Patents

Literature

274results about "Alginate artificial filaments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

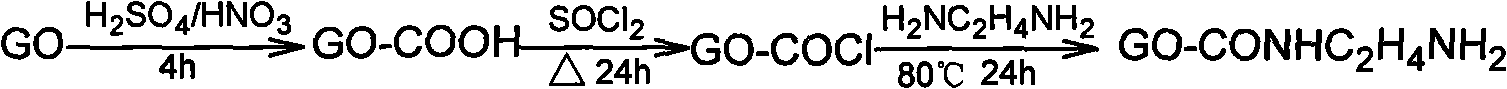

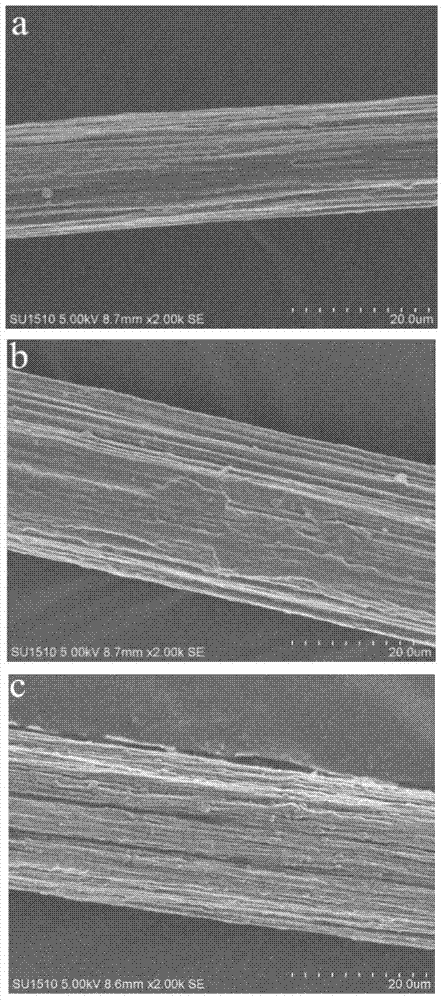

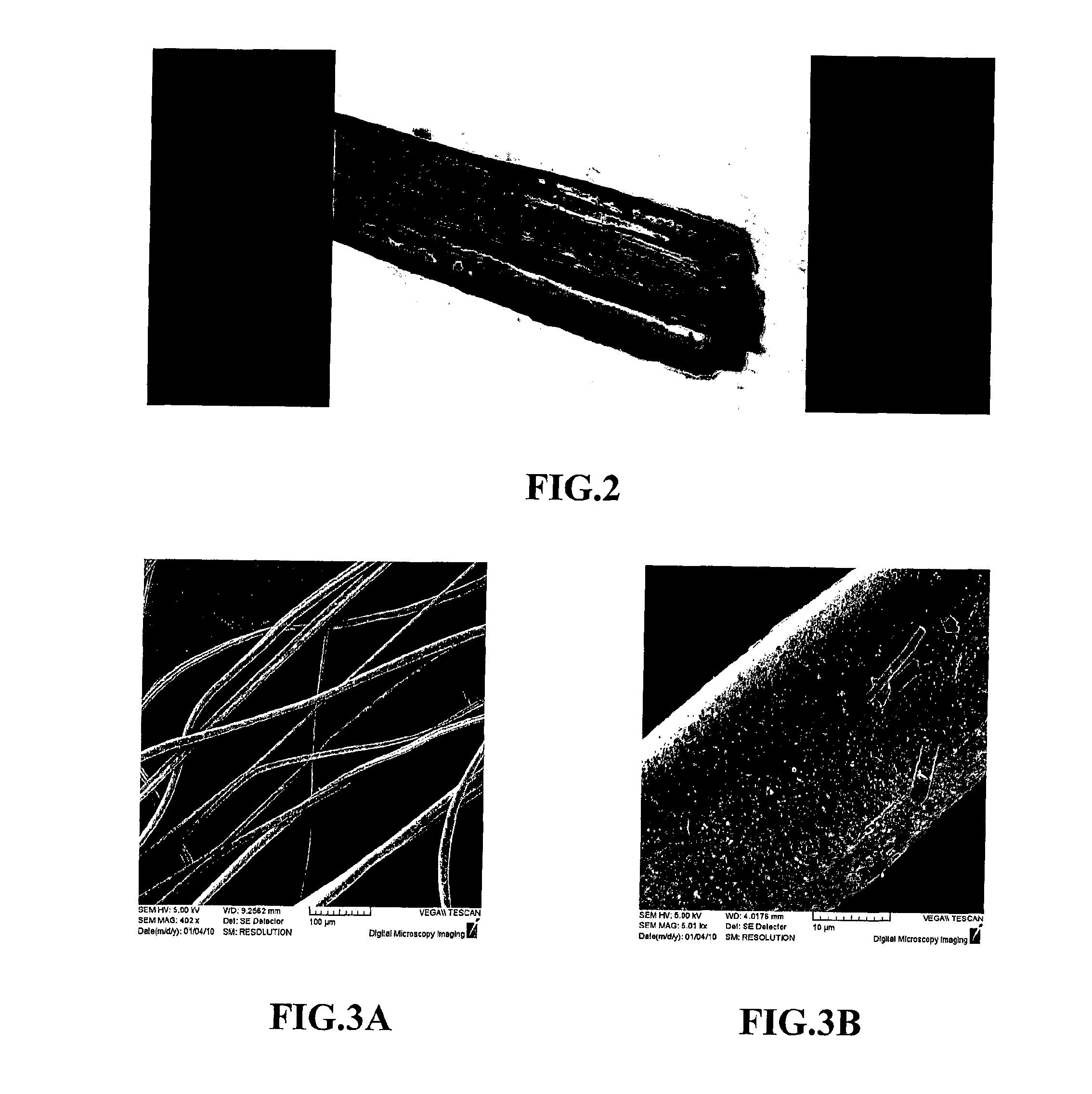

Method for preparing graphene functionalized alginate fibers

ActiveCN102181961AEffective orientationUniform and stable dispersionAlginate artificial filamentsWet spinning methodsFiberChemical reaction

The invention discloses a method for preparing graphene functionalized alginate fibers. The method comprises the following steps: firstly adding a defined amount of graphene to a sodium alginate solution to obtain a graphene / alginate spinning solution; or aminating the defined amount of graphene and then ensuring the aminated graphene to covalently bind with sodium alginate through a chemical reaction to obtain a graphene-alginate spinning solution; then ensuring the graphene / alginate spinning solution or the graphene-alginate spinning solution to respectively undergo a coagulation bath to obtain graphene / alginate as-spun fibers or graphene-alginate as-spun fibers; and then drawing, setting and oiling the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers after ensuring the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers to undergo a preheating bath and a drawing bath respectively to obtain graphene / alginate functionalized fibers or graphene-alginate functionalized fibers which are called graphene functionalized alginate fibers. The prepared graphene functionalized alginate fibers integrate the excellent performances of the graphene and the sodium alginate and have the excellent performances such as high tensile strength, good biocompatibility, antistatic performance, light weight, high elasticity, antibacterial performance and the like.

Owner:QINGDAO UNIV

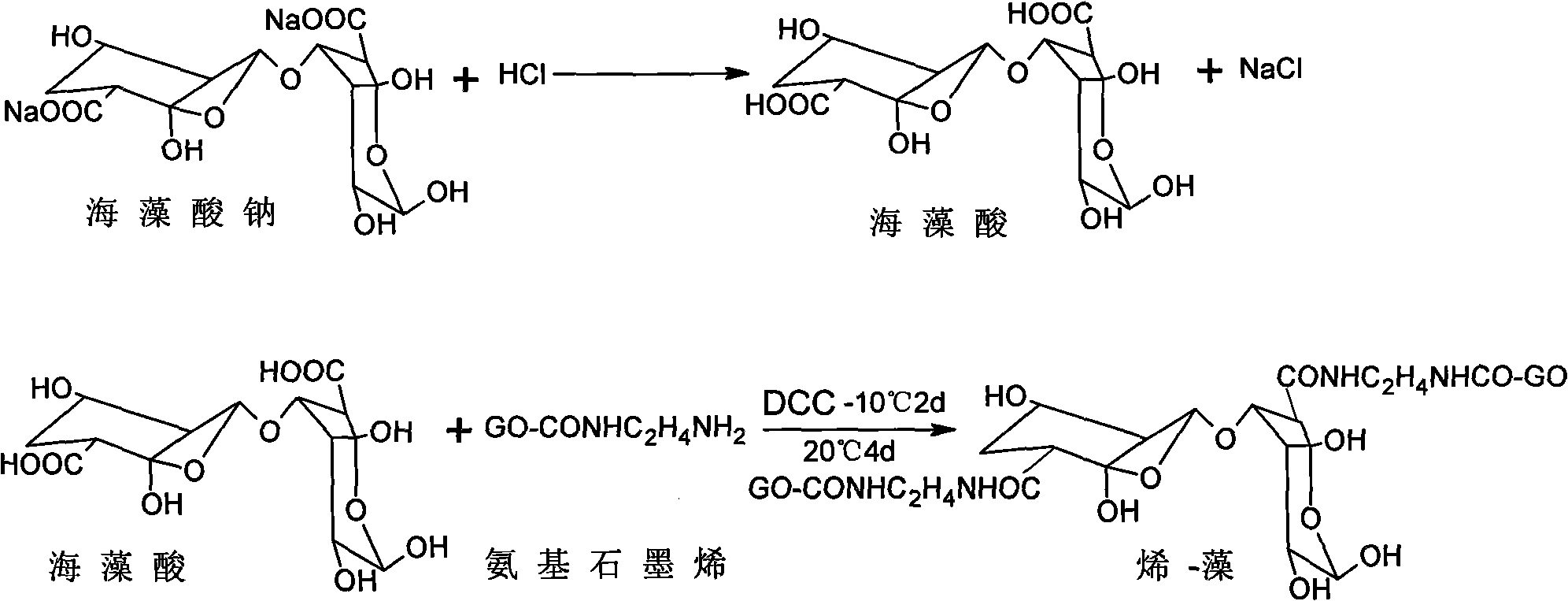

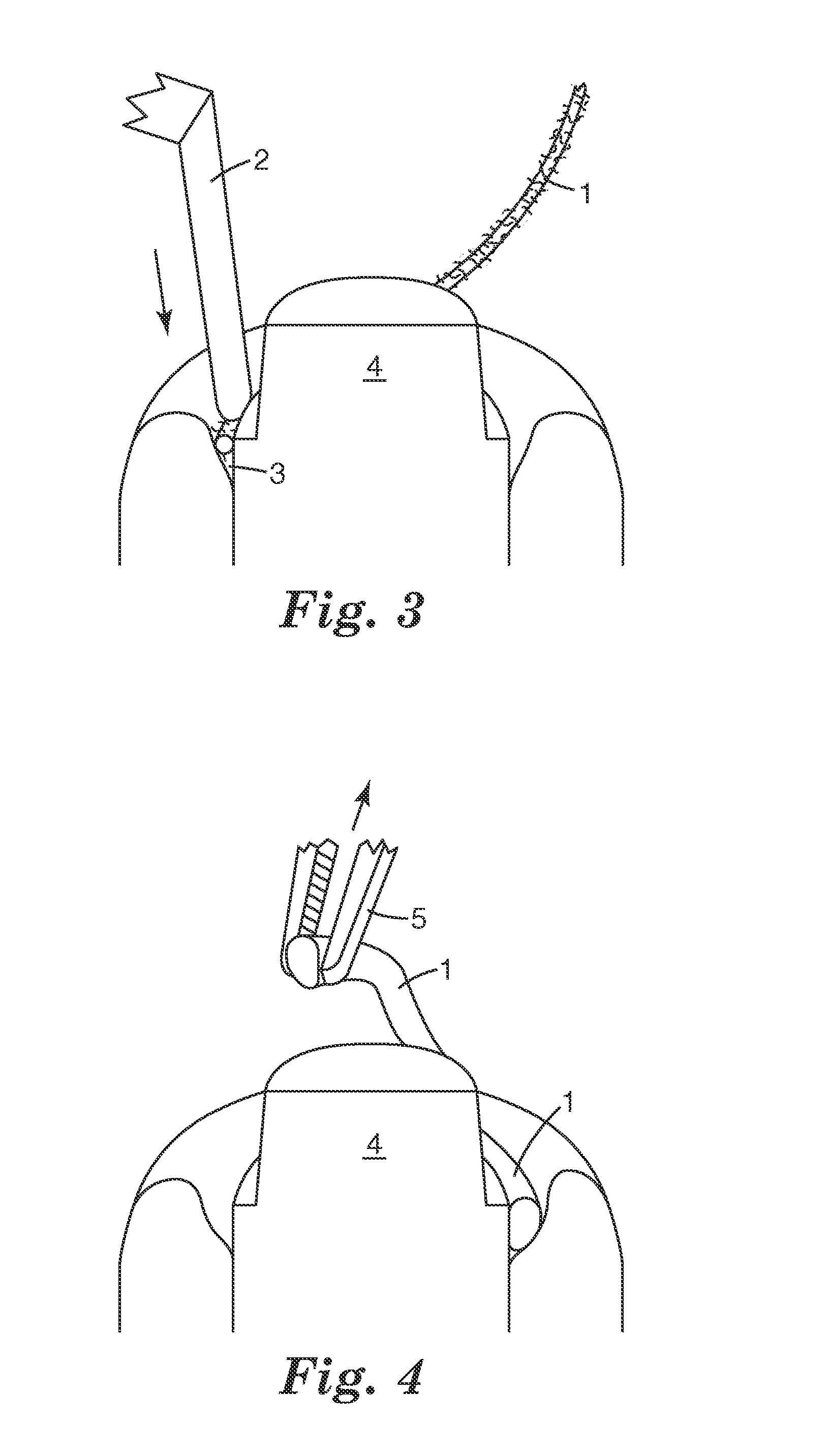

Dental Retraction Device and Process of its Production

The invention relates to dental retraction device having the shape of a yarn comprising twisted staple fibers, the twisted staple fibers comprising an alginate containing component, wherein the length of the staple fibers is in a range of about 10 to about 200 mm and / or wherein the staple fiber fineness is at least about 1 dtex. The invention also relates to a method for producing such a device as well as the use of this device in a process for retracting dental tissue.

