Patents

Literature

781 results about "Phase diagram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A phase diagram in physical chemistry, engineering, mineralogy, and materials science is a type of chart used to show conditions (pressure, temperature, volume, etc.) at which thermodynamically distinct phases (such as solid, liquid or gaseous states) occur and coexist at equilibrium.

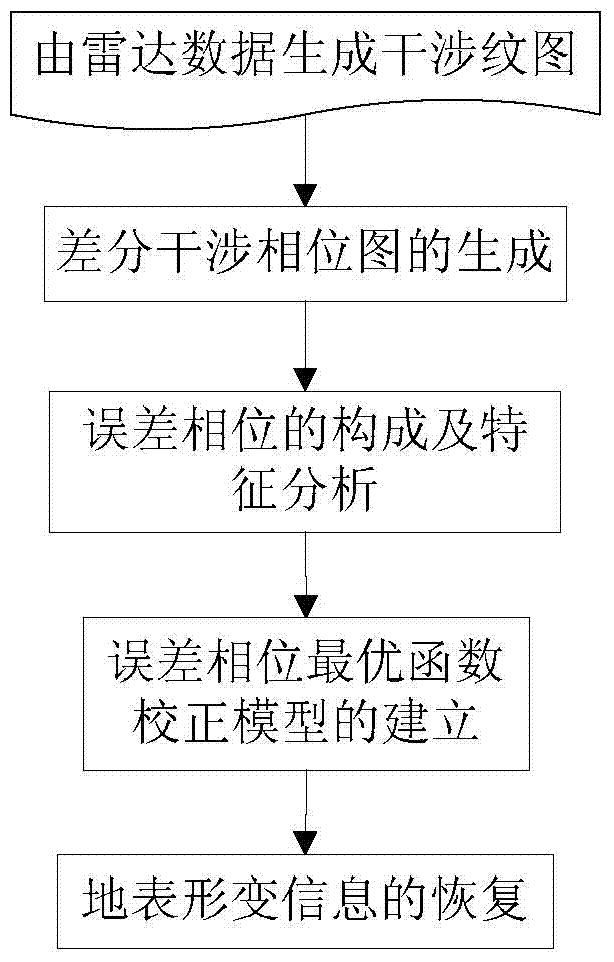

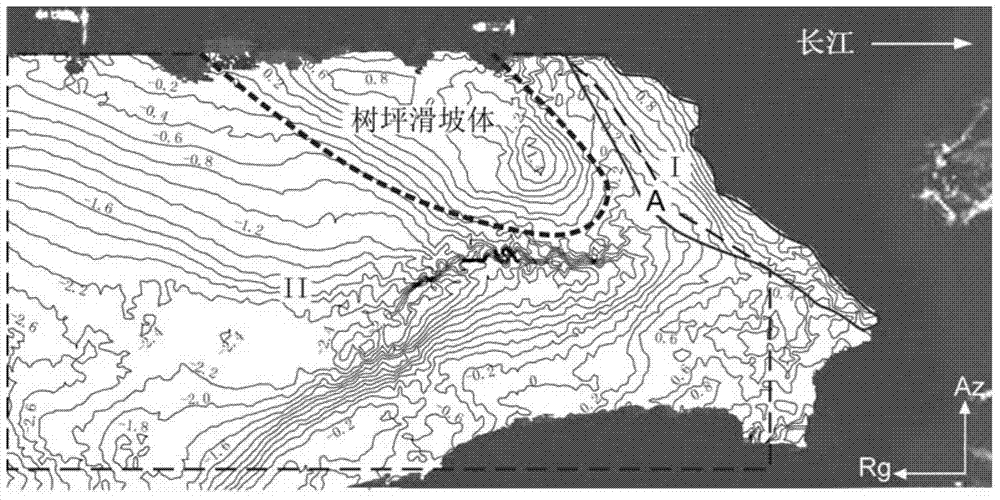

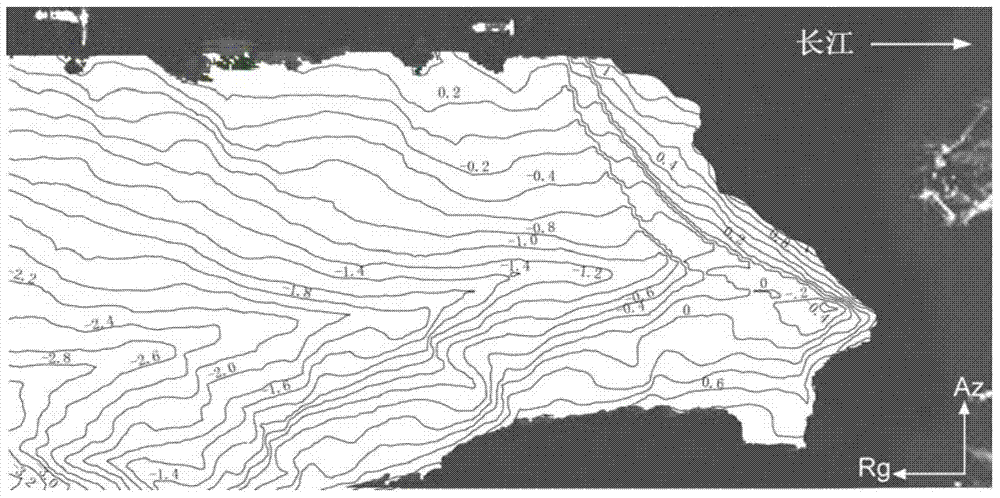

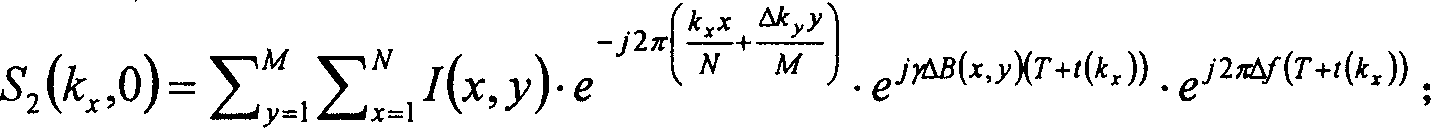

Method for improving earth surface shape change monitoring precision of InSAR (Interferometric Synthetic Aperture Radar) technology based on high-precision DEM (Digital Elevation Model)

InactiveCN103675790AError Phase CancellationHigh precisionRadio wave reradiation/reflectionShape changeInterferometric synthetic aperture radar

The invention discloses a method for improving earth surface shape change monitoring precision of an InSAR (Interferometric Synthetic Aperture Radar) technology based on a high-precision DEM (Digital Elevation Model). The method comprises five steps below: step 1, generating an interferogram by using radar data; step 2, generating a differential interference phase diagram; step 3, establishing error phases and performing feature analysis; step 4, establishing an error phase optimal function calibration model; step 5, recovering earth surface shape change information of a monitoring region based on results of steps 2 and 4. According to the invention, the error phases and elevation values or the error phases, the elevations and coordinate values along a distance / azimuth of different regions of a research region are extracted, the optimal function calibration models of the error phases of corresponding regions are established respectively based on a least square method, and a simulative error phase is finally removed from the differential interference phase diagram to further recover shape change information along a direction of a sight line of a radar in the monitoring region. The method for improving the earth surface shape change monitoring precision of the InSAR technology based on the high-precision DEM has practical value and wide application foreground in the application field of a satellite borne synthetic aperture radar monitoring technology for earth surface shape change.

Owner:CHINA AERO GEOPHYSICAL SURVEY & REMOTE SENSING CENT FOR LAND & RESOURCES

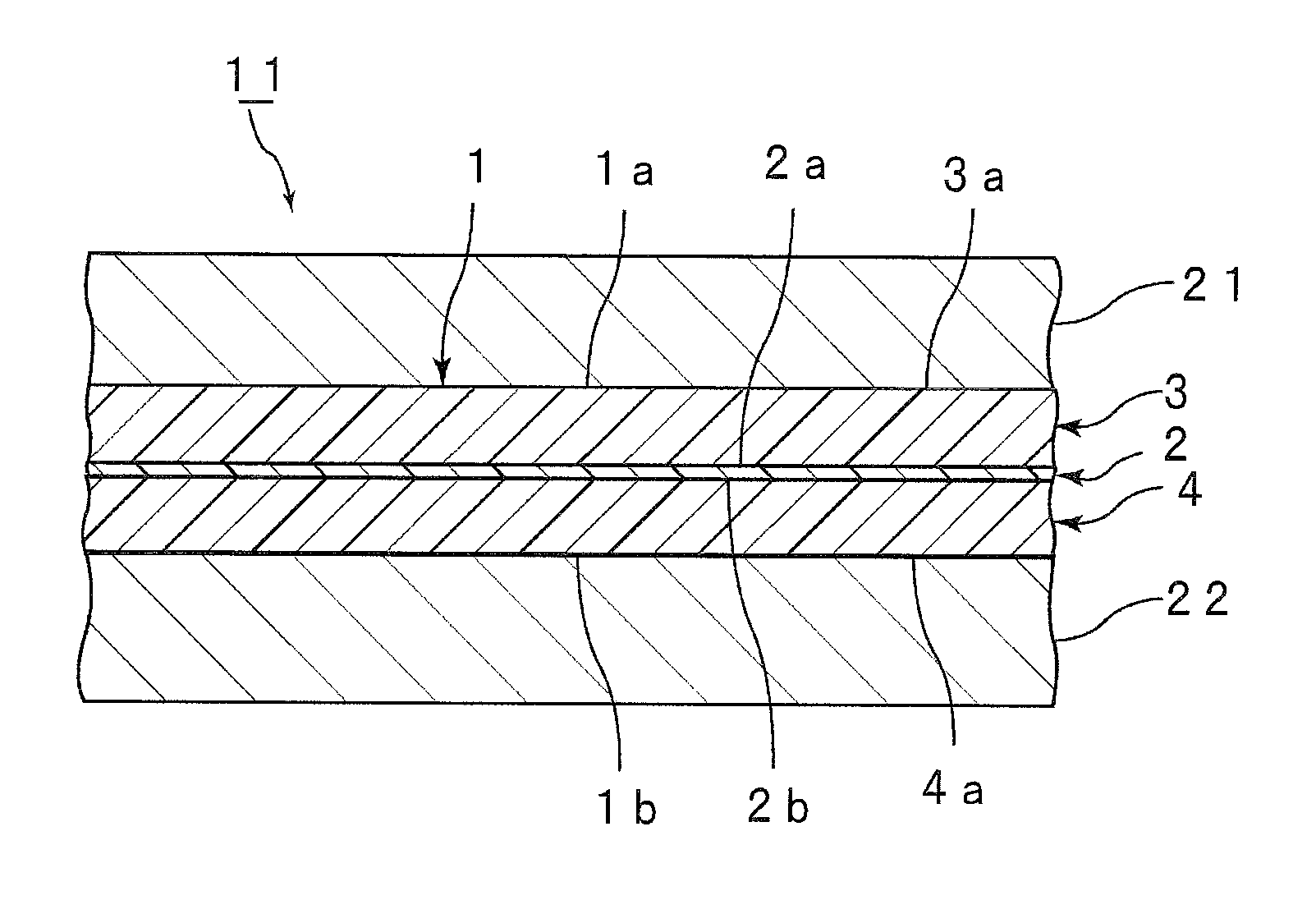

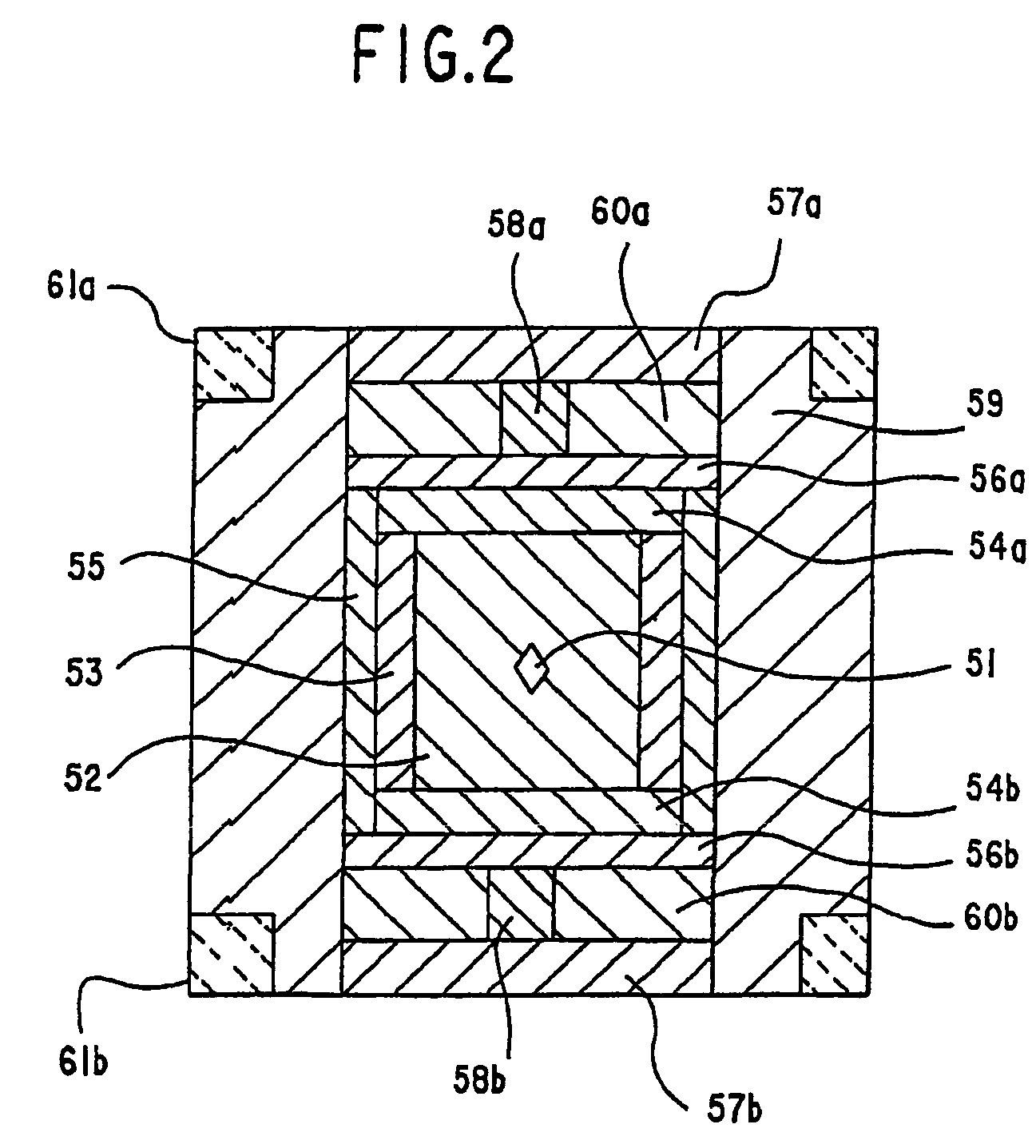

Laminated glass intermediate film and laminated glass

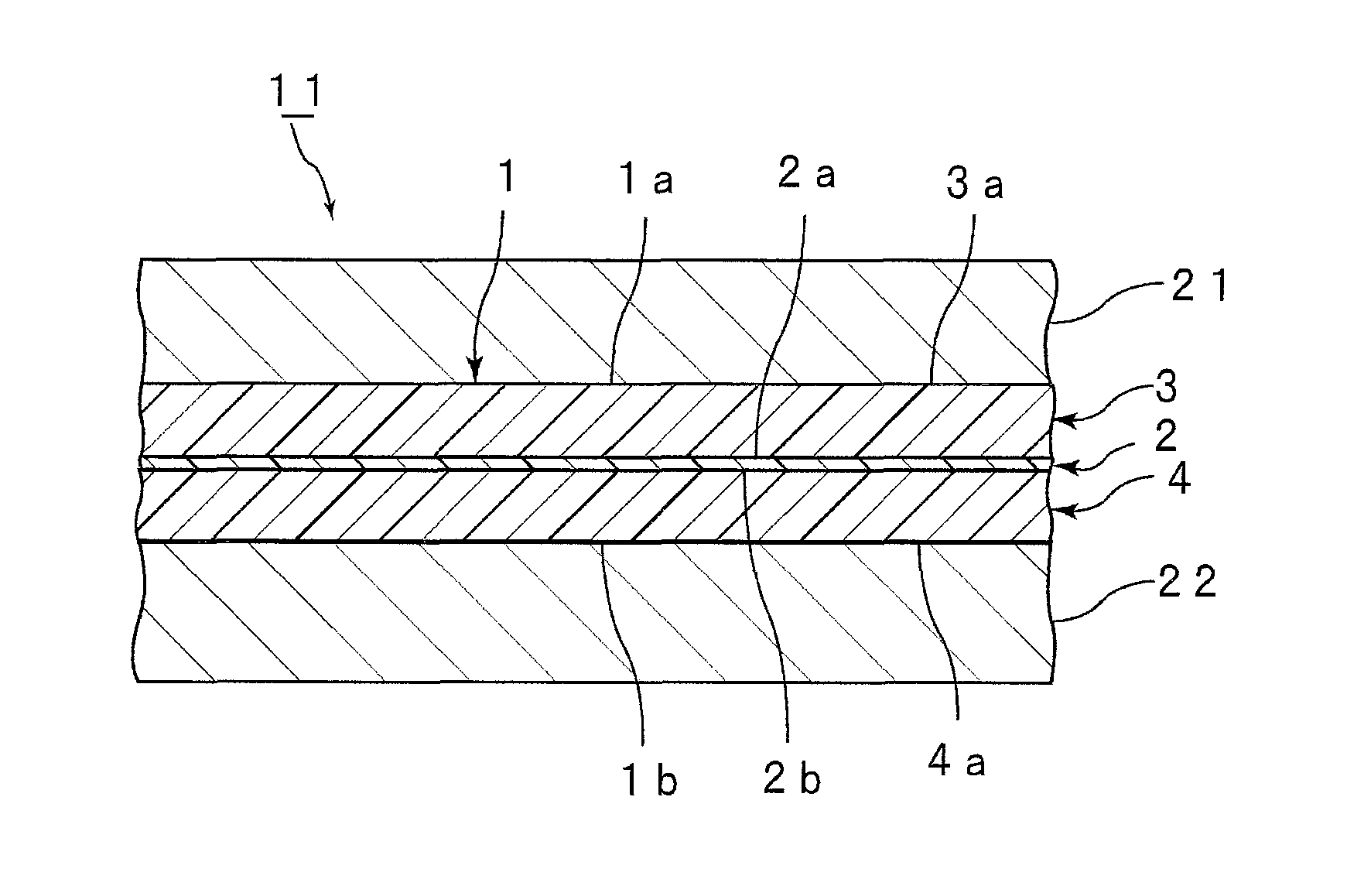

ActiveUS20130323516A1Improve sound insulationSynthetic resin layered productsGlass/slag layered productsPlasticizerPolyvinyl alcohol

