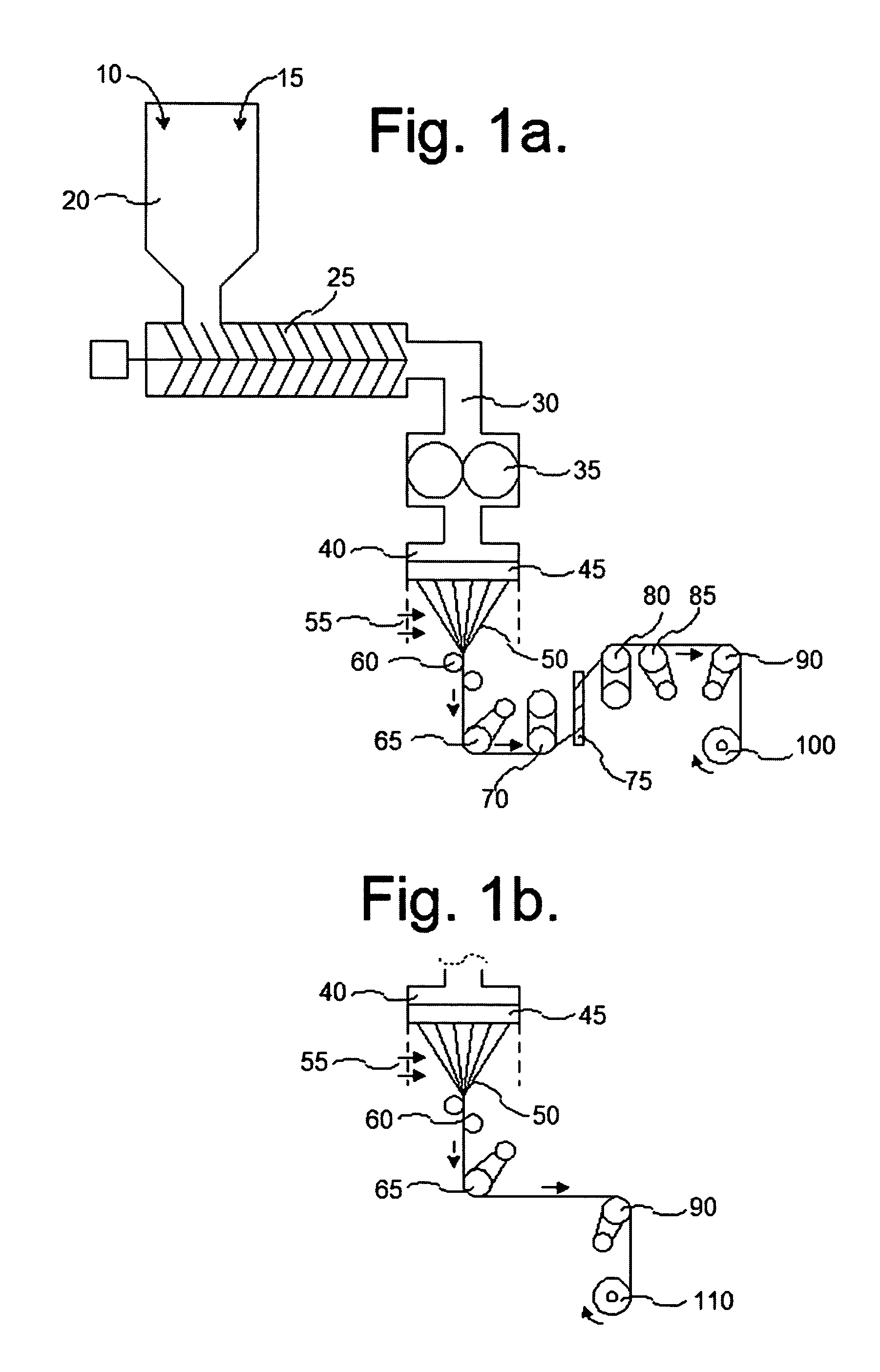

Methods and systems for manufacturing the manufacture of layered three-dimensional forms

ActiveUS20080237933A1Efficiently reclaim and re-useEfficient use ofAdditive manufacturing apparatusArtificial filament recoveryParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

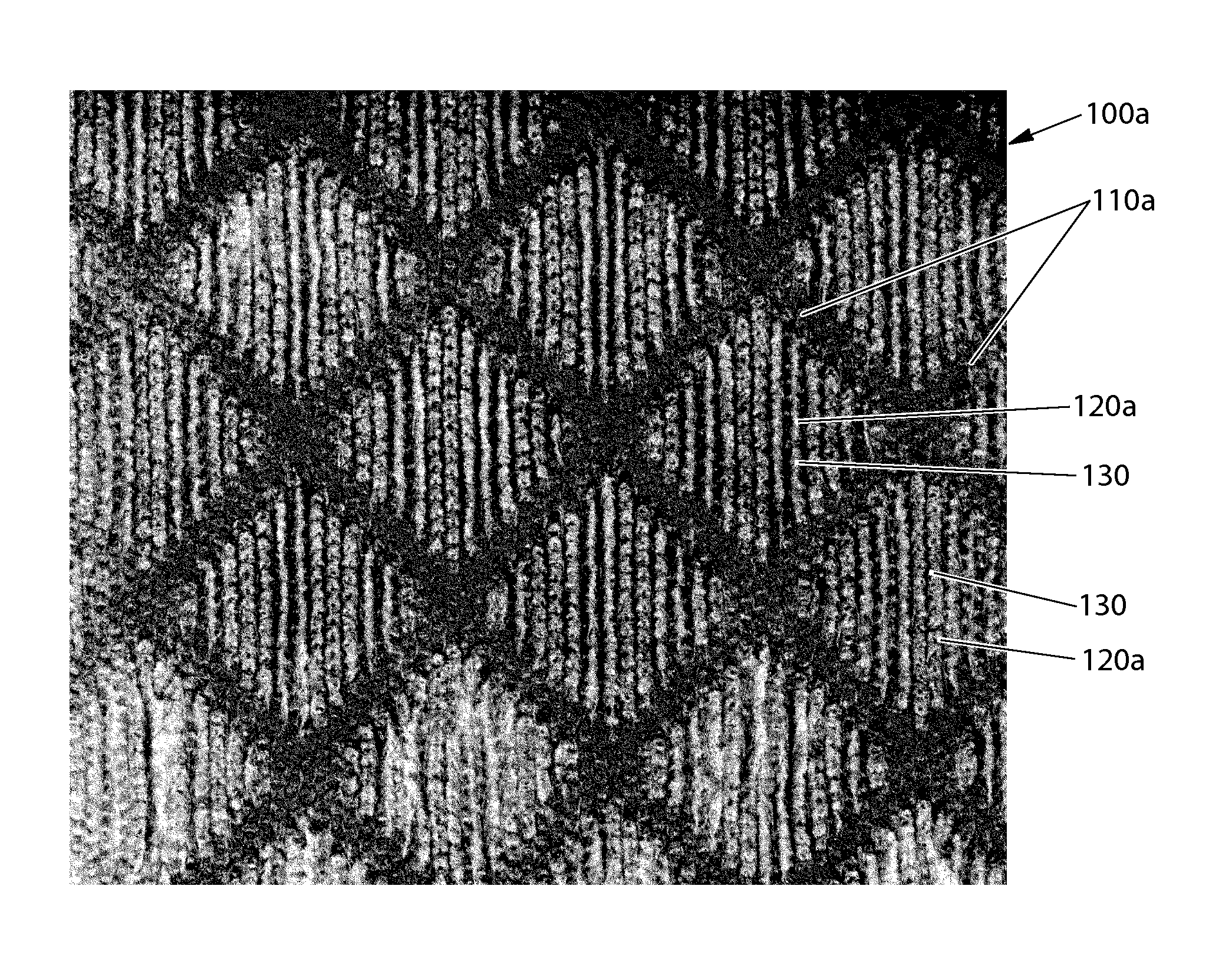

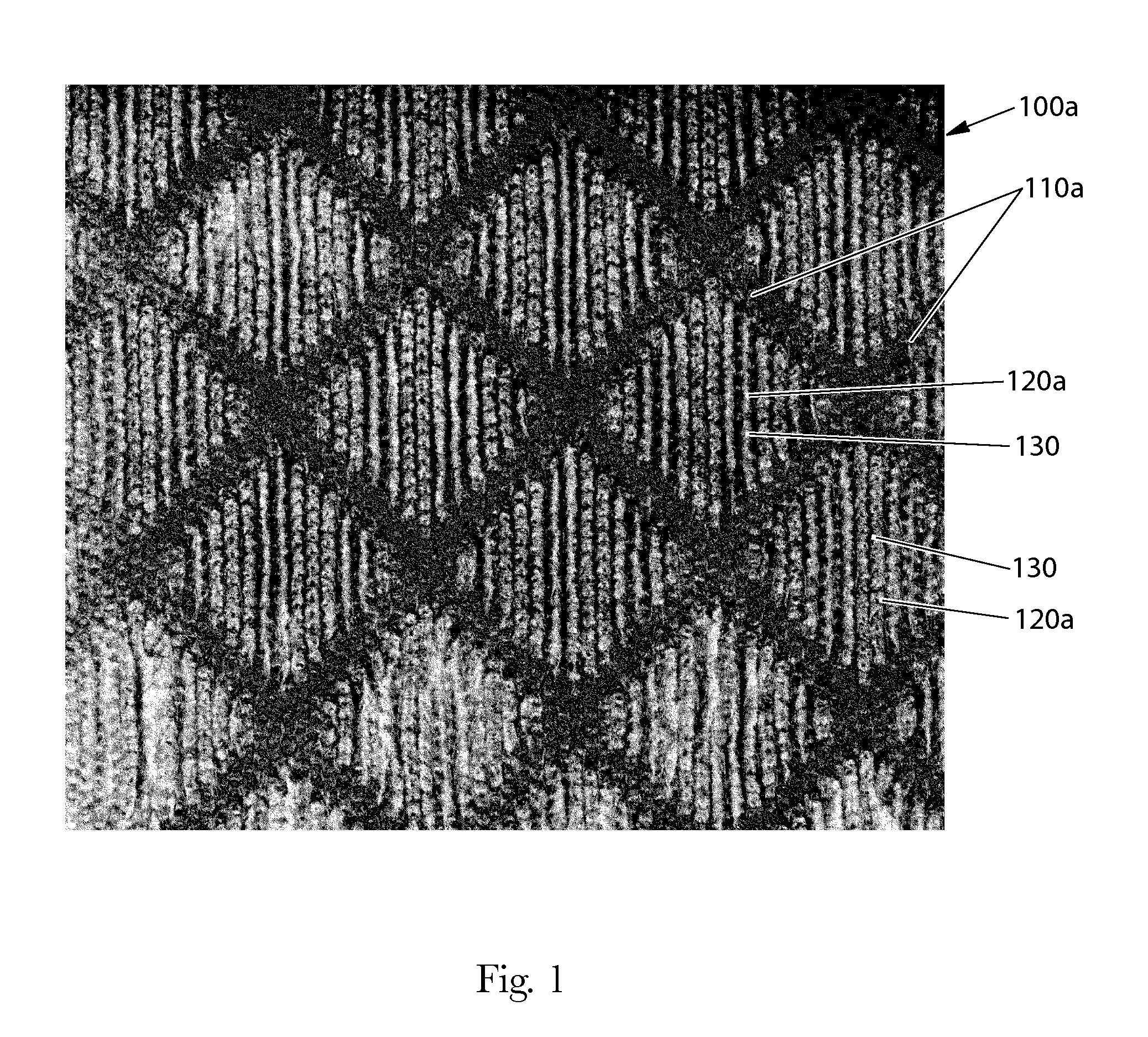

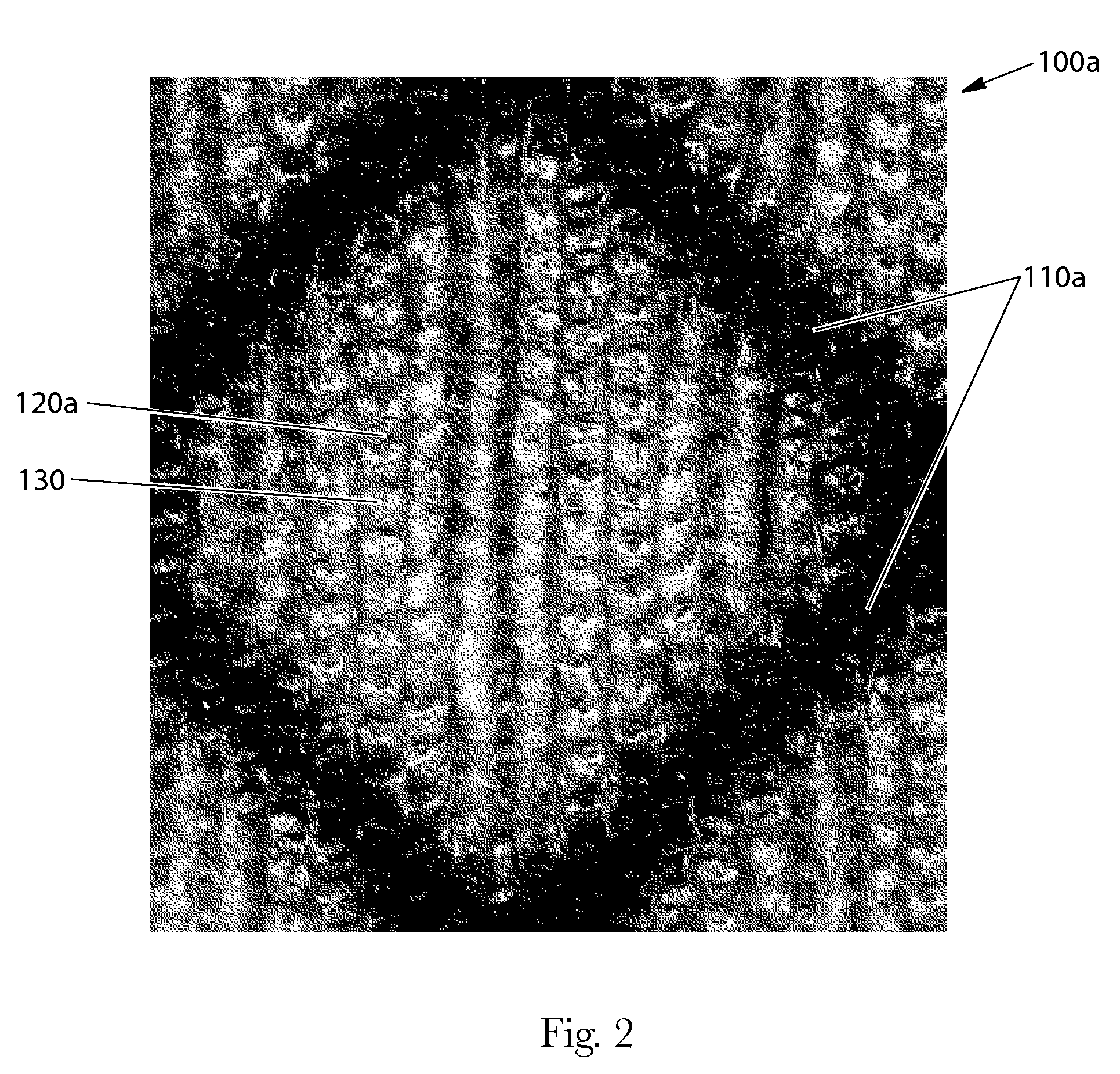

Method of Producing a Web Substrate Having Activated Color Regions in Deformed Regions