Owner:3M INNOVATIVE PROPERTIES CO

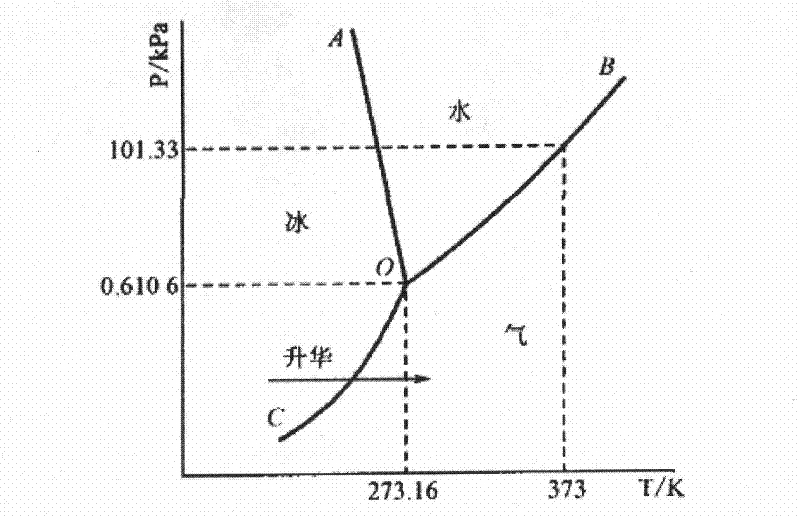

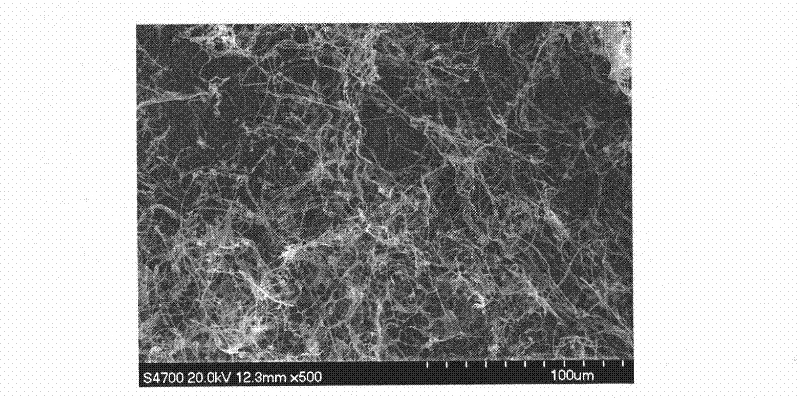

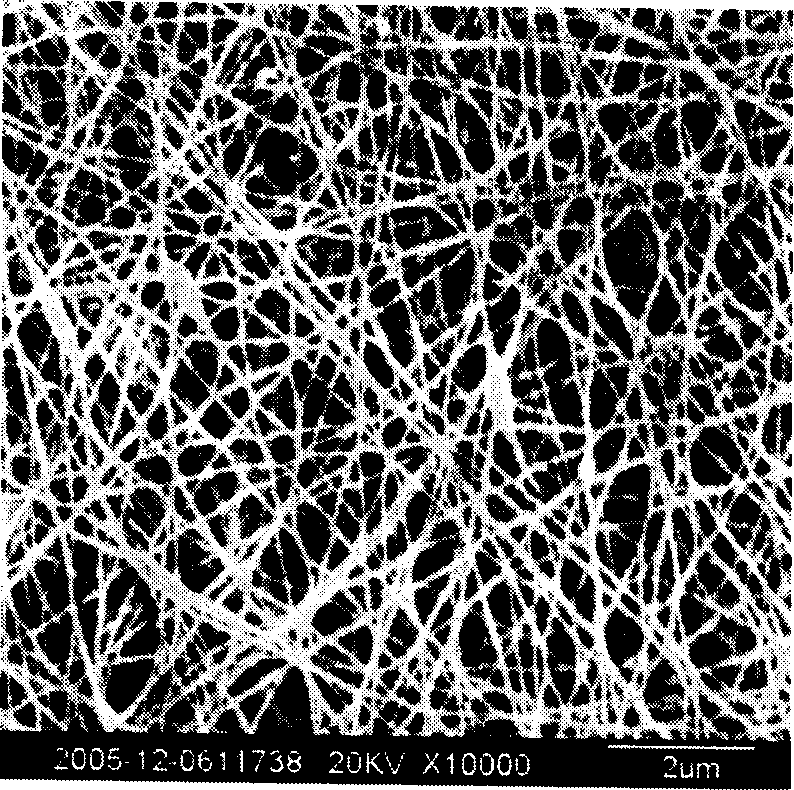

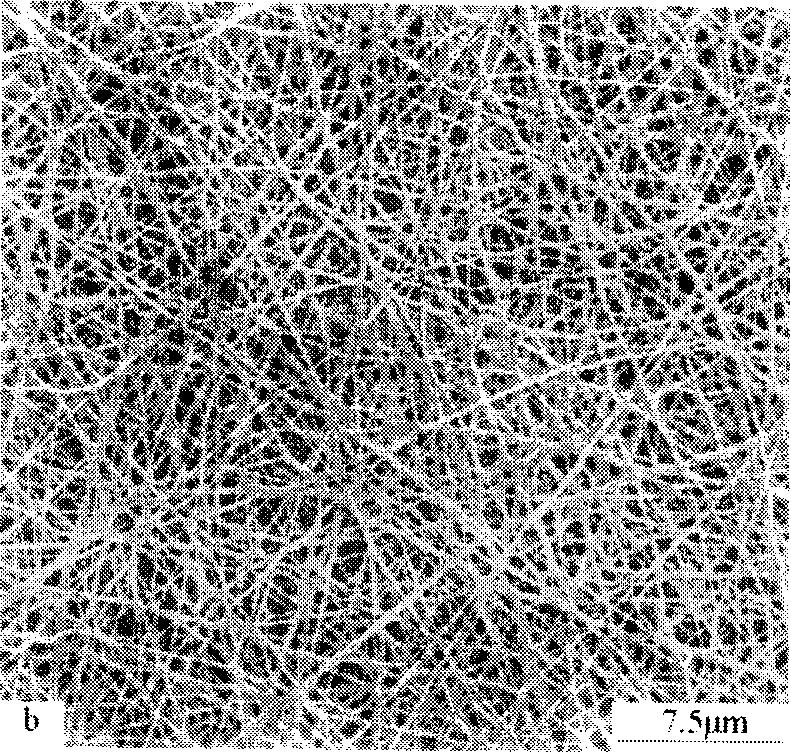

Natural polymer-based nano-fibrous membrane prepared by freeze-drying method

The invention relates a biodegradable and absorbable natural polymer-based nano-fibrous membrane prepared by a freeze-drying method, and the application thereof. The natural polymer-based nano-fibrous membrane is prepared through the following steps of: dissolving natural polymer powder into a corresponding solvent so as to prepare an extremely-dilute solution with the concentration of 0.001-0.1wt %; after the natural polymer powder is completely dissolved in the solvent, transferring the obtained natural polymer solution into a liquid nitrogen refrigerating device, so that the natural polymer solution is rapidly frozen in a liquid nitrogen environment; then, carrying out freeze-drying treatment on the obtained product in a freeze drier for 12-48 hours to obtain natural polymer-based nano fibers; and carrying out cross-linking on the obtained natural polymer-based nano fibers by a corresponding cross-linking agent to obtain a natural polymer-based nano-fibrous membrane, and then carrying out MTT (methyl thiazolyl tetrazolium) cytotoxicity test and cell vaccination experiments on the natural polymer-based nano-fibrous membrane, with the obtained results showing that the obtained fibrous membrane has no toxicity but has excellent cell adhesion and proliferation properties. The natural polymer-based nano-fibrous membrane disclosed by the invention is simple in the operation process, easy to control and low in cost; and by using the nano-fibrous membrane disclosed by the invention, ultra-fine natural polymer-based nano fibers can be prepared continuously on a large scale.

Owner:BEIJING UNIV OF CHEM TECH

Wound dressings

InactiveUS20070275043A1Low costExquisite structureBiocideAlginate artificial filamentsParticulatesWound dressing

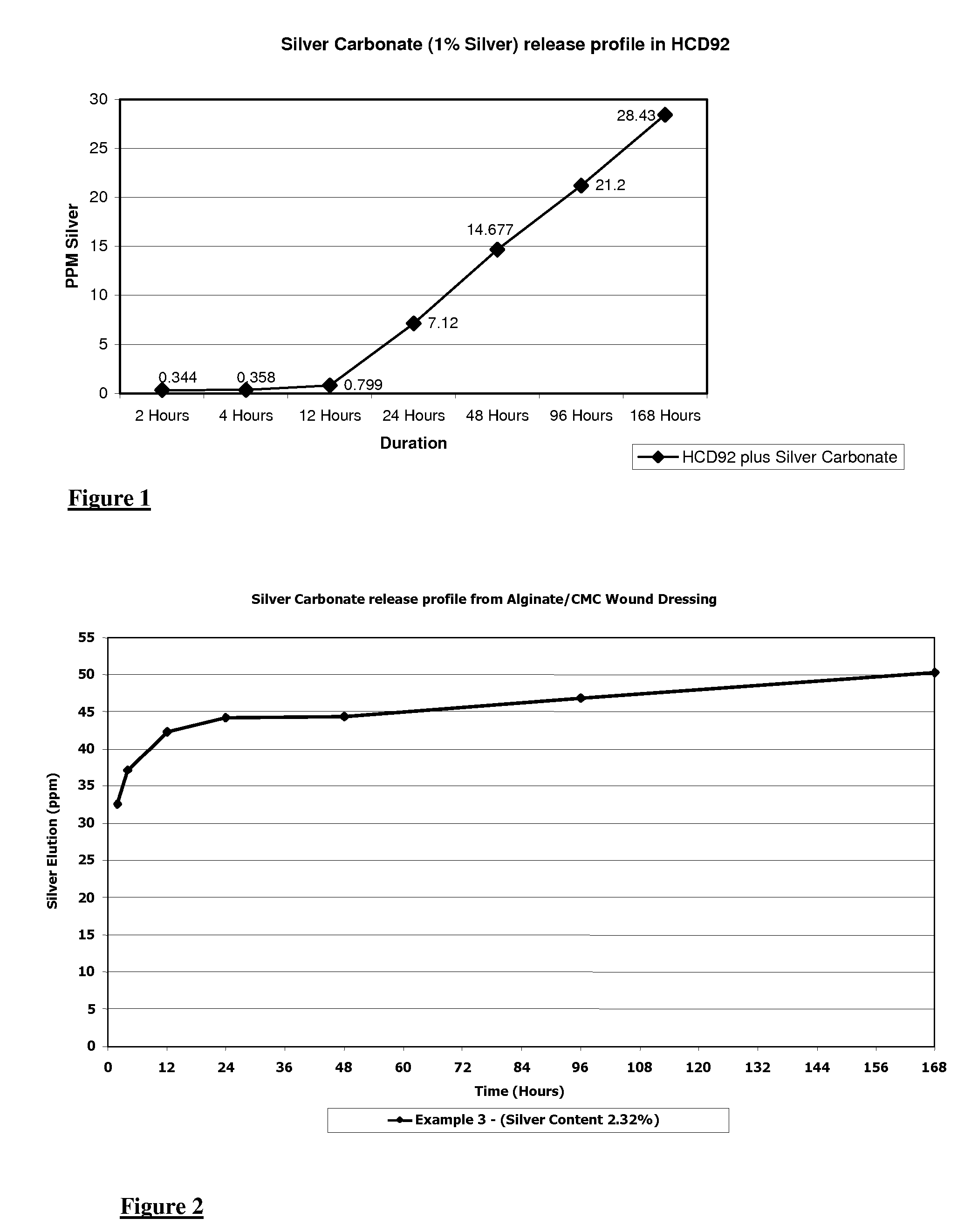

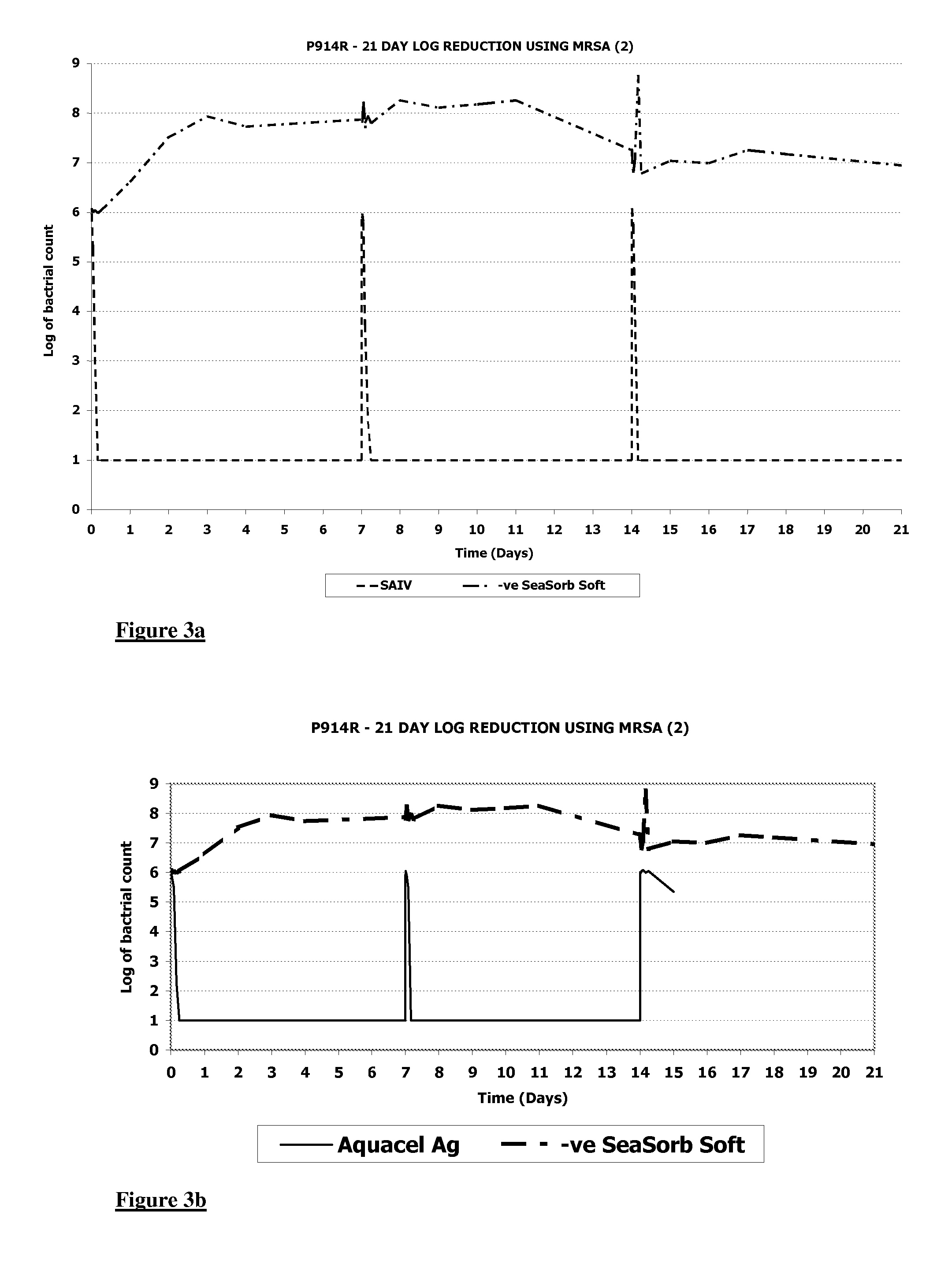

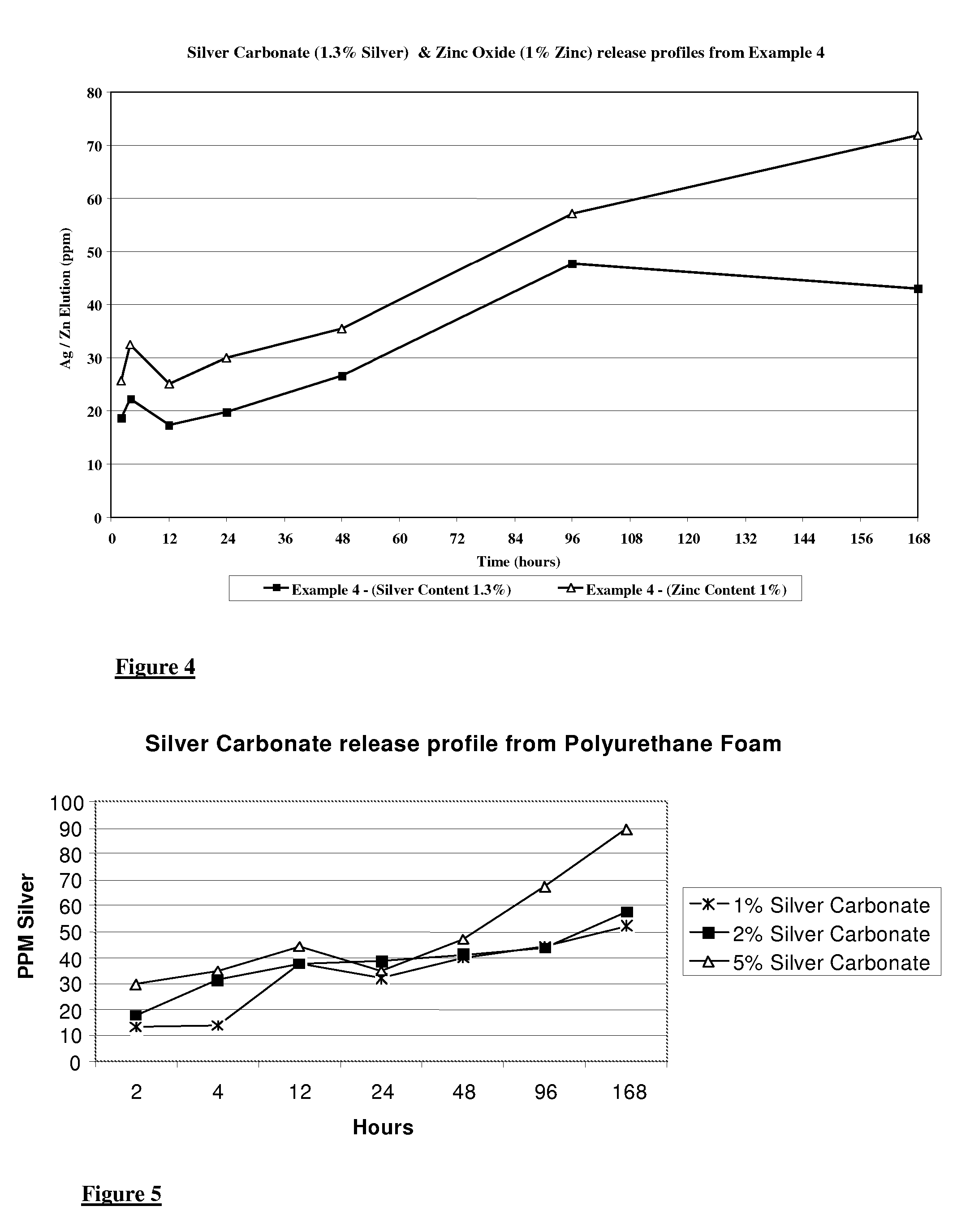

A wound dressing comprises a wound contacting material incorporating a therapeutically effective amount of a particulate, water insoluble, inorganic silver salt containing at least 50% by weight (based on the weight of the salt) of silver for delivering silver to a wound. The preferred water-soluble, inorganic silver salt is sodium carbonate. The wound contacting material may comprise an alginate.