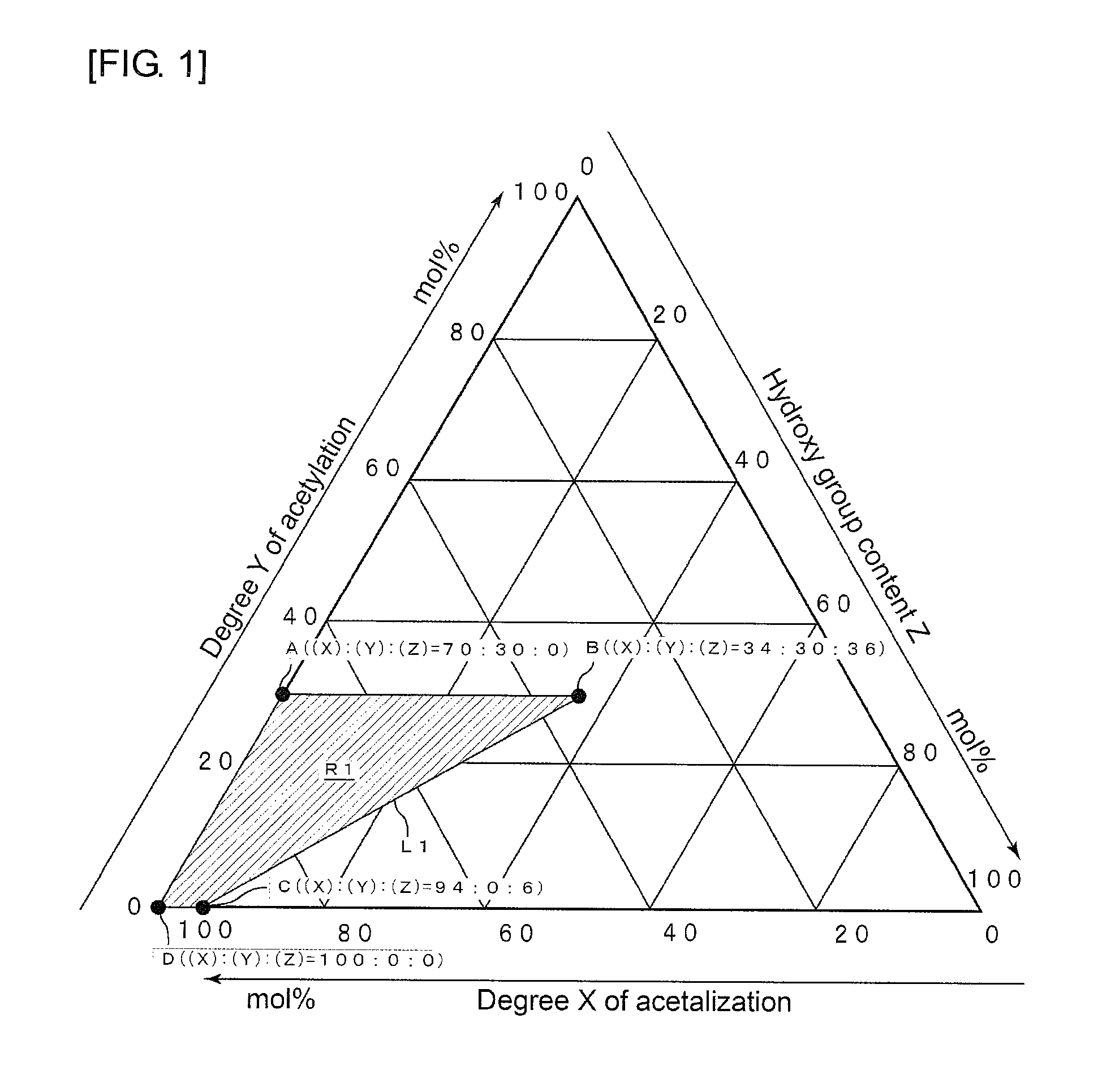

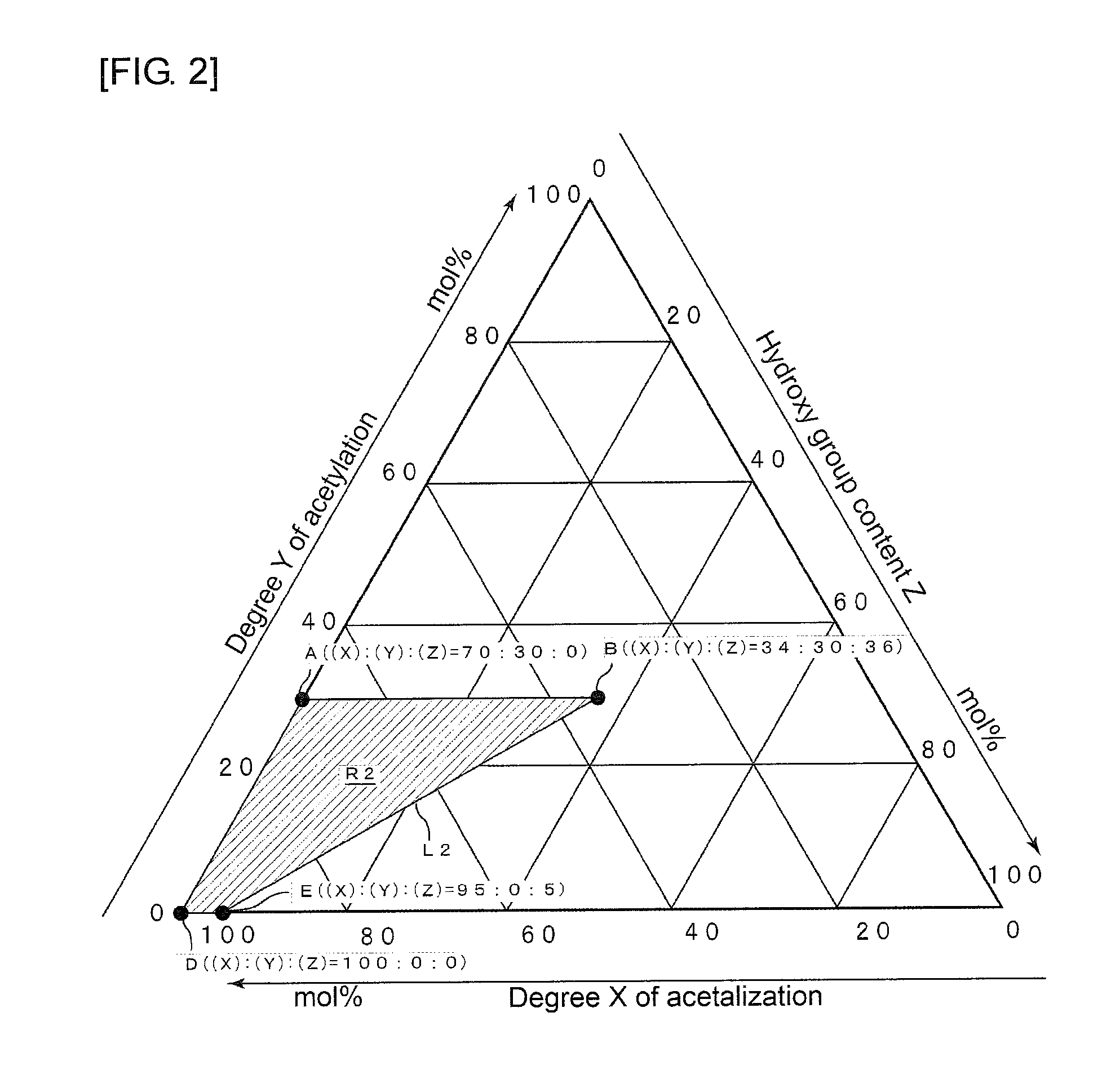

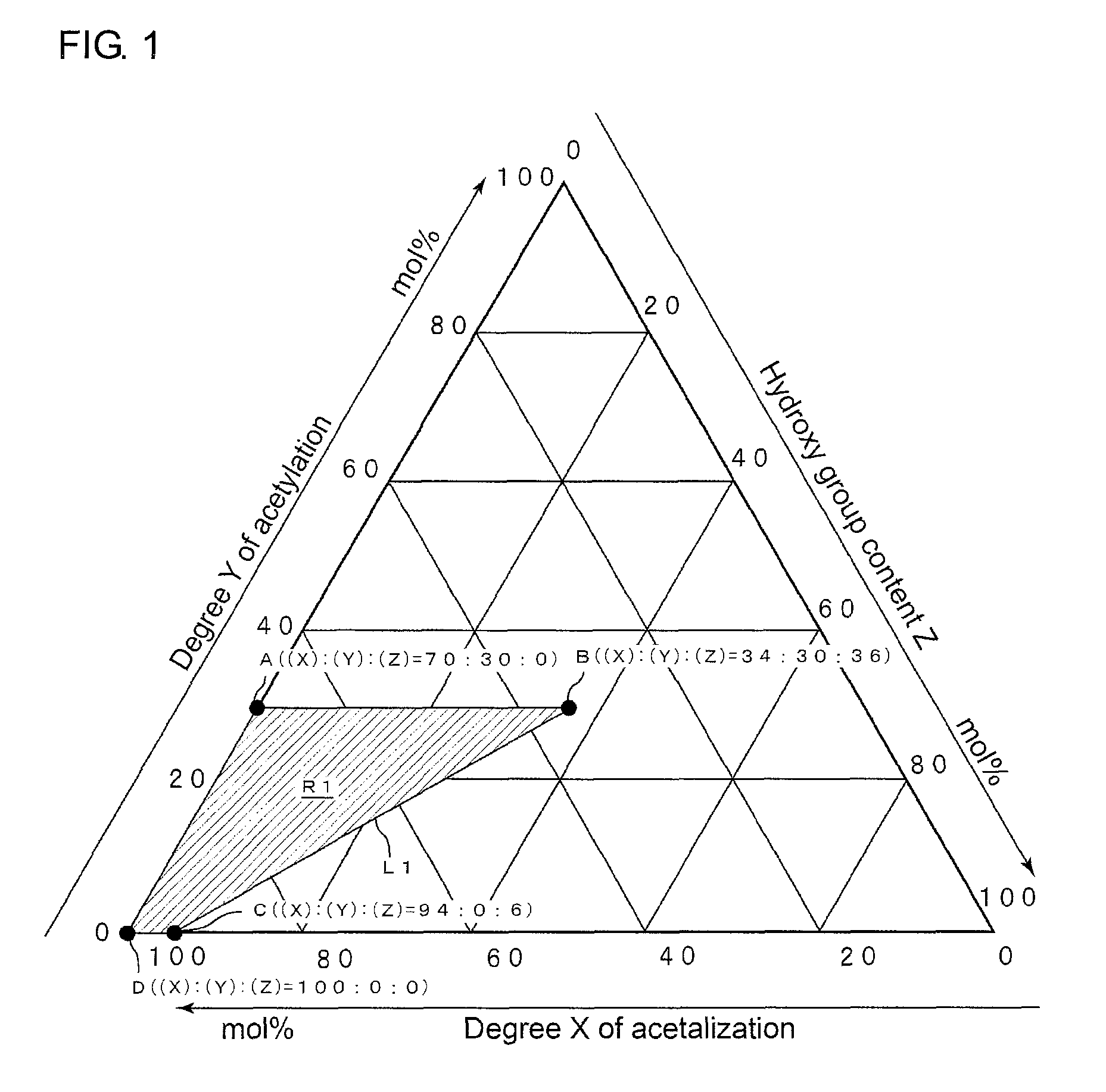

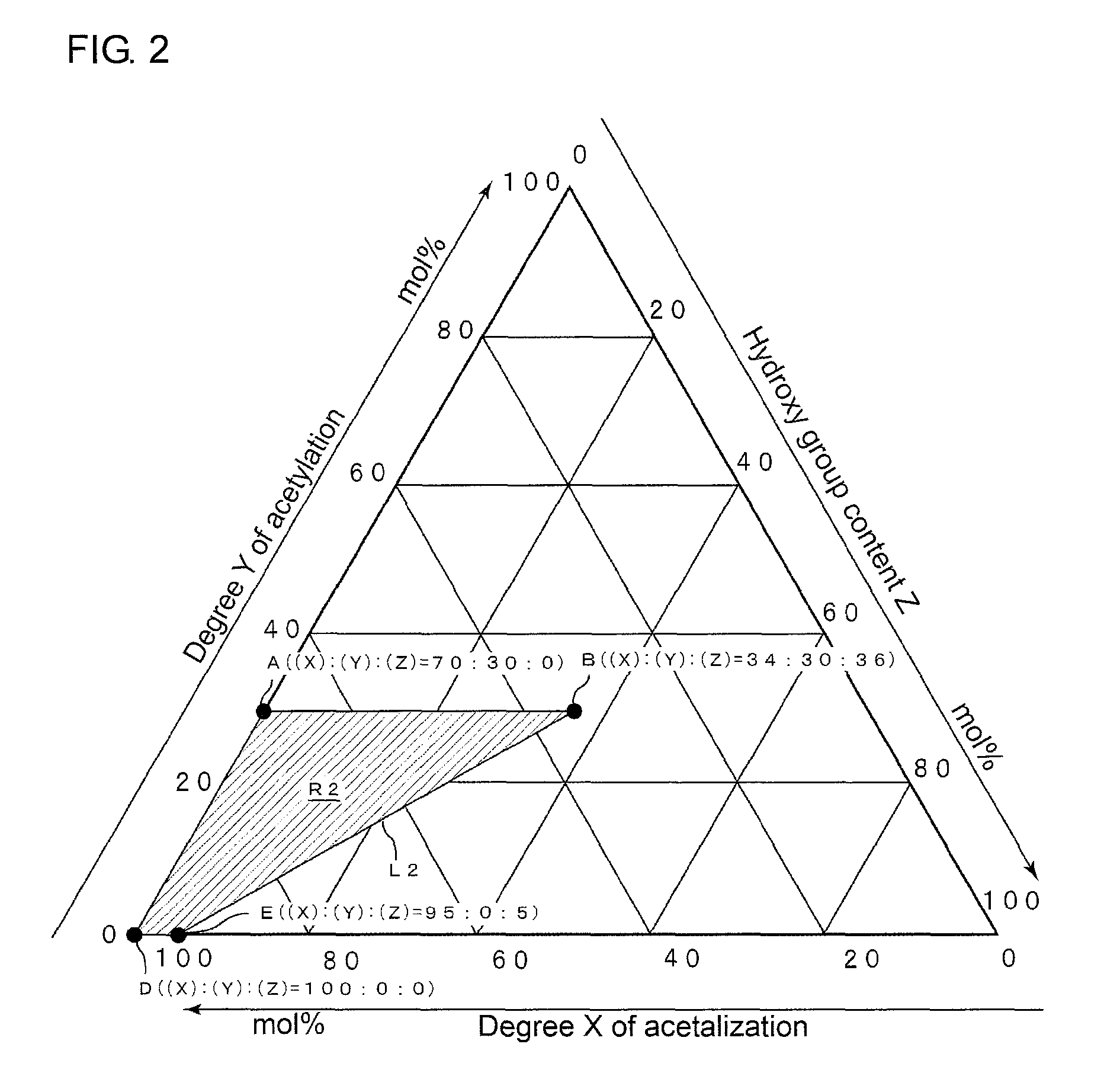

The present invention provides an intermediate film for laminated glass which can improve the sound-insulating property. The intermediate film for laminated glass according to the present invention has a layered structure including at least two layers, comprising: a first layer containing a polyvinyl acetal resin and a plasticizer; and a second layer positioned on a first surface of the first layer. In a phase diagram of three values including a degree of acetalization, a degree of acetylation, and a hydroxy group content of the polyvinyl acetal resin contained in the first layer, the values of the degree of acetalization, the degree of acetylation, and the hydroxy group content each fall within a region surrounded by a line including four straight lines connecting a first coordinate (degree of acetalization:degree of acetylation:hydroxy group content=70 mol %:30 mol %:0 mol %), a second coordinate (degree of acetalization:degree of acetylation:hydroxy group content=34 mol %:30 mol %:36 mol %), a third coordinate (degree of acetalization:degree of acetylation:hydroxy group content=94 mol %:0 mol %:6 mol %), and a fourth coordinate (degree of acetalization:degree of acetylation:hydroxy group content=100 mol %:0 mol %:0 mol %) in the stated order.

Owner:SEKISUI CHEM CO LTD

Stability control method and system for electric automobile with four independently driven wheels

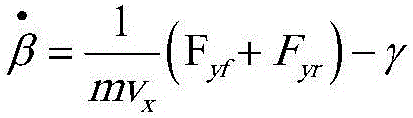

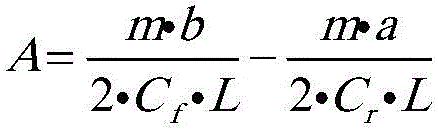

The invention discloses a stability control method for an electric automobile with four independently driven wheels. Stability is judged by jointly utilizing a phase diagram and a safe speed zone, and whether the current running state of an automobile is stable or not is accurately judged in real time. At the same time, the invention provides a stability control system for the electric automobile with the four independently driven wheels. Four wheel independent driving systems and four wheel independent brake systems of an electric automobile with four independently driven wheels are comprehensively controlled by utilizing an optimal moment distribution method, so that four wheels work in a more coordinated manner. The accuracy and the practicability of a stability controller on the electric automobile with the four independently driven wheels are improved.