Owner:THE PROCTER & GAMBLE COMPANY

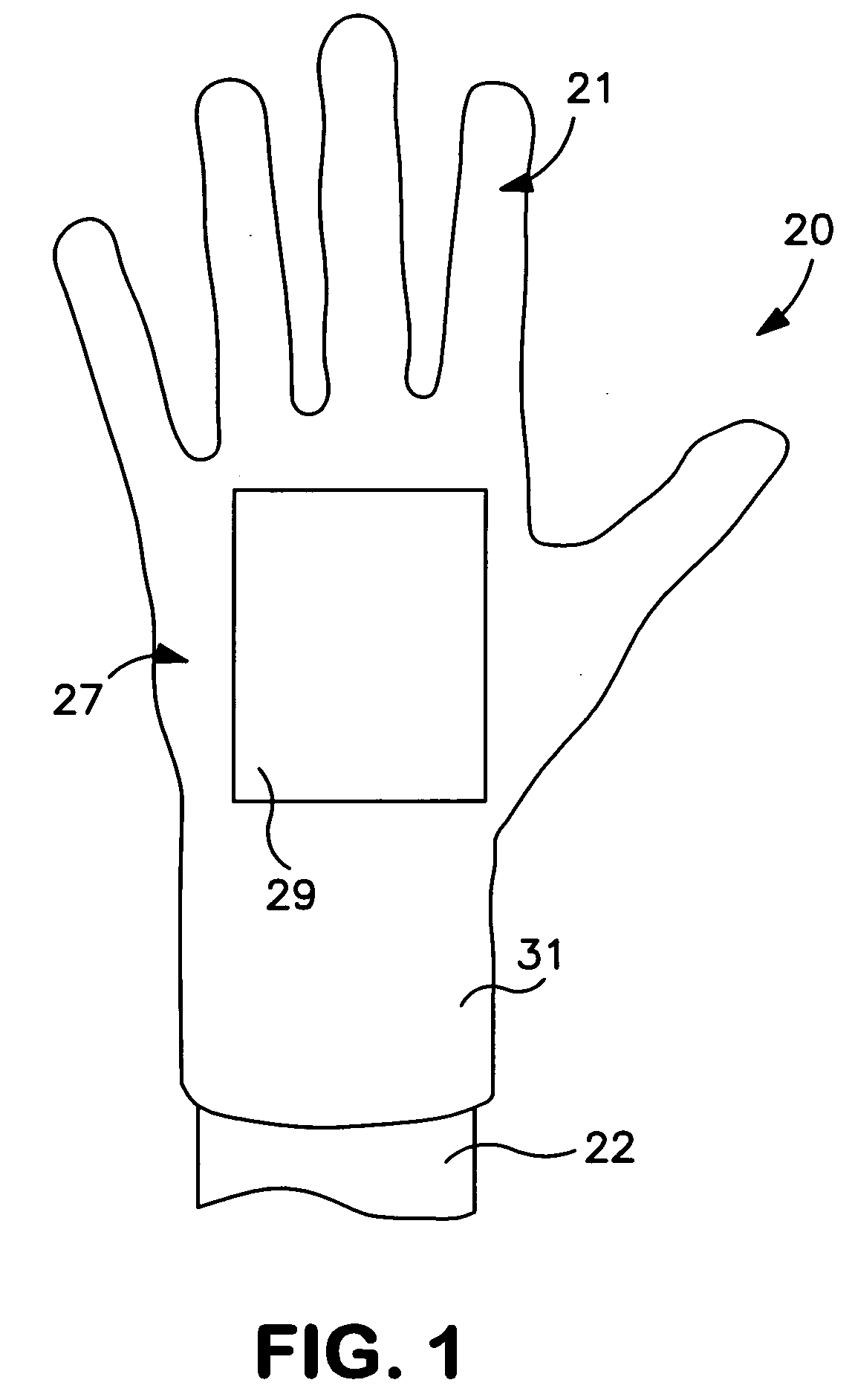

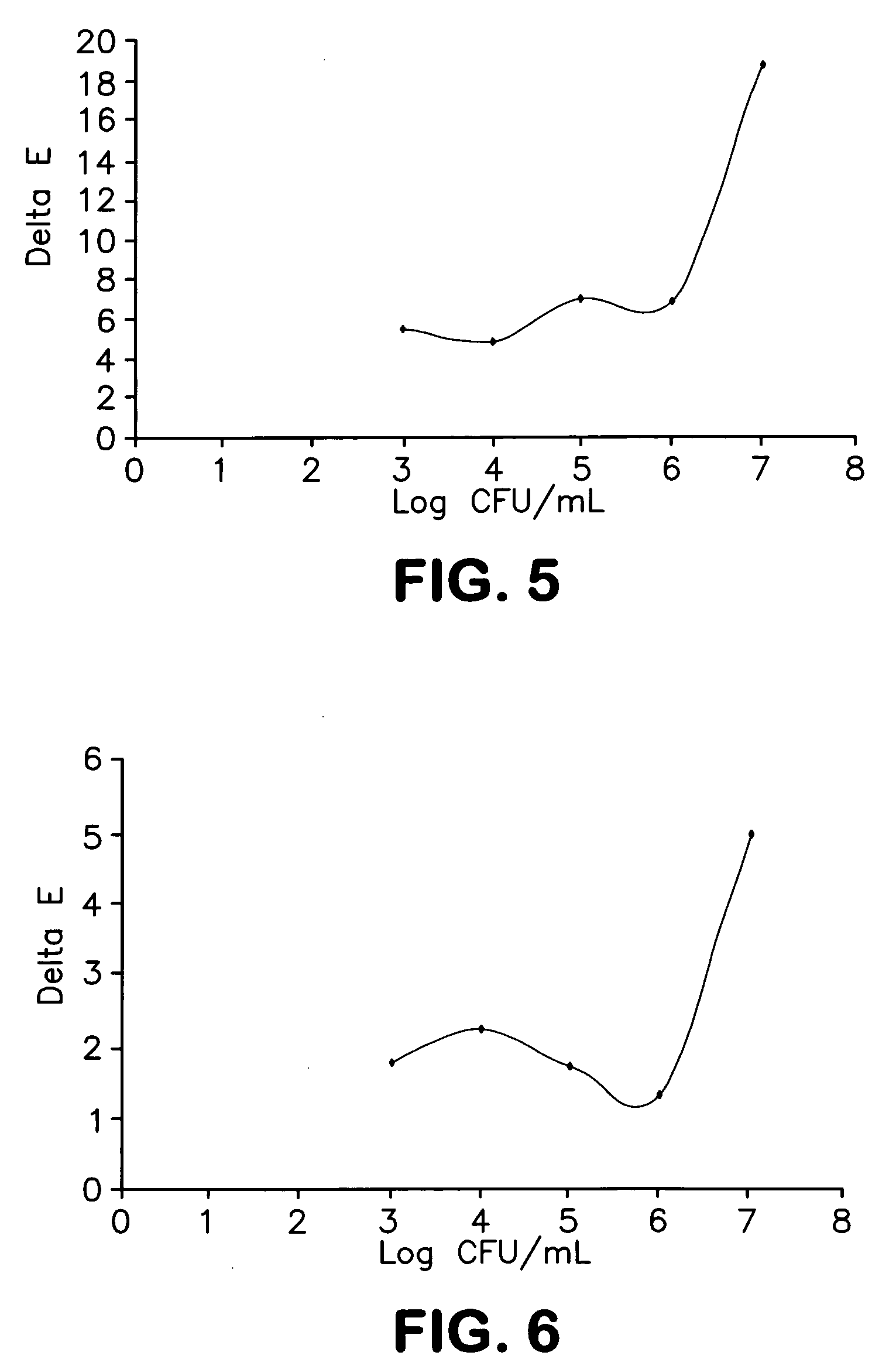

Detection of microbe contamination on elastomeric articles

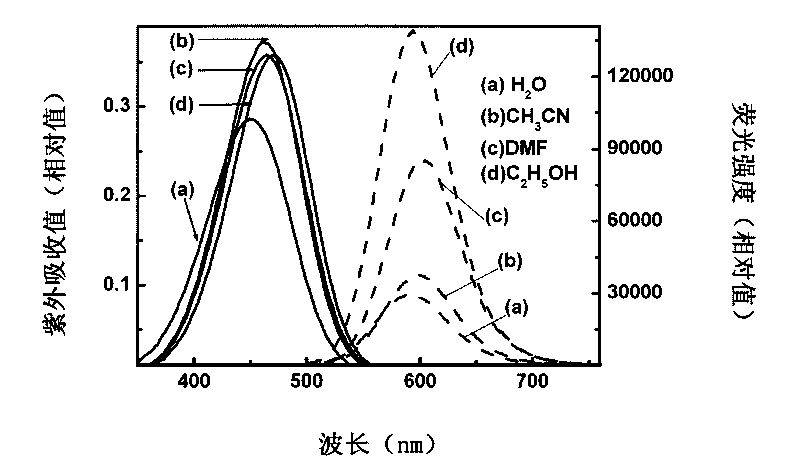

ActiveUS20060134613A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismOxidation-Reduction Agent

An elastomeric article that contains a chromogen that undergoes a detectable change in color in the presence of one or more microbes is provided. For example, in one embodiment, the chromogen is a solvatochromic dye (e.g., Reichardt's dye) that undergoes a color change in the presence of bacteria or other microbes. More specifically, such dyes may respond to differences in polarity between microbe components (e.g., cell membrane, cytoplasm, etc.) and the environment outside the cell. Alternatively, other mechanisms may be wholly or partially responsible for the interaction between the dye and the microbe, such as acid-base reactions, redox reactions, and so forth.