Owner:ADVANCED MEDICAL SOLUTION

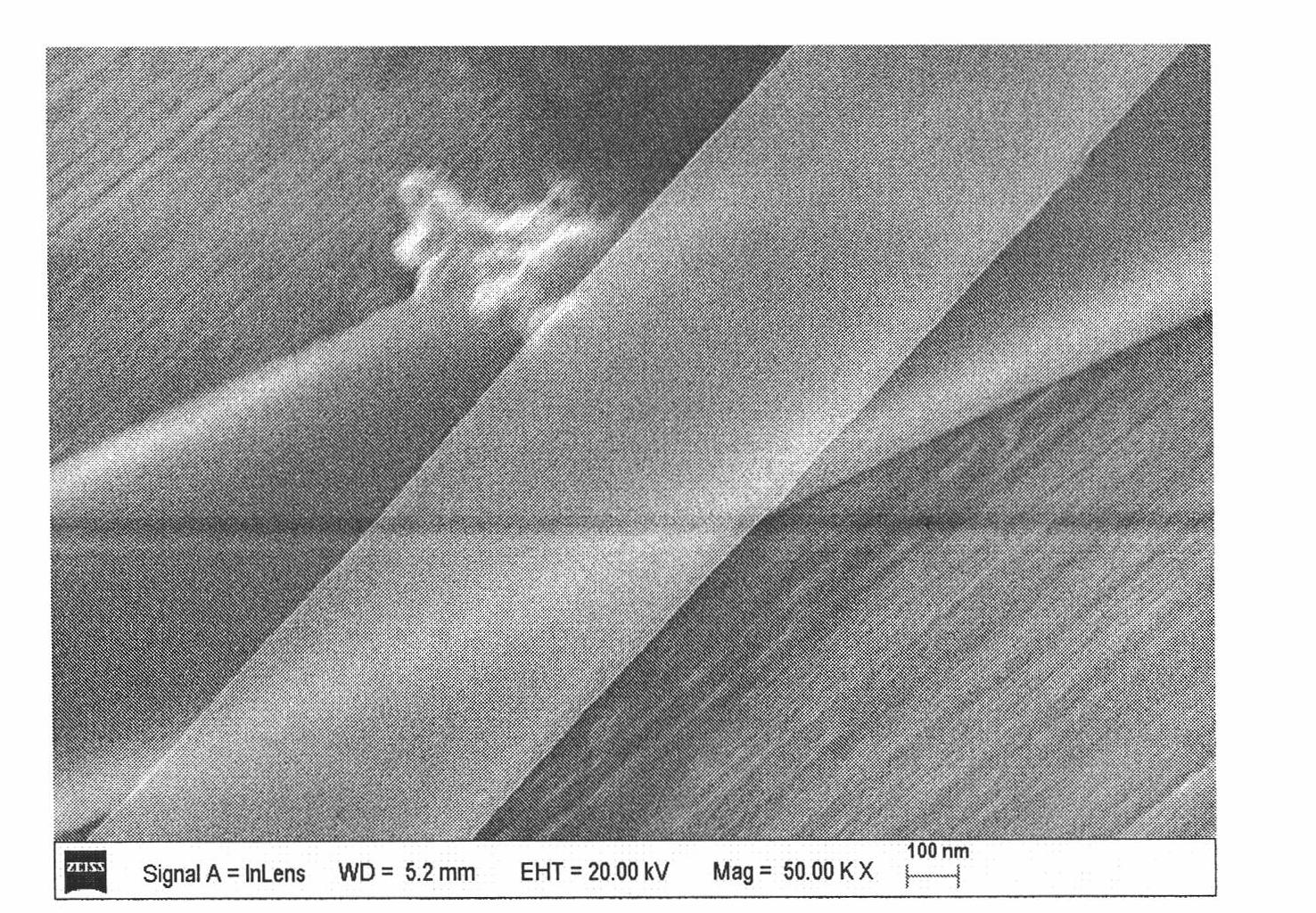

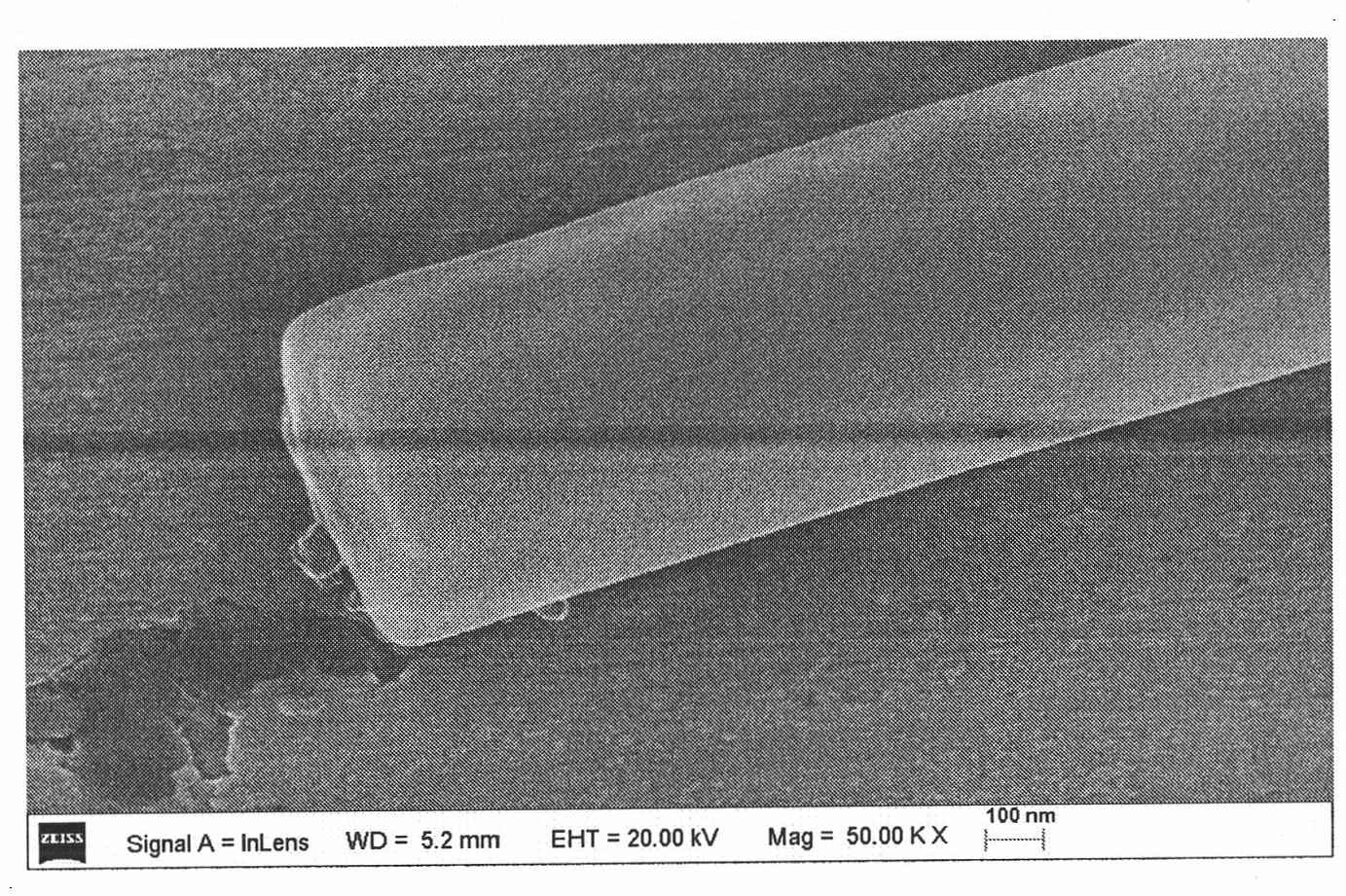

Method for preparing pure sodium alginate nano fiber membrane material

The invention belongs to the macromolecule material technology field, which relates to a preparation method of biodegradable and bio-absorbable macromolecule nanometer fiber non-woven fabric material, in particular to the preparation method of natural high polymer biological material, namely, sodium alginate electrostatic spinning solution, and the preparation method of pure sodium alginate nanometer fiber membrane material. The preparation method and the technical principle of the invention comprise the following steps: aiming at the characteristics of rigidity and stretching ability of the sodium alginate molecular chain in the aqueous solution, a solvent type strong polar modifying agent, namely, polyhydroxylated compound is induced in the aqueous solution of the sodium alginate, and through the strong polarity and the low surface tensile force, etc. of the compound, the physical property of the aqueous solution of the sodium alginate is effectively adjusted, thereby realizing that the transforming from the non-spinning of the aqueous solution of the sodium alginate to the spinning of the aqueous solution of the sodium alginate, and obtaining the even and smooth pure sodium alginate nanometer fiber membrane material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

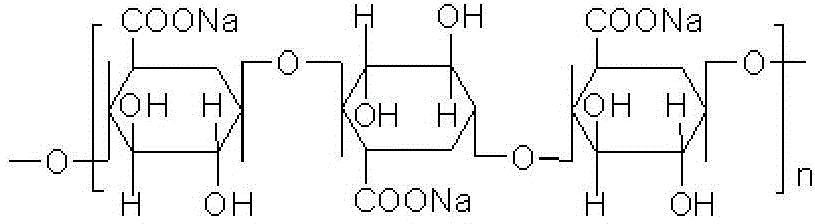

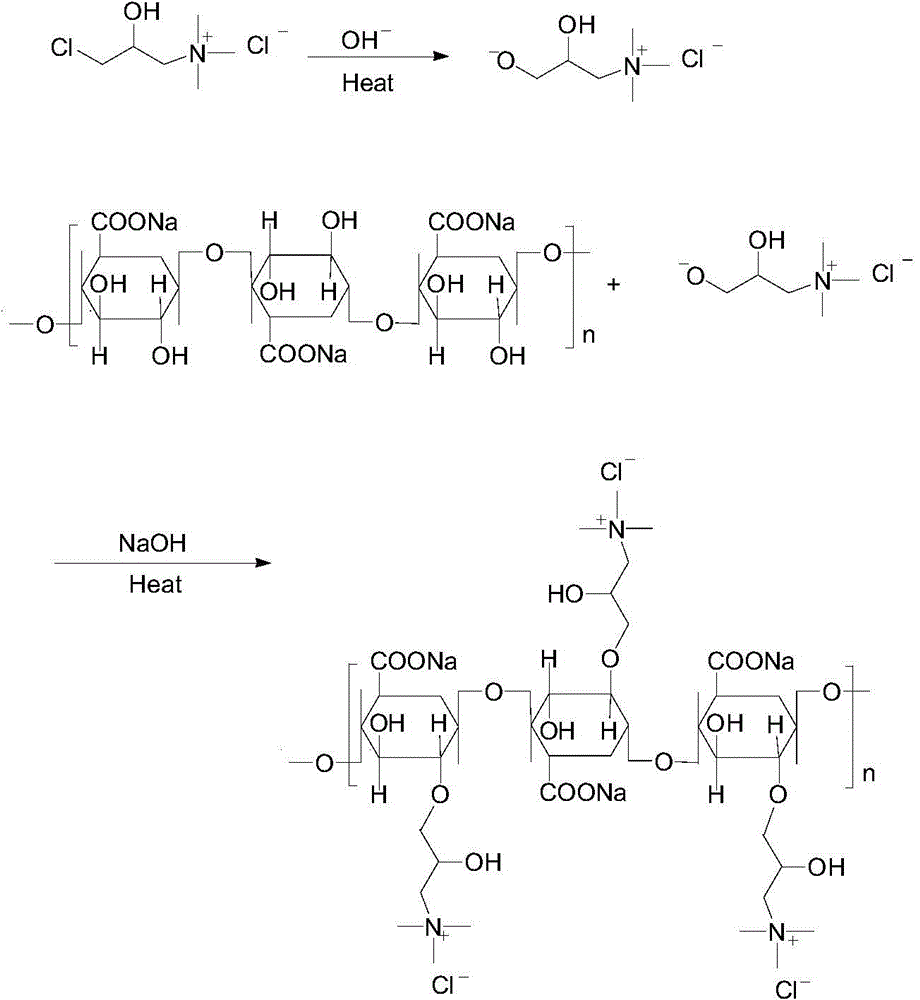

Method for producing antimicrobial calcium alginate fiber

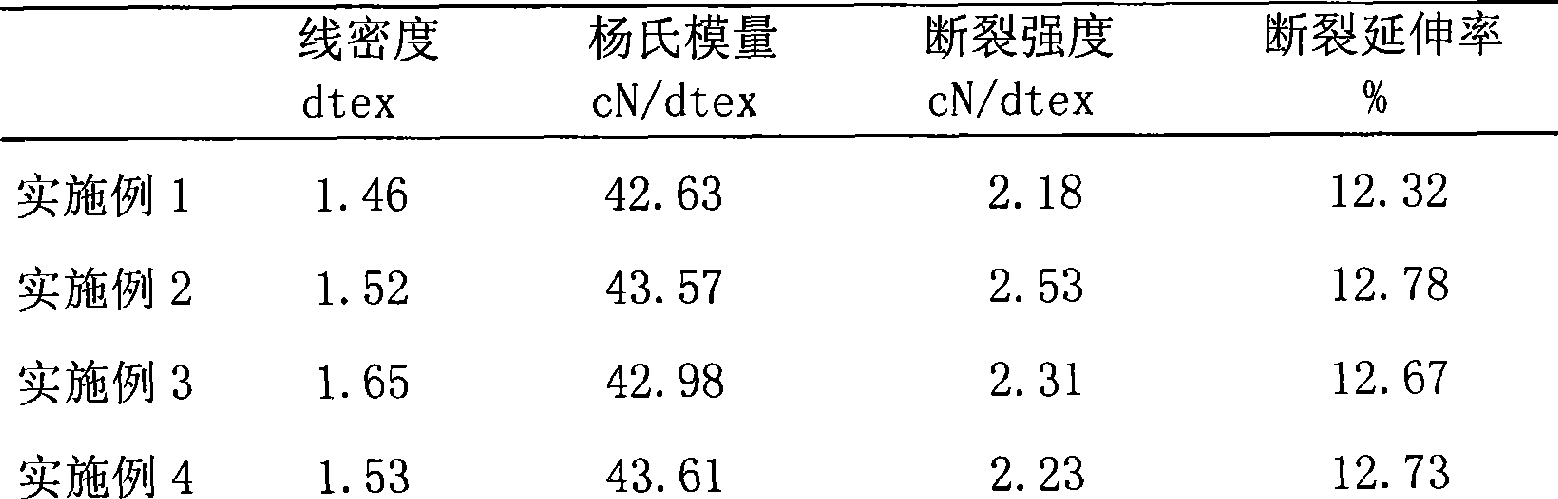

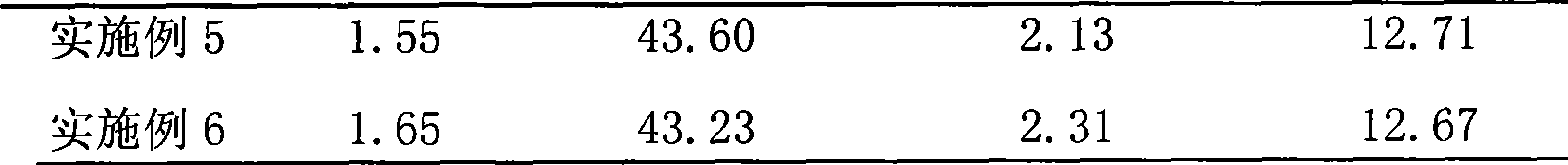

ActiveCN101381907AEvenly distributedImprove antibacterial propertiesAlginate artificial filamentsAbsorbent padsCalcium alginateMechanical property

The invention discloses a method for manufacturing an antimicrobial calcium alginate fibre. A sodium alginate is used as spinning stock solution; in a solidification bath containing an antimicrobial agent, the antimicrobial calcium alginate fibre is obtained by a wet-method spinning process; and the antimicrobial agent is a cationic compound which is combined with large molecules of the calcium alginate fibre through ionic bonds. The antimicrobial calcium alginate fibre obtained by the method has no toxicity and no side effect on human body; the antimicrobial agent and the large molecules of the fibre are combined by the ionic bonds in order that the antimicrobial agent has long-lasting antimicrobial function; in addition, the fibre retains the excellent quality of the calcium alginate fibre, has excellent hygroscopic property and good mechanical property, can be used for manufacturing medical dressings, has the advantages of convenient use, comfortable application and good ventilation, the acceleration of the healing of wound, the relieving of the pains of patients and the like, can be also used for manufacturing clothing and industrial textiles by pure spinning or blended spinning with cotton, mucilage glue, bamboo pulp, fur, ramie, soybean protein fibre and the like.