Owner:DALIAN UNIV OF TECH

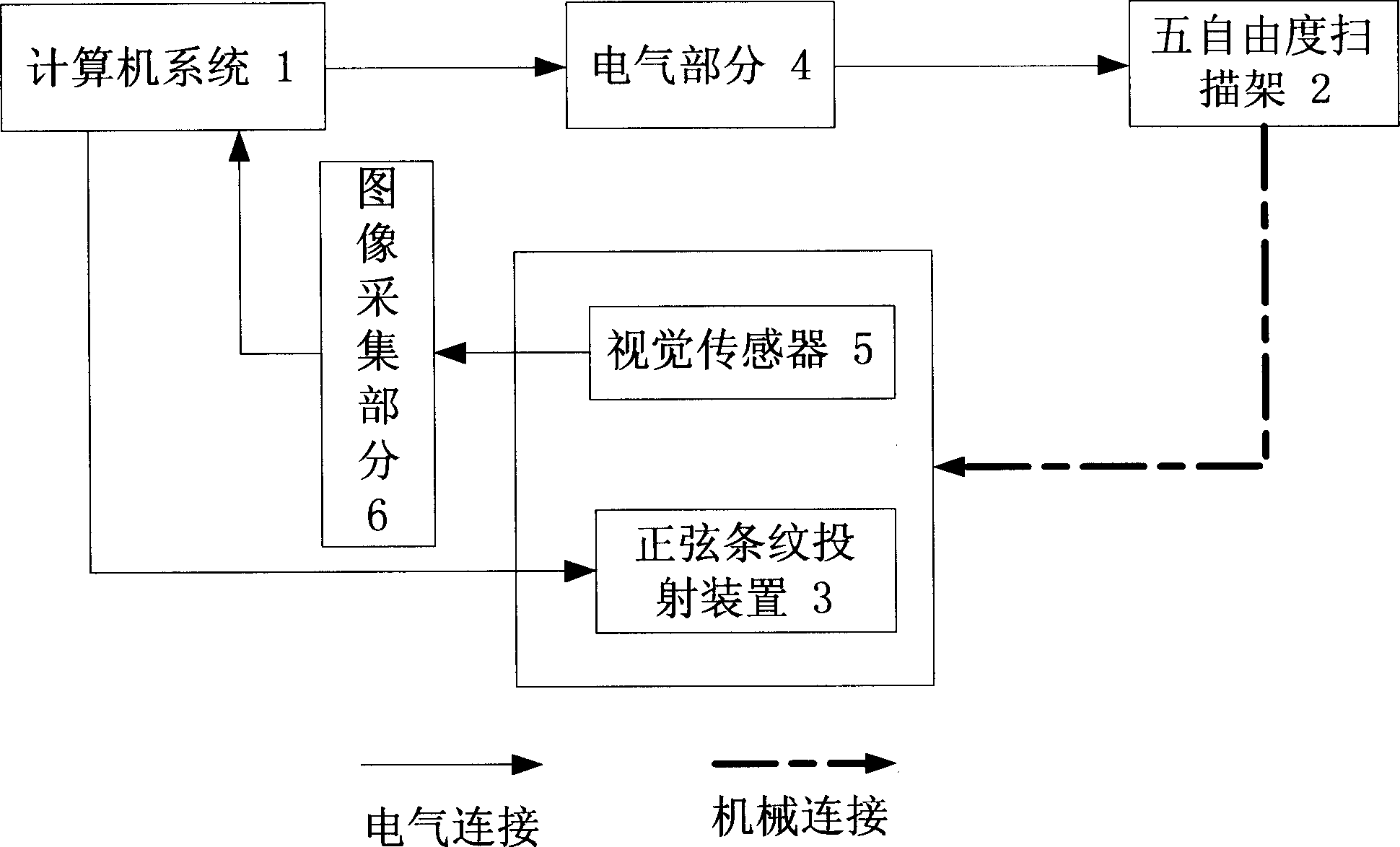

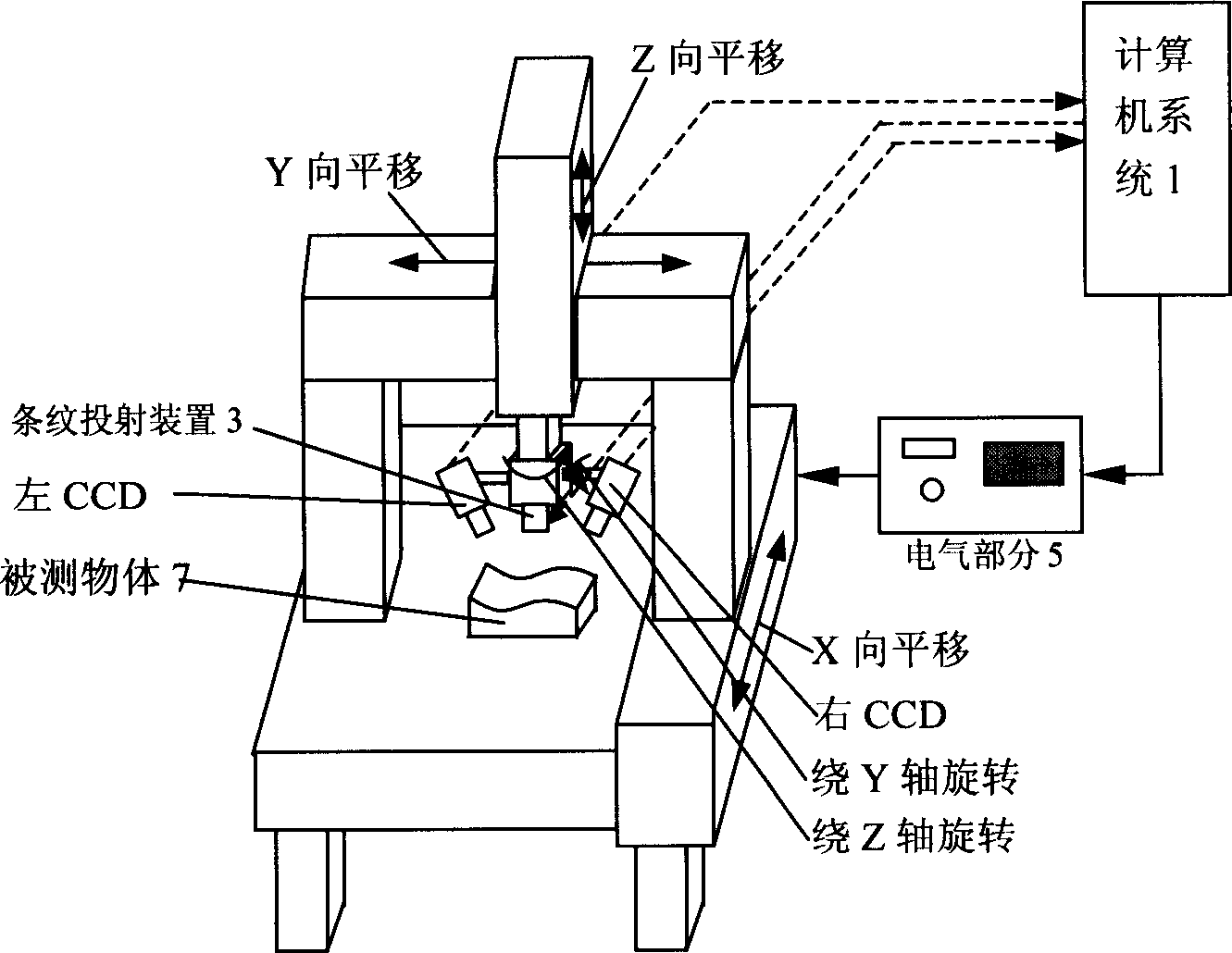

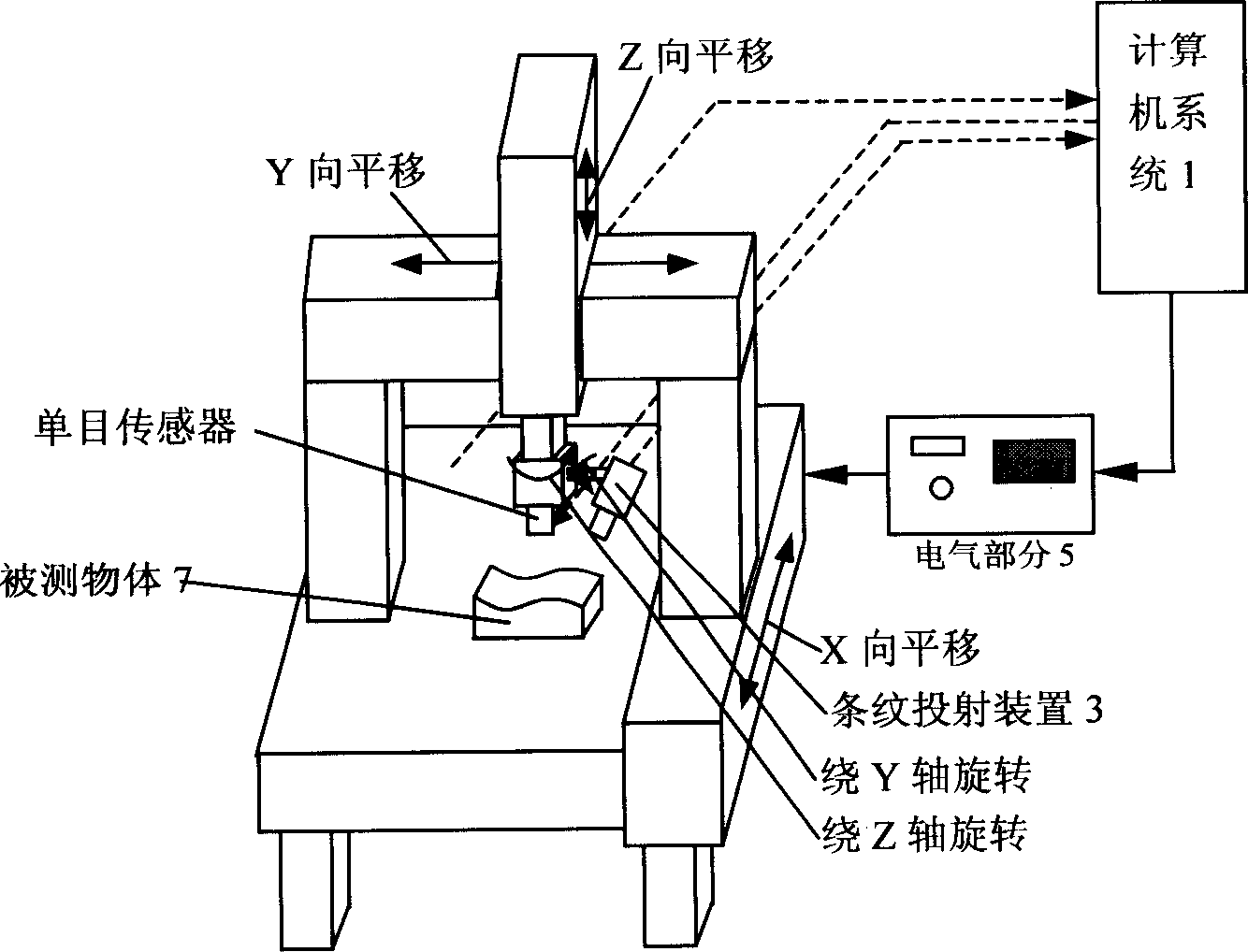

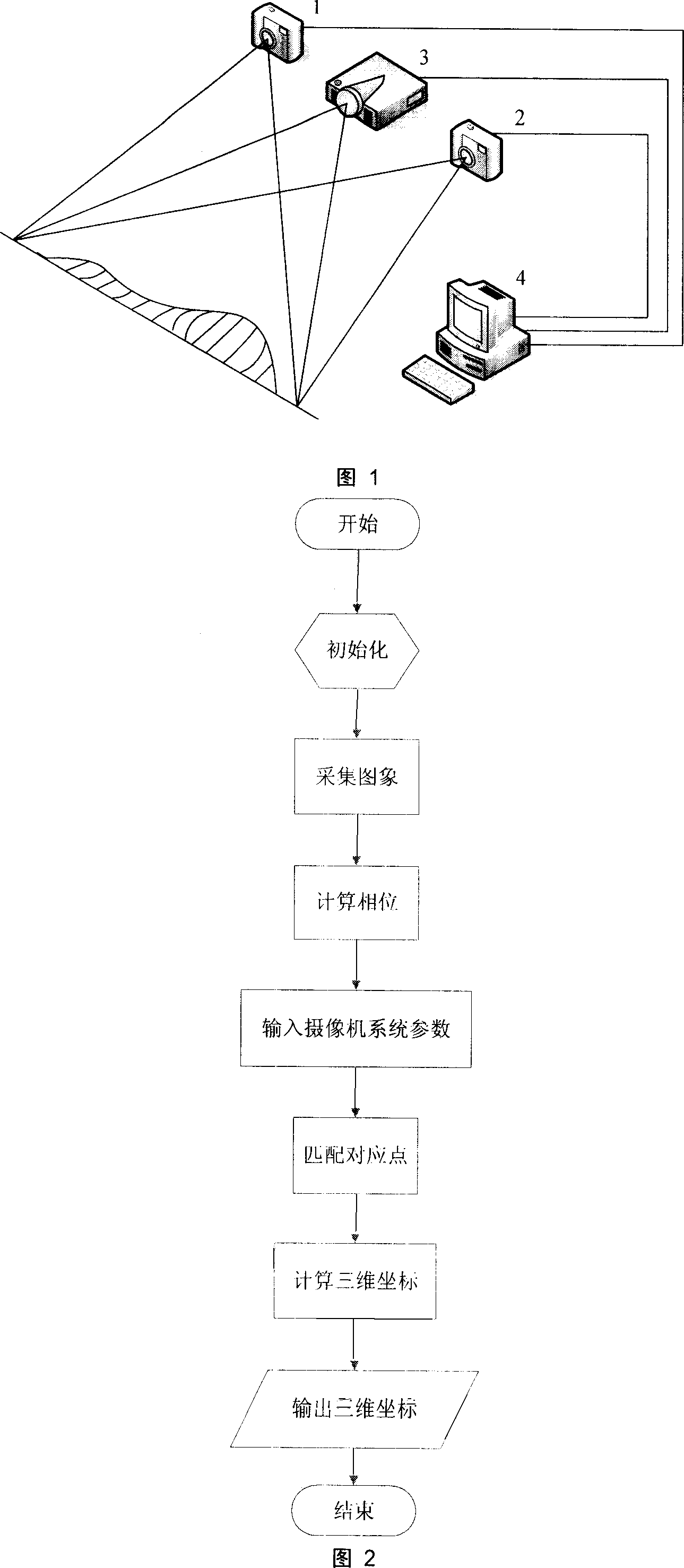

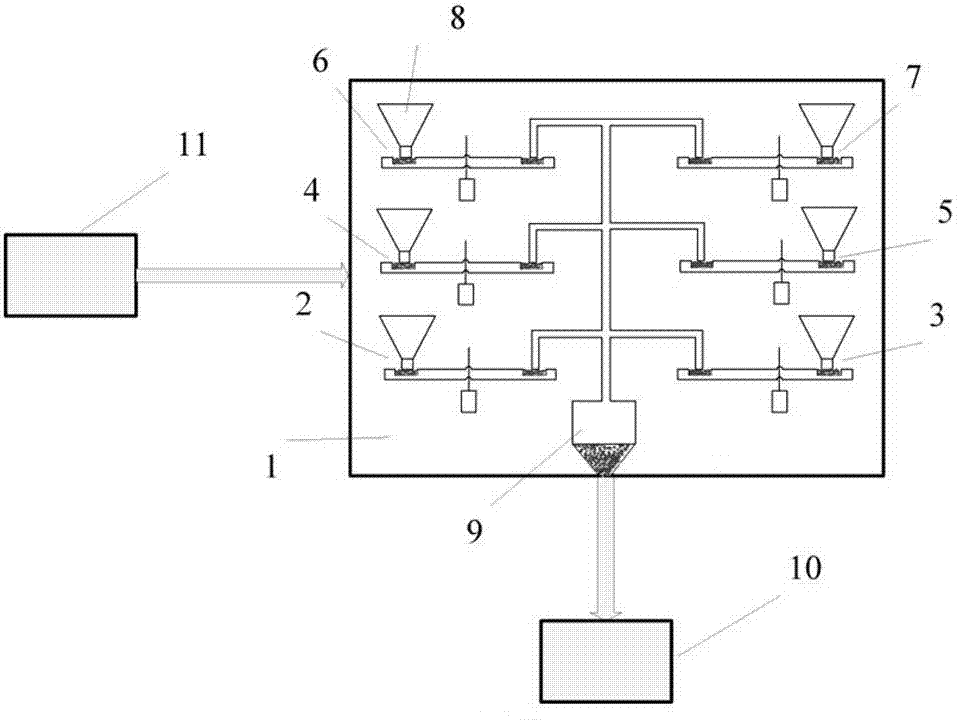

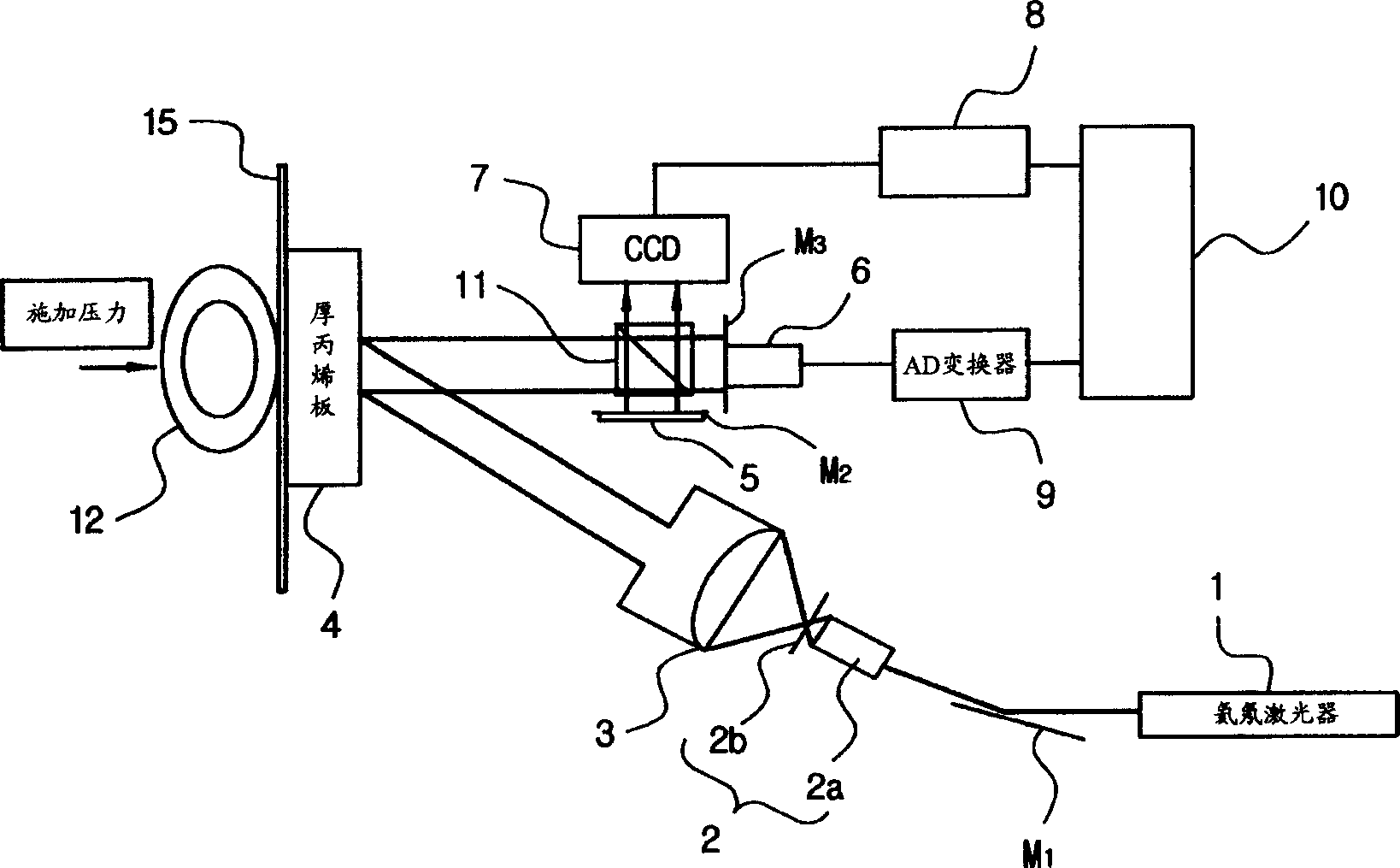

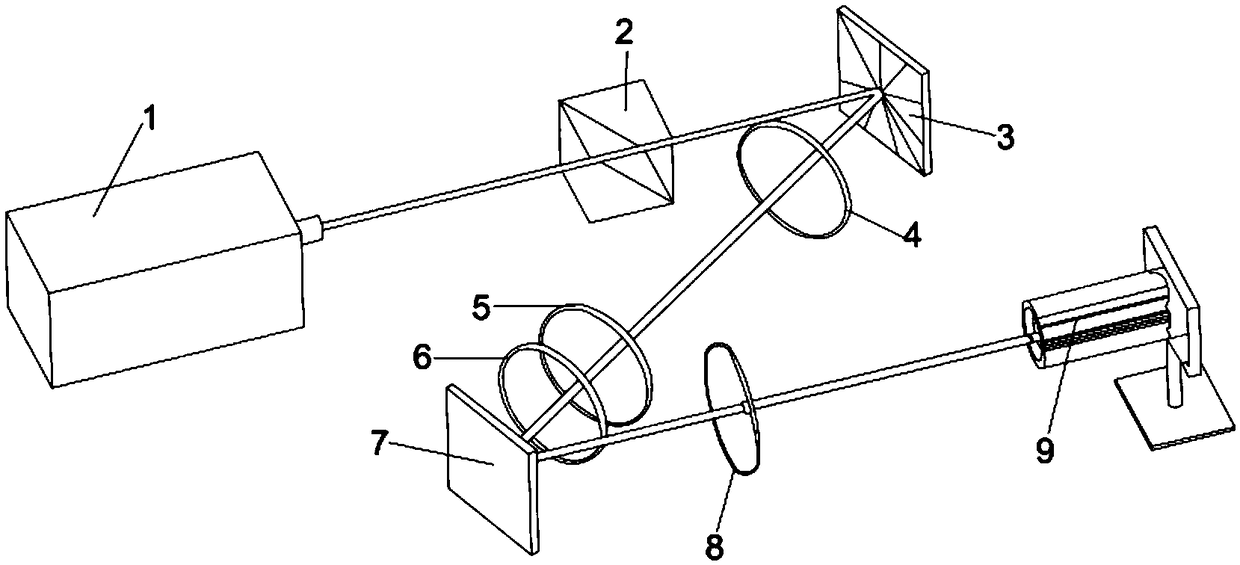

Stereo vision detection system based on adaptive sine streak projection

A stereoscopic visional detecting system based on the adaptive sine fringe projection is composed of computer system, 5D scanning frame, sine fringe projector based on acousto-optic deflector, electric unit, visional sensor and image acquisition unit. When multiple sine rasters are projected onto surface of object, a series of images with different phases is captured by image sensor, then sent to image acquisition unit, and finally processed by computer to obtain the phase diagram about the 3D information of object.

Owner:BEIHANG UNIV

Laminated glass intermediate film and laminated glass

The present invention provides an intermediate film for laminated glass which can improve sound insulation. The intermediate film has a layered structure including at least two layers, comprising: a first layer containing a polyvinyl acetal resin and a plasticizer; and a second layer positioned on a first surface of the first layer. In a phase diagram of three values including a degree of acetalization, a degree of acetylation, and a hydroxyl group content of the polyvinyl acetal resin contained in the first layer, the values of the degree of acetalization, the degree of acetylation, and the hydroxyl group content each fall within a region surrounded by a line including four straight lines connecting first, second, third, and fourth coordinates, which respectively have a degree of acetalization:degree of acetylation:hydroxyl group content of 70 mol %:30 mol %:0 mol %, 34 mol %:30 mol %:36 mol %, 94 mol %:0 mol %:6 mol %, and 100 mol %:0 mol %:0 mol %.

Owner:SEKISUI CHEM CO LTD

High pressure and high temperature production of diamonds

InactiveUS7241434B2Good colorDecrease cracking and breakageEdge grinding machinesUltra-high pressure processesNitrogenGraphite

The present invention is directed to a method for treating discolored natural diamond, especially Type IIa diamond and Type IaA / B diamond with nitrogen as predominantly B centers, for improving its color. The method includes preblocking and preshaping a discolored natural diamond to prevent its breakage in a high pressure / high temperature (HP / HT) press, placing said discolored natural diamond in a pressure transmitting medium which is consolidated into a pill. Next, the pill is placed into a HP / HT press at elevated pressure and elevated temperature within the graphite-stable or diamond-stable range of the carbon phase diagram for a time sufficient to improve the color of said diamond. Finally, the diamond is recovered from said press. Colorless and fancy colored diamonds can be made by this method.

Owner:BELLATAIRE INT

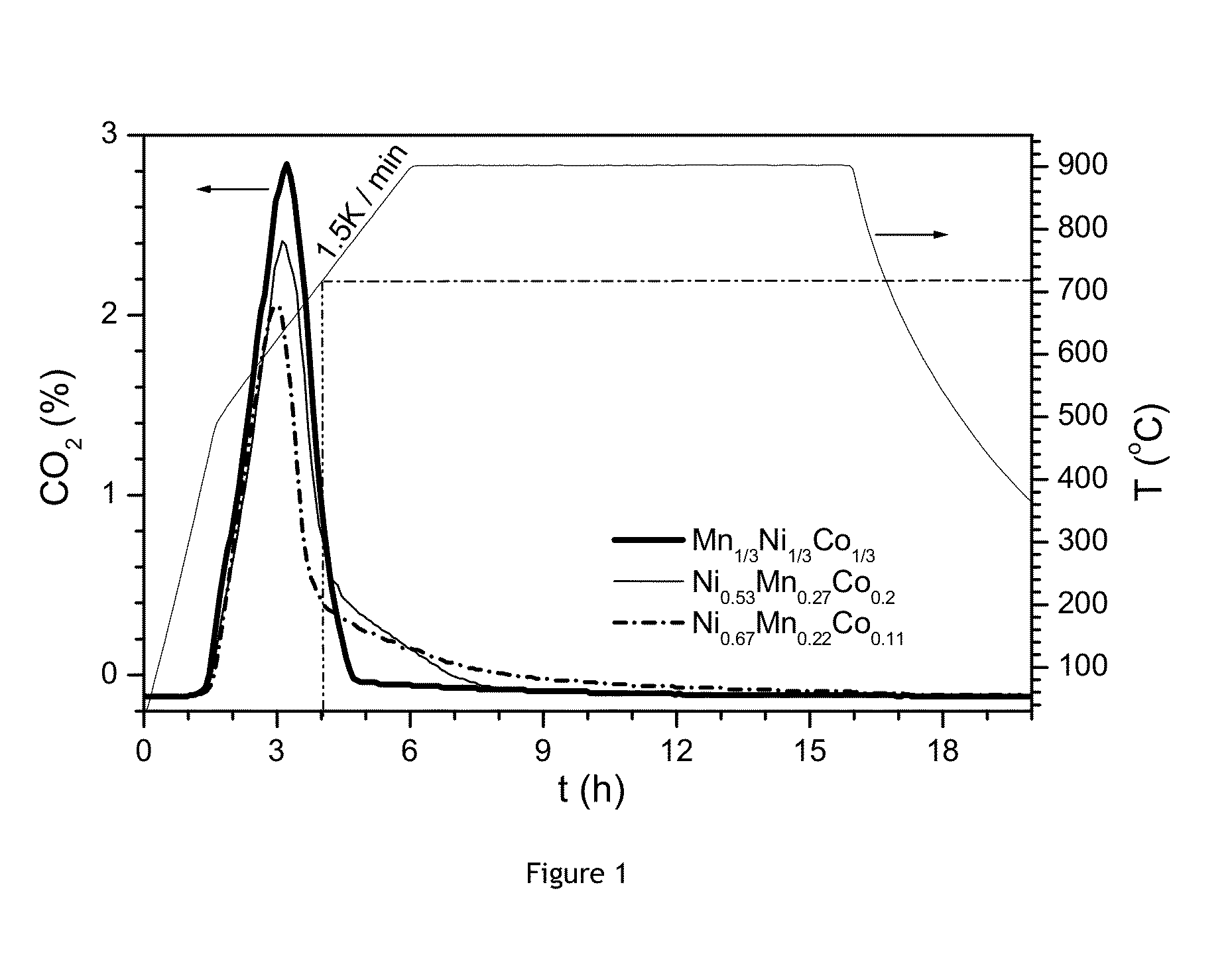

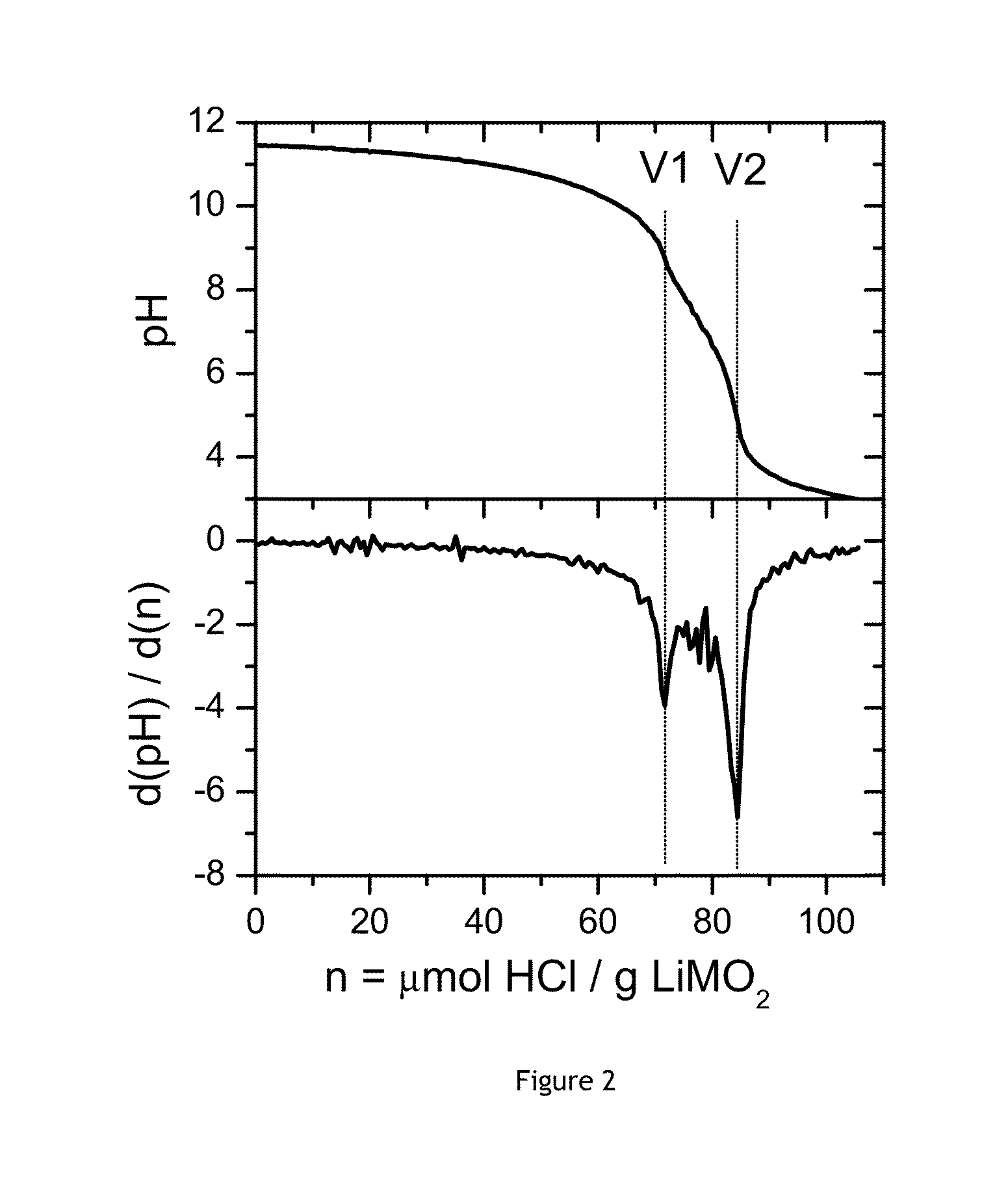

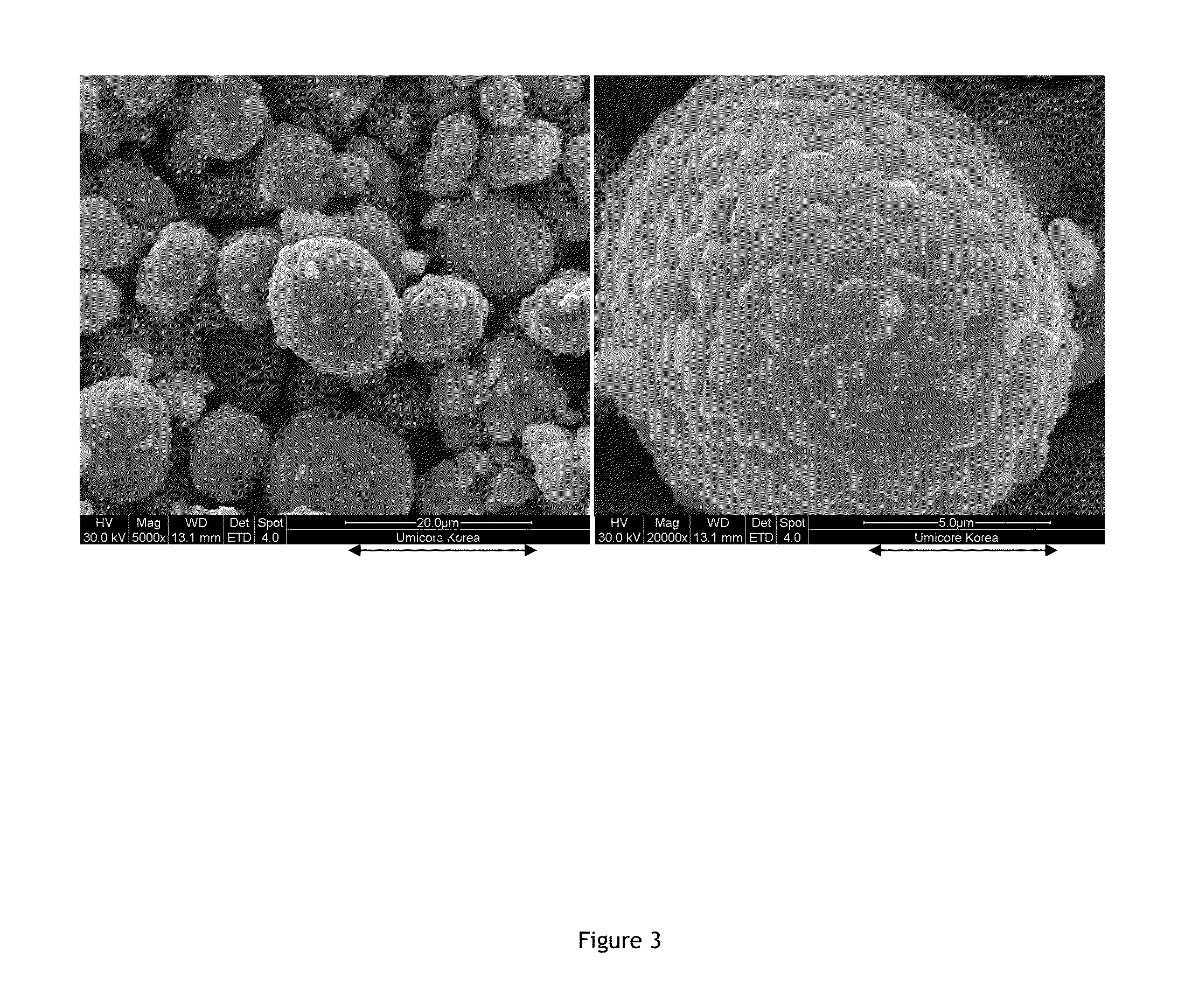

High nickel cathode material having low soluble base content

ActiveUS20140054495A1Improve performanceSecondary cell gas removalLi-accumulatorsDopantCathode material

The invention relates to cathode materials for Li-ion batteries in the quaternary phase diagram Li[Li1 / 3Mn2 / 3]O2—LiMn1 / 2Ni1 / 2O2—LiNiO2—LiCoO2, and having a high nickel content. Also a method to manufacture these materials is disclosed. The cathode material has a general formula Lia((Niz(Ni1 / 2Mn1 / 2)yCox)1-kAk)2-aO2, wherein x+y+z=1, 0.1≦x≦0.4, 0.36≦z≦0.50, A is a dopant, 0≦k≦0.1, and 0.95≦a≦1.05, and having a soluble base content (SBC) within 10% of the equilibrium soluble base content.

Owner:UMICORE AG & CO KG

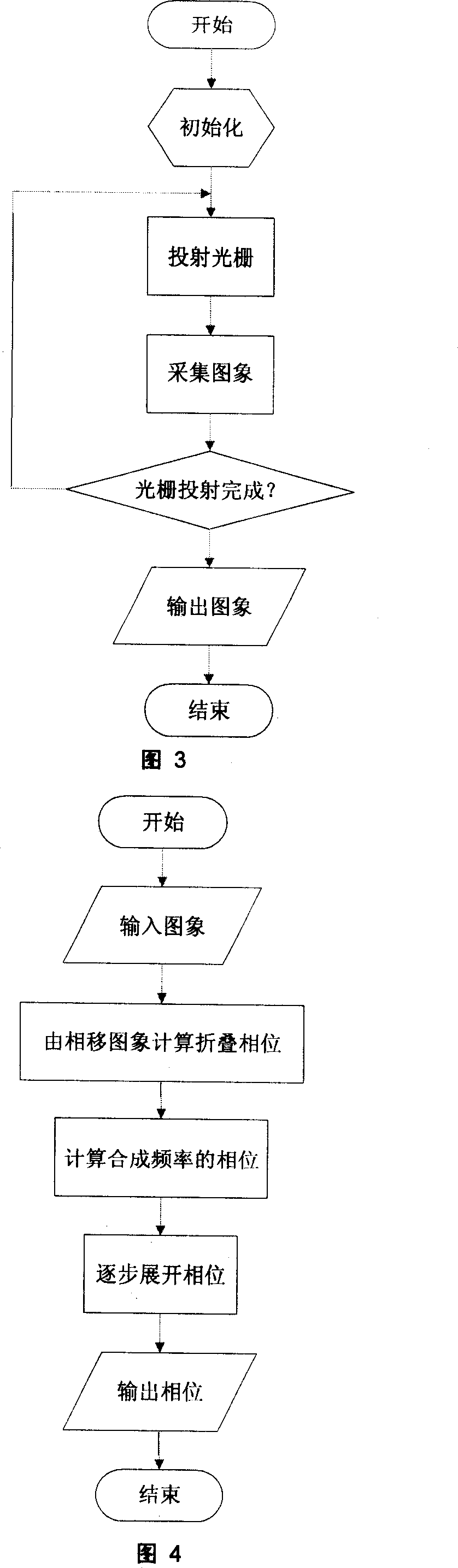

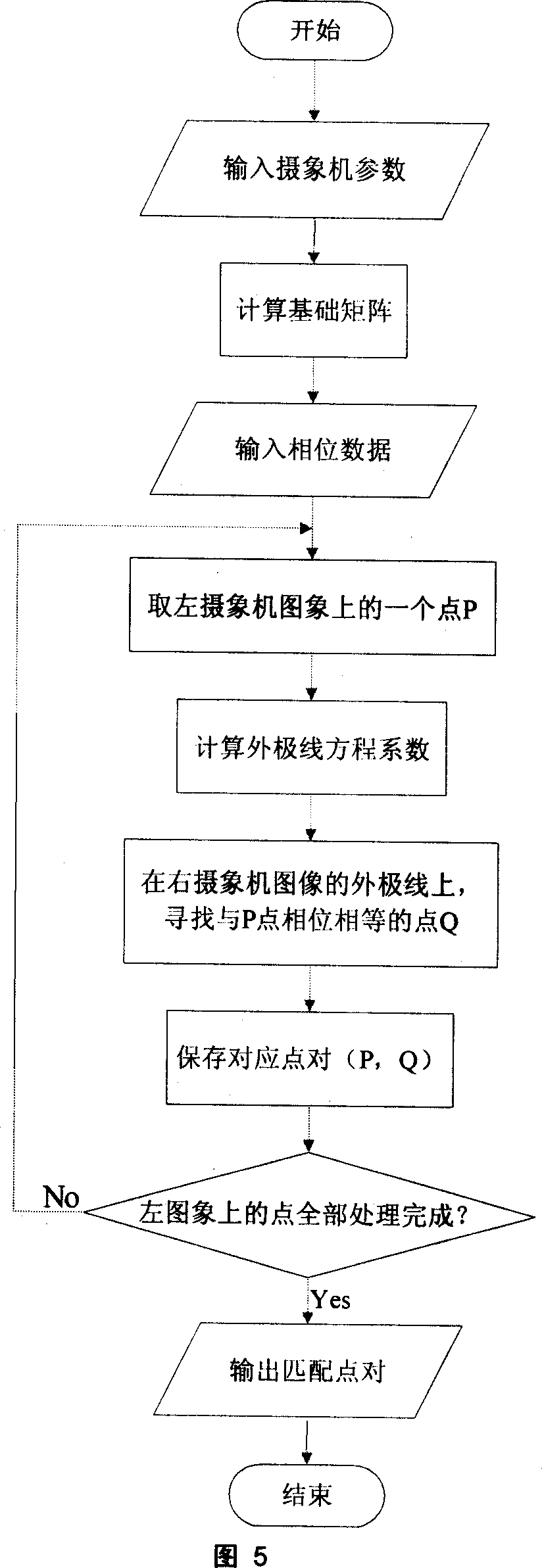

Vision measuring method for projecting multiple frequency grating object surface tri-dimensional profile

The invention belongs to the field of 3D contour measurement on object surface. The main technical features comprise: (1) projecting gratings with different frequencies to the object surface to obtain multiple phase diagrams; (2) unwrapping the phase diagrams with frequency synthesis method to obtain high-precision unwrapped phase; (3) matting corresponding points to external polar line with the unwrapped phase and calculating 3D contour of the object surface; and (4) in order to make the calculation result more reliable, using modulation degree as reliable reference of phase unwrapping and masking the phase with modulation degree less than the set threshold. The invention has the advantages of simple structure, non-contact, high precision, high speed, and easy implementation.