Owner:O&M HALYARD INC

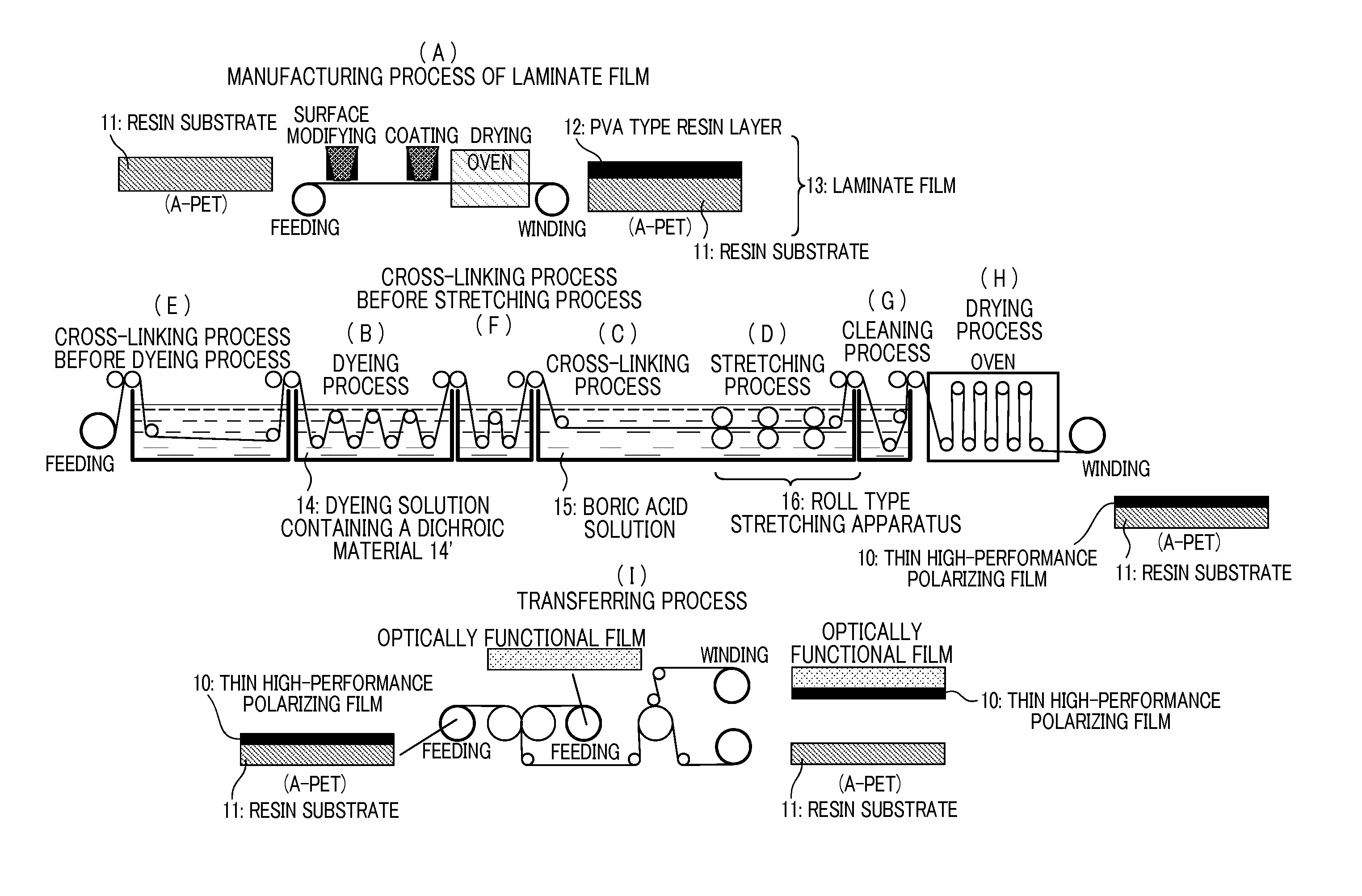

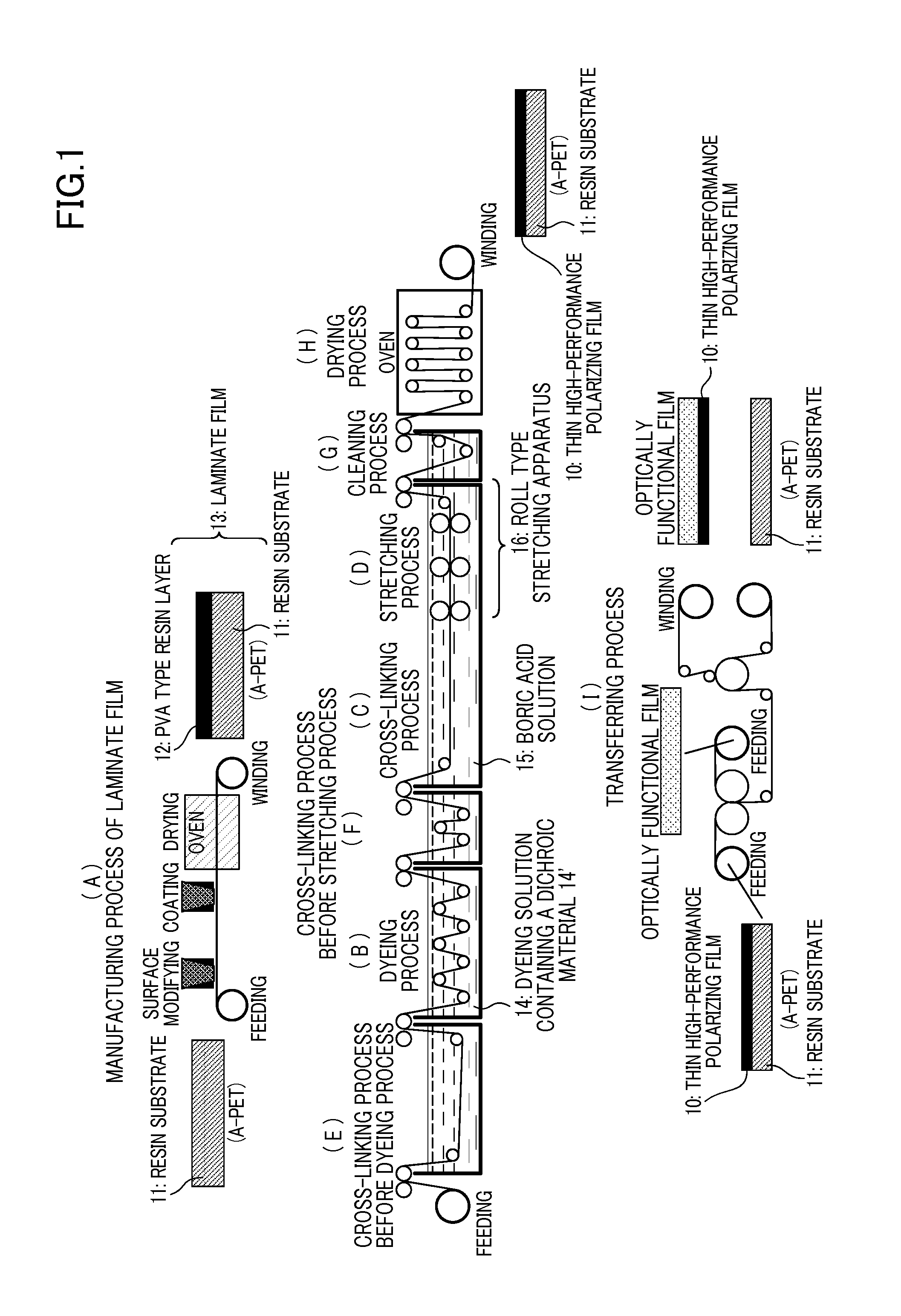

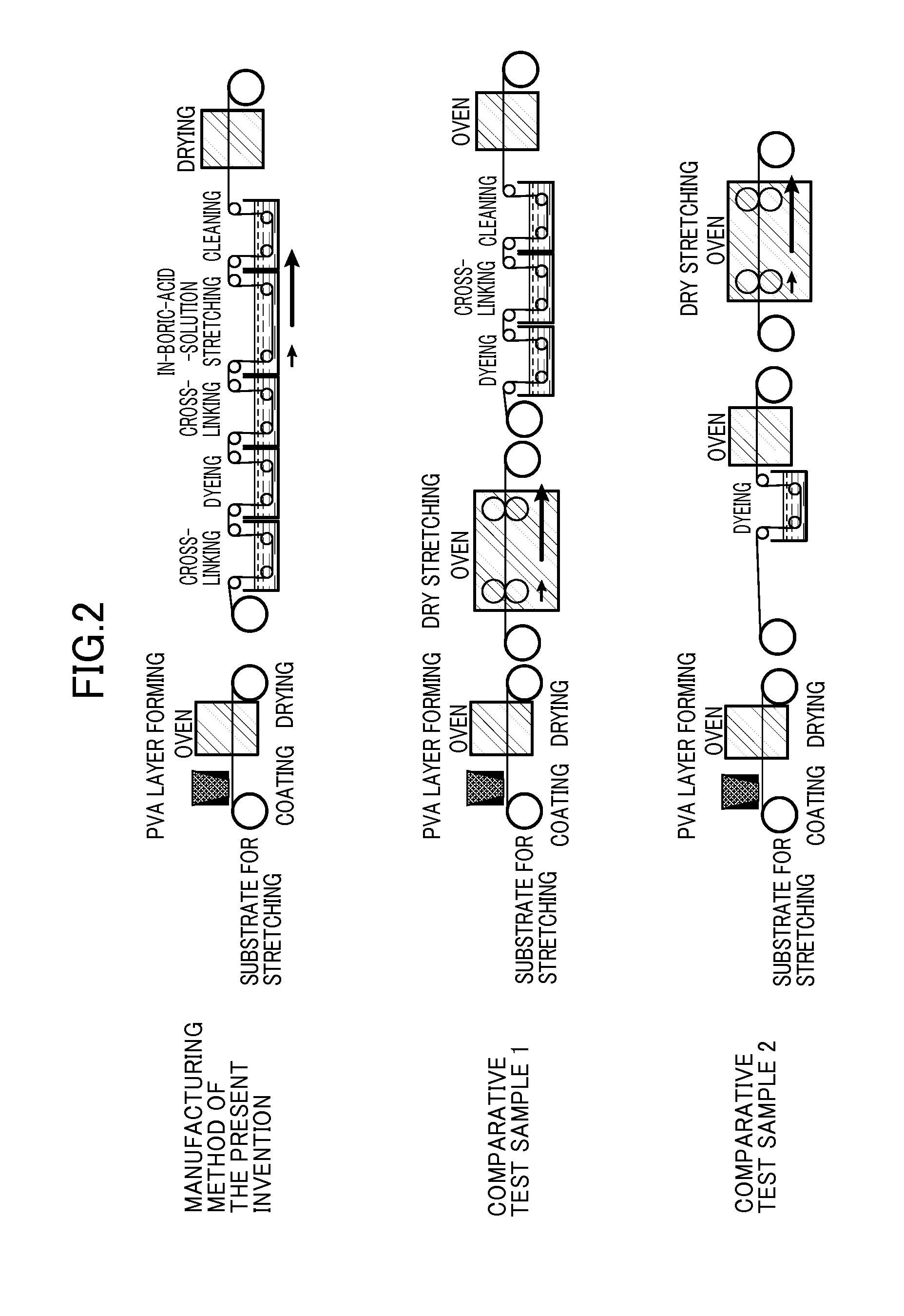

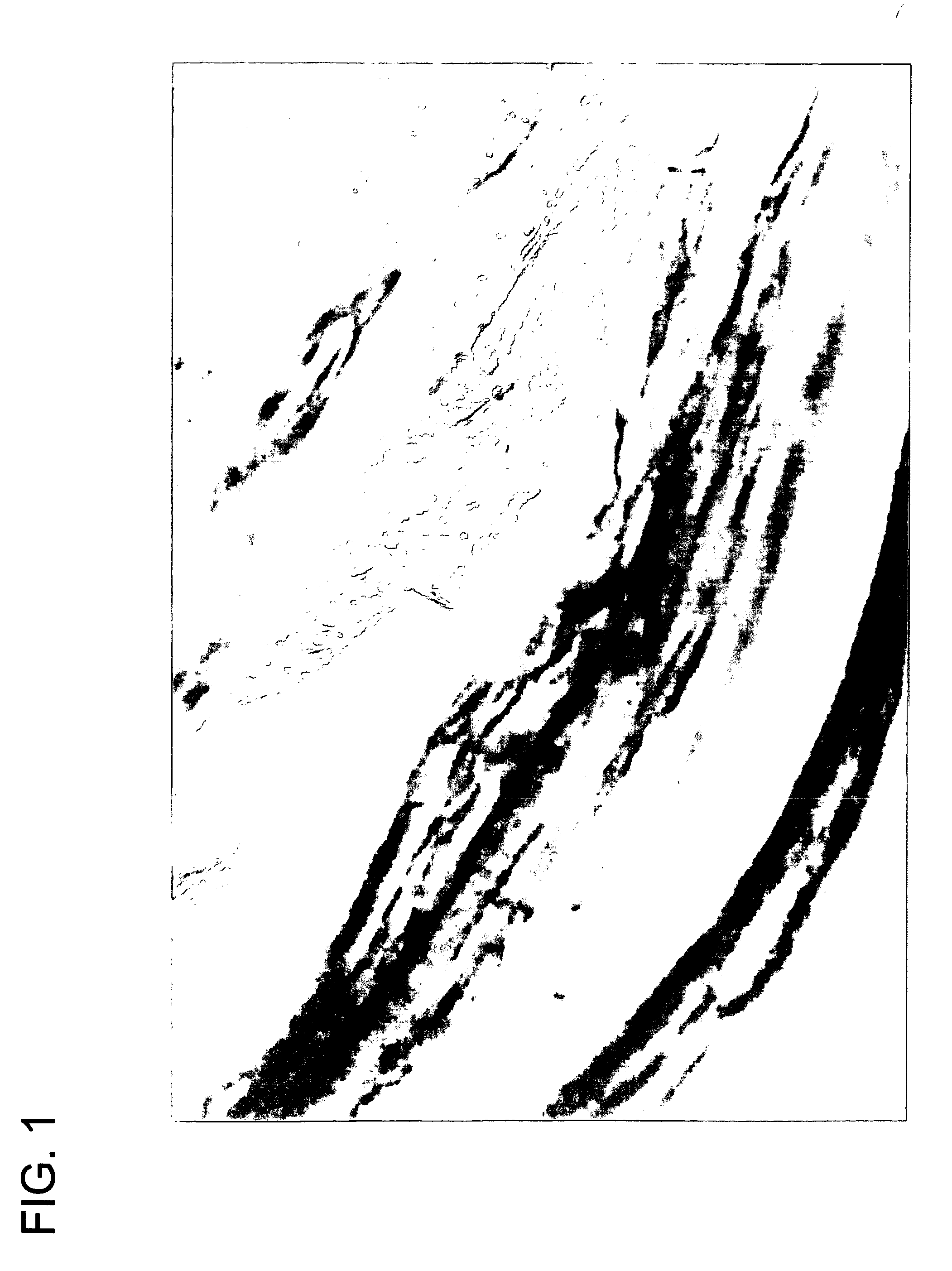

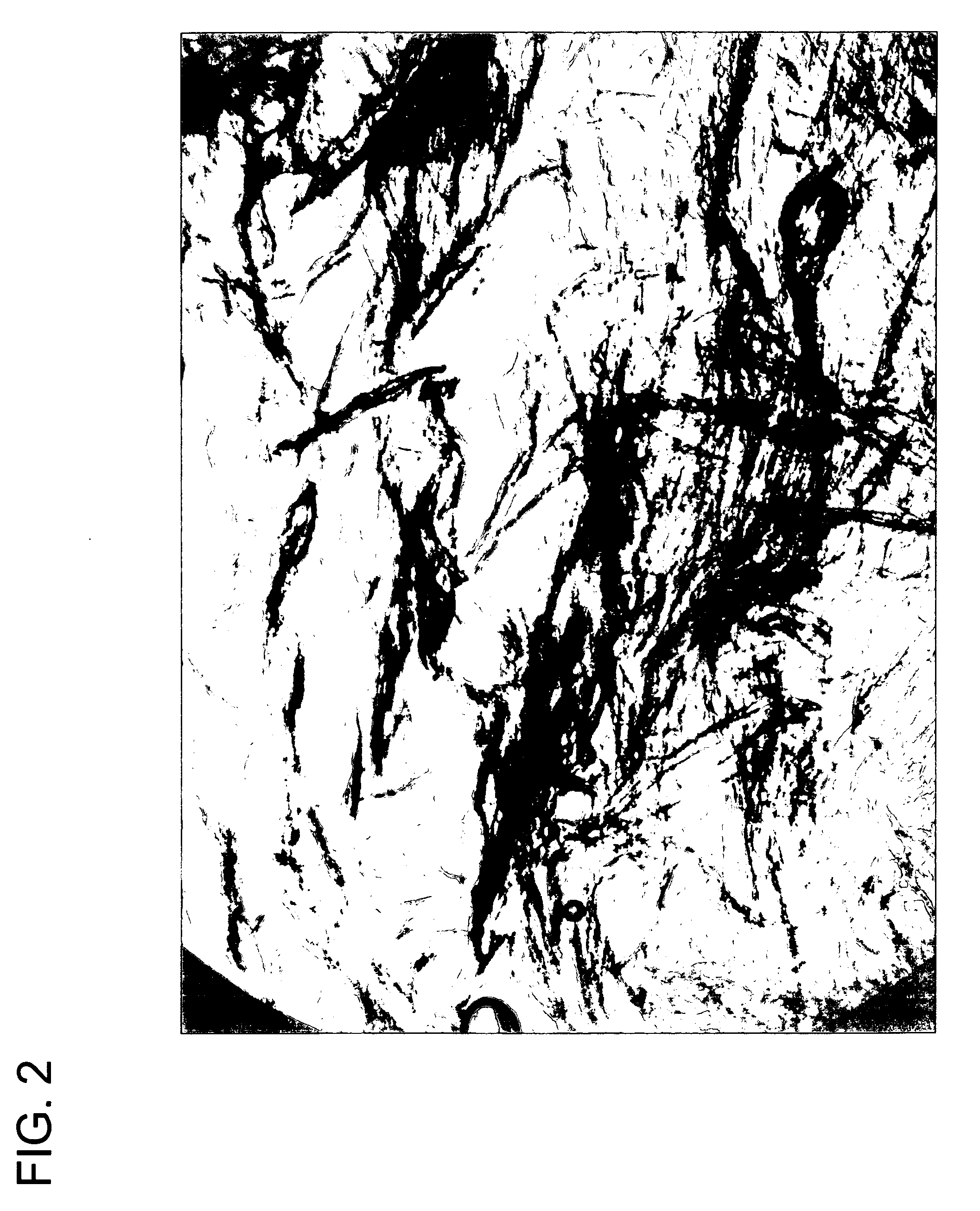

Thin high-performance polarizing film and method for manufacturing the same

InactiveUS20110315306A1High magnificationReduced optical performanceMonocomponent cellulose artificial filamentPolarising elementsStretch ratioBoric acid

A method for manufacturing a thin high-performance polarizing film includes coating a polyvinyl alcohol type resin on a resin substrate having a thickness of at least 20 μm and then drying the resin to thereby form a polyvinyl alcohol type resin layer, immersing thus produced polyvinyl alcohol type resin layer in a dyeing solution including a dichroic material to thereby have the dichroic material impregnated in the polyvinyl alcohol type resin layer, stretching the polyvinyl alcohol type resin layer having the dichroic material impregnated therein together with the resin substrate in a boric acid solution such that a total stretching ratio of 5.0 or more of the original length is achieved.

Owner:NITTO DENKO CORP

Colored Structured Protein Products

InactiveUS20080254199A1Monocomponent protein artificial filamentConfectioneryProtein fiberColoring agents

The present invention provides a process for producing a colored structured protein product with protein fibers that are substantially aligned and the resultant product. Specifically, the plant protein is combined with a colorant and extruded, forming a colored structured protein product with protein fibers that are substantially aligned and the resultant product.