Owner:山东康康新材料科技有限公司

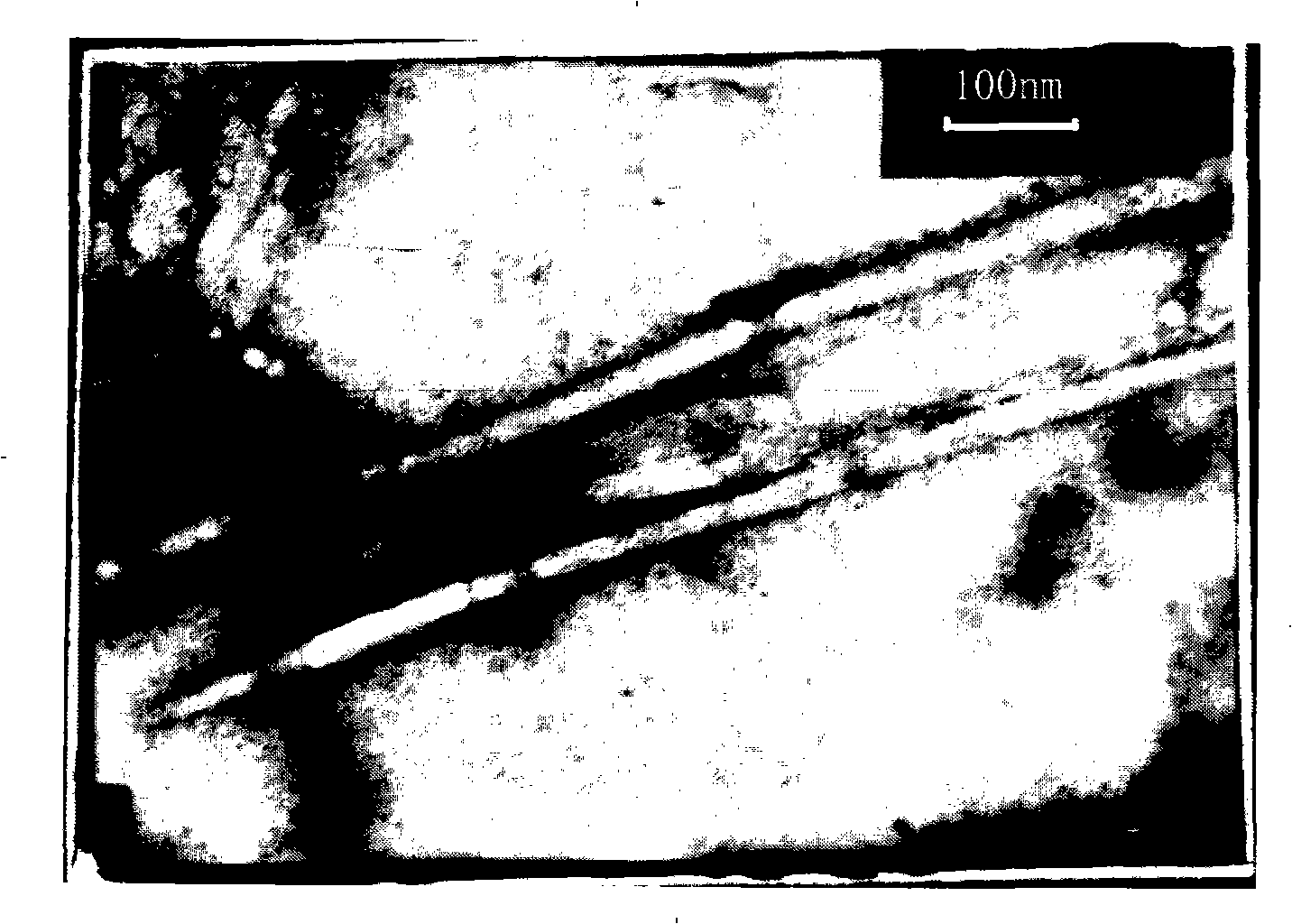

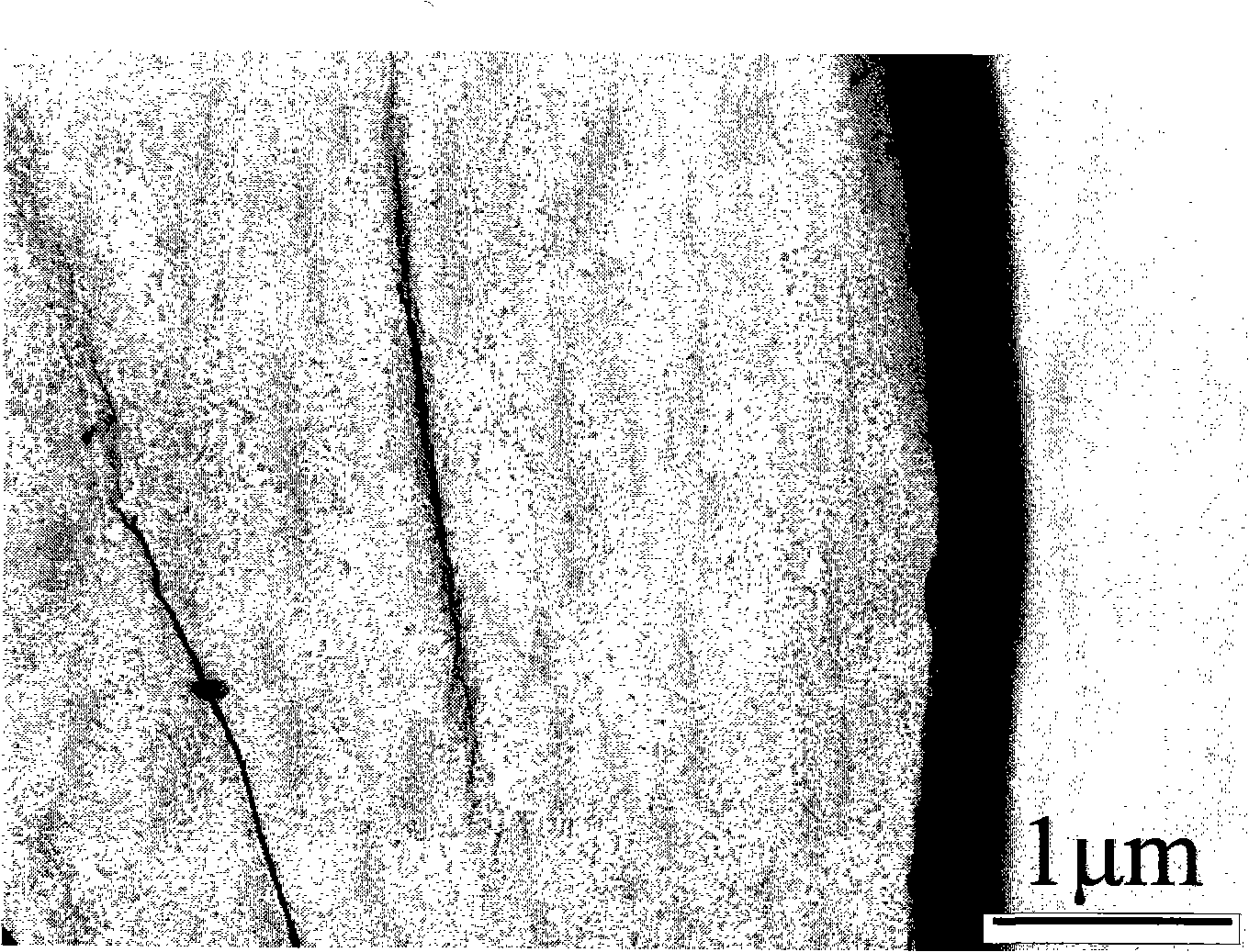

Multifunctional high-performance carbon-based nanoparticle/sodium alginate composite fibers and preparation method thereof

ActiveCN104178845AEvenly dispersedHigh tensile strengthElectroconductive/antistatic filament manufactureAlginate artificial filamentsFiberSpinning

The invention discloses a preparation method of carbon-based nanoparticle / sodium alginate composite fibers. The method comprises the steps of firstly, preparing a sodium alginate water solution with a certain concentration; then, feeding graphene oxide into the solution, fully mixing, and carrying out ultrasonic dispersion to obtain a graphene oxide / sodium alginate water solution; feeding a certain quantity of carbon nano tubes into the solution, fully mixing, and carrying out the ultrasonic dispersion to obtain a carbon nano tube / graphene oxide / sodium alginate spinning solution with the good dispersion; filtering the spinning solution, defoaming, and carrying out solution spinning at the room temperature to prepare the carbon-based nanoparticle / sodium alginate composite fibers. According to the carbon-based nanoparticle / sodium alginate composite fibers prepared by adopting the method, the uniform dispersion and the formation of a network structure of carbon-based nanoparticles in the fibers can be realized, the effective orientation of the carbon-based nanoparticles in the fibers can be realized, and the tensile strength, the electrical conductivity and the degradability resistance of the fibers are improved; furthermore, the adsorbability of the fibers is effectively improved, so that the carbon-based nanoparticle / sodium alginate composite fibers can be used for absorbing heavy metal ions and dye in water solutions.

Owner:QINGDAO UNIV

Preparation method of nano-silver alginate fiber

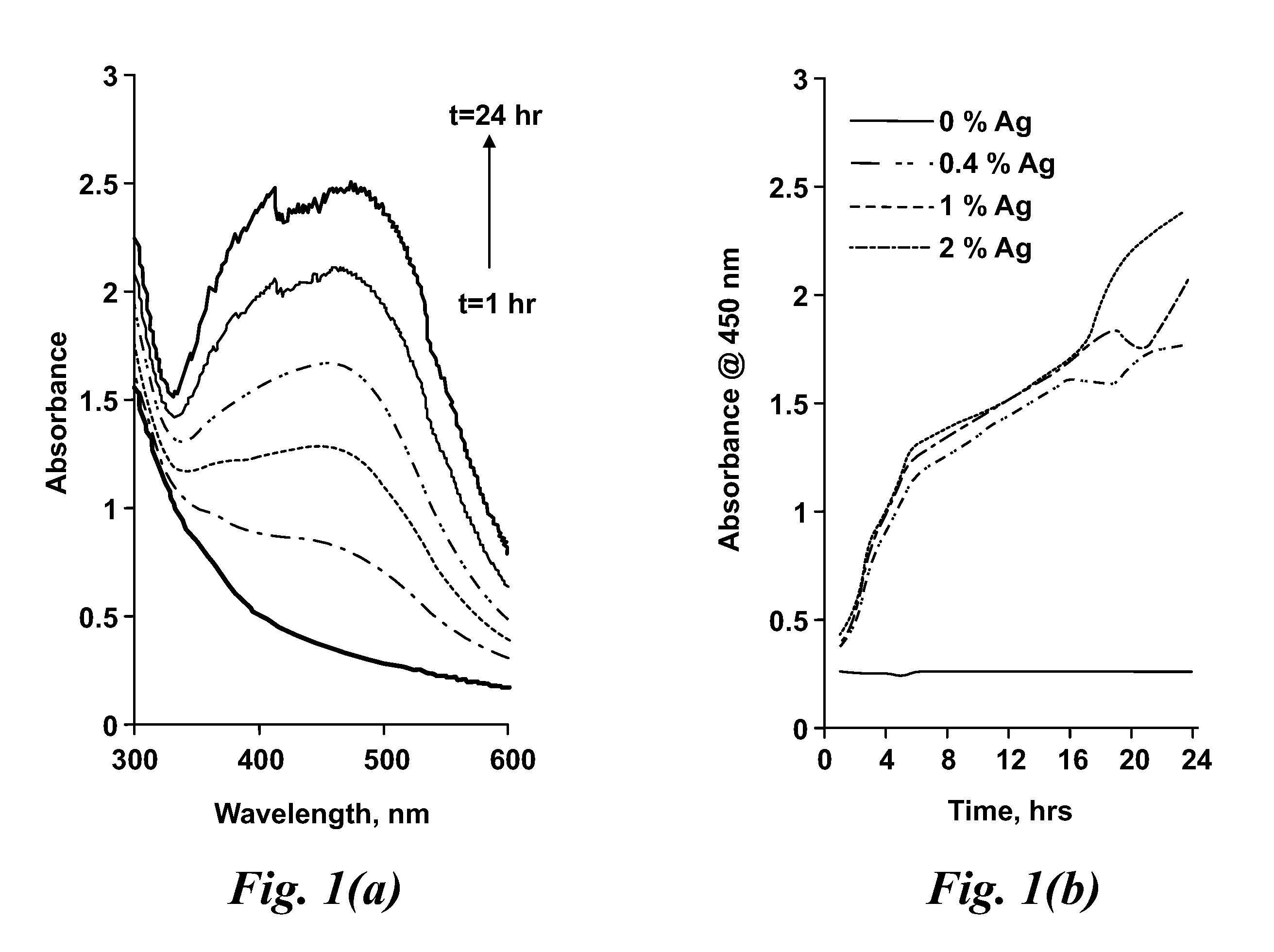

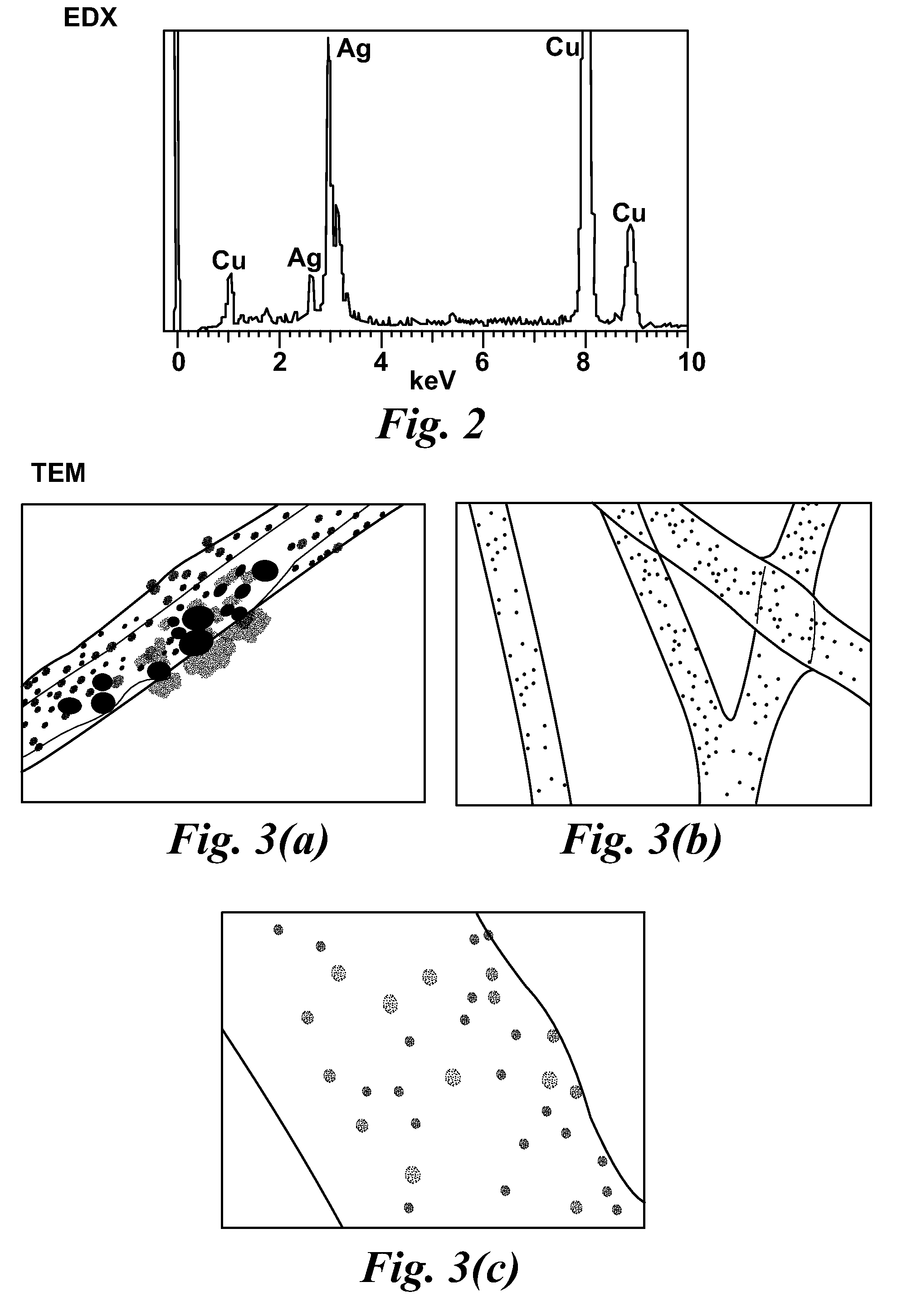

ActiveCN103147167ASmall particle sizeUniform particle size distributionAlginate artificial filamentsWet spinning methodsFiberBiocompatibility Testing

The invention discloses a preparation method of a nano-silver alginate fiber. The preparation method comprises the following steps of: preparing an alginic acid silver complex which is a precursor of nano-silver by using algal polysaccharides and soluble silver salts, and then preparing a sodium alginate based nano-silver colloid system through a chemical reduction method; then adding fiber-grade sodium alginate into the sodium alginate based nano-silver colloid system to obtain a nano-silver algae spinning solution; and finally, obtaining a nano-silver algae primary fiber through wet spinning, and carrying out stretching, sizing, drying and oiling treatments to obtain the nano-silver alginate fiber. The prepared nano-silver alginate fiber integrates the excellent performances of the nano-silver and the alginate fiber, so that the novel fiber has excellent flame retardance, biocompatibility, moisture absorption permeability and the like, also has excellent antimicrobial performance, antistatic performance and irradiation resistance and can be widely used in medical treatment, the fire-fighting field, the military field, the aerospace field, the health textile field and the like.