Owner:北京智启维恩科技开发有限公司

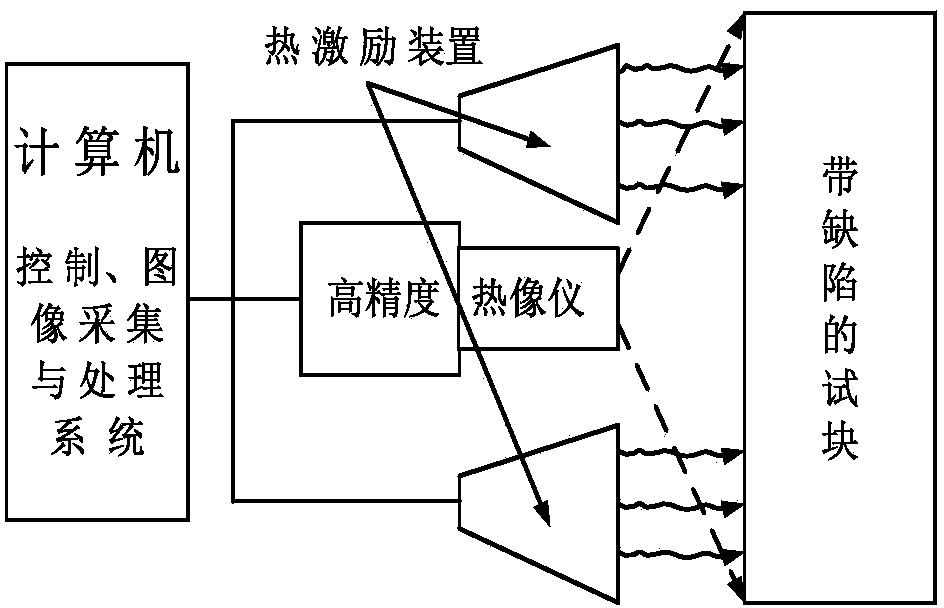

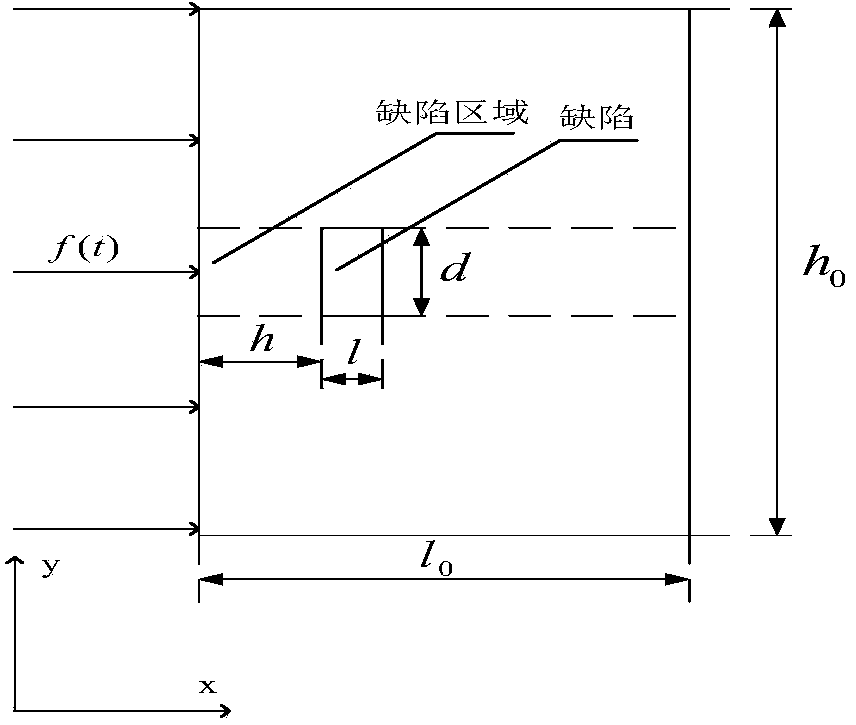

Non-destructive detection method of pulse-excited infrared thermal wave phase of fixed viewing field

InactiveCN104359944AEasy to detectFlexible useMaterial flaws investigationFrequency spectrumImage sequence

The invention relates to a non-destructive detection method of pulse-excited infrared thermal wave phase of a fixed viewing field. The non-destructive detection method comprises the following steps: comprehensively applying a multiple-modulation Zoom-FFT refining spectrum method, a thermal-wave data fitting extension method and a zero-phase digital filter method, and carrying out high-accuracy spectral analysis on acquired continuous equally-spaced infrared thermal-wave image sequences before and after thermal excitation, thus quickly obtaining precise ultralow-frequency thermal-image phase diagram and amplitude diagram, and further realizing detection and recognition for defects or damages of equipment. Compared with the prior art, the non-destructive detection method has the beneficial effects that not only can the acquisition frequency, the acquisition time, the acquisition frame number and the refining degree of analysis of thermal images be flexibly set, but also the detection speed, the refining degree and the precision degree can be increased by ten times respectively, the multiplied increase of the detection effect and the detection depth of the defects also can be realized, simultaneously the requirement for computer hardware is also reduced, so that the method is flexible in use, is especially suitable for non-destructive detection of the infrared thermal wave on site and has a wide application prospect.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

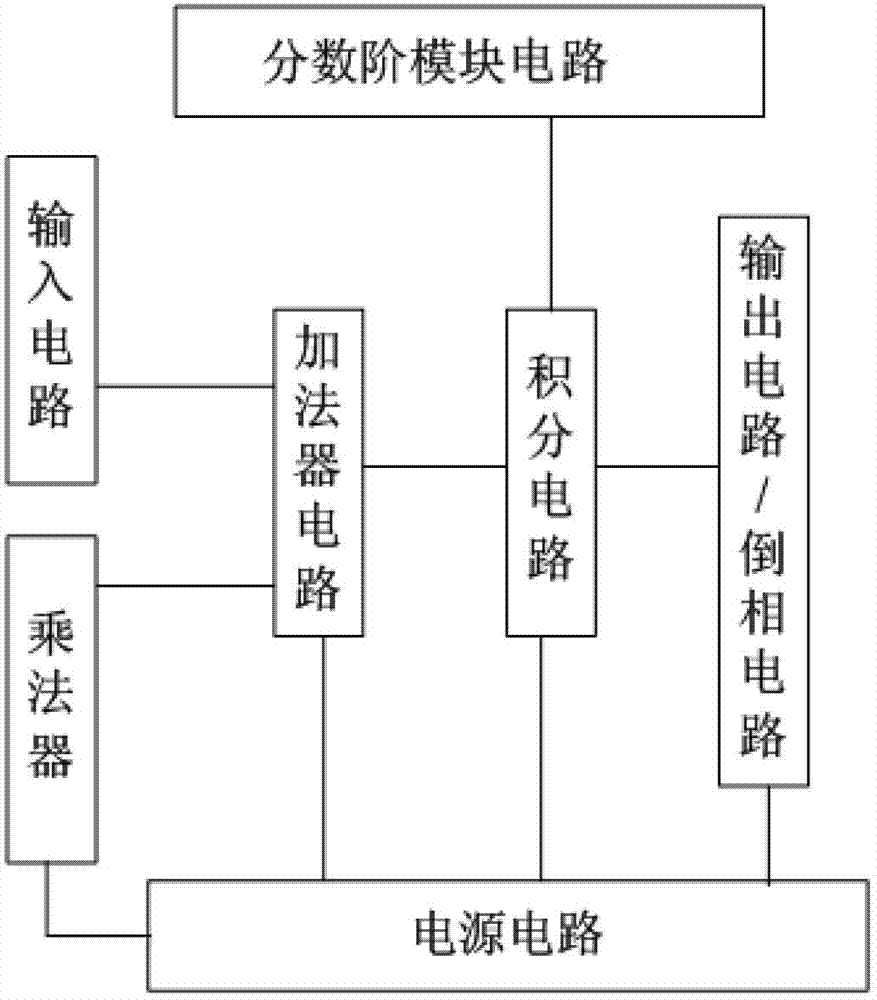

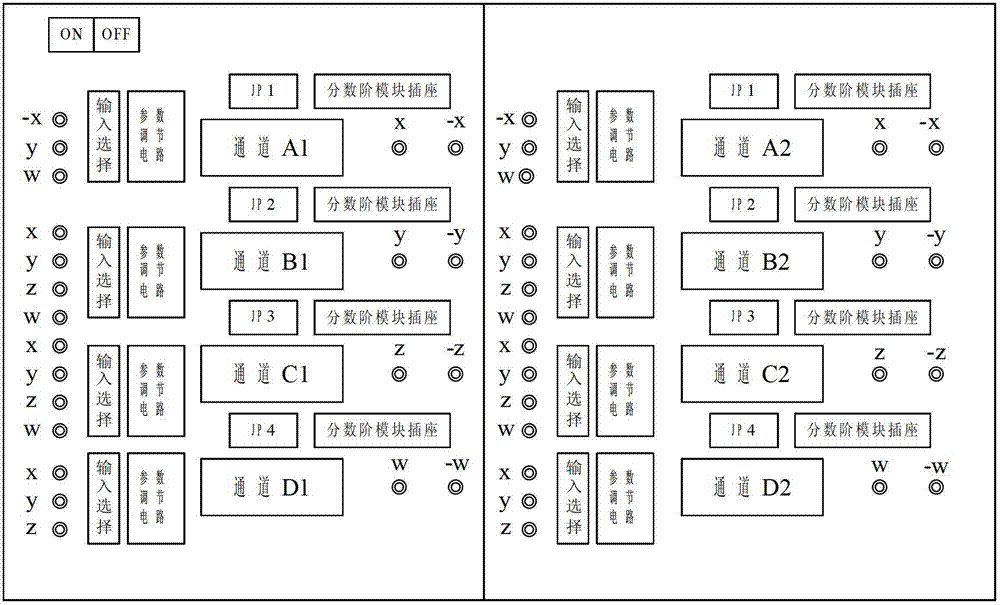

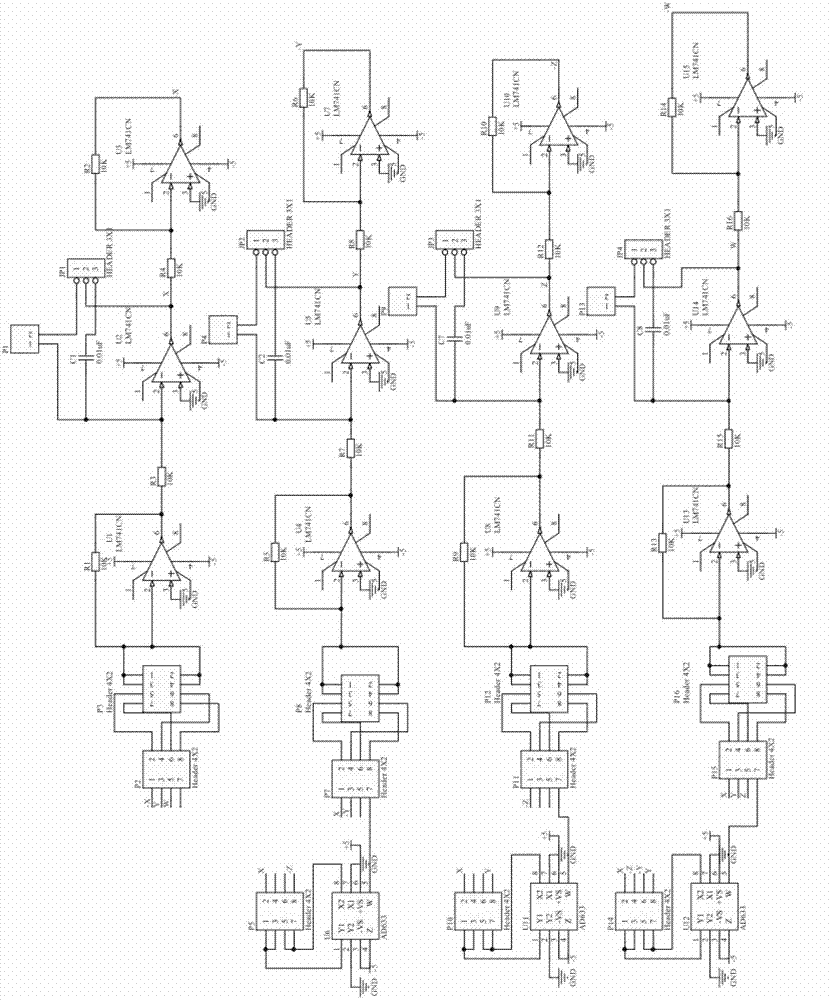

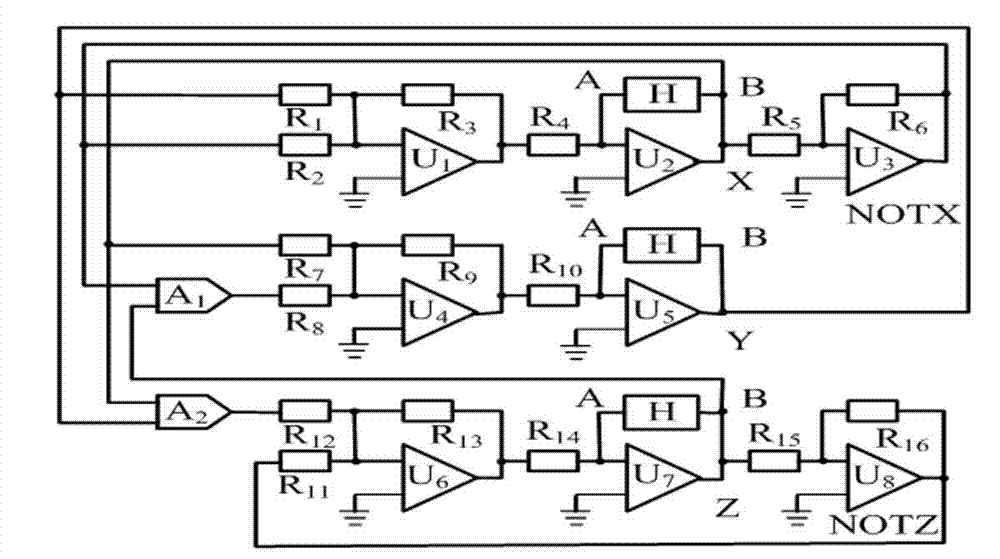

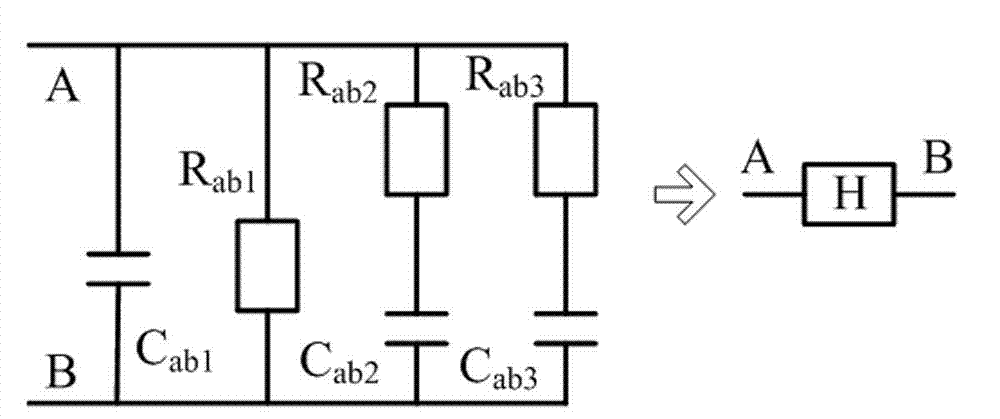

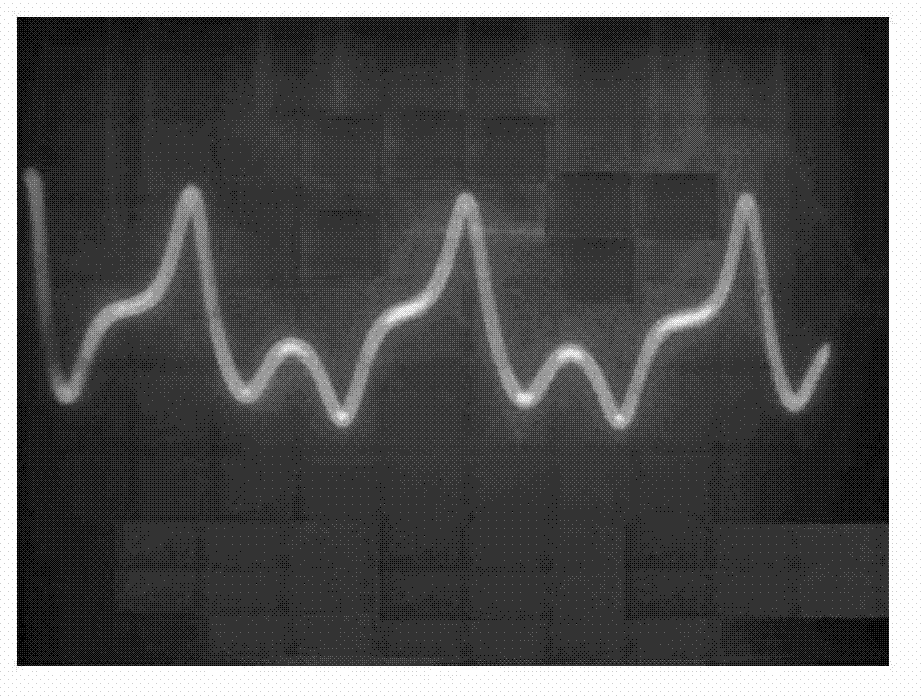

Integer-order and fractional-order multifunctional chaotic experiment instrument

InactiveCN102903282ASimple structureImprove stabilityEducational modelsChaotic systemsPhysical laboratory

The invention discloses an integer-order and fractional-order multifunctional chaotic experiment instrument, which can be used for realizing experiment of a three-dimensional or four-dimensional integer-order or fractional-order chaotic system and can output a time-sequence diagram or a phase diagram by a dual-trace oscilloscope. The integer-order and fractional-order multifunctional chaotic experiment instrument comprises a shell and an internal circuit board, wherein the internal circuit board is arranged in the shell; the internal circuit board is provided with a power circuit, an I-part circuit and an II-part circuit; the I-part circuit and the II-part circuit are used for generating chaotic signals and are the same in circuit structure; each part consists of four channels; each channel comprises a signal input circuit, an adder circuit, an integral circuit and a chaotic signal output circuit; each adder circuit is respectively connected with the corresponding signal input circuit and the corresponding integral circuit; and the output end of each integral circuit is connected with the corresponding chaotic signal output circuit. The integer-order and fractional-order multifunctional chaotic experiment instrument disclosed by the invention is simple and reasonable in structure, good in stability, high in reliability and strong in practicability, can be used for teaching in a physical laboratory of the college, can also be used as common scientific and research equipment of the research institutions, and completely meets the research need of the current chaotic phenomenon.

Owner:YULIN NORMAL UNIVERSITY

Method for producing nickel coating on metal surface

A method for preparing nickel coating on metal surface relates to metal plating and provides a method for preparing nickel coating on the metal surface. The metal surface goes through oil removal and is placed in a solution tank and plated with tin coating and then placed in the solution tank; after being plated with tin, the metal surface is plated with the nickel coating; the metal plated with the nickel coating is placed in the solution tank for passivation treatment, heat preservation, hydrogen removal from the nickel coating, diffusion annealing treatment and stress relief heat treatment. High interfacial strength single-phase solid solution is obtained by rapid cooling after adopting thick nickel and tin coating, adding thin tin coating and diffusion annealing treatment. Plating bath is not added with a brightening agent while the plating coat is bright and smooth and forms a single-phase solid solution structure, thus enhancing interface combining power of the plating coat and a base plate. The method makes use of the principle predicted by a binary phase diagram that tin and nickel are mutually exclusive within a large composition range, so as to lead iron uncoated rate and copper uncoated rate to tend to be zero under the effect of a tin diffusion blocking layer, thus the plating coat can keep relatively high antiseptic property. Other machinery properties are also good; therefore, the nickel coating prepared by the method of the invention can serve as multifunctional antirust coating.

Owner:XIAMEN UNIV

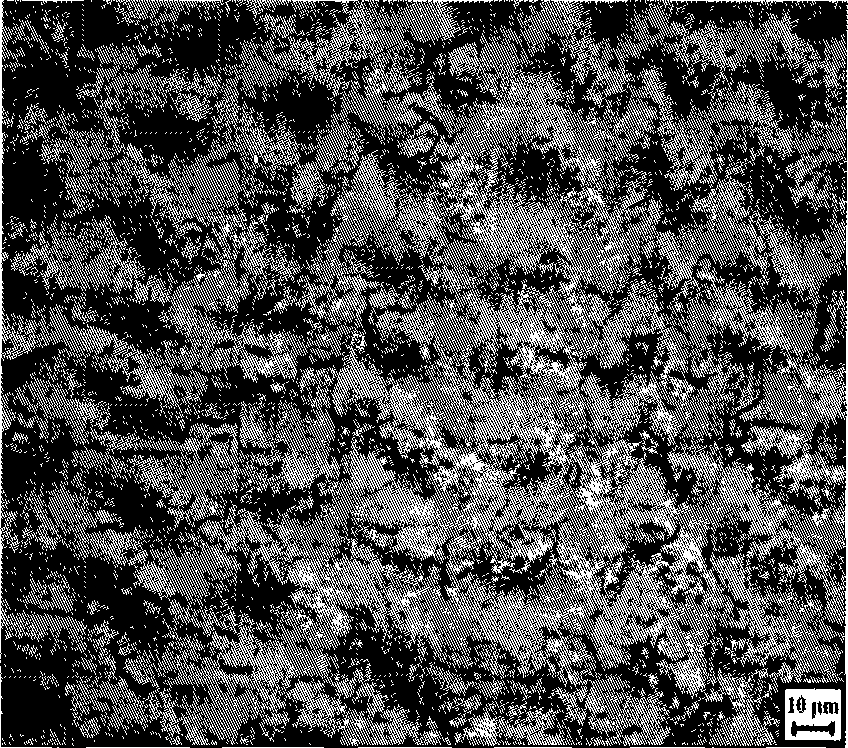

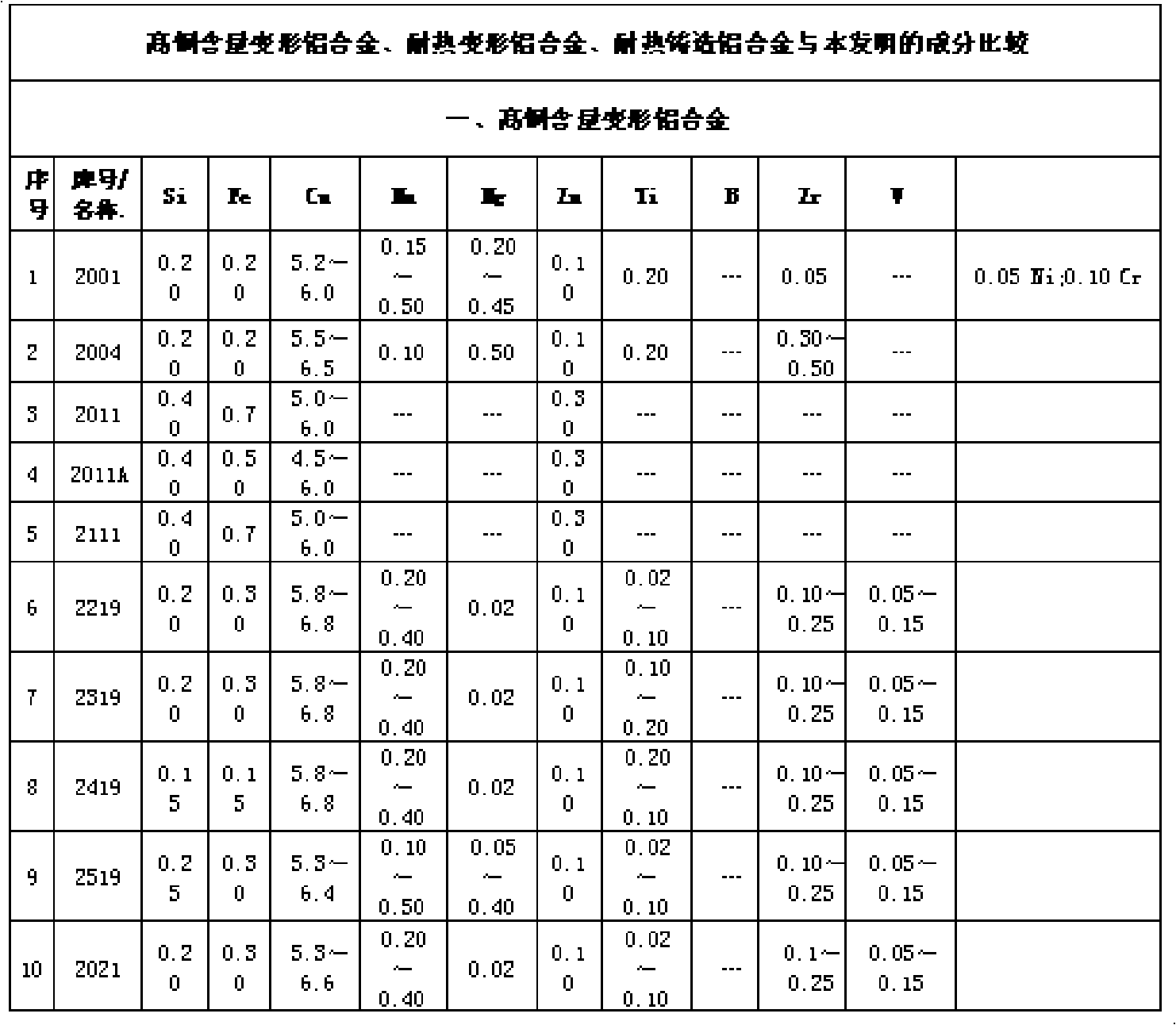

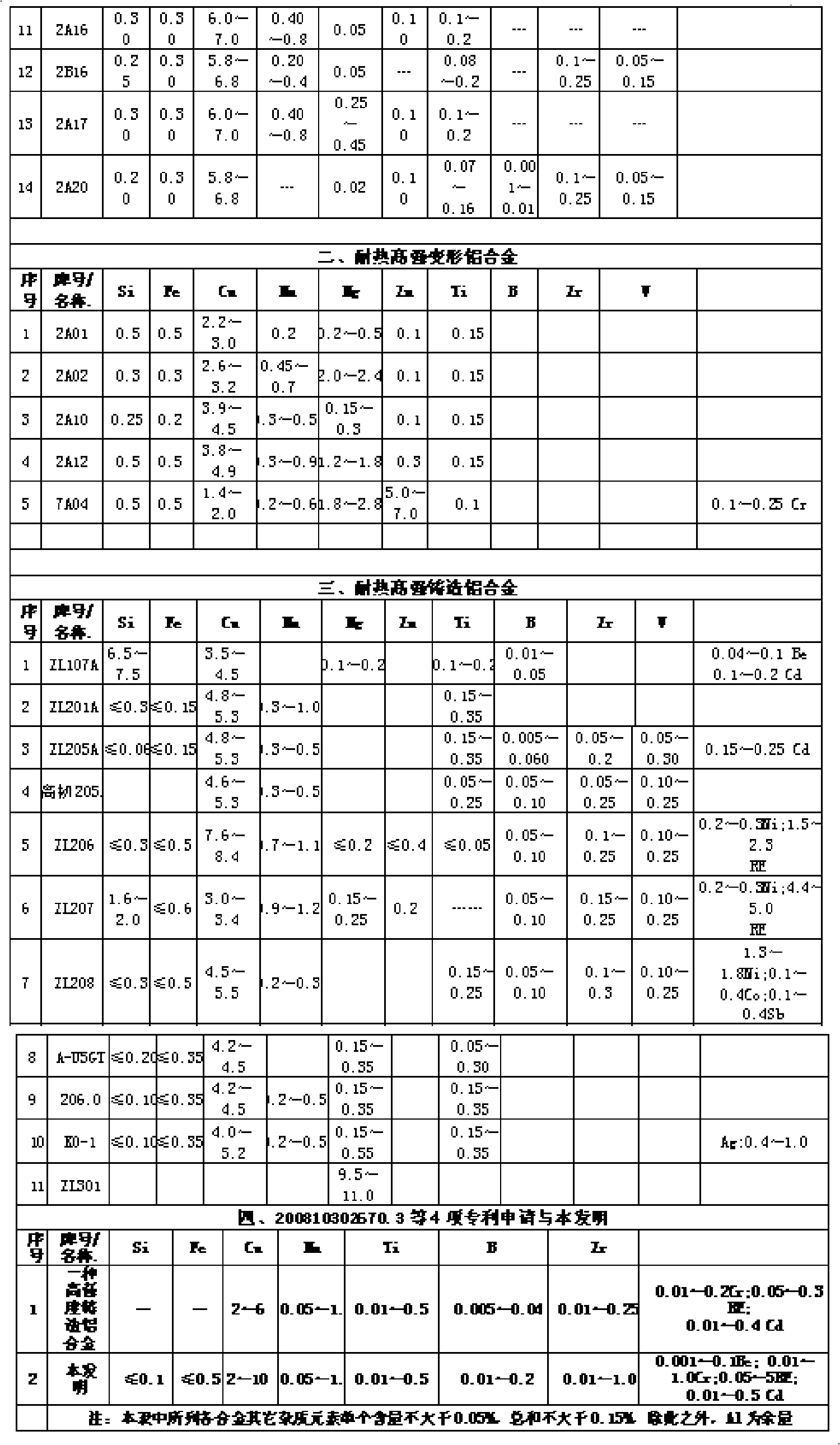

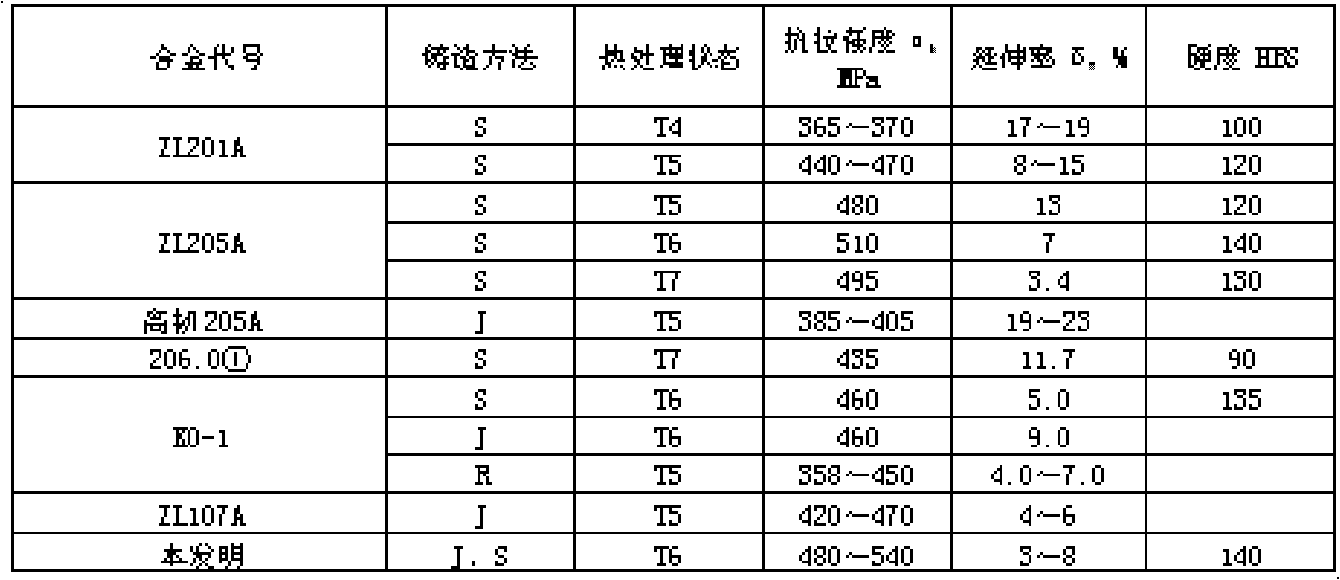

Be-Cr-RE high-strength heat-resisting aluminum alloy material and production method thereof