Owner:SOLAE LLC

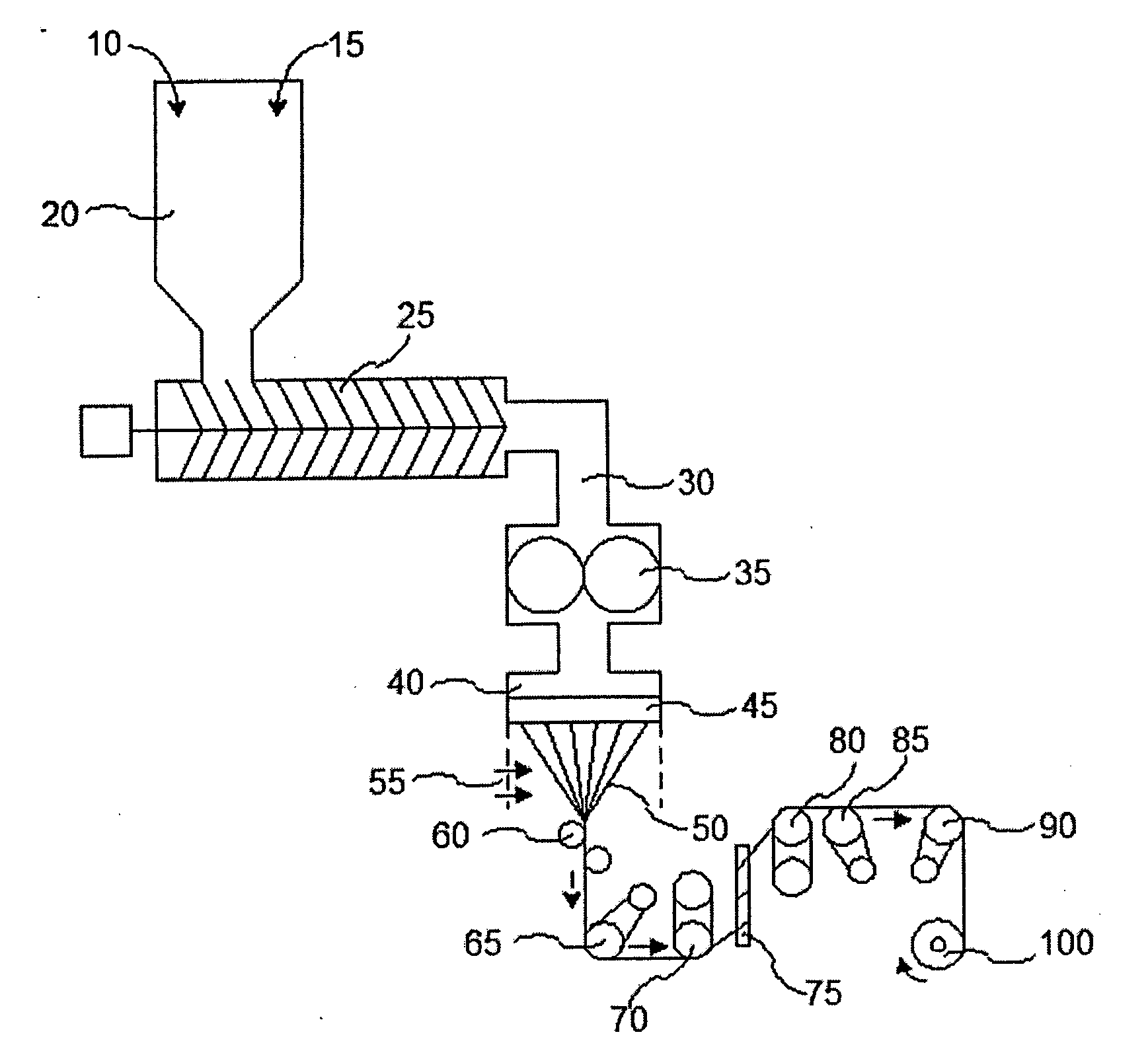

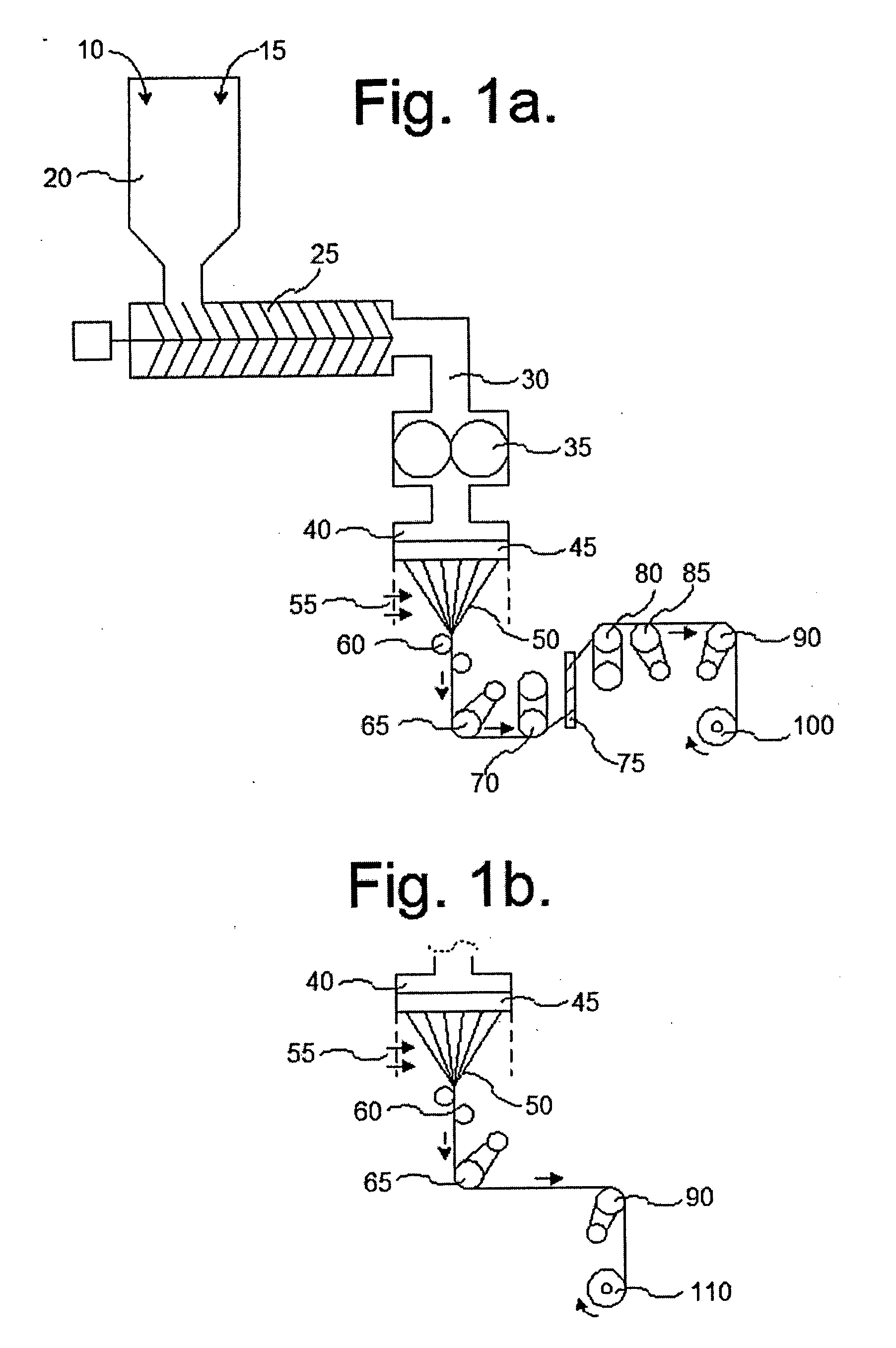

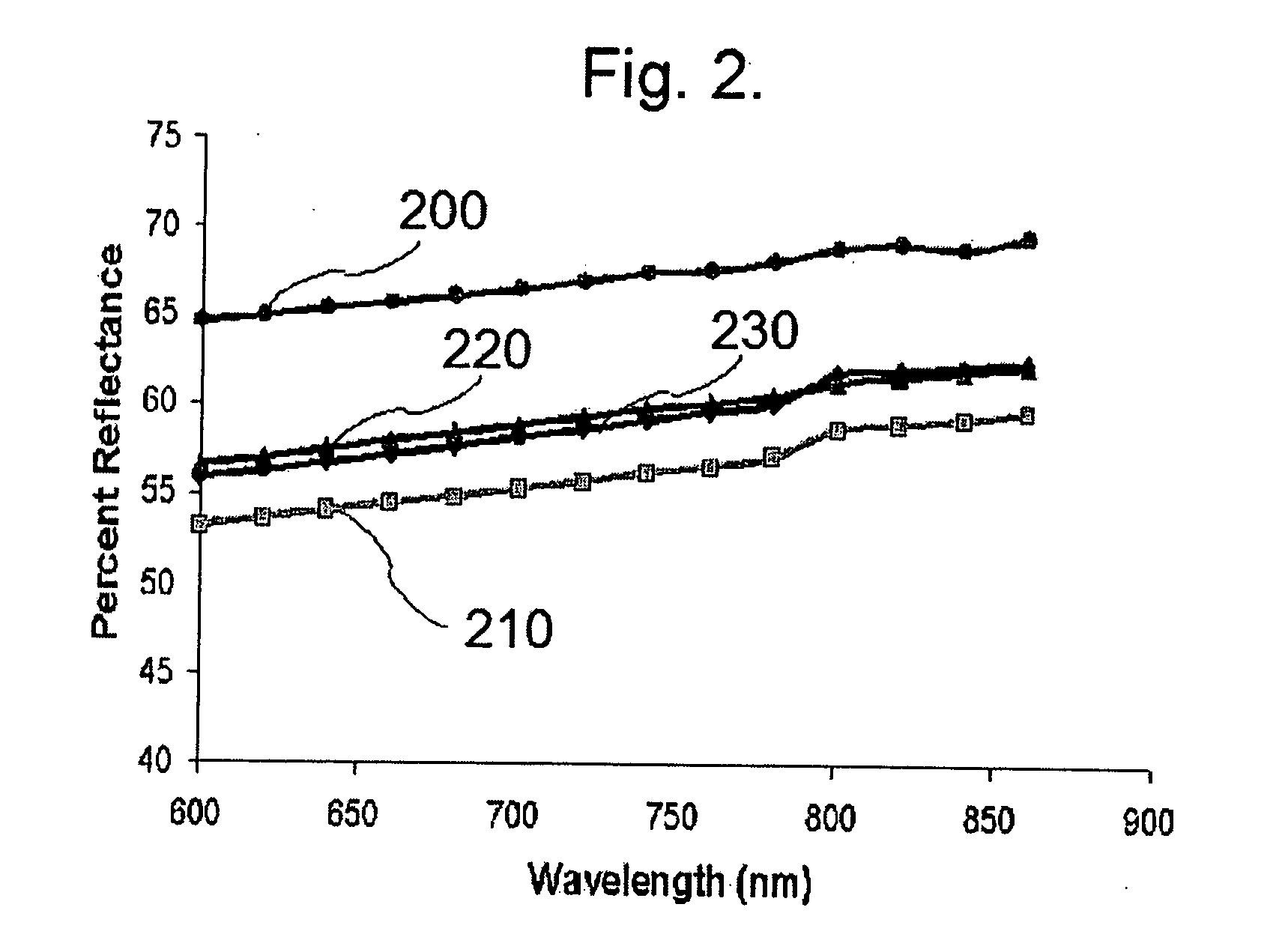

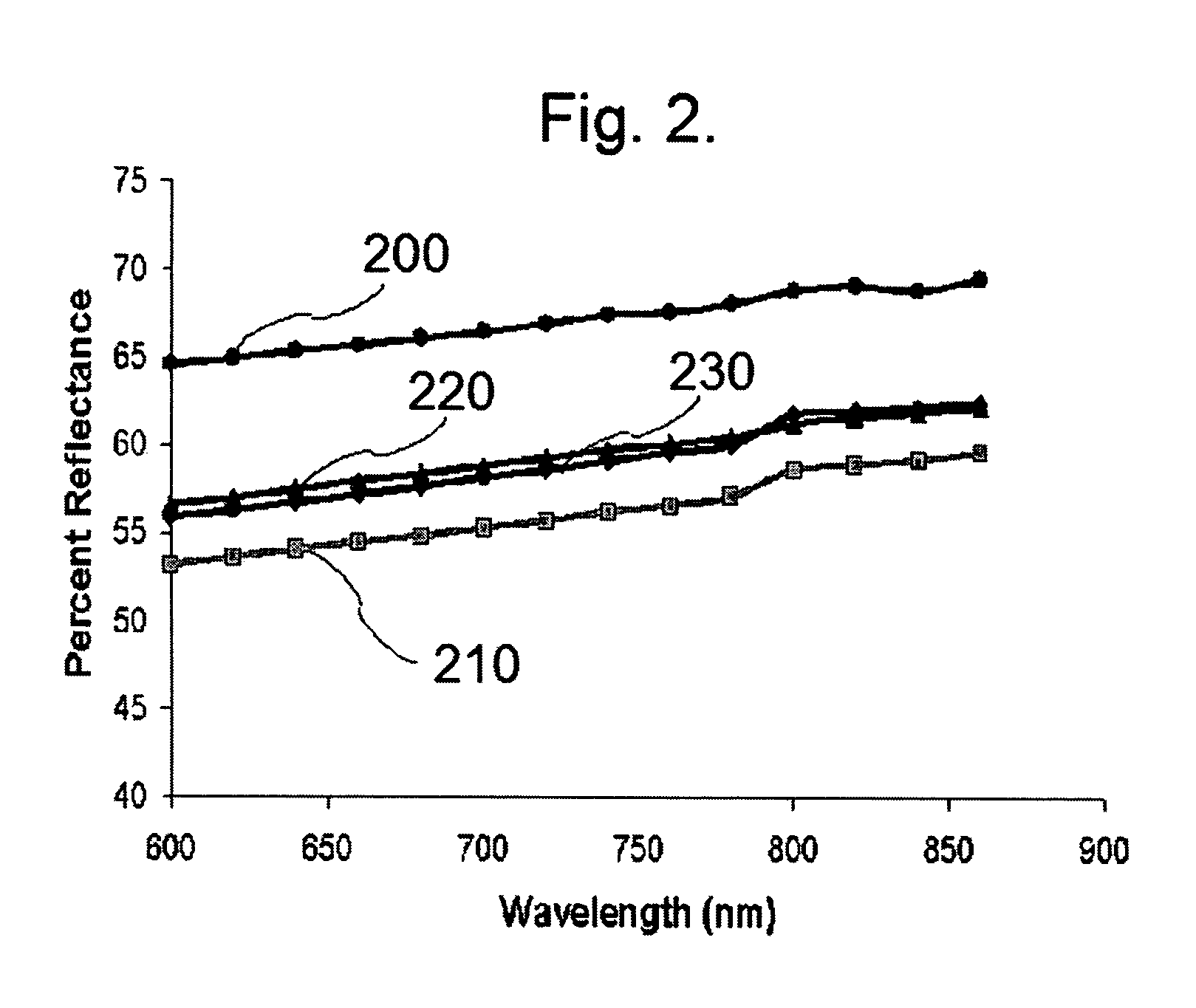

Polymer fibers, fabrics and equipment with a modified near infrared reflectance signature

InactiveUS20060234050A1Readily dyed and printedHigh dye absorption propertyFilament/thread formingCamouflage devicesPolyamideNear infrared reflectance

A modified synthetic polymer filament and multifilament yarn of polyamide or polyester filament containing a carbon black polymer additive, and fabrics from these yarns, are disclosed. These melt spun filaments are especially well-suited for use in garments and equipment where a modified Near Infrared Reflectance (NIR) signature is desired. The yarn and fabrics made from this yarn may be advantageously dyed or printed to provide a camouflage fabric for use in desert sand dominated environments, urban environments and multi-terrain environments.

Owner:INVISTA NORTH AMERICA S A R L

Polyurethane fibers and films

InactiveUS6203901B1Monocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberPolyurethane

Owner:INVISTA NORTH AMERICA R L

Process for manufacturing powder coating compositions introducing hard to incorporate additives and/or providing dynamic color control

InactiveUS20050212159A1Sufficiently dispersedGood colorMonocomponent cellulose artificial filamentPowdery paintsMaterials sciencePowder coating

An extrusion process for manufacturing thermosetting powder coating compositions is disclosed. A base material is fed to an extruder body such as from a pre-mix hopper; in one embodiment, hard to incorporate additives, such as pigments, are added to the base material after they exit from the pre-mix hopper and before they exit from the extruder body. In another embodiment, hard to incorporate additives in a dried form are added with the base material. The combined base material and hard to incorporate additives are mixed through at least a portion of the extruder body to form a homogeneous thermosetting powder coating composition. The output of the extruder body may be monitored for composition accuracy, wherein the amount of hard to incorporate additives added is dynamically adjusted based upon the monitored output. The process may be repeated for thermosetting powder coating compositions having distinct hard to incorporate additives utilizing a common base material in the pre-mix hopper. Use of one or more hyperdispersed pigments in the formation of a powder coating is also disclosed.

Owner:PPG IND OHIO INC

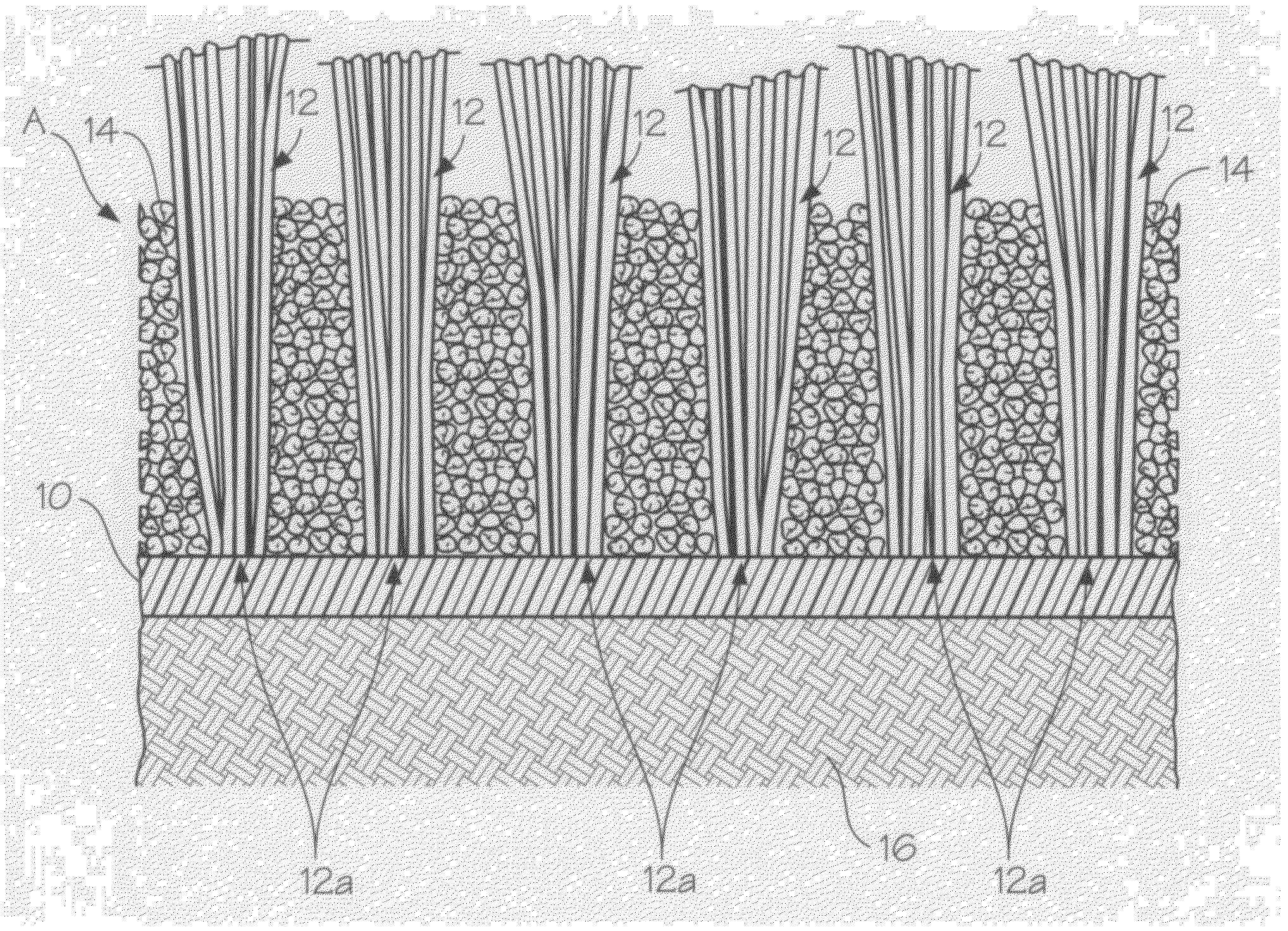

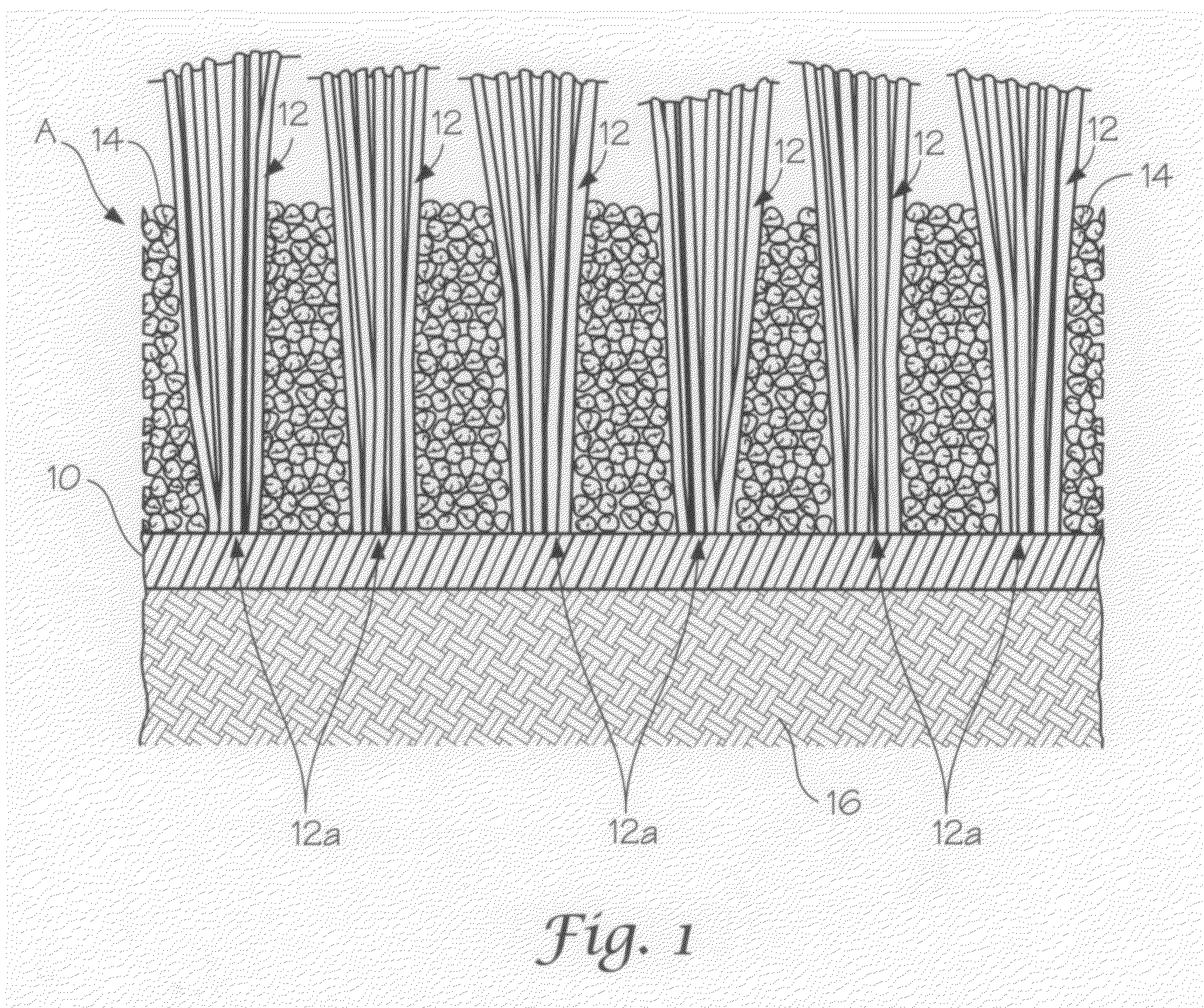

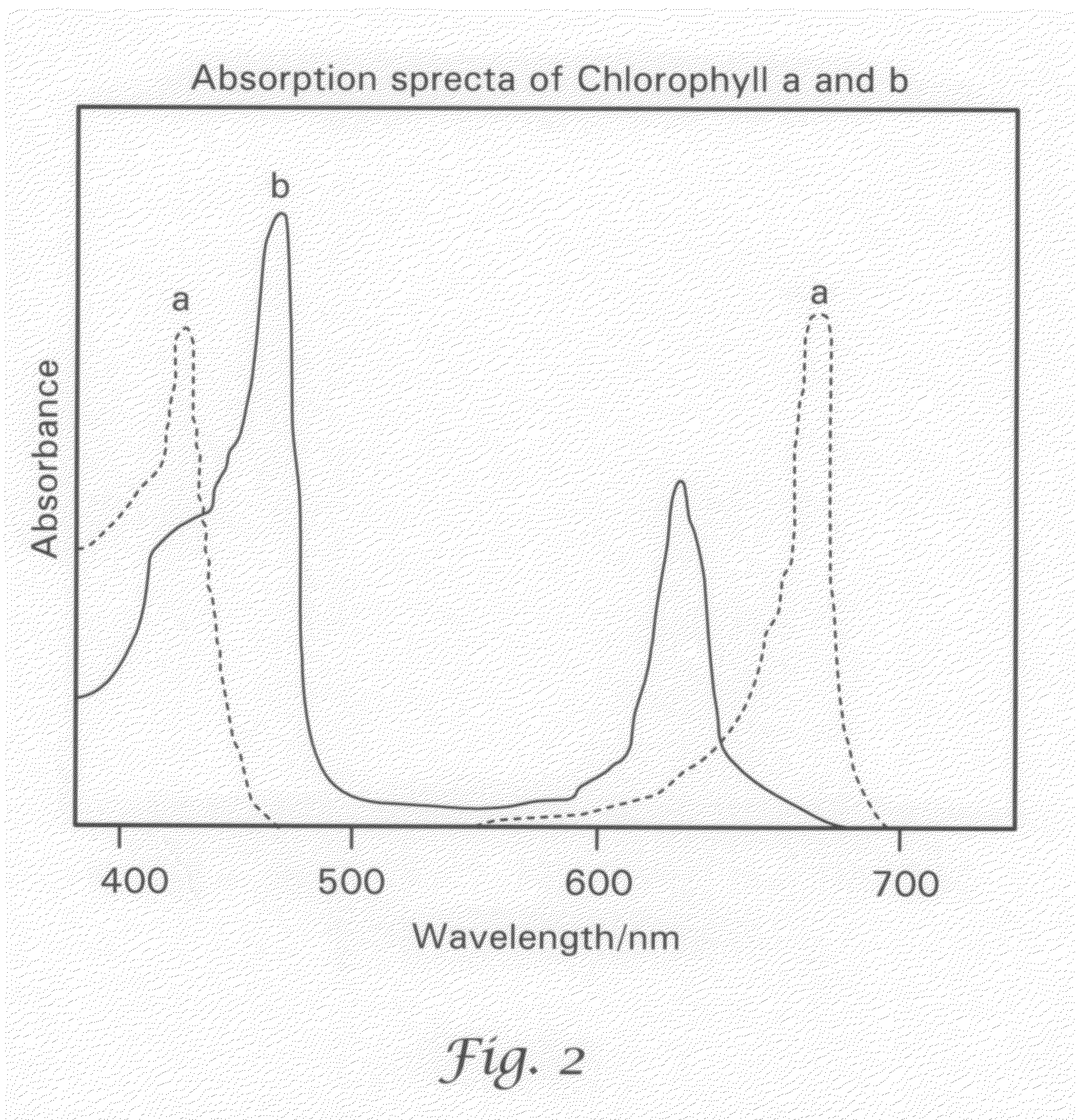

Chlorophyll cooling agent for synthetic turf components

InactiveUS20130034671A1Good lookingReduce heatDead plant preservationArtificial flowers and garlandsArtificial turfEngineering

An artificial turf is disclosed having a base and a plurality of synthetic fibers attached to and extending upward from the base, the fibers comprising a chlorin-based organic colorant and the colorant reflects infrared radiation in the range of 700 to 1,100 nm.

Owner:CHLOROCOOL

Polymer fibers, fabrics and equipment with a modified near infrared reflectance signature

ActiveUS7008694B1Readily dyed and printedHigh dye absorption propertyFilament/thread formingCamouflage devicesTerrainPolyamide

A modified synthetic polymer filament and multifilament yarn of polyamide or polyester filament containing a carbon black polymer additive, and fabrics from these yarns, are disclosed. These melt spun filaments are especially well-suited for use in garments and equipment where a modified Near Infrared Reflectance (NIR) signature is desired. The yarn and fabrics made from this yarn may be advantageously dyed or printed to provide a camouflage fabric for use in desert sand dominated environments, urban environments and multi-terrain environments.