Owner:QINGDAO UNIV

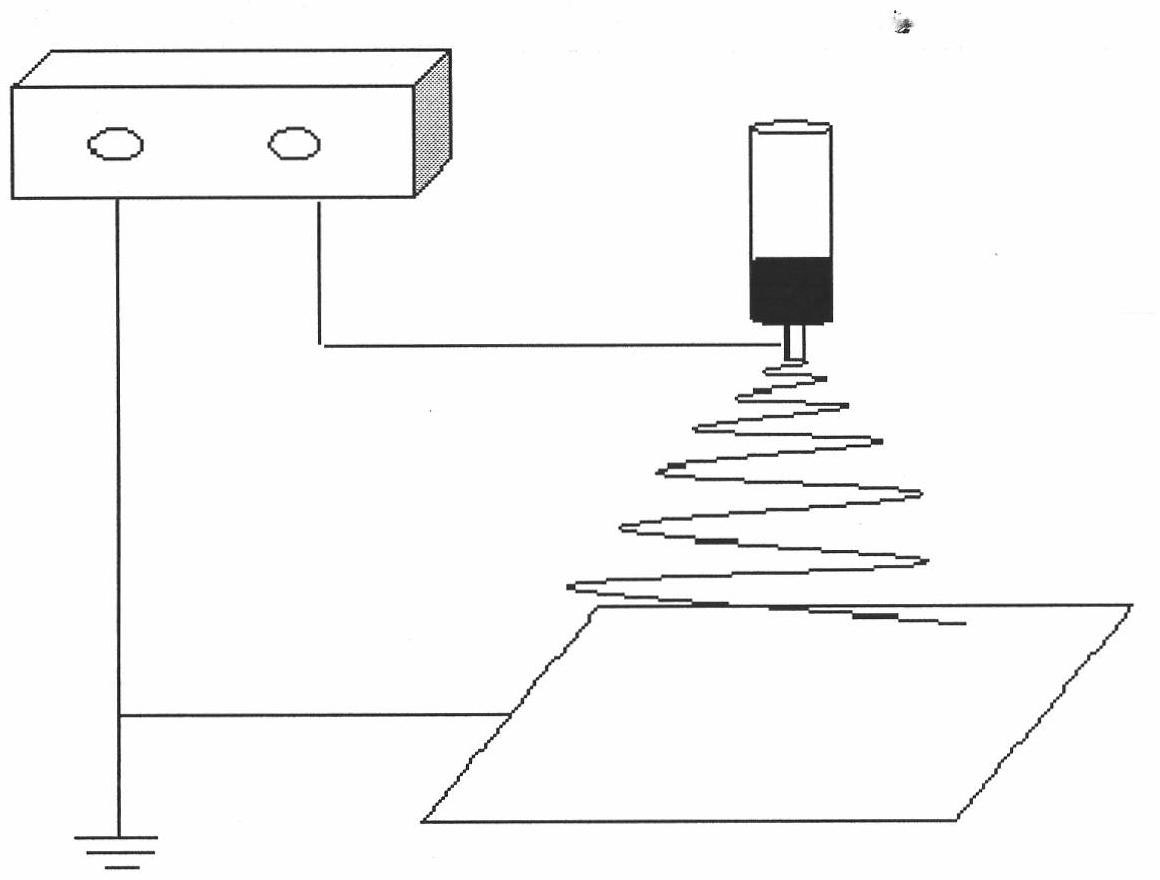

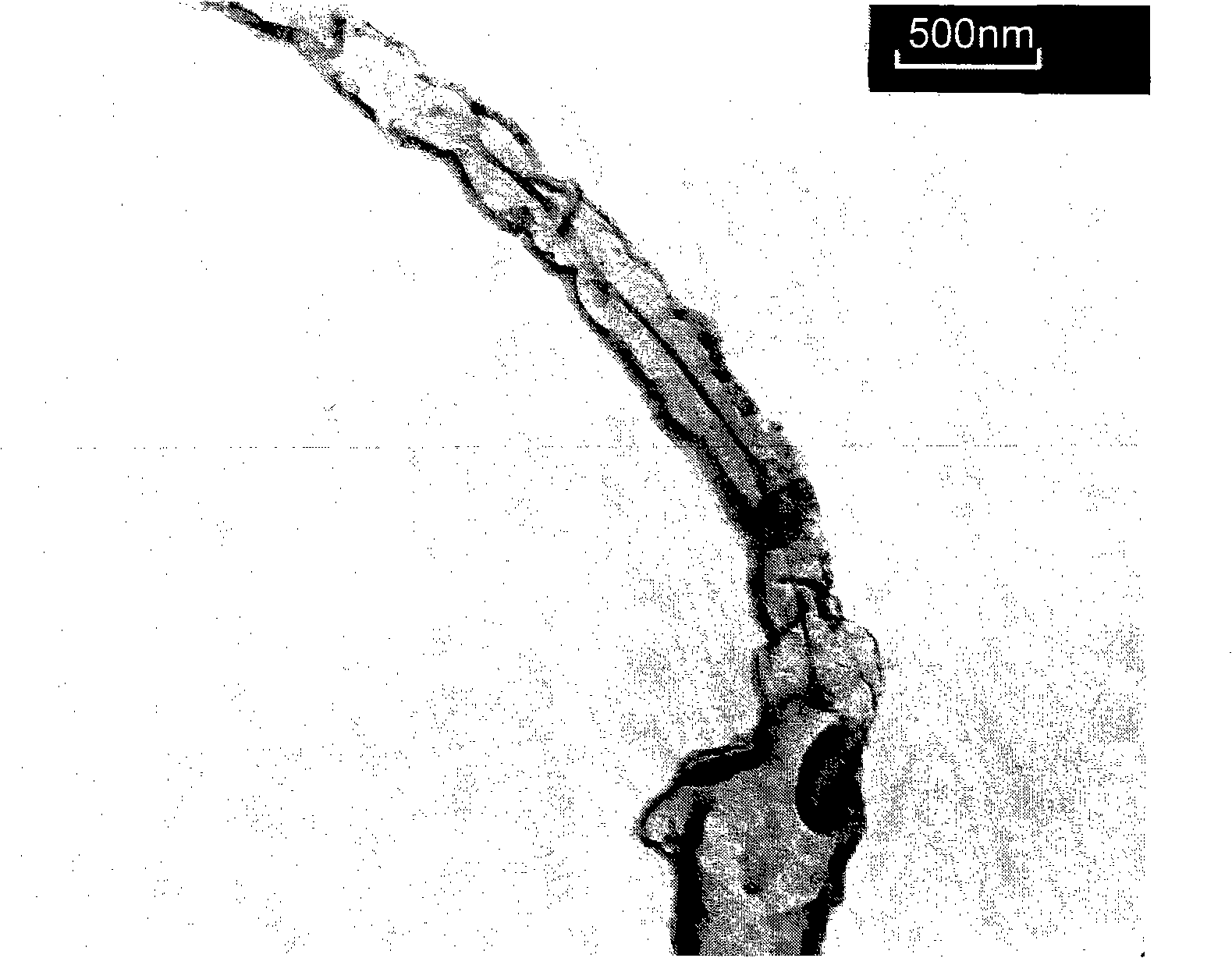

Preparation method of sodium alginate nanofiber

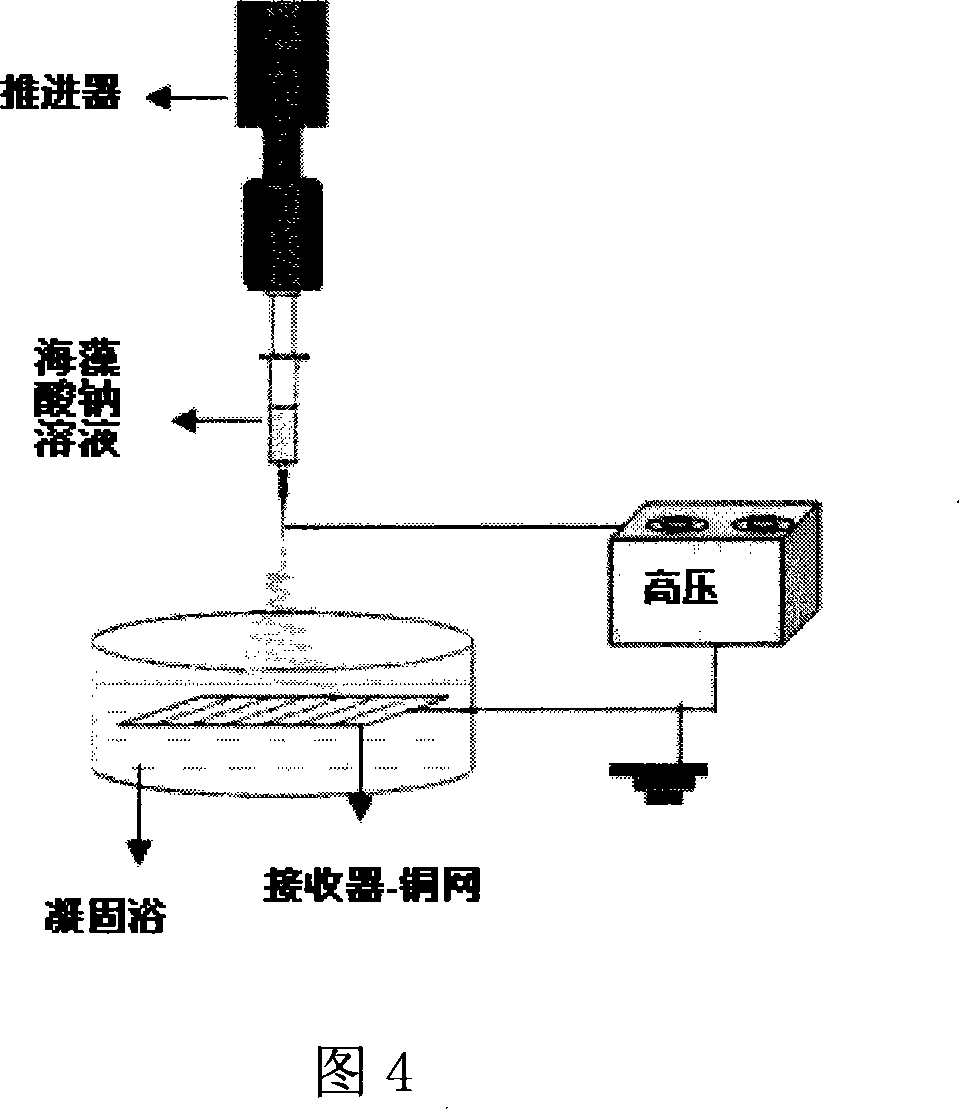

InactiveCN102071497ASolve drippingSolve the problem of not forming a jetFilament/thread formingAlginate artificial filamentsDimethyl formamideInjector

The invention relates to a preparation method of a sodium alginate nanofiber, belonging to the field of natural biological polymer materials. The preparation method comprises the following steps: dispersing sodium alginate powder in an ethanol solution, and adding water to regulate the concentration to 4-6 wt%; dropwise adding a crosslinking agent while stirring, and then standing, wherein the content of the crosslinking agent is 1-3 wt% of the sodium alginate; after bubbles emerge, dropwise adding a N,N-dimethyl formamide water solution while stirring, and then standing, thereby obtaining a sodium alginate spinning solution the concentration of which is 0.5-2 wt% after the bubbles emerge; adding the spinning solution into an injector, regulating the voltage to 10-25kV, regulating the distance between a sprayer and a receiver to 5-25cm, and regulating the flow rate to 0.1-1 ml / h; and starting a spinning device. The invention aims at the complicated after-treatment processes of crosslinking, washing, drying and the like for obtaining a pure SA (sodium alginate) nanofiber at present. The method can be used for directly preparing a slightly-crosslinked SA nanofiber, and a solvent can sufficiently volatilize in the spinning process.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing high-strength alginic acid/gelatin cross-blend fiber and its use

ActiveCN1978718AImprove mechanical propertiesImprove water absorptionSurgeryAlginate artificial filamentsCross-linkFiber

The invention discloses high strength alginic acid / gelatin blended fiber manufacturing method and use. The method includes the following steps: making sodium alginate solution with 3-6% mass percent; making gelatin aqueous solution with 6-12% mass percent and 8.0-9.0 pH; mixing them as 10-50:100 volumetric ratio; stirring to homogeneous phase system; decompress; de-bubbling; using wet spinning method to make fiber under 33 degree centigrade of which total draft is 10-30%. The invention makes cross blend spinning fluid be cross linking with Ca2+ divalent metal ion, and makes the fiber under acidity with polyelectrolyte effect which can further increase fiber cross linking level, breaking tenacity to improve fiber physical mechanical properties. Thus it can be used to make non-woven fabrics such as hospital gauze, dressing etc.

Owner:青岛海赛尔新材料科技有限公司

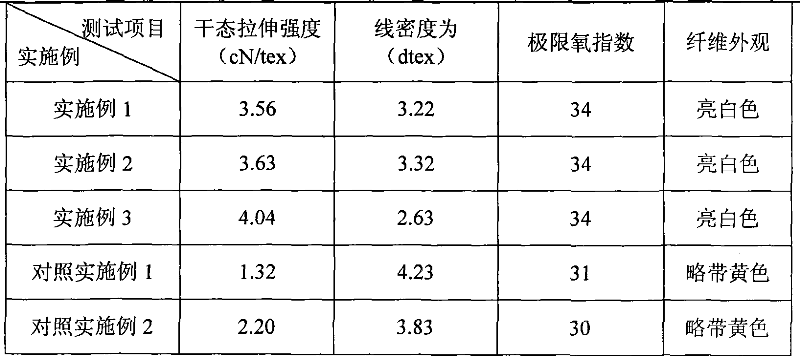

Preparation method of flame-proof sea silk new material

ActiveCN101037814AIntrinsically flame retardantHas flame retardant propertiesAlginate artificial filamentsWet spinning methodsFiberPolymer science

This invention disclosed a method of produce new material of flame retardant alginate fiber: make sure the proportion of G chain segment and M chain segment which in the molecular structure is 1:1 - 1:3, the potassium alginate's weight percent of solute is 4-7% or the mixture of potassium alginate and sodium alginate be fully predissolved and dissolved and after adjustment viscosity, filter and defoamed by sodium hypochlorite or hydrogen peroxide, produce alginate fiber material by solution spinning at room temperature, the draft proportion of fiber is 120-300%. The limited oxygen index of the fiber reaches to 34, the fiber's tensile strength is more than 3.5cN / tex, the linear density is 2.2-3.5 dtex. The fiber produced by this method is flame retardant, high strength of fracture and bio-degradable, and so on, so which can be used to produce flame retardant textiles by pure spinning or blended. This invention disclosed a method of produce a new material of flame retardant alginate fiber: make sure the proportion of G chain segment and M chain segment which in the molecular structure is 1:1 - 1:3, the potassium alginate's weight percent of solute is 4-7% or the mixture of potassium alginate and sodium alginate be fully predissolved and dissolved and after adjustment viscosity, filter and defoamed by sodium hypochlorite or hydrogen peroxide, produce alginate fiber material by solution spinning at room temperature, the draft proportion of fiber is 120-300%. The limited oxygen index of the fiber reached to 34, the fiber's tensile strength is more than 3.5cN / tex, the linear density is 2.2-3.5 dtex. The fiber produced by this method is flame retardant, high strength of fracture and bio-degradable, and so on, so which can be used to produce flame retardant textiles by pure spinning or blending.

Owner:QINGDAO UNIV

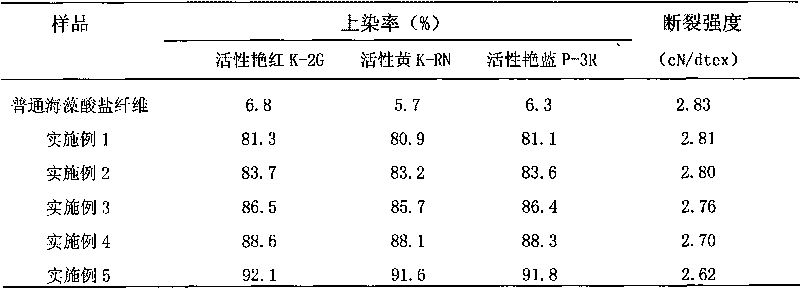

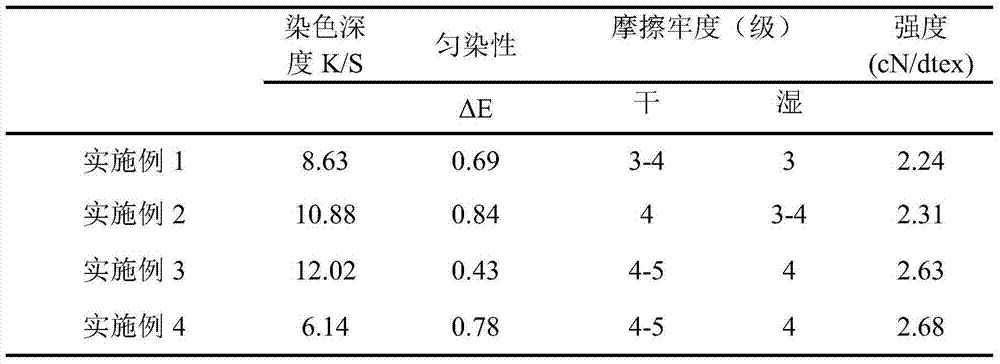

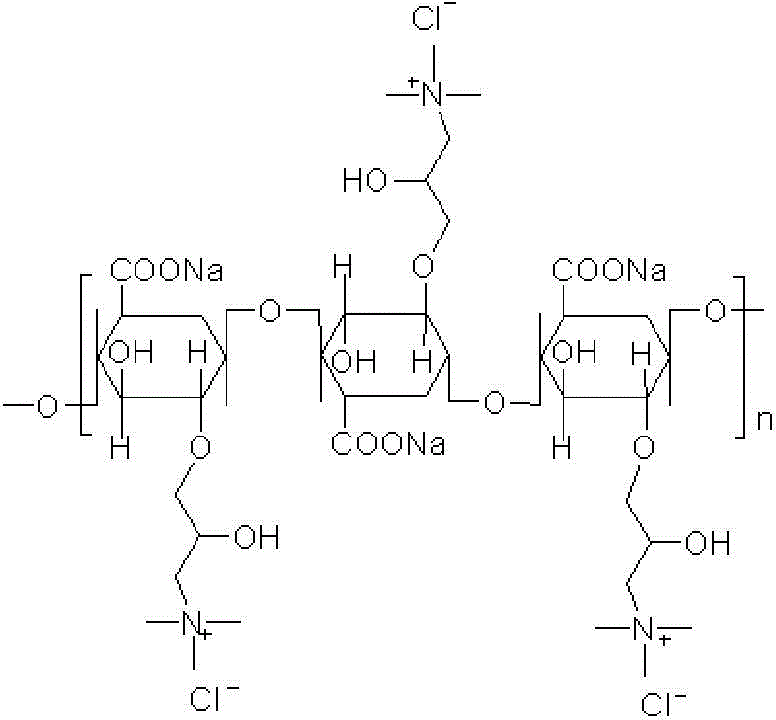

Manufacturing method of stainable alginate fibers

ActiveCN101736440AAchieve dyeingMeet diverse needsAlginate artificial filamentsWet spinning methodsColour fastnessState of art

The invention disclose a manufacturing method of stainable alginate fibers, which comprises the following steps of: adding a water-soluble dendrimers compound into a alginate fiber spinning solution, and solidifying, drafting, water washing and post-processing by adopting wet spinning equipment and technology to obtain the alginate fibers with excellent staining property, wherein the content of dendrimers in the alginate fibers is 1-10 percent. Compared with a traditional alginate fiber production technology, the invention has the advantages that the prepared alginate fibers can be applied to direct dyes and active dyes under a salt-free condition to realize staining and have higher dye uptake rate which generally reaches above 80 percent and is 10-15 times that of the alginate fibers produced by the traditional technology. In addition, the alginate fibers prepared by the invention has better color fastness and particularly excellent wet-processing fastness which reaches above grade 4.

Owner:QINGDAO TIANYI GROUP

Method for coloring alginate fiber stoste by adopting lake colors

ActiveCN104264280AIncrease profitHigh color fastnessAlginate artificial filamentsDye addition to spinning solutionSolventFine chemical

The invention discloses a method for coloring alginate fiber stoste by adopting lake colors, and belongs to the field of fine chemical engineering and material science. The method comprises the following steps: adding sodium alginate into deionized water, and stirring so as to dissolve sodium alginate fully to prepare alginate fiber spinning stoste; then adding lake colors into the alginate fiber spinning stoste, stirring and mixing uniformly, filtering and defoaming to obtain the lake color colored alginate fiber stoste, and preparing further to obtain lake color colored alginate fibers. The method overcomes the problem of damage of traditional dye dying on fibers; the prepared colored alginate fibers have the advantages of bright colors, high color fastness, good solvent mobility resistance and the like.

Owner:JIANGNAN UNIV

Bacterial cellulose/sodium alginate composite fiber and preparation method thereof

ActiveCN101613893AGood physical and mechanical propertiesThe dissolution process is simpleConjugated cellulose/protein artificial filamentsAlginate artificial filamentsFiberMicro nano

The invention discloses a bacterial cellulose / sodium alginate composite fiber and a preparation method thereof. The bacterial cellulose and the sodium alginate composite fiber are obtained by adding sodium alginate micro-nano powder to a bacterial cellulose solution, uniformly dispersing the sodium alginate micro-nano powder by ultrasonic waves and carrying out wet spinning, wherein the content of the sodium alginate in the composite fiber reaches 5 percent to 20 percent, and the content of the bacterial cellulose in the composite fiber reaches 80 percent to 95 percent. The preparation method comprises the following steps: dissolving an appropriate amount of bacterial cellulose into imidazole chloride ionic liquid to obtain the bacterial cellulose solution with the concentration in the mass percent of 5 percent-10 percent; then adding, uniformly dispersing and deaerating a certain amount of sodium alginate micro-nano powder to obtain spinning dope; squeezing the spinning dope into a coagulation bath through a spinning nozzle and stretching and drying the mixture to the bacterial cellulose and the sodium alginate composite fiber. The bacterial cellulose / sodium alginate composite fiber has high hygroscopicity, excellent physical and mechanical properties and effects of diminishing inflammation, relieving itching, beautifying on human skin, and the like.