InactiveCN101805844AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a Be-Cr-RE high-strength heat-resisting aluminum alloy material and a production method thereof. The Be-Cr-RE high-strength heat-resisting aluminum alloy material comprises the following components in percentage by weight: Cu: 1.0-10.0%; Mn: 0.05-1.5%; Cd: 0.01-0.5%; Ti: 0.01-0.5%; B: 0.01-0.2%; Zr: 0.01-1.0%; Cr: 0.01-1.0%; Be: 0.001-0.1%; RE: 0.05-5%; and the balance of Al. By adopting a high-quality melt, solid solution and phase diagram theory as guide and preferring main alloy element formula of Cu, Mn and RE, the invention reduces an alloy quasi solid phase temperature range and solves the problems of large heat crack tendency in casting, low high-temperature strength of products, and the like; in addition, by preferring a multiple microalloying element formula, the invention provides a material condition for culture and grain refining of a high temperature phase and a strengthening phase in the solid solution and finally produces the high-strength heat-resisting aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

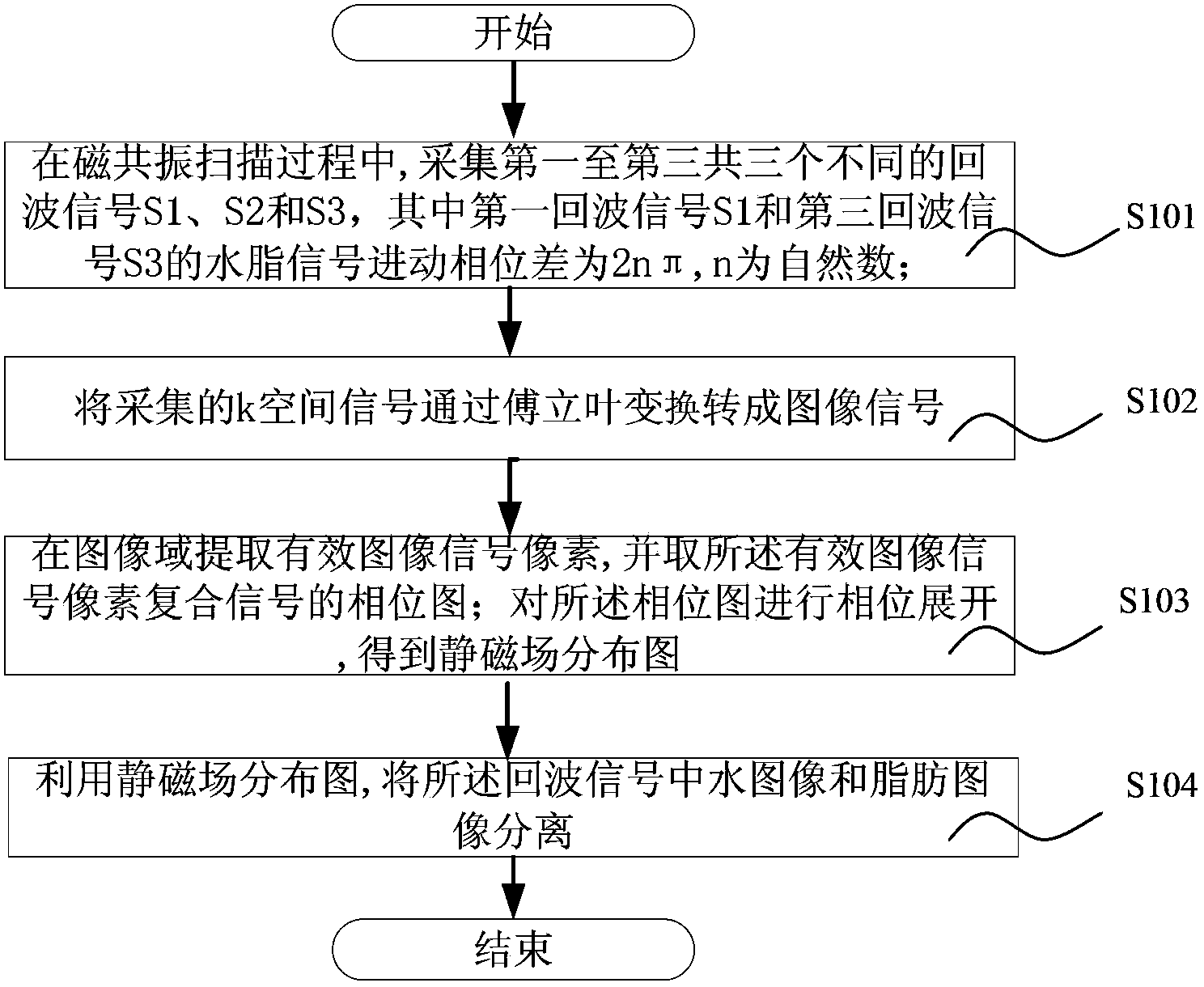

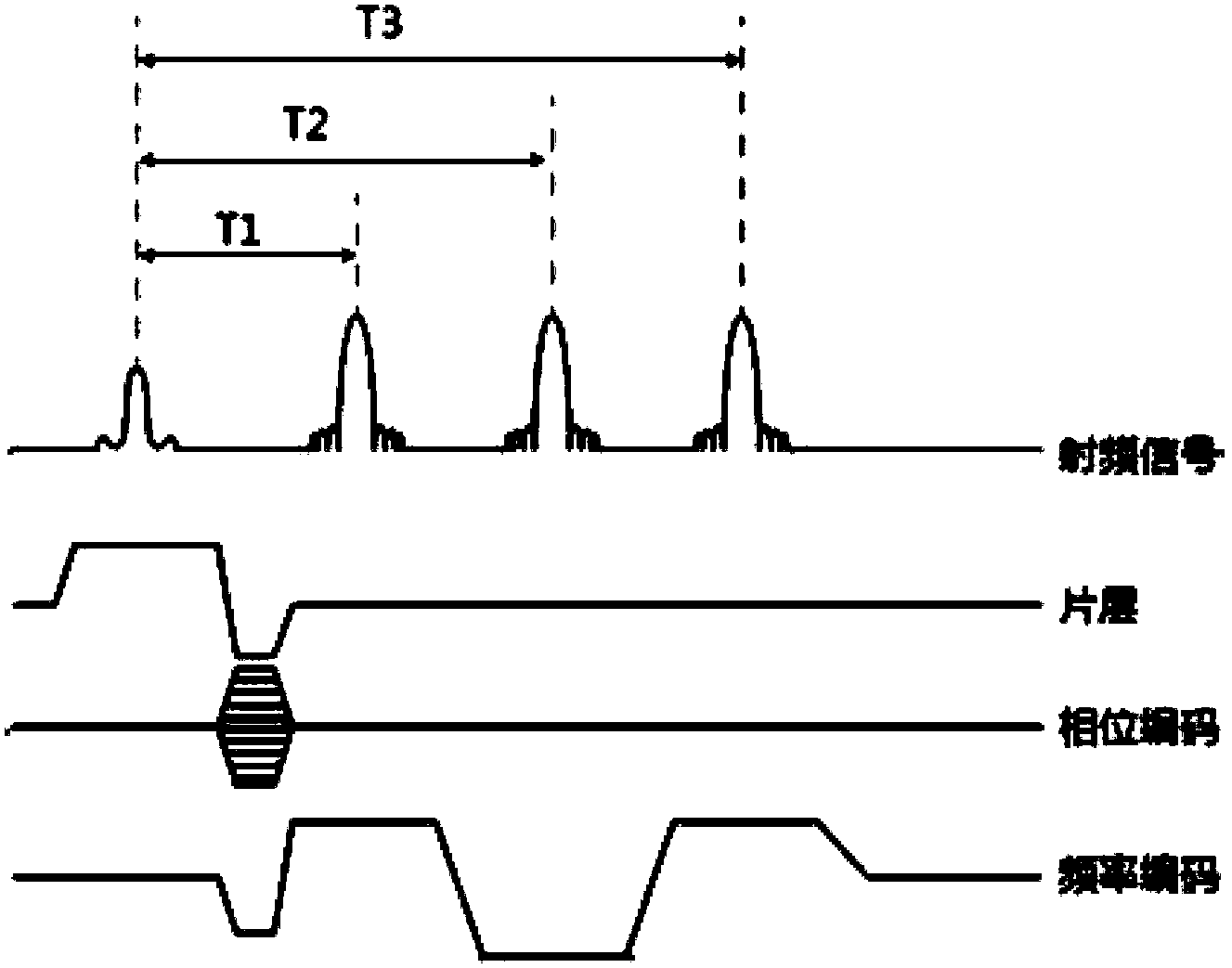

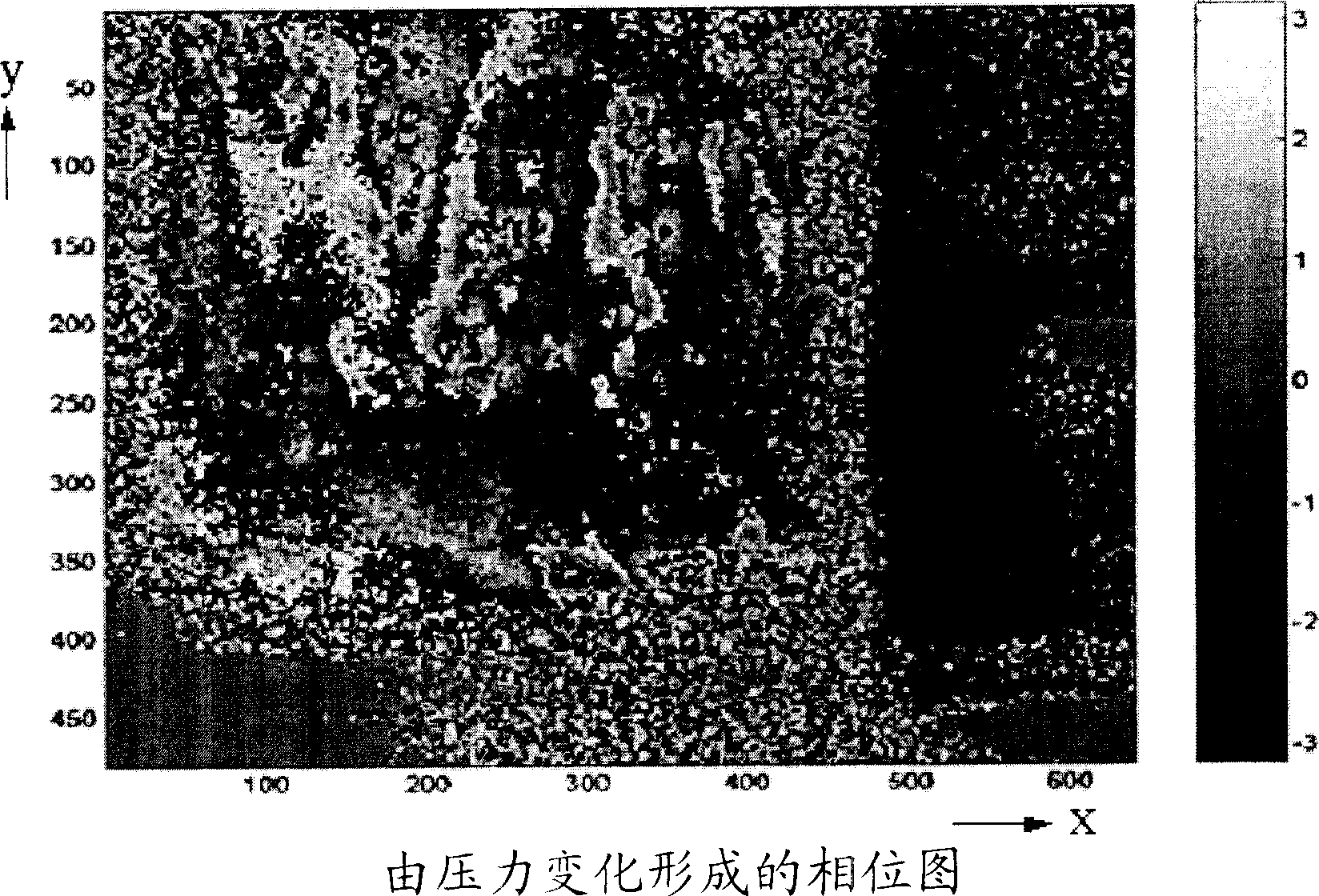

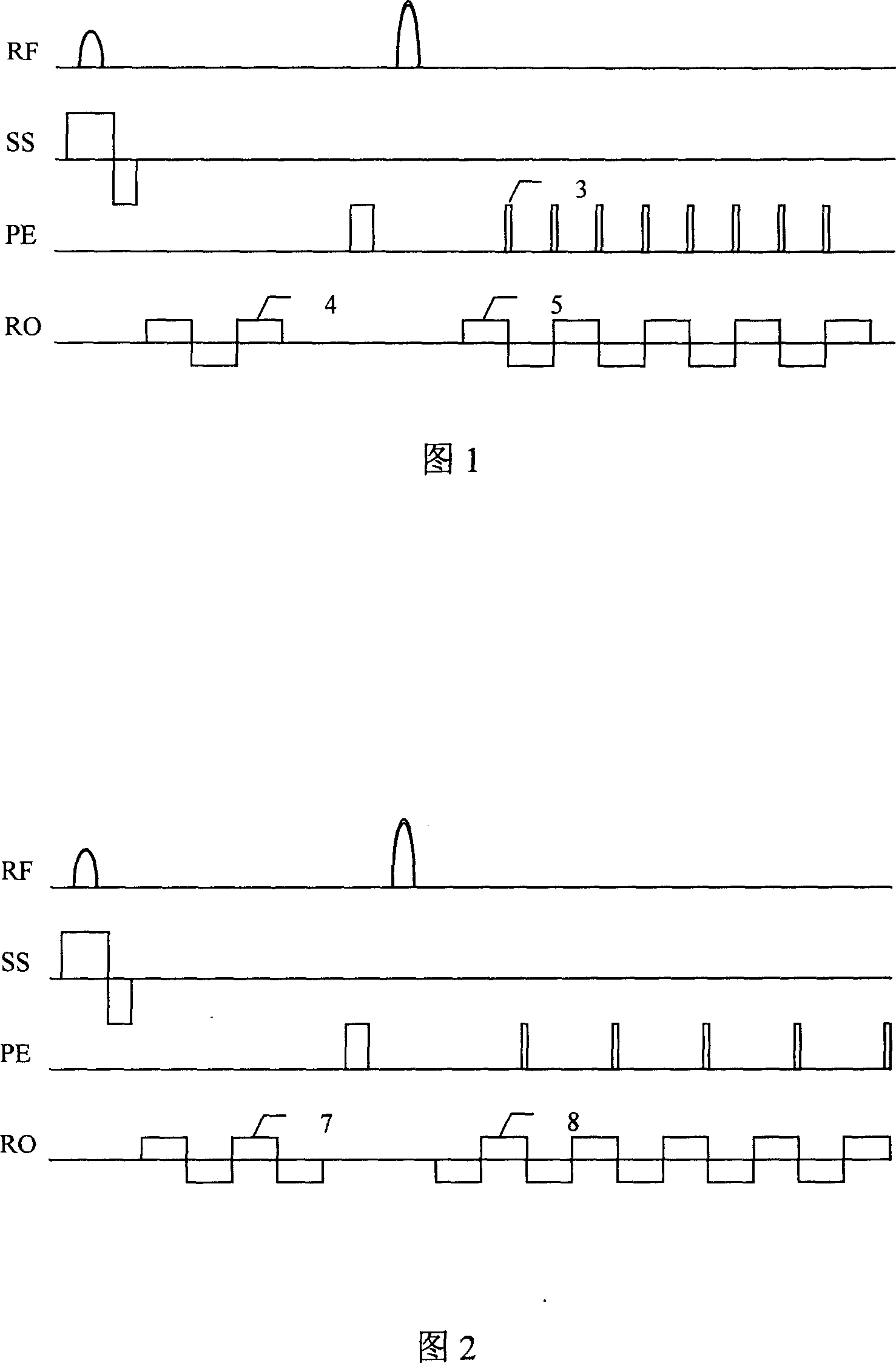

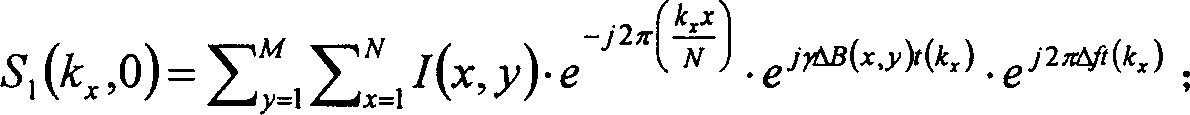

DIXON water-fat separation method in magnetic resonance imaging

ActiveCN103513202AIncrease flexibilityReduce restrictionsMagnetic measurementsPhase differenceFourier transform on finite groups

The invention discloses a DIXON water-fat separation method in magnetic resonance imaging. The method comprises the following steps: a) in the magnetic resonance scanning process, three different echo signals including the first echo signal S1, the second echo signal S2 and the third echo signal S3 are acquired, wherein the water-fat signal procession phase difference of the first echo signal S1 and the third echo signal S3 is 2npi, and n is a natural number; b) the acquired k space signals are converted into image signals through Fourier transform; c) effective image signal pixels are extracted in a image domain, the phase diagram of the effective image signal pixel composite signal is extracted, and phase unwrapping is performed on the phase diagram to obtain a static magnetic field distribution diagram delta B0; d) and the water image and the fat image in the echo signals are separated by utilizing the static magnetic field distribution diagram delta B0. According to the DIXON water-fat separation method provided in the invention, the echo time can be set flexibly according to a magnetic resonance imaging sequence and application requirements, so not only data can be processed by applying the conventional DIXON algorithm, and but also the limitation on imaging sequence parameter setting can be reduced at the same time.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

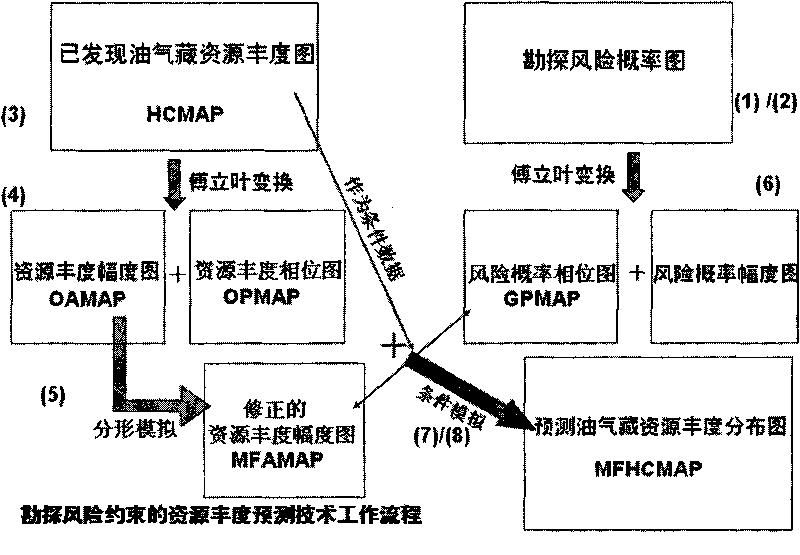

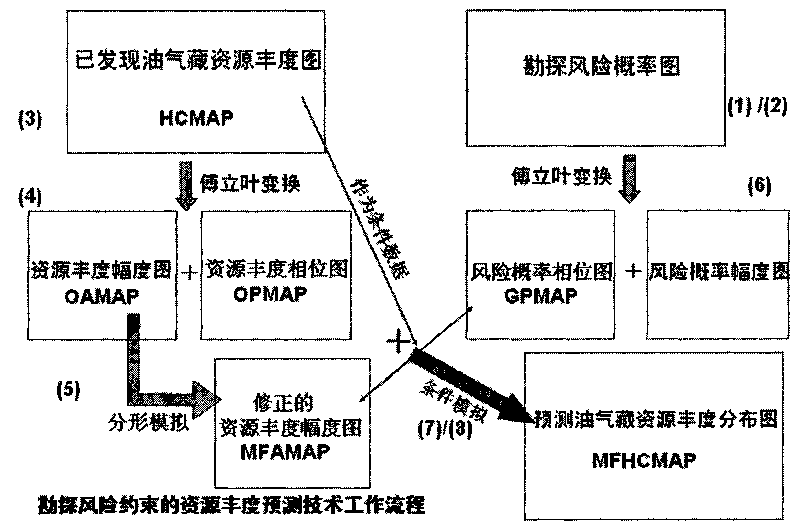

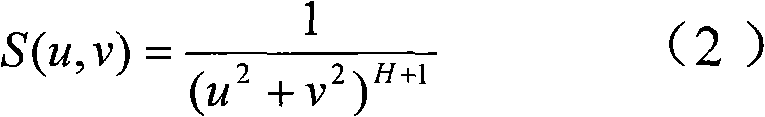

Risk-constrained oil and gas resource spatial distribution forecasting method

The invention relates to a risk-constrained oil and gas resource spatial distribution forecasting method which comprises the following steps of: (1) integrating seismic information and geologic information; (2) forecasting the exploration risk probability of a entire region; (3) establishing a resource abundance diagram of the discovered oil and gas accumulation; (4) establishing a resource abundance amplitude diagram and a resource abundance phase diagram; (5) establishing a modified resource abundance amplitude diagram; (6) establishing a risk probability amplitude diagram and a risk probability phase diagram; (7) establishing a forecast oil and gas resource abundance distribution diagram of the entire region; and (8) calculating the resource quantities of different risk regions: excluding the oil and gas accumulation with low abundance; excluding grid data points with high exploration risk; and verifying and modifying according to the data of the explored wells. The method can forecast the resource quantities in different risk regions and the spatial distribution positions of the remained oil and gas resources. A forecasting model and the method have strong operability. The invention can enhance the drilling decision level and the oil and gas exploration efficiency.