Owner:INV PERFORMANCE MATERIALS LLC

Polyamide composition with improved heat stability and whiteness

InactiveUS20080090945A1Improved in whiteness appearancePermanent whiteness improvementGroup 4/14 element organic compoundsDye addition to spinning solutionYarnPolyamide

A polyamide composition, which includes an optical brightener together with an anti-oxidant stabilizer, is disclosed. This composition is suitable for making yarns, such as sewing thread, and fabrics, garments, molded articles or other articles such as carpets from these yarns. Processes for incorporating optical brighteners into polyamide compositions, polymers and yarns to make fabrics and molded articles that exhibit superior whiteness after heat-setting are also disclosed.

Owner:INVISTA NORTH AMERICA R L

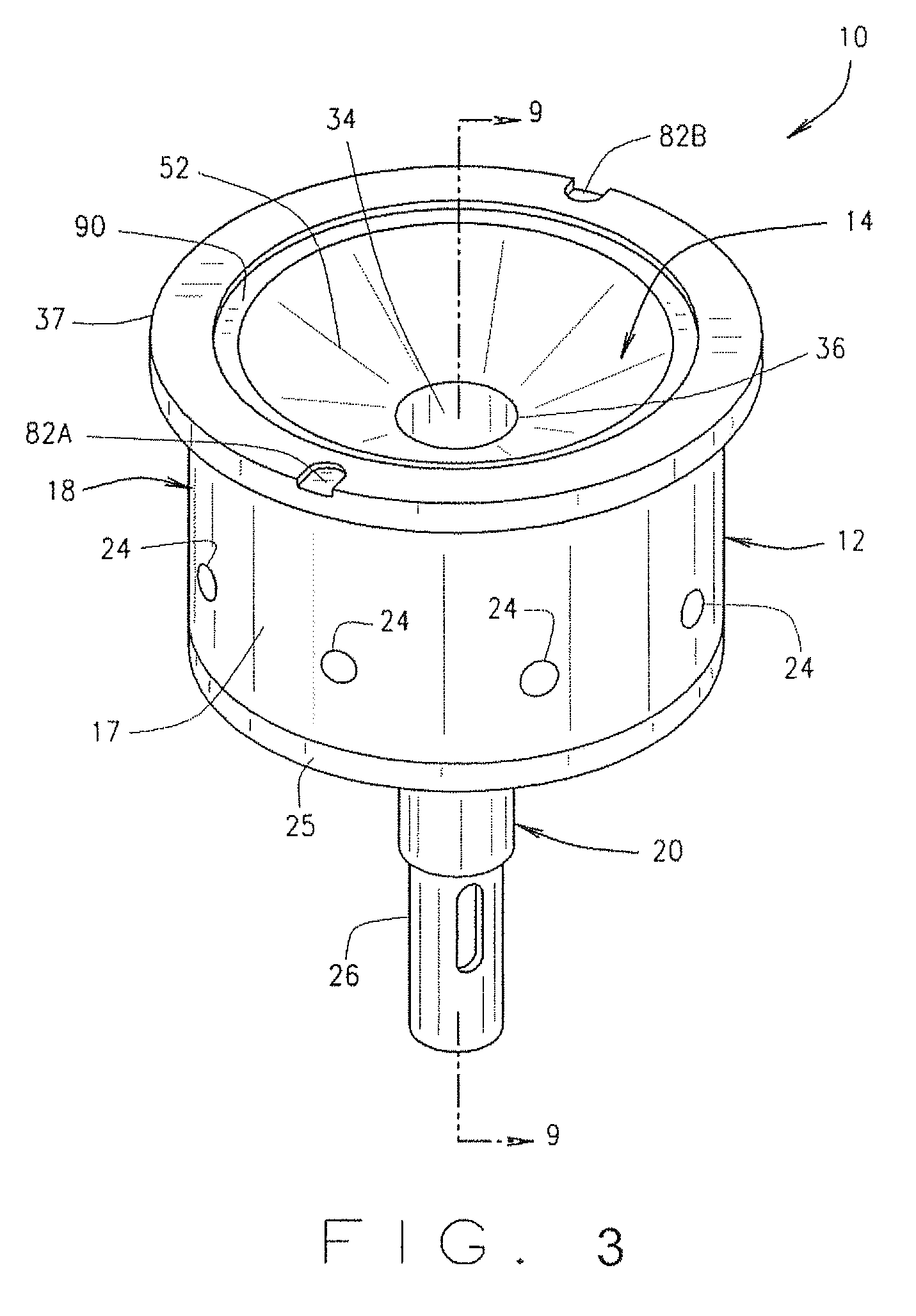

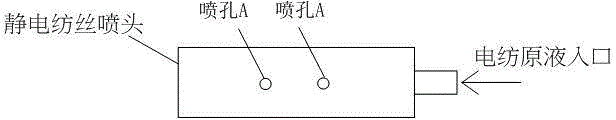

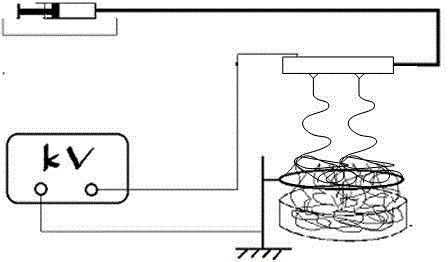

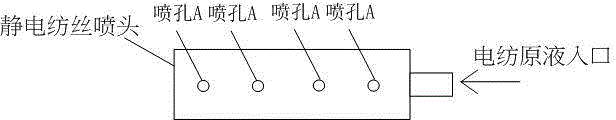

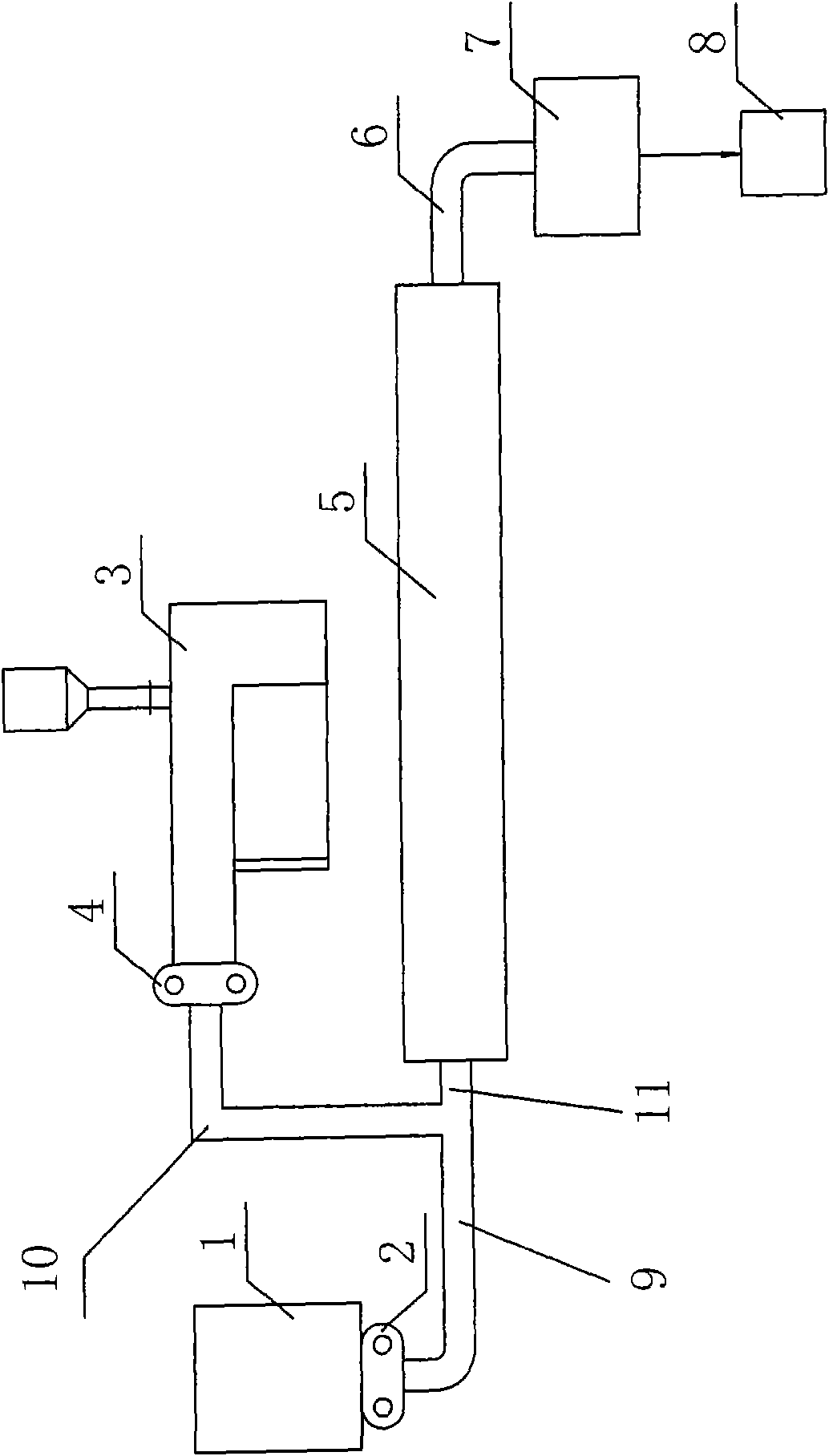

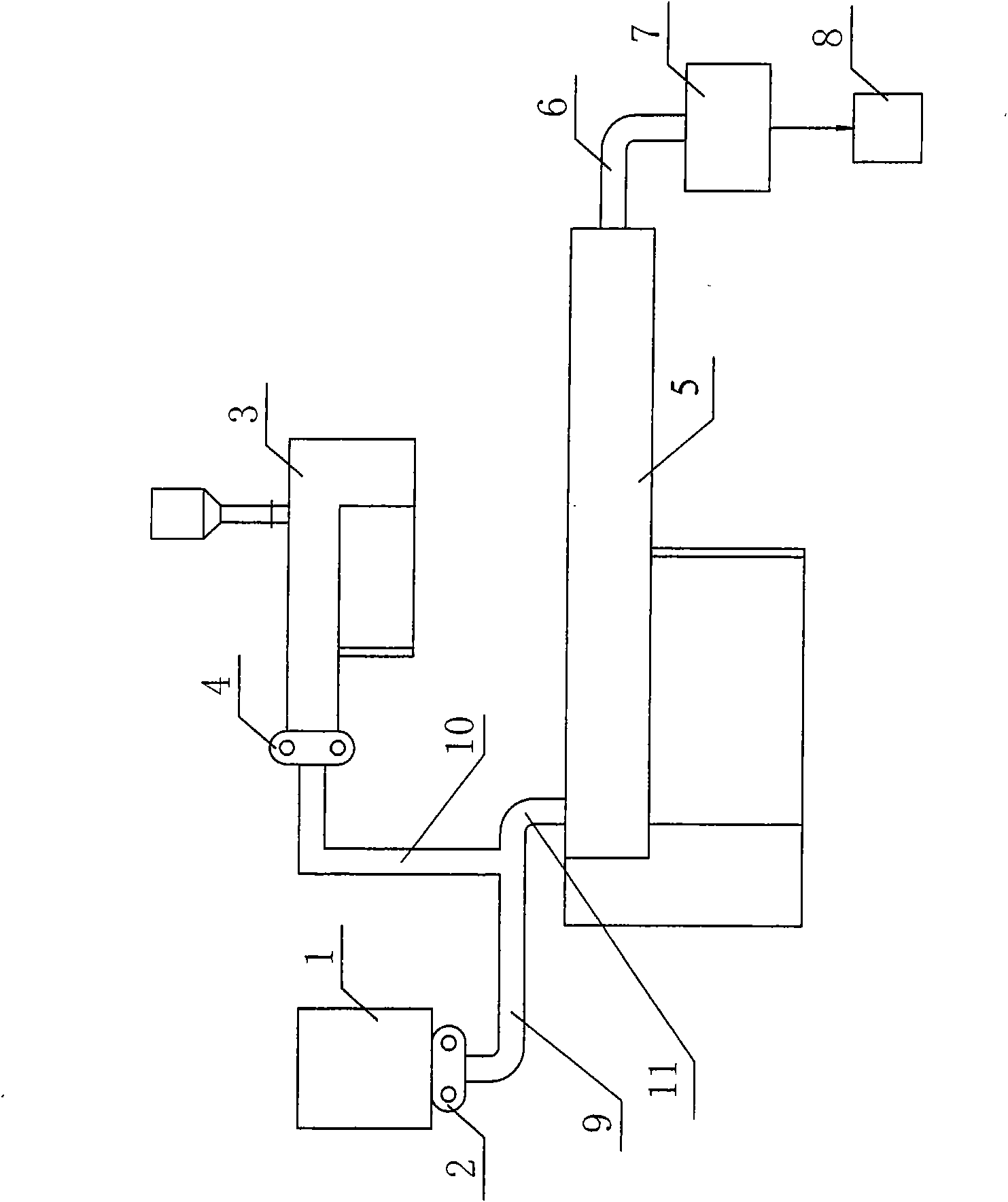

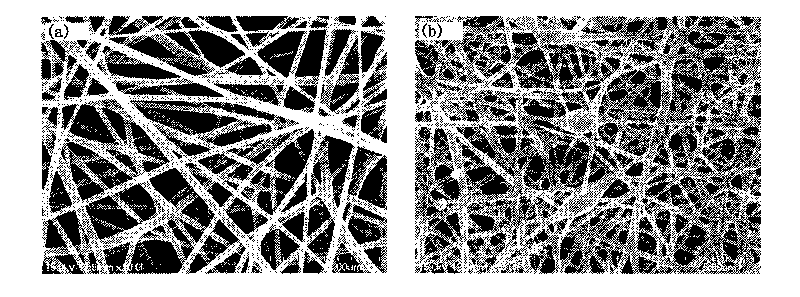

Preparing device and method for forming micro-nanofiber

InactiveCN104451912AHigh yieldImprove diameter preparation issueFilament/thread formingMonocomponent synthetic polymer artificial filamentYarnMicro nano

The invention provides a preparing device and method for forming micro-nanofiber, and belongs to the field of biological materials and tissue engineering. An electrostatic spinning sprayer is provided with different holes arranged side by side, an appropriate amount of original electricity texture liquid is injected into the electrostatic spinning sprayer through a micro-injection pump, a plurality of taylor cones are formed by the parallel spraying holes in the electrostatic spinning sprayer at the same time through externally added high voltage, and therefore the different sizes of original electricity texture yarns can be obtained through the single step, the yield of the original electricity texture yarns is effectively increased, and the micro-nanofiber is prepared. By means of the method for electrostatic spinning, and the electrostatic spinning yield can be increased and is obviously higher than that of single-needle electrostatic spinning; the effective means for adjusting the diameter of the spinning fiber is provided, the uniform micro-nanofiber or micro-nanofiber with different sizes can be prepared, the range of the diameter of the fiber can be controlled to range from 50 nm to 1 mm, and the problem of the productivity and size adjusting in the related fields of the electrostatic spinning micro-nanofiber is effectively solved.

Owner:ZHEJIANG UNIV

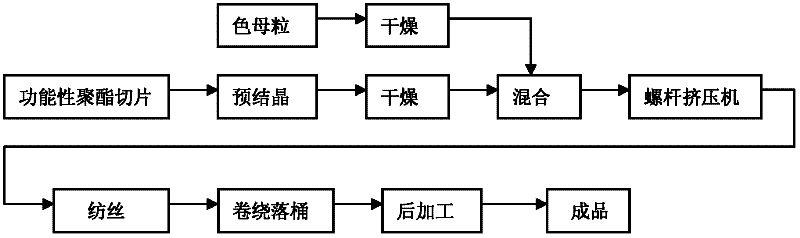

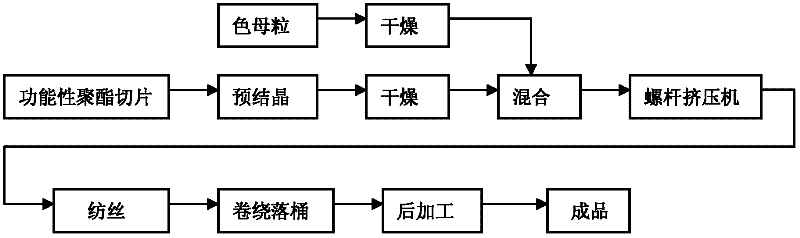

Method for producing differential terylene color yarns

InactiveCN102392317AReduce pollutionHigh fastnessFilament forming substance formingMelt spinning methodsYarnPolyester

The invention discloses a method for producing differential terylene color yarns. The method comprises the following steps of: pre-crystallizing a functional polyester chip at the temperature of between 144 and 146 DEG C for 20 to 60 minutes, and drying at the temperature of between 149 and 151 DEG C for 4 to 6 hours, so that the moisture content of the dried functional polyester chip is less than or equal to 17 ppm; and drying masterbatches for 1 to 2 hours, mixing the dried masterbatches and the dried functional polyester chip fully, adding the mixture into a screw extrusion spinning machine, spinning by using a spinneret plate of the screw extrusion spinning machine, winding and dropping into a bucket, and processing to obtain the differential terylene color yarns. In the method, the masterbatches are added into the functional polyester chip to be spun into the color yarns, the masterbatches and the functional polyester chip are mixed uniformly in a mode of dynamic mixing or static mixing in a screw extruder, and the color yarns are produced through the spinneret plate. By the method, the color fastness and stability of the products are improved, the production cost is reduced, and environmental pollution is reduced.

Owner:ZHEJIANG SANZHI TEXTILES

Active and adaptive photochromic fibers, textiles and membranes

InactiveCN1942612AElectro-spinningMonocomponent synthetic polymer artificial filamentFiberElectrospinning

A process to make a dyed fiber which has the steps of mixing a dye capable of changing color and a polymer into a solution at a temperature below the temperature at which the dye or polymer degrades to form a polymer dye solution and electrospinning said polymer dye solution to form a fiber wherein the dye penetrates more than the surface of the fiber. The invention also relates to the fiber and use of the fiber.

Owner:UNIVERSITY OF DELAWARE

Method for coloring alginate fiber stoste by adopting lake colors

ActiveCN104264280AIncrease profitHigh color fastnessAlginate artificial filamentsDye addition to spinning solutionSolventFine chemical

The invention discloses a method for coloring alginate fiber stoste by adopting lake colors, and belongs to the field of fine chemical engineering and material science. The method comprises the following steps: adding sodium alginate into deionized water, and stirring so as to dissolve sodium alginate fully to prepare alginate fiber spinning stoste; then adding lake colors into the alginate fiber spinning stoste, stirring and mixing uniformly, filtering and defoaming to obtain the lake color colored alginate fiber stoste, and preparing further to obtain lake color colored alginate fibers. The method overcomes the problem of damage of traditional dye dying on fibers; the prepared colored alginate fibers have the advantages of bright colors, high color fastness, good solvent mobility resistance and the like.