Owner:QINGDAO TIANYI GROUP

Protein and alginate composite fiber and manufacturing method thereof

InactiveCN101654813AConjugated cellulose/protein artificial filamentsAlginate artificial filamentsFiberTextile processing

The invention relates to a protein and alginate composite fiber which is a regenerated protein composite fiber containing 5-90% of natural protein and 10-95% of natural alginate. The protein and alginate composite fiber is manufactured by the technological processes of raw liquid preparation, wet spinning, crosslink finishing and the like. The protein and alginate composite fiber has good hydroscopic property, antistatic property, dyeing property and flame resistance, can be completely degraded biologically, is a real green ecological textile material, has soft and smooth hand feel, is suitable for spinning and processing underclothes, articles for bedrooms, articles for health care and the like, and is suitable for manufacturing hairline for wigs because of good flame resistance.

Owner:陈福库

Polysaccharide nanofibers having antimicrobial properties

Polysaccharide nanofibers having anti-microbial properties, said nanofibers comprising an alginate and having silver nanoparticles dispersed throughout the nanofibers.

Owner:CONVATEC TECH INC

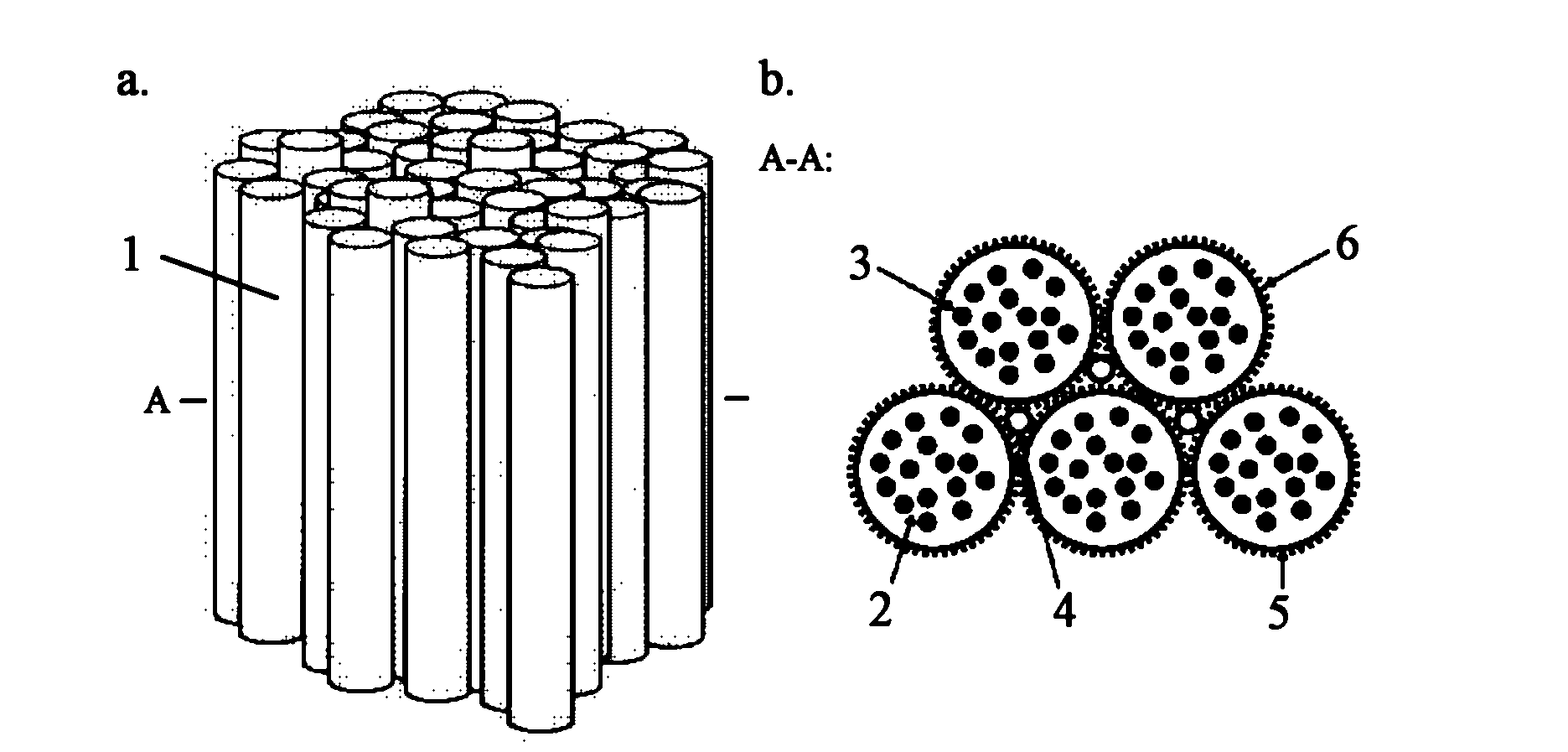

Tissue engineering fiber bundle structure body and preparation method thereof

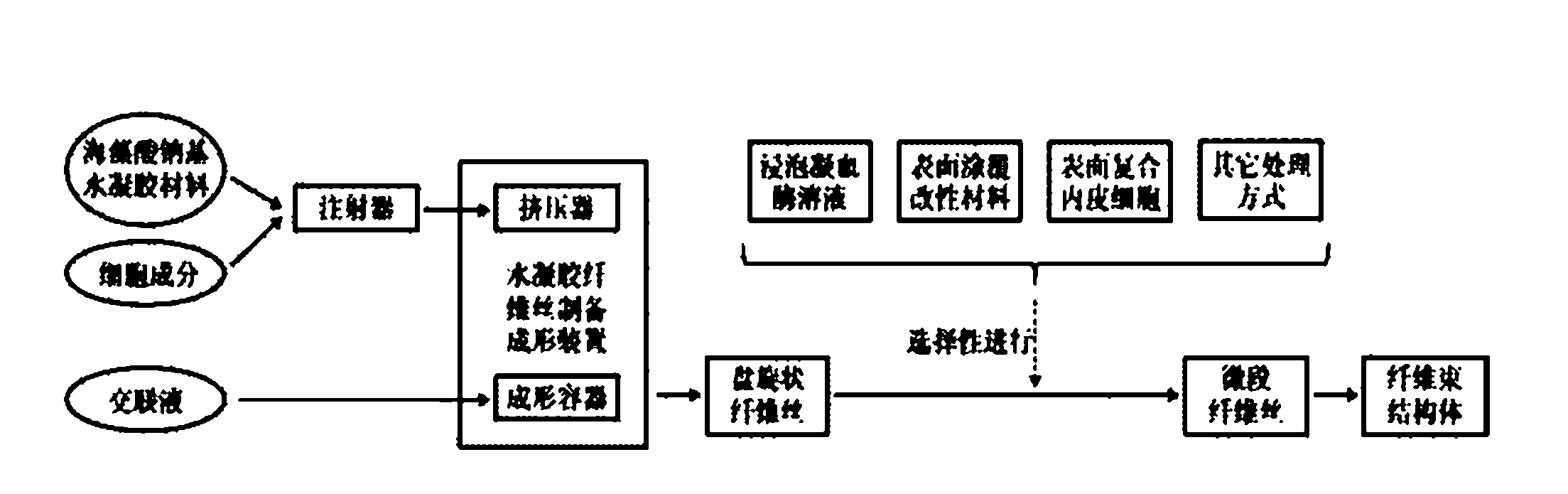

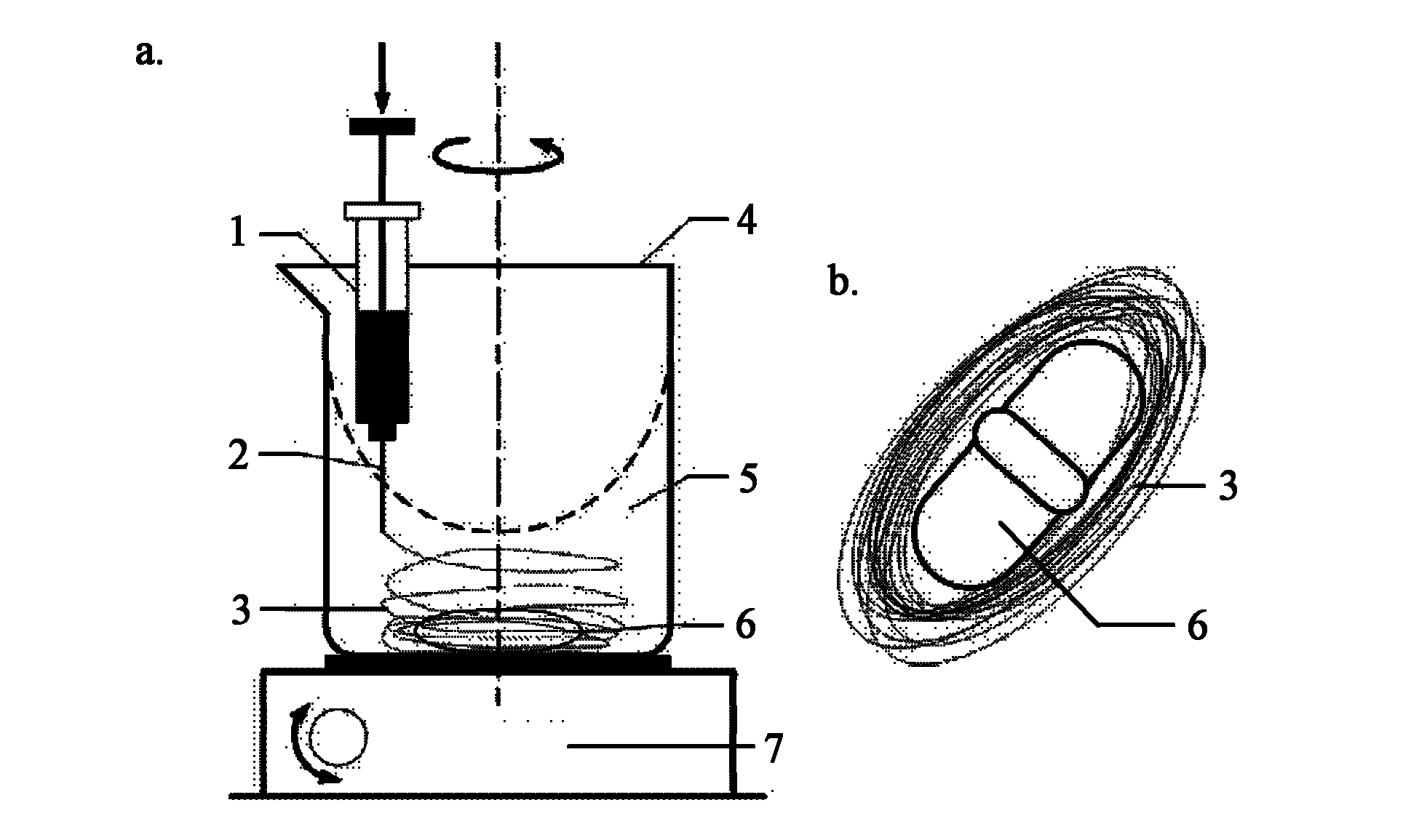

ActiveCN102505184ABionic effect is goodAdapting to Oxygen Diffusion Distance LimitationsBiochemical fibre treatmentMicrobiological testing/measurementCellular componentHigh density

The invention discloses a tissue engineering fiber bundle structure body and a preparation method thereof. The invention provides a method A or B for preparing hydrogel fiber filaments containing cellular components. The method A comprises the following steps: 1) compositing a hydrogel material utilized as a matrix with cellular components to obtain a mixture containing cellular components; and 2) putting the mixture obtained in the step 1) into crosslinked fluid corresponding to the matrix to undergo crosslinking, thus obtaining the hydrogel fiber filaments containing cellular components. Experiments prove that the design can comprehensively meet the special bionic requirements of high-density cell composition, good vascularization development trend and achievement of directionally ordered structure in tissue engineering, so that the structure body is good in vascularization development prospect and can hopefully break through the development bottleneck that the tissue engineering can not become large and thick at present.

Owner:TSINGHUA UNIV

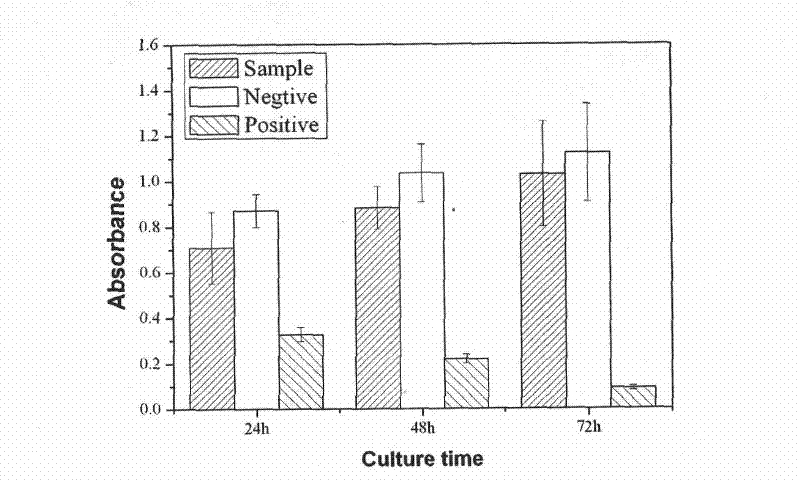

Preparation and application of chitosan-based nano-fiber

InactiveCN101280467AGood cell compatibilityRegulated release rateInorganic material artificial filamentsFilament/thread formingFiberCell-Extracellular Matrix

The invention relates to a preparation method and application of chitosan-based nano-fiber, in which the preparation method includes the following steps that the drugs or bio-activator such as growth factors are dissolved or dispersed in the chitisan adipic acid solution with the concentration of 0.01% to 3% (g / ml), and then the gelatin or collagen are added to dissolve. The biodegradable polyanion is dissolved in the de-ionized water and in preaparation to be the solution with the same concentration as that of the chitisan. The mixed chitisan solution is slowly added into the polyanion solution. After stirred uniformly, the nano-fiber loaded with the bio-activator is obtained through centrifuging, washing and cooling-drying. The chitosan-based nano-fiber prepared through the invention is biodegradable and has the imitated extracellular matrix structure, in which the controlled release of bio-activator can be achieved. By the adding of collagen or gelatin, the cellular compatibility of nano-fiber or the control of the release speed of the bio-activator can be improved. Therefore, the invention has a broad prospect in the fields of tissue engineering, clinical wound healing and so on.

Owner:JINAN UNIVERSITY

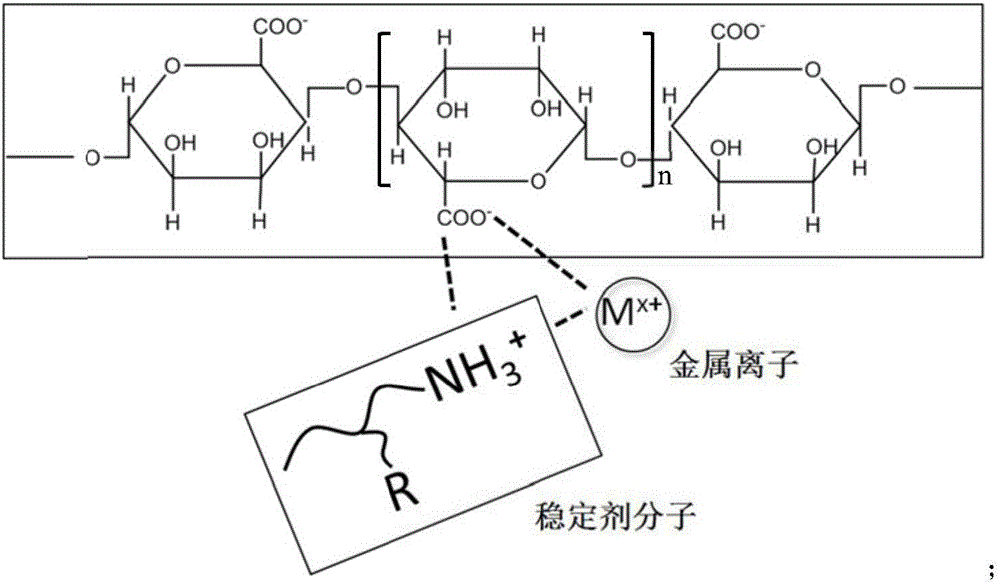

Sodium alga acid flame retardant fibers loaded with metal ions and manufacture method thereof

ActiveCN105821523AHigh breaking strengthBiodegradableFlame-proof filament manufactureAlginate artificial filamentsFiberBreaking strength

The invention provides sodium alga acid flame retardant fibers loaded with metal ions and a preparation method thereof. The sodium alga acid flame retardant fibers are prepared by the following steps: dissolving a water soluble sodium alga acid hybrid material loaded with metal ions in water to prepare a spinning solution, and performing a wet spinning process, wherein the water soluble sodium alga acid hybrid material loaded with metal ions is composed of sodium alga acid, stabilizer molecules and the metal ions with flame retardant effect. The fibers produced by the method disclosed by the invention have the characteristics of high flame retardant property and high breaking strength. The limit oxygen index of the fibers can be 34% and above, the tensile strength of the fibers is higher than 3.5cN / tex, and the linear density is 2.2-3.5dtex.