Owner:PETROCHINA CO LTD

Cream solder and method of soldering electronic part

ActiveUS20120018048A1Improve adhesionHigh strength stabilityPrinted circuit assemblingPrinted circuit aspectsThermal stabilityUltimate tensile strength

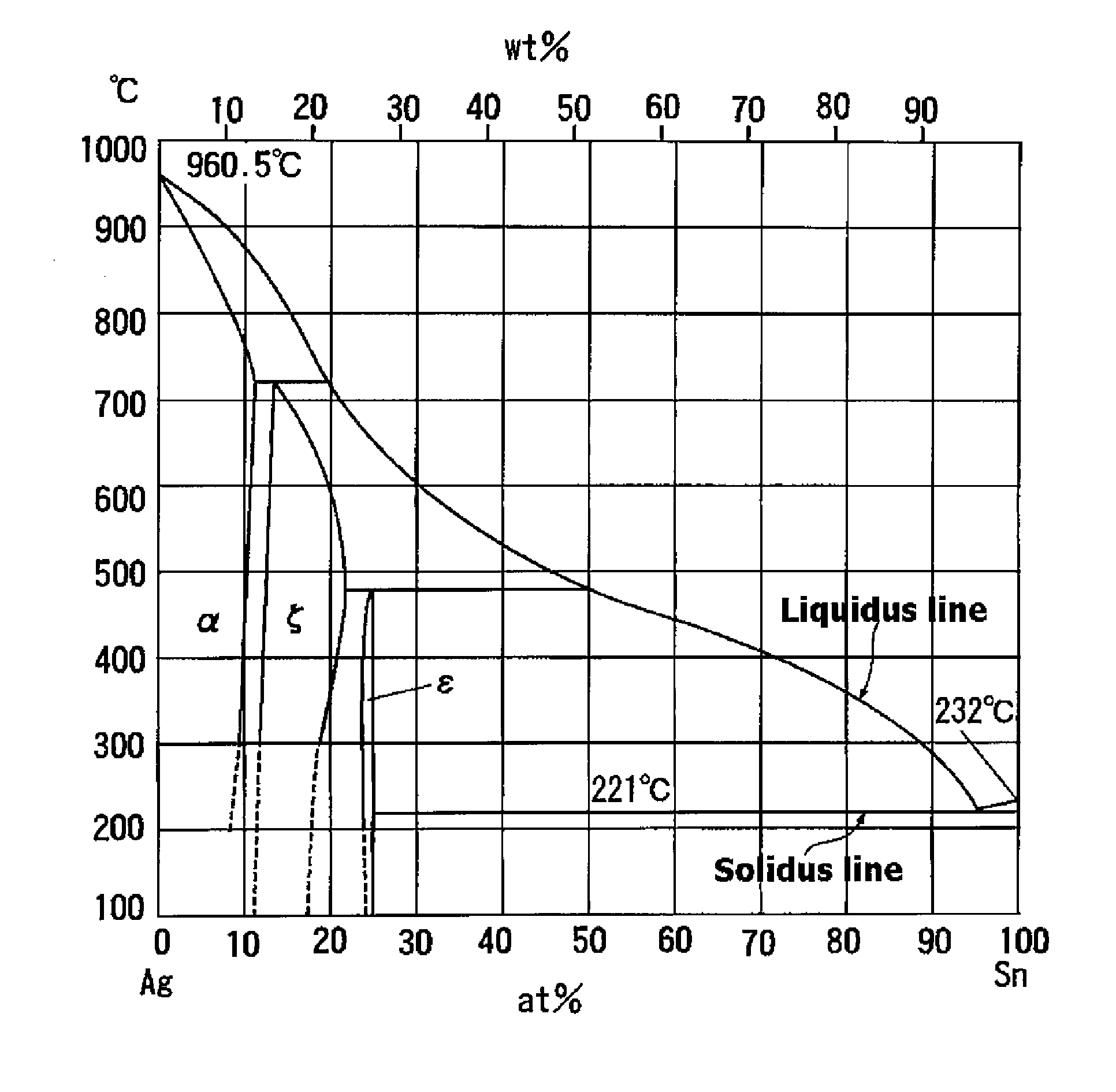

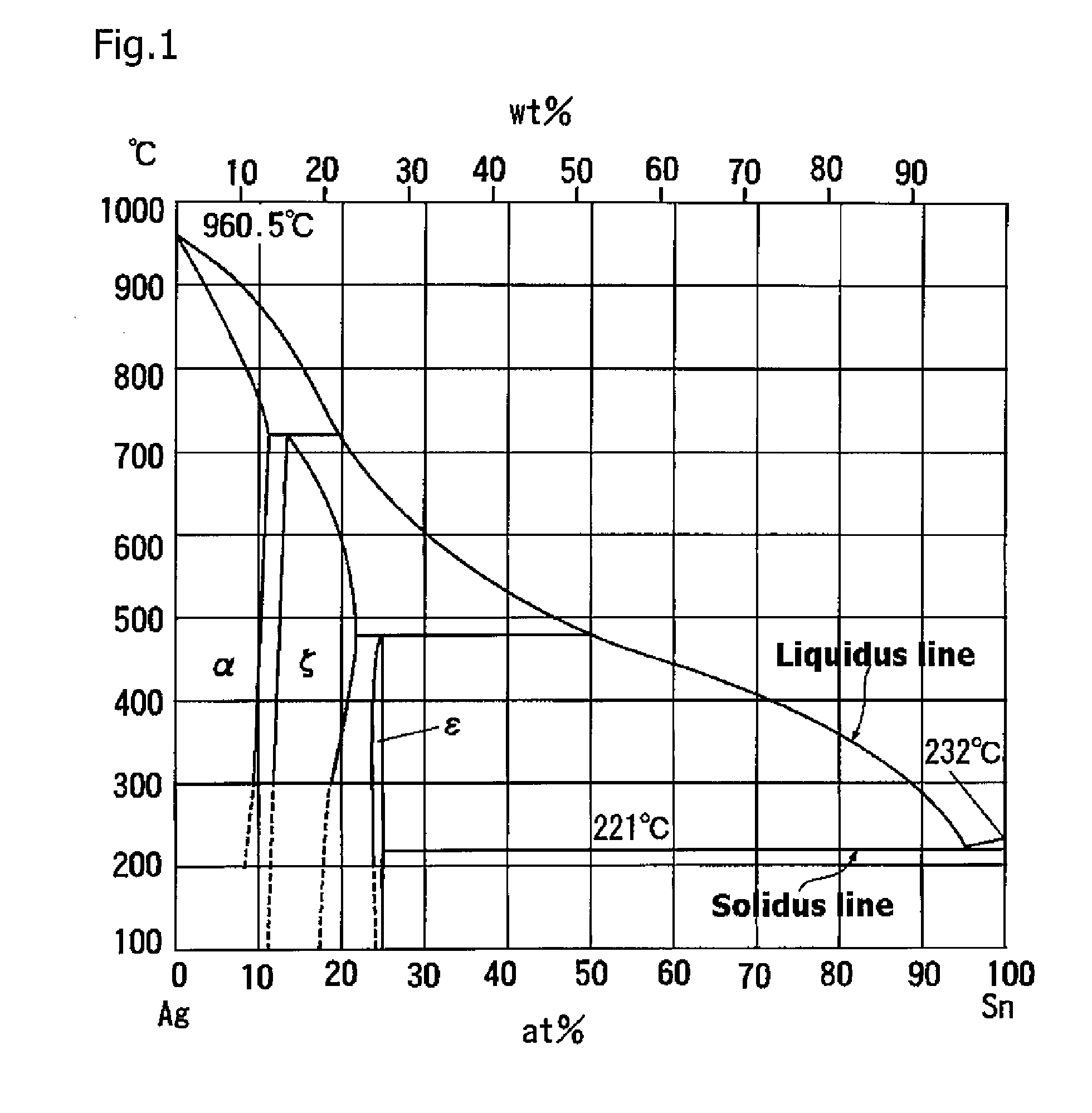

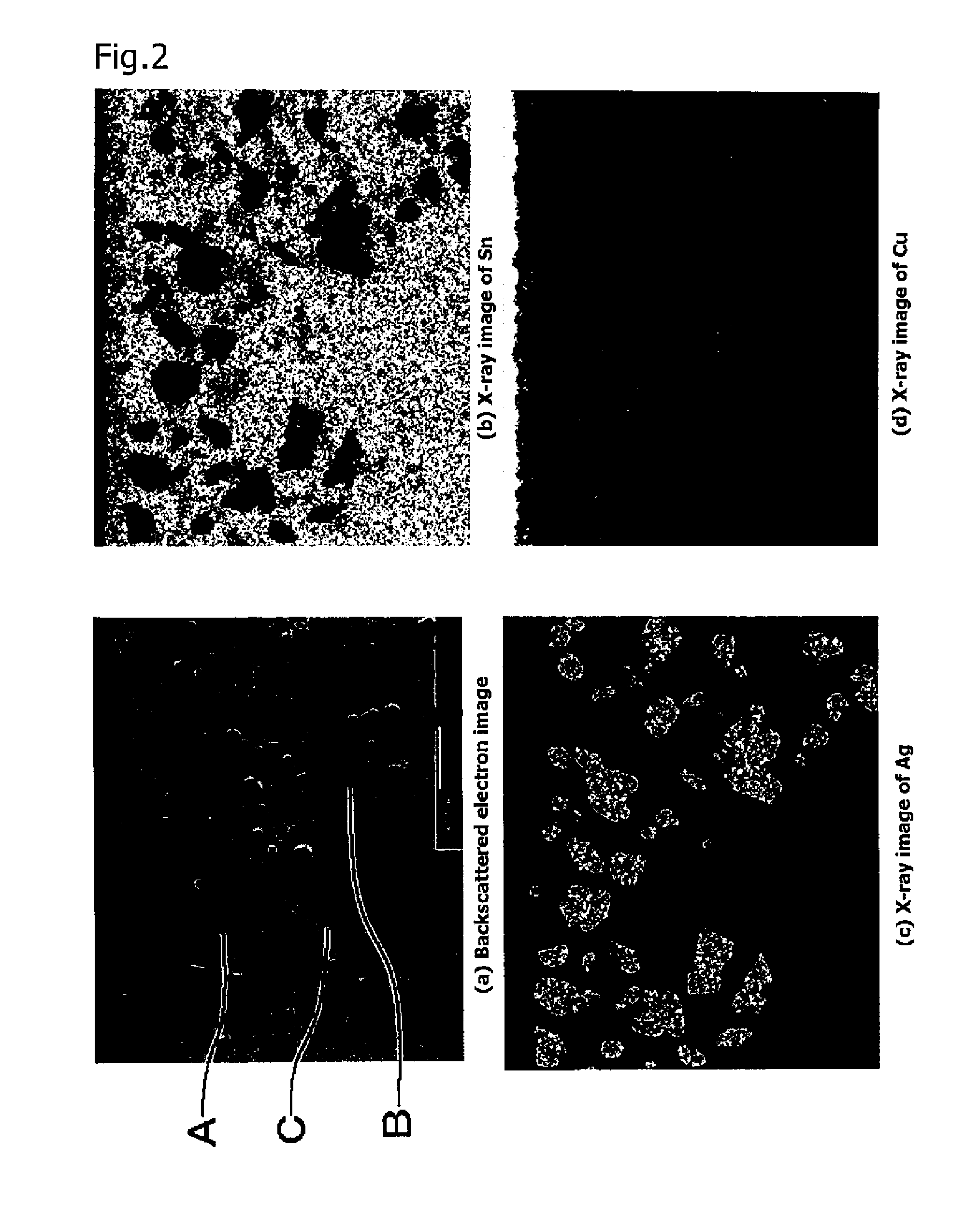

A cream solder obtained by kneading an Sn—Ag—Cu alloy together with a flux, wherein the Sn—Ag—Cu alloy includes a mixture of a first powdery alloy and a second powdery alloy, the first powdery alloy is represented by an Sn—Ag phase diagram having a solid-liquid coexistence region and has a given silver amount which is larger than that in the eutectic composition (3.5 wt. % silver), and the second powdery alloy has a silver amount which is that in the eutectic composition (3.5 wt. % silver) or which is close to that in the eutectic composition and is smaller than that in the first powdery alloy. This cream solder has excellent strength and thermal stability, and satisfactory bonding properties. It is based on an inexpensive Sn—Ag—Cu solder alloy. It is suitable for use as a high-temperature-side lead-free solder material conformable to temperature gradation bonding. Also provided is a method of soldering.

Owner:NIHON HANDA +1

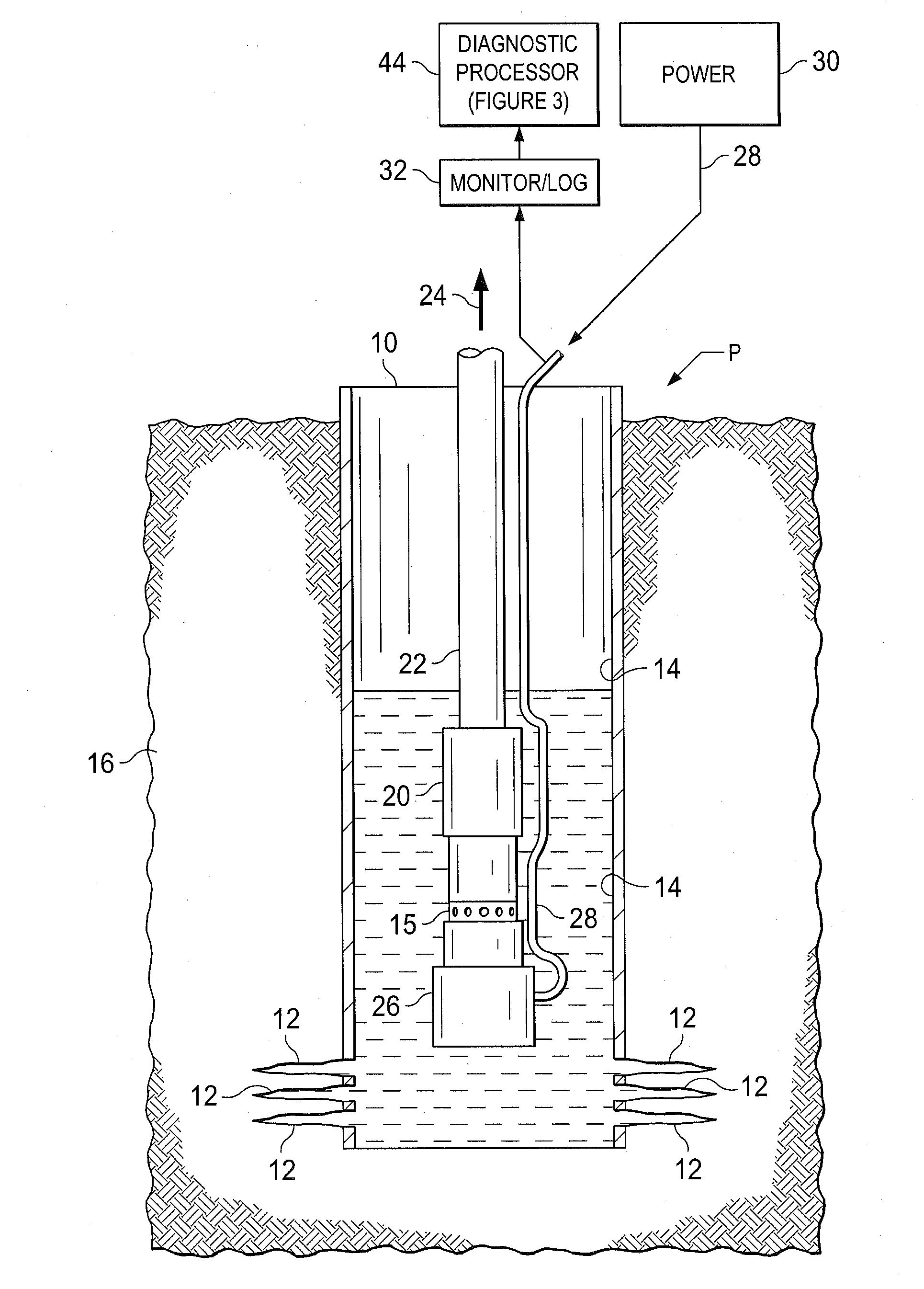

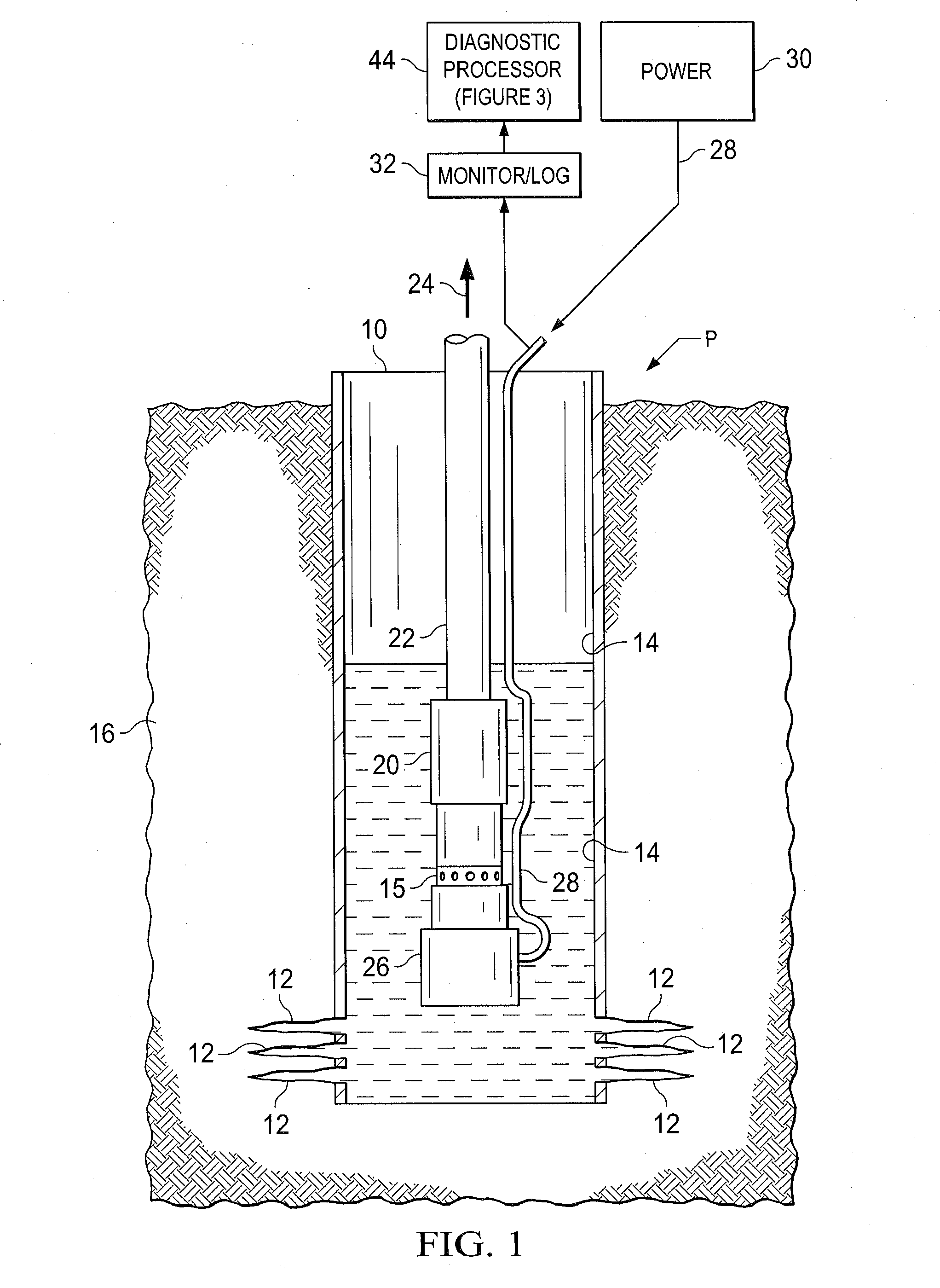

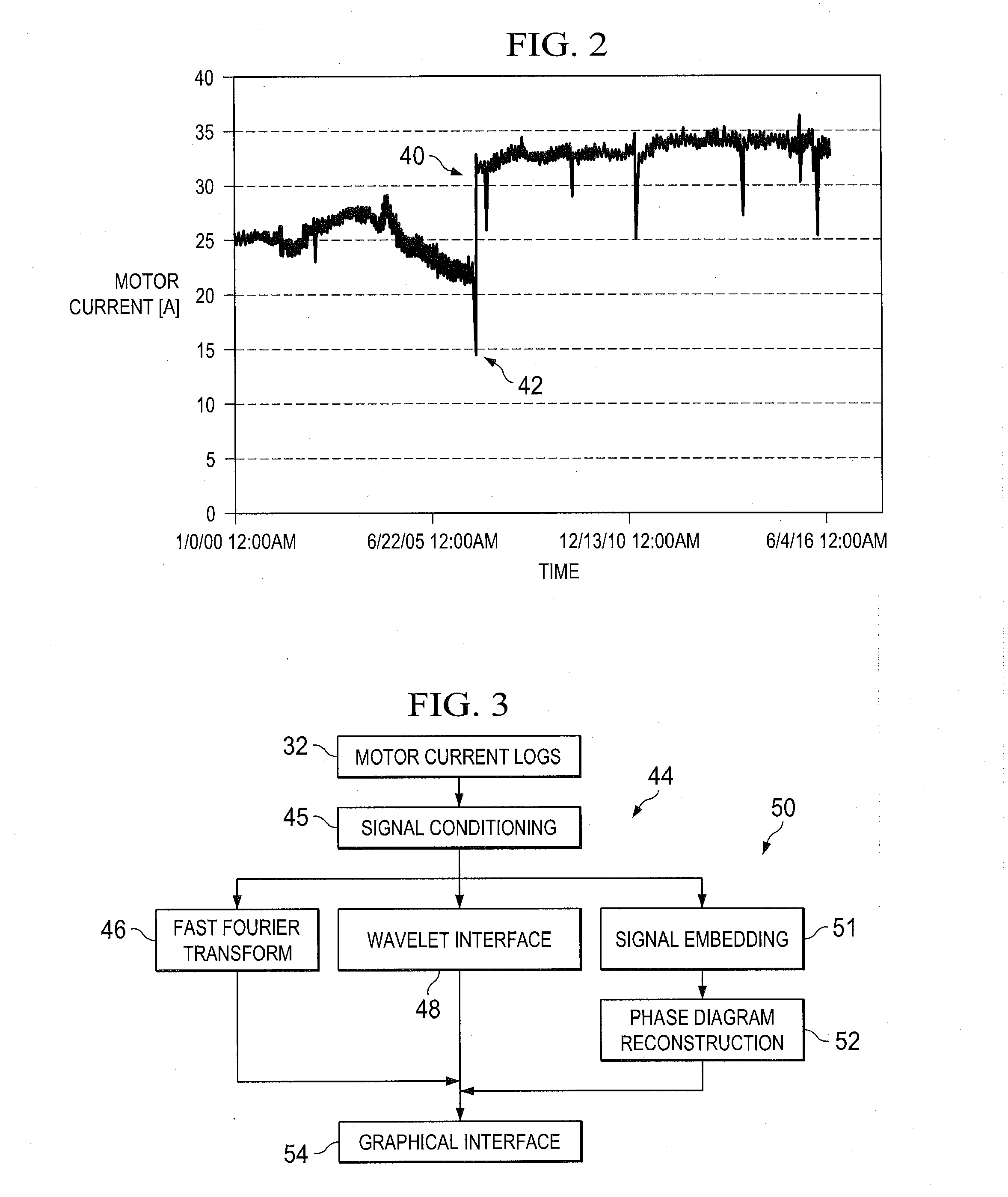

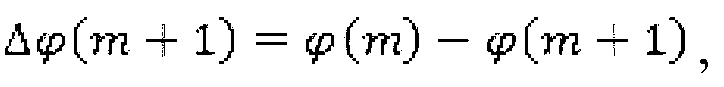

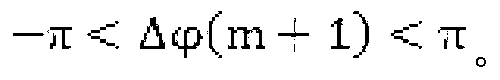

Electrical Submersible Pump Monitoring and Failure Prediction

ActiveUS20130151156A1Electric/magnetic detection for well-loggingElectric motor controlElectricityEngineering

Current supplied to electrical submersible pumps in wells is monitored, and signal processing based on wavelet analysis and phase diagram analysis is performed on the data obtained from monitoring. An incipient malfunction of the electrical submersible pump, such as one due to scale build-up in and around the pump, can be detected at an early stage.

Owner:SAUDI ARABIAN OIL CO

Quality map guide method and branch cutting method-based interferogram unwrapping method

The invention discloses a quality map guide method and branch cutting method-based interferogram unwrapping method. The method comprises the following steps of primarily unwrapping an interferogram by adopting a branch cutting method to obtain an unwrapped phase diagram and a binary distribution map of unwrapped phases, finding non-unwrapped pixel points on a boundary line of a non-unwrapped area and an unwrapped area based on a branch cutting line distribution map in the branch cutting method and the binary distribution map of the unwrapped phases, finding a pixel point with the highest quality adjacent to the non-unwrapped pixel points on a branch cutting line according to a quality map, unwrapping pixels adjacent to the pixel point with the highest quality, which serves as a starting reference point, in the non-unwrapped area by using a quality map guide method, connecting the phases of disconnected areas on two sides by using a pixel phase on the branch cutting line, and unwrapping a small part of the disconnected areas separated by the branch cutting line by utilizing the quality map guide method. The size of an image to be unwrapped is greatly reduced, the calculation amount of the quality map guide method can be reduced, and the operation time is further reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

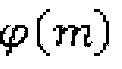

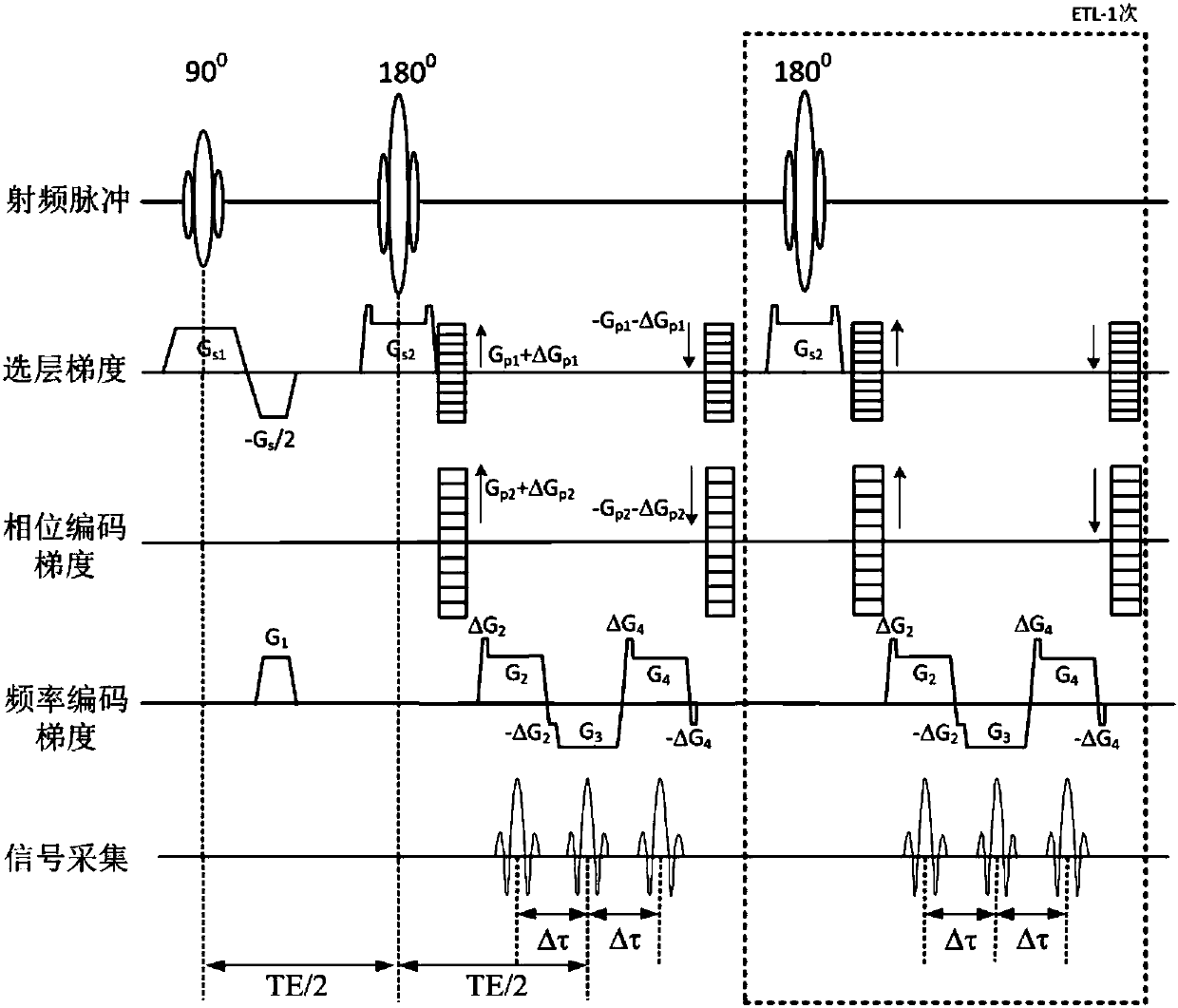

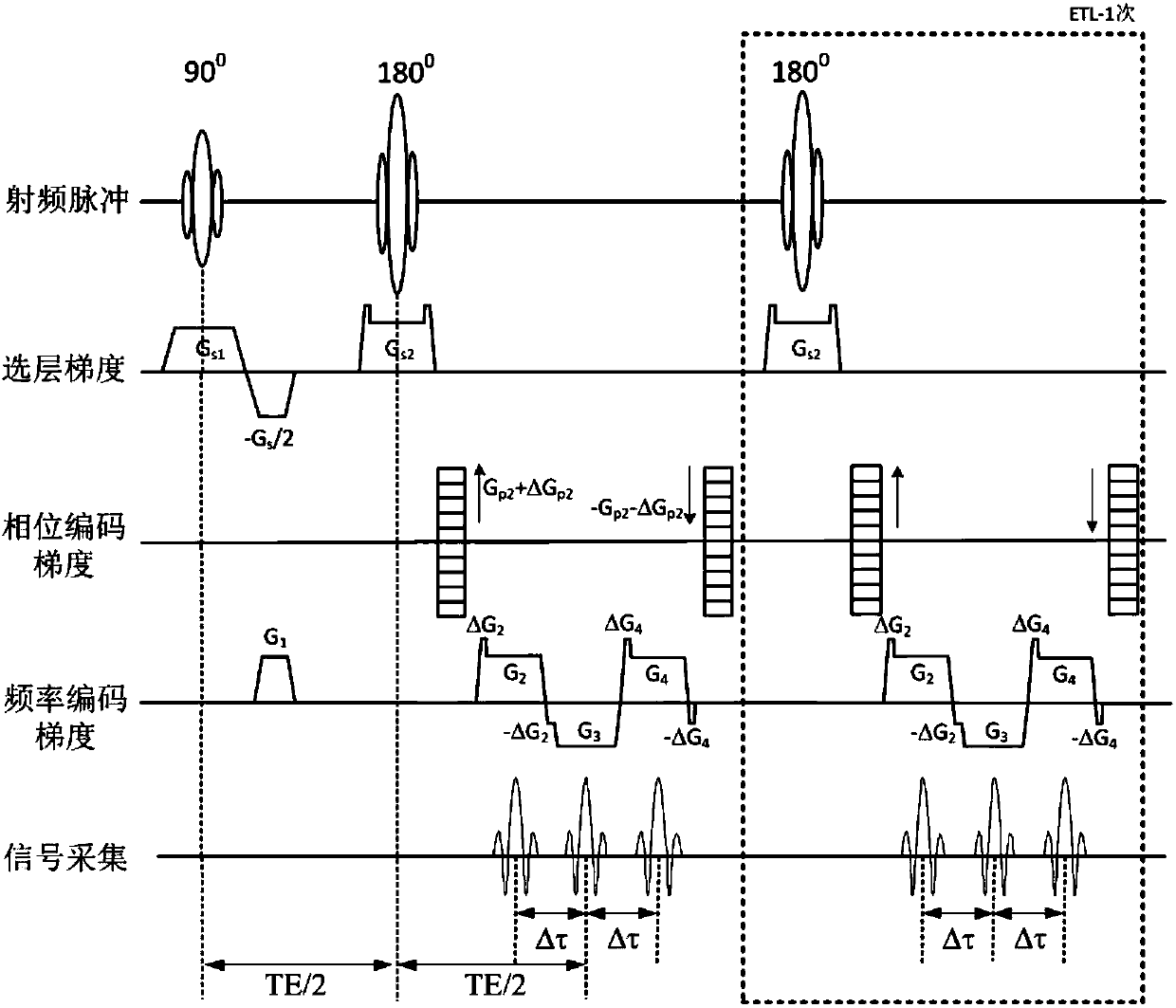

Synchronous acquisition and calibration method for three-dimensional multi-parameter weighted magnetic resonance imaging

ActiveCN107271937AIncrease optionalityReduce dependenceMeasurements using NMR imaging systemsReconstruction methodT2 weighted

The invention discloses a synchronous acquisition and calibration method for three-dimensional multi-parameter weighted magnetic resonance imaging. A three-dimensional / two-dimensional fast multi-echo water-fat separation sequence and a signal debugging method, a pre-scanning method, a scanning method, a data preprocessing method and an image reconstruction method thereof can obtain a water-fat separation image and T2 weighted (T1 weighted or PD weighted) image by one-time scanning. The three-dimensional multi-parameter weighted synchronous scanning and calibration method can maximize the number of images obtained in a single scan, including, an in-phase image, a reverse-phase image, a fat image, a fat-pressed image water, a conventional T2 weighted (or T1 weighted / PD weighted ) image, and a T2weighted images, significantly shortens clinical scanning time and increases the selectivity of clinical scanning schemes, and has less reliance on the hardware performance of an MRI system.