Owner:JIANGNAN UNIV

Process for coloring a textile substrate

InactiveUS7018429B1Good light fastnessDurable lightfastnessPretreated surfacesDyeing processYarnUltraviolet protection

The present invention relates to methods of imparting color and ultraviolet protection to synthetic yarns or substrates. More specifically, the present invention is directed to a method of solution dyeing a polymeric material during polymerization to form a base color shade, and subsequently dyeing the polymeric material by either yarn dyeing or piece dyeing. Ultraviolet protection is also provided in the solution dyeing step, by introducing an ultraviolet stabilizing agent into the polymer. The base shade may then be transformed into a useful color pallet with enhanced lightfastness properties by applying a final color shade late in the fabric formation process.

Owner:SAGE AUTOMOTIVE INTERIORS INC

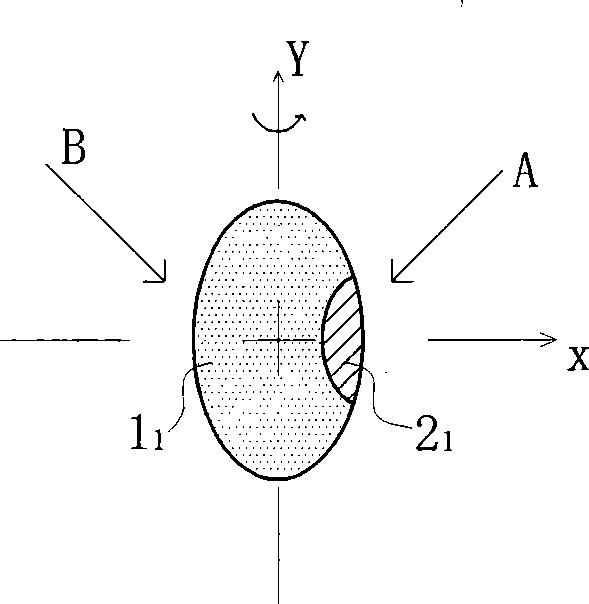

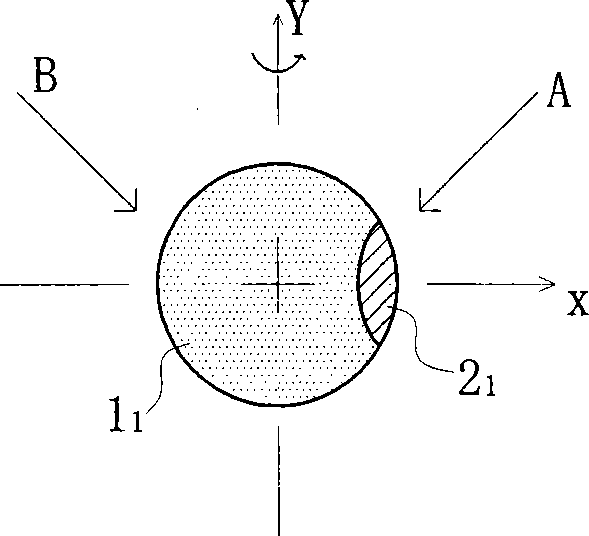

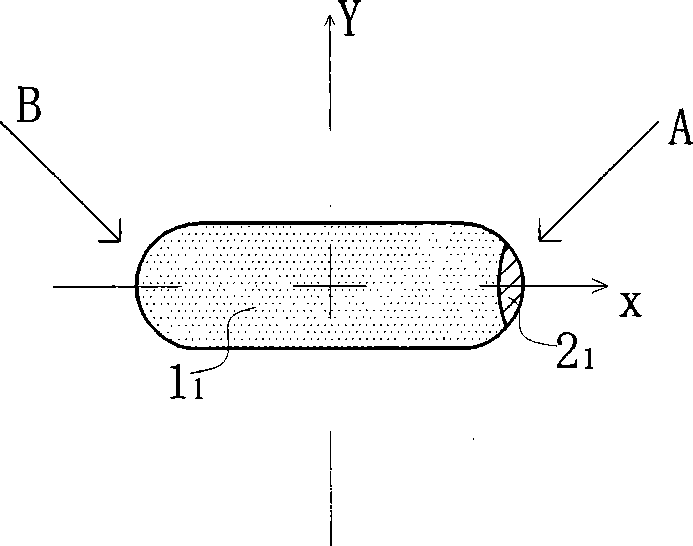

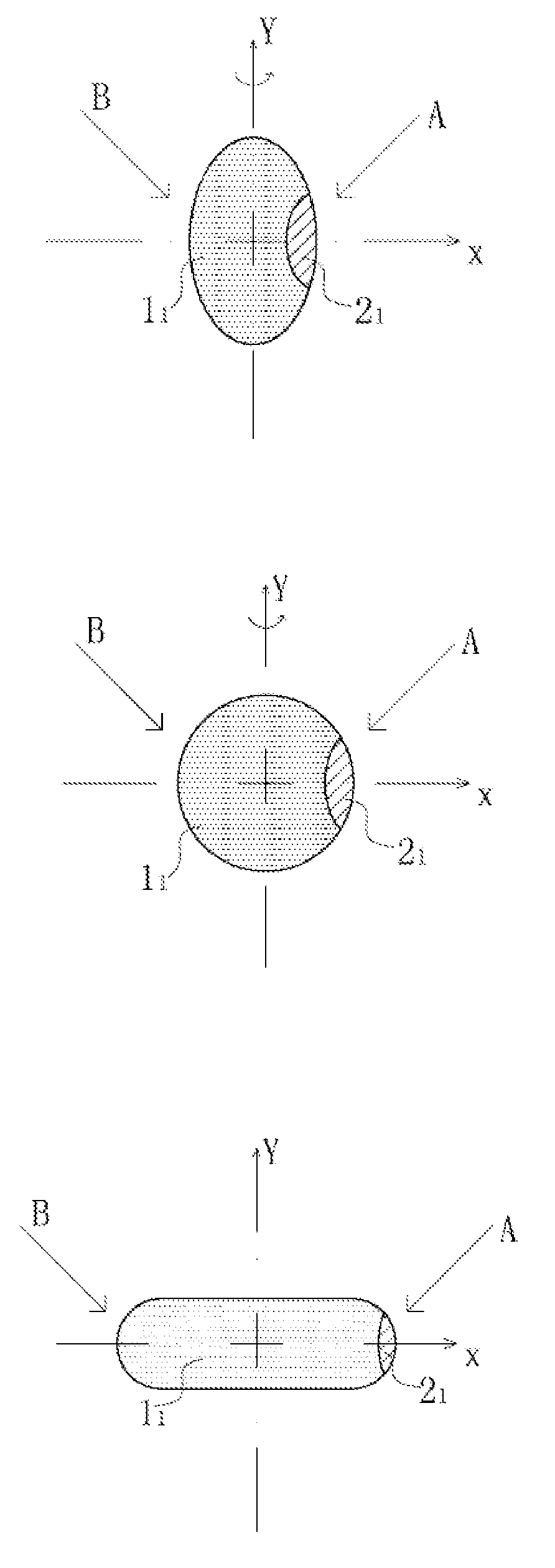

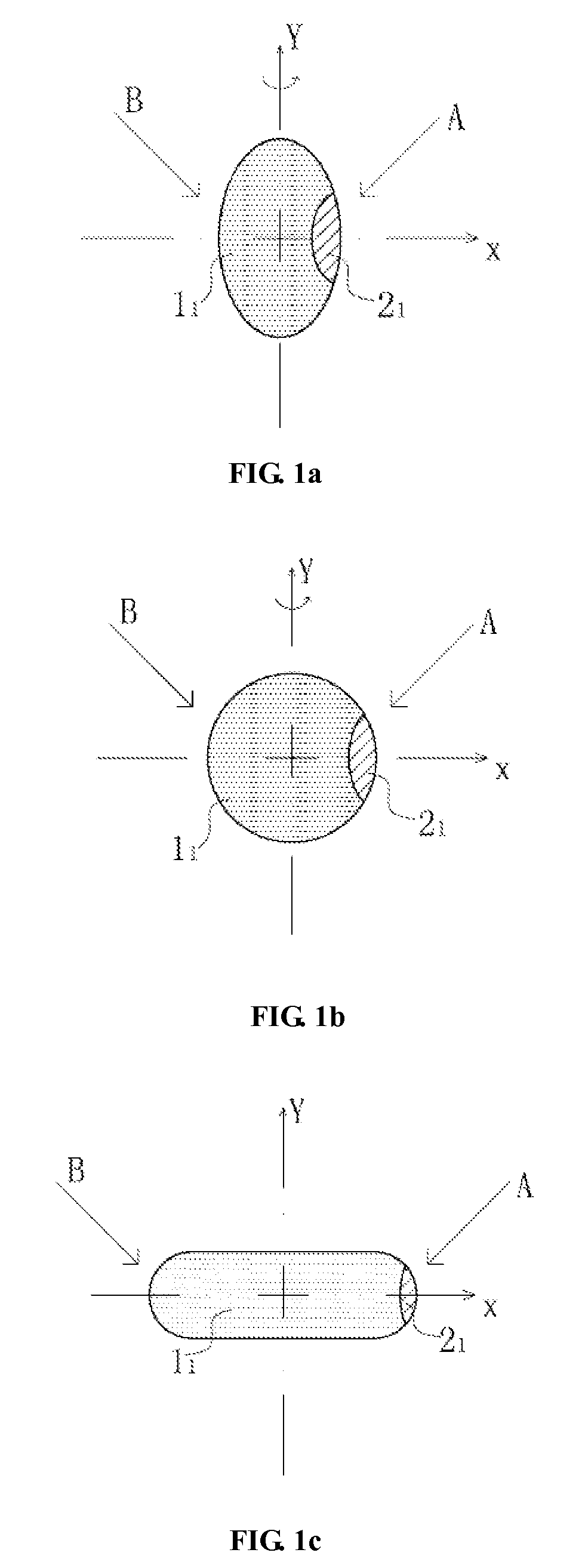

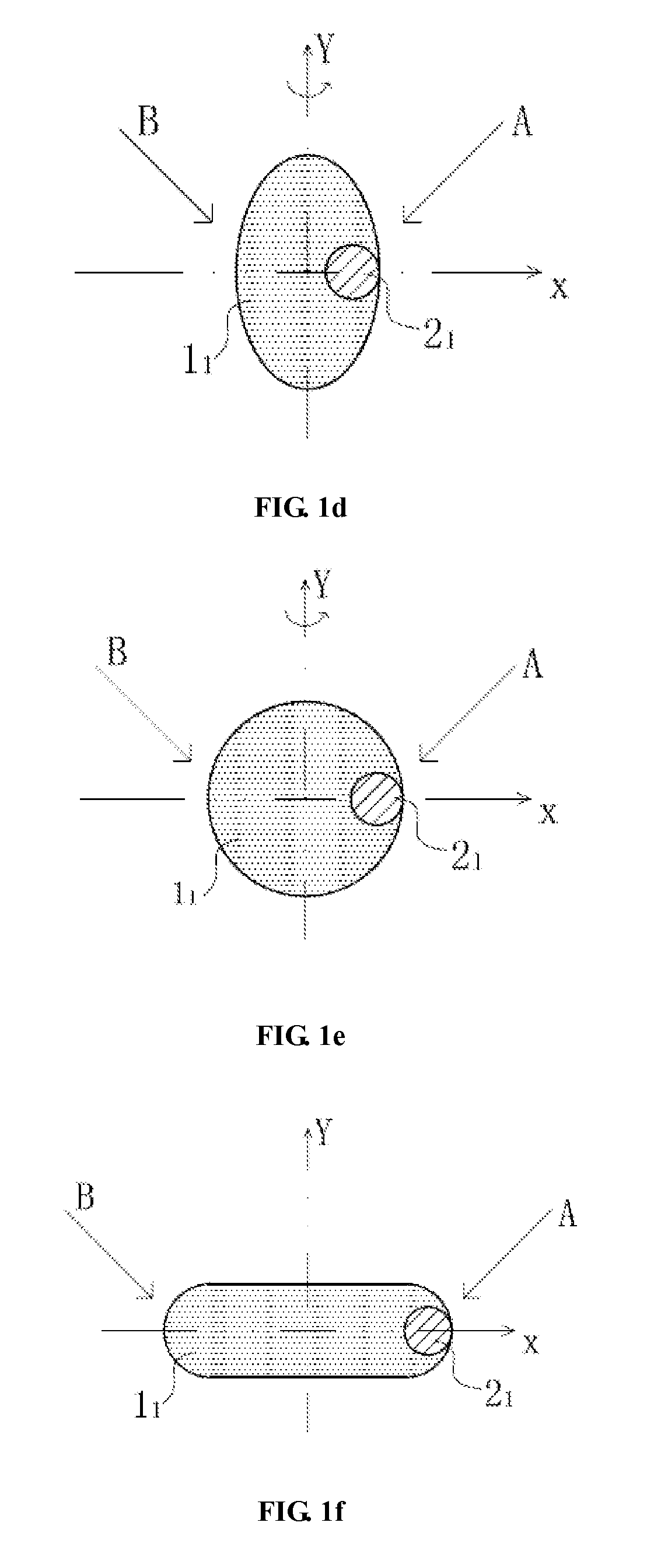

Anti-counterfeiting fiber with fluorescence fiber color changing with the change of optic angle of exciting light and anti-counterfeiting material

ActiveCN101519857AProcesses to Solve Directional BendingEasy to produceNon-fibrous pulp additionPaper/cardboardFiberFine line

The invention provides an anti-counterfeiting fiber with fluorescence fiber color changing with the change of an optic angle of exciting light and an anti-counterfeiting material, which relates to fluorescence fiber with illuminant color changing with the change of the illumination angle of exciting light and an anti-counterfeiting material. The anti-counterfeiting fiber is combined by at least two material components extending parallelly without twisting along the length direction of the fiber, at least one component contains luminescent material and the anti-counterfeiting fiber is characterized in that: the distribution of at least two components of the fiber at the cross section causes the fiber to construct an exciting light shielding structure which can shield the exciting light and an oriented structure with oriented direction, thus ensuring that at least two illumination angles A and B of the exciting light exist at the upper space of the plane when the fiber falls down to a plane parallel to the horizontal plane due to free-fall gravity; and the illuminant color has obvious visual differences when the two angles illuminate to the fiber. The method solves the difficult problem that the visual characteristic of fluorescence anti-counterfeiting material is easy to be imitated by printing fine line for the first time in the world.

Owner:SHANGHAI KOS SECURITY PAPER TECH CO LTD

Ultrafine fiber with high color fastness and manufacturing method thereof

InactiveCN101445973AAvoid wastingEliminate heavy pollutionFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterSpinning

The invention relates to ultrafine fiber with high color fastness and a manufacturing method thereof. The method comprises the steps of adding 3-40% coloring agent into a polymer powder to make into colored stock particles; adding the colored stock particles into spinning polymer polyester and / or polyamide in a ratio of 0.2-15%, and mixing; melt extruding the spinning polymer with a conjugate spinning machine, and coiling to obtain colored POY composite fiber; stretching and false-twist texturing to obtain colored fiber with high color fastness; and splitting with a basic hydrolysis method to obtain colored ultrafine fiber with high color fastness. The colored ultrafine fiber with high color fastness has excellent handfeel and color fastness to washing and light, and contains mass-colored dyeing components, so as to dispense with dyeing after being made into a textile. The colored ultrafine fiber has the advantages of simple process, low cost, low pollution, small product color difference, good color fastness, low fading liability, wide color spectra, and vivid and bright color.

Owner:段宏伟

Method for direct preparation of coloured polylactic acid fiber by polylactic acid polymer melt

InactiveCN101597814AEnsure color consistencyAvoid chromatic aberrationNon-woven fabricsPigment addition to spinning solutionFiberPolymer science

The invention relates to a method for direct preparation of coloured polylactic acid fiber by polylactic acid polymer melt, belonging to the technical field of high polymer material application. The method comprises the following steps: conveying raw white polylactic acid polymer melt obtained from polymerization reaction in a polylactic acid polymerization reaction device to a melt mixing device through a termination device of the polylactic acid polymerization reaction device; mixing the raw white and colored polylactic acid melt in the melt mixing device to obtain colored polylactic acid mixed melt; leading the colored polylactic acid mixed melt into a spinning tank to be spun to obtain colored polylactic acid fiber. The method of the invention has the following advantages: avoiding causing chromatic aberration in the process of dying fiber or fabrics; saving energy, and preventing waste water generated by printing from polluting the environment; saving resources, and avoiding causing damage to the soil and water source after abandonment of the coloured polylactic acid fiber; providing technical guarantees for promotion and application of the polylactic acid fiber and products produced therewith.