Owner:DONGHUA UNIV

High-strength alginate composite fiber, and preparation method and use thereof

InactiveCN106702533AHigh mechanical strengthAntibacterialAlginate artificial filamentsFiberBiocompatibility Testing

The invention relates to a high-strength bio-based fiber technology, and especially relates to a preparation method of an alginate composite fiber used in medical treatment and beauty treatment. The preparation method comprises the following steps: adding water-soluble alginate and a biological cross-linking agent which are mixed according to a certain ratio to water, heating and stirring the obtained water to uniform dissolve the water-soluble alginate and the biological cross-linking agent, and defoaming the obtained solution to obtain a composite spinning solution; and extruding the obtained spinning stock solution into coagulation bath formed by mixing an ethanol solution and a calcium chloride solution, and carrying out wet spinning. The fracture strength of the alginate composite fiber reaches 4-10 cN / detx, and the elongation at break is 14-20%. The biological cross-linking agent adopted in the invention is carboxymethyl chitosan calcium or carboxymethyl chitosan zinc, so the composite fiber has high mechanical strength and good processibility (spinnability and knittability), and keeps the original characteristics of low toxicity, wound healing promotion, good biocompatibility and high safety of alginates.

Owner:吴玉松

Antibacterial fibre containing nano-metal, fabric and wound dressing, and preparation method thereof

ActiveCN102453968AAvoid infectionLong-term and effective antibacterial functionBiocidePharmaceutical delivery mechanismFiberWound dressing

The invention relates to antibacterial fibre containing nano-metal, fabric and wound dressing, and a preparation method thereof; nano-metal particles are uniformly distributed in the fibre structure and on the fibre surface; a colloid protective agent for preventing nano-metal from condensing does not exist in the fibre; the content of the nano-metal particles is 1.1-20% by weight; the fibre wound dressing as the wound treating dressing has the capability of continuously releasing enough nano-metal particles; and the fibre wound dressing is particularly applied to chronic wound therapy and can provide long-term and effective antibacterial function and effectively prevent various bacteria and microorganisms from infecting wounds.

Owner:GUANGDONG BAIHE MEDICAL TECH CO LTD

Preparation method of oriented conductive hydrogel fiber material

ActiveCN109750387AMake up for the lack of physical performanceImprove conductivityElectroconductive/antistatic filament manufactureFilament/thread formingMatrix strengthUltrasonic dispersion

The invention discloses an oriented conductive hydrogel fiber material and a preparation method thereof. The preparation method comprises the steps: firstly, conductive particle dispersion solutions with different concentrations are obtained through an ultrasonic dispersion method, and dispersed conductive particles are turned into an evenly dispersed state from a mutually agglomerated or wound state so as to meet the subsequent requirements of enhancing the matrix strength and conductivity; then the conductive particles are composited into an organic polymer solution capable of being gelifiedto form a composite electrospinning precursor solution meeting the electrospinning concentration and viscosity; and electrospinning is conducted through a liquid rotary receiving disc, and a polymercomposite conductive particle hydrogel fiber with an oriented micro-nanofiber structure is prepared. Different from the traditional design of hydrogel single physical factor introduction, the orientedmicro-nanofiber structure, sensitive variable conductivity and mechanical strength are simultaneously introduced into a hydrogel system, the hydrogel fiber material with excellent performance is prepared, and a new preparation technique is provided for material preparation of the fields such as biomedical stent materials, flexible electrode materials and biosensors.

Owner:UNIV OF SCI & TECH BEIJING

Alginate fiber anti-bacteria facial mask base cloth

InactiveCN104963086AExtended shelf lifeHigh antibacterial rateCosmetic preparationsToilet preparationsBiotechnologyEngineering

The invention discloses an alginate fiber anti-bacteria facial mask base cloth. The alginate fiber anti-bacteria facial mask base cloth is prepared by the steps that, by weight, 90-99 percent of regenerated cellulose fiber and, by weight, 1-10 percent of alginic acid copper fiber are uniformly mixed, and the cloth is obtained through a spunlace nonwoven technology. The alginate fiber anti-bacteria facial mask base cloth can be used for sticking-type facial masks. When essence fluid is added on the alginate fiber anti-bacteria facial mask base cloth, no preservative is needed, and the quality guarantee period is three years. In the quality guarantee period, it can be guaranteed that the colony count of a product is controlled within the national standard prescribed range. According to the alginate fiber anti-bacteria facial mask base cloth, no preservative is needed to be adopted, in addition, production, logistics, storage and use have no difference with those of current products with the addition of preservatives, the quality guarantee period is long, the antibacterial rate is high, and good news is brought to consumers.

Owner:厦门百美特生物材料科技有限公司

Method of producing a swellable polymer fibre

ActiveUS20160222548A1Reduce solubilityEnhanced hydrogen bondingBiocideSpinning solution de-aeratingFiberWound dressing

A swellable polymer based fibre and a method of preparing the same optionally comprising glycol, lecithin and optionally an antimicrobial metal species suitable, for example, for medical applications including wound dressings. A method of manufacture may comprise fibre extrusion or spinning involving one or a plurality of in-series coagulation baths to add single or multiple antimicrobial metal species to the as-formed fibre.

Owner:XIROS

Alginate knitted or woven gauze and preparation method thereof

InactiveCN102877204AHigh hygroscopic gel formingHigh ease of removalWeft knittingWarp knittingYarnFiber

The invention belongs to the technical field of medical biological high-polymer materials and textile science, relates to a preparation method of medical gauze and provides alginate knitted or woven gauze. The alginate knitted or woven gauze is characterized by being formed by blending or crosslinking alginate with polyving akohol, spinning to obtain fiber filaments by the wet process and the dry process, then spinning to manufacture yarns and knitting the yarns by a knitting machine or a loom. The alginate knitted or woven gauze has excellent strength.

Owner:WUHAN BIOMTEK

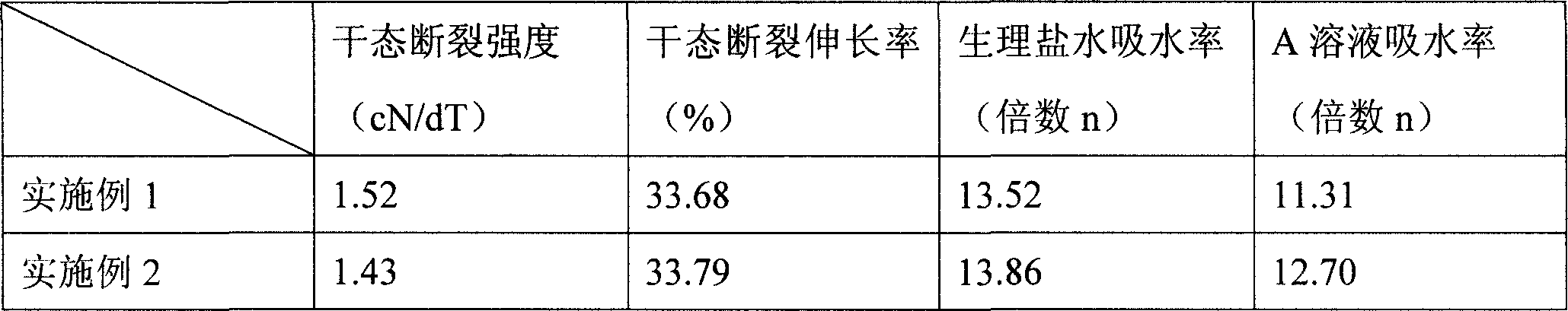

Biodegradable super-absorbent non-woven fabric

InactiveCN104532401AImprove antibacterial propertiesAlginate artificial filamentsWet spinning methodsPolymer scienceSuper absorbent

The invention discloses biodegradable super-absorbent non-woven fabric. The non-woven fabric comprises, by weight, 30% to 50% of multifunctional super-absorbent alginate fibers and 50% to 70% of polylactic acid fibers in a compounded mode, and heat bonding net fixing is achieved. The non-woven fabric has the good water absorbing property, the good water retaining property, the good antibacterial property and the good biodegradability, and is mainly used for disposable hygienic products. The invention further discloses a method for preparing the multifunctional super-absorbent alginate fibers.