Owner:南京拓谱医疗科技有限公司

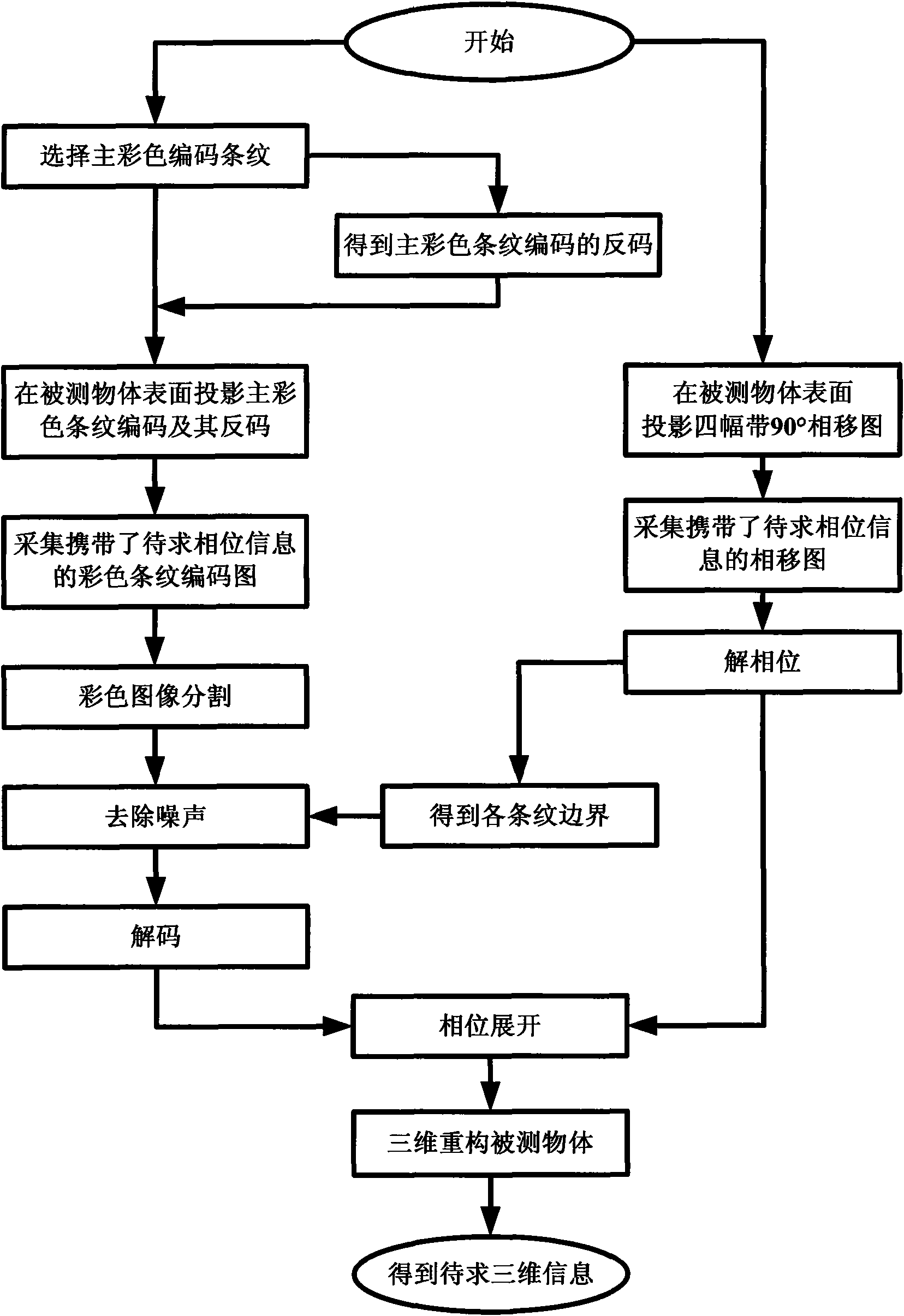

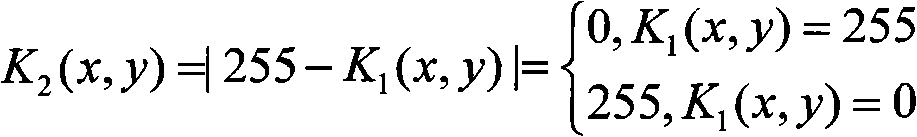

Three-dimensional measuring method based on positive and inverse code color encoding stripes

InactiveCN101666631AEfficient measurementHigh precisionImage enhancementUsing optical meansPattern recognitionColor image

The invention relates to a three-dimensional measuring method based on positive and inverse code color encoding stripes, which comprises the following steps: selecting a group of color encoding stripes as main color encoding stripes, wherein the color encoding stripes have better performance and only contain a plurality of pure colors; obtaining the inverse codes of the color encoding stripes as auxiliary stripes, designing a color image segmenting method which is not influenced by the surface color of an measured object and illumination by combining a four-step phase shift method; accuratelyjudging the color of each pixel in the main color encoding stripes; then obtaining a periodically changing folding phase diagram from a four-step band 90-degree phase shift diagram; using the periodicboundary of folding phases as the boundary of each stripe in a color image segmenting diagram to further process the color image segmenting diagram, eliminate the noise effect, improve the precisionof color image segmentation, so as to further improve the precision of decoding and three-dimensional measurement.

Owner:海安东华纺织印染有限公司 +1

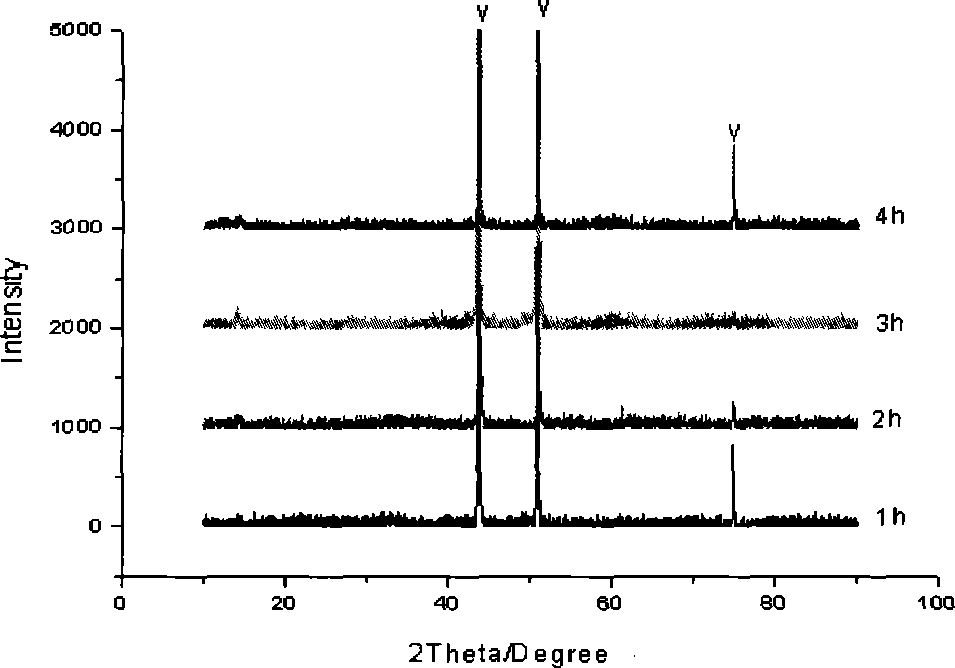

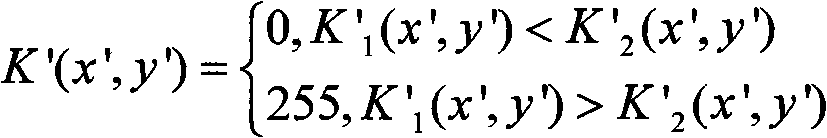

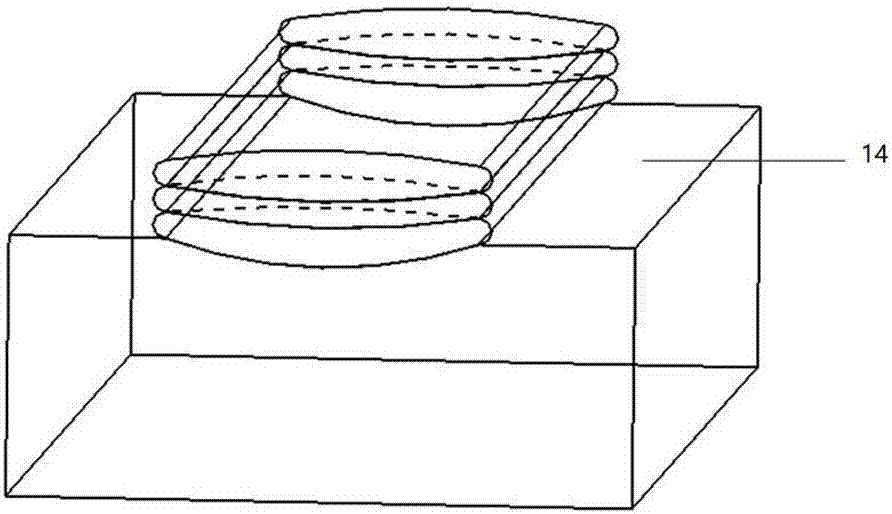

Additive manufacturing method of surface high-entropy alloying gradient metallurgy layer

InactiveCN107971490AReduce distortionImprove work efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysUltimate tensile strength

The invention discloses an additive manufacturing method of a surface high-entropy alloying gradient metallurgy layer, and belongs to the field of surface alloying. The additive manufacturing method comprises the following steps that step one, high-entropy alloying components are obtained through calculation based on a phase diagram; step two, an LMD technological strategy is designed, wherein anLMD technology is designed to carry out laser multilayer melting and sedimentation and increase the content of alloy powder in mixed powder layer by layer from the bottom up, and powder delivering schemes of different gradient coatings are formulated to design a multichannel and separable control powder delivering system; and step three, laser melting and sedimentation machining is carried out, thus the high-entropy alloying gradient metallurgy layer is obtained. The additive manufacturing method achieves the effects that the high-entropy alloying gradient layer excellent in properties is prepared on the surface of a cheap base material, the requirement that the surface properties of a formed part are outstanding is met, the production cost is lowered substantially, the bonding strength between the material surface metallurgy layer and a base is improved, and cracking of the metallurgy layer is inhibited effectively.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

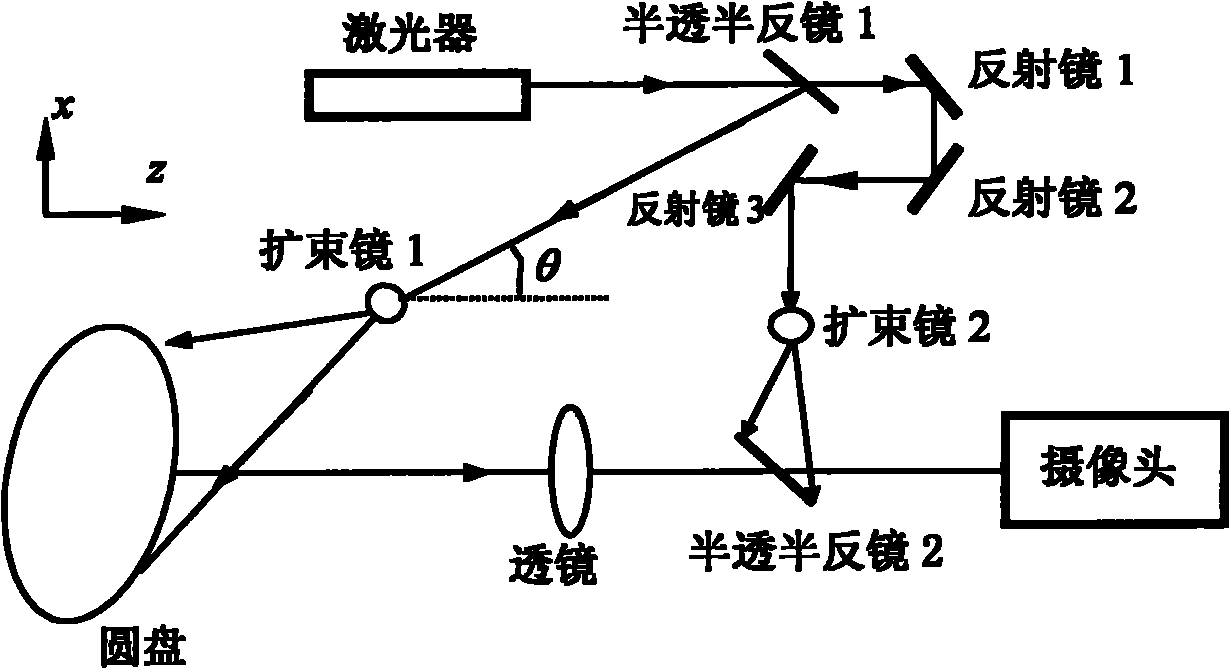

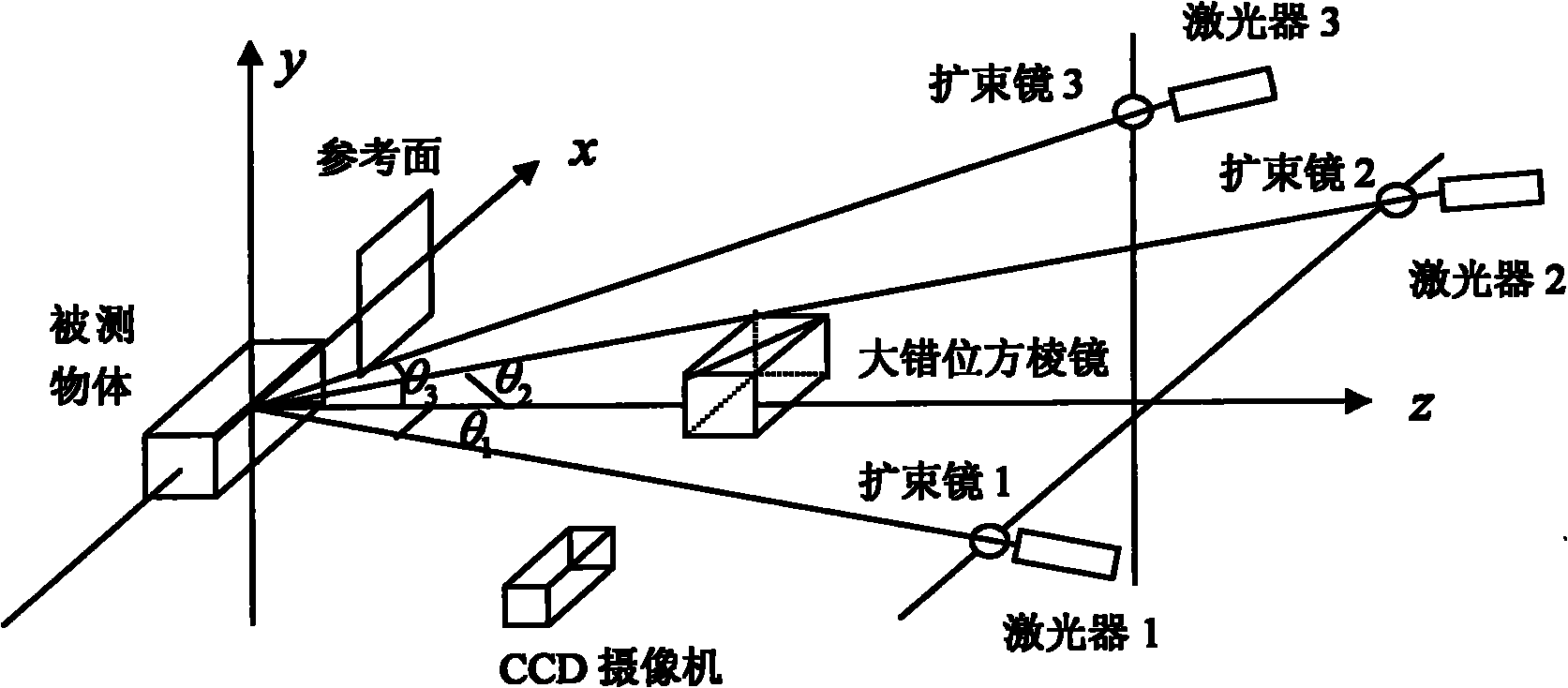

Detection method of electronic speckles for synchronous carrier-frequency modulation in three-dimensional deformation field

InactiveCN101871769AEasy to operateHigh measurement accuracyUsing optical meansIn planeShortest distance

The invention provides a detection method of electronic speckles for synchronous carrier-frequency modulation in a three-dimensional deformation field. The method comprises the following steps: achieving short-distance illumination of three lasers and short-distance stack imaging on an object surface to be detected and a reference object surface by adopting a large-dislocation square prism; introducing carrier fringe patterns by deflecting the reference object surface, and then carrying out one-time modulation on a speckle interference fringe field lighted by the three lasers; when bending deformation occurs on the carrier fringe patterns under modulation of objection deformation after loading an object, independently measuring the deformed object by the three lasers, collecting the carrier fringe patterns before and after object deformation and the modulated carrier fringe patterns, and then respectively demodulating the carrier fringe patterns by a Fourier transform method to obtain a three-bitmap phase diagram containing off-plane and in-plane information; and finally carrying out phase operation to separate three components of a displacement field. By using the detection method, modulation of three speckle interference fringe fields by deflecting the reference object surface is achieved to obtain high-quality modulation fringe patterns. The method has the advantages of simple light path, relatively simple operation and high measuring precision.

Owner:SHANDONG NORMAL UNIV

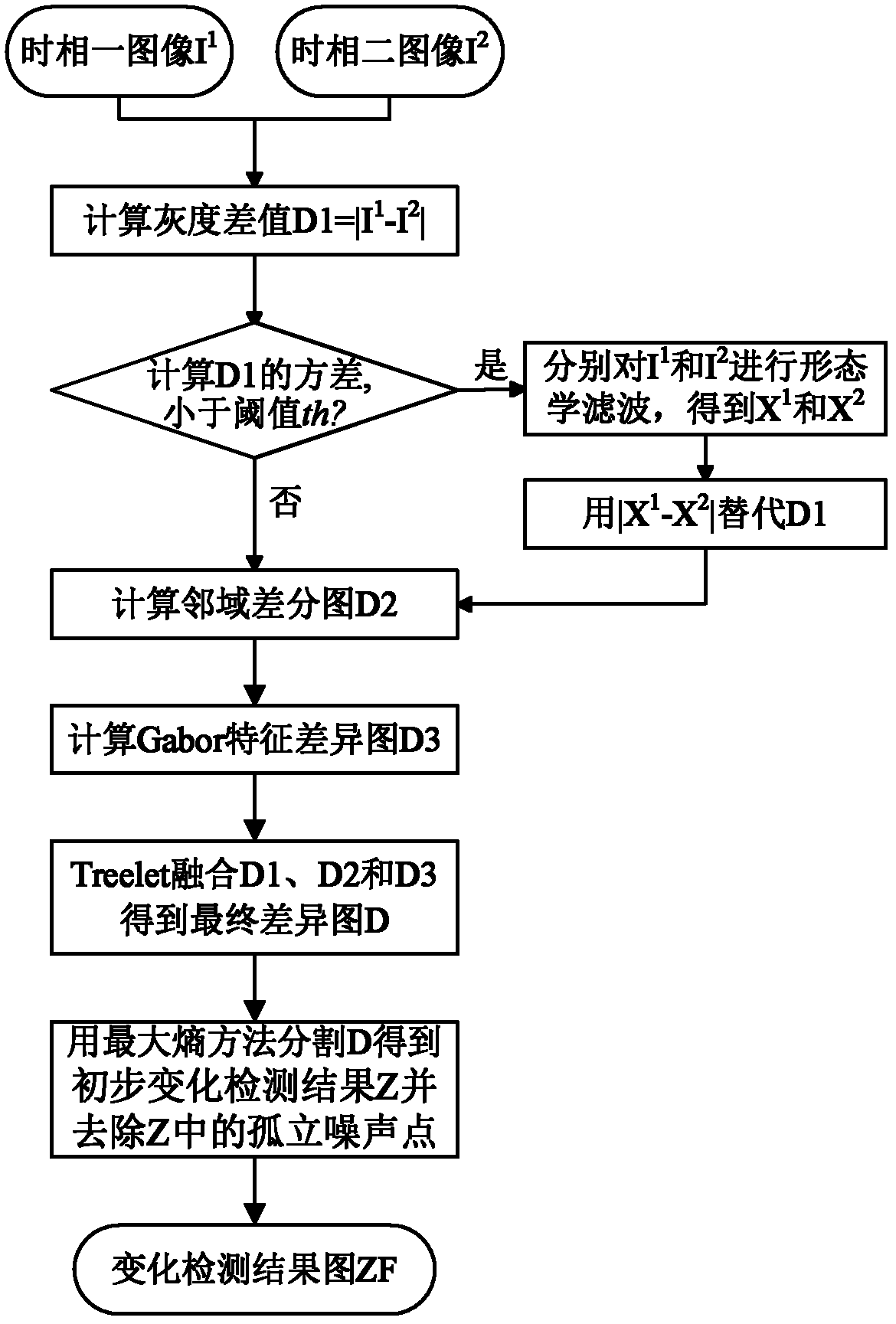

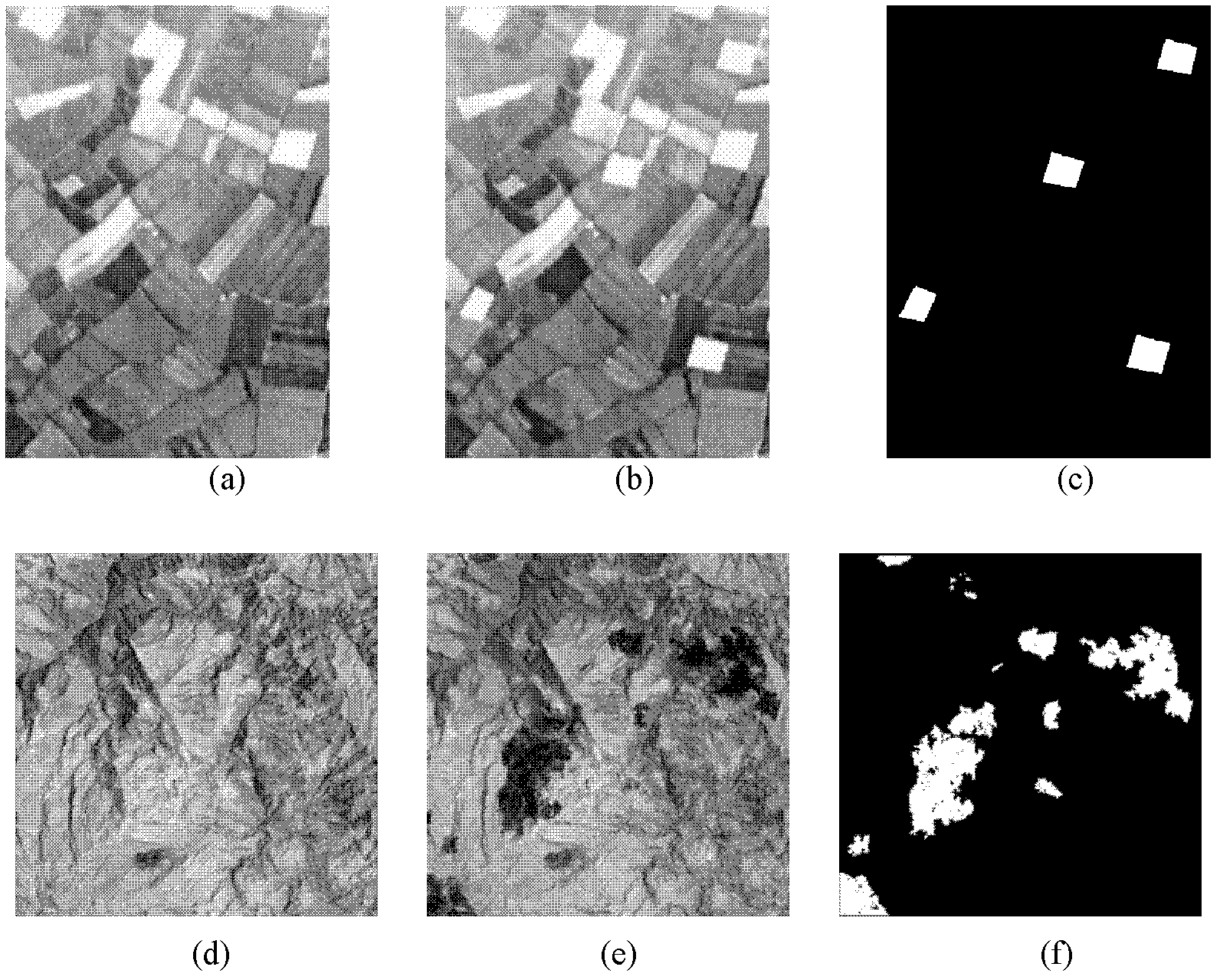

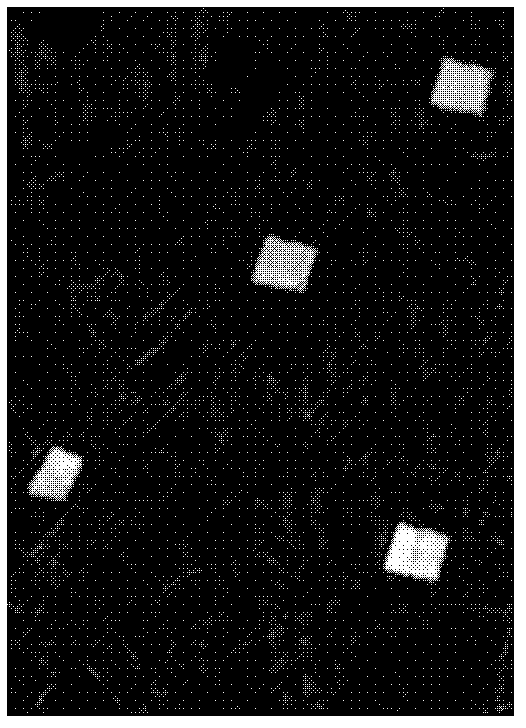

Remote sensing image change detection method based on multi-feature fusion

InactiveCN102629378AReduce missed detection rateImprove immunityImage enhancementImage analysisNatural disasterComputer science

The invention discloses a remote sensing image change detection method based on multi-feature fusion. By using current change detection method, an omission ratio is high and whole change detection precision is not high. By using the method of the invention, the above problems can be solved. The method comprises the following steps: firstly, inputting difference of two time phase remote sensing images, acquiring a gray scale difference graph, calculating a variance of the gray scale difference graph and setting a threshold so as to determine whether to carry out morphology pretreatment on the two time phase images; then, calculating a neighborhood difference graph and a Gabor texture feature difference graph, using a Treelet algorithm to fuse three groups of difference graphs, and carrying out maximum entropy segmentation on the fused difference graphs so as to obtain an initial detection result; finally, using an area threshold method to remove parts of isolated pseudo change information so as to obtain a final detection result graph. Experiment shows that by using the method of the invention, an edge feature of a region of variation can be maintained, noise interference can be effectively restrained and the omission ratio can be reduced simultaneously. The method of the invention can be used in environment protection, city program construction and natural disaster detection fields.