Owner:恒天长江生物材料有限公司

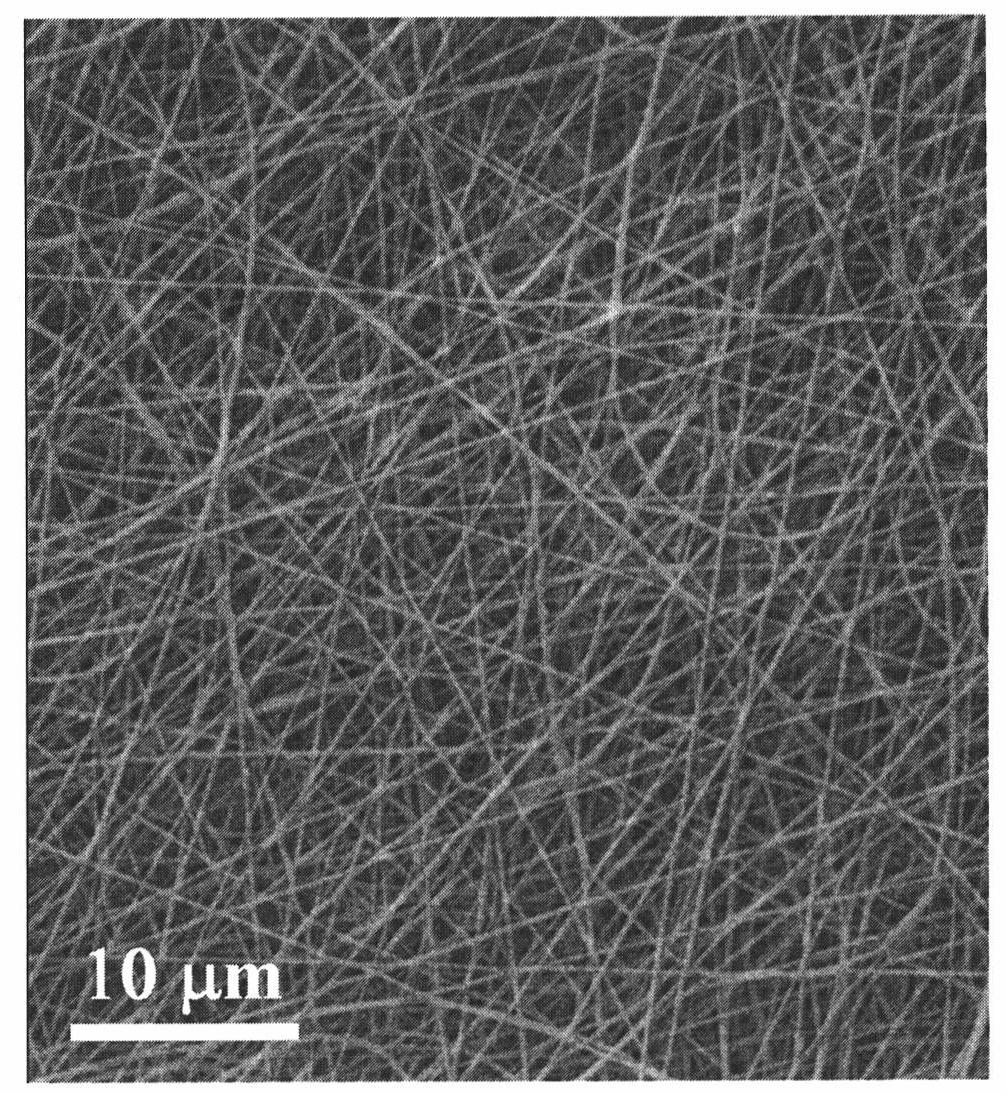

Electrostatic spinning nano-fiber film, and preparation method and finger detection method of electrostatic spinning nano-fiber film

ActiveCN102115953ARaw materials are easy to getLow costPerson identificationFilament/thread formingHigh volume manufacturingMass ratio

The invention discloses an electrostatic spinning nano-fiber film, and a preparation method and a finger detection method of the electrostatic spinning nano-fiber film. The finger detection method has the advantages of simplicity, rapidity, high sensitivity and no toxicity or harm, and dispenses with large instruments. The prepared fiber film has a wide range of practical objects, is rapid and convenient for operation, and is easy for mass production, and the raw material of the fiber film can be easily acquired. The invention mainly adopts the electrostatic spinning technology to prepare the polymer-based dye hybridization nano-fiber film, and the film can be used for direct fingerprint extraction and rapid fingerprint display at a certain temperature. The electrostatic spinning nano-fiber film disclosed by the invention is a polymer nano-fiber film in which dyes are evenly dispersed, wherein, the mass ratio of polymer and the dyes is 2-100 to 1, and the nano-fiber diameter is uniform and ranges from 50nm to 1,000nm.

Owner:江苏仁通节能科技有限公司

Bicomponent fibers, textile sheets and use thereof

InactiveCN101952491ANo need to change process parametersWoven fabricsConjugated synthetic polymer artificial filamentsFiberPolyester

Disclosed are bicomponent fibers with aliphatic polyester forming a first component and a polyolefin forming a second component wherein the polyolefin contains an adjuvant improving the biodegradability of said polyolefin. Textile sheets comprising these bicomponent fibers are comparable in their mechanical properties to polyolefin based textile sheets while these are more efficiently decomposed by the action of microorganisms as polyolefin based textile sheets.

Owner:博爱科罗温有限公司 +1

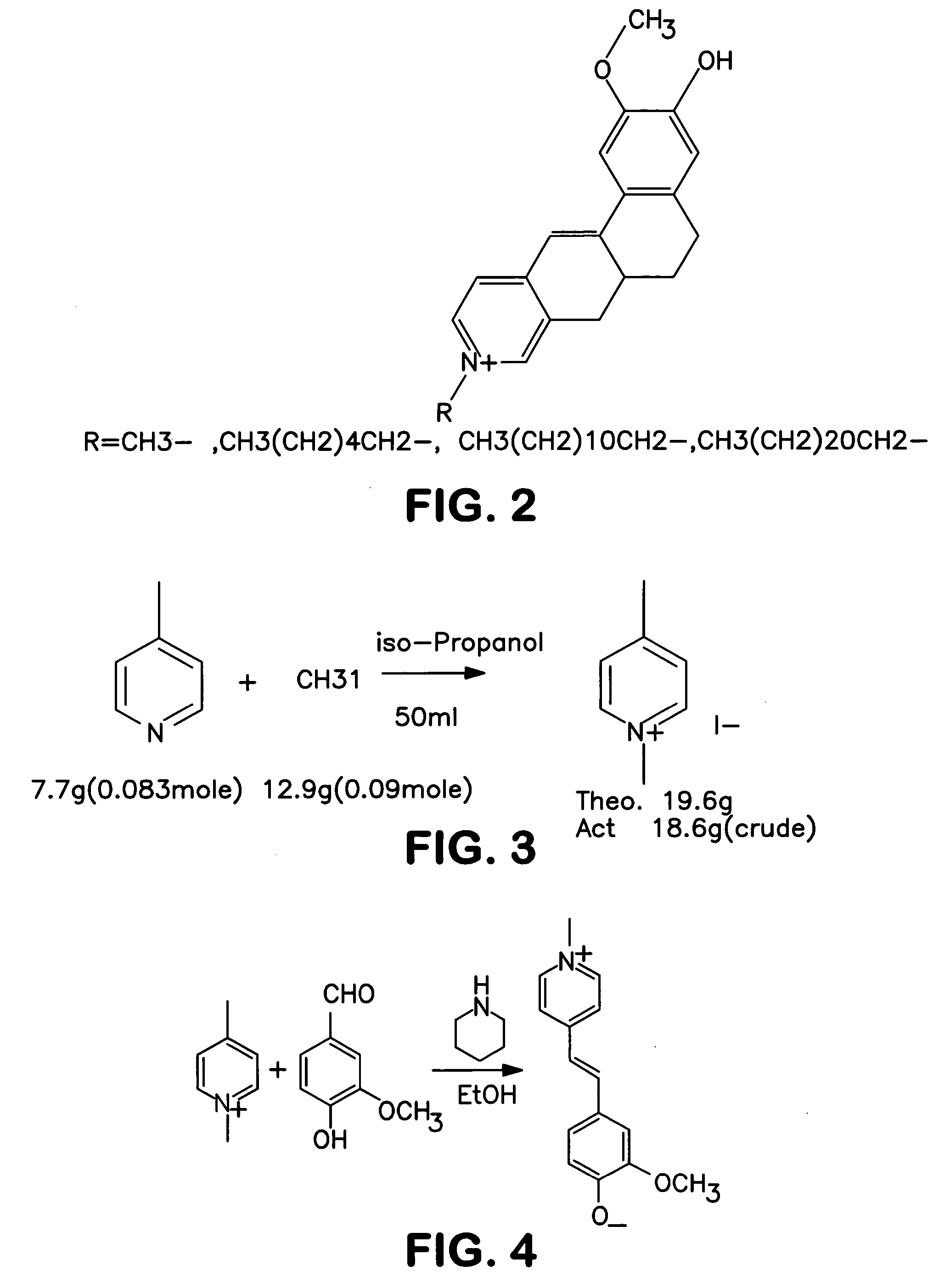

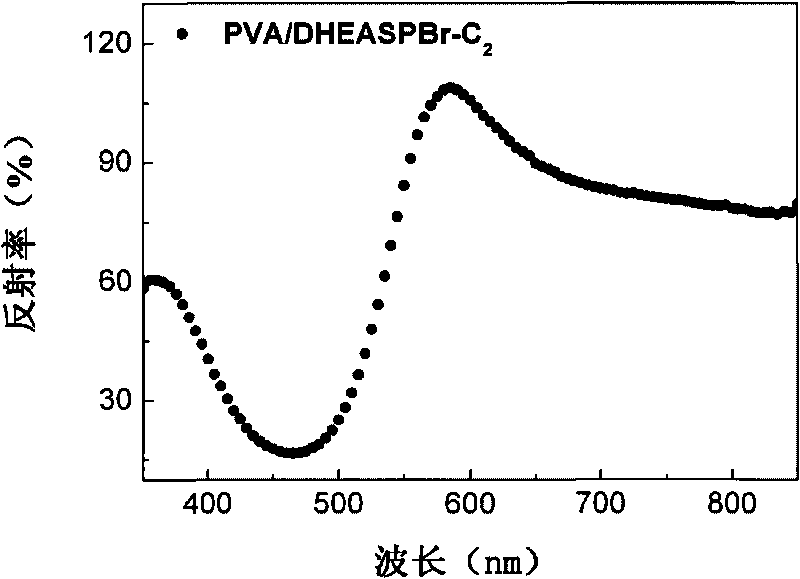

Method for preparing fluorescent fiber membrane

ActiveCN101735801AExcellent linear optical performanceEasy to getMonocomponent synthetic polymer artificial filamentLuminescent compositionsFiberSolubility

The invention discloses a method for preparing fluorescent fiber membrane, in particular to a method taking derivatives of styrene pyridinium as fluorescent dye to blend with polyving akohol (PVA) to prepare spinning solution and perform electrostatic spinning. The method comprises the following steps: taking styrene pyridinium as fluorescent dye, mixing the fluorescent dye with the mass concentration of 1-10% (fluorescent dye / PVA) into PVA water solution, and then performing electrostatic spinning to obtain the orange fluorescent fiber membrane. The styrene pyridinium provided by the invention has good liner optical property, good water solubility and good consistency with PVA water solution; the highest reflectivity of the obtained fibrous membranes is more than 100%, and the wavelengthcorresponding to the max peak is 605nm; and the fluorescent emission spectrum excited by laser with the excitation wavelength of 254nm is within the range of 500-750nm, and CIE color coordinate calculated value is within a yellowish orange fluorescent zone, thus having application prospect.

Owner:SUZHOU UNIV

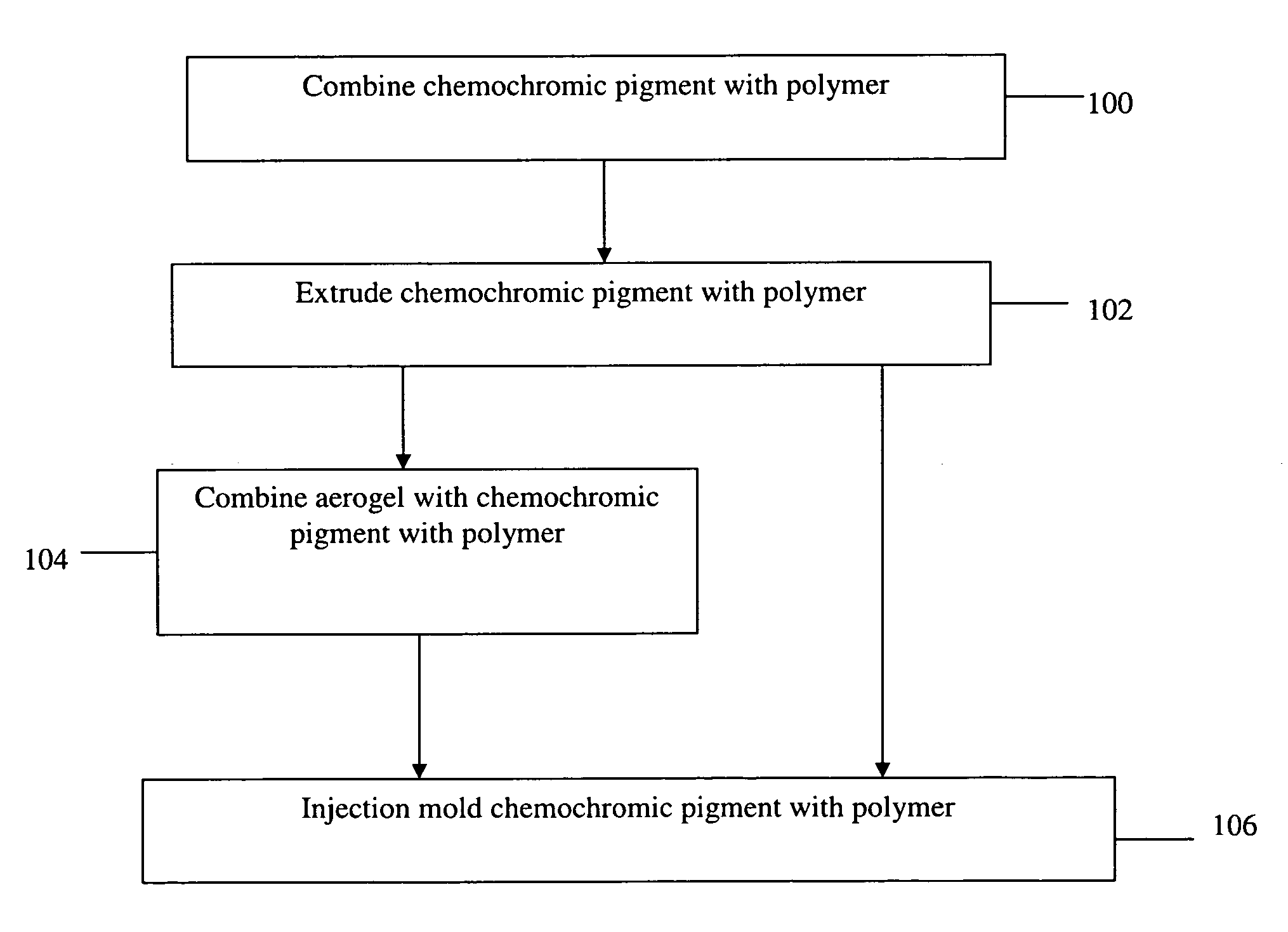

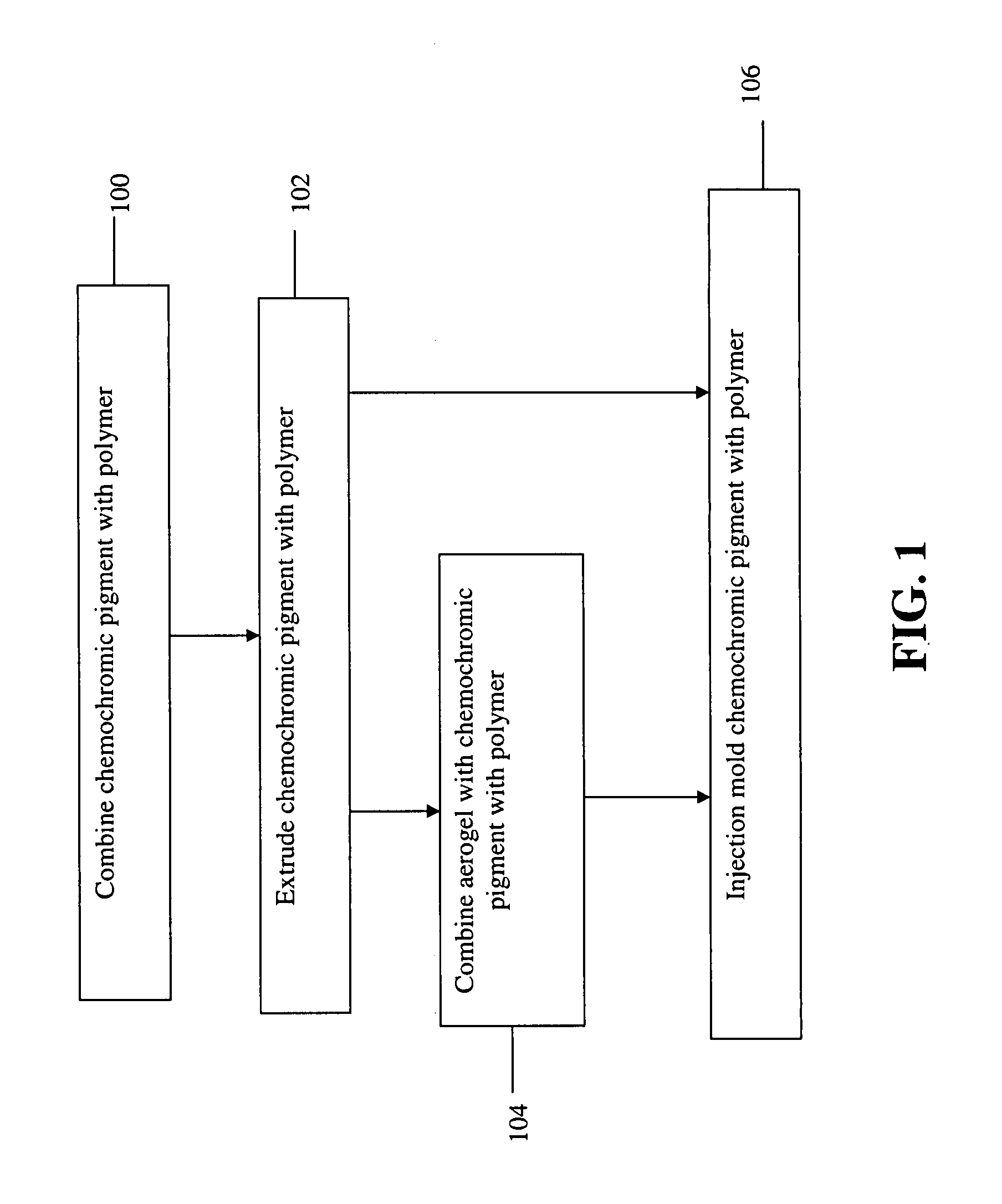

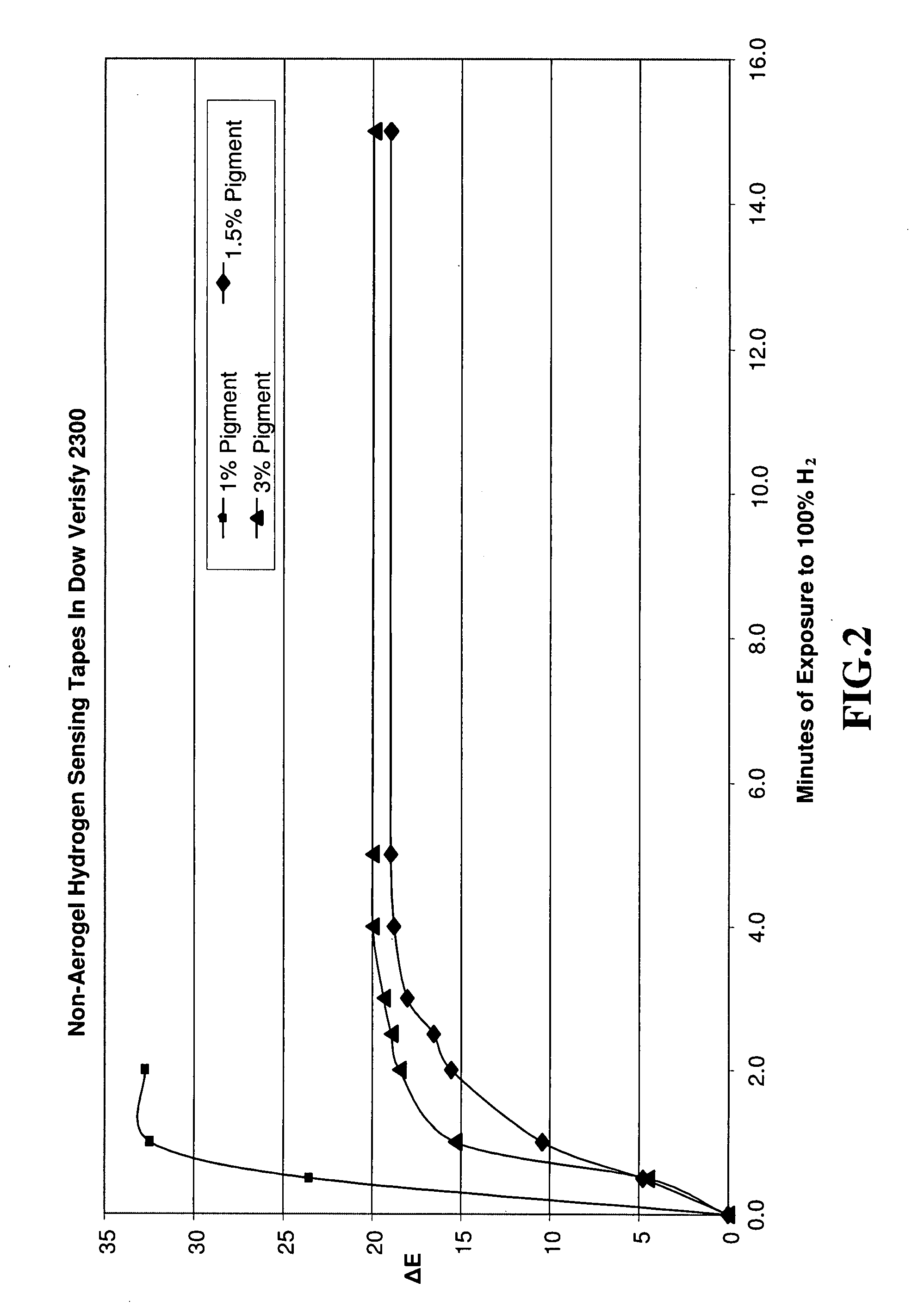

Chemochromic Detector for Sensing Gas Leakage and Process for Producing the Same

ActiveUS20110171066A1No power requiredEasy to disassembleAnalysis using chemical indicatorsChemical analysis using combustionHydrogenCombustible gas