Owner:FUJIAN HENGAN HLDG CO LTD +2

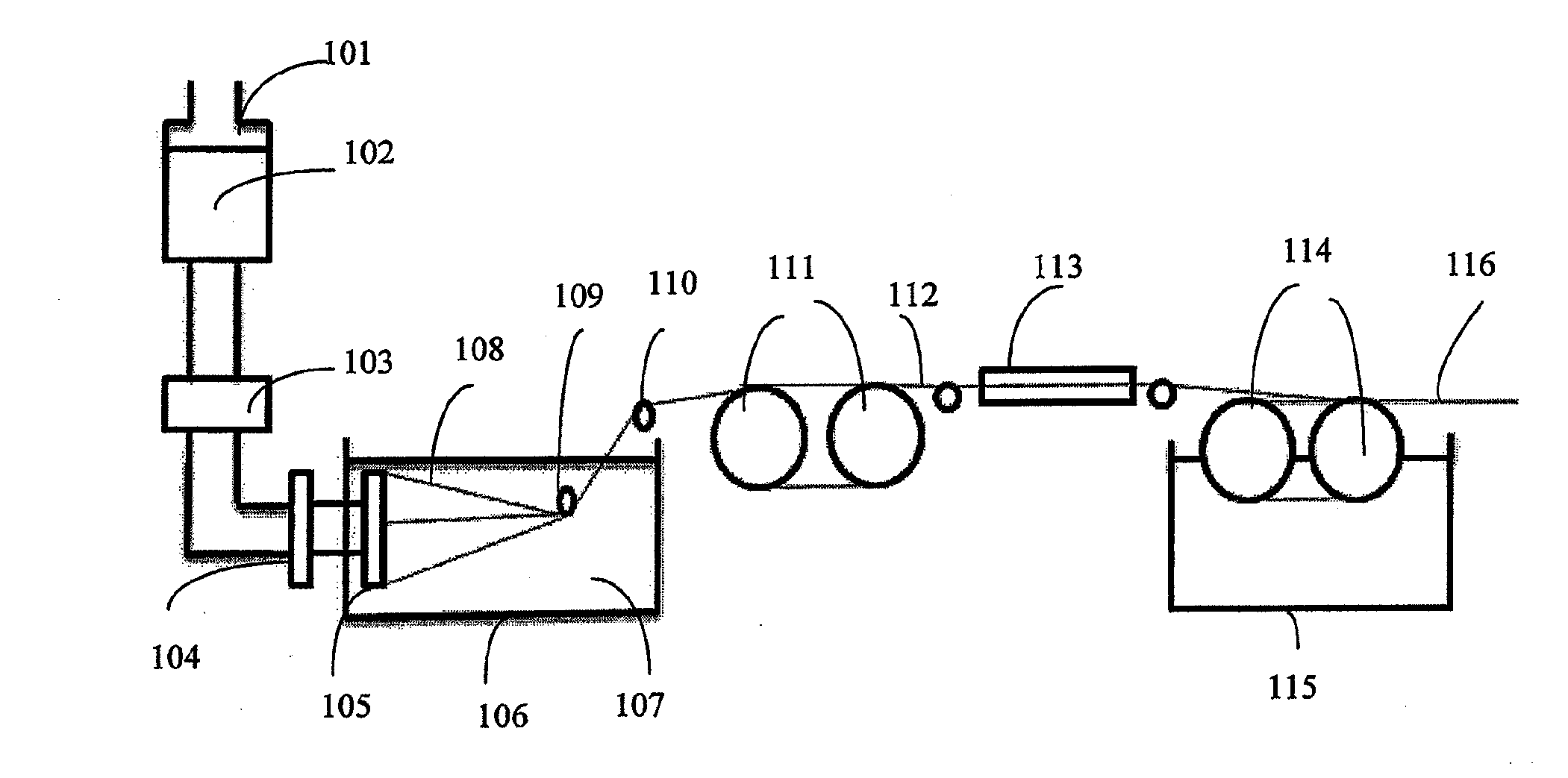

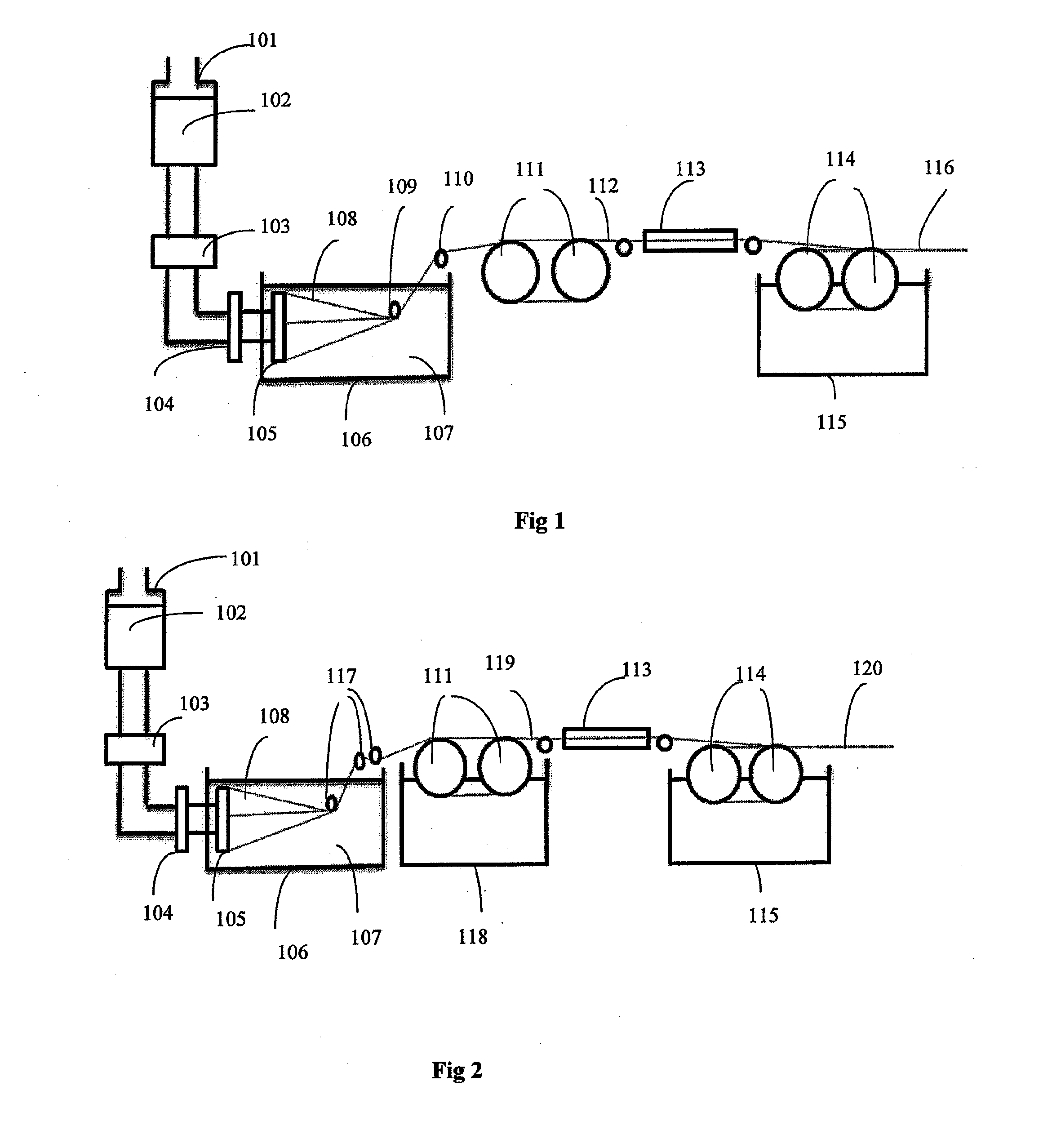

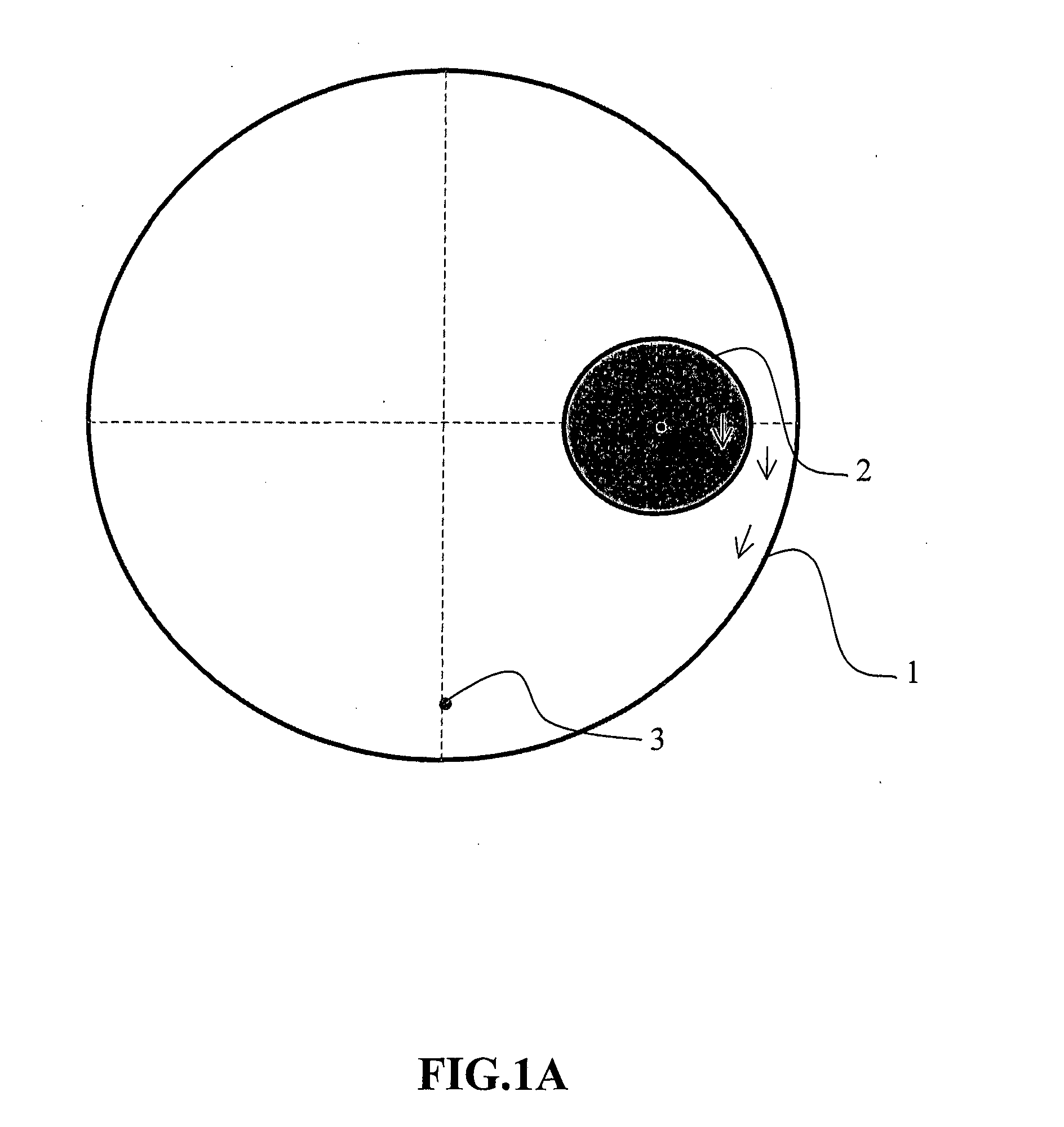

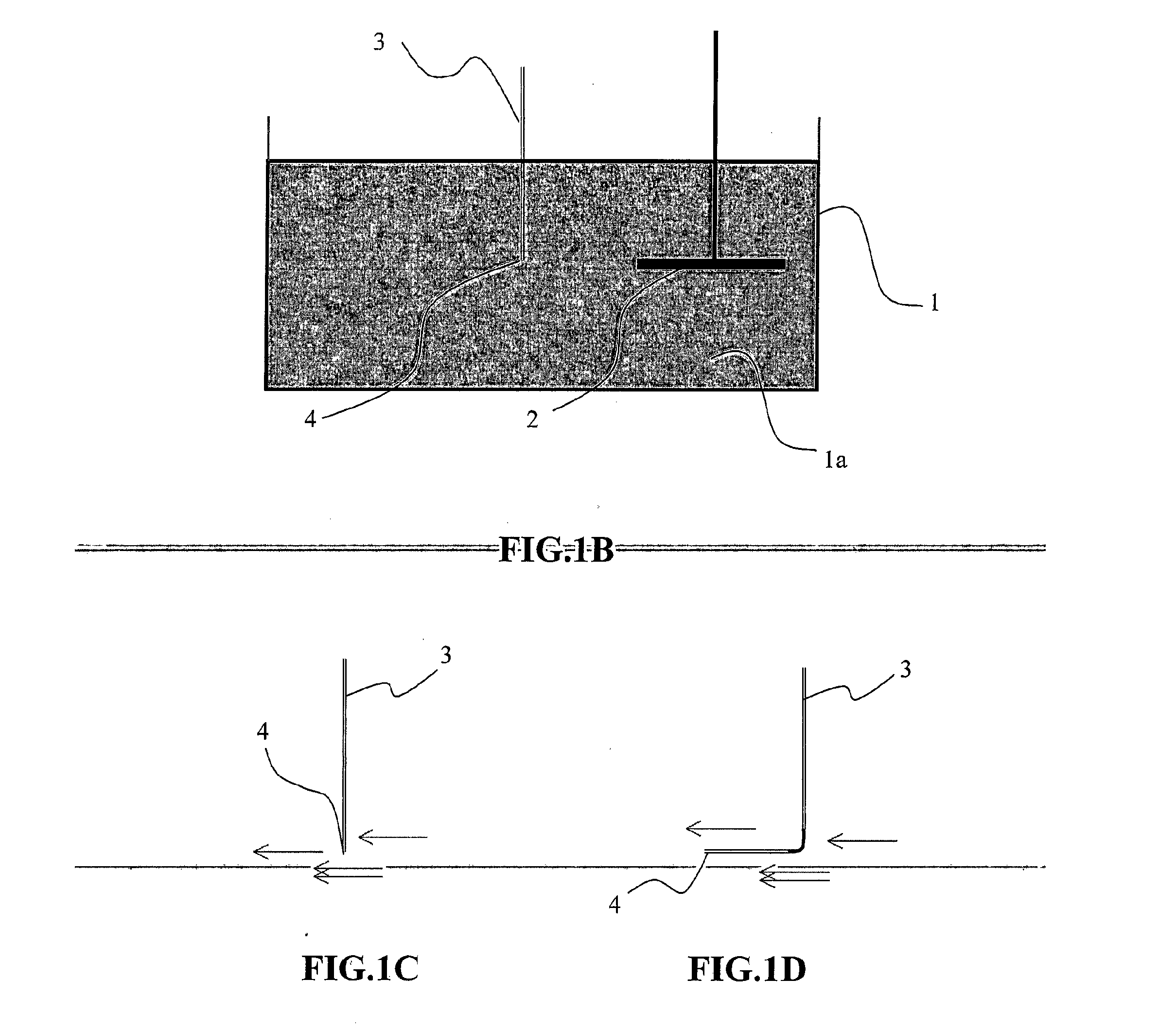

Method of Preparation of Polysaccharide Fibres, Wound Covers that Contain Them, Method of Manufacturing of Wound Covers, and Apparatus for Preparation of Polysaccharide Fibres

InactiveUS20150119783A1Low areal weightEasy to useNon-adhesive dressingsSpinning head liquid feederFiberCarboxymethyl cellulose

The invention relates to the method of the preparation of polysaccharide fibers based on hyaluronic acid, a compound comprising hyaluronic acid and metal ions, schizophylan, chitin / chitosan-glucan complex, a compound comprising chitin / chitosan-glucan complex and metal ions, internal mixture of chitin and chitosan, a compound comprising internal mixture of chitin and metal ions, sodium alginate, potassium alginate, ammonium alginate, xanthane, xanthane sodium salt, xanthane potassium salt, oxycellulose, oxycellulose sodium salt, oxycellulose potassium salt, carboxymethyl cellulose, carboxymethyl cellulose sodium salt, and carboxymethyl cellulose potassium salt, or a mixture of polysaccharides, in a non-stationary coagulation bath. Further the invention relates to covers of internal and external wounds and skin defects based on these fibers, and a method of production thereof, and the apparatus for the preparation of polysaccharide fibers.

Owner:CONTIPRO BIOTECH

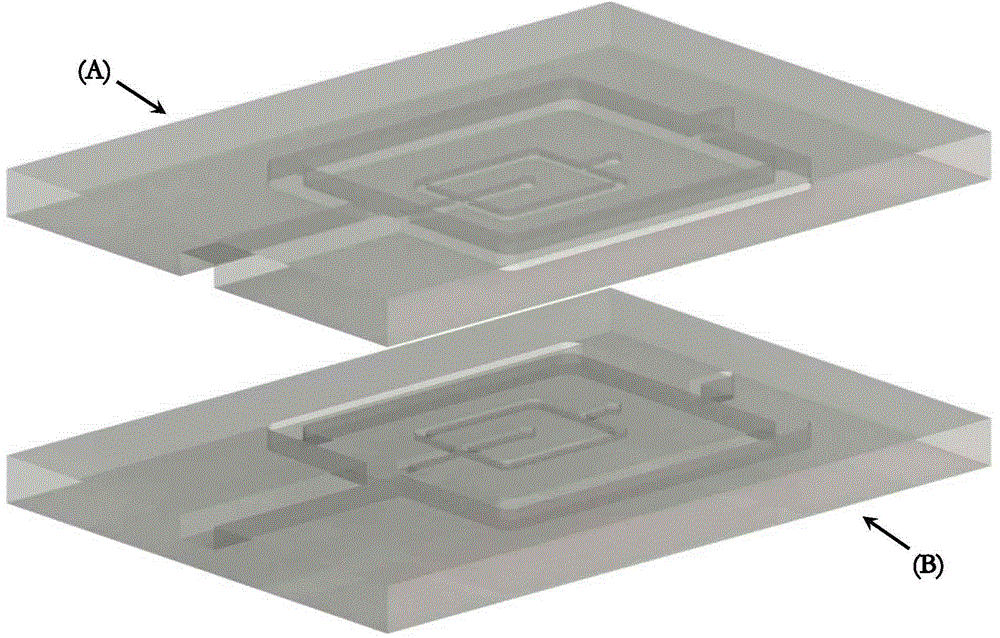

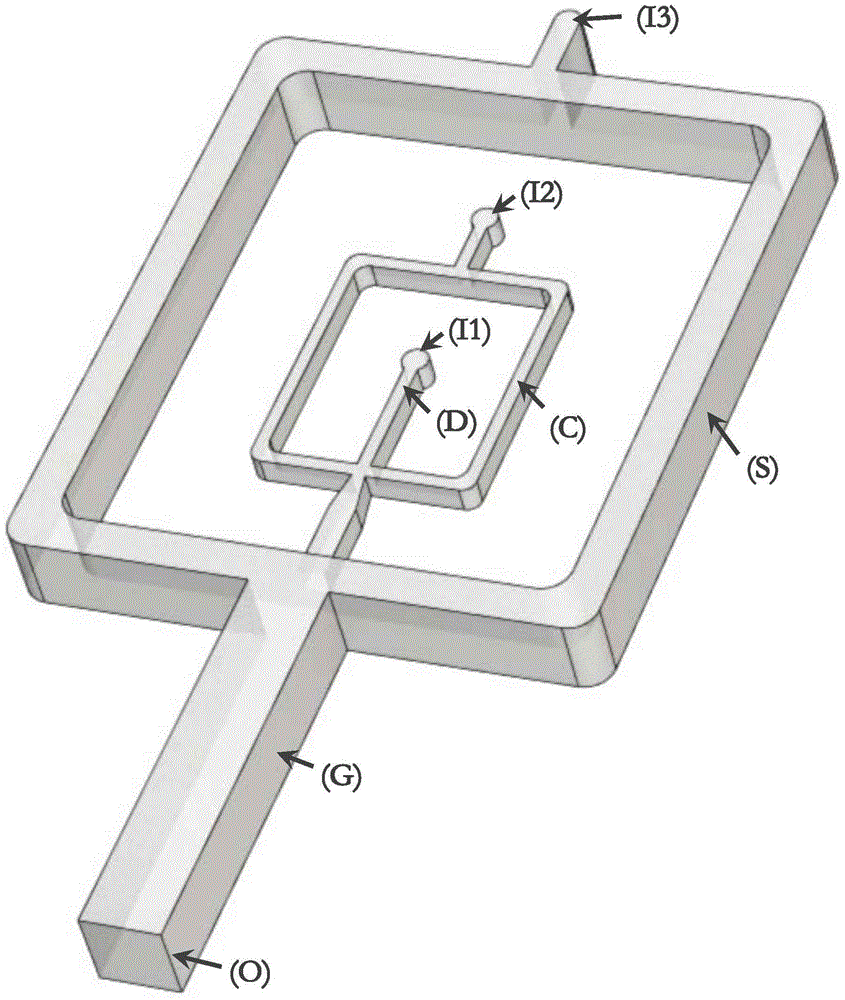

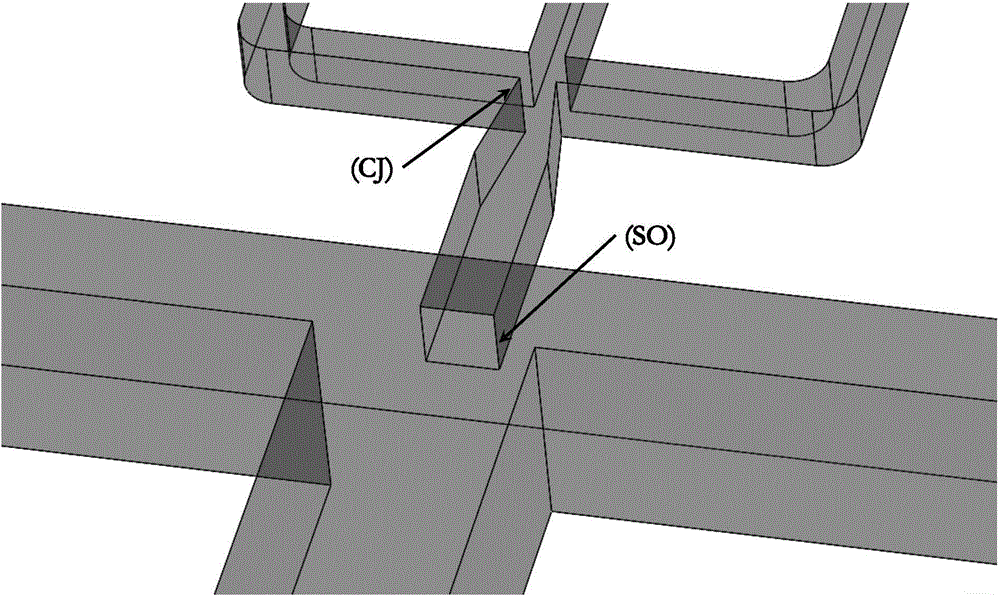

Preparation method for spherical cavity equipped polymer fiber and special microfluidic chip

ActiveCN104695052ARich varietyAggregation methods are flexibleHollow filament manufactureFilament/thread formingFiberWide field

The invention relates to a preparation method for a spherical cavity equipped polymer fiber and a special microfluidic chip. With the chip and the method, polymer fiber with a diameter ranging from micron level to millimeter level can be prepared. Spacing and size controllable spherical cavities can continuously be formed in the polymer fiber, and various inclusions can be loaded in the cavities. The method combines a droplet microfluidic technology and a spinning microfluidic technology, utilizes the droplet microfluidic technology to disperse a volatile liquid uniformly in the continuous flow of a polymer monomer solution in the form of droplets, and utilizes the spinning microfluidic technology to form polymer fiber and arrange the droplets therein orderly. The droplet solution is removed from solidified polymer fiber by means of its volatilization characteristic so as to form the spherical cavities with uniform and controllable size and adjustable spacing. The substances added into the droplets in advance can be loaded into the fiber cavities, and the material can be endowed with flexible performance so as to be expected for application in wide fields.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Biological activity marine alga cellulose viscose and manufacturing method therefor

ActiveCN101096776AImprove bindingStrong ability to adsorb and chelate metal ionsFibre treatmentArtificial filaments from viscoseCelluloseZinc

The invention discloses a biological activity sea weed glue fiber, which is characterized by the following: incorporating sea weed in the glue fiber; setting the grain size not more than 3 mum; setting the mass percent of the sea weed at 5%-15% related to cellulose; incorporating silver or zinc in the glue fiber; setting the mass percent of the silver or zinc at 0.25%-1.0% relative to the cellulose. This invention also related to a preparing method of the biological activity sea weed glue fiber. This glue fiber possesses good hygienic function for skin, which can be fit for various textile raw material and textile.

Owner:潍坊欣龙生物材料有限公司

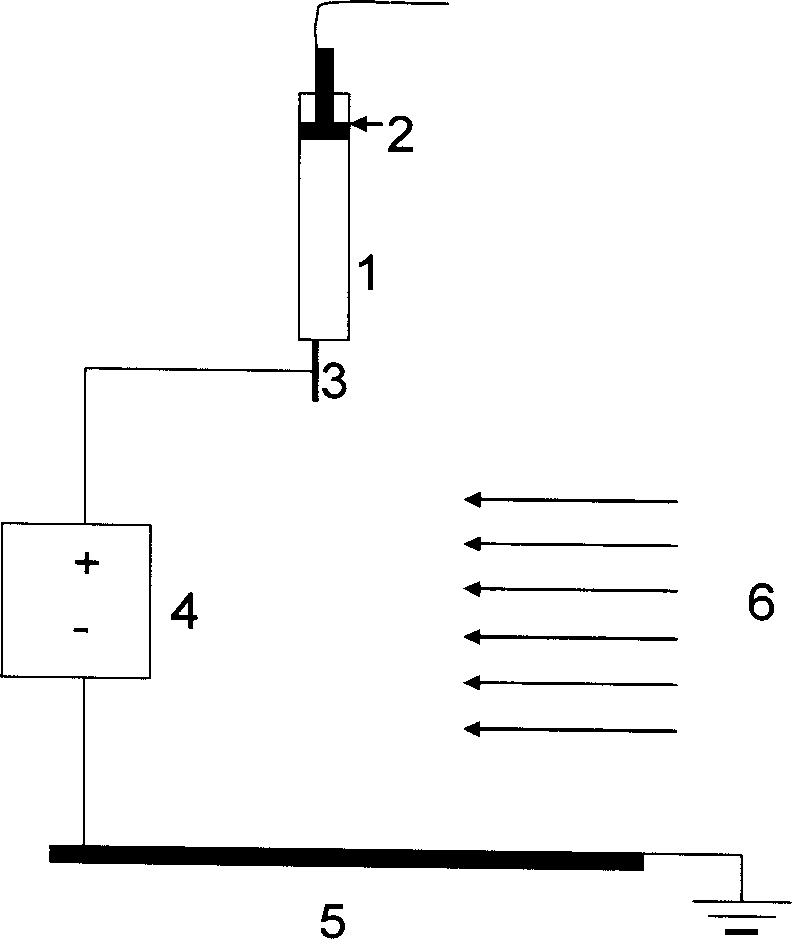

Electric spinning-in-situ photopolymerization apparatus and process for preparing nanometer fiber

InactiveCN1847473AVolatile fastHigh mechanical strengthMonocomponent cellulose artificial filamentFilament/thread formingPolymer scienceSpinning

The electric spinning and in-situ photopolymerization apparatus and process for preparing nanometer fiber belongs to the field of electric spinning technology. The electric spinning apparatus includes one common electric spinning apparatus and one ultraviolet or visible light generator set between the spinning nozzle and the accepting screen of the common electric spinning apparatus. The electric spinning process includes the following steps: compounding water solution or organic solvent solution of water soluble polymer and adding polyfunctional monomer and photoinitiator to the solution through homogeneous mixing; electrically spinning the solution while irradiating, with the central light strength being 100-400 mw / sq cm; and soaking nanometer fiber non-woven fabric in acetone, and drying to obtain nanometer fiber non-woven fabric. The nanometer fiber non-woven fabric has high mechanical strength and no toxicity, and may be used widely.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com