Natural polymer-based nano-fibrous membrane prepared by freeze-drying method

A natural polymer and nanofiber membrane technology, applied in fiber treatment, spinning solution preparation, fiber chemical characteristics, etc., can solve the troublesome post-processing of the preparation method, high requirements for process factors and environmental factors, and poor repeatability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Sodium alginate is dissolved in deionized water to prepare 20mL of a solution with a weight percentage of 0.001wt%, and then the solution is fully stirred so that it is completely dissolved to form a sodium alginate solution.

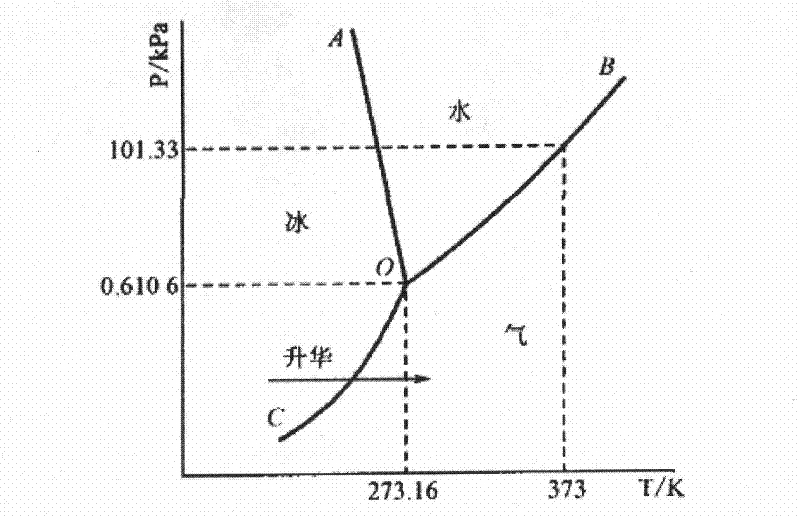

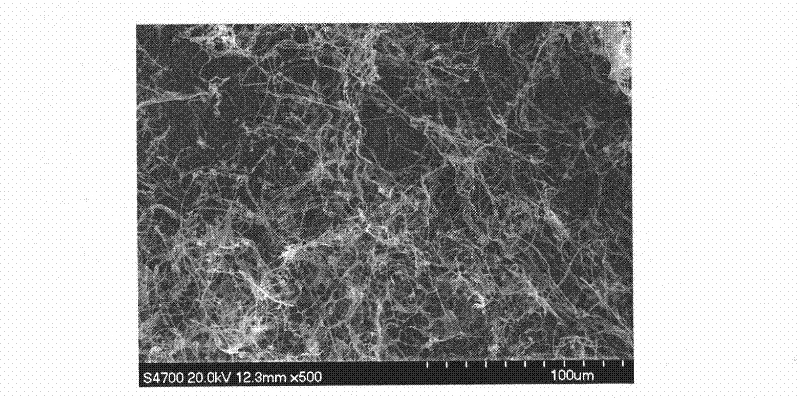

[0026] (2) Transfer the sodium alginate solution prepared in step (1) to a liquid nitrogen freezer, turn on the freezer, freeze the prepared sodium alginate solution rapidly in a liquid nitrogen environment, and then freeze at -80°C and under the condition that the degree of vacuum is 600 Pa, the frozen sodium alginate solution is subjected to freeze-drying treatment in a freeze dryer for 24 hours to obtain sodium alginate nanofibers.

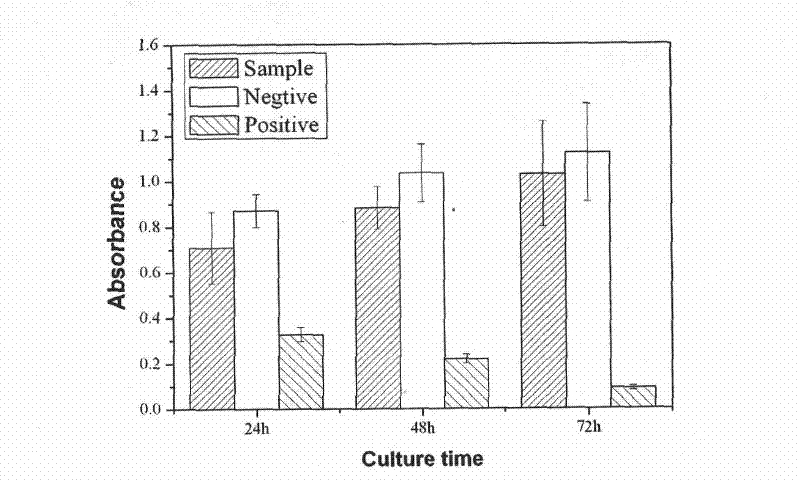

[0027] (3) The sodium alginate nanofibers obtained in step (2) were crosslinked with 10mmol / L calcium chloride for 2 hours at 25°C, and the excess chlorine in the crosslinked sodium alginate nanofibers was Calcium was washed away with deionized water, and the treated nanofiber nonwoven was vacuum-dried at 60 °...

Embodiment 2

[0031] (1) Dissolve hyaluronic acid in deionized water to prepare 20mL of a solution with a weight percentage of 0.015wt%, and then stir the solution fully so that it is completely dissolved to form a hyaluronic acid solution.

[0032] (2) Transfer the hyaluronic acid solution prepared in step (1) to a liquid nitrogen freezing device, turn on the freezing device, and rapidly freeze the prepared hyaluronic acid solution in a liquid nitrogen environment, and then the freezing temperature is -10°C and under the condition that the degree of vacuum is 200 Pa, the frozen hyaluronic acid solution was freeze-dried in a freeze dryer for 12 hours to obtain hyaluronic acid nanofibers.

[0033] (3) The hyaluronic acid nanofibers obtained in step (2) were crosslinked with 5 mmol / L carbodiimide for 2 hours at 20°C, and the excess hyaluronic acid nanofibers after crosslinking The carbodiimide was washed away with deionized water, and the treated nanofiber non-woven fabric was vacuum-dried at...

Embodiment 3

[0037] (1) Chitosan is dissolved in 1wt% acetic acid solution to prepare 20mL of a 0.1wt% solution by weight, and then the solution is fully stirred so that it is completely dissolved and the chitosan solution is obtained.

[0038] (2) The chitosan solution prepared in step (1) is transferred to a liquid nitrogen freezer, the freezer is opened, and the prepared chitosan solution is rapidly frozen in a liquid nitrogen environment, and then the freezing temperature is -40°C Under the condition that the degree of vacuum is 1 Pa, the frozen chitosan solution is subjected to freeze-drying treatment in a freeze dryer for 36 hours to obtain chitosan nanofibers.

[0039] (3) The chitosan nanofibers obtained in step (2) were cross-linked for 2 hours with 2mmol / L genipin at 40°C, and the excess genipin in the crosslinked chitosan nanofibers was Nippin was washed off with absolute ethanol, and the treated nanofiber non-woven fabric was vacuum-dried at 50 for 6h to obtain a chitosan nanof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com