A chemochromic sensor for detecting a combustible gas, such as hydrogen, includes a chemochromic pigment mechanically mixed with a polymer and formed into a rigid or pliable material. In a preferred embodiment, the chemochromic detector includes aerogel material. The detector is robust and easily modifiable for a variety of applications and environmental conditions, such as atmospheres of inert gas, hydrogen gas, or mixtures of gases, or in environments that have variable temperature, including high temperatures such as above 100° C. and low temperatures such as below −196° C.

Owner:NASA

Preparation method for stoste coloring anti-flaming copolyester fibers

ActiveCN103409845AReduce pollutionMeet the flame retardant performance requirementsFlame-proof filament manufacturePigment addition to spinning solutionPolymer scienceCopolyester

The invention relates to a preparation method for stoste coloring anti-flaming copolyester fibers. The preparation method comprises the following steps: (1) mixing anti-flaming copolyester and pigments or dyes through melt blending to obtain stoste coloring anti-flaming copolyester color master batches, wherein the weight percent of the pigments or the dyes in the stoste coloring anti-flaming copolyester color master batches is 20-40 percent; and (2) producing the stoste coloring anti-flaming copolyester fibers by performing melt spinning on the stoste coloring anti-flaming copolyester color master batches and anti-flaming copolyester, wherein the weight percent of the pigments or the dyes in the stoste coloring anti-flaming copolyester fibers is 1-2 percent. According to the preparation method, the technology is simple, the production is flexible, the production period is short, the environment pollution is reduced, and a requirement on the anti-flaming performance of a material can be met.

Owner:DONGHUA UNIV

Fluorescent Anti-counterfeit fiber of which optical color is variable with irradiation angle of exciting light and Anti-counterfeit material

InactiveUS20110008606A1Reduce and even eliminate influenceReduce the impactNon-fibrous pulp additionNatural cellulose pulp/paperFiberFluorescence

A fluorescent fiber and an anti-counterfeiting material have an optical color that varies with irradiation angles of exciting light. The anti-counterfeiting fiber includes at least two components of materials that extend parallel along the longitudinal direction without twisting. At least one component contains photoluminescence material. The distribution of the components makes the anti-counterfeit fiber form a shielding structure for exciting light, and has an orientation structure. The exciting light shielding structure and orientation structure enable, when the anti-counterfeit fiber falls freely into a plane paralleled to the horizontal plane, the existence of at least two irradiation angles of exciting light above the plane paralleled to the horizontal plane, from which exciting light irradiates on the anti-counterfeit fiber respectively. The anti-counterfeit fiber thereby displays obvious visual difference between two different luminescent colors. In this manner, the visual characteristic of fluorescent anti-counterfeit fiber cannot be imitated by the printing filament.

Owner:SHANGHAI KOS SECURITY PAPER TECH CO LTD

Ultrawhite ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers and preparation process thereof

ActiveCN101962819AIntensity is not affectedModulus is not affectedArtificial filament heat treatmentWet spinning methodsFiberPolymer science

The invention relates to ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers and a manufacturing method thereof, in particular to ultrawhite ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers and a preparation process thereof, which are applicable in fields of various protective textiles with an ultrawhite color requirement. In the invention, ultrahigh-molecular weight polyethylene is used as a raw material and is mixed with white oil to form a mixture, a diphenylethyl dibenzimidazole compound is added into the mixture as an additive to form spinning solution, and the ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers are obtained by a spinning process, wherein the amount of the additive is 0.01 to 0.05 percent based on the weight of the ultrahigh-molecular weight polyethylene. The preparation process comprises the following steps: preparing the spinning solution; performing gel spinning; balancing semi-finished product gel spinning; extracting; displacing; drying; and hot high drafting. The fibers are ultrawhite and brighter and can meet requirement for differentiation; meanwhile, the biological indexes such as strength and modulus of the finished fibers are not affected, the manufacturing method is simple, and the production cost is low.

Owner:长青藤高性能纤维材料有限公司

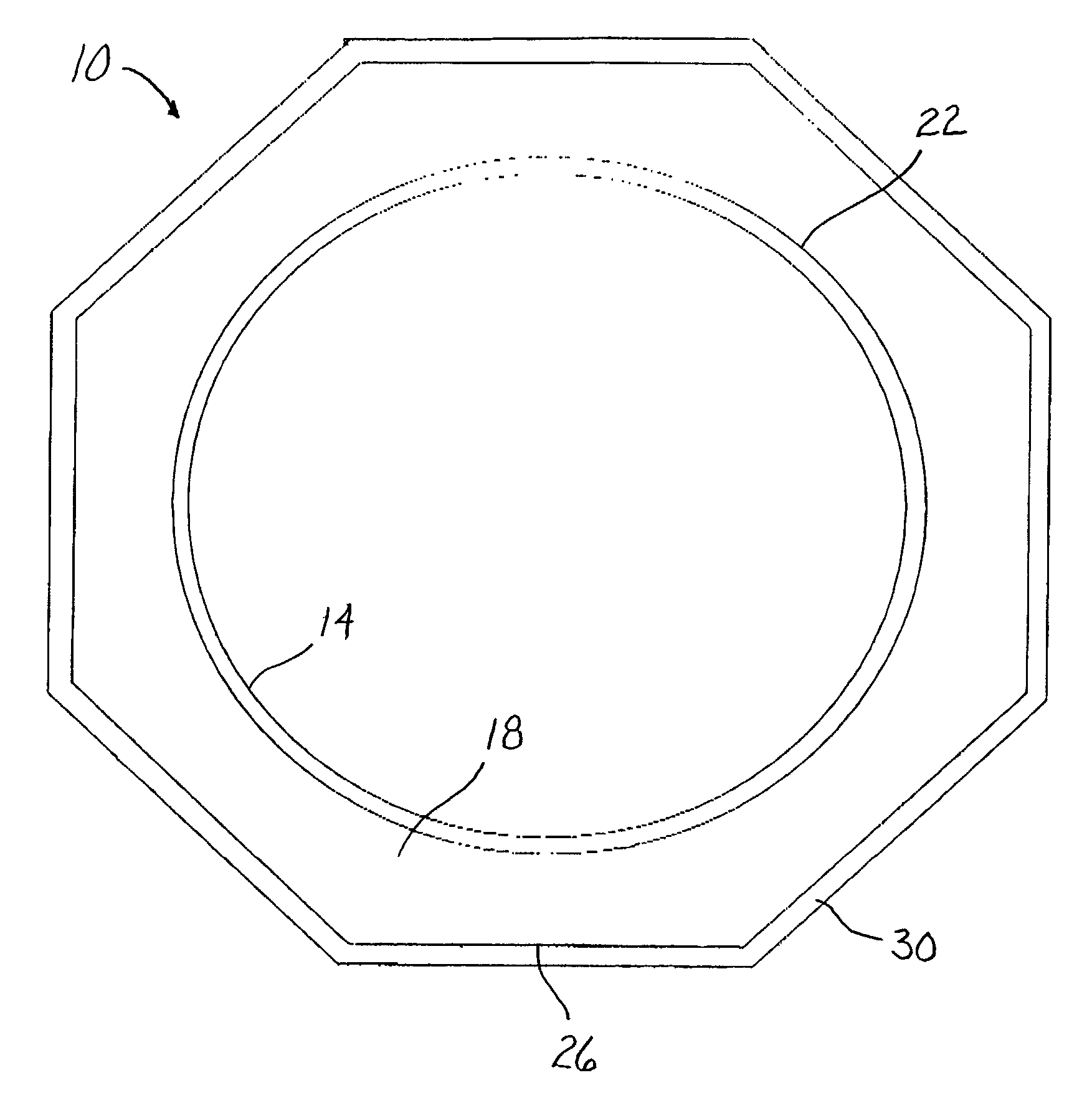

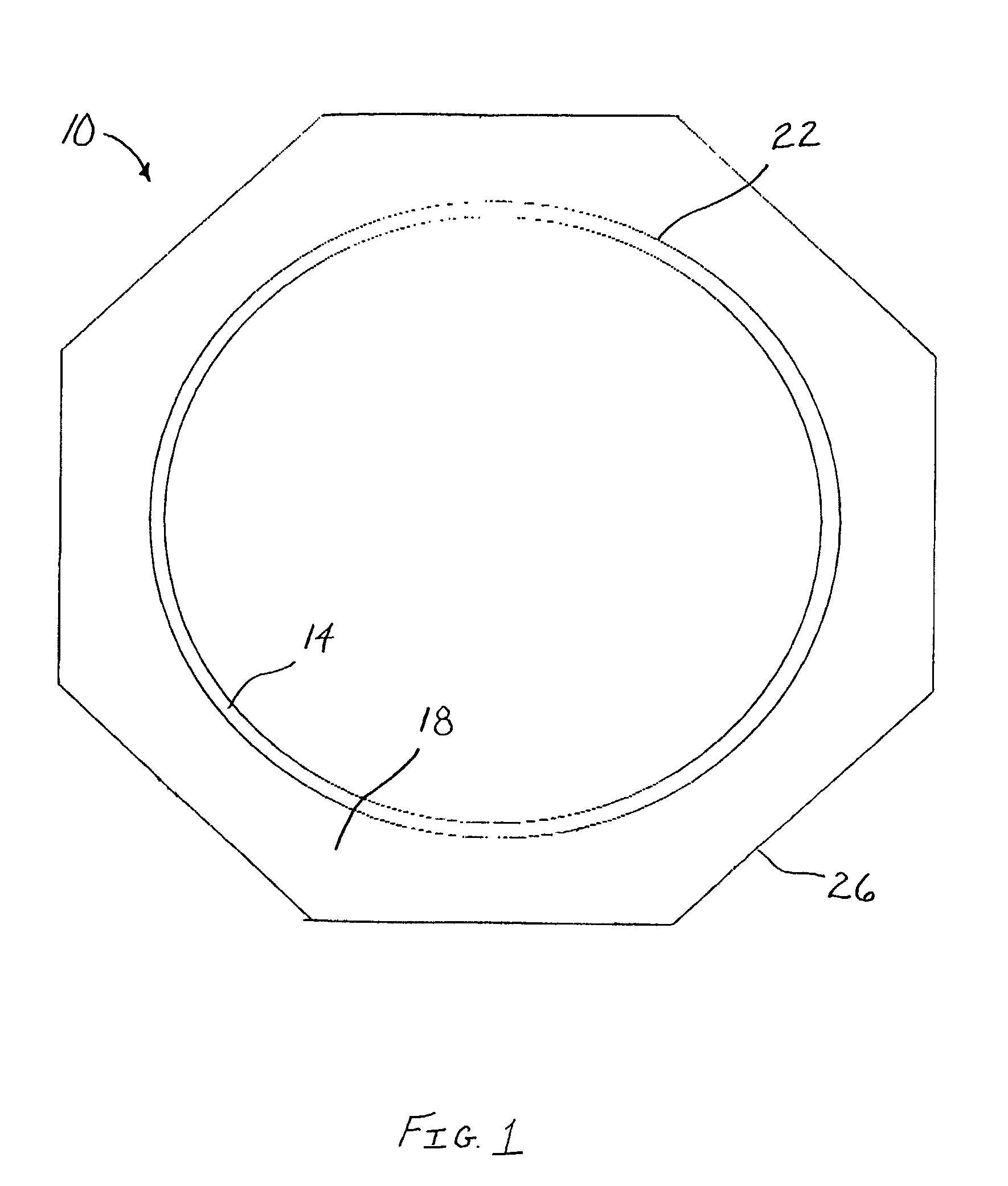

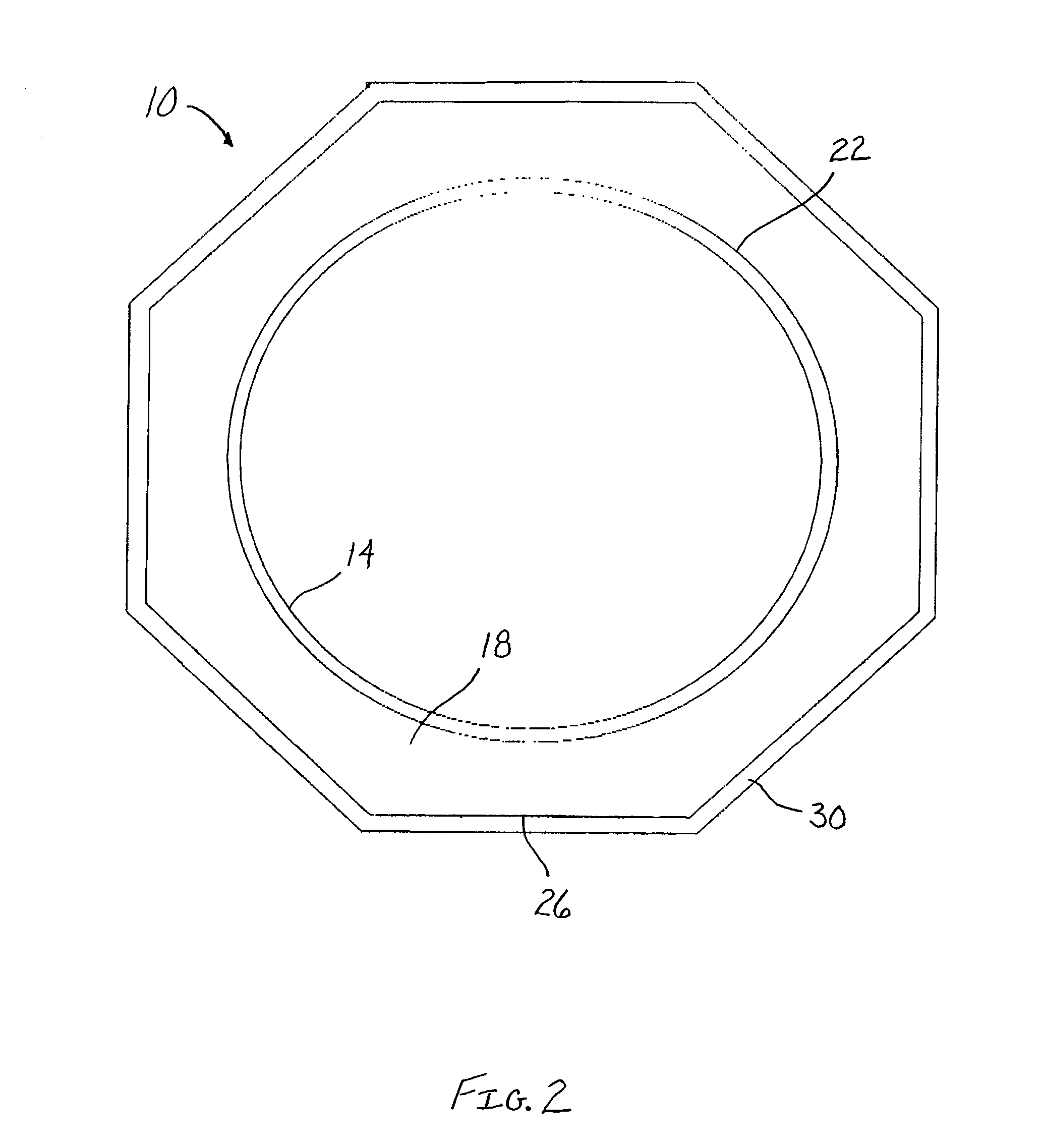

Method of manufacturing composite utility poles

InactiveUS7022270B2Layered productsMonocomponent cellulose artificial filamentMaterials scienceUtility pole

A composite pole including a structural member and a cured resin layer adjacent the structural member and defining an exterior surface. The composite pole can be manufactured by providing a mold, inserting a structural member within the mold to define a space between the structural member and the mold, filling the space between the structural member and the mold with a liquid thermosetting resin, curing the liquid thermosetting resin to define an exterior surface, and removing the cured liquid thermosetting resin and structural member from the mold. The composite pole can also be manufactured by casting a jacket onto an installed pole by applying a mold around the installed pole, filling a space between the installed pole and the mold with a liquid thermosetting resin, curing the liquid thermosetting resin to define an exterior surface, and removing the mold from around the cured liquid thermosetting resin and the installed pole.

Owner:W J WHATLEY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com