Owner:XIDIAN UNIV

Bismuth-based molybdenum-based microwave dielectric ceramic material sintered at ultra low temperature and manufacture of the same

InactiveCN101318815ALower sintering temperatureLow dielectric lossCeramicsPermittivityStructural formula

The invention discloses a bismuthino molybdenum ultralow temperature sintering microwave medium ceramic material. A phase map of Bi2O3-MoO3 binary system is taken as a beginning, a single-phase compound is taken as a basis, and a series of microwave medium material which has good microwave dielectric property (the permittivity is between 10 and 45, and the Qf is between 4,000 and 25,000GHz) and can be sintered into ceramics at a low temperature of between 550 and 900 DEG C is prepared through the methods of adjusting the proportion of the binary system and substitution for equivalent and unequivalent ions. The structural formula is (1-x)[(Bi1-yAy)2O3]-x[(Mo1-zBz)O3], wherein, A is equal to La<3+>, Nd<3+>, and Sm<3+>, B is equal to W<6+>, Nb<5+>, Ta<5+>, Sb<5+>, Ti<4+>, Zr<4+>, and Sn<4+>, x is more than or equal to 0.01 and less than or equal to 1, y is more than or equal to 0 and less than or equal to 0.20, and z is more than or equal to 0 and less than or equal to 0.20.

Owner:XI AN JIAOTONG UNIV

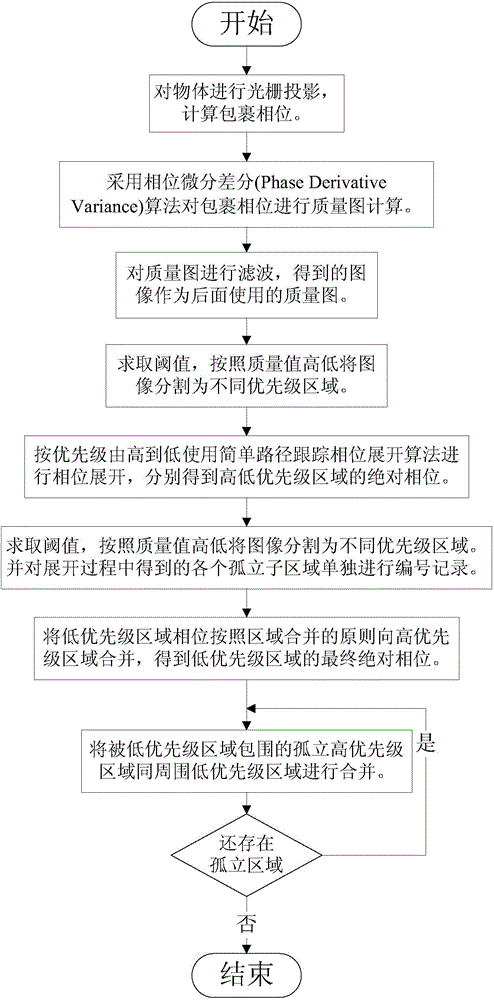

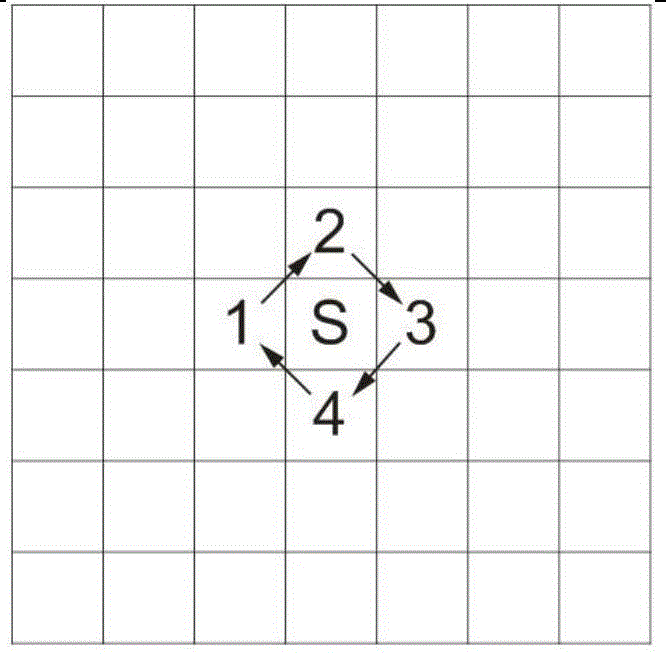

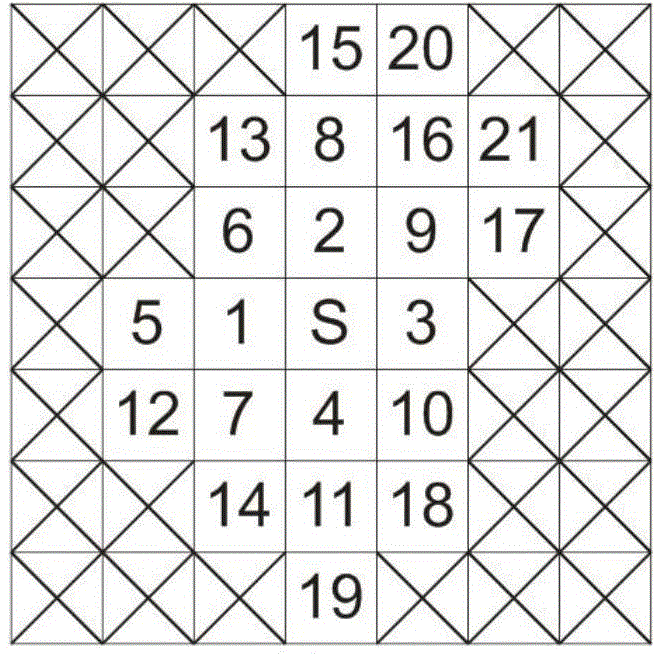

Rapid phase unwrapping method based on quality diagram region segmentation

InactiveCN103913128AAvoid the impact of unwrapping accuracyImprove operational efficiencyUsing optical meansDifferential algorithmThree dimensional measurement

The invention belongs to the technical field of computer measurement, and particularly relates to a rapid phase unwrapping method based on quality diagram region segmentation. The rapid phase unwrapping method includes the steps of capturing wrapped phase diagrams obtained through processing with a camera, calculating quality diagrams according to the wrapped phase diagrams, filtering the quality diagrams with a phase differential-difference algorithm, automatically obtaining a region segmentation threshold value, dividing the wrapped phase diagrams into regions with different priorities with the obtained region segmentation threshold value, completing region phase unwrapping with a simple path tracking phase unwrapping algorithm, conducting phase unwrapping, and combining sets after phase unwrapping according to the priority sequence from high to low. By means of the rapid phase unwrapping method, the simple path tracking phase unwrapping algorithm based on region segmentation is adopted, and the phase unwrapping speed can be quickened on the premise that the phase unwrapping accuracy is not reduced to the greatest extent. By means of the rapid phase unwrapping method, the requirements for high accuracy, rapid unwrapping, noise jamming resistance and the like of structured light vision three-dimensional measurement are met.

Owner:HARBIN ENG UNIV

Tyre touchdown shape measuring device using laser disperse spot shearing interference method

InactiveCN1916563AAccurate measurementForce measurement by measuring optical property variationUsing optical meansNon destructiveMeasurement device

The present invention relates to a device using laser disperse spot shearing interference method to measure the tread deformation and the touchdown pressure in the tire touchdown plane. The measuring device of the present invention is configured in such a way: after the tire and the knurl are fixed on the acrylic panel irradiated by laser, the coherent beams of laser or the like are irradiated thereon; the phase diagram of the light irradiating to the tire surface is obtained; thus the differential value of the object surface dislocation corresponding the physical quantity is obtained quantificationally. The present invention adopts the universe descriptive laser disperse spot shearing interference method which obtains the deformation distribution by nondestructive checking method, and adopts a structural characteristics of using the common light path.

Owner:HANKOOK TIRE WORLDWIDE

Method for correcting echo wave plane imaging sequence

ActiveCN101109791ACorrect displacementImprove accuracyMagnetic property measurementsMeasurements using NMR imaging systemsPhase differenceImaging data

The invention provides a way for correcting the imaging sequence of an echo plane. A plurality of echo signals are collected, the phase difference of the echo signals is calculated to correct the image data. Wherein, the phase difference goes through multi-order fitting, a fitting coefficient reflecting the cross-infection volume and frequency drift is worked out to carry out phase correction for the image data. The invention collects the EPI signals of two echoes to form two images, the info on time difference for collecting the two images is used to calculate the phase diagram reflecting the unevenness in the magnetic field, and the phase diagram is used to carry out deformation correction for the image. The invention takes full consideration of the influence from the uneven field during the calculation, basically corrects the displacement of the image, improves the accuracy for deformation correction in subsequent images without using additional sequence to get phase diagram, and saves scanning time.

Owner:SIEMENS HEALTHINEERS LTD

Modelling method of reservoir space physical property parameters

The invention relates to a modelling method of reservoir space physical property parameters, comprising the steps of: 1) digitalizing a deposition phase diagram of a reservoir space to be simulated, and performing integer coding identification, so as to obtain the coordinates of each grid node and the deposition phase identification parameter corresponding to the coordinates; 2) analyzing the correlation between the physical property parameters of the reservoir space to be simulated and the seismic data acting as the constraint data, and regarding the seismic data having the closest correlation with the physical property parameters as 'a second variable' for simulation; 3) performing variation function analysis of the known data by regarding the deposition phase identified in the step 1) and the seismic attributes on the reservoir space obtained in the step 2) as the constraints; 4) performing two-dimensional physical property modelling by regarding the deposition phase identified in the step 1) and the spatial seismic attributes as the constraints; and 5) building a three-dimensional model of the reservoir space physical property parameters according to various two-dimensional physical property models obtained in the step 4).

Owner:CHINA NAT OFFSHORE OIL CORP +1

Novel fractional order chaotic circuit

The invention discloses a novel fractional order chaotic circuit which comprises two analog multipliers, eight calculation amplifiers, resistors and capacitors. According to the novel fractional order chaotic circuit, oscillograms of X, Y and Z output ends can be observed on an ordinary oscilloscope, and X-Y, X-Z and Y-Z phase diagrams can also be observed. The novel fractional order chaotic circuit is based on an integer order chaotic system, the fractional order calculus theory and a fractional order unit circuit are applied, a frequency domain approximation method based on a bode diagram is adopted, a fractional order chaotic system is realized, and the understand of people on the fractional order chaotic system and the integer order chaotic system is deepened. The novel fractional order chaotic circuit is applicable to chaotic science, experiment teaching and demonstration, science popularization and experiment demonstration and the like in colleges.

Owner:HEFEI UNIV OF TECH

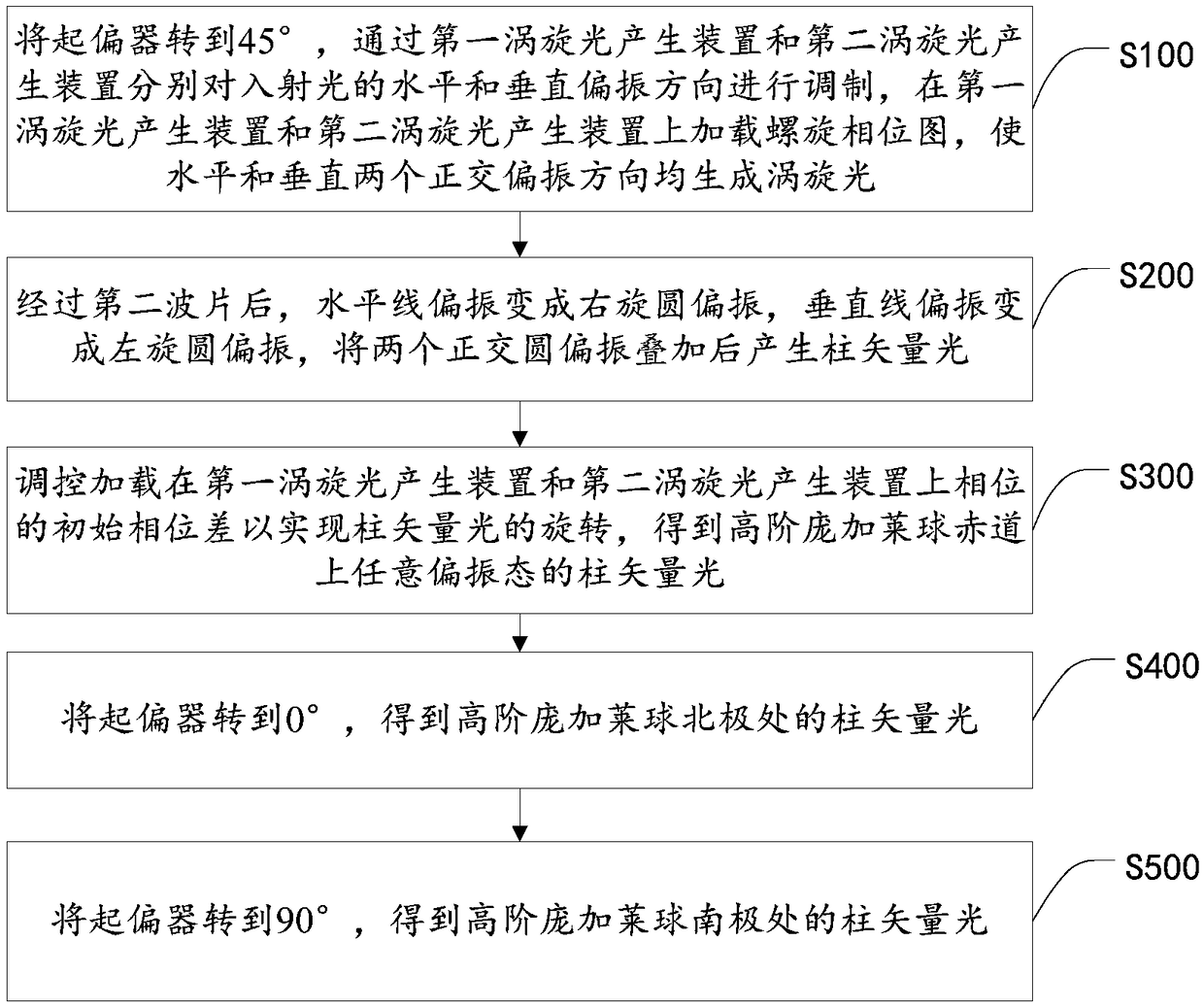

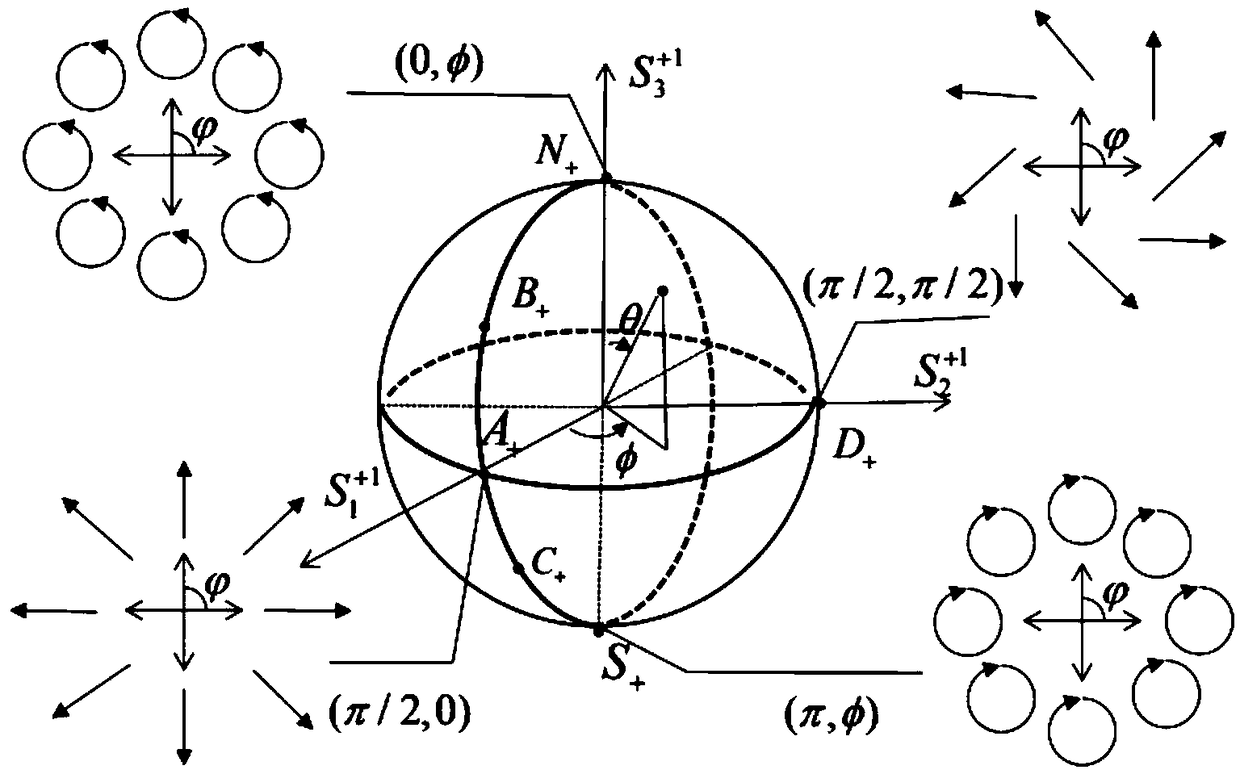

Arbitrary column vector light generating device and method based on orthogonal polarization modulation

InactiveCN109270697AGood repeatabilitySimple light pathOptical elementsPhase differenceOptoelectronics

The invention discloses an arbitrary column vector light generating device and an arbitrary column vector light generating method based on orthogonal polarization modulation. The arbitrary column vector light generating device comprises a linearly polarized light generating module, an orthogonal polarization modulation module and a light intensity detection module, wherein the linearly polarized light generating module is used for generating linearly polarized incident light satisfying requirements; the orthogonal polarization modulation module is used for performing orthogonal polarization modulation on the linearly polarized incident light to obtain column vector light in an arbitrary polarization state; and the light intensity detection module is used for detecting the obtained column vector light. According to the arbitrary column vector light generating device, left-handed circularly polarized vortex light and right-handed circularly polarized vortex light synthesizing the columnvector light are generated by means of two vortex light generating devices respectively, and the column vector light in an arbitrary polarization state can be obtained through modulating a phase difference between phase diagrams loaded on the two vortex light generating devices; the arbitrary column vector light generating device has the advantages of simple and reasonable light path and high repeatability; and the entire device just needs one beam of light to realize the generation of the column vector light, the energy utilization rate is high, the generated light beam is more stable and thequality is higher.

Owner:SHENZHEN UNIV

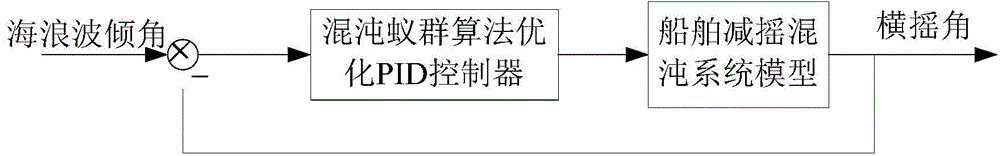

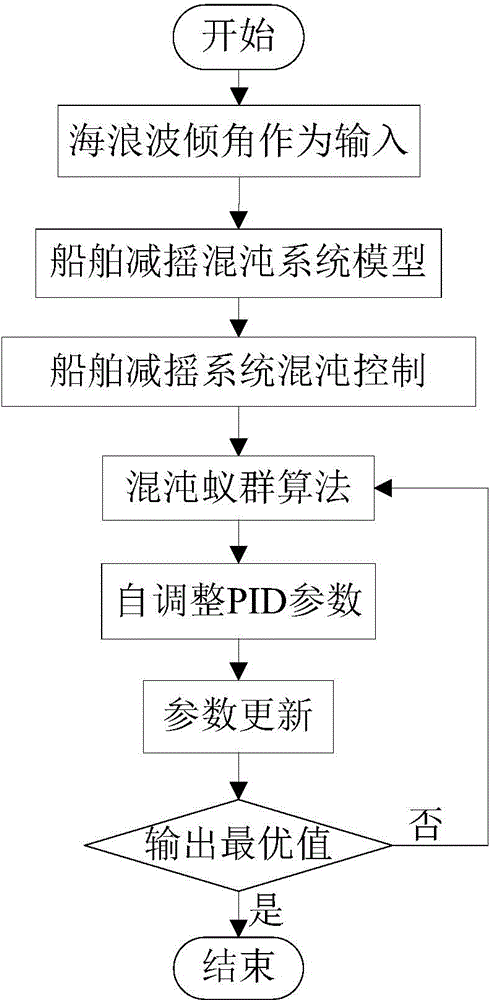

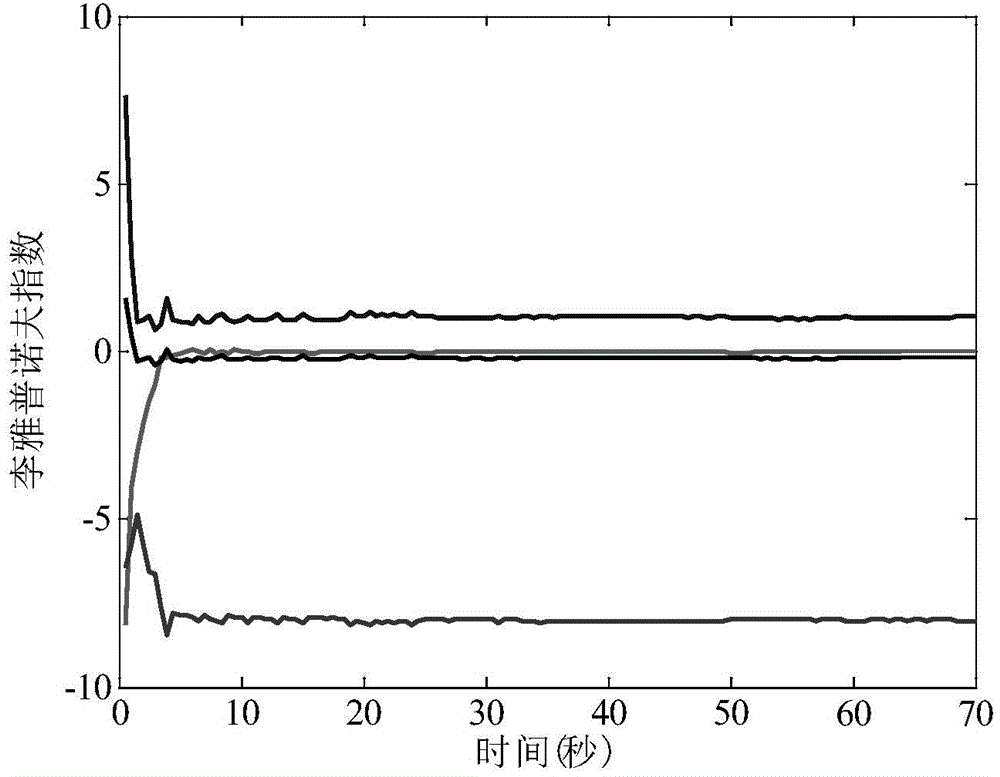

Integrated stabilization chaotic system based PID (Proportion Integration Differentiation) controller optimization control method

ActiveCN104527944AImprove control effectChaotic Dynamics Behavior ImprovementsVessel movement reduction by foilsMovement controllersSystem dynamics modelGlobal optimization

The invention provides an integrated stabilization chaotic system based PID (Proportion Integration Differentiation) controller optimization control method. The analysis is performed on an integrated stabilization system dynamic model equation to obtain a chaotic system so as to solve the problem of ship stabilization. The chaotic behavior of the system under the certain conditions is verified by a phase diagram and Lyapunov exponent spectrum analysis method, controlled parameters are selected, and the chaotic behavior of the system can be effectively controlled by a nonlinear feedback control method. According to the integrated stabilization chaotic system based PID controller optimization control method, the chaotic dynamics behavior of the system is improved and the original dynamic characteristics of the system are reserved; a chaotic search algorithm is combined with an ant colony algorithm to implement the optimization of the PID control parameters and accordingly the global optimization capability of the ant colony algorithm is high, meanwhile the system convergence speed is improved, and accordingly the control system performance is significantly improved; the value of application to a controller device is high, wherein the ship rolling motion is effectively designed through the controller device.